Patents

Literature

135 results about "Sol gel coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organosilane Coating Compositions and Use Thereof

InactiveUS20100330380A1Increase flexibilityReduce presencePigmenting treatmentLayered productsSilanesSol gel coating

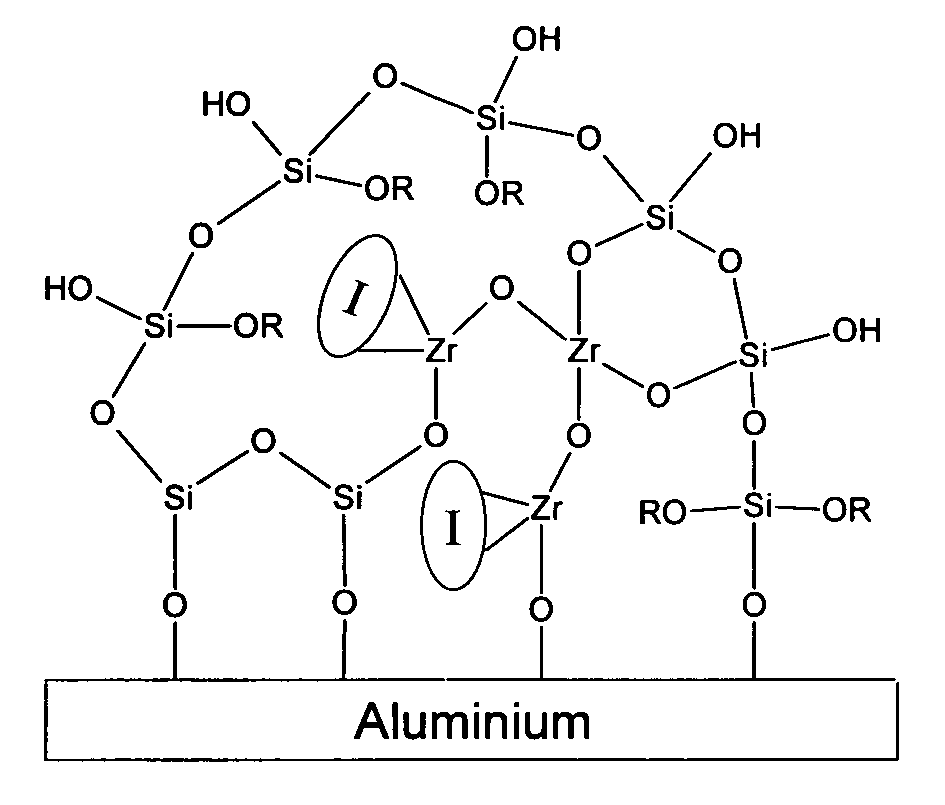

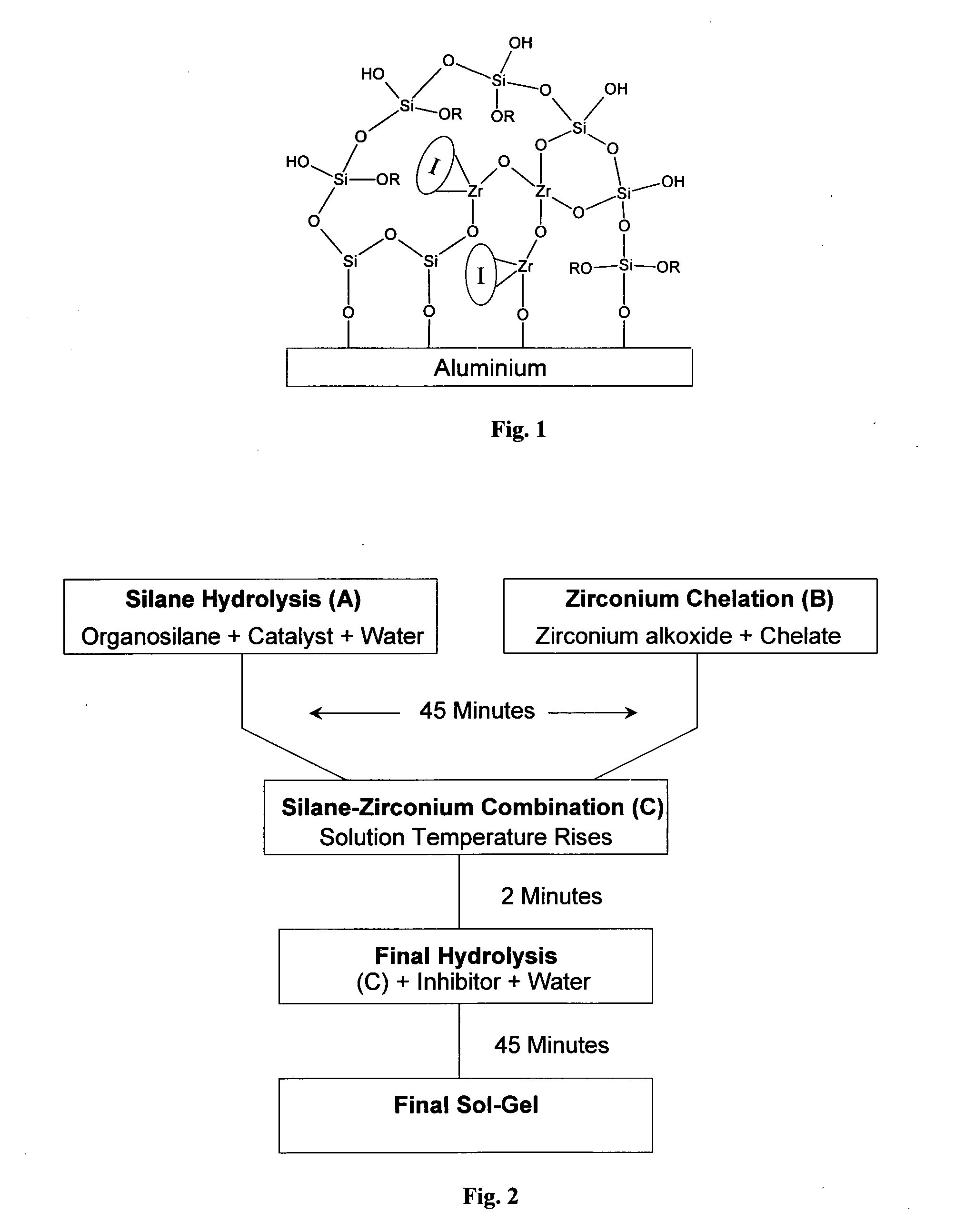

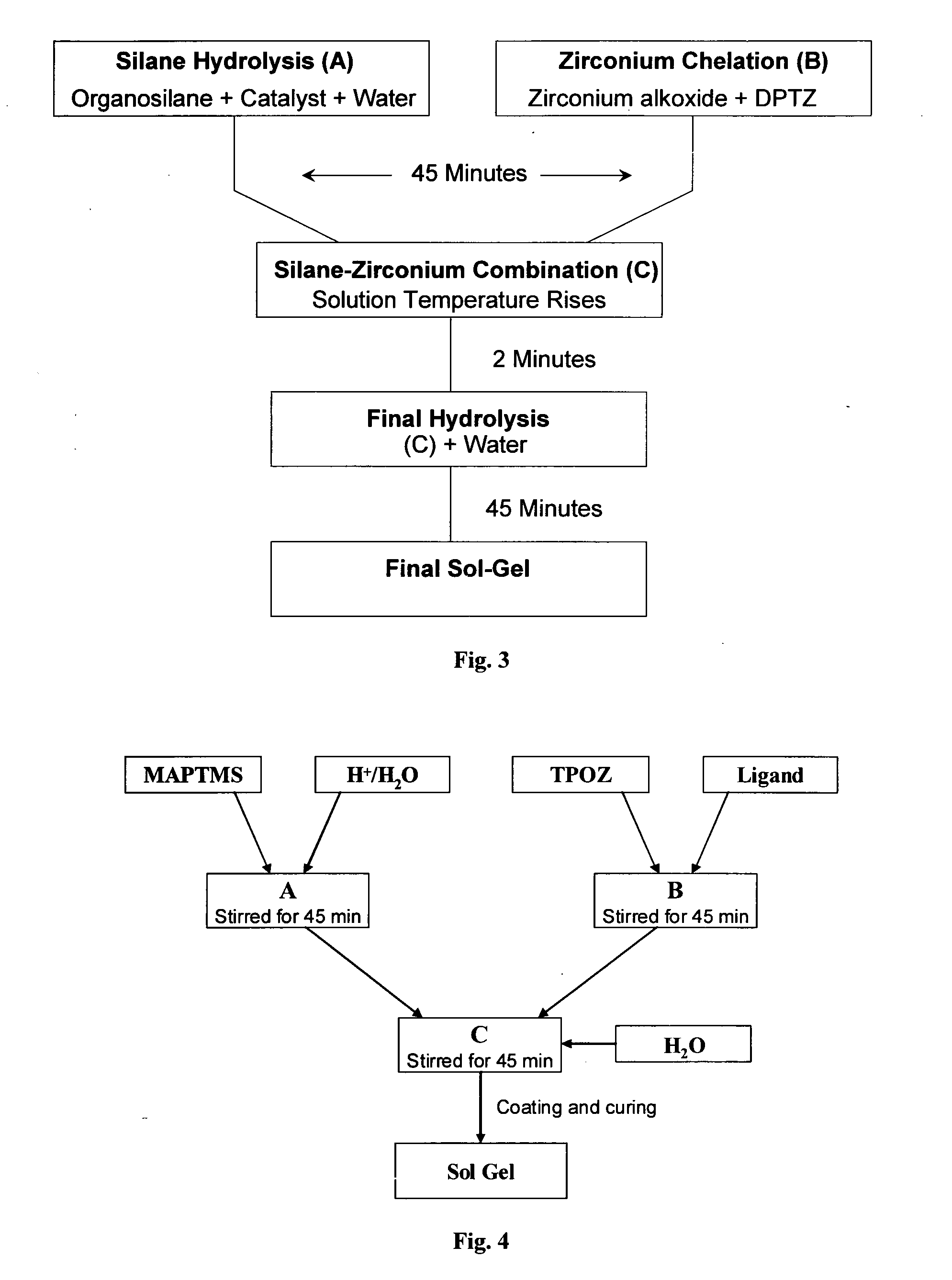

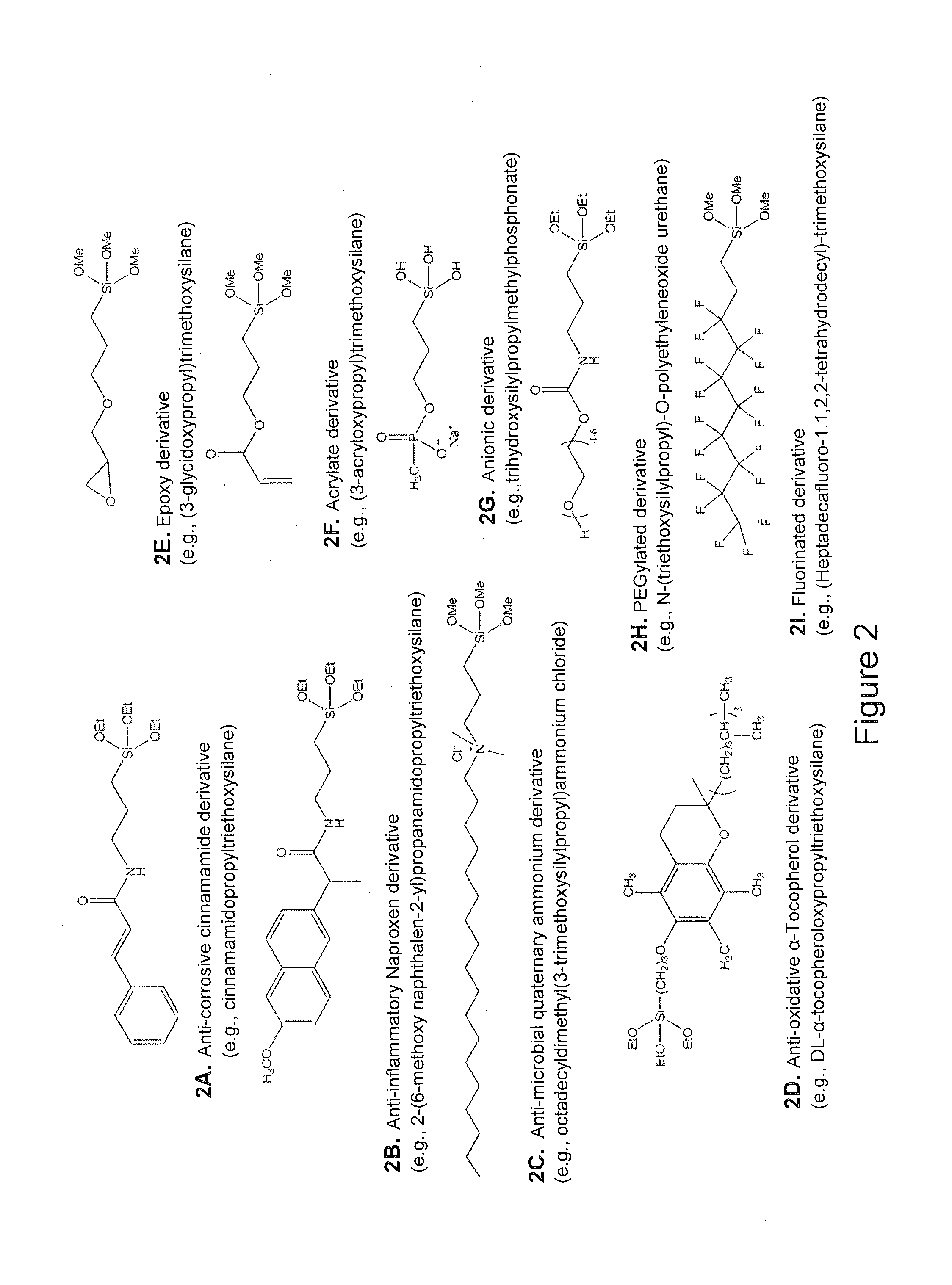

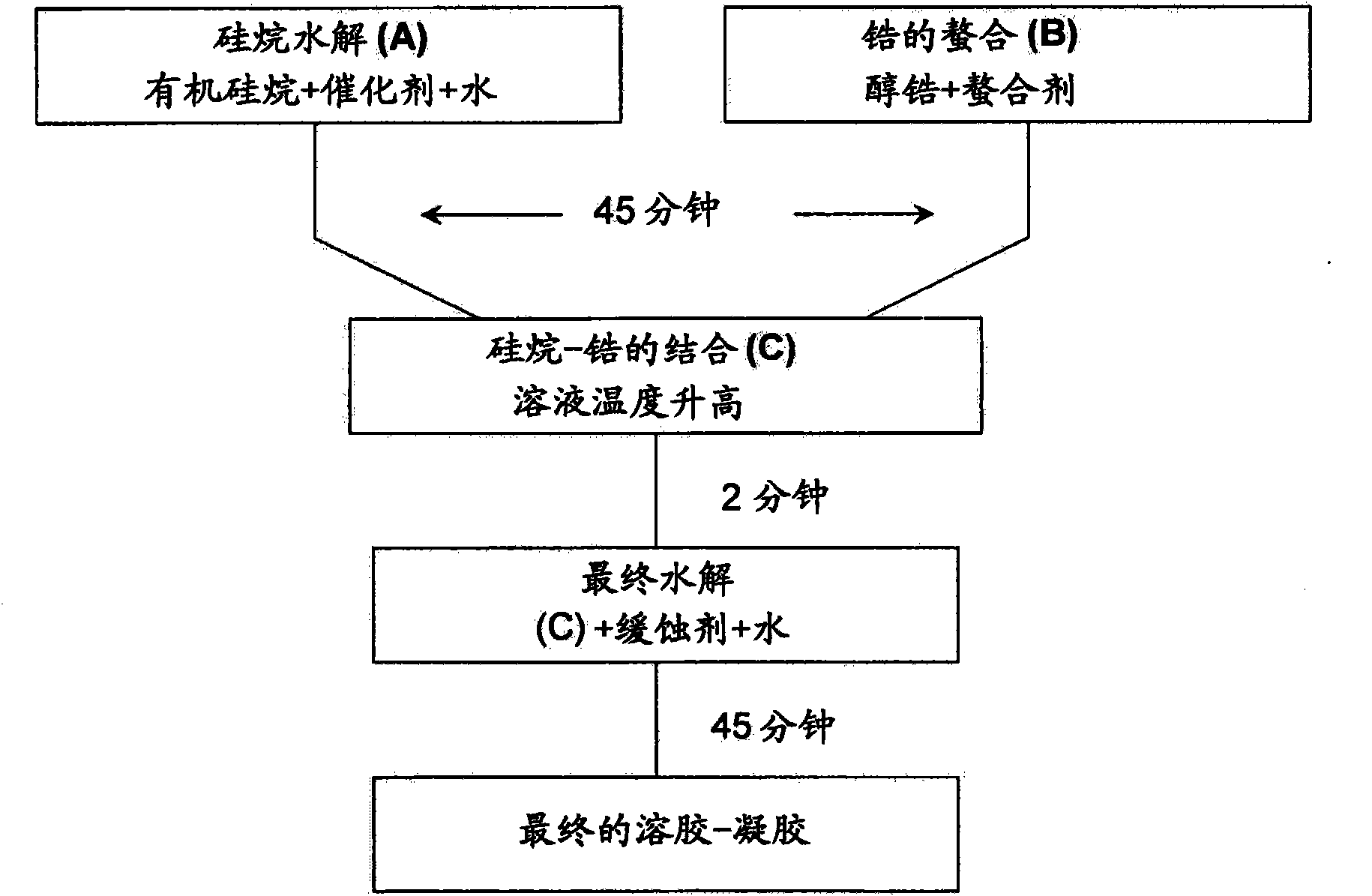

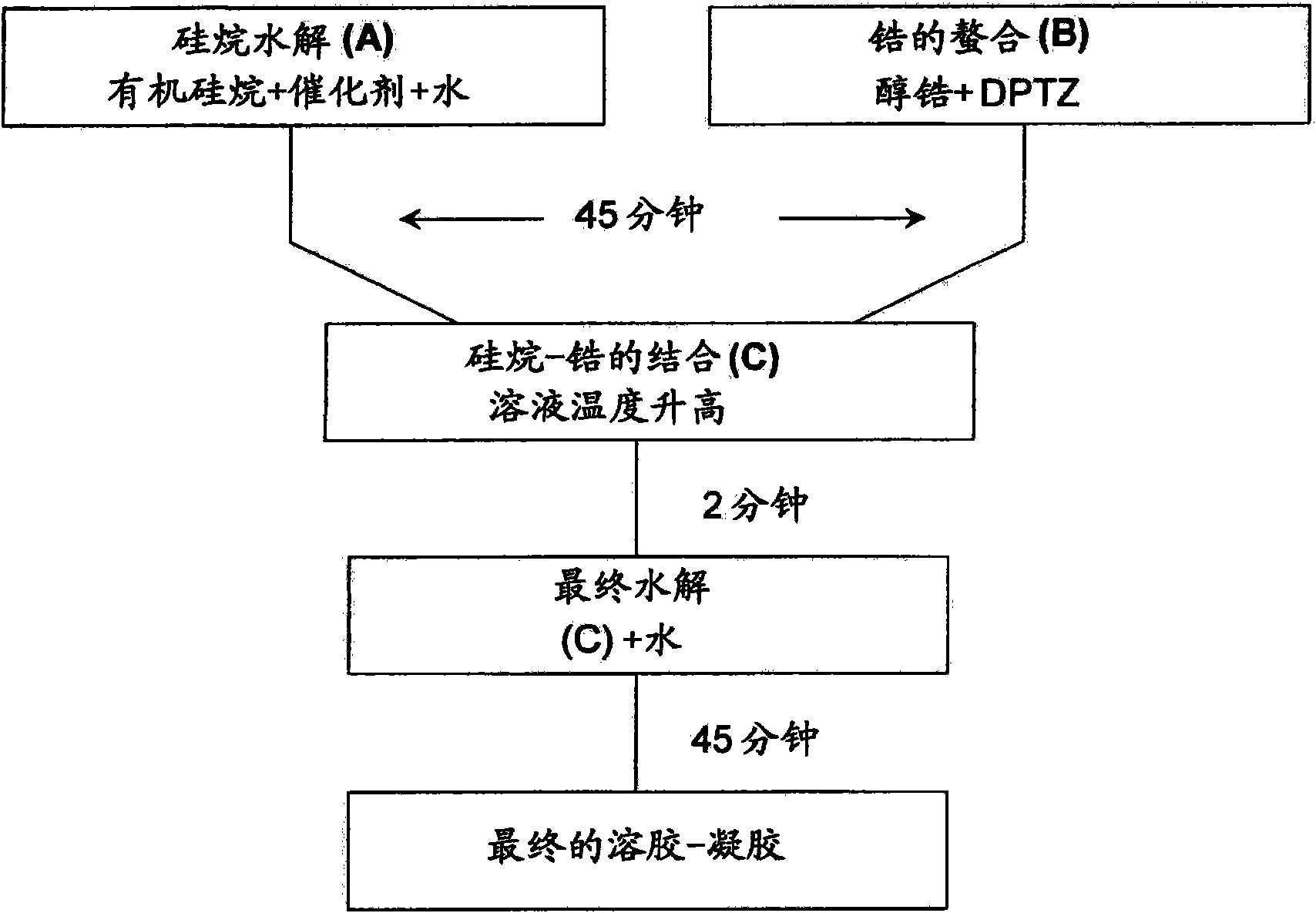

A sol-gel coating composition comprising a hydrolysed organosilane, an organometallic precursor and a corrosion inhibitor, wherein the corrosion inhibitor is a chelator for the organometallic precursor. The corrosion inhibitor and the organometallic precursor may form a nanoparticulate complex. The coating composition may comprise one or more additive selected from: an antimicrobial additive, a hardener, a water repelling additive, a dye, a scratch resistant additive and a flexibility enhancing additive. A process for preparing a sol gel coating composition is also described, the process comprising the steps of: hydrolysing an organosilane in the presence of a catalyst; chelating an organometallic precursor; mixing the hydrolysed silane and the chelated organometallic precursor; and hydrolysing the organosilane-organometallic precursor mixture.

Owner:DUBLIN CITY UNIVERSITY +1

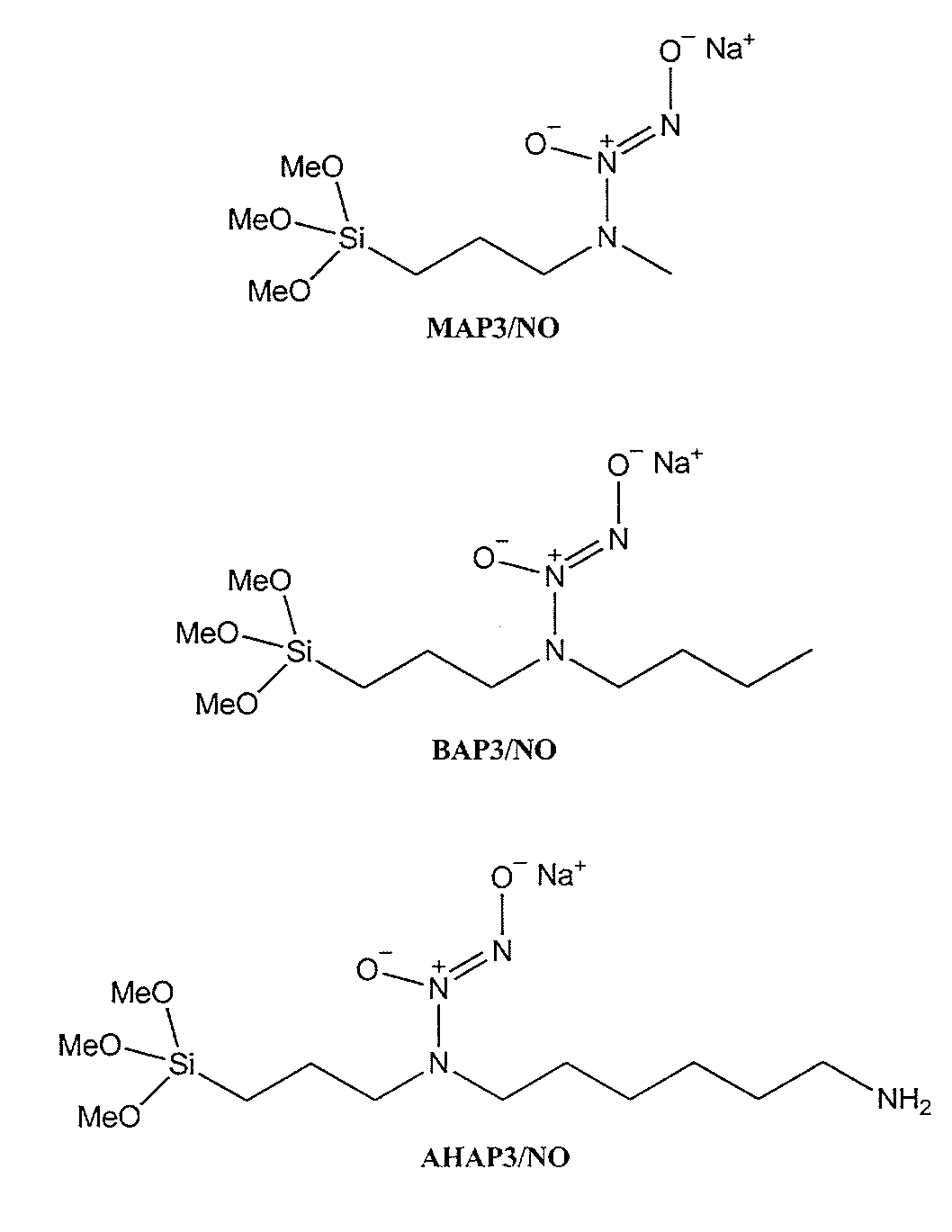

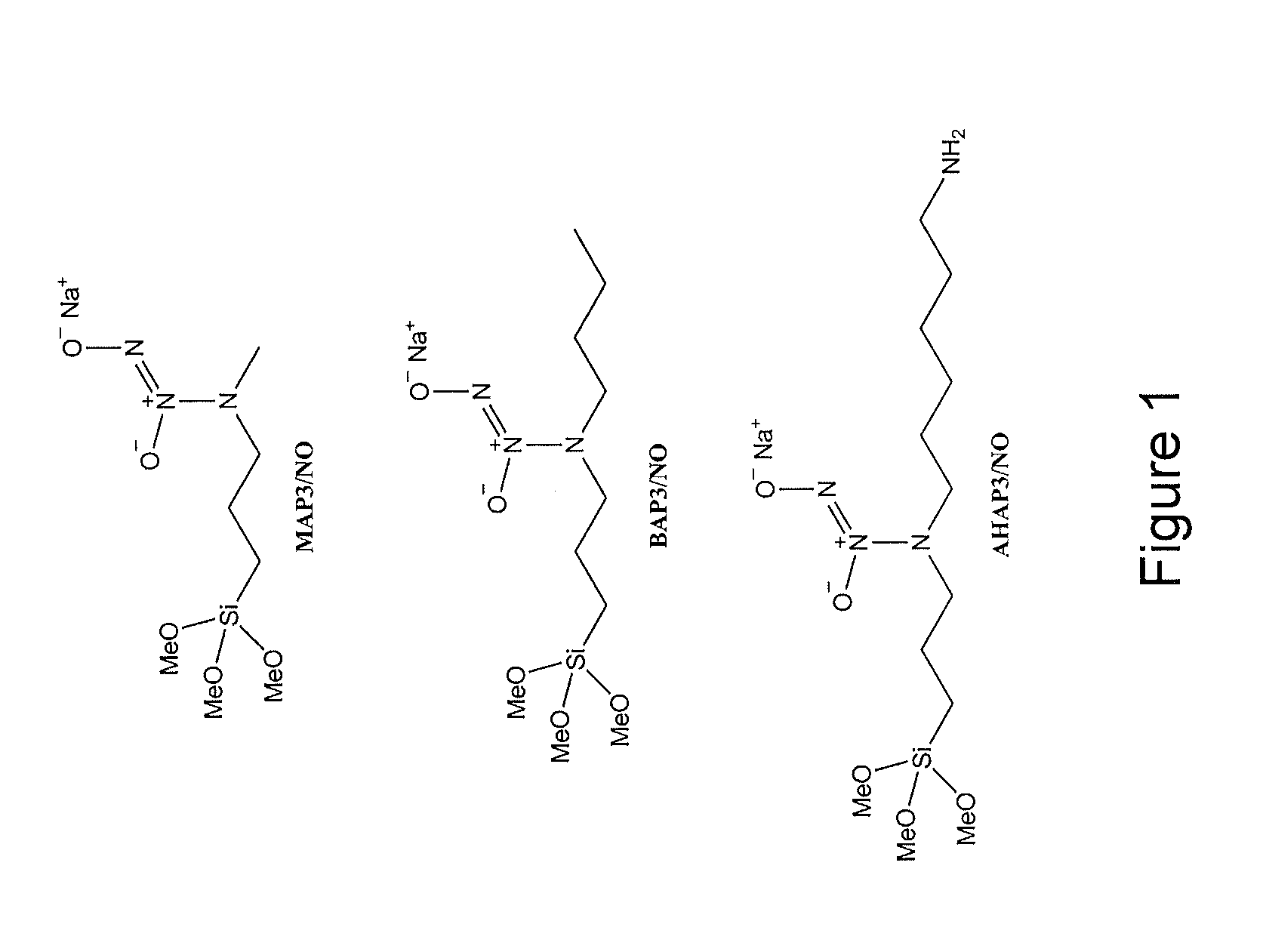

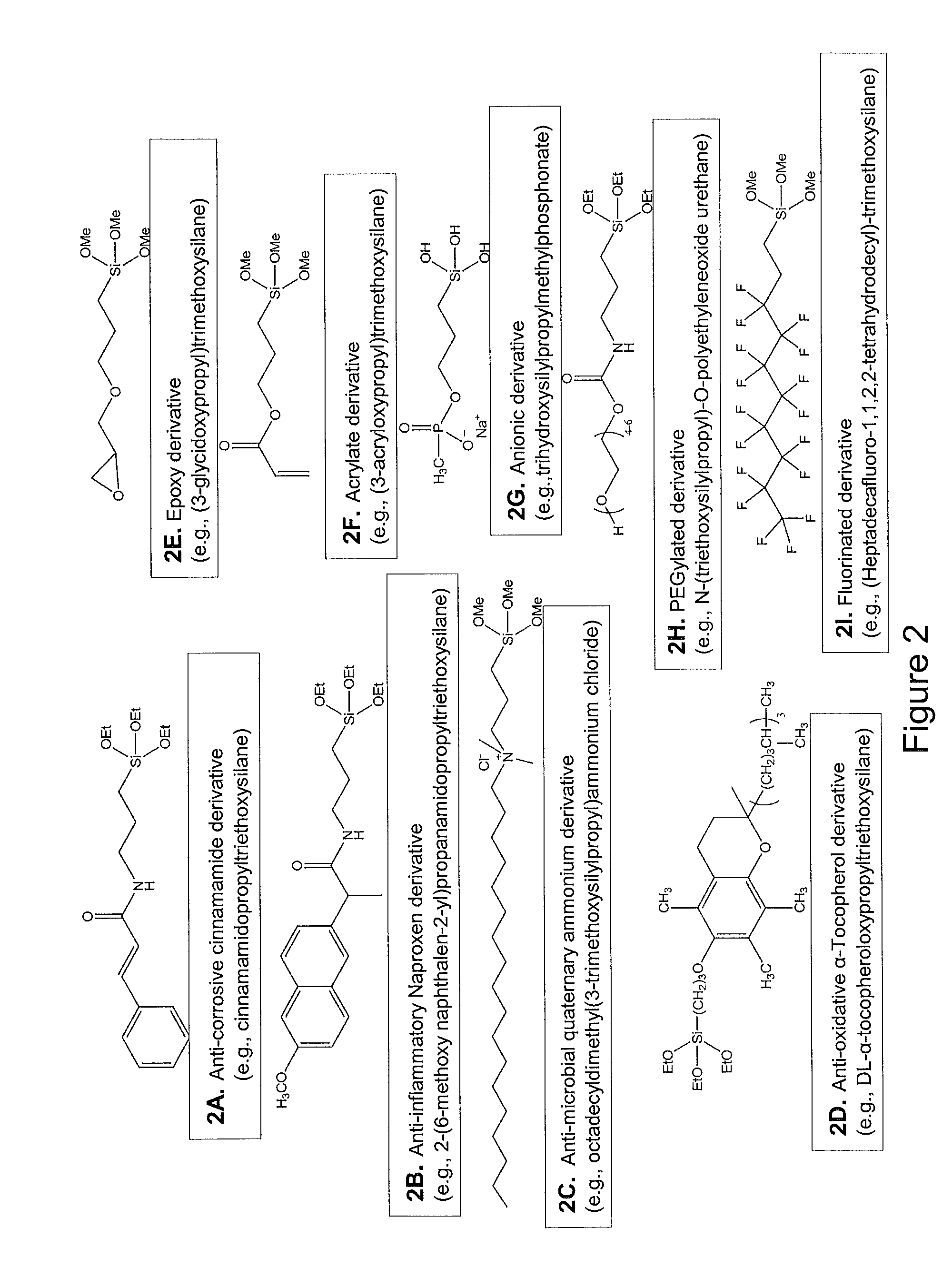

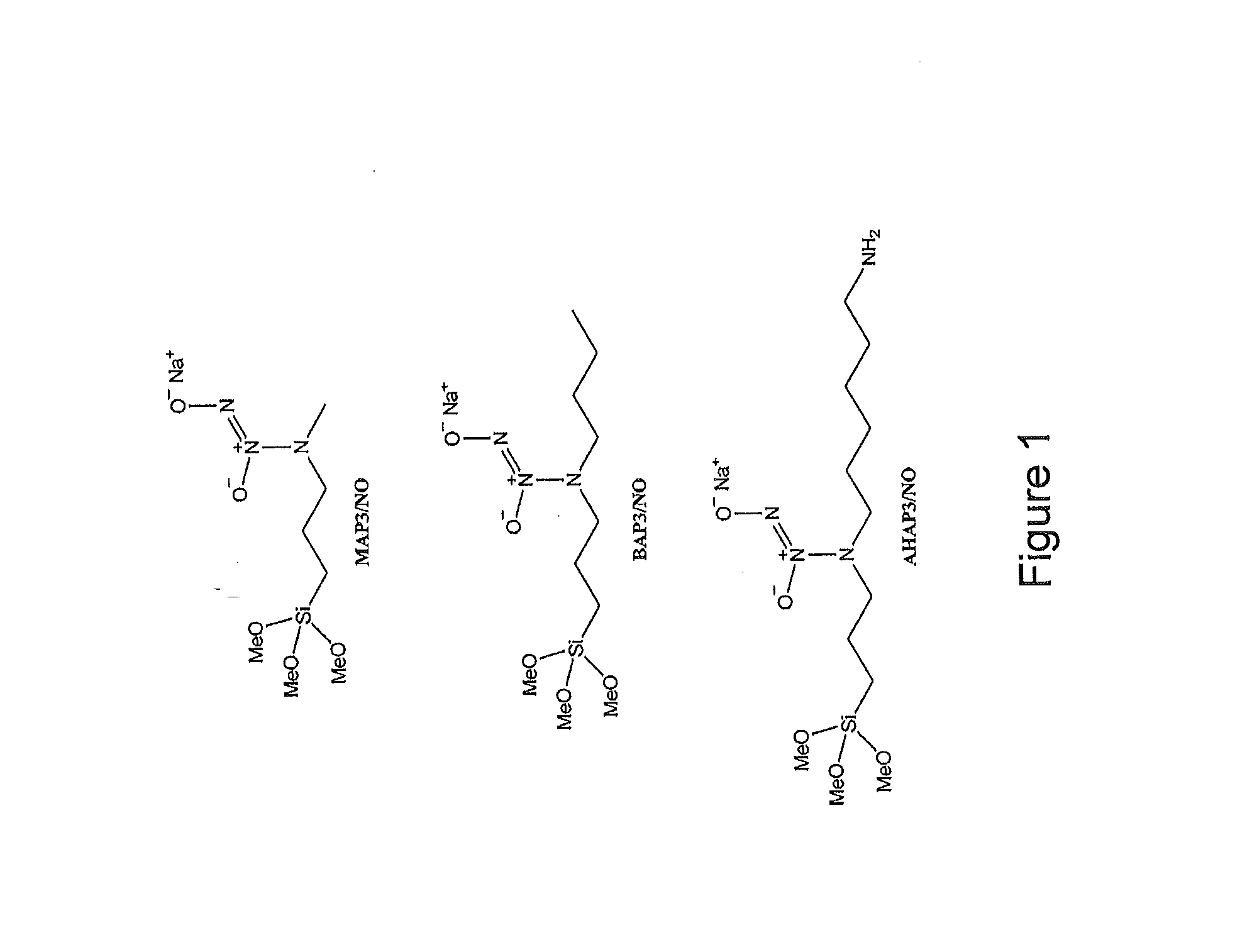

Nitric oxide-releasing coatings

Provided according to embodiments of the invention are NO-releasing sol-gel coating formed from a sol precursor solution comprising a backbone alkoxysilane and a diazeniumdiolate-modified alkoxysilane. Further provided are methods of producing NO-releasing sol-gel coatings. Such methods may include (a) co-condensing a sol precursor solution comprising a backbone alkoxysilane and a diazeniumdiolate-modified alkoxysilane in a solvent to form a sol; (b) coating a substrate with the sol; and (c) drying the sol to form the NO-releasing sol-gel coating.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL +1

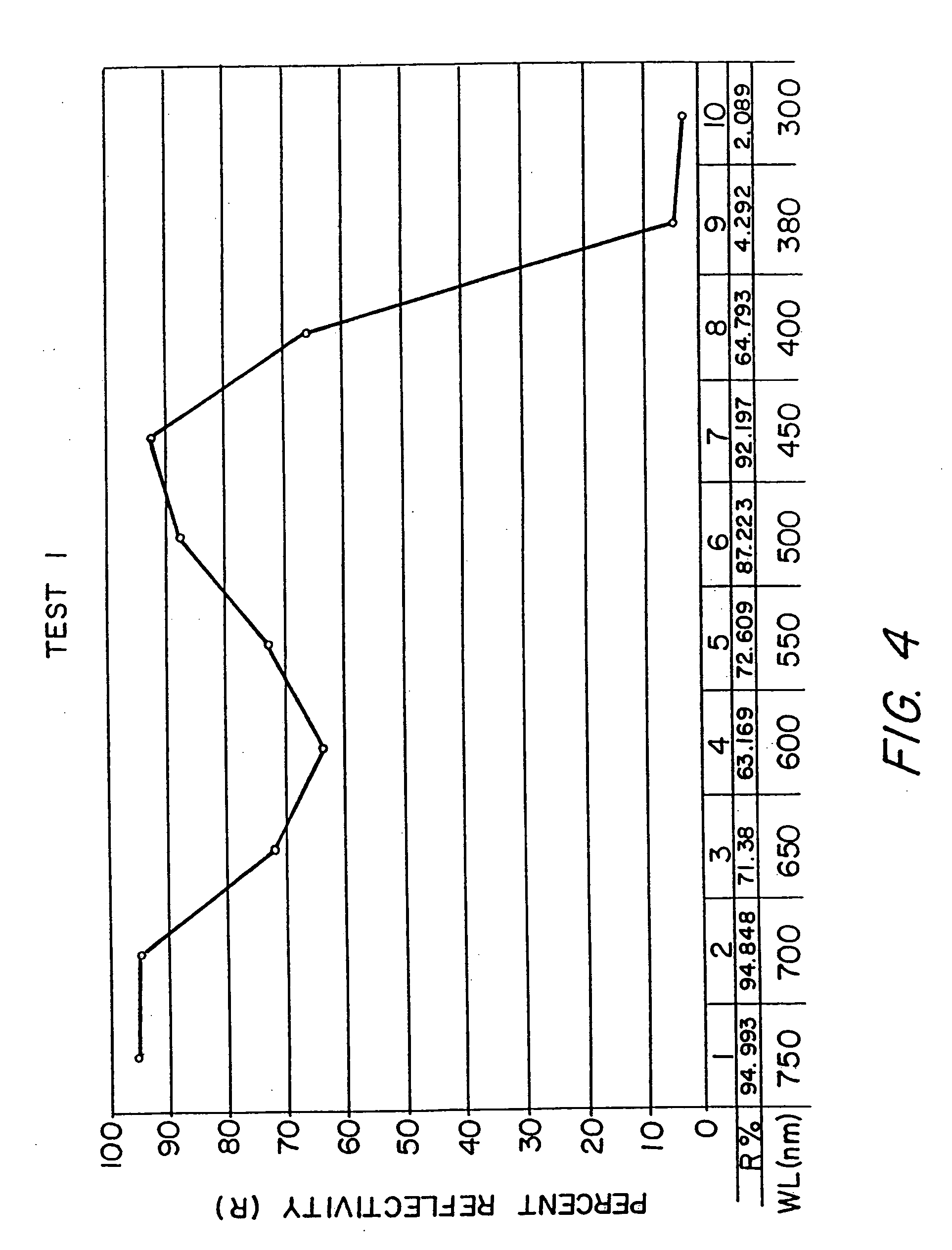

Reflector

A weather and corrosion-resistant reflector with high overall reflection in the visible and infrared wavelength ranges. The reflector contains a reflector body with a reflection surface of an aluminum or aluminum alloy or a reflector body with a reflection coating of an aluminum or aluminum alloy. The reflector also contains an outer, final transparent protective layer of a sol-gel coating which is thicker than 1 μm. The transparent sol-gel coating is a polymer of cross-linked inorganic siloxanes with alcohol groups that are bonded to the silicon with a carbon bond. The sol-gel coating is produced in a sol-gel process and, after having been applied to the reflector body, is dried and hardened using heat. The protective layer has excellent resistance to weather, corrosion and abrasion.

Owner:CONSTELLIUM SWITZERLAND

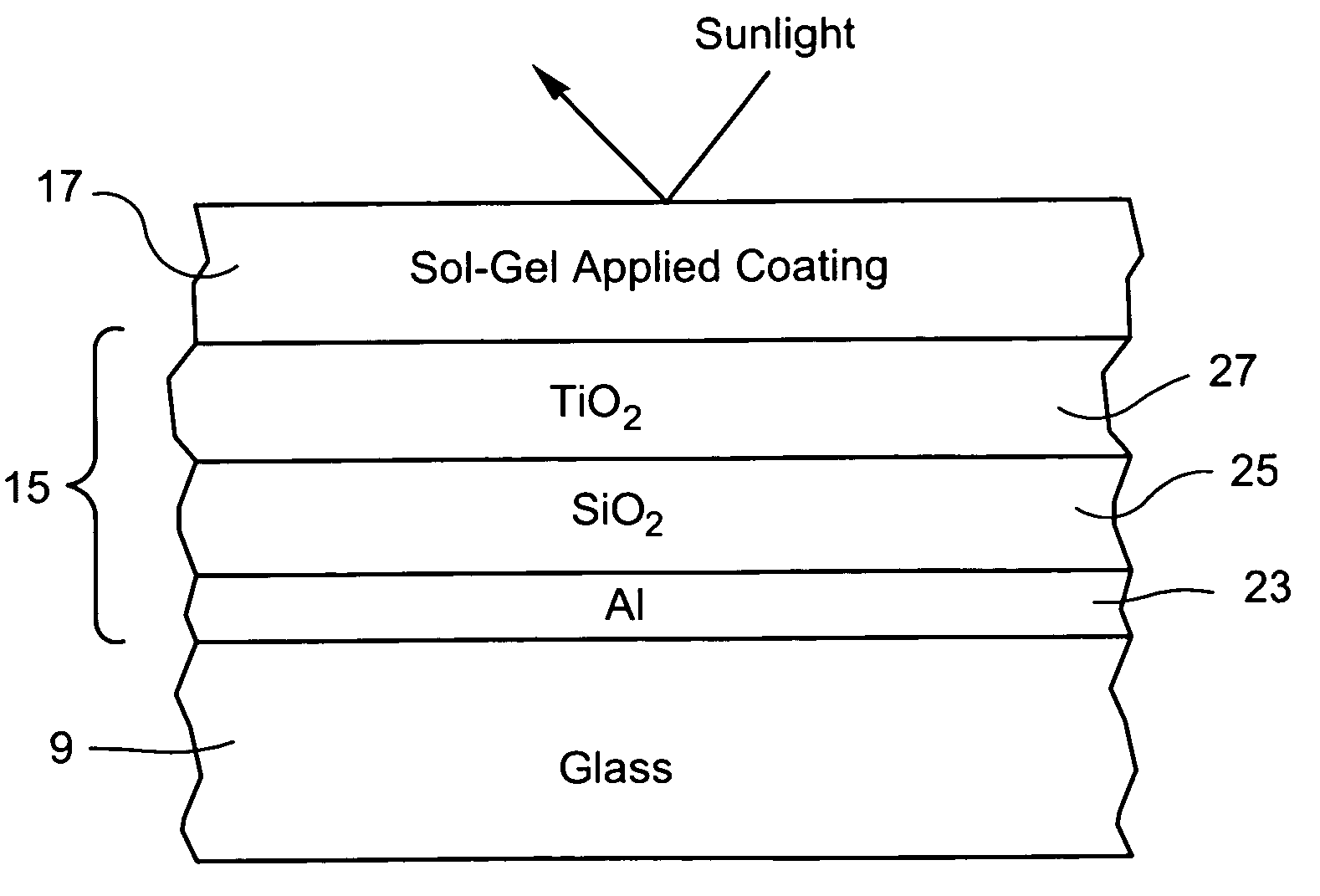

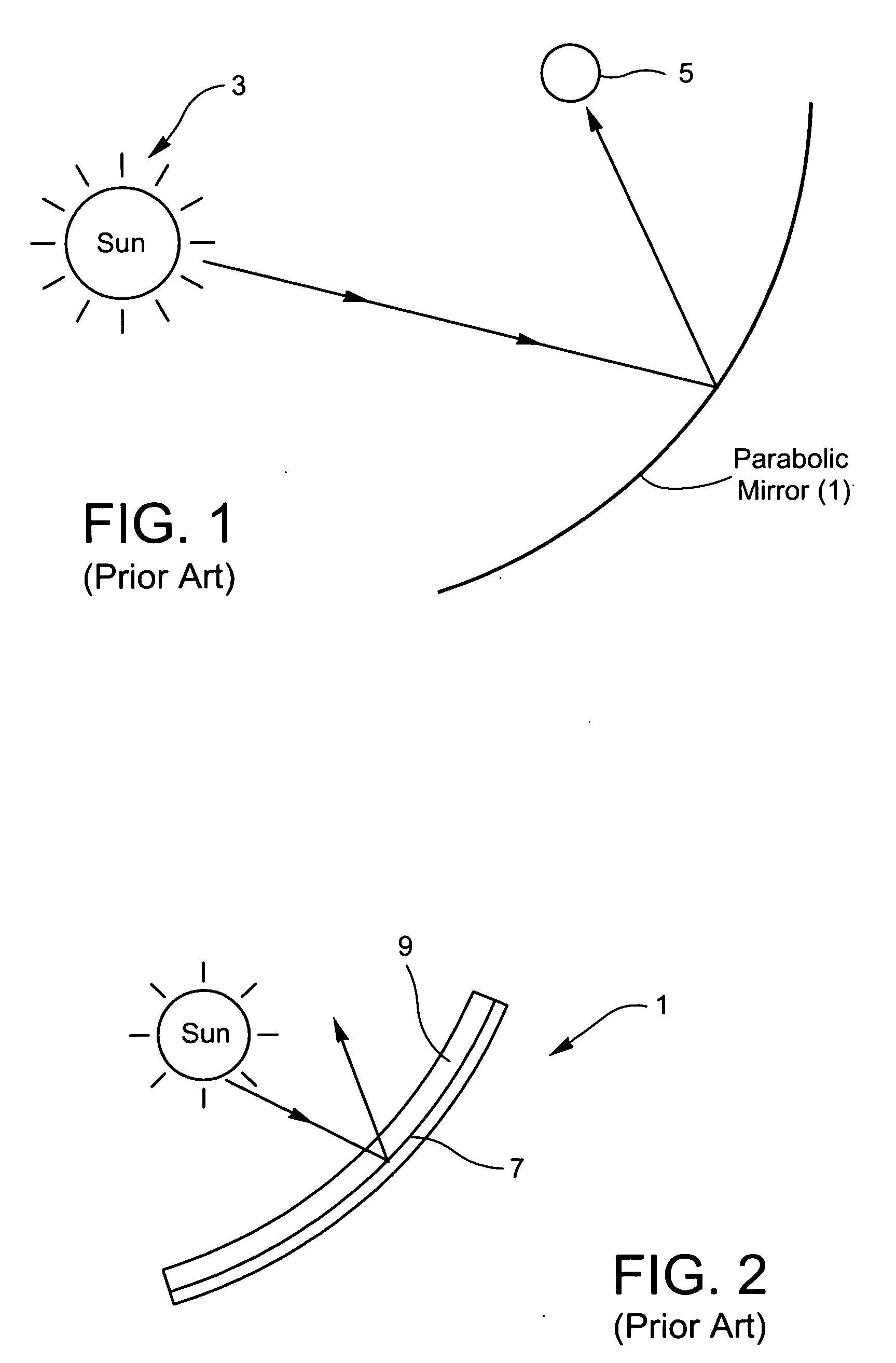

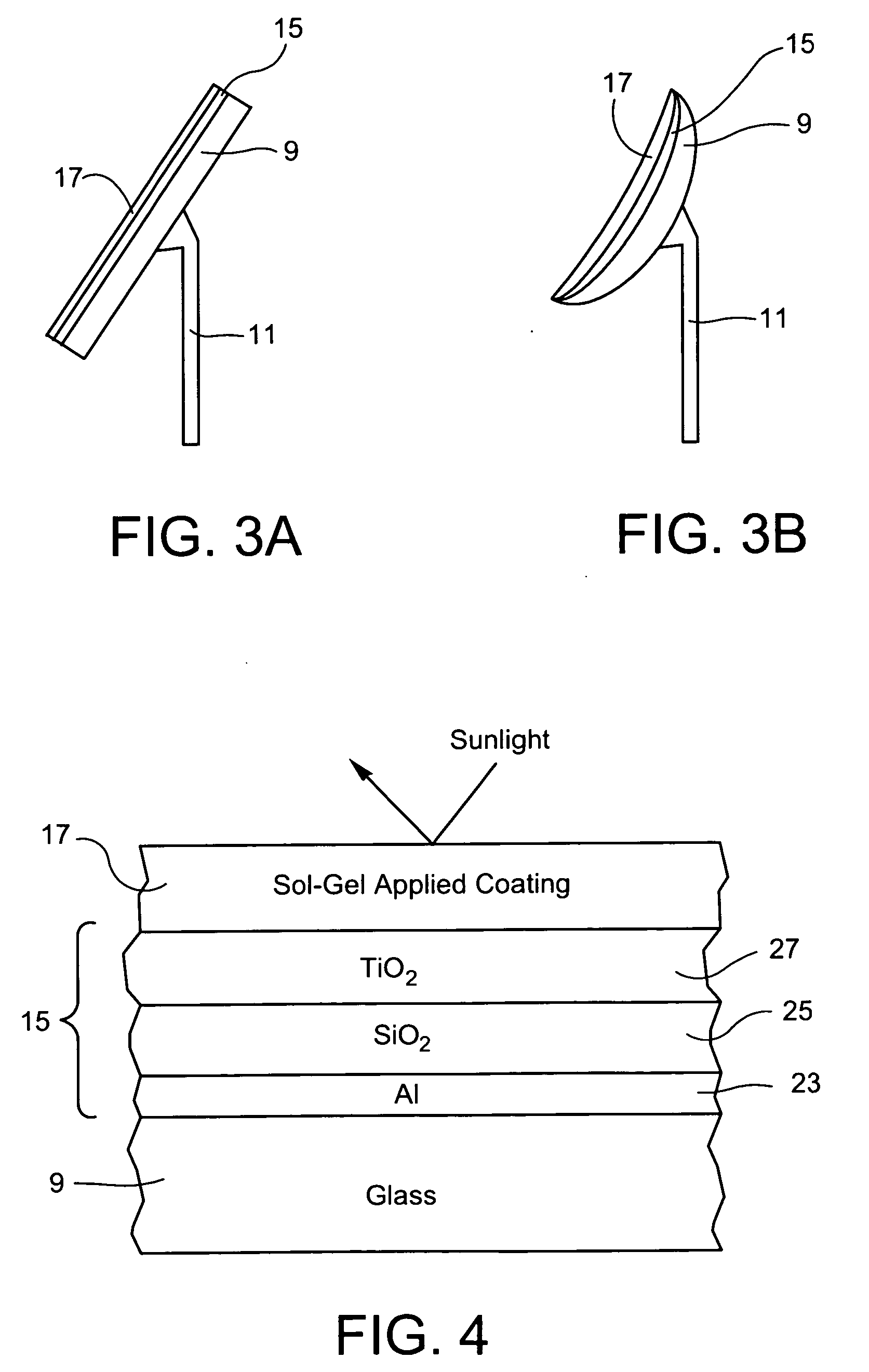

First surface mirror with sol-gel applied protective coating for use in solar collector or the like

InactiveUS20070178316A1Not to damageIncreased durabilitySolar heating energySolar heat devicesSilicon dioxideSol gel coating

A first-surface mirror includes protective coating and is for use in a solar collector or the like. In certain example embodiments, a sol-gel coating is applied, in a wet form, over a reflective coating of a first surface mirror. The sol-gel coating is then heated following its application, to drive off liquid(s) of the sol-gel so that the coating densifies and forms a solid protective coating over the reflective coating. In certain example embodiments, the protective coating may be of or include silica or the like so as to protect the reflective coating and improve durability.

Owner:GUARDIAN GLASS LLC

Sample pre-concentration tubes with sol-gel surface coatings and/or sol-gel monolithic beds

Owner:UNIV OF SOUTH FLORIDA

Colloidal composite sol gel formulation with an expanded gel network for making thick inorganic coatings

InactiveUS20040258611A1Inhibition formationRelieve pressurePretreated surfacesCatalyst activation/preparationColloidSol gel coating

Owner:DATEC COATING CORP

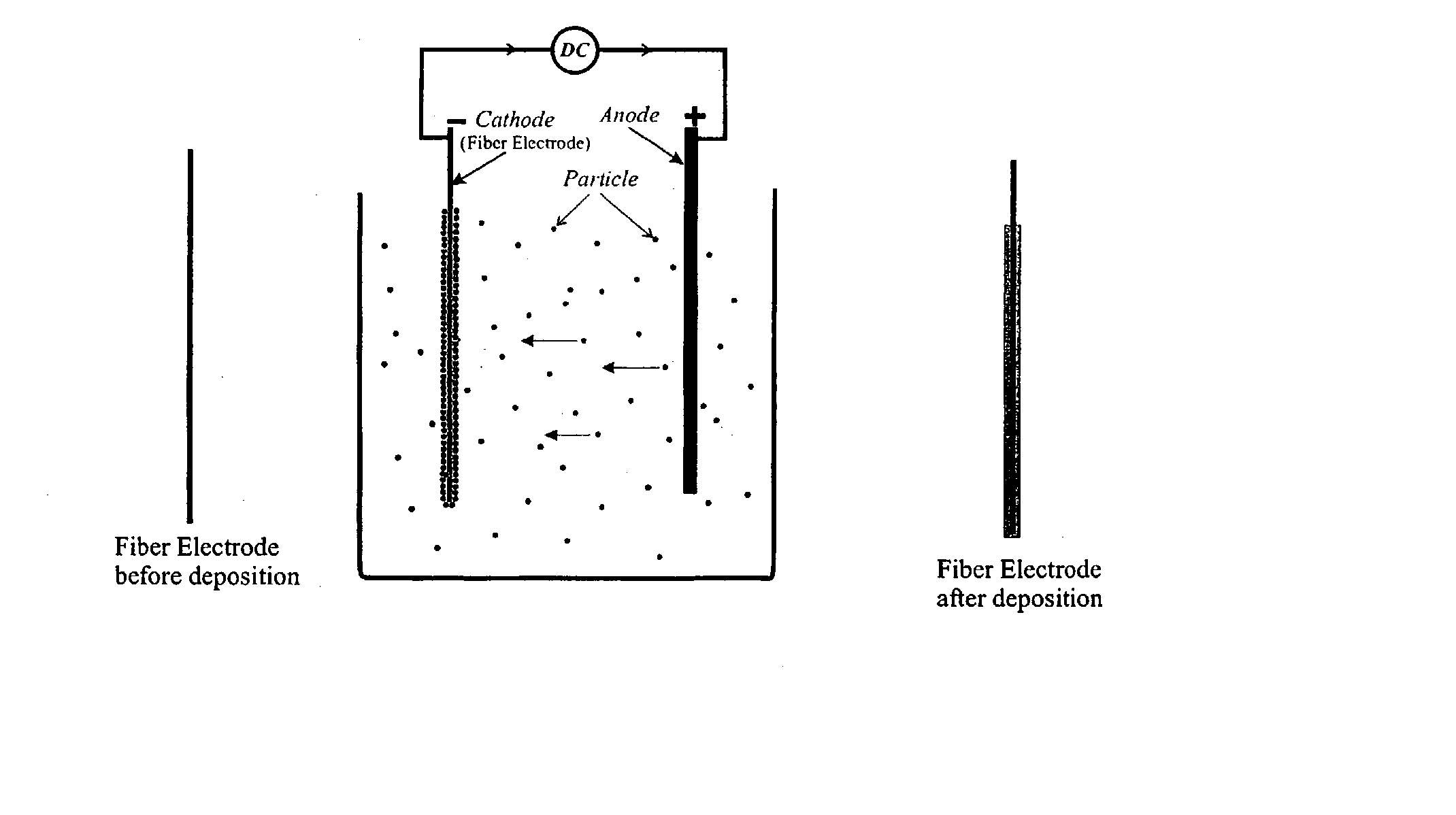

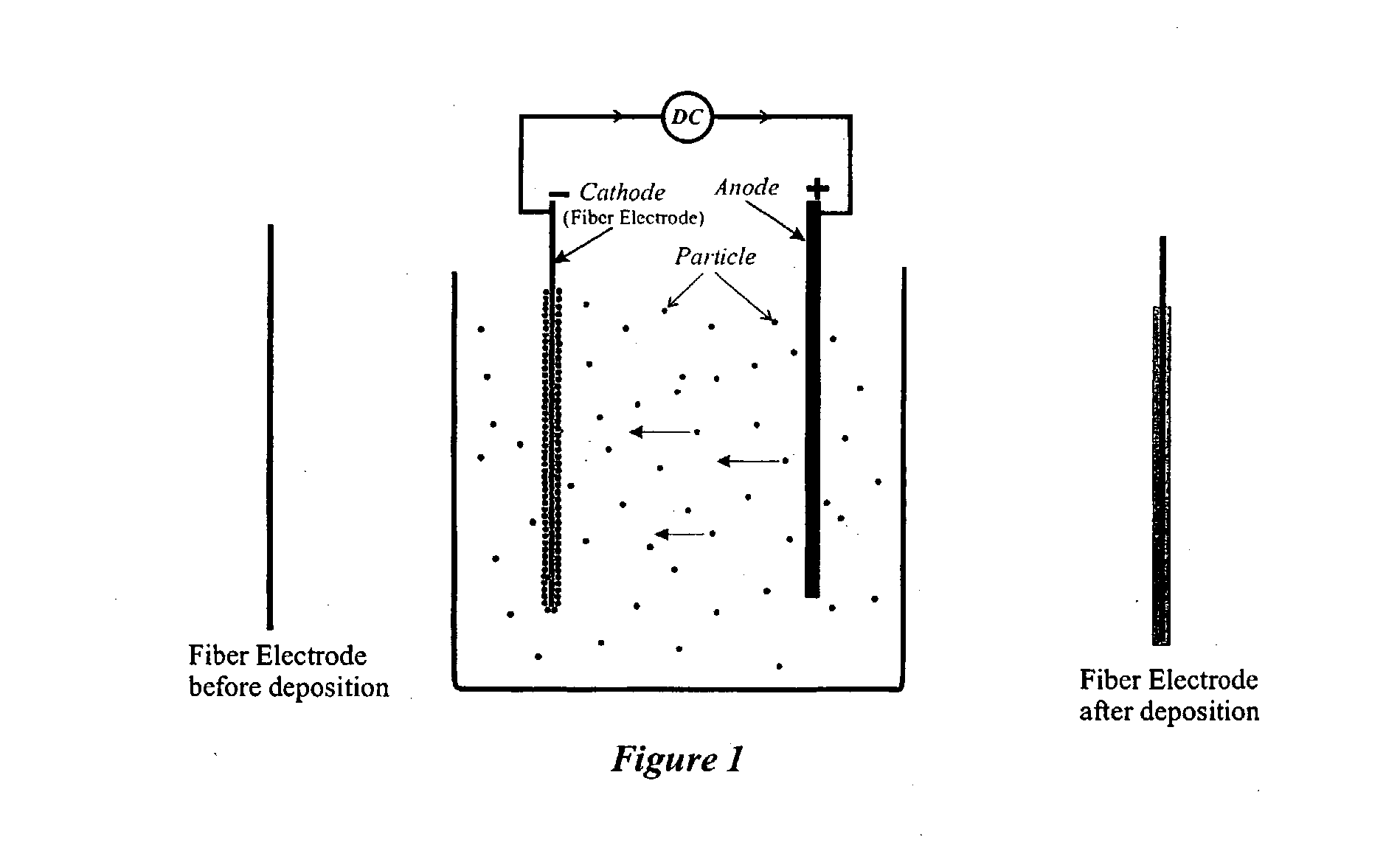

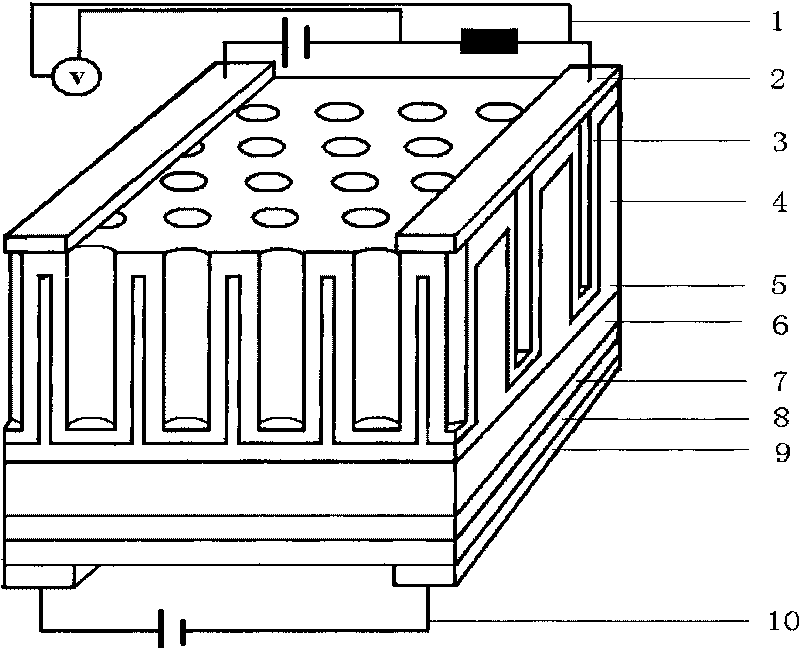

Production of hollow ceramic membranes by electrophoretic deposition

InactiveUS20030178307A1Prevent penetrationReduce porosityFinal product manufactureCell electrodesMetallurgyElectrophoresis

The present invention provides methods for producing hollow ceramic membranes by electrophoretic deposition. The hollow ceramic membranes may have a small cross-sectional area of about 1.0x10<-5 >mm<2 >to about 25 mm<2>. The cross-sectional configuration of the hollow ceramic membranes may be any geometry such as circular, square, rectangular, triangular or polygonal. The hollow ceramic membranes produced by the methods of the present invention may have multiple layers but always the innermost layer, or the first deposited layer is porous and made by electrophoretic deposition. Subsequent layers may be porous or non porous and deposited before or after sintering the first layer. If it is deposited after sintering, it may require additional sintering steps. Additional layers may be deposited by further electrophoretic deposition, sol-gel coating, dip coating, vacuum casting, brushing, spraying or other known techniques.

Owner:INNOTECH ALBERTA INC

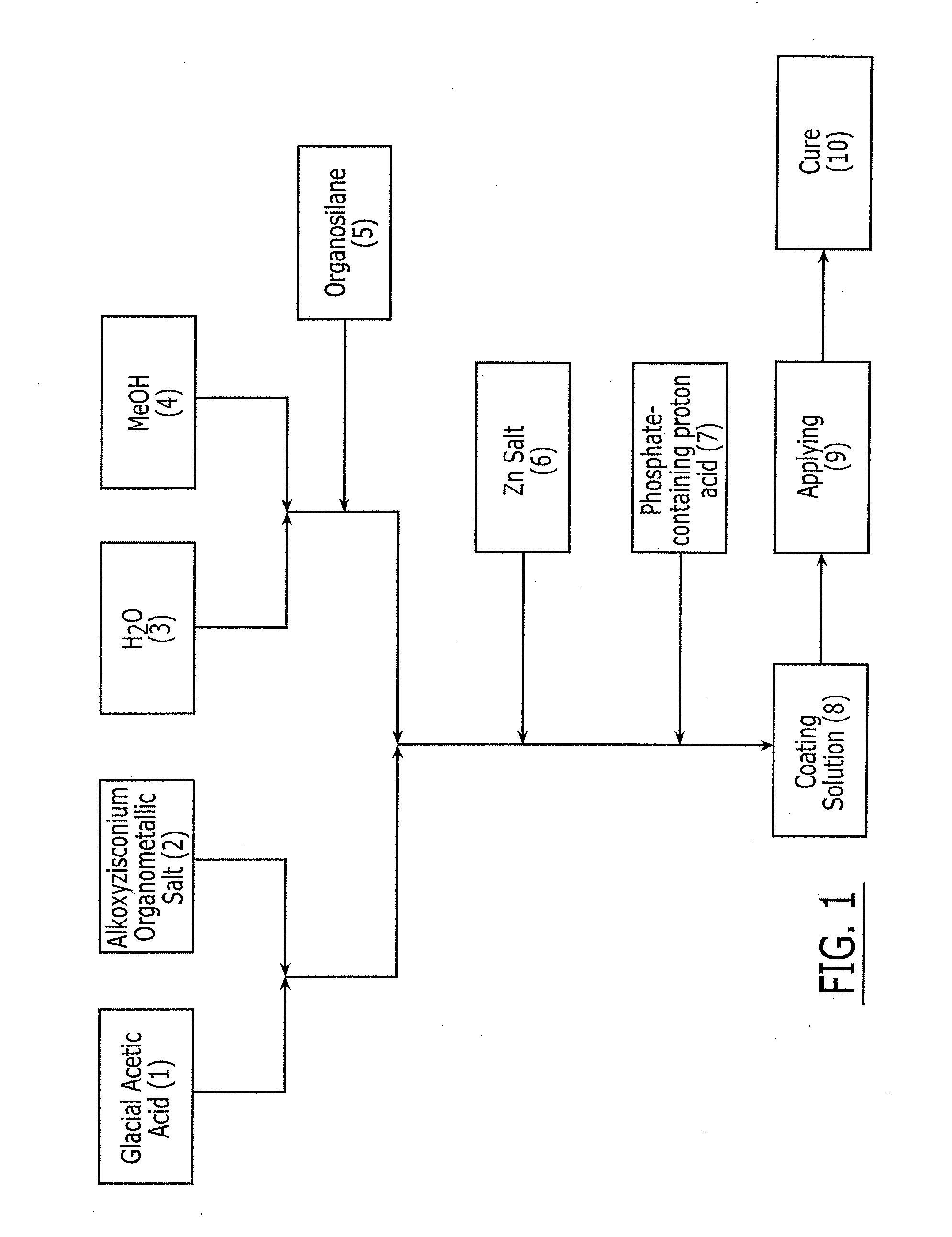

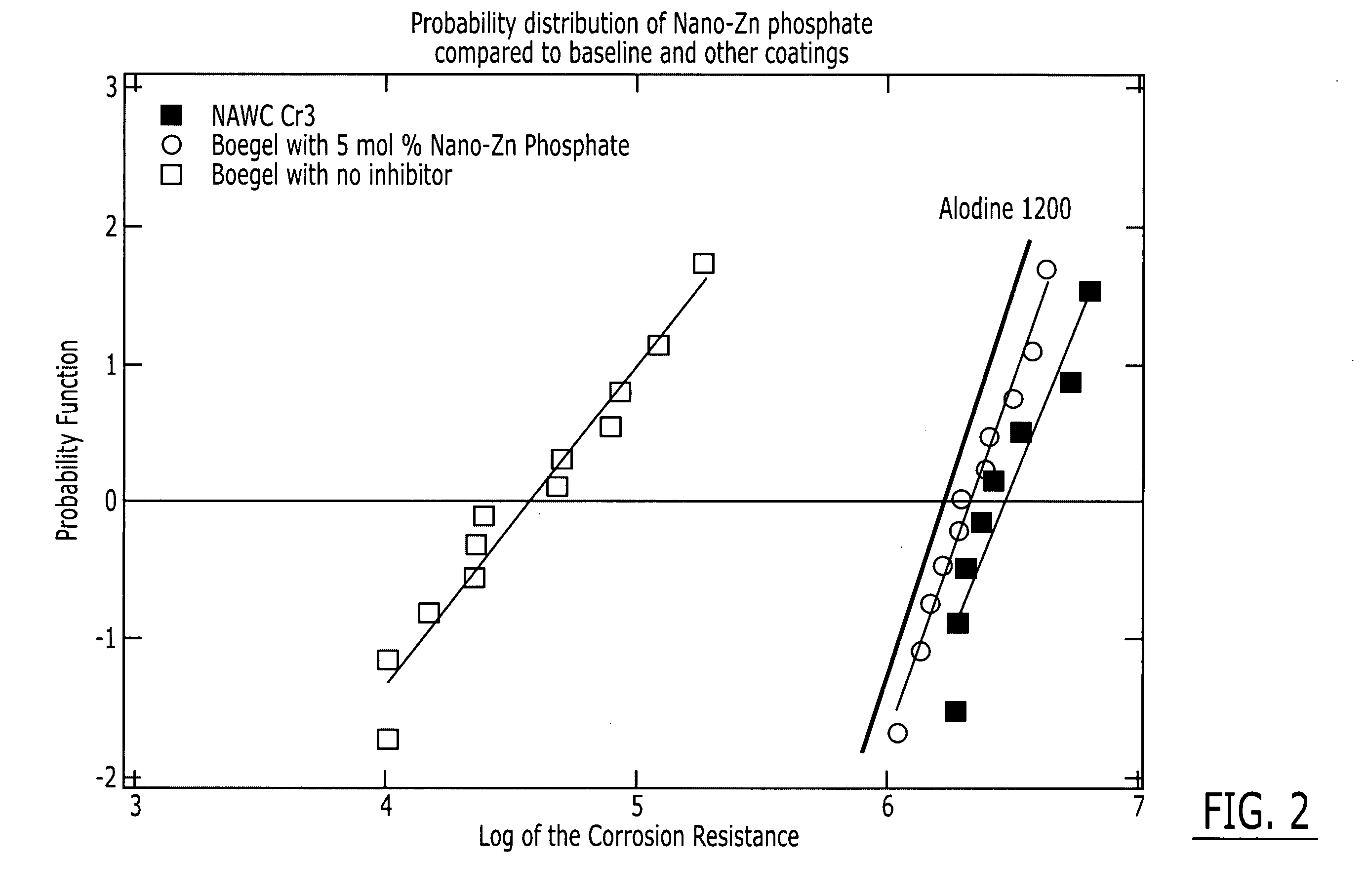

Nano-structured inorganic zinc phosphate corrosion protective coating for metal alloys

ActiveUS20090192251A1Trend downSuperior metal to resin adhesiveLiquid surface applicatorsEfficient propulsion technologiesZinc phosphateOrganic acid

A method is provided for enhancing corrosion resistance of a metal surface that includes the step of forming a sol-gel coating in which nanostructured zinc phosphate (Zn3(PO4)2) and zinc oxide (ZnO) phases are present in the mixture. The method may include the steps of mixing an organosilane, organometallic, organic acid, water, and alcohol and allowing the components of the mixture to partially hydrolyze, followed by adding at least one component having zinc functionality and at least one component having phosphate functionality to the partially hydrolyzed mixture, wherein the zinc component and phosphate component are added in a molar ratio of from about 1.5:1 to about 5:1 (Zn:PO4). The resulting mixture can be applied as a coating to a metal surface to improve the corrosion resistance of the metal and to enhance the adhesion of resinous materials to the metal surface.

Owner:THE BOEING CO

Nitric oxide-releasing coatings

InactiveUS20140134321A1Easy to storeInorganic active ingredientsPharmaceutical containersSolventSol gel coating

Provided according to embodiments of the invention are NO-releasing sol-gel coating formed from a sol precursor solution comprising a backbone alkoxysilane and a diazeniumdiolate-modified alkoxysilane. Further provided are methods of producing NO-releasing sol-gel coatings. Such methods may include (a) co-condensing a sol precursor solution comprising a backbone alkoxysilane and a diazeniumdiolate-modified alkoxysilane in a solvent to form a sol; (b) coating a substrate with the sol; and (c) drying the sol to form the NO-releasing sol-gel coating.

Owner:NAVAN INC +1

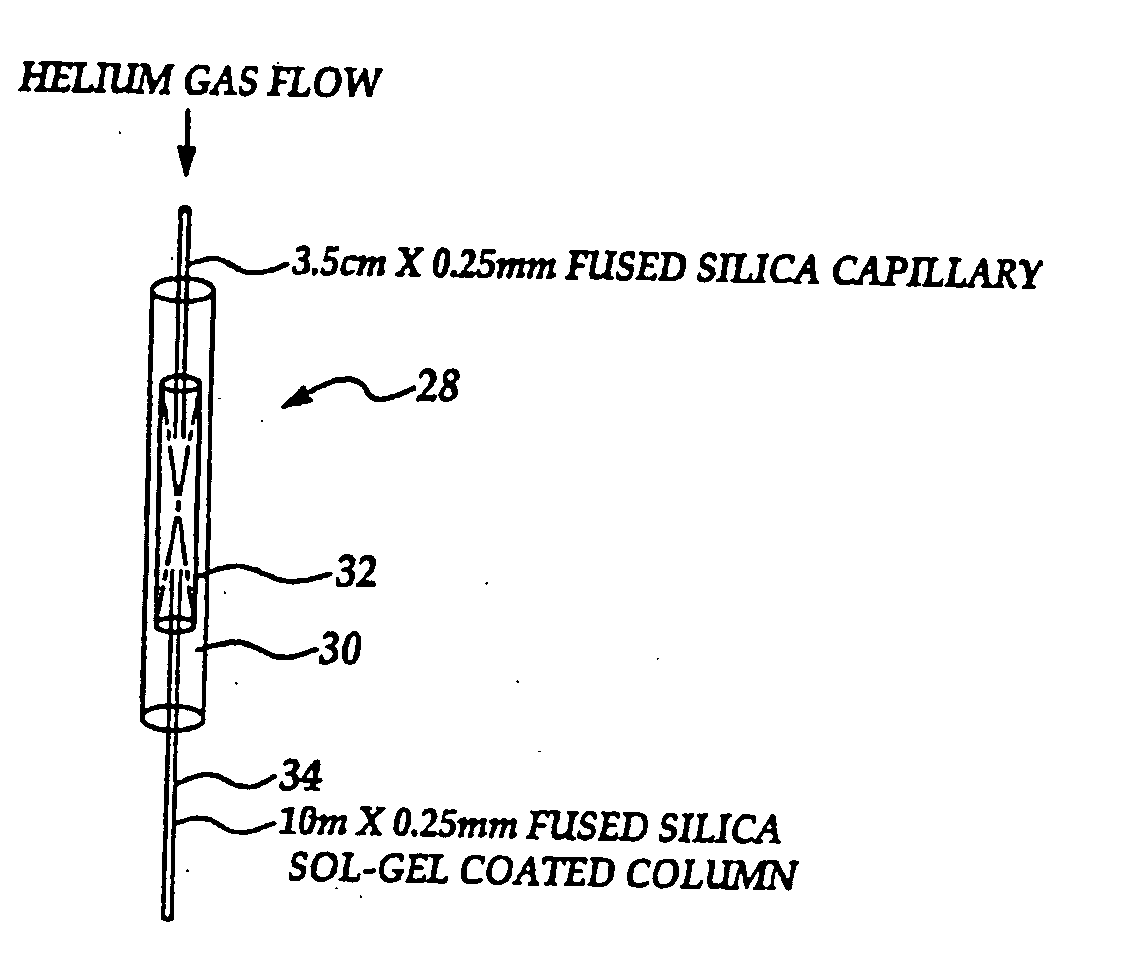

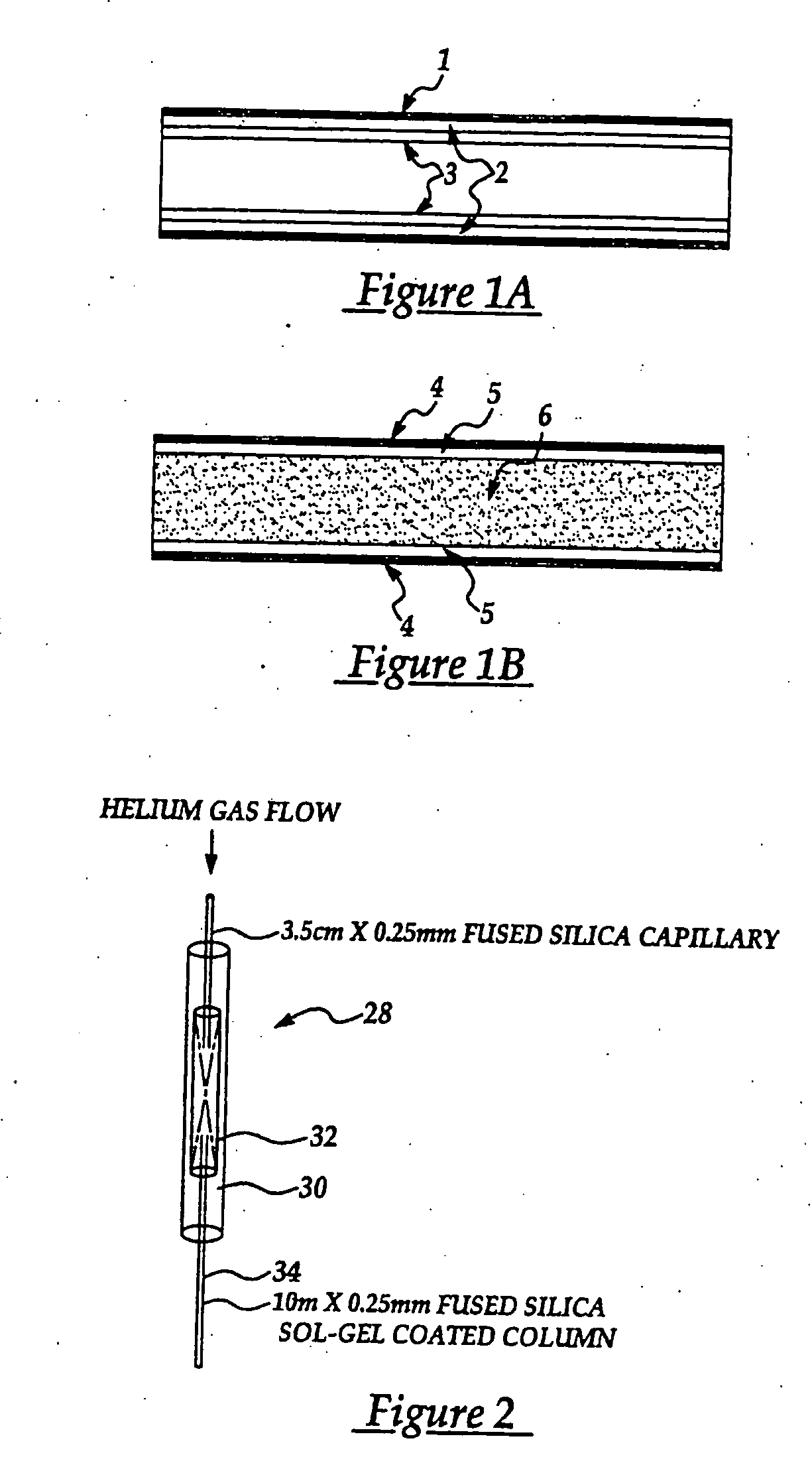

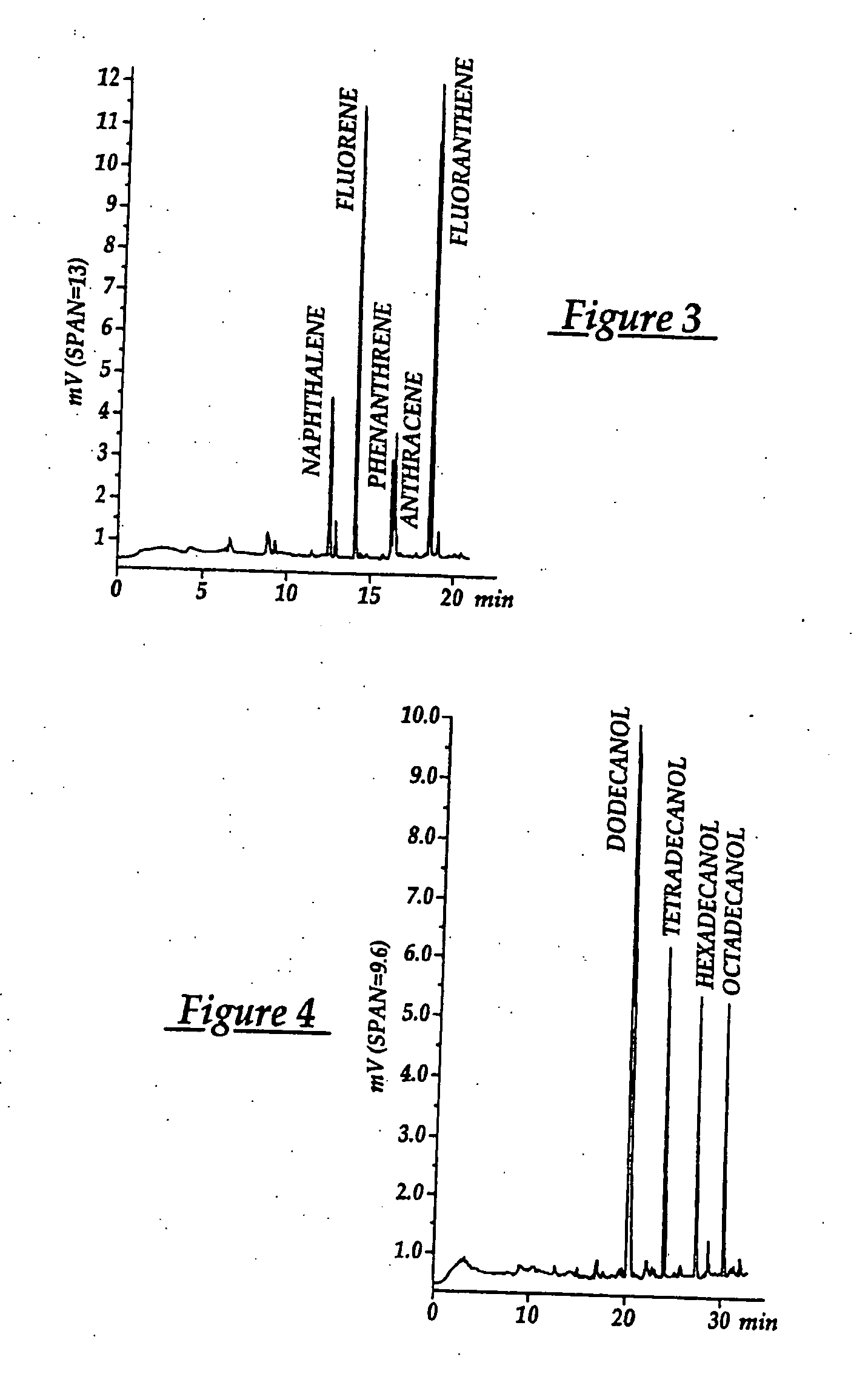

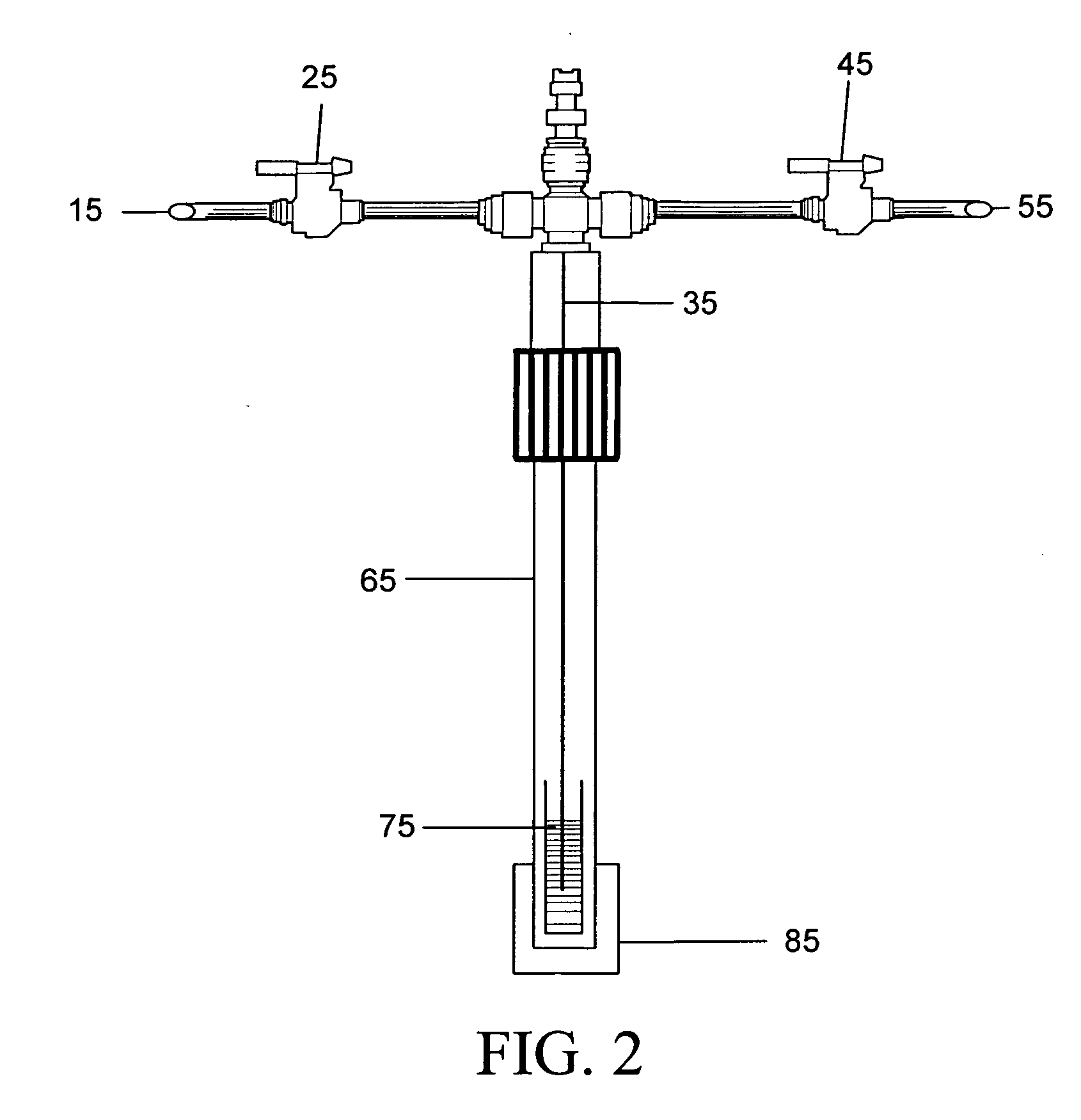

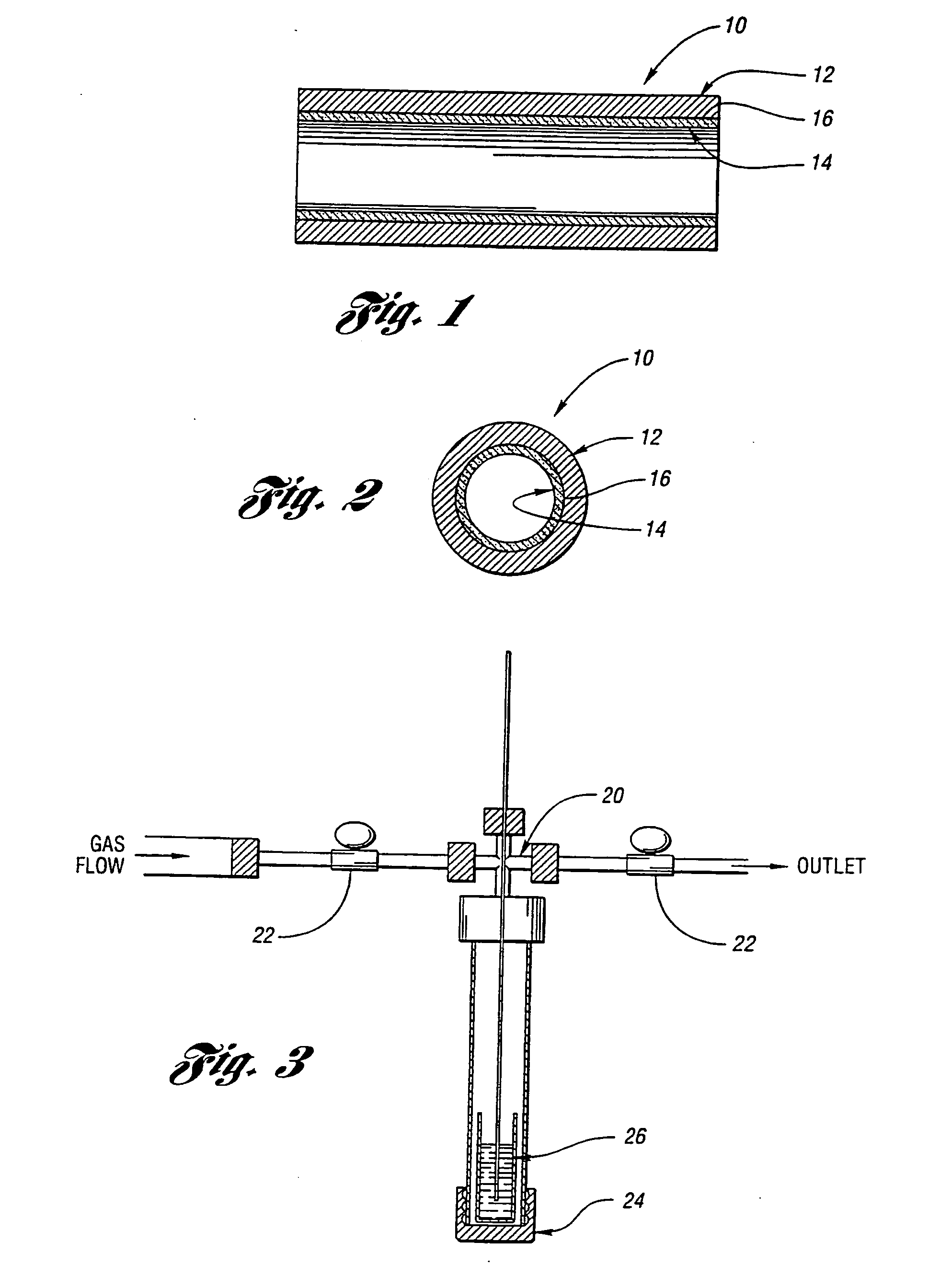

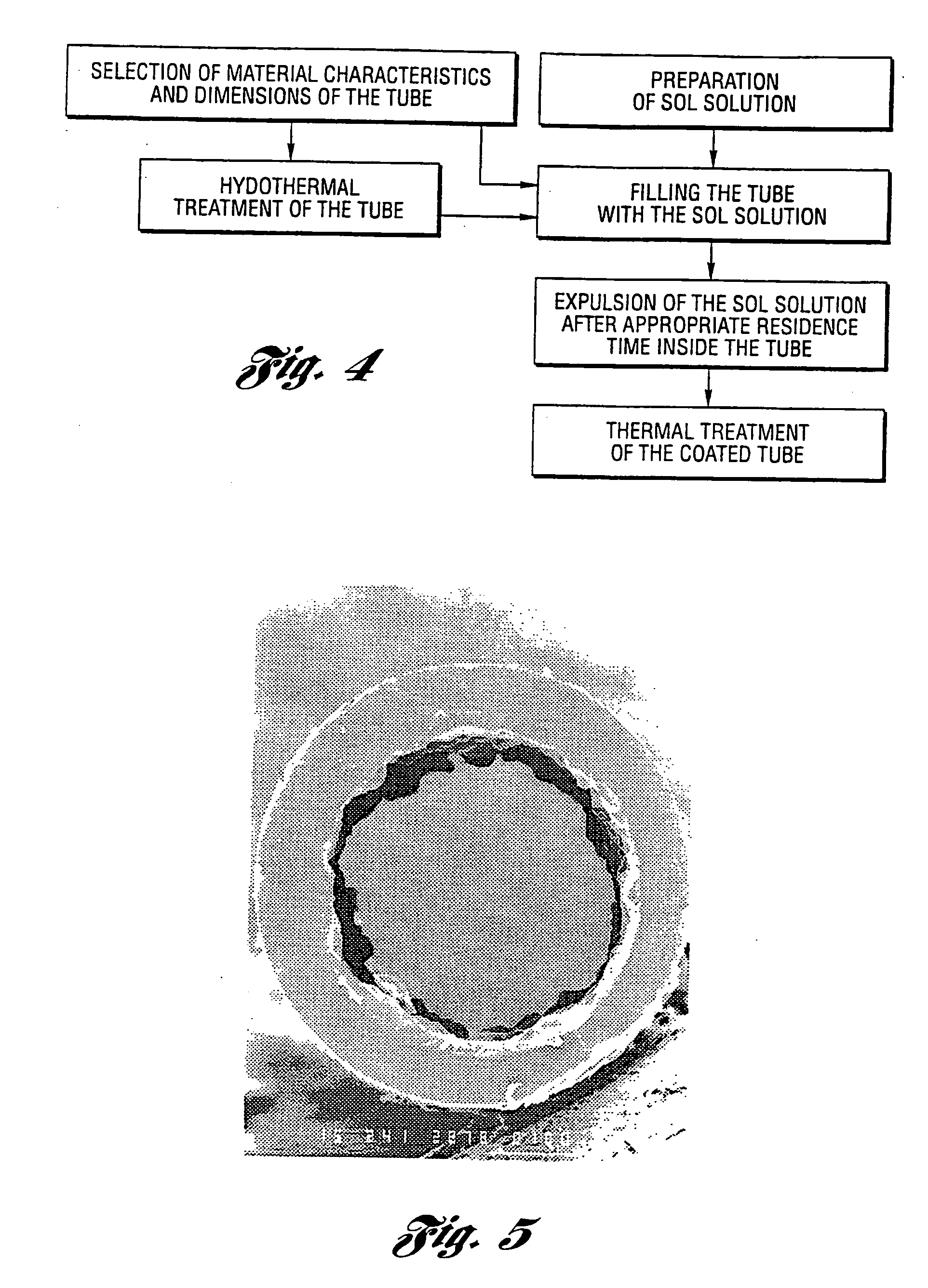

Tube structure with sol-gel zirconia coating

InactiveUS20070095736A1Improve stabilityUnique surface chemistryIon-exchange process apparatusOther chemical processesKetoneHYDROSOL

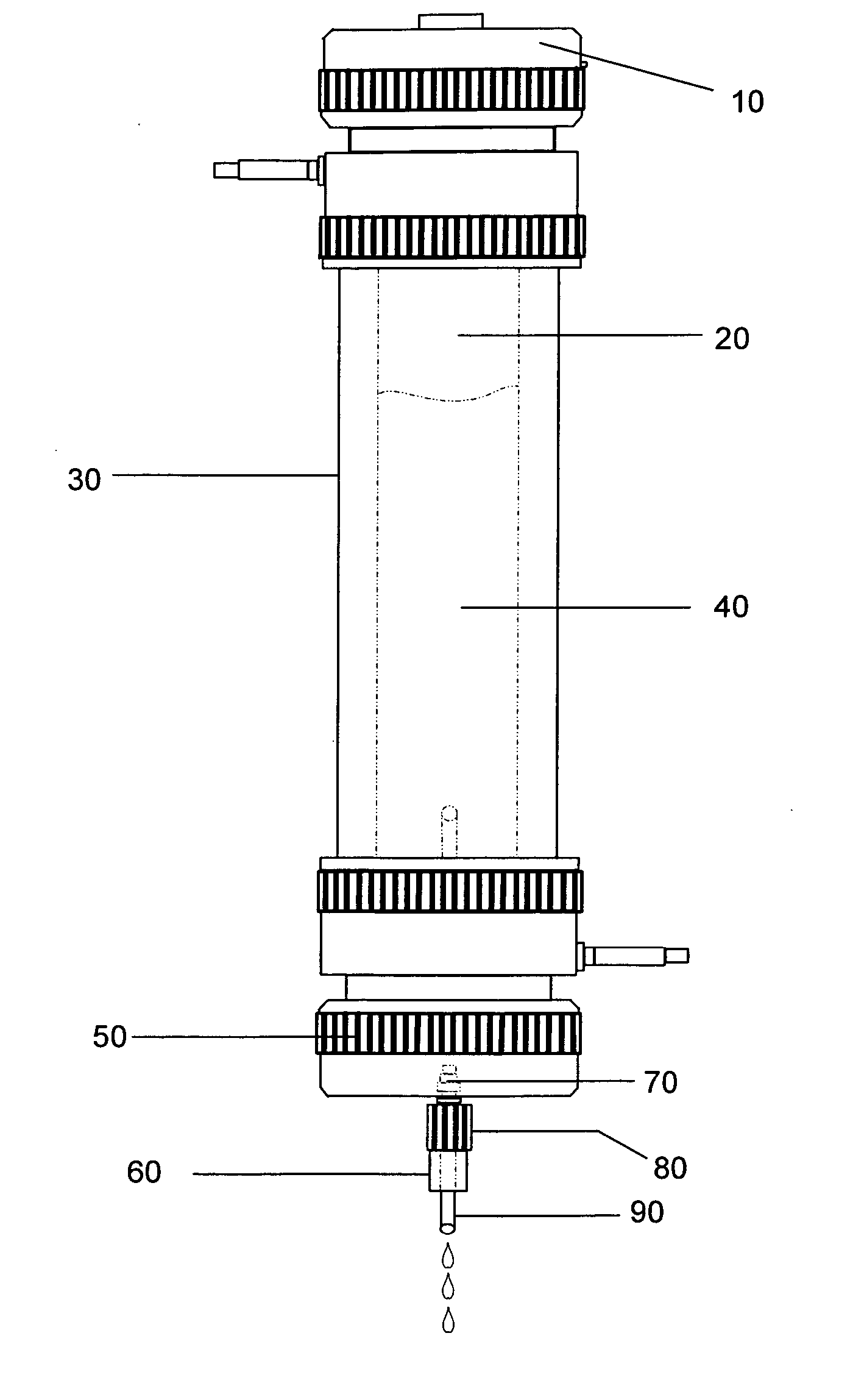

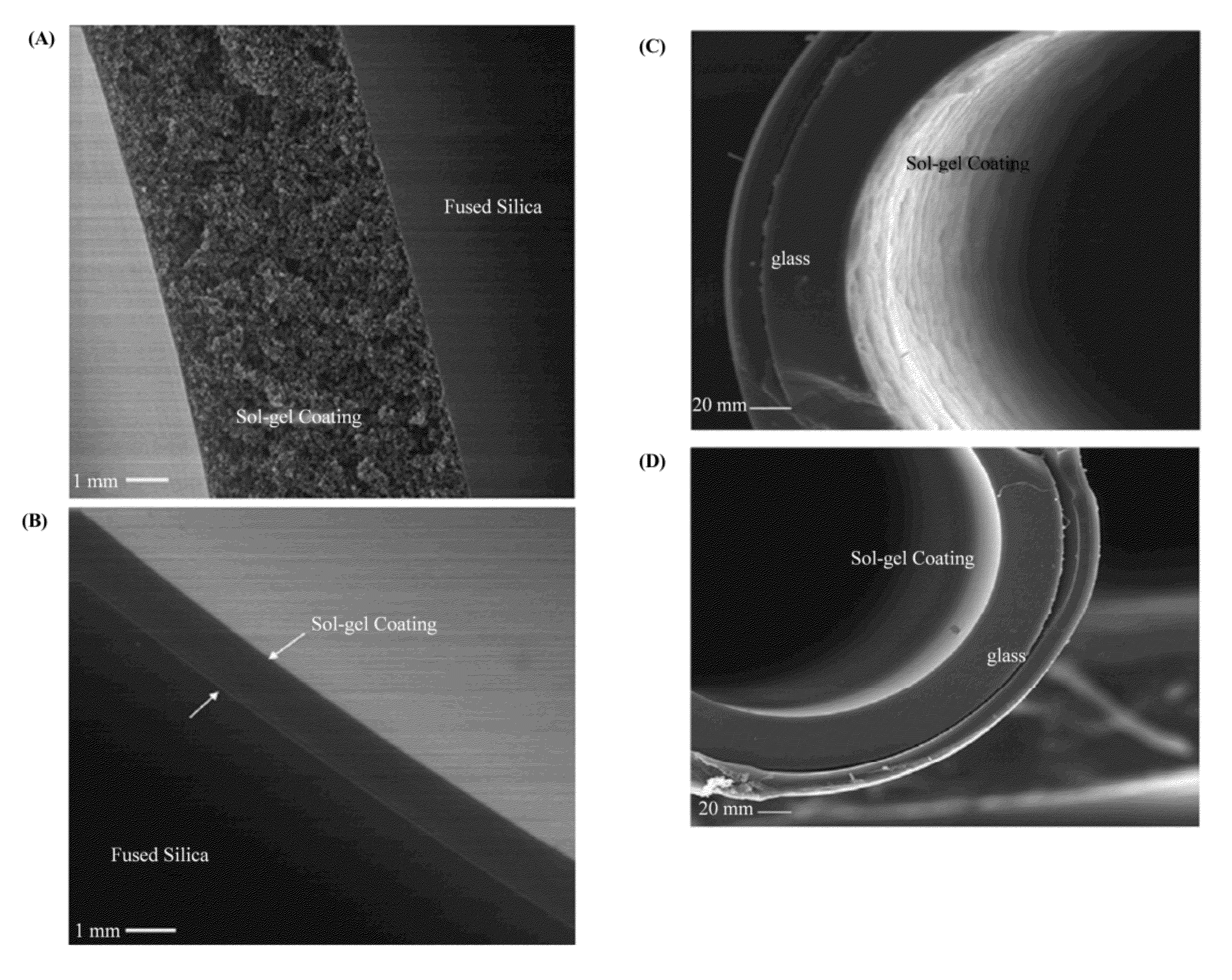

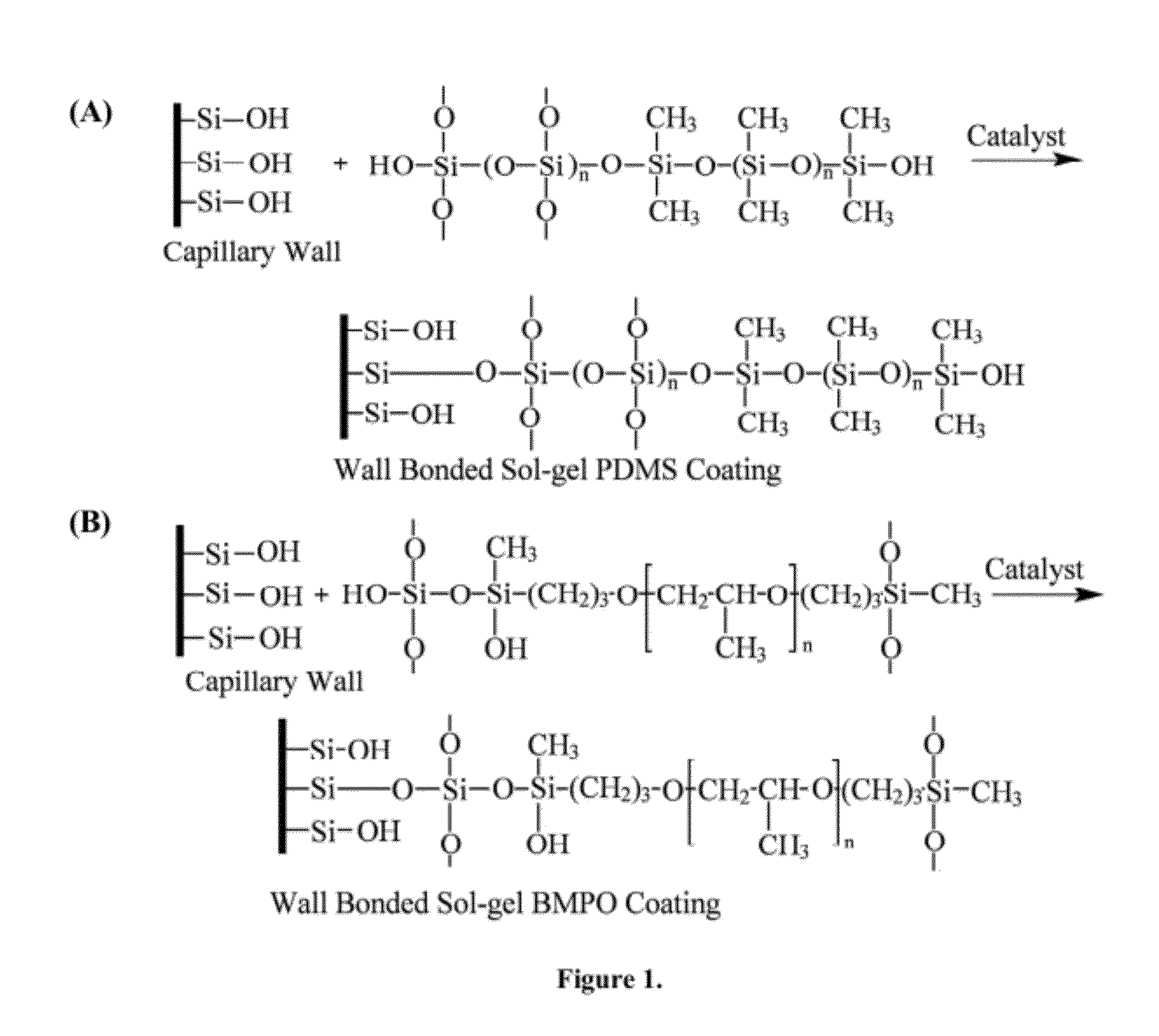

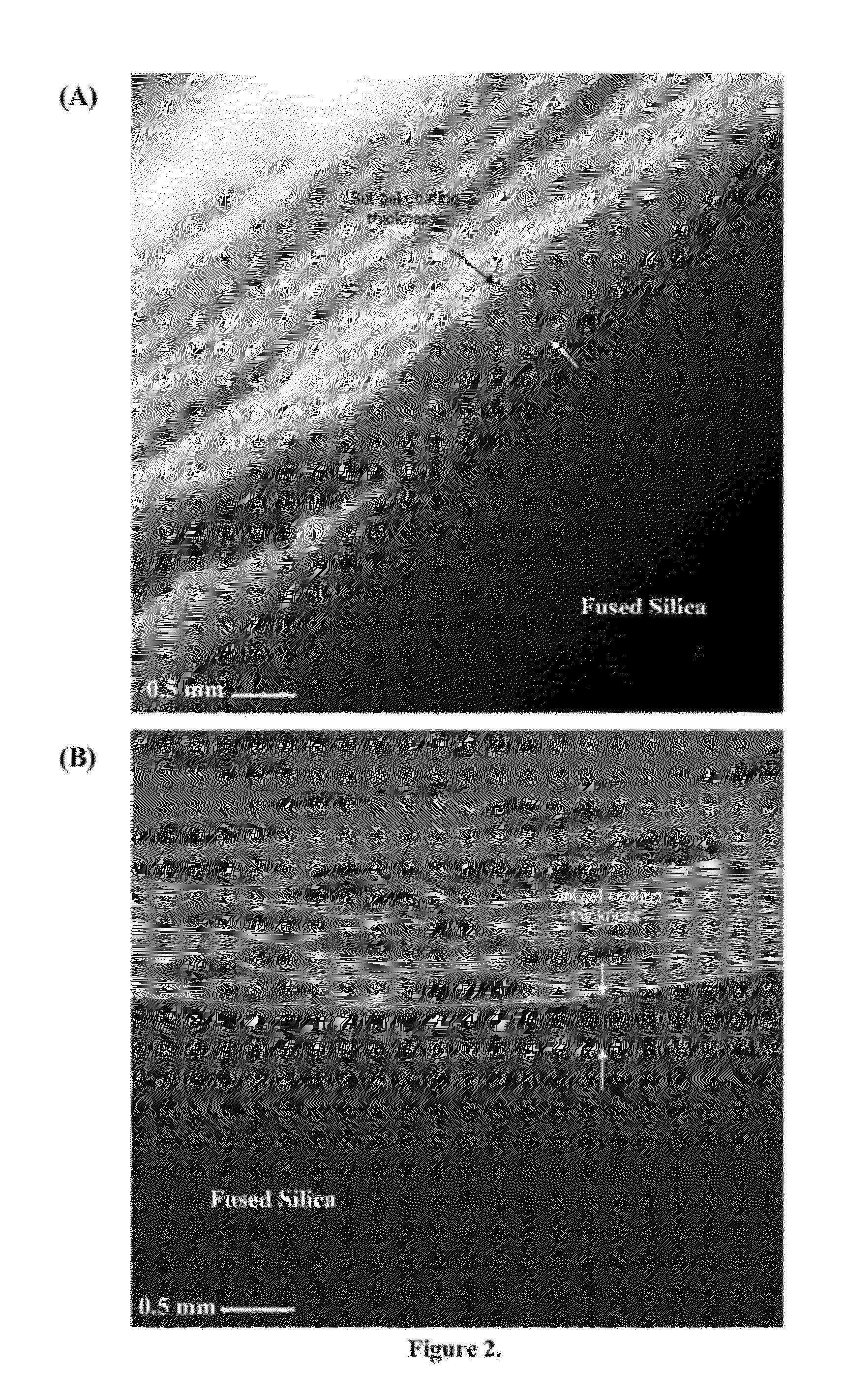

The subject invention concerns zirconia-based hybrid organic-inorganic sol-gel coating for optional use as a stationary phase in capillary microextraction (CME), gas chromatographic (GC), high performance liquid chromatography (HPLC), capillary electrophoresis (CE), capillary electrochromatography (CEC) and related analytical techniques. Sol-gel chemistry is employed to chemically bind a hydroxy-terminated silicone polymer (polydimethyldiphenylsiloxane, PDMDPS) to a sol-gel zirconia network. In one embodiment, a fused silica capillary is filled with a properly designed sol solution to allow for the sol-gel reactions to take place within the capillary. In the course of this process, a layer of the evolving hybrid organic-inorganic sol-gel polymer becomes chemically bonded to the silanol groups on the inner capillary walls. The unbonded part of the sol solution is expelled from the capillary under helium pressure, leaving behind a chemically bonded sol-gel zirconia —PDMDPS coating on the inner walls of the capillary. Polycyclic aromatic hydrocarbons, ketones, and aldehydes are efficiently extracted and preconcentrated from dilute aqueous samples followed by GC separation of the extracted analytes.

Owner:MALIK ABDUL +1

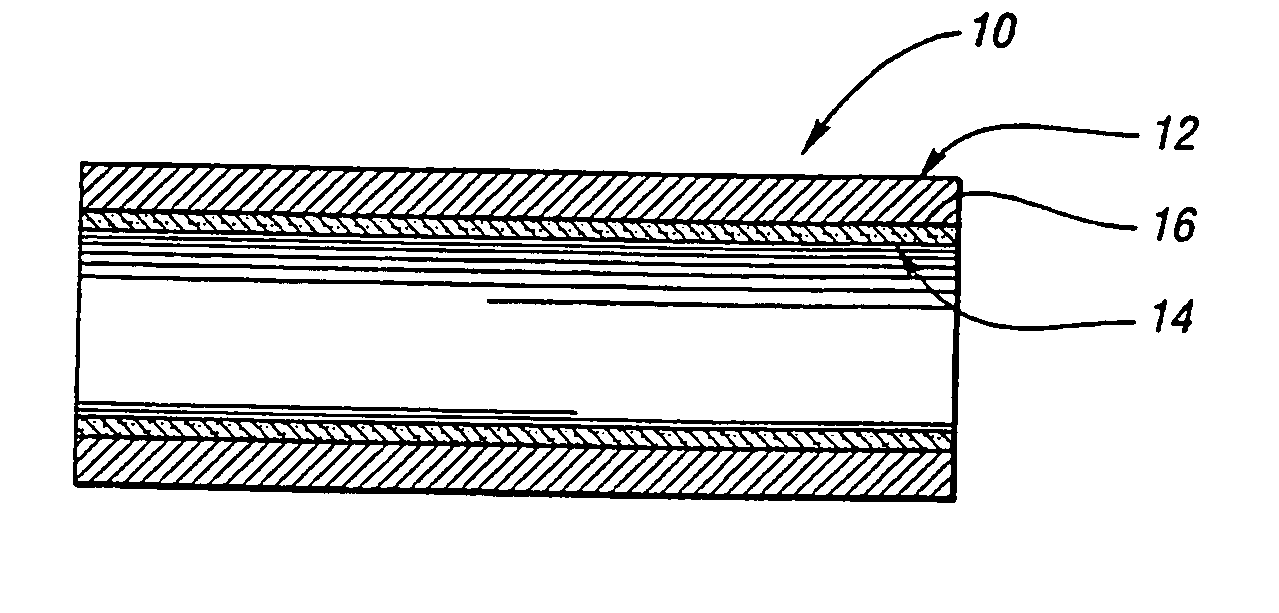

Capillary column and method of making

InactiveUS20070172960A1Simple and rapid methodQuick and easy to manufactureComponent separationDispersed particle separationStationary phaseAnalyte

The present invention concerns a new and useful structure for forming a capillary tube, e.g. for gas chromatography, and methods for forming the capillary tube are described. The capillary tube comprises a tube structure, and a deactivated surface-bonded sol-gel coating on a surface of the tube structure to form a stationary phase coating on that surface of the tube structure. According to the present invention the deactivated stationary phase sol-gel coating enables separation of analytes while minimizing adsorption of analytes on the separation column structure.

Owner:MALIK ABDUL +1

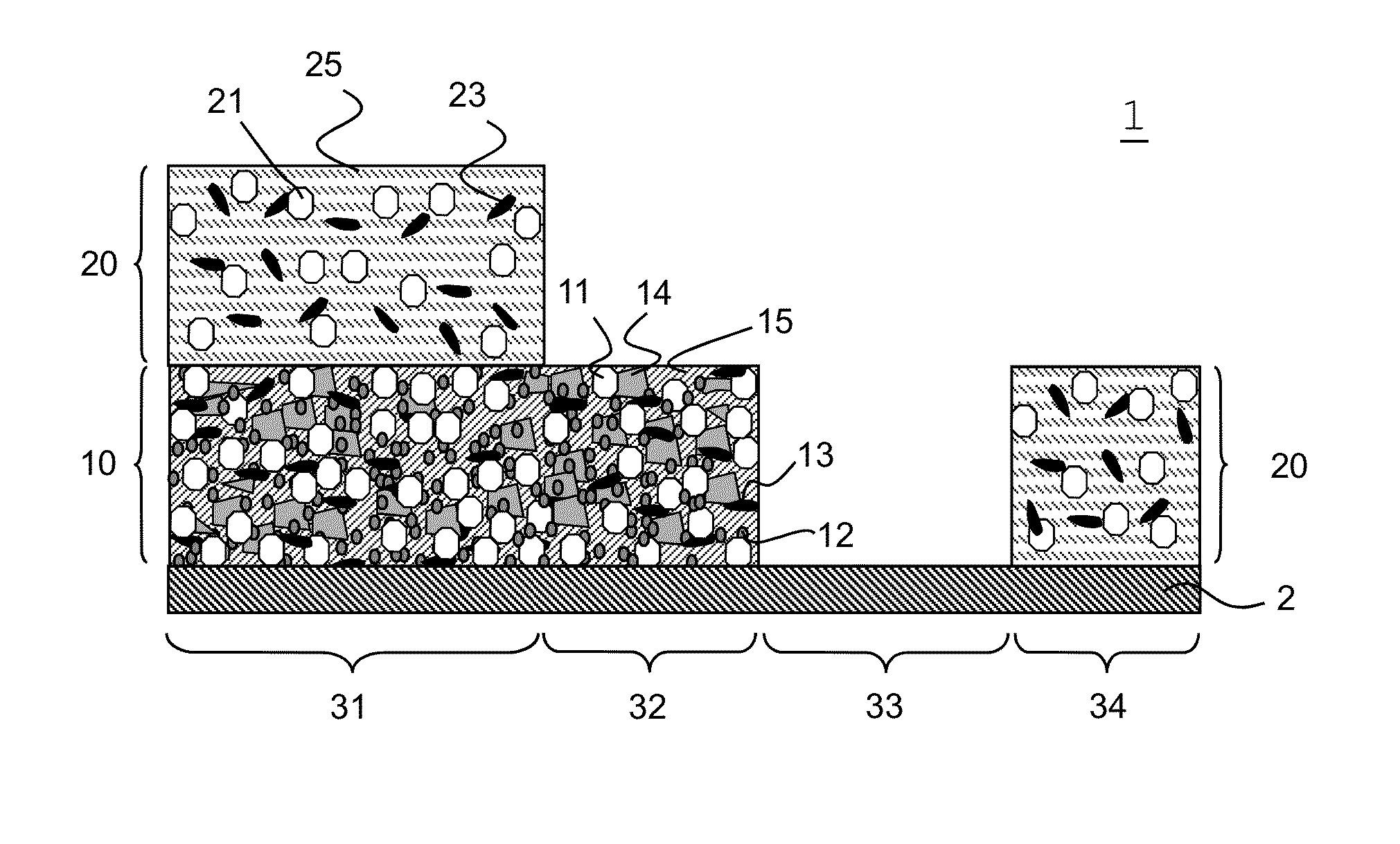

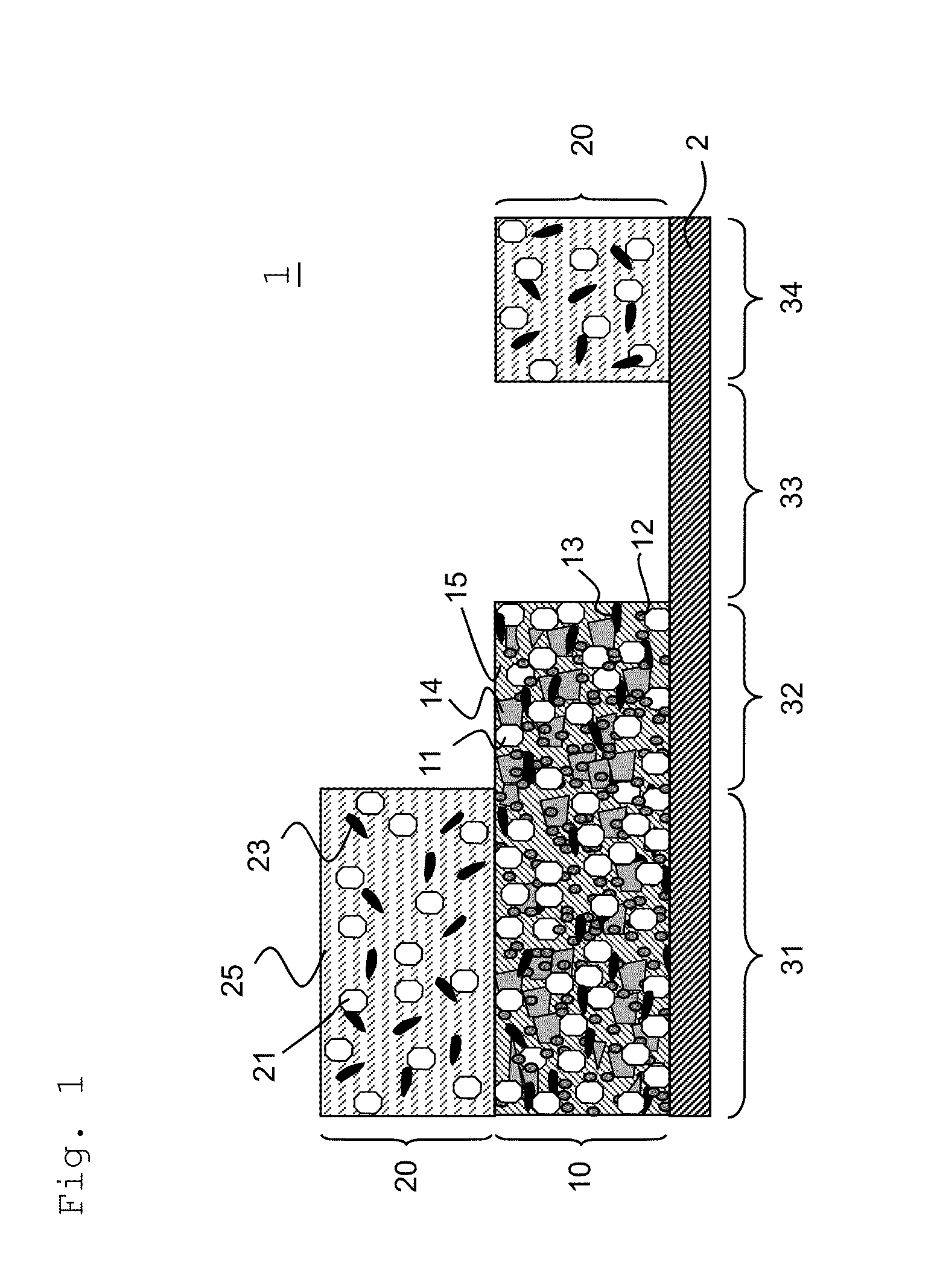

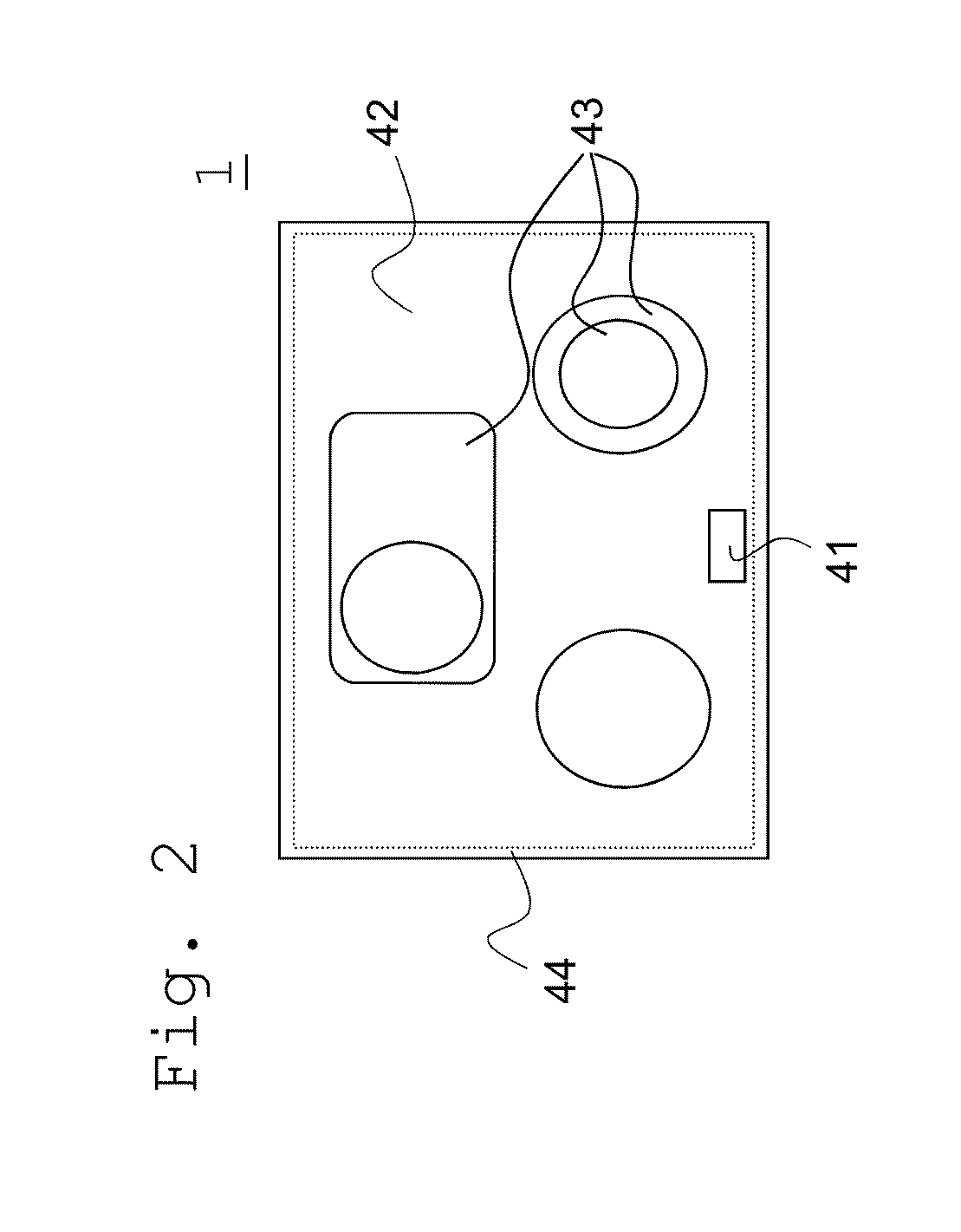

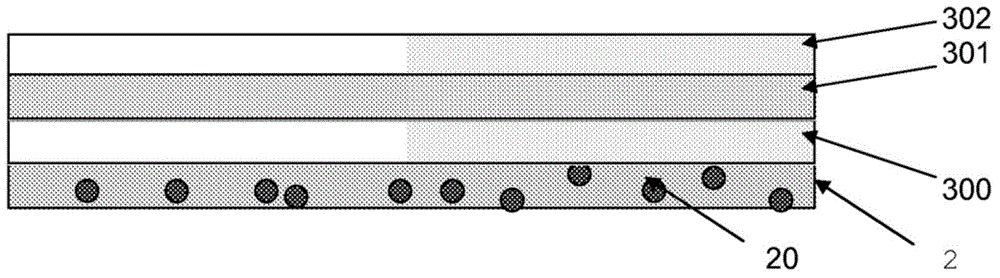

Silicone coating as a sealing layer for a decoration layer

InactiveUS20130266781A1Fulfil requirementsSimple and fast productionStoves/ranges topsGlass/slag layered productsMetallurgySolid particle

A glass or glass ceramic article is provided that has a glass or glass ceramic substrate with a decorative coating. The decorative coating includes a decoration layer and a sealing layer. The decoration layer is applied to at least some surface portions of the glass or glass ceramic substrate, and the sealing layer is applied to at least portions of the decoration layer. The decoration layer is a cured sol-gel coating having inorganic solid particles, and the sealing layer is a cured silicone coating comprising inorganic solid particles. Methods for producing such glass or glass ceramic articles are also provided.

Owner:SCHOTT AG

Organosilane coating compositions and use thereof

A sol-gel coating composition comprising a hydrolysed organosilane, an organometallic precursor and a corrosion inhibitor, wherein the corrosion inhibitor is a chelator for the organometallic precursor. The corrosion inhibitor and the organometallic precursor may form a nanoparticulate complex. The coating composition may comprise one or more additive selected from: an antimicrobial additive, a hardener, a water repelling additive, a dye, a scratch resistant additive and a flexibility enhancing additive. A process for preparing a sol gel coating composition is also described, the process comprising the steps of: hydrolysing an organosilane in the presence of a catalyst; chelating an organometallic precursor; mixing the hydrolysed silane and the chelated organometallic precursor; and hydrolysing the organosilane-organometallic precursor mixture.

Owner:DUBLIN INST OF TECH +1

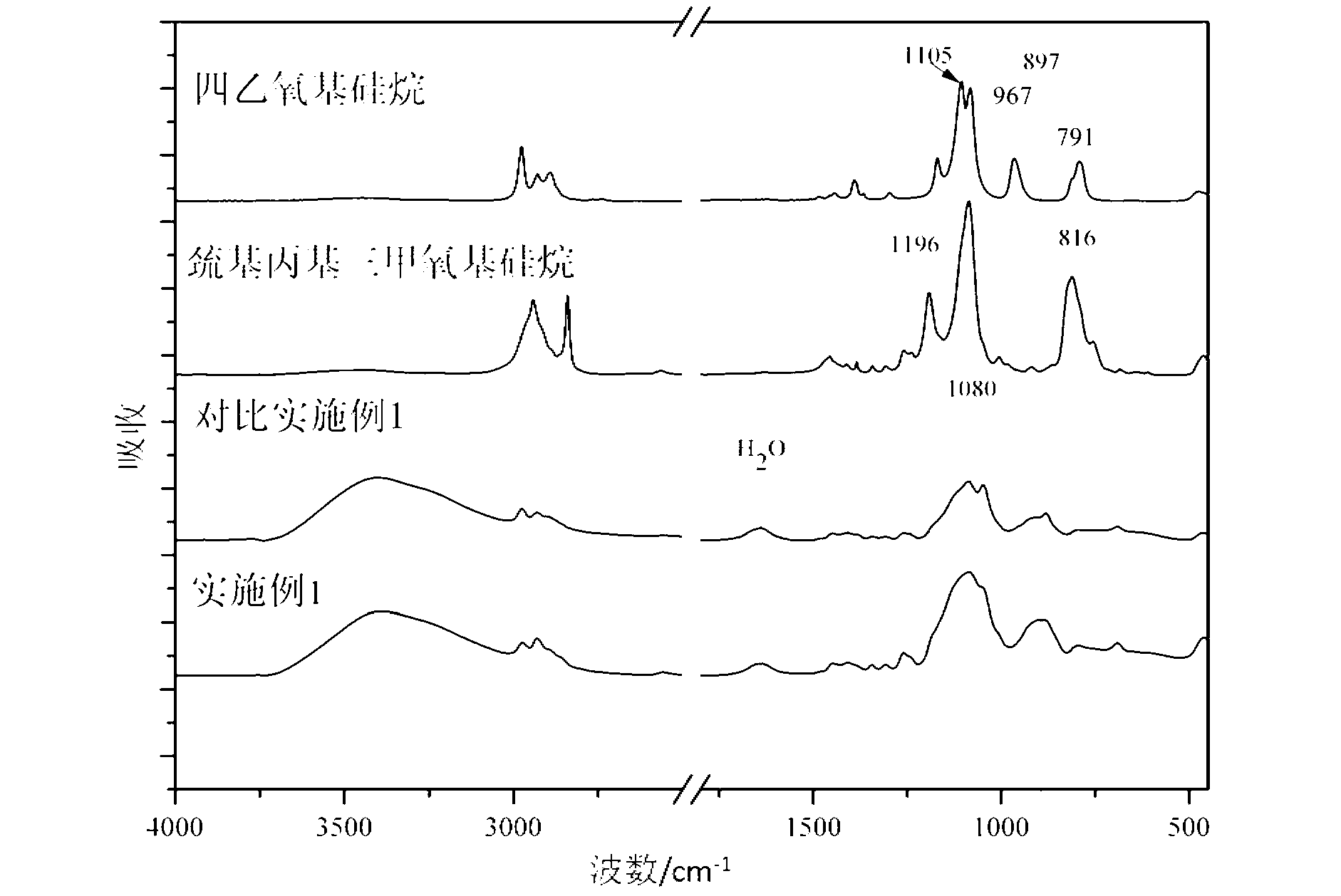

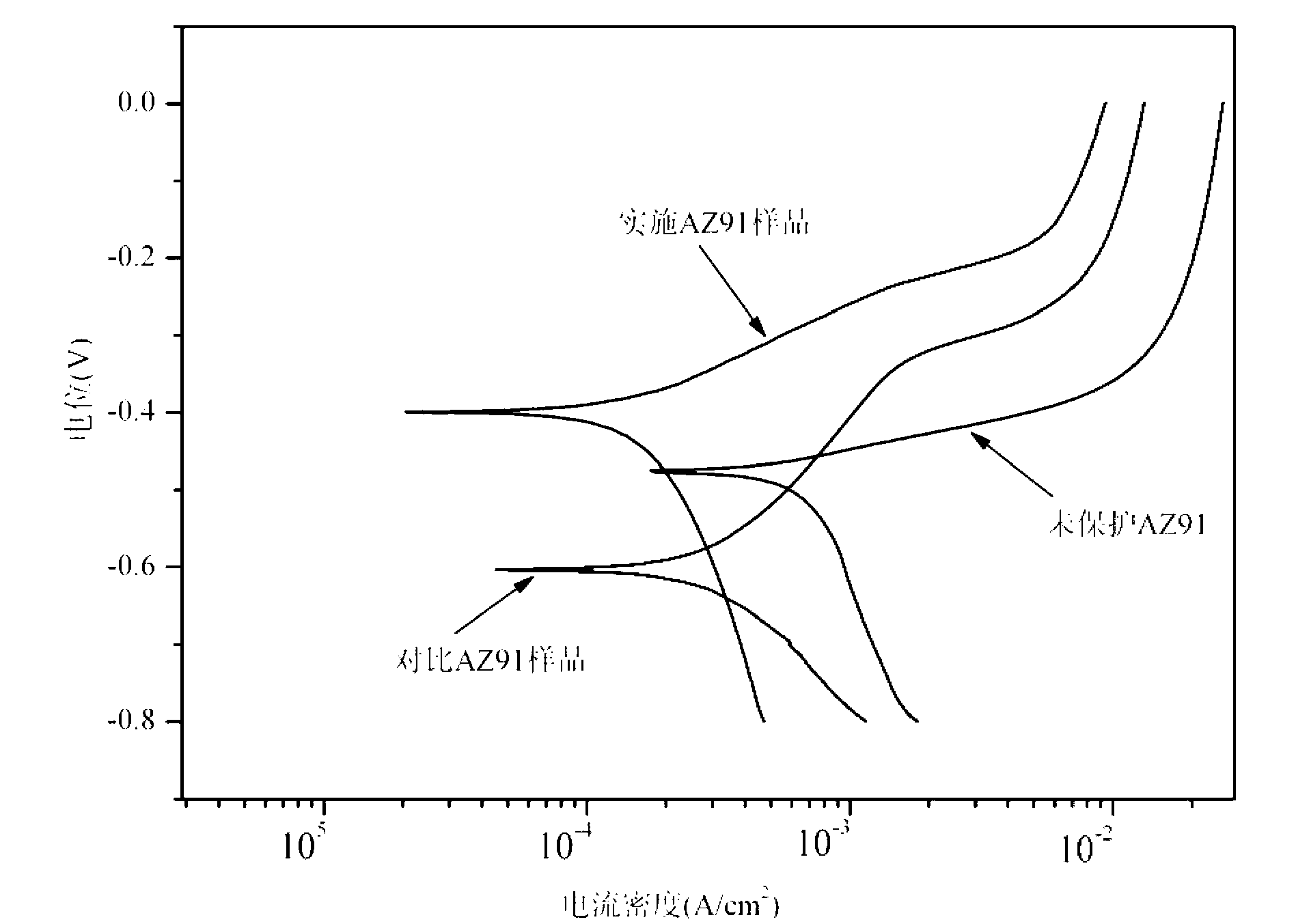

Preparation method of organosilicon sol-gel coating for magnesium alloy substrate surface corrosion resistance

InactiveCN103254762APromote hydrolysisReduce adverse effectsAnti-corrosive paintsMetallic material coating processesSilanesCerium

The present invention provides a preparation method of an organosilicon sol-gel coating for magnesium alloy substrate surface corrosion resistance. According to the preparation method, alkoxy silane is adopted as a precursor, a salt compound of a metal cerium and / or a salt compound of a metal lanthanum is adopted as a catalyst, and a hydrolysis-condensation reaction is performed to obtain an organosilicon sol-gel coating. Experiment results confirm that: compared with conventional acid catalysts, the catalyst of the present invention provides high catalytic hydrolysis capability on alkoxy silane, and has a metal corrosion slowing effect, such that the organosilicon sol-gel coating prepared by using the catalyst can provide a good corrosion resistance effect for magnesium alloys compared with the organosilicon sol-gel coating prepared by using the conventional acid catalyisi.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

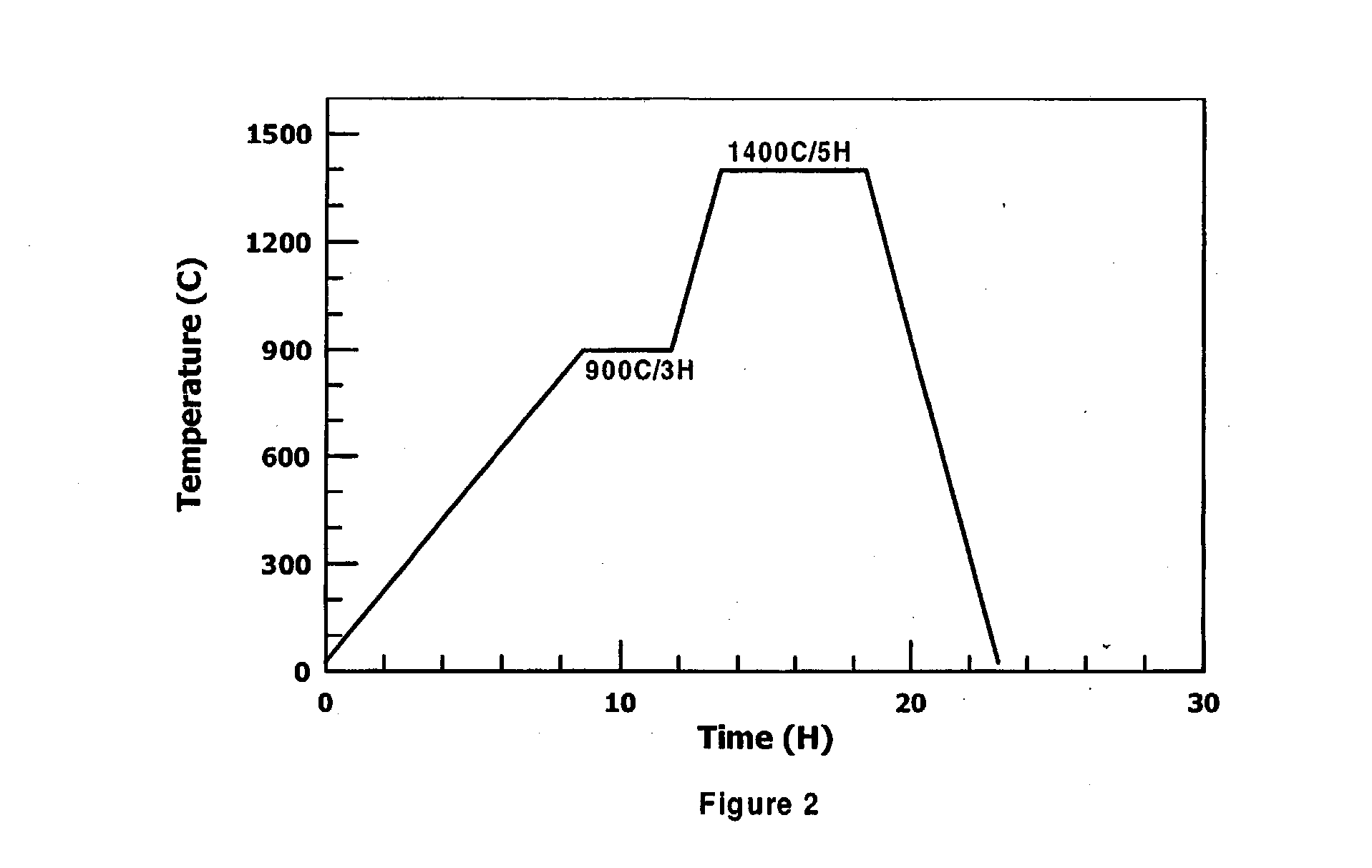

Method for producing thick ceramic films by a sol gel coating process

A method for producing thick ceramic films of greater than 10 mu m on selected substrates is described. Conventional sol gel solutions are loaded with up to about 90% by weight of finely divided ceramic particles and mixed. The resulting slurry or paint can be either spun or dip coated or sprayed or painted onto a planar or other substrate, fired to remove the organic materials and to develop a microcrystalline structure. The fired film may then be heated. Composite films are also contemplated.

Owner:DATEC COATING CORP

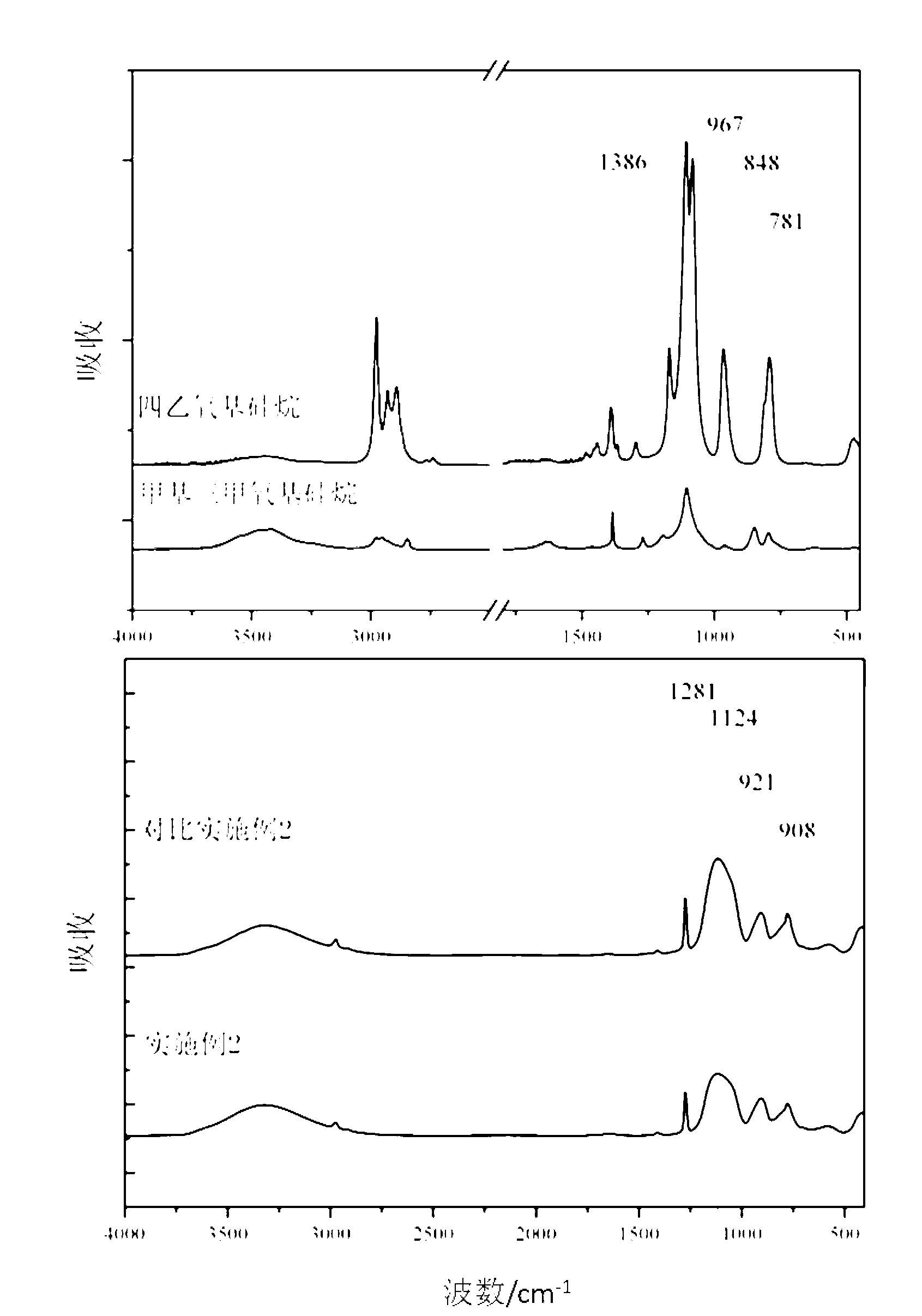

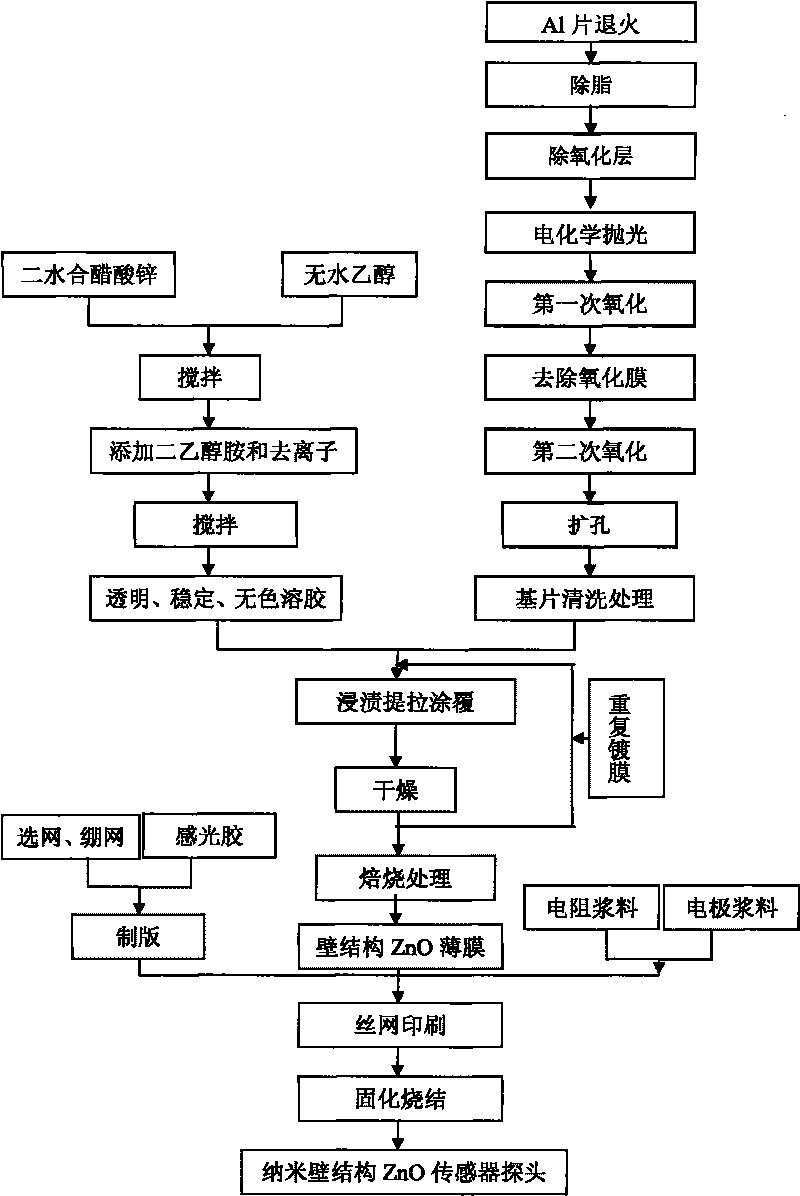

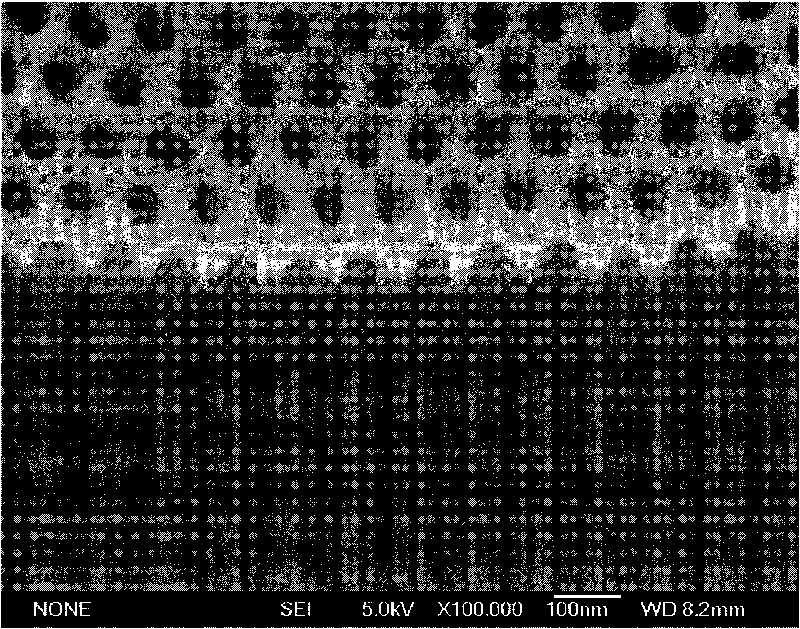

Gas-sensitive transducer with nano wall structure and preparation method thereof

InactiveCN101701928AIncreased sensitivitySimple structureNanostructure manufactureScreen printersScreen printingTransducer

The invention provides a gas-sensitive transducer with a nano wall structure and a preparation method thereof. The transducer sequentially comprises a measurement circuit, a measurement electrode, a nano wall structure sensitive material, porous alumina, compact alumina, pure aluminum, a sensitive material, a heating material, a heating electrode and a heating circuit which are in close contact from top to bottom. The preparation method of the transducer comprises the steps of: preprocessing the pure aluminum, and then forming a porous anode oxidation template by using a secondary anode oxidation method, wherein the surface of the porous anode oxidation template is provided with the porous alumina and the bottom layer is provided with the compact alumina; preparing the sensitive material with the nano wall structure on the template by adopting a sol-gel coating method; and preparing the measurement circuit, the measurement electrode, the heating material, the heating electrode and the heating circuit by adopting a screen printing method, i.e. assembling the gas-sensitive transducer with the nano wall structure. The transducer has better sensitivity, optimized performance and controllable structure.

Owner:WUHAN UNIV OF TECH

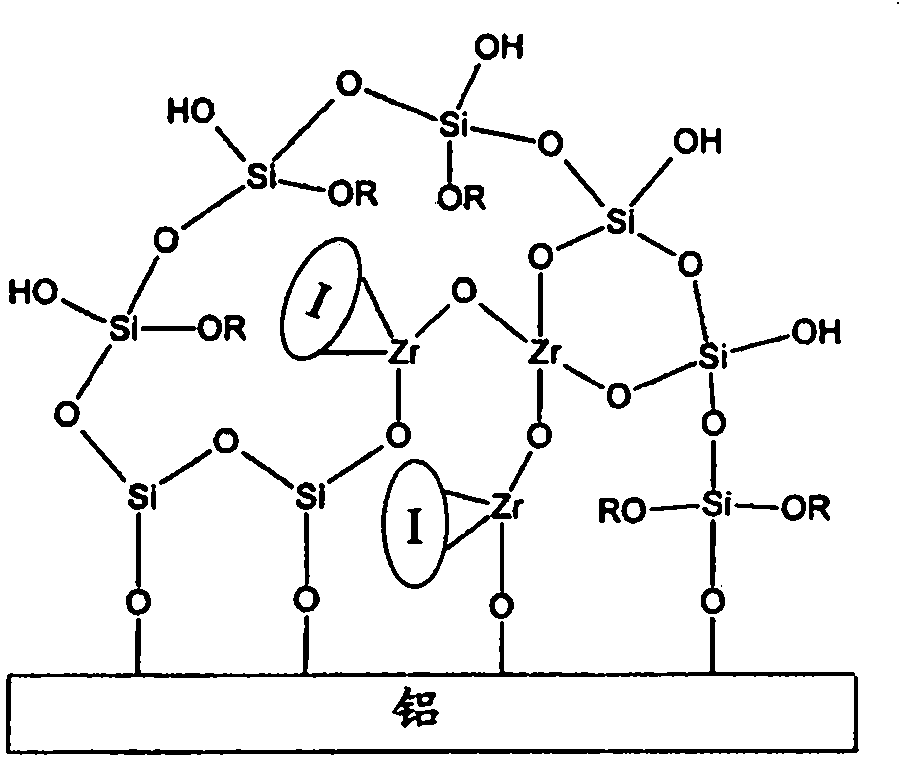

Pigmented alkoxyzirconium sol

InactiveUS7001666B2Suitable appearanceImprove adhesionPigmenting treatmentPretreated surfacesSolventReflectivity

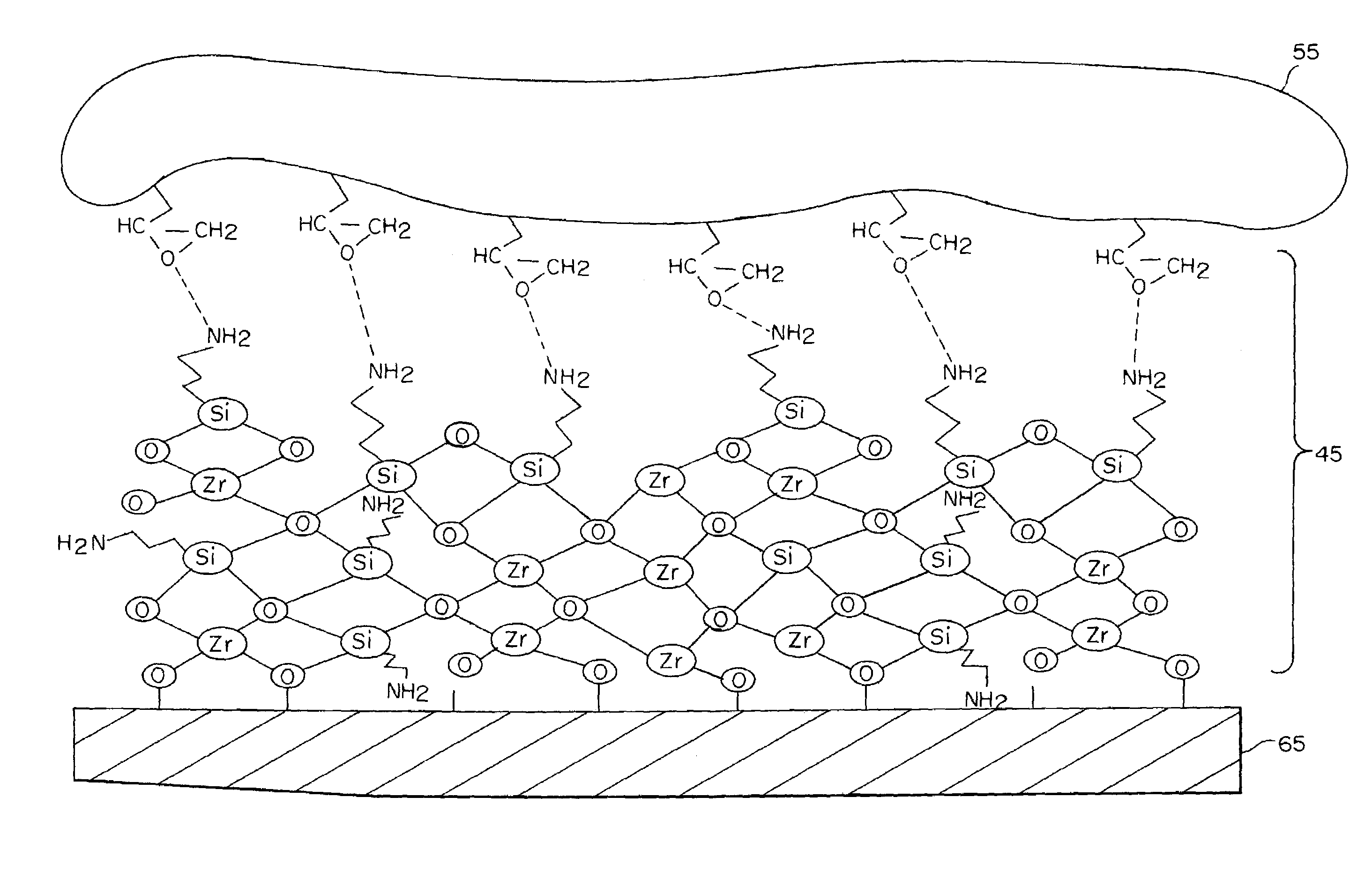

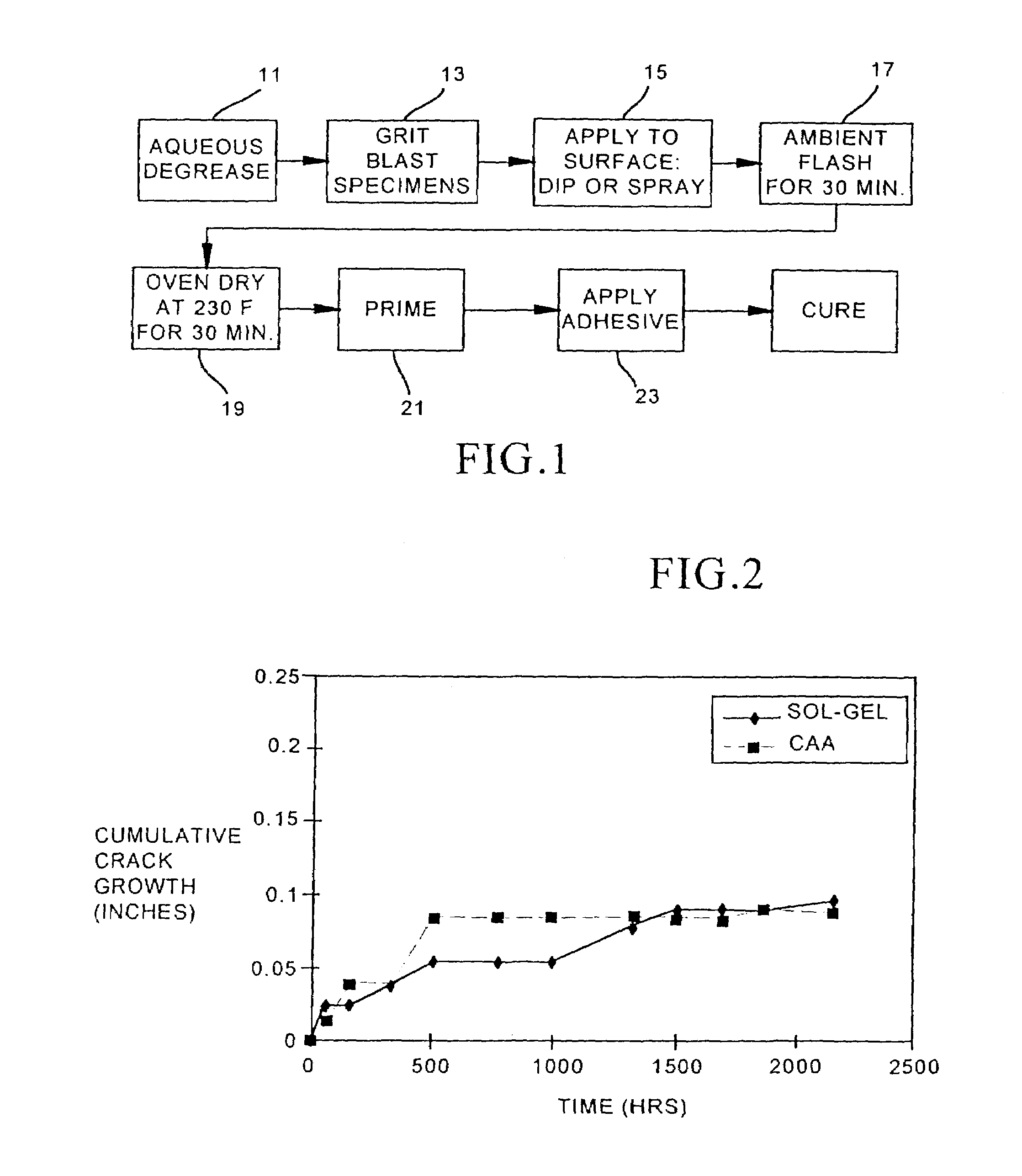

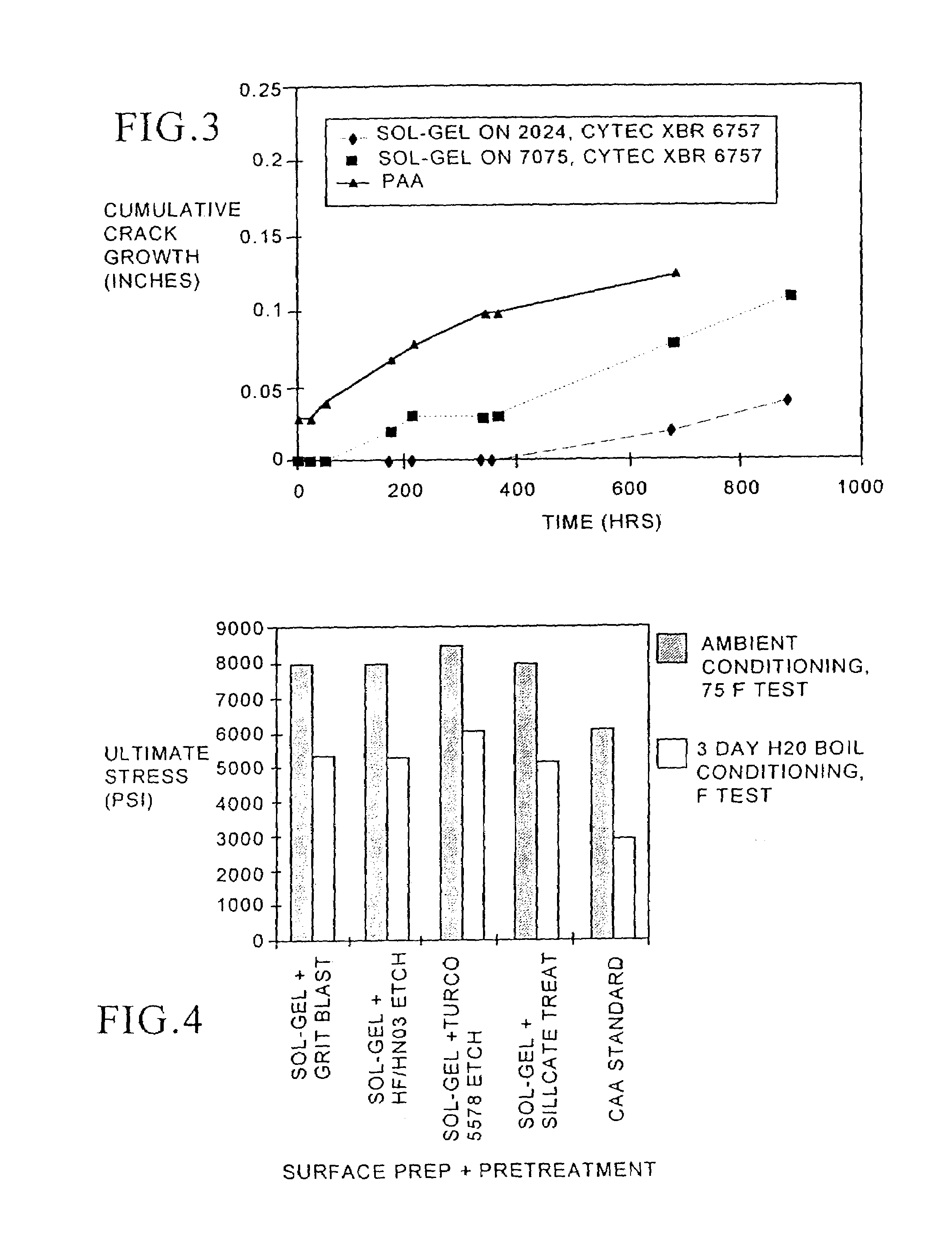

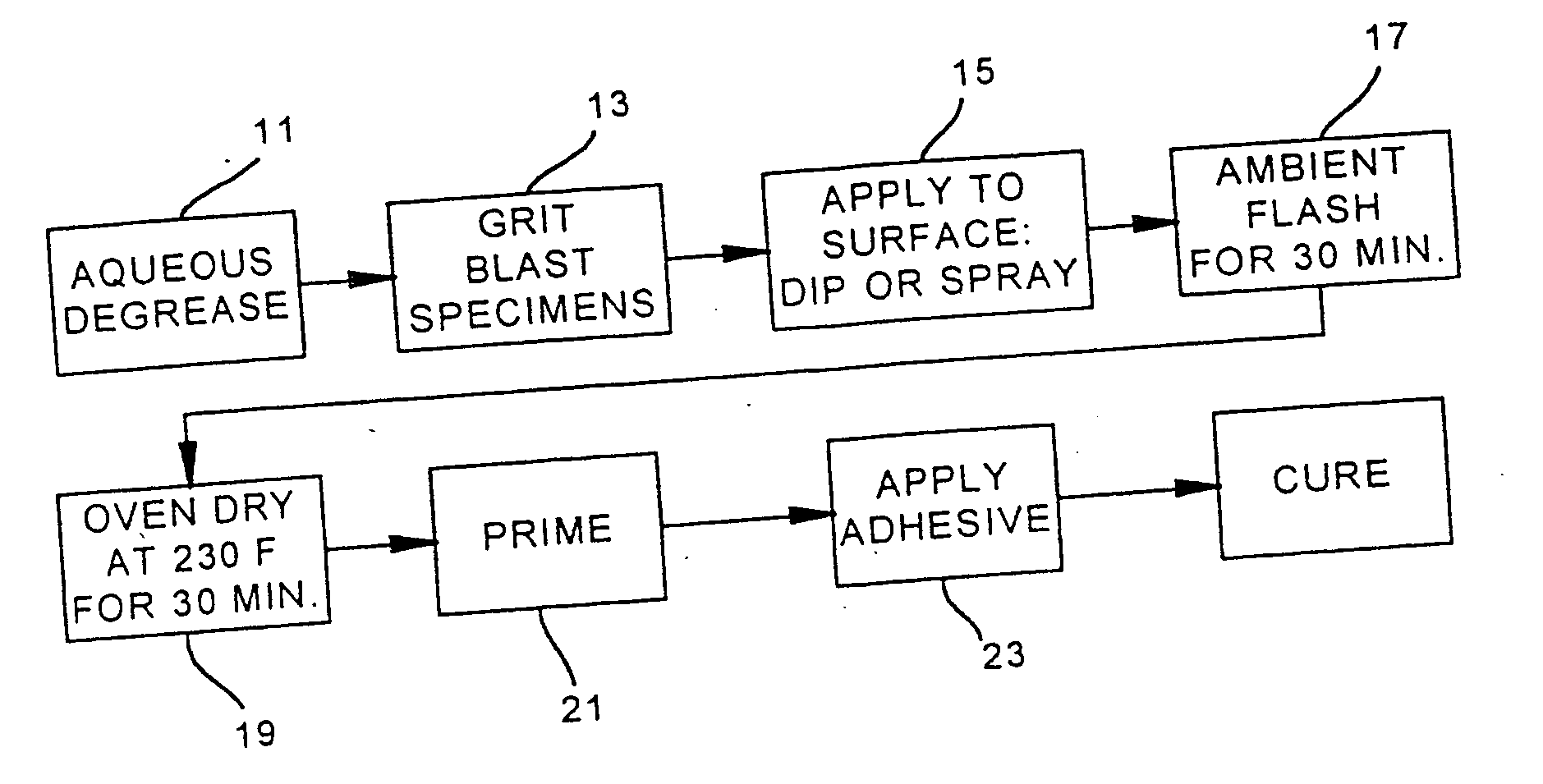

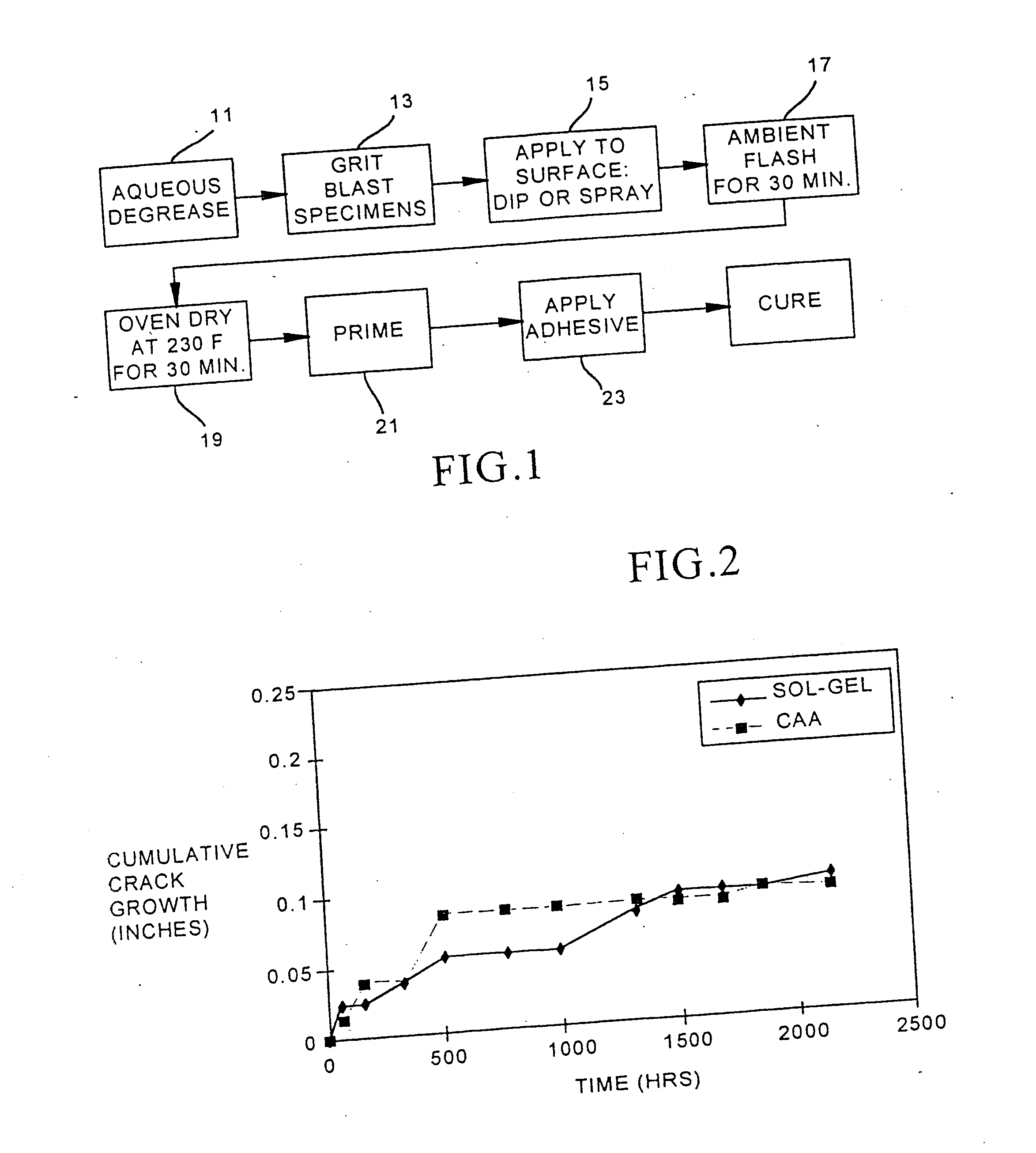

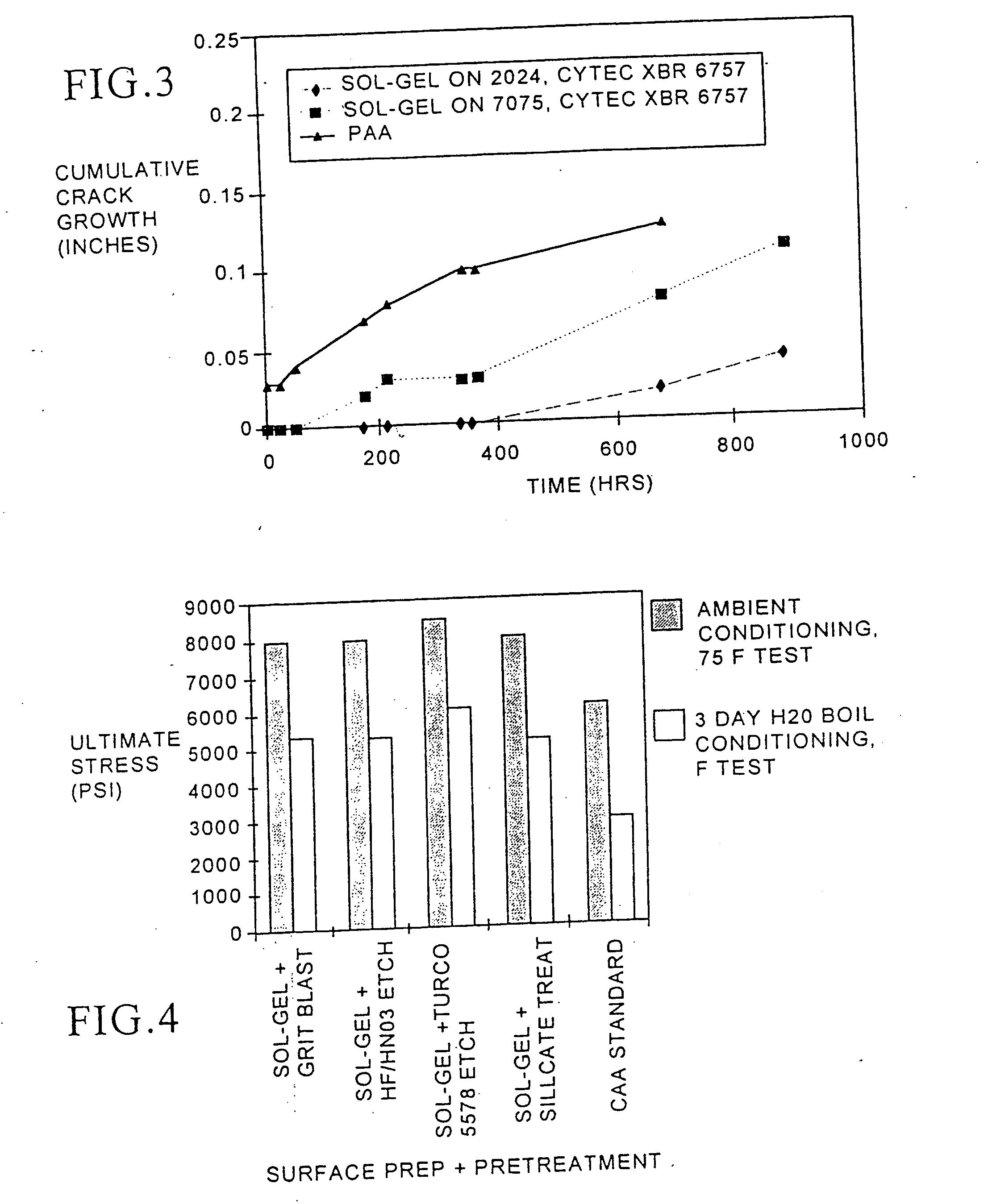

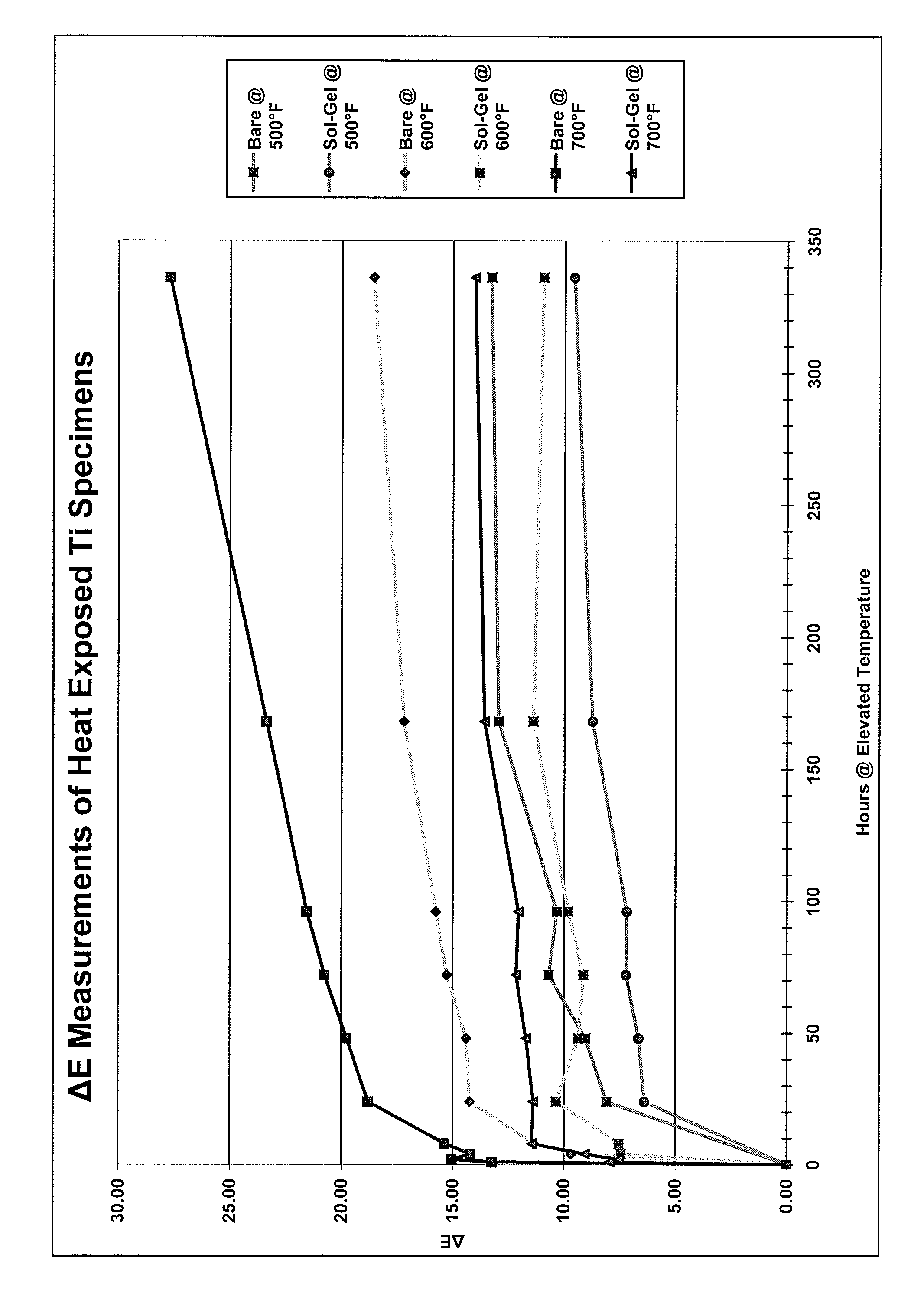

A surface treatment, especially for titanium and aluminum alloys, forms a pigmented sol-gel film covalently bonded on the metal surface to produce desired color, gloss, reflectivity, electrical conductivity, emissivity, or a combination thereof usable over a wide temperature range. The coating retains its characteristics and impact resistance following exposures to temperatures at least in the range from −321° F. to 750° F. An aqueous sol containing an alkoxyzirconium and an organosilane with an organic acid catalyst and zirconium stabilizer is applied to etched or grit blasted substrates by dipping, spraying, or drenching, to produce bonds in a single application comparable in strength and performance to standard anodize controls. Parameters affecting performance include the sol composition, the Si / Zr ratio, the ratio of sol ingredients, the concentration of the sol, the carrier solvent, solution age, catalysts, surface pretreatment, application method, curing process, and primer used. The sol-gel coating may be graded in its ceramic character by adjusting the organosilane component between TEOS and silanes that have more distinctive organic character by virtue of organic ligands attached to the silicon.

Owner:THE BOEING CO

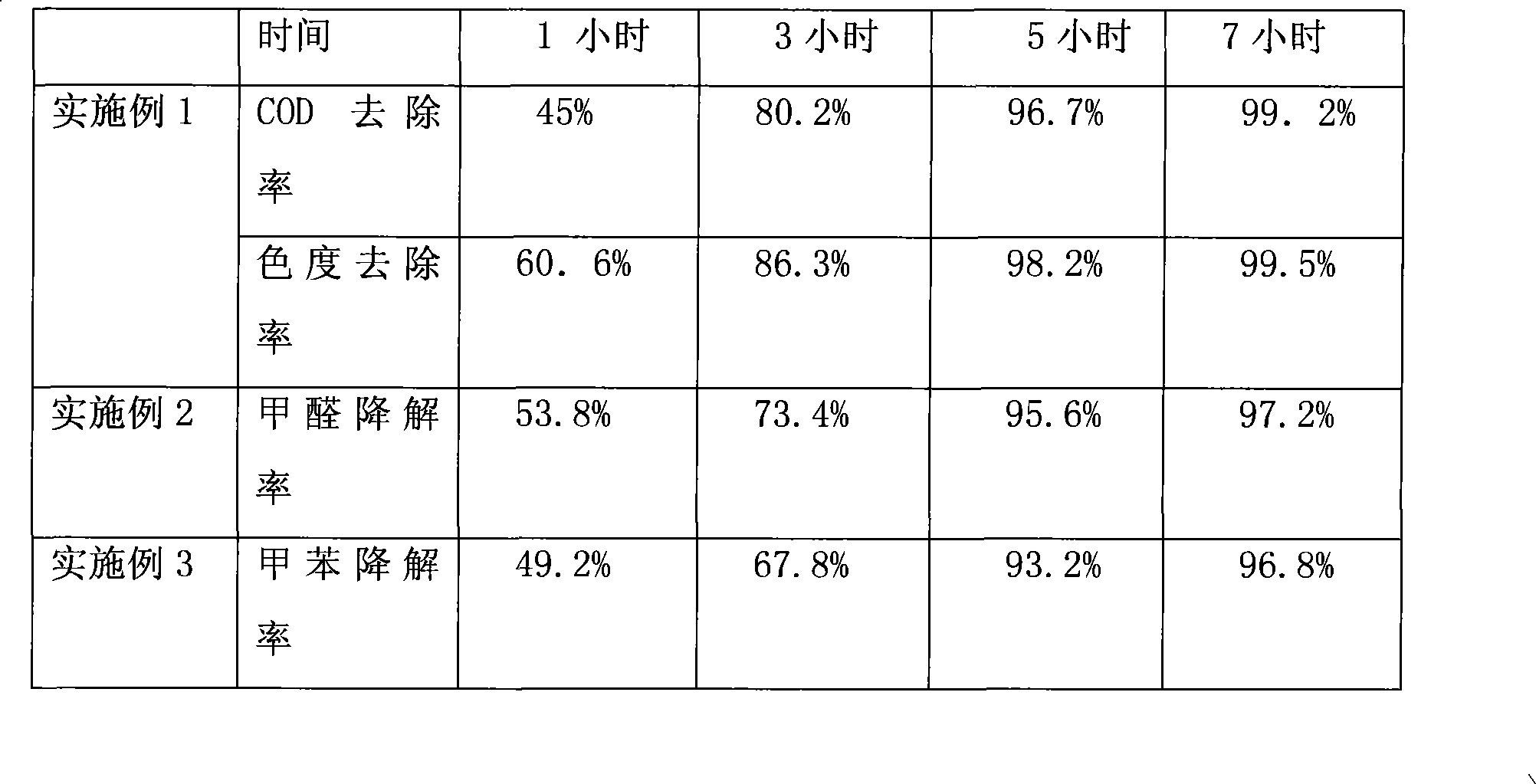

Preparation method of laser modified titanium dioxide photocatalyst

InactiveCN101391210AEasy to manufactureSolve the load problemOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterFiber

The invention discloses a preparation method of a laser modified titanium dioxide photocatalyst, which belongs to the technique field of environmental pollution treatment and the research field of new energy sources, and the method comprises the following steps: 1) surface treatment of a high-strength and high-elasticity porous polyester fiber net; 2) loading the titanium dioxide photocatalyst; and 3) modification of a titanium dioxide film by laser. The method is to sequentially carry out the protective sorting to the polyester fiber net according to the cleaned fiber net surface, then coat a film on the fiber net surface by using a sol-gel-coating method and taking tetra-iso-propyl titanate and isobutyl alcohol as raw materials under the weak base condition, and modify the film in a textile laser processor. The invention has advantages of extensive sources of raw materials, simple process, low cost, good stability of the prepared titanium dioxide film, and high photo-catalytic activity and efficiency, and has the antifouling, self-cleaning, antibacterial and air-cleaning effects, and the method can be used for the degradation of environmental harmful substance, and can serve as air purification material and dyeing wastewater treatment photocatalysis material.

Owner:DONGHUA UNIV

Pigmented organometallic sol

InactiveUS20050229816A1Improve bindingSuitable appearancePigmenting treatmentPretreated surfacesOrganic acidEmissivity

A surface treatment, especially for titanium and aluminum alloys, forms a pigmented sol-gel film covalently bonded on the metal surface to produce desired color, gloss, reflectivity, electrical conductivity, emissivity, or a combination thereof usable over a wide temperature range. The coating retains its characteristics and impact resistance following exposures to temperatures at least in the range from −321° F. to 750° F. An aqueous sol containing an organometallic alkoxide containing either Ti or Al and an organosilane with an organic acid catalyst and stabilizer is applied to etched or grit blasted substrates by dipping, spraying, or drenching, to produce bonds in a single application comparable in strength and performance to standard anodize controls. The sol-gel coating may be graded in its ceramic character by adjusting the organosilane component between TEOS and silanes that have more distinctive organic character by virtue of organic ligands attached to the silicon.

Owner:THE BOEING CO

Sol-gel coating method and composition

InactiveUS8592042B2Promote oxidationReduce impactSynthetic resin layered productsPretreated surfacesOxidation resistantSol gel coating

A coating composition and a method for coating metallic substrates, such as aircraft components exposed to elevated temperatures and / or oxidative conditions. The coating composition includes an aqueous mixture having about 2 vol % to about 50 vol % organosilane, about 0.3 to about 25 vol % metal alkoxide, and about 0.1 to about 30 vol % organic complexing agent. The coating composition may be deposited on a metallic substrate and cured to form a sol-gel coating on the surface of the substrate that is adherent to the substrate, and oxidation and discoloration resistant.

Owner:THE BOEING CO

Ionic liquid mediated sol-gel sorbents

Ionic liquid (IL)-mediated sol-gel hybrid organic-inorganic materials present enormous potential for effective use in analytical microextraction. One obstacle to materializing this prospect arises from high viscosity of ILs significantly slowing down sol-gel reactions. A method was developed which provides phosphonium-based, pyridinium-based, and imidazolium-based IL-mediated advanced sol-gel organic-inorganic hybrid materials for capillary microextraction. Scanning electron microscopy results demonstrate that ILs can serve as porogenic agents in sol-gel reactions. IL-mediated sol-gel coatings prepared with silanol-terminated polymers provided up to 28 times higher extractions compared to analogous sol-gel coatings prepared without any IL in the sol solution. This study shows that IL-generated porous morphology alone is not enough to provide effective extraction media: careful choice of the organic polymer and the precursor with close sol-gel reactivity must be made to ensure effective chemical bonding of the organic polymer to the created sol-gel material to be able to provide the desired sorbent characteristics.

Owner:UNIV OF SOUTH FLORIDA

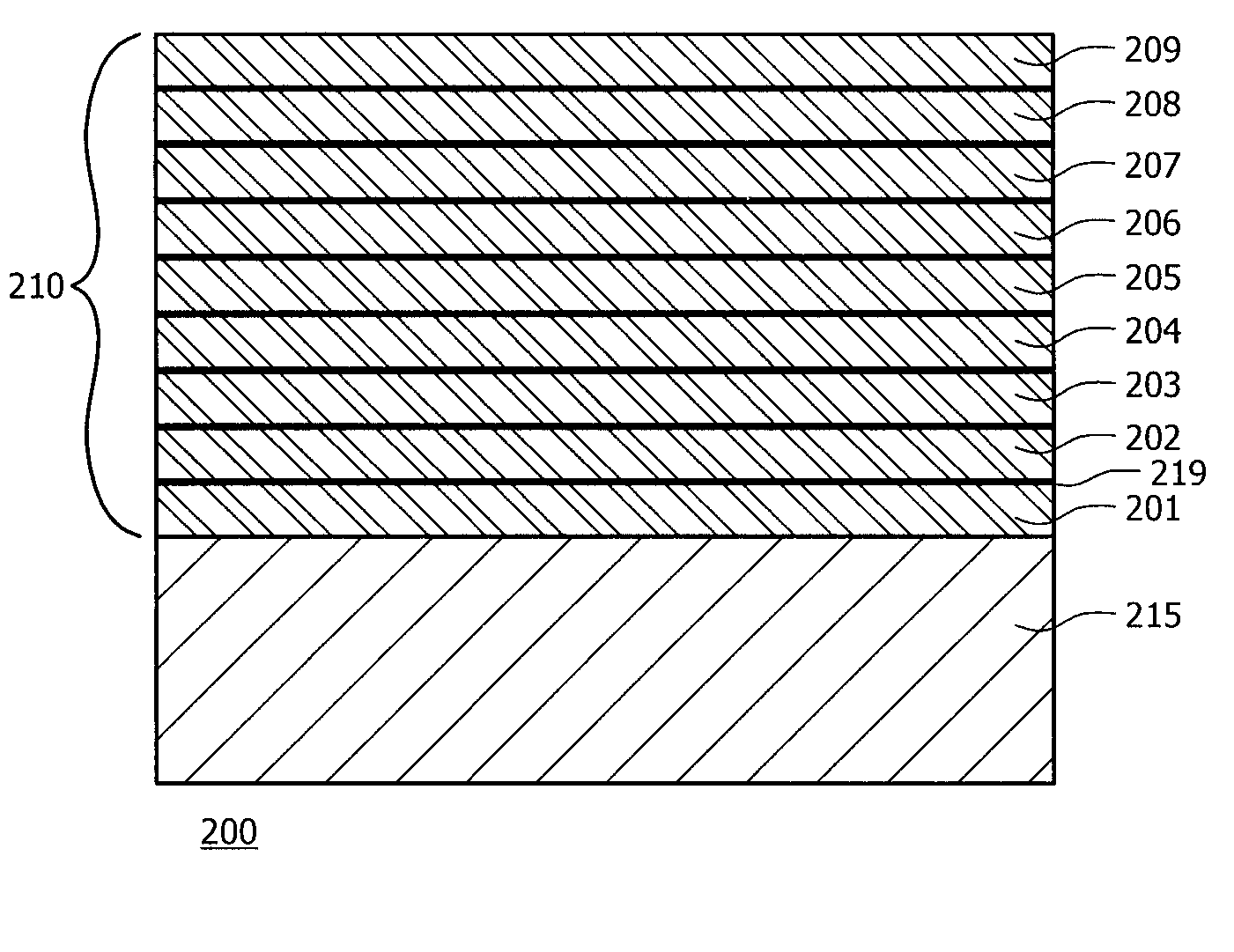

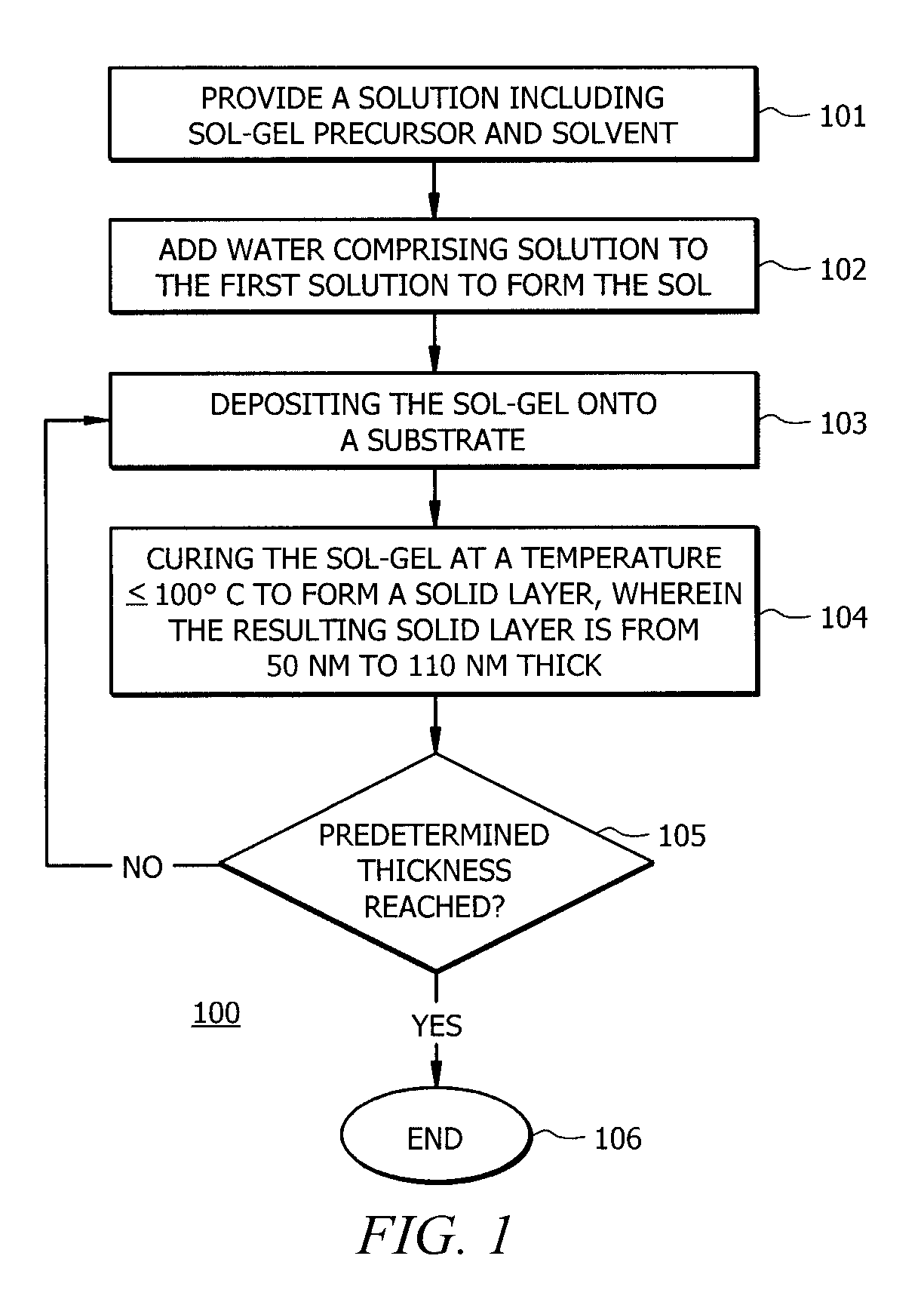

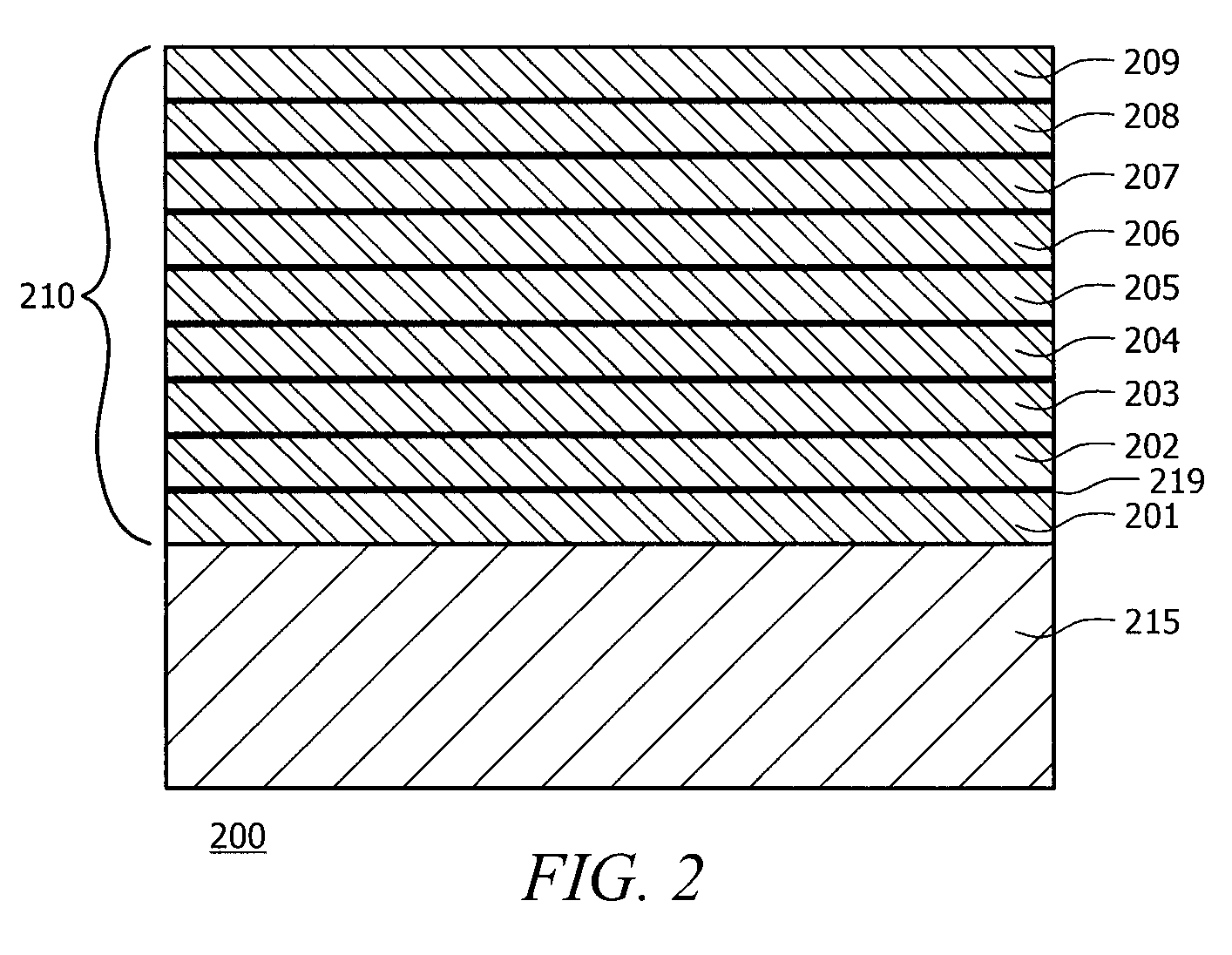

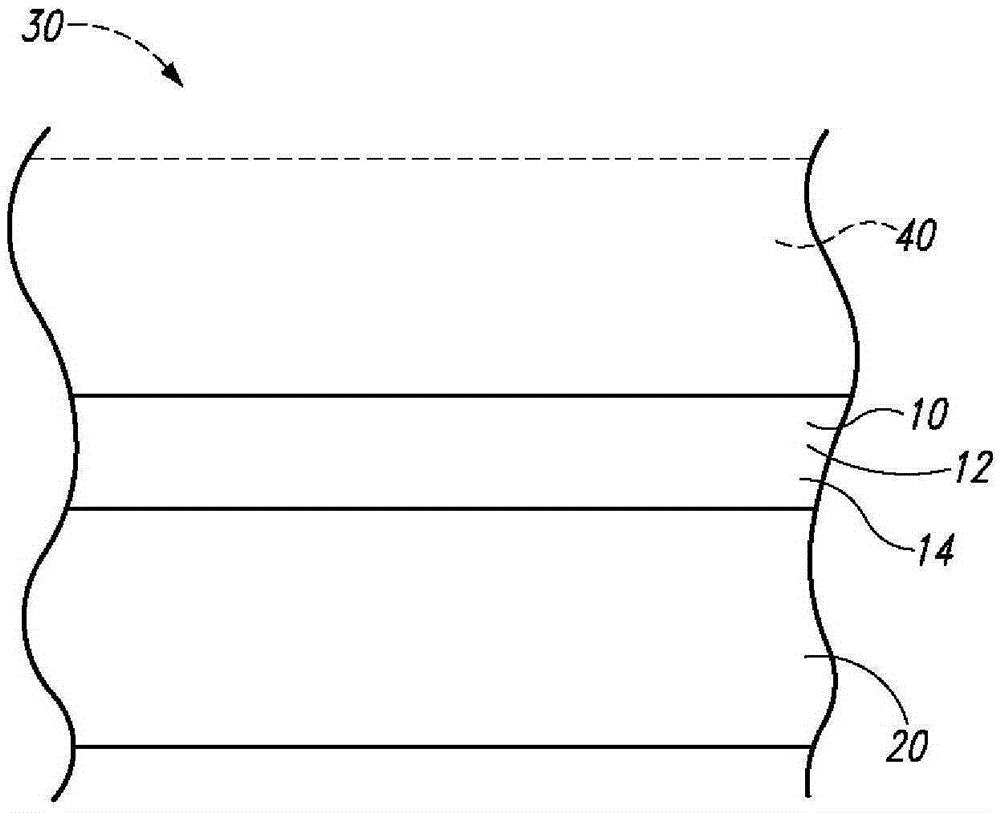

Sol-gel coating methods and thin film coated substrates therefrom

A method for depositing sol-gel derived coatings on substrates to form coated substrates includes the steps of providing a first solution including at least one sol precursor and at least one solvent. A water comprising solution is added to the first solution to form a sol-gel. The sol-gel is deposited on a substrate. The sol-gel layer on the substrate is dried / cured at a temperature ≦100° C. for at least 10 minutes to form a solid layer, wherein the solid layer has a thickness from 50 nm to 110 nm. The depositing and curing steps are repeated at least once until combined thickness of the solid layers forms a coating of a predetermined thickness. The resulting solid layers are low water content layers that can be evidenced by transmission measurements. The coated substrate can be an IR transmissive substrate having a recrystallization temperature <130° C. and each of the solid layers provide a transmission at λ=2950 nm, normal incidence and 1 mW power if placed on the IR transmissive substrate of ≧99% of the transmission directly through the IR transmissive substrate.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

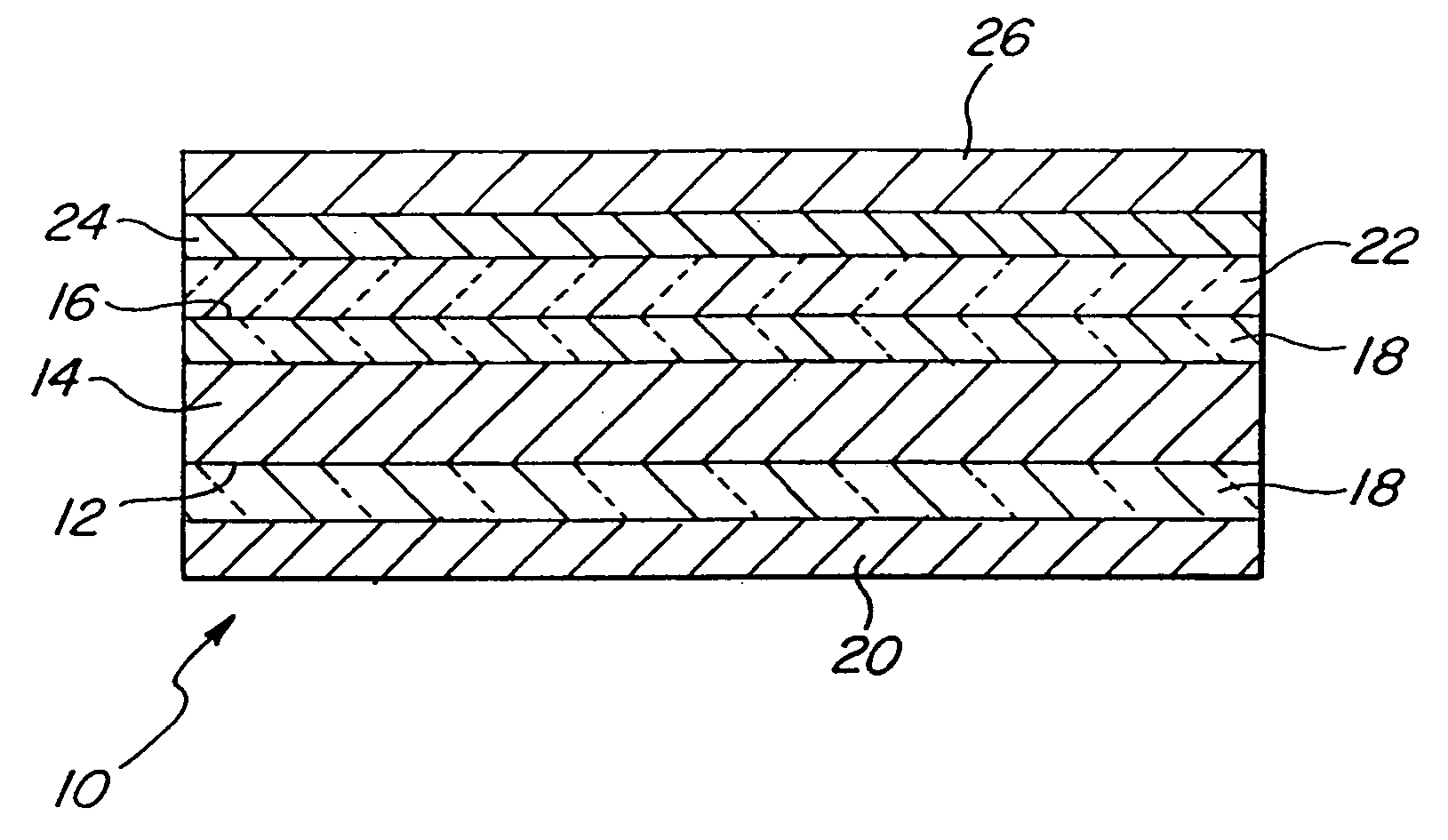

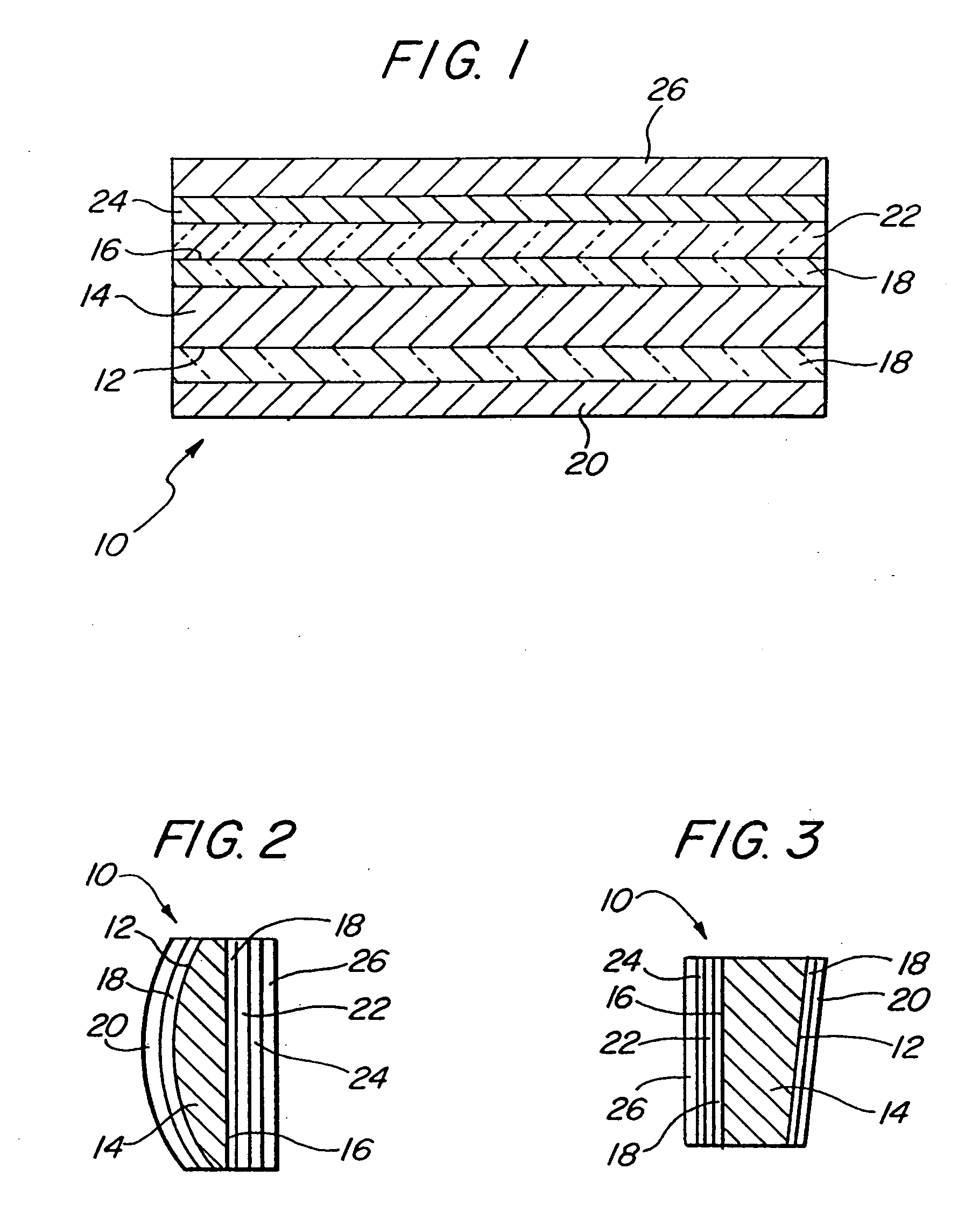

Transparent plastic optical components and abrasion resistant polymer substrates and methods for making the same

InactiveUS20060087755A1Good weather resistanceIncreased durabilityMirrorsSynthetic resin layered productsThermoplasticPolymer substrate

A polymer-based component formed from a synthetic thermoplastic or thermoset resin substrate, such as polymethyl methacrylate, which is resistant to warping and distortion from moisture. A composite multi-layer surface-hardening coating is formed on at least the anterior surface of the resin substrate. The component can include a composite multi-layer reflective coating to form a mirror. A protective back-coat layer is deposited on a posterior surface of the mirror. A multi-layer weather-resistant coating may optionally be applied to the anterior surface of the polymer-based mirror in order to increase the weatherability and durability of the mirror. The various layers coating the synthetic resin substrate have their moisture permeabilities selected so that substantially equal amounts of moisture permeate through to both the anterior and posterior side of the synthetic resin substrate. A sol-gel coating can be used to deposit the multi-layers in a single step by providing gradient zones of zirconia / silica while enabling a hydrophobic or a hydrophilic exterior surface.

Owner:RICHARD DAVID A

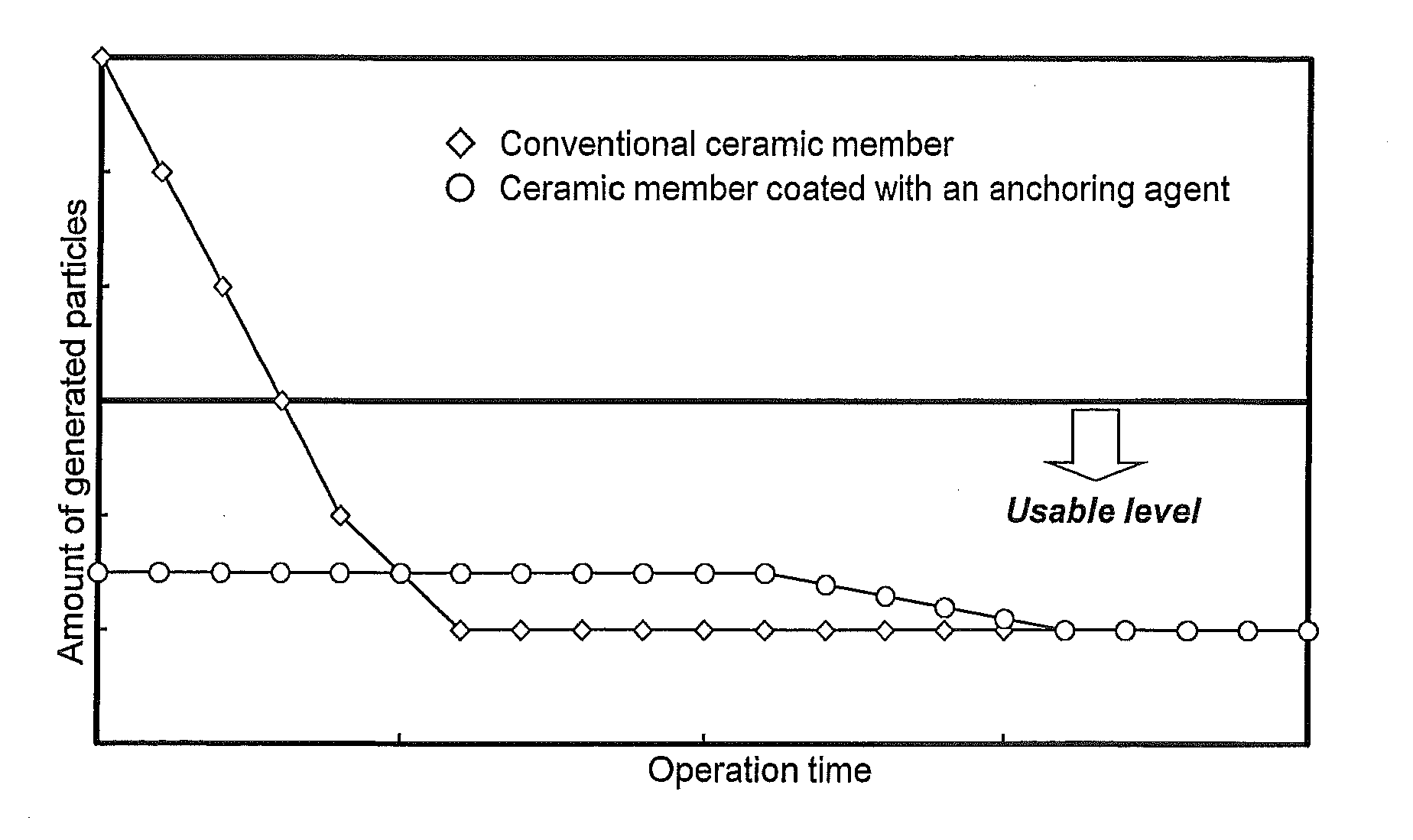

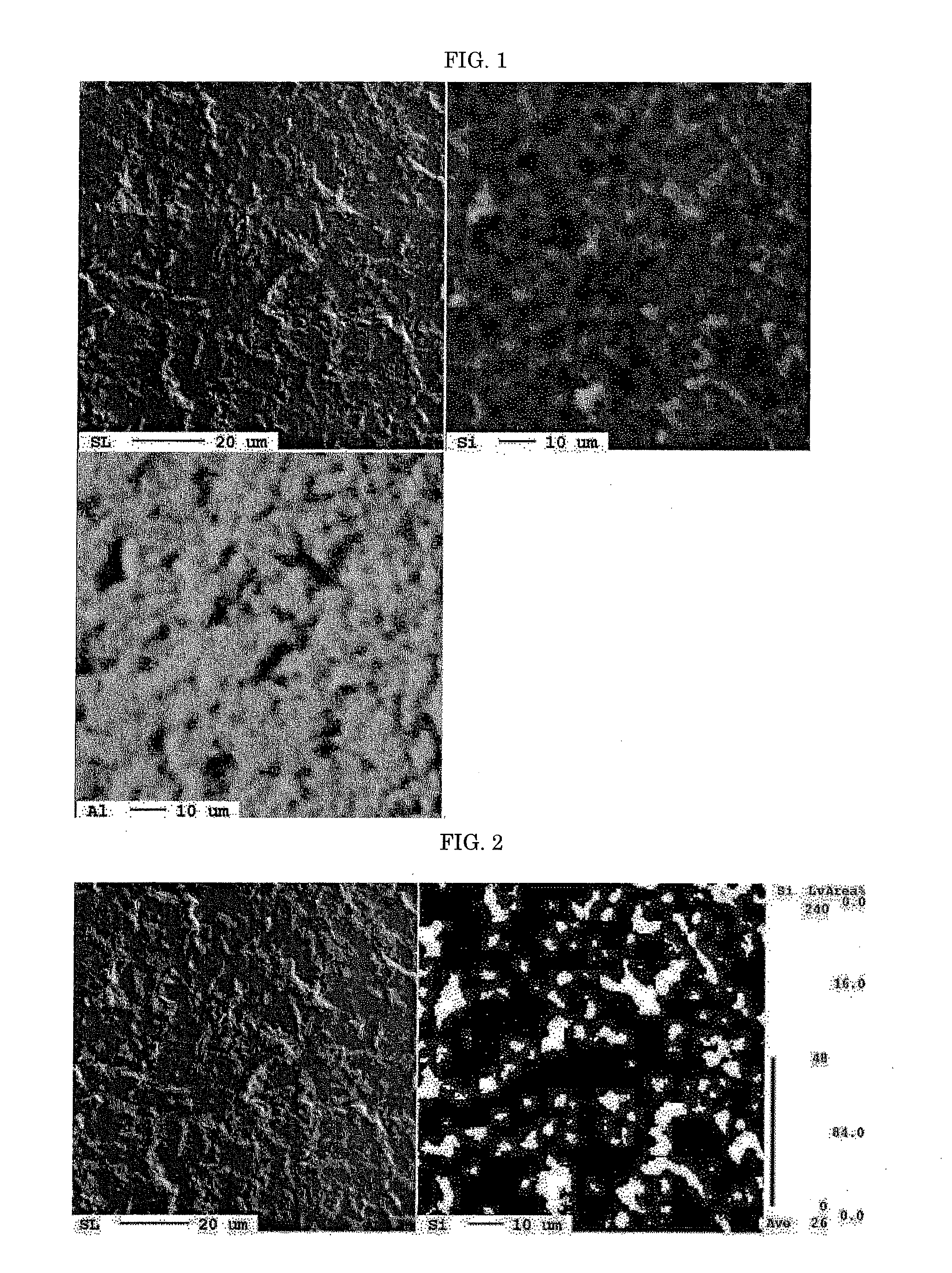

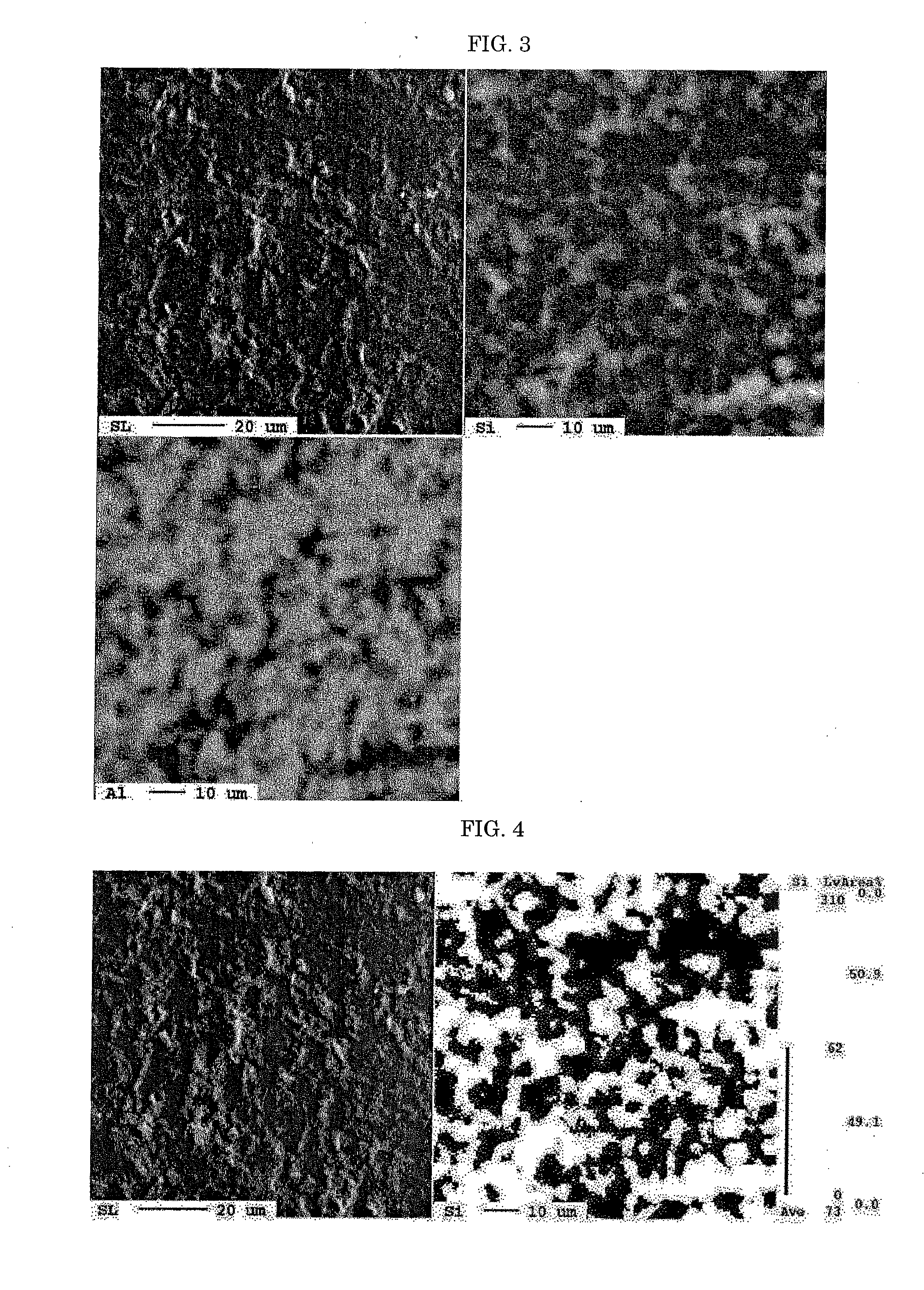

Surface-treated ceramic member, method for producing the same and vacuum processing apparatus

Disclosed is a surface-treated ceramic member which has a coating film-formed surface comprising a ceramic sintered body with a porosity of 1% or less and a sol-gel coating film of a silicon alkoxide compound polymer formed on at least a part of a ceramic sintered body, wherein the coating film and the surface of the body are coexistent in the coating film-formed surface. Specifically the area of the sol-gel coating film accounts for 5 to 80% of the total area of the coating film-formed surface. The surface-treated ceramic member has excellent corrosion resistance and is free from scattering of particles.

Owner:ULVAC INC +1

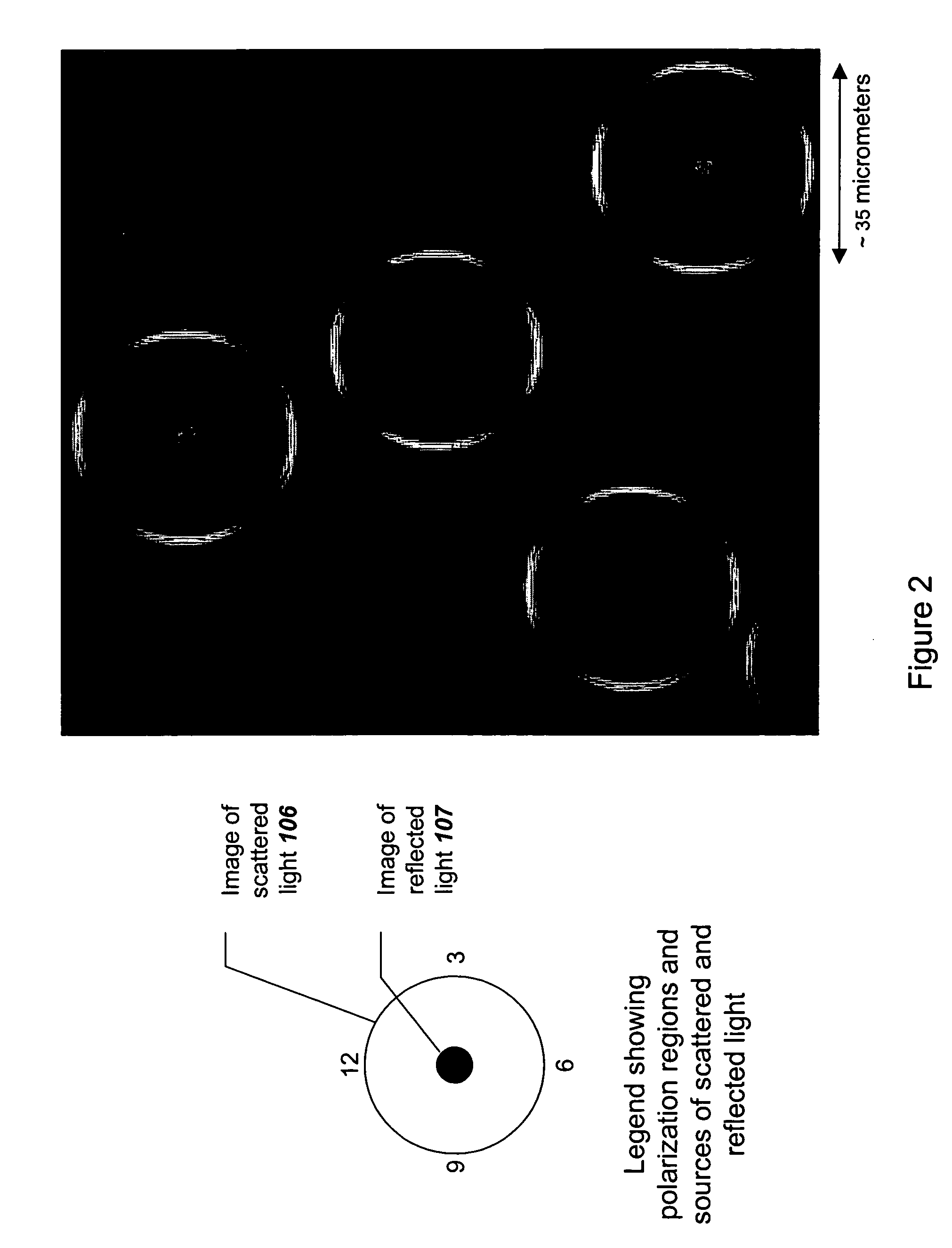

Sol-gel coated glass microspheres for use in bioassay

InactiveUS20070117089A1Bioreactor/fermenter combinationsMaterial nanotechnologyMicrosphereSol gel coating

A microsphere for use in a bioassay comprising a glass core coated with a sol-gel comprising a bioactive probe is provided. The sol-gel coating enhances the density of bioprobe loading on the surface of the microspheres, resulting in enhanced dynamic range and sensitivity in bioassays. The particle may be used in detection systems where resonant light scattering properties of the particle are useful.

Owner:EI DU PONT DE NEMOURS & CO

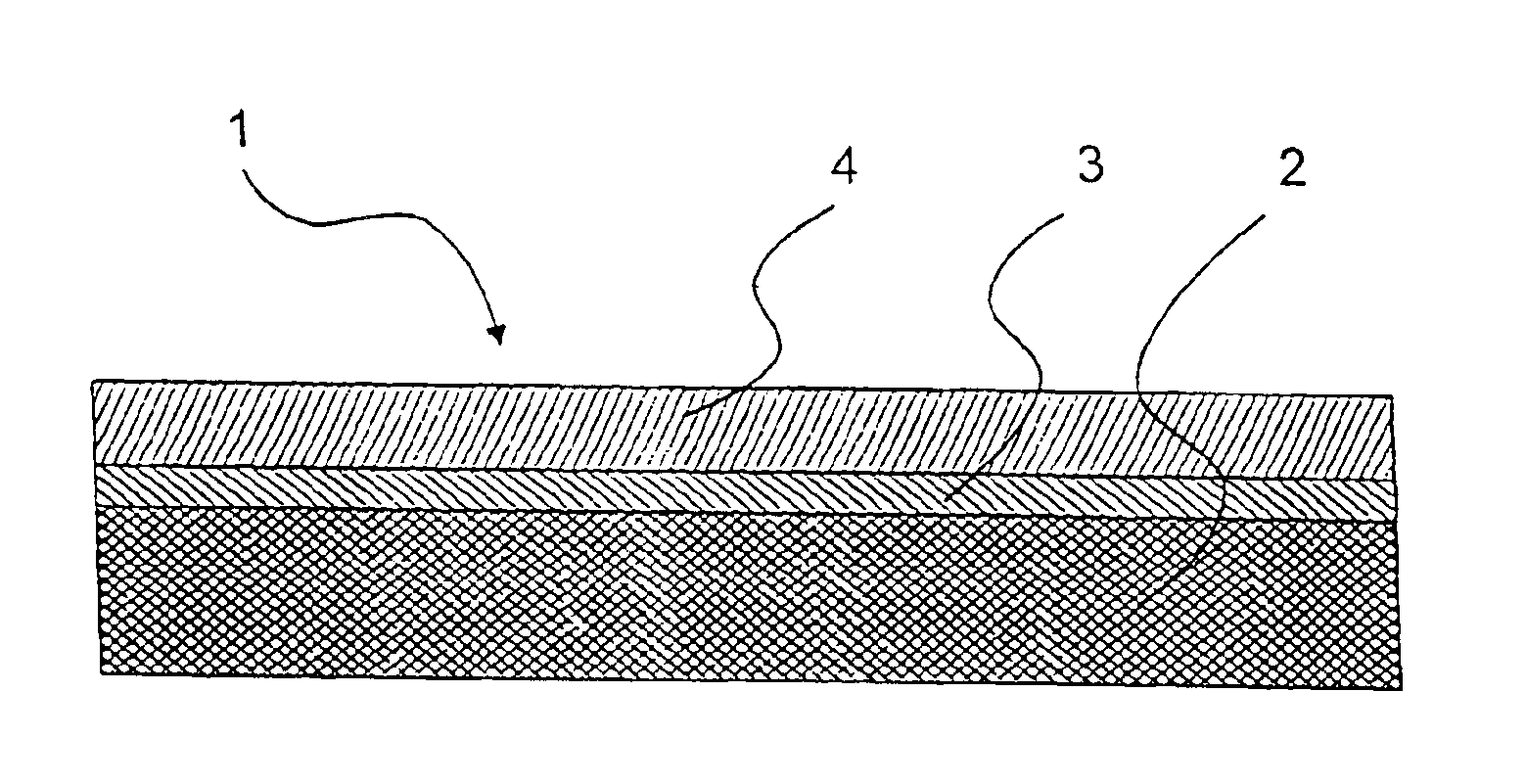

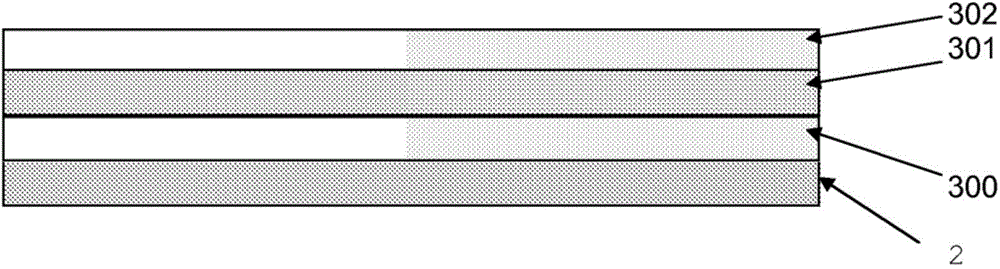

Sol-gel coating comprising a fluorinated filler and culinary article equipped with such a coating

ActiveCN103562324ACooking-vessel materialsLiquid/solution decomposition chemical coatingSol gel coatingPolymer chemistry

The present invention relates to a sol-gel coating (2) taking the form of a continuous film of a material comprising a matrix formed using at least one metal polyalcoxylate. According to the invention, the sol-gel coating (2) comprises at least one fluorinated filler taking the form of particles of fluorocarbon resin coated with a polyethylene wax or a fluorinated polyether. The present invention also relates to a culinary article equipped with such a coating and a process for applying at least one coating to a face of a support.

Owner:SEB SA

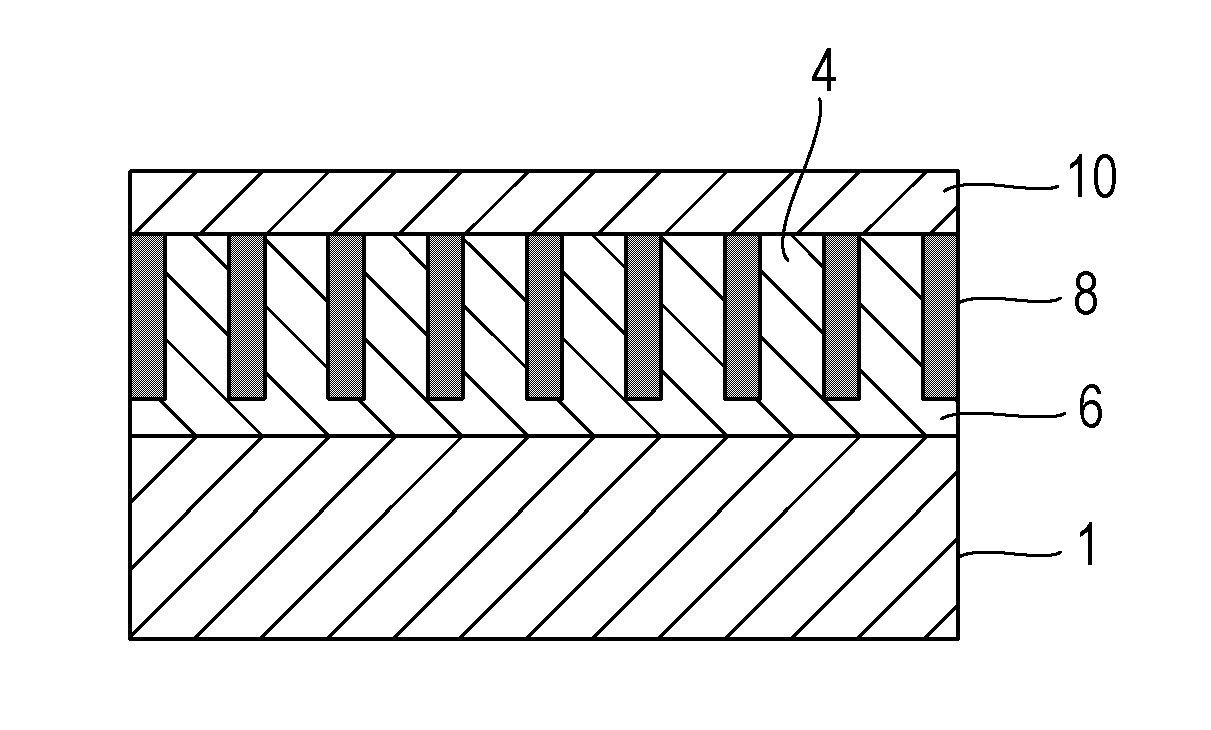

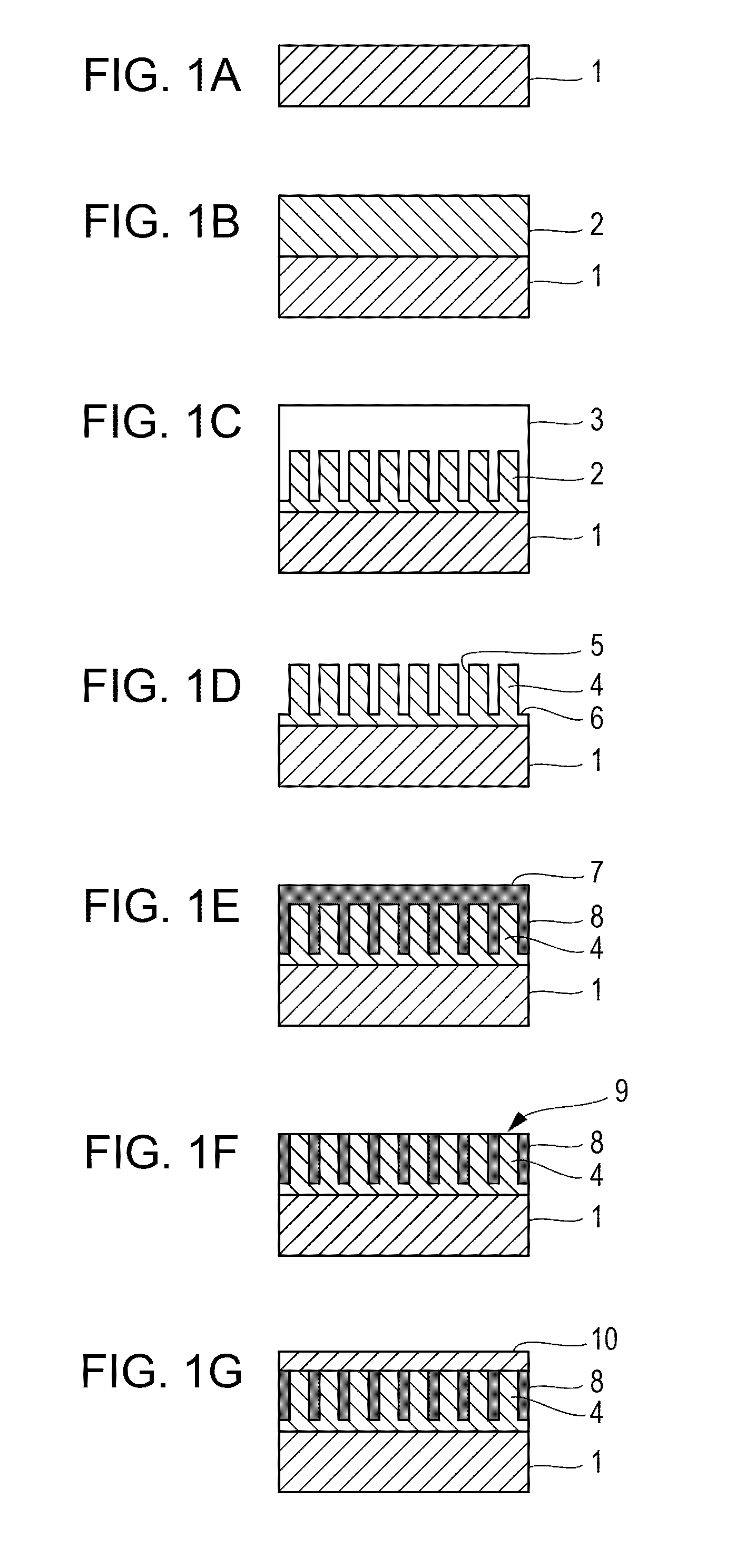

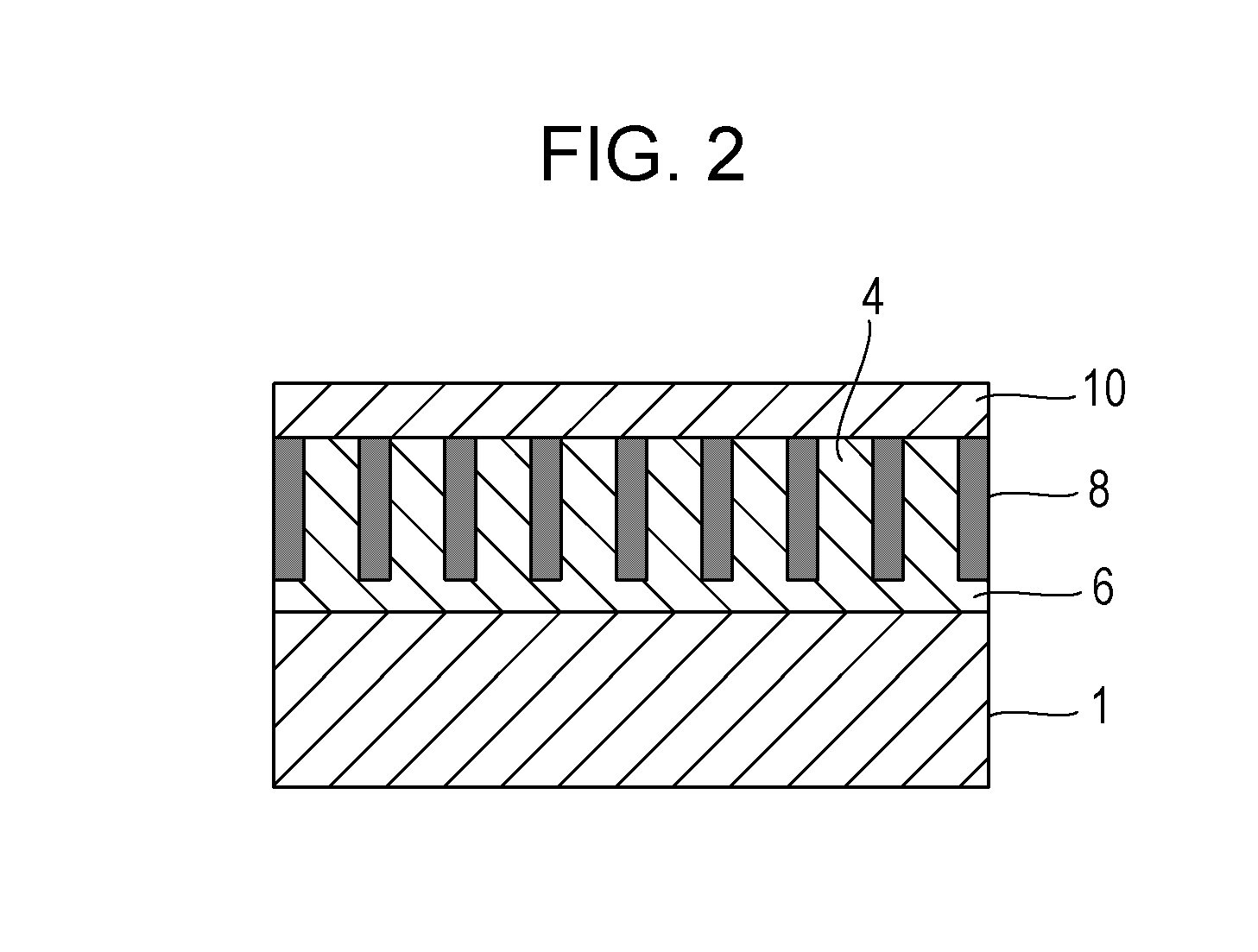

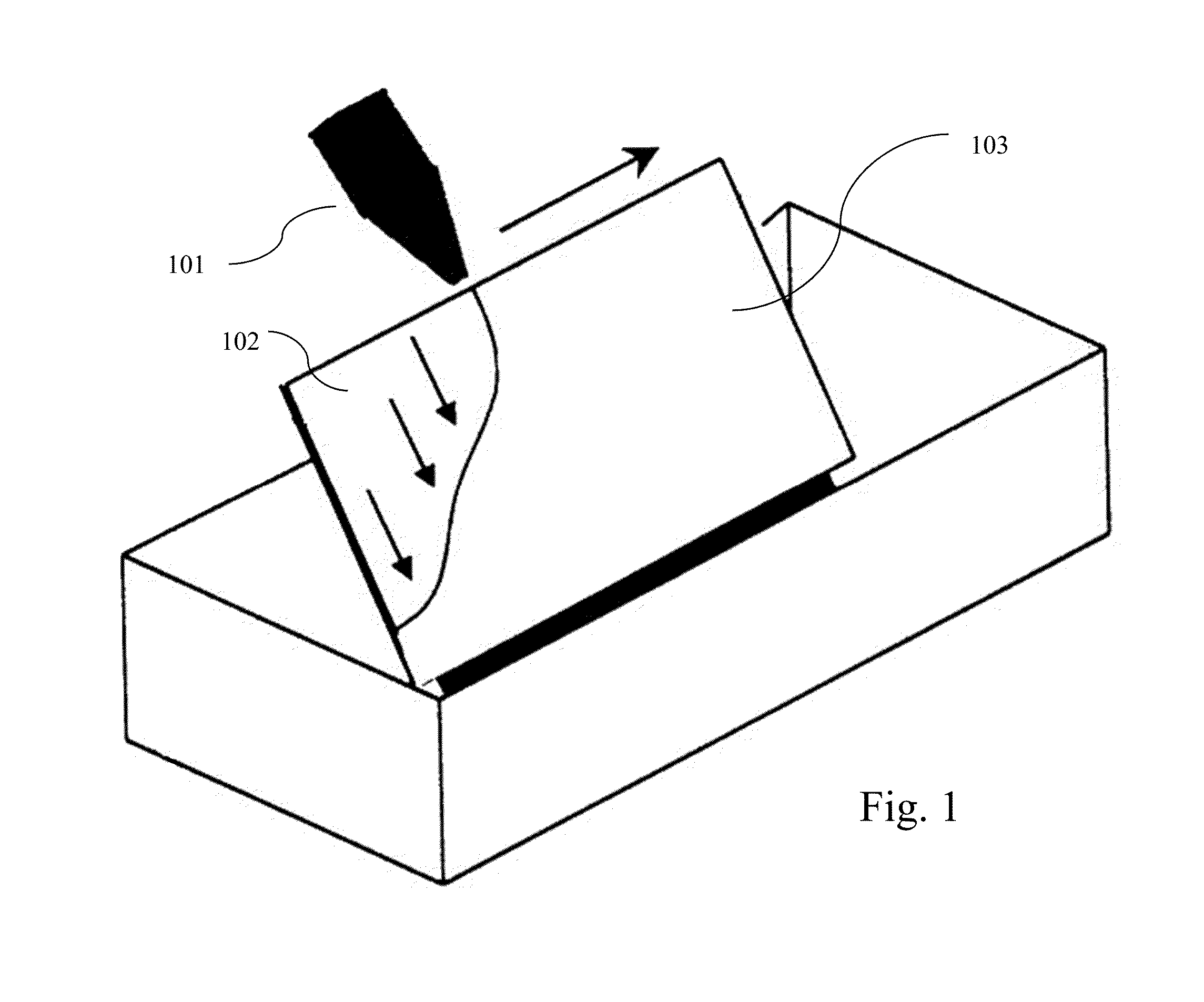

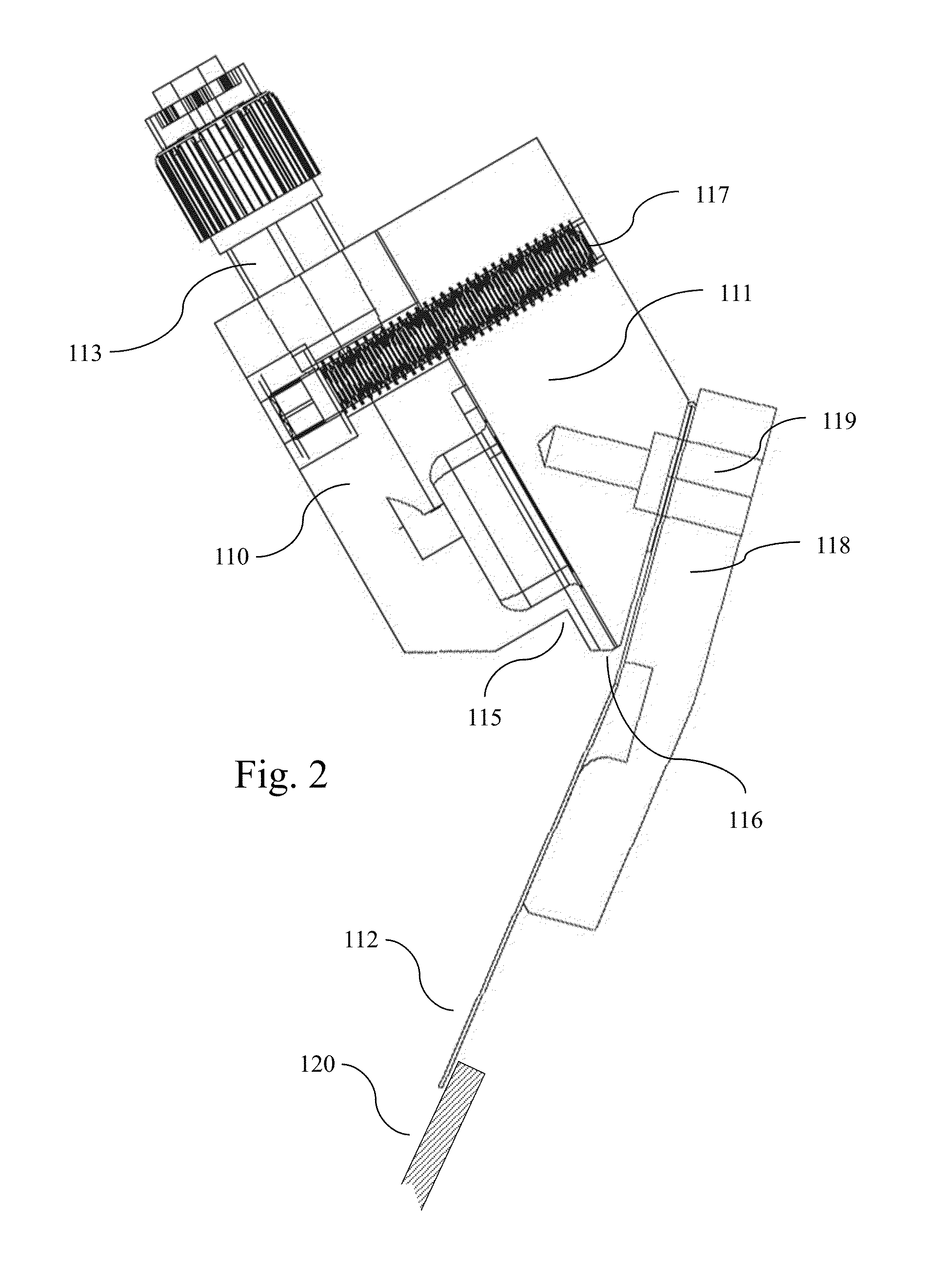

Method of producing wire-grid polarizer and wire-grid polarizer

InactiveUS20120176676A1High extinction ratioLow production costPolarising elementsCoatingsProduction lineWire grid

A line-and-space structure having a line portion and a space portion is formed by applying a sol-gel coating on a substrate and transferring a structure of a mold to the coating, and an embedded metal portion is formed by filling the space portion with a molten metal. As the metal to be molten, a metal material having a melting point of not higher than 650° C. and showing, after the solidification, an average extinction coefficient of higher than 5.0 or an average extinction coefficient of higher than 4.5 and an average refractive index of less than 1, at a wavelength range of 400 to 700 nm, is selected to improve optical characteristics.

Owner:CANON KK

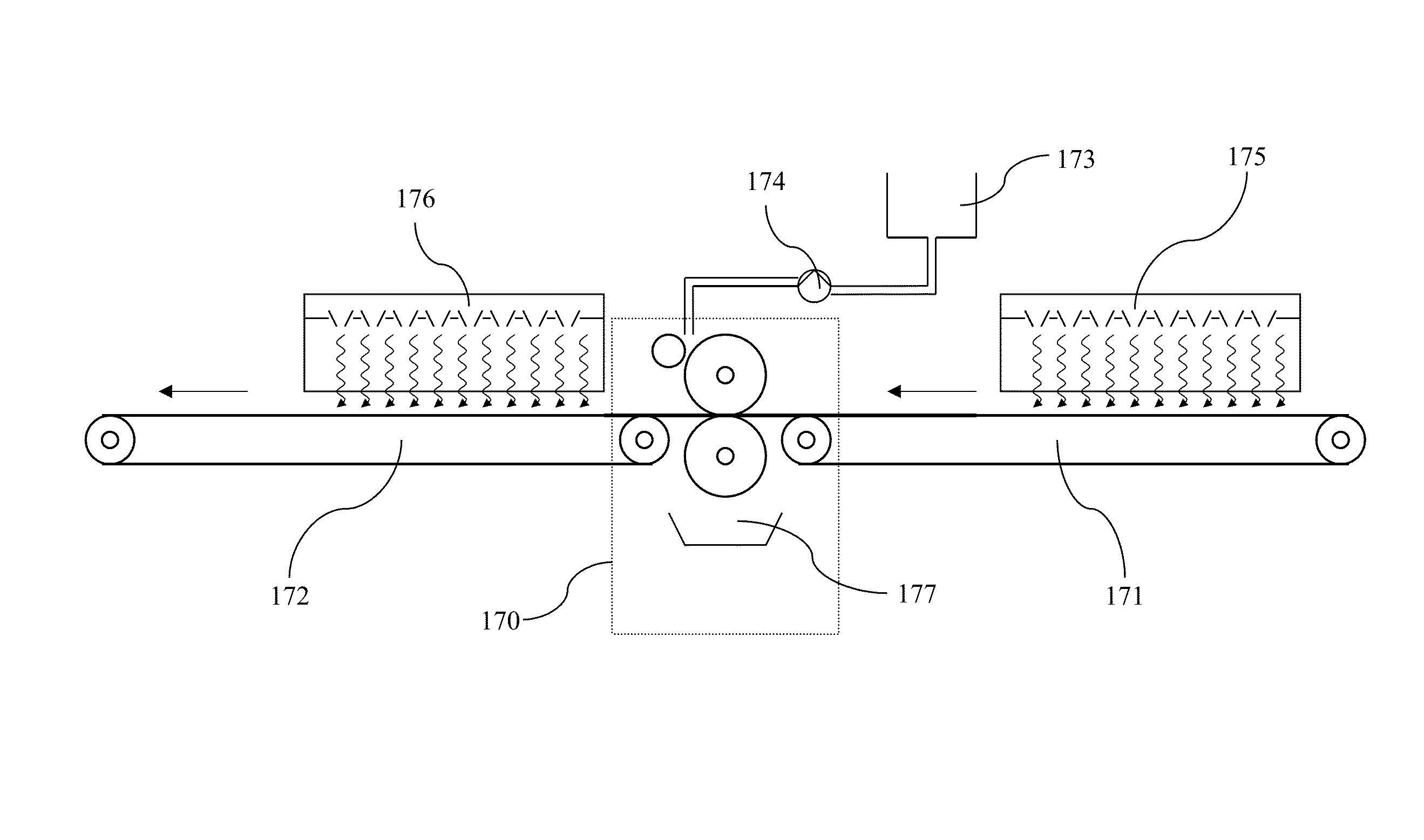

Coating and curing apparatus and methods

ActiveUS9314811B1High hardnessIncrease heating capacityLiquid surface applicatorsLiquid/solution decomposition chemical coatingDisplay deviceAir knife

Disclosed is a coating apparatus including flow coating and roll-coating that may be used for uniform sol-gel coating of substrates such as glass, solar panels, windows or part of an electronic display. Also disclosed are methods for substrate preparation, flow coating and roll coating. Lastly, systems and methods for curing sol-gel coatings deposited onto the surface of glass substrates using high temperature air-knives, infrared emitters and direct heat applicators are disclosed.

Owner:FIRST SOLAR INC (US)

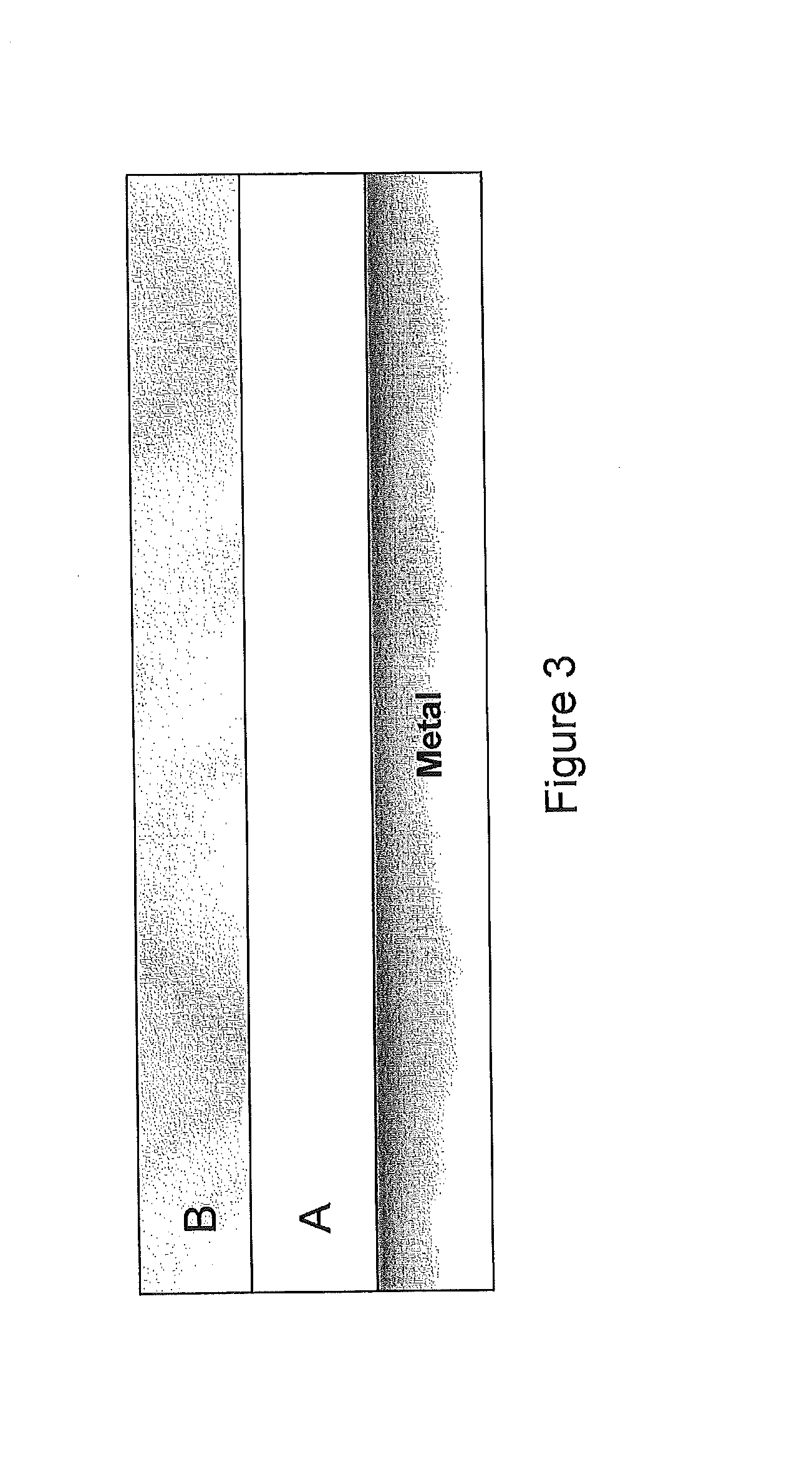

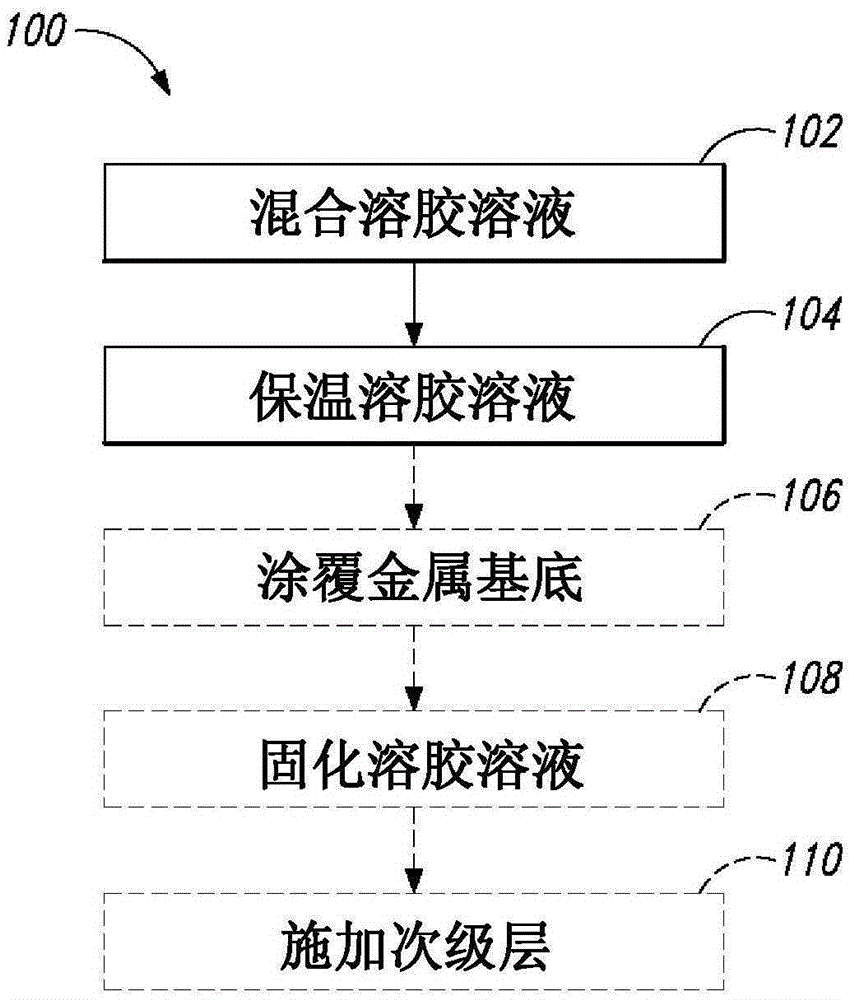

Corrosion-inhibiting sol-gel coating systems and methods

InactiveCN105624659AAnti-corrosive paintsLiquid/solution decomposition chemical coatingSol gel coatingMaterials science

The invention relates to corrosion-inhibiting sol-gel coating systems and methods. Corrosion-inhibiting coating materials comprise a sol-gel and a corrosion-inhibiting compound with at least one disulfide group. The corrosion-inhibiting compound is contained within the sol-gel. Coated and / or laminated structures may include the corrosion-inhibiting coating materials on a metal substrate, and may include a secondary layer (e.g., a paint, etc.) adhered to the coating material opposite the metal substrate. Methods of forming a corrosion-inhibiting sol-gel comprise mixing organo-metallic compounds and the corrosion-inhibiting compound into a sol solution and incubating (e.g., reacting) the sol solution to form the corrosion-inhibiting sol-gel with the corrosion-inhibiting compound contained within the sol-gel. Generally, corrosion-inhibiting coating materials are hexavalent chromium free.

Owner:THE BOEING CO

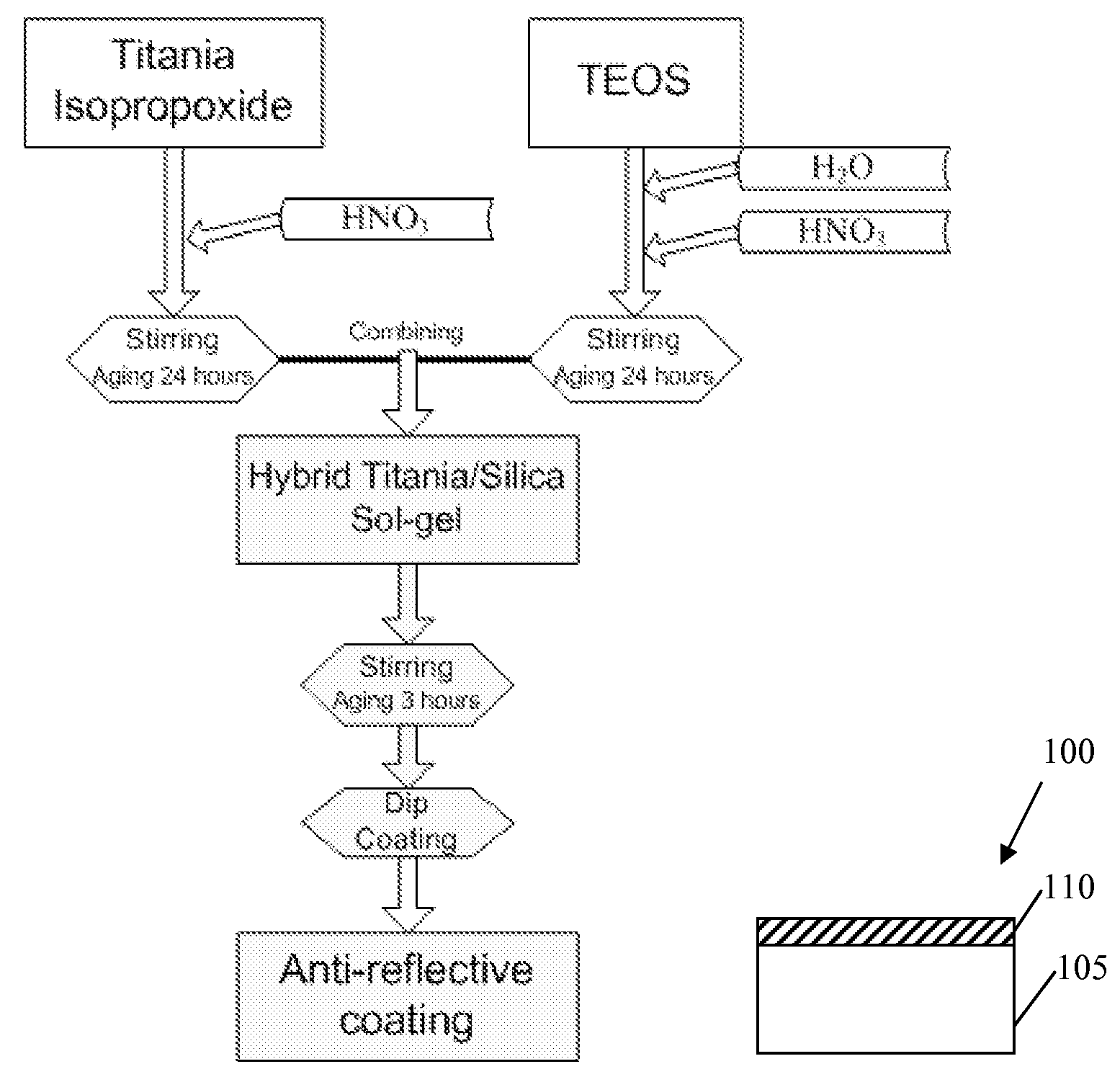

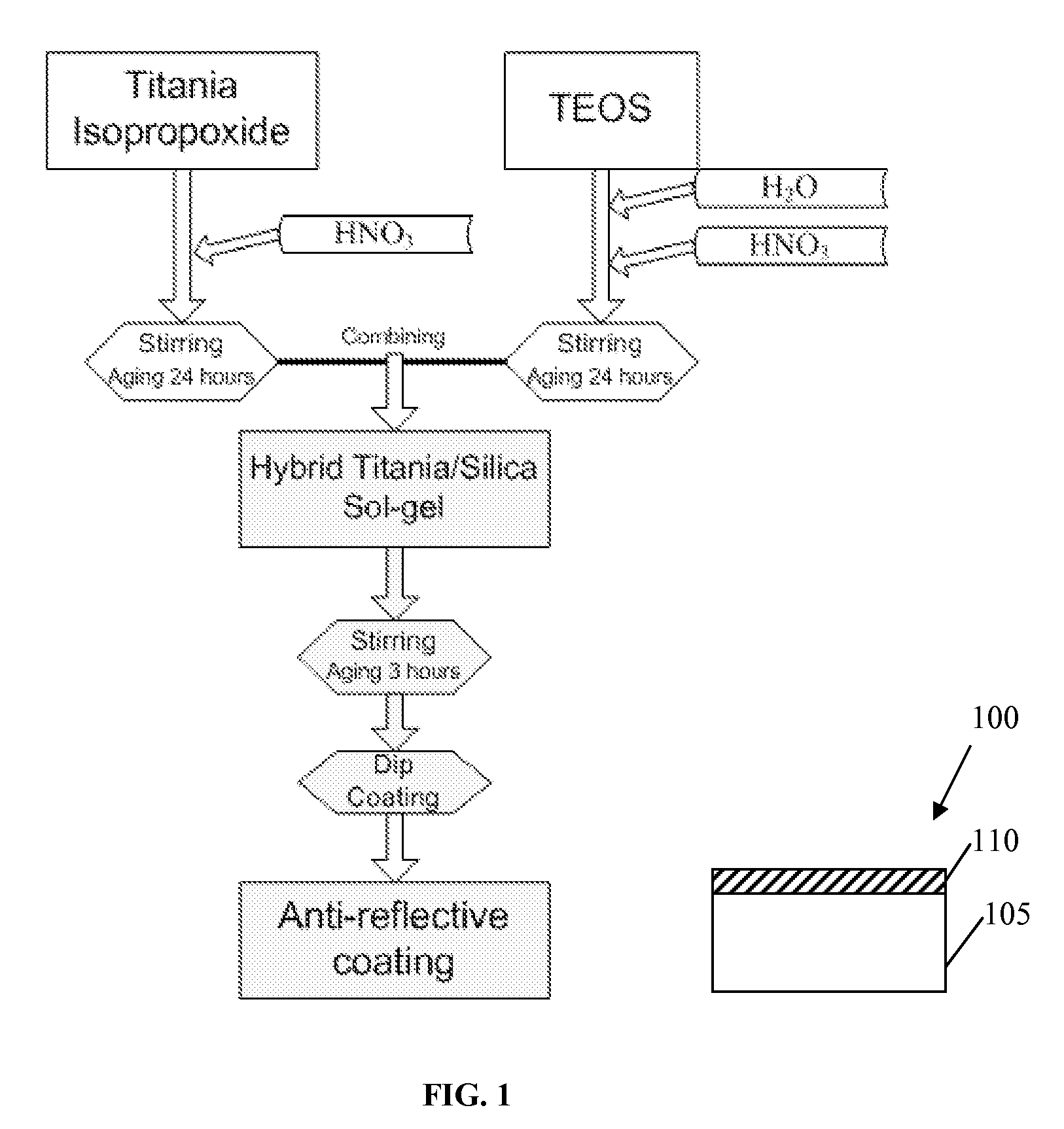

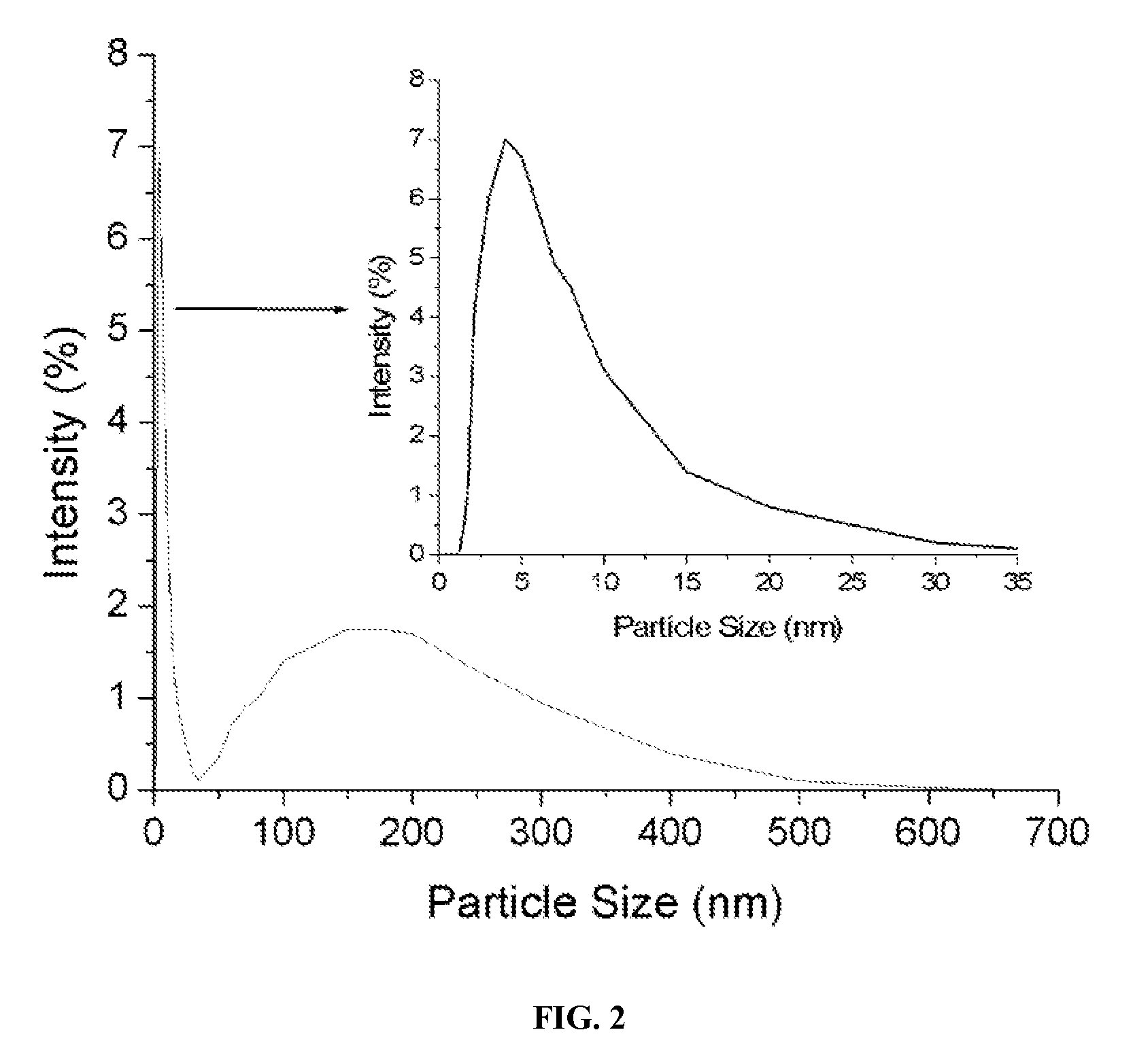

Sol-gel composite ar coating for ir applications

InactiveUS20070207325A1Pretreated surfacesGlass/slag layered productsRefractive indexSol gel coating

An infrared transmissive article includes an infrared transmissive substrate and a single layer anti-reflective (AR) composite broadband sol gel coating on a surface of the substrate. The AR coating includes a first chalcogenide including compound, and a second chalcogenide including compound intermixed with the first chalcogenide including compound. The percentages of the first chalcogenide and the second chalcogenide in the AR coating are selected to provide a refractive index of the AR coating that approximates the square root of a refractive index of the substrate.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com