Patents

Literature

712 results about "Sprue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sprue is the passage through which liquid material is introduced into a mold. In many cases it controls the flow of material into the mold. During casting or molding, the material in the sprue will solidify and need to be removed from the finished part. This excess material is also called a sprue.

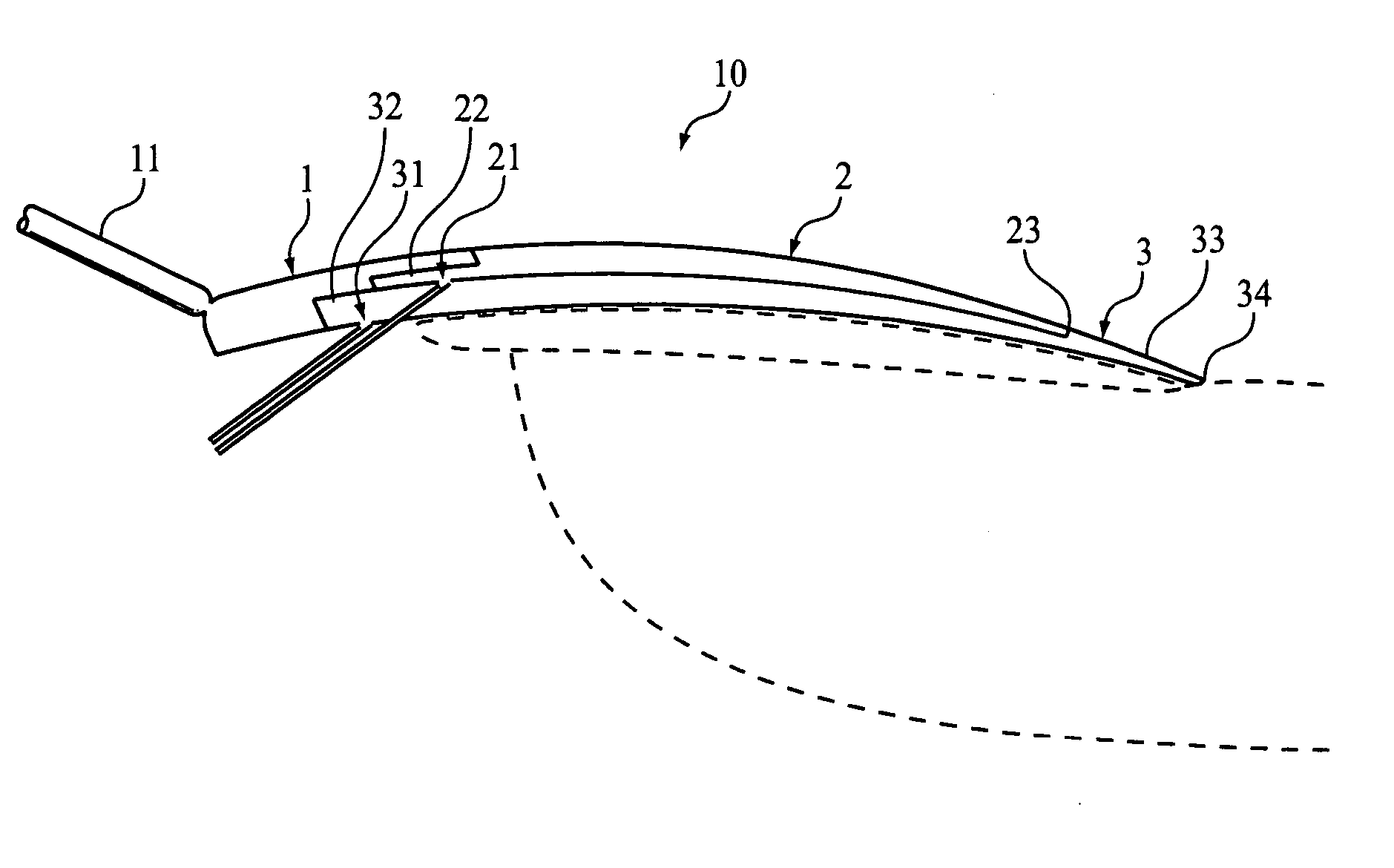

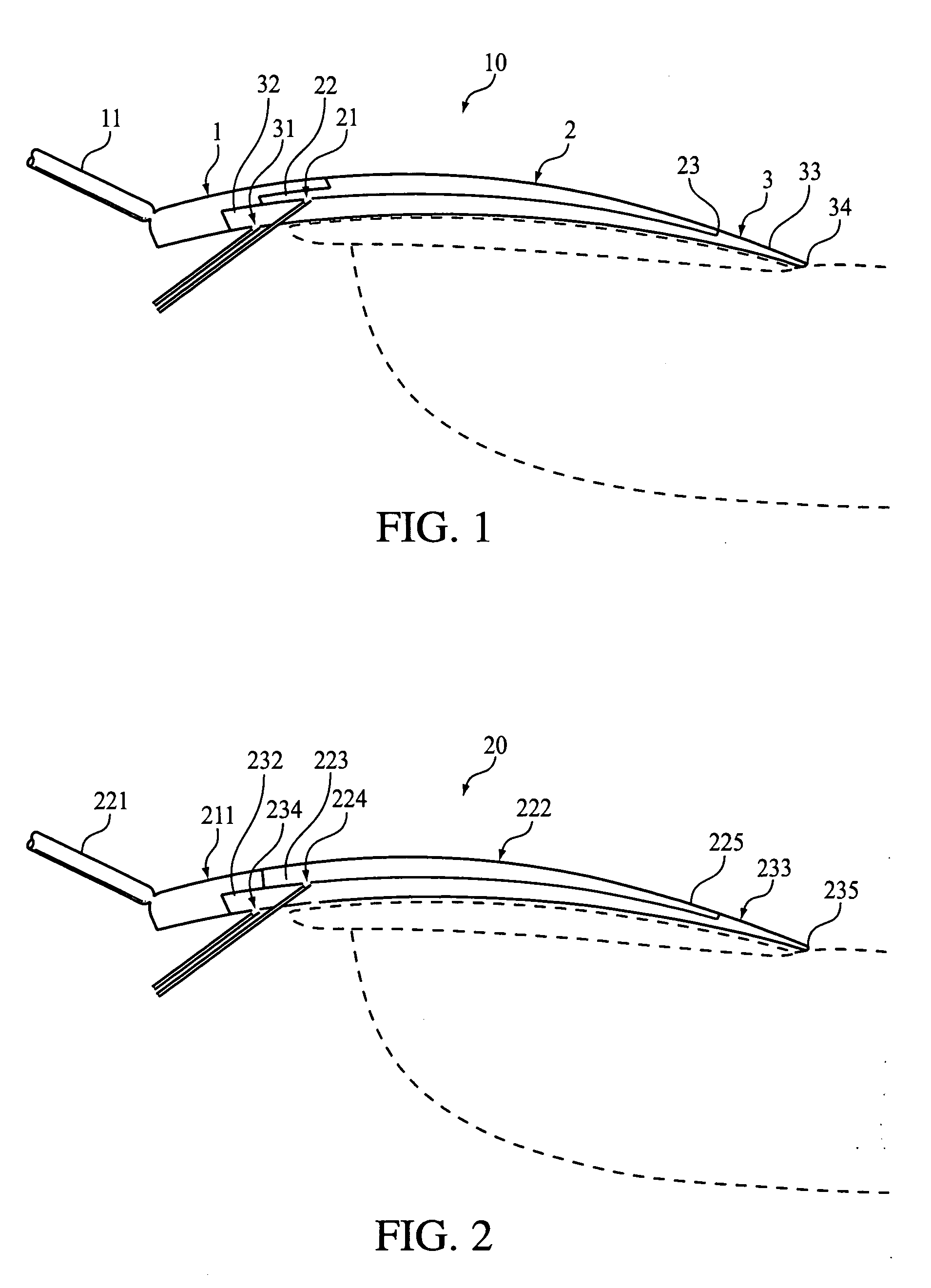

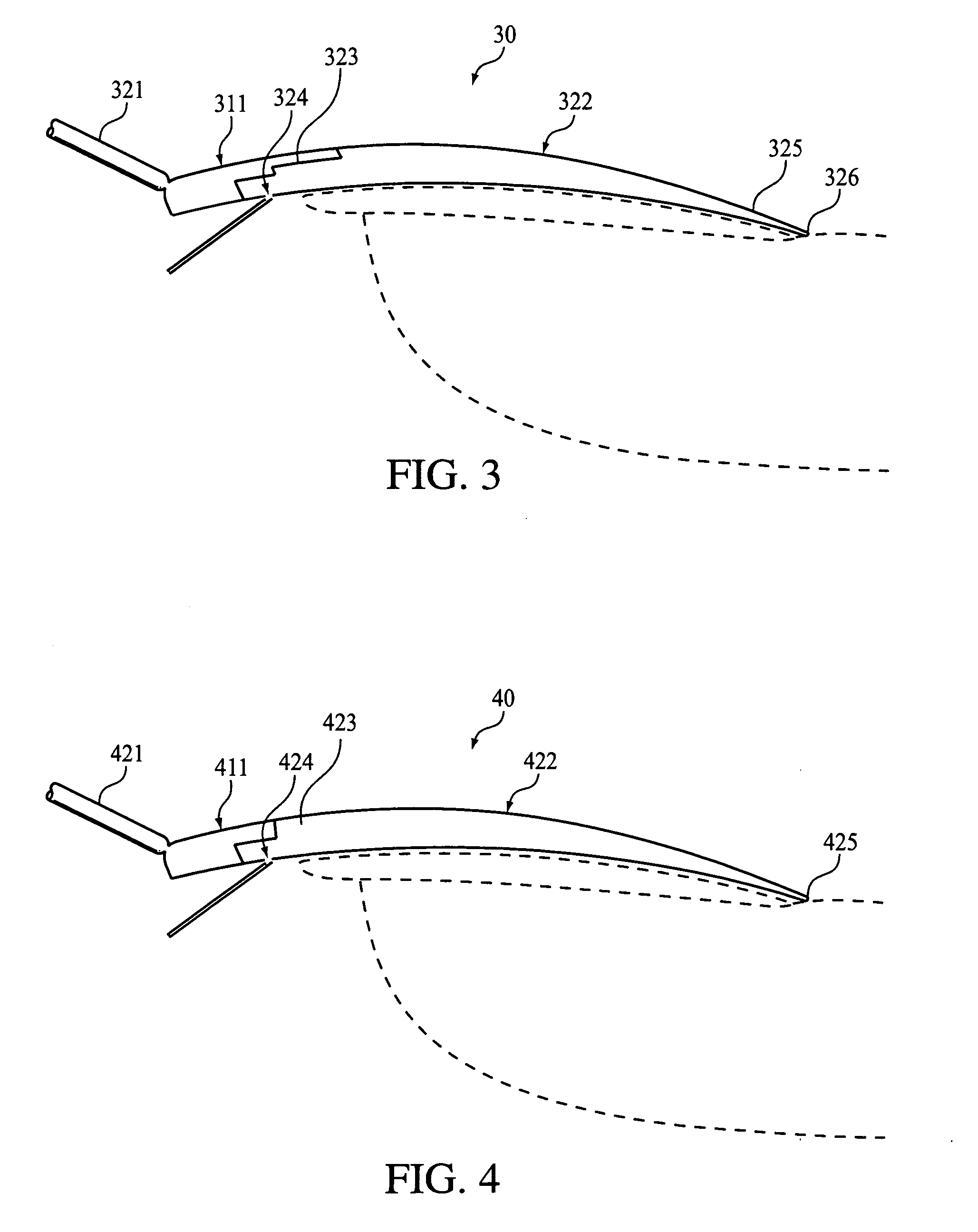

Artificial nail and method of forming same

ActiveUS20060237027A1Improve fitStrong mechanical bondCurling devicesManicure/pedicureInjection mouldingMaterials science

An artificial nail is formed by injection molding a first section and a second section. The first section and second section are adjacent to one another. One of the sections defines a front distal tip of the artificial nail and is formed by injecting a quantity of heated material under pressure from a nozzle into a sprue, through a runner and through a cavity gate into a mold cavity. The other section is formed by injecting another quantity of heated material under pressure from a heated nozzle through another cavity gate into the mold cavity.

Owner:KISS NAIL PRODS

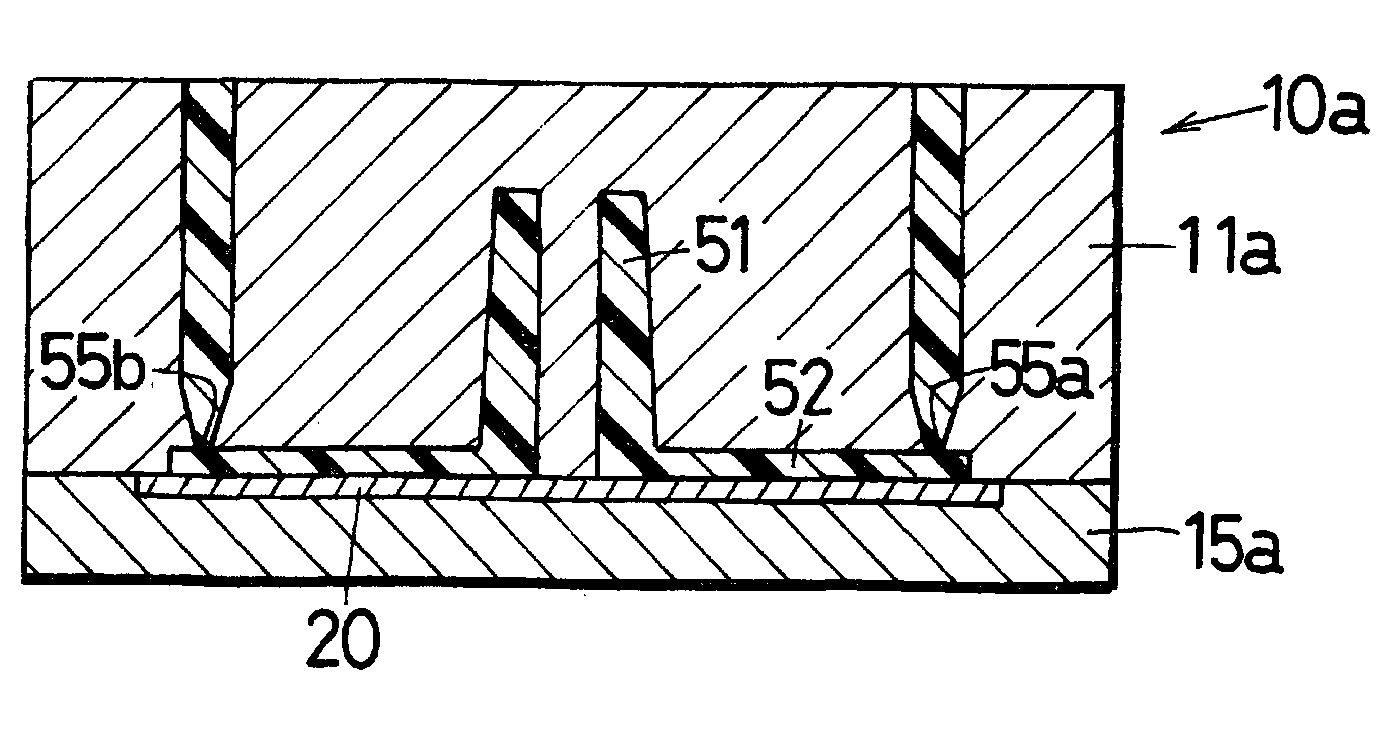

Composite of metal and resin, and method for manufacturing same

ActiveUS20090117401A1Reduced strengthPowerful joint strengthArtificial flowers and garlandsConfectioneryPolyresinMetal

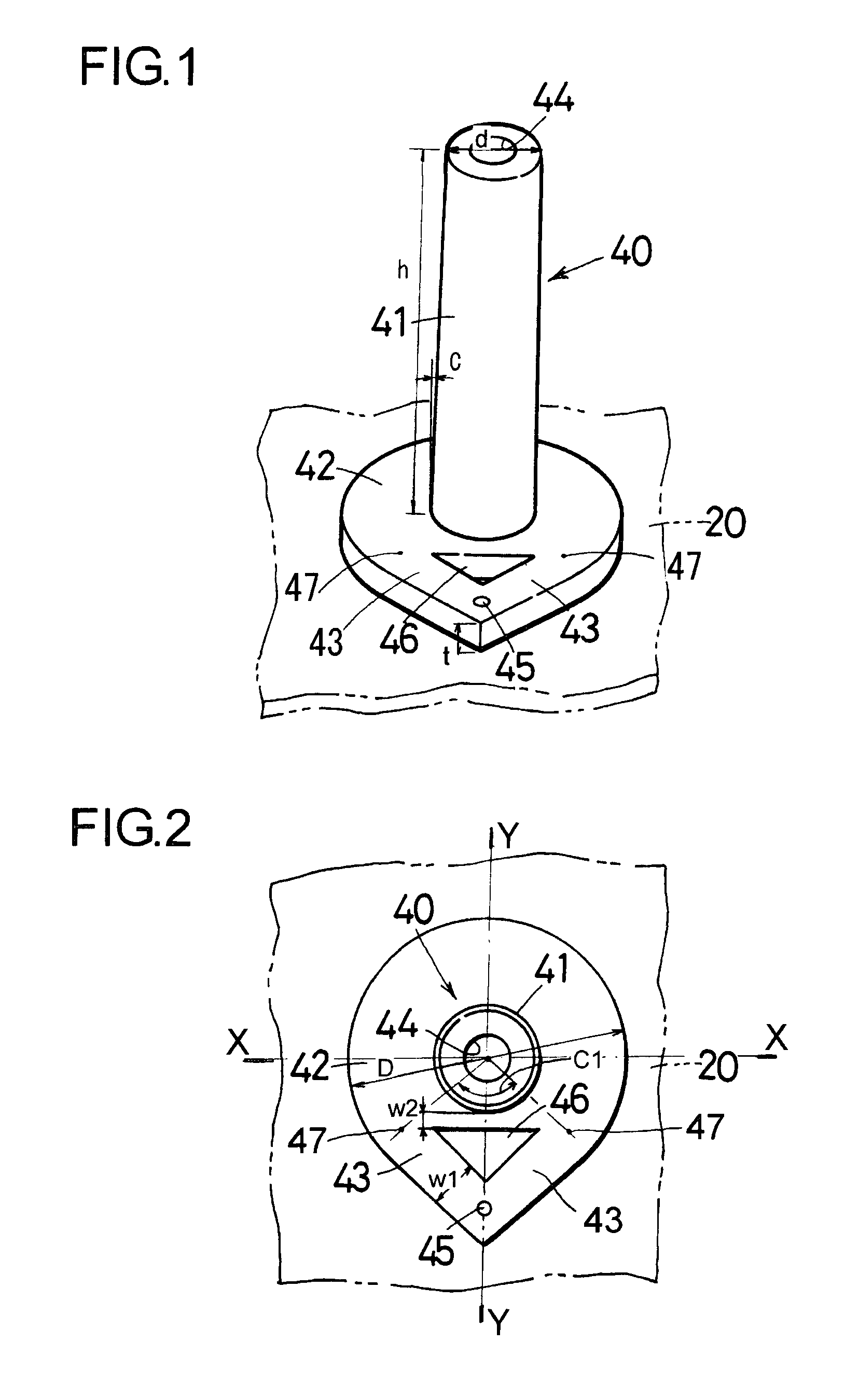

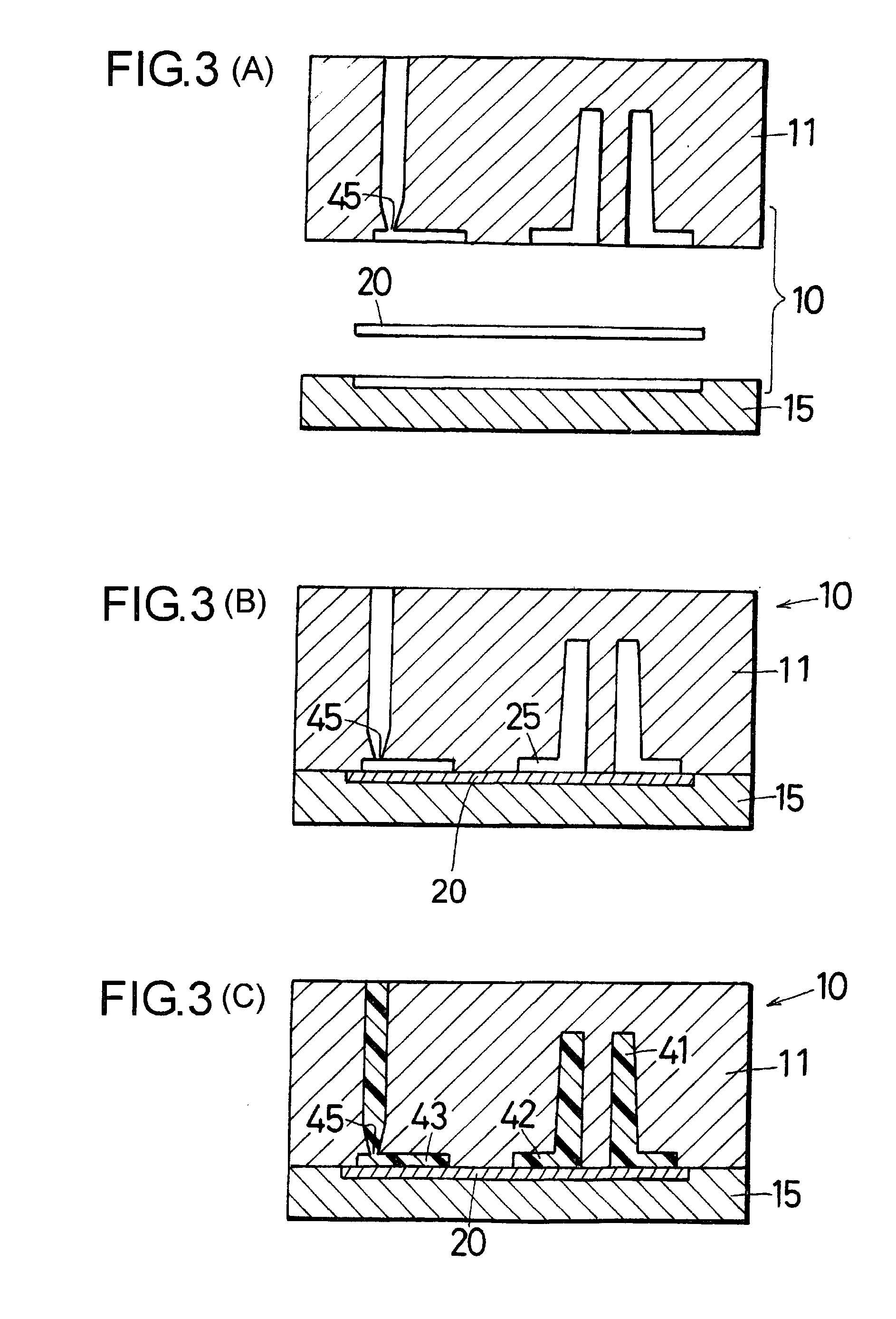

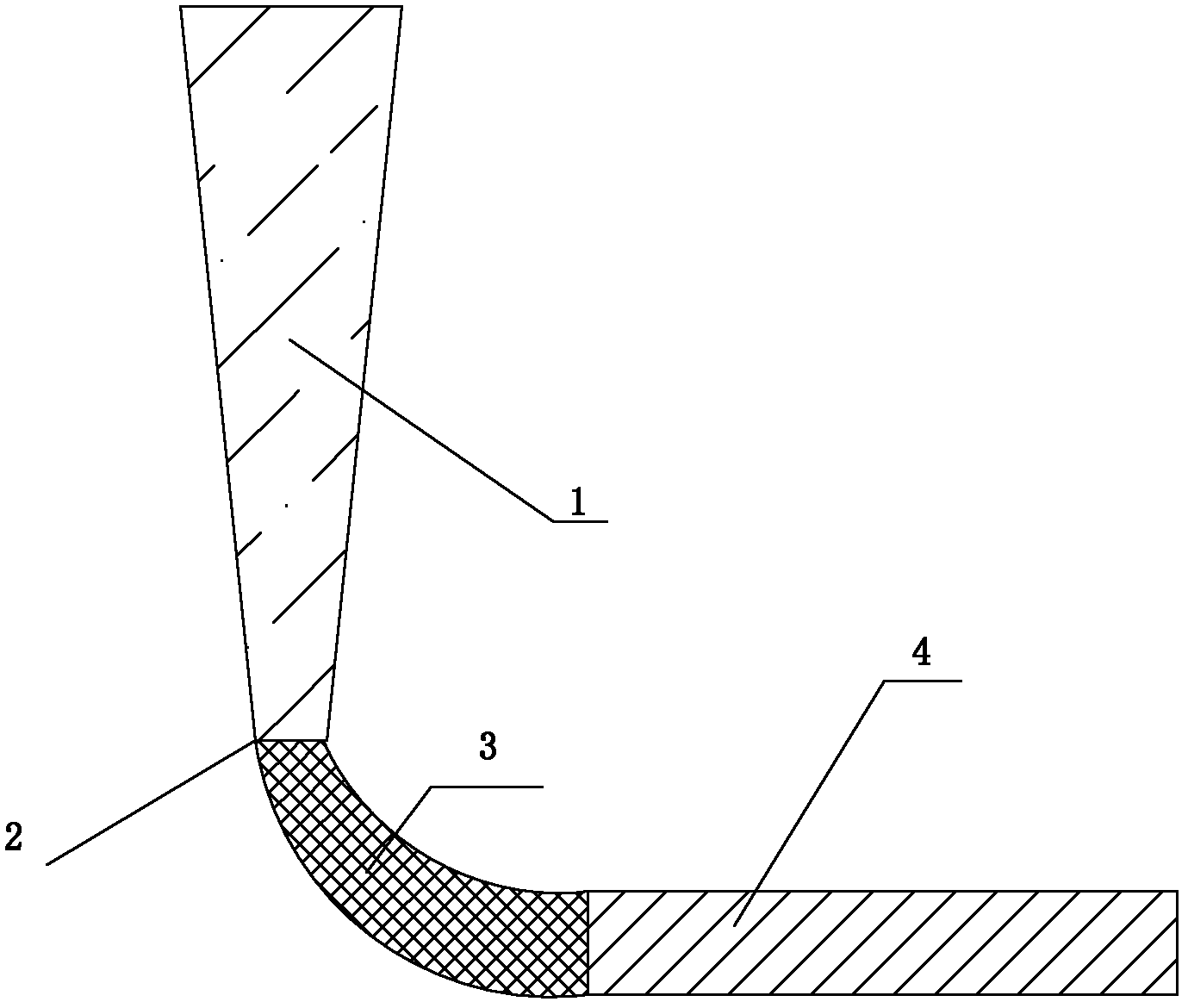

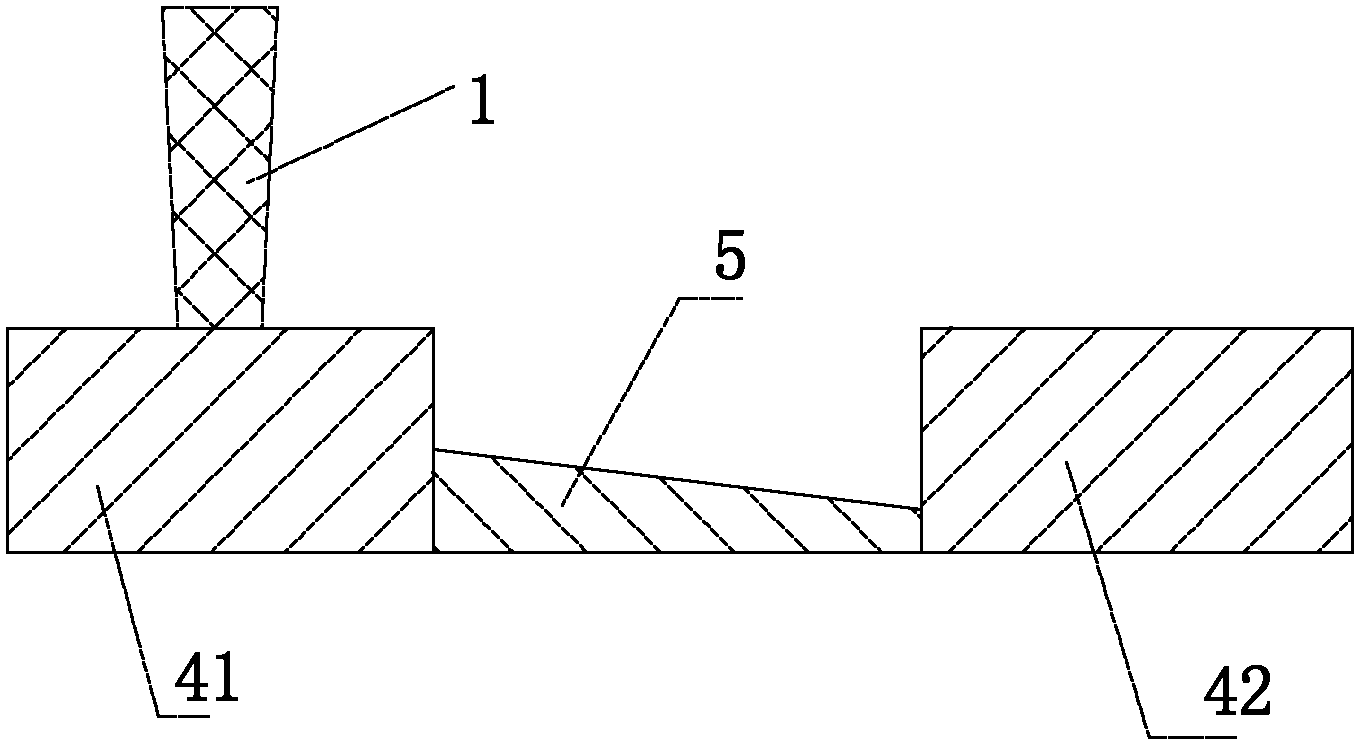

A composite of a metal and a resin, in which a shaped metal and a shaped thermoplastic resin are integrally joined by injection molding, and in which the perpendicular precision of the thermoplastic shaped body with respect to the shaped metal is improved, as well as a method for manufacturing the composite. A composite 40 of a metal and a resin is composed of a shaped metal 20 and a shaped thermoplastic resin that is integrally joined to this shaped metal 20 by injection molding. The shaped thermoplastic resin comprises a seat 42 and a boss 41 that protrudes from the seat 42. A runner 43 is provided which communicates with the seat 42 via two sprues and through which a molten thermoplastic resin that has been injected through an injection gate 45 flows into the boss 41 and the thermoplastic resin injected through the injection gate 45 flows through the sprues 47 to opposite locations of the boss 41 substantially uniformly, thereby filling the locations. As a result, the boss 41 can be joined perpendicularly to the shaped metal 20 by injection joining.

Owner:TAISEI PLAS CO LTD

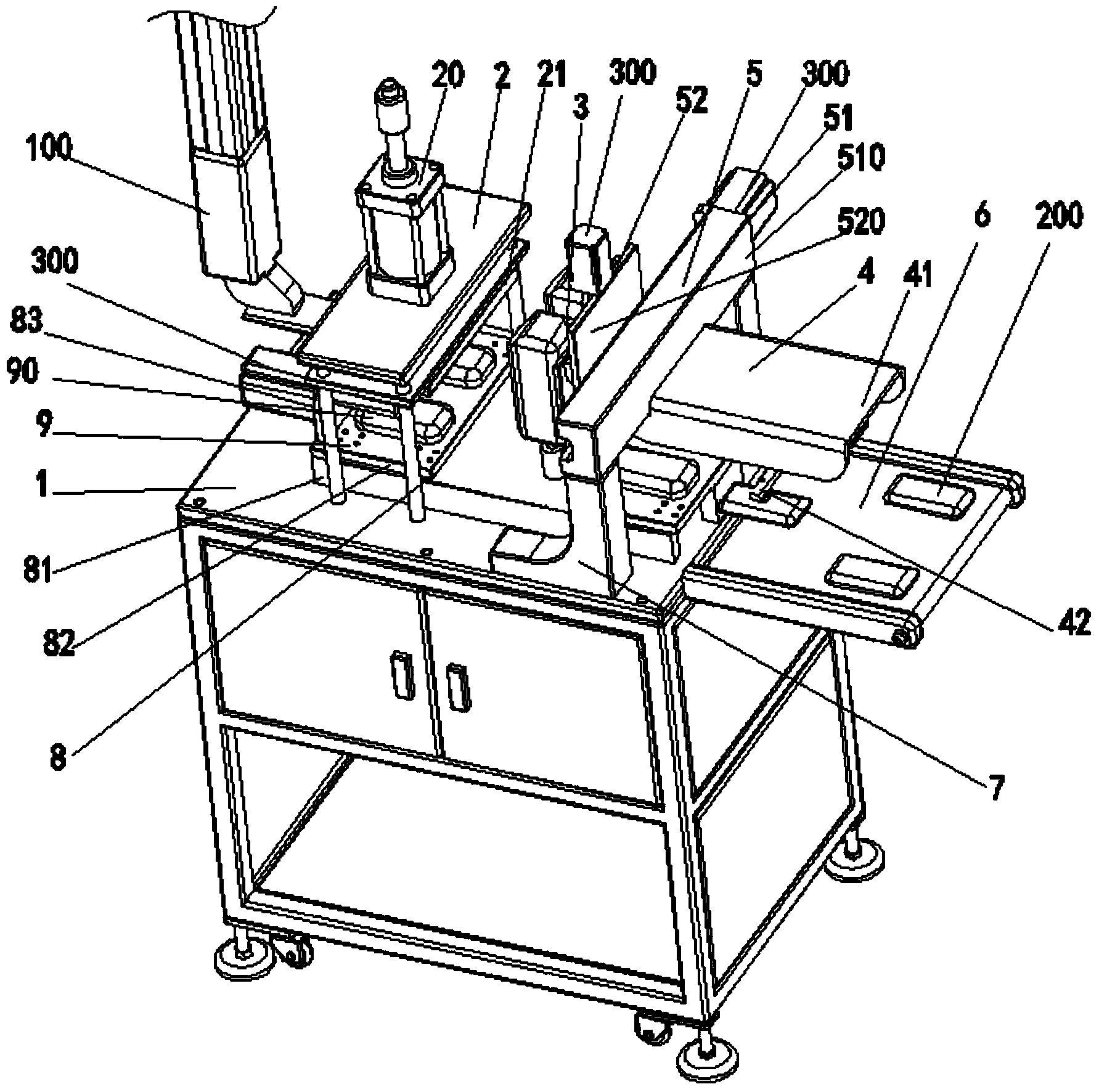

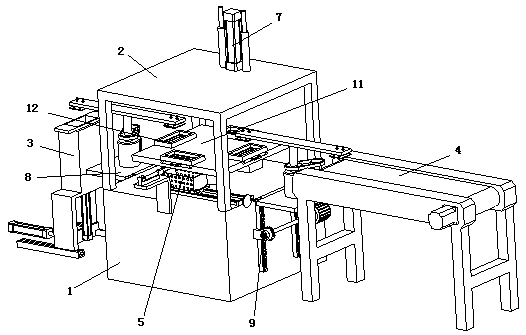

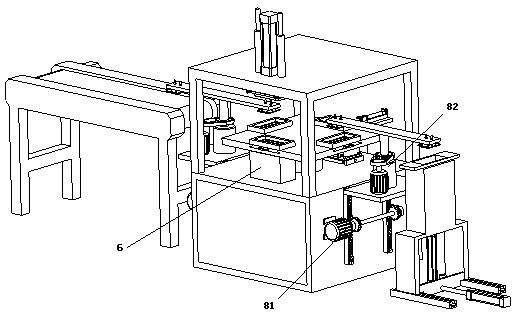

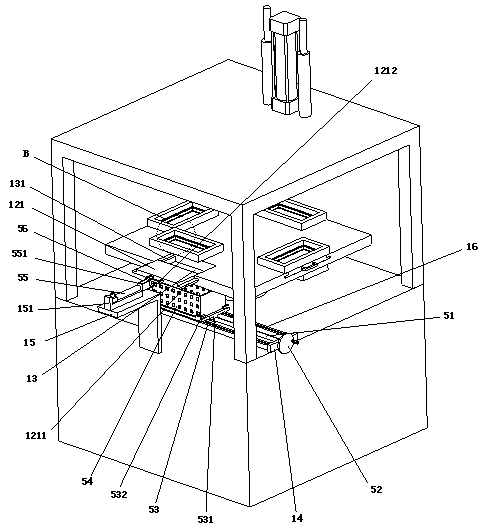

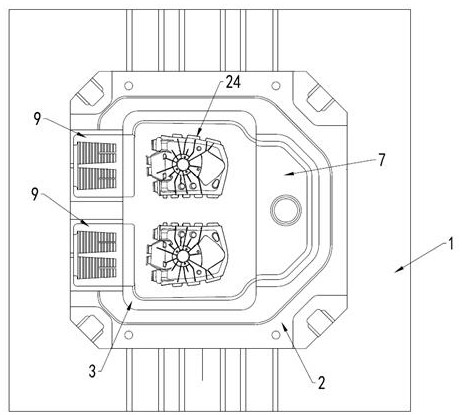

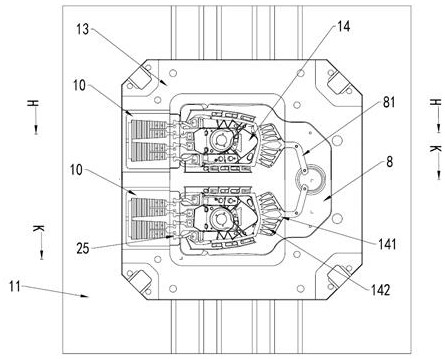

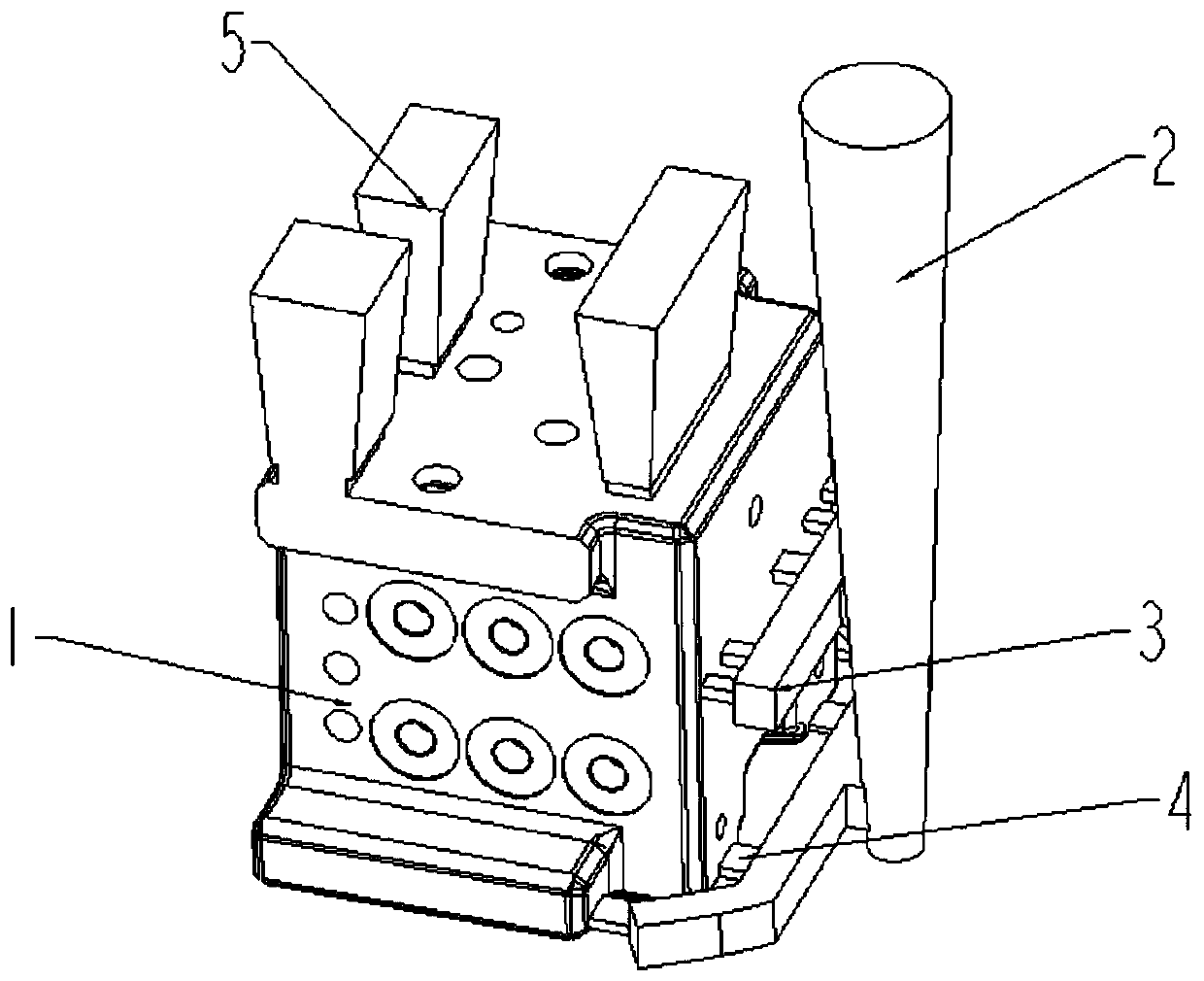

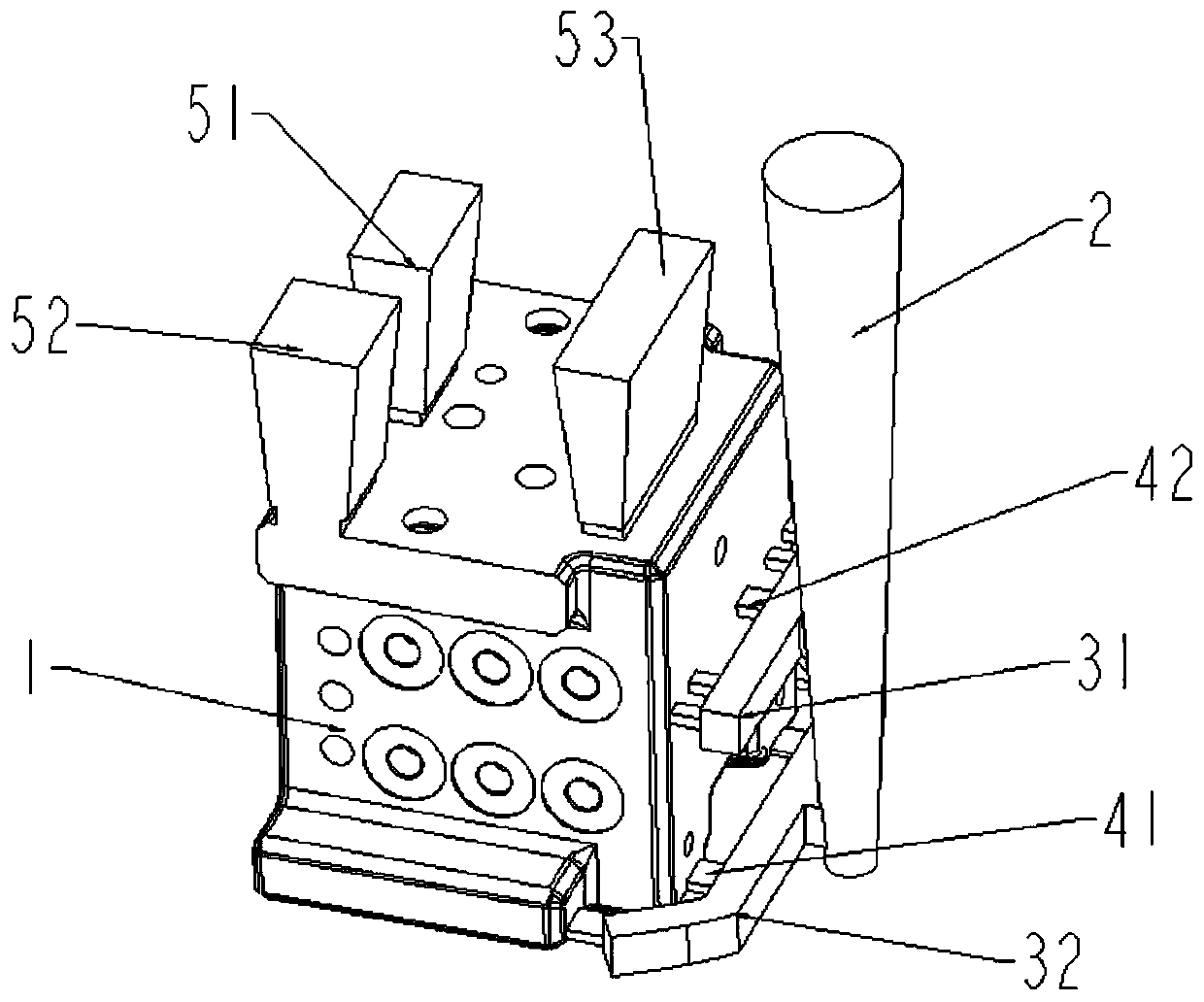

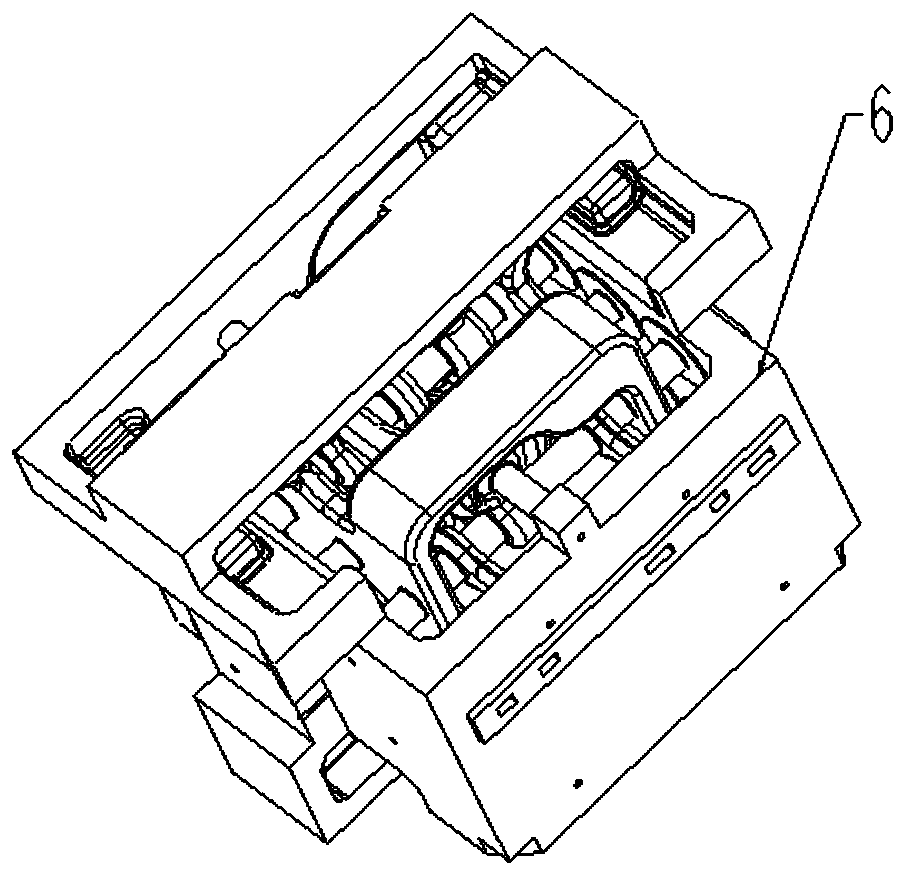

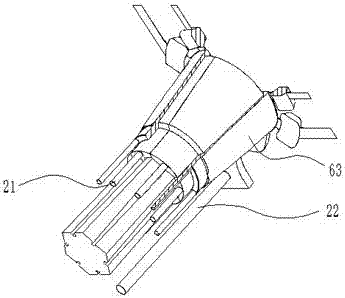

Automatic sprue cutting-away and grinding equipment for digital device shell injection molding

InactiveCN104057587AReduce labor costsIncrease productivityEdge grinding machinesGrinding feedersProcess engineeringMechanical engineering

The invention discloses automatic sprue cutting-away and grinding equipment for digital device shell injection molding, and belongs to the field of digital device production and manufacturing. The equipment comprises a base, a sprue cutting-away device fixed to the base, and a grinding device fixed to the base. An automatic feeding device used for conveying products is also arranged on the base. The automatic feeding device is provided with a product positioning base used for positioning the products. The sprue cutting-away device and the grinding device are arranged in sequence in the conveying direction of the automatic feeding device. The grinding device is fixed to the base through a grinding feeding mechanism. The equipment further comprises a product taking and placing device which is fixed to the grinding feeding mechanism. According to the automatic sprue cutting-away and grinding equipment for digital device shell injection molding, a sprue formed after digital device shell injection molding is completed can be automatically cut away and ground, mechanical and automatic production is achieved, the product quality is improved, the labor cost is greatly reduced, and the production cost of a digital device shell is reduced.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

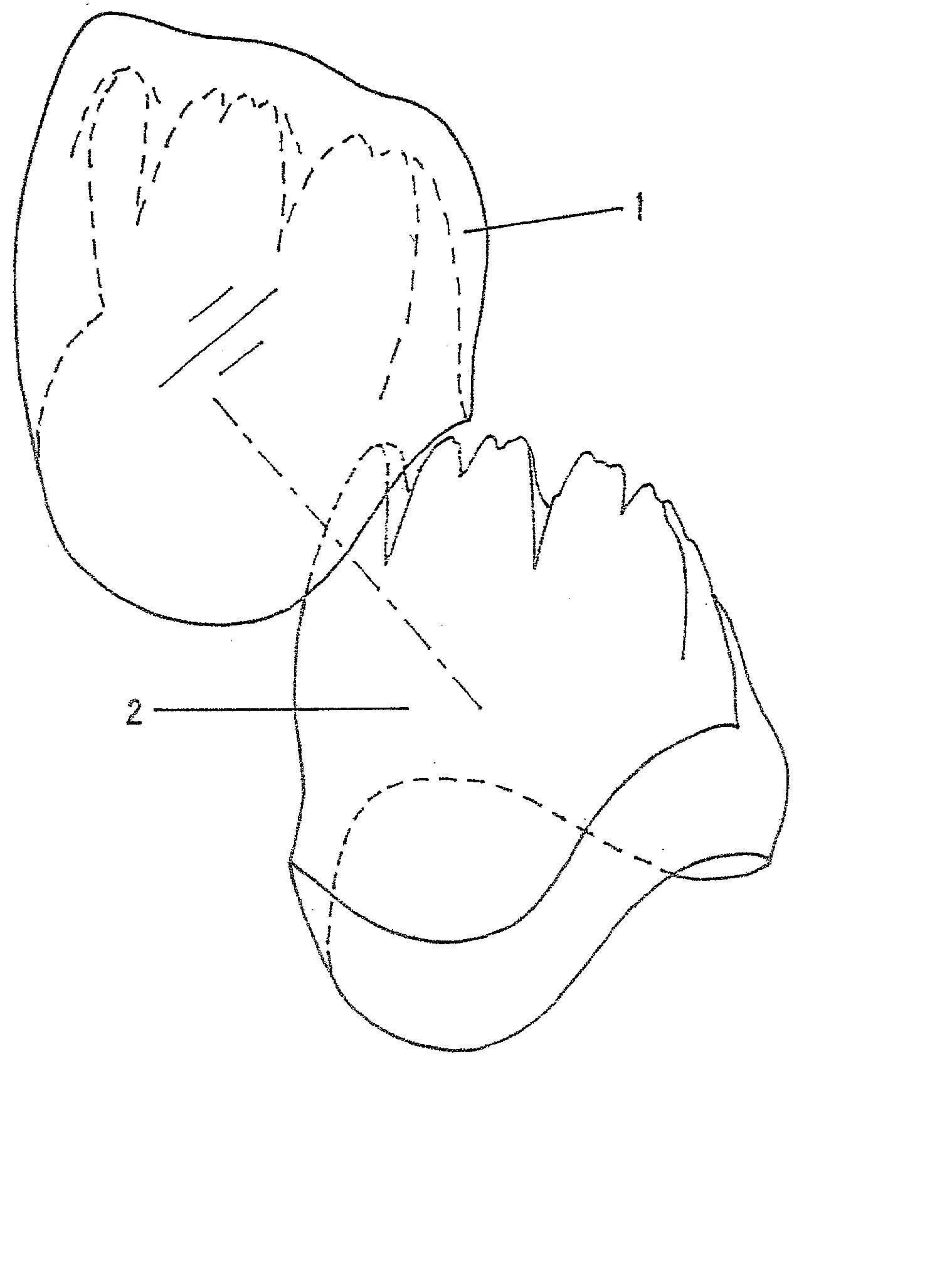

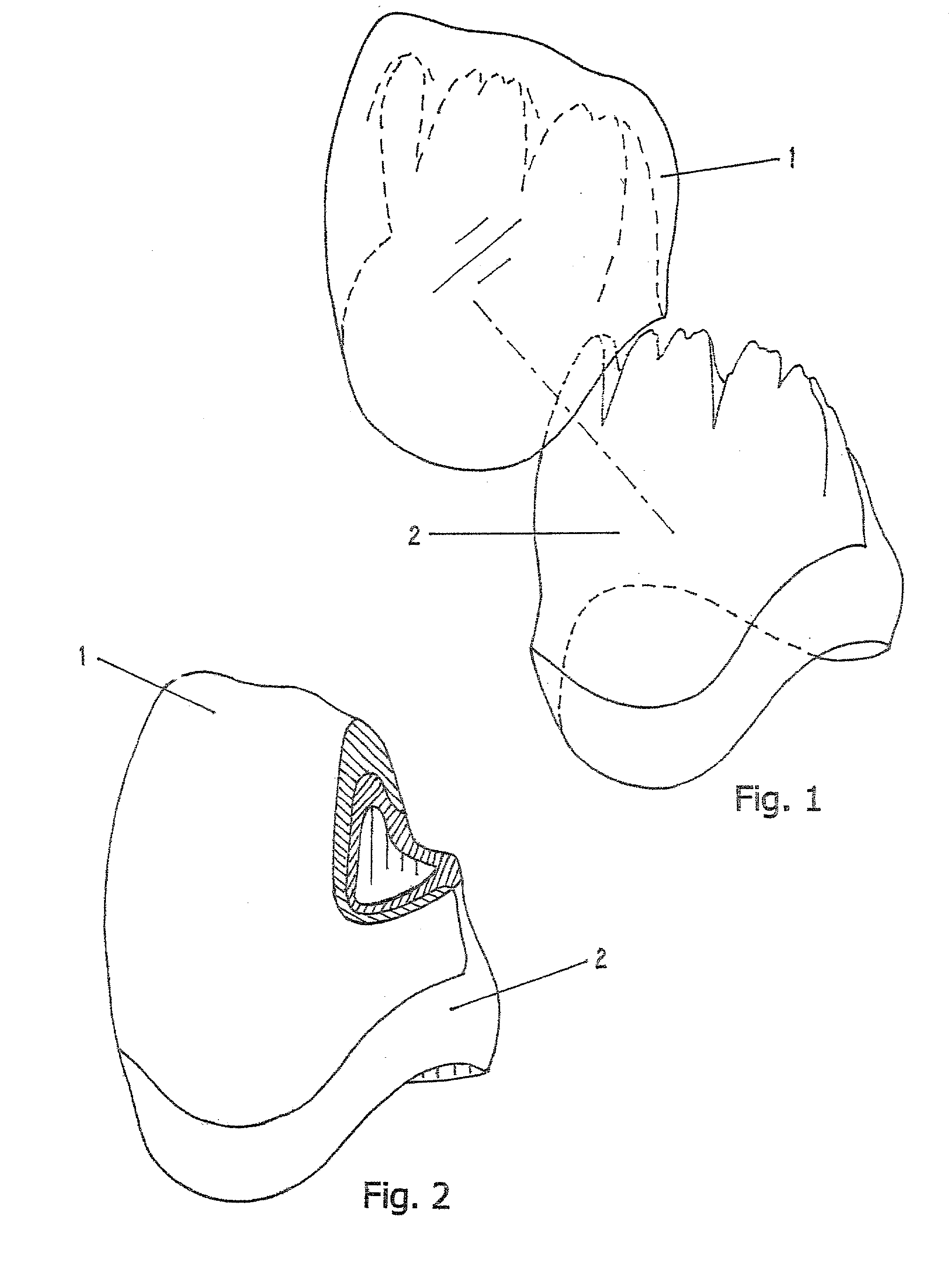

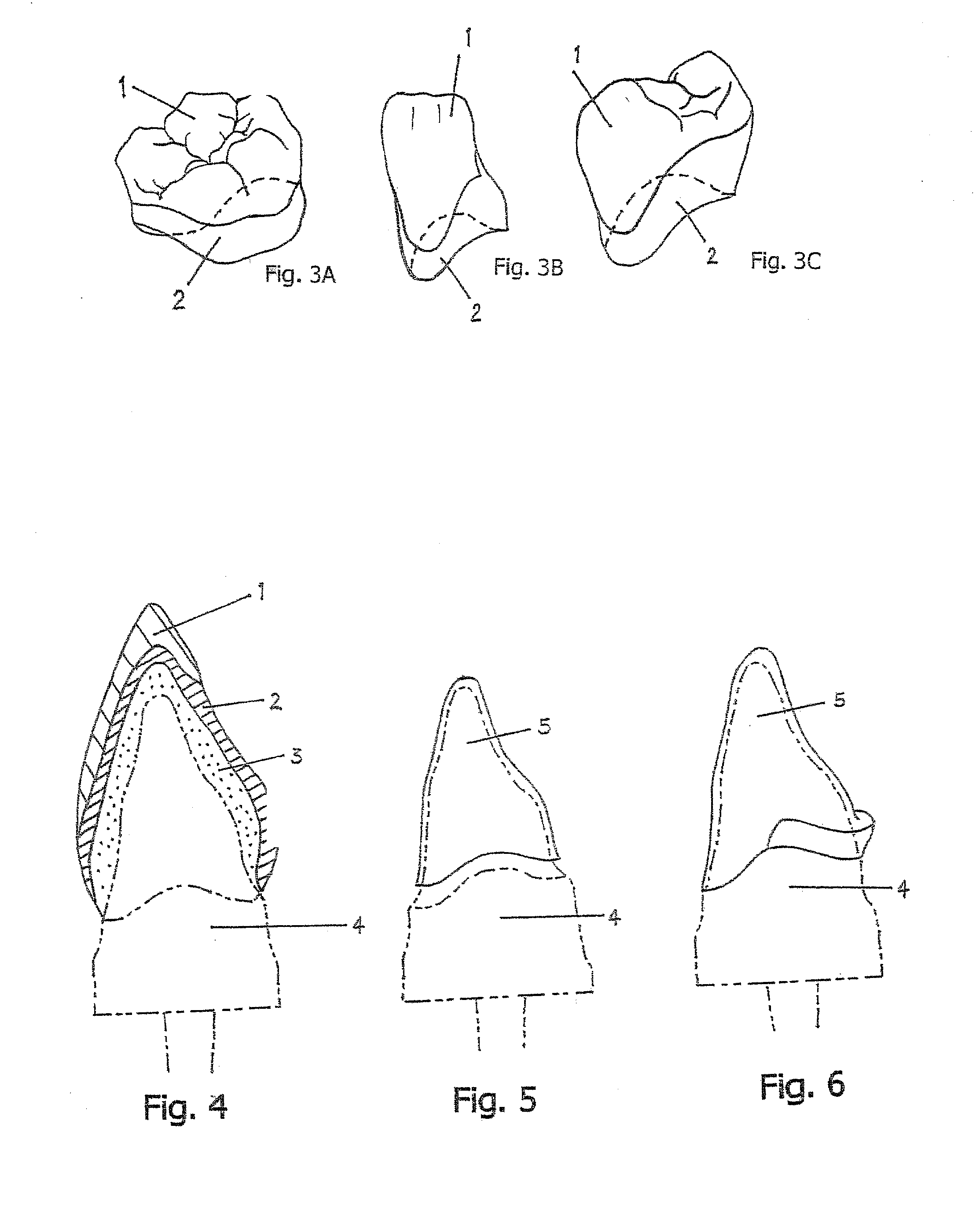

Back casting prefabricated incisal veneers

An improved lost wax method for fabricating dental devices, a prefabricated incisal veneer (1) is selected from among a group of said veneers having predetermined shapes, shades, and sizes. Wax is applied (2 and 3) to the incisal veneer to create a wax buildup onto a model (4) or prefabricated coping (5). Subsequently, a sprue is attached to the applied wax (2 and 3) and the wax buildup is removed from the model (4) for investing and burnout to create a lost wax mold. For a crown with a substructure, the incisal veneer (1) and the coping (5) are both cast in place with press ceramic, press thermoplastic material, or by injecting a curable resin, composite, or epoxy material into the lost wax mold.

Owner:JAMES R GLIDEWELL DENTAL CERAMICS

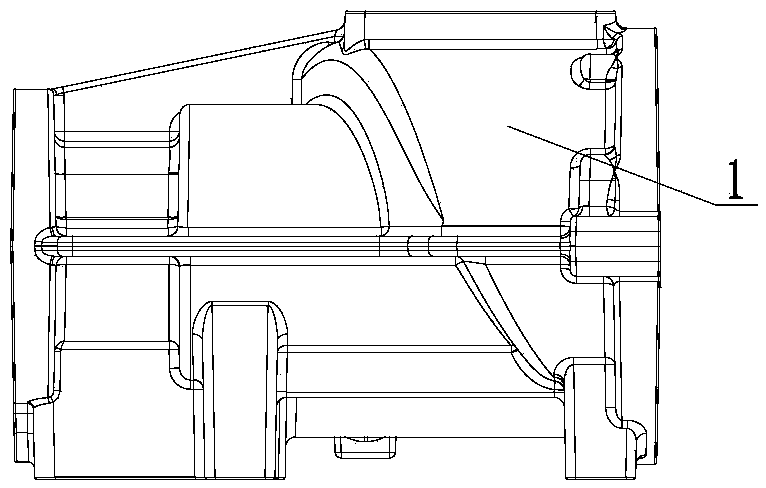

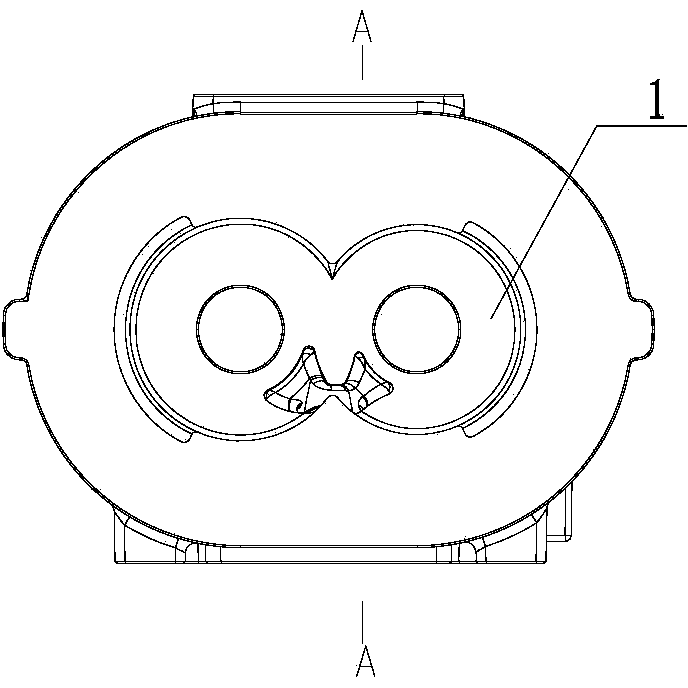

Sand mold structure for integrally molded screw compressor case and manufacture and use method of sand mold structure

ActiveCN103464680AShort structure lengthGuaranteed assembly accuracyFoundry mouldsFoundry coresCastabilityUltimate tensile strength

The invention relates to a sand mold structure for an integrally molded screw compressor case. The sand mold structure comprises a lower sand mold, an upper sand mold, a second sand core and a first sand core, wherein the upper sand mold is provided with a plurality of air outlet holes for communicating a mold cavity with the outer part of the sand mold structure and a sprue for injecting molten iron. The invention also provides a manufacture and use method of the sand mold structure. The manufacture and use method comprises the following steps: modeling, manufacturing a core, milling a pouring cup and air holes, combining boxes, casting and cleaning. The sand mold structure and the manufacture and use method of the sand mold structure have the advantages that a bearing seat and a cast main body are integrally molded, so that the structure length of the case is short, the quantity of needed high-strength bolts is less and the cost is reduced; by means of castability of casting pieces, the strength and the sealability are guaranteed, and safe and reliable effects are achieved; the rotor assembling accuracy is guaranteed only by adopting a positioning pin for the air suctioning end, and a bearing hole and a rotor hole in the air exhausting end are machined by one step, so that high accuracy is guaranteed.

Owner:SUZHOU TORIN MACHINERY CASTING

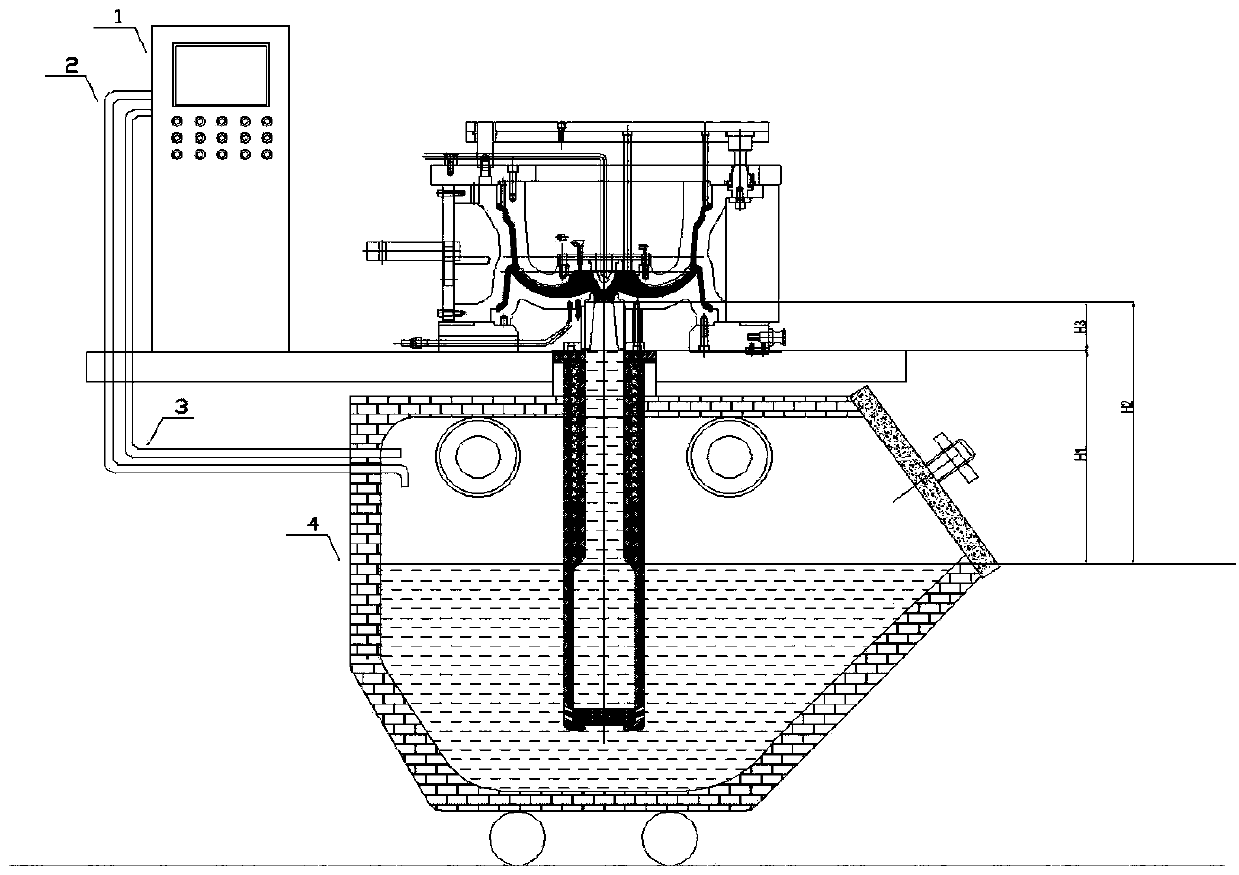

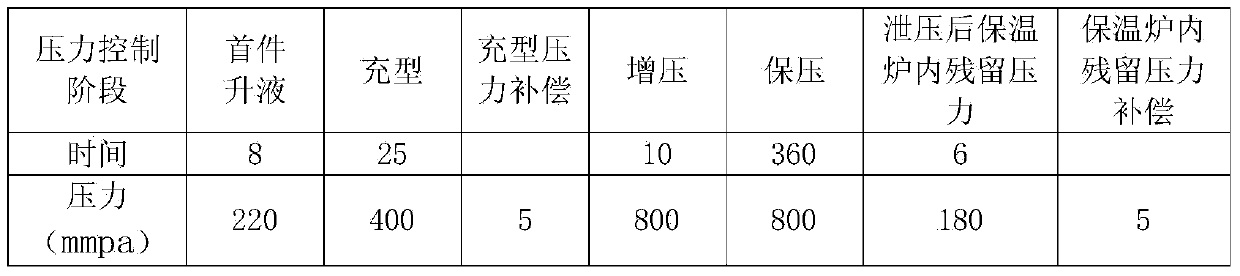

Low-pressure casting device for aluminum alloy wheels of automobile

A low-pressure casting device for aluminum alloy wheels of an automobile is composed of a low-pressure casting system control cabinet, a pressurization air inlet tube, a pressure relief air outlet tube, a molten aluminum heat preservation furnace, an iron sprue, a ceramic heat preservation cup, a molten aluminum lifting tube, a heat insulation layer, twelve to sixteen buffer holes and a ceramic filter net. The two ends of the pressurization air inlet tube and the two ends of the pressure relief air outlet tube are connected with the low-pressure casting system control cabinet and the molten aluminum heat preservation furnace. A pressure control valve is installed in the low-pressure casting system control cabinet and arranged at the end of the pressure relief air outlet tube. A pressure relief zero return button and a cumulative number zero clearing button are arranged in the low-pressure casting system control cabinet. The iron sprue is assembled at a die feed inlet, the ceramic heat preservation cup is assembled under the iron sprue, the molten aluminum lifting tube is assembled in the molten aluminum heat preservation furnace, the upper end of the molten aluminum lifting tube is provided with the heat insulation layer, the inner diameter of the part, immerged in molten aluminum, of the lower end of the molten aluminum lifting tube is greater than that of the upper end, the buffer holes with the diameter of 10-12mm are formed in the lower end of the molten aluminum lifting tube, and the included angle formed between each buffer hole and the vertical plane ranges from 15 degrees to 20 degrees. The low-pressure casting device for the aluminum alloy wheels of the automobile can remarkably reduce the burning loss, the heat loss, needle holes and slag holes.

Owner:JIANGSU KAITE AUTO PARTS

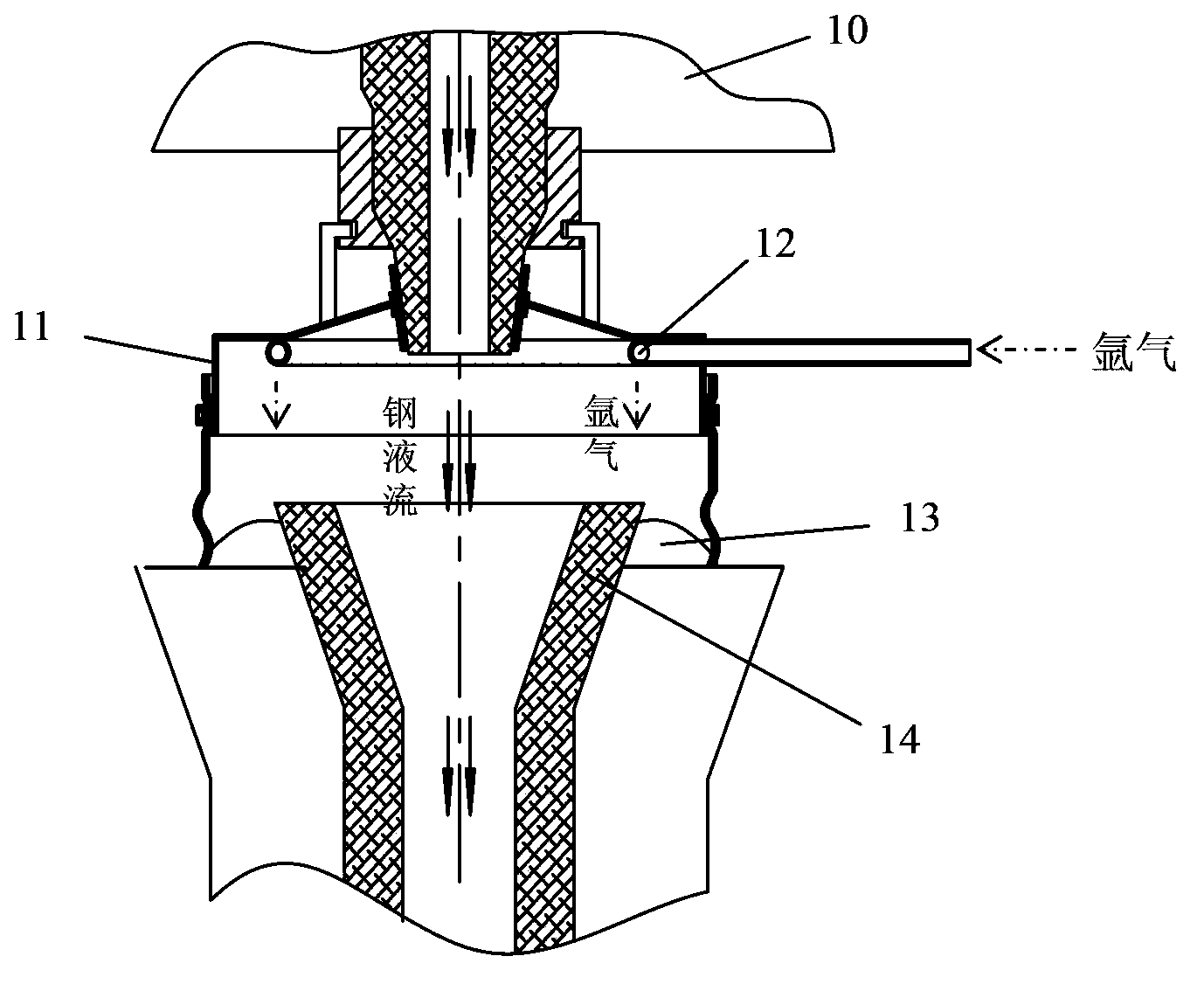

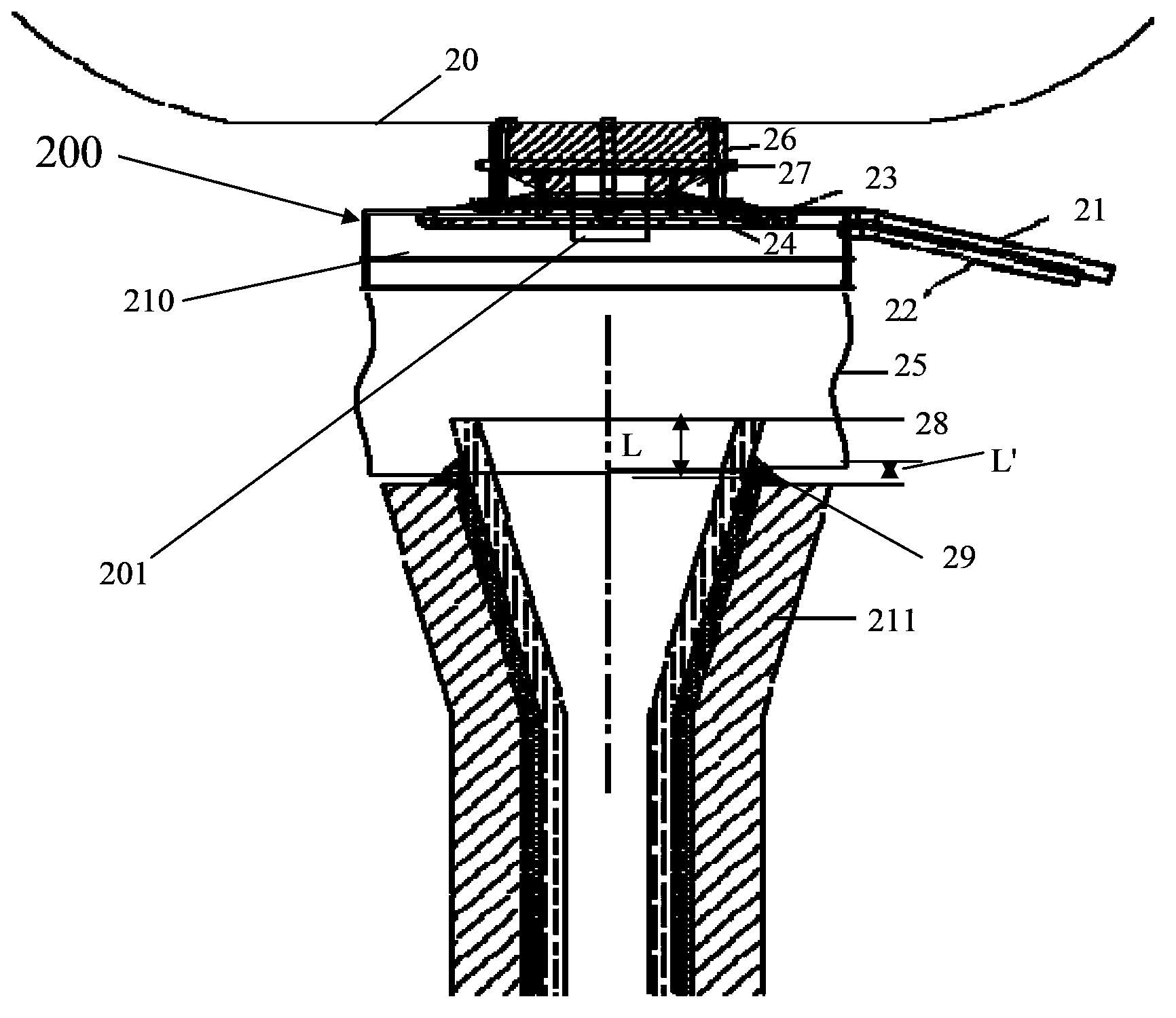

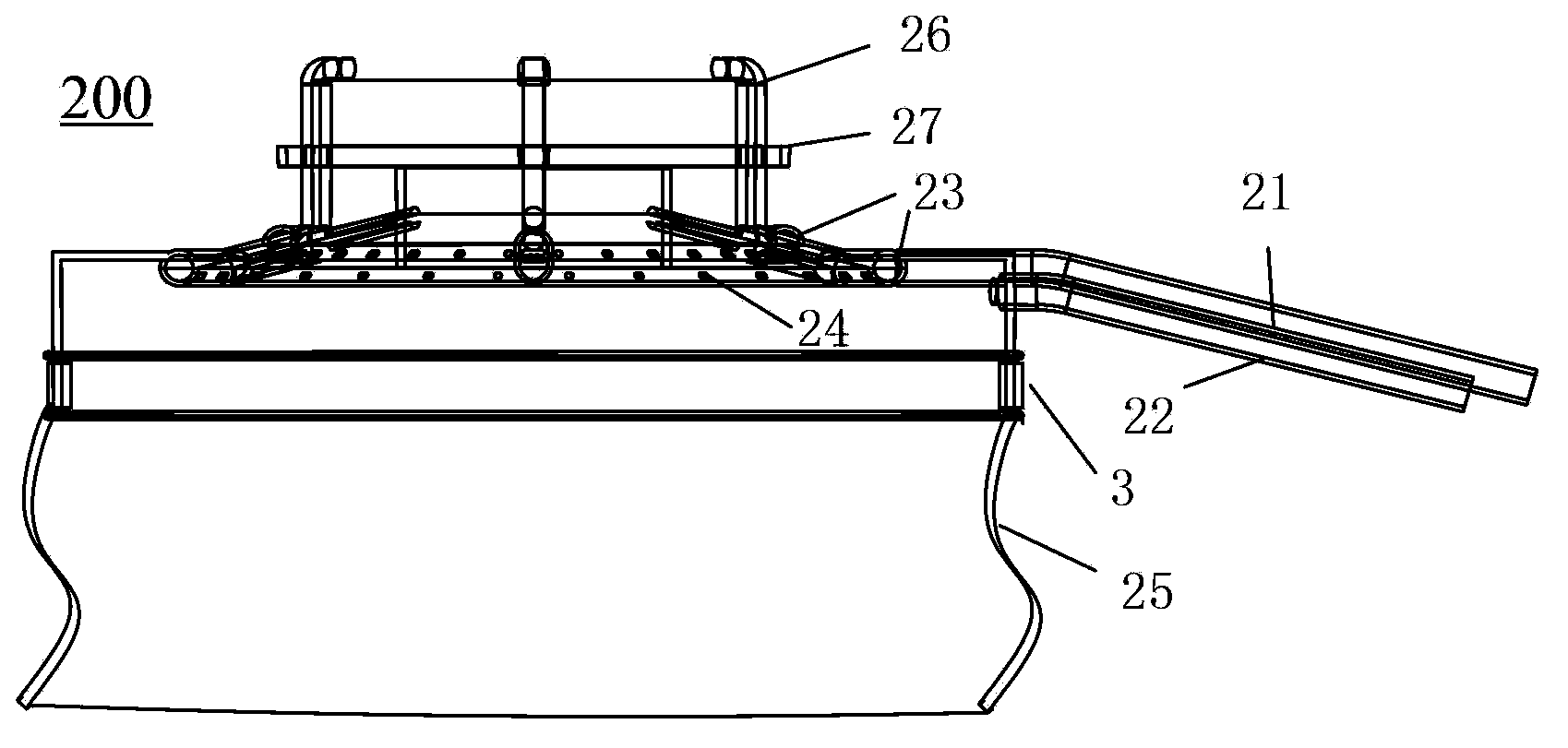

Injection flow protection device and method for die casting pouring

The invention discloses an injection flow protection device and method for die casting pouring, relates to die casting pouring technology and solves the problem of secondary oxidation of molten steel. A protection cover is mounted between the bottom of a steel ladle for die casting pouring and a middle injection pipe sprue of die casting pouring equipment and comprises an outer cover, an argon blowing pipe, a sampling pipe, two argon rings, an argon protection overskirt and three supporting feet, each argon ring is composed of a big ring pipe and a small ring pipe which are disposed in the outer cover and communicated, and multiple argon feeding holes formed in the ring pipes horizontally face the center of a circular ring; a gap is reserved between the bottom of the argon protection overskirt and the middle injection pipe sprue, the supporting feet are connected with the protection cover and are detachable connecting parts of the protection cover and the steel ladle, the tops of the supporting feet are disposed in a T-shaped round clamping groove of an outer ring of a water port at the bottom of the steel ladle in a clamped manner, and vertical distance between the middle injection pipe sprue of the die casting pouring equipment and a hollow injection pipe iron shell. By the injection flow protection device and method, argon flow can be controlled effectively during die casting pouring work, and secondary oxidation of the molten steel is avoided while pouring is unaffected.

Owner:宝武特种冶金有限公司

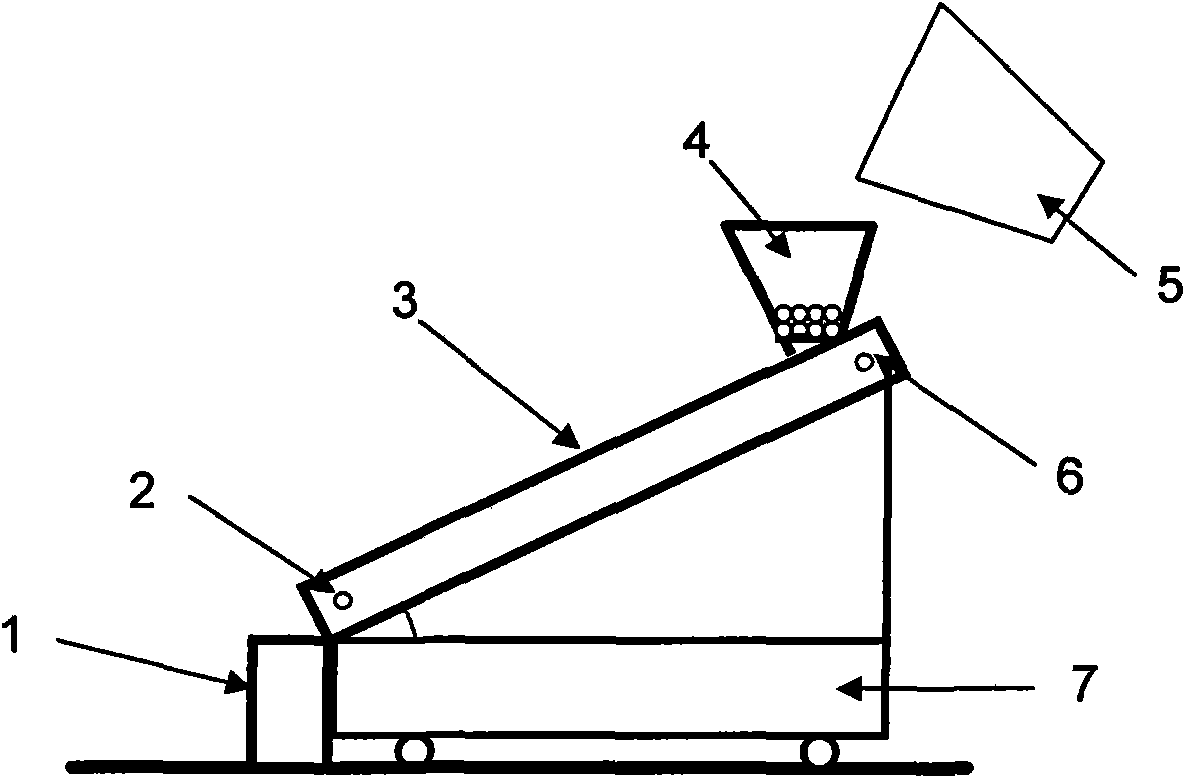

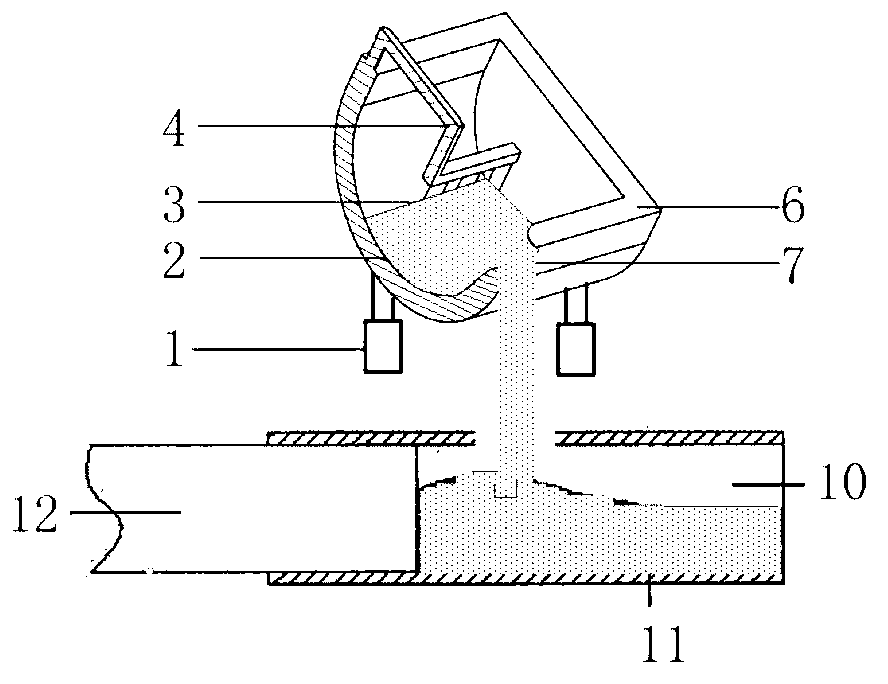

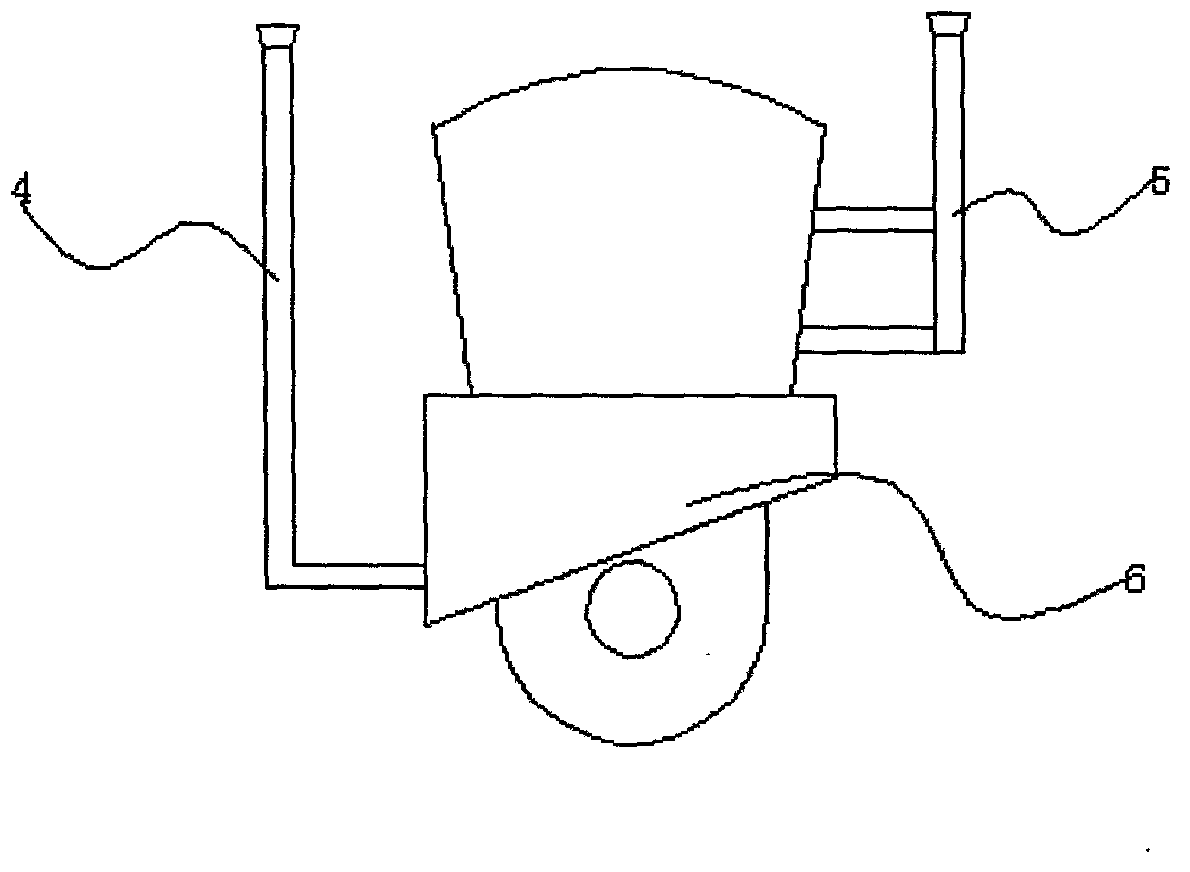

Device and method for preparing metal semi-solid slurry

The invention relates to a device and a method for preparing metal semi-solid slurry. In the device, a bracket 7 is arranged on a working plane, an alloy trough 3 is formed on an inclined plane on the upper part of the bracket 7; the device is provided with a casting ladle 5 for conveying melted metal; a funneled sprue cup 4 is arranged at the upper end of the alloy trough 3; the upper end opening of the sprue cup 4 is opposite to the casting ladle 5, while the lower end is communicated with the alloy trough 3; a cast 1 of which the internal cavity is communicated with the alloy trough 3 is arranged at the lower end of the alloy trough 3; and a cooling hole with a cooling water outlet 2 and a cooling water inlet 6 is formed on the alloy trough 3. The method for preparing the metal semi-solid slurry by using the device comprises the following steps of: processing a small metal block, namely a self-inoculating agent with the same components of the processed alloy; introducing the self-inoculating agent into the melted alloy melt; controlling the temperature of adding the self-inoculating agent into the melt and the temperature of pouring to be 50 to 150 DEG C higher than that of alloy liquidus; and performing conventional melt treatment after the self-inoculating agent is melted.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Gating system capable of effectively controlling air entrainment and slag entrainment and design method thereof

ActiveCN102319891ANot easy to cause cracksNot easy to cause defects such as loosenessMolten metal pouring equipmentsFoundry mouldsSlagAir entrainment

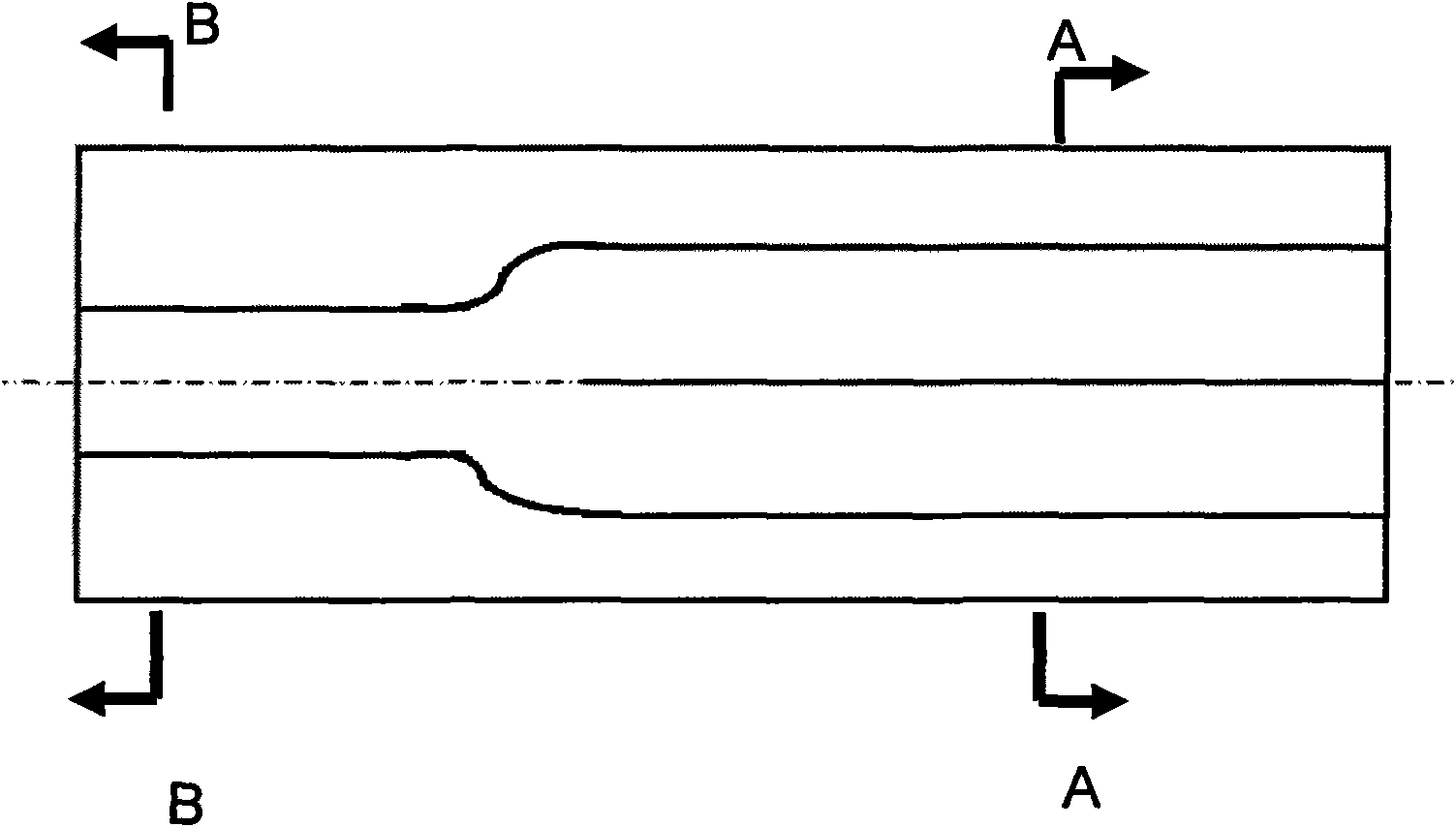

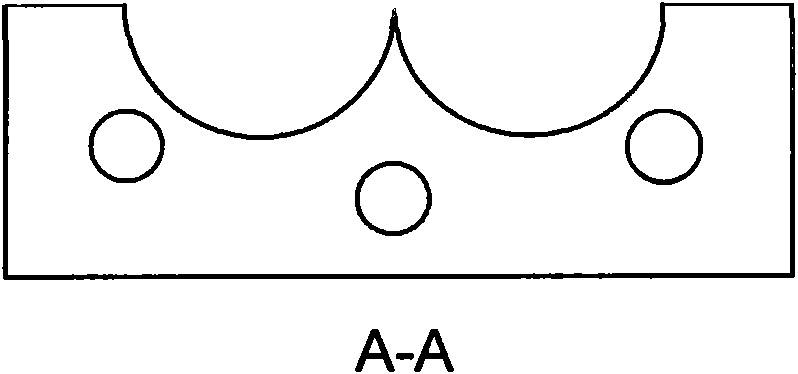

The invention relates to a gating system capable of effectively controlling air entrainment and slag entrainment and a design method thereof. The gating system comprises a sprue, a runner and a plurality of ingates; the sprue is of a big-end-up conical structure, and the maximum cross-sectional area of the upper end is 1.5 to 3 times larger than the minimum cross-sectional area of the lower end; the runner is connected with the lower end of the sprue through a smooth curve, the radius of the curve is 1 to 5 times larger than the equivalent diameter of the runner, the cross-sectional radius ofthe curve is reduced, and the radius-reducing change is between 1 and 5 times larger than the cross-sectional equivalent radius of the runner; the ingates are connected with the runner, and the sum of the cross-sectional areas of the ingates is 2 to 10 times larger than the cross-sectional area of the runner. The invention solves the problem that the conventional gating system is not reasonable and can hardly guarantee the smooth filling and purity of molten metal, the phenomena of secondary oxidation, air entrainment and slag entrainment are prevented in the process of pouring molten metal, so that the quality of castings can be guaranteed, and the invention is suitable for the design of gating systems for the sand mold casting, metal mold casting, casting blank casting and precision casting of non-ferrous metal, ferrous metal, high-temperature alloy and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for producing aluminum alloy ingot

The invention discloses a method for producing an aluminum alloy ingot. A smelting furnace is preheated before being used, reaction time can be shortened, and the phenomenon that materials do not fully react can be avoided; a powdery dreg remover is scattered into the surface of melt, Al2O3 included slag brought from an electrolytic cell can be preliminarily removed, and furnace wall hanging slag can be reduced; coating painting treatment is carried out through a launder, and it is ensured that a launder lining is completely dry before the launder is used; a gas refining system in a heat preservation furnace is started, H2 and oxide inclusions in the aluminum melt can be fully removed, and meanwhile impurities Na can be removed well; and the launder, a sprue, the lining, a coating and seams are inspected while pretreatment so as to guarantee that molten aluminum can be injected into the heat preservation furnace fast and stably.

Owner:惠州卫生职业技术学院

Casting system and method for castings

ActiveCN107363224AReduce usageImprovement of casting structureFoundry mouldsFoundry coresEconomic benefitsMaterials science

The invention discloses a casting system for castings. The casting system for the castings comprises a sprue and is characterized in that the sprue communicates with a cross gate, and the cross gate is provided with a plurality of ingates; each ingate is provided with a plurality of molds communicating with the corresponding ingate; the molds on the same ingate are stacked in the vertical direction; independent secondary ingates are arranged between every two adjacent molds; and the mold at the uppermost side is provided with a casting head. The invention further discloses a casting method using the casting system. According to the system and method disclosed by the invention, the multiple molds can be overlaid onto each ingate, the secondary ingates are arranged between every two molds and can conduct feeding on the adjacent molds below, the problems that a casting structure without a chilling block or with the chilling block not capable of being arranged conveniently is low in rate of finished products, low in production efficiency and poor in economic benefit are avoided, and the advantages of being high in percent of pass and high in production efficiency are achieved.

Owner:四川共享铸造有限公司

Method for preparing ductile iron exhaust manifold

InactiveCN101225497AOvercome the problem of unsatisfactory product qualityExhaust apparatusSilencing apparatusSilicon alloyManganese

The invention relates to a preparation method for ductile iron exhaust manifold, the ductile iron mainly comprises iron, phosphorous, sulfur, magnesium, antimony, tin, boron, aluminum, chromium, nickel, lead, titanium, vanadium, manganese, copper, molybdenum, carbon and silicon alloy elements; wherein, according to weight content, the manganese is 0.10 to 0.20%, the copper is less than 0.20%, the molybdenum is 0.80% plus or minus 0.03%, the carbon is less than 3.35%, and the silicon is less than 3.65 as well as 0.15% plus or minus 0.05% metal-stream inoculant. The exhaust manifold is cast and formed by a casting device comprising a sprue, a water inlet, a cross gate and a feeder head; wherein, the water inlet is a pipe string body; a groove inclined outwards is arranged on a pipe wall near the position near the joint of the water inlet and the casting pieces; an included angle is formed between the tail end of the water inlet and the cross gate. The preparation method for ductile iron exhaust manifold has the advantages of increasing thickness of joint of water inlet and the casting pieces body, improving connecting strength between the casting pieces and the water inlet, and effectively reducing damage to the casting pieces when the stream is removed.

Owner:天津勤美达工业有限公司

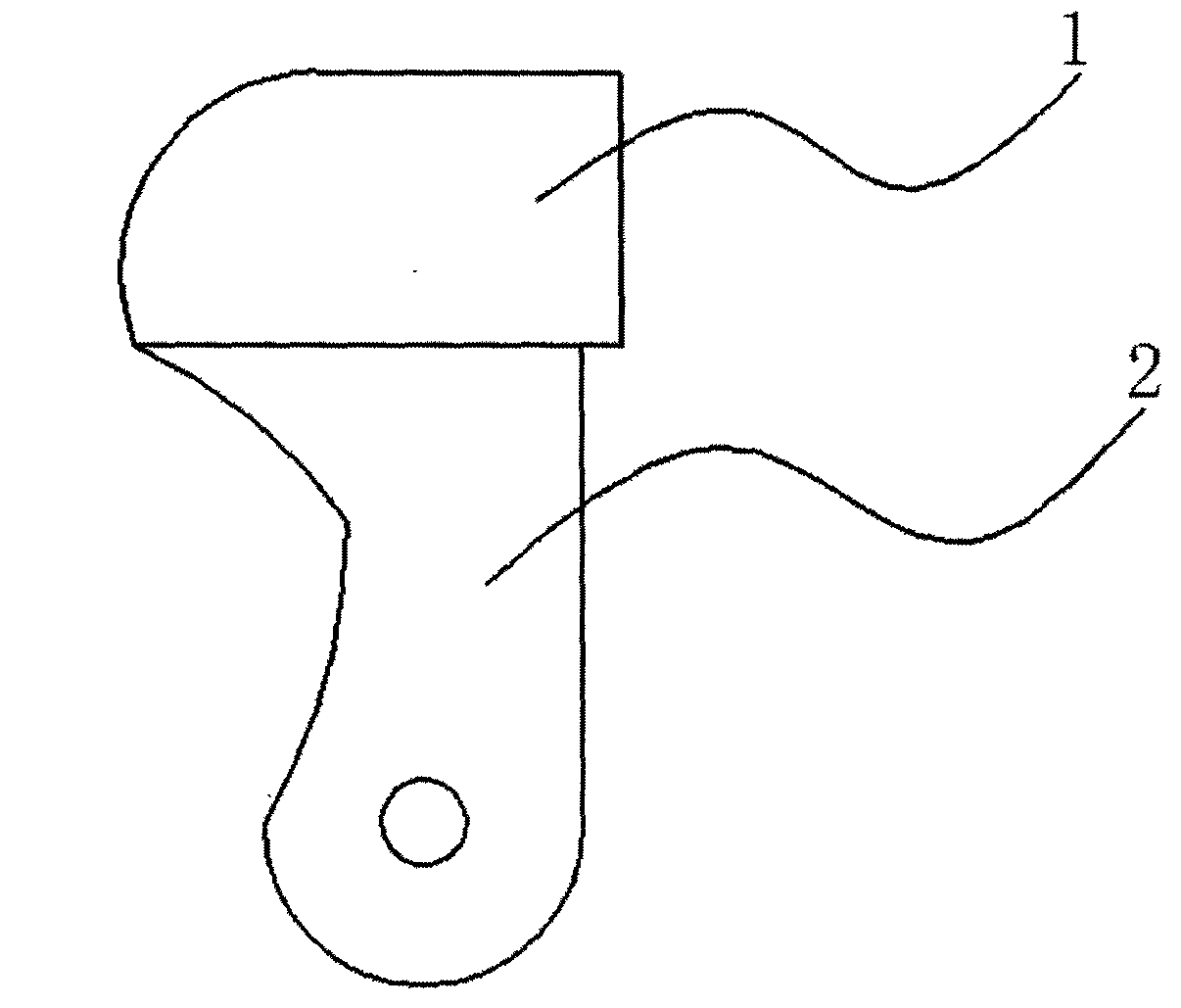

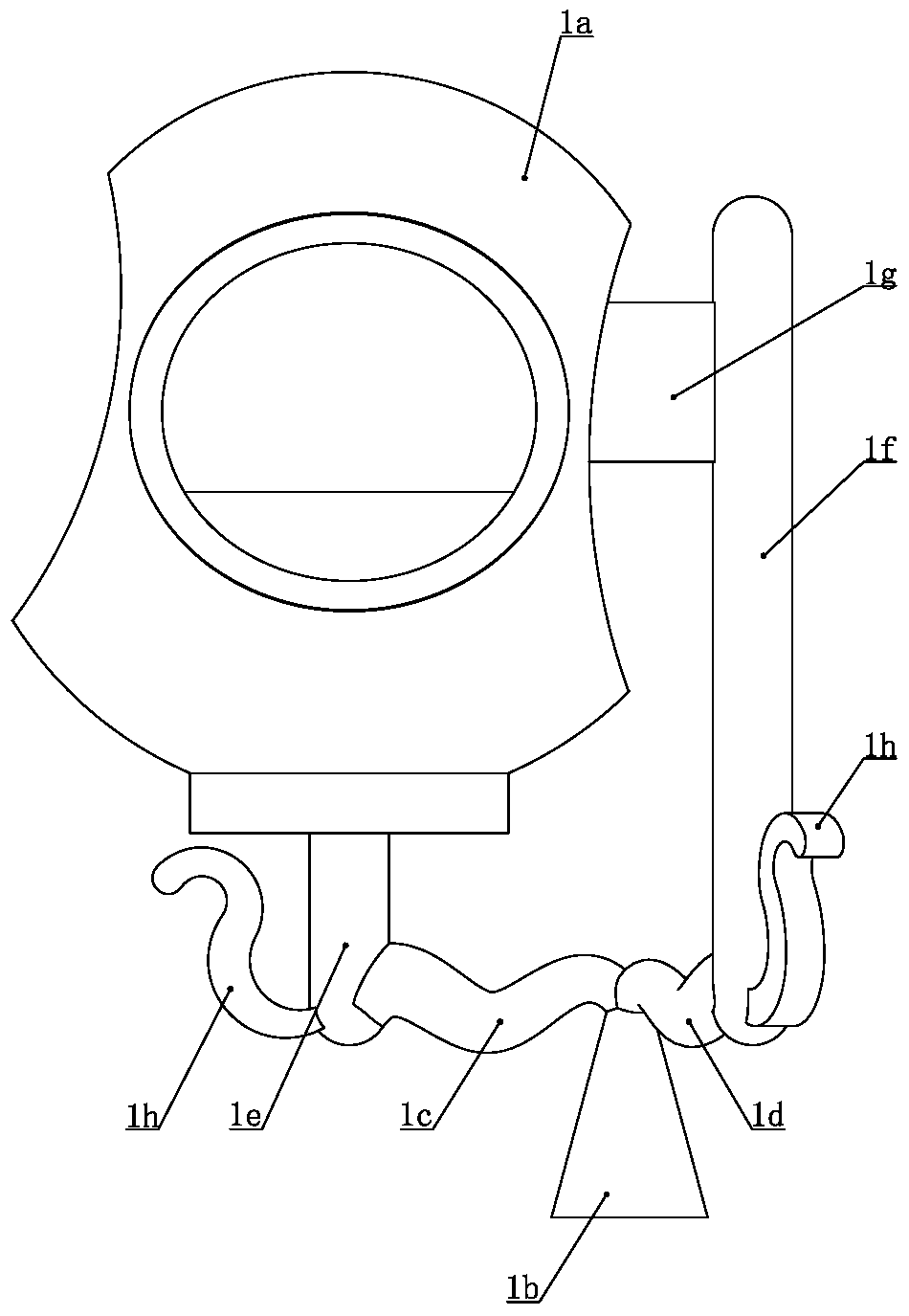

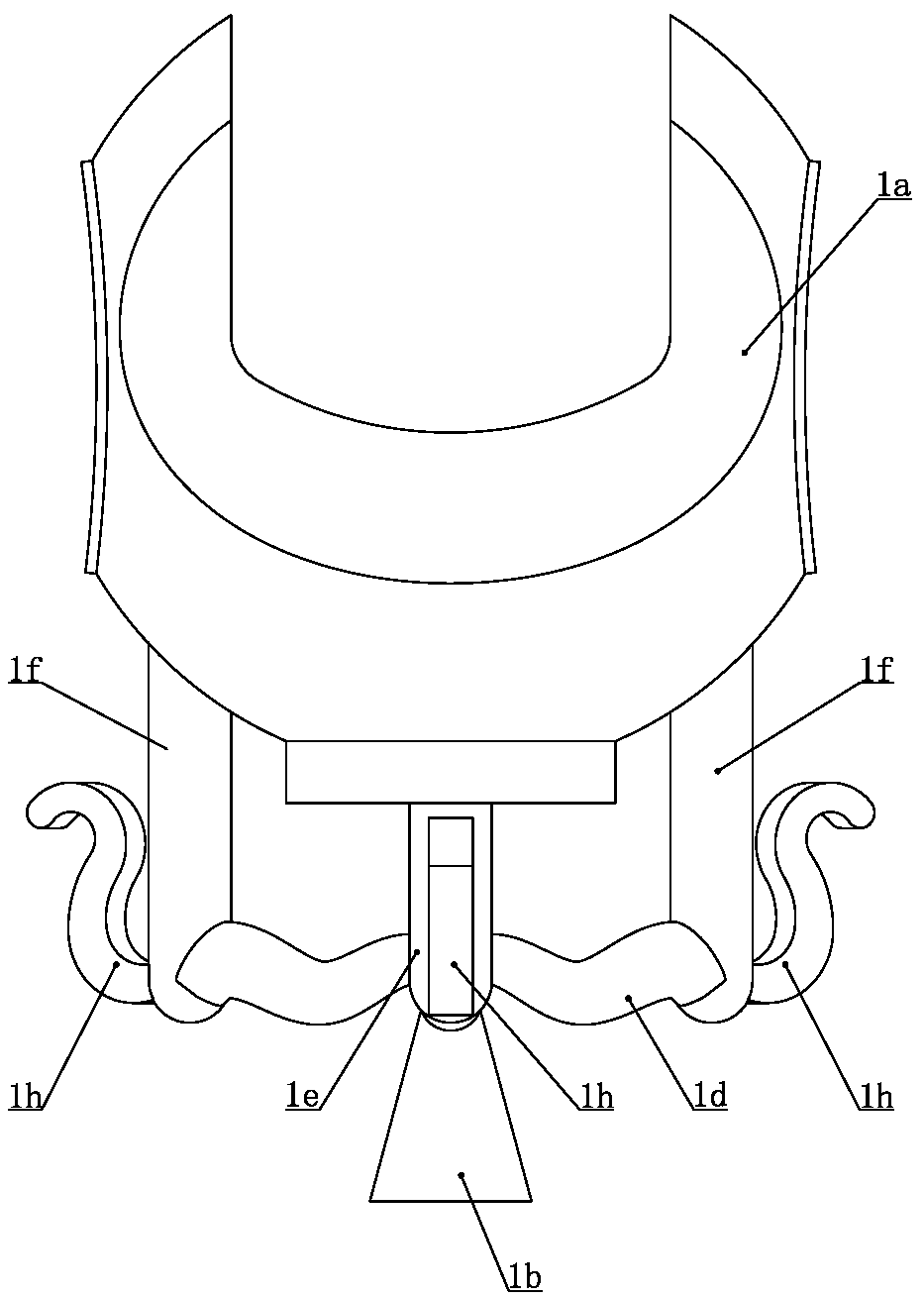

Automatic cutting device for electroplated part sprue

ActiveCN110814148ARealize automatic feeding processImprove securityMetal-working feeding devicesPositioning devicesElectric machineryEngineering

The invention discloses an automatic cutting device for an electroplated part sprue and belongs to the technical field of electroplated part processing and treatment. The device comprises a workbenchand a support. The support is fixed to the top of the workbench, a driving motor is arranged in the workbench, and an output end of the driving motor is provided with a rectangular bearing disc. Fourlower cutter dies are arranged on the rectangular bearing disc, the front and rear sides of the workbench are provided with a material containing mechanism and a discharging conveying belt respectively, and the left and right ends of the top of the workbench are provided with a waste removal collection mechanism and an abutting block respectively. The support is provided with a lifting mechanism,the lifting mechanism is provided with an upper cutter die, a first carrying mechanism is arranged between the workbench and the material containing mechanism, and a second carrying mechanism is arranged between the workbench and the discharging conveying belt. According to the automatic cutting device, through cooperation of the first carrying mechanism and the material containing mechanism, untreated electroplated parts are automatically fed into the lower cutter dies, through the waste removal collection mechanism, waste in the lower cutter dies can be automatically removed, the safety is improved, and processing is not influenced.

Owner:常德威尔博金属表面处理股份有限公司

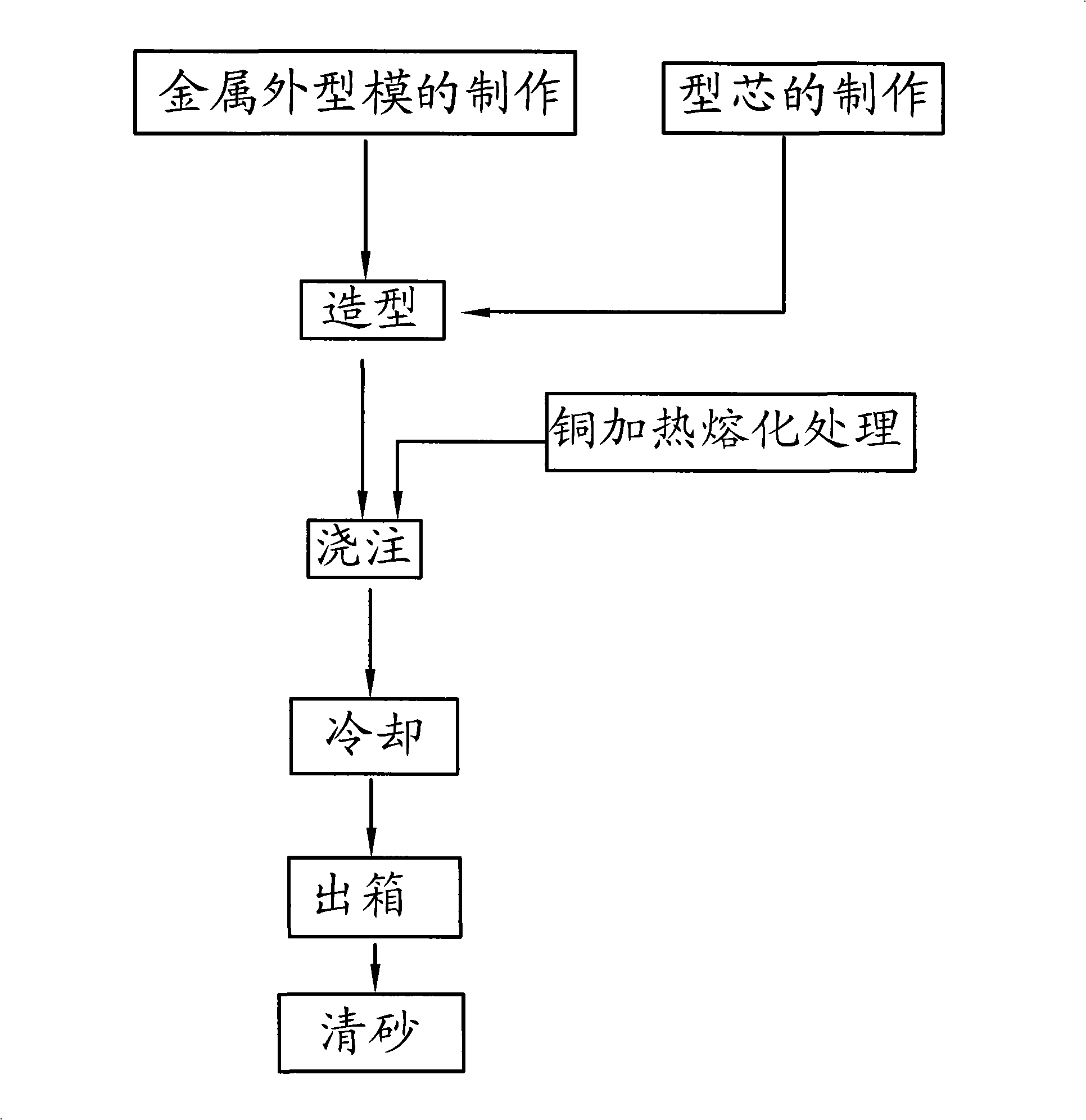

Method for casting brass ware

InactiveCN101293276AAdvantages of casting methodImprove manufacturing precisionFoundry mouldsFoundry coresRoom temperatureRoughcast

The invention pertains to the mechanical technology field and relates to a method for casting a copper device. The method for casting the copper device includes the following steps: A. manufacturing a metal epimorph and a core: metal blank is adopted for manufacturing the metal epimorph, after fine sand and colophony are mixed together, the core is manufactured in a molding core pressing machine; B. molding: an upper sand mold and a lower sand mold are manufactured, a sprue gate is reserved, and the upper sand mold and the lower sand mold are carried out die assembly; C. processing of copper heating and melting and pouring; copper is heated and melted to liquid condition, then the copper liquid is poured in the sand mold; D. cooling and outbox: the mould in which the copper liquid is poured is gradually cooled in the still station at the room temperature, and the sprue and offal of copper ashes are taken out and removed; E. cleaning off sand: after the step of outbox, the semi-finished product is put into a platen for cleaning off the external sand, and the excrescent fins are polished. The metal epimorph is adopted in the method for casting a copper device, so that deformation and damage can not be caused easily; the cost is low, and the core and the product can be separated easily.

Owner:ZHEJIANG WORLD BRASS

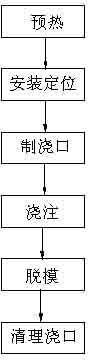

Casting method of water-cooling aluminum engine base embedded with support

InactiveCN102009159AGuaranteed mechanical strengthReduce weightGearingCylindersEngineeringMechanical engineering

The invention discloses a casting method of a water-cooling aluminum engine base embedded with a support. The method is characterized by comprising the following steps: preheating an iron support and a die, wherein, the iron support is wound with a cooling copper pipe; installing and positioning the iron support wound with a cooling copper pipe in the die; making a sprue; casting; demolding; and cleaning a casting head. By adopting the casting method, the iron support is taken as a skeleton to successfully carry out inlay casting on the water-cooling copper pipe aluminum engine base, the overall mechanical strength of the engine base is ensured, and the purpose for reducing the weight of the engine base is achieved.

Owner:CHONGQING ELECTRIC MACHINE FEDERATION

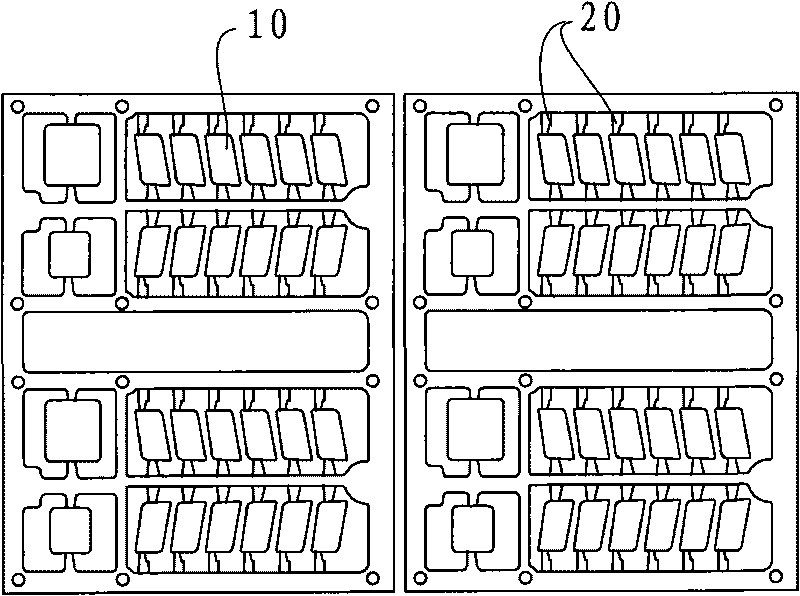

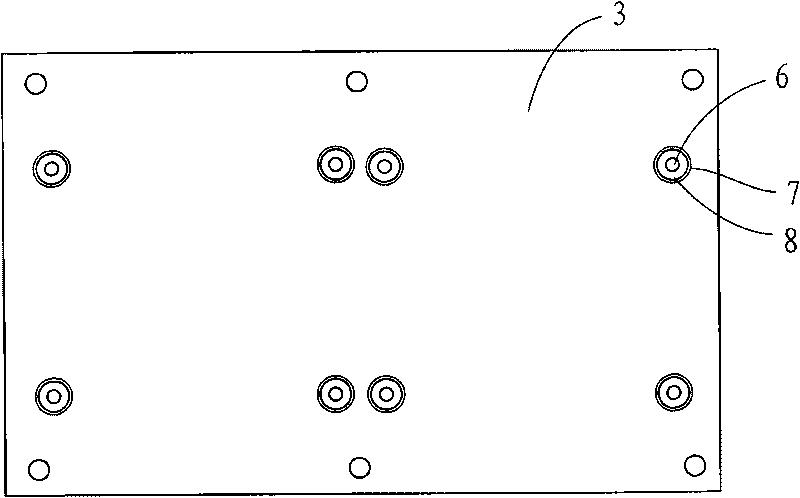

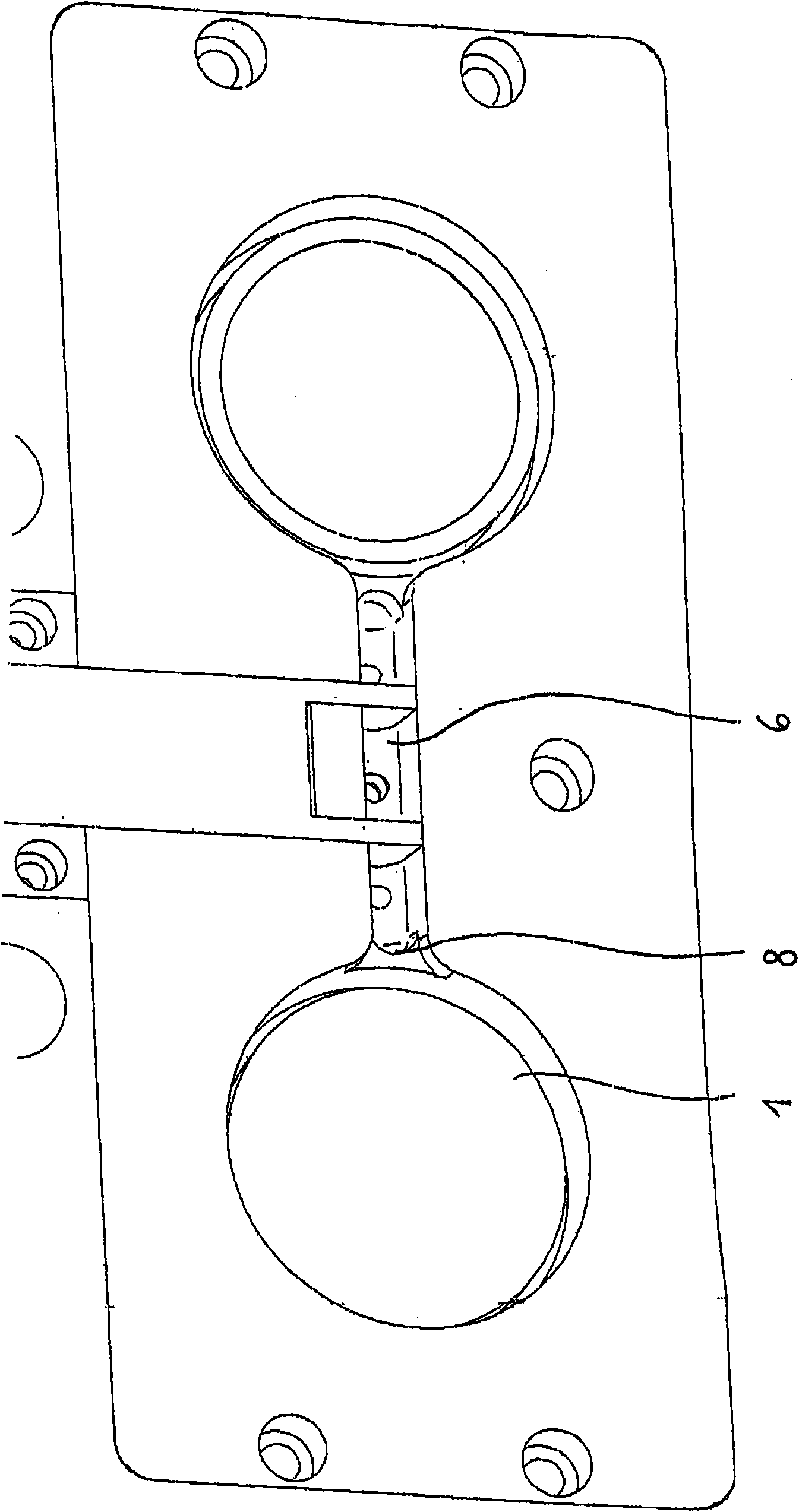

Method for mold-unloading and cooling thin and small injection molding part and part taking board

The invention relates to the injection molding process technology of injection molding parts, in particular to a method for mold-unloading and cooling a thin and small injection molding part and a part taking board thereof. The method comprises the following steps of: adding a local air cooling structure to the part taking board, cooling a mold with water to a mold-unloading temperature before unloading the mold and taking the part, and locally cooling the joint of the part and the sprue of the injection molding part after unloading the mold before sucking up in vacuum. Therefore, the problem that the sprue of the product is easily drawn out when the thin and small injection molding part is sucked up in vacuum is solved. Because of the little temperature drop of the mold, the invention greatly improves the production efficiency of the equipment, saves the energy, reduces the cost and increases the economic benefit.

Owner:DONGMING XINGYE SCI TECH CO LTD

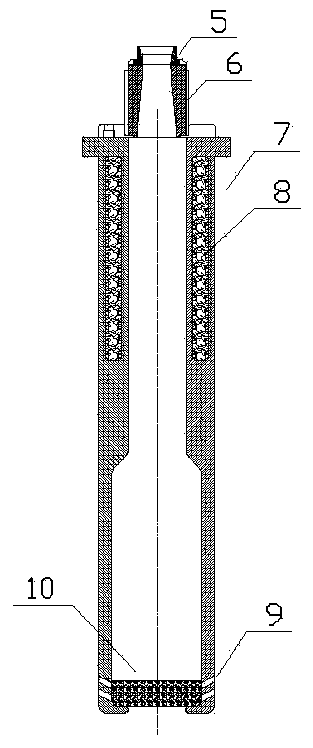

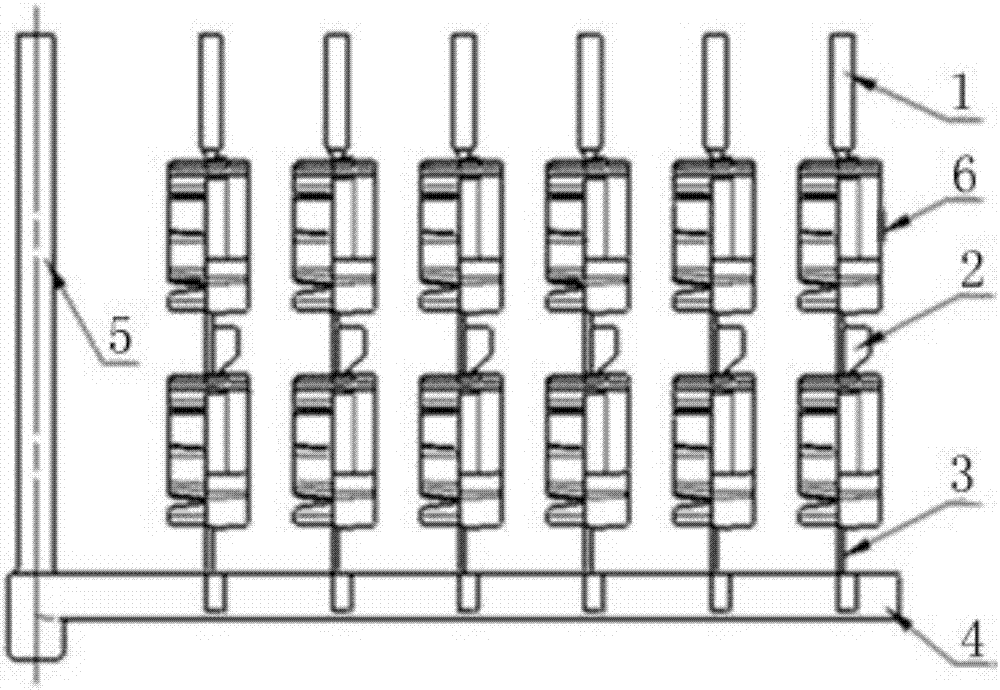

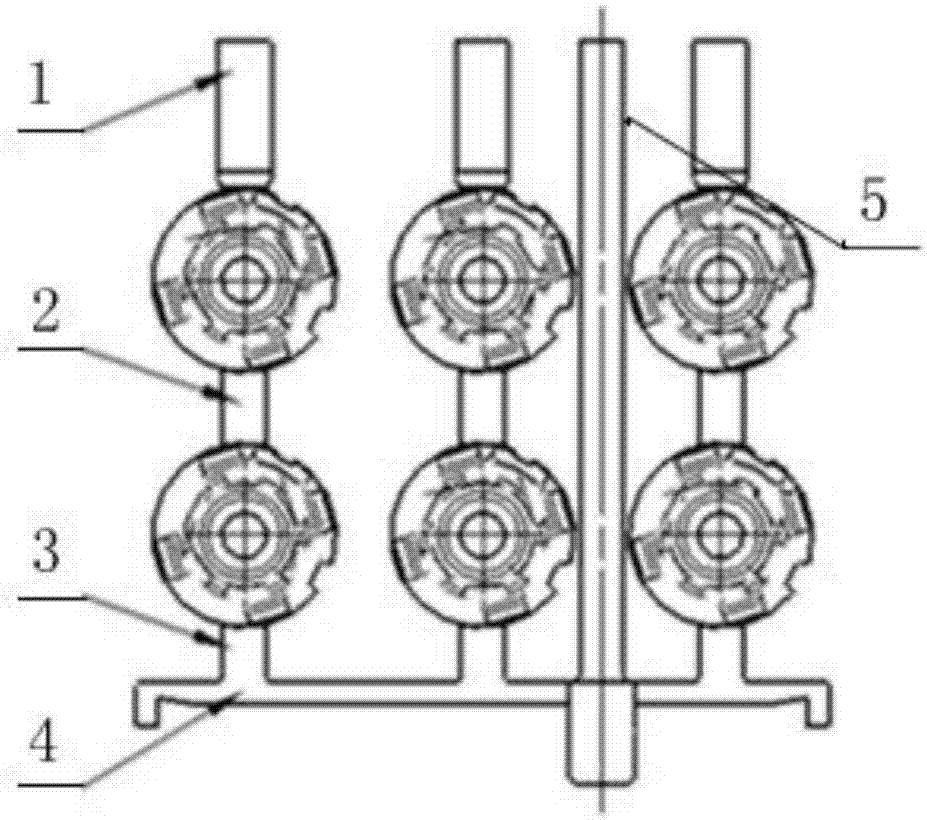

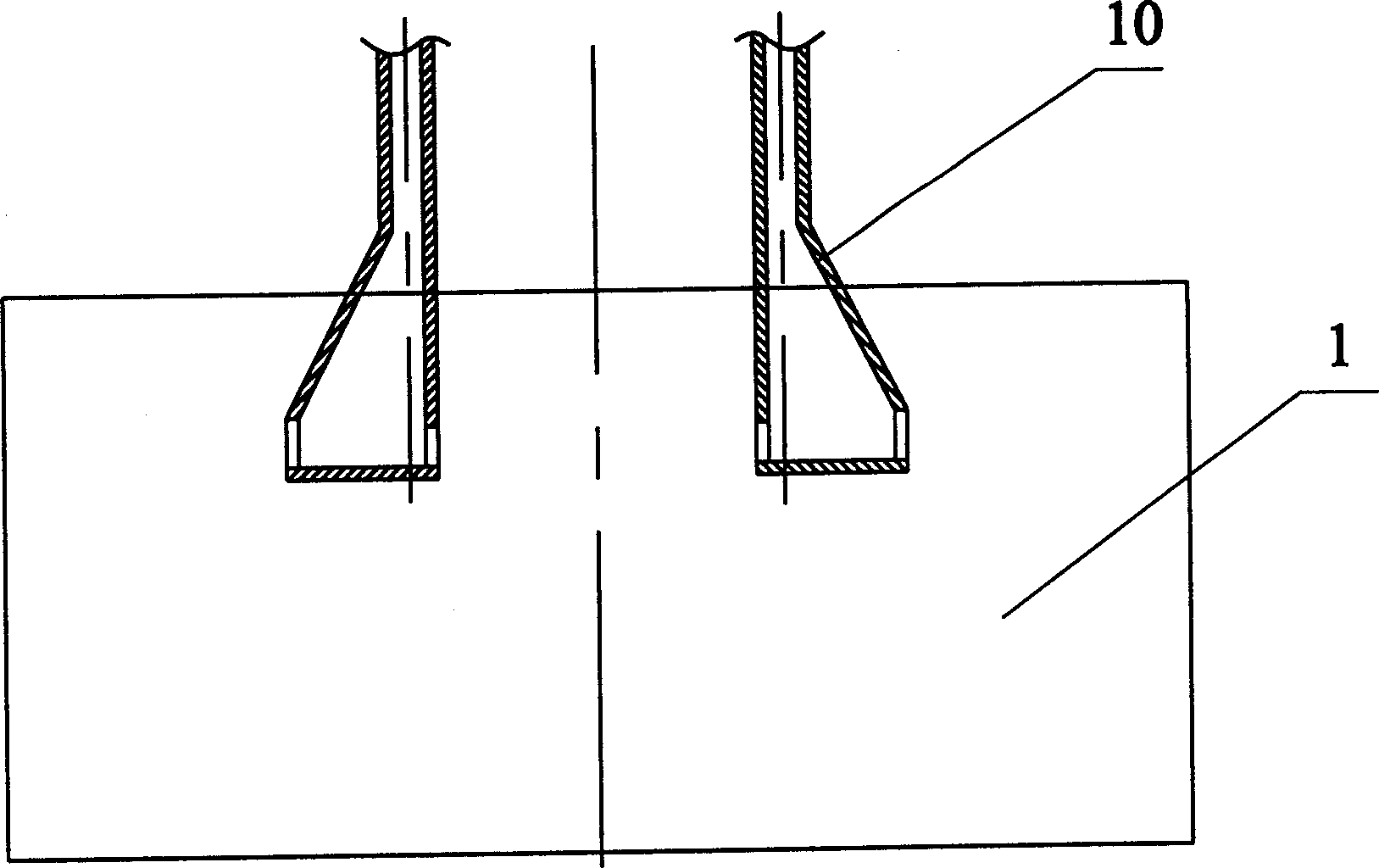

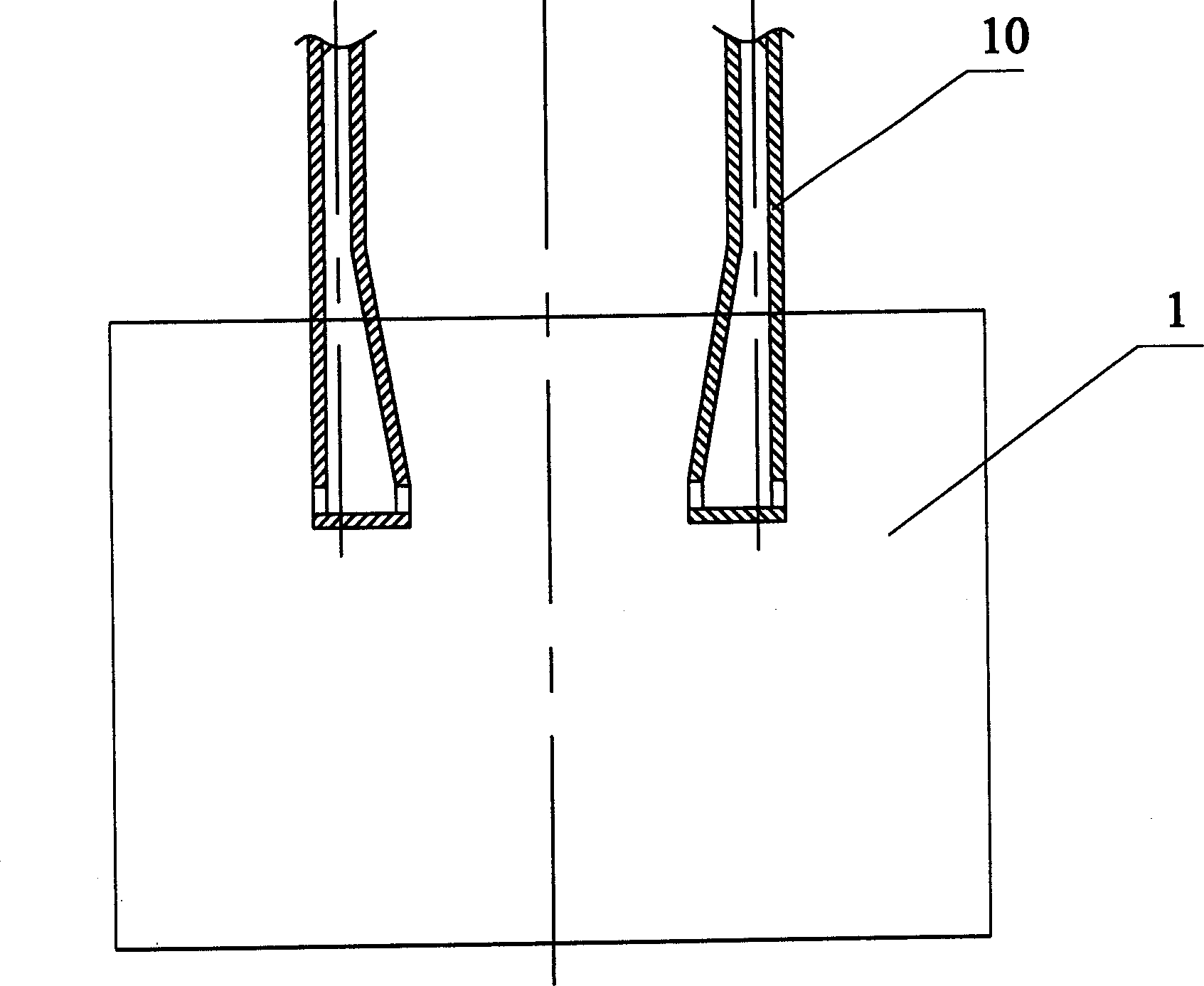

Centrifugal aluminium casting method of cage type rotor of motor

InactiveCN102430734AAvoid air holesPrevent shrinkageManufacturing stator/rotor bodiesElectric machineAluminium casting

The invention provides a centrifugal aluminum casting method of a cage type rotor of a motor. The centrifugal aluminum casting method comprises the following steps of: 1, preheating a rotor iron core; 2, preheating an aluminum casting die; 3, melting aluminum; 4, centrifugally casting: clamping the rotor iron core and the aluminum casting die which reach preheating requirement onto a centrifugal machine, starting the centrifugal machine to stably rotate according to a set initial rotating speed, rapidly injecting aluminum liquid from an upper die sprue of the aluminum casting die at the time, starting a centrifugal machine accelerating button when a die cavity is filled with the aluminum liquid, so that the centrifugal machine rotates according to the set full speed; and 5, dismantling the die after the centrifugal machine naturally stops and the aluminum liquid is solidified. The centrifugal aluminum casting method disclosed by the invention gives different centrifugal machine rotating speeds according to rotors of different diameter sections and effectively avoids castings from generating object quality defects, such as air pores, shrinkage cavities, tissue loosening and the like.

Owner:XIANGTAN ELECTRIC MFG CORP LTD

Aluminum alloy plate excellent in press formability and continuous resistance spot weldability and method for production thereof

The present invention provides an aluminum alloy sheet having excellent compression formability and continuous resistance spot weldability and a method for producing the same. The aluminum alloy plate includes: 0.3-1.0% magnesium by mass fraction, 0.3-1.2% silicon, 0.10-1.0% iron and 0.05-0.5% manganese; here iron + manganese ≥ 0.2%; the rest includes aluminum and unavoidable impurities, where the average recrystallized particle size is 25 μm or less, and the interlayer compound with a circumferential equivalent diameter of 1-6 μm is at least 5000 particles / mm2. It may further contain 0.5-1.0% copper, 0.1-0.4% zinc, 0.05% or less titanium or 0.05% or less titanium and 0.01% or less boron. The present invention also provides a method for preparing an aluminum alloy plate, which includes pouring the melt of the above composition into a relatively rotating belt casting machine that is forced to cool; when pouring the melt, the cooling rate is 40-90°C / sec to form a 5-10mm thick the slab; stretching the slab from the opposite side of the melt pouring sprue; direct rolling or winding into coils; followed by solution heat treatment.

Owner:NIPPON LIGHT METAL CO LTD

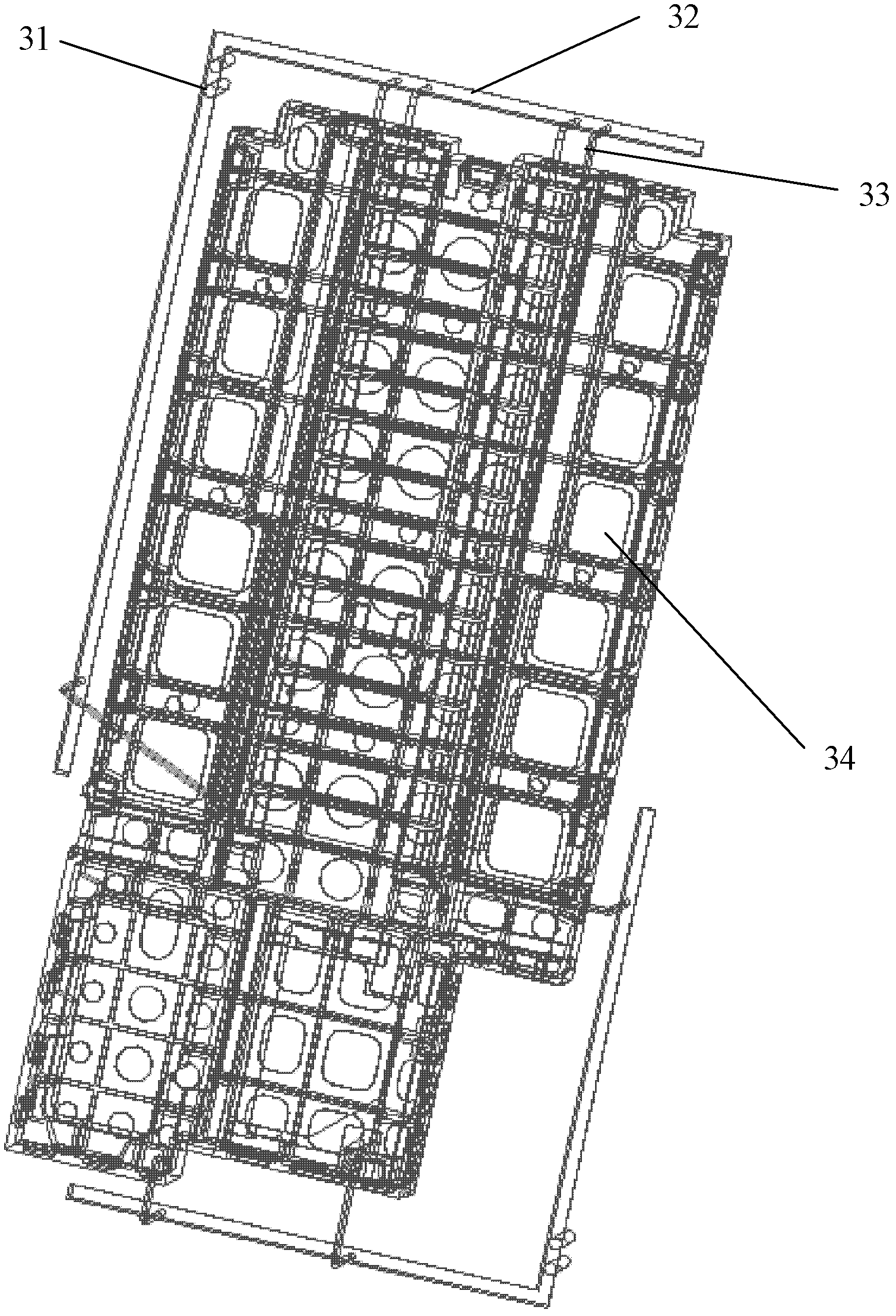

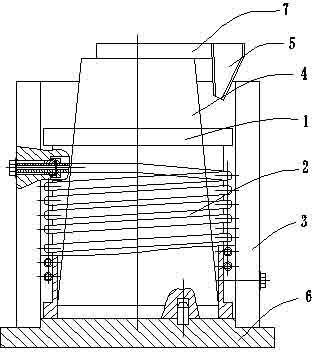

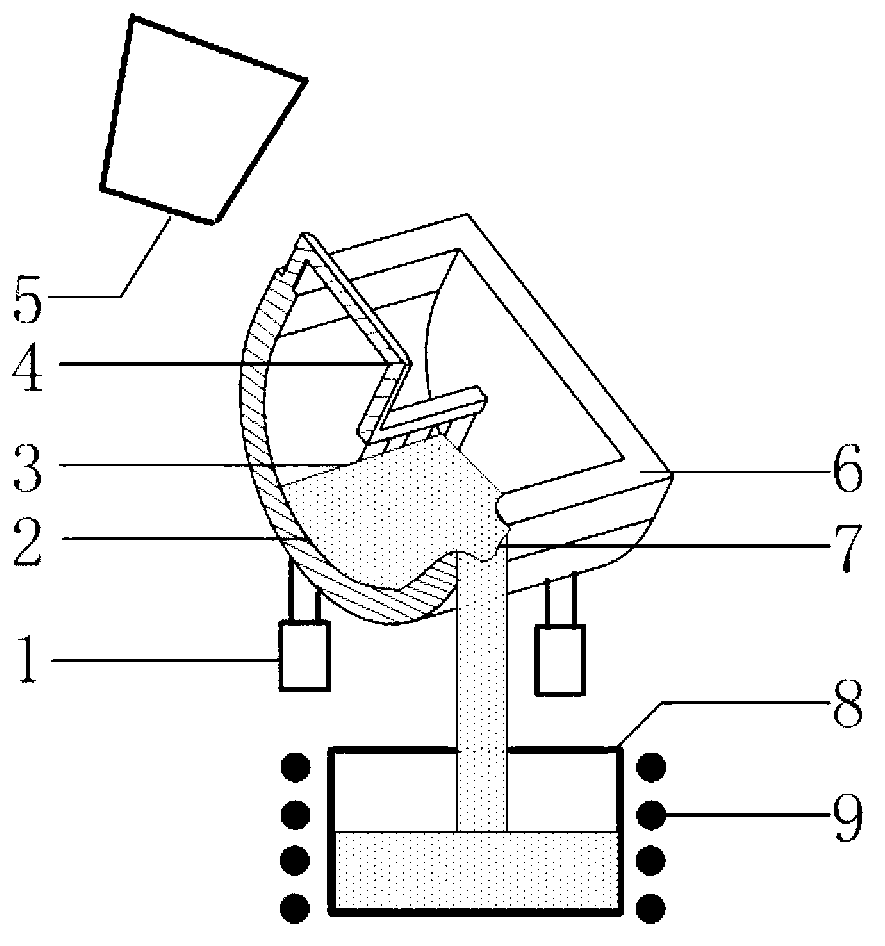

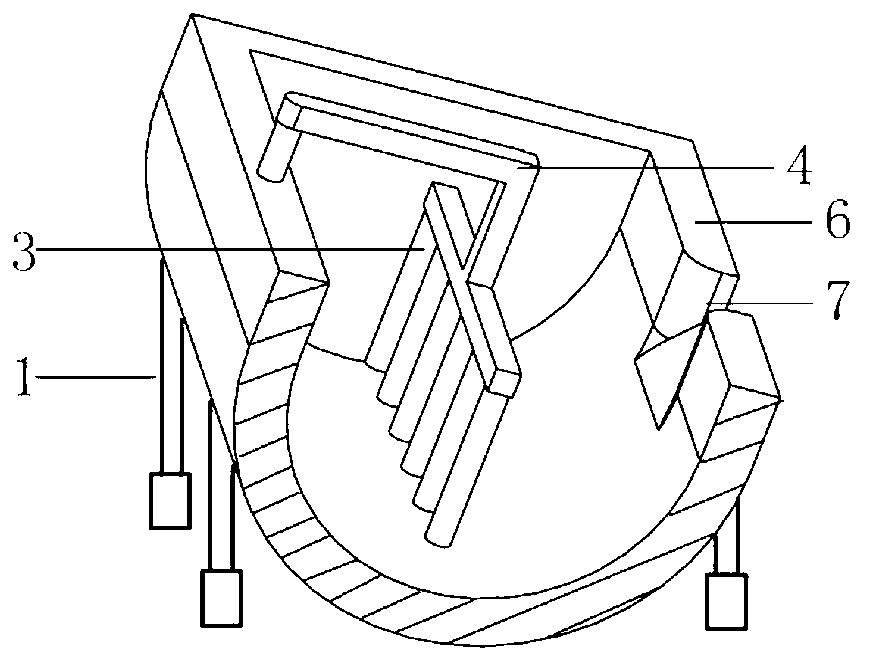

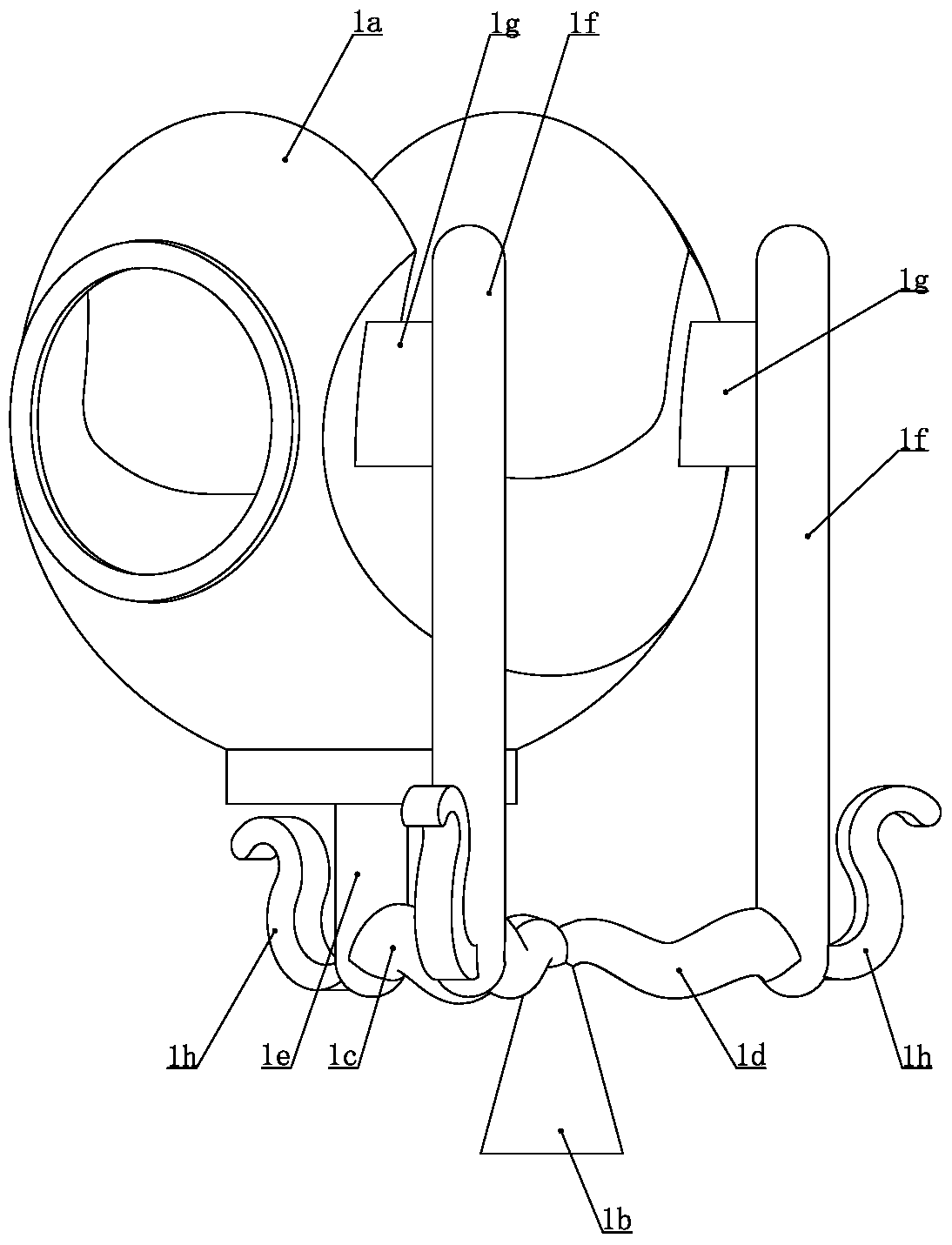

Swing stirring device for preparing semisolid slurry and rheoforming equipment

InactiveCN103341612AReduce manufacturing costReduce the difficulty of pouringShaking/oscillating/vibrating mixersMetal machiningSemi solid

The invention provides a swing stirring device for preparing semisolid slurry and rheoforming equipment, and belongs to the field of semisolid metal processing technology. The swing stirring device for preparing the semisolid slurry is composed of swing lifting rods, a swing power device, an alloy melt, fixed stirring rods, a supporting frame, a pony ladle, a stirring chamber, a small sprue, a crucible, heating elements, a die-casting machine, a pressing chamber of the die-casting machine, the semisolid slurry, an injection punch, an extruding machine, a pressing chamber of the extruding machine, an extruding punch and the like. Based on the principles of cooling and stirring, the alloy melt flows in the stirring chamber under the action of the swing stirring rods, the nucleation of the alloy melt is promoted to prepare the semisolid slurry under the stirring action of the fixed stirring rods, and the rheoforming equipment achieves rheoforming easily when matched with forming equipment, such as the die-casting machine, the extruding machine or a forging machine. The swing stirring device for preparing the semisolid slurry and the rheoforming equipment are simple in structure, small in investment, low in production cost, stable and reliable in continuous preparation work, and quite suitable for preparation and forming production of the semisolid metal slurry or blank.

Owner:UNIV OF SCI & TECH BEIJING

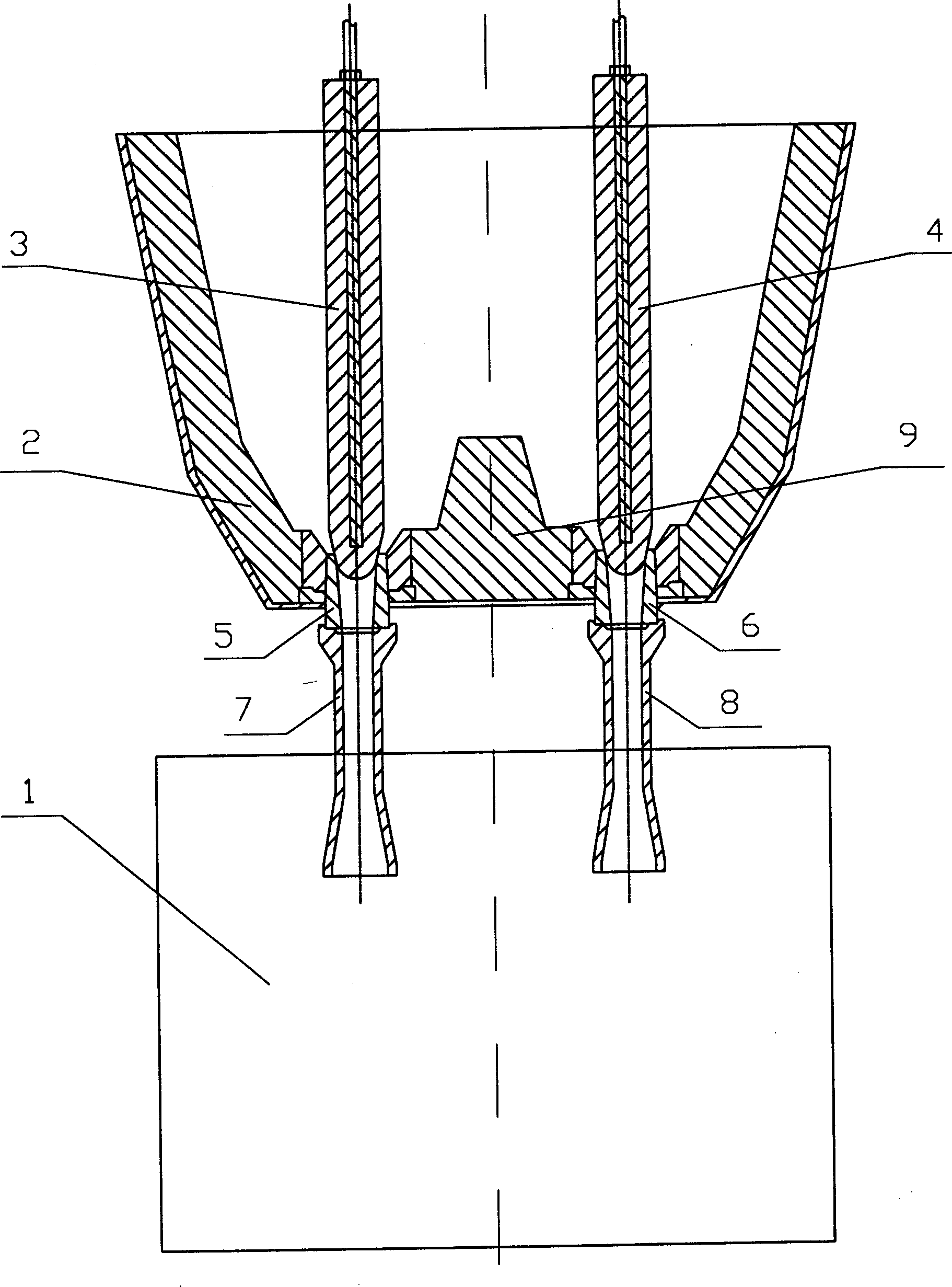

Method and device for slab continuous casting using two pouring openings

InactiveCN1448234ASuitable for continuous castingSafe replacementMelt-holding vesselsMetallurgyContinuous casting mold

The present invention is continuous plate blank casting method and apparatus with two sprues used. Into one continuous plate blank casting crystallizer, there are two immersed sprues inserted and each of the immersed sprues is connected to an upper sprue inside the pouring basket, so that two independent inpouring passages are formed between the pouring basket and the crystallizer. Over each ofthe upper sprues, there is one stopper for controlling flow rate of inpouring and controlling liquid level in the crystallizer. Using the present invention makes it possible to replace stopper inside the pouring basket while controlling liquid level and to shut down and replace one of the sprues while maintaining the inpouring, and this can prolong the continuous casting period greatly and improve the molten steel flow field distribution and temperature distribution inside the crystallizer. The present invention is especially suitable for continuous casting of very wide and thin plate blanks.

Owner:BAOSHAN IRON & STEEL CO LTD

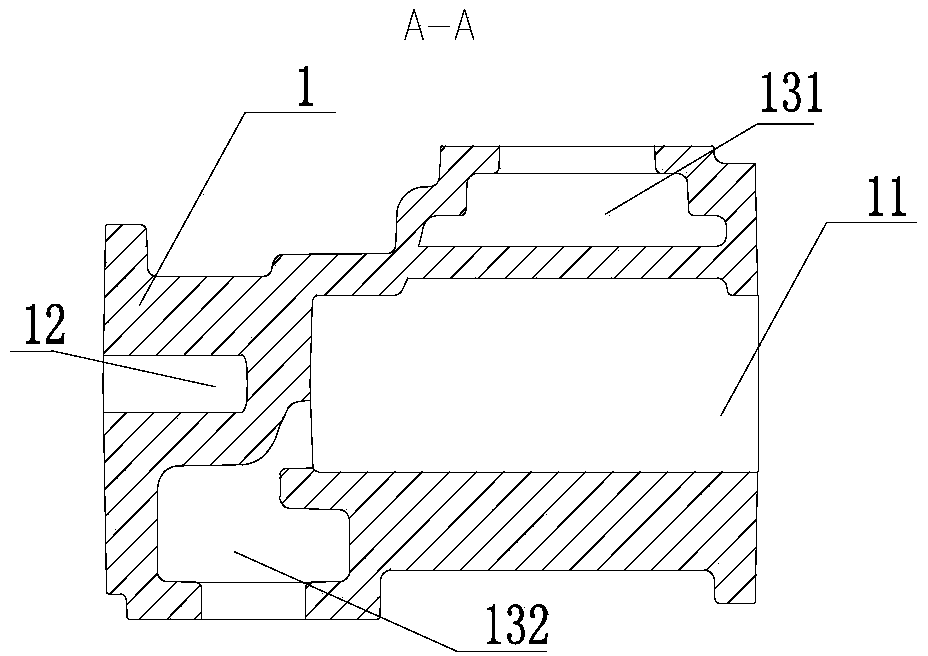

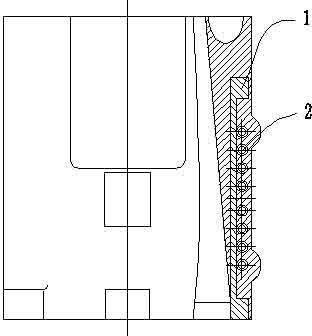

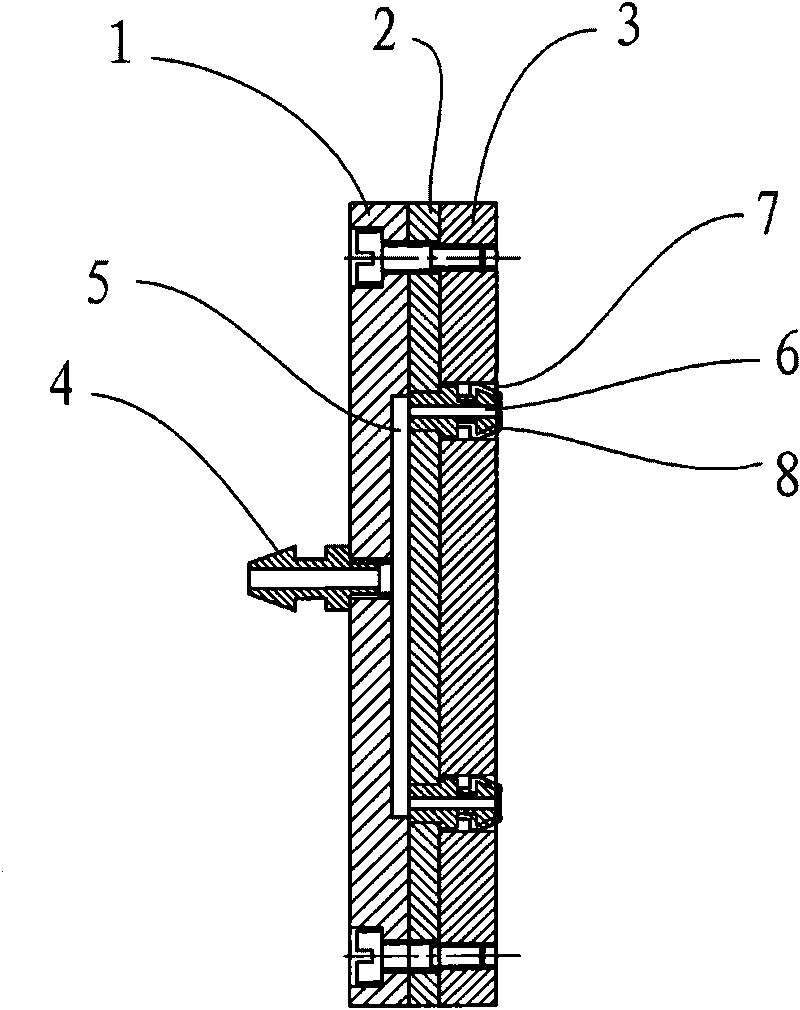

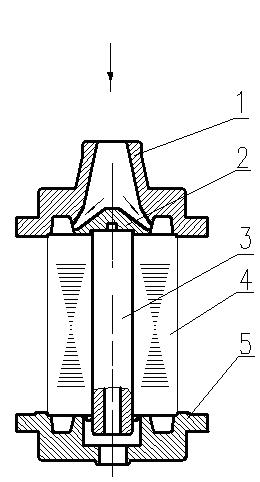

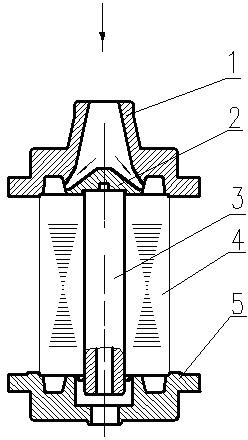

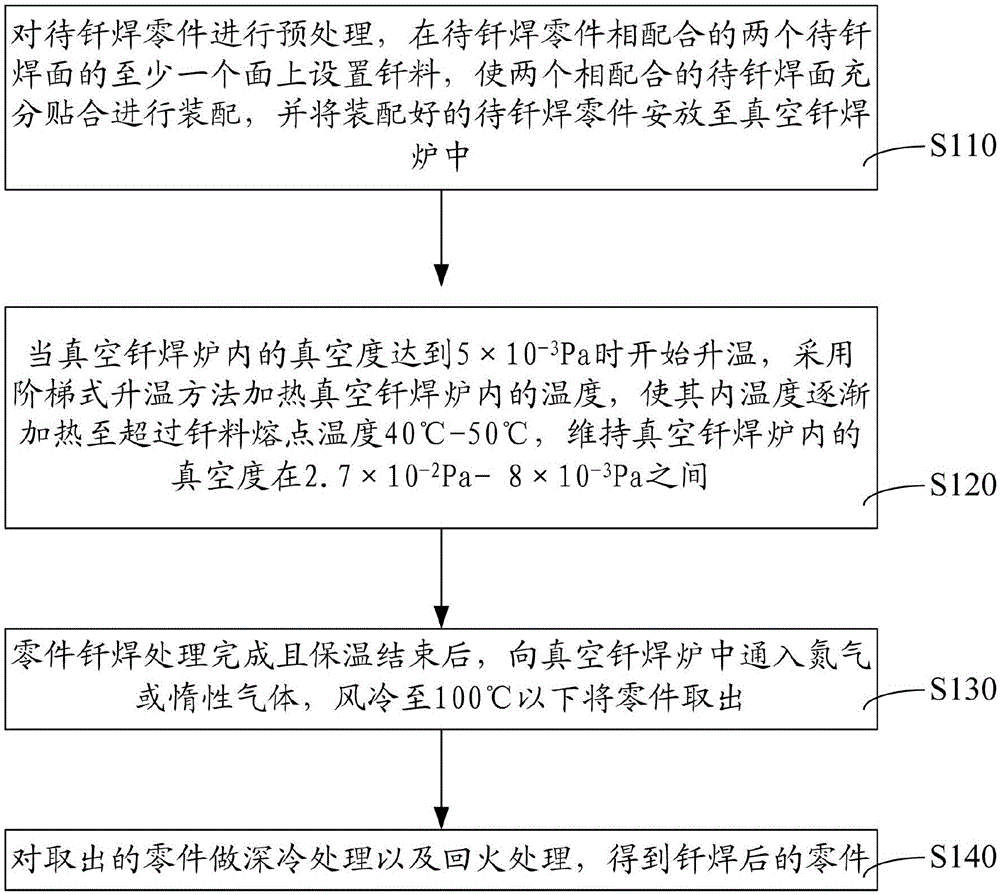

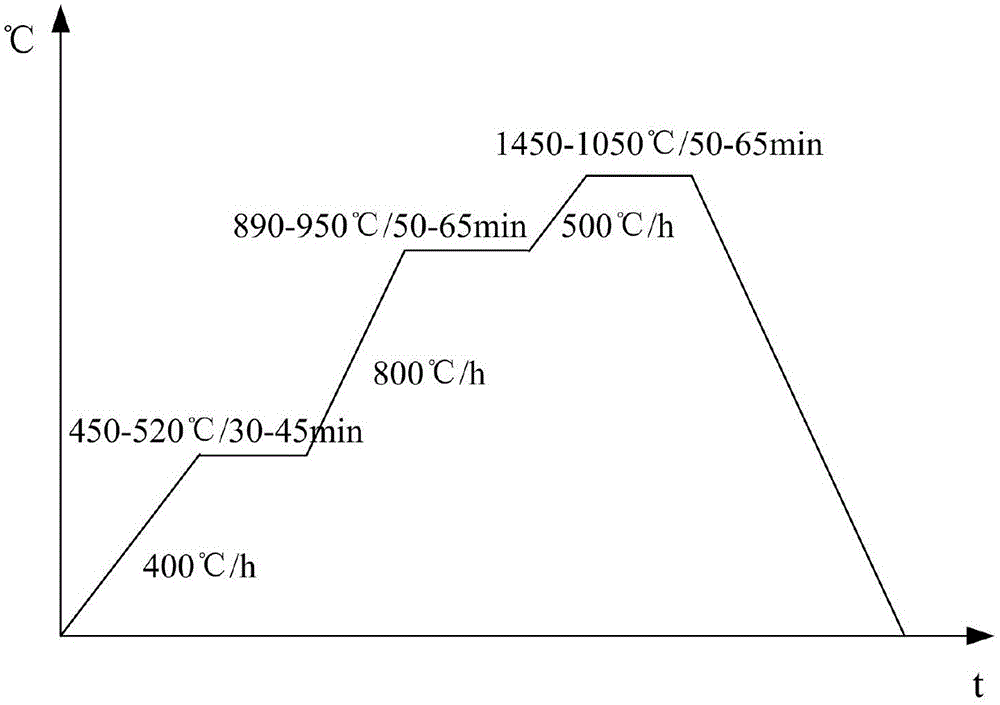

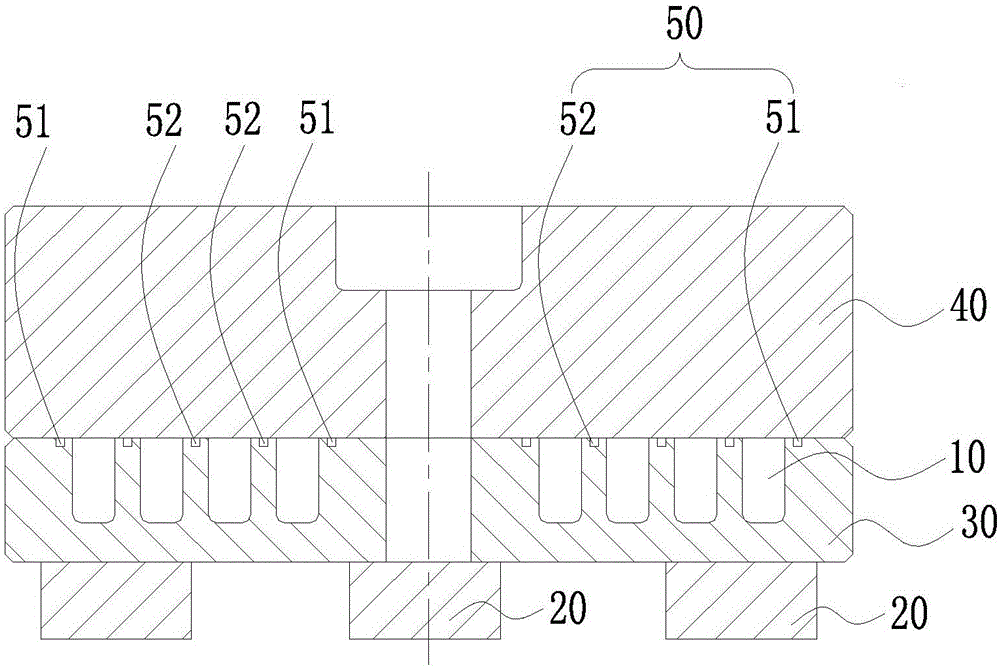

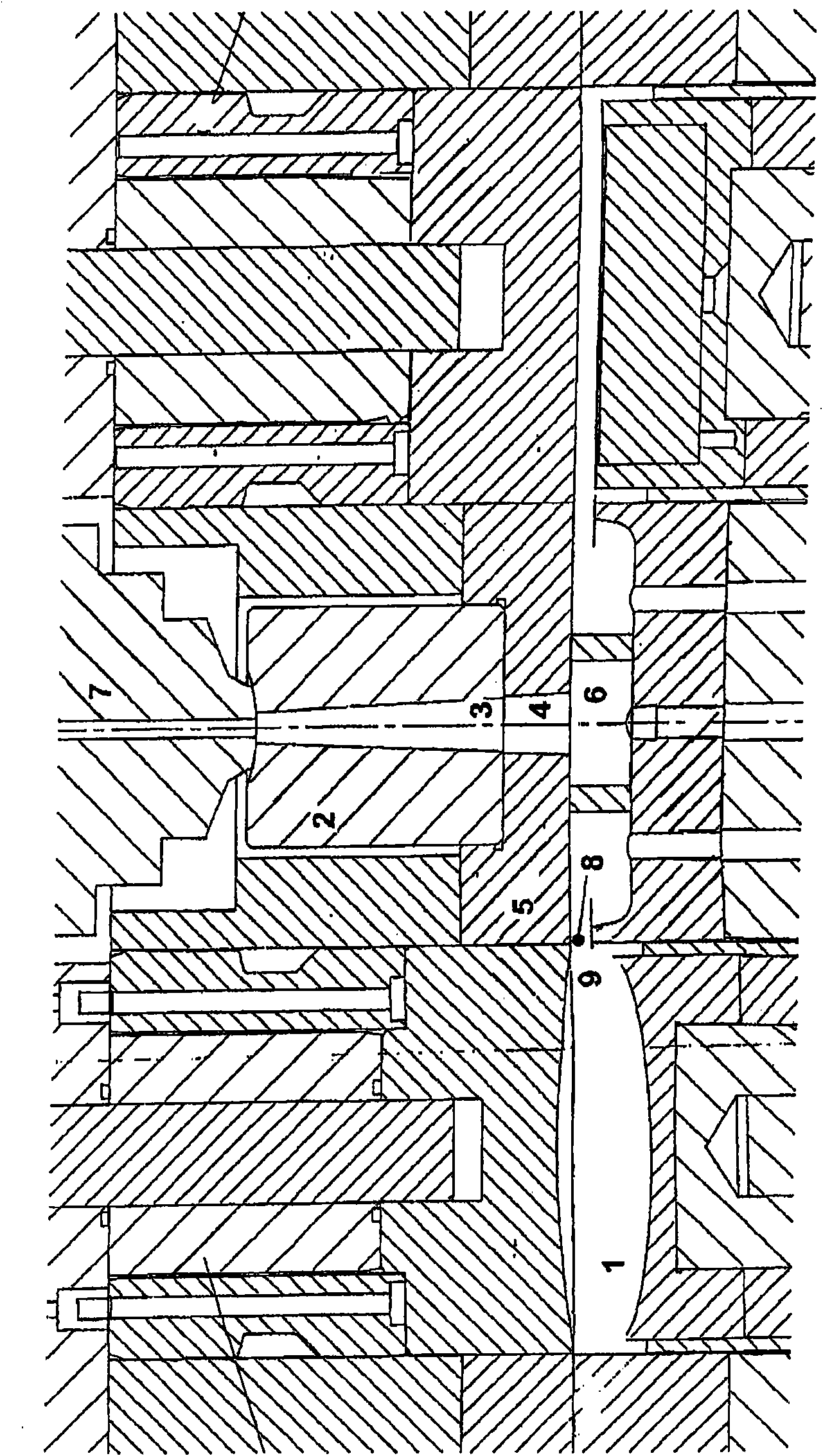

Vacuum brazing method, sprue bush and die core

InactiveCN105033388AExcellent brazeabilityQuality improvementWelding/cutting media/materialsSoldering mediaMetallurgyNitrogen

The invention discloses a vacuum brazing method, a sprue bush and a die core. The vacuum brazing method includes the following steps that pretreatment is conducted on brazing parts; the temperature starts to rise when the vacuum degree in a vacuum brazing furnace reaches 5*10<-3> Pa, the interior of the vacuum brazing furnace is heated through a step-wise temperature rising method, the interior of the vacuum brazing furnace is heated to exceed the brazing filler metal melting temperature by 40 DEG C to 50 DEG C, and the vacuum degree in the vacuum brazing furnace is kept between 2.7*10<-2> Pa to 8*10<-3> Pa; nitrogen or inert gas is introduced into the vacuum brazing furnace to cool the parts in the air to below 100 DEG C, and the parts are taken out; and deep-cooling treatment and tempering treatment are conducted on the taken parts. By means of the vacuum brazing method, the sprue bush and the die core, the parts are integrated, good in brazing quality and good in airtightness. The sprue bush and the die core are good in airtightness, the temperature can be adjusted and controlled quickly and effectively, and the quality of die forming products and production efficiency are improved.

Owner:江西优信普科技有限公司

Method and device for producing thick-walled plastic components, in particular optical components

The invention relates to a process for producing plastic components, in particular optical lenses or optical light-guides, wherein plastic melt is injected via a sprue (3, 4, 6, 8) into a cavity (1) of a moulding tool shaping the component and additional plastic melt is after-pressed into the cavity (1) for the purpose of compensating a volume contraction of the injected plastic melt due to cooling. The process is characterised in that the plastic melt located in the sprue (3, 4, 6, 8) is kept flowable by means of energy introduced in the region of the sprue until such time as the molten core of the plastic component has solidified in the course of the after-pressing of plastic melt for the purpose of compensating the volume contraction due to cooling (holding-pressure). The invention further relates to an apparatus for implementing the process.

Owner:BAYER MATERIALSCIENCE AG

Reduction gearbox shell casting process

ActiveCN104785731AImprove work efficiencySimple structureFoundry mouldsFoundry coresThermodynamicsReduction drive

The invention relates a reduction gearbox shell casting process, which comprises the following steps: preparing molding sand and oil core sand first, then preparing a mold, wherein the mold comprises a sand box, a sand mold, a sand core and a pouring system; the pouring system comprises a sprue, cross gates and a pair of auxiliary cross gates arranged between two pouring cavities the sides of which are adjacent to each other; the sprue is vertically arranged at the center of four pouring cavities; an outer sprue is formed in the top of the sprue; the bottom end of the sprue is communicated with the inner sprue of a corresponding pouring cavity through cross gates at two sides and a cross gate; and finally the product is put in storage after falling sand cleaning checking. The reduction gearbox shell casting process has the advantages that the mold is reasonable in design and high in work efficiency; the auxiliary cross gates are additionally arranged in the mold design and the pouring temperature is controlled, so that the phenomena of cold shut and hot spot are reduced; by virtue of the oil sand core prepared during tool preparation, the surface of a casting is smooth; by virtue of a hollow molding core and exhaust pins distributed at equal intervals, the ventilation is facilitated and the pore defect is avoided.

Owner:江苏力源金河铸造有限公司

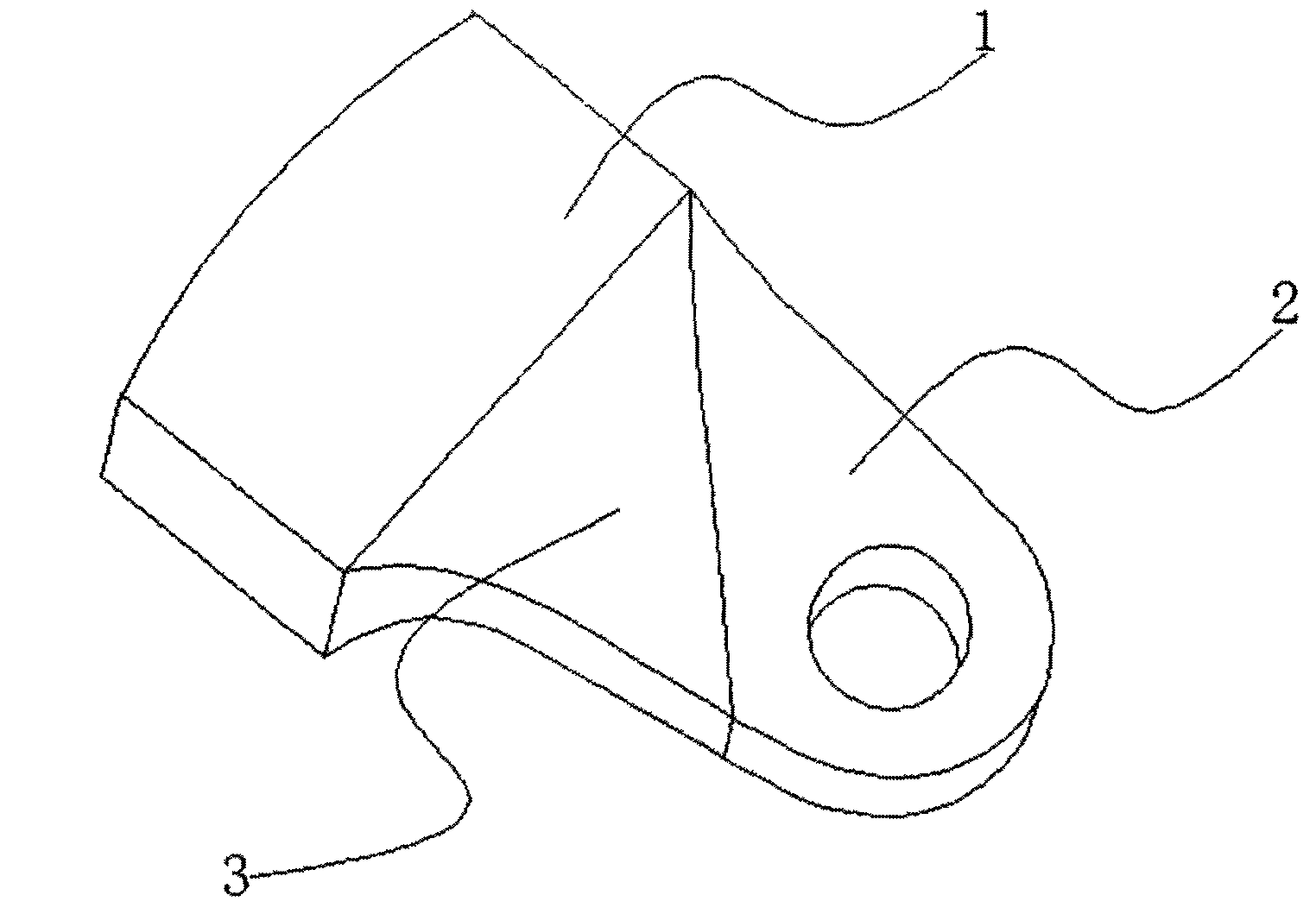

Bi-metal hammer head and casting process thereof

InactiveCN103182478AWith wear resistanceExtended service lifeFoundry mouldsFoundry coresWear resistantOblique cutting

The invention discloses a bi-metal hammer head and a casting process thereof. The hammer head comprises a hammer head body and a hammer handle connected with the former, wherein a wear-resistant area is arranged at the joint of the hammer handle and the hammer head body and is extended, in a downward oblique cutting manner, from the hammer head body to the root part of the hammer handle. The casting process comprises the following steps: first, low alloy steel or common cast steel is filled in a sprue of the hammer handle to cast a hammer handle; and then, when the steel liquid in the hammer handle is near the composite interface of the hammer handle and the hammer head body, filling high-chromium iron or high alloy steel into a sprue of a hammer head body after 3-20s, so as to cast a hammer head body. According to the invention, a double-liquid bi-metal composite casting method is adopted to produce a hammer type hammer head, the working surface has very high wear resistance, the hammer handle part of a traditional hammer head is more resistant to wear; and meanwhile, the hammer handle part has favorable impact ductility, so that the characteristics of all materials are fully utilized, thereby prolonging the service life of the hammer head.

Owner:JIAMUSI UNIVERSITY

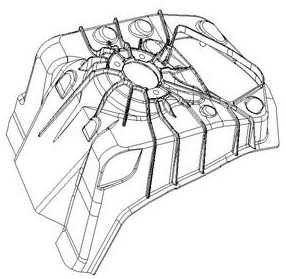

Die-casting die for manufacturing damping tower and vacuum die-casting method of damping tower

The invention discloses a vacuum die-casting die for manufacturing a damping tower and a vacuum die-casting method of the damping tower. The vacuum die-casting die comprises a fixed die, a movable die, an ejection system arranged in the movable die and a cooling system used for cooling the die and a casting. The ejection system can eject the casting out of a die cavity after die opening. In the die assembly state, molten metal is added into a pressure chamber from a feeding port of a material cylinder, a punch moves and blocks the feeding port, a vacuumizing system is started, vacuumizing is started, and when the punch moves to the high-speed switching position, the vacuumizing system is closed. The punch continues to move at a high speed, the molten metal enters two transverse main runners through a flow dividing cone, then enters the die cavity through a transition transverse runner and an inner sprue which communicate with the two transverse main runners, and the die cavity is rapidly filled with the molten metal. After the molten metal in the die cavity is cooled to the set time in a pressure maintaining manner, the casting is formed.

Owner:CHONGQING UNIV OF TECH

Investment casting system and method for U-shaped magnesium alloy parts

ActiveCN107855467AReduce impactImprove performanceFoundry mouldsProcess efficiency improvementInvestment castingMold filling

The invention discloses an investment casting system and method for U-shaped magnesium alloy parts. The investment casting system comprises a U-shaped cavity with two arms facing upwards. The upper end opening of a sprue cup is connected with S-shaped variable cross-section main and auxiliary cross gates. The S-shaped variable cross-section cross gates both have circular cross sections and the sectional area of the S-shaped variable cross-section cross gates is gradually increased in the flowing direction. The rear end of the main cross gate is connected with a main gate sprue, and the upper end of the main gate sprue is connected with the bottom center of the same end of the U-shaped cavity. The two auxiliary cross gates are connected with transition gate sprues correspondingly, and the upper portions of the two transition gate sprues are connected with the thinnest positions of the two arms of the U-shaped cavity through gap sprues separately. The bottoms of the gate sprues are all connected with S-shaped slag collecting buffers. The investment casting method sequentially includes the steps of manufacturing an appearance mold and a core box mold, manufacturing a soluble mold core, conducting mold assembly and mold material injection, taking out a mold, dissolving the mold core, performing mold assembly, conducting degreasing and brushing, carrying out dewaxing, roasting, modelling, mold filling, pressure rising, pressure maintaining and pressure relieving, and obtaining the U-shaped magnesium alloy parts by means of cooling. By adoption of the casting system and method, the rate of certified products is high.

Owner:YANGZHOU FENG MING METAL PROD

Casting method and system suitable for integral multi-way valve based on 3D printing

PendingCN111468678AReduce breakageImprove consistencyAdditive manufacturing apparatusFoundry mouldsMold fillingEngineering

The invention discloses a casting method and system suitable for an integral multi-way valve based on 3D printing, and belongs to the technical field of valve casting. According to the casting methodand system, inner sprues of multiple layers, multiple cross gates connected with the inner sprues of all the layers and a sprue connected with the multiple cross gates are determined according to thestructural parameters of the to-be-cast integral multi-way valve, and the integral sand mold is printed through 3D printing technology, so that the multi-layer combined type pouring casting method andthe corresponding casting system are achieved, the influences of gravity, scouring force and the like in the liquid mold filling process can be dispersed and balanced, and the casting defects of sandcore breakage, internal defect flashes, main valve hole bending and the like are reduced. And the consistency between the integral sand molds through 3D printing is good, no bonding gap exists in theintegral sand molds, the quality stability and the surface quality of a valve body casting obtained after pouring can be guaranteed, meanwhile, rapid casting of the integral hydraulic valve can be achieved, the integral hydraulic valve is suitable for batch and normalized manufacturing, and rapid upgrading of large-scale integral hydraulic multi-way valve products is better supported.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

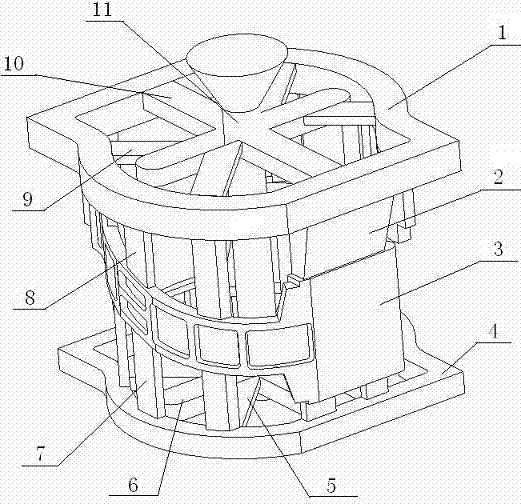

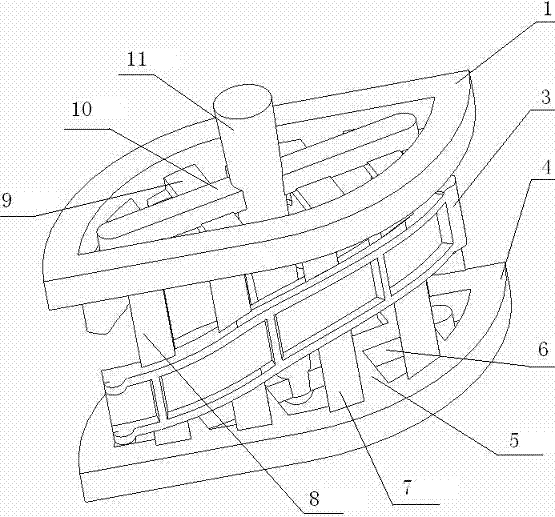

Space curve type casting anti-deformation box cage structure and machining method

InactiveCN105436419APrevent excessive deformationCounteract internal stressFoundry mouldsFoundry coresMachine buildingEngineering

The invention relates to a process method with the space curve type casting anti-deformation function, and belongs to the field of machine manufacturing. By means of a casting method for changing an upper guide rail casting and a lower guide rail casting, an upper annular cavity type tie bar, a lower annular cavity type tie bar, upper follow-up cavity type tie bars and lower follow-up cavity type tie bars are communicated with a straight sprue, transverse sprues and inner sprues to form a box cage structure. The number of times of deformation in the casting forming process is controlled, and the deformation is controlled within 0.5 mm. In the pouring and heat treatment process, under the alternating stress action of heating and cooling, the castings bear irresistible residual stress which cannot be fully offset in the shell expansion and casting shrinkage process, and irregular and disordered permanent plastic deformation is generated. For deformation, a one-mold two-piece process is adopted, the heads and tails are oppositely arranged, the box cage structure is designed, and the deformation of the castings is reduced. The residual stress of the castings is removed through subsequent heat treatment, and it is guaranteed that no excessive deformation is generated after casting cleaning.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

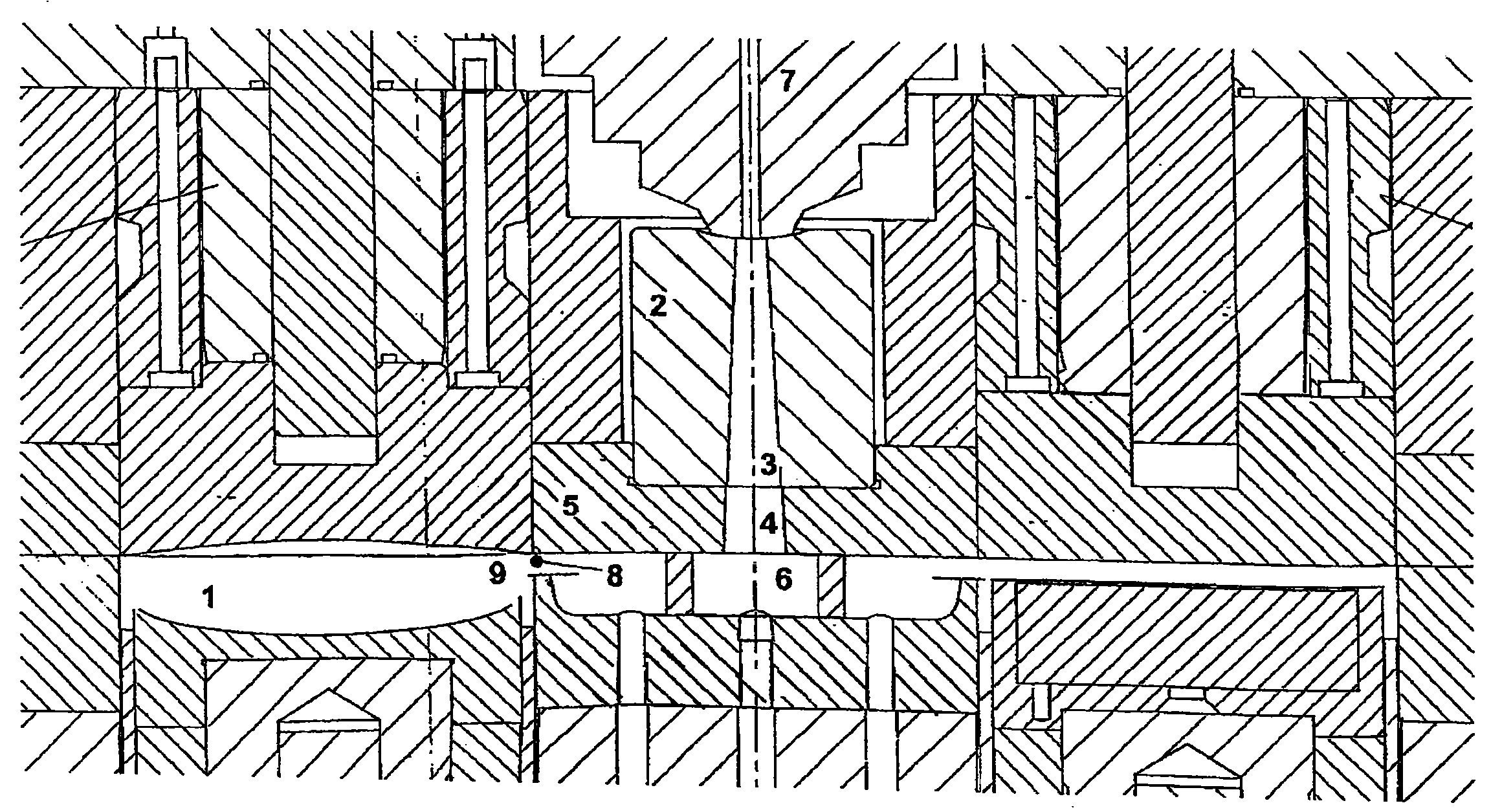

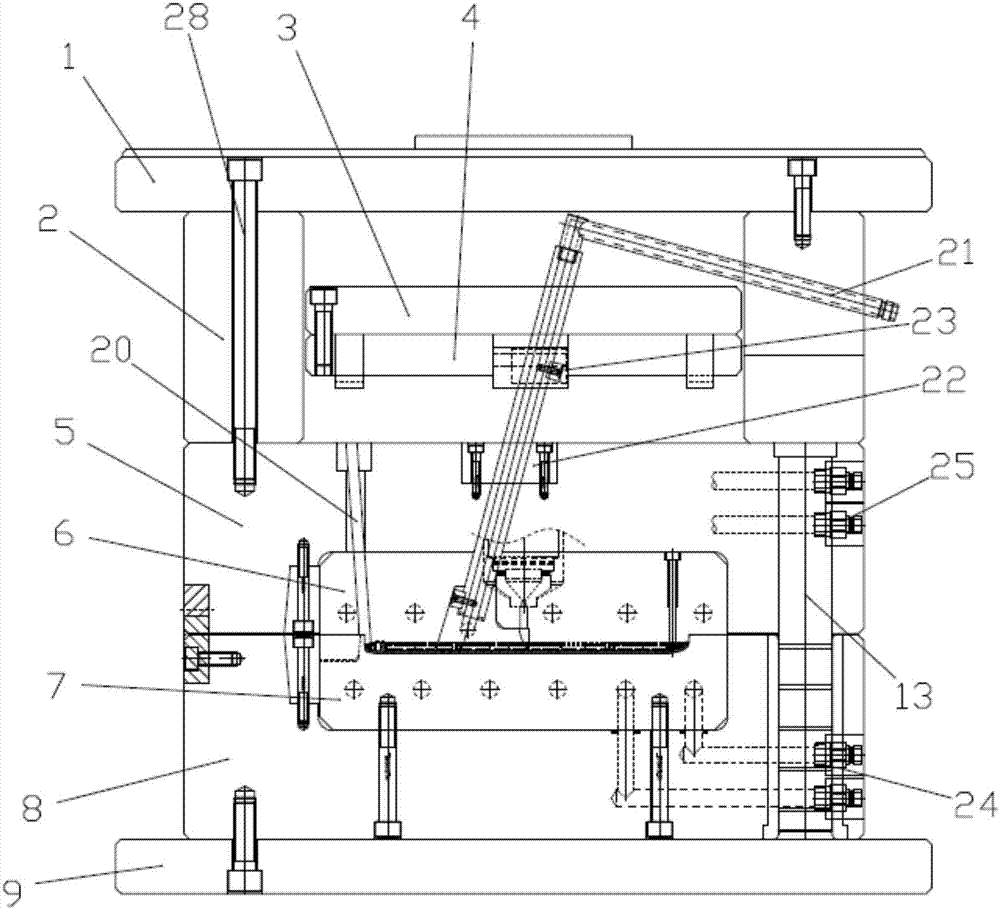

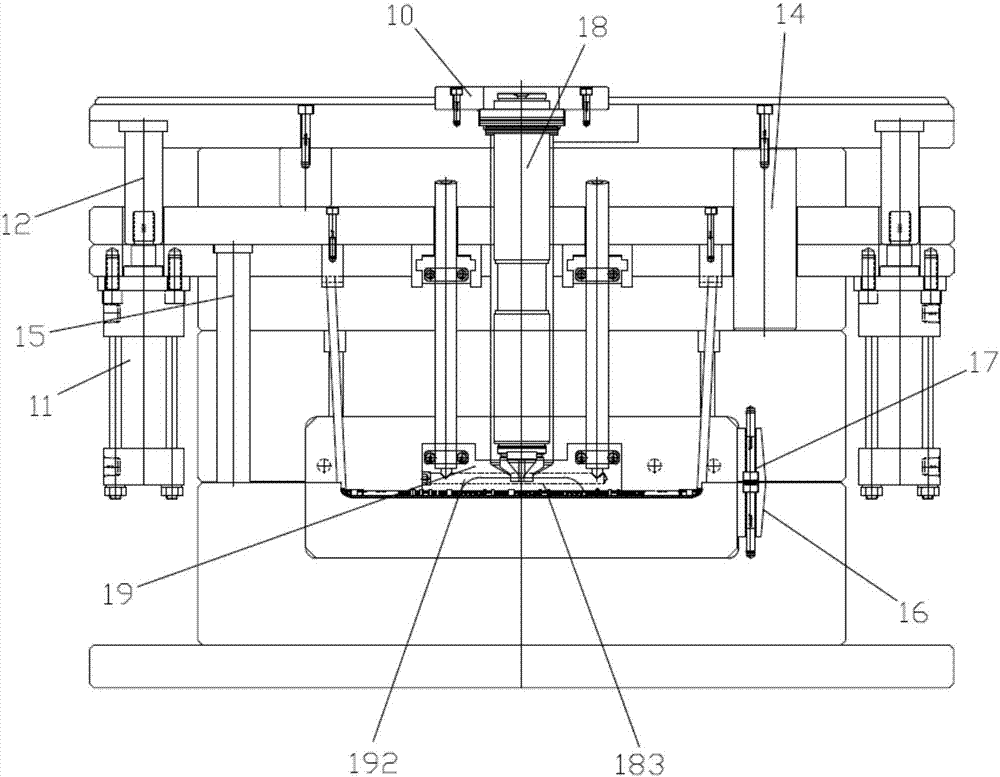

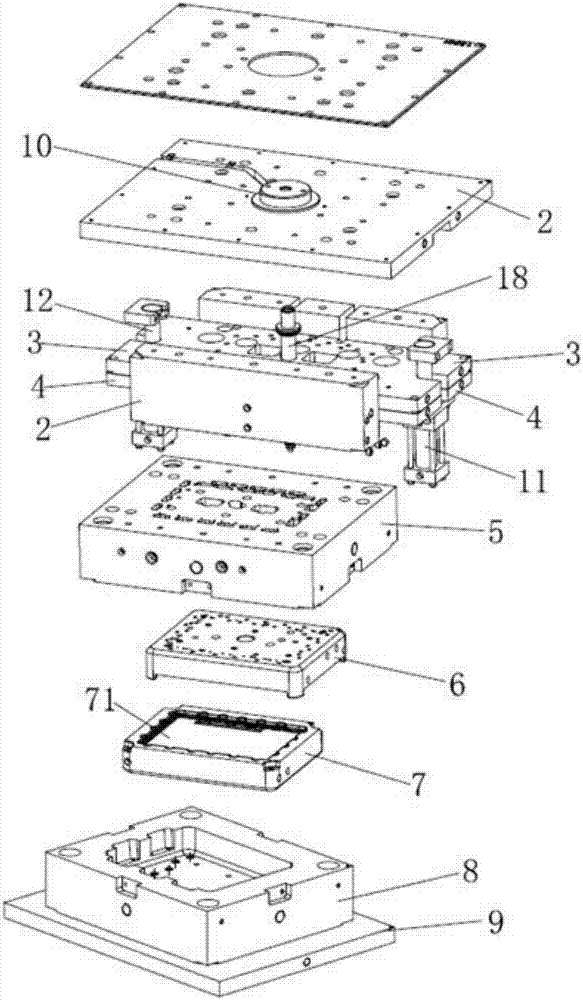

Forming mould and forming method of notebook face shell

The invention discloses a forming mould and forming method of a notebook face shell. The mould comprises a fixed mould part and a movable mould part. The fixed mould part comprises a fixed mould face plate (1), square iron (2), an ejector pin bottom plate (3), an ejector pin face plate (4), a fixed mould plate (5), a fixed mould core (6) and a hot sprue (18). The movable mould part comprises a movable mould base plate (9), a movable mould plate (8) and a movable mould core (7). A mould cavity (71) which is the same as the face shell (100) in inner shape and a mould cavity (71) which is the same as the face shell (100) in outer shape are formed between the fixed mould core (6) and the movable mould core (7). A fixed mould core insert (19) is arranged on the fixed mould core (6). A casting system communicates with the mould cavities (71) through the fixed mould core insert (19). After mould closing, mould filling, compaction, pressure maintaining and cooling are conducted, a reverse buckling part and a glue inlet and gate part of a product are pushed out through a push-out system, and finally, the product is taken out. A carbon fiber composite material is used as a face shell material of the reverse mould, and the manufactured face shell product is low in mass, small in thickness, high in strength, good in electromagnetic shielding property, good in surface quality and good in performance.

Owner:KUNDA MOLD SHENZHEN

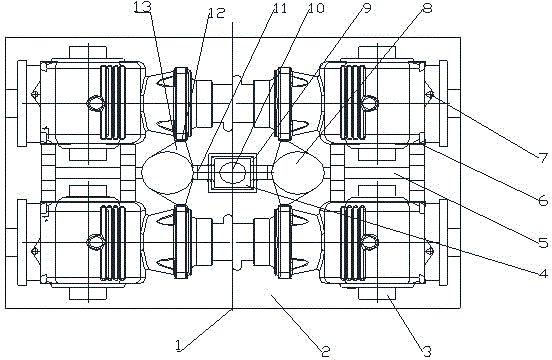

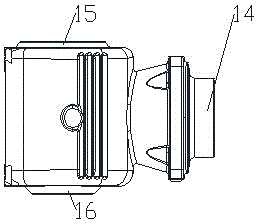

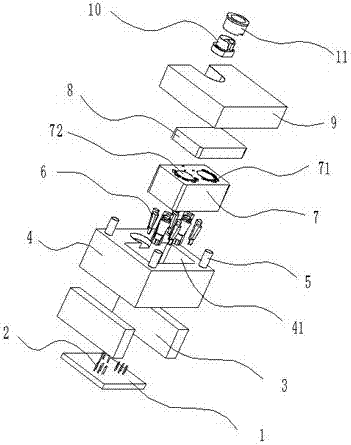

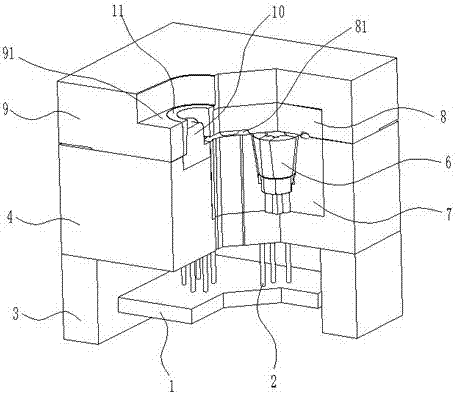

Casting mold of mold core combination structure

PendingCN107470558AHassle-free ease of demouldingEasy to demouldFoundry mouldsFoundry coresEngineeringCasting mold

The invention discloses a casting mold of a mold core combination structure. The casting mold comprises a push plate, push rods, cushion blocks, a movable mold plate, a guiding column, mold cores, a fixed mold plate, a sprue and a sprue sleeve. The push rods are arranged on the upper surface of the push plate. The cushion blocks are arranged on the same push plate surface where the push rods are located. The movable mold plate is provided with an inner sunken movable mold cavity and a movable mold insert matched with the movable mold cavity, the movable mold cavity is internally provided with the multiple mold cores, and the lower ends of the mold cores are connected with the movable mold plate. Each mold core is composed of a mold core kernel and a plurality of mold core sliding blocks surrounding the mold core kernel. The lower surface of the fixed mold plate is provided with a fixed mold insert, and the sprue and the sprue sleeve are arranged on the upper surface of the fixed mold plate. In mold opening, the multiple mold core sliding blocks, surrounding the exteriors of the mold core kernels, in the mold cores can move towards the fixed mold plate and are finally separated from the mold core kernels. After a casting and the mold core sliding blocks are separated from the mold, one single mold core sliding block can be independently taken out from the interior of the casting and reused. The time and manual cost which are increased due to new sand cores needing to be manufactured in each time of casting are reduced in the casting process.

Owner:ZHEJIANG TRENDY KITCHENWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com