Method for manufacturing casting blank of refrigerator inner container die by using lost foam casting process

A technology of lost foam casting and refrigerator liner, which is applied in the field of mold manufacturing, can solve the problems of difficult operation technology, low foam material strength, and long production cycle of wooden molds, so as to eliminate the labor force of wooden molds, reduce labor costs and manufacturing costs , Reduce the effect of labor intensity and technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

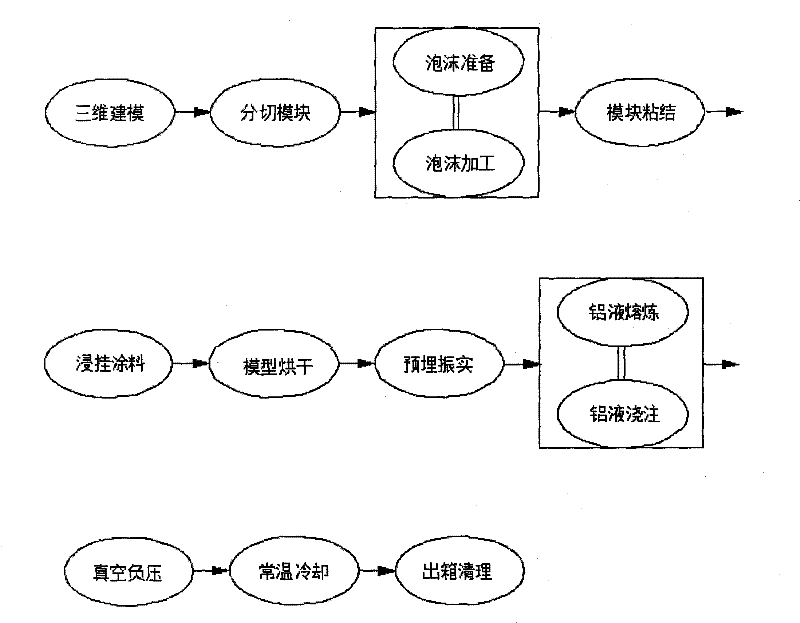

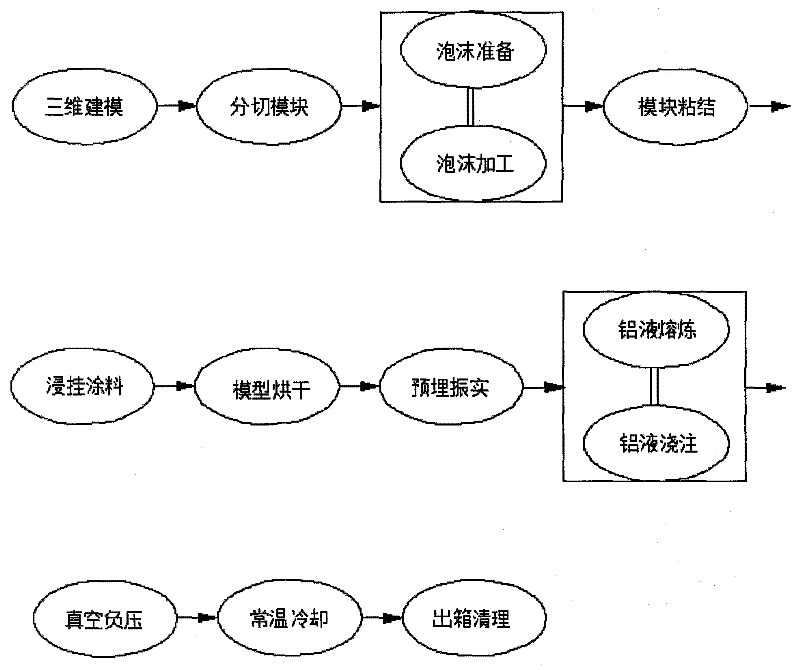

[0030] Use the lost foam casting process to manufacture the casting billet of the refrigerator liner mold. ① Carry out three-dimensional modeling and design of the mold, and cut it into 6 splicing modules. The required size, and each module is processed and formed on the CNC machine tool; ③ Assemble and bond each forming module into a whole, and bond it to the pouring system, ④ Dip-coat special paint 1 to 3 on the surface of the bonded model ⑤Put the dip-coated model into a drying room with a temperature of about 45°C and a relative humidity below 35% for drying treatment; ⑥Place the dried model in a sand box, Add sand to pre-embed, and do micro-adjustment and vibration; ⑦Pour in the smelted aluminum solution, and after the aluminum solution is filled to the sprue cup, quickly connect the vacuum system. Release the vacuum in about 40 seconds; ⑧After 2 hours of natural cooling, take the mold out of the box, and after cleaning, you can get the casting billet of the refrigerator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com