Solar cell substrate, manufacturing method of solar cell and crucible used for same

A technology of solar cells and crucibles, applied in chemical instruments and methods, circuits, electrical components, etc., can solve problems such as difficulty in matching corrosive agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

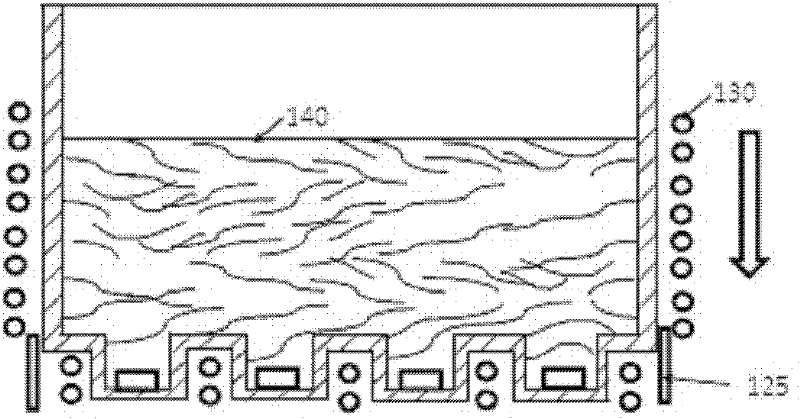

[0017] Embodiments of the present invention enable the production of solar cells at reduced cost while reducing health and environmental hazards in conventional solar cell manufacturing processes. Contrary to conventional teaching, the present invention discloses a method of using metallurgical grade silicon (MGSi) of 3N-5N purity to fabricate substrates and solar cells. Various embodiments of the present disclosure combine the benefits of crystalline silicon solar cells and thin film silicon solar cells based on thin film technology cells with conversion efficiencies greater than 16%. In order to improve the conversion efficiency, the short-circuit current, JC, is increased by texturizing the surface of the silicon wafer before fabricating the solar cell. By casting metallurgical-grade silicon on multiple crystals, the percentage of crystals can be increased to facilitate the texturing process.

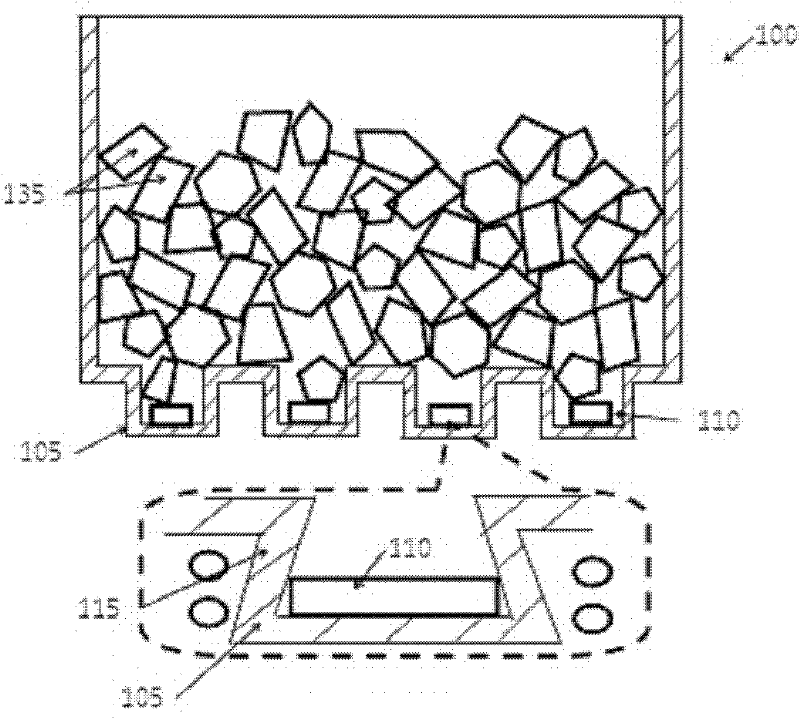

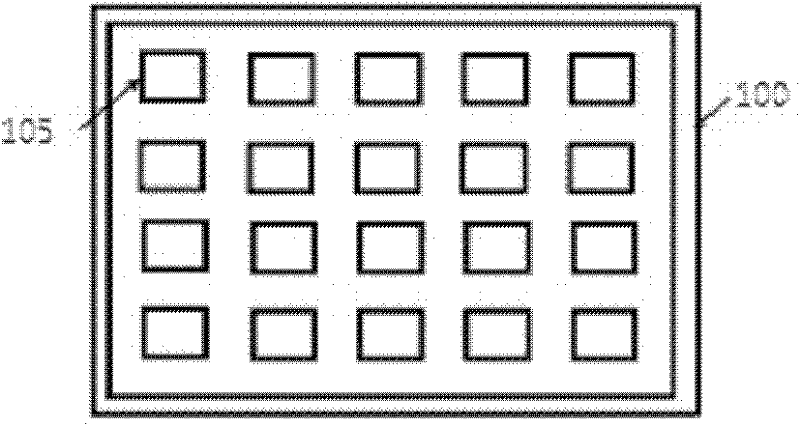

[0018] figure 1 is a casting crucible 100 shown according to an exemplary em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com