Patents

Literature

1074 results about "Lost-foam casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lost-foam casting (LFC) is a type of evaporative-pattern casting process that is similar to investment casting except foam is used for the pattern instead of wax. This process takes advantage of the low boiling point of polymer foams to simplify the investment casting process by removing the need to melt the wax out of the mold.

Powdery paint for lost foam casting of cast iron

The invention discloses a special coating for pulverous expendable pattern casting and casting iron, and the special coating comprises 60-70 percent of 180-200 mesh refractory materials, 2.0-3.0 percent of suspending agent, 1.5-2.5 percent of adhesive, 0.3-0.6 percent of organosilicon defoamer, 0.01-0.03 percent of preservative agent and 180-200 mesh residual mica powder in balancing amount. When the special coating is prepared, various pulverous materials are weighed according to the required proportion, interposed into the powder stirrer in sequence to stir for 20 to 40 minutes at a low speed and then discharged and packed. When the coating is used, appropriate water is interposed into the stirred vessel by the powder-to-water ratio of 1 to (1.1-1.4). After the stirred vessel is turned on, the powder coating weighed is interposed in batches. The coating is utilized after preparing into slurry; therefore, the special coating has the advantages of good suspension property, high intensity, uniform coating, good thixotropy, good leveling property, glabrous surface, no bubbles, no cracks and the like. Moreover, the user can adopts the dip-coating method, the hang-coating method and the brush-coating method, the viscosity change of coating materials can be decided upon the demands of the user, and different viscosities can realize different coating thicknesses.

Owner:HUAZHONG UNIV OF SCI & TECH

Expendable pattern casting (EPC) molding shell paint for casting steel and preparation method thereof

InactiveCN102407275AHigh strengthImprove breathabilityFoundry mouldsFoundry coresFiberPolyvinyl alcohol

The invention relates to an expendable pattern casting (EPC) molding shell paint for casting steel, and the EPC molding shell paint comprises surface a layer fireproof paint and a back layer reinforcing paint, wherein the surface layer fireproof paint comprises the following components in parts by weight: 80-90 parts of high-chromium alundum powder, 10-20 parts of calcined kaolinite, 6-8 parts ofcalcium rectorite powder, 1-3 parts of sodium tripolyphosphate, 3-5 parts of polyvinyl formal solution, 0.3-0.5 part of ethoxylated alkyl sodium sulfate, 0.6-1.0 part of polyether type modified polydimethylsiloxane and 60-75 parts of water; and the back layer reinforcing paint comprises the following components in parts by weight: 75-85 parts of coal gangue sand, 15-25 parts of kaolinite, 3-6 parts of feldspar powder, 8-13 parts of calcium rectorite powder, 8-10 parts of sodium tripolyphosphate, 1.5-2.0 parts of wood fiber and 30-45 parts of water. A molding shell manufactured by the surface layer fireproof paint and the back layer reinforcing paint has the characteristics of high strength and refractoriness, good air permeability and the like.

Owner:HUBEI UNIV OF TECH

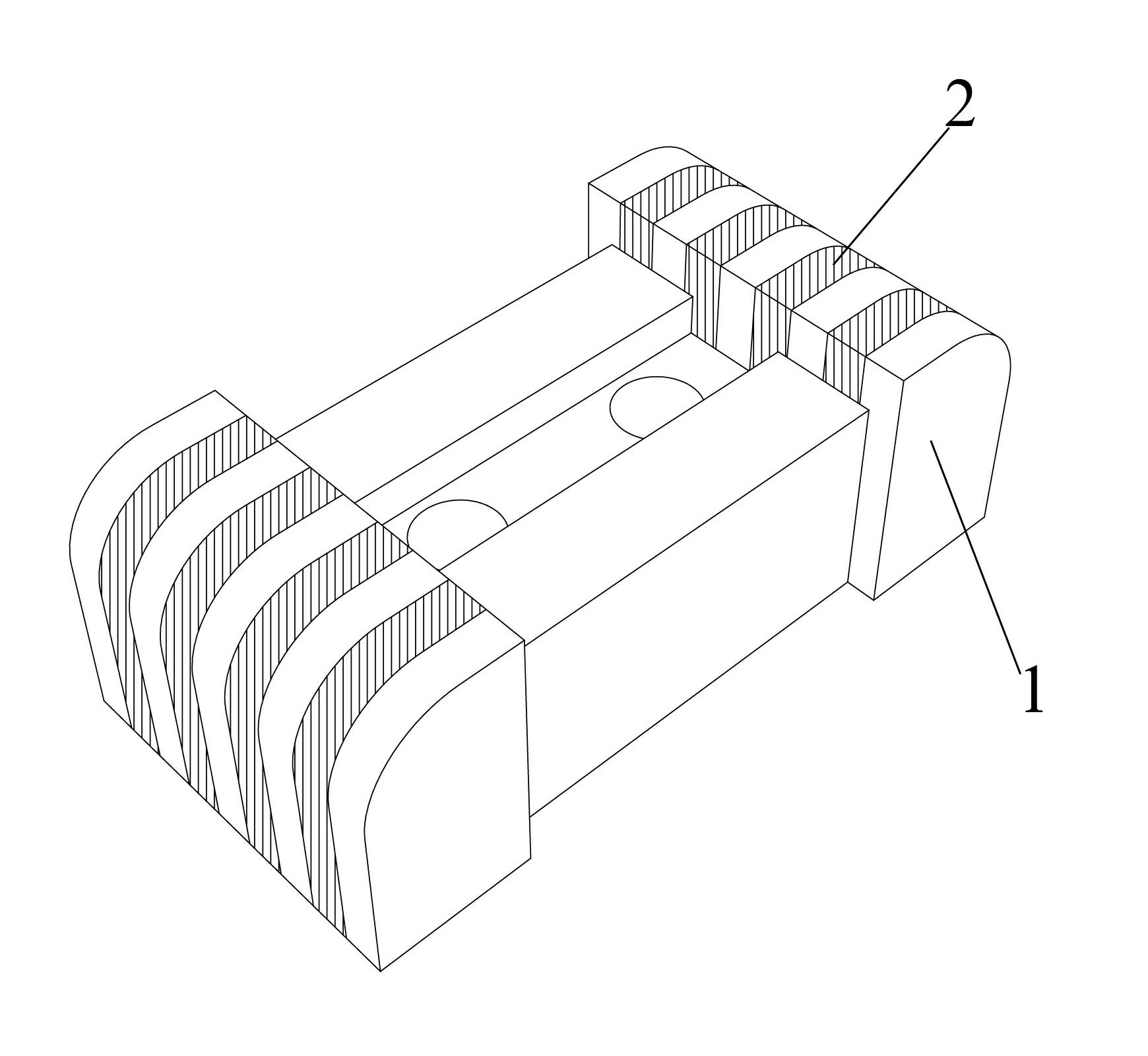

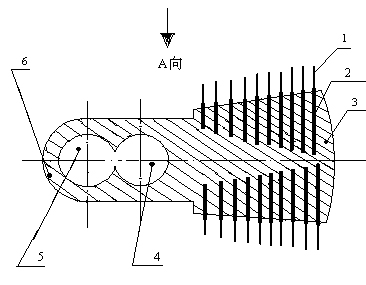

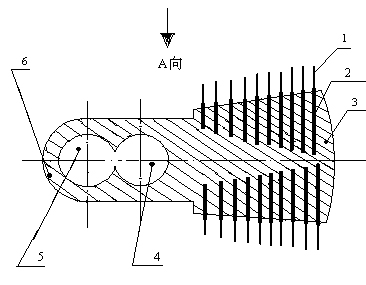

Method of in situ synthetic steel bond hard alloy casting composite hammerhead and hammerhead

A method of an in situ synthetic steel bond hard alloy casting composite hammerhead adopts a vacuum lost foam casting technology, wherein Ti powder, graphite powder, W powder and metal powder are mixed, and are added with an adhesion agent to produce a powder coating paste, the powder coating paste is filled in a reinforcement groove or a hole of a working part of an expanded poly styrol (EPS) foaming plastic modal of a hammerhead casting, during the pouring process, the high temperature of liquid steel is utilized to initiate the self propagating synthesis reaction, the reactions of Ti plus C->TiC and W plus C->WC are carried out, so the TiC and WC-based hard alloy phases are formed, the liquid steel is filled into the clearance of a hard phase, so an in situ synthetic titanium carbide and tungsten carbide steel bond hard alloy is obtained, and the hard alloy is embedded in the steel base body of the working part of the hammerhead. When the hammerhead which is produced through the method of the in situ synthetic steel bond hard alloy casting composite hammerhead is used, because the hard alloy and the casting are completely, metallurgically and firmly combined together, the hammerhead has high wear resistance and impact resistance during the use, has a simple technological process, low production cost, and is applicable to large-scale industrial production.

Owner:KING STRONG MATERIAL ENG LTD

Crusher hammerhead cast of steel bond hard alloy bar and casting method of vanishing mould thereof

InactiveCN101717895AGood effectSimple processFoundry mouldsFurnace typesChemical compositionHardness

The invention discloses a crusher hammerhead cast of a steel bond hard alloy bar and a casting method of a vanishing mould thereof. The hammerhead is cast by low-alloy steel and is cast with the steel bond hard alloy bar in the casting process; the low-alloy steel contains the following chemical components by weight percent: 0.24 wt% to 0.295 wt% of C, 1.32 wt% to 1.56 wt% of Si, 0.028 wt% to 0.035 wt% of S, 0.032 wt% to 0.038 wt% of P, 0.82 wt% to 1.22 wt% of Mn, 1.67 wt% to 2.10 wt% of Cr, 0.42 wt% to 0.51 wt% of Mo, 0.05 wt% to 0.08 wt% of V, 0.05 wt% to 0.07 wt% of Ti, 0.08 wt% to 0.15 wt% of RE and 93.942 wt% to 95.29 wt% of Fe. The casting method of the hammerhead comprises the production process of the low-alloy steel, and the casting process and the thermal treatment process of the vanishing mould. The hammerhead product cast with the steel bond hard alloy bar has the advantages of good strength and toughness and high rigidity and abrasive resistance, is suitable for various working conditions, and can crush objects with different hardness.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

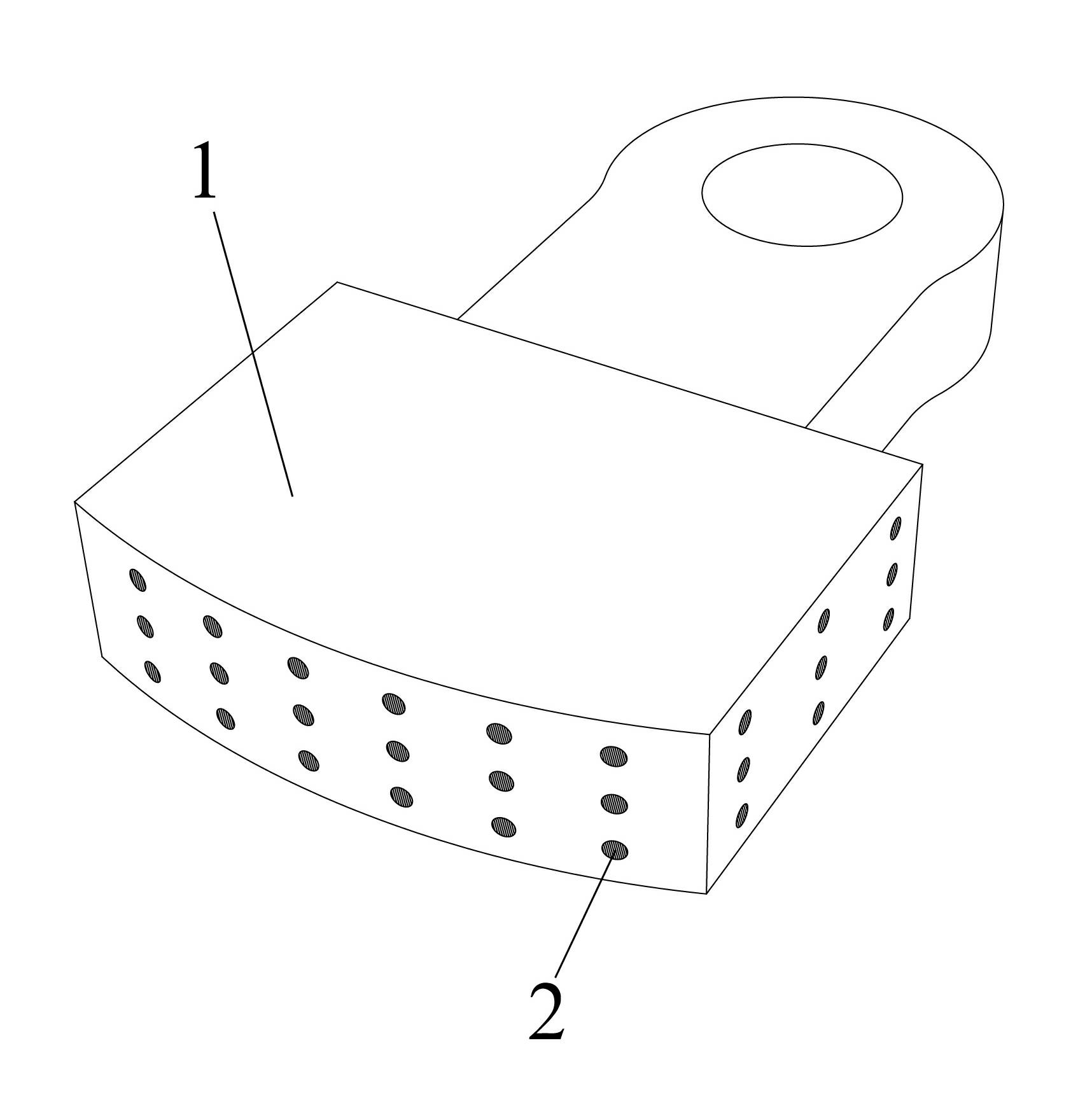

Grinder hammerhead with ceramic wearing coat and casting method thereof

InactiveCN101314145ANot easy to wearAvoid breakingFoundry moulding apparatusGrain treatmentsSurface layerHardness

The invention discloses a crusher hammer with a ceramic abrasion-resistant layer and a casting method thereof. The hammer adopts high boron cast steel as a parent body and a ceramic particle composite layer as a surface layer of the hammer, and is produced through a shape casting method that evaporated pattern casting is combined with casting by a cast-penetration process, and high temperature molten steel is taken as a parent body and is penetrated into the ceramic particle composite layer to form metallurgical bonding. The produced hammer has good strength and toughness as well as high hardness and wearing resistance.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Method for lost foam casting of composite two-liquor bimetallic hammerhead of crusher

InactiveCN102873308ASimple production processImprove efficiencyFoundry mouldsFoundry coresThermal insulationDry sand

The invention discloses a method for lost foam casting of a composite two-liquor bimetallic hammerhead of a crusher. The method includes: embedding a crusher hammerhead molded body made of foam plastics into dry sand of a sand box, and vacuumizing; then respectively preparing high-chromium iron casting liquor and carbon steel casting liquor; after melting down and deoxidizing the two kinds of metallic casting liquor, performing carbon steel pouring (1300-1400 DEG C) prior to high-chromium iron pouring (1550-1650 DEG C), and rapidly covering high-chromium iron liquor by thermal insulation agents after pouring is completed; subjecting a molded crusher hammerhead casting to thermal treatment at the temperature of 900-1000 DEG C, then rapidly discharging the casting and cooling the casting in air; and tempering at the temperature of 250-300 DEG C finally.

Owner:XI AN JIAOTONG UNIV

Lost foam casting coating and preparation method thereof

The invention discloses a lost foam casting coating, which comprises fire-proof powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol, wherein the fire-proof powder includes bauxite and quartz powder. The bauxite is formed by uniformly mixing the following components: 80% of particles with the granularity ranging from -280 to -310, 14% of particles with the granularity ranging from -280 mesh to -190 mesh and 6% of particles with the granularity ranging from -90 mesh to -190 mesh. The preparation method of the lost foam casting coating is as follows: calcining selected bauxite ore at the temperature of 1510-1550 DEG C; grinding calcined clinkers to acquire the granularity particles with the granularities respectively; evenly mixing the particles according to the composition proportion; and mixing the mixed bauxite with quartz powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol. According to the invention, bauxite is distributed according to particle sizes, and bauxite particles of different sizes are alternately arranged after even mixing. As a result, the compactness is changed, the air permeability is strengthened, the cold shut phenomenon occurring between liquid metal and the coating is avoided, and finally the quality of the casting produced through lost foam casting is improved.

Owner:ANYUE COUNTY JINLONG MACHINERY MFG

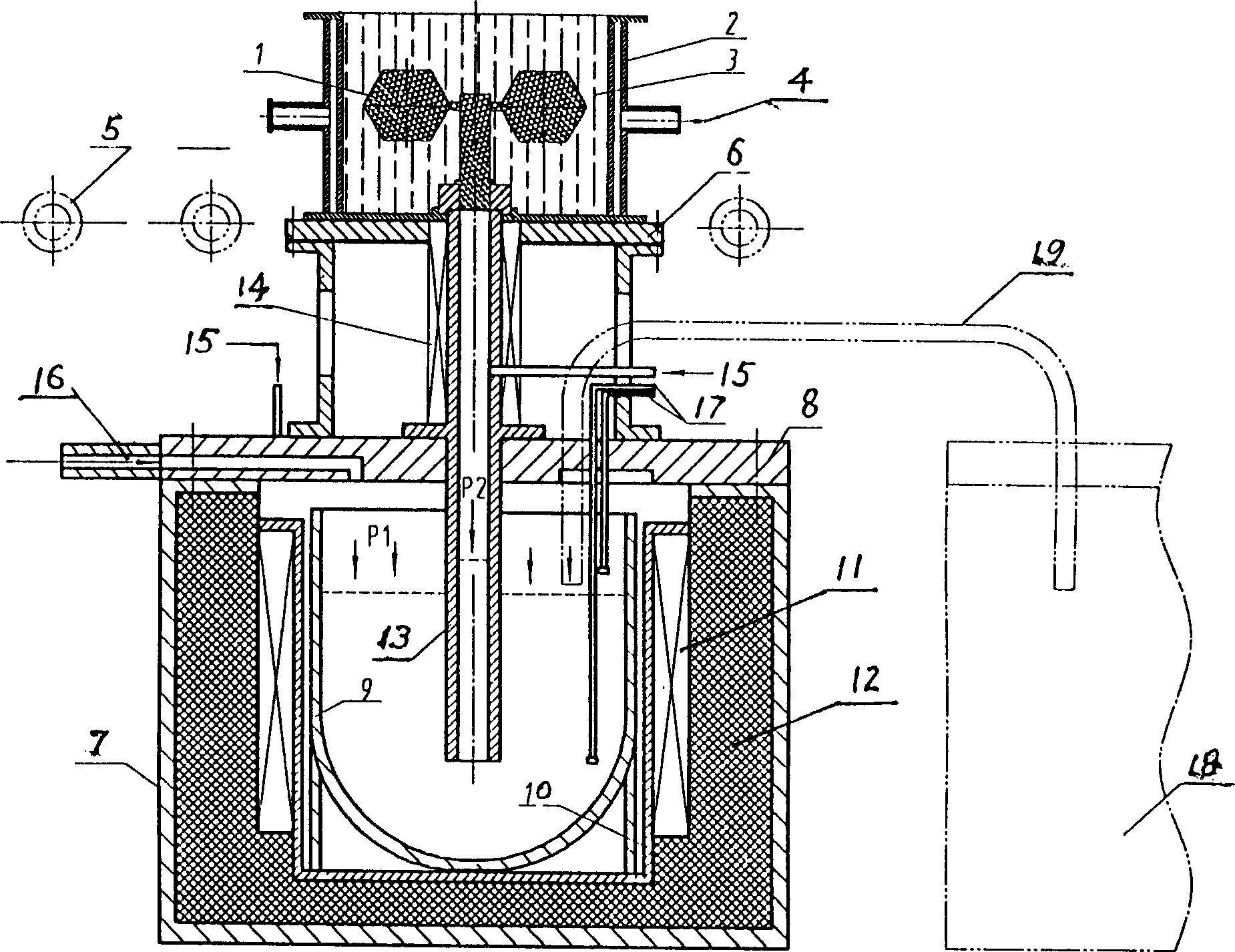

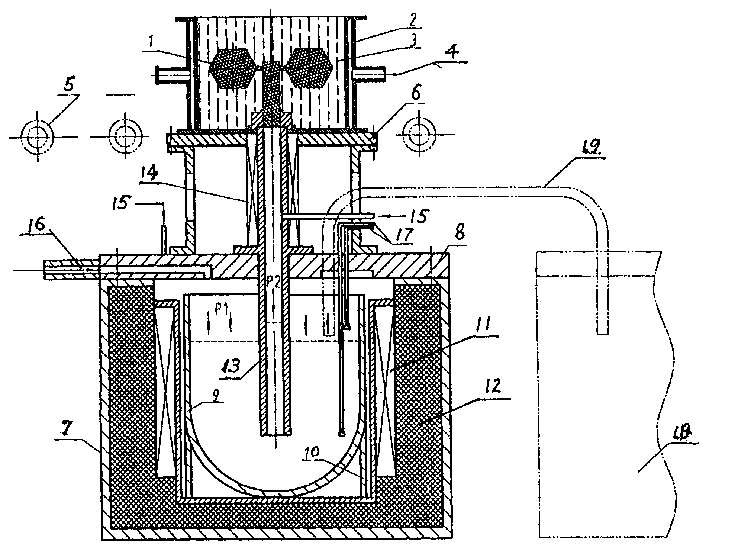

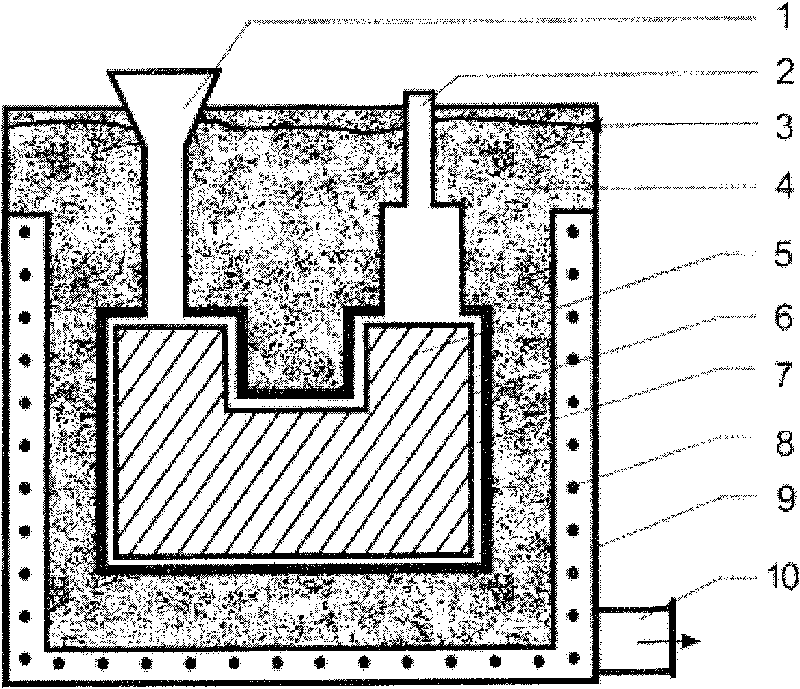

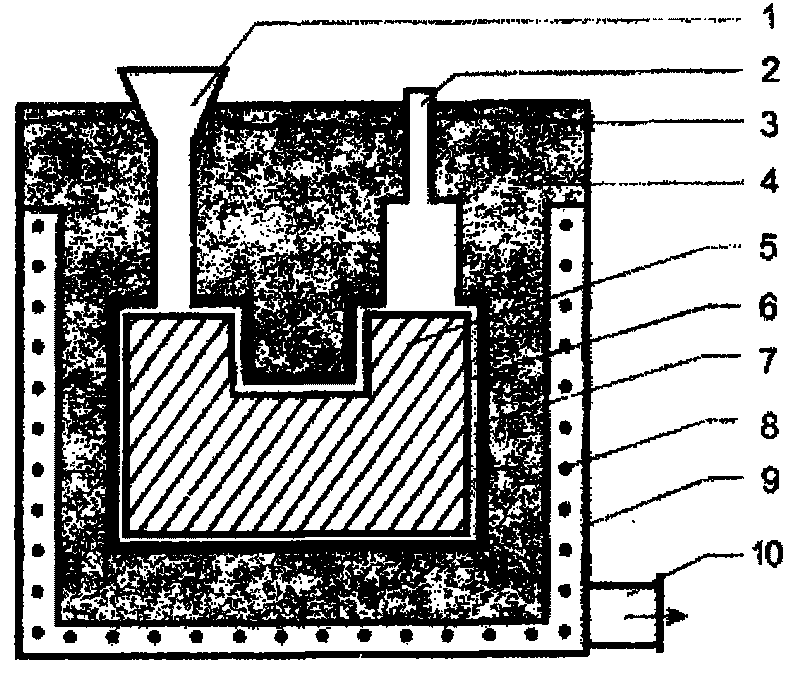

Antigravitational vacuum method and apparatus for asting Mg allor or Al alloy with lost mould

InactiveCN1382542ASuitable for mass productionImprove automationFoundry mouldsFoundry coresCrucibleShielding gas

An antigravitational casting technology includes putting a lost mould in a bottom running type sand box, adding sand, vibration compacting, loading molten MgAl alloy in filler while introducing protecting gas, introducing the pressure controllable inertial gas to the filler, and pouring the molten alloy into said sand box to gasify said list mould. Its apparatus is composed of filler, sand box, pouring pipe, crucible in the filler, and heating coil surrounding said pouring pipe. It is suitable for precision casting.

Owner:HUAZHONG UNIV OF SCI & TECH

Lost foam casting vibration clotting method

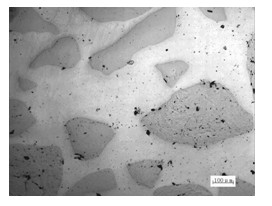

The invention relates to a vibration solidification method of lost mold casting, pertaining to the precision casting field, which aims at fining the organization of castings of the lost mold casting, reducing the cost and enhancing the performance of castings. The invention comprises three steps of: production of foamy mold, imbedding the foamy mold into a casting box for filling and compacting sand as well as casting of molten metal; the invention is characterized in that: before and during the period of casting molten metal, during the solidification period, or the solidification period after the period of casting molten metal, casting box filled with foamy mold and scattered sand is vibrated at the frequency ranging from 10 to 100Hz and the amplitude ranging from 0.1 to 3.0mm, and rotation speed of a vibration motor that drives the vibration is 750 to 3000 rpm, and the vibration is stopped after the solidification of casting is completed. The invention has the advantages of low cost, easy operation and control, obvious fining effect of casting organizations, greatly improving performance and no environmental pollution, which is both suitable for the casting of the lost molds of nonferrous metals components, such as aluminum alloy, magnesium alloy, copper alloy, etc., and is also suitable for the casting of the lost mold of ferrous metal components, such as cast iron, cast steel and so on.

Owner:HUAZHONG UNIV OF SCI & TECH

Technique for producing dual-liquid dual-metal composite wear-resistant lining plate by lost foam casting

Owner:武汉智科耐磨材料科技发展有限公司

Vacuum negative-pressure los mould casting technique

InactiveCN101332501AHigh precisionImprove casting qualityFoundry mouldsFoundry coresLost-foam castingMaterials science

The invention relates to a vacuum negative pressure lost foam casting process, which belongs to the technical field of casting. The process comprises the following steps: an integral mold of a screw is obtained by using resin bonded sand with a nut which has the same inner surface geometric parameters as that of or a little bigger internal diameter than that of a screw hole to be processed; the mold of the screw is taken out, coated with a coating and baked dry; then a hole is cut at the position of the screw hole to be processed on the integrally cast overall mold; finally the screw mold is inserted into the cutting hole and assembled to form the final mold; that is, the vacuum negative pressure lost foam casting process can be directly used for casting a casting with the screw hole, which creates a precedent of directly casting small-aperture screw holes without reprocessing in the casting field. The screw hole processed by the process can ensure precision and needs no reprocessing. The vacuum negative pressure lost foam casting process is especially applicable to the vacuum negative pressure lost foam casting of the casting with a plurality of screw holes, small size and high precision.

Owner:泰州市永昌冶金设备有限公司

Lost wax shell-based negative pressure dry sand and iron shot chilling vibrational casting process method

InactiveCN102240778AHigh strengthReduce the number of hanging coatsFoundry mouldsFoundry coresWaxHigh density

The invention discloses a lost wax shell-based negative pressure dry sand and iron shot chilling vibrational composite casting process method. The method is characterized by comprising the following steps of: feeding a shell manufactured by a lost wax process into a chilling sand box; loading steel shots in the gap between the shell and the chilling sand box; feeding the chilling sand box into a sand box with a vacuumized negative pressure model; fully filling dry sand between the chilling sand box and the sand box with the vacuumized negative pressure model; paving a plastic film; placing a pouring cup; and pouring under the simultaneous vacuumizing and vibrating condition. By the method, the strength of molding sand is high, a chilling effect is good, the process characteristics of lost foam casting and hot investment casting are combined, the defect of foam-gasified carbon special for the lost foam casting is overcome, the chilling effect of the iron shots is fully exerted, the pouring is performed under the vibration condition, and alloy grains are refined, so that wear-resisting castings have higher density, hardness and wear resistance.

Owner:HUBEI GENGLIAN WEAR RESISTANT MATERIALS TECH

Lost foam casting cast iron coating for preventing carbon defects and preparation method thereof

InactiveCN101767184AGood suspensionImprove thixotropyFoundry mouldsFoundry coresPolyvinyl alcoholOctanol

The invention discloses a lost foam casting cast iron coating for preventing carbon defects, which comprises the following components by weight percent: 60.5%-64.5% of bauxite, 13.5-17.5% of kaolin, 3.5%-6.0% of talc powder, 1.7%-3.5% of attapulgite, 0.4%-0.8% of sodium lignosulphonate, 2.5%-6.0% of aluminum sulfate, 1.7%-3.5% of polyvinyl alcohol, 3.5%-5.0% of silica sol, 0.1%-0.2% of iron oxide powder and 0.01%-0.02% of n-octanol, and the sum of the components is 100%. The lost foam casting cast iron coating is prepared by respectively preparing water solution of the attapulgite, the polyvinyl alcohol and the aluminum sulfate, evenly mixing the bauxite, the kaolin, the talc powder and the iron oxide powder for preparing mixed powder material, mixing the water solution of the attapulgite, the polyvinyl alcohol and the aluminum sulfate, the silica sol and the refractory mixed powder material with the n-octanol, stirring and grinding. The coating has the advantages of good thixotropy, good coating property, high coating strength and good gas permeability; and the surface of a cast is smooth and has no wrinkles and other carbon defects.

Owner:NANTONG XINZHENGDA SPECIAL STEEL

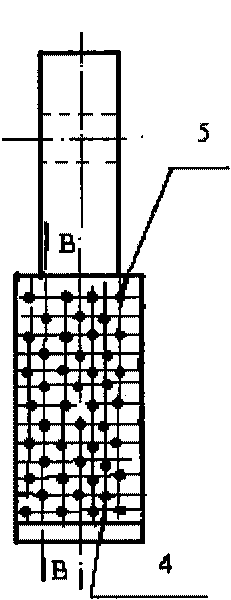

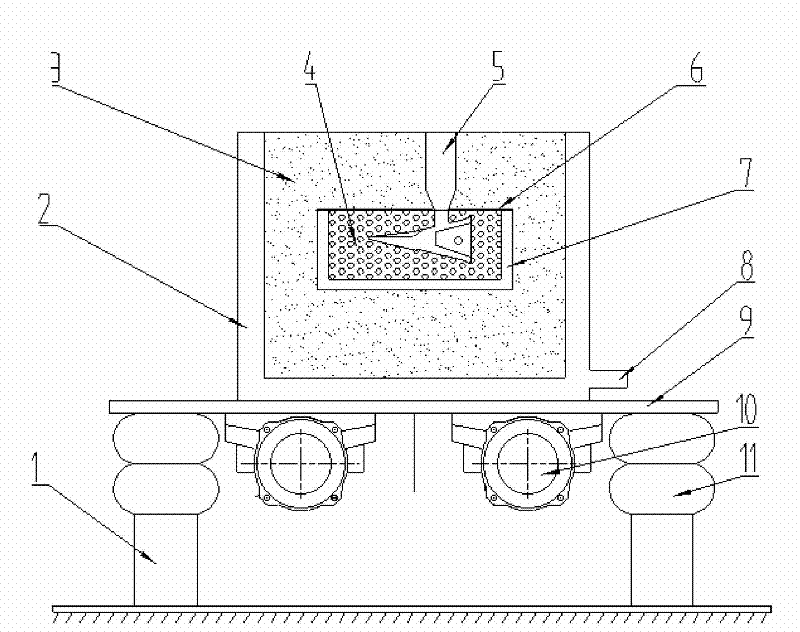

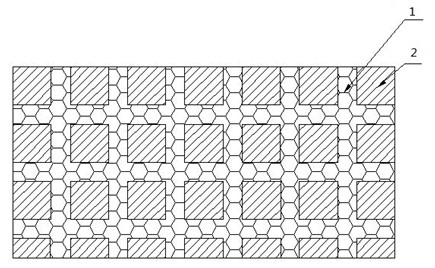

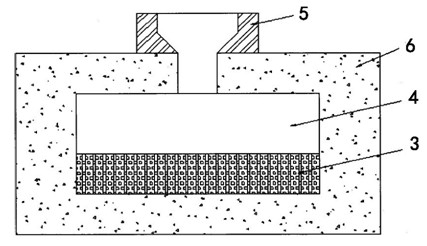

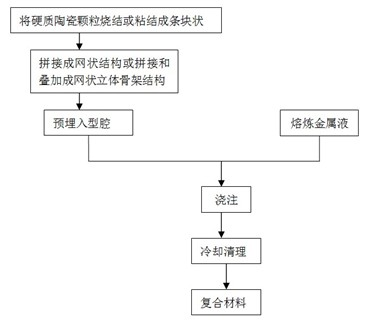

Method for preparing ceramic particle reinforced steel-based mesh material

The invention provides a method for preparing a ceramic particle reinforced steel-based mesh material, which comprises: forming a mixture of hard ceramic particles and alloy powder into strip blocks by powder sintering or by using and adhesive; joining the strip blocks into a corresponding mesh structure or joining and overlapping the strip blocks into mesh three-dimensional framework structure; and performing normal sand casting or lost foam casting, namely melting a substrate metal material, pouring the molten substrate metal material in a molding cavity, allowing the molten substrate metal material to cool and condense at room temperature, removing sand and obtaining the ceramic particle reinforced steel-based mesh material. The obtained ceramic particle reinforced steel-based mesh material gives full play to the high wear resistance of the ceramic particle hard phase and the toughness of the steel base; and the method with convenience for regulation and reliable process solves the problem of incomplete reaction of the composite material, nonuniform reinforcing phase particle distribution, pollution weakening on a reinforcing phase interface and the like and is used in wear resistance fields of mines, power, metallurgy, coal, building materials and the like.

Owner:KUNMING UNIV OF SCI & TECH

Lost-foam casting method for water pump thin-wall part

InactiveCN101698218AHigh precisionReduce processing costsFoundry mouldsFoundry coresPolystyrene beadLost-foam casting

The invention relates to a lost-foam casting method for a water pump thin-wall part, which belongs to the technical field of lost-foam casting. The invention provides the lost-foam casting method for the water pump thin-wall part with high casting precision and stable quality. The invention adopts a technical scheme that the lost-foam coasting method for the water pump thin-wall part comprises the steps of beads foaming, molding, hanging paint, drying and casting, wherein GP-4S standard level polystyrene beads are selected to be added in a foaming tank to be prefoamed, and the foamed beads are added into a mould preheated to 90 to 110 DEG C to be molded; secondly, the white mould is fully cured, dip-coated for three times and assembled into a cluster to be dried; and finally, casting is performed. The method is applied to the casting technology of water pump thin-wall parts.

Owner:SHANXI TIANHAI PUMP IND CO LTD

Method for eliminating carbon defects by adopting high-performance coating, negative-pressure firing, vacant shell pouring and quick airflow cooling in lost foam casting

InactiveCN101690976AEliminate carbon defectsGrain refinementFoundry mouldsFoundry coresDry sandPlastic film

The invention discloses a method for eliminating carbon defects by adopting a high-performance coating, negative-pressure firing, vacant shell pouring and quick airflow cooling in lost foam casting. The process comprises the following steps: placing a mould into a sand box; filling dry sand into the sand box; sealing the upper surface of a sand layer with a plastic thin film; starting a vacuum pump, igniting and gasifying the foam mould from a pouring gate under a negative pressure condition so as to form an intact vacant shell cavity, wherein over 95 percent of carbon is discharged out of the molding sand box; pouring molten iron and steel; lifting or cutting the sealing thin film on the top surface of the sand box when the molten iron and steel is in a temperature area where a liquid phase and a solid phase coexist, and then sucking cold airflow into the sand box so as to quickly cool a cast piece; and after stopping the pouring, continuing extracting air for 3 to 6 minutes, and then stopping the vacuum pump. The method can realize the elimination of the carbon defects of the cast piece, grain refinement, and easy falling-off of the coating by discharging and reducing carbon and pouring the vacant shell in the lost foam casting, makes the cast piece have bright and clean surface to comprehensively improve the quality of the cast piece, saves energy and reduce consumption, is high in efficiency and benefit and is applied to industrialized mass production.

Owner:刘玉满 +1

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Production method of water based paint special for lost foam

InactiveCN101288897ANo pollution in the processImprove adhesion strengthFoundry mouldsFoundry coresWater basedFiber

The invention provides a production method for water-based coating which is specially used for lost die. The composition of the water-based coating comprises: amorphous graphite powder, flaky graphite powder, bentonite, hydroxymethyl fiber, milk-white glue, corn starch, dextrin and BY adhesive. The composition proportion is 50% of the amorphous graphite powders, 50% of flaky graphite powders, 5-10% of bentonite, 3-5% of hydroxymethyl fiber, 1.5-3% of milk-white glue, 3-5% corn starch, 3-5% of dextrin and 2-3% of the BY adhesive. The method of the invention solves the problems that the currently usually used lost die is easy to cause that the casting is easy to be deformed, cracked, delaminated, stuck with sand on the surface, non-smooth and difficult to remove the stuck sand, thereby affecting the quality of the casting and being suitable for application in the casting production of the lost die.

Owner:QINGDAO HAILONG MACHINERY GRP

Preparation method of water-based coating for lost foam casting

The invention discloses a preparation method of a water-based coating for lost foam casting. A coating prepared by the preparation method has excellent performances, good suspensibility, thixotropy and permeability, and high surface strength. The preparation method overcomes the defects that refractory powder adopted by the conventional casting coating preparation technology is very expensive and a coating production cost of the conventional casting coating preparation technology is high. A casting coating obtained by the preparation method is smooth and has appropriate viscosity. Through the preparation method, a high-quality casting coating can be prepared from cheap raw materials through simple production processes. Therefore, the preparation method reduces a coating production cost and realizes good finished product quality.

Owner:南通江海港建设工程有限公司

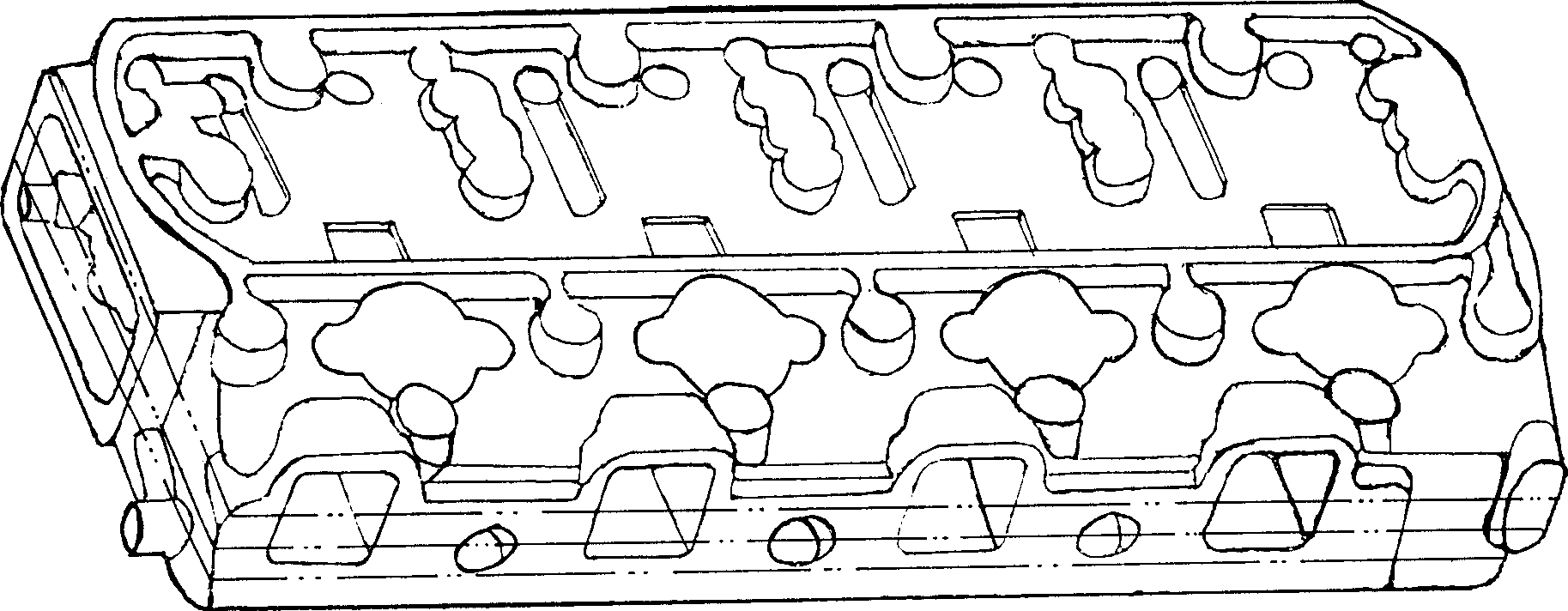

Lost-foam casting process for cylinder body and cylinder cap of diesel engine and gasoline engine

InactiveCN1843657AReduce labor intensityReduce consumptionFoundry mouldsFoundry coresDiesel engineLost-foam casting

The invention discloses a method for casting disappear mould of the cover of diesel engine and petrol engine that based on disappear mould technique, which can solve the problems of present sand casting technique with high material consumption, heavy cast, and environment pollution, etc. The invention slices matter into several mould plates to prepare the mould; than filling the material of disappear mould into mould to attain the mould plate of disappear mould which is the same with said matter; dipping disappear mould dope on the mould plate and arranging it into sand tank to be vibrated and poured to melt mould plate into carbon monoxide and carbon dioxide to be discharged to attain the cast of said matter. The invention has the advantages that save raw material, reduce labor intensity and improve property.

Owner:ANHUI TIANYU MACHINERY

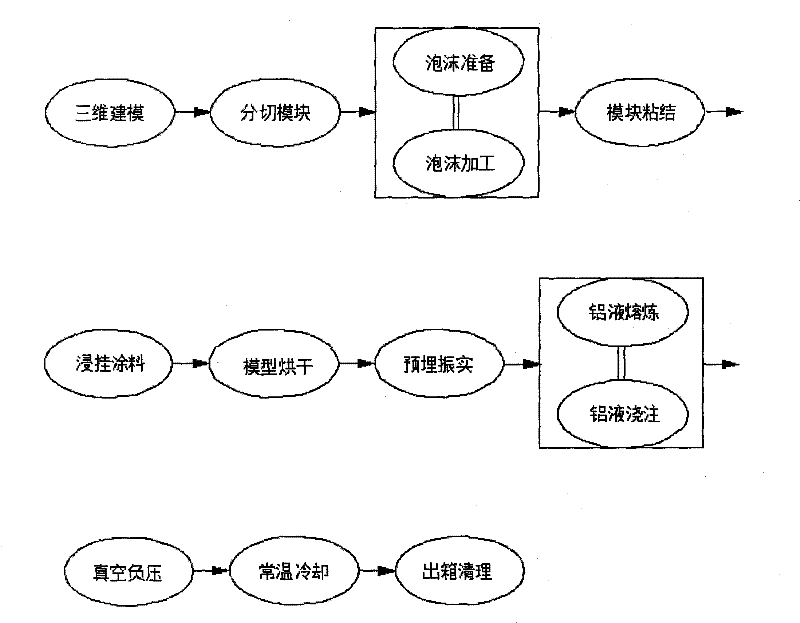

Method for manufacturing casting blank of refrigerator inner container die by using lost foam casting process

InactiveCN102198488APrecise and stable billet sizeReserved machining allowance is smallFoundry mouldsFoundry coresLost-foam castingDimensional modeling

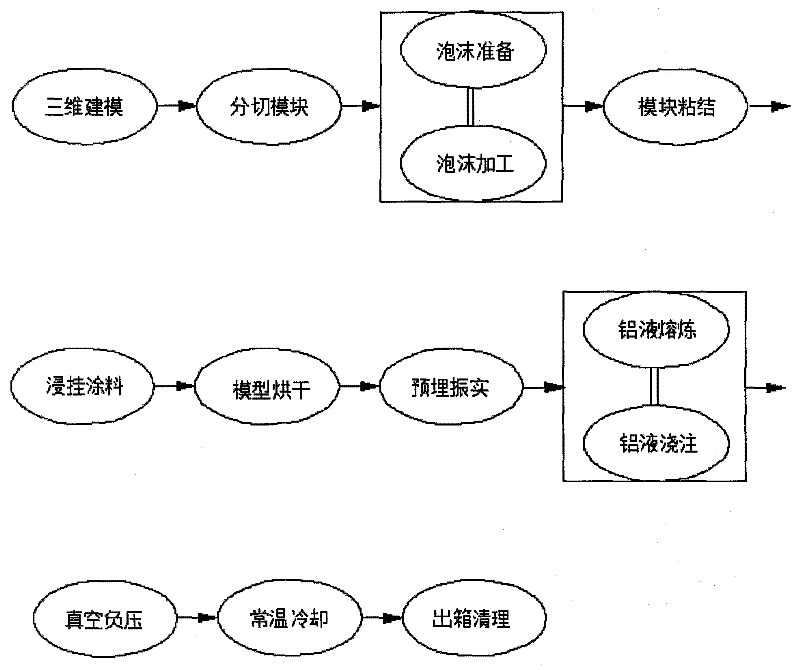

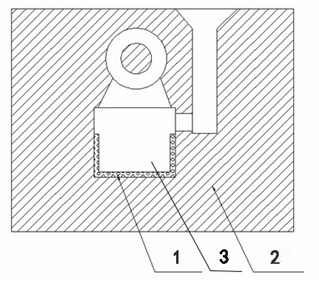

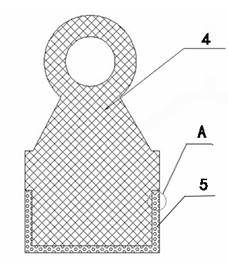

The invention discloses a method for manufacturing a casting blank of a refrigerator inner container die by using a lost foam casting process, and relates to the technical field of die manufacture. The method comprises the following steps of: three-dimensional modeling, module segmentation, foam processing, module adhesion, coating immersion, model drying, embedded compaction, molten aluminum pouring, vacuum negative pressure, normal-temperature cooling, un-boxing and clearing to obtain the casting blank of the refrigerator inner container die. The casting die has short blank casting period, the natural shape wall thickness of the die is accurate, the casting is light in weight, the labor intensity of a worker is low, the production efficiency is high, and the labor cost and the manufacturing cost are reduced; and the method is an energy-saving and environment-friendly 'green' project.

Owner:CHUZHOU JINNUO INDAL

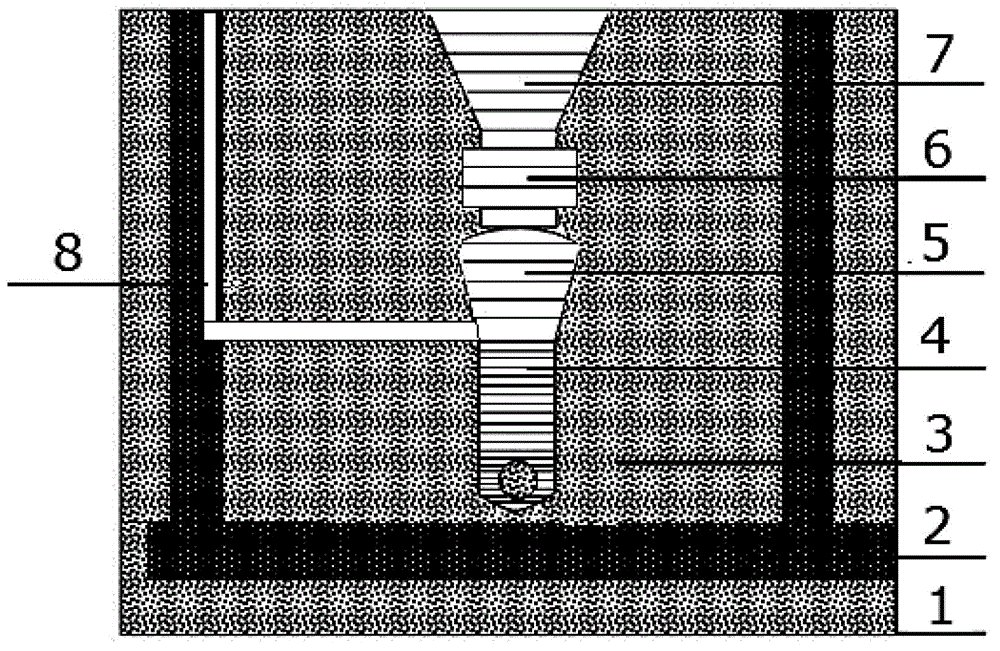

Method for preparing heat-fatigue-resistance wear-resistance laminated particle reinforced composite material

The invention provides a method for preparing a heat-fatigue-resistance wear-resistance laminated particle reinforced composite material. The method prepares the wear-resistance laminated particle reinforced composite material consisting of a heat-fatigue-resistance laminated composite wear-resistance layer, a metallurgical transitional layer and a substrate metal layer by the following steps: mixing nickel-based self-melting alloy powder and hard ceramic particle uniformly, adding an adhesive, and forming a prefabricated block; and performing common sand mold coating or lost foam casting, namely melting a substrate metal material to a pouring temperature, pouring the molten substrate metal material into a molding cavity in which the prefabricated block is placed, allowing the molten substrate metal material to cool and condense at room temperature, and removing sand. The combined preparation process disclosed by the invention has the characteristics of high controllability, simple operation, high yield, high overall performance and stable production quality; and the heat-fatigue-resistance laminated composite wear-resistance layer and the substrate metal layer are metallurgically combined, and the composite material can be used in heat-fatigue-resistance and wear-resistance fields of mines, power, metallurgy, coal, building materials and the like. The method is suitable for industrial large-scale production.

Owner:KUNMING UNIV OF SCI & TECH

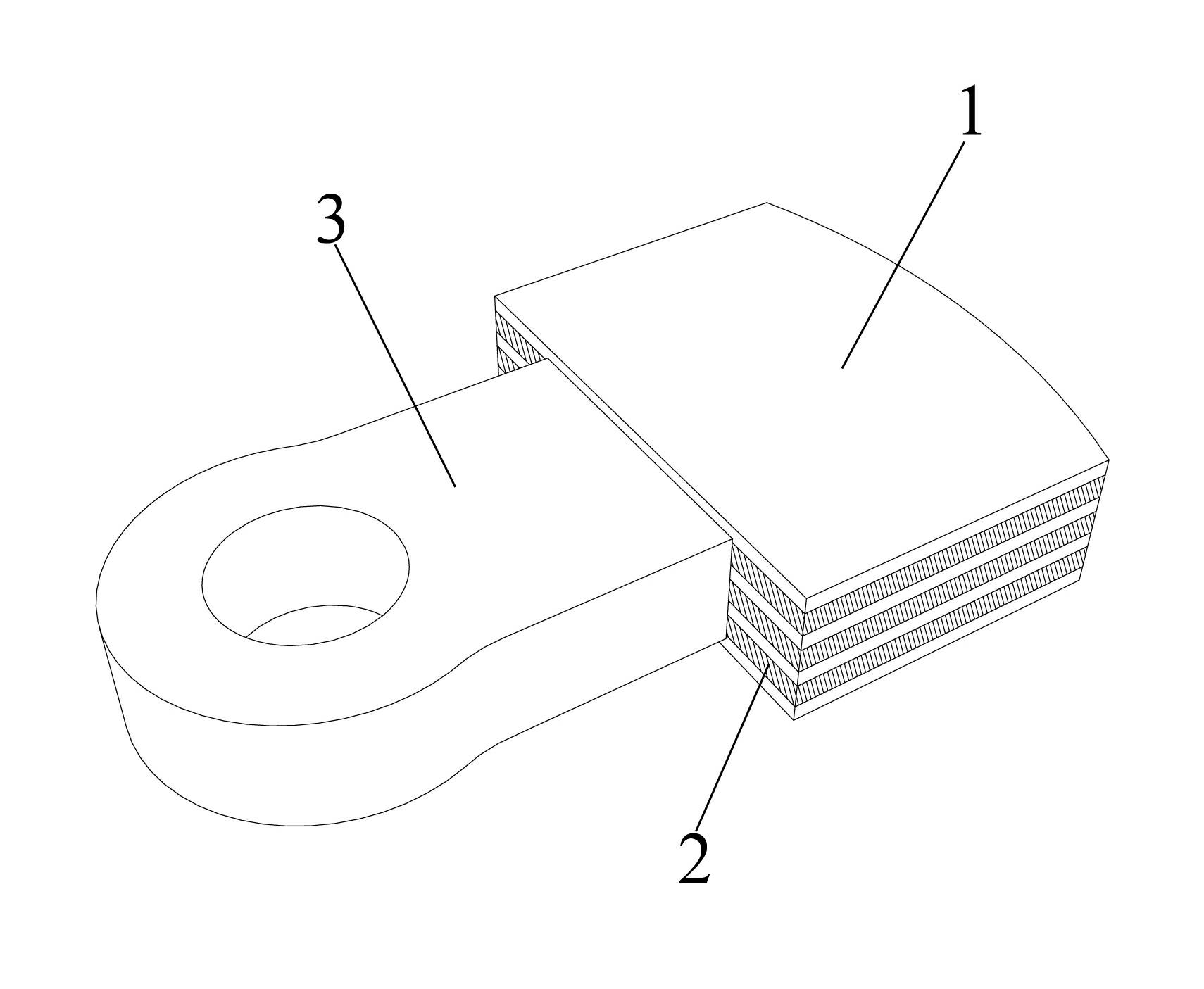

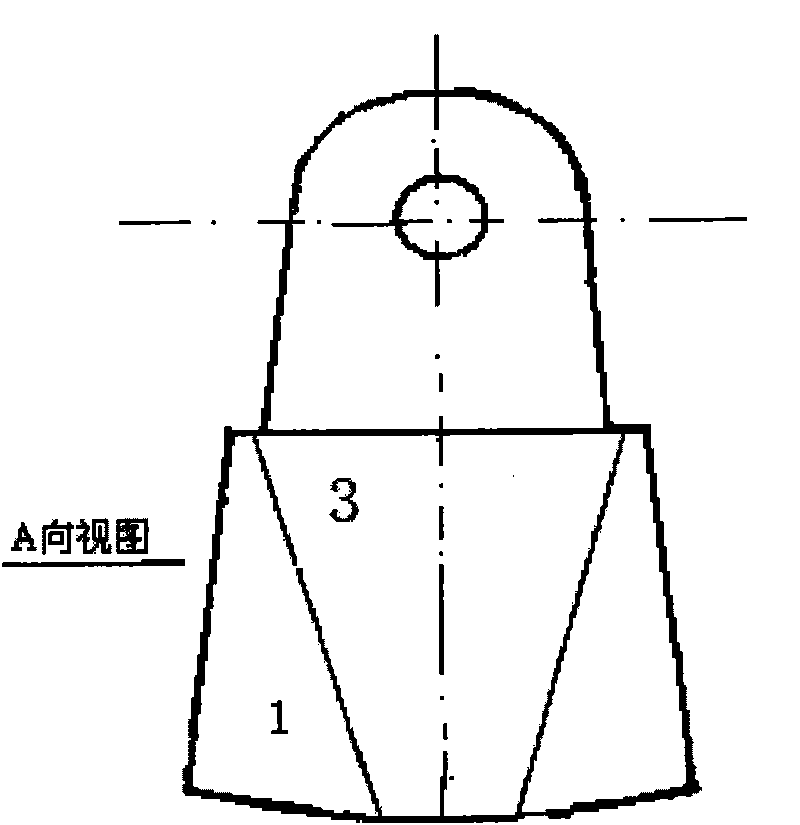

Wear-resistant hammer head of hammer crusher with movable installation position and manufacturing method thereof

InactiveCN101920216AExtended service lifeSimple processFoundry mouldsFoundry coresManganeseStructural engineering

The invention discloses a wear-resistant hammer head of a hammer crusher with movable installation position and a manufacturing method thereof. The hammer head is manufactured by super-high manganese as raw material by lost foam casting. The hammer head comprises an end part (3) and a handle part (6); hard alloy bars (2) are cast in the two working surfaces of the end part (3) of the hammer head; and an first installation hole (4) and an second installation hole two (5) are formed on the handle part (6) of the hammer head at a distance. The hammer head has good strength and toughness and high hardness and wear resistance and is applicable to the crusher hammer head with single magnitude between 500 and 700 N. When a certain length of the end part of the hammer head is worn, the installation position is moved and the hammer head can be continuously used, being equivalent to replace a new hammer head, so that the purpose of prolonging the service life of the hammer head is fulfilled.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

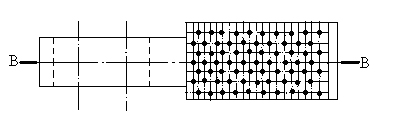

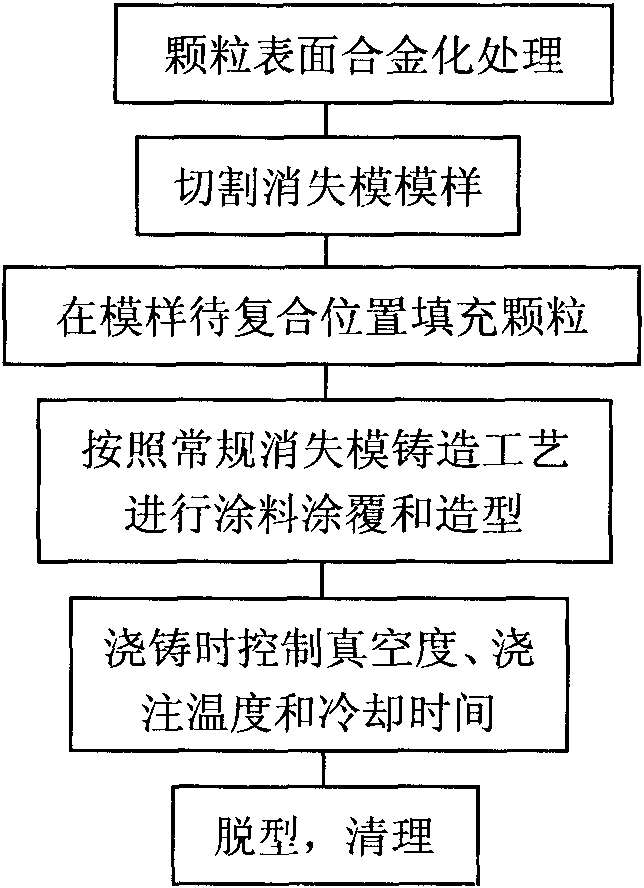

High manganese steel Sic ceramic particles composite preparation method

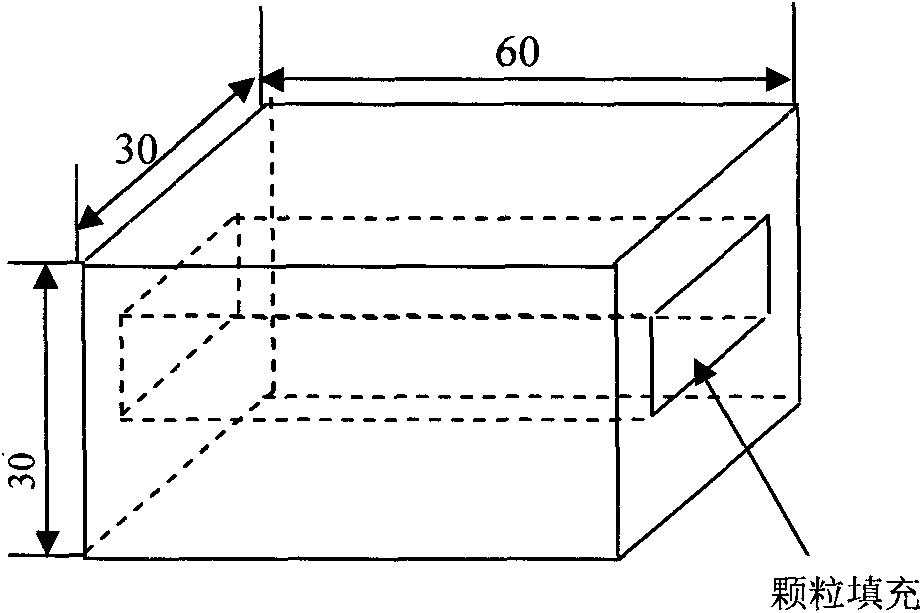

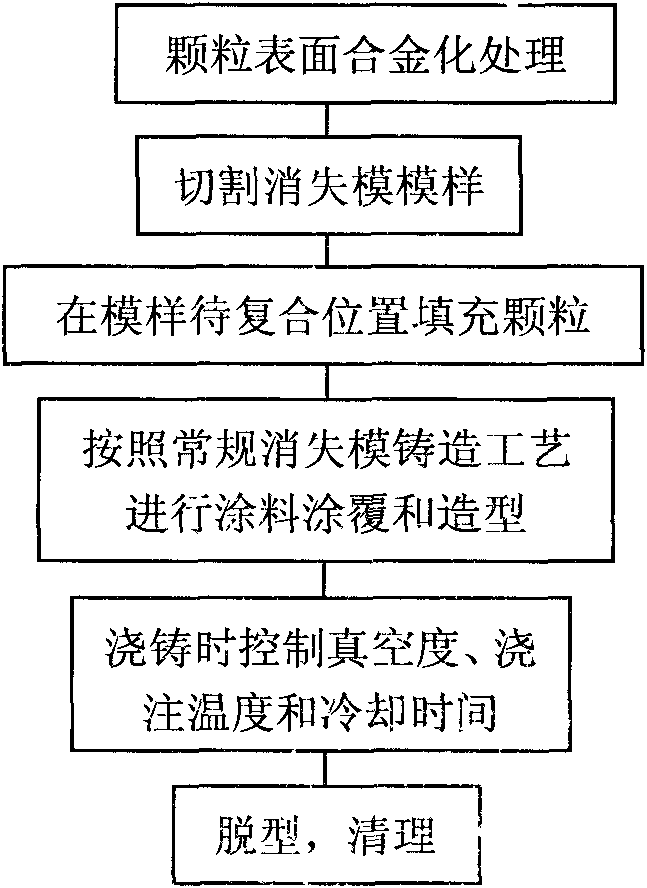

The invention discloses a high manganese steel Sic particles composite preparation method. In the method, the surface of Sic particles is alloyed at first, a lost foam pattern is cut, particles are filled at the position of the foam pattern to be composited, the coating of dope and molding are carried out according to the normal lost foam casting technology, the vacuum degree, the coating temperature and the cooling time are controlled in the coating process, and the high manganese steel Sic particles composite is obtained through demoulding and cleaning. The method improves the while strength, rigidity, abrasion resistance of the high manganese steel surface ceramic composite prepared through the method, makes the abrasion on the abrasion resistant surface of parts reduced, prolongs the service life of the composite, has the advantages of simple technology and strong applicability and can be extensively applied to metallurgy, mine, building material and other industries.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for casting miodle trough casting of coal mine scraper conveyor using demould

InactiveCN1911557AImprove wear resistanceExtended service lifeFoundry mouldsFoundry coresHigh carbonPolystyrene

The present invention discloses vanish mold casting process of middle channel casting. The vanish mold casting process includes the following steps: 1. forming casting mold through filling cured foamed polystyrene into mold and stoving casting mold; 2. spraying paint onto the casting mold and drying at 55 deg.c for 12-15 hr to form coating of 1.2-1.5 mm thickness; 3. setting the casting mold into sand box, filling mold sand, vibrating in vibrator to densify and covering the upper port of the sand box with plastic film; and 4. casting through turning on the vacuum pump, pouring molten steel, shaking out sand after cooling for 1 hr, cleaning and spraying paint. The present invention has the following features: main material comprising waste steel and small amount of alloy elements resulting in low cost, precise size, smooth surface and high carbon layer formed in the surface of casting resulting in raised wear resistance and long service life.

Owner:冯玉全

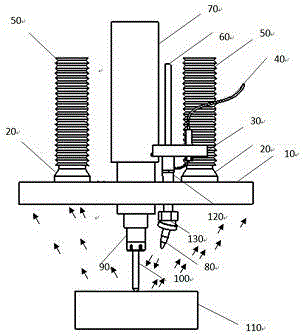

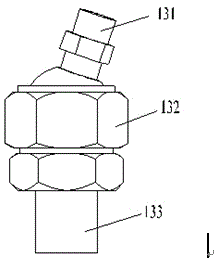

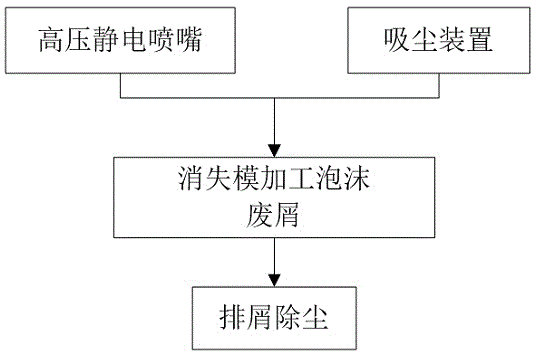

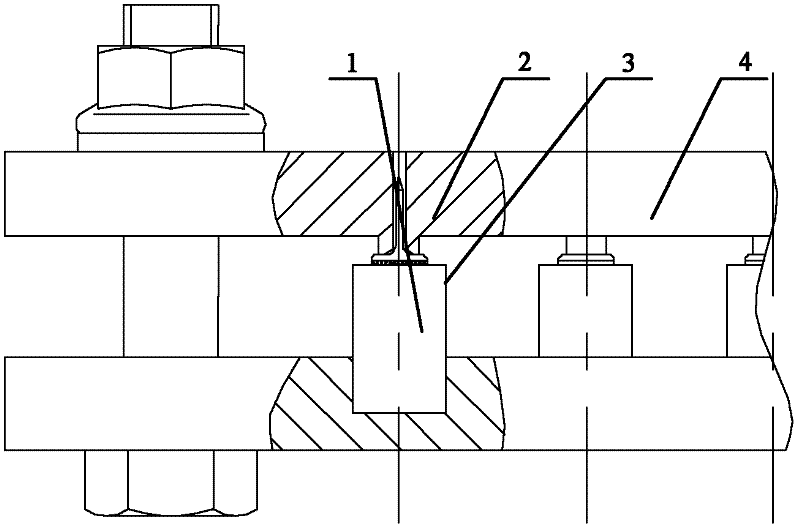

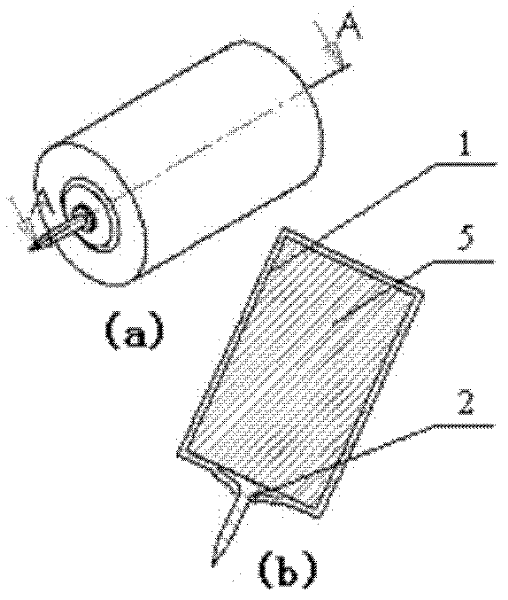

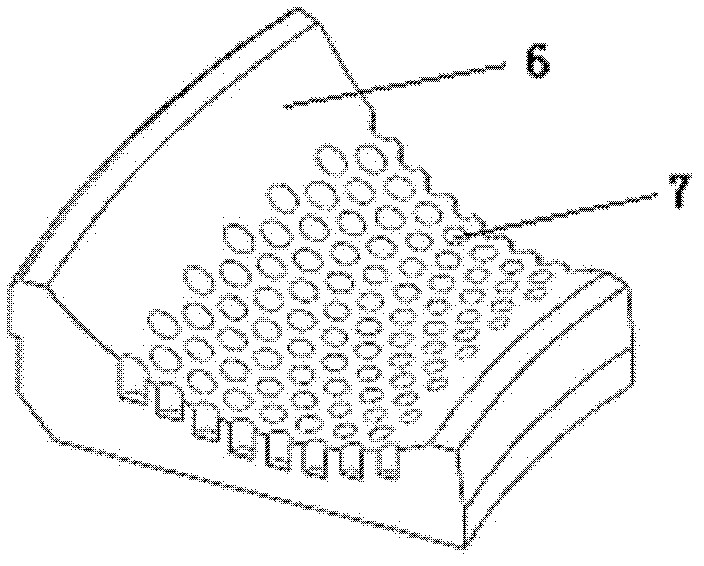

Electrostatic eliminating, chip removing and dust sucking device for lost foam casting forming machine

InactiveCN104096696AEffective cutting and dust removal effectImprove cutting efficiencyElectrostatic cleaningDirt cleaningSpray nozzleEngineering

The invention relates to a chip removing, dust sucking and electrostatic eliminating method and a chip removing, dust sucking and electrostatic eliminating device for a lost foam casting forming machine. A blowing and sucking integrated chip removing and dust sucking device comprises a dust sucking cover, a single ion spray nozzle and an air pipe; the dust sucking cover is connected with a main shaft of a machine tool; the single ion spray nozzle is arranged on a positioning seat of the main shaft of the machine tool in an angle adjustable manner through a ball joint; the air pipe is connected with the ion spray nozzle. A method for neutralizing chip ions by high-voltage ions comprises the following steps: generating air flow through an air compressor; connecting the electrostatic dust removal spray nozzle at an air outlet, wherein a large number of ion bodies generated by a high-voltage electric field flow with the air flow to be in contact with foam chips to neutralize the charges of the foam chips, and moreover, a large number of form chips can be blown near the negative-pressure dust sucking cover by high-speed air flow; chips fly near an air tool can be sucked away by the dust sucking cover and can be filtered and collected by a dust collection device through a pipeline. A small number of remaining chips fall down around a cutting surface along with the gravity, and are machined and collected in a unified manner. According to the blowing and sucking integrated device, the problems about blowing, removing and collecting the chips in the prior art are solved; a chip removal effect is good; the production cost can be reduced; the machining quality can be improved; the service life of the tool can be prolonged.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Shell casting method through contraction and then gasification of high-performance coating foam and mold sample of evanescent mode

InactiveCN102672103AStrong enoughSufficient dimensional accuracyFoundry mouldsFoundry coresSurface finishInvestment casting

The invention discloses a shell casting method through contraction and then gasification of high-performance coating foam and a mold sample of an evanescent mode. The method comprises the following steps of: manufacturing the mold sample; preparing an inner-layer coating and an outer-layer coating; spreading the coatings; drying the coatings; performing reduction and contraction; performing gasification and evanescence; and packing and casting, wherein the inner-layer coating is prepared by mixing and stirring an additive special for a Guilin No. 5 evanescent mode coating, refractory aggregate powder with 180-220 meshes and water; and the outer-layer coating is prepared by mixing and stirring an additive special for a Guilin No. 5 evanescent mode coating, refractory aggregate powder with thickness being 70-100 meshes and180-220 meshes in half and water; According to the method, the mold sample has sufficient strength, dimensional accuracy and surface smoothness; carbon defects such as recarburization, slag inclusion, air holes, cockles and carbon black caused by the foam mold sample can be eliminated; the method is applicable in casting the evanescent mode with any steel; the situation that 5-10 layers of coatings are coated, and 5-10 layers of dry sand are spread when in investment casting does not needed; roasting at the temperature of 1000 DEG C in a kiln is unnecessary; and the process is simple, has low cost, and has energy conservation and emission reduction.

Owner:刘翔 +1

Pyrophillite lost foam casting coating and preparation method thereof

InactiveCN101444827AGood suspensionImprove thixotropyFoundry mouldsFoundry coresSoluble glassOctanol

The invention discloses a pyrophillite lost foam casting coating and a preparation method thereof. The coating comprises the following components by the mass percentage: 90% to 95.8% of pyrophillite refractory powder, 0.2% to 0.7% of sodium carboxymethyl cellulose, 1.9% to 4.4% of swell soil, 1.9% to 5.3% of soluble glass, 0.1% to 0.18% of polyethylene alkyl polyol ether, and 0.05% to 0.1% of N-octanol, and the mass percentage of the components is 100% in total, wherein, pyrophillite refractory powder is pyrophillite or mixture of pyrophillite and other refractory materials. The invention has the advantages that the pyrophillite lost foam casting coating has favorable suspension property and thixotropy, as well as excellent ventilation property and relatively high surface strength; and the preparation technology is simple, the operation is convenient, the raw material is abundant and the production cost is low. The invention is mainly used for producing refractory material on the surface of foam plastic mould of lost foam pieces.

Owner:HAIAN HENGYE SILK

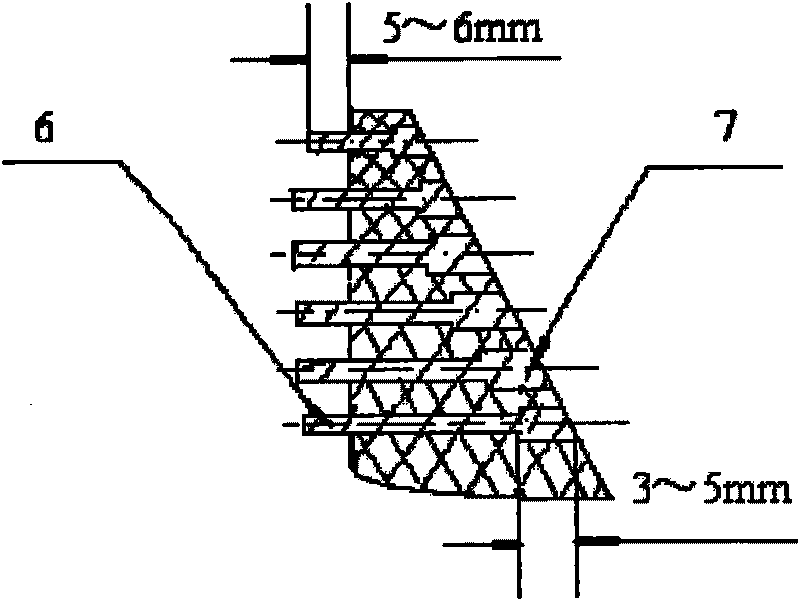

Preparation method of hard alloy/high-chromium alloy-based wear-resistant composite material

InactiveCN102380605AEvenly distributedLarge volume fraction controllable rangeFoundry mouldsFoundry coresHeat-affected zoneElement model

The invention provides a preparation method of a hard alloy / high-chromium alloy-based wear-resistant composite material, which comprises the following steps: firstly manufacturing a hard alloy / enhancement body, welding an iron nail at one end of the hard alloy enhancement body, then plating a metal buffer layer on the surface of the hard alloy enhancement body welded with the iron nail, further manufacturing a wearable element model, further inserting the well prepared hard alloy into the wearable element model on the premise of enabling the iron nail to face towards outside, adopting the expendable pattern casting process to cast high-chromium alloy, taking out a cast after casting molding, cutting off the iron nail, using a diamond grinding wheel to polish the working surface to be smooth, and then performing heat treatment on a workpiece. The composite material is uniform in distribution of enhancement phase, large in controllable range of volume fraction, small in residual stress of an interface, small in heat-affected zone and good in combination, hard alloy of the composite material is positioned in the surface layer of the working surface of a wearable element, the thickness is 10-15mm, and the composite material can be used for manufacturing normal-temperature or high-temperature wear-resistant wearable elements in the fields of mines, building, metallurgy, electric power and the like.

Owner:XI AN JIAOTONG UNIV

Vacuum negative pressure real type phenolic sand molding lost foam casting method

InactiveCN101342573AImprove casting precisionGuaranteed to be smooth and tidyFoundry mouldsFoundry coresVacuum pumpingProduct gas

The present invention relates to a method for casting a vacuum sub-pressure solid resin sand molding lost mould, and belongs to the casting technical field, in particular relates to a method for casting a vacuum sub-pressure lost mould, which mainly comprises the steps such as molding, coating, sand-box patternmaking, tapping, pouring, vacuum pumping, heat preservation and cooling, and adopts the casting steps: a. foam plastic mould is made according to the shape of the casting piece; b. the outer surface of the foam plastic mould is coated with coating; c. the foam plastic mould that is coated with coating is arranged inside a sand box, and the patternmaking is performed with resin sand; d. the sand box after the patternmaking is arranged inside a tapping device so as to tap the patternmaking sand inside the box and to be dried; e. while pouring the iron liquid, the sand box is vacuum pumped synchronically by a vacuum pumping machine, and the gas that is obtained from the vacuum pumping is discharged after being purified; f. after the pouring is completed, the vacuum pumping is stopped, and the casting piece is taken out to be arranged inside a heat-preservation oven, so that the temperature is increased to 1100 DEG C, and the casting piece can be produced after the heat preservation and cooling. The method of the present invention has simple process, precise processing, easy operation and low production cost.

Owner:QUEJING CHENGJIE SHIXIN FOUND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com