Patents

Literature

536results about How to "Full flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

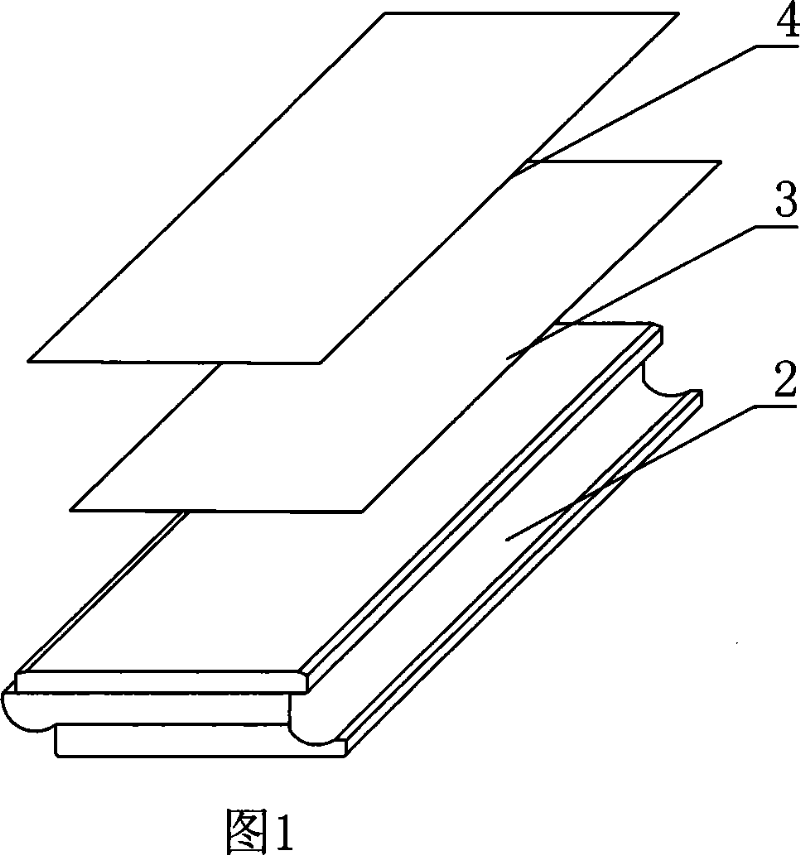

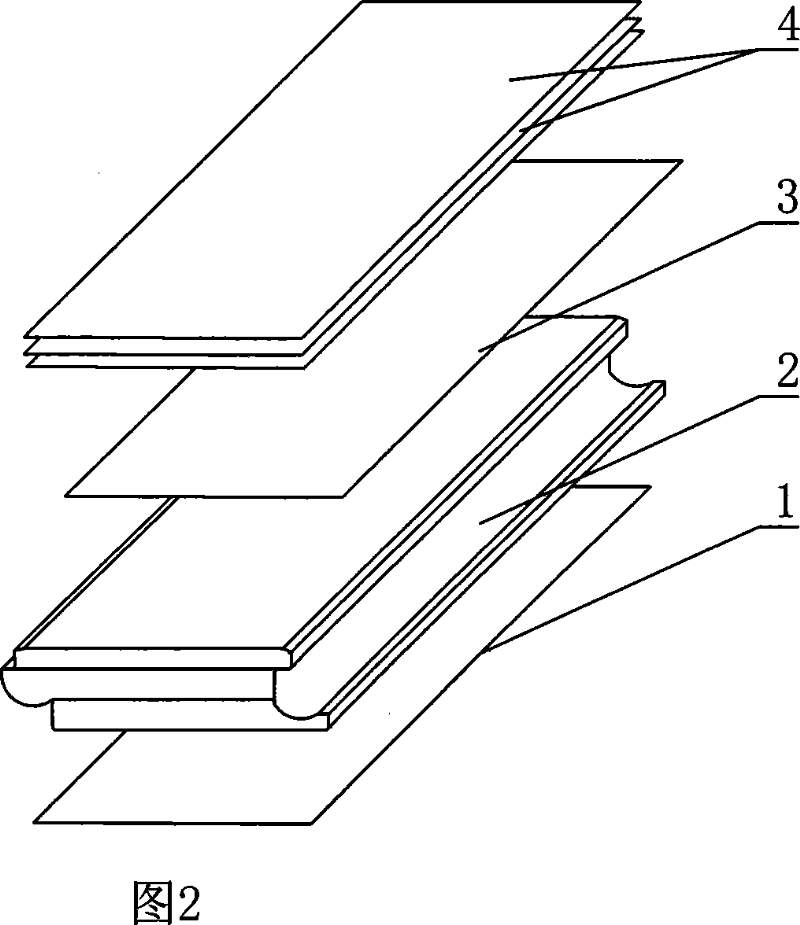

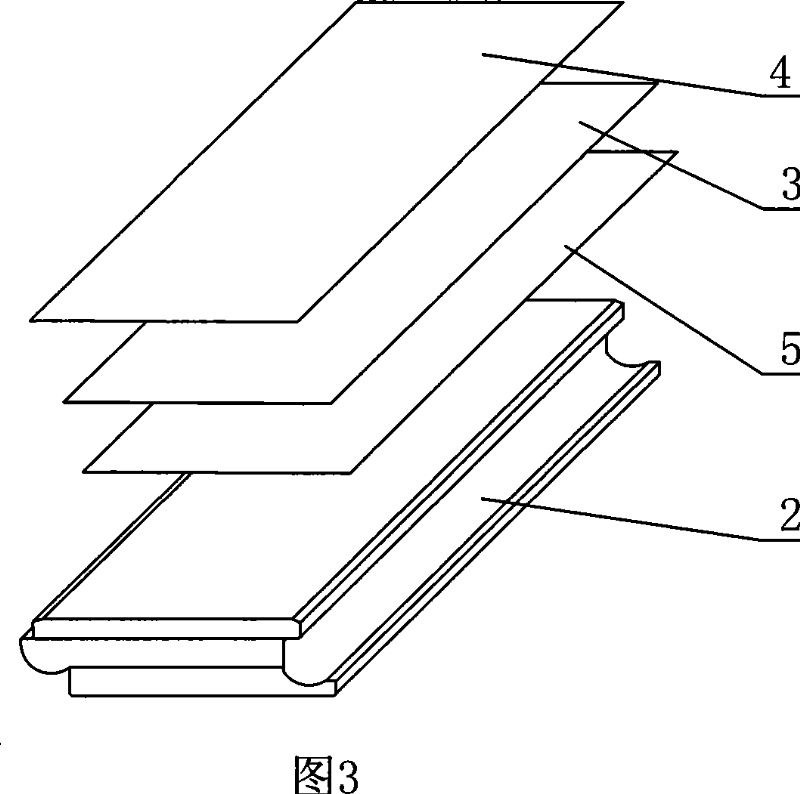

Method for making water-proof floor

A water proof floor is made by dipping 1-3 pieces of anti wearing paper and decorative paper into melamine and dried, applying 2MPa-10MPa pressure with the heating press with these two kinds of paper stacked, in the temperature of 185deg.C-230deg.C, keeping the pressure for 25-60s and cooling naturally to form into the panel, roughening the upper surface of the wood slab or free wax fiber slab to form into uneven surface, applying adhesive agent on the upper surface of the slab, one side of the decorative paper of the panel attached on the up surface of the slab, applying 15MPa-45MPa pressure in normal temperature for 15-60 minutes, sticking the panel to the slab to make a big plate, cutting the big plate to the required strip, having key way vertically and horizontally to make the final product. The floor is not only anti wearing, and water proof, it is also being anti shock, fire resistant, anti erosion, and environment protective in nature.

Owner:高建忠

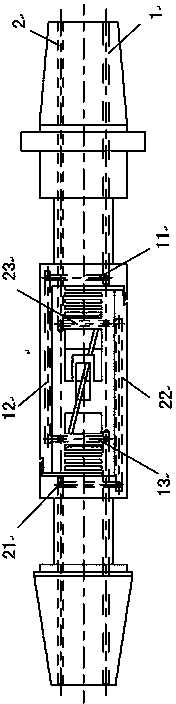

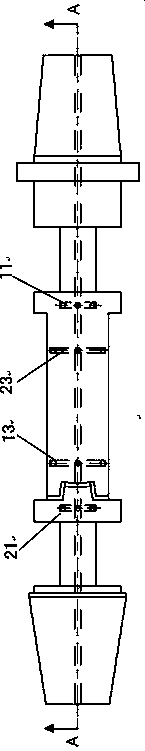

Water cooling balance

ActiveCN104180966AEliminate the effects of aerodynamic measurementsExtended service lifeAerodynamic testingLeaking waterCooling effect

The invention discloses a water cooling balance which comprises a rod-type balance and a water-cooled jacket. Two water flow pipelines are arranged in the rod-type balance. The two ends of each water flow pipeline are arranged on the two end faces of the rod-type balance respectively. A switching joint is arranged between the water-cooled jacket and the rod-type balance and fixed to one end face of the rod-type balance through a screw. A water inlet switching pipeline and a water outlet switching pipeline are arranged on the switching joint. One end of the water inlet switching pipeline and one end of the water outlet switching pipeline correspond to openings of the two water flow pipelines on the end faces of the rod-type balance in position and the other end of the water inlet switching pipeline and the other end of the water outlet switching pipeline correspond to a water inlet and a water outlet of the water-cooled jacket in position. The defects that a corrugated pipe type water cooling balance is large in drag measurement error and inconvenient to install and use and a corrugated pipe is prone to being damaged and leaking water are overcome. In addition, due to the fact that corrugated pipe related devices are omitted, the length of the balance is reduced, the diameter of the balance is increased, the rigidity and the cooling effect of the balance are greatly improved, the temperature effect is reduced, and measurement uncertainty is obviously reduced.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

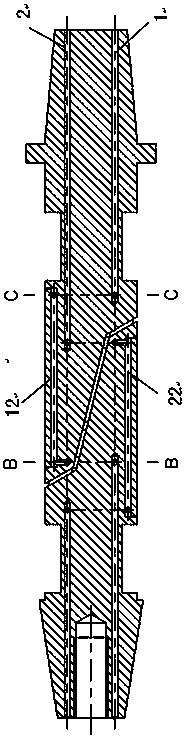

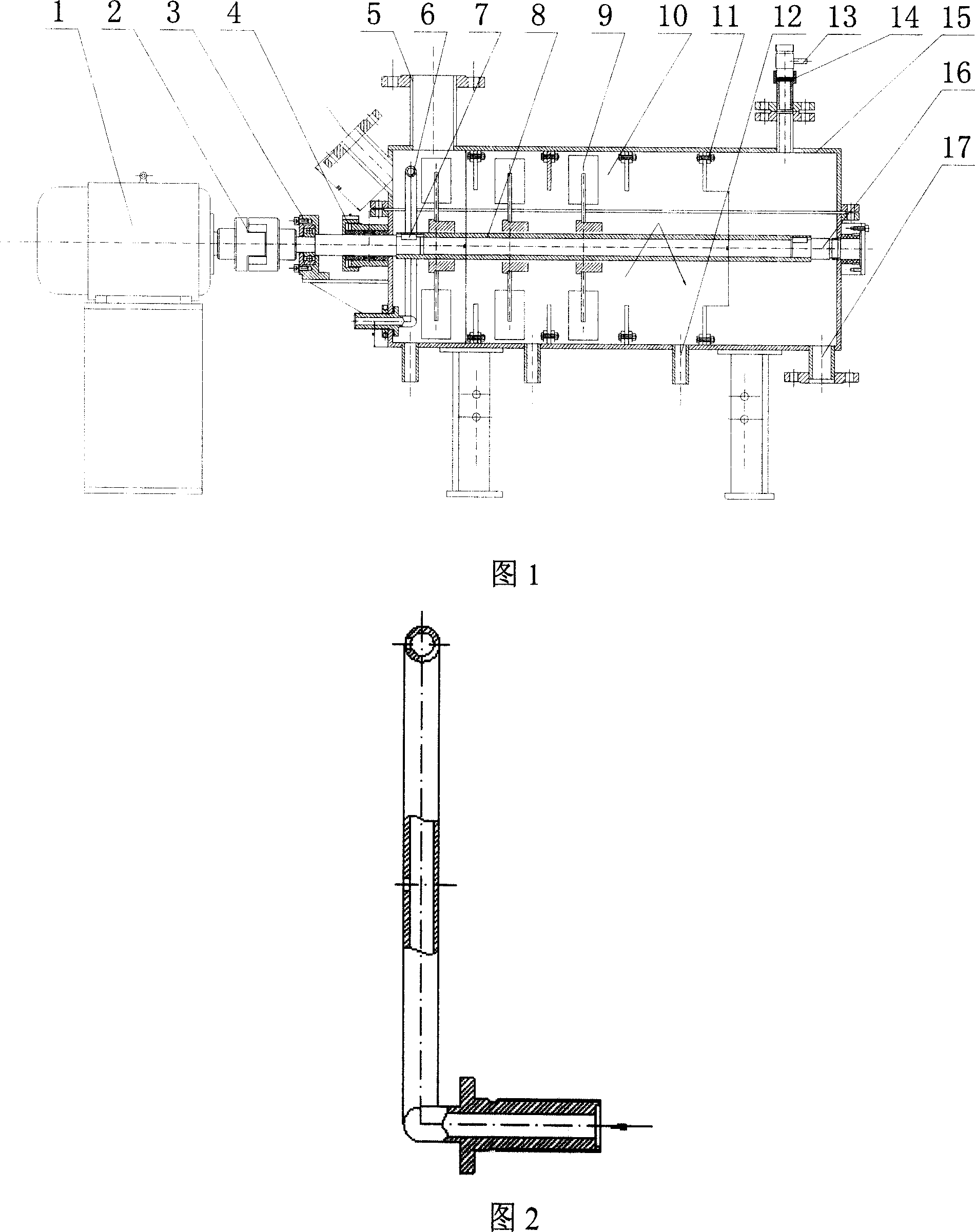

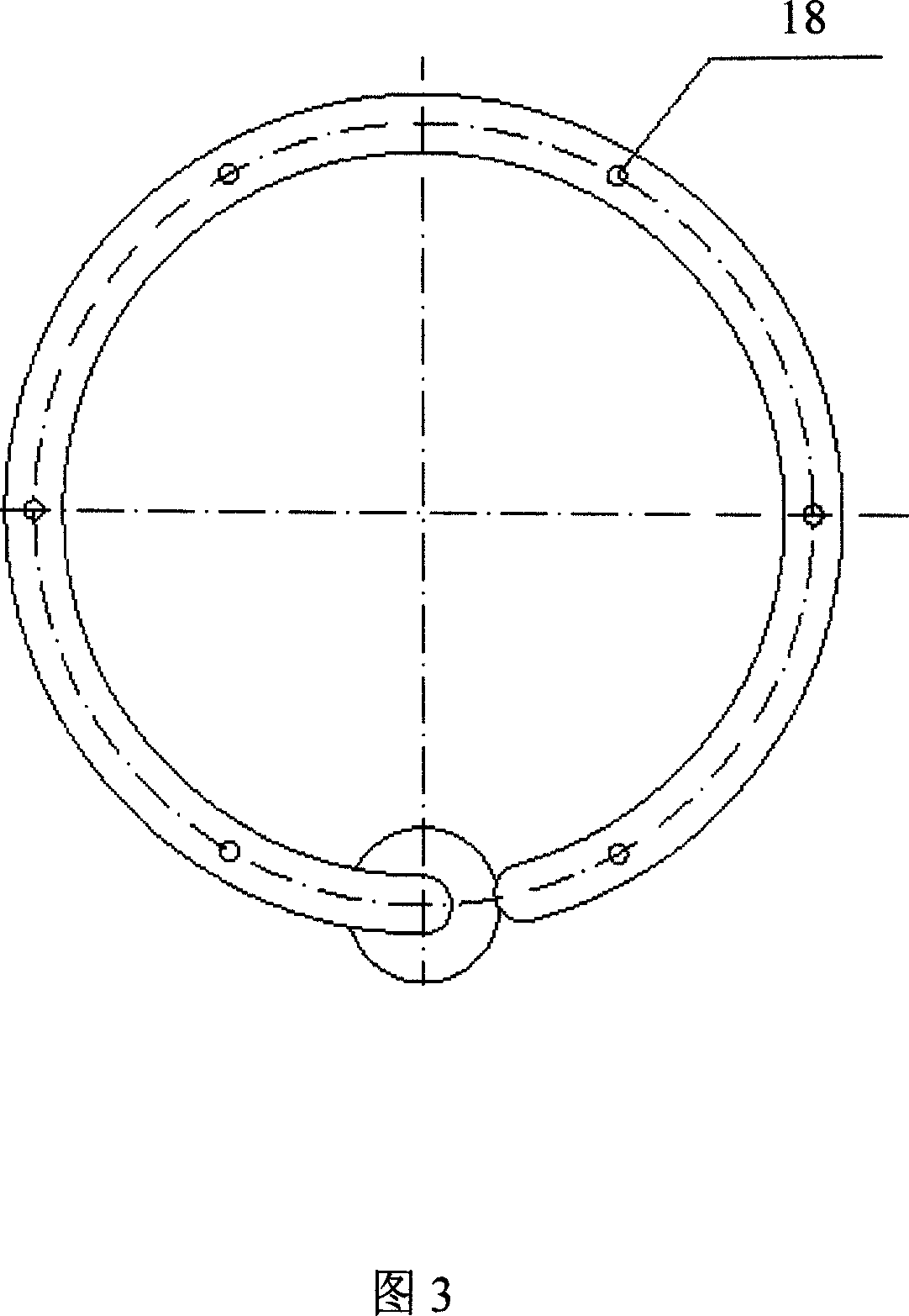

Horizontal solid-liquid mixer

The horizontal solid-liquid mixer includes a speed reducer, bearing seats, mixing chambers of a barrel with powder inlet and liquid inlet in the upstream and discharge port and gas outlet in the downstream, a stirring shaft in the center of the barrel and with ends connected through the rotating shaft to the bearing seats, stirring vane wheel fixed onto the stirring shaft, baffles on the wall of the barrel to separate the barrel into several chambers in the changeable size, and stirring oars fixed onto the stirring vane wheel. Compared with available technology, the present invention has the advantages of high mixing efficiency, high mixing speed, high mixed material homogeneity, and wide application range.

Owner:SHANGHAI RES INST OF CHEM IND

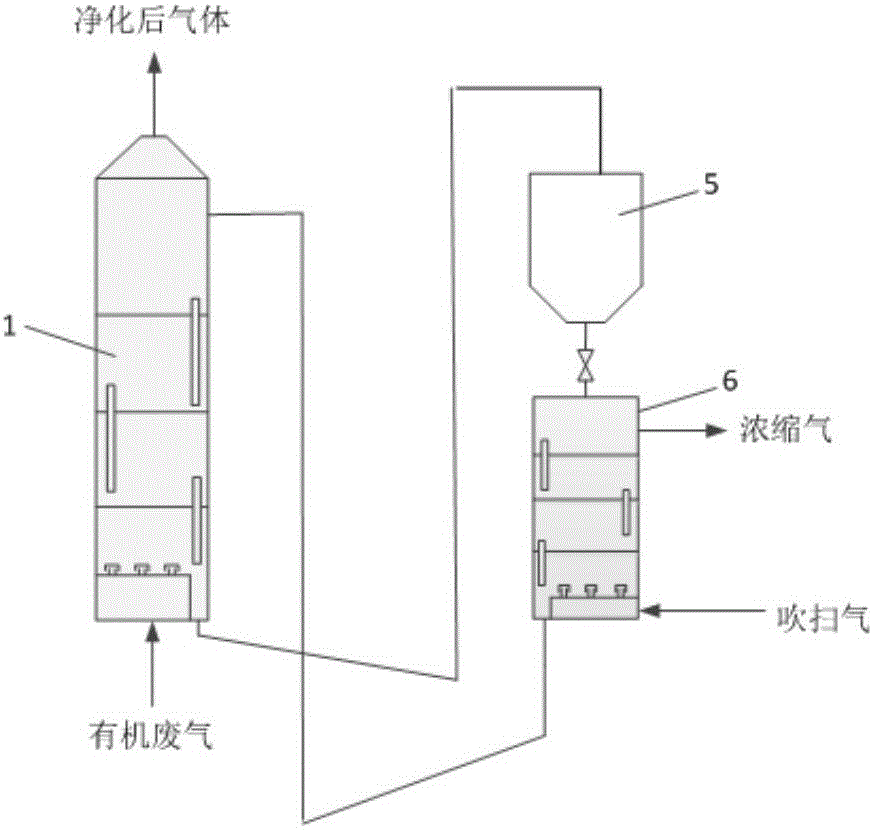

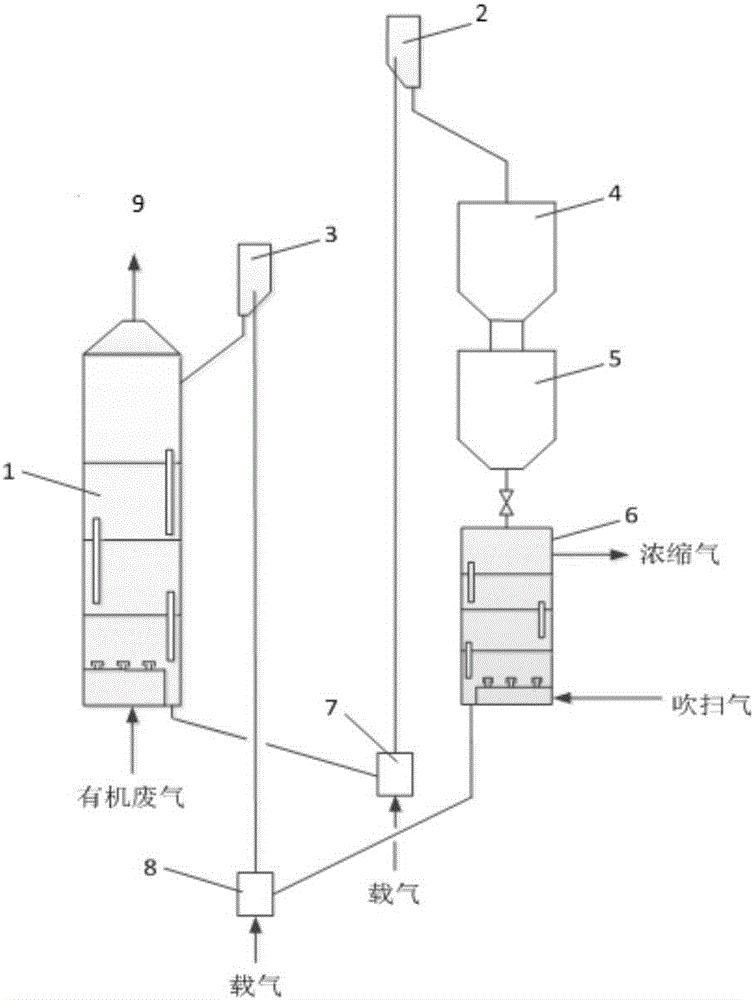

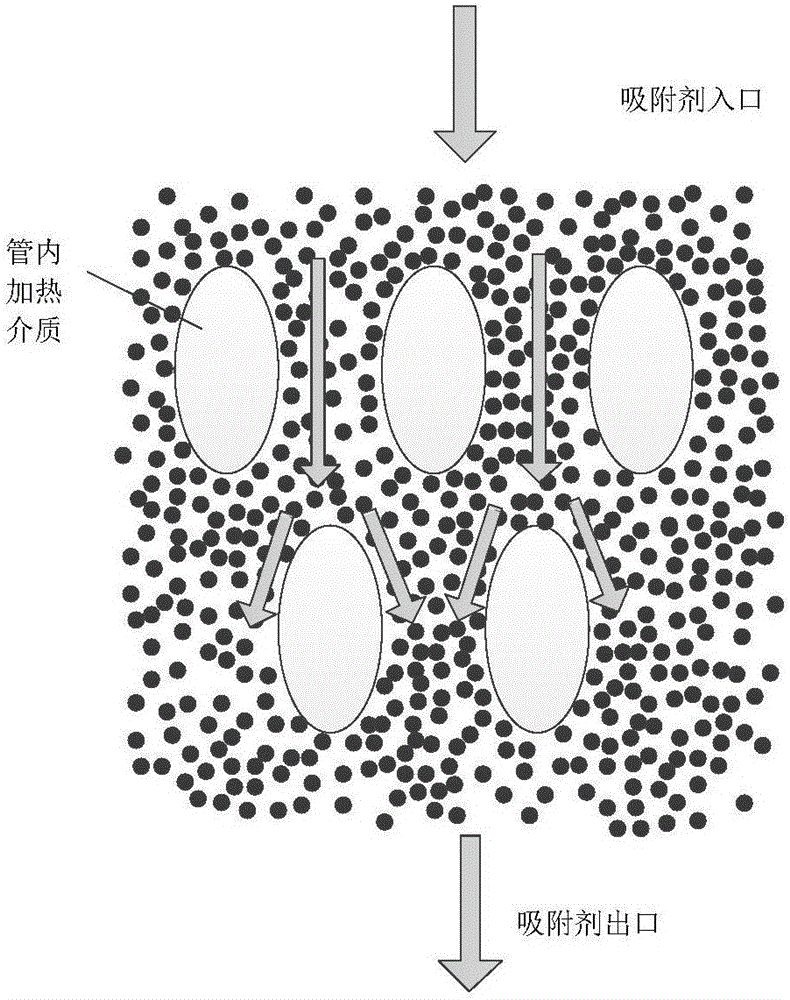

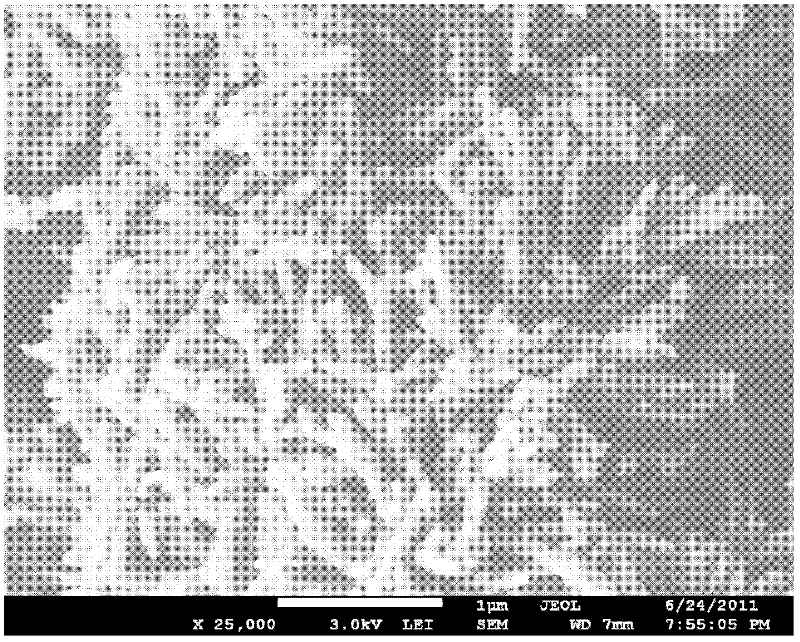

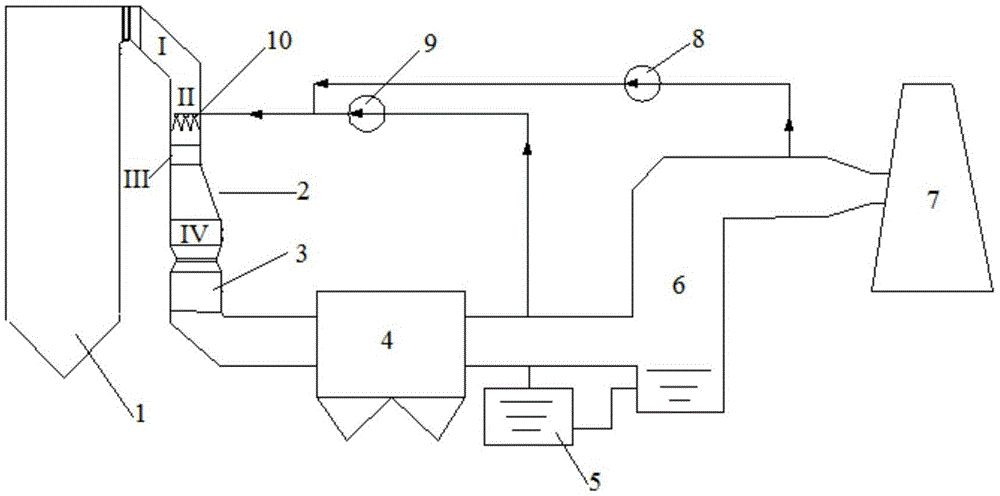

Double-fluidized bed adsorption and desorption device and method for continuous treatment of organic waste gas

InactiveCN106390681AEnhance heat and mass transferAvoid heat buildupGas treatmentDispersed particle separationHigh concentrationDesorption

The invention relates to the field of organic waste gas treatment and resource utilization and particularly relates to a double-fluidized bed adsorption and desorption device and a method for continuous treatment of organic waste gas. The device provided by the invention comprises a fluidized bed adsorption device (1), a preheater (5) and a fluidized bed desorption device (6), wherein an adsorbent outlet at the bottom of the fluidized bed adsorption device (1) is connected with a feed port of the preheater (5); a discharge port of the preheater (5) is connected with a feed port of the fluidized bed desorption device (6); and a solid outlet of the fluidized bed desorption device (6) is connected with a solid inlet of the fluidized bed adsorption device (1). In the invention, continuous treatment of high-concentration organic waste gas can be realized, heat accumulation can be prevented, and the problems such as bed fire and explosion caused by the dissipation failure of the reaction heat due to the excessively high concentration of the high-concentration organic waste gas are avoided; and moreover, the desorption effect of the adsorbent and the exit concentration of concentrated VOC gas are improved, and the catalytic combustion or solvent recycling is facilitated.

Owner:东莞市佳明环保科技有限公司 +1

Method for preparing rose calcium carbonate from low-grade limestone

InactiveCN102502749AFull flowImprove mass transfer efficiencyCalcium/strontium/barium carbonatesChemical industryPorosityHigh surface

The invention discloses a method for preparing rose calcium carbonate from low-grade limestone, which comprises the following steps: 1) proportionally calcining low-grade limestone and blind coal to prepare calcium oxide; 2) screening under vibrations to remove coal ash and lime powder, thereby obtaining lumpy lime; 3) adding water to slake the lumpy lime, removing impurities by hydrocyclone and vibration screening to obtain fine emulsion slurry, adding a whitener, and aging to obtain the Ca(OH)2 prime slurry; 4) after regulating the temperature and concentration of the Ca(OH)2 prime slurry, adding a crystal form control agent, carrying out bubbling carbonation reaction, and adding a dispersant; when the pH value of the slurry is lower than or equal to 7, stopping carbonation to obtain a cured slurry; and 5) after the cured slurry is thickened, dehydrating to obtain the rose calcium carbonate. Compared with common light calcium carbonate, the rose calcium carbonate disclosed by the invention has the advantages of higher crystal completeness, high surface porosity, high light scattering coefficient and stronger covering power; and the invention is applicable to the industries of paper making, rubber, plastics and paint.

Owner:福建省万旗非金属材料有限公司

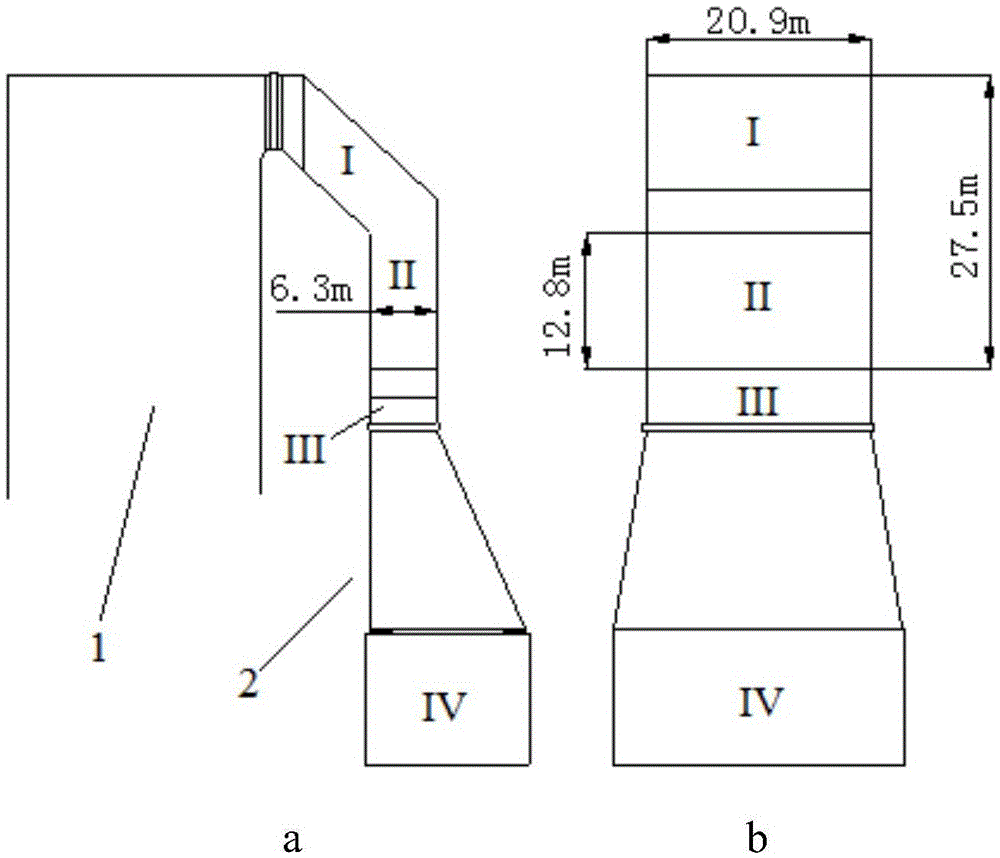

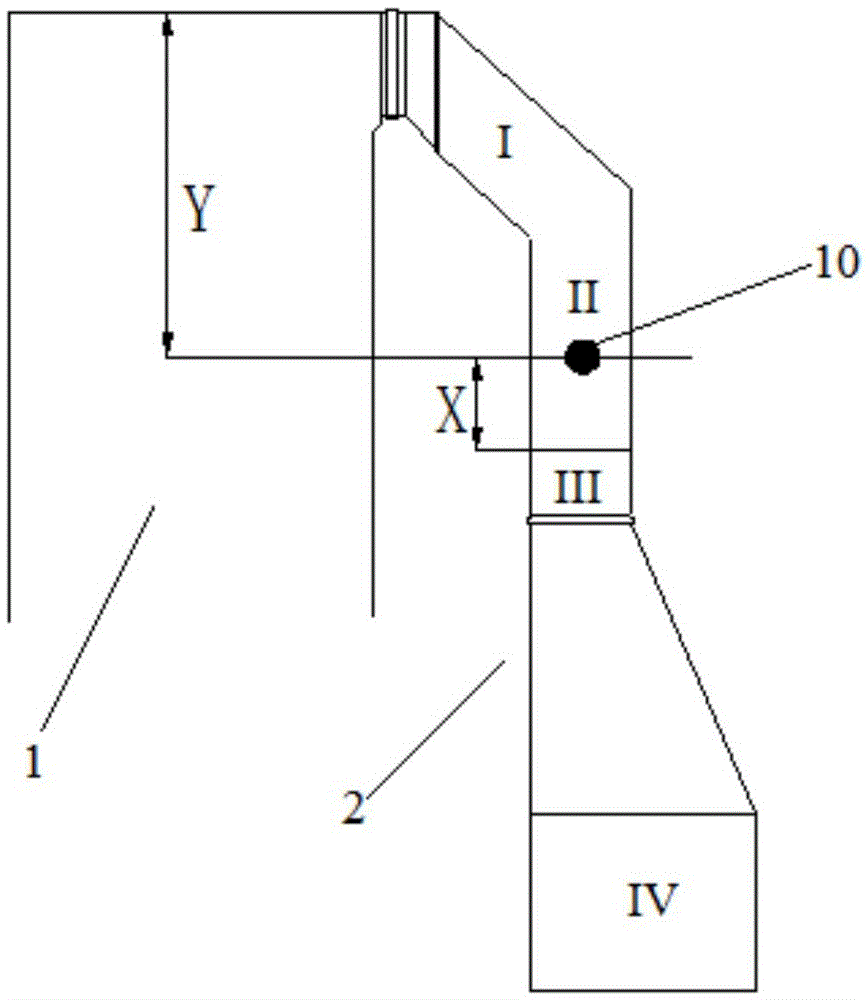

Process for atomizing desulfurization waste water through recycled flue gas of tower type boiler

InactiveCN105457468AEasy installationAvoid corrosionGas treatmentDispersed particle separationFlueStilling basin

The invention relates to a process for atomizing desulfurization waste water through recycled flue gas of a tower type boiler. The process comprises the steps that the desulfurization waste water of a desulfurization tower is drained to a stilling basin for preliminary sedimentation, and then the desulfurization waste water is pressurized through a pump and conveyed to a pipeline of a nozzle; part of the desulfurized flue gas is sent to the pipeline of the nozzle through a recirculation fan, so that the recirculation flue gas is in contact with the desulfurization waste water in the pipeline of the nozzle, and the initial temperature of the desulfurization waste water is raised; the nozzle is installed in a vertical flue located at the tail of the boiler, the desulfurization waste water is jetted and atomized, atomization liquid drops into the flue and evaporates quickly, and all ions in the desulfurization waste water are separated by crystallization quickly, captured by a dust remover when entering the dust remover along with the flue gas and discharged outward along with dust. By means of the design of the process, atomization performance of the desulfurization waste water is improved, evaporation of the desulfurization waste water is accelerated, blocking of a jet system can be prevented, the desulfurization waste water is effectively prevented from being jet to the pipe wall, the problem of corrosion of the wall surface of a flue which is caused easily when ordinary flues are used for treating desulfurization waste water is avoided, innocent treatment of the desulfurization waste water in the real sense is achieved, reconstruction investment is small, and operation cost is low.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

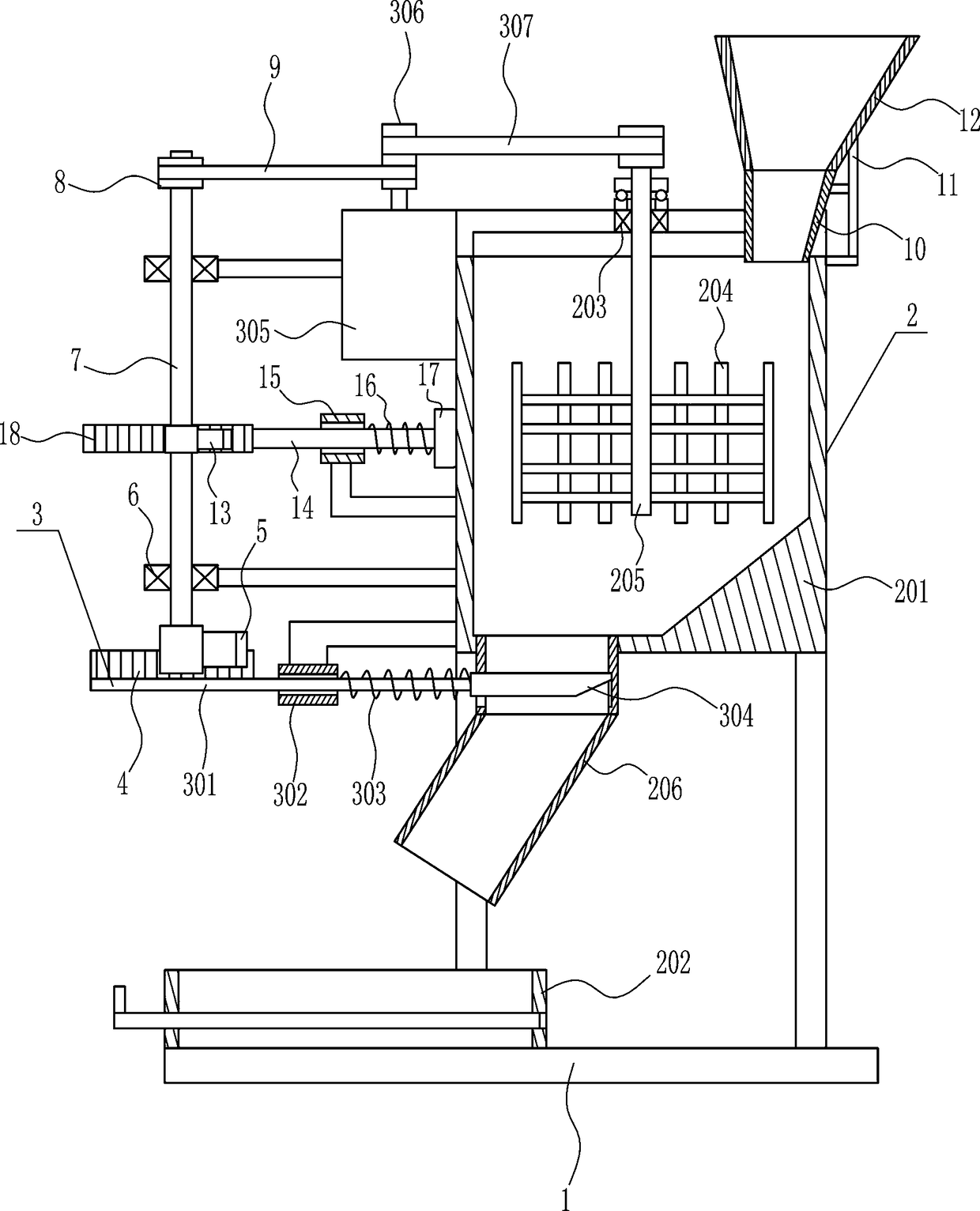

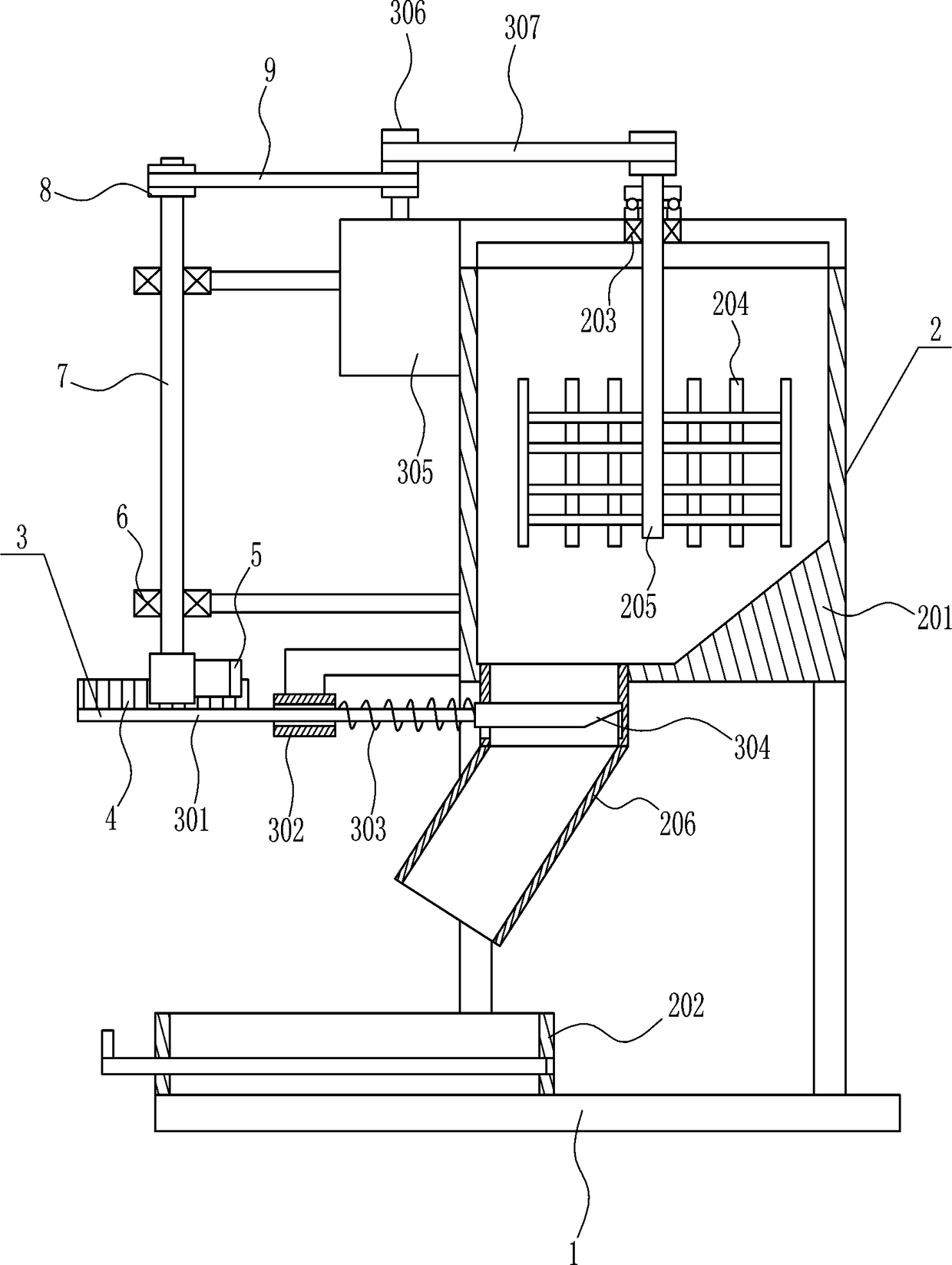

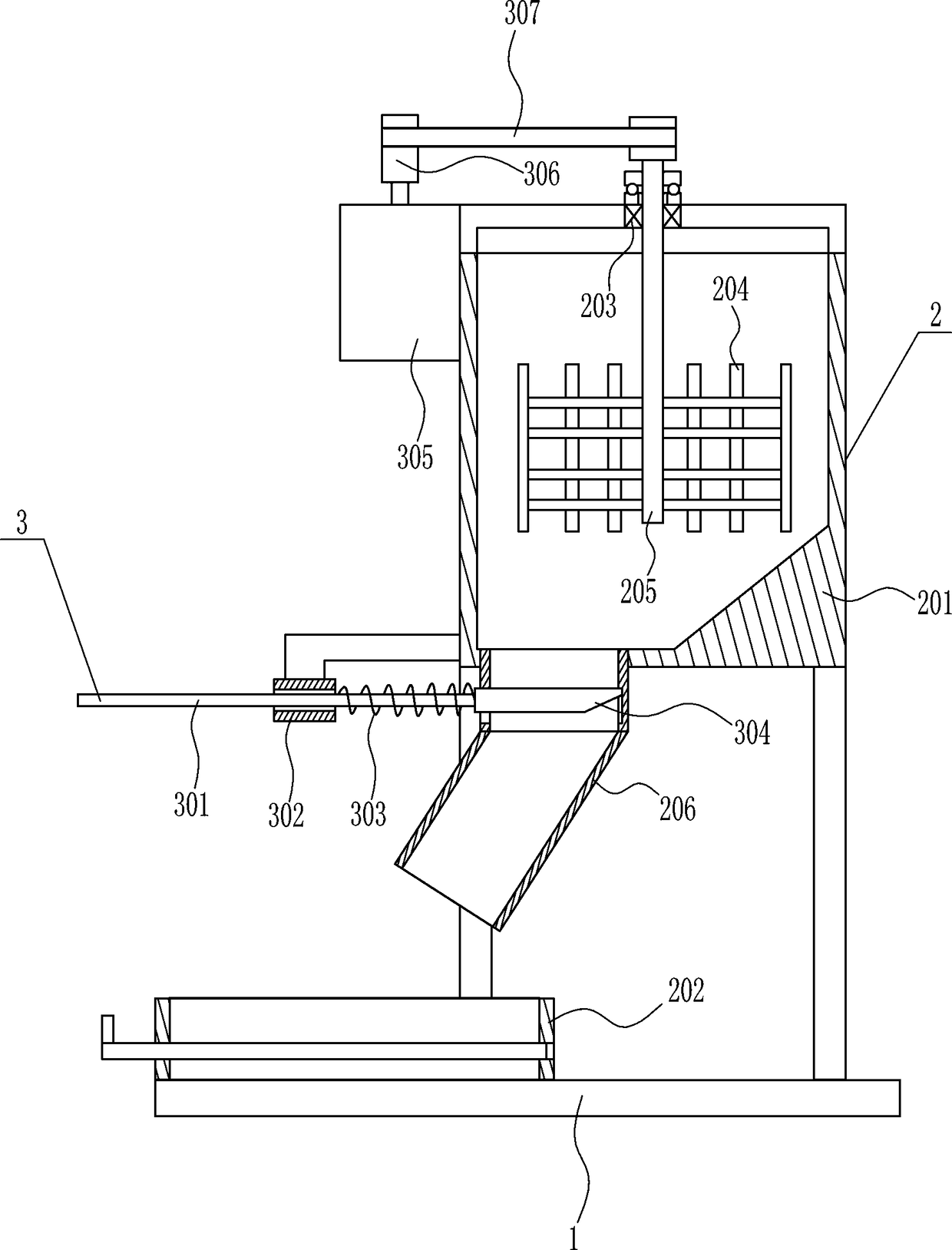

Building cement slab casting device

ActiveCN108789836AEasy to castPlay a cleaning roleFeeding arrangmentsCement mixing apparatusCement boardMaterials science

The invention relates to a casting device, in particular to a building cement slab casting device. The building cement slab casting device is aims to fully stir the mixing material of a cement slab and be capable of controlling the continuous intermittent outflow of the stirred cement. According to the technical scheme, the building concrete slab casting device includes a bottom plate and the like; and the top of the bottom plate is connected with a stirring mechanism, and the upper side of the stirring mechanism is connected with a driving mechanism. By means of the building cement slab casting device, the effects that the mixing material of the concrete slab can be fully stirred, and the continuous intermittent outflow of the stirred cement can be controlled are achieved, an arranged stirring rod can effectively and fully stirred the material in a stirring box, the uniformity of the amount of the cement and sand in the cast concrete slab is facilitated, and an arranged manual pullingfirst sliding rod move leftwards to control the outflow amount of a discharging hopper, in this way, the cement slab is casted more conveniently.

Owner:浙江大春科技股份有限公司

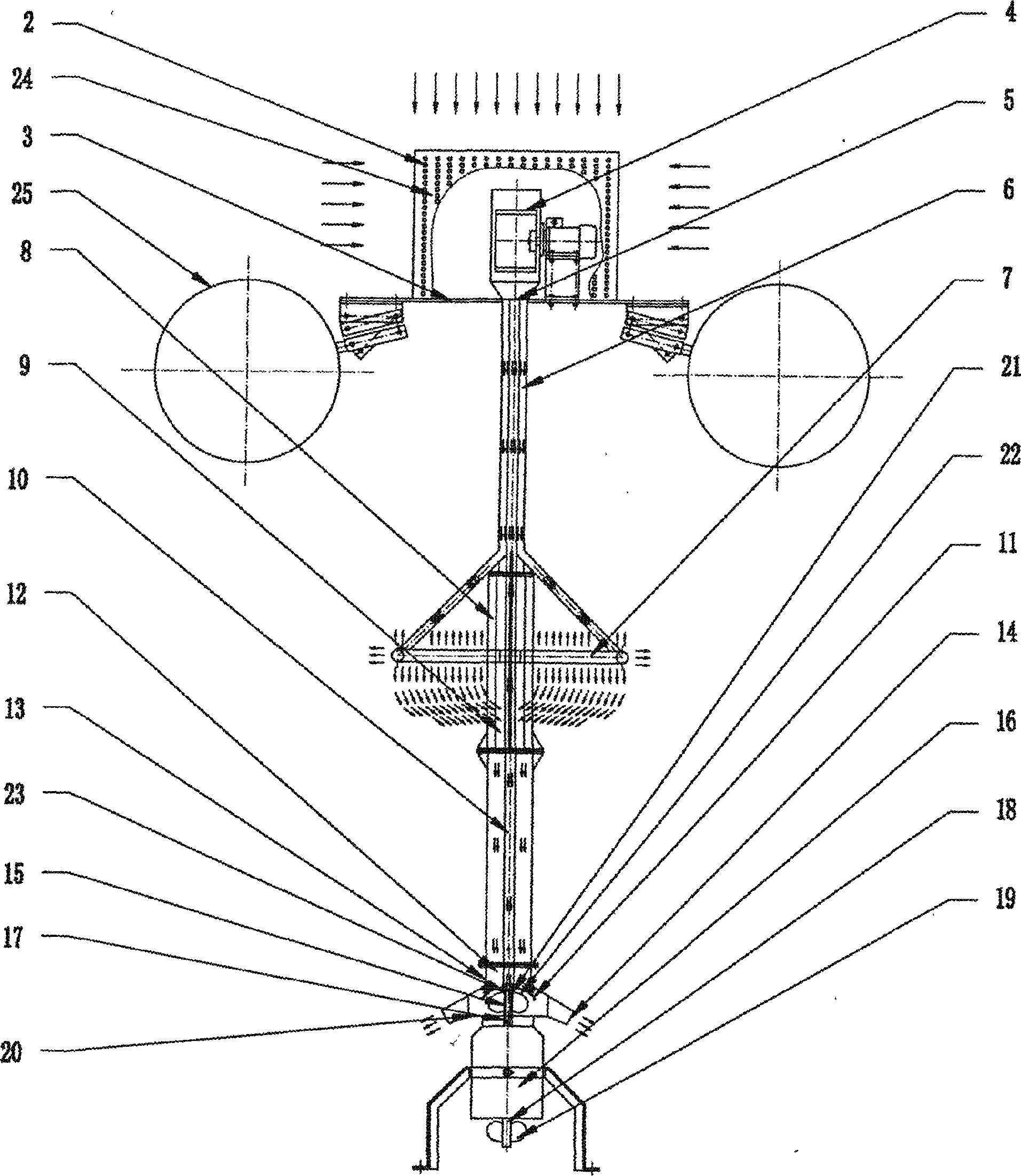

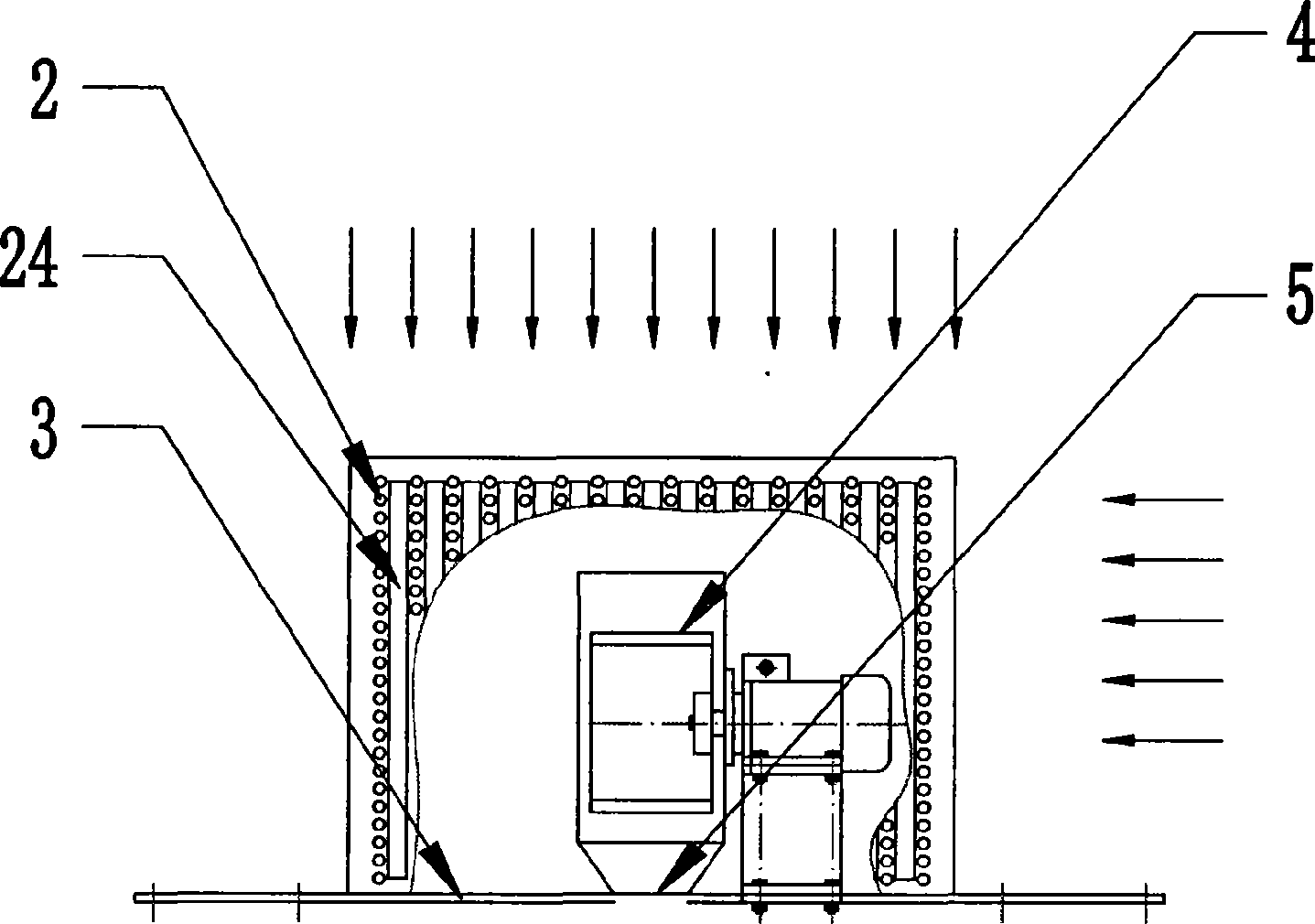

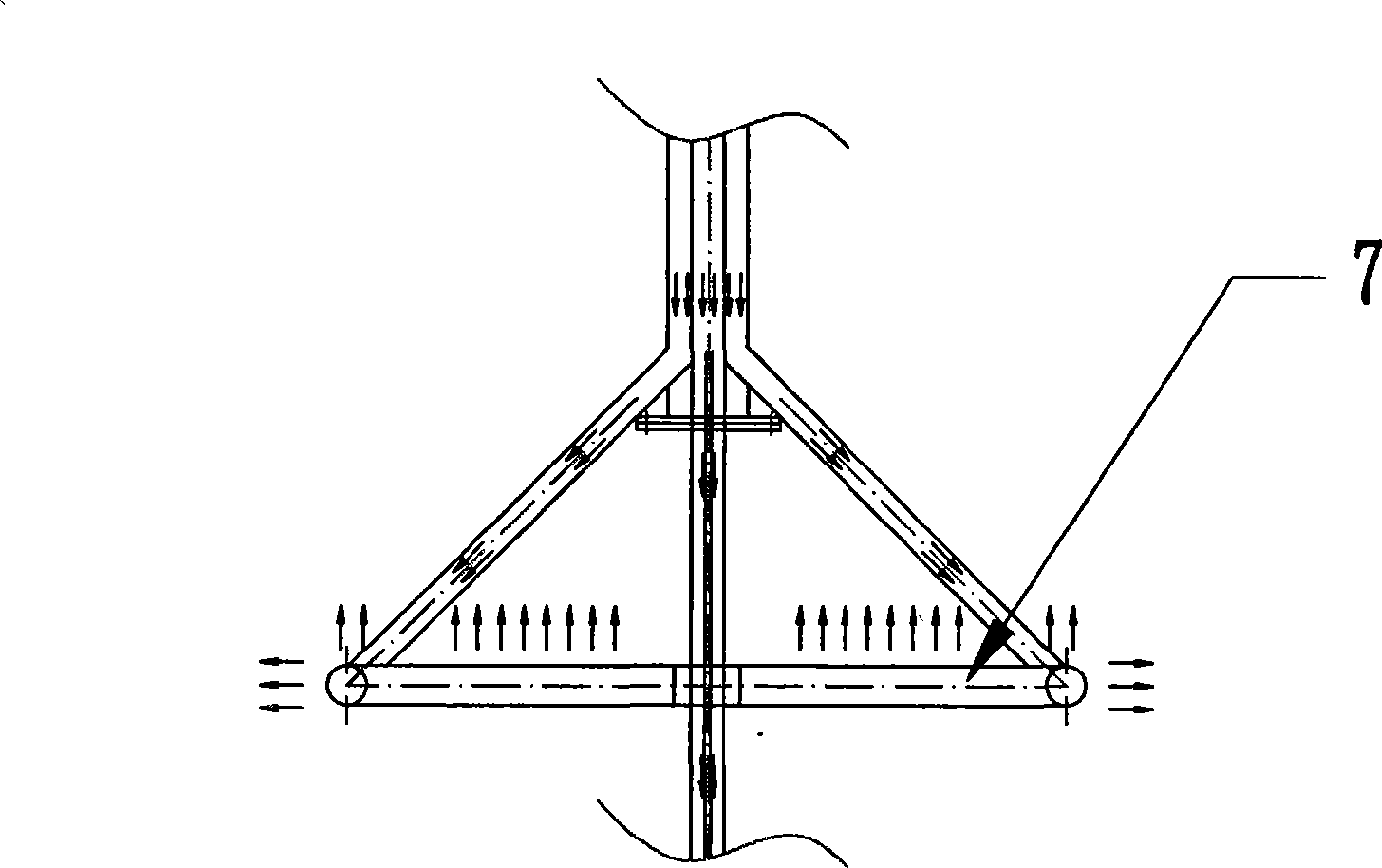

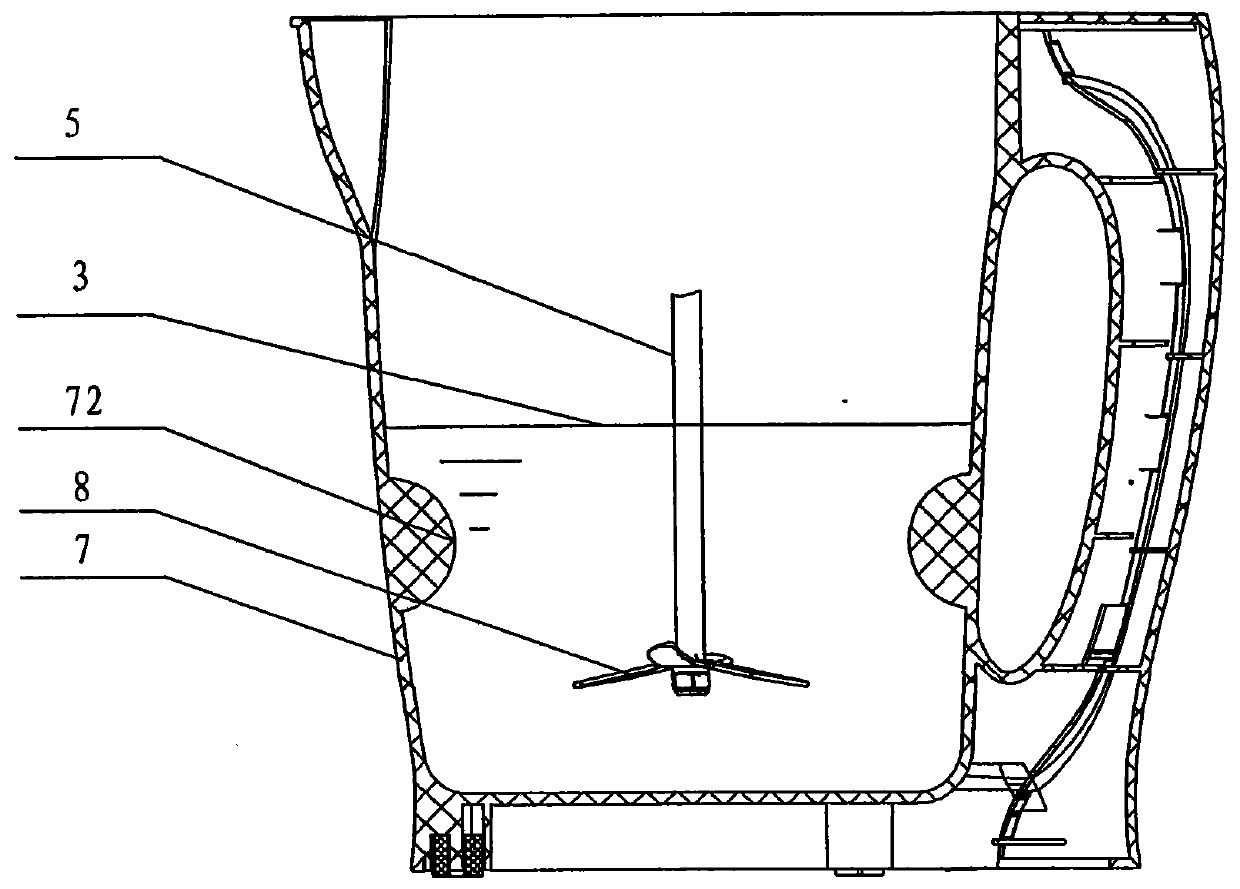

Floating multi-layer deep water oxygen increasing machine

InactiveCN101367584AWell mixedStir wellWater aerationSustainable biological treatmentFailure rateSludge

The invention provides a float type multilayer deepwater oxygen increasing machine, belongs to the water, wastewater, sewage or sludge treatment field. The machine comprises a magnetic shield, a compressing blower, a middle layer aerator, a water-gas mixture circulator and a submersible motor. The air inlet of the blower is connected with a vent pipe. The middle layer aerator is connected with the vent pipe. The water-gas mixture circulator comprises a holding frame, a bowl shaped air outlet and a circulator. The holding frame is a hollow pipe. The lower outlet of the holding frame is connected with the circulator. The bowl shaped air outlet on the lower end of the vent pipe is fixed with the holding frame. The submersible motor is provided with an upper end output shaft and a lower end output shaft. The machine has a simple structure, and solves the problems of great deepwater oxygen increasing pressure, hard transferring of the air and the dissolution. The transfer rate and the utilization rate of the oxygen are high, the failure rate is low, the maintenance is simple and convenient and the deepwater aeration effect is good.

Owner:刘君

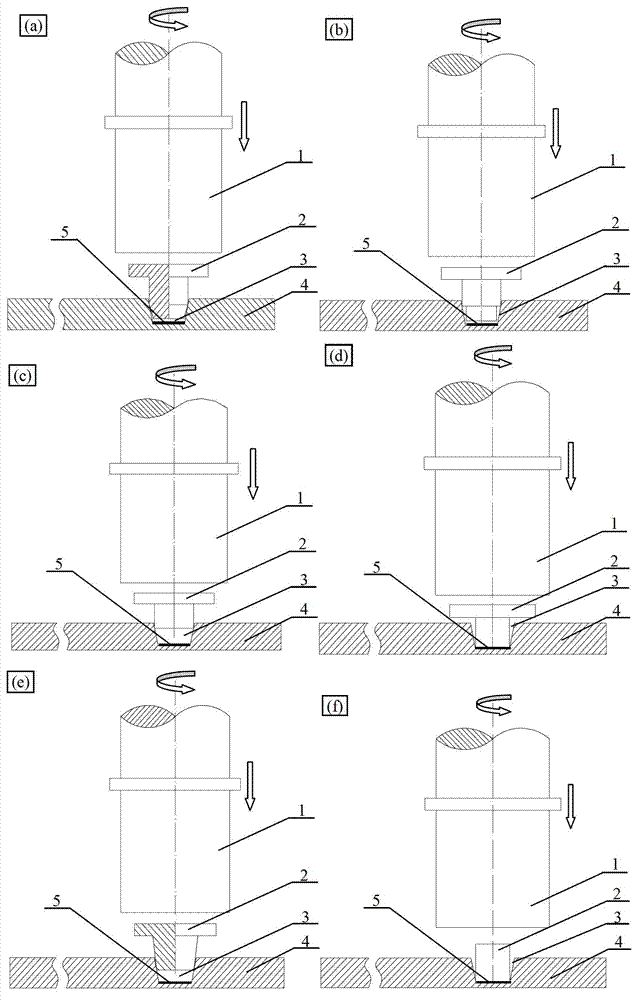

Method of brazing alloy extrusion and backflow stuffing for carrying out stirring and friction of welding keyhole

InactiveCN103071911AAvoid smallImprove liquidityNon-electric welding apparatusFilling materialsBraze alloy

The invention discloses a method of brazing alloy extrusion and backflow stuffing for carrying out stirring and friction of a welding keyhole. The method comprises the following steps that brazing alloy is preset in a keyhole, then a stuffing block is added in the keyhole, a T-typed stuffing block is subjected to rotation and friction through a needleless stirring head and is compressed down, the brazing alloy is heated to be softened, liquid brazing alloy is extruded and stirred by the stuffing block in an enclosed environment formed by the keyhole and the stuffing block, the liquid brazing alloy is stuffed in a driving and flowing way, and the liquid brazing alloy is enabled to be filled into a gap on the bottom of the keyhole; and due to the property of non-compression of the liquid brazing alloy, the liquid brazing alloy back flows along a side wall interface upward to stuff the remaining gap of the side wall, the side wall interface is dissolved, and compact alloying of the side wall and the bottom interface is realized. When the welding keyhole is repaired in batches, the replacement of tools is not needed, reduction of a welded keyhole does not exist or is extremely small, stuffing materials are saved, preset operation of the brazing alloy and the stuffing block is convenient, and the shaping of a surface of a stirring area is smooth.

Owner:XI AN JIAOTONG UNIV

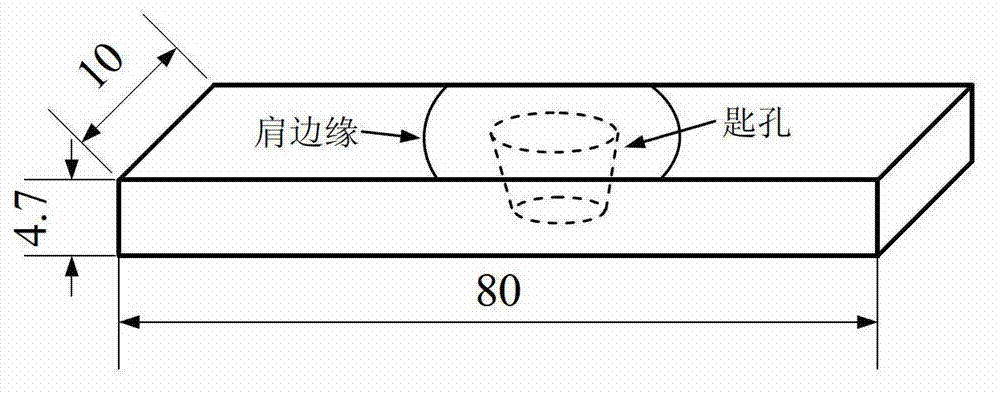

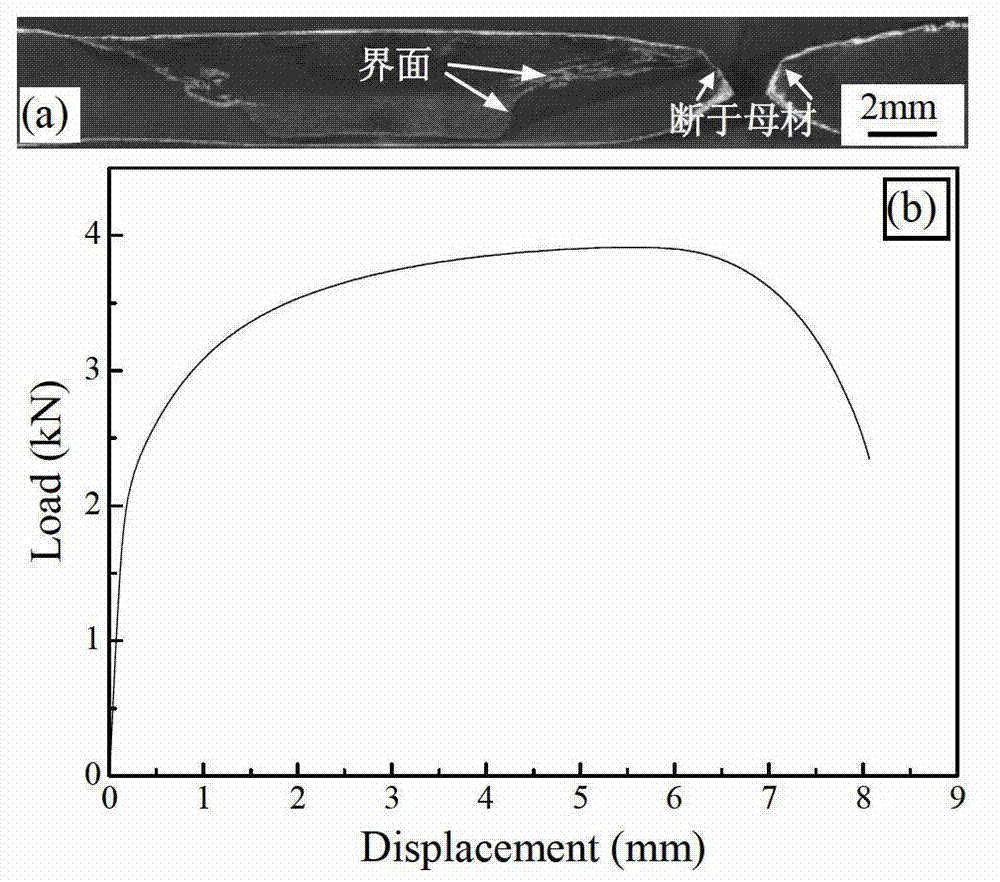

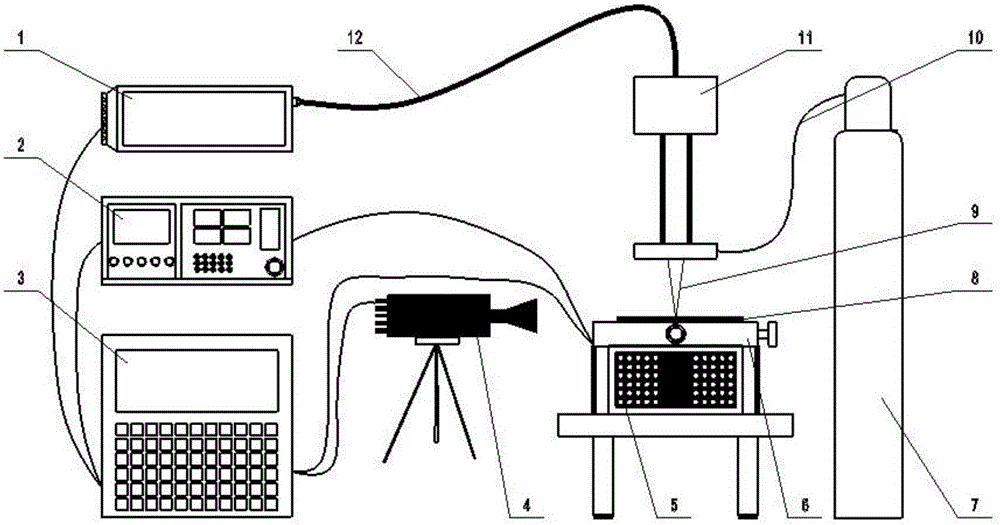

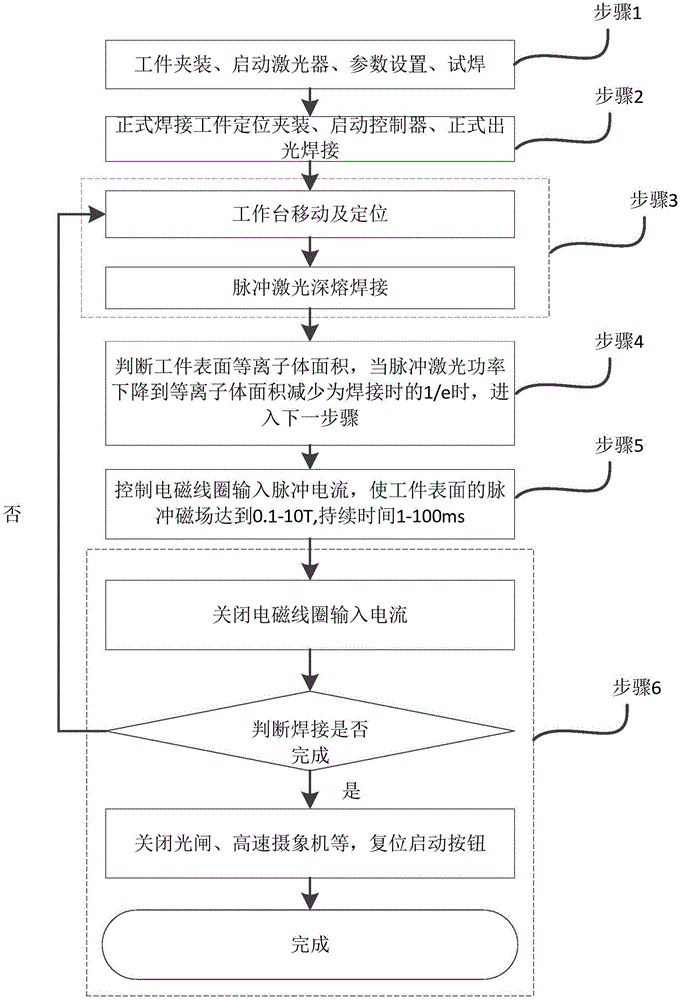

Pulse laser welding method and device assisted by electromagnetic force

ActiveCN105057887AFull flowInhibitionLaser beam welding apparatusElectromagnetic interferenceShielding gas

The invention discloses a pulse laser welding method assisted by electromagnetic force. The method includes the following steps that step1, a workpiece to be machined is fixed; step2, a pulse laser is adopted for welding weld seams on the surface of the workpiece under protection of protective gas, the plasma area of the surface of the workpiece is acquired, and the power of the pulse laser is gradually reduced within one pulse width or in the middle-later period of one pulse width; step3, supposing that the time when the plasma area of the surface of the workpiece is reduced to 1 / e of the maximum plasma area in welding in the pulse laser application process is t, a magnetic field is applied to the workpiece at any moment from t to t+1 ms, wherein the intensity of the magnetic field is 0.1-10 T, and the duration of the magnetic field is 1-100 ms. By means of the pulse laser welding method assisted by electromagnetic force, the comprehensive mechanical properties of a welded joint can be significantly improved. The invention further provides a welding device adopting the welding method.

Owner:SOUTH CHINA NORMAL UNIVERSITY

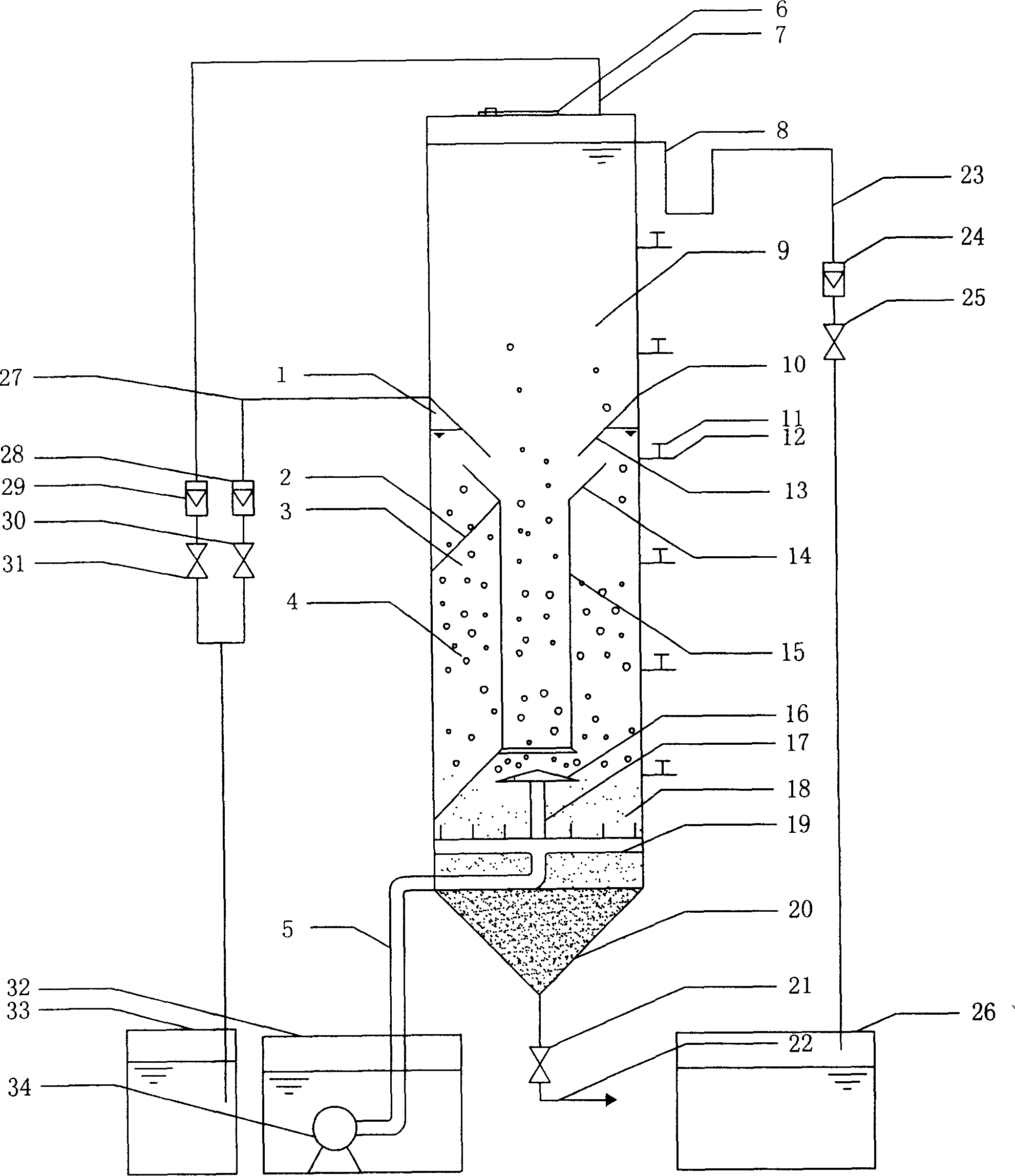

Anaerobic inner circulating reflux type immobilization microorganism fluidized bed reactor

InactiveCN101012086AImprove utilization efficiencyEasy to handleTreatment with anaerobic digestion processesSludgeDistributor

The invention discloses an aerobic inner loop reflux typed immobilized microbe fluid-bed reactor, which comprises the following parts: sediment area, reacting area, depositing area from upwards to downwards, wherein the sludge hopper is set in the depositing area with water distributor on the top; the support pipe is set on the water distributor with reflective board on the upper end; the fixed microbe fill and inner circulation reflux pipe are set in the reacting area; the first and second hopper typed baffles are set on the upper end of inner circulating reflux pipe; three-phase separator is set on the connecting part of first hopper typed baffle and reactor bulk, which connects the second draining pipe, second gas rotor flow meter and second needle valve and water tank through gas chamber; several sampling holes are set on the external wall of reactor bulk, which connects outlet pipe, liquid rotor flow meter, second stop valve and outlet tank through U-shaped pipe.

Owner:ZHEJIANG UNIV

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

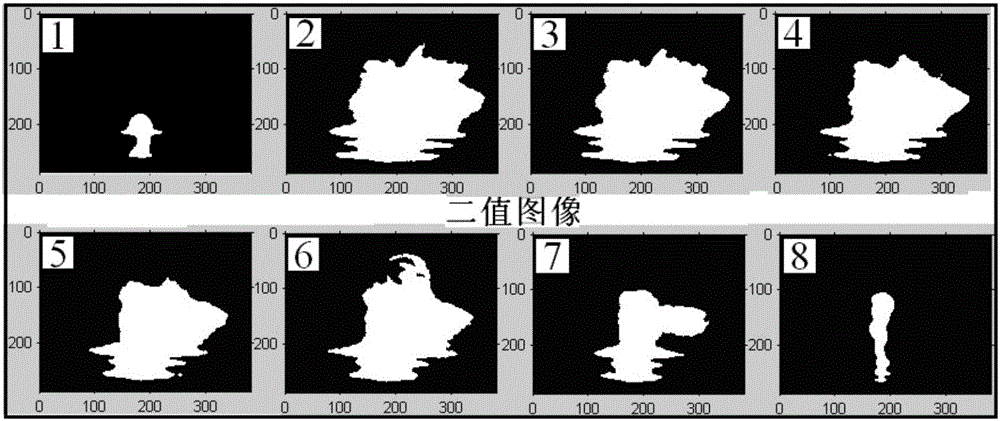

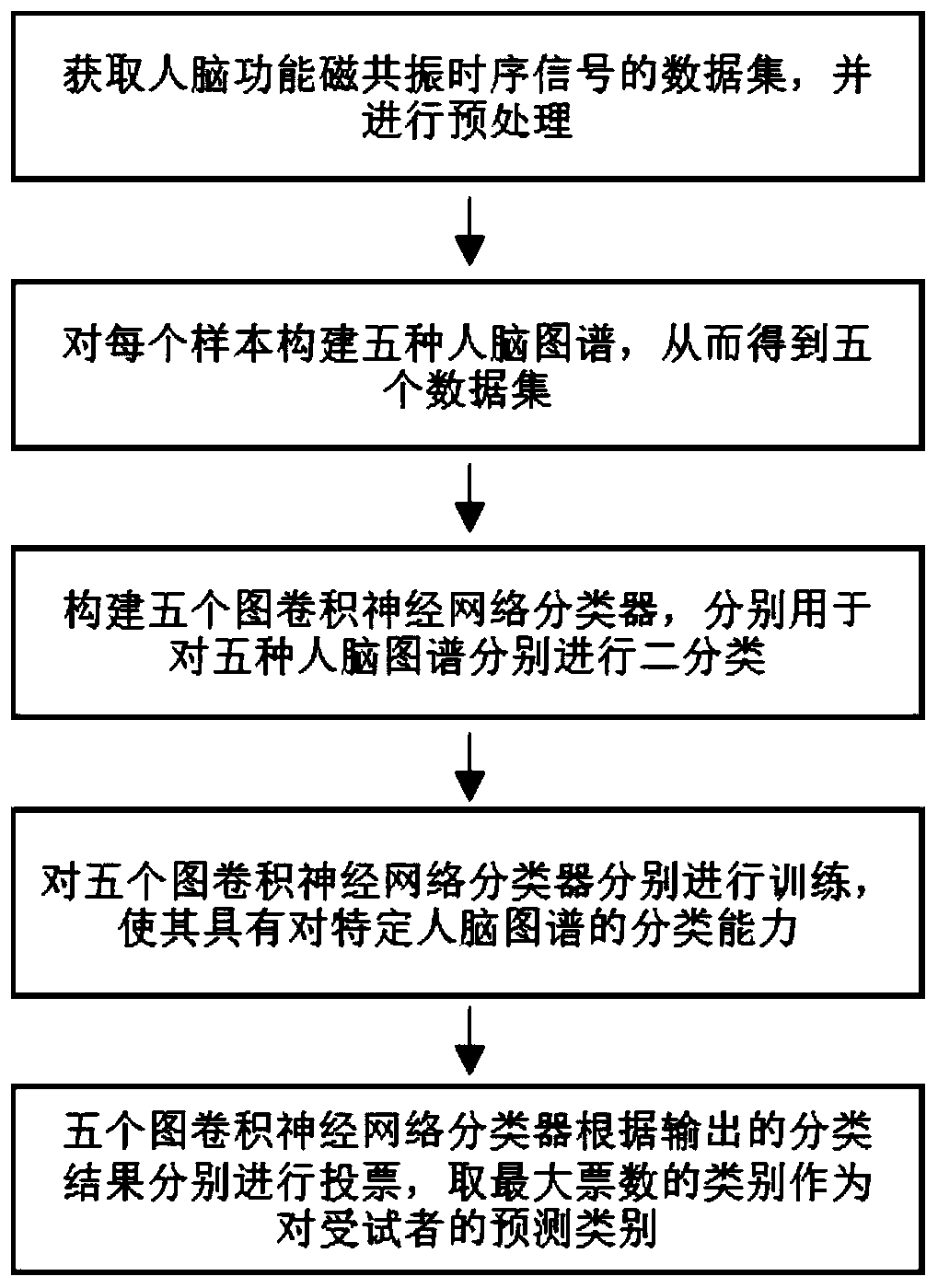

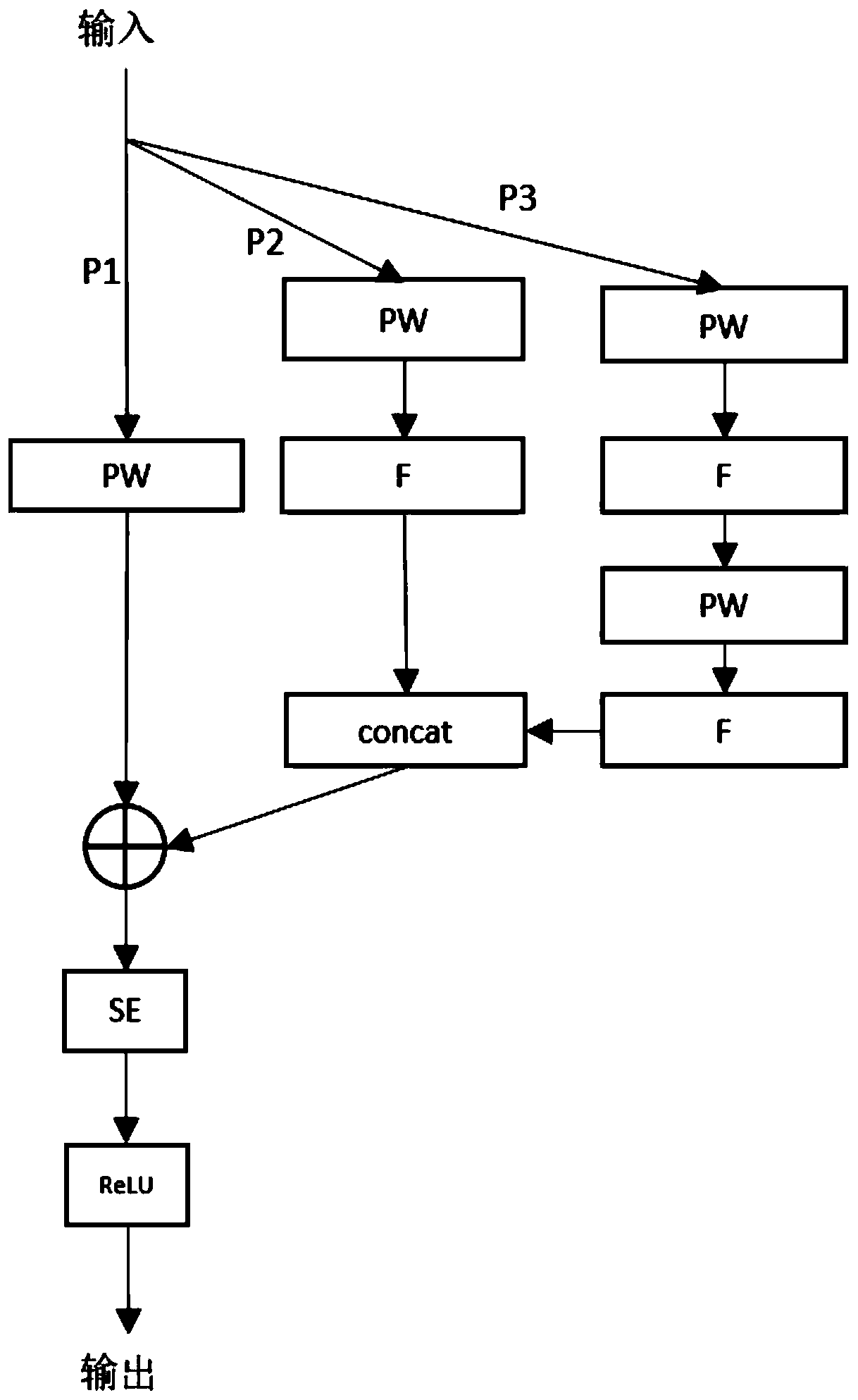

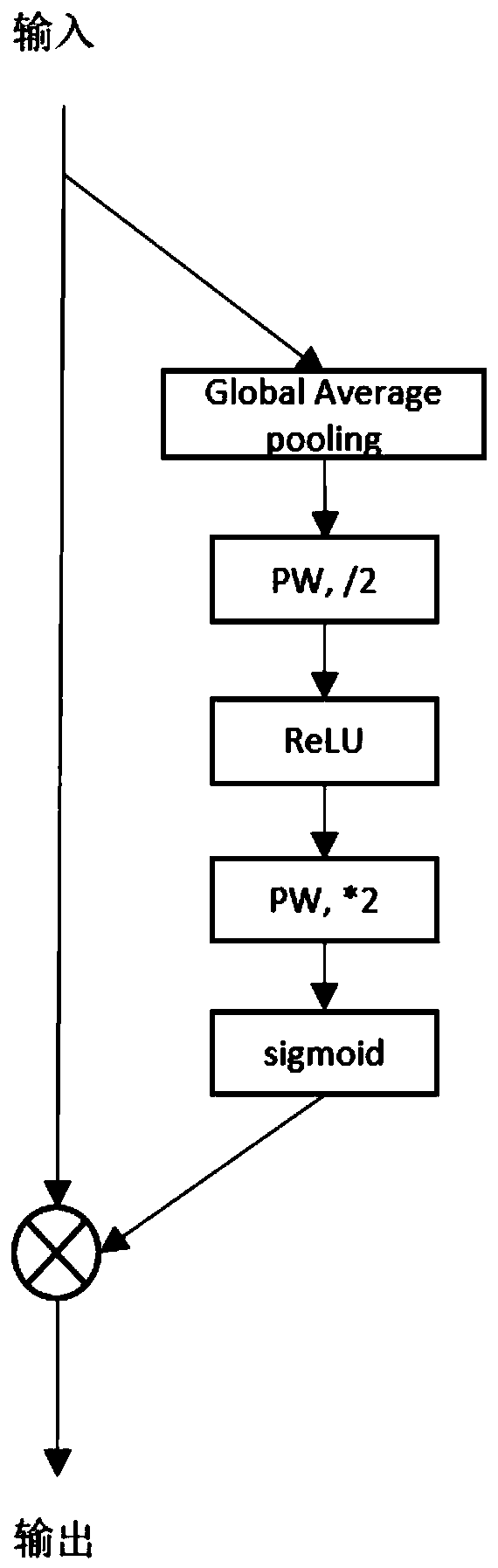

Subject classification method fusing multiple human brain atlases based on graph convolutional neural network

ActiveCN111563533AIncrease diversityThe classification results are objective and accurateCharacter and pattern recognitionNeural architecturesFunctional connectivityData set

The invention discloses a subject classification method fusing multiple human brain atlases based on a graph convolutional neural network. The human brain atlas is a data structure and represents interaction information between different brain regions in the human brain. The method performs classification prediction on a subject by identifying five human brain atlases of the subject, and belongs to the field of brain science research and deep learning research. The classification method comprises the following steps: acquiring and preprocessing human brain functional magnetic resonance time sequence signals; constructing five types of human brain atlases for each sample according to different functional connection strength calculation methods so as to obtain five data sets; constructing five graph convolutional neural network classifiers; carrying out training on the corresponding human brain atlas data sets separately, and therefore obtaining the binary classification capacity of thespecific human brain atlas; and integrating prediction results of the five graph convolutional neural network classifiers, and performing classification prediction on the subject, i.e., predicting which kind of person the subject belongs to.

Owner:SOUTH CHINA UNIV OF TECH

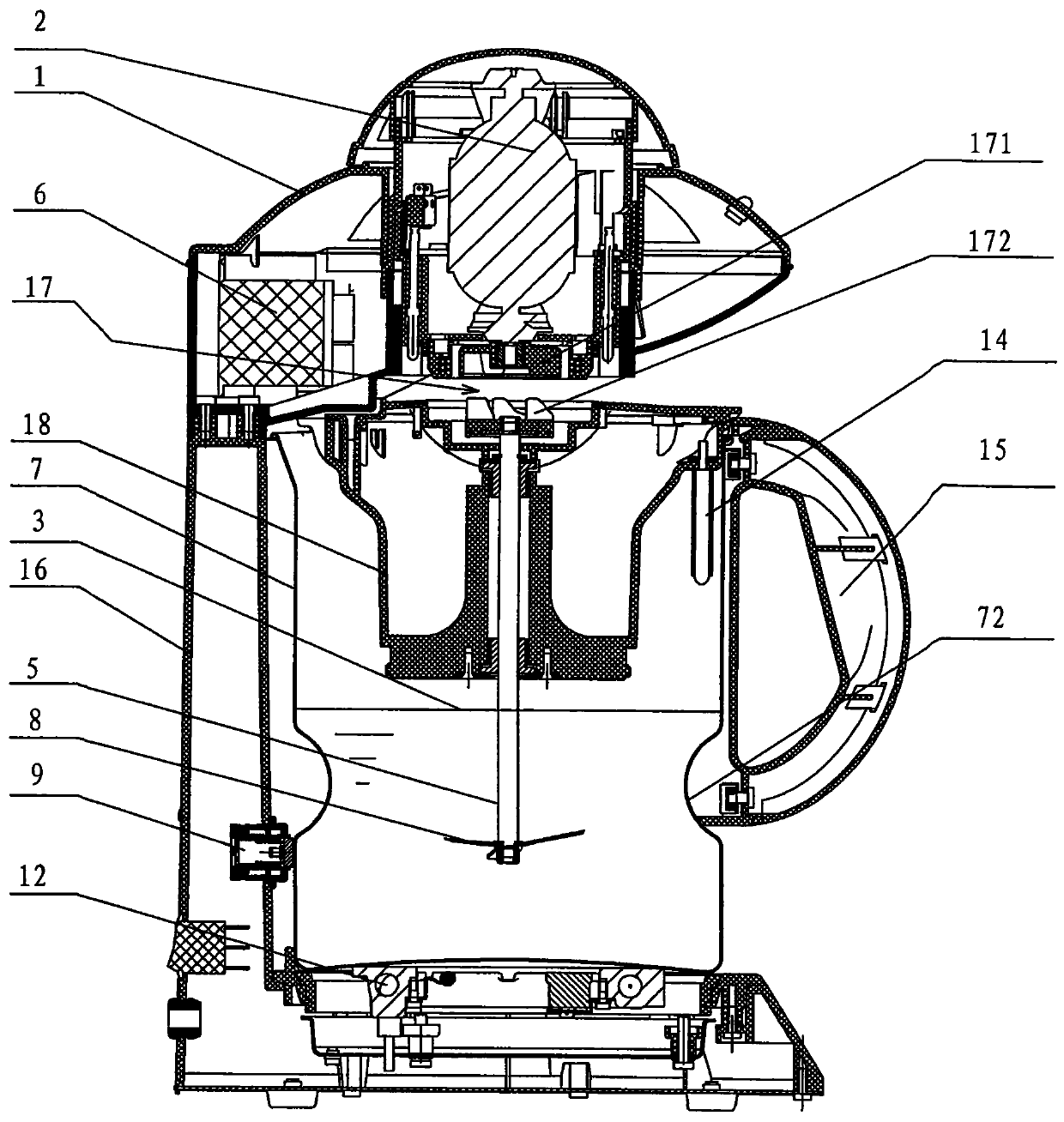

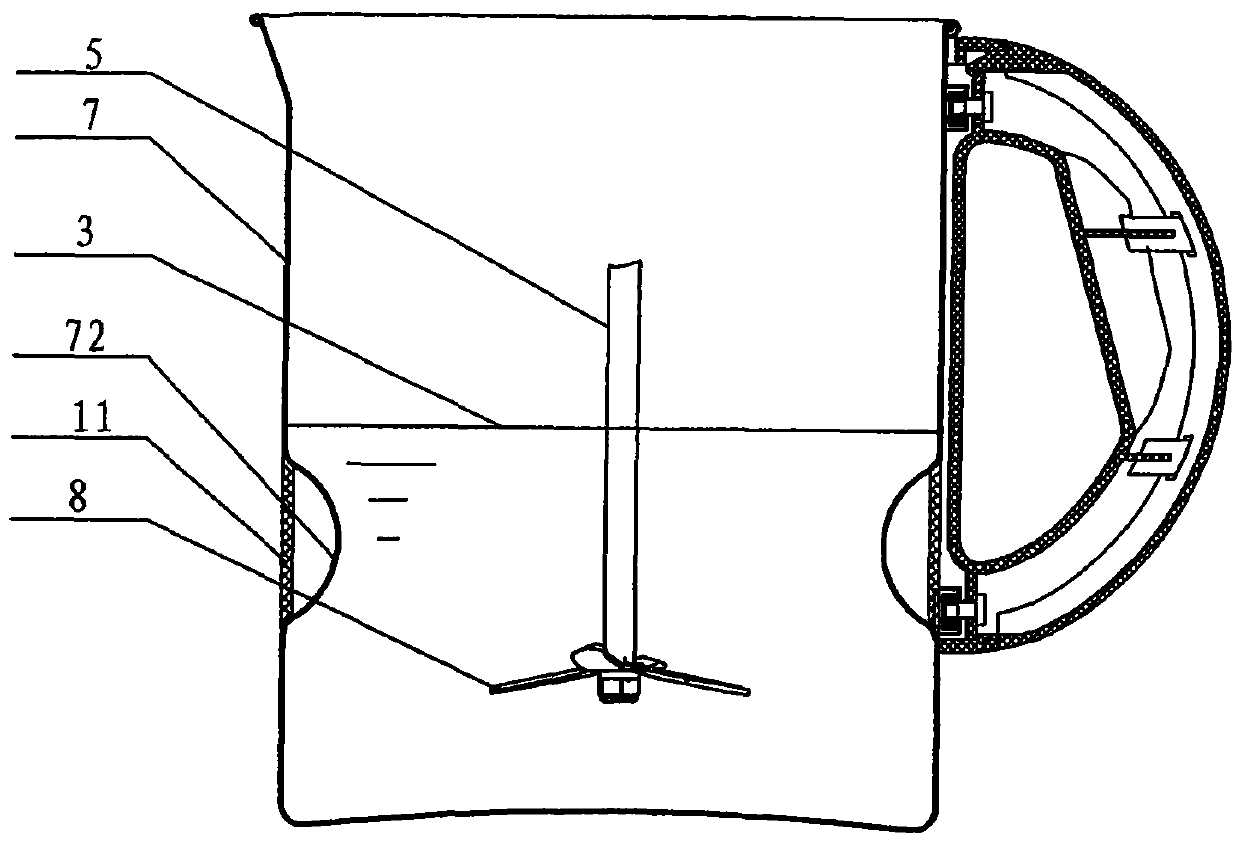

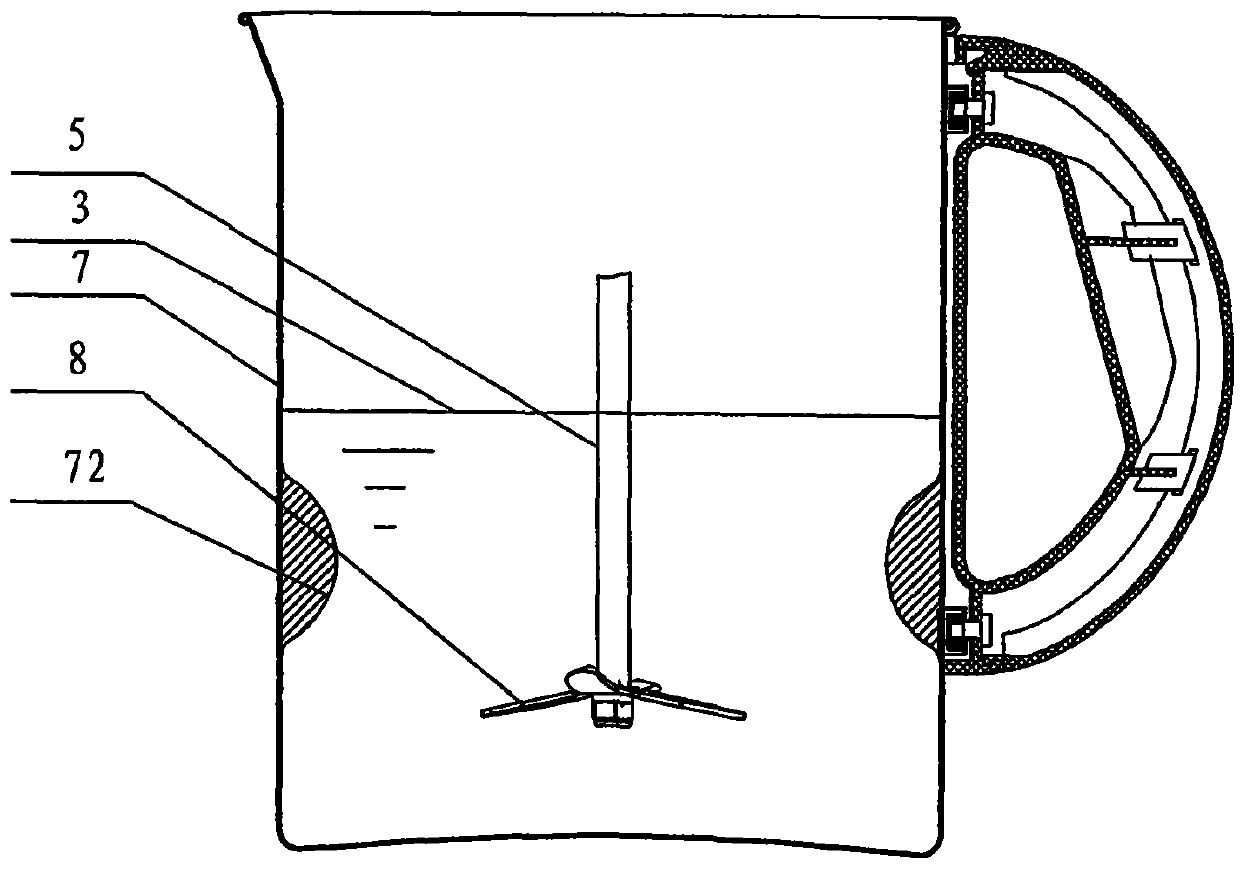

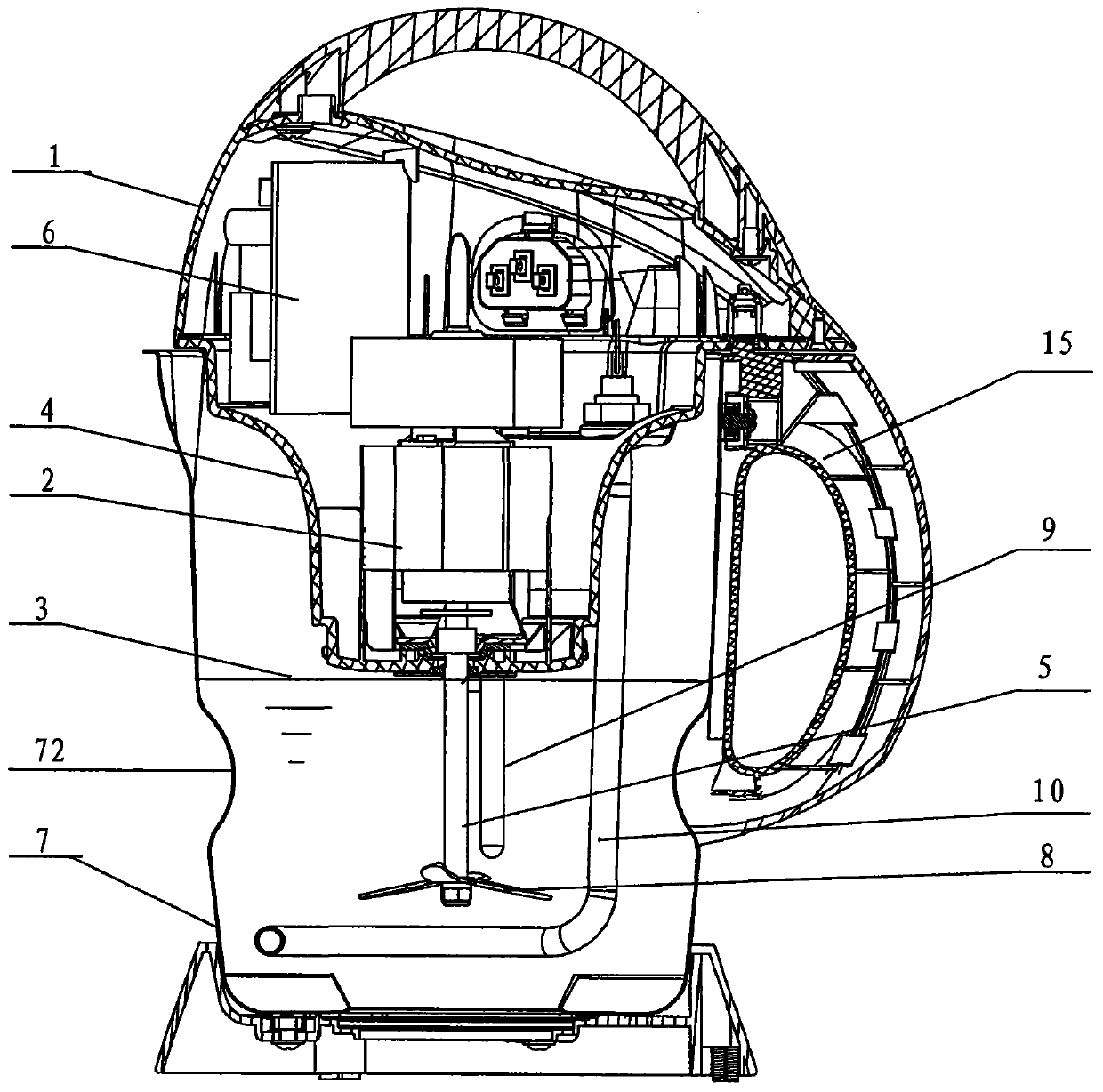

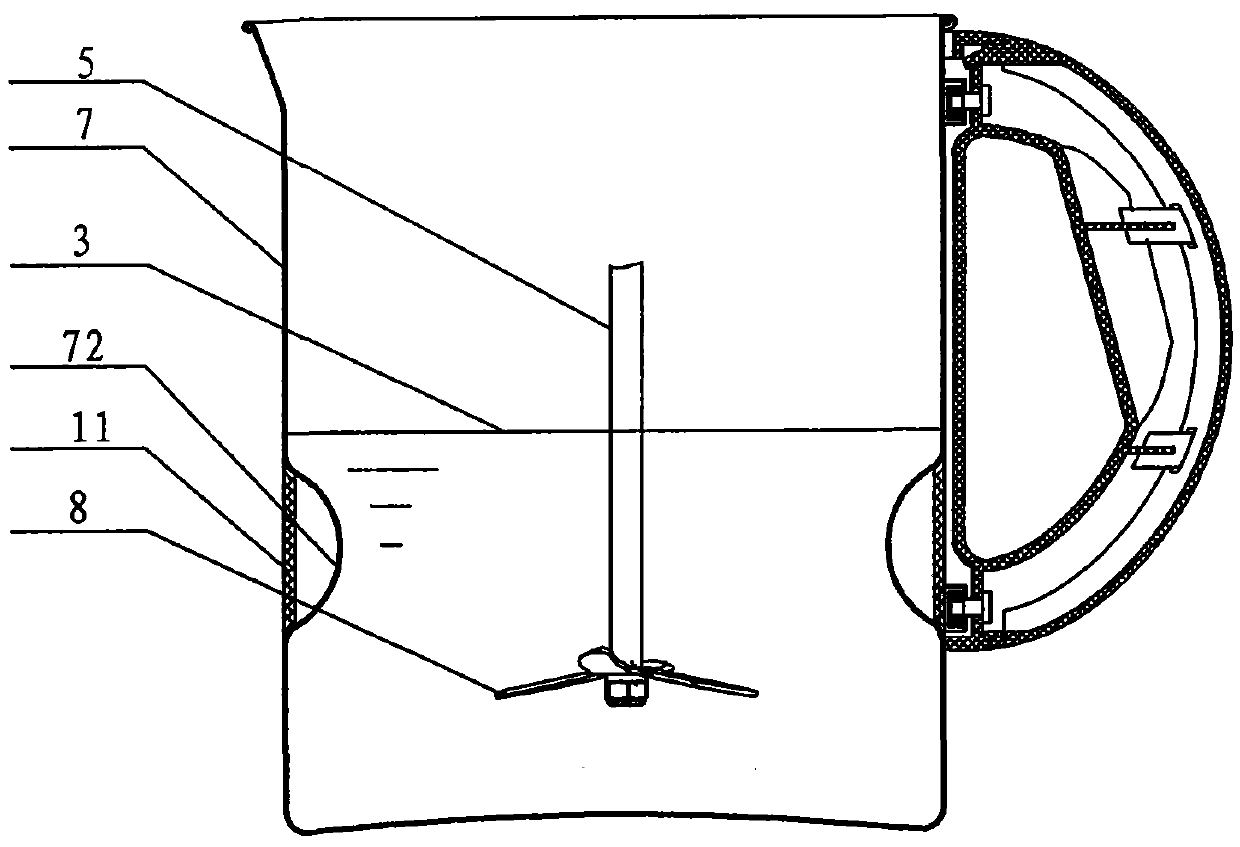

Household soya-bean milk maker

InactiveCN101028170AFully boiledEffective cookingBeverage vesselsFood preparationCouplingEngineering

A domestic soybean milk maker is composed of a cup body with turbolating ring on its inner surface and cover, a main body, a machine head on said cup body and with upper and lower covers, a motor in said machine head, an arbor extended in said cup body, an axle coupling for coupling motor shaft with arbor, breaking cutter installed to front end of arbor, and a control circuit board.

Owner:SHANDONG JOYOUNG HOUSEHOLD ELECTRICAL APPLIANCES

Method for controlling laser welding

ActiveCN105108338AFull flowLower weld stayWelding/soldering/cutting articlesLaser beam welding apparatusHelical lineWeld seam

The invention discloses a method for controlling laser welding. The method comprises the following steps that 1, the weld seam width w of a workpiece to be welded is measured; 2, the locus of laser welding is controlled as x0=x1+delta*cos beta, y0=y1+delta*sin beta, x=x0+R*cos alpha, y=y0+R*sin alpha, wherein w=2R+phi, x0 and y0 serve as coordinates of a point on a straight line, x1 and y1 serve as starting point coordinates of the straight line, delta serves as a point distance of the straight line, beta serves as an inclination angle of the straight line, R serves as a shaking radius, alpha serves as a polar angle, x and y serve as coordinates of a point on a circle (that is a helical line locus), phi serves as a welding point diameter, and delta is smaller than phi. According to the method for controlling laser welding, the locus of a welding helical line is adjusted by adjusting the shaking radius and the point distance for changes of the weld seam width, therefore, a molten pool can flow more fully, the problems of weld seam depression, undercut, point burst and needle holes which are brought by traditional laser welding can be effectively solved, the welding performance is improved, and the quality rate of products is improved.

Owner:UNITED WINNERS LASER CO LTD

Household souya-bean milk maker

ActiveCN101028169AFully boiledEffective cookingBeverage vesselsFood preparationSlurryControl circuit

A domestic soybean milk maker is composed of a cup body with turbolating ring on its inner surface, a machine head on said cup body and with upper and lower covers, a motor in said machine head, an arbor extended in said cup body, breaking cutter installed to front end of arbor, and a control circuit board.

Owner:JOYOUNG CO LTD

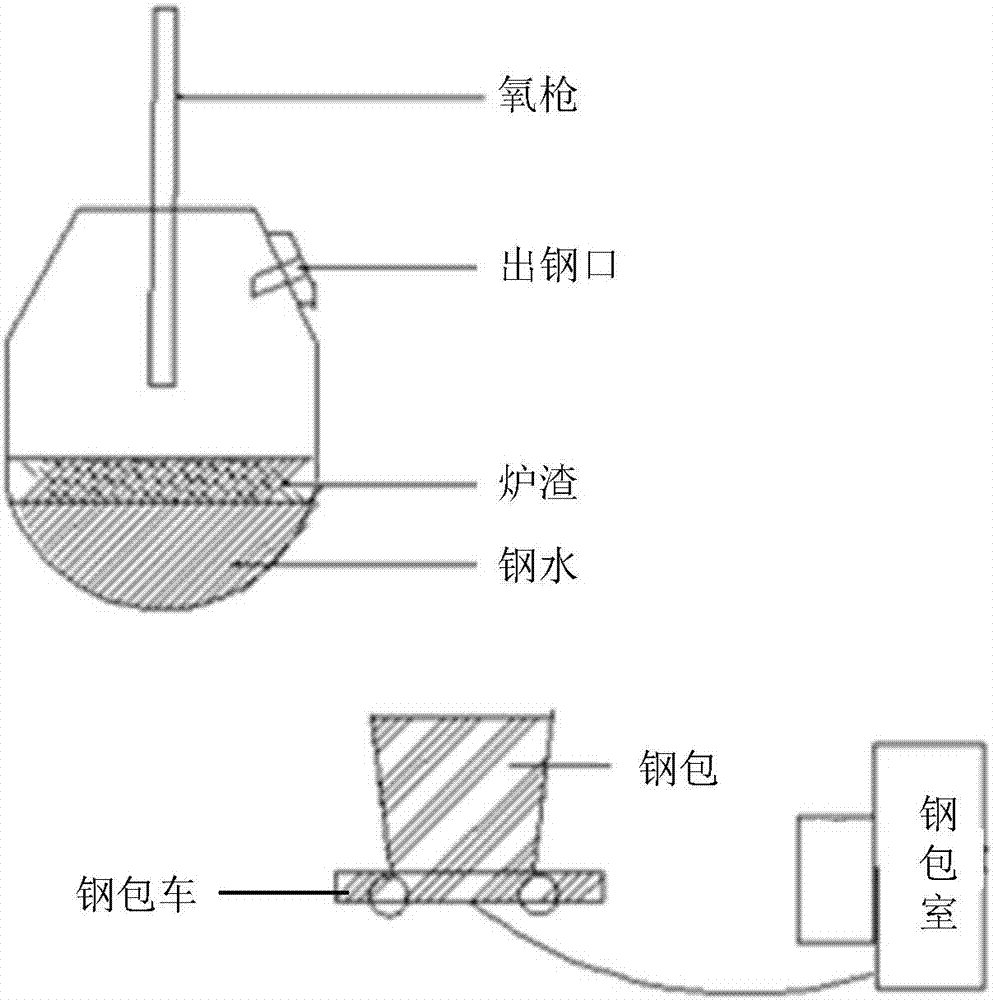

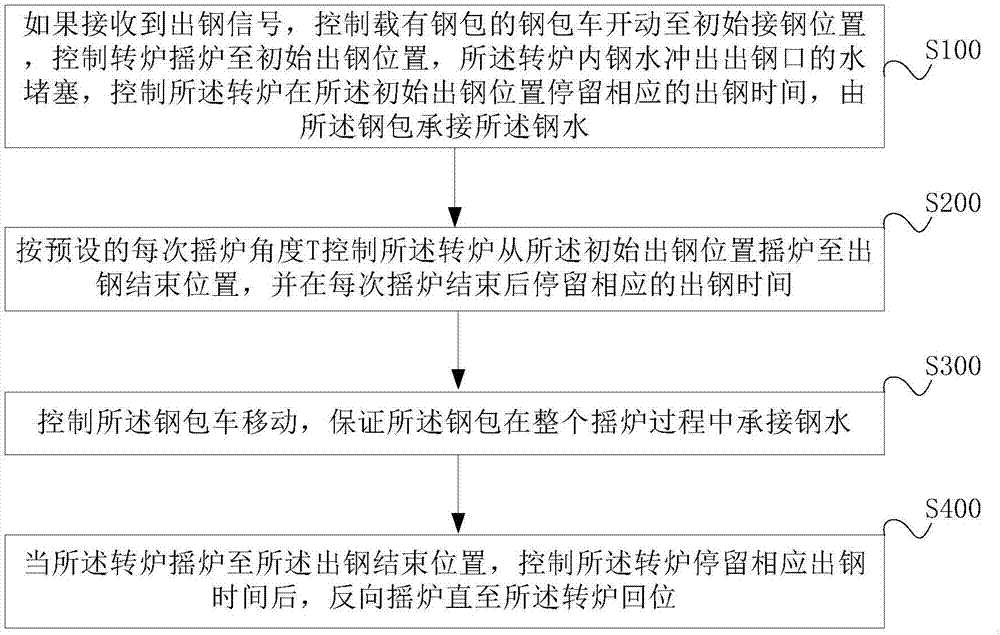

Auto tapping control method and auto tapping control system of converter

The application discloses an auto tapping control method and an auto tapping control system of a converter. The method includes the steps of: 1) when a tapping signal is received, controlling a ladle trolley which carries a ladle to move to an initial receiving position, and controlling the converter to be rocked to an initial tapping position, so that molten steel in the converter rushes out from a water seal of a tapping hole, and controlling the converter to remain at the initial tapping position for a corresponding tapping time so as to receive the molten steel by the ladle; 2) according to preset converter rocking angles T in every time, controlling the converter to rock from the initial tapping position to a tapping finish position, and after every time of the converter rocking operation, enabling the converter to remain for a corresponding tapping time; 3) controlling the ladle trolley to move to ensure that the ladle can receive the molten steel in the whole converter rocking process; and 4) when the converter is rocked to the tapping finish position, controlling the converter to remain for a corresponding tapping time, closing a slag baffle, and performing reverse converter rocking until the converter returns to the initial position. The method can achieve automatic tapping, improves tapping efficiency, can avoid a problem that slag flows out with the molten steel, and improves tapping quality.

Owner:SHANDONG IRON & STEEL CO LTD

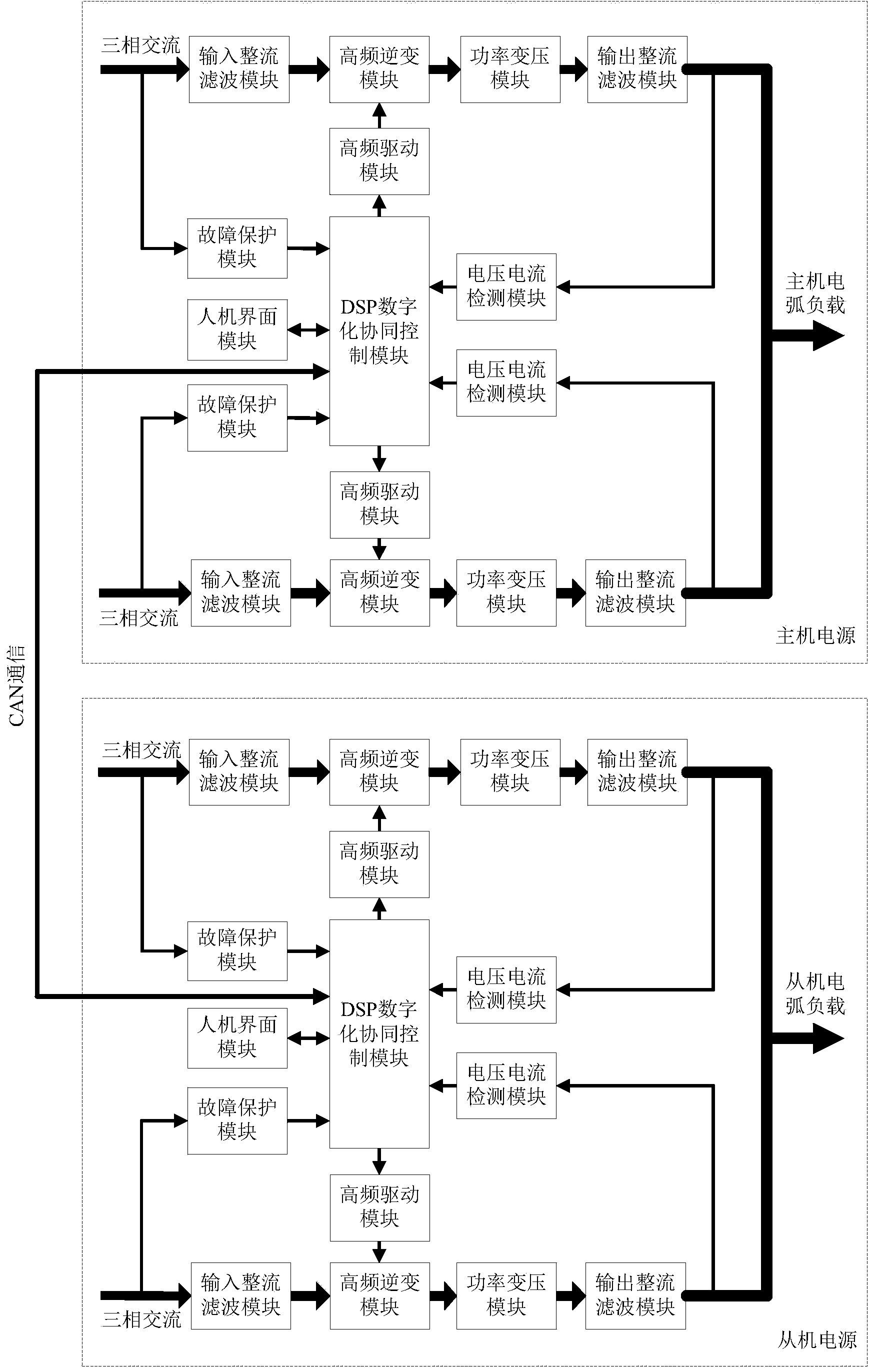

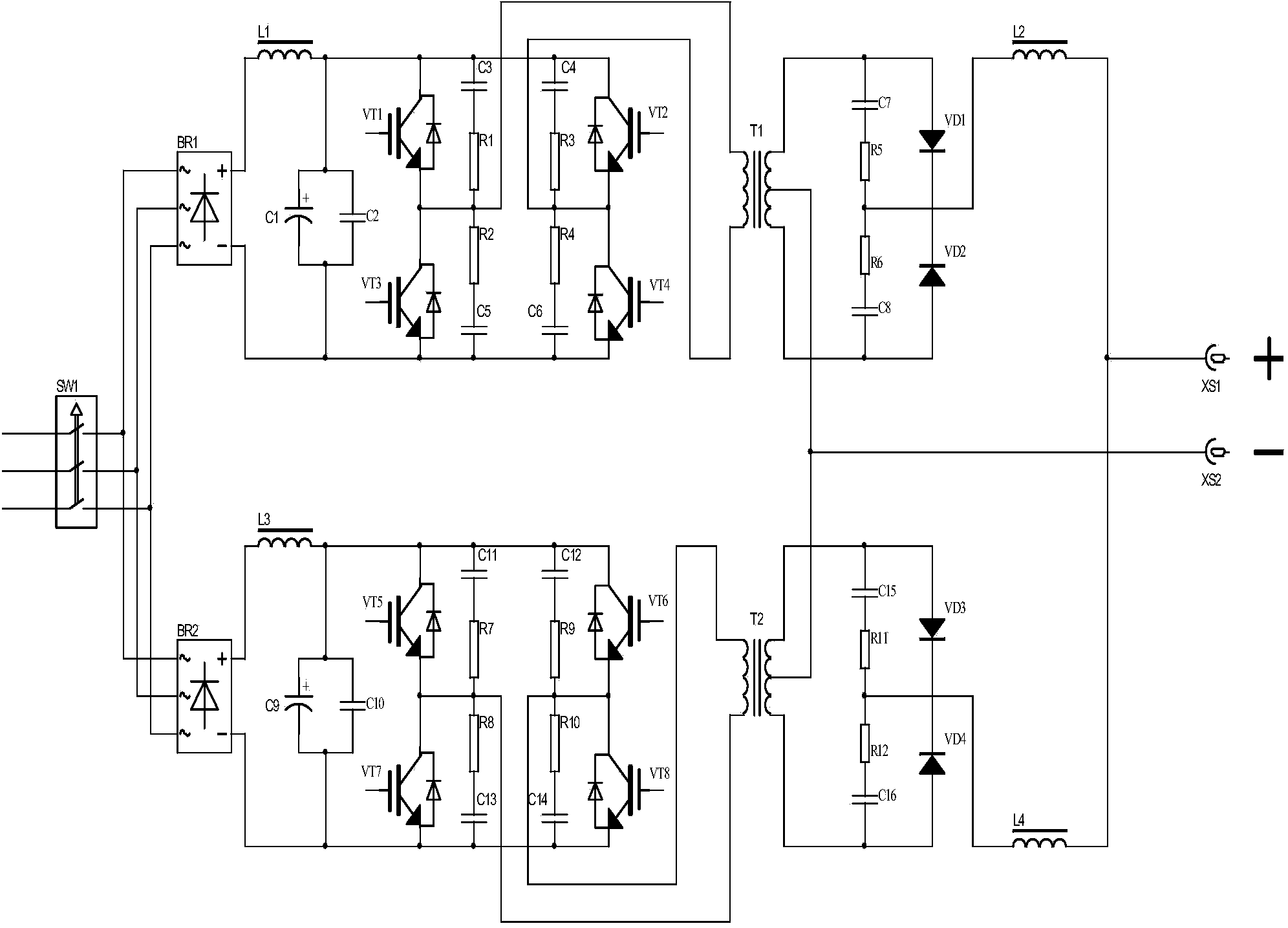

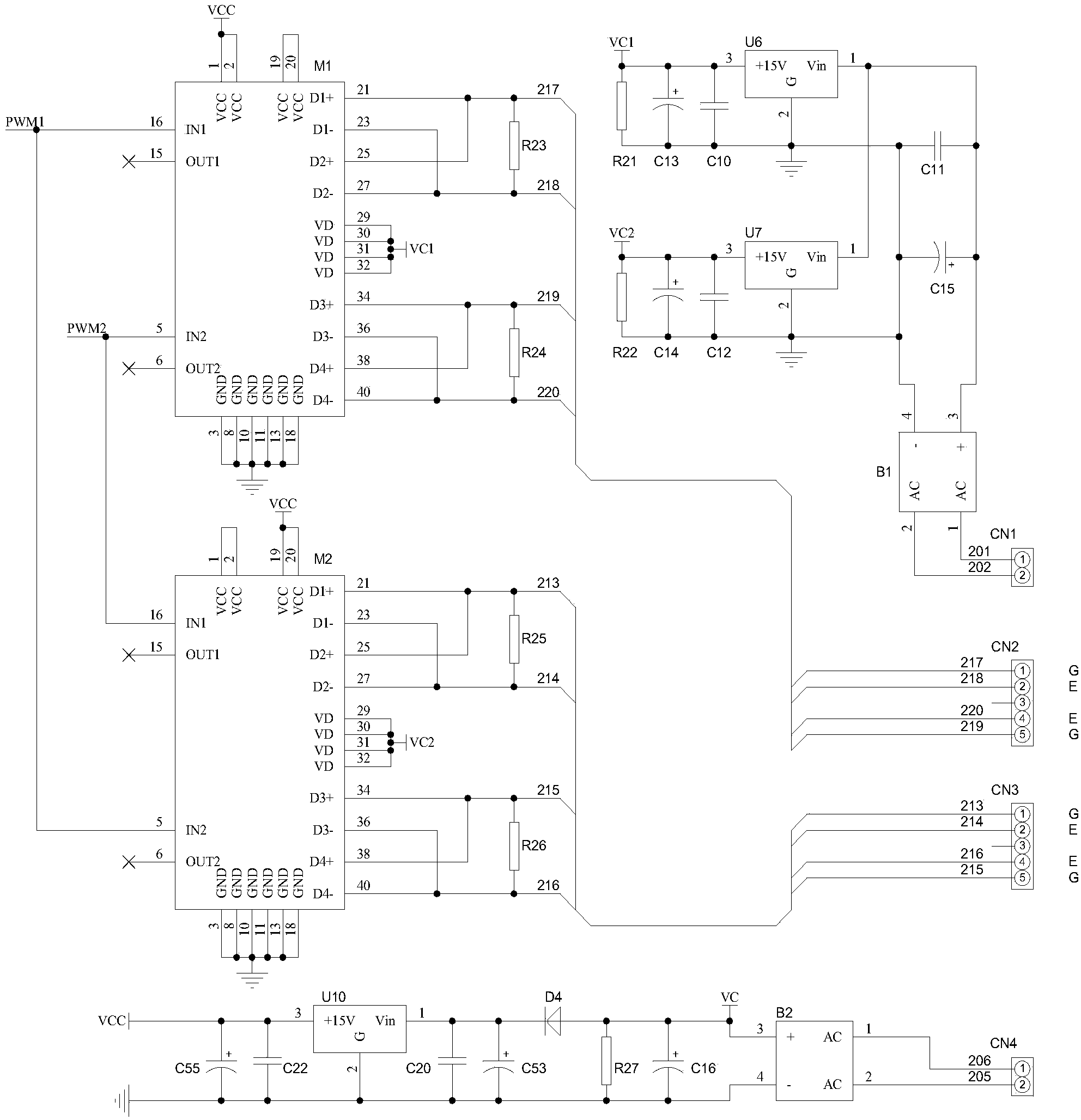

High-power two-wire pulse MIG inverter power supply system and digital cooperative control method thereof

InactiveCN103480945ALarge output currentThe output current is consistentArc welding apparatusHuman–machine interfaceFull bridge

The invention discloses a high-power two-wire pulse MIG inverter power supply system and a digital cooperative control method thereof. The system comprises a host power supply and a slave power supply which are connected through a CAN bus, each of the host power supply and a slave power supply comprises a main circuit and a control circuit, each main circuit is formed by parallel connection of two or more full bridge inverters and comprises an input rectifying and filtering module, a high frequency inverting module, a power transformation module and an output rectifying and filtering module, each input rectifying and filtering module is connected with a three-phase alternating current input power grid, each output rectifying and filtering module is connected with an electric arc load, and each control circuit comprises a voltage and current detection module, a fault protection module, a DSP digital cooperative control module, a human-machine interface module and a high frequency driving module. The output power, the welding speed and the fusion covering efficiency of welding wires are doubly improved by adopting the main circuits formed by parallel connection of the full bridge inverters and in combination with the DSP digital cooperative control technology.

Owner:SOUTH CHINA UNIV OF TECH

Agricultural greenhouse with marsh gas heating auxiliary system

ActiveCN106857099AImprove economySave energyBioreactor/fermenter combinationsBiological substance pretreatmentsGreenhouseWater storage tank

The invention provides an agricultural greenhouse with a marsh gas heating auxiliary system. The technical problem that in a cold environment, an existing agricultural greenhouse is low in indoor temperature, poor in heat preservation property and the like is solved. The agricultural greenhouse with the marsh gas heating auxiliary system comprises a greenhouse frame and a transparent greenhouse film; the marsh gas heating auxiliary system comprises a marsh gas fermentation pond, a transparent flow guide pipe is laid on the top face of the greenhouse film, a terrestrial heat pipe is laid on the ground in the greenhouse, and the terrestrial heat pipe is connected with a marsh gas heating device. Marsh gas generated by the marsh gas fermentation pond is connected with the marsh gas heating device through a gas conveying pipe, the liquid inlet end of the flow guide pipe is connected with a water storage tank, and the water storage tank is further connected with an output opening of a first circulating pump. An input opening of the first circulating pump is connected with the liquid outlet end of the flow guide pipe through a connecting pipe, and heat collecting sheets are arranged in the water storage tank. The agricultural greenhouse has the advantages of saving energy, being good in greenhouse heat preservation effect and the like.

Owner:李梦颖

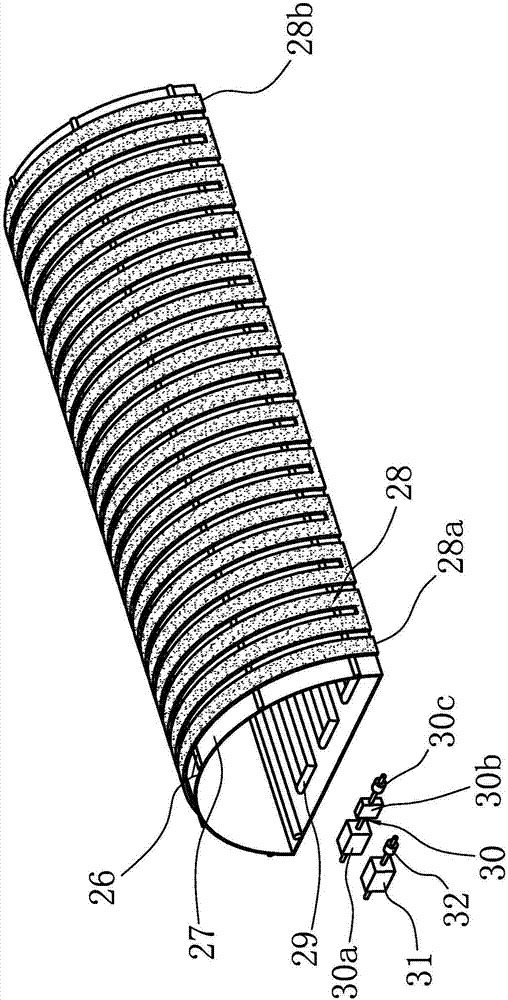

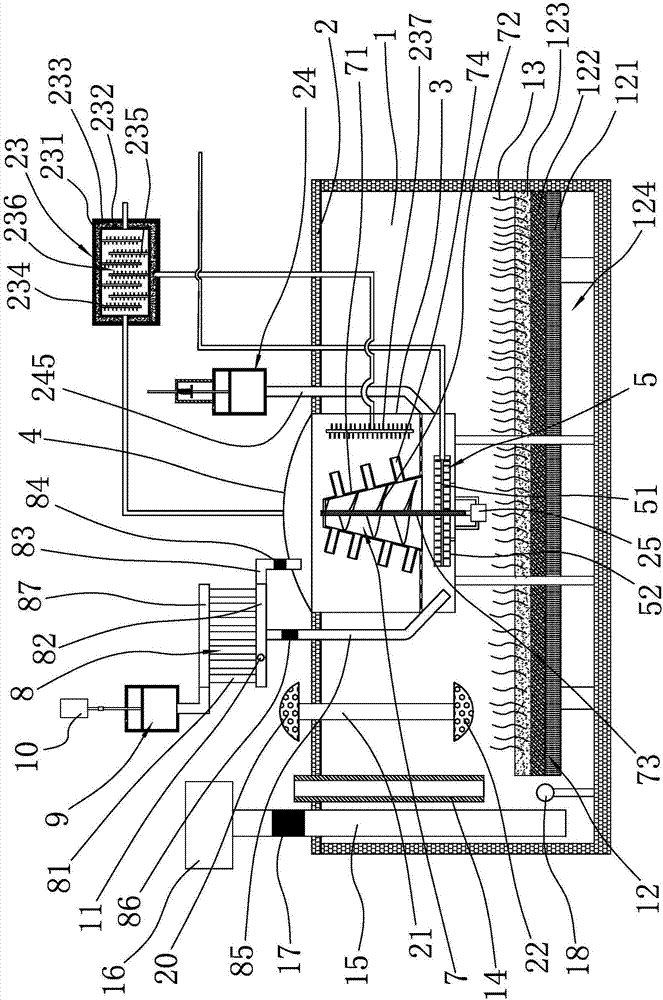

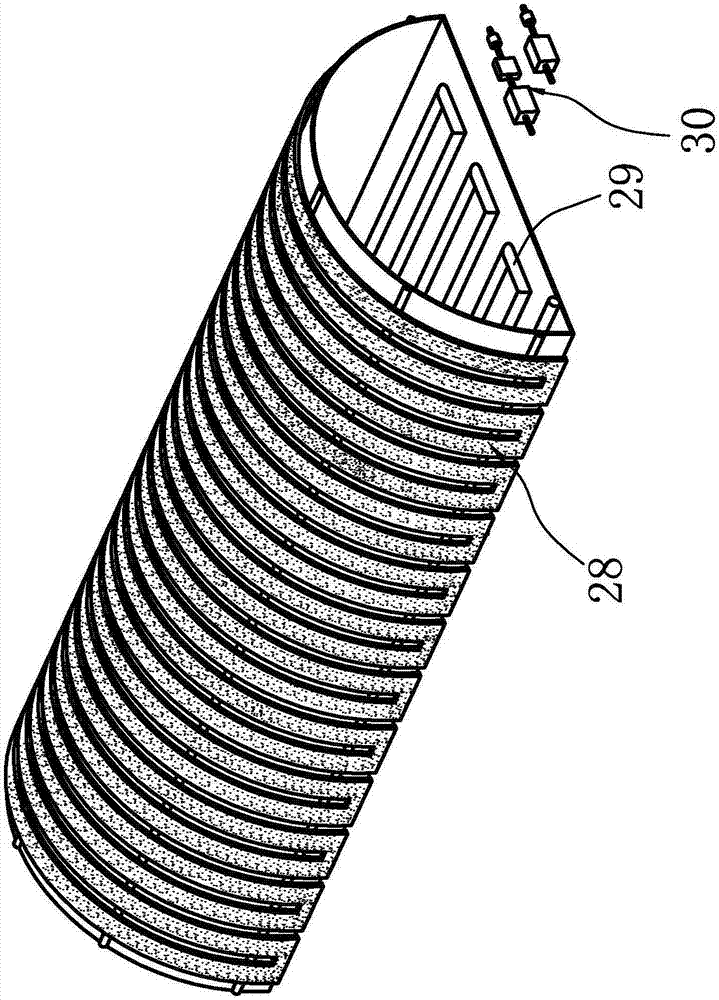

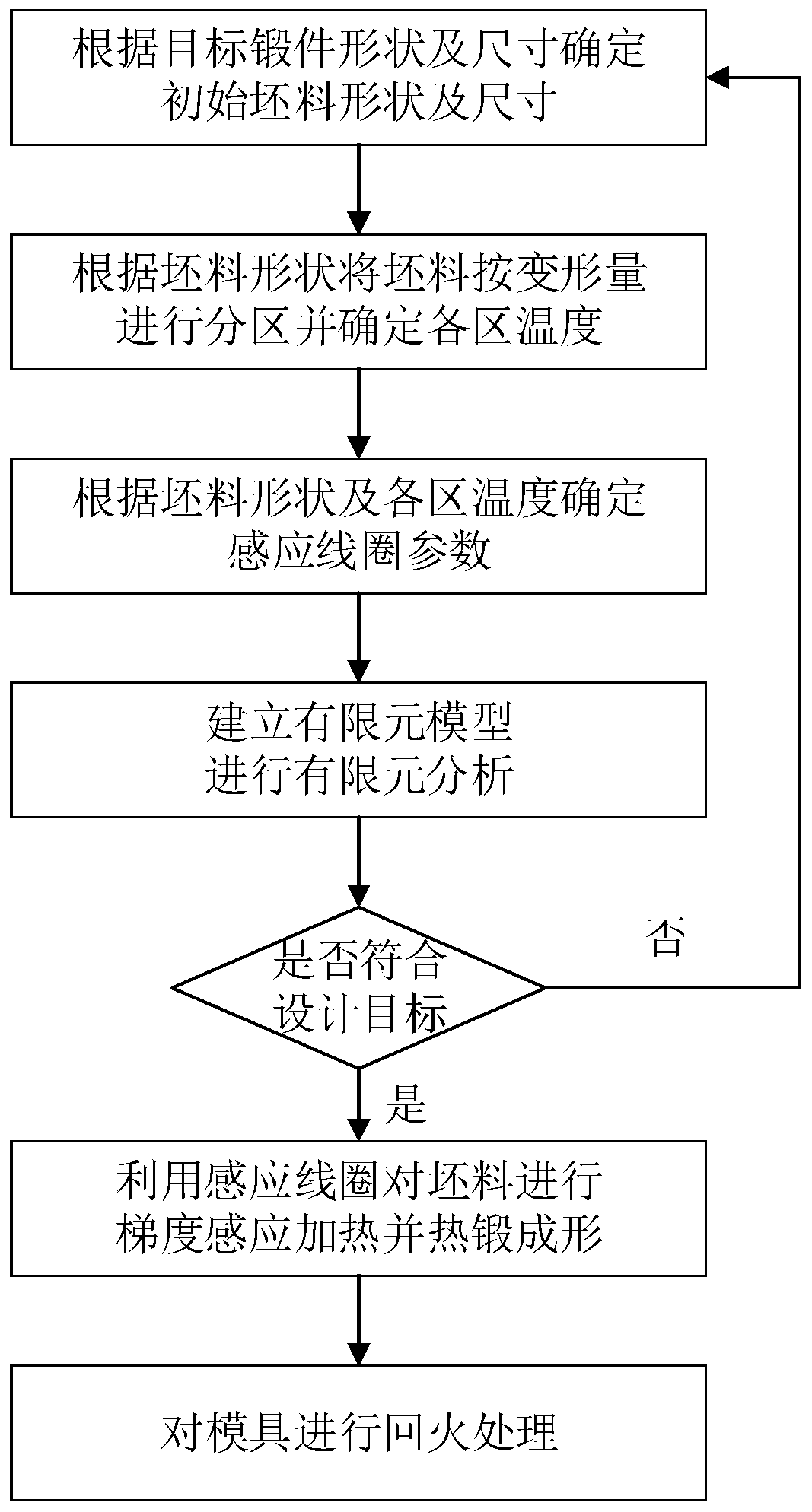

Gradient induction heating based thermal deformation workpiece blank heating method and machining method

ActiveCN109773099ARealize Controlled DesignGuaranteed dimensional accuracyHeating/cooling devicesThermoplasticThermal deformation

The invention discloses a gradient induction heating based thermal deformation workpiece blank heating method and a processing method and belongs to the field of meal thermoplastic forming. Accordingto the gradient induction heating based thermal deformation workpiece blank heating method and the processing method, a blank is designed according to the shape of a workpiece; parts, with different deformations, of the blank are subjected to rapid induction heating to different temperatures through a gradient induction heating coil, the temperature difference of different deformation parts of theblank is realized, and the continuity of the temperature of the surface of the blank is ensured. The plastic deformation resistance of areas hard to deformable is effectively reduced. The equipment tonnage can also be effectively reduced. Meanwhile, under the coupling effect of the temperature and deformation of the parts with the different deformations, the uniformity of the microstructure of awhole forged piece can be ensured, and the mechanical performance of a material is remarkably improved. Besides, the labor environment can be remarkably improved, the forged piece with the high dimensional precision, the uniform microstructure and excellent comprehensive performance is integrally formed, and automated and standardized production is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

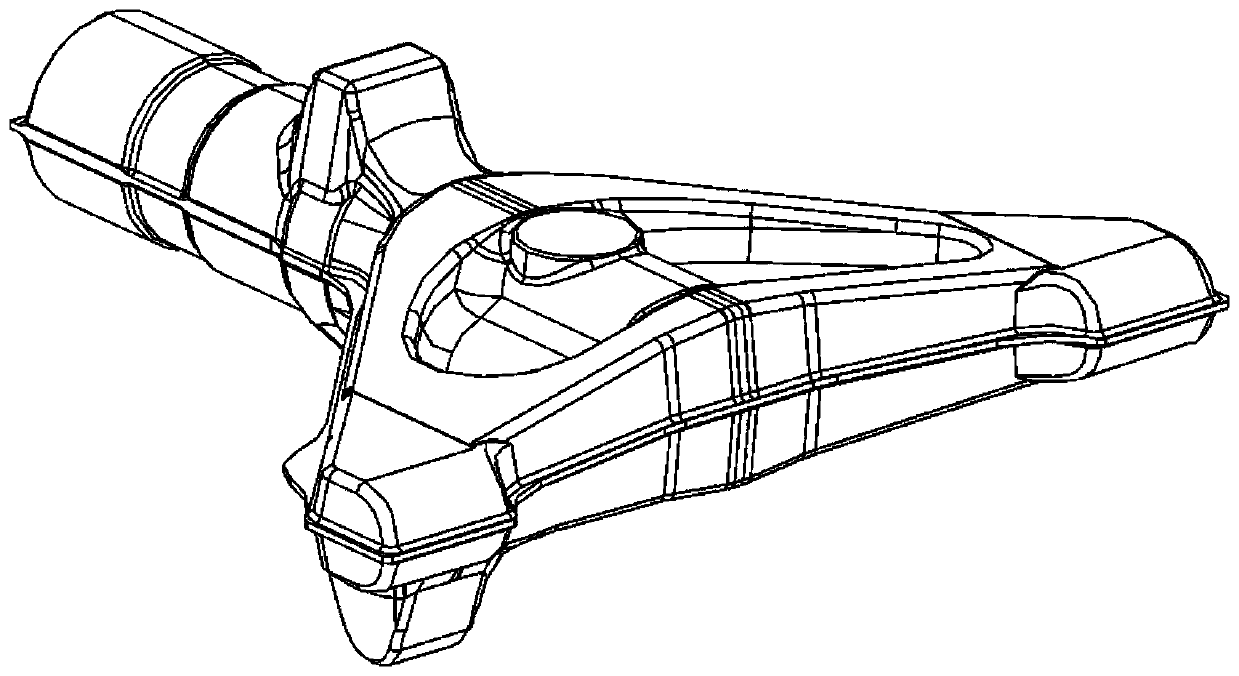

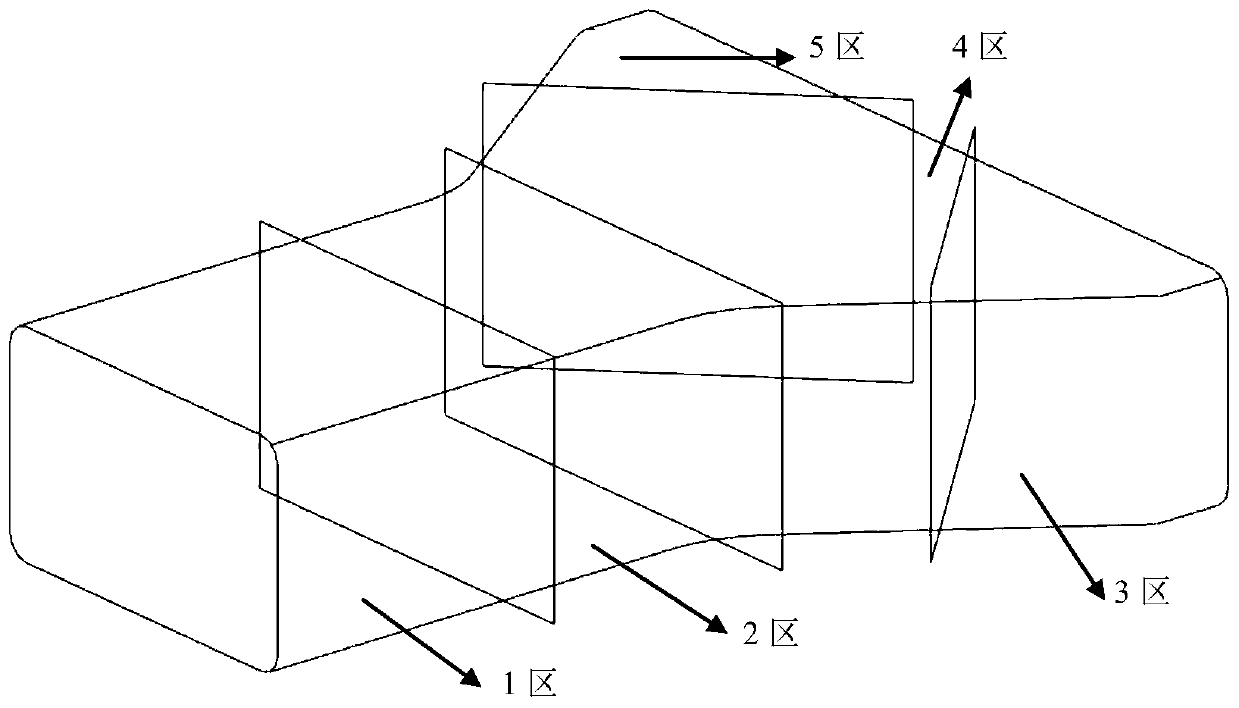

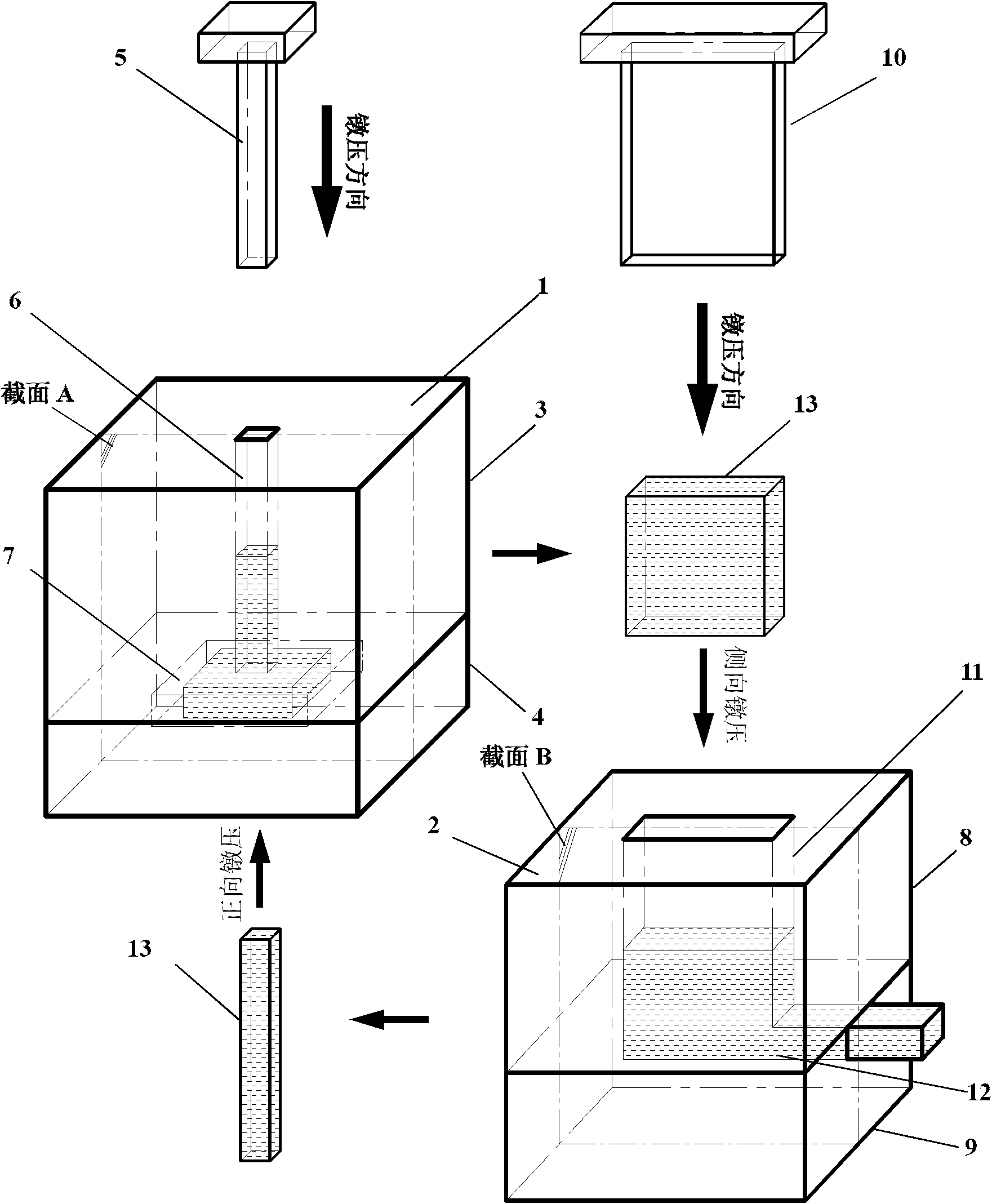

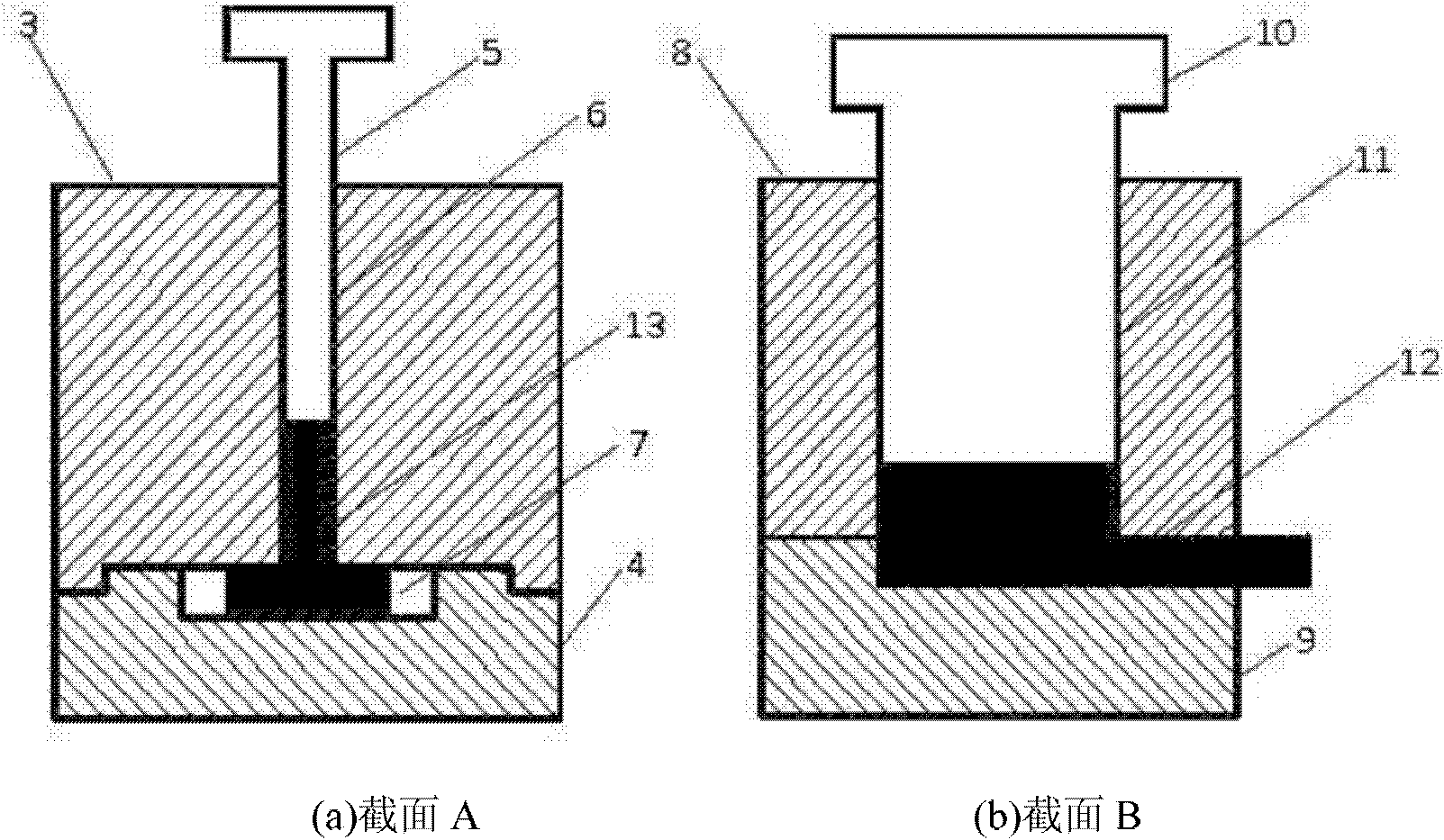

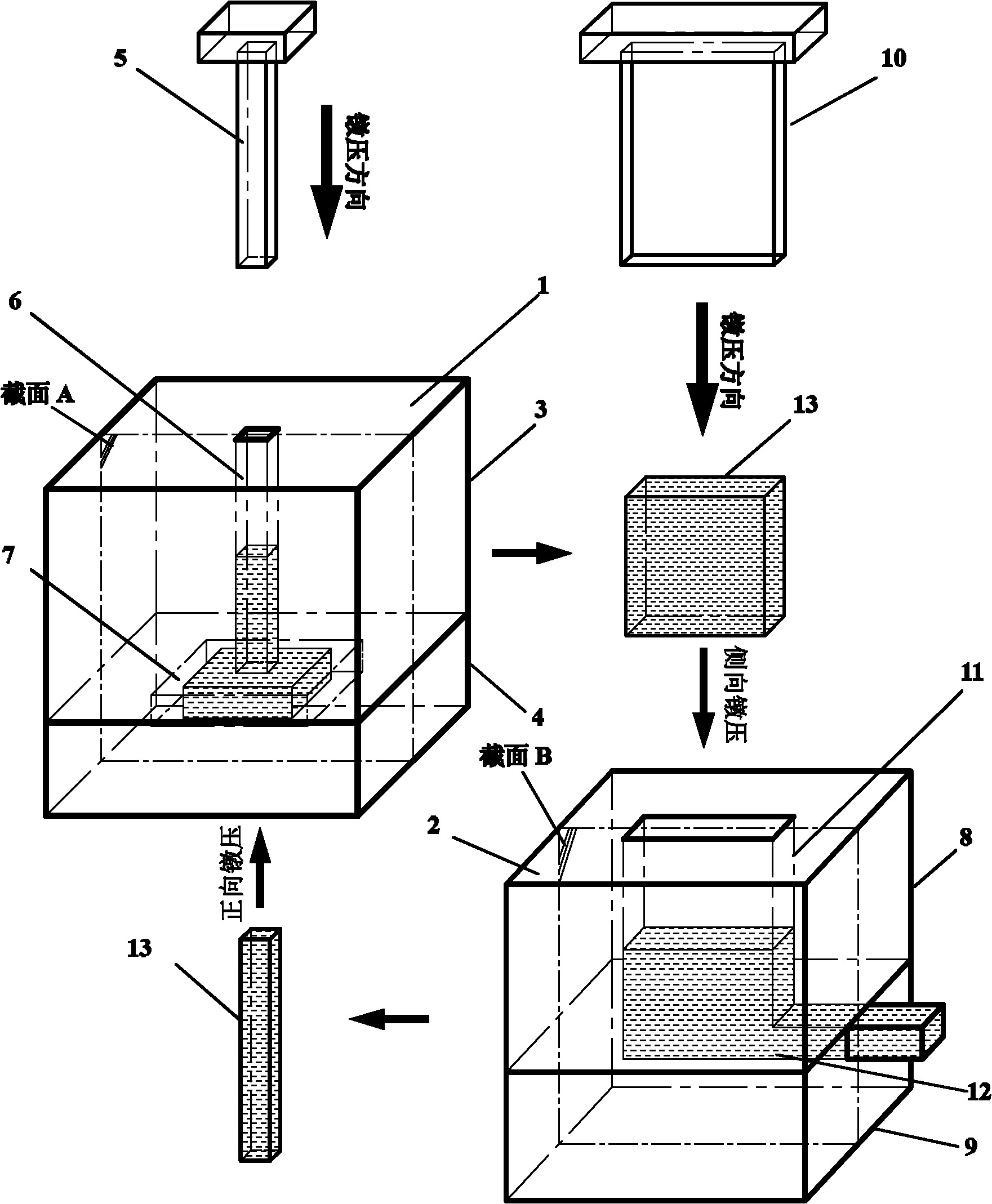

Multidirectional combined type circulating upsetting device and upsetting method

The invention relates to a multidirectional combined type circulating upsetting device and an upsetting method thereof, and belongs to the technical field of plastic forming. The upsetting device comprises a forward upsetting device and a lateral upsetting device. The method comprises the following steps of: in the forward upsetting process, prearranging bar blanks of which the cross sections are square in a forward upper die cavity of the forward upsetting device, so that the blanks are subjected to compressive plastic deformation downwards to fill in a forward lower die cavity finally; opening the forward upsetting device, taking the blanks out and putting the blanks in a lateral upper die cavity of the lateral upsetting device, with the side face facing downward, so that test samples are subjected to lateral upsetting deformation towards an lateral opening in a lateral lower die, and stopping pressing until a lateral punch presses to a parting surface of the lateral upsetting device; and repeating the steps for multiple times to perform multidirectional combined type upsetting circularly. By the upsetting device, superfine crystal blocks with uniform tissue can be prepared, so the upsetting device is used for preparing various superfine crystal materials such as pure metals, alloys, intermetallic compounds, composite materials, high polymer materials, semiconductor materials and the like.

Owner:上海治实合金科技有限公司

Blood filter material and process for preparing same

The invention relates to a blood filtering material and its preparation method. The material is formed from filtration substrate and surface modified layer, wherein the filtration substrate is macromolecular nonwoven material processed by using melt-blowing method with density of 10-1000g / cm2, mean pore size of 0.1-100 mu m, thickness of 0.01-50mm, fiber diameter of 0.01-50 mu m; surface modified layer is formed from fibroin protein and polyurethane blended aqueous solution in 90-10:10-90 by weight; Conventional coating method is adopted, comprising blending medical polyurethane aqueous solution and self-made fibroin protein, applying the above blend on the surface of filtration substrate, drying, bonding, and curing. In the invention, the price of raw materials is low, and the products are provided with excellent blood compatibility, wettability, permeability and high filter efficiency which can be used as blood filtering materials.

Owner:DONGHUA UNIV

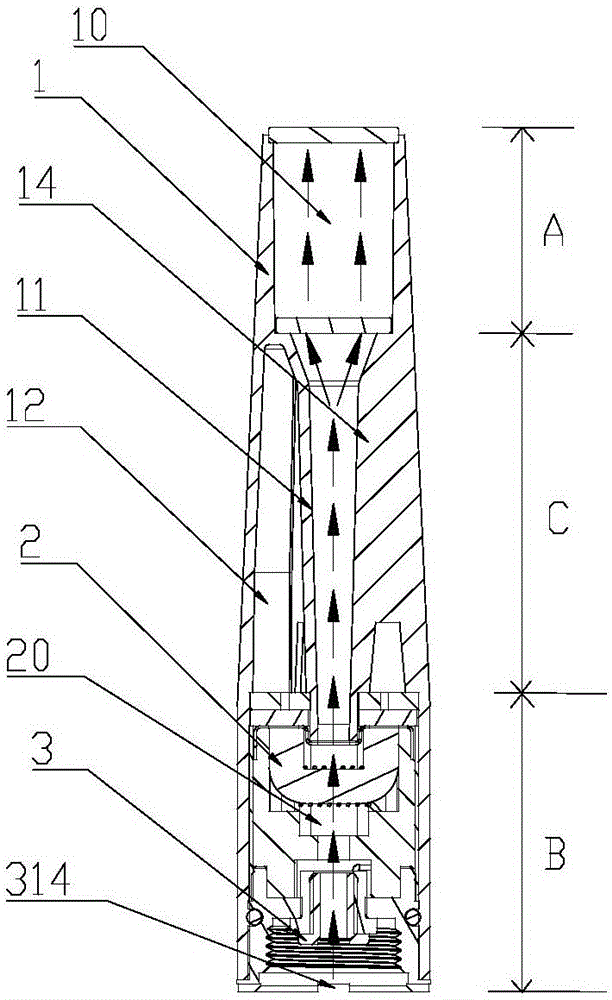

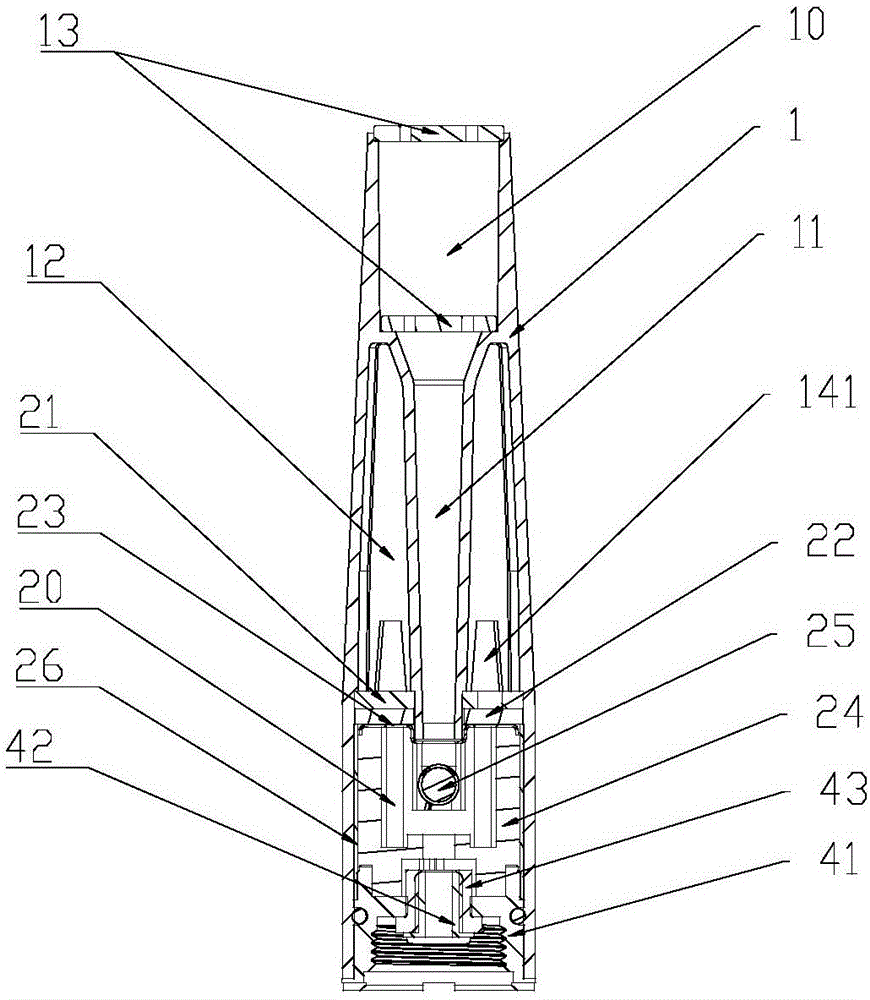

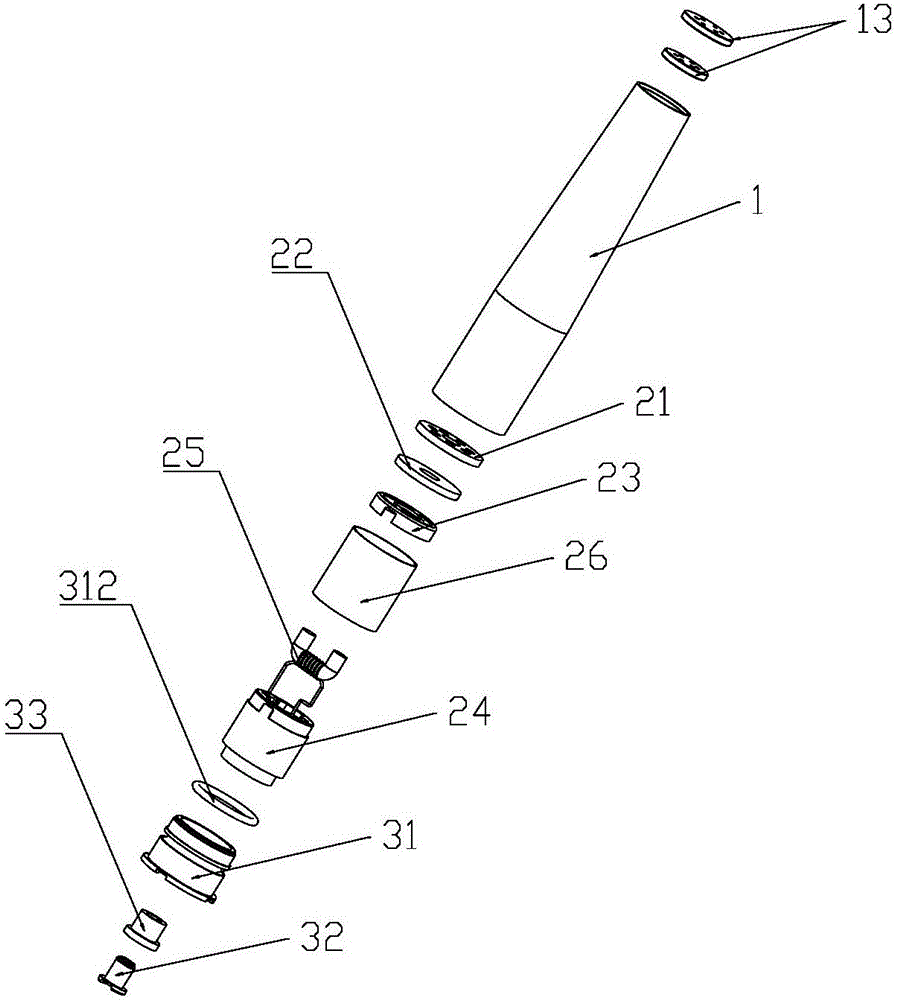

Electronic cigarette atomizer with divergent smoke outlet pipe

The invention discloses an electronic cigarette atomizer with a divergent smoke outlet pipe. The electronic cigarette atomizer comprises an atomizer pipe, an atomization device and a connecting part; one end of the atomizer pipe is provided with a suction nozzle segment, the other end of the atomizer pipe is provided with an atomization connecting segment, the middle of the atomizer pipe is provided with a liquid storage segment, a suction nozzle containing cavity which has the large section and can contain additives is formed in the suction nozzle segment, the smoke outlet pipe which is integrally formed with the atomizer pipe is arranged at the central axis inside the liquid storage segment, the two ends of the smoke outlet pipe are communicated with an atomization cavity and the suction nozzle containing cavity respectively, and the inner diameter of the smoke outlet pipe is gradually increased from one end of the atomization cavity to one end of the suction nozzle containing cavity; a liquid storage cavity used for storing cigarette liquid is formed between the smoke outlet pipe and the atomizer pipe; the atomization device is connected with the liquid storage cavity and the smoke outlet pipe, so that the cigarette liquid in the liquid storage cavity is atomized and then exhausted through the smoke outlet pipe. The electronic cigarette atomizer has the advantages that the volume of smoke sucked from a suction nozzle is increased, the smoke flow rate of the end, located in the atomization cavity, of the smoke outlet pipe is increased, therefore, it is guaranteed that air in the atomization cavity fully flows and quickly brings the smoke out, and the atomization efficiency is improved.

Owner:林光榕

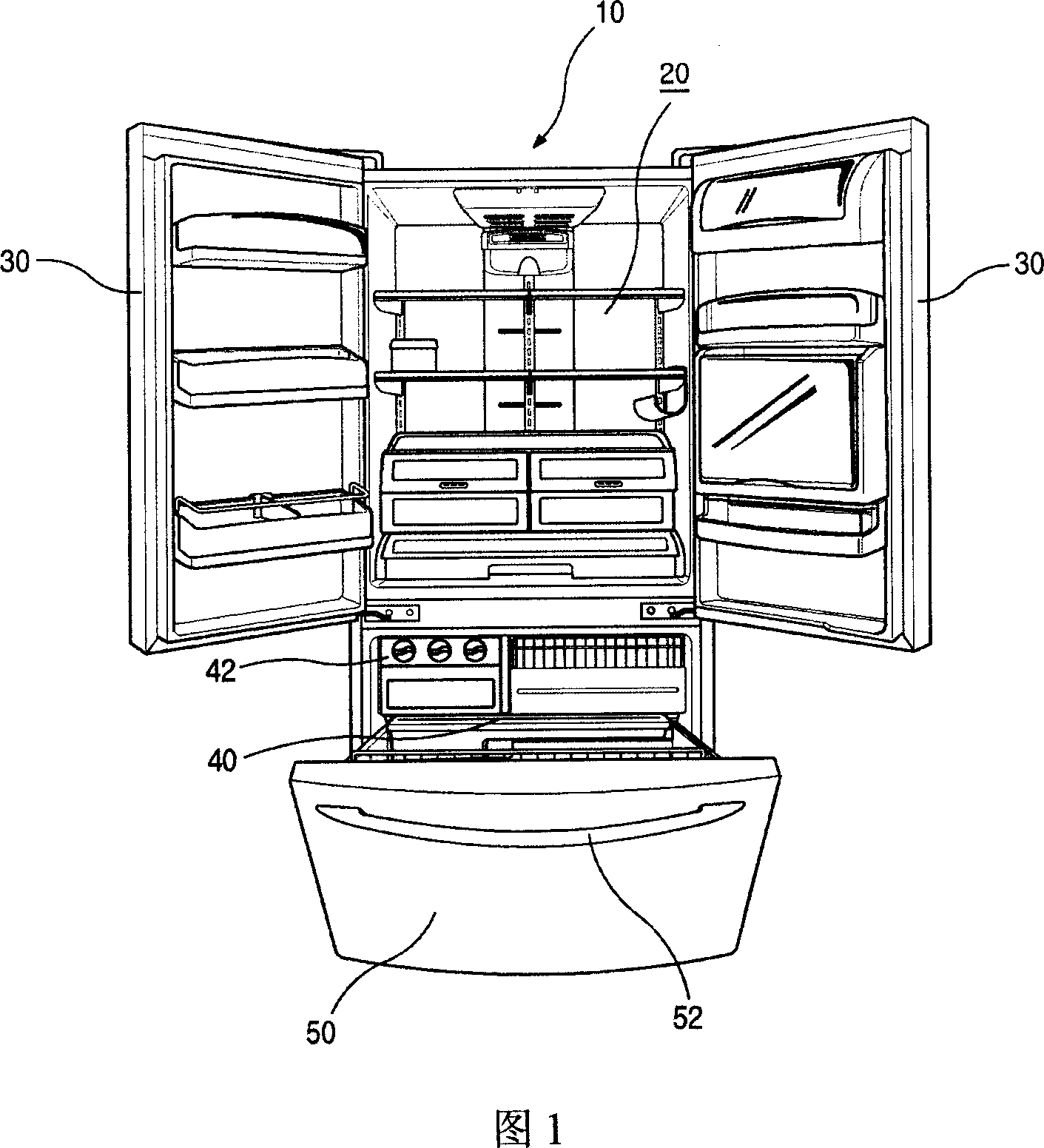

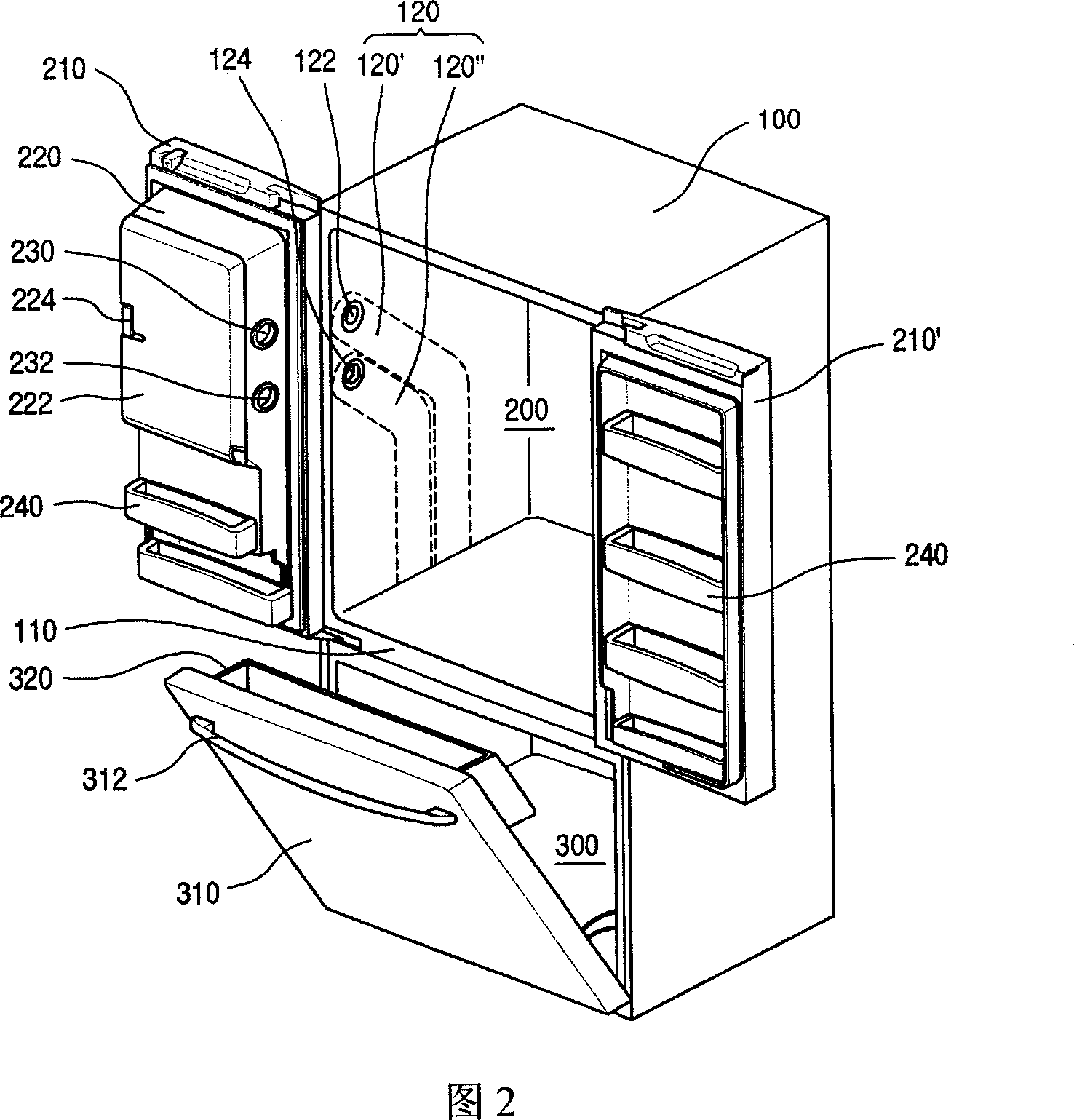

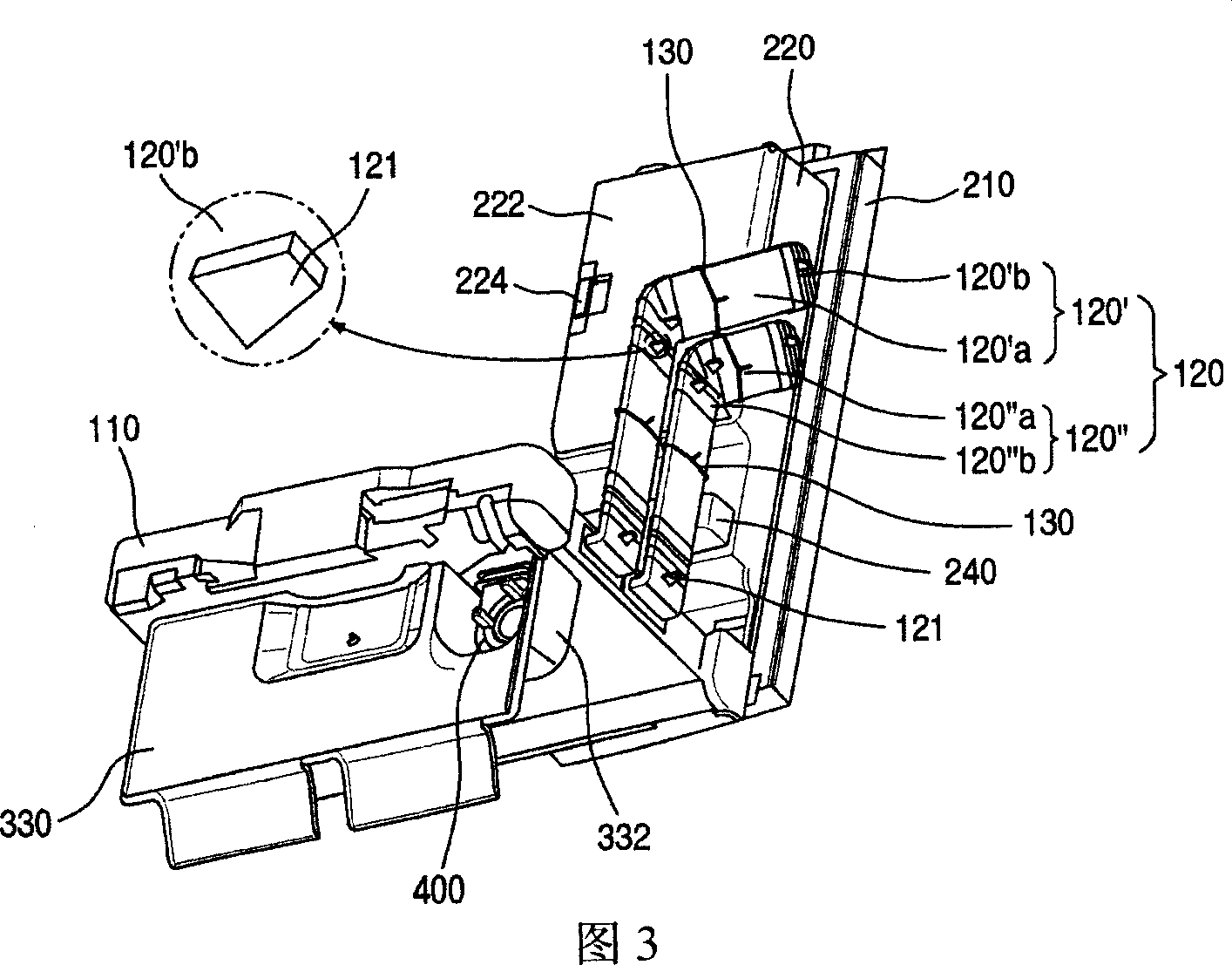

Refrigerator

InactiveCN101074818AEasy to useLow costLighting and heating apparatusDomestic refrigeratorsCold airFoaming agent

This invention discloses a refrigerator, it consist of freezing room, cold storage room, the door of the freezing room and storage room, ice forming room, cold air pipeline and support of the pipe assembly in the inside wall of the cold storage room which is introduce the location of the cold air pipe, and it can import part of the cold air to the freezing room by the pipes, so this can avoid setting another separate freezing device for the form of ice., and take advantage of the cold air and save the cost. In addition, the support of the pipe in this invention can prevent the movement of the cold air pipe, and make sure that the pipe is in the right position, so there is some space between cold air pipe and the outside and inside case of the storage room's wall which is in the storage room. At last, this can make the vesicant filled in the wall of the storage room flowing more fluently and filling more sufficiently, and it can prevent lose of the cold and hot air in the cold air pipe and improve the heat-proof effectiveness.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

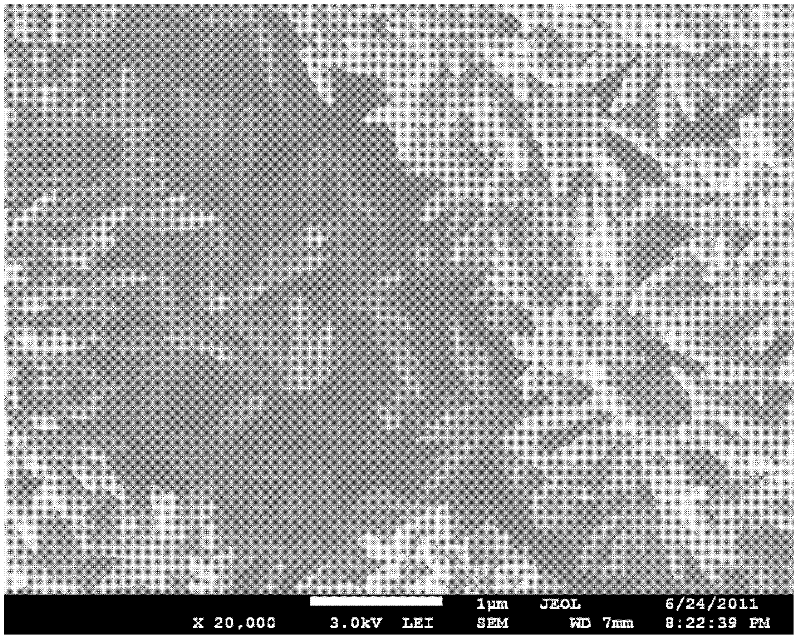

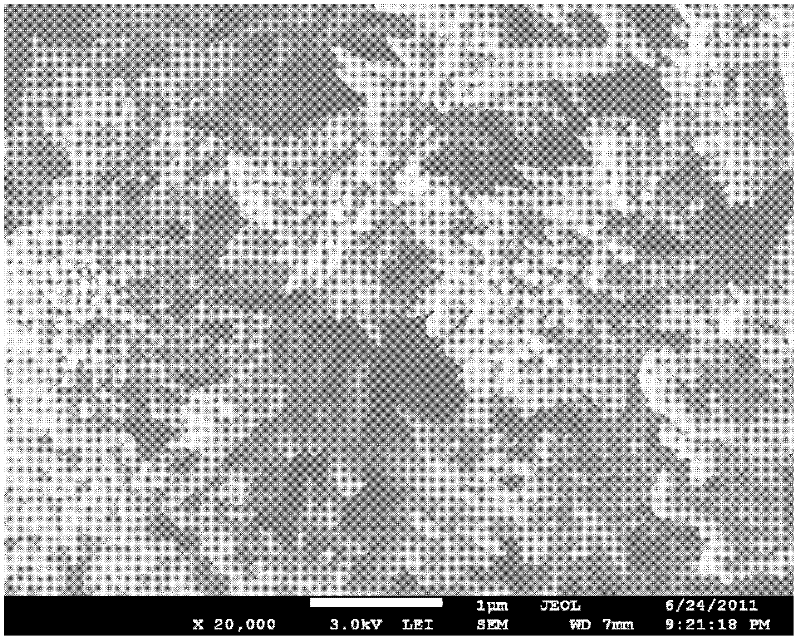

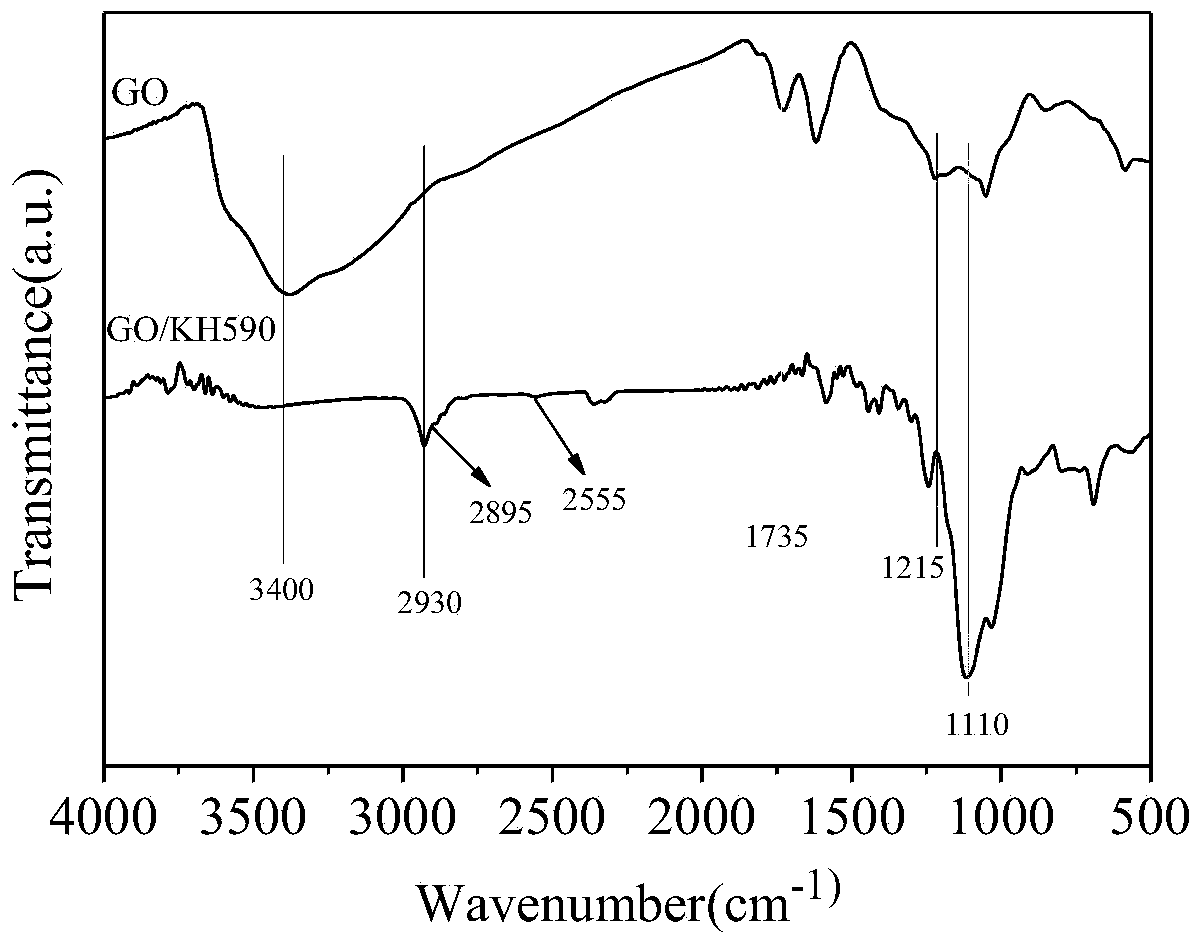

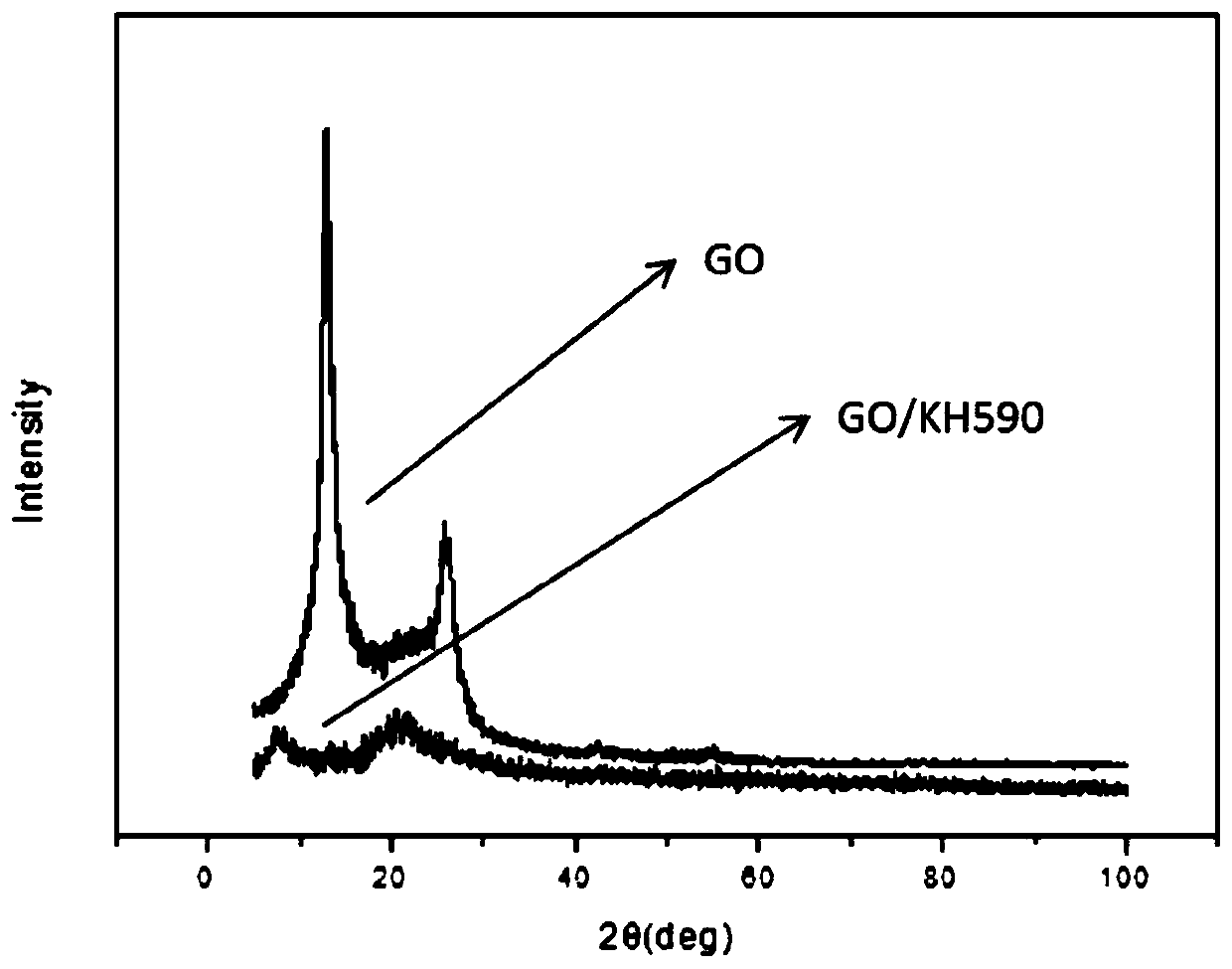

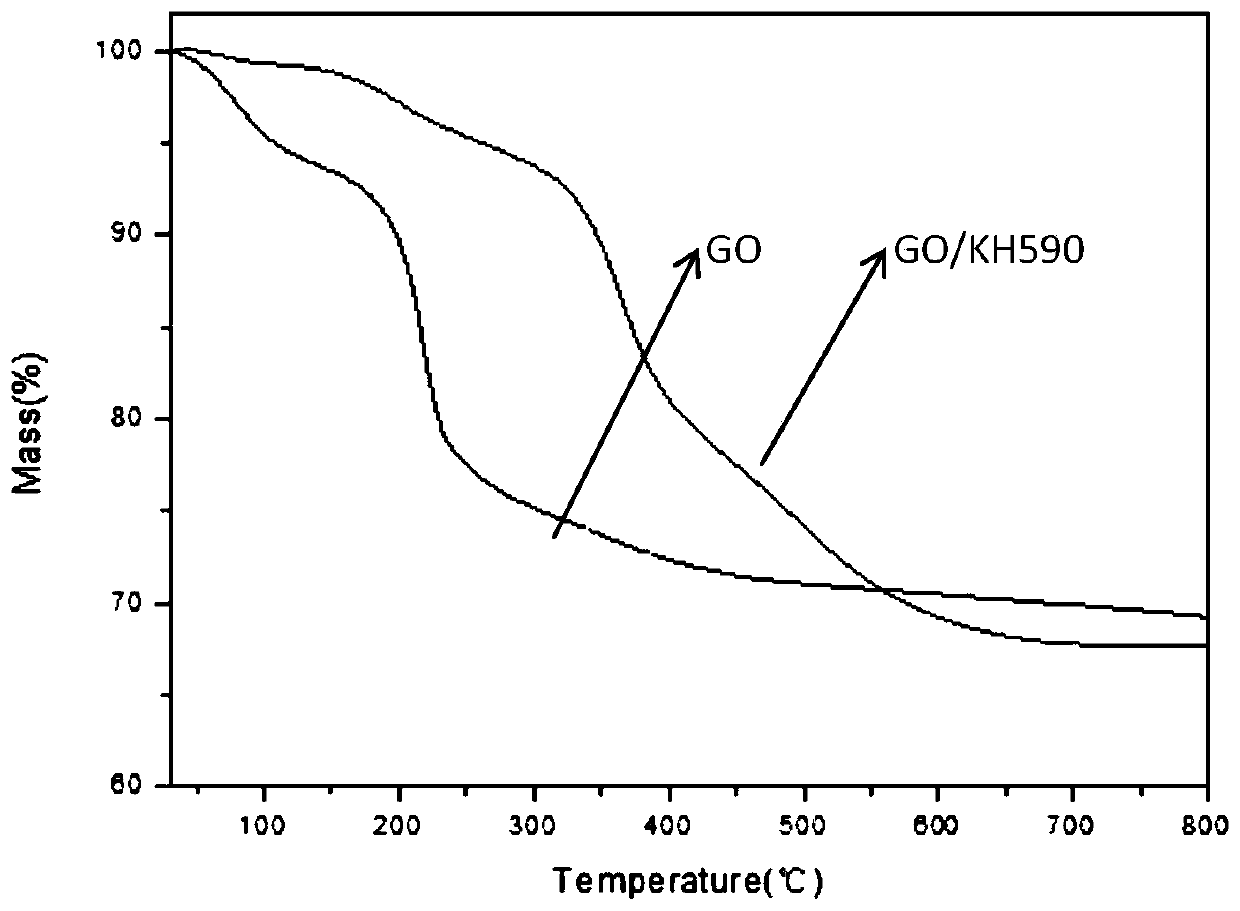

Graphene modified nitrile rubber and preparation method thereof

ActiveCN110343299ASolve the problem of poor high and low temperature resistanceImprove mechanical propertiesNitrile rubberPolymer science

The invention belongs to the technical field of graphene rubber composite materials, and provides a graphene modified nitrile rubber and a preparation method thereof. The graphene modified nitrile rubber is prepared from the following components in parts by weight: 70-90 parts of a nitrile rubber, 10-30 parts of a modified graphene oxide-carboxyl nitrile rubber master batch, 1.5-2 parts of a vulcanizing agent, 0.5-2.0 parts of a vulcanizing accelerator, 3-5 parts of a vulcanizing activator, 1-3 parts of a plasticizer, 1-2 parts of an antioxidant and 20-30 parts of fillers; and the modified graphene oxide-carboxyl nitrile rubber master batch is prepared from the modified graphene oxide and further prepared from carboxyl nitrile rubber latex, wherein mercapto-siloxane after hydrolysis reactswith the graphene oxide by being subjected to dehydration synthesis, and the modified graphene oxide is obtained. Through the technical scheme, the problem of poor high and low temperature resistanceof the nitrile rubber in the prior art is solved.

Owner:石家庄贝克密封科技股份有限公司 +1

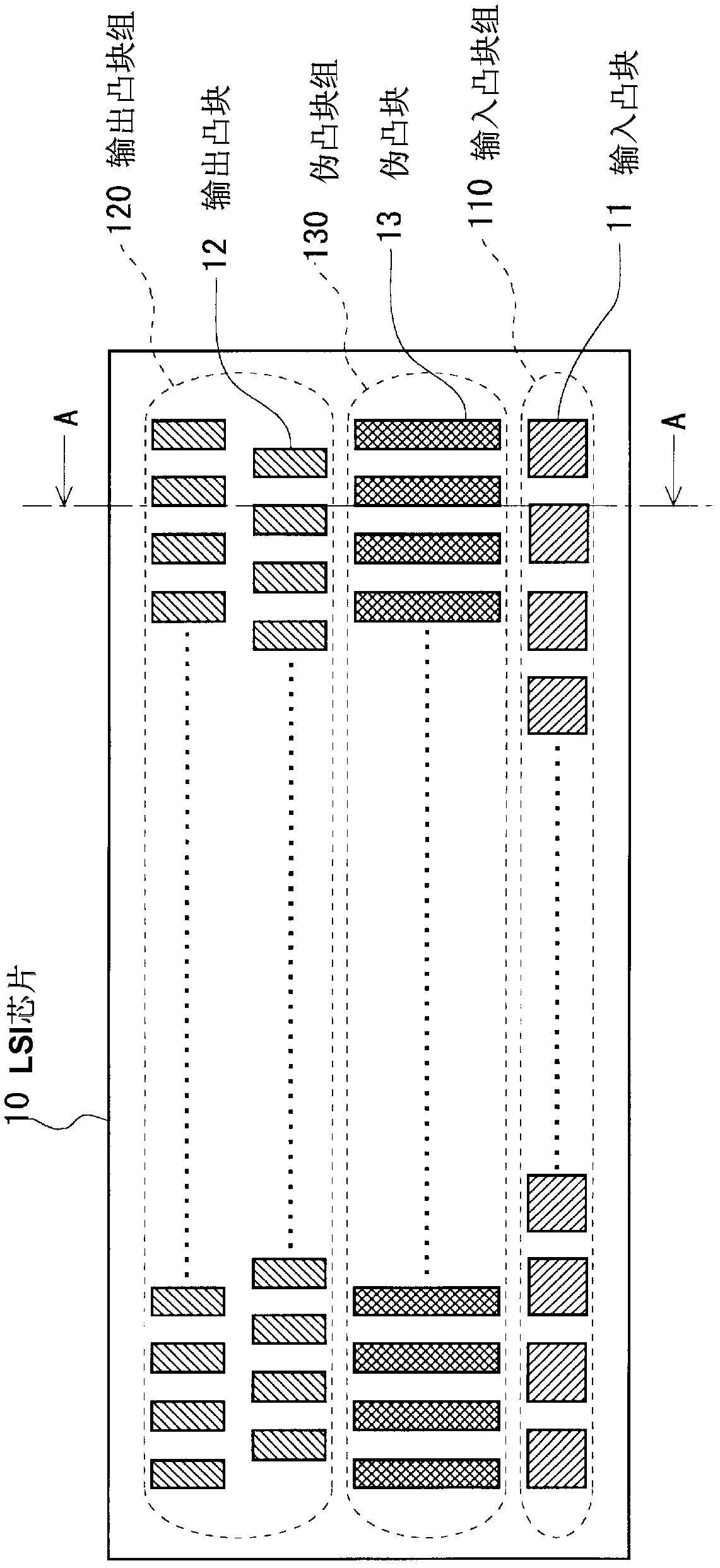

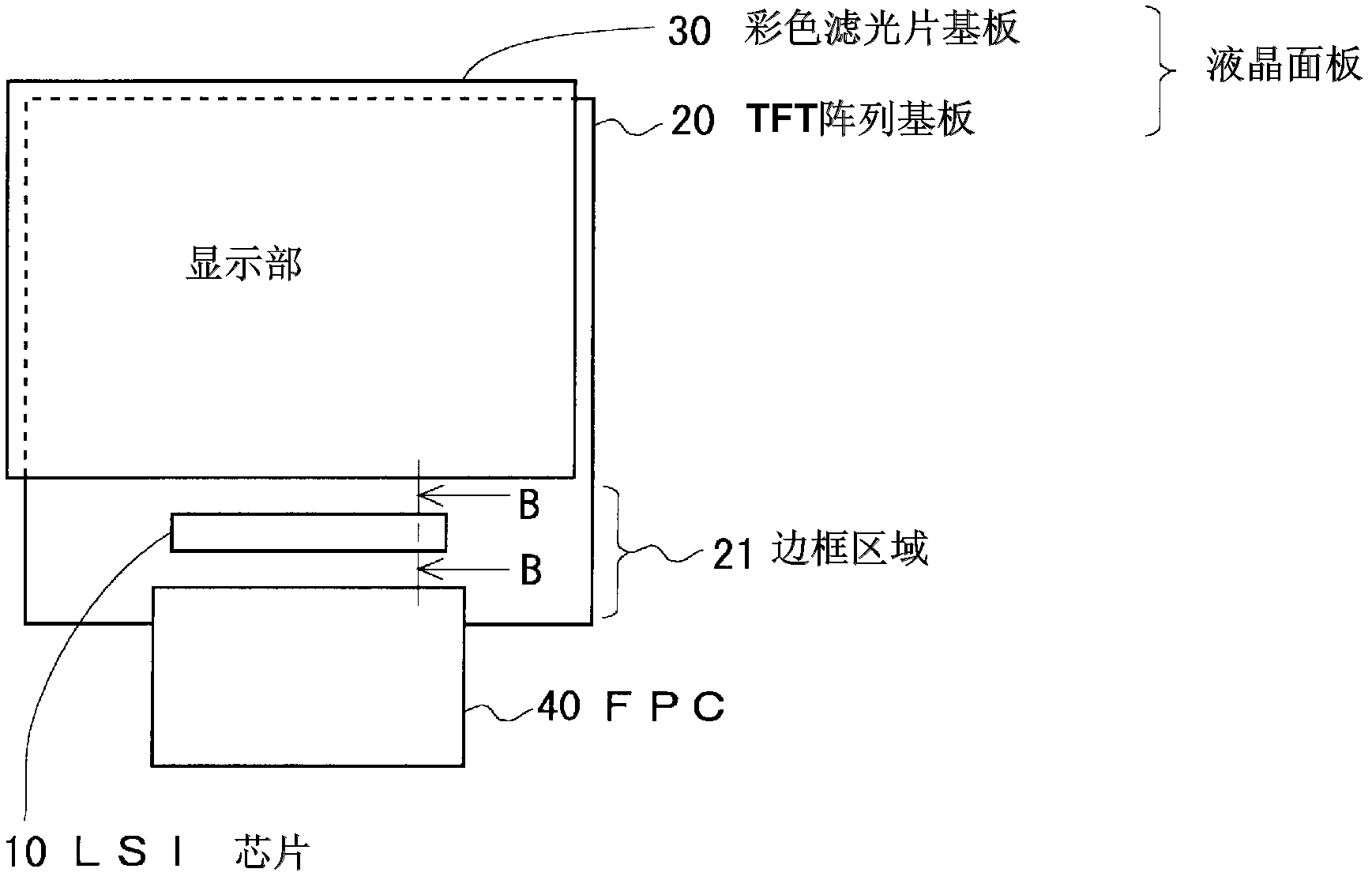

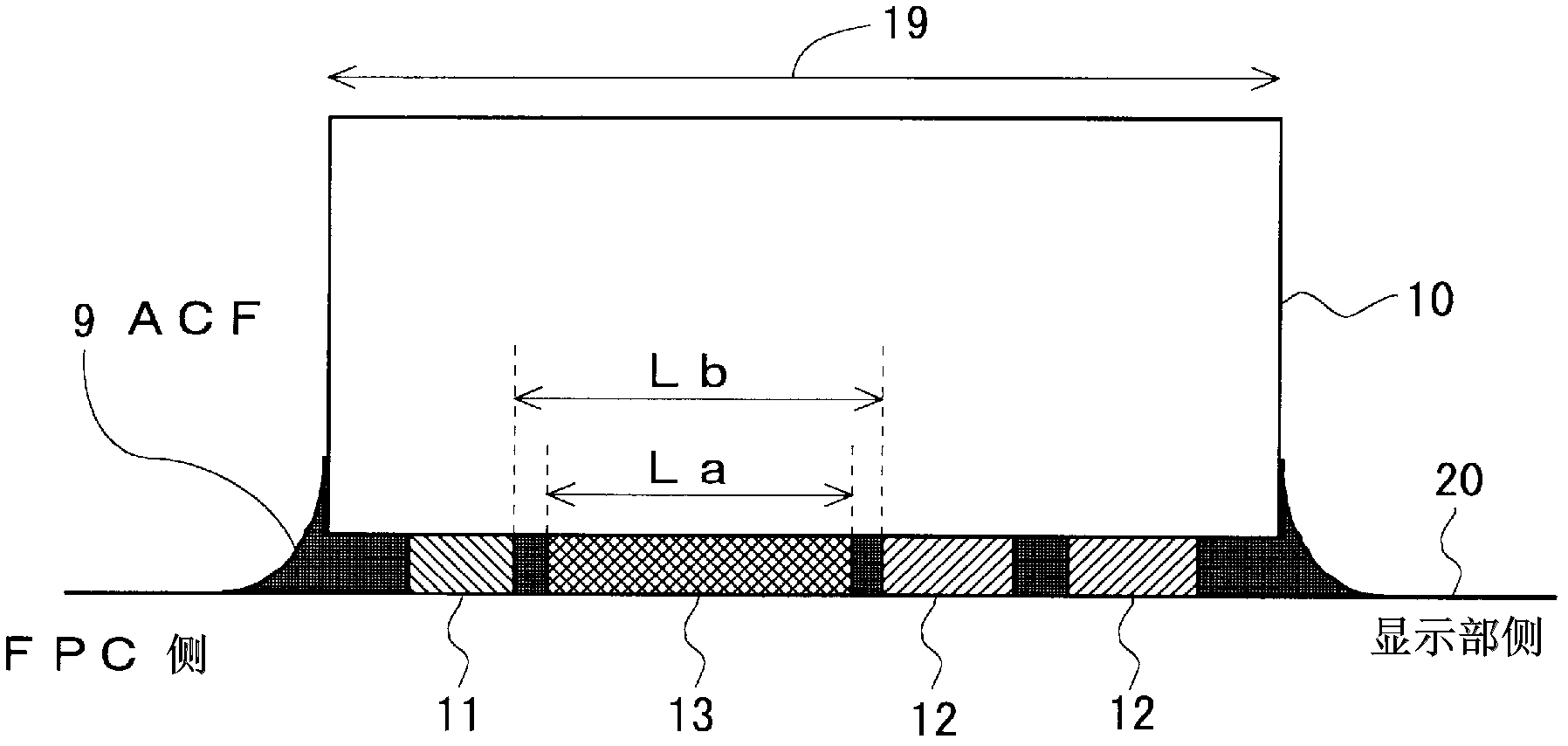

Semiconductor chip and structure for mounting same

InactiveCN102460668AFull flowSuppress bad connectionSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

Provided is a semiconductor chip which can suppress generation of failures of connection with a substrate having the semiconductor chip mounted thereon and has a narrow pitch between the terminals. The LSI chip (10) includes an input bump group (110), which is composed of a plurality of input bumps (11) disposed in a row along one of the long sides of the bottom surface, and an output bump group (120), which is composed of a plurality of output bumps (12) disposed in zigzag arrangement along the other long side of the bottom surface. In the LSI chip, a dummy bump group (130) composed of a plurality of rectangular dummy bumps (bumps not having an electrically connecting function) (13), each of which has, as the long sides, the sides extending in the direction perpendicular to the long sides of the bottom surface is provided in the region between the region provided with the input bump group (110) and the region provided with the output bump group (120).

Owner:SHARP KK

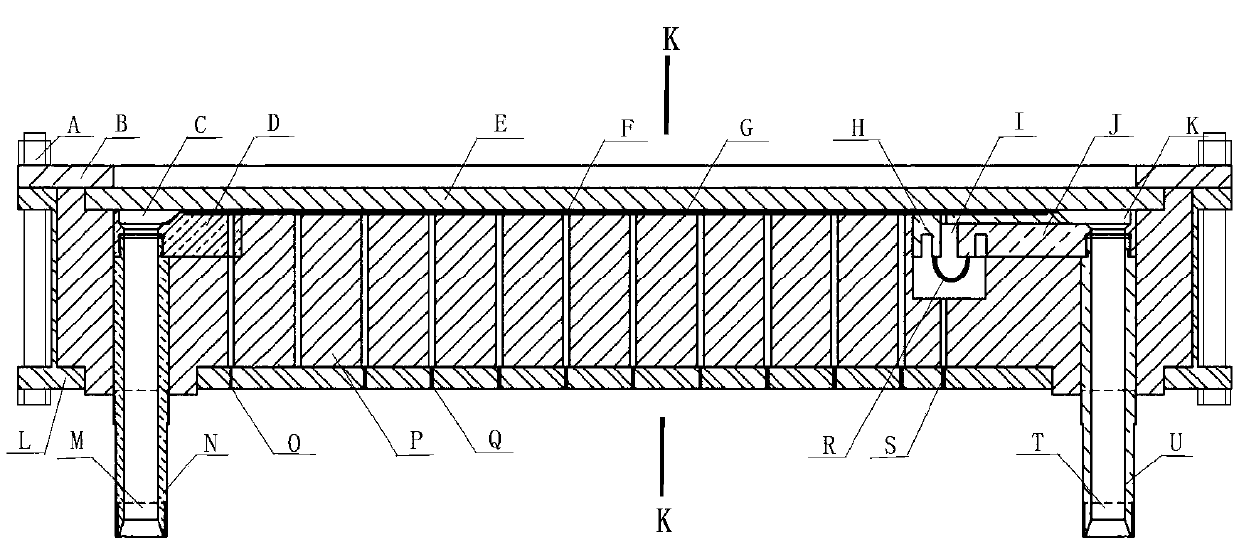

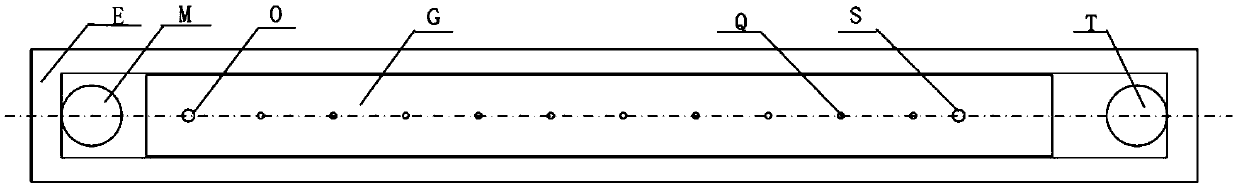

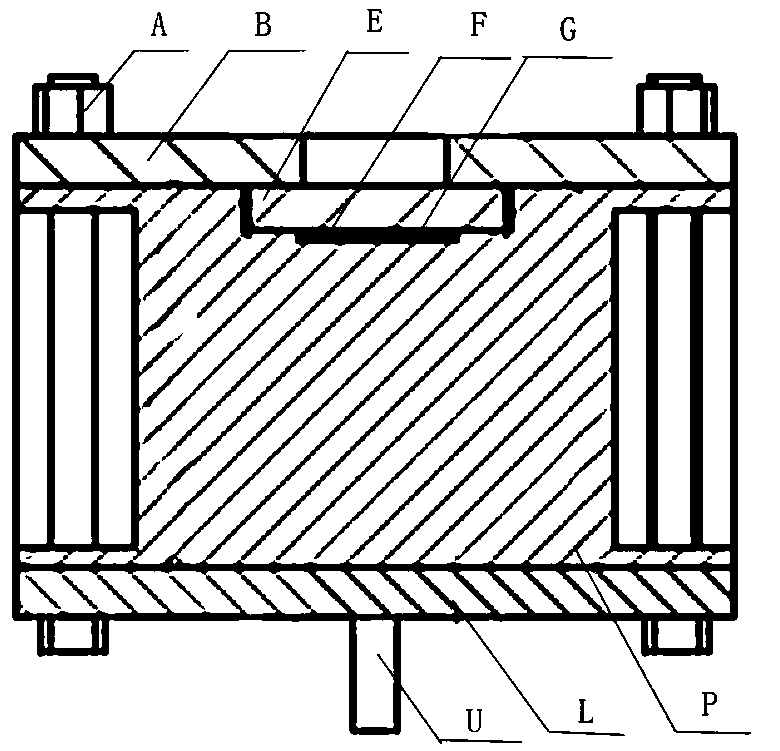

High-temperature-resistant high-pressure-resistant visual rectangular narrow slot channel experiment device

The invention discloses a high-temperature-resistant high-pressure-resistant visual rectangular narrow slot channel experiment device. The device comprises a conductive loop composed of an inlet conductive copper column, an inlet fixed electrode, a copper pigtail, a sliding electrode, a heating plate, an outlet fixed electrode and an outlet conductive copper column, a fluid flow channel composed of an inlet channel, an inlet buffer cavity, a rectangular narrow slot channel, an outlet buffer cavity and an outlet channel, a rectangular narrow slot channel which can bear high-temperature and high-pressure vapor-liquid two-phase fluid impact and is composed of a heating plate and quartz glass embedded in a groove of a ceramic matrix, a pressure measuring assembly embedded in the ceramic matrixand used for measuring relevant experimental parameters, and a thermocouple assembly. A fluid enters the rectangular narrow slot channel after passing through the inlet channel and the inlet buffer cavity; in the rectangular narrow slot channel, the fluid is boiled after being heated to form a vapor-liquid two-phase flow type structure; and bubble behaviors and flow type transition in the channelcan be effectively observed through the quartz glass, so that an experimental guarantee condition is provided for deeply researching flow and heat transfer mechanisms in the narrow channel.

Owner:XI AN JIAOTONG UNIV

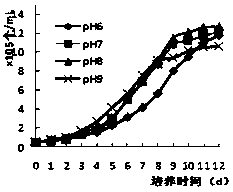

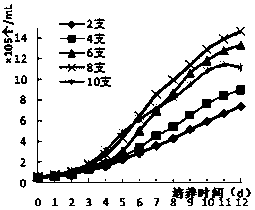

Scale production method for high-content astaxanthin haematococcus pluvialis

InactiveCN106906142AFull flowFull exchange compensationUnicellular algaeMutant preparationGreen cellStress conditions

The invention discloses a scale production method for high-content astaxanthin haematococcus pluvialis. The scale production method includes algae species culture, species bottle culture, closed tubular photobioreactor culture, indoor pond photobioreactor culture and outdoor pond reactor astaxanthin accumulation culture. Algae species rapidly grow and breed under an optimized growth condition in a laboratory and are accumulated to reach a certain cell concentration and then inoculated to a closed tubular photobioreactor by a sterile tube for secondary enlarged culture, the algae species are inoculated to an indoor pond photobioreactor for tertiary growth culture to reach the highest algae cell quantity after haematococcus pluvialis grows to a certain density, cultured haematococcus pluvialis green cells are transferred into the outdoor pond photobioreactor and accumulate a large quantity of astaxanthin under stressed conditions, and the scale production process of the haematococcus pluvialis is finally finished. Compared with the prior art, the scale production method has the advantage that the astaxanthin content exceeds international level reported at present and reaches 7.2% or more.

Owner:烟台布鲁拜尔生物制药有限公司

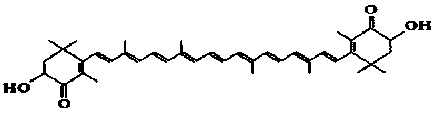

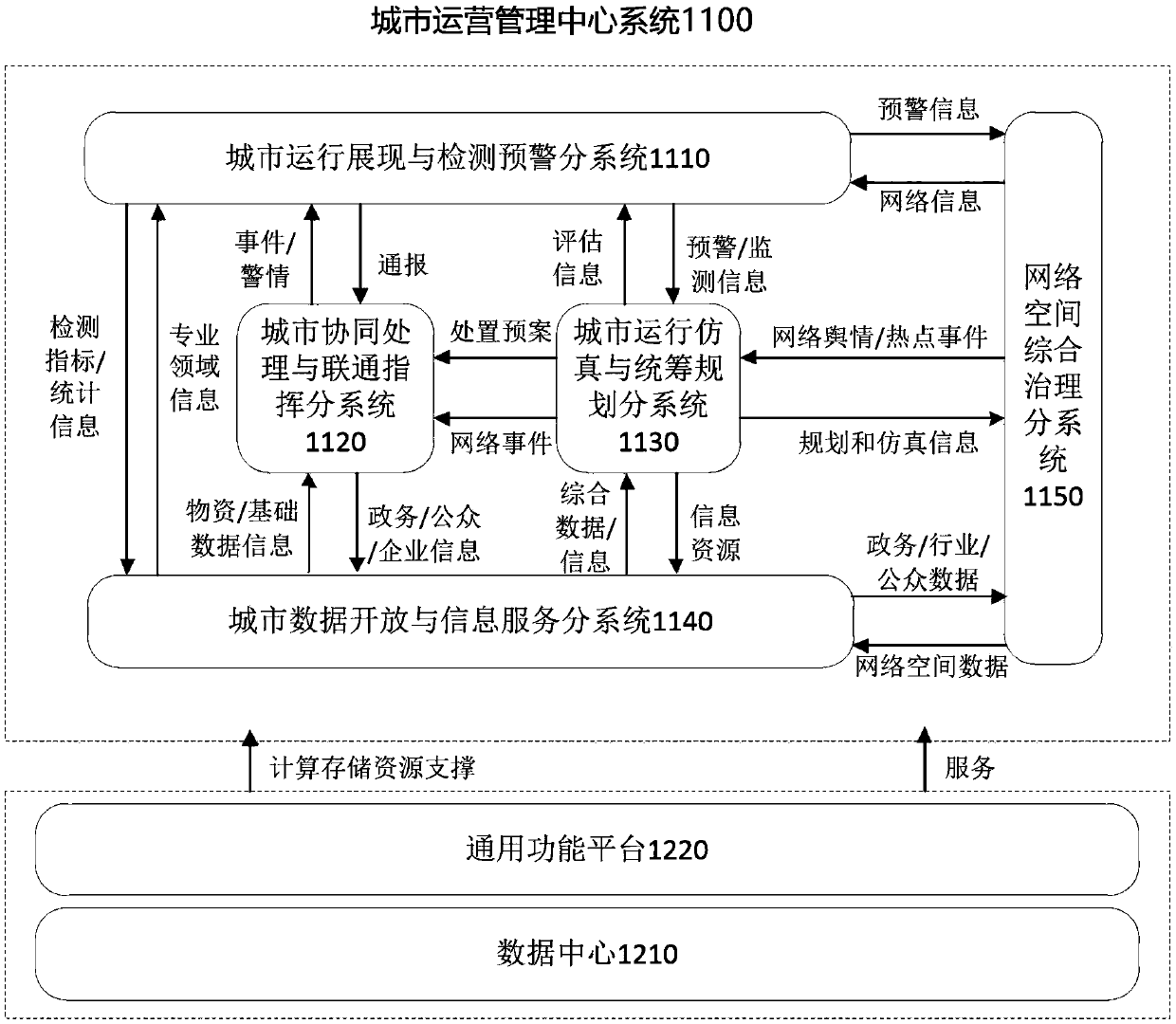

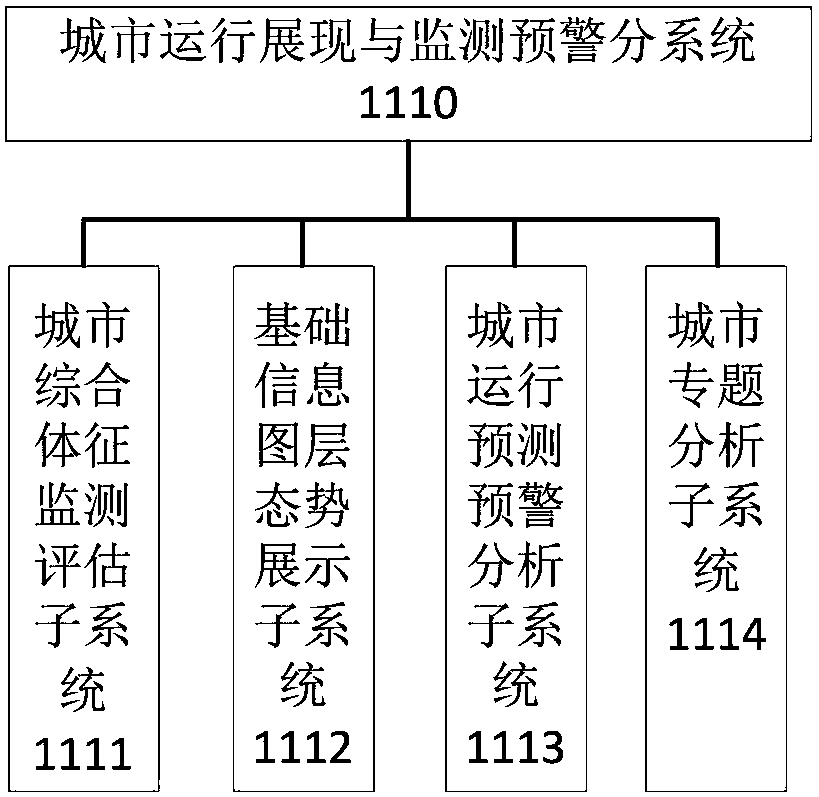

Framework and engineering system for city operation center

InactiveCN107871204AAchieve integrationAchieve sharingResourcesDaily operationCritical information infrastructure

The invention provides a framework and engineering system for a city operation center. The framework comprises a city data open and information service subsystem, a city coprocessing and linkage command subsystem, a network space comprehensive treatment subsystem, a city operation simulation and overall planning subsystem and a city operation revealing and monitoring early warning subsystem, wherein the city data open and information service subsystem carries out uniform fusion and packaging on user information resources; the city coprocessing and linkage command subsystem deeply mines a business relationship among departments and establishes an integral coprocessing system for city daily operation, and a linkage command system for disposing an emergency; the network space comprehensive treatment subsystem carries out integrated supervision on the network safety of a city key information infrastructure operation situation, and realizes the uniform situation and the system response of city network space safety; the city operation simulation and overall planning subsystem provides data-driven knowledge information support for city development planning, major affair decision and majorevent disposal decision; and the city operation revealing and monitoring early warning subsystem shows and realizes basic information for governing cities, provides the key sign information of the city operation and carries out macroscopic display and early warning analysis on the city operation situation.

Owner:THE 28TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Preparation method of high density tungsten-base alloy

ActiveCN110564998AReduce aggregationImprove the degree of mixingAdditive manufacturing apparatusIncreasing energy efficiencyThree dimensional modelTungsten

The invention discloses a preparation method of a high density tungsten-base alloy. The preparation method comprises the following steps: I, preparing non-main body alloy powder from elements, excepttungsten, in a tungsten-base alloy; II, rolling and mixing tungsten powder with the non-main body alloy powder to obtain a mixture; III, drying the mixture to obtain mixed powder; IV, drawing a three-dimensional model of the tungsten-base alloy and layering the model to obtain cut-layer data and cut-layer scanning data; V, preheating a formed bottom plate; VI, carrying out pre-sintering and fusionscanning successively after paving the powder to form a single-layered solid sheet; and VIII, carrying out formed bottom preheating, powder paving, pre-sintering and fusion scanning processes repeatedly to obtain the tungsten-base alloy. According to the preparation method, low-melting-point elements in the tungsten-base alloy are prepared into non-main body alloy powder which is rolled and mixedwith the tungsten powder first, so that a powder gathering phenomenon is reduced. Then low speed fusion scanning after pre-sintering is carried out, so that element powder except tungsten is adheredto each other, and therefore, movement caused by electron beam impact is avoided and the uniformity and density of the tungsten-base alloy are improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com