Patents

Literature

1018results about "Wood boring tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

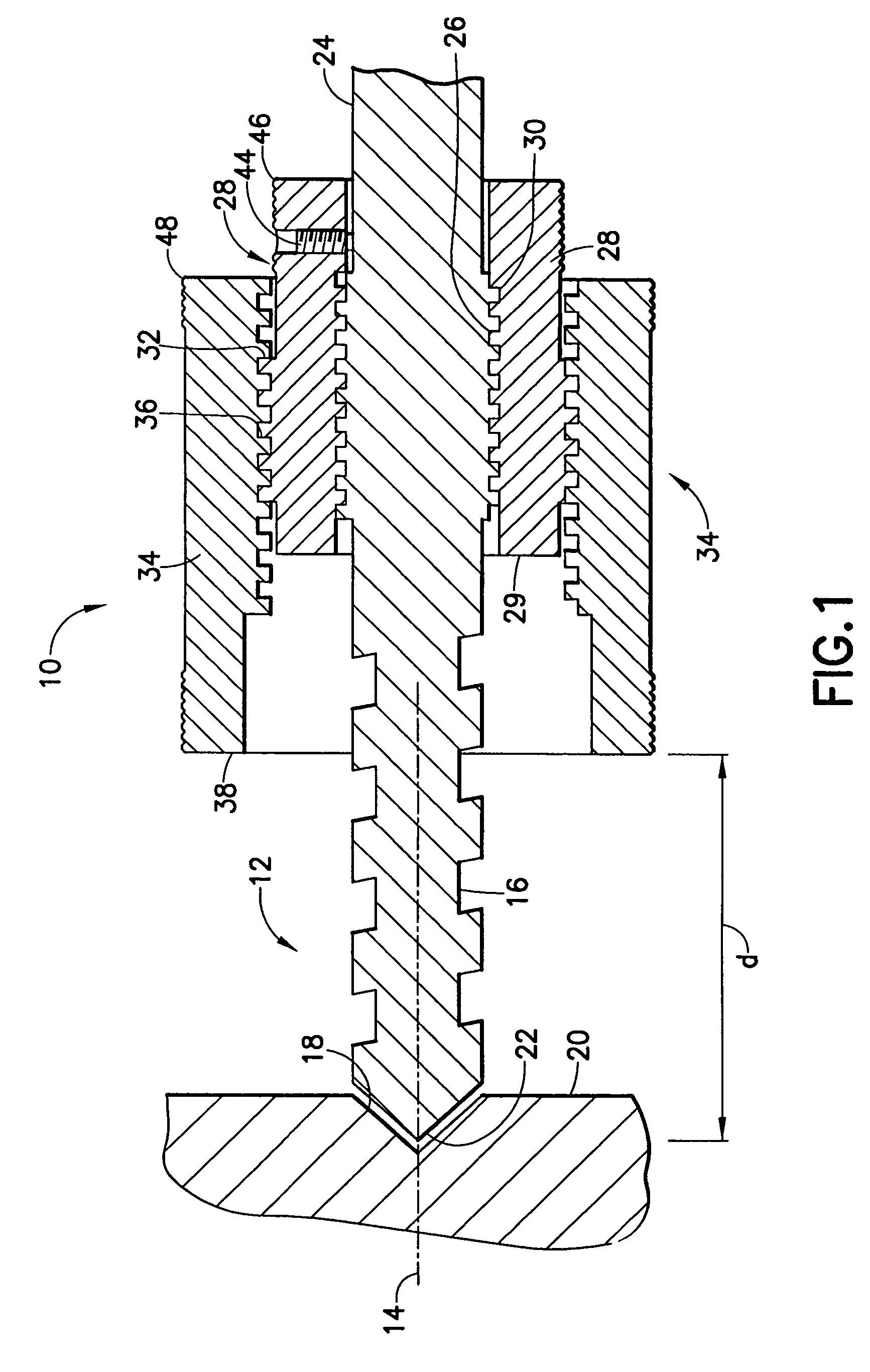

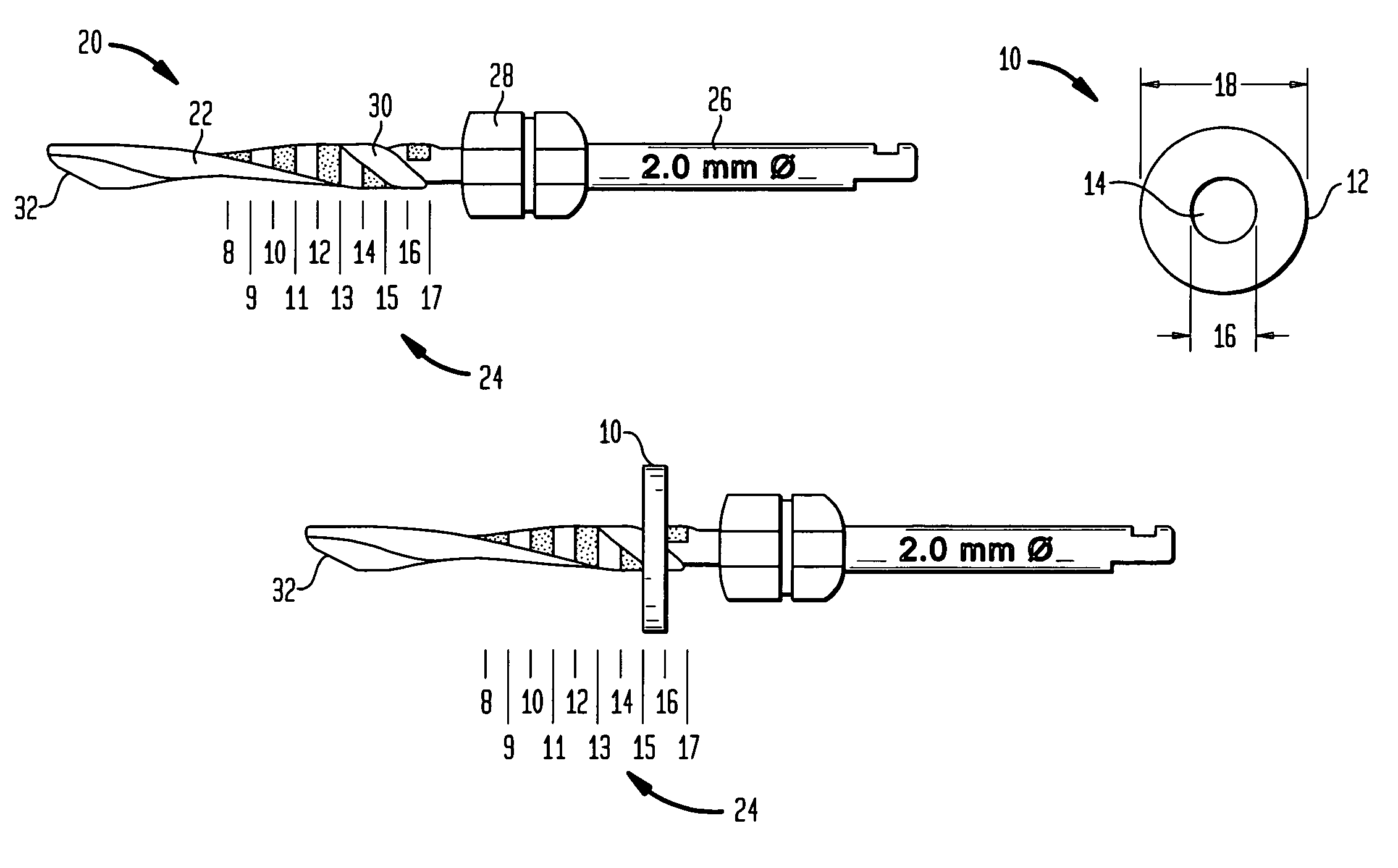

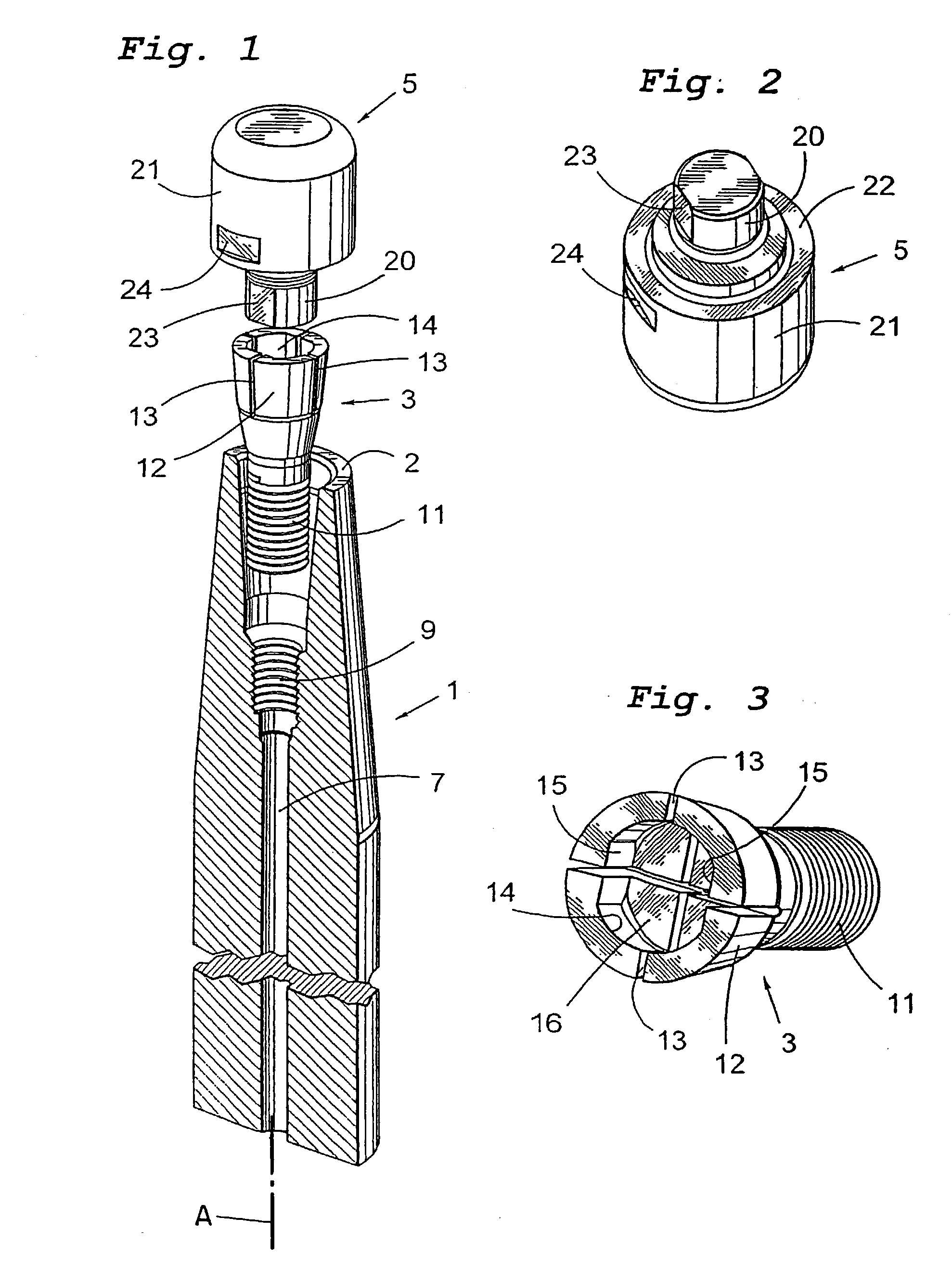

Sleeved stop for a drill bit

A stop for use with an electric drill bit, the stop having at least one threaded sleeve for positioning the stop relative to a surface into which the drill bit will extend. The stop may have both an inner and an outer sleeve. The sleeves are mounted coaxially, one inside the other about the drill bit. One of the sleeves, preferably the inner sleeve, provides coarse adjustment of the position of the shoulder relative to the tip of the bit, while the other, preferably the outer sleeve, provides fine adjustment of the position of the shoulder relative to the top of the bit.

Owner:3D SCAN GUIDE LLC

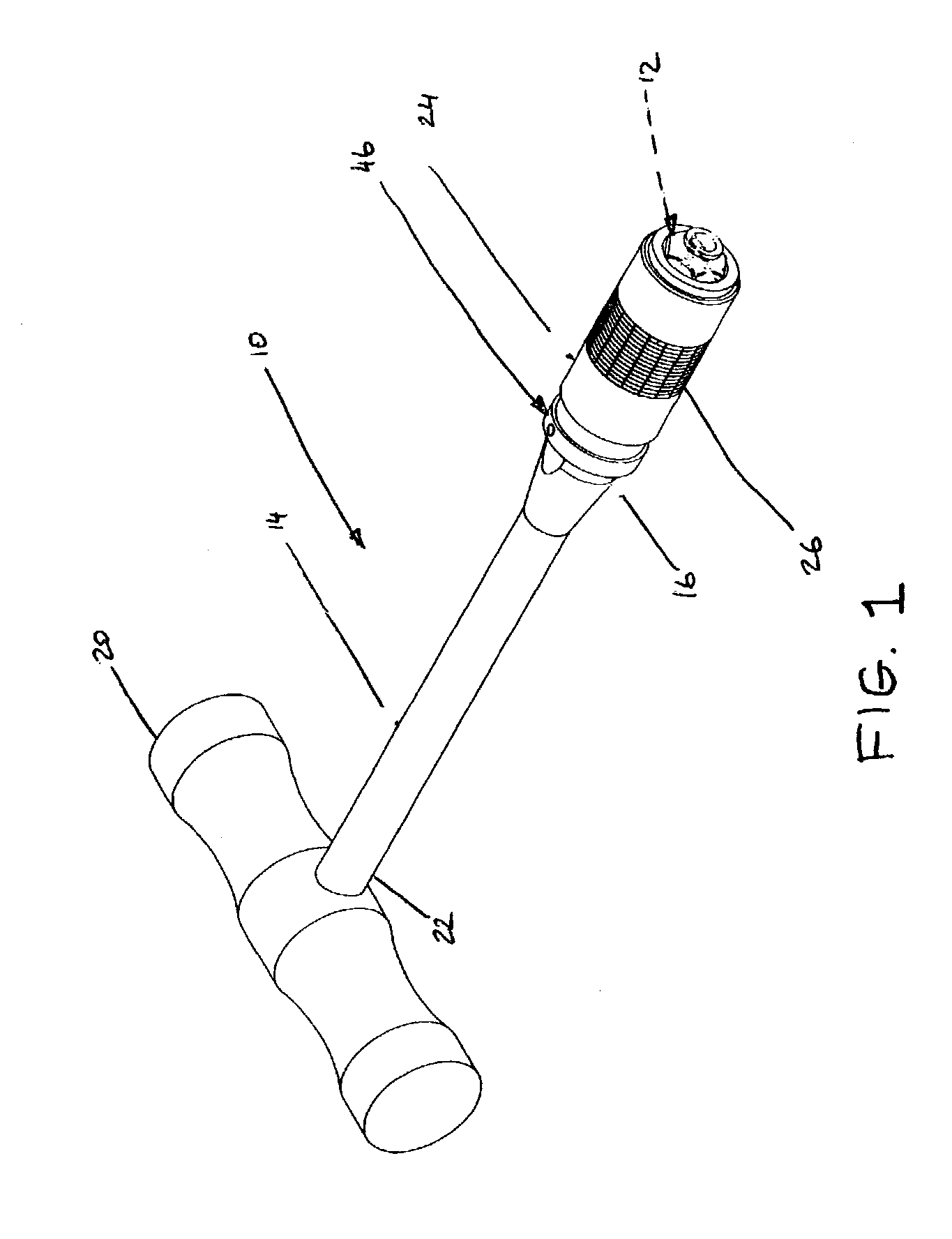

Hand-held instrument holder for surgical use

A surgical instrument holder has a shank having a coupling end, a handle attached to an opposite end of the shank, a coupling device, and a locking mechanism. The coupling end has an interface thereon for receiving an instrument. The locking mechanism has an annular locking component, a spring, a ring which slides on the shank, and a locking device. The annular locking component is mounted so as to slide along the shank. The locking device cooperates with the locking component so as to lock the instrument onto the interface. The spring biases the locking component in a locking direction and bears on the ring. The ring is disengageably lockable to the shank via a connection device so as to enable quick disassembly for cleaning and component sterilization.

Owner:VIANT AS&O HLDG LLC

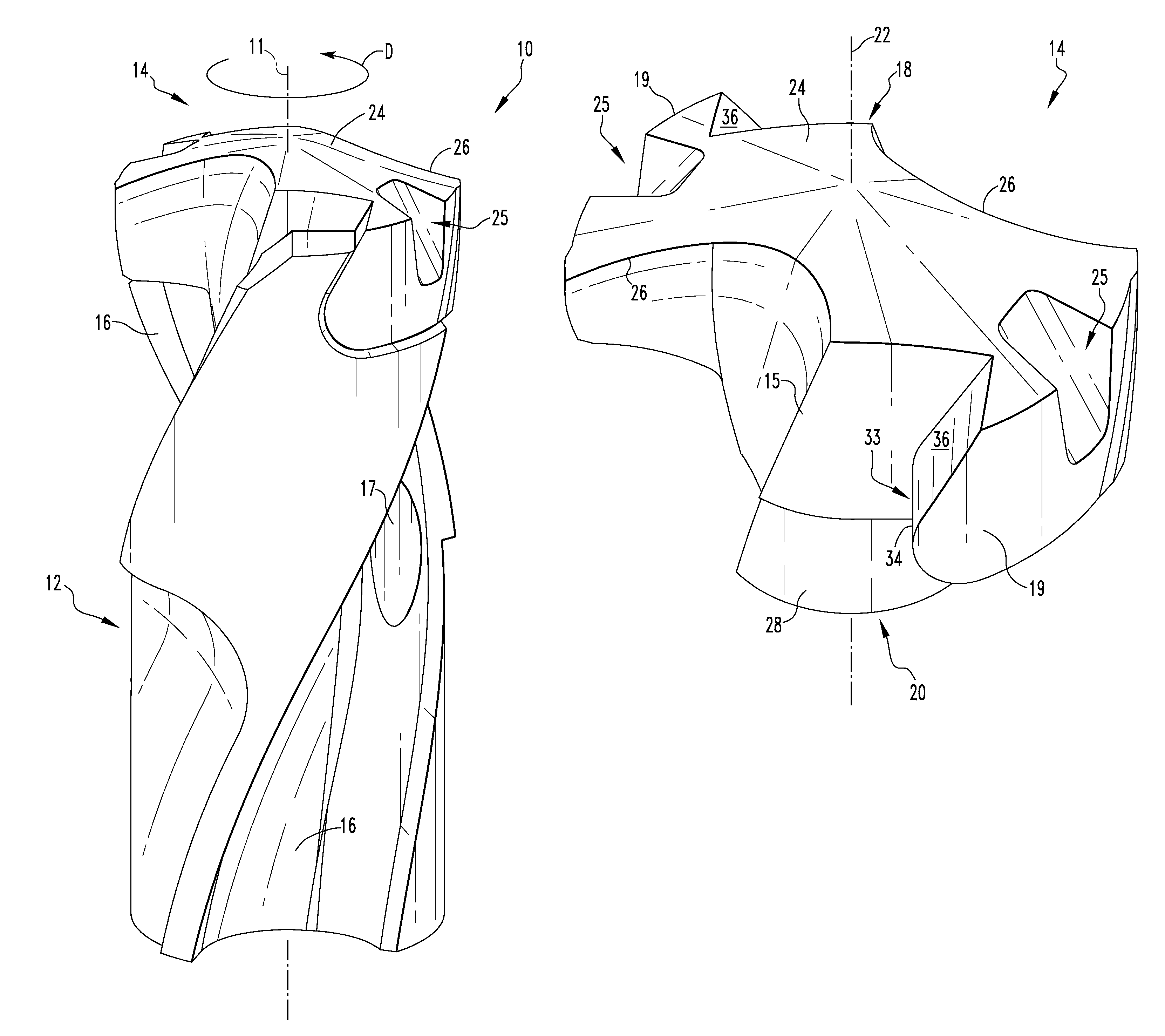

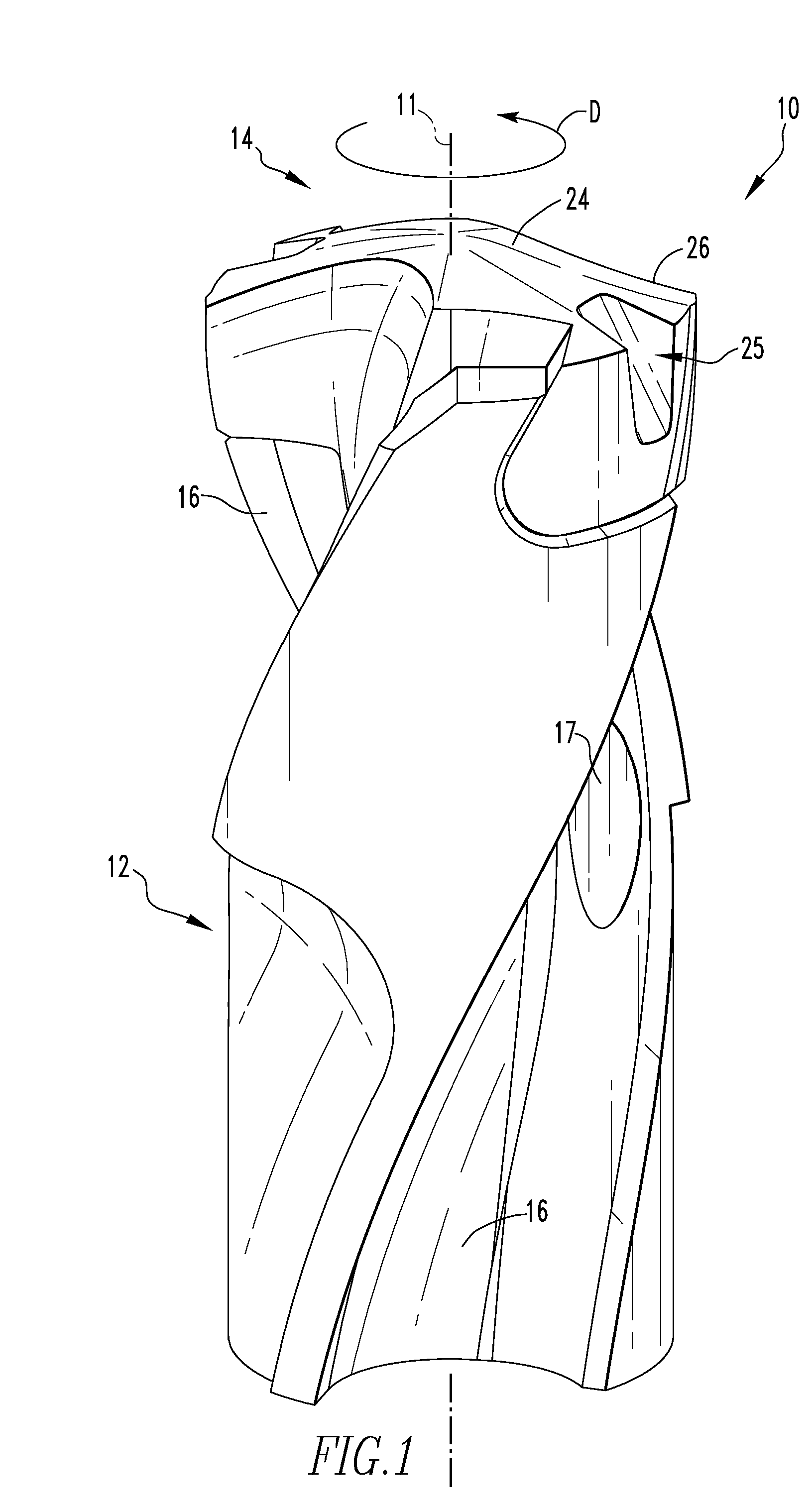

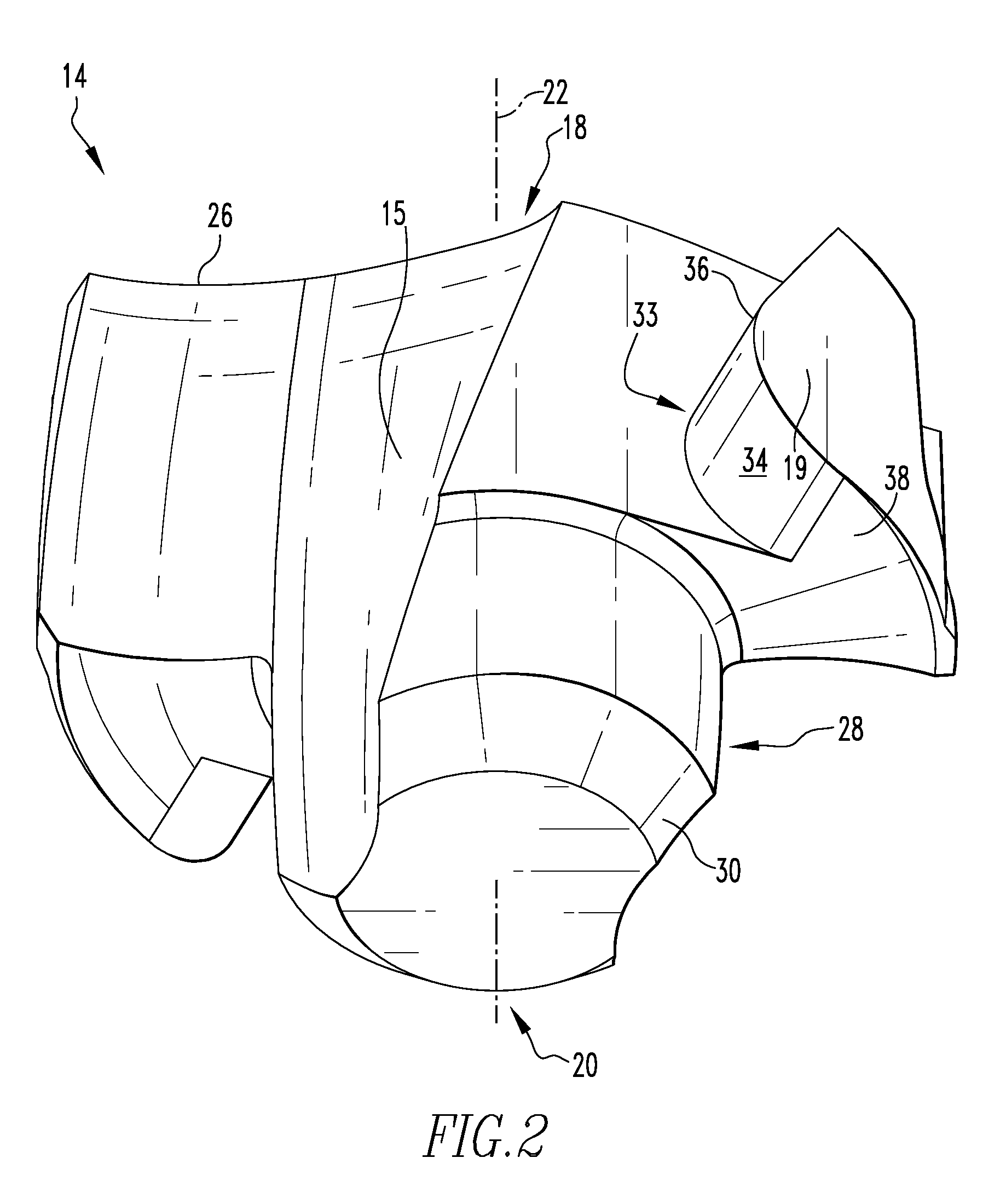

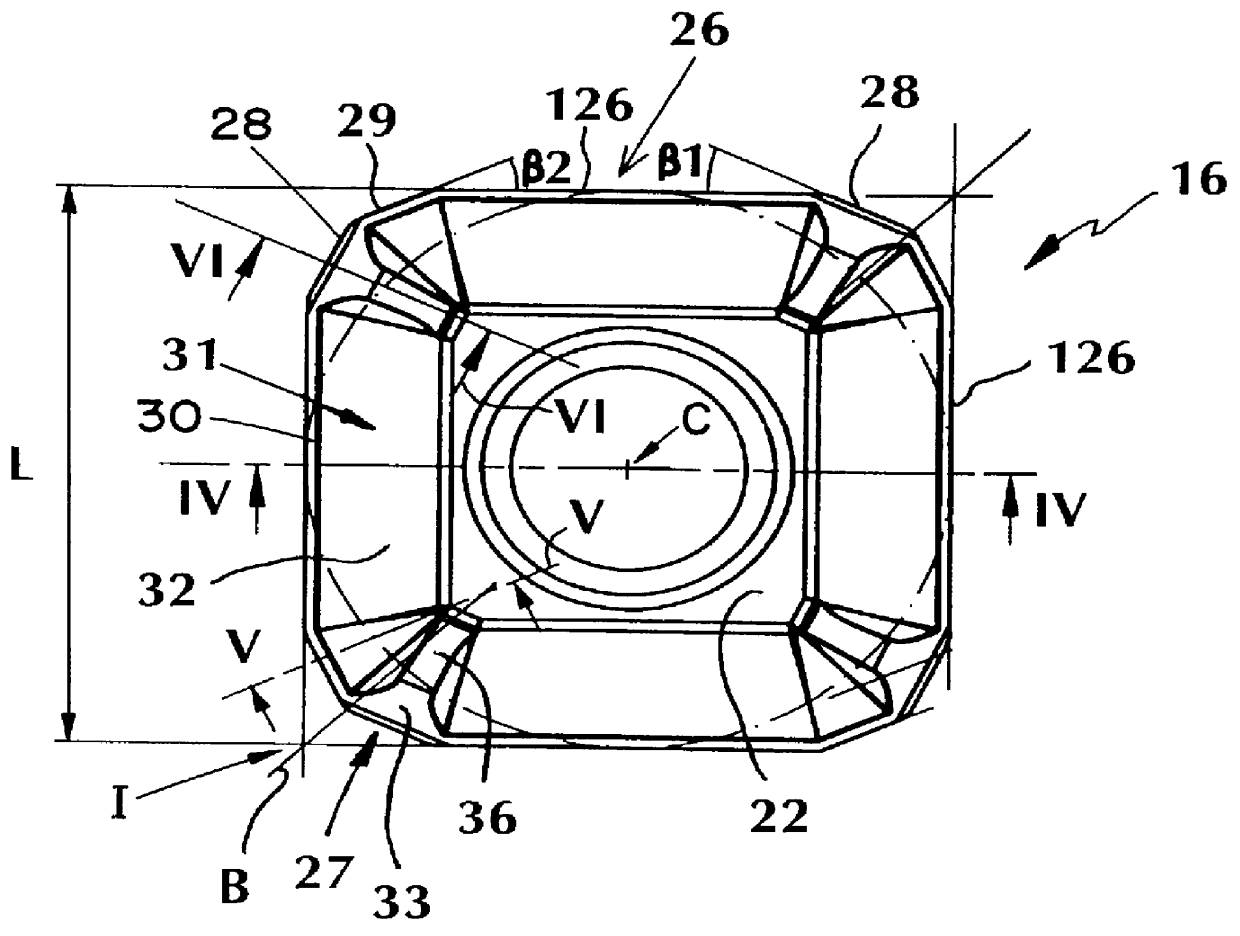

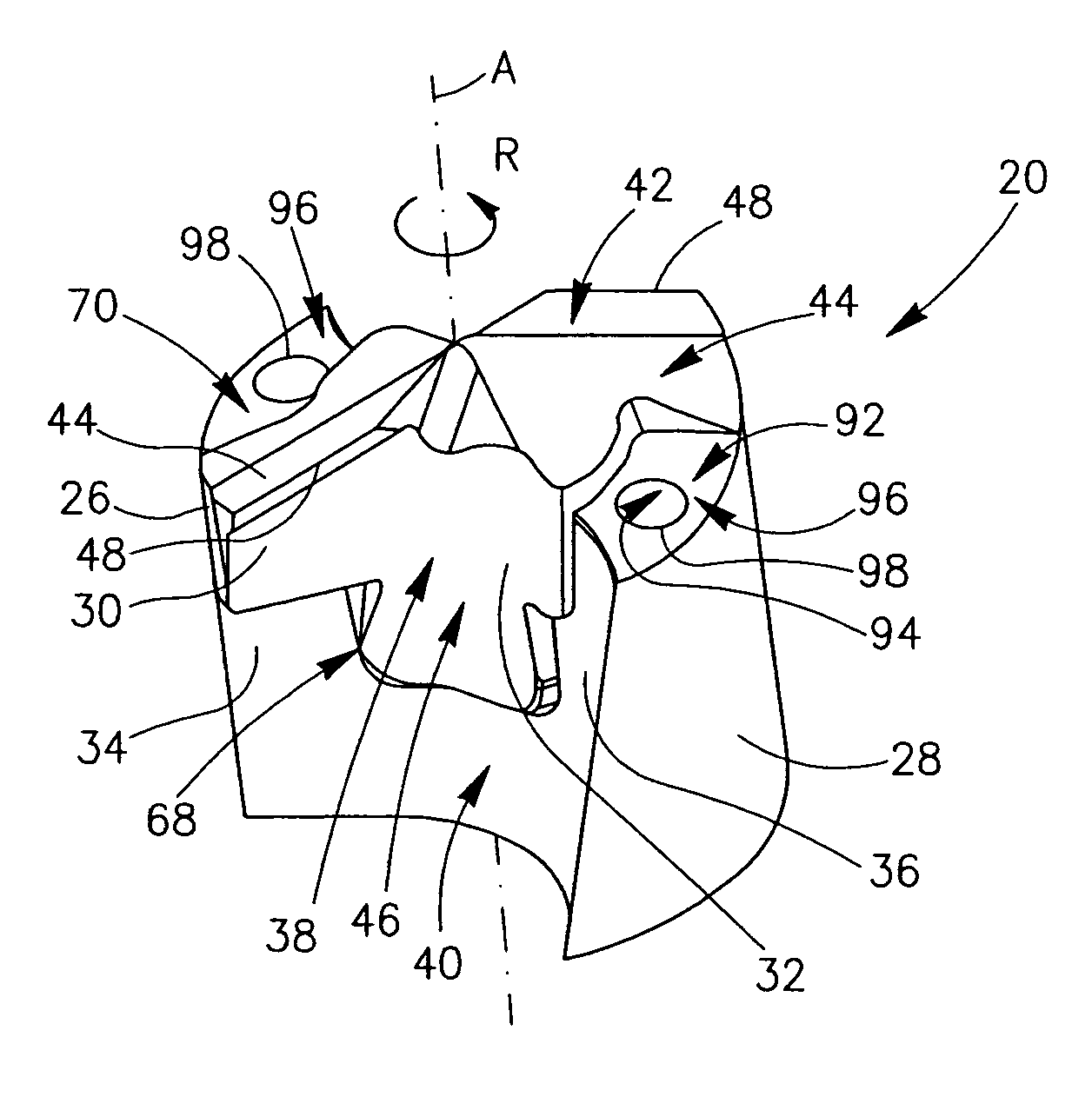

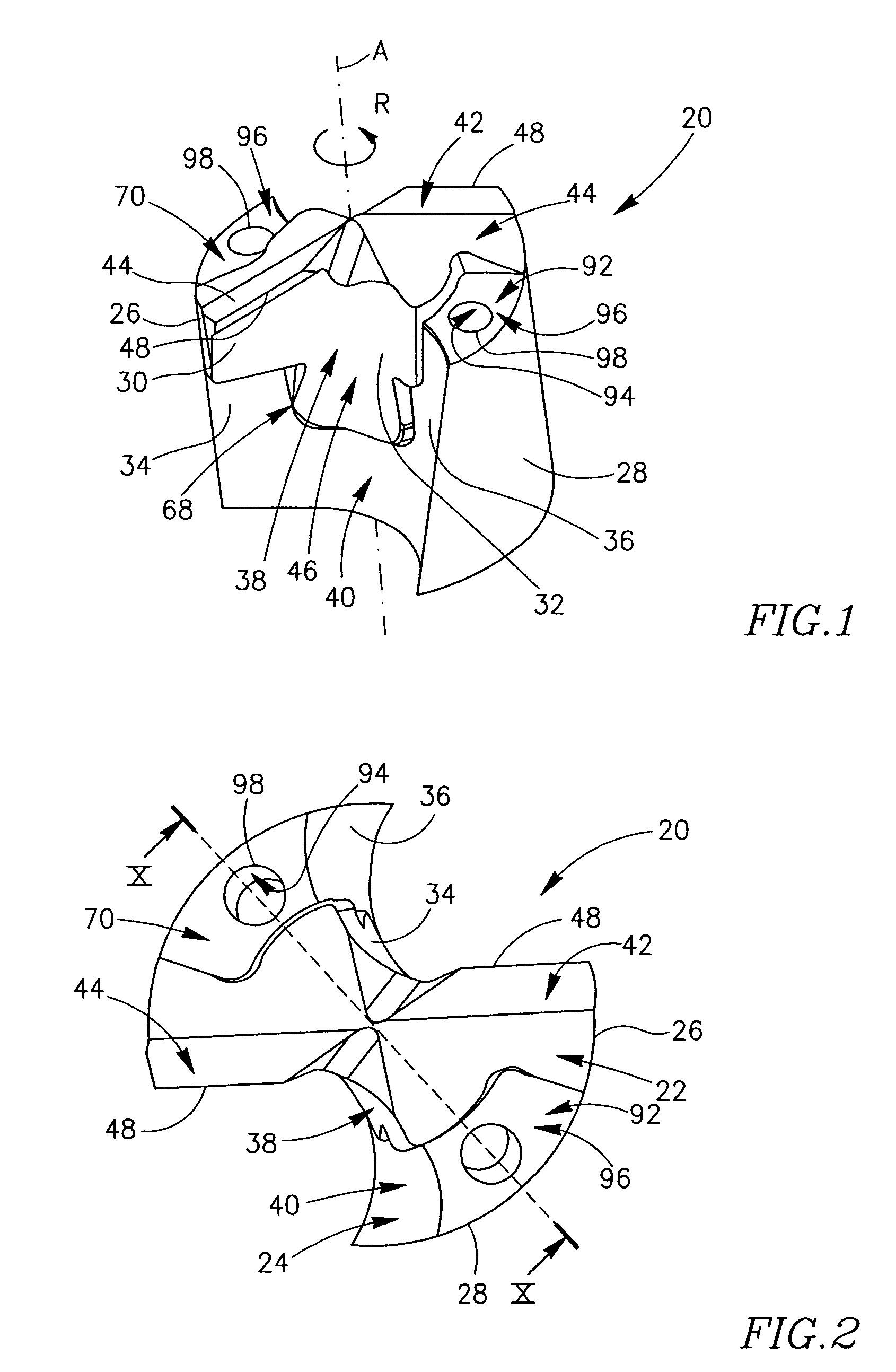

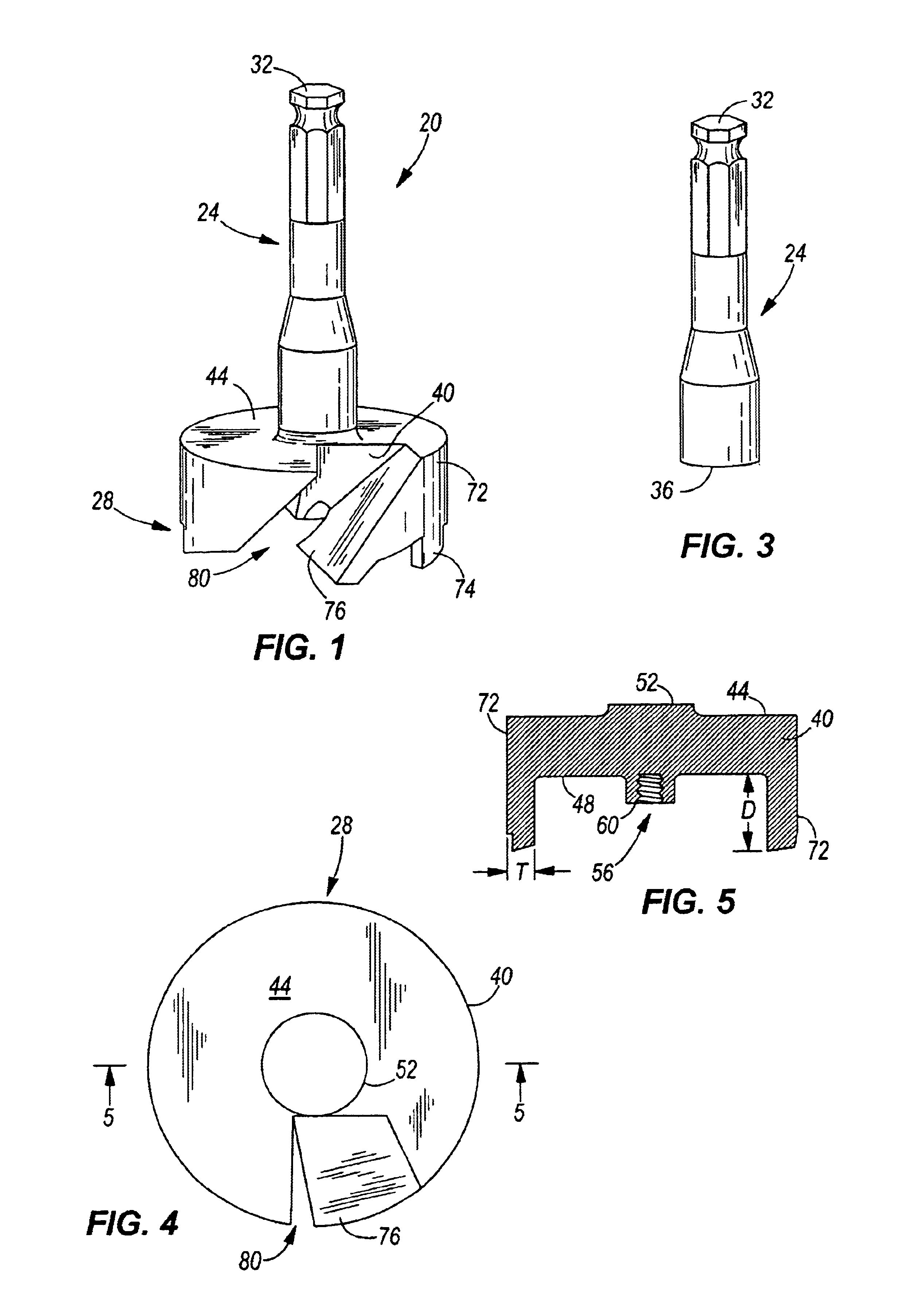

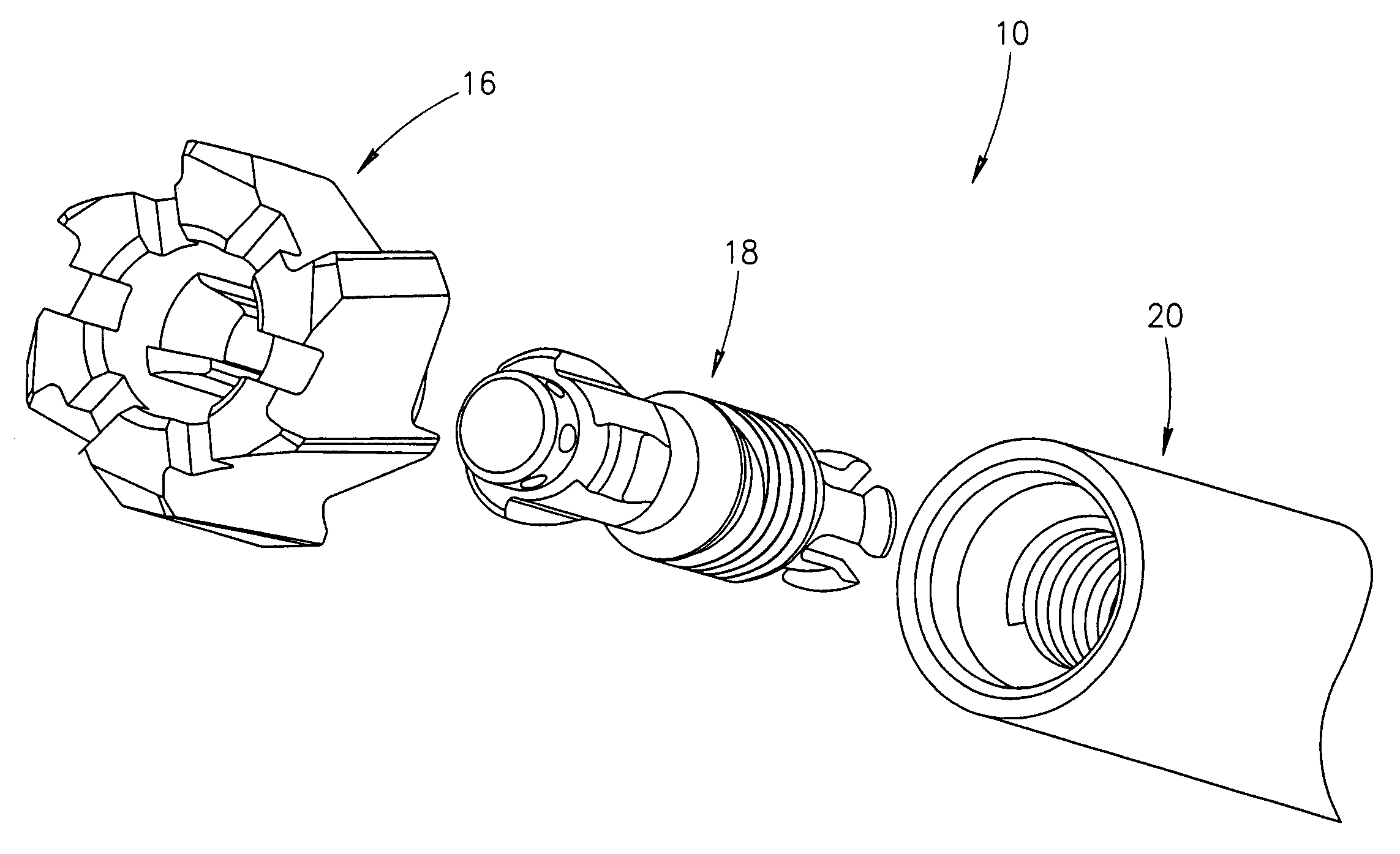

Rotary cutting tool assembly and cutting insert and tool shank therefor

A tool shank and a replaceable cutting insert are provided for a rotary cutting tool assembly. The tool shank has a drive surface including a central portion, a first portion of generally planar shape extending away from the central portion and a second portion of generally planar shape extending away from the central portion in a direction generally transverse to a central axis of the tool shank. The replaceable cutting insert has a driven surface including another central portion, a first portion of generally planar shape extending away from the other central portion and a second portion of generally planar shape extending away from the other central portion in a direction generally transverse to a central axis of the insert. The central portion of the driven surface has a curved surface transitioning between the first portion and the second portion of the driven surface. A portion of the driven surface of the replaceable cutting insert is engaged by a corresponding portion of the drive surface of the tool shank.

Owner:KENNAMETAL INC

Tool with deployable cutting blade

A tool having a deployable cutting blade for making an undercut in a substrate is disclosed. The tool has a chamber positioned between its cutting tip and its tang. The cutting blade is movably mounted within the chamber. The blade is movable by sliding, pivoting or deflecting on a cantilever mounting and is movable between a retracted position within the chamber and an extended position projecting outwardly to engage and cut the substrate. Actuators for moving the blade include an eccentric cam mounted on a camshaft, a push rod and an inflatable balloon. Blades are also resiliently mounted and oriented so that their engagement with the substrate will cause them to retract into the chamber when the tool rotates in one direction and deploy into the extended position when the tool rotates in the opposite direction.

Owner:STOUT MEDICAL GROUP

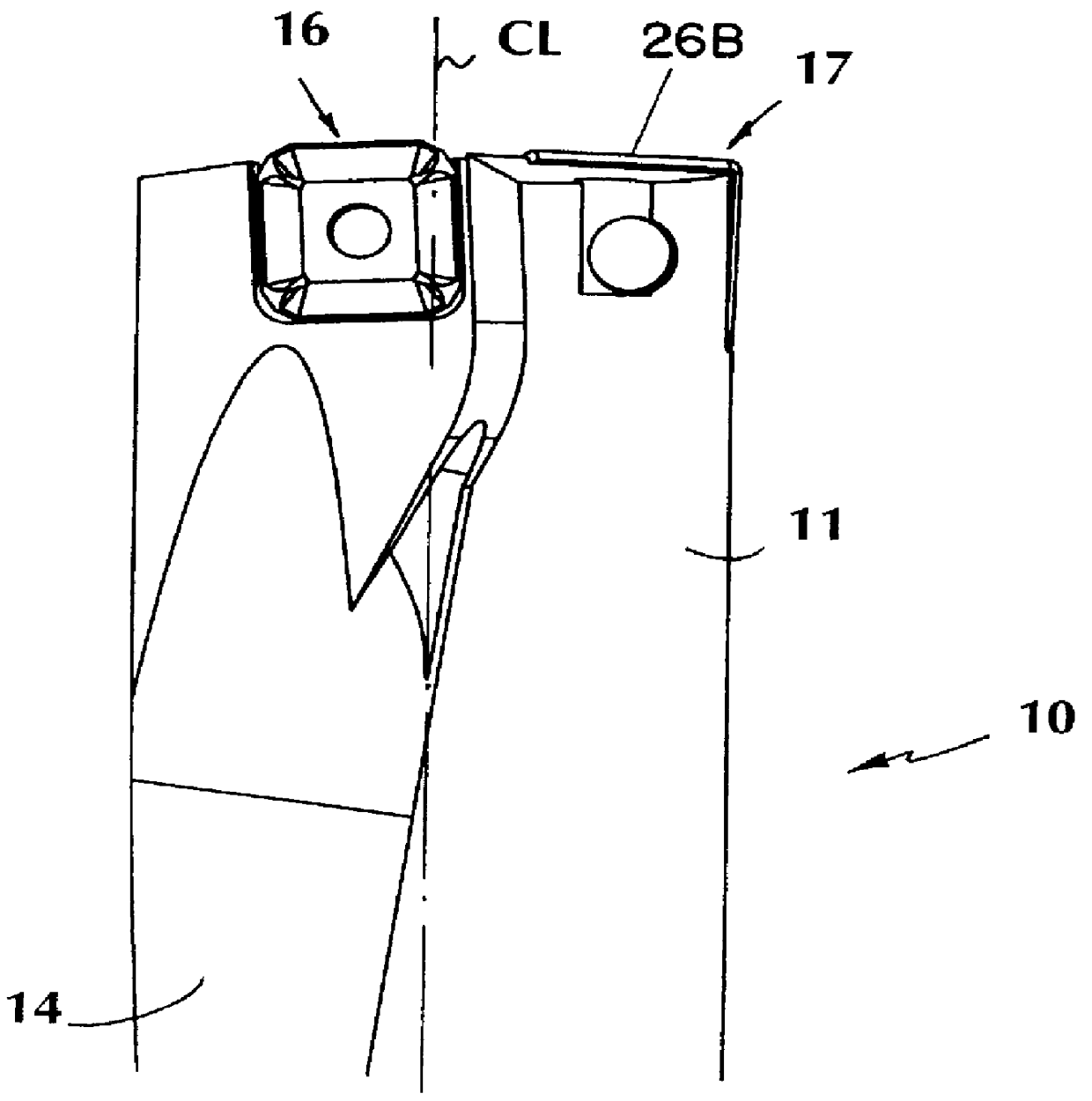

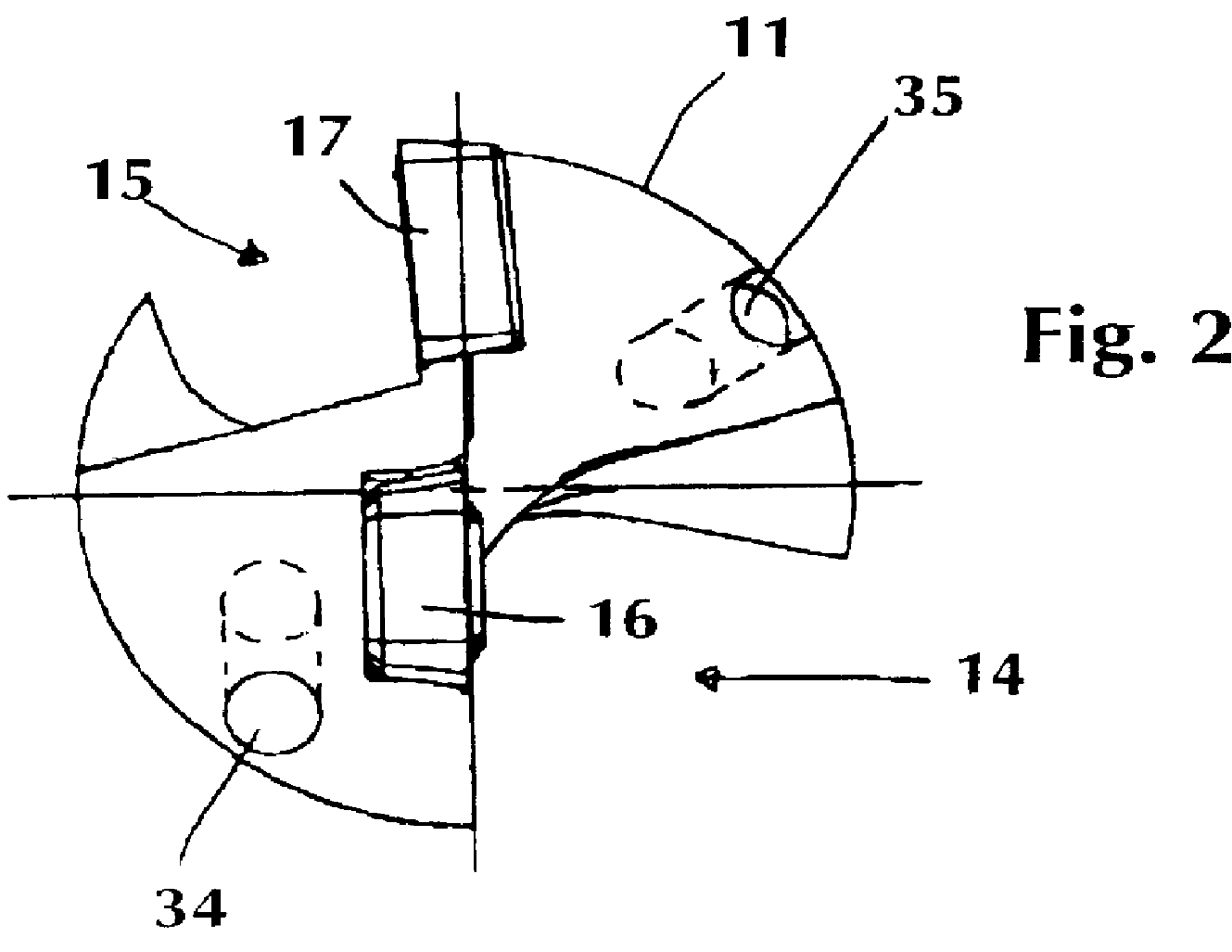

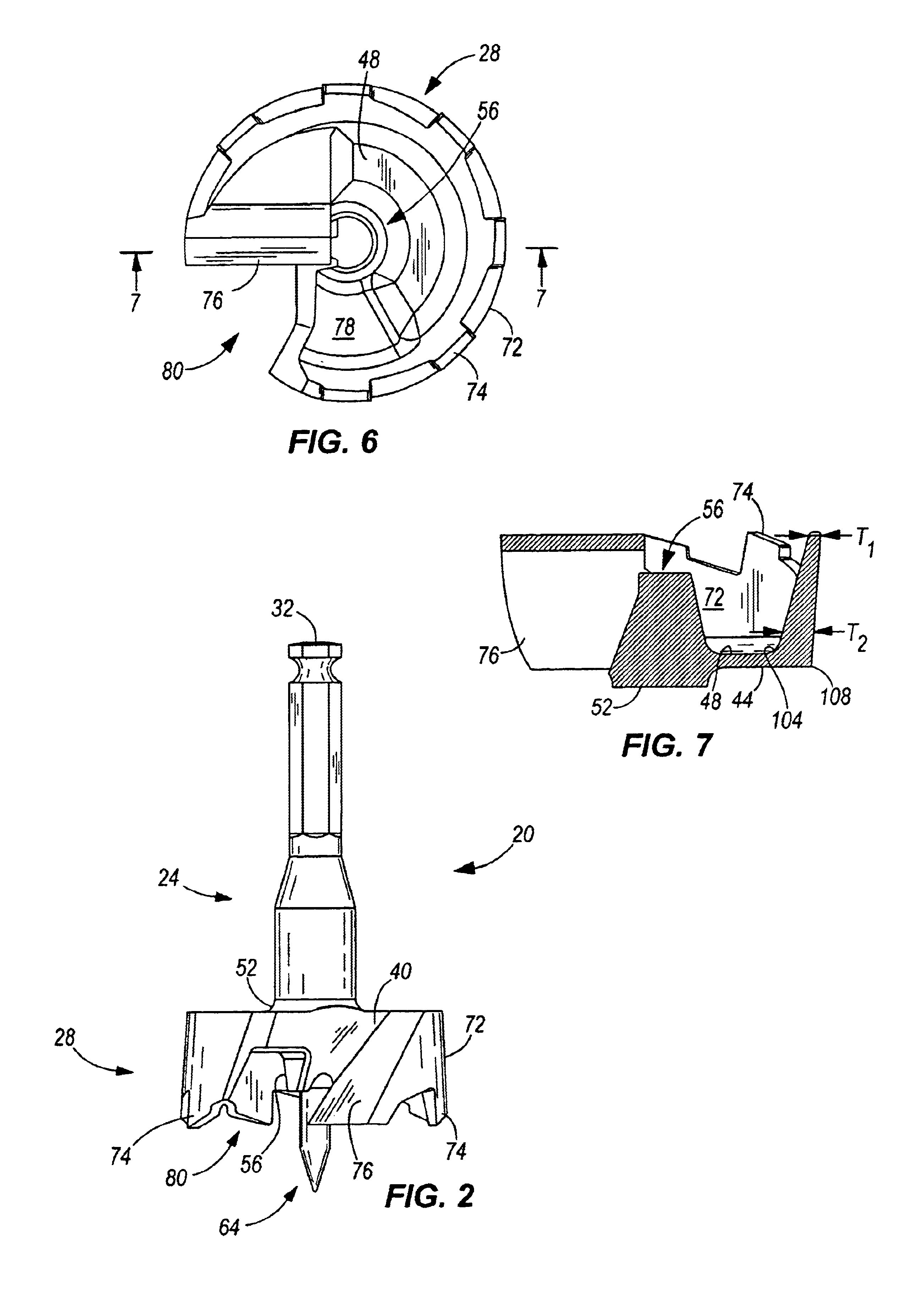

Drill having radially overlapping indexable cutting inserts

A drill includes a shank, a central insert and a peripheral insert. The shank defines a central axis of rotation and has pockets which carry the peripheral and central inserts. Chip flutes are formed in an outer periphery of the shank for conducting chips cut by the respective inserts. The peripheral insert includes a first operative cutting edge, and the central insert includes a second operative cutting edge which overlaps the first cutting edge at an overlap region. The central insert forms a rake surface adjacent to the second cutting edge. The rake surface includes a first portion disposed at the overlap region, and a second portion disposed at the axis of rotation of the shank. The first portion has a larger rake angle than the second portion.

Owner:SECO TOOLS AB

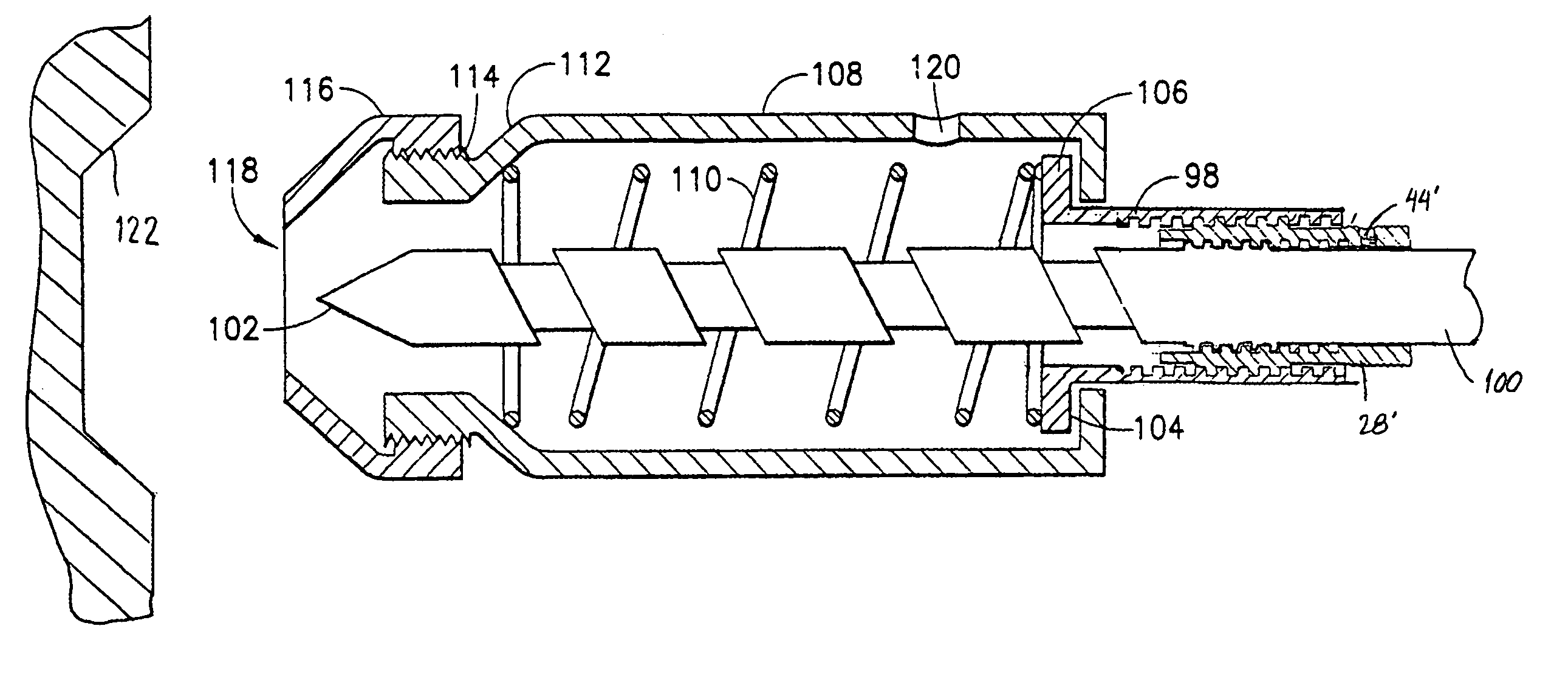

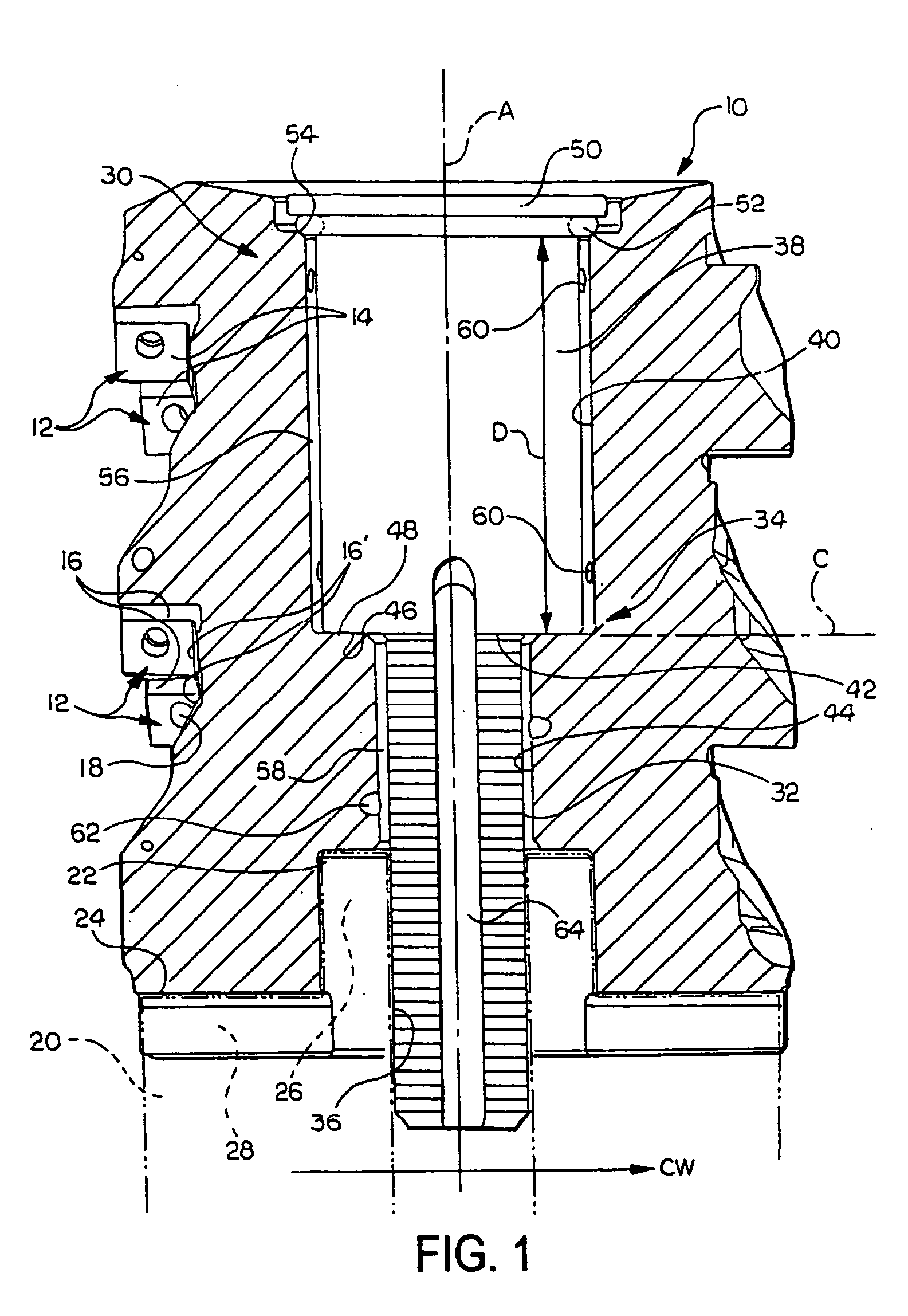

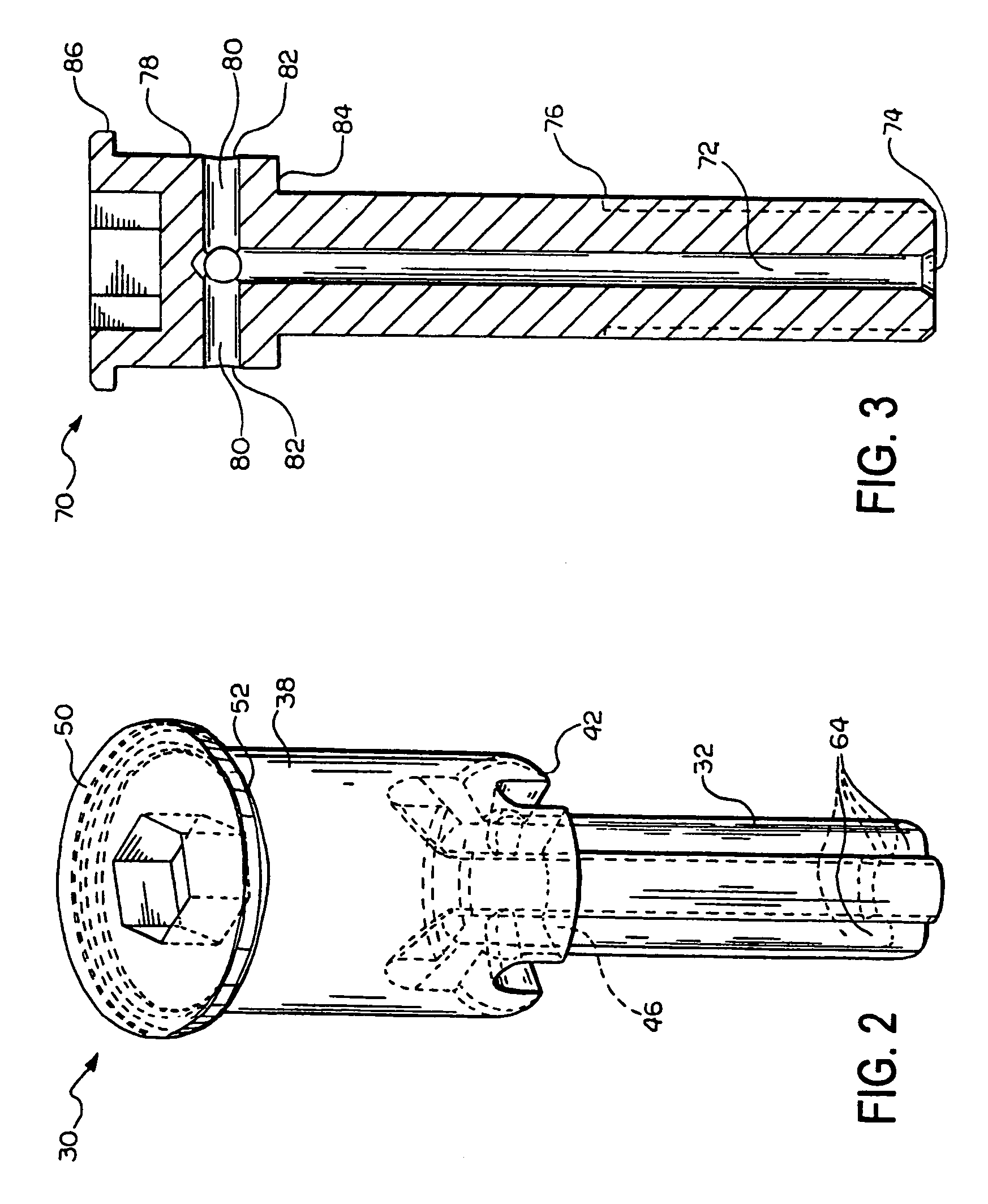

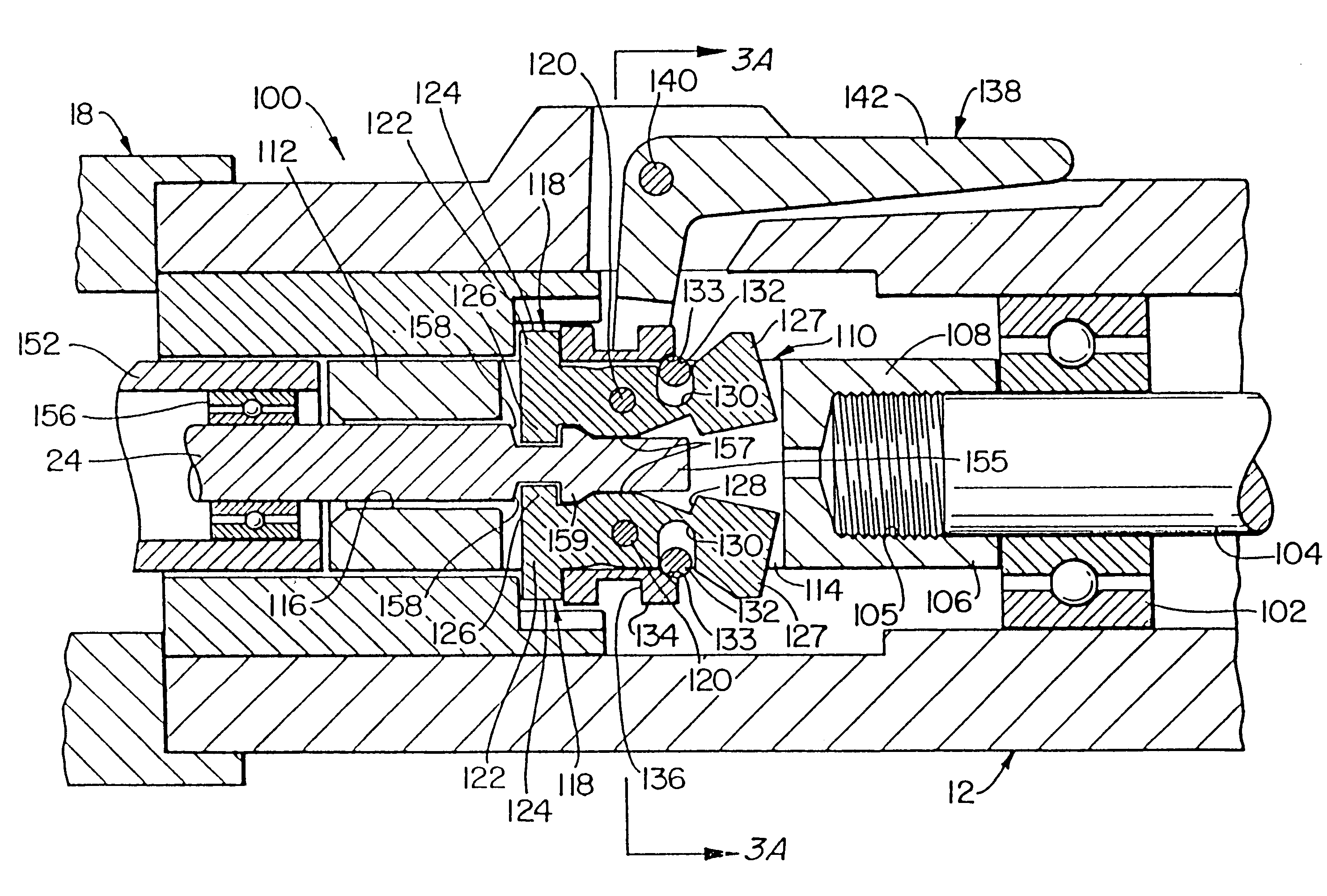

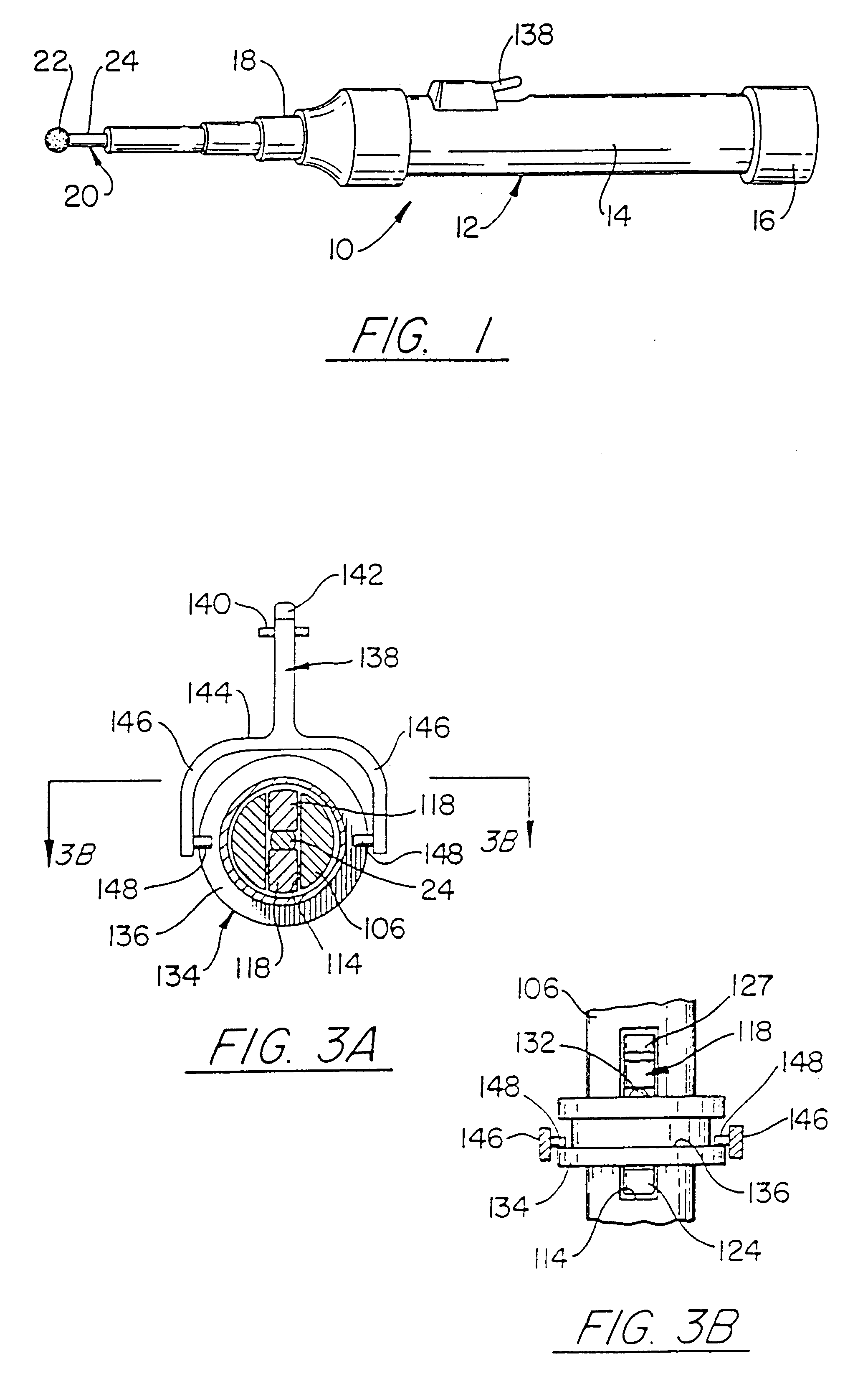

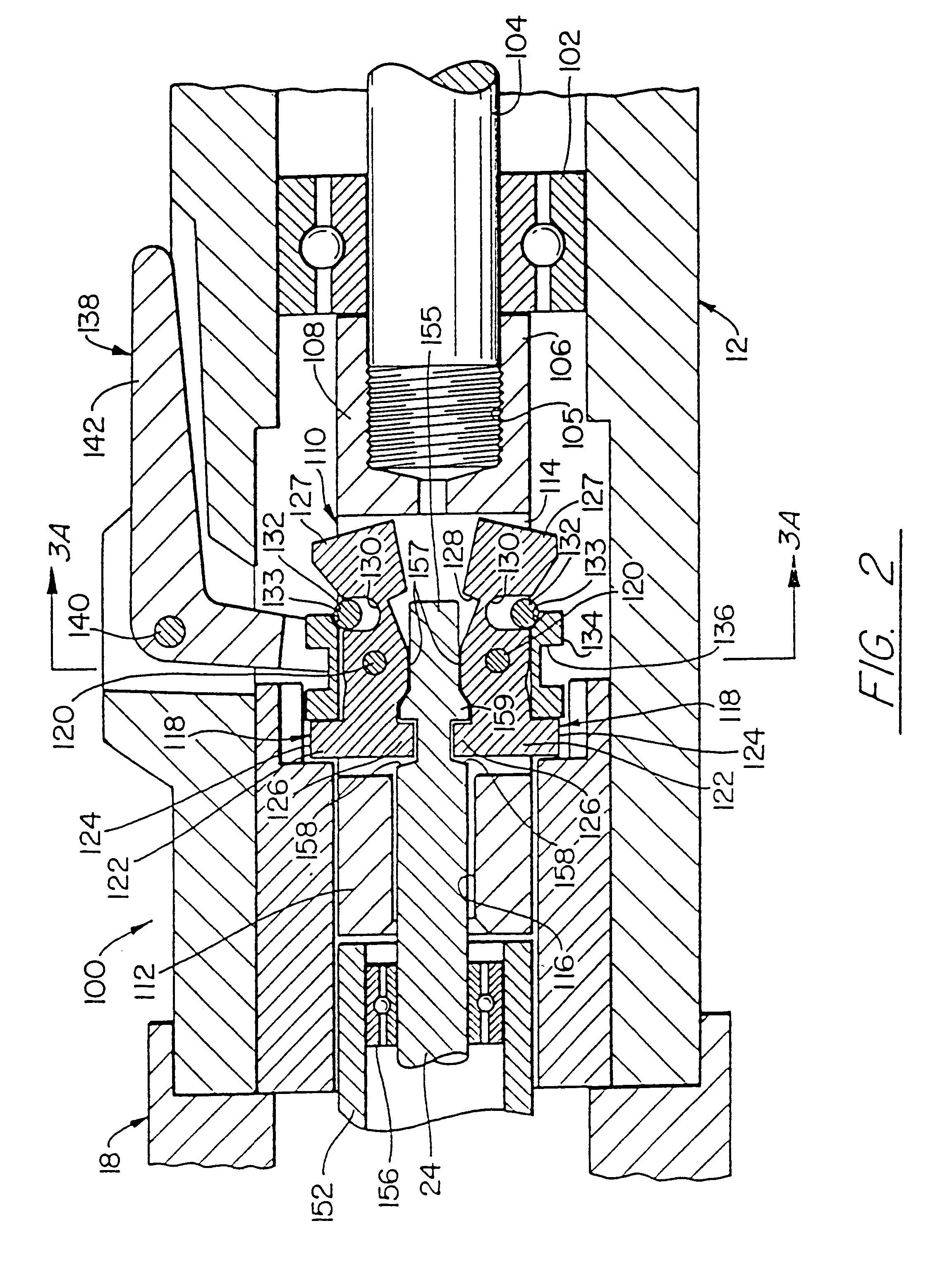

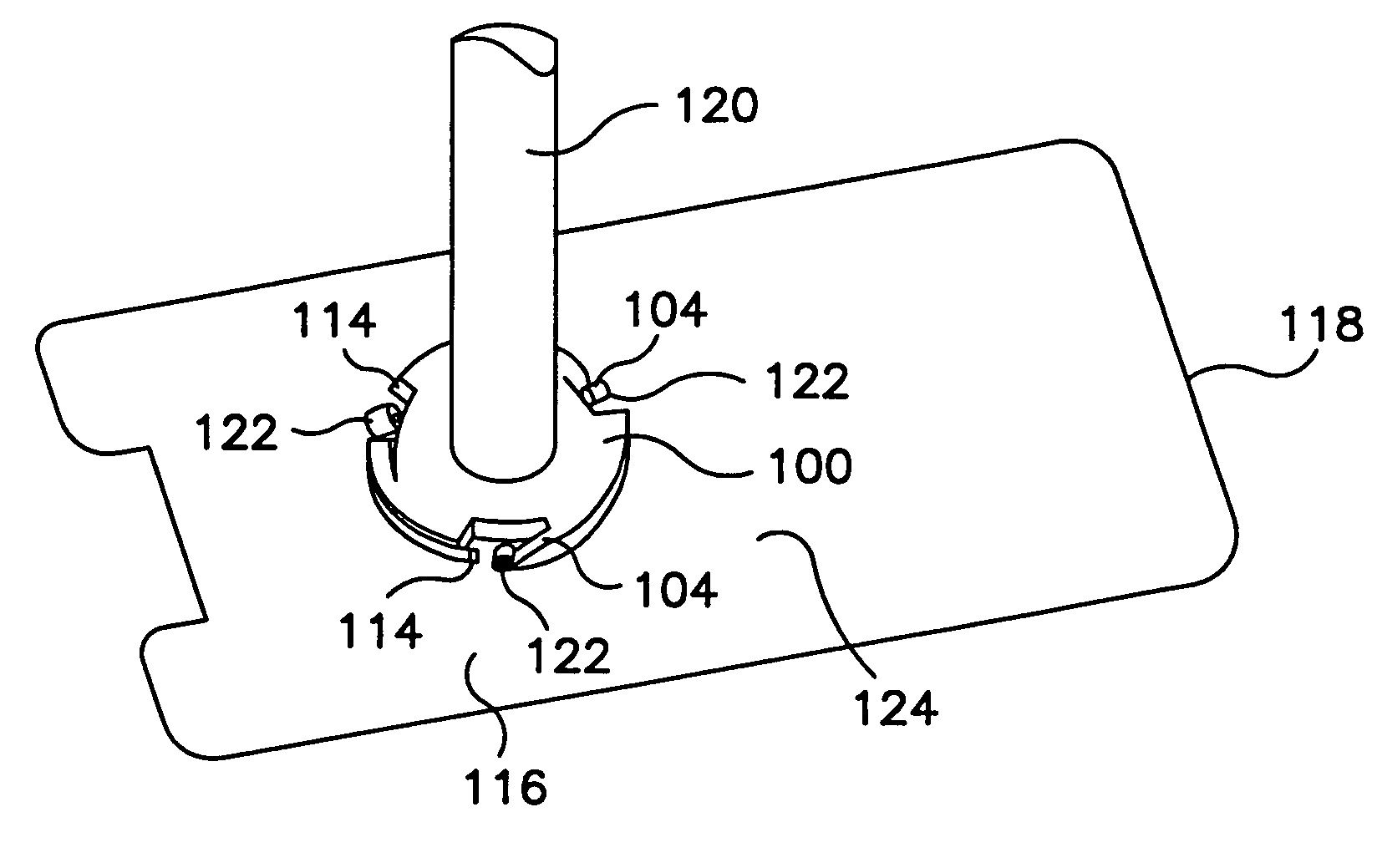

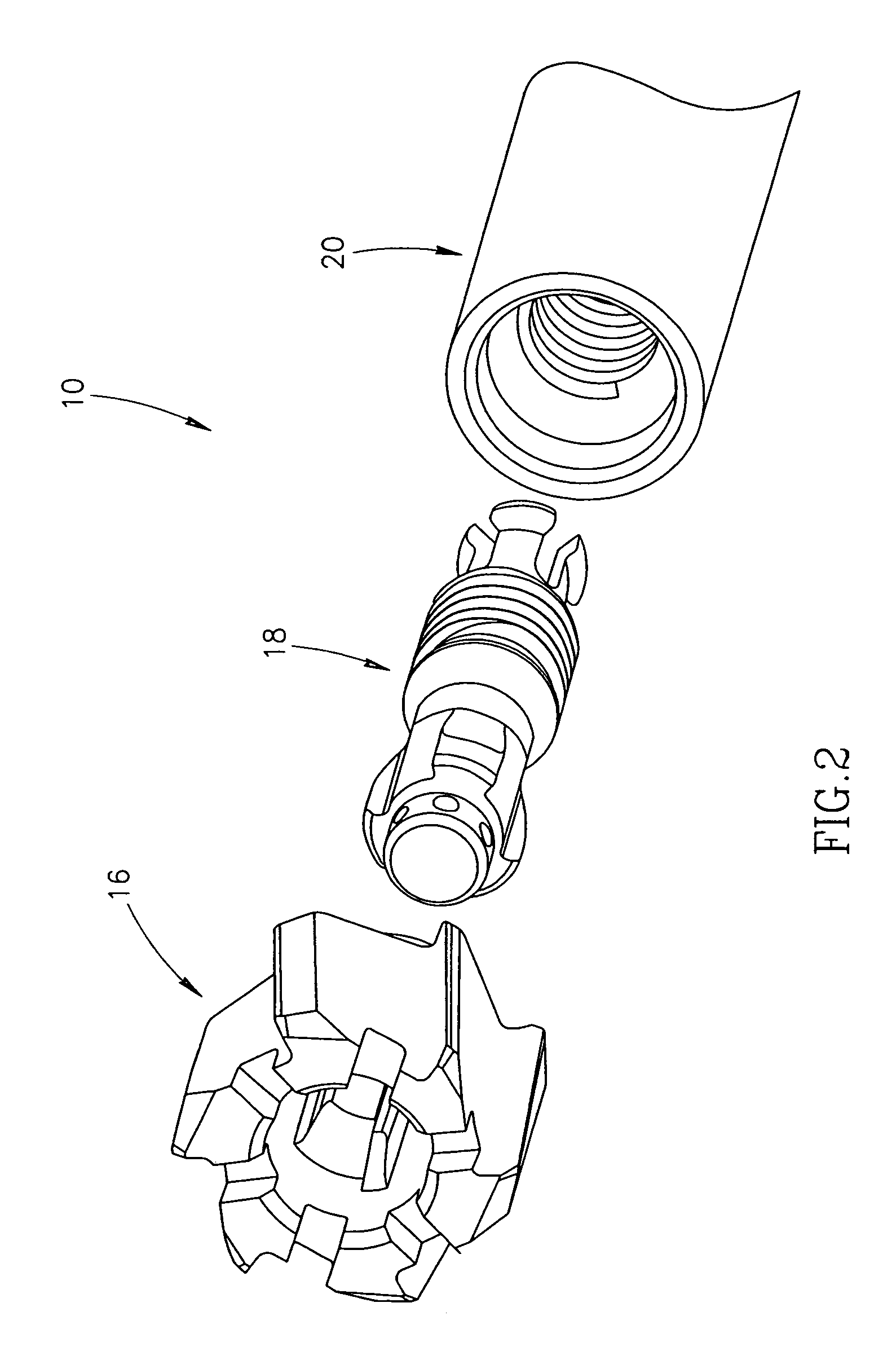

Tool holding mechanism for a motor driven surgical instrument

InactiveUSRE37358E1Eliminate usePrevent rotationSleeve/socket jointsWood turning toolsTool bitMotor drive

A surgical instrument has a housing which contains a motor that drives a spindle. A tool bit is attached to the motor by a holder that includes a body with a first end portion connected to the spindle, a central portion with a cavity therein, and a second end portion having an aperture through which a shaft of the tool bit passes into the cavity. A pair of lock pawls are pivotally mounted in the cavity with each one having a first tab that enters a slot in the shaft when the lock pawls are in a first position to hold the tool bit in the instrument. The first tabs retract from the slot when the lock pawls are in a second position for changing the tool bit. The lock pawls have second tabs that engage a restrainer only in the second position to prevent the body from rotating. A ring extends around the body and pivots the lock pawls between the first and second positions when the ring moved longitudinally along the body. A manually operable shift lever is pivotally coupled to the housing and move the ring longitudinally along the body.

Owner:ANSPACH EFFORT

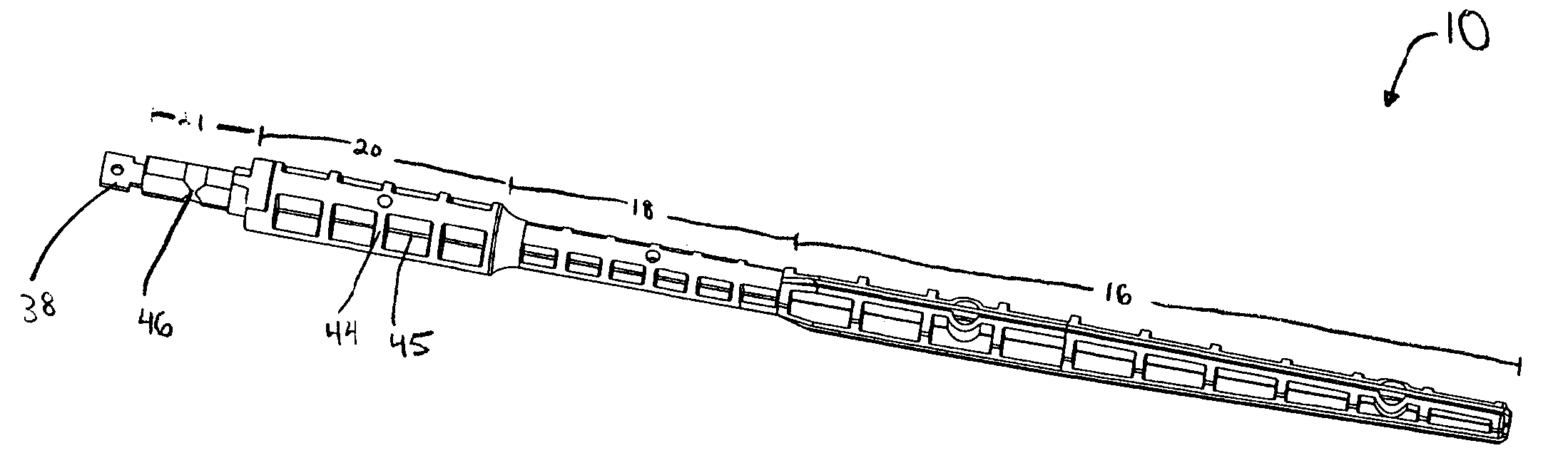

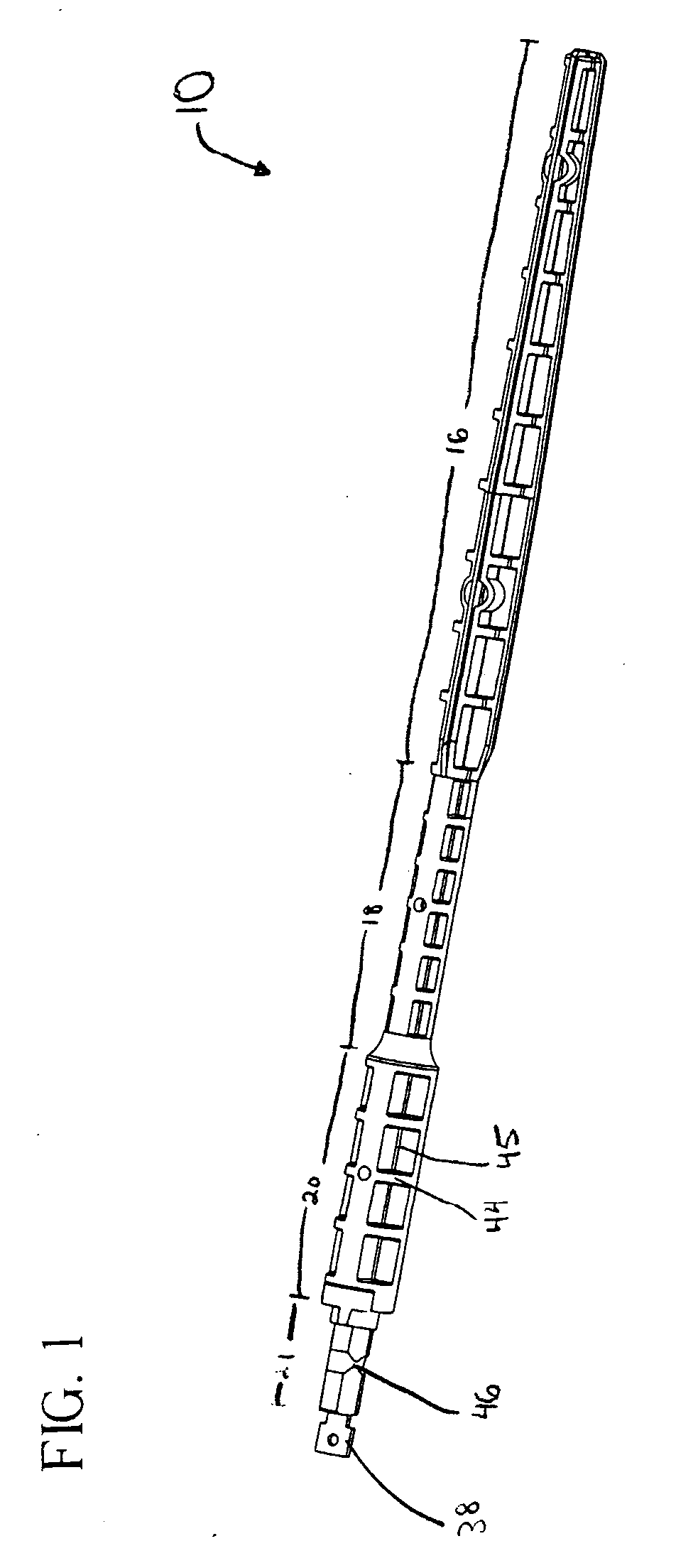

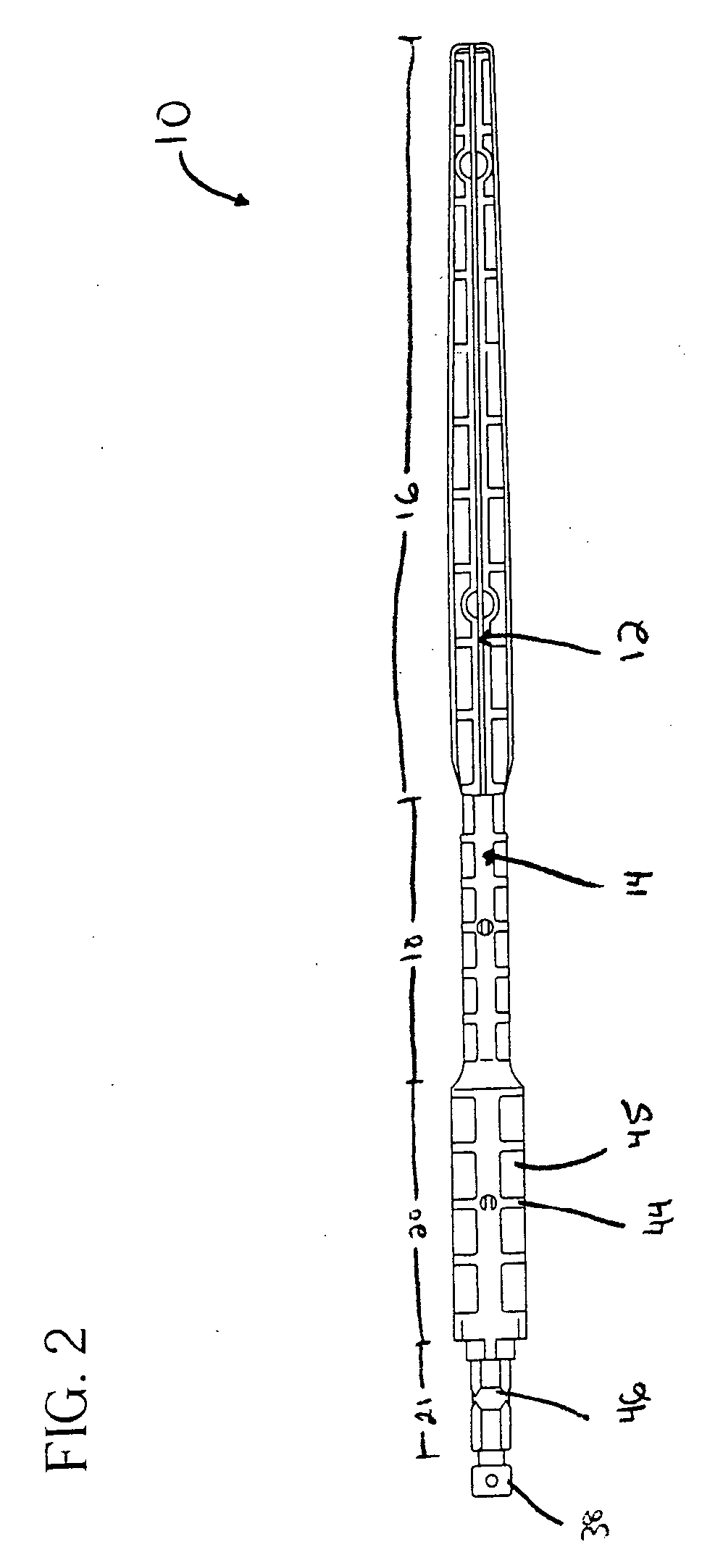

Drill measurement stops

InactiveUS7048477B2Easy to identifyReduce manufacturing costThread cutting toolsDental implantsEngineeringVisual perception

A depth stop for use with a drill bit comprises a tubular body having an opening therethrough. Used with a drill bit whose bit portion includes a cutting end, and a shank portion, the depth stop is frictionally positionable on the bit portion at a specified point from the cutting end, thereby indicating a specified depth. Depth stops are manufactured in different colors, each color corresponding to a specified range of drill bits that the depth stops will fit. The depth stops, manufactured from a sterilizable material, are intended for single use. The depth stop can be used with a drill bit and drill extender, where one or more depth stops provide multiple visual points of reference for the operator. The depth stops can be quickly mounted onto most any manufacturer's drill bits.

Owner:IDMS

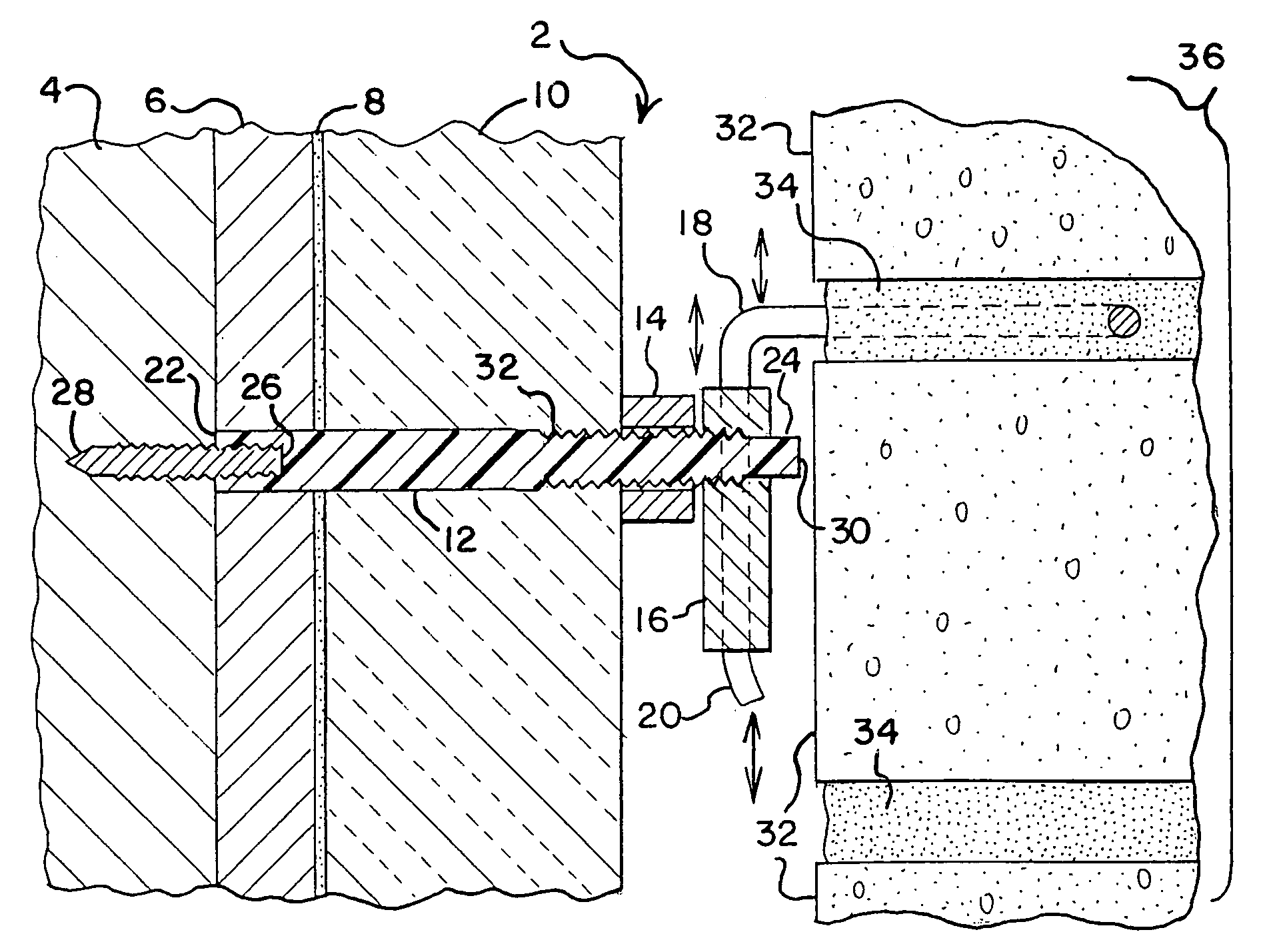

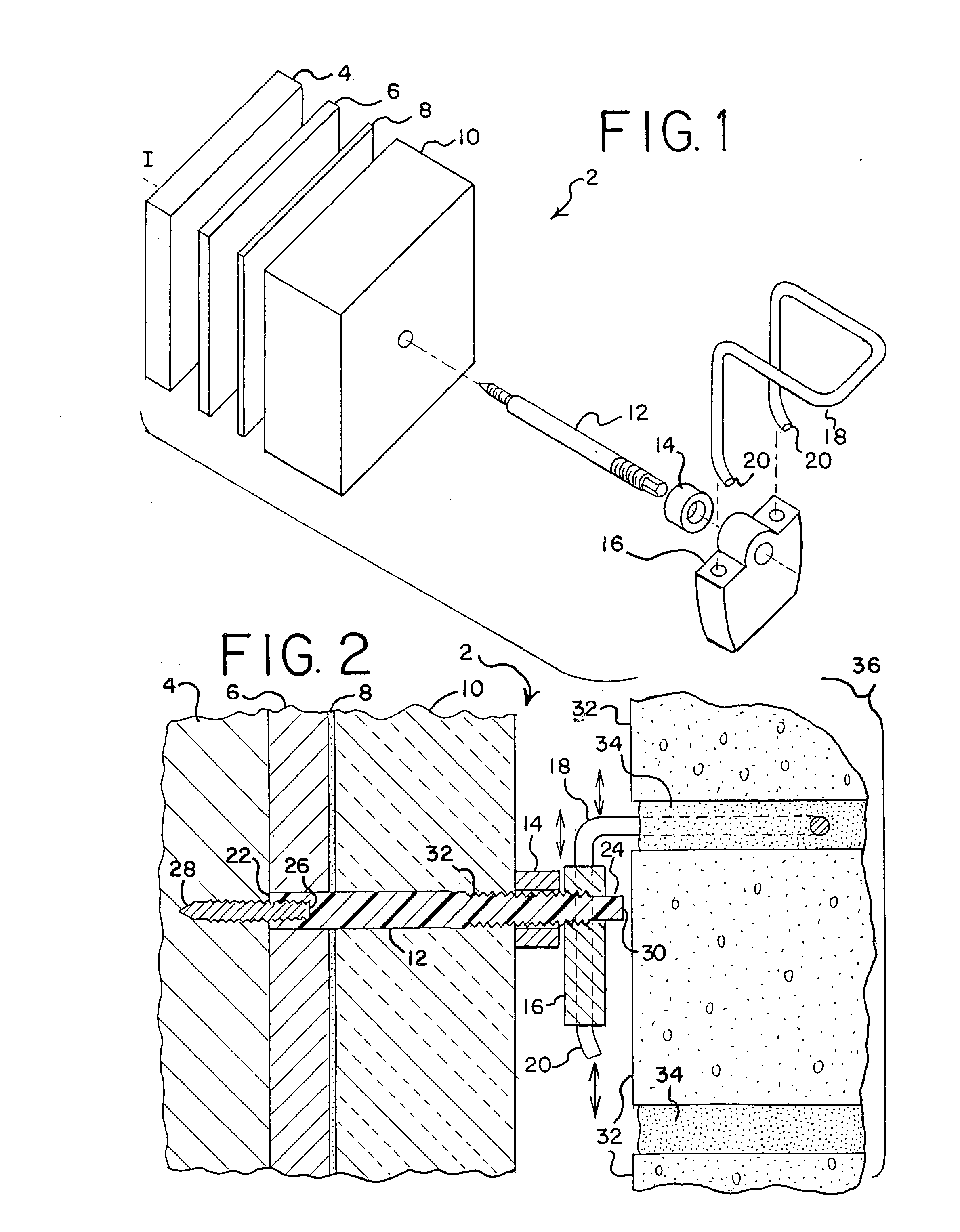

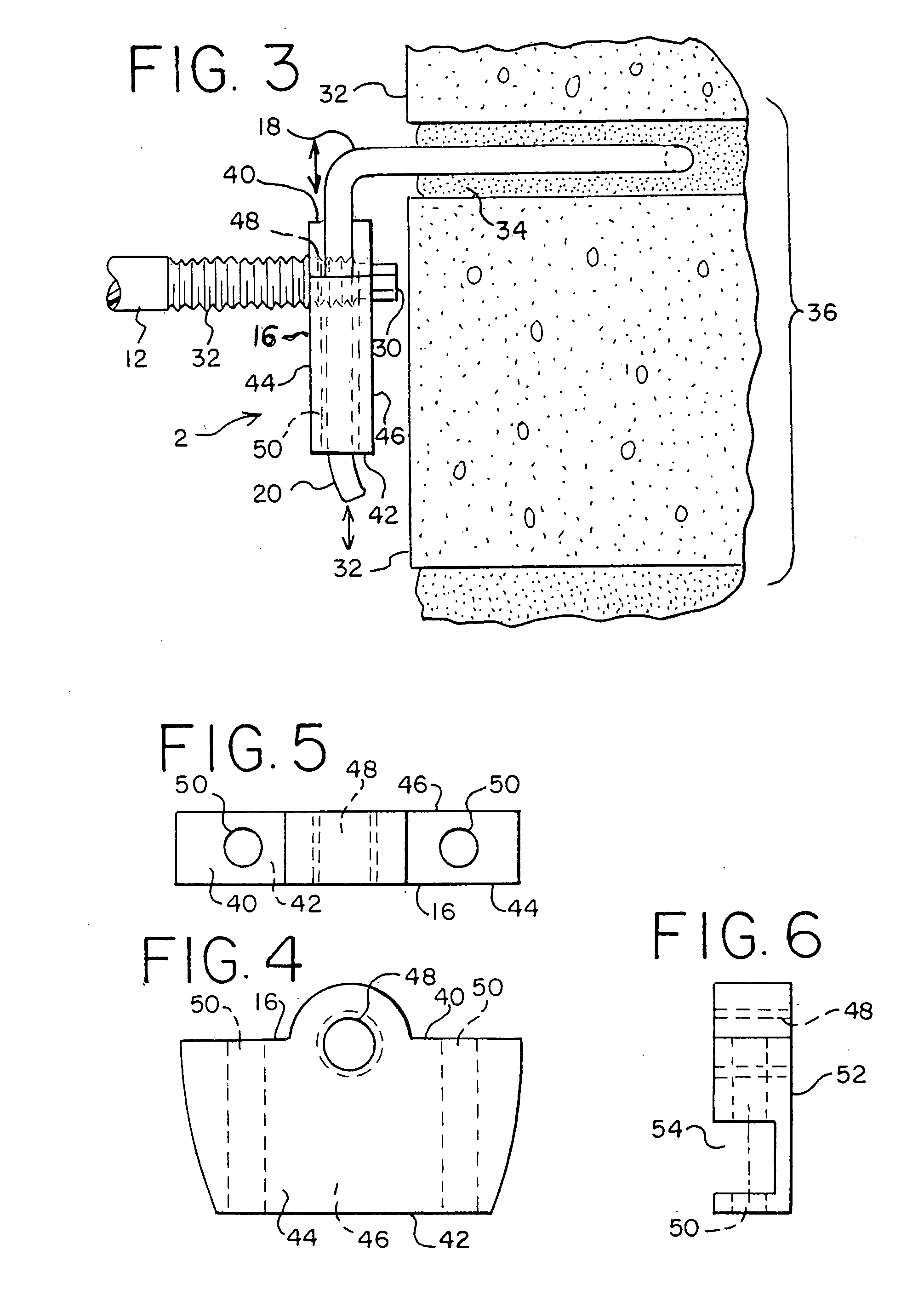

Composite fastener, belly nut, tie system and/or method for reducing heat transfer through a building envelope

InactiveUS20090133357A1Reduce heat transferLow thermal conductive valueWashersTransportation and packagingBuilding envelopePolymeric matrix

A composite fastener, a belly nut, a tie system and / or a method reduce heat transfer through a building envelope. The composite fastener, the belly nut, the tie system and / or the method secure a wall to a backup structure. The composite fastener is constructed from a fiber reinforced polymer that has fibers embedded in a polymeric matrix. The composite fastener has a low thermal conductive value (k-value) and has non-corrosive properties. The belly nut has a fastening hole on a first side of the belly nut to attach the composite fastener to the belly nut. Further, the belly nut has a pathway to receive a leg of a pintle from a top surface of the belly nut to a bottom surface of the belly nut. The pathway is sized to allow for greater vertical adjustment eccentricity between the belly nut and the pintle without creating large horizontal deflections of the tie system.

Owner:RICHARDS JOSEPH P

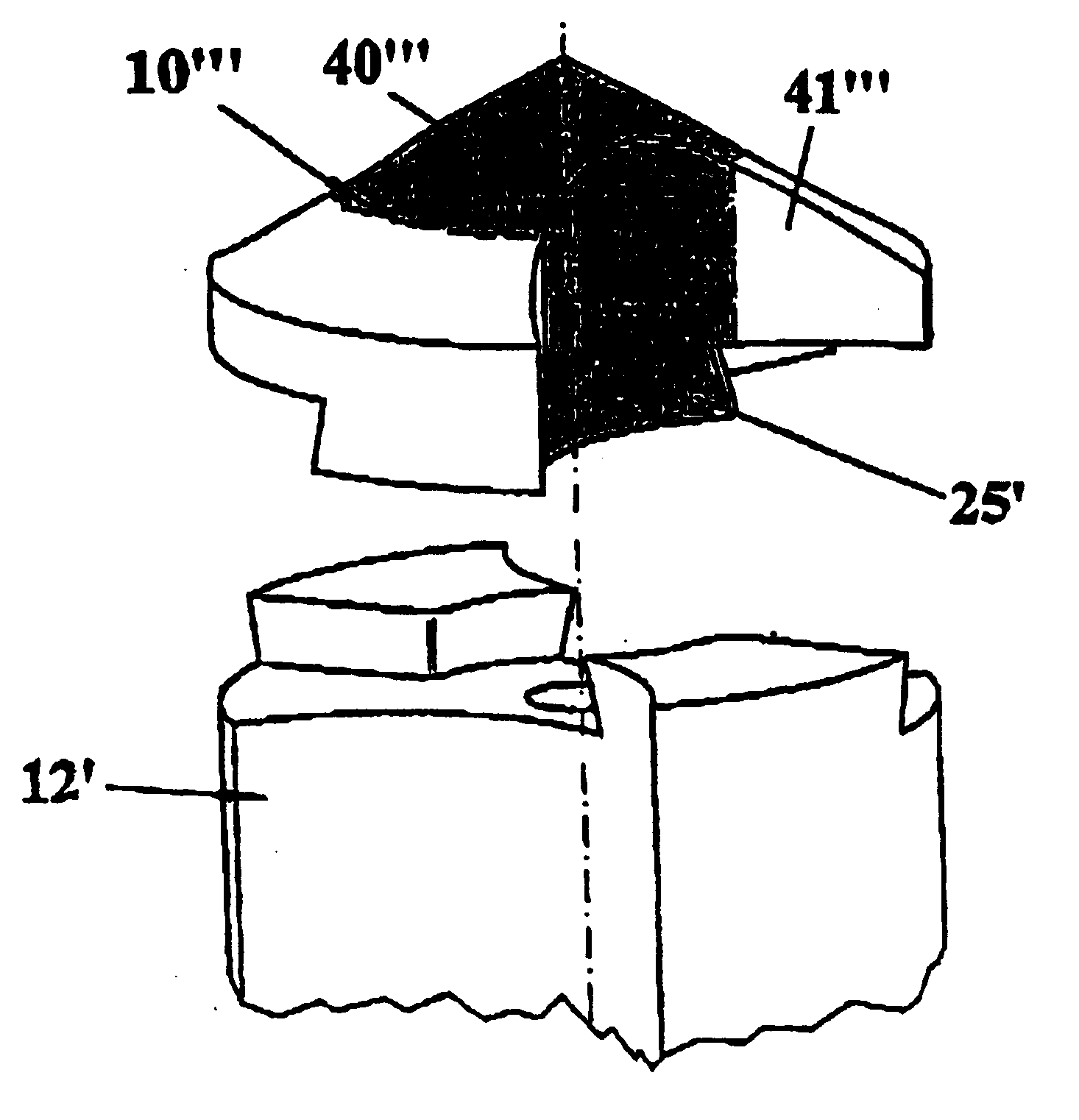

Tool for rotary chip removal, a tool tip and a method for manufacturing a tool tip

InactiveUS6551035B1Eliminate the problemWood turning toolsTransportation and packagingCouplingScrew thread

A rotary chip-removing tool includes a rotary tool body and a tool tip fastened on a front end thereof. The tool tip is formed of an injection molded body which has an integral cutting edge at its front end, and a coupling structure at its rear end. The coupling structure can be in the form of a threaded hole, or a rearward projection, for coupling the tool tip against the tool body. The tool tip is formed of first and second materials. The first material forms at least part of the cutting edge, and the second material forms the coupling structure. The first material is more brittle than the second material, and the second material is tougher than the first material.

Owner:SECO TOOLS AB

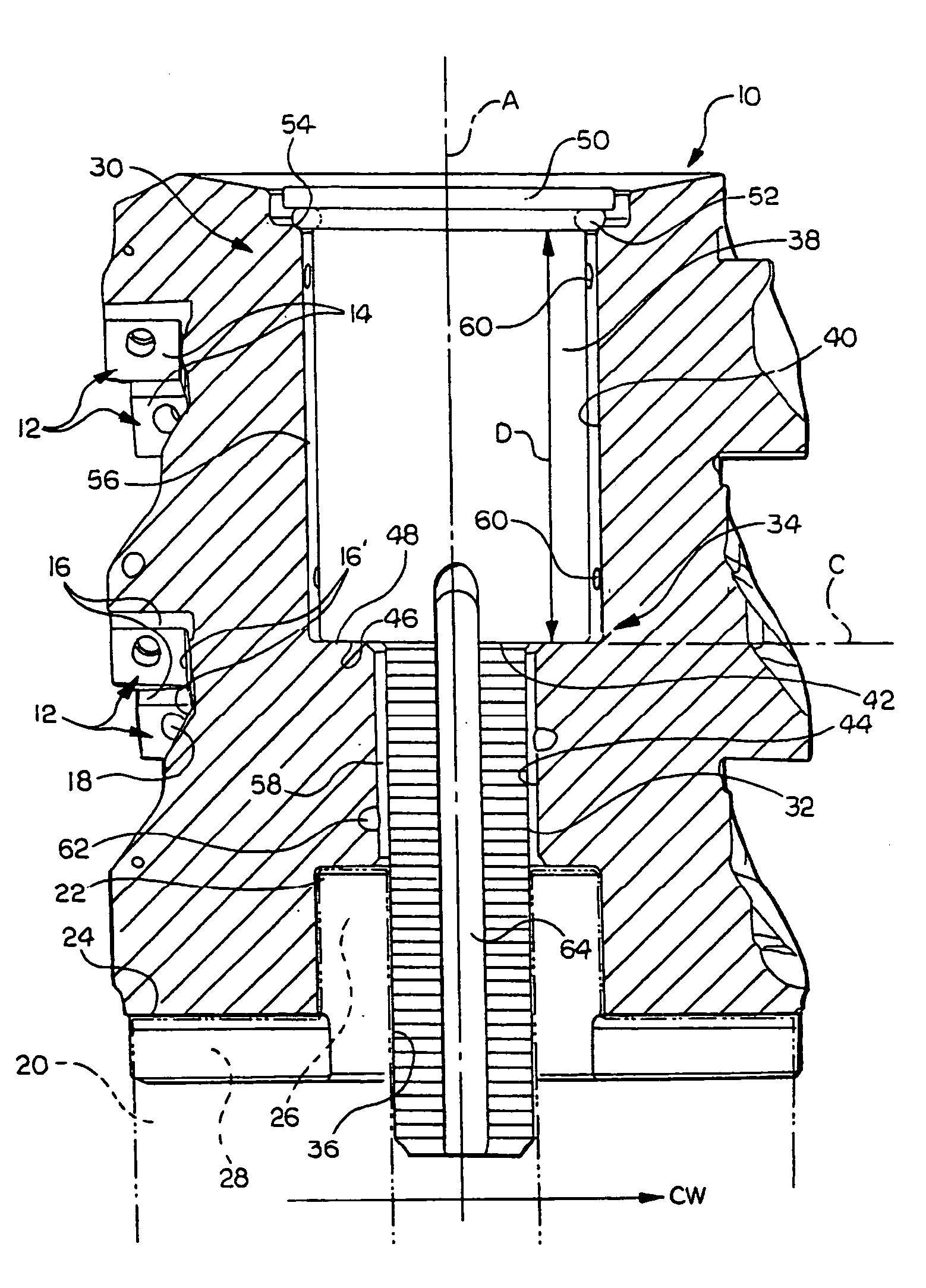

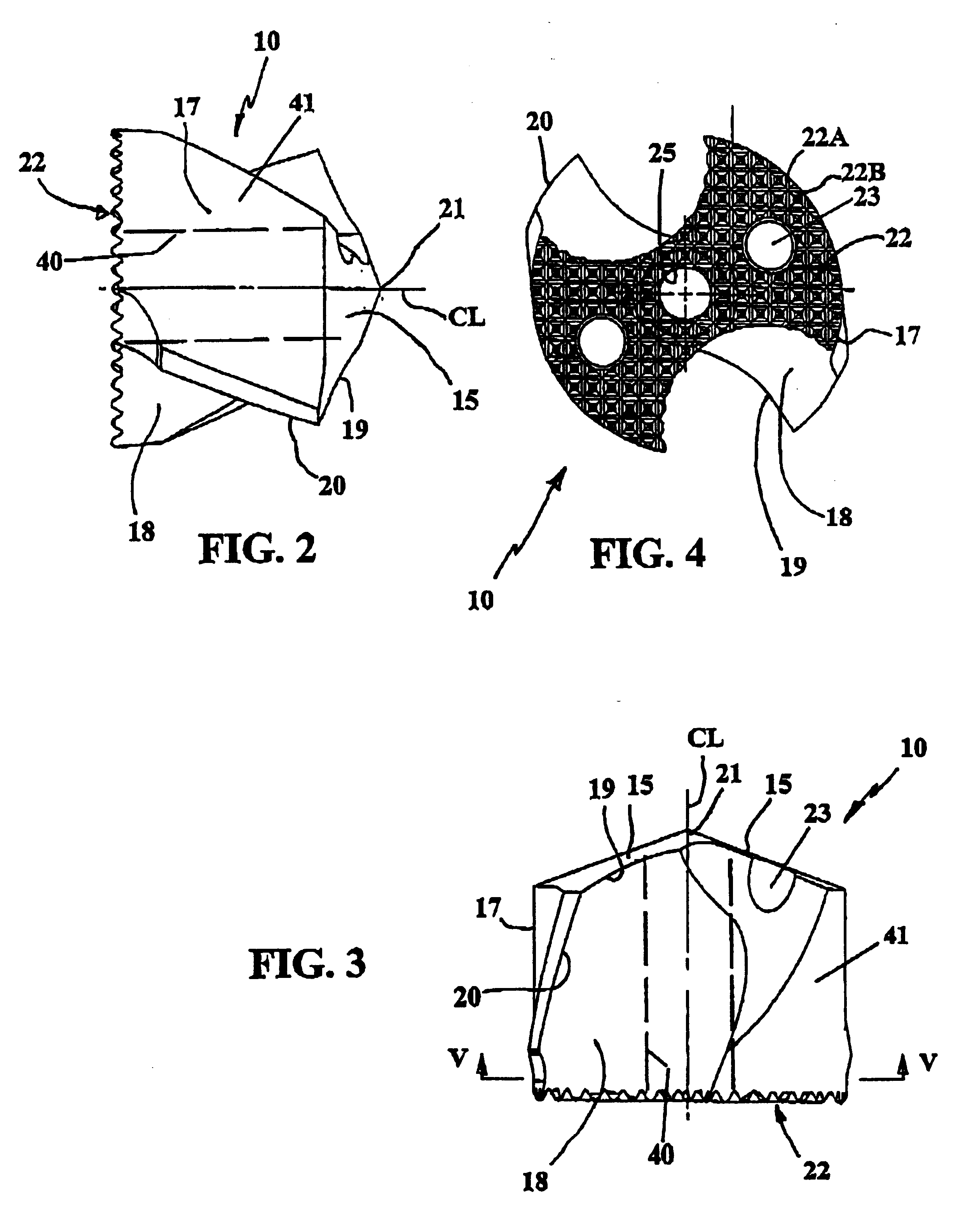

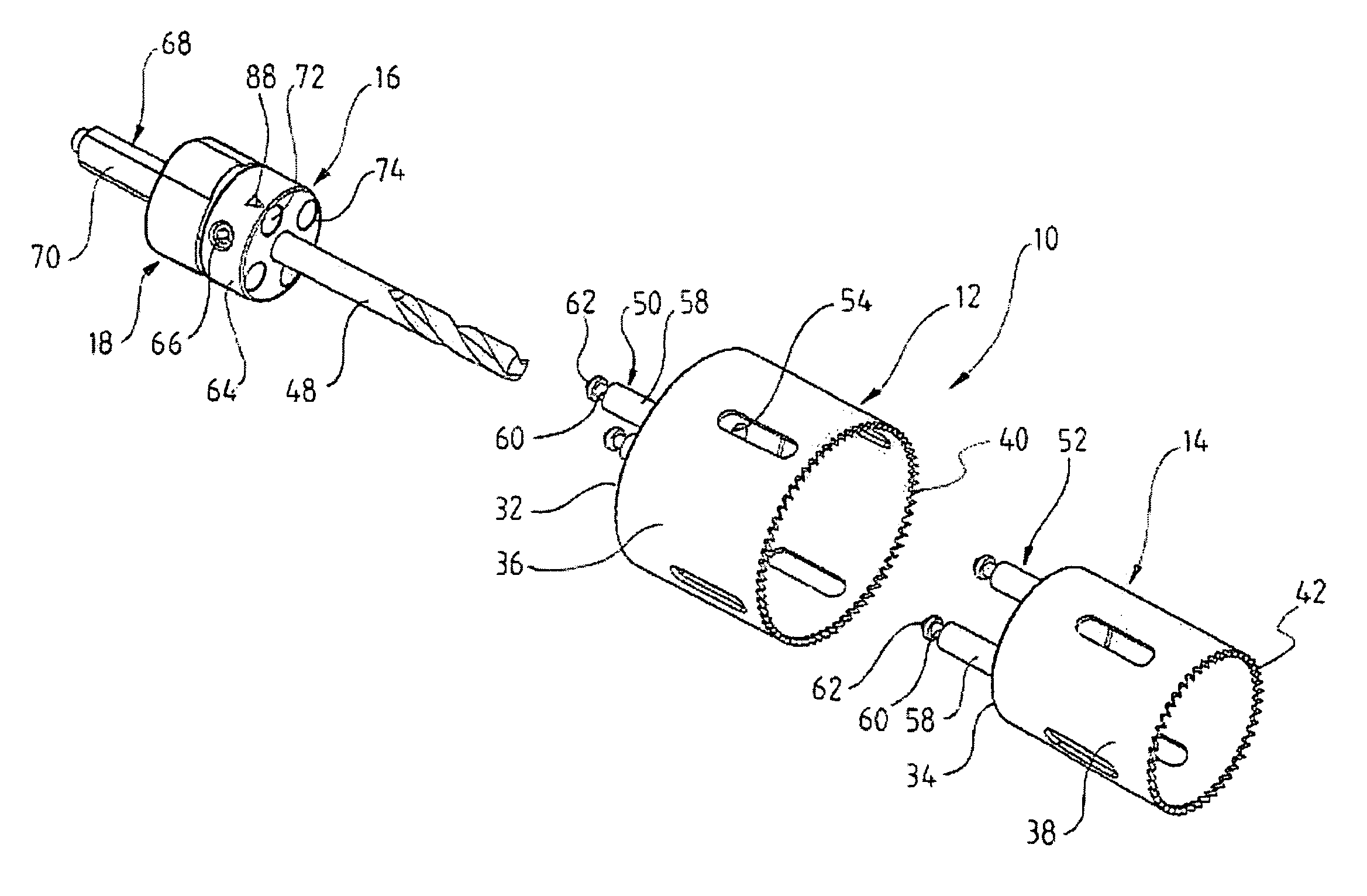

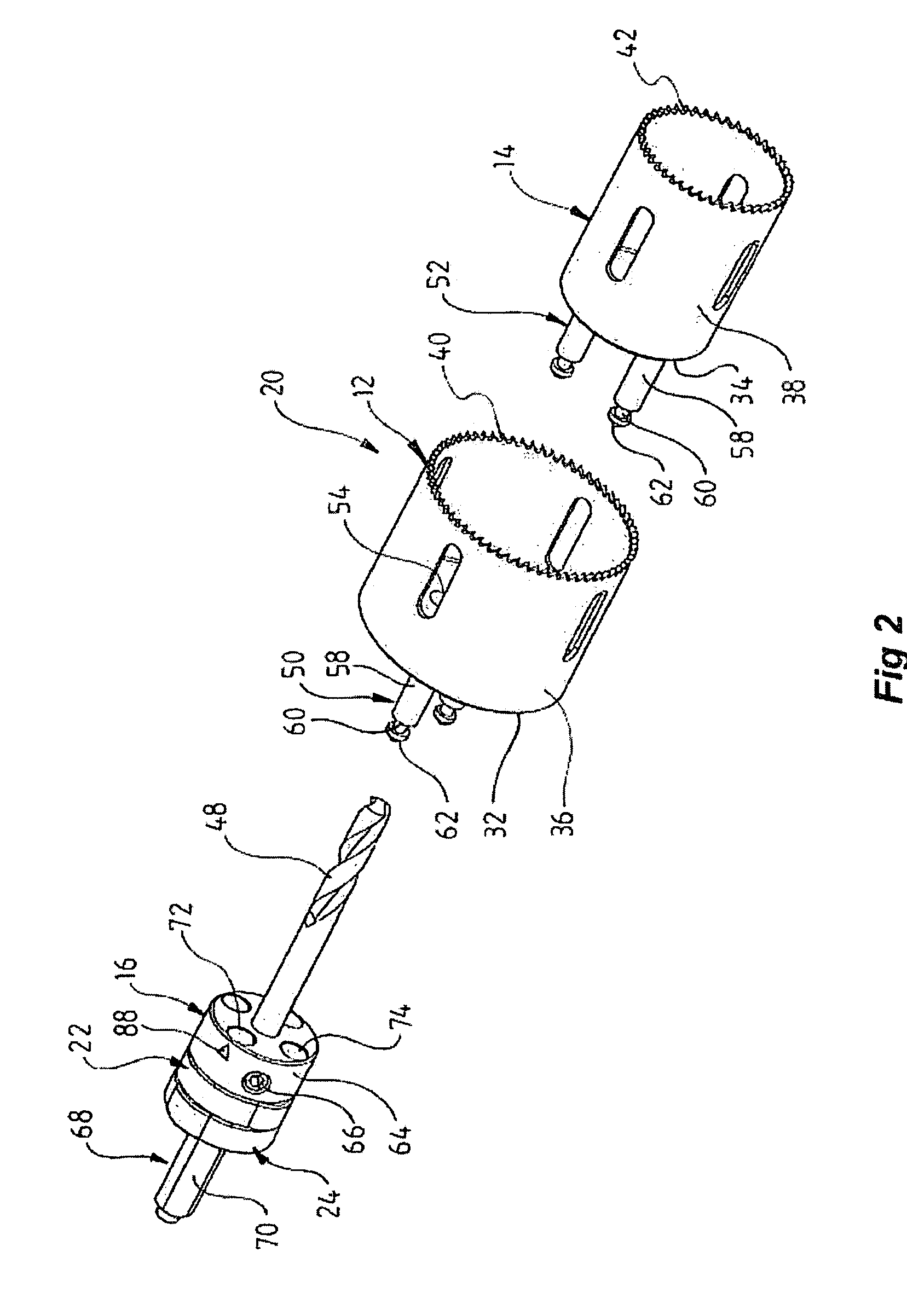

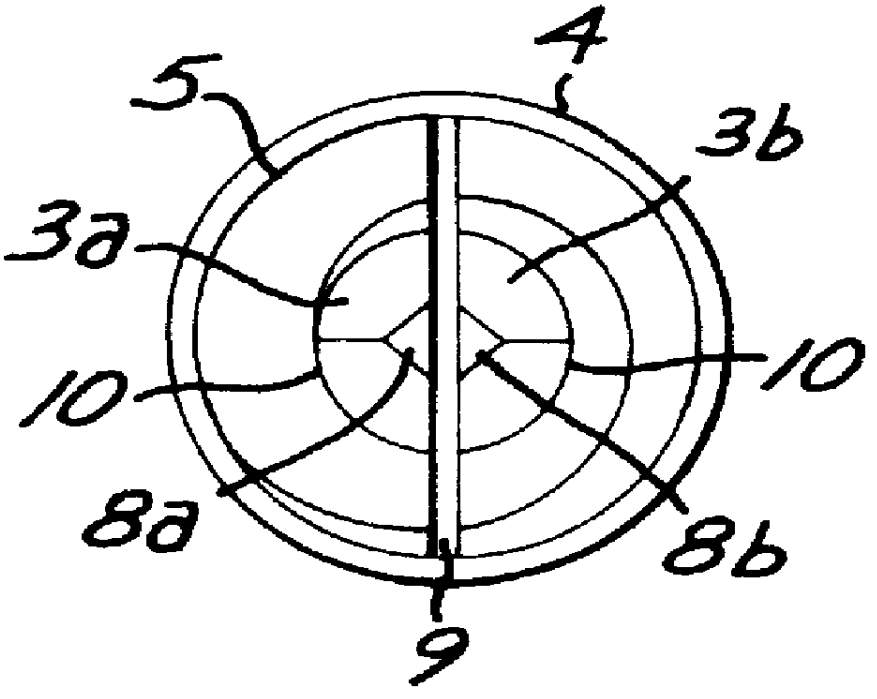

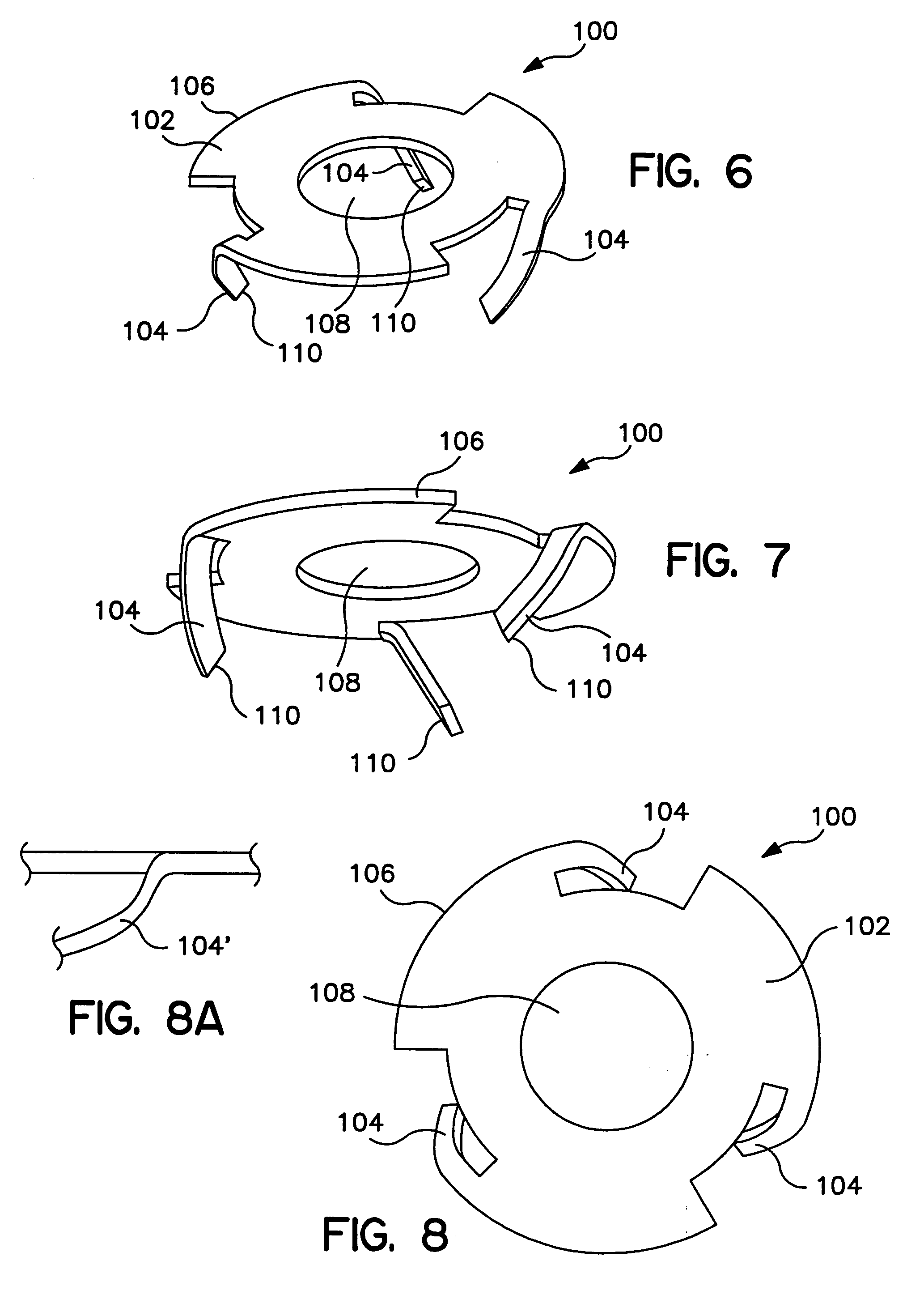

Hole-saw assembly including two hole-saws

The present invention relates to an improved hole-saw assembly and in particular, to a mandrel engageable by a drill and including at least one locking ring or annulus that allows for the base of two hole-saws of different diameter to be quickly and easily mountable and demountable from the mandrel. The hole-saw assembly includes a first hole-saw having a base that includes a pair of drive-pins extending outwardly therefrom and a pair of apertures for insertion therethrough of the drive pins of a second hole-saw. The drive pin pairs are then inserted through corresponding apertures in the mandrel to engage an annulus coupled to the mandrel. The present invention provides for each drive pin to be engaged by the annulus despite the difference in longitudinal length of the drive pins beyond the base of the first hole-saw. The hole-saws are snap-fit within the annulus and may be disengaged by simply rotating the annulus to a second position. A further embodiment of the present invention further allows one to insert the hole-saws into any one of the mandrel insertion points without being concerned about whether it contains the correct engaging means or not. A still further embodiment of the invention prevents slight longitudinal movement which is known to occur when the hole-saws are coupled to the mandrel.

Owner:KEIGHTLEY KYM JOHN

Rotatable tool for chip removing machining and appurtenant cutting part therefor

A rotatable tool for chip removing machining includes two parts, viz. a holder part, rotatable around a geometrical center axis, and a replaceable cutting part, which is rigidly connectable to a front end of the holder part via a male / female coupling. The coupling includes a tapering seat in the holder part and a tapering male member, protruding rearwardly from the cutting part. In the seat, there is a slot, which separates two elastically deflectable projections, that may be inwardly deflected towards each other during clamping of the male member in the seat. The male member is elongated in a radial direction, and the seat is in the form of a radial groove into and out of which the sheath body is transversely movable. The male member includes a dove-tail shaped portion received in a dove-tail shaper portion of the groove. A centering button on the male member enters a depression in the holder part to axially center the cutting part.

Owner:PROCTER & GAMBLE CO +1

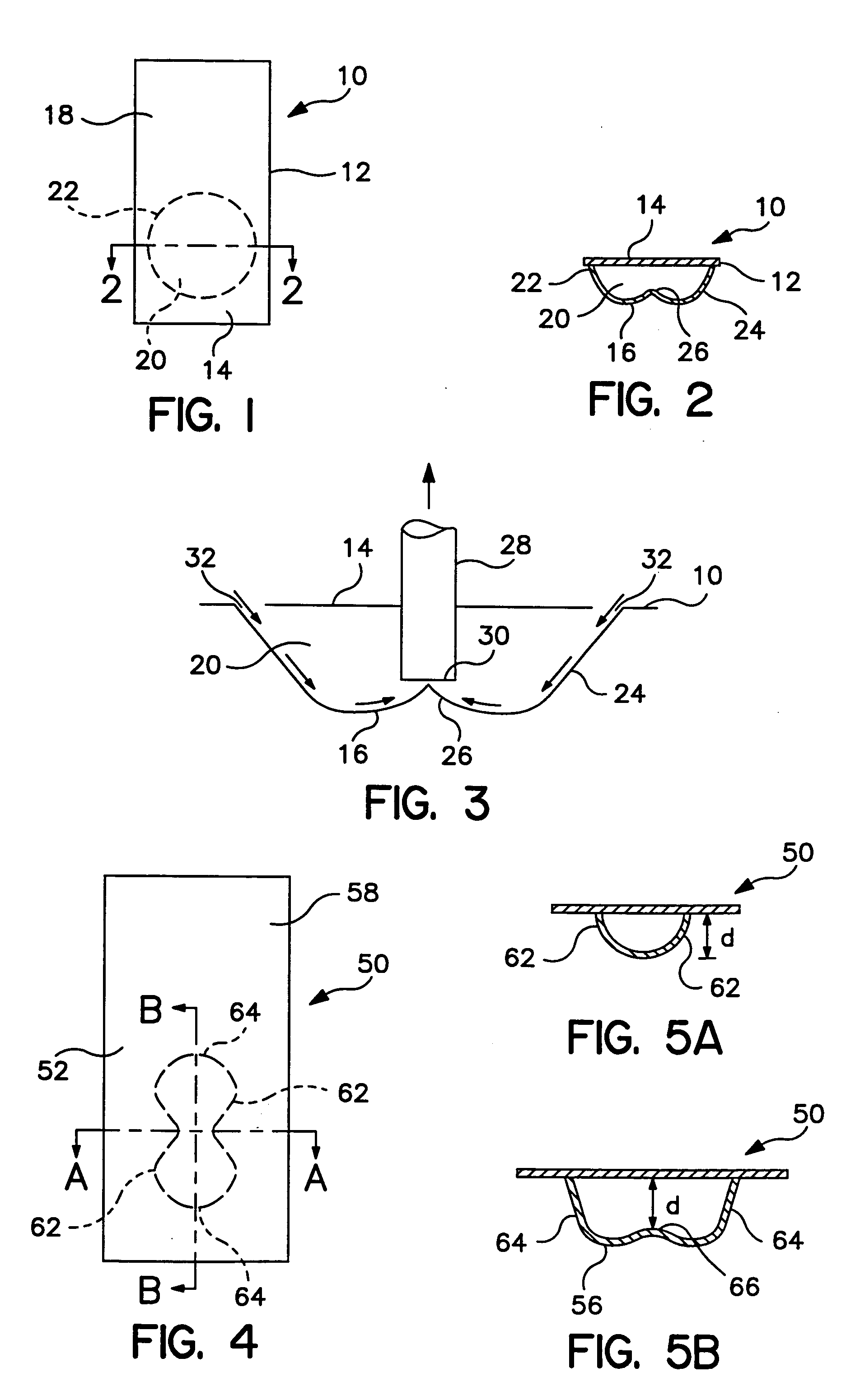

Depth limiting device and hole forming apparatus containing the same

ActiveUS7258513B2Facilitates and promotesAvoid damageThread cutting toolsDrilling/boring measurement devicesEngineeringMechanical engineering

A depth limiting device includes a stop collar having a an open end portion and an workpiece engaging portion extending along the open end portion thereof for contacting a workpiece; a spindle extending axially through the shell, the spindle including a first end extending from the exterior of the stop collar for attachment to a hole forming apparatus, and an second end interior to the stop collar for attachment to a hole forming bit, wherein the attached hole forming bit projects through the open end portion of the stop collar at a predetermined length corresponding to the desired depth of the hole in the workpiece; and a bearing assembly operatively associated with the stop collar and the spindle for isolating the rotation of the spindle from the stop collar whereby the stop collar ceases to rotate when contacting the workpiece without generating sufficient frictional contact to mar or otherwise damage the workpiece.

Owner:FAR NORTH

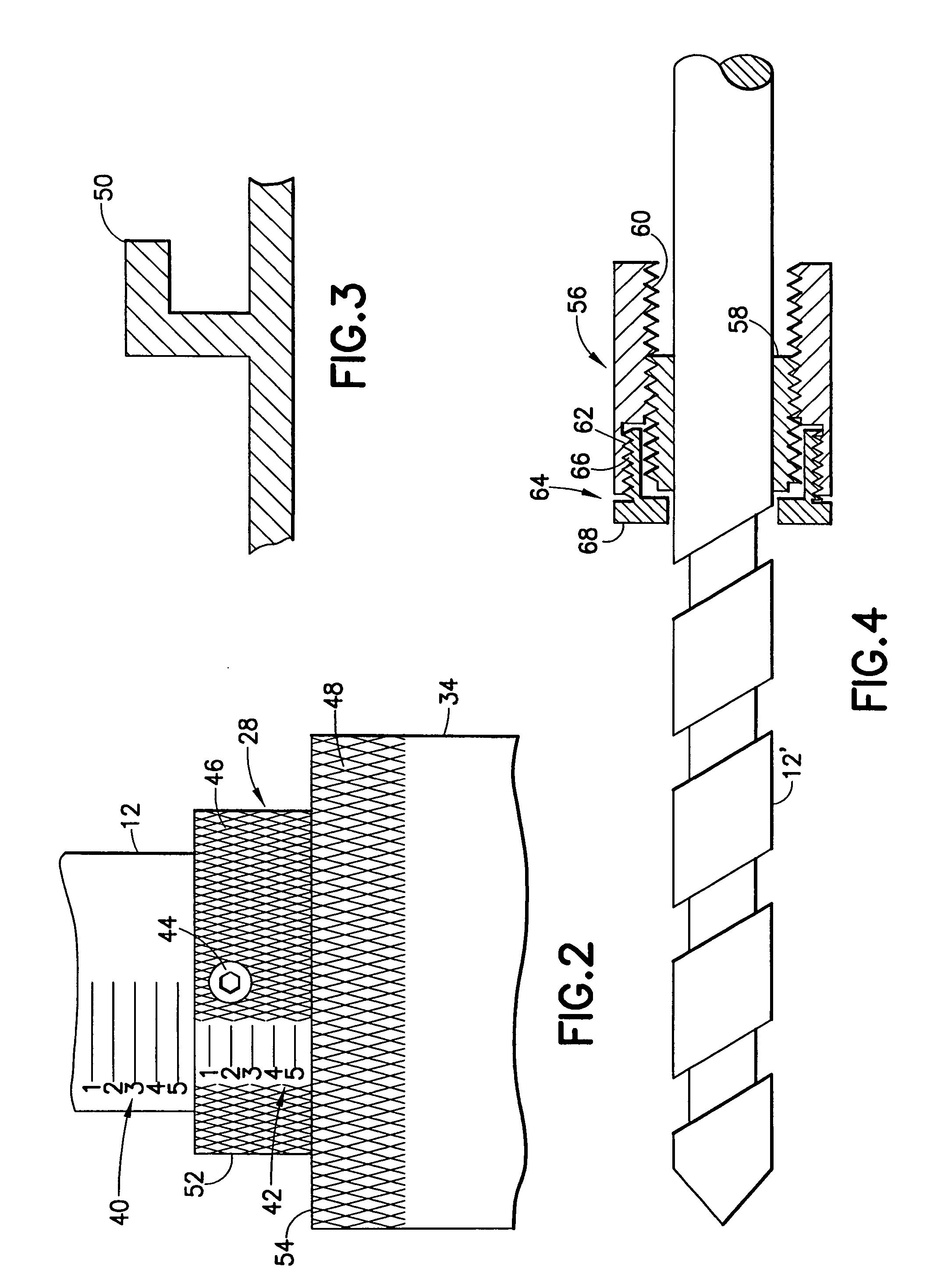

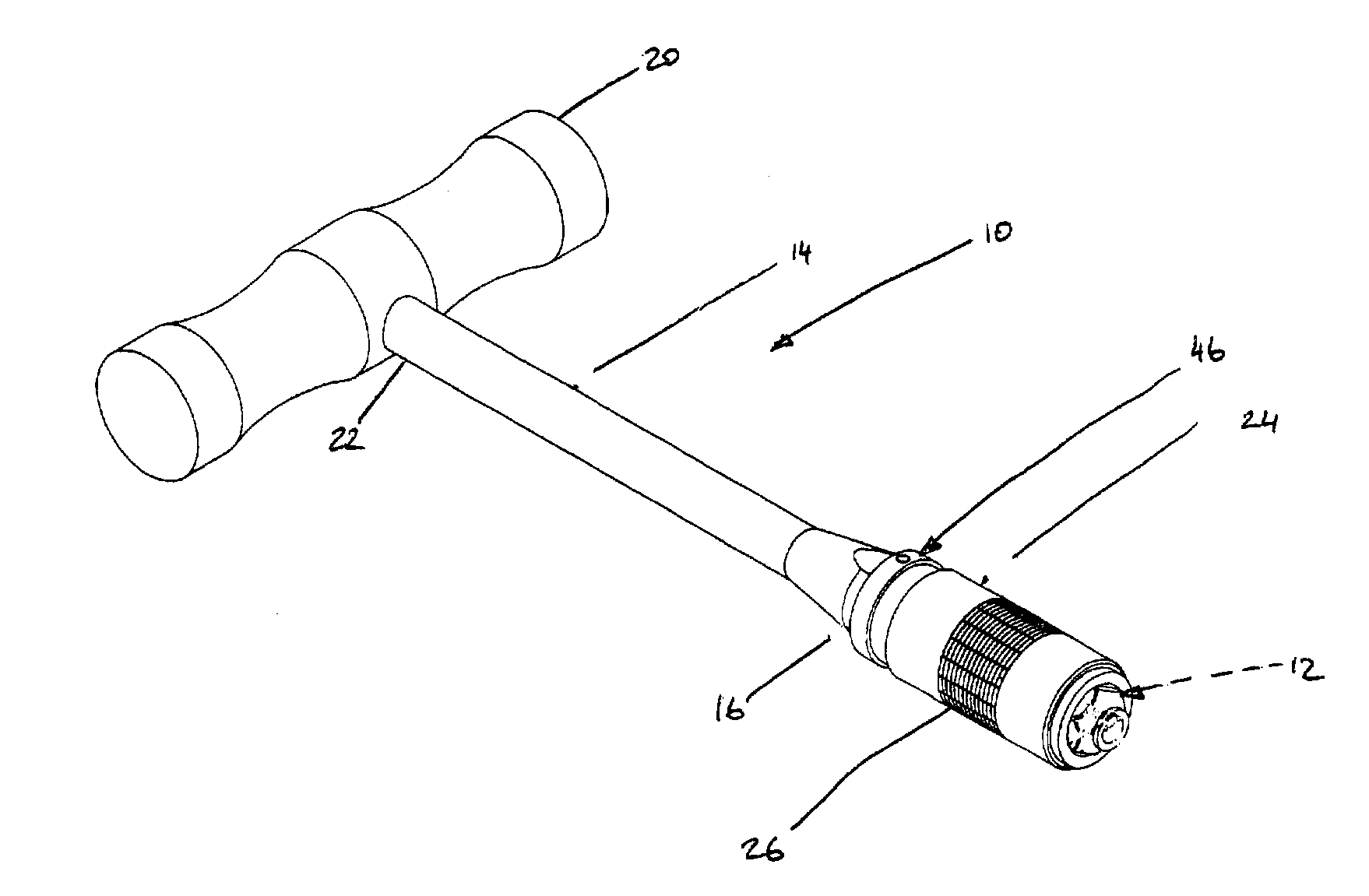

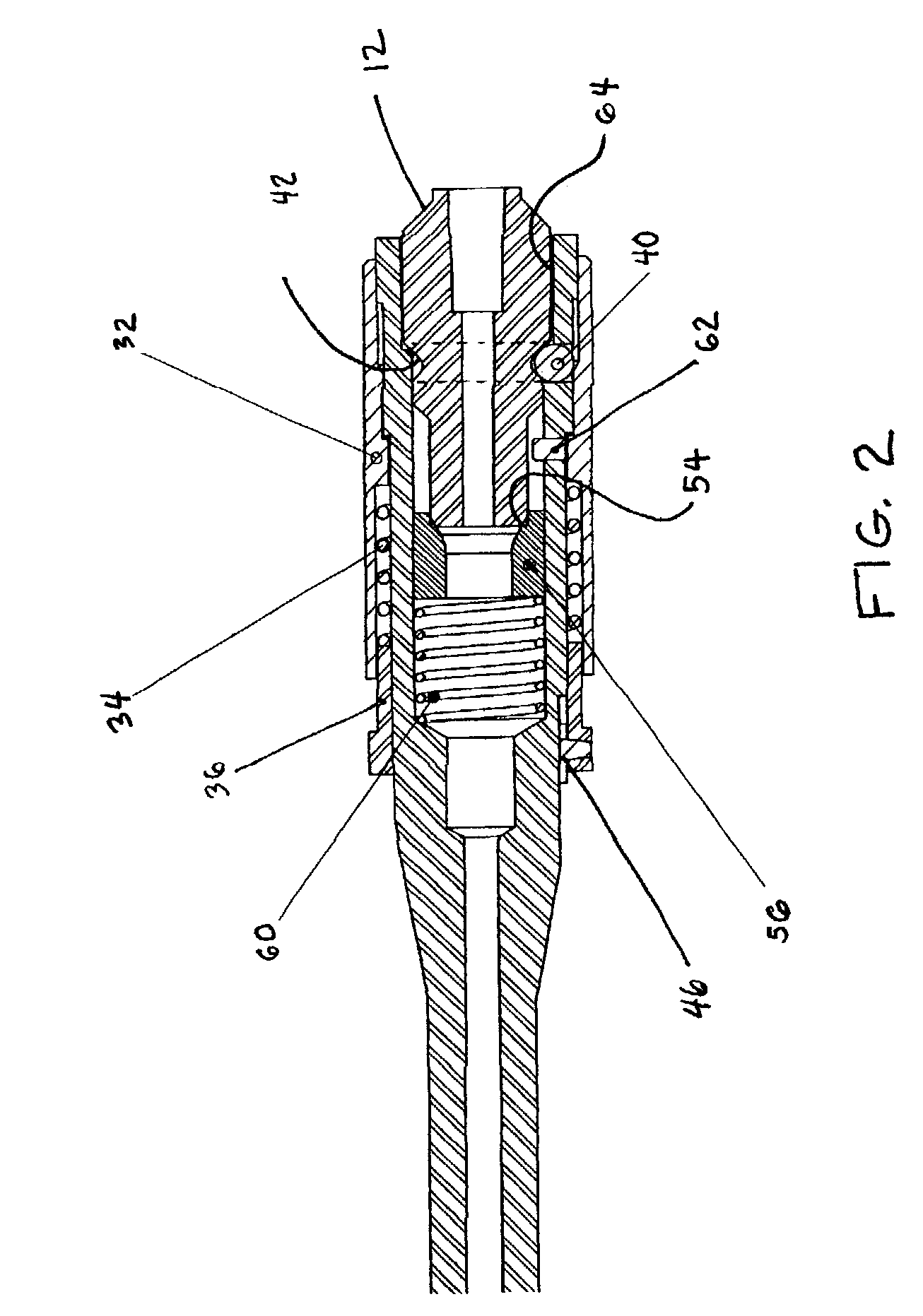

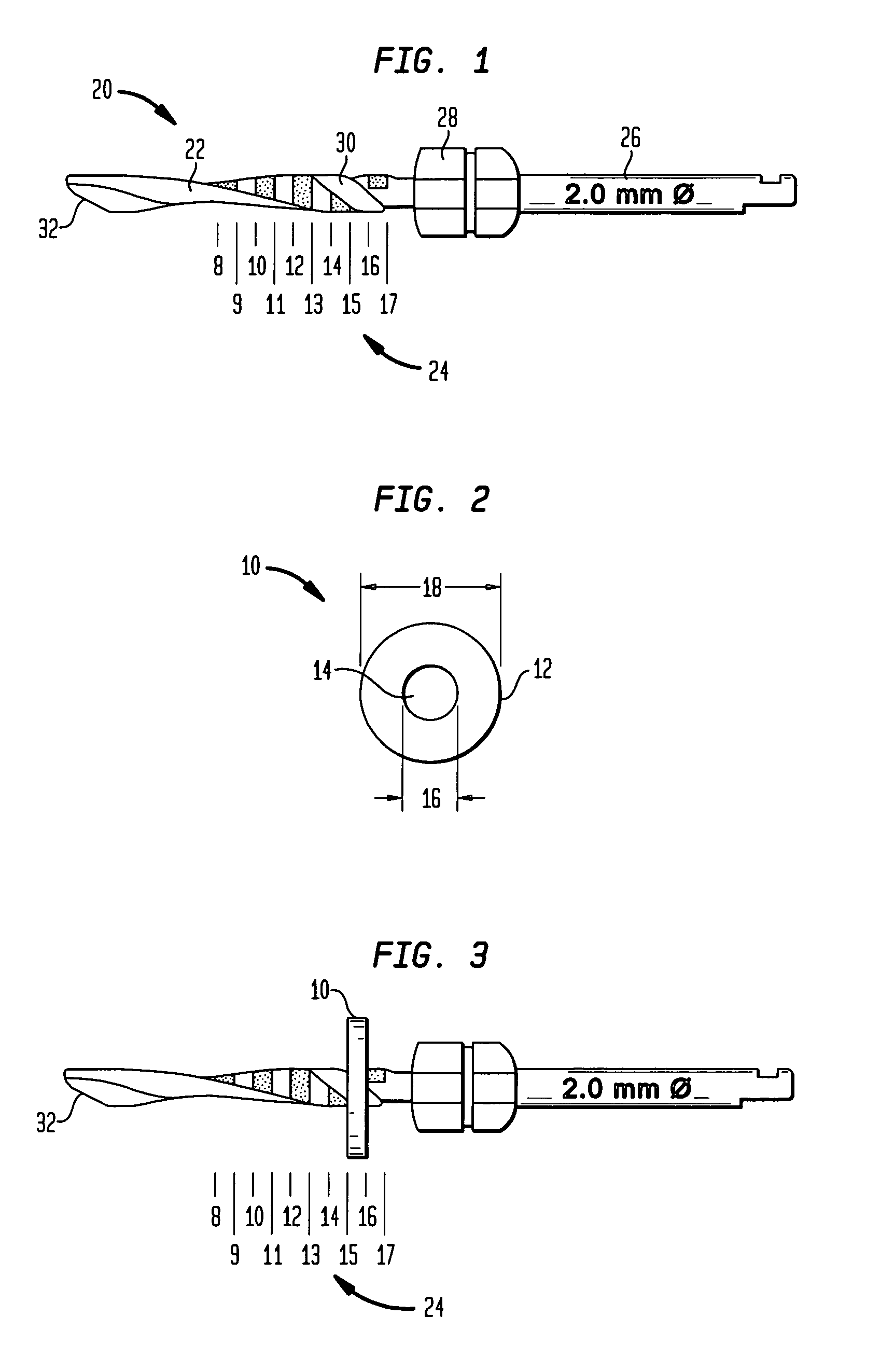

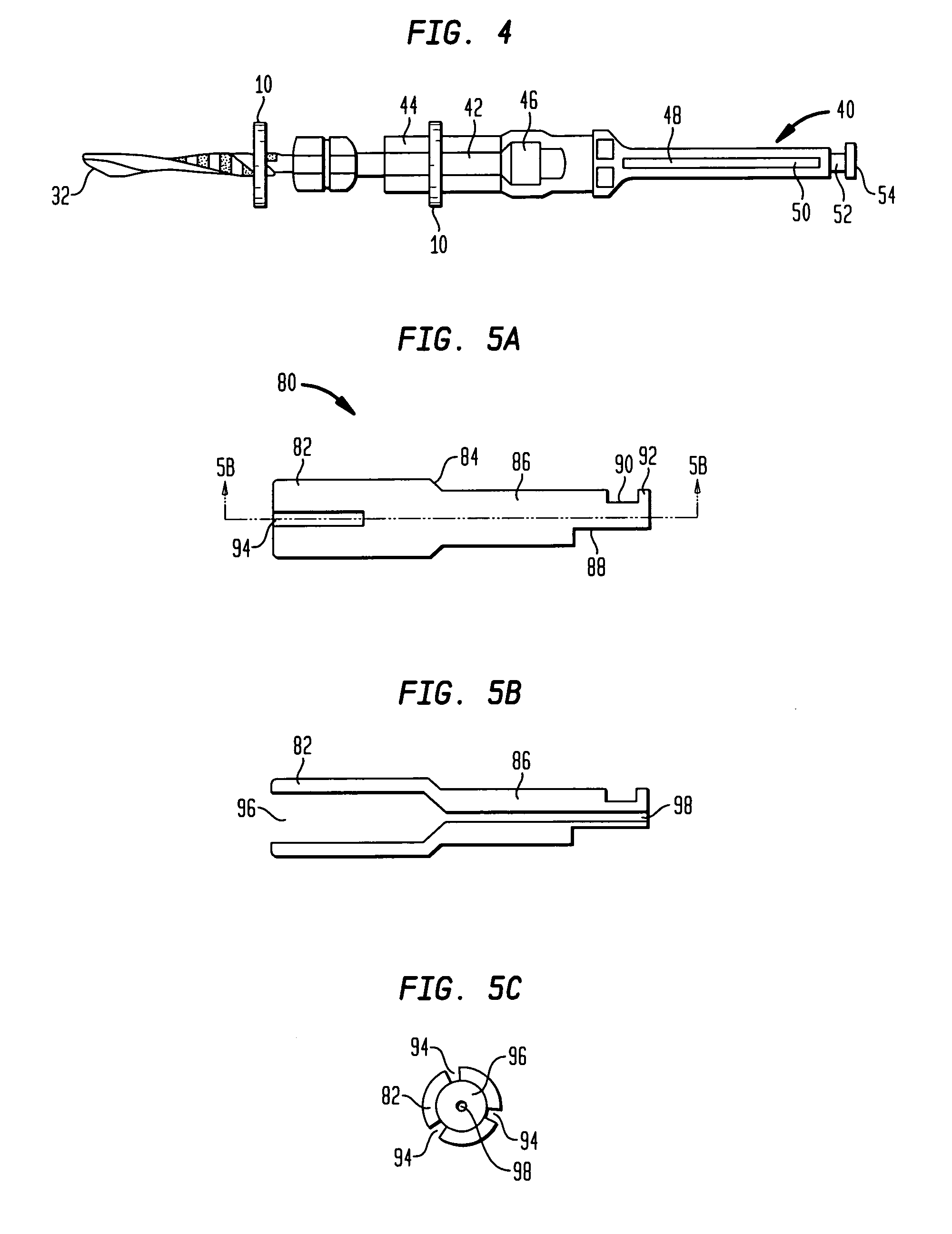

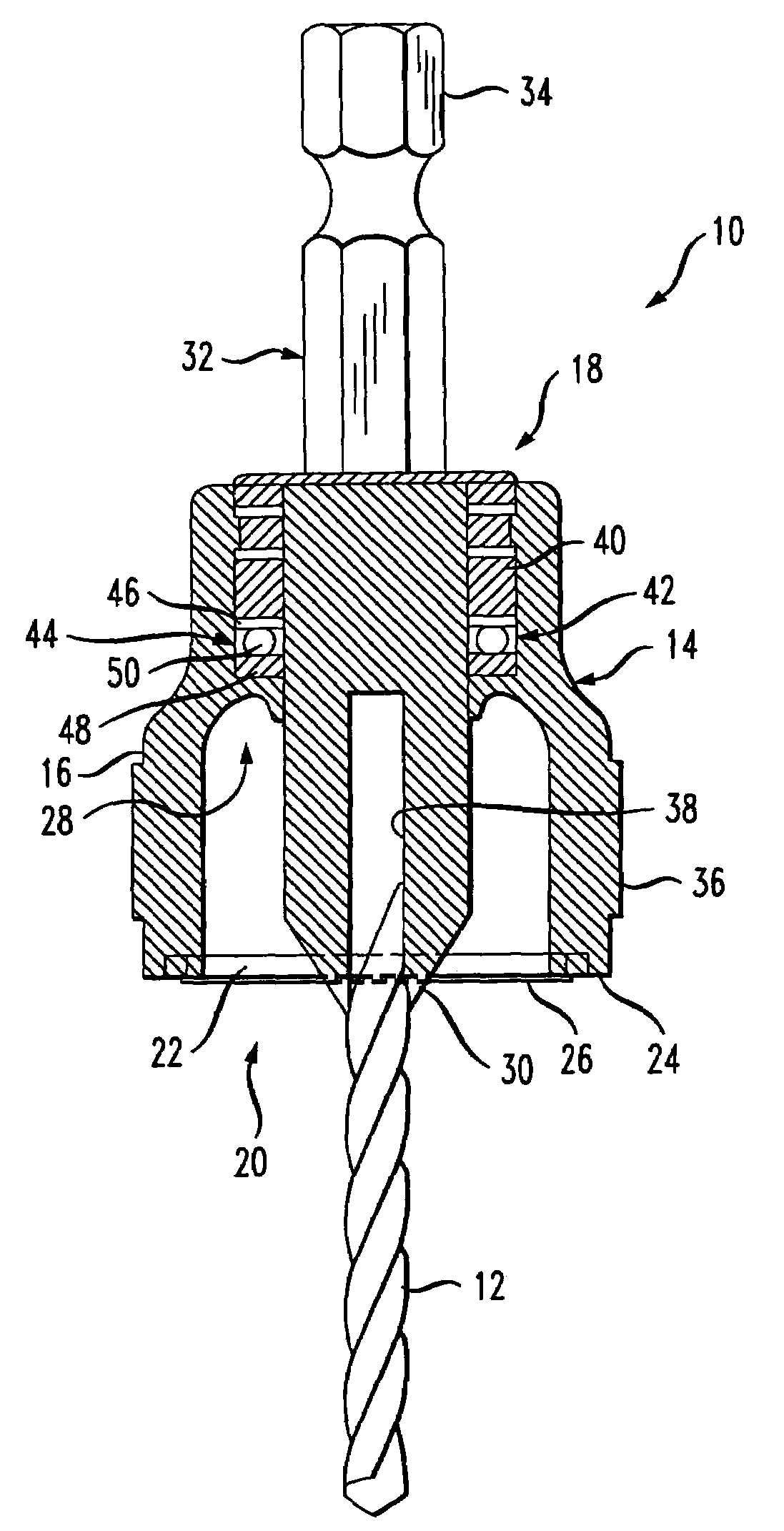

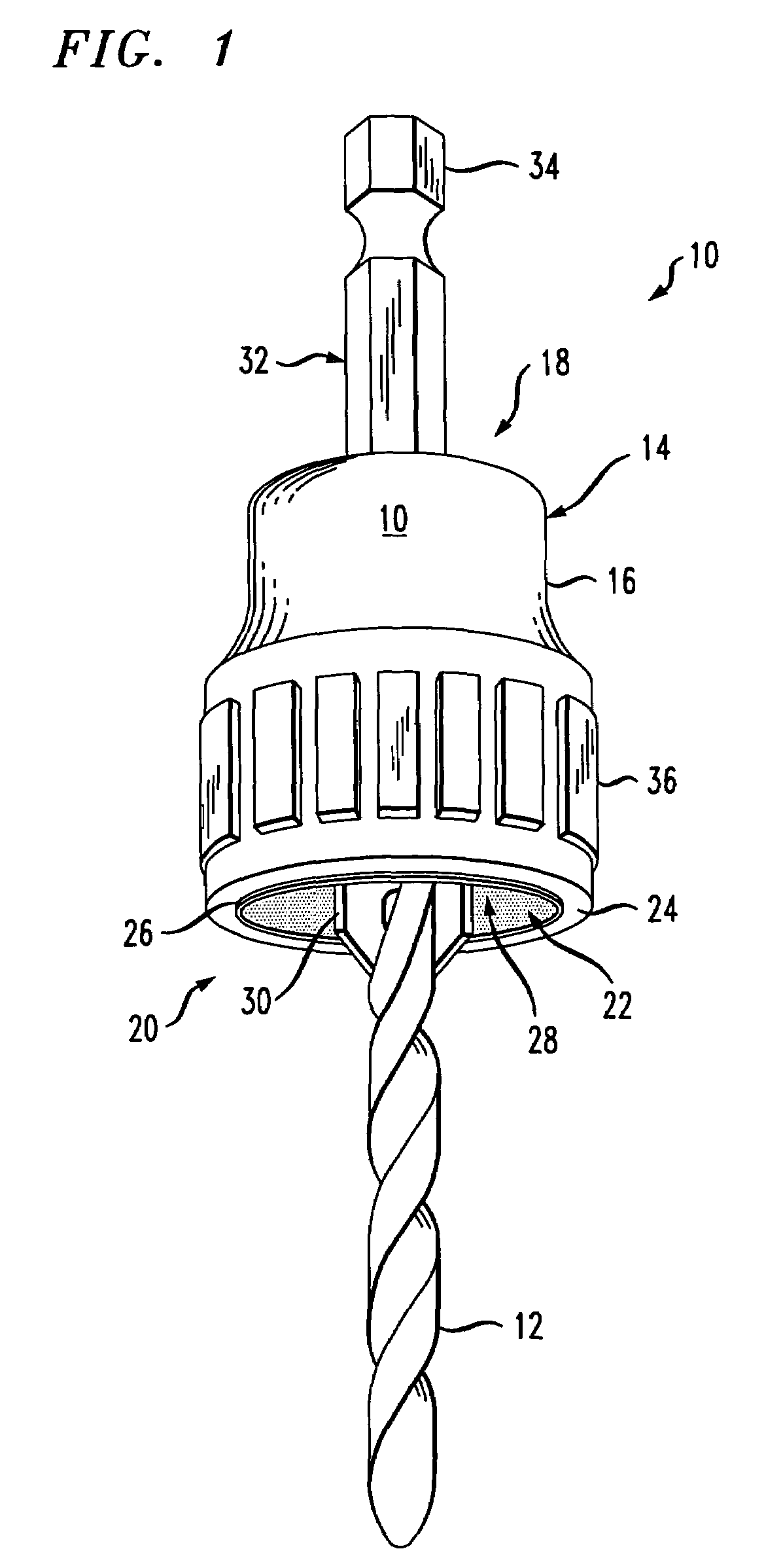

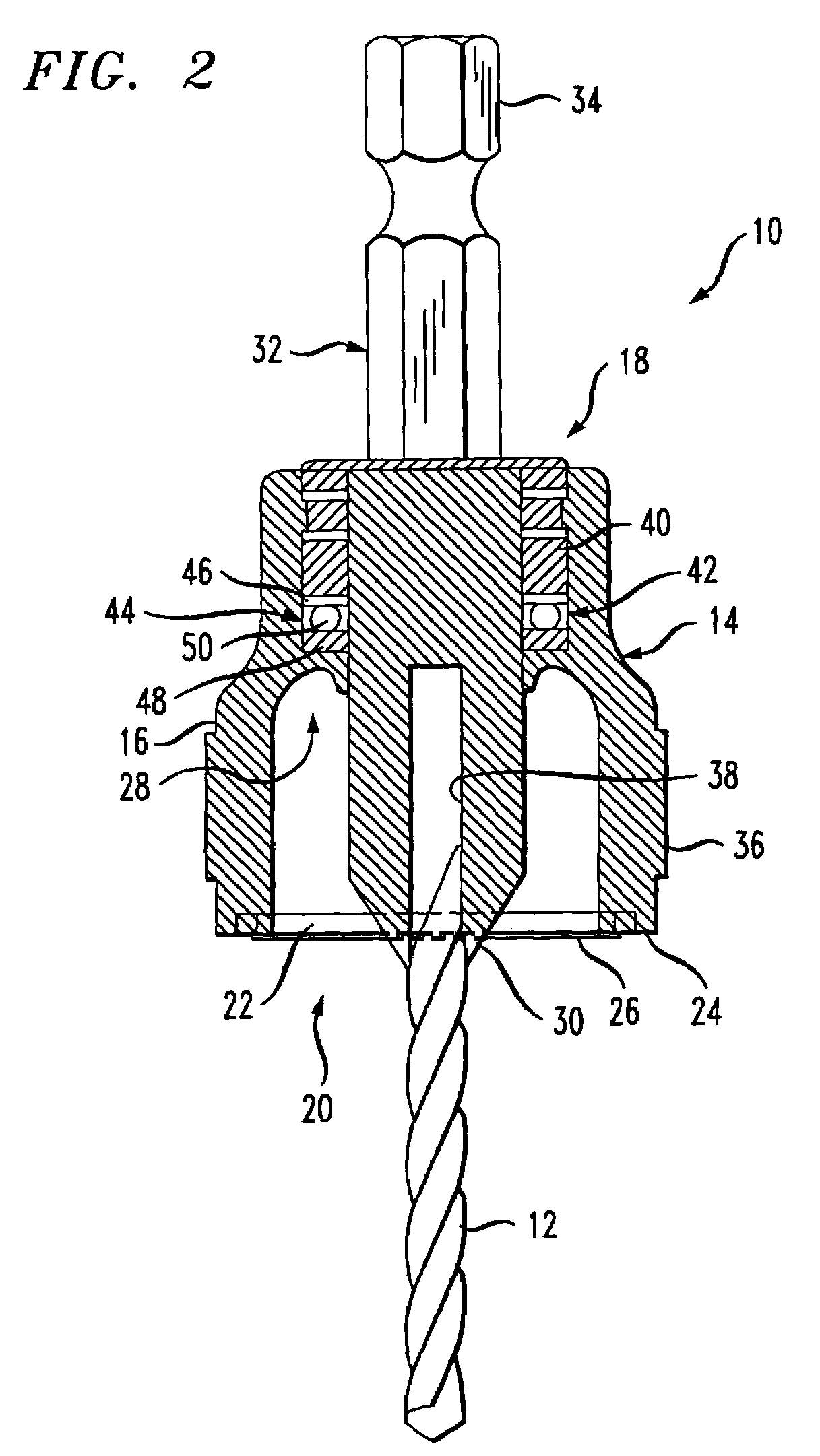

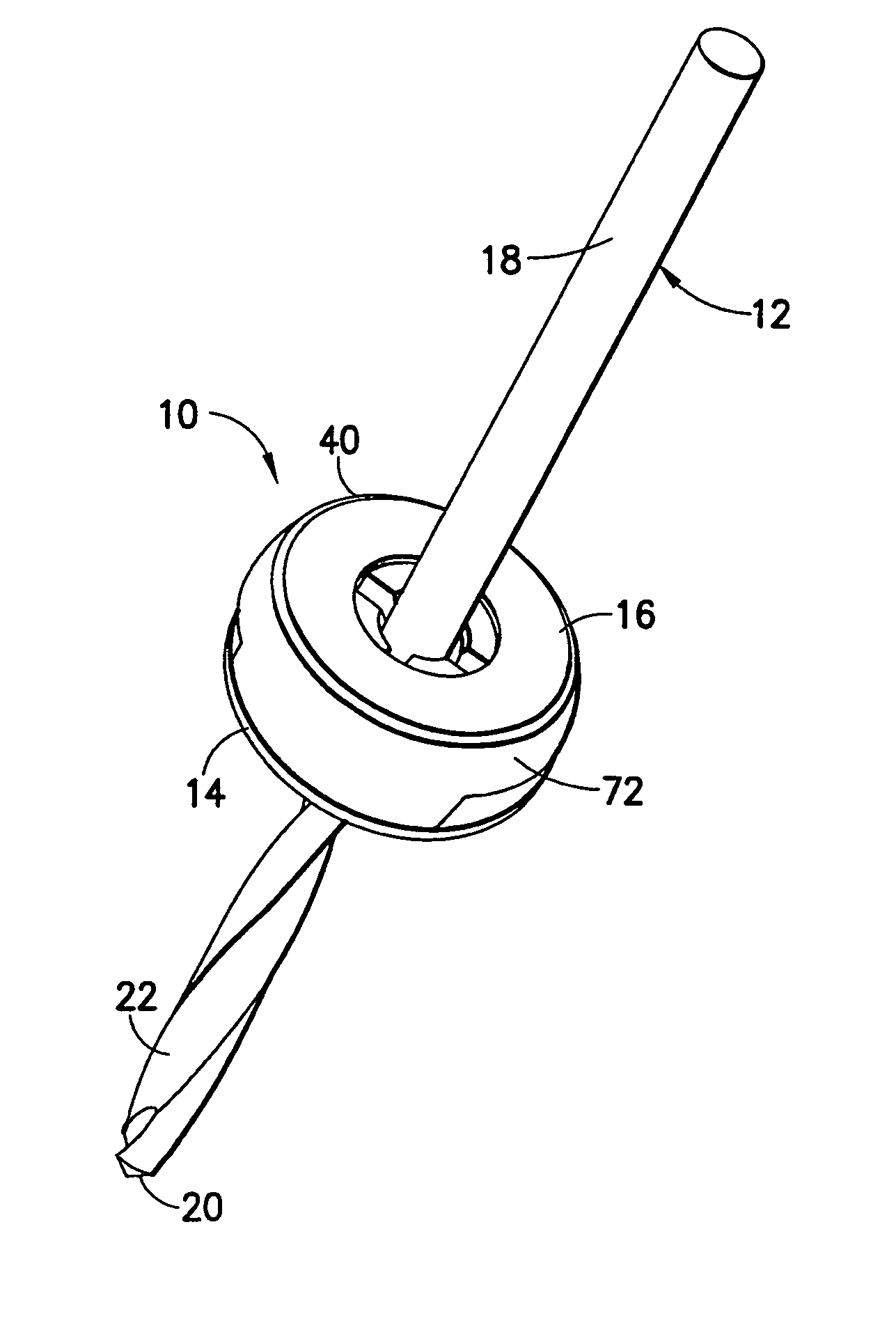

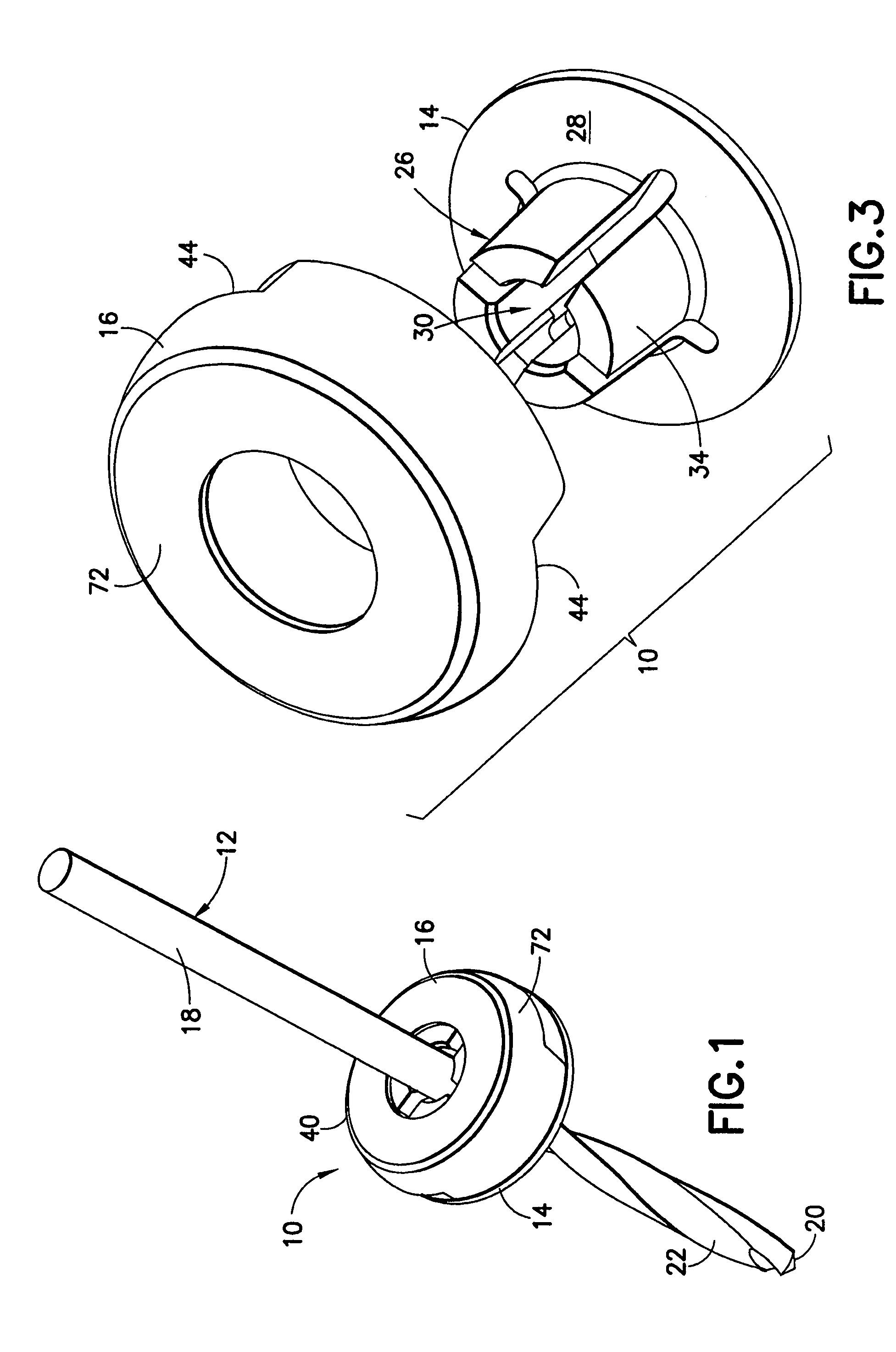

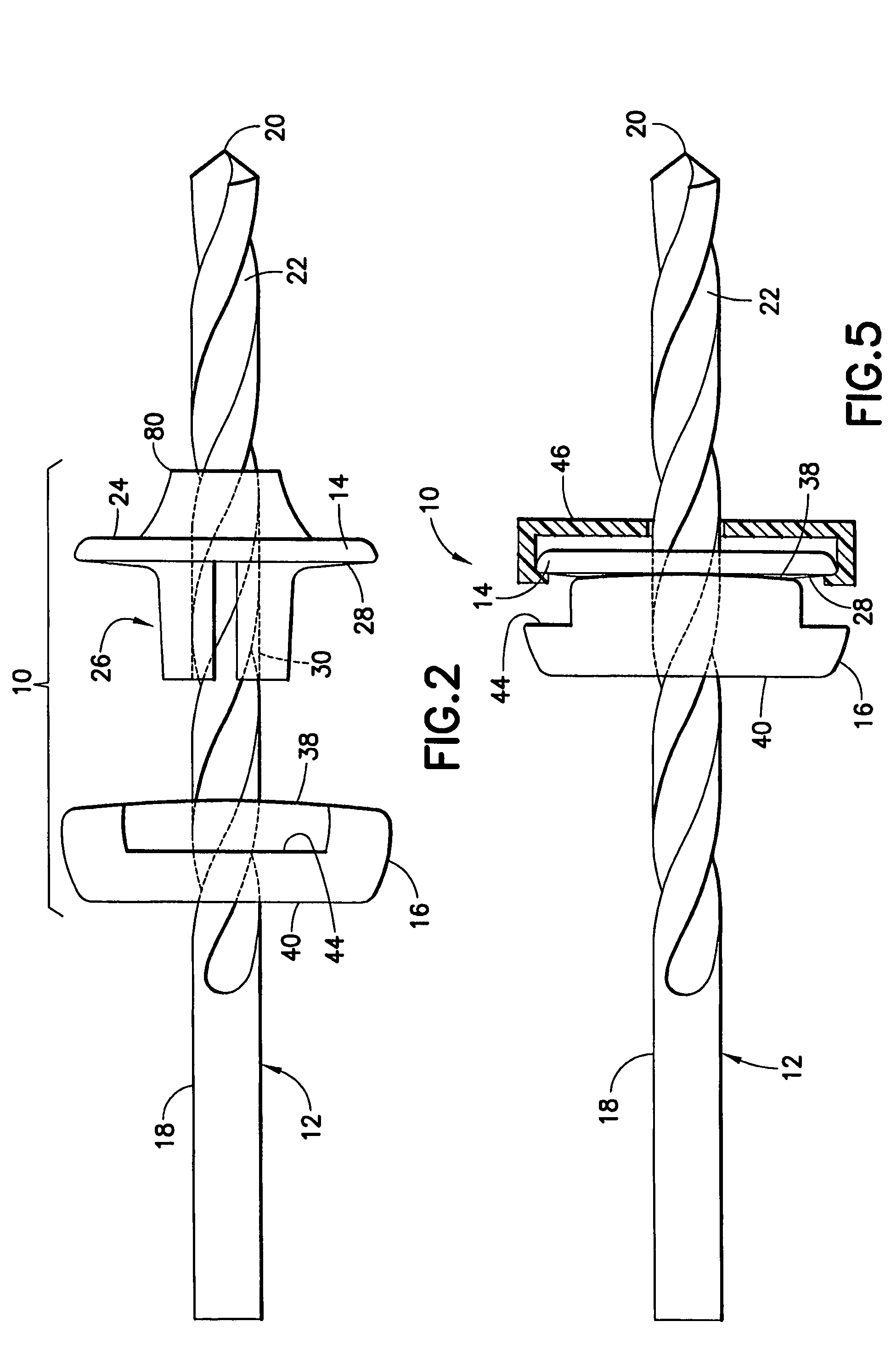

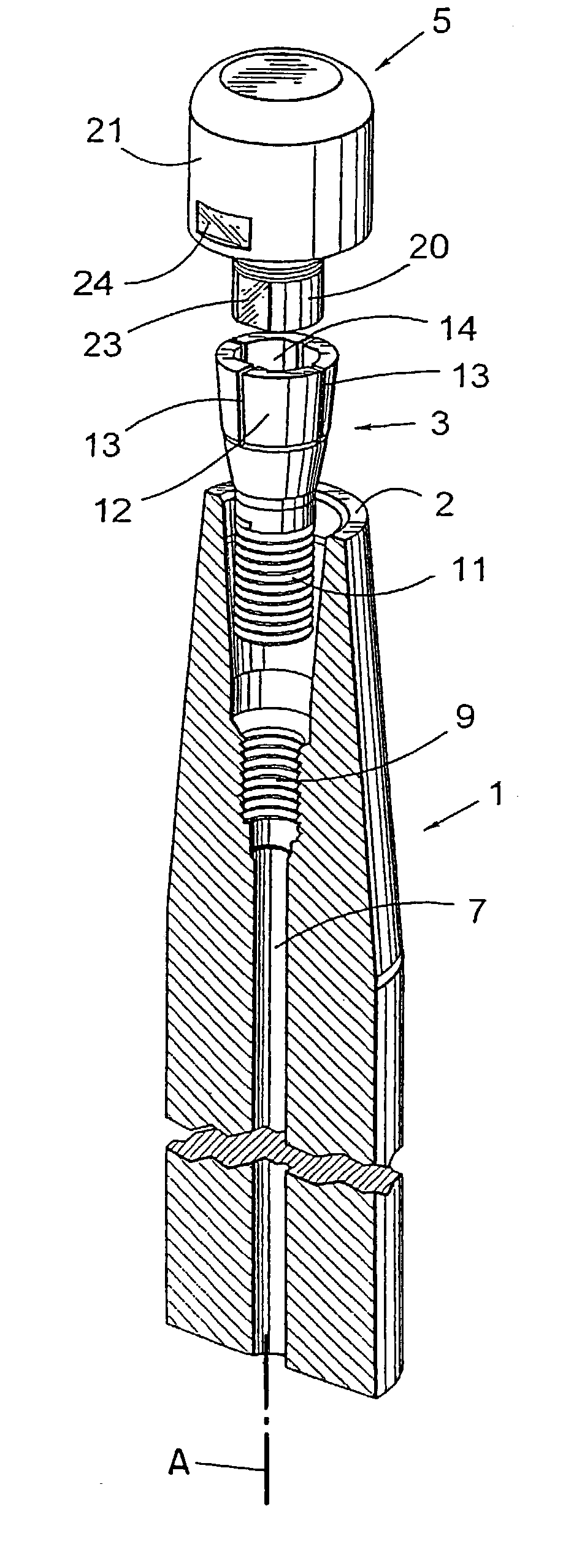

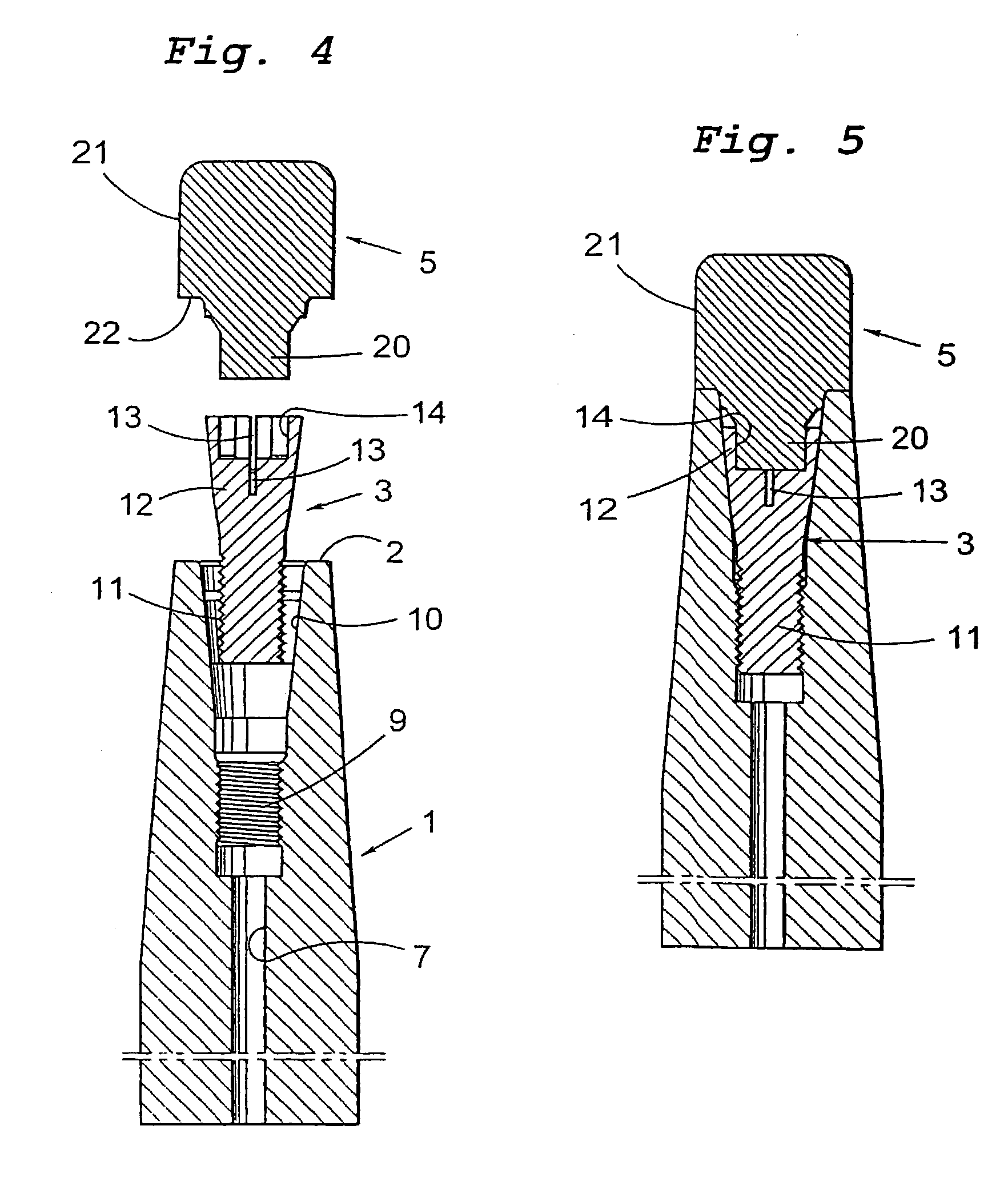

Collet collar stop for a drill bit

InactiveUS7513722B2Thread cutting toolsDrilling/boring measurement devicesDepth of penetrationEngineering

A stop for a drill bit having a shaft, the stop having a first member which includes a collet. The collet is configured to receive the shaft of the drill bit and is positionable along the shaft of the drill bit. The stop also has a second member which includes a clamp, for clamping the first member in a desired position along the shaft of the drill bit by securing the collet in a desired position along the shaft of the drill bit. The stop further has an abutment surface on one of the first and second members, for limiting the depth of penetration of the drill bit into an object, the abutment surface being disposed in a fixed position along the shaft of the drill bit by the clamping of the first and second members.

Owner:GREENBERG SURGICAL TECH

Board anchor

An anchor that screws directly into a board without requiring a tap drill hole. A male screw is provided around the shaft part of the anchor with a drill part at one end and a flange part at the other end; at the end where the flange part is provided, a turning tool engagement hole and a female screw formed hole part continuous therewith are provided. The drill part is formed into a tapered-pyramid shape, multiple split shaft parts being formed by providing a slit that extends from the end surface of the pyramid-shaped drill part to midway up the shaft part. The tip of the split shaft part incorporate connected multiple drill bits that are formed by splitting the pyramid-shaped drill part.

Owner:KOYOKIZAI

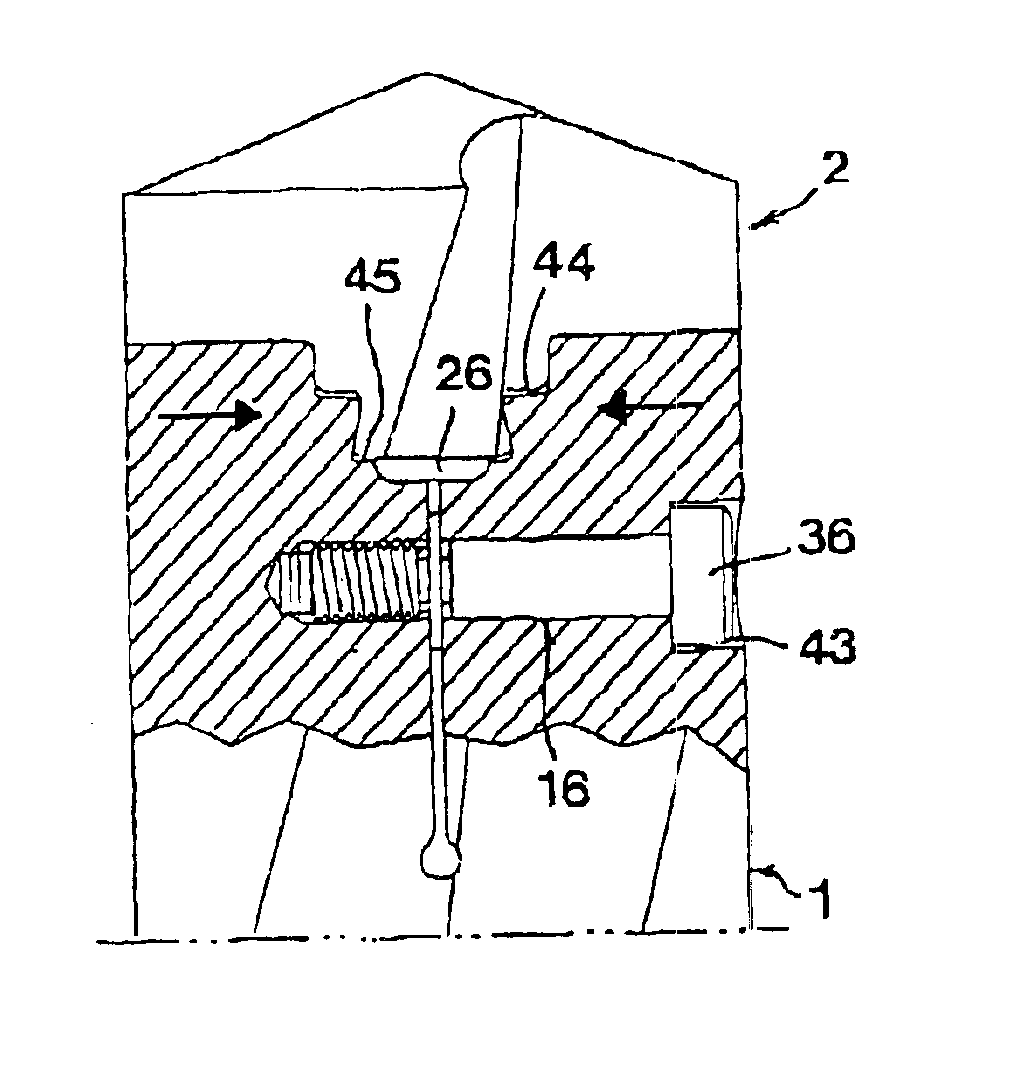

Drilling tool including a shank and a cutting body detachably secured thereto

InactiveUS6481938B2The way is simple and fastImprove cooling effectWood turning toolsTransportation and packagingPre stressPre stressing

A drilling tool includes a shaft having a front end to which a cutting body provided with cutting edges is detachably connected. In the front end of the shaft, a seat is formed which is delimited by spaced-apart protrusions between which there is a bottom surface. In the protrusion, there is a threaded hole for a screw, which when tightened applies pre-stressing forces to the cutting body. On the inside of the opposite protrusion, there is a supporting shoulder against which the cutting body is pressed when the screw is tightened and applies a lateral pre-stressing force to the cutting body. The protrusions are laterally displaced in relation to each other in order to freely expose the screw beside one of the protrusions.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

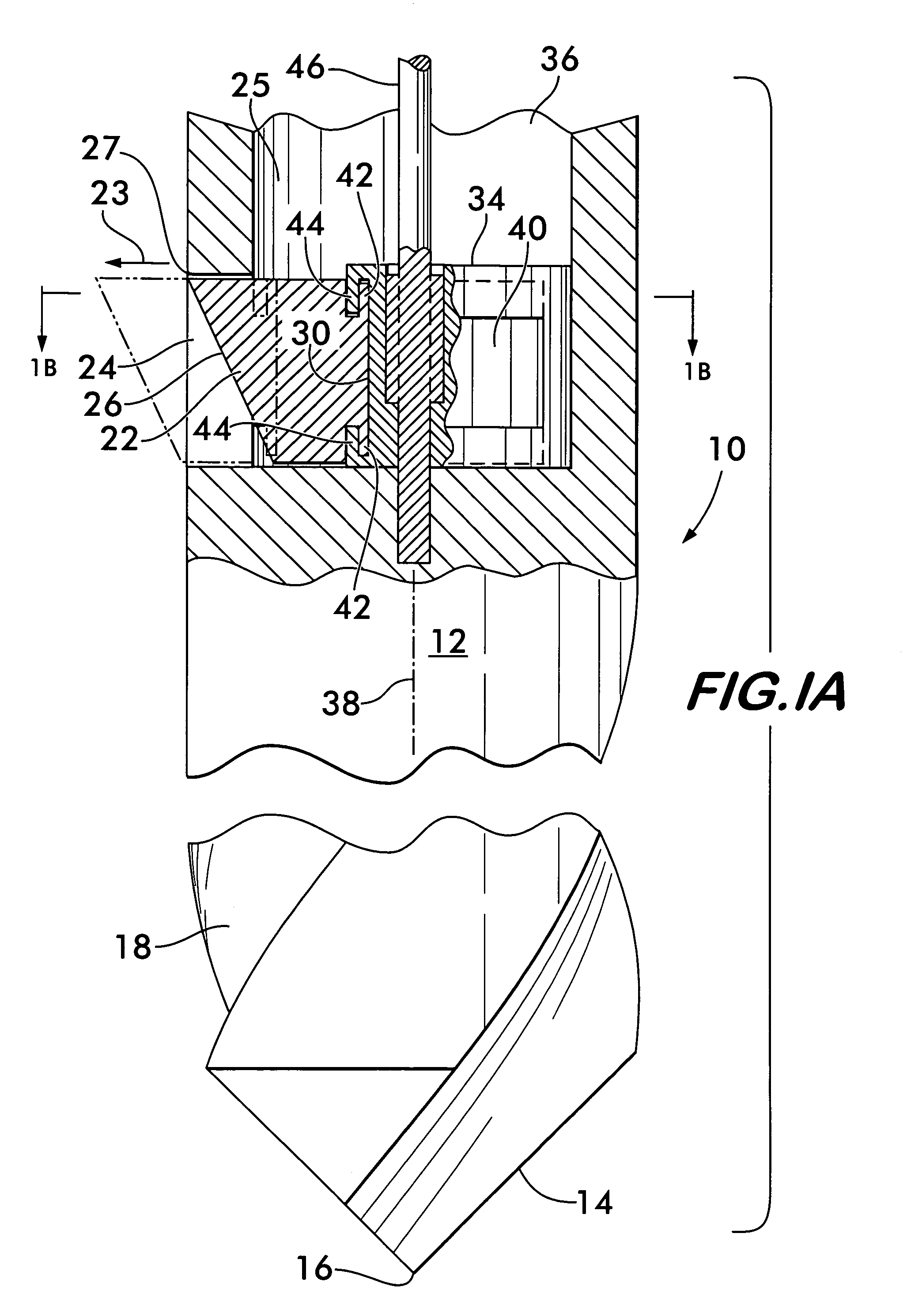

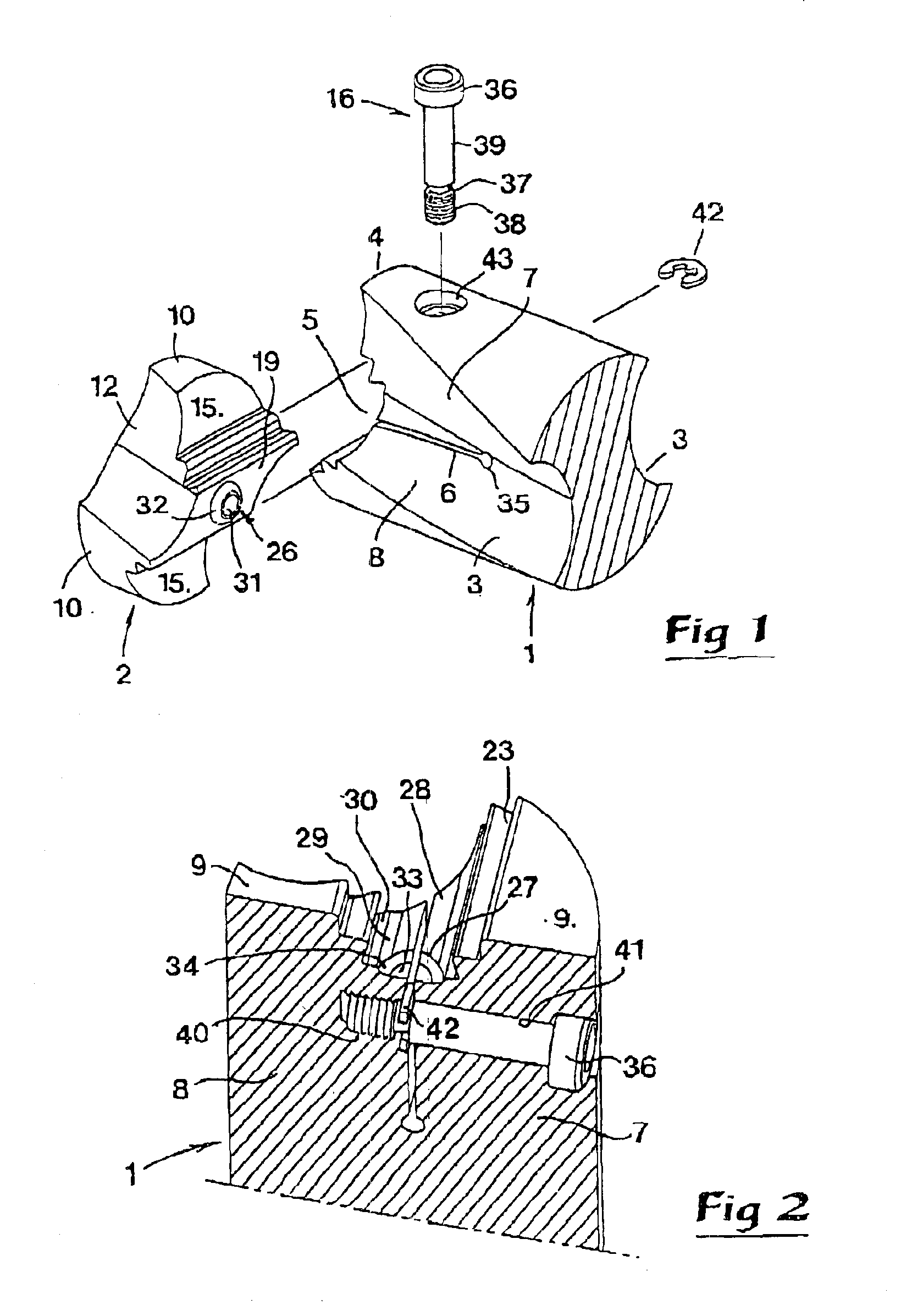

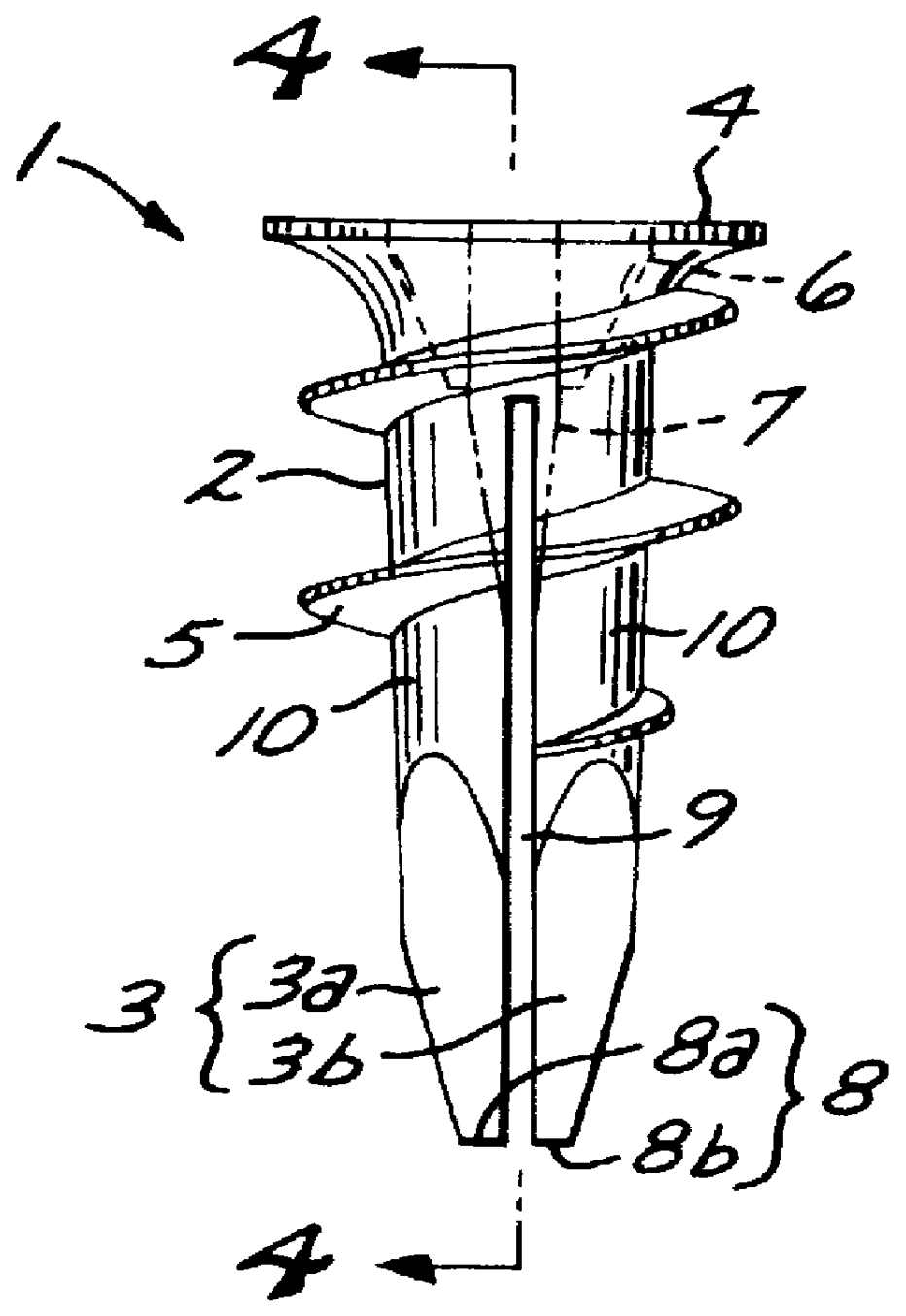

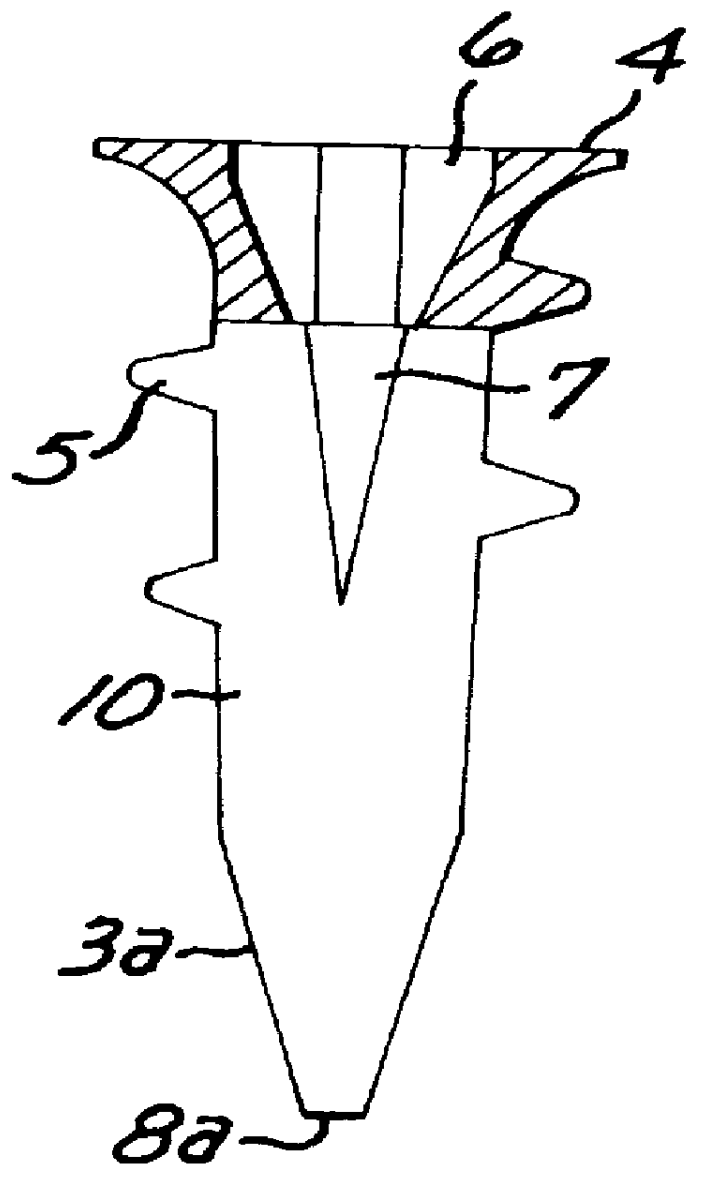

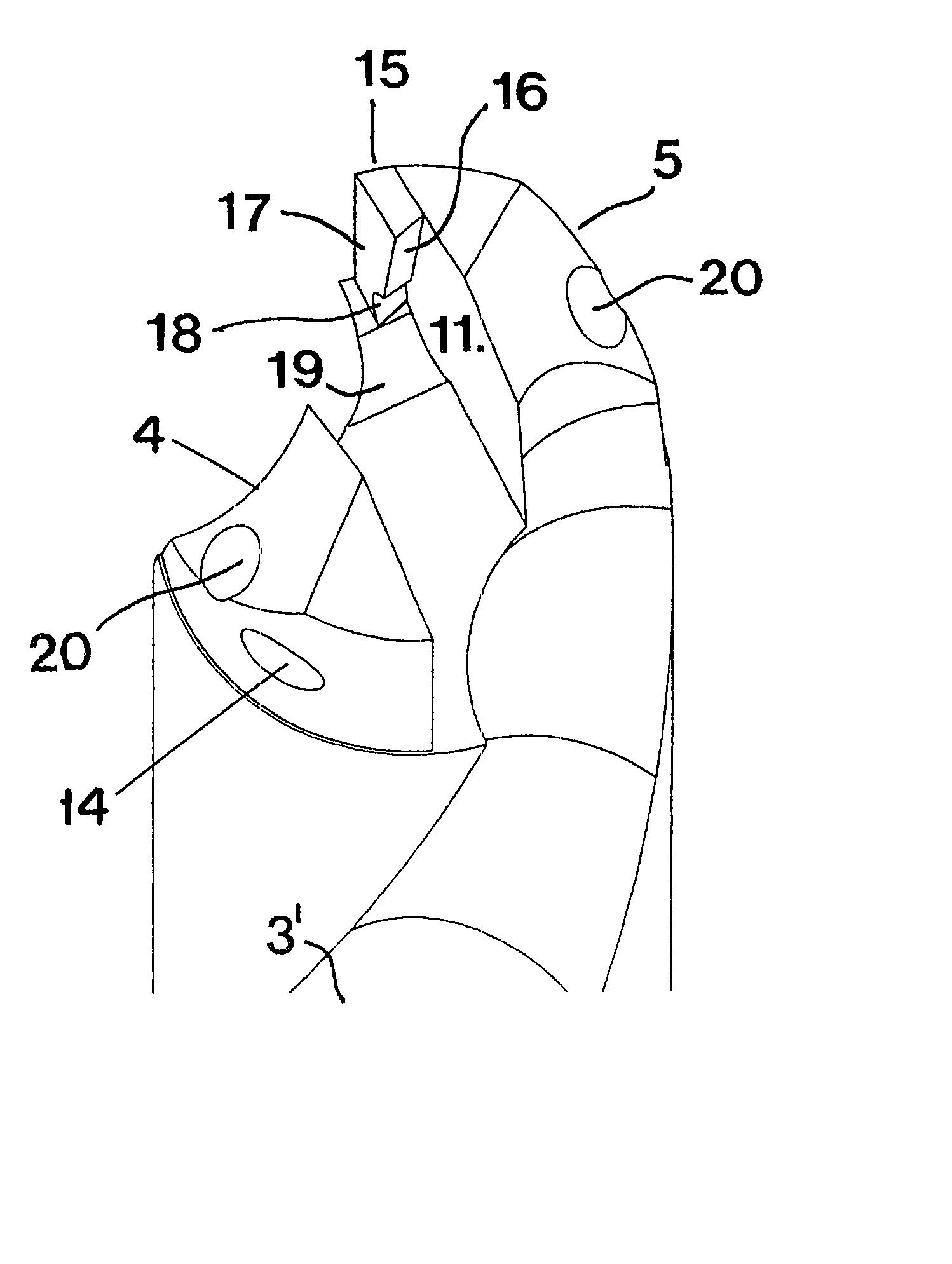

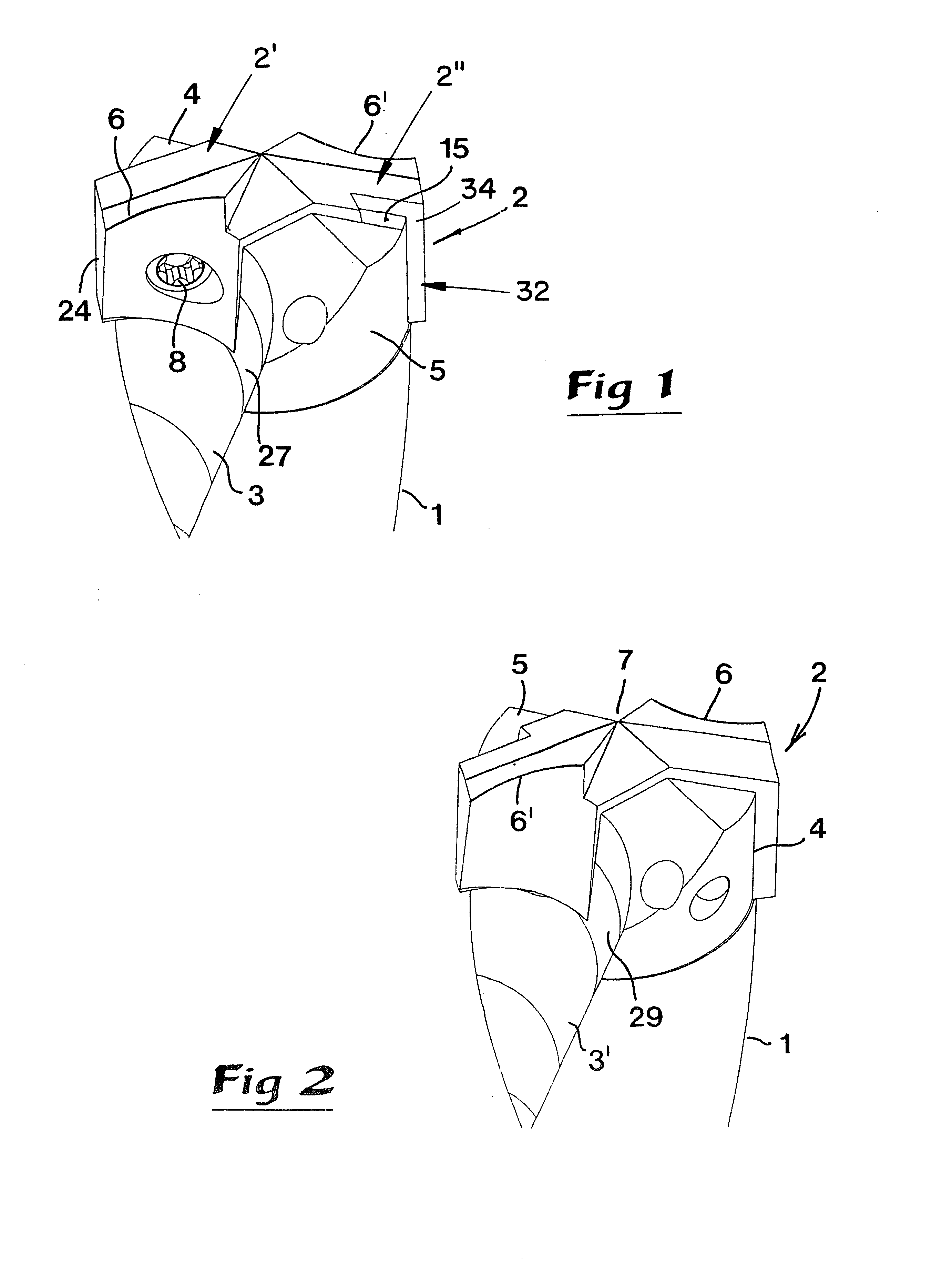

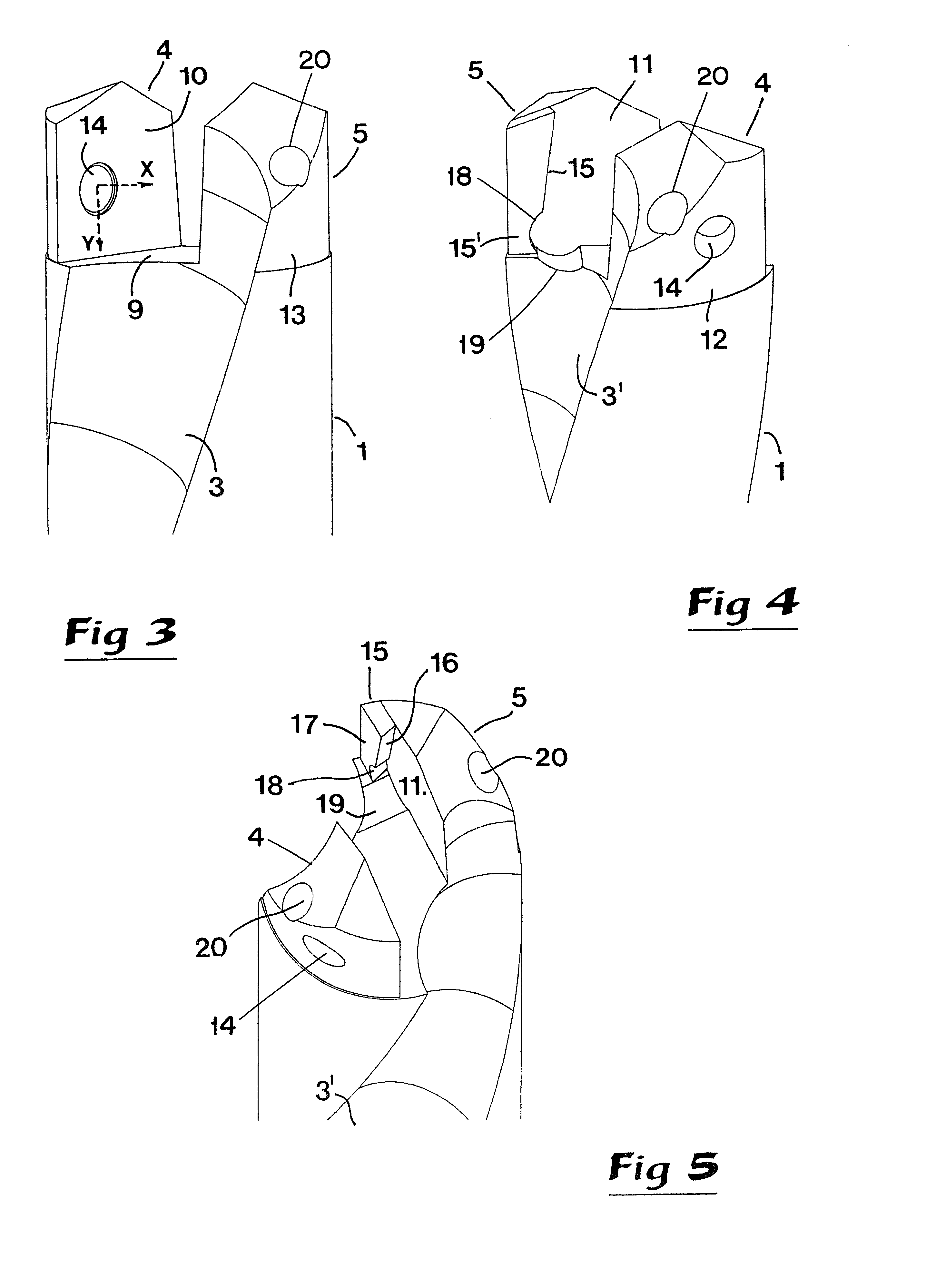

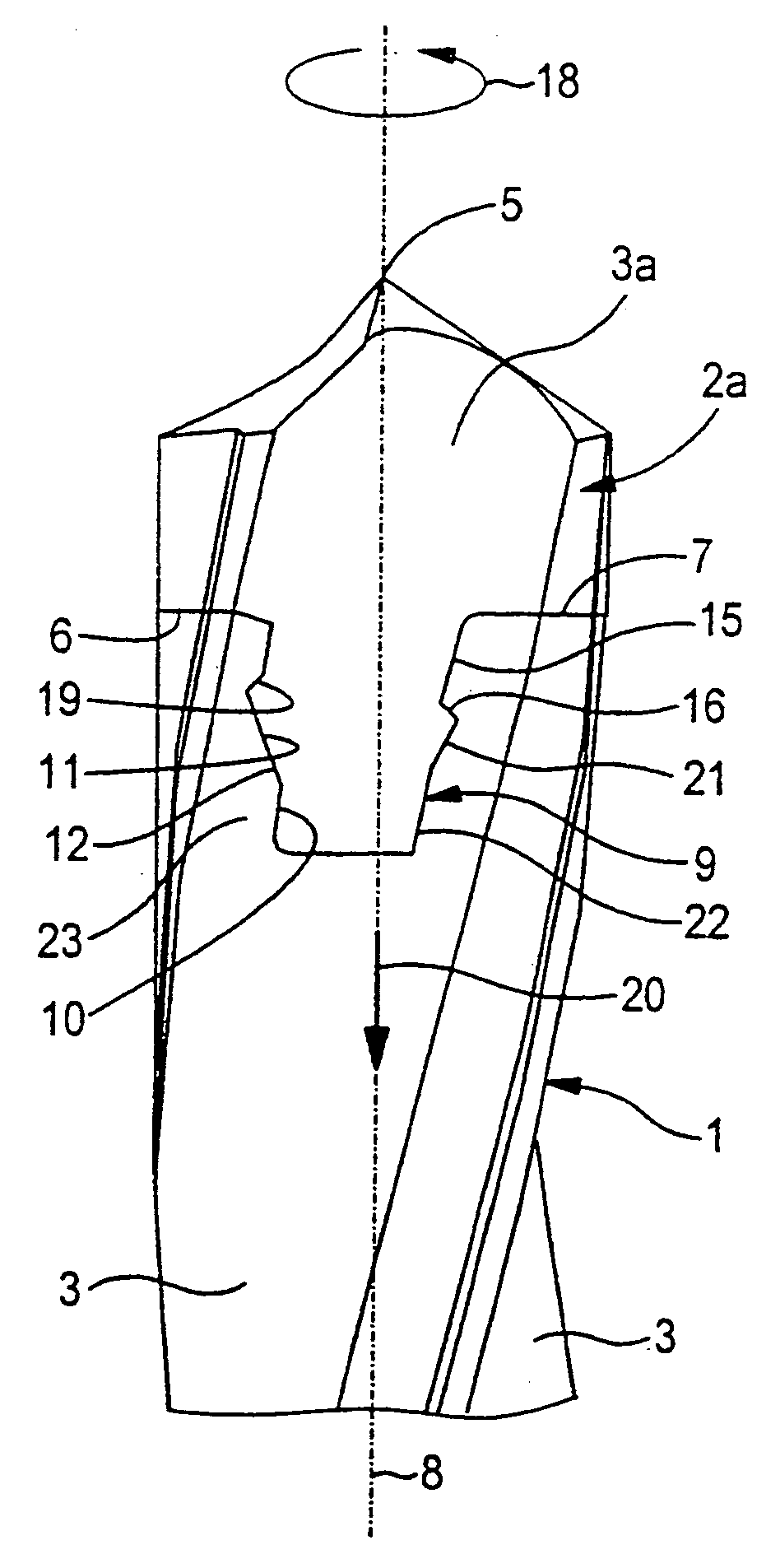

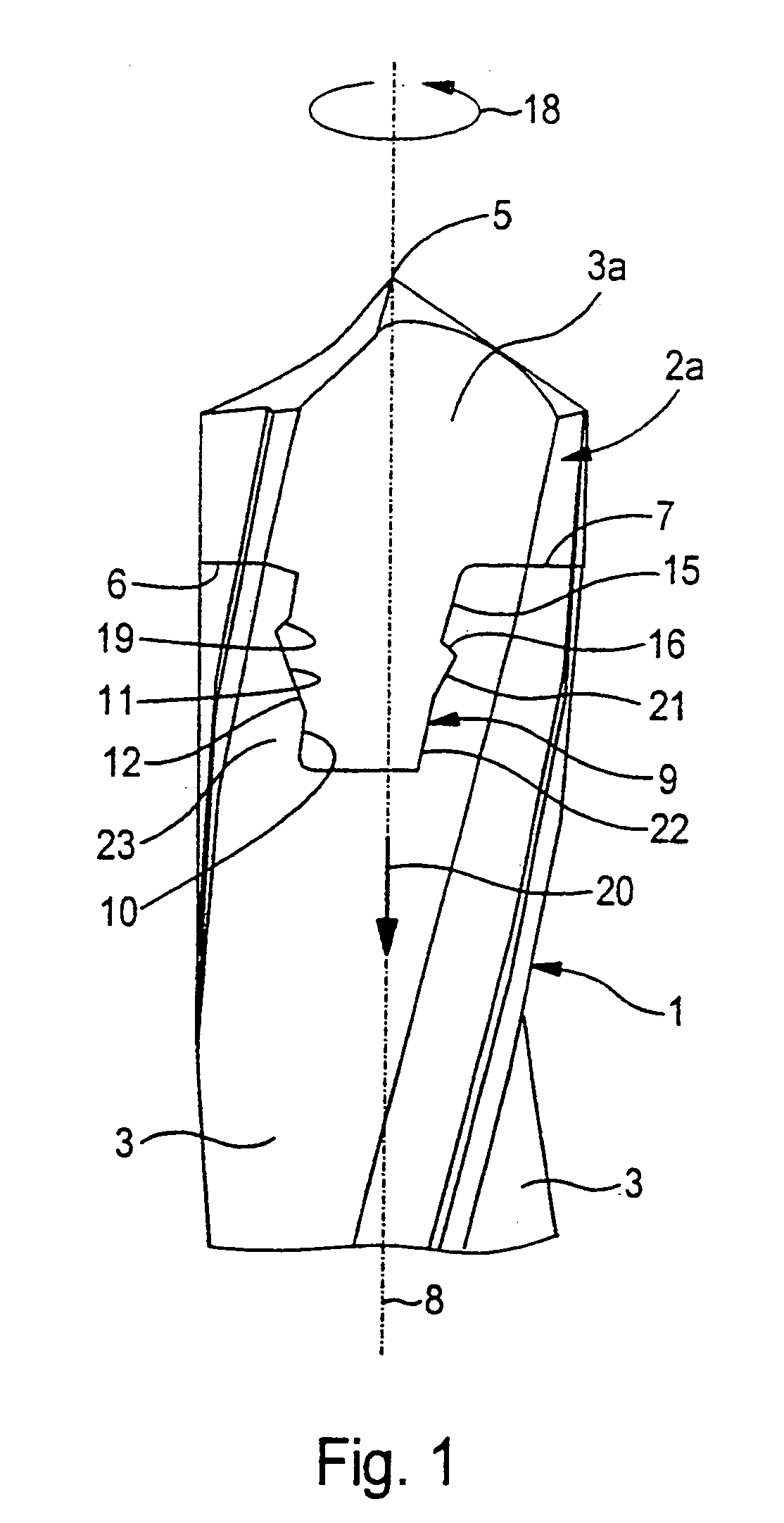

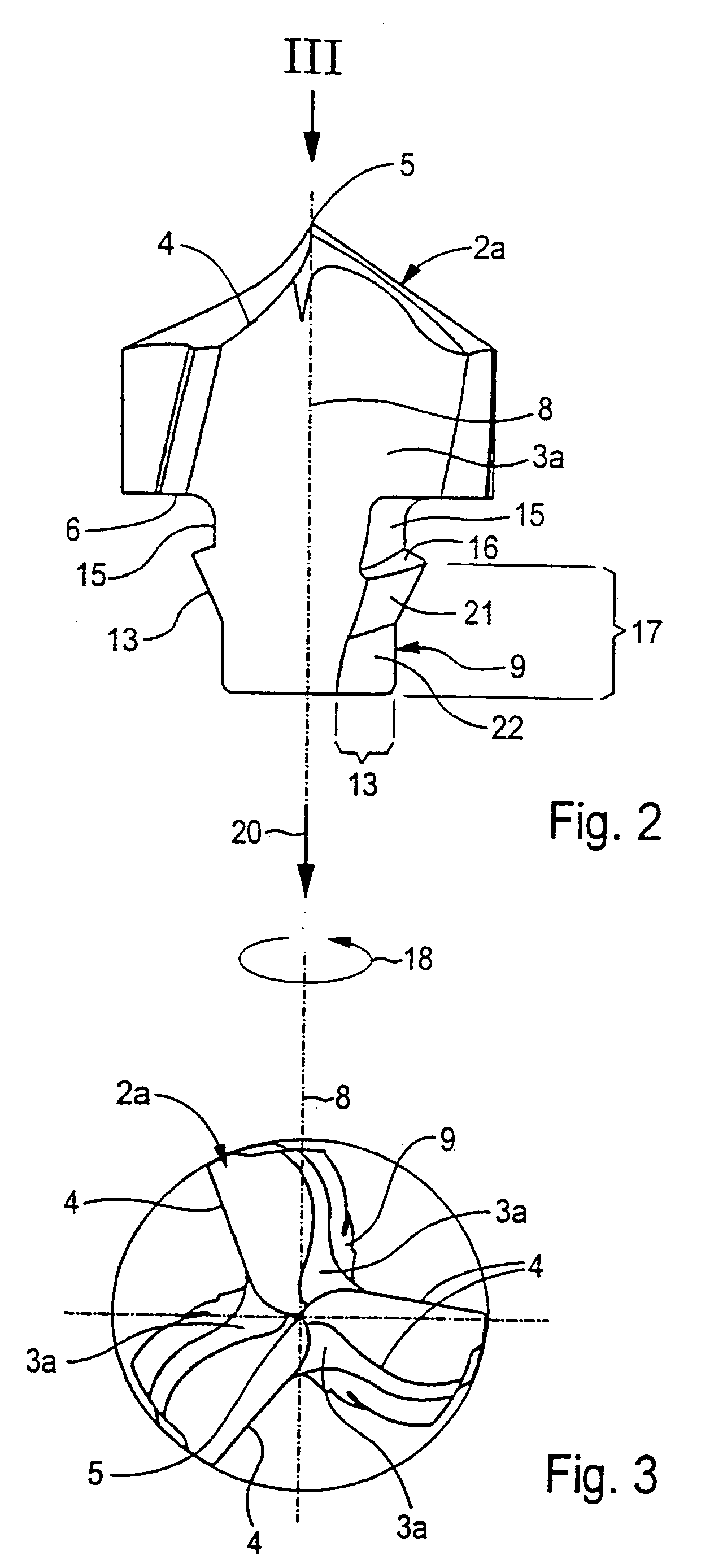

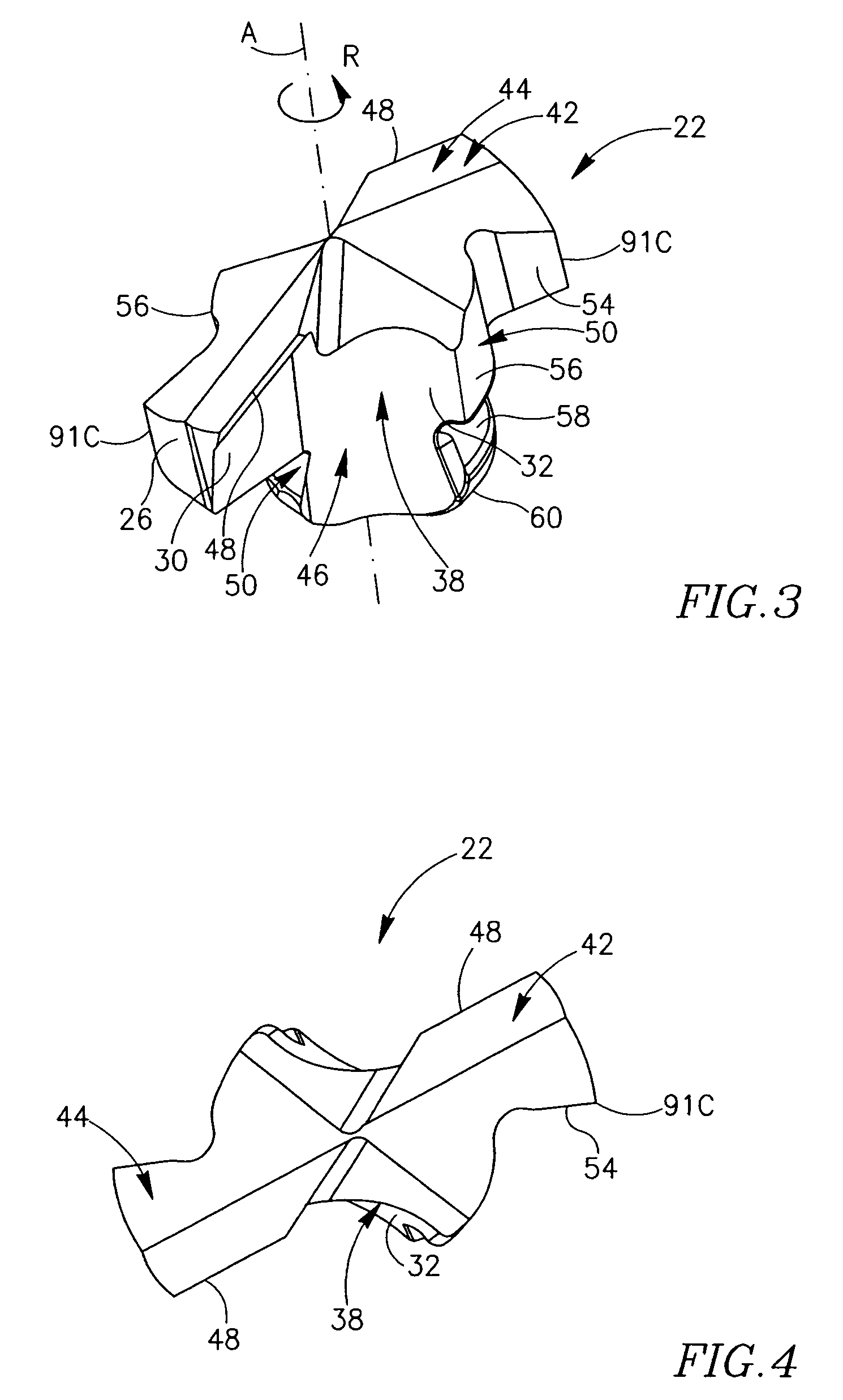

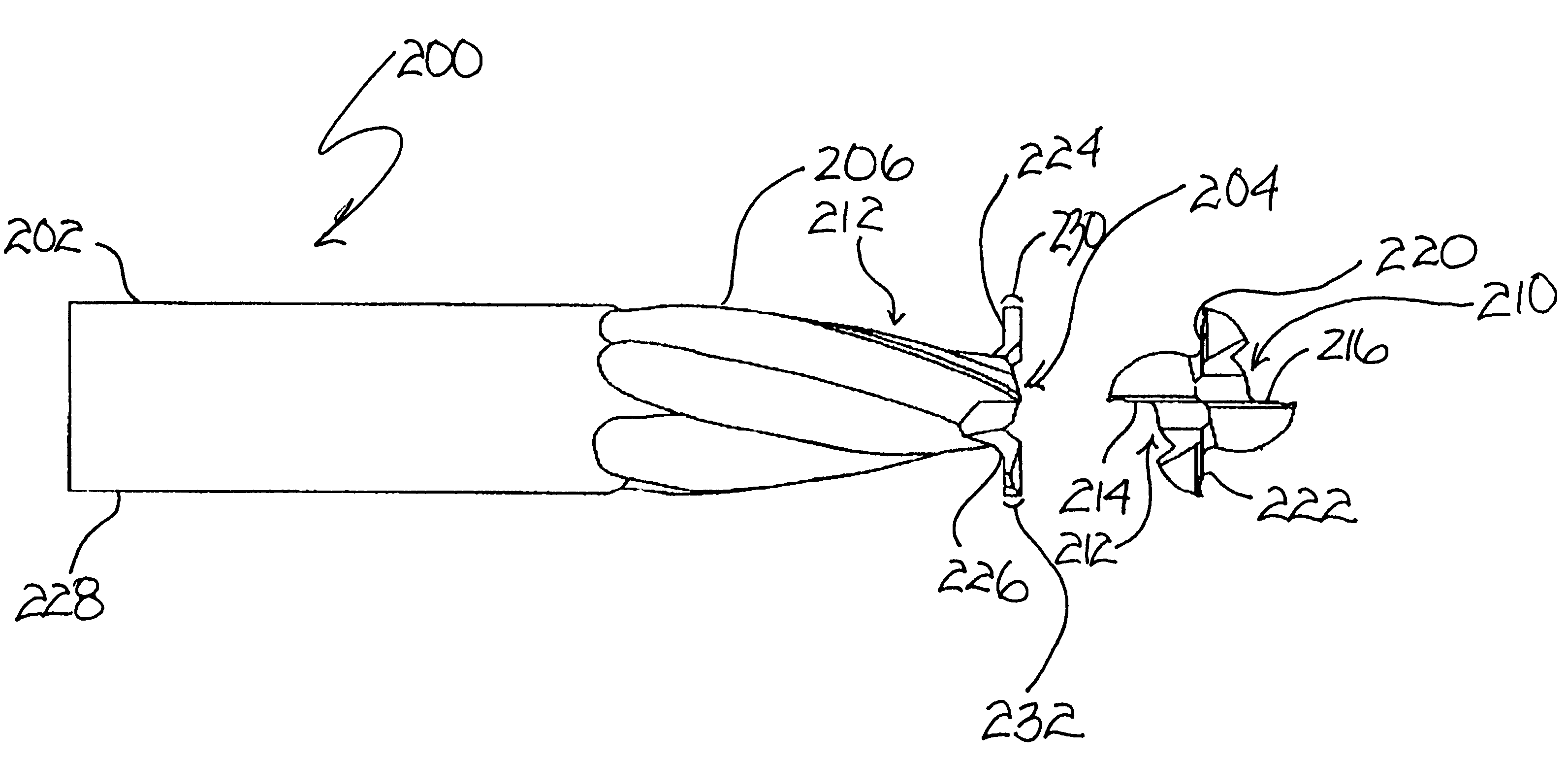

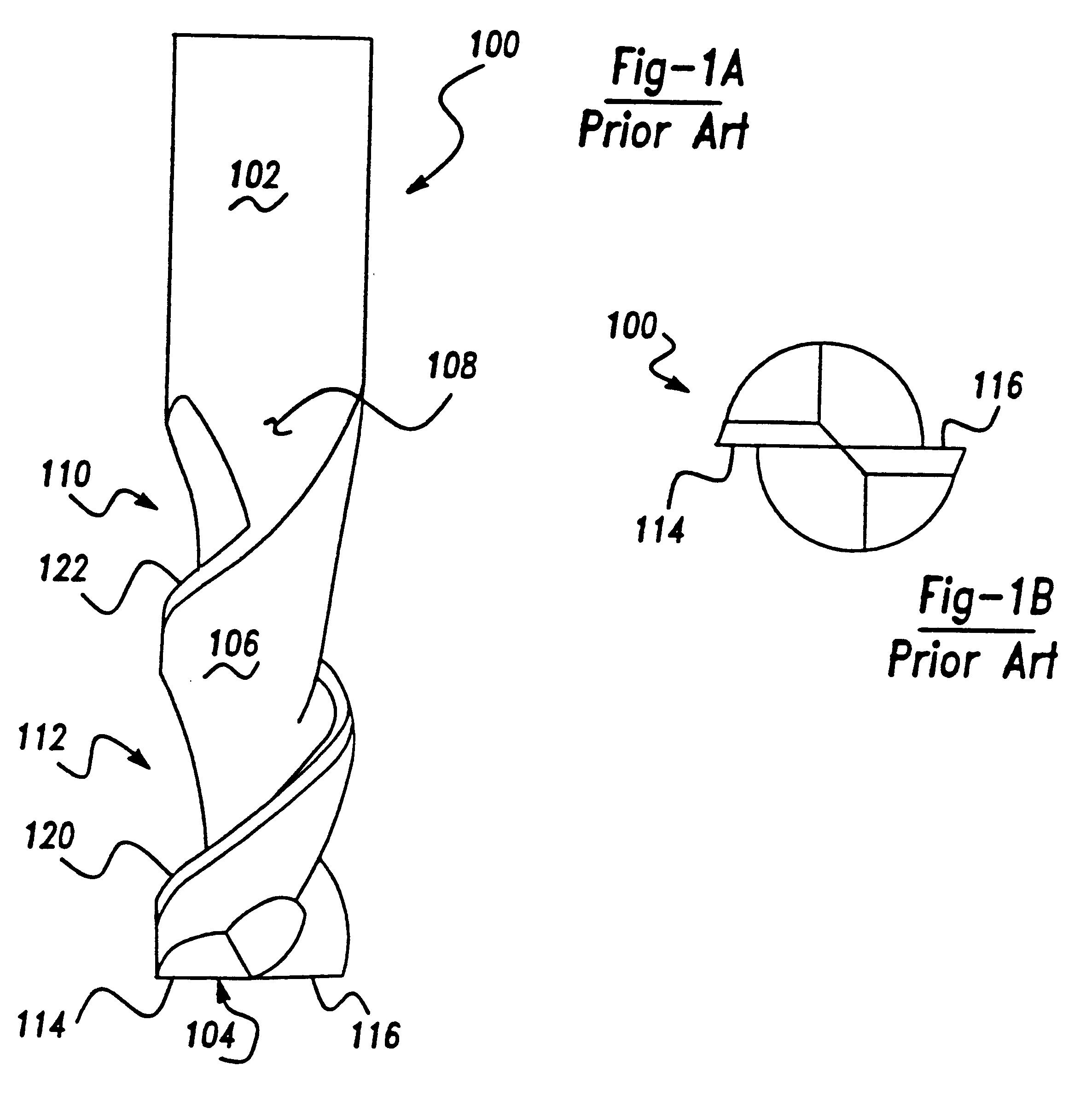

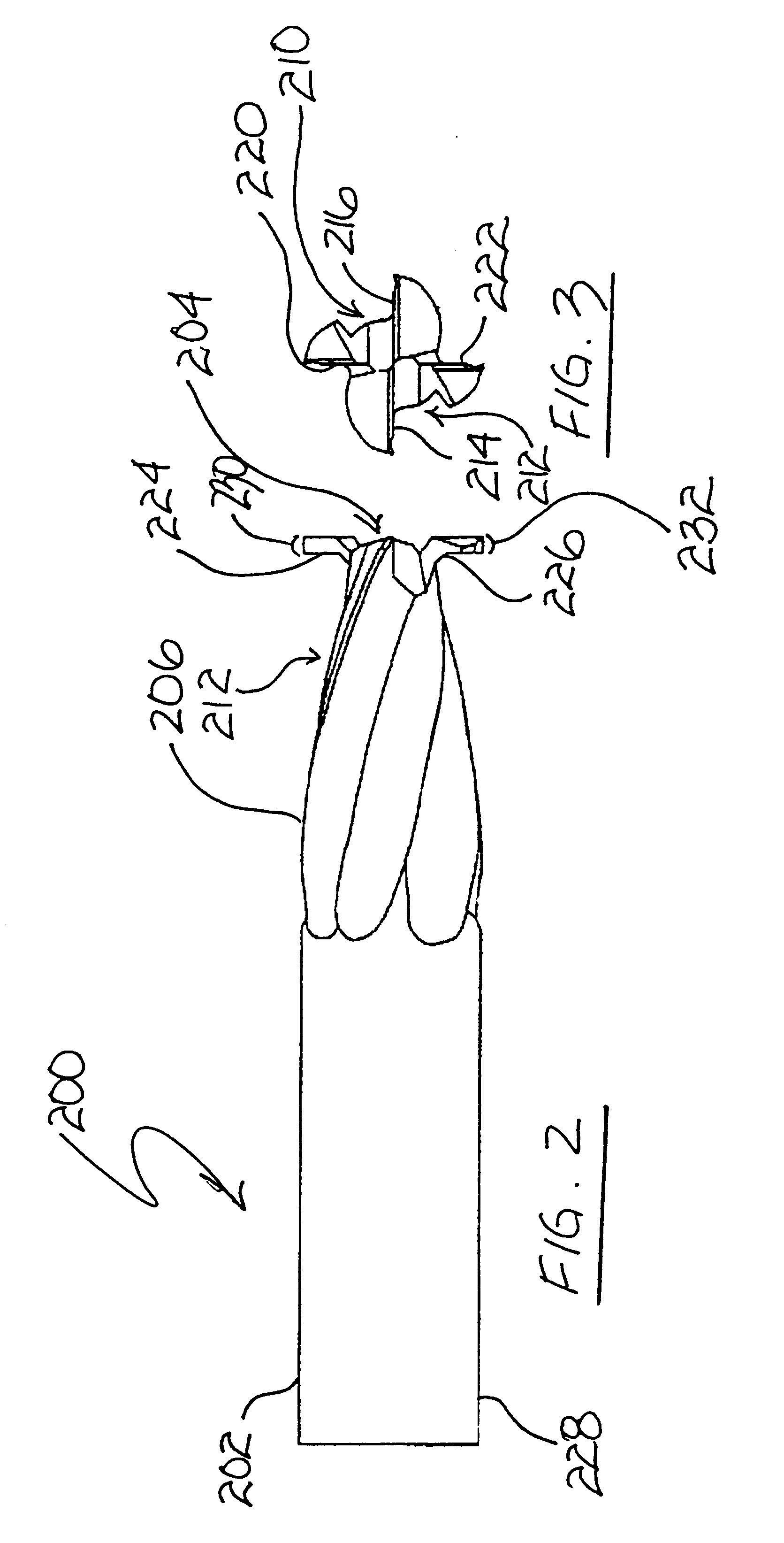

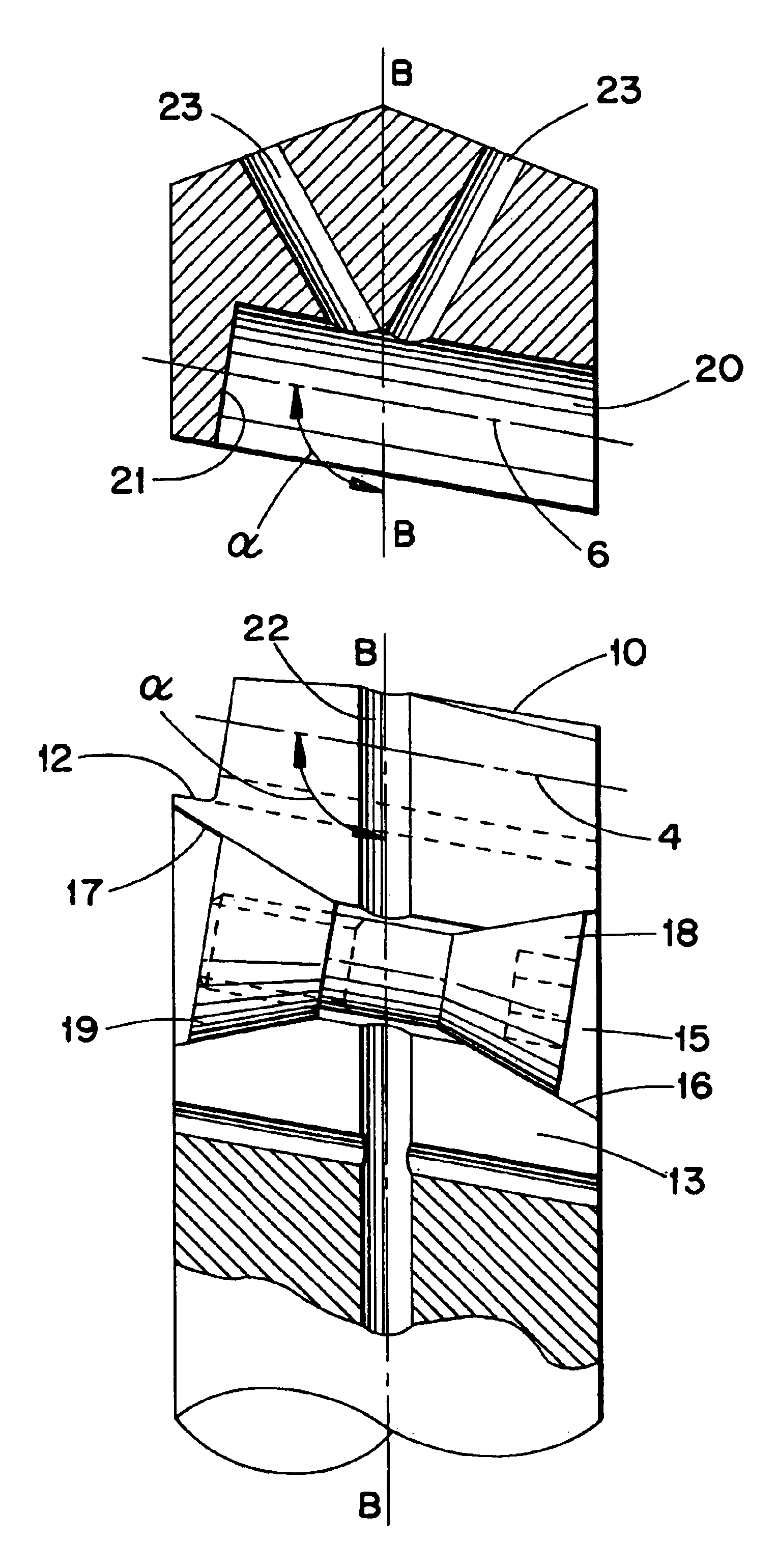

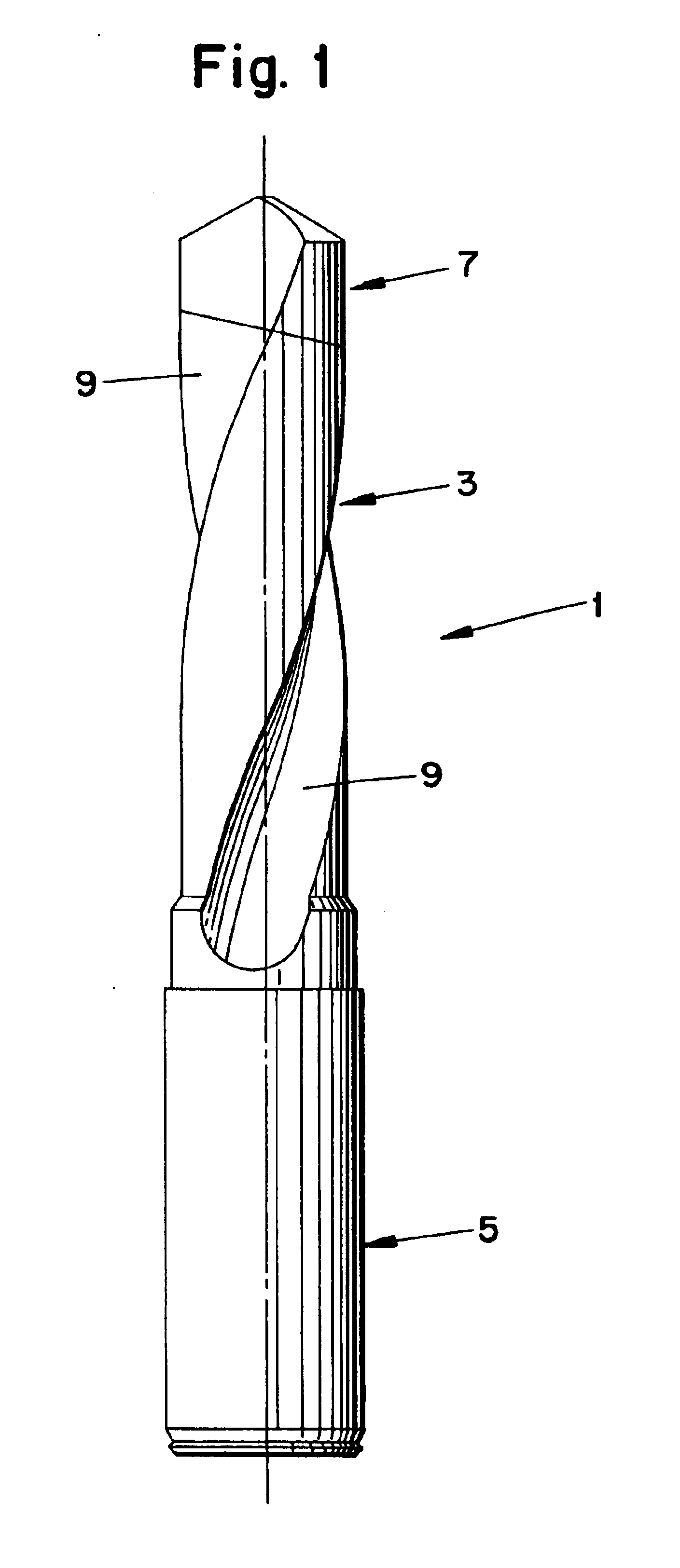

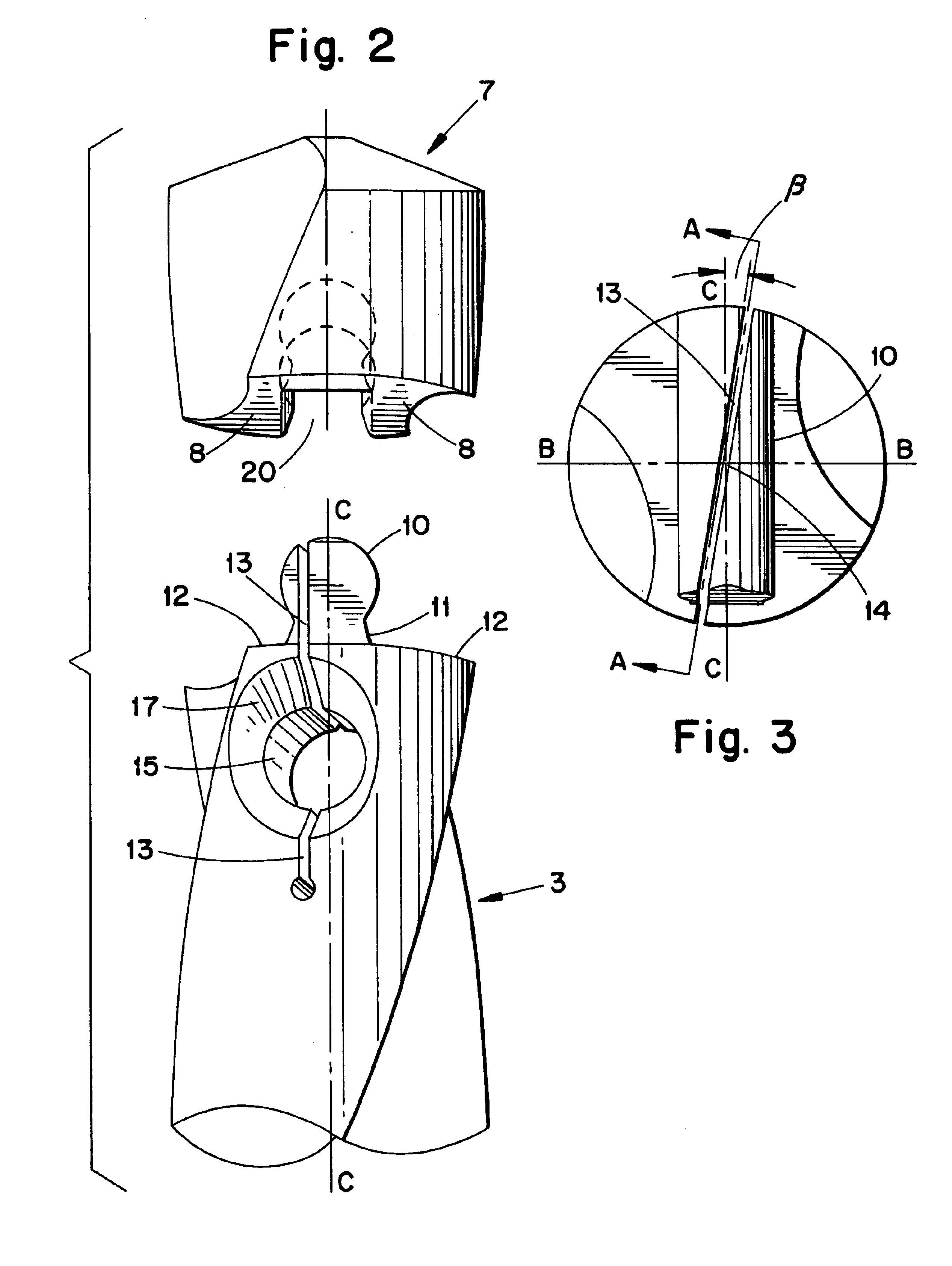

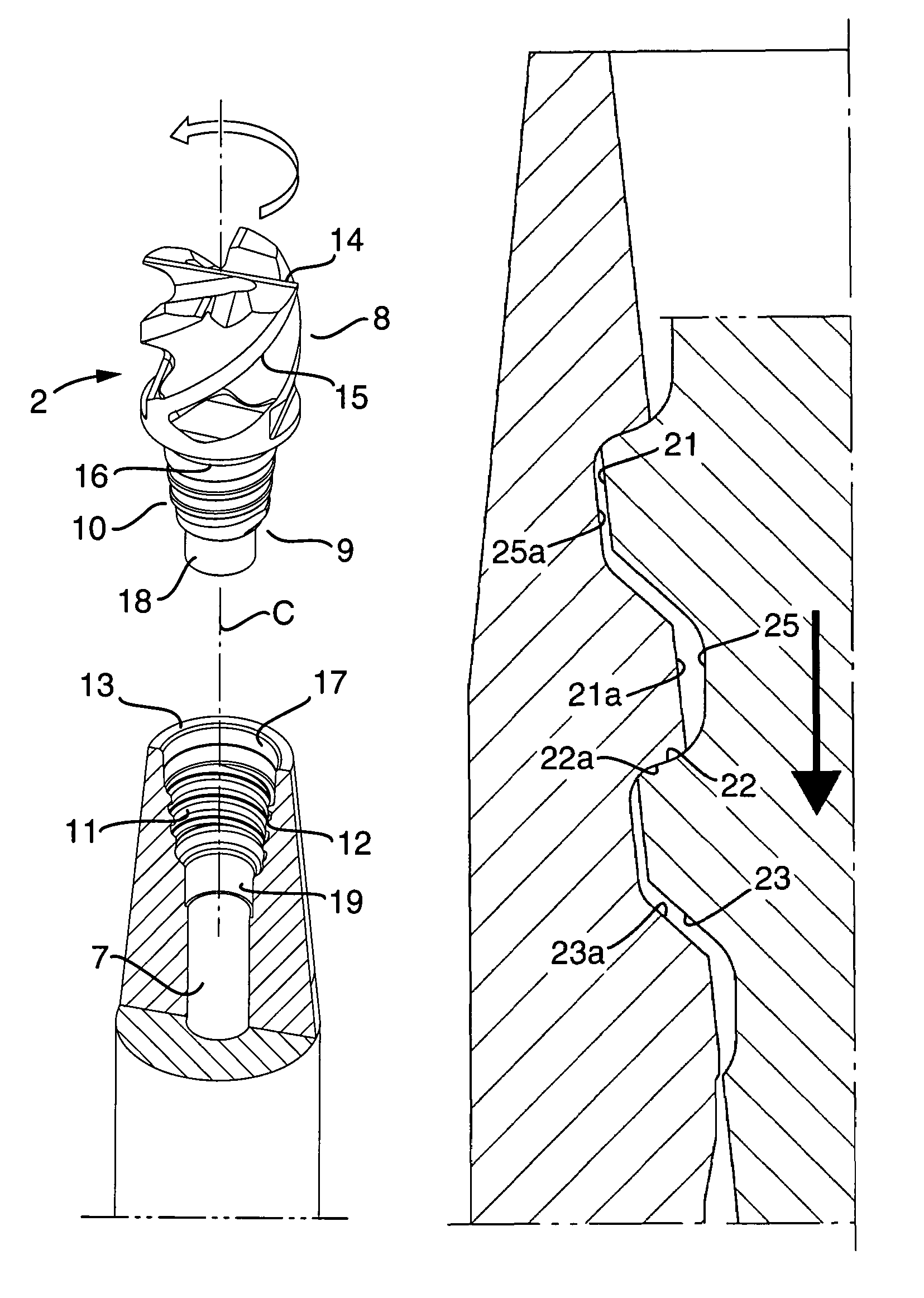

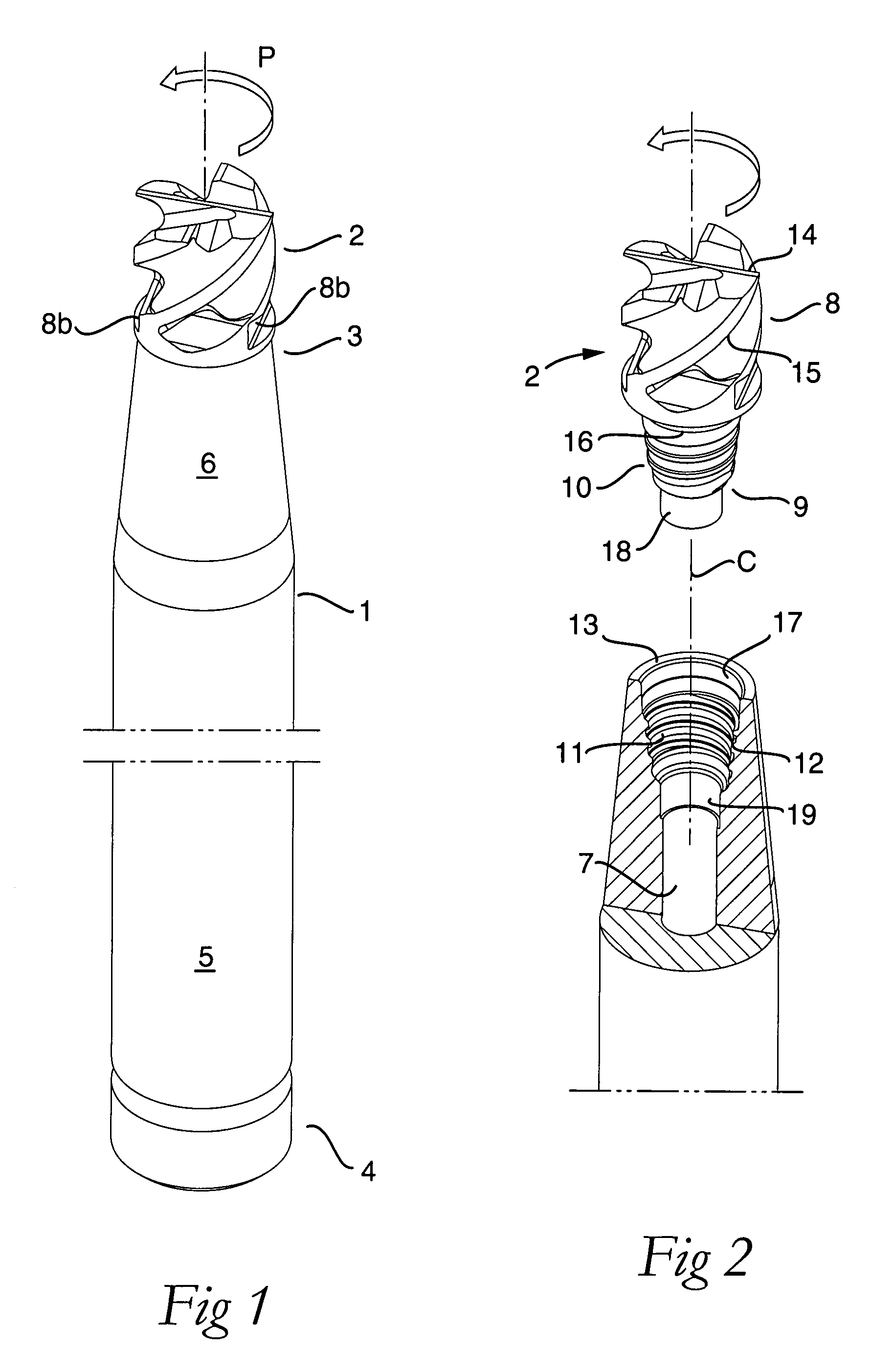

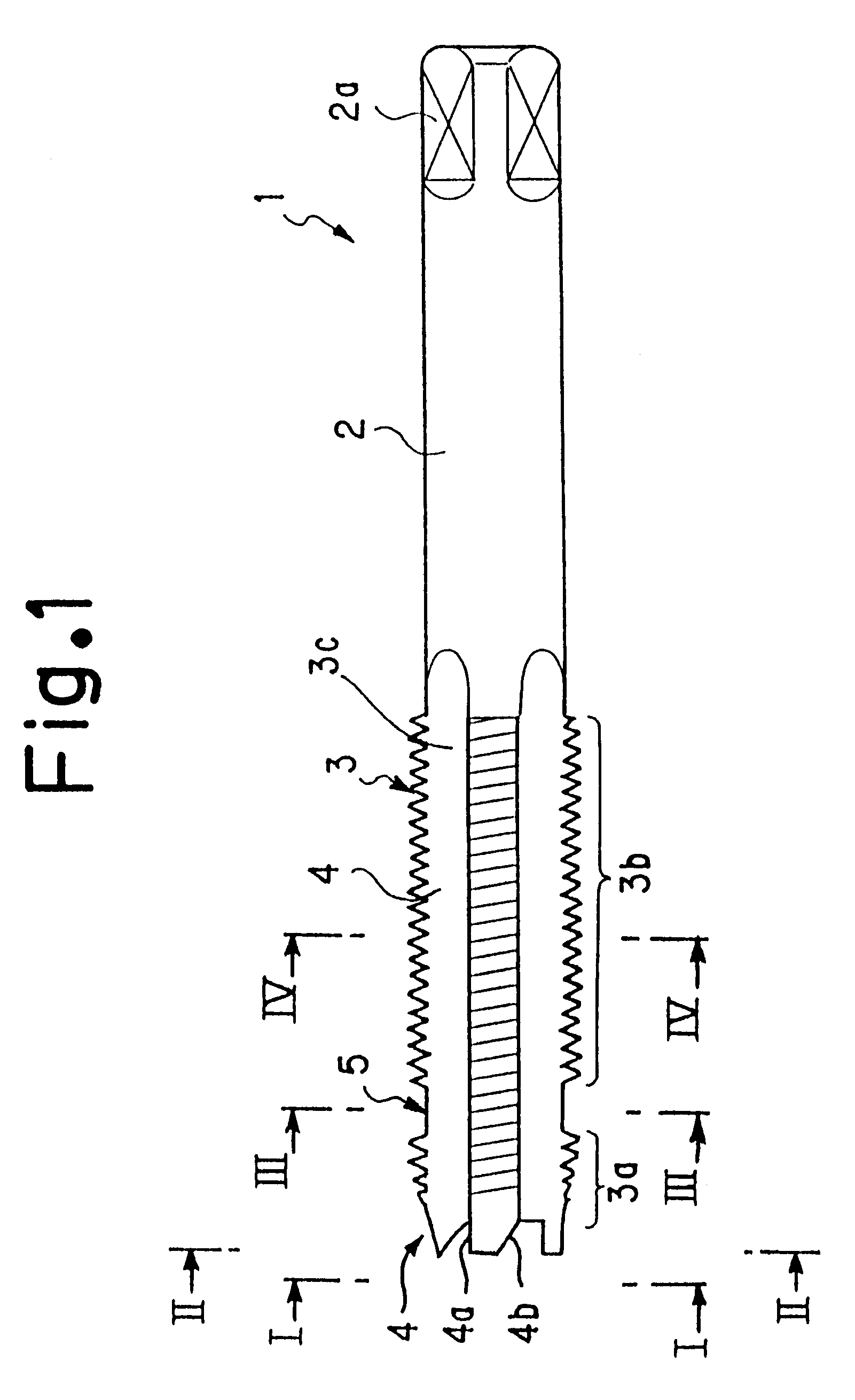

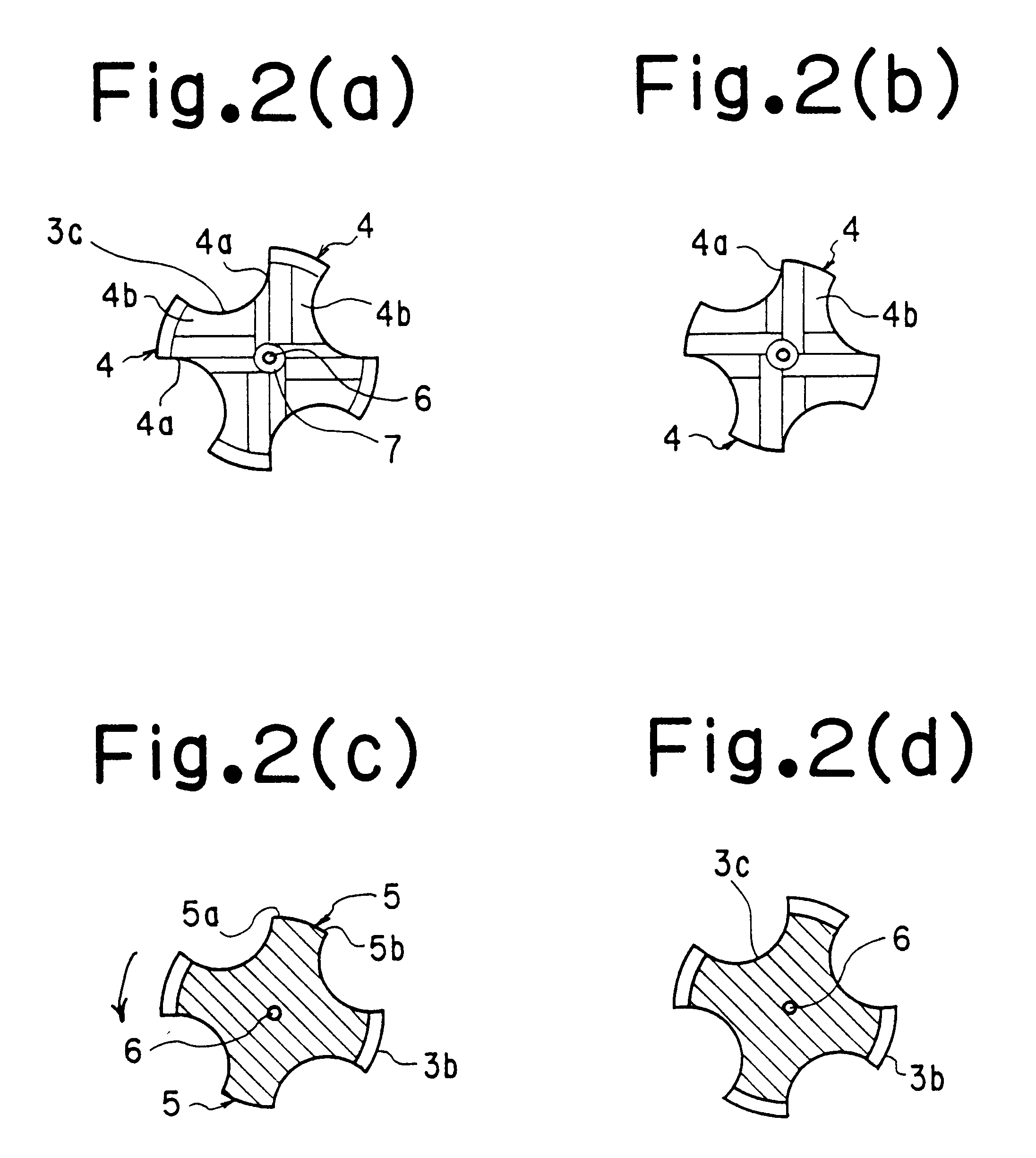

Twist drill for drilling having a replaceable drill tip, and a replaceable drill tip for use in a twist drill

InactiveUS7070367B2Avoid damageAvoid pullingWood turning toolsTransportation and packagingFluteEngineering

A twist drill, having a replaceable drill tip, comprising a drill bit shaft (1), a cutting insert (2) which is detachably fixed thereto and which forms the tip area of the twist drill, and comprises a flute (3) that continues into the cutting insert (2). The cutting insert rests, with a bearing surface (6) extending orthogonal to the center longitudinal axis (8) of the drill bit, on the face (7) of the drill bit shaft (1) and extends with a fixing stud (9), which centrally protrudes from the bearing surface (6), into a receiving recess (10) which is configured complementary thereto and which is provided in the face (7) of the drill bit shaft (1). At least one peripheral section (13) of the fixing stud (9) comprises a first longitudinal section (15) that, with a screw surface (16) which points away from the drill bit shaft (1), which slopes upward to the drill bit tip (5) in a direction of rotation of the drill bit, and which interacts with an opposite surface (19) on the inner wall (14) of the receiving recess (10), merges into a second longitudinal section (17).

Owner:KENNAMETAL INC

Cutting tool assembly and cutting head therefor

A rotary cutting tool comprising a solid cutting head mounted to a shank. The cutting head comprises a cutting portion adjacent a cutting head front face and a mounting portion integrally formed therewith and extending rearwardly therefrom. The shank comprises a receiving portion extending rearwardly from a shank front face. When the cutting head is secured to the shank, the mounting portion is received in the receiving portion, and the shank front face is forwardly exposed and adjacent the cutting head front face.

Owner:ISCAR LTD

Rotary tool and cutting part comprised in the tool

InactiveUS20030210963A1Acceptable toleranceTransportation and packagingMilling cuttersInterference fitMilling cutter

A rotary tool for chip removing machining, for example a milling cutter or a drill, includes a shaft, a holder, and a cutting part. The shaft has a conical seating arranged in its front end. The holder has a slightly conical recess, whose cross-sectional dimension decreases toward the open end of the recess. The cutting part has a slightly conical pin designed to be received in the recess and has a cross-sectional dimension which increases in the direction of the free end of the pin. The recess is formed by a wall which is elastically flexible in a radial direction. When the holder is drawn axially into the seating, the wall is flexed radially inwardly, causing the conical surface of the recess to tightly grip the conical surface of the pin and create an interference fit of the pin in the recess.

Owner:SANDVIK AB

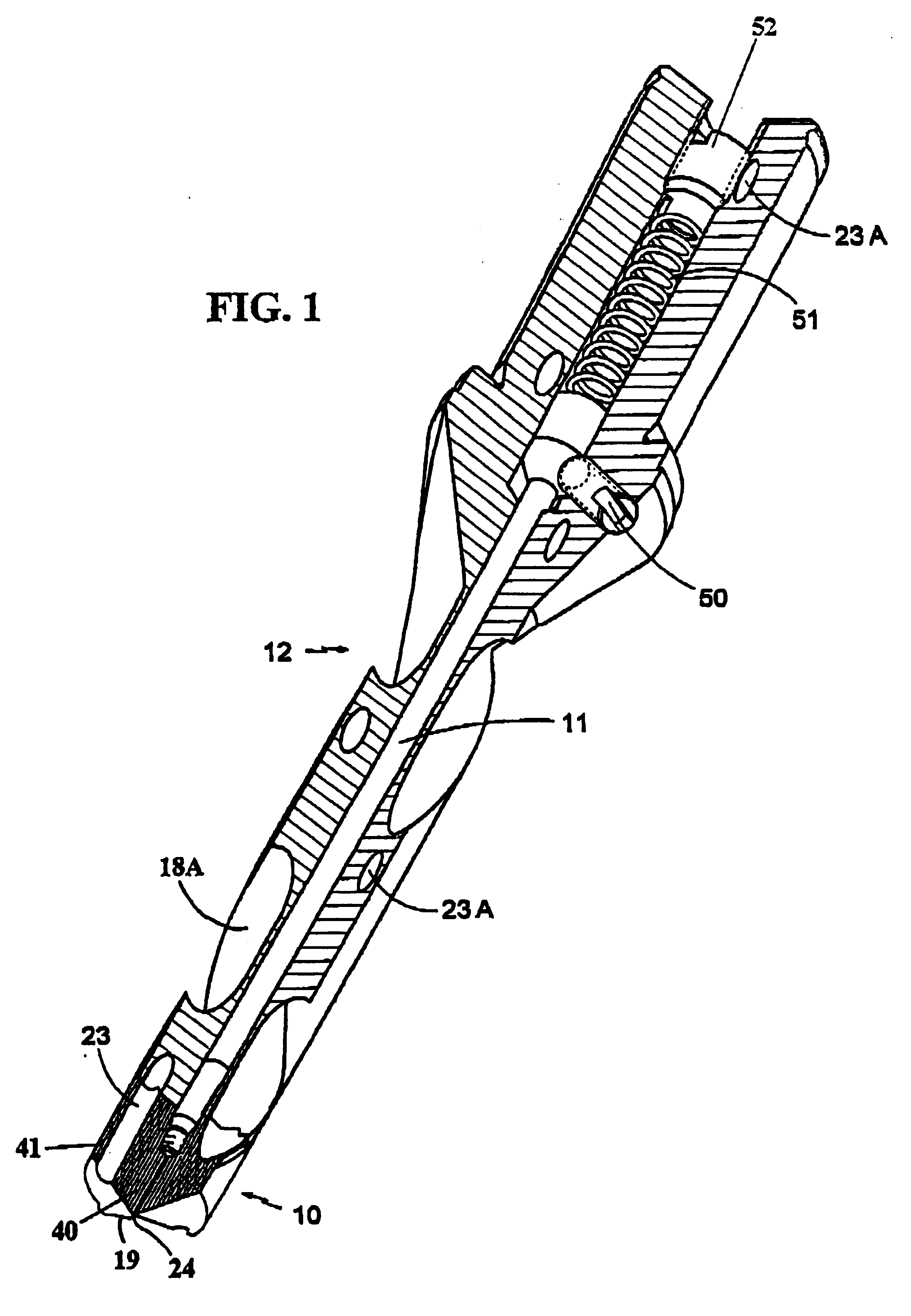

Trocar-tipped drill bit

InactiveUS20100145341A1Reduce in quantityDental implantsWood turning toolsBiomedical engineeringAbdominal trocar

Owner:AETON MEDICAL

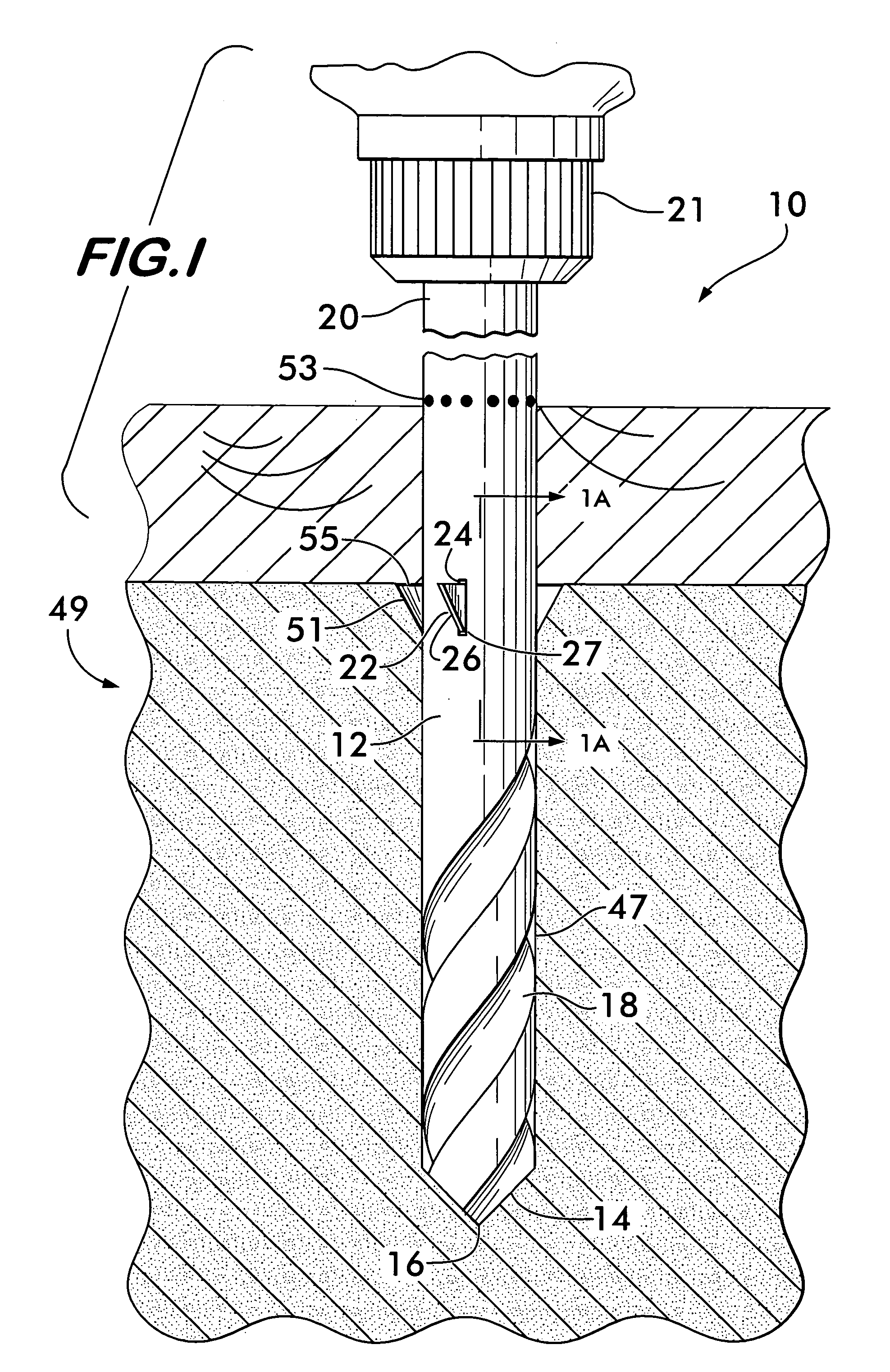

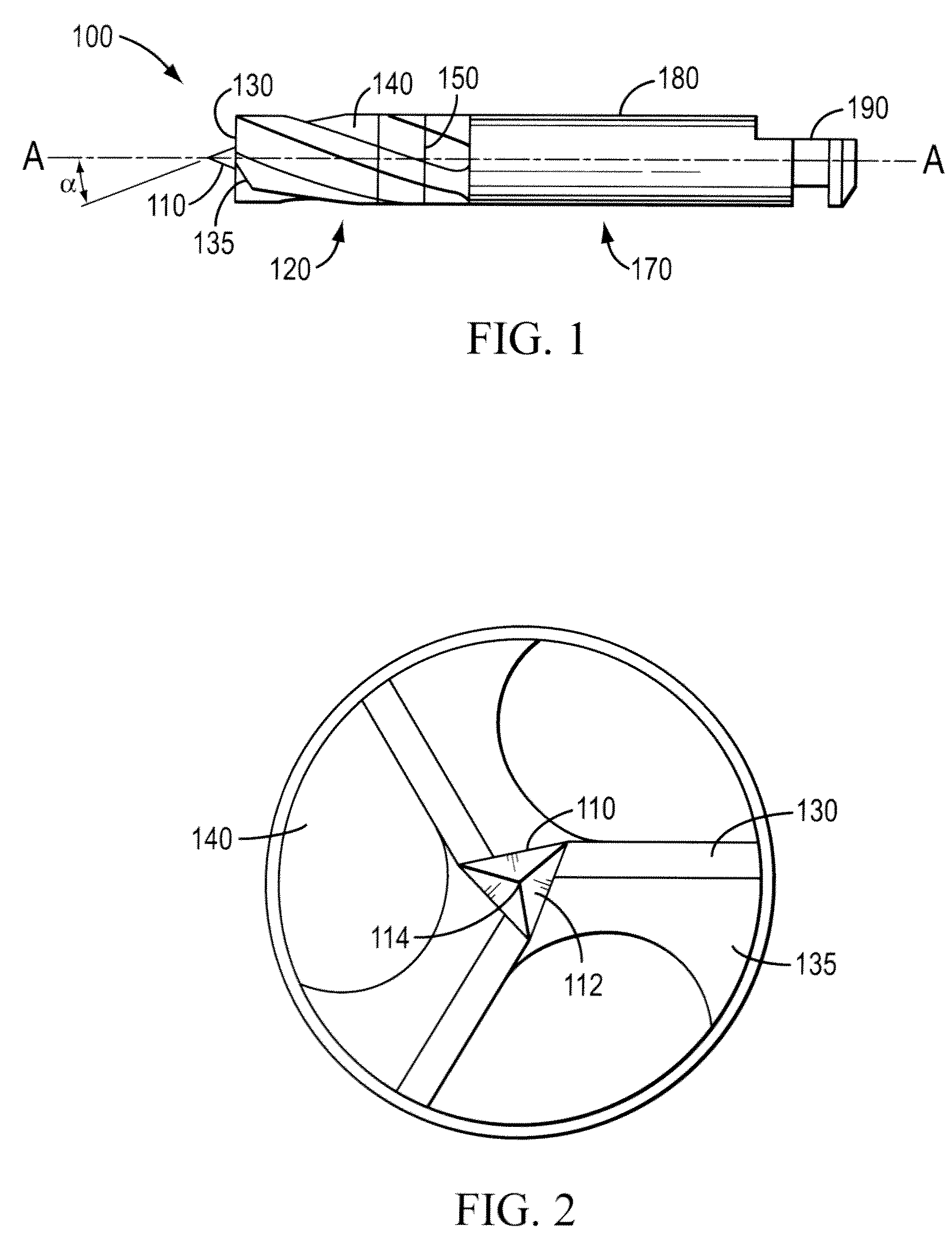

End-mill tool with multiple cutting edges

The present invention provides an end-mill tool which includes a shank, a point, and a main body portion located intermediate the shank and the point. A first flute is formed on the main body portion along a first helix. A second flute is formed on the main body portion along a second helix. The first and second flutes preferably extend helically along the body of the tool. Two distinct helical cutting surfaces are defined by the first flute and the second flute. The point of the tool includes two additional cutting edges formed by ears extending outward from the point of the tool adjacent the first flute and the second flute.

Owner:WARDELL LON J

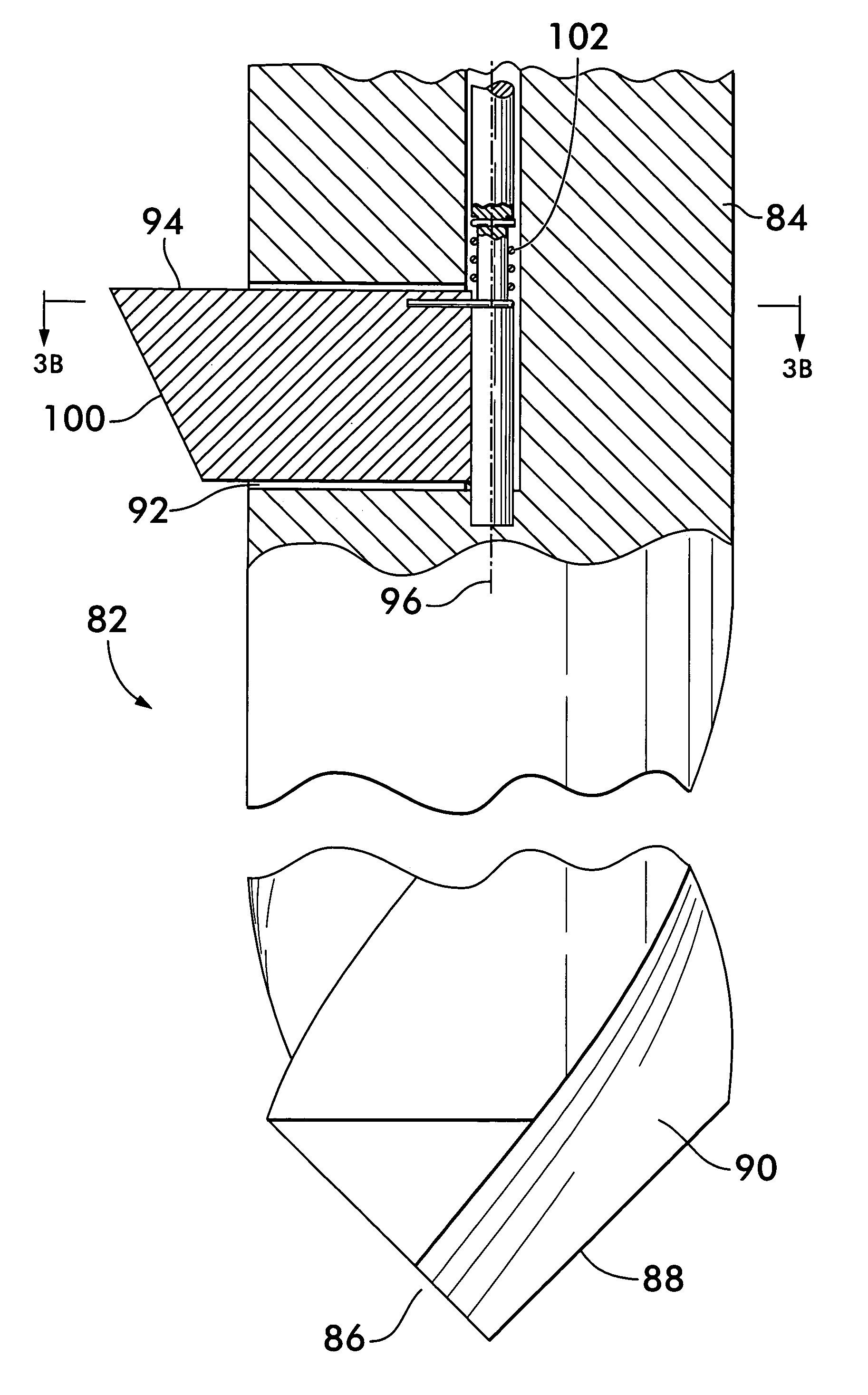

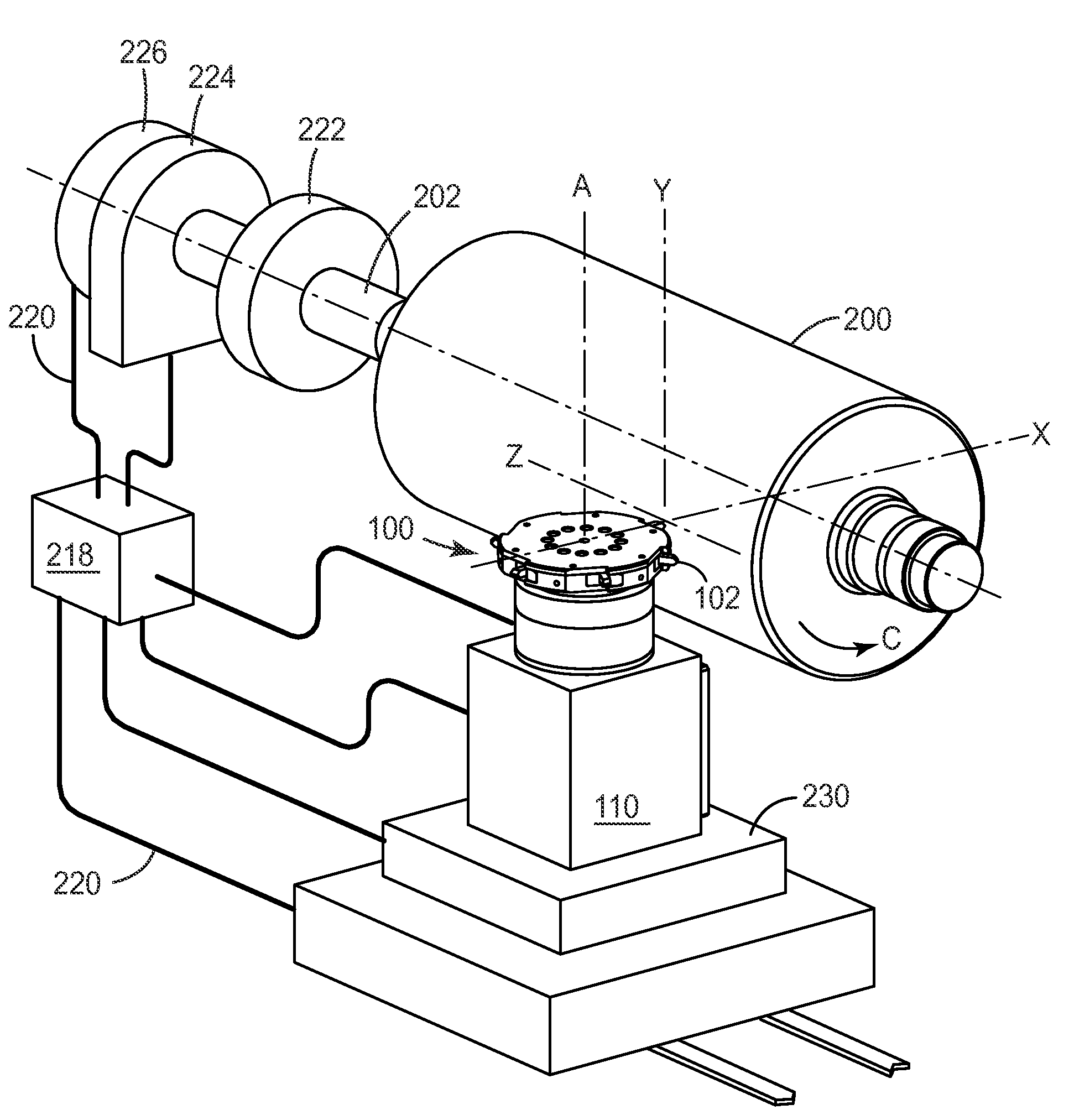

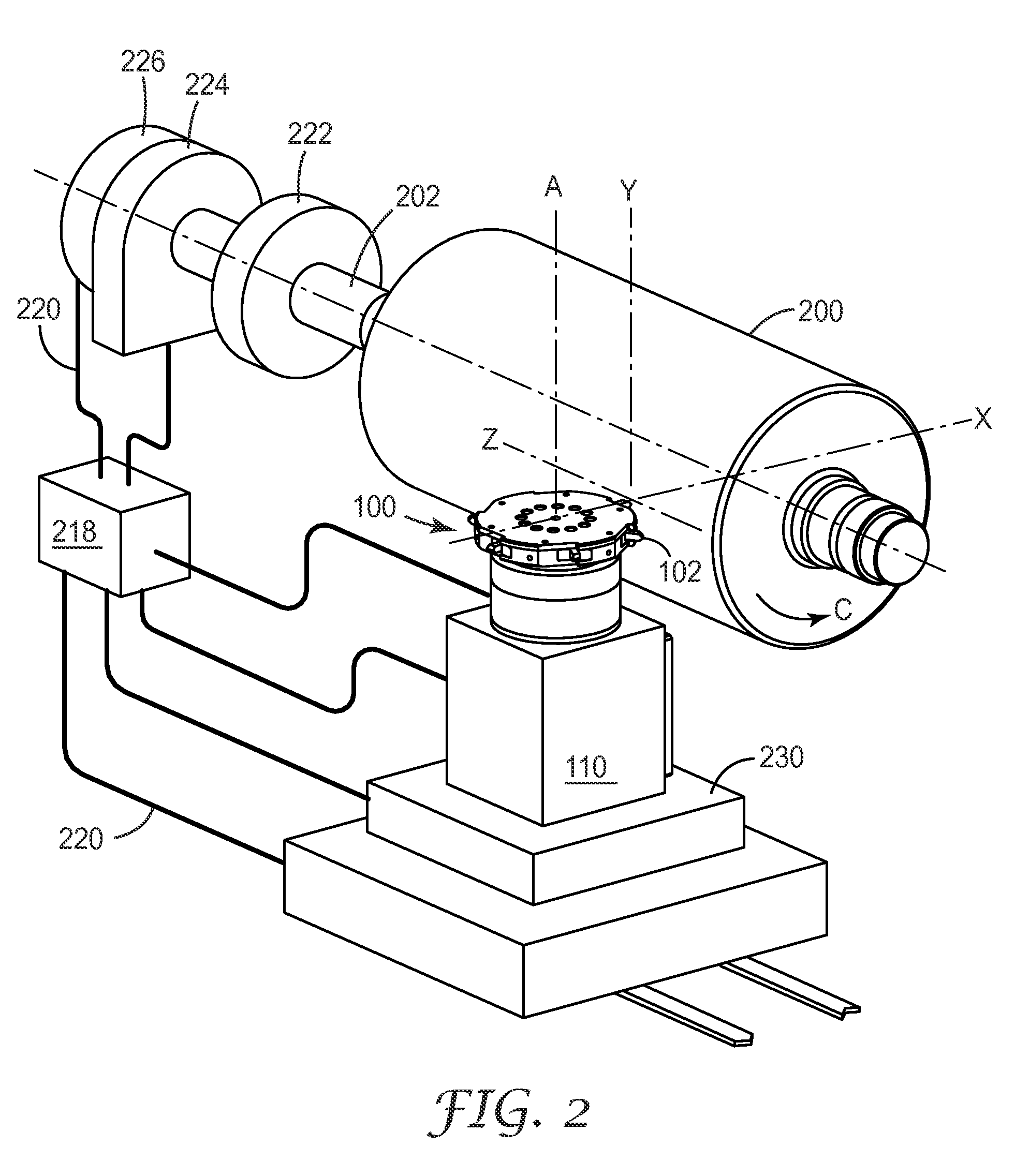

Fly-cutting system and method, and related tooling and articles

Methods of fly-cutting a workpiece are disclosed, and in methods in which the position of a fly-cutting head or its associated cutting element is known as a function of time. Also disclosed are methods of forming features, such as grooves or groove segments, in a workpiece such as a cylindrical roll. The features may be provided according to one or more disclosed patterns. Articles made using tools machined in the manner described are also provided, such as polymeric film or sheeting that exhibit certain beneficial properties.

Owner:3M INNOVATIVE PROPERTIES CO

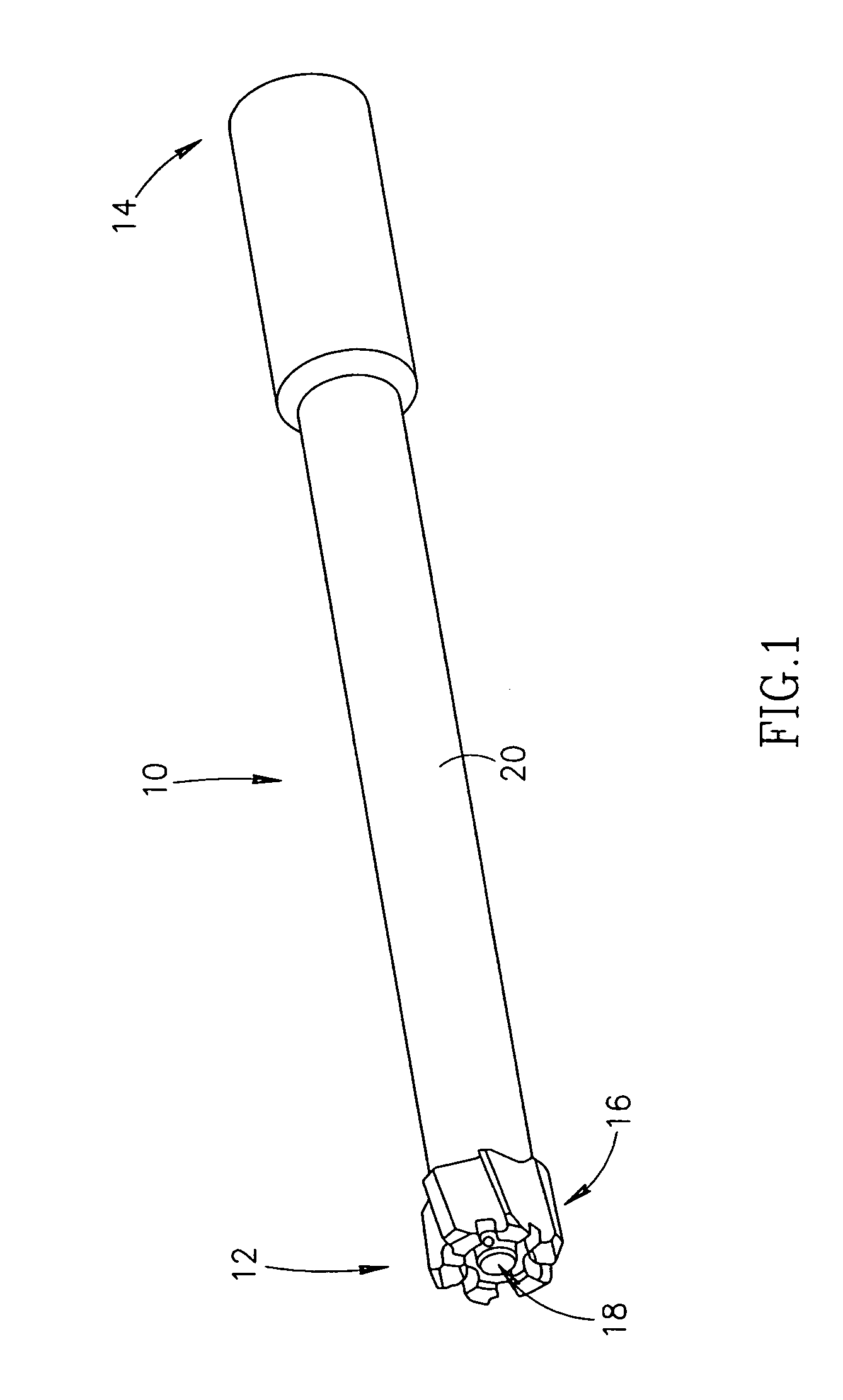

Orthopedic reamer

An orthopedic reamer for use in creating and sizing canals in a bone is disclosed. The orthopedic reamer includes a non-polymeric cutting portion having at least one cutting surface thereon and a polymeric body portion covering at least a portion of the cutting portion. The at least one cutting surface is not covered by the polymeric body portion.

Owner:HOWMEDICA OSTEONICS CORP

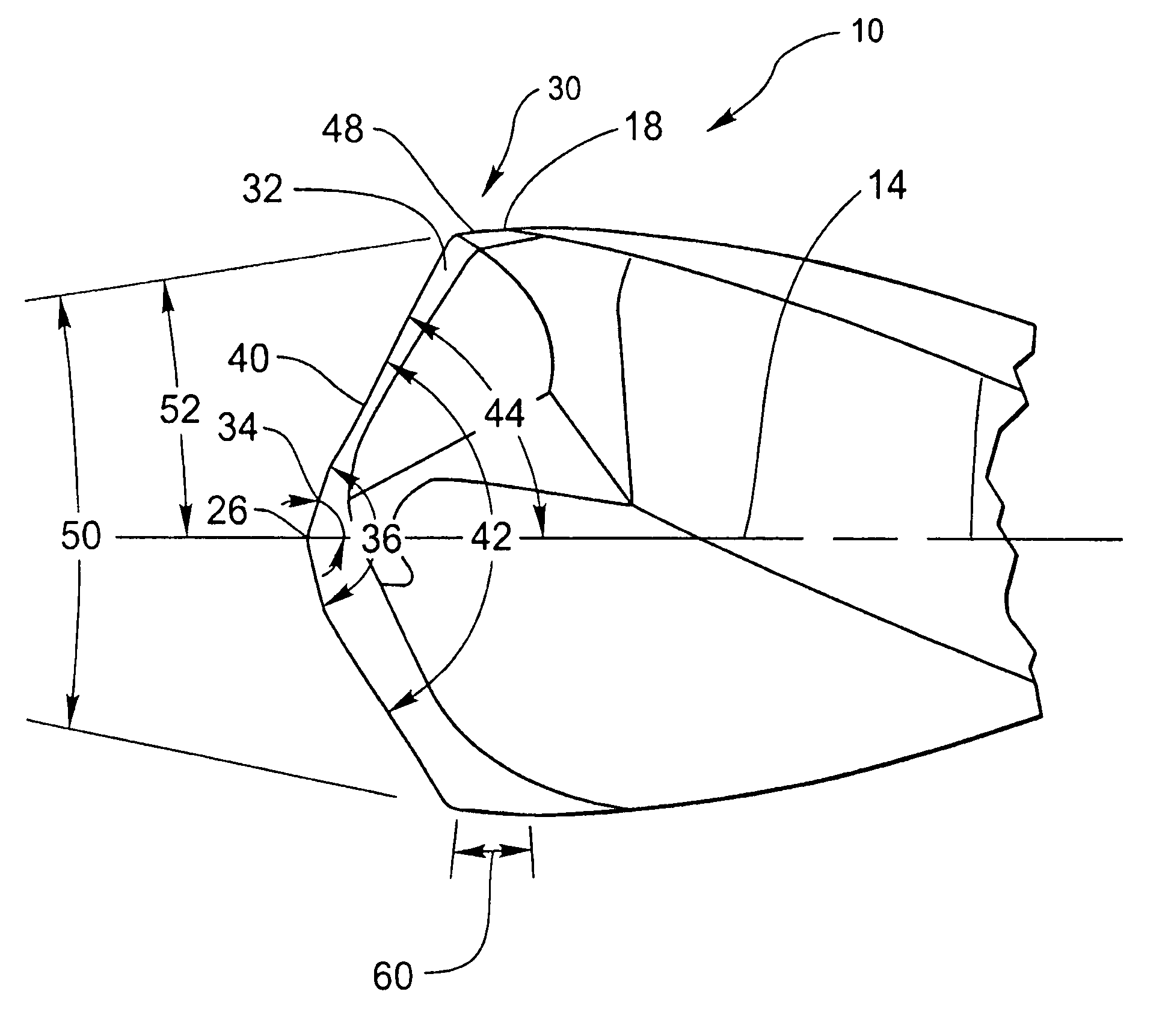

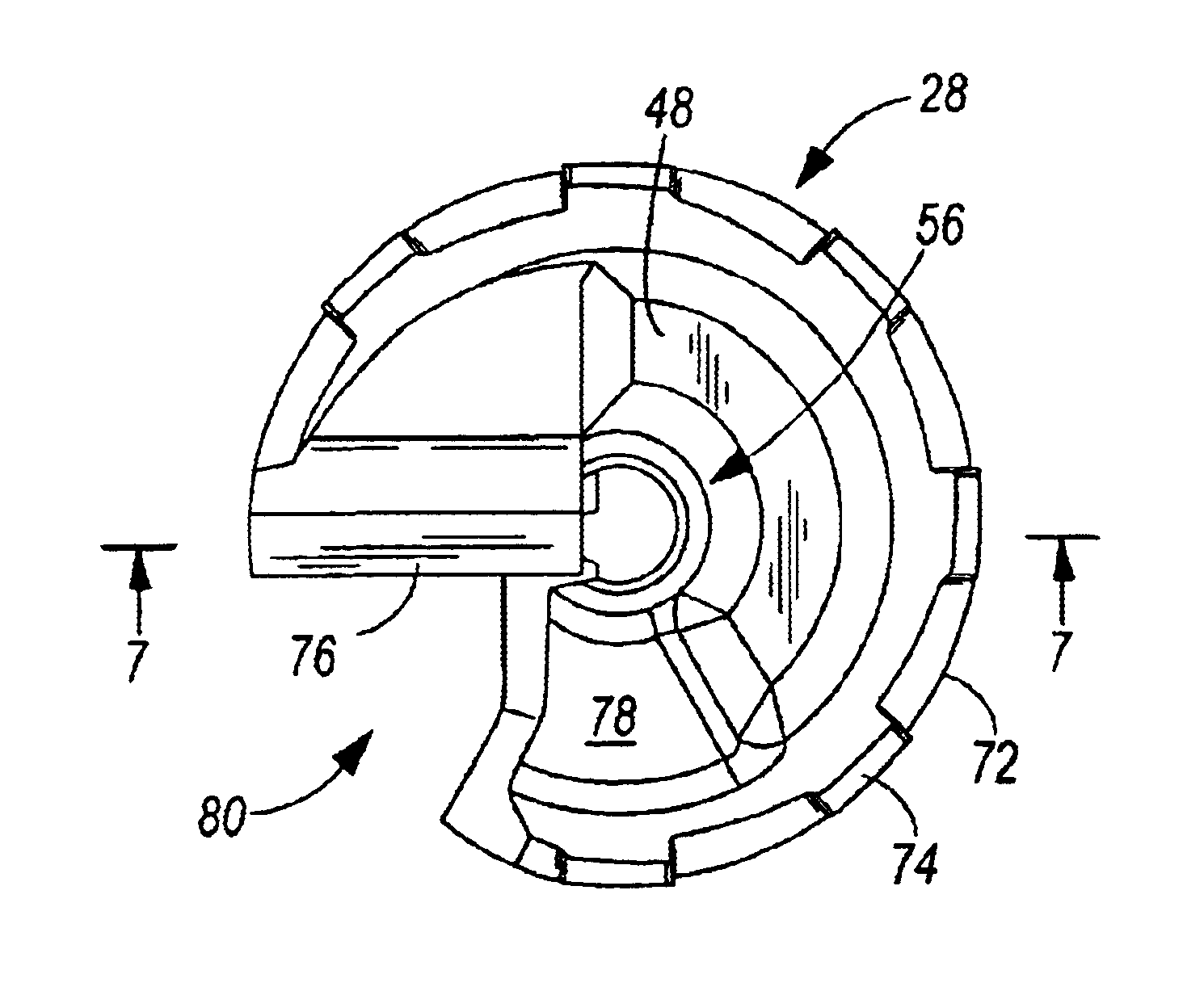

Rotatable tool having a replaceable cutting tip secured by a dovetail coupling

A rotatable cutting tool includes a rotatable tool body and a replaceable cutting tip for chip removing machining. The tool body includes a forward free end having a first dovetail coupling part formed thereon. The cutting tip includes a front cutting end and a rear mounting end. The mounting end includes a second dovetail coupling part joined to the first dovetail coupling part. An actuator, such as a screw, is provided which is arranged for elastically deforming one of the dovetail coupling parts to create a tightly clamped relationship between the first and second dovetail coupling parts. Insertion of a replacement cutting tip is performed by laterally mating the dovetail coupling parts until one of the coupling parts abuts a laterally facing stop surface of the other coupling part.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

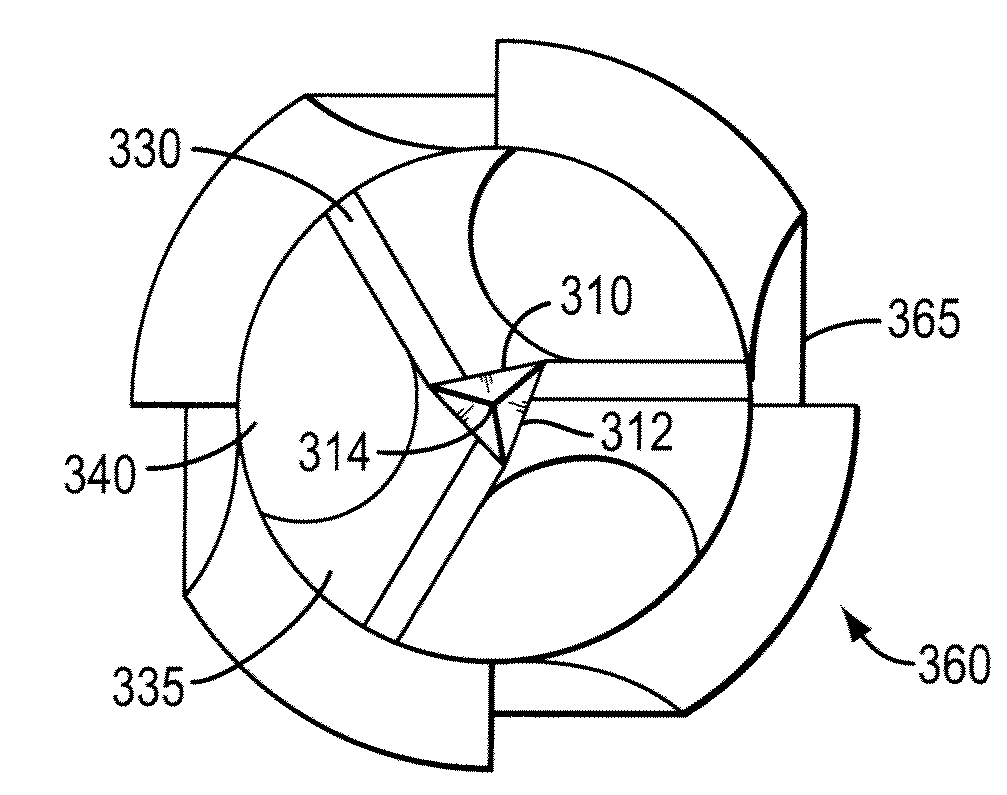

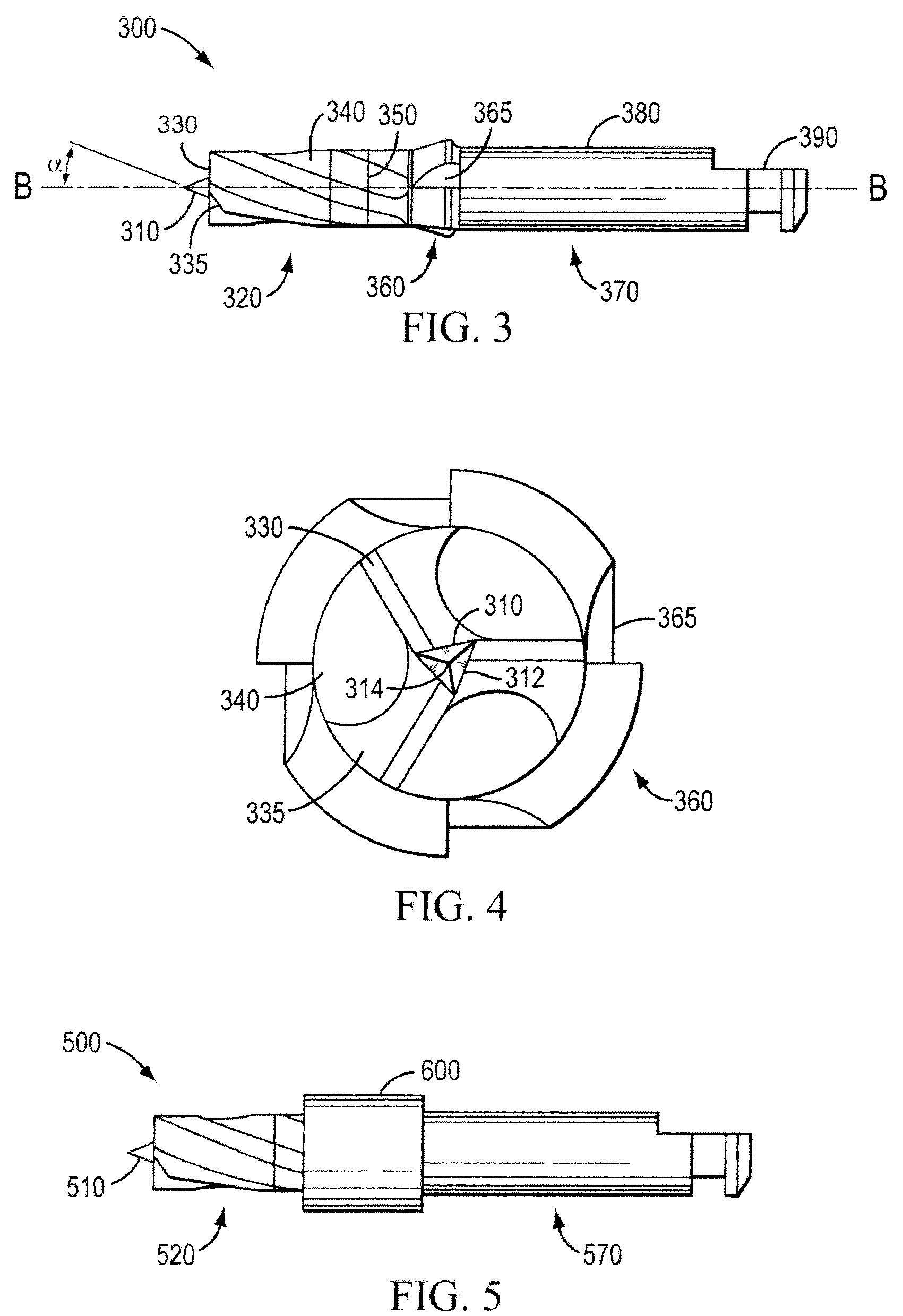

PCD drill for composite materials

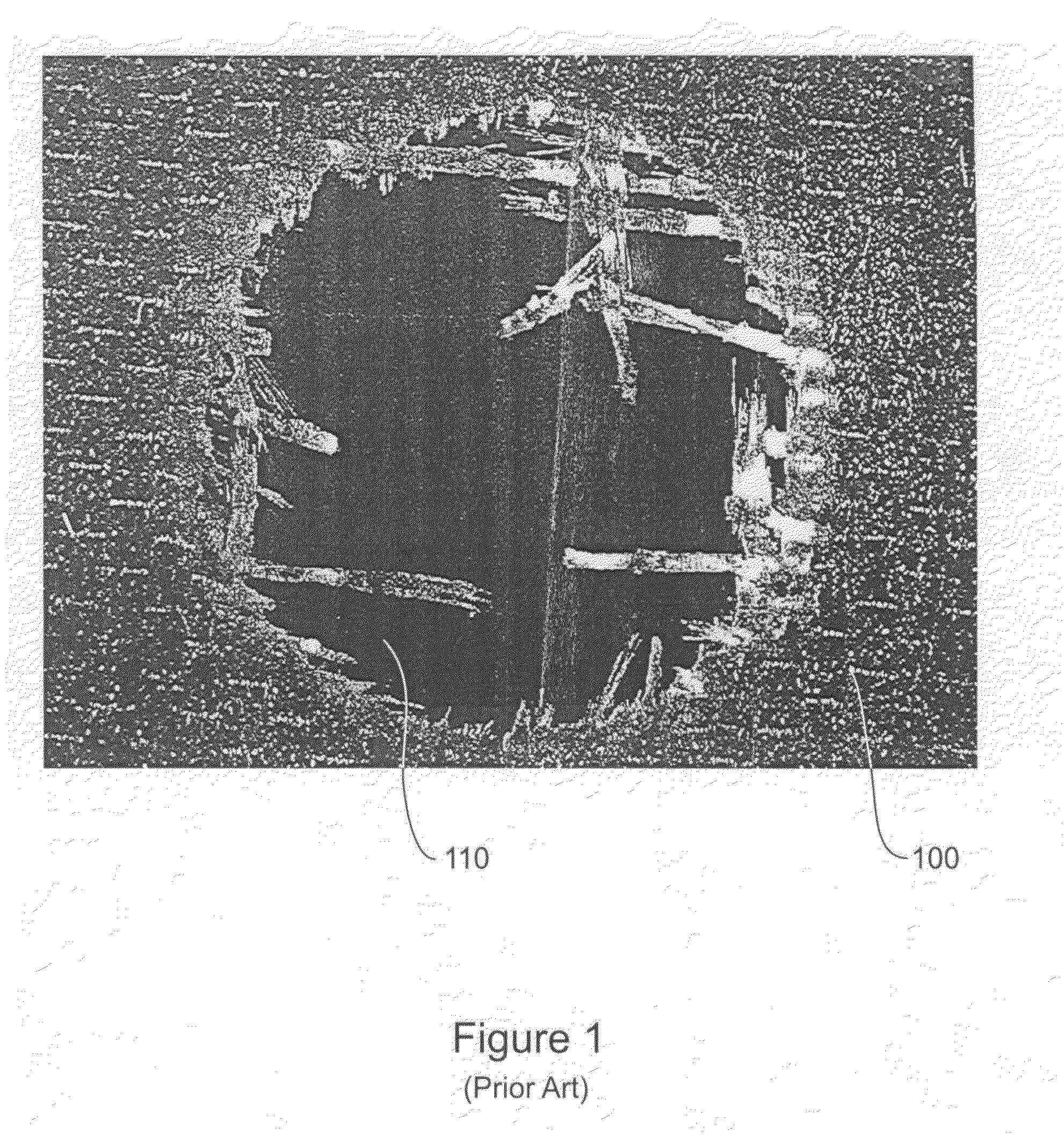

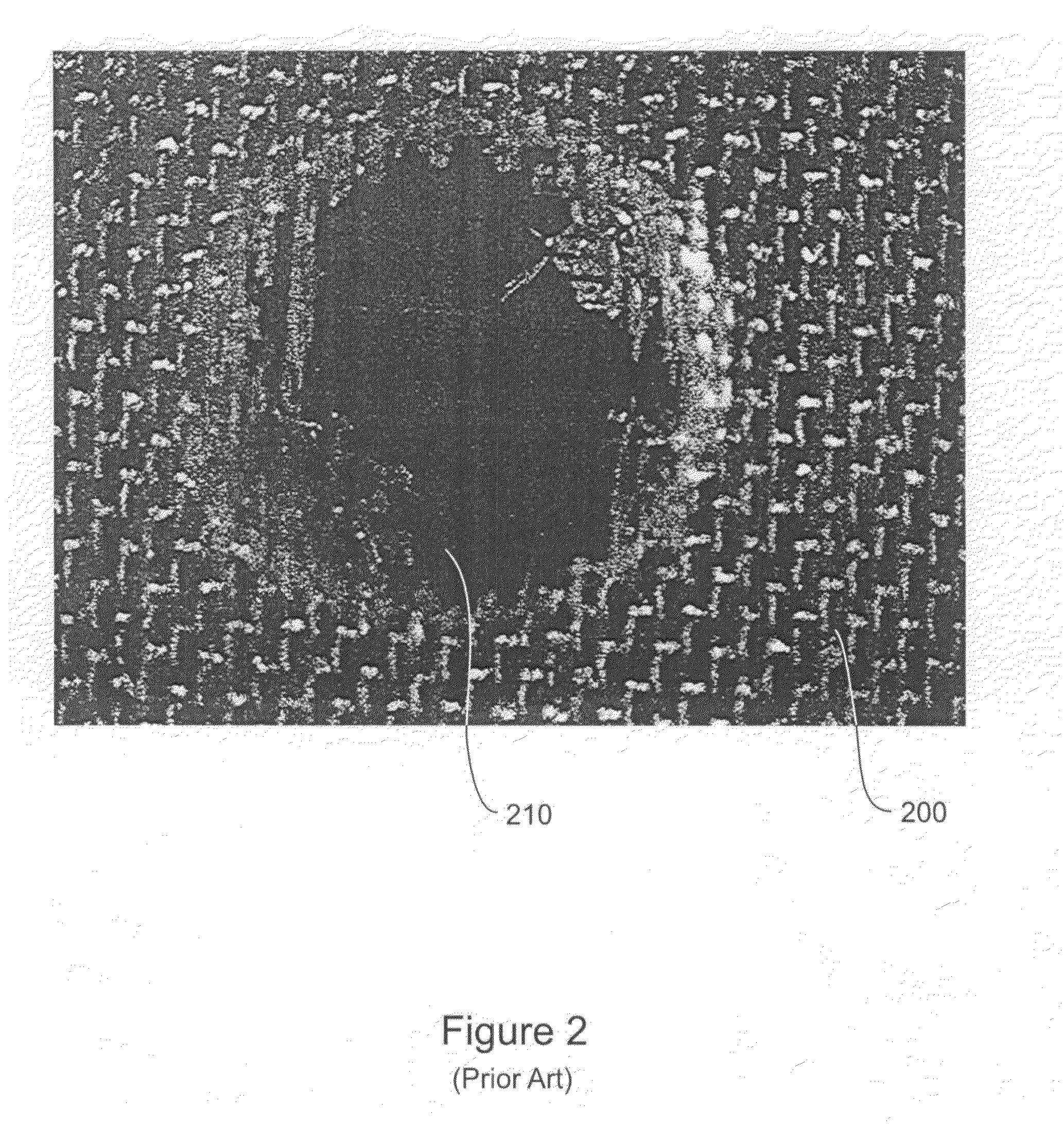

ActiveUS7575401B1Increase chanceMinimal delaminationWood turning toolsTransportation and packagingFiberProduction rate

A PCD drill for producing close tolerance holes in multi layer laminates, such as carbon fiber reinforced composites, with minimum fraying of the fibers on both entrance and exit from the hole is provided. The drills provided include a symmetrical cutting point with a self-centering split point and a high shear second cutting lip positioned at the outer diameter of the drill. The drills of the invention may allow for increased cutting speeds and feeds when used with such advanced composite materials, thus increasing tool productivity and providing increased performance.

Owner:PRECORP INC

Systems devices and methods for opening receptacles having a powder to be fluidized

InactiveUS20050161041A1Easy extractionConveniently formedLiquid surface applicatorsPowdered material dispensingEngineeringSurface cover

A method for forming at least one opening in a receptacle comprises the steps of providing a receptacle having a cover with an exterior surface and an interior surface covering a cavity. A cutting mechanism is also provided having at least one blade. The cover is pierced with the blade, and the blade is moved through the cover to cut a portion of the cover and create an opening in the cover to provide access into the cavity. Further, the cut portion curls on top of the exterior surface as the opening is created.

Owner:NOVARTIS AG

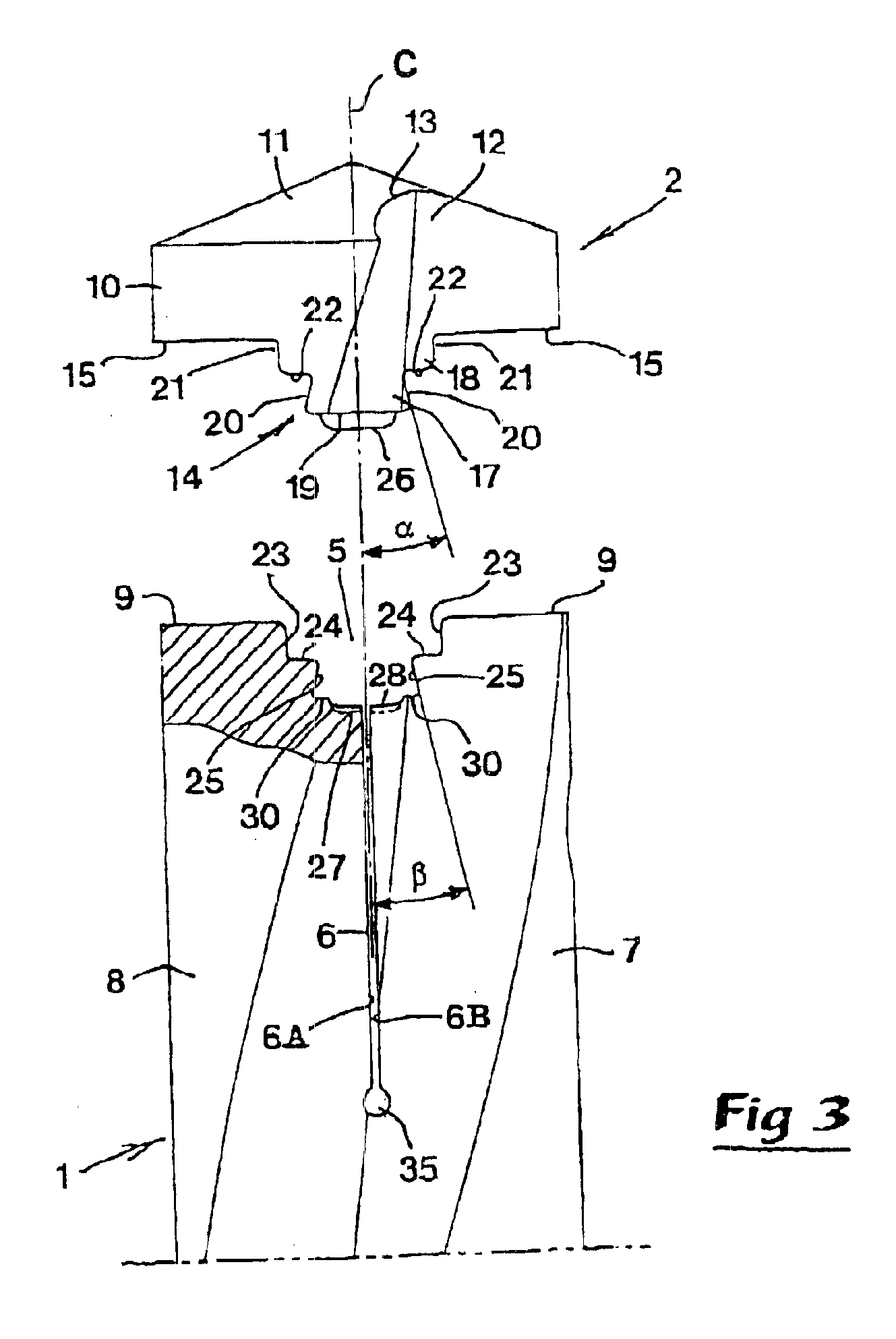

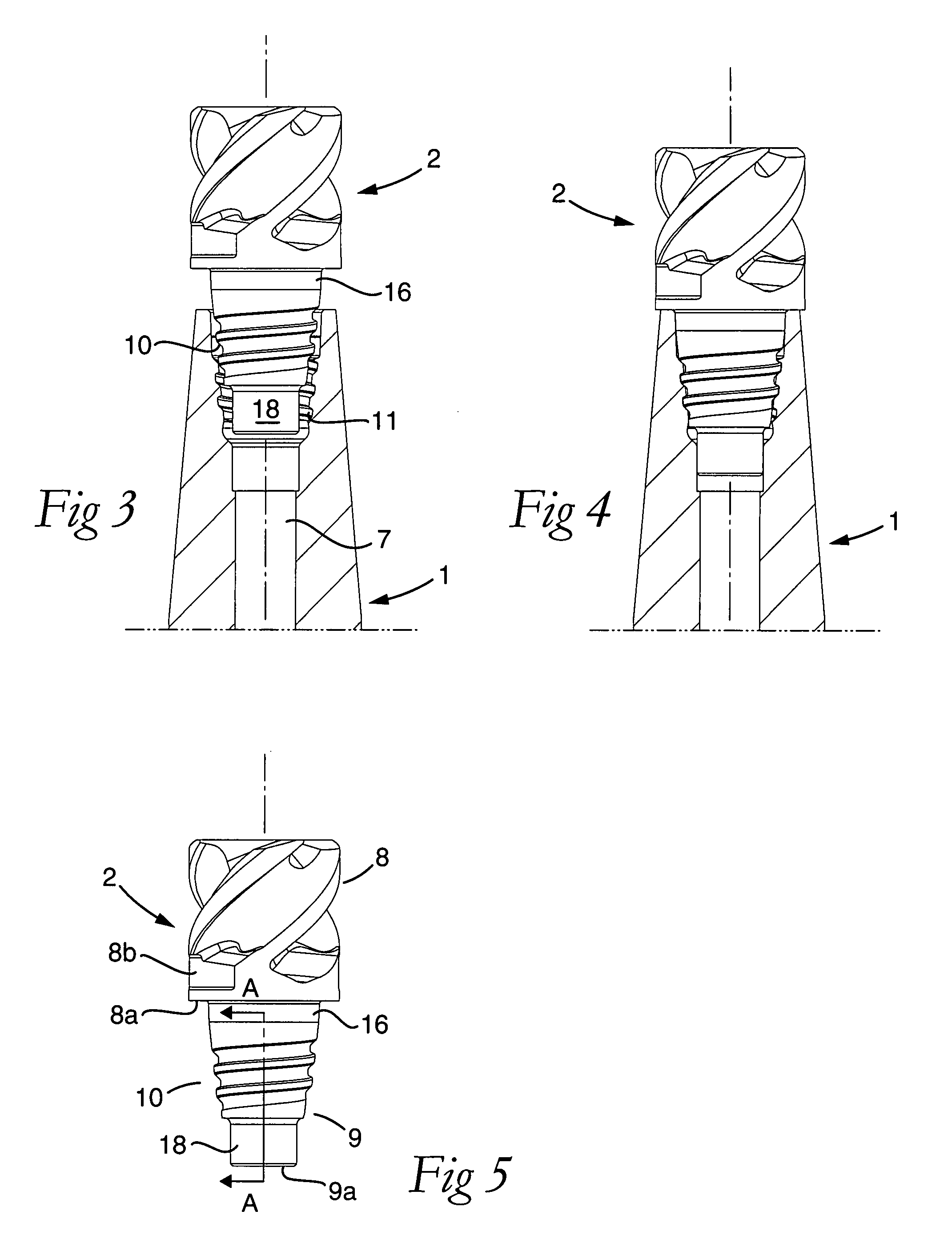

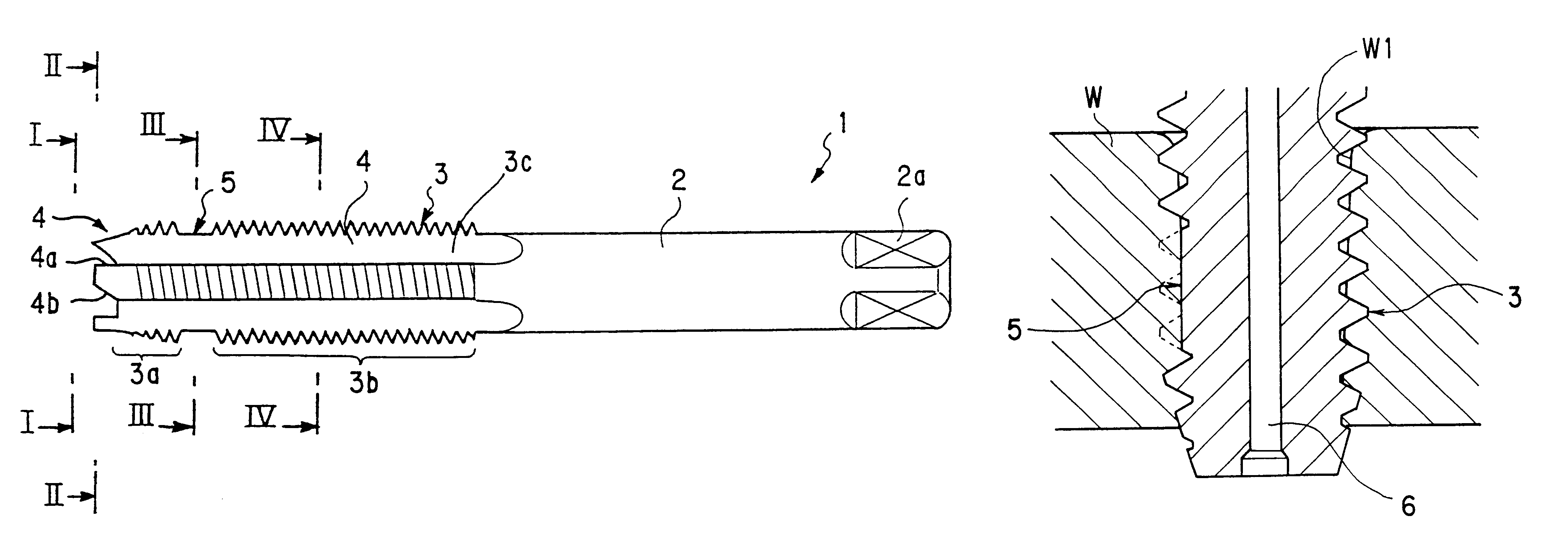

Tool for chip removing machining as well as a part and threaded joint therefor

ActiveUS7611311B2Improved propertyGenerating large tightening forces without jeopardizing the durability of the thread ridgesTool workpiece connectionThread cutting machinesPull forceEngineering

A cutting tool, and a loose top therefore, includes two parts detachably connected to each other via a threaded joint in which co-operating male and female threads are included in the form of helicoidal ridges. The profile shape of each helicoidal ridge is defined by a top and two flanks, which delimit a helicoidal groove having a bottom. The first flank is inclined in relation to a center axis of the tool at a first angle that is smaller than a second angle of the second flank in relation to the center axis. Accordingly, the thread ridge is reinforced in comparison with thread ridges having a symmetrical profile shape, whereby larger tensile forces than compressive forces can be applied to the threaded joint while avoiding damage to the thread ridges.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Boring bit and methods for manufacturing boring bits

InactiveUS6874978B2Reduce extra spaceReduce spacingThread cutting toolsWood turning toolsEngineeringPower tool

Boring bits and methods for manufacturing boring bits. The method includes the acts of forming a shank including one end connectable to a power tool and an opposite end, molding a cutting head separate from the shank, the cutting head including a base wall and a side wall extending from the base wall, the base wall having an interior base surface and an exterior base surface, and bonding the shank and the cutting head as a unit including bonding the opposite end of the shank to the exterior base surface.

Owner:MILWAUKEE ELECTRIC TOOL CORP

Tap

InactiveUS6499920B2Reduce processing timeImprove productivityThread cutting toolsWood turning toolsFluteEngineering

A cutting tap comprises a threaded portion including a lead whose thread diameter gradually decreases toward a front end of the lead, a complete thread portion continued from the lead, and four flutes arranged at equal intervals in a circumferential direction. In the cutting tap, a first cutting edge portion for processing a prepared hole is formed at a front end surface of the lead, and a second cutting edge portion for finishing a minor diameter of an internal thread is formed in a part of an outer periphery of the complete thread portion, the second cutting edge portion being one or more pitches long. The cutting tap can perform processing of a prepared hole, tapping, and finishing of a minor diameter by a single step, and can also perform tapping even if a prepared hole for an internal thread is a blind hole or the like and does not have enough space.

Owner:TANOI MFG CO LTD

Rotary cutting tool

A rotary cutting tool has a cutting head, a screw member and a tool shank. The cutting head has an axially directed through bore with locking wings protruding from the bore surface. Each locking wing having a sloping locking surface and stopper with a stop surface. The screw member has outwardly radially protruding clamping wings each having a sloping clamping surface, and an associated side abutment surface. The screw member is in threaded engagement with the tool shank, with the clamping wings and locking wings aligned in pairs with the locking and clamping surfaces of each pair in abutment, and with each stop surface in abutment with a given side abutment surface.

Owner:ISCAR LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com