Method for local heat treatment on panel

A local heat treatment and plate technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems that the performance of the base metal, the melting zone and the heat affected zone cannot be optimized, and the application of three temperatures can improve the utilization of energy. rate and heating efficiency, ensure the quality of processing, easy and precise control of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

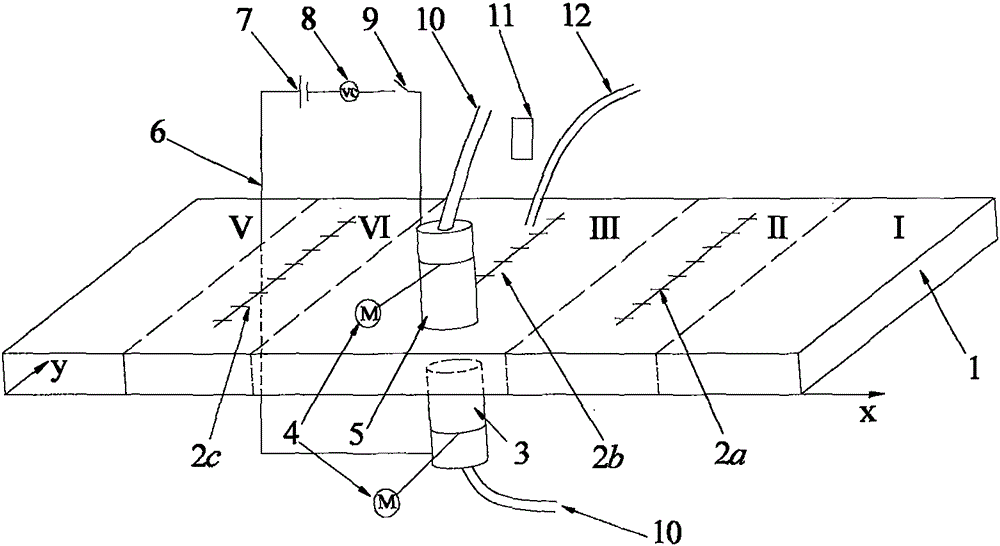

[0021] A method for local heat treatment of plates is characterized in that: the steps of the method;

[0022] Step 1: Divide tailor welded blank 1 into base metal zone I, heat affected zone II, fusion zone III, heat affected zone VI and base metal zone V along the x direction. 1~10mm on both sides of III are heat-affected zone II and heat-affected zone VI respectively, and the rest are base metal zone I and base metal zone V;

[0023] Step 2: Design the position of the heating line 2a in the heat-affected zone II, design the position of the heating line 2b in the melting zone III, and design the position of the heating line 2c in the heat-affected zone VI. The main points are the heating line 2a, 2b and 2c are the centerlines of heat-affected zone II, melting zone III and heat-affected zone VI respectively;

[0024] Step 3: Prepare electrodes A and B with elliptical cross-sections. The ratio of the long and short axis of the ellipse is not more than 10. The cross-sectional a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com