Patents

Literature

108results about How to "No burning phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biodegradable coated compound fertilizer and preparation method thereof

The invention relates to a coated compound fertilizer, in particular to a totally biodegradable coated compound fertilizer and a preparation method thereof. The coated compound fertilizer consists of a coated layer and a compound fertilizer core. The main body of the coated layer is polylactic acid and / or polybutylene succinate. The coating process adopts fluidized bed spraying-coated technology, and comprises the following steps: dissolving polylactic acid and / or polybutylene succinate in trichloromethane, adding carboxymethylcellulose, urease and / or nitrification inhibitor, organic and / or inorganic conditioner in the solution, spraying and coating the surfaces of the fluidized compound fertilizer granules after uniformly mixing the mixture under the stirring of a stirrer to form the uniform and complete organic polymeric membrane layer. The process has the advantages of easy implementation, and capacity of effectively slowing down the release of the fertilizer nutrient to the outside and the conversion rate of nitrogen in soils, effectively controlling the release and conversion of the fertilizer nutrient in soils, and reducing the pressure on environment caused by the rapid release of nutrient. The coated material can be totally biodegradable, and the degradation products have no secondary pollution to the environment.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Release control urea and its preparing process

InactiveCN1666972AHydrolysis controlControl supplyAgriculture gas emission reductionFertilizer mixturesAcrylic resinNitrification inhibitors

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Biodegradable coated carbamide and preparation method thereof

InactiveCN101723751AReduce releaseReduce rateUrea compound fertilisersFertilizer mixturesCoated ureaNitrification inhibitors

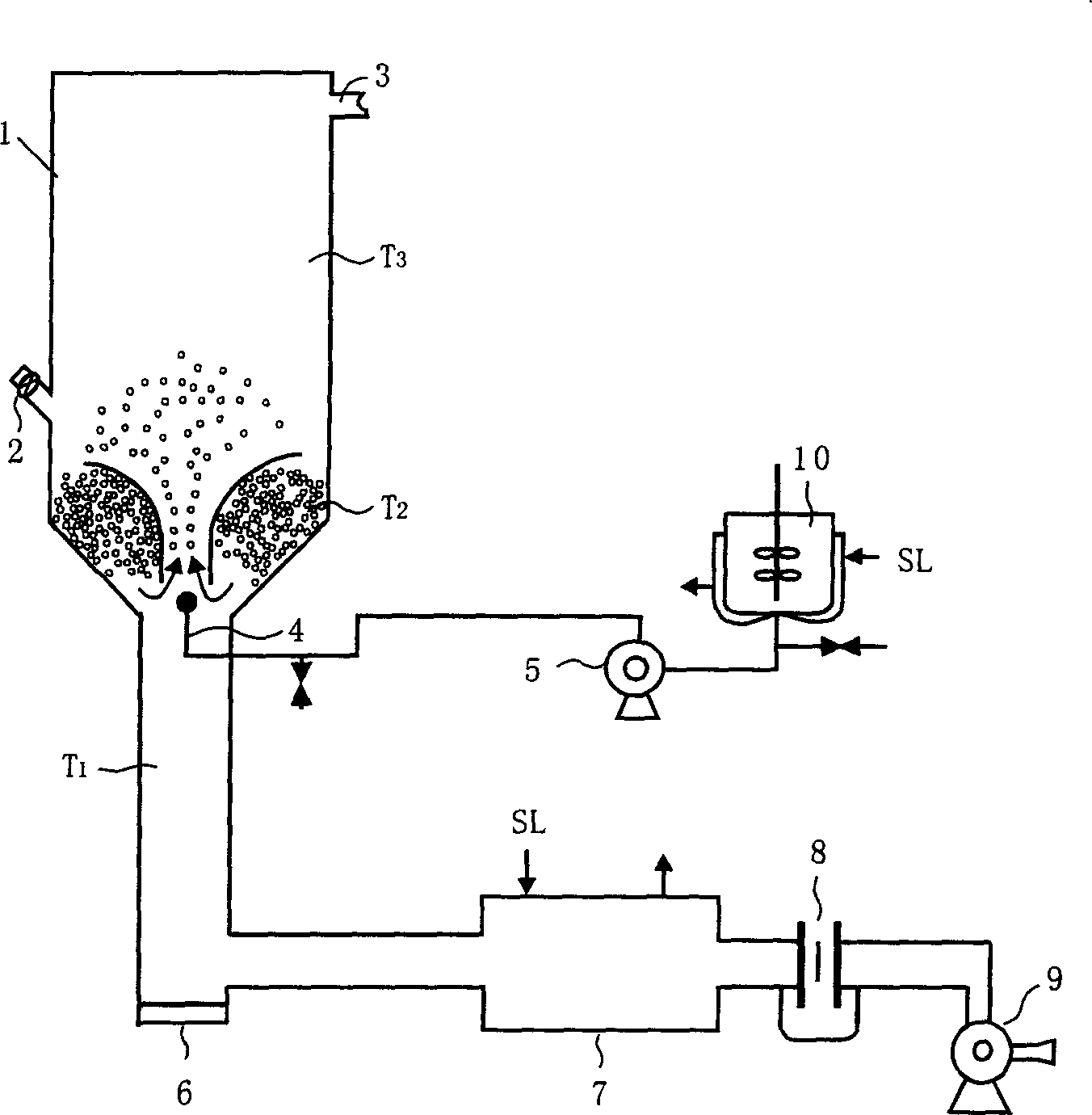

The invention relates to coated carbamide, in particular to a totally biodegradable coated carbamide and a preparation method thereof. The coated carbamide consists of a coated layer and a carbamide core. The main body of the coated layer is polylactic acid and / or polybutylene succinate. The coating process adopts fluidized bed spraying-coated technology, and comprises the following steps: dissolving polylactic acid and / or polybutylene succinate in trichloromethane, adding carboxymethylcellulose, organic and / or inorganic conditioner, urease and / or nitrification inhibitor in the solution, spraying and coating the surfaces of the fluidized carbamide after uniformly mixing the mixture under the stirring of a stirrer to form the uniform and complete organic polymeric membrane layer. The process has the advantages of easy implementation, and capacity of effectively slowing down the release of the nutrient to the outside and the conversion rate of nitrogen in soils, effectively controlling the release of the nitrogen nutrient in soils, and reducing the pressure on environment caused by the rapid release of nutrient. The coated material can be totally biodegradable, and the degradation products have no secondary pollution to the environment.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

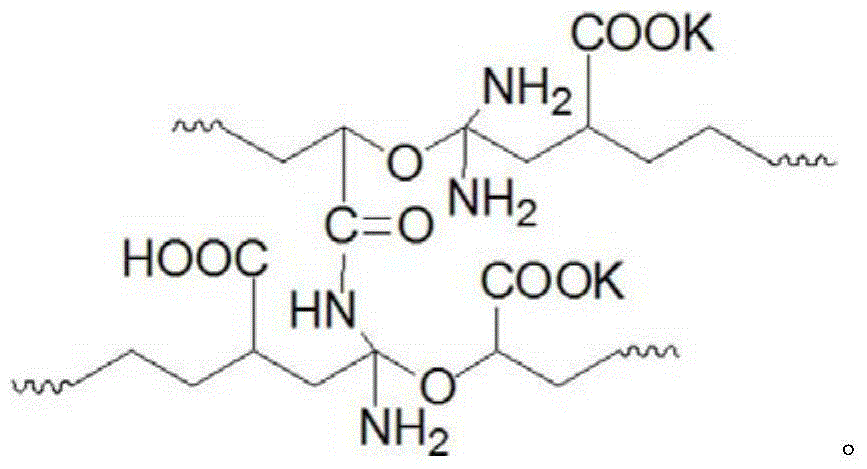

Slow release urea containing gamma-polyglutamic acid and urease inhibitor and preparation method thereof

InactiveCN102584495AEffective absorptionImprove solubilityUrea compound fertilisersFertilizer mixturesUrease InhibitorsGamma-polyglutamic Acid

The invention discloses slow release urea containing gamma-polyglutamic acid and a urease inhibitor. The slow release urea is obtained by spraying a coated slow release solution onto the outer surface of urea particles and drying, wherein the coated slow release solution contains gamma-polyglutamic acid and a urease inhibitor. The invention further discloses a preparation method of the slow release urea. The gamma-polyglutamic acid and the urease inhibitor in the slow release urea have synergic actions, and the gamma-polyglutamic acid can form a layer of protective film on the surfaces of a fertilizer and the urease inhibitor, so that the utilization ratio of the fertilizer is increased, and environmental pollution is lowered.

Owner:NANJING SHINEKING BIOTECH CO LTD +1

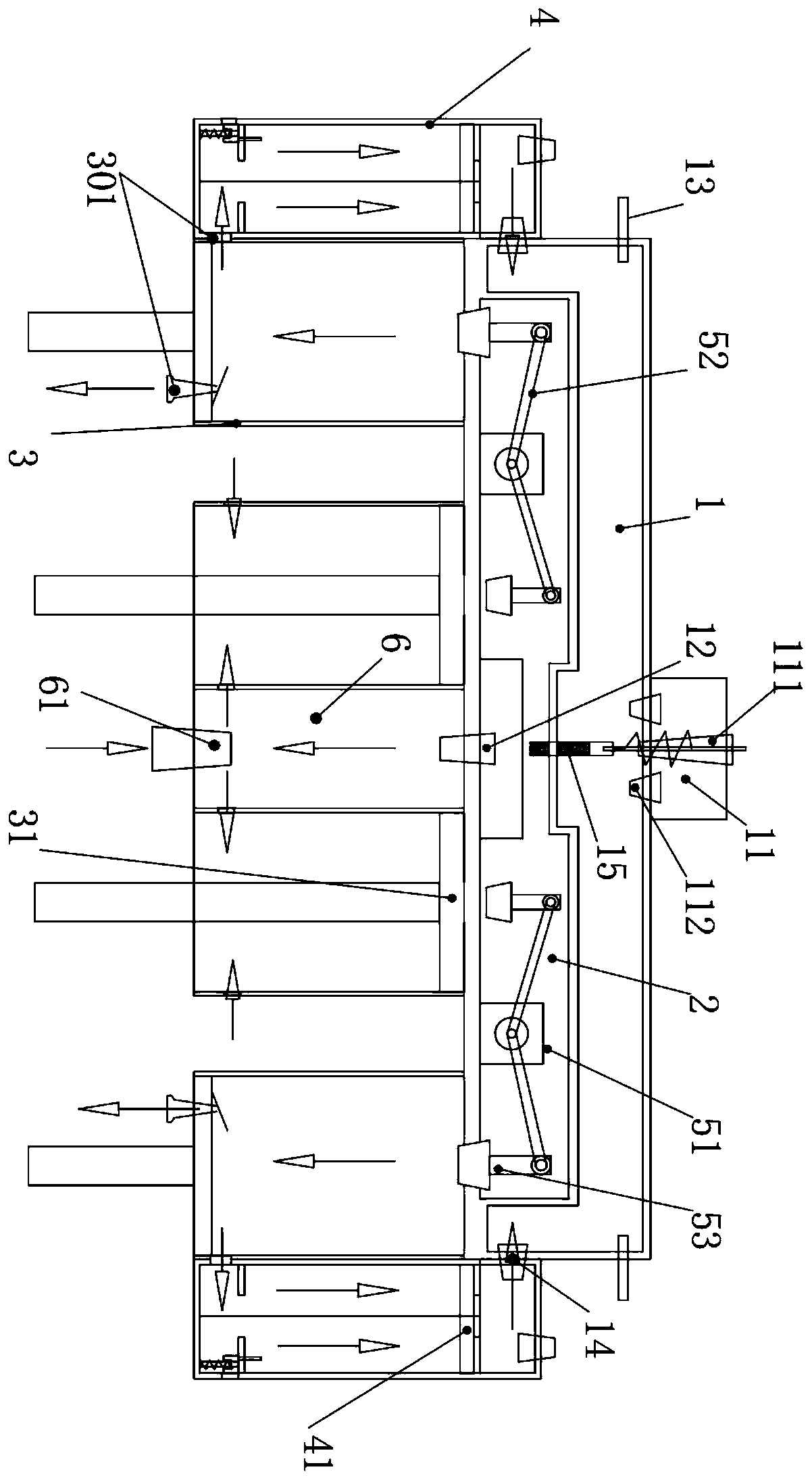

Method for pouring hollow fibrous membrane assembly

InactiveCN102600727AAvoid inconvenienceEffective protectionSemi-permeable membranesFiberUltimate tensile strength

The invention relates to a method for pouring a hollow fibrous membrane assembly, belonging to the technical field of membrane separation. The method for pouring the hollow fibrous membrane assembly is characterized by comprising the following steps of: assembling a hollow fibrous membrane into a membrane assembly, firstly passivating two ends of a hollow fibrous membrane beam, and pouring a pouring sealant to adhere and fixing the hollow fibrous membrane on an assembly shell to form relatively sealed separation environment. According to the method for pouring the hollow fibrous membrane assembly, disclosed by the invention, the purposes of adhering, fixing, wire-burning resisting and root protecting can be realized as long as once pouring is carried out on a membrane assembly; and the method for pouring the hollow fibrous membrane assembly, disclosed by the invention has the advantages of simple process, low cost, effective protection on the root of membrane fiber, no wire burning phenomenon, improvement on mechanical strength of the root of the membrane fiber, difficulty for breaking wires, simpleness, convenience, feasibility, wide application and the like.

Owner:天津华泉环保设备有限公司

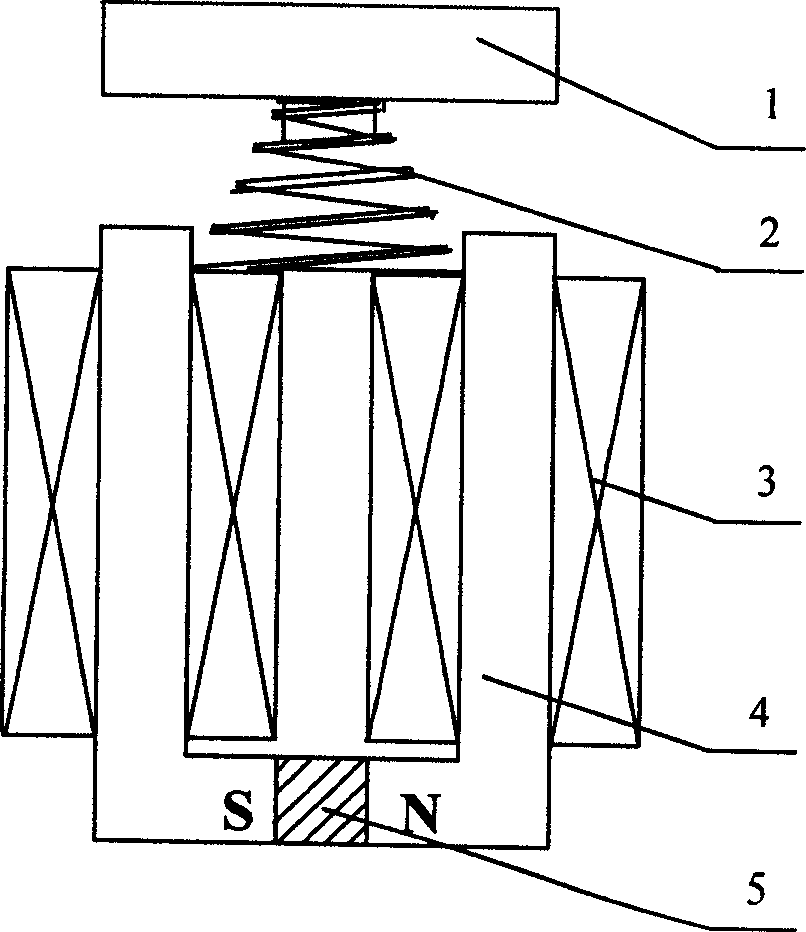

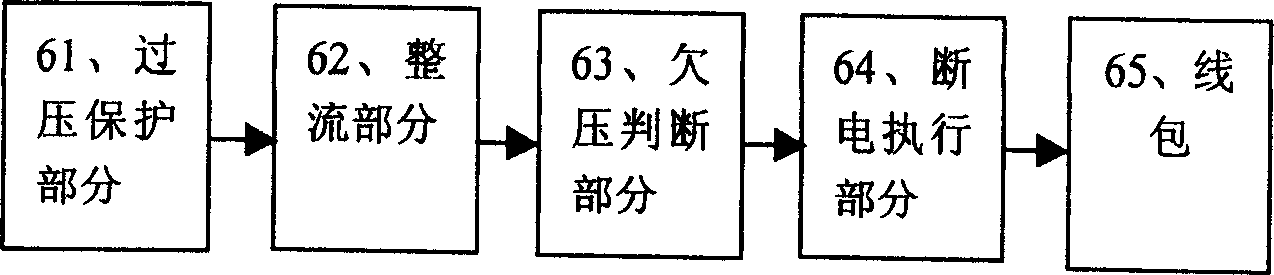

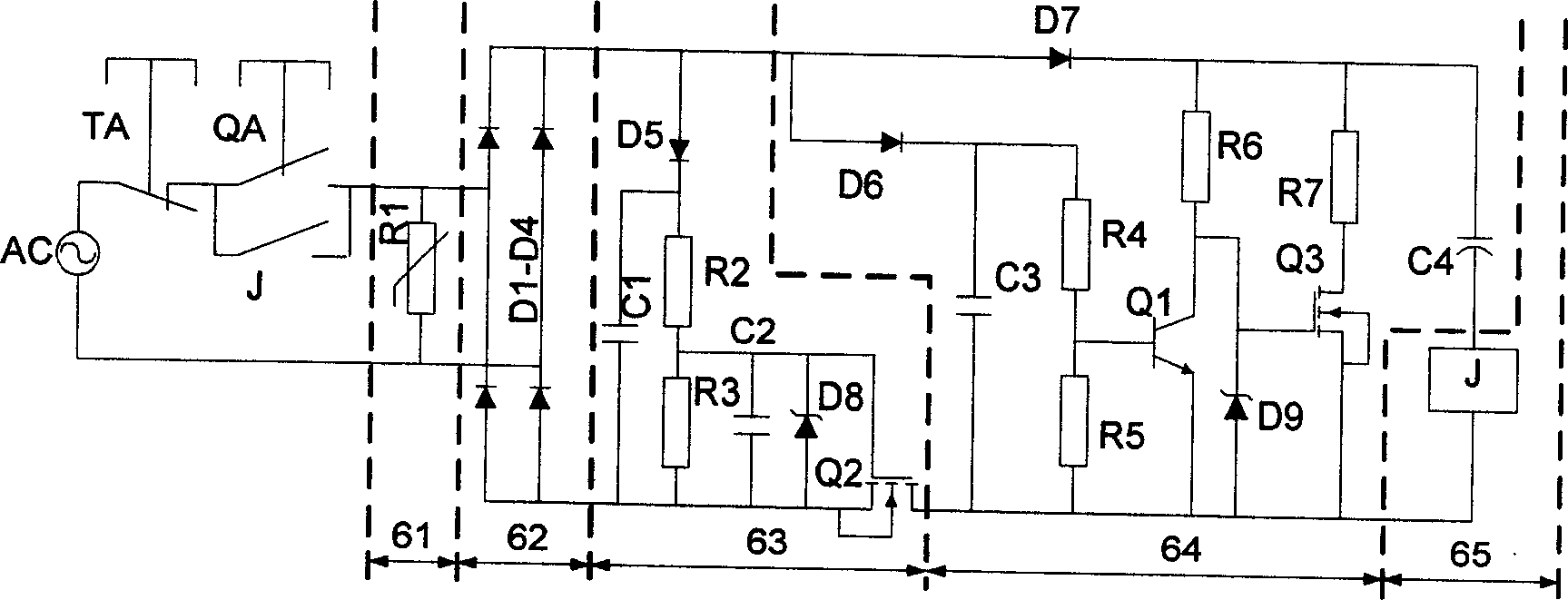

Permanent magnetic contactor and control device thereof

InactiveCN1725411ANo burning phenomenonNo tremorsEmergency protective circuit arrangementsNon-polarised relaysLow voltageElectrical polarity

A permanent magnetic contactor and its control device are used in starting switch control devices and engines and switching on and off the master circuit. A permanent magnetic steel is set between two static cores to form a U-like bulk, two iron cores connected in series and in a same polarity, a tower spring supports the framework of the packet, the top of the tower spring is connected with a dynamic core. The output over voltage protection part of said control device is connected with the rectification part, output of which is connected with a low-voltage judgment part the output of which is connected with a shut off executing part and the output of which is connected with the wire packet.

Owner:SOUTHEAST UNIV

Sulphur-based gamma-biological compound fertilizer and preparation method thereof

InactiveCN105016849AImprove disease resistanceImprove stress resistanceFertilizer mixturesMicrobial agentPhosphate

The invention discloses sulphur-based gamma-biological compound fertilizer and a preparation method thereof. The sulphur-based gamma-biological compound fertilizer comprises gamma-poly(glutamic acid), wheat straw extract, microbial agents and secondary elements, namely, nitrogen elements, phosphorus elements and potassium elements. The gamma-poly(glutamic acid) and the microbial agents are prepared through the fermentation process. The wheat straw extract is obtained by extracting and processing young wheat straw seedlings. The secondary elements are obtained through related compound powder. The sulphur-based gamma-biological compound fertilizer comprises 0.1-5.0 parts of gamma-poly(glutamic acid), 3-12 parts of wheat straw extract, 2-6 parts of microbial agents, 20-30 parts of urea, 55-85 parts of monoammonium phosphate and 30-50 parts of potassium sulfate, wherein microelements include calcium, magnesium, sulphur, manganese, zinc, boron and molybdenum. By means of the sulphur-based gamma-biological compound fertilizer, the nitrogen nutrition utilization rate can be increased, and by means of the supplementary effect of synergistic interaction of the gamma-poly(glutamic acid) and the wheat straw extract, the soil microenvironment is improved, the nutrient absorption is promoted, the crop yield is increased, and the disease-resistant, stress-resistant, anti-interference and successive crop prevention capacity of plants is improved.

Owner:KUNSHAN BOERRI BIOTECH

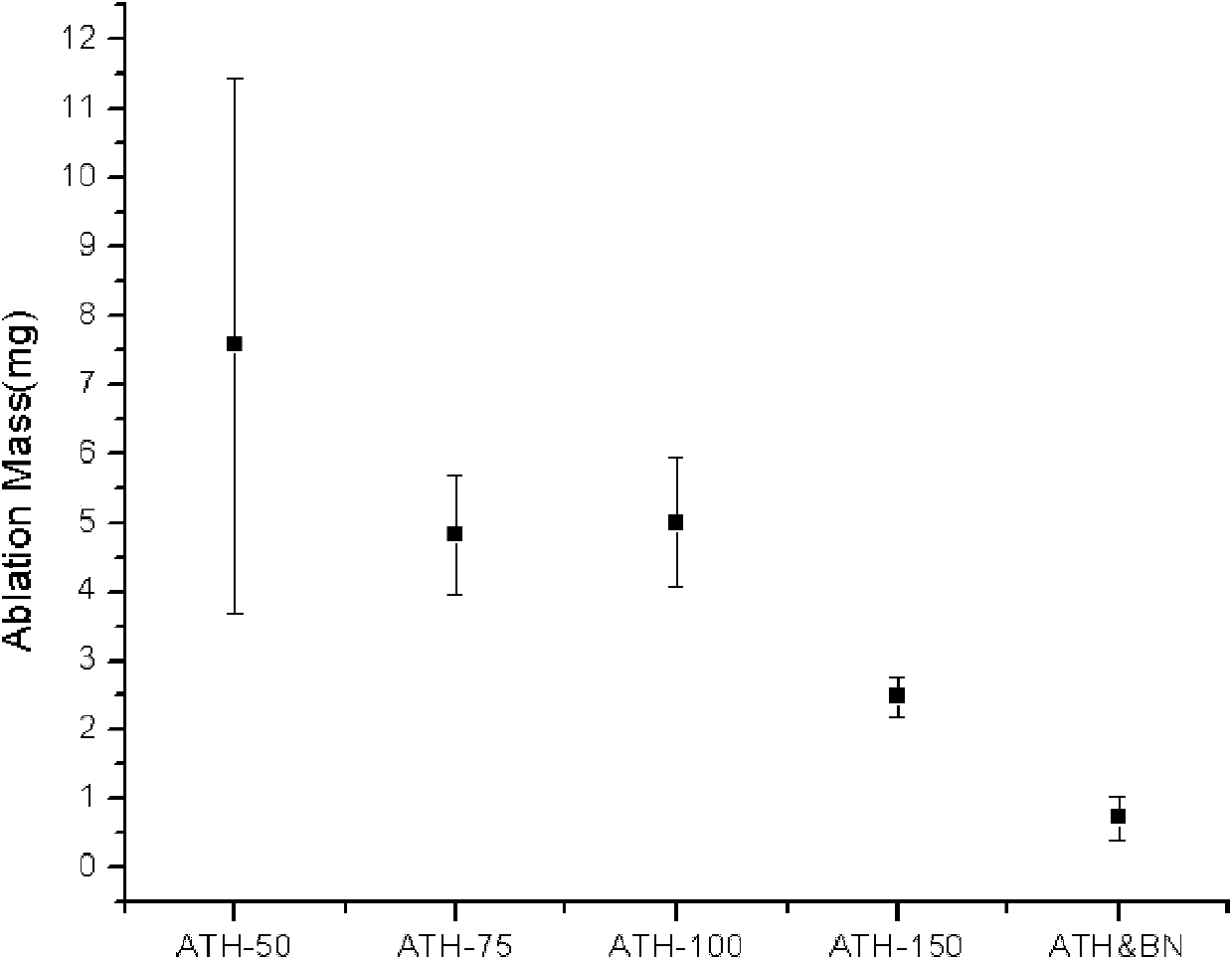

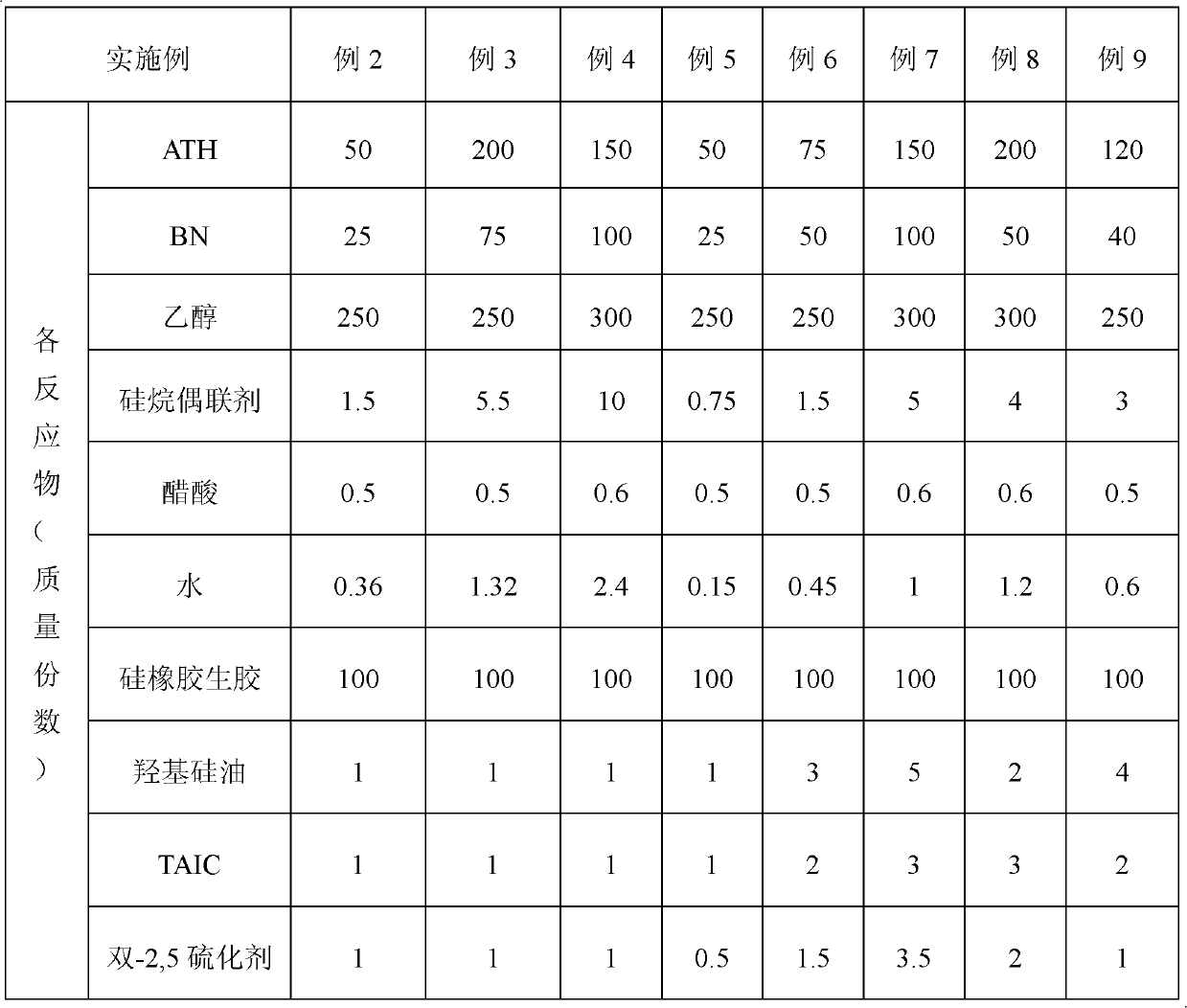

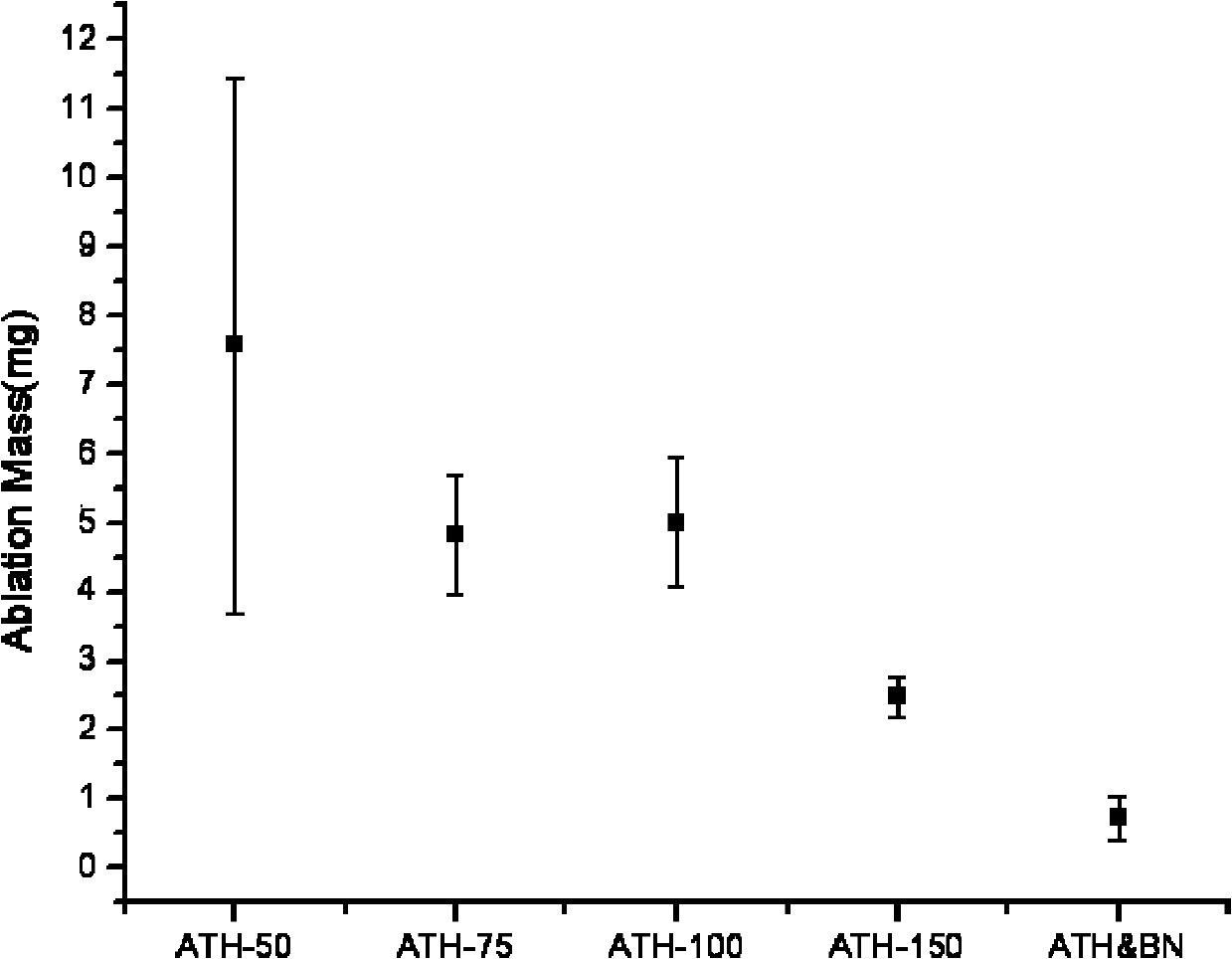

Silicon rubber with excellent electric arc resistant performance and preparation method thereof

The invention provides silicon rubber with excellent electric arc resistant performance and a preparation method thereof. The silicon rubber comprises the following raw materials in parts by weight: 100 parts of crude silicon rubber, 50-200 parts of ATH (Aluminum Hydroxide), 25-100 parts of BN (Boron Nitride), 0.5-3.5 parts of vulcanizer, 1-3 parts of TAIC (Triallyisocyanurate), 1-5 parts of hydroxyl silicone oil, 1-5 parts of silane coupling agent and 100 parts of inorganic filler, wherein the inorganic filler is composed of the ATH and the BN. According to the silicon rubber provided by theinvention, an emulsion and the crude silicon rubber is directly subjected to emulsion blending on a double roller rubber mixing mill, thereby improving the dispersion and avoiding rising of nano-particles; by adding the BN on the basis of filling the ATH, the silicon rubber has less mass loss after high-voltage low current arc resistance test; meanwhile, the electric arc is always disassociated on the surface of the material in the electric arc ablation process; furthermore, the surface of the material has no burning phenomenon; the surface of the material only appears little yellowing after the test; and little black residue appears near an electrode.

Owner:XI AN JIAOTONG UNIV

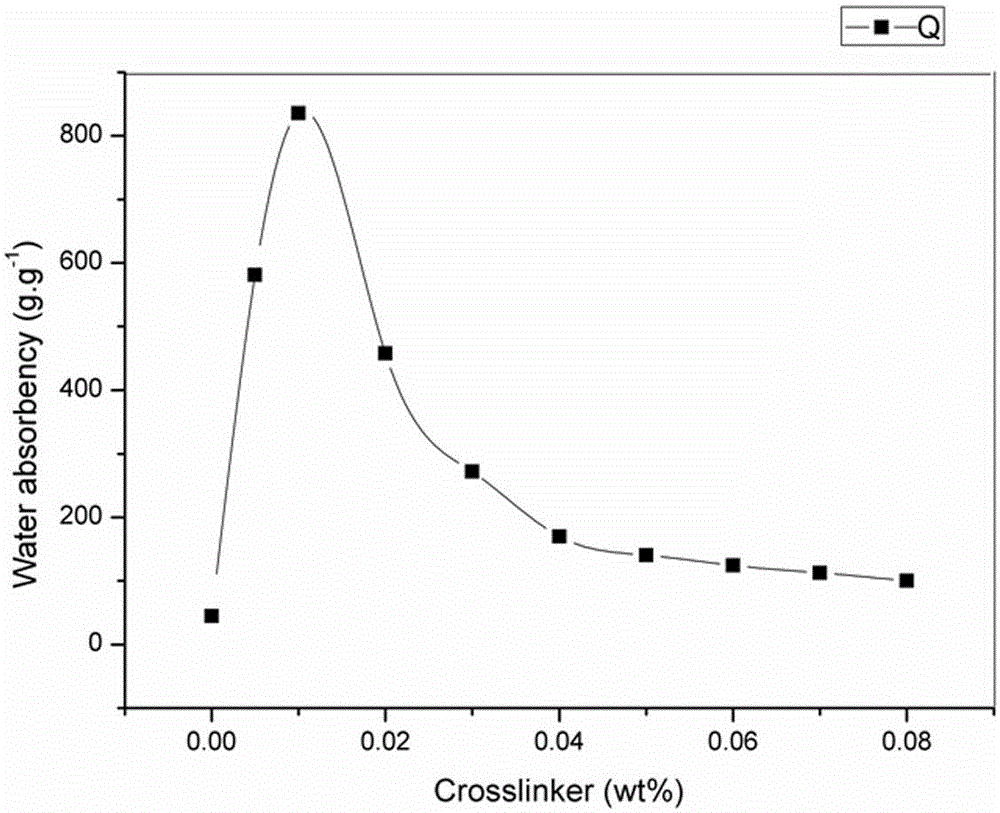

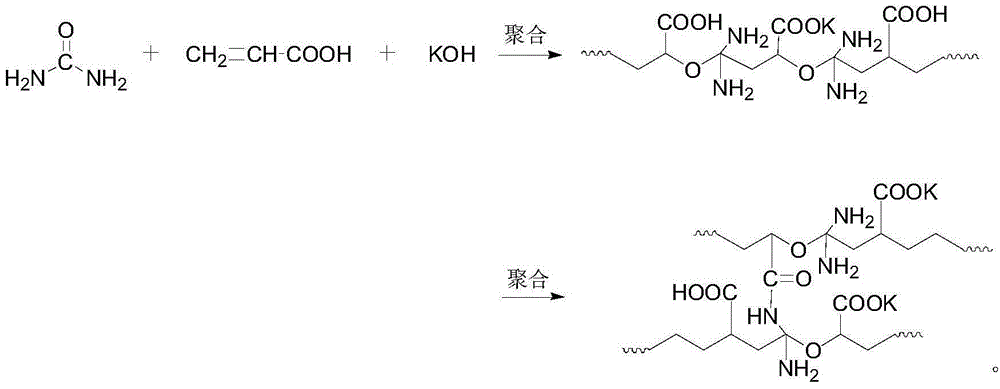

Water-retaining high-molecular slow-release nitrogen-potassium fertilizer and preparation method thereof

ActiveCN105175197ASimple production processLow costFertilizer mixturesPotassium persulfateChemical synthesis

The invention relates to the field of water-retaining slow / controlled-release fertilizers, specifically to a water-retaining high-molecular slow-release nitrogen-potassium fertilizer and its preparation method. The preparation method comprises the following steps: (1) adding a potassium hydroxide solution and acrylic acid into a reaction vessel, and stirring in an ice bath until the reactants are mixed uniformly; then adding urea and stirring until urea is completely dissolved; adding an initiator potassium persulphate, stirring until potassium persulphate is completely dissolved; and adding a cross-linking agent N,N'-methylene bisacrylamide, stirring until the cross-linking agent is completely dissolved, and continuously stirring for 30 min until the solution is mixed uniformly; and (2) sealing the uniformly-mixed solution, reacting at 25-75 DEG C for 2-6.5 h, granulating, and drying so as to obtain the water-retaining high-molecular slow-release nitrogen-potassium fertilizer. The preparation method is a solution polymerization method. The technology is simple and easy to operate. The prepared water-retaining high-molecular slow-release nitrogen-potassium fertilizer is a chemically synthesized water-retaining slow-release fertilizer and can make up the defect of a film-coated water-retaining slow-release fertilizer that nutrient release is limited by a coated material and a technology is complex.

Owner:ZHONGBEI UNIV

Chlorine-based gamma-biological compound fertilizer and preparation method thereof

InactiveCN105016848AImprove disease resistanceImprove stress resistanceFertilizer mixturesMicrobial agentPhosphate

The invention discloses chlorine-based gamma-biological compound fertilizer and a preparation method thereof. The chlorine-based gamma-biological compound fertilizer comprises gamma-poly(glutamic acid), wheat straw extract, microbial agents and secondary elements, namely, nitrogen elements, phosphorus elements and potassium elements. The gamma-poly(glutamic acid) and the microbial agents are integrally prepared through the fermentation process. The wheat straw extract is obtained by extracting and processing young wheat straw seedlings. The secondary elements are obtained through related compound powder. The chlorine-based gamma-biological compound fertilizer comprises 0.1-5.0 parts of gamma-poly(glutamic acid), 3-12 parts of wheat straw extract, 2-6 parts of microbial agents, 20-30 parts of urea, 55-85 parts of monoammonium phosphate and 30-40 parts of potassium chloride, wherein the number of microorganisms in each gram of the microbial agents is two billion or larger. By means of the chlorine-based gamma-biological compound fertilizer, the nitrogen nutrition utilization rate can be increased, and by means of the supplementary effect of synergistic interaction of the gamma-poly(glutamic acid) and the wheat straw extract, the soil microenvironment is improved, the nutrient absorption is promoted, the crop yield is increased, and the disease-resistant, stress-resistant, anti-interference and successive crop prevention capacity of plants is improved.

Owner:KUNSHAN BOERRI BIOTECH

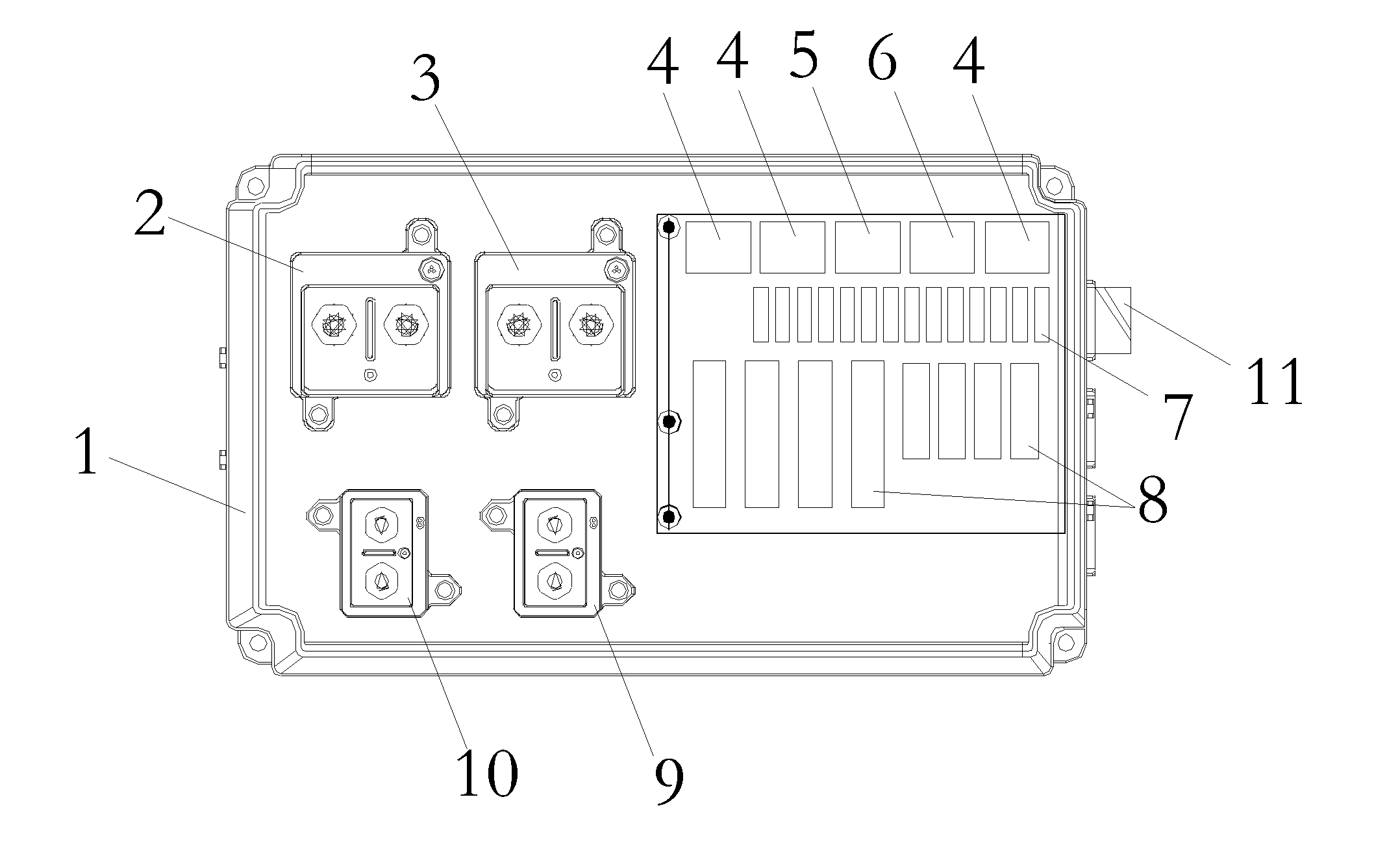

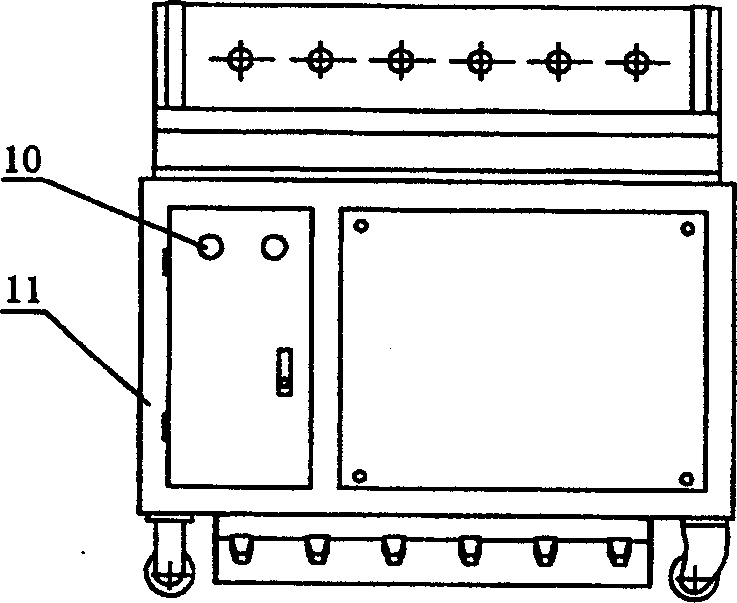

Electric control box for buses

InactiveCN102740621ARealize overheat and overcurrent protection functionNo burning phenomenonCircuit arrangements on support structuresSupport structure mountingPower switchingElectric control

The invention relates to an electric control box for buses. The electric control box comprises a casing, a mounting plate, and a printed circuit board, wherein the printed circuit board is fixed on the mounting plate and the mounting plate is fixed in the casing. The printed circuit board is provided with a power-on switch, a power switch, a five-point relay, a diode group, a time-delay relay, a preheat relay, a starting relay, and a fuse module. Compared with the prior art, the electric control box of the invention has the advantages of ability of realizing functions of overheating protection and over-current protection, good safety, small size, and the like.

Owner:ZHANGZHOU JINLONG BUS

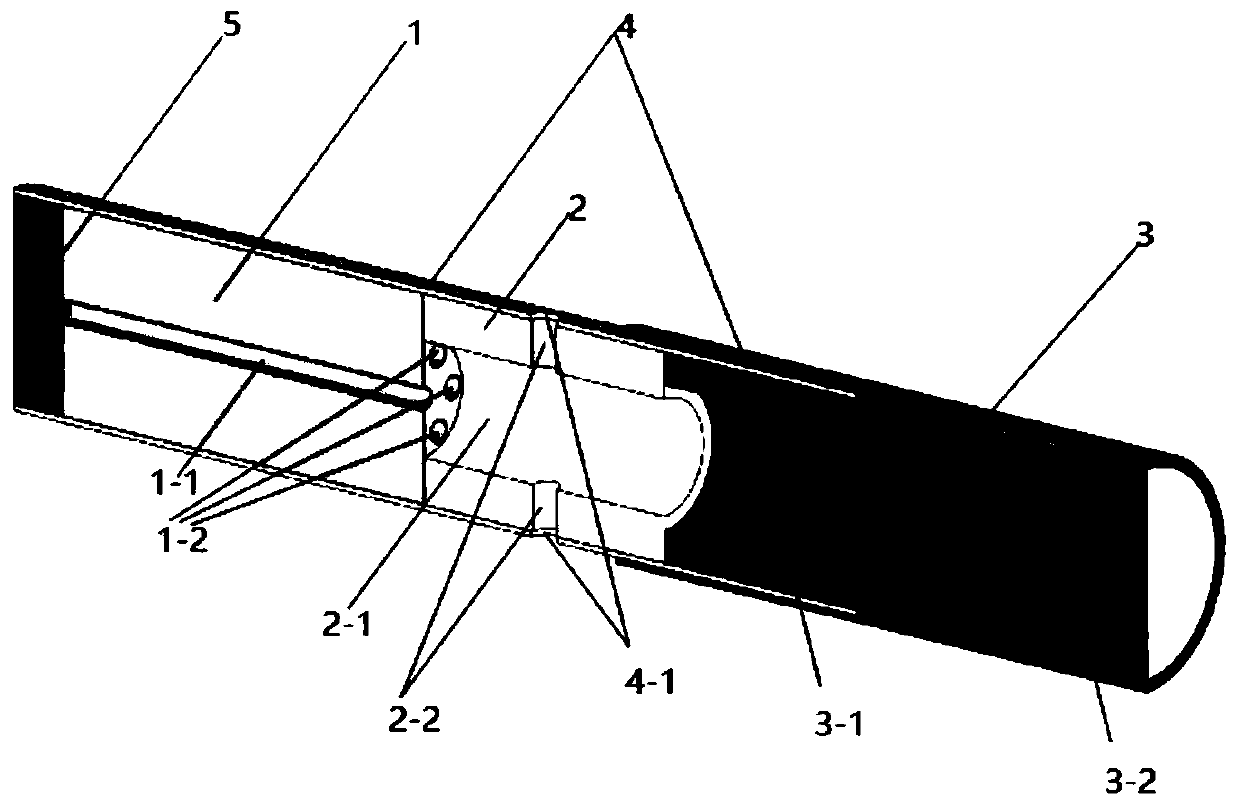

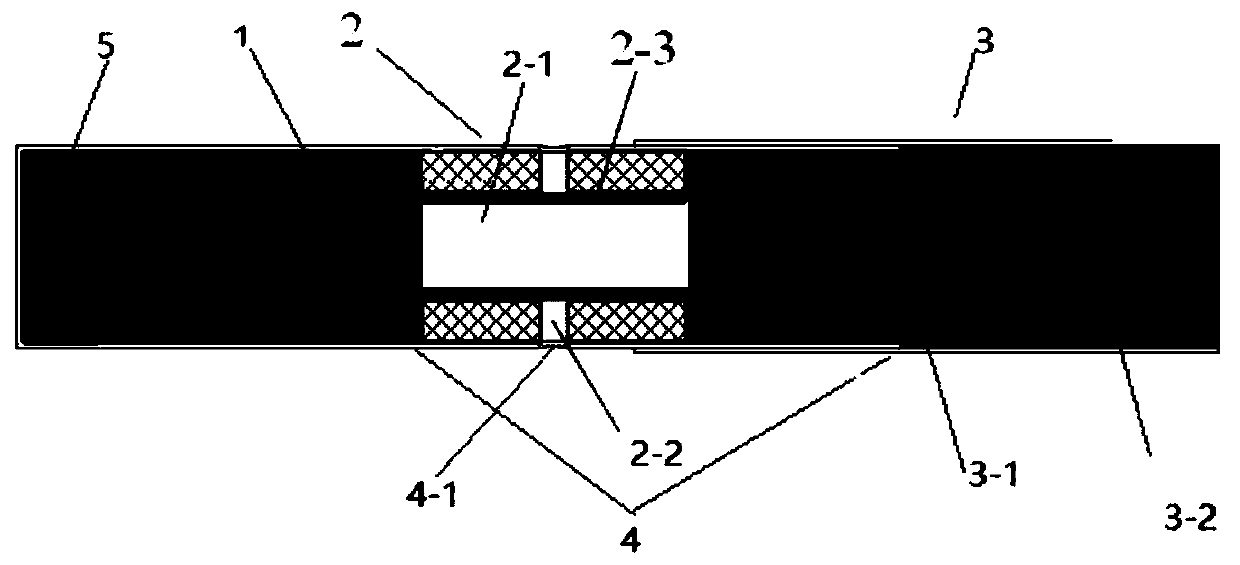

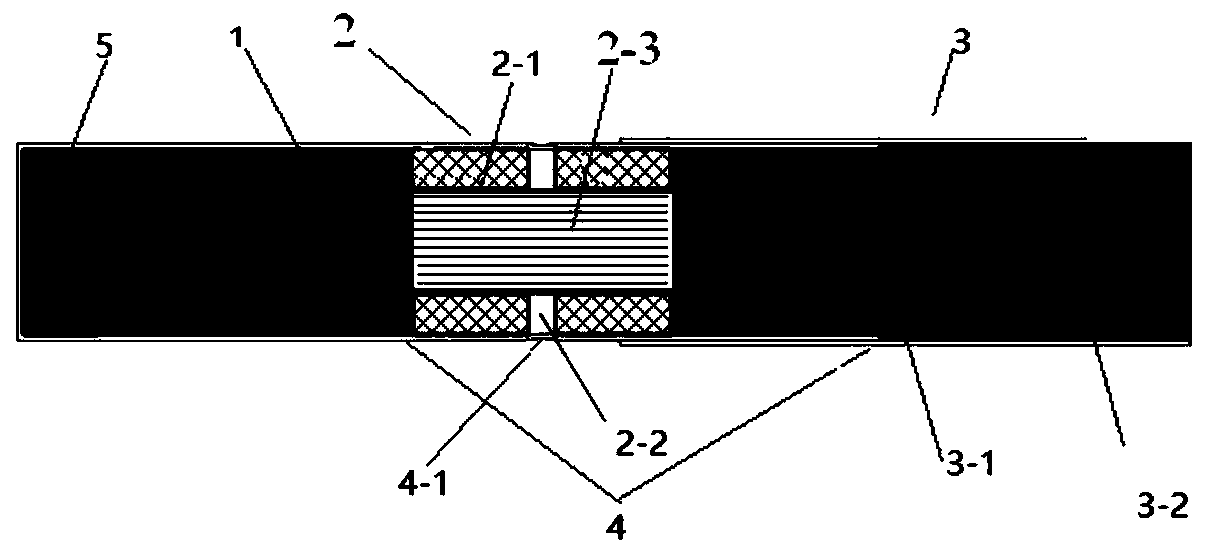

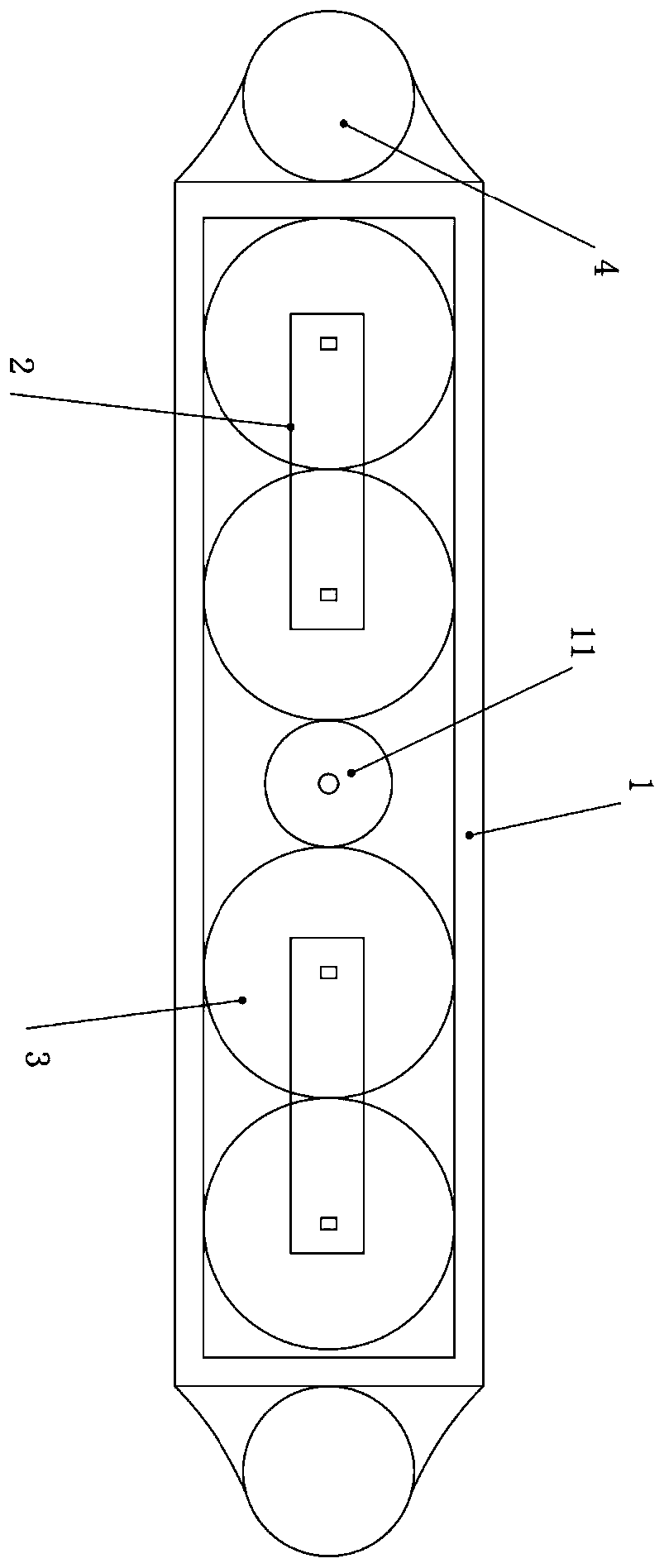

Closed heating type cigarette with smoke channel

PendingCN111567863ALower oxygen levelsFull release of aroma componentsCigar manufactureBurn cigaretteEngineering

The invention belongs to the field of heat-not-burn cigarettes, and particularly relates to a closed heating type cigarette with a smoke channel. The cigarette comprises a plug (5), a tobacco section(1), a low-suction-resistance section (2) and a functional filter tip section (3) which coaxially abut against one another in sequence from upstream to downstream, and the cigarette is wrapped with anouter wrapping piece (4). The low-suction-resistance section (2) is a pipe body provided with an axial center cavity (2-1) and at least one circumferential side wall through hole (2-2), and an axialfirst smoke channel (1-1) is formed in the axis of the tobacco section (1). According to the cigarette, a plurality of axial channels are designed in the tobacco section for the first time, and diffusion of smoke in the tobacco section is facilitated.

Owner:CHINA TOBACCO YUNNAN IND +1

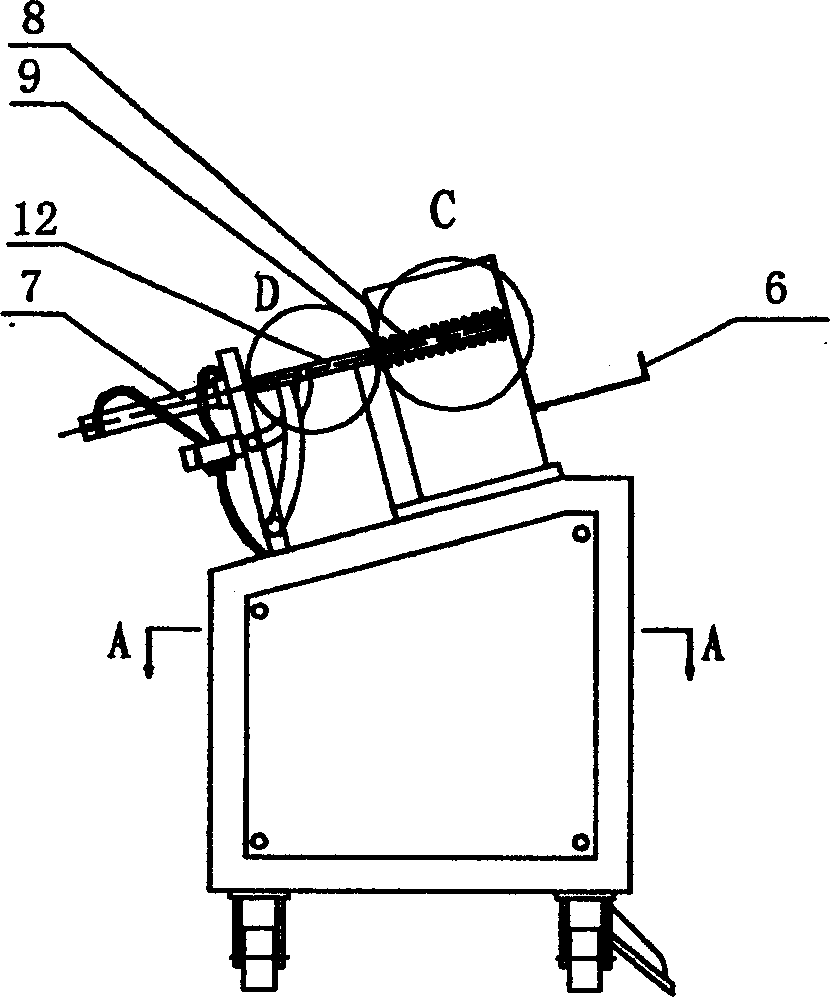

Electromagnetic induction rivet heater

InactiveCN1425516AEradicate pollutionImprove heating qualityInduction heating apparatusElectromagnetic inductionRivet

The electromagnetic induction rivet heater consists of one heater on the main body, one ejecting mechanism and one cooling system. The heater consists of lining and induction coil on the outer wall of the lining; the ejecting mechanism consists of one cylinder and one material ejecting pin capable of entering into or withdrawing from the lining in the same axis; and the cooling system has circulation water union communicated with the induction coil and the material ejecting pin. The lining is inclined and has material discharging end higher than the entering end of the material ejecting pin. The cooling system is equipped with low water pressure warning and water failure protecting system. The present invention has simple rivet heating process, low cost, high efficiency and other advantages.

Owner:JILIN UNIV

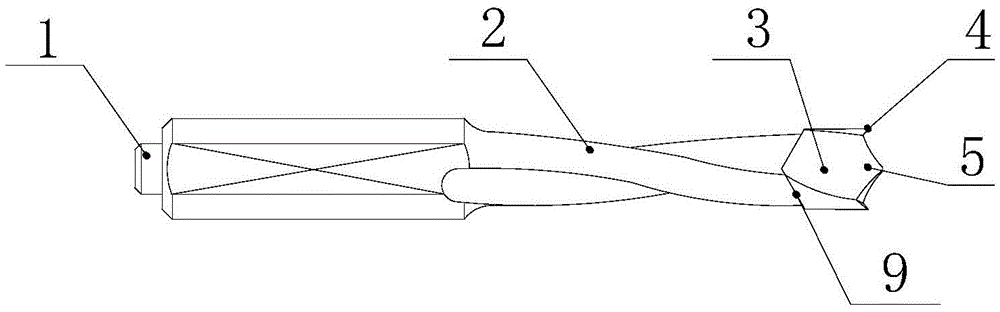

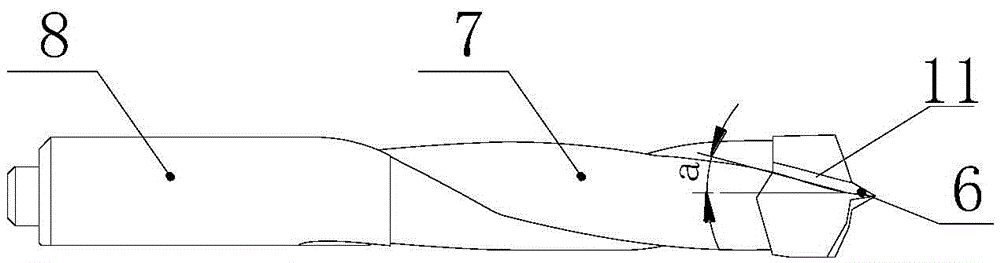

Carbide drill and machining process thereof

The invention relates to a carbide drill and a machining process thereof, and aims at providing a carbide drill with good wear resistance, good chip discharge performance and a long service life and a machining process thereof. The carbide drill comprises a drill tip, a tool body and a tool handle. The tool body and the tool handle are integrally formed, a plurality of spiral grooves are formed in the tool body, an included angle is formed between each spiral groove and the horizontal plane, and the included angle ranges from 10 degrees to 15 degrees. The left end section of the drill tip is a conical face, the end face, close to the drill tip, of the tool body has an inner conical angle with the taper identical to the taper of the left end section of the drill tip, and the end face, close to the drill tip, of the tool body is welded and fixed to the drill tip in a V-shaped butt welding mode. The drill tip comprises a drill tip body and a drill tip head, the surface of the drill tip body is in a W shape, a cross edge is arranged on the drill tip head, two cylindrical edge strips tangent to the outer circle of the drill tip are arranged on the drill tip, a marking edge parallel to the tool handle is arranged on the edge of the drill, and negative relief angle design is adopted in the marking edge. An adjusting screw capable of adjusting the length of the drill is arranged at the tail end of the tool handle.

Owner:ZHEJIANG LANGCHAO PRECISION MACHINERY

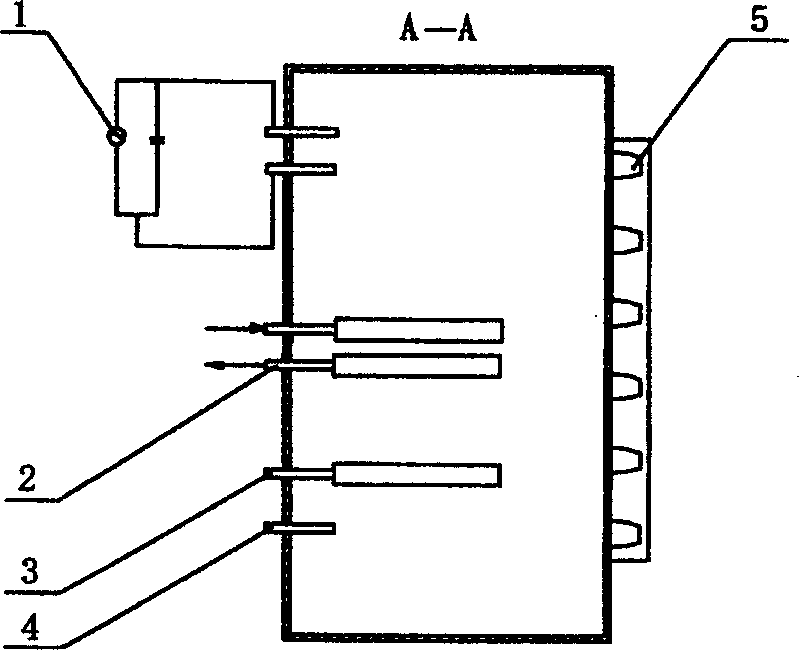

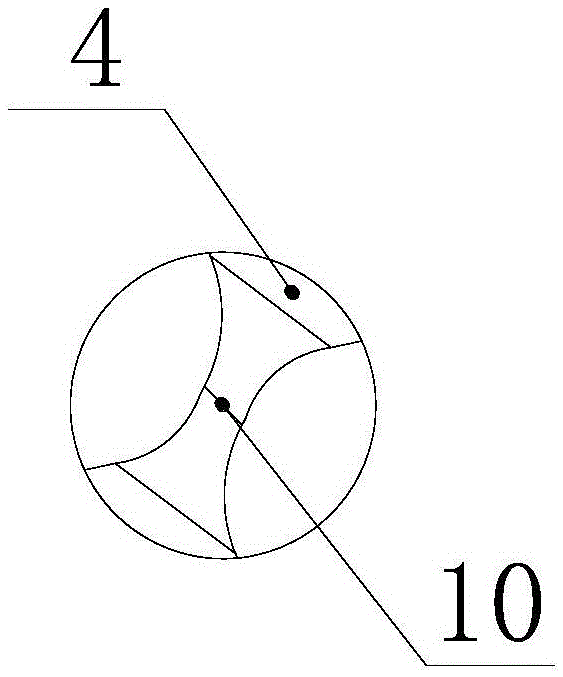

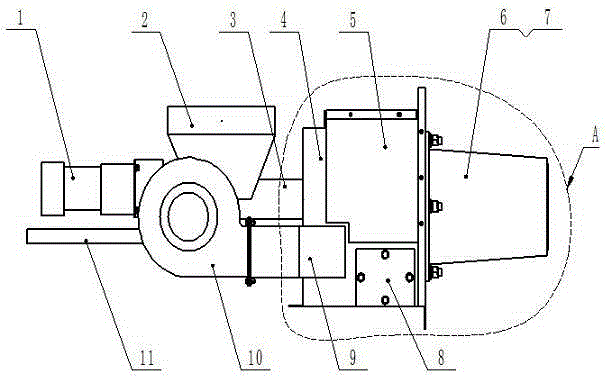

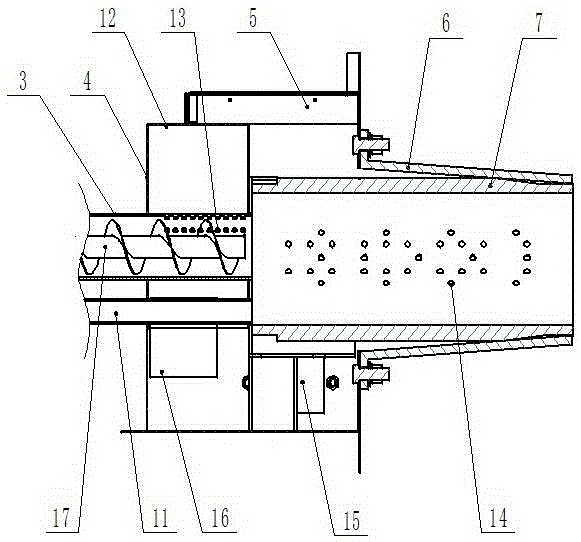

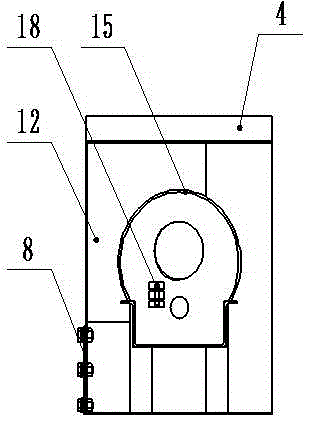

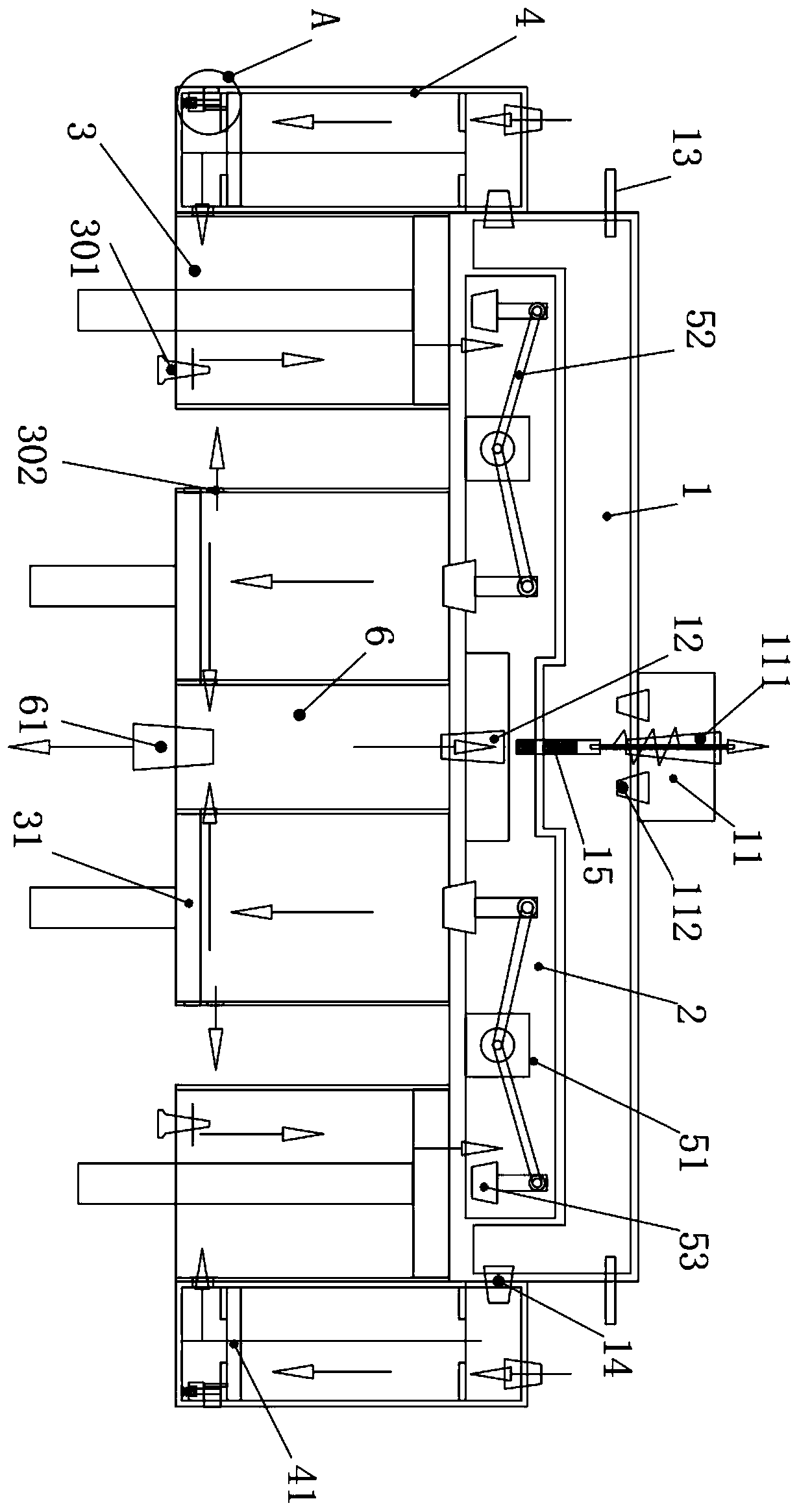

Biomass particle combustor

InactiveCN105240840ANo burning phenomenonFully dispersedSolid fuel combustionBlast-producing apparatusCombustorBiomass particle

The invention provides a biomass particle combustor. The biomass particle combustor comprises feeding equipment, combustion equipment and blast air supply equipment, wherein the feeding equipment comprises a material pipe; the combustion equipment comprises an inner fire outlet pipe and an outlet fire guide pipe; the blast air supply equipment comprises a blast pipe, an outer air box and an inner air box; the inner air box is arranged inside the outer air box, and the blast pipe is communicated with the outer air box and the inner air box; the material pipe penetrates through the inner air box to be communicated with the inner fire outlet pipe; the inner fire outlet pipe is arranged on the outer wall of the inner air box and penetrates through the outer air box, and vent holes are formed in the inner fire outlet pipe; the outlet fire guide pipe is fixed to the outside of the outer air box to sleeve the part, outside the outer air box, of the inner fire outlet pipe, and a gap is reserved between the outlet fire guide pipe and the inner fire outlet pipe and communicated with the outer air box. The biomass particle combustor is reasonable in structural design, low in cost and high in combustion efficiency.

Owner:广西节得乐生物质能源科技有限公司

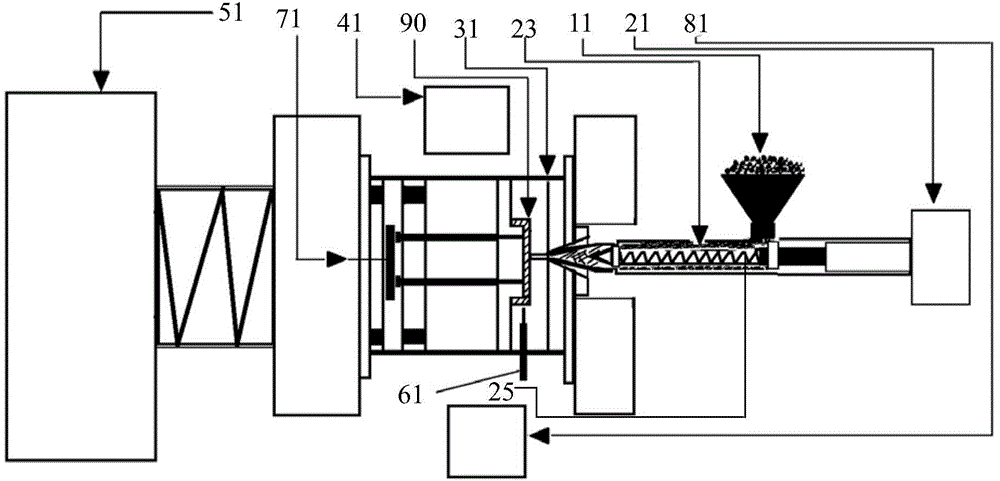

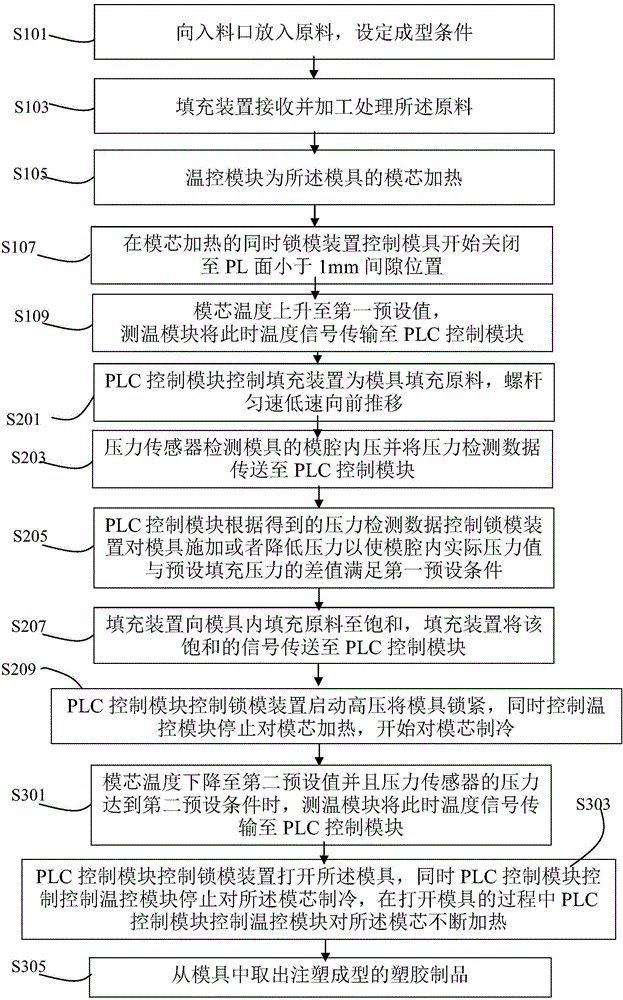

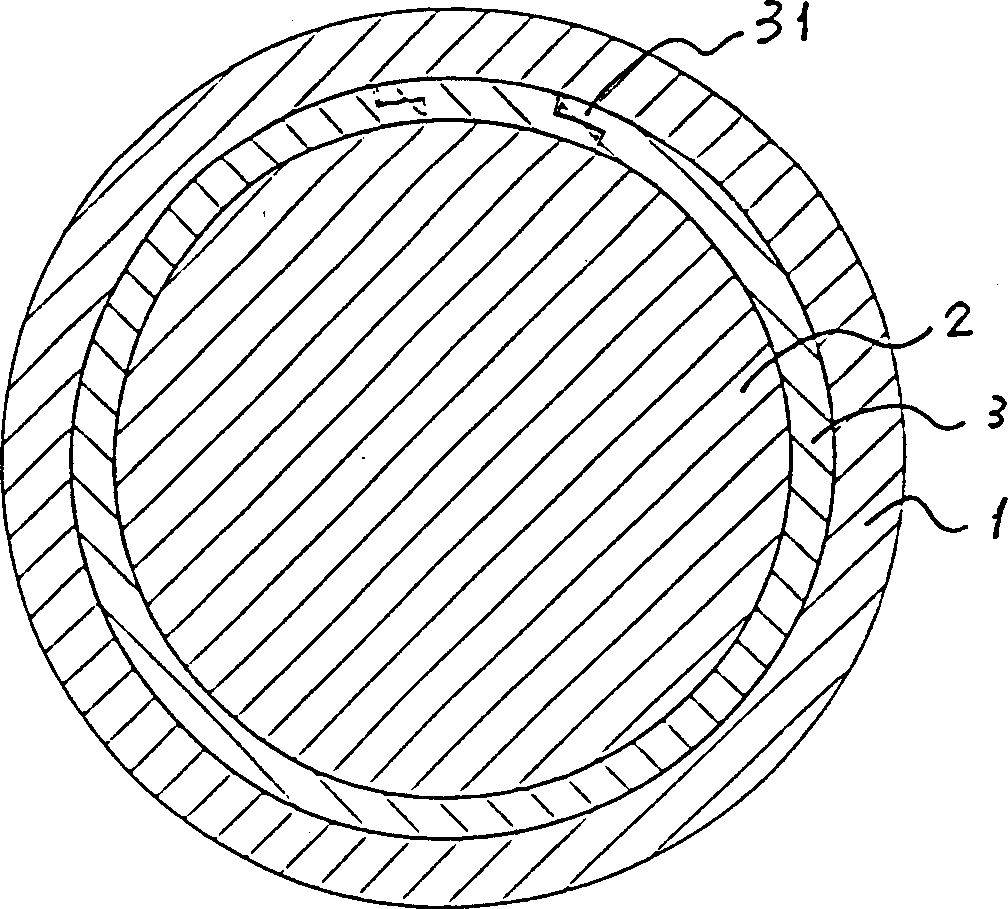

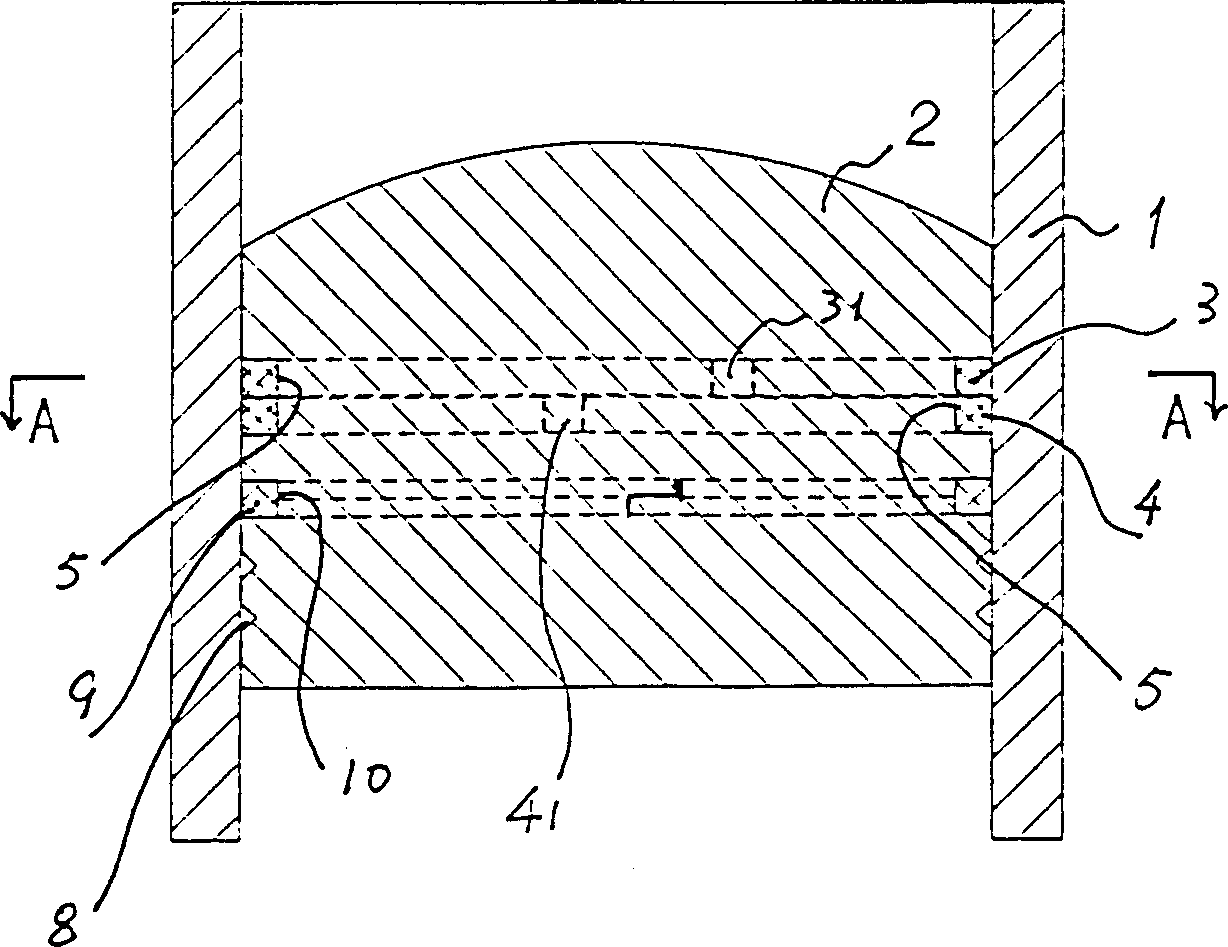

Injection molding method and system

The invention provides an injection molding method and system. The injection molding system comprises a feed opening, a filling device, a mold, a temperature control module, a mold locking device, a temperature measurement module, a pressure sensor and a PLC control module, wherein the feed opening is used for feeding raw materials; the filling device is connected with the feed opening and is used for receiving and processing the raw materials and injecting the raw materials into the mold; the mold is connected with the filling device and is used for performing injection molding; the temperature control module is connected with the mold and is used for heating or refrigerating a mold core of the mold; the mold locking device is connected with the mold and is used for controlling the opening and closing degree of the mold; the temperature measurement module is connected with the mold and is used for detecting the actual temperature of the mold; the pressure sensor is arranged on the mold and is used for detecting an actual pressure value of a mold cavity of the mold; and the PLC control module is respectively connected with the filling device, the temperature control device, the mold locking device and the temperature measurement module, and data of a first preset value, a second preset value, a first preset condition and a second preset condition are stored in the PLC control module. By implementing the injection molding method and system provided by the invention, an injection molding method and system which can be used for completely changing and improving conventional injection molding process steps and are low in cost and high in yield rate can be obtained.

Owner:SHENZHEN QIANHAI ANNAN INT SUPPLY CHAINMANAGEMENT SERVICE

Improved cylinder

InactiveCN1391033AImprove sealingNo burning phenomenonPiston ringsMachines/enginesPiston ringControl theory

An improved cylinder features that two parallel piston rings are in a slot on piston, the joint of piston ring is butt connected in step mode, the joints of two piston rings are staggered. It is possible that two piston rings are sleeved together. Its advantages are high durability and sealing performance, and elongated service life of engine.

Owner:段华

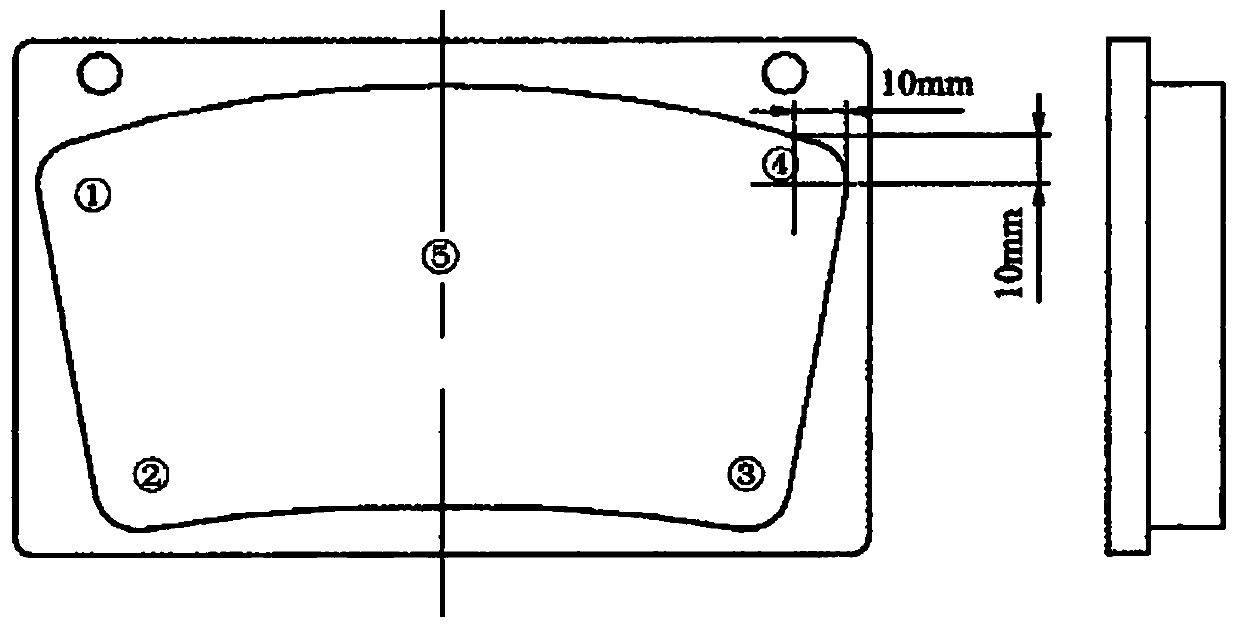

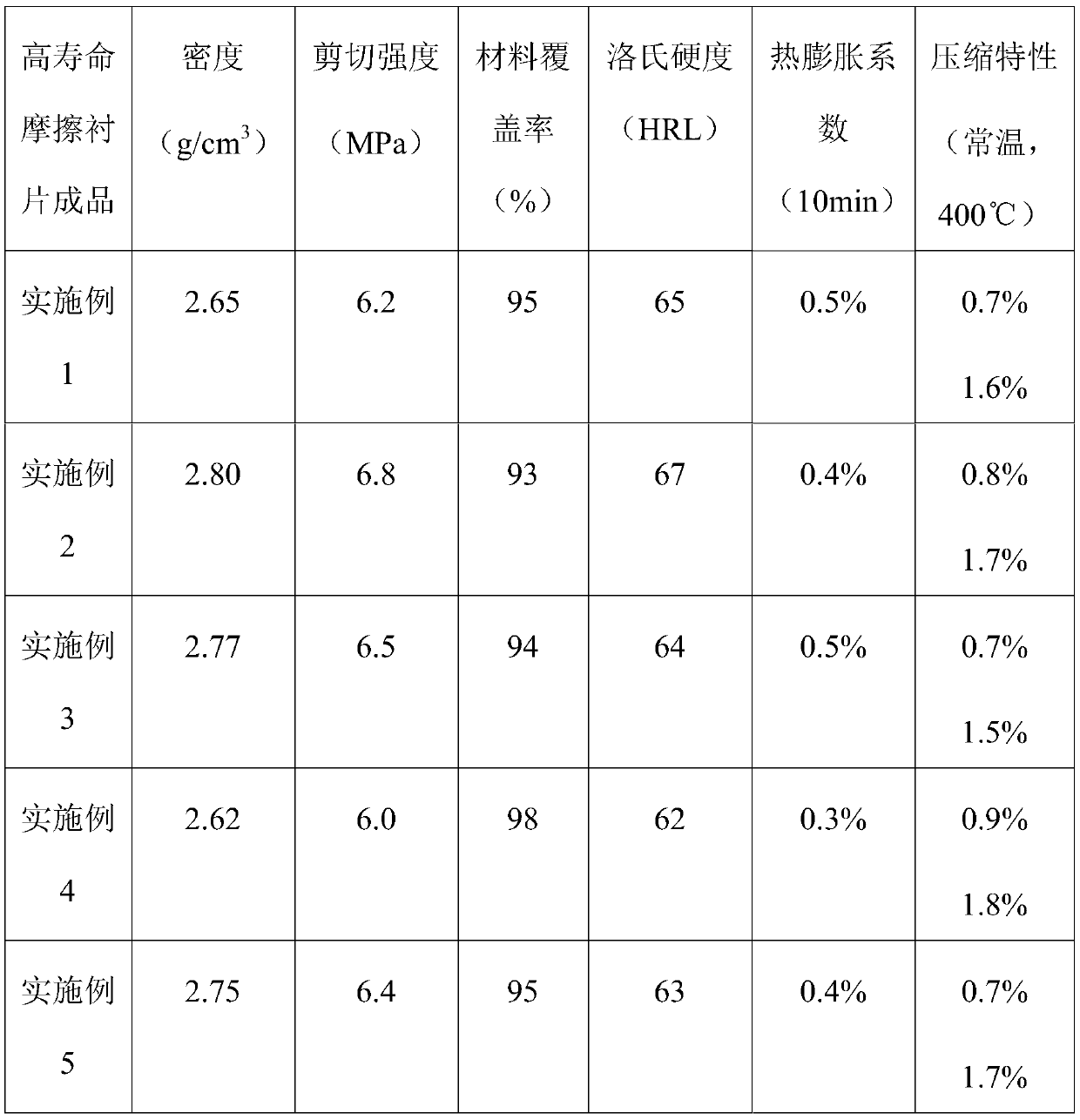

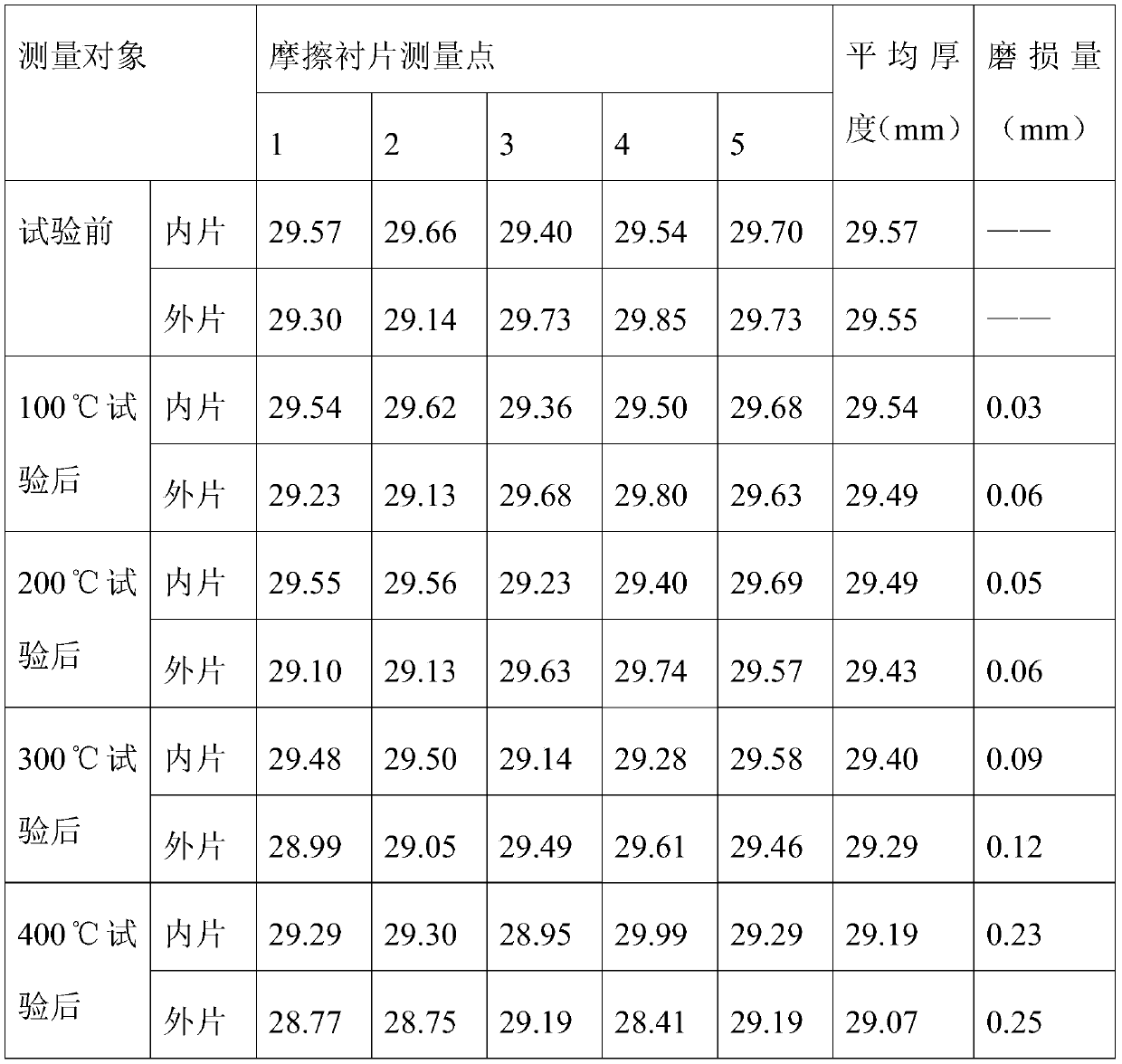

Friction material, long-life friction lining and preparation method thereof

The invention provides a friction material, a long-life friction lining and a preparation method thereof. The friction material comprises the following raw materials, by weight, 5-8 parts of basalt fiber; 10-15 parts of steel fiber; 5-6 parts of composite mineral fiber; 6-10 parts of butyronitrile modified phenolic resin, 3-8 parts of powdered acrylonitrile-butadiene rubber, 5-9 parts of graphite,10-15 parts of precipitated barium sulfate, 2-5 parts of aramid pulp, 2-5 parts of titanate lamellar crystals, 9-15 parts of light calcium carbonate, 7-12 parts of magnesium oxide, 3-6 parts of calcined aluminum oxide, 5-8 parts of red copper fibers, 5-9 parts of ferrous sulfide and 9-12 parts of fluorite. By reasonably setting the content of each component, the components generate a synergisticeffect, when the components are proportioned together to be used for the friction lining, it is confirmed through loading test and verification that the service life of the friction lining reaches 120,000 km or above, and the friction lining is complete and free of edge and corner falling, delaminating and scorching phenomena.

Owner:BEIJING TIANRENDAOHE NEW MATERIAL CO LTD

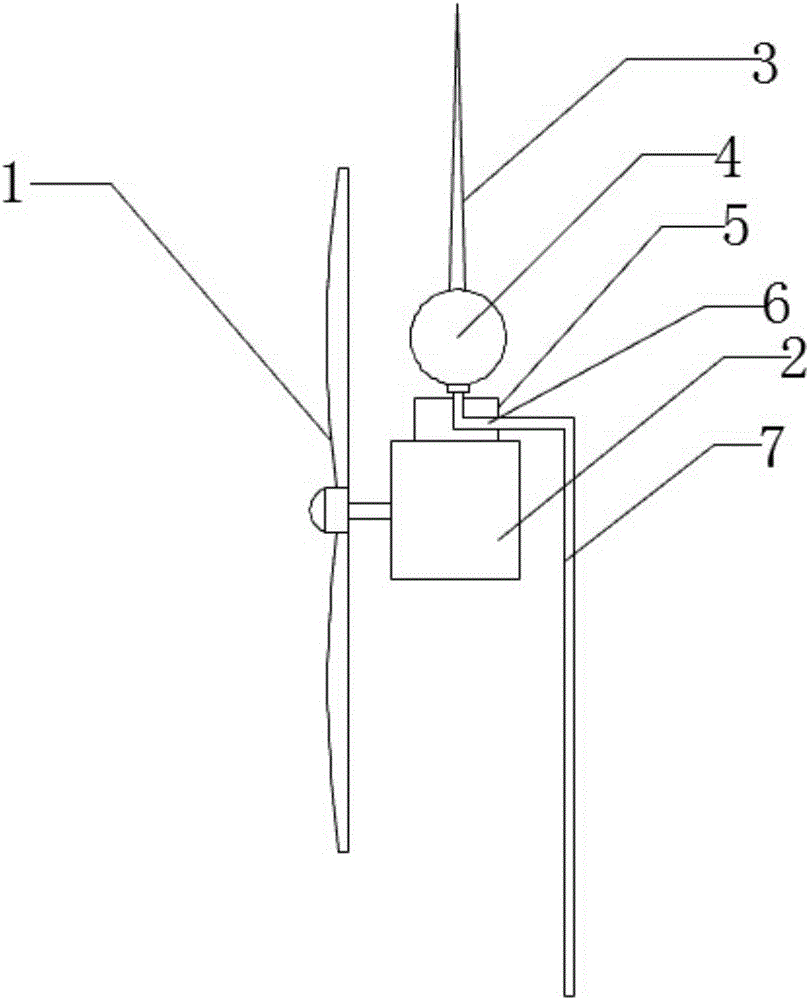

Lightning protection system for wind power generation device

InactiveCN106762467ANo burning phenomenonEffective lightningMachines/enginesWind energy generationPower flowLightning rod

The invention discloses a lightning protection system for a wind power generation device. The system comprises an electric field shielding box mounted on the outer side of a wind turbine unit, wherein a lightning rod is mounted a the top of the electric field shielding box, and the top end height of the lightning rod is larger than the height of blades of the wind turbine unit; a lightning ball is further mounted on the lightning rod; an earthing wire is connected with the bottom of the lightning rod and mounted in the electric field shielding box, and a composite structure is adopted in the electric field shielding box. The lightning rod and the lightning ball are used for effectively triggering lightning, and the electric field shielding box is arranged close to the wind turbine unit, thus, burning of internal circuit elements in the wind turbine unit can be avoided even if high currents of the earthing wire leak.

Owner:YUNNAN ENERGY INVESTMENT HAIZHUANG NEW ENERGY EQUIP

Closed heating type cigarette capable of reducing sidestream smoke

PendingCN111567862AReduce churnFull release of aroma componentsCigar manufactureEngineeringMechanical engineering

The invention belongs to the field of cigarettes, and particularly relates to a closed heating type cigarette capable of reducing sidestream smoke. The cigarette comprises a tobacco section (1), a low-suction-resistance section (2) and a functional filter tip section (3) which are sequentially and coaxially connected in an abutting mode from upstream to downstream, wherein the low-suction-resistance section (2) is a pipe body with an axial central cavity (2-1) and a circumferential side wall through hole (2-2); and the low-suction-resistance section (2) further comprises barrier layers (2-3) which are arranged on the circumferential side wall of the central cavity (2-1) and have certain air permeability. According to the cigarette, the barrier layers covering the circumferential side wallof the central cavity and the side wall through holes are arranged on the low-suction-resistance section, the cigarette has certain air permeability, and inflow of external air is not affected duringsmoking; and when the cigarette is not sucked, the smoke cannot escape through the side wall through holes, so that the smoke loss can be effectively reduced.

Owner:CHINA TOBACCO YUNNAN IND +1

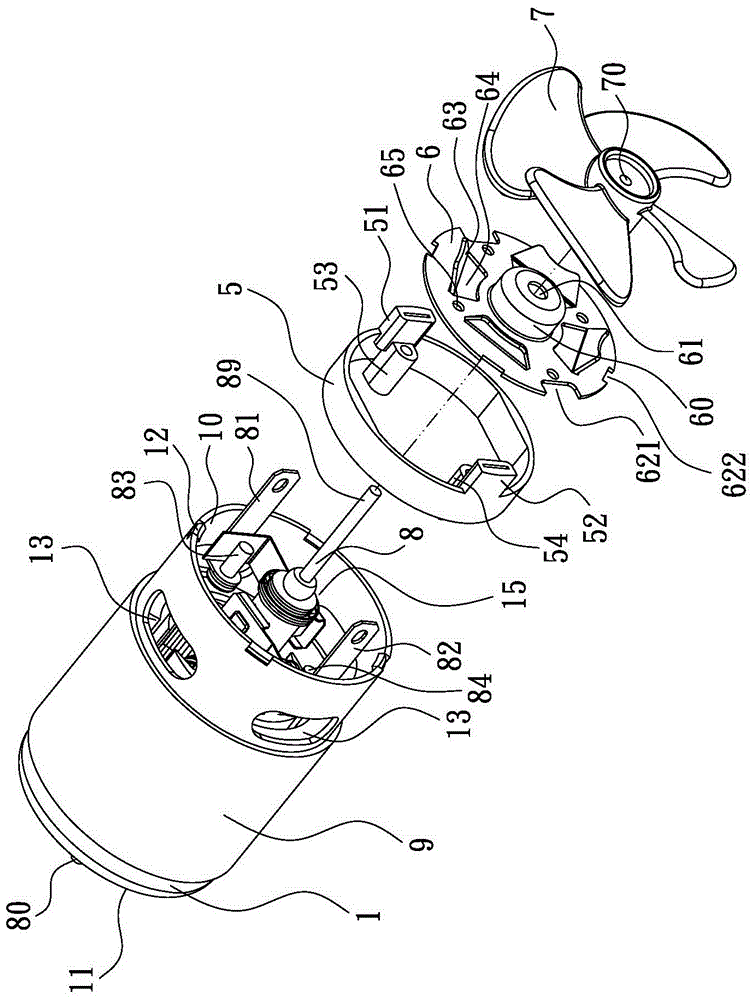

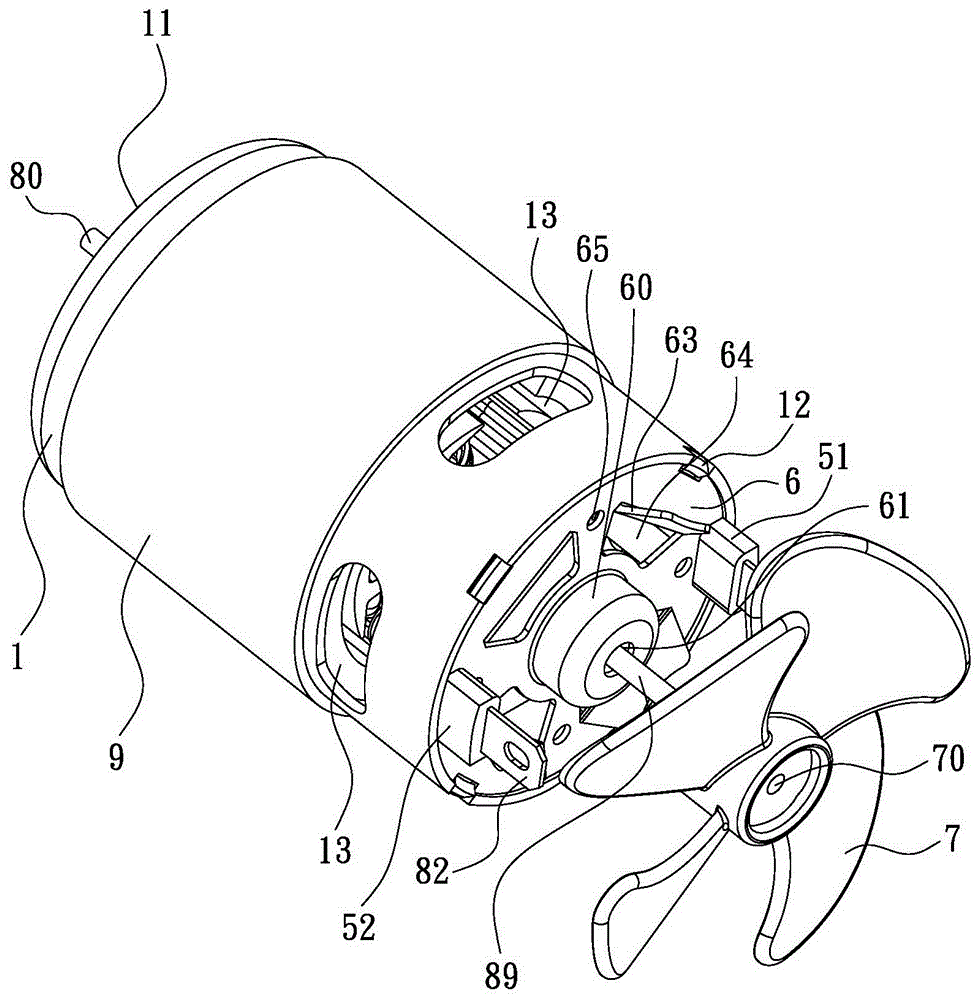

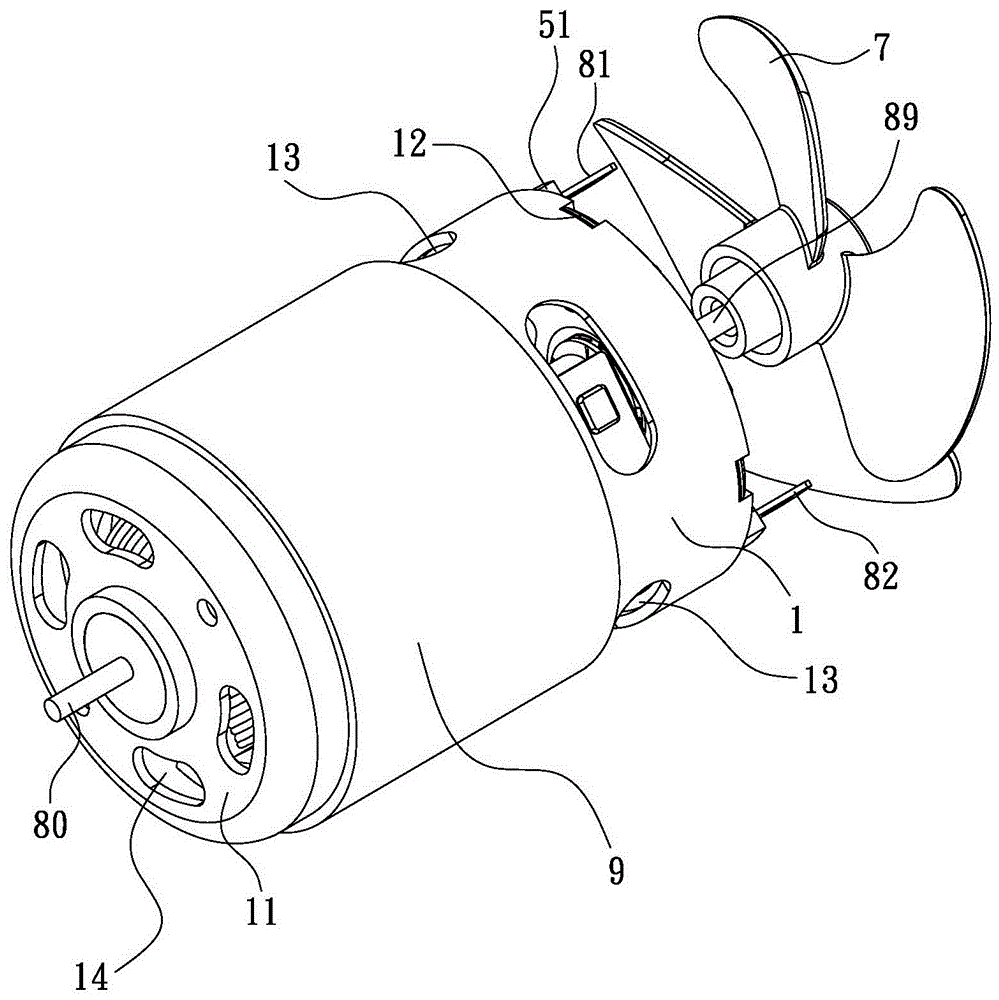

Motor heat dissipation structure

InactiveCN106329828AEfficient cooling and coolingNo burning phenomenonPositive displacement pump componentsPiston pumpsEngineeringFront cover

A motor heat dissipation structure is provided; revolution airflow formed by a cooling fan installed in the motor side in operation can be quickly led into the motor housing to play the role of heat dissipation, so that the motor is not easy to accumulate heat inside; the front end of the motor housing is provided with a front cover having a plurality of wind guide plates and a drain port, and the circular swirling forward airflow generated when the cooling fan rotates can be directly blocked by the wind guide plates of the front cover, and can directly enter the motor housing by the drain port; the outer part of the circular swirling forward air flow can also be blown from the outer periphery of the housing to the outer surface of the housing, so that the outer housing is also dissipated at the same time, thus forming multiple heat dissipation paths, and exerting more effective heat dissipation; the inner side of the motor housing cannot accumulate heat, so the motor operational maximum output power can be realize , thus enhancing the motor operating efficiency, and also extending the life of the motor.

Owner:周文三

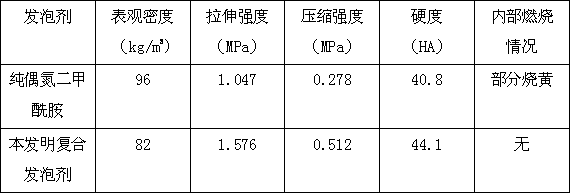

Composite foaming agent for rigid PVC foam material

The invention discloses a composite foaming agent for a rigid PVC foam material. The foaming agent comprises the following raw materials, by weight: 5-10 parts of azodicarbonamide, 2-4 parts of diethyl azodicarboxylate, 2-3 parts of OBSH, 0.5-1.5 parts of lauryl sodium sulfate, 1-2 parts of sodium bicarbonate, 1-2 parts of zinc carbonate, 1-3 parts of urea, 0.5-0.8 part of lead stearate, 2-4 parts of citric acid, and 15-20 parts of glycol propyl ether. According to the invention, raw materials including urea, zinc carbonate, sodium bicarbonate, sodium dodecyl sulfate are adopted for modification of azodicarbonamide to prepare the composite foaming agent for rigid PVC foam material; and the composite foaming agent has advantages of decomposition temperature within the range of molding processing of rigid PVC foam material, basically balanced heat absorption-release, smooth decomposition rate, large deflating amount and no abruptness. The rigid PVC material prepared from the composite foaming agent has good mechanical properties, uniform and fine pores, thin pore wall, easily controlled processing conditions, and no emergence of burning.

Owner:安徽艾柯泡塑股份有限公司

Superspeed pure-tin electroplating additive

The invention belongs to the technical field of electroplating, and relates to a superspeed pure-tin electroplating additive which is prepared from a formula as below: 3 to 5 percent by weight of non-ionic surface active agent, 5 to 10 percent by weight of beta-naphthol polyoxyethylene ether, 1 to 3 percent by weight of alkyl glycoside, 0.1 to 0.3 percent by weight of naphthol sulfonic acid, 0.5 to 1 percent by weight of EO / PO copolymer, 1 to 2 percent by weight of catechol, and the balance deionized water. According to the superspeed pure-tin electroplating additive provided by the invention,the electric current density of electrotinning can be improved to 40ASD, no scorching phenomenon occurs, the electroplating efficiency is greatly accelerated, and in addition, the superspeed pure-tinelectroplating additive is good in oxidation resistance, easy to degrade and more environmental-friendly.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

Closed heating type cigarette with controllable suction resistance

PendingCN111588079ALower oxygen levelsReduce churnCigar manufactureBurn cigaretteMechanical engineering

The invention belongs to the field of heat-not-burn cigarettes, and particularly relates to a closed heating type cigarette with controllable smoking resistance. The cigarette comprises a tobacco section (1) with a sealed upstream end, a controllable suction resistance section (2) and a functional filter tip section (3) which are sequentially and coaxially connected in an abutting mode from upstream to downstream, and the cigarette is wrapped with an outer wrapping piece (4). The controllable suction resistance section (2) is a pipe body with an axial central cavity (2-1) and a circumferentialside wall through hole (2-2), and the controllable suction resistance section (2) further comprises a limiting flow guide element (2-3) which is arranged in the center cavity (2-1) and provided withan axial channel. According to the cigarette, a blocking layer covering the circumferential side wall of the central cavity and the side wall through holes is arranged on the controllable suction resistance section, the cigarette has certain air permeability, inflow of external air is not affected during suction, and when the smoke is not sucked, the smoke cannot escape through the side wall through holes, so that the smoke loss can be effectively reduced.

Owner:CHINA TOBACCO YUNNAN IND +1

Oil-free aerodynamic engine

PendingCN110486185ANo burning phenomenonWide range of usesOpen-cycle gas positive displacement engine plantControl systemInlet valve

The invention discloses an oil-free aerodynamic engine. The oil-free aerodynamic engine comprises a vacuum heat insulation box, wherein a heating box is arranged in the vacuum heat insulation box, a metal heating element is arranged in the heating box, an air pressure variable speed cylinder is arranged inside or outside the heating box, one or more air inlet valves are arranged on the side, closeto air cylinders, of the interior of the variable speed cylinder, and an air pressure control box is arranged outside the heating box; an air pressure control valve and a control system are arrangedin the air pressure control box, a steel wire system formed by an air needle, an air inlet guide pipe, a reset spring and a remote controller is arranged, the magnitude of air pressure energy enteringthe variable speed cylinder from a heating chamber can be controlled, the amount of work done by the air cylinders can be controlled by the change of the magnitude of the air pressure energy in the variable speed cylinder, and thus the effect of accelerating or decelerating the engine is realized; and air cylinder barrels are arranged on the left side and the right side of the heating box, the air cylinder barrels feed air into the heating box and supplement air into the heating box in the acting process, and the air cylinder barrels also play a role in supplementing the air to the air cylinders in the A set.

Owner:朱国钧

Non-penetration copper build up welding method on D406A steel surface

InactiveCN103170709AClear interfaceNeat interface rulesArc welding apparatusWelding/cutting media/materialsHeat-affected zoneHigh intensity

The invention discloses a non-penetration copper build up welding method on a D406A steel surface. The non-penetration copper build up welding method on the D406A steel surface is characterized by including the following steps: (1) conducting thermal refining process on D406A steel, (2) soaking and fixing the D406A steel which is processed through thermal refining in the step (1) in quenching liquid, keeping the surface to be welded above the liquid surface of the quenching liquid, or spraying the quenching liquid to a reverse face of the to-be-welded surface of the D406A steel, and (3) conducting copper build up welding on the to-be-welded surface of the D406A steel by using CuSi3 welding wires through the cold metal transfer (CMT) welding method. According to the non-penetration copper build up welding method on the D406A steel surface, heat input is extremely low in welding process, a heat affected zone is extremely small, diffusion amount of copper to a substrate is fewer and even, diffusion depth is not more than 0.1 millimeter, interfaces between different kinds of materials are distinct, neat and regular, no burning loss occurs, and high strength metallurgical bonding is achieved and influence from the welding process on steel substrate performance is reduced at the same time.

Owner:湖北三江航天江北机械工程有限公司

Preparation process of high-thermal-conductivity eutectic aluminum alloy material

The invention discloses a preparation process of a high-thermal-conductivity eutectic aluminum alloy material, and belongs to the technical field of eutectic aluminum alloy material preparation. According to the preparation process, a nanoscale seed crystal refiner adding and filtering purification process is added in the preparation process, so that the effective residual amount of the B elementand the purity of molten aluminum are controlled, aluminum alloy is fully refined, the B element in the aluminum alloy does not have oxidation and burning loss phenomena, a product has a long-acting and stable effect, by fully filtering and purifying high-temperature molten aluminum alloy, harmful impurities in the product are effectively controlled, the product performance is effectively guaranteed, intermediate modifiers and refiners do not need to be added again in the die-casting process, and the process has the excellent characteristics of being efficient and rapid.

Owner:南通鸿劲金属铝业有限公司

Non-combustible 360 DEG-spraying baking-oven cleaning aerosol, and preparation method thereof

InactiveCN107189868AImprove permeabilityImprove decontamination abilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCooking & bakingNitrogen gas

The invention discloses a non-combustible 360 DEG-spraying baking-oven cleaning aerosol, and a preparation method thereof. The non-combustible 360 DEG-spraying baking-oven cleaning aerosol comprises, by weight, 100 parts of deionized water, 3 to 15 parts of triethanolamine, 0.5 to 10 parts of isopropanol, 0.5 to 10 parts of fatty alcohol polyoxyethylene ether, 0.2 to 2 parts of sodium benzoate, 0.05 to 1.5 parts of an essence, and 0.01 to 1.5 parts of nitrogen. According to the preparation method, the non-combustible 360 DEG-spraying baking-oven cleaning aerosol is prepared via reasonable combination of mild and environment-friendly components such as surfactants; penetration capacity and decontamination capacity are excellent; no irritation is caused; no pollution is caused; the non-combustible 360 DEG-spraying baking-oven cleaning aerosol is used for cleaning heavy oil stain accumulated on smoke exhaust ventilators and baking ovens caused by long term use, and effect is excellent.

Owner:雄县碧海日化有限公司

Method for rapidly drying ophiopogon japonicus in production place

InactiveCN107062805AQuality improvementSimple processDrying solid materials without heatPreliminary solid treatment for dryingSurface moistureFibril

The invention discloses a method for rapidly drying ophiopogon japonicus in a production place. According to the method for rapidly drying the ophiopogon japonicus in the production place, the problems that in the prior art, the drying product quality and drying efficiency of ophiopogon japonicus in a production place cannot be taken into account, the shape of obtained ophiopogon japonicus is incomplete, and the quality is influenced are solved. The method for rapidly drying the ophiopogon japonicus in the production place comprises the following steps that A, the ophiopogon japonicus is harvested, fibril and impurities are removed, cleaning is conducted, surface moisture is aired, and the fresh ophiopogon japonicus is obtained; B, the fresh ophiopogon japonicus obtained in the step A is placed in a vacuum dryer to be heated and dried; and C, the dried ophiopogon japonicus is cooled to the indoor template and packed, and the ophiopogon japonicus is obtained. The process is simple, and operation is easy; and by adopting the method to dry the production place ophiopogon japonicus, time is short, labor intensity is low, and the quality of an obtained finished product is high.

Owner:成都众宜坊农业开发有限公司

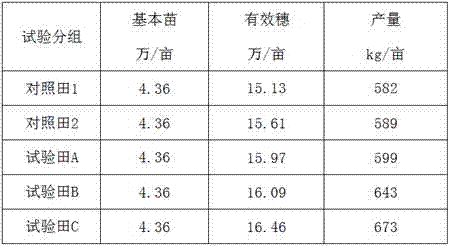

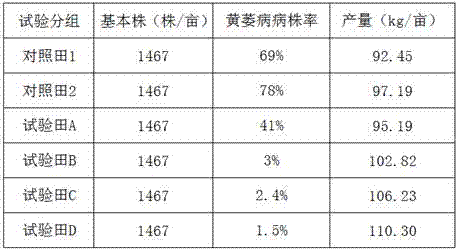

Fermentation technology of biological organic bacterial manure

ActiveCN107188724AHigh activityWarming up fastBio-organic fraction processingExcrement fertilisersBiotechnologyOil processing

The invention relates to a fermentation technology of biological organic bacterial manure, and belongs to the technical field of biological organic bacterial manure manufacturing. The technology includes the steps that the raw materials of chicken manure, tobacco waste and cereal, cotton and oil processing plant waste are piled at the normal temperature to be naturally dehydrated; then, a compound fermentation strain is added, and after two times of fermentation and ageing treatment, the biological organic bacterial manure is obtained. By means of the technology, escherichia coli, ascaris eggs and some infectious germs in the chicken manure can be killed in the decomposing process, worm eggs or harmful pathogens or weed seeds in the mixed materials can be thoroughly killed through ageing treatment, and thus the biological bacterial manure is deeply decomposed and has high fertilizer efficiency. The technology is environmentally friendly in production process, short in decomposing period and small in nutrient loss; experiments on the crops of rice, lactuca sativa L, cotton and the like show that the yield is greatly increased, and pest and disease damage is effectively controlled. The problems that in a traditional fermentation method, maturity is low, pathogens and weed seeds in raw materials can not be completely killed, the fermentation process pollutes the environment and fertilizer efficiency is low are solved.

Owner:HUBEI SHUANGGANG AGRI SCI & TECH TRADE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com