Method for controlling laser welding

A technology for laser welding and workpieces to be welded, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., which can solve the problems of low welding strength of dissimilar materials, high probability of explosion point, affecting product welding performance and appearance, etc. , to achieve the effect of improving welding performance and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

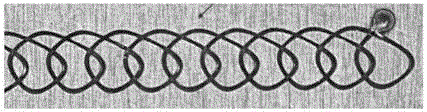

Image

Examples

Embodiment Construction

[0009] In order to make the technical problems solved by the present invention, the technical solutions adopted, and the technical effects obtained easy to understand, the specific implementation manners of the present invention will be further described below in conjunction with the specific drawings.

[0010] The invention discloses a method for controlling laser welding, comprising the following steps:

[0011] a) Measure the weld width w of the workpiece to be welded;

[0012] b) Establish the circular polar coordinate mode and the linear polar coordinate mode, and use the two fitting trajectories as the trajectory path of laser welding: x 0 =x 1 +Δ*cosβ,y 0 =y 1 +Δ*sinβ, x=x 0 +R*cosα,y=y 0 +R*sinα; where x 0 with y 0 is the coordinate of the point on the line, x 1 with y 1 The coordinates of the starting point of the straight line, Δ is the point distance of the straight line, β is the inclination angle of the straight line, R is the shaking radius, α is the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com