Patents

Literature

257results about How to "Reduce pinholes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

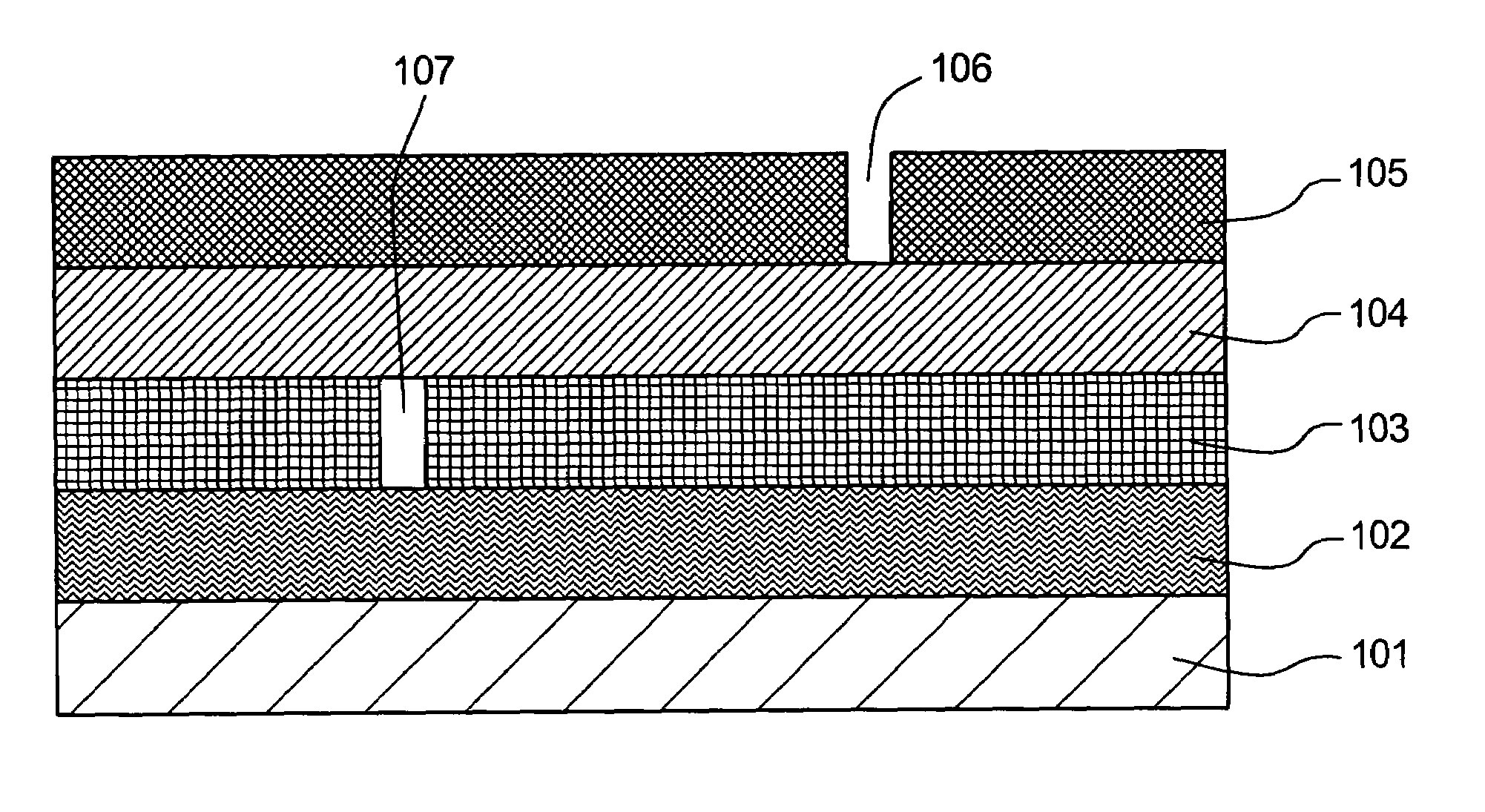

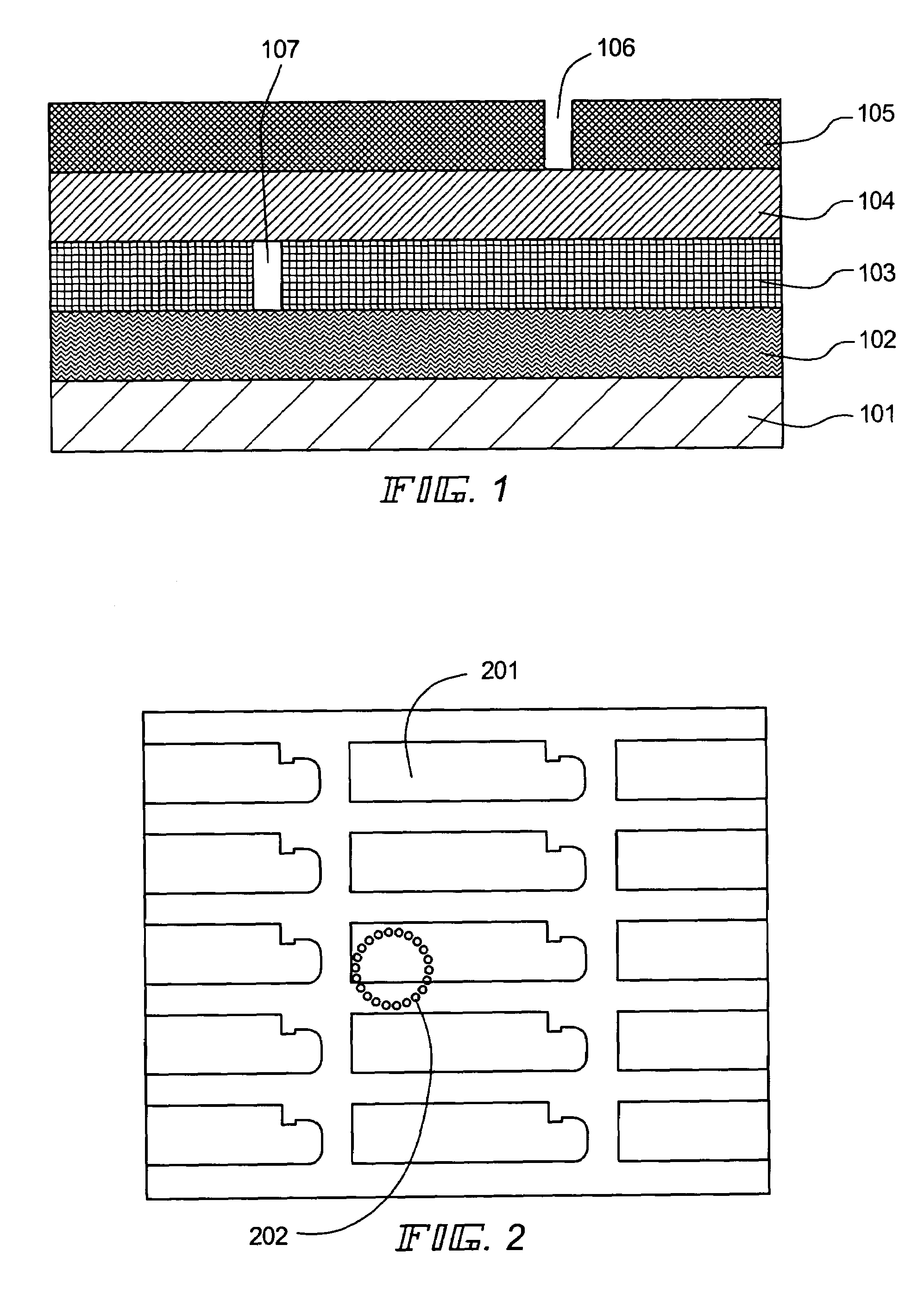

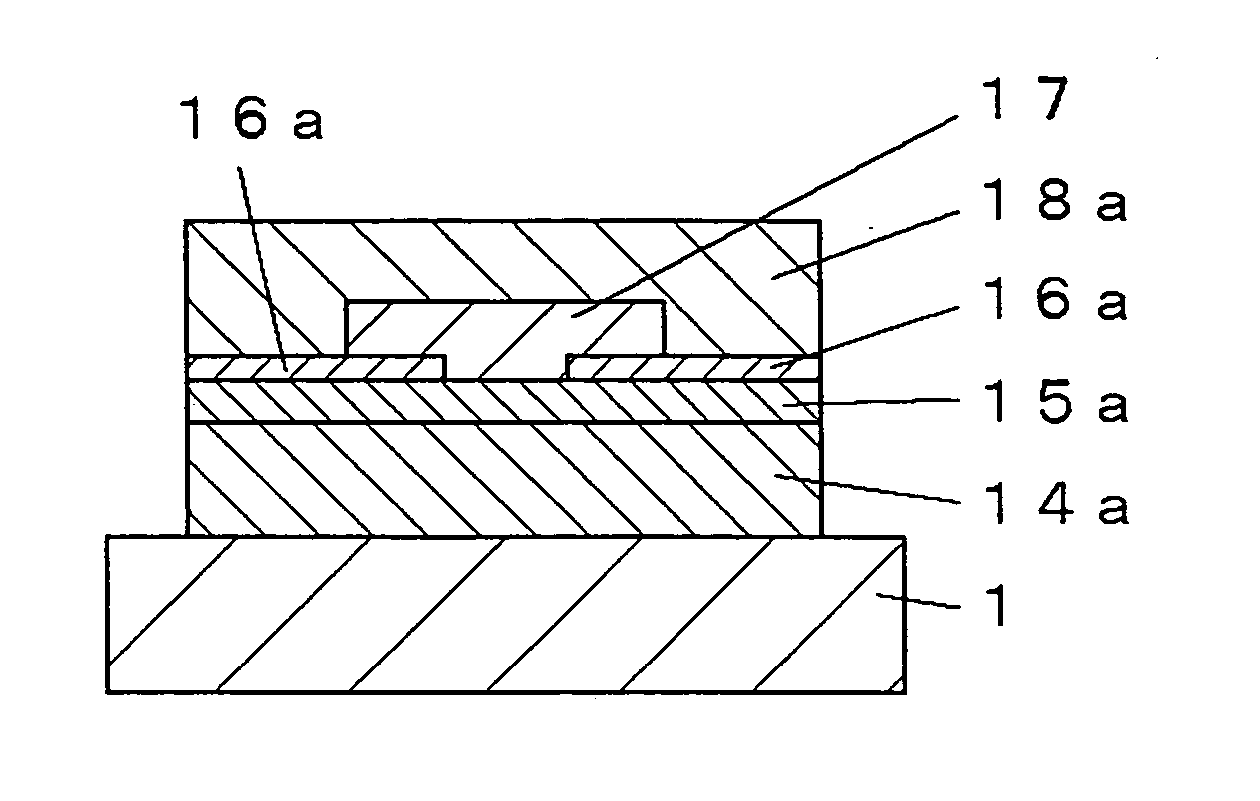

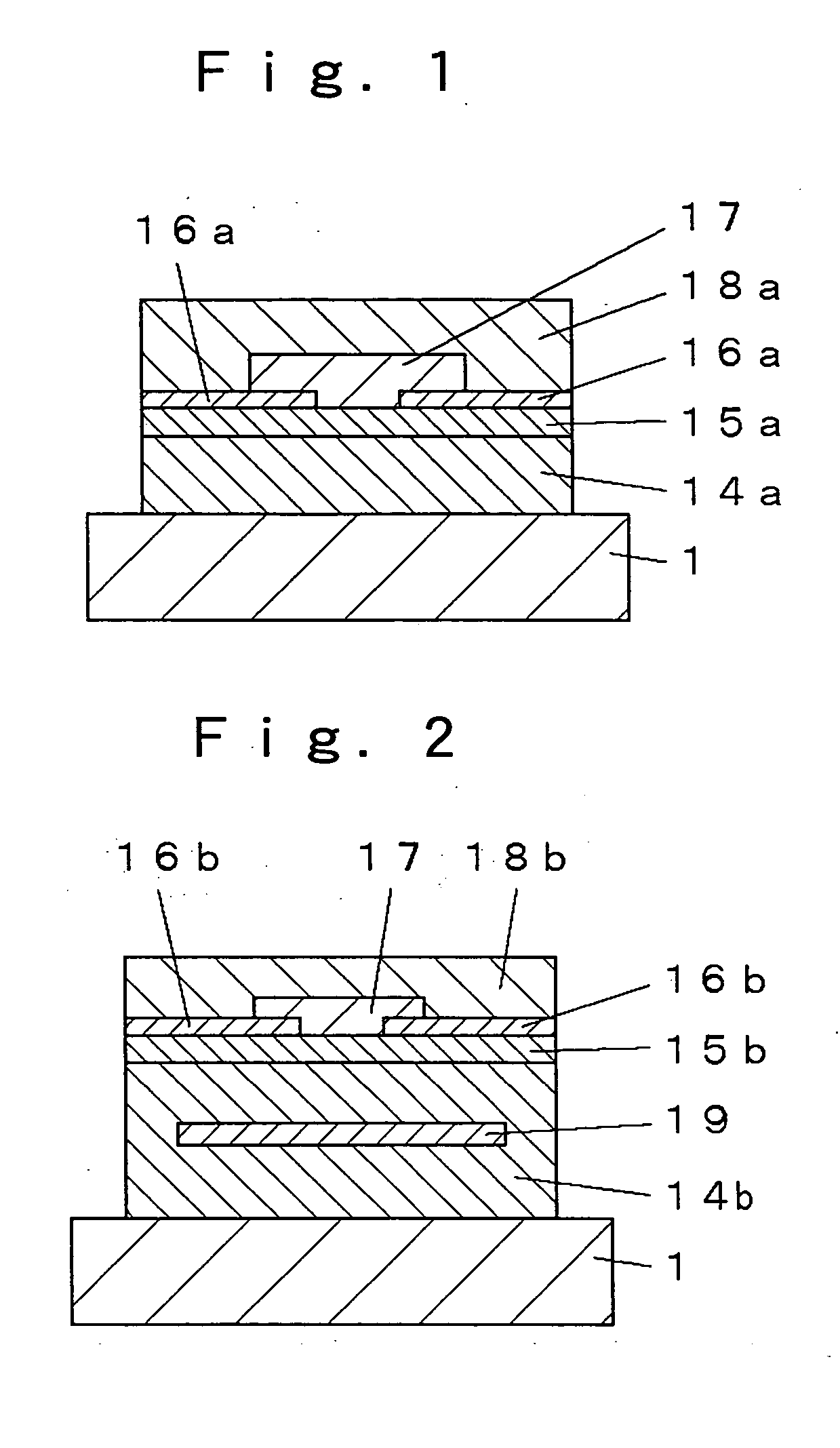

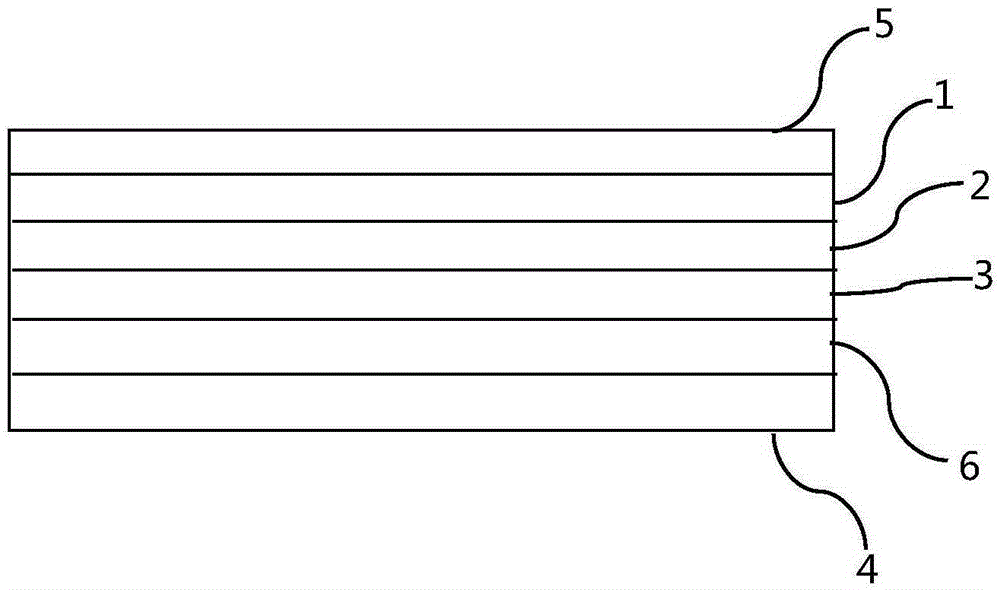

Light-emitting device having electrode formed by laminate of at least first inorganic film, organic film, and second inorganic film and method for manufacturing the same

InactiveUS7045822B2Reduce pinholesImprove reliabilityDischarge tube luminescnet screensElectroluminescent light sourcesOrganic filmDark spot

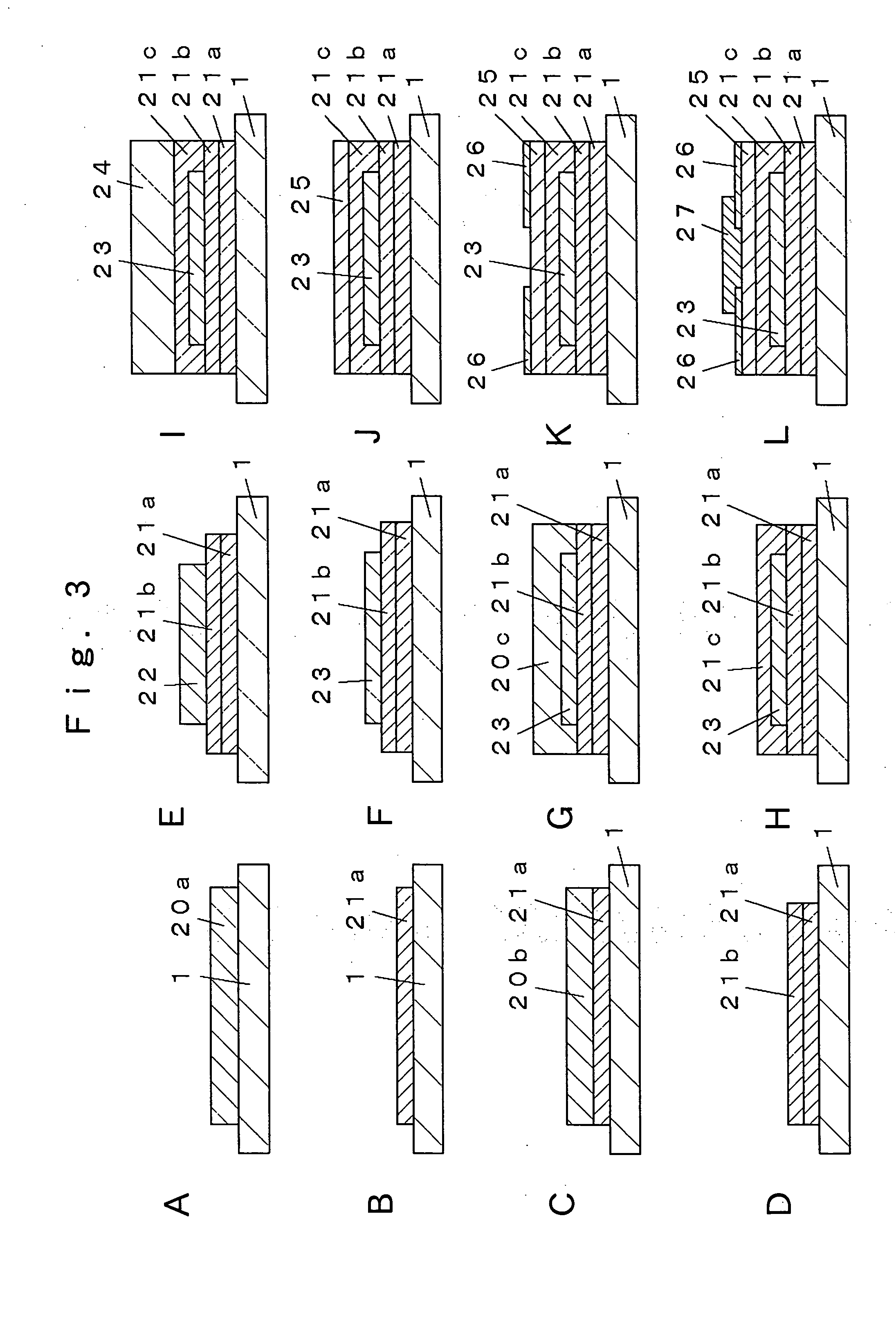

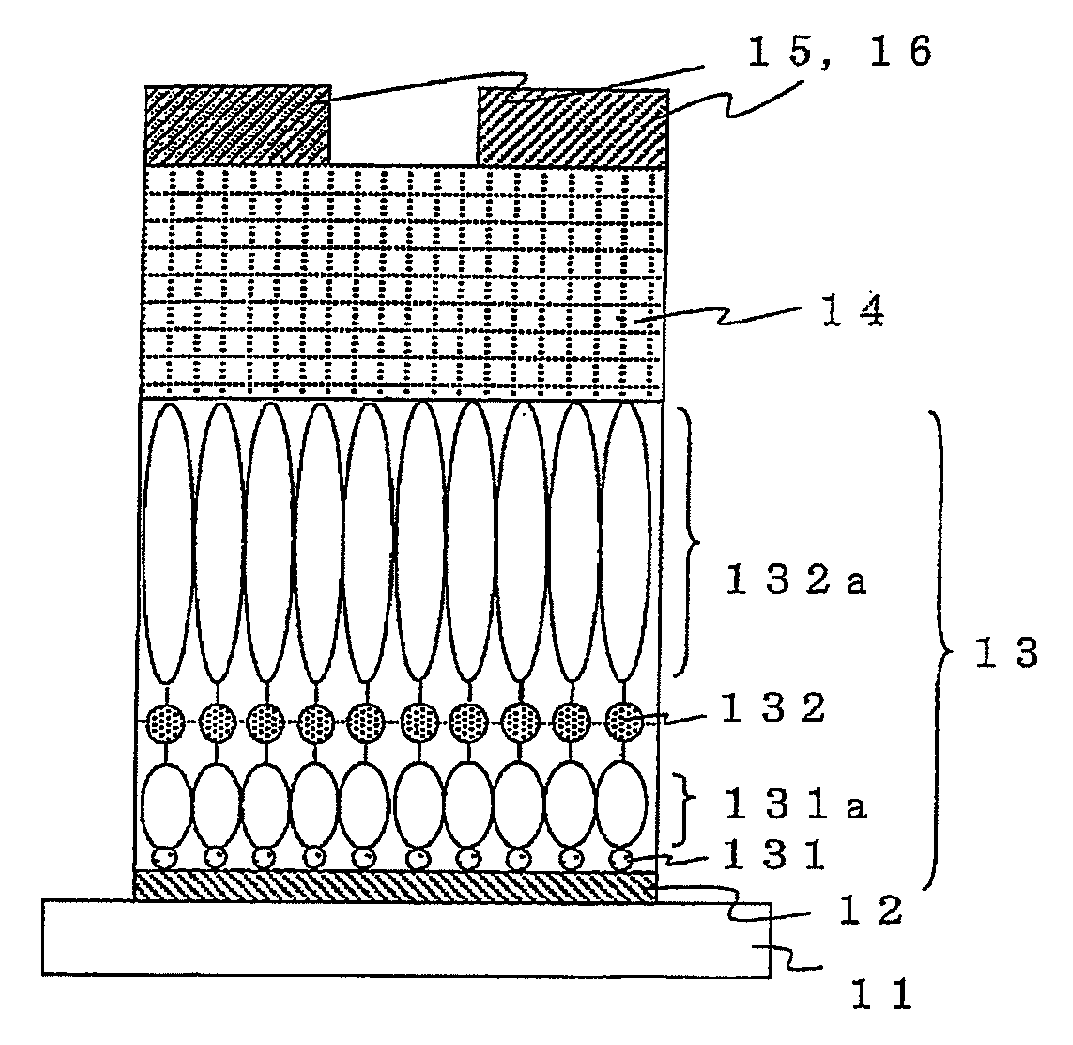

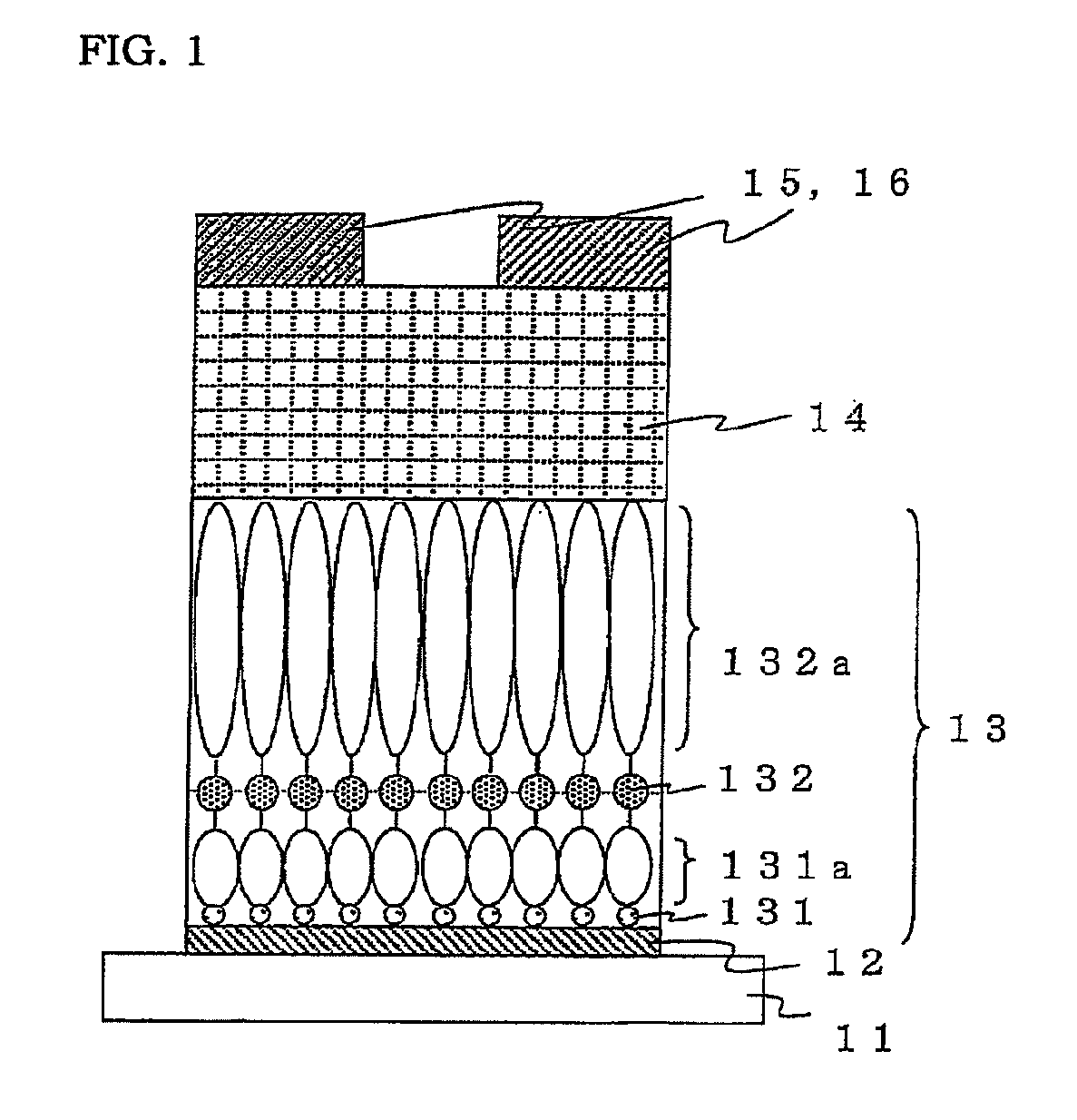

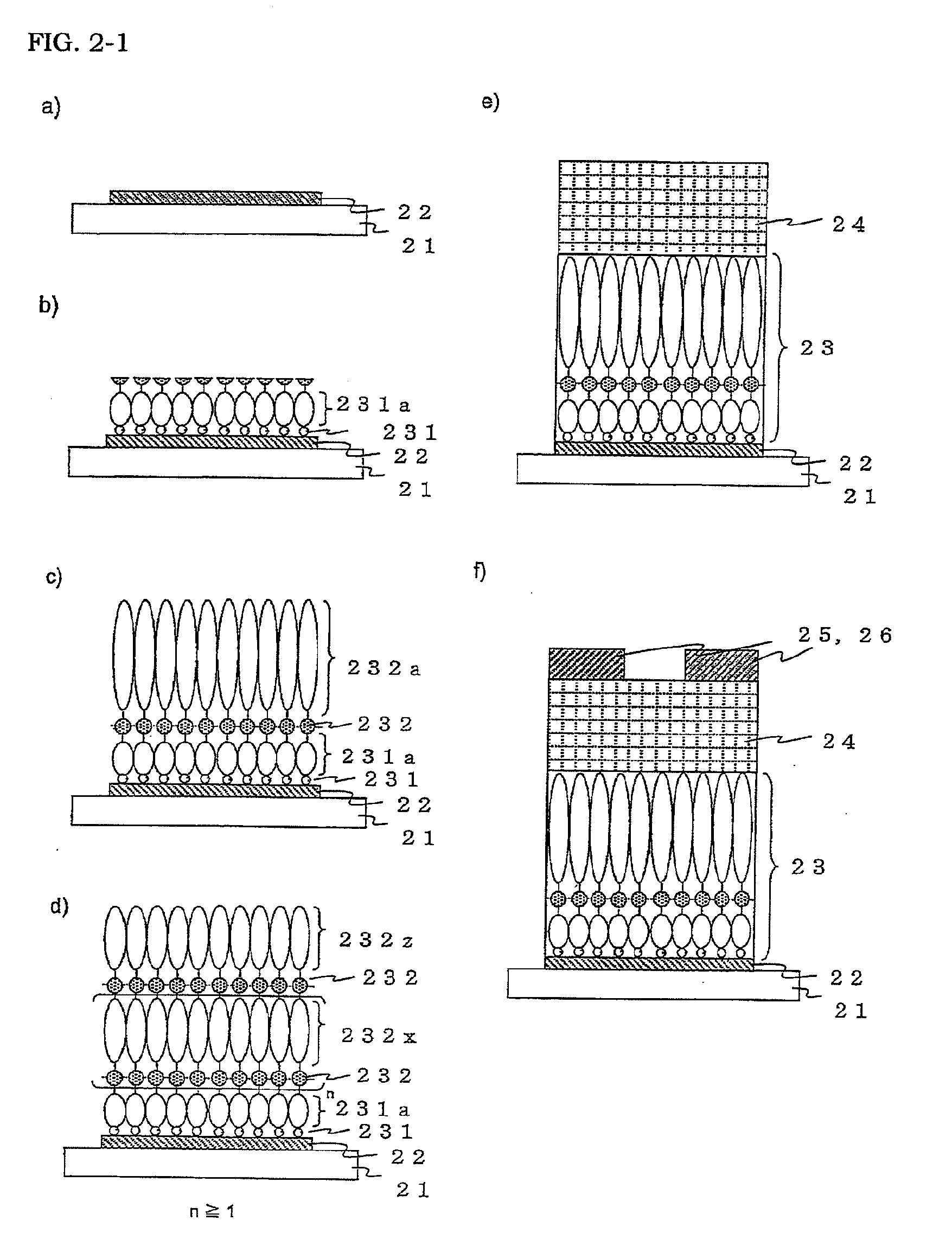

The present invention provides an organic light-emitting element where a lower electrode, an organic compound layer and an upper electrode are laminated on a substrate, wherein the upper electrode of the organic EL element is formed by a laminate of at least a conductive first inorganic film, a conductive organic film and a conductive second inorganic film, in order to suppress the occurrence of dark spot, so that the occurrence of pinholes in the upper electrode leading to dark spots is suppressed. Here, pinholes refer to holes in the upper electrode that penetrate upper electrode from the organic compound layer underneath to the atmosphere above.

Owner:SEMICON ENERGY LAB CO LTD

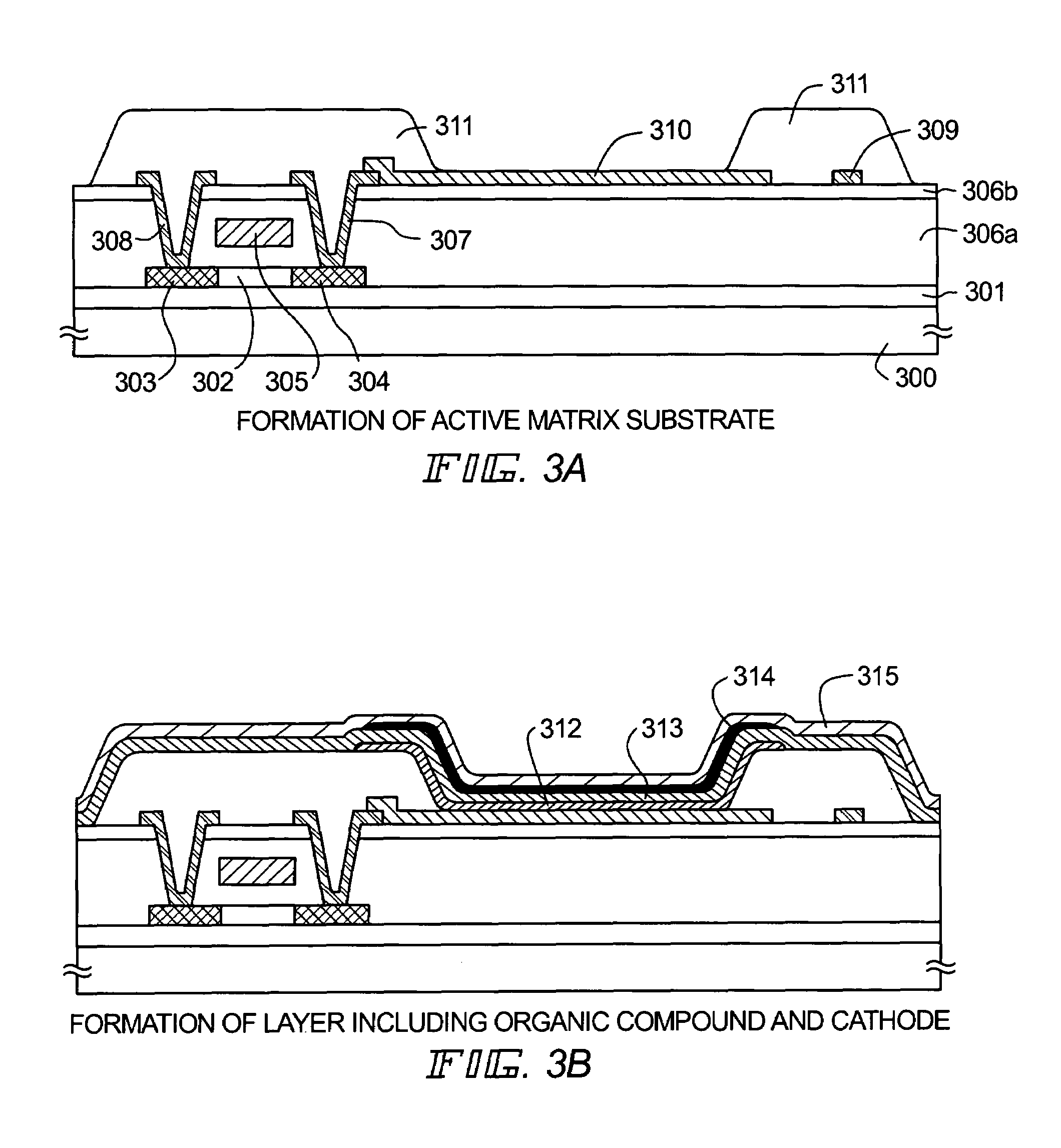

Double zero aluminum foil with thickness of 0.004-0.0048 mm, and preparation method thereof

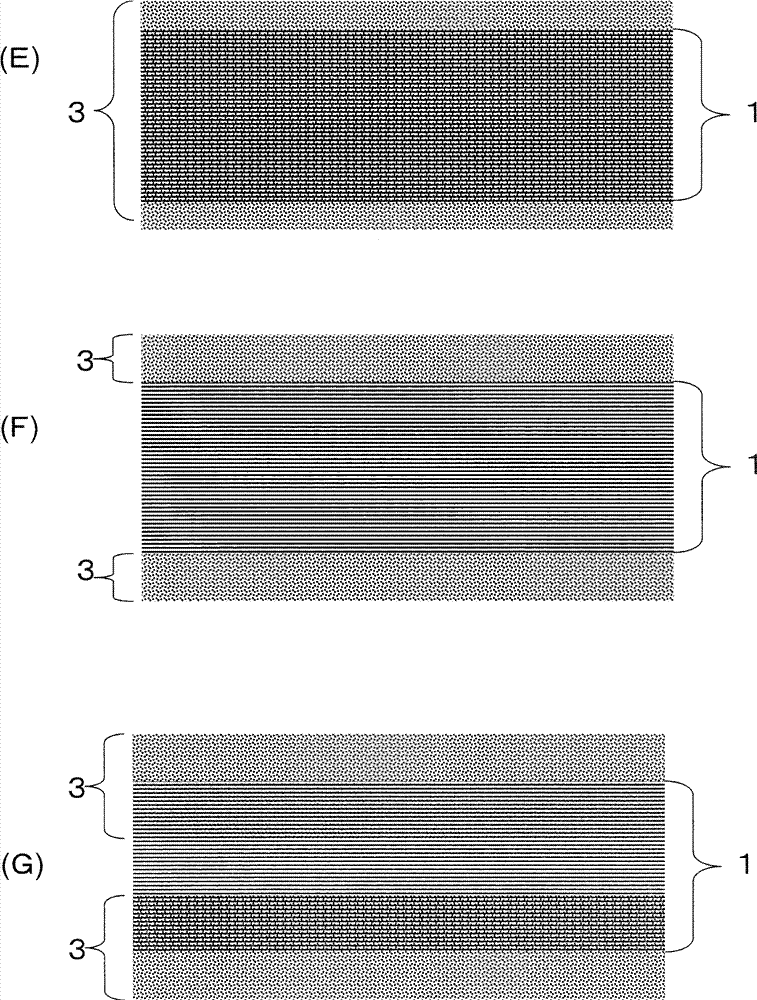

The present invention relates to a double zero aluminum foil with a thickness of 0.004-0.0048 mm. The double zero aluminum foil has the following components, by weight, 0.38-0.45% of Fe, 0.10-0.15% of Si, less than or equal to 0.06% of titanium (Ti), less than or equal to 0.03% of copper (Cu), less than or equal to 0.03% of manganese (Mn), less than or equal to 0.03% of magnesium (Mg), less than or equal to 0.03% of zinc (Zn), less than or equal to 0.03% of vanadium (V), and the balance of aluminum (Al). The present invention further relates to a main production process for the double zero aluminum foil with the thickness of 0.004-0.0048 mm, wherein the production process comprises: smelting, casting rolling, cold rolling, intermediate annealing, cold rolling, rough rolling, medium rolling, double folding with a folding coiler, four folding with the folding coiler, four folding fine rolling, coil cutting, slitting, finished product annealing, and packaging.

Owner:浙江中金铝业有限公司

Light gauge aluminum foil woolen produced with AL-Ti-C wire refiner and preparation method

InactiveCN102181754AReduced responseLess rigidRoll mill control devicesMetal rolling arrangementsMaterials preparationFiltration

The invention relates to a light gauge aluminum foil woolen produced with AL-Ti-C wire refiner and a preparation method. The iron-silicon rate of the woolen ranges between 4.3-5.3. The process of the preparation technology is sequentially as follows: material preparation, batching, feeding, melting, stirring, primary refining of a smelting furnace, drossing, sampling, ingredient adjustment, secondary refining of the smelting surface, drossing, converter, primary refining in a holding furnace, intensified refining in the holding furnace, online addition of AL-Ti-C wire intermediate alloy refiner, Ar online degassing, filtration, continuous casting into 7.0-7.5mm cast rolling plates, cold rolling, high-temperature homogenizing annealing of a primary sheet strap, cold rolling, trimming of a rereeling machine, cold rolling, intermediate annealing of a secondary sheet strap, cold rolling to 0.26-0.32mm, trimming of the rereeling machine, and packaging. The cost is low, the quality is stable, the calendaring of the aluminum foil and grain refining are good in effect, and the probability of generating pinholes is low during production.

Owner:江阴新仁铝业科技有限公司

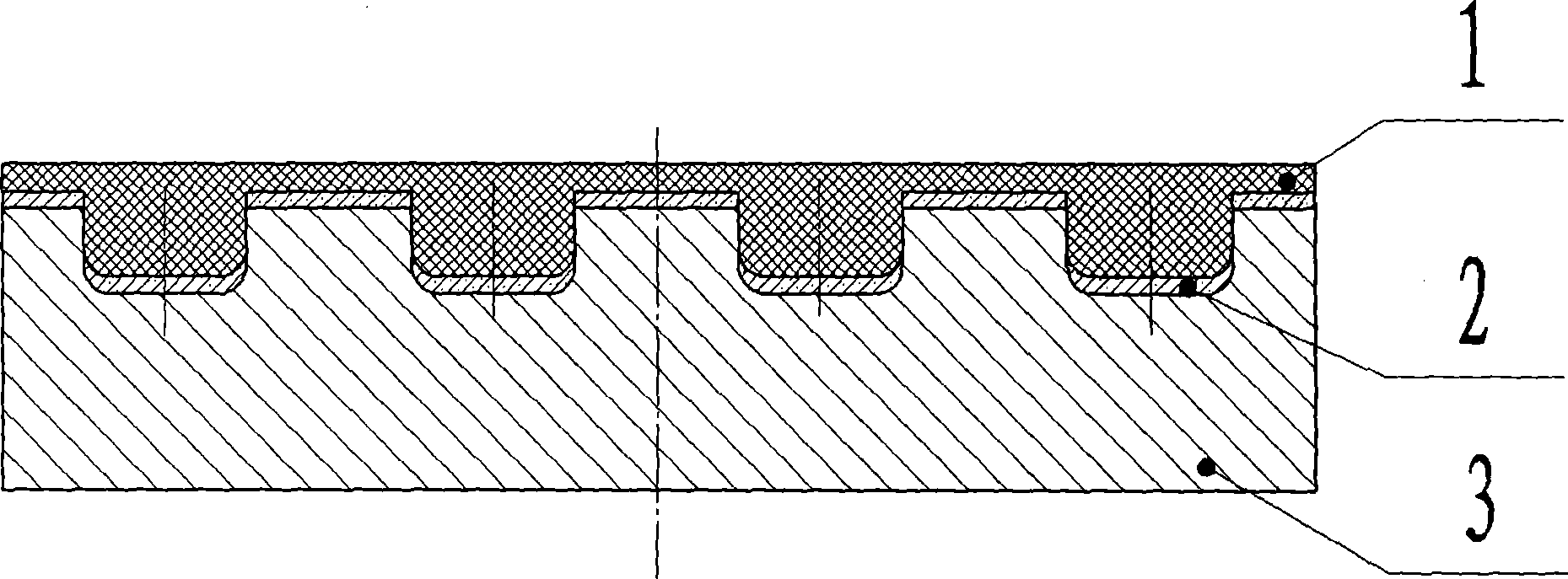

Metal and plastic composite self-lubricating material and preparation method thereof

ActiveCN101544080AHigh bonding strengthGood heat resistanceLiquid surface applicatorsLaminationThioetherPolyether ether ketone

The invention discloses a metal and plastic composite self-lubricating material and a preparation method thereof. The metal and plastic composite self-lubricating material comprises a metal layer, a plastic binding layer and a plastic working layer, wherein the plastic binding layer binds the metal layer and the plastic working layer together through a chemical bond of a molecule; one part of theplastic working layer is embedded in a drop pit of the metal layer; the plastic working layer includes the material components according to the mass percent as follows: 60-90 of polyether-ether-ketone, 5-20 of polyfluortetraethylene, 7 of graphite, 1 of MoS2 and 5-10 of aluminium oxide; and the plastic binding layer includes the material components according to the mass percent as follows: 70-90 of polyether-ether-ketone, 5-20 of polyphenyl thioether and 5-10 of aluminium oxide. By adding the plastic binding layer between the metal layer and the plastic working layer, the invention further improves the binding strength of metal and plastic, has favorable heat resistance and resistance to chemical corrosion, no environment pollution, low noise and energy saving; in addition, the usage temperature is -60 DEG C to 250 DEG C, the friction coefficient is 0.08-0.32 and the wear rate is 0.8-3.5*10<-6>mm<3> / N. m.

Owner:JIANGSU UNIV

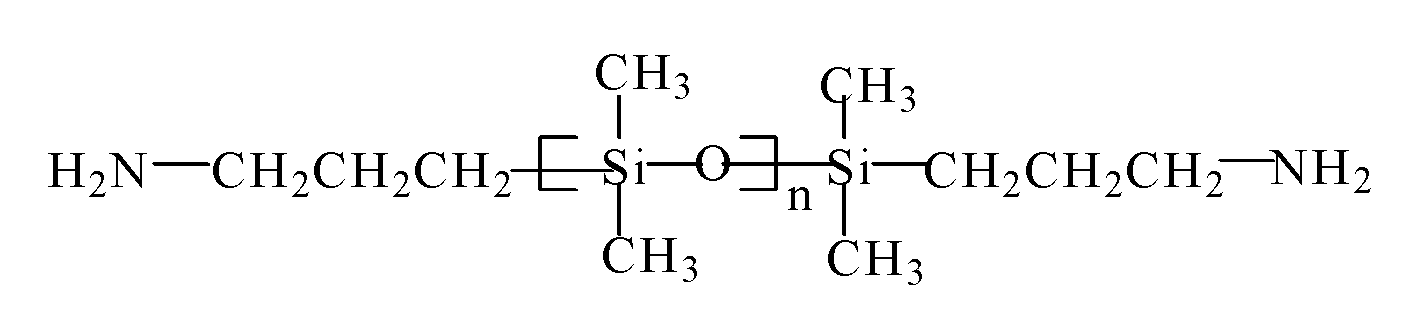

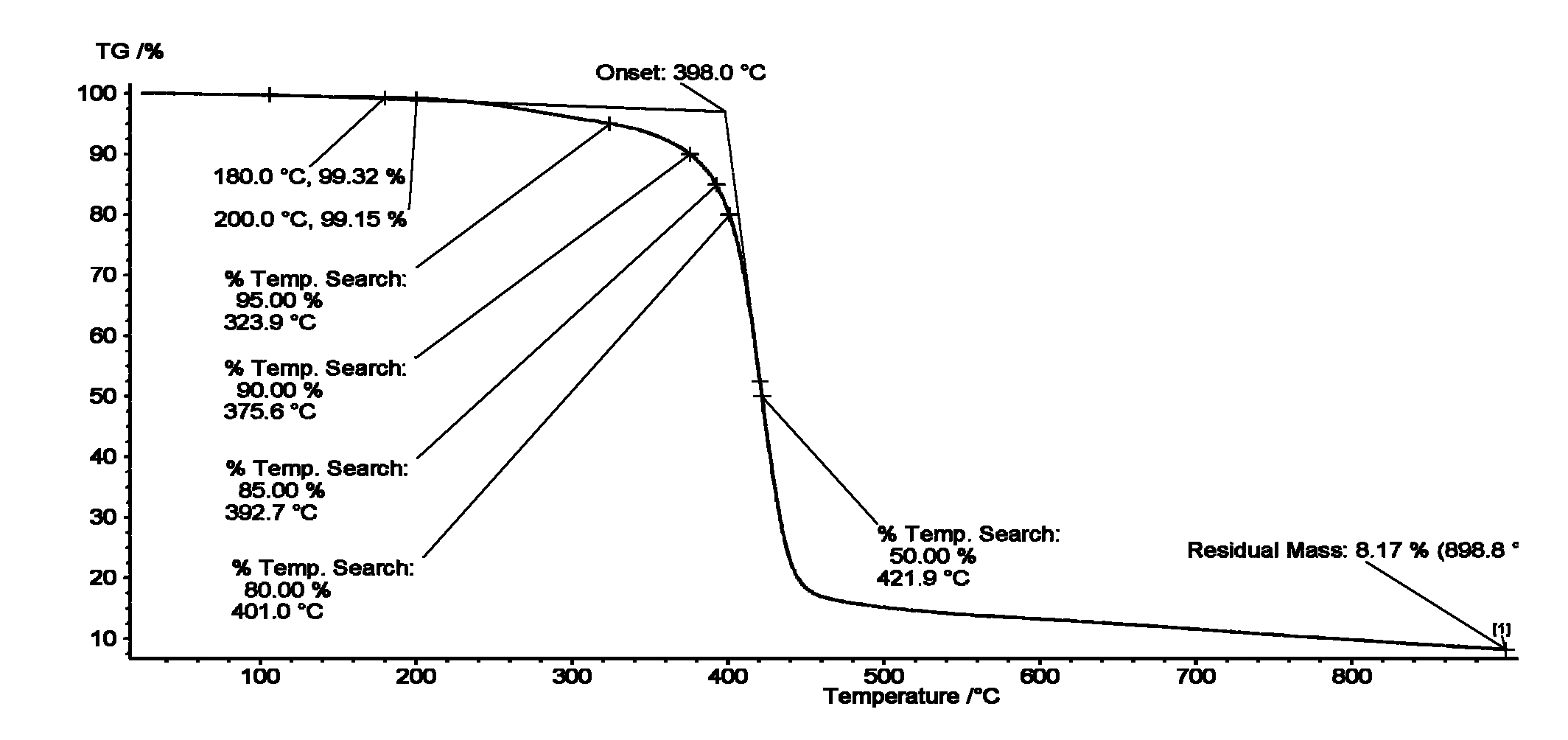

Heat-resistant solvent-free immersion paint and preparation method thereof

InactiveCN101921529AConvenient sourceSimple preparation processEpoxy resin coatingsHeat resistanceElectric machine

The invention relates to a heat-resistant solvent-free immersion paint which comprises the following components in percentage by weight: 10%-15% of organosilicon polyfunctional epoxy resin, 15%-35% of silicon-free polyfunctional epoxy resin, 5%-10% of curing agent and 45%-65% of reactive diluent. The preparation method thereof comprises the following steps: adding the organosilicon polyfunctional epoxy resin, the reactive diluent and the silicon-free polyfunctional epoxy resin into a kettle, reacting for 0.5h at the temperature of 100 DEG C, cooling, adding the curing agent, and evenly stirring at room temperature, thus obtaining sticky liquid, i.e. the heat-resistant solvent-free immersion paint. The preparation process is simple, the cost is low, and the industrialized production can be easily realized; the room-temperature longitudinal shear strength of the heat-resistant solvent-free immersion paint is high; and the heat-resistant solvent-free immersion paint has excellent heat resistance, strong hydrophobic property and wide application prospects in the fields of high-power traction electric machines, high-power generators, drilling motors, mining motors and the like.

Owner:DONGHUA UNIV +1

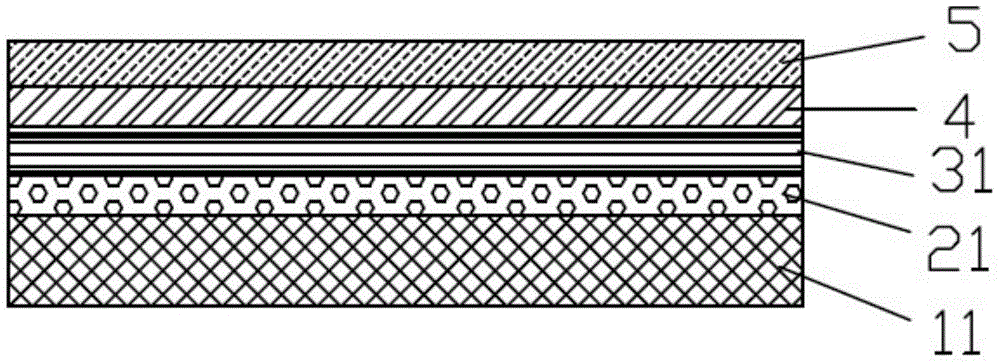

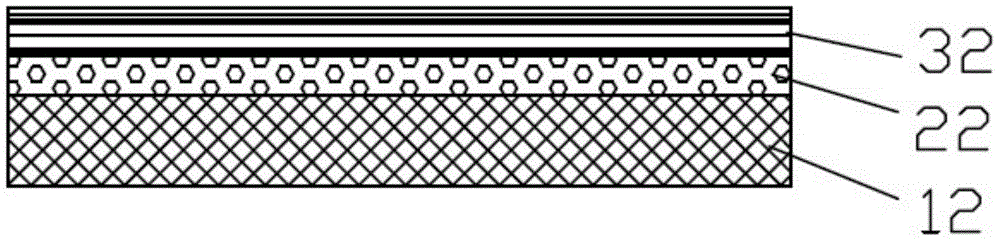

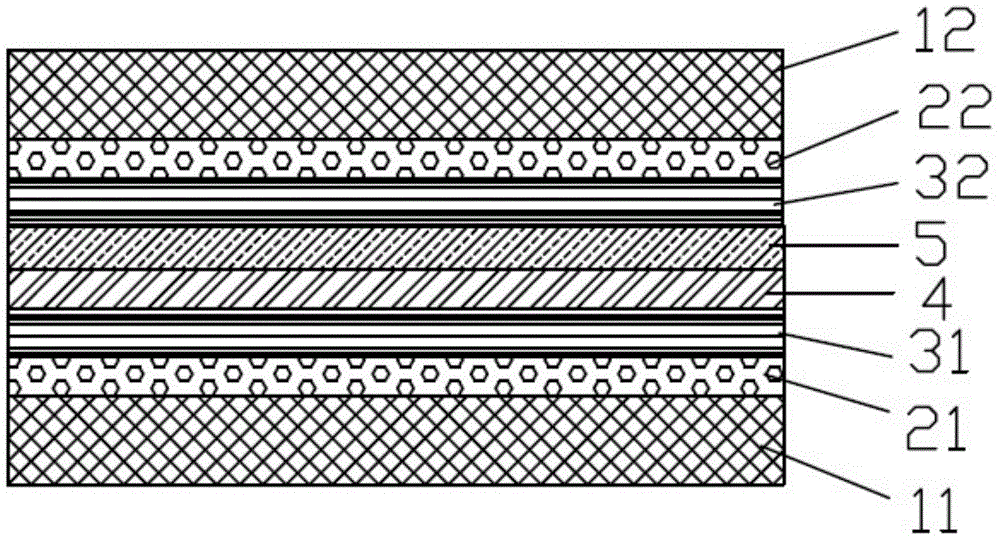

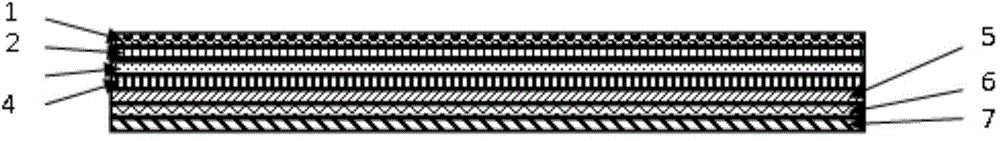

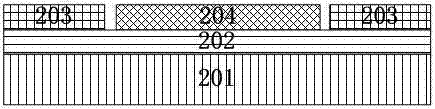

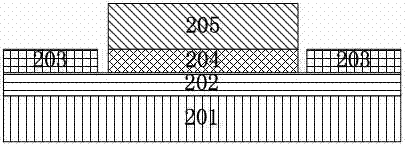

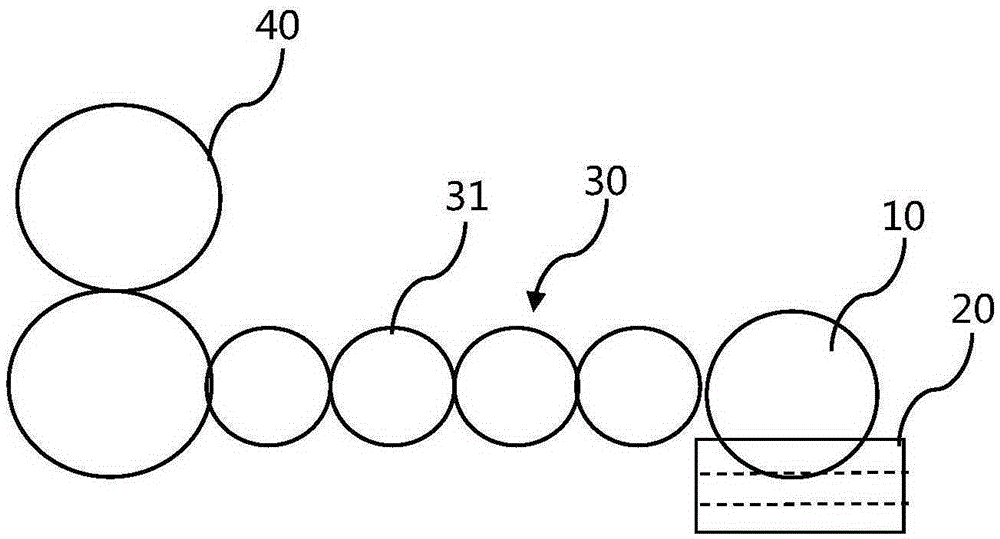

Manufacturing method of flexible display device and flexible display device manufactured by adopting same

InactiveCN104576970AImprove film densityReduce pinholes and grain boundariesSolid-state devicesSemiconductor/solid-state device manufacturingPolymer substrateEngineering

The invention provides a manufacturing method of a flexible display device. In the manufacturing method, a water and oxygen barrier layer is directly arranged on a flexible polymer substrate, and then arranged on an organic light-emitting diode in a bonding manner, so that the film-forming compactness of the inorganic barrier layer can be improved, and accordingly the water vapor and oxygen permeation preventing capability of the water and oxygen barrier layer is improved, degradation and deterioration of various materials in the organic light-emitting diode are prevented and the service life of the flexible display device is prolonged; the manufacturing process of the organic light-emitting diode and the manufacturing process of the water and oxygen barrier layer are not required to be sequentially carried out, the water and oxygen barrier layers on a first flexible polymer substrate and a second flexible polymer substrate can be manufactured synchronously or manufactured on the same flexible polymer substrate, and a cutting process is performed as required, so that a production process can be simplified and purposes of improving the production efficiency and reducing the cost are achieved. The invention further provides the flexible display device manufactured by the manufacturing method. The flexible display device is relatively long in service life.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

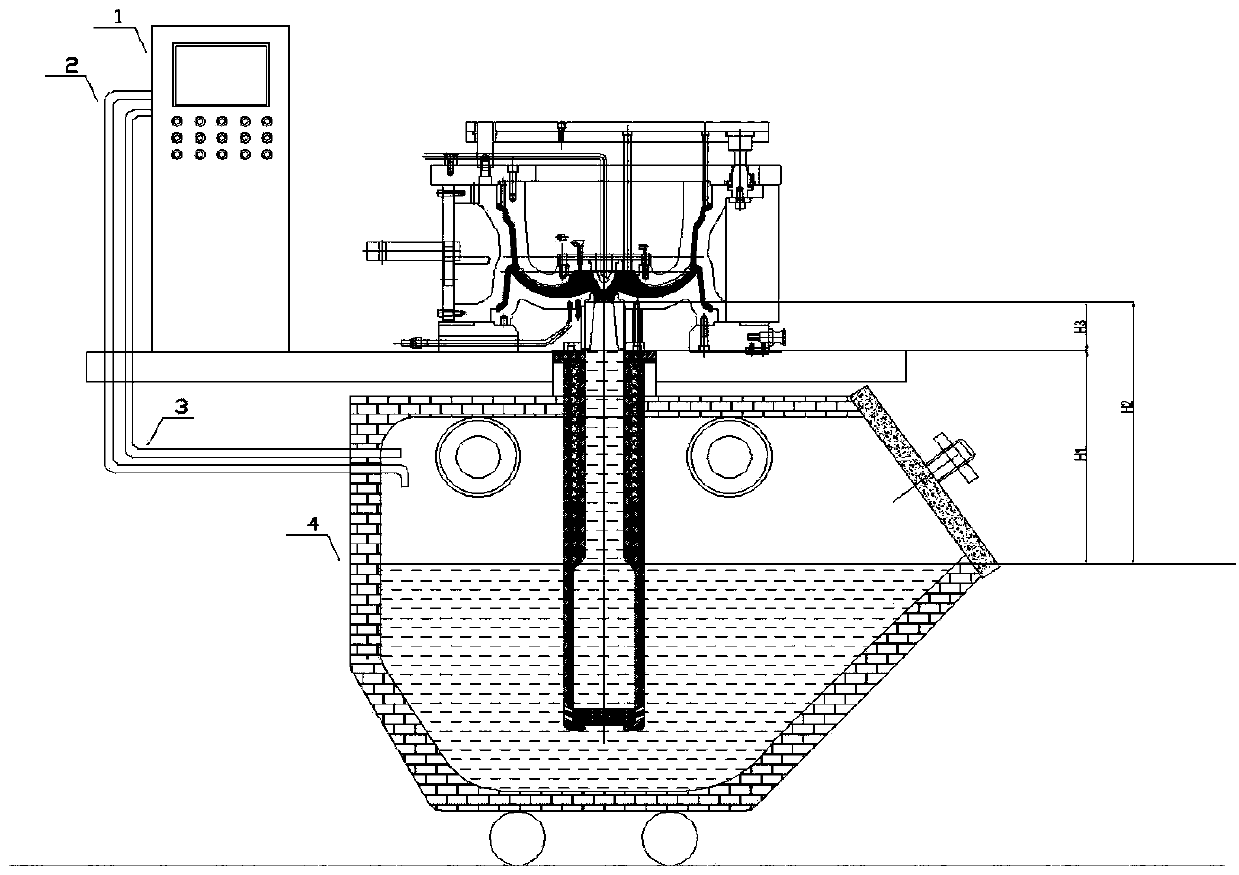

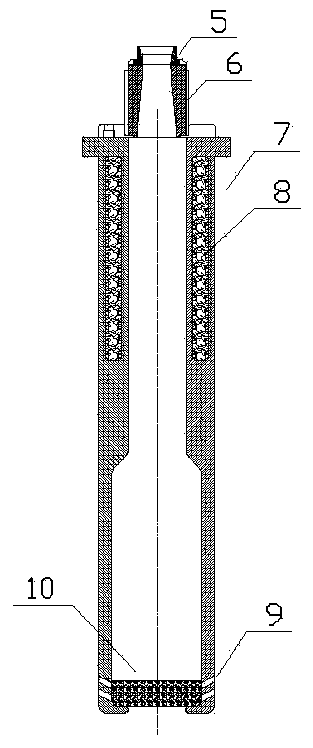

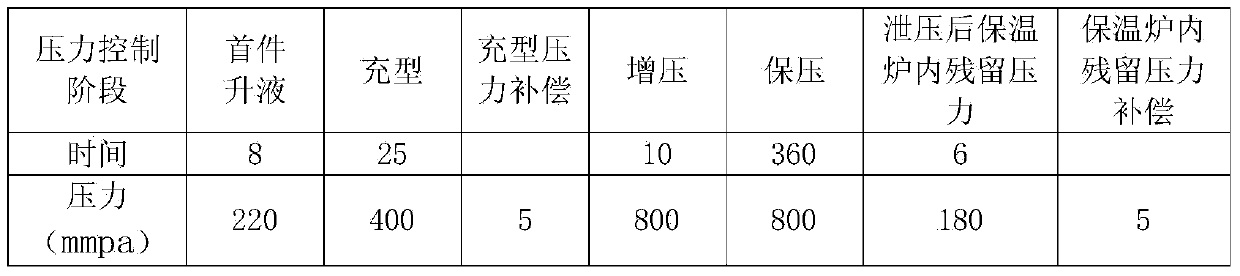

Low-pressure casting device for aluminum alloy wheels of automobile

A low-pressure casting device for aluminum alloy wheels of an automobile is composed of a low-pressure casting system control cabinet, a pressurization air inlet tube, a pressure relief air outlet tube, a molten aluminum heat preservation furnace, an iron sprue, a ceramic heat preservation cup, a molten aluminum lifting tube, a heat insulation layer, twelve to sixteen buffer holes and a ceramic filter net. The two ends of the pressurization air inlet tube and the two ends of the pressure relief air outlet tube are connected with the low-pressure casting system control cabinet and the molten aluminum heat preservation furnace. A pressure control valve is installed in the low-pressure casting system control cabinet and arranged at the end of the pressure relief air outlet tube. A pressure relief zero return button and a cumulative number zero clearing button are arranged in the low-pressure casting system control cabinet. The iron sprue is assembled at a die feed inlet, the ceramic heat preservation cup is assembled under the iron sprue, the molten aluminum lifting tube is assembled in the molten aluminum heat preservation furnace, the upper end of the molten aluminum lifting tube is provided with the heat insulation layer, the inner diameter of the part, immerged in molten aluminum, of the lower end of the molten aluminum lifting tube is greater than that of the upper end, the buffer holes with the diameter of 10-12mm are formed in the lower end of the molten aluminum lifting tube, and the included angle formed between each buffer hole and the vertical plane ranges from 15 degrees to 20 degrees. The low-pressure casting device for the aluminum alloy wheels of the automobile can remarkably reduce the burning loss, the heat loss, needle holes and slag holes.

Owner:JIANGSU KAITE AUTO PARTS

Matte Surface Multilayer Films Having Improved Sealing Properties, Their Methods of Manufacture, and Articles Made Therefrom

InactiveUS20110083796A1Reduced tightnessImprove seal strengthRecord information storageMagnetic recordingPolymer scienceSurface roughness

A multilayer film is provided which has a core layer, a matte tie layer, and a sealant skin layer. The matte tie layer is intermediate the core and sealant skin layers and includes a first polymer component and a second polymer component. The multilayer film has a surface roughness (Ra) of at least 0.25 μm and a peak count (Pc) of at least 30 as measured by surface profilometry, and a seal of the sealant layer to itself has a seal strength of greater than about 1400 g / 2.54 cm at 127° C. The multilayer film may be oriented in at least one direction and may be metallized, coated, printed, and / or laminated. The multilayer film may be usefully in packaging applications.

Owner:JINDAL FILMS AMERICAS LLC

Process for preparing functional heat transfer surface

ActiveCN1748877AImprove performanceHigh temperature resistance and good thermal stabilityChemical industrySpecial surfacesResistWater vapor

The present invention relates to heat transfer and energy saving technology, and is especially technology of modifying metal surface with functional coating and applying the modified metal surface in heat exchanger. The present invention features that paint is coated in the surface of heat exchanger and high temperature heat treated to resist corrosionú¼resist scale and raise heat efficiency. The coating contains fluoro resin in 60-70 wt%, adhesion promoting resin 20-25 wt%, heat conducting stuffing 5-10 wt%, and nanometer particle 0.5-3 wt%, and has thickness of 5-15 micron and thermal conductivity of 0.3-1.5 W / m.K. The coating makes condensed water in the heat exchange surface form drops with high heat conductance, and results in high anticorrosion and long service life of the coated heat exchanger.

Owner:DALIAN UNIV OF TECH

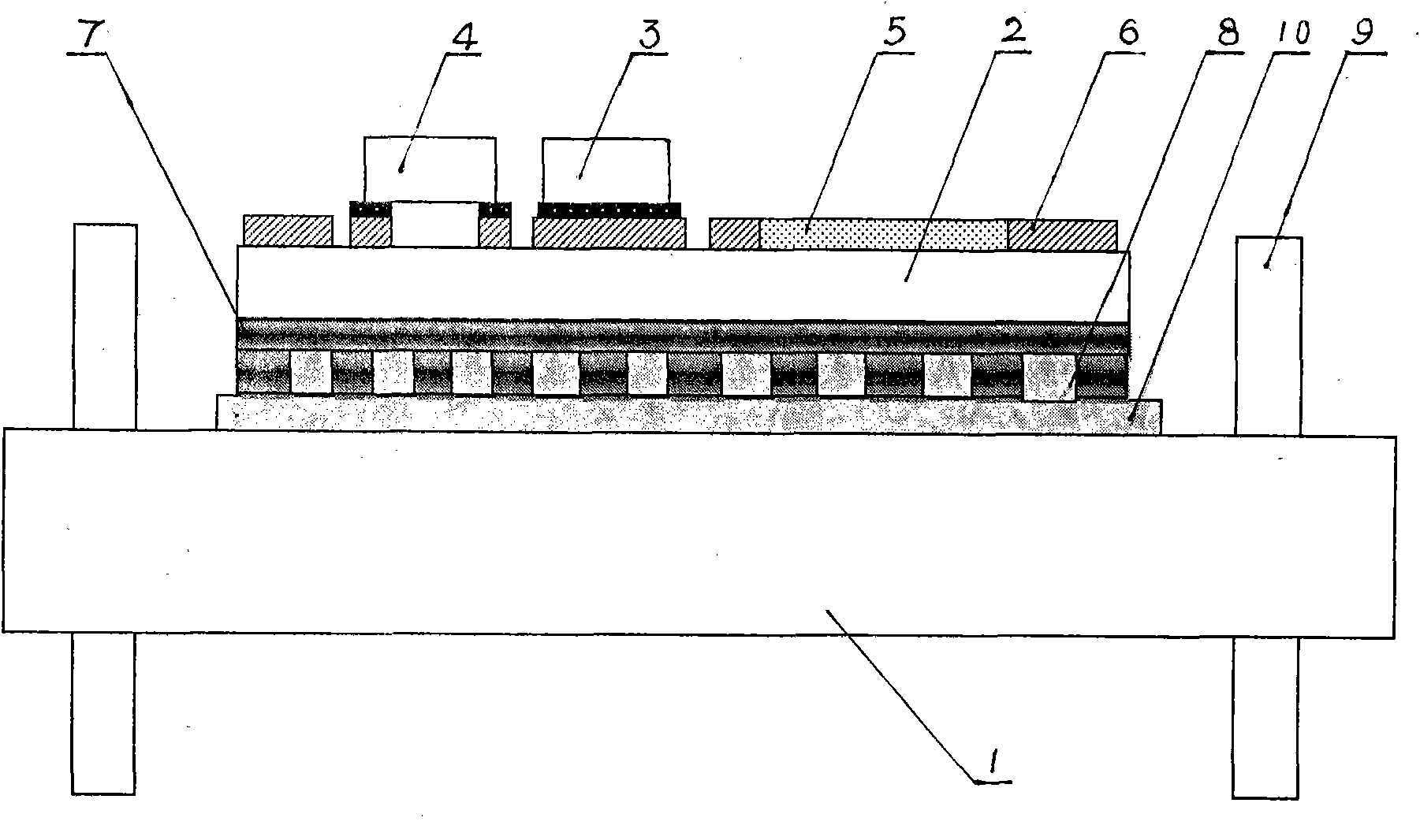

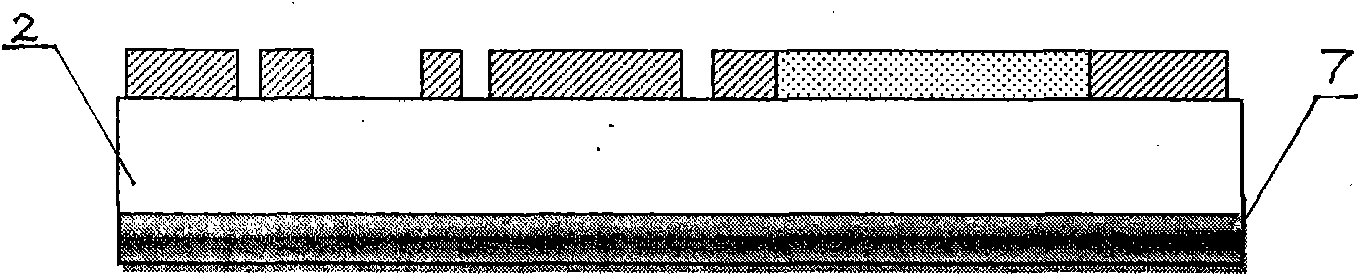

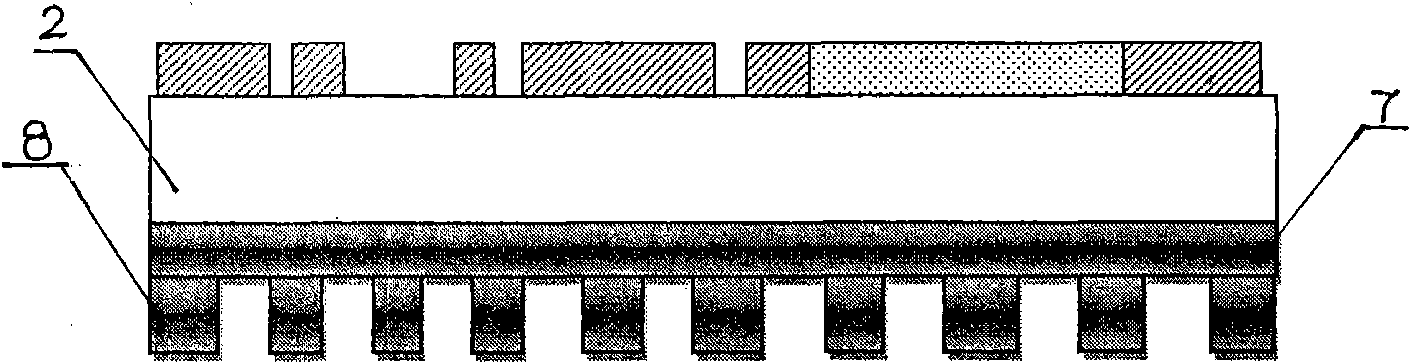

Integration method of high-reliability power hybrid integrated circuit

InactiveCN101866861AExcellent performanceGuaranteed compactnessSolid-state devicesSemiconductor/solid-state device manufacturingHybrid integrated circuitIntegrated circuit

The invention discloses an integration method of a high-reliability power hybrid integrated circuit. The method comprises the following steps of: (1) firstly, washing an original thick film substrate with ultra sound and drying; (2) forming a multilayer Cu-Ni-Cr-Au composite film at the back of a ceramic substrate in a high-vacuum magnetically-controlled sputtering platform in one step by using a high-vacuum sputtering method; (3) selectively sputtering another Cu-Ni-Cr-Au composite film again on the basis so that a multilayer metal film grooved mesh is formed in a selected region; (4) then, annealing at a high temperature to obtain a thick film substrate; and (5) assembling the thick film substrate on a shell base, assembling a semiconductor chip and other separate devices, bonding with silicon-aluminum wires to connect the circuit and seal a lid to obtain a made high-reliability power hybrid integrated circuit. The integrated circuit made by the method has favorable welding system compactness, adhesion, heat conductivity, rapid radiation and circuit reliability and is widely applied to the fields of aerospace, aviation, ships, precise instruments, geological exploration, oil exploration, communication, and the like.

Owner:GUIZHOU ZHENHUA FENGGUANG SEMICON

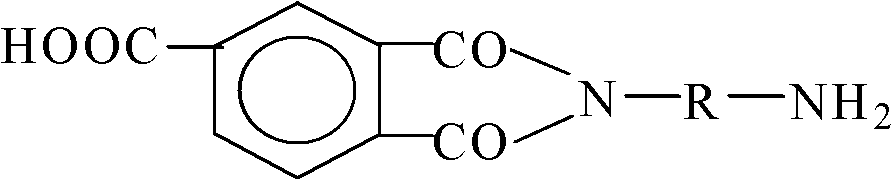

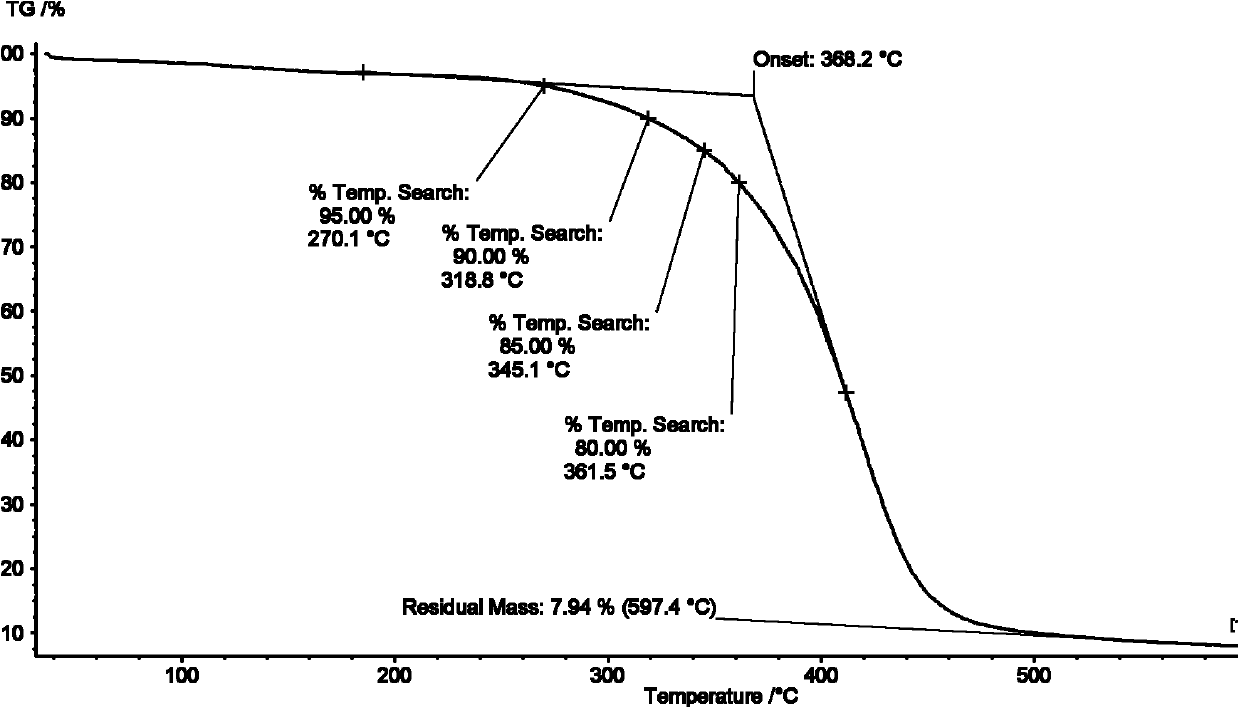

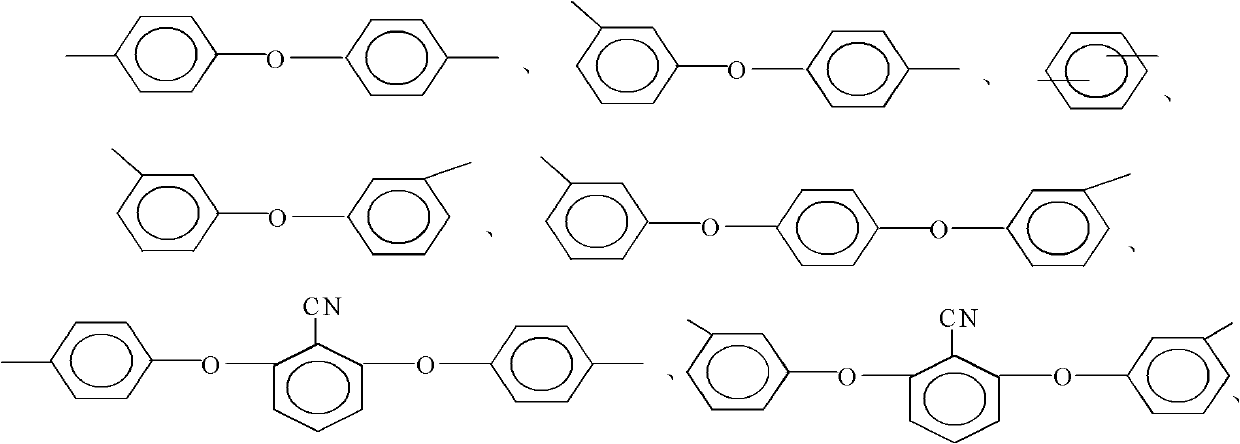

Active phthalimide epoxy solvent-free dripping impregnating varnish and preparation method thereof

InactiveCN101921531AConvenient sourceSimple preparation processEpoxy resin coatingsEpoxyHeat resistance

The invention relates to an active phthalimide epoxy solvent-free dripping impregnating varnish and a preparation method thereof. The varnish has the following components: 10wt%-15wt% of active phthalimide, 35wt%-45wt% of epoxy resin, 5wt%-10wt% of active toughening agent, 5wt%-10wt% of curing agent, 20wt%-45wt% of active diluent. The preparation method comprises the preparation of the active phthalimide and the solvent-free dripping impregnating varnish. The preparation features simple process and low cost and contributes to the realization of industrialized production; in addition, the solvent-free dripping impregnating varnish enjoys excellent comprehensive property, fine manufacturability and cohesiveness, excellent heat resistance and hydrophobicity, thus enjoying bright application prospect in fields such as motors of electric tools, small electric machine and the like.

Owner:DONGHUA UNIV +1

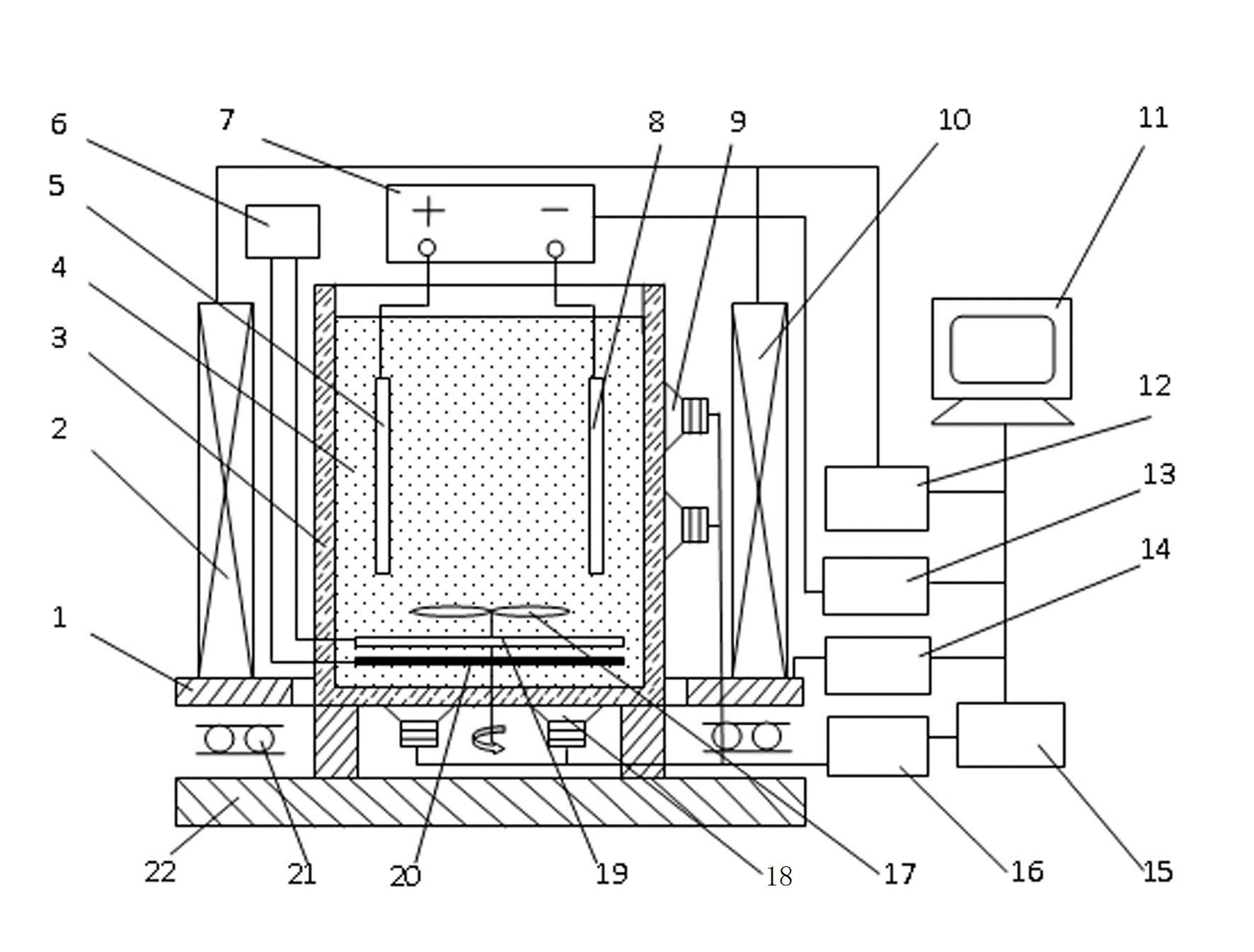

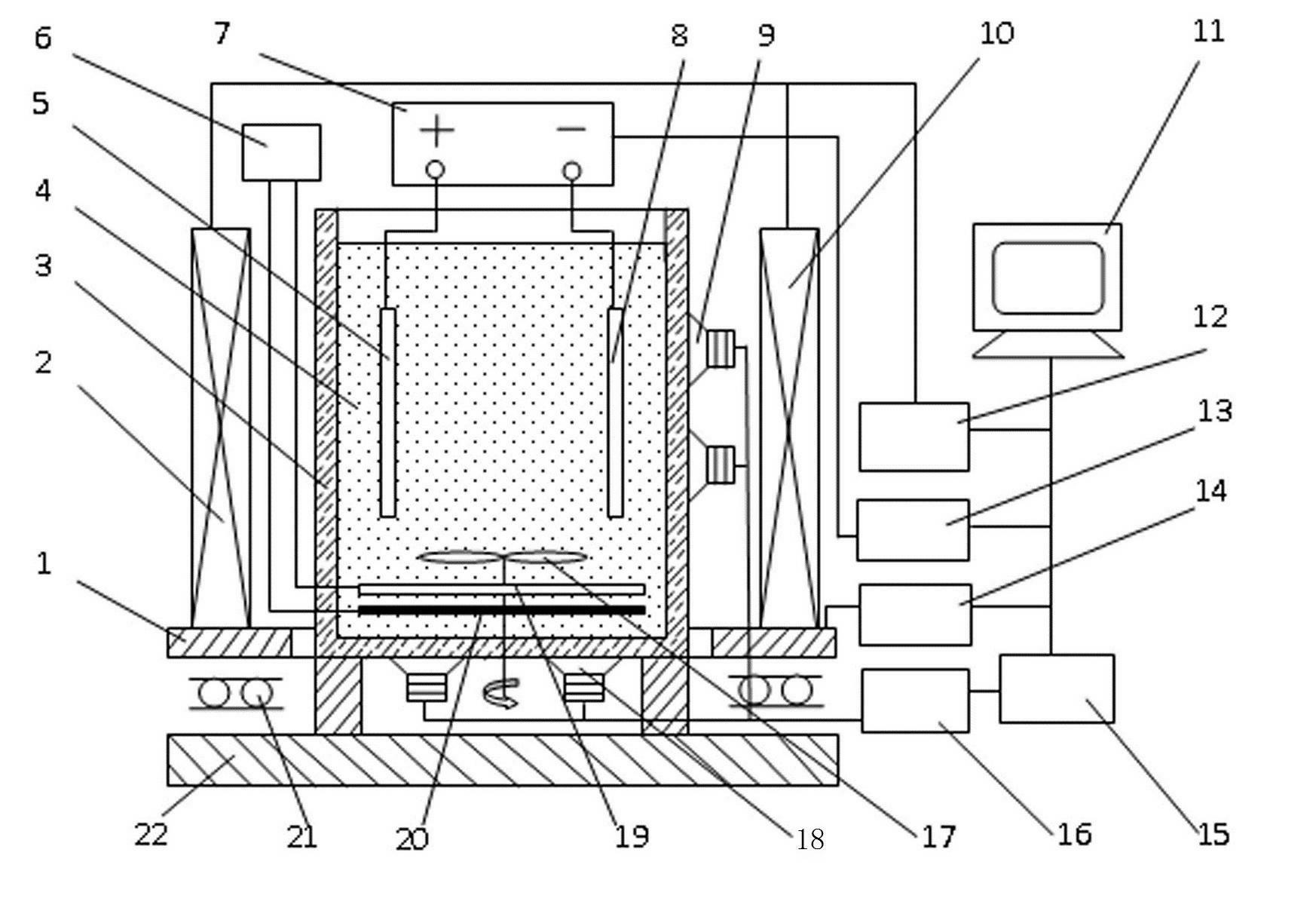

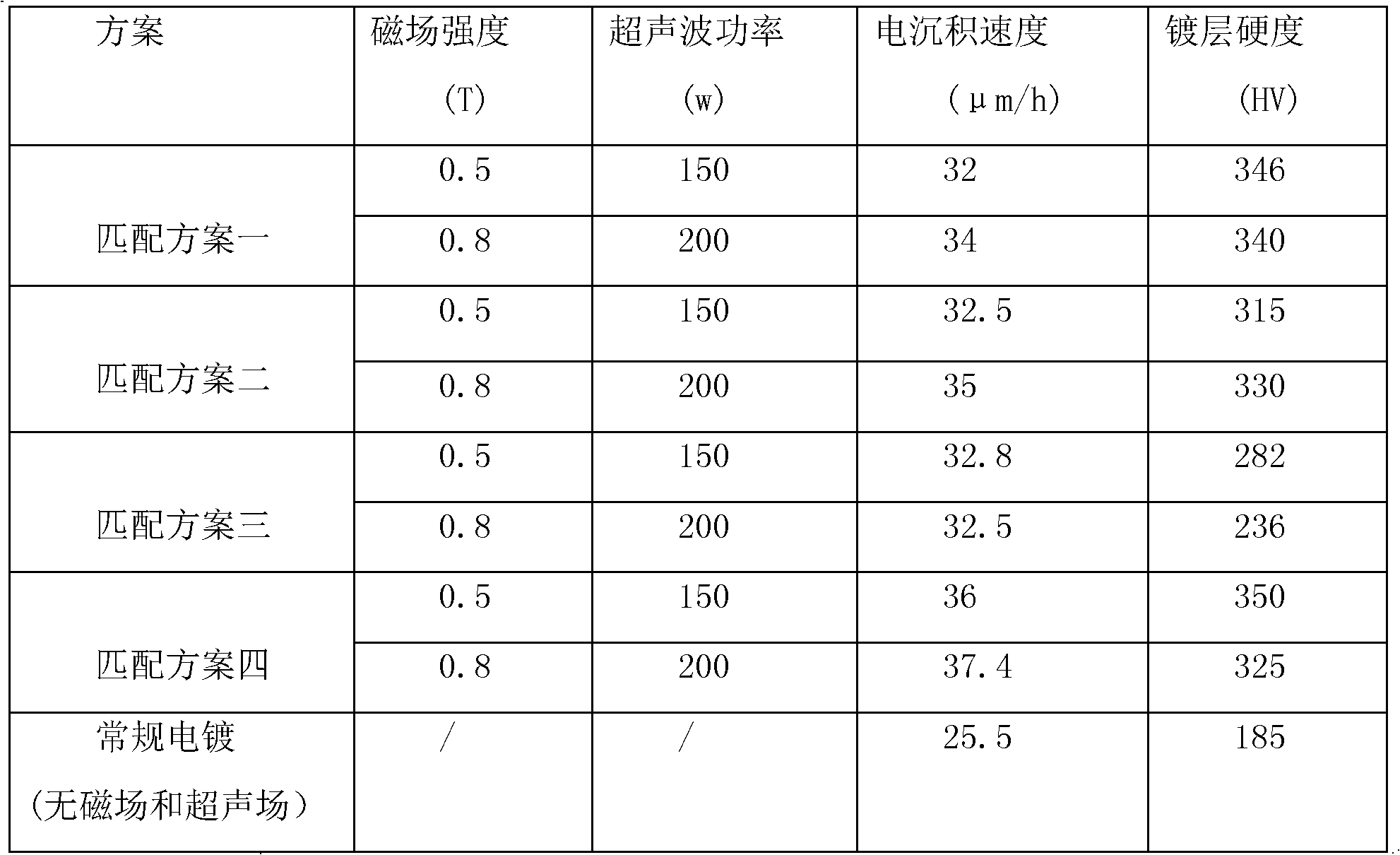

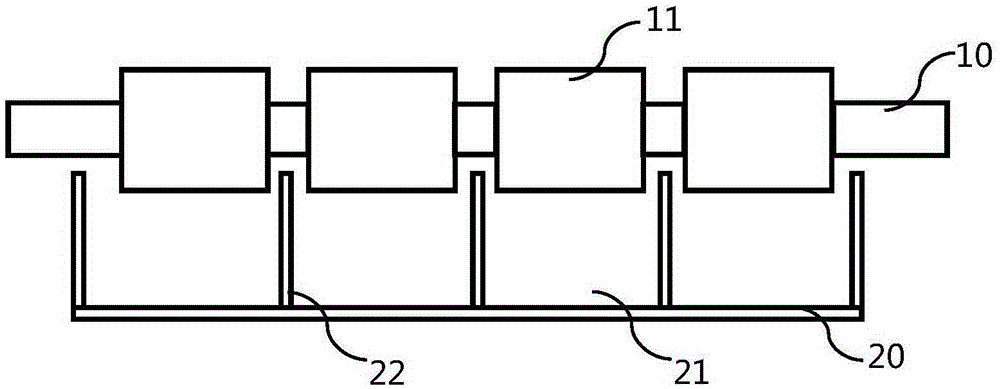

Metal electrodeposition device

The invention discloses a metal electrodeposition device which comprises an electrodeposition tank and a power supply. An electroacoustic transducer system emitting ultrasonic waves parallel or perpendicular to the electric field direction to electrolyte during electrodeposition is arranged on the outer side of the electrodeposition tank, a magnetic pole N and a magnetic pole S for applying the magnetic field parallel or perpendicular to the electric field in the electrolyte during electrodeposition are arranged on the outer side of the electrodeposition tank and are distributed on two sides of the electrodeposition tank correspondingly. The intensity B of the magnetic field applied in the electrolyte by the magnetic pole N and the magnetic pole S ranges from 0.5 to 1.0T. A mixer used for mixing the electrolyte during electrodeposition and a heating system used for keeping the temperature of the electrolyte in the electrodeposition tank stable are arranged in the electrodeposition tank. In the process of metal electrodeposition of a cathode, the ultrasonic waves, the power and the magnetic field jointly act on the electrolyte by selecting the direction of the ultrasonic waves to coordinate and couple with the direction and the intensity of the power and the magnetic field, so that speed and density of electrodeposition are increased.

Owner:HENAN UNIV OF SCI & TECH

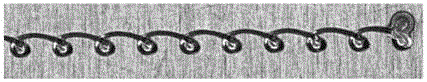

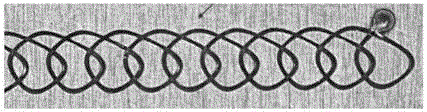

Method for controlling laser welding

ActiveCN105108338AFull flowLower weld stayWelding/soldering/cutting articlesLaser beam welding apparatusHelical lineWeld seam

The invention discloses a method for controlling laser welding. The method comprises the following steps that 1, the weld seam width w of a workpiece to be welded is measured; 2, the locus of laser welding is controlled as x0=x1+delta*cos beta, y0=y1+delta*sin beta, x=x0+R*cos alpha, y=y0+R*sin alpha, wherein w=2R+phi, x0 and y0 serve as coordinates of a point on a straight line, x1 and y1 serve as starting point coordinates of the straight line, delta serves as a point distance of the straight line, beta serves as an inclination angle of the straight line, R serves as a shaking radius, alpha serves as a polar angle, x and y serve as coordinates of a point on a circle (that is a helical line locus), phi serves as a welding point diameter, and delta is smaller than phi. According to the method for controlling laser welding, the locus of a welding helical line is adjusted by adjusting the shaking radius and the point distance for changes of the weld seam width, therefore, a molten pool can flow more fully, the problems of weld seam depression, undercut, point burst and needle holes which are brought by traditional laser welding can be effectively solved, the welding performance is improved, and the quality rate of products is improved.

Owner:UNITED WINNERS LASER CO LTD

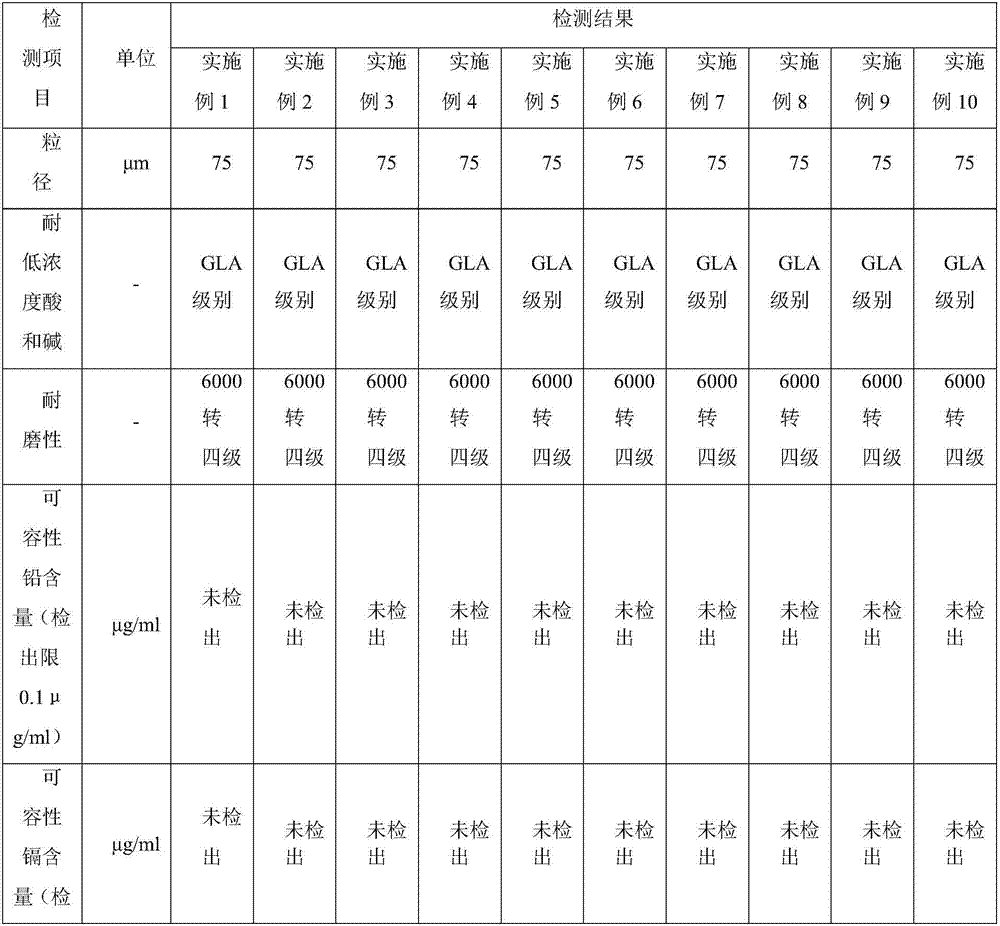

High-performance transparent ceramic whiteware glaze and production method thereof

ActiveCN107162424AImprove thermal shock resistanceHigh melting temperatureMaterials preparationKaolin clay

The invention discloses a high-performance transparent ceramic whiteware glaze and production method thereof, and belongs to the technical field of daily ceramic glazes. The high-performance transparent ceramic whiteware glaze mainly comprises water-milled potassium feldspar, kaolin, calcined talcum, dolomite, barium carbonate, calcined zinc oxide, water-milled quartz, a glaze stabilizer and an expansion coefficient regulator. The production method of the high-performance transparent ceramic whiteware glaze includes the following steps: material preparation, ageing and glaze firing. The high-performance transparent ceramic whiteware glaze produced from the above raw materials has the advantages of high melting temperature, wide melting temperature range of 1290-1330 DEG C, small affection by the fluctuation of the kiln temperature, few pinholes of the glaze surface, bright and smooth glaze surface, adjustable expansion coefficient of the glaze surface, and increase of one stress to the surface of a ceramic body to realize no cracking in the 200-20 DEG C one-shot quick cooling and heating process.

Owner:FUJIAN DEHUA FIVE CONTINENTS CERAMIC MFG CO LTD

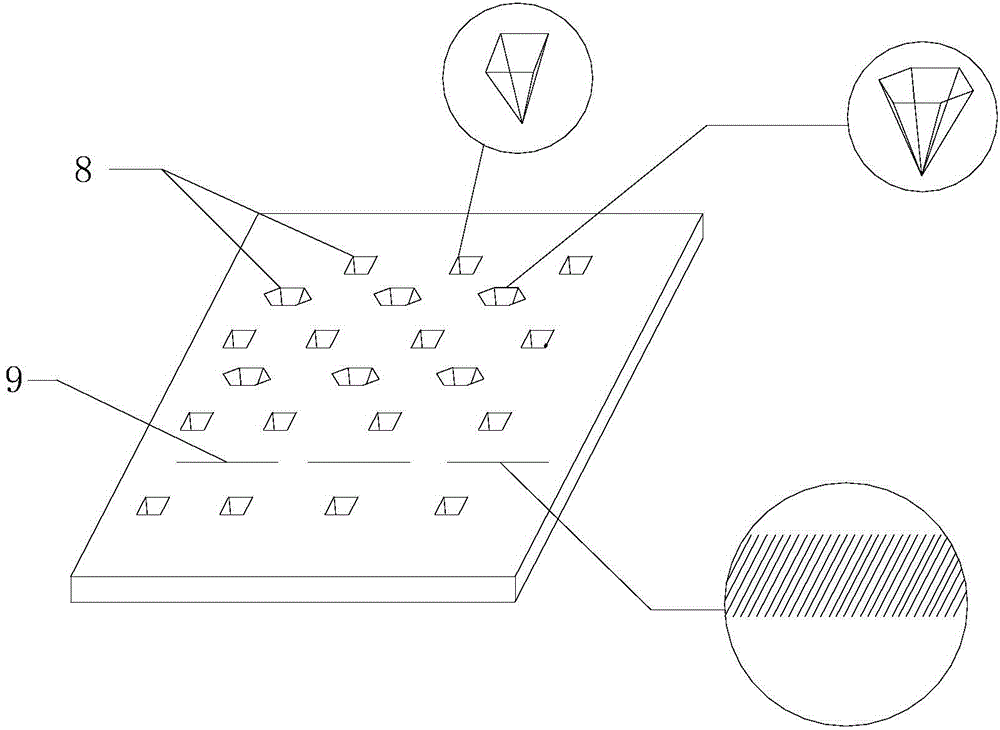

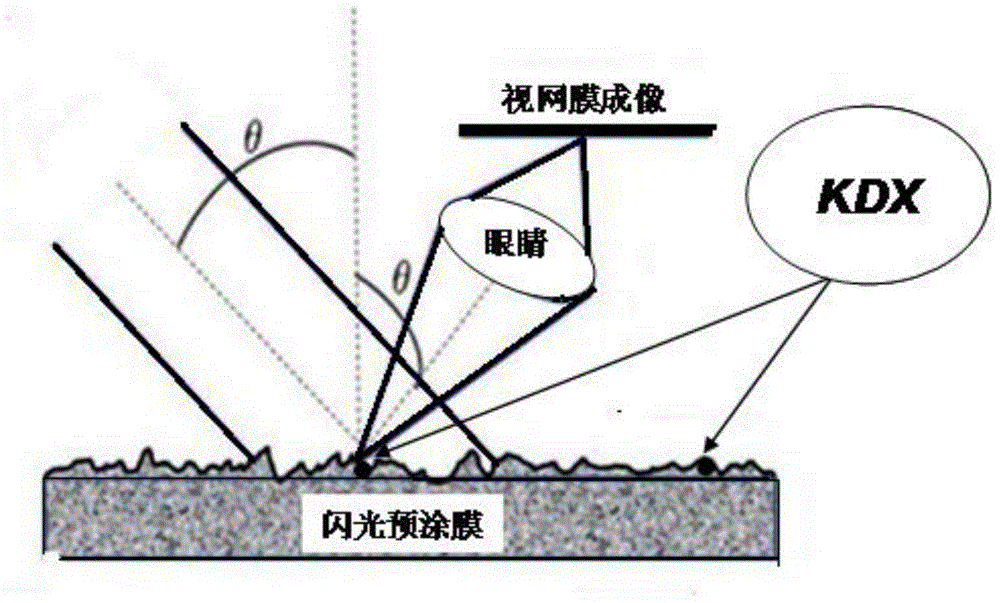

Metallic surface glittering effect simulated pre-coated film for packaging and manufacturing method of metallic surface glittering effect simulated pre-coated film

ActiveCN104553217AHas multiple anti-counterfeiting effectsReduce pinholesFlexible coversWrappersGratingMetal sheet

The invention discloses a metallic surface glittering effect simulated pre-coated film for packaging and a manufacturing method of the metallic surface glittering effect simulated pre-coated film. The metallic surface glittering effect simulated pre-coated film sequentially comprises a printing or coating color layer, an aluminum coated layer, an enhanced aluminum-coated resin layer, a molding resin layer, a film layer, a base coating layer and a hot melt adhesive layer, wherein a glittering pattern with pyramid nicks and an anti-counterfeiting encryption image having the laser holographic effect and with grating nicks are arranged on the molding resin layer, the pyramid nicks are shaped like a rectangular pyramid, a hexagonal pyramid or rectangular pyramid and hexagonal pyramid mixed nicks, the depth of each pyramid nick is 10-20 microns, and the depth of the grating nick is below 1 micron. The metallic surface glittering effect simulated pre-coated film is mainly characterized of having the granular glittering effect, being provided with the glittering point combined pattern designed by computer software, having an anti-counterfeiting function, and being environmentally-friendly, and can be applied to laminated films of stationery, clothes, furniture decoration, package of luxuries, substitute metal sheets and the like.

Owner:张家港保税区康得菲尔实业有限公司

Separator for lithium ion cell

ActiveCN104521029ALower internal resistanceReduce leakage currentCell component detailsElectrolyte accumulators manufactureLithiumInorganic particle

A separator for a lithium ion cell, the separator comprising at least a porous body principally made of inorganic particles, wherein the separator is characterized in that the organic particles are of amorphous configuration. The performance of the separator for a lithium ion cell is such that internal resistance is low, pinholing and flaking is minimal, and current leakage is small.

Owner:MITSUBISHI PAPER MILLS LTD

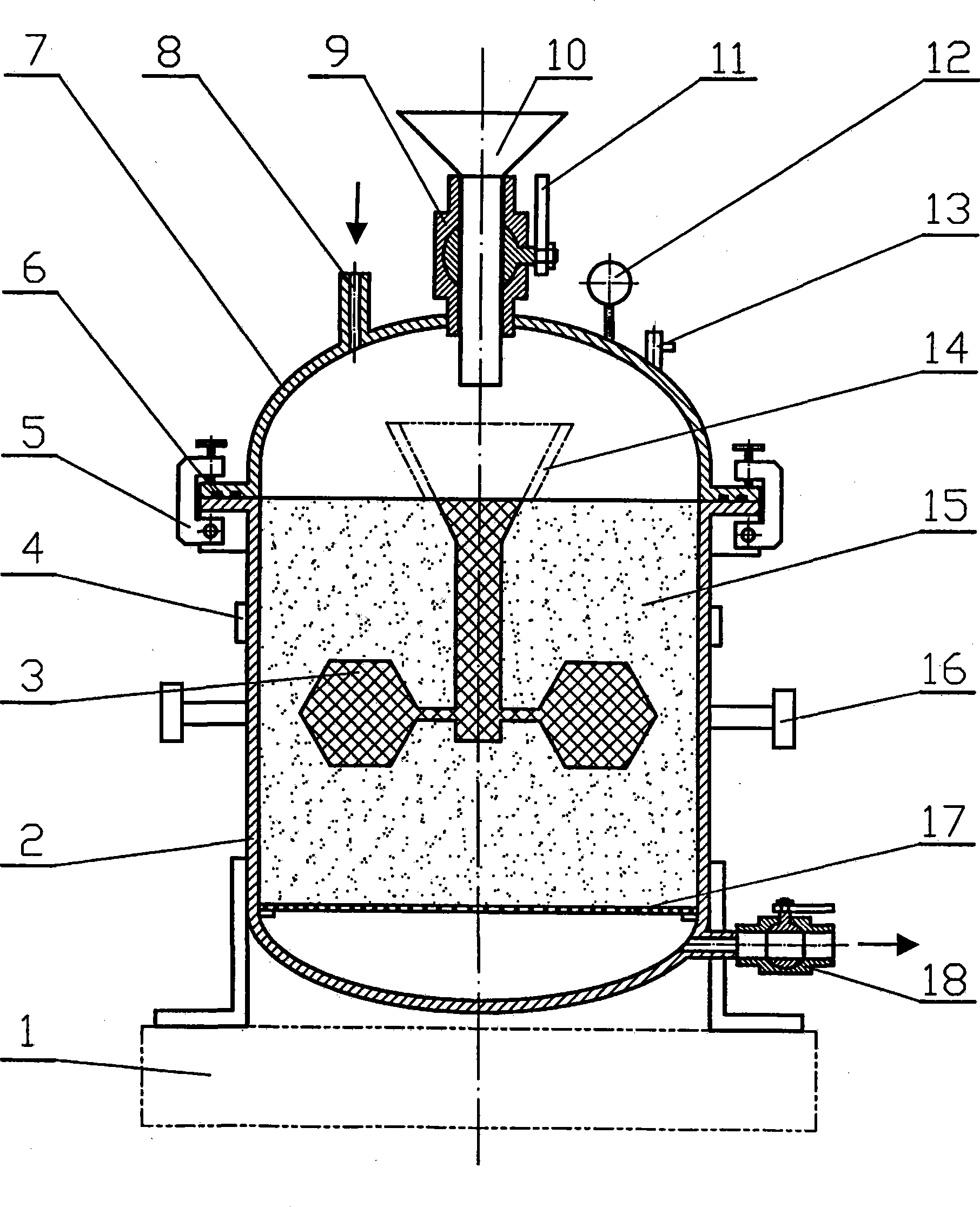

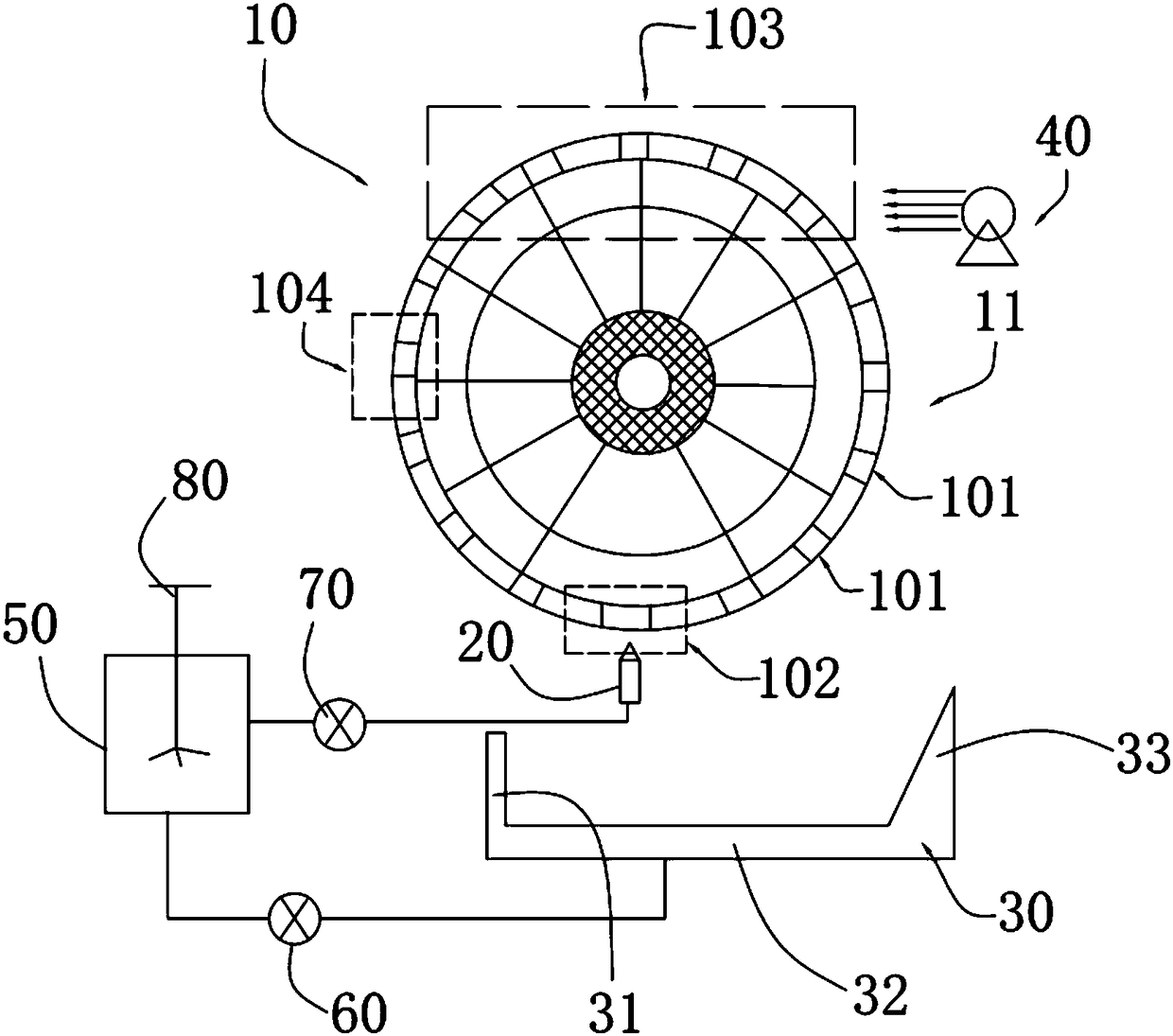

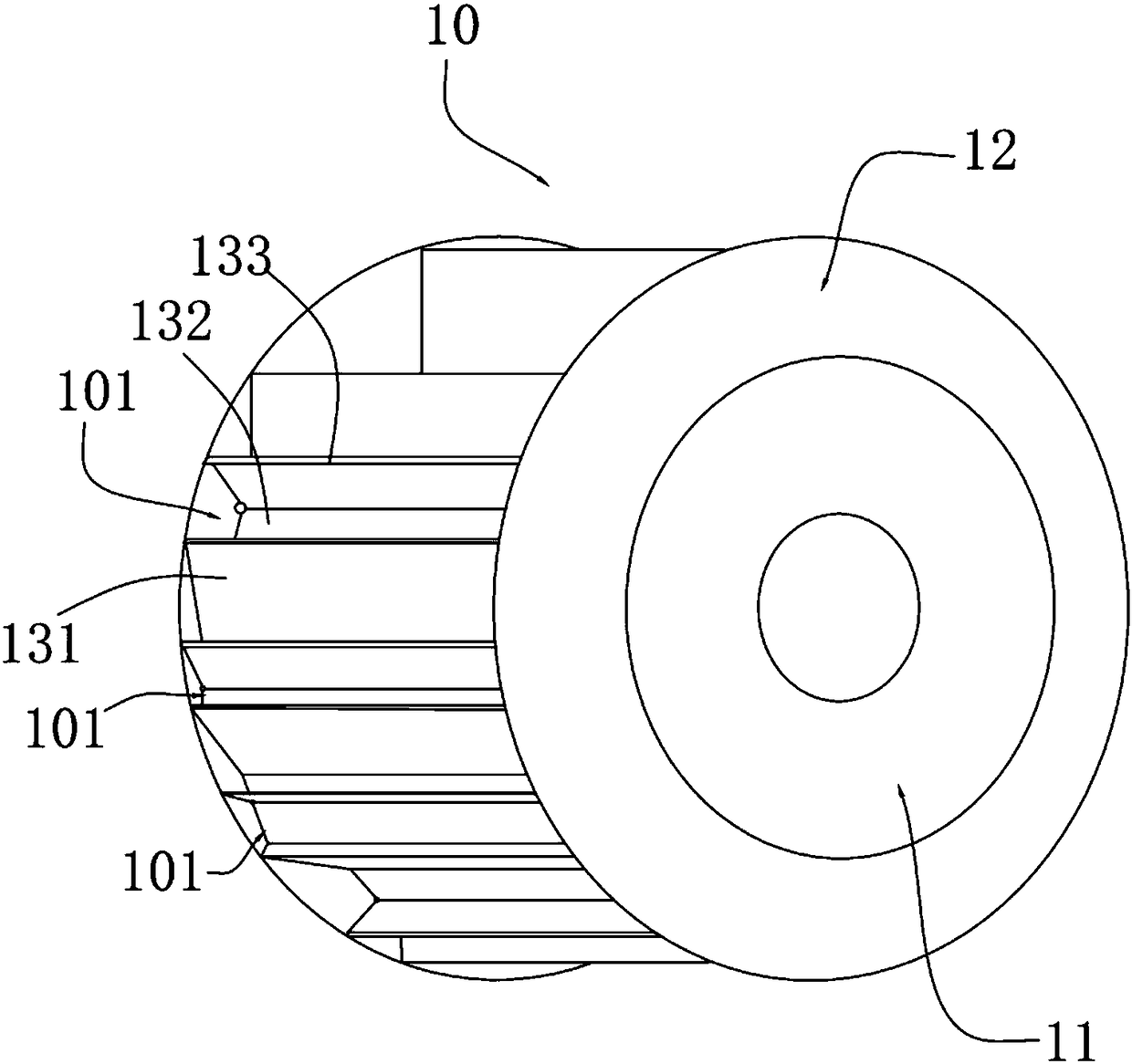

Aluminium alloy or magnesium alloy evaporative-pattern casting compression solidification method and device thereof

InactiveCN101391298AHigh densityGrain refinementFoundry mouldsFoundry coresExhaust valve5005 aluminium alloy

The invention relates to an aluminium alloy or magnesium alloy lost mould casting pressuring solidification method and a device thereof, and the invention belongs to the field of special precision casting. The aluminium alloy or magnesium alloy lost mould casting pressuring solidification method comprises compacting, vacuuming, pouring, pressuring and depressurizing. A pressure resistant sand box of the device is a cylinder-shaped container, the bottom is provided with an exhaust valve, and the inner lower part or the side wall is provided with a ventilation interlayer; the upper surface of a cover of the pressure resistant sand box is respectively provided with a switch valve, a safety valve and a pressure gauge; and the side surface of the pressure resistant sand box or the cover of the pressure resistant sand box is provided with an intake pipe. The aluminium alloy or magnesium alloy lost mould casting pressuring solidification method can obviously reduce casting defects of shrinkage cavity, shrinkage porosity, and the like in aluminium alloy lost mould casting, can effectively reduce pinhole in the aluminium alloy, enhances density of the casting, thins alloy crystal grains, and improves the surface quality and mechanical property of the aluminium alloy or magnesium alloy lost mould casting. The device simplifies lost mould casting pressuring solidification technique, and low production cost, convenient operation, good sealing effect, short sealing time of the sand box and fast pressuring speed.

Owner:HUAZHONG UNIV OF SCI & TECH

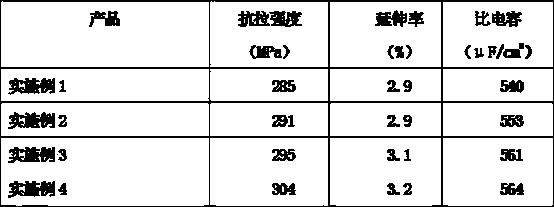

Low-manganese aluminum alloy for cathode foil and preparation method thereof

The invention relates to a low-manganese aluminum alloy for a cathode foil and a preparation method thereof. The low-manganese aluminum alloy is characterized by comprising the following chemical components in percentage by weight: 0.30-0.60% of Mn, 0.20-0.40% of Fe, 0.10-0.20% of Cu, Si not higher than 0.15%, Mg not higher than 0.08%, Zn not higher than 0.05%, Ti not higher than 0.15%, other impurity elements with single content not higher than 0.05%, other impurity elements with total content not higher than 0.15%, and the balance of Al. According to the low-manganese aluminum alloy of the present invention, the content of alloy elements is reduced, so that the alloy strength is reduced, the rolling force during rolling is reduced, the processing difficulty is reduced, and the energy is saved; and the cathode foil produced by the low-manganese aluminum alloy has the advantages of good surface quality, no dust, uniform structure and high specific capacitance.

Owner:广西南南铝加工有限公司

Alterant for ADC12 aluminum alloy and alteration method of alloy

The invention relates to an alterant for an aluminum alloy and an alteration method of the alloy, and particularly relates to an alterant for an ADC12 aluminum alloy and an alteration method of the alloy. The invention aims to solve the problems that an existing alterant for the ADC12 aluminum alloy is unstable in refining effect and easy to decline, and an ADC12 aluminum alloy as-cast structure is massive alpha-Al treelike crystal and flaky cocrystallized silicon and is poor in mechanical property. The alterant of the ADC12 aluminum alloy, which is disclosed by the invention, consists of an Al-5Ti-B intermediate alloy and an Al-10RE intermediate alloy. The alteration method comprises the following steps: 1, smelting; 2, refining; 3, adding the Al-5Ti-B intermediate alloy; 4, adding the Al-10RE intermediate alloy; and 5, pouring. The alterant disclosed by the invention has the advantages that 1, the refining effect is stable, 2, the problems of serious separation and poor mechanical property of the ADC12 aluminum alloy are solved, and the tensile strength is improved by 25-30%, and 3, the alterant is easy to obtain and the cost can be saved. According to the alternant and the alteration method, the ADC12 aluminum alloy with excellent property can be obtained.

Owner:HARBIN INST OF TECH +1

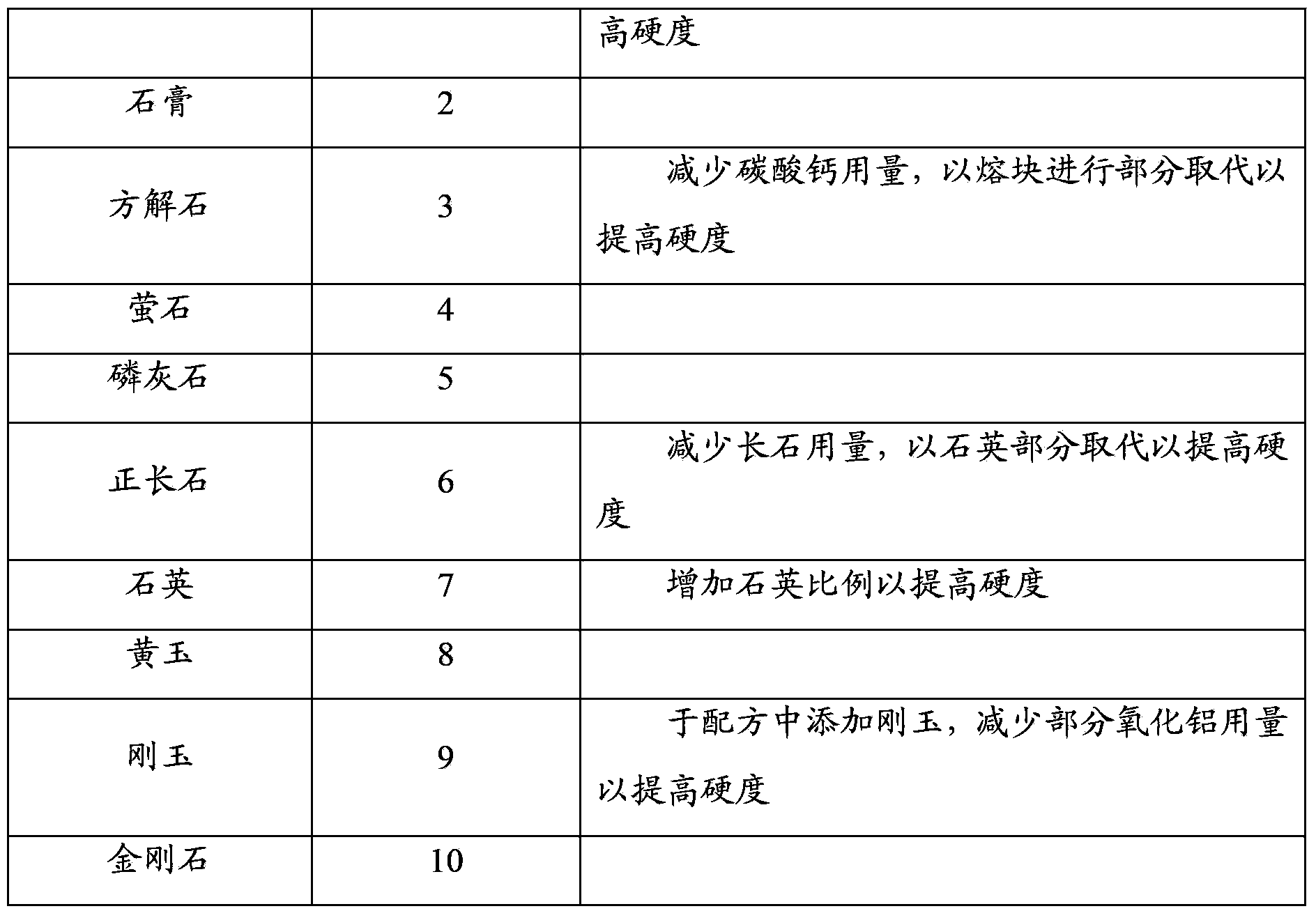

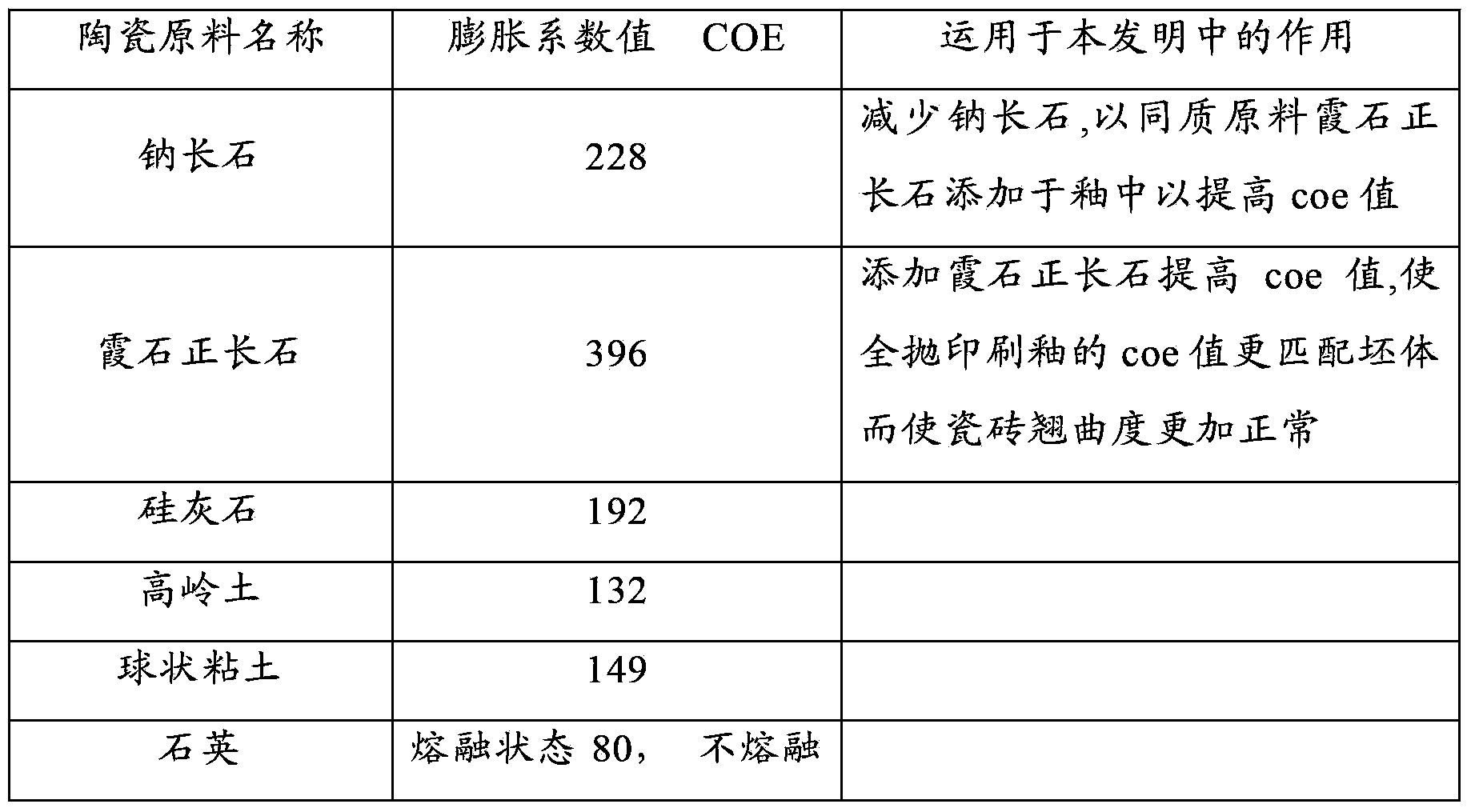

Novel printing glaze material and production method thereof

The invention provides a novel printing glaze material and a production method thereof. The novel printing glaze material consistent with standards is produced by putting the following components into a ball mill for grinding, wherein the components are as follows in percentage by weight: 36% to 42% of albite, 8% to 10% of nepheline orthoclase, 6% to 8% of wollastonite, 4% to 8% of kaolin, 2% to 5% of ball clay, 4% to 7% of quartz, 3% to 5% of aluminium oxide, 5% to 8% of corundum, 8% to 10% of calcium carbonate, 1% to 2% of barium carbonate, 4% to 10% of clinker and 6% to 10% of fluxing agent. The produced novel printing glaze material solves the problems of needle hole, poor permeability, poor sewage suction performance, poor abrasive resistance and poor warping degree.

Owner:CARLOBBIA GLAZE KUNSHAN

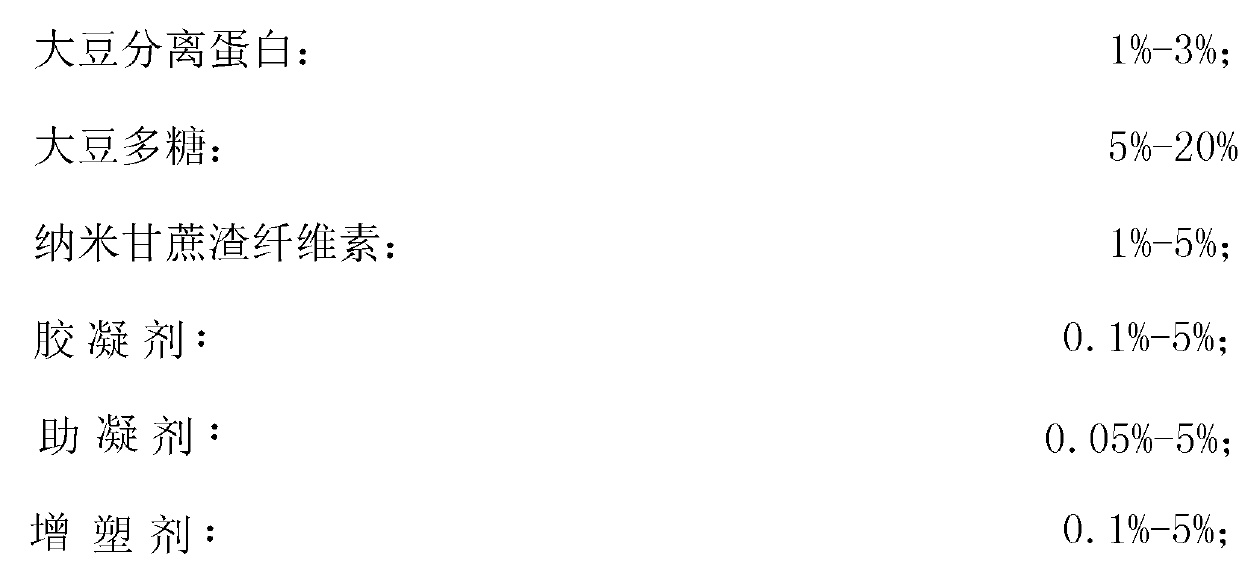

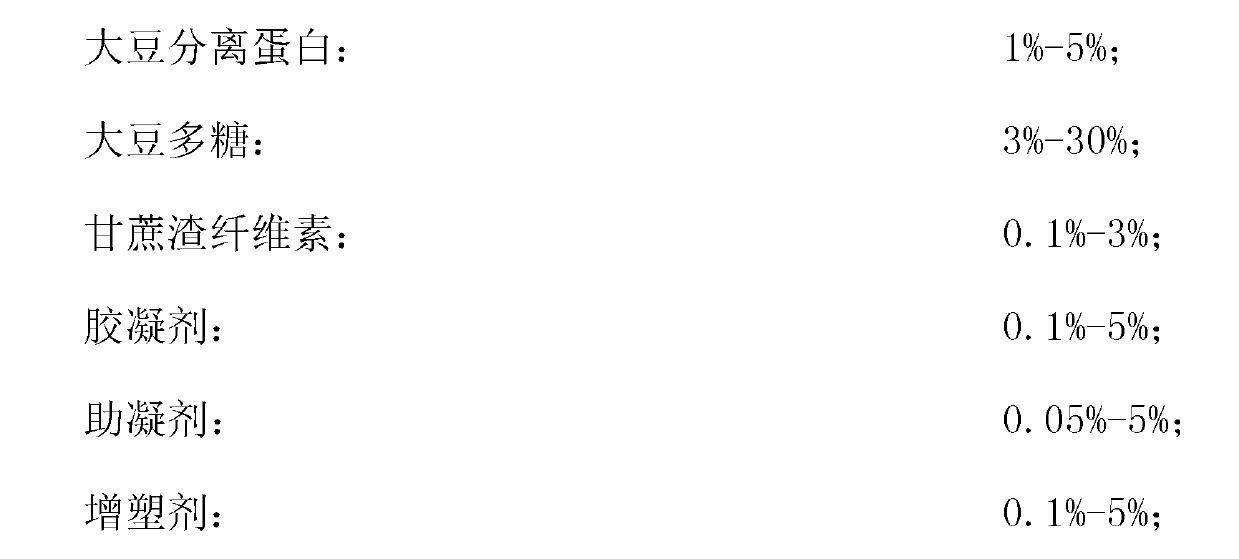

Plant empty capsule and preparation method thereof

InactiveCN103127029AHigh barrierImprove mechanical propertiesCapsule deliveryFood shapingCellulosePlasticizer

The invention discloses a plant empty capsule and a preparation method thereof. The plant empty capsule takes soy isolate protein, soybean polysaccharide and bagasse cellulose which are of different proportions as main raw materials. The preparation method comprises the following steps of a. after mixing the soy isolate protein, the soybean polysaccharide and nanometer bagasse cellulose, and adding a plasticizer so as to prepare and obtain a glue solution I; b. adding a gelling agent and a coagulant aid into deionized water so as to prepare and obtain a glue solution II; c. mixing the glue solution I and the glue solution II so as to prepare and obtain a glue solution III; d. putting the glue solution III at 40-50 DEG C and decompressing and defoaming; and e. preparing the empty capsule through a membrane dipping manner.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

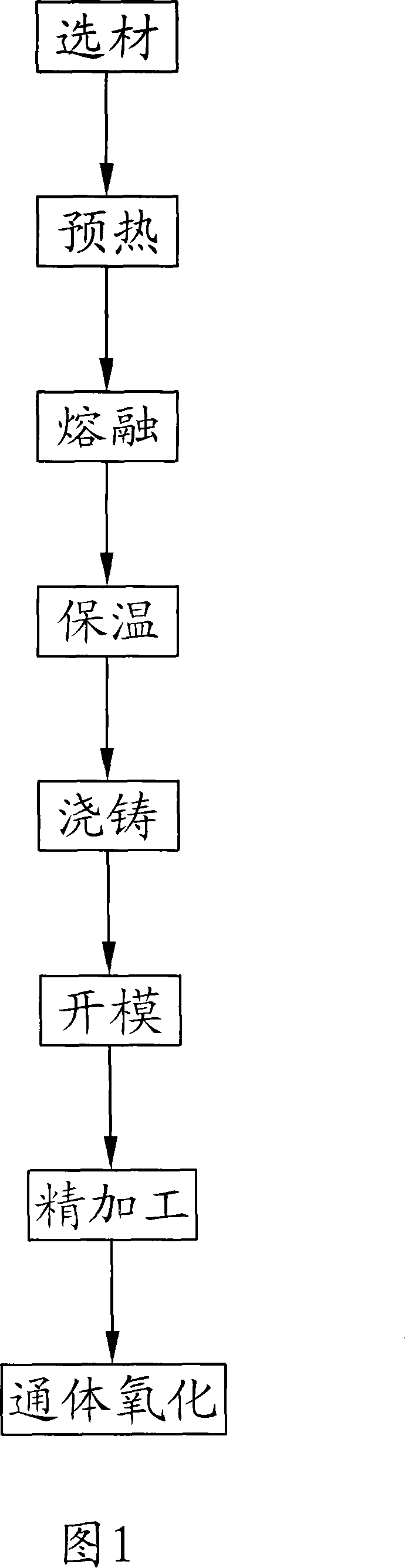

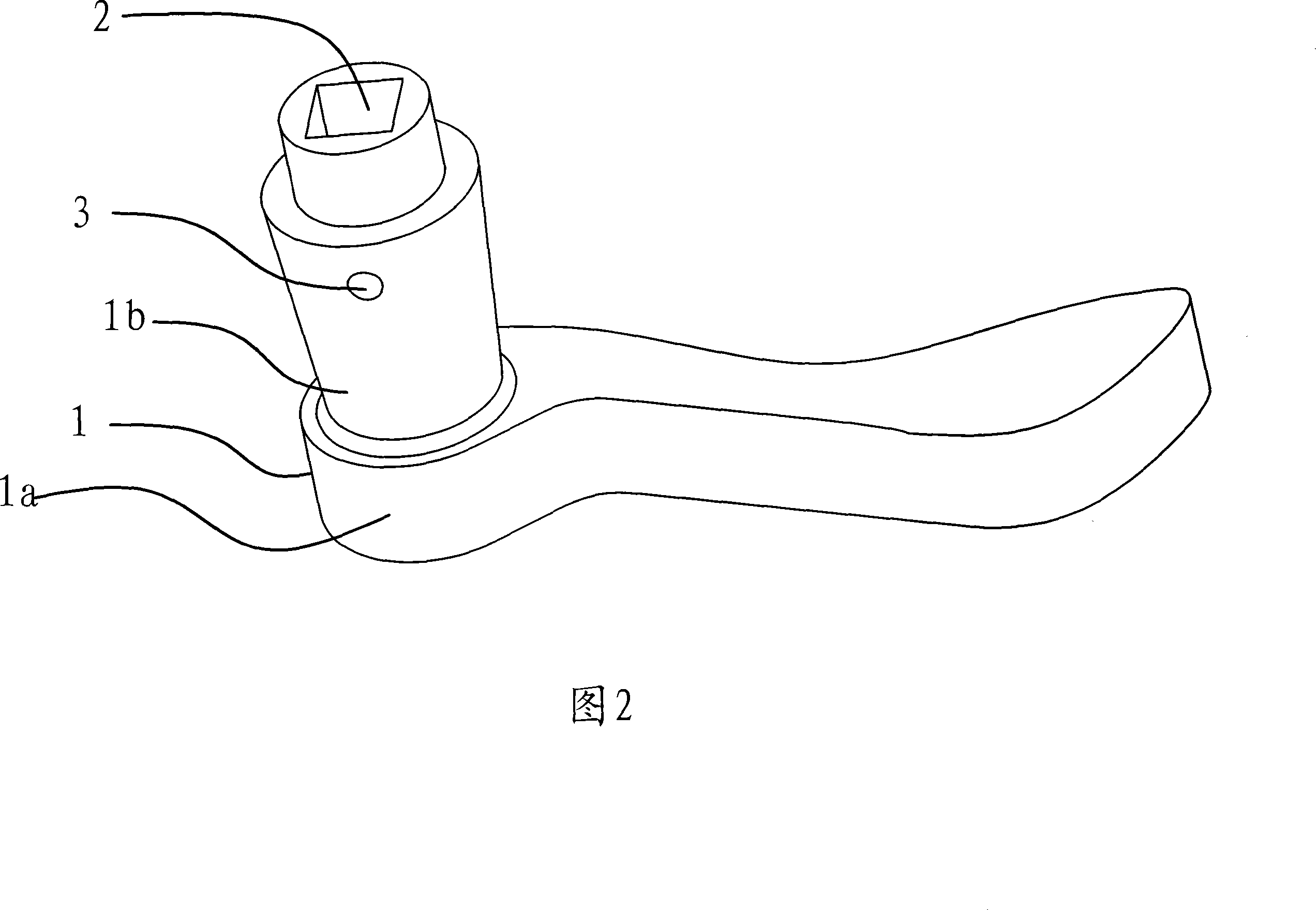

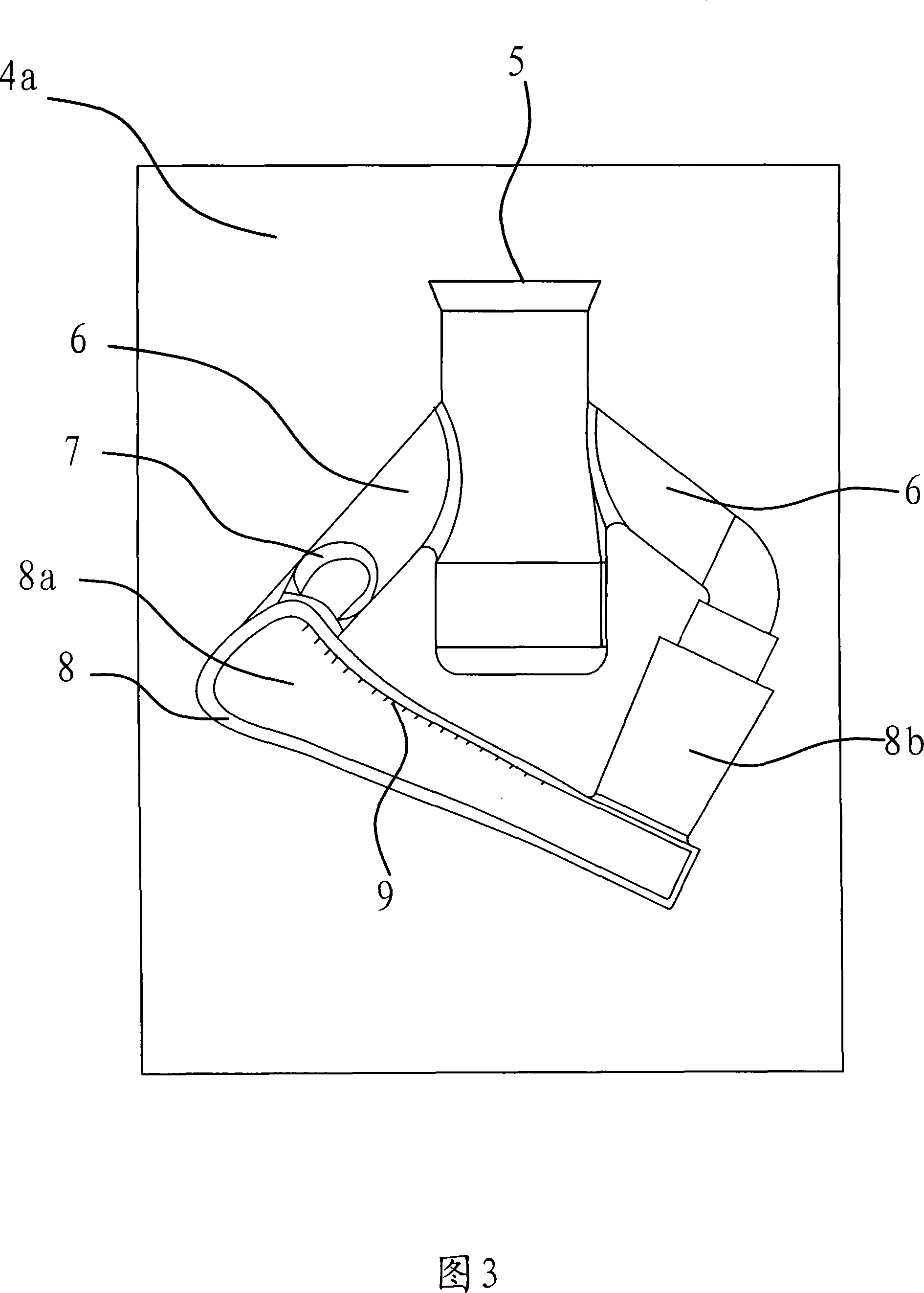

Manufacturing method of stainless aluminum handle, product and module thereof

InactiveCN101224539AImprove mechanical propertiesGood appearanceWing handlesFoundry mouldsMachiningMaterials science

The invention provides a manufacturing method of a stainless aluminium handle, a product and a die thereof, which belongs to the mechanical technical field. The manufacturing method of the stainless aluminium handle comprises the steps of material selection, melting, pouring, finish machining, oxidation, etc. The invention also provides a handle which is fabricated by the manufacturing method and a die used for fabricating the handle; the manufacturing method of the stainless aluminium handle has simple process flow and reasonable design; the fabricated product has good tensile strength and beautiful appearance; the die has long service life and is not easy to damage.

Owner:郑金星

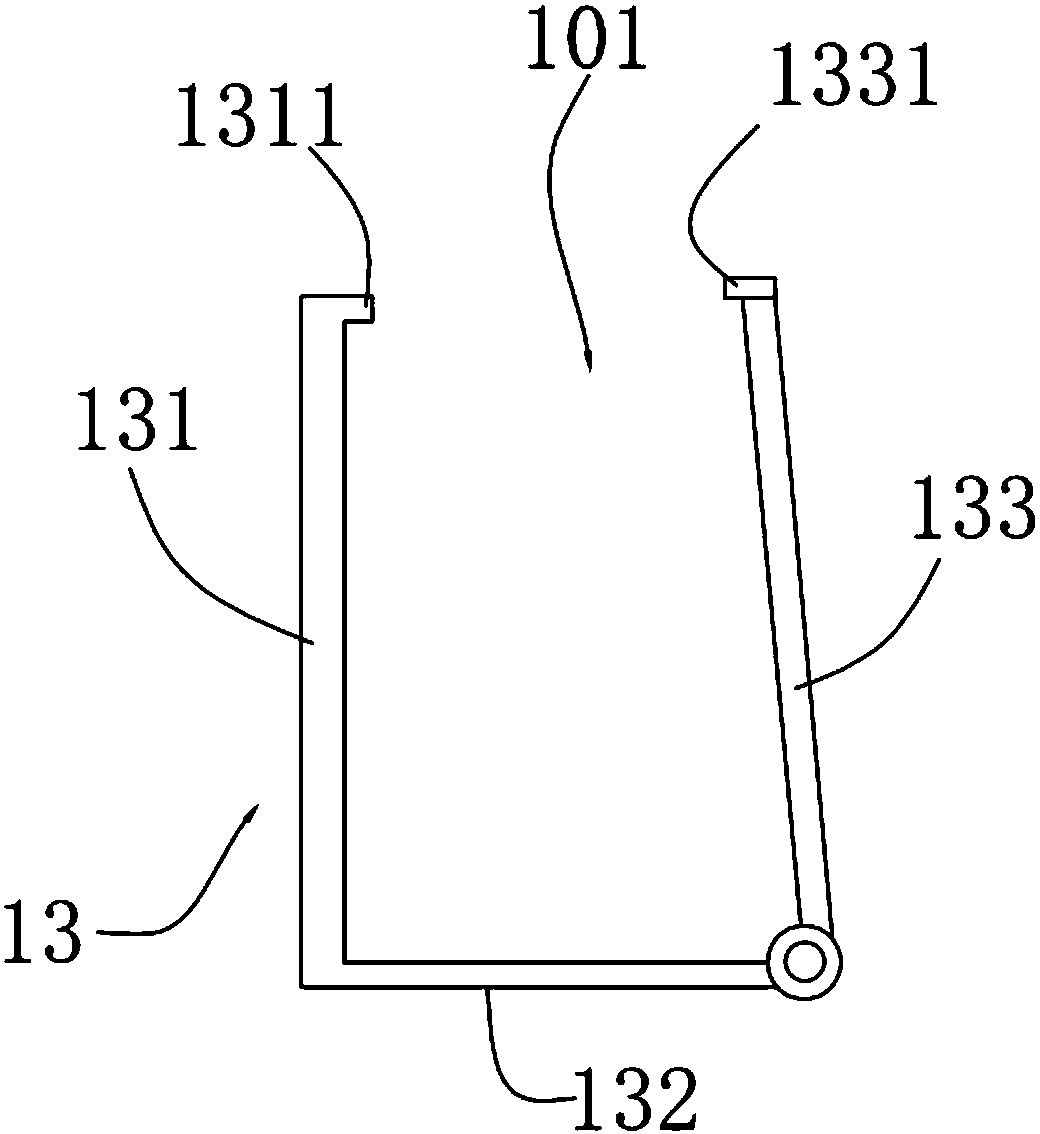

Ceramic slurry jetting forming device

InactiveCN108274584AReduce pinholesSimple structureAuxillary shaping apparatusClay mixing apparatusAutomatic controlMetallurgy

The invention provides a ceramic slurry jetting forming device. The ceramic slurry jetting forming device comprises a rotating component used for fixing multiple molds, and multiple nozzles used for slurry jetting; the multiple molds rotate along with the rotating component, and when slurry jetting openings of the molds right face the nozzles, the nozzles jet the slurry into the molds to form blank bodies. According to the ceramic slurry jetting forming device, the nozzles are used for jetting the slurry into the slurry jetting openings of the molds, the blank bodies are formed in the molds, the structure is simple, automatic control is easy, production efficiency can be improved, and manual cost is reduced.

Owner:许光权

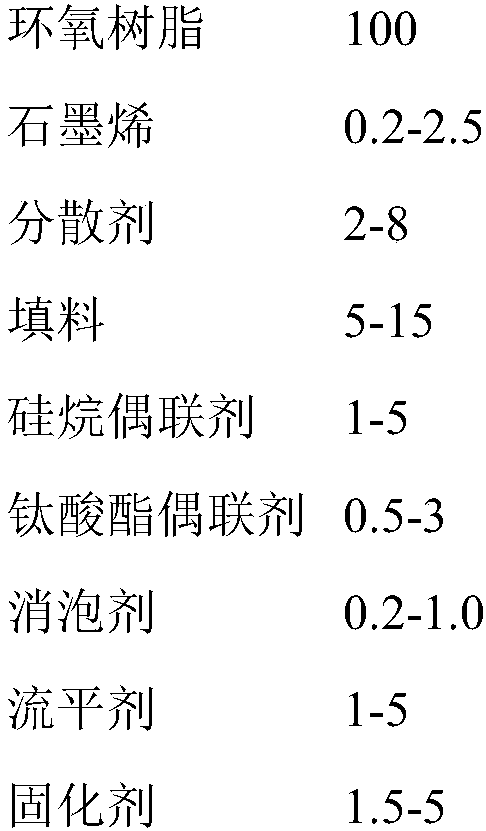

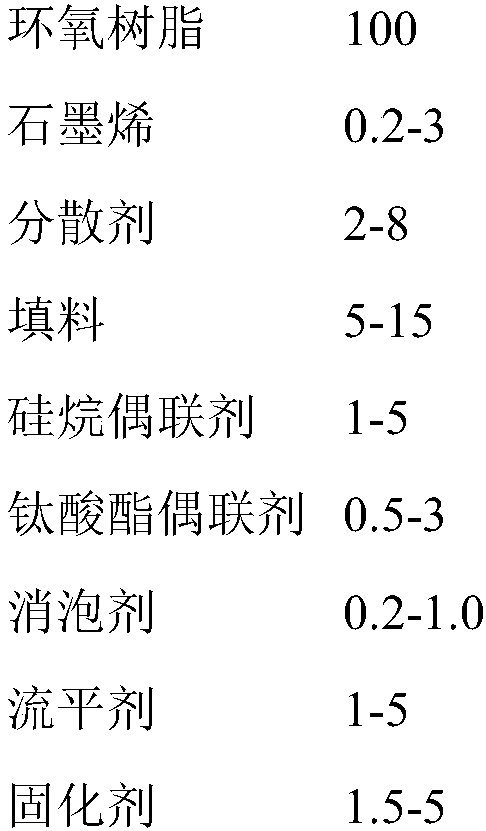

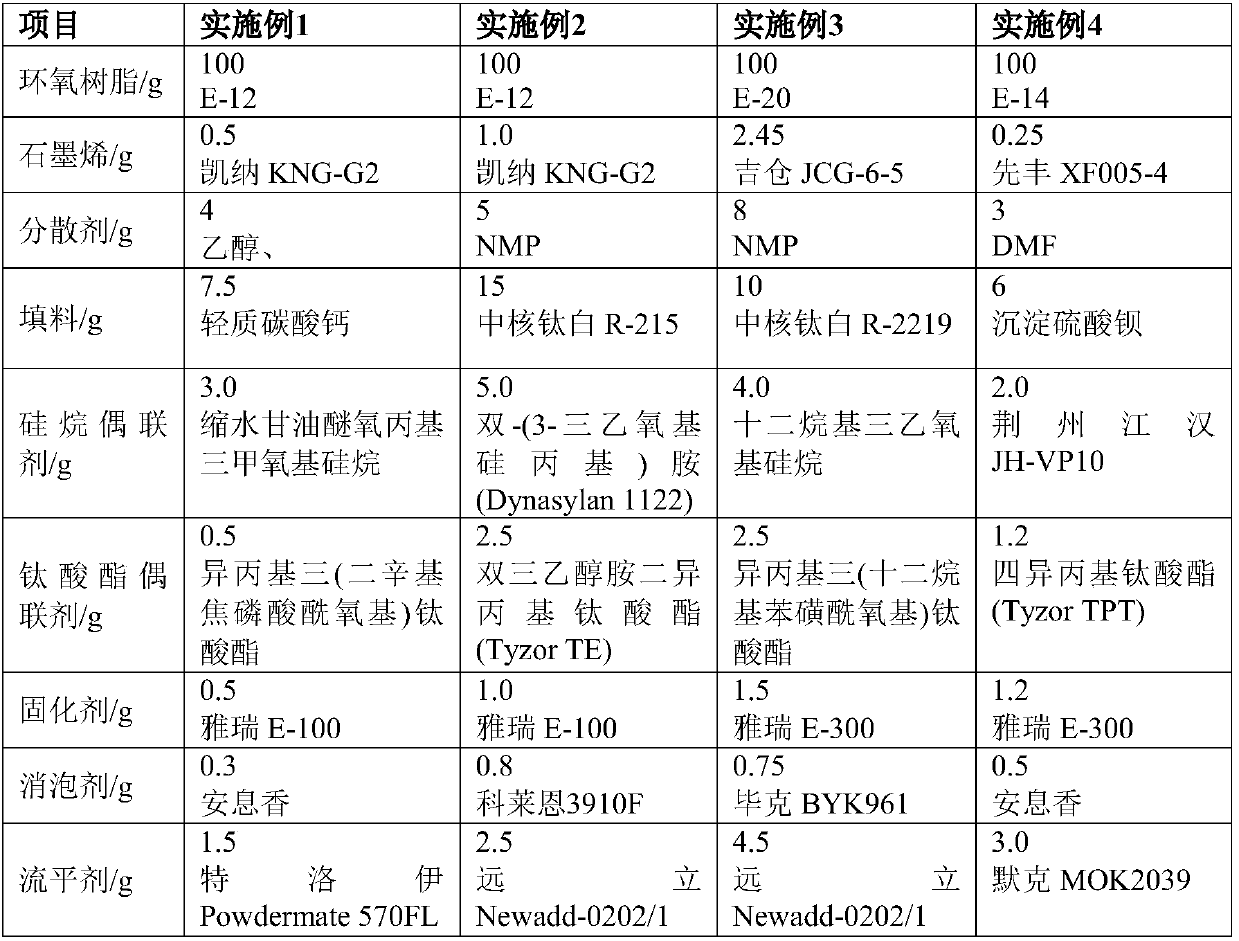

Graphene conductive powder coating before wooden product coating as well as preparation and application thereof

InactiveCN107760164AAvoid bloomingHigh strengthPowdery paintsEpoxy resin coatingsEpoxyConductive coating

The invention provides a graphene conductive powder coating before wooden product coating as well as preparation and application thereof. The conductive powder coating is composed of the following components: epoxy resin, graphene, a dispersing agent, a filler, a silane coupling agent, a coupling agent of organic titanate, a flatting agent, a curing agent, an antifoaming agent and the like. The conductive powder coating can be applied to conductive treatment before wooden product coating, and the wooden product is treated and dried and cured to form a flat and dense conductive coating on the surface. The conductive powder coating is capable of closing pores on the surface of the wooden product base material and does not diffuse and permeate on the surface, so that the conductivity performance on the surface of the base material is improved, the electrostatic spraying coating quality of the wooden product is improved, phenomena such as pinholes, bubbles and cracking occurring in the coating flatting and curing process are avoided, and the adhesive force between the wooden product base material and the coating is promoted. The graphene conductive powder coating is excellent in hardness and resistance, is capable of improving the durability of the wooden products and can be widely applied to coating treatment industries of the wooden products.

Owner:杭州五源科技实业有限公司 +2

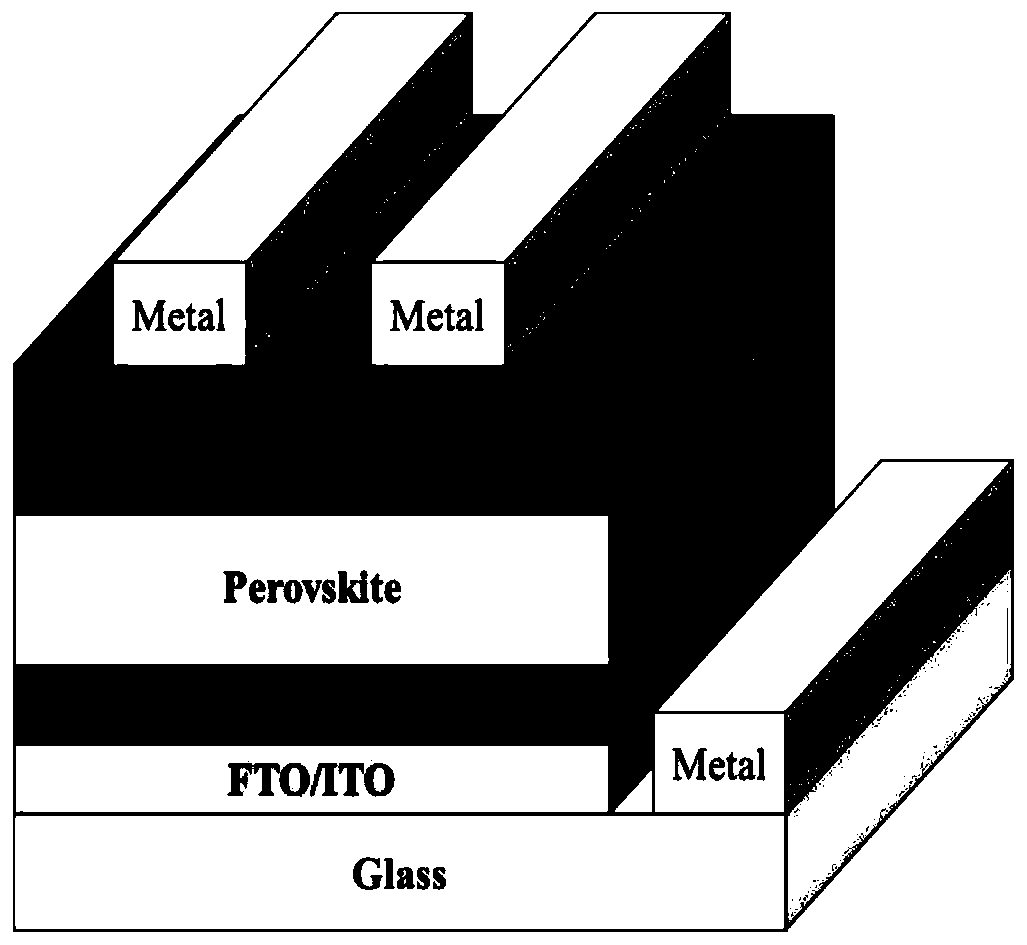

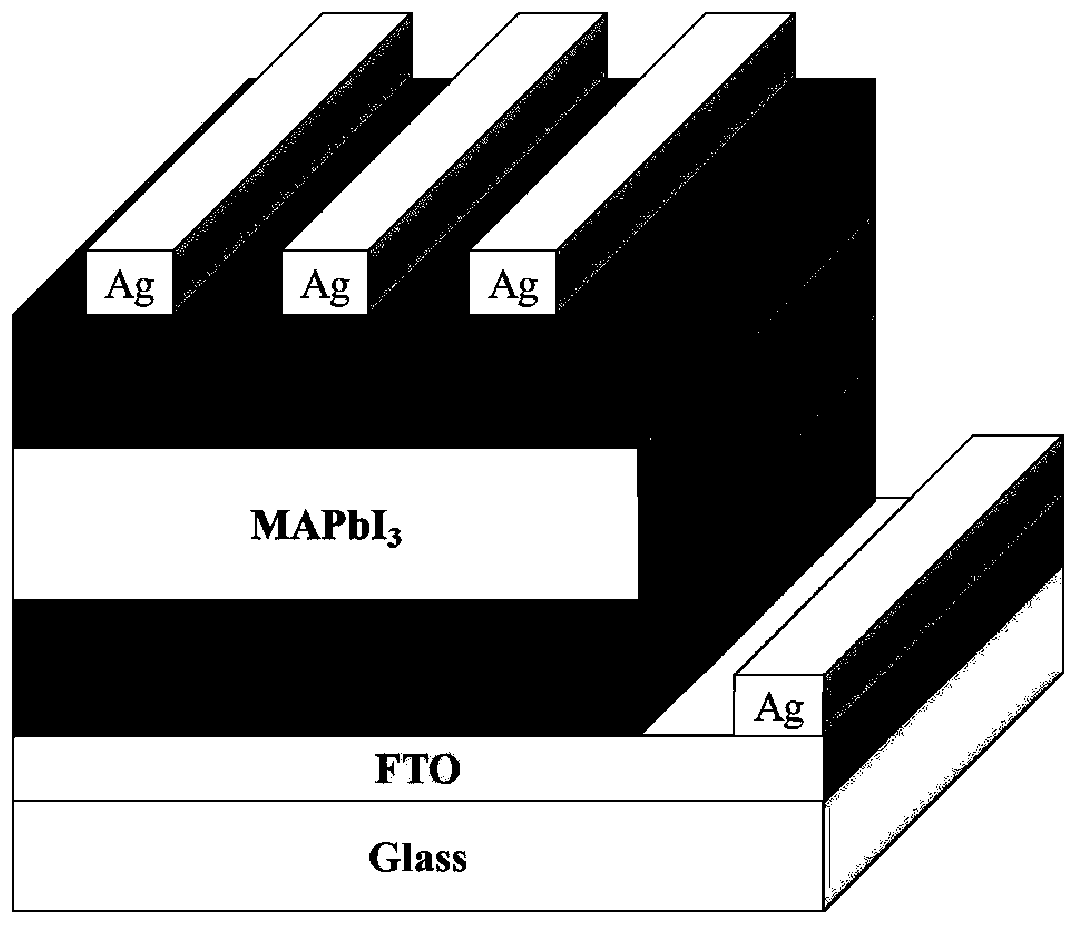

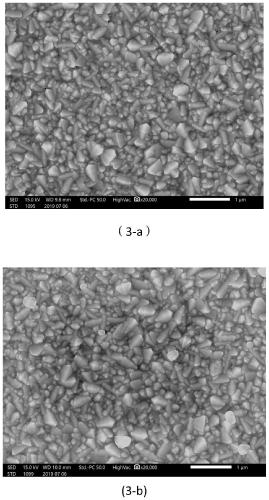

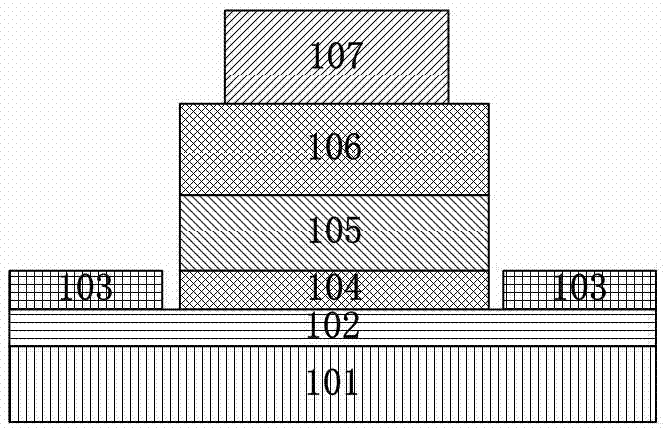

Inversion perovskite solar cell containing alkali metal halide hole modification layer and preparation method thereof

PendingCN111223990AImprove performanceEasy to prepareSolid-state devicesSemiconductor/solid-state device manufacturingMetallic electrodePerovskite solar cell

The invention discloses an inversion perovskite solar cell containing an alkali metal halide hole modification layer. The perovskite solar cell comprises a conductive substrate, a hole transport layer, a perovskite light absorption layer, an electron transport layer and a metal electrode which are stacked in sequence, wherein the hole transport layer is made of nickel oxide, a hole transport layermodification layer is further arranged between the hole transport layer and the perovskite light absorption layer, and the hole transport layer modification layer is made of alkali metal halide. Theinvention also provides a preparation method of the inversion perovskite solar cell containing the alkali metal halide hole modification layer. By adding the alkali metal halide hole modification layer, the adhesive force between the nickel oxide and the perovskite layer is enhanced, pinholes in the surface of the nickel oxide thin film are reduced, and the interface recombination loss of carriersis reduced, so the overall performance of the perovskite solar cell is effectively improved. The method for preparing the perovskite solar cell is simple and low in cost, and the performance of the perovskite solar cell is greatly improved.

Owner:SOUTHWEST PETROLEUM UNIV

Flexible charge trap storage based on oxidized graphene

InactiveCN103489870AGood film uniformityReduce pinholesSolid-state devicesSemiconductor devicesGate dielectricEngineering

The invention belongs to the technical field of semiconductor devices and particularly relates to a flexible charge trap storage based on oxidized graphene and a preparation method thereof. According to the flexible charge trap storage and the preparation method, the storage relies on the three-layer structure of an existing charge trap storage, namely, the tunneling layer / charge trap layer / control gate dielectric layer structure, a flexible substrate is utilized as a substrate, and the oxidized graphene is adopted to replace the traditional charge trap layer. The method comprises the specific preparation steps of using a low-temperature atomic layer deposition method, firstly, depositing the dielectric tunneling layer on the flexible substrate, coating the flexible substrate with the oxidized graphene in a rotating mode under the indoor temperature situation, and then, similarly adopting the low-temperature atomic layer deposition technology to grow and control the gate dielectrics. The flexible charge trap storage and the preparation method have the advantages that the low-temperature atomic layer deposition technology and the process of coating the flexible substrate with the oxidized graphene at the indoor temperature in the rotating mode are used, the characteristics of the oxidized graphene is utilized, window erasing is ensured, meanwhile, the process thermal budget is greatly reduced, and practical and reliable schemes are provided for flexible electronic devices in future.

Owner:FUDAN UNIV

Load sensor and method of manufacturing the load sensor, paste used for the method, and method of manufacturing the paste

InactiveUS20050085393A1Well formedReduce manufacturing costConductive materialForce measurementEngineeringMultiple layer

The present invention relates to a load sensor and provides a highly accurate load sensor with multi-layered wiring at low costs. It provides crystallized glass and non-crystalline glass which are best for a load sensor, and combines these to form multi-layered wiring, and further, makes a glass layer of composite type as needed, and reduces uneven printing in printing multiple layers with use of hardening type paste.

Owner:PANASONIC CORP

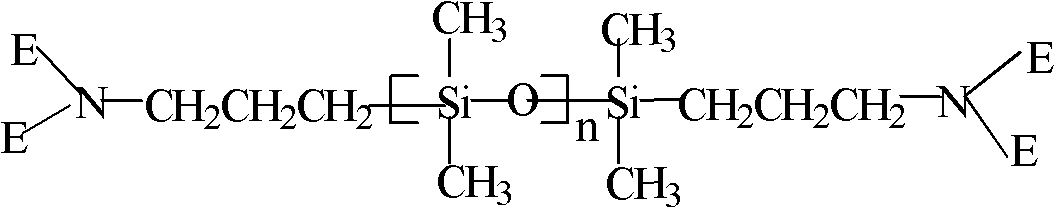

Organic transistor and method for producing the same

InactiveUS20100237337A1Strengthen interactionReduction of pinholeSolid-state devicesSemiconductor/solid-state device manufacturingOrganic crystalMolecular film

An organic transistor comprising:at least a gate electrode and a gate insulating layer formed on the gate electrode,the gate insulating layer including, on a surface of the gate electrode, a stacked molecular film composed ofa first organic molecular layer binding in a direction substantially perpendicular to the surface of the gate electrode through a first covalent bond anda second organic molecular layer binding to an unreacted end of the first organic molecular layer through a second covalent bond, whereinthe second covalent bond and another second covalent bond adjacent to each other form a hydrogen bond in a direction of a surface perpendicular to a major axis direction of the stacked molecule.

Owner:SHARP KK

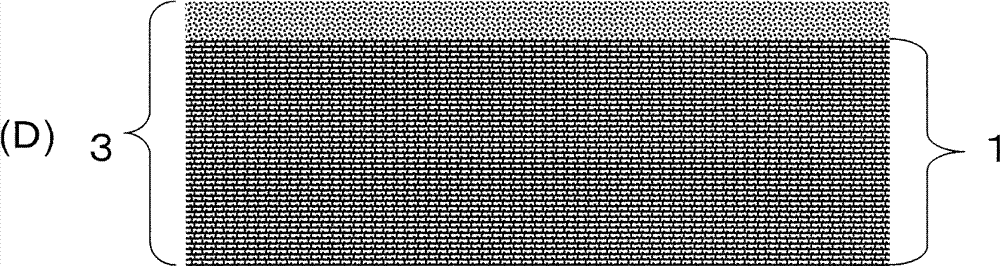

Multicolor pre-coating film

ActiveCN105346296AReduce pinholesLow costSynthetic resin layered productsPattern printingPolyesterKetone

The invention provides a multicolor pre-coating film. The multicolor pre-coating film comprises a thin film layer, a colored layer, a laser layer, a hot melt adhesive layer and a protecting layer, wherein the thin film layer is taken as a carrier of each coating layer and is made of polyester materials; the inner surface of the thin film layer is coated with the colored layer which includes multiple colors printed simultaneously; the radium emanating layer is matched with the colored layer to form a predetermined pattern; the colored layer and the radium emanating layer are sealed in the inner surface of the thin film layer through the hot melt adhesive layer; the outer surface of the thin film layer is coated with the protecting layer which has the weather resistance and / or the scratch resistance. The pre-coating film can be directly stuck and connected to paper, furniture, a board, a plastic board, an aluminum-plastic panel, a steel plate and other materials through the hot melt adhesive layer under the condition of heating and pressurization and then can be covered. In the manufacturing and machining processes of the pre-coating film, benzene and ketones additives are not needed, and the total amount of residual solvents is less than or equal to 5.0 mg / m<2>, so that the national standard of GB / T10004-2008 is met. Pinholes of the pre-coating film are few, so that stainless steel plates or other metal plates are not needed to be used for conducting surface mechanical machining, and a great deal of cost can be reduced.

Owner:张家港保税区康得菲尔实业有限公司

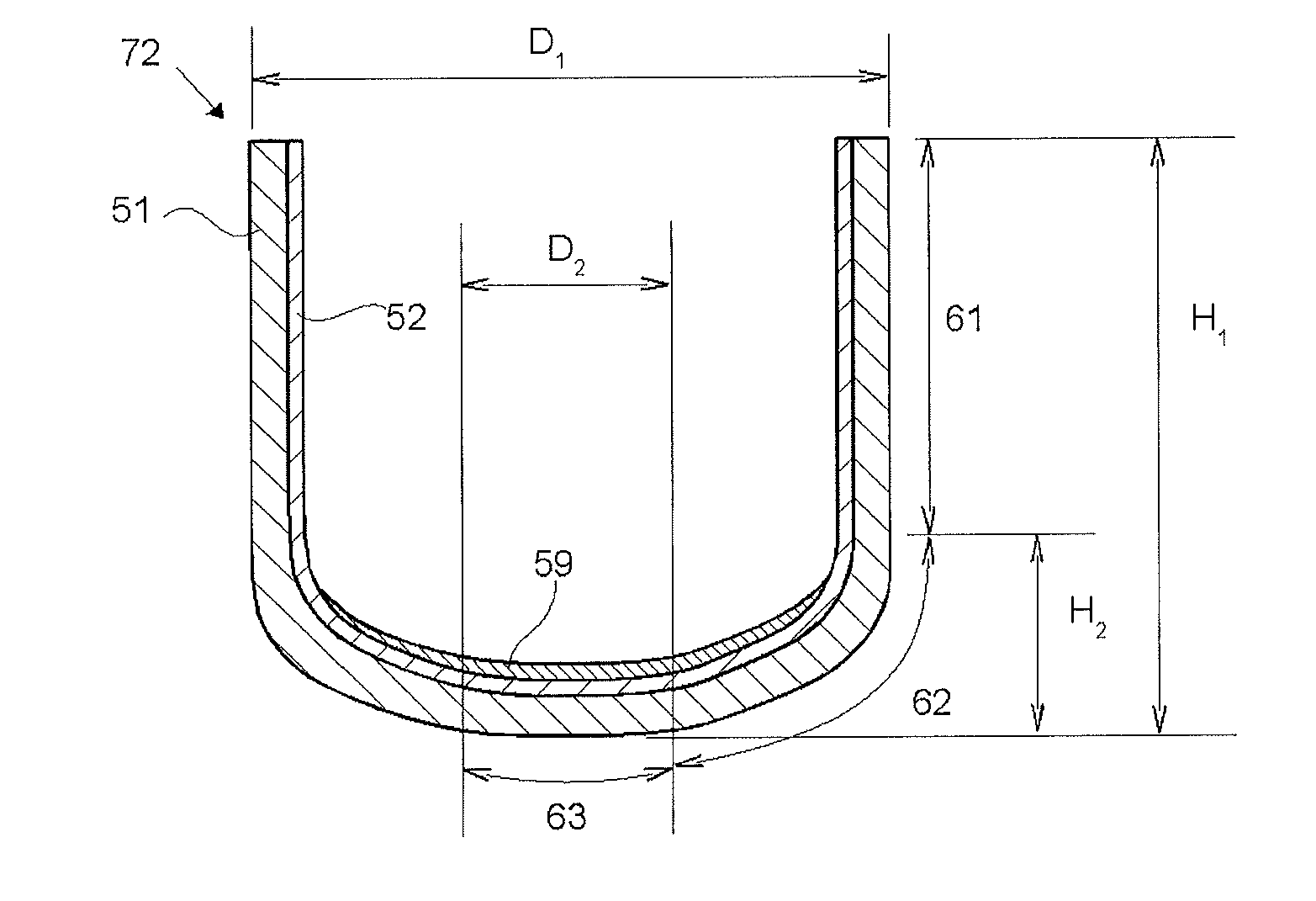

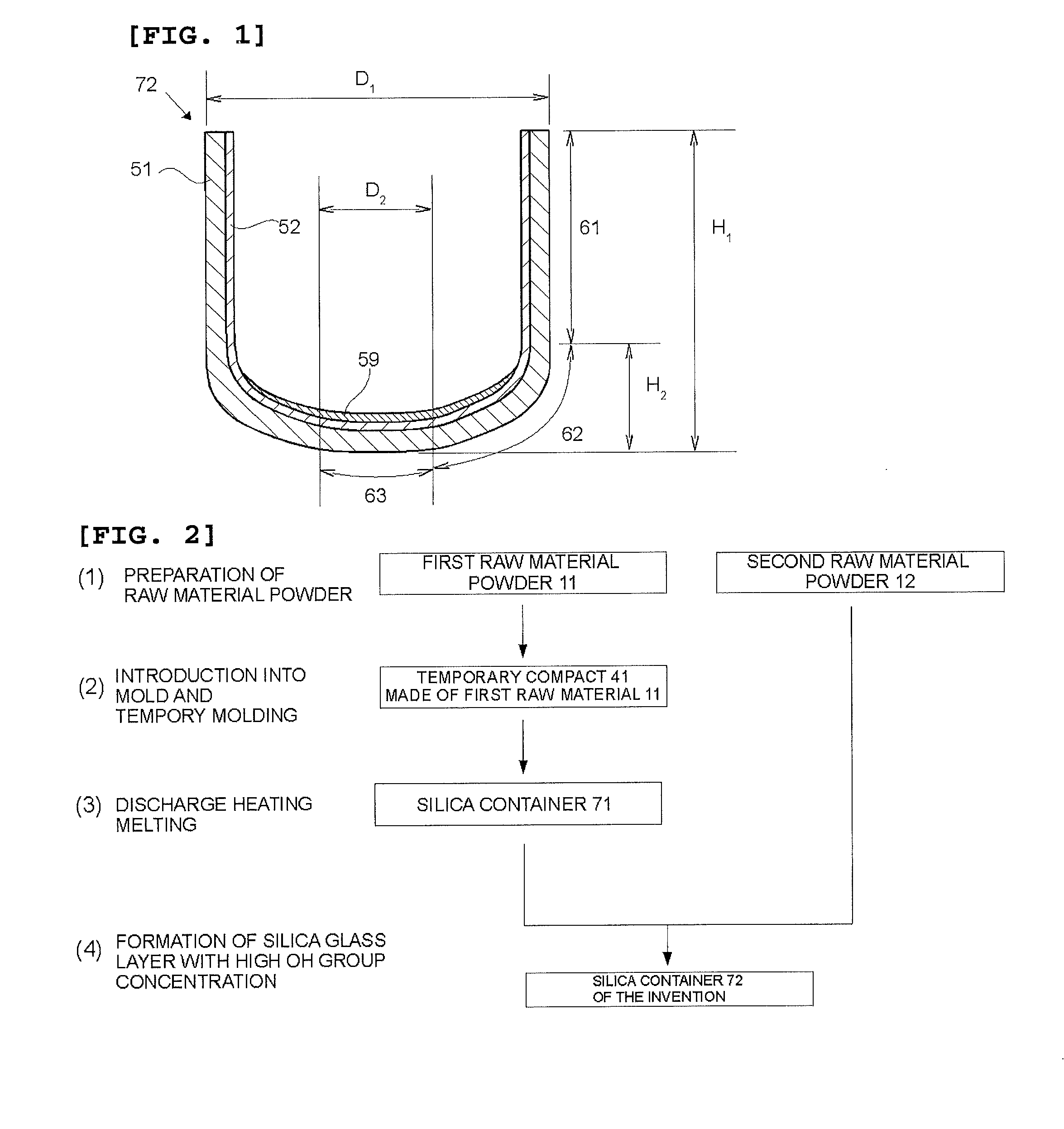

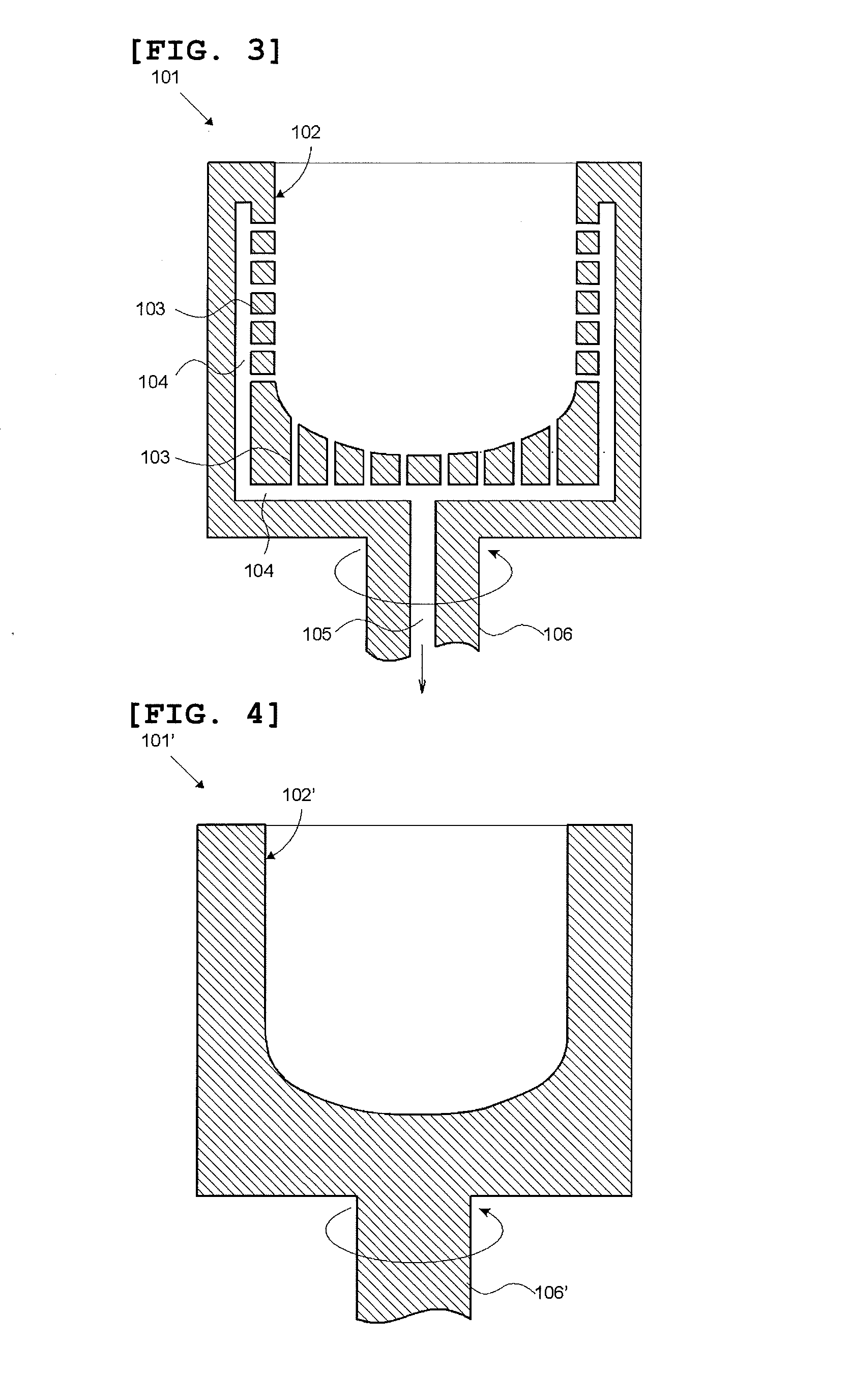

Silica container for pulling single crystal silicon and method for producing the same

InactiveUS20140041575A1Reduce pinholesLow costAfter-treatment apparatusPolycrystalline material growthSilica glassMaterials science

The present invention is directed to a silica container for pulling single crystal silicon, the silica container including a straight body portion, a curved portion, and a bottom portion, wherein the outside of the silica container is made of opaque silica glass containing gaseous bubbles, the inside of the silica container is made of transparent silica glass containing substantially no gaseous bubble, and, on the inner surface of the bottom portion, a silica glass layer containing the OH group in a concentration of more than 300 ppm by mass but 3000 ppm by mass or less, the silica glass layer having a thickness of 20 μm or more but 1000 μm or less, is formed. As a result, a low-cost silica container for pulling single crystal silicon, the silica container that can reduce cavity defects called voids and pinholes in pulled single crystal silicon, is provided.

Owner:SHIN ETABU QUARTZ PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com