Patents

Literature

2416results about How to "Prevent floating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efem

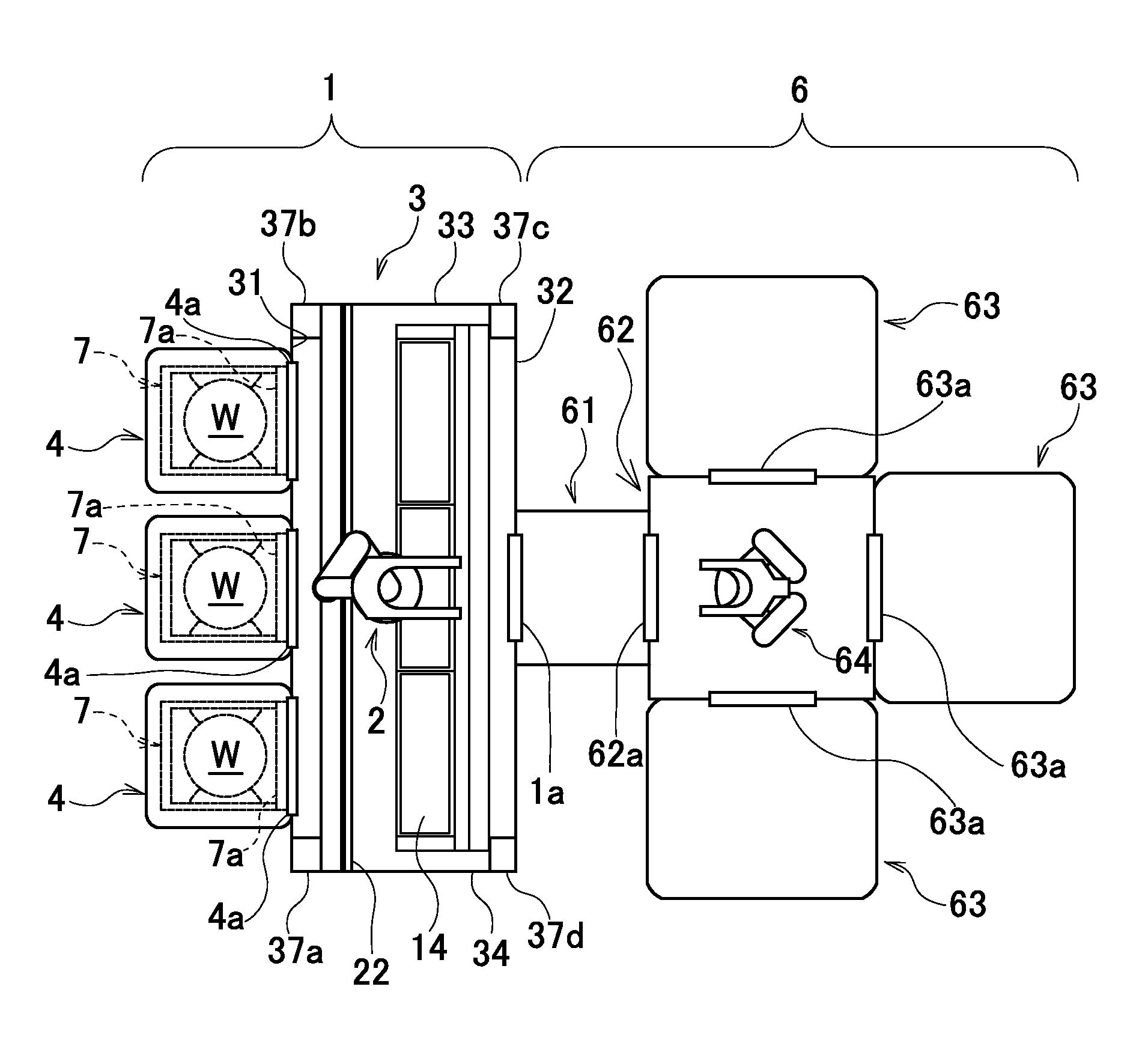

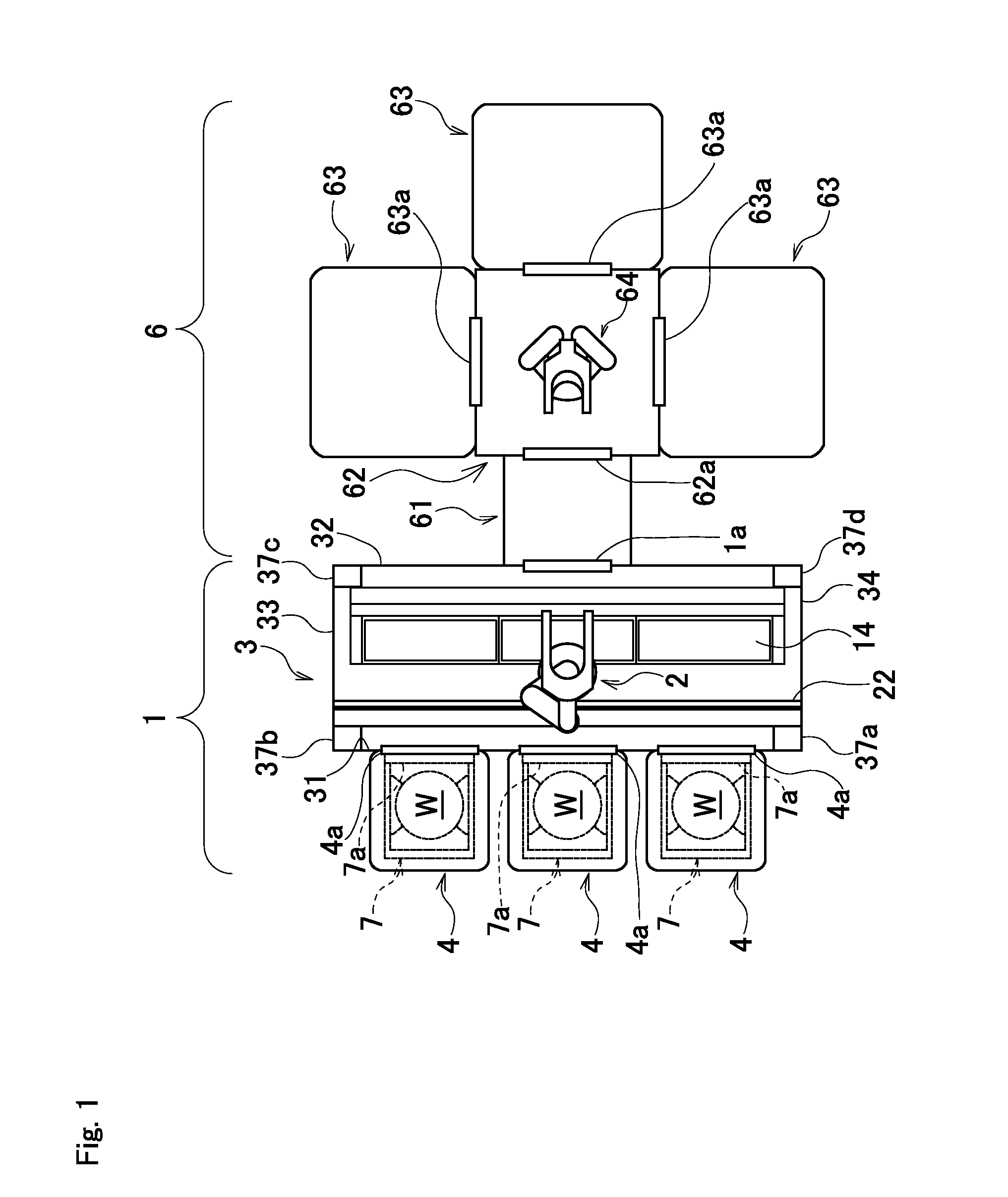

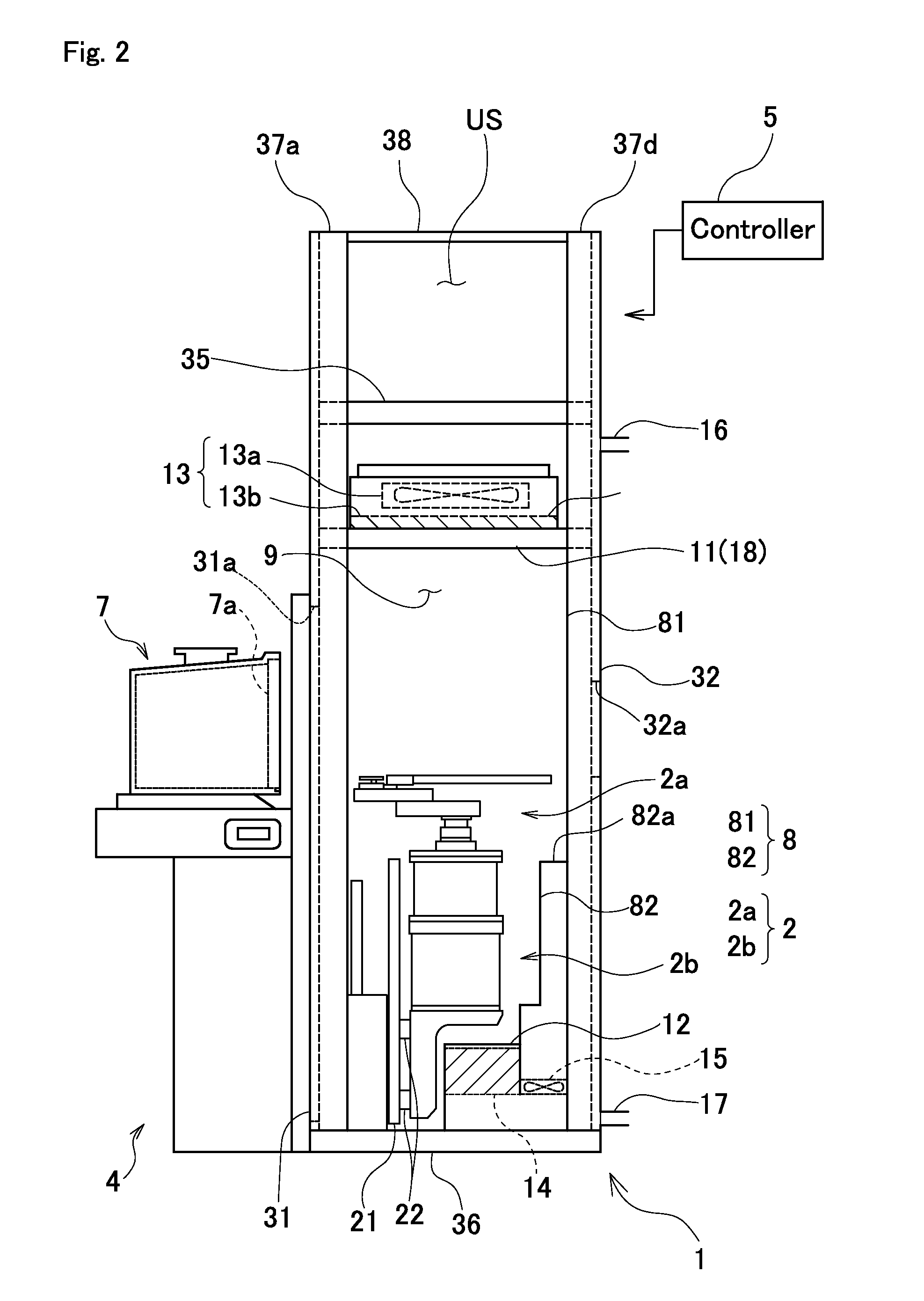

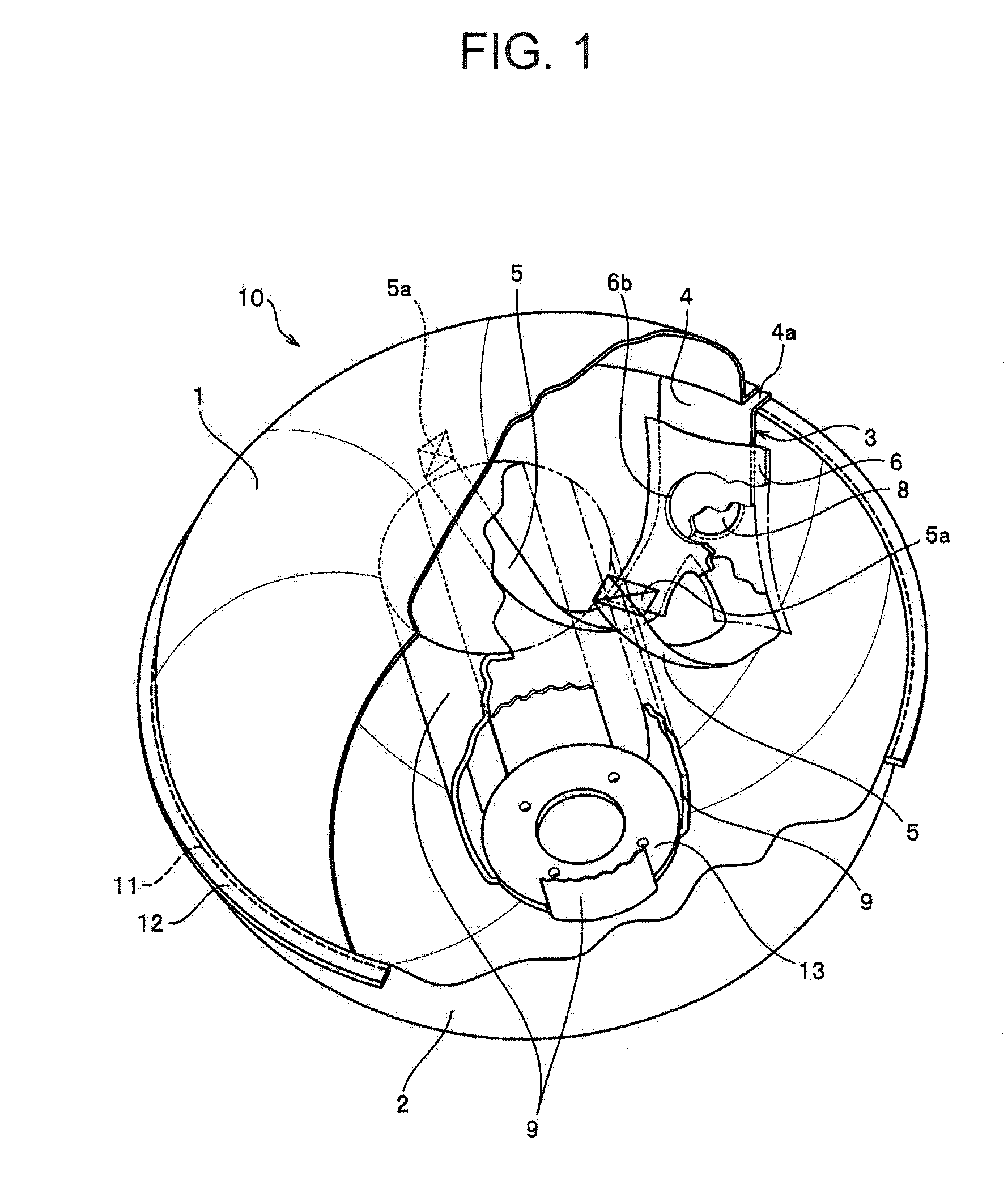

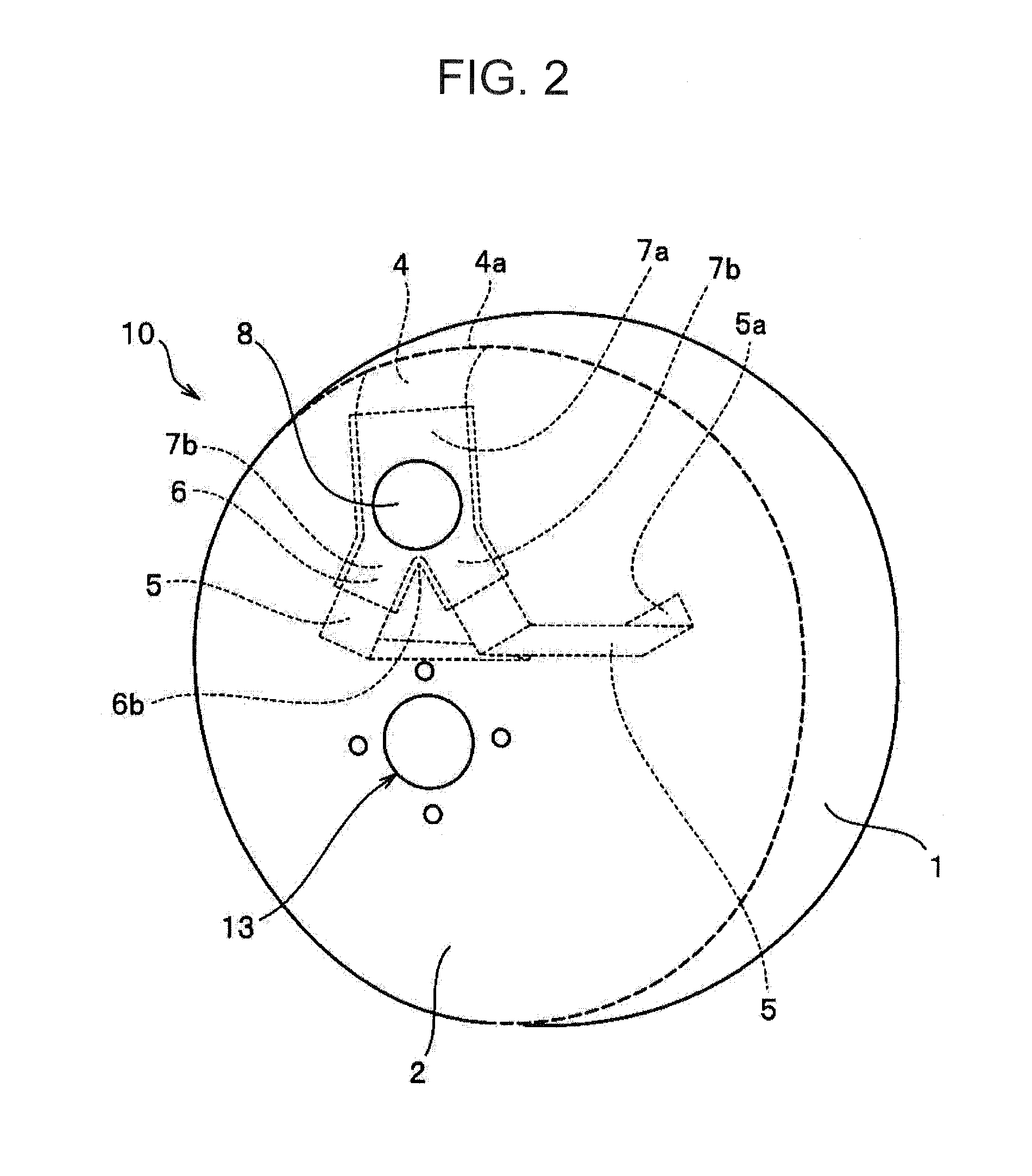

ActiveUS20150170945A1Avoid yield lossMaintain normal stateSemiconductor/solid-state device manufacturingConveyor partsWaste managementFOUP

An EFEM includes a housing 3 that constitutes a wafer transport chamber 9 that is substantially closed by connecting load ports 4 to an opening 31a provided on a wall 31, and connecting a processing apparatus 6; a wafer transport apparatus 2, and transports a wafer between the processing apparatus 6 and the FOUPs 7 mounted on the load ports 4; a gas delivery port 11; a gas suction port 12; a gas feedback path 10; and a FFU 13 that includes a filter 13b that is provided in the gas delivery port 11, and eliminates particles contained in the delivered gas, wherein the gas in the wafer transport chamber 9 is circulated by generating a downward gasflow in the wafer transport chamber 9 and feeding back the gas through the gas feedback path 10.

Owner:SINFONIA TECHNOLOGY CO LTD

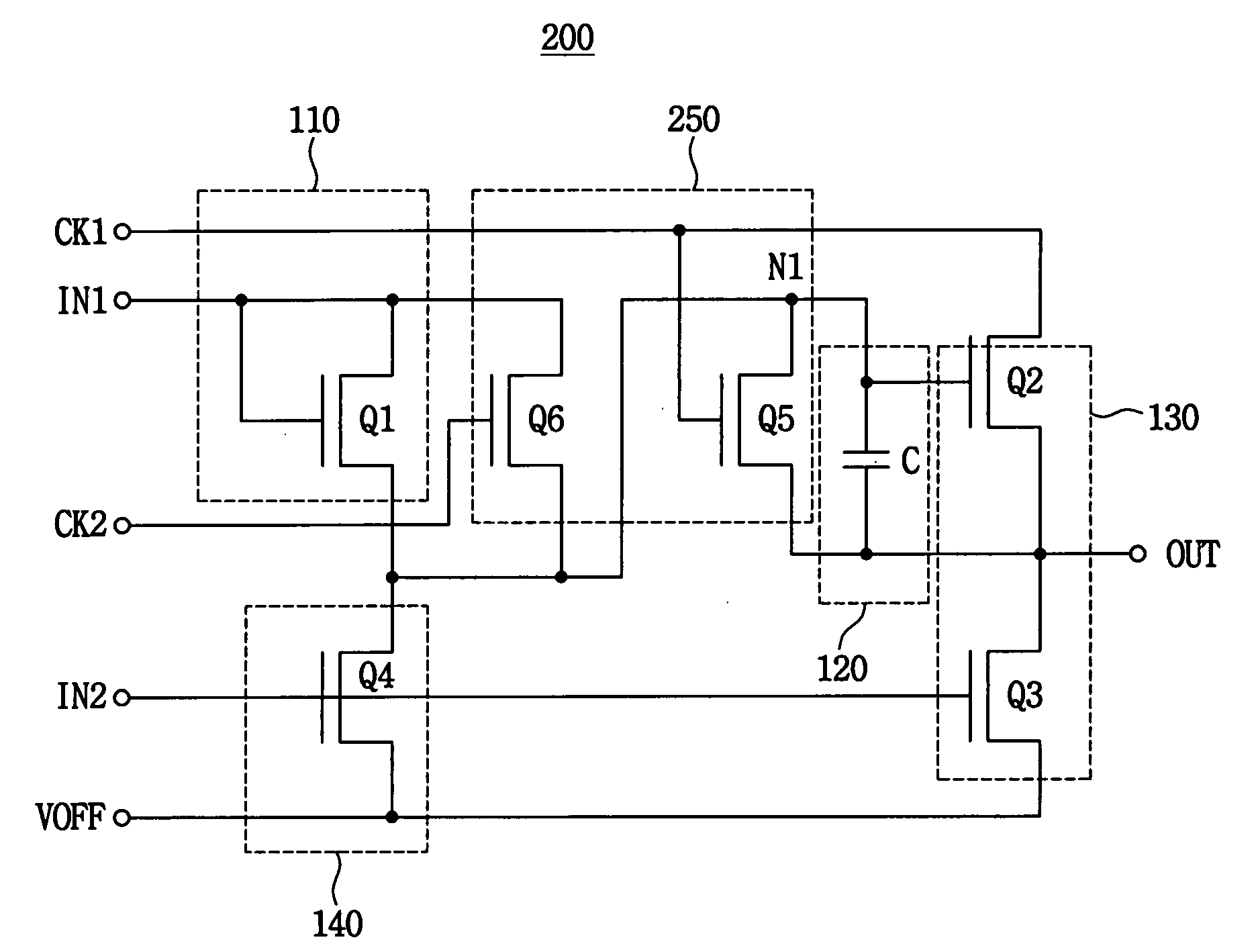

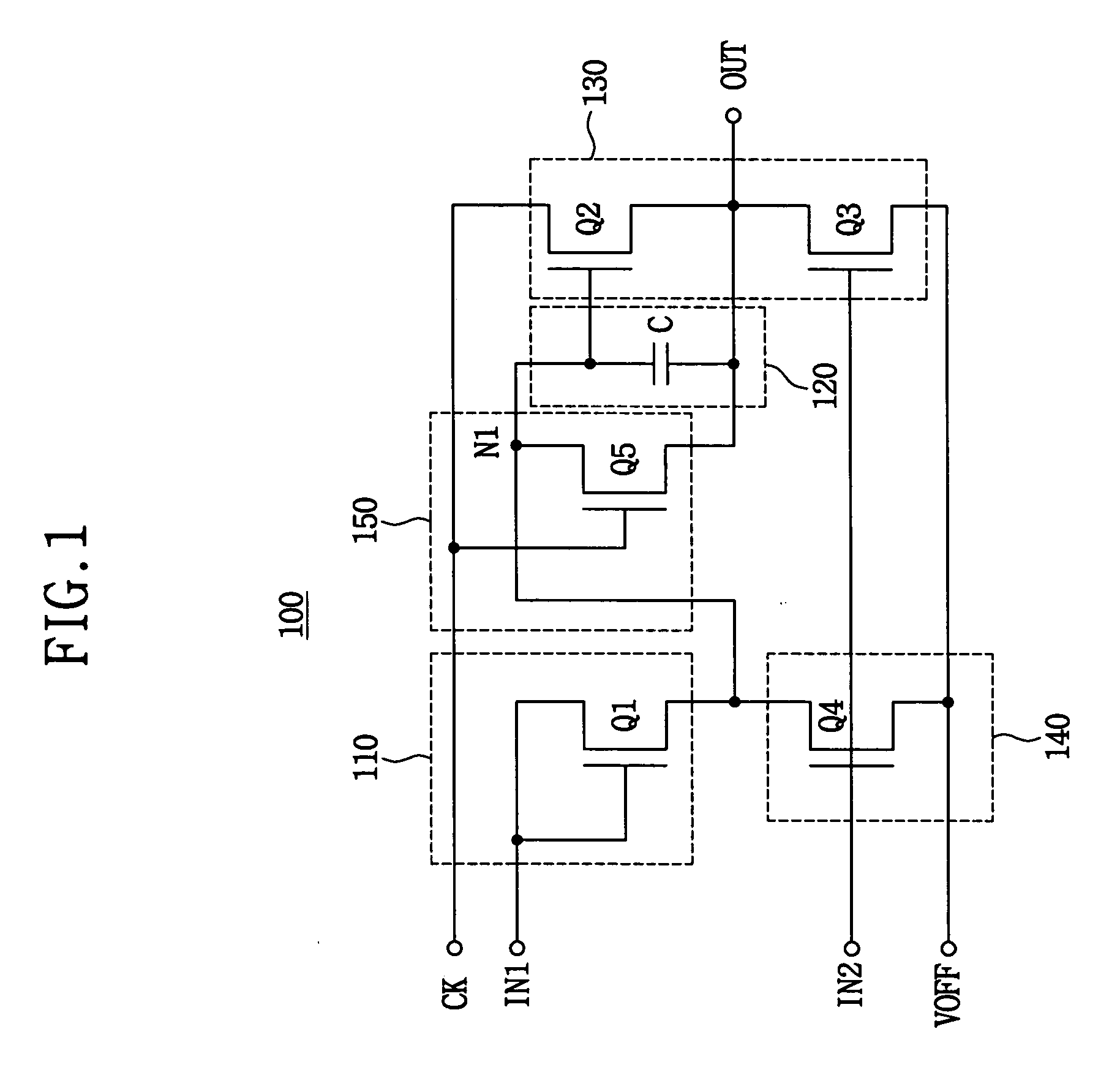

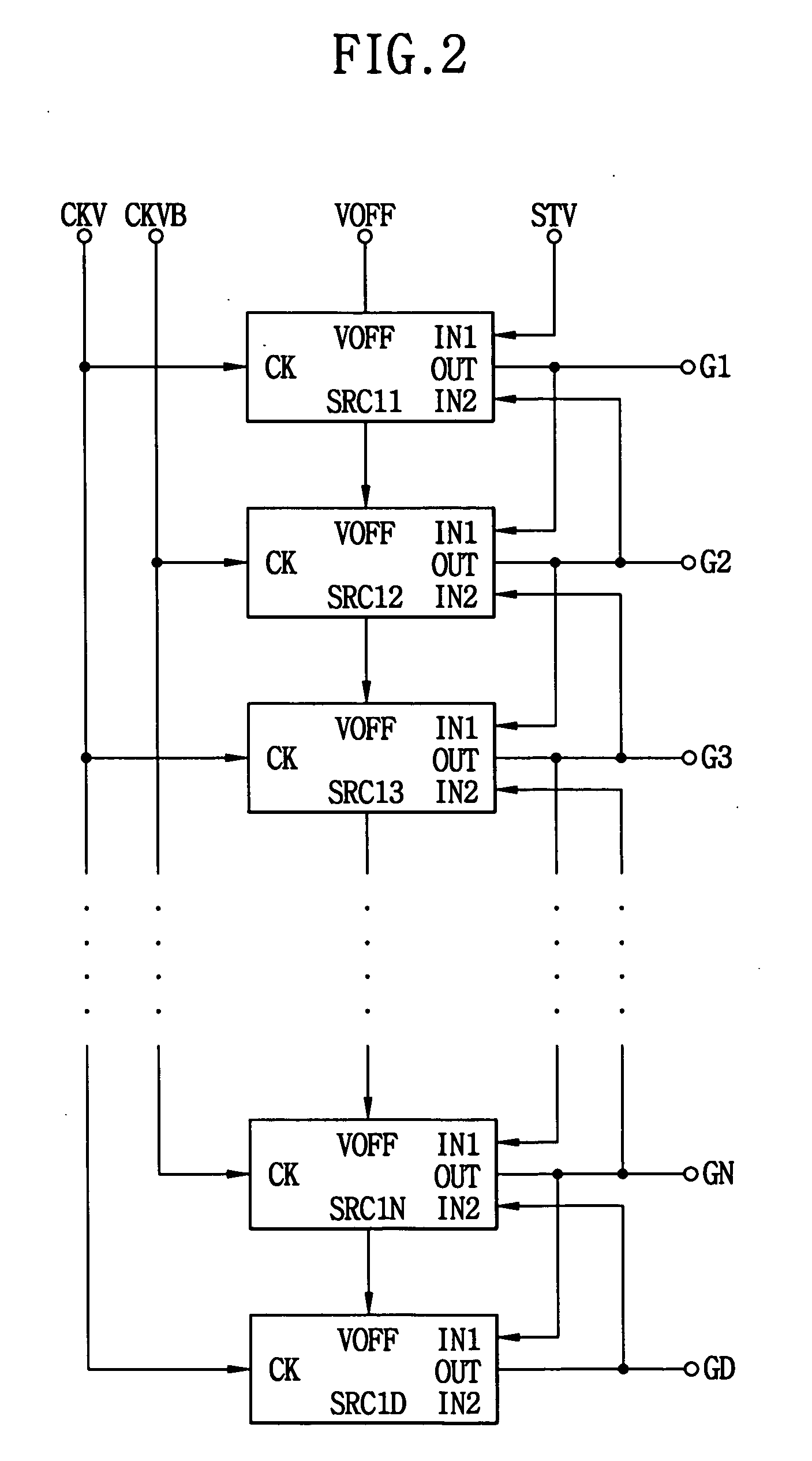

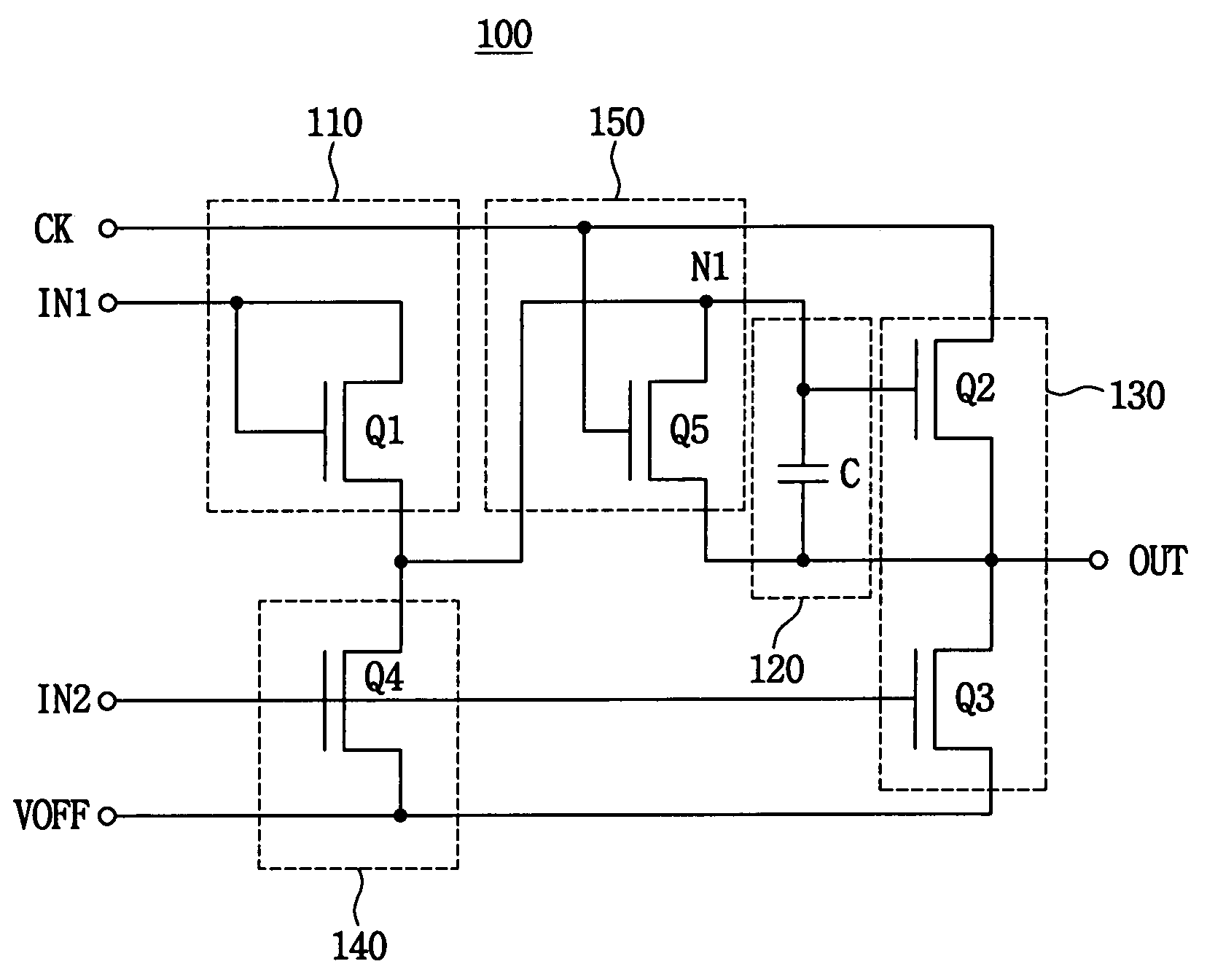

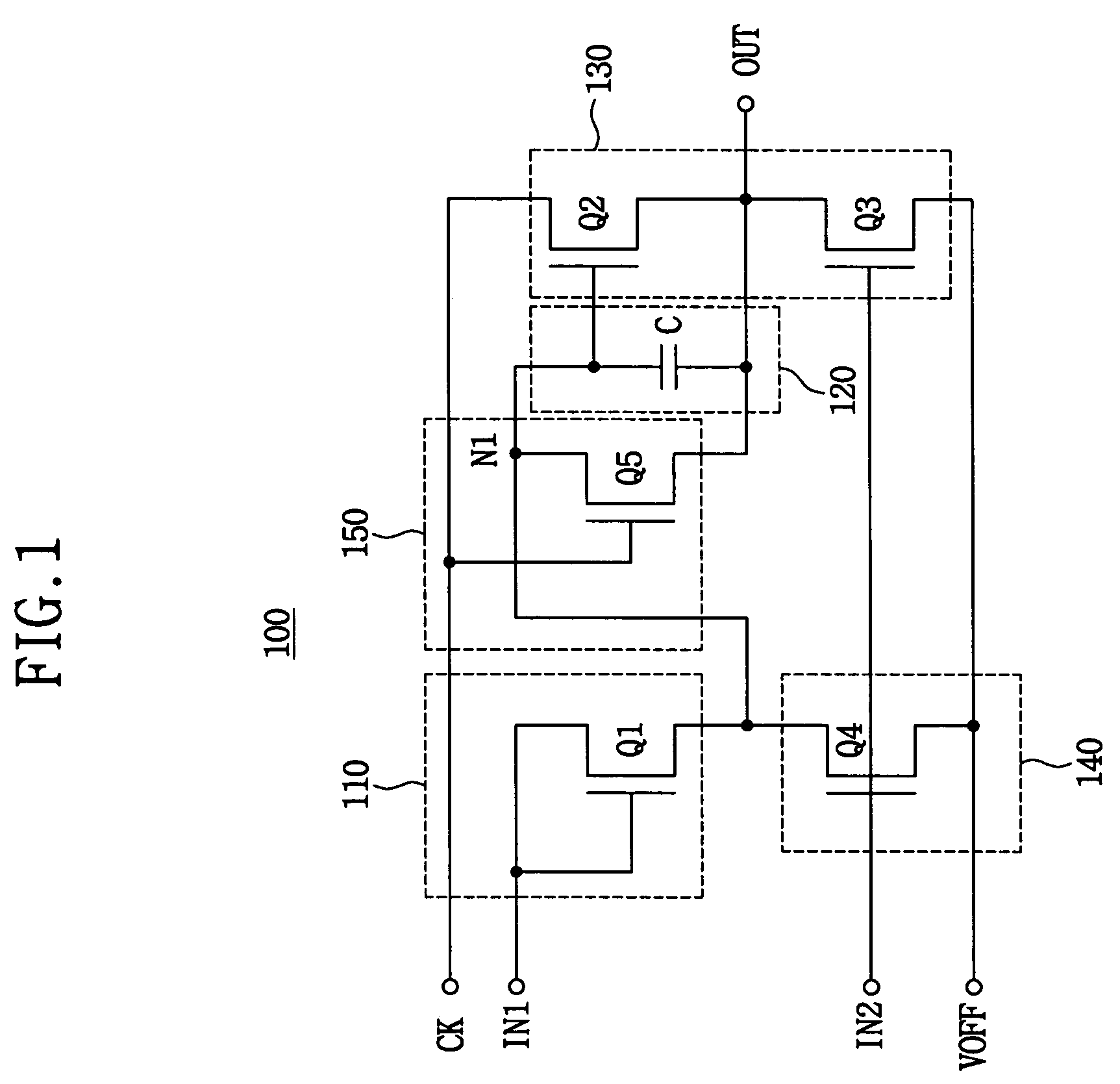

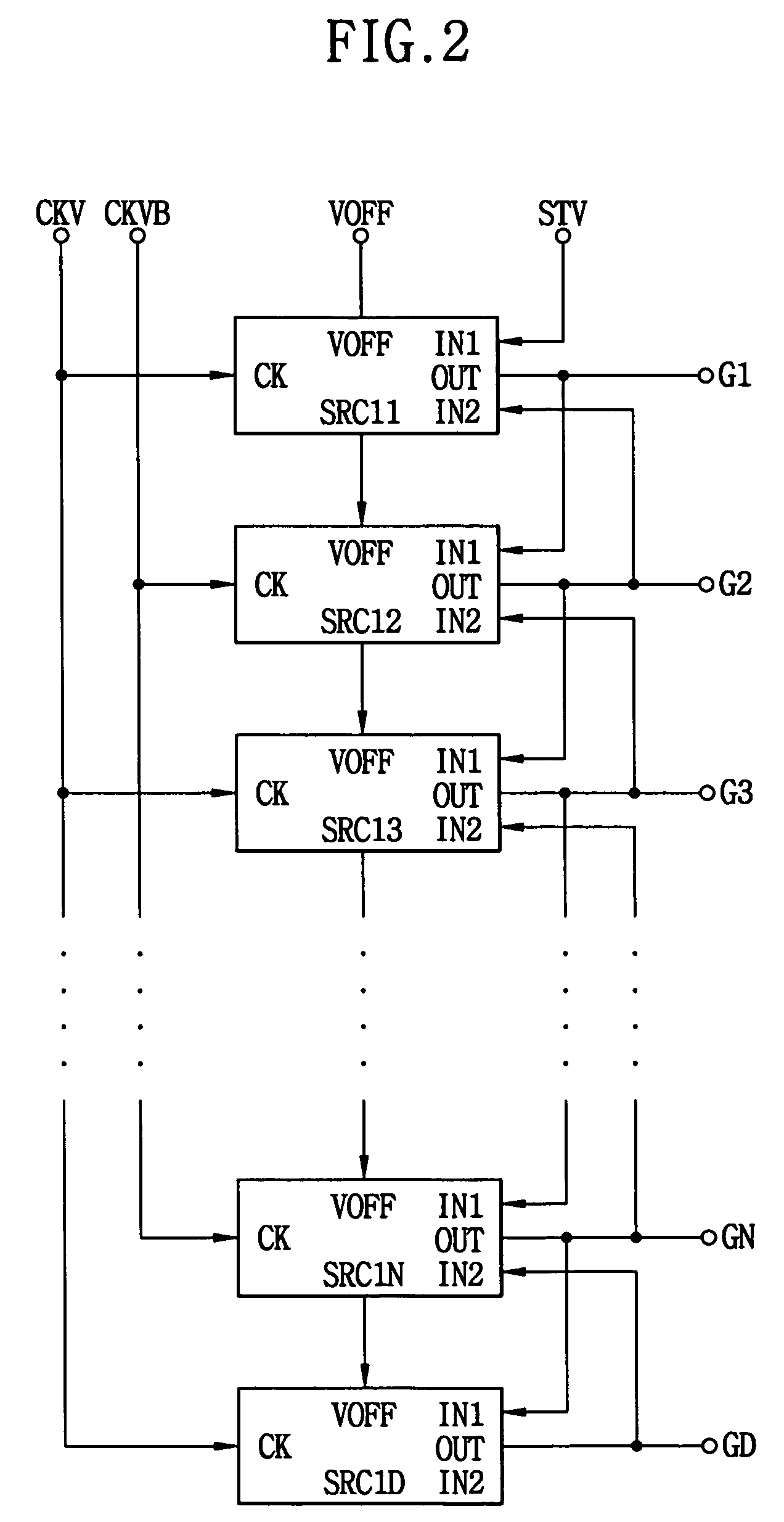

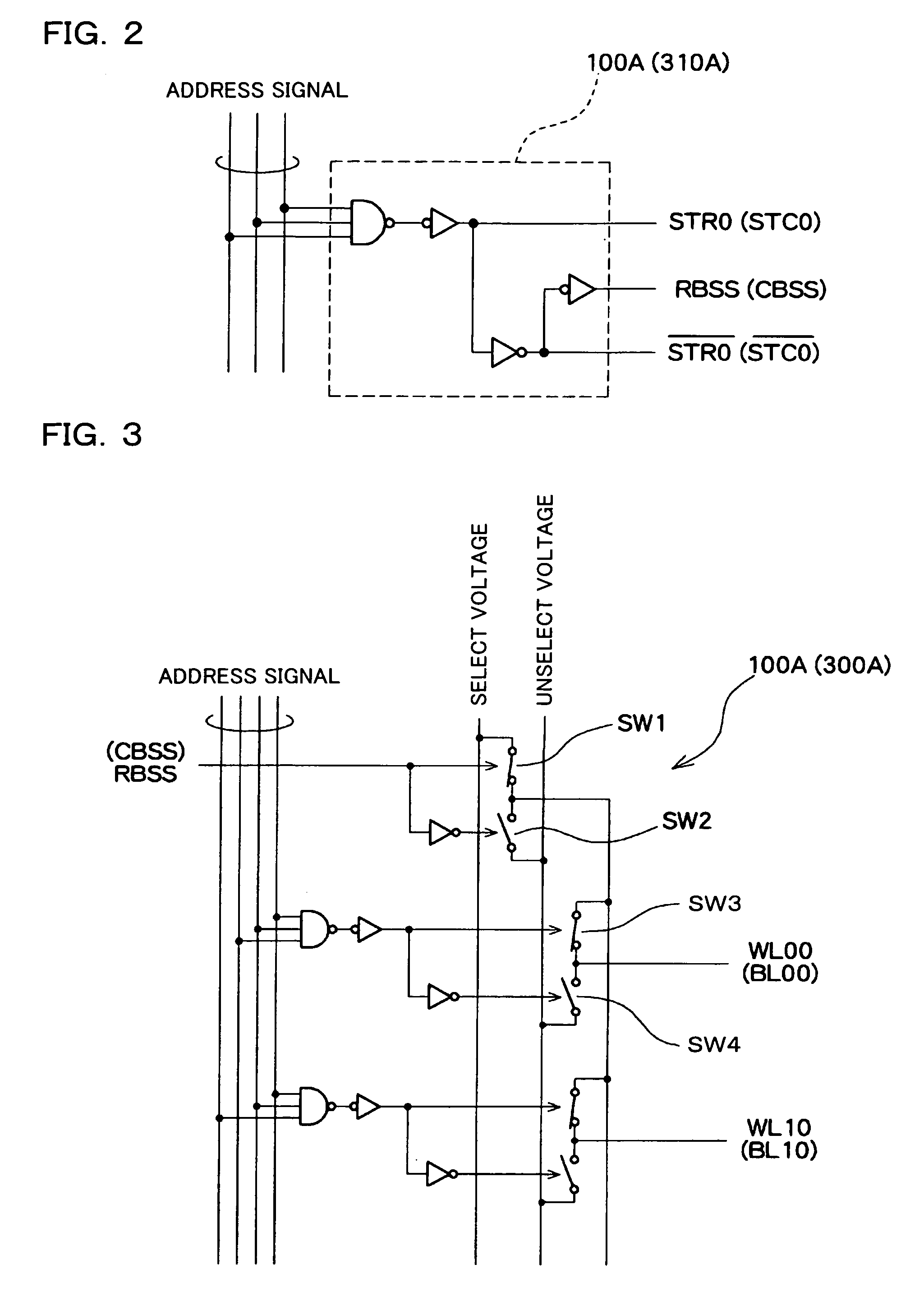

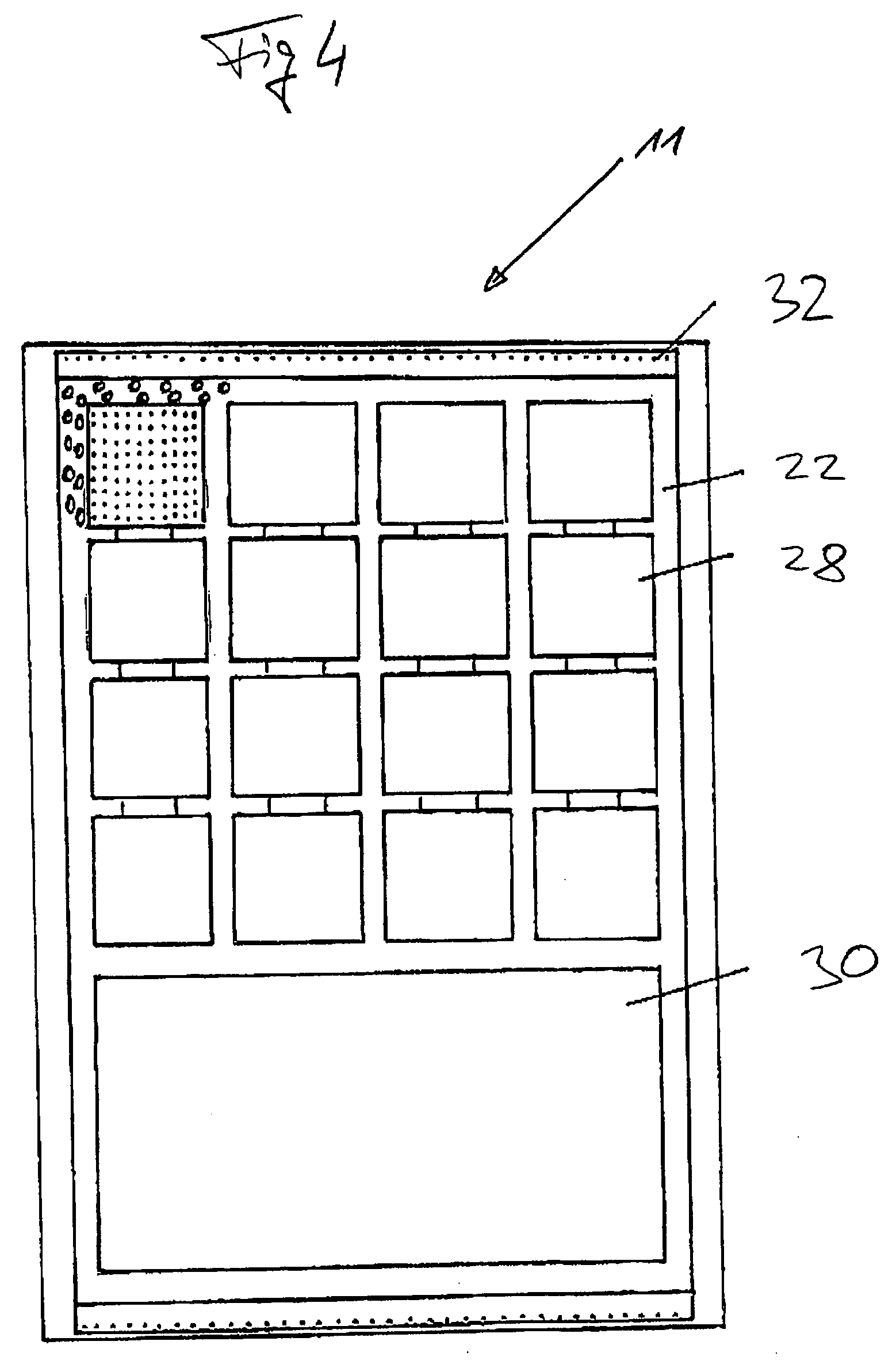

Shift register, scan driving circuit and display apparatus having the same

ActiveUS20050008114A1Reduce parasitic capacitancePrevent floatingStatic indicating devicesDigital storageStart signalEngineering

A shift register includes a plurality of stages to generate a plurality of output signals, in sequence. Each of the stages includes a driving circuit, a charging circuit, a discharging circuit and a holding circuit. The driving circuit is configured to generate a first output signal in response to a first clock signal or a second clock signal having a phase different from the first clock signal. The charging circuit is configured to charge an electric charge in response to a scan start signal or a second output signal of an adjacent previous stage. The discharging circuit is configured to discharge the electric charge in response to a third output signal of an adjacent next stage. The holding circuit is configured to maintain the first output signal within a first voltage when the first output signal is in an inactive state. Therefore, a parasite capacitance is decreased to prevent a floating of a pull-up transistor.

Owner:SAMSUNG DISPLAY CO LTD

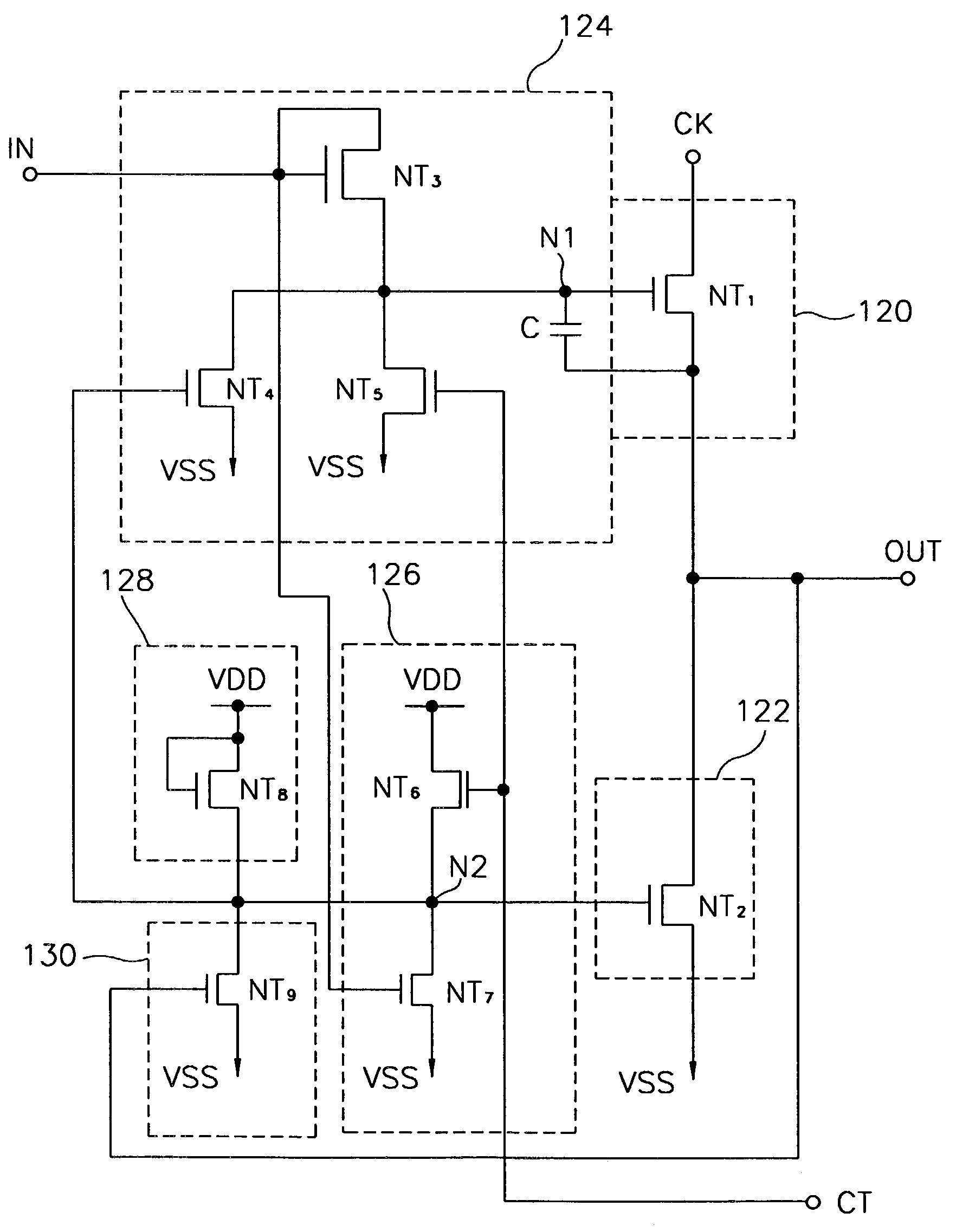

Shift register, scan driving circuit and display apparatus having the same

ActiveUS7486269B2Reduce parasitic capacitancePrevent floatingStatic indicating devicesDigital storageShift registerParasitic capacitance

A shift register includes a plurality of stages to generate a plurality of output signals, in sequence. Each of the stages includes a driving circuit, a charging circuit, a discharging circuit and a holding circuit. The driving circuit is configured to generate a first output signal in response to a first clock signal or a second clock signal having a phase different from the first clock signal. The charging circuit is configured to charge an electric charge in response to a scan start signal or a second output signal of an adjacent previous stage. The discharging circuit is configured to discharge the electric charge in response to a third output signal of an adjacent next stage. The holding circuit is configured to maintain the first output signal within a first voltage when the first output signal is in an inactive state. Therefore, a parasite capacitance is decreased to prevent a floating of a pull-up transistor.

Owner:SAMSUNG DISPLAY CO LTD

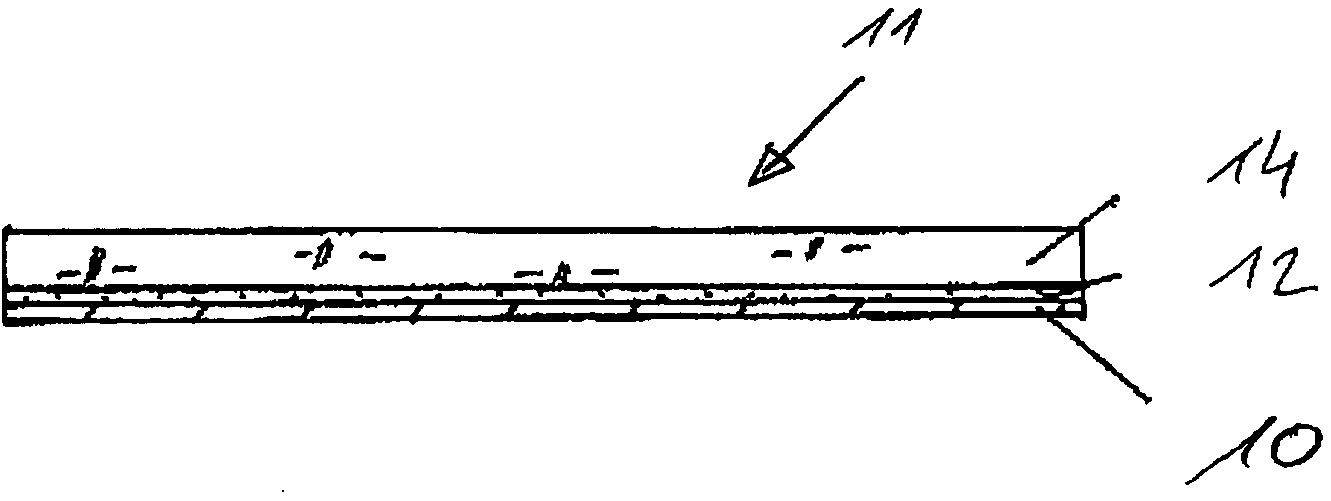

Method for supplementing lithium for negative electrode of lithium ion battery

ActiveCN102916165AAvoid LithiumAvoid deformationElectrode manufacturing processesElectrolyte/reactants regenerationMetallic lithiumElectrical battery

The invention belongs to the technical field of lithium ion batteries, in particular to a method for supplementing lithium for a negative electrode of a lithium ion battery. The method comprises the following steps: spraying or dripping an organic lithium solution on a surface of a negative electrode in an inert atmosphere, so that lithium ions in the organic lithium solution are reverted to metal lithium which is embedded into the negative electrode; and drying the negative electrode. Compared with the prior art, in the method, the organic lithium solution is sprayed or dipped on the surface of the negative electrode evenly so as to realize lithium supplementation in a wet process, thereby effectively avoiding metallic lithium powders floating in the air in a dry process to ensure safe production; and the whole process is simple, the cost is lower, the amount of the lithium supplementation can be controlled accurately through the amount and the time by spraying or dripping the organic lithium solution so as to supplement the lithium evenly, thereby preventing lithium precipitation and deformation of the negative electrode and improving the initial efficiency of the battery. Therefore, the the energy density of the battery is improved. Additionally, the invention further discloses another method for supplementing the lithium for the negative electrode of the lithium ion battery.

Owner:DONGGUAN AMPEREX TECH +1

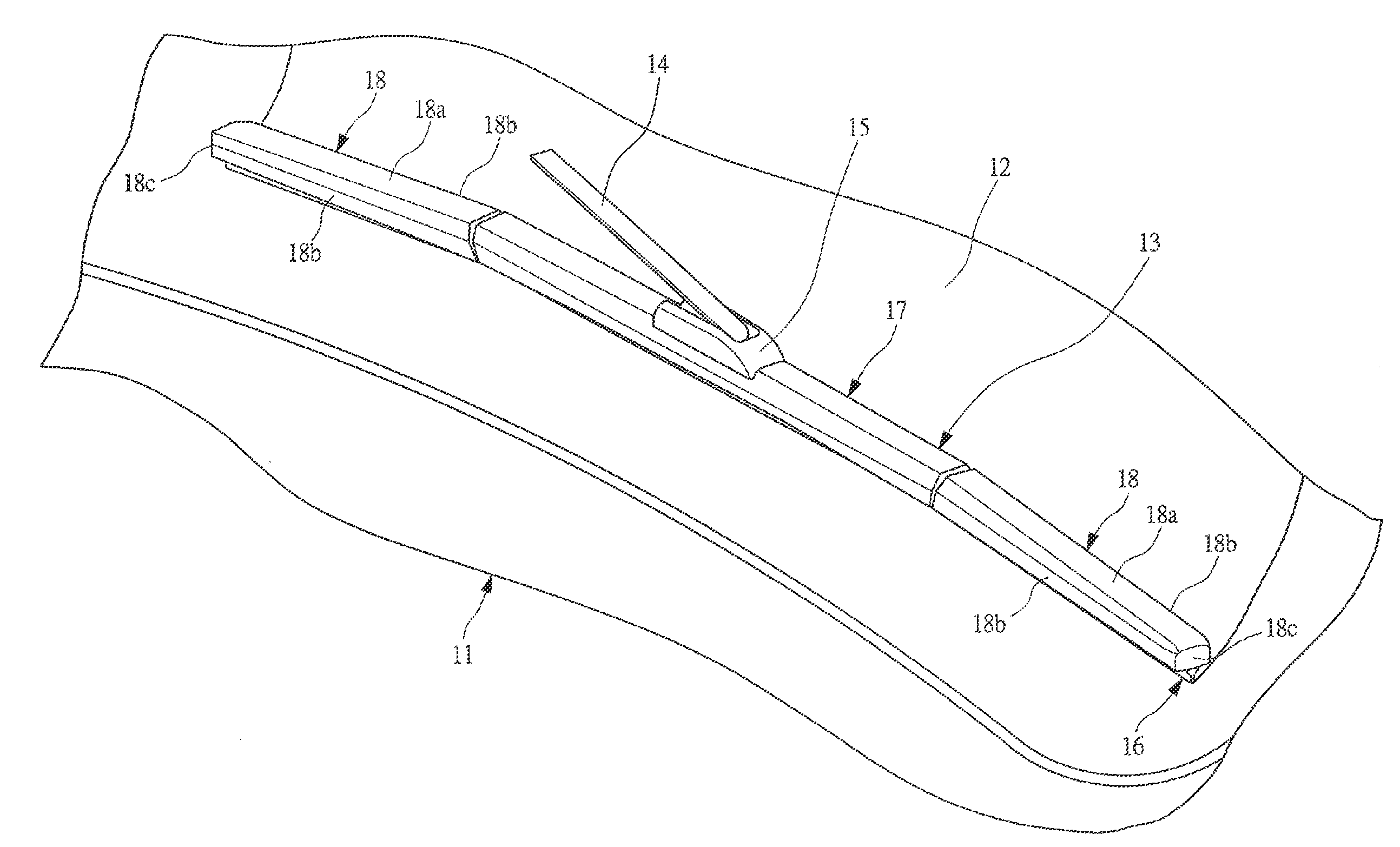

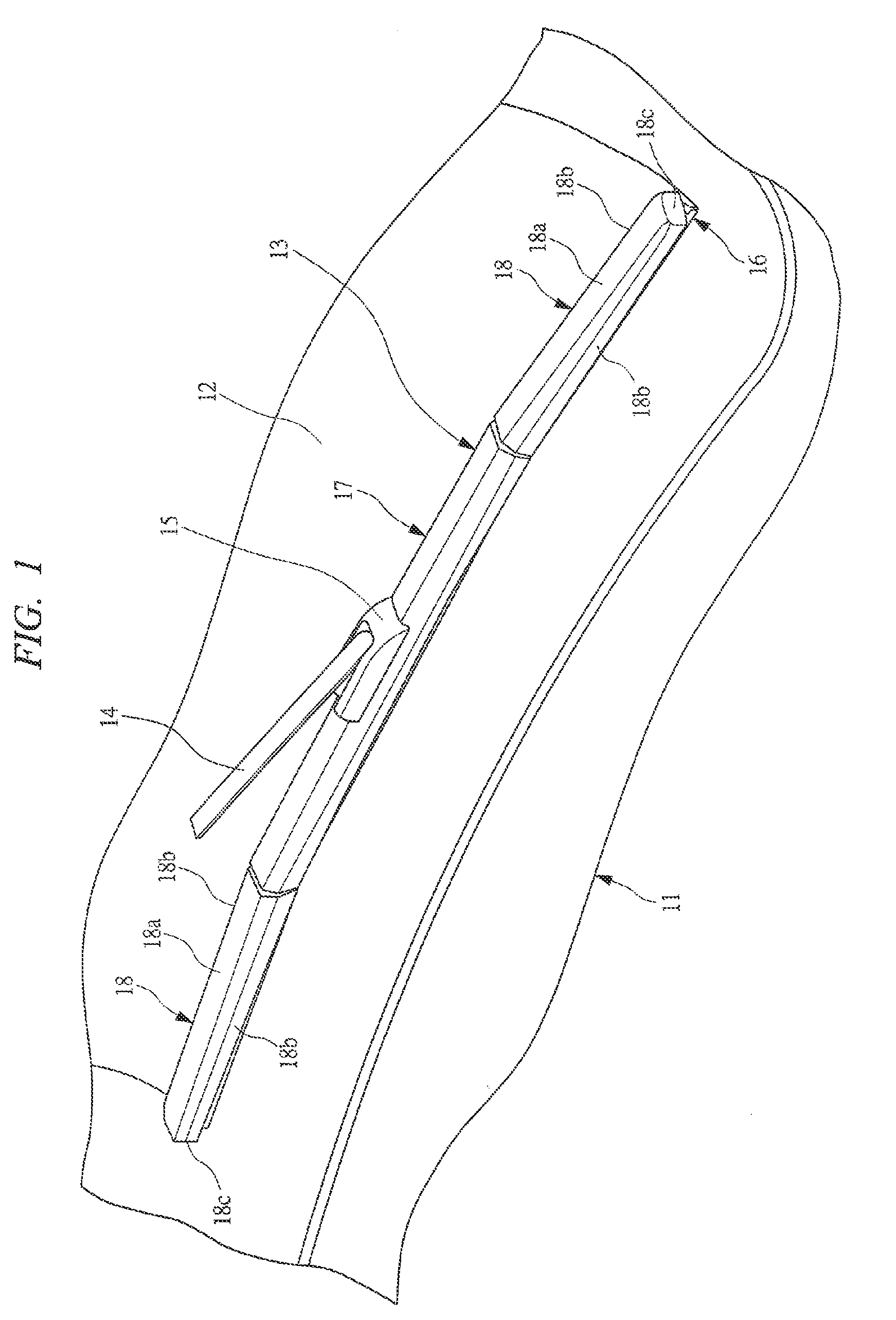

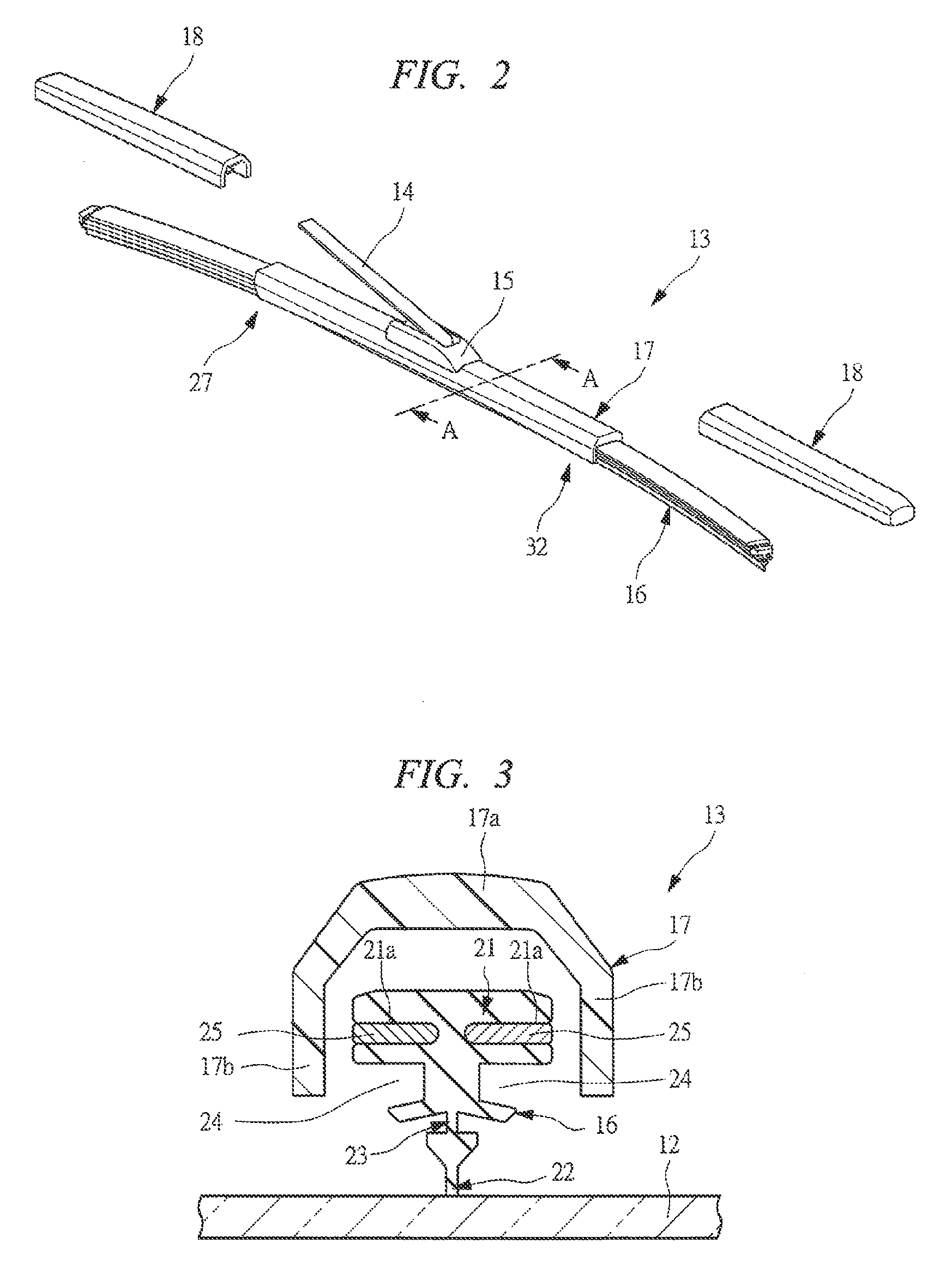

Wiper Blade

ActiveUS20080098559A1Fine appearance be improveEnhance versatilityWindow cleanersVehicle cleaningEngineeringWindshield

A wiper blade 13 comprises a rubber holder 17 attached to a tip of a wiper arm 14 and a blade rubber 16 supported by the rubber holder 17. The rubber holder 17 is formed into a U-shaped cross section, and an intermediate portion of the blade rubber 16 is covered with the rubber holder 17. Also, both sides of the rubber holder 17 are provided with covers 18 in a longitudinal direction in series. Each of the cover 18 becomes rotatable to the rubber holder 17 in a direction perpendicular to a front windshield glass 12, and exposed portions from the rubber holder 17 of the blade rubber 16 are covered with these covers 18 in an elastically deformable state.

Owner:MITSUBA CORP

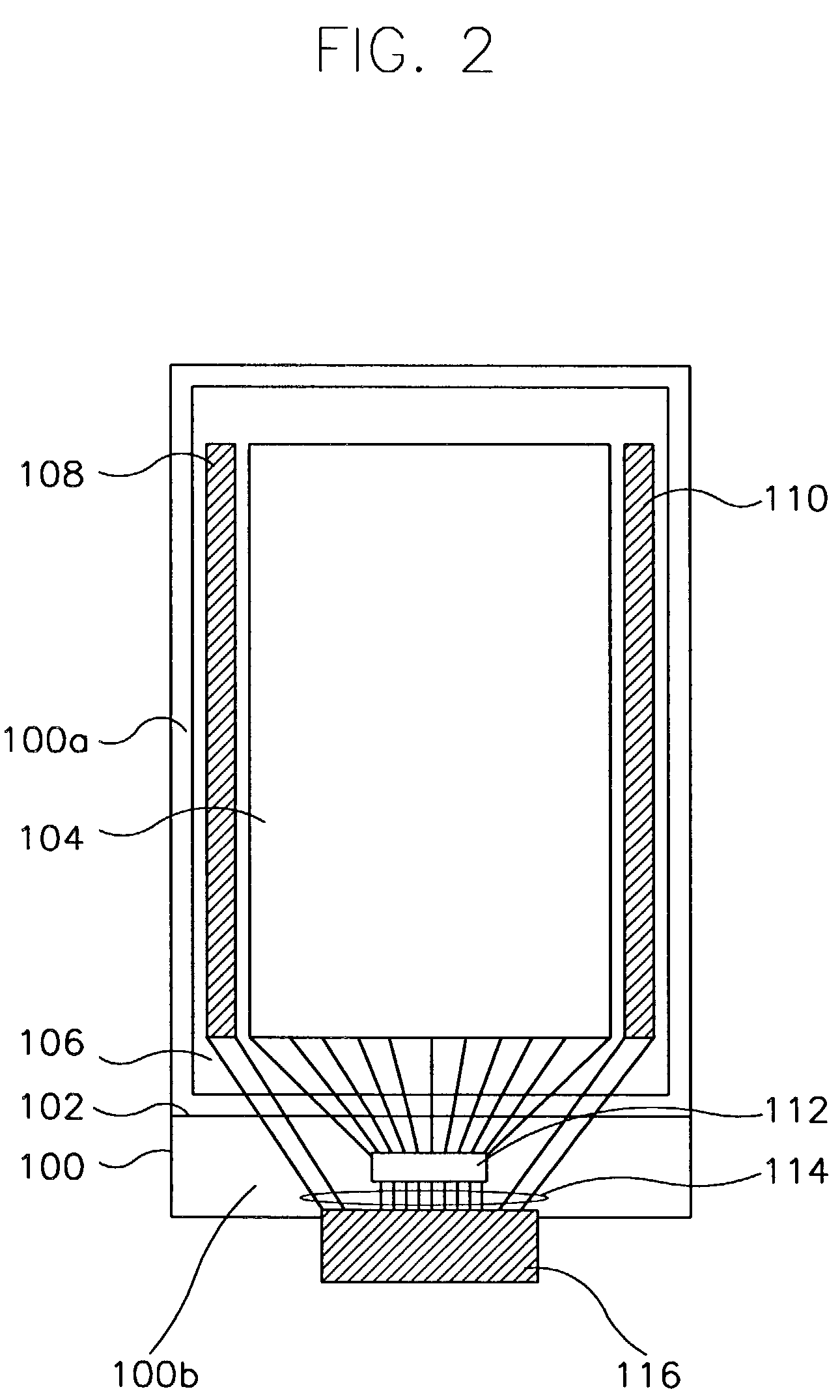

Liquid crystal display apparatus

InactiveUS7522145B2Prevent floatingSmall sizeTransistorStatic indicating devicesLiquid-crystal displayTransistor

A liquid crystal display apparatus is disclosed. A plurality of pixel electrodes are arranged on a display region of a substrate in a matrix form having a plurality of column lines and a plurality of row lines. Each of a plurality of thin film transistors has a first current electrode connected to a corresponding one of the plurality of pixel electrodes. Each of a plurality of data lines is arranged between odd column line and even column line of a pair of the plurality of column lines and is connected to second current electrodes of thin film transistors which are coupled to odd column line and even column line of the pair. Each of a plurality of first gate lines is connected to gate electrodes of odd thin film transistors which are coupled to one of the plurality of row lines. Each of a plurality of second gate lines is connected to gate electrodes of even thin film transistors which is coupled to the one of the plurality of row lines. A data driving circuit is provided for driving the data lines. At least two gate driving circuits having a first gate driving circuit and a second gate driving circuit are provided, wherein the first gate driving circuit is connected to the plurality of first gate lines and the second gate driving circuit is connected to the plurality of second gate lines.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

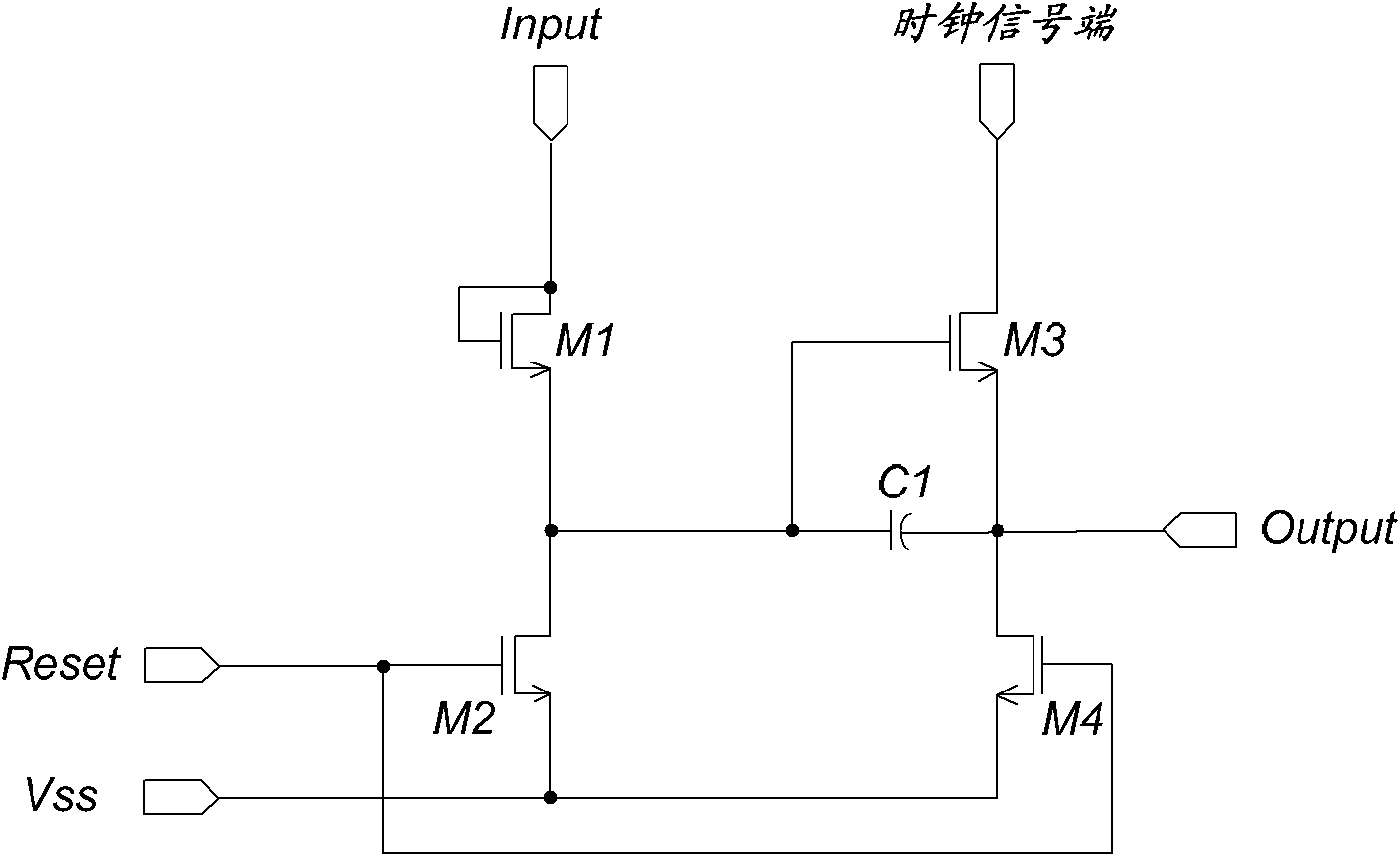

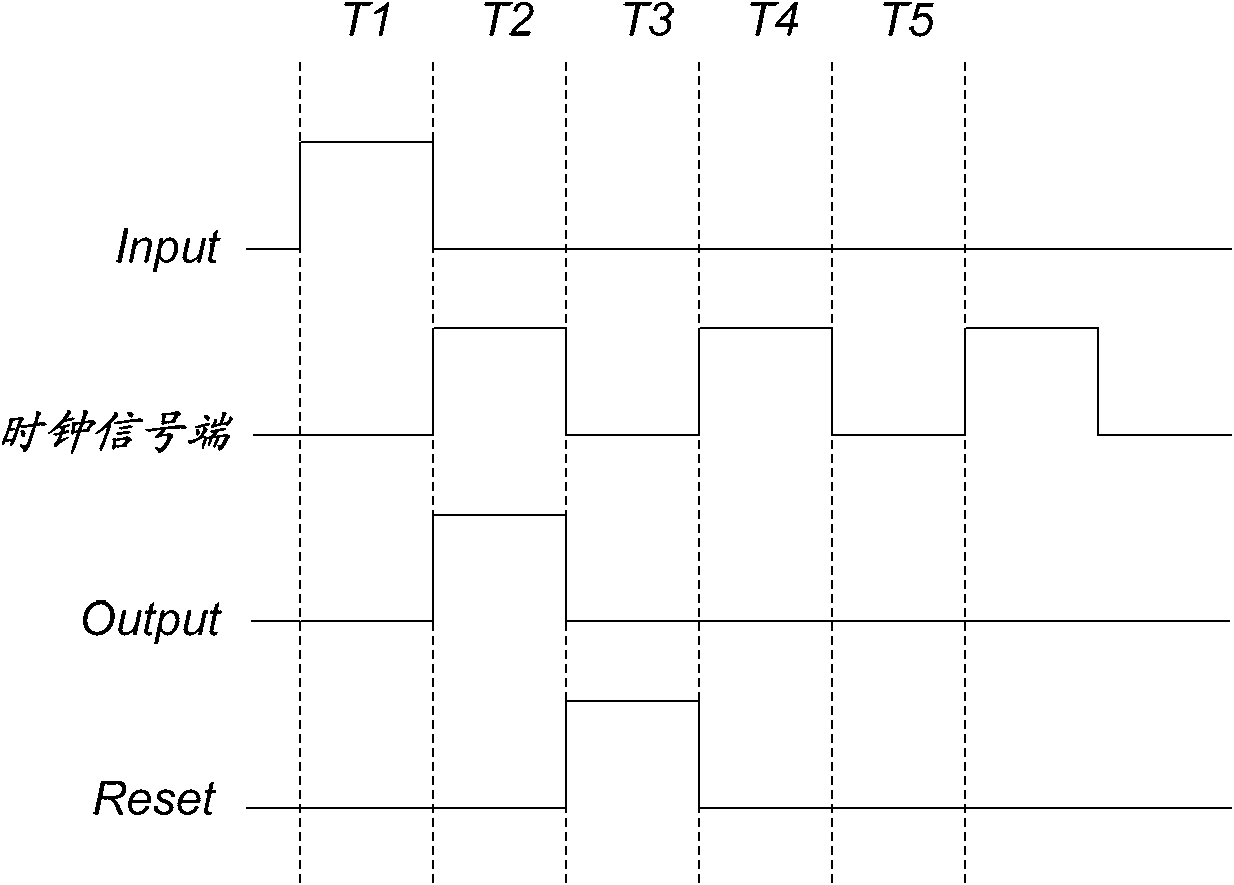

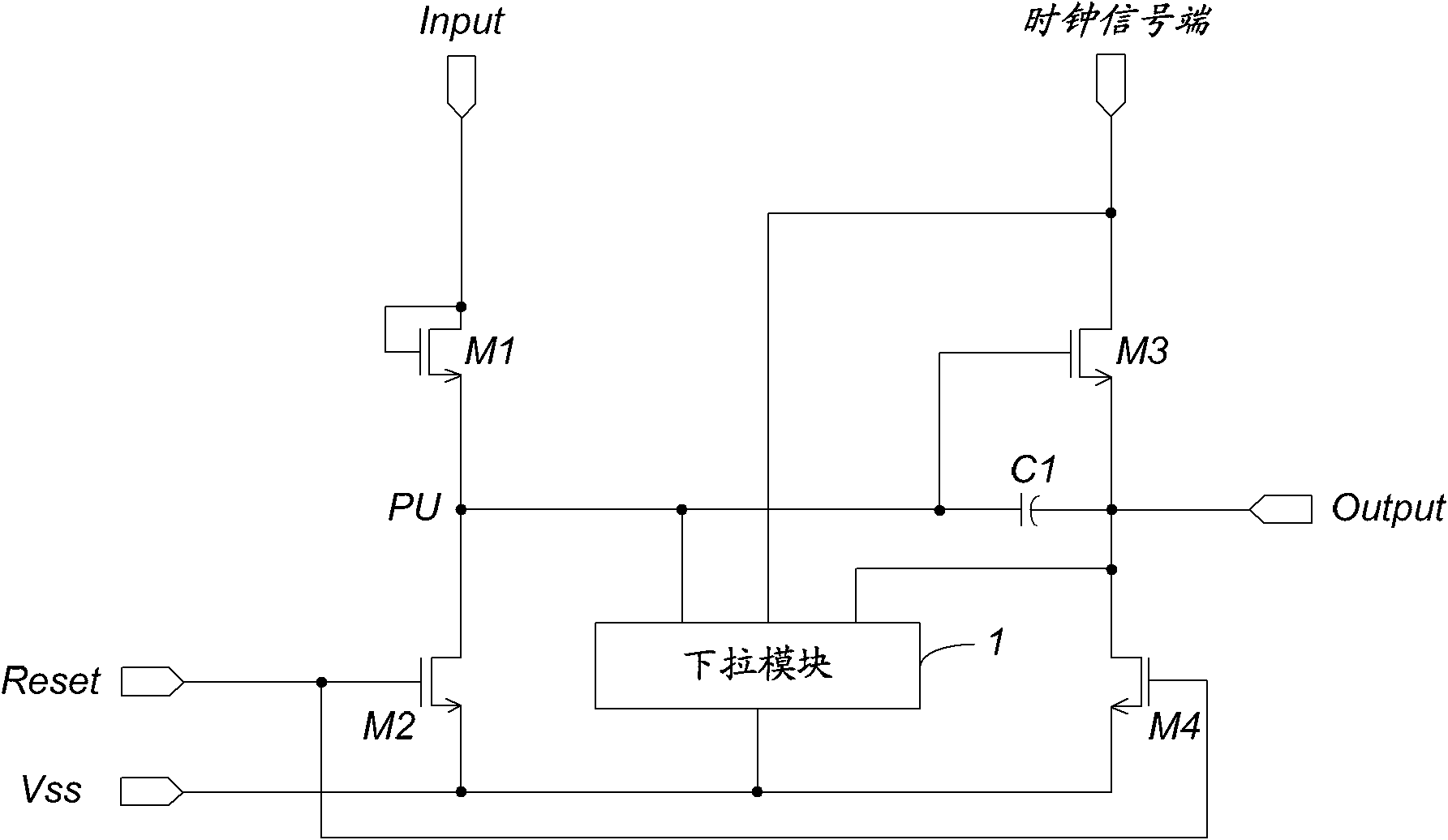

Shift register and grid line driving device

ActiveCN102651186AReduce noise interferencePrevent floatingStatic indicating devicesDigital storageLiquid-crystal displayCapacitance

The invention discloses a shift register and a grid line driving device, which relate to the technical field of liquid crystal display. In order to reduce noise jamming of the shift register at the standby unattended time, the shift register and the grid line driving device are invented. The shift register comprises a first thin film transistor, a second thin film transistor, a third thin film transistor, a fourth thin film transistor, a capacitor and a drop-down module, wherein the drop-down module connected among a clock signal end, a first node and a signal output end is connected with a low level signal end and used for maintaining the first node and the signal output end to have a low level at the standby unattended time of the shift register. The grid line driving device comprises a plurality of the shift registers which are connected in series. The grid line driving device can be used for driving a grid line.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

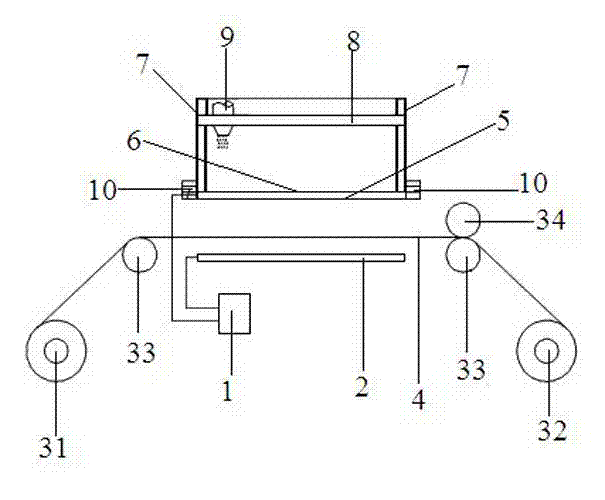

Method for supplementing lithium powder to lithium-ion battery negative plate

ActiveCN102779975AImprove first-time efficiencyIncrease battery capacityElectrode manufacturing processesElectric fieldLithium electrode

The invention belongs to the technical field of lithium-ion battery, and in particular relates to a method for supplementing lithium powder to a lithium-ion battery negative plate. The method comprises the following steps: a first step, putting the cold-pressed negative plate on an unwinding and rewinding mechanism, and putting lithium powder to a feeding mechanism above the negative plate; a second step, adding electric fields and opening the feeding mechanism, so that the lithium powder is adsorbed on the surface of the negative plate under the action of the electric fields; and a third step, rolling the negative plate adsorbed with the lithium powder. Compared with the prior art, the method can control the movement of the lithium powder to overcome the flotation of metal lithium powder in air through electrostatic effect provided by the electric fields, and can simultaneously control the addition of the lithium powder and the dispersion degree of the lithium powder on the negative plate, thereby uniformly, quantitatively and precisely dispersing the lithium powder on the surface of the negative plate. Besides, the whole process provided in the invention is only needed to be carried out in a drying environment without adding the lithium powder in a process of preparing slurry, has a simple manufacture process and low cost, and is suitable for large-scale production.

Owner:NINGDE AMPEREX TECH

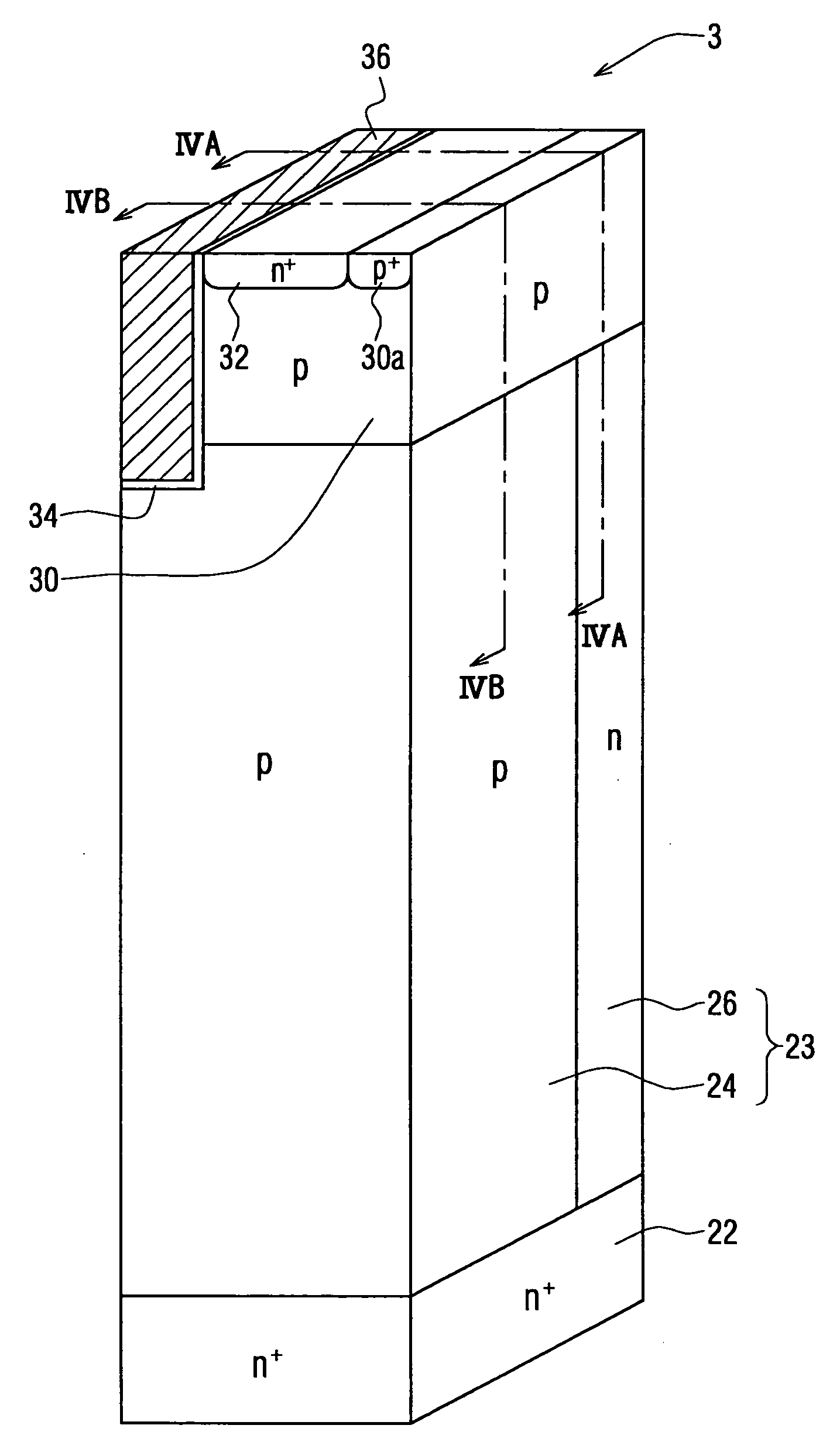

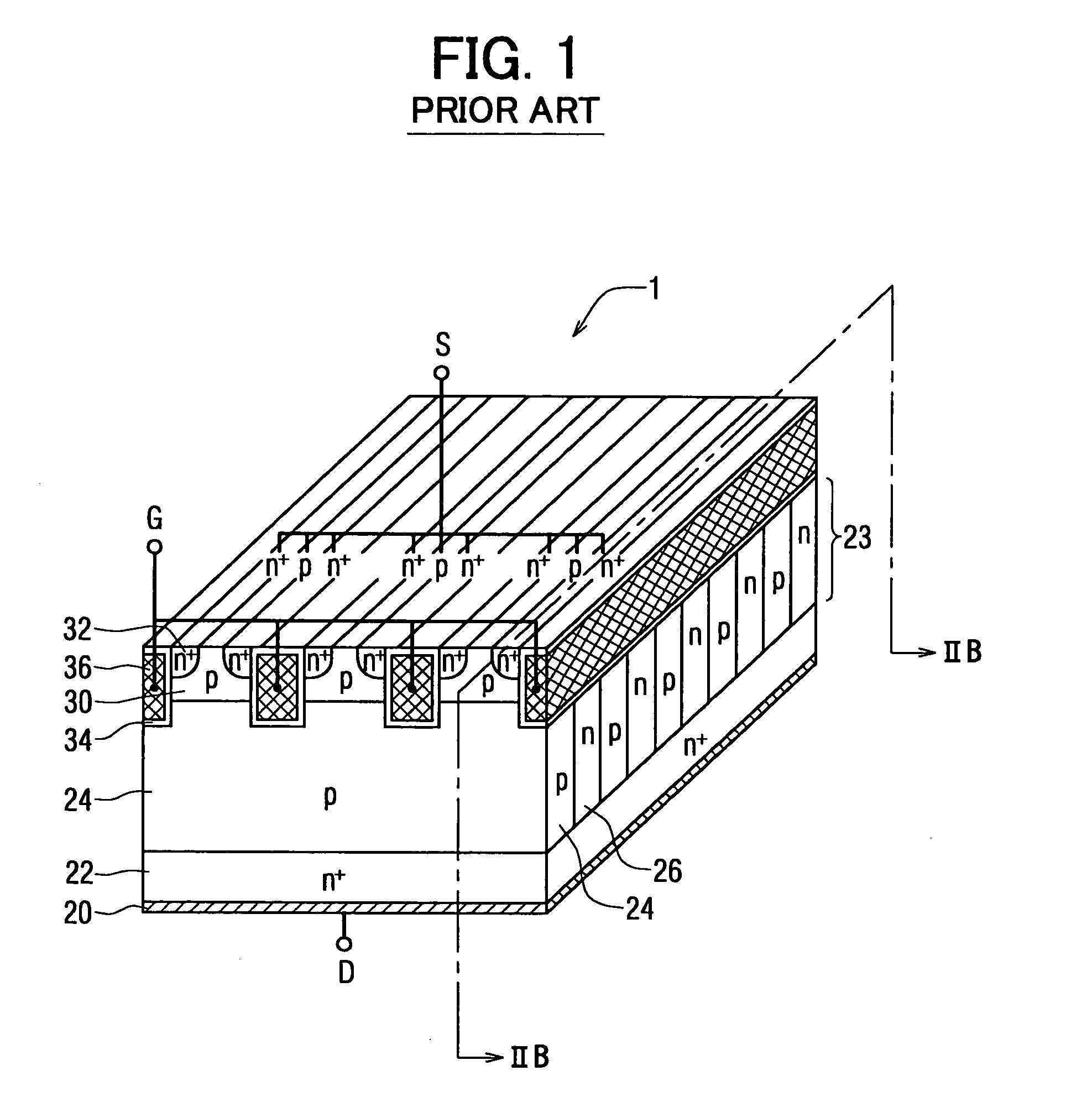

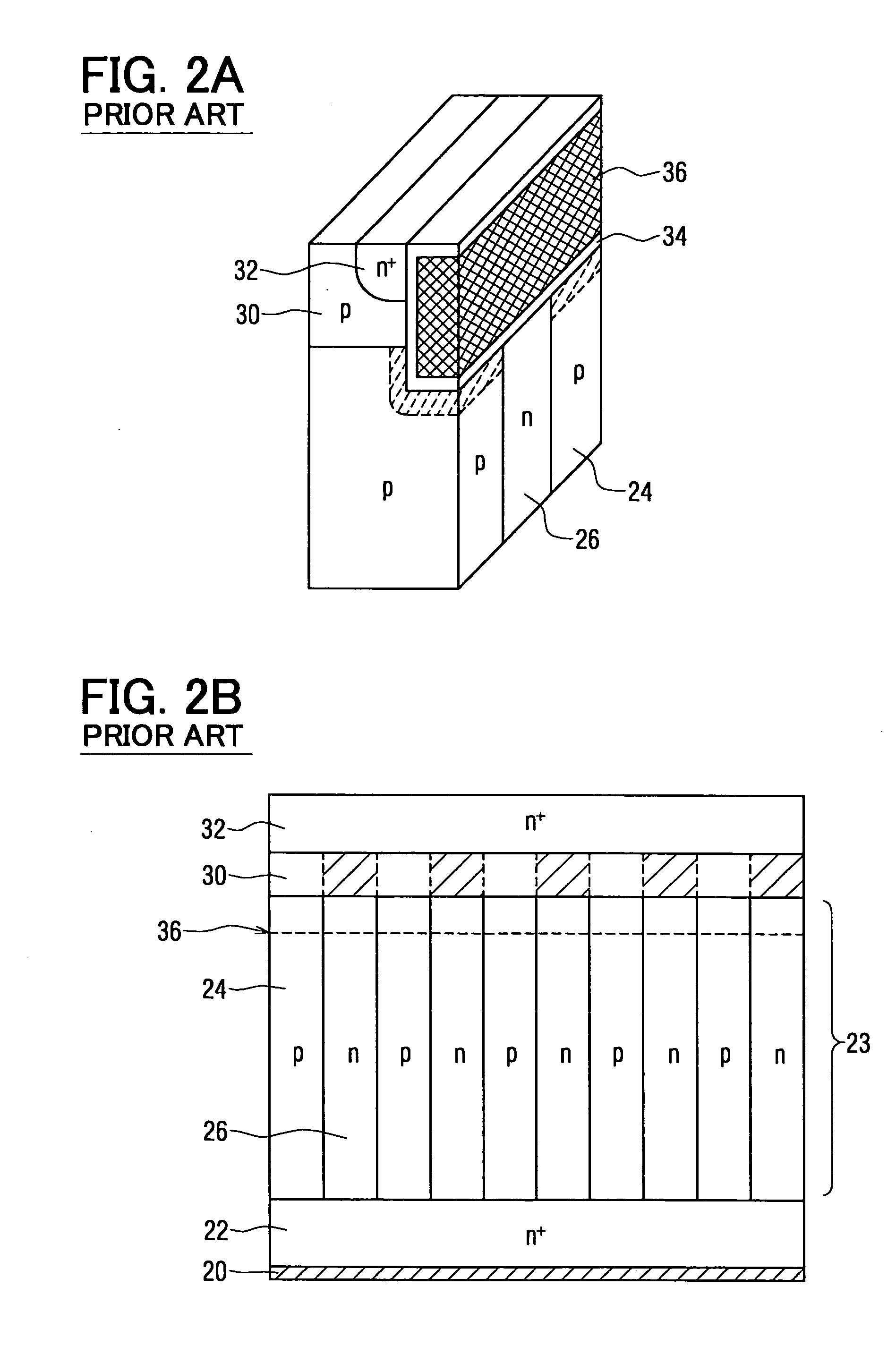

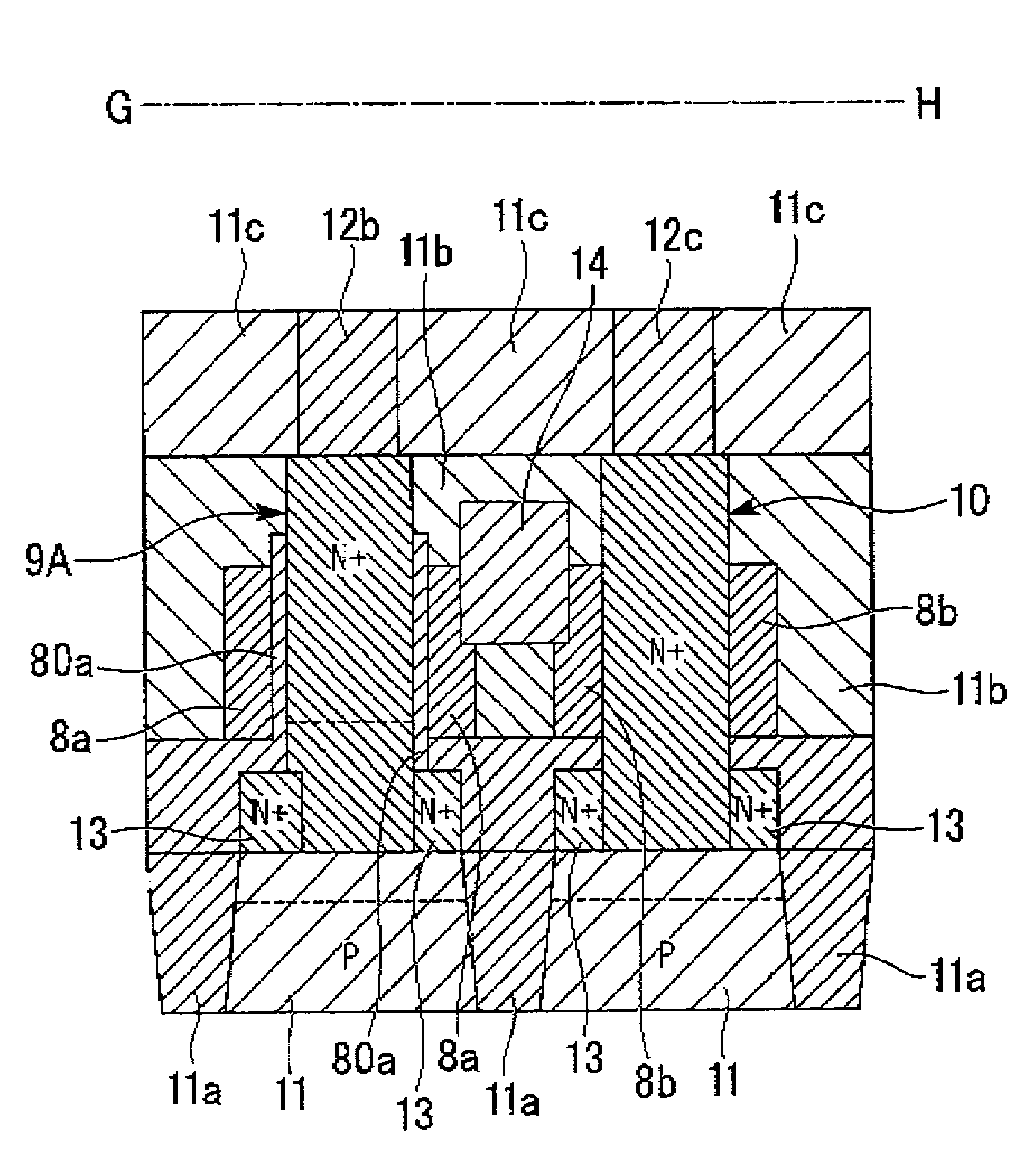

Semiconductor device having super junction construction and method for manufacturing the same

InactiveUS20050006717A1Low manufacturing costStable withstand voltageSemiconductor/solid-state device manufacturingSemiconductor devicesPhysicsBody region

A semiconductor device includes a body region, a drift region having a first part and a second part, and a trench gate electrode. The body region is disposed on the drift region. The first and second parts extend in an extending direction so that the second part is adjacent to the first part. The trench gate electrode penetrates the body region and reaches the drift region so that the trench gate electrode faces the body region and the drift region through an insulation layer. The trench gate electrode extends in a direction crossing with the extending direction of the first and second parts. The first part includes a portion near the trench gate electrode, which has an impurity concentration equal to or lower than that of the body region.

Owner:DENSO CORP

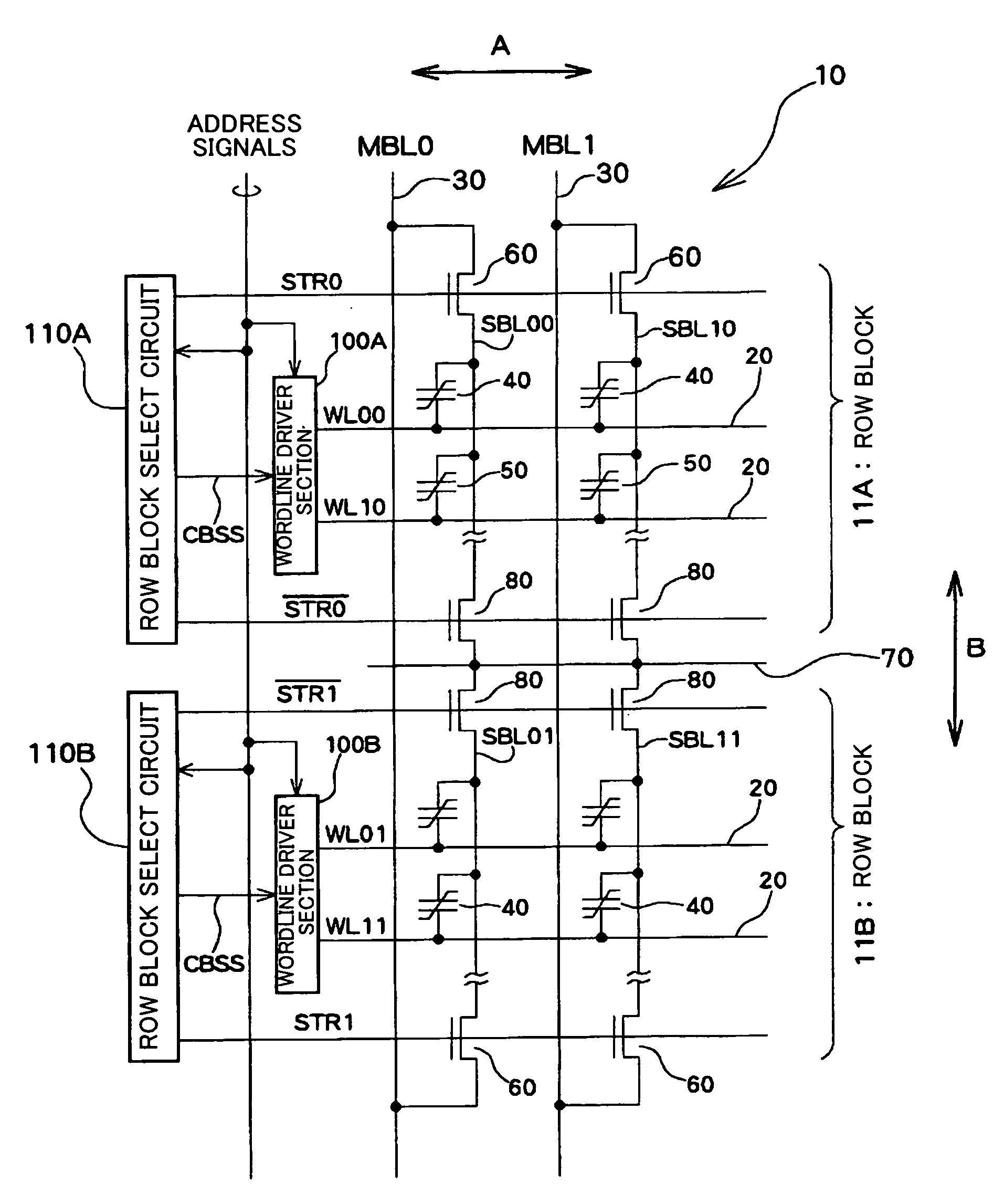

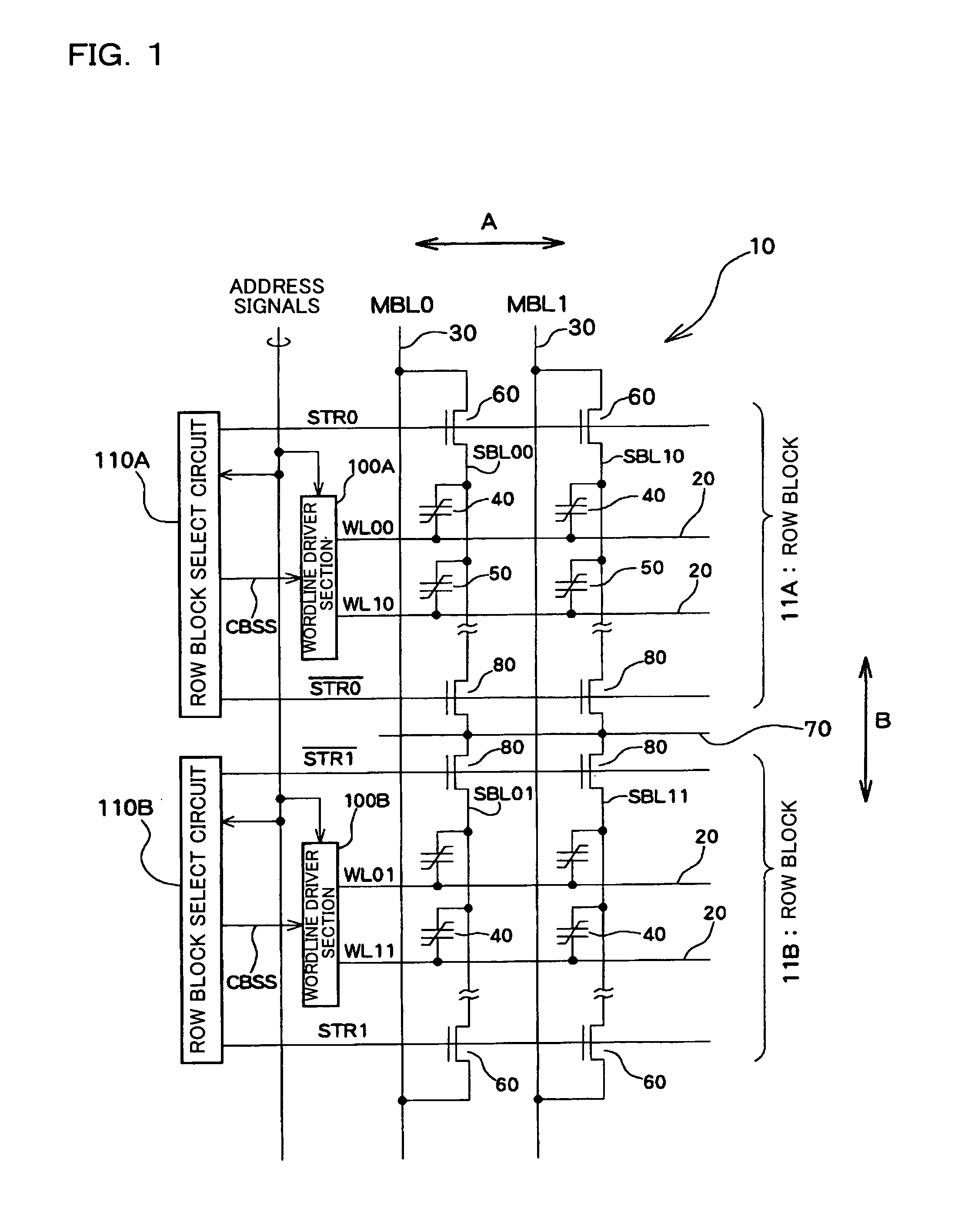

Ferroelectric memory device

A ferroelectric memory device including a memory cell array region having reduced influence of disturbance noise and divided into row blocks for every sub-bitline subordinate to main bitlines. One end of each sub bitline is connected to the main bitline through a first sub bitline select switch. The other end of the sub bitline is connected to a common potential supply line through a second sub-bitline select switch which is turned on complementarily with the first sub-bitline select switch.

Owner:SEIKO EPSON CORP

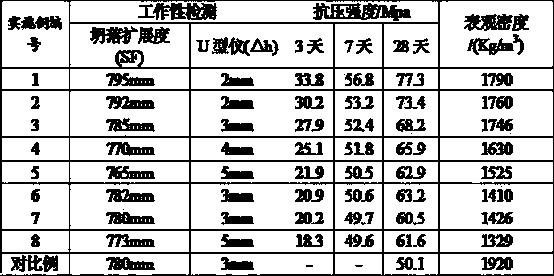

Self-compacting light aggregate concrete and preparation method thereof

InactiveCN103803904ALow densityLow apparent densitySolid waste managementStructural engineeringWater reducer

The invention provides self-compacting light aggregate concrete and a preparation method thereof, and belongs to the technical field of concrete preparation. The self-compacting light aggregate concrete consists of such raw materials as cement, fly ash, silica fume, floating beads, light fine aggregate, light coarse aggregate, a water reducing agent and water. The self-compacting light aggregate concrete provided by the invention has the advantages of being low in appearance density, high in slump expansion degree and capable of avoiding floating of the floating beads; self-compacting light aggregate concrete differing in grade, especially self-compacting light aggregate concrete with strength grade above C60 and appearance density at 1400-1800kg / m<3>, can be prepared through the raw materials.

Owner:北京中联新航建材有限公司

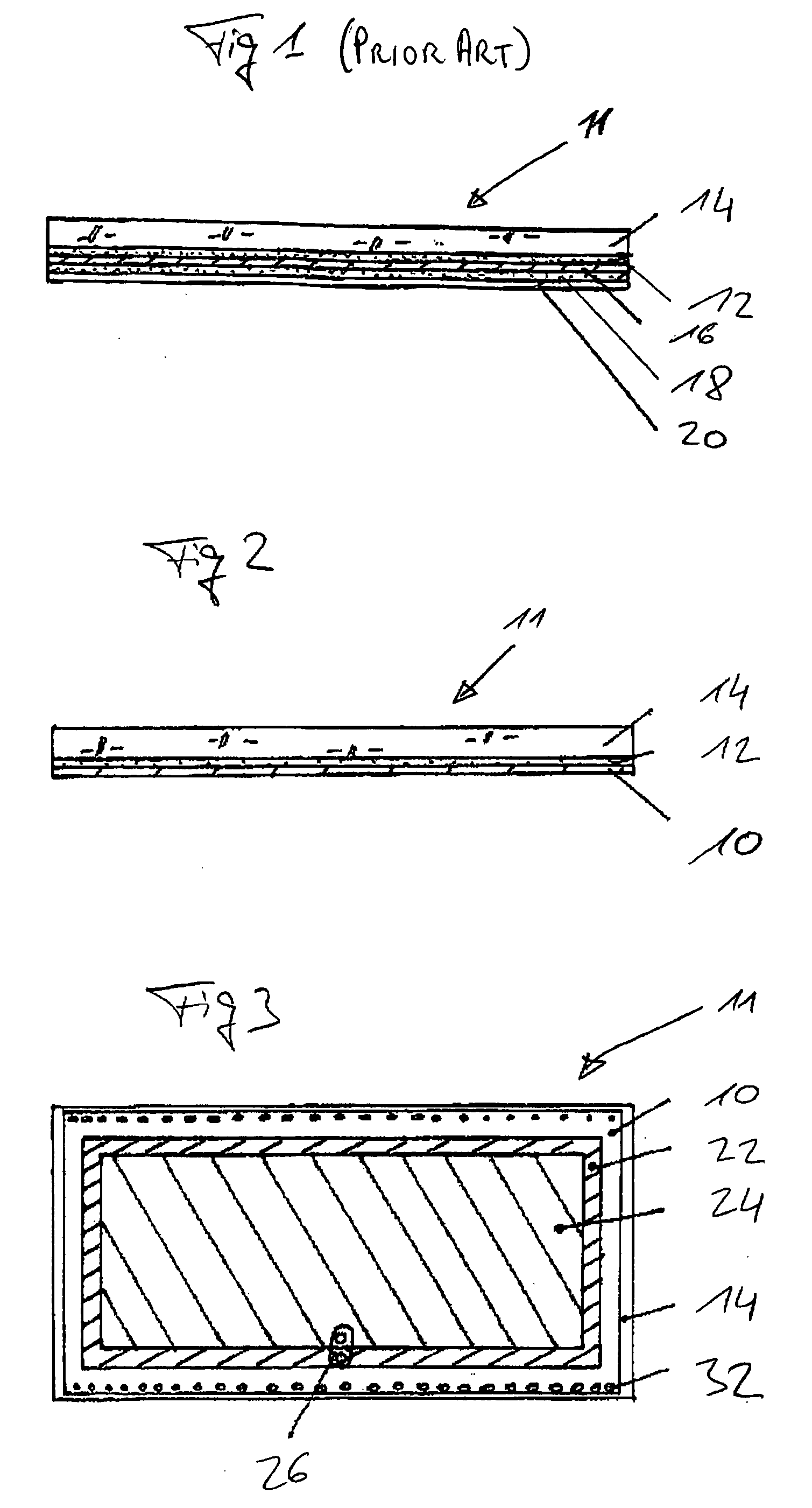

Process for producing a cover with a glass pane and electrical function elements

InactiveUS20050001456A1Simple and reliable processEasy to manufacturePV power plantsMetal-working apparatusMobile vehicleEngineering

Owner:WEBASTO AG

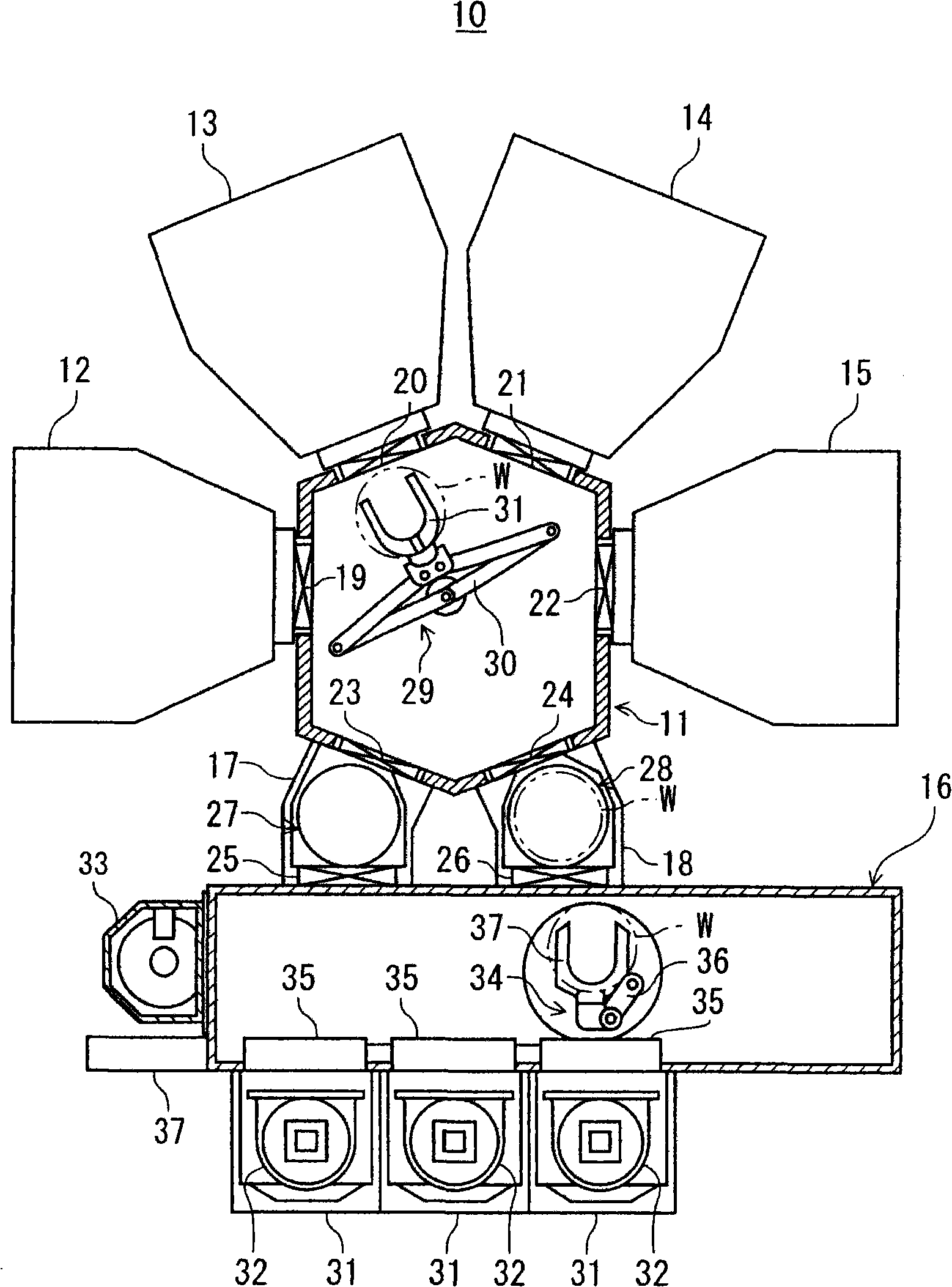

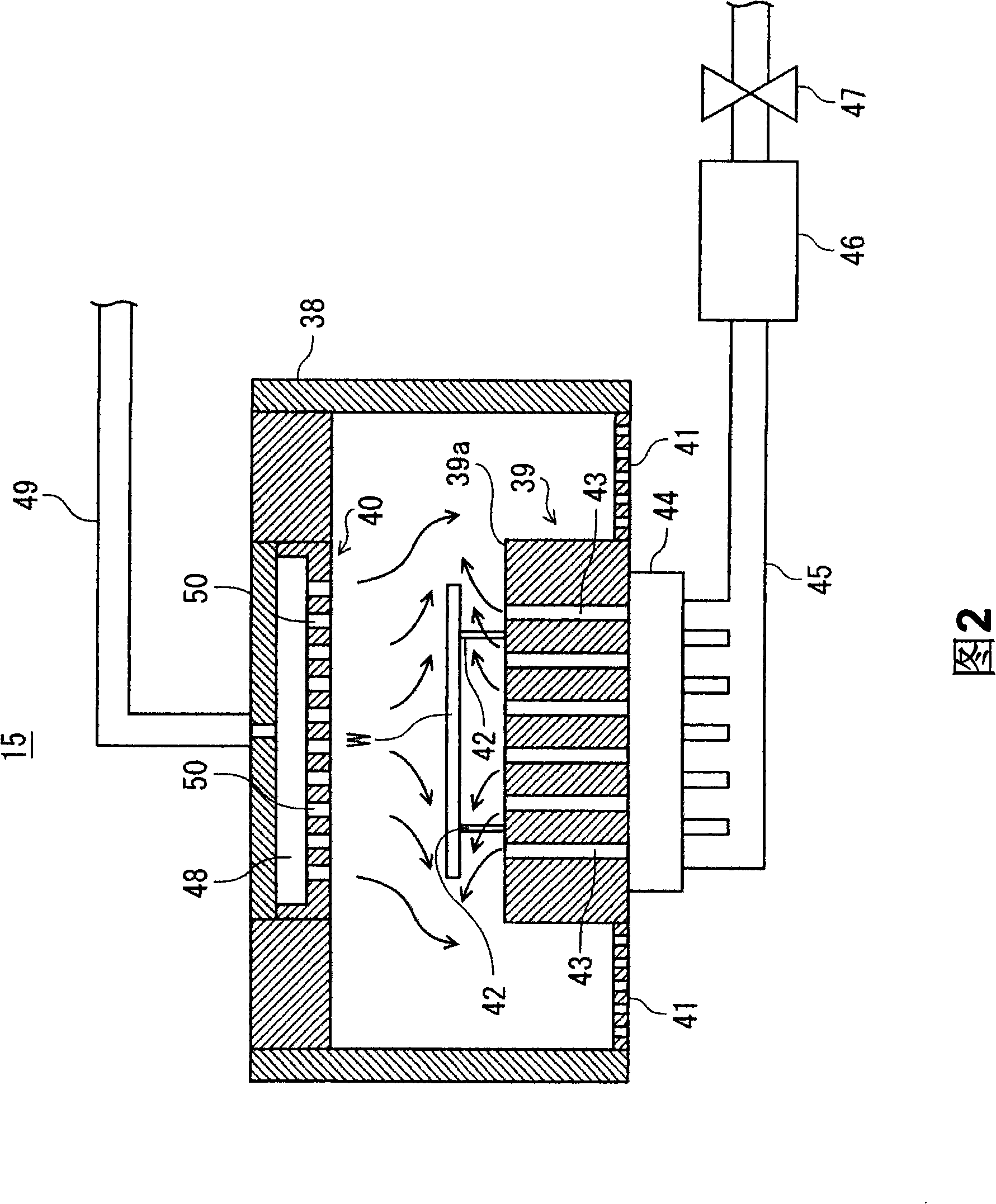

Substrate processing system and substrate cleaning apparatus

InactiveCN101276739AReduce gravityReliable removalSemiconductor/solid-state device manufacturingCleaning using liquidsForeign matterGas phase

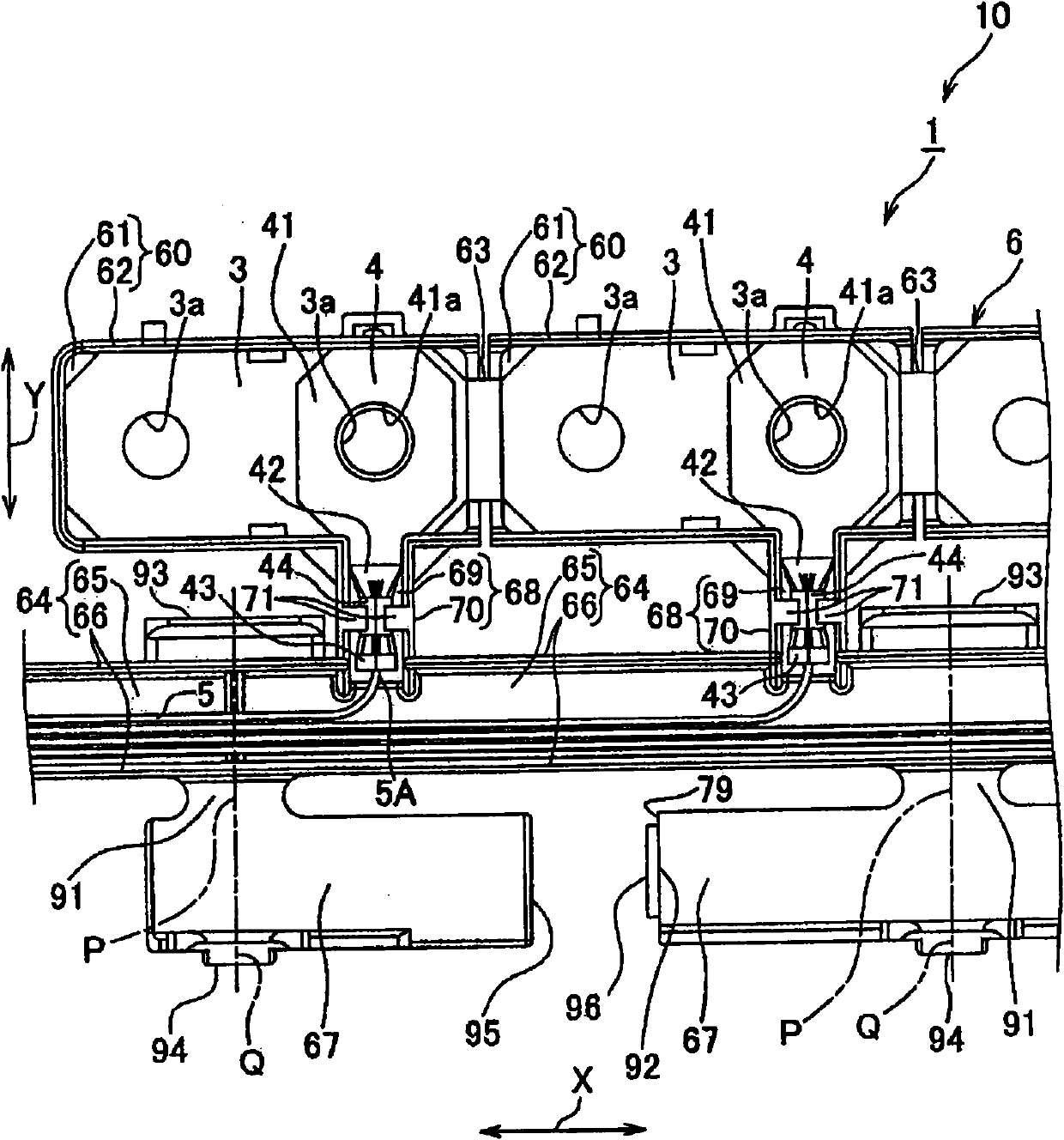

This invention provides a substrate processing system that enables foreign matter adhered to a rear surface or a periphery of a substrate to be completely removed. A processing assembly (15) of a substrate cleaning apparatus of the substrate processing system (10) including: a chamber (38) for accepting a wafer (W); a holding table (39) configured at the bottom of the chamber (38) and for placing the wafer W; a spray head configured at the top in the chamber (38) and opposite to the holding table (39).The holding table (39) jets the mixed cleaning agent of cleaning substrate (such as pure water) and inactive gas (such as N2) in two phases of a gas phase and a liquid phase at the back side or edge part facing to the wafer (W). The spray head (40) generates the down-flow facing to the surface of the wafer (W).

Owner:TOKYO ELECTRON LTD

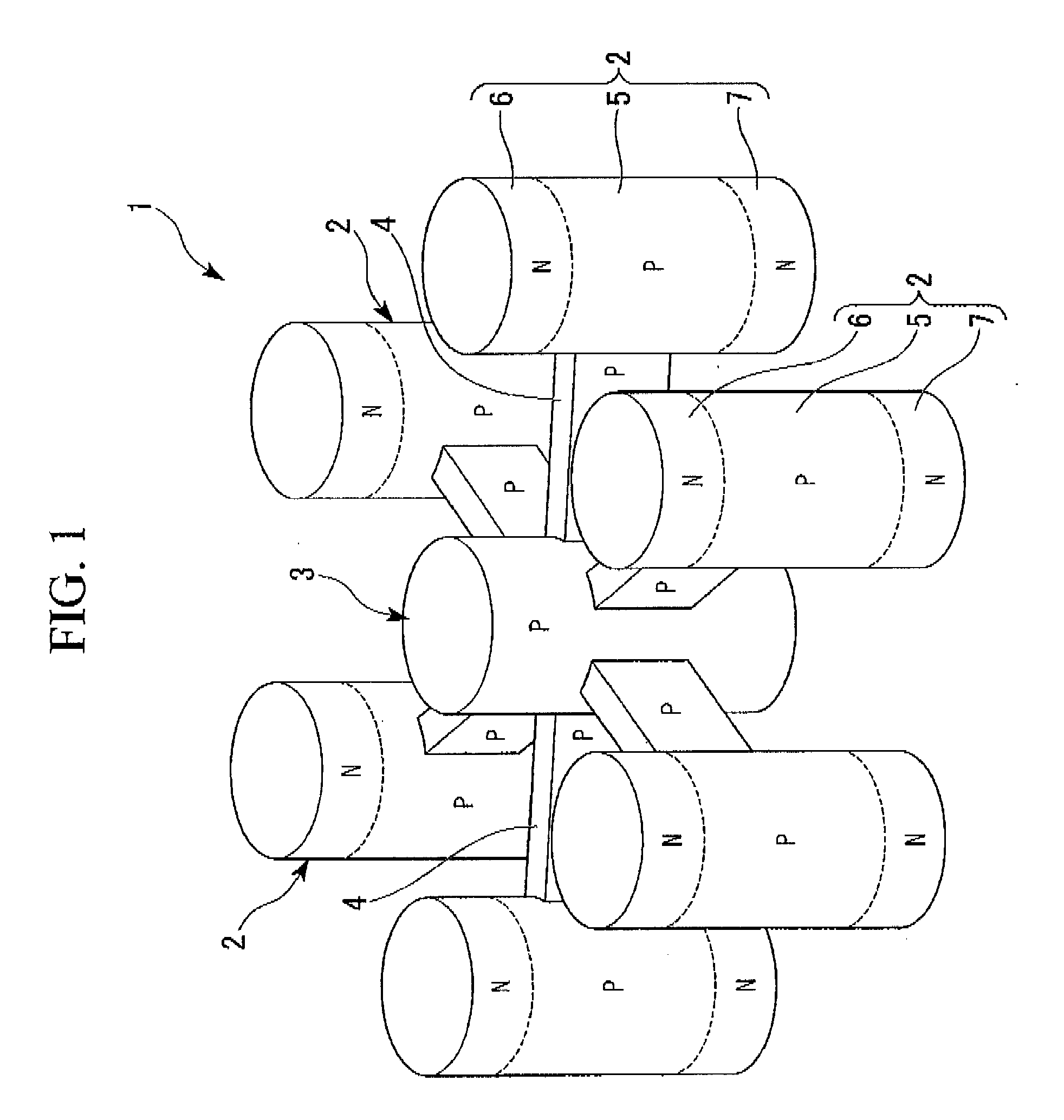

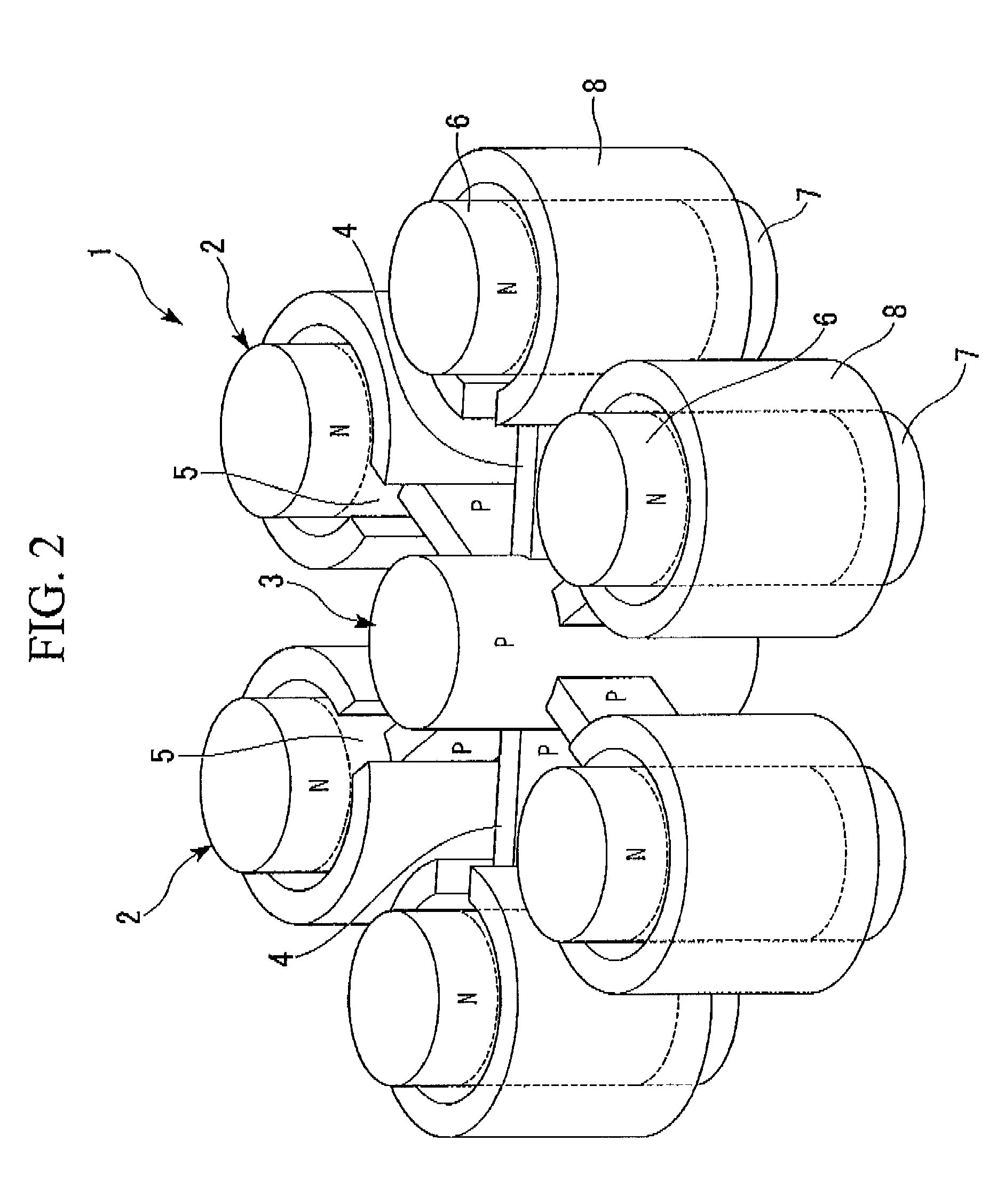

Semiconductor apparatus and production method of the same

InactiveUS20080303083A1Complex structureOptimize layoutTransistorSolid-state devicesEngineeringSemiconductor

In order to provide a highly integrated semiconductor apparatus and a production method thereof which can avoid the floating of a channel portion that causes a problem when constituting a memory cell from three-dimensional transistors, a semiconductor apparatus includes: multiple three-dimensional transistors each of which includes: a first pillar; a channel portion provided at the first pillar; diffused layers formed at both an upper portion and a lower portion of the channel portion; and a gate electrode provided around the channel portion via a gate insulation film; and a second pillar which is electrically conductive, wherein the multiple three-dimensional transistors are arranged on a well area while surrounding the second pillar, the multiple three dimensional transistors share the second pillar, and the channel portions of the multiple three dimensional transistors are each connected to the second pillar by a channel connection portion. In addition, six three-dimensional transistors preferably share the second pillar which is a single pillar.

Owner:LONGITUDE LICENSING LTD

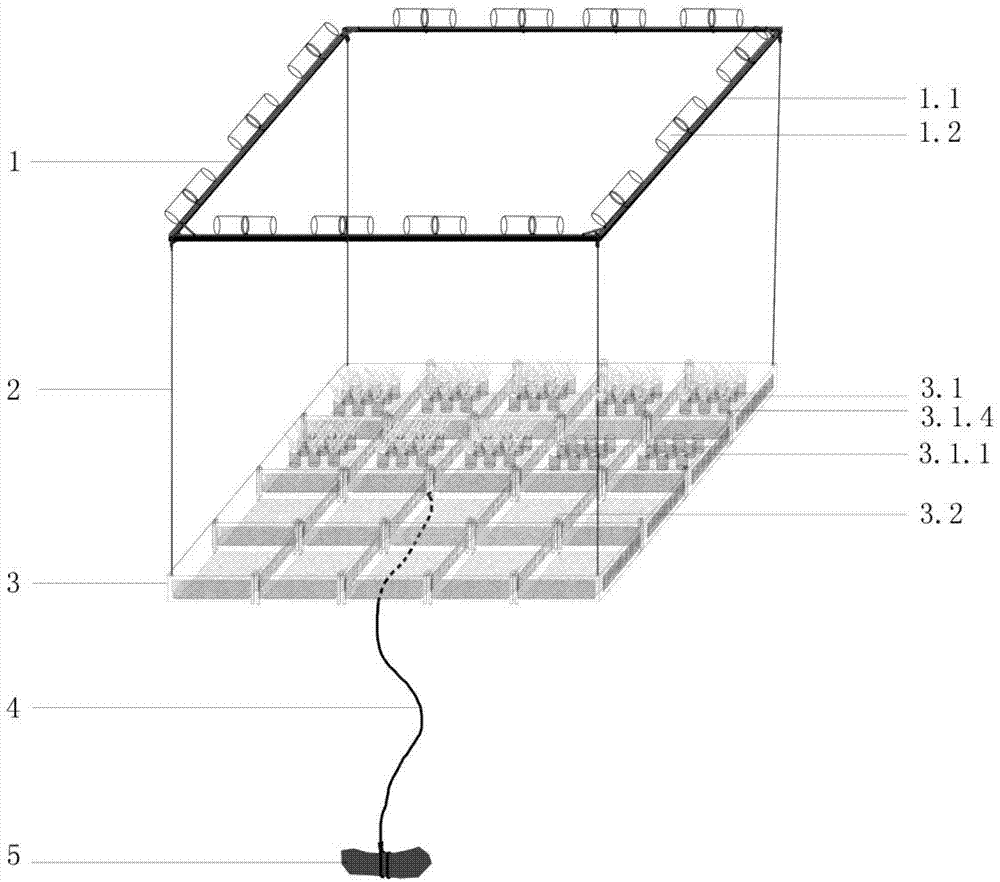

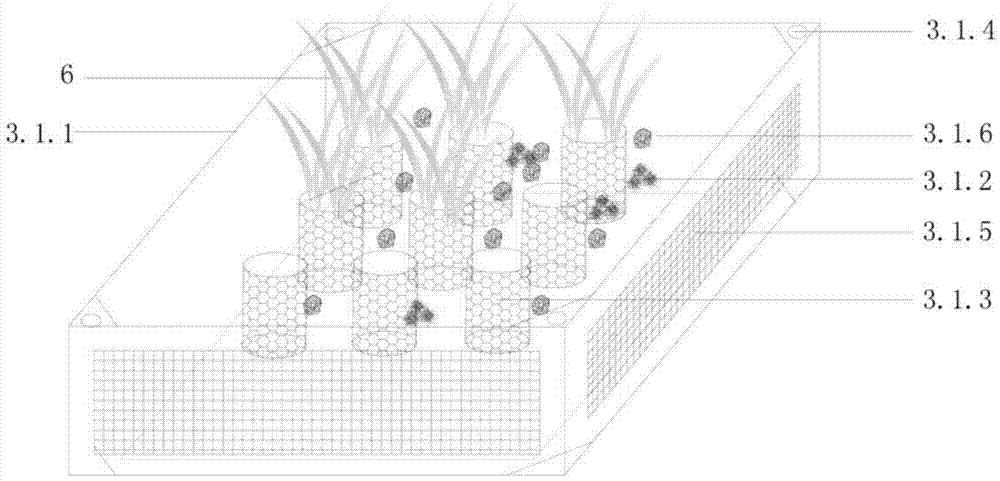

Submerged plant planting device

InactiveCN103936169AFit wellEnlarged surface areaSustainable biological treatmentReceptacle cultivationAgricultural engineeringBiology

The invention discloses a submerged plant planting device, comprising a buoyancy layer, connection ropes, a submerged plant planting layer, a fixed rope an and anchor, wherein the buoyancy layer is formed by a peripheral frame and 12-20 float bowls fixed on the peripheral frame; the submerged plant planting layer is formed by 10-30 planting bricks connected through connecting pegs; each planting brick is formed by a hollow frame and planting matrix filled into the hollow frame, and can adapt to a plurality of submerged plant propagule such as sprouts, clints, seeds and the like; the buoyancy layer is connected with the submerged plant planting layer through four connection ropes; a connecting peg is arranged at the center part of the submerged plant planting layer and connected with the fixed rope; the other end of the fixed rope is connected with the anchor and arranged at the water bottom; the submerged plant planting layer floats up and down along with water-level fluctuation, but the distance to the water level is kept constant all the time. The planting brick structure and the submerged plant root are good to fit, the device is stable in form for a long period of time, the effect on the submerged plant caused by drastic change of water level and stormy waves can be effectively avoided, and the overall device is simple to assemble, and free of labor management in the actual operation process.

Owner:HUBEI NORMAL UNIV

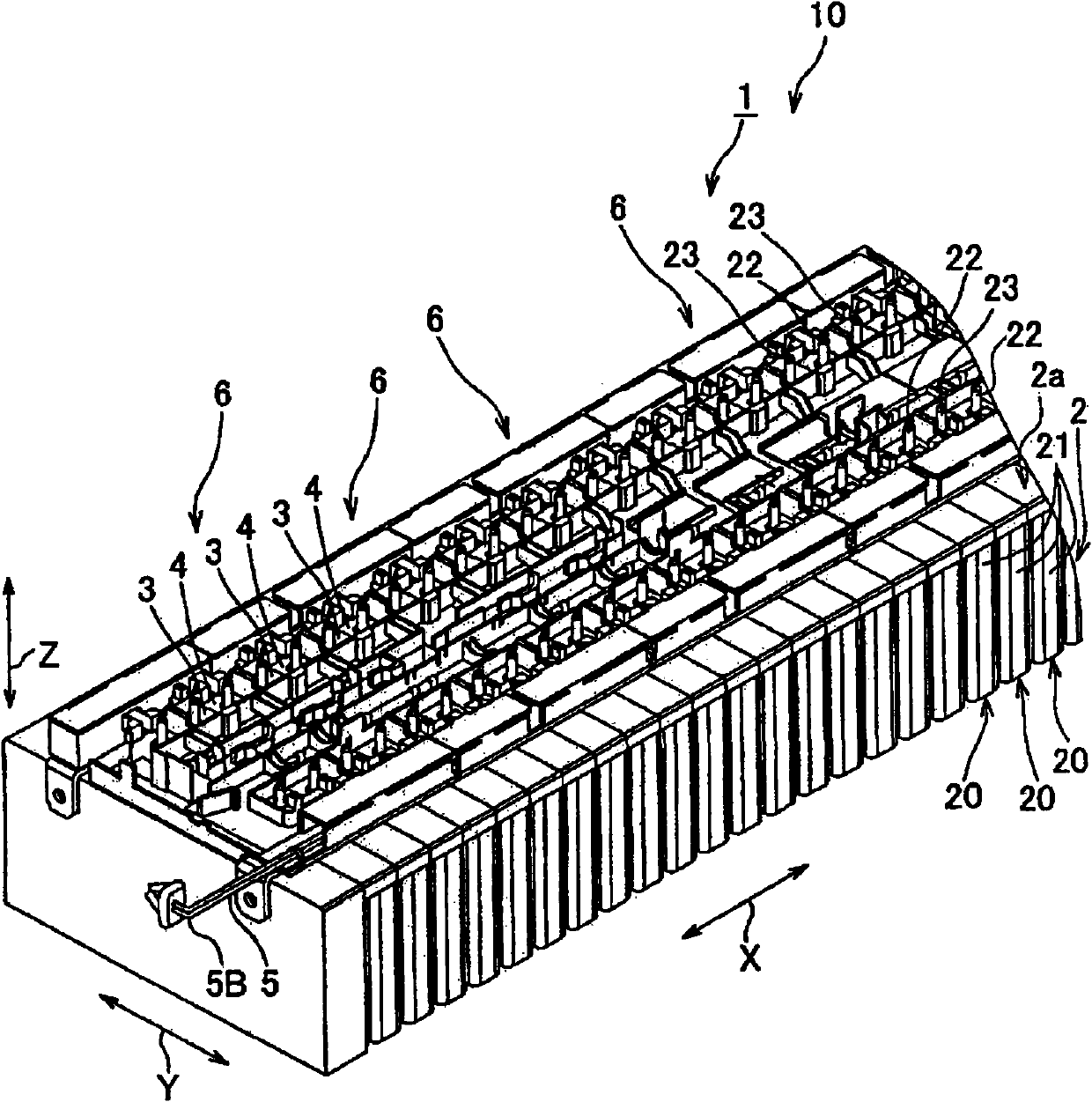

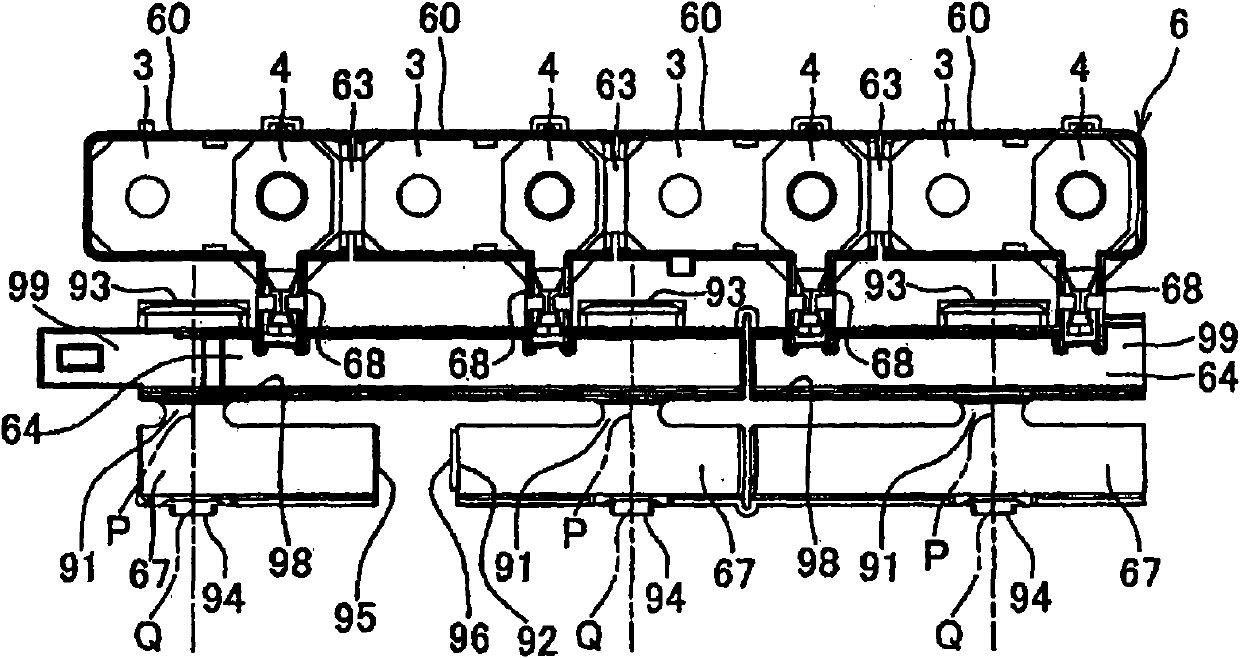

Wire arrangement body, busbar module and power-supply unit

Owner:YAZAKI CORP

Vacuum expendable pattern casting (V-EPC) molding method of large complex castings

ActiveCN101607299AGood product qualityAvoid driftingFoundry mouldsFoundry coresLost-foam castingMolding sand

The invention discloses a vacuum expendable pattern casting (V-EPC) molding method of large complex castings. A flask for molding comprises three parts including flask bottom, a flask body and an up draught pneumatic hoist press bar; each part is provided with an independent vacuum air duct. The molding procedures comprise the following steps: filling sand and carrying out vibrating molding on the bottom of the expendable pattern, turning over the flask, removing a supporting plate and a tire plate rack and placing the up draught pneumatic hoist press bar, filling the sand, exerting pressure for vibrating molding, sealing the flask and carrying out pouring after vacuumizing. The parts with blind holes and grooves are filled with resin sand and core irons and a floating crane is employed to fix the core irons; local compaction is carried out on loose parts. Being adopted, the method of the invention ensures compact and uniform molding sand, solves the difficult problems frequently appearing in the process of V-EPC of large castings, including sand crushing, sand drop, sand inclusion and deformation, can ensure the accuracy of the blind holes, deep grooves and entire castings, can enable the pattern to be almost free from floating and deformation in the process of vibration and can produce high quality large complex castings.

Owner:BOTOU QINGFENG MACHINERY

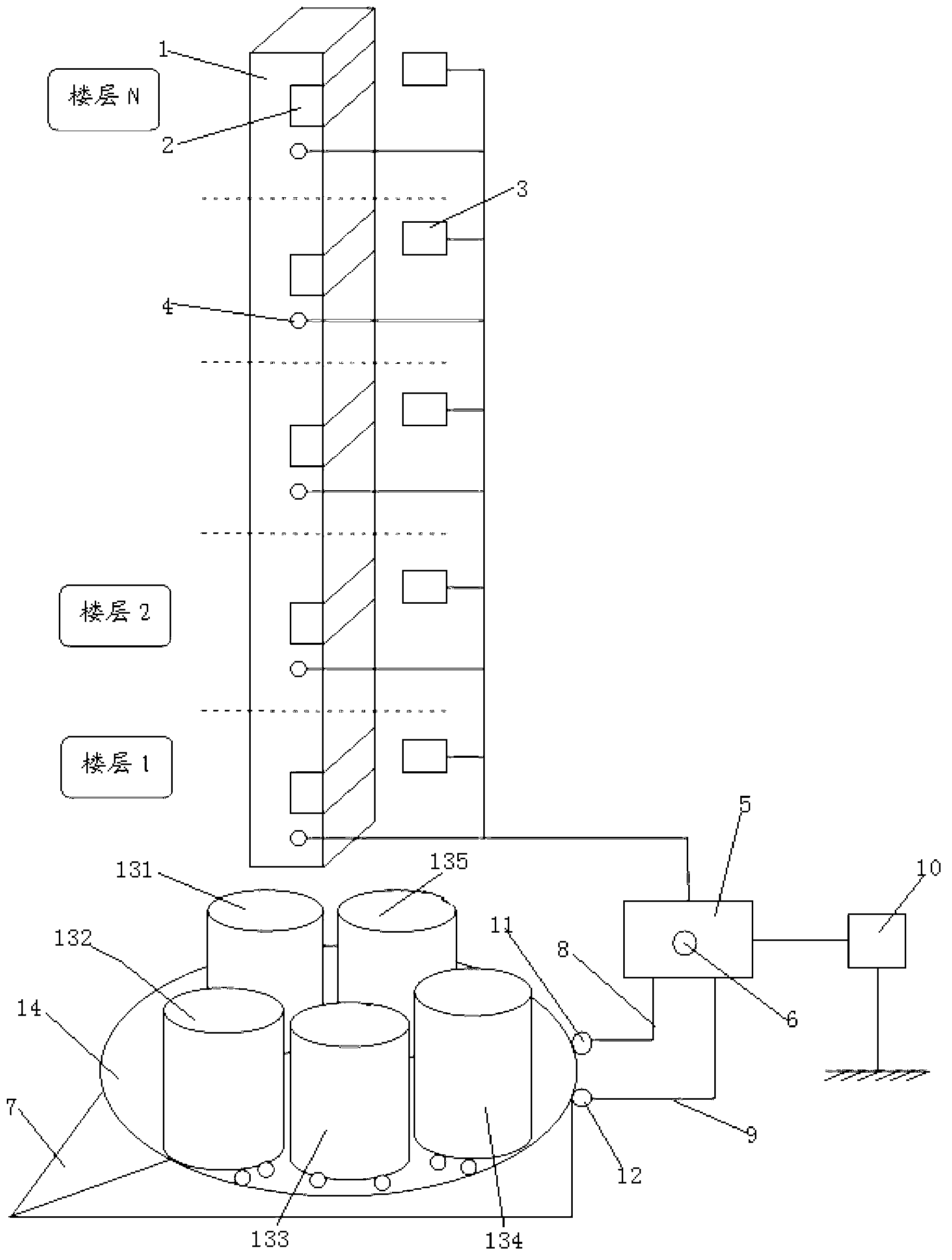

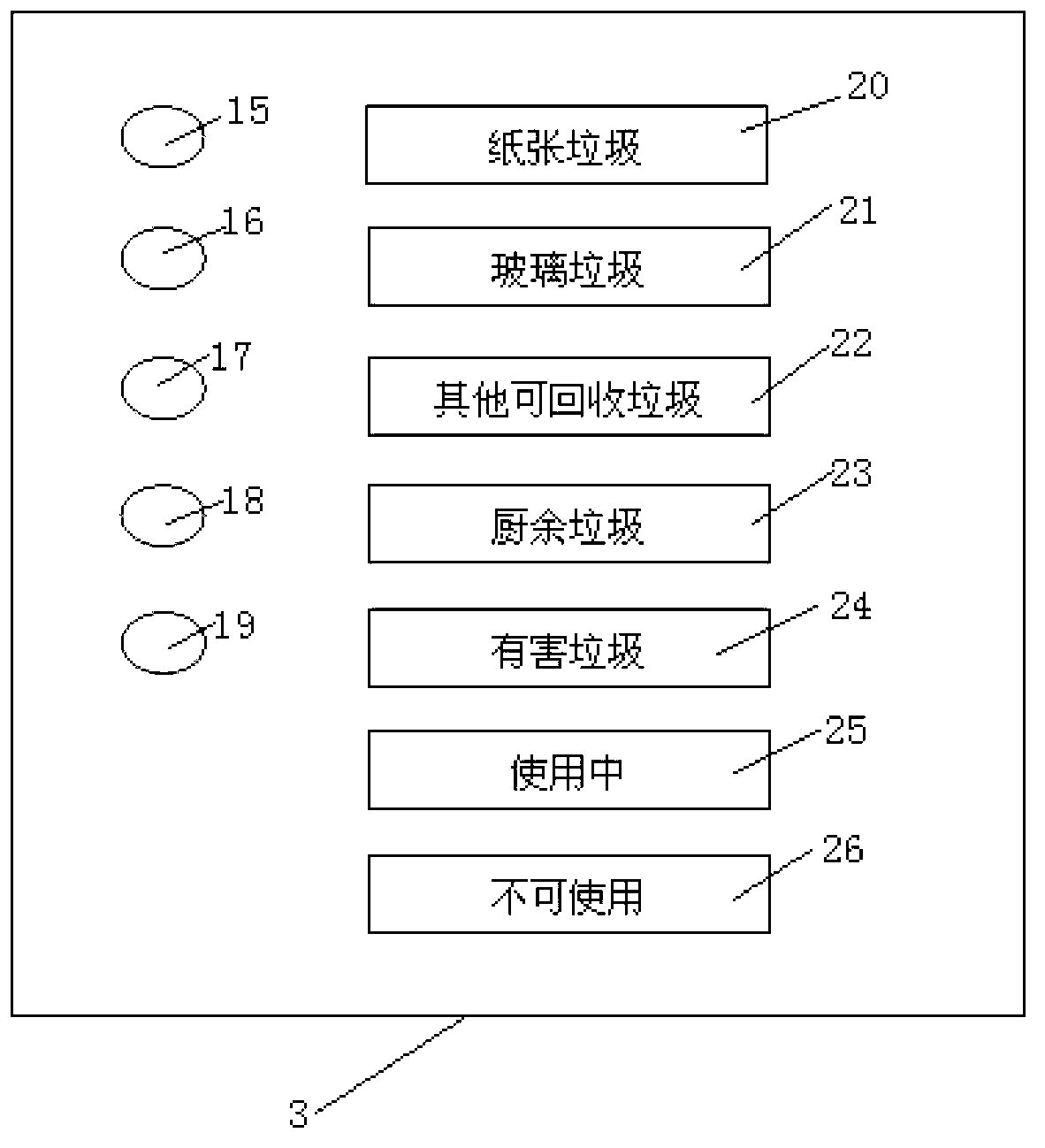

Garbage classification and collection system for high-rise building

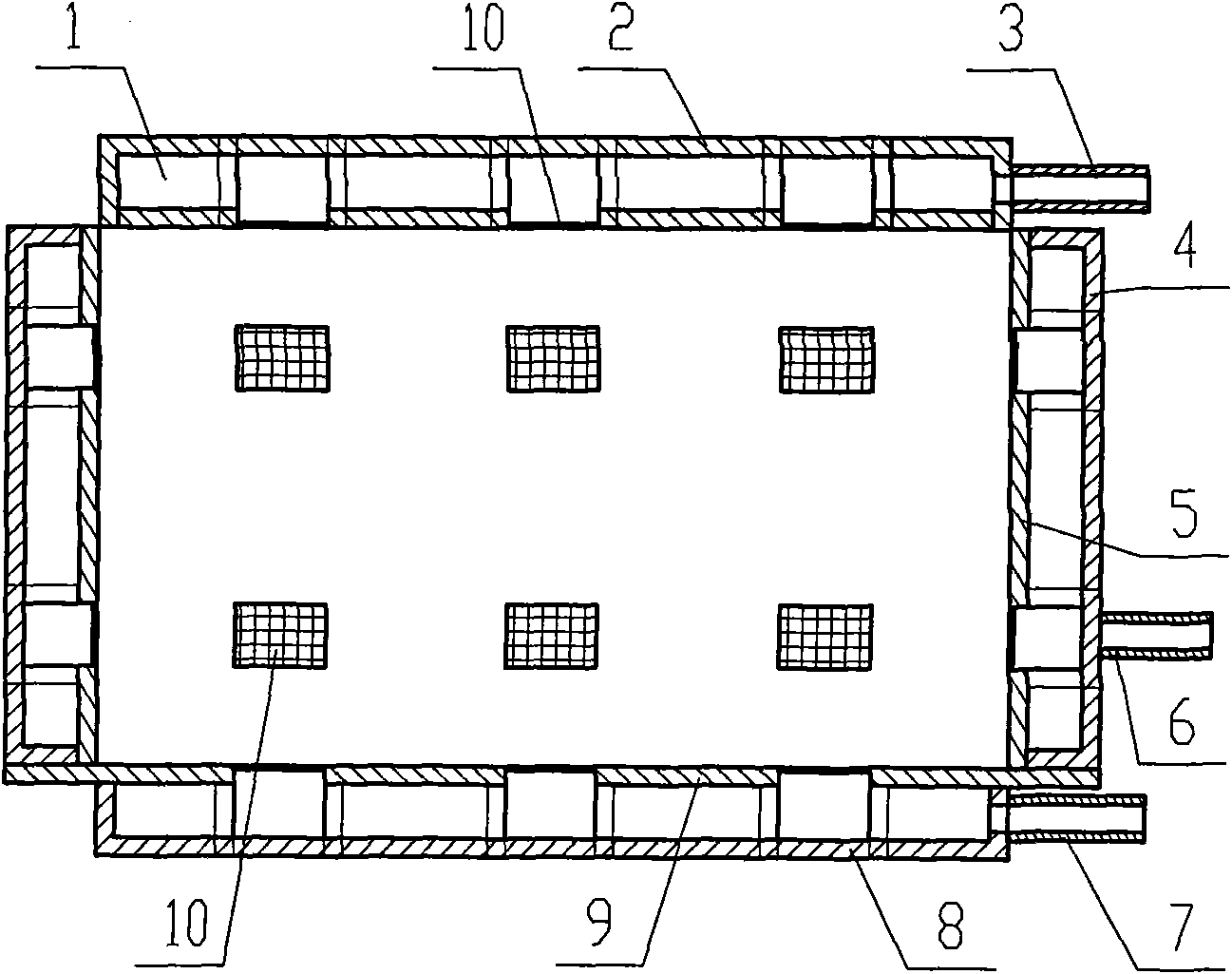

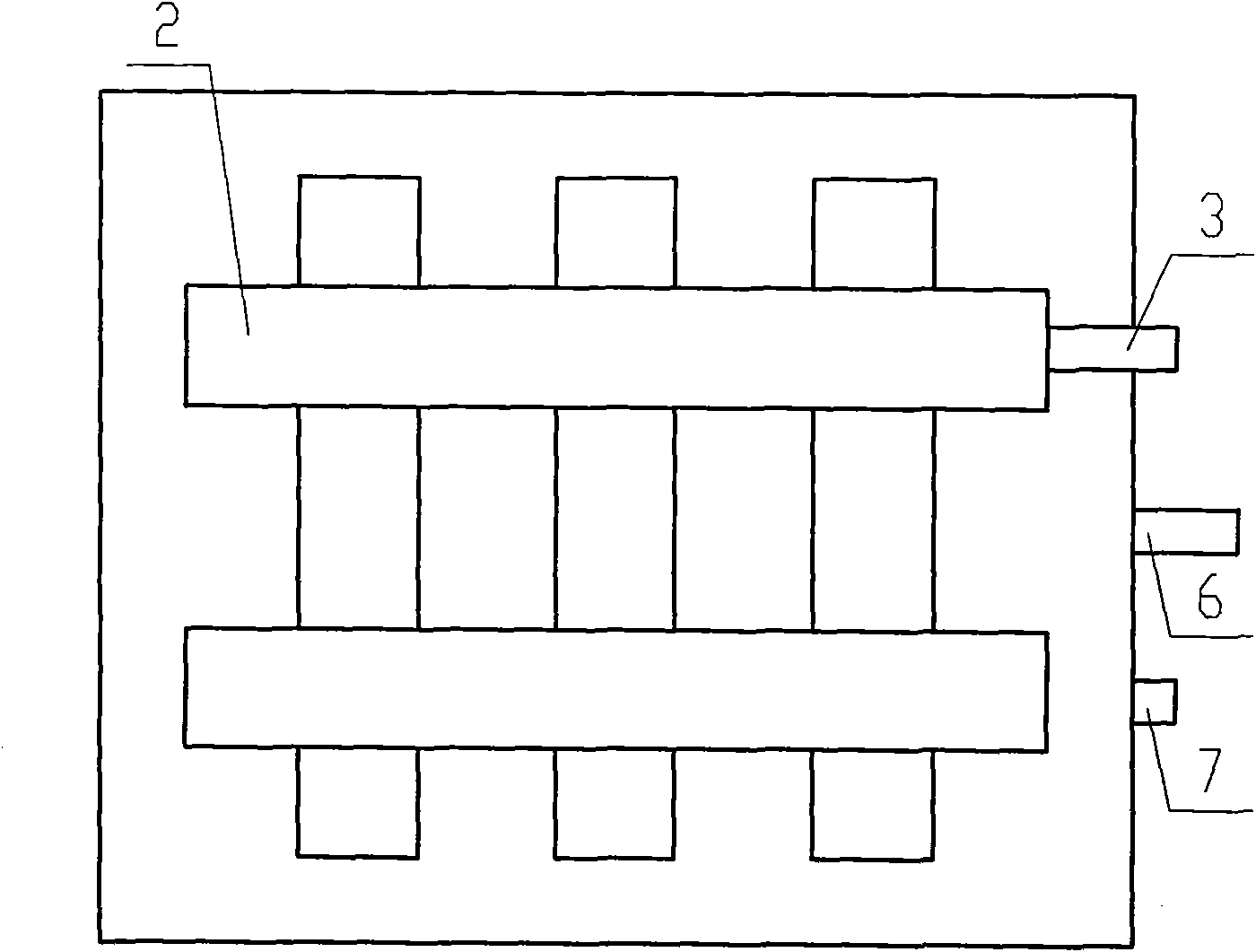

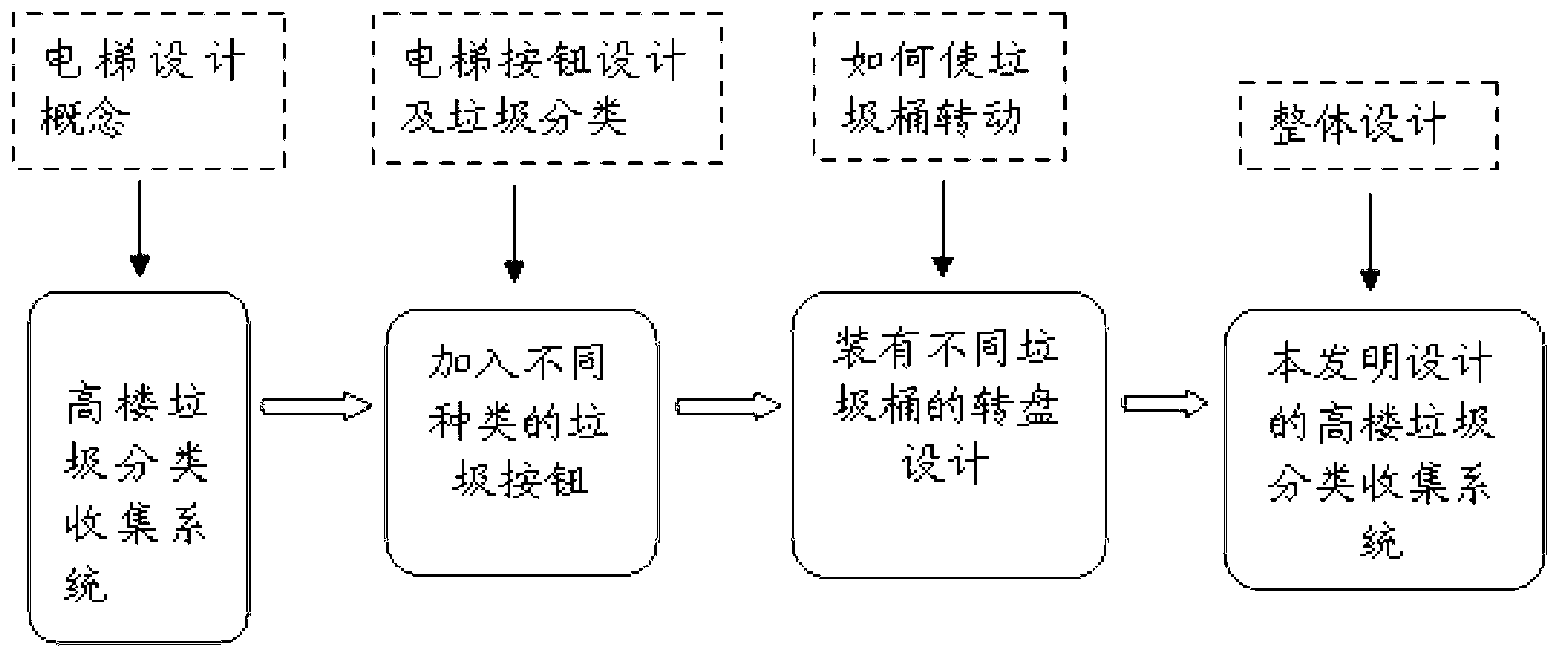

A garbage classification and collection system for a high-rise building comprises a vertical slideway, a control device, various kinds of garbage cans and at least one lifter. The vertical slideway serves as a garbage conveying passage for the high-rise building. The control device comprises a control panel of each floor and is used for controlling operation of the garbage classification and collection system. The various kinds of garbage cans are used for containing various kinds of garbage. Each lifter is disposed in the vertical slideway. The various kinds garbage cans are disposed on the lifters. The control device controls the lifters according to received instructions to drive the garbage cans to move up and down in the vertical slideway and rest at appointed floors. Compared with the existing garbage classification and collection system for high-rise buildings, the garbage classification and collection system adopts innovative thoughts, garbage can be classified and collected, and influence of garbage odor on residents of the high-rise building is reduced due to the fact that the garbage cans are disposed in the slideway. The garbage classification and collection system is simple in structure and easy in maintenance and late modification, and total automation can be achieved.

Owner:SHENZHEN SMART SECURITY & SURVEILLANCE SERVICE ROBOT CO LTD

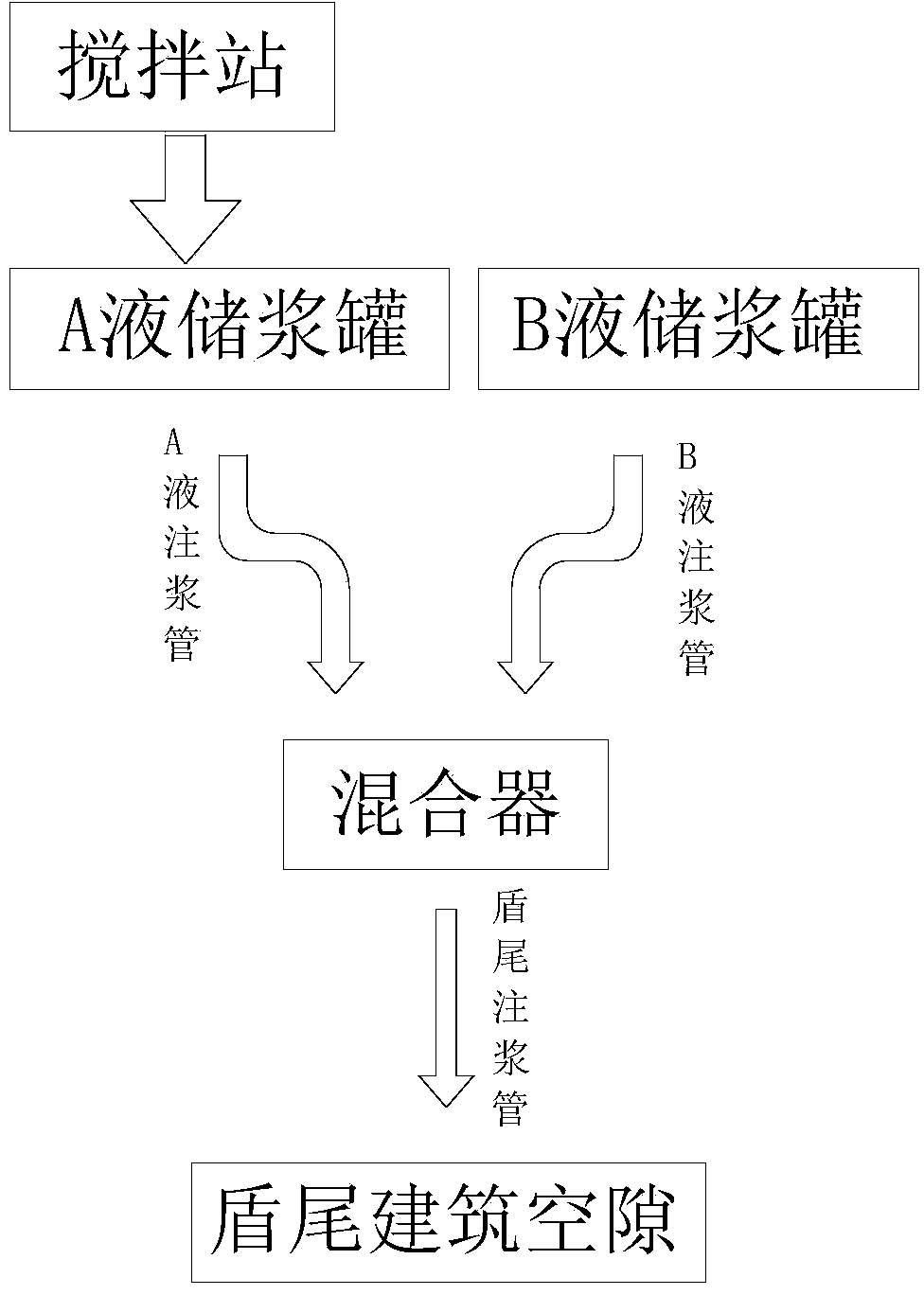

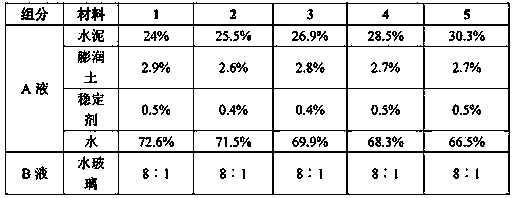

Shield synchronous grouting construction method and construction material

ActiveCN104074530AImprove stabilityShort entry into initial setting timeUnderground chambersTunnel liningSlurryMaterials science

The invention discloses a shield synchronous grouting construction method and a construction material. The construction material comprises liquid A and liquid B, wherein the liquid A comprises 25.5 weight percent of cement, 2.6 weight percent of bentonite, 0.4 weight percent of stabilizing agents and 71.5 weight percent of water; the liquid B is water glass; and the volume ratio of the liquid A to the liquid B is 8:1-15:1. During synchronous grouting construction, the liquid A is prepared in a mixing station, and the liquid A and the liquid B are respectively conveyed into a liquid A slurry storage tank and a liquid B slurry storage tank which are arranged on a shield machine; the liquid A and the liquid B are respectively conveyed into a mixer positioned at the shield tail part of the shield machine through a liquid A slurry injection pipe and a liquid B slurry injection pipe; and the liquid A and / or the liquid B in the mixer are / is synchronously injected into a shield tail building gap through a shield tail slurry injection pipe. The shield synchronous grouting construction method solves various problems in subsequent grouting, synchronous single slurry injection, in-time grouting and secondary grouting in the prior art through utilizing good performance of the liquid A and the liquid B before and after the mixing of the liquid A and the liquid B and combining a primary synchronous grouting process.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP

Positive Electrode Mixture for Nonaqueous Battery and Positive Electrode Structure

ActiveUS20100266882A1Loss of electrode performanceIncrease energy densityNon-metal conductorsFinal product manufactureOrganic acidCarbon black

A positive electrode mixture for nonaqueous batteries, is formed by adding 0.5 to 10 wt. parts of an organic acid per 100 wt. parts of an electroconductive additive, to a mixture of a composite metal oxide as a positive electrode active substance, a higher order-structured carbon black as the electroconductive additive, a binder of a fluorine-containing copolymer of at least three comonomers including vinylidene fluoride, tetrafluoroethylene and a flexibility-improving fluorine-containing monomer, and an organic solvent. Further, the mixture is applied on at least one side of an electroconductive sheet, and then dried and compressed to form a positive electrode mixture layer. As a result, it is possible to provide a positive electrode structure having a thick and sound positive electrode mixture layer of a high energy density.

Owner:KUREHA KAGAKU KOGYO KK

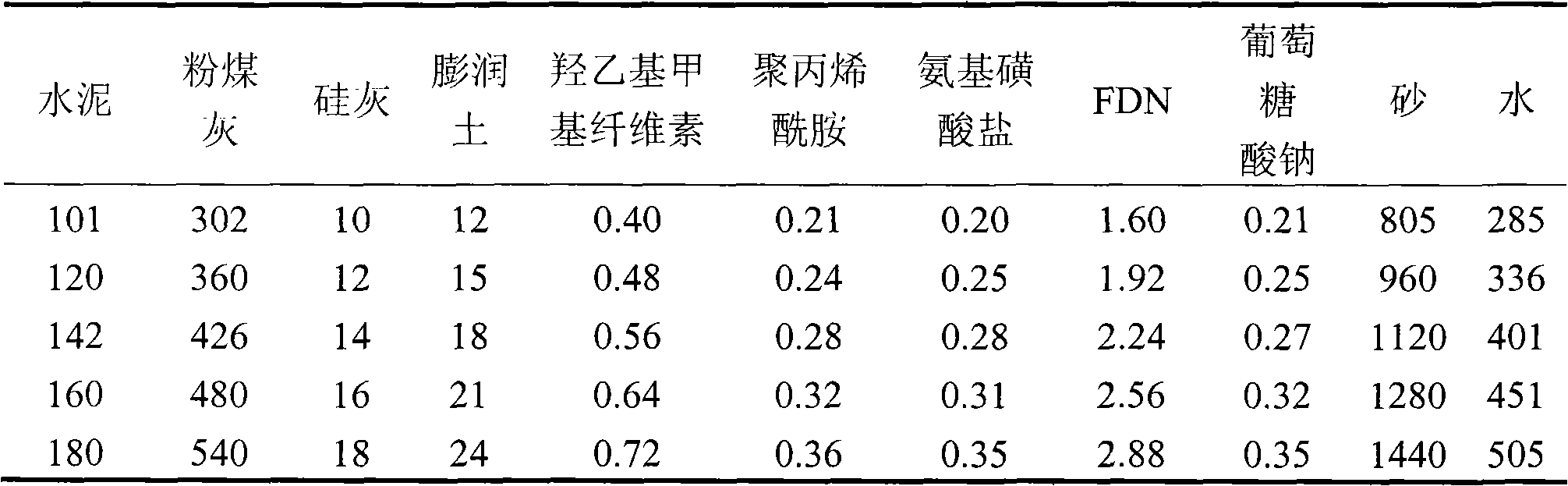

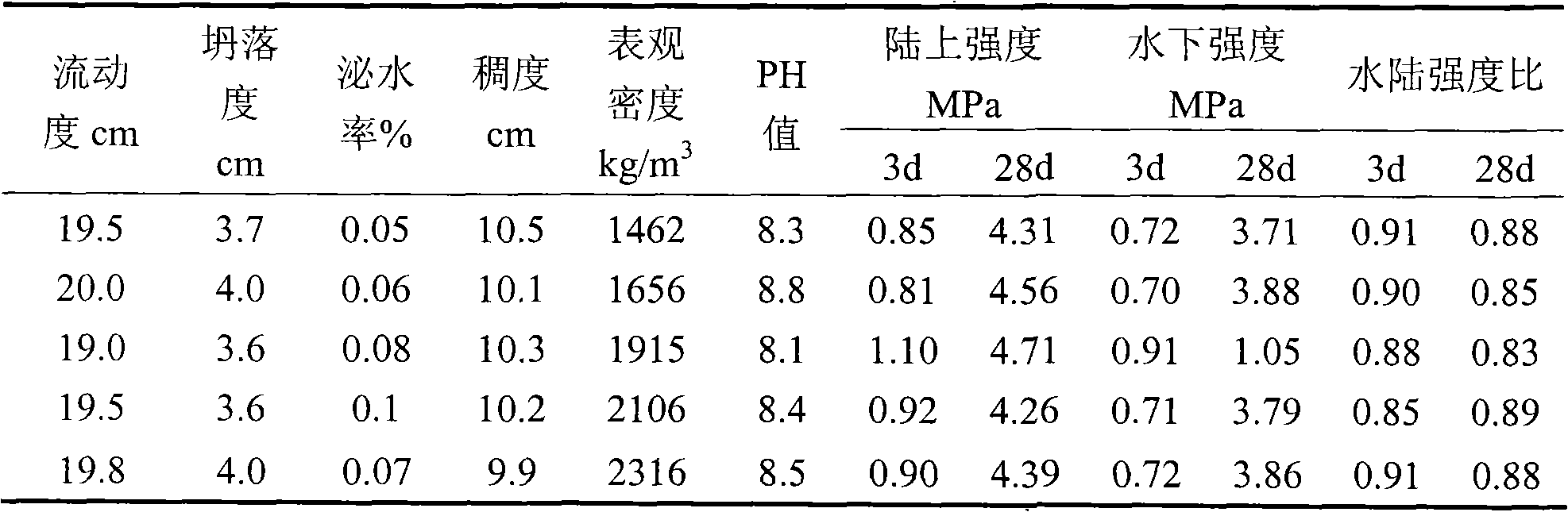

Tunnel backing cloth slip casting material capable of preventing duct piece float upward and preparation method thereof

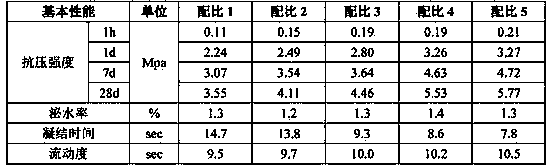

InactiveCN101269938AAchieve underwater non-dispersionPrevent floatingSolid waste managementPost injectionPolyacrylamide

The present invention relates to tunnel-wall post-injection pulp material and a preparation method of the tunnel-wall post-injection pulp material. Tunnel back-lining pulp-injection material that can prevent the upward-floating of the duct piece is characterized in consisting of a substrate compound A and an additive compound B, wherein, the substrate compound A includes cement, fly ash, sand and water; the additive compound B includes silicone ash, swell soil, droxyethylcellulose, polyacrylamide, sulfamate, naphthaline water-reducing agent and gluconic acid sodium salt; the ratio of the ingredients (kg / m<3>): 100 to 200 portions of cement, 300 to 600 portions of fly ash, 800 to 1600 portions of sand, 280 to 560 portions of water, 10 to 40 portions of silicone ash, 12 to 30 portions of swell soil, 0.4 to 0.8 portions of droxyethylcellulose, 0.2 to 0.4 portions of polyacrylamide, 0.2 to 0.4 portions of sulfamate, 1.6 to 2.9 portions of naphthaline water-reducing agent and 0.2 to 0.4 portions of gluconic acid sodium salt. The present invention can realize the high stability, high water dispersion prevention, high-efficient water-reducing plasticity preservation and adjustable performance of the pulp-injection material the condensation under the conditions of high water pressure and water satuation, thereby greatly improving the working performance and the durance of the pulp-injection material.

Owner:WUHAN UNIV OF TECH +1

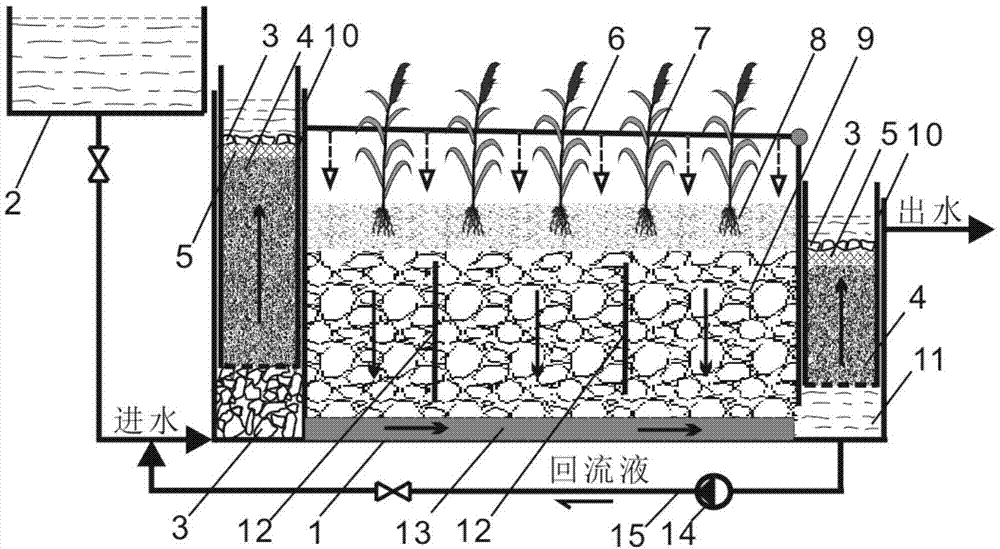

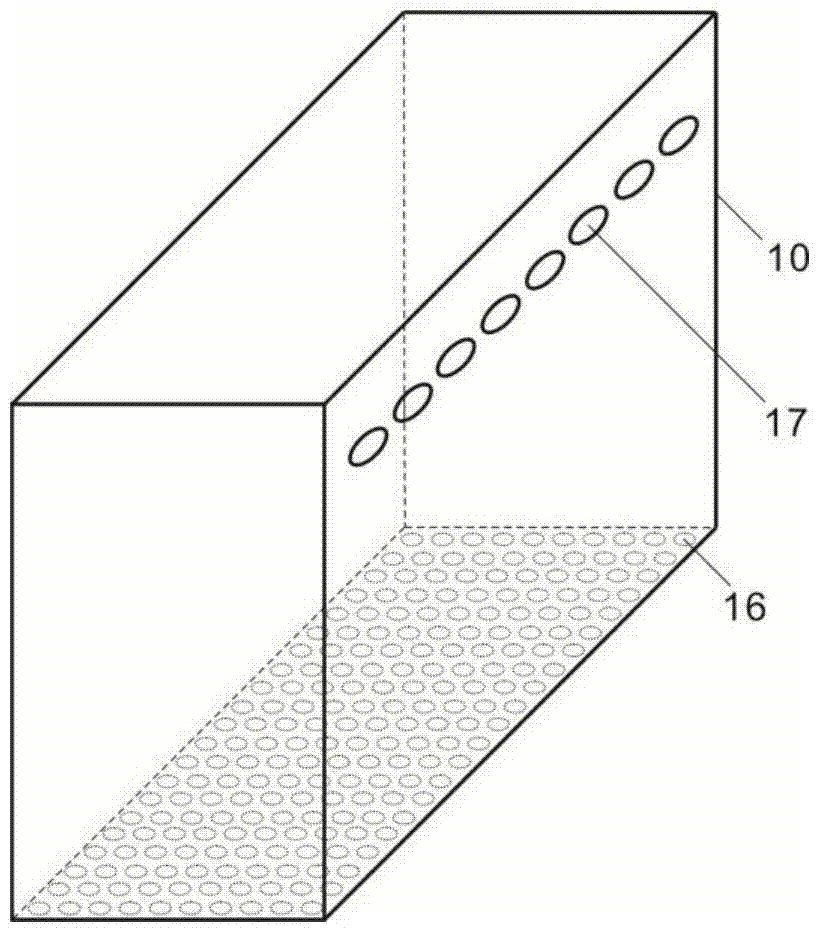

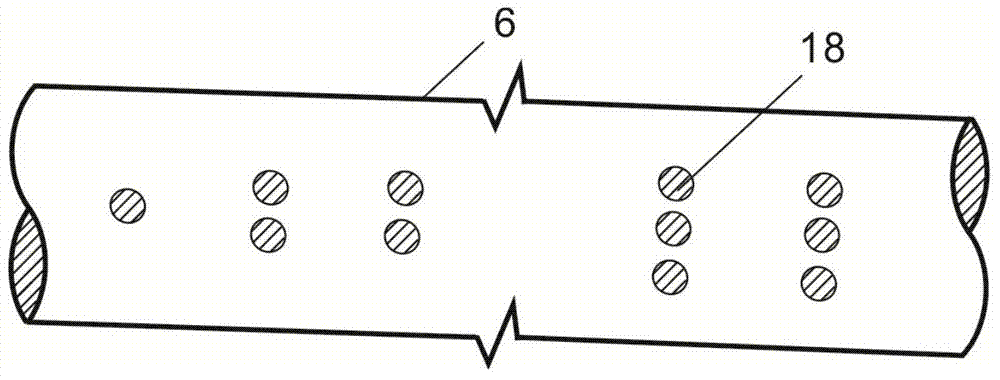

Biological carbon modular composite vertical-flow artificial wetland system

ActiveCN104761057AImprove adsorption capacityEfficient removalSustainable biological treatmentTreatment with microorganism supports/carriersCarbon layerMicrobial transformation

The invention relates to a biological carbon modular composite vertical-flow artificial wetland system which comprises a wetland bed body, a water inlet tank, a gravel layer, a modular biological carbon layer, a mixed filler layer, a filtering medium layer, wetland plants, a reflux unit and a water distributor. When the wetland operates, influent water passes through the anoxic gravel layer and biological carbon layer, the aerobic mixed filler layer, and the anoxic biological carbon layer and filtering medium layer. The reflux unit is arranged inside, and pollutants in sewage are removed under the filtration-adsorption-precipitation action, microbial conversion action and plant absorption action. The biological carbon modular composite vertical-flow artificial wetland system has the advantages of blockage prevention, high hydraulic load, favorable nitrogen / phosphorus removal effect, stable operation and the like.

Owner:SHANDONG UNIV

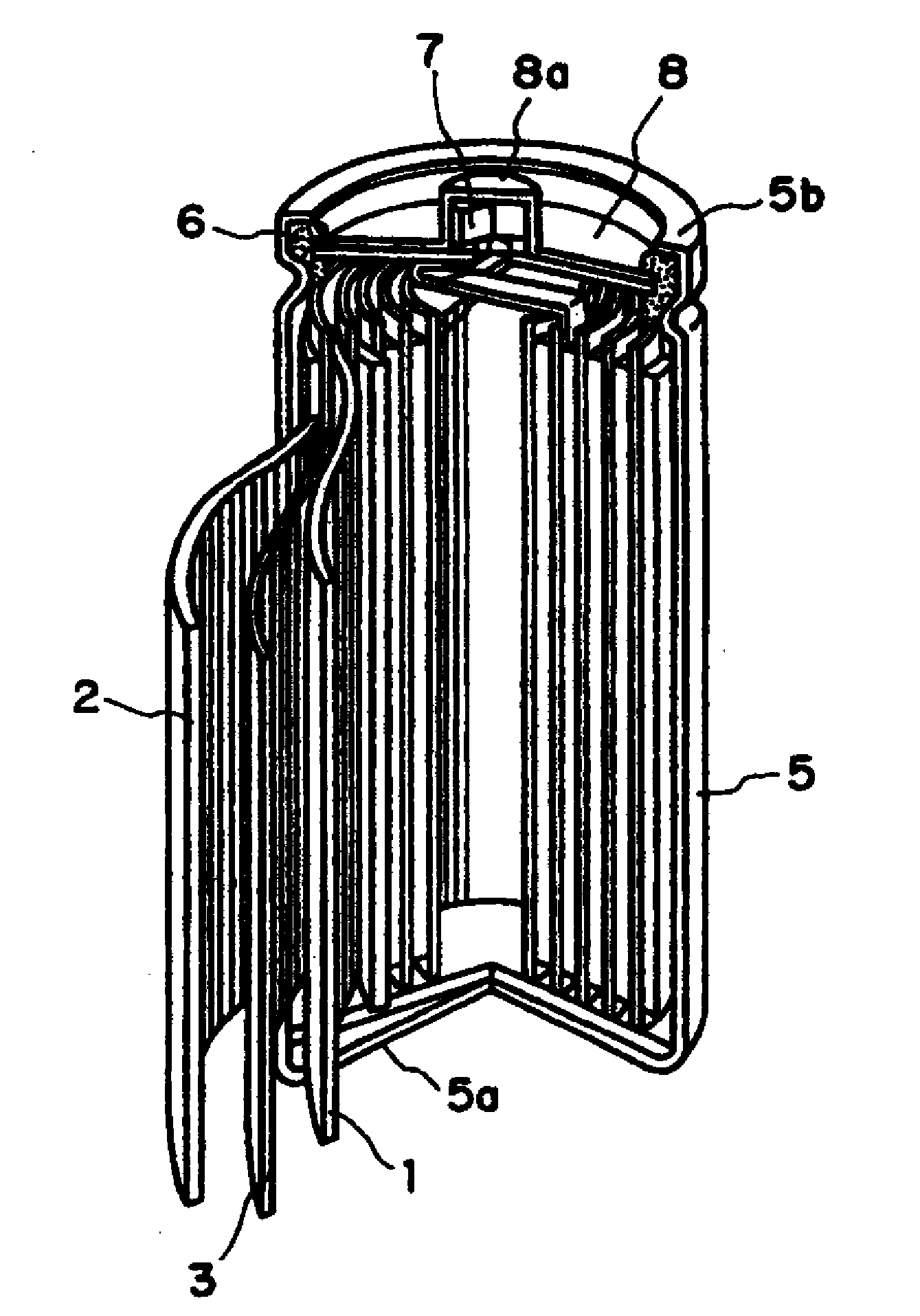

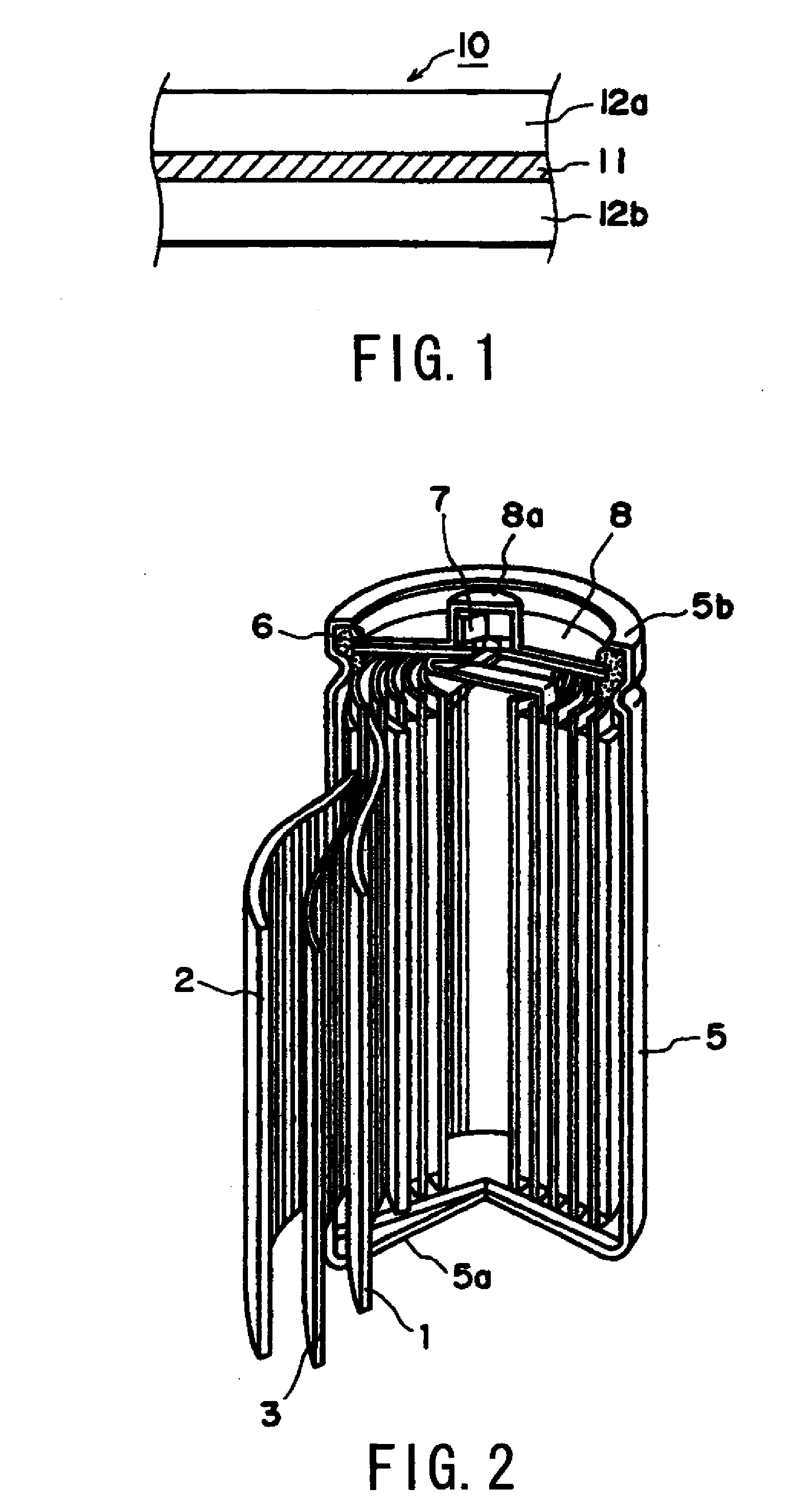

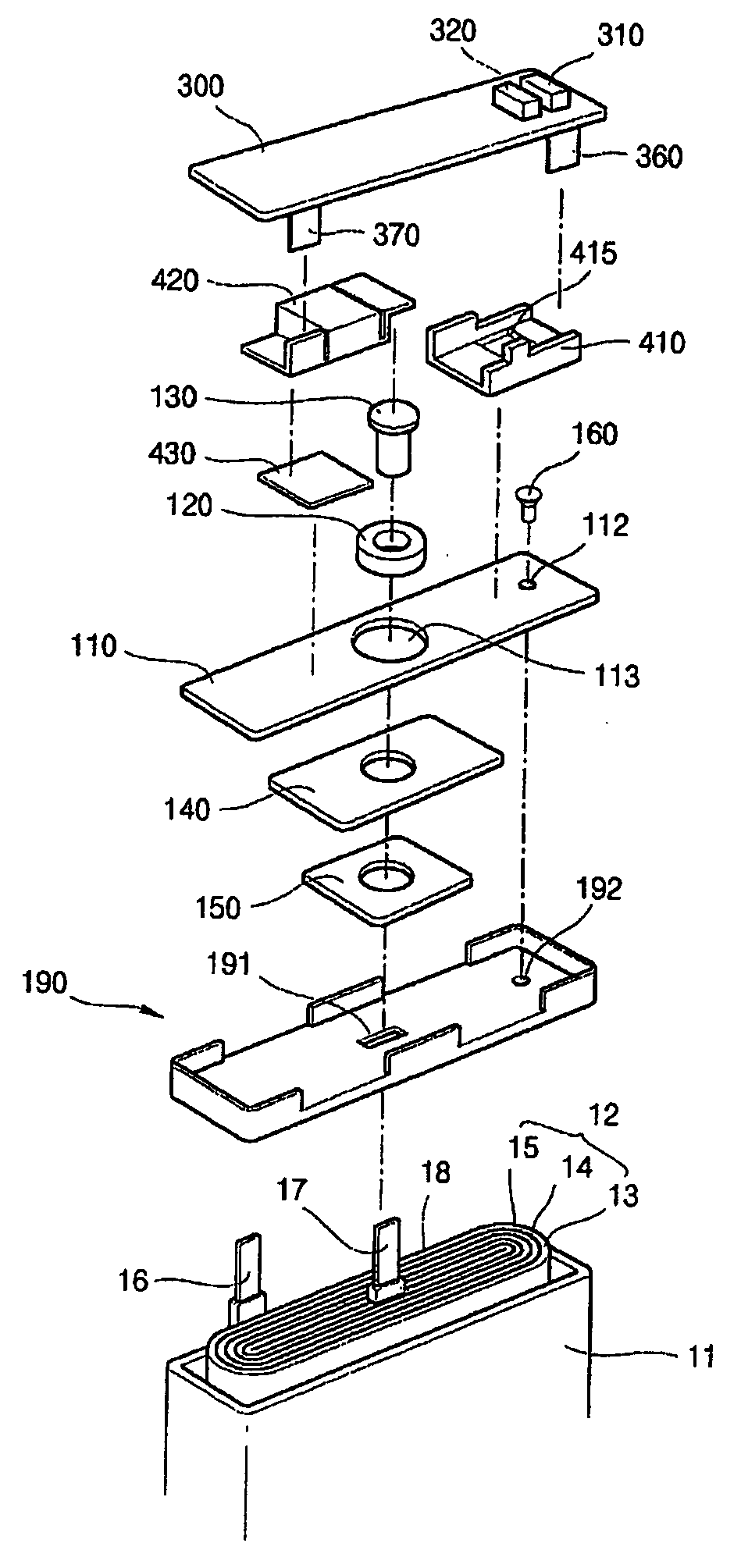

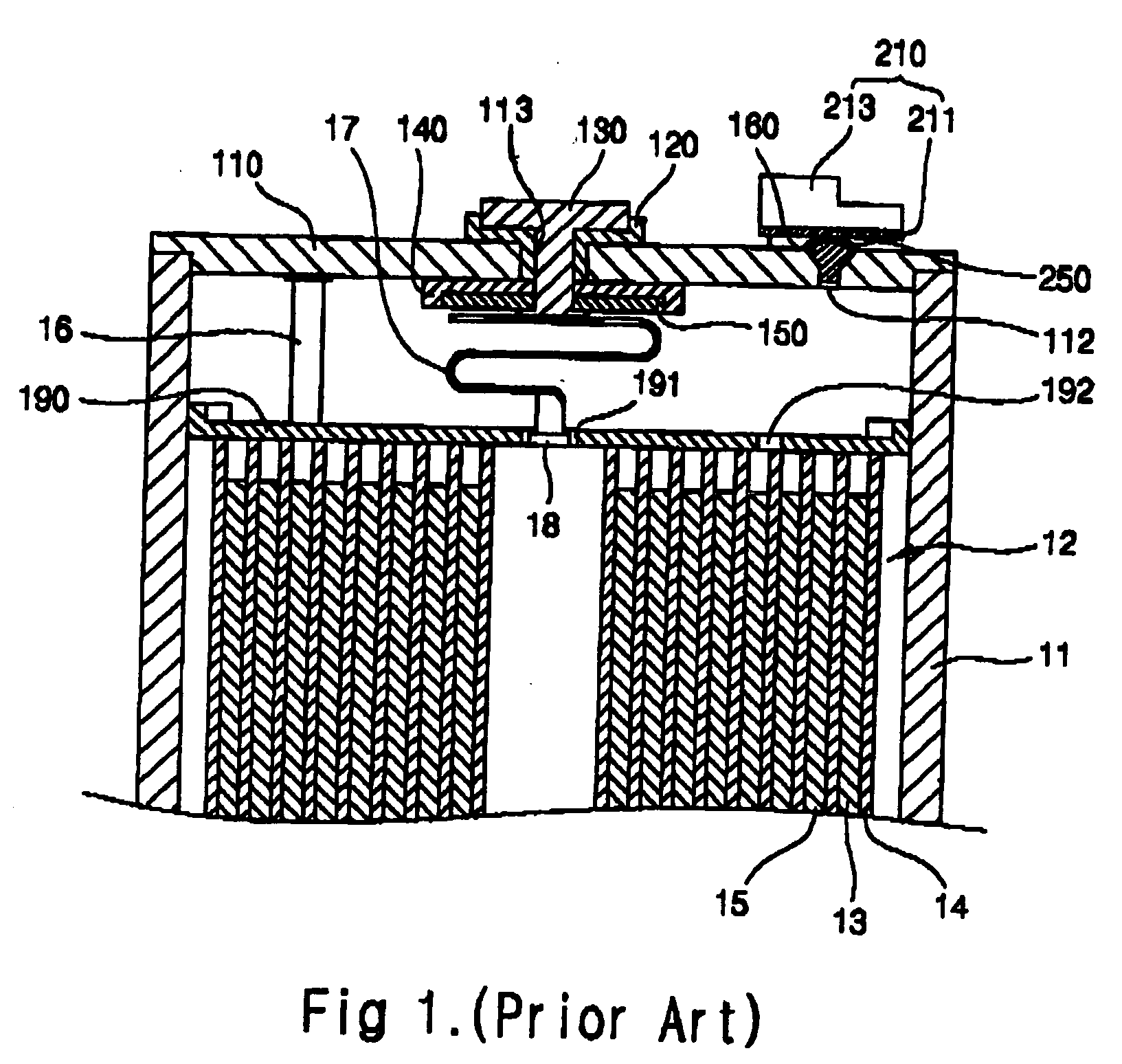

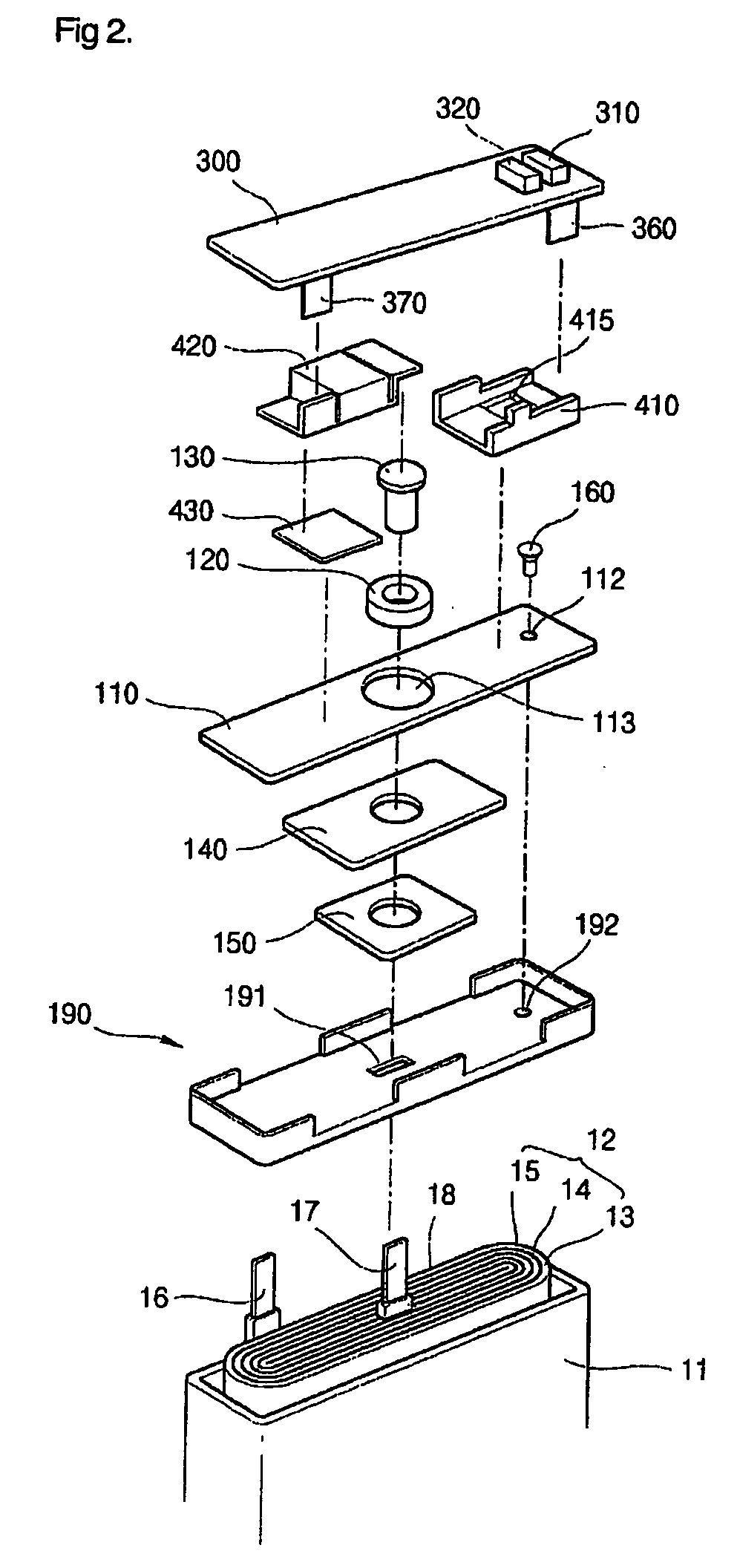

Secondary battery having lead plate attached thereto

ActiveUS20050221174A1Easy to weldReliable strengthFinal product manufacturePrimary cellsEngineeringElectrolyte

A secondary battery comprises a bare cell including an electrode assembly composed of positive and negative electrodes and a separator, a can acting as a container for containing the electrode assembly and an electrolyte, and a cap assembly having a cap plate for covering the open upper end of the can and a lead plate coupled to a part of the cap plate, wherein an electrolyte injection hole is positioned on a side of the cap plate. The lead plate has a bottom portion which covers the electrolyte injection hole and at least a part of which is coupled to a surface of the cap plate. Additionally, a part of the lead plate, which corresponds to the electrolyte injection hole of the bottom portion, is removed to form a hole so that a cap which seals the electrolyte injection hole is exposed.

Owner:SAMSUNG SDI CO LTD

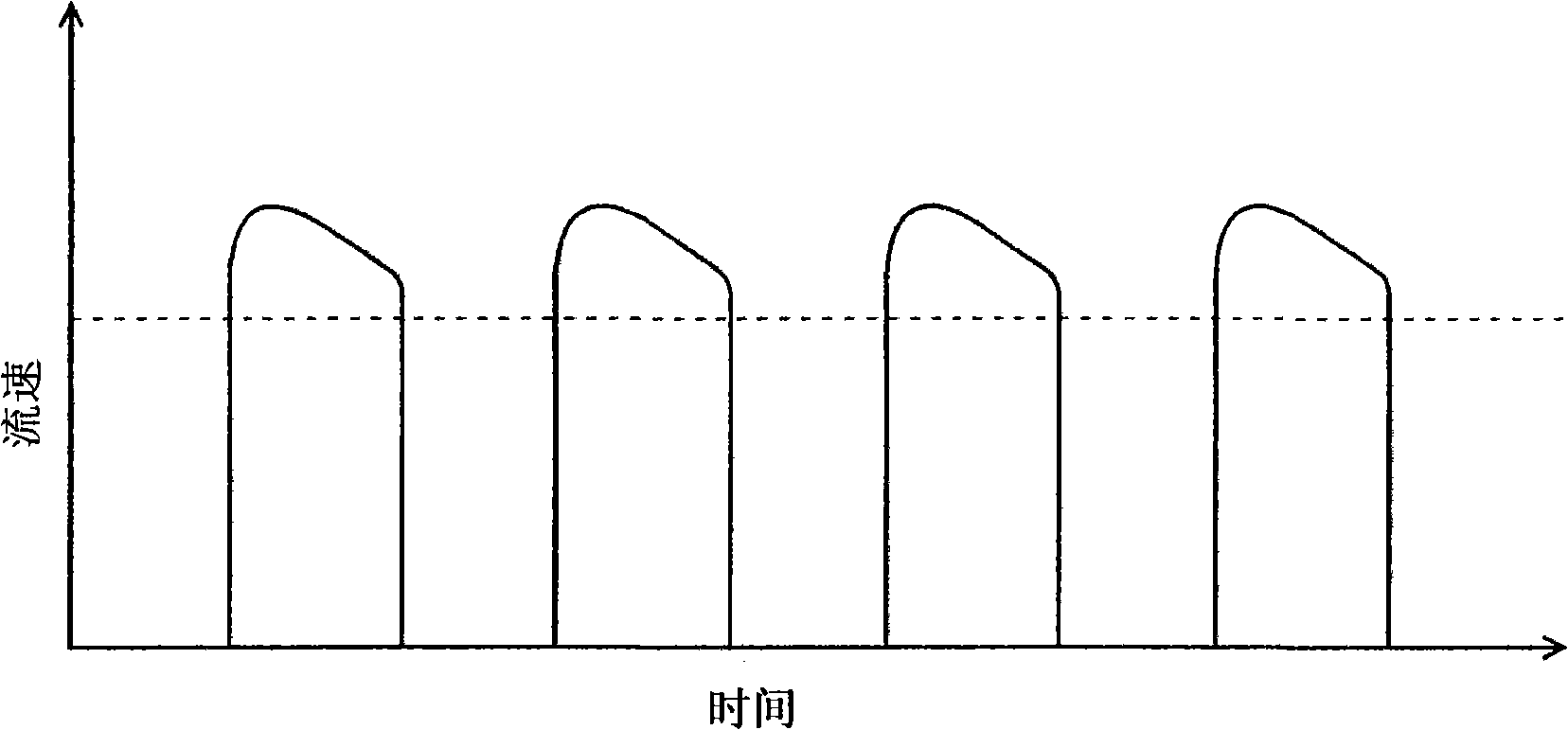

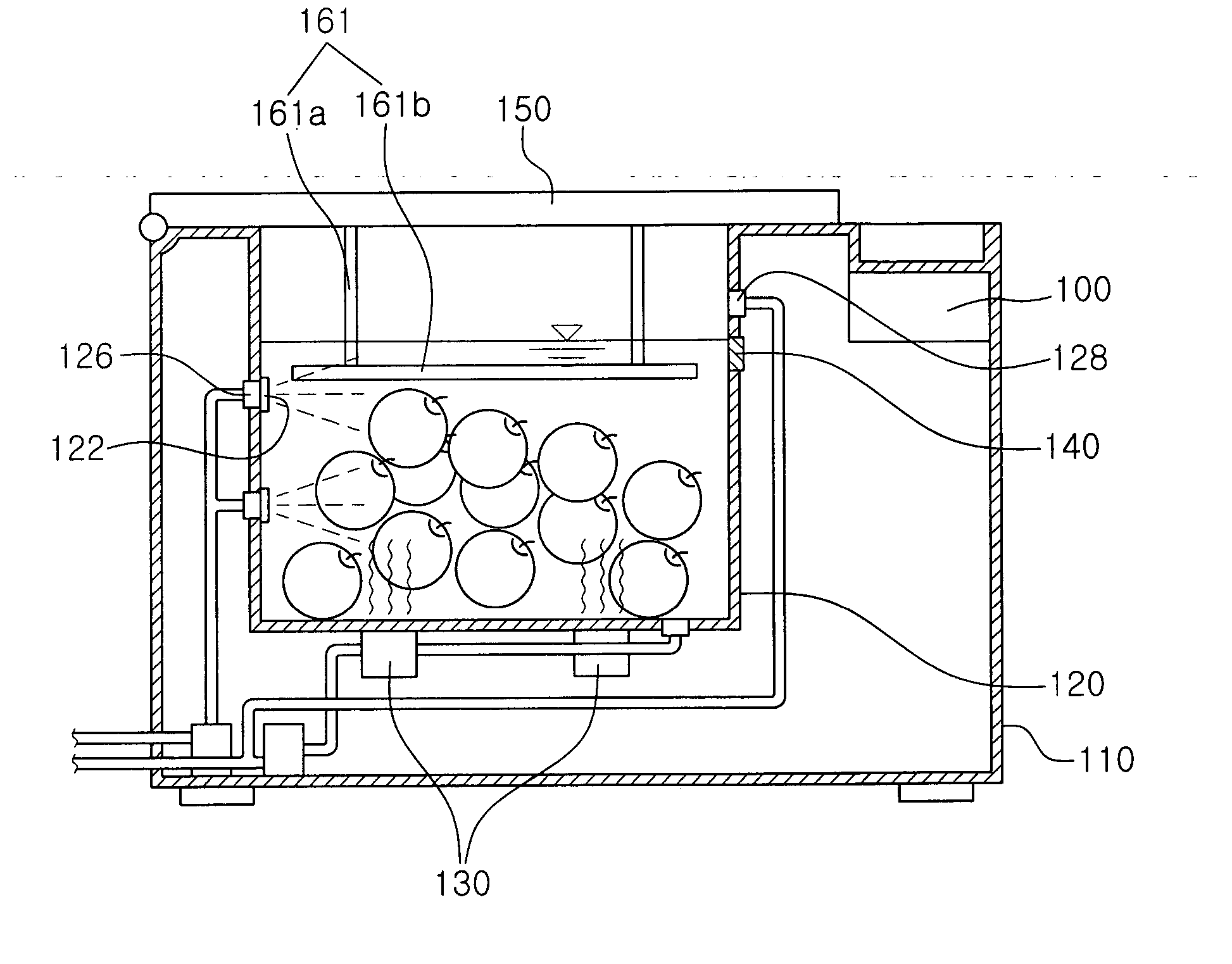

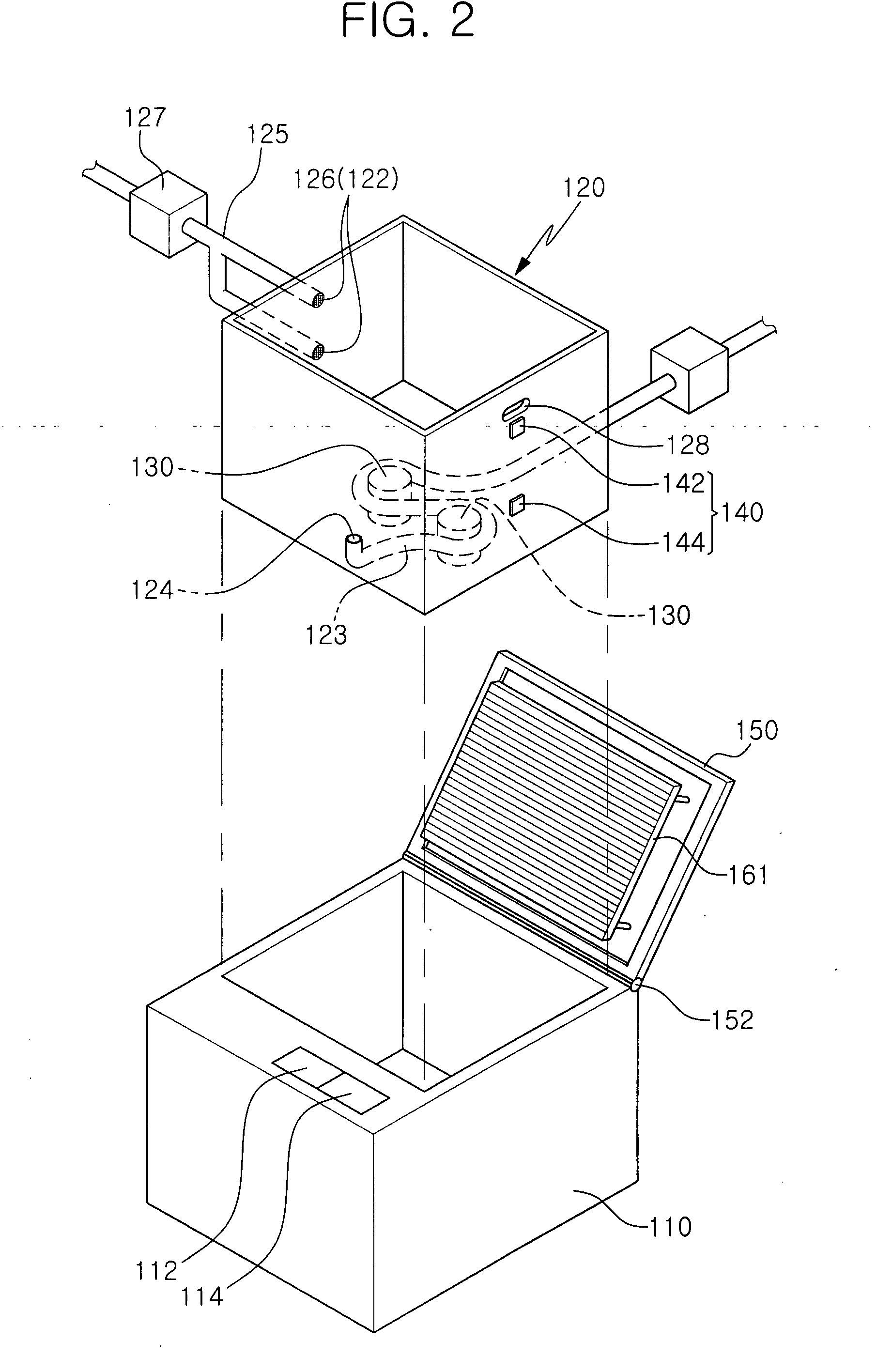

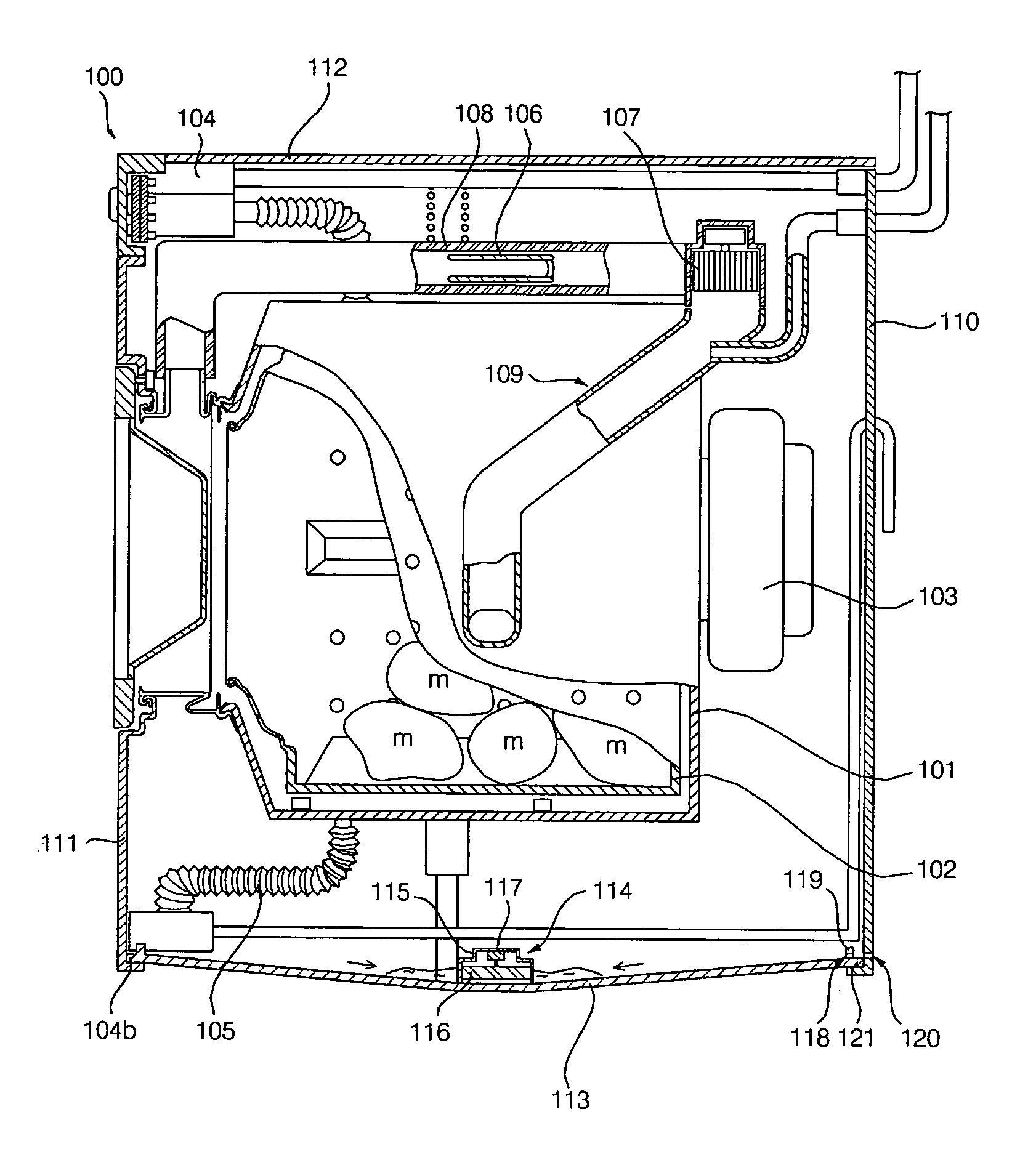

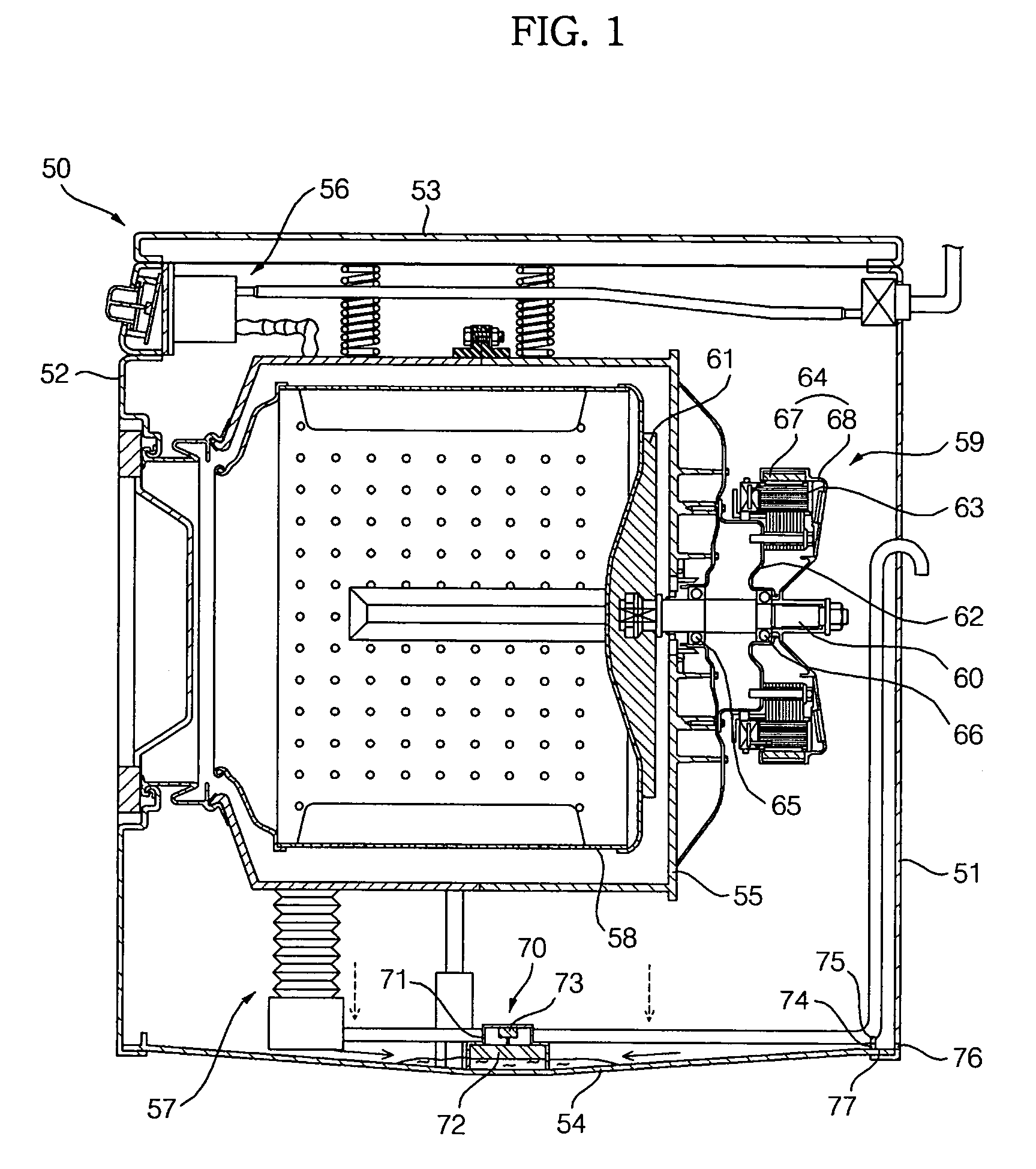

Washer and operation control method therefor

InactiveUS20070056610A1Washing time is relatively longKeep for a long timeTableware washing/rinsing machine detailsHollow article cleaningForeign matterProcess engineering

A washer and a method of controlling operation of the washer is provided. The washer includes a main body; a washing chamber which is disposed in the main body and accommodates a stuff to be washed, including a water outlet formed on the bottom surface thereof and a water feed inlet on one end of which a shower nozzle is formed; an ultrasonic oscillator generating vibration in the washing chamber; and a control unit which can control a washing process, wherein the washing chamber includes an overflow hole through which washing water can overflow from the washing chamber. The washer performs an initial washing operation and a main washing operation in combination. In the initial washing operation, stuffs to be washed such as fruits and vegetables are contained in the washing chamber and then water is supplied on the stuffs to be washed through the shower nozzle in a showering manner to then be discharged so that foreign matter stick to the stuffs can be primarily removed. In the main washing operation, water is re-supplied into the washing chamber to fill the washing chamber up, to then perform the main washing operation called an ultrasonic washing operation through the ultrasonic oscillator. During performing the main washing operation, water is additionally fed in every period of time in a manner that a certain amount of floating matter can be flown out through the overflow hole. As a result, light foreign matter floating in the water among the foreign matter detached from the stuffs to be washed is flown out together with the water, to thereby prevent floating foreign matter from sticking again to the stuffs during washing and improve a washing effect. The washer can automatically and cleanly wash stuffs such as fruits and vegetables to be washed which requires a long washing time, to thereby provide an effect of shortening the whole washing time.

Owner:WINIAMANDO

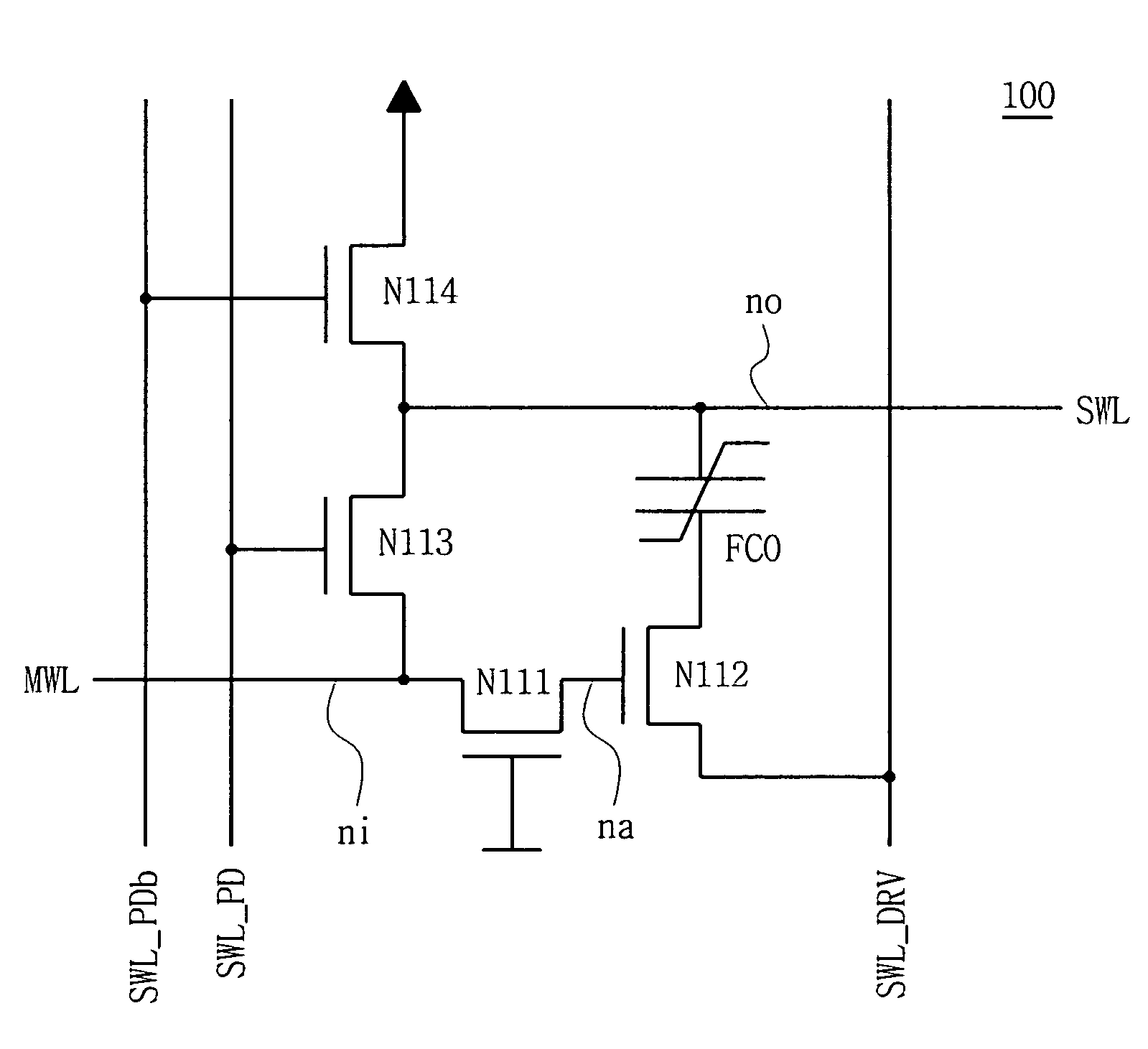

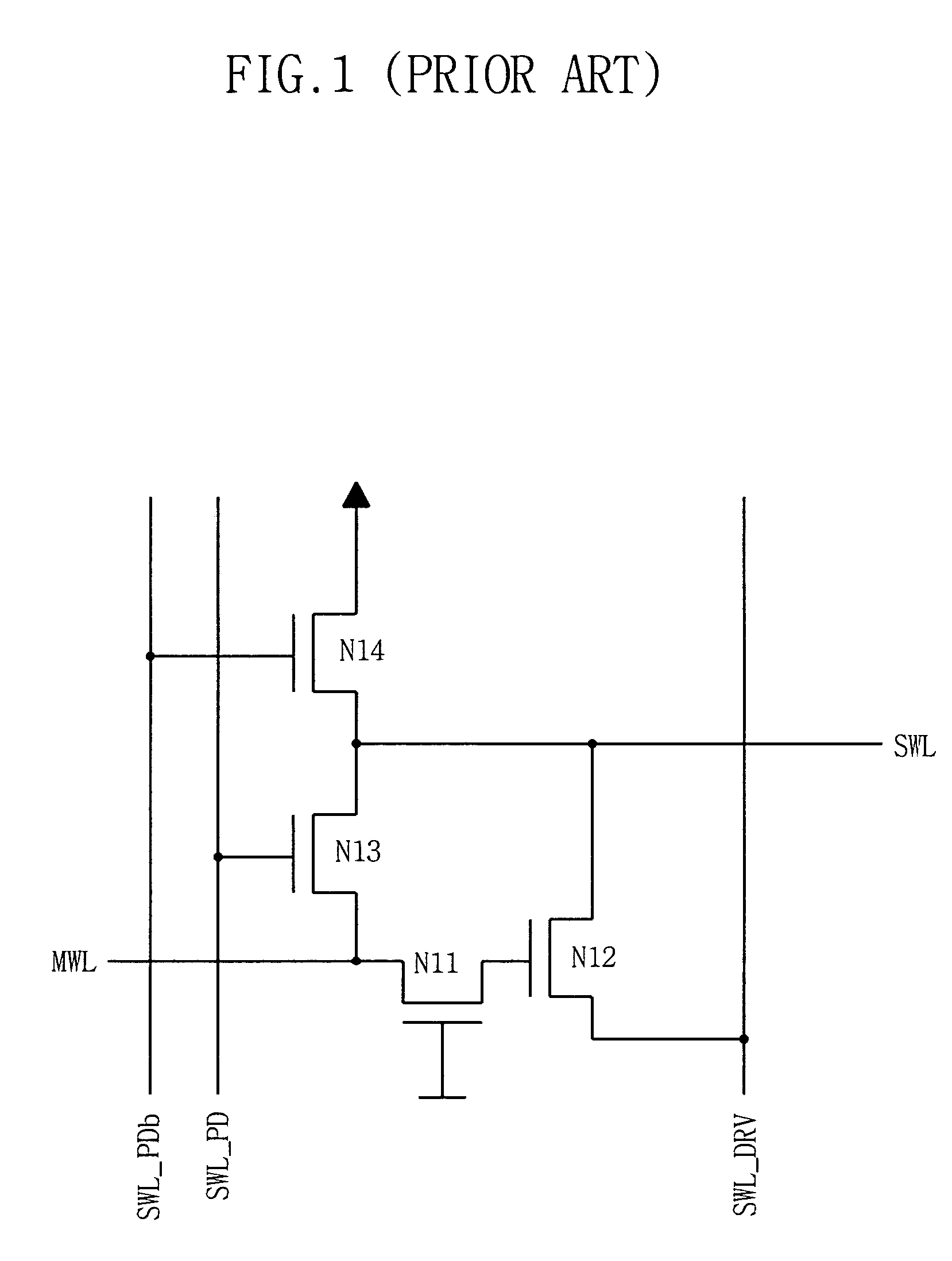

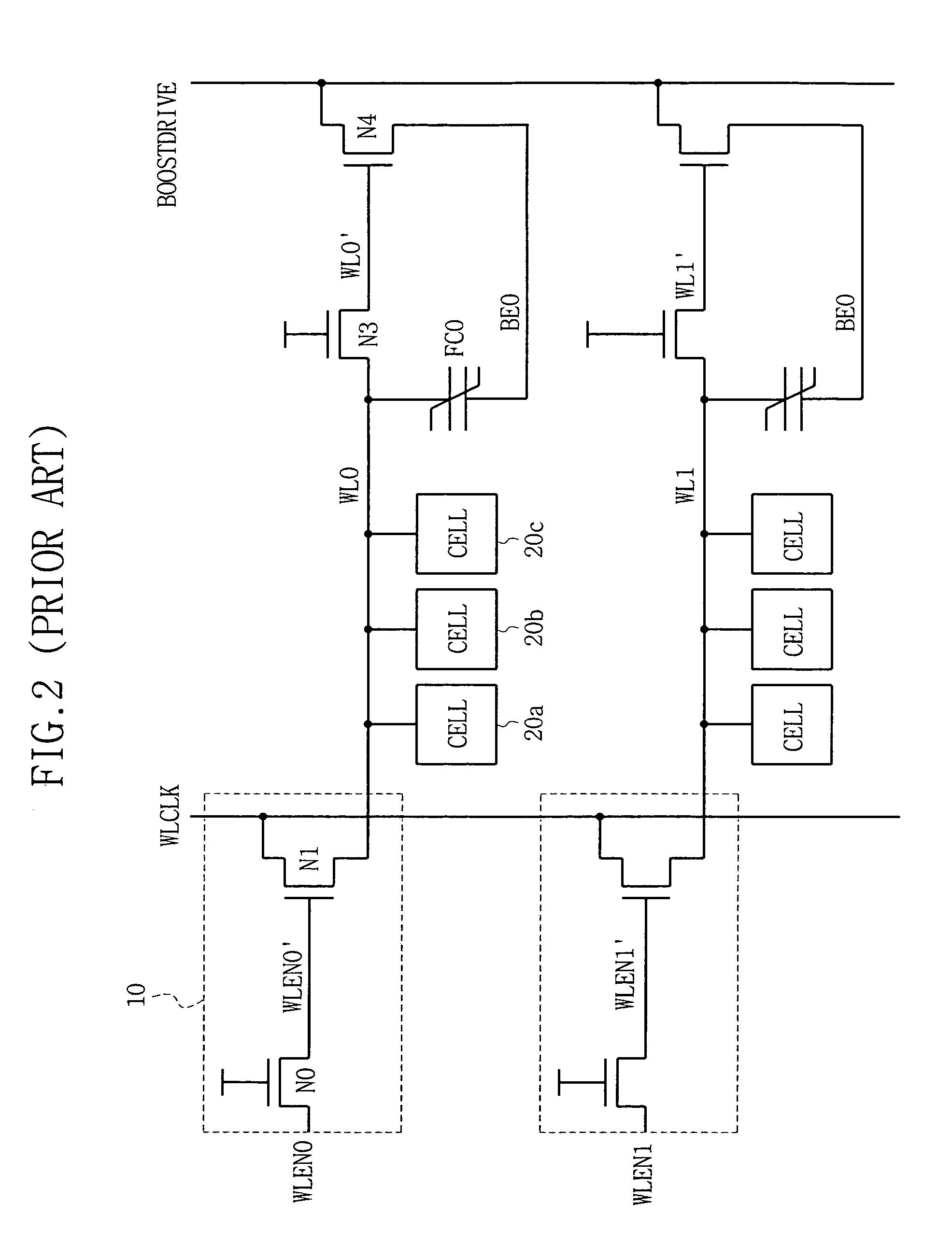

Word line driver circuits for use in semiconductor memory and driving method thereof

Disclosed is a word line driver circuit and a driving method thereof. An input to the circuit has a ground voltage level during a non-selected operating mode and, as the output signal of a word line decoding circuit, is applied at a power source voltage level during a selected operating mode. The output of the circuit has a ground voltage level during the non-selected operating mode and applies a higher voltage than the power source voltage to a word line connected to a memory cell during the selected operating mode. Optionally, a capacitor boosts the output voltage during the selected operating mode.

Owner:SAMSUNG ELECTRONICS CO LTD

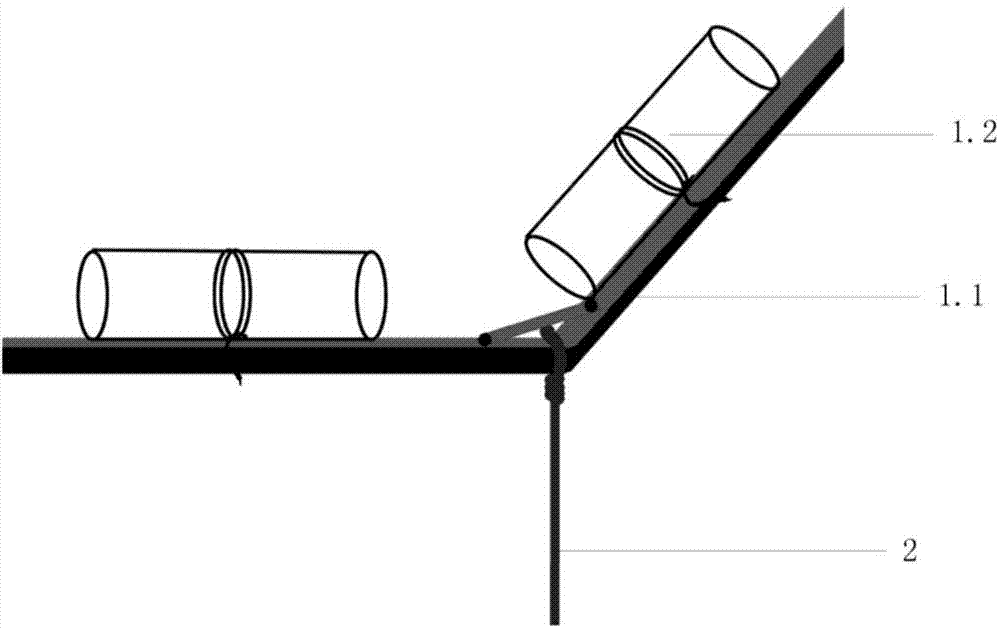

Pipe jacking construction method

ActiveCN104455725AControl level deviationControl high-level deviationPipe laying and repairComing outArchitectural engineering

The invention discloses a pipe jacking construction method. The pipe jacking construction method is characterized by comprising the steps that firstly, surveying and setting out are carried out; secondly, working well construction is carried out; thirdly, assembling type back wall installation is carried out; fourthly, a guide rail is installed; fifthly, a main jacking jack is installed; sixthly, a pipe jacking auxiliary device is installed; seventhly, a pipeline is jacked; eighthly, deviation is rectified, and mould weights are stacked at the front end of a water draining pipe to increase the weight of a pipe section; ninthly, coming out of a hole is carried out. According to the pipe jacking construction method, the horizontal deviation and high-level deviation of a pipe jacking axis are effectively controlled, the stability of an excavation face can be effectively kept, the disturbance on the soil body around a pipe body is small, and the pipeline floating is avoided.

Owner:鸿昊建设集团有限公司

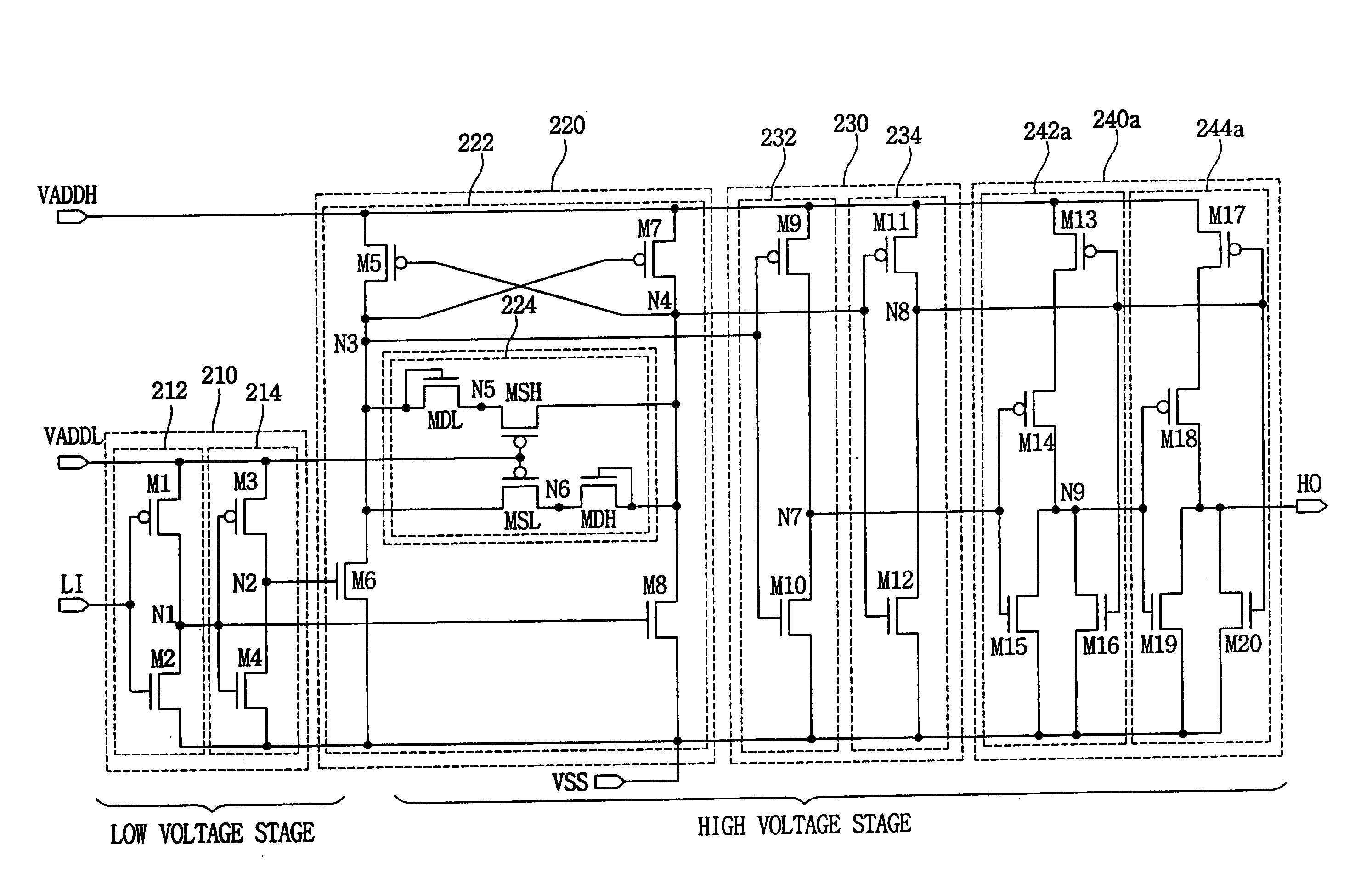

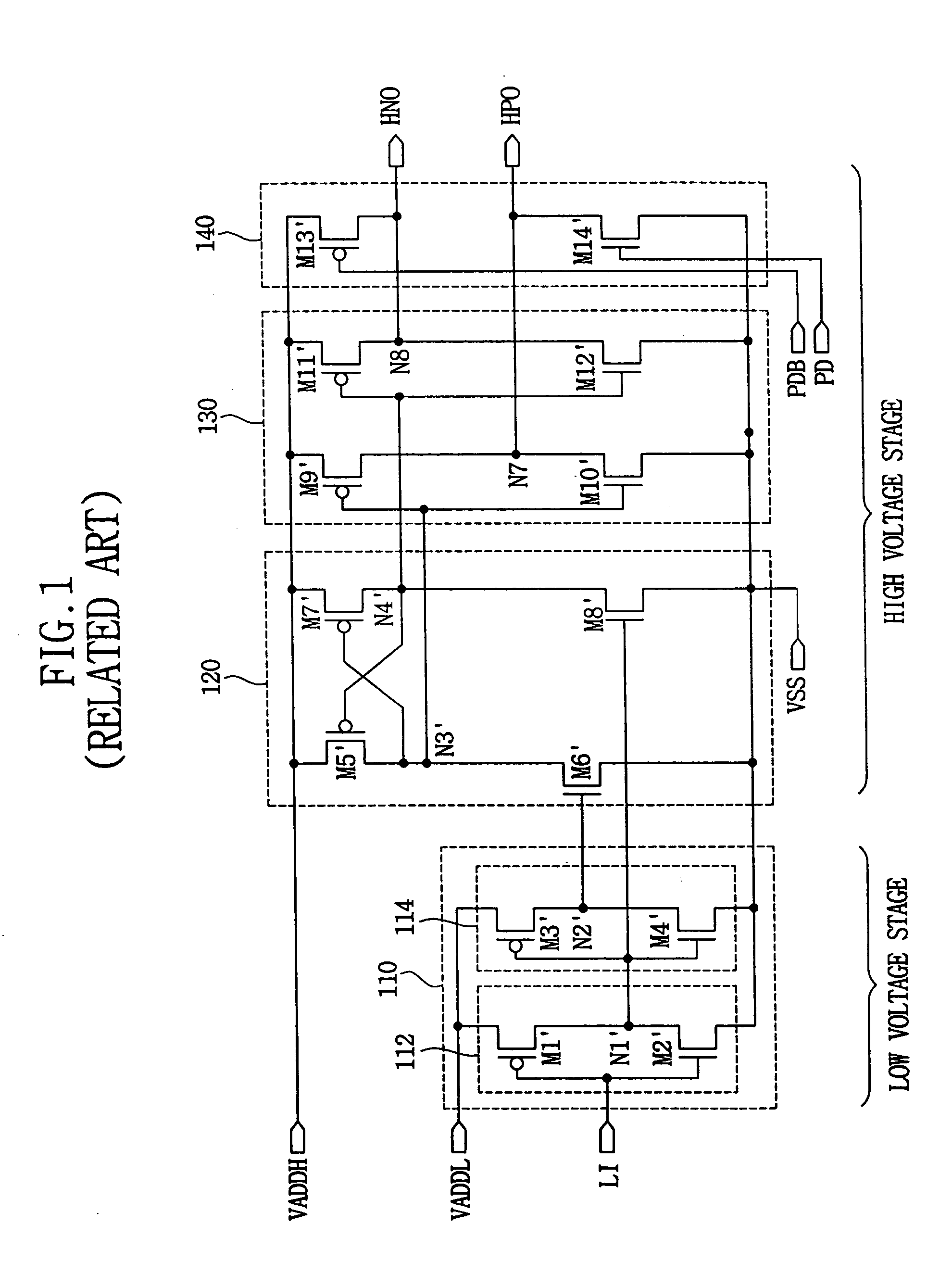

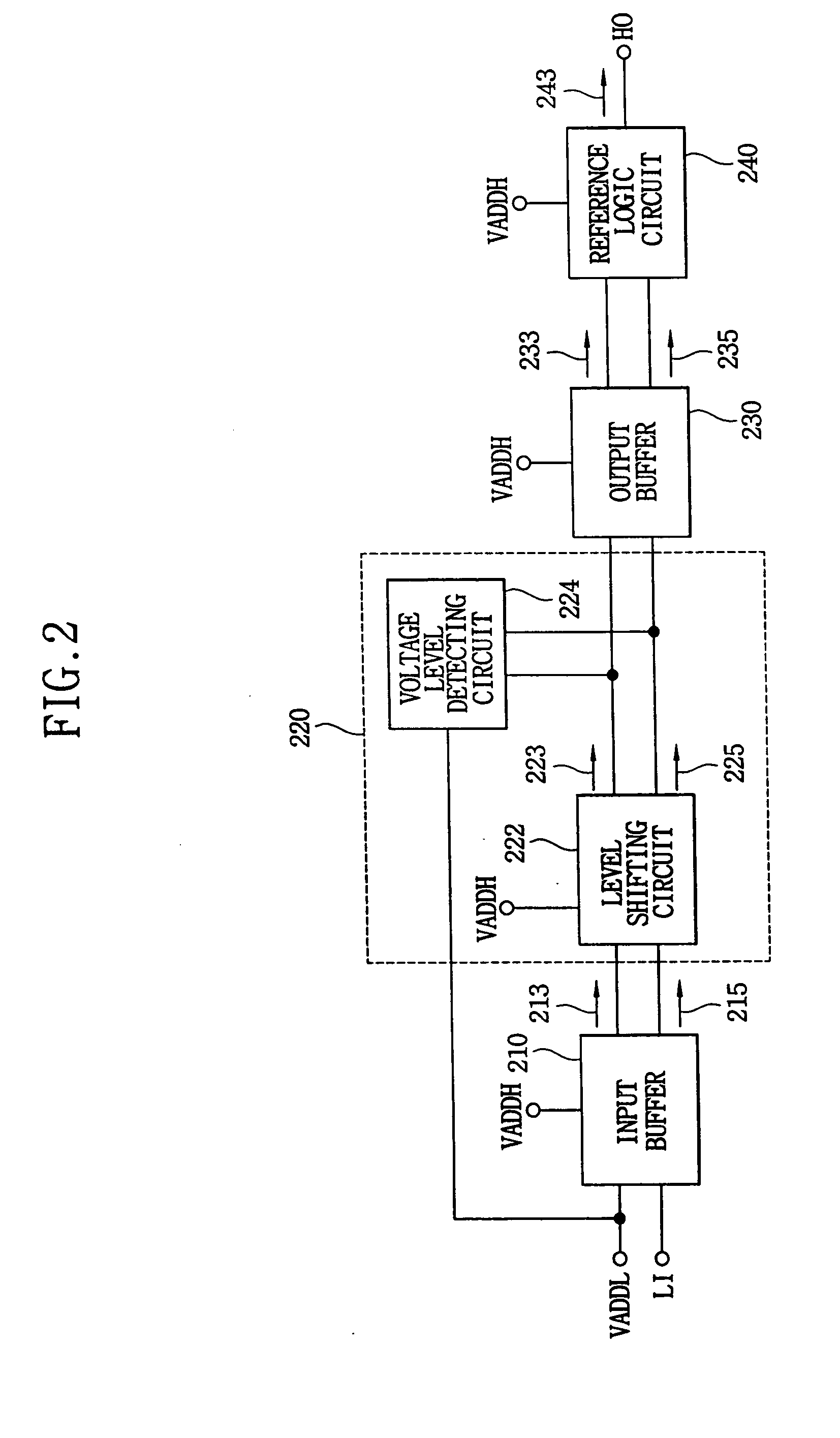

Level shifter for detecting grounded power-supply and level shifting method

ActiveUS20050024088A1Prevent floatingElectric pulse generatorLogic circuit coupling/interface arrangementsLevel shiftingElectricity

A level shifter includes an input buffer, a level shifting circuit, a voltage level detecting circuit, an output buffer and a reference logic circuit. The input buffer buffers a small range input signal to output a small range signal. The level shifting circuit transforms the small range signal into a first wide range signal. The voltage level detecting circuit detects whether a power voltage of a low voltage stage is at the ground level, and prevents an indefinite logic state of the level shifter. The output buffer buffers the first wide range signal to output a second wide range signal. The reference logic circuit generates a wide range signal having a predetermined logic status when the power voltage is at the ground level. Thus, a leakage current of the level shifter is reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

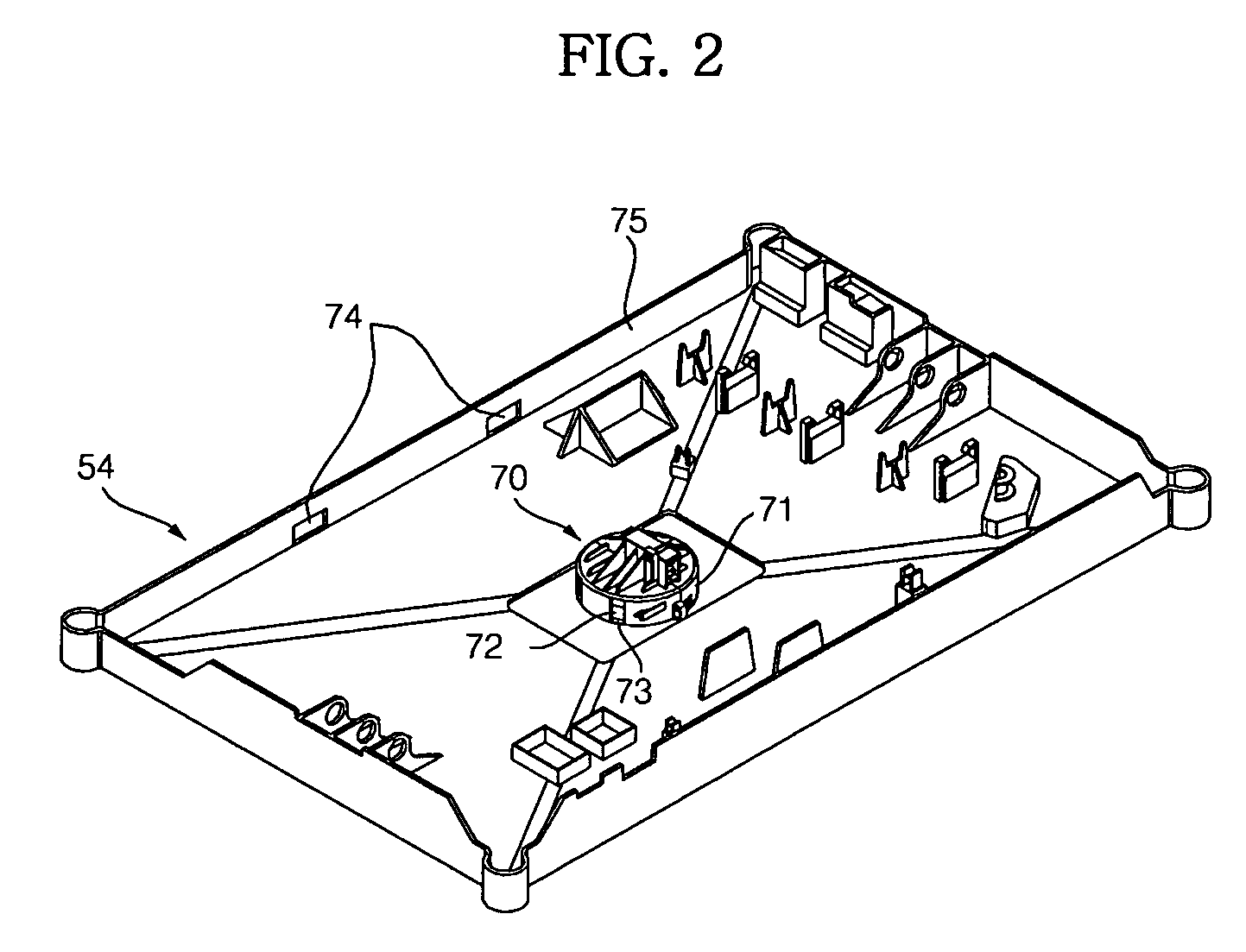

Washing apparatus

InactiveUS20060081014A1Reduce processing costsReduce material costsOther washing machinesControl devices for washing apparatusWater leakageWaste management

Disclosed herein is a washing apparatus in which the top of a base pan is inclined downward toward a mounting position of a water leakage sensor, so that water, dropped onto the base pan, is gathered toward the water leakage sensor regardless of a water drop position, thereby enabling prompt operation of the water leakage sensor and achieving an enhancement in reliability. Furthermore, the washing apparatus comprises holders by which the water leakage sensor is vertically caught after being vertically press fitted to the base pan, thereby enabling the water leakage sensor to be mounted to the base pan via a single vertical press-fitting operation, resulting in an enhancement in assembling efficiency.

Owner:LG ELECTRONICS INC

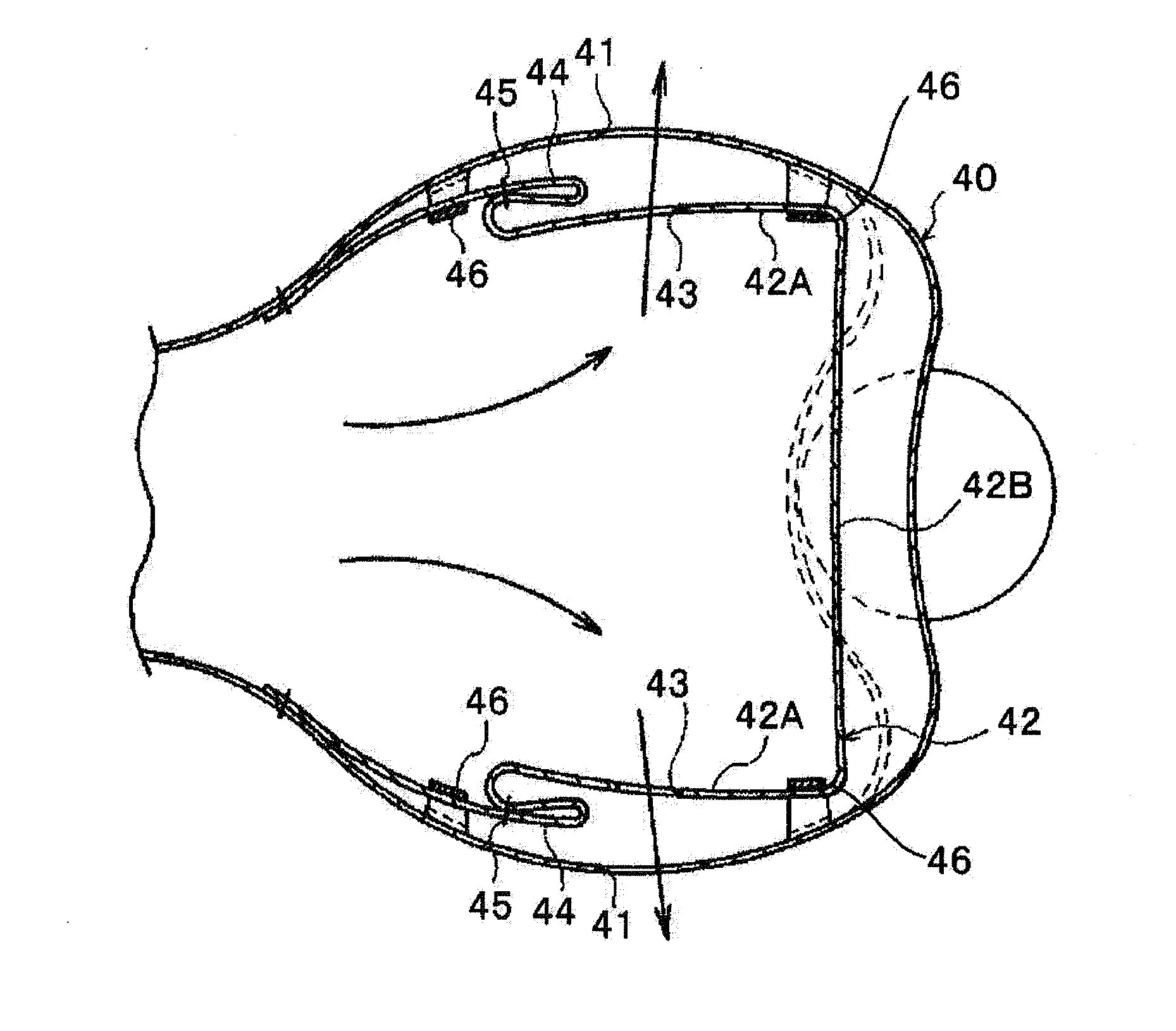

Airbag device

ActiveUS20120068444A1Preventing excessive inflationPrevent outflowPedestrian/occupant safety arrangementInternal pressureBand shape

The present invention provides an airbag device that is capable of restraining a rectification cloth that switches a vent hole to an opened or closed state so as not to be twisted, and that is capable of switching the vent hole from an opened state to a closed state, and further, switching to the opened state. At an initial stage at which an airbag main body inflates and expands, the vent hole 8 is arranged between the leg portions 5, and when the airbag main body is in a predetermined internal pressure state, the vent hole is closed by means of the band-shaped portion 4. If an occupant or the like comes into contact with the airbag main body, a tense state of each of the leg portions is released, the rectification cloth is established in a slackened state, and the vent hole 8 is established in an opened state.

Owner:NIHON PLAST CO LTD

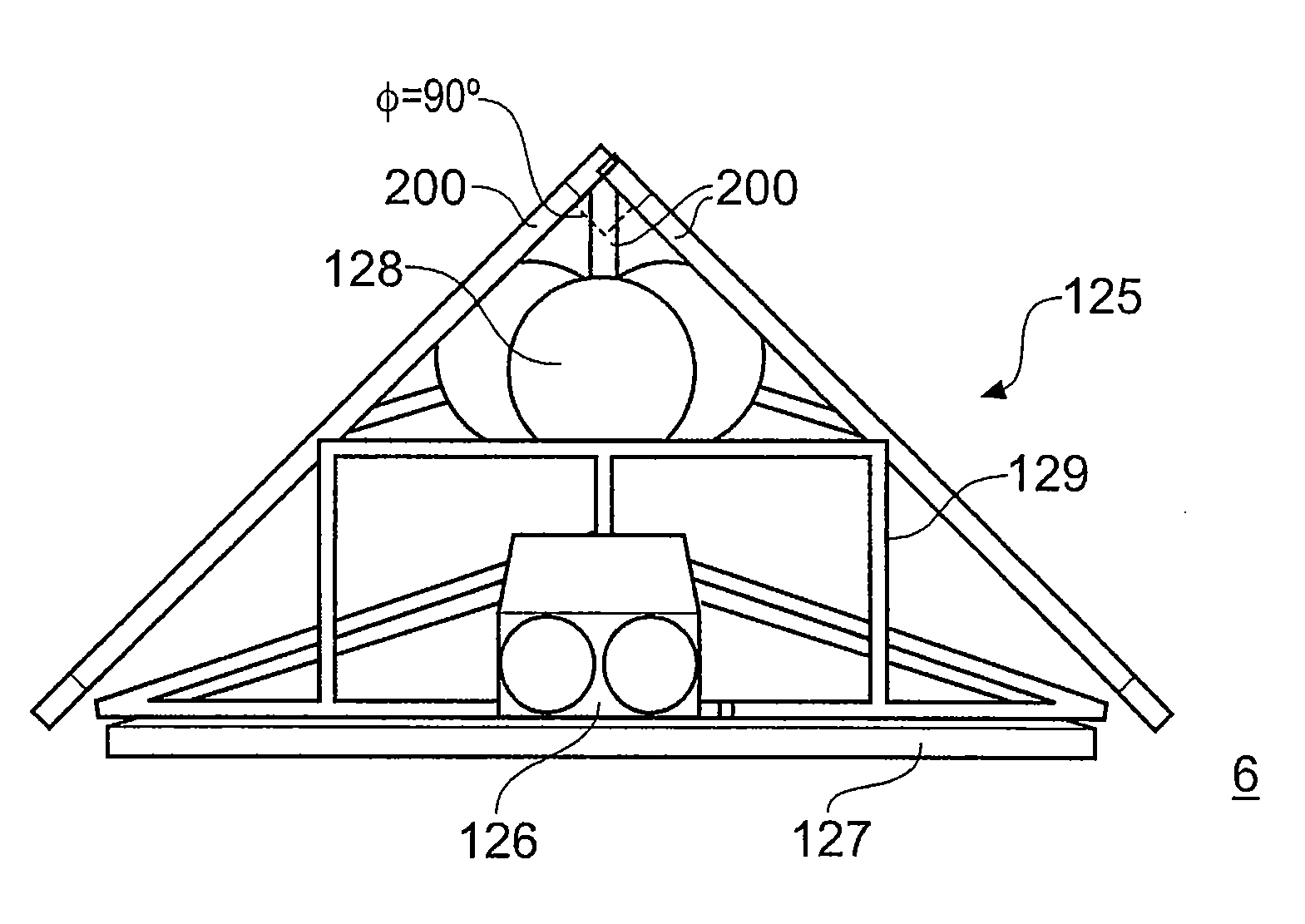

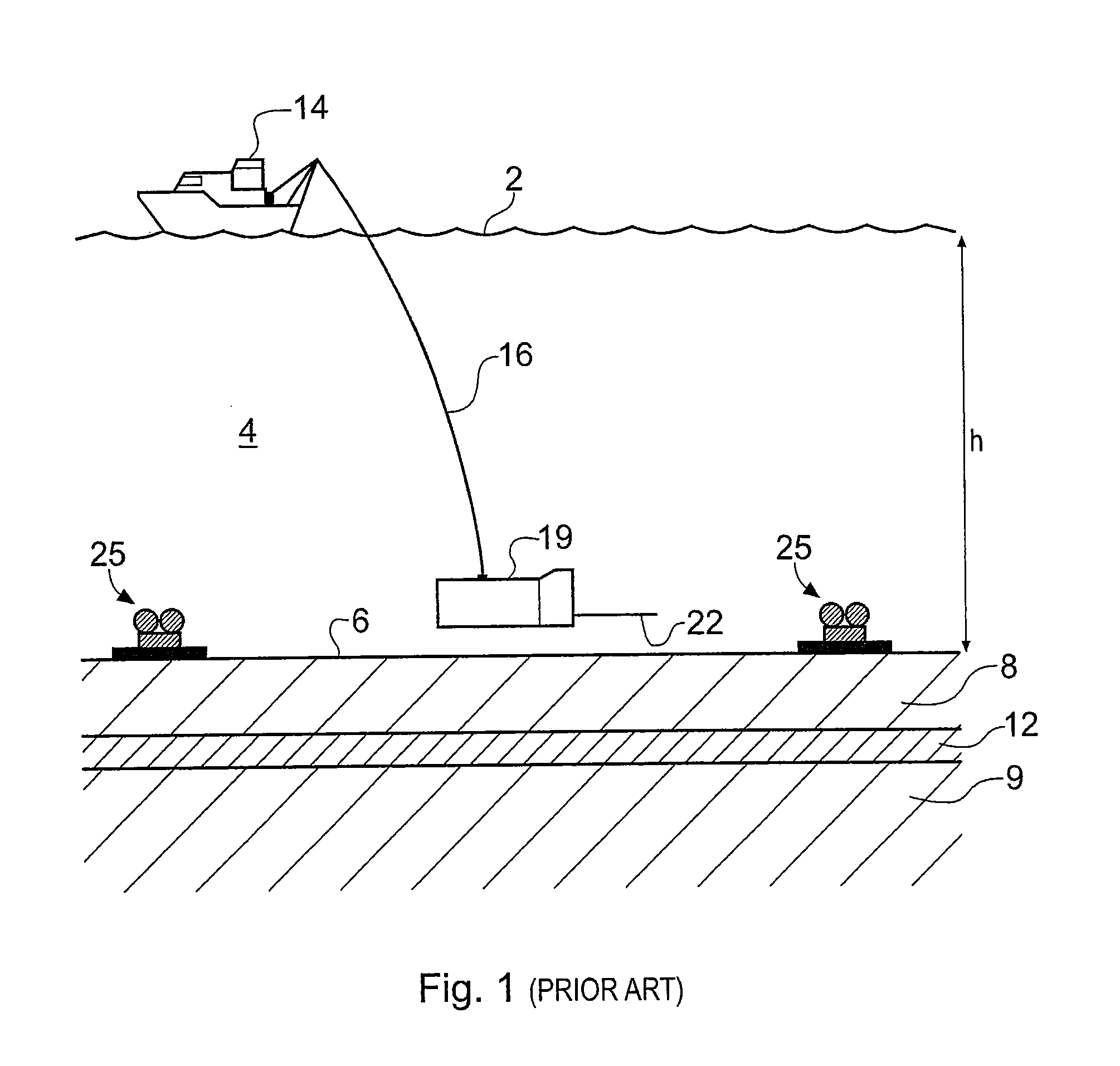

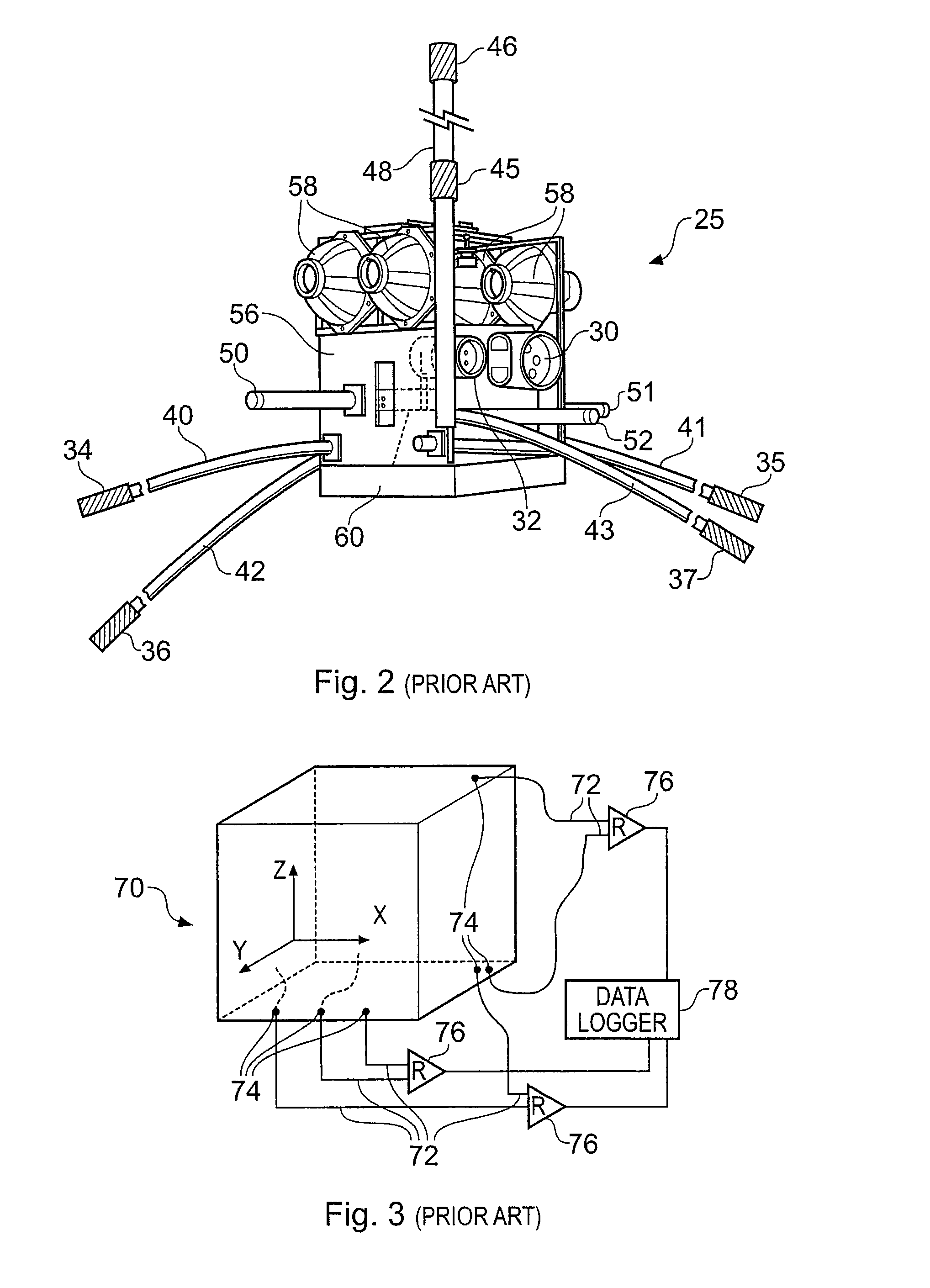

Electromagnetic detector for marine surveying

InactiveUS20080309346A1Improve measurement statisticCompact and stable shapeDetection using electromagnetic wavesAcoustic wave reradiationDipole antennaSurveyor

A detector for underwater electromagnetic surveying is described. The detector comprises first, second, third and fourth electrodes which are arranged to define first, second and third electric dipole antennae extending between pairs of the electrodes. Each dipole antennae extends between a pair of the electrodes and the fourth electrode is common to all three dipole antennae. Thus the first electrode is separated from the fourth electrode along a first direction to provide the first dipole antenna, the second electrode is separated from the fourth electrode along a second direction to provide the second dipole antenna, and the third electrode is separated from the fourth electrode along a third direction to provide the third dipole antenna. The electrodes are arranged so that the first, second and third directions are inclined at an angle of between 20 and 70 degrees to a surface on which the detector rests when in normal use.

Owner:OHM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com