Patents

Literature

159results about How to "Suitable for acidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

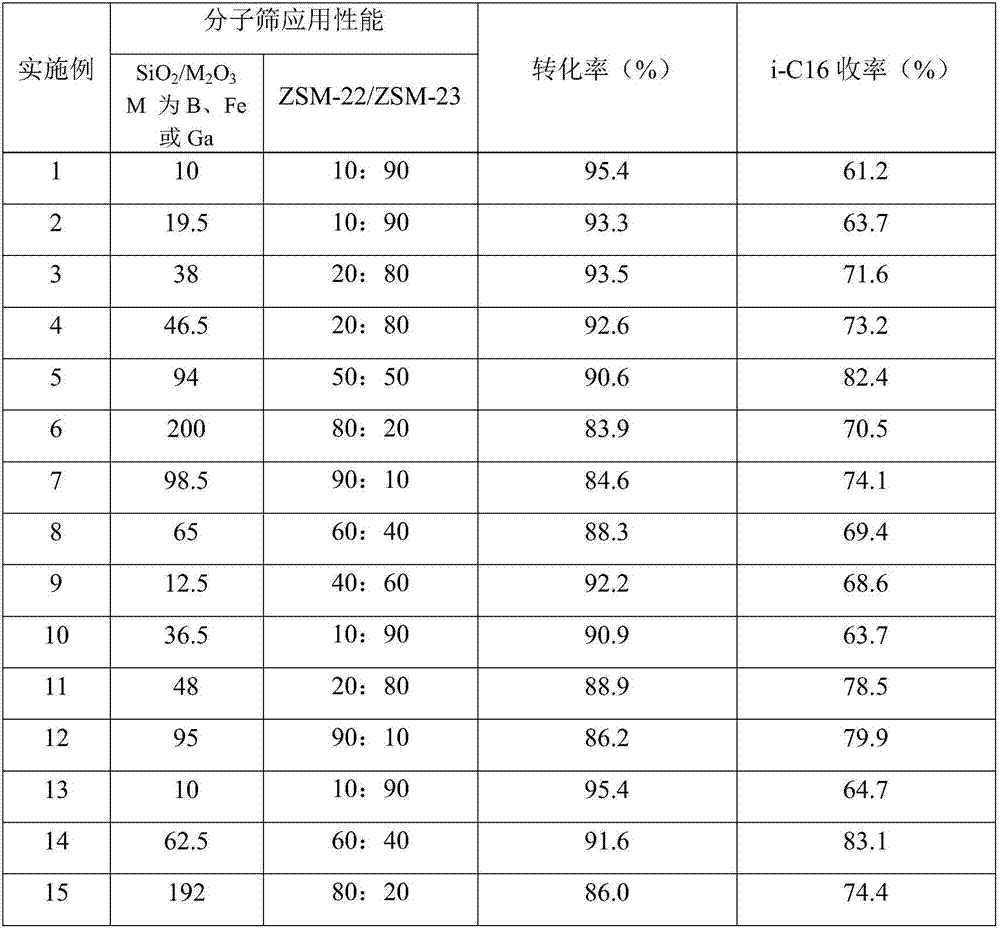

Hydro-isomerization catalyst for paraffine, and its preparing method and application

InactiveCN1792451ASuitable for acidityHigh yieldHydrocarbon by isomerisationMolecular sieve catalystsMolecular sieveAlkane

A catalyst for the hydroisomerizing reaction of paraffin is composed of the active component (0.05-5.0 Wt%) chosen from Pt, Pd and Ir, and the composite molecular sieve ZSM-22 / ZSM-23 (or ZSM-23 / ZSM-22). It has high catalytic activity and selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Composite molecular sieve in ten-element cyclic structure and its synthesis process

InactiveCN1772611AGood synergyHigh yieldMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesPhosphoric acidChemistry

The composite molecular sieve in ten-element cyclic structure has ten-element cyclic Si-Al structure and ten-element cyclic aluminum silicon phosphate structure. It is prepared through adding ZSM-22, ZSM-23, ZSM-5, EU-1, NU-87 or other ten-element cyclic structure Si-Al molecular sieve into aluminum silicon phosphate sol obtained via mixing Si source, Al source, P source, water and template agent to obtain primary sol; and subsequent hydrothermal crystallization to obtain the compound molecular sieve. The synthesis conditions may be altered based on the requirement to change the two phase ratio and the Si / Al ratio. Normally, the added amount of ten-element cyclic Si-Al molecular sieve is 0.01-0.6 time the total oxide weight in the aluminum silicon phosphate sol. The composite molecular sieve in ten-element cyclic structure may be used in the isometric dewaxing of lubricant oil and the isometric pour point depression of diesel oil and exhibits excellent catalytic performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Colloidal composite sol gel formulation with an expanded gel network for making thick inorganic coatings

InactiveUS20040258611A1Inhibition formationRelieve pressurePretreated surfacesCatalyst activation/preparationColloidSol gel coating

Owner:DATEC COATING CORP

Inferior diesel hydrogenation catalyst

InactiveCN1778873AHigh yieldWeak ring opening cracking performanceRefining to eliminate hetero atomsLanthanumChemistry

A hydrotreating catalyst of inferior diesel consists of alumina 20.0í½80.0wt% and molecular sieve 3.0í½60.0w%. The catalyst is prepared by loading at least one Fe, Co and Ni metal of ó° family and MO and W metal of ó÷B family as metal active component and adding one or above oxide or fluorinated compound of titanium, magnesium, zirconium, lanthanum, iron, phosphorus, silicon and boron as active auxiliaries. It can decrease content of sulfur and arenes and increase cetyl value in products. It can be used for cryogenic hydrogenation desulfurization, denitridation and hydrogenation dearomatization.

Owner:PETROCHINA CO LTD +1

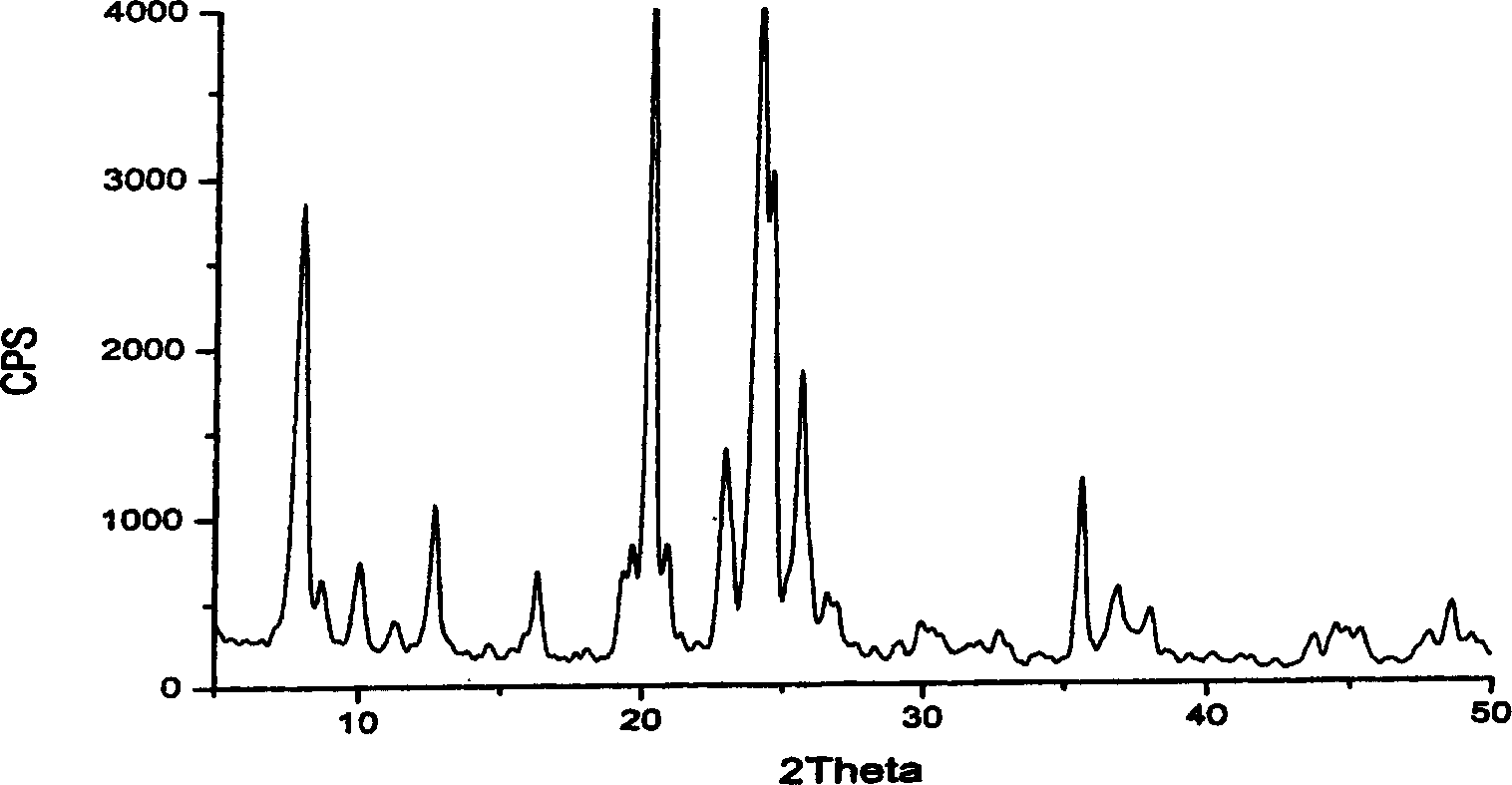

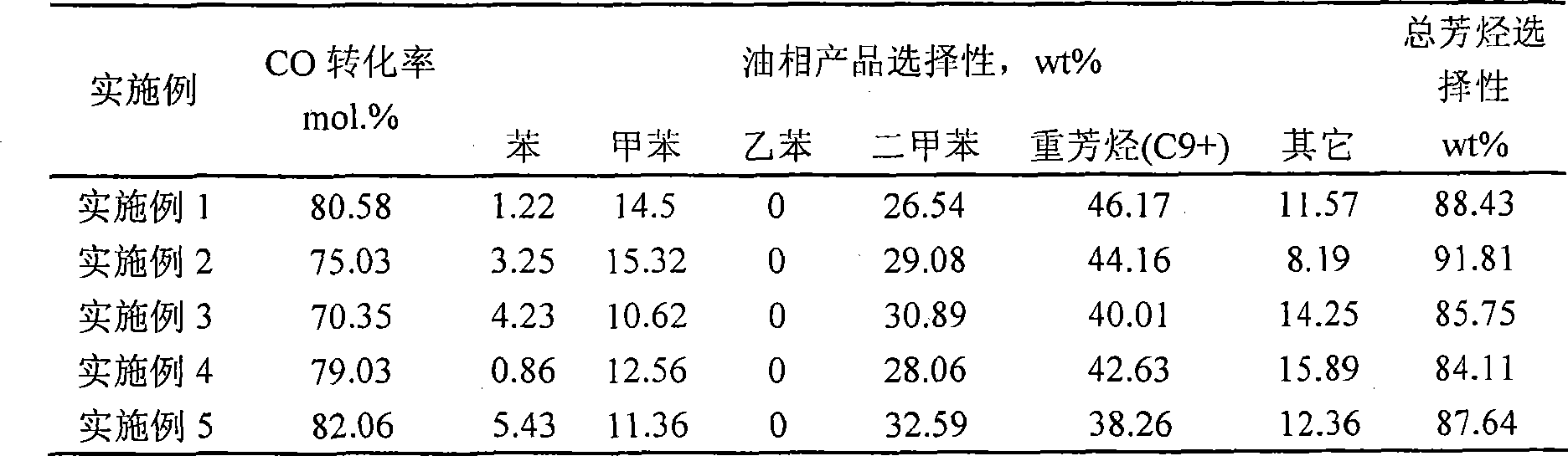

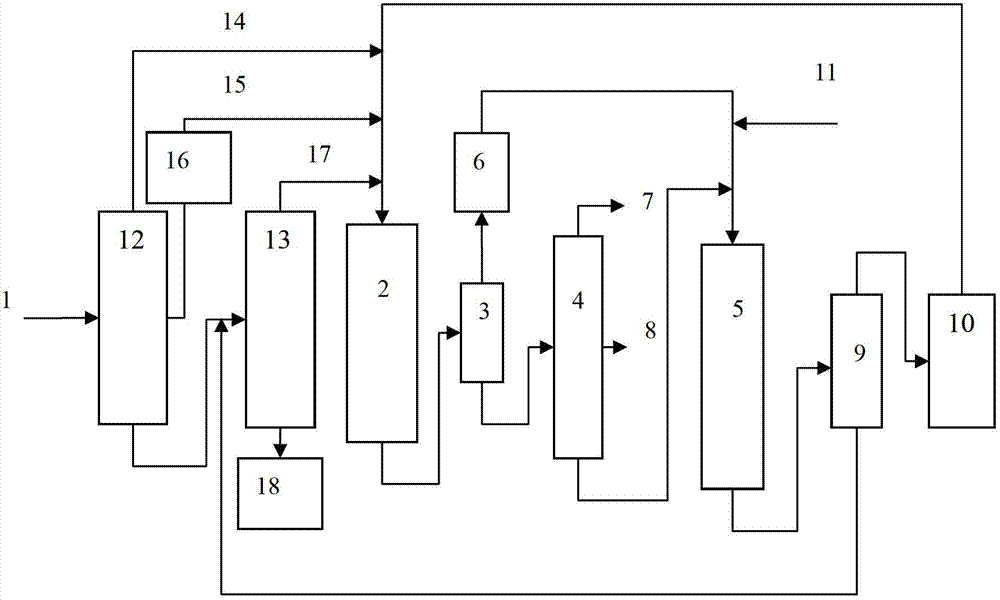

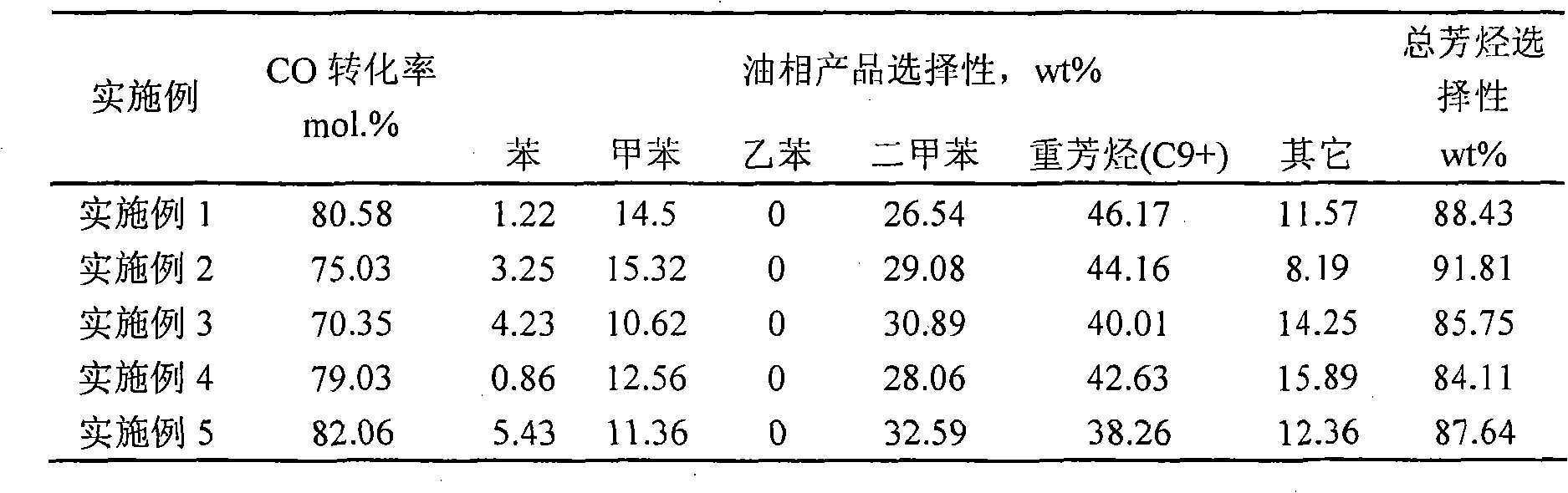

Catalyst for direct synthesis of arene by synthesis gas and production method and use thereof

InactiveCN101422743ASuitable for aciditySimple processHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a catalyst for directly synthesizing aromatic hydrocarbon by synthesis gas, which has the composition with following weight ratio: HNKF-5:aluminophosphate molecular sieve:Ga2O3:ZnO:BaO equal to 1:1-3:0.01-0.3:0.01-0.3:0.01-0.3. The invention has the advantages of simple technical process, medium catalyst acidity of aromatic hydrocarbon synthesis, better aromatization performance, and high aromatic hydrocarbon content.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Hydrofining catalyst and preparation method thereof

InactiveCN101590417AImprove physical and chemical propertiesImprove adsorption capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsTitaniumBoron

The invention provides a hydrofining catalyst and a preparation method thereof. The catalyst comprises an aluminum oxide carrier which is modified by an assistant and VIII group and VIB group metal oxides which are loaded on the carrier, wherein, the assistant is at least one of boron, phosphorus, silicon and titanium compounds. The catalyst is prepared by an immersion method which is characterized in that an organic stabilizer is added into immersion fluid; the number of metal active centers of the catalyst is increased with the addition of the organic stabilizer; the physicochemical properties of the catalyst is improved by the way the aluminium oxide is modified by the assistant; therefore, the hydrofining catalyst prepared by the method in the invention has high desulfuration and denitrification activity, and is applicable to the hydrotreating process of various distillate oil, in particular to poor quality diesel oil.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

A silicone modified aluminum hydroxide solid elastomer and preparation method thereof

ActiveCN1951554AHigh specific surface areaLarge specific surface areaCatalyst carriersOrganosiliconSalt solution

The invention relates to a method for preparing aluminum hydroxide wafer which is modified by silicon. Wherein, said wafer is baked and converted into silicon-modified gamma-Al203, to obtain following properties, that specific surface area is 400-600m2 / g, the hole capacity is 1.0-2.0cm3 / g, and the silica mass percentage is 2%-20%. In its preparation, after the neutralization between acid aluminum salt solution and alkali compound solution, it adds organic silicon to age, and composite via general steps. The invention has simple method.

Owner:CHINA PETROLEUM & CHEM CORP +1

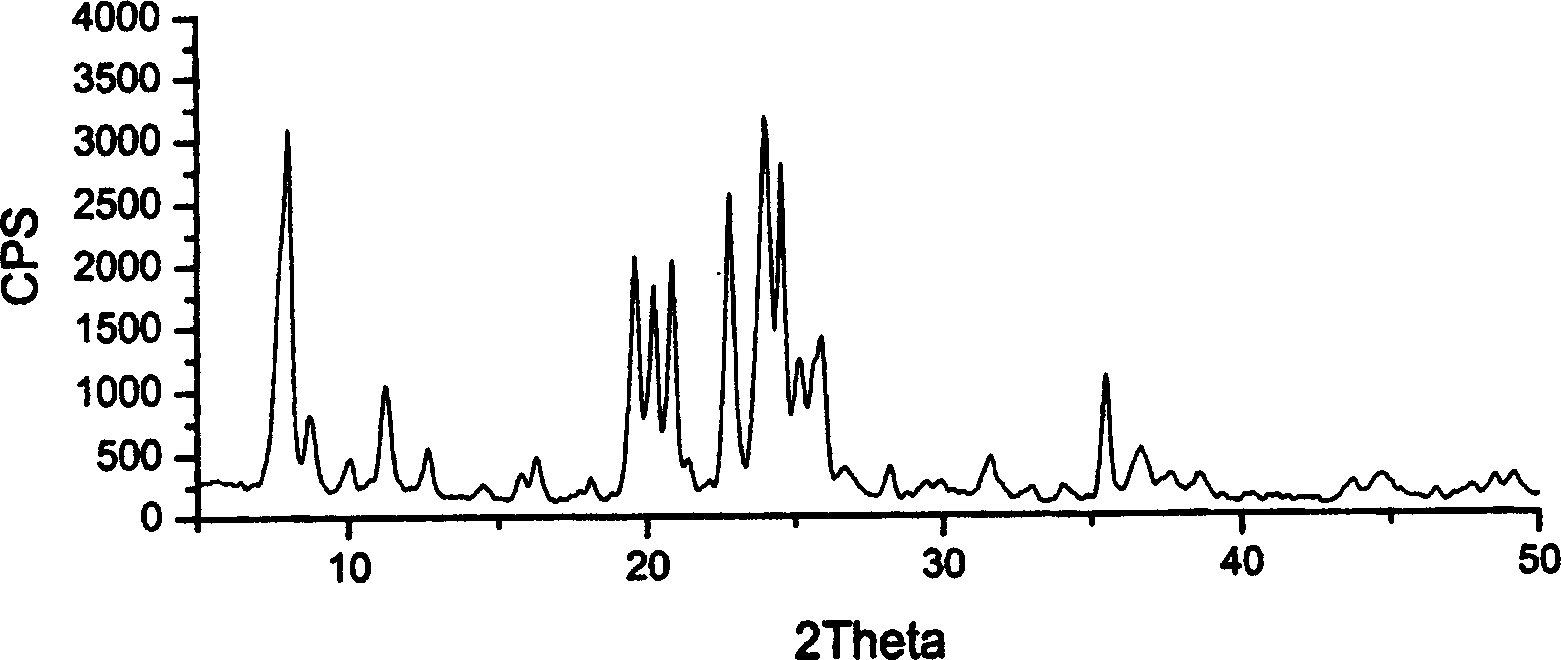

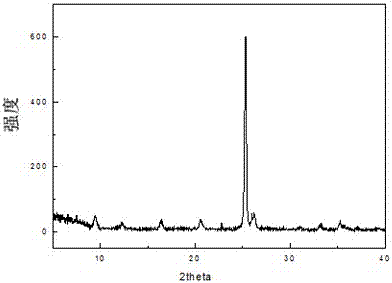

ZSM-22/ZSM-23 composite molecular screen and its preparation method

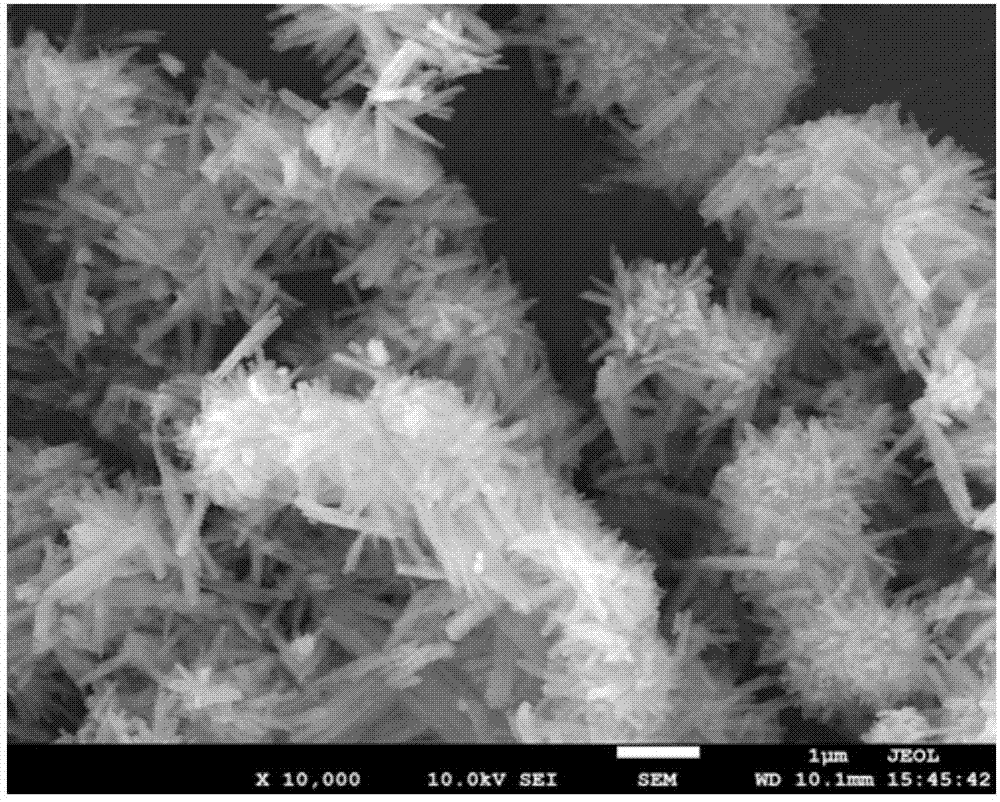

InactiveCN1769173AHigh yieldHigh viscosity indexCrystalline aluminosilicate zeolitesMolecular sieveCarbon source

The invention relates to a ZSM-22 / ZSM-23 composite molecular sieve and a method for synthesis it, which contains: mixing ZSM-22 molecular sieve with alumina silica colloid prepared by mixing carbon source, aluminum source, inorganic base, water with template agent, and adjusting the acid-base quality of the solution with inorganic acid to prepare initial colloid, the mole composition of the colloid being: SiO2 / Al2O3= 60-300, R / SiO2= 0.05-3, OH- / SiO2= 0.05-0.5, M / SiO2=0.1-0.5, H2O / SiO2= 10-65, the usage of ZSM-22 molecular sieve being 1-60% of silica dioxide by weight, and the temperature agent being one or more of pyrrolidine, isopropyl amine or isobutylamine. The ZSM-22 / ZSM-23 composite molecular sieve is prepared by hydrothermal crystallization of initial colloid.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

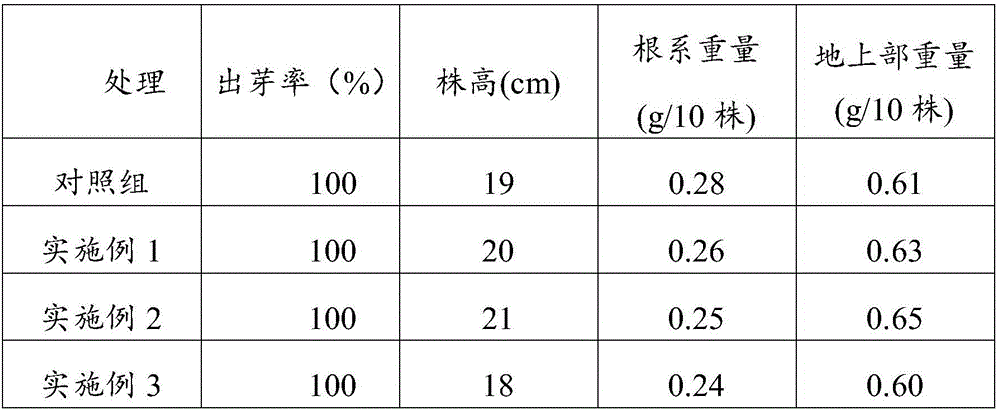

Carbon-based rice seedling raising substrate for rice and preparation method thereof

InactiveCN105924268ASolve the problem that it is difficult to directly make rice seedling raising substrateReduce leachingBio-organic fraction processingExcrement fertilisersDiseasePotassium

The invention discloses a carbon-based rice seedling raising substrate for rice. The carbon-based rice seedling raising substrate comprises biochar, a straw fermented product, yellow soil, vermiculite and an inorganic fertilizer, wherein a volume ratio of the biochar to the straw fermented product to the yellow soil to the vermiculite is (10-20): (15-30): (25-35): (15-25); the inorganic fertilizer comprises nitrogen, phosphorus pentoxide and potassium oxide; and per 10 m<3> of the carbon-based rice seedling raising substrate for the rice comprises 12 to 18 g of a nitrogen fertilizer, 4 to 7 g of a phosphorus fertilizer and 5 to 16 parts of a potassium fertilizer. The invention also discloses a preparation method of the carbon-based rice seedling raising substrate for the rice. According to the invention, by utilizing the biochar and the fermented product which are prepared from widely-available farmland organic wastes like rice straws, and inorganic substances like the yellow soil and the vermiculite, the carbon-based rice seedling raising substrate for the rice is prepared. The substrate provided by the invention has the characteristics of fertility holding, water holding and good air permeability, and can effectively prevent the occurrences of bakanae disease, sheath blight and the like in a seedling stage.

Owner:CHINA NAT RICE RES INST

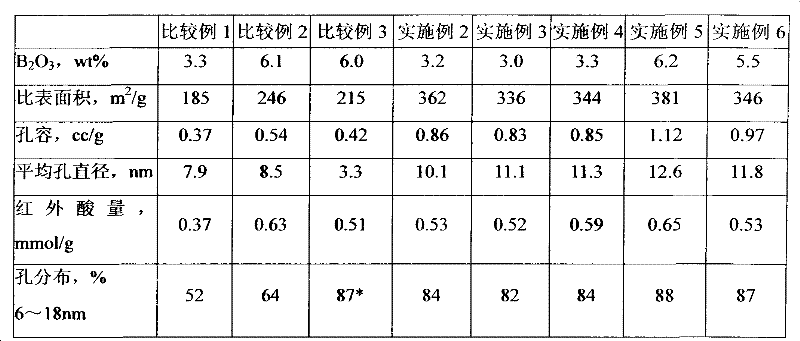

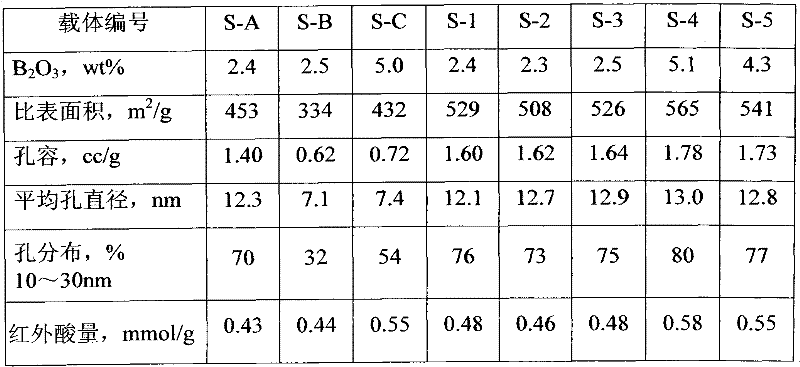

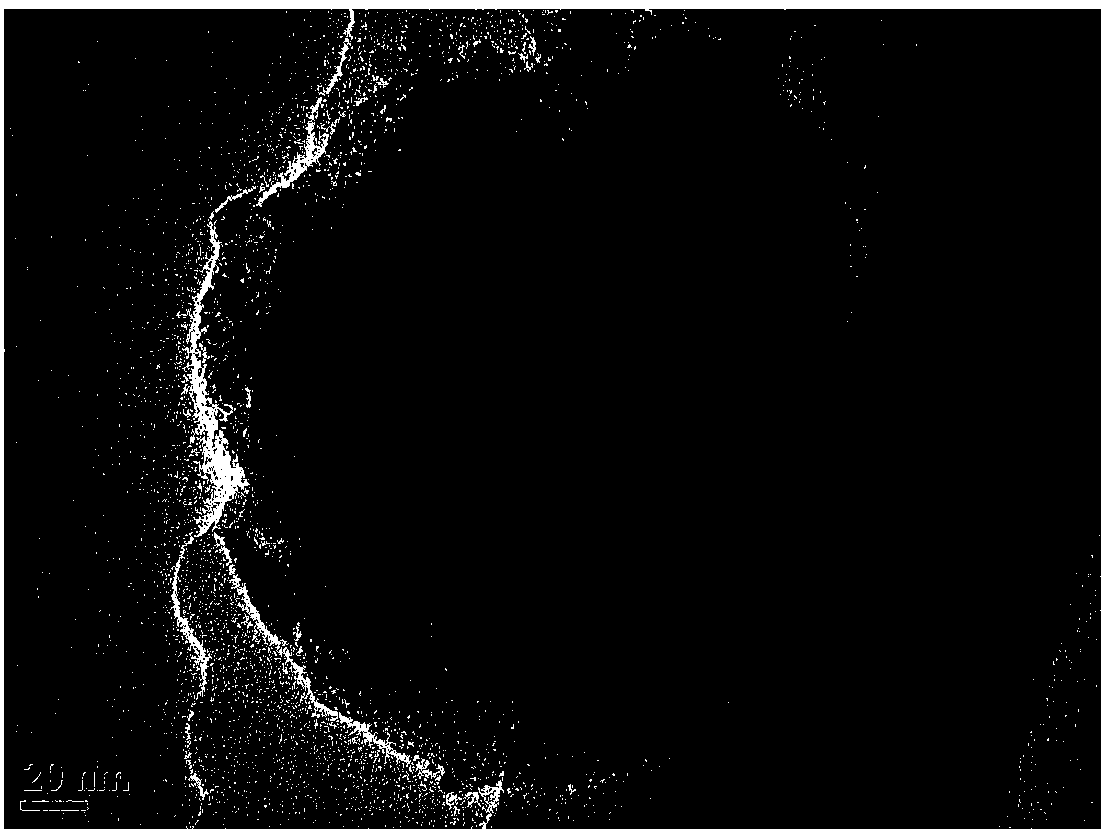

Preparation method of hydrotreatment catalyst

ActiveCN102728374ARegular hole structureEvenly distributed holesMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsLarge poreAluminium hydroxide gel

The invention discloses a preparation method of a hydrotreatment catalyst, comprising the following steps of: introducing silicon and boron additives in the way that an organic silicon source is added after aluminium hydroxide gel forming and then a boron-containing organic compound solution is added, so as to obtain silicon and boron containing aluminium hydroxide, mixing parts of an active metal component with boron-containing aluminium hydroxide by a kneading method, carrying out three-stage roasting to obtain a catalyst intermediate, loading residual part of the active metal onto the catalyst intermediate by dipping, and drying to obtain the hydrotreatment catalyst. By the adoption of the method provided by the invention, the silicon and boron additives and the active metal component are uniformly distributed on the surface of the catalyst. In addition, the active metal component has different existing forms in the catalyst when introduced in the two modes, loss rate of the catalyst activity is reduced by mutual cooperation, and running period of a device is prolonged. The catalyst has large pore volume, large specific surface area, appropriate pore structure and acidity, and is especially suitable for hydrodenitrogenation process of heavy hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

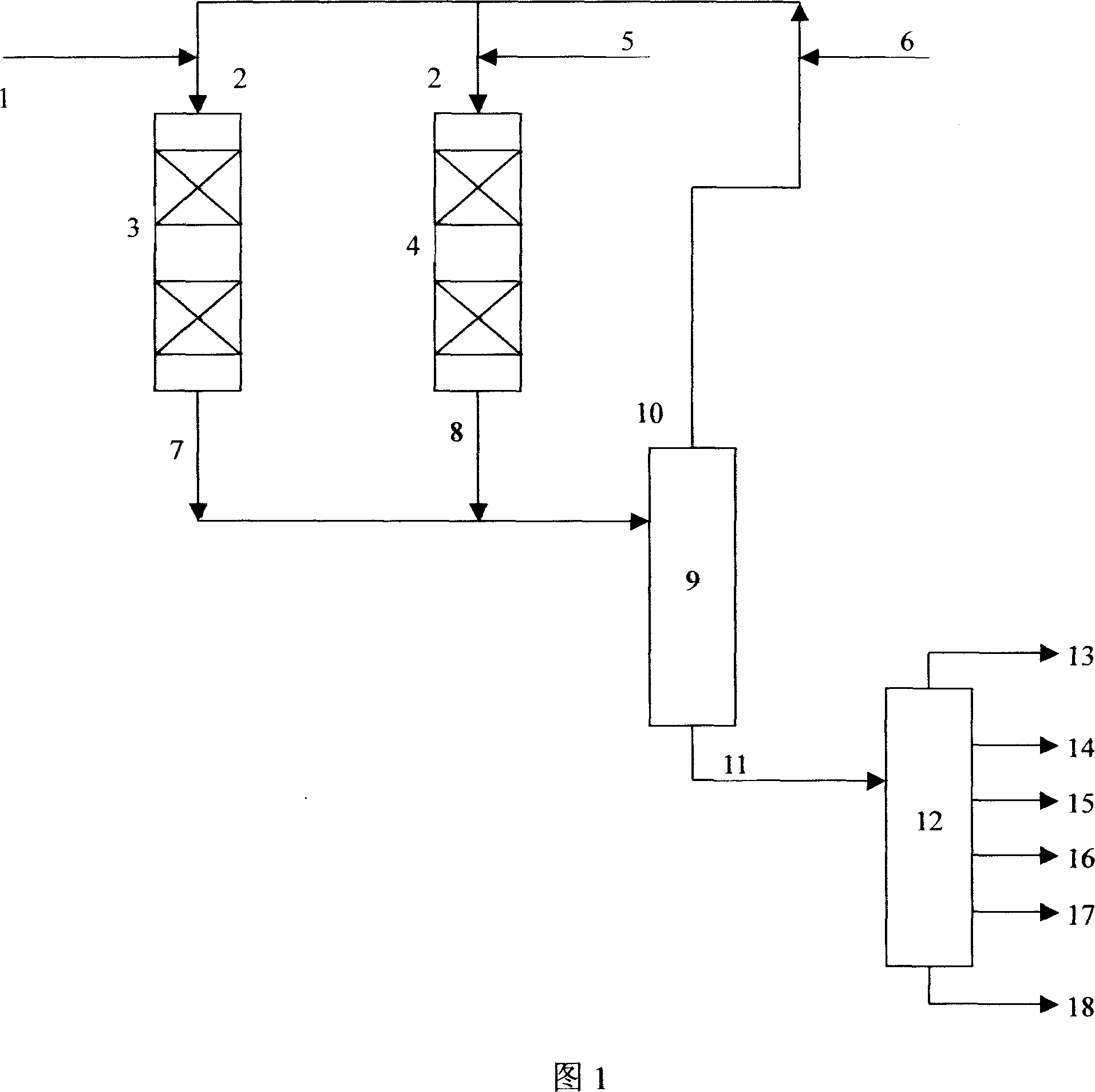

Parallel hydrocracking method

ActiveCN1955259ALow BMCIIncrease the molar ratio of silicon to aluminumTreatment with hydrotreatment processesHexadecaneCatalytic reforming

This invention discloses a hydrocracking method, and this invention is used for producing high aromatic hydrocarbon heavy naphtha and high quality end oil.It includes that heavy distillate oil and poor quality catalytic cracking diesel hydrocracks separately, and the mixture of the cracking products is conducted gas liquid separation. Light naphtha, heavy naphtha, aviation kerosene, diesel oil and end oil will be obtained by distillating the liquid phase. The density of the poor quality catalytic cracking diesel oil is above 0.9g / ml, and the aromatic hydrocarbon is over 60wt% and the value of hexadecane is under 30. It is a adequate utilization of catalytic cracking craft to produce high aromatic hydrocarbon heavy naphtha and high quality end oil with heavy distillate oil and poor quality catalytic cracking diesel, which can be separately used as catalytic reforming material and making ethylene material by steam cracking method. High aromatic hydrocarbon heavy naphtha in this invention will produce a large amount of reforming hydrogen after catalytic reforming treatment, which can be used in the process of hydrocracking to make this preparation more ecnomical and reasonable.

Owner:CHINA PETROLEUM & CHEM CORP +2

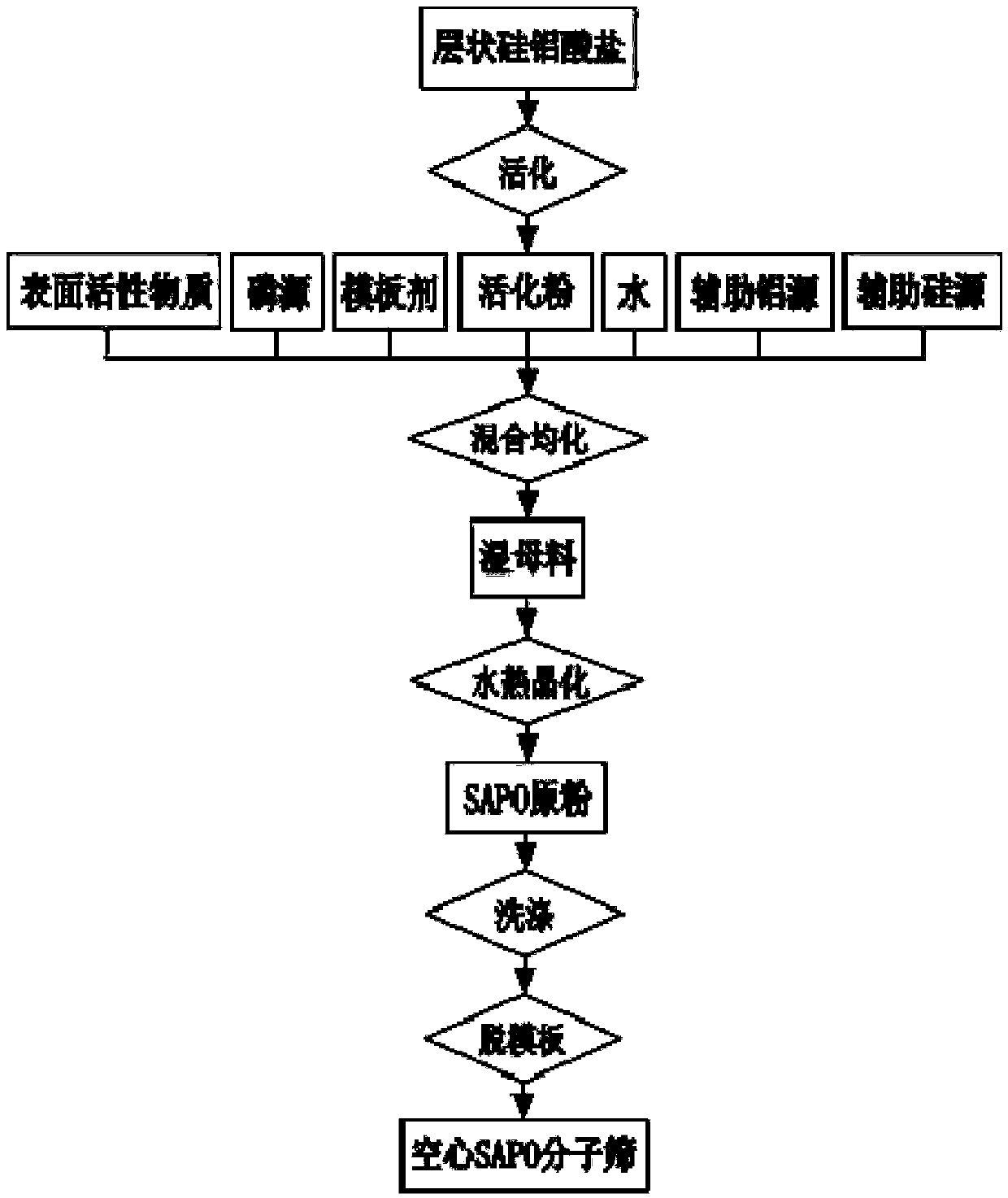

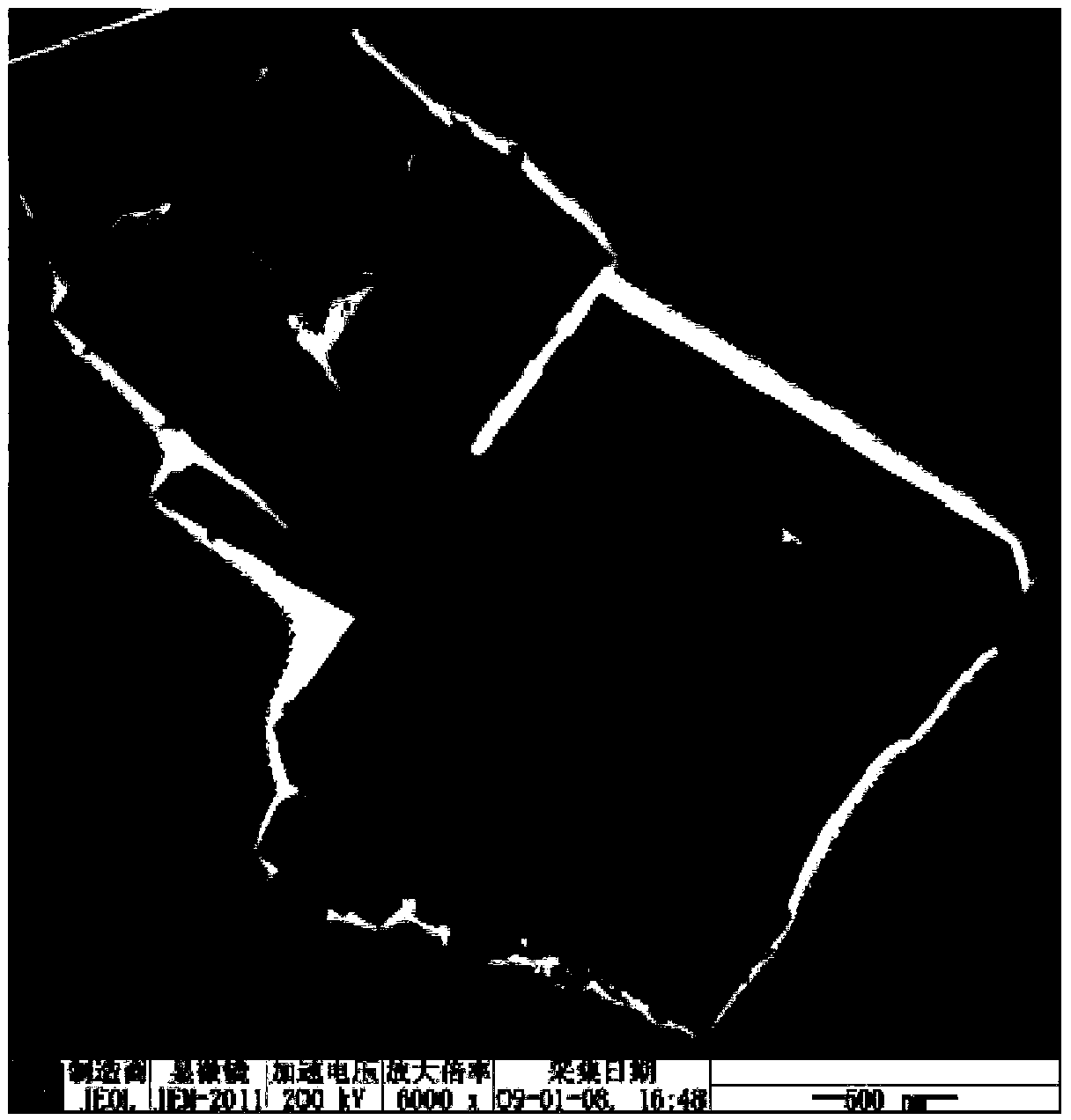

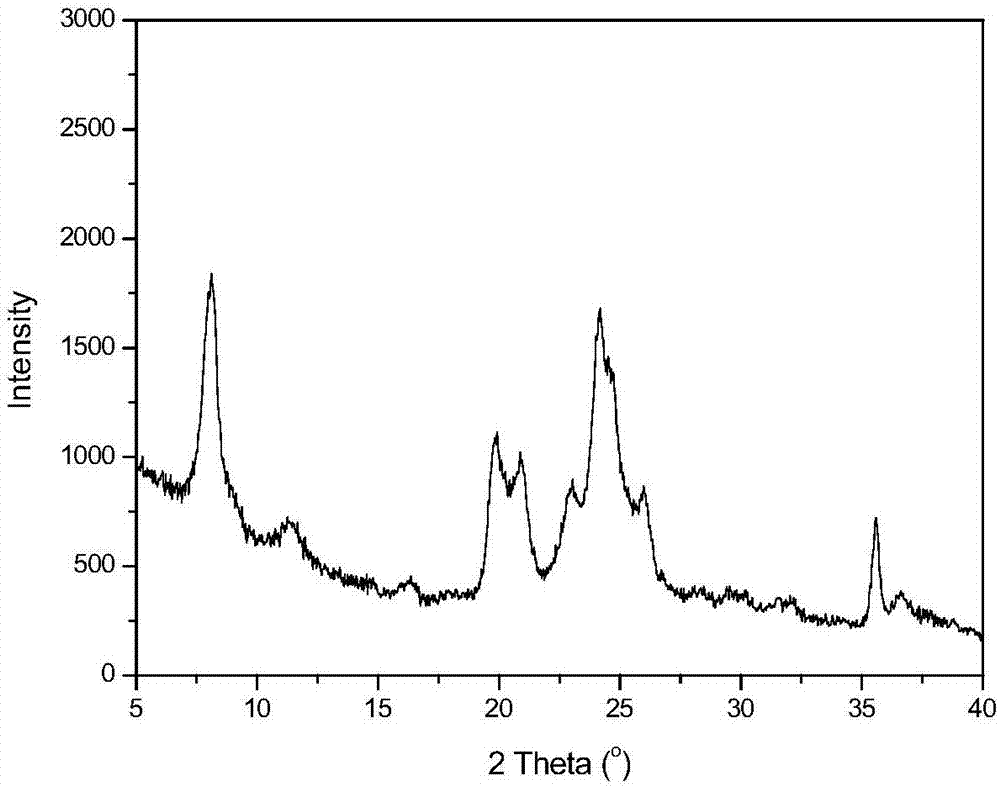

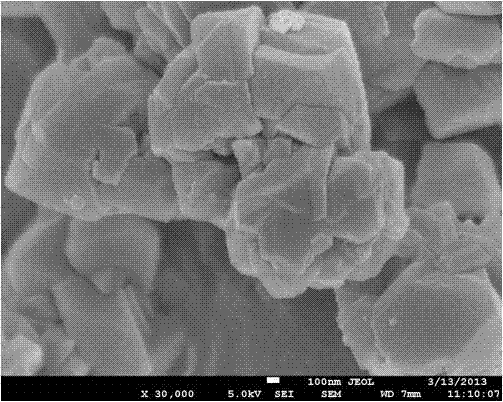

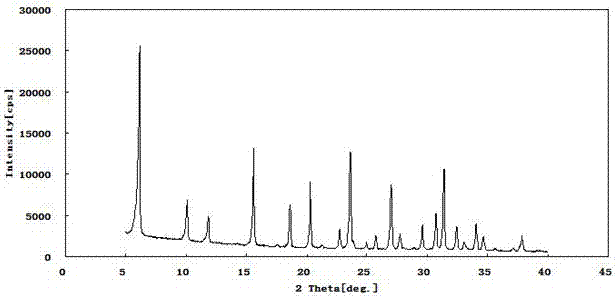

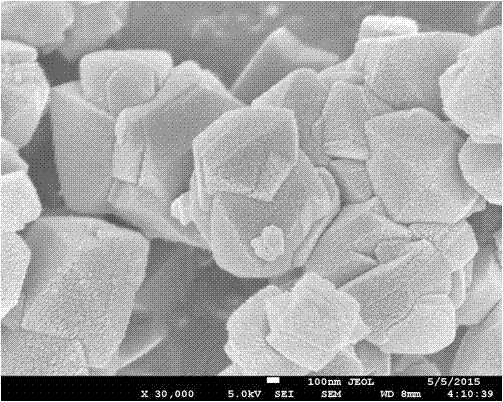

SAPO molecular sieve, and preparation method and purpose thereof

ActiveCN103964456ASuitable for acidityExtend your lifeMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveSingle crystal

The invention discloses an SAPO molecular sieve, which has hollow single crystals. The SAPO molecular sieve has optional pore structure, adjustable silicon content and distribution, controllable strength and density of acid site, and long service life of catalyst. The invention also discloses a preparation method of the SAPO molecular sieve. The method uses layered silicate as a raw material, which is subjected to activation, and mixed and homogenized with a phosphorus source, an auxiliary aluminum source and water to obtain a wet masterbatch; and the wet masterbatch is subjected to hydrothermal crystallization to obtain a raw powder of the hollow SAPO molecular sieve, wherein the molar ratio of Al and Si in the wet masterbatch is higher than 1. The method use easily available raw materials, has low cost and can be prepare the SAPO molecular sieve with hollow structure.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

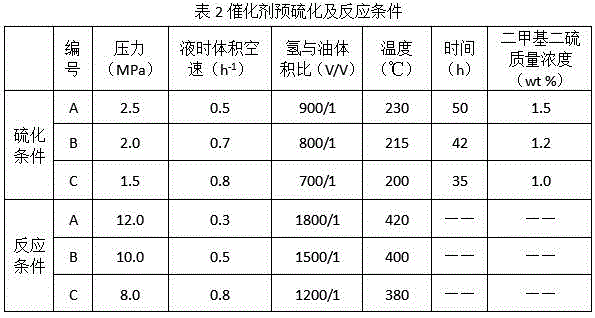

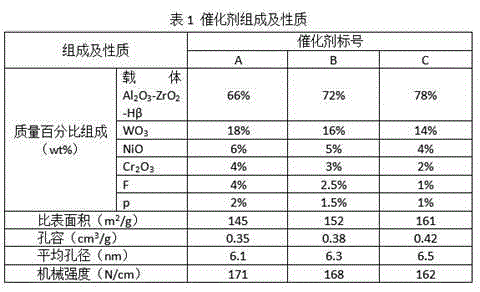

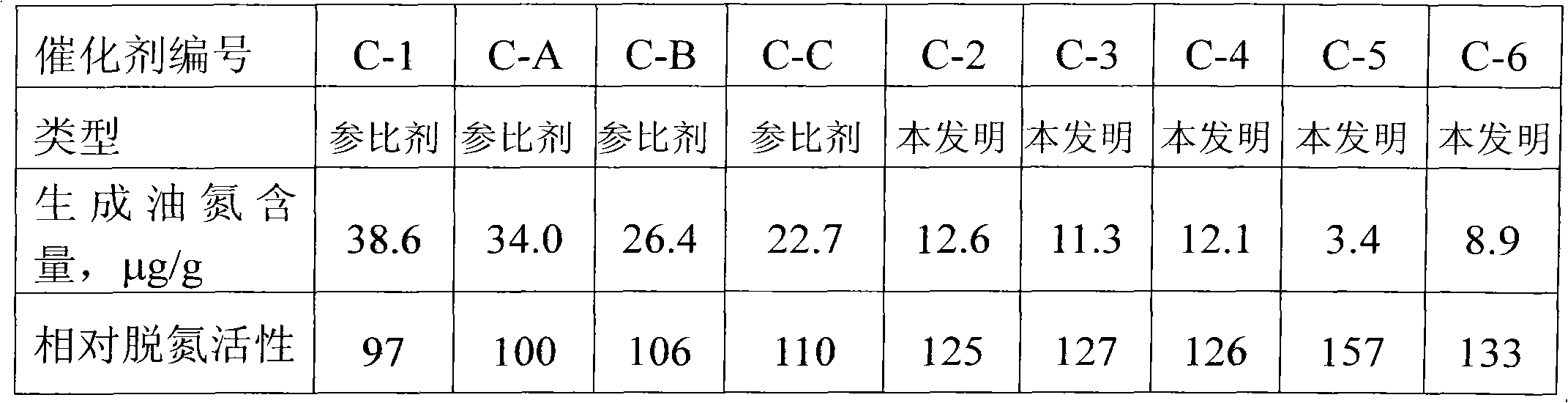

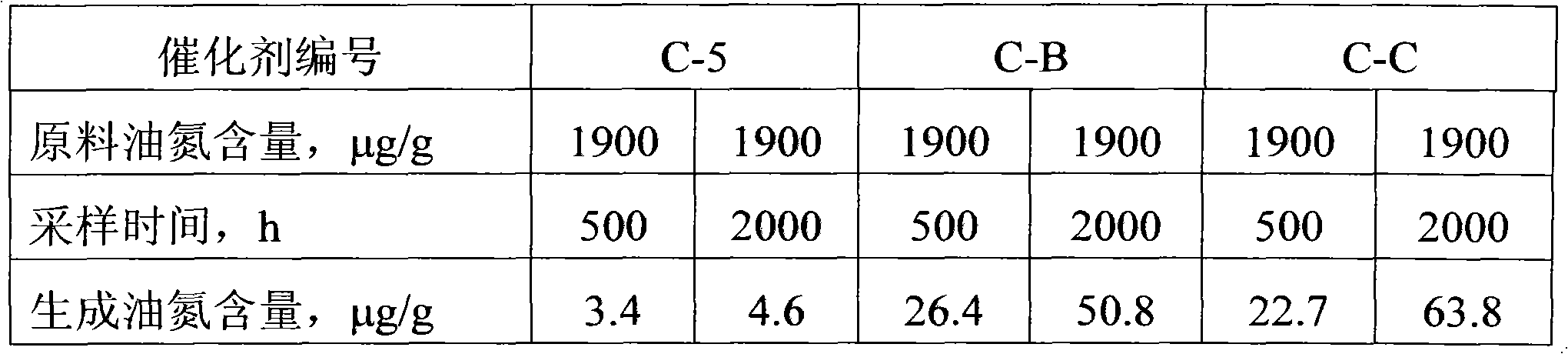

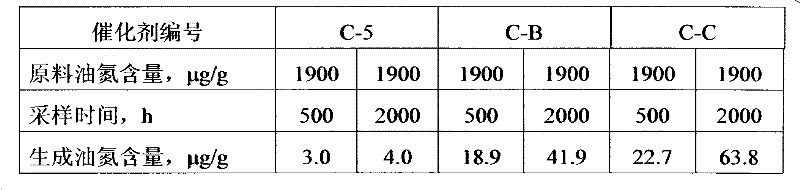

Hydrodenitrogenation catalyst capable of removing nitrogen-containing compound from coal tar, and preparation method and application thereof

ActiveCN102614909AIncreased total phenolic contentImprove water resistanceMolecular sieve catalystsHydrocarbon oils refiningNickel MonoxideChromium(III) oxide

The invention belongs to the technical field of catalysts for hydrodenitrogenation of coal tar. The technical problem to be solved is to provide a hydrodenitrogenation catalyst capable of deeply removing a nitrogen-containing compound from coal tar and provided with high mechanical strength, wear resistance and water resistance, and a preparation method and application thereof. The invention adopts the technical scheme that in the hydrodenitrogenation catalyst capable of removing nitrogen-containing compound from coal tar, active components consist of tungsten trioxide, nickel monoxide and chromium sesquioxide; aids comprise fluorine and phosphorus; and a carrier consists of aluminum oxide, zirconium oxide, a Hbeta molecular sieve, a binder and an extrusion aid. By adopting the hydrodenitrogenation catalyst capable of deeply removing the nitrogen-containing compound from the coal tar, the oil nitrogen content of the hydrogenation product can be reduced to be below 50 micrograms / gram; and the hydrodenitrogenation property is high, so that the oil sulfur content of the hydrogenation product can be reduced to be below 40 micrograms / gram.

Owner:山西中科化美科技有限责任公司

Synthetized modification HZSM-5 zeolite catalyst and method for preparing the same and use thereof

ActiveCN101081371AEfficient desulfurizationReasonable composition and distributionMolecular sieve catalystsHydrocarbon oils treatmentOrganic acidAqueous solution

The present invention relates to one kind of comprehensively modified HZSM-5 zeolite catalyst and its preparation process and use. The process of preparing the catalyst includes the following steps: mixing HZSM-5 zeolite and adhesive in the weight ratio of 1-4, adding sesbania powder and water solution of HNO3 into the mixture to reach sesbania powder concentration of 1-3 wt% and HNO3 concentration of 2-5 wt%, kneading, extruding, drying and roasting to form catalyst carrier intermediate, hydrothermally modifying and organic acid treating the intermediate to obtain catalyst carrier, supporting active metal components onto the carrier, drying, and roasting to form catalyst product. The comprehensively modified HZSM-5 zeolite catalyst is applied in the hydrogenating modification of catalytically cracked gasoline, and can lower its olefin and sulfur content and improve its anti-knock index.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Hydrotreating catalyst and preparation method thereof

ActiveCN102039203AHigh activityImprove stabilityCatalyst carriersCatalyst activation/preparationSimple Organic CompoundsAluminium hydroxide

The invention discloses a hydrotreating catalyst and a preparation method thereof. In the method, a boron aid is introduced by adding stable boron-containing organic compound solution after aluminium hydroxide is gelatinated, so that the boron aid is uniformly distributed in the catalyst and the activity phase transformation promoting effect of the boron acid is enhanced; moreover, the obtained catalyst has a high pore volume, a large specific surface area, an appropriate pore structure and appropriate acidity, enhances the activity and stability of the catalyst and is particularly suitable for the hydro-denitrogenation process of heavy hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Medium and low temperature combination processing method of coal tar

ActiveCN102851073AHigh yieldLow yieldTreatment with hydrotreatment processesTar working-up by distillationLighter fuelHigh pressure

The invention comprises a combination processing method of coal tar. The method comprises the steps of: (a) subjecting a coal tar raw material to atmospheric distillation to obtain light distillate oil, phenol oil and bottom oil; dephenolizing the phenol oil to obtain the dephenolized oil; sending the bottom oil and a liquid phase from a hot high pressure separator in a step (d) into a vacuum distillation tower to obtain a heavy distillate with asphaltene removed; and conducting a hydrotreating reaction on the light distillate, dephenolized oil and the heavy distillate; (b) fractionating a liquid phase from the hydrotreating reaction into a light fraction and a heavy fraction; (c) subjecting the heavy fraction from the step (b) to a hydrocracking reaction; and (d) sending an effluent from the hydrocracking reaction into the hot high pressure separator, and sending the separated liquid phase to the vacuum distillation tower in the step (a). Compared with prior art, the method provided by the invention increases yield of light fuel production from coal tar, prolongs the service life of catalyst, and improves operation cycle of the device.

Owner:吉林省弘泰新能源有限公司

Catalyst for direct synthesis of arene by synthesis gas and production method and use thereof

InactiveCN101422743BSuitable for aciditySimple processHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveAromatization

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

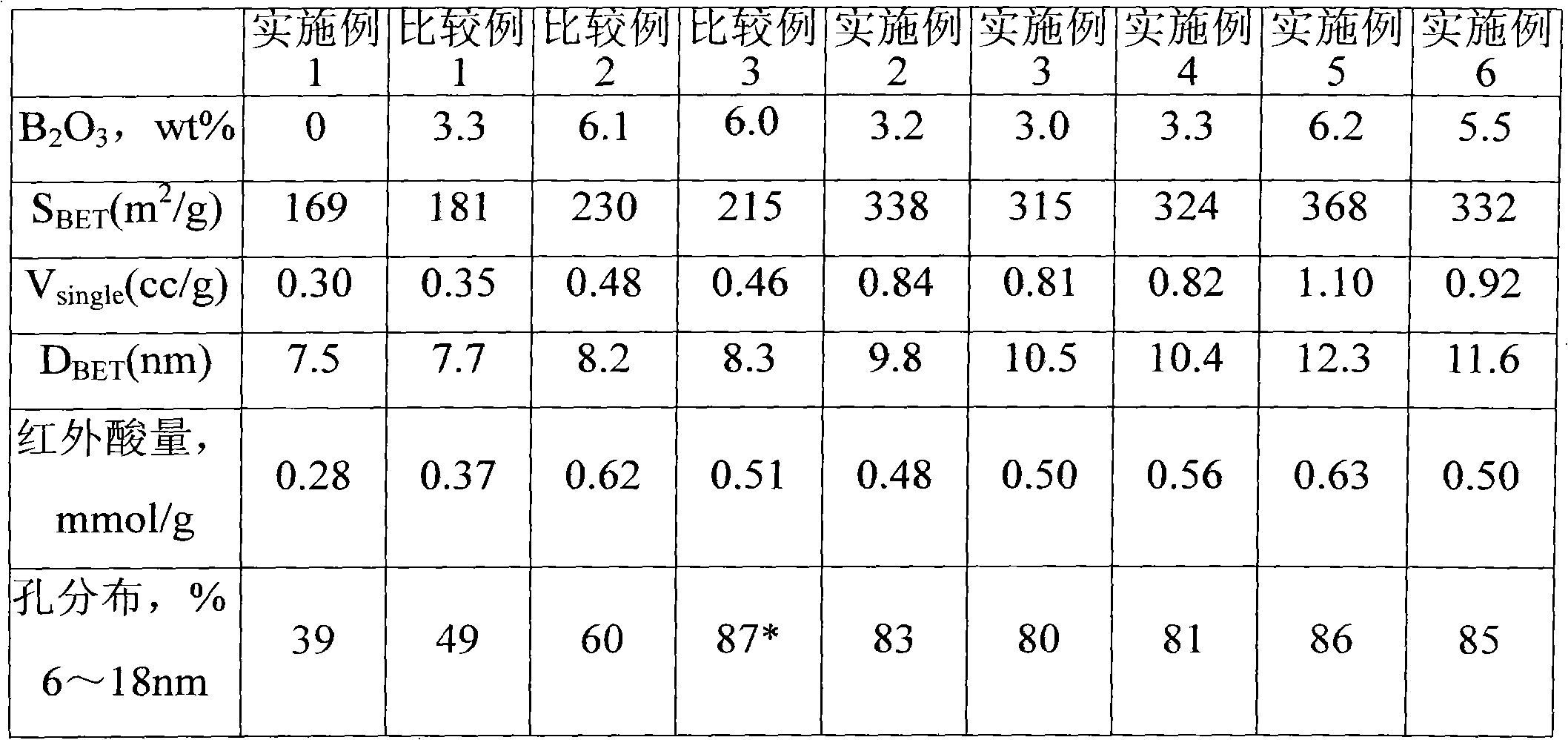

Preparation method of boron-modified alumina carrier

ActiveCN102728335ASuitable for acidityImprove pore structureCatalyst carriersRefining to eliminate hetero atomsSupersaturationSurface tension

The invention relates to a preparation method of a boron-modified alumina carrier. The method comprises the following steps of: firstly wetting an alumina precursor by the use of a low carbon alcoholic solution, adding a boron-containing solution formed by polyol and boric acid, and preparing the boron modified alumina carrier. By the adoption of the method, local supersaturation adsorption phenomenon caused by directly adding the boron-containing solution into the alumina precursor can be avoided, and the solution will not be over-absorbed into internal pores. Simultaneously, with the increase of the temperature during the kneading process, volatilization of low carbon alcohol and low surface tension help boron to uniformly disperse onto the surface of the alumina carrier. In addition, the method is beneficial to improving specific surface area and pore volume of the carrier. The boron modified alumina carrier provided by the invention is especially applicable to being used as a carrier for a hydrodenitrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

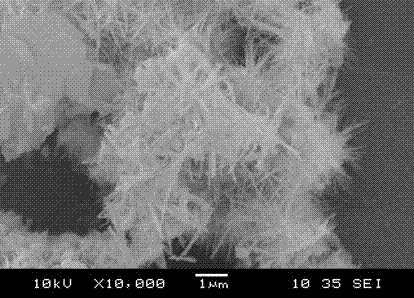

Nanometer needle-shaped SAPO-34 molecular sieve, as well as preparation and application thereof

ActiveCN107055563AHigh crystallinityImprove transmission performanceMaterial nanotechnologyMolecular-sieve and base-exchange phosphatesMolecular sieveActive component

The invention relates to a nanometer needle-shaped SAPO-34 molecular sieve, as well as preparation and application thereof. A gel decondensation hydrothermal synthesis method is adopted and particularly comprises the following steps: (1) mixing an aluminum source, a phosphorus source, a silicon source, deionized water and a template agent, heating and stirring to obtain gel A; (2) adding excessive HF solution into the gel A, wherein the gel is decondensed into a solution at this moment; (3) performing hydrothermal crystallization: transferring the solution obtained in the step (2) into a polytetrafluoroethylene reaction kettle, performing high-temperature crystallization, rapidly cooling after the crystallization is completed, filtering and washing the obtained solid, drying and roasting to obtain the nanometer needle-shaped SAPO-34 molecular sieve. The preparation process is simple and easy to operate, and the molecular sieve has important application in methanol to olefin reaction; meanwhile, due to the special shape, the molecular sieve can serve as a carrier of catalyst active components and has potential industrial application prospect.

Owner:SHANTOU UNIV

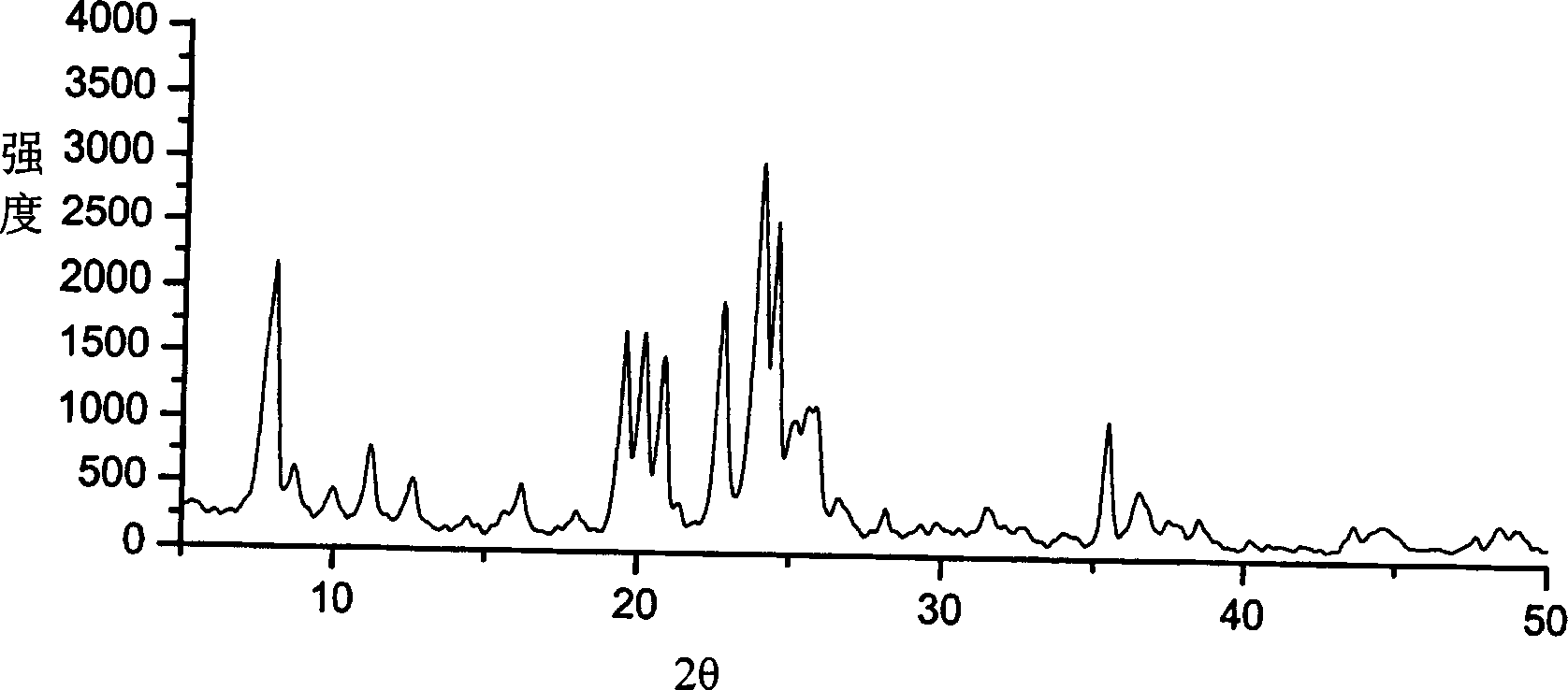

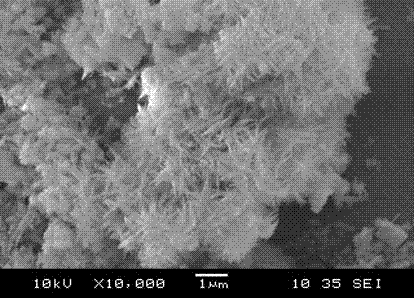

Zeolite molecular sieve containing TON/MTT skeleton topology structure and preparation method of zeolite molecular sieve

ActiveCN107416860AEasy to adjust the lengthAdjustable lengthMolecular sieve catalystsFerrosilicatesIsomerizationSeed crystal

The invention relates to a non-aluminium zeolite molecular sieve containing a TON / MTT skeleton topology structure and a preparation method of the zeolite molecular sieve. The preparation method comprises the steps of dissolving an inorganic alkaline source by using deionized water, then adding a template agent A, a boron source, an iron source or a gallium source, dissolving completely, then adding a template agent B or a silicon source, and adding an-all silicon ZSM-22 molecular sieve as seed crystal into obtained initial gel and then performing ultrasound; utilizing microwave radiation to heat a mixture subjected to the ultrasound so as to obtain a non-aluminum zeolite molecular sieve with a TON / MTT composite topology structure after crystallization. According to the method, the non-aluminium zeolite molecular sieve replaced with a heteroatom is utilized, the acidity is moderate, and the multilevel acidity distribution is adjustable; by adopting the preparation method provided by the invention, the synthesis time is short, the miscellaneous crystal is less, the particle size is uniform, and the repeatability is good. The composite molecular sieve has a huge potential application value in the aspects such as hydrocracking and isomerization.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

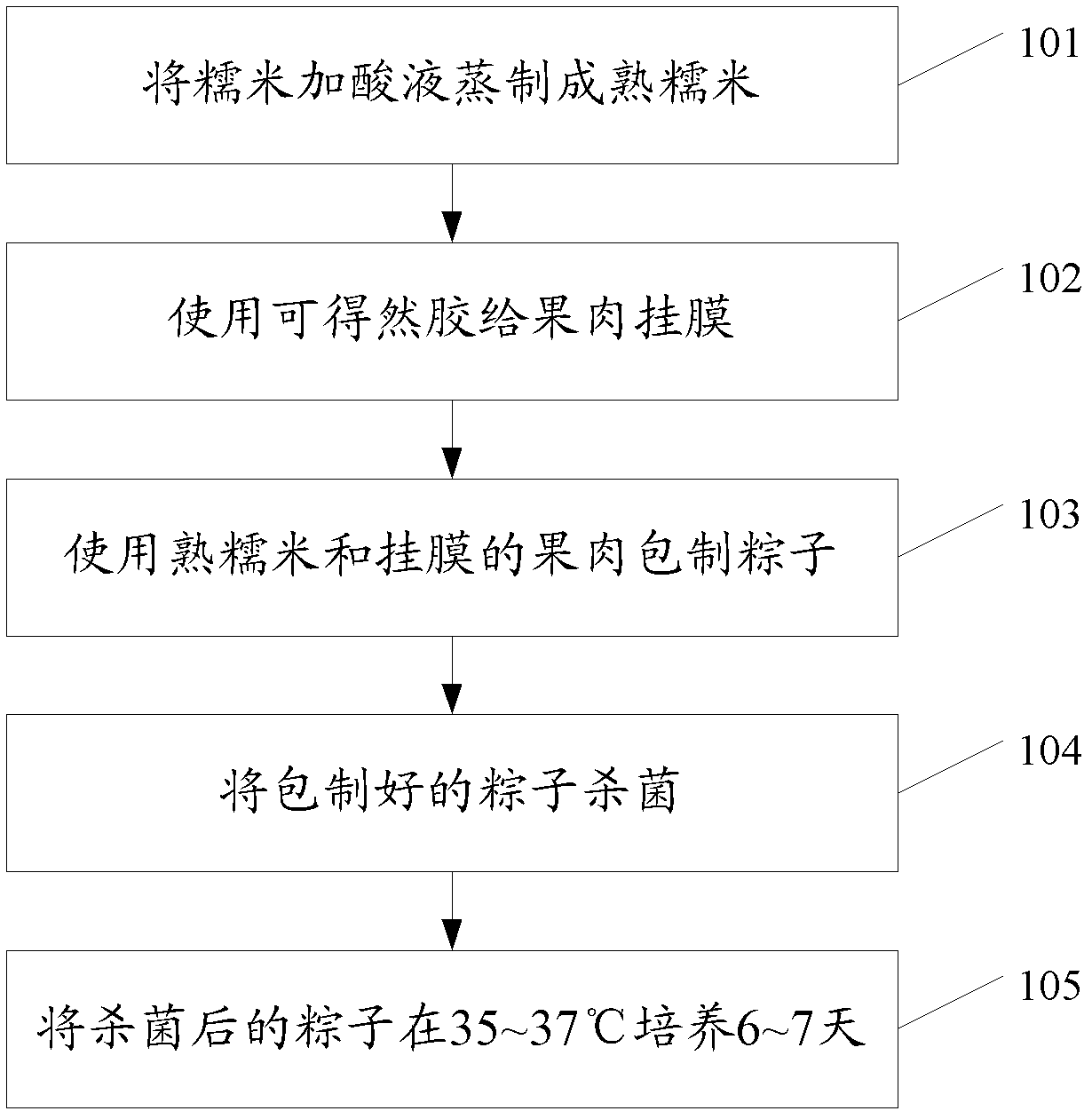

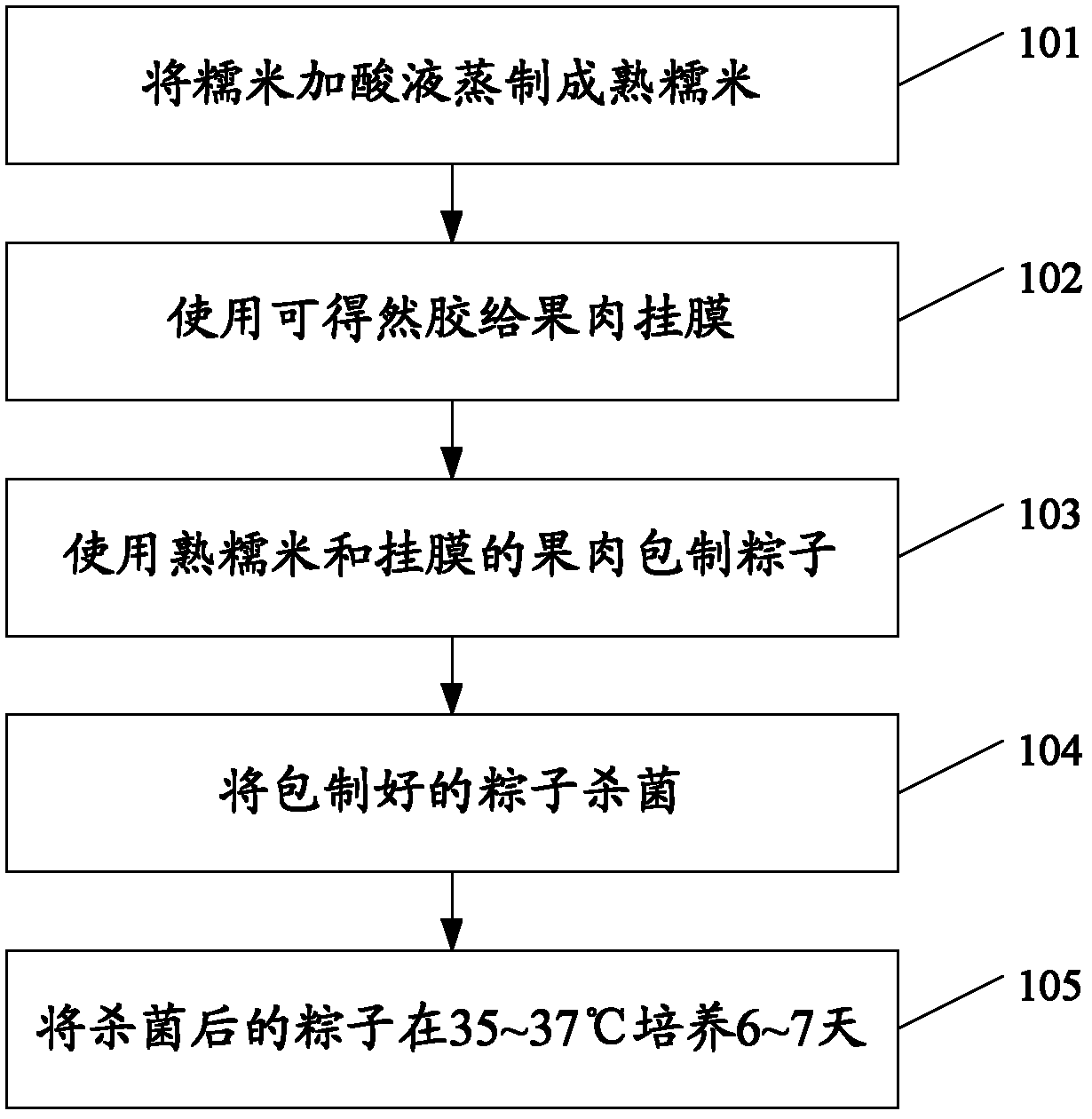

Fruit rice dumpling and preparation method thereof

The invention provides a fruit rice dumpling and a preparation method thereof. The preparation method of the fruit rice dumpling comprises the following steps: steaming glutinous rice together with an acid liquid until cooked, coating fruit grains with curdlan gum, wrapping cooked glutinous rice and fruit grains with bamboo leaves, and sterilizing the rice dumpling product. The invention also provides the fruit rice dumpling which comprises 50 to 60 parts of cooked glutinous rice, 0.8 to 1.2 parts of coated fruit grains and 0.1 to 0.3 parts of glutinous rice flour. According to the fruit ricedumpling and the preparation method thereof provided by the invention, the color of fruit grains is not changed after the fruit rice dumpling is sterilized, and the fruit grains are full and the fruit juices do not flow out when the fruit rice dumpling is stored at room temperature.

Owner:SANQUAN FOOD

Petroleum fraction hydrofining catalyst and preparing method thereof

InactiveCN1552815AImprove hydrogenation activityHigh viscosityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPhosphoric acidBULK ACTIVE INGREDIENT

A catalyst for petroleum fractions hydrogenation and its preparation are disclosed. It includes preparing silicon binder, fully mixing pseudooligaaqueous aluminum oxide, fluo-compound and compound containing VIB family metals such as molybdenum or tungsten with silicon binder, kneading, stripping, shaping, drying, and high temperature roasting to form Mo(W) / F-SiO2-Al2O3 as carrier, immersing in an aqueous phosphoric acid solution containing VIIIB family metals such as nickel or cobalt, drying and high temperature roasting to obtain the catalyst of petroleum fractions hydrogenation. Its advantages include simple preparation, easy operation, low cost, good active ingredient dispersing status, large specific area and pore volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method

ActiveCN107345155AThe skeleton structure is stable and perfectElimination of non-skeletal structuresMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking method which comprises the following steps that a straight-run diesel oil raw material is in contact with a hydrocracking catalyst to carry out hydrocracking reaction, and an obtained hydrocracking product is separated to obtain heavy naphtha, diesel oil, a jet fuel and hydrogenation tail oil, wherein the used hydrocracking catalyst adopts a modified Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide as carriers, and the modified Y-shaped molecular sieve is an Y-shaped molecular sieve which is rich in meso pores and is concentrated in effective pore size distribution. The hydrocracking method is particularly suitable for a hydrocracking technology for carrying out hydro-conversion on straight-run diesel oil to produce the jet fuel, and has very high catalytic activity and aviation fuel product yield and the quality of a product is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-silicon macroporous amorphous silicon aluminum dry glue by using carbonation method

ActiveCN103785481AReduce manufacturing costImprove solubilityCatalyst carriersCarbonationPressure reactor

The invention relates to a preparation method of high-silicon macroporous amorphous silicon aluminum dry glue by using a carbonation method. The preparation method comprises steps of: (1) separately preparing a sodium aluminate solution and a silicon-containing compound material; (2) adding the sodium aluminate solution into a sealed pressure reactor, feeding carbon dioxide under stirring, with the pressure being raised to 0.2-2.0 MPa, the reaction temperature being controlled to be 10-35 DEG C and the reaction pressure during a reaction process being maintained; (3) adding a measured solution of the silicon-containing compound in to the reactor, feeding the carbon dioxide under stirring, with the reaction pressure being controlled at 0.2-2.0 MPa, the reaction temperature being controlled at 10-35 DEG C and the reaction pressure being maintained during the reaction process; and (4) ageing after the neutralization reaction is finished, filtering, washing and drying to obtain an amorphous silicon aluminum dry glue product. Compared with the prior art, the preparation method increases the utilization rate of the carbon dioxide, improves the environment of the neutralization reaction, and facilitates quality improvement of the amorphous silicon aluminum dry glue product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing catalyst by hydrotreatment

ActiveCN102451699ACentralized distributionRegular hole structureMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSimple Organic CompoundsAluminium hydroxide

The invention discloses a method for preparing a catalyst by hydrotreatment. The method comprises the following steps: gelatinizing aluminum hydroxide and adding a stable boron-containing organic compound solution, introducing a boron auxiliary agent to obtain the boron-containing aluminum hydroxide, mixing active metal ingredients with boron-containing aluminum hydroxide by a wet-mixing-kneadingmethod, three-segment roasting to obtain a catalyst intermediate, dipping the residual partial active metal and loading on the catalyst intermediate, drying to obtain the hydrotreatment catalyst. According to the invention, the boron auxiliary agent and the active metal ingredients are uniformly distributed on the surface of the catalyst, active metal ingredients introduced by two modes has different forms in the catalyst, mutual cooperation enables reduction of activity loss rate of the catalyst, and the running period of the apparatus can be prolonged. The catalyst has the characteristics of large pore volume and large specific surface area, and possesses proper pore structure and acidity, is especially suitable for hydrodenitrogenation process of heavy hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

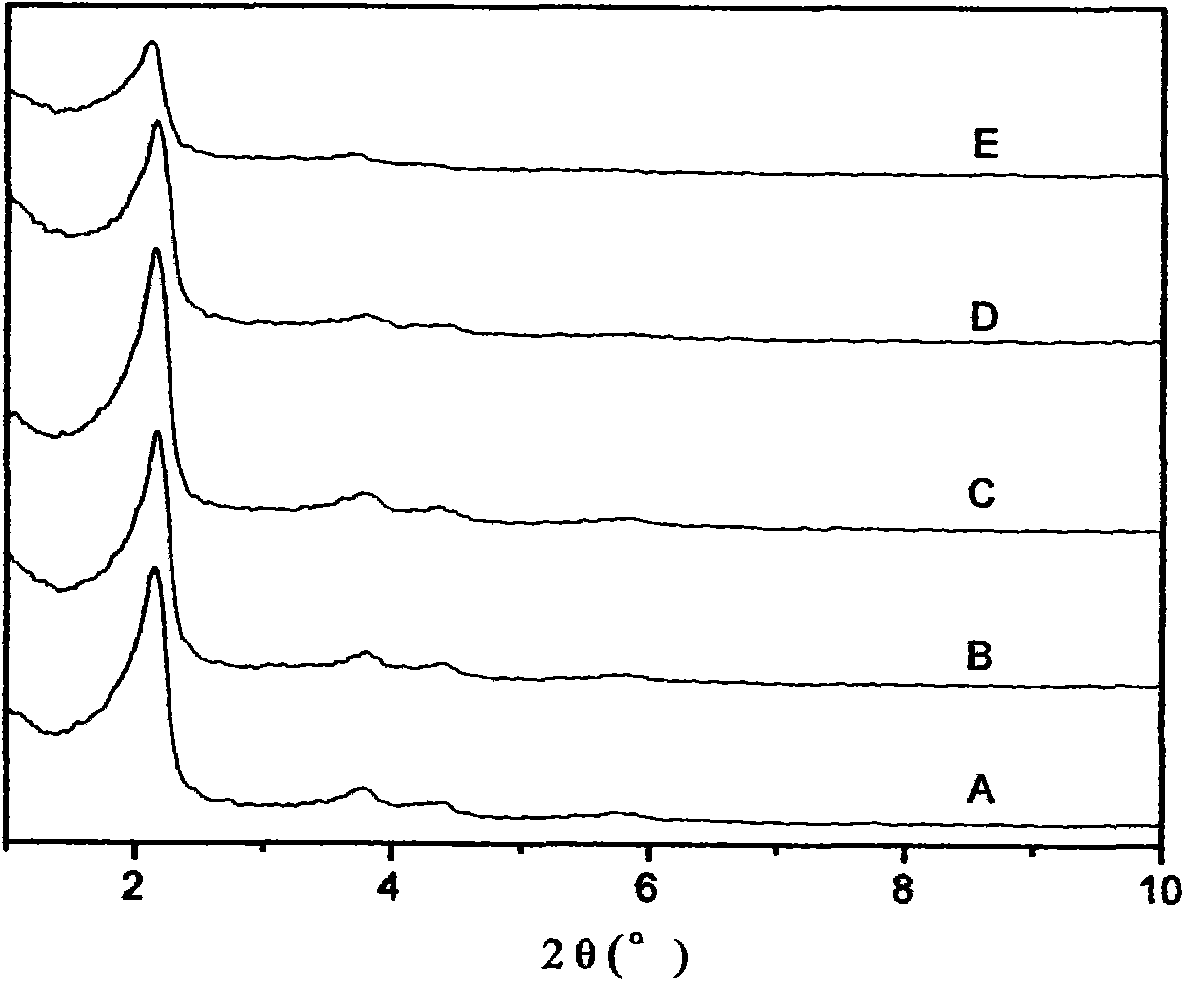

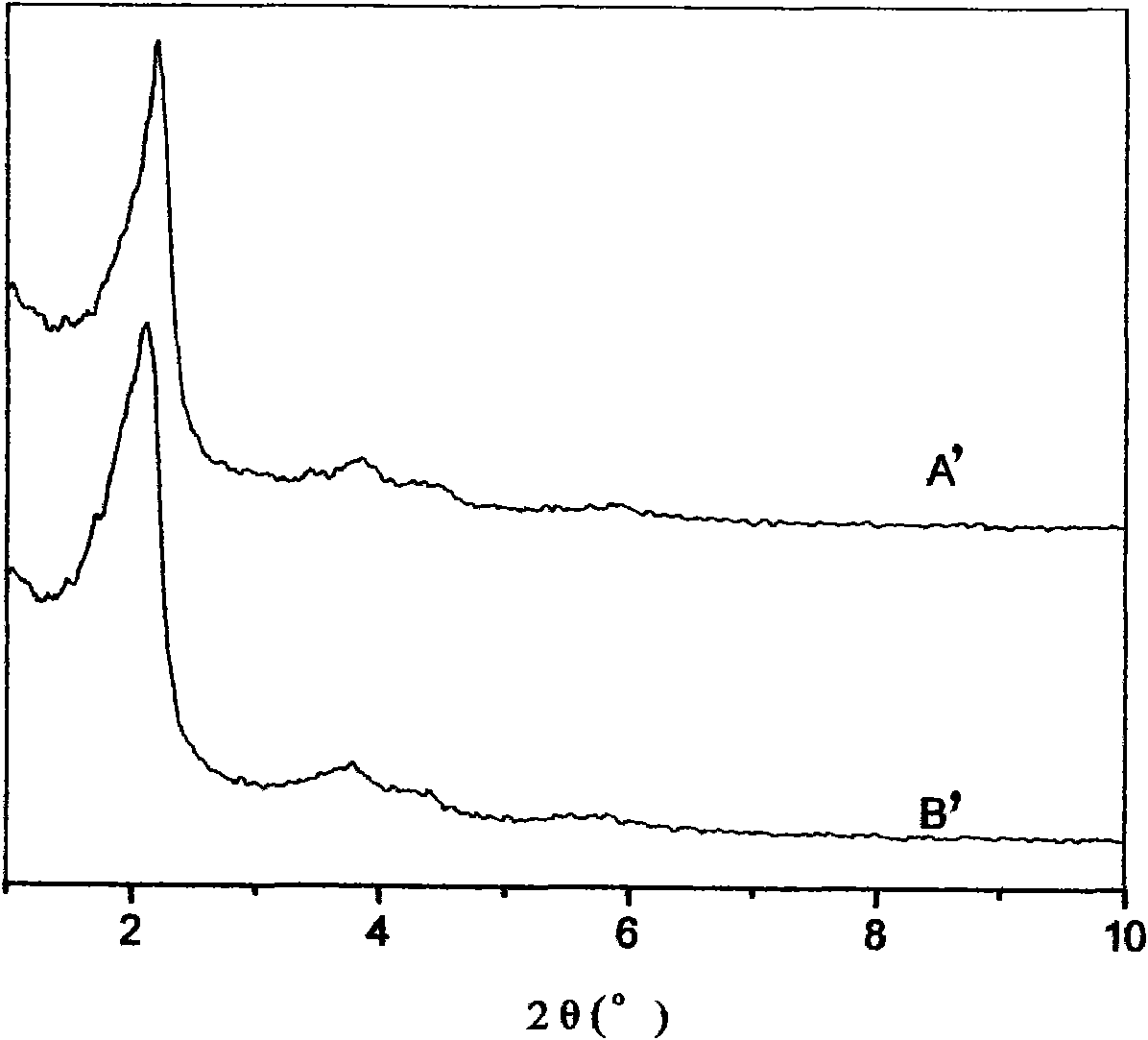

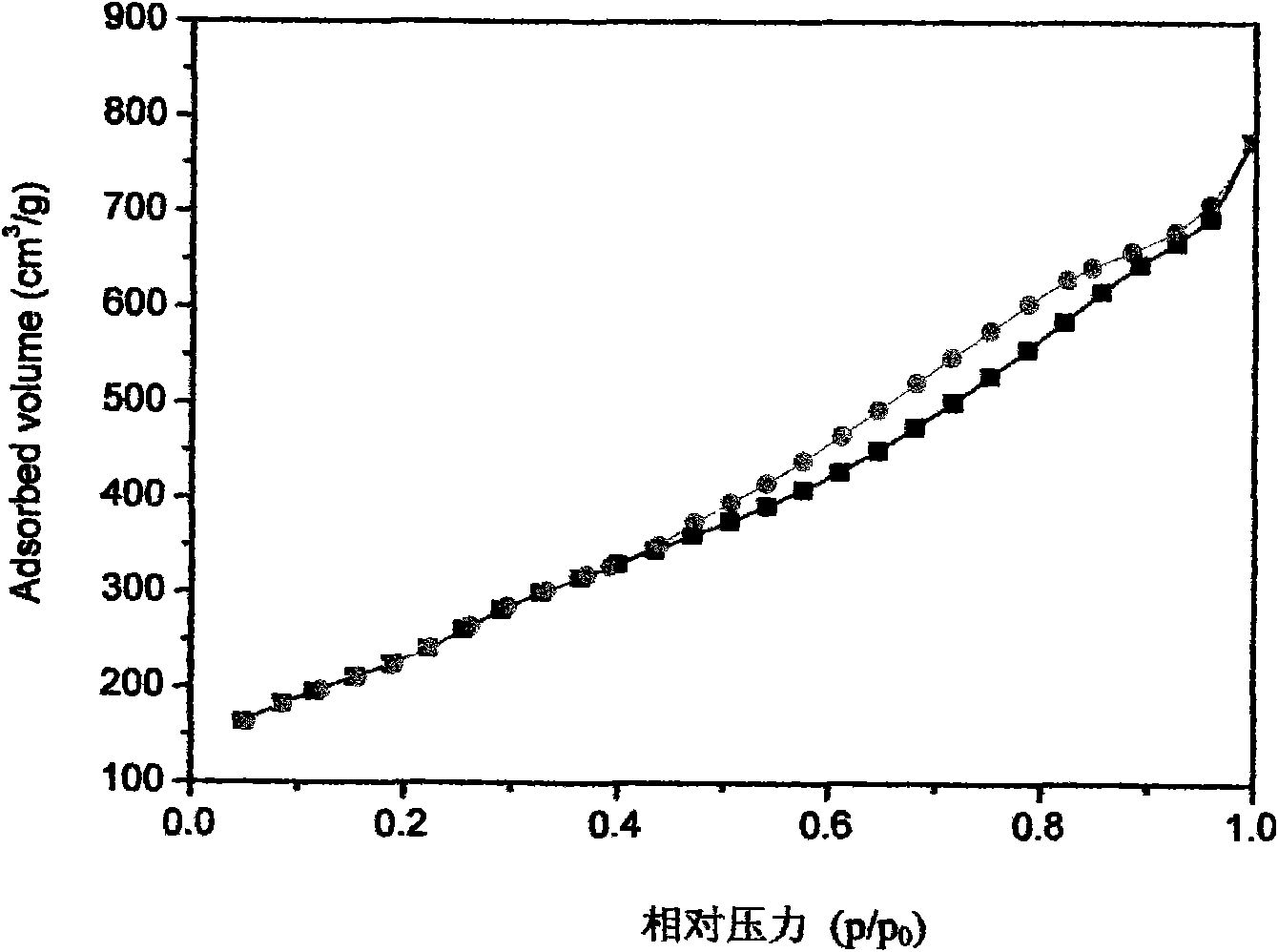

Method for preparing mesoporous material with high hydrothermal stability by ZSM-5

ActiveCN101618879AIncrease useSuitable for acidityCrystalline aluminosilicate zeolitesMesoporous materialAqueous solution

The invention relates to a method for preparing a mesoporous material with high hydrothermal stability by ZSM-5, which is characterized by comprising the following steps: dissolving microporous molecular sieve ZSM-5 under the condition of the existence of a template agent R; adjusting a pH value of a system by a dilute acid aqueous solution; and after the solution is separated, dried and roasted, obtaining the mesoporous material with high hydrothermal stability and long-range order. After the material is roasted, the specific surface area of the material is 400 m<2> / g to 1,200 m<2> / g, and the pore volume is 0.1 cm<3> / g to 1.3 cm<3> / g. After being refluxed for 500 hours by boiling water, the material still maintains about 80 percent of specific surface area and pore volume.

Owner:SHANGHAI NOVEL CHEM TECH

Boron-containing alumina carrier and preparation method thereof

ActiveCN102451771AEffectively regulates acidityImprove anti-cokingCatalyst carriersAdhesiveAluminium hydroxide

The invention discloses a preparation method of a boron-containing alumina carrier. The method comprises the following steps of: gelling the conventional aluminum hydroxide; adding into a stable boron-containing organic compound solution; aging, filtering, washing and drying to obtain dry boron-containing aluminum hydroxide gel; mixing and molding with an adhesive; and heating and performing gradual programmed heating and baking to obtain the boron-containing alumina carrier. Boron-containing alumina is a high-performance carrier component, which can be used for providing a large pore volume and a large specific surface area, has an appropriate pore structure and acidity, and is particularly suitable for a catalyst material needed by a heavy hydrocarbon catalytic processing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Meso-microporous composite molecular sieve, catalyst as well as preparation methods and application thereof

ActiveCN108452839AEvenly distributedEffective dispersionMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationMolecular sieveBULK ACTIVE INGREDIENT

The invention discloses a meso-microporous composite molecular sieve, a catalyst as well as preparation methods and application thereof. The molecular sieve is prepared from a raw material of a USY molecular sieve and by adding an alkali source, a template agent and a silicon source to perform crystallization treatment. The catalyst is prepared from a carrier and an active ingredient Pt which is evenly loaded on the carrier, wherein the carrier is the molecular sieve, the particle size distribution of the active ingredient Pt is 1.0 to 5.0nm, and the Pt loading amount is 0.1 to 1.0% of the total mass of the catalyst. The invention further provides preparation methods and application of the molecular sieve and the catalyst. According to the catalyst disclosed by the invention, the meso-microporous composite molecular sieve with a high specific surface area is utilized as the carrier and can effectively disperse the active ingredient; under the premise of a low noble metal content, the catalyst still has higher catalytic activity; the catalyst is especially suitable for selective ring-opening reaction of diesel arene.

Owner:CHINA NAT OFFSHORE OIL CORP +4

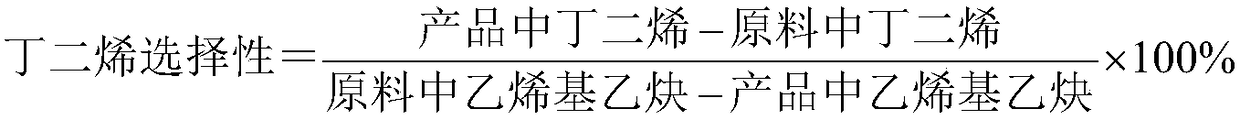

Method for increasing butadiene yield

ActiveCN108863697ASuitable for acidityIncrease productionHydrocarbon by hydrogenationHeterogenous catalyst chemical elementsDispersityAlkyne

The invention discloses a method for increasing butadiene yield. According to the method, carbon-4 cut fraction rich in alkyne after butadiene extraction is utilized as a raw material; under the existence of a catalyst, an adiabatic reactor is utilized, and selective hydrogenation is performed to obtain 1,3-butadiene; utilized hydrogenation operation conditions are that an inlet temperature of thereactor is 20 to 70 DEG C, reaction pressure is 0.8 to 3.0 MPa, and a liquid space velocity is 10 to 30 h<-1>. The catalyst is a palladium-silver-lead series catalyst which is prepared from a nickel-containing aluminum oxide carrier with a specific crystal form, so that dispersity and a utilization rate of active metal can be greatly improved, and hydrogenation performance of the catalyst is improved. The method disclosed by the invention has very obvious good effects on effectively utilizing carbon-4 cut fraction rich in alkyne after butadiene extraction, reducing resource waste and improving economical benefits.

Owner:PETROCHINA CO LTD

Synthetic method of 3-methyl-3-buten-1-ol, catalyst and preparation method of catalyst

ActiveCN107930686ASuitable for acidityHigh activityMolecular sieve catalystsOrganic compound preparationMolecular sieveAluminium

The invention relates to a synthetic method of 3-methyl-3-buten-1-ol, a catalyst and a preparation method of the catalyst, and relates to the technical field of catalyst synthesis. The preparation method of the catalyst for synthesis of 3-methyl-3-buten-1-ol includes the steps: baking a phosphorus-silicon-aluminum molecular sieve at the temperature of 300-600 DEG C for 3.5-5 h, carrying out equivalent-volume impregnation in an alkaline phosphate solution, then aging, drying, and baking. The preparation method is simple to operate and prone to industrialized production; the 3-methyl-3-buten-1-ol catalyst prepared by the method has good catalytic effect; when the catalyst is applied in the synthesis of 3-methyl-3-buten-1-ol, the yield of 3-methyl-3-buten-1-ol is effectively improved, the production efficiency is effectively improved and the preparation cost is reduced.

Owner:SHANDONG YUHUANG CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com