Efficient ultrasonic recirculating-type reaction device

A reaction device and ultrasonic technology are applied in the field of new gas-liquid-solid three-phase circulation reaction devices to achieve the effects of shortened reaction time, narrow particle size distribution and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

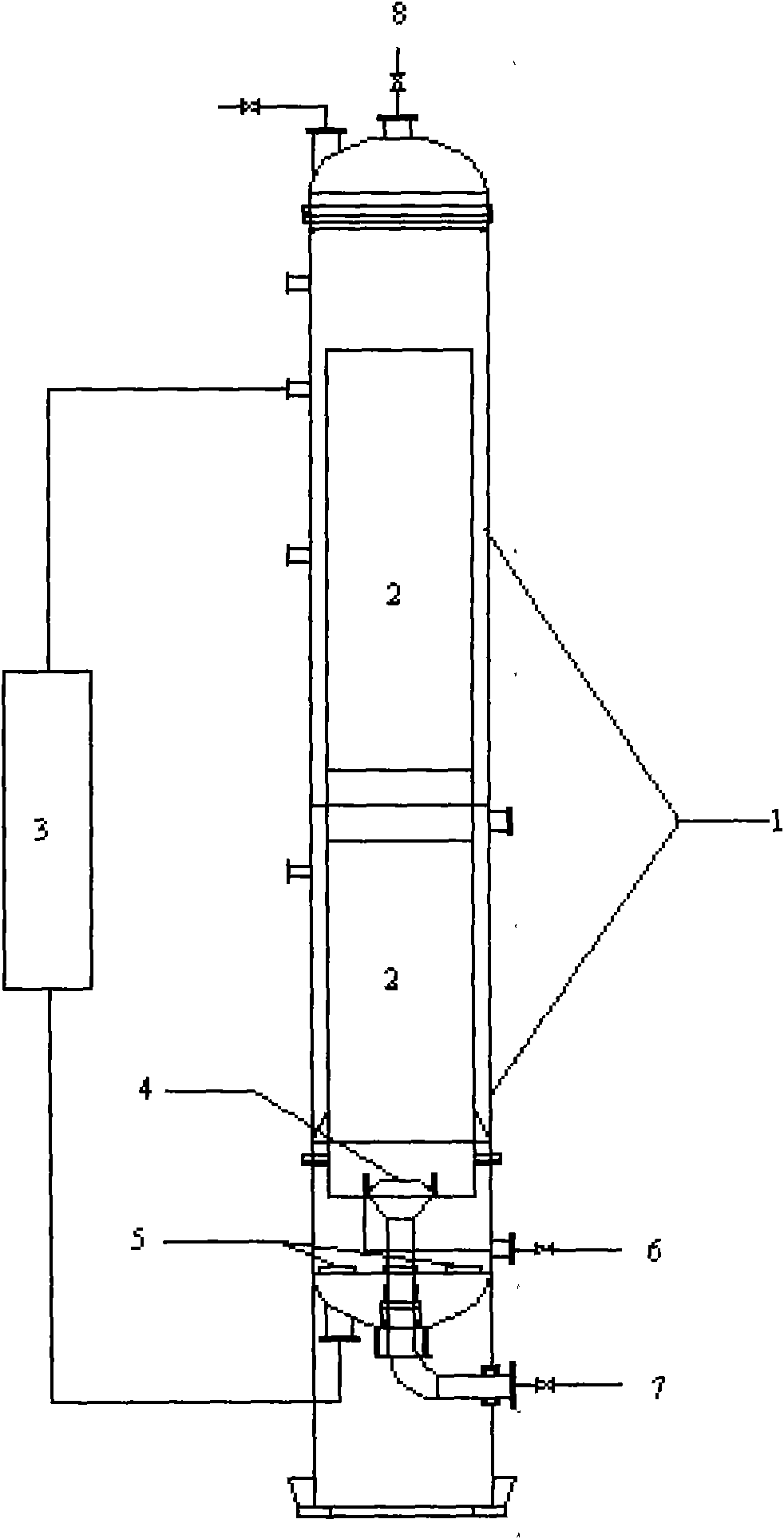

[0020] The tower body 1 with a diameter of 160mm and a height of 2000mm has air intake at the bottom of the tower, a vent 8 and a pressure gauge on the top of the tower, a thermometer in the middle of the tower body 1, a feed port 9 and a discharge port 6 on the tower body, and ultrasonic waves are built in the bottom of the tower. Generator 5.

[0021] Add 500g of fruit shell activated carbon, 12000g of water, 3000g of bisglyphosate, and 900g of 25% ammonia water into a stainless steel empty tower with a diameter of 160mm and a height of 2000mm, heat, and feed oxygen into the reaction solution at a linear velocity of 0.03m / s , control the pressure in the tower to 0.3MPa, turn on the ultrasonic generator (200KHz, power is 50W), the temperature rises to 67°C, and the complete reaction of diglyphosate is detected by phosphorus spectrum, and the reaction selectivity of glyphosate is 89.6%. After the reaction was completed, activated carbon was filtered, and the filtrate was adjus...

Embodiment 2

[0023] Inner circulation airlift reactor 1 with a diameter of 50mm and a height of 800mm, a diversion barrel 2 with a height of 300mm, air intake at the bottom, a pressure gauge, a thermometer and a vent 8 at the top, and ultrasonic generators on the side of the bottom and middle part of the top of the tower 5.

[0024] Add 7.50 grams of activated carbon, 1000 grams of water, and 122 grams of bisglyphosate in the tower. Heating, air is passed into the reaction solution, the gas line velocity is 0.10m / s, the pressure at the top of the tower is controlled to 0.3MPa, the ultrasonic generator (80KHz, power is 80W) is turned on, the temperature rises to 75°C, and the phosphorus spectrum detects that the diglyphosate is completely Reaction, reaction about 1.0 hour, glyphosate reaction selectivity 94.0%.

Embodiment 3

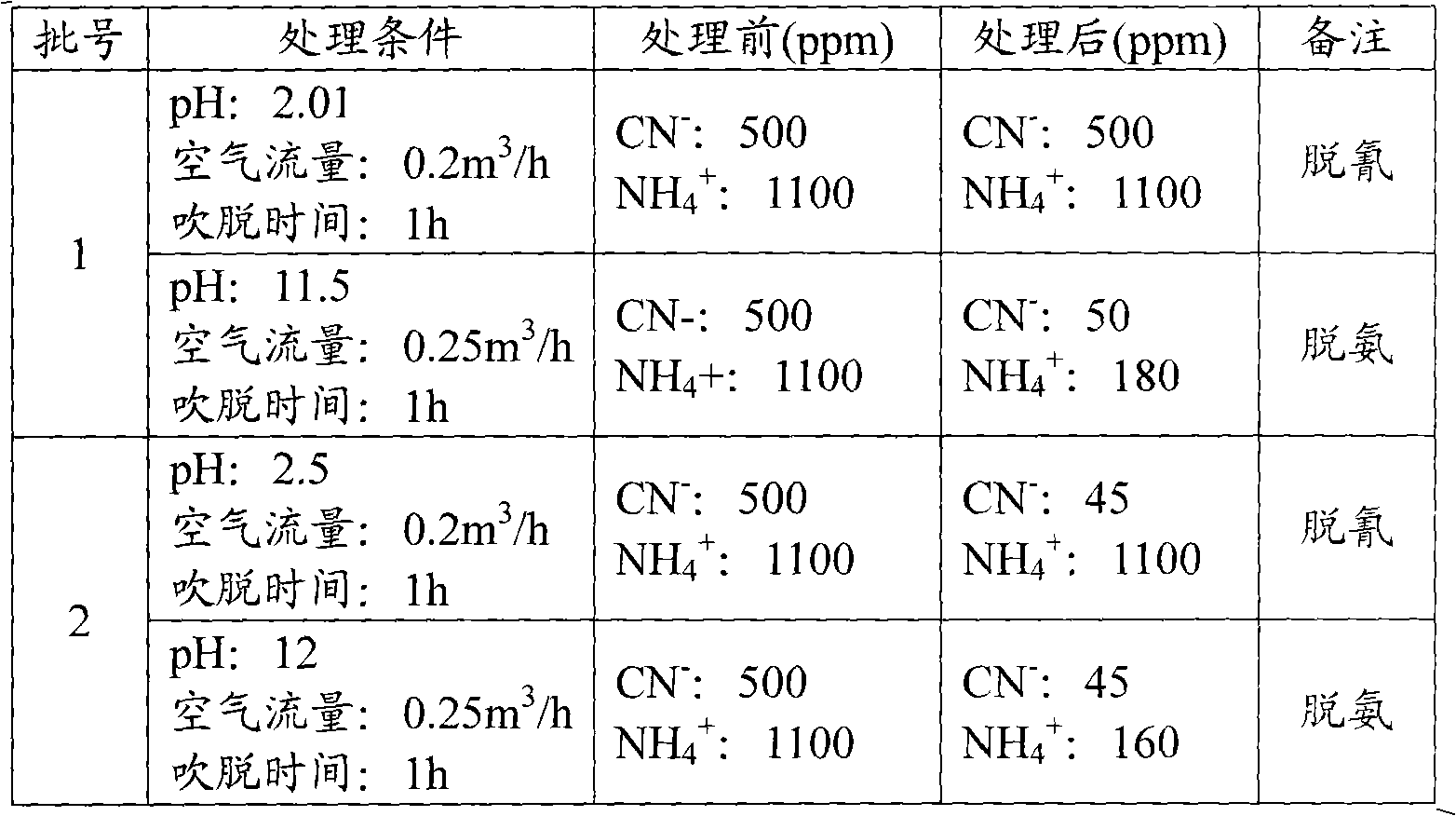

[0026] Get waste water in example 2 reactor, pass into compressed air and blow off cyanogen, effect is ideal, and concrete data sees the following table:

[0027] batch number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com