Preparation method of laser modified titanium dioxide photocatalyst

A technology of titanium dioxide and photocatalyst, which is applied in the field of environmental pollution control and new energy research, can solve the problems of low photocatalytic quantum efficiency, aggravate environmental pollution, cumbersome and complicated process, etc., and achieve large specific surface area, good stability and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

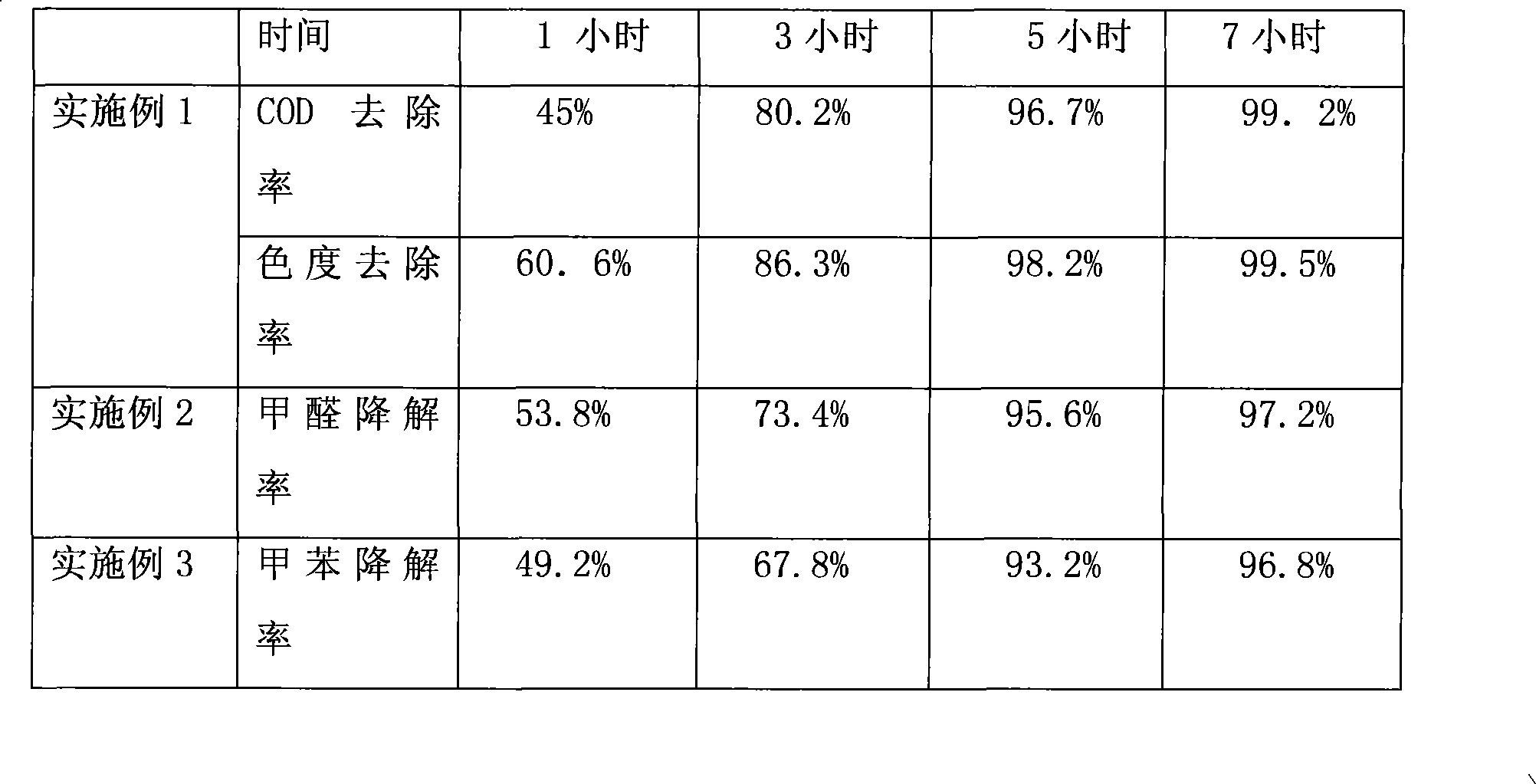

Embodiment 1

[0028] A preparation method of laser modified titanium dioxide photocatalyst, the specific steps are:

[0029] Step 1: Treat the surface of the porous polyester fiber web at 60°C for 20 minutes with a solution containing 0.3g / l acetic acid, 0.05g / l Ping Pingjia, 0.2g / l Tween 20, and 0.3g / l detergent, add 0.4 Neutralize with g / L baking soda, wash with water, apply 10g / l polyester fiber protective agent solution on the porous polyester fiber mesh with a coating thickness of 0.15mm, dry at 60°C for 10 minutes, and cool naturally. The solvent of the agent solution is ethanol and water with a mass ratio of 10:1;

[0030] The second step: Slowly add isobutanol to tetraisopropyl titanate dropwise, add inhibitor acetylacetone and catalyst 1.5g / l sulfuric acid, stir for 30min, add deionized water for hydrolysis reaction, add silver nitrate and three Ferric chloride is calcined at 300°C to obtain nano-titanium dioxide powder; wherein, the mass ratio of isobutanol, tetraisopropyl titana...

Embodiment 2

[0037] A preparation method of laser modified titanium dioxide photocatalyst, the specific steps are:

[0038]Step 1: Treat the surface of the porous polyester fiber web with a solution containing 0.5g / l acetic acid, 0.15g / l Ping Pingjia, 0.4g / l Tween 20, and 0.5g / l detergent at 70°C for 40 minutes, add 0.6 Neutralize with g / L baking soda, wash with water, apply 6g / l polyester fiber protective agent solution on the porous polyester fiber mesh with a coating thickness of 0.05mm, dry at 90°C for 20 minutes, and cool naturally. The solvent of the agent solution is ethanol and water with a mass ratio of 5:1;

[0039] The second step: Slowly add isobutanol to tetraisopropyl titanate dropwise, add inhibitor acetylacetone and catalyst 0.8g / l sulfuric acid, stir for 50min, add deionized water for hydrolysis reaction, add silver nitrate and three Ferric chloride is calcined at 400°C to obtain nano titanium dioxide powder; wherein, the mass ratio of isobutanol, tetraisopropyl titanate,...

Embodiment 3

[0046] A preparation method of laser modified titanium dioxide photocatalyst, the specific steps are:

[0047] Step 1: Treat the surface of the porous polyester fiber web with a solution containing 0.4g / l acetic acid, 0.1g / l Ping Pingjia, 0.3g / l Tween 20, and 0.4g / l detergent at 65°C for 30min, add 0.5 Neutralize with g / L baking soda, wash with water, apply 8g / l polyester fiber protective agent solution on the porous polyester fiber mesh with a coating thickness of 0.1mm, dry at 75°C for 15 minutes, and cool naturally. The solvent of the solvent solution is ethanol and water with a mass ratio of 7.5:1;

[0048] The second step: Slowly add isobutanol to tetraisopropyl titanate dropwise, add inhibitor acetylacetone and catalyst 1.15g / l sulfuric acid, stir for 40min, add deionized water for hydrolysis reaction, add silver nitrate and three Ferric chloride is calcined at 350°C to obtain nano-titanium dioxide powder; wherein, the mass ratio of isobutanol, tetraisopropyl titanate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com