Patents

Literature

142 results about "Fusion zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

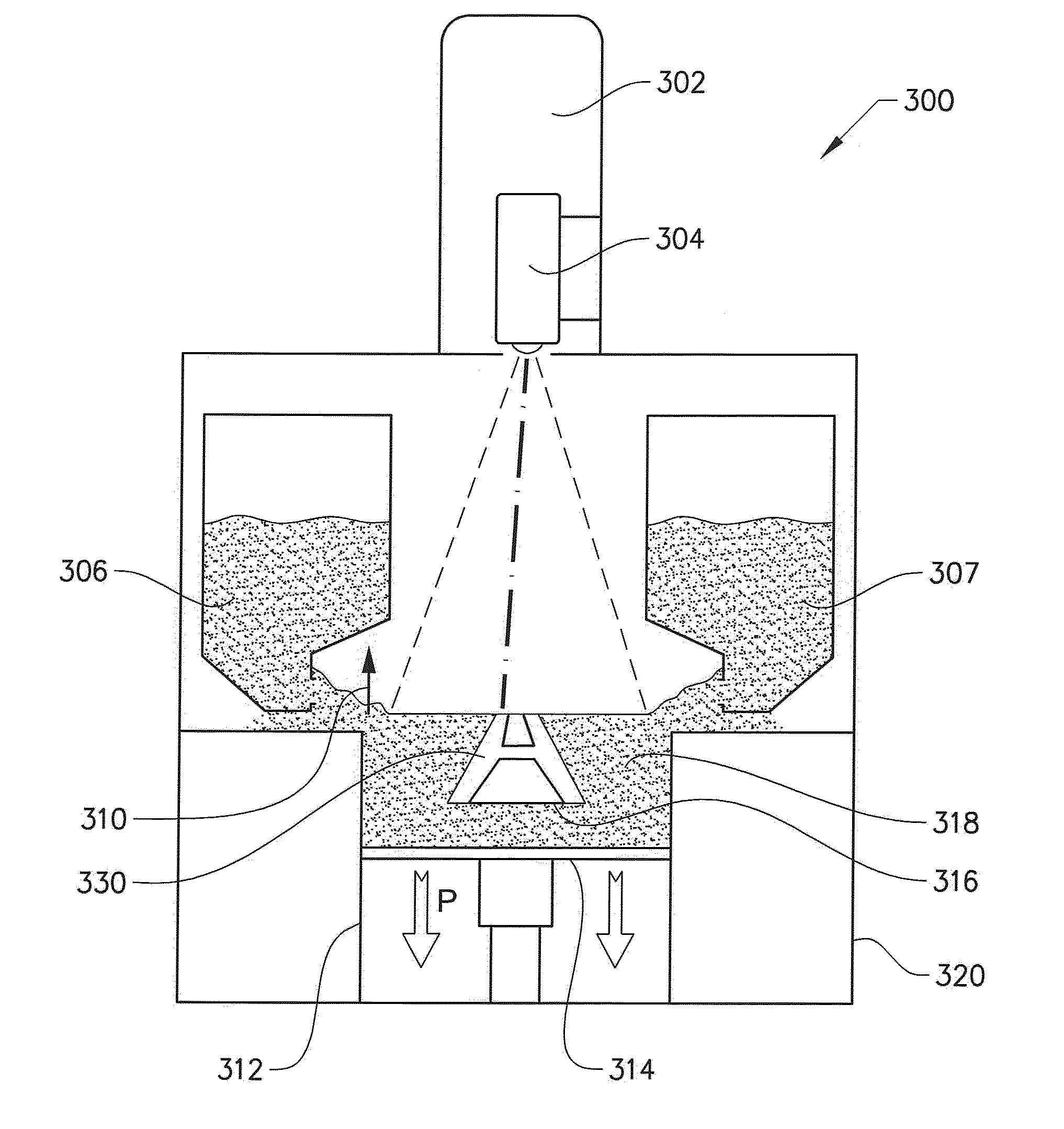

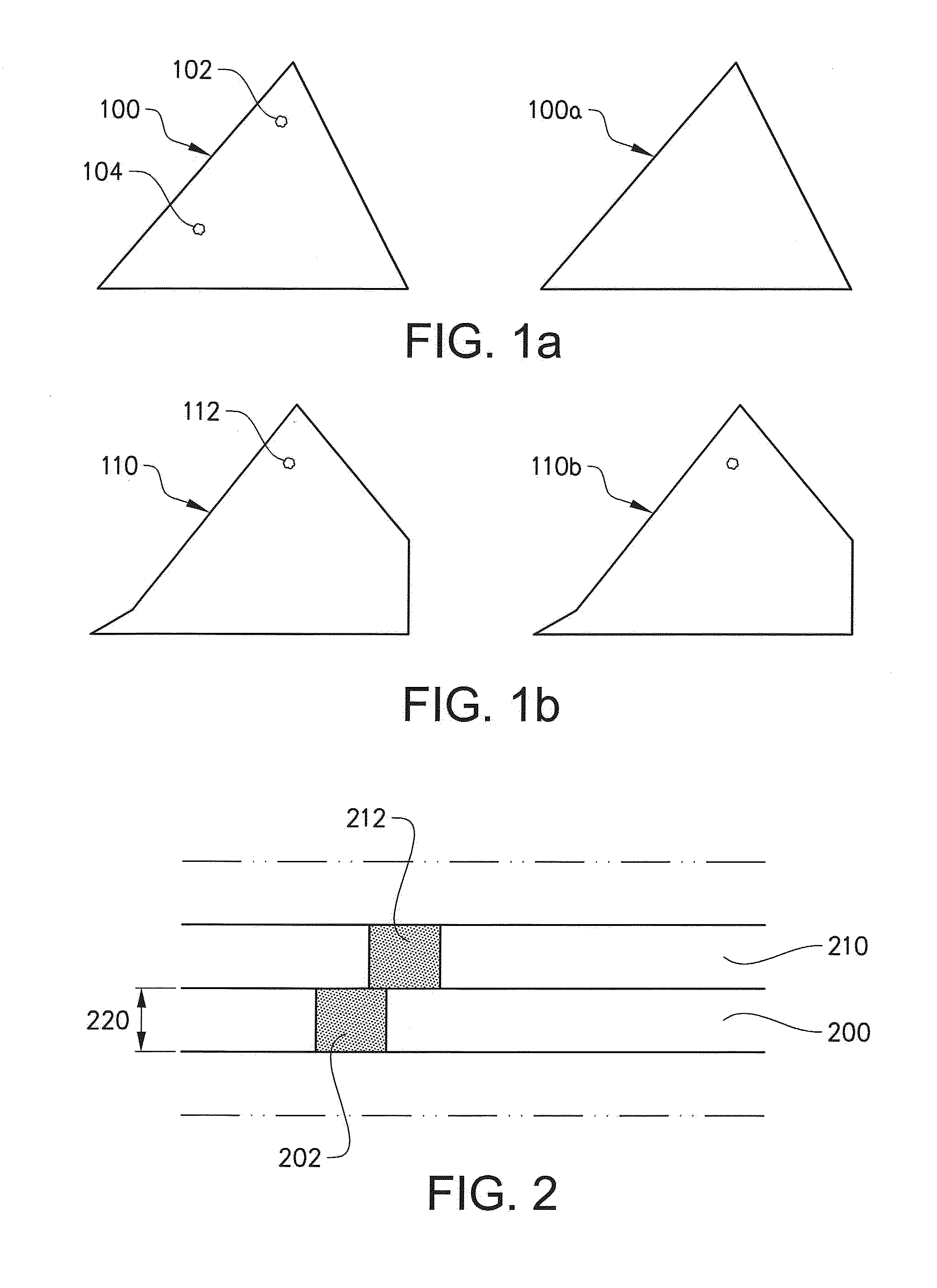

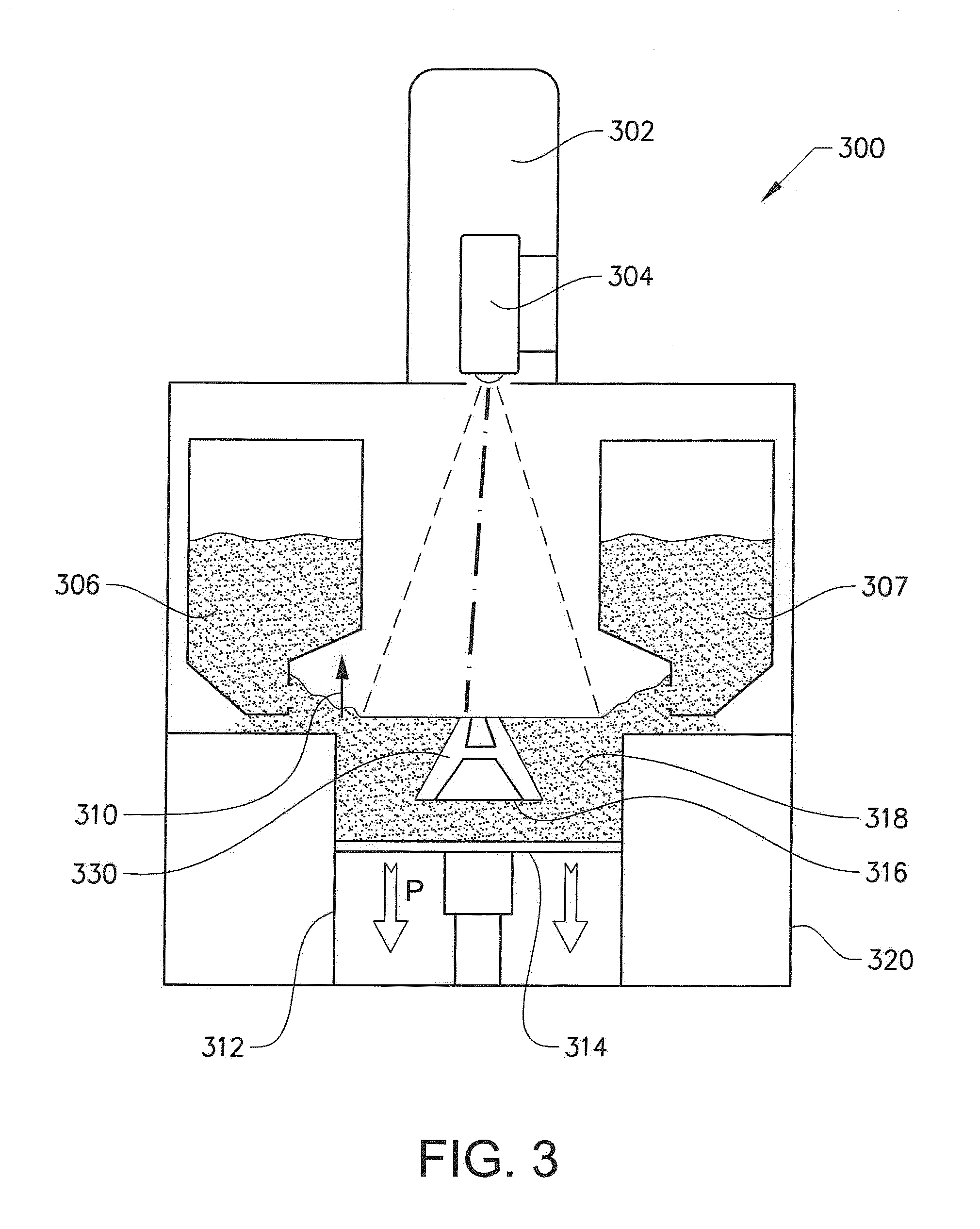

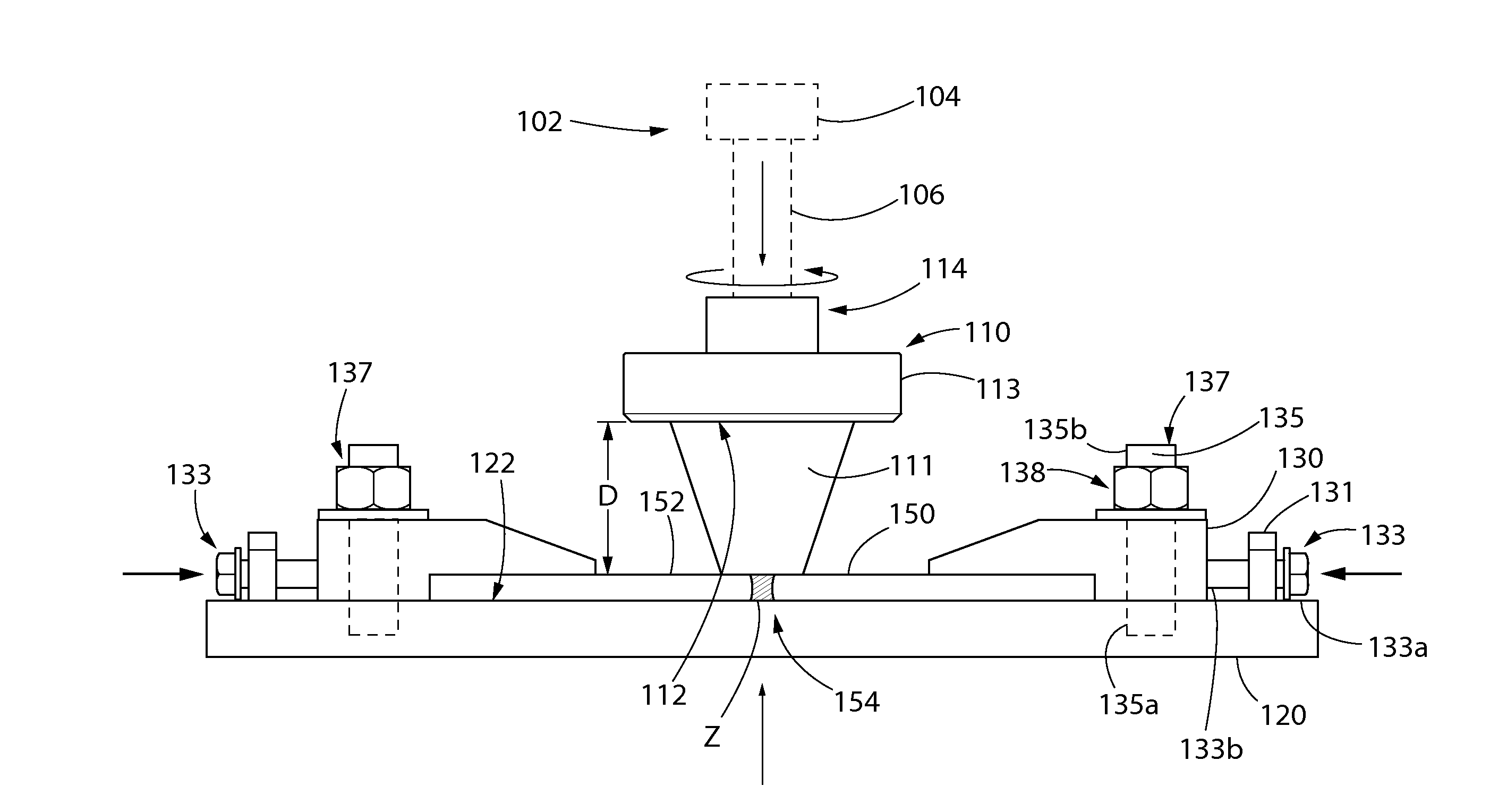

Method and apparatus for detecting defects in freeform fabrication

ActiveUS20140308153A1Improve reliabilityReduce amountAdditive manufacturing apparatusMaterial analysis by optical meansMaterials scienceFusion zone

A method for detecting defects in three-dimensional articles. Providing a model of said article. Providing a first powder layer on a substrate, directing an energy beam over said substrate causing said first powder layer to fuse in selected locations forming a first cross section of said three-dimensional article, providing a second powder layer on said substrate, directing the energy beam over said substrate causing said second powder layer to fuse in selected locations to form a second cross section of said three-dimensional article. A first and second image of a first and second fusion zone of said first powder layer respectively is captured. Comparing said first and second images with corresponding layers in said model. Detecting a defect in the three-dimensional article if a deviation in said first image with respect to said model is at least partially overlapping a deviation in said second image with respect to said model.

Owner:ARCAM AB

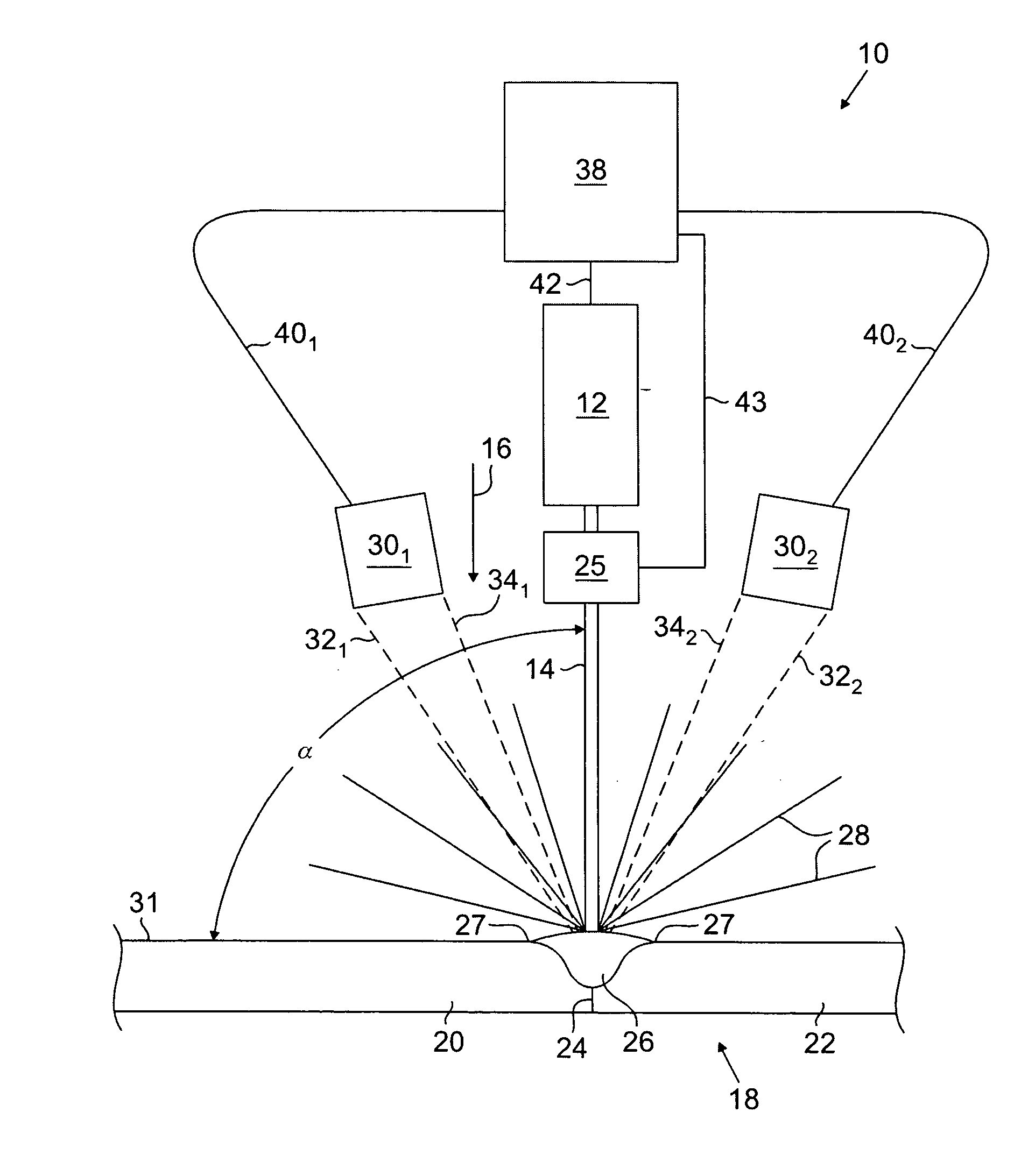

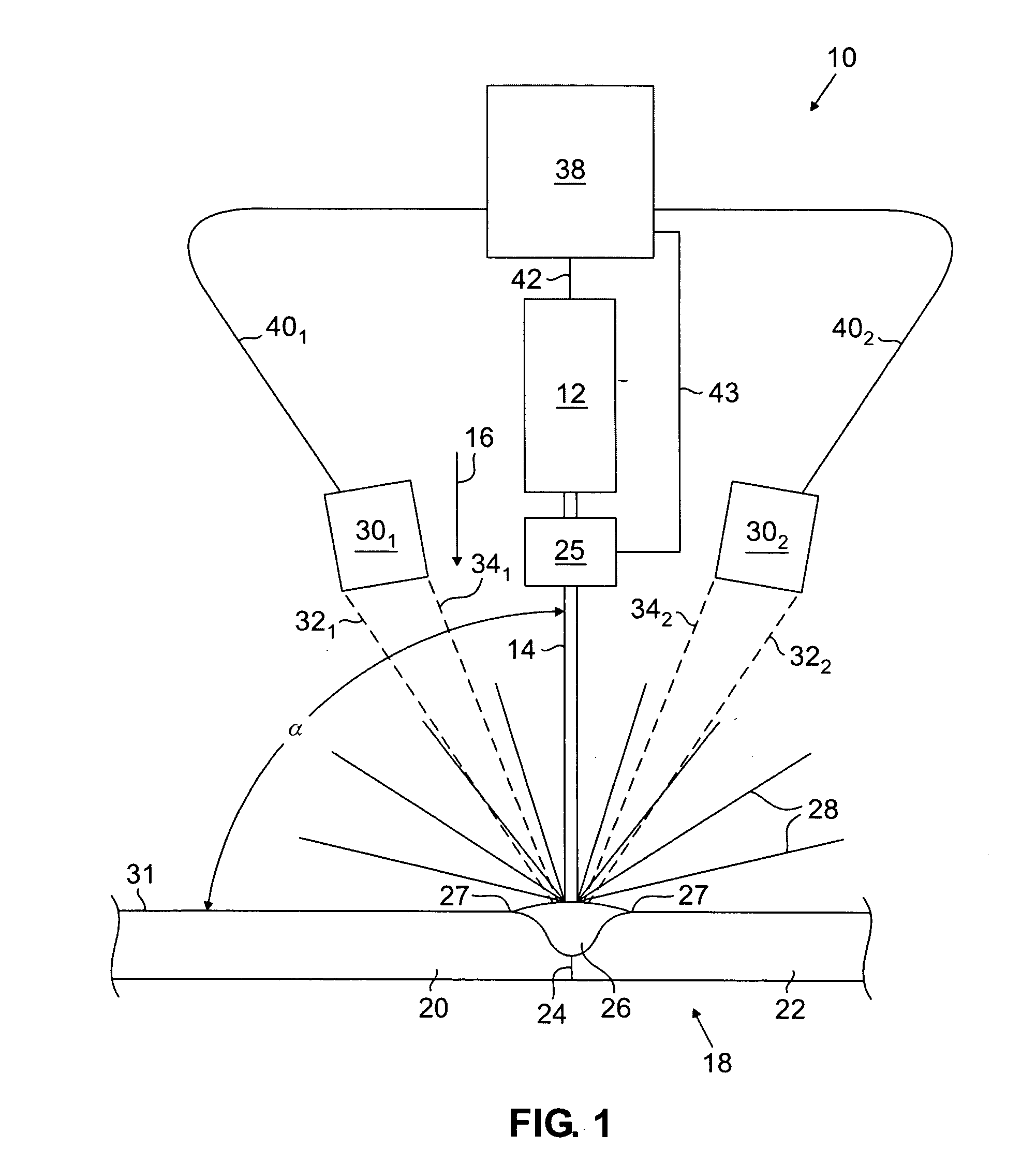

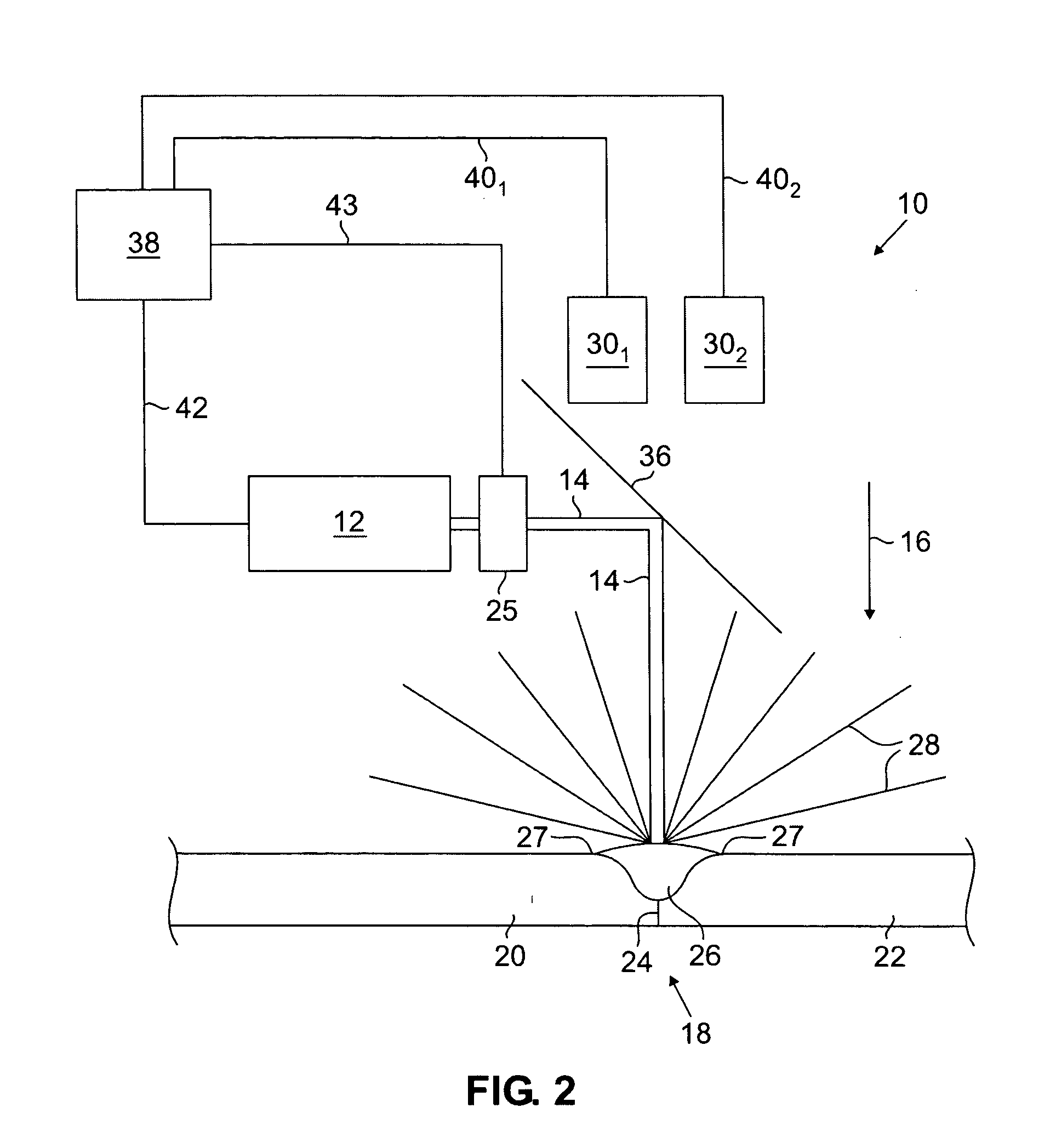

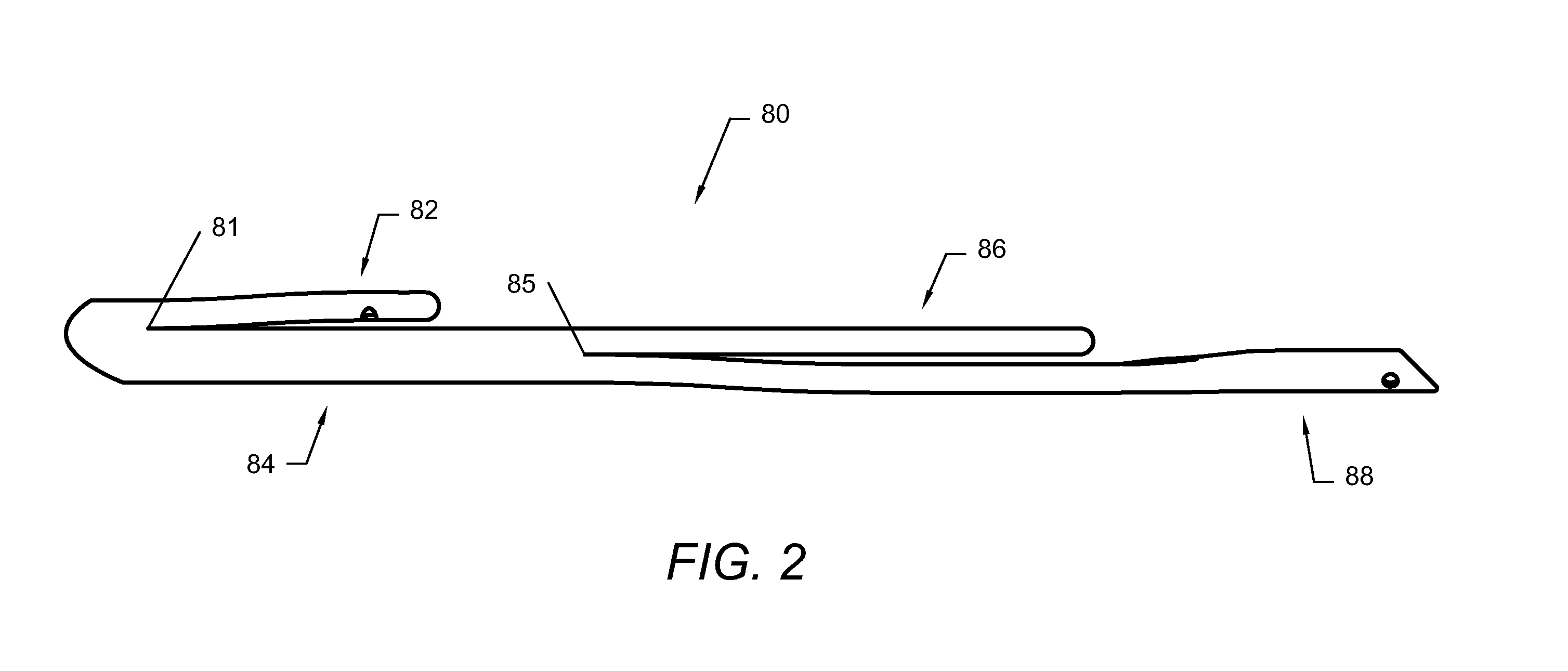

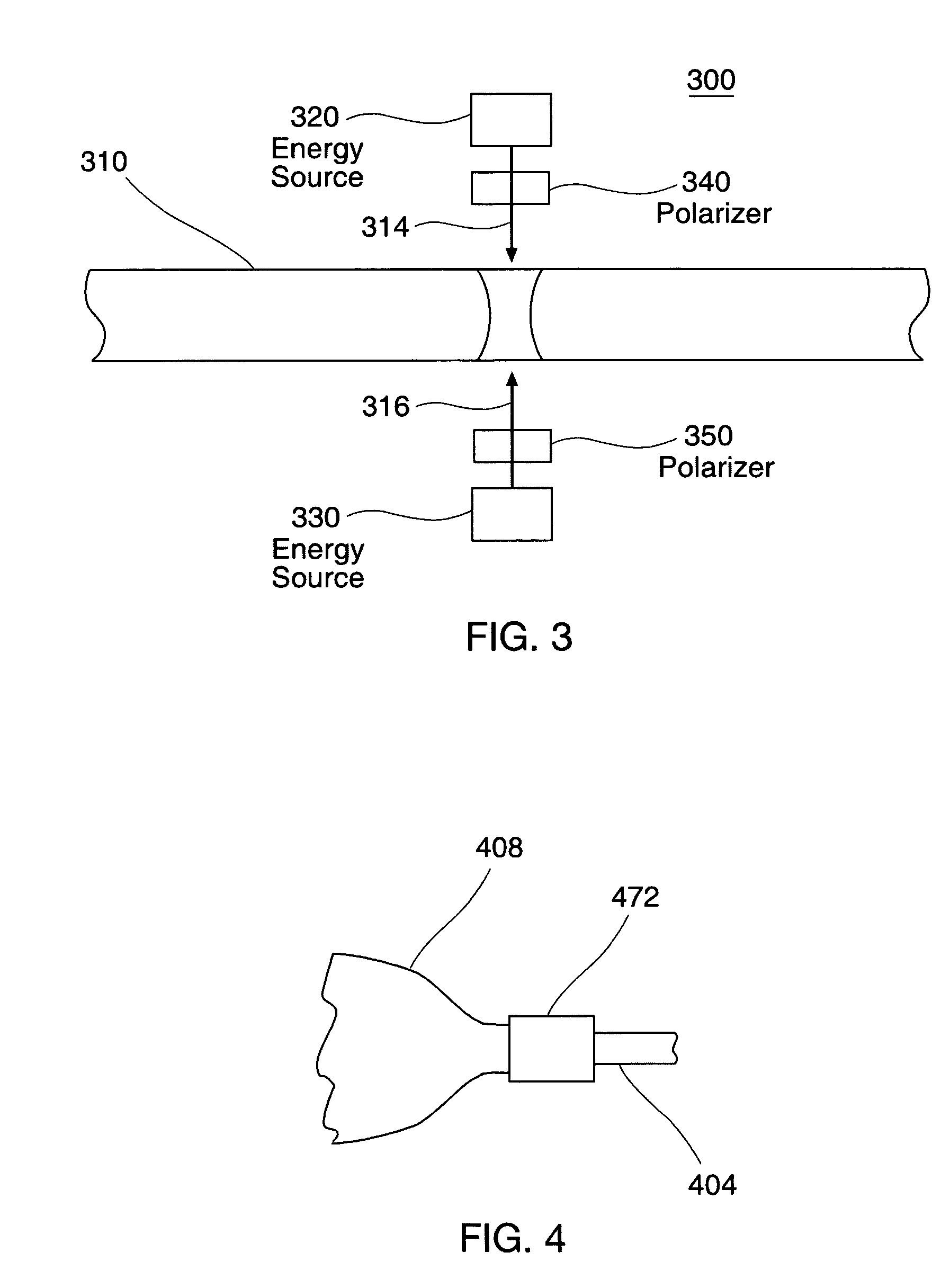

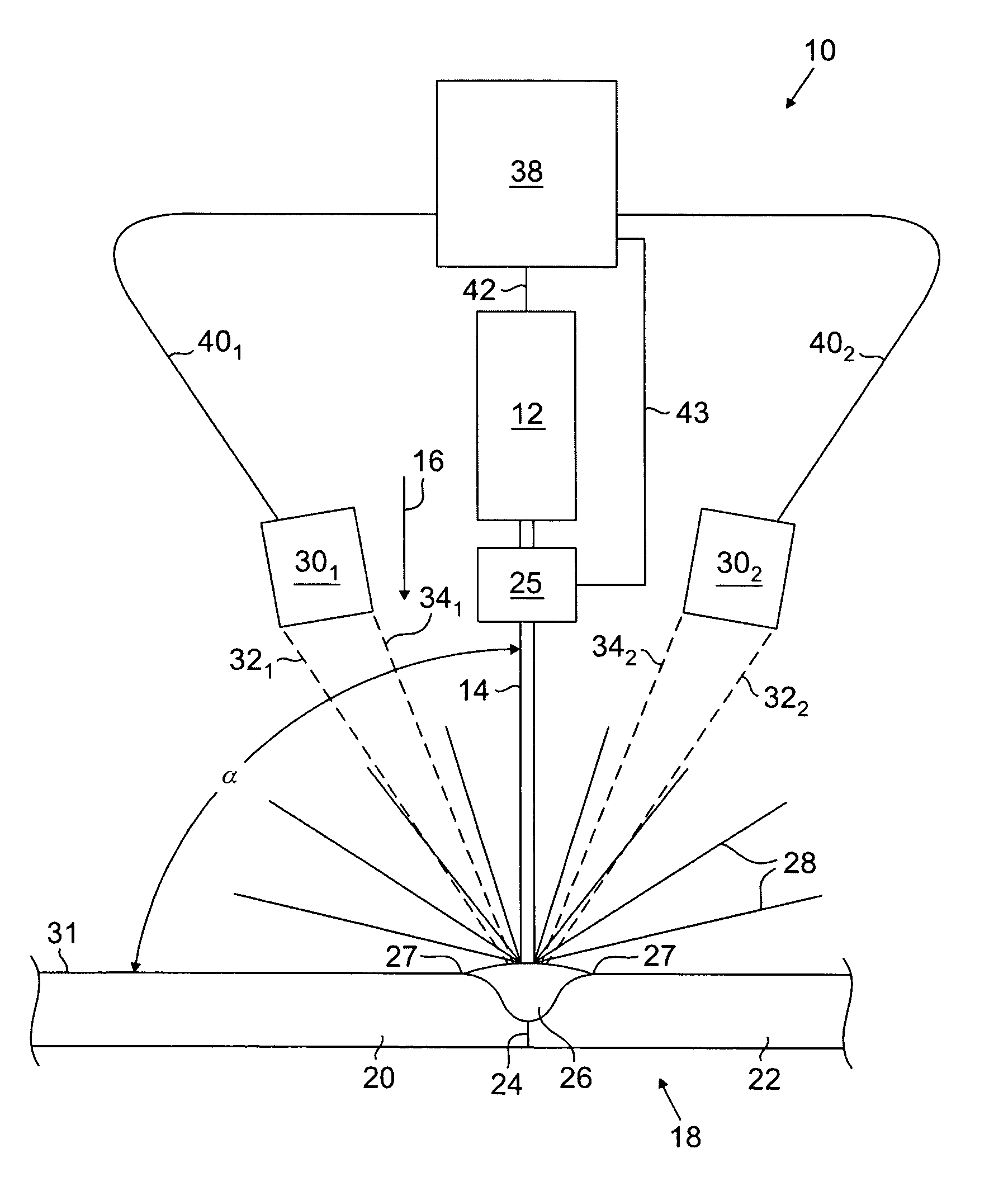

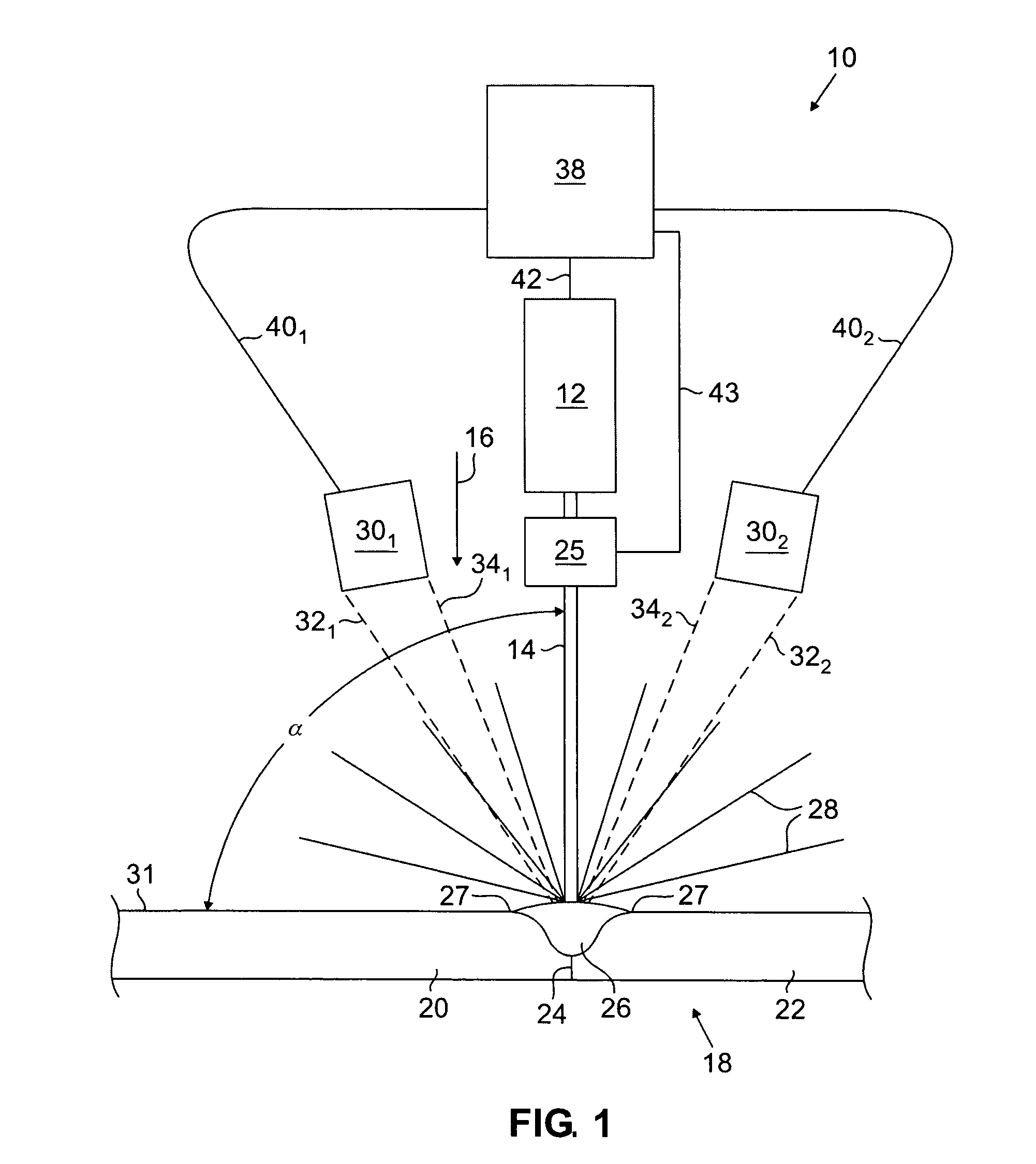

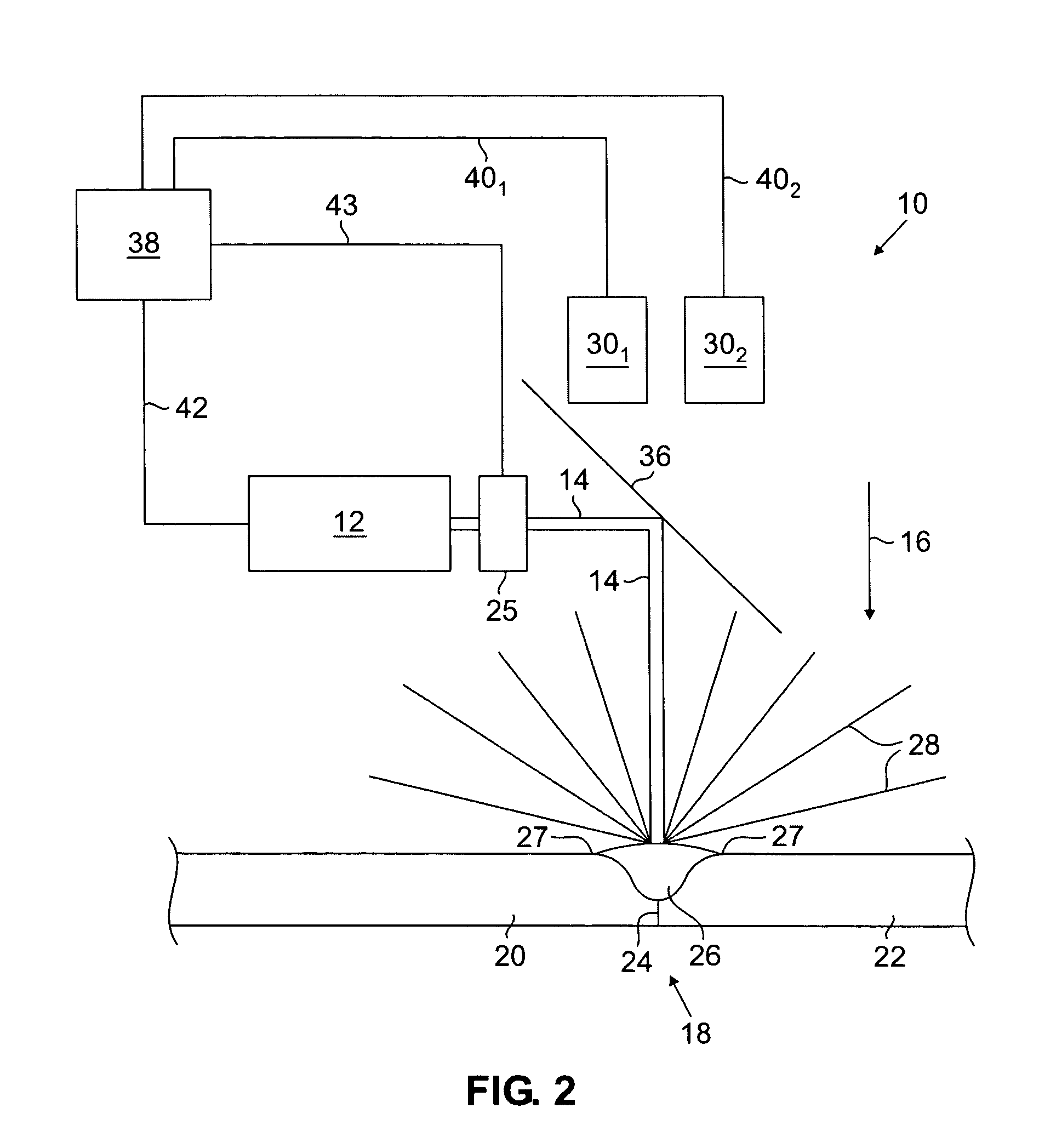

Method and apparatus for controlling and adjusting the intensity profile of a laser beam employed in a laser welder for welding polymeric and metallic components

InactiveUS20060000812A1Enhanced signalImprove signal-to-noise ratioMechanical working/deformationLamination ancillary operationsLight beamOptoelectronics

A method and apparatus is provided for forming a fusion bond between two materials such as two components of a catheter. The method begins by forming a bond site by positioning a portion of a first body with respect to a portion of a second body so that a fusion bond site is formed. A laser beam is generated that has an intensity profile across its width. The laser beam is directed onto at least a portion of the first and second bodies within the bond site so that a fusion zone having an increased temperature is formed. After the laser beam is generated, the intensity profile of the laser beam that is directed onto the bond site is controllably adjusted by an optical element such as a dynamically-adjustable beam shaping element

Owner:BOSTON SCI SCIMED INC

Multi-lumen catheter with separate distal tips

ActiveUS20080021417A1Reduce deliveryImprove flow characteristicsMulti-lumen catheterOther blood circulation devicesDistal portionUltimate tensile strength

A multi-lumen catheter including tip sections distal to a dividing point, the tip sections releasably joined by a method that produces a variable separation force between the tip sections along a length thereof. An increasing separation force may be imparted to the tip sections by providing an increasing bond strength in fusion zones from a distal portion of the tip sections toward the dividing point.

Owner:CR BARD INC

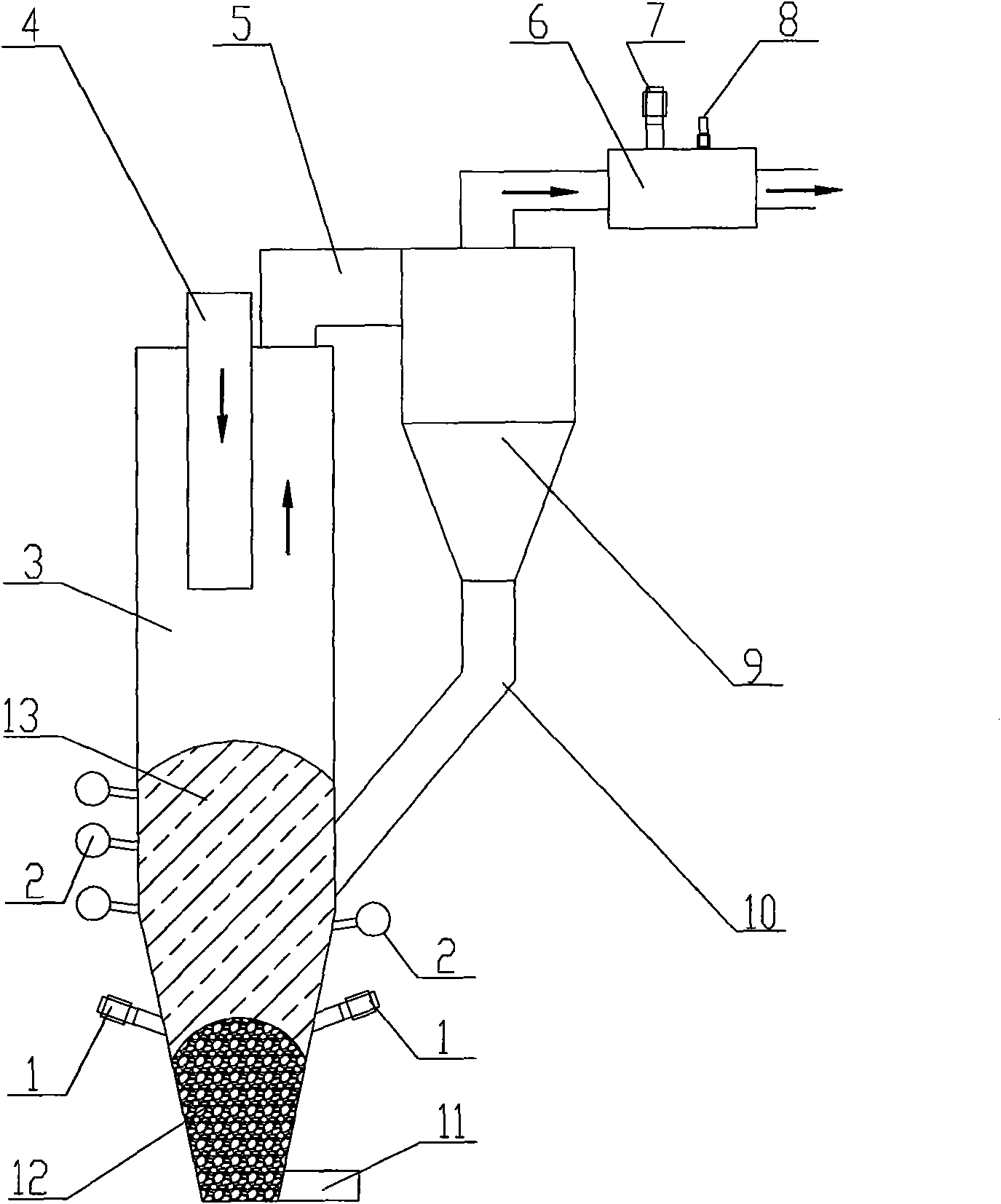

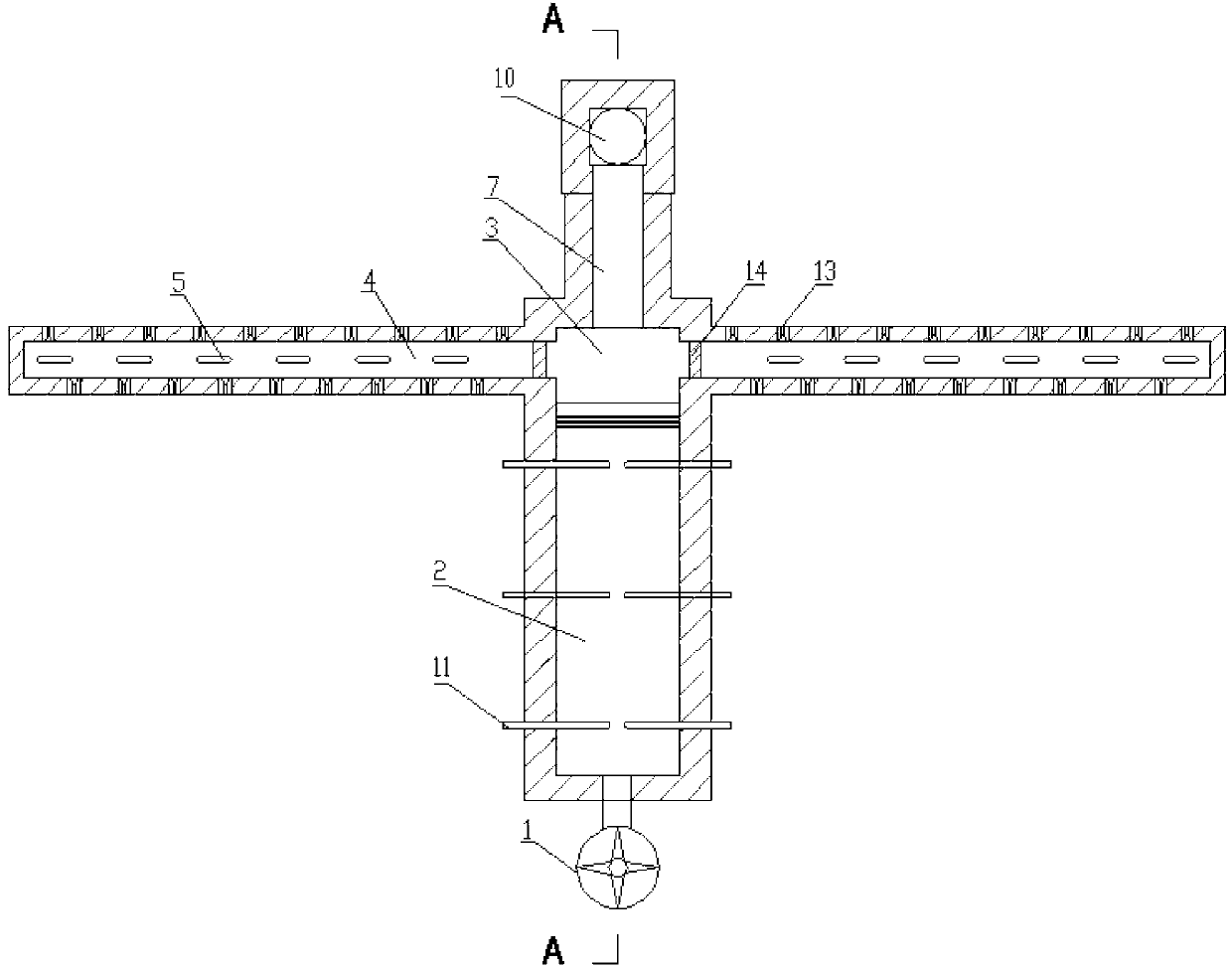

Combustible material plasma high-temperature gasification technique and equipment thereof

ActiveCN101671578AImprove gasification efficiencyImprove carbon conversionCombined combustion mitigationFixed-bed gasificationSyngasSlag

The invention relates to a combustible material plasma high-temperature gasification technique and equipment thereof. The technique comprises the following steps: firstly, laying a coke bed layer at the bottom part of a gasification furnace; secondly, putting the combustible material, a fluxing agent and an extra coke on the coke bed layer continuously to form a fuel bed layer; then injecting a primary oxidizing agent, starting a first-stage plasma torch to generate high temperature and high heat, forming a fusing zone at the joint of the coke bed layer and the fuel bed layer, forming a gasifying zone above the fusion zone, gasifying the combustible material to generate crude synthesis gas, and discharging the generated fused slag from the bottom part of the gasification furnace; then introducing the crude synthesis gas into a gas-solid separator for removing impurities to obtain purified synthesis gas; and finally introducing the purified synthesis gas into a detarrer, injecting a secondary oxidizing agent, starting a second-stage plasma torch to generate high temperature and high heat, cracking residual tar therein to obtain fined synthesis gas. The equipment mainly comprises three parts, namely the gasification furnace, the gas-solid separator and the detarrer. The fuel has good adaptability, high gasification efficiency, few tar content in the synthesis gas and high activeingredient.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

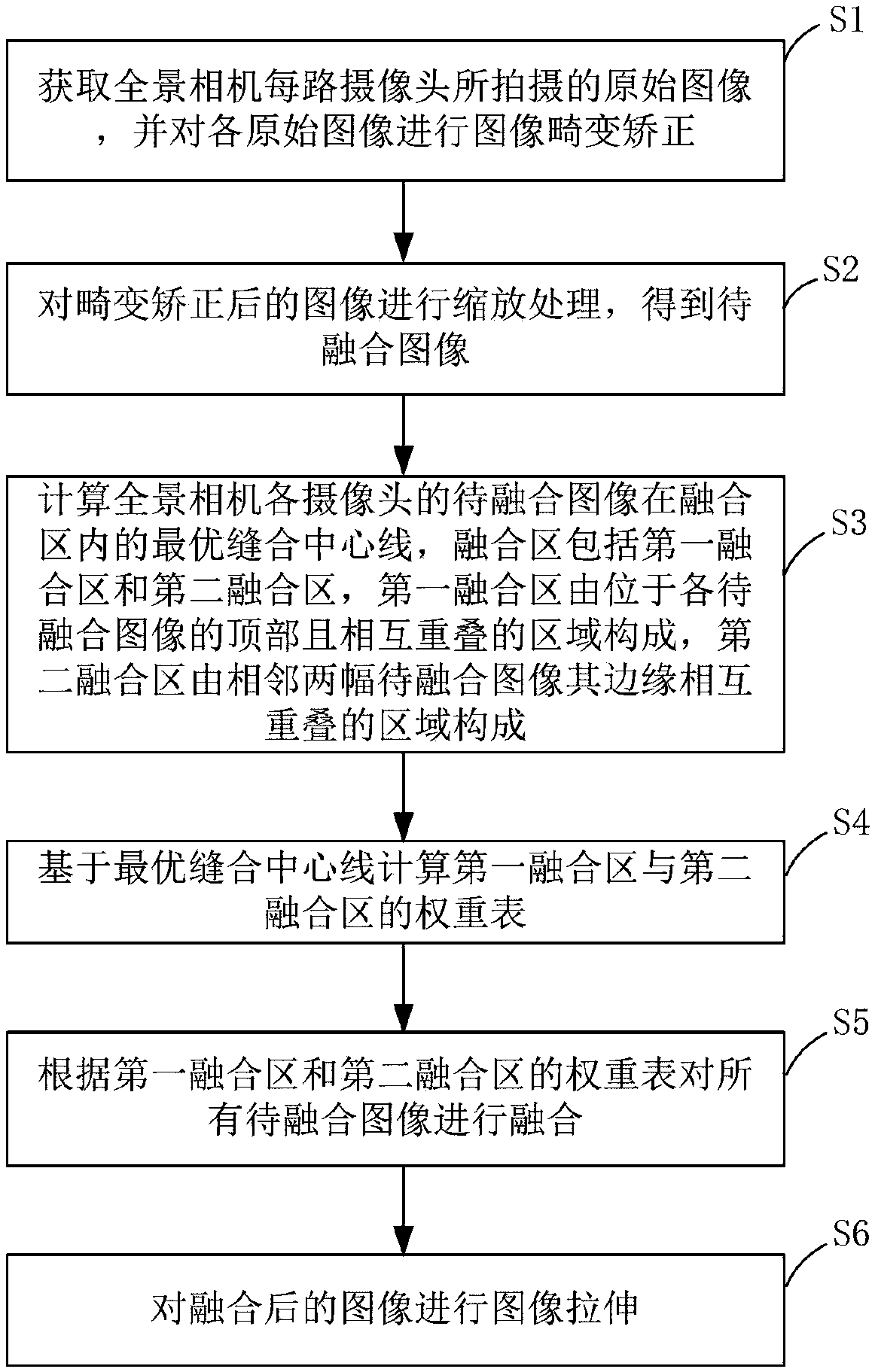

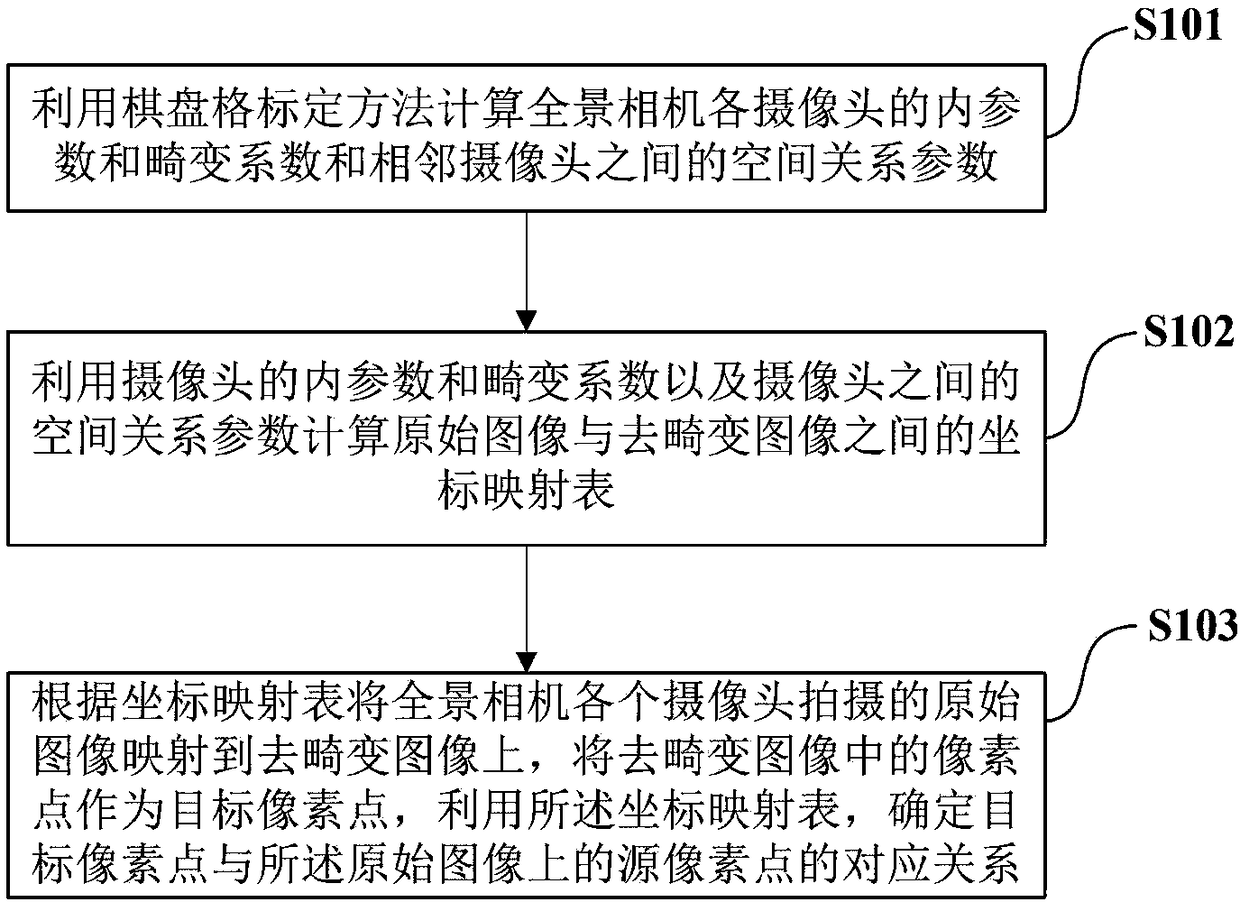

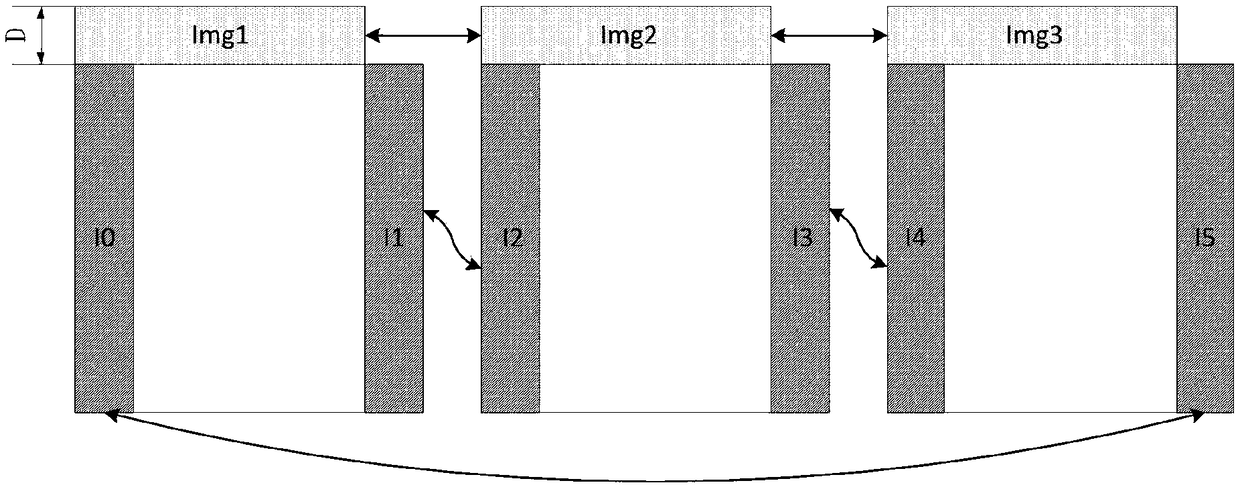

Panoramic image stitching method

A panoramic image stitching method is provided. The method comprises the steps of: acquiring an original image taken by each camera of a panoramic camera, and performing image distortion correction oneach original image; performing scaling processing on the image after being subjected to the distortion correction to obtain a to-be-fused image; calculating an optimal stitching center line of the to-be-fused image of each camera of the panoramic camera, in a fusion zone, wherein the fusion zone comprises a first fusion zone and a second fusion zone, the first fusion zone is composed of regionswhich are located at the tops of different to-be-fused images and overlap each other, and the second fusion zone is composed of the regions overlapping on the edges of two adjacent to-be-fused images;calculating a weight table of the first fusion zone and the second fusion zone based on the optimal stitching center line; according to the weight table of the first fusion zone and the second fusionzone, fusing all the to-be-fused images; and performing image stretching on the fused image. According to the panoramic image stitching method provided by the present invention, gentle transition isrealized, and the image stitching looks more natural.

Owner:CHANGSHA PANODUX TECH CO LTD

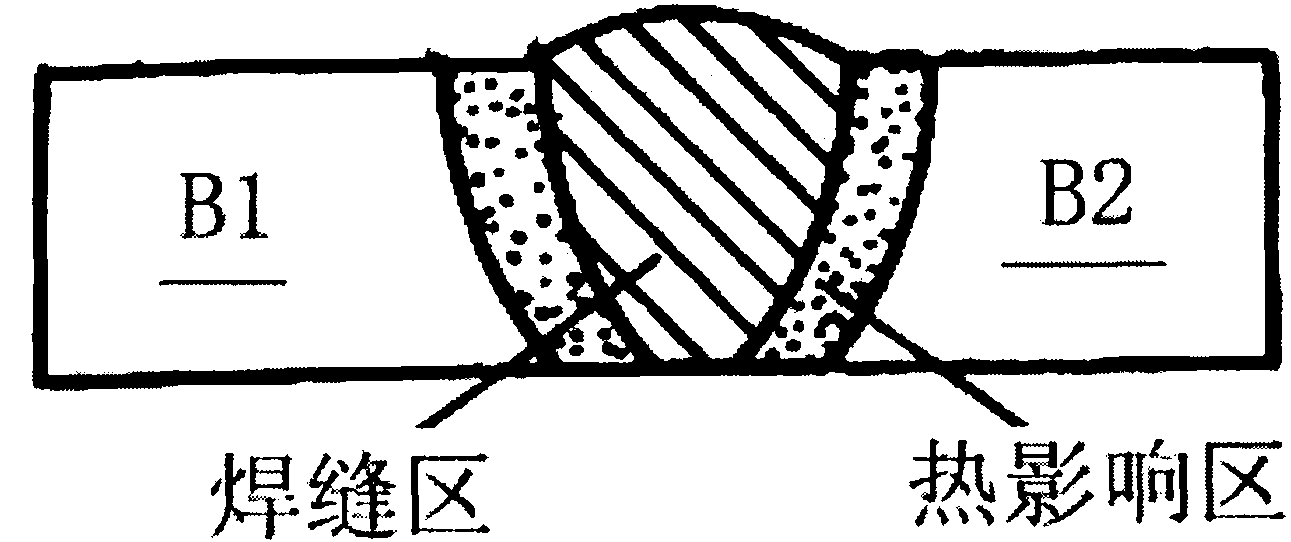

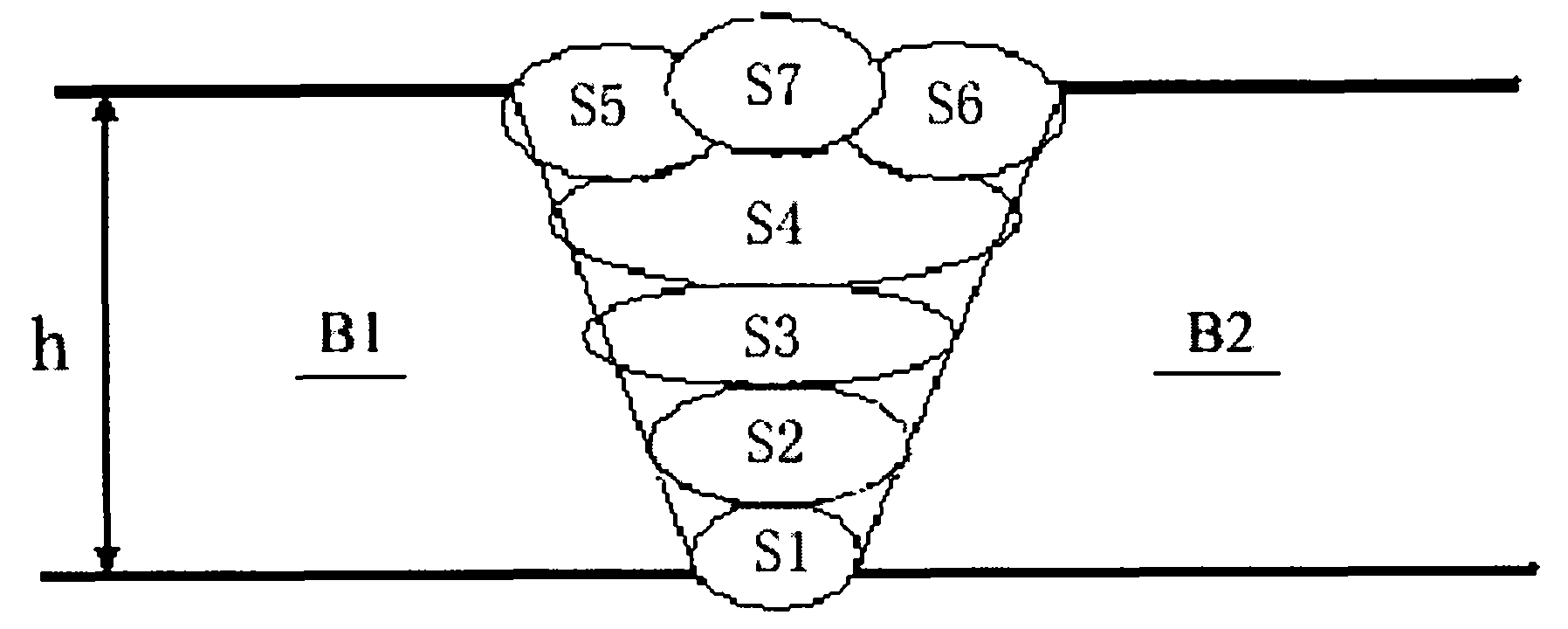

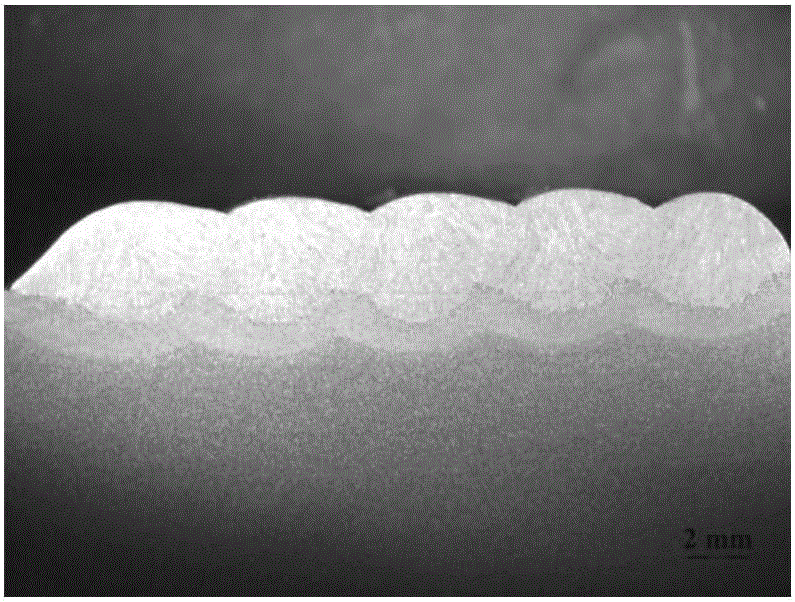

Method for welding steel plate by multi-layer welding

The invention discloses a method for welding a steel plate by multi-layer welding. The method comprises priming welding, filling welding and cosmetic welding, wherein the cosmetic welding comprises the steps of respectively performing first pass welding and second pass welding on the surfaces of two steel plates to be welded so as to form a first-pass weld pass and a second-pass weld pass, then performing third pass welding on the first-pass weld pass and the second-pass weld pass to form a third-pass weld pass connecting the first-pass weld pass and the second-pass weld pass. The method for welding the steel plate by multi-layer welding can play the role of slowing down the cooling of the first-pass weld pass and the second-pass weld pass through the third-pass weld pass, and simultaneously, normalizing is carried out on welding points. After being austenitized, the steel plate tissues in a heat affected zone and a fusion zone slowly cool down, so that the welding points form pearlite tissues with fine pearlites, thereby improving the mechanical properties of the welding points such as toughness and the like.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +3

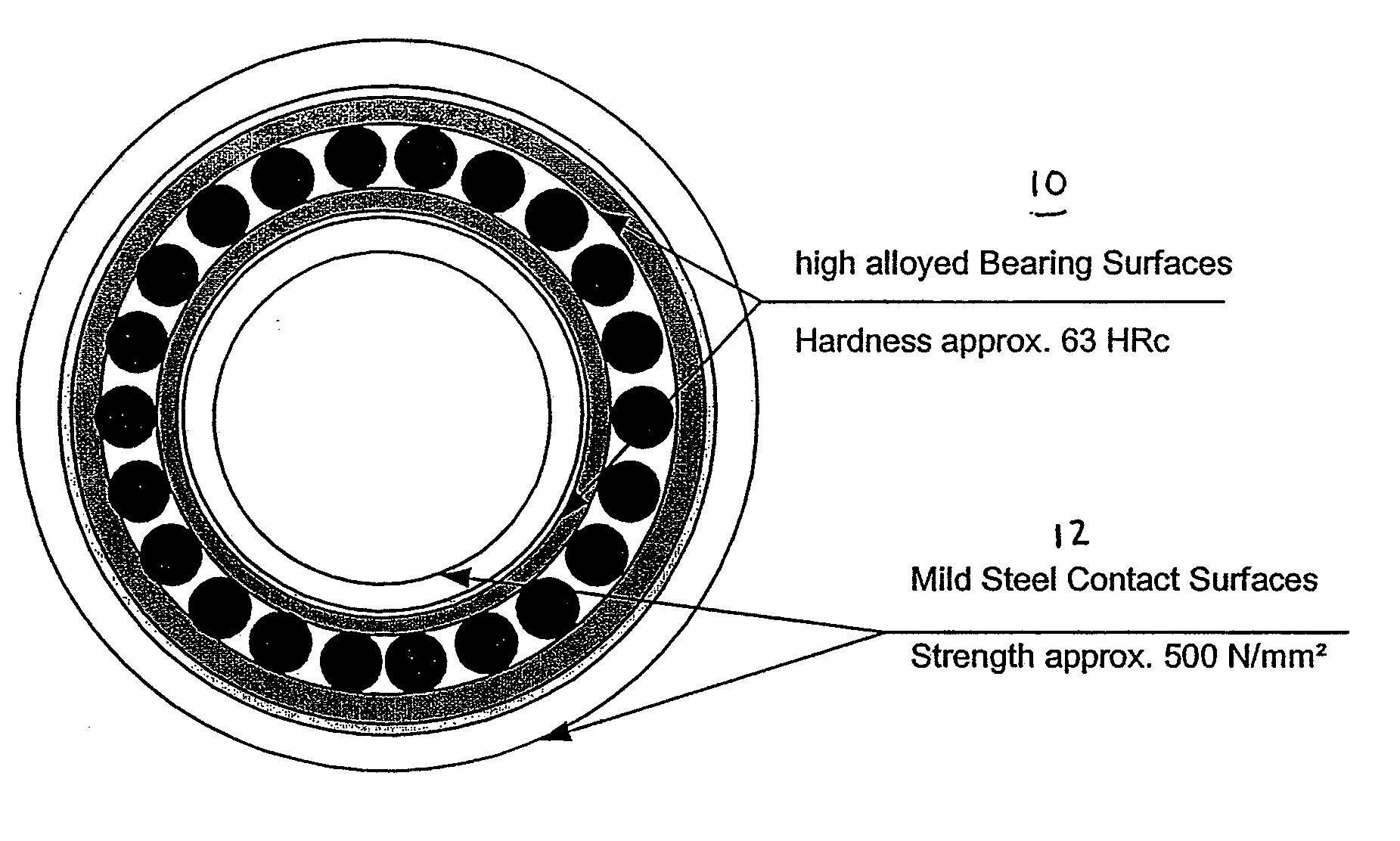

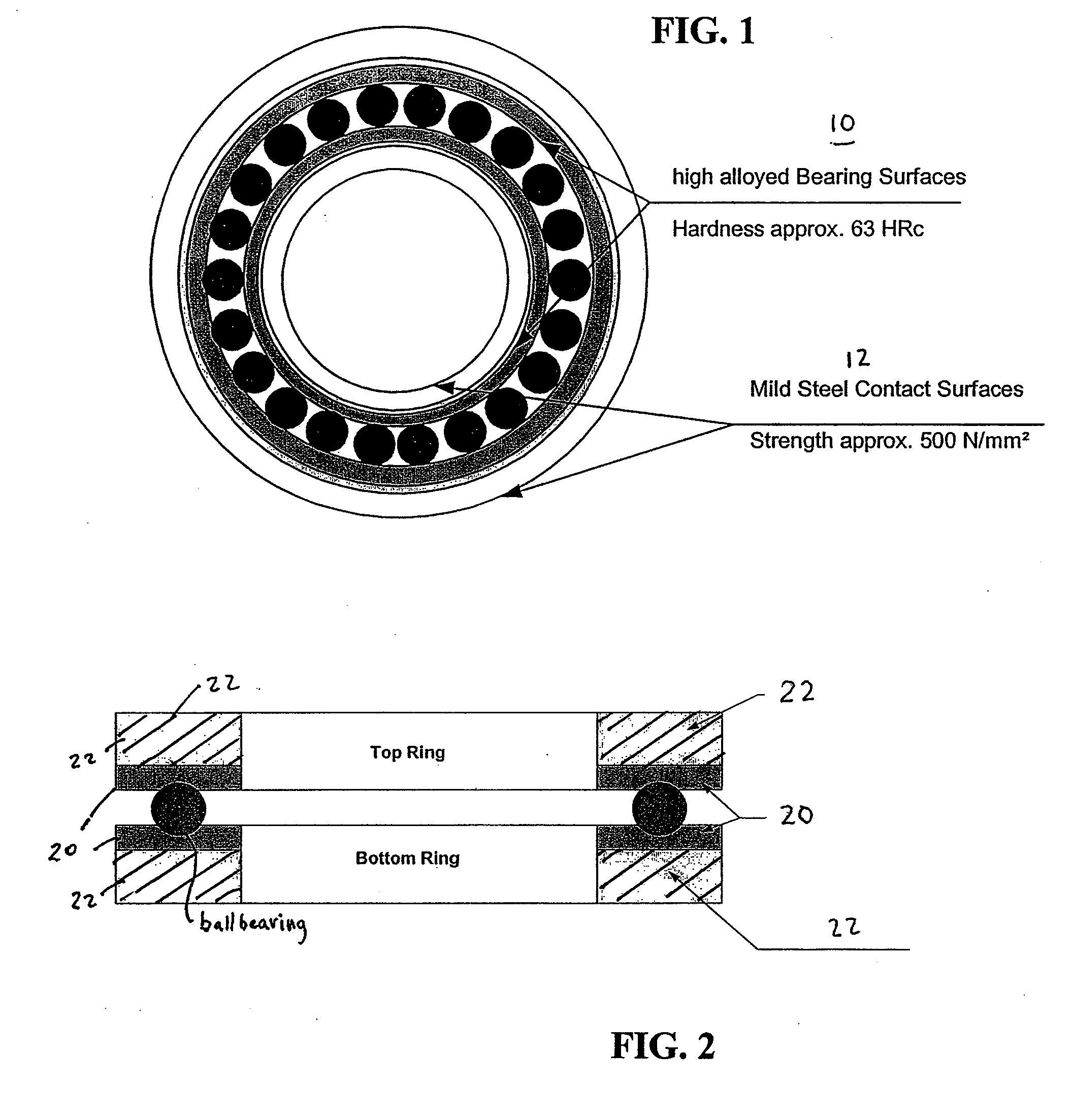

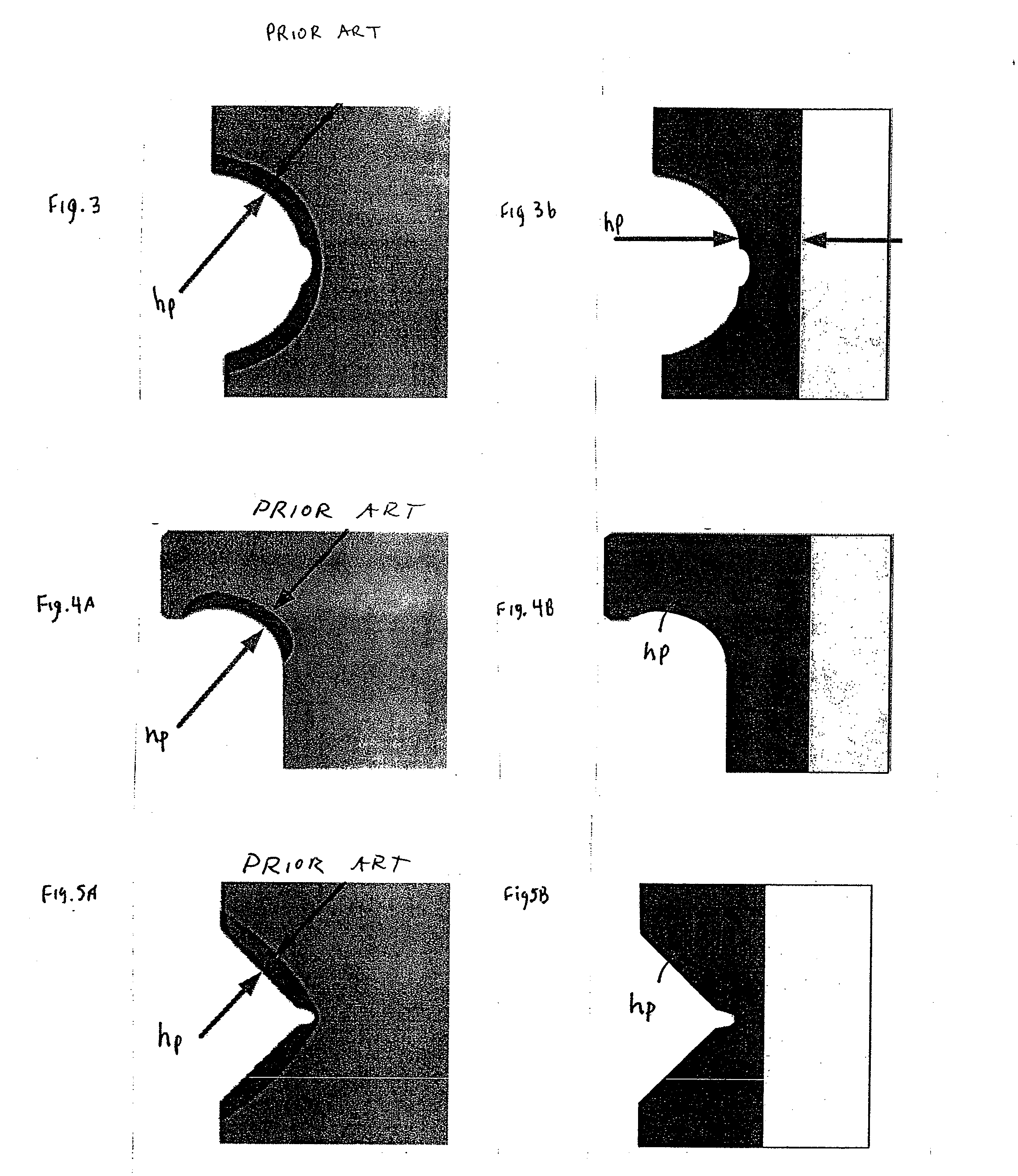

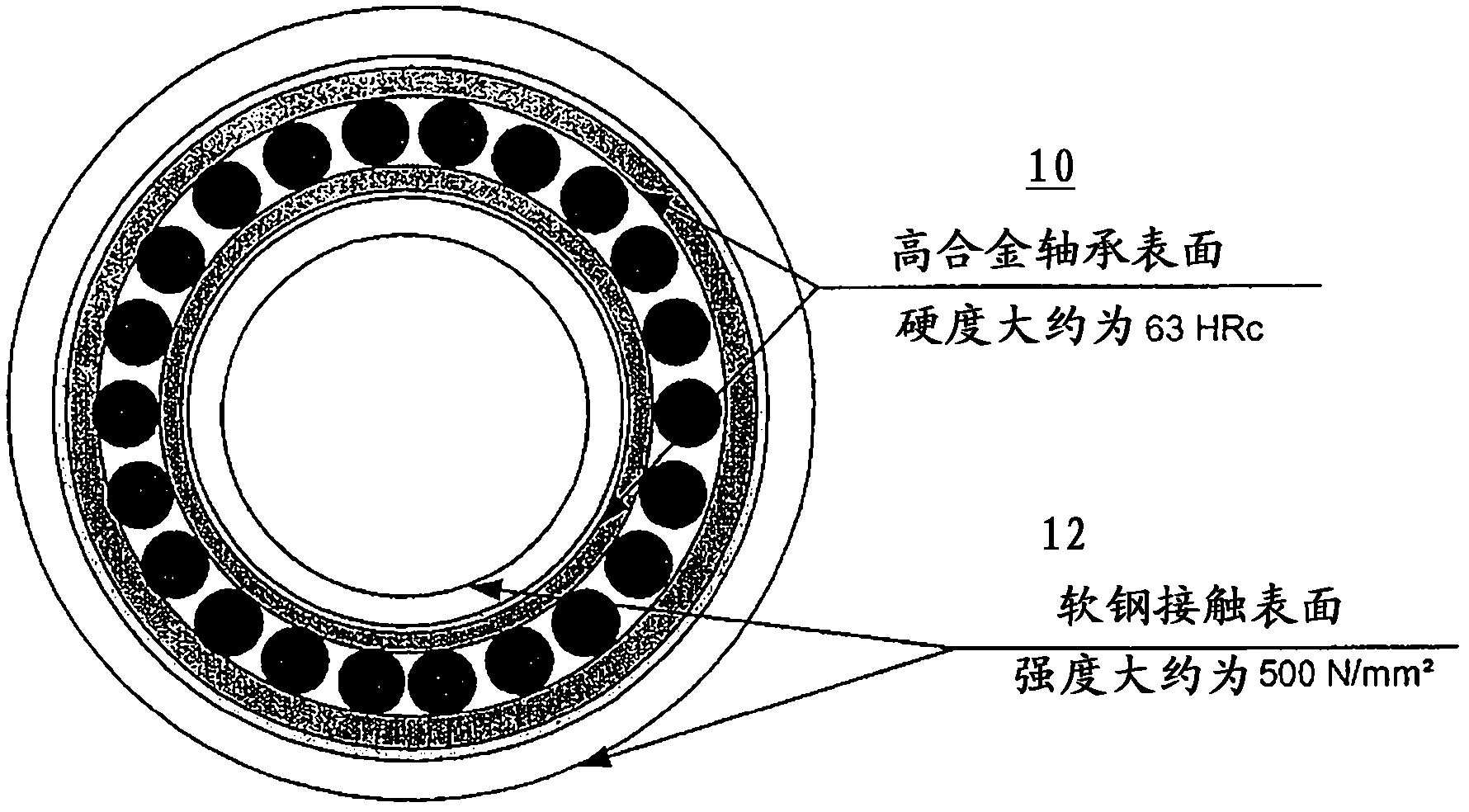

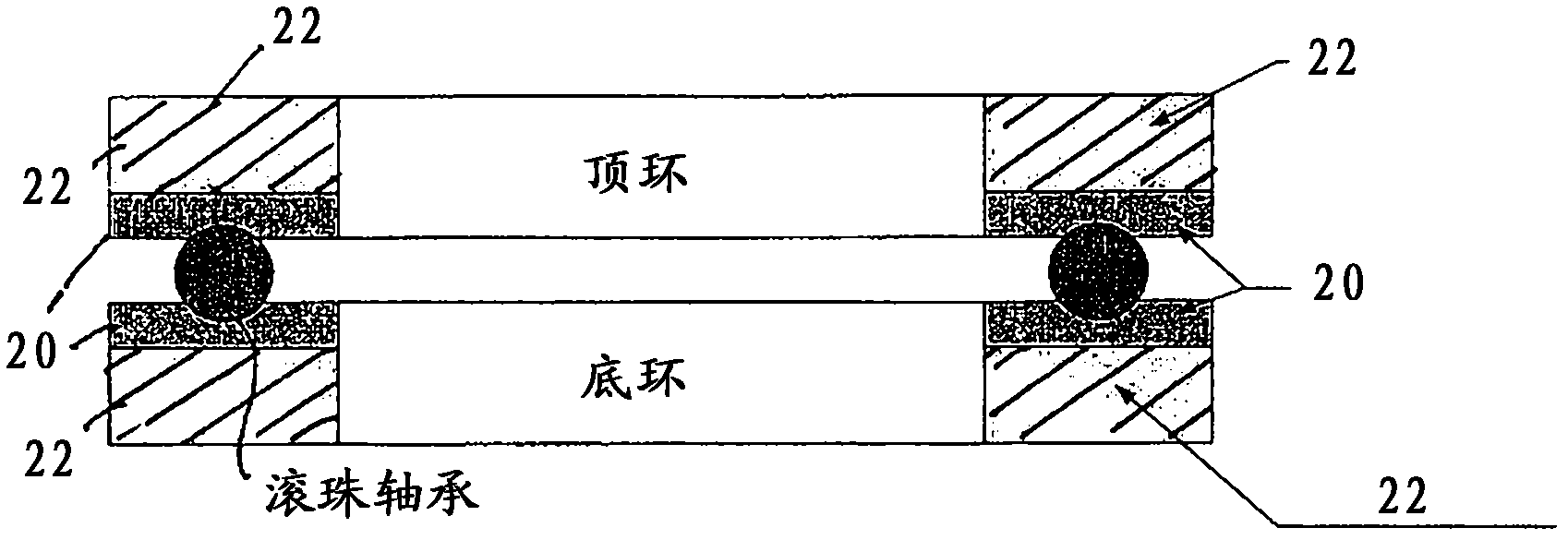

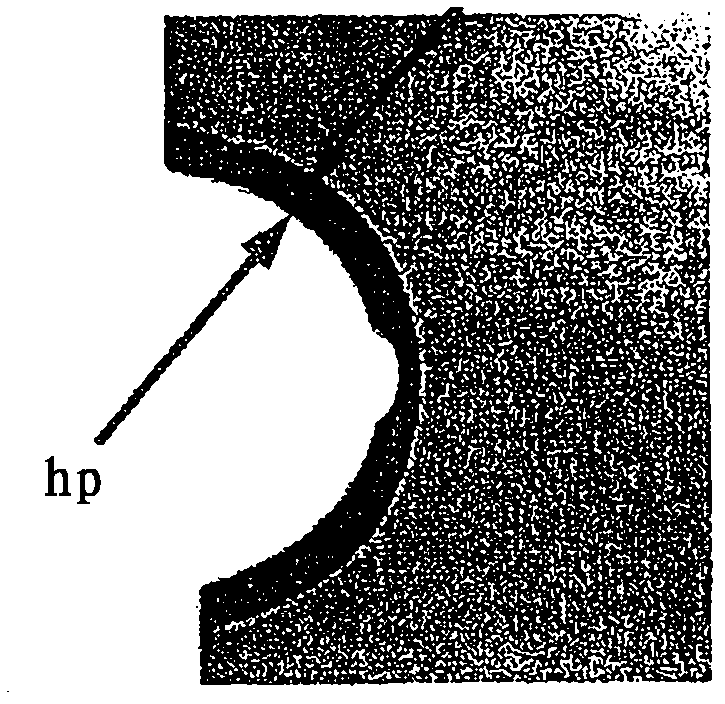

Compound Steel Bearings and Methods of Manufacturing

InactiveUS20110311362A1Avoid excessive hardnessImprove ductilityPropellersPump componentsMetallurgyFusion zone

A bearing comprising a high tensile steel layer and a mild steel base layer with said layers being fused together across a fusion zone, a raceway machined across the bearing, with said raceway having a bearing support depth which is substantially greater than a bearing support depth obtainable using traditional steel hardening processes, and a retention structure machined into at least the mild steel base layer and utilized to retain the bearing to an underlying bearing support.

Owner:CORTS JOCHEN

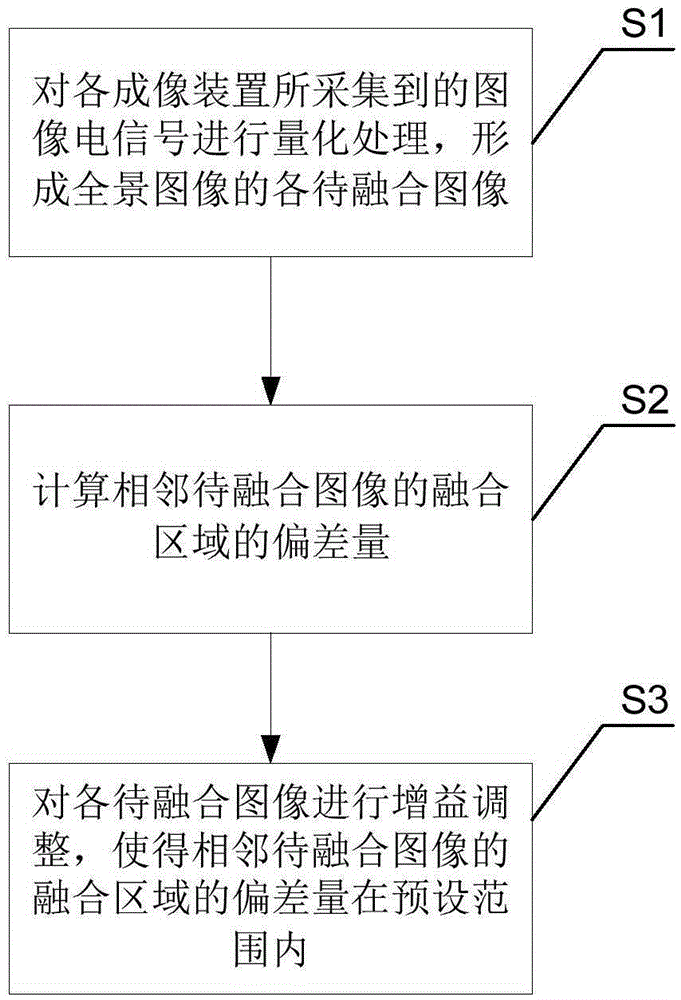

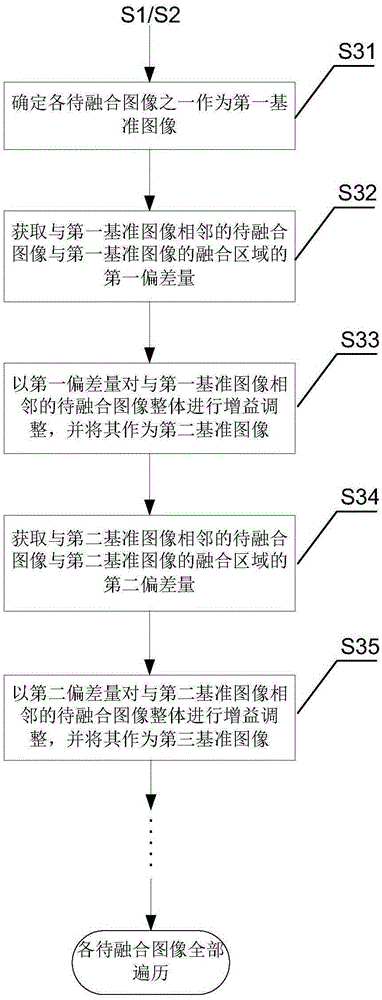

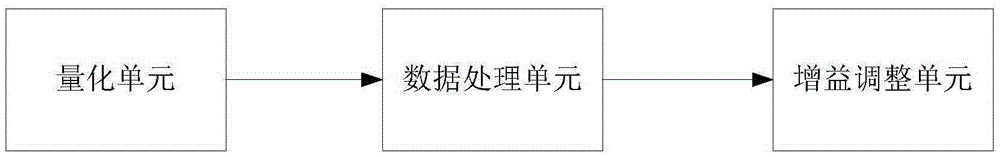

Method and system for overcoming abrupt color change in image fusion processes

ActiveCN105894449AUniform output brightnessUniform chromaticityImage enhancementImage analysisImaging processingResource consumption

The invention discloses a method and system for overcoming abrupt color change in image fusion processes and a panorama device. The method is suitable for the panorama device comprising N imaging apparatuses and comprises the following steps: electric image signals collected by all image apparatuses are subjected to quantification operation, all images to be fused of a panorama image are formed, deviation amounts of fusion zones of adjacent images to be fused are calculated, all the images to be fused are subjected to gain adjustment operation, and the deviation amounts of the fusion zones of the adjacent images to be fused are enabled to be in a preset scope. Via use of a technical solution provided of the method and system for overcoming abrupt color change in image fusion processes, all fusion zones of the adjacent images to be fused can be enabled to be basically same in output brightness and chromaticity; problems of effectiveness, excessive resource consumption and processing efficiency caused by brightness and chromaticity adjustment realized via an image processing algorithm can be overcome.

Owner:FAFA AUTOMOBILE (CHINA) CO LTD

Method for measuring temperature field in laser welding process

ActiveCN102967374AUnquestionable accuracyAccurate dataRadiation pyrometryLaser beam welding apparatusThermodynamicsMelting Point Temperature

The invention belongs to the technical field of measurement and relates to a method for measuring a temperature field in a laser welding process. In the laser welding process, a fusion line of a welding joint section and a represented temperature value (a material melting point temperature value) during metal welding are utilized, so that a method for measuring the temperature field in the laser welding process is designed, the thermal imagery and temperature field obtained by utilizing the conventional thermal infrared imager and software processing system thereof are accurately calibrated, and the important problems that the result of the temperature field obtained by the conventional thermal infrared image system has a large error compared with the actual result and an accurate calibration is absent because of the influence of essential factors such as metal steam / plasma radiation, fast temperature change and the like during the current laser welding are solved. The obstacle in the process of measuring the laser welding temperature field by utilizing the thermal infrared imager at present is offset, and a way is provided for accurately measuring the temperature field distribution of a fusion zone and a thermal influence area in the laser welding process.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

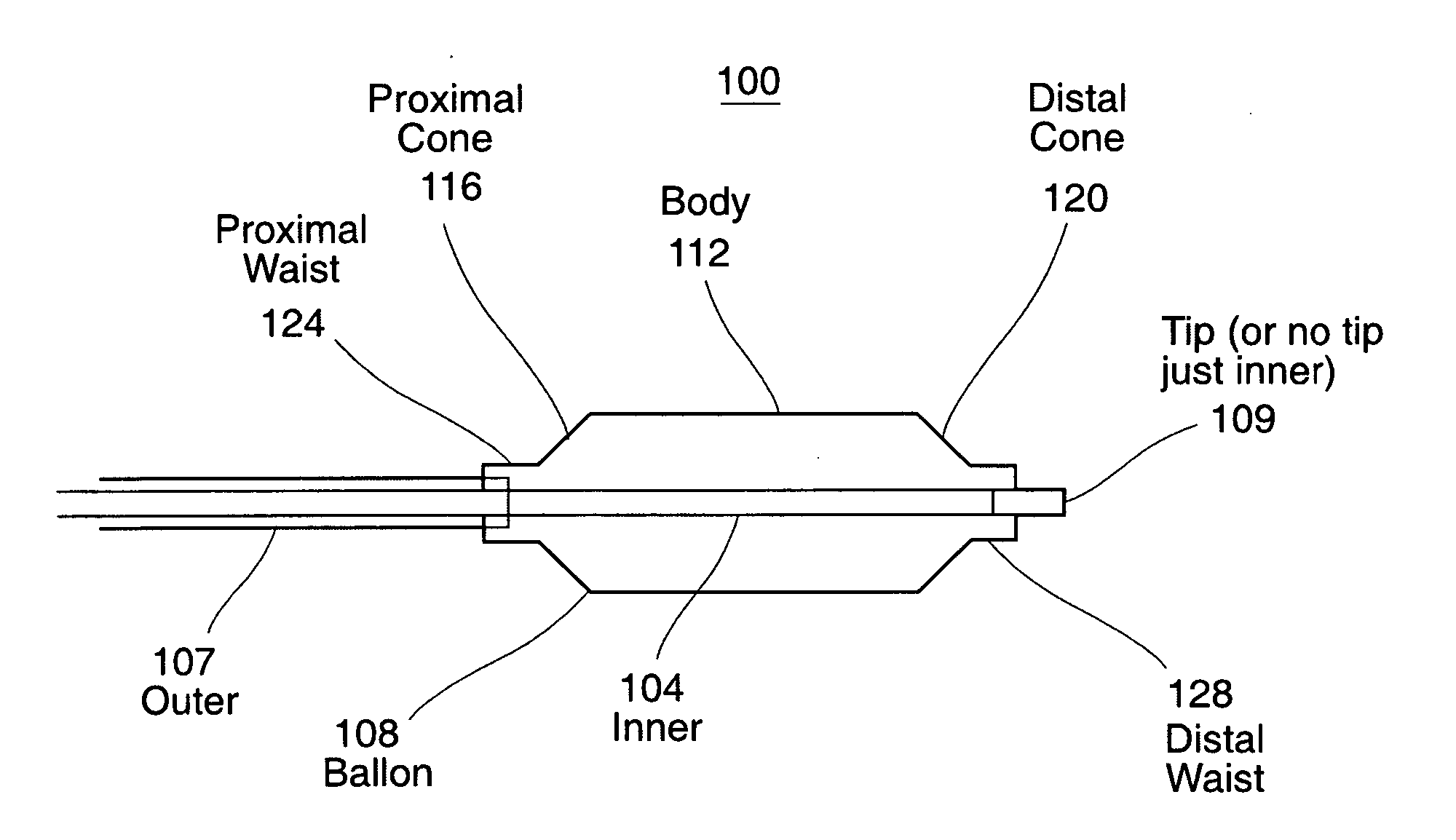

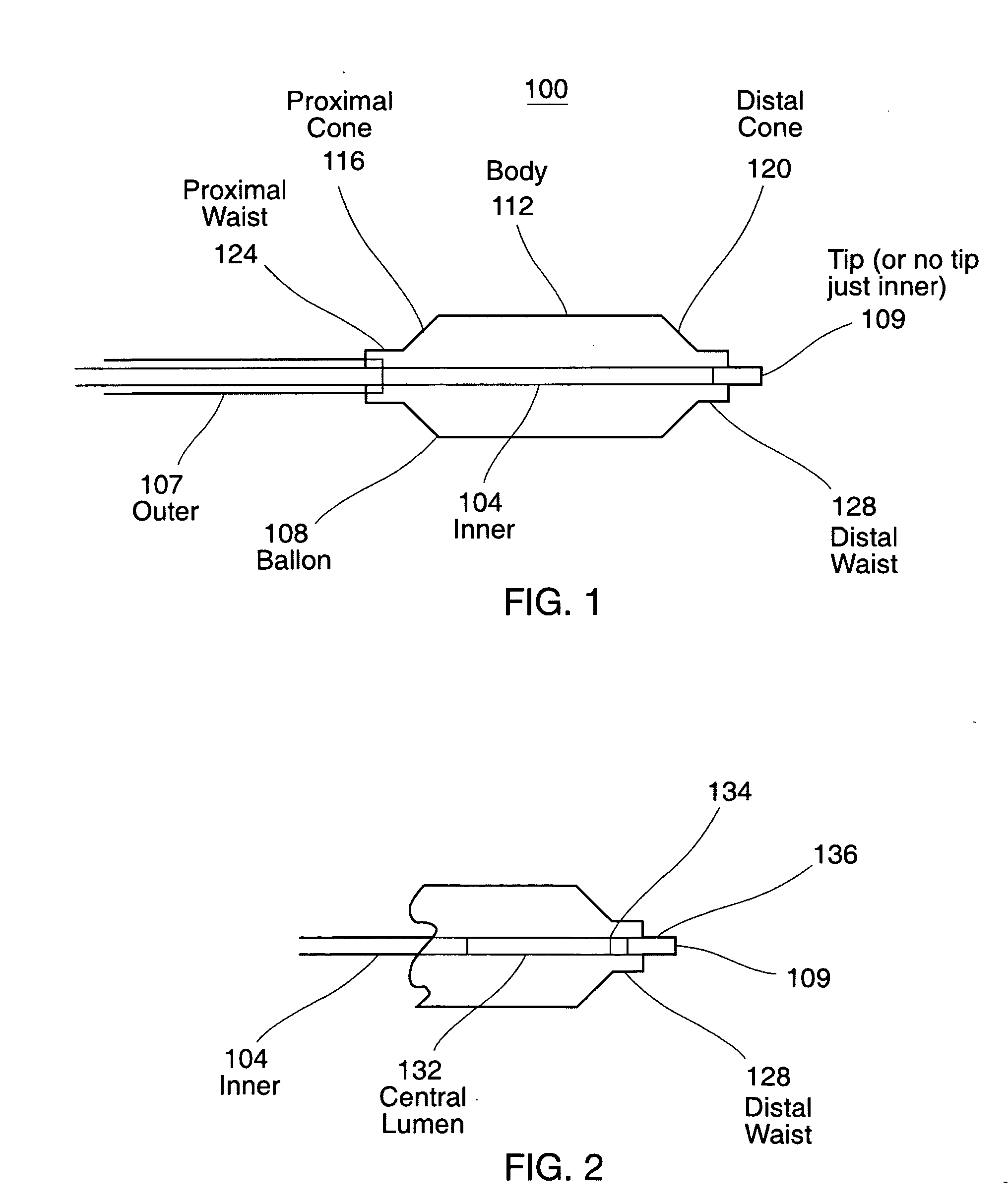

Method of applying one or more electromagnetic beams to form a fusion bond on a workpiece such as a medical device

A process and apparatus is provided for forming a fusion bond between two materials. The process begins by forming a bond site by positioning a portion of a first body with respect to a portion of a second body. The first and second bodies may be components of a medical device such as a catheter, for example. At least one collimated beam of electromagnetic energy is generated and directed onto portions of the first and second bodies within the bond site so that at least one fusion zone having an increased temperature is formed.

Owner:BOSTON SCI SCIMED INC

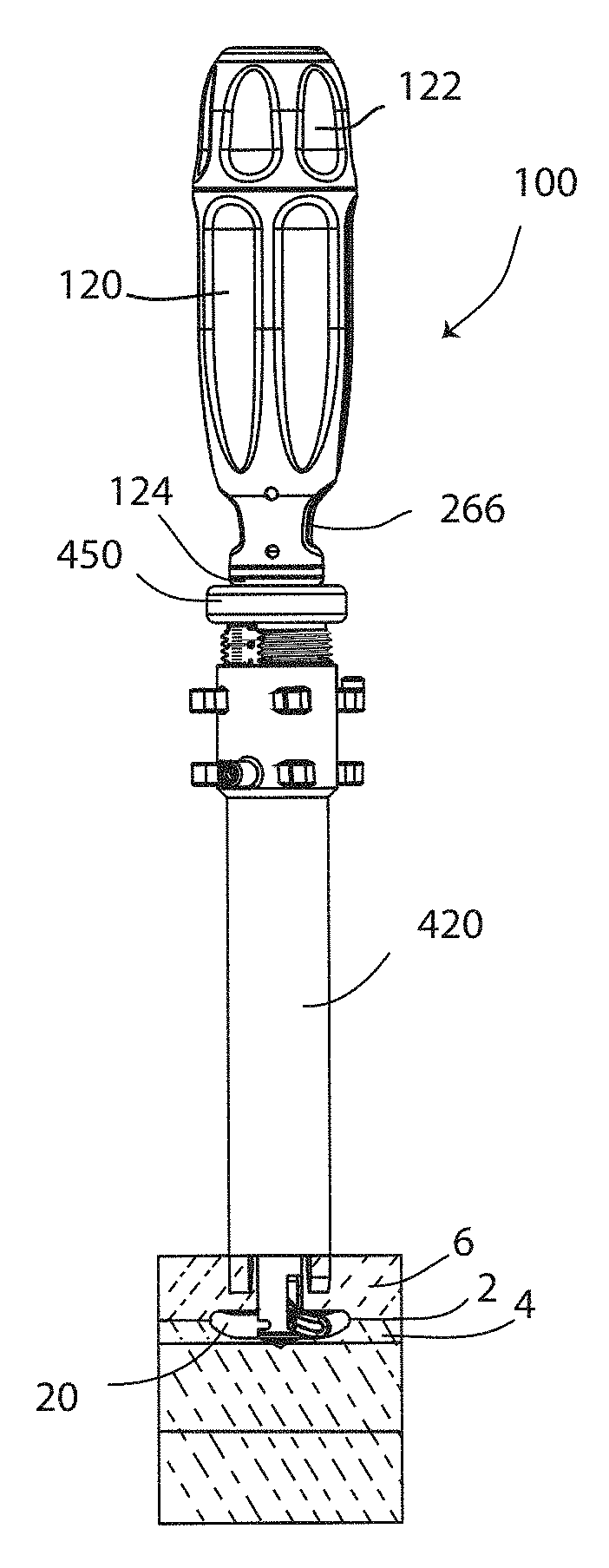

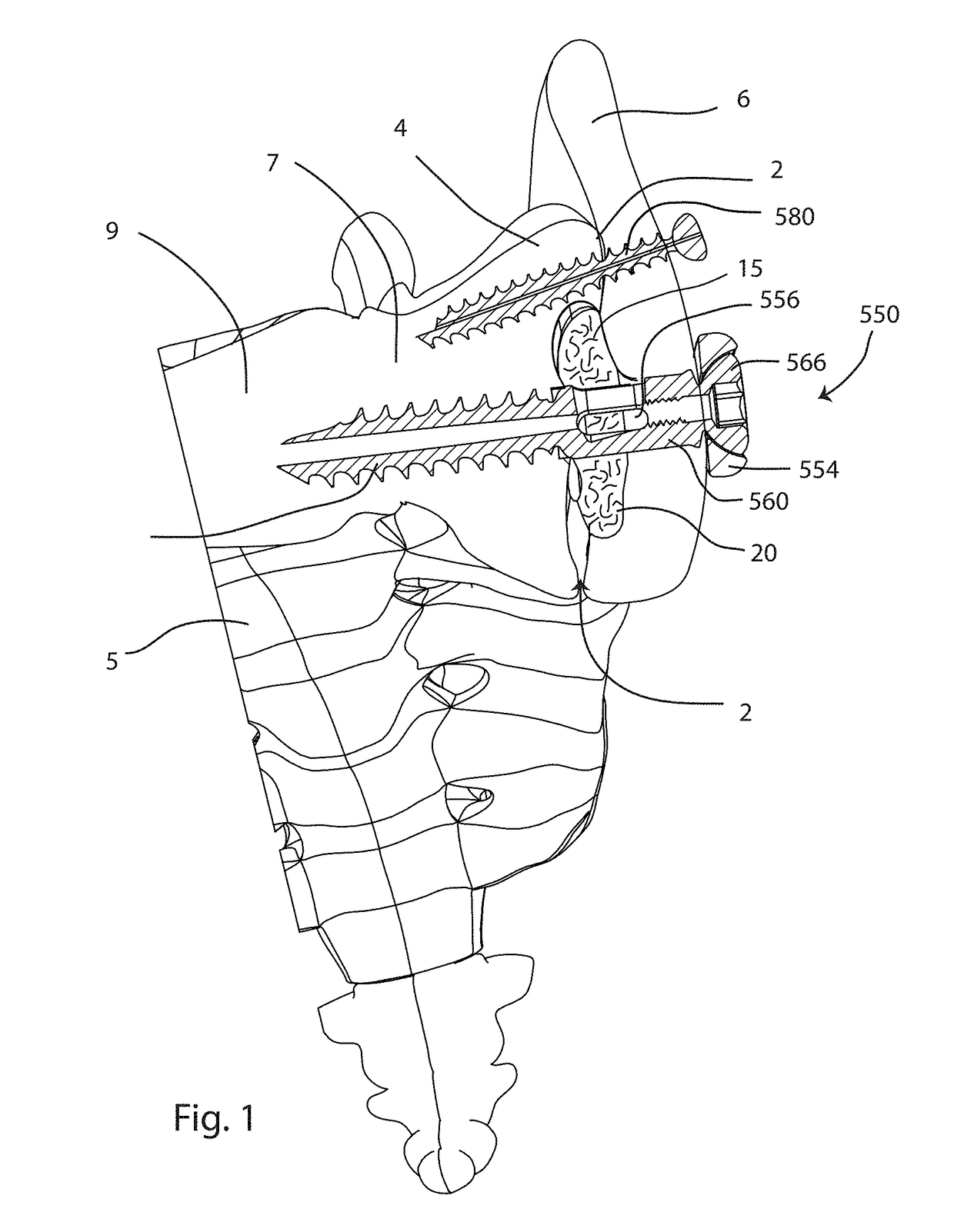

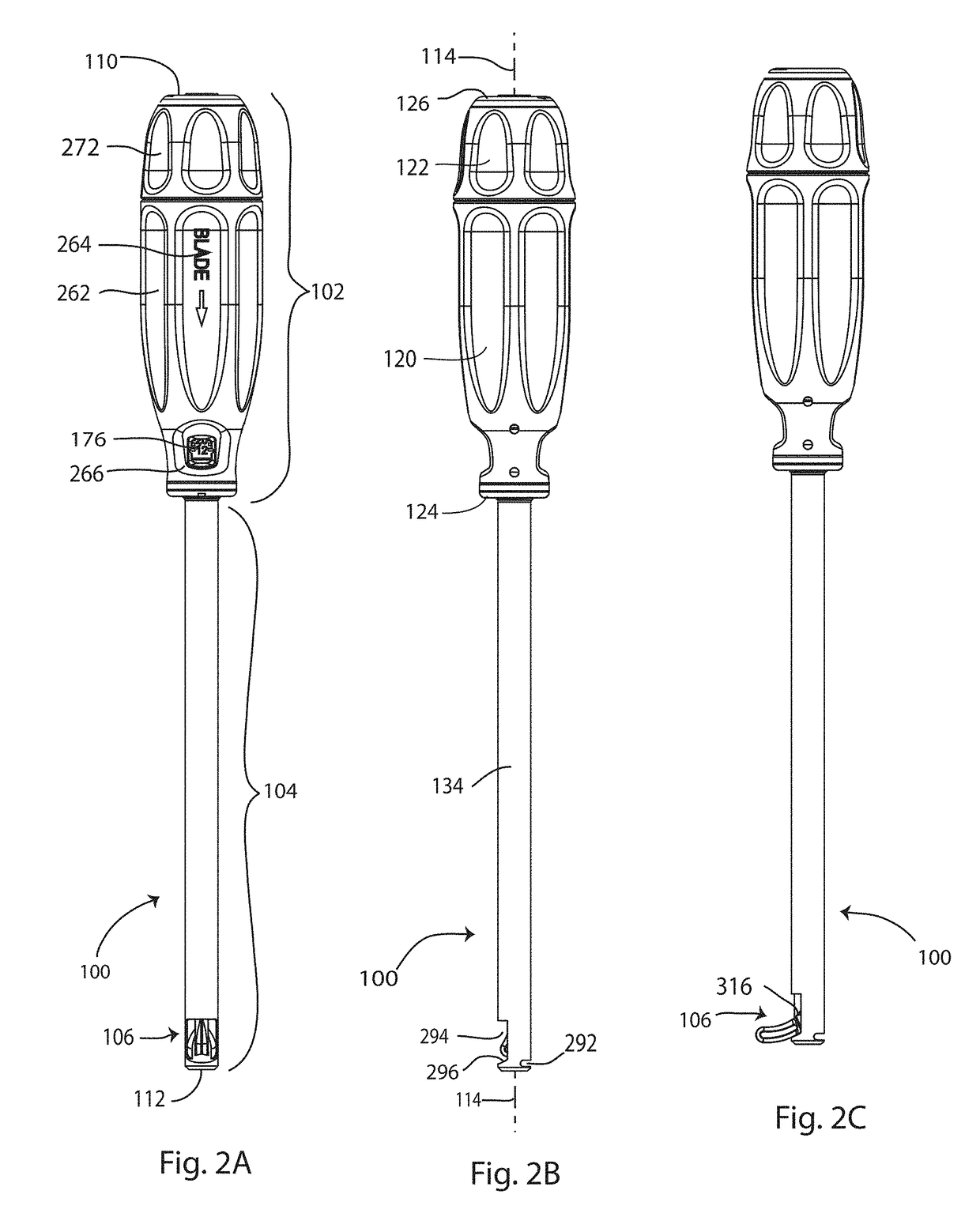

Joint fusion implant and methods

ActiveUS20170303972A1Small incisionShort operating timeInternal osteosythesisFastenersSurface finishSacral vertebral body

An implant for fusing a joint between first and second bone portions. The implant includes a screw member, and a washer polyaxially rotatable relative to the screw member. The screw member includes a head, a lag zone, and a threaded engagement zone. The implant includes a fusion zone for joint compression, extending from the washer to the proximal end of the engagement zone. Fenestrations may be present in the fusion zone. The length of the fusion zone ranges from about 10 mm to about 37 mm. Different surface finishes including roughened and non-roughened may be applied selectively to selected portions of the implant. In an embodiment, the joint is a sacro-iliac joint, and upon implantation the implant extends from the exterior of the ilium, across the joint and into the sacral vertebral body. Instrumentation and methods for preparing the joint and implanting the implant are disclosed.

Owner:IMDS CORPORATION +1

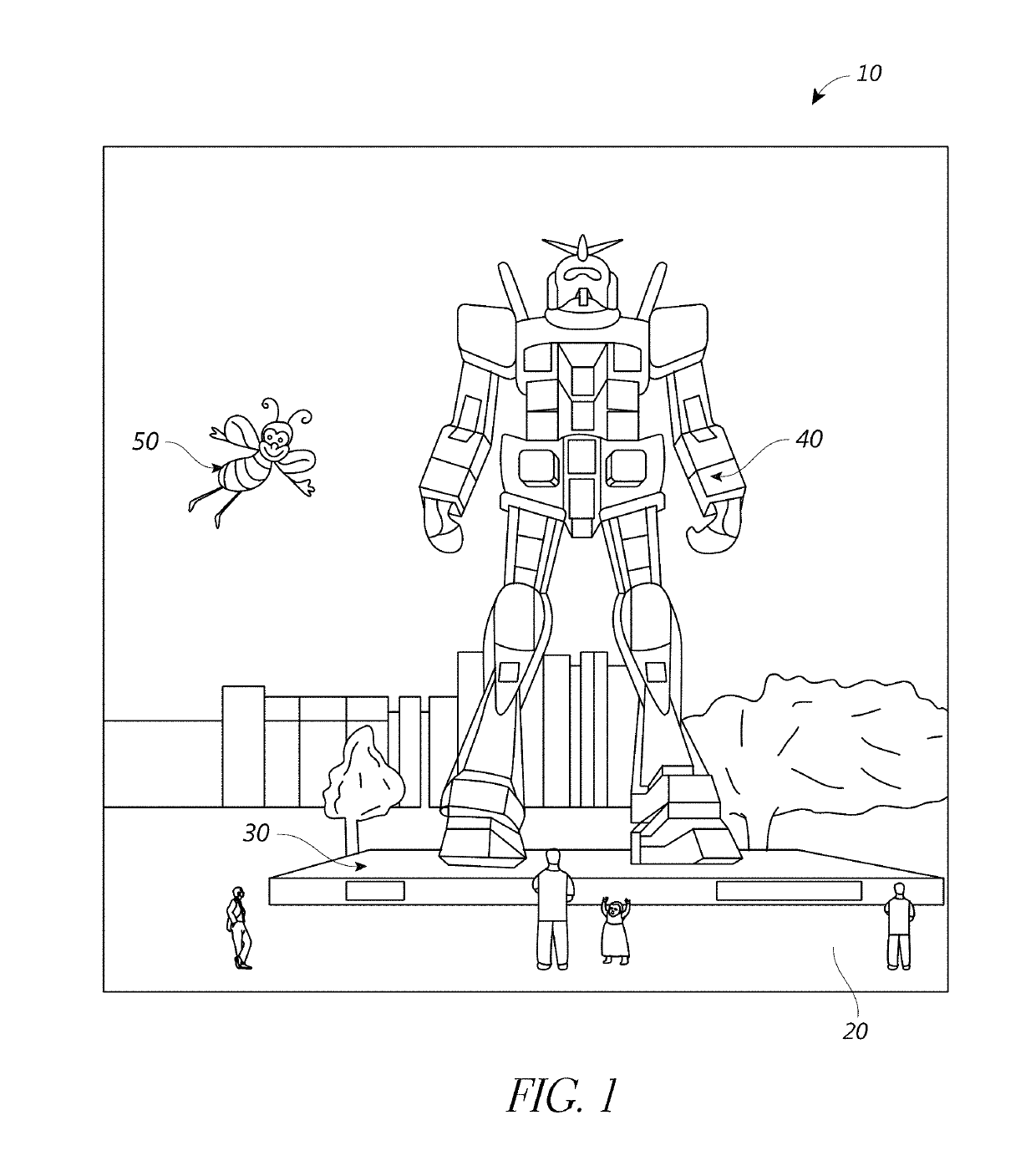

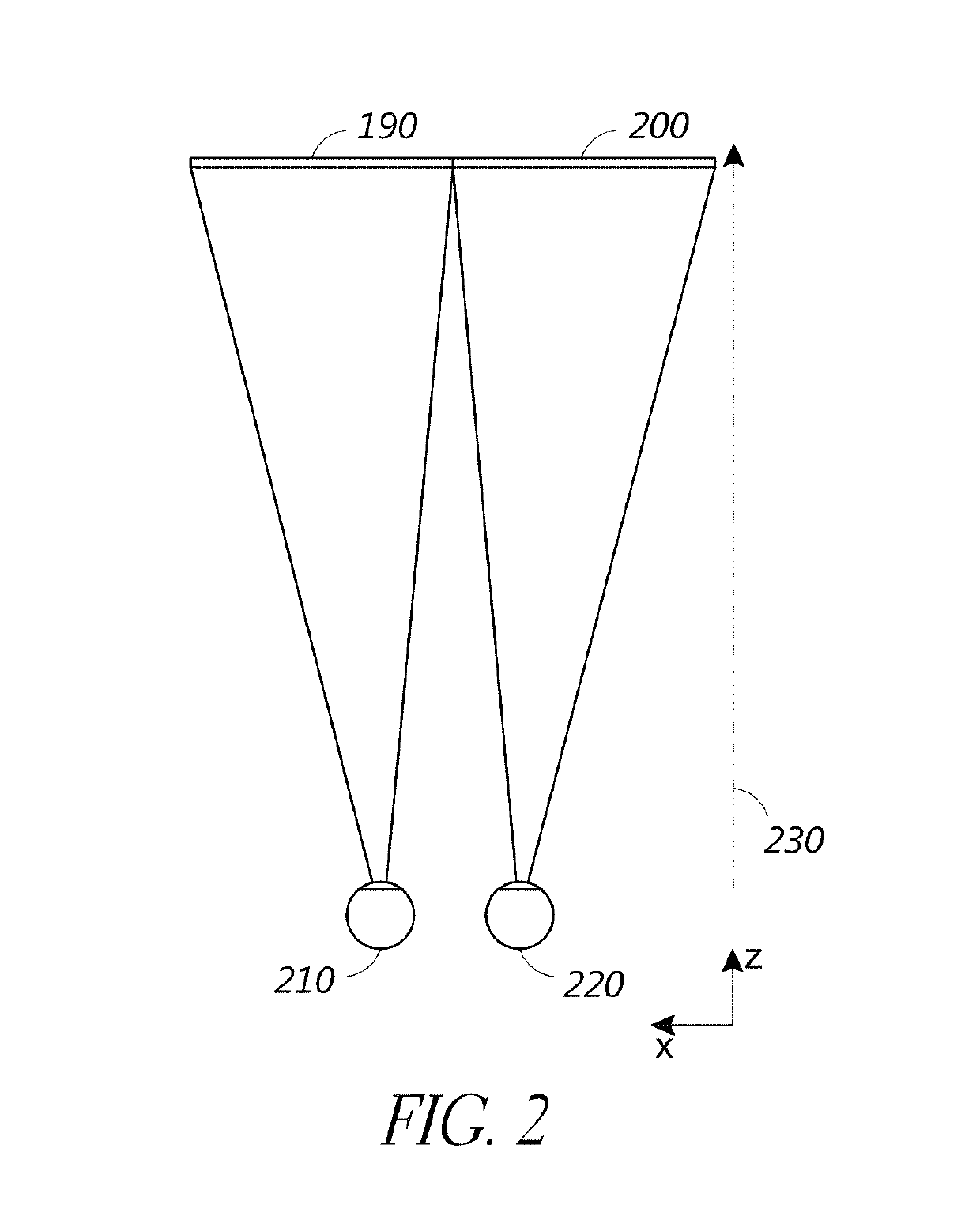

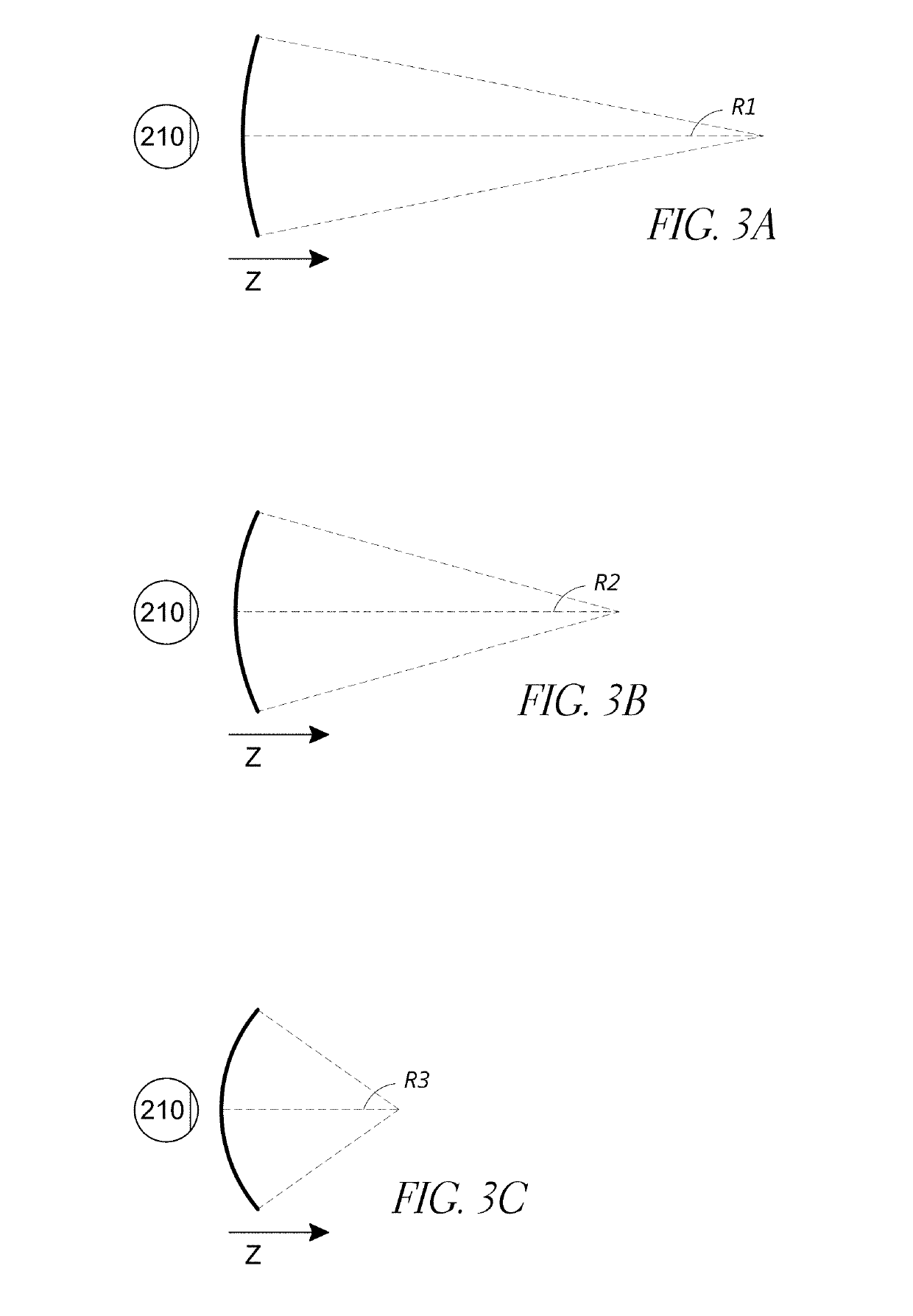

Display systems and methods for clipping content to increase viewing comfort

ActiveUS20190311527A1Steroscopic systemsInput/output processes for data processingVergenceVirtual reality

Augmented and virtual reality display systems increase viewer comfort by reducing viewer exposure to virtual content that causes undesirable accommodation-vergence mismatches (AVM). The display systems limit displaying content that exceeds an accommodation-vergence mismatch threshold, which may define a volume around the viewer. The volume may be subdivided into two or more zones, including an innermost loss-of-fusion zone (LoF) in which no content is displayed, and one or more outer AVM zones in which the displaying of content may be stopped, or clipped, under certain conditions. For example, content may be clipped if the viewer is verging within an AVM zone and if the content is displayed within the AVM zone for more than a threshold duration. A further possible condition for clipping content is that the user is verging on that content. In addition, the boundaries of the AVM zone and / or the acceptable amount of time that the content is displayed may vary depending upon the type of content being displayed, e.g., whether the content is user-locked content or in-world content.

Owner:MAGIC LEAP

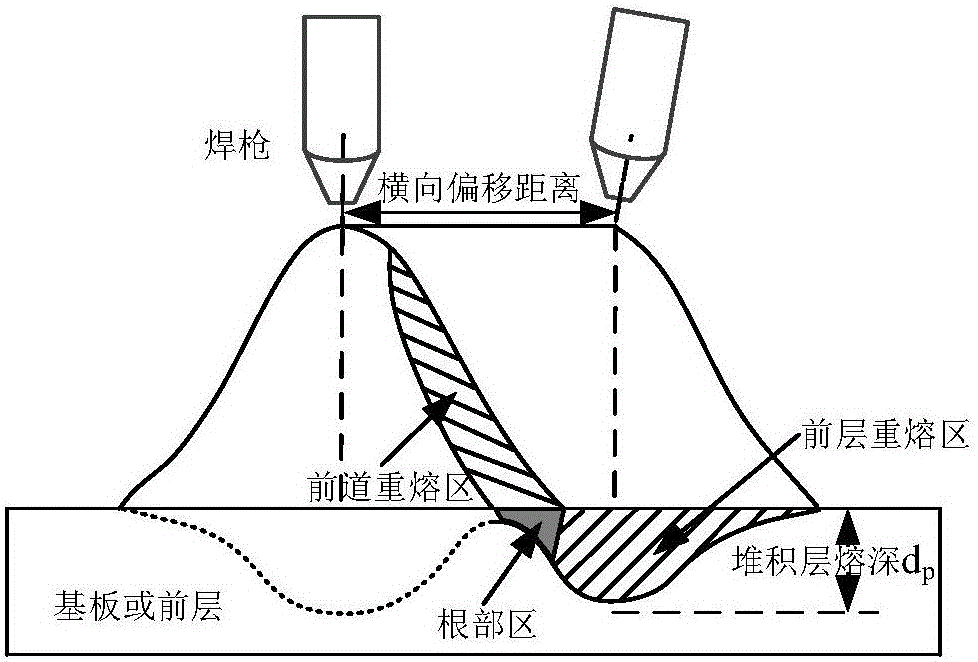

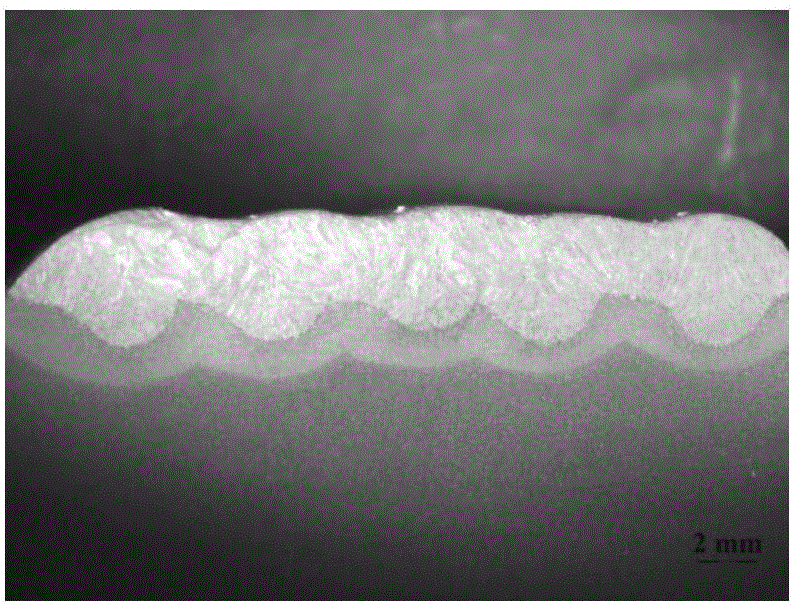

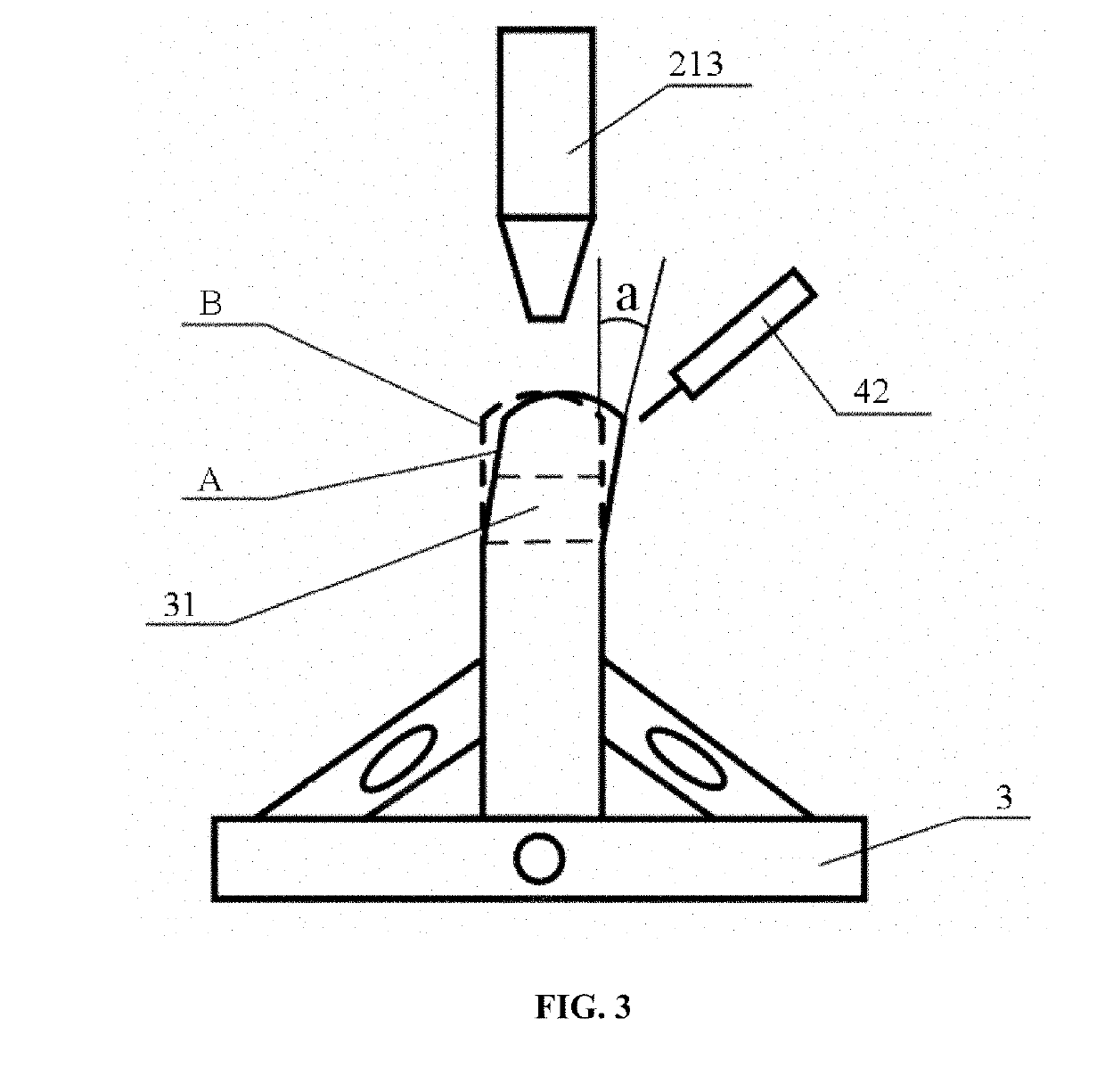

Fusion penetration method for arc wire filling additive manufacturing root zone of thick-wall structural element

InactiveCN106808062AStrong penetrating powerEliminate hole defectsElectrode supporting devicesEngineeringThick wall

The invention provides a fusion penetration method for an arc wire filling additive manufacturing root zone of a thick-wall structural element. The thick-wall structural element is of a multi-layer structure of two or more layers; each layer is composed of at least two accumulating ways; a multi-layer and multi-way structure is formed through an arc wire filling additive manufacturing method; each layer sheet is formed by means of mutual overlap joint of at least two accumulating ways; the first accumulating way of each layer sheet is formed in the manner that a welding gun is perpendicular to a substrate; the other accumulating ways are formed in the manner that the axis of the welding gun and the surface of the substrate form a 65-85 degree angle; and the axis of the welding gun points to the root zone so that the maximum arc force can directly act on the root zone. The method can guarantee good fusion penetration of the root zone, eliminate the hole defect of the root zone and achieve good metallurgical connection of the root zone, a front-way re-fusion zone and a front-layer re-fusion zone; and meanwhile fusion on the front-layer re-fusion zone can be reduced, excessive re-fusion on the front-layer re-fusion zone is avoided, and effective utilization of the arc energy in the arc wire filling additive manufacturing process of the thick-wall structural element is further achieved.

Owner:SOUTHWEST JIAOTONG UNIV

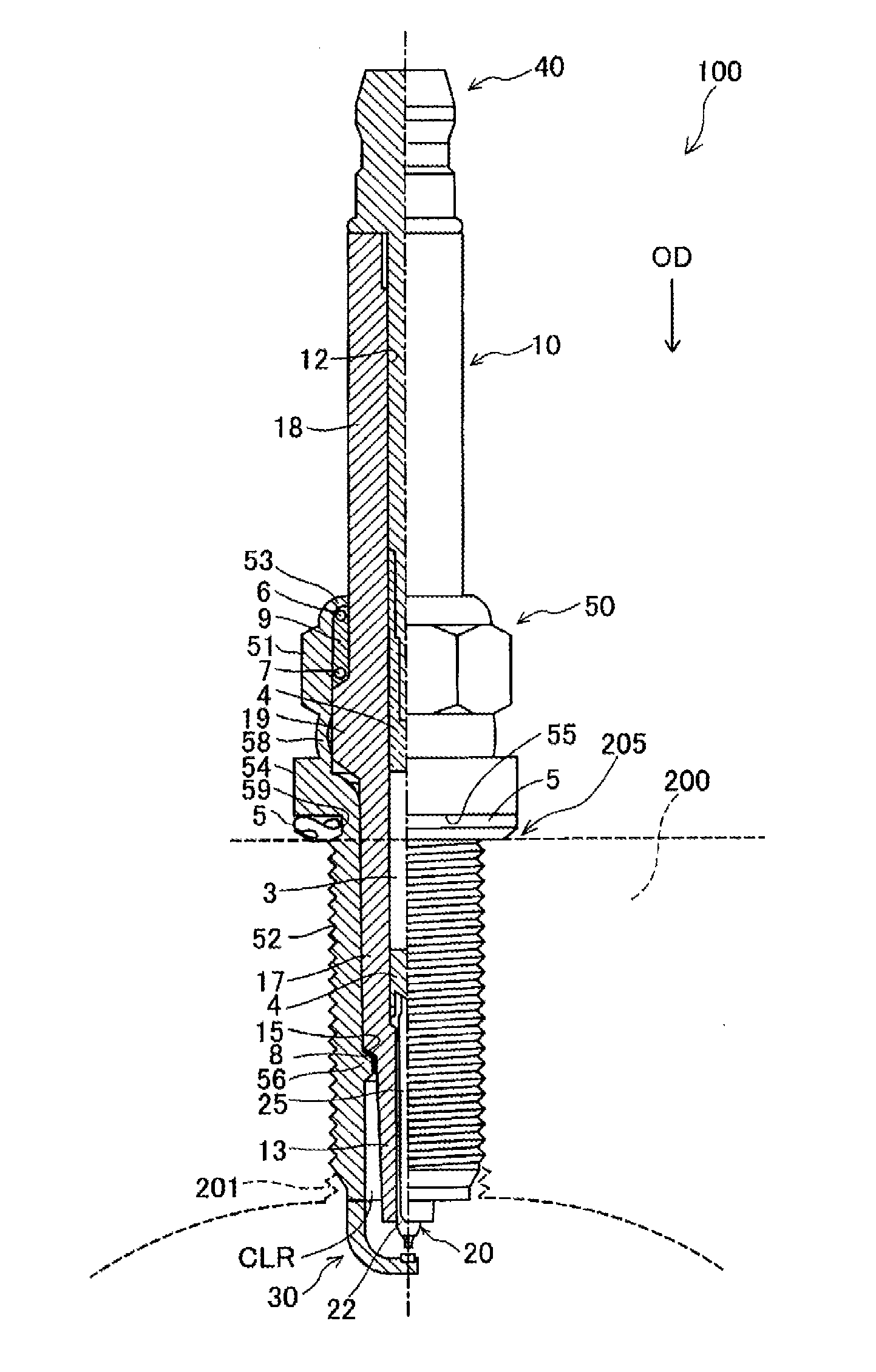

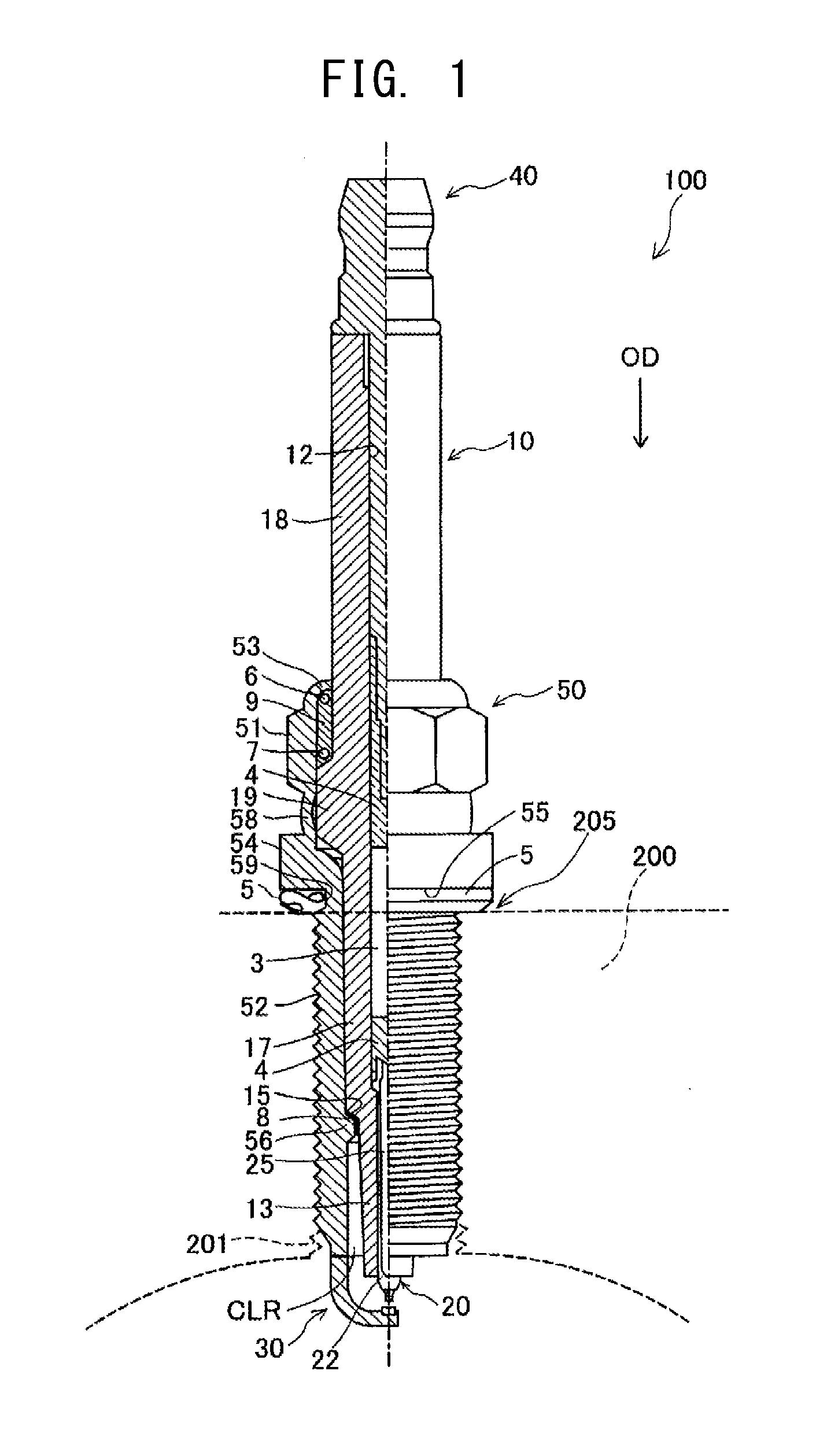

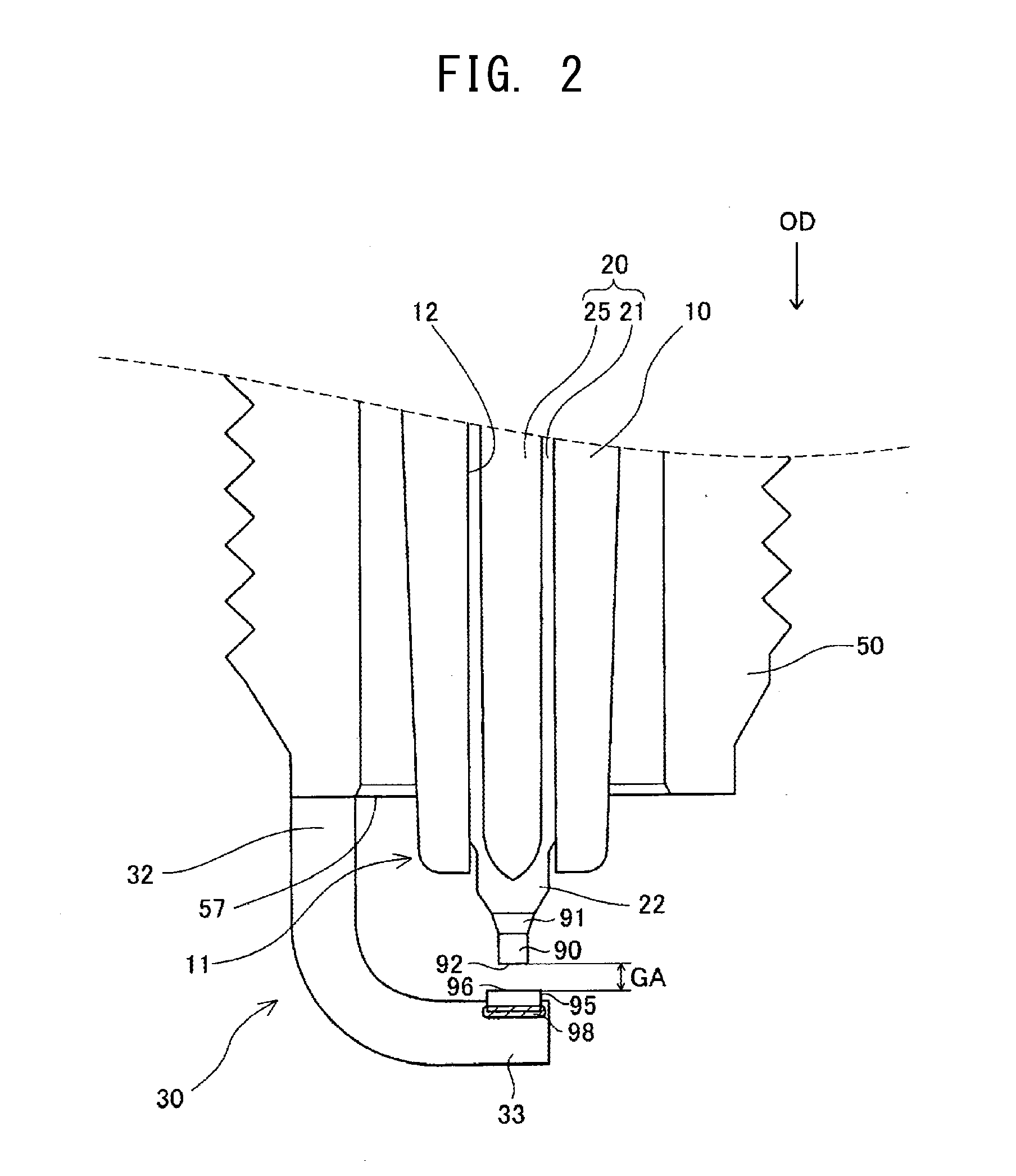

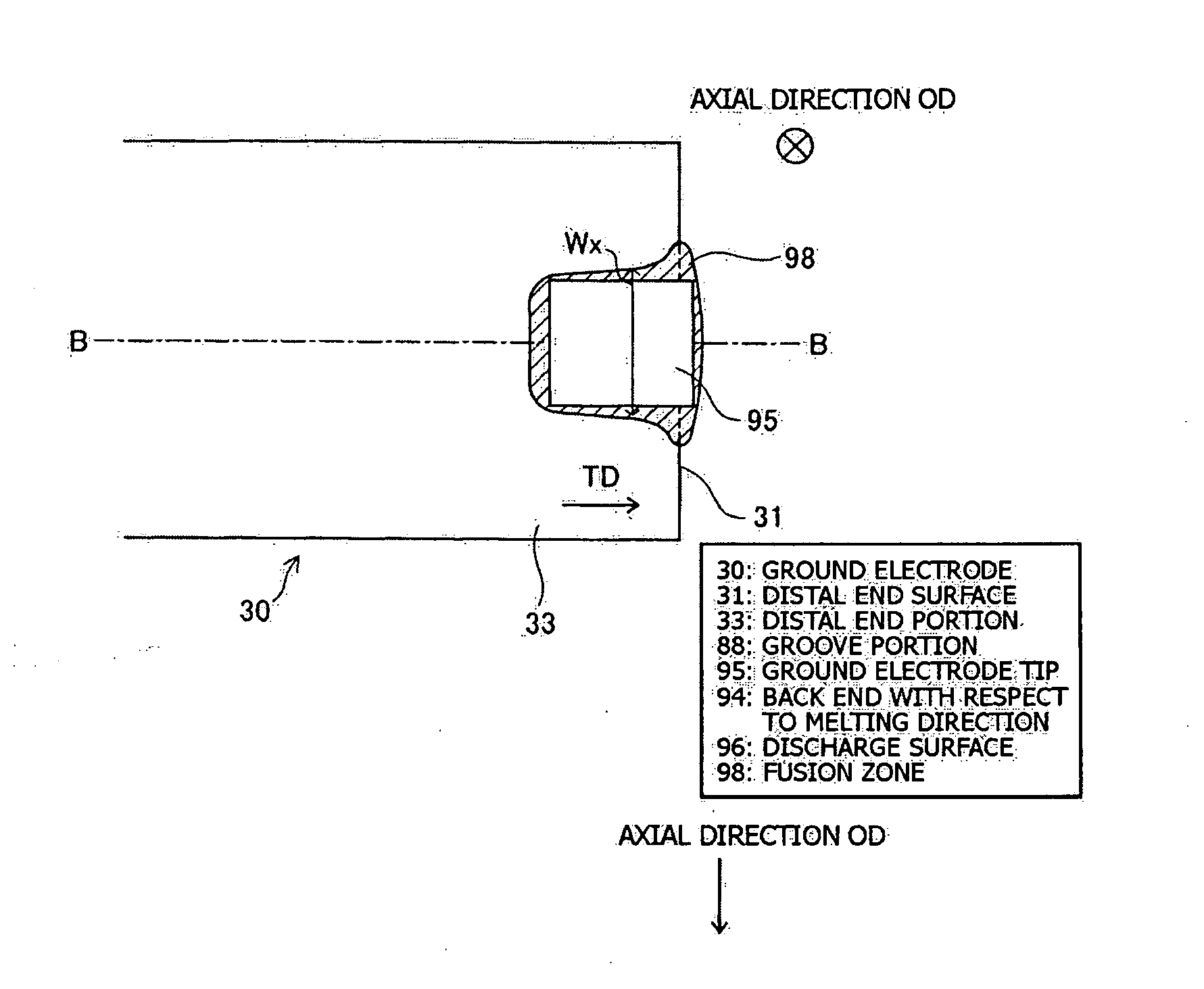

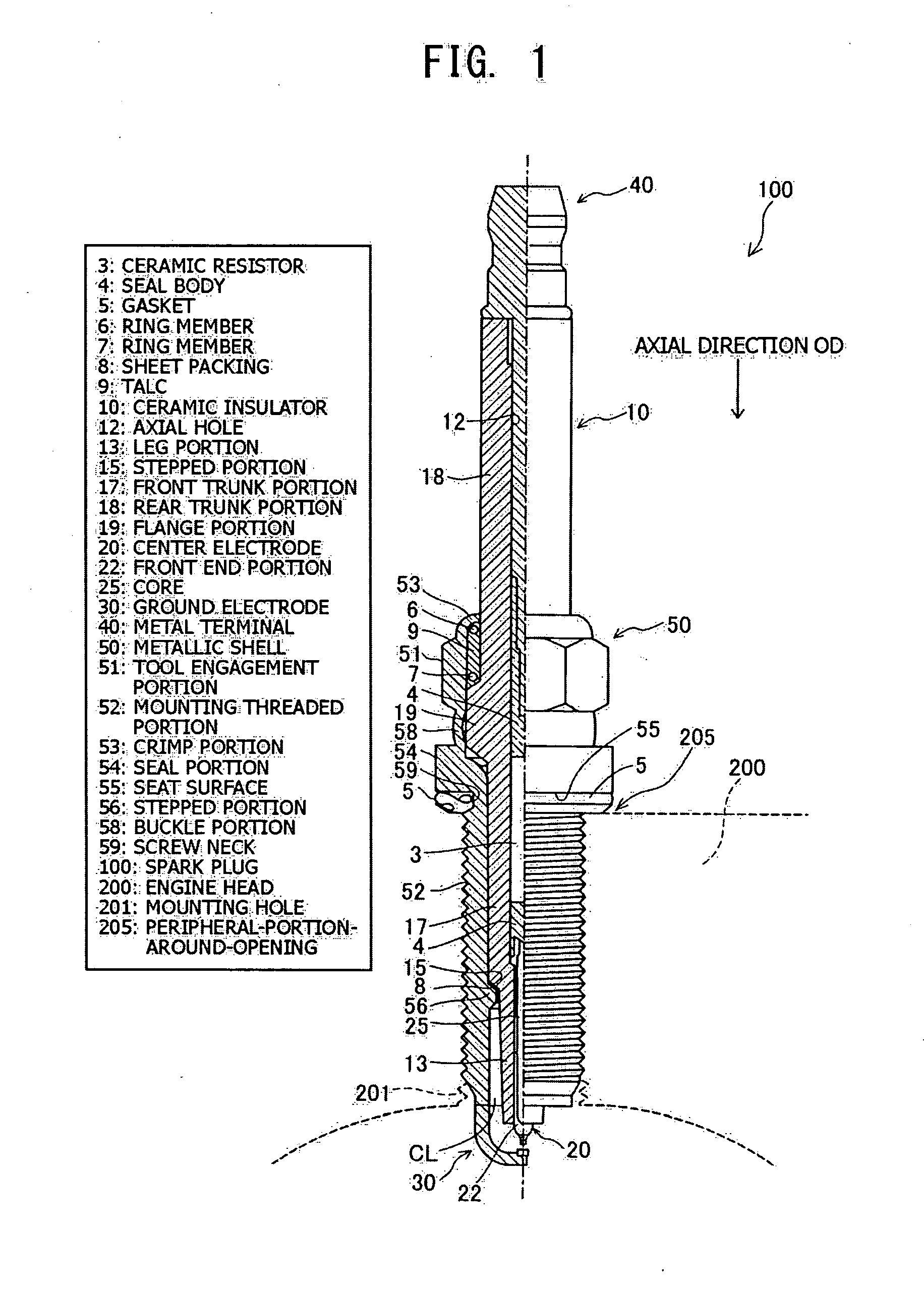

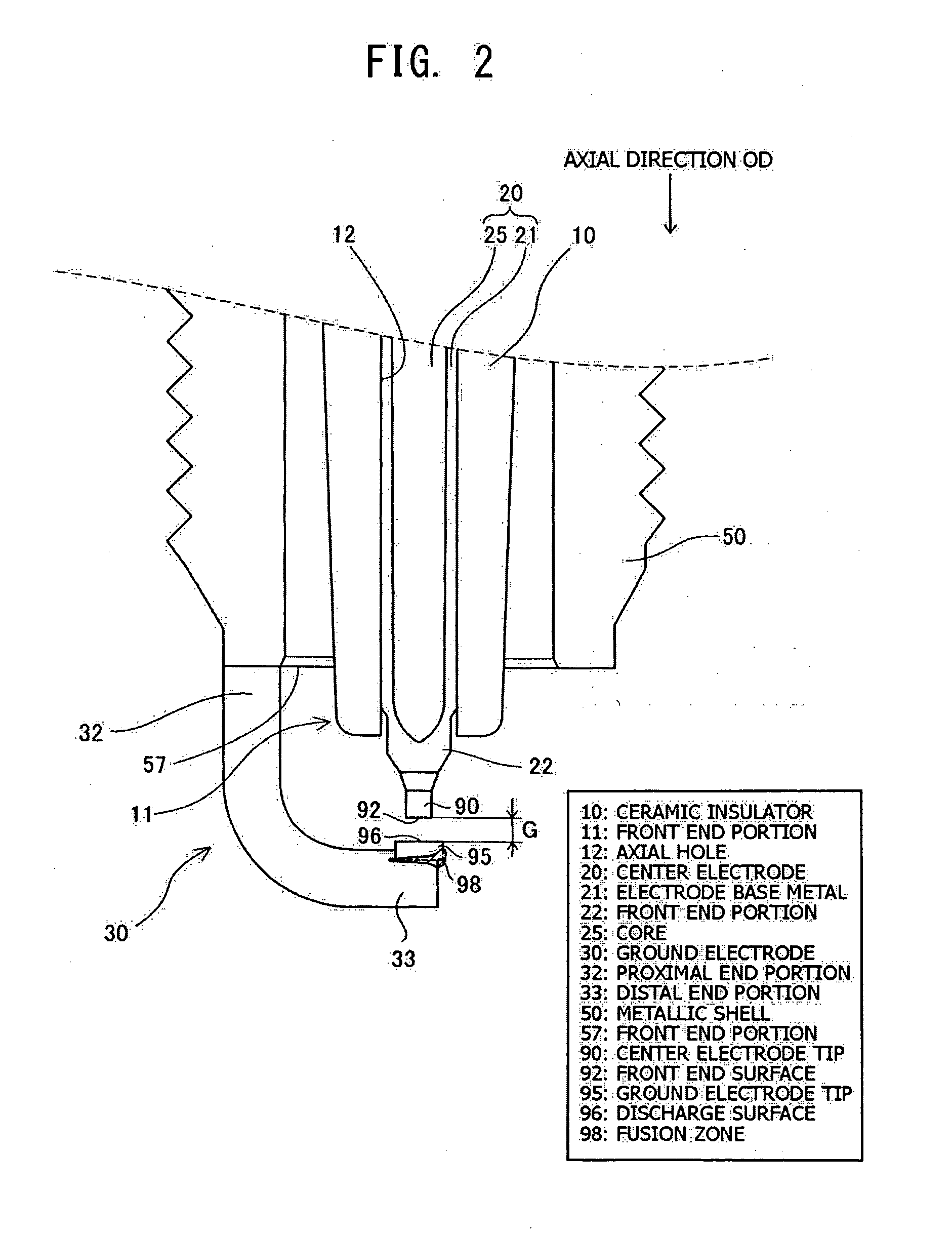

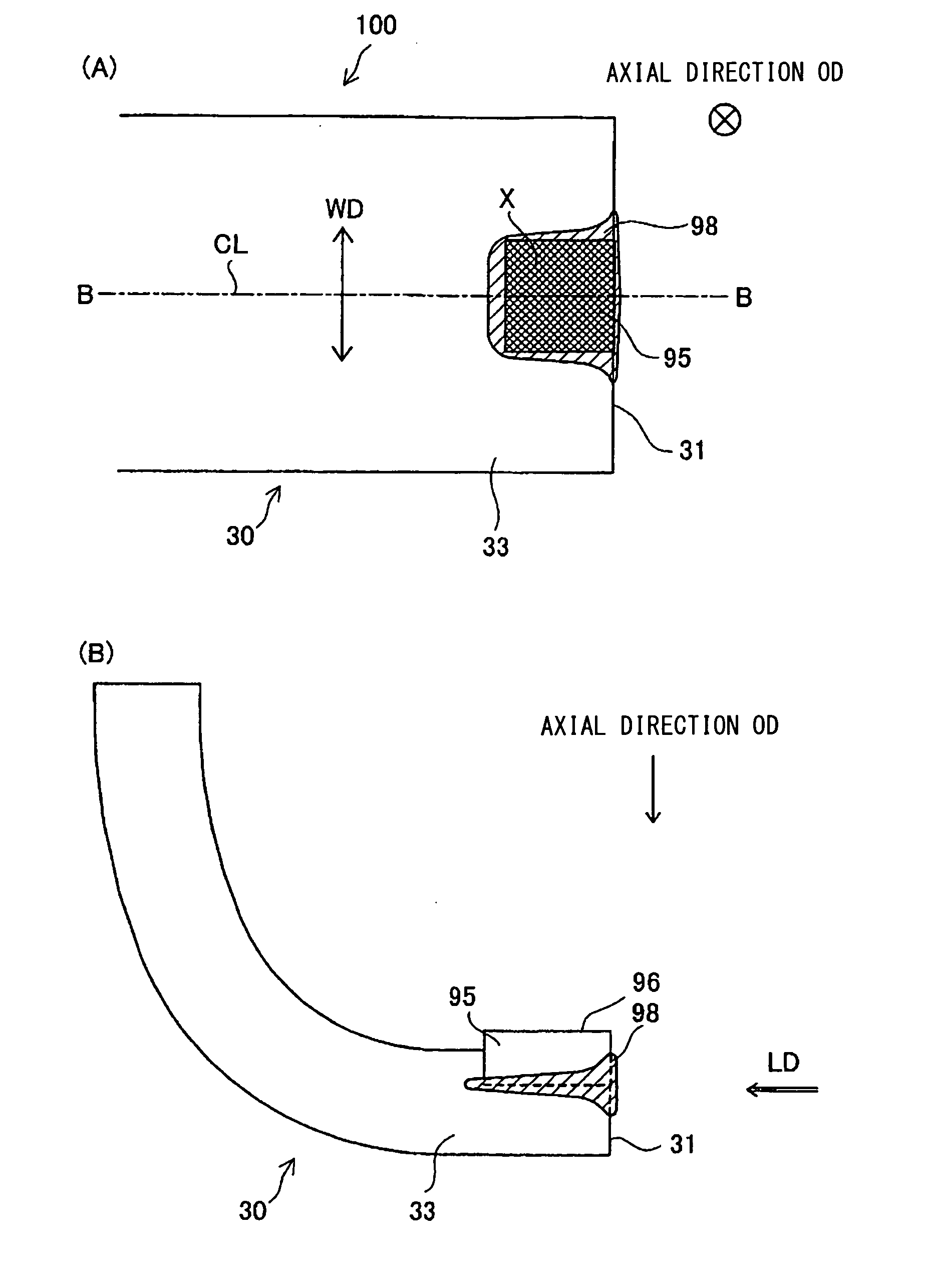

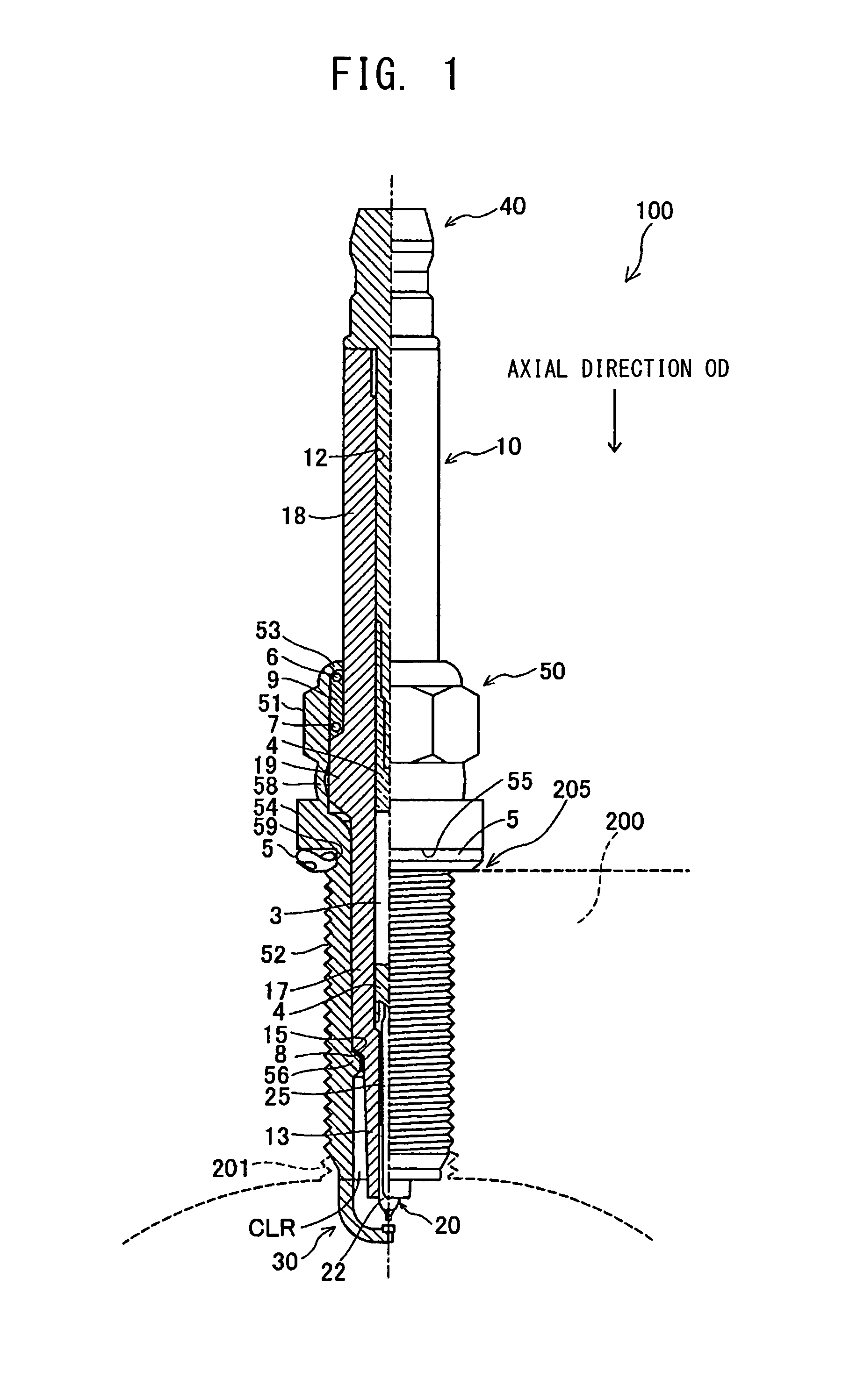

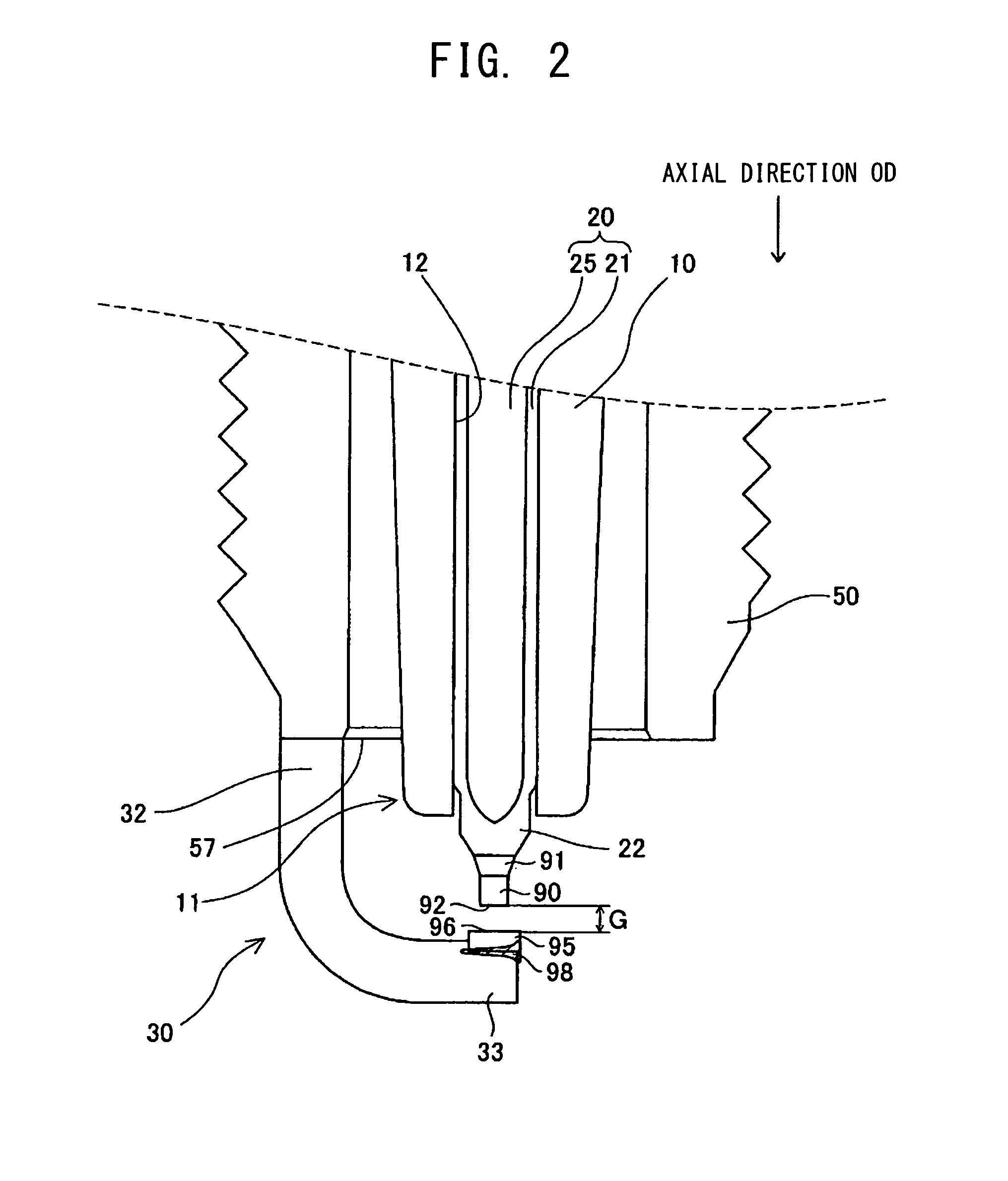

Spark plug

In a spark plug, a fusion zone where a ground electrode and a noble metal tip are fused together is formed in at least a portion of an interfacial region between the ground electrode and the noble metal tip. When the fusion zone is projected in the axial direction, the projected fusion zone overlaps 70% or more of the area of the noble metal tip. As viewed on a section which passes through the center of gravity of the noble metal tip and is perpendicular to the longitudinal direction of the ground electrode, the relational expression 1.3≦B / A is satisfied, where A is the greatest thickness of the fusion zone along the axial direction, and B is the length from a portion having the greatest thickness of the fusion zone to the inner end of the fusion zone.

Owner:NGK SPARK PLUG CO LTD

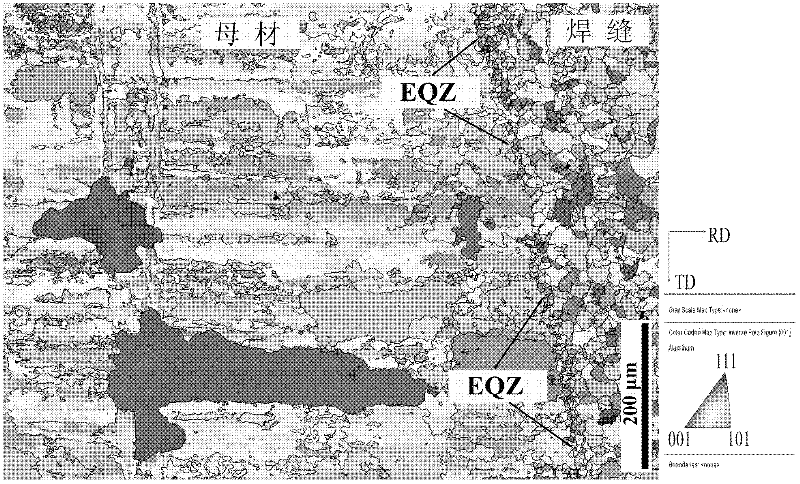

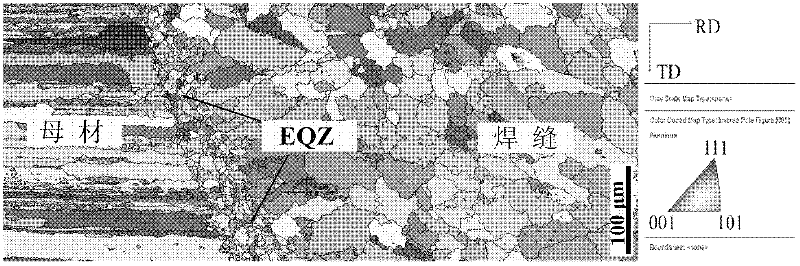

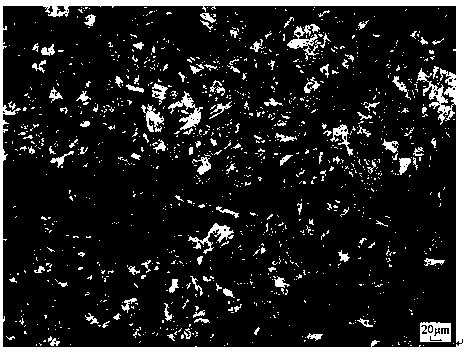

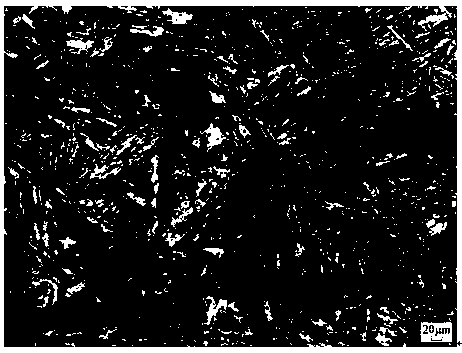

Method for displaying EQZ (Equiaxed Grain Zone) textures of welded joints and fusion zones of 5A90 aluminum-lithium alloy laser welding

InactiveCN102507619AQuality improvementConfidenceMaterial analysis using wave/particle radiationPreparing sample for investigationLithiumElectron

The invention discloses a method for displaying EQZ (Equiaxed Grain Zone) textures of welded joints and fusion zones of 5A90 aluminum-lithium alloy laser welding, belonging to the technical field of material analysis. The method comprises the following steps of mechanical polishing of a joint sample, preparation of electrolytes, electrolytic polishing, EBSD (Electron Back Scattering Diffraction) test and the like. The method disclosed by the invention has the advantages of successfully solving the difficult problem of displaying the EQZ textures of the welded joints and the fusion zones of the 5A90 aluminum-lithium alloy laser welding, and clearly displaying the characteristics, such as form, size and grain orientation, of the EQZ textures of the welded joints and the fusion zones of the 5A90 aluminum-lithium alloy laser welding. The method disclosed by the invention has the advantages of simpleness in equipment, convenience for operation, and capability of being applied to observation of the EQZ textures of fusion zones of various types of aluminum alloy welded joints.

Owner:BEIJING UNIV OF TECH

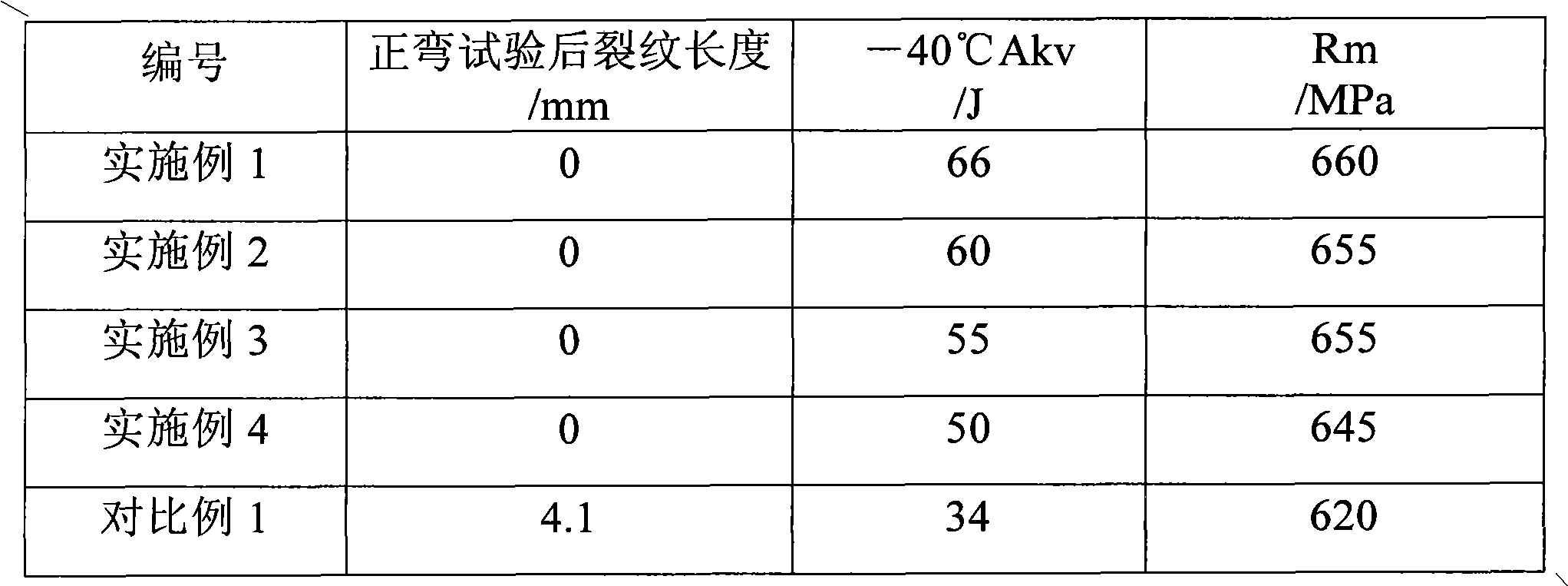

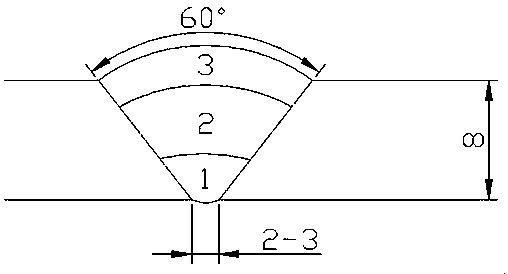

GMAW welding method of low-alloy super-strength steel Q1100E thin sheet

Provided is a GMAW welding method of a low-alloy super-strength steel Q1100E thin sheet. The thickness of each steel plate is 8-12 mm, and every two steel plates same in thickness are combined in buttjoint. The method includes the following steps of machining of V-shaped edges; pretreatment; rigid control over preheating temperature, interlayer temperature and heat input amount of bottom welding,filling welling and cover surface welding for single-face welding and double-face molding; hydrogen removal treatment after welding; weld reinforcement treatment. Welding connectors have high toughness and a great cold bending property, wherein the tensile resistance strength is higher than or equal to 1,000 MPa, d is equal to 6a, and surface bending and back bending at the angle of 180 degrees are both qualified. The impact energy of weld joints, a fusion zone and a heat affected zone at -40 DEG C is higher than or equal to 27 J; meanwhile, a welding process is high in operability, industrial application is convenient, the production efficiency is high, and the welding method has an application and popularization prospect.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Method and apparatus for controlling and adjusting the intensity profile of a laser beam employed in a laser welder for welding polymeric and metallic components

InactiveUS7820936B2Enhanced signalImprove signal-to-noise ratioMechanical working/deformationLamination ancillary operationsLight beamOptoelectronics

A method and apparatus is provided for forming a fusion bond between two materials such as two components of a catheter. The method begins by forming a bond site by positioning a portion of a first body with respect to a portion of a second body so that a fusion bond site is formed. A laser beam is generated that has an intensity profile across its width. The laser beam is directed onto at least a portion of the first and second bodies within the bond site so that a fusion zone having an increased temperature is formed. After the laser beam is generated, the intensity profile of the laser beam that is directed onto the bond site is controllably adjusted by an optical element such as a dynamically-adjustable beam shaping element.

Owner:BOSTON SCI SCIMED INC

Spark plug

Owner:NGK SPARK PLUG CO LTD

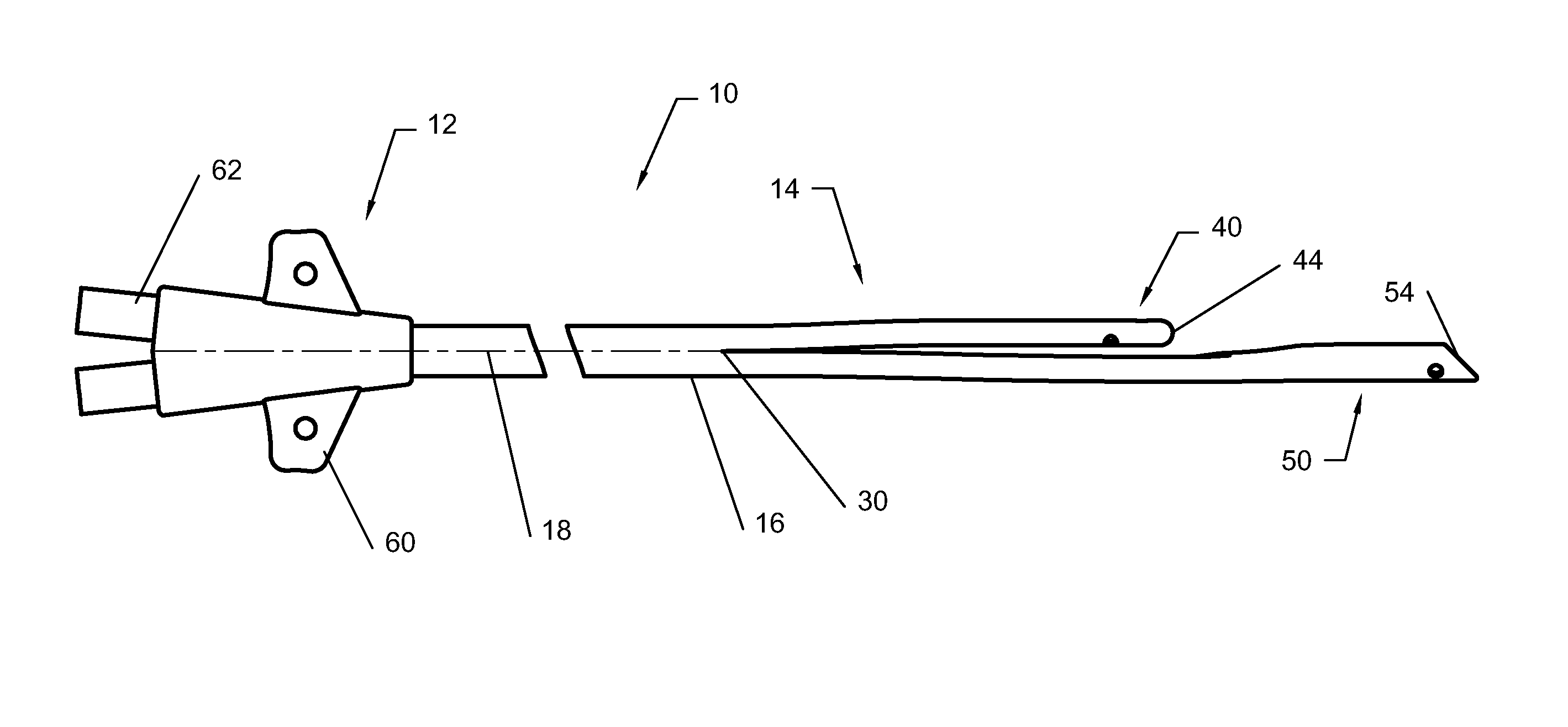

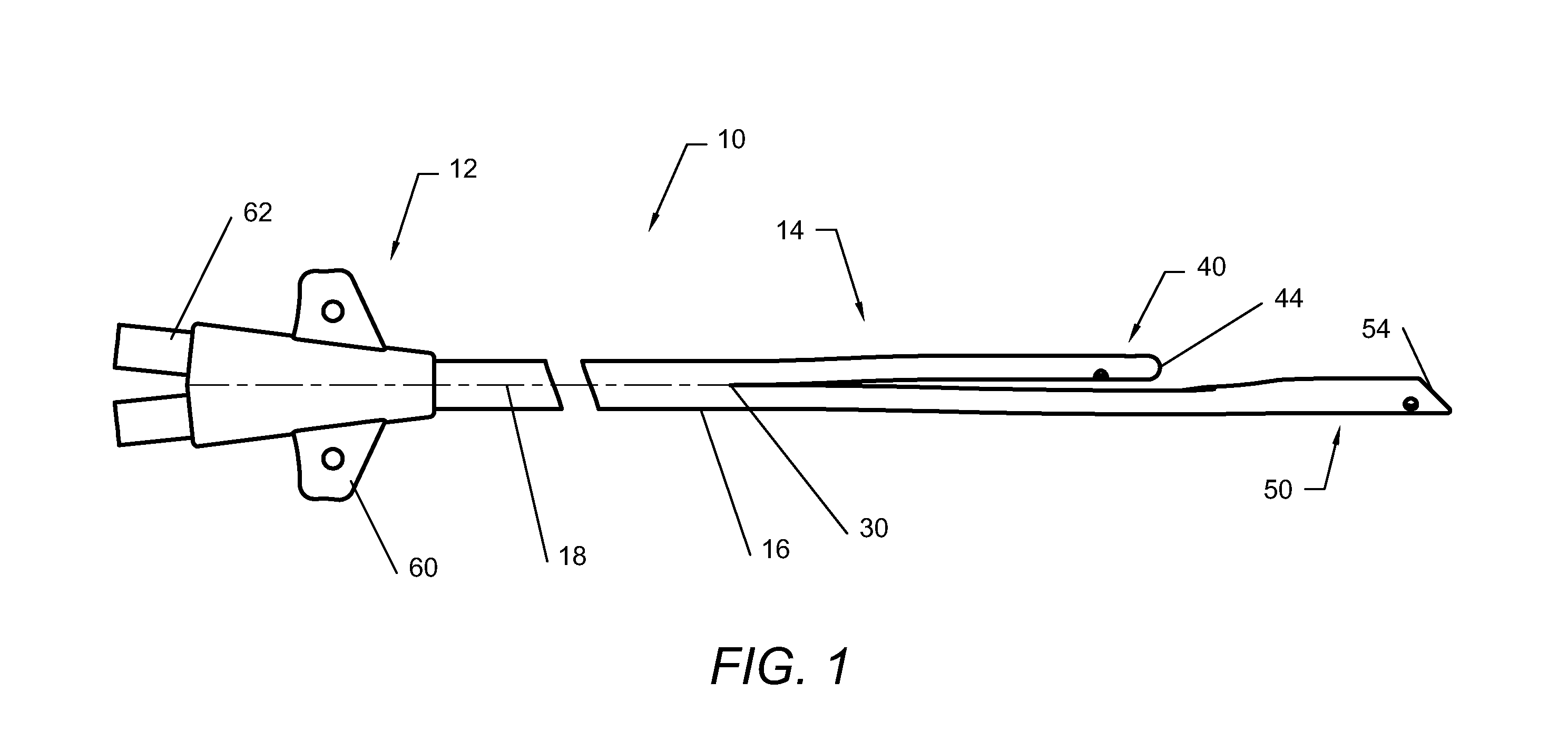

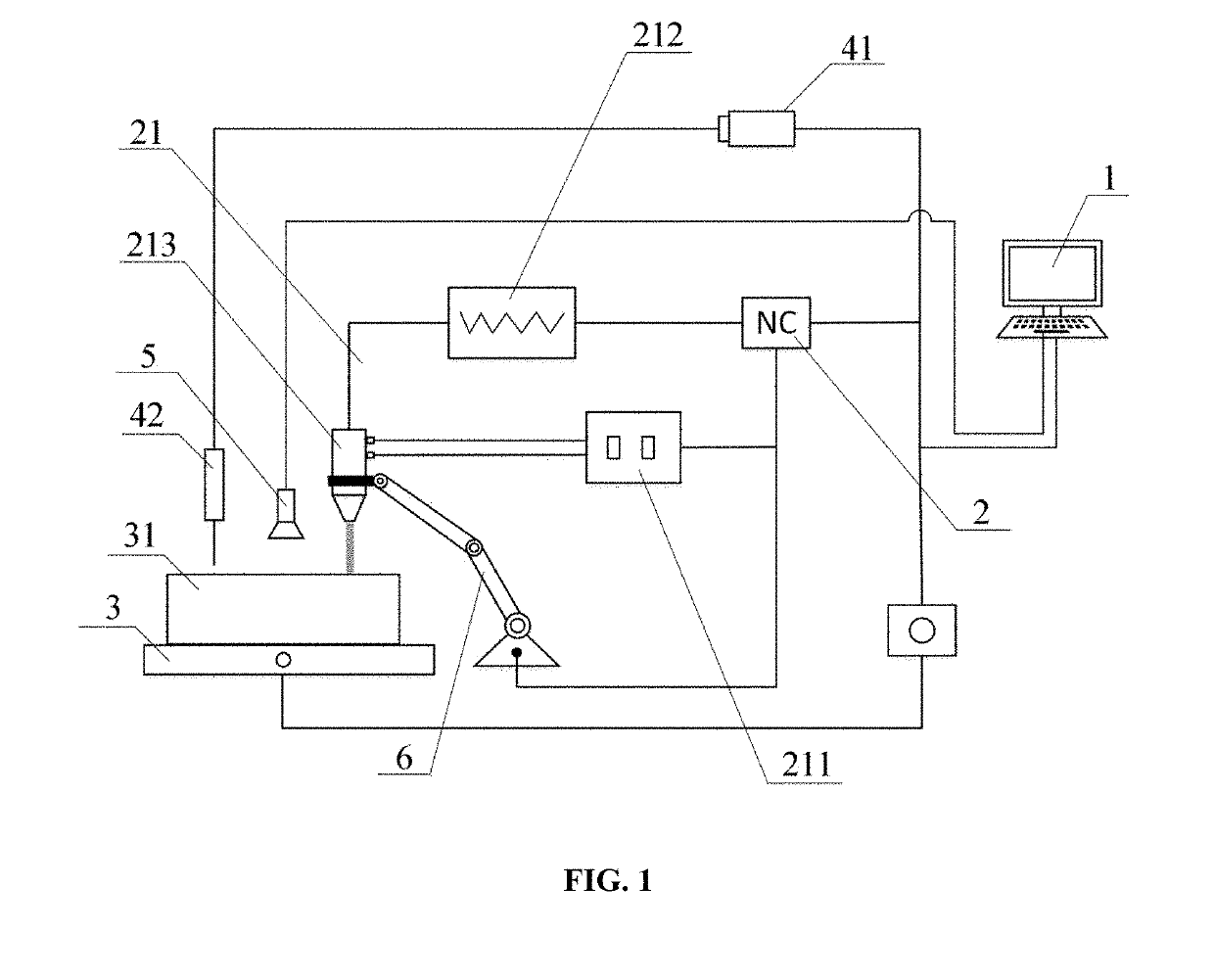

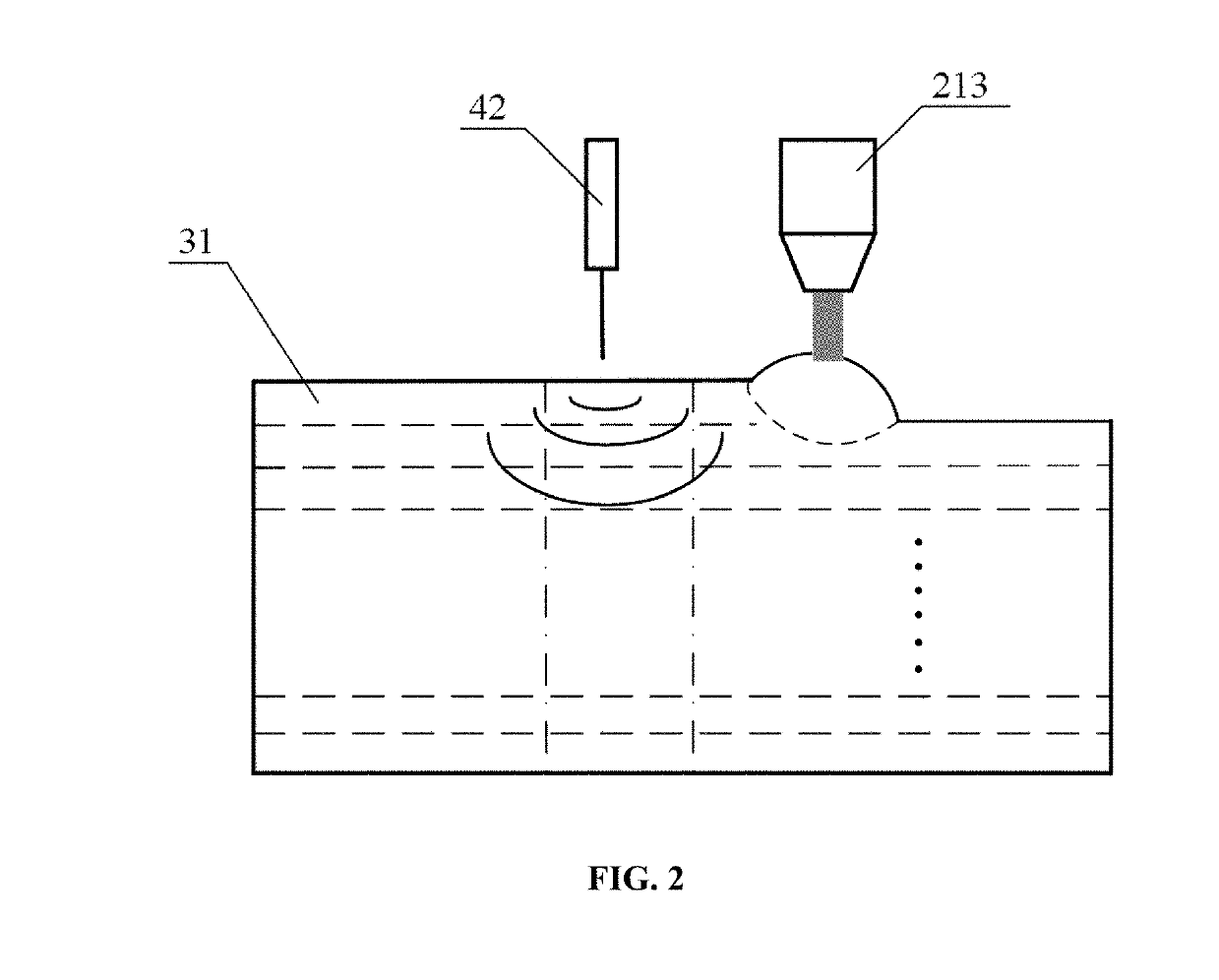

Method for rapidly forming a part using combination of arc deposition and laser shock forging and device implementing same

ActiveUS20190337079A1Fast formingImprove production efficiencyAdditive manufacturing apparatusArc welding apparatusNumerical controlOptoelectronics

A method for rapidly forming a part using combination of arc deposition and laser shock forging, including: 1) dividing a preforming part model into one or more simple forming units by the simulation system and determining a forming order of the forming unit; 2) controlling, by the numerical control device, an arc welding device to perform a melting deposition forming of a processing material layer by layer on a processing substrate of a motion platform to form a melting deposition layer; 3) controlling, by the computer, a movement of the motion platform to keep a fusion zone always in a horizontal state, at the same time, a pulse laser beam of a laser device to perform a synchronous shock forging on an arc deposition region at a plastic deformation temperature. A device for implementing the method.

Owner:GUANGDONG UNIV OF TECH

Method of manufacturing sparkplugs

ActiveUS20120015578A1Improve welding strengthReduced strengthSpark gapsSparking plugs manufactureEngineeringSpark discharge

A method of manufacturing a spark plug having an insulator, a center electrode, a metallic shell, a ground electrode, and a noble metal tip provided on the ground electrode and having a discharge surface forming a spark discharge gap in cooperation with the center electrode. The method of manufacturing includes a fusion-zone formation step of forming a fusion zone through radiation of a high-energy beam to the boundary between the ground electrode and the noble metal tip.

Owner:NGK SPARK PLUG CO LTD

Preparation method of intercrystalline corrosion sample for coating metal of?metallurgy composite tube

InactiveCN102564827AGuaranteed to be free from interferenceReliable test resultsPreparing sample for investigationEpoxyTectorial membrane

The invention discloses a preparation method of an intercrystalline corrosion sample for coated metal of a metallurgy composite tube, comprising the following steps: (1) cutting down the coating metal from a fusion zone of the metallurgy composite tube to form a sample; (2) pasting a piece of paper on a test surface of the sample, and then preheating the sample; (3) spraying epoxy resin powder on non-test surfaces and edges of the sample to cover the non-test surfaces of the sample; and (4) putting the sample with the epoxy resin powder into a small resistance furnace for heating, and taking out the sample till the epoxy resin powder forms a layer of compactly cured protective film on the non-test surfaces of the sample, and then uncovering the paper on the test surface and finishing the preparation of the sample. The preparation method of the invention has the following beneficial effect: the result of an acid corrosion test of the sample is more accurate and reliable by spraying a layer of protective film on the contact surfaces and edges of the fusion zone of the sample of the coating metal of the metallurgy composite tube.

Owner:XINXING DUCTILE IRON PIPES CO LTD

Solar cell substrate, manufacturing method of solar cell and crucible used for same

InactiveCN102605418APrevent floatingPolycrystalline material growthFrom frozen solutionsCrucibleCrystal orientation

The invention relates to a method used for preparing a silicon substrate with a majority of crystal orientation being (100) and a crucible with multiple pockets at the bottom of with the crucible. A silicon seed crystals with (100) crystal orientation is placed in each pocket of the crucible, a silicon material is filled in the crucible for casting, the crucible is placed in a casting unit, and the pockets are positioned below a heating and fusion zone; and heating and melting begin from the top of the crucible. Once the silicon material is melted to the bottom, the silicon fluid flows in the pockets and contacts with the child crystal; and then, the crucible is slowly lowered, a lower molten part begins to solidify and grows along the (100) direction of the seed crystals.

Owner:上澎太阳能科技(嘉兴)有限公司

Composite steel bearing and manufacturing method

InactiveCN102292562AIncrease the bearing forceRolling contact bearingsShaftsMechanical engineeringMaterials science

A bearing comprising: layers of high-strength steel and a base layer of mild steel fused together via a fusion zone; raceways machined across the bearing and having a higher strength than can be achieved using conventional steel hardening processes A much greater bearing support depth is obtained; and a retaining structure machined into at least the base layer of mild steel and used to retain the bearing on the underlying bearing support.

Owner:约亨科茨

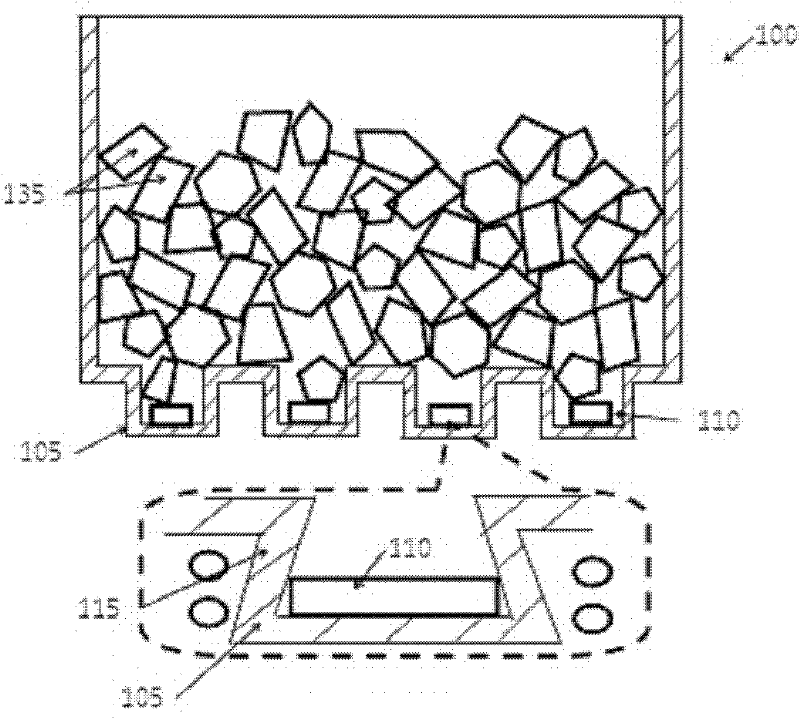

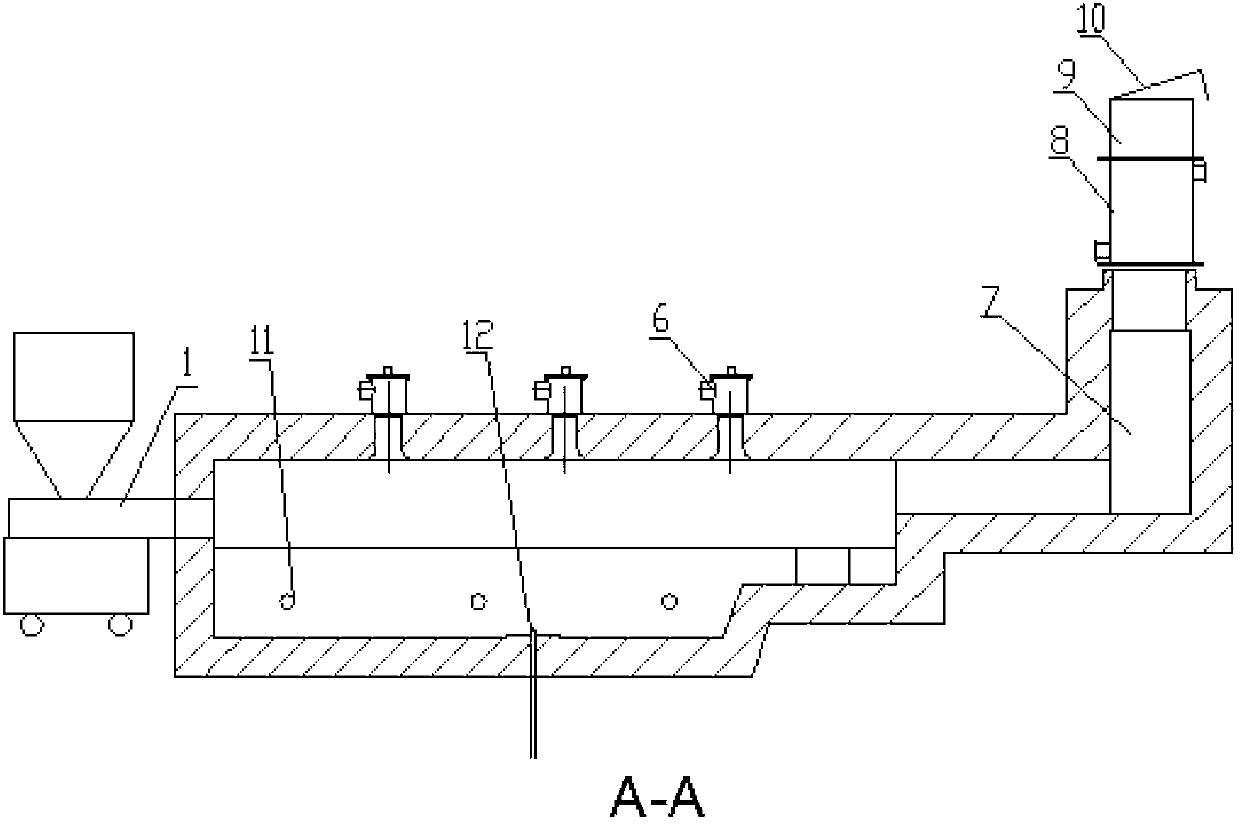

Large thermal power combination tank furnace for producing basalt continuous fibers

The invention discloses a large thermal power combination tank furnace for producing basalt continuous fibers. The large thermal power combination tank furnace comprises a batch feeder, a fusing zone, a homogenizing zone and two forming zones, wherein the discharge hole of the batch feeder is connected at one end of the fusion zone; the other end of the fusion zone is connected with one end of the homogenizing zone; the other end of the fusion zone or the homogenizing zone is connected with a chimney by a flue; one forming zone is connected on each of the left end and the right end of the homogenizing zone; a side-insertion electrode is arranged on the side wall of the fusion zone; the electrode is arranged below the melt liquid surface; a combustor is arranged on the top of the fusion zone; a plurality of uniformly and densely arranged gas nozzles are arranged on the side walls of the forming zones; the gas nozzles are arranged above the melt liquid surface; a plurality of leakage plates are uniformly arranged on the bottoms of the forming zones along the length direction of the forming zones; an air-cooled type heat exchanger is arranged on the flue; a hot air outlet of the air-cooled type heat exchanger is connected with an air inlet of the combustor; and a smoke outlet of the air-cooled type heat exchanger is connected with the chimney.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Joining process for neutron absorbing materials

InactiveUS20150336204A1Cooking-vessel materialsPortable shielded containersPlastic materialsBoron carbide

A method and associated system for joining workpieces formed of neutron absorbing materials. The method includes positioning first and second workpieces together to form a joint, heating the first and second workpieces at the joint to a plastic condition, intermingling plastic material from the first and second workpieces together at the joint, and cooling the intermingled plastic material to a solid state forming a welded fusion zone comprised of material from the first and second metal matrix composite workpieces. The workpiece material at the joint is not melted by the heating. The heating may be perforated by frictionally heating the materials with a rotary tool, in one non-limiting embodiment, the neutron absorbing workpieces may be formed of metal matrix composites comprising aluminum or aluminum alloy and boron carbide.

Owner:HOLTEC INT

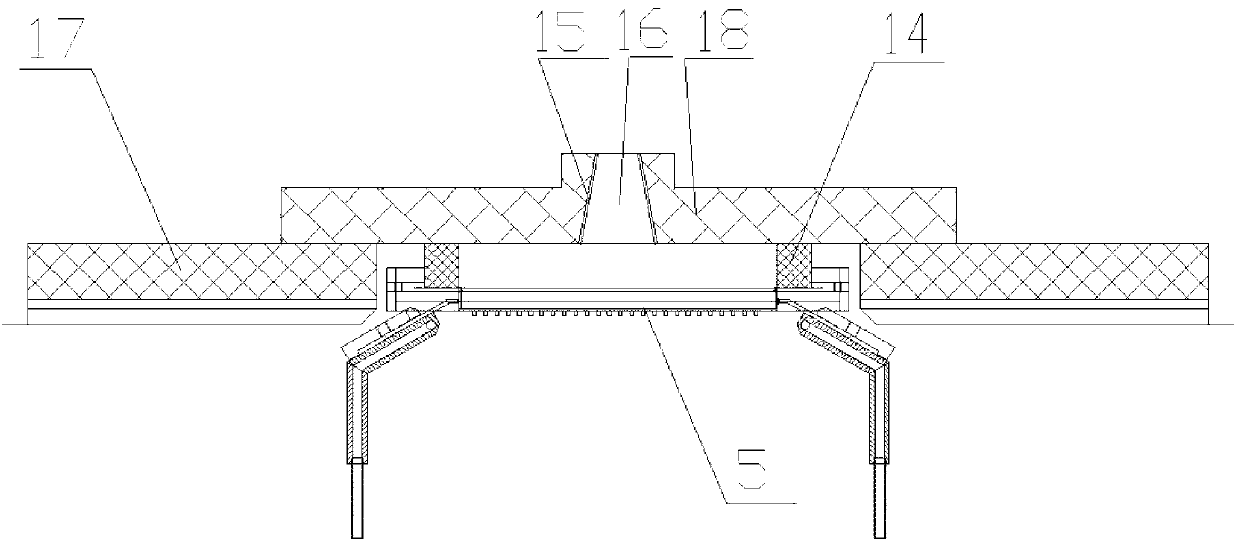

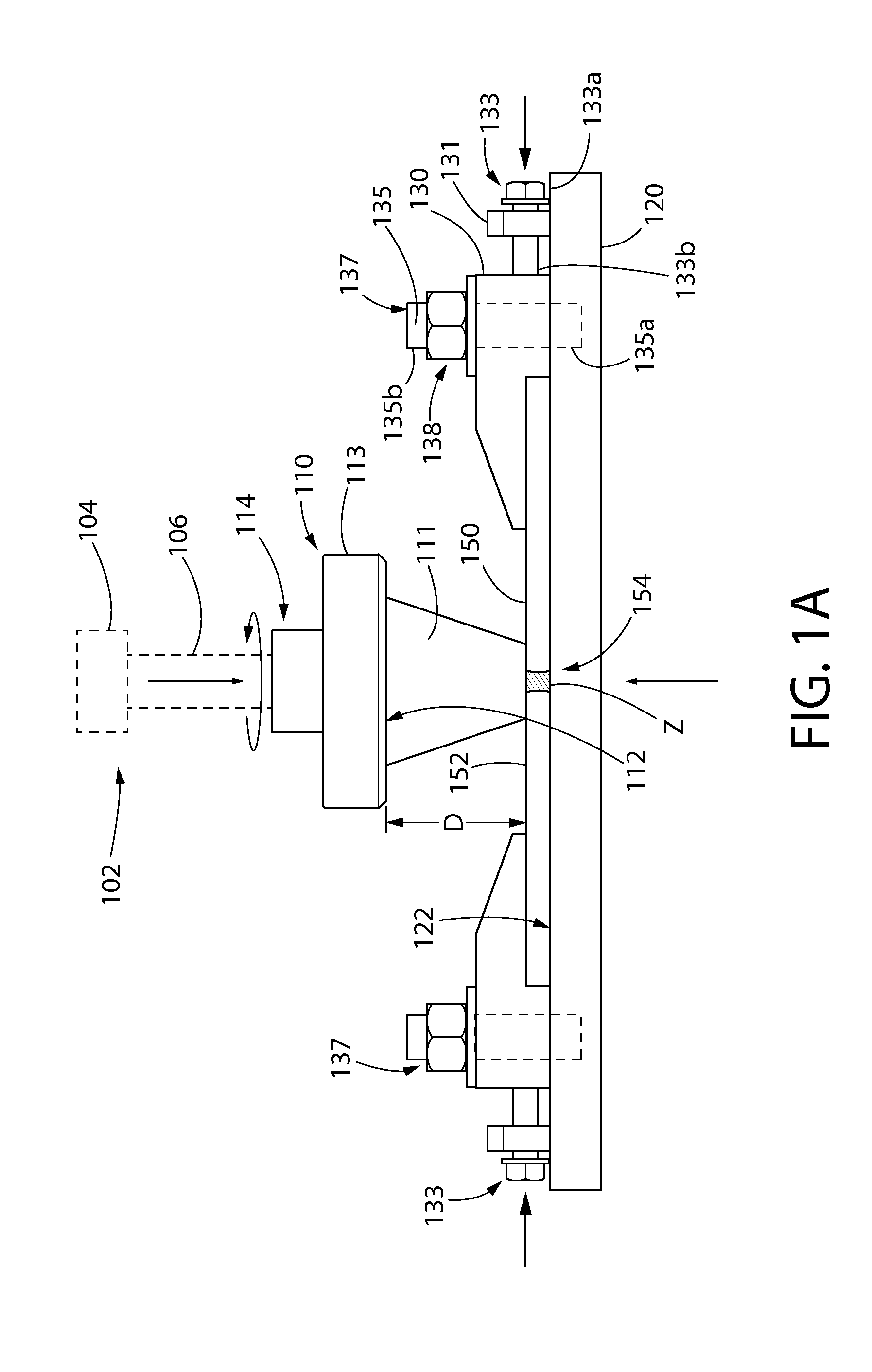

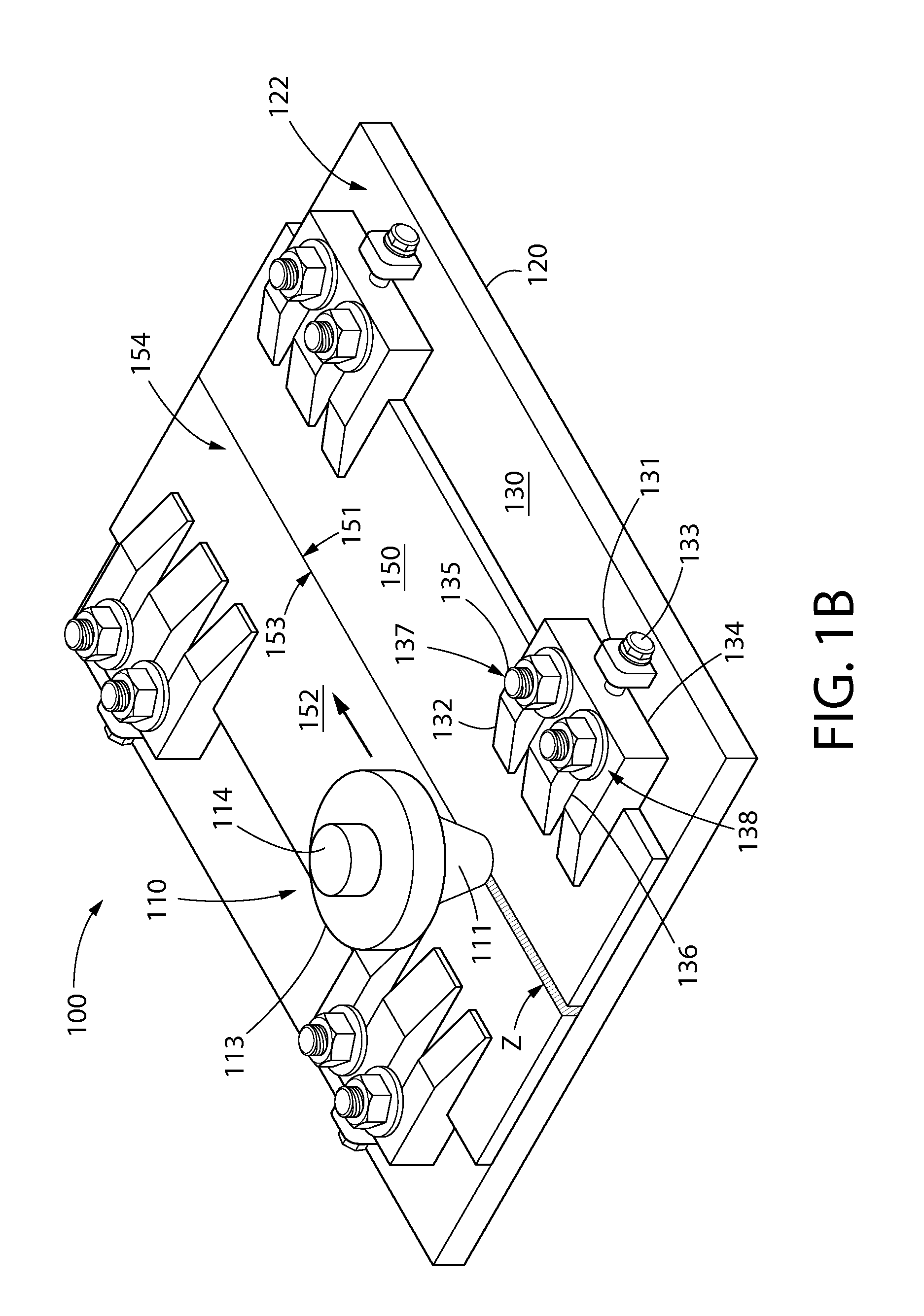

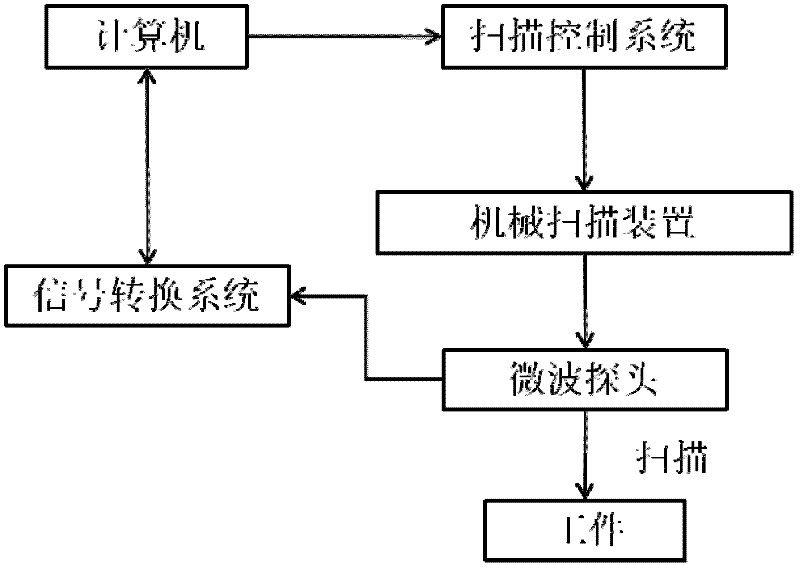

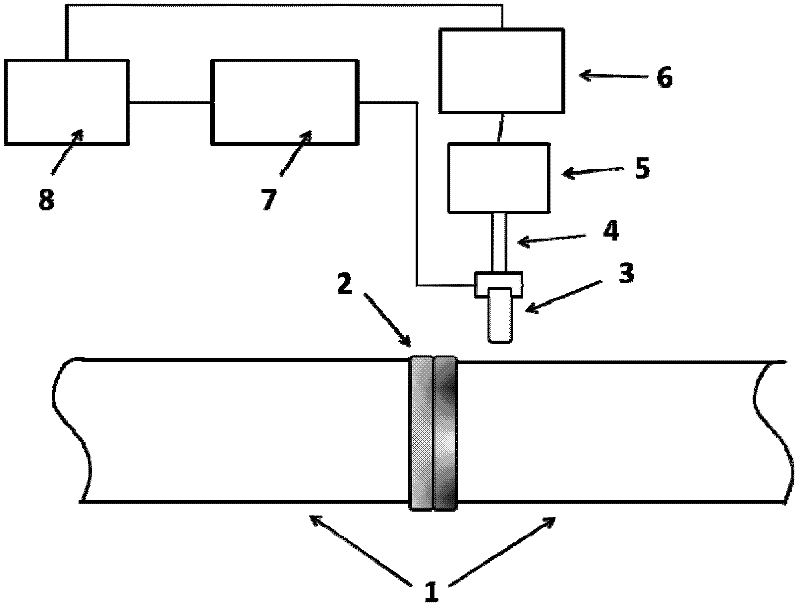

Microwave scanning detection method and microwave detection device of polyethylene pipe hot-molten joint

InactiveCN102384919AReliable detectionSolve pollutionFlaw detection using microwavesMicrowave emissionElectric cables

The invention relates to the field of pressure pipe detection, and specifically, relates to a microwave scanning detection method and a microwave detection device of a polyethylene pipe hot-molten joint in welding quality. The microwave scanning detection method based on the microwave detection device can detect multiple types of defects, especially, can effectively technical detects of cold welding, has the advantages of high sensitivity, high detection precision and good reliability. The microwave scanning detection method capable of detecting polyethylene pipe hot-molten joint defects comprises the following steps that a microwave probe comprising a microwave transmitting and receiving device is positioned on a side of an outer surface of a fusion zone of a polyethylene pipe hot-moltenjoint; the microwave probe comprising the microwave transmitting and receiving device is moved along the outer surface of the polyethylene pipe hot-molten joint at a certain speed for scanning; and obtained microwave signals is subjected to signal transition and computer processing to form a scanned image. The microwave detection device comprises the microwave probe comprising the microwave transmitting and receiving device, a mechanical scanning device, a scanning control device, a signal transition system, a computer and connection cables. The microwave detection device is convenient for operation and has a low cost.

Owner:嘉兴市特种设备检验检测院

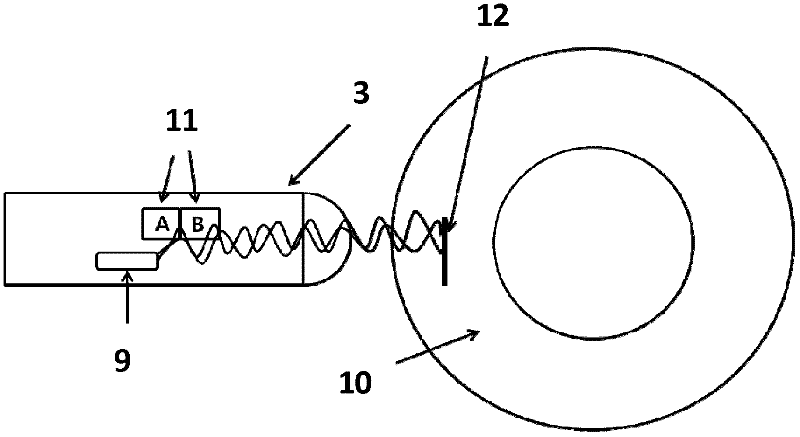

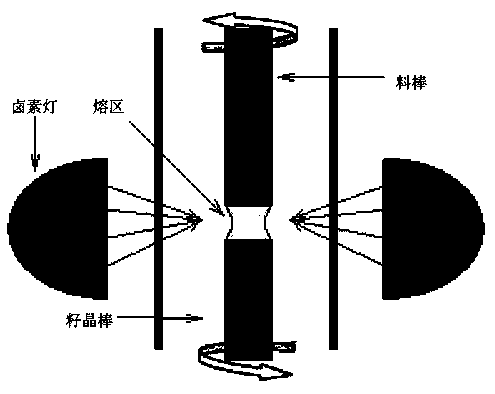

Method for growth of oversized crystal with the photo-magnetic function of rare earth orthoferrite

InactiveCN104389013APolycrystalline material growthBy zone-melting liquidsPhysical chemistryEngineering

The invention relates to a method for growth of an oversized crystal with the photo-magnetic function of rare earth orthoferrite, and belongs to the technical field of crystals with the photo-magnetic function. The preparation method comprises the following steps: taking high-purity R2O3 and Fe2O3 as raw materials; weighing Sm2O3, Tb2O3 and Fe2O3 at a molar ratio of 1:1:2, and weighing Pr6O11 and Fe2O3 at a molar ratio of 1:3; sintering the weighed materials in the air to prepare a polycrystalline charging bar; conducting pretreatment on the obtained charging bar at a high temperature close to the melting point of the charging bar, and then placing the pretreated charging bar in a floating-zone furnace for growth. The method has the characteristics that the lower end of the upper charging bar takes the shape of a reverse cone, which facilitates not only the butt joint between the upper charging bar and the lower charging bar but also diameter extension of the crystal; however, power needs to be improved and airflow needs to be adjusted during the diameter extension, so that fusion in a fusion zone can be uniform; optimum growth power can be selected for steady growth in the later period; the diameter of the prepared crystal exceeds 18 mm and breaks through a design limitation of the optical floating-zone furnace (15 mm); the prepared crystal is longer than 25 mm; the prepared oversized crystal can provide a technical basis for subsequent device applications.

Owner:SHANGHAI UNIV

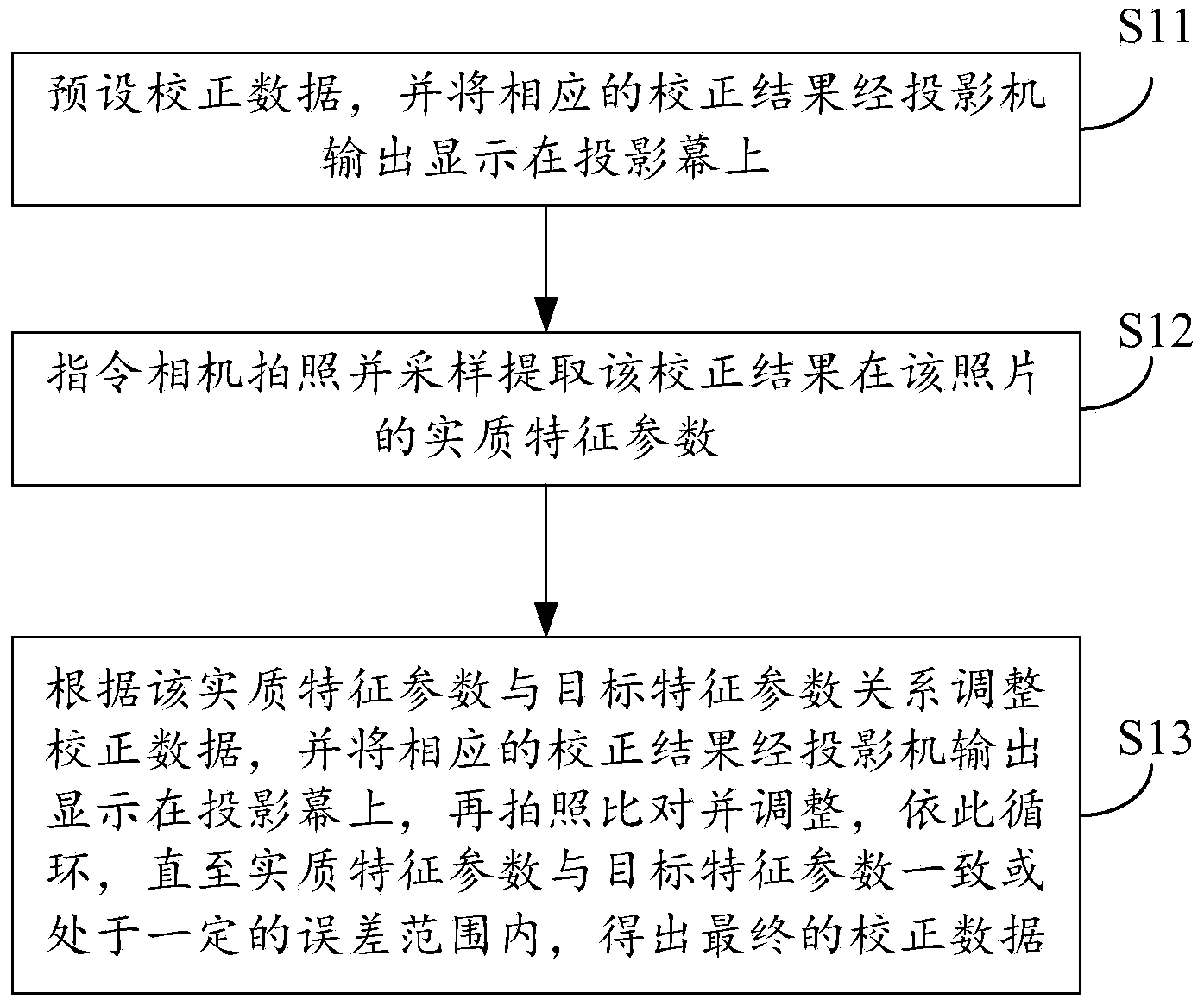

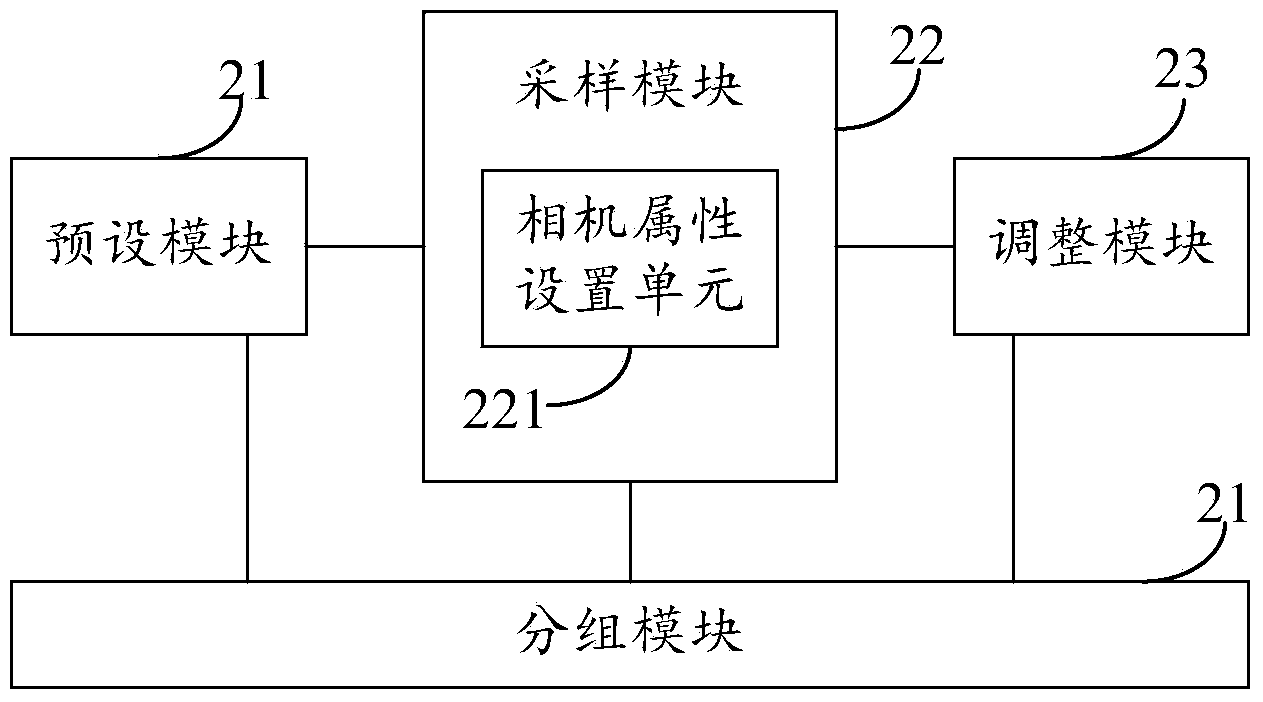

Camera auxiliary correcting method, device and system based on image fusion processing

InactiveCN103716603AHigh precisionGuaranteed accuracyPicture reproducers using projection devicesProjection screenColor correction

The invention discloses a camera auxiliary correcting method, device and system based on image fusion processing, so that efficiency and precision of geometric correction, color correction and / or fusion zone correction and relevant corrections are improved. The method comprises the steps that correction data are preset, and corresponding correction results are output and displayed on a projection screen through a projector; a camera is ordered to take a photo, and the essence characteristic parameters of the correction results on the photo are sampled and extracted; the correction data are adjusted according to the relationship between the essence characteristic parameters and target characteristic parameters, corresponding correction results are output and displayed on the projection screen through the projector, and then photo taking, comparison and adjustment are carried out, according to the loop, the process is over until the essence characteristic parameters and the target characteristic parameters are consistent or within a certain error range, and the final correction data are obtained.

Owner:BEIJING TRICOLOR TECH

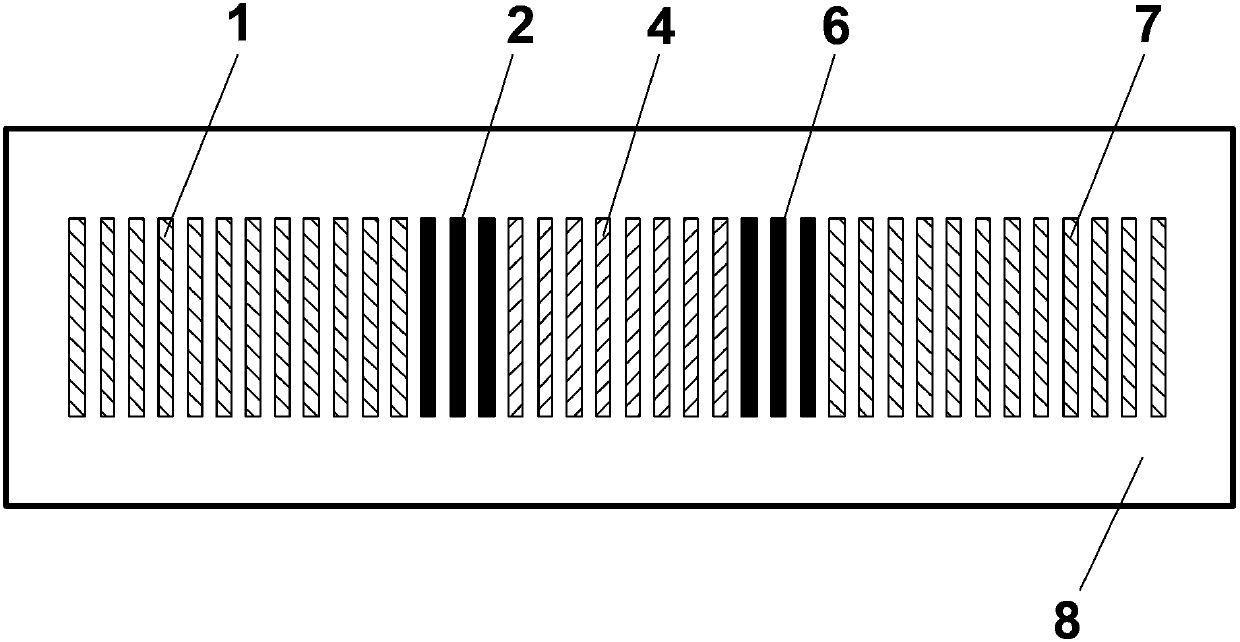

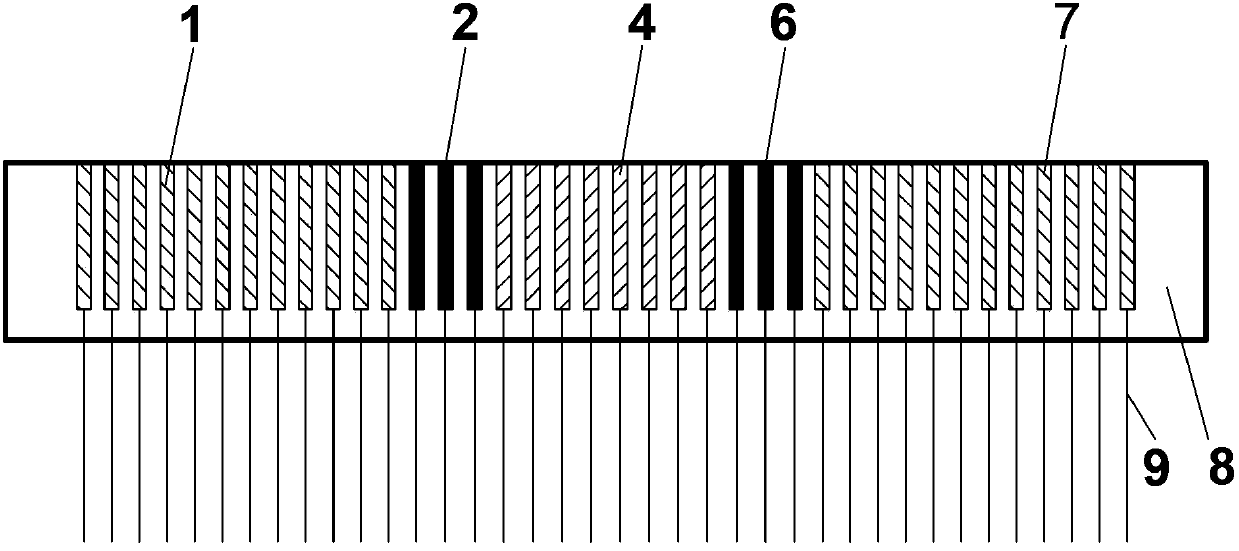

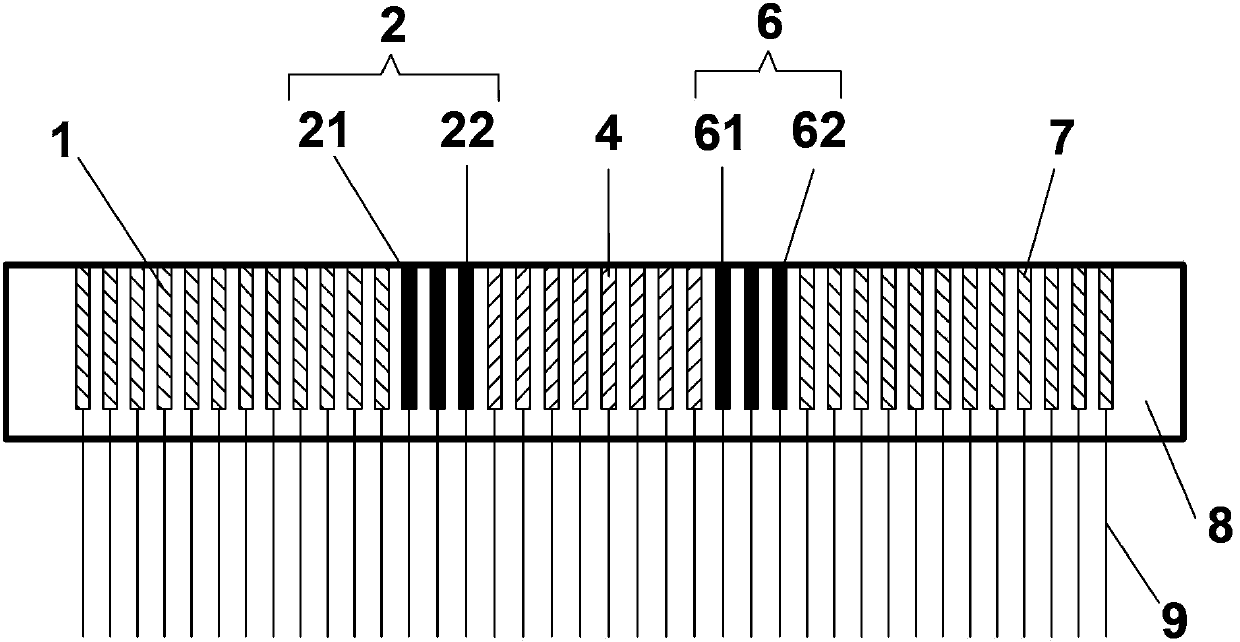

Modularized array electrode of precision simulate welded joint and manufacturing method thereof

InactiveCN103418924AMaintain longitudinal stressAvoid Mixed Electrode SituationsWelding apparatusMicroelectrodeArea ratio

The invention relates to a modularized array electrode of a precision simulate welded joint and a manufacturing method thereof. The modularized array electrode comprises three microelectrode modules: a base metal module, a welding heat affected zone module and a weld metal module, wherein the welding heat affected zone module is arranged between the base metal module and the weld metal module. According to the manufacturing method of the modularized array electrode of the precision simulate welded joint, sample preparations of a base metal zone, a welding heat affected zone, a fusion zone and a weld zone are conducted respectively, the base metal zone, the welding heat affected zone, the fusion zone and the weld zone are recombined and renatured according to the structure features of the welded joint, and therefore the array electrode is manufactured and obtained. The precision simulate welded joint is similar to an actual welded joint in structure and performance and is accurate in simulation and adjustable in area ratio. Through a modularized combination and manufacturing method, an individual test for a certain microelectrode in a certain module can be achieved, coupling tests and scan tests for a certain module or all the modules can be achieved, and the modularized array electrode is especially suitable for galvanic corrosion testing of a multielectrode system.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

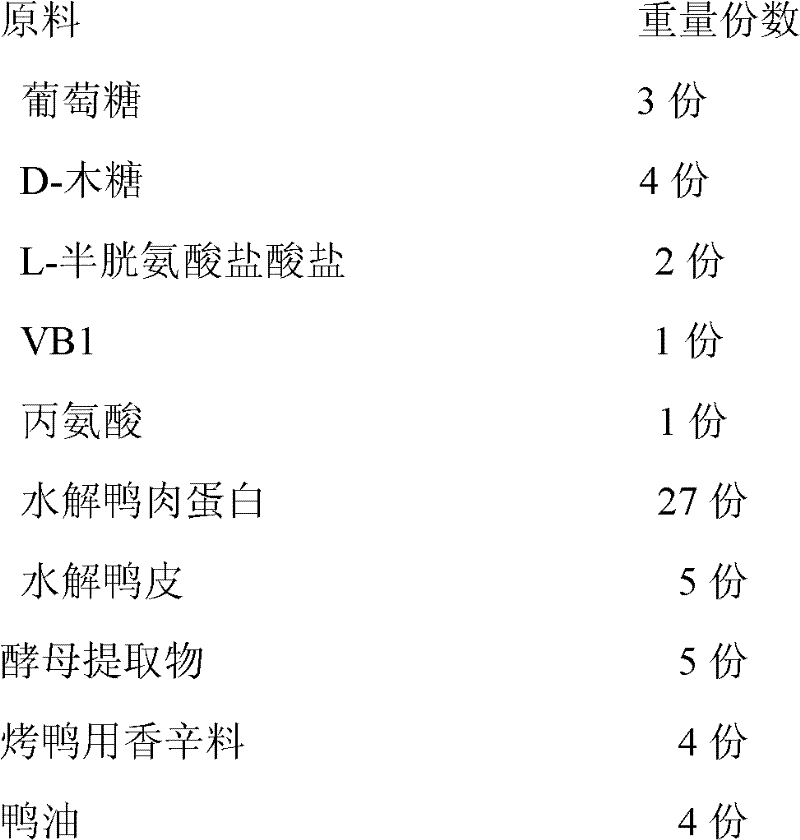

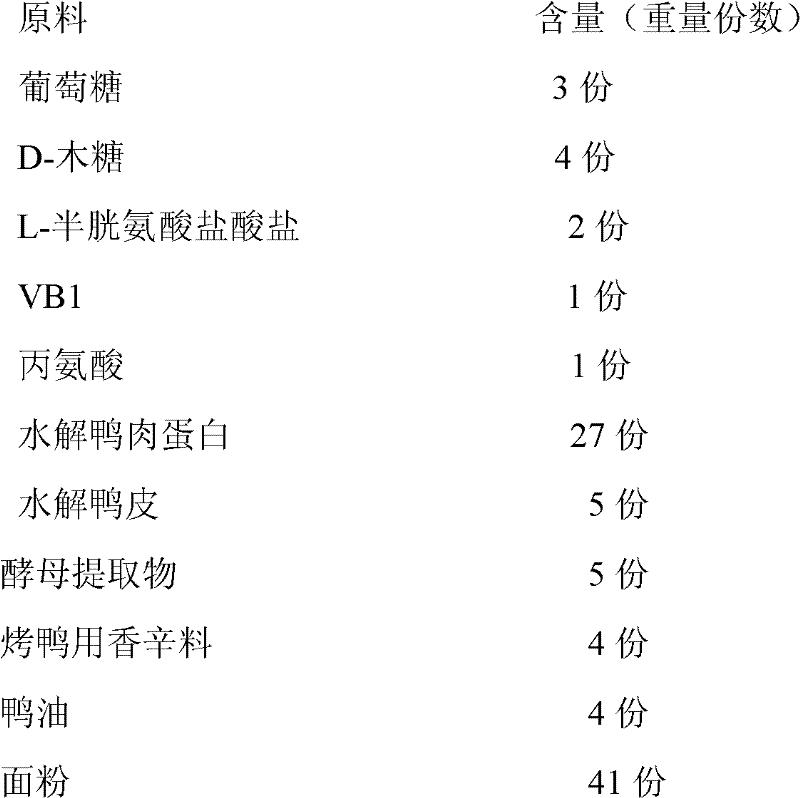

A duck meat flavor essence prepared by extrusion technology

The invention relates to a duck flavor essence prepared with an extrusion technology. The essence is obtained through a preparation method comprising the following steps: 1, mixing raw materials; and 2, extrudion reacting: preheating a twin-screw extruder to an assigned temperature, wherein the temperature of a mixing zone is 60-130DEG C, the temperature of a shearing zone is 90-160DEG C, and thetemperature of a fusion zone is 120-190DEG C, adding a raw material mixture obtained in step 1 to the charging hopper of the extruder, starting screws, adjusting the rotating speed of the screws to 100-400rpm, charging at a uniform speed, controlling the charging speed at 20-500kg / h, conveying and extruding the raw materials in the extruder, extruding from a die port of the extruder, cooling extrudates to room temperature, and pulverizing with a pulverizer to obtain the powdery essence. The essence prepared in the invention has a heavy duck flavor.

Owner:TIANJIN CHUNFA BIO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com