Patents

Literature

8594 results about "Fixed bed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

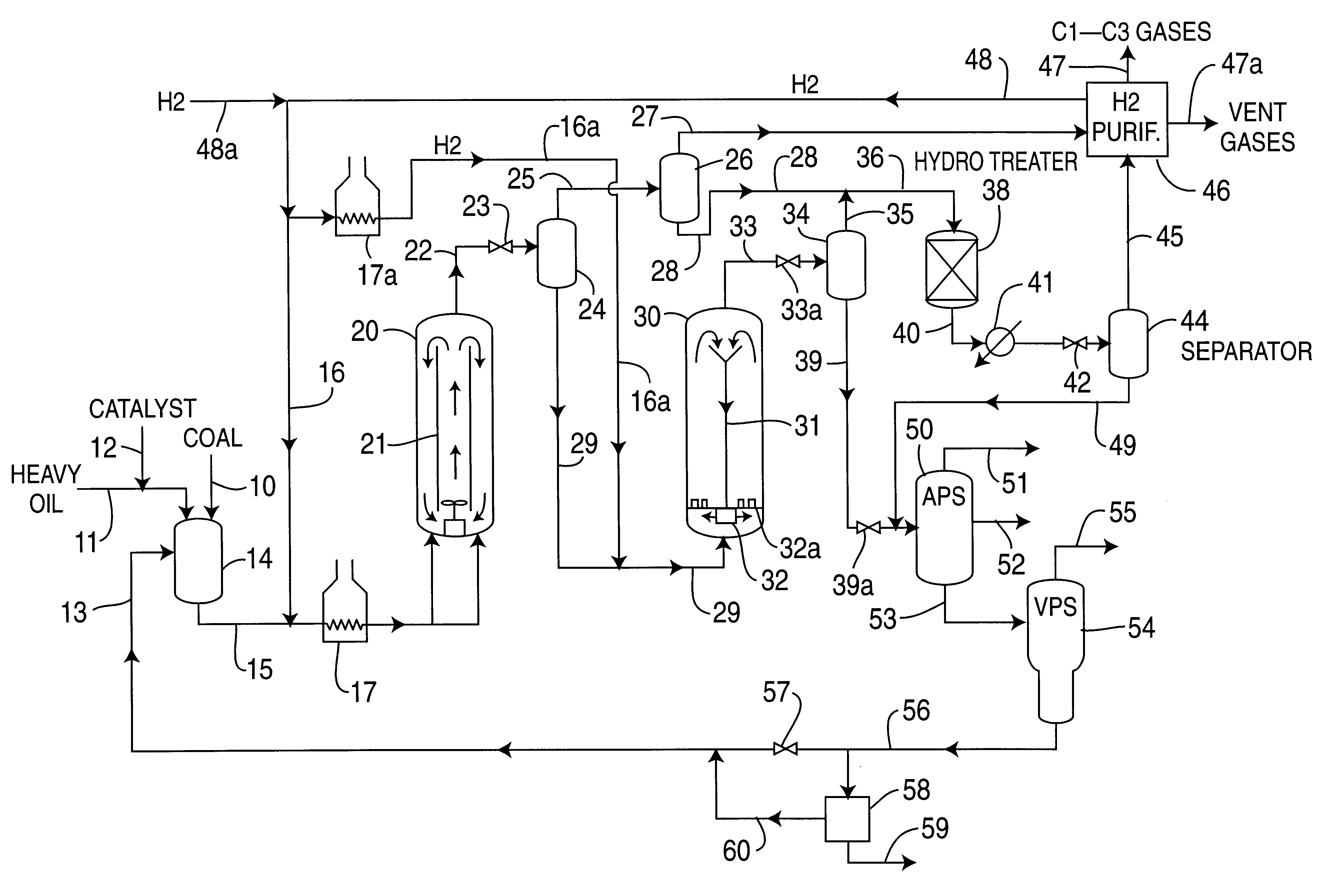

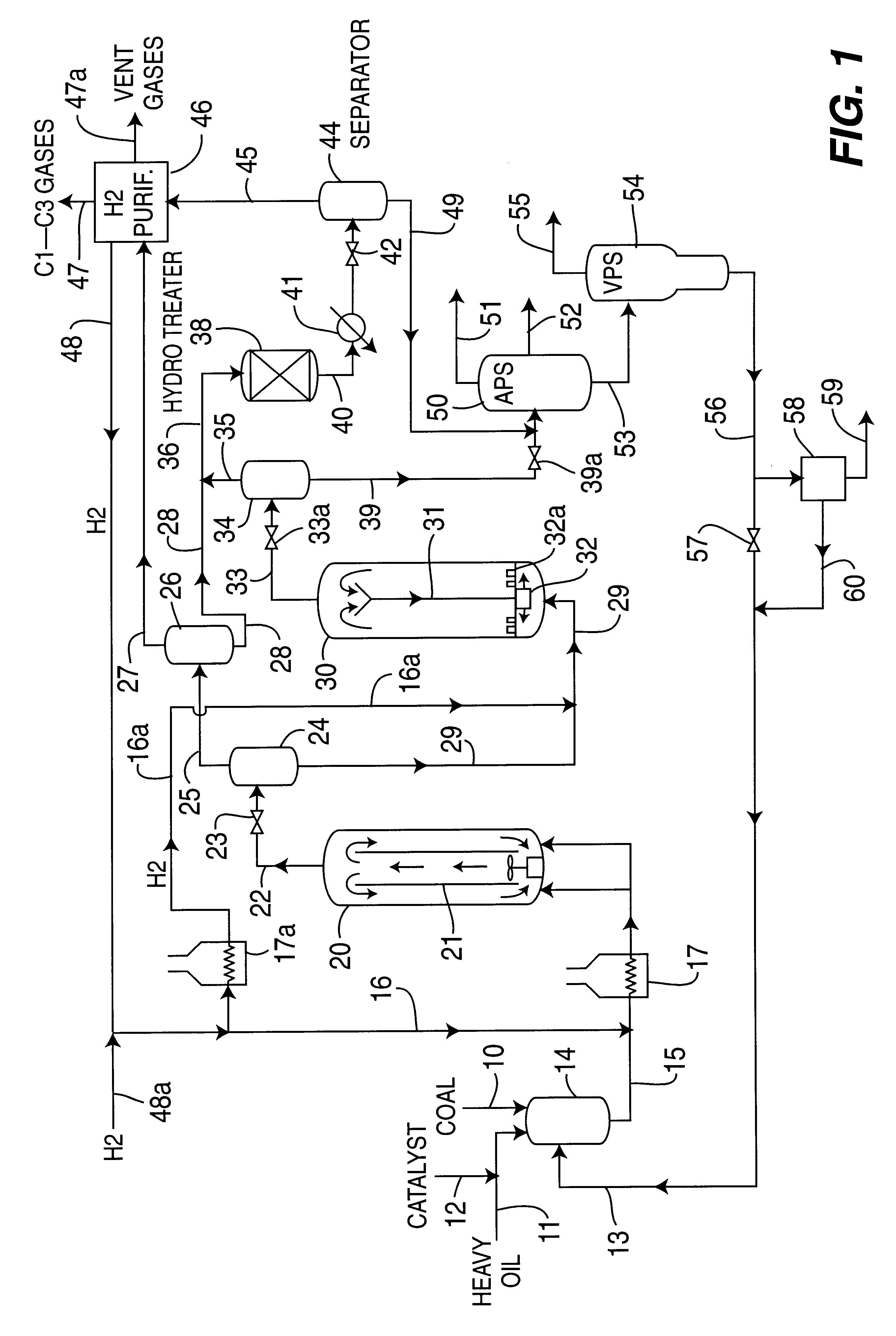

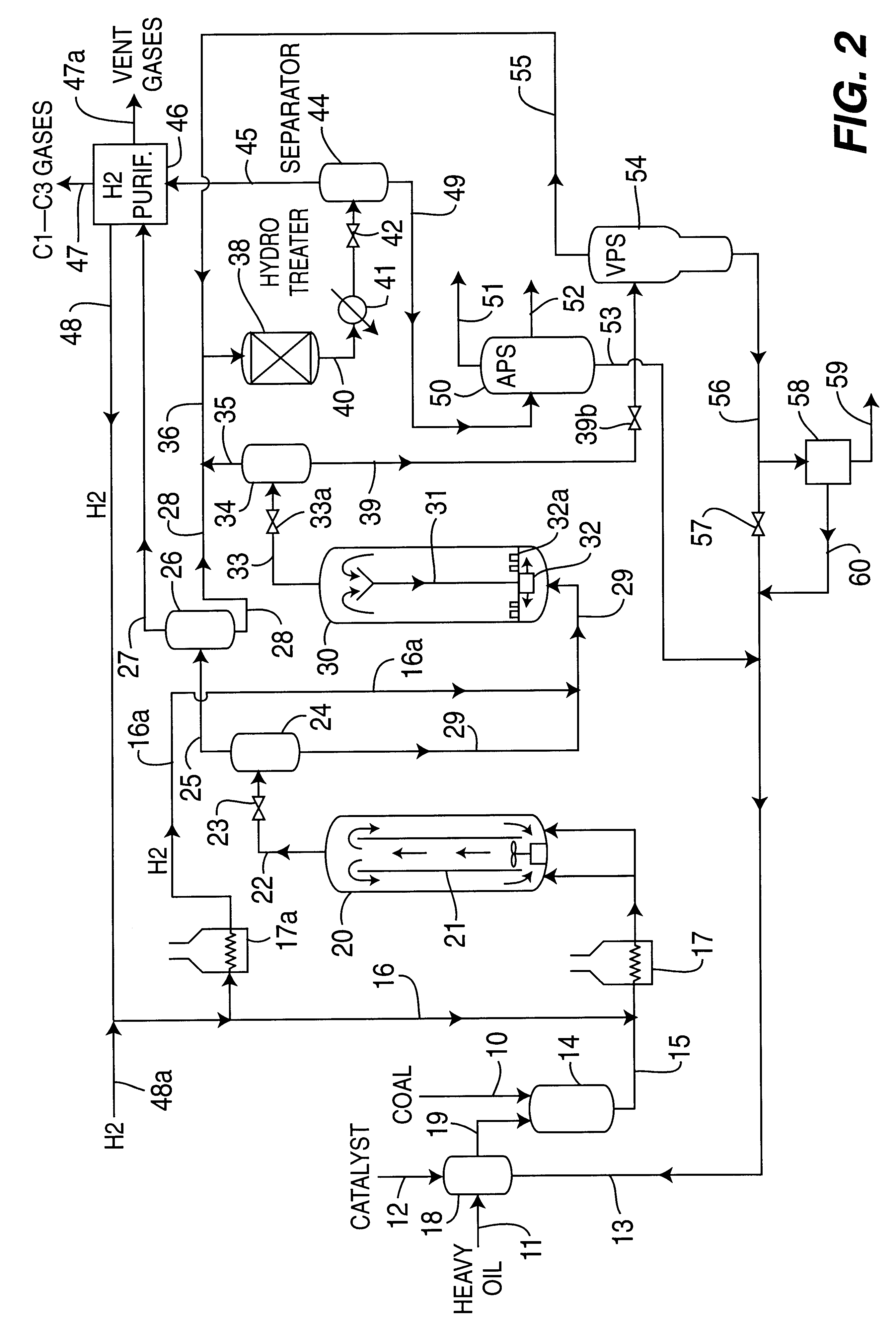

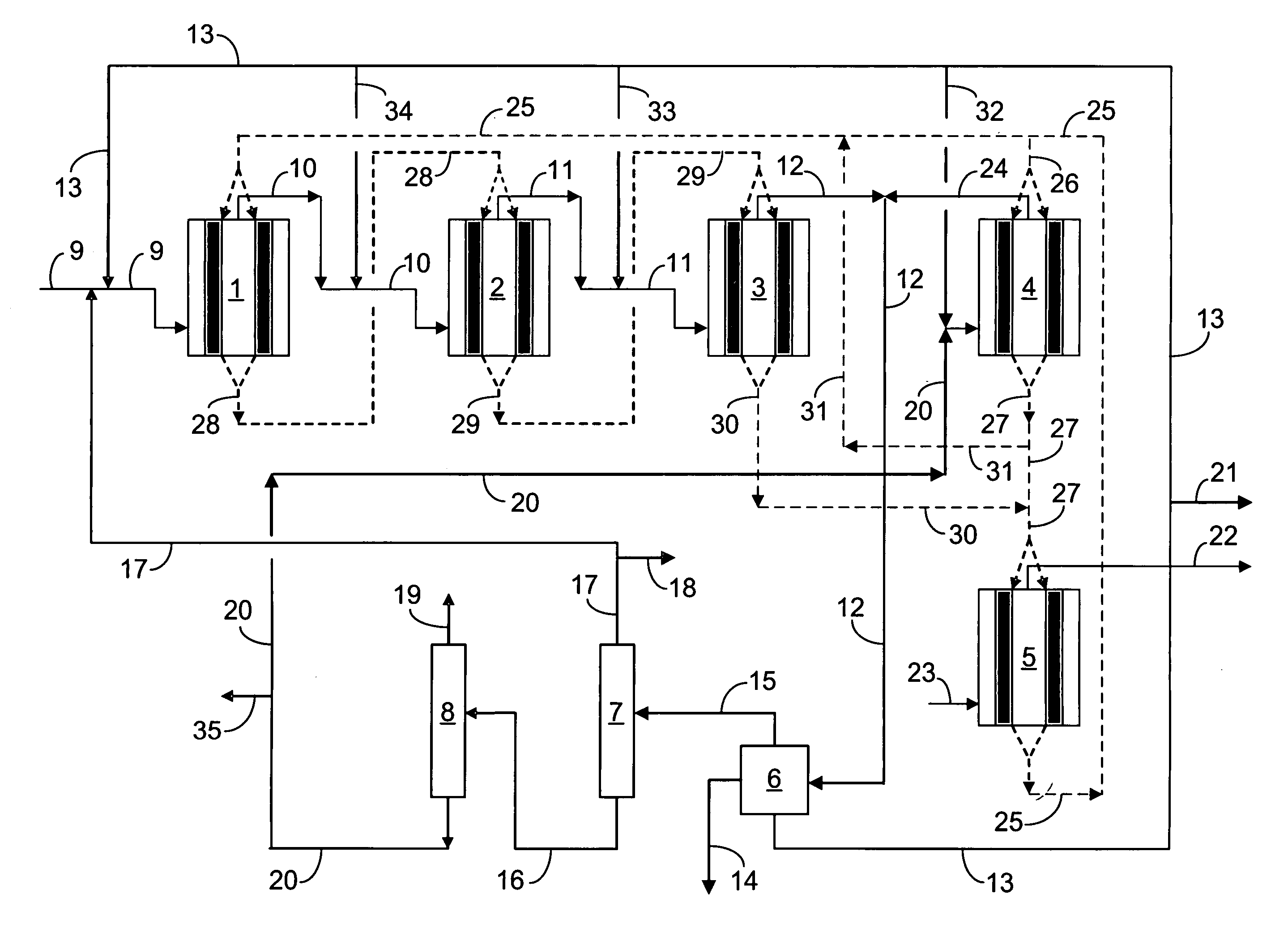

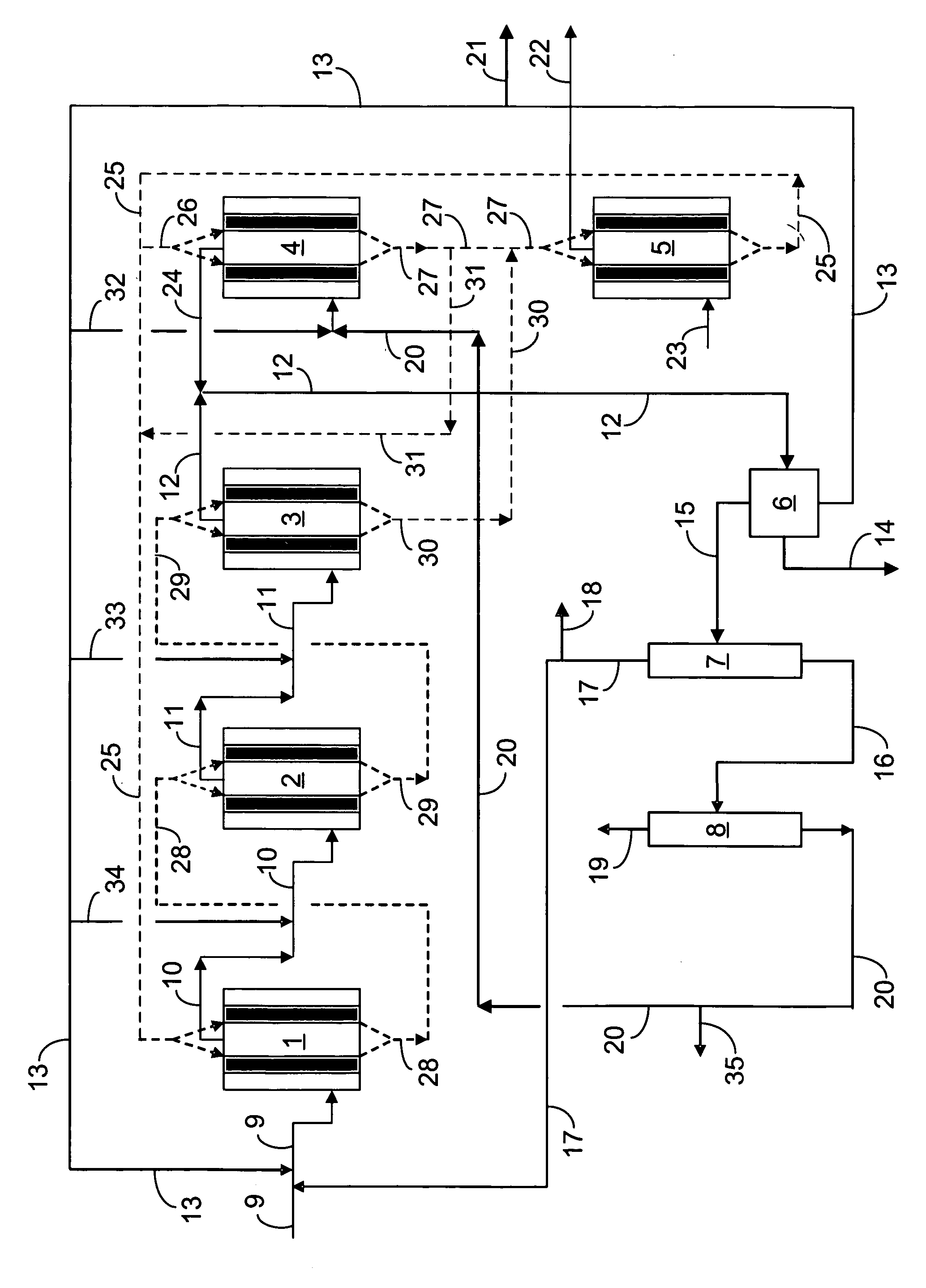

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

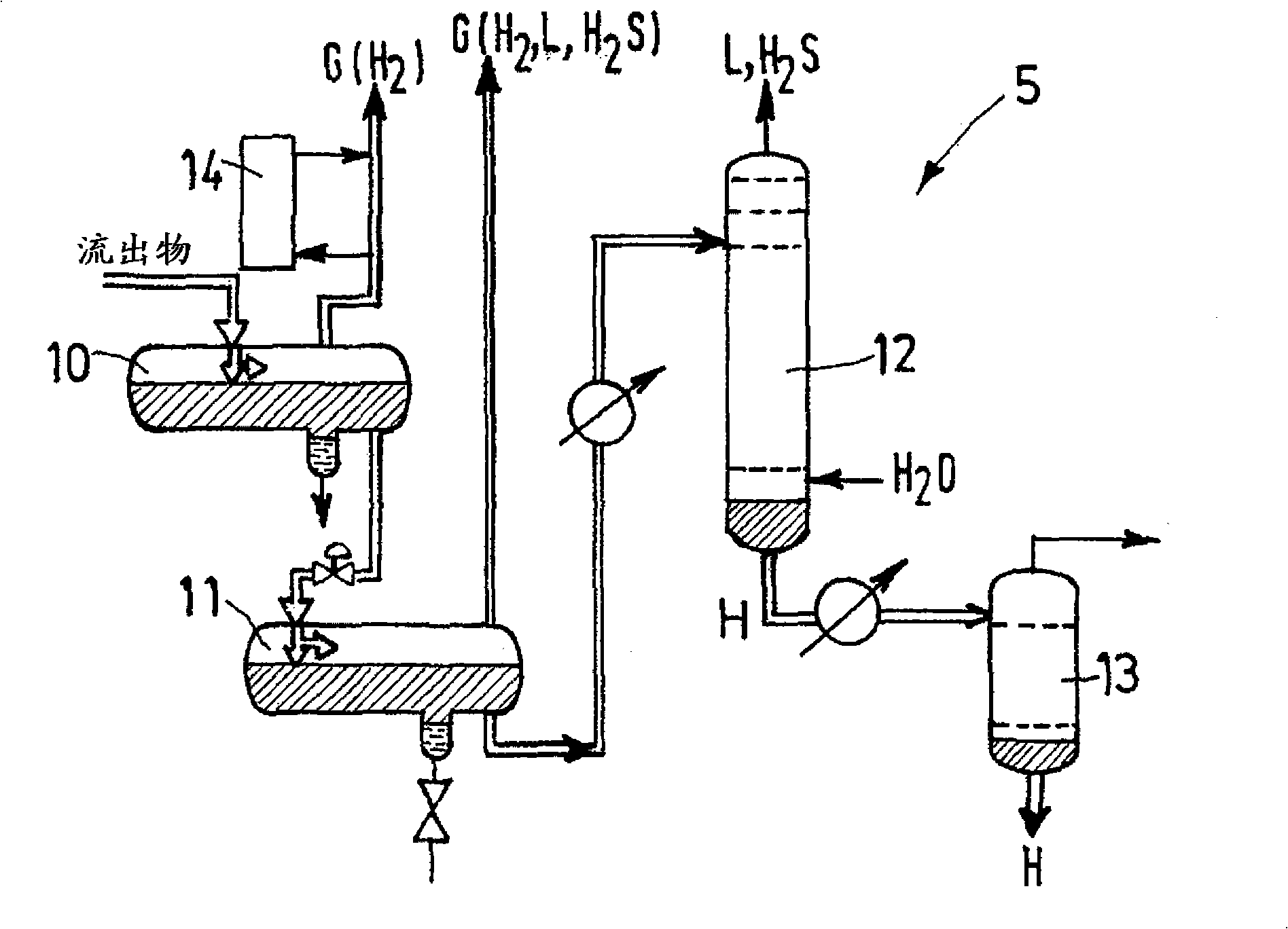

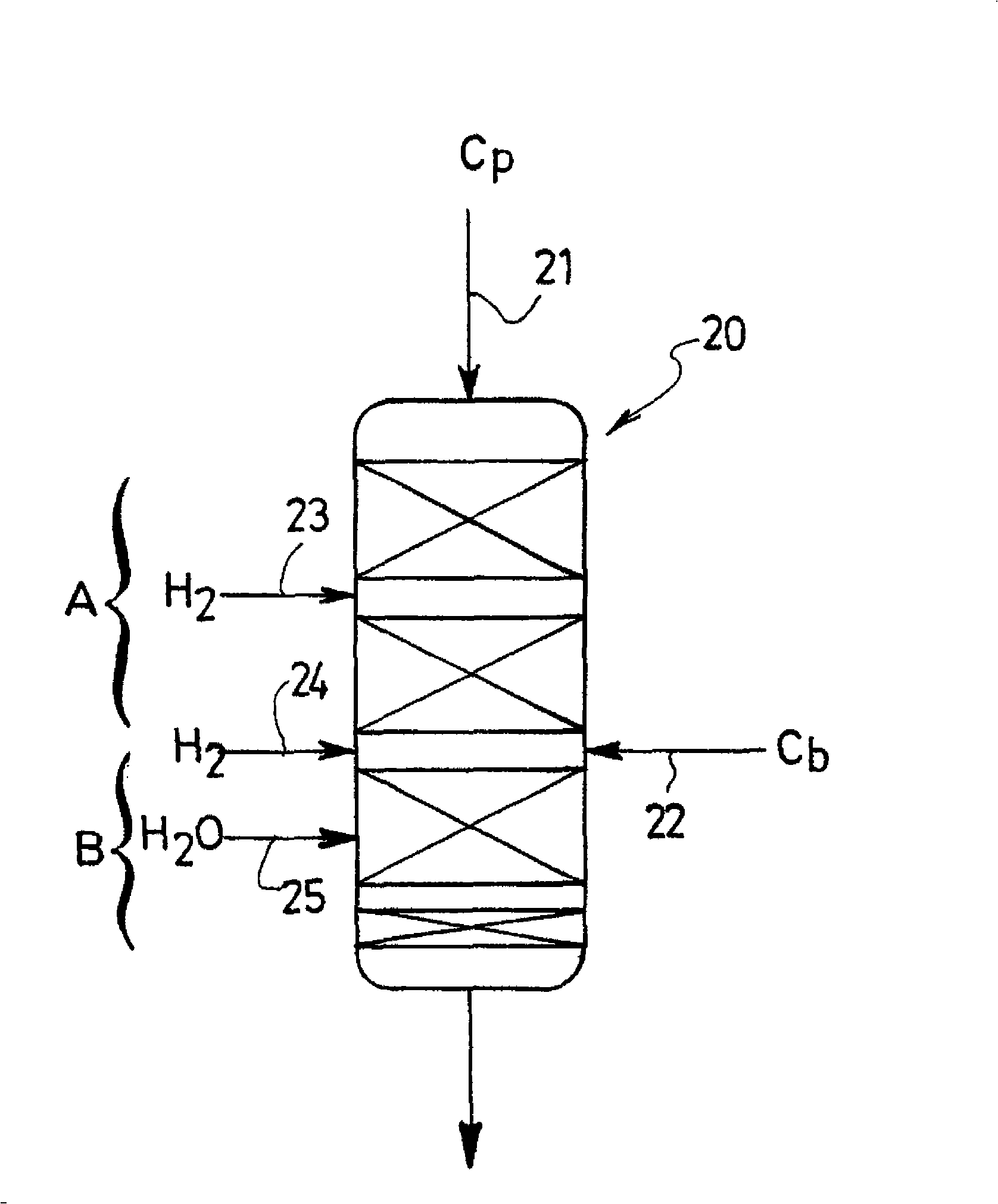

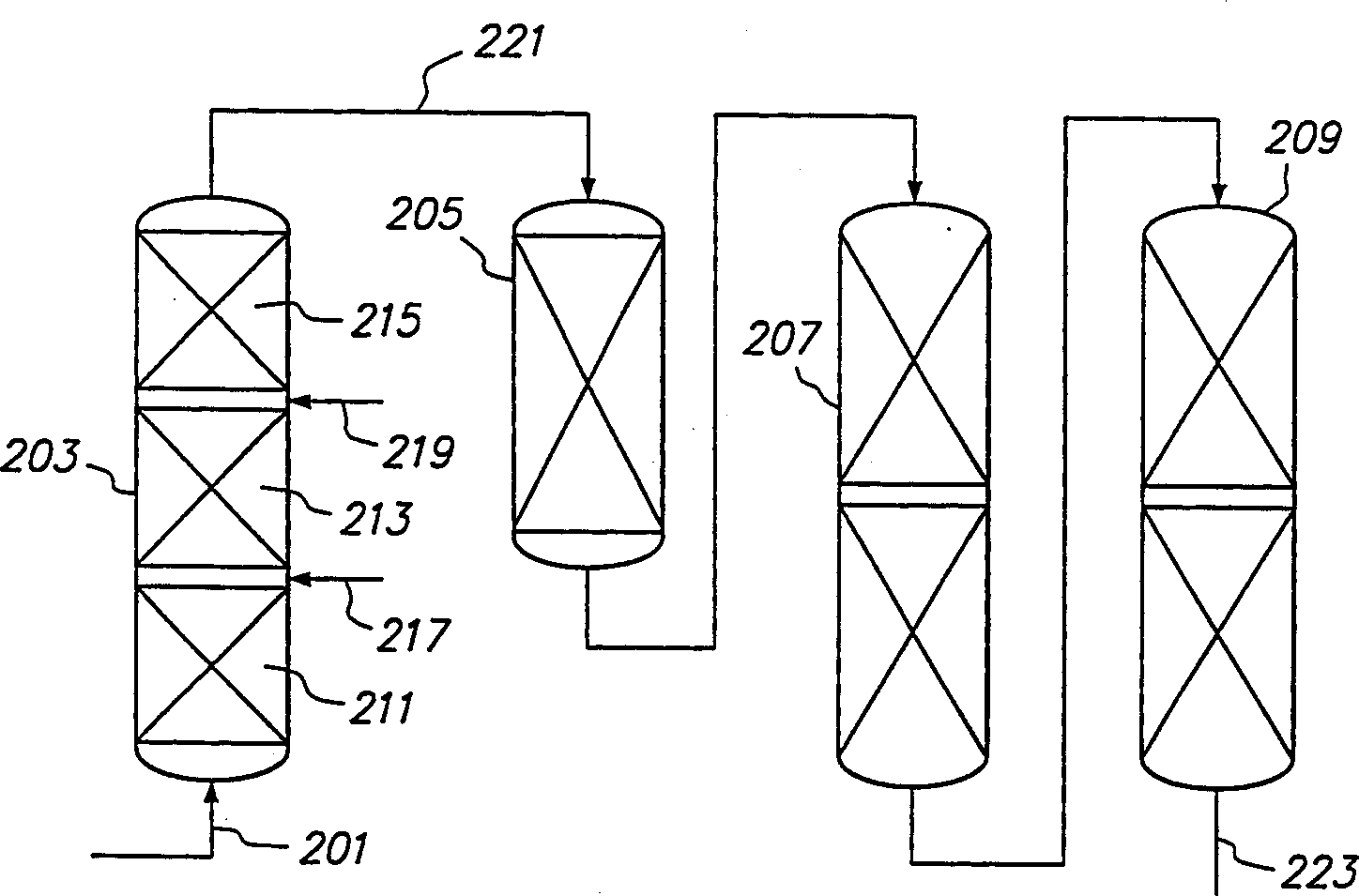

Method for the hydro-processing of a gas oil feedstock, and corresponding hydro-refining unit

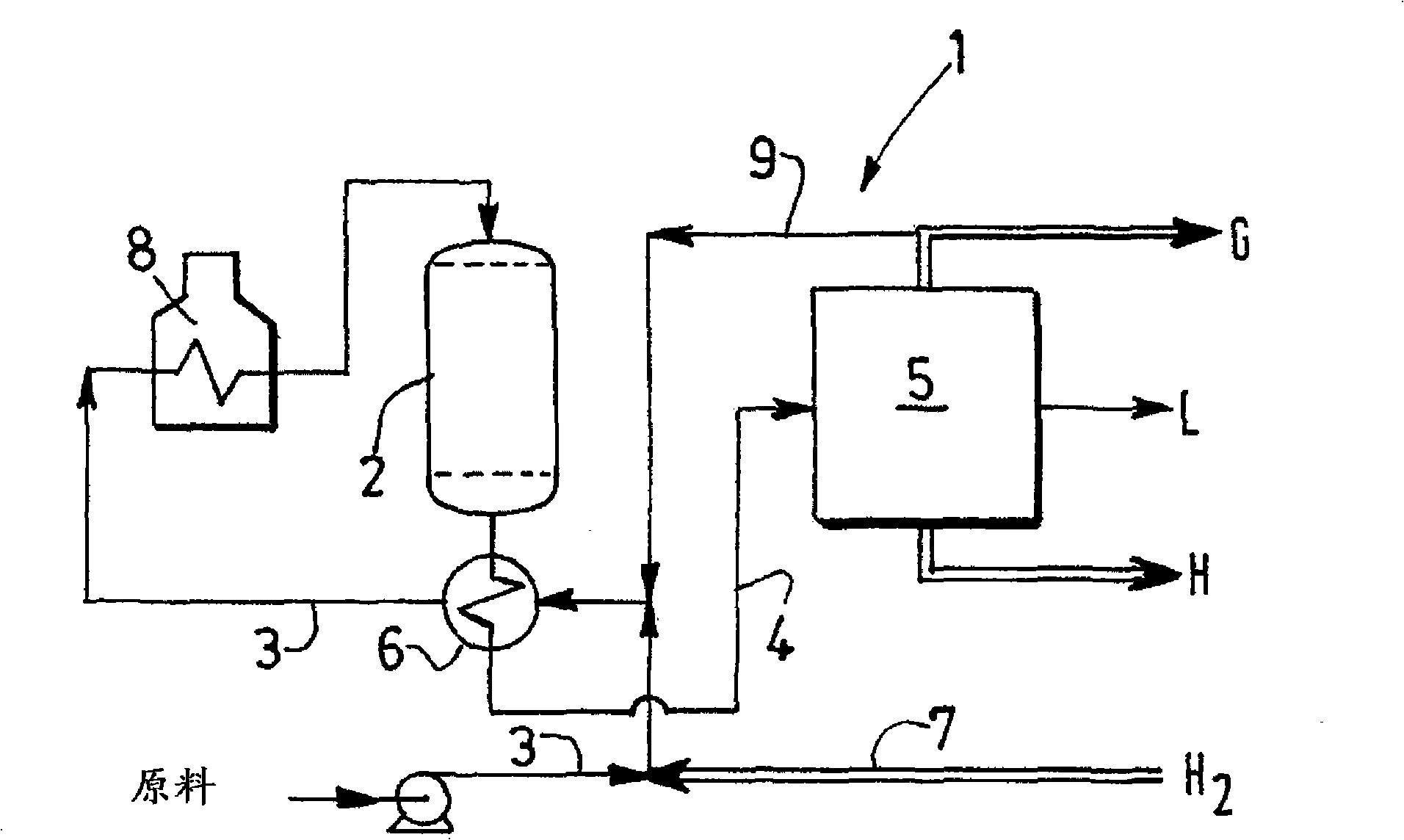

InactiveCN101517038AShort stayReduce volumeLiquid hydrocarbon mixture productionEthylene productionFixed bedPetroleum

The invention relates to a method for the catalytic hydro-processing of a petroleum feedstock of the gas oil type and of a biological feedstock containing vegetal oils and / or animal fats, in a catalytic fixed-bed hydro-processing unit, said method being characterised in that the petroleum feedstock is introduced into the reactor upstream from the biological feedstock. The invention also relates to a catalytic hydro-processing unit for implementing said method, and to a corresponding hydro-refining unit.

Owner:TOTAL RAFFINAGE MARKETING

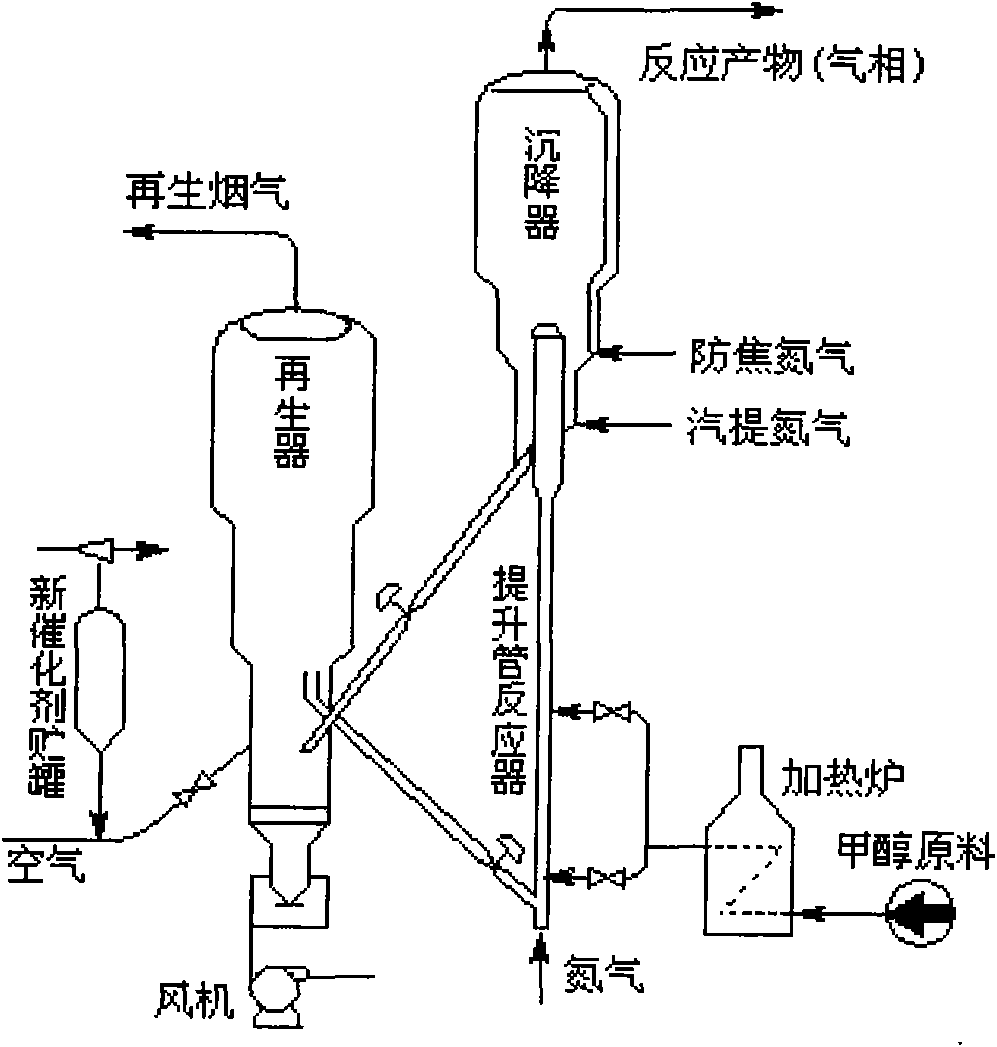

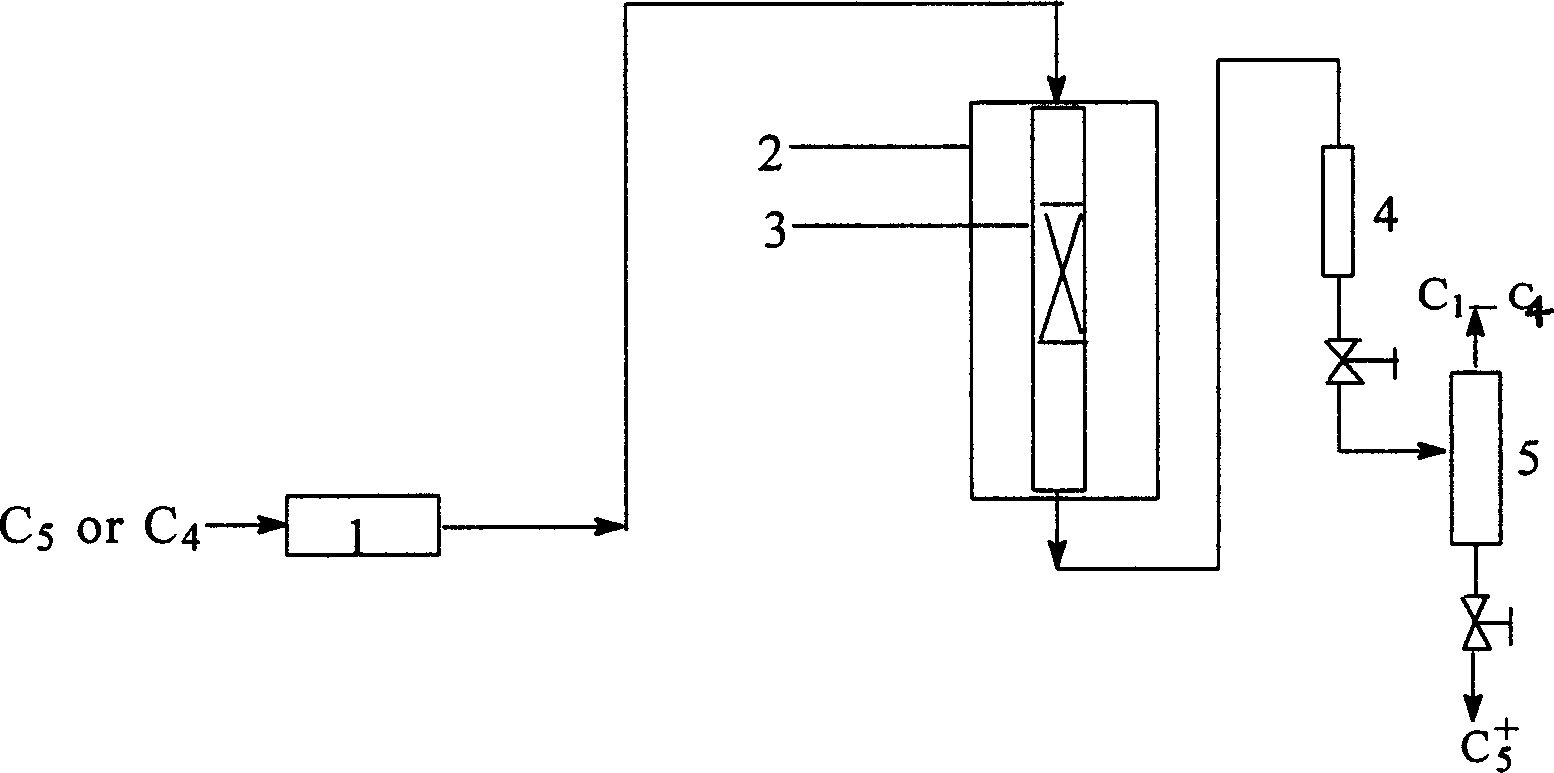

Process for preparing arene selectivity by enhancing methanol aromatizatian and process for preparation of catalyst thereof

ActiveCN101550051AImprove methodHigh yieldMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationMolecular sieveFixed bed

The invention relates to a process for preparing arene selectivity by enhancing methanol aromatizatian. The process uses methanol as raw material, compositely modifies HZSM-5 molecular sieve catalyst by active ions like Ga, Zn, Cu, Cr and Ag for catalyzing methanol aromatizatian, employs the fixed bed continuous process or the floating bed continuous process, wherein the reaction pressure is 0.1-3.5MPa; the reaction temperature is 380-500 DEG C; the space velocity of raw material liquid is 0.1-10.0 h; and N2 space velocity is 120-800 h. The advantages of the invention lie in collocation combination of mixing ion modification, and arene selectivity reaches to 70%.

Owner:TIANJI COAL CHEM IND GROUP +1

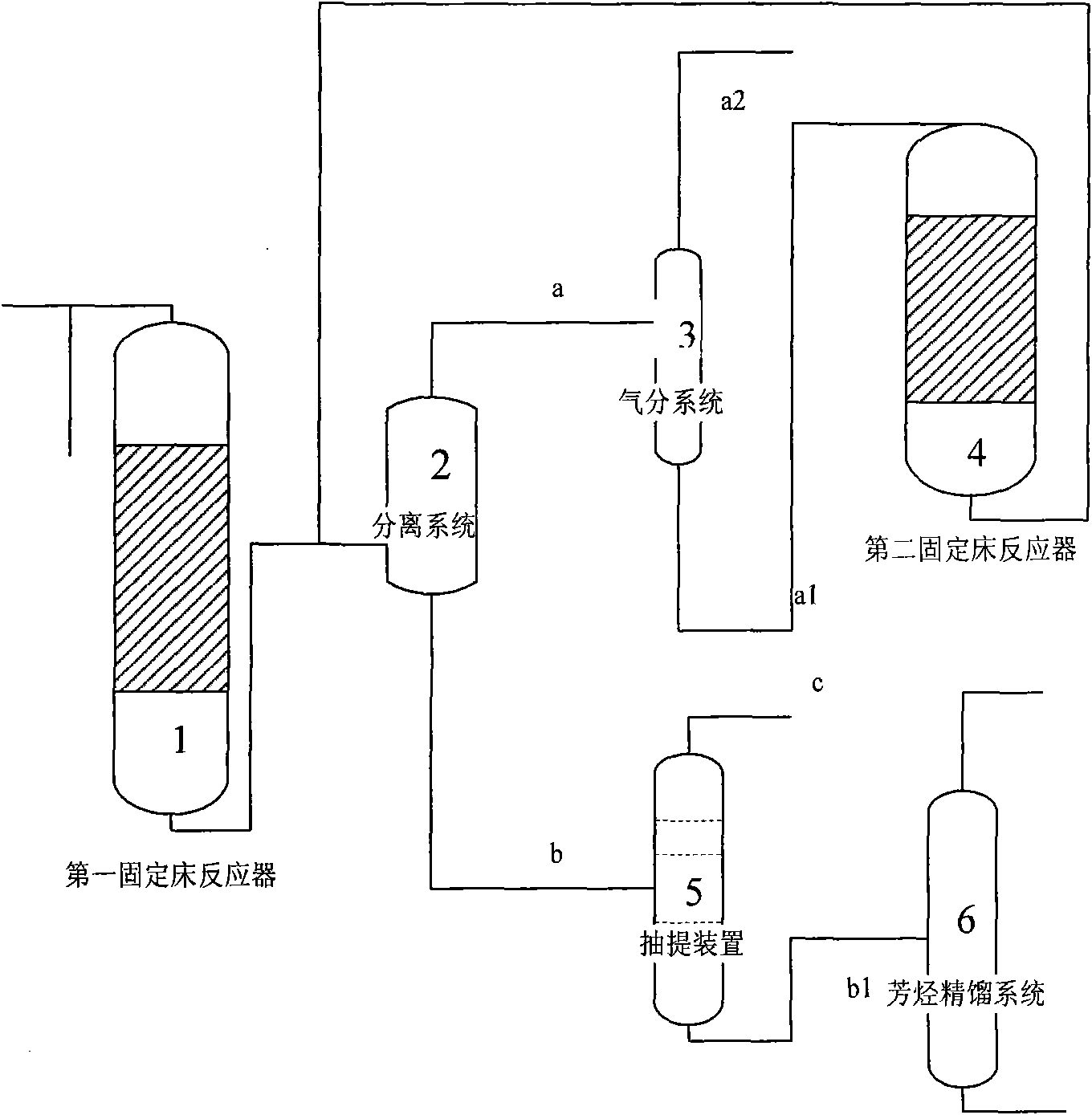

Method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol/dimethyl ether

InactiveCN101607858AHigh selectivityIncrease added valueMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMolecular sieveFixed bed

The invention discloses a method for preparing aromatic hydrocarbons and propylene simultaneously employing methanol / dimethyl ether, comprising the following steps: 1) placing raw materials containing methanol or / and dimethyl ether, metals and molecular sieve based catalyst which is modified through silanizing in a first fixed bed reactor to perform catalytic reaction; 2) separating the products obtained in step 1) to obtain propylene, then placing propylene in a second fixed bed reactor with molecular sieve based catalyst which is modified by using metals to react, then performing aromatization on the obtained product in step 1) and obtaining aromatic hydrocarbons; then separating to obtain toluene and sending toluene back to the outlet of the first fixed bed reactor as a raw material. In the method, methanol is converted and prepared to aromatic hydrocarbons while propylene is produced at the same time and the content of paraxylene in aromatic hydrocarbons is high. In the products prepared by the method, the content of propylene can reach above 20%, the content of aromatic hydrocarbons can reach above 58wt% and the content of paraxylene in aromatic hydrocarbons is more than 35wt%.

Owner:CHINA NAT OFFSHORE OIL CORP +2

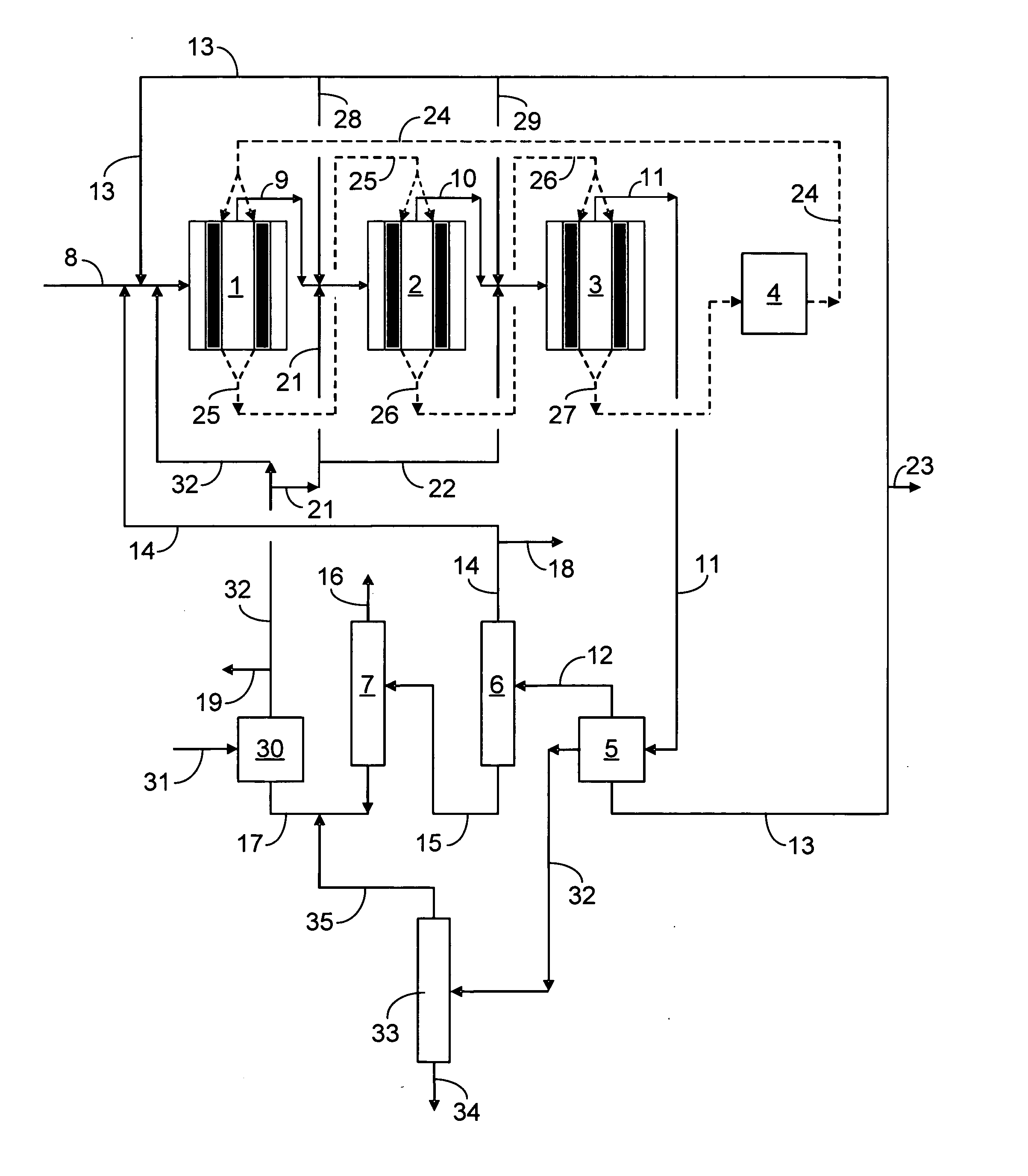

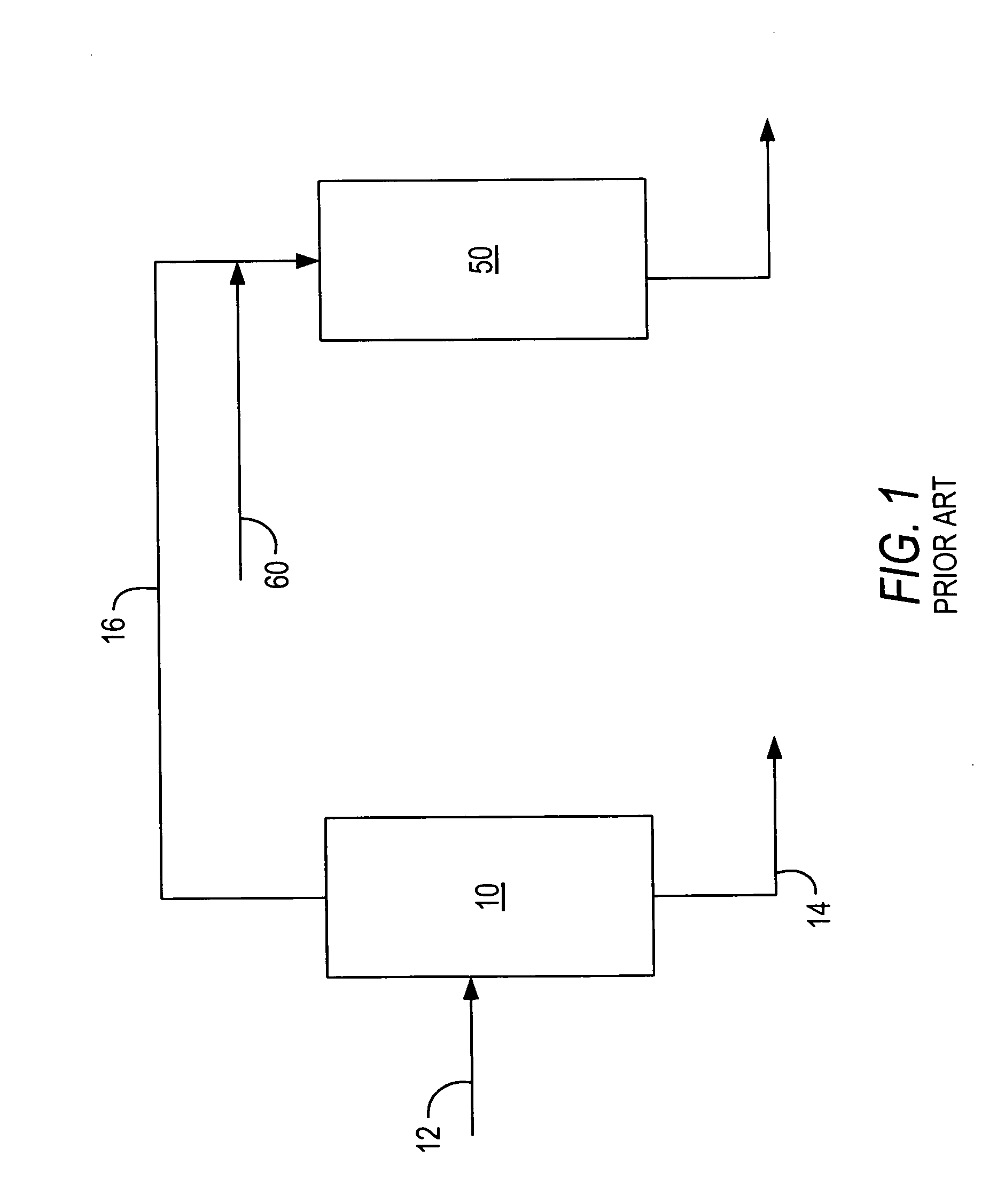

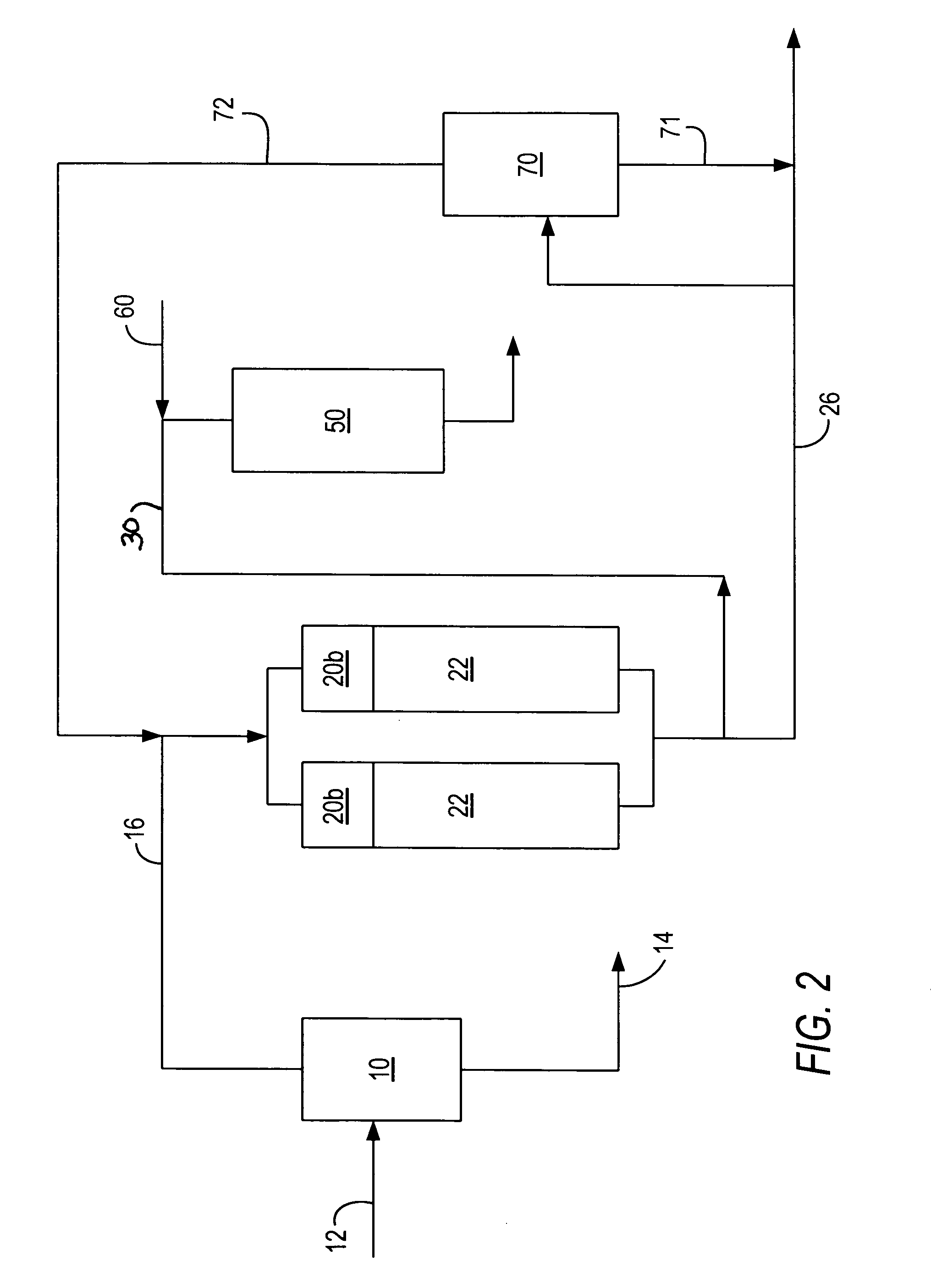

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS20060161035A1Improve economyEfficient OTP processMolecular sieve catalystCatalystsFixed bedOxygenate

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

Process for removal of nitrogen and poly-nuclear aromatics from hydrocracker feedstocks

A feedstream to a hydrocracking unit is treated to remove or reduce the content of polynuclear aromatics and nitrogen-containing compounds by contacting the feedstream with an adsorbent compound selected from attapulgus clay, alumina, silica gel and activated carbon in a fixed bed or slurry column and separating the treated feedstream that is lower in the undesired compounds from the adsorbent material. The adsorbent can be mixed with a solvent for the undesired compounds and stripped for re-use.

Owner:SAUDI ARABIAN OIL CO

Synthesis gas process comprising partial oxidation using controlled and optimized temperature profile

ActiveUS7261751B2Low selectivityRisk of explosion can be minimizedHydrocarbon from carbon oxidesCarburetting by solid carbonaceous material pyrolysisPartial oxidationFixed bed

Owner:PHILLIPS 66 CO

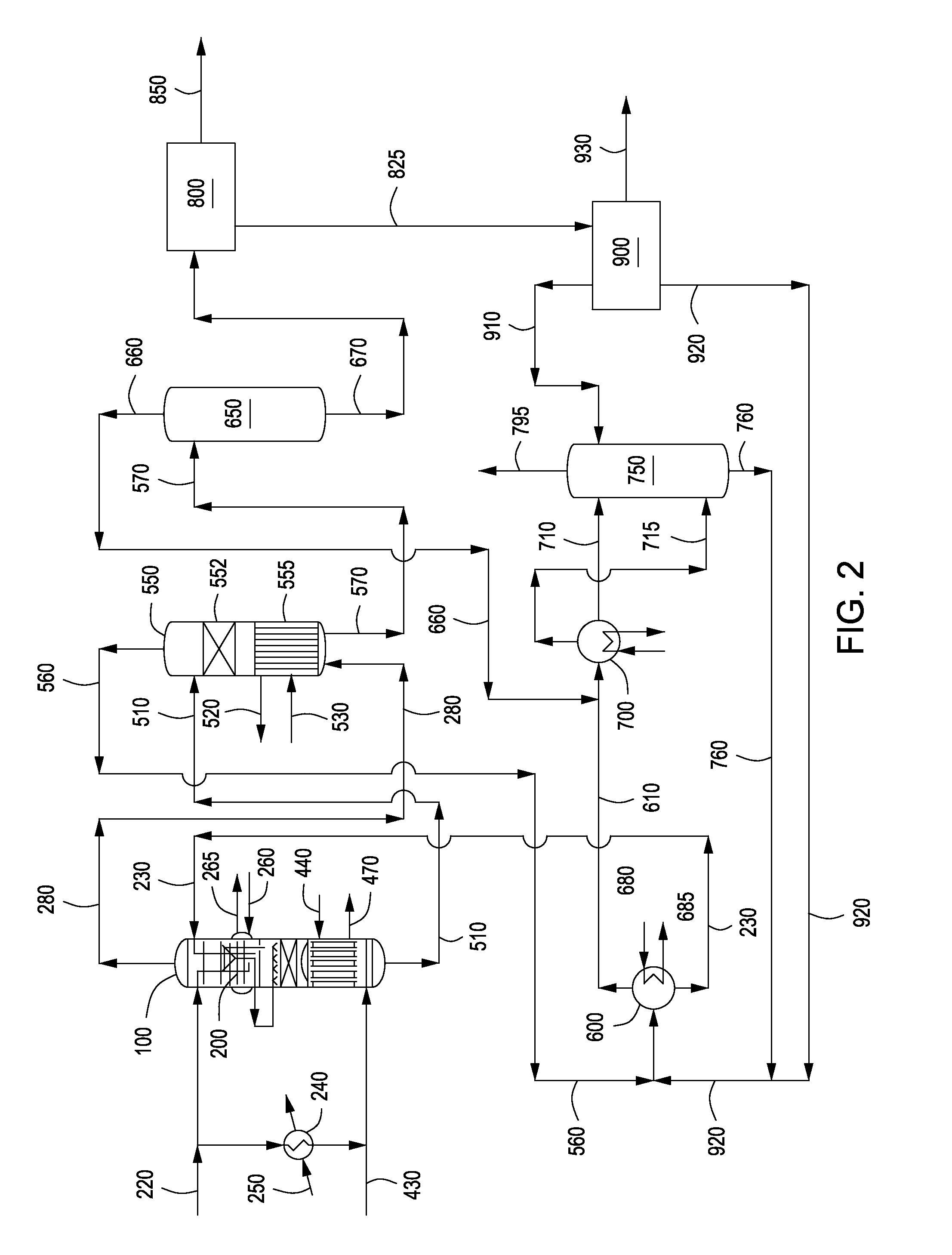

Synthesis gas process comprising partial oxidation using controlled and optimized temperature profile

ActiveUS20060029539A1Risk of explosion can be minimizedIncrease the molar ratioHydrocarbon from carbon oxidesCarburetting by solid carbonaceous material pyrolysisForming gasPartial oxidation

This invention relates to methods for reacting a hydrocarbon, molecular oxygen, and optionally water and / or carbon dioxide, to form synthesis gas. The preferred embodiments are characterized by delivering a substochiometric amount of oxygen to each of a multitude of reaction zones, which allows for optimum design of the catalytic packed bed and the gas distribution system, and for the optimization and control of the temperature profile of the reaction zones. The multitude of reaction zones may include a series of successive fixed beds, or a continuous zone housed within an internal structure having porous, or perforated, walls, through which an oxygen-containing stream can permeate. By controlling the oxygen supply, the temperatures, conversion, and product selectivity of the reaction can be in turn controlled and optimized. Furthermore the potential risks of explosion associated with mixing hydrocarbon and molecular oxygen is minimized with increased feed carbon-to-oxygen molar ratios.

Owner:PHILLIPS 66 CO

Acetylene hydrocarbon selective hydrogenation method

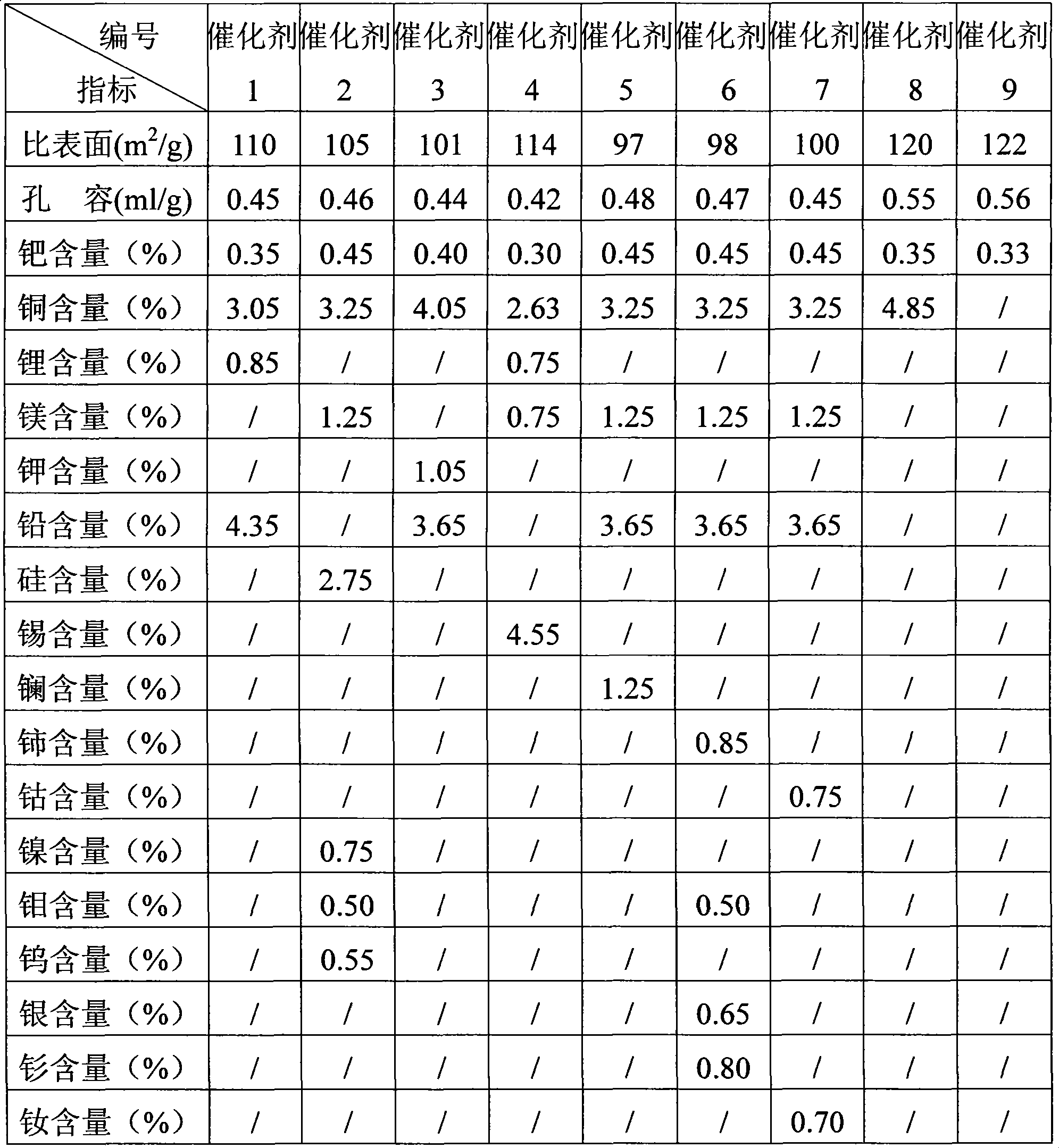

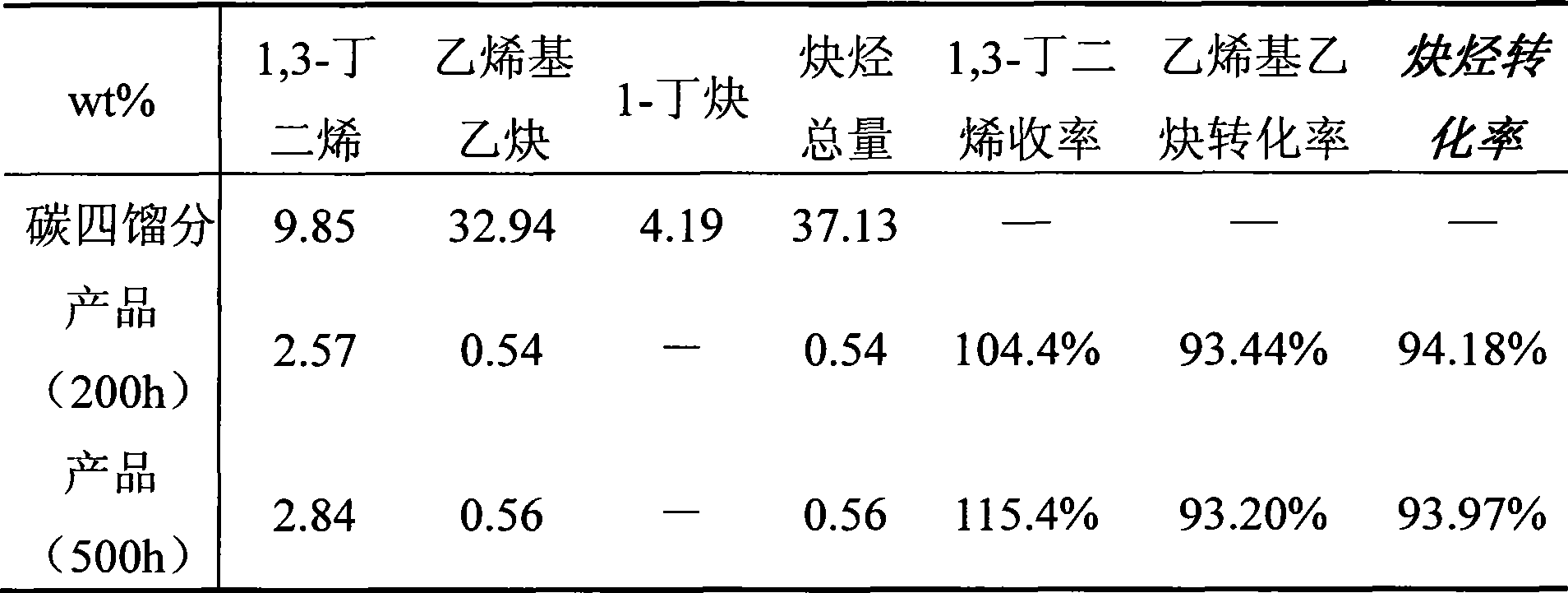

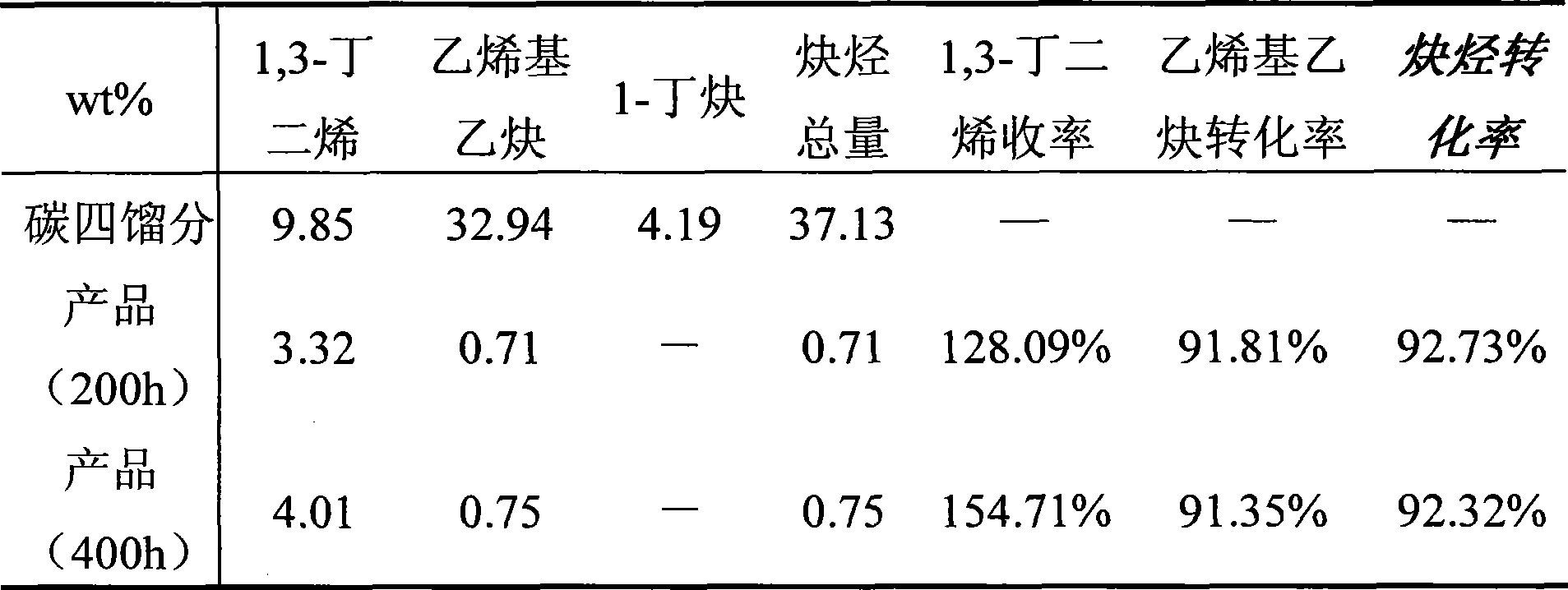

ActiveCN101434508AGood hydrogenation effectImprove hydrogenation activityHydrocarbon by hydrogenationHydrocarbon purification/separationButadiene DioxideUnsaturated hydrocarbon

The invention relates to a selective hydrogenation method of high unsaturated hydrocarbons in C4 fractions, which is characterized in that salvage stores which are rich in acetylene hydrocarbon and prepared by extracting butadiene are used as the material, and a fixed bed reactor is adopted to obtain 1, 3-budiene by selective hydrogenation under the existence of a catalyst. The adopted process conditions are as follows: the reaction temperature is between 30 DEG C and 90 DEG C, the reaction pressure is between 1.0 MPa and 4.0 MPa and the liquid space velocity is 7 to 20h<-1>. The catalyst is preferably a palladium system catalyst with alumina as a carrier, the specific surface is 50 to 150m<2> / g and the specific pore volume is 0.25 to 1.0ml / g. The method has remarkable good effects on reducing waste of resources and improving economic benefits by effectively utilizing the salvage stores rich in acetylene hydrocarbon and prepared by extracting butadiene.

Owner:PETROCHINA CO LTD

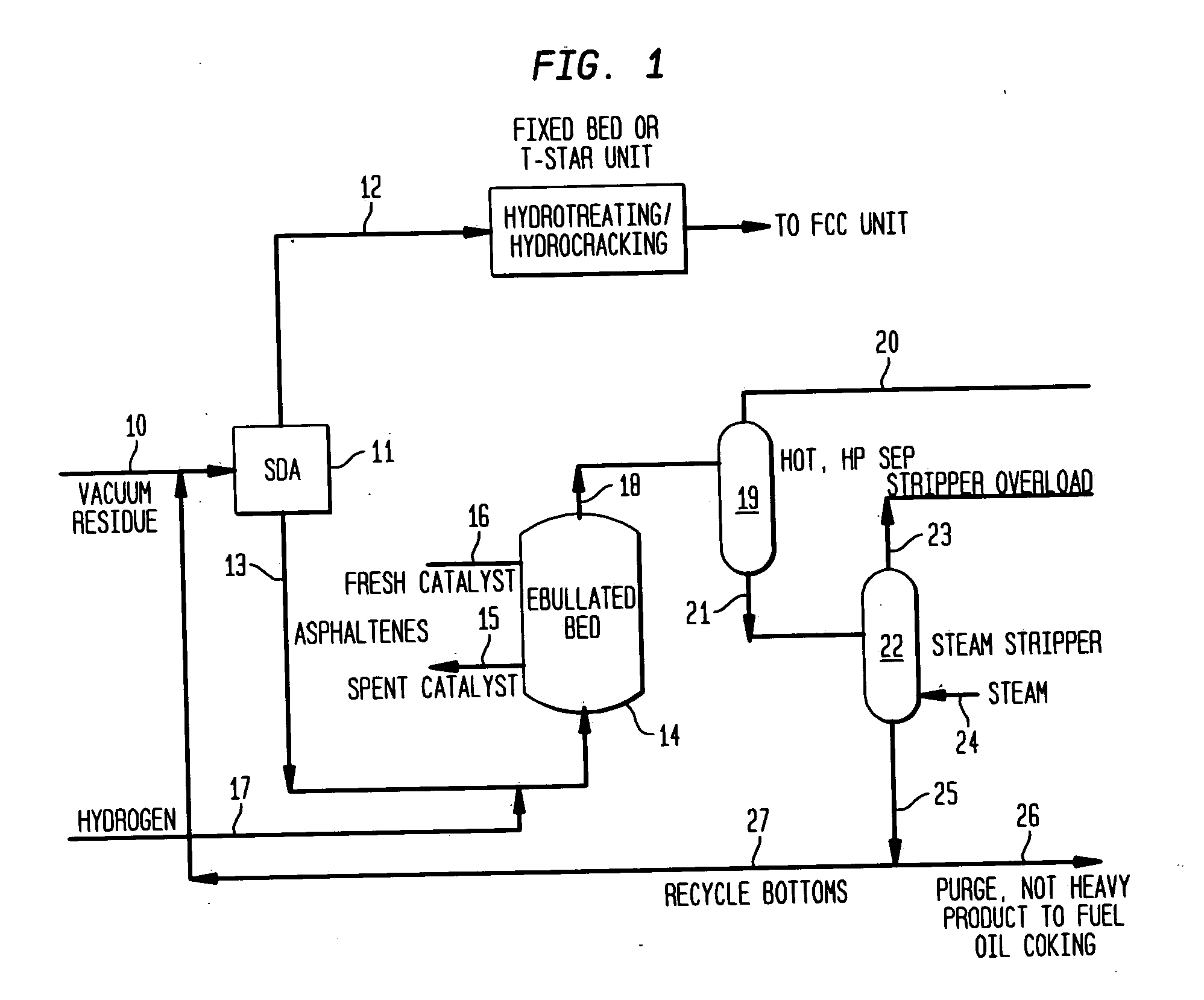

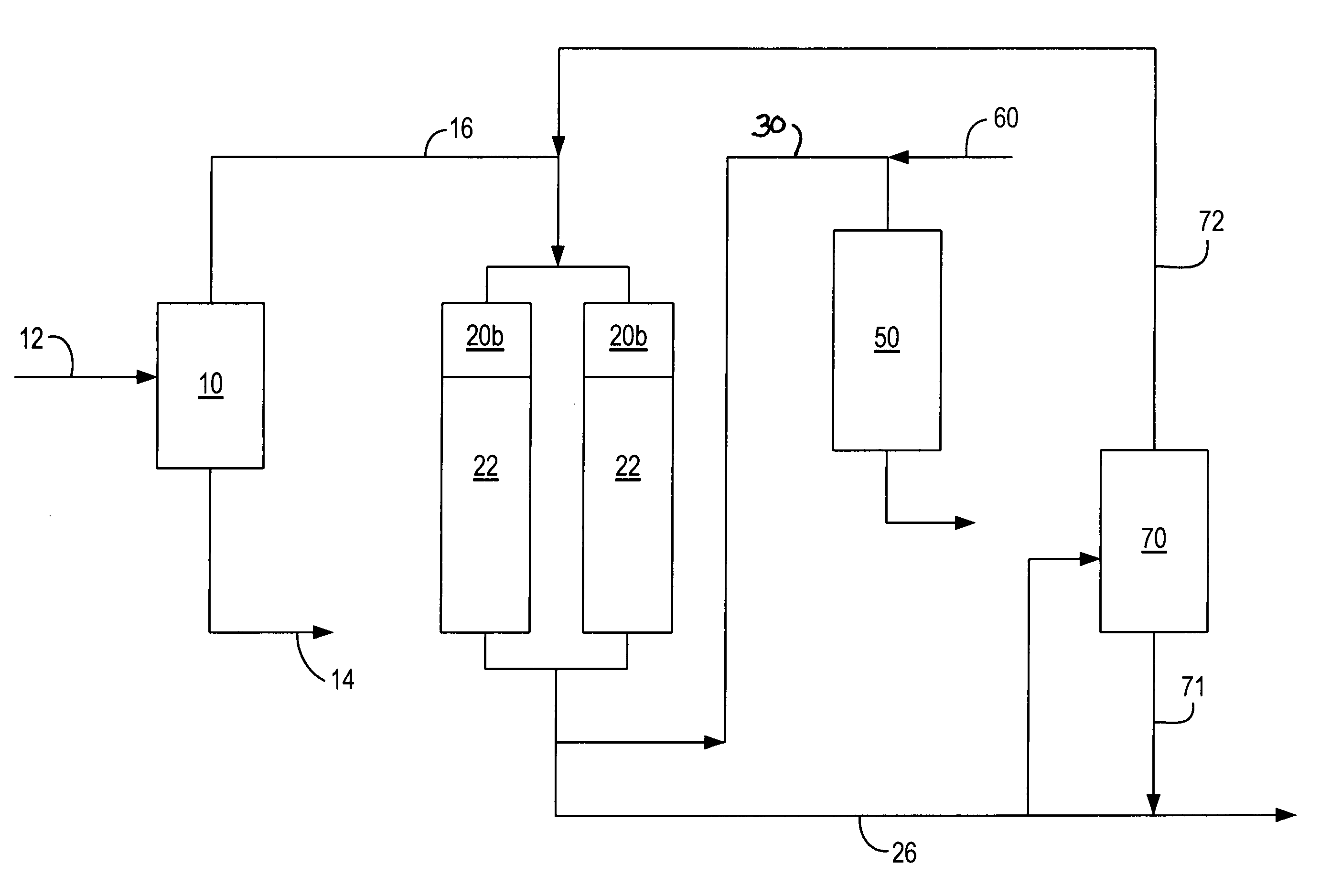

Integrated SDA and ebullated-bed process

ActiveUS20060118463A1Most efficientMinimizing chanceTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyBiochemical engineeringFixed bed

This invention relates to a novel integrated method for economically processing vacuum residue from heavy crude oils. This is accomplished by utilizing a solvent deasphalter (SDA) in the first step of the process with a C3 / C4 / C5 solvent such that the DAO product can thereafter be processed in a classic fixed-bed hydrotreater or hydrocracker. The SDA feed also includes recycled stripper bottoms containing unconverted residue / asphaltenes from a downstream steam stripper unit. The asphaltenes from the SDA are sent to an ebullated-bed reactor for conversion of the residue and asphaltenes. Residue conversion in the range of 60-80% is achieved and asphaltene conversion is in the range of 50-70%. The overall residue conversion, with the DAO product considered non-residue, is in the range of 80 W %-90 W % and significantly higher than could be achieved without utilizing the present invention.

Owner:INST FR DU PETROLE

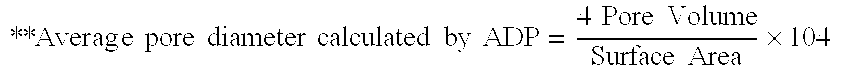

Skeletal iron catalyst having improved attrition resistance and product selectivity in slurry-phase synthesis processes

InactiveUS6277895B1High particle strengthGood attristion resistanceHydrocarbon from carbon oxidesOrganic compound preparationFixed bedSlurry

Particulate skeletal iron catalyst is provided which contain at least about 50 wt. % iron with the remainder being a minor portion of a suitable non-ferrous metal and having characteristics of 0.062-1.0 mm particle size, 20-100 m2 / g surface area, and 10-40 nm average pore diameter. Such skeletal iron catalysts are prepared and utilized for producing synthetic hydrocarbon products from CO and H2 feeds by Fischer-Tropsch synthesis process. Iron powder is mixed with non-ferrous powder selected from aluminum, antimony, silicon, tin or zinc powder to provide 20-80 wt. % iron content and melted together to form an iron alloy, then cooled to room temperature and pulverized to provide 0.1-10 mm iron alloy catalyst precursor particles. The iron alloy pulverized particles are treated with NaOH or KOH caustic solution at 30-95° C. temperature to extract and / or leach out most of the non-ferrous metal portion, and then screened and treated by drying and reducing with hydrogen and to provide the smaller size skeletal iron catalyst material. Such skeletal iron catalyst is utilized with CO+H2 feedstream for Fischer-Tropsch reactions in either a fixed bed or slurry bed type reactor at 180-350° C. temperature, 0.5-3.0 mPa pressure and gas hourly space velocity of 0.5-3.0 L / g Fe / hr to produce desired hydrocarbon products.

Owner:INST OF COAL CHEM ICCCHINESE ACADEMY OF SCI +1

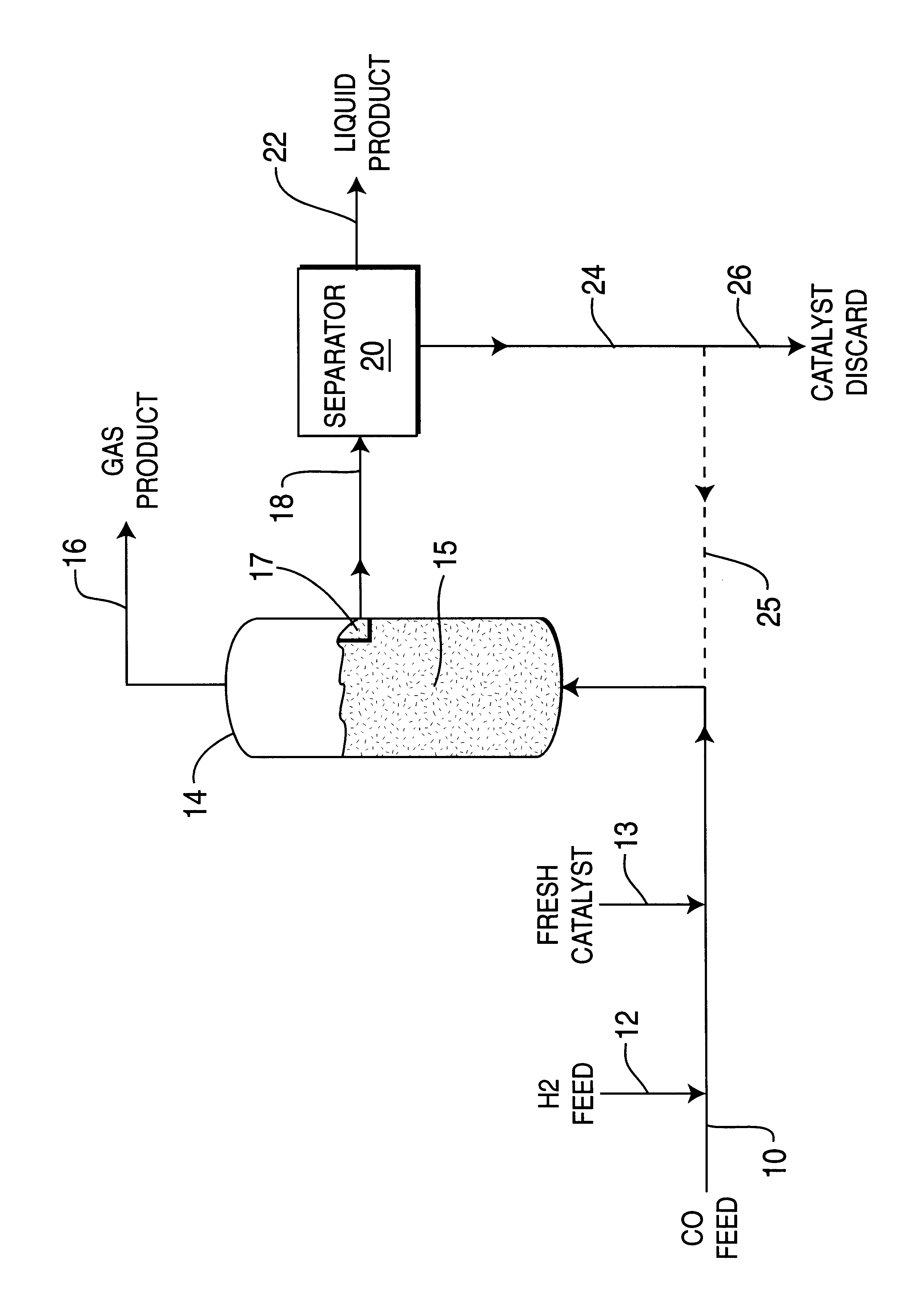

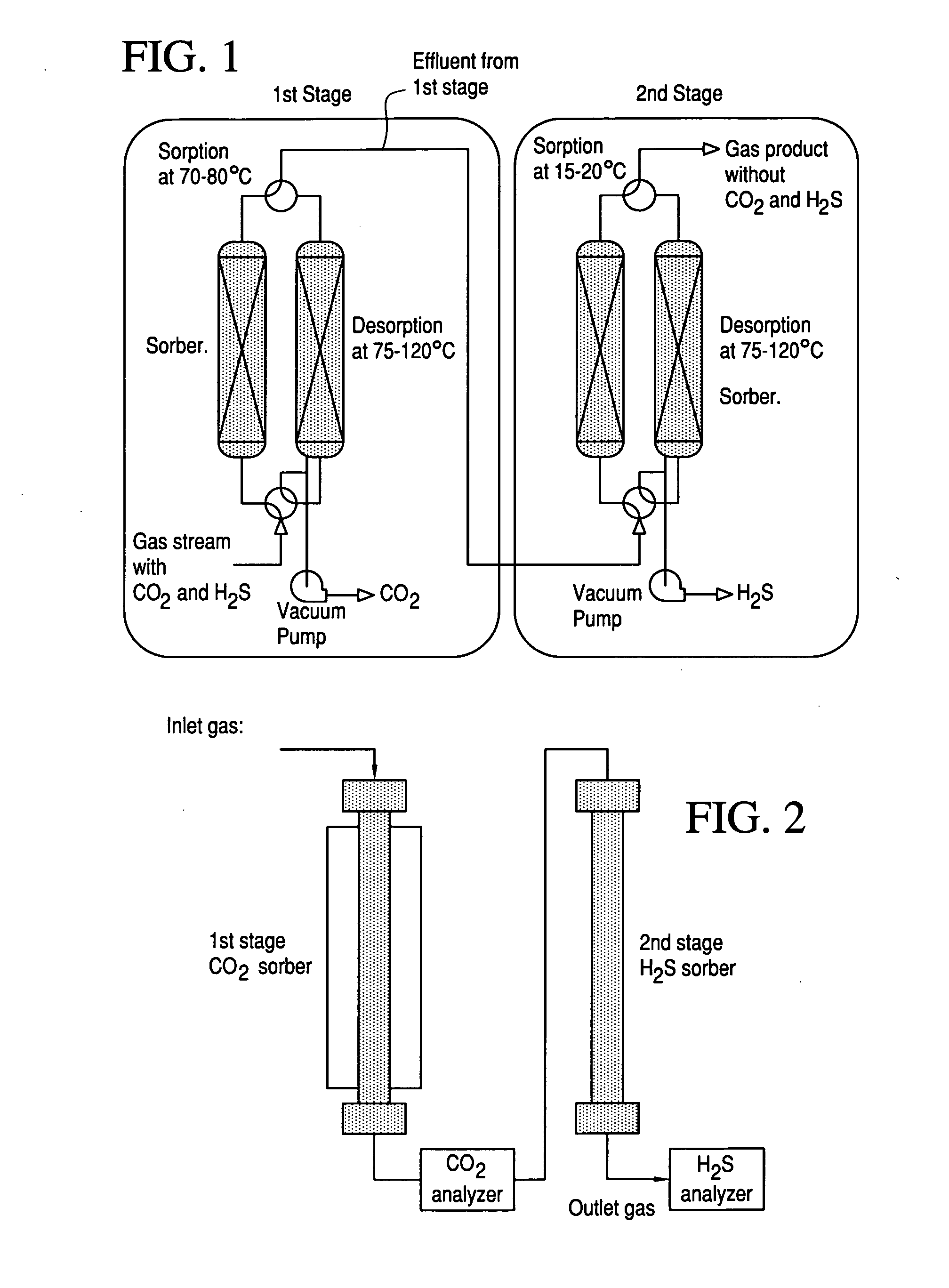

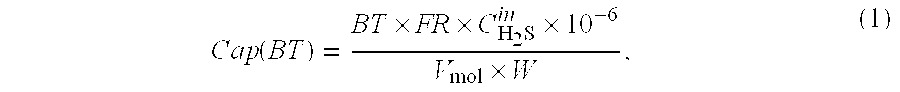

Novel sorbents and purification and bulk separation of gas streams

InactiveUS20080264254A1Large capacityLittle and no corrosive effectNitrous oxide captureGas treatmentSorbentDesorption

Porous-material-supported polymer sorbents and process for removal of undesirable gases such as H2S, COS, CO2, N2O, NO, NO2, SO2, SO3, HCl, HF, HCN, NH3, H2O, C2H5OH, CH3OH, HCHO, CHCl3, CH2Cl2, CH3Cl, CS2, C4H4S, CH3SH, and CH3—S—CH3 from various gas streams such as natural gas, coal / biomass gasification gas, biogas, landfill gas, coal mine gas, ammonia syngas, H2 and oxo-syngas, Fe ore reduction gas, reformate gas, refinery process gases, indoor air, fuel cell anode fuel gas and cathode air are disclosed. The sorbents have numerous advantages such as high breakthrough capacity, high sorption / desorption rates, little or no corrosive effect and are easily regenerated. The sorbents may be prepared by loading H2S—, COS—, CO2—, N2O, NO—, NO2—, SO2—, SO3—, HCl—, HF—, HCN—, NH3—, H2O—, C2H5OH—, CH3OH—, HCHO—, CHCl3—, CH2Cl2—, CH3Cl—, CS2—, C4H4S—, CH3SH—, CH3—S—CH3-philic polymer(s) or mixtures thereof, as well as any one or more of H2S—, COS—, CO2—, N2O, NO—, NO2—, SO2—, SO3—, HCl—, HF—, HCN—, NH3—, H2O—, C2H5OH—, CH3OH—, HCHO—, CHCl3—, CH2Cl2—, CH3Cl—, CS2—, C4H4S—, CH3SH—, CH3—S—CH3-philic compound(s) or mixtures thereof on to porous materials such as mesoporous, microporous or macroporous materials. The sorbents may be employed in processes such as one-stage and multi-stage processes to remove and recover H2S, COS, CO2, N2O, NO, NO2, SO2, SO3, HCl, HF, HCN, NH3, H2O, C2H5OH, CH3OH, HCHO, CHCl3, CH2Cl2, CH3Cl, CS2, C4H4S, CH3SH and CH3—S—CH3 from gas streams by use of, such as, fixed-bed sorbers, fluidized-bed sorbers, moving-bed sorbers, and rotating-bed sorbers.

Owner:PENN STATE RES FOUND +1

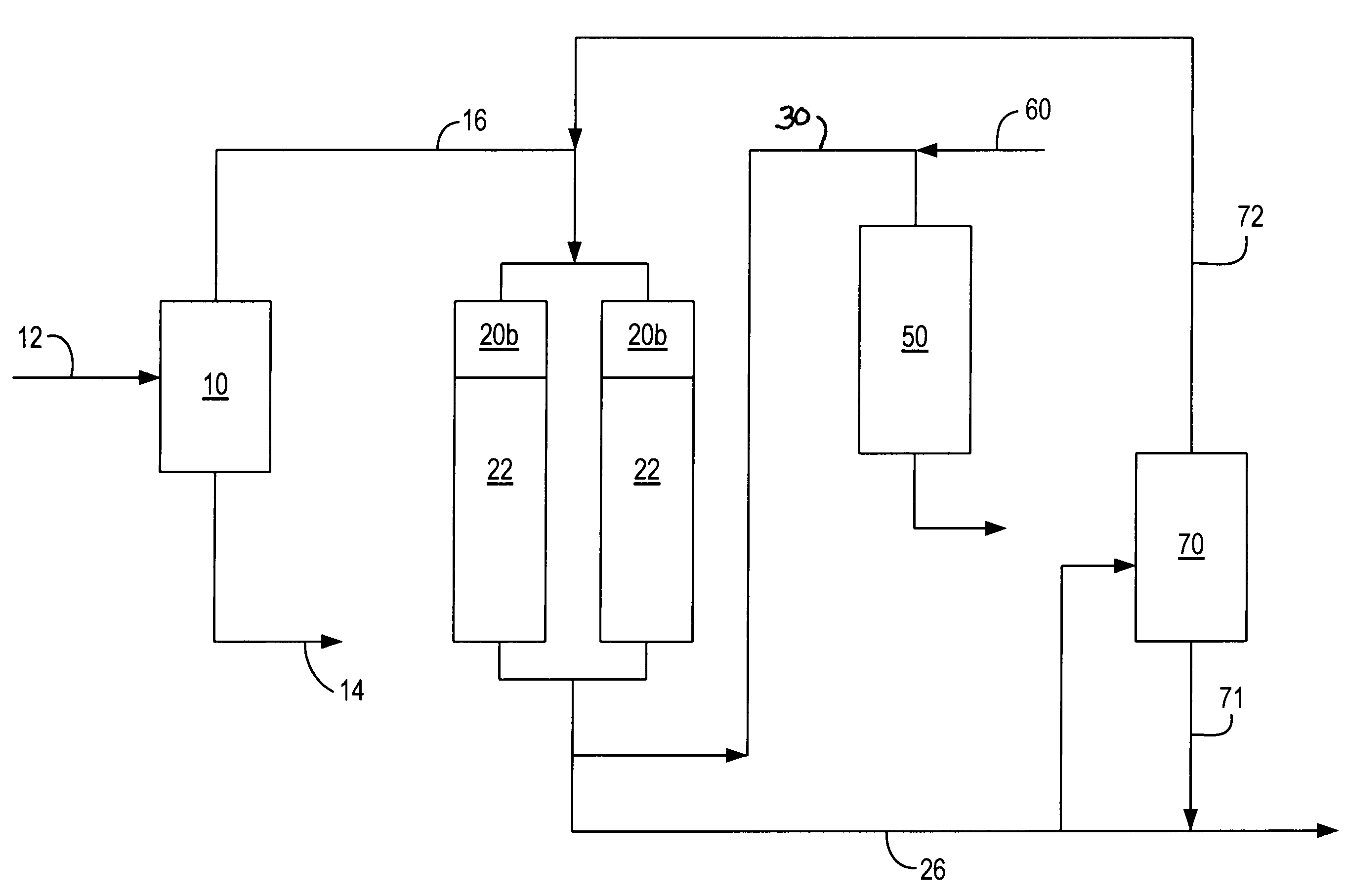

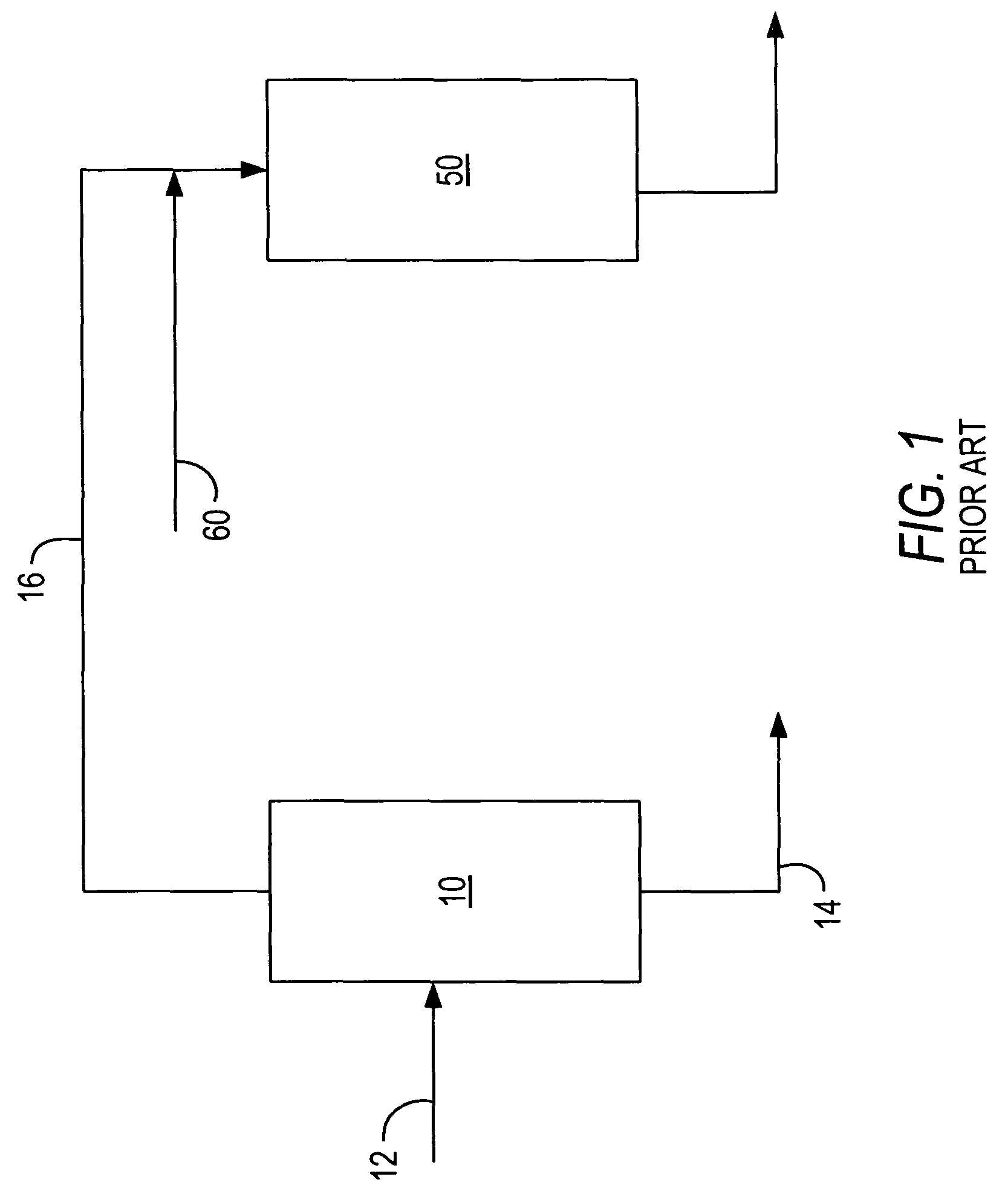

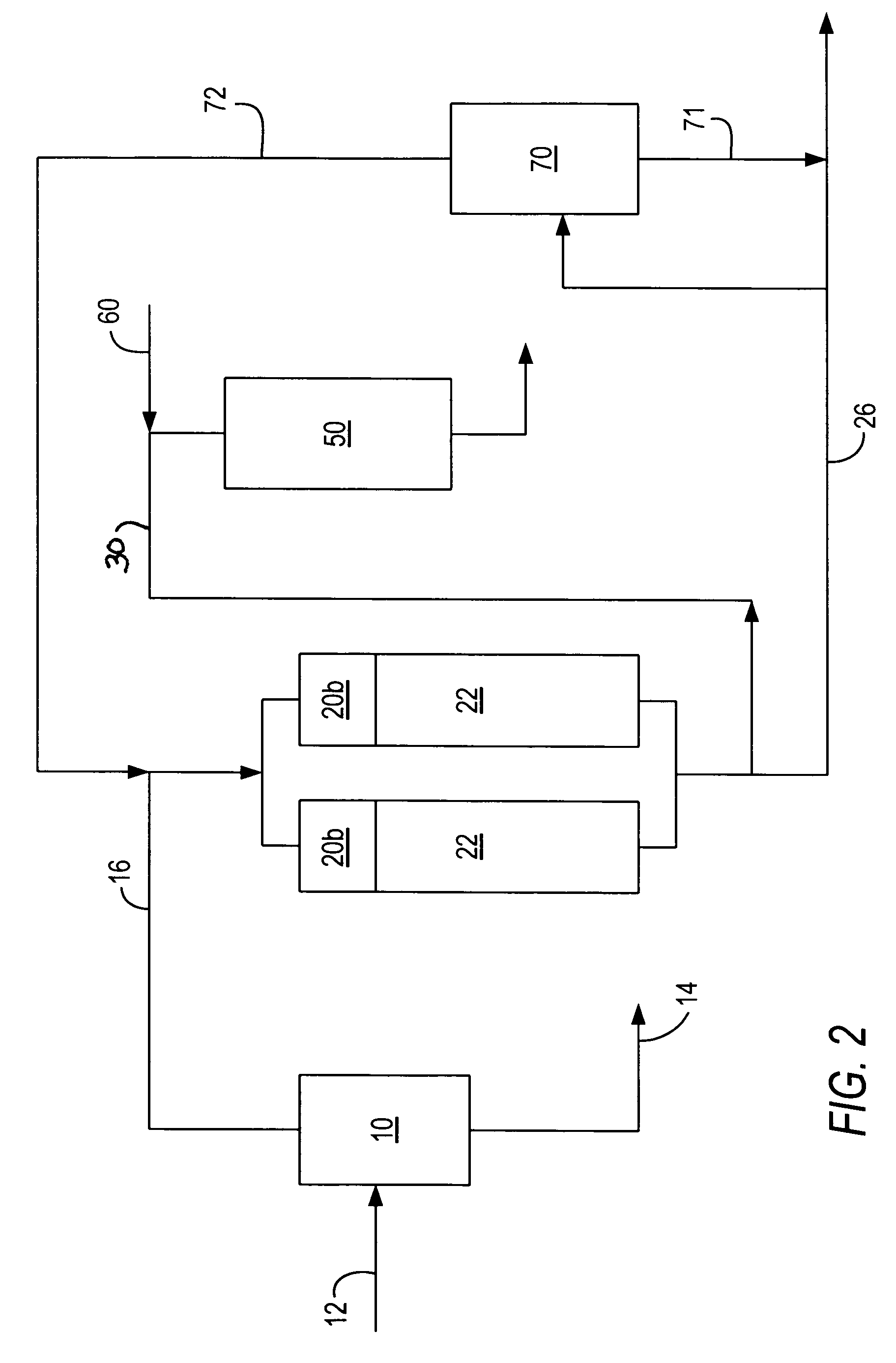

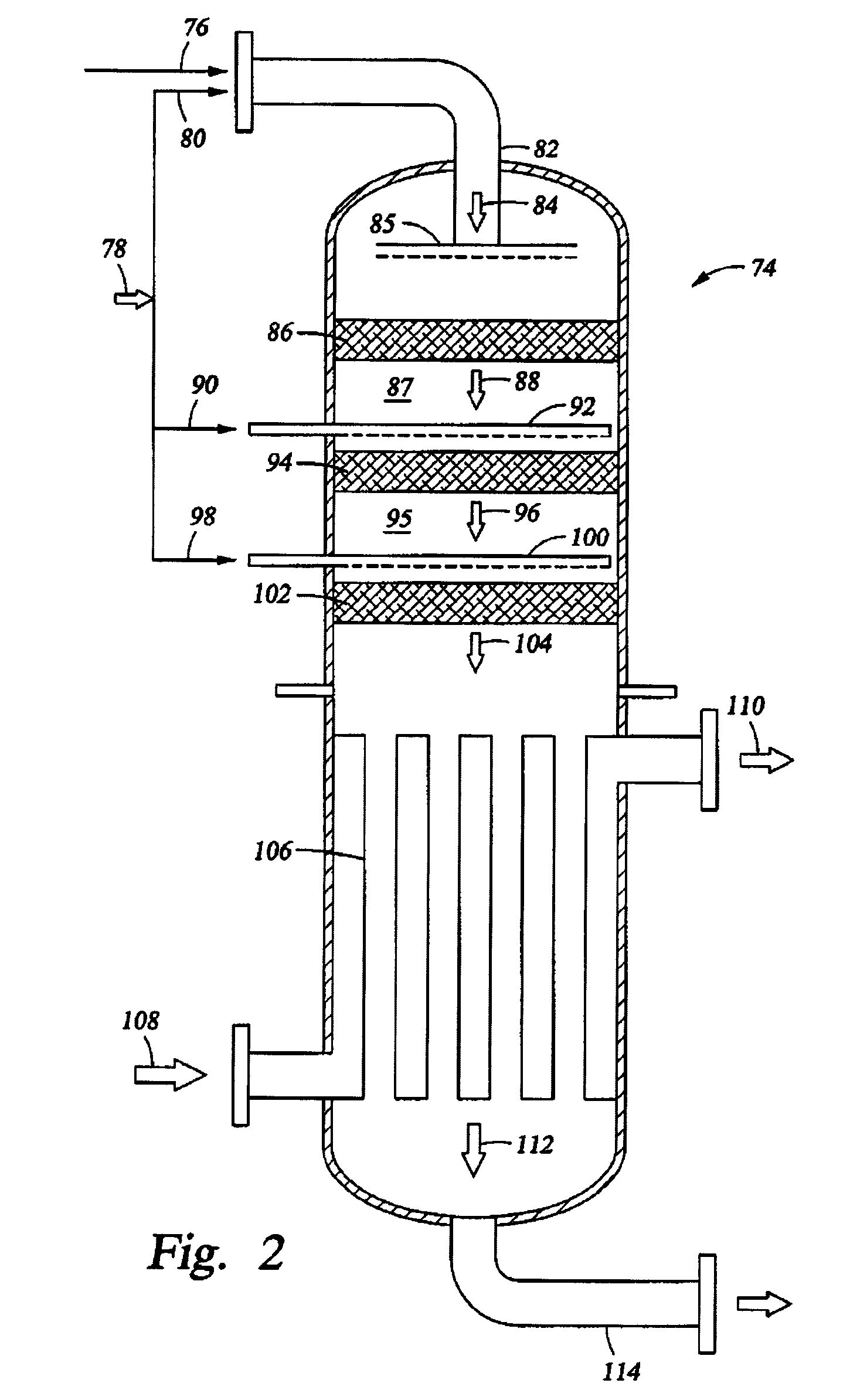

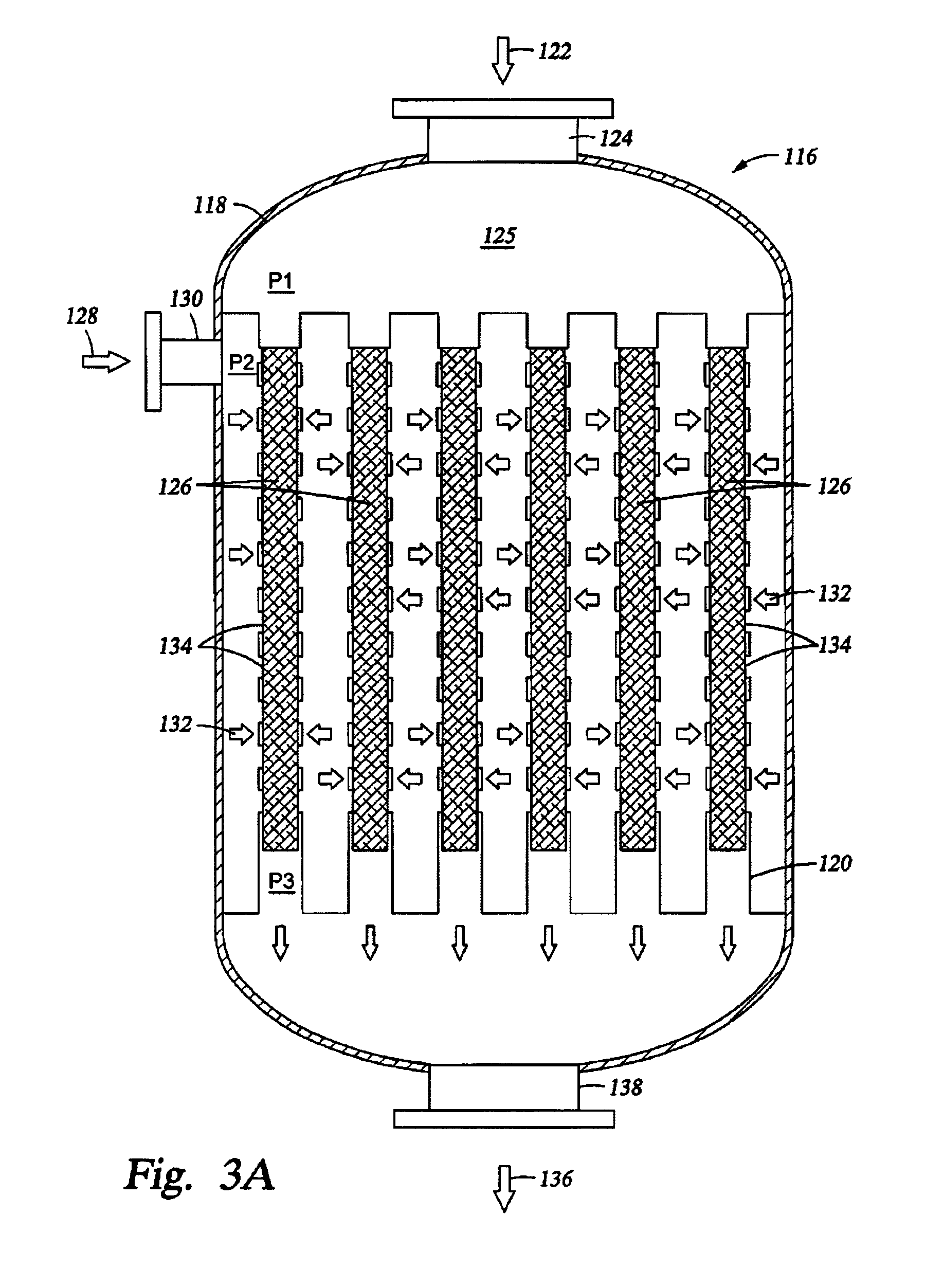

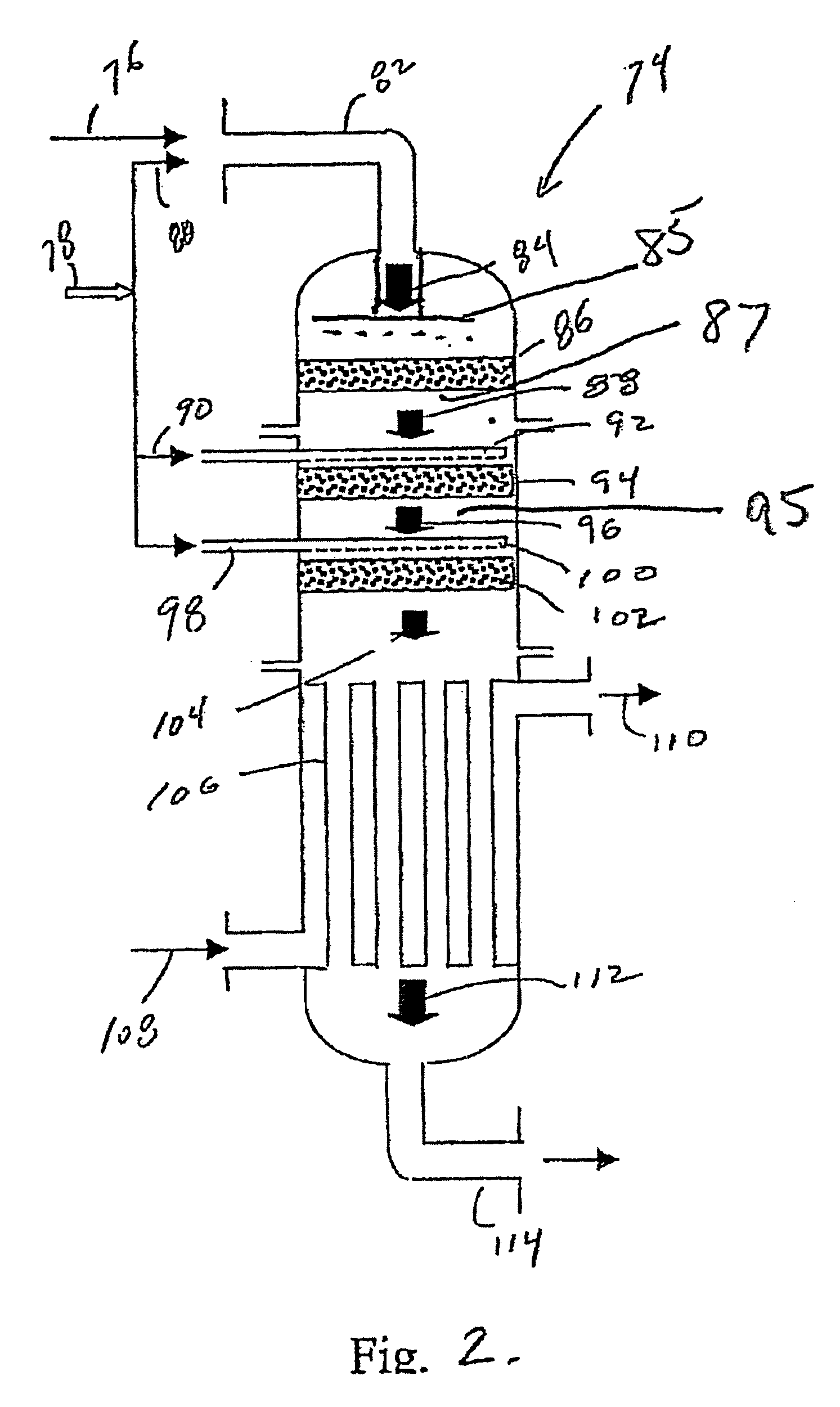

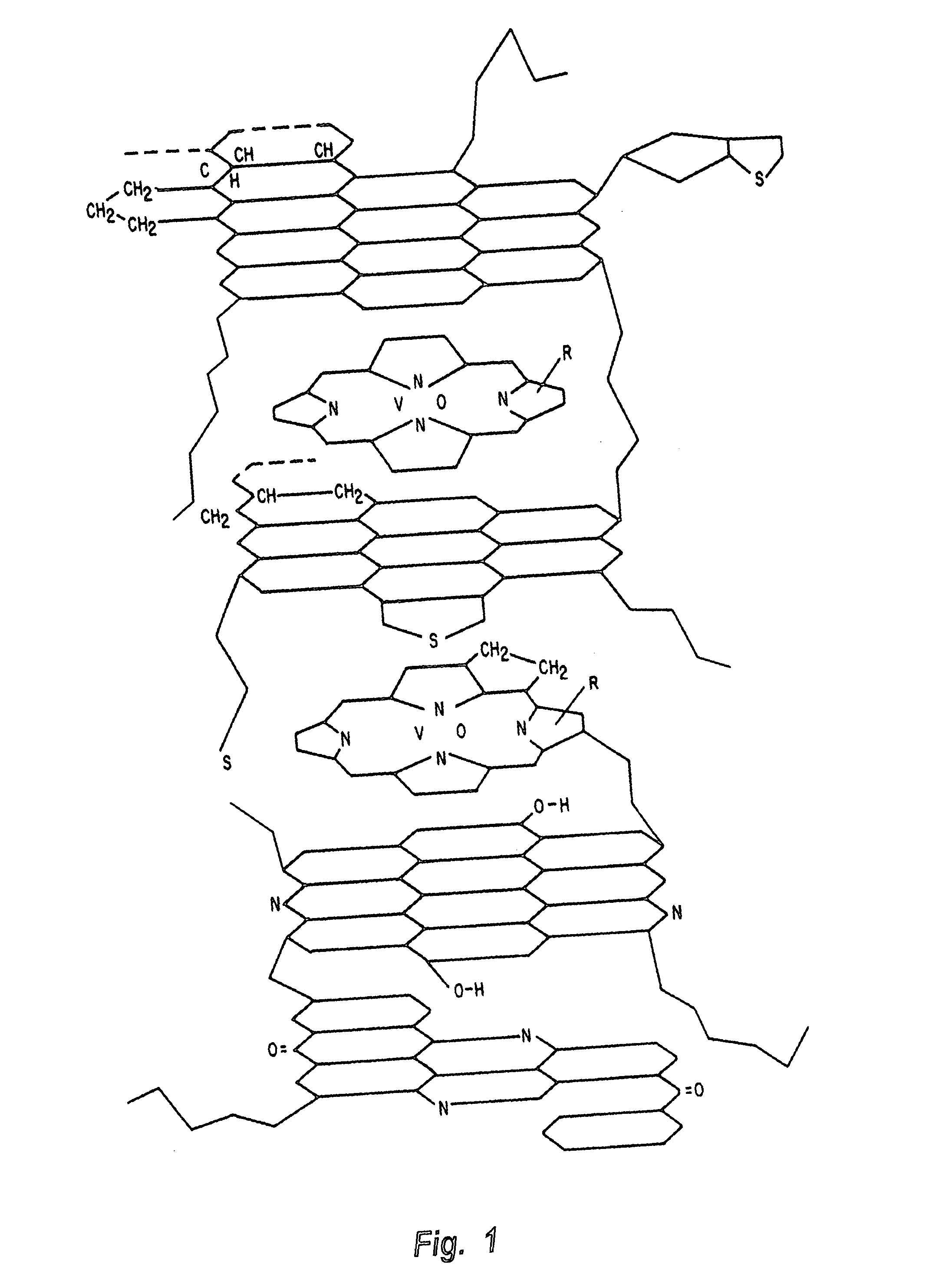

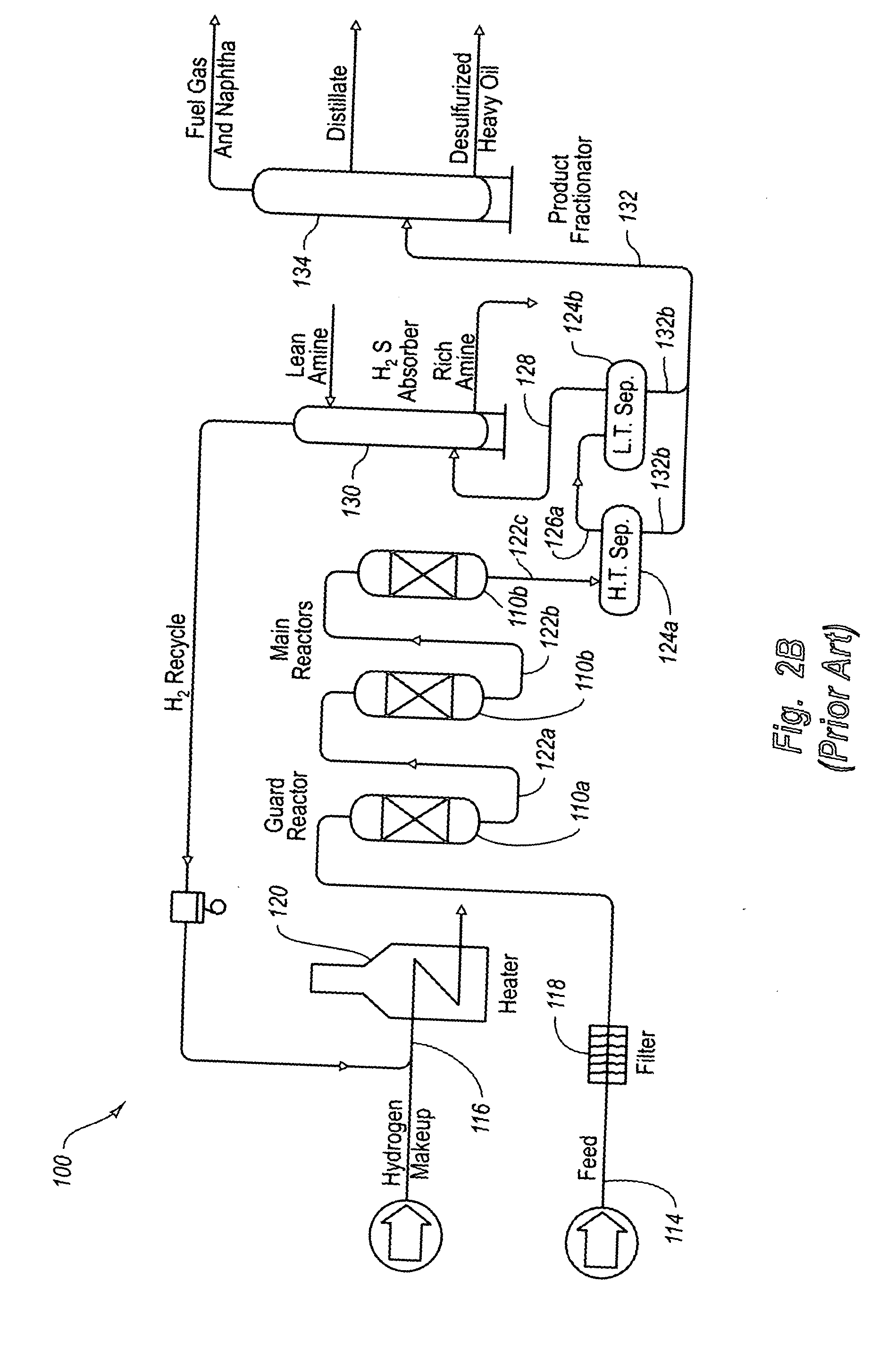

Fixed bed hydroprocessing methods and systems and methods for upgrading an existing fixed bed system

ActiveUS20050241992A1Quality improvementReduce formationCatalyst regeneration/reactivationCatalyst activation/preparationDecompositionFixed bed

A fixed bed hydroprocessing system, and also a method for upgrading a pre-existing fixed bed hydroprocessing system, involves preliminarily upgrading a heavy oil feedstock in one or more slurry phase reactors using a colloidal or molecular catalyst and then further hydroprocessing the upgraded feedstock within one or more fixed bed reactors using a porous supported catalyst. The colloidal or molecular catalyst is formed by intimately mixing a catalyst precursor composition into a heavy oil feedstock and raising the temperature of the feedstock to above the decomposition temperature of the precursor composition to form the colloidal or molecular catalyst in situ. Asphaltene or other hydrocarbon molecules otherwise too large to diffuse into the pores of the fixed bed catalyst can be upgraded by the colloidal or molecular catalyst. One or more slurry phase reactors may be built and positioned upstream from one or more fixed bed reactors of a pre-existing fixed bed system and / or converted from one or more pre-existing fixed bed reactors.

Owner:HEADWATERS TECH INNOVATION LLC

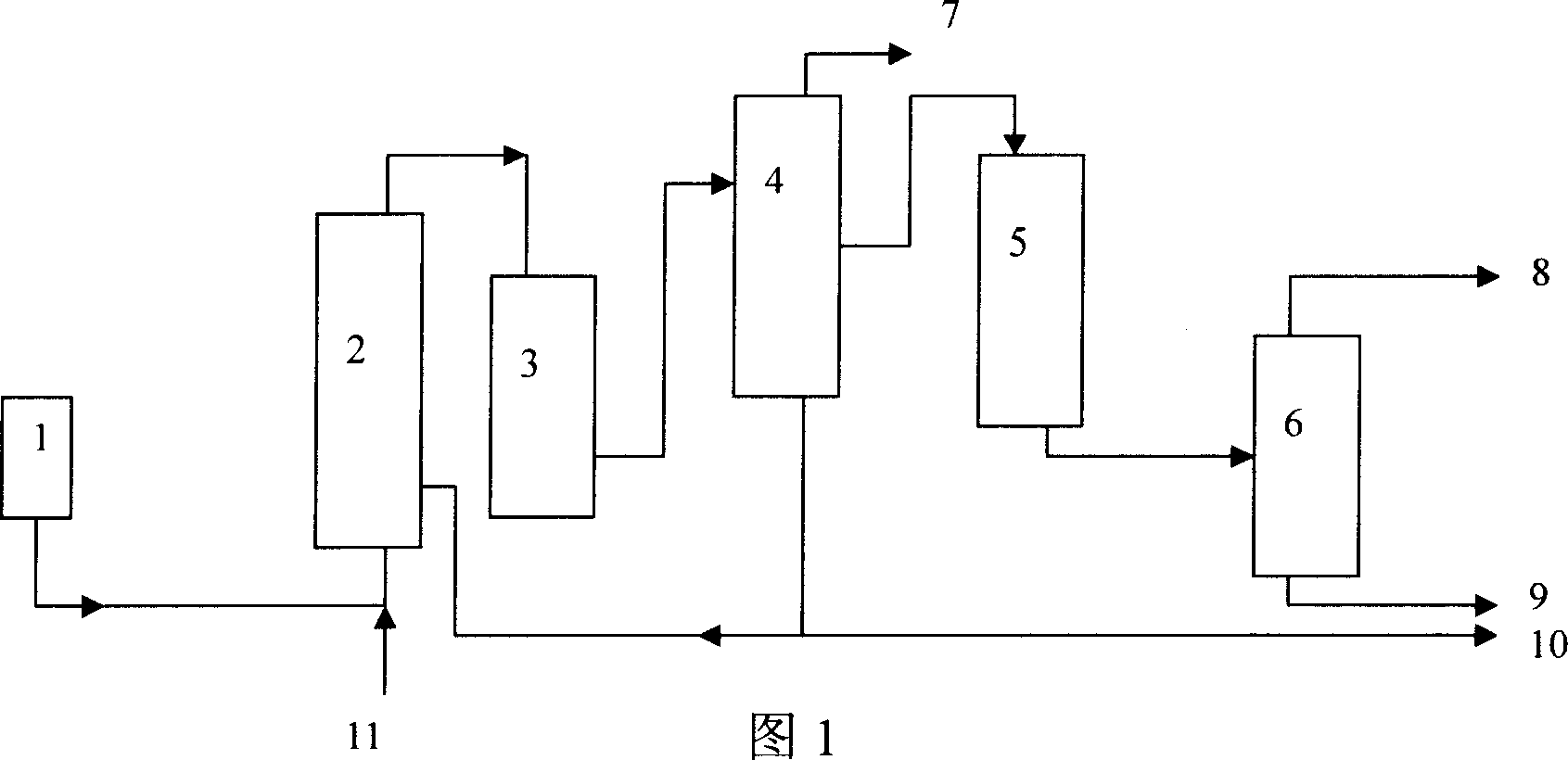

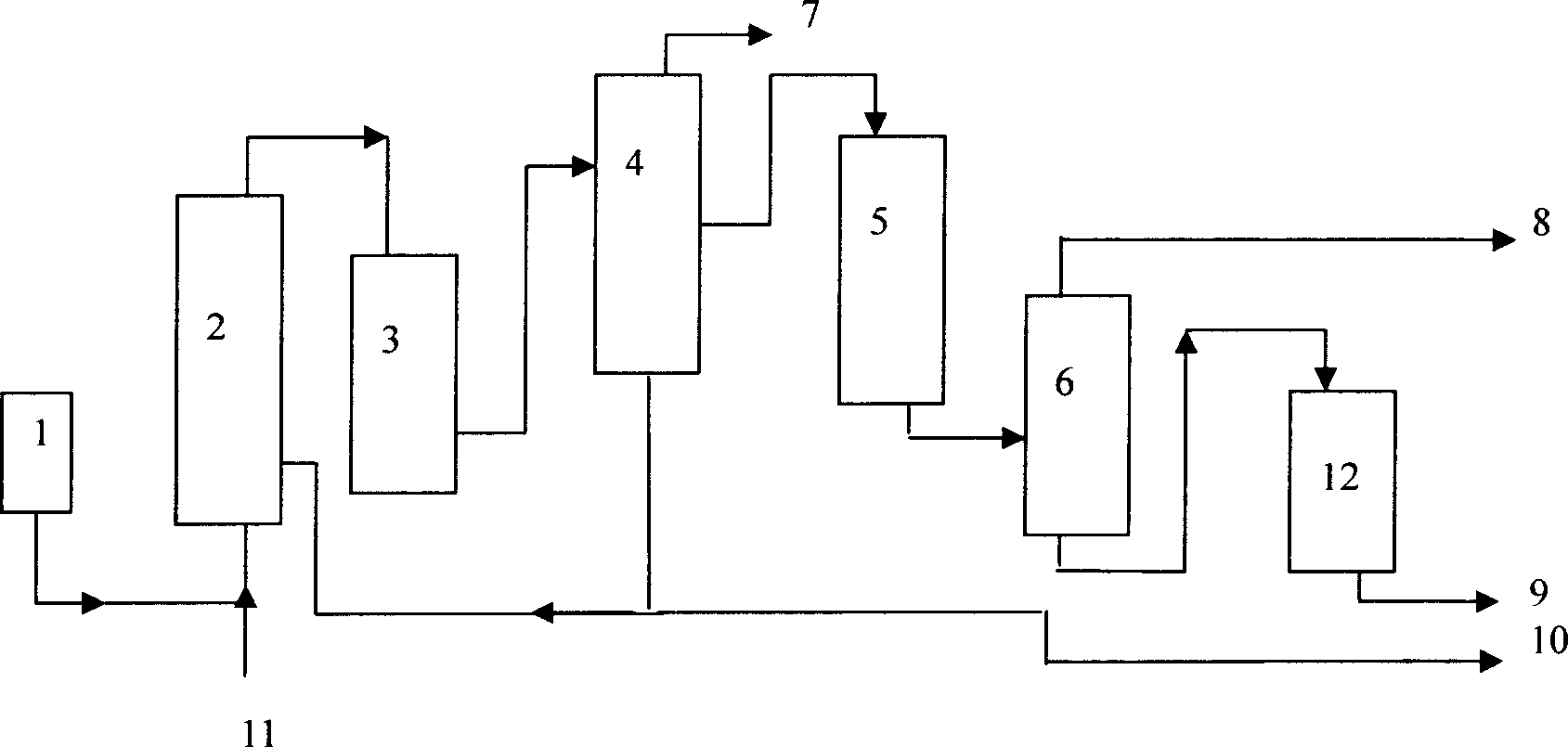

Coal tar whole fraction hydrotreatment process

ActiveCN1766058AImprove operating conditionsSimple processTreatment with hydrotreatment processesFixed bedGasoline

The invention discloses a hydrocracking treatment technique for coal tar total distillate, which comprises: first mixing with homogeneous catalyst, or adding impurity, gum, asphaltene and coal oil total distillate contained much oxygen element directly into suspended-bed hydrogenation device; cutting the stream with distilling plant to discharge water, distillate less than 370Deg that enters fixed bed reactor for hydrorefining reaction to cut gasolene less than 150Deg and diesel oil 150-370Deg, and tail oil less than 370Deg that recycles to said reactor and converts into light oil product. Compared with prior art, this invention is simple, but high conversion rate and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

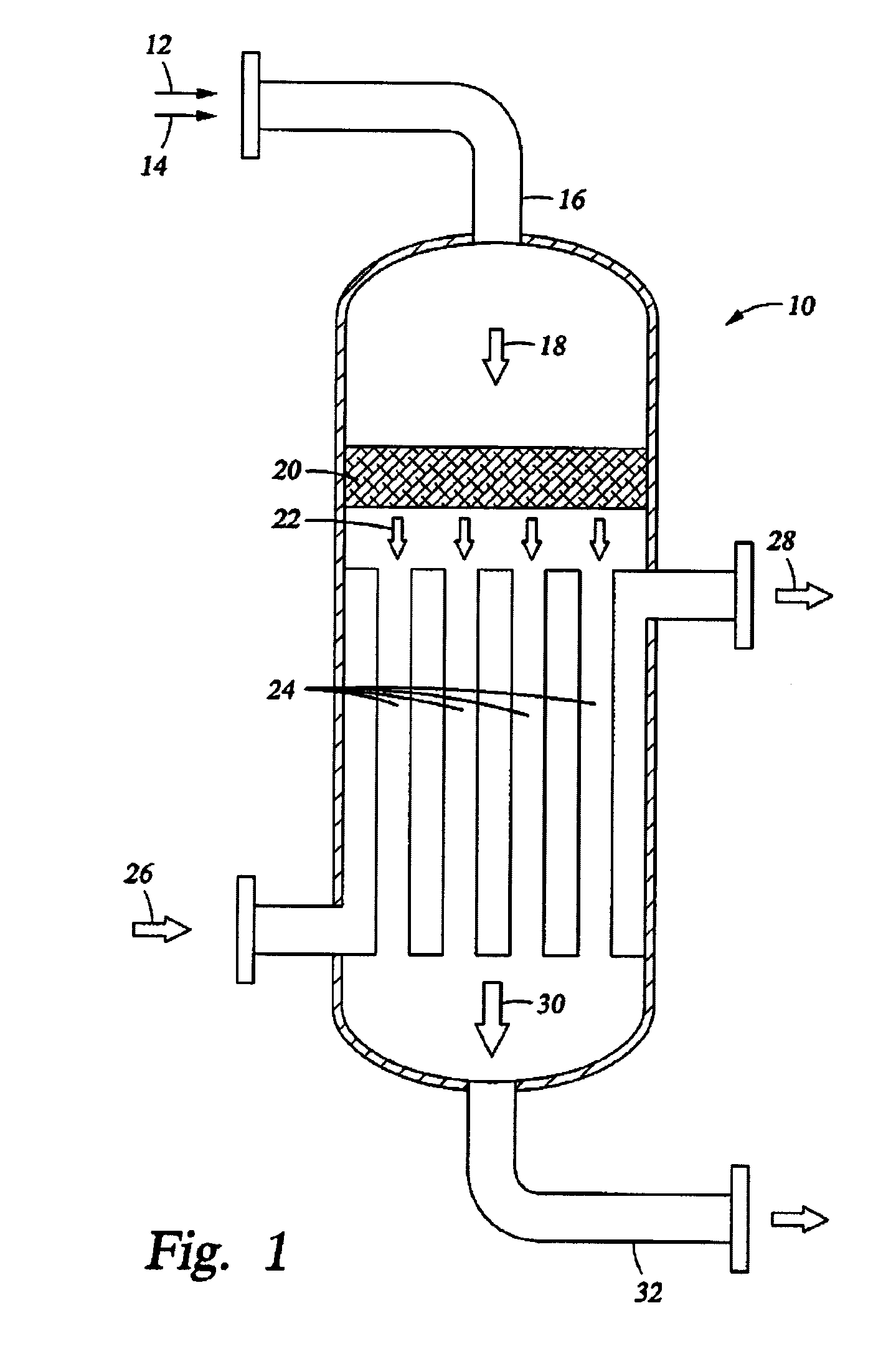

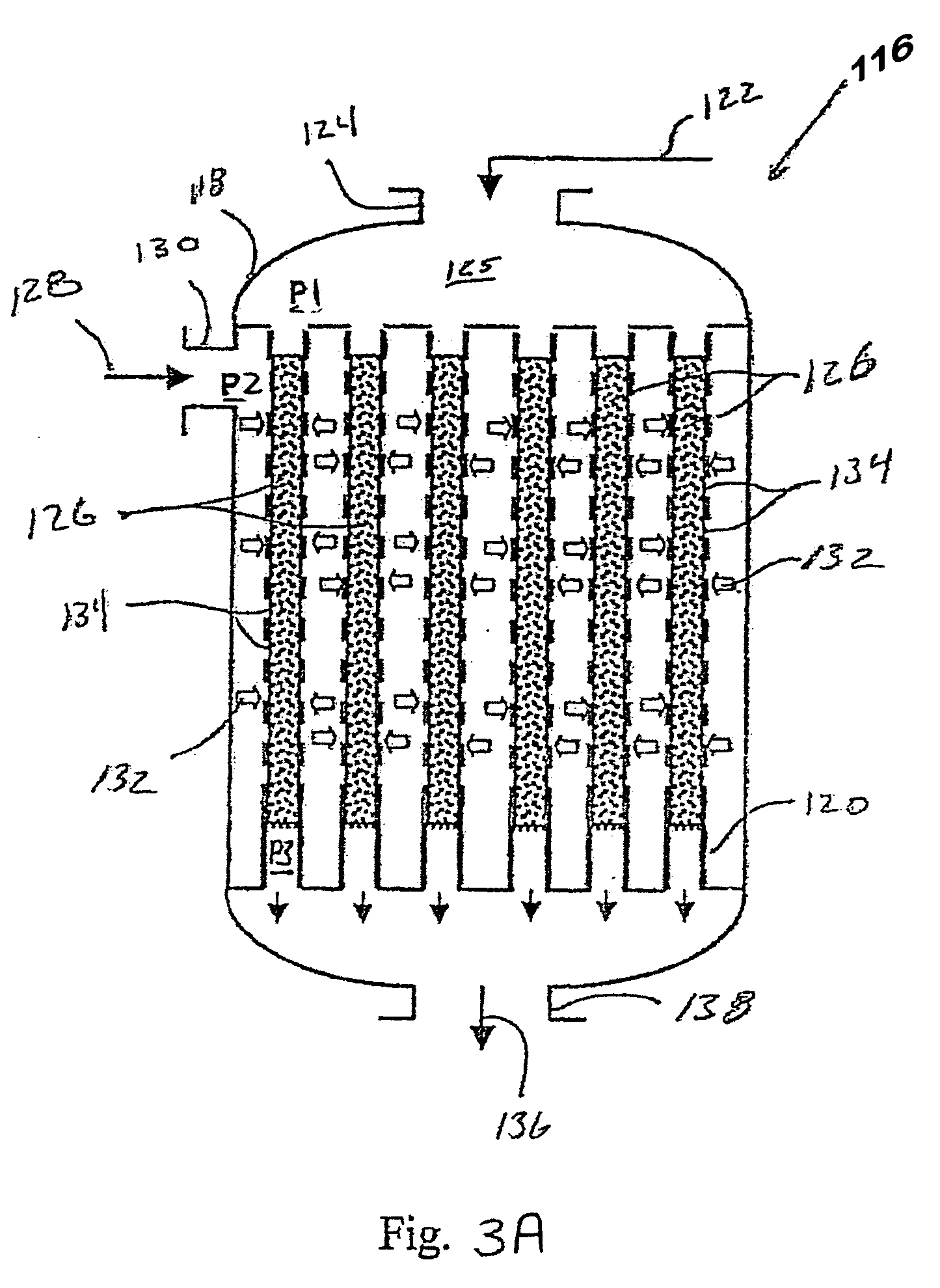

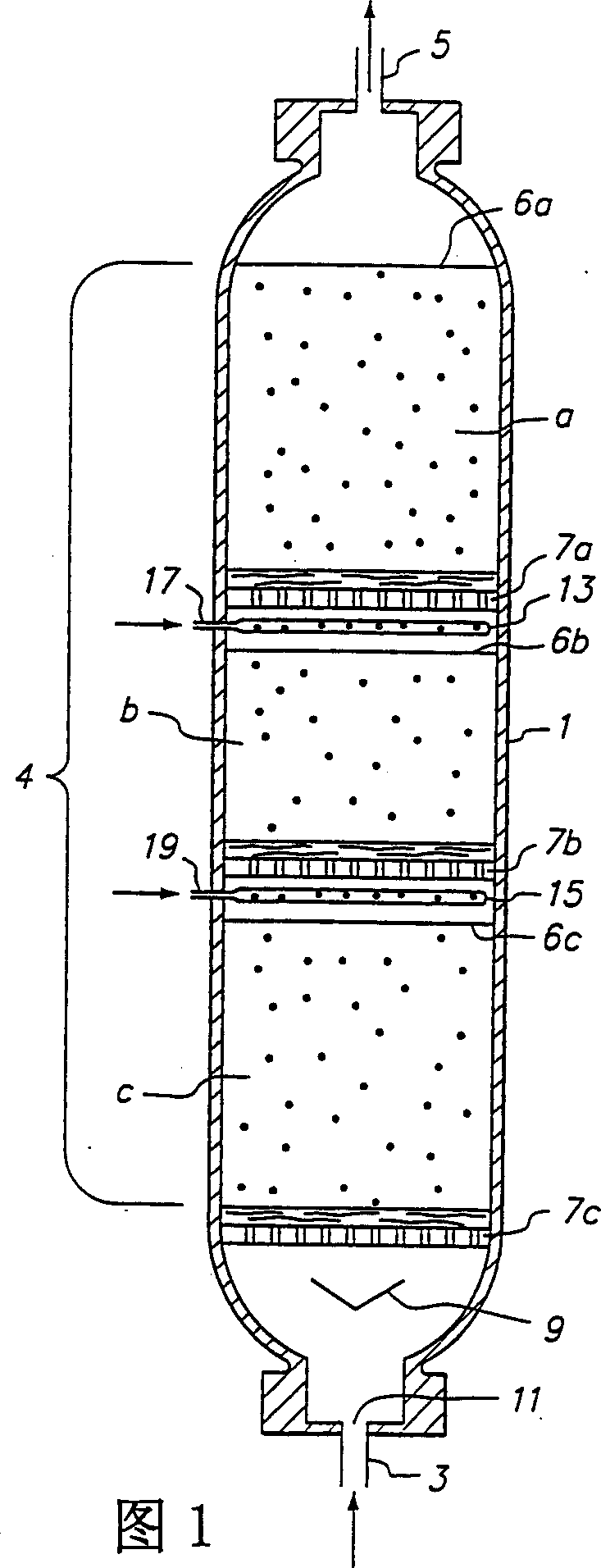

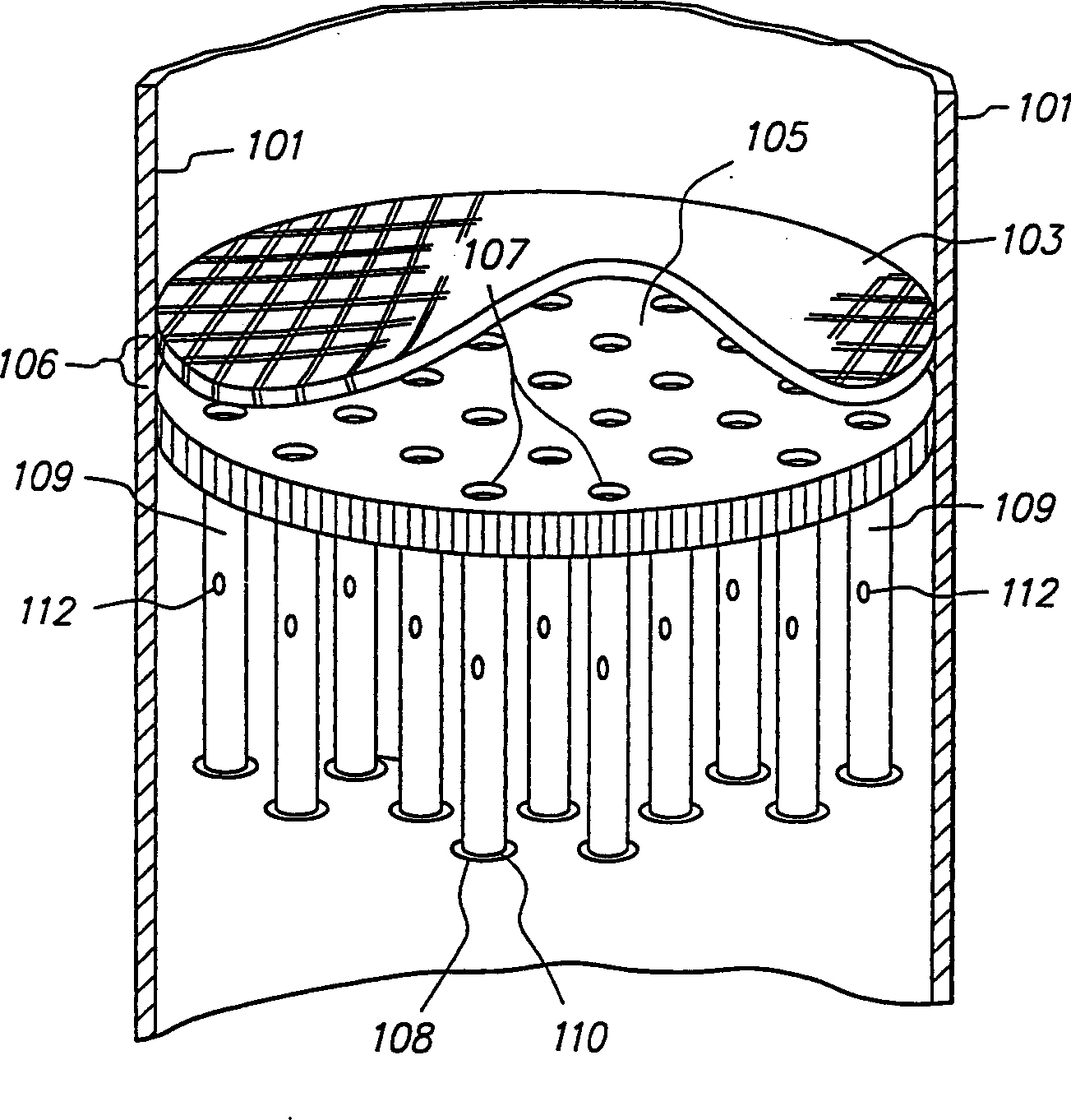

Upflow reactor system with layered catalyst bed for hydrotreating heavy feedstocks

InactiveCN1349554ATreatment with hydrotreatment processesBed hydrotreatment processes apparatusReactor systemSulfur

A reactor system and process for hydrotreating a heavy feedstock contaminated with metals sulfur and carbon residue using an upflow fixed bed reactor with at least two catalyst layers having different hydrogenation activity.

Owner:CHEVROU USA INC

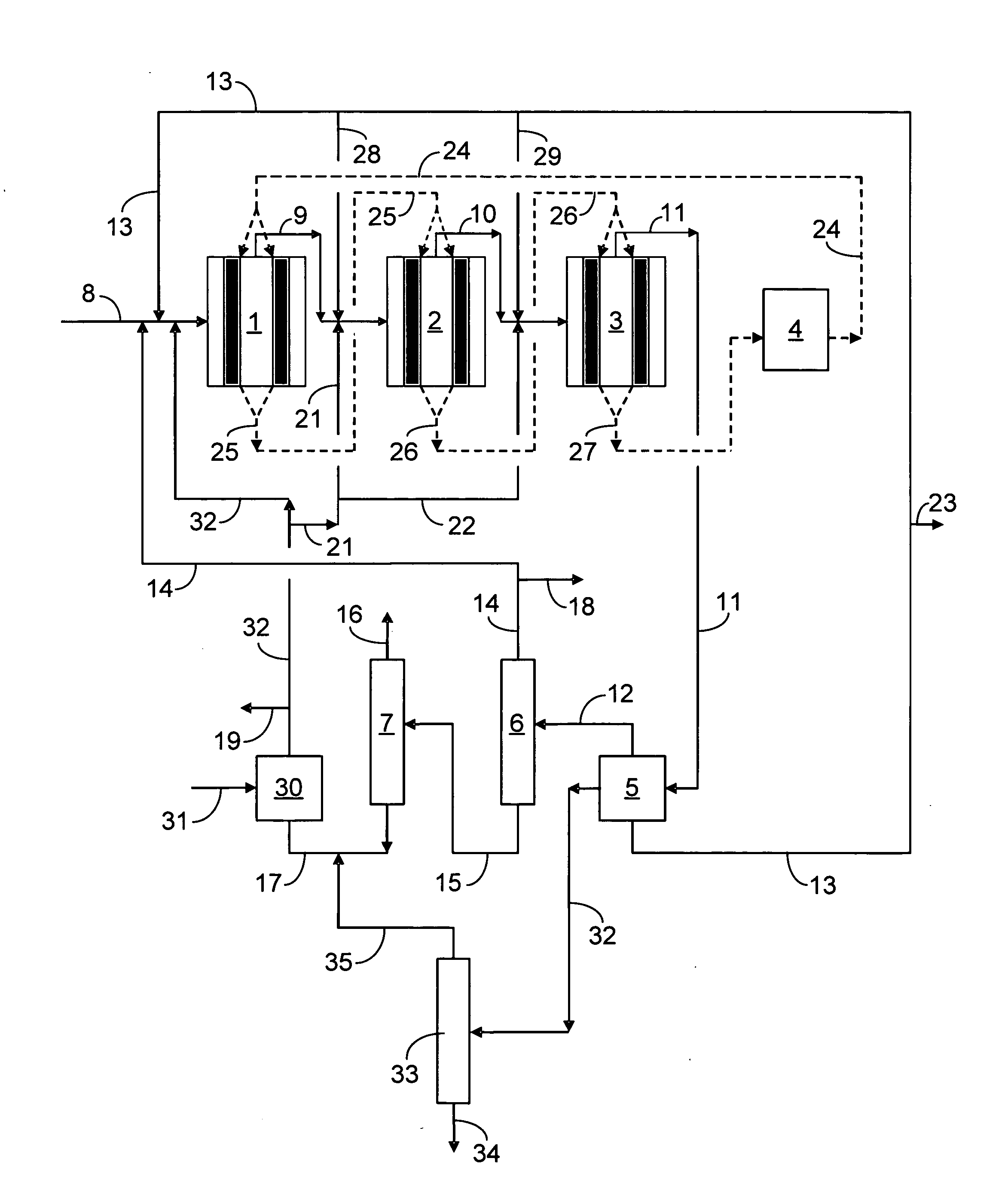

Selective conversion of oxygenate to propylene using moving bed technology and a hydrothermally stabilized dual-function catalyst

ActiveUS20060106270A1Improve economyAvoid severe deactivationMolecular sieve catalystCatalystsMolecular sieveFixed bed

The average propylene cycle selectivity of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the hydrocarbon synthesis portion of the OTP flow scheme in lieu of the fixed bed technology of the prior art; 2) a hydrothermally stabilized and dual-functional catalyst system comprising a molecular sieve having dual-function capability dispersed in a phosphorus-modified alumina matrix containing labile phosphorus and / or aluminum anions; and 3) a catalyst on-stream cycle time of 400 hours or less. These provisions stabilize the catalyst against hydrothermal deactivation and hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield near or at essentially start-of-cycle levels.

Owner:UOP LLC

Hydrotreating guard catalyst and application thereof

ActiveCN101890381AMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPore distributionFixed bed

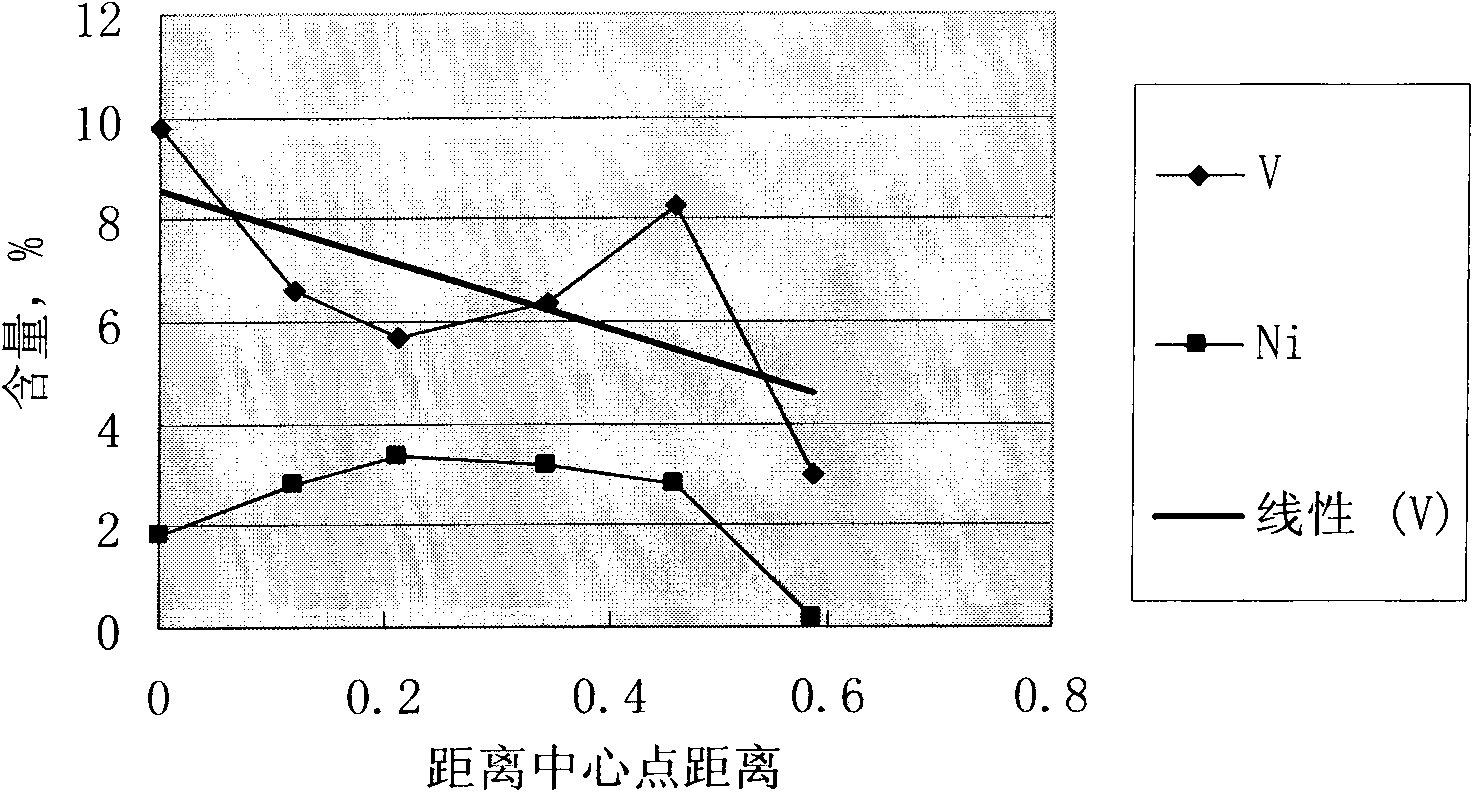

The invention discloses a hydrotreating guard catalyst for residual oil and application thereof. The catalyst has the advantages of large pore volume, large aperture, high porosity, rational pore distribution, larger external orifice, high pore canal penetrability and over 36 percent of 1,000nm pore canals, and is particularly applied to a hydrotreating method of a residual oil fixed bed to ensure that precipitated metals are uniformly deposited on the whole catalyst bed and impurities, namely vanadium and calcium, can be deposited inside the pore canals so as to improve the utilization ratio of pores and maintain long-period running.

Owner:CHINA PETROLEUM & CHEM CORP +1

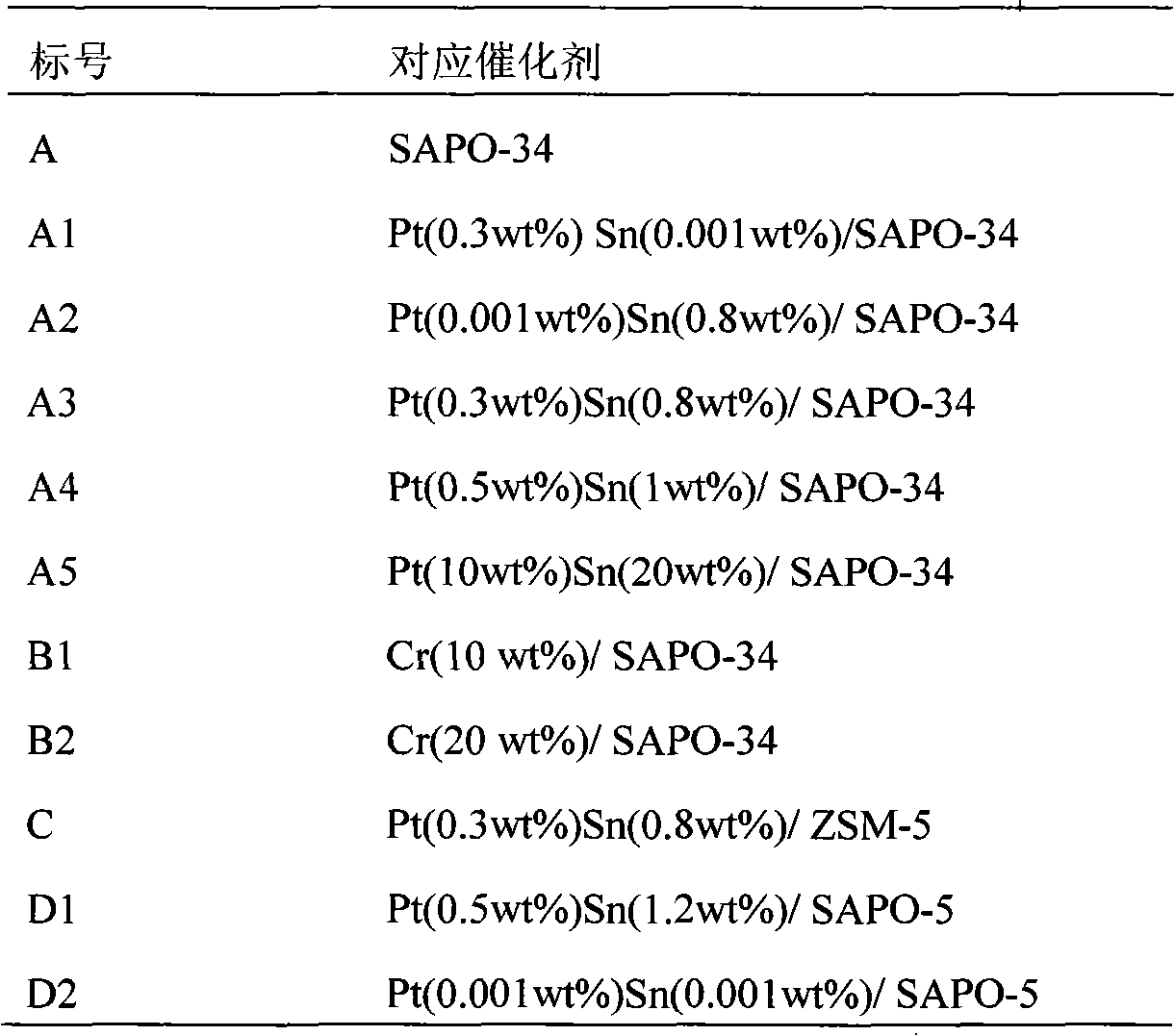

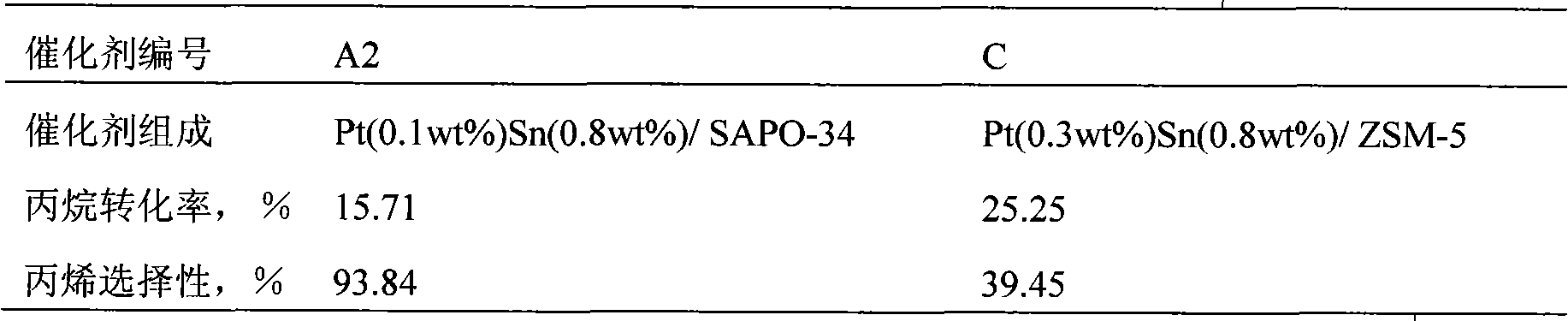

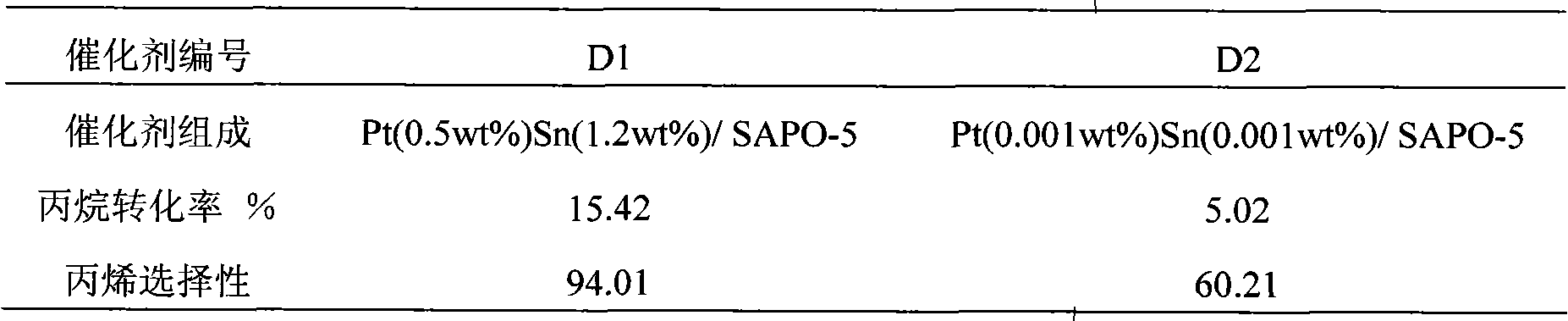

Catalyst for preparing olefin by dehydrogenating low-carbon alkane, and preparation method and application thereof

InactiveCN101623633AHigh selectivitySuitable for acidityCatalyst activation/preparationHydrocarbonsAlkaneMolecular sieve

The invention relates to a catalyst for preparing olefin by dehydrogenating low-carbon alkane, and a preparation method and an application thereof, which belong to the technical field of the preparation of basic organic chemical raw materials. The catalyst is prepared by a dipping method of using an aluminium silicophosphate molecular sieve as a carrier, VIII group or VIB group elements as active constituents and IVA group elements as an auxiliary agent. In the process for preparing olefin by dehydrogenating low-carbon alkane, the catalyst is firstly reduced by hydrogen gas, then participates in a reaction, and is finally regenerated. Compared with the existing catalyst for preparing olefin by dehydrogenating low-carbon alkane, the catalyst has a pore shape selecting function and moderate acidity, thereby the selectivity of the low-carbon alkane can reach more than 90 percent in the process for preparing olefin by dehydrogenating low-carbon alkane. The preparation method of the catalyst is simple; the regeneration process flow of the reaction has a large choice, a fixed bed, a fluidized bed or a moving bed can be used as a reactor, and the catalyst can be regenerated in the reactor or outside the reactor.

Owner:TSINGHUA UNIV

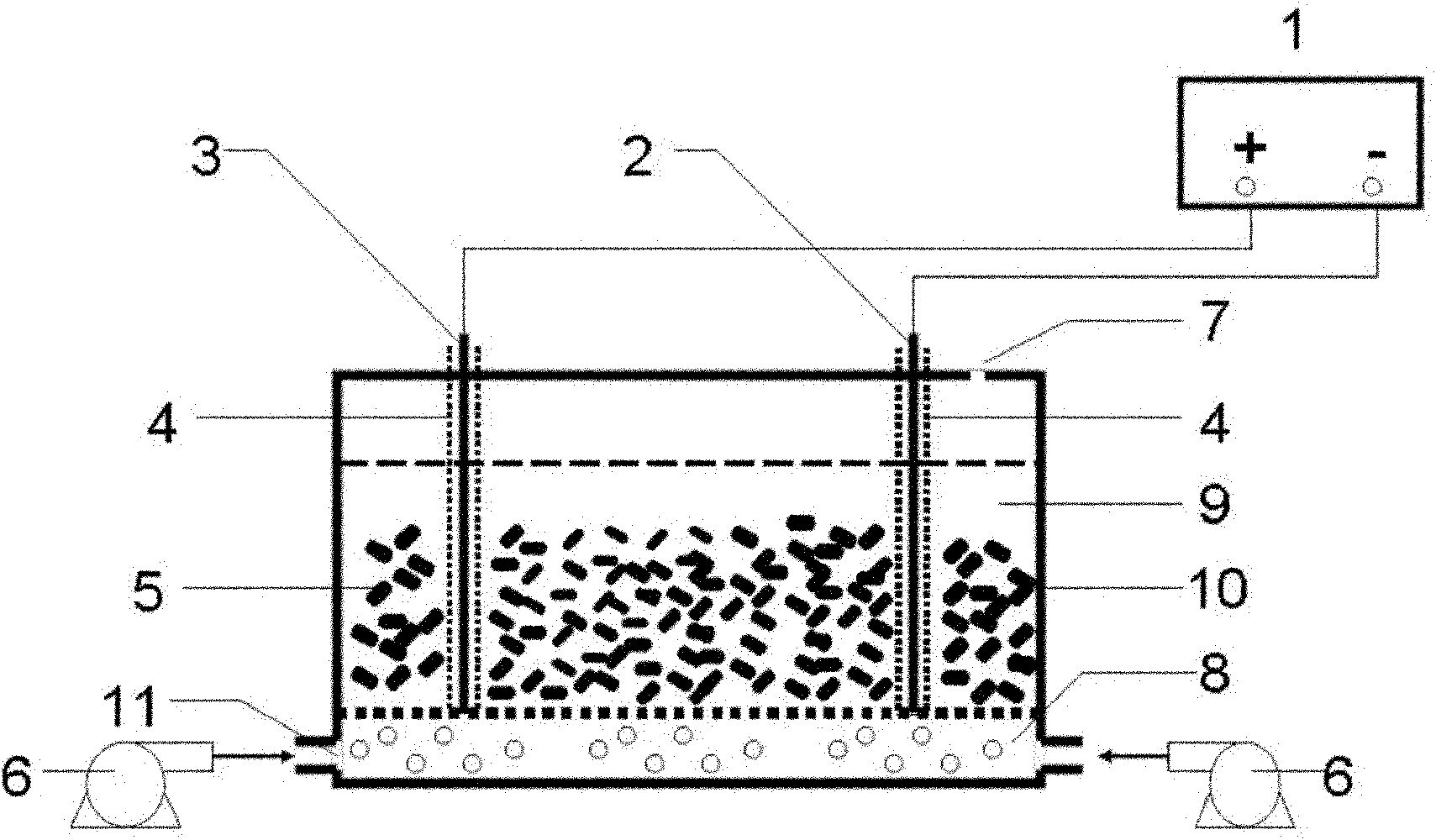

Method for removing organic matters in water by utilizing three-dimensional electrode electro-fenton and device thereof

InactiveCN102070230AIncrease contact areaExtension of timeWater/sewage treatment by oxidationFenton reagentFixed bed

The invention relates to a method for carrying out oxidation treatment on organic waste water by utilizing a three-dimensional electrode electro-fenton and a device thereof. The device comprises a reactor shell, a carbon material cathode, an iron plate anode, a three-dimensional particle electrode of a fixed bed, a direct-current voltage-stabilizing power supply, a microporous aeration plate and an air pump, wherein a reactor consists of a reaction chamber and a gas chamber; the carbon material cathode, the iron plate anode and the particle electrode are positioned in the reaction chamber at the upper part of the reactor; and the gas chamber is formed between the bottom of the reactor and the microporous aeration plate. After direct current is introduced, the iron anode is oxidized to generate iron ions, oxygen in the gas chamber is reduced on the surface of the cathode to generate hydrogen peroxide, and the iron ions and the hydrogen peroxide form a fenton reagent to oxidize and remove organic matters in waste water; and simultaneously, due to the particle electrode, the contact area and the contact time of the waste water and the fenton reagent are increased, and the mass transfer effect of the waste water in the reactor is reduced. The invention is applicable to treatment of various types of organic waste water, the equipment is compact, the operation is easy, the whole reactor is easy to control, and the requirements of an actual water treatment unit are met.

Owner:HUAZHONG NORMAL UNIV

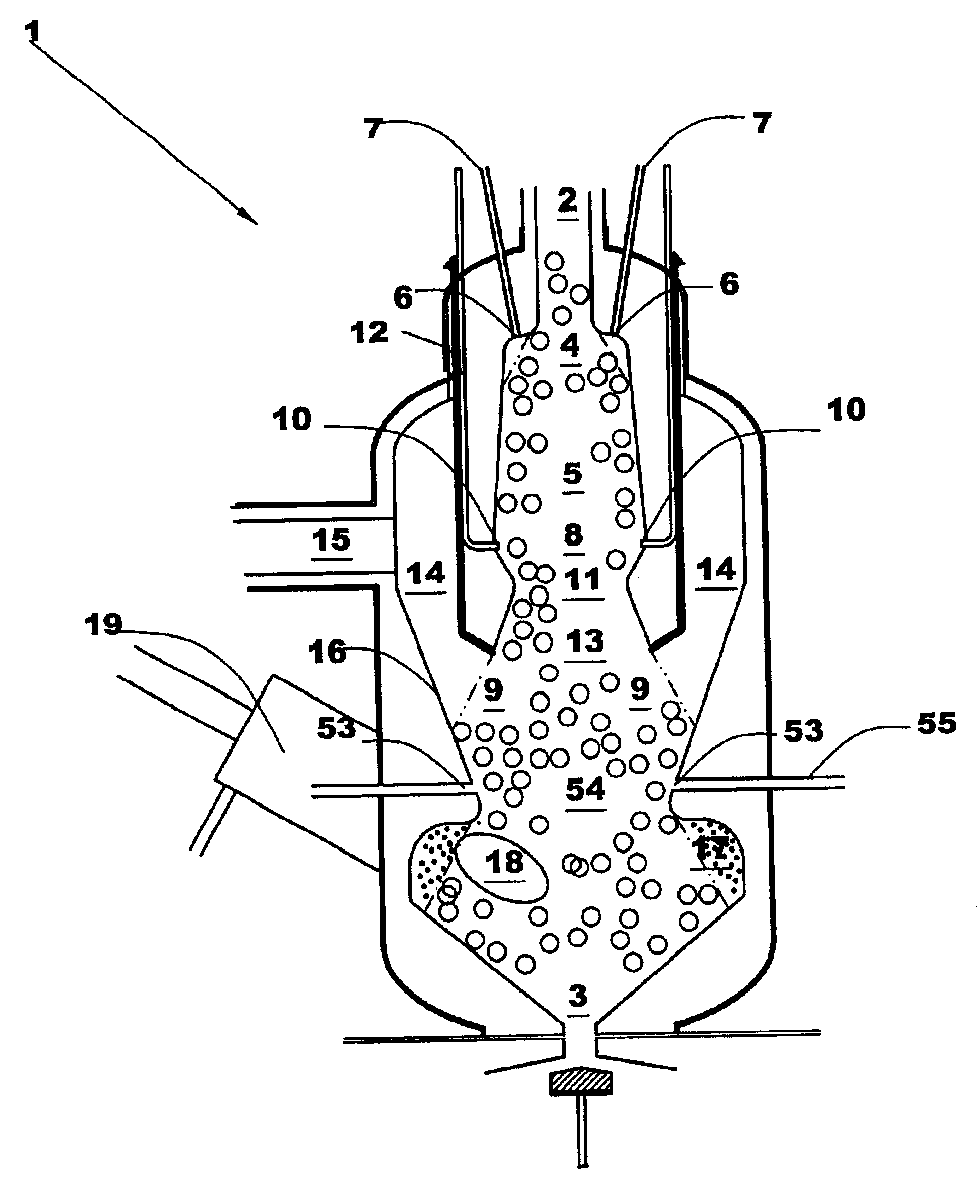

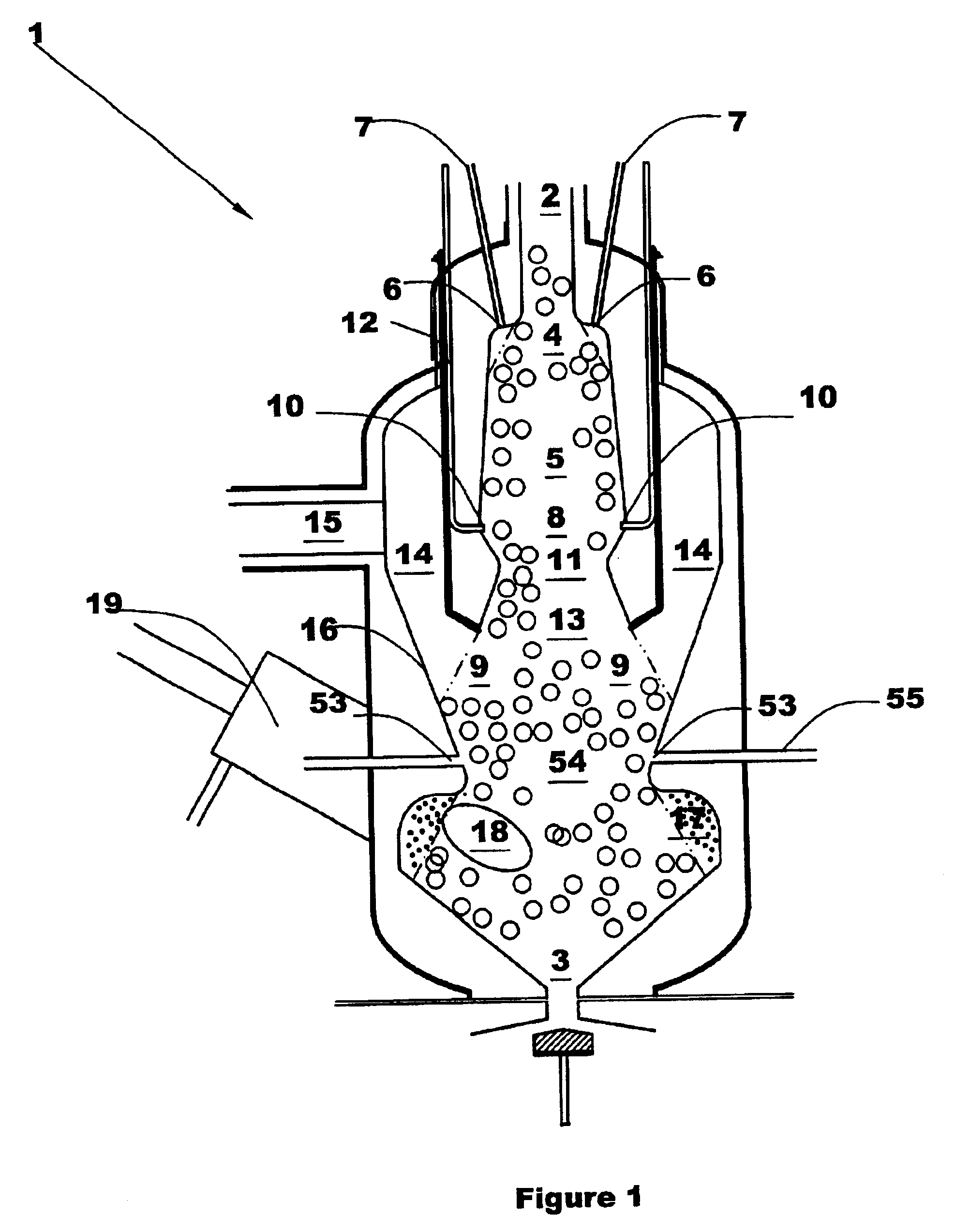

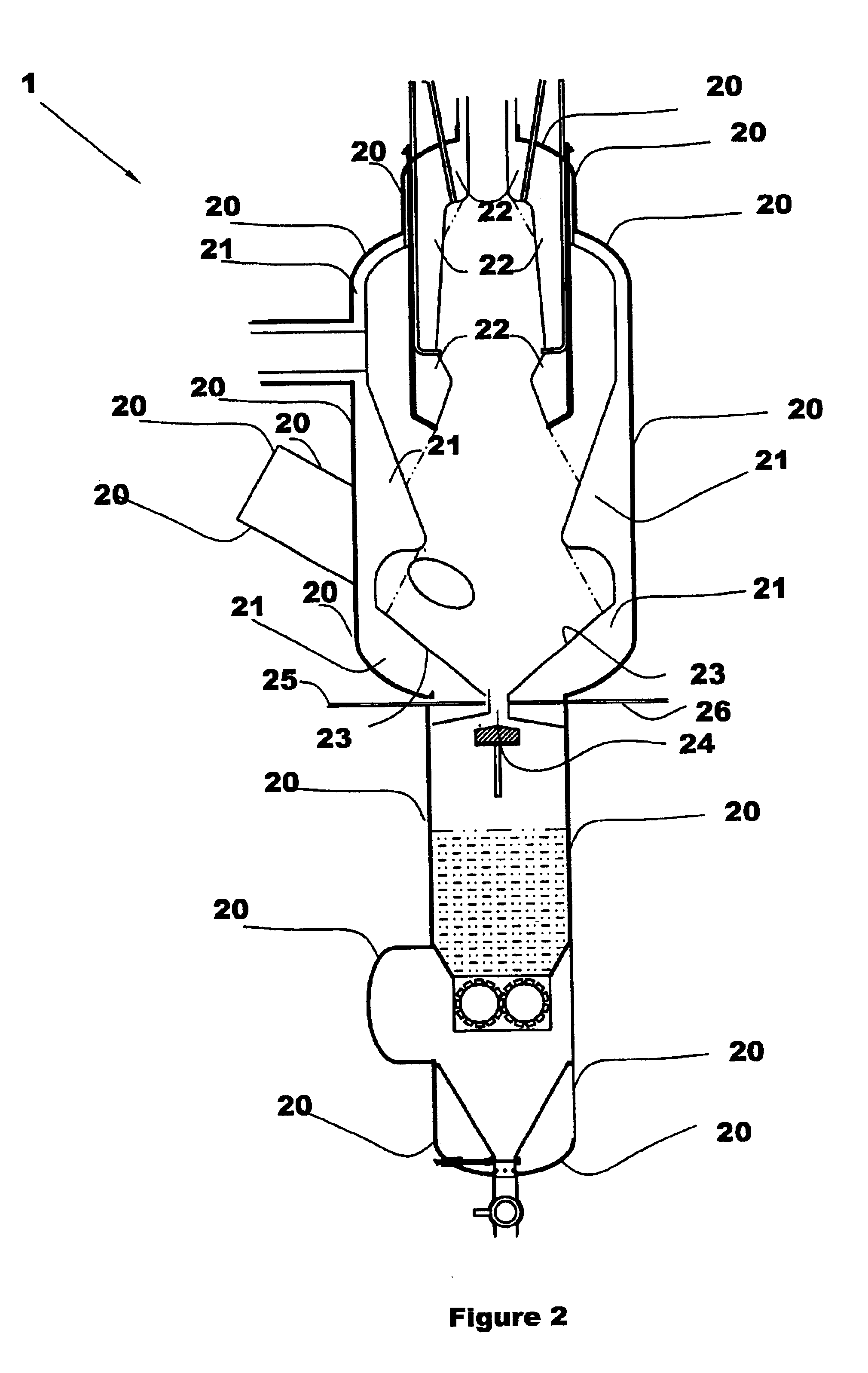

Multi-faceted gasifier and related methods

InactiveUS6960234B2Increased hydrogen productionImprove overall plant economicsLiquid degasificationCoke ovensActivated carbonInjection port

A gasifier is disclosed combining a fixed bed gasification section where coarse fuel is gasified and an entrained flow gasification section where fine fuel is gasified. The fixed bed section includes upper and lower sections. Coarse fuel is devolatilized in the upper fixed bed section and subjected to elevated temperatures sufficient to crack and destroy tars and oils in the effluent gases. The entrained flow gasification section is disposed in a lower plenum adjacent the lower fixed bed section. A plurality of injection ports are configured to introduce oxygen, steam, or air into different sections of the gasifier to control temperature and operating conditions. Activated carbon may be formed in the upper fixed bed section and in the entrained flow section. The activated carbon may be used as a sorbent to remove pollutants from the effluent gases. The gasifier may be used with various coarse and fine fuel feedstocks.

Owner:EMERY ENERGY

Catalyst for C4 liquefied petroleum gas aromatization and its preparing method

InactiveCN1586721ALess modification stepsLow costMolecular sieve catalystsLiquid hydrocarbon mixtures productionHigh carbonFixed bed

The present invention belongs to the field of catalyst preparation in petrochemical technology, and especially one kind of catalyst for the aromatization of liquefied C4 petroleum gas in fixed bed reactor and its preparation process. Technologically, the catalyst features that its mother substance is high-silicon zeolite with crystal granulation of 10-500 nm and the zeolite is alumina formed and prepared into the hydrogen type catalyst via conventional process, and the hydrogen type catalyst is vapor treated to regulate the acidity and acid treated to expand the pores and restore the pore passage. The catalyst is used in the aromatization of liquefied C4 petroleum gas, and has low reaction temperature, high olefin converting rate and high carbon deposition resistance.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH

Fixed bed catalysts

InactiveUS6284703B1Promote hydrogenationHigh activityOrganic compound preparationPreparation by hydrogenationRheniumPowder mixture

A shaped, activated, fixed-bed Raney metal catalyst prepared by a method comprising preparing a mixture of powders comprising at least one catalyst alloy of (1) at least one catalytically active Raney process metal, a leachable alloy component and optionally a promoter, (2) at least one binder containing at least one pure Raney metal and (3) a moistening agent. Shaping, calcining and activating said catalyst and doping said catalyst with rhenium.

Owner:DEGUSSA AG

Process for removal of nitrogen and poly-nuclear aromatics from hydrocracker and FCC feedstocks

ActiveUS20080105595A1Increase heightCatalytic crackingTreatment with plural serial stages onlyActivated carbonSorbent

A feedstream to a hydrocracking unit is treated to remove or reduce the content of polynuclear aromatics and nitrogen-containing compounds by contacting the feedstream with an adsorbent compound selected from attapulgus clay, alumina, silica gel and activated carbon in a fixed bed or slurry column and separating the treated feedstream that is lower in the undesired compounds from the adsorbent material. The adsorbent can be mixed with a solvent for the undesired compounds and stripped for re-use.

Owner:SAUDI ARABIAN OIL CO

Catalyst for desulfurizing and denitrating at the same time and its application method

InactiveCN1475305AHigh porosityRelieve pressureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonSulfur

A desulfurizing-denitrating catalyst contains cellular activated carbon (90-99.9 wt.%) and V2O5. It is applied through putting it on supporter in fixed-bed reactor and reacting on fume at 150-250 deg.C and 500-5000 / hr of space speed. Its advantage is high transform rate of 80% for SO2 and 50-100% for NO.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

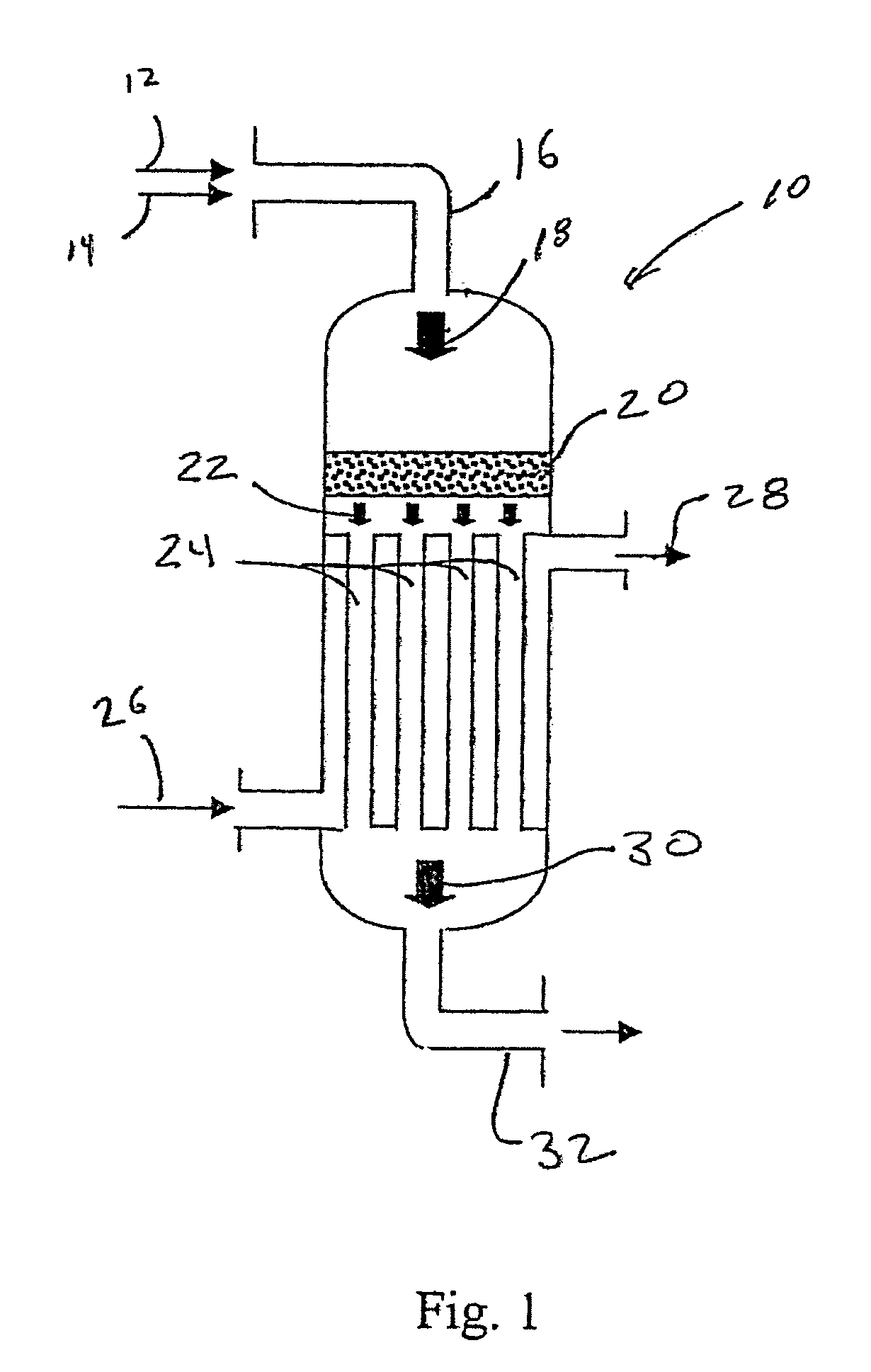

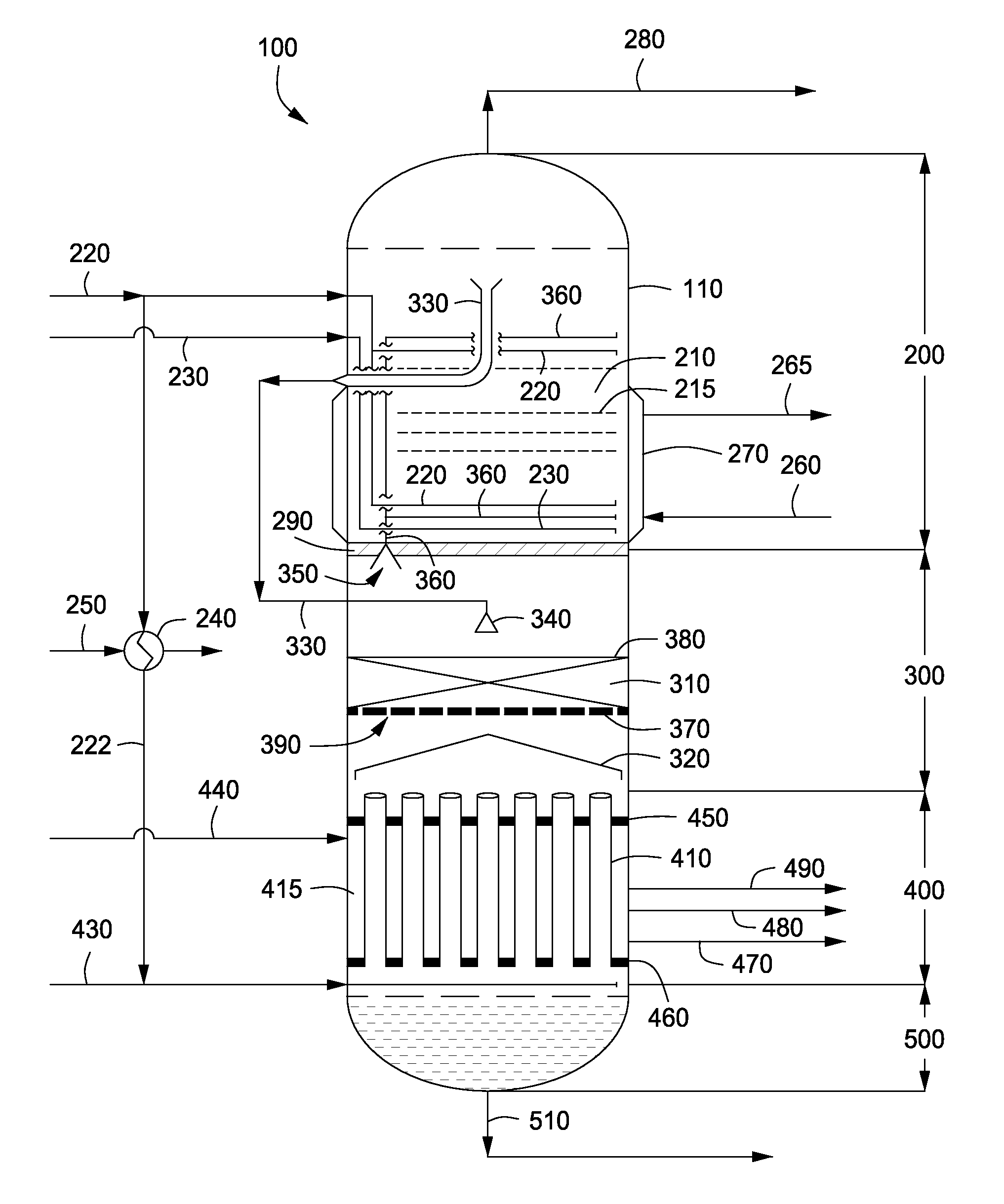

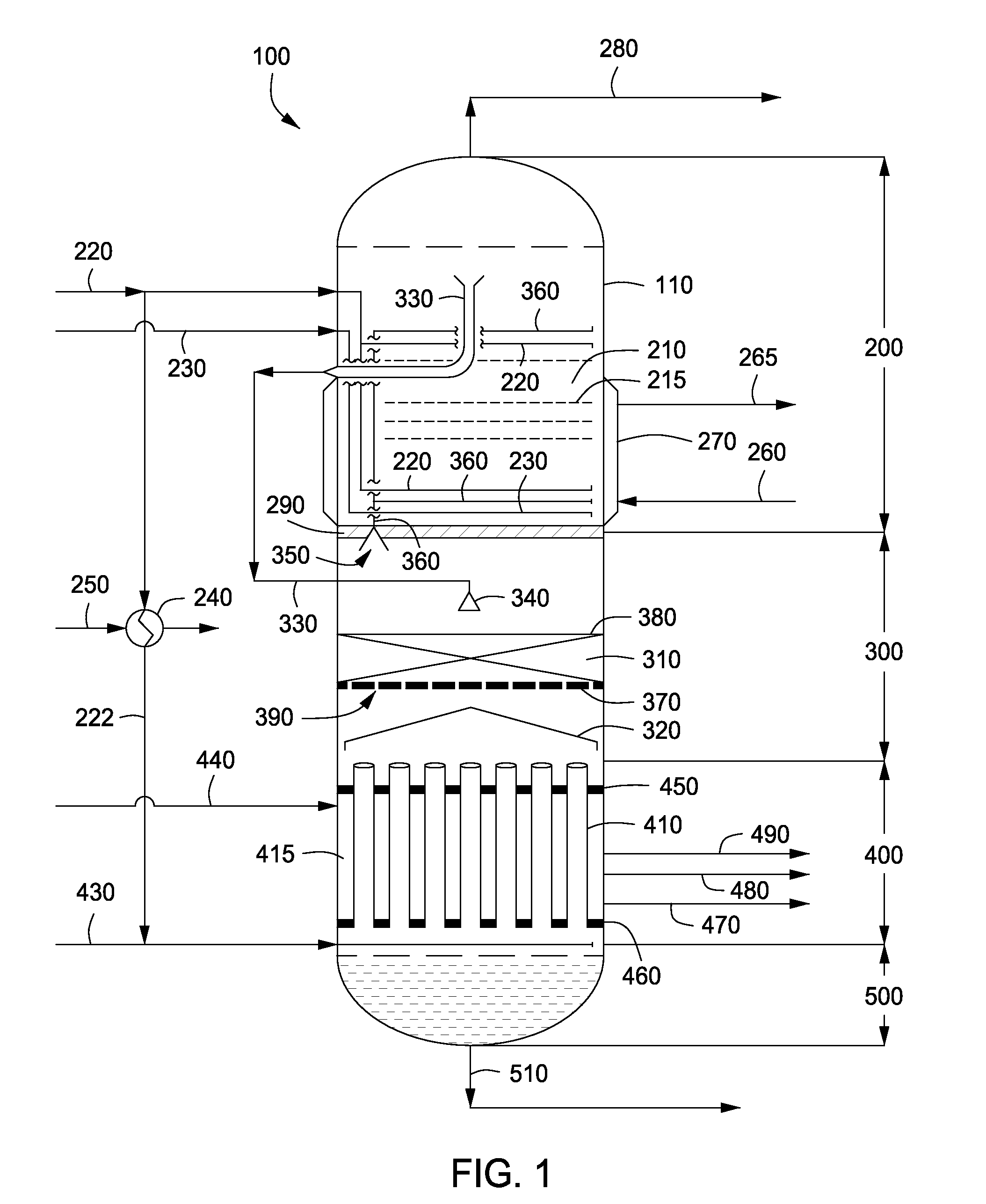

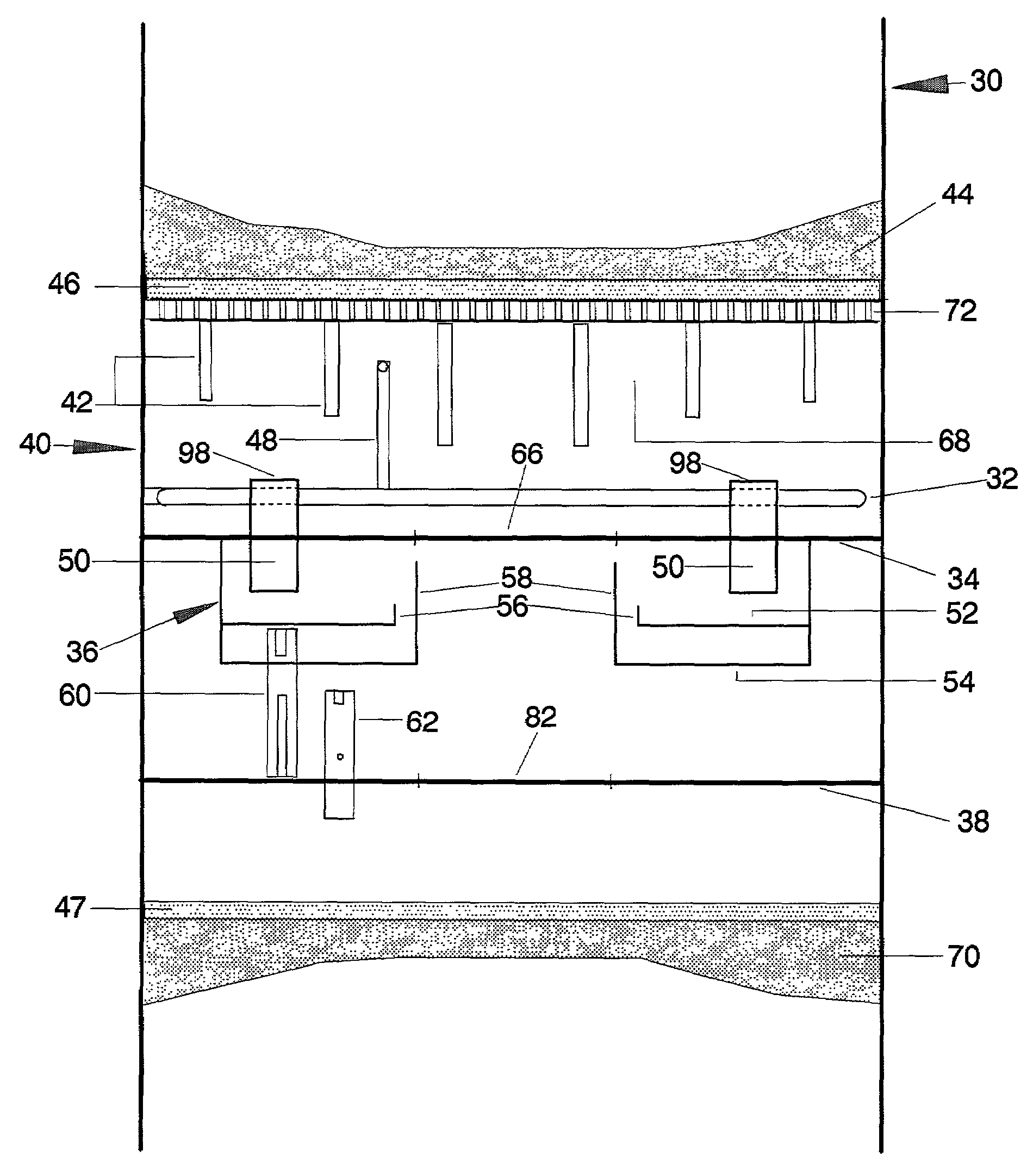

Apparatus and methods for urea production

Apparatus and methods for producing urea are provided. In one or more embodiments, an apparatus for producing urea can include a first zone, which can include a first flow channel in fluid communication with a first tube disposed about a first end of a plurality of trays, a second flow channel in fluid communication with a second tube disposed about the first end of the trays and a second end of the trays, and a third flow channel in fluid communication with a third tube disposed about the first and second ends of the trays. The apparatus can include a second zone, which can include a fixed bed comprising one or more inert packing materials disposed therein to provide additional surface area. The apparatus can include a third zone, which can include a plurality of tubes disposed therein. The second zone can be disposed between the first and third zones.

Owner:KELLOGG BROWN & ROOT LLC

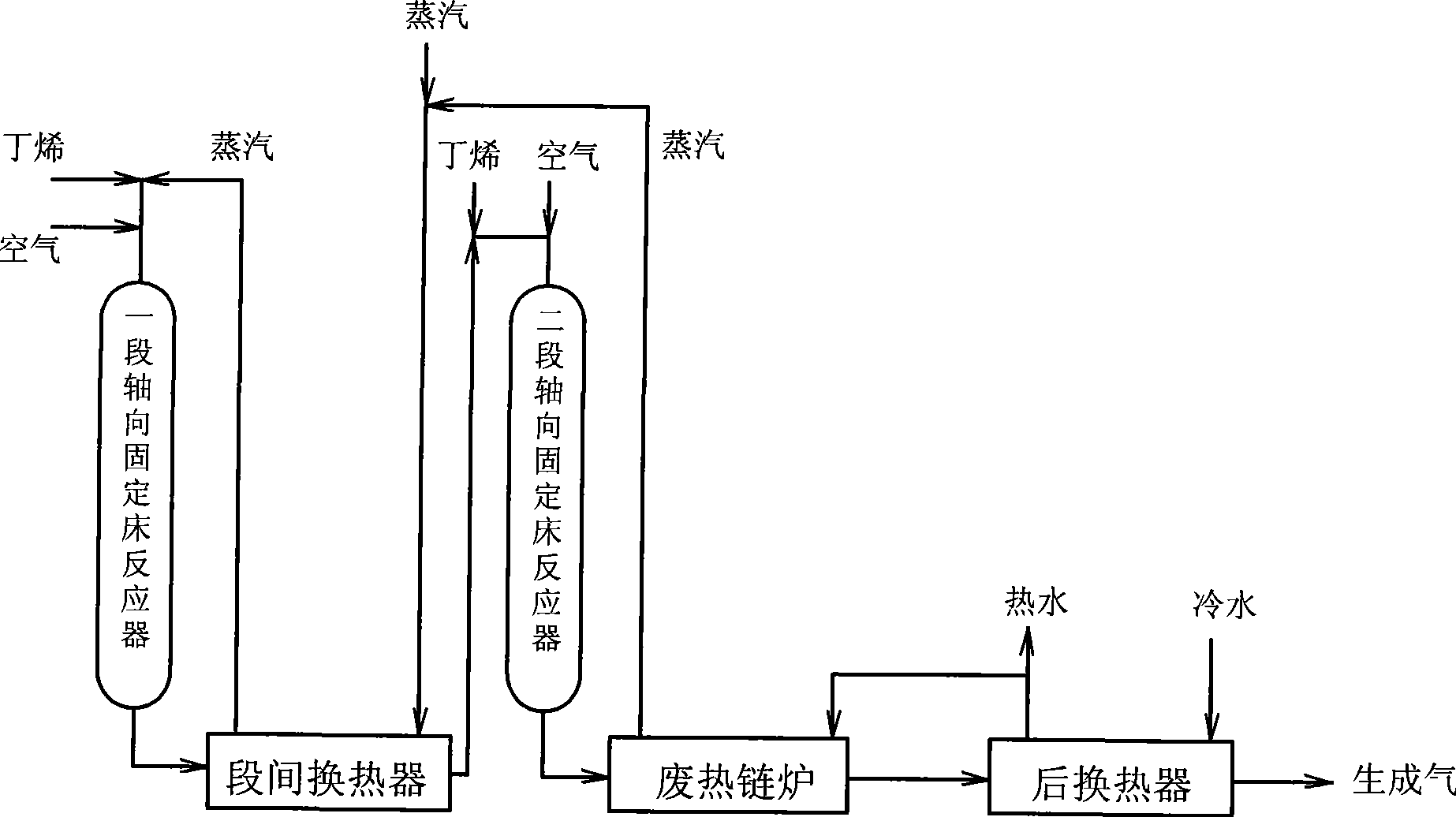

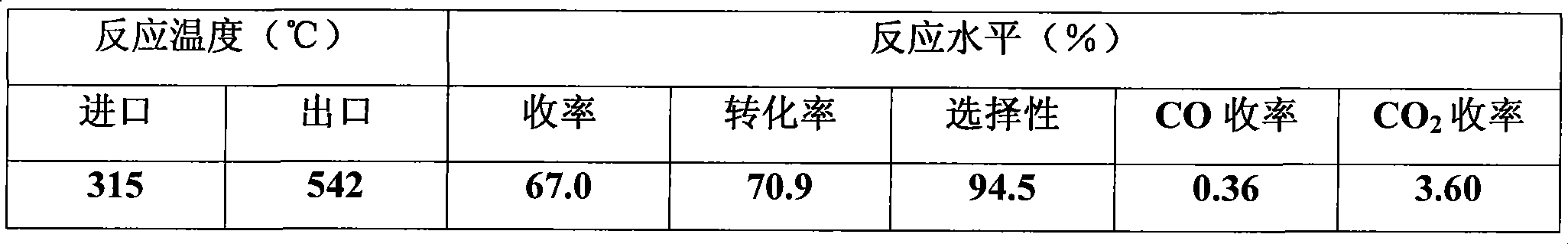

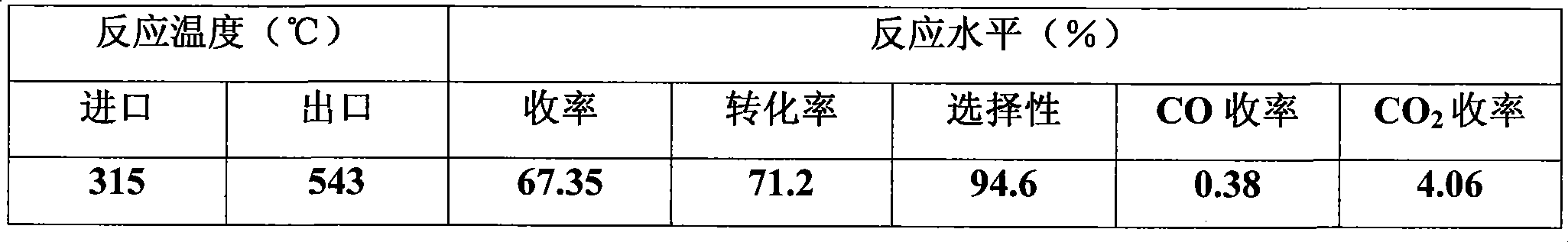

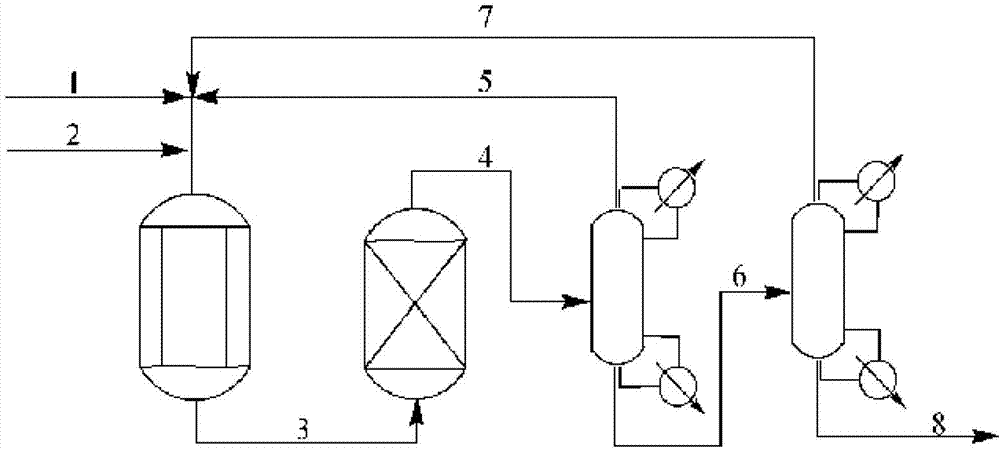

Method for preparing butadiene with butylene oxo-dehydrogenation of axially-located bed

ActiveCN101367702AIncrease productionReduce unit consumptionHydrocarbonsHydrocarbon preparationInlet temperatureFixed bed

The invention relates to a method of preparing butadience with a butylene oxydehydrogenation device in a fixed bed, which belongs to the chemical technical field. The butylene, air and water vapor give an oxydehydrogenation reaction in an axial fixed bed reactor and generate the butadience. The axial fixed bed reactor has two segments. Process equipment consists of a first segment of axial fixed bed reactor, an inter -segment heat exchanger, a second segment of axial fixed bed reactor, a waste heat boiler and a back heat exchanger in turn. The reactor is filled with iron-based catalyst. The ingredient of the water vapor of the first segment of reactor acts with the first segment via the inter-segment heat exchanger to generate gas in addition to exchanging heat and raising temperature and then is mixed with the ingredient butylene and the air of the first segment to achieve the inlet temperature of the first segment of reactor. The ingredient of the first segment enters to the first segment of reactor to react. After heat exchange and temperature reduction through the inter-segment heat exchanger, the gas generated in the first segment is mixed with the feed butylene of the second segment and the air to achieve the inlet temperature of the second segment of reactor and reacts in the second segment of reactor. The invention has the advantages of high yield coefficient, high selectivity and steam of low unit consumption. Heat energy can be used reasonably.

Owner:ZIBO QIXIANG TENGDA CHEM

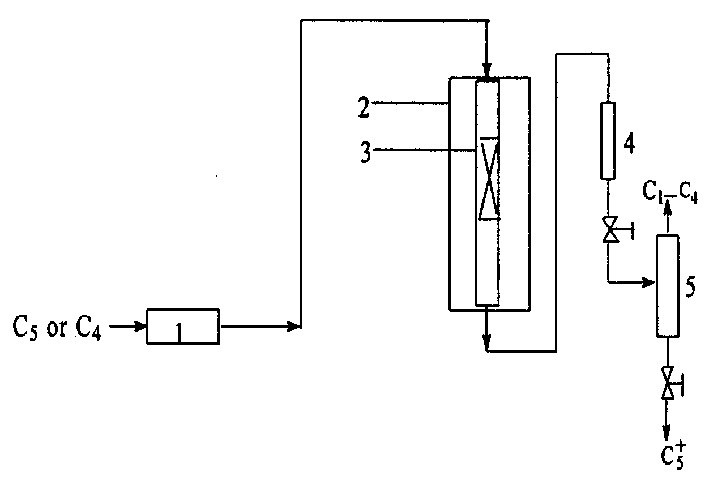

Method for preparing ethene and propylene

InactiveCN1490287AImprove anti-coking performanceSimple processHydrocarbon by hydrocarbon crackingHydrocarbon mixturesFixed bed

A process for preparing ethylene and propylene from the hydrocarbon mixture containing C4 (or C5) olefine includes such steps as contacting the zeolite contained catalyst in fixed-bed reactor, reacting at 350-500 deg.C and 1-10 / hr of space speed under 0.6-1.0 MPa to obtain the mixture of ethylene and propylene, and cooling separating. Said catalyst contains Al2O3 or SiO2, high-Si zeolite and modifier.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for continuous production of polyformaldehyde dimethyl ether

InactiveCN102786397ARealize industrial productionImprove stabilityOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention provides a method for continuous production of polyformaldehyde dimethyl ether. The method is characterized by comprising the following steps: a) feeding dimethoxymethane and hot-melted paraformaldehyde into a fixed bed reactor and adopting an acidic resin catalyst, so as to prepare polyformaldehyde dimethyl ether (DMM3-8), wherein the reaction temperature is 120-180 DEG C and the pressure is 0.1-10 MPa; b) cooling the reaction product, and then performing adsorptive separation through a dehydrating tower, so as to obtain polyformaldehyde dimethyl ether of which most water, cytidine glycol and hemiacetal are desorbed; c) feeding the polyformaldehyde dimethyl ether subjected to desorption into a distillation tower for separation, wherein most of a low-boiling component (dimethoxymethane (DMM)), poly-di-formaldehyde dimethyl ether (DMM2), a by-product (methanol) and triformol are extracted first, and then the materials in a tower kettle are fed into a rectifying tower in the next step, so as to extract the rest of the DMM2 and the triformol; and d) returning the low-boiling component (dimethoxymethane (DMM)), the methanol, the DMM2 and the triformol, which are evaporated out by the distillation tower and the rectifying tower in the last step, into the fixed bed reactor to continue to react to prepare polyformaldehyde dimethyl ether.

Owner:CHINA NAT OFFSHORE OIL CORP +1

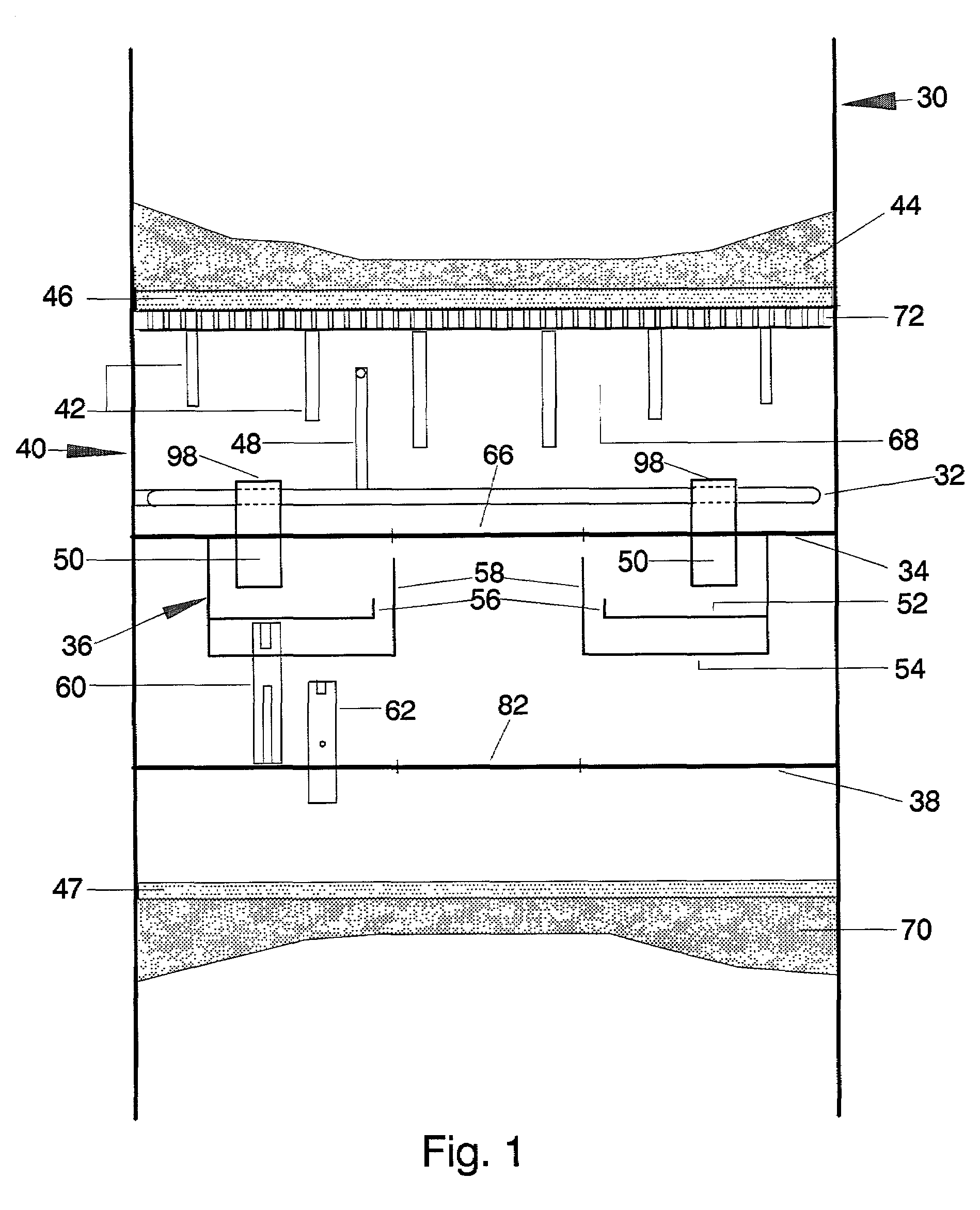

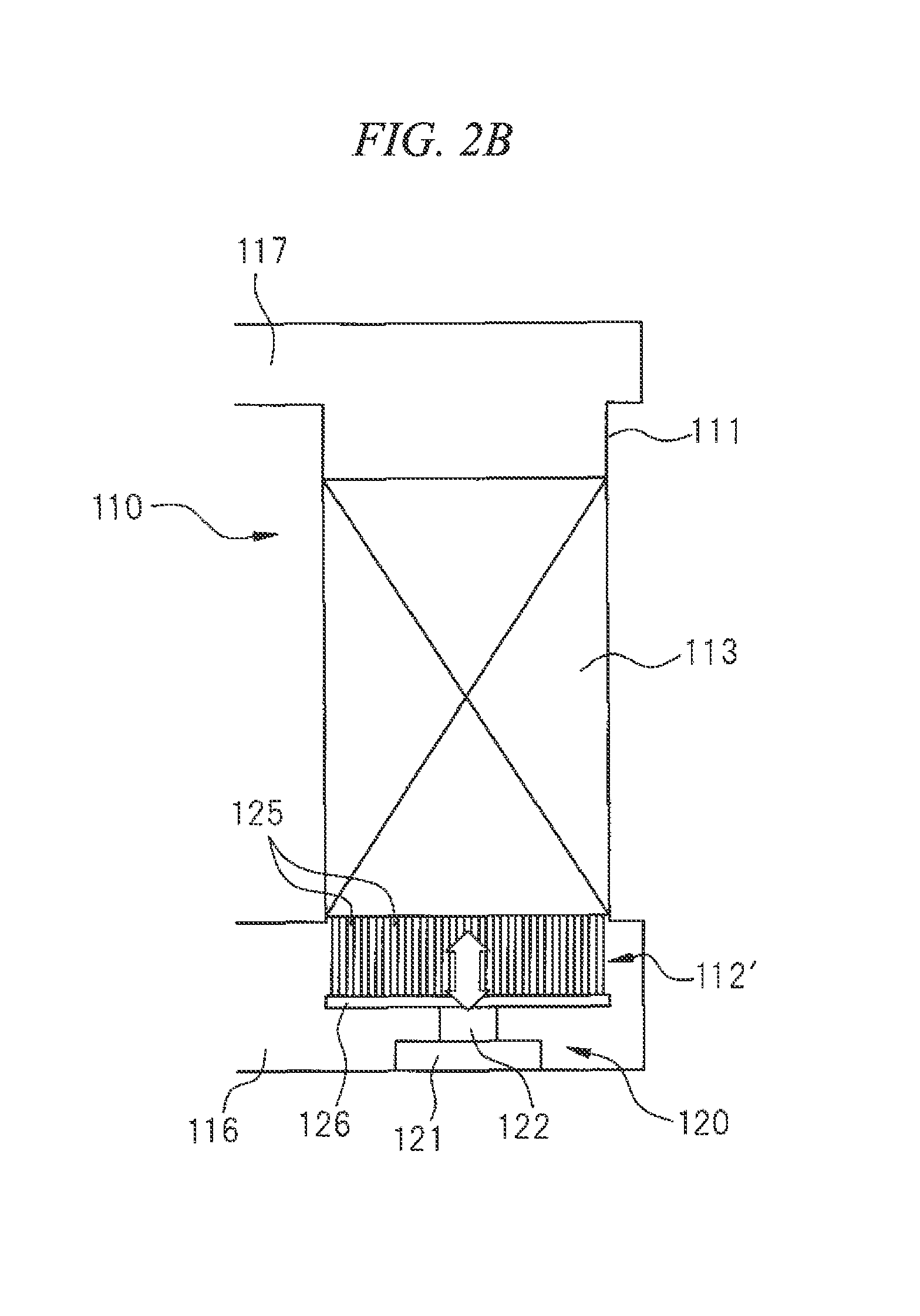

Quench box for a multi-bed, mixed-phase cocurrent downflow fixed-bed reactor

InactiveUS7112312B2Reduce in quantitySimple designPhysical/chemical process catalystsFlow mixersFixed bedEngineering

Owner:H2ADVANCE

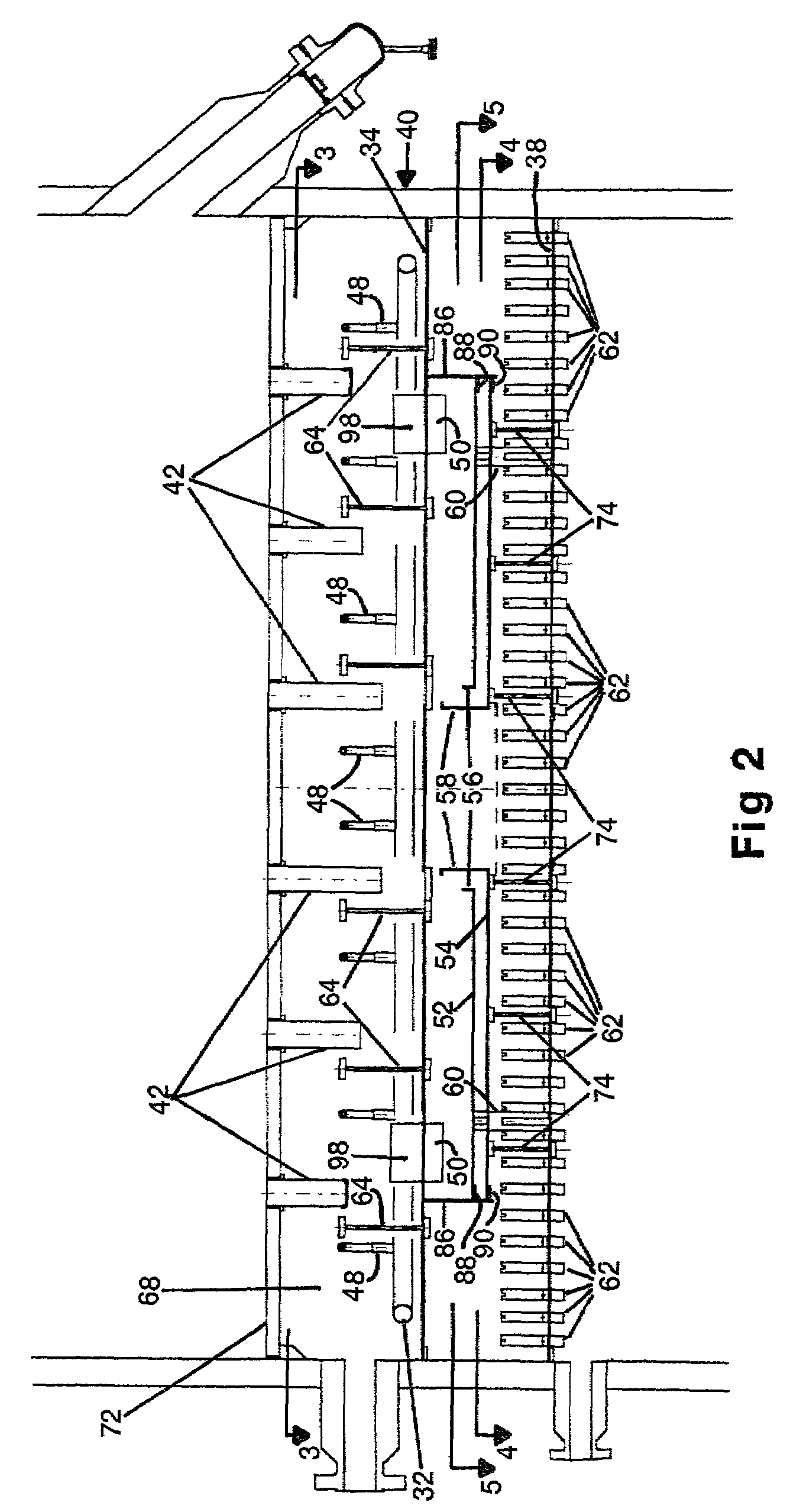

Continuous fixed-bed catalytic reactor and catalytic reaction method using same

ActiveUS20150010467A1Efficient removalImprove efficiencyCatalytic gas-gas reactionGaseous chemical processesFixed bedChemistry

A continuous fixed-bed catalytic reactor includes an inflow path for raw material gas for a catalytic reaction and an outflow path for reformed gas, a catalytic reaction container that is connected to the inflow path and the outflow path and holds a clumpy catalyst, catalyst holders that have a ventilation property and hold the clumpy catalyst, and a driving mechanism that moves the clumpy catalyst up and down by moving the catalyst holders up and down.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com