Patents

Literature

84results about How to "Control aperture size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

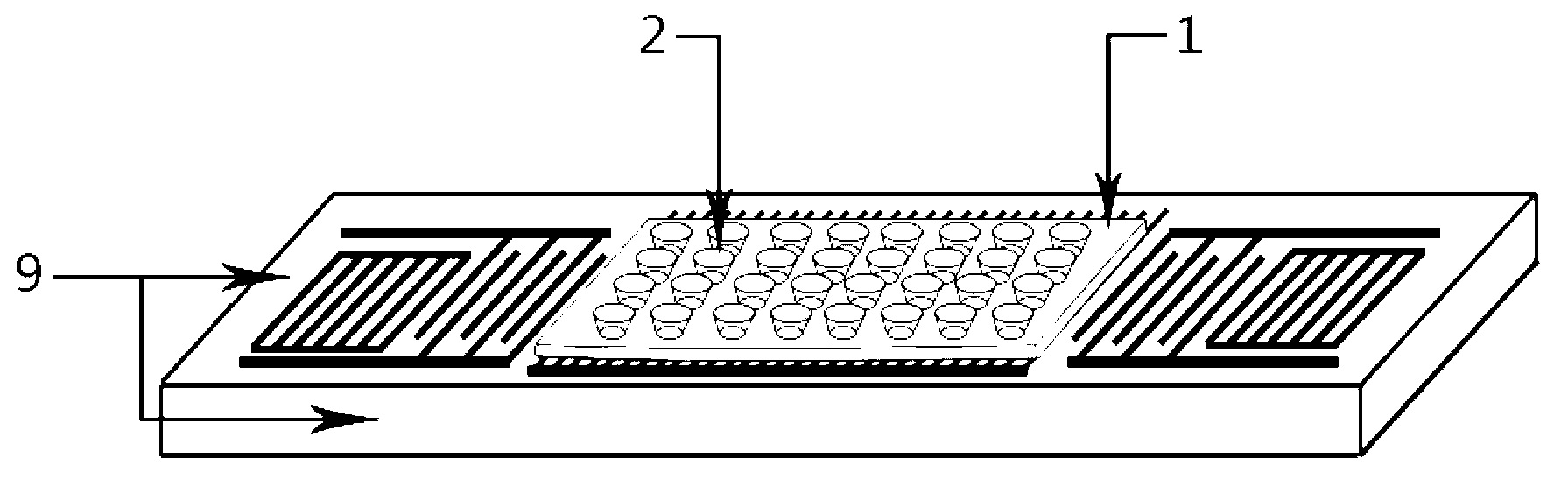

Release controlling fertilizer and its prepn

InactiveCN1417172AReduce lossesIncrease profitFertiliser formsFertilizer mixturesControl releaseOrganic solvent

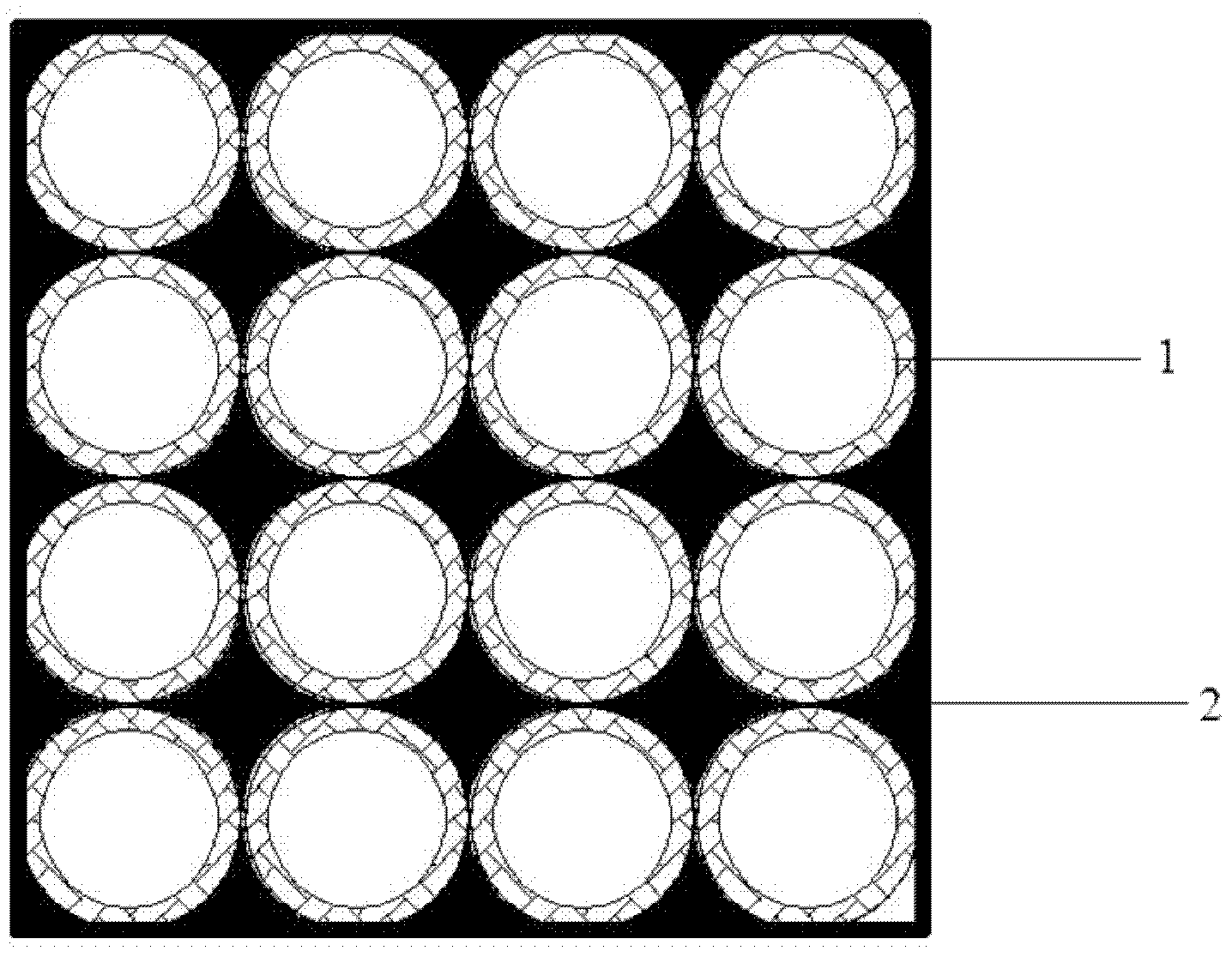

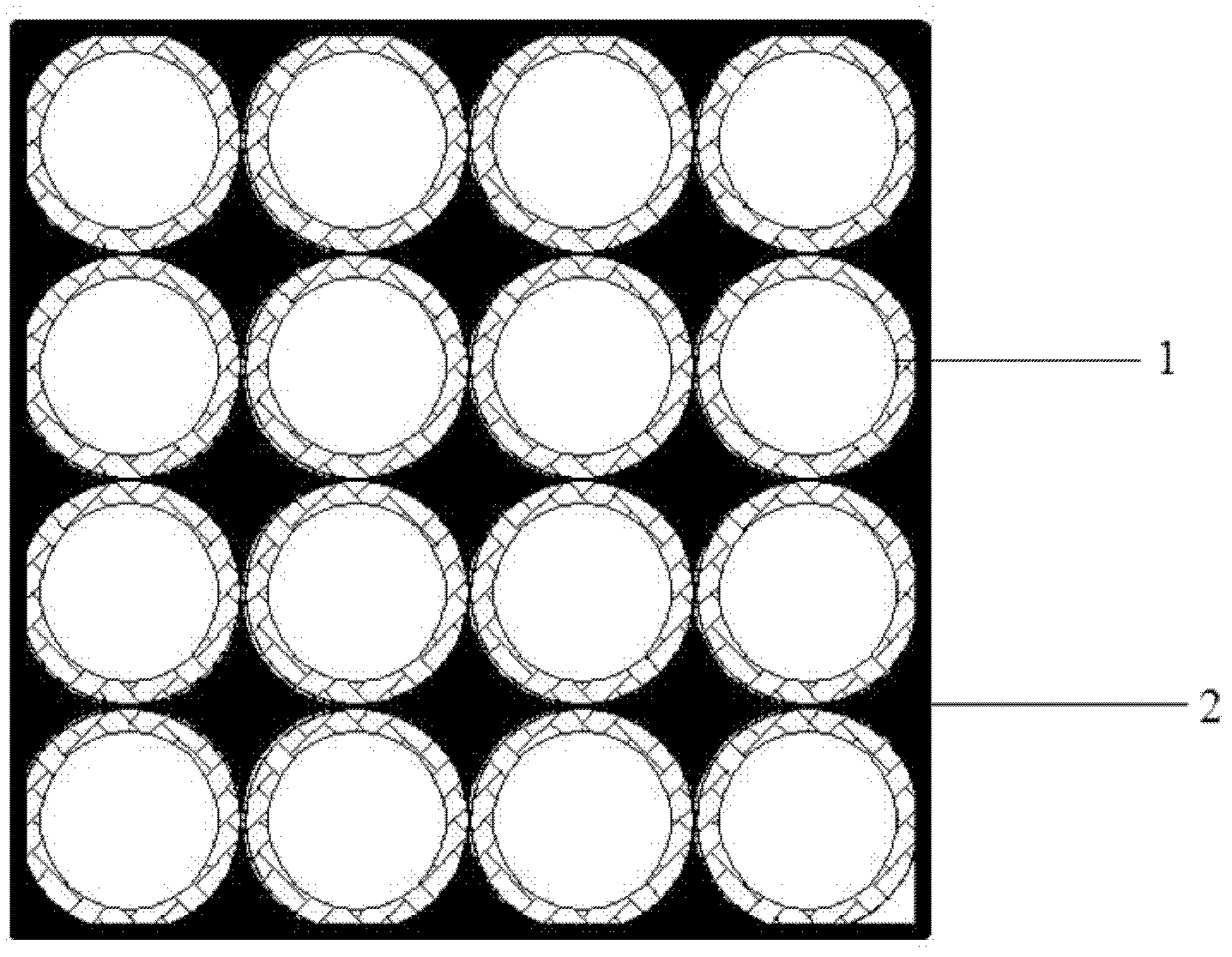

The present invention relates to a controlled release fertilizer, especially, a new controlled release fertilizer and its production process. The controlled release fertilizer comprising coating of environmentally friendly material and fertilizer core, which is nitrous fertilizer containing urease inhibitor and / or nitration inhibitor. The production process includes fertilizer core preparation via spray granulating in fluidized bed, or spray granulating in rotating drum, or disc mixing granulating; and physical coating via spraying in fluidized bed. The fertilizer has good controlled release effect and wide application range, and is environmentally friendly and low in cost.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

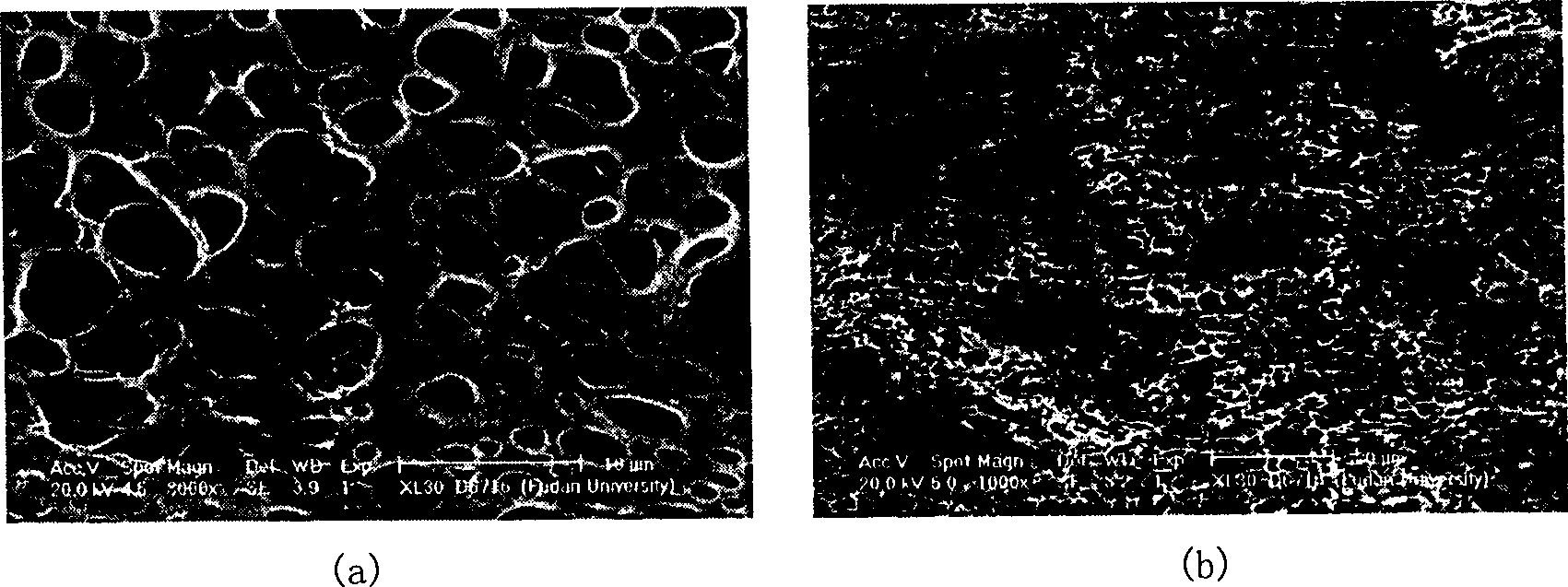

Preparation of porous sericin sponge material

Preparation of sponge-like porous materials of silk protein is carried out by converting its conformation with denaturant at low temperature to have frozen phase separation to obtain the product. Its parameters can be regulated by controlling concentration of the silk protein, amount of denaturant or its characteristics, freezing time or post-treatment in porosity, pore size, and mechanical performance. Neither cross-linker nor pore-generating agent nor surfactant nor organic solvent with strong toxicity is used. It is produced in a simple process, and has a uniform texture, high porosity up to 98%, good toughness and elasticity and reliability, water absorbing rate up to 5000%, elastic recovery rate 100% and press deformation >90%.

Owner:FUDAN UNIV

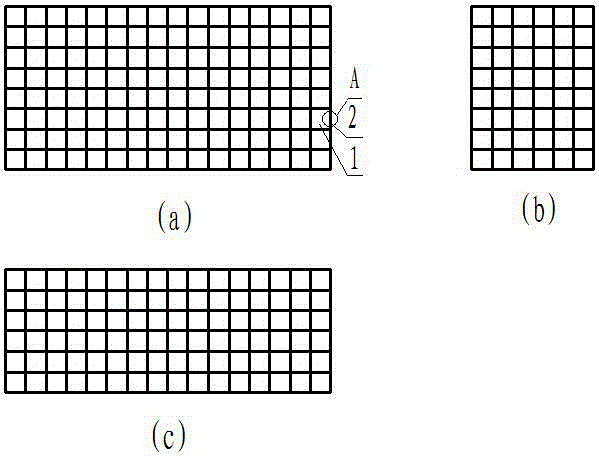

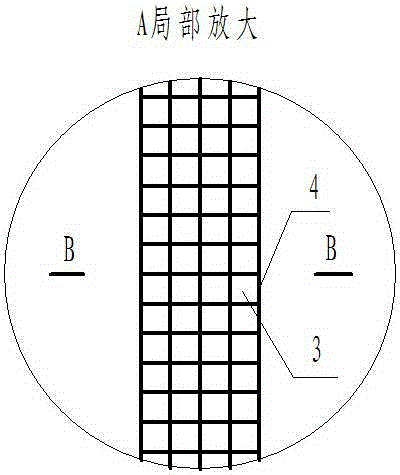

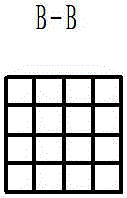

Method of semi-vitreous extrusion molding manufacturing for portiforium type millipore plastics extrusions

InactiveCN101229682ASolve technical problemsSimplify the molding processPlastic materialsMelt extrusion

The invention relates to a method for preparing opening micropore plastic material though slack-melting, extruding and molding. The method includes the processes: after reaching from a feeding device arranged on a double piston extruder to a heating material cylinder, preheating plastic powder with particle size of 40-1500 meshes is extruded by the piston driven by a hydraulic driver and compacted, transported and heated constantly; when the surface temperature of the plastic powder reaches the melt temperature of Tf plus or minus 20 DGE C, the power is extruded from a machine head and a die. Then, extruding matters are cooled and set by a cooling-traction device and the products are finished. By regulating the particle size of the powder, addictive and forming process conditions and so on, the invention can control opening rate, size and distribution of the aperture; the invention has simple process, short production cycle, low forming temperature and pressure as well as short forming time; besides, the invention can greatly reduce the production cost can not be degraded easily when the plastic is processed and can be widely applicable to molding of the opening micropore products of thermoplastic powders, thermosetting power and so on.

Owner:SICHUAN UNIV

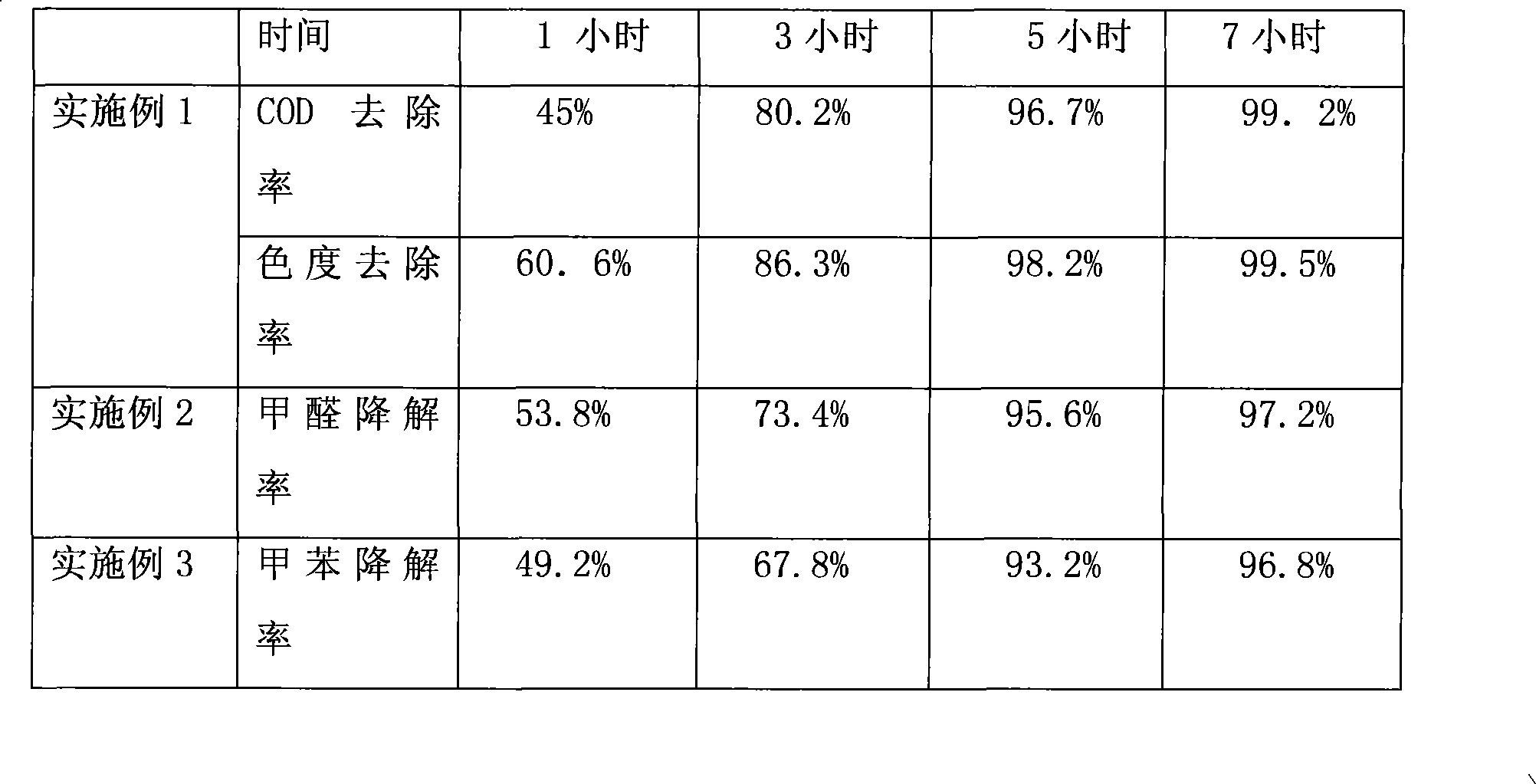

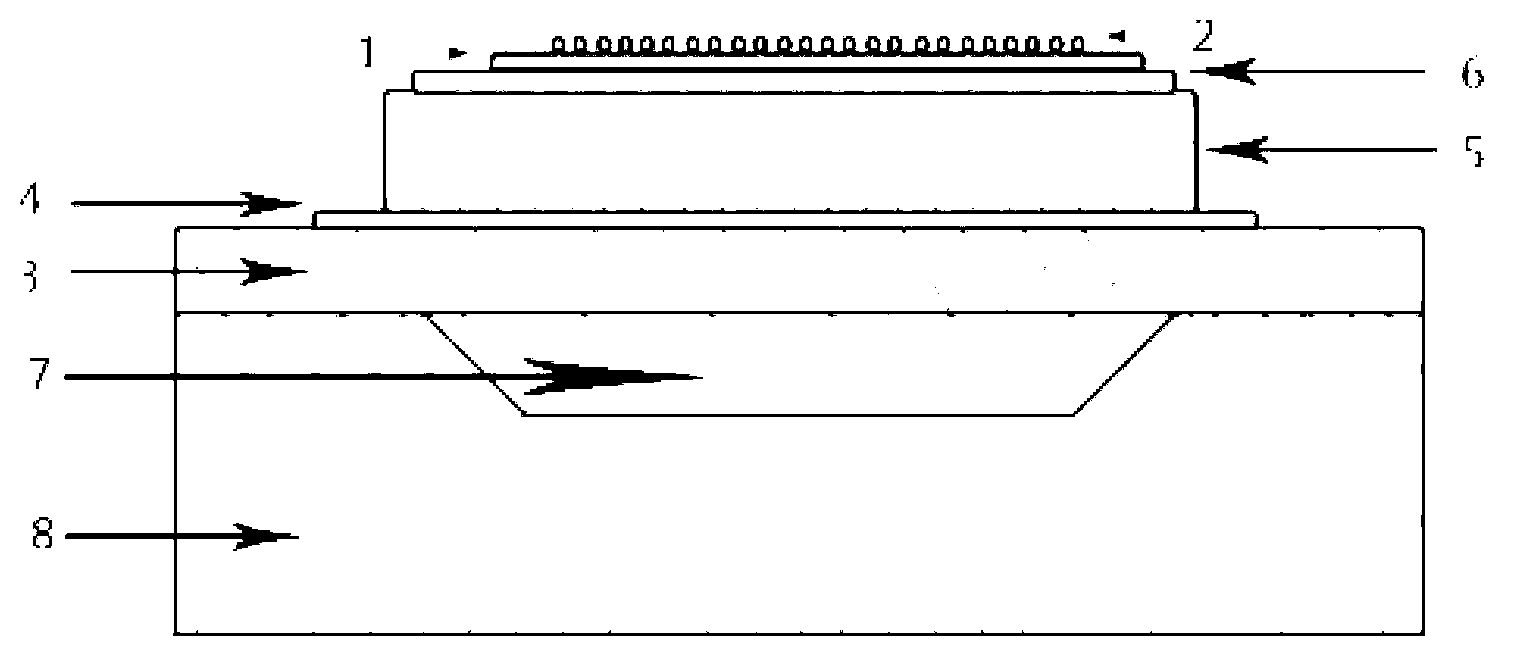

Method of loading titanium dioxide photo catalyst on metal surface

InactiveCN1410158AEasy to manufactureSolve the load problemCatalyst activation/preparationPhotocatalytic reactionPowder suspension

A process for carrying TiO2 photocatalyst on metal surface includes such steps as cleaning metal surface, anodizing in acidic medium, hydrolyzing, leaching and coating tetrabutyl titanate and TiO2 film under the weak alkaline condition by the sol-gel-powder suspension method, and igniting at proper temp. Its advantages are strong photocatalysis action for degradating organic pollutants, and good electric conductivity and machinability.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

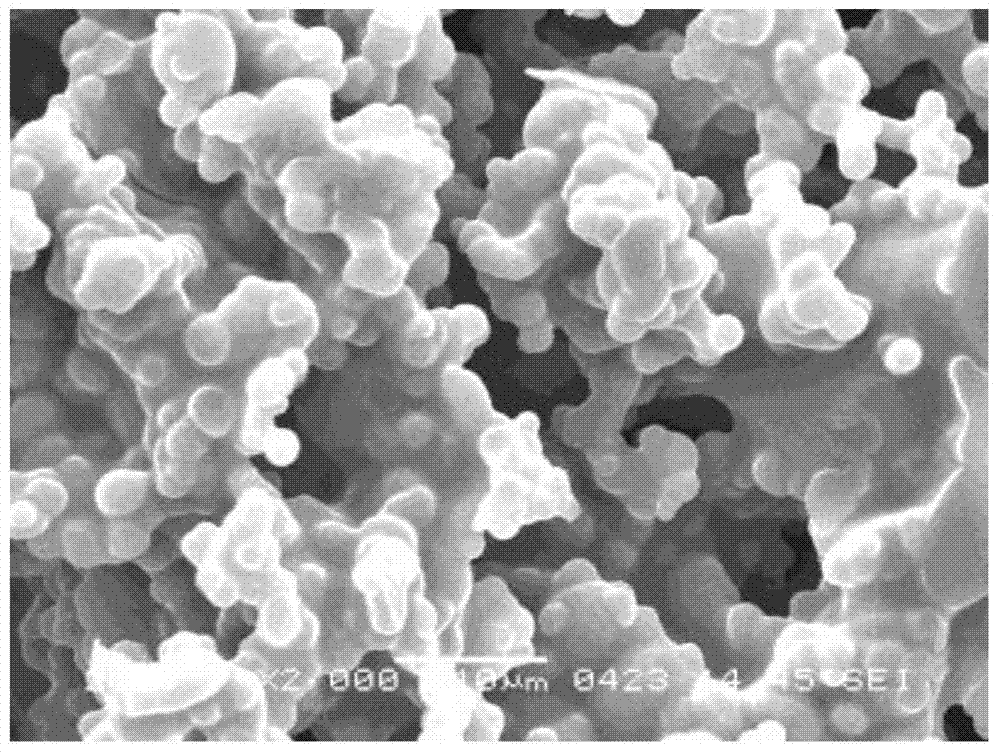

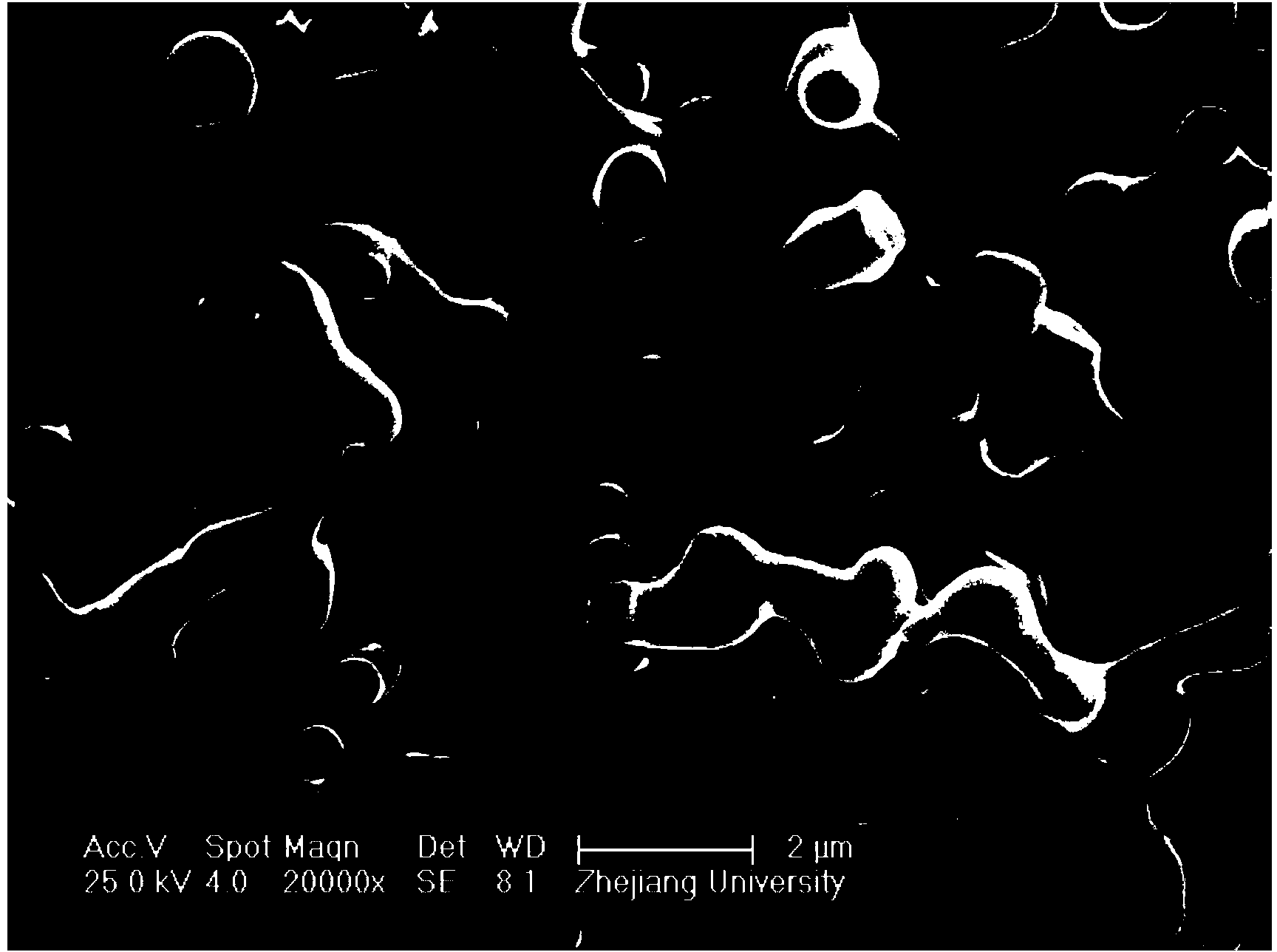

Preparation method of organic nano porous fiber film having controllable ultra-high specific area

InactiveCN101942704ASimple production methodLow costFilament/thread formingArtificial filaments from cellulose derivativesElectrospinningSolvent

The invention provides a preparation method of an organic nano porous fiber film having a controllable ultra-high specific area, which is characterized by comprising the following steps: 1. adding hydrophobic polymer to a closed vessel filled with a solvent at room temperature, placing onto a magnetic stirring apparatus, and stirring at a rotation speed of 10-200rpm to dissolve the polymer so as to obtain a macromolecular solution having uniform properties; and 2. putting the macromolecular solution prepared in Step 1 into a closed injector under the condition of room temperature and 25-75% in humidity, and spinning on electrostatic spinning equipment to obtain the organic nano porous fiber film having a controllable ultra-high specific area. By using the method, the organic nano porous fiber film having an ultra-high specific area can be obtained.

Owner:DONGHUA UNIV

Preparation of porous sericin sponge material

Preparation of sponge-like porous materials of silk protein is carried out by converting its conformation with denaturant at low temperature to have frozen phase separation to obtain the product. Its parameters can be regulated by controlling concentration of the silk protein, amount of denaturant or its characteristics, freezing time or post-treatment in porosity, pore size, and mechanical performance. Neither cross-linker nor pore-generating agent nor surfactant nor organic solvent with strong toxicity is used. It is produced in a simple process, and has a uniform texture, high porosity up to 98%, good toughness and elasticity and reliability, water absorbing rate up to 5000%, elastic recovery rate 100% and press deformation >90%.

Owner:FUDAN UNIV

Preparation method of laser modified titanium dioxide photocatalyst

InactiveCN101391210AEasy to manufactureSolve the load problemOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterFiber

The invention discloses a preparation method of a laser modified titanium dioxide photocatalyst, which belongs to the technique field of environmental pollution treatment and the research field of new energy sources, and the method comprises the following steps: 1) surface treatment of a high-strength and high-elasticity porous polyester fiber net; 2) loading the titanium dioxide photocatalyst; and 3) modification of a titanium dioxide film by laser. The method is to sequentially carry out the protective sorting to the polyester fiber net according to the cleaned fiber net surface, then coat a film on the fiber net surface by using a sol-gel-coating method and taking tetra-iso-propyl titanate and isobutyl alcohol as raw materials under the weak base condition, and modify the film in a textile laser processor. The invention has advantages of extensive sources of raw materials, simple process, low cost, good stability of the prepared titanium dioxide film, and high photo-catalytic activity and efficiency, and has the antifouling, self-cleaning, antibacterial and air-cleaning effects, and the method can be used for the degradation of environmental harmful substance, and can serve as air purification material and dyeing wastewater treatment photocatalysis material.

Owner:DONGHUA UNIV

Gas-sensitive film and sensor applied to FBAR (film bulk acoustic resonator) and SAW (surface acoustic wave) sensor

InactiveCN102937624AHigh sensitivityQuick responseAnalysing fluids using sonic/ultrasonic/infrasonic wavesMolecular sieveResonator

The invention relates to a gas-sensitive film and a sensor which are applied to an FBAR (film bulk acoustic resonator) and an SAW (surface acoustic wave) sensor. The gas-sensitive film adopts a calixarene / hydrogen-containing diamond structure. The invention has the beneficial effect that the gas-sensitive film based on the calixarene / hydrogen-containing diamond structure has the advantages of high sensitivity, high response speed, high repeatability, good hydrophobicity, insensitivity to temperature variation and no tendency of glass transition compared with the current common nano molecular sieve type gas-sensitive film and microporous polymer gas-sensitive film.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Light-weight closed-pore ceramic heat insulating board

InactiveCN102838377AHigh strengthLower sintering temperatureCeramic materials productionCeramicwarePorositySludge

The invention relates to a light-weight closed-pore ceramic heat insulating board, which is prepared by using the following main raw materials in percent by weight: 20-50 percent of phosphate tailing, 10-24 percent of sludge, 20-30 percent of feldspar, 4-15 percent of shale, 3-15 percent of kaolin, 10-20 percent of yellow sand and 1-2.5 percent of foaming agent, wherein the foaming agent is mixture of silicon carbide, calcium carbonate and ferric oxide, the grain size of the mixture is less than or equal to 0.045mm, and the weight percents of silicon carbide, calcium carbonate and ferric oxide are respectively 40-60 percent, 25-45 percent and 15-35 percent. The light-weight closed-pore ceramic heat insulating board has great importance on efficiently utilizing the phosphate tailing and reducing environmental pollution caused by industrial solid wastes so as to improve the natural environment, use cheap raw materials and decrease the production cost; and at the same time, the produced light-weight closed-pore ceramic heat insulating board has the advantages of higher porosity, higher strength and lower sintering temperature.

Owner:WUHAN UNIV OF TECH

Porous cordierite block preparation method

The present invention discloses a porous cordierite block preparation method, which sequentially comprises: 1) at a room temperature, dissolving magnesium chloride hexahydrate, aluminum chloride hexahydrate and polyacrylamide in a solvent, adding tetramethyl orthosilicate in a dropwise manner, and continuously carrying out a stirring reaction for 50-70 min at a temperature of 50-70 DEG C; 2) naturally cooling the transparent clear solution obtained in the step 1) to a room temperature, adding propylene oxide, and uniformly stirring; 3) placing the homogeneous solution obtained in the step 2) into a container, sealing, and carrying out gelation for 3-5 min at a temperature of 35-45 DEG C; 4) placing the wet gel obtained in the step 3) in an environment with a temperature of 35-45 DEG C, and aging for 60-80 h; and 5) placing the aged gel obtained in the step 4) in an environment with a temperature of 50-70 DEG C, carrying out normal pressure drying for 72-96 h, and carrying out a heat treatment for 4-6 h at a temperature of 900-1300 DEG C. The porous cordierite block prepared by using the preparation method has characteristics of porous structure, high porosity and the like.

Owner:ZHEJIANG UNIV

Porous material and preparation method thereof

ActiveCN106466494AMeet a variety of functional needsMeet functional requirementsTransportation and packagingMetal-working apparatusMaterial Pore SizeInsertion stent

The invention discloses a porous material and a preparation method thereof. The material comprises a material body, wherein the material body comprises pore cavities graded according to the material pore size and cavity walls enclosing to form the pore cavities, the cavity wall encloses to form the upper-level cavity in a three-dimensional space manner while is provided with the lower-level pore cavity, and various levels of the pore cavities are respectively communicated to each other and penetrate through each other. The preparation method comprises: mixing raw material powder and a pore forming agent for preparing the smallest-level pore cavity of a porous material to prepare a slurry, uniformly filling the slurry into a polymer material stent to form a billet, drying, breaking to obtain mixed particles, uniformly mixing the mixed particles and a pore forming agent for preparing the upper-level pore cavity more than the smallest-level pore cavity of the porous material to form a compact billet, carrying out vacuum sintering, and carrying out routine subsequent treatment according to the raw material process of the porous material. According to the present invention, the porous material has characteristics of good penetrating property and uniform performance, each level of the porous material has the own physical and chemical properties, a variety of function requirements can be met, the obtained porous material can be used as the biological material, the separation material and other materials, and the preparation method is simple and easy to achieve.

Owner:CHONGQING RUNZE PHARM CO LTD

Amorphous alloy cellular material and preparation method thereof

The invention relates to an amorphous alloy cellular material and a preparation method of the amorphous alloy cellular material, belonging to the field of material preparation. The amorphous alloy cellular material is compounded by a hollow pipe and amorphous alloy, wherein the hollow pipe is taken as a straight through hole, the amorphous alloy is taken as a base body, the melting point of the hollow pipe is higher than that the amorphous alloy, and the amorphous alloy cellular material has higher strength. The amorphous alloy cellular material is prepared as follows: after two ends of the hollow pipe are sealed, the hollow pipe is arranged into a prefabricated body to be placed into a metal mold, an alloy or the amorphous alloy is completely melted through heating to obtain a melt under the protection of inert atmosphere, the melt is pressurized to be impregnated into a gap between a prefabricated body hollow pipe in the metal mold and the hollow pipe, and the melt is enabled to be rapidly cooled and solidified to form the amorphous alloy base body. In the invention, the porosity, the hole diameter and the overall dimension of the amorphous alloy cellular material can be conveniently controlled.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

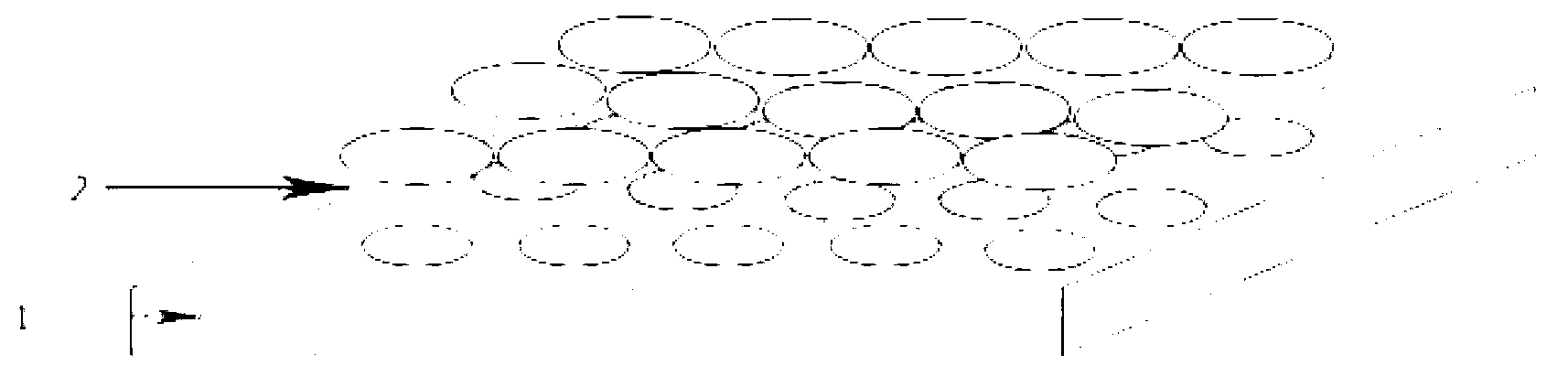

Preparation method of multifunctional nano-crystalline cellulose composite separation filter membrane and application thereof

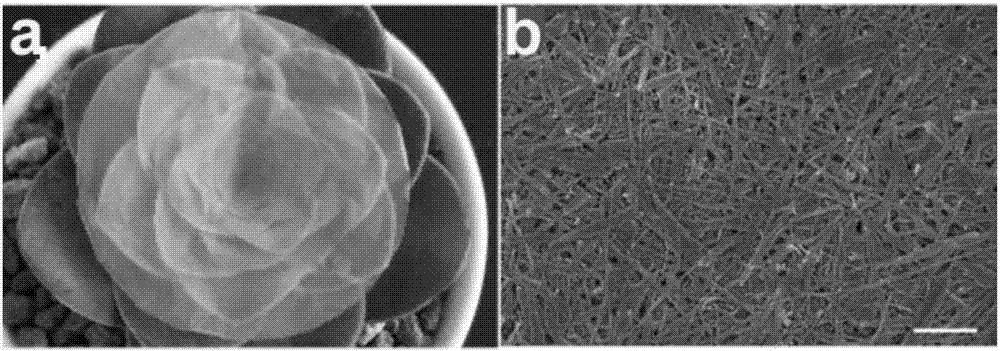

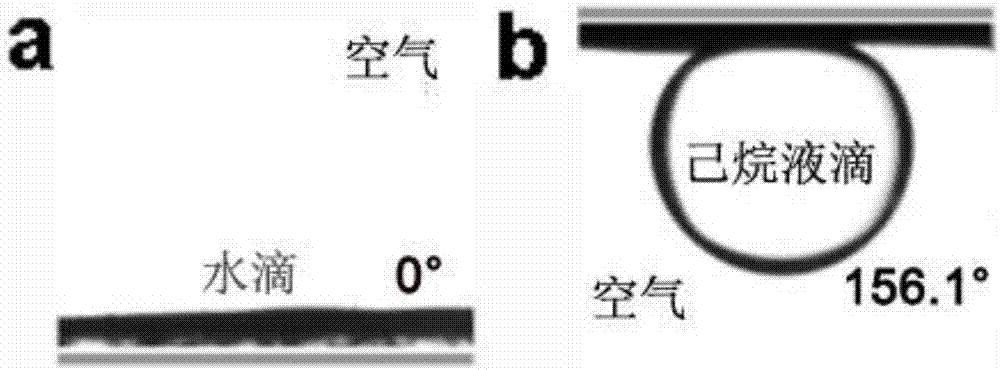

InactiveCN107983179AFlexible control of aperture sizeControl aperture sizeSemi-permeable membranesWater contaminantsFiltrationOil water emulsion

The invention discloses a preparation method of a multifunctional nano-crystalline cellulose composite separation filter membrane and application thereof. The method comprises the following steps: adding attapulgite into nano-crystalline cellulose suspension to be mixed, and preparing nano cellulose crystal / attapulgite suspension. An ordinary filter membrane serves as a substrate, and the suspension is subjected to vacuum filtration to form the filter membrane. According to the filter membrane, the pore size, thickness and water flux of the membrane can be controlled by regulating the usage amount of cellulose in unit area. According to the wettability characteristic that the filter membrane is super-hydrophilic and is super-oleophobic in oil, application of the filter membrane in aspectssuch as oil-water emulsion, heavy metals and dye separation is realized. The filter membrane disclosed by the invention is simple, feasible, low in cost and non-toxic.

Owner:WUHAN UNIV

Production method of heat pipe with porous aluminum core

The invention belongs to the technology field of heat pipes, and particularly relates to a preparation method of a heat pipe with a porous aluminum core. The manufacturing method of the heat pipe with the porous aluminum core is characterized in that the method includes the following steps: (1) material selection: selecting 58-62 wt% of NaCl particles with the diameter being 5-40 Mum and 38-42 wt% of Al powder with the diameter being 5-10 Mum in reserve; (2) mixing the NaCl particles with the Al powder; placing on an aluminum substrate; and then sintering by employing the pulse current technique with the sintering technological parameters of the pre-pressure being 13-17 MPa, the sintering temperature being 570-590 DEG C and the sintering time being 3-5 minutes; and boiling sintering blocks in the water for 35-50 minutes to obtain composite plates with porous aluminum core; (3) welding the obtained composite plates into flat heat pipes, vacuum-pumping, inletting the working medium, and sealing to obtain the heat pipe. The preparation method is characterized by high porosity, controllable pore diameter and tight connection.

Owner:WUHAN UNIV OF TECH

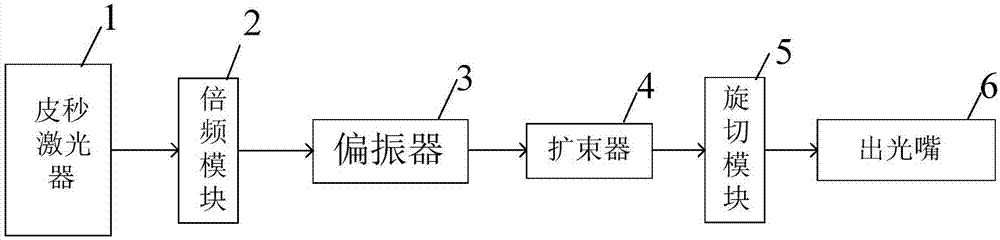

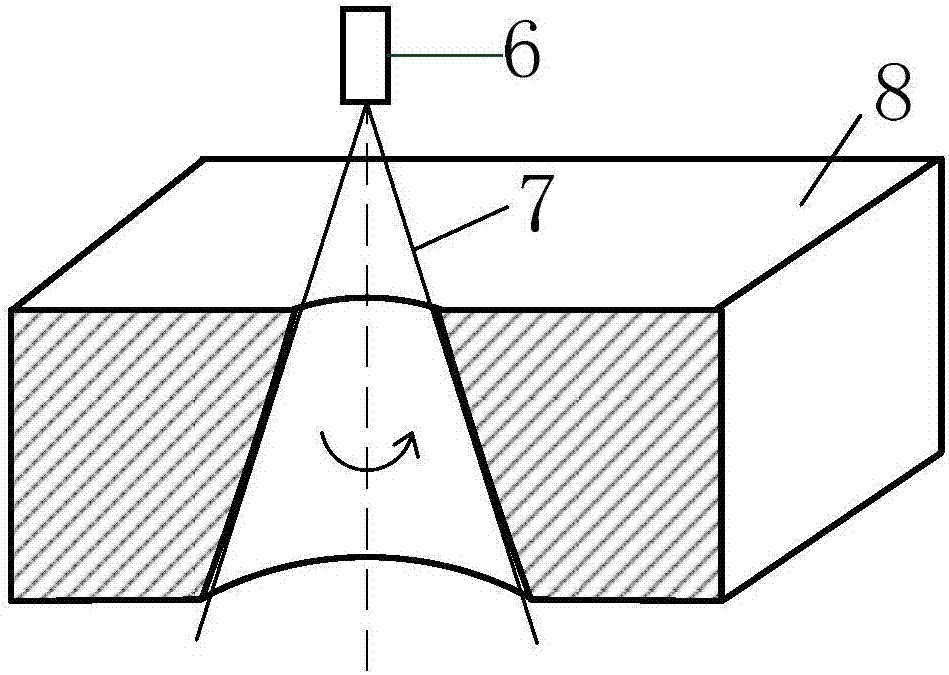

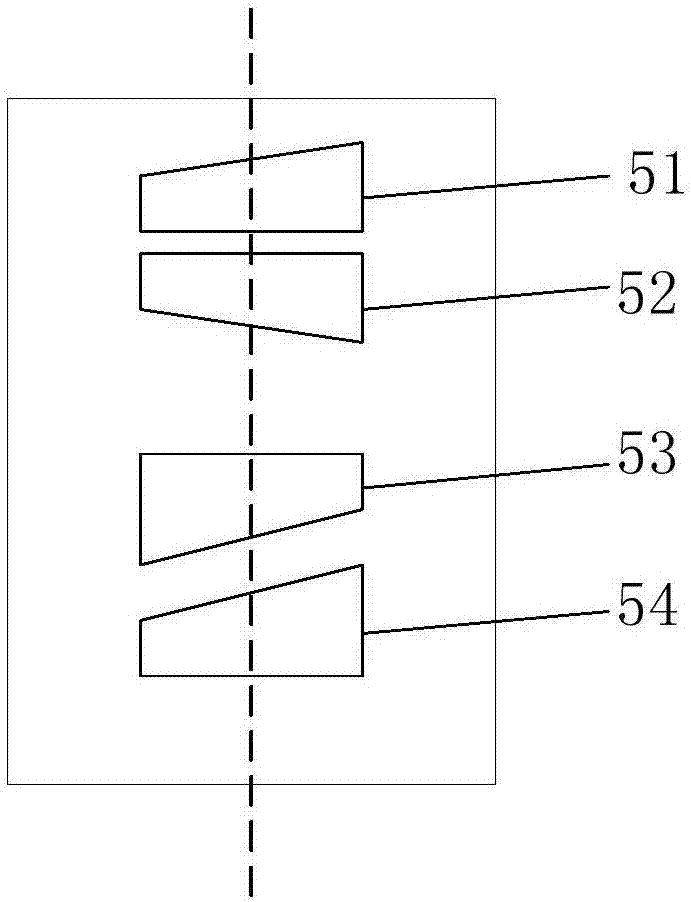

Device and method for ultrafast laser processing of micro inverted cone hole

InactiveCN107262943AReduce energy lossAvoid damageLaser beam welding apparatusPicosecond laserOptical processing

The invention discloses a device and method for ultrafast laser machining of micro-inverted taper holes. The laser transmission module includes a picosecond laser, a frequency doubling module, a polarizer and a beam expander arranged in sequence along the transmission direction of the optical path. The optical processing module includes a The rotary cutting module and the optical nozzle are arranged in sequence in the transmission direction of the optical path, and the output end of the beam expander is connected to the rotary cutting module; the picosecond laser outputs laser light, which is converted by the frequency doubling module to output base frequency light, double frequency light or triple frequency light Light, the laser beam output by the frequency doubling module passes through the polarizer to convert the output wave form linearly polarized laser beam into a wave form circularly or elliptically distributed circularly polarized laser beam, and then the beam is transmitted into the beam expander for amplification , to obtain a wider parallel beam, the enlarged parallel beam is transmitted to the rotary cutting module, the rotary cutting module adjusts the deflection angle of the beam, controls the aperture size and taper of the processing hole, and finally outputs it through the light nozzle. It is easy to realize the processing of fine reverse taper hole.

Owner:WENZHOU UNIVERSITY

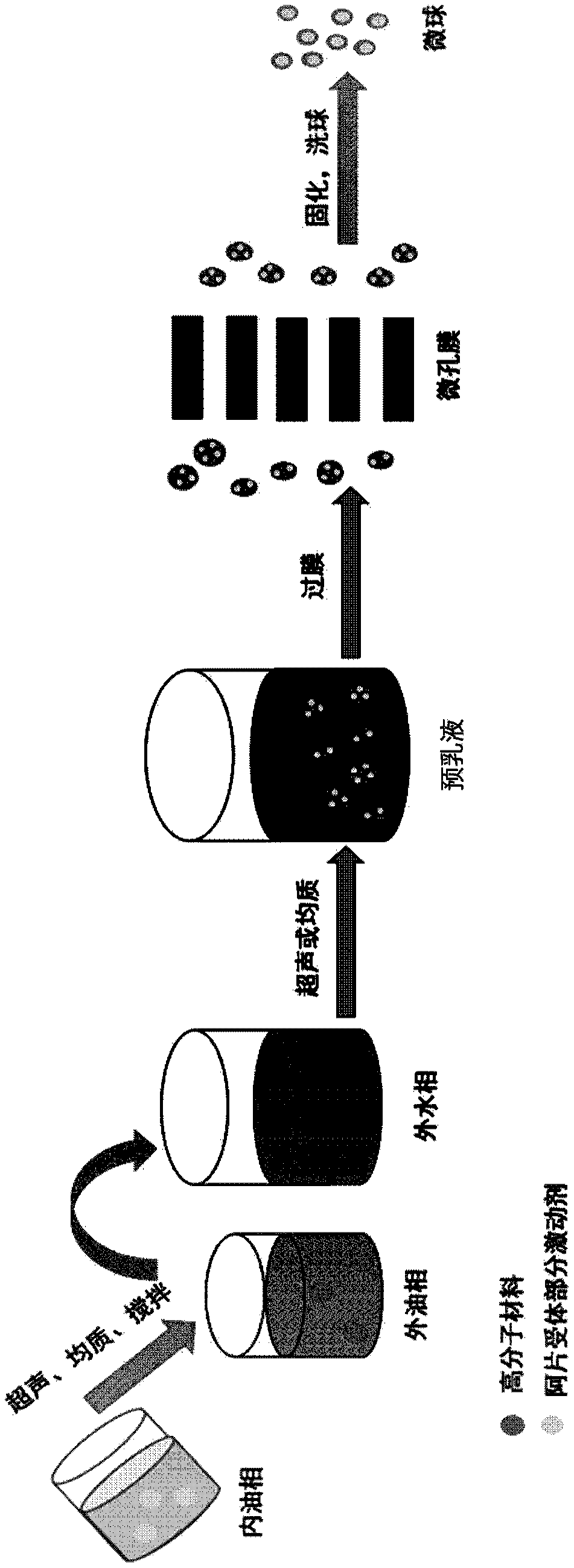

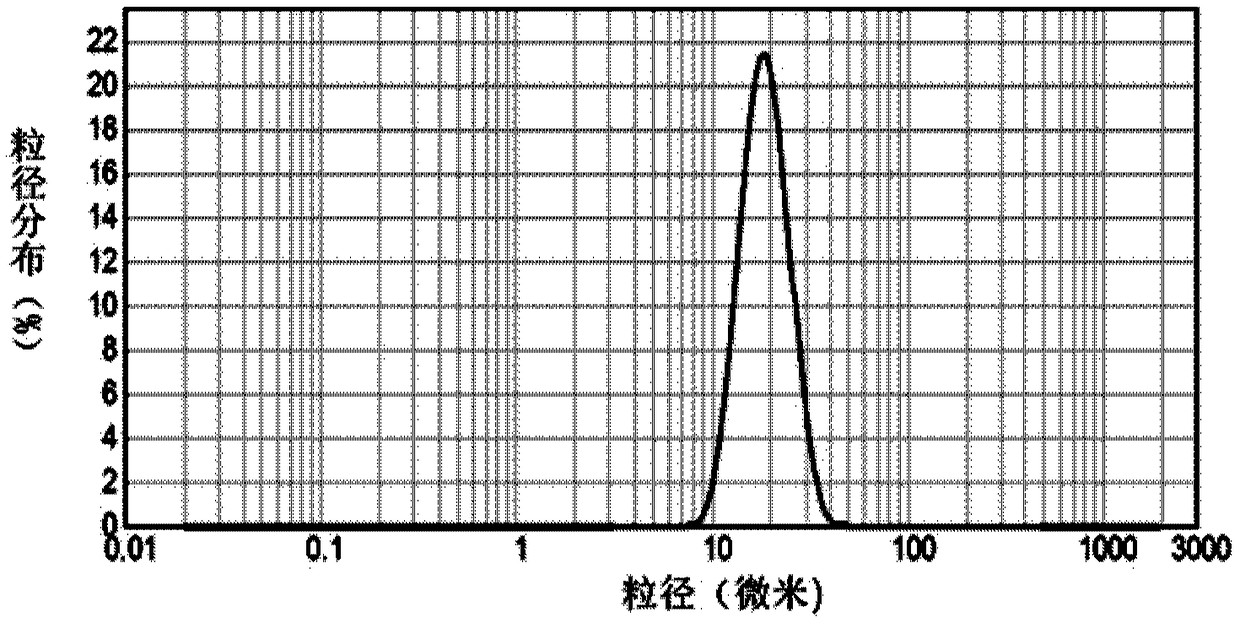

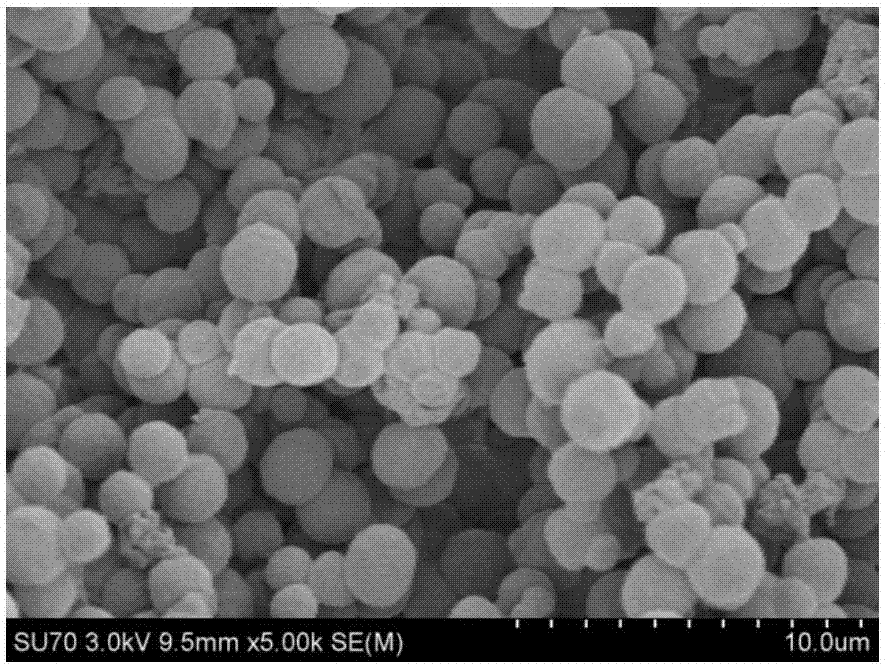

Opioid receptor partial agonist supported sustained release microsphere as well as preparation method and application thereof

ActiveCN108704137AHigh drug loading rateGuaranteed repeatabilityOrganic active ingredientsNervous disorderDrugPartial agonist

The invention discloses an opioid receptor partial agonist supported sustained release microsphere as well as a preparation method and application thereof. The opioid receptor partial agonist supported sustained release microsphere has a drug embedding rate of higher than 80%, the initial burst release of the drug is lower than 20% within half an hour, and the drug can realize sustained release ata constant speed for 1-15 days. The preparation method disclosed by the invention is simple in process, the prepared product is uniform in particle size, the repeatability of each batch of products is excellent, industrial production is easily realized, the repeatability of the product is ensured, the curative effect of the drug is stable, the prepared microsphere has excellent re-suspending property in water, and industrial production cost is saved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for enlarging pore diameter of yeast cell microcapsule wall

InactiveCN103060307AAvoid dependenceReduce manufacturing costOn/in biological cellPore diameterMacromolecular Substances

The invention relates to a method for enlarging the pore diameter of a yeast cell microcapsule wall. A right amount of pore-enlarging agent is added to process the yeast cell wall to cause macromolecular substance to enter into the cell walls. Raw materials and equipment used in the method are familiar common raw materials and equipment, so that the dependence on expensive raw materials and instruments is avoided in the industrial production process, and the production cost is greatly reduced. Mannanase is adopted to degrade part of yeast cell wall, the pore diameter of a yeast cell can be effectively enlarged in the interval ultrasonic processing, the yeast cell wall on the same part cannot be exceedingly continuously hydrolyzed, and the pore diameter of the whole yeast cell wall is effectively controlled. The method has simple operation, the in vitro activity of macromolecule proteins is greatly prolonged, the stability of the macromolecule proteins is ensured, the production cost is reduced, and the production process is simplified.

Owner:HUNAN AGRICULTURAL UNIV

Preparation method, regeneration method and application of chelating microfiltration membrane

ActiveCN106621842AGood removal effectEfficient removalMembranesWater contaminantsGlycidyl methacrylateCarbon chain

The invention belongs to the field of heavy metal waste water treatment, and particularly relates to a preparation method, a regeneration method and application of a chelating microfiltration membrane. The invention is characterized in that a PVDF (polyvinylidene fluoride) casting membrane solution is prepared into a flat sheet membrane by a TIPS (thermally induced phase) method; then, the PVDF membrane is defluorinated by a basic potassium permanganate solution; then, GMA (glycidyl methacrylate) is used as a grafted monomer lengthened carbon chain; finally, melamine and the GMA are used for performing nucleophilic substitution reaction to prepare high-flux high-capacity heavy metal capturing and enriching chelating microfiltration membrane. The preparation process of the chelating microfiltration membrane is simple; the cost is low; the hydrophilia is good; the pollution-resistant performance is good; the excellent capturing performance of high speed, great capacity and the like are realized on heavy metal ions; the efficient purification treatment of heavy metal waste water can be realized; the methods provided by the invention are applicable to heavy metal involving industry waste water, are also applicable to integral wastewater biochemical tail water in industrial parks, polluted surface water, underground water and the like, and have a wide application range.

Owner:NANJING UNIV

Preparation method for copper aluminate spinel porous block

The invention discloses a preparation method for a copper aluminate spinel porous block. The preparation method comprises the following steps: first, dissolving a phase separation inducing agent in a solvent; then, adding copper chloride dihydrate, aluminium chloride hexahydrate and a complexing agent, and stirring until the copper chloride dihydrate, the aluminium chloride hexahydrate and the complexing agent are completely dissolved; next, adding a gelatinization accelerator dropwise and stirring uniformly to obtain a homogeneous solution; later on, sealing the homogeneous solution in a container, and gelatinizing for 1 to 5 minutes at 60 to 80 DEG C to obtain wet gel; finally, aging the wet gel for 6 to 12 hours at 60 to 80 DEG C, drying the aged wet, and performing heat treatment for 1 to 3 hours at 500 to 900 DEG C to obtain the copper aluminate spinel porous block.

Owner:ZHEJIANG UNIV

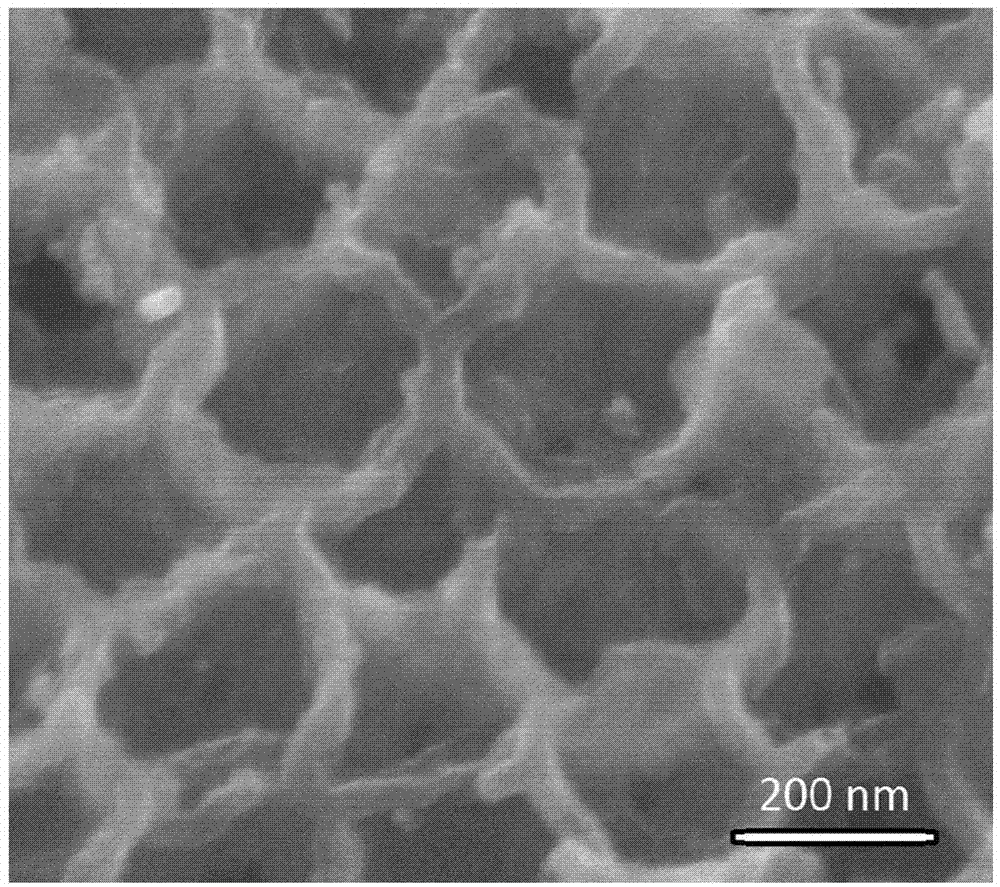

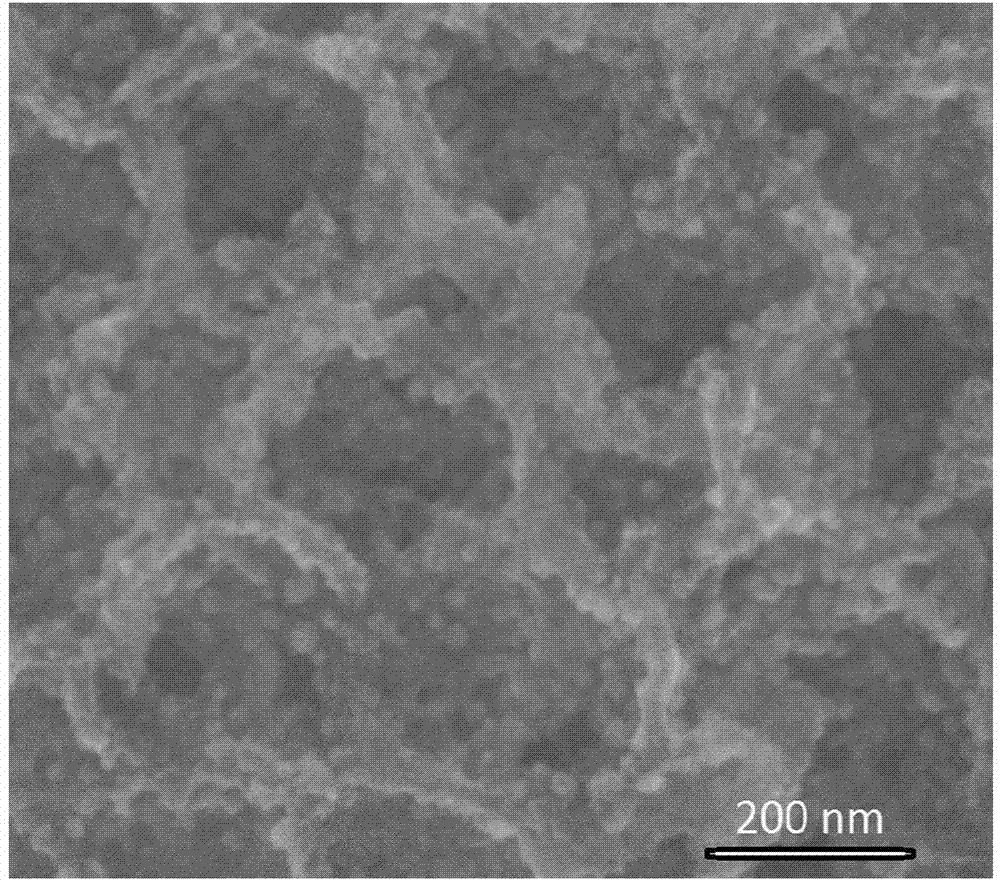

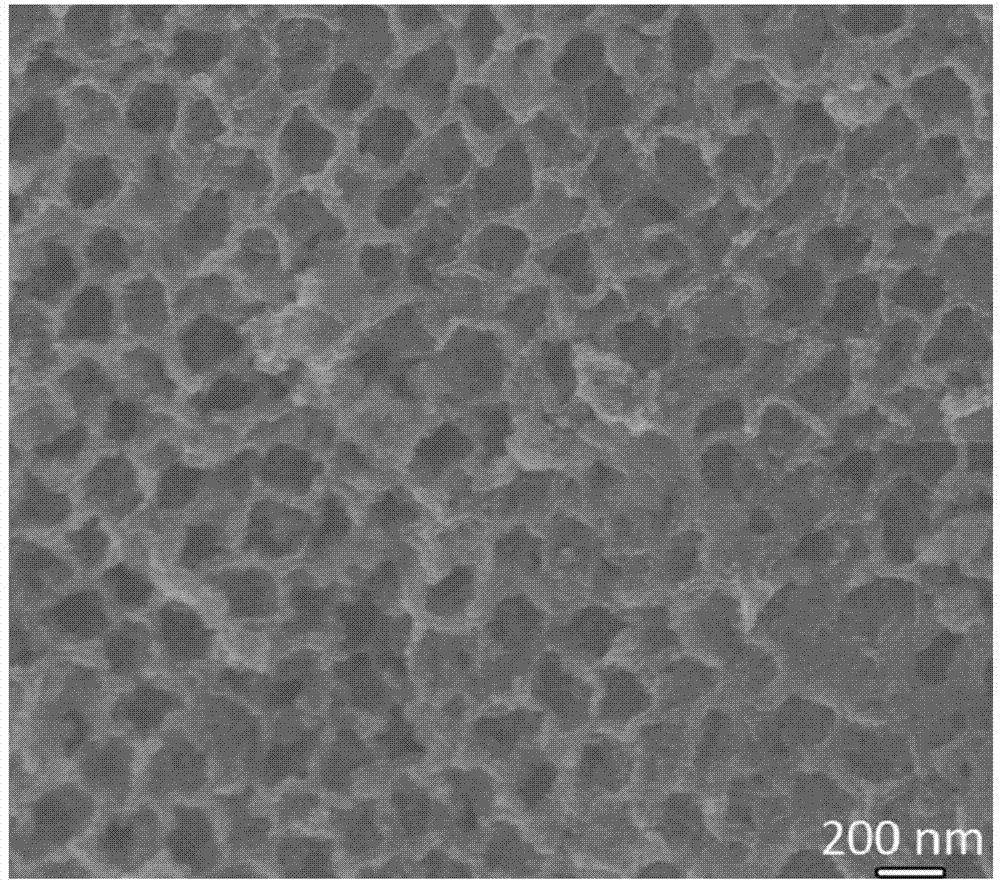

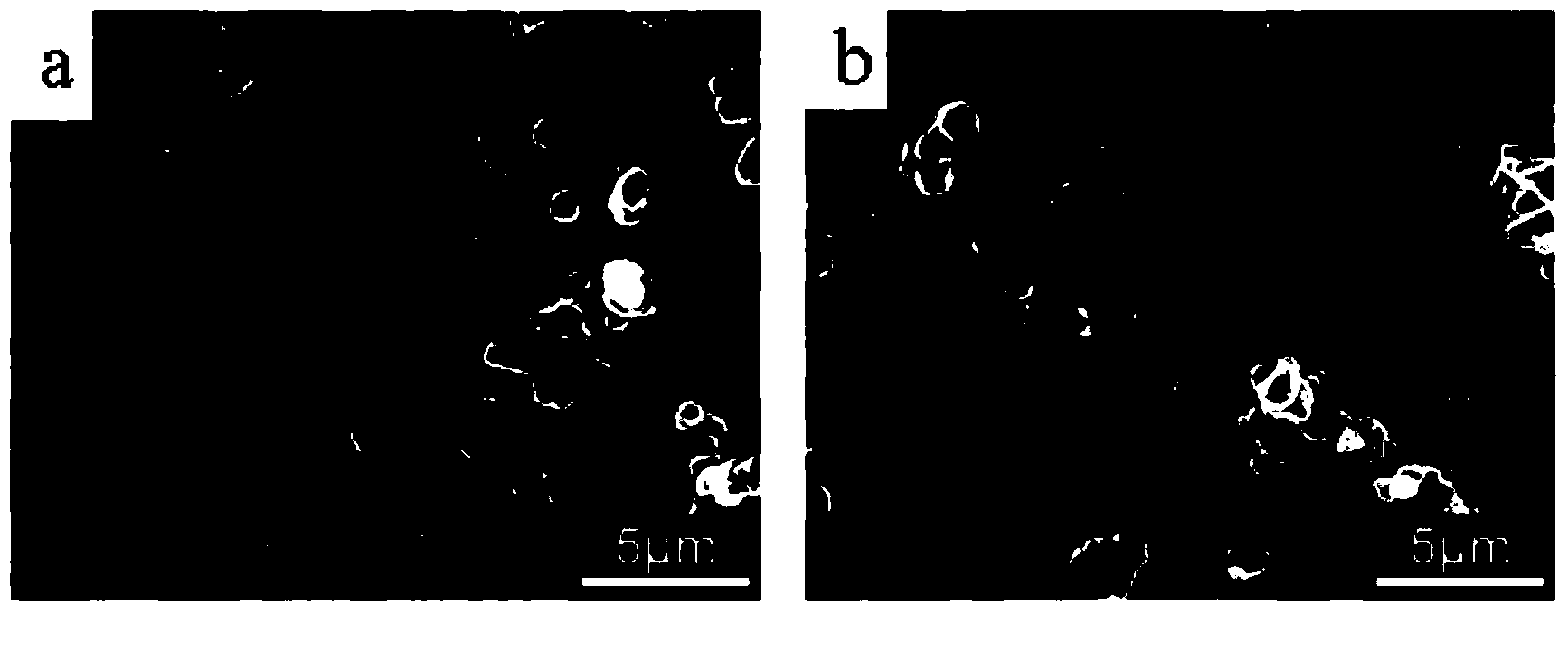

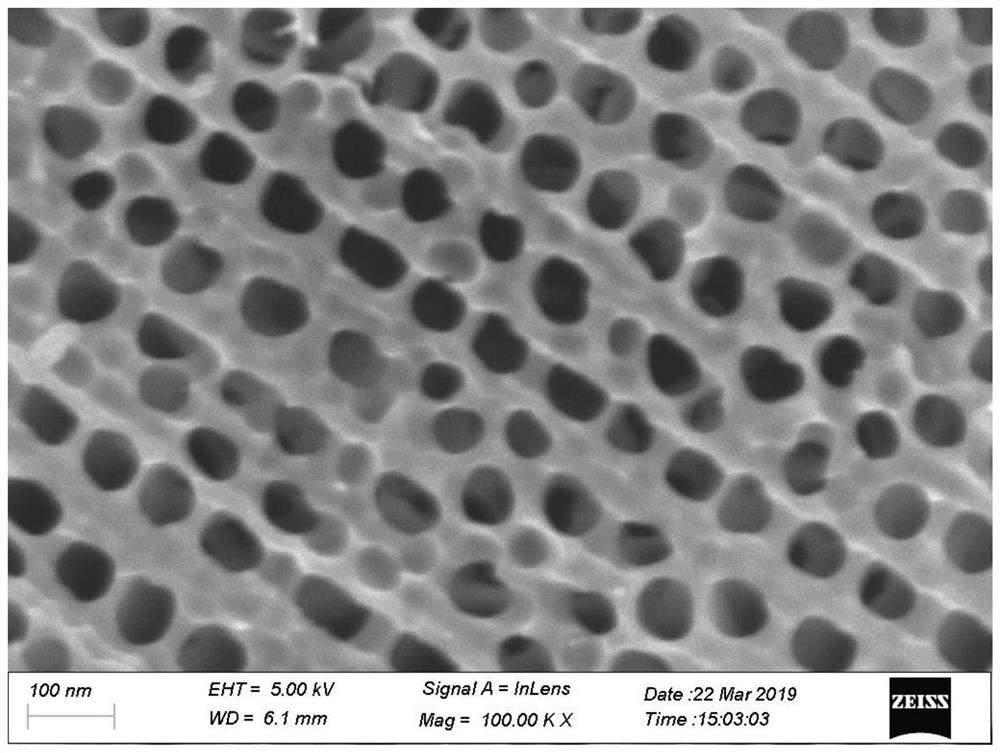

Three-dimensional macro-porous structured molybdenum dioxide supported palladium particle material and synthetic method thereof

InactiveCN104841423AEffective control of aperture sizeControl aperture sizeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsMicrosphereMass ratio

The invention discloses a three-dimensional macro-porous structured molybdenum dioxide supported palladium particle material and a synthetic method thereof. A mass ratio of molybdenum dioxide to palladium is 20:(0.06-0.6), the aperture of molybdenum dioxide is 200-400nm, the particle size of palladium particles is 5-10nm, an ordered polymethyl methacrylate microsphere colloid crystal template is used to prepare a three-dimensional macro-porous molybdenum dioxide structure, and the palladium particles are supported on the three-dimensional macro-porous molybdenum dioxide structure. The synthetic method has the advantages of low enforcement cost, simple operation, low pollution, high efficiency and economy, and the material disclosed in the invention has a stable structure and has an electrocatalysis performance.

Owner:TIANJIN UNIV

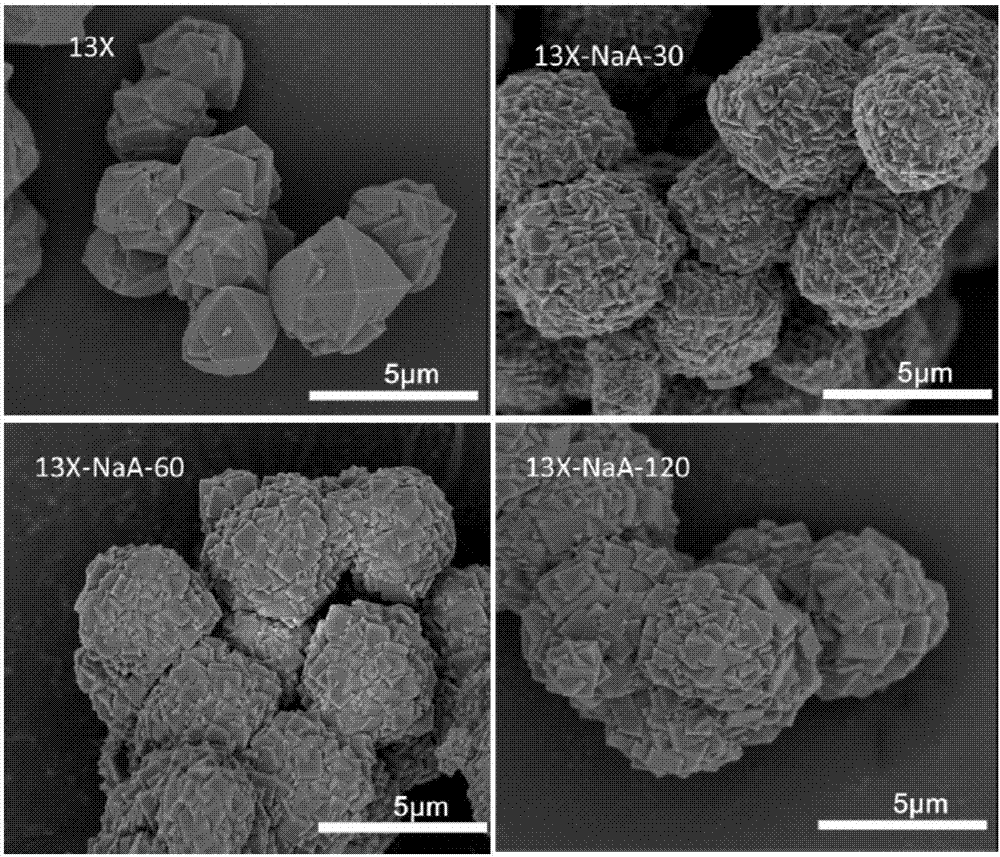

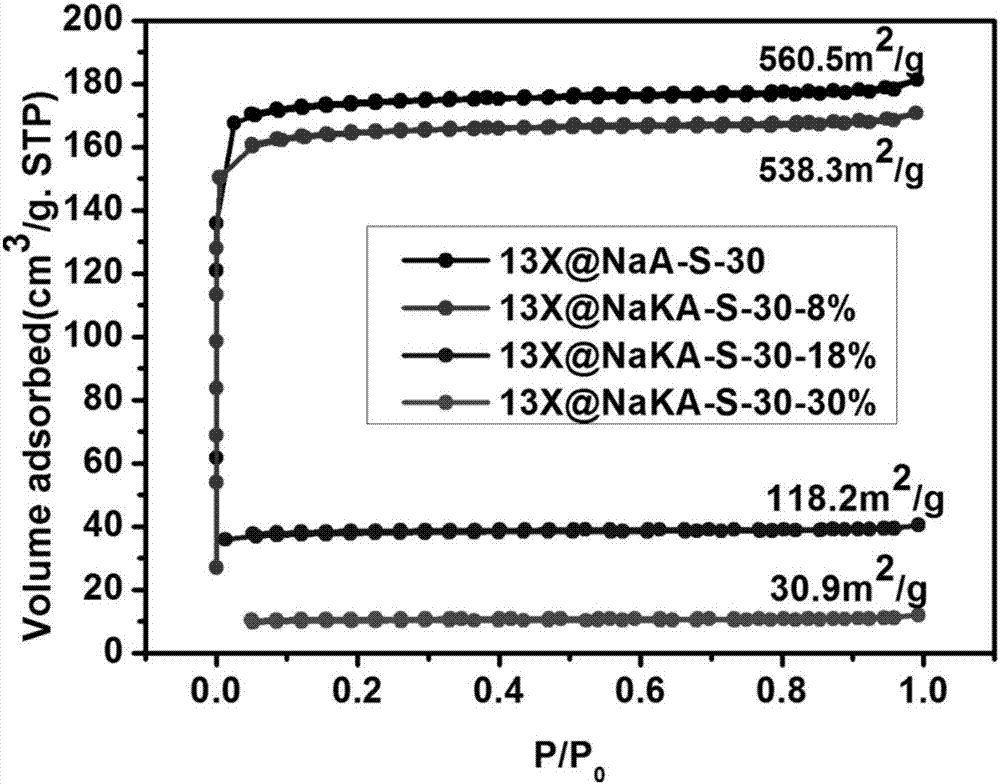

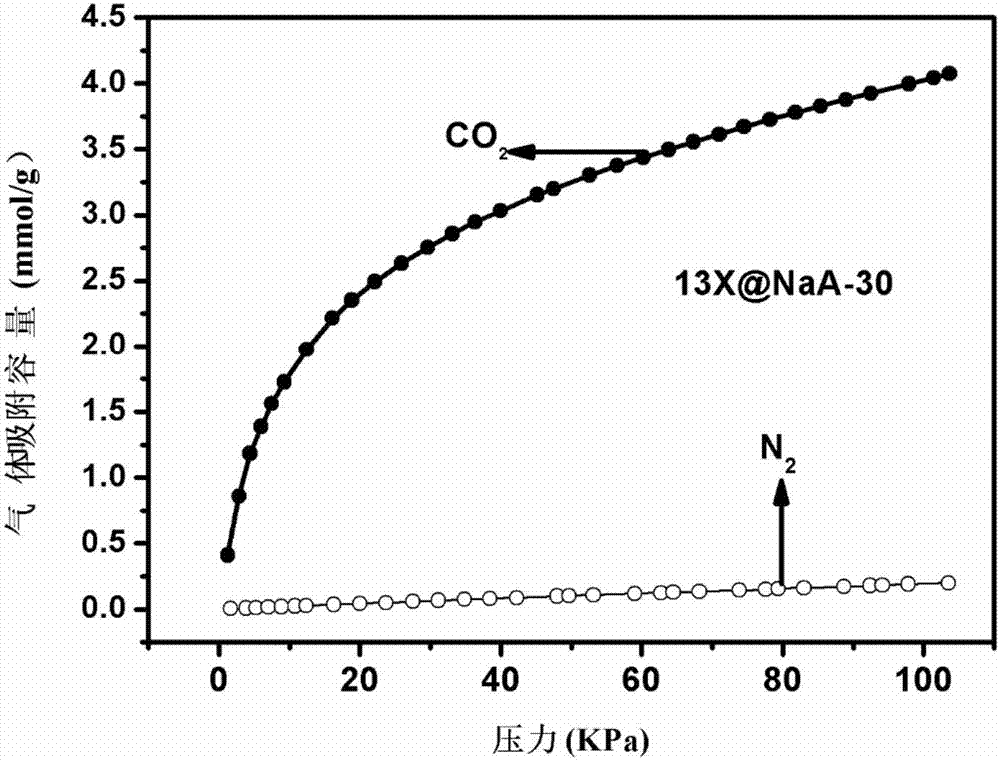

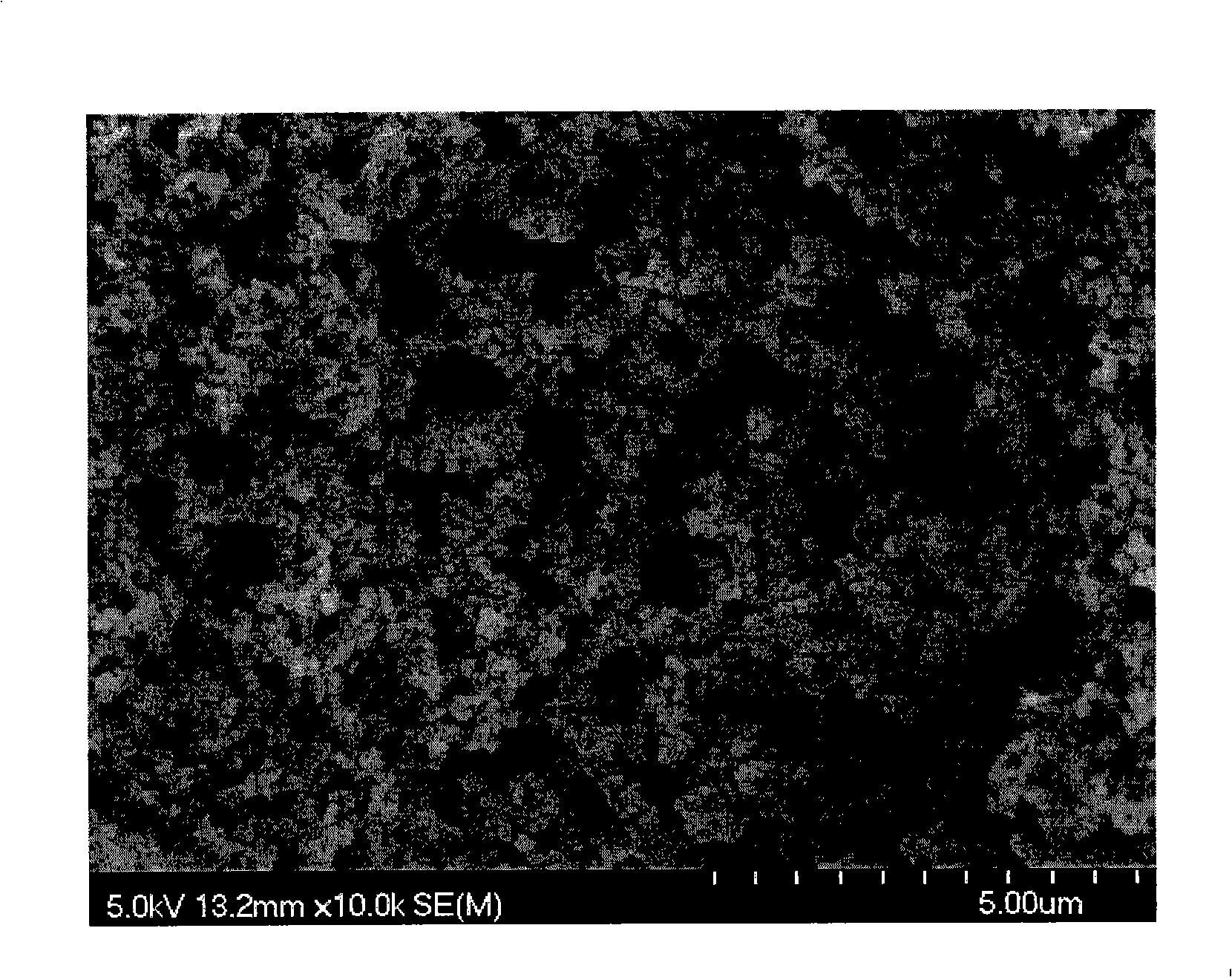

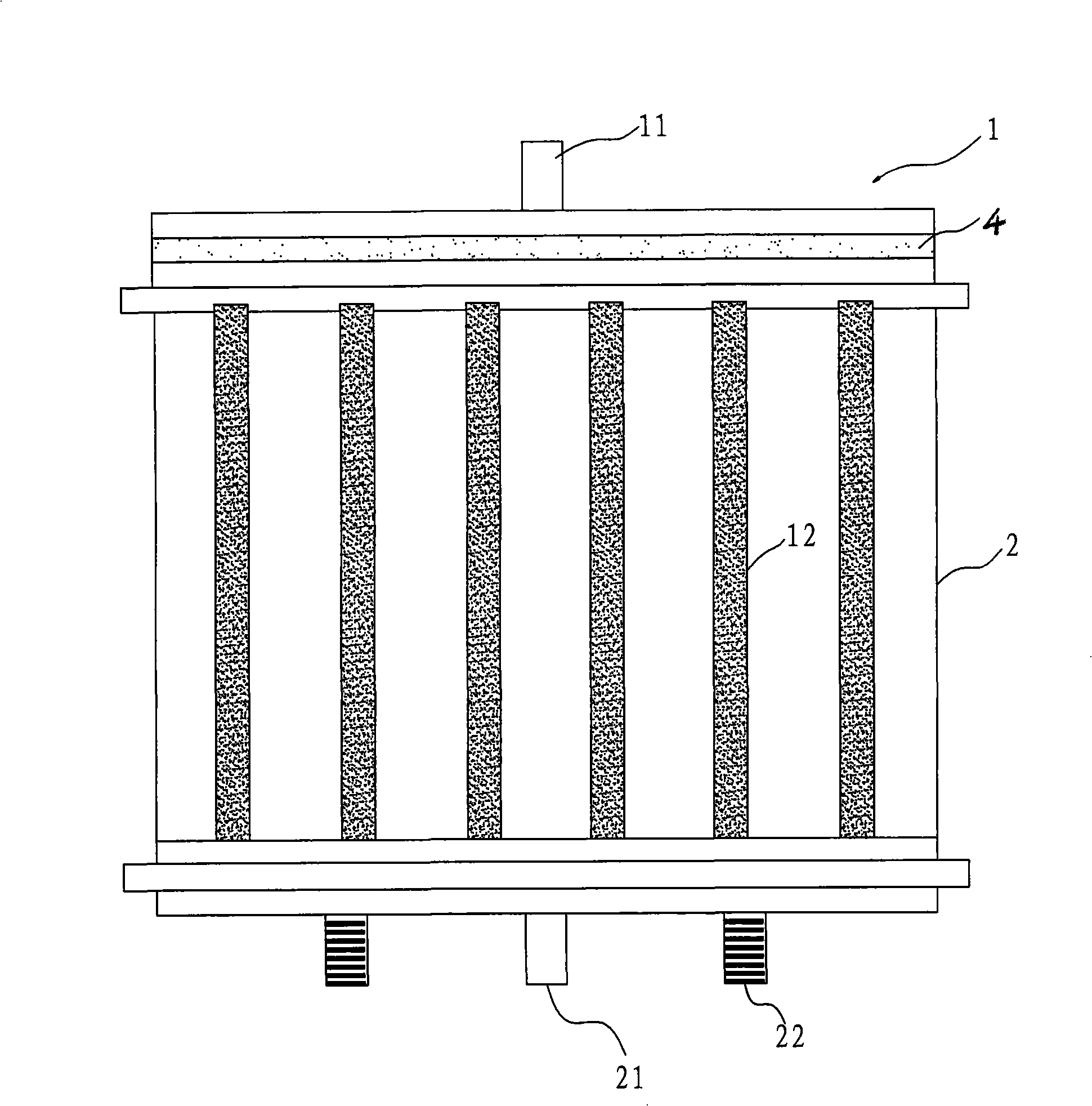

Core-shell composite molecular sieve and application of core-shell composite molecular sieve to carbon dioxide separation

ActiveCN107185488AImprove adsorption capacityHigh selectivityGas treatmentOther chemical processesIon exchangeLayer thickness

A core-shell-structured composite molecular sieve material is formed in the way that based on the difference between the molecular kinetic diameters of carbon dioxide and nitrogen, through crystallization and ion exchange, a porous material which selectively allows carbon dioxide to penetrate but prevents other gases is built on the surface of a zeolite molecular sieve. Through building core-shell composite molecular sieve materials with different shell-layer thicknesses, and the shell-layer molecular sieve apertures are adjusted through ion exchange, while the excellent adsorption capacity of the original zeolite molecular sieve is maintained, the adsorption selectivity is carbon dioxide is improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing epoxy resin base polyalcohol integral pole and special mold thereof

InactiveCN101293148AEasy to manufactureMild reaction conditionsOther chemical processesSolid sorbent liquid separationChemical structureFirming agent

The invention relates to a preparation method of epoxy resin-based polymer monolithic column; a given quantity of the epoxy resin and firming agents and a low molecular weight polymer mixture with a good compatibility used as pore-forming agents are added in an empty tube column; solidification temperature is controlled so as to regulate the speed of polymerization reaction; after the solidification is finished, the pore-forming agents are removed by washing so as to get the polymer monolithic column. The preparation process of the invention is simple and environmental friendly. The invention also discloses a dedicated mould. The monolithic column can be made into various specifications and forms as required and has the advantages of evenly distributed aperture, adjustable size, strong hydrophilic property, acid and alkali resistance, solvent resistance and good thermostabilization; and a large number of reactive functional groups are contained in the chemical constitution of the material of the monolithic column, which is suitable for performing a plurality of chemical modifications to an inner surface of a pore canal so as to further functionalize. The preparation method of the epoxy resin-based polymer monolithic column can be applied extensively to the fields such as the extraction and recovery of solid phase, the preparation of chromatogram, the separation of biological medicines, the environmental protection and the catalysis etc.

Owner:NINGBO UNIV

Preparation method of porous aluminum titanate block

The invention discloses a preparation method of a porous aluminum titanate block. The preparation method comprises the following steps: (1) dissolving aluminum chloride hexahydrate, citric acid monohydrate, tetrabutyl titanate and polyoxyethylene in a solvent in sequence at room temperature; (2) cooling a transparent clear solution obtained in the step (1) to -1 DEG C to 1 DEG C, adding formamide, and uniformly stirring; (3) putting a uniform solution obtained in the step (2) into a container, sealing the container, and gelling at 55-70 DEG C for 20-40 minutes; (4) ageing wet gel obtained in the step (3) at 55-70 DEG C for 20-30 hours; (5) performing normal pressure drying on aged gel obtained in the step (4) at 50-70 DEG C for 40-50 hours and performing heat treatment at 1,300-1,350 DEG C for 2-5 hours. The porous aluminum titanate block prepared by the method has the characteristics of continuous macroporous structure, continuous framework, high porosity and the like.

Owner:ZHEJIANG UNIV

Heavy metal ion porous adsorbent as well as preparation method and application thereof

ActiveCN107446096AControl Aperture SizeLow densityOther chemical processesWater contaminantsSorbentAdsorption effect

The invention provides a heavy metal ion porous adsorbent as well as a preparation method and application thereof. The preparation method of the heavy metal ion porous adsorbent comprises the following steps: (1) dropwise adding a dispersion phase containing an initiator and an electrolyte into a continuous phase containing ethyl glycidyl acrylate, divynyl benzene and an emulsifier, thus obtaining concentrated emulsion; (2) carrying out polymerization reaction on the concentrated emulsion, and washing and drying a polymerization reaction product, thus obtaining a porous polymer; (3) carrying grafting reaction on polyacrylic acid and the porous polymer under the existence of a catalyst, thus obtaining the heavy metal ion porous adsorbent. The heavy metal ion porous adsorbent provided by the invention has good adsorption effect on various heavy metal ions.

Owner:CRRC TANGSHAN CO LTD

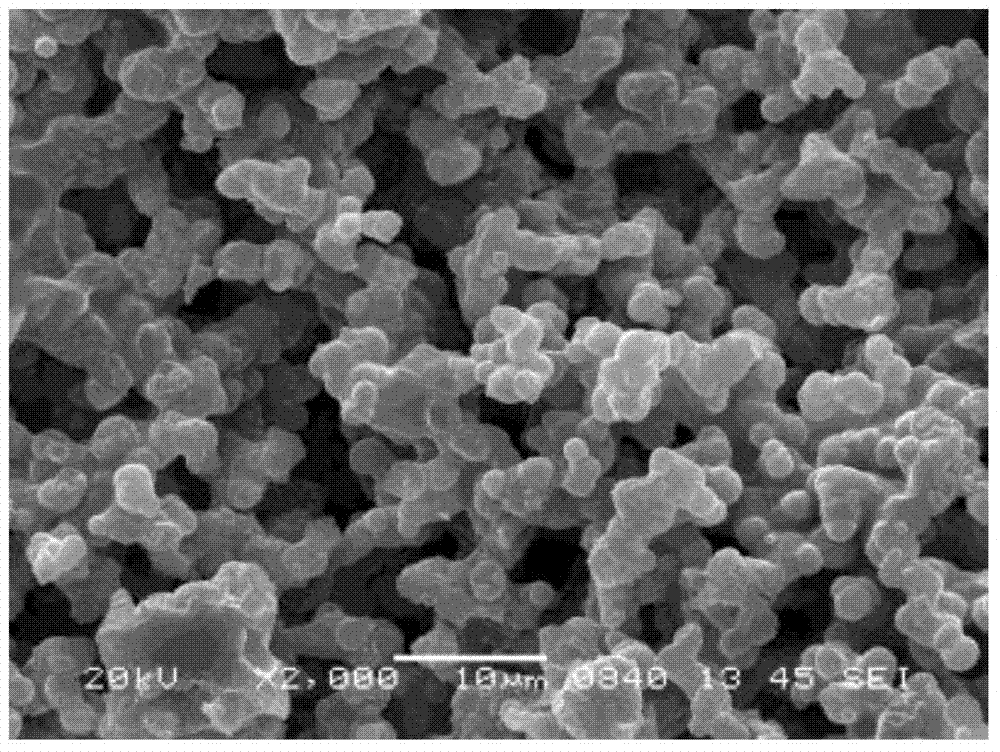

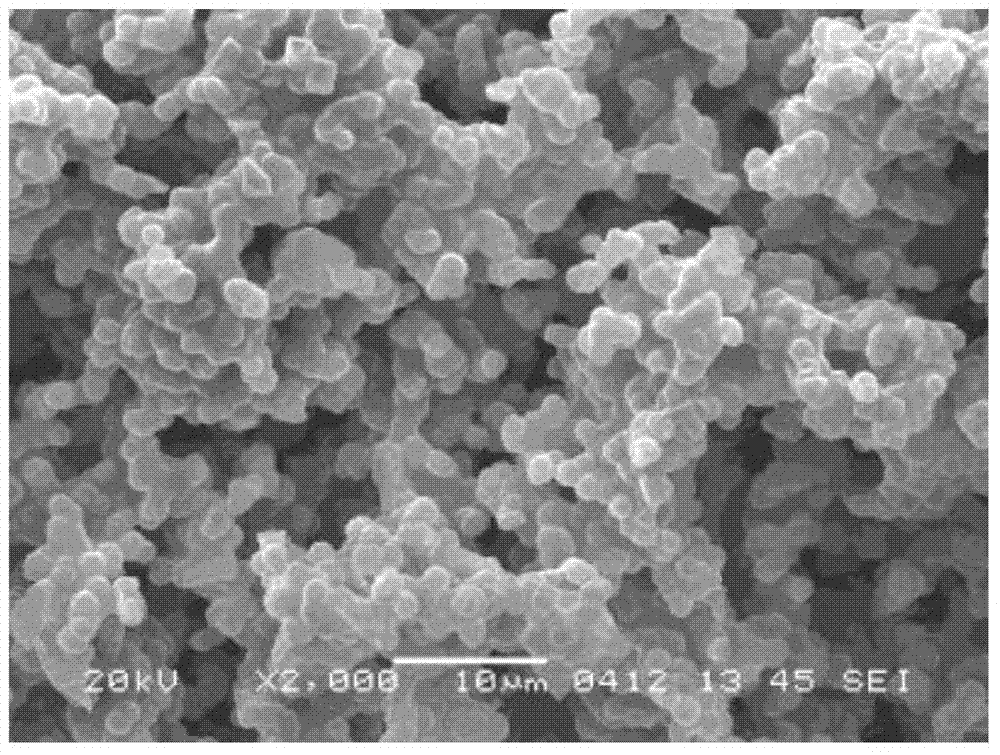

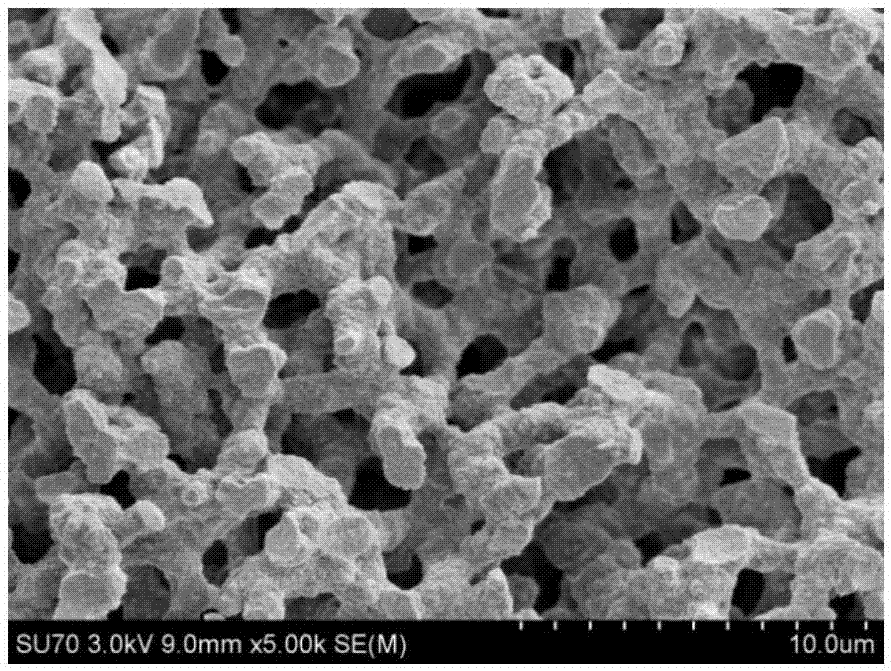

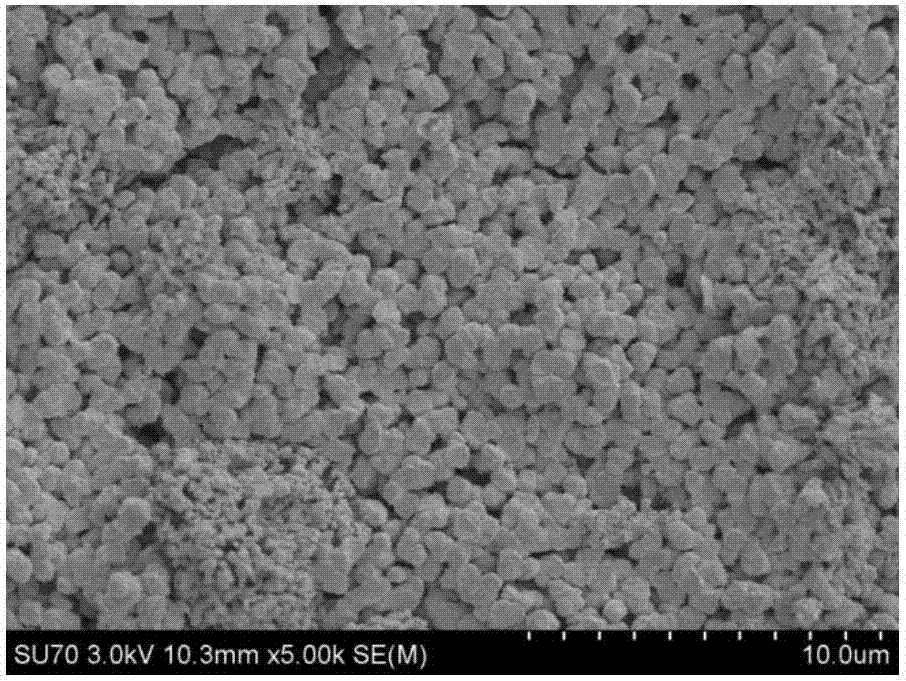

Method for preparing nickel porous materials based on nickel oxalate and sodium chloride co-mixing reducing method

The invention discloses a method for preparing nickel porous materials based on a nickel oxalate and sodium chloride co-mixing reducing method, relates to a nickel porous material preparing method, and belongs to the technical field of metal porous material preparing. After nickel oxalate powder and sodium chloride powder are subjected to ball grinding and evenly mixed, reducing is conducted, thereducing temperature is 400-450 DEG C, and nickel powder and sodium chloride powder evenly-mixed powder is obtained; then, pressing is conducted at 100 MPa-200 MPa, sintering is conducted at 700-800 DEG C, and a sintered blank with certain strength is obtained; and finally, a water dissolving method is used for removing sodium chloride in the sintered blank, and the nickel porous materials are obtained. The preparing method has environment friendliness, and the prepared porous materials have the characteristics that porosity is high, hole distribution is uniform, and the hole diameter is controllable.

Owner:CENT SOUTH UNIV

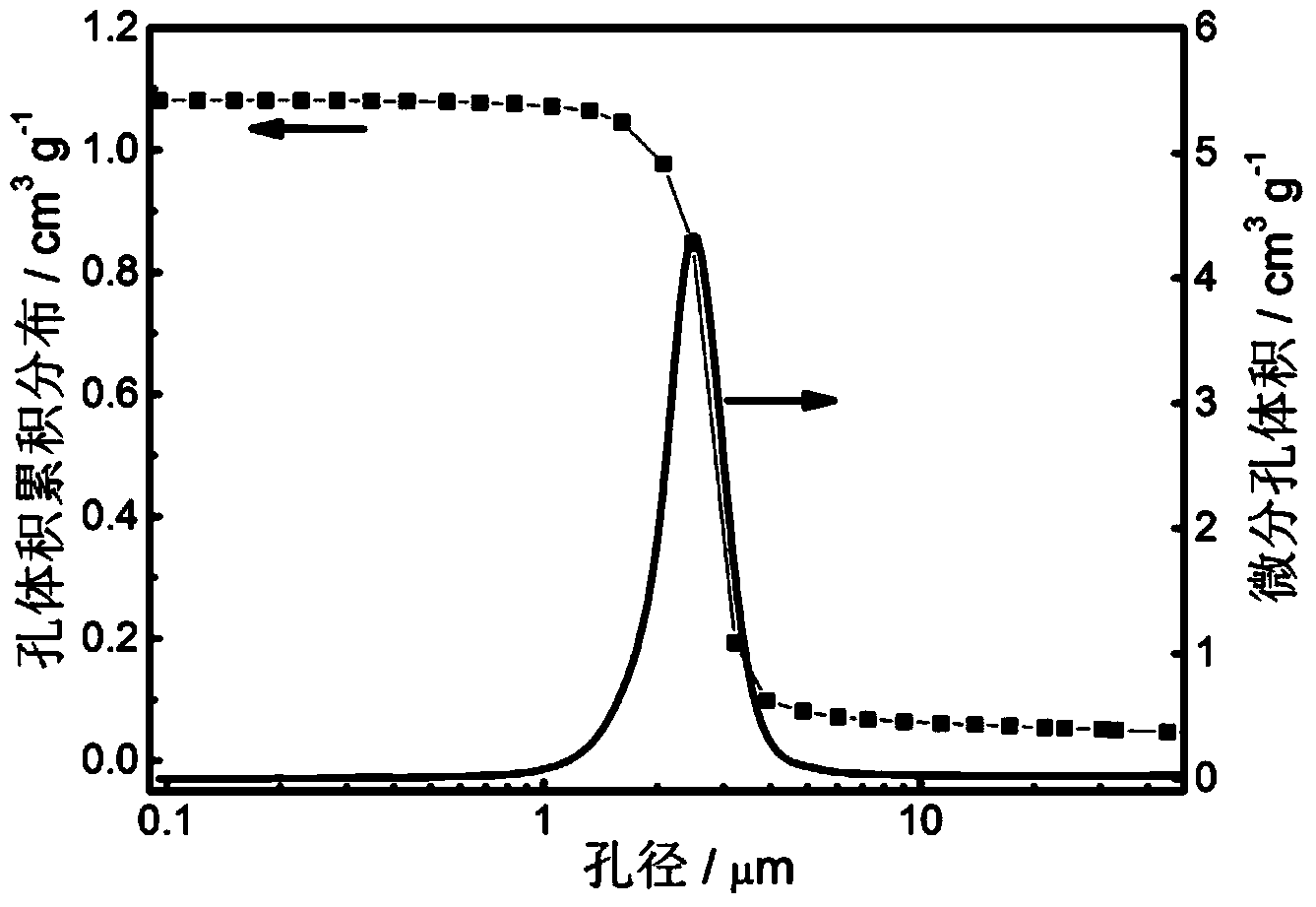

Preparation method of porous aluminum phosphate block

ActiveCN103663400AWith strengthControl Aperture SizePhosphorus compoundsAluminium chlorideCalcium Chloride Hexahydrate

The invention discloses a preparation method of a porous aluminum phosphate block. According to the preparation method, aluminum chloride hexahydrate is taken as an aluminum source, phosphoric acid is taken as a phosphorus source, a mixture of deionized water and absolute methanol is taken as a solvent, propylene epoxide is taken as a gel accelerator, and polyoxyethylene is taken as a phase separation inductive agent; the following steps are sequentially performed: 1), aluminum chloride hexahydrate and polyoxyethylene are put in a reaction flask, deionized water, absolute methanol and phosphoric acid are doped, and stirring is performed until polyoxyethylene is dissolved completely; 2), under the condition of ice bath, propylene epoxide is doped into a solution obtained in step 1), stirring is continuously performed until propylene epoxide is dissolved completely; 3), the reaction flask is sealed and aged, then a lid is opened, and drying is performed; and 4), obtained xerogel is processed for 1.5-2.5 hours at the temperature of 1,050-1,150 DEG C so as to obtain the porous aluminum phosphate block. The porous aluminum phosphate block can be directly applied to the fields of catalysis, separation, absorption, extraction, degradation, curing and the like.

Owner:ZHEJIANG UNIV

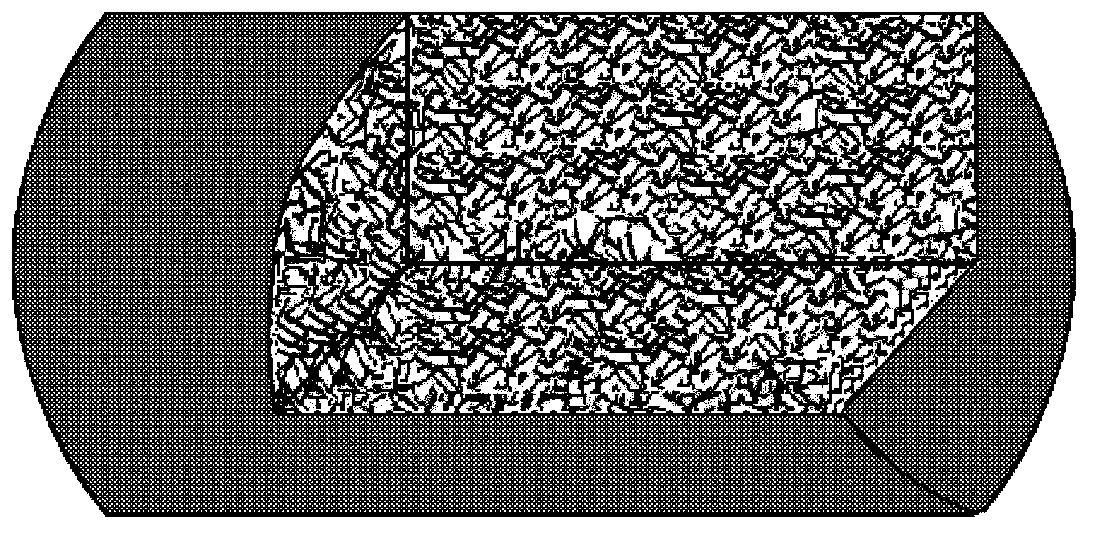

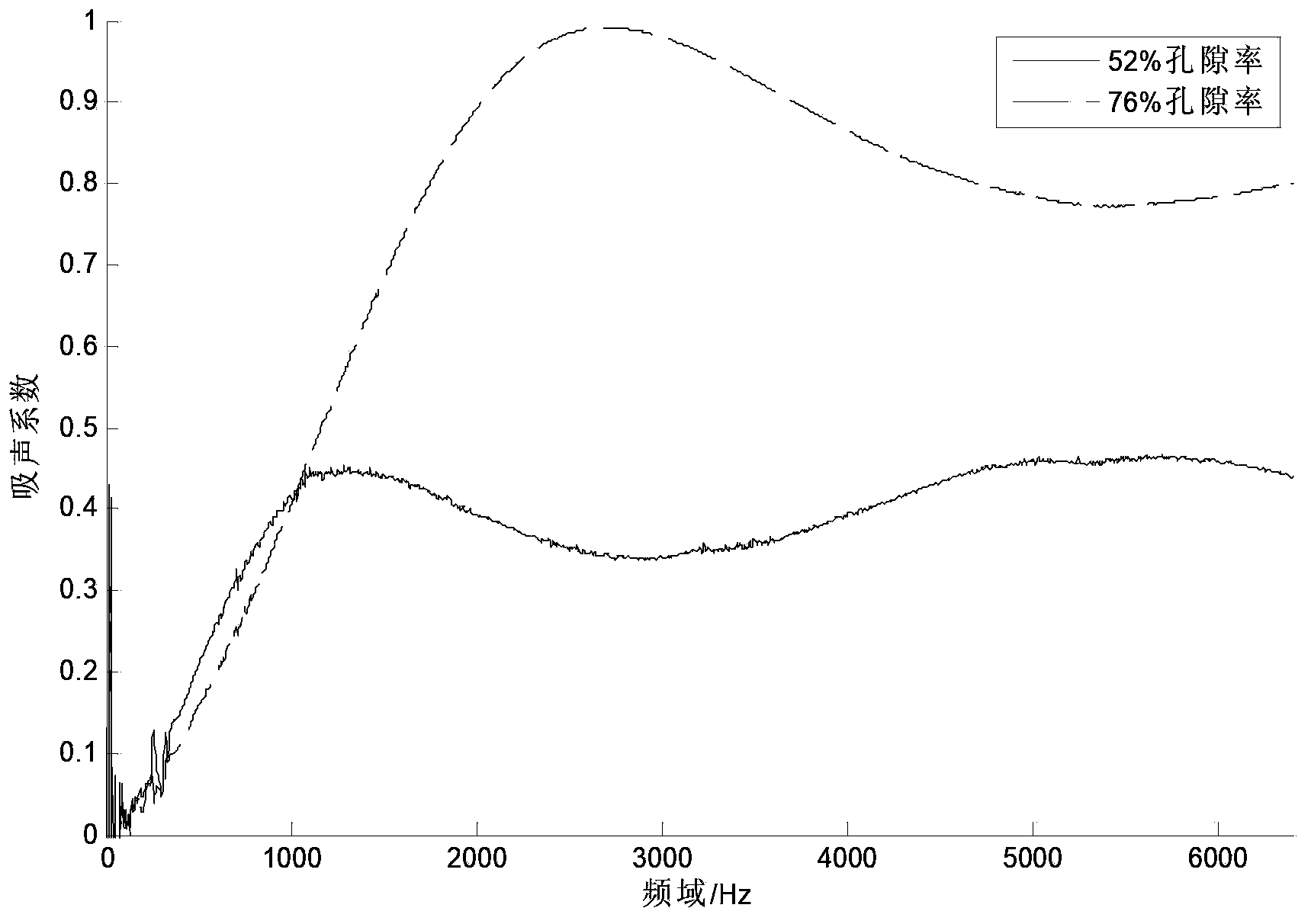

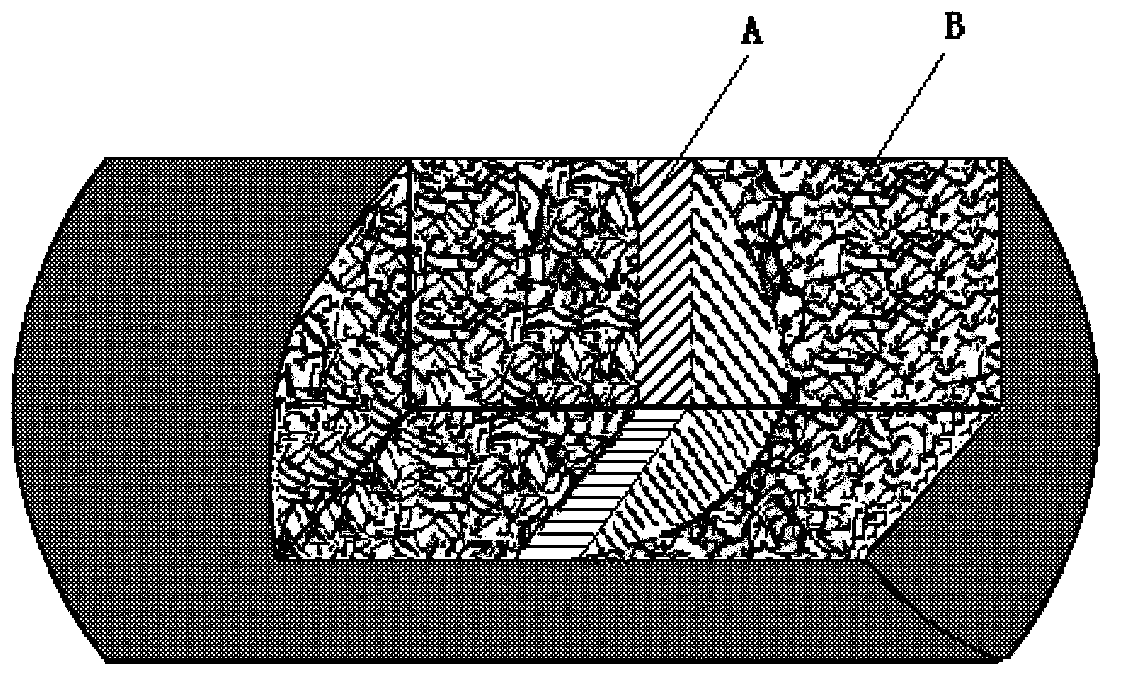

Method for preparing high-sound-absorptivity porous silicate material by molding and sintering inorganic salt

The invention discloses a method for preparing a high-sound-absorptivity porous silicate material by molding and sintering inorganic salt and belongs to the field of inorganic materials. According to the method, the porous glass material is prepared in such a manner that inorganic salt is mixed with glass power, the mixture is pressed and sintered, and the inorganic salt is dissolved out. The method is characterized in that porosity, pore sizes, pore forms and the connectivity among pores are controllable. The method has the benefits as follows: porosity, pore sizes, pore forms and connectivity among pores can be controlled as required; the porous glass material with excellent sound absorption property is obtained. The validity of the method is further validated through a number of examples.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Non-woven paper ion battery diaphragm and preparation method thereof

PendingCN110649210ASmall average pore sizeControl aperture sizeSecondary cellsCell component detailsBarium titanatePhysical chemistry

The invention belongs to the technical field of ion batteries, and particularly relates to a non-woven paper ion battery diaphragm and a preparation method thereof. The preparation method for the non-woven paper ion battery diaphragm comprises the following steps: 1, modified barium titanate powder is mixed with an organic solution to obtain coating slurry; 2, the surface of the non-woven paper iscoated with the coating slurry, hot pressing is carried out to obtain a non-woven paper ion battery diaphragm, barium titanate is modified, the flame retardant effect of barium titanate is improved.Under the action of the organic solution, the compatibility of the modified barium titanate powder is improved; the particle size of the modified barium titanate powder can be a single particle size and can also be different particle sizes; and the coating slurry is embedded into micropores of the non-woven paper through hot-pressing treatment, so that the pore diameter of the micropores of the non-woven paper is reduced, the pore diameter and the thickness of the non-woven paper are controlled, the problem of lithium dendrites is solved, and the technical defects that the existing non-woven paper is overlarge in pore diameter and thickness and cannot be applied to an ion battery are overcome.

Owner:GUANGDONG UNIV OF TECH

Foamed aluminum supercritical preparation method with controllable hole diameters

ActiveCN109434111AStable pore structureImprove porosity controllabilityRecycling and recovery technologiesDecompositionNitrogen gas

The invention belongs to the technical field of aluminum materials, and particularly relates to a foamed aluminum supercritical preparation method with controllable hole diameters. The method includesthe steps that 1, ethyecellulose is added into absolute ethyl alcohol for ultrasonic treatment for 5-10 min, and dispersive alcohol liquid is obtained; 2, broken aluminum skimmings are added into thedispersive alcohol liquid to be stirred for 20-50 min, and suspended alcohol liquid is obtained; 3, supercritical carbon dioxide fluid is flushed into the suspended alcohol liquid for a constant-pressure microwave reaction for 1-3 h, and mixed liquid is obtained after settling is completed; 4, the mixed liquid is put in a metal mold for a heating constant-pressure reaction for 1-3 h and a slow constant-temperature pressure relief reaction for 2-4 h, cooling is carried out after nitrogen purging, and a foamed aluminum precursor is obtained; and 5, the foamed aluminum precursor is subjected toan illumination decomposition reaction for 2-4 h, and a foamed aluminum material is obtained. The problems that structural parameters cannot be controlled or adjusted at will are completely solved; the preparation method is simple, batched production is facilitated, and the production cost is low; and the prepared foamed aluminum has a stable and uniform pore structure, and the pore controllability is improved.

Owner:SHAOXING UNIVERSITY

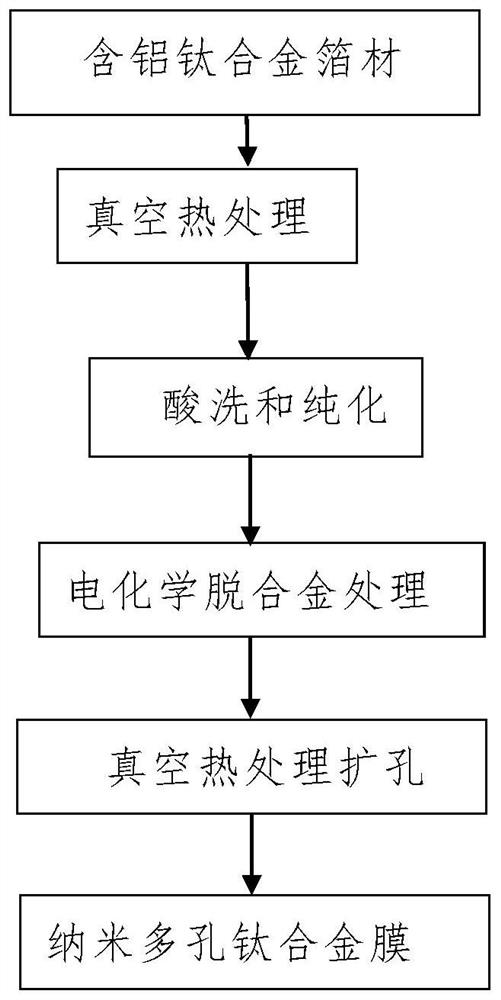

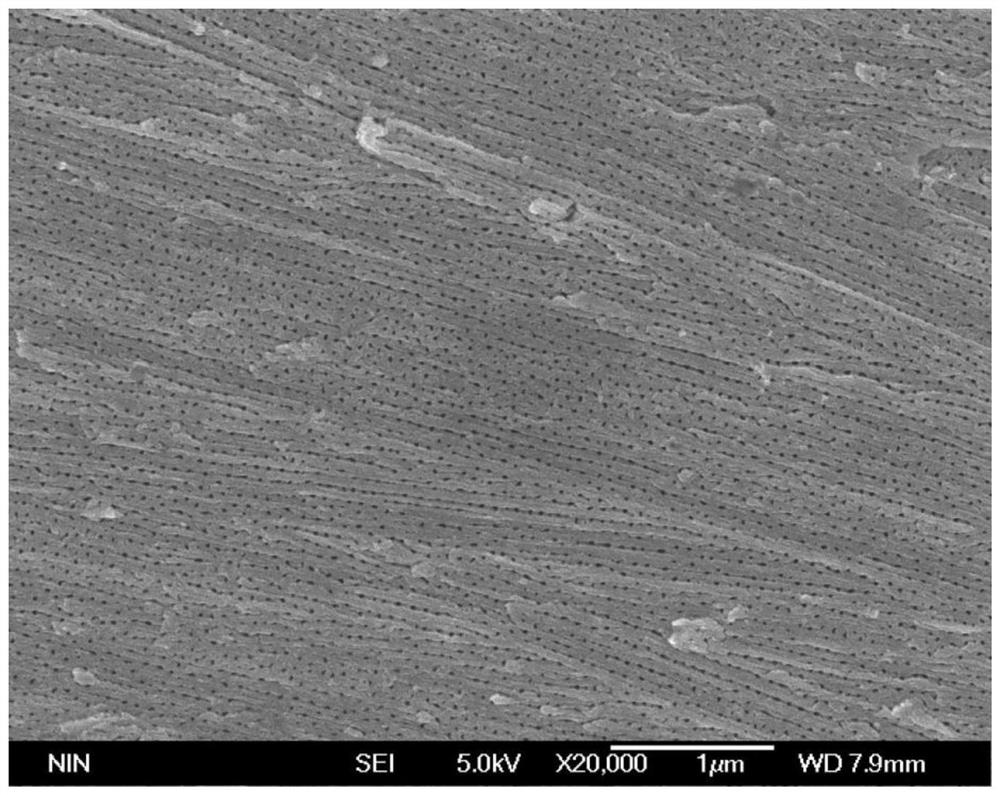

Preparation method of nano porous titanium alloy film

The invention discloses a preparation method of a nano porous titanium alloy film. The method comprises the steps that firstly, vacuum heat treatment is carried out on aluminum-containing titanium alloy foil; secondly, surface pickling and purification are carried out in sequence; thirdly, electrochemical dealloying treatment is carried out, and a porous titanium alloy film crude product is obtained through cleaning and drying; and fourthly, vacuum heat treatment is carried out so as to achieve hole expanding, and the nano porous titanium alloy film is obtained. According to the method, through the difference of electrochemical potentials of aluminum and titanium in an alkaline solution, the aluminum element in the aluminum-containing titanium alloy foil is selectively dissolved through electrochemical dealloying treatment, and therefore straight-through pores are formed in the original position of dissolved and removed aluminum, the sizes and depths of the pores are controlled by combining a heat treatment hole expanding process, and the nano porous titanium alloy film with uniform pore distribution and uniform pore diameters is obtained; and the high-precision application requirements in the fields of micro-flow control, filtration separation, gas sensors, electrodes of supercapacitors, high-catalytic-activity systems, biomedical implant materials and the like are met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com