Low-pressure casting device for aluminum alloy wheels of automobile

A low-pressure casting, aluminum alloy technology, applied in the field of low-pressure casting of automobile aluminum alloy wheels, can solve the problems of many pinholes, high energy consumption, large burning loss and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

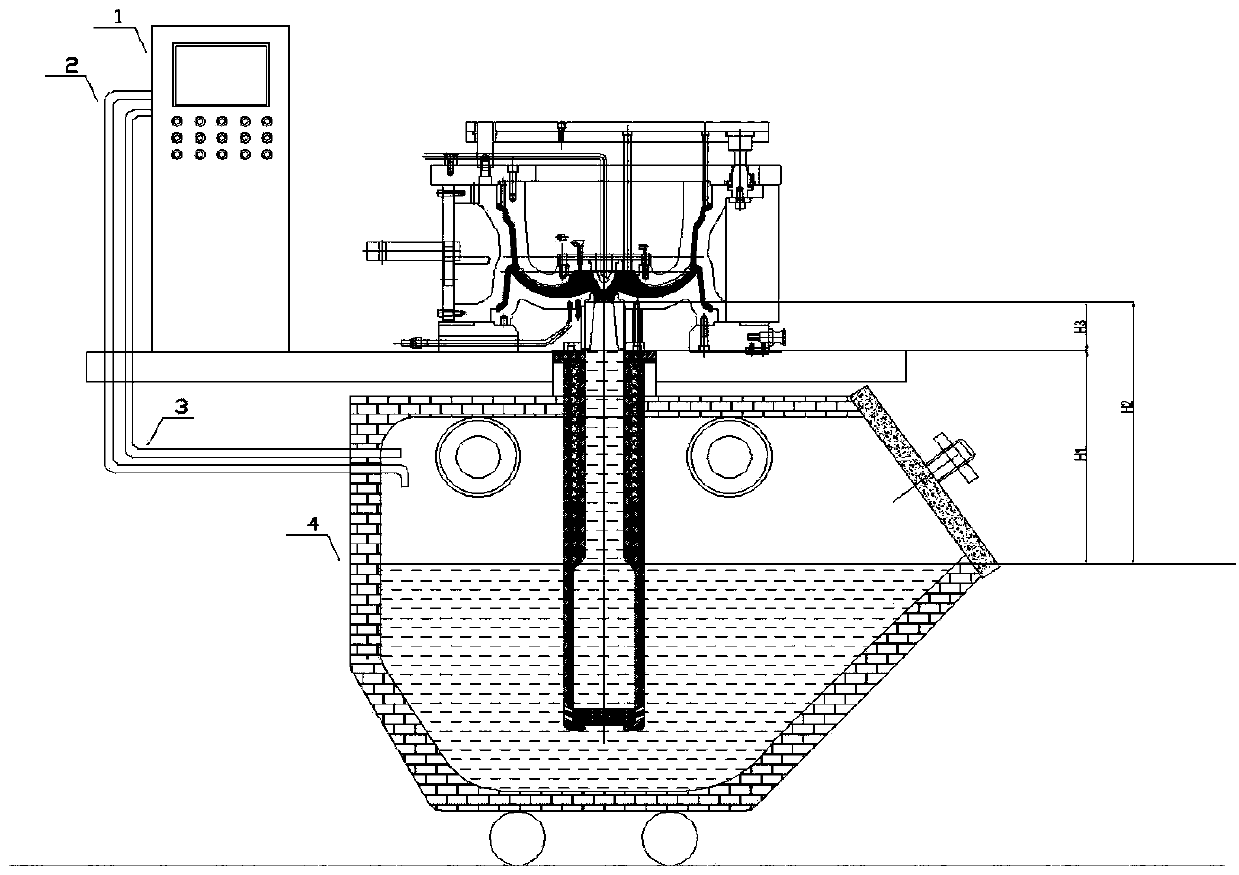

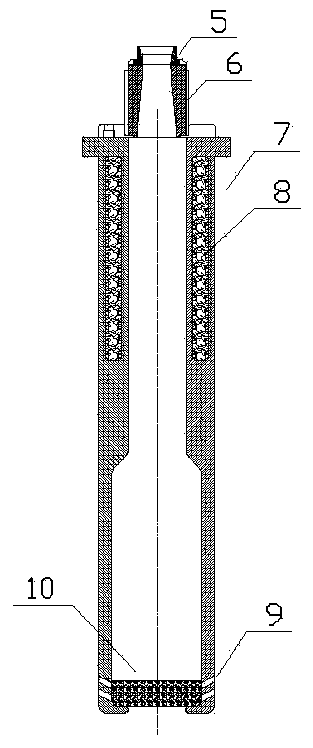

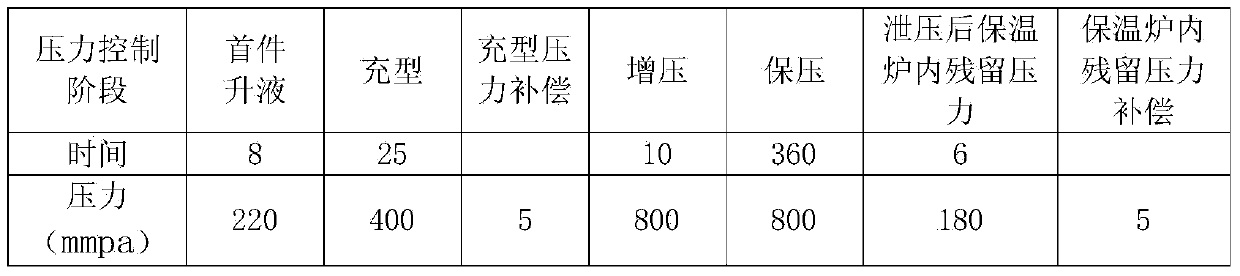

[0008] Such as figure 1 , 2 As shown, a low-pressure casting device for an automobile aluminum alloy wheel, taking a 903-2210 aluminum alloy wheel low-pressure casting process as an example, consists of a low-pressure casting system control cabinet 1, a pressurized intake pipe 2, a pressure relief exhaust pipe 3, an aluminum Liquid holding furnace 4, iron sprue 5, ceramic insulation cup 6, liquid riser 7, heat insulation layer 8, buffer hole 9 and ceramic filter screen 10. The two ends of the pressurized inlet pipe 2 and the pressure relief exhaust pipe 3 are respectively connected with the low pressure casting system control cabinet 1 and the aluminum liquid holding furnace 4; Valve, the pressure control valve is used to control the pressure in the holding furnace to maintain a certain pressure of 140KPa to 170KPa after pressure relief, so that the aluminum liquid can be kept in the riser pipe at the height from the upper port of the riser pipe to the middle position of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com