Patents

Literature

710results about How to "Enhance heat and mass transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

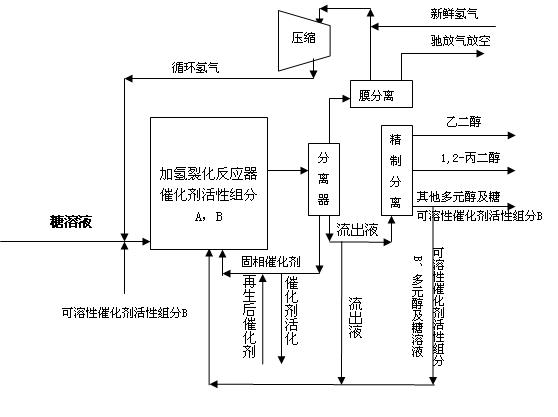

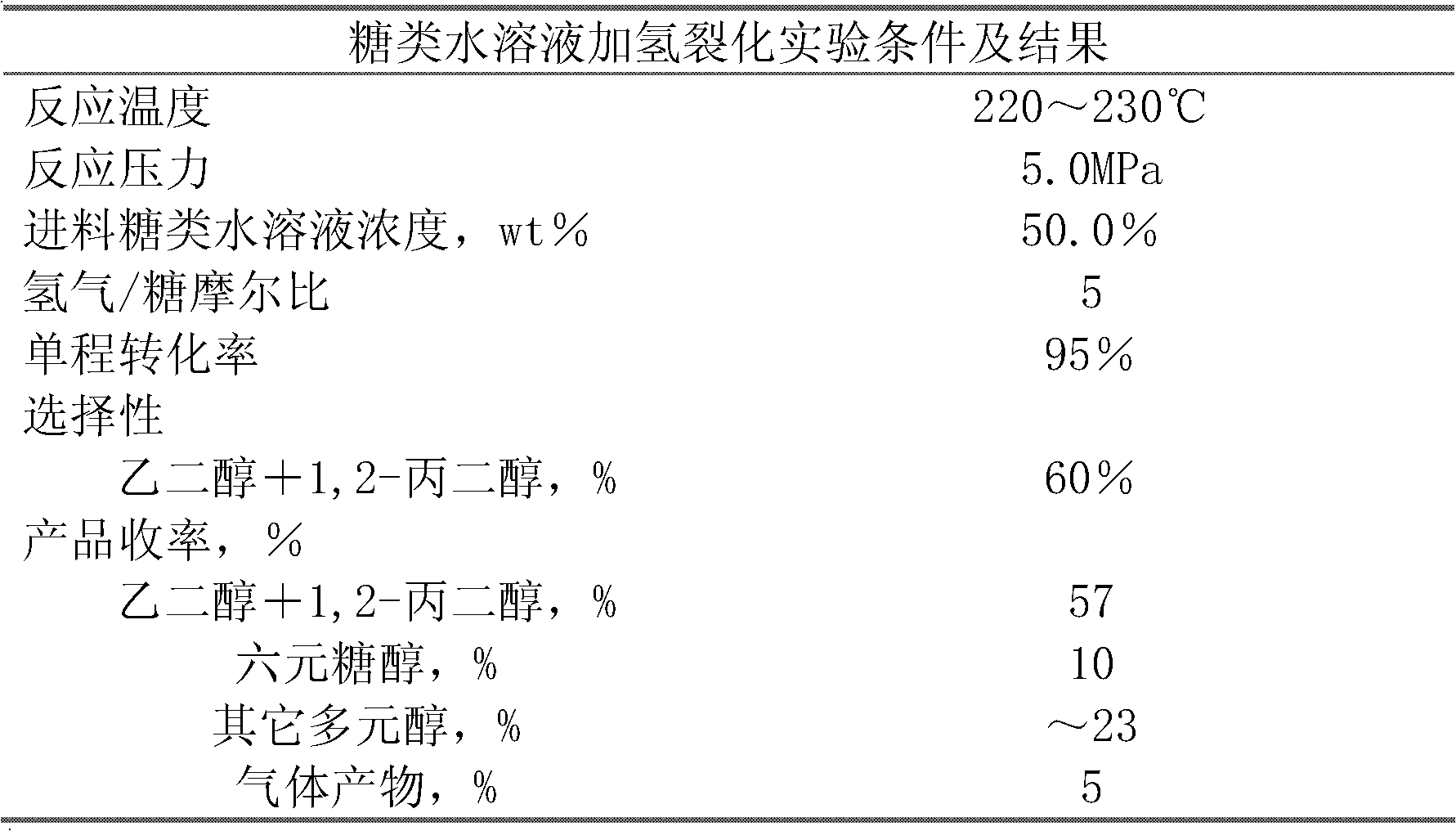

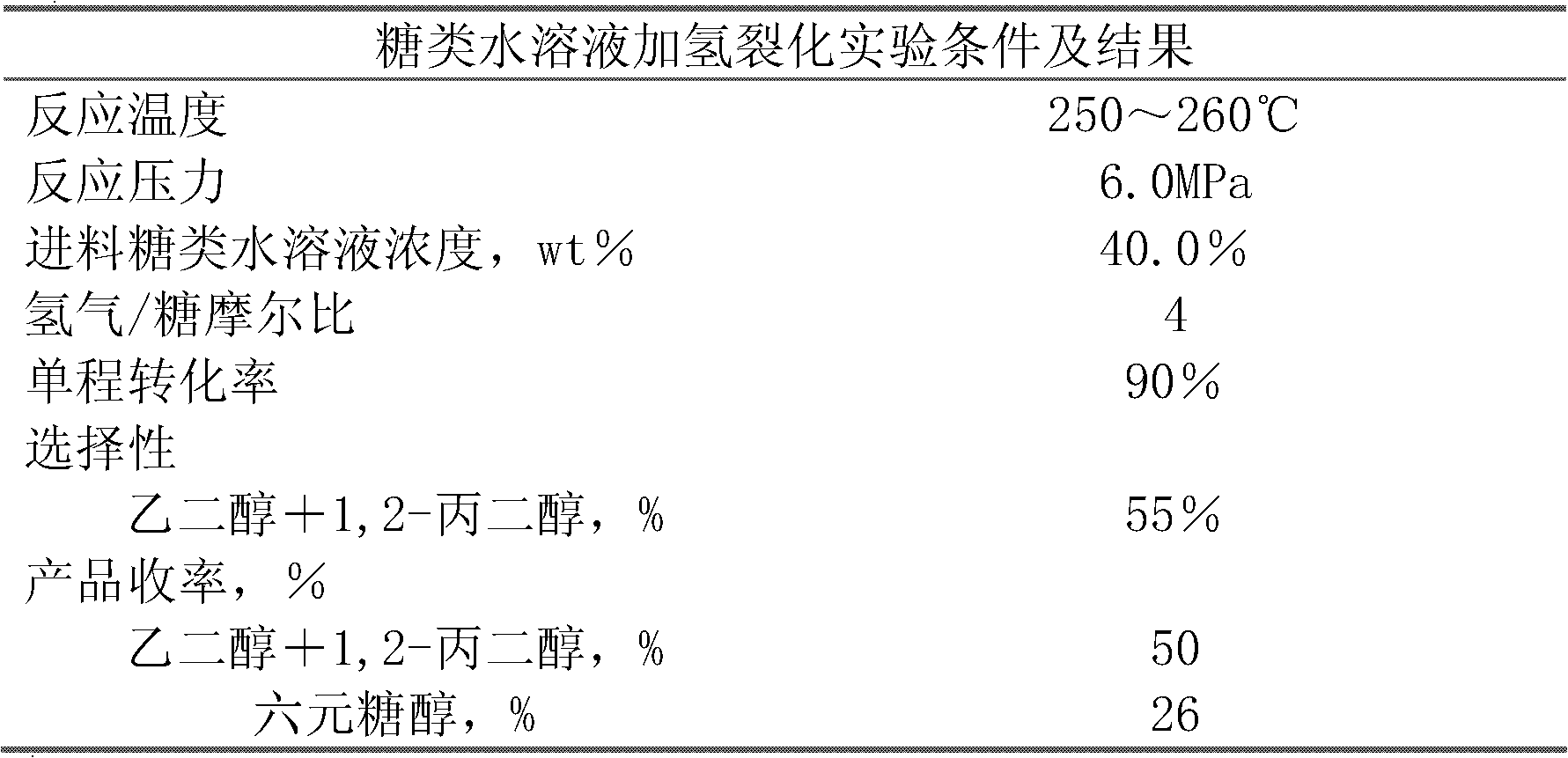

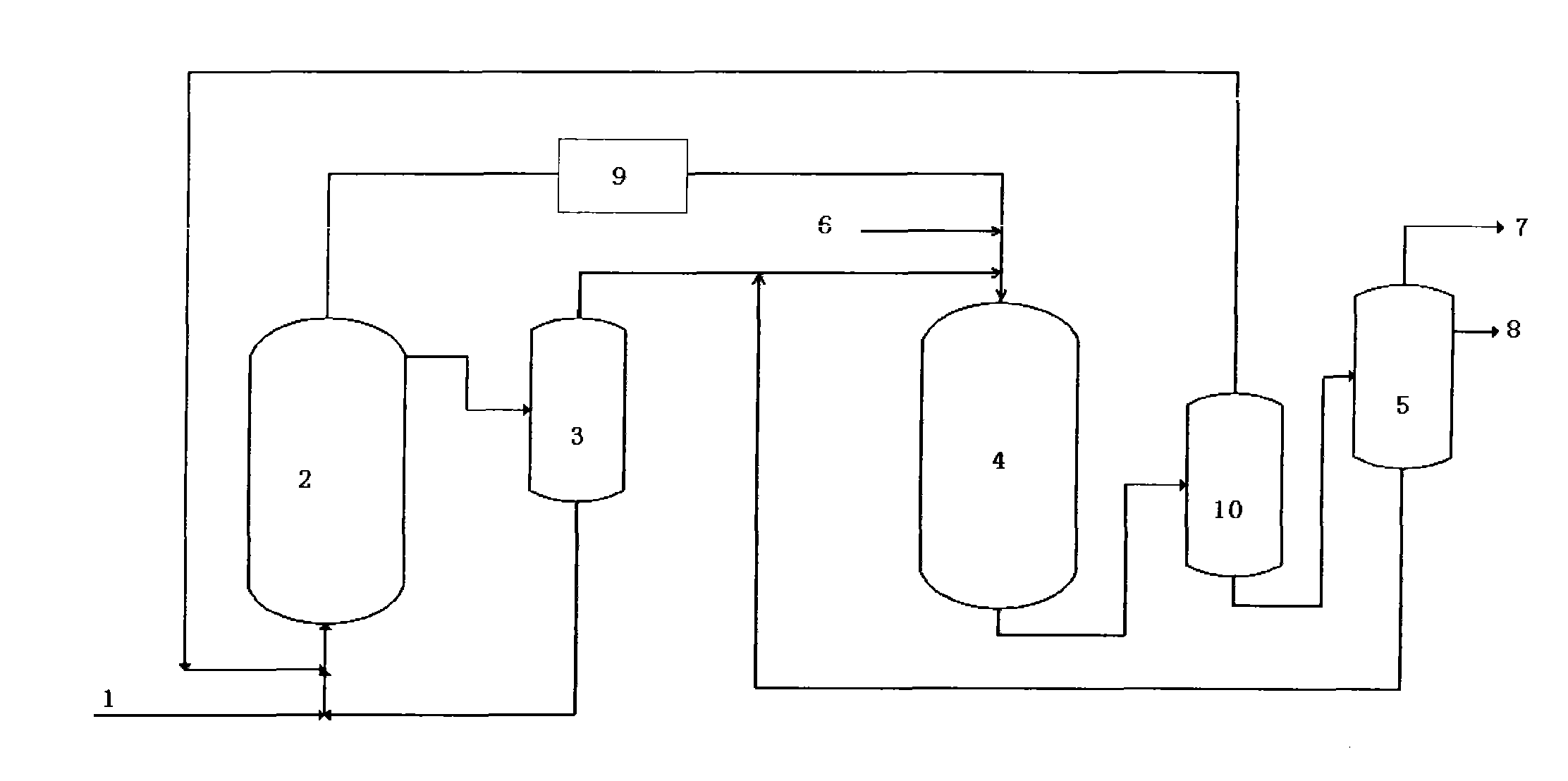

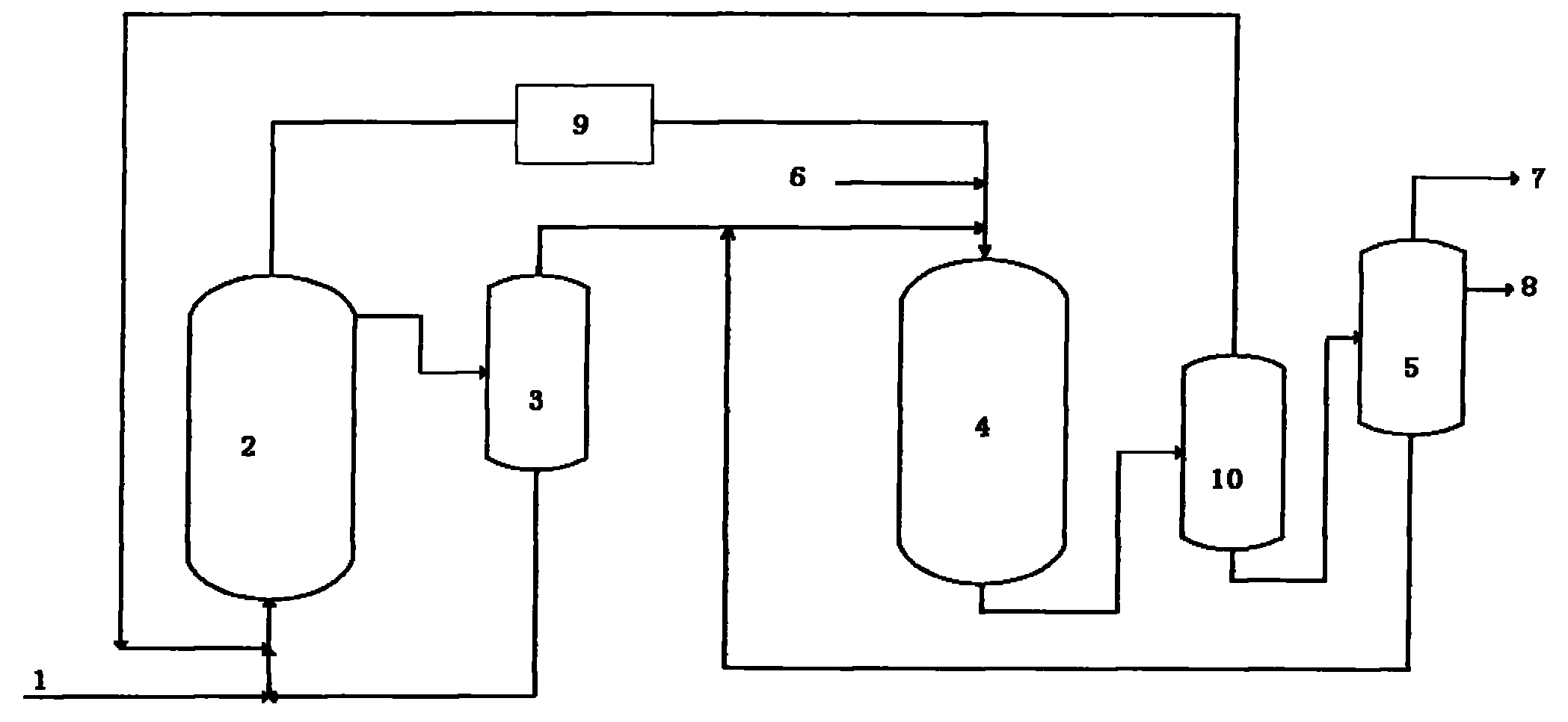

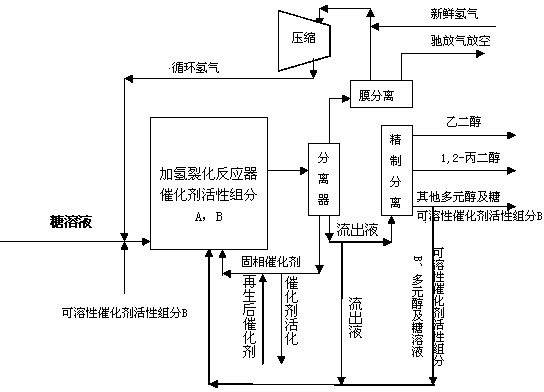

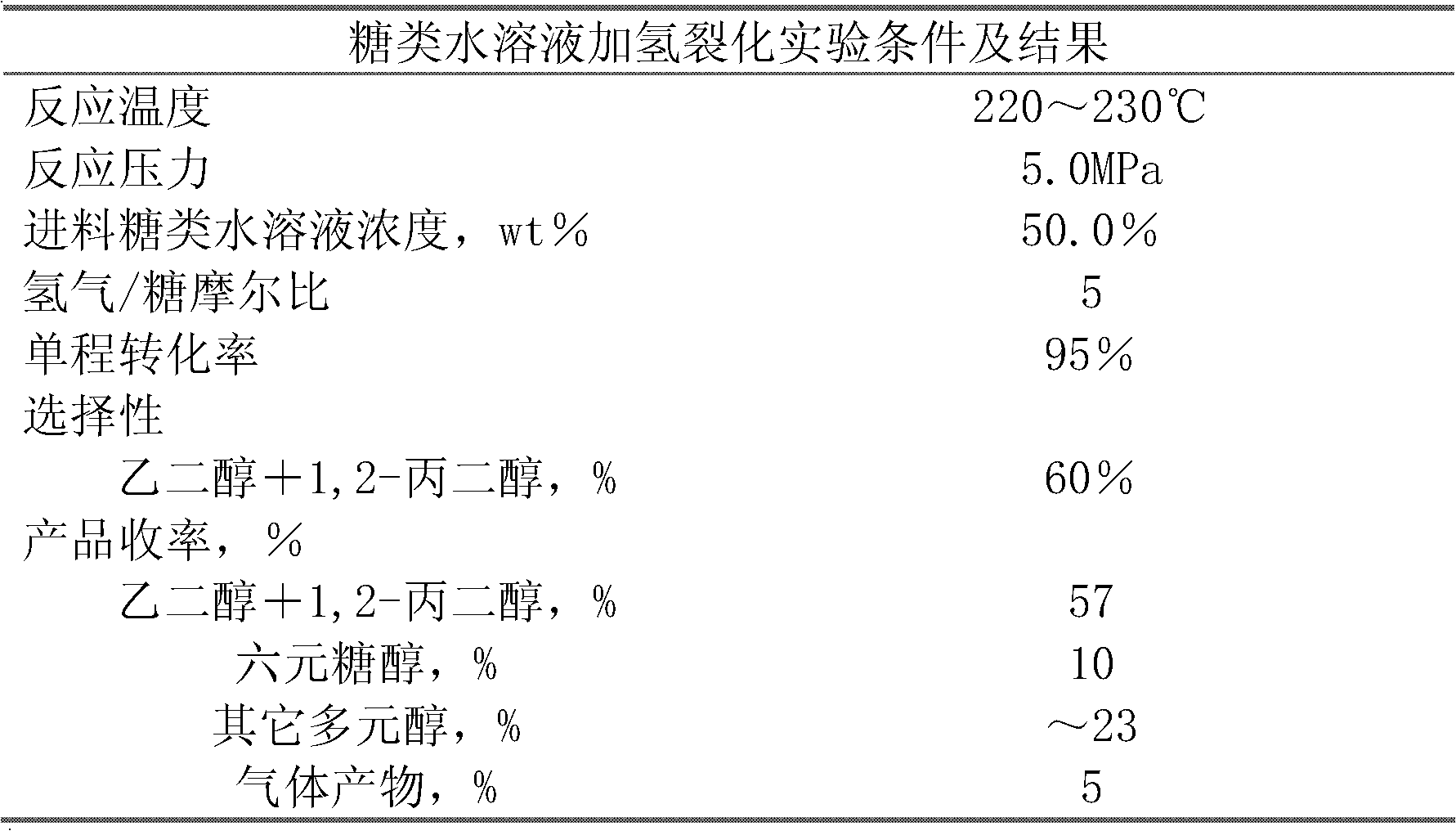

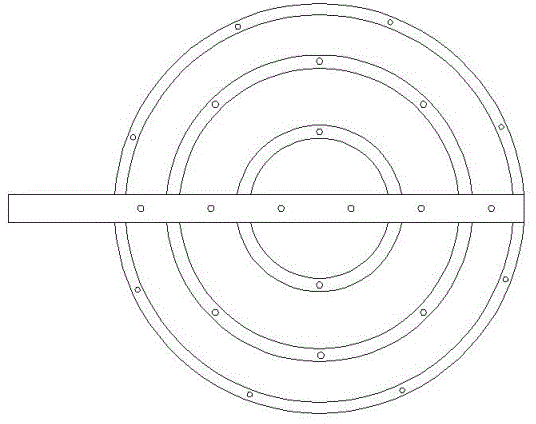

Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

ActiveCN102643165ARealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationGas phaseOligosaccharide

The invention relates to a continuous reaction process flow for producing ethylene glycol and 1, 2-propylene glycol through continuous hydrocrackin of sugars and provides a method for producing the ethylene glycol and the 1,2-propylene glycol through continuous hydrocrackin of sugars. In the process flow, sugars (comprising one or more than two of sugar, glucose, fructose, xylose, soluble xylo-oligosaccharide and starch) are hydrocracked in the presence of a catalyst in a reactor and the hydrocracked product enters a separating system. Hydrogen gas in a gas phase is recycled by separating and recovering; a liquid phase product partially reflows to the reactor and other liquid phase products are refined and separated to form the ethylene glycol, the propylene glycol and other polyhydric alcohols; and concentrated soluble catalyst components in the refined and separated residual component liquid phase are partially returned to the reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

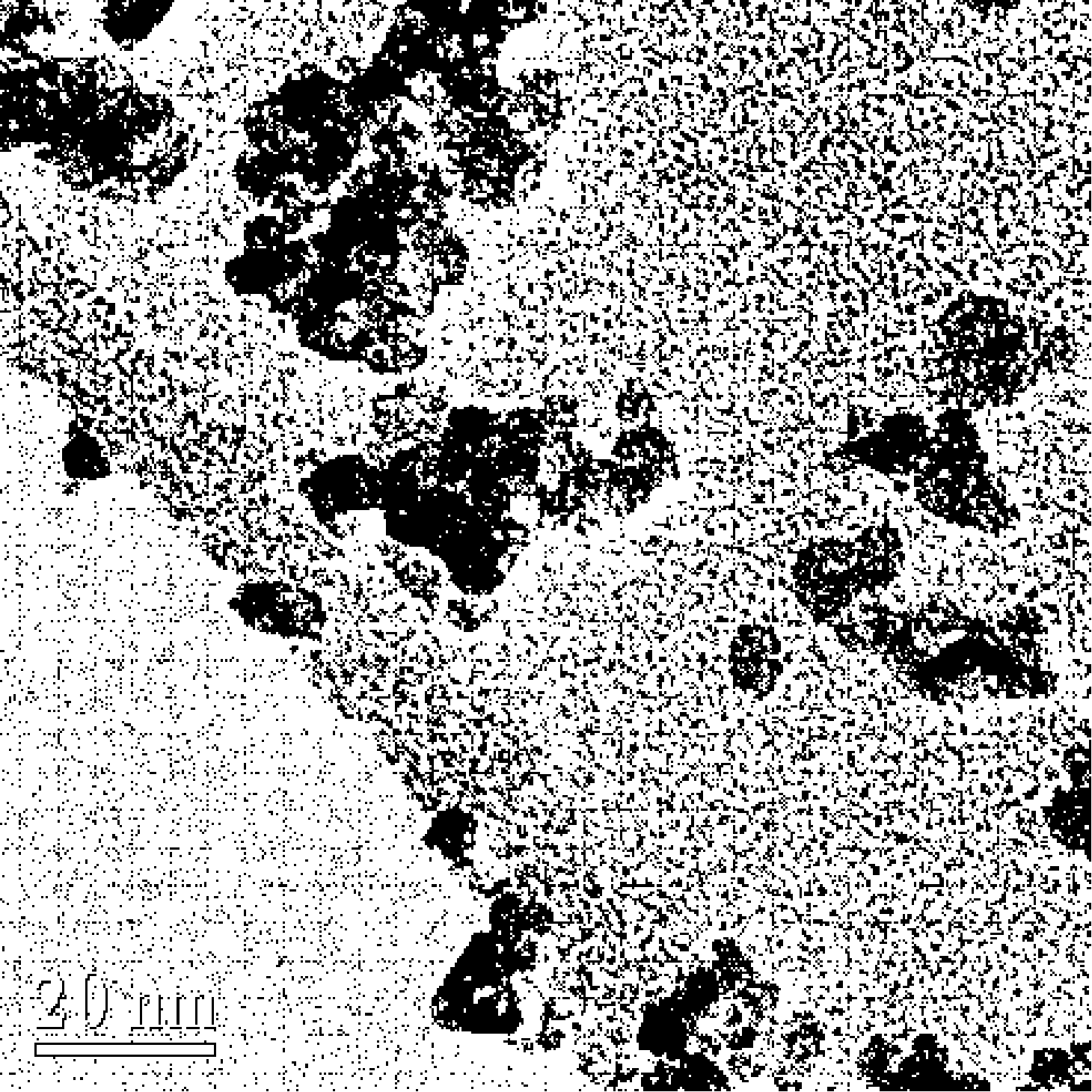

Catalyst for hydrogen production from methane vapor reforming and preparing method thereof

InactiveCN101224427AEasy to prepareHigh reactivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsChemistryComposite oxide

The invention discloses a methane reforming catalyst for the production of hydrogen and a preparation method thereof, which more particularly relates to a Ni methane vapor reforming catalyst for the production of hydrogen which takes a nanometer cerium zirconium composite oxide as the carrier and the corresponding preparation method, and belongs to the methane reforming catalyst field. The catalyst comprises 5-30 wt% of active Ni, 0-10 wt% of noble metal catalytic promoter, 0-10 wt% of rare earth and / or the catalytic promoter of alkaline earth oxide, 50-95 wt% of nanometer cerium zirconium composite oxide carrier with the particle diameter of 5-20 nm. The invention is characterized by simple preparation method, high reactivity, strong anti carbon performance, good stability, low cost, etc.; when the invention is applied to the methane vapor reforming catalyst for producing hydrogen, the requirements of industrialization on catalyst reactivity and usage life can be satisfied. The invention can be largely applied in fuel cell-hydrogen area.

Owner:HANERGY TECH

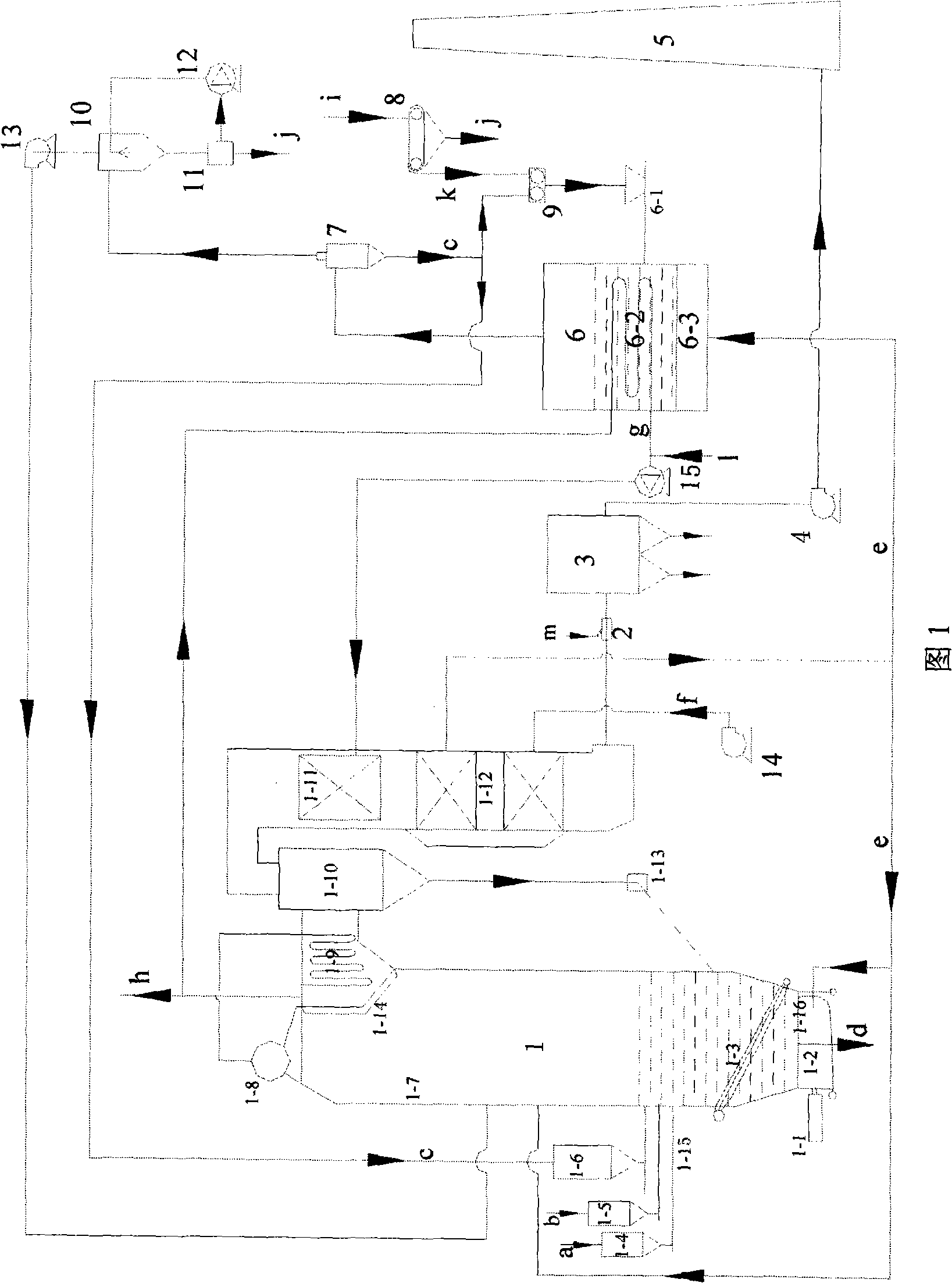

Sludge drying burning combination treatment method

ActiveCN101265008ASimple processLower the altitudeSludge treatment by de-watering/drying/thickeningIncinerator apparatusFluidized bed dryingTreatment effect

The invention relates to a sludge drying and incineration combined treatment method with good treatment effect, wide sludge adaptability, and safe and stability system. To avoid agglomeration of mechanically dewatered sludge (k) in a fluidized bed dryer (6), a part of dried sludge (c) is premixed with the mechanically dewatered sludge (k) and then fed into the fluidized bed dryer (6). The dried sludge (c) is incinerated into a circulating fluidized bed incinerator (1) to generate superheated vapor. The superheated vapor is condensed to hot water in a heat exchange tube (6-2) of the fluidized bed dryer (6) and then recycled to the circulating fluidized bed incinerator (1). The arrangement of buried pipes (1-3) and fractional air supply inside the circulating fluidized bed incinerator (1) can effectively control the lower temperature of the circulating fluidized bed incinerator (1) to prevent deflagration of dried sludge. The entire system has no emission of pollutants such as unpleasant odor, acidic gases, heavy metals and dioxin; is safe and reliable; and can operate for a long time.

Owner:JIANGSU JINSHAN SOLID WASTE RESOURCE TECH

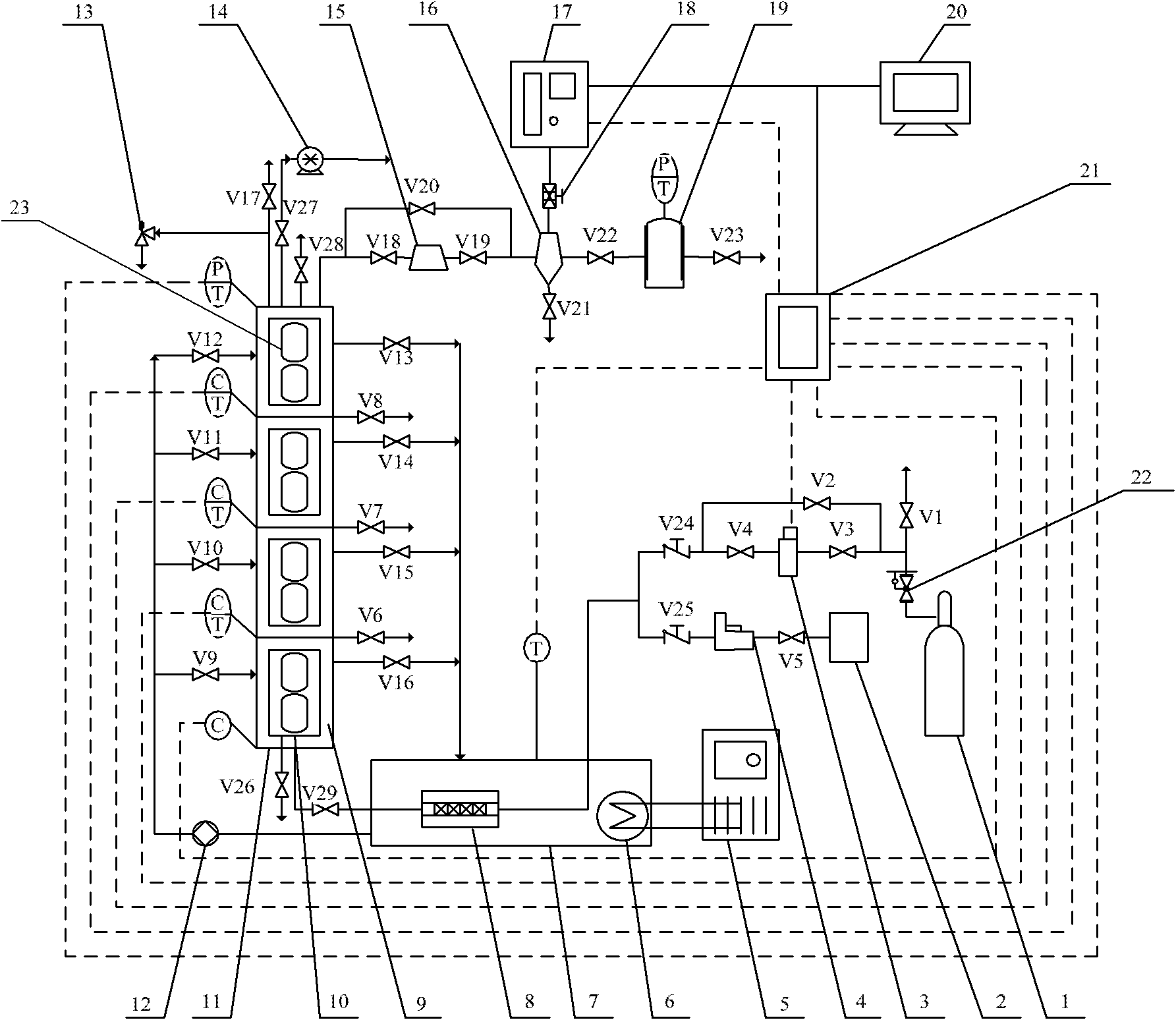

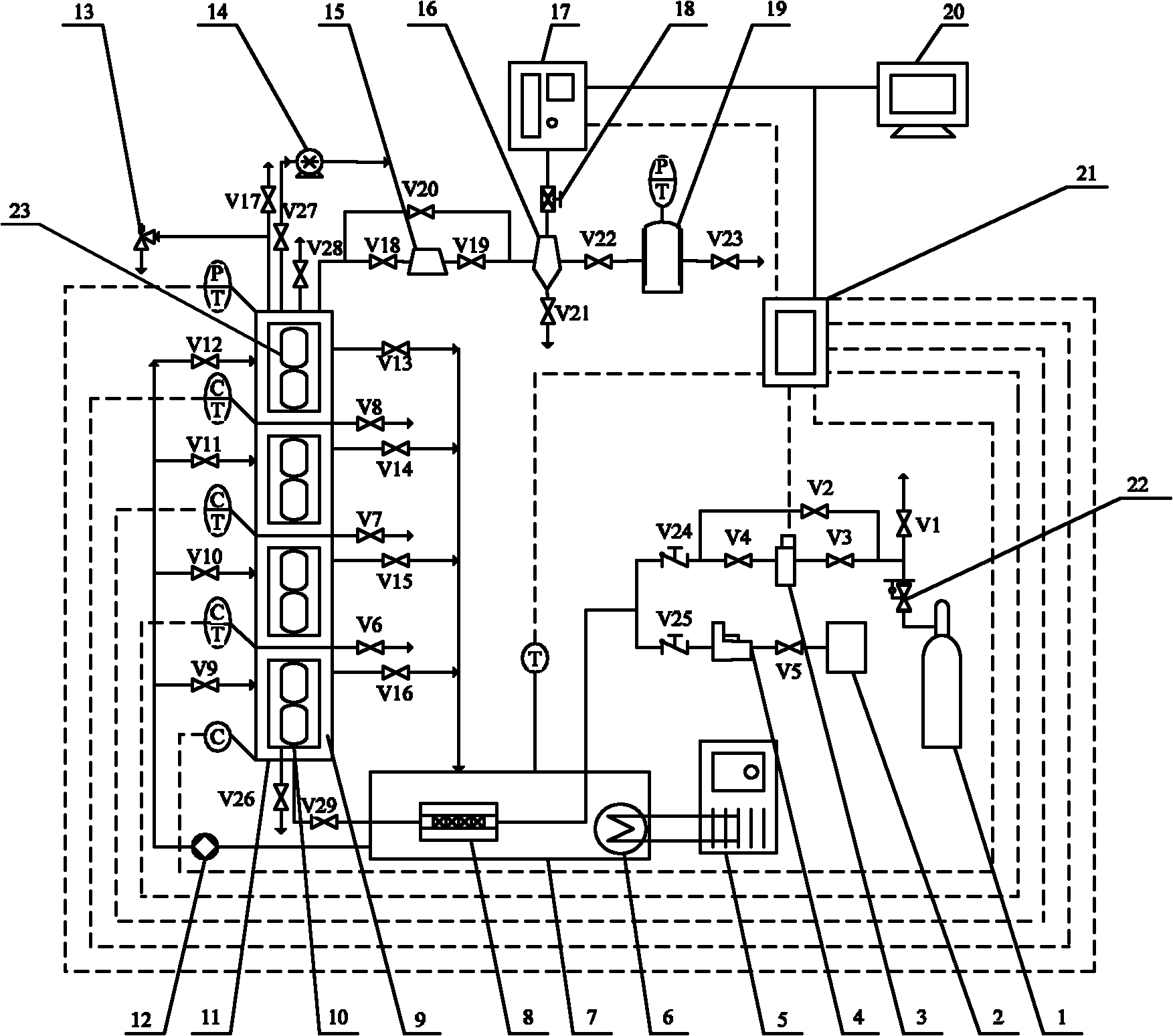

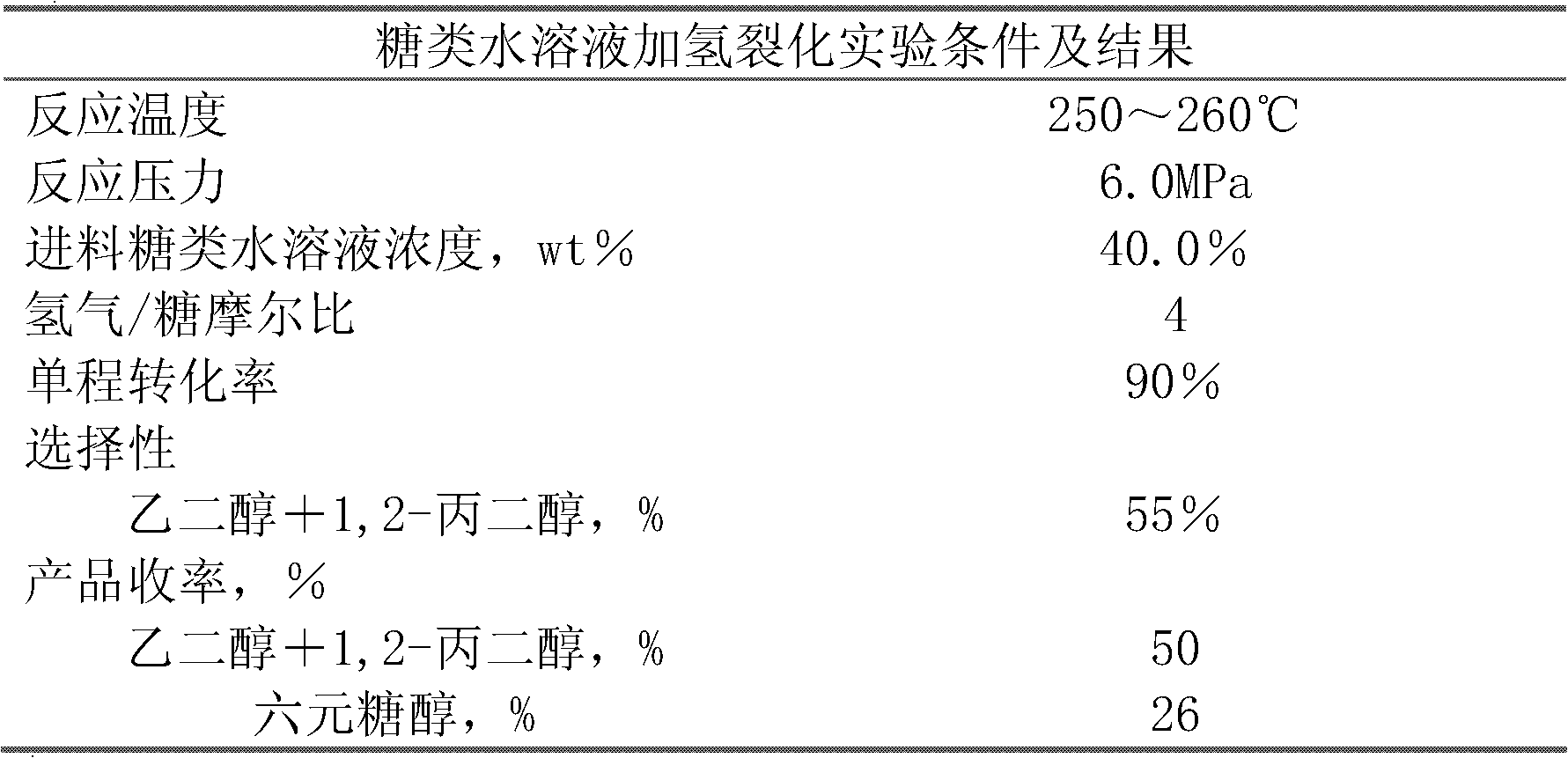

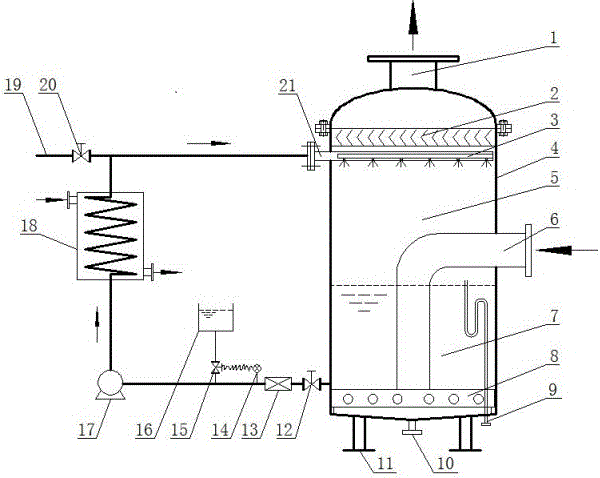

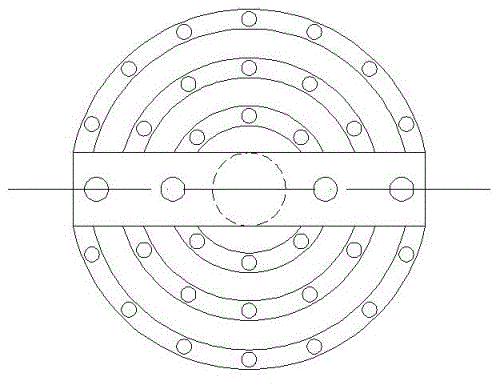

Visual gas hydrate experimental device

ActiveCN102141560AImprove solubilityIncrease the rate of formationChemical methods analysisTemperature controlDecomposition

The invention discloses a visual gas hydrate experimental device. The visual gas hydrate experimental device comprises a reactor, a constant-current gas supply system, a constant-current liquid supply system, a temperature control system, a constant-pressure gas exhaust system, a sampling analysis system and a data acquisition and processing system, wherein the reactor is divided into a plurality of sections; each section is provided with a window; a water jacket is arranged on an external wall without the window; a feeding hole is formed at the bottom; the constant-current gas supply system and the constant-current liquid supply system supply gas and a solution to the reactor respectively at a constant speed; the temperature control system controls the gas and the solution which are to be supplied to the reactor and controls a temperature of each water jacket; the constant-pressure gas exhaust system is used for exhausting the gas from the reactor and controlling a pressure in the reactor to be constant; the sampling analysis system takes samples from the interior of the reactor and carries out component analysis; and the data acquisition and processing system acquires the data of the constant-current gas supply system, the constant-current liquid supply system, the reactor and the temperature control system and carries out analysis. By adoption of the scheme, fast and efficient generation of a gas hydrate can be realized, on-line real-time observation of the crystal structure and the appearance of the hydrate in the process of hydrate composition / decomposition can be also realized, and the crystal structure and the appearance of the hydrate are analyzed by image processing software.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

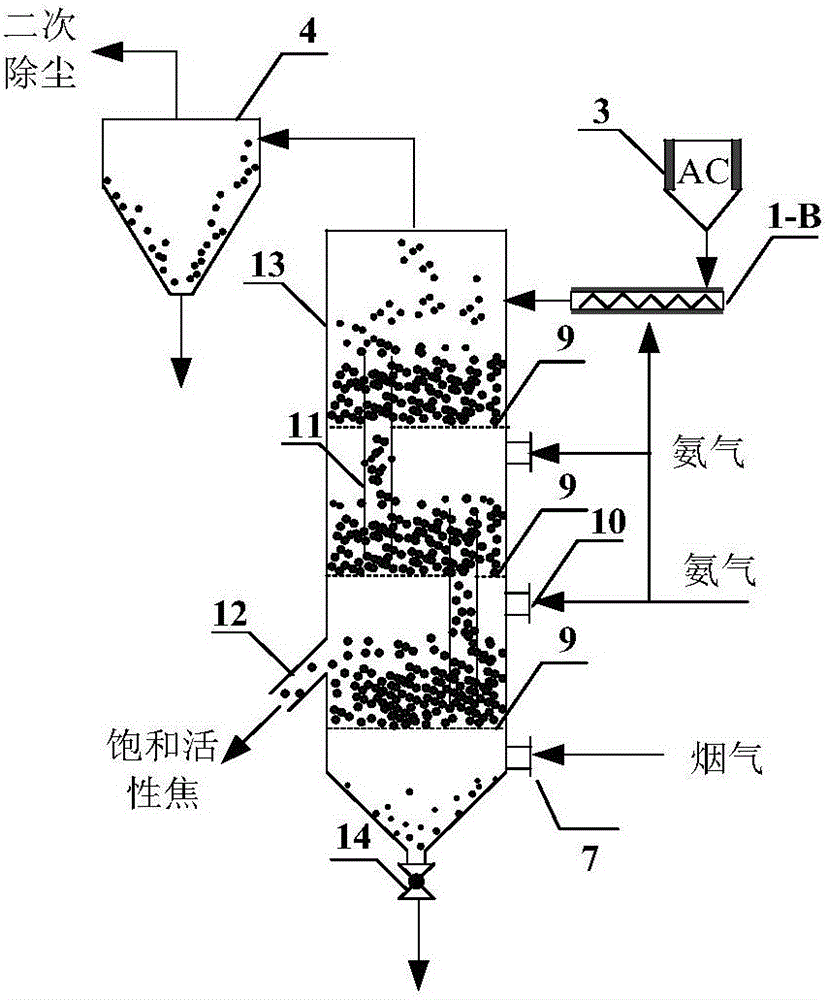

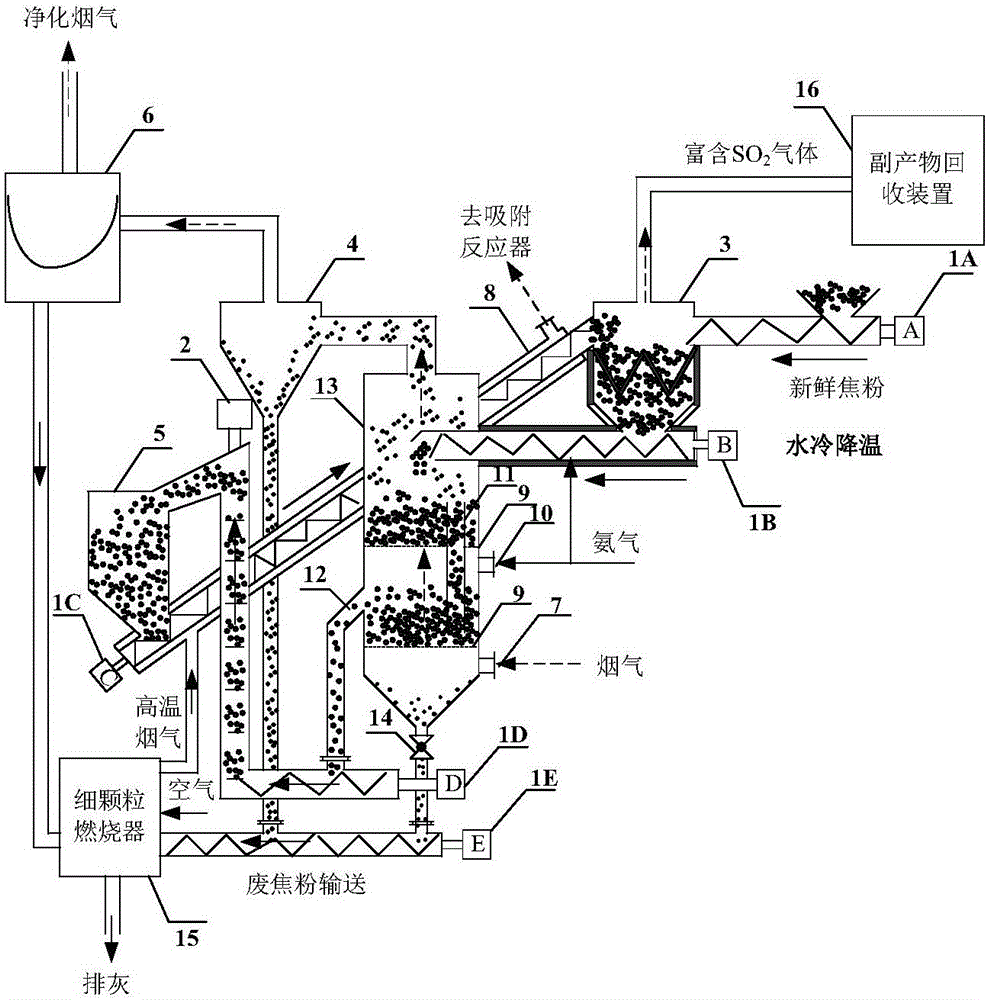

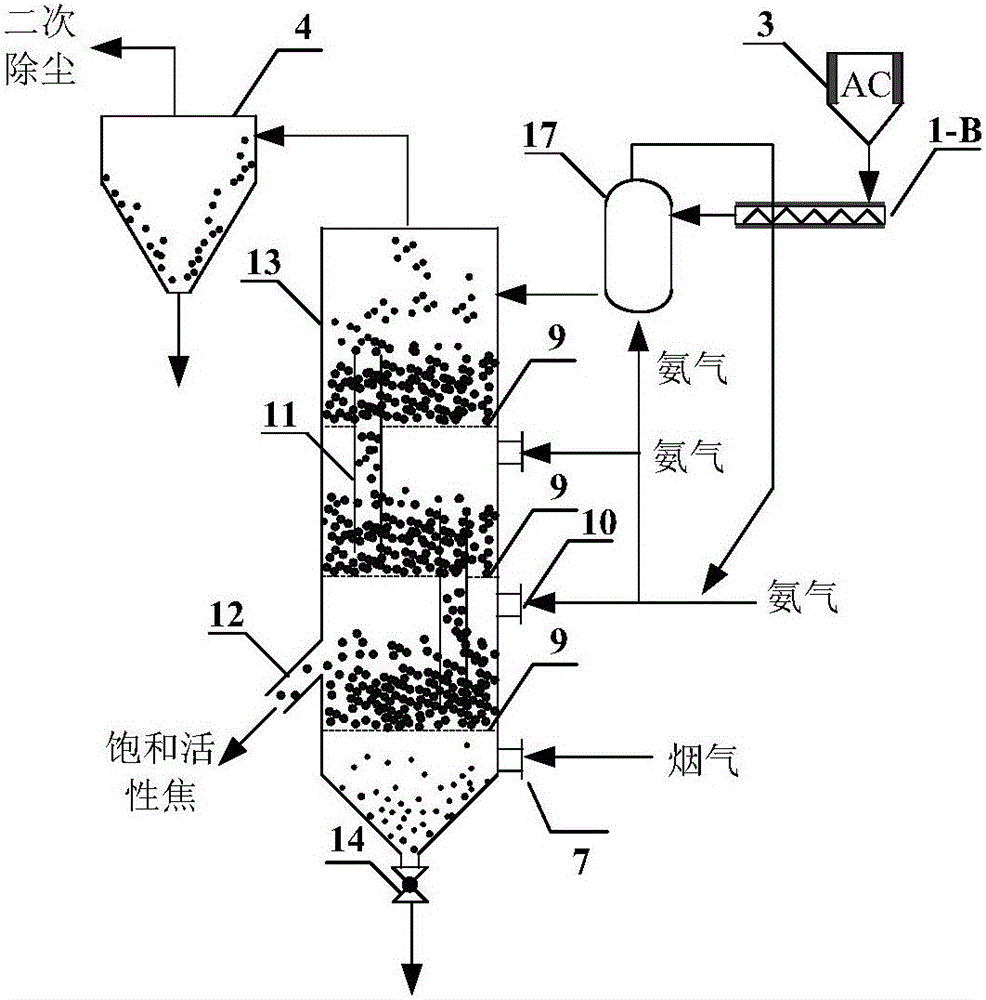

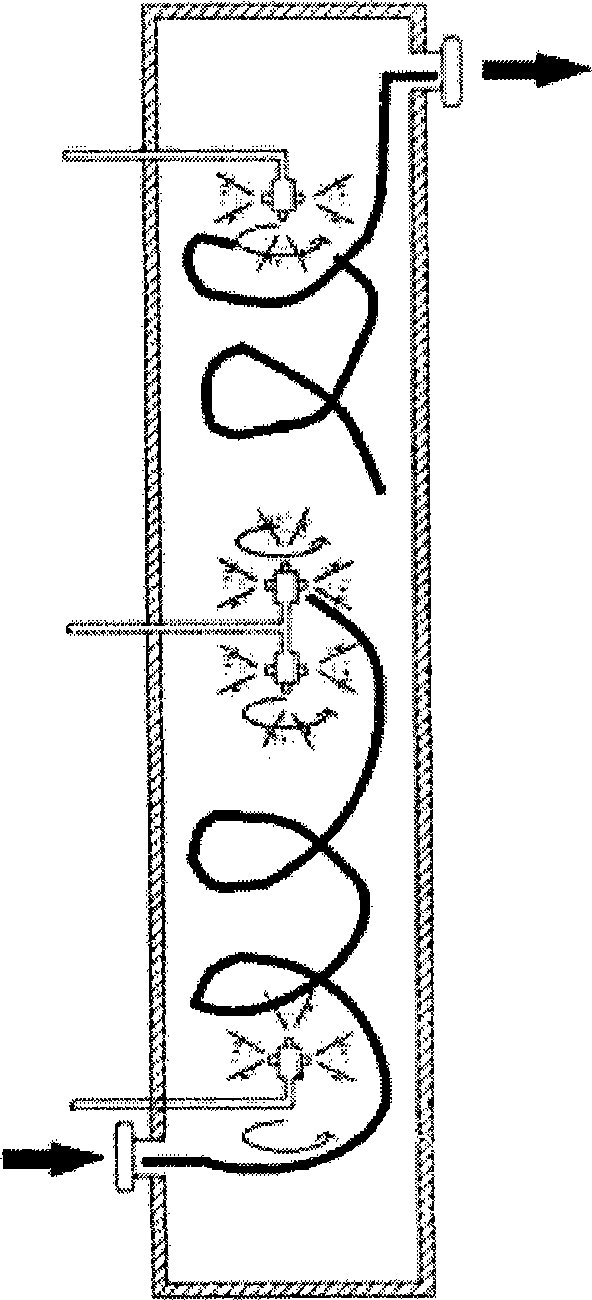

Multi-layer fluidized bed two-stage activated carbon/coke flue gas simultaneous-desulfurization and denitrification system and method

ActiveCN105727708ASave spaceEfficient use ofGas treatmentDispersed particle separationInjection portFluidized bed

The invention relates to the field of industrial flue gas pollution control. A multi-layer fluidized bed two-stage activated carbon / coke flue gas simultaneous-desulfurization and denitrification system of the invention comprises a dust removal device (4) and further comprises a desulfurization and denitrification multi-layer fluidized bed reactor (13), wherein a feed port of the dust removal device (4) is communicated with the top of the desulfurization and denitrification multi-layer fluidized bed reactor (13); the desulfurization and denitrification multi-layer fluidized bed reactor (13) is divided into an upper denitrification section and a lower desulfurization section; the denitrification section comprises several layers of fluidized beds; an ammonia gas injection port (10) is formed in a side wall corresponding to a position below the bottom of each layer of fluidized bed; the desulfurization section comprises several layers of fluidized beds; a flue gas inlet (7) is formed in the side wall corresponding to the position below the bottom of a lowest layer of fluidized bed. The system provided by the invention can enhance the mass transfer and heat transfer, improve the efficiency of desulfurization and denitrification, replace high-cost formed activated carbon / coke with fine granular activated carbon / coke to reduce the costs for desulfurization and denitrification, and is suitable for the flue gas purification of power plant boilers, industrial boilers, heating boilers and coking industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Heavy hydrocarbon hydrogenation combined process

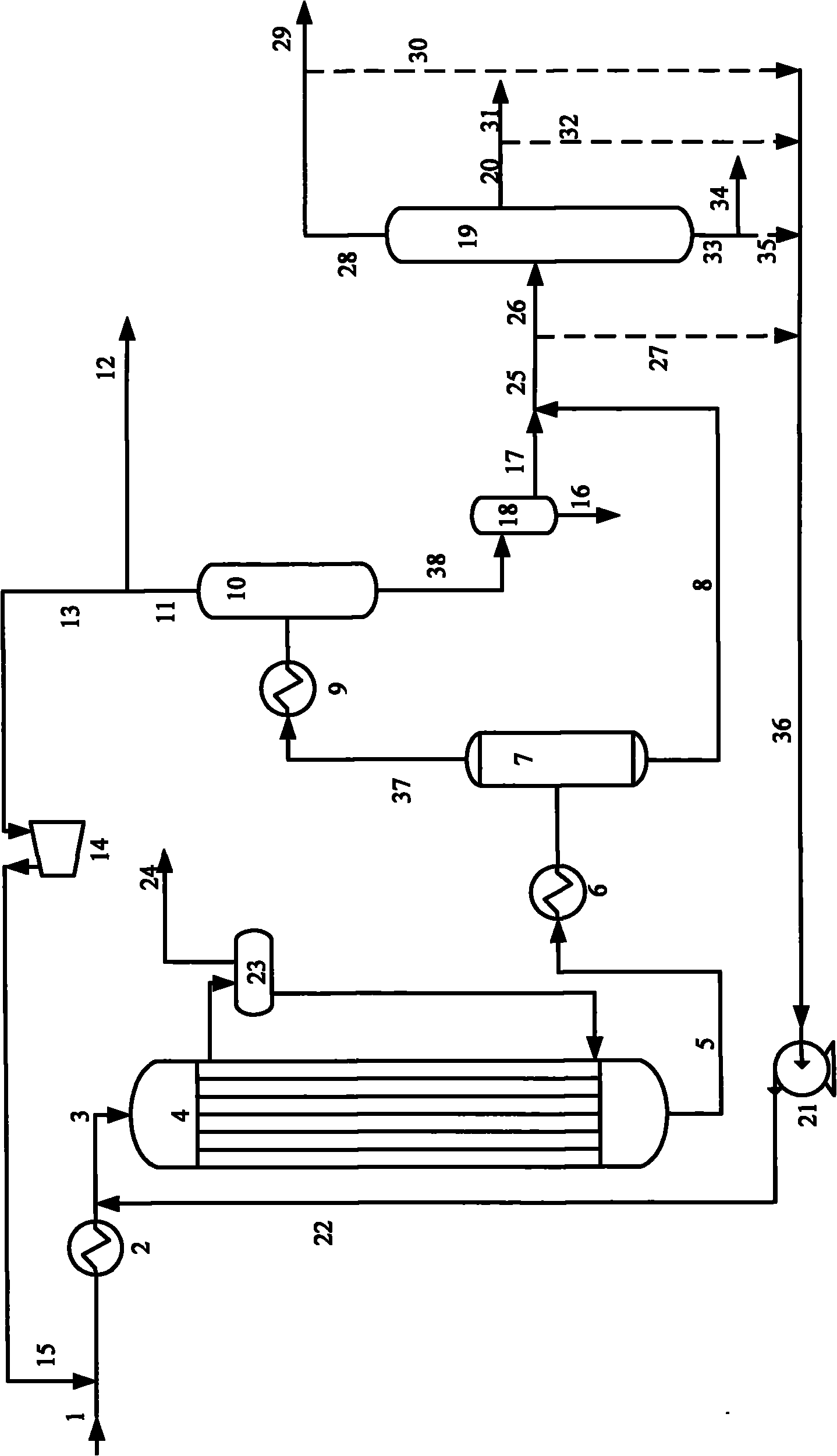

ActiveCN102041084AWide range of processingGood quality light oil productsTreatment with hydrotreatment processesGas phaseHydrogenation reaction

The invention discloses a heavy hydrocarbon hydrogenation combined process which comprises: (a) heavy hydrocarbon raw material and a gas-phase outflow substance from the fixed bed hydrogenation reaction are mixed and enter a boiling bed hydrogenation reactor; (b) the gas-phase outflow substance from the boiling bed hydrogenation reaction in the step (a) is subjected to hydrogen sulfide removal and then used for the fixed bed hydrogenation reaction of the gas-phase outflow substance of the boiling bed hydrogenation reaction in the step (a); and (c) the gas-phase outflow substance of the fixed bed hydrogenation reaction in the step (b) is directly used for the boiling bed hydrogenation reaction process in the step (a), and the liquid-phase outflow substance of the fixed bed hydrogenation reaction in the step (b) is fractionated to obtain a gasoline fraction, a diesel fraction and unconverted tail oil. In the combined process, the boiling bed technique and the fixed bed technique are combined by fully considering the technical characteristics of the boiling bed and the fixed bed as well as the features of the reaction materials, thereby providing a new operation mode which is flexible, efficient and energy-saving; and on the premise of ensuring the smooth operation of the device, the reaction heat is fully utilized, high product quality is provided, and the operational process can be flexibly adjusted according to the requirements of refineries.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for intermediate phase asphalt

InactiveCN101525543AEnhance heat and mass transferUniform responseWorking-up pitch/asphalt/bitumen by chemical meansMicroscopic morphologyHydride

The invention provides a preparation method for intermediate phase asphalt, which comprises the following steps: (1) refined naphthalene, fluorine hydride and boron triflouride are mixed according to the mass ratio of 10:1-5:2-6 and sent into a polymeric kettle; (2) the polymeric kettle is opened and the mixture is stirred, the pressure is controlled to be 10-25 Mpa, the temperature is 150-200 DEG C, and the reaction lasts for 4-6 hours; (3) and the pressure is increased to be 25-30Mpa, the temperature is increased to be 260-310 DEG C and the reaction continously lasts for 4-6 hours, thus obtaining the intermediate phase asphalt. The method has simple process and low preparation cost. Except of few of superficial globules, most of the optical anisotropy microscopic morphology of the obtained intermediate phase asphalt presents streamline state or large field melting bodily form state. The intermediate phase asphalt is excellent, has low softening point, low ash content, good spinnability, excellent structure, high tensile strength and module.

Owner:汝南县东旭碳材塑料有限公司

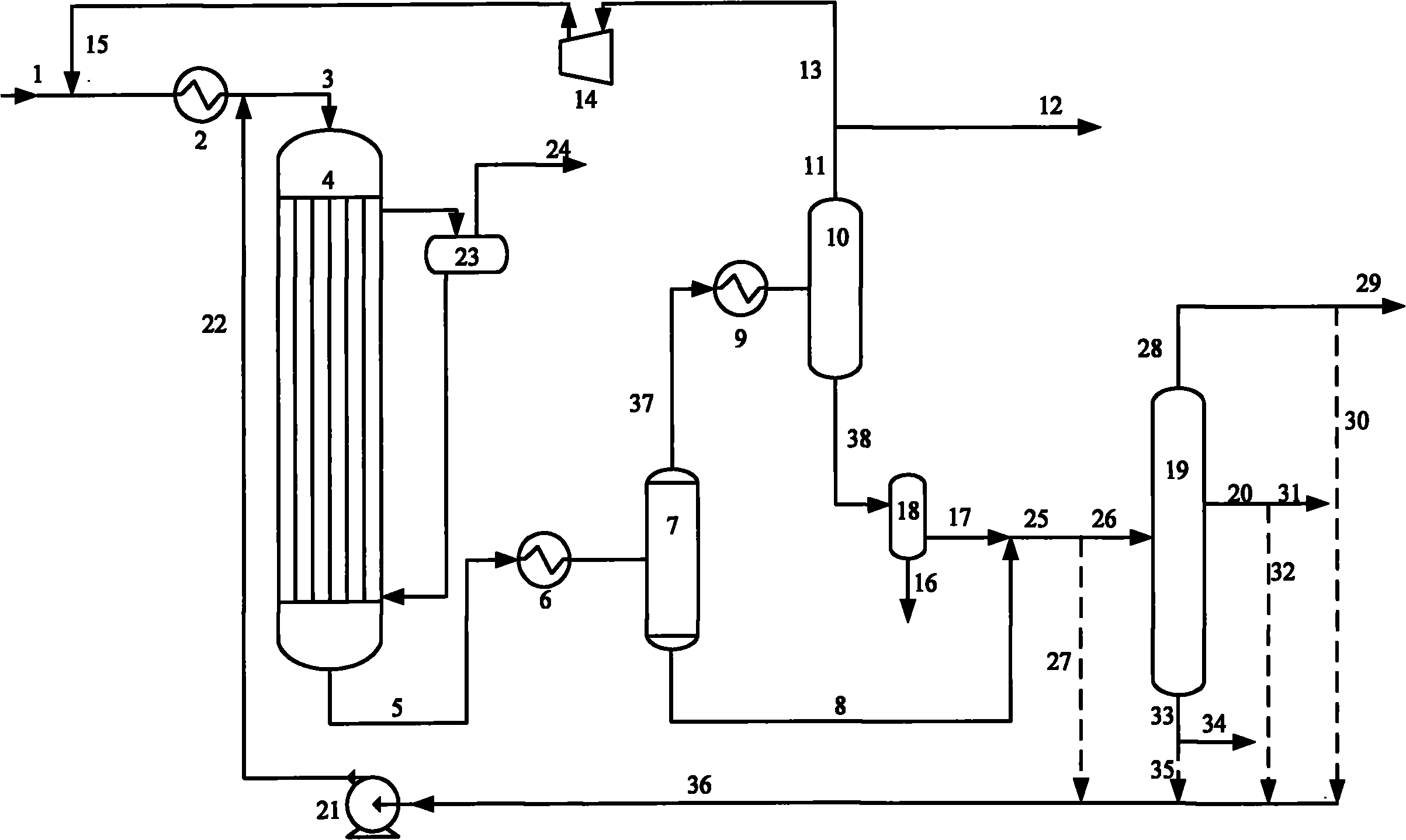

Method for producing ethylene glycol and 1,2-propylene glycol through continuous hydrocrackin of sugars

ActiveCN102643165BRealize continuous inputReduce consumptionOrganic compound preparationPreparation by OH group eliminationSucroseGas phase

The invention relates to a continuous reaction process for producing ethylene glycol and 1,2-propanediol by catalytic hydrocracking sugar conversion, and provides a method for producing ethylene glycol and 1,2-propanediol by continuous hydrogenation cracking sugar conversion. During this process, sugars (including one or more of sucrose, glucose, fructose, xylose, soluble xylooligosaccharides, and starch) are hydrocracked by catalysts in the reactor and then enter the separation system. The hydrogen in the gas phase is separated and recovered for recycling; part of the liquid phase product is returned to the reactor, and the rest of the liquid phase product is refined to separate ethylene glycol, propylene glycol, and other polyols; it exists in the remaining heavy components after refining and separation. Concentrate in the liquid phase The soluble catalyst components are partially recycled back to the reactor.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Heat supplying device for smoke purification and waste heat recovery

InactiveCN104791823AEvenly distributedReduce resistanceCombustion technology mitigationWater heatersThermal engineeringWaste heat recovery unit

The invention discloses a heat supplying device for smoke purification and waste heat recovery. The heat supplying device comprises a direct contact type waste heat recovery device and a circulating water system and is characterized in that the direct contact type waste heat recovery device comprises a bubbler, a smoke inlet pipe, an overflow pipe, a cylinder, a bubbling section, a spraying section, a sprayer, a water inlet pipe, a demister and a smoke exhaust pipe. The high temperature smoke enters cooling water in the bubble form through the bubbler and carries out direct contact type heat and mass transfer in the bubbling section; smoke discharged from the cooling water enters the spraying section and is in direct contact with the cooling water sprayed out of the sprayer again to transfer heat and mass; the cooling water absorbing heat enters the circulating water system, and a heat medium is heated through a heat exchanger in the circulating water system so as to supply heat outwards; the purified and cooled smoke is exhausted from a chimney at the upper portion of the cylinder. Two-section type direct contact of the smoke and the cooling water is adopted in the heat supplying device to transfer heat and mass, so that the smoke is fully cooled and completely purified, and the heat supplying device is suitable for smoke purification and waste heat recovery of all gas thermal engineering equipment.

Owner:ZHENGZHOU UNIV

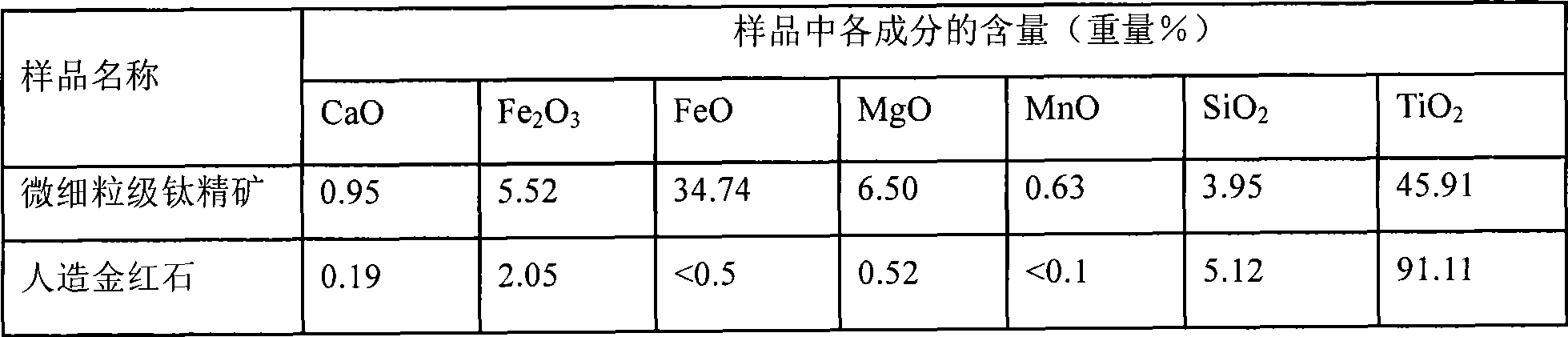

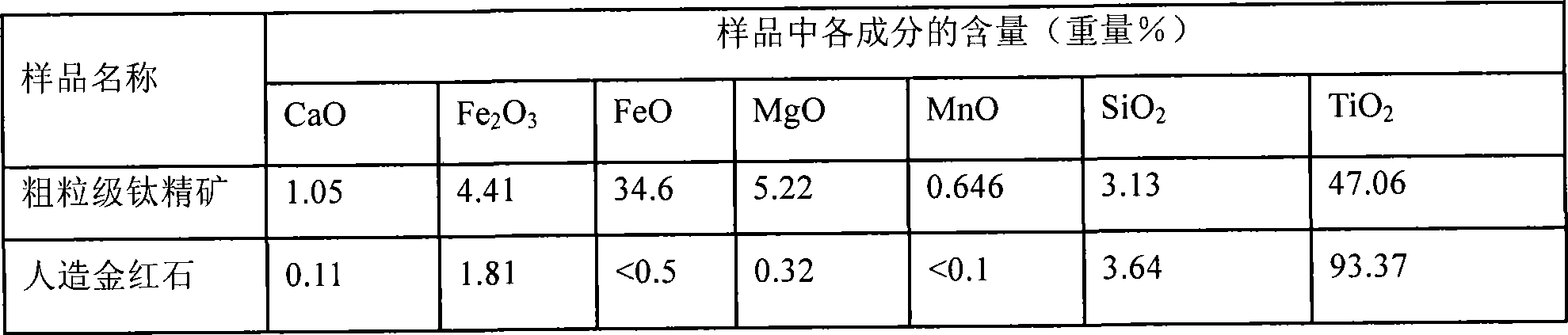

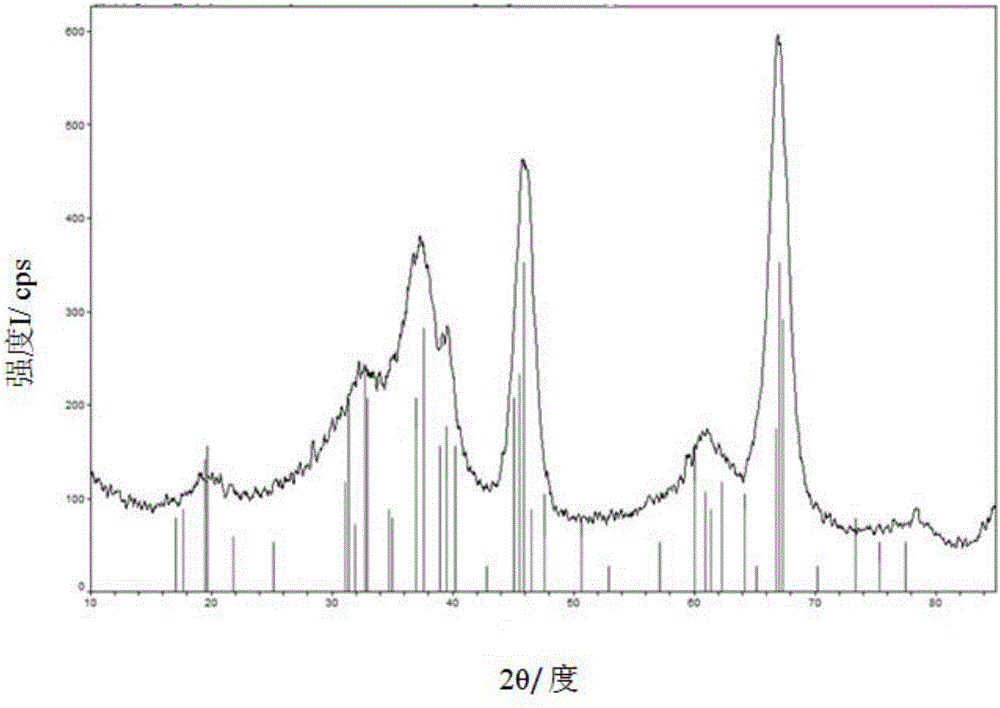

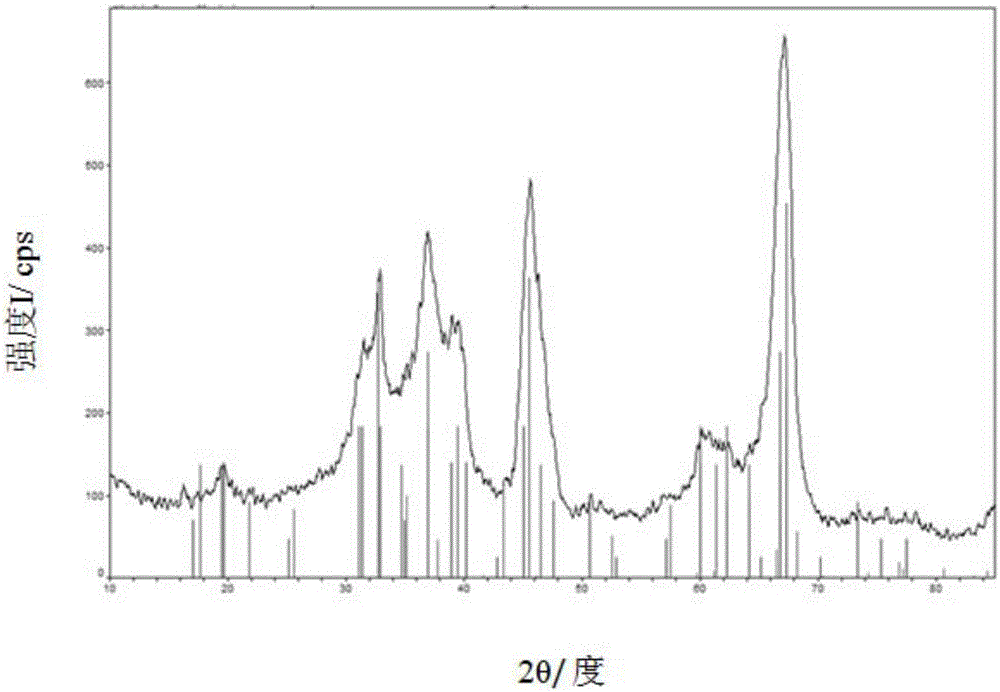

Preparation of synthetic rutile

The invention provides a method for preparing artificial rutile. The method comprises the following steps: titanium concentrate is subjected to oxidizing roasting and reducing roasting for removing impurities in oxidizing roasting products; and the products of which the impurities are removed are calcined, wherein the oxidizing roasting is performed in the presence of oxidizing gas, the reducing roasting is performed in the presence of reducing gas, and the oxidizing roasting and the reducing roasting are performed in a fluidized bed reactor. By adoption of the method, the high-grade artificial rutile can be prepared by adopting coarse fraction titanium concentrate as a raw material and can also be prepared by adopting micron-sized fraction titanium concentrate as the raw material.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

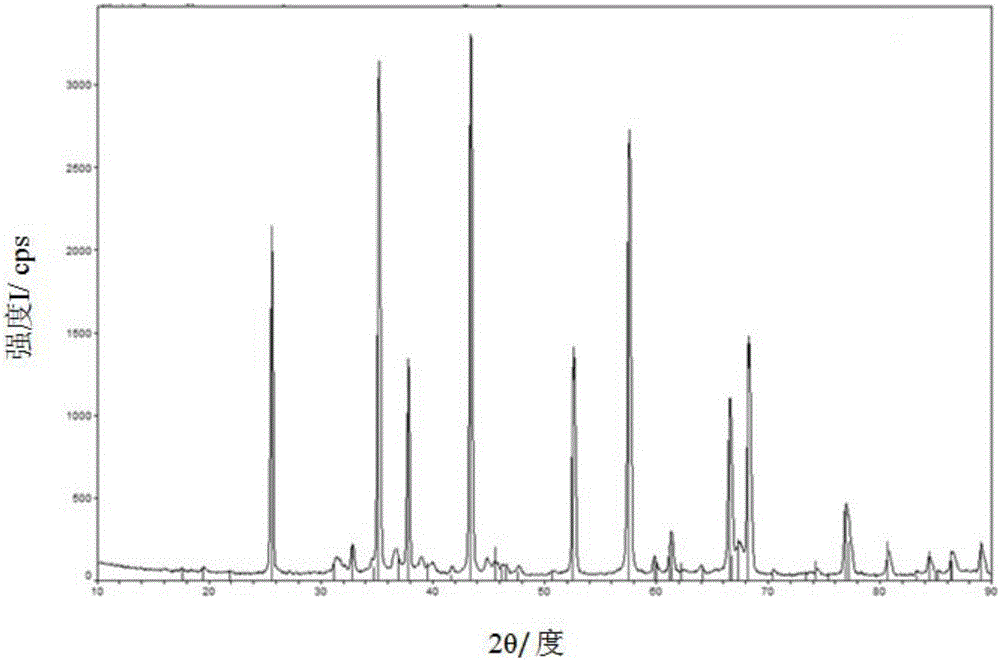

Perovskite type methane combustion catalyst as well as preparation method and application thereof

ActiveCN106732647AExtended service lifeIncrease loadHeterogenous catalyst chemical elementsIncinerator apparatusRare-earth elementAlkaline earth metal

The invention provides a perovskite type methane combustion catalyst as well as a preparation method and application thereof. The catalyst comprises an active component and a carrier, wherein the active component has a general formula: Al-xA'xB1-yB'yO3; in the formula, A is a rare earth metal element; A' is an alkaline earth metal element; B and B' represent transition metal elements; x is more than or equal to 0 but less than or equal to 0.9; y is more than or equal to 0 but less than or equal to 0.9; the carrier consists of spherical aluminum oxide of at least two crystal phases in delta-Al2O3, theta-Al2O3 or alpha-Al2O3, The aluminum oxide carrier has larger specific surface area, so that the loading capacity of the active component on the carrier can be improved; meanwhile, the uniform dispersion of the active component is facilitated, so that the sintered agglomeration of the active component is prevented, and the service life of the catalyst is prolonged; in addition, the catalyst provided by the invention is good in activity, and the selectivity of the reaction of methane and oxygen for CO2 is high; the perovskite type methane combustion catalyst has the advantages of being low in initiation temperature, high in combustion efficiency, good in mass transfer and heat transfer performance, and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

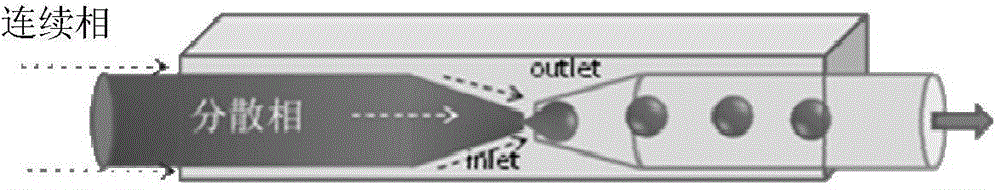

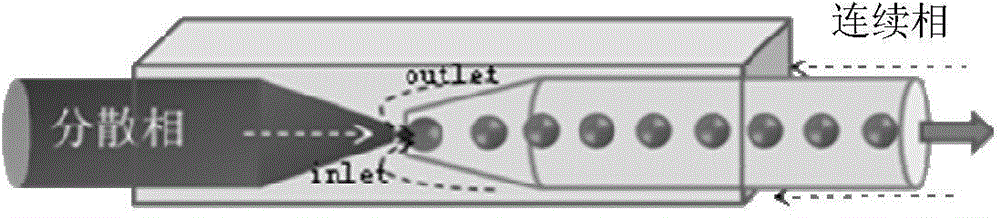

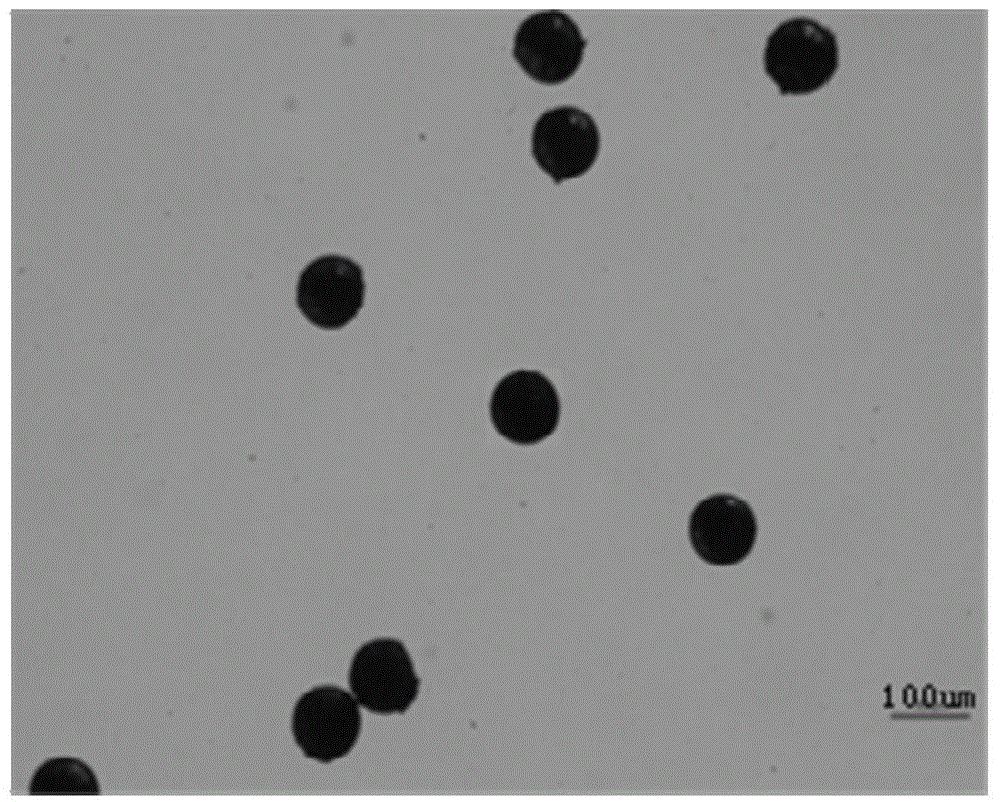

A preparing method of a monodisperse phenolic resin carbon microbead

A preparing method of a monodisperse phenolic resin carbon microbead is provided. The method includes following steps of: forming water-in-oil phenolic resin liquid drops in a micro-channel reactor by a microfluidic liquid drop technique; preparing the phenolic resin liquid drops into phenolic resin microbeads by thermocuring; washing and separating the phenolic resin microbeads to obtain a monodisperse phenolic resin microbead; and subjecting the monodisperse phenolic resin microbead to high-temperature carbonization in an inert atmosphere to form the monodisperse phenolic resin carbon microbead. The method overcomes the defects in the prior art, namely complex processes, difficulty in accurate control of product particle sizes, irregular morphology, and the like, and has advantages of simple and rapid preparation process, controllable microbead particle size, uniform particle size, good degrees of sphericity, and the like.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

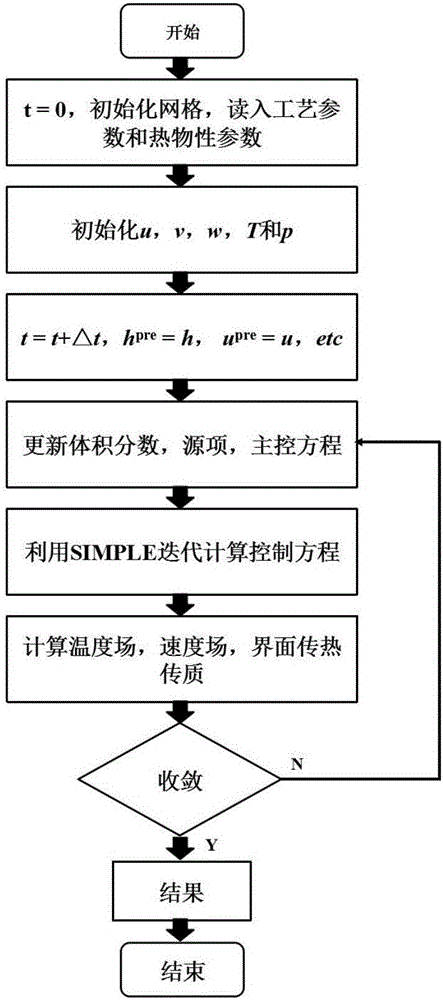

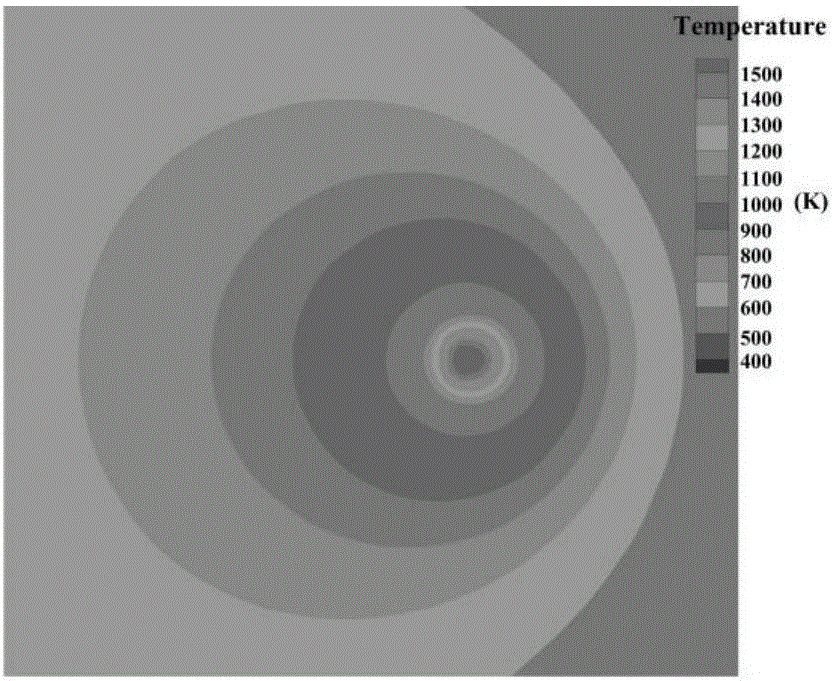

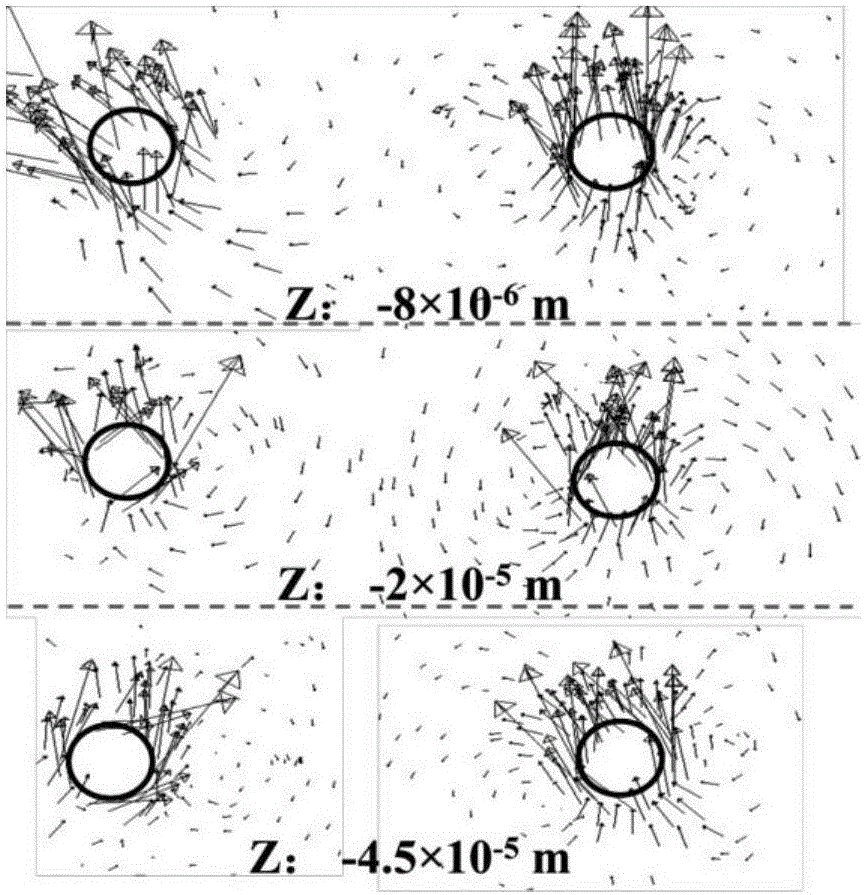

Method for simulating heat and mass transfer of reinforcement phase and melt interface in laser 3D printing composite material molten pool

ActiveCN105868434AAccurate prediction of heat and mass transferImprove distributionSpecial data processing applicationsMelting tankPhysical model

The invention relates to a method for simulating heat and mass transfer of a reinforcement phase and a melt interface in a laser 3D printing composite material molten pool, and aims at the temperature fields and velocity fields in the neighborhood of reinforced particles in the molten pool as well as distribution condition of the particles in samples after the final solidification. The method comprises the following steps: establishing a physical model of heat and mass transfer between the reinforced particles and melts; controlling the heat and mass transfer through a master control equation; and solving a control equation on the basis of calculation fluid dynamics software so as to obtain the temperature fields, the velocity fields and the distribution condition of the reinforced particles. According to the method for simulating the heat and mass transfer of the reinforced particles and the melt interface in the laser processing molten pool, a flow field model for disturbing the interior of the molten pool via laser and influencing the heat and mass transfer process between the reinforced particles and the melts is established aiming at a process of processing and preparing metal-matrix composite materials (MMCs) via laser, and the problems of powder, phase change and solidification in the laser processing process are considered, so that physical metallurgical behaviors of the reinforced particles and matrixes are correctly obtained, and the calculation results are favorably identical with experiments.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Gas hydrate generation accelerant and preparation method thereof

ActiveCN103663451AEnhance heat and mass transferShorten the timeCarbon compoundsGeneration processLiquid water

The invention belongs to the field of gas hydrate production and utilization and in particular relates to an accelerant capable of reinforcing gas hydrate generation and a preparation method thereof. The hydrate generation accelerant is a mixed water solution formed by compounding nano dispersed particles with a surfactant and dissolving the compound in water, wherein nano graphite powder is adopted as the nano dispersed particles; SDBS (sodium dodecylbenzenesulfonate) is adopted as the surfactant; based on the total amount of the mixed water solution, the mass fraction of the nano graphite powder is 0.05-1.5%, the mass fraction of SDBS is 0.02-0.08% and the balance is water. The accelerant has the obvious advantages that the mass and heat transfer processes of the hydrate can be greatly reinforced, the overall time of hydrate generation can be shortened and the synthetic efficiency of the hydrate can be improved by adopting the accelerant to reinforce the hydrate generation process; the graphite nano-particles can flow out along with liquid water and can be reused, thus saving the cost.

Owner:溧阳常大技术转移中心有限公司

Catalyst for catalytic combustion of VOCs and preparation method thereof

PendingCN110614101AHigh activityGood mass and heat transferHeterogenous catalyst chemical elementsDispersed particle separationAlkaline earth metalRare earth

The invention discloses a catalyst for catalytic combustion of VOCs and a preparation method of the catalyst. Cordierite honeycomb ceramic or a porous metal material is used as a carrier, the carrieris coated with a nano coating material, precious metal compound transition metal is used as an active component, compound rare earth oxide is used as a catalyst aid, and a solid solution prepared froman alkaline earth metal compound and main group metal oxide is used as a carrier modifier; the carrier and the active component are coated through an automatic production line; the catalyst has advantages of high substrate bonding force, high adhesive force between the active component and the carrier after high-temperature roasting, difficult shedding, high activity, good thermal stability, goodsulfur resistance and long service lifetime, is a broad-spectrum VOC oxidation catalyst, can be used for catalytic combustion treatment of VOCs in the industries of spraying, printing, electronics and the like, and is suitable for CO and RCO catalytic combustion devices.

Owner:ZHENJIANG EAST CHINA ELECTRIC POWER EQUIP FACTORY CO LTD

Tropsch synthesis method of fixed bed

ActiveCN101928194AImprove mass and heat transfer performanceSimple equipmentHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionChemistryLiquid hydrocarbons

The invention relates to a tropsch synthesis method of a fixed bed, which is one-section tropsch synthesis, and comprises the steps of: leading fresh raw material gas H2 and CO to enter a tropsch synthesis reactor of the fixed bed, carrying out tropsch synthesis reaction under the action of tropsch synthesis catalyst, separating the reaction effluent, and obtaining gas hydrocarbon product, liquidhydrocarbon product and water, wherein the liquid hydrocarbon product is separated into light fraction oil, intermediate fraction oil and heavy fraction oil; and returning part of the gas hydrocarbonproduct and the liquid hydrocarbon product back to an inlet of the tropsch synthesis reactor. The invention solves the problems of difficult temperature control of a bed layer of the tropsch synthesis catalyst of the fixed bed, overhigh temperature of the bed layer and poor product selectivity. The invention improves the distribution of the synthetic oil product, and effectively reduces the olefin content of the light synthetic oil product.

Owner:CHINA PETROLEUM & CHEM CORP +1

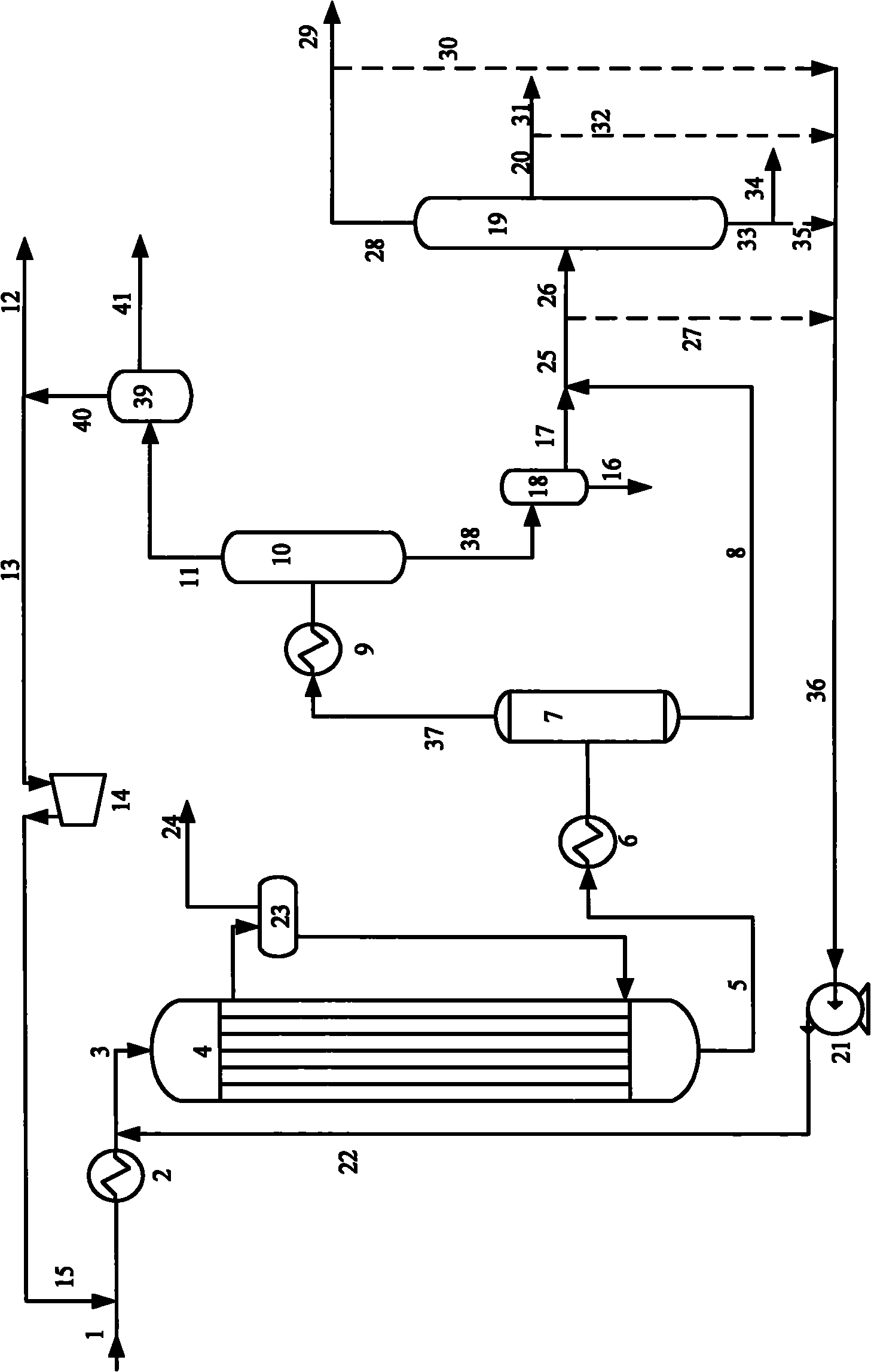

Hydrogenation method of heavy hydrocarbon multi-segment fluidized bed

ActiveCN101724453AReduce heat loadSave heatHydrocarbon oil crackingTreatment with hydrotreatment processesGas phaseFuel oil

The invention discloses a hydrogenation method of a heavy hydrocarbon multi-segment fluidized bed. The technical process comprises the steps of: mixing thick heavy hydrocarbon raw materials with gas phase material flow which is discharged from a fluidized bed hydrogenation-desulfuration reactor and a hydrogenation-denitrification reactor to enter into a hydrogenation-demetalization reactor; cooling and purifying reacted gas phase material flow to be taken as recycle hydrogen; mixing the demetallized liquid phase material flow with hydrogen to enter into the fluidized bed hydrogenation-desulfuration reactor; mixing the desulfurated liquid phase material flow with hydrogen to enter into the hydrogenation-desulfuration reactor; and leading the denitrified liquid phase material flow to enter into a separating device. The technology adopts a new reactor assembly mode to machine heavy oil raw materials with high viscosity and bad quality, can provide a new flexible, high-efficiency and energy-saving operation mode, organically combines the performances of the raw materials with the characteristic of each hydrogenation reaction, makes full use of reaction heating on the premise that a device is guaranteed to be stably operated, provides a product with good quality, and can flexibly adjust the operation process according to the requirement of a refinery.

Owner:CHINA PETROLEUM & CHEM CORP +1

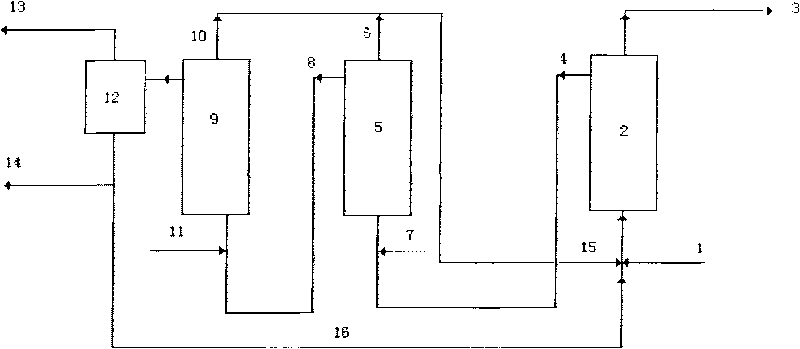

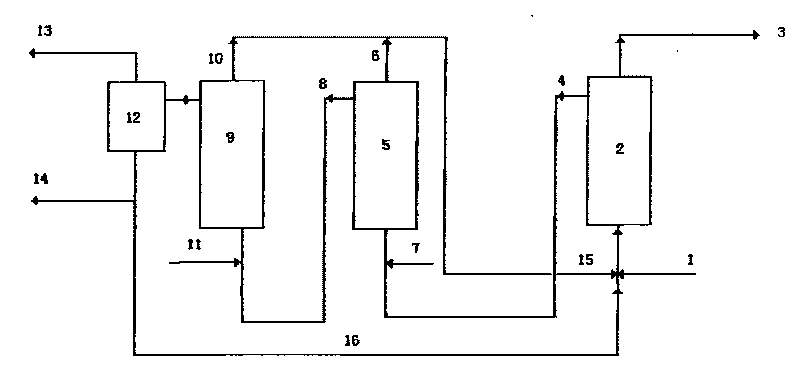

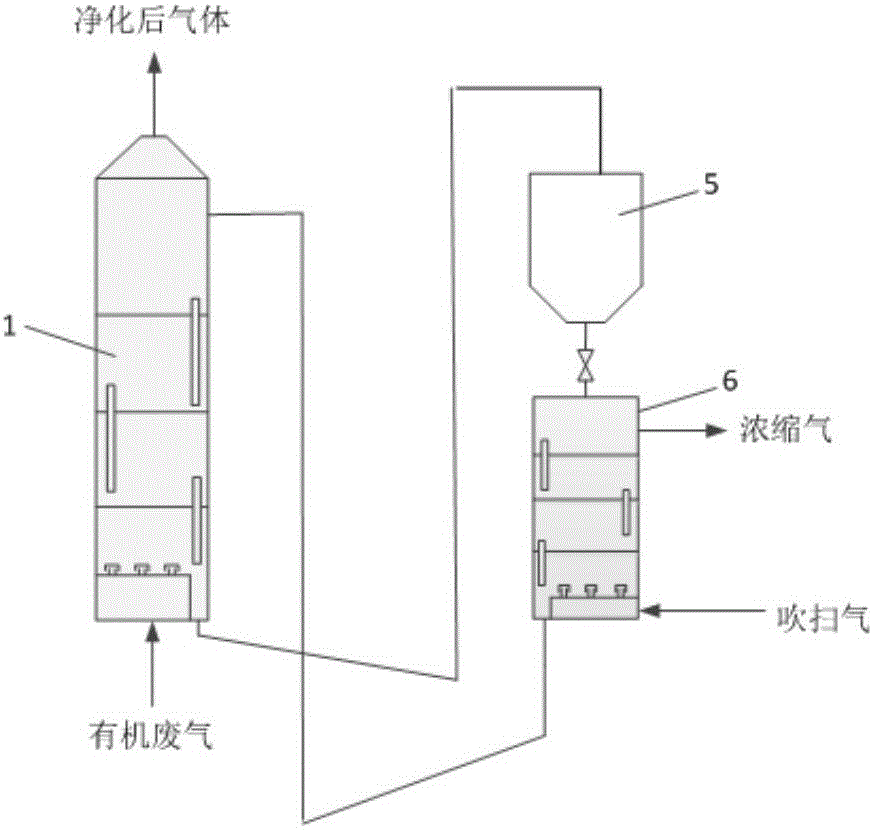

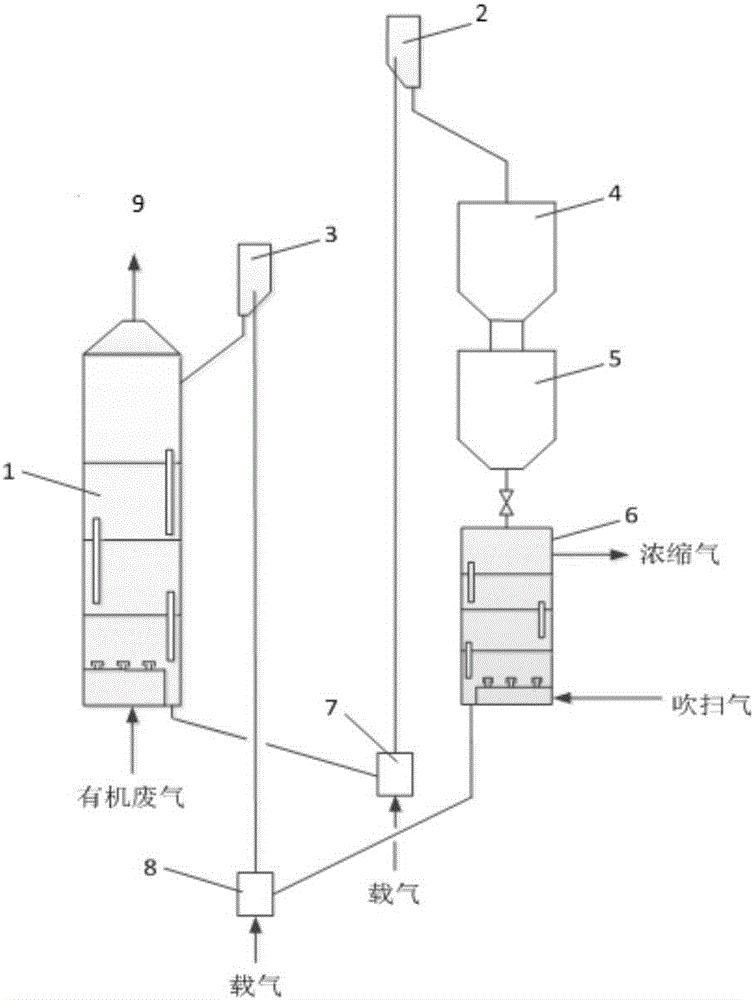

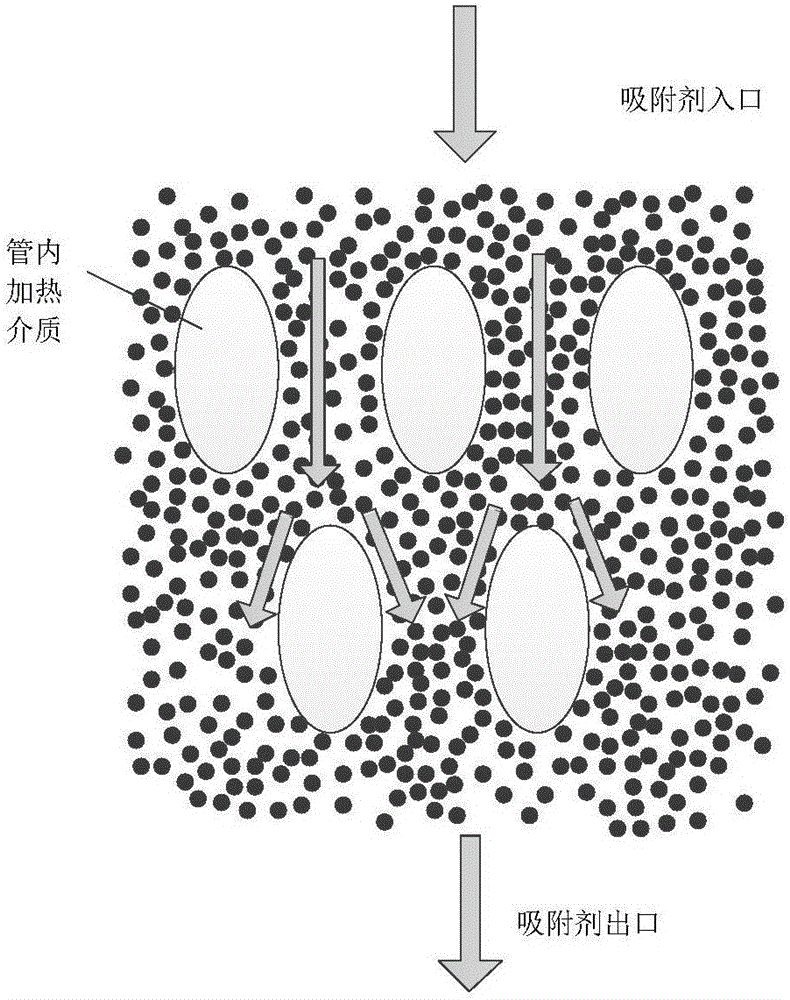

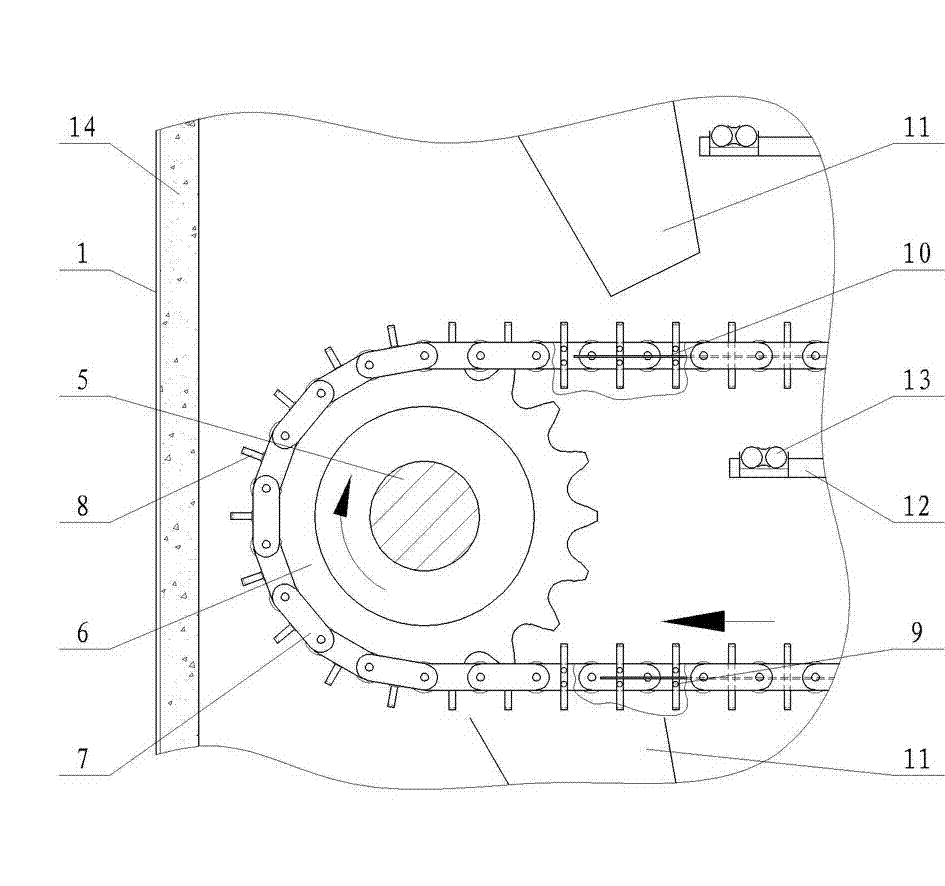

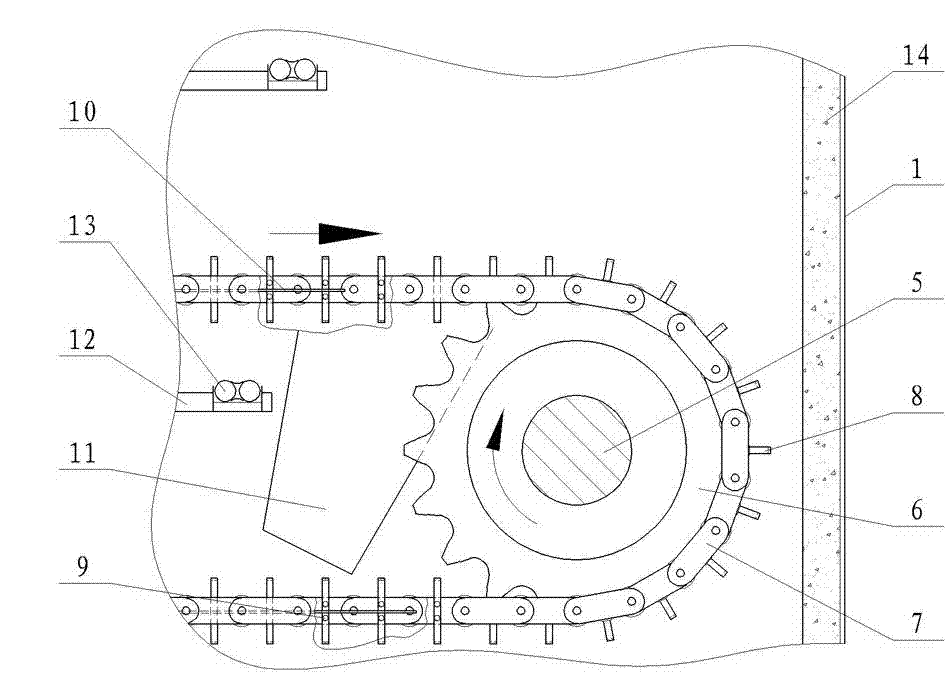

Double-fluidized bed adsorption and desorption device and method for continuous treatment of organic waste gas

InactiveCN106390681AEnhance heat and mass transferAvoid heat buildupGas treatmentDispersed particle separationHigh concentrationDesorption

The invention relates to the field of organic waste gas treatment and resource utilization and particularly relates to a double-fluidized bed adsorption and desorption device and a method for continuous treatment of organic waste gas. The device provided by the invention comprises a fluidized bed adsorption device (1), a preheater (5) and a fluidized bed desorption device (6), wherein an adsorbent outlet at the bottom of the fluidized bed adsorption device (1) is connected with a feed port of the preheater (5); a discharge port of the preheater (5) is connected with a feed port of the fluidized bed desorption device (6); and a solid outlet of the fluidized bed desorption device (6) is connected with a solid inlet of the fluidized bed adsorption device (1). In the invention, continuous treatment of high-concentration organic waste gas can be realized, heat accumulation can be prevented, and the problems such as bed fire and explosion caused by the dissipation failure of the reaction heat due to the excessively high concentration of the high-concentration organic waste gas are avoided; and moreover, the desorption effect of the adsorbent and the exit concentration of concentrated VOC gas are improved, and the catalytic combustion or solvent recycling is facilitated.

Owner:东莞市佳明环保科技有限公司 +1

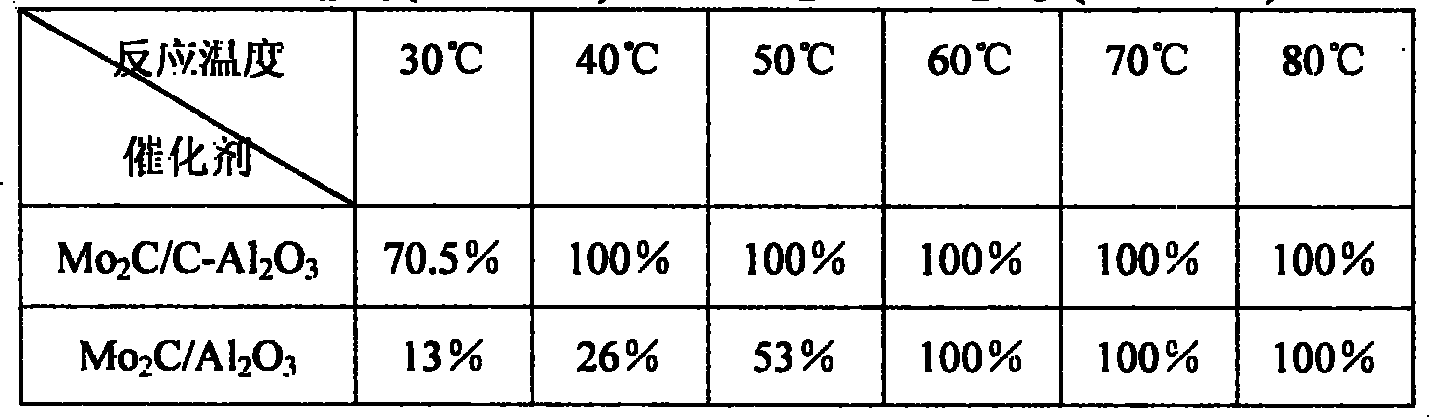

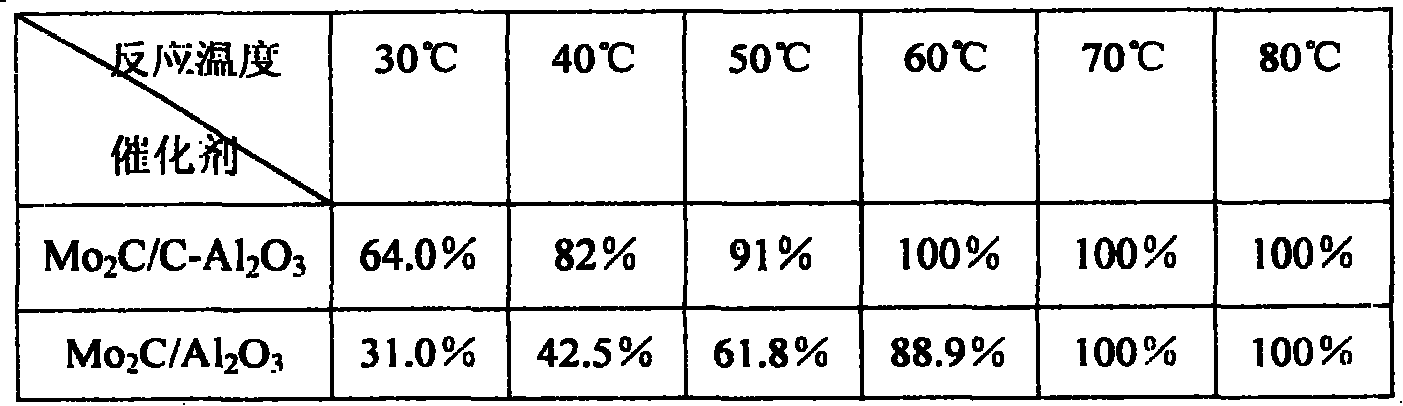

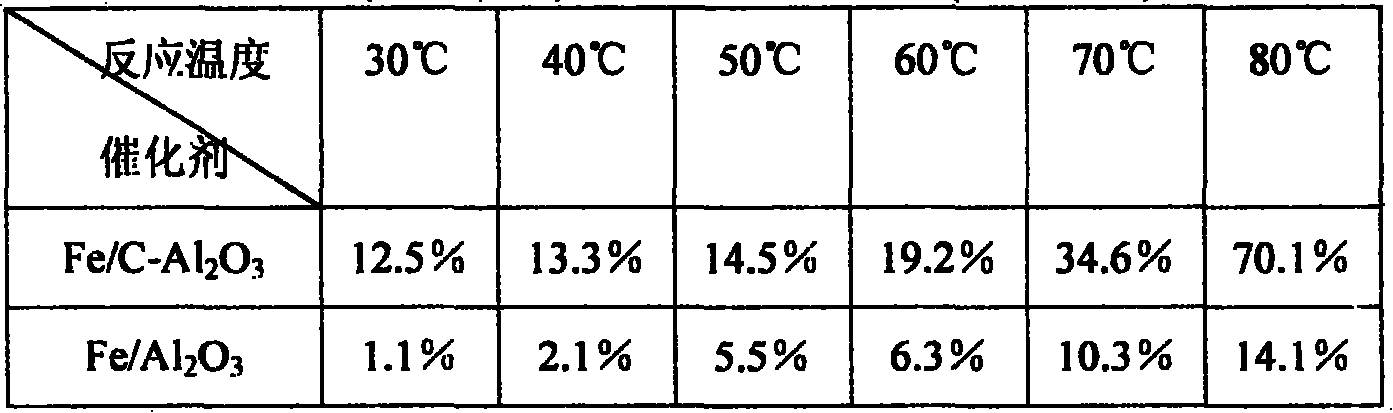

Carbon/aluminum oxide composite carrier catalyst for hydrazine decomposition reaction and preparation thereof

InactiveCN101209424AAvoid carbon deactivationEasy to makeCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsDecompositionHydrazine compound

The invention provides a carbon / alumina composite carrier catalyst used for hydrazine decomposition reaction and a preparation method thereof. The catalyst showed in the formula is A / C-Al2O3, C-Al2O3 is the carbon / alumina composite carrier, and active constituent A is transition metal Mo, W, Fe, Co, Ni, Ru, Rh, Pd, Ir, Pt or carbonization, nitride and phosphide thereof; wherein, the content of the A is 2-40wt percent and the preparation temperature of the A is 300-900 DEG C. The invention has simple preparation, especially for the preparation of active species of the transitional metal carbonization, which uses H2 instead of CH4 / H2 gas used in the past preparation to have direact reduction; the invention prevents carbon deposition on the surface of the carbonization from inactivating, thus being beneficial to acquire more catalytic active sites.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

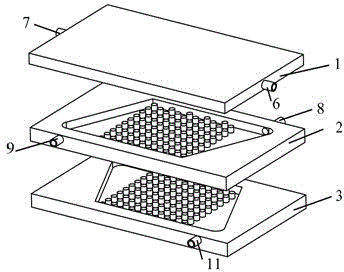

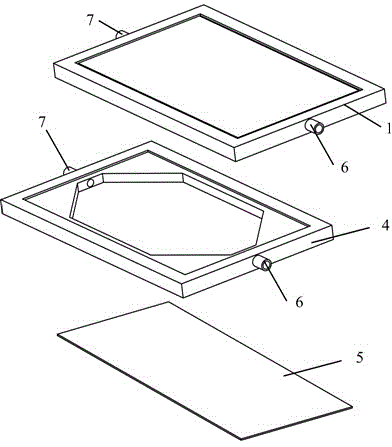

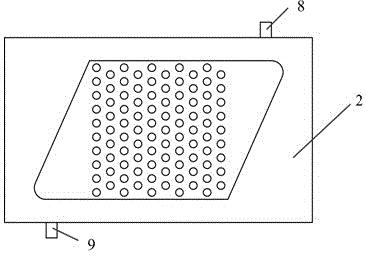

Self-heating staggered-arrangement micro-boss array type alcohol reforming device

InactiveCN103601151AEnhance heat and mass transferHigh heat and mass transfer efficiencyHydrogenHydrogen fuel cellHydrogen fuel

The invention discloses a self-heating staggered-arrangement micro-boss array type alcohol reforming device. The self-heating staggered-arrangement micro-boss array type alcohol reforming device comprises a hydrogen purification component, a reforming hydrogen production plate and a catalytic combustion plate sequentially from top to bottom. A reforming hydrogen production cavity is arranged in the reforming hydrogen production plate and loaded with a hydrogen production catalyst which is used for alcohol reformation so as to produce hydrogen; a catalytic combustion cavity is arranged in the catalytic combustion plate and loaded with a combustion catalyst which is used for alcohol combustion and heat supply. Heat is supplied for the reforming hydrogen production through alcohol combustion, so that the natural operation of the alcohol reforming device can be realized. Staggered-arrangement micro-boss array structures are arranged in the reforming hydrogen production cavity and the catalytic combustion cavity, so that the specific area is large and the heat transfer and mass transfer efficiency is high. In addition, the alcohol reforming device comprises the hydrogen purification component, so that the fuel conversion efficiency of the reforming hydrogen production cavity can be improved, and hydrogen at an outlet can be directly used for a hydrogen fuel battery. The self-heating staggered-arrangement micro-boss array type alcohol reforming device is compact in structure, convenient for catalysts to load, easy for the whole structure to assemble, and capable of being used in intermediate and small flow alcohol reforming hydrogen production situations.

Owner:ZHEJIANG UNIV

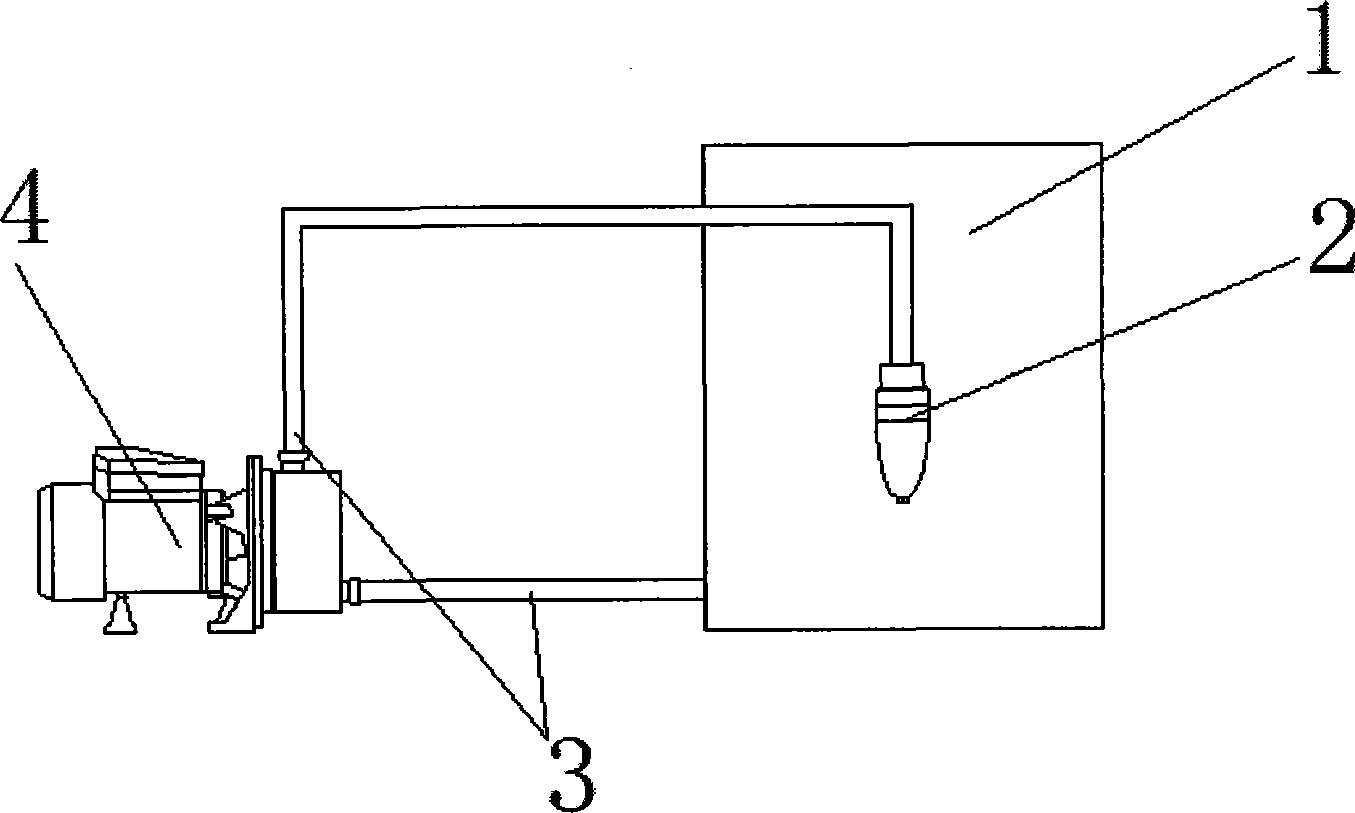

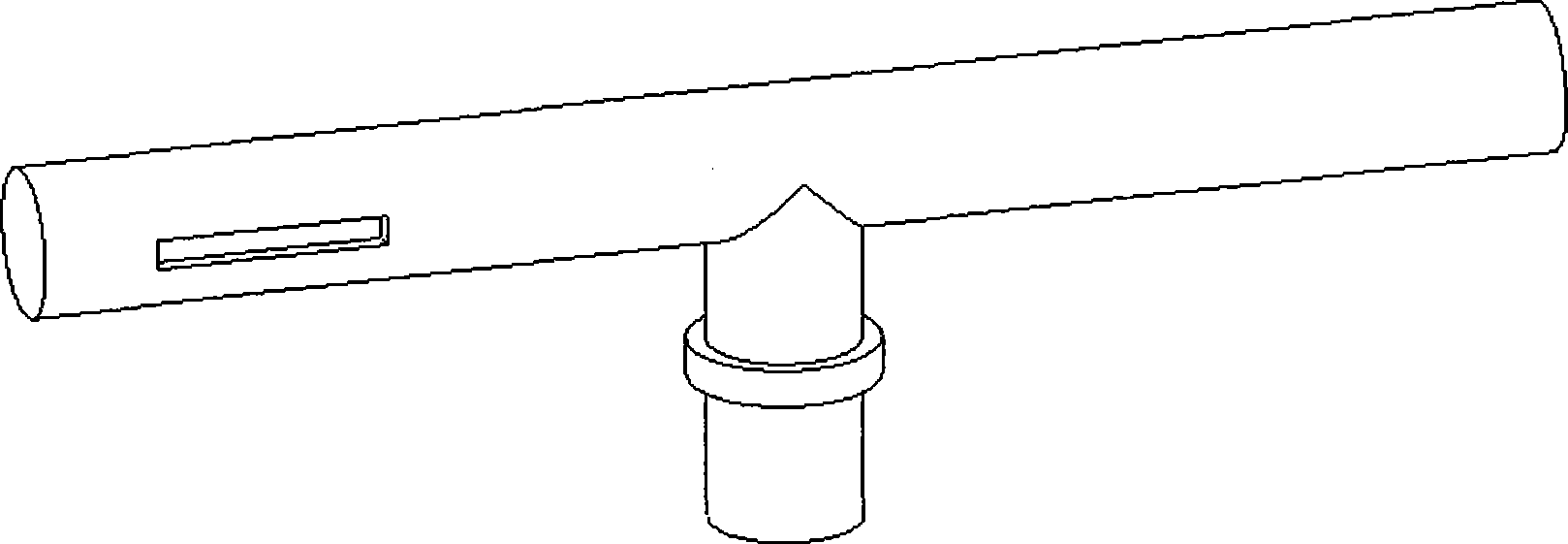

Novel swirl dispersing device

InactiveCN104128106ASolving mass and heat transfer problemsFacilitate multiphase contactCombination devicesFlow mixersVolume variationGas phase

The invention relates to a novel swirl dispersing device which mainly includes a rotating spray nozzle, a pump, a container and pipelines. Energy in transmission processes, which is not concerned up to now, are successfully applied in various reaction processes and mass and heat transmission processes intelligently. Rotation is generated by means of kinetic energy of system input or circulating materials and a pressure gradient is formed through a rapid change of a gas temperature or / and a volume change due to absorption. A tornado-like effect can be automatically induced in a gas phase and a swirl-like flow is forcedly formed in a liquid phase so that a mixing effect which is better than that generated from mechanical stirring and a circulator, thereby significantly increasing a mass and heat transmission efficiency in various processes. The novel swirl dispersing device is an important innovation of devices in process intensification, is simple and practical, is low in cost, is energy-saving and high-efficient, has a long effective distance, is good in the effects of mass and heat transmission and dispersion and separation, is wide in application and is strong in universality. The novel swirl dispersing device can solve uniform mass and heat transmission in a gas-phase system, a liquid-phase system, a gas-liquid system, a gas-solid system and a gas-liquid-solid system.

Owner:XIAMEN UNIV

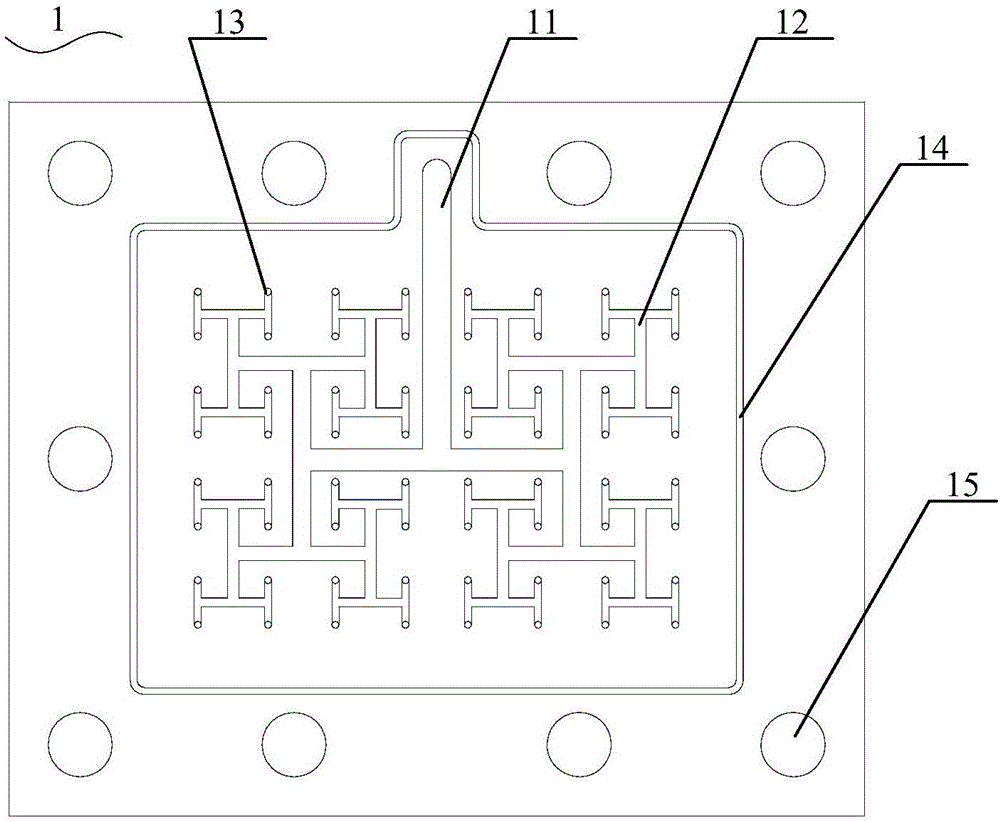

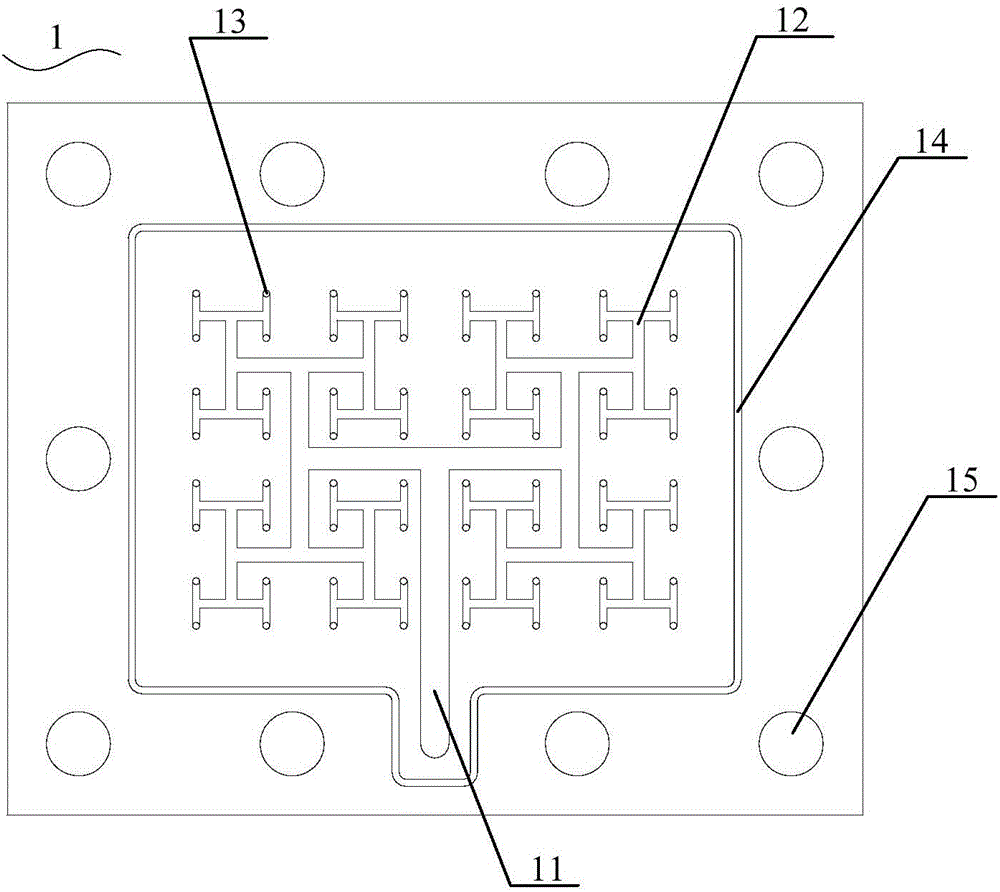

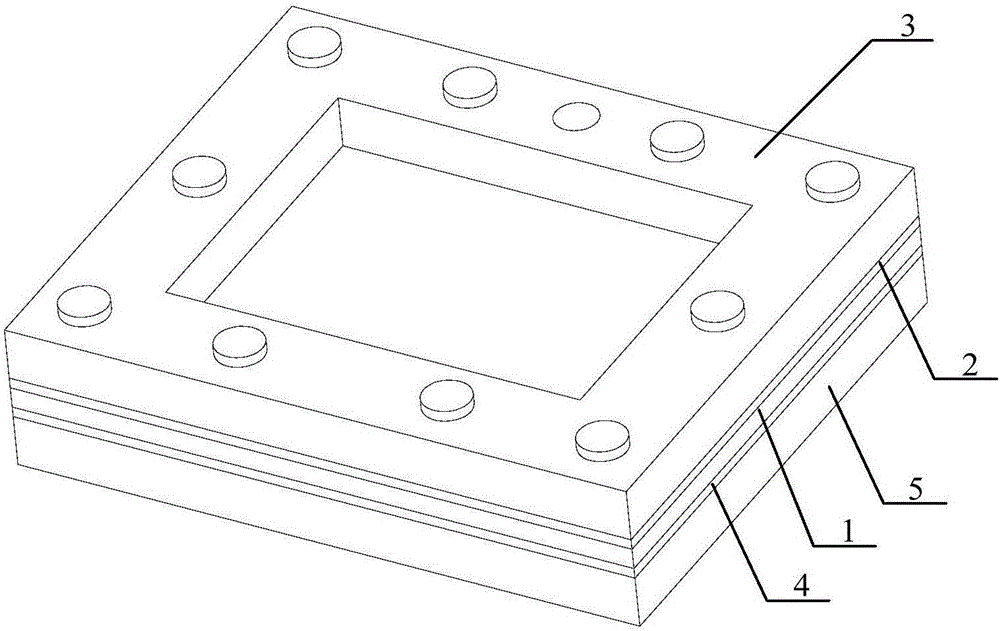

Microchannel plate with fractal structure, photocatalytic reactor and application thereof

InactiveCN106311110AControl flowControl dwell timeChemical/physical/physico-chemical microreactorsEnergy based chemical/physical/physico-chemical processesPhotocatalytic reactionThree-phase

The invention provides a microchannel plate with a fractal structure, a photocatalytic reactor and an application thereof. The microchannel plate with the fractal structure comprises a first surface and a second surface which are opposite; the first surface and the second surface of the microchannel plate with the fractal structure each is provided with a main pipeline microchannel and multistage H-shaped fractal bifurcated microchannels which are connected with one end of the corresponding main pipeline microchannel, and the H-shaped fractal bifurcated microchannels of the first surface of the microchannel plate with the fractal structure communicate with those of the second surface of the microchannel plate with the fractal structure through connecting through holes. According to the microchannel plate with the fractal structure, the photocatalytic reactor and the application thereof, through forming fractal-structured microchannels in the upper and lower surfaces of the microchannel plate with the fractal structure, three phases, i.e., gas, liquid and solid phases can be effectively distributed, heat transfer and mass transfer are strengthened, the problem in collection of reactants of fractal distribution can be effectively solved, meanwhile, the length of the microchannels can be increased, and the control on reaction flux and reactant residence time is better facilitated.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

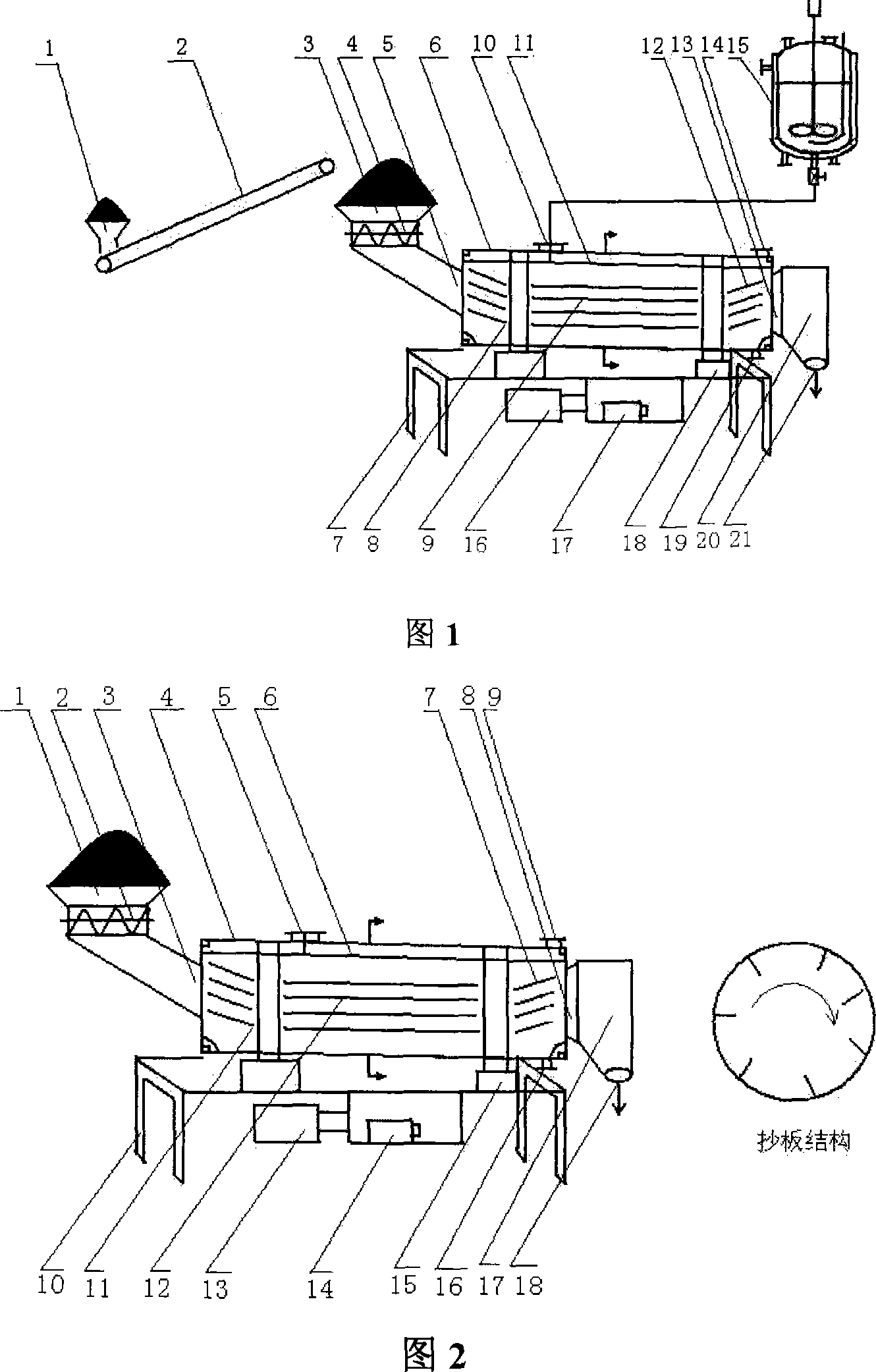

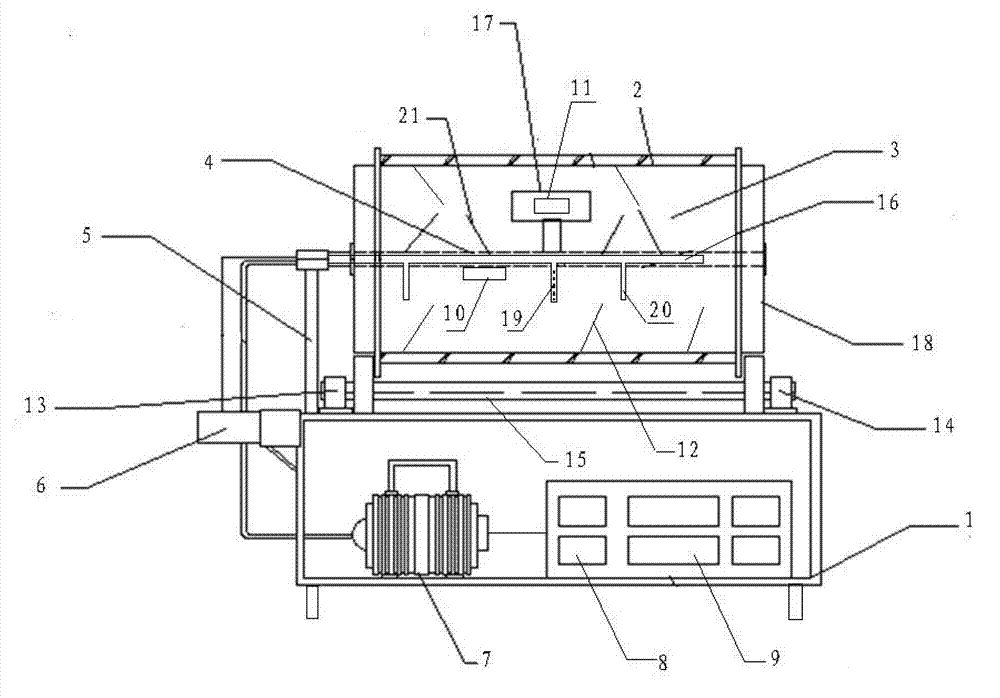

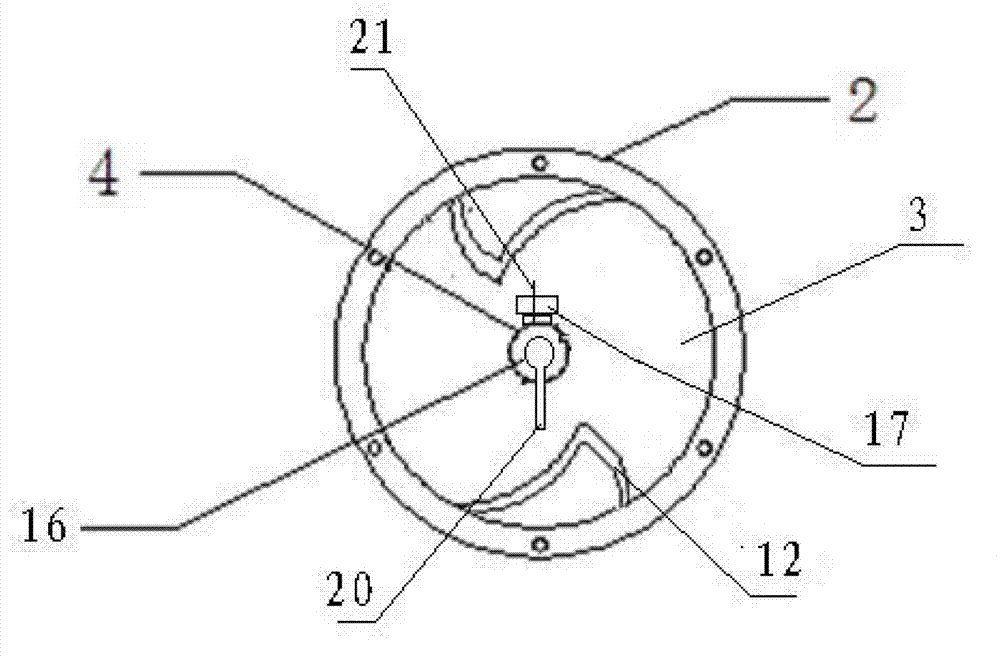

Solid-state fermentation method and system for producing ethyl alcohol based on sugariness raw material

InactiveCN101220378AEfficient conversionHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsSprayerLiquid fuel

The invention relates to a solid-state fermentation method for ethanol production based on sweet sorghum stalks (including other sugar raw materials, such as, sugar beet, sugar cane, Jerusalem artichoke, etc) and a system, which pertains to the technical field of the processing of biomass liquid fuel. The method mainly includes the following key processes and core equipments: (1) smashed materials are fed into a tank with the help of the rotary motion of a cylinder body of a rotating drum type solid-state fermentation tank and the dual-function of the inclined angle of the tank body (1 to 15 degrees) and a feeding stirring board so as to be evenly mixed with the high-yield ethanol TSH-Sc-1 yeast liquid which is prayed from a sprayer; (2) the solid-state fermentation is carried out in the facultative oxygen environment, the fermentation tank is rotated at an even speed to promote the mixing of materials and the strengthening of heat transfer, thus the fermentation is always in a best condition and the fermentation time is shortened; (3) on-line monitoring is carried out: the solid-state fermentation is affected by a plurality of factors, such as, the distribution of the on-line regulation temperature of a computer, spray amount, the concentration of dissolved O2, filling factors, the mixing degree of the smashed materials and the yeast liquid, the pH value of yellow slurry, CO2 concentration, ethanol concentration, the migration of bacteria species and other parameters so as to ensure that the solid-state fermentation is carried out under a best working condition; (4) the automatic discharge of the fermentation material from the tank is realized with the help of the rotation of the tank body and the push of a discharging stirring board, and a closed tunnel belt is adopted for conveying the fermentation material to an ethanol-dreg separation unit.

Owner:TSINGHUA UNIV

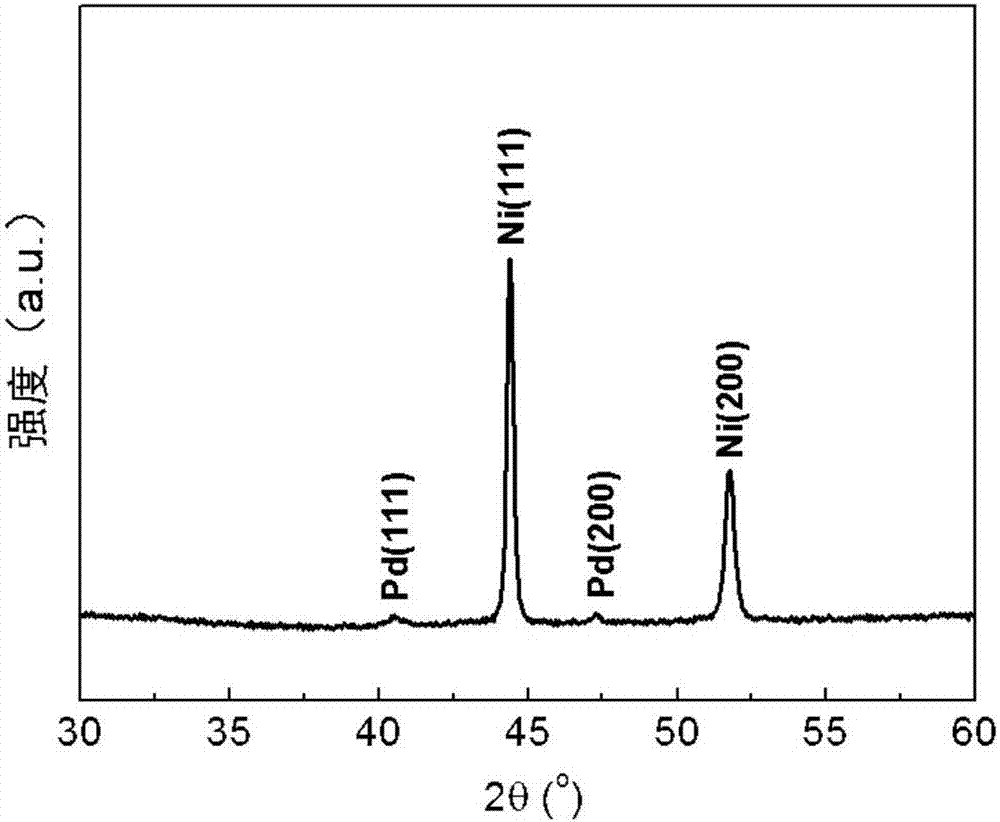

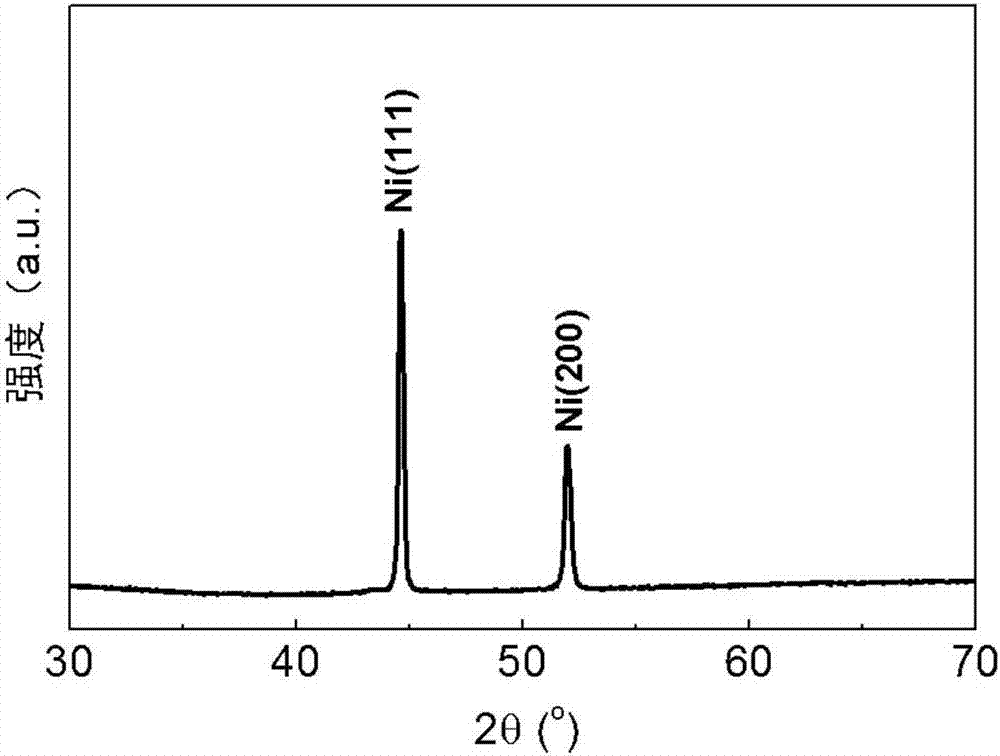

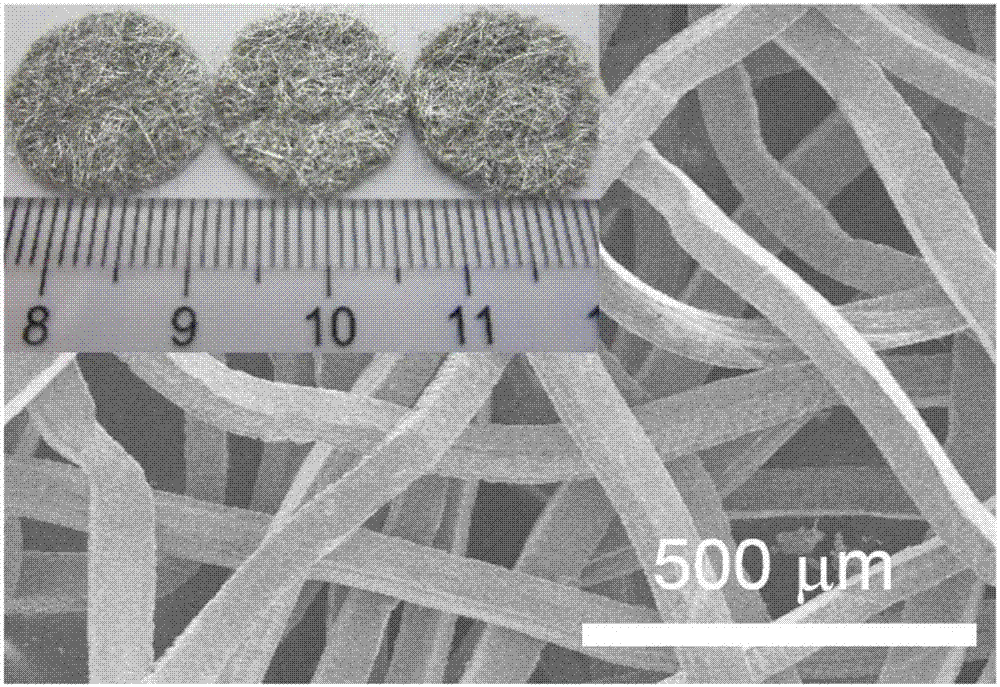

A self-supporting catalyst having a core-shell structure, a preparing method thereof and applications of the catalyst

PendingCN107537478AOptimal Control StructureStable structureHydrogenDispersed particle separationCatalytic oxidationCalcination

A self-supporting metal or metal oxide catalyst having a core-shell structure is disclosed. The general formula of the catalyst is xM-yMO@zShell / mAlO / ZT, wherein the x is 0-5% by mass, the y is 0-10%by mass, the z is 0.5-20% by mass, the m is 0.1-20% by mass, and the catalyst includes the M, the Mo, the Shell and the AlO, with the balance being the ZT. The catalyst is prepared by a method including (1) a step of subjecting the ZT to hydrothermal treatment and / or thermal treatment in pure water or an aqueous solution containing an aluminum source and an alkali source to prepare a self-supporting AlO / ZT composite carrier, and (2) a step of soaking the prepared AlO / ZT carrier by utilizing an organic solution containing at least one metal M ion and coordinated with a coupling agent, and performing drying, calcination and reduction to prepare the catalyst. The catalyst can be used for catalytic oxidation of low-concentration methane and volatile organic compounds (VOCs), catalytic oxidation of carbon monoxide, lower olefin preparation from synthetic gas (FTO), and methane conversion to prepare synthetic gas.

Owner:EAST CHINA NORMAL UNIV

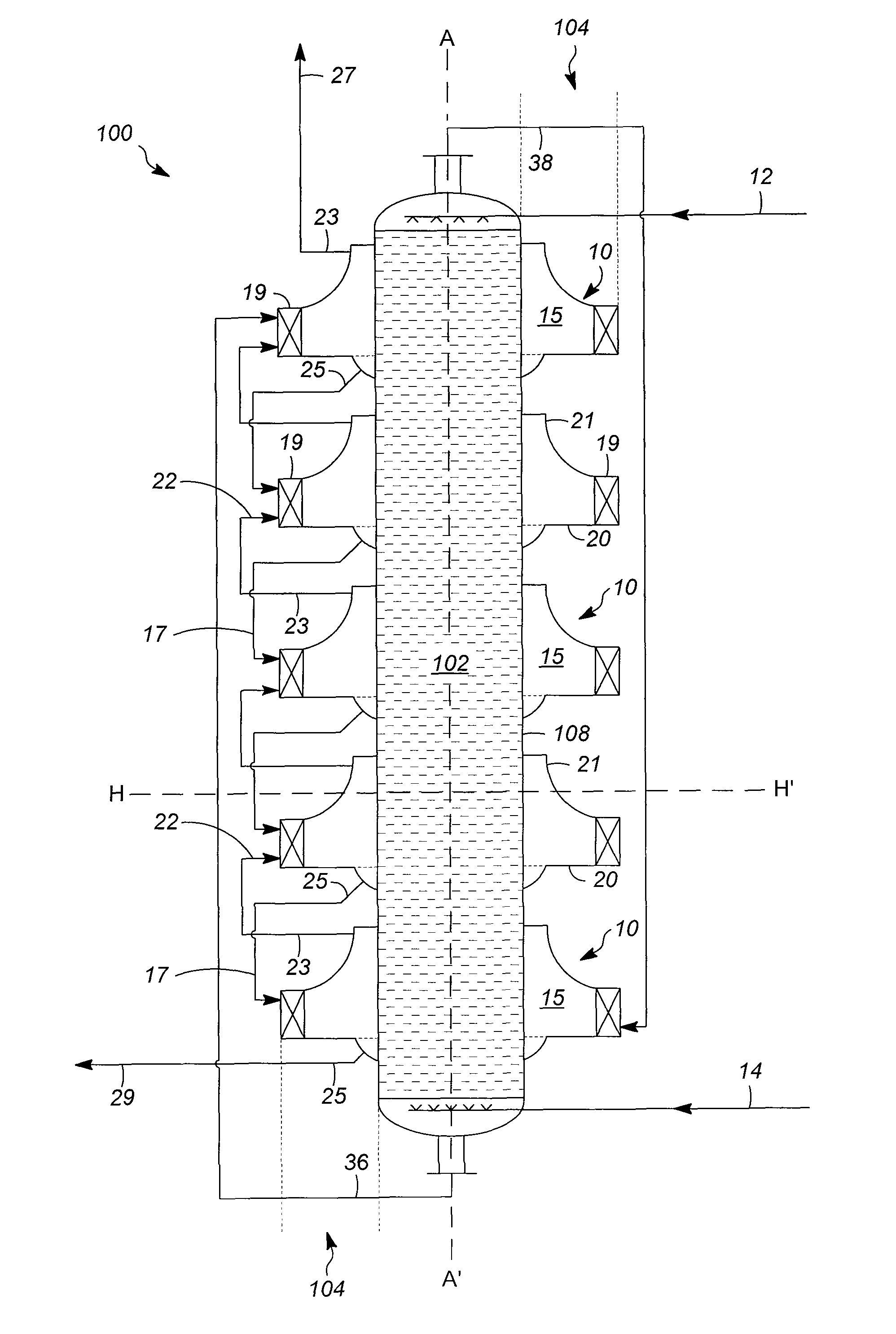

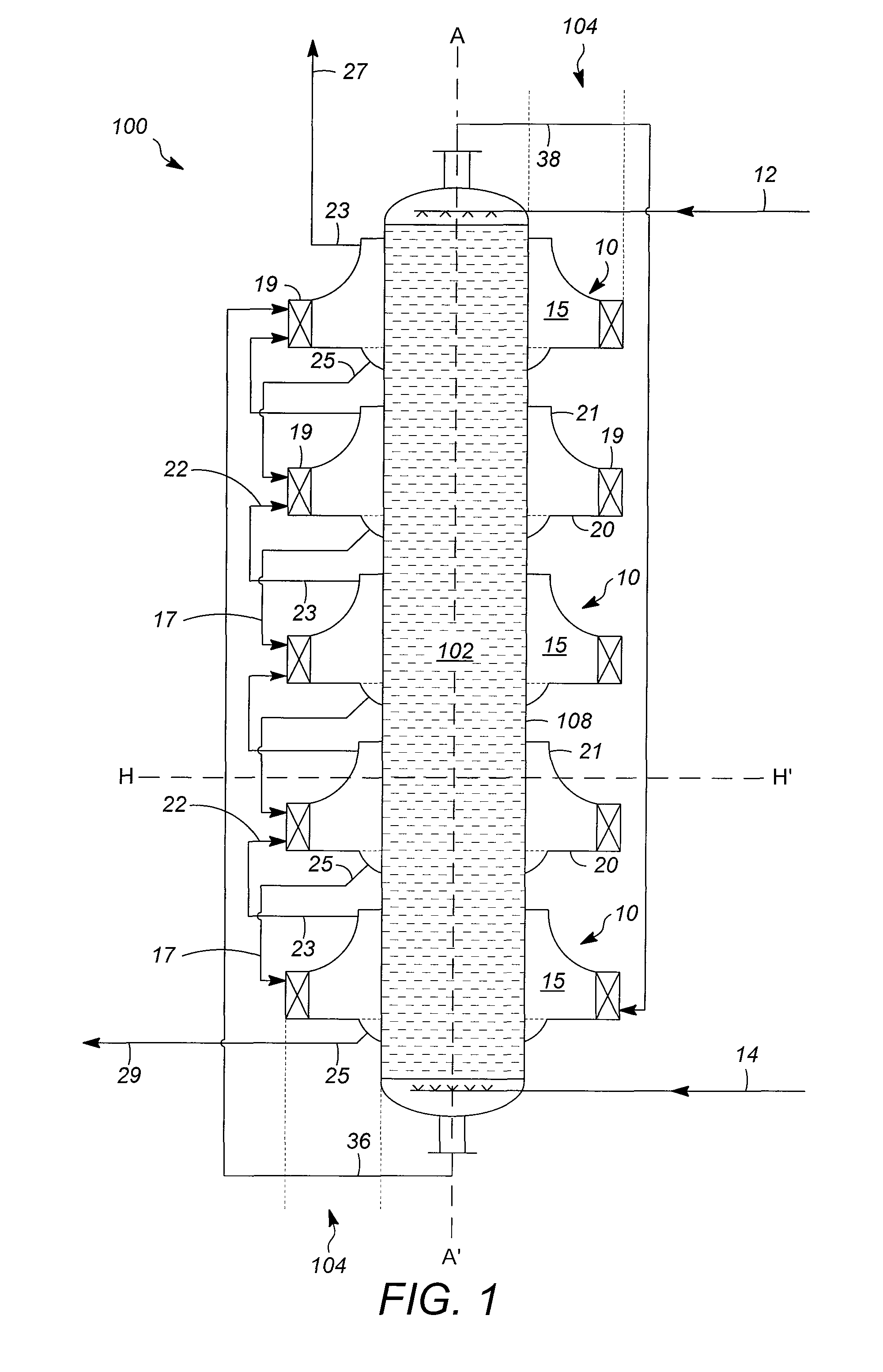

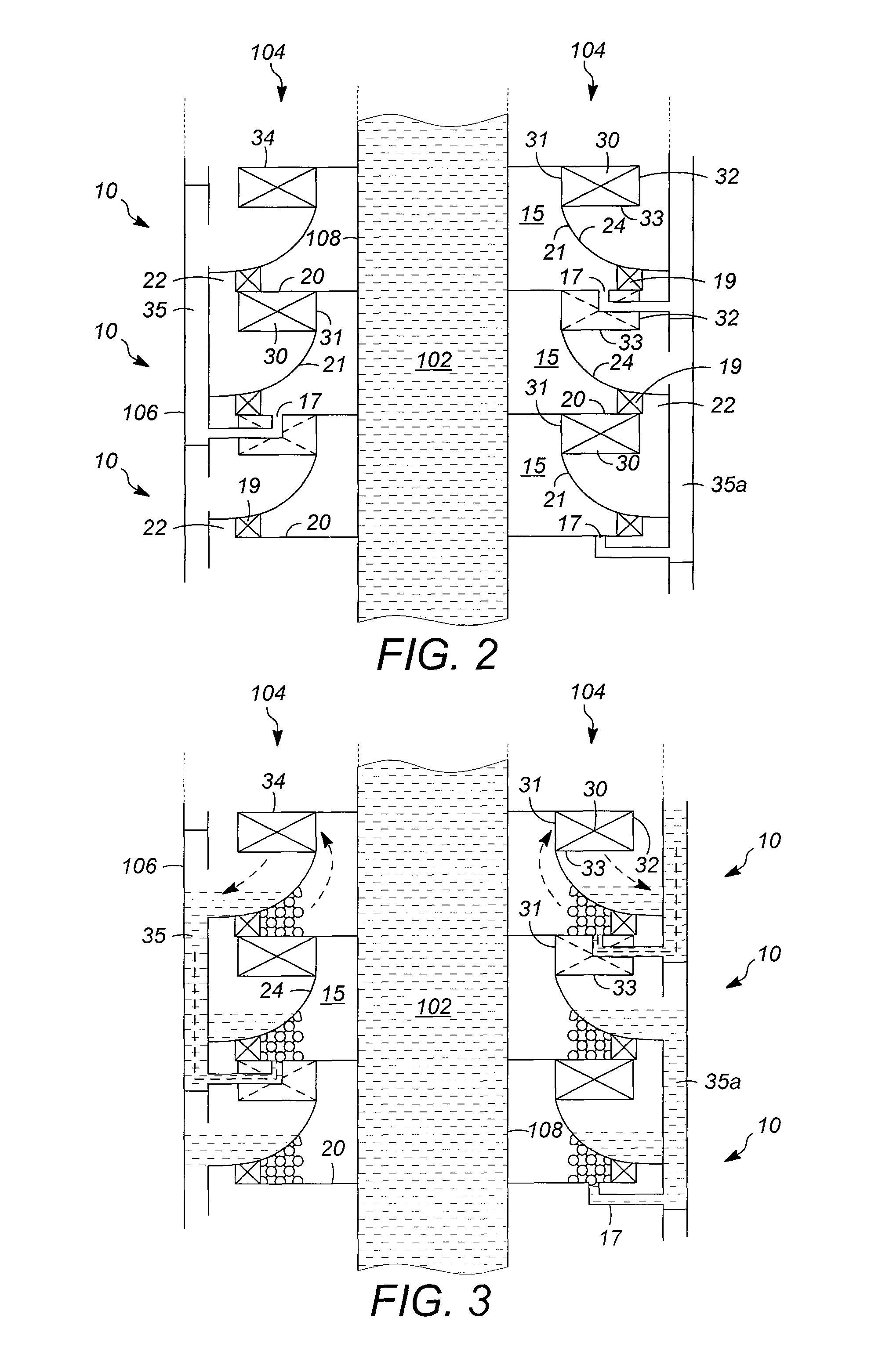

Vapor-liquid contacting apparatuses having a secondary absorption zone with vortex contacting stages

InactiveUS8268049B2Enhance heat and mass transferSmooth connectionLiquid degasificationFlow mixersVapor liquidProduct gas

Vapor-liquid contacting apparatuses comprising both a primary absorption zone and a secondary absorption zone comprising a plurality of vortex contacting stages are described. The apparatuses provide improved heat and mass transfer between vapor and liquid phases in processes such as absorption, to selectively solubilize contaminants (e.g., acid gases) from an impure vapor (e.g., sour natural gas). Vortex contacting stage(s) in a zone of vapor-liquid contacting, such as a secondary or finishing absorption zone, are used following bulk absorption in a primary or main absorption zone.

Owner:UOP LLC

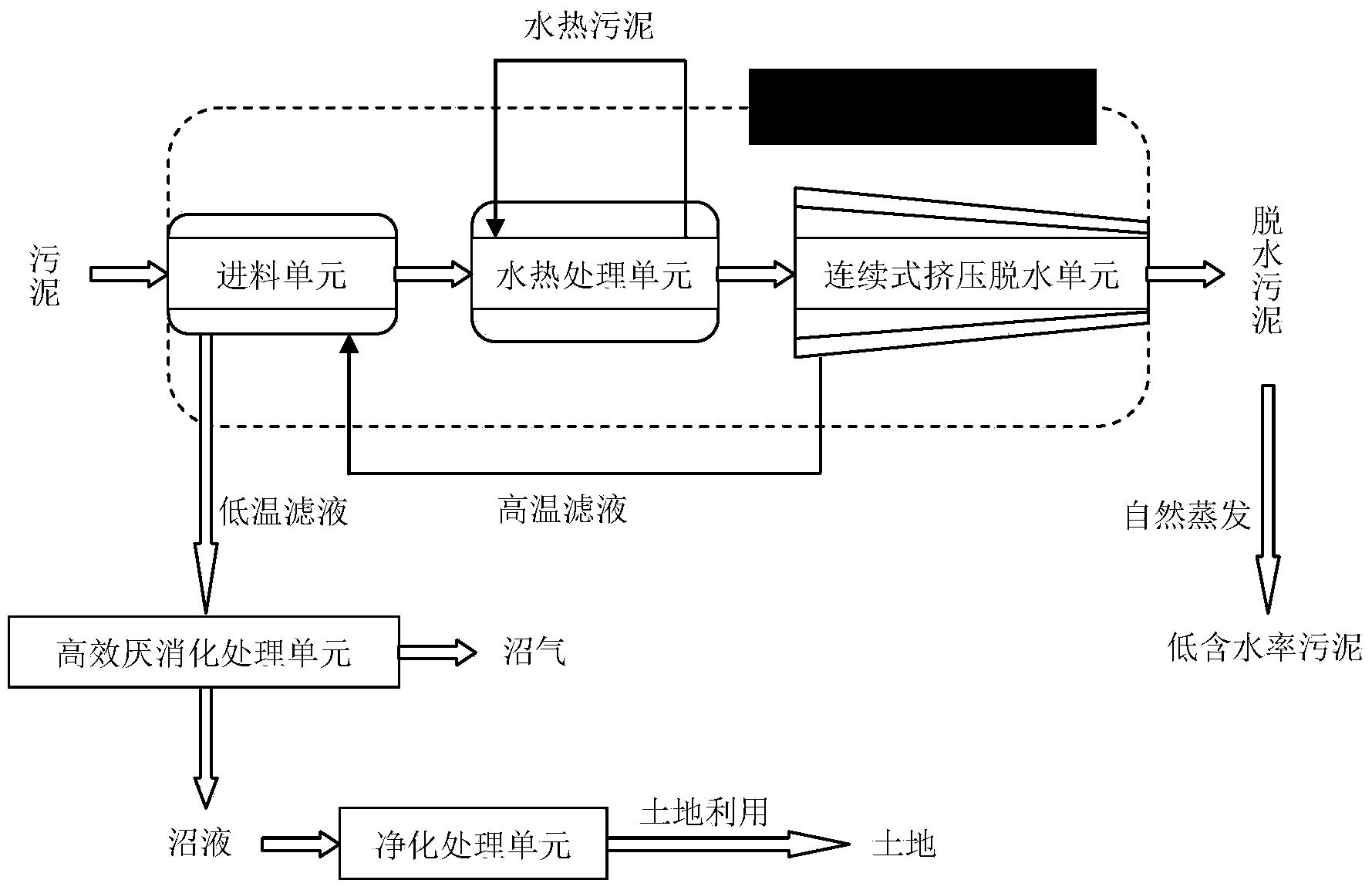

Continuous sludge dewatering method based on hydro-thermal treatment

ActiveCN103964662AAvoid heat consumptionHigh calorific valueSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal treatmentThermal reaction

The invention relates to a continuous sludge dewatering method based on hydro-thermal treatment, and belongs to the field of sludge treatment. An external heat exchanger of a feeding unit is filled with high temperature filtrate, sludge is continuously introduced in the feeding unit, and the high temperature filtrate is used for preheating the sludge; the sludge after preheating enters a hydro-thermal treatment unit under the pushing of the feeding unit, and is heated to above 150 DEG C for a hydro-thermal reaction through a heating device arranged on the outside of the hydro-thermal treatment unit; the standing time of the sludge inside the hydro-thermal treatment unit is controlled by an accelerator arranged at the interior of the hydro-thermal treatment unit; partial sludge after hydro-thermal treatment is flown back to the hydro-thermal treatment unit; the sludge passing through the hydro-thermal treatment unit is introduced in a continuous extrusion dewatering unit to realize continuous dewatering of the hydro-thermal sludge, and a cavity in the dewatering process is at a sealed state. According to the dewatering method, based on the hydro-thermal treatment for improving the sludge structure and physicochemical characteristics, the energy sources are fully utilized and recycled while the energy consumption input is saved, and the sludge dewatering in a liquid form is realized continuously.

Owner:DALIAN UNIV OF TECH

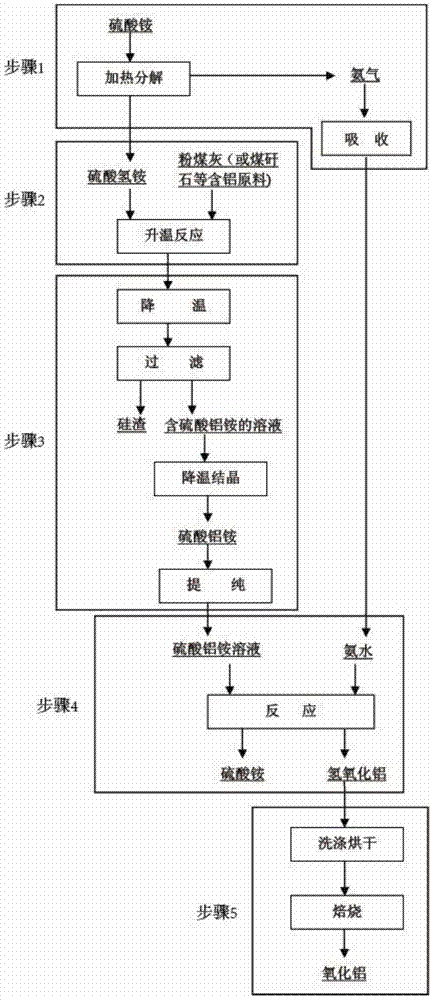

Method for extracting aluminum oxide

InactiveCN103693666AHigh purityReduce side effectsAluminium oxide/hydroxide preparationCoal gangueAluminium salts

The invention relates to a method for extracting aluminum oxide. The method comprises the following steps: heating and decomposing ammonium sulfate to generate ammonium hydrogen sulfate or ammonia gas, preparing an ammonium hydrogen sulfate solution, and collecting the ammonia gas for preparing ammonia water; grinding coal ash, mixing the coal ash with the ammonium hydrogen sulfate solution according to a certain ratio, heating while stirring, and reacting to generate ammonium aluminum sulfate; re-crystallizing and purifying ammonium aluminum sulfate to prepare an ammonium aluminum sulfate solution, and reacting with the ammonia water to generate aluminum hydroxide; drying aluminum hydroxide and roasting to generate aluminum oxide. According to the method, aluminum oxide can be extracted from not only the coal ash but also aluminum-containing raw materials such as coal gangue, slag, bauxite, red mud, tailings, kaolin and mullite; the technological process is shorter, equipment is simple, and large-scale industrialization production is easy to realize.

Owner:BEIJING JIAYI CHUANGJING SCI & TECH

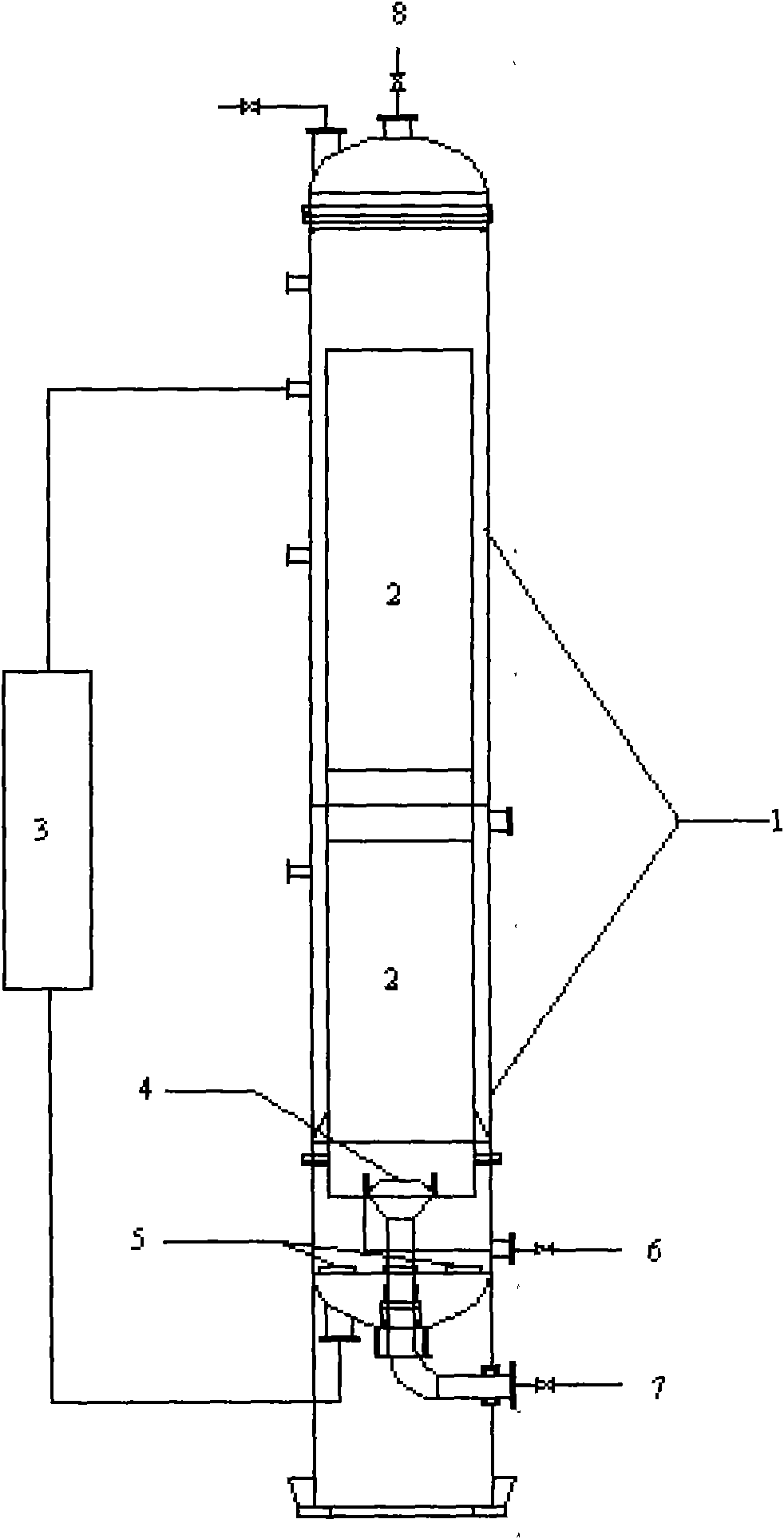

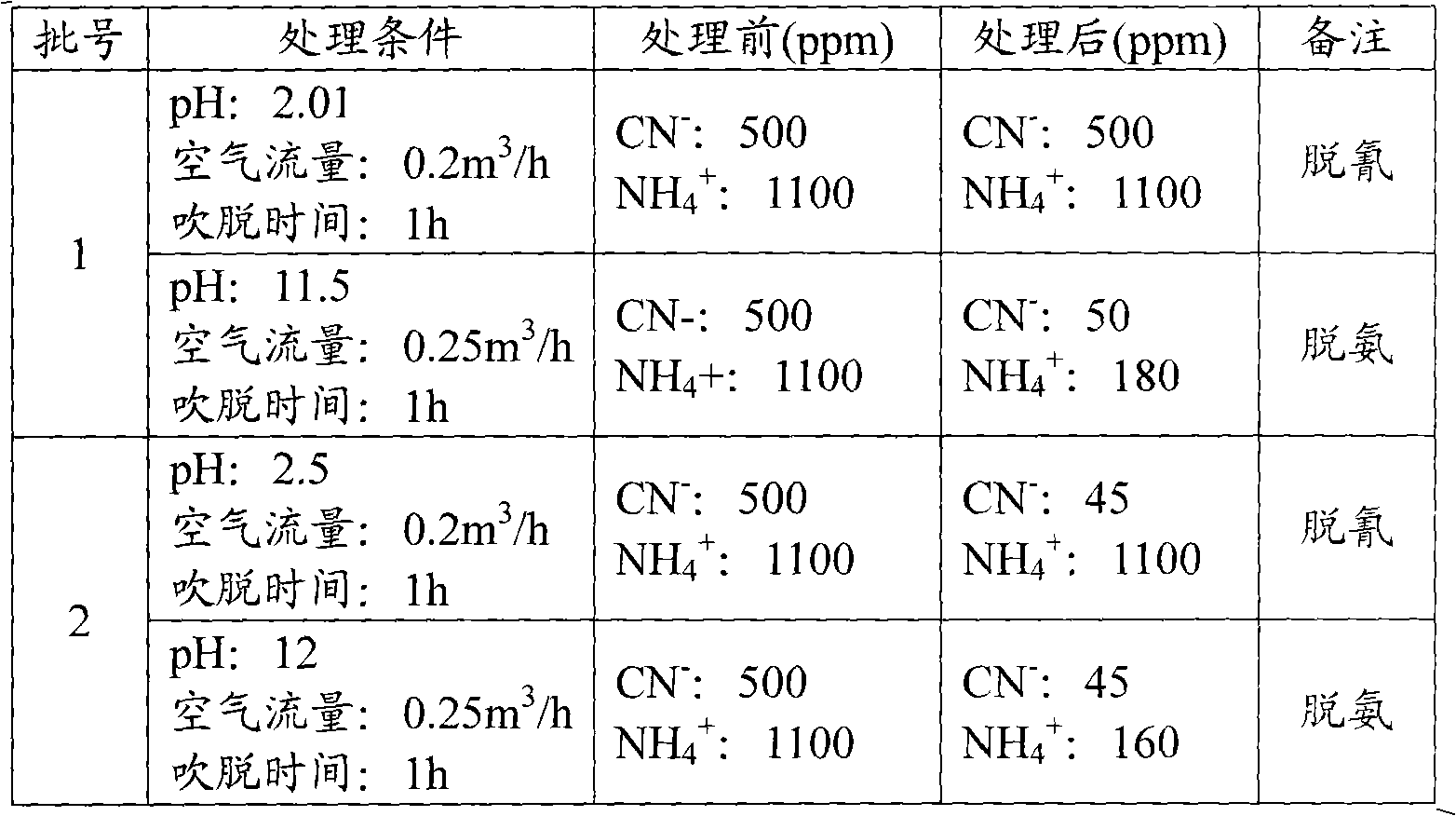

Efficient ultrasonic recirculating-type reaction device

InactiveCN101590385ALarge amount of processingEnhance heat and mass transferEnergy based chemical/physical/physico-chemical processesProcess engineeringPolyphase system

The invention relates to improved recirculating-type reactor equipment. The device mainly comprises a tower body, a heat exchanger, a gas distributor, an ultrasonic generator, and other components. The introduction of the ultrasonic generator can greatly increase the using efficiency of the tower. The reactor can be widely used in polyphase systems in chemical fields such as catalysis, oxidation, hydrogenation, removal of hydrocyanic acid / ammonia, deposition and crystallization. Moreover, the improved recirculating-type reactor equipment has the advantages of high reaction efficiency, small amplification effect, ideal mass and heat transfer, low energy consumption, and the like.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

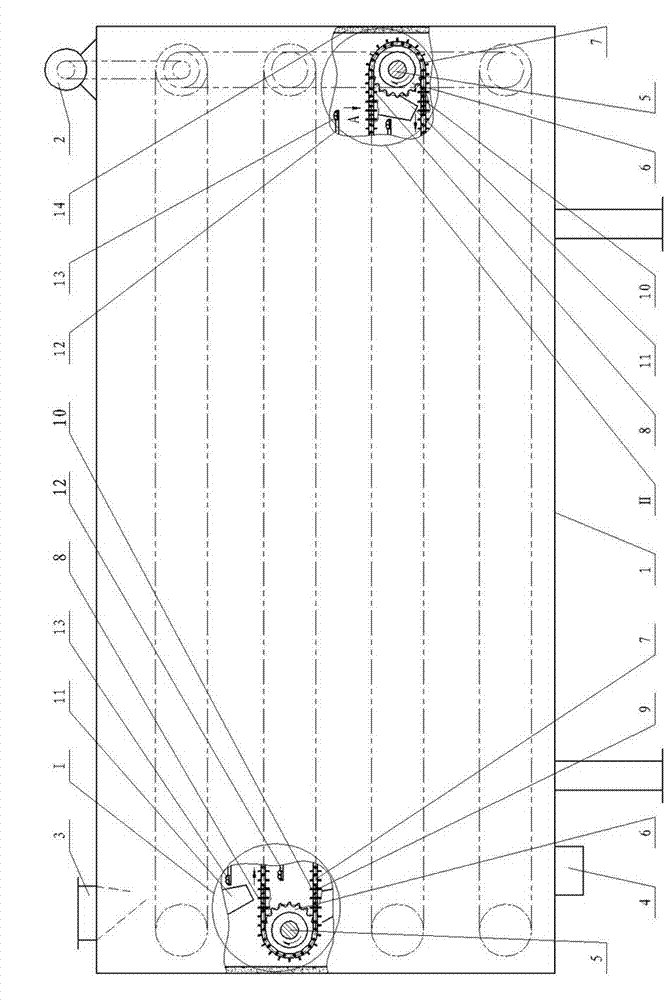

Continuous type infrared corncob drying machine

InactiveCN103081991ASolve the problem of high breakage rateImprove heat transfer efficiencyFood processingSeed preservation by dryingInfraredEngineering

The invention provides a continuous type infrared corncob drying machine which is characterized in that a box body is internally provided with a plurality of conveying devices driven by a transmission device to run, wherein I type and II type material pulling rods with two different lengths are fixedly arranged between two chains of the same conveying device at an interval; parts of each conveying device, which correspond to upper and lower sections of horizontal sections of the chains, are respectively provided with material supporting plates; material guide grooves are arranged below the tail ends of the material supporting plates; radiation devices are arranged above the material supporting plates; radiation racks of the radiation devices are suspended on the box body; the two ends of an infrared radiation element which downwards radiates infrared rays in a single direction are mounted on the radiation racks; and a feeding opening is arranged on the top of the box body, and a discharging opening is formed at the bottom of the box body. The continuous type infrared corncob drying machine disclosed by the invention has the advantages of high heat transferring efficiency, low energy consumption and good drying uniformity.

Owner:SHANDONG UNIV OF TECH

Movable rotary drum type composting reactor

ActiveCN102924146AWell mixedEnhance heat and mass transferBio-organic fraction processingOrganic fertiliser preparationProcess engineeringFeedback control

The invention belongs to the field of solid wastes recycling utilization, and in particular relates to a movable rotary drum type composting reactor. The composting reactor is horizontal rotary drum type, wherein one or a plurality of 'V'-shaped baffles are arranged in the inner side of a rotary drum, so that materials can be lifted along with the rotary drum; one end of the rotary drum is a material inlet / outlet, a central pipe is inserted from the other end of the rotary drum, and a plurality of dispersion baffles with different angles and a sensor chamber with a sensor are assembled on the upper part of the pipe; a vent pipe is arranged in the central pipe, and is connected with a plurality of air distribution pipes, and small holes are densely distributed on the air distribution pipes; a temperature sensor is assembled on the lower part of the central pipe; the working time and efficiency of the reactor are controlled through setting the senor data or time and the like; and the devices are all assembled on a rack with movable wheels. The reactor can be used for effectively solving the problems of difficult uniform mixing of solid materials and poor mass transfer and heat transfer and can realize the real-time monitoring and feedback controlling of critical parameters, and thus, the composting reaction efficiency is effectively improved; and in addition, the reactor also has the characteristic of convenience in moving.

Owner:内蒙古跃阳生物环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com