Patents

Literature

211results about How to "Conveniently formed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

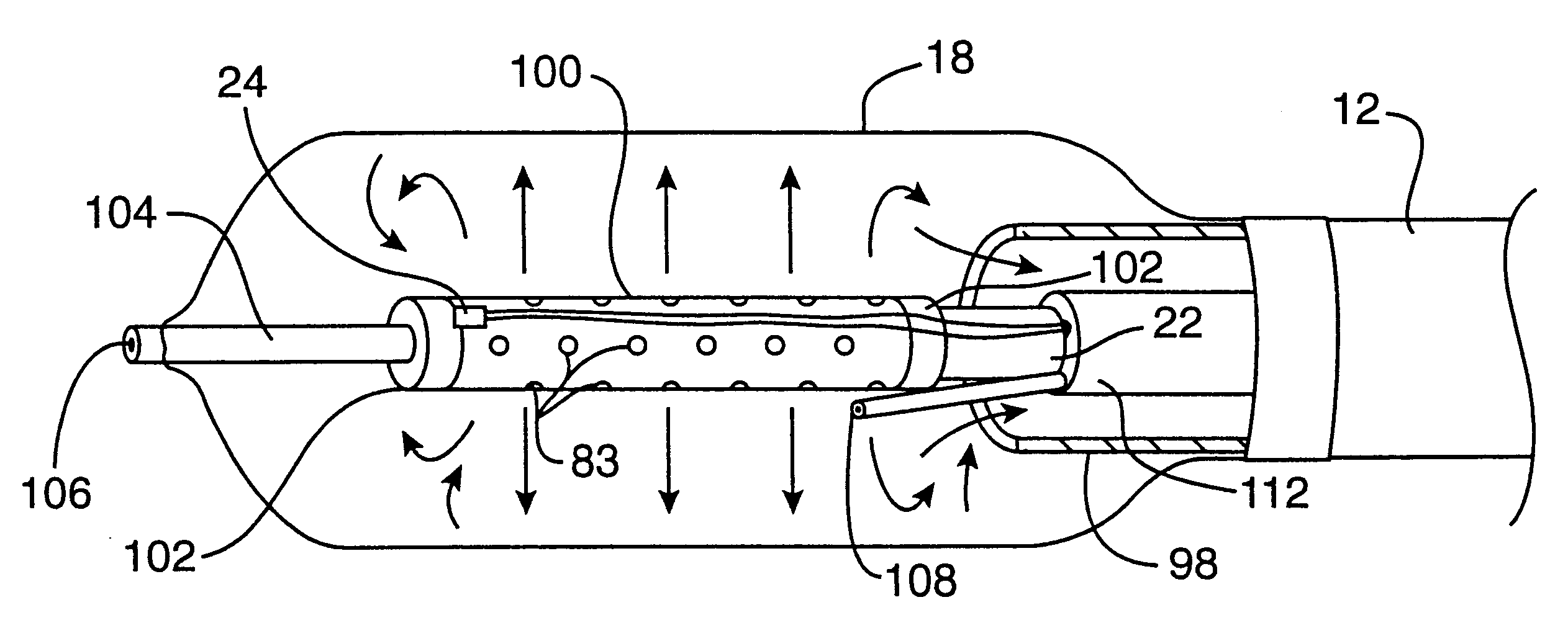

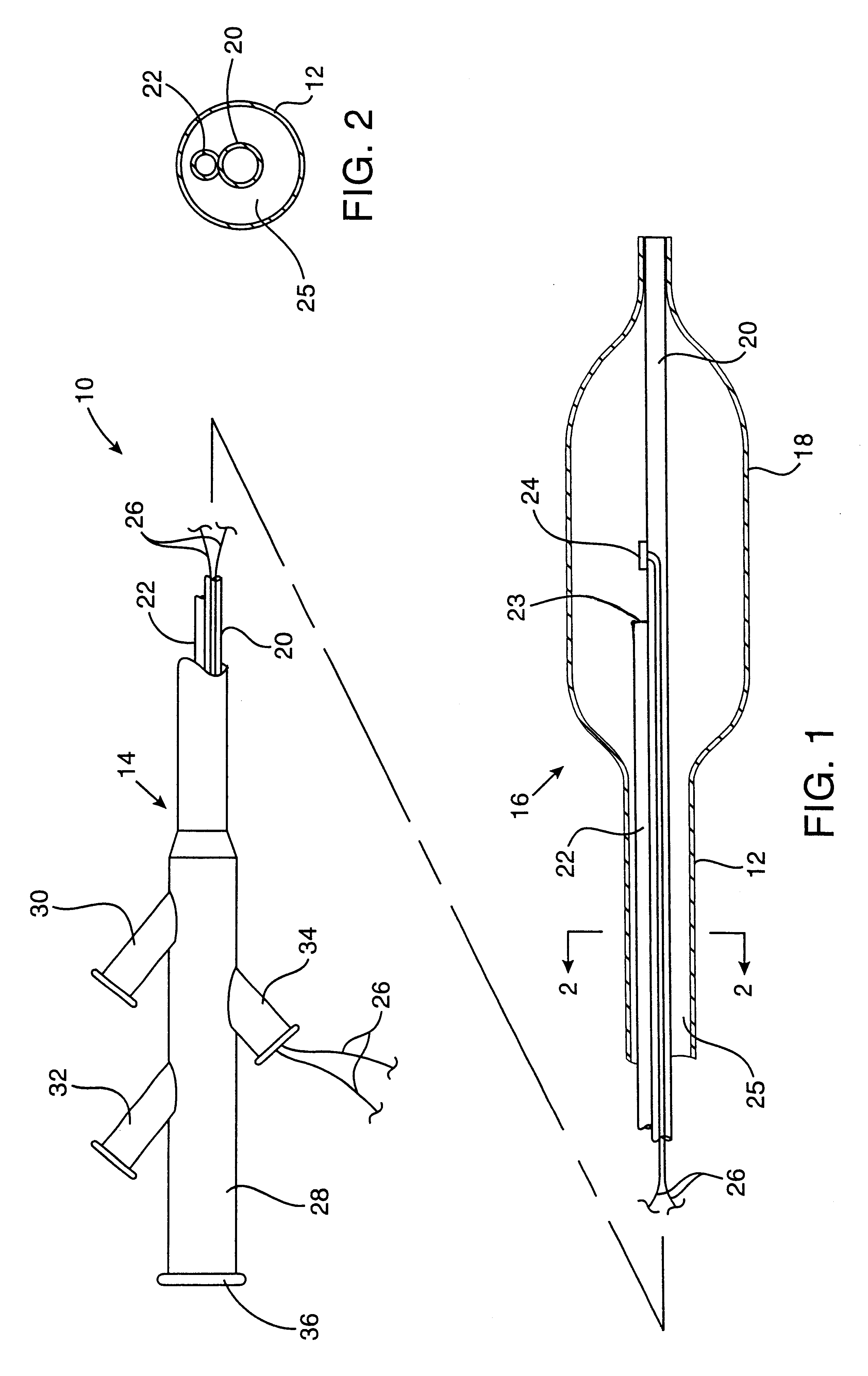

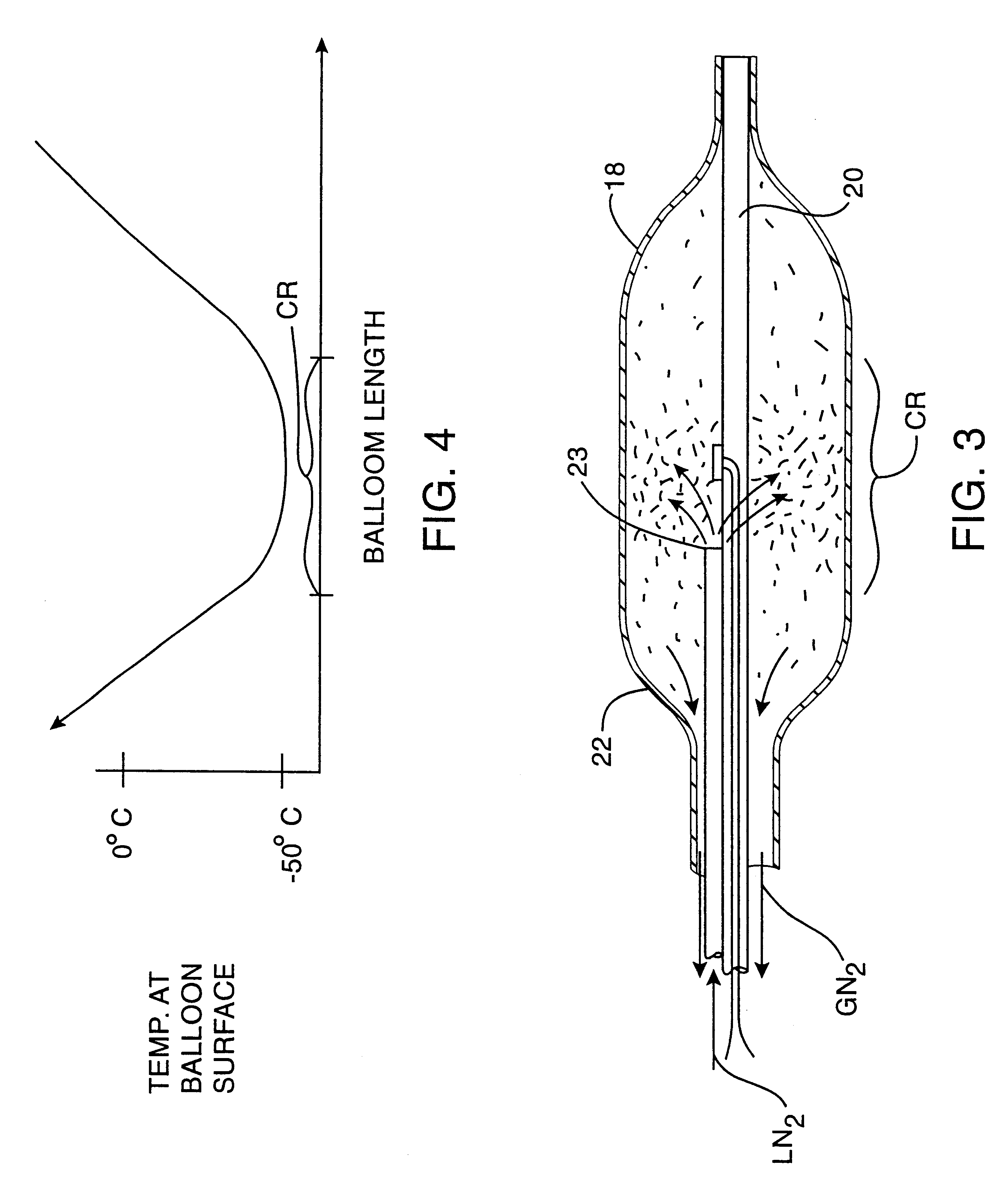

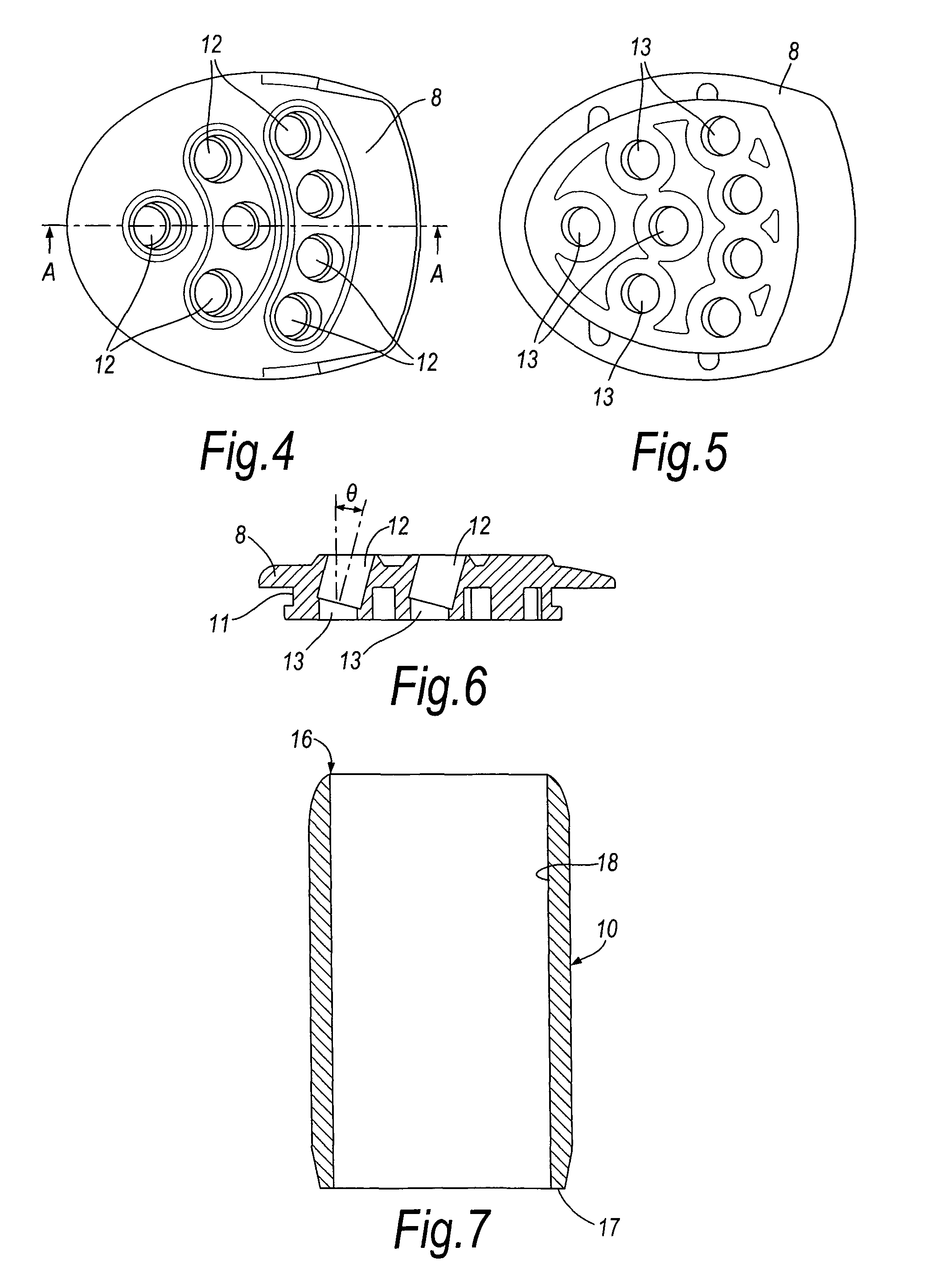

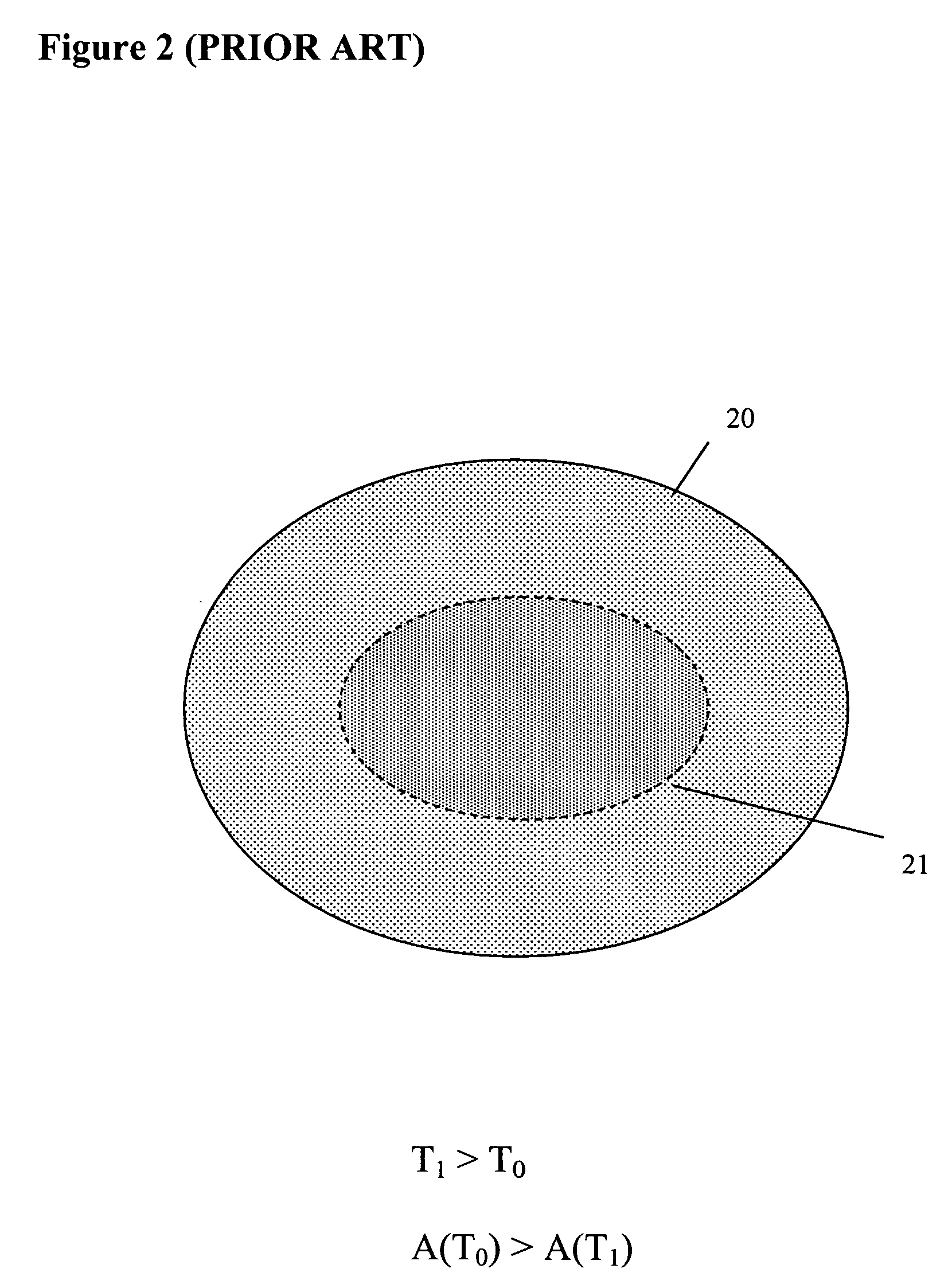

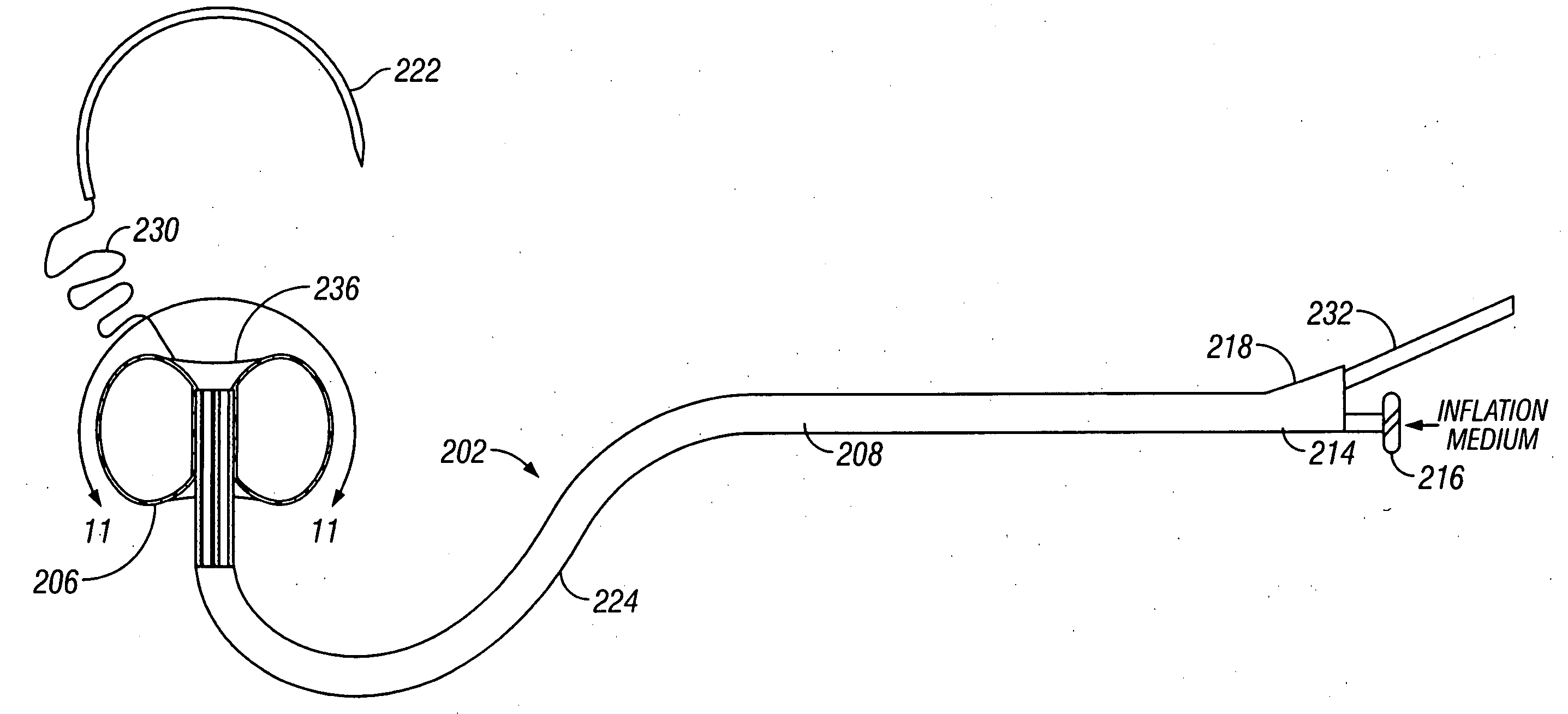

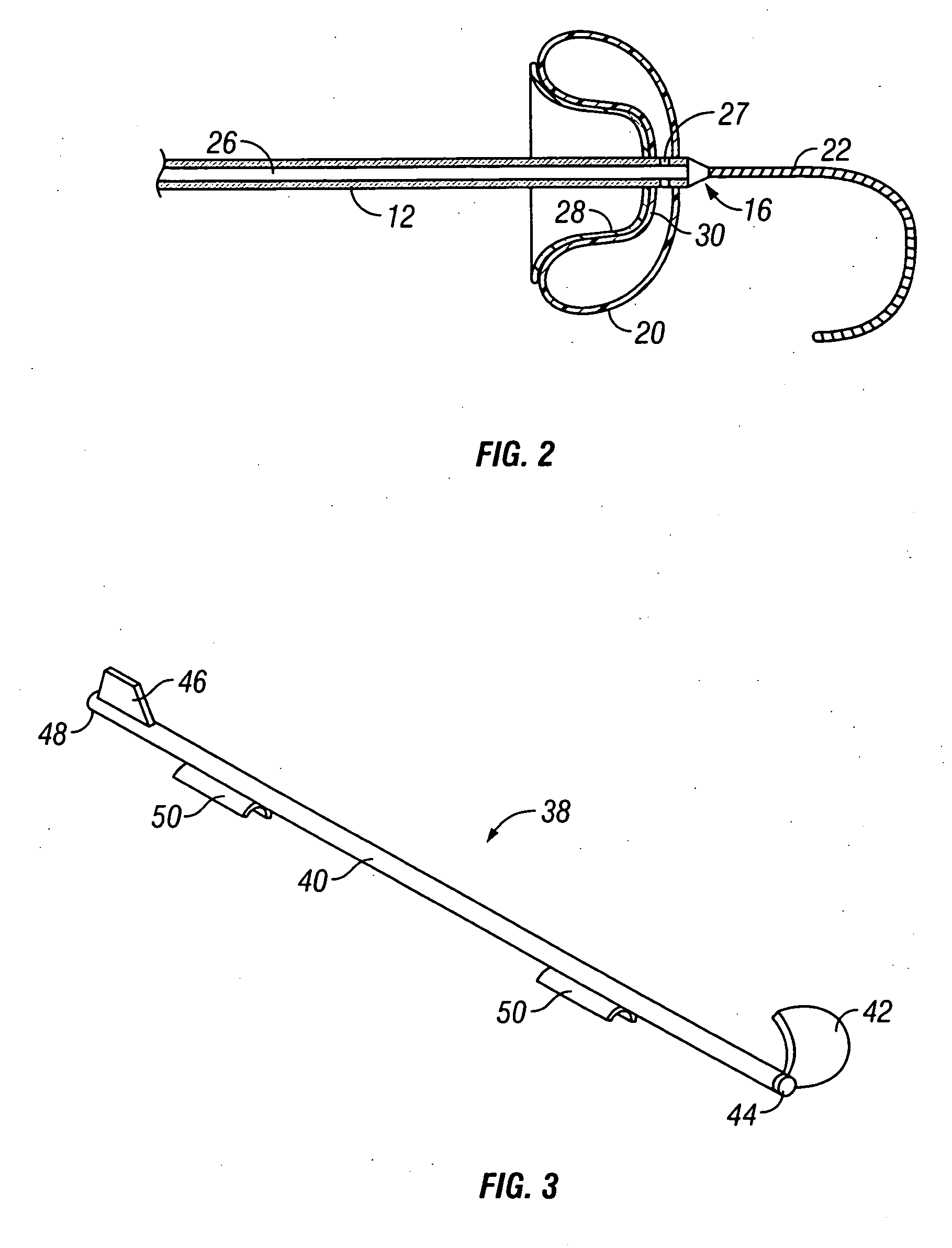

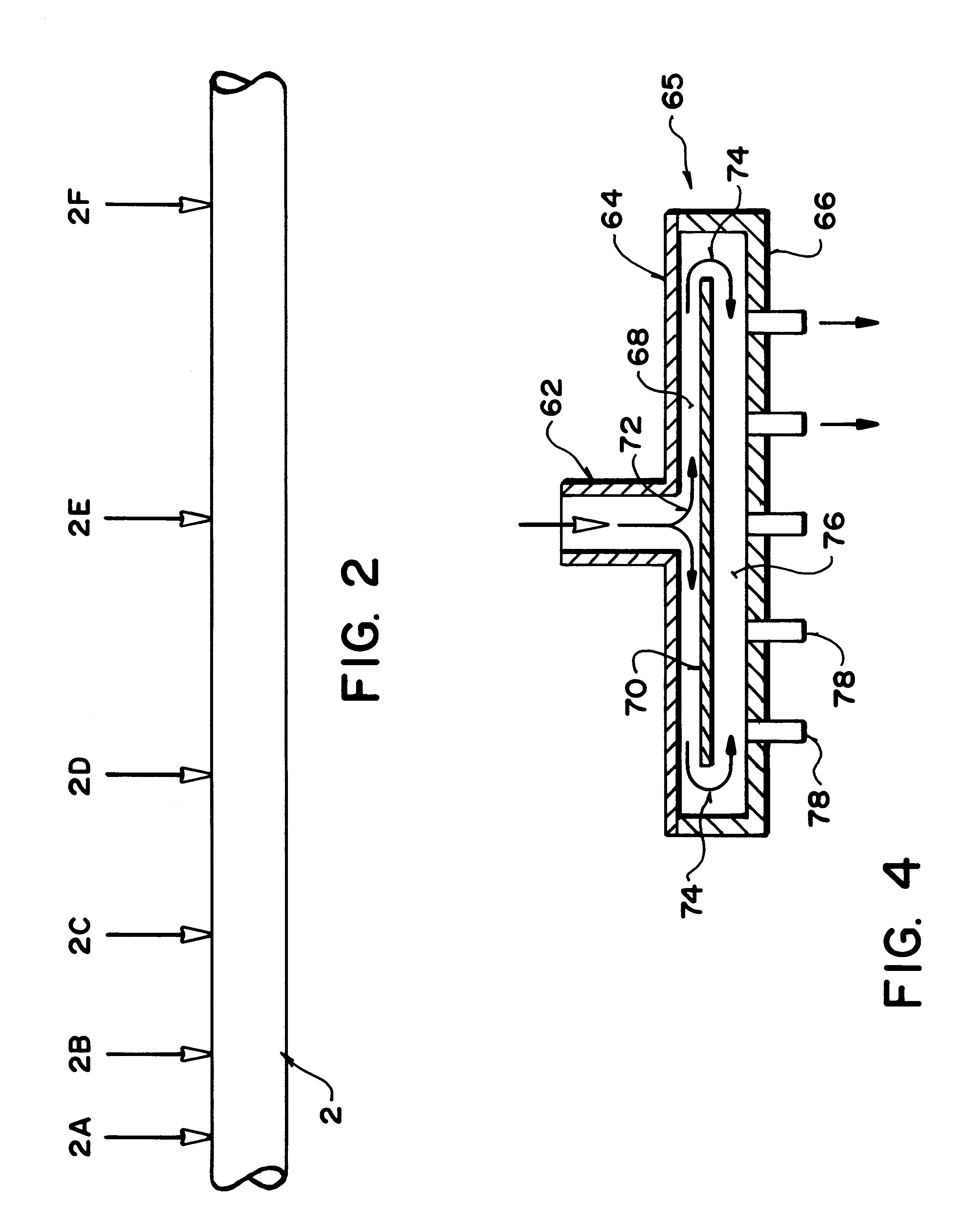

Apparatus and method for cryogenic inhibition of hyperplasia

InactiveUS6355029B1Enhanced inhibitory effectEasy to controlCatheterSurgical instruments for coolingPercutaneous angioplastyBalloon catheter

Post-angioplasty hyperplasia in blood vessels is treated using a cryosurgical balloon catheter. The balloon catheter is positioned at a target region within the blood vessel, and the balloon inflated by expanding a cryogenic fluid, such as liquid nitrogen, across an expansion orifice into a balloon. The balloon will be constructed so that cooling is achieved primarily in the central regions of the balloon, with the proximal and distal regions being less cold and acting to insulate adjacent regions of the blood vessel from excessive cooling.

Owner:BOSTON SCI SCIMED INC

Assay devices

InactiveUS6187269B1Improve storage stabilityConveniently formedAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorAntibodyBiomedical engineering

Storage stability of an assay device, comprising an assay strip and sensitive reagents such as antibodies within a plastics casing, is maintained by moulding some or all of the casing from dessicant-containing plastics material, especially a blend of about 60-65% polystyrene and about 30% silica dust. Ideally the desiccant-containing plastics material is used in the moulding of a removable cap for the device. The cap can be made by sandwich injection moulding, using the dessicant-containing polystyrene as a core, surrounded by conventional polystyrene.

Owner:INVERNESS MEDICAL SWITZERLAND GMBH

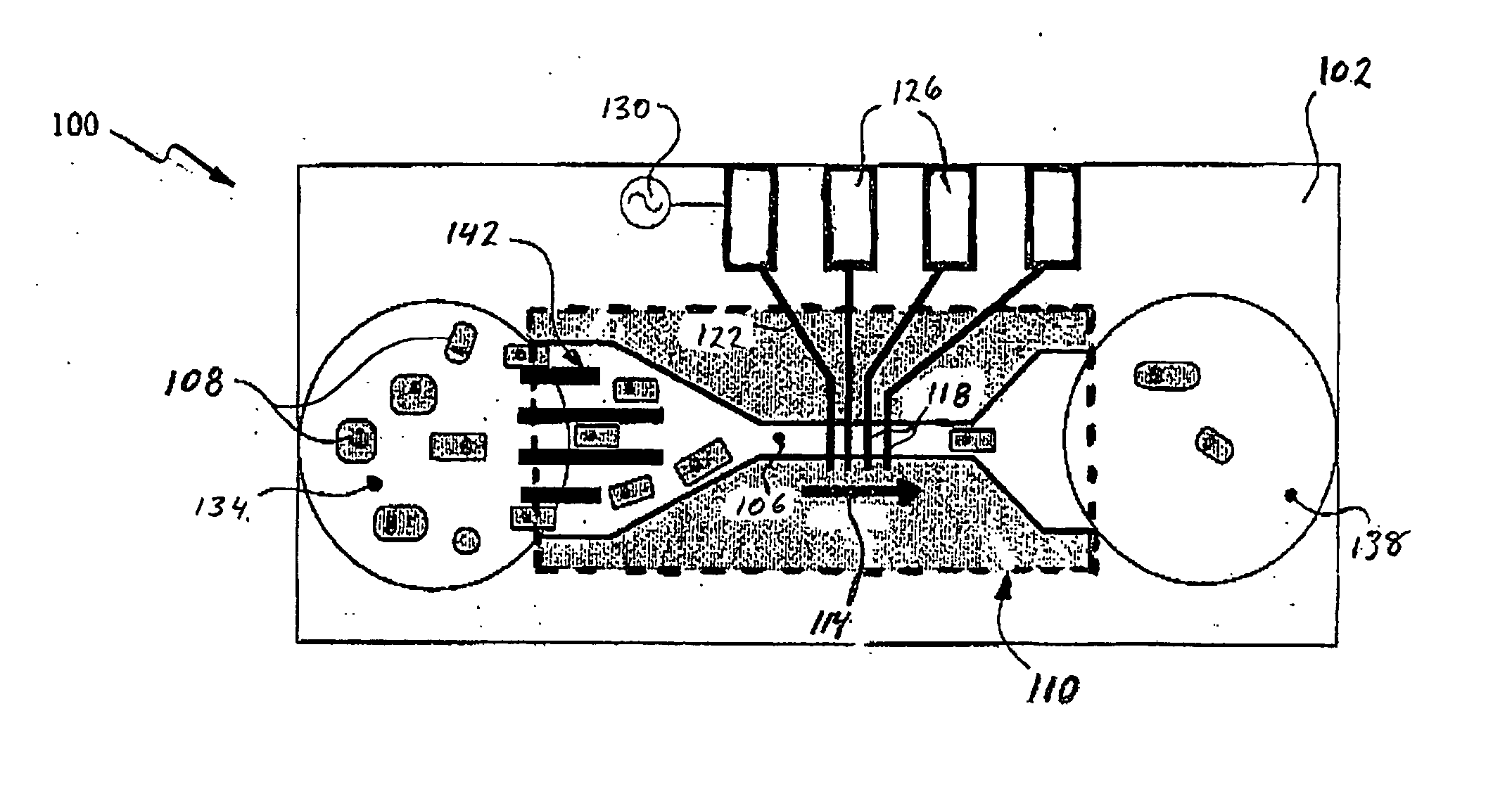

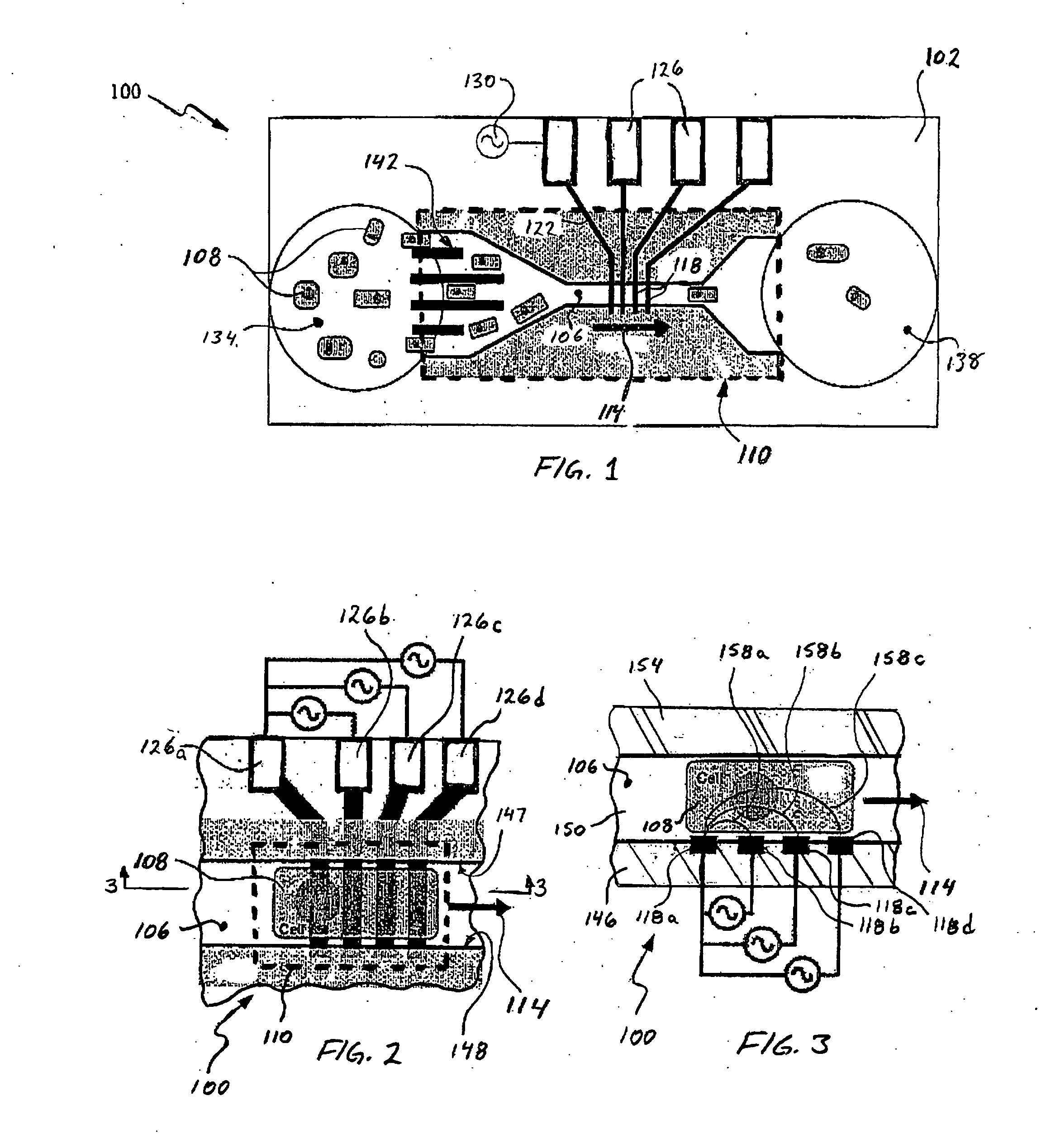

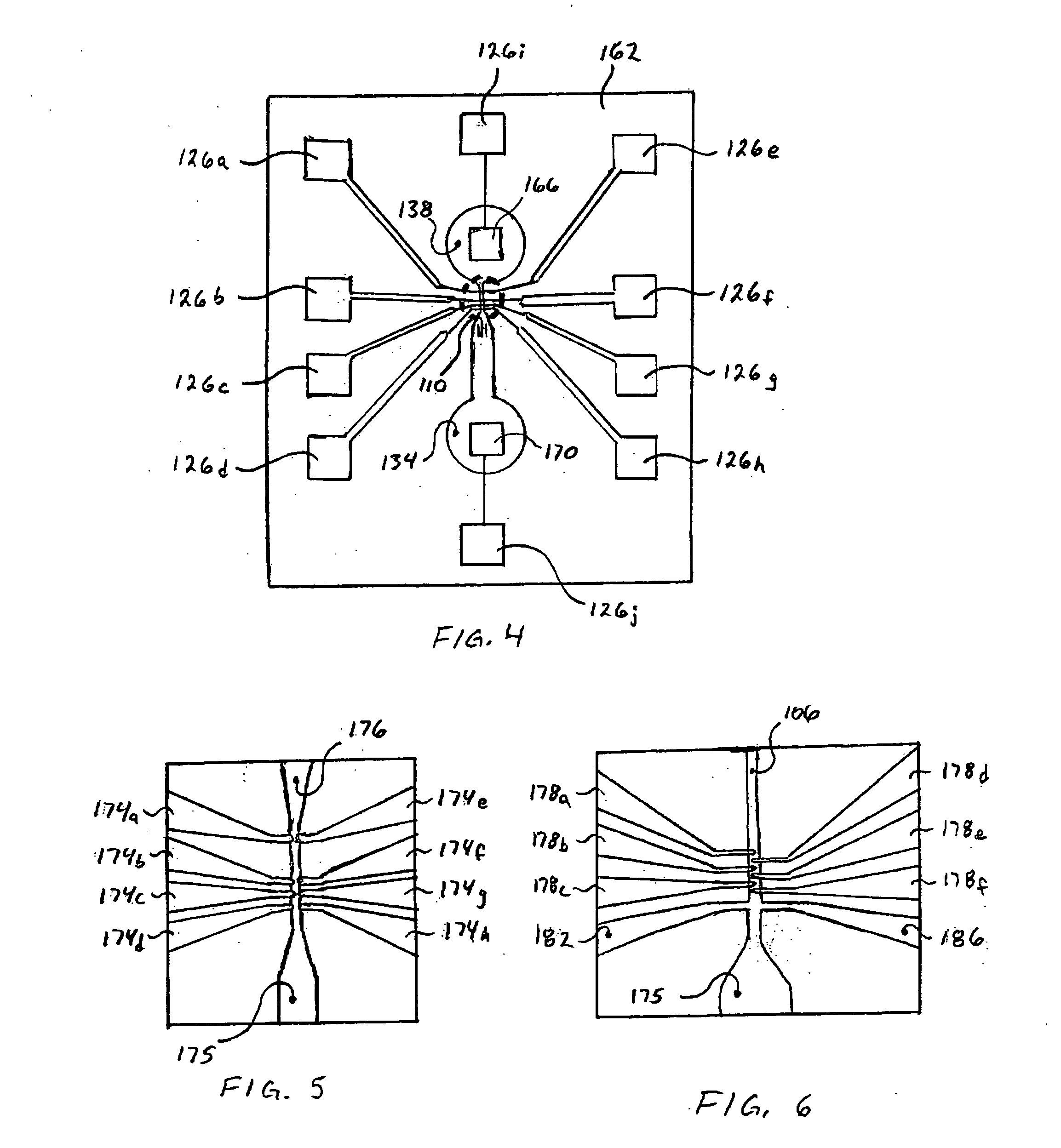

Electrical detectors for microanalysis

InactiveUS20050118705A1Improve sensitivity and accuracyHigh sensitivityBioreactor/fermenter combinationsBiological substance pretreatmentsMicroelectrodeElectricity

Apparatus and methods for performing microanalysis of particles using a microelectrical-mechanical system (MEMS) chip to electrically interrogate the particles. The MEMS chip is typically manufactured using known lithographic micromachining techniques, employed for example, in the semiconductor industry. A substrate carries a plurality of microelectrodes disposed in a detection zone and spaced apart along an axis of a microchannel. The microchannel is sized in cross-section to cause particles carried by a fluid to move past the electrodes in single file. Impedance is measured between one or more pairs of electrodes to determine the presence of a particle in the detection zone. In certain embodiments used in cell manipulation, an electroporation signal may be applied between one or more pairs of electrodes to enhance permeability of a cell membrane. A structural arrangement may be provided to introduce a treatment substance into the microchannel in the vicinity of a cell, which may be restrained for a period of time in a treatment zone.

Owner:UNIV OF UTAH RES FOUND

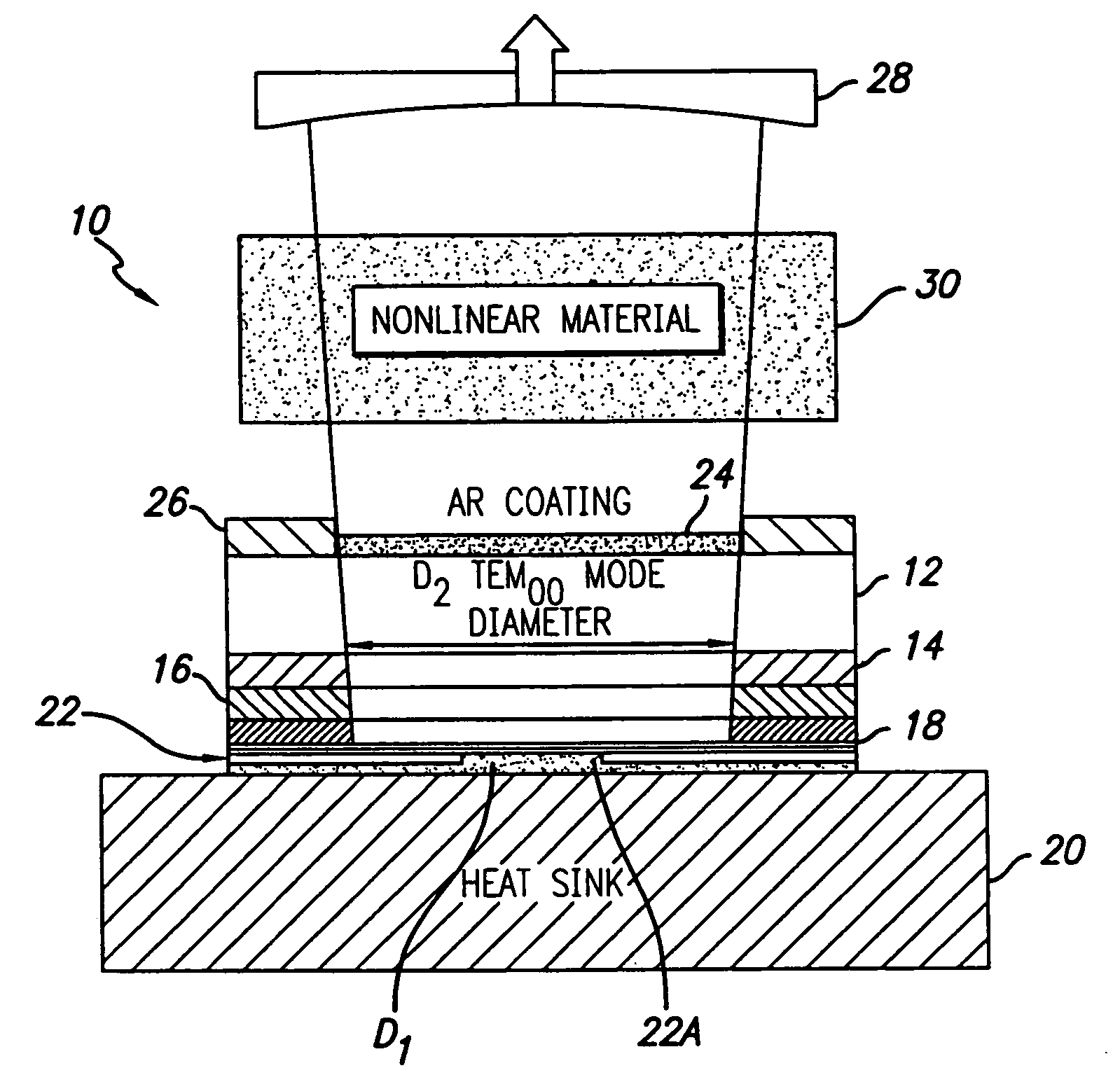

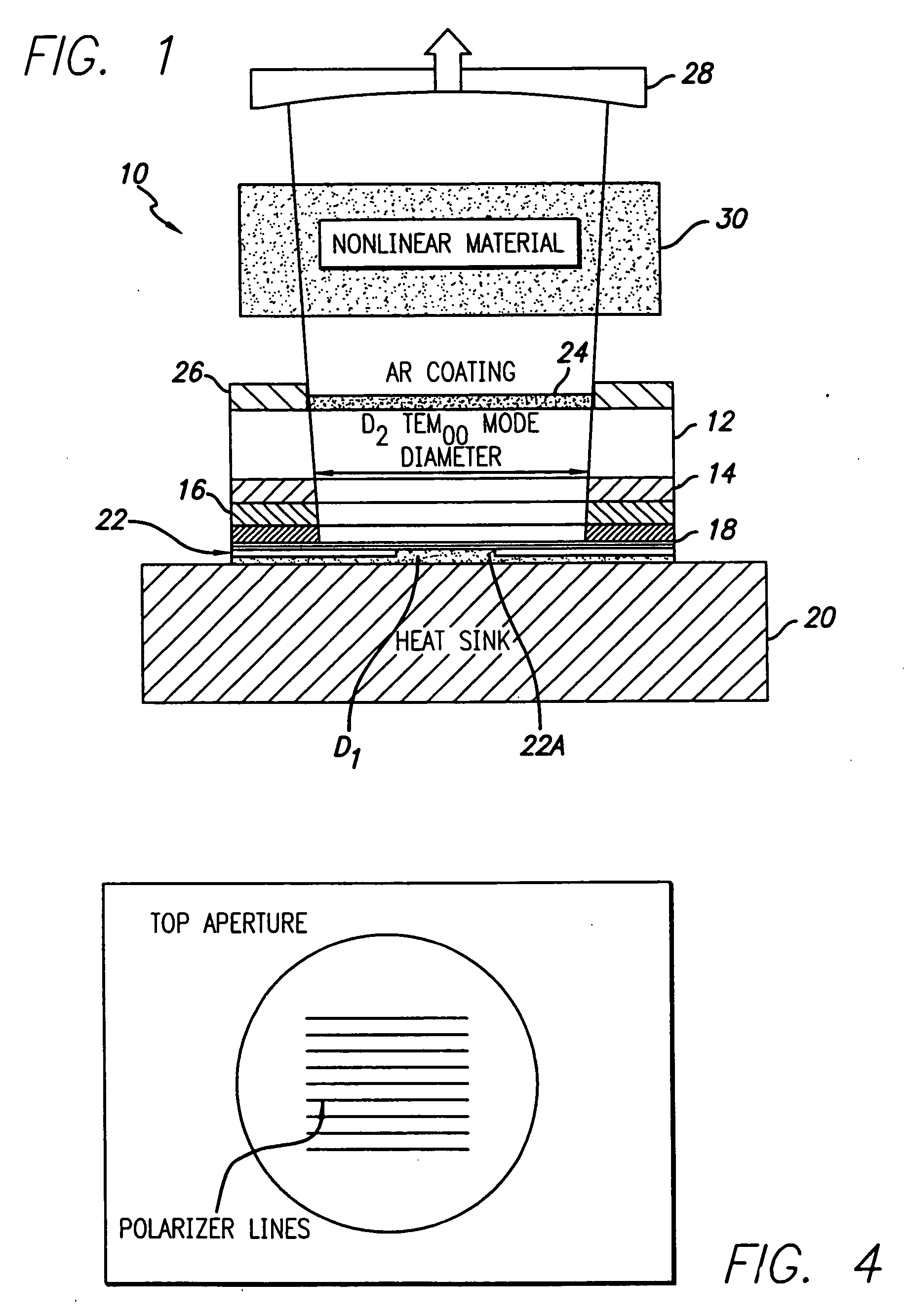

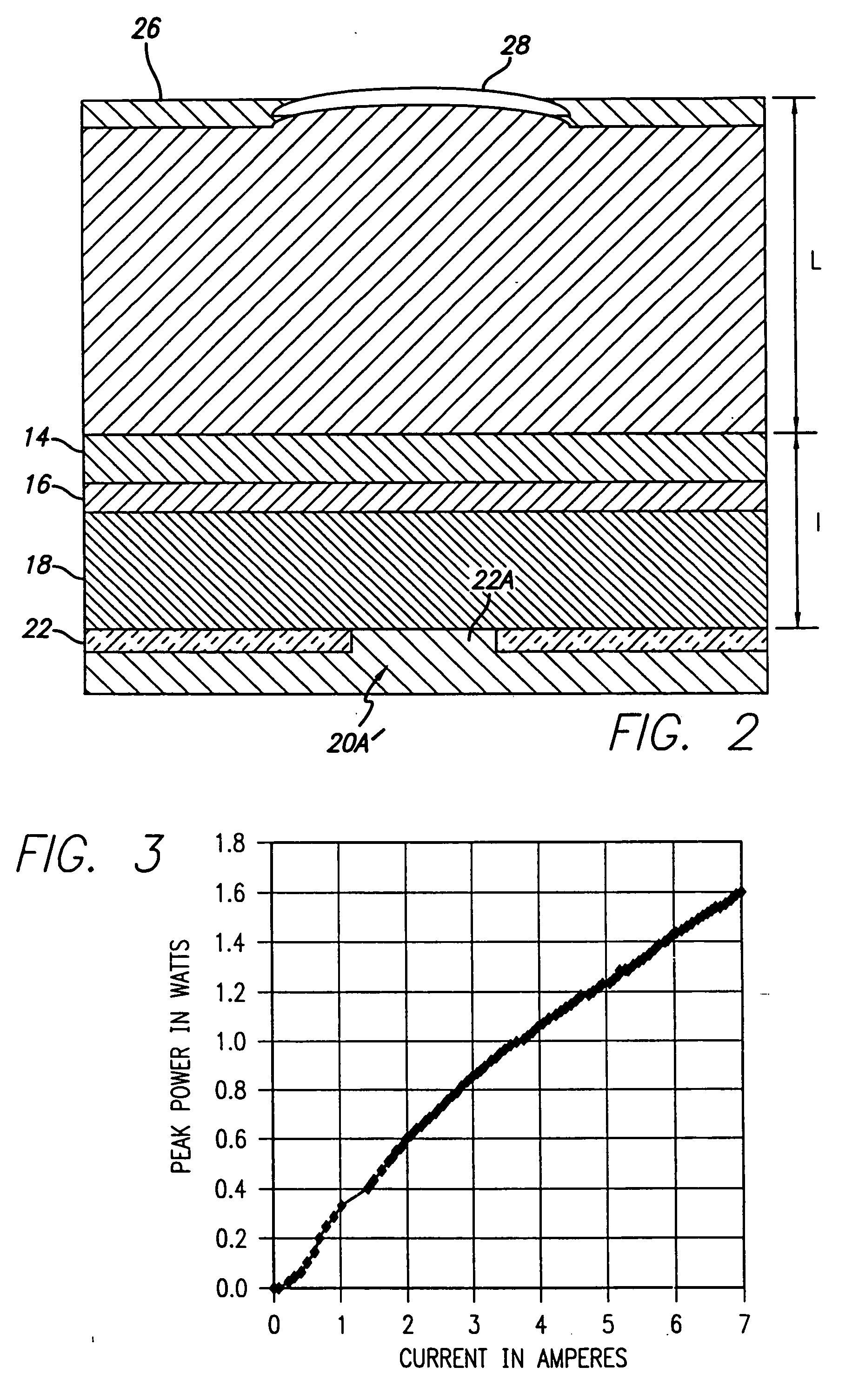

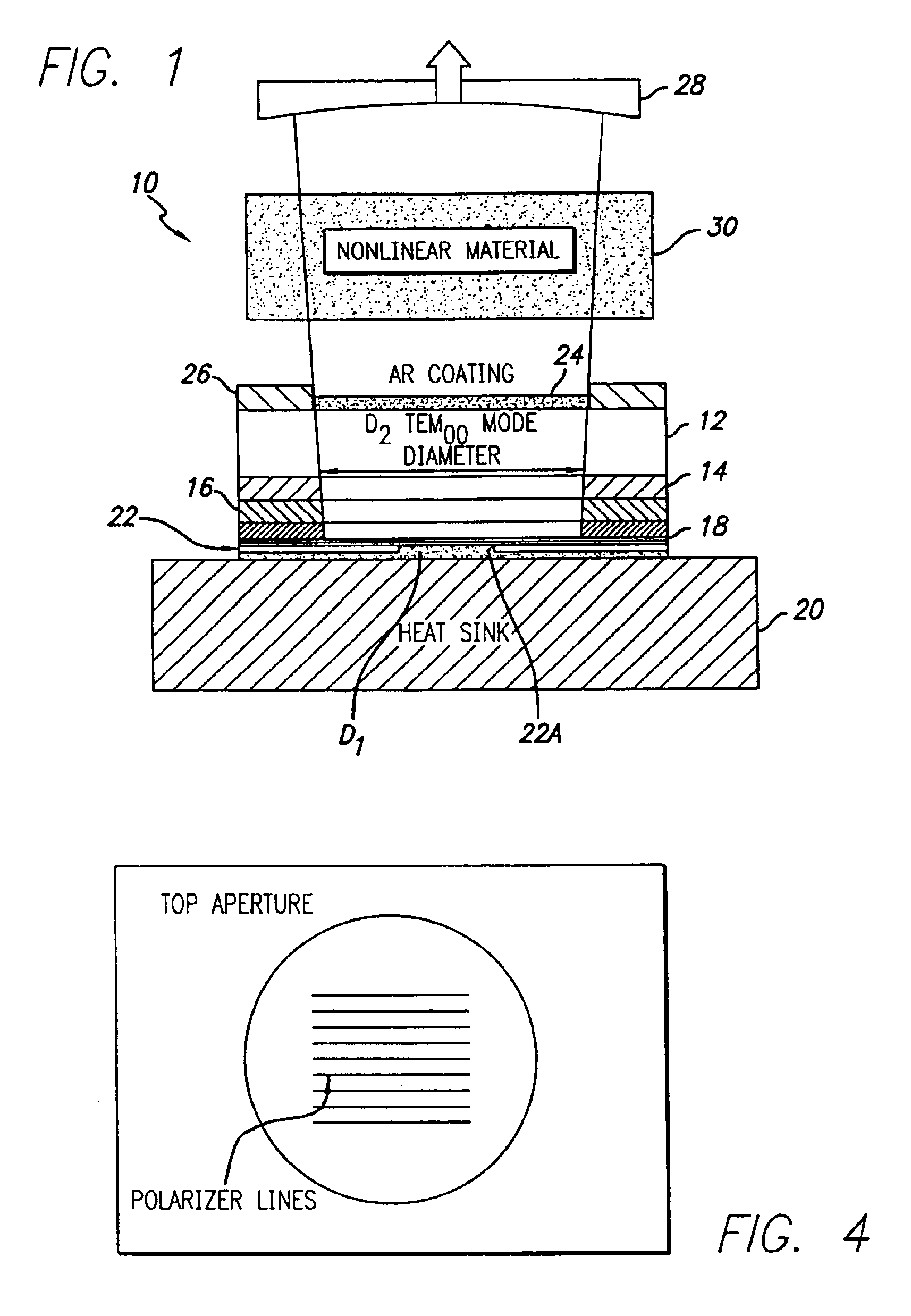

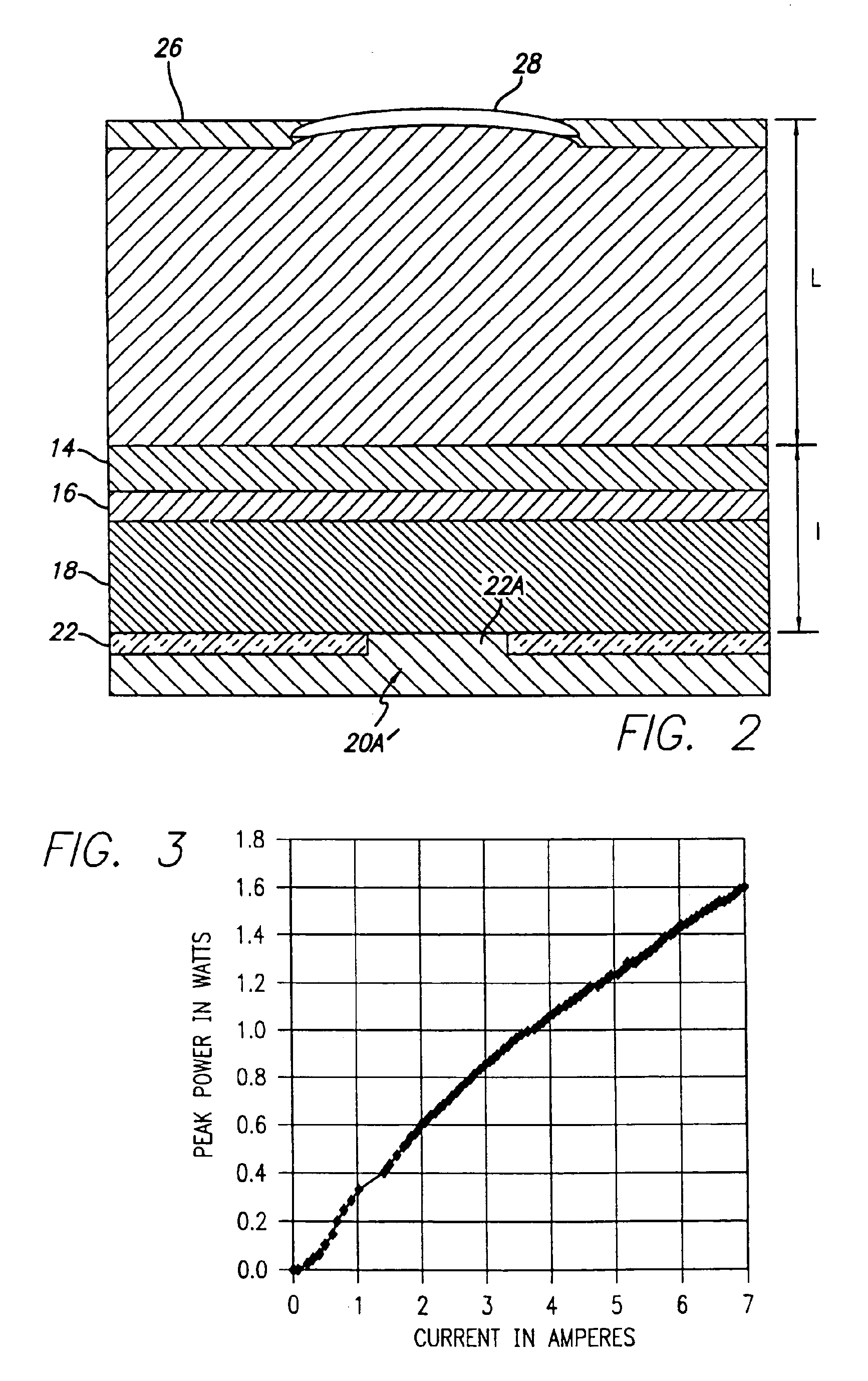

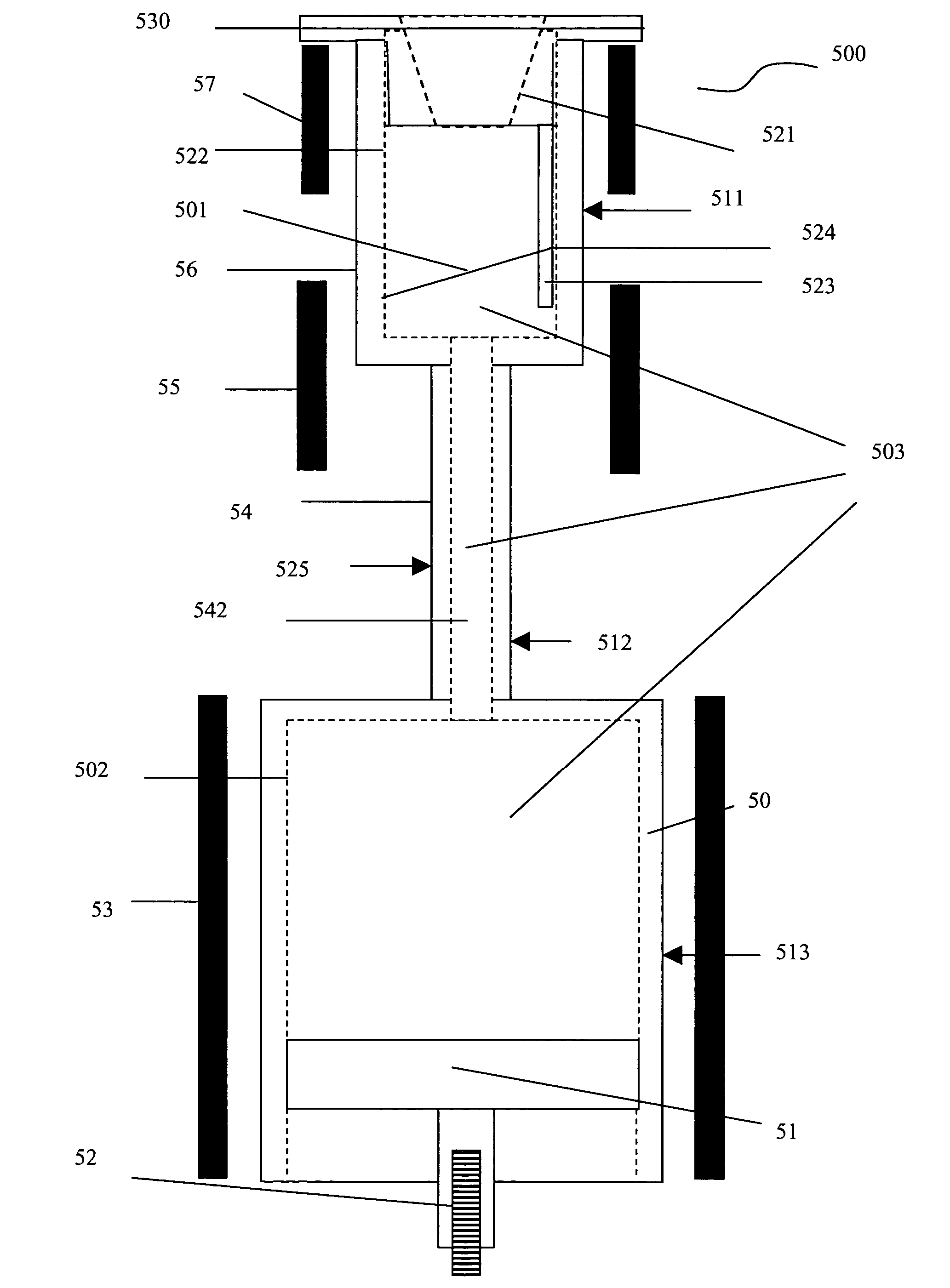

Coupled cavity high power semiconductor laser

InactiveUS20060029120A1Maximize circulating fundamental laser powerConvenient registrationOptical resonator shape and constructionSemiconductor lasersFundamental frequencyPartial reflection

An active gain region sandwiched between a 100% reflective bottom Bragg mirror and an intermediate partially reflecting Bragg mirror is formed on a lower surface of a supporting substrate, to thereby provide the first (“active”) resonator cavity of a high power coupled cavity surface emitting laser device. The reflectivity of the intermediate mirror is kept low enough so that laser oscillation within the active gain region will not occur. The substrate is entirely outside the active cavity but is contained within a second (“passive”) resonator cavity defined by the intermediate mirror and a partially reflecting output mirror, where it is subjected to only a fraction of the light intensity that is circulating in the gain region. In one embodiment, non-linear optical material inside each passive cavity of an array converts an IR fundamental wavelength of each laser device to a corresponding visible harmonic wavelength, and the external output cavity mirror comprises a Volume Bragg grating (VBG) or other similar optical component that is substantially reflective at the fundamental frequency and substantially transmissive at the harmonic frequency. The VBG used in an array of such devices may be either flat, which simplifies registration and alignment during manufacture, or may be configured to narrow the IR spectrum fed back into the active resonant cavity and to shape the spatial mode distribution inside the cavity, thereby reducing the size of the mode and compensating for any deformations in the semiconductor array.

Owner:ARASOR ACQUISITION +1

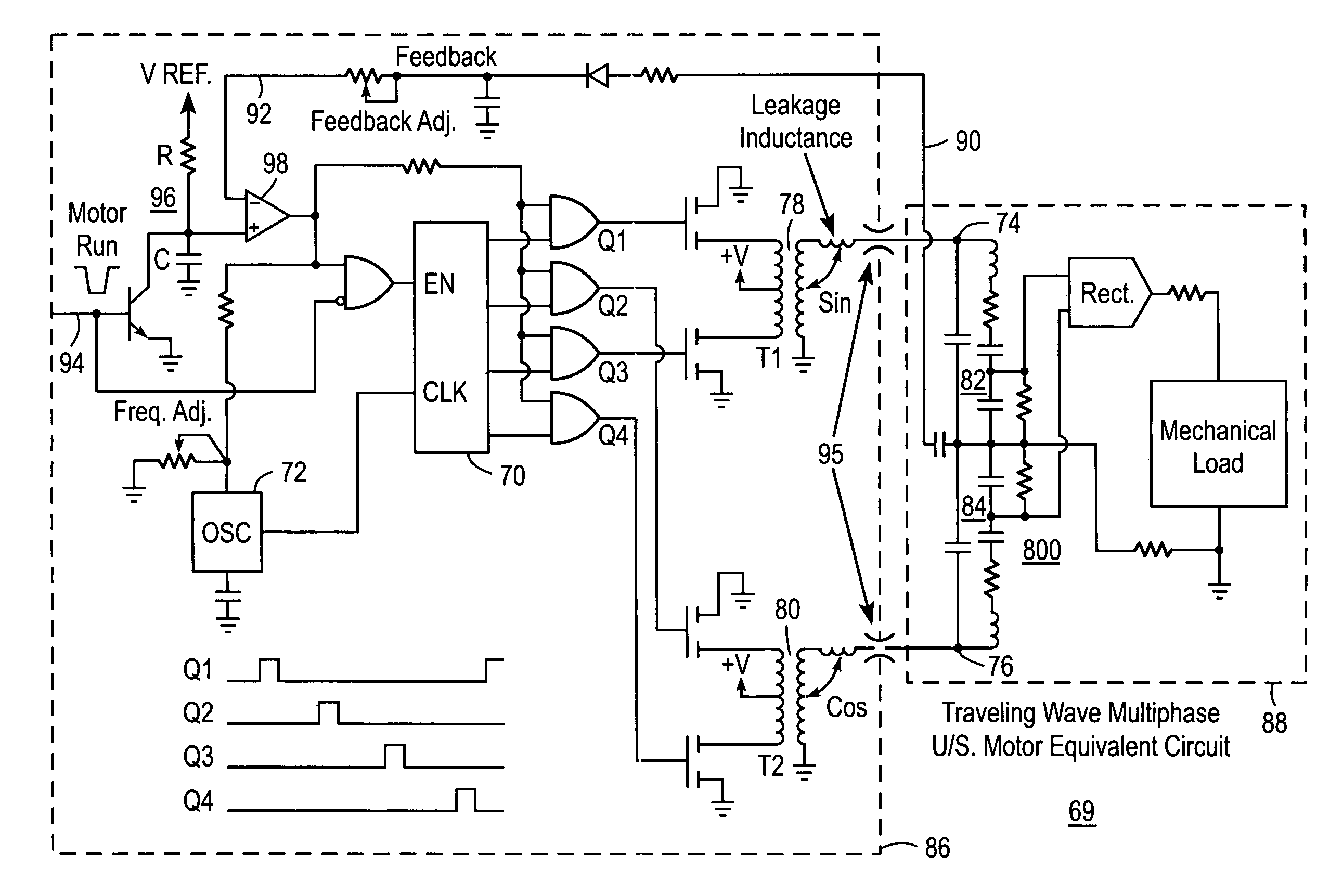

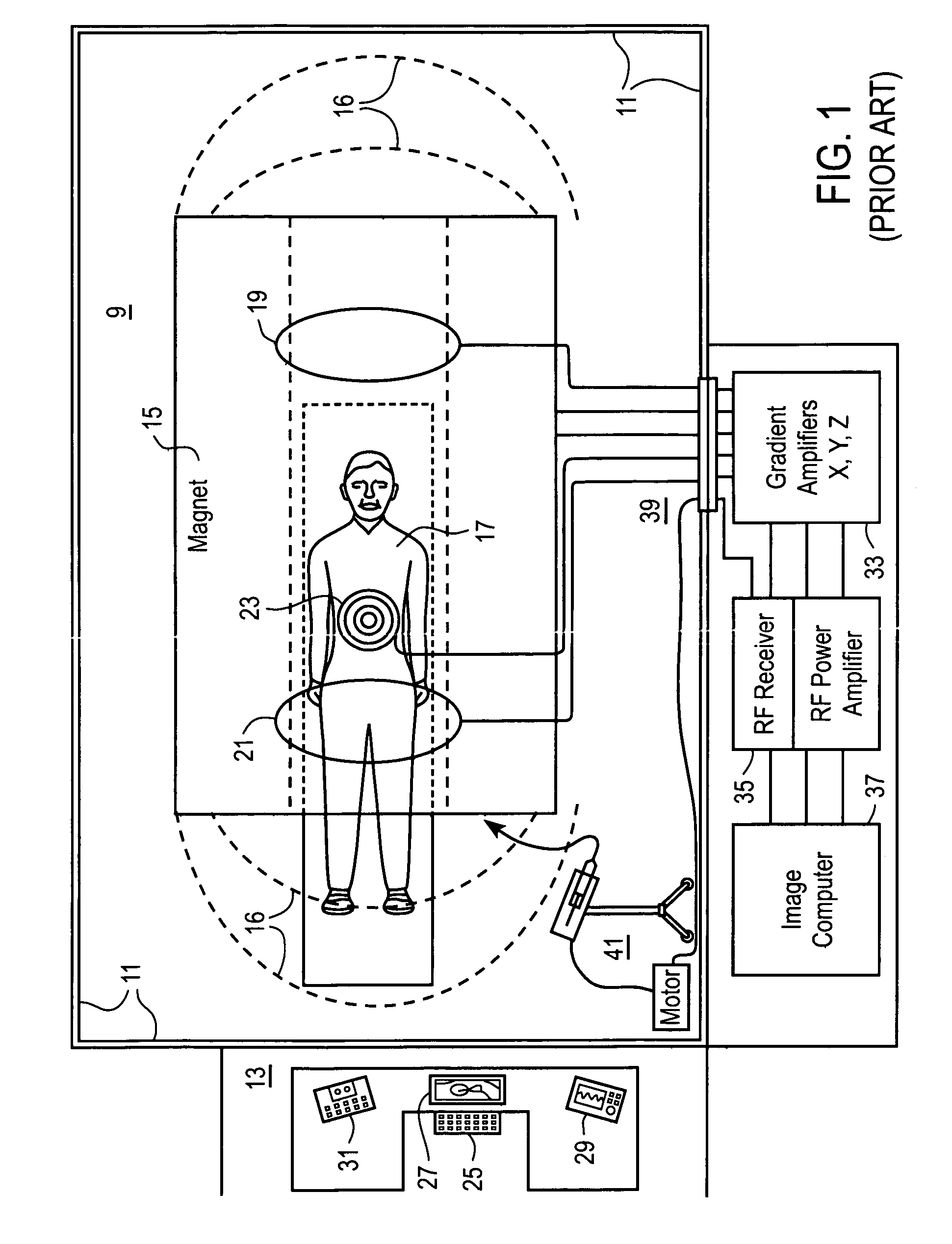

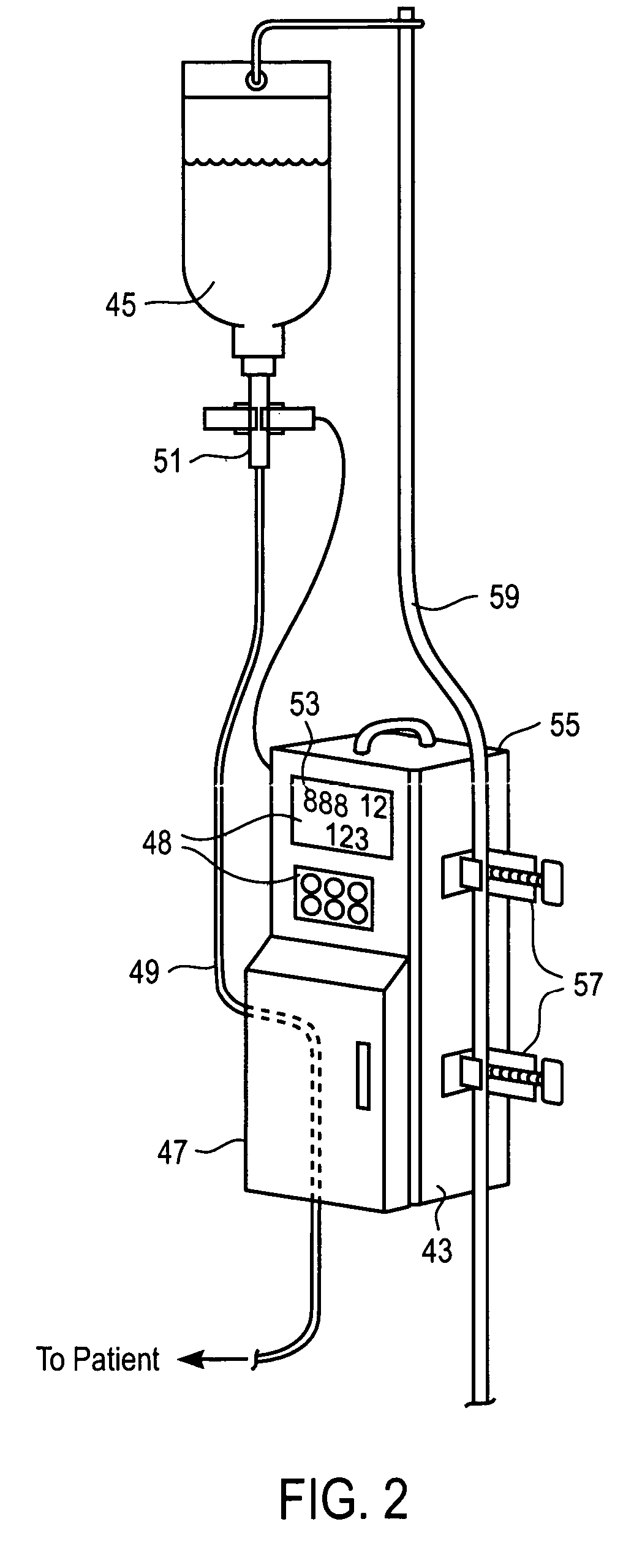

Liquid infusion apparatus

InactiveUS7553295B2Reduce materialEasy to controlDC motor speed/torque controlFlexible member pumpsPeristaltic pumpEngineering

Liquid infusion apparatus includes non-magnetic materials in a pumping structure and ultrasonic drive motor therefor, and in a controller that supplies drive signals to the motor to facilitate convenient operation in intense magnetic fields without distorting the magnetic fields and without radiating objectionable radio-frequency interference. A non-MRI-compatible liquid infusion apparatus is temporarily replaced with MRI-compatible, non-magnetic liquid infusion apparatus without disconnecting a patient from an installed intravenous infusion set to continue infusing liquid within the MRI environment. The pumping apparatus operates on a segment of a liquid conduit that is mounted in tension between a linear peristaltic pump and platen, with associated safety interlocks to assure proper operation of infusing liquid into a patient compatibly with conditions in an MRI environment. Drive circuitry generates low-harmonic signals for operating the ultrasonic motor at variable speeds to compensate for flow rate discontinuities through the peristaltic pumping cycles.

Owner:IRADIMED CORP

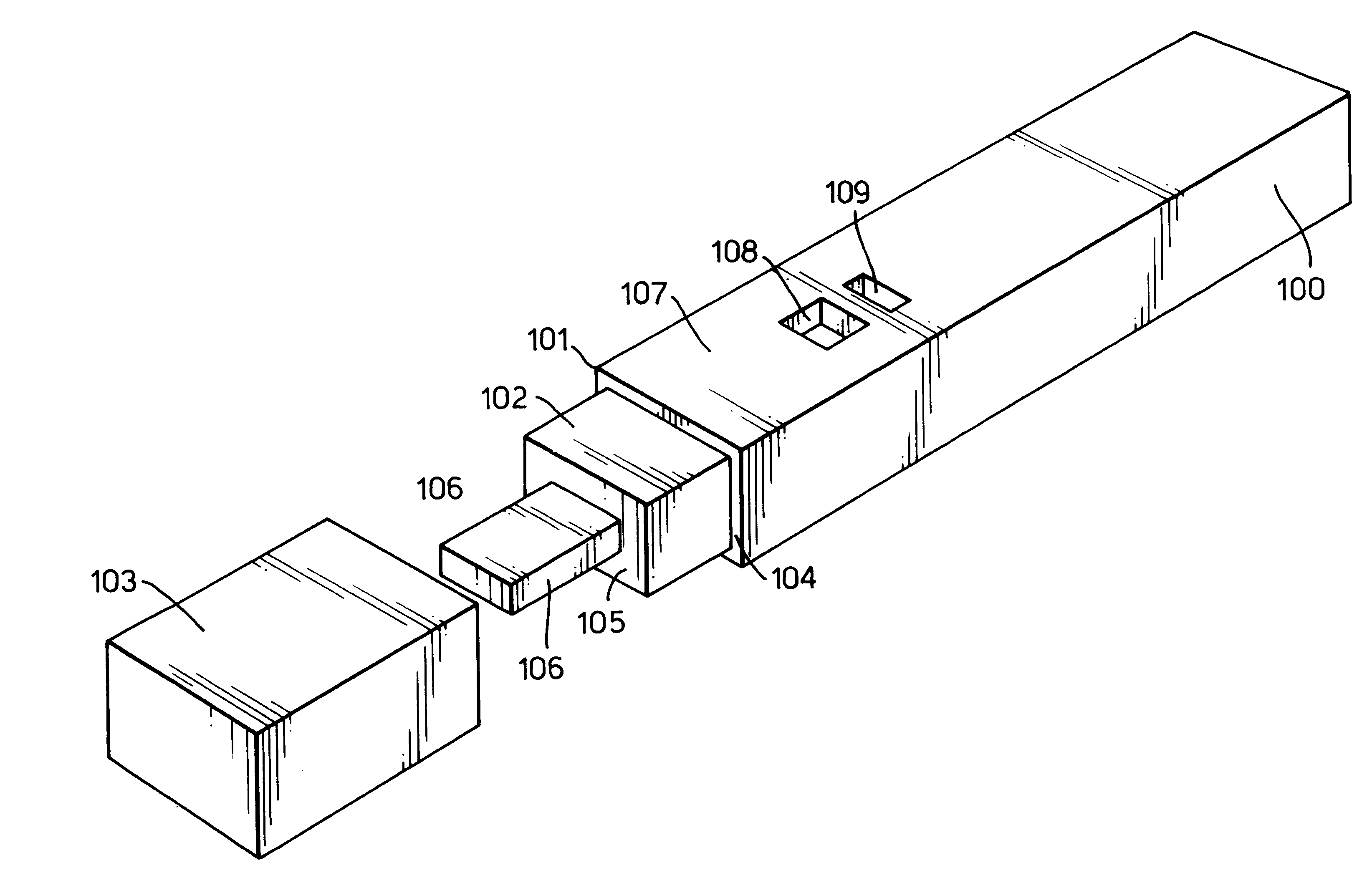

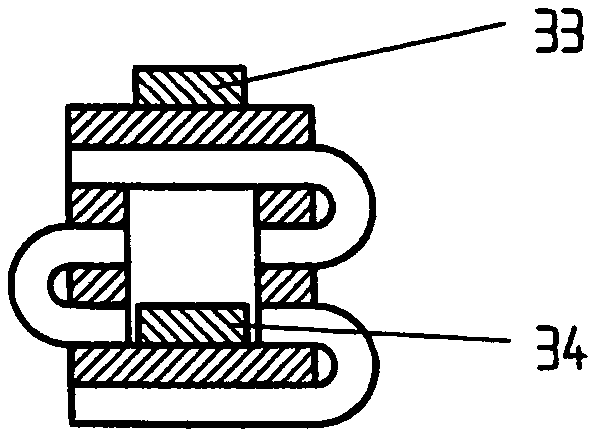

Multilayer circuit including stacked layers of insulating material and conductive sections

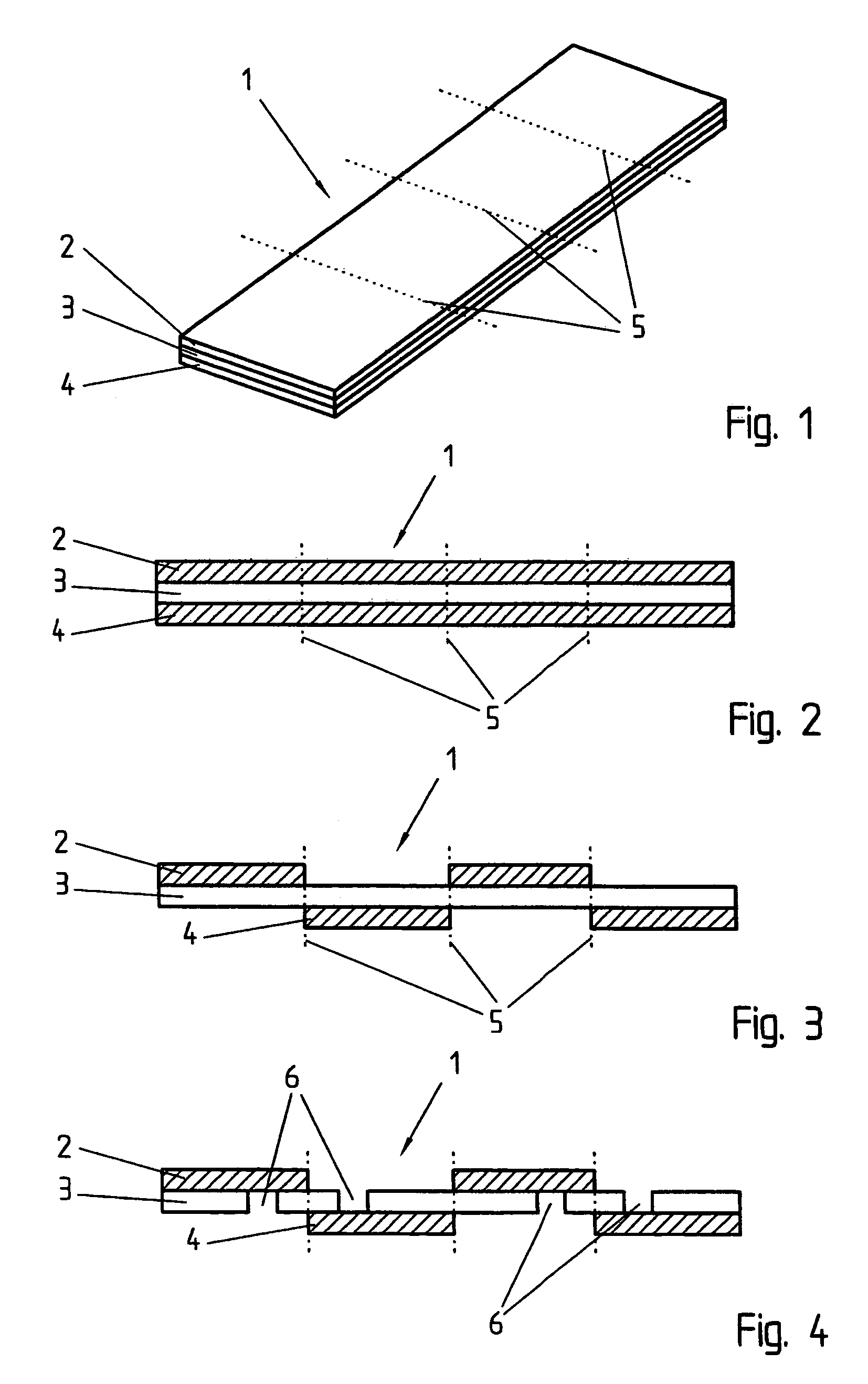

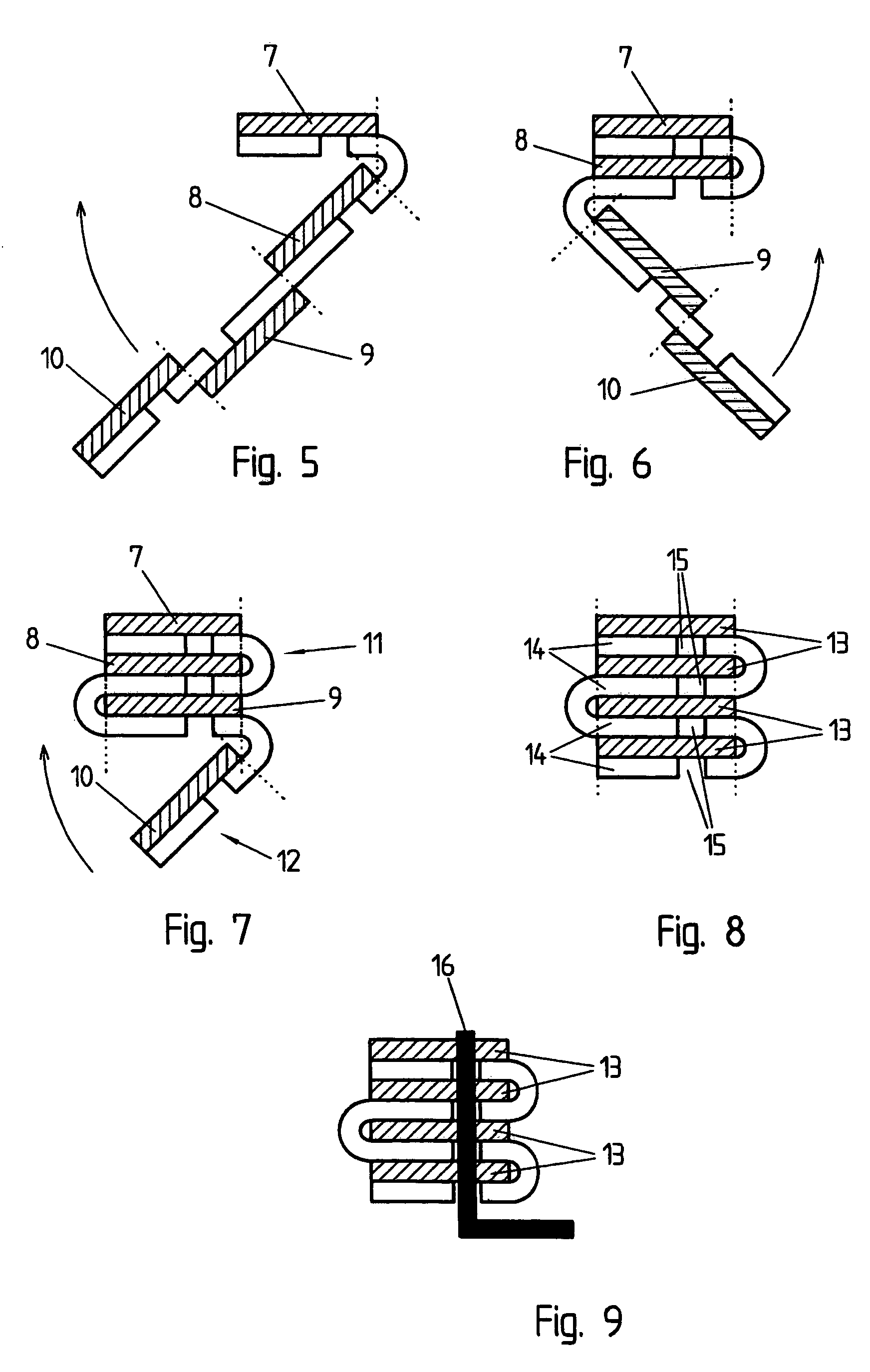

InactiveUS7205655B2Improve power densityEasy to manufactureSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsElectrical conductorTransformer

The invention relates to the manufacturing of a multilayer structure and especially it relates to the manufacturing of a three-dimensional structure and its use as an electronics assembly substrate and as a winding for transformers and inductors. When a multilayer structure is manufactured by folding a conductor-insulator-conductor laminate, where the conductor layers to be separated from each other follow each other on opposite sides of the conductor-insulator-conductor laminate in the sections following each other and where the insulator has been removed from the places where the conductor layers are to be connected together after folding, it is possible to manufacture a wide range of three-dimensional multilayer structures where the volume occupied by the windings over the total volume can be maximized. Alternatively, by using the method it is also possible to manufacture a multilayer structure where components have been buried inside. The method makes it also possible to make connections between layers in a flexible manner. Among other issues, the method can be easily automated for mass-production.

Owner:SCHAFFNER EMV AG

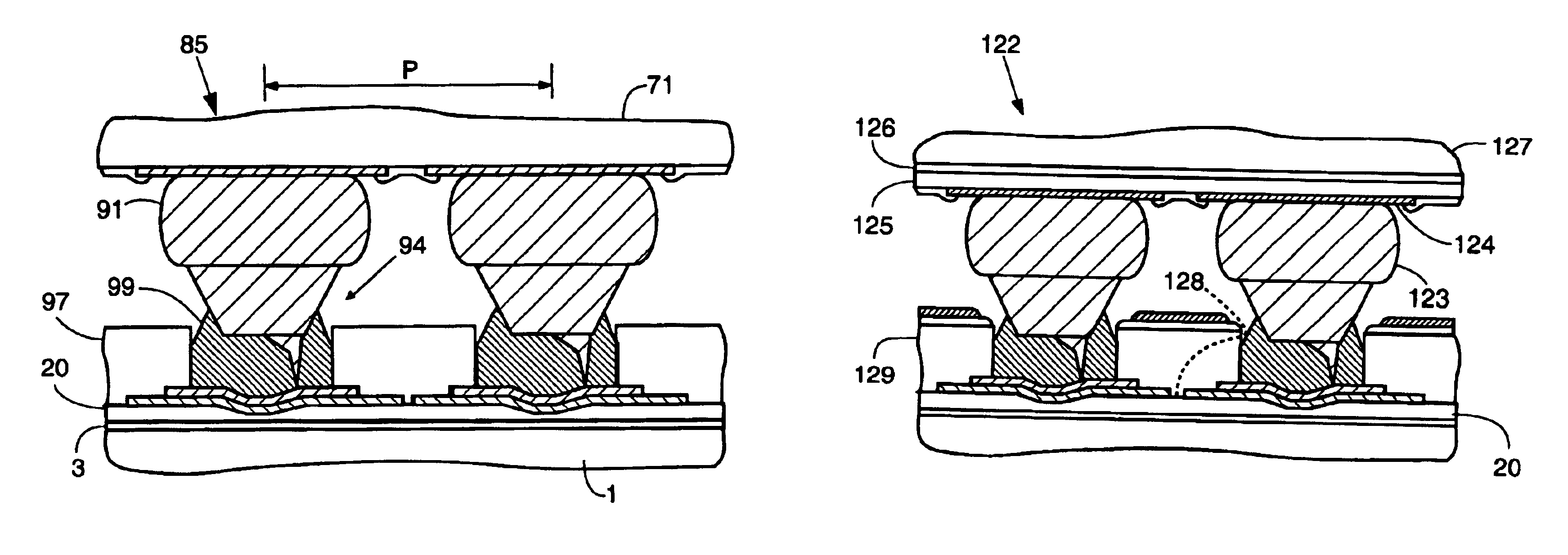

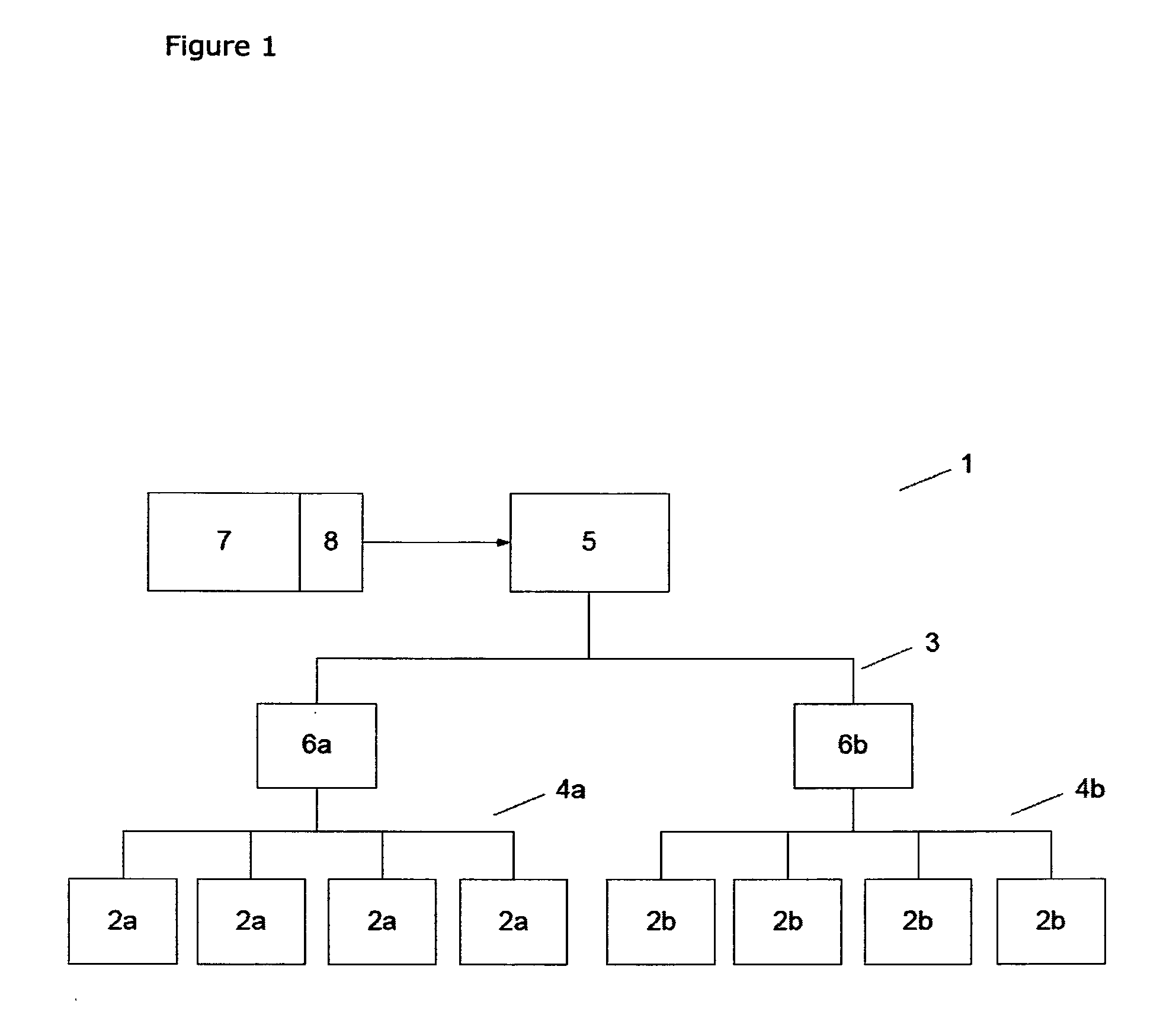

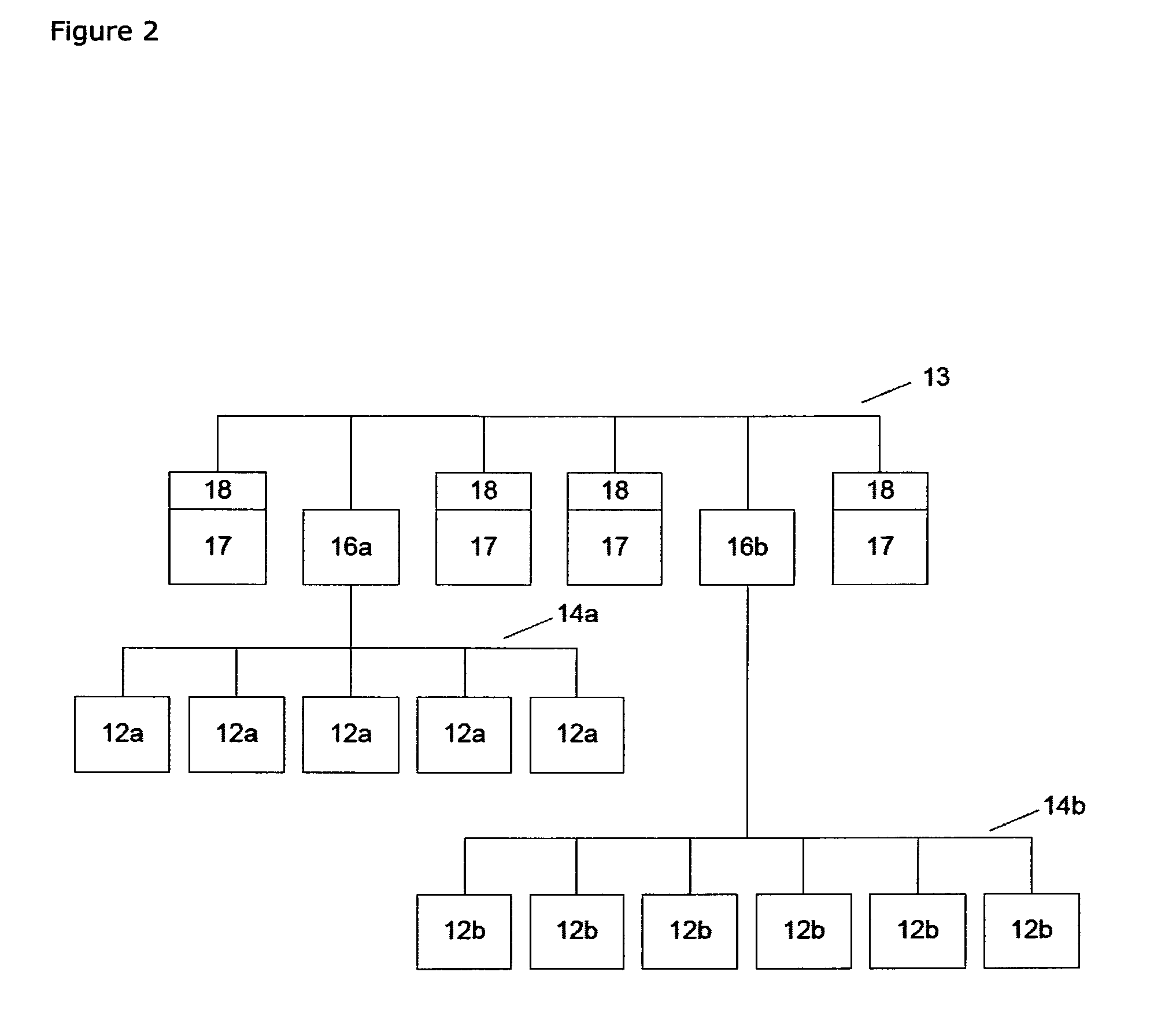

Electronic system modules and method of fabrication

InactiveUS6927471B2Good dimensional stabilityLow costPrinted circuit assemblingFinal product manufactureDielectricEngineering

This specification describes techniques for manufacturing an electronic system module. The module includes flexible multi-layer interconnection circuits with trace widths of 5 microns or less. A glass panel manufacturing facility, similar to those employed for making liquid crystal display, LCD, panels is used to fabricate the interconnection circuits. A polymer base layer is formed on a glass carrier with an intermediate release layer. Alternate layers of metal and dielectric are formed on the base layer, and patterned to create an array of multi-layer interconnection circuits on the glass panel. A thick layer of polymer is deposited on the interconnection circuit, and openings formed at input / output (I / O) pad locations. Solder paste is deposited in the openings to form wells filled with solder. After dicing the glass carrier to form separated interconnection circuits, IC chips are stud bumped and assembled using flip chip bonding, wherein the stud bumps on the components are inserted into corresponding wells on the interconnection circuits. The IC chips are tested and reworked to form tested circuit assemblies. Methods for connecting to testers and to other modules and electronic systems are described. Module packaging layers are provided for hermetic sealing and for electromagnetic shielding. A blade server embodiment is also described.

Owner:SK HYNIX INC

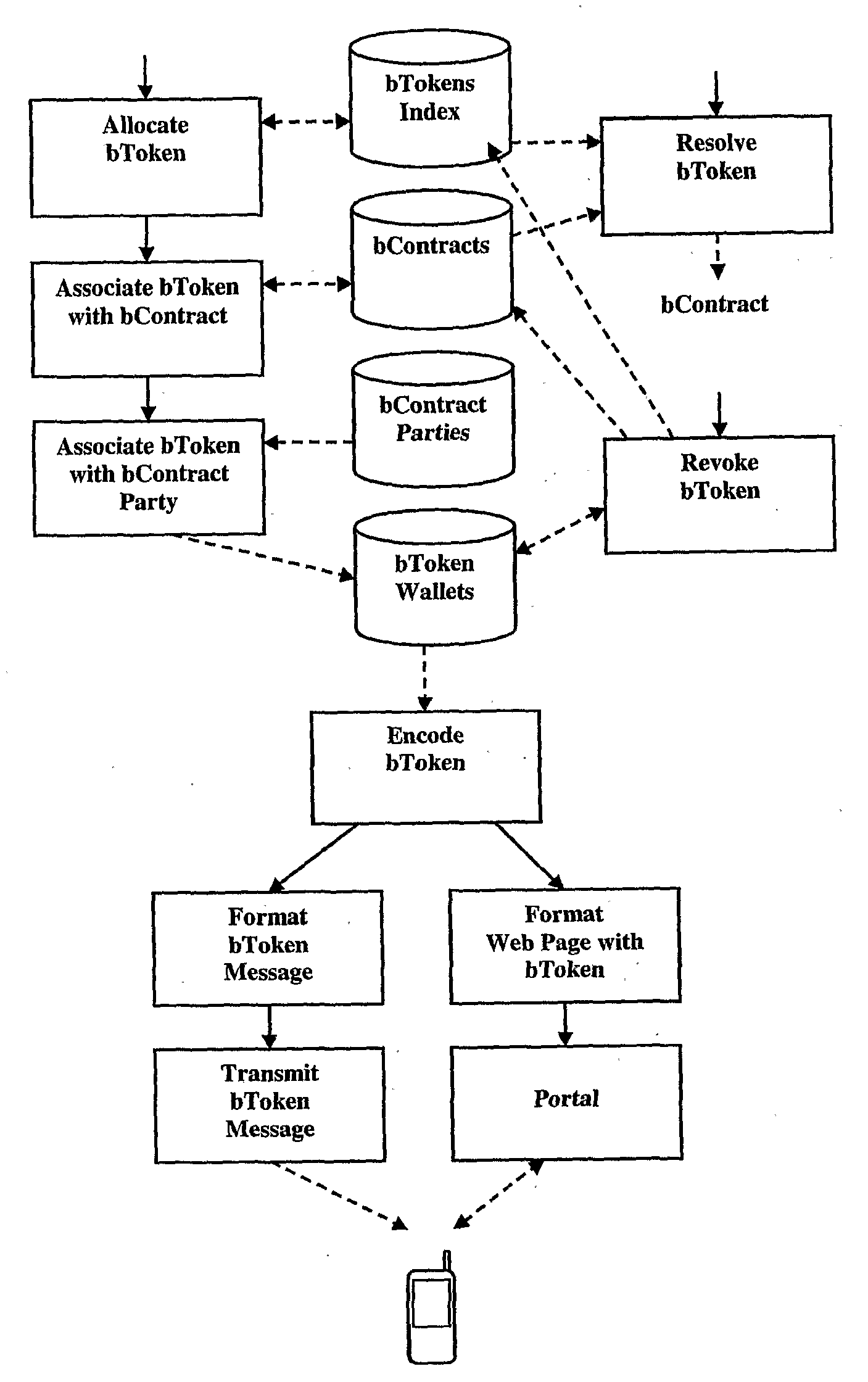

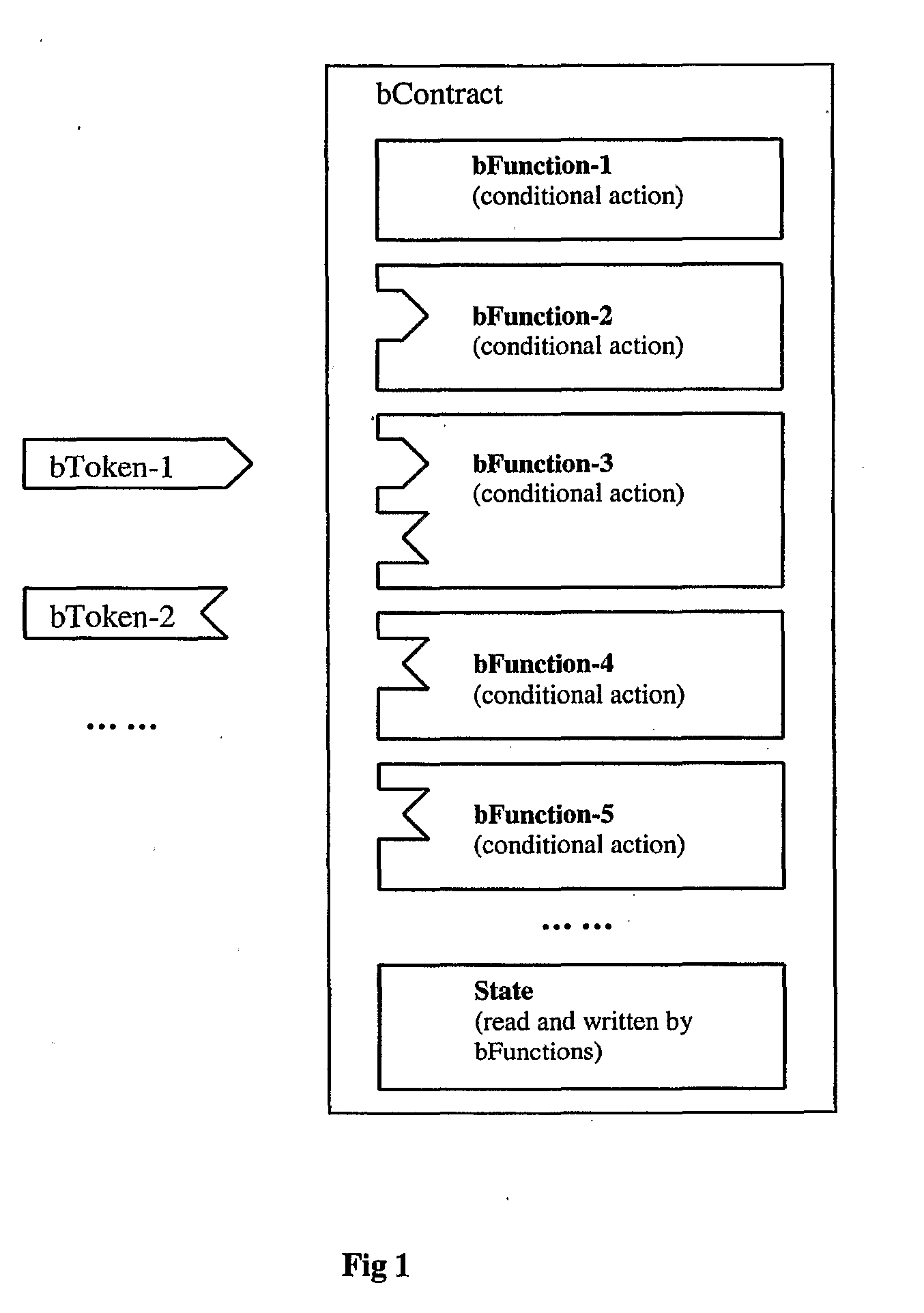

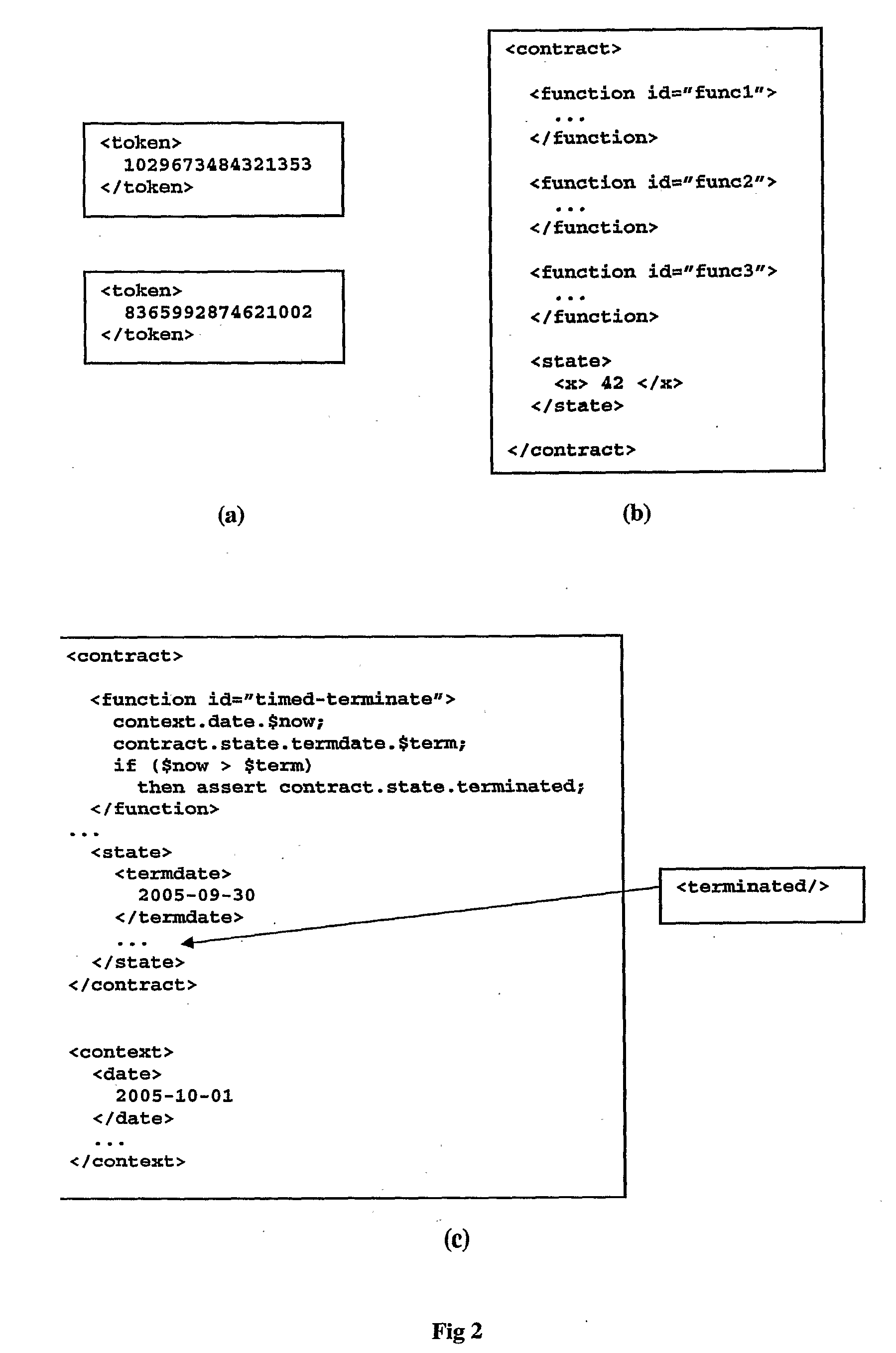

Electronic Commerce System, Method and Apparatus

InactiveUS20090125387A1Conveniently formEfficiently conductAdvertisementsReservationsOperating systemE-commerce

An electronic commerce method that includes publishing an offer for a product or service, receiving the published offer and conditionally accepting the offer, and forwarding the conditional acceptance to a matching processor to request the product or service. The matching processor receives the conditional acceptance by the matching processor, determines whether conditions present in the conditional acceptance can be fulfilled, and forwards at least one option for acceptance. The at least one option for selection is displayed and the user, selects any one of the at least one options. Upon selection, a token is provided to the user. The token is configured to be used to redeem the service or product, be transferable to another user device, or to be stored for future redemption of the product or service.

Owner:MOBILE TECH HLDG LTD +1

Food cooking container provided with a thermal indicator

ActiveUS8783947B2Well formedConveniently formedThermometer detailsSealingThermal energyElectronic temperature

A food cooking container provided with an electronic temperature monitoring device, the electronic temperature monitoring device being powered by converting thermal energy into electrical energy by the parasitic exploitation of temperature differences generated between the hot container and a heat dissipating metal mass, and activates a device in the form of a piezoelectric buzzer or LEDs, to indicate pre-set safety temperature limits. The electronic temperature monitoring device includes an electronic thermoelectric harvesting sensor for converting thermal energy into electrical energy via its electronic thermoelectric harvesting system.

Owner:BALLARINI PAOLO E FILI SPA

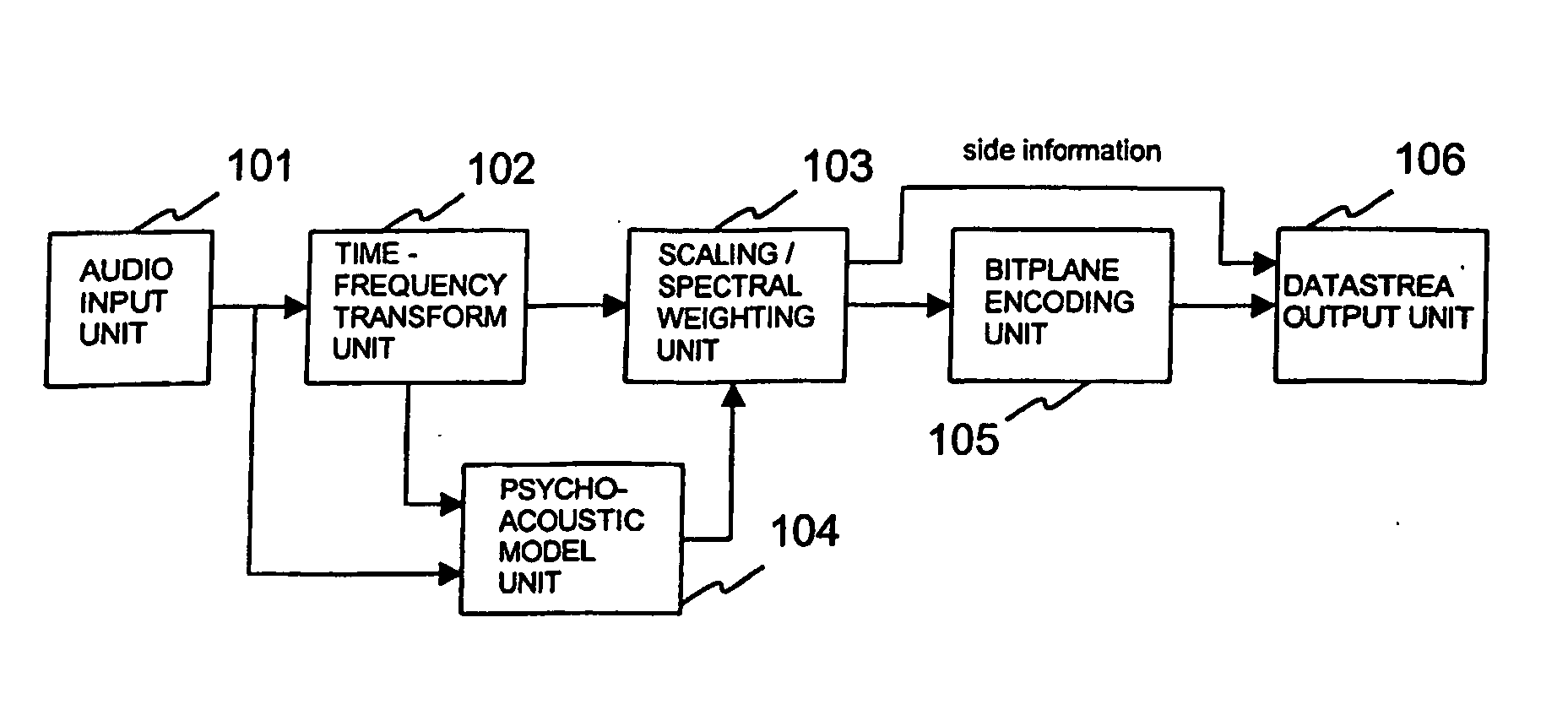

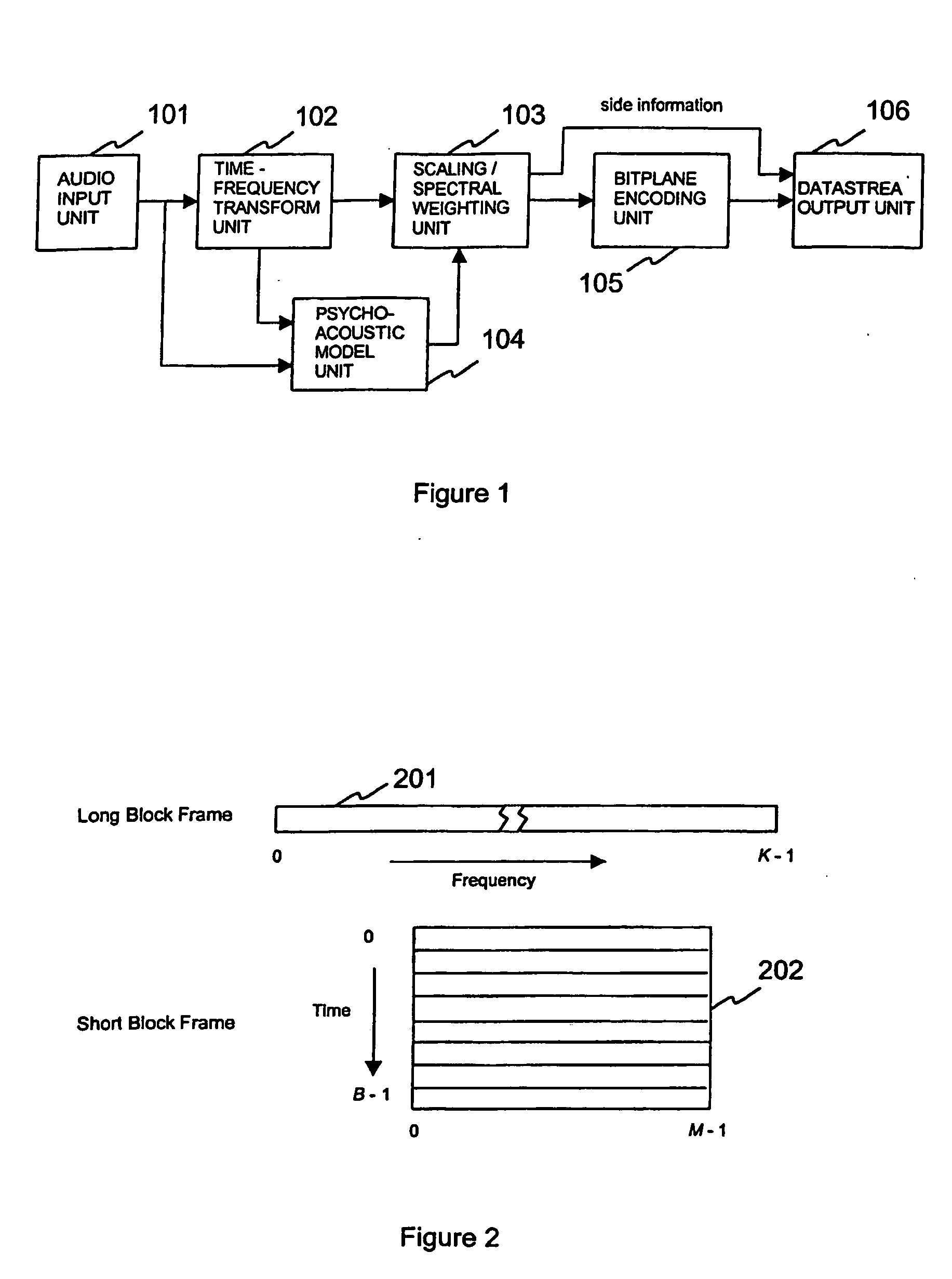

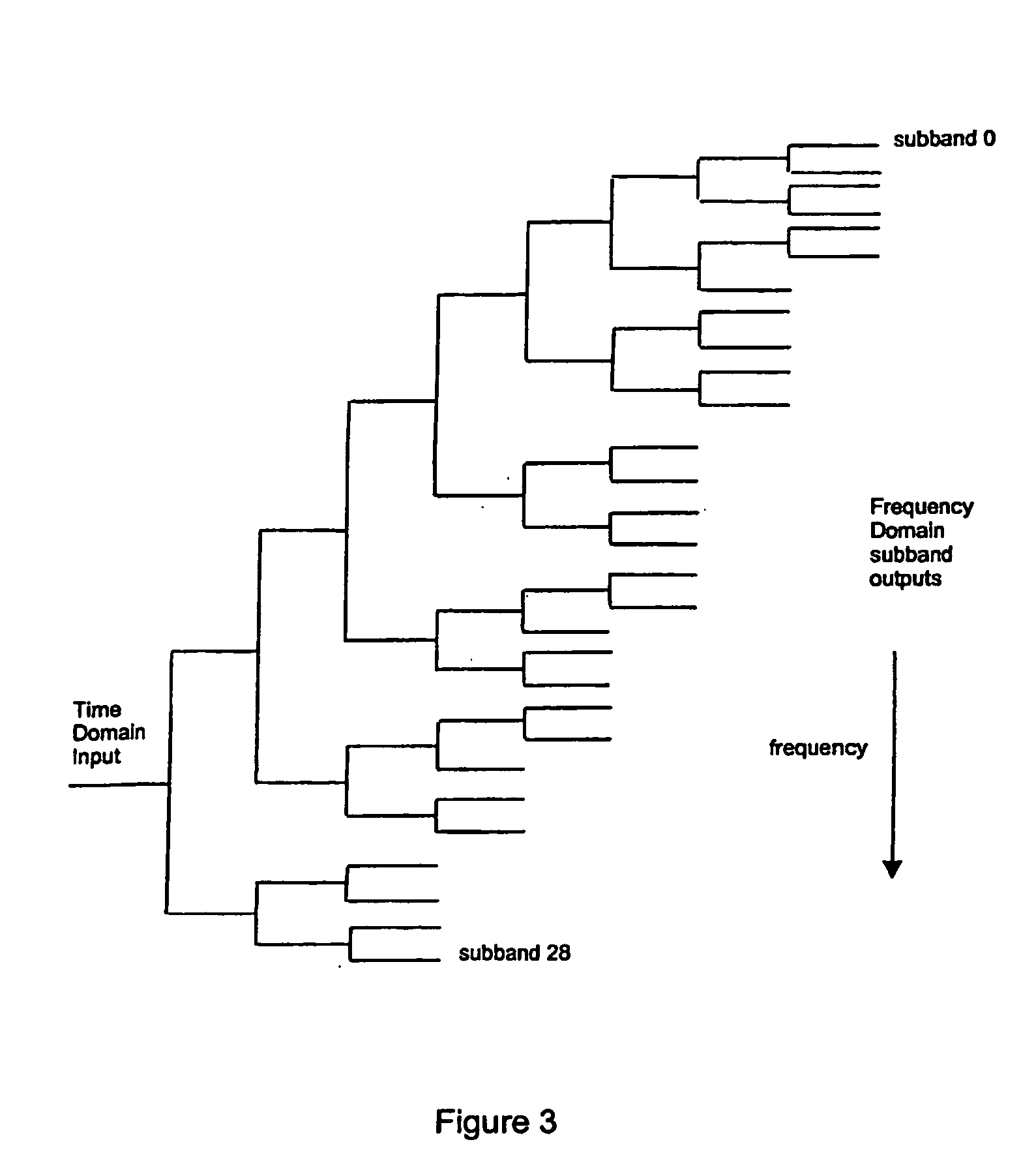

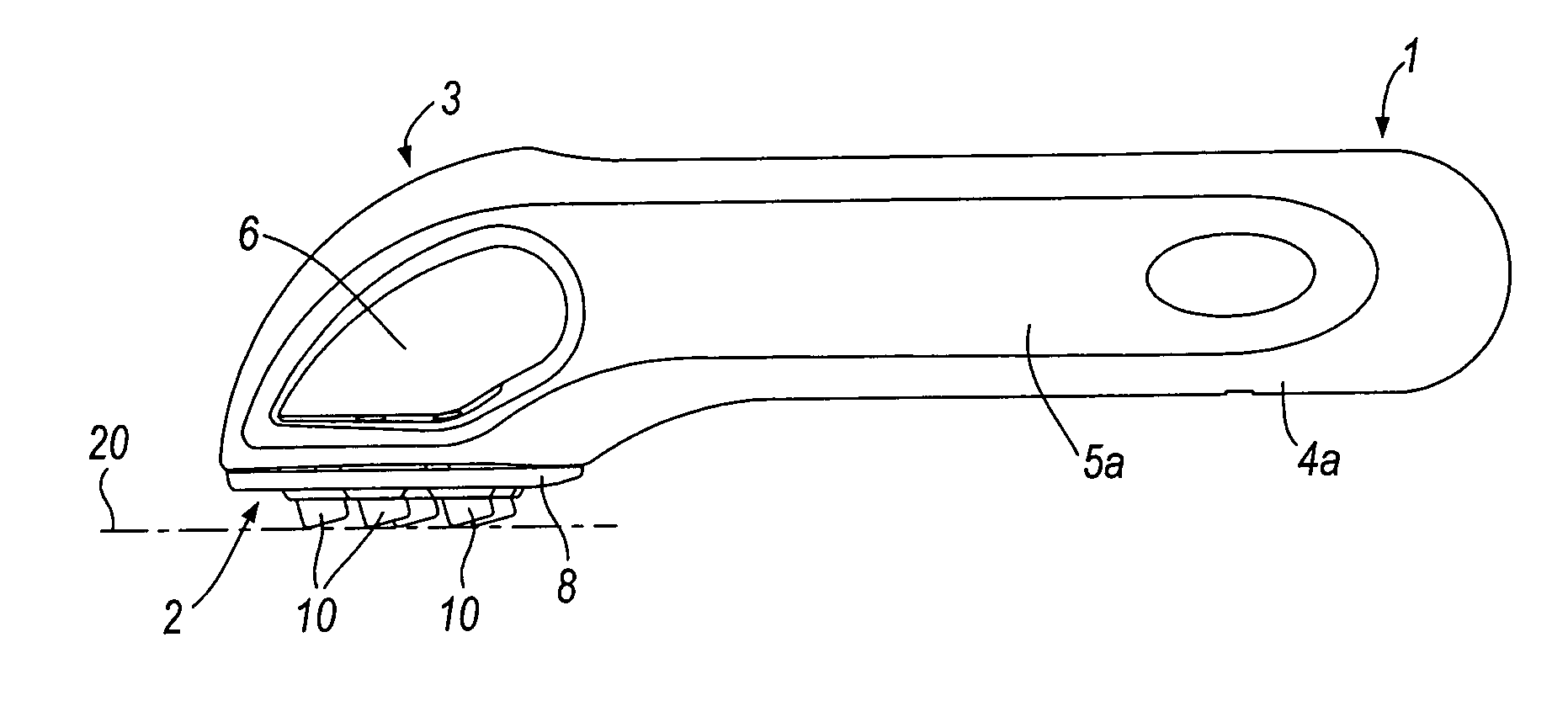

Audio compression

InactiveUS20050231396A1Low compute complexityHigh efficiencySpeech analysisCode conversionFrequency domainAudio frequency

Owner:SCALA TECH

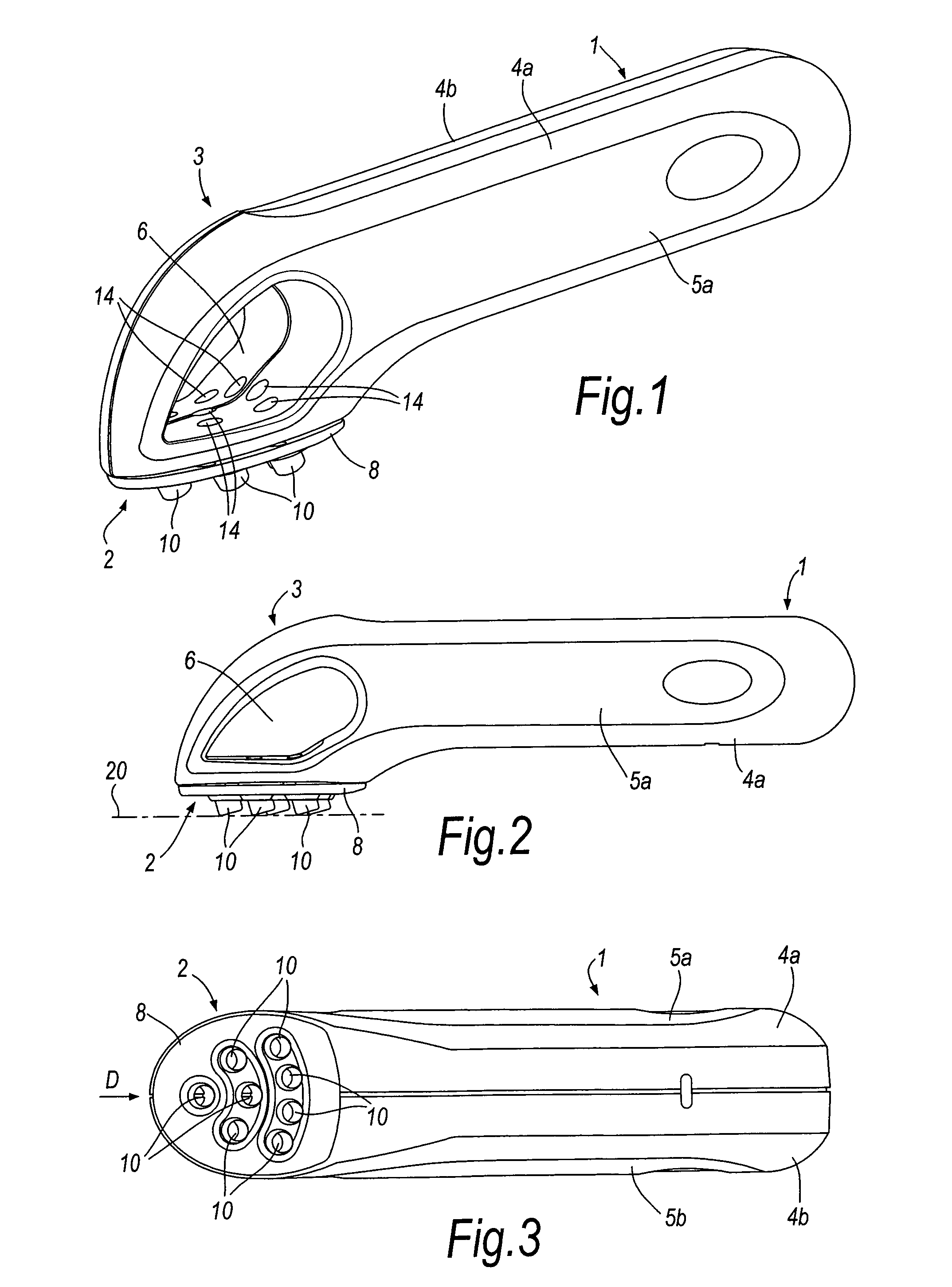

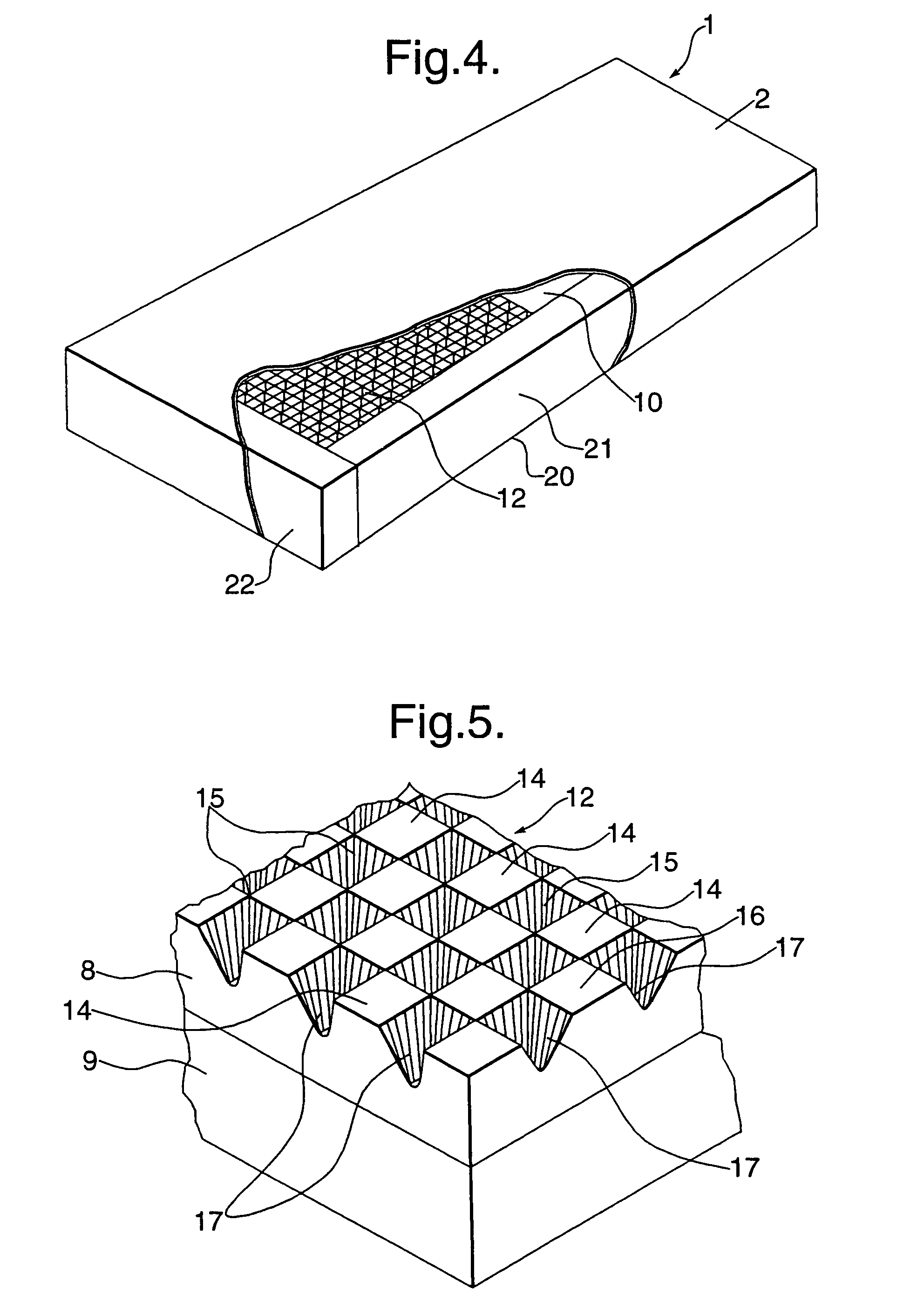

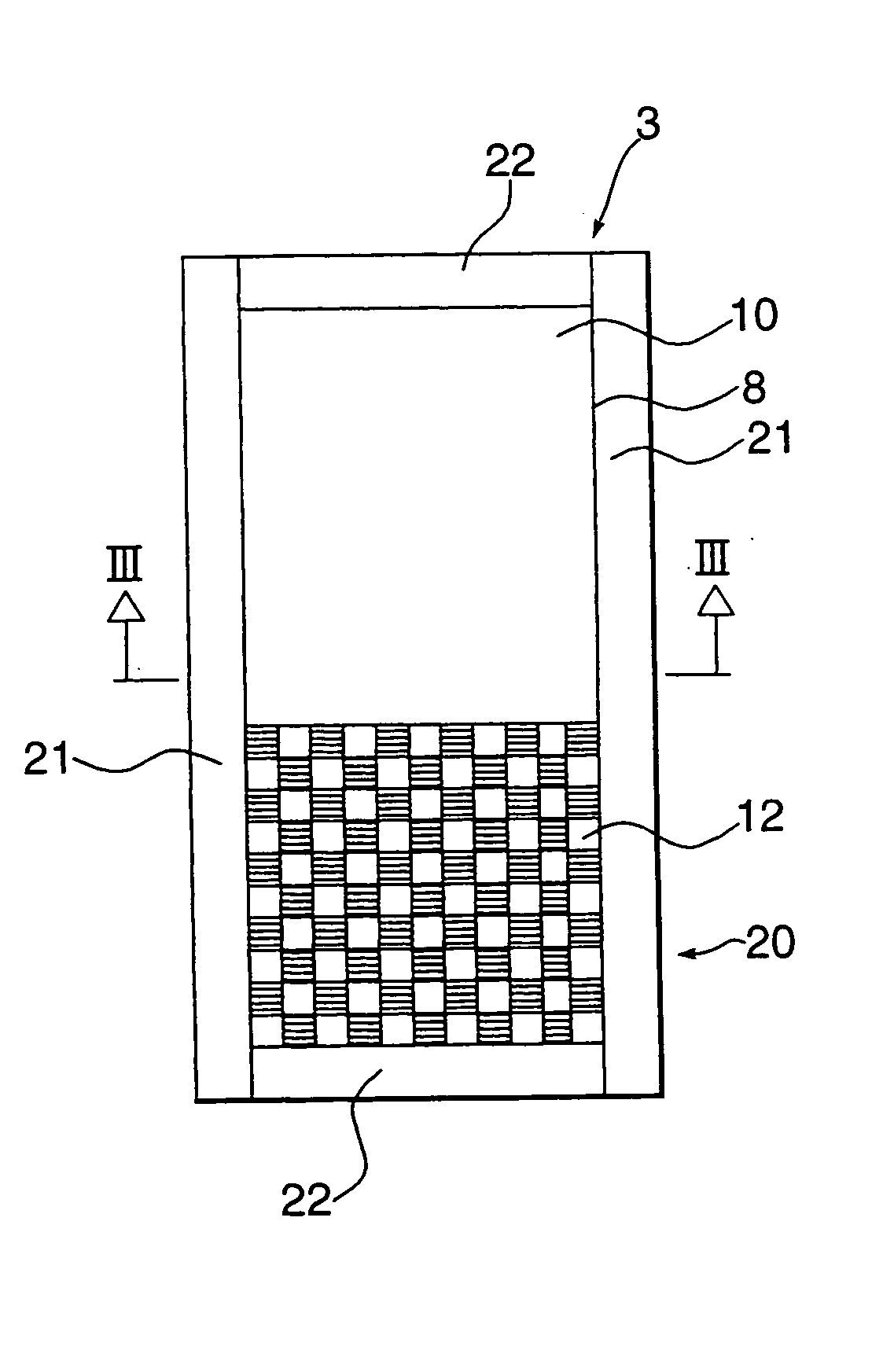

Skin treating device

ActiveUS8540731B2Facilitate grippingFacilitate movementAbrasive surgical cuttersBiomedical engineeringHand held devices

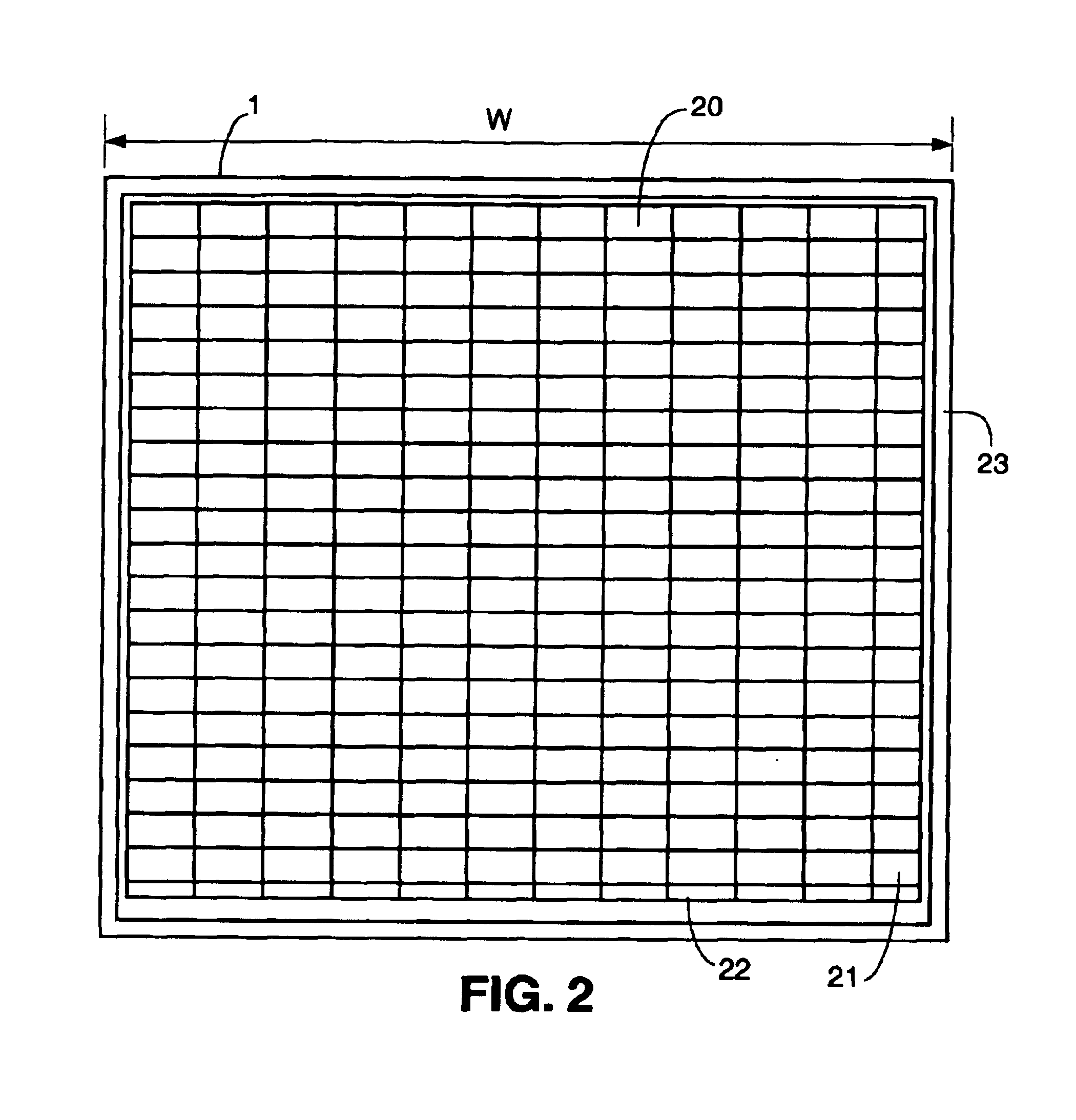

A hand held device for removing hard skin from calluses comprises a handle (1) and a cutting head (2) having a base plate (8), and several tubular cutting elements (10) inclined so that their cutting edges lie in inclined planes at an angle of 5° to 45° to a skin contact plane defined by the extremities of the cutting elements. The cutting elements can be arranged in an array of staggered rows.

Owner:LRC PROD LTD

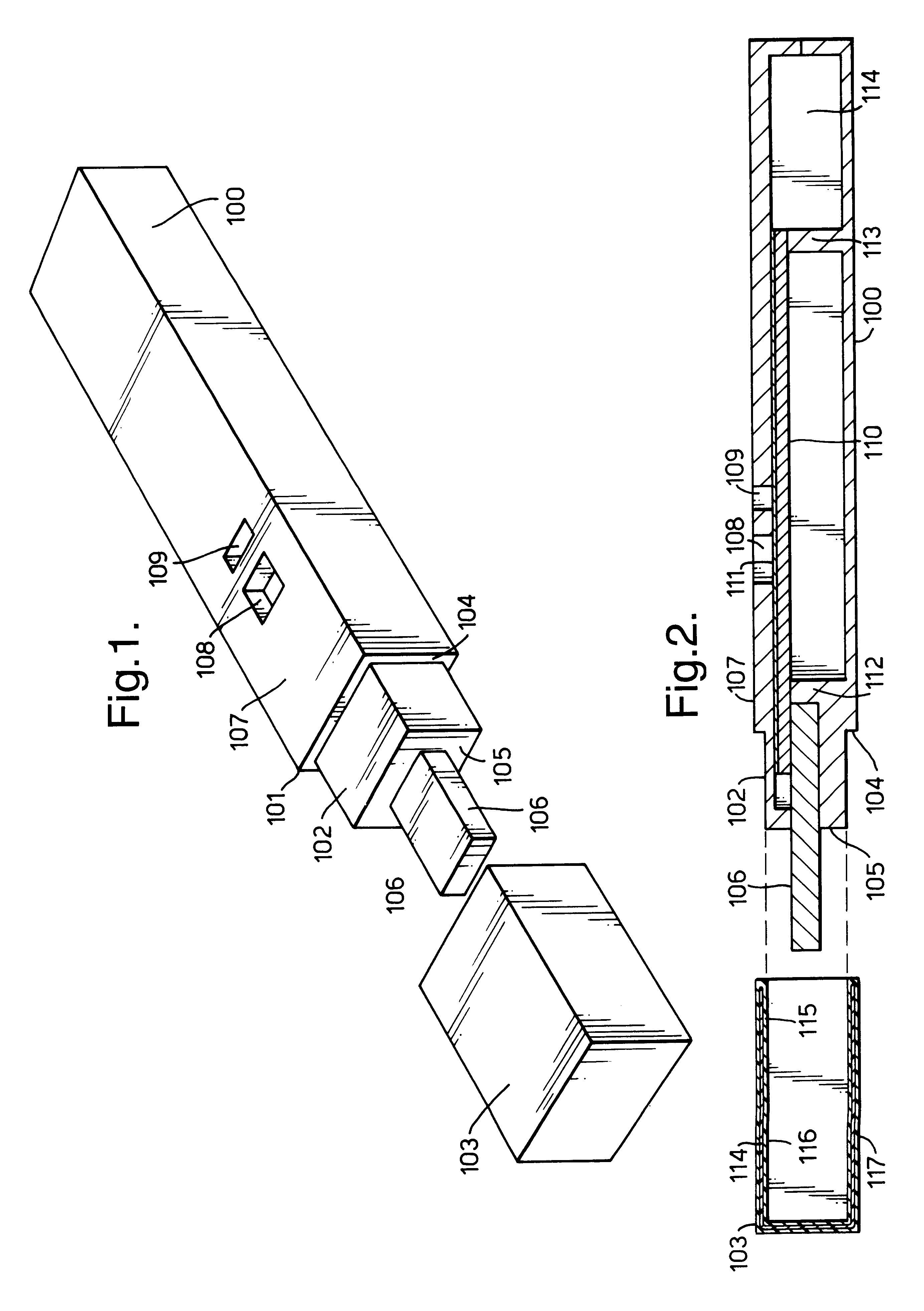

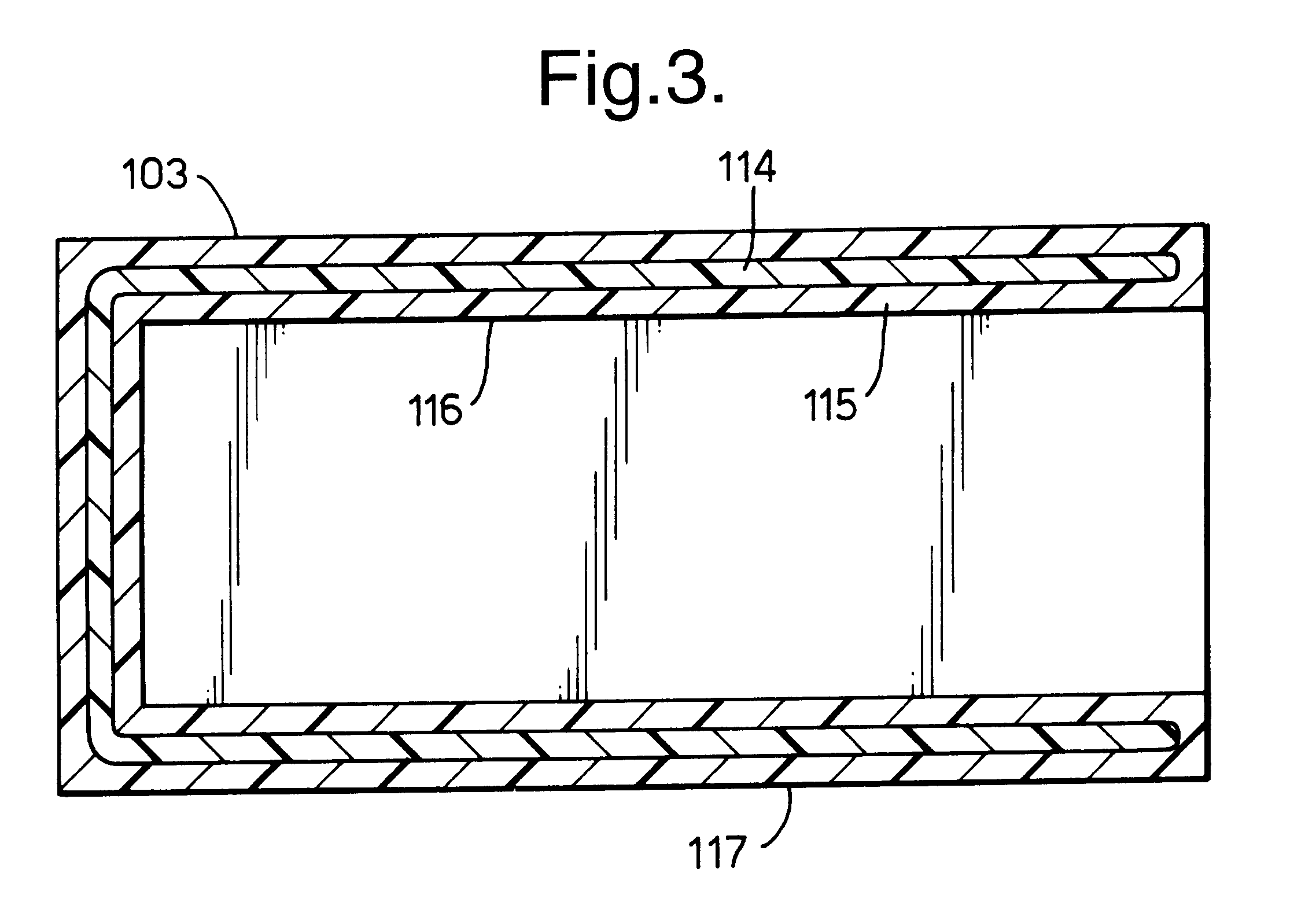

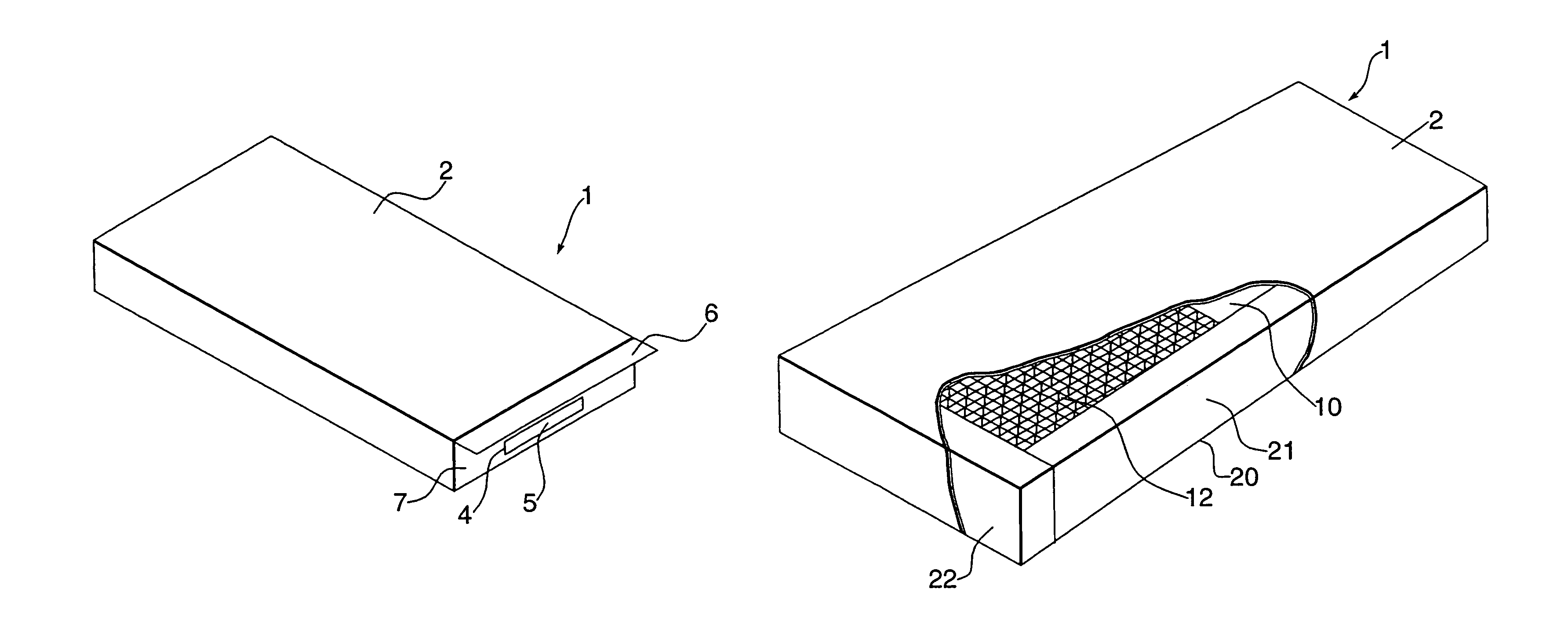

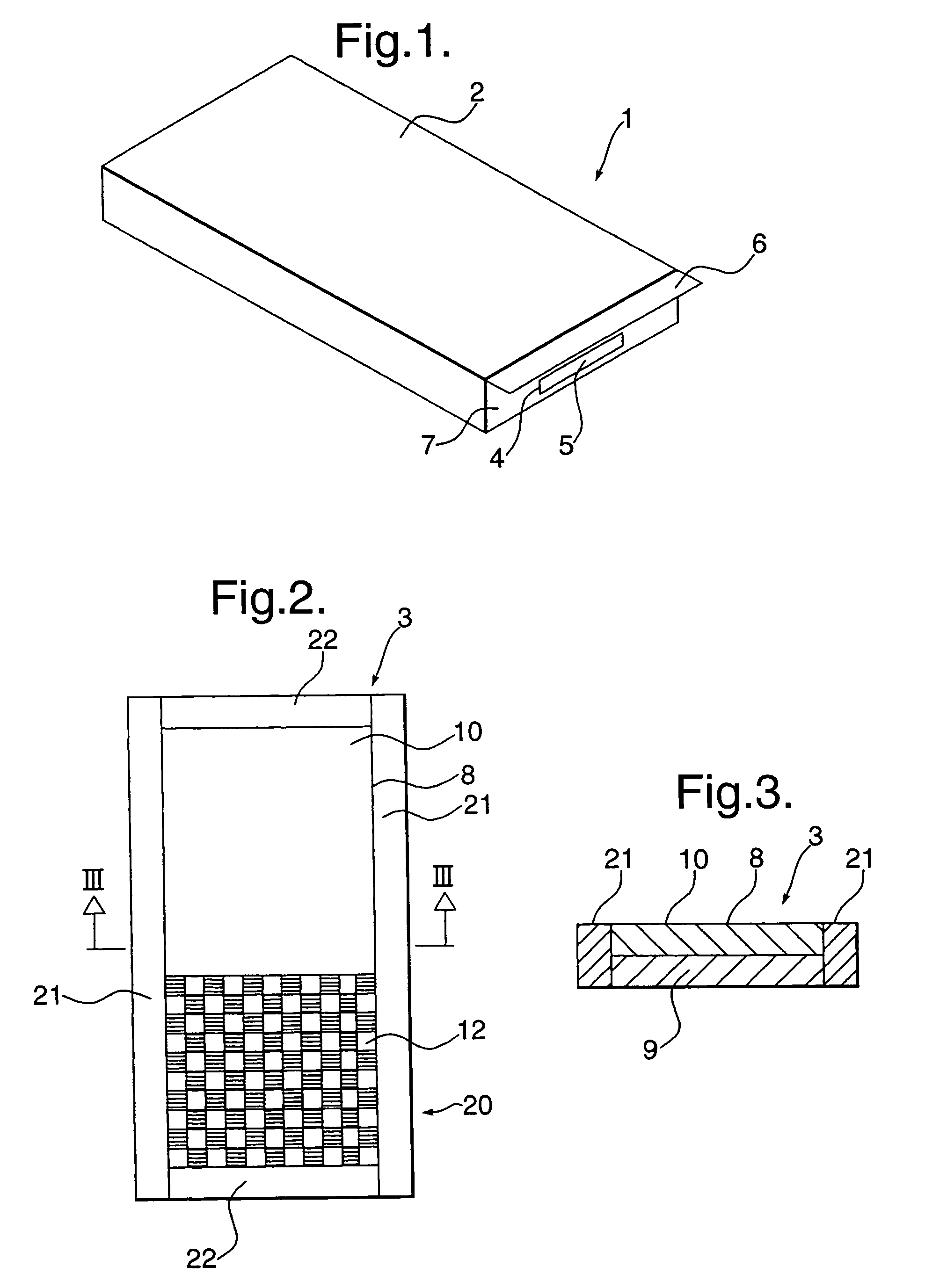

Mattress

InactiveUS7059001B2Conveniently formedPoint becomes highStuffed mattressesSpring mattressesEngineeringMechanical engineering

A mattress comprises a sealed outer casing within which is mounted a resilient support formed by a composite foam core. At least an upper portion of the resilient support is formed by a visco-elastic foam. A vent is provided in a side wall of the casing and is covered by a filter which prevents ingress of bacteria into the cover. A flap is mounted on the cover and in use extends down over the vent to prevent the filter being damaged by fluids.

Owner:LANCASTRIA

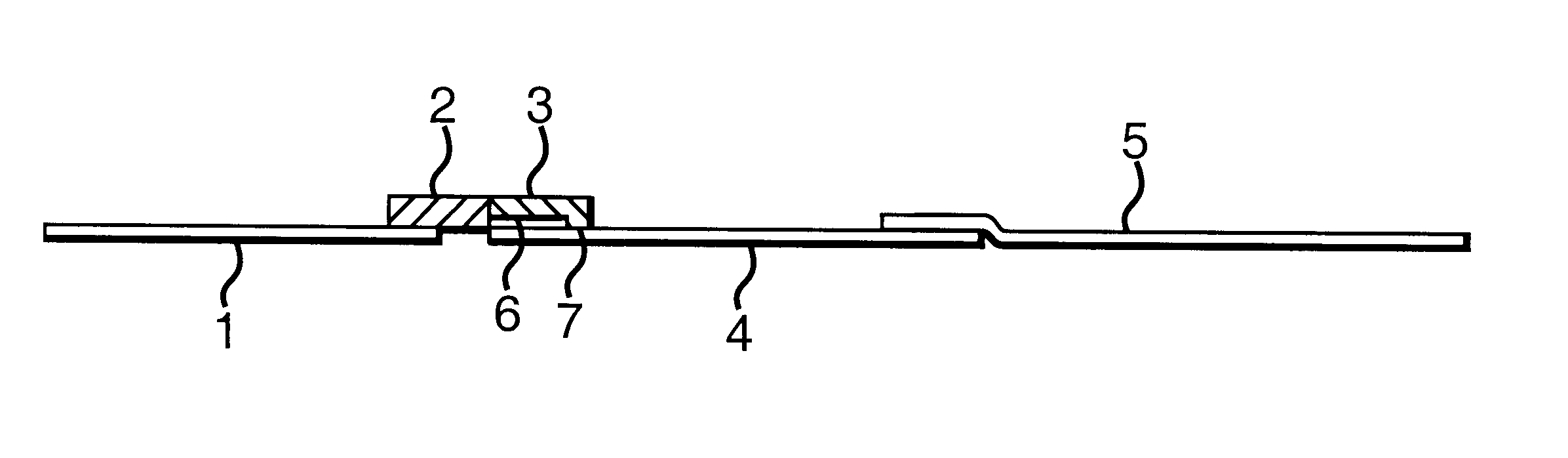

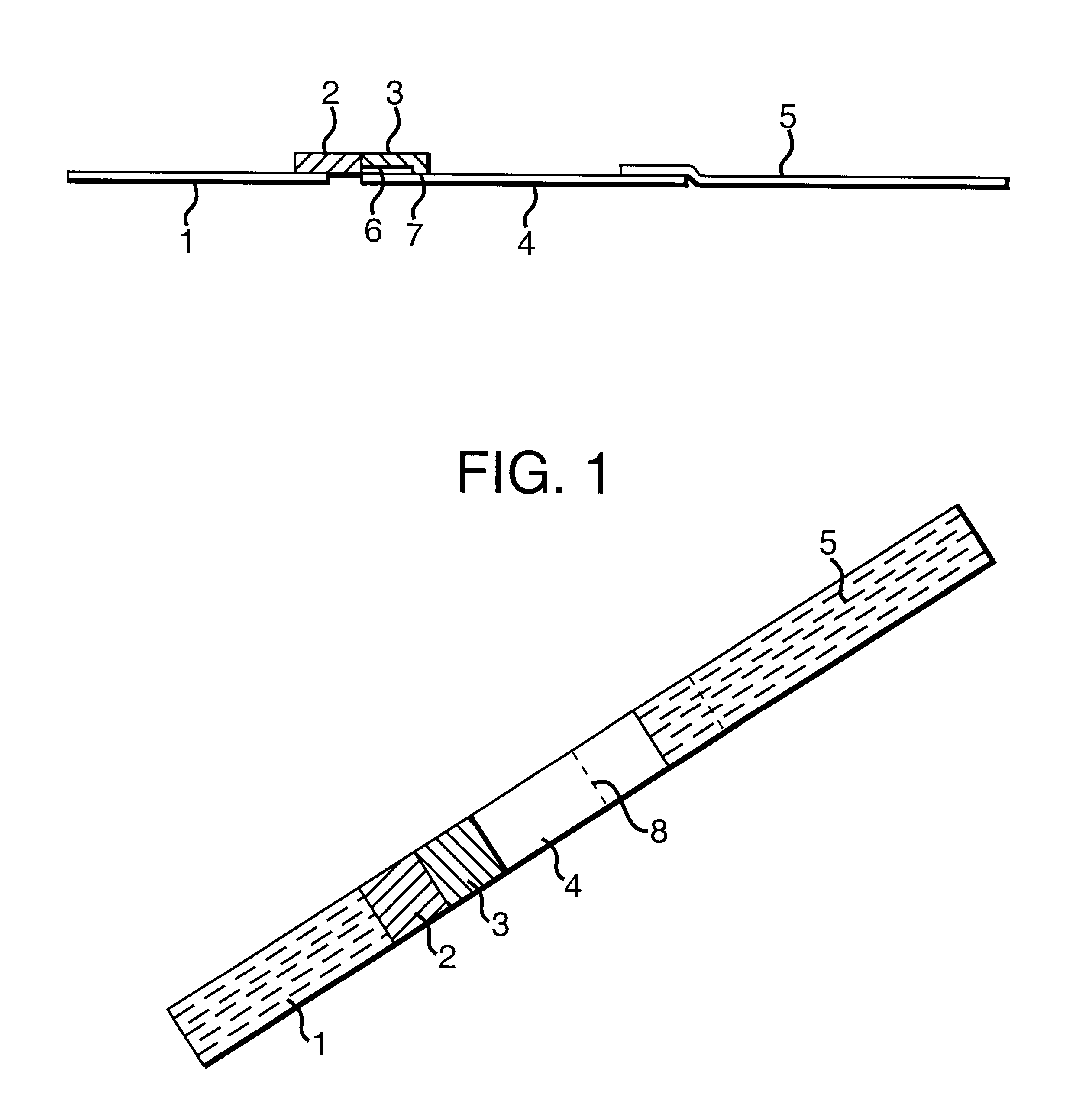

Assay using porosity-reduction to inhibit migration

InactiveUS6472226B1Small sizeConveniently formedBioreactor/fermenter combinationsBiological substance pretreatmentsPorosityAnalyte

Device for assaying an analyte, comprising a labelling zone, where a label can bind to the analyte, in communication with a capture zone, wherein the pore size of the capture zone is such that label which is not bound to the analyte can migrate therethrough, whereas label which is bound to the analyte cannot. During migration from the labelling zone (large pore size) to the capture zone (small pore size), unbound label can pass into and through the capture zone, whereas bound label will be captured at the junction of the labelling zone a the capture zone. The device relies upon the label being smaller than the analyte, such that free label is not retarded by the capture zone. It is particularly suitable for assying analytes such as spermatozoa, which are large in comparison with a label such as a labelled antibody.

Owner:GENOSIS UK

Coupled cavity high power semiconductor laser

InactiveUS6898225B2Reduce lossesConveniently formedLaser optical resonator constructionSemiconductor laser arrangementsElectricityThermal contact

An active gain region sandwiched between a 100% reflective bottom Bragg mirror and an intermediate partially reflecting Bragg mirror is formed on a lower surface of a supporting substrate, to thereby provide the first (“active”) resonator cavity of a high power coupled cavity surface emitting laser device. The bottom mirror is preferably in direct thermal contact with an external heat sink for maximum heat removal effectiveness. The reflectivity of the intermediate mirror is kept low enough so that laser oscillation within the active gain region will not occur. The substrate is entirely outside the active cavity but is contained within a second (“passive”) resonator cavity defined by the intermediate mirror and a partially reflecting output mirror, where it is subjected to only a fraction of the light intensity that is circulating in the gain region. The active gain region is preferably electrically excited, with a circular bottom electrode formed by an oxide current aperture between the bottom mirror and the heat sink, and with an annular top electrode formed on an upper surface of the substrate.

Owner:NECSEL INTPROP +1

Means and method for a liquid metal evaporation source with integral level sensor and external reservoir

InactiveUS20050229856A1Long operating timeReduce hydrostatic pressureVacuum evaporation coatingSputtering coatingEvaporation (deposition)Engineering

A liquid metal evaporation source for use in Molecular Beam Epitaxy and related metal vacuum deposition techniques. An evaporator is maintained at a high temperature to evaporate a liquid metal, a reservoir for holding the liquid metal source is maintained at a temperature above the melting point of the metal but below the temperature in the evaporator, and a hollow transport tube connecting the evaporator and reservoir is maintained at a temperature between these temperatures. The reservoir is in the shape of a hollow cylinder with a close-fitting cylindrical piston which is used to force the liquid metal through the hollow transport tube into the evaporator. The liquid metal will not flow past the piston seal if a suitably small gap is formed between the piston and the reservoir walls wherein the surface tension of the liquid metal will exceed its hydrostatic pressure against the piston thus forming a leak-tight seal.

Owner:RJM SEMICON

Mattress

InactiveUS20050188467A1Conveniently formedPoint becomes highStuffed mattressesSpring mattressesEngineeringMechanical engineering

A mattress comprises a sealed outer casing within which is mounted a resilient support formed by a composite foam core. At least an upper portion of the resilient support is formed by a visco-elastic foam. A vent is provided in a side wall of the casing and is covered by a filter which prevents ingress of bacteria into the cover. A flap is mounted on the cover and in use extends down over the vent to prevent the filter being damaged by fluids.

Owner:LANCASTRIA

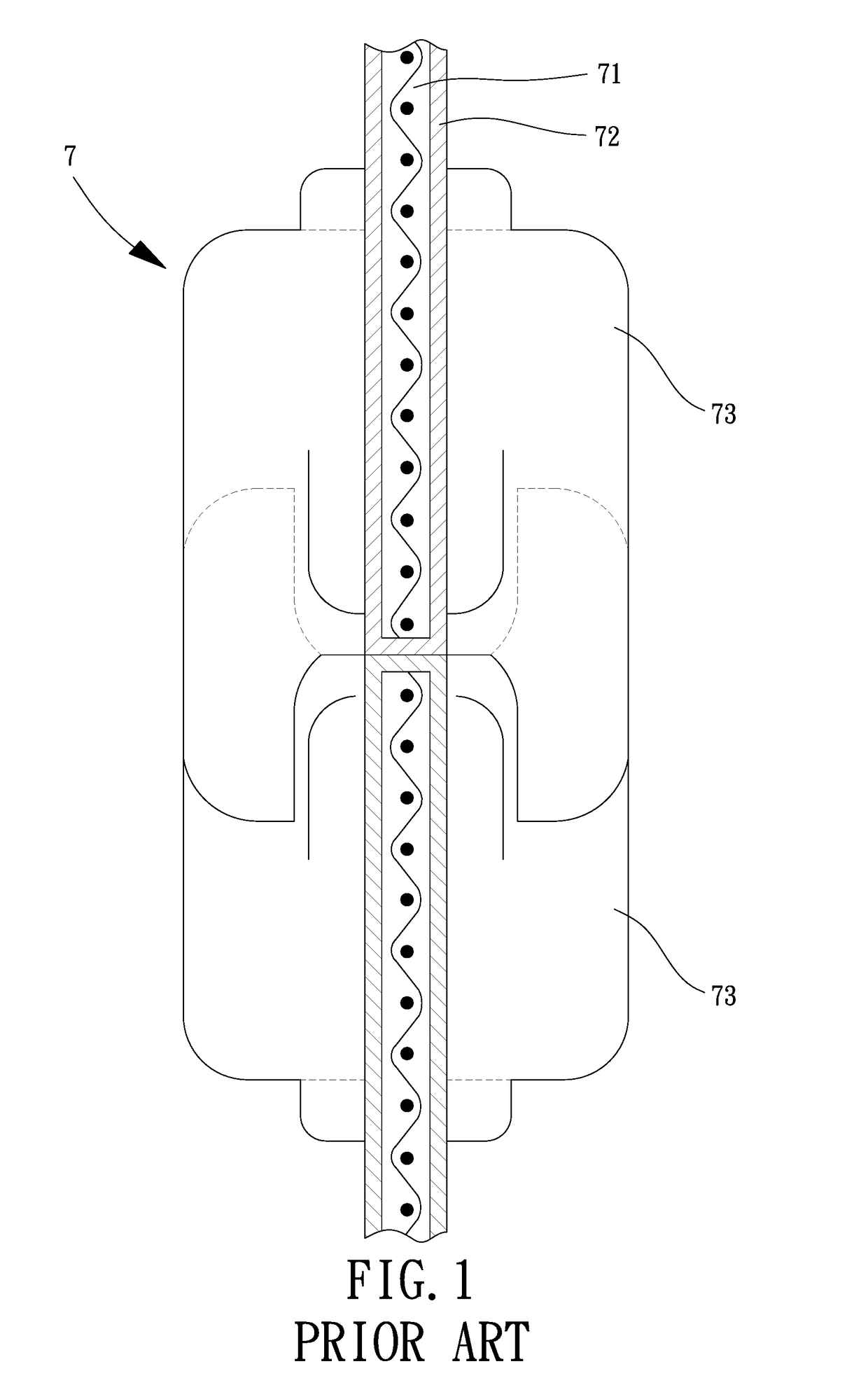

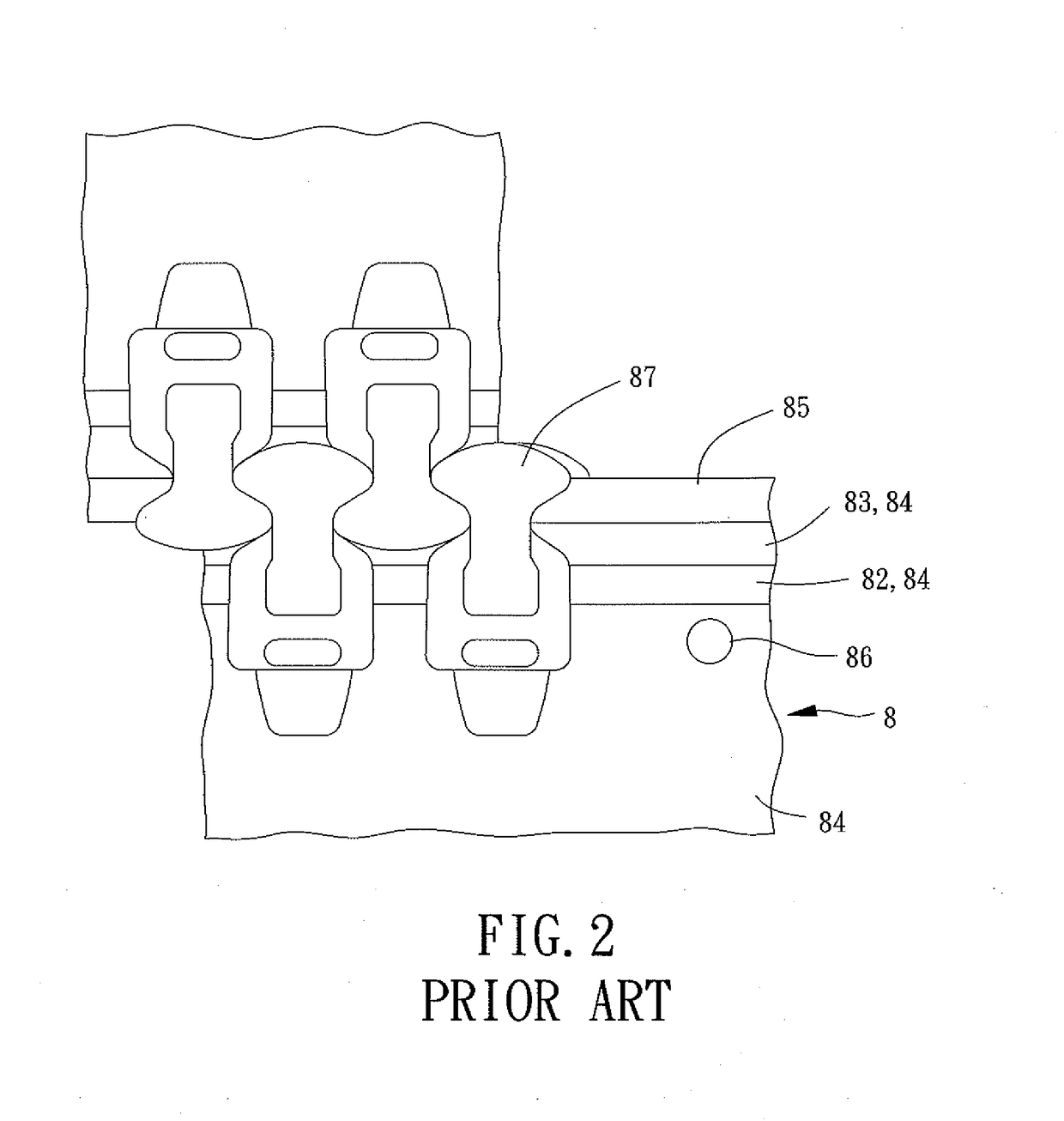

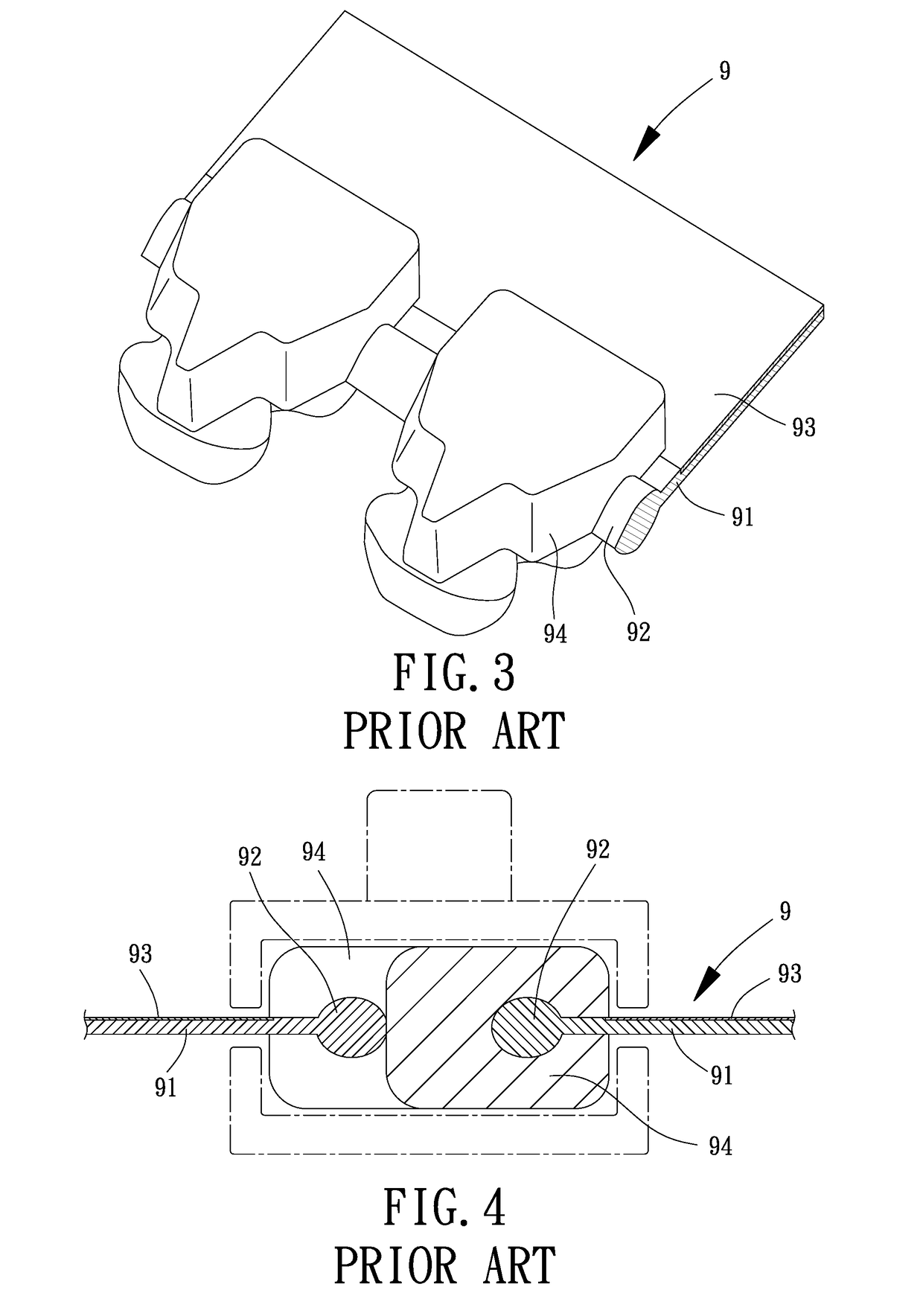

Waterproof Fastener Tape and Watertight Slide Fastener Including the Same

A waterproof fastener tape of a watertight slide fastener includes a fabric tape and a waterproof layer. The fabric tape includes a first surface, a second surface, a first edge, a second edge, a first cord portion, and an extension portion. The first cord portion protrudes from the first surface. The first and second edges are connected between the first and second surfaces. The first cord portion is spaced from the first edge at a smaller distance than from the second edge. The extension portion extends between the first edge and the first cord portion. The second surface is planar. The waterproof layer covers the first surface, the second surface, the first cord portion, the first edge and the second edge.

Owner:UNITECH ZIPPER & MACHINERY

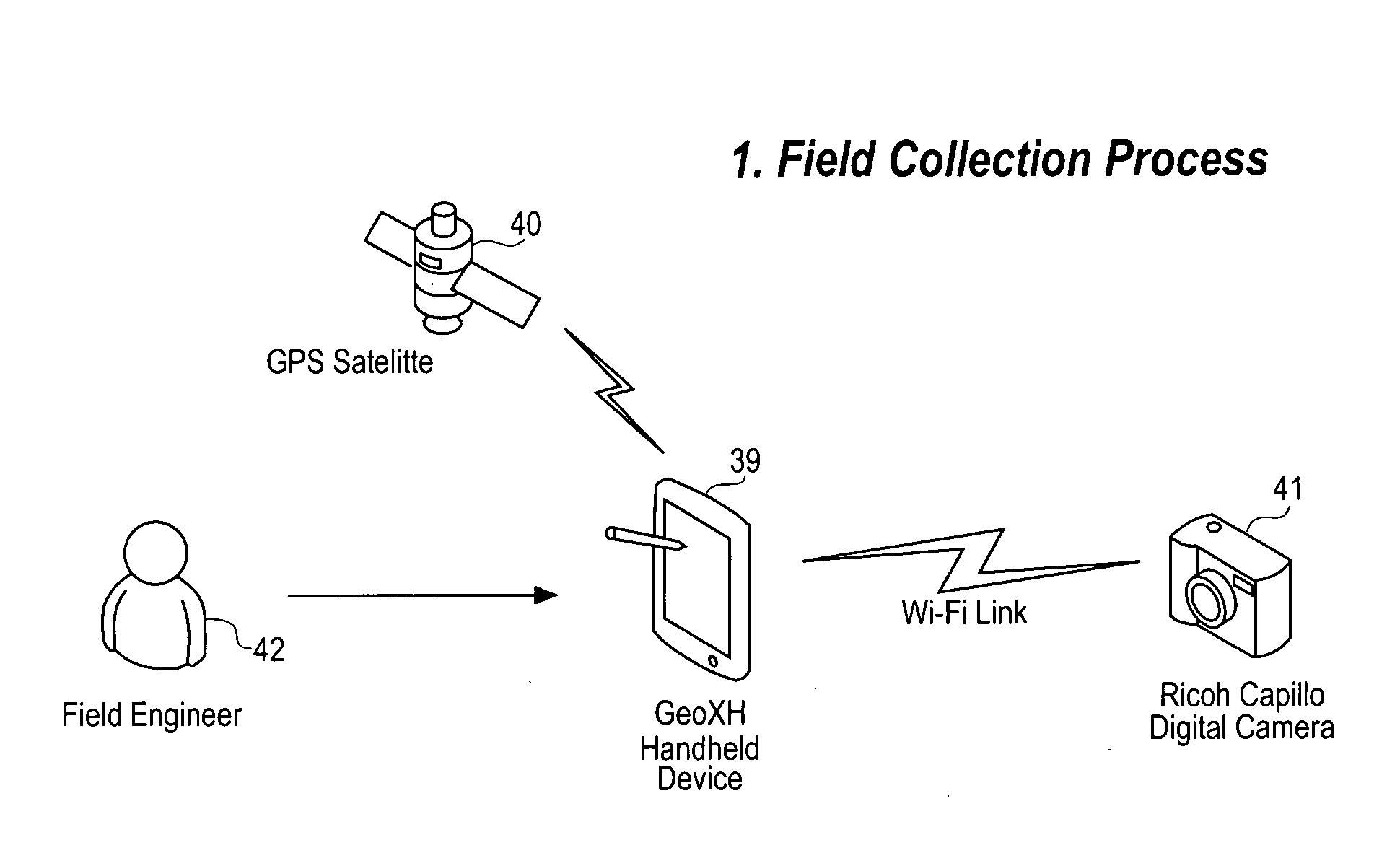

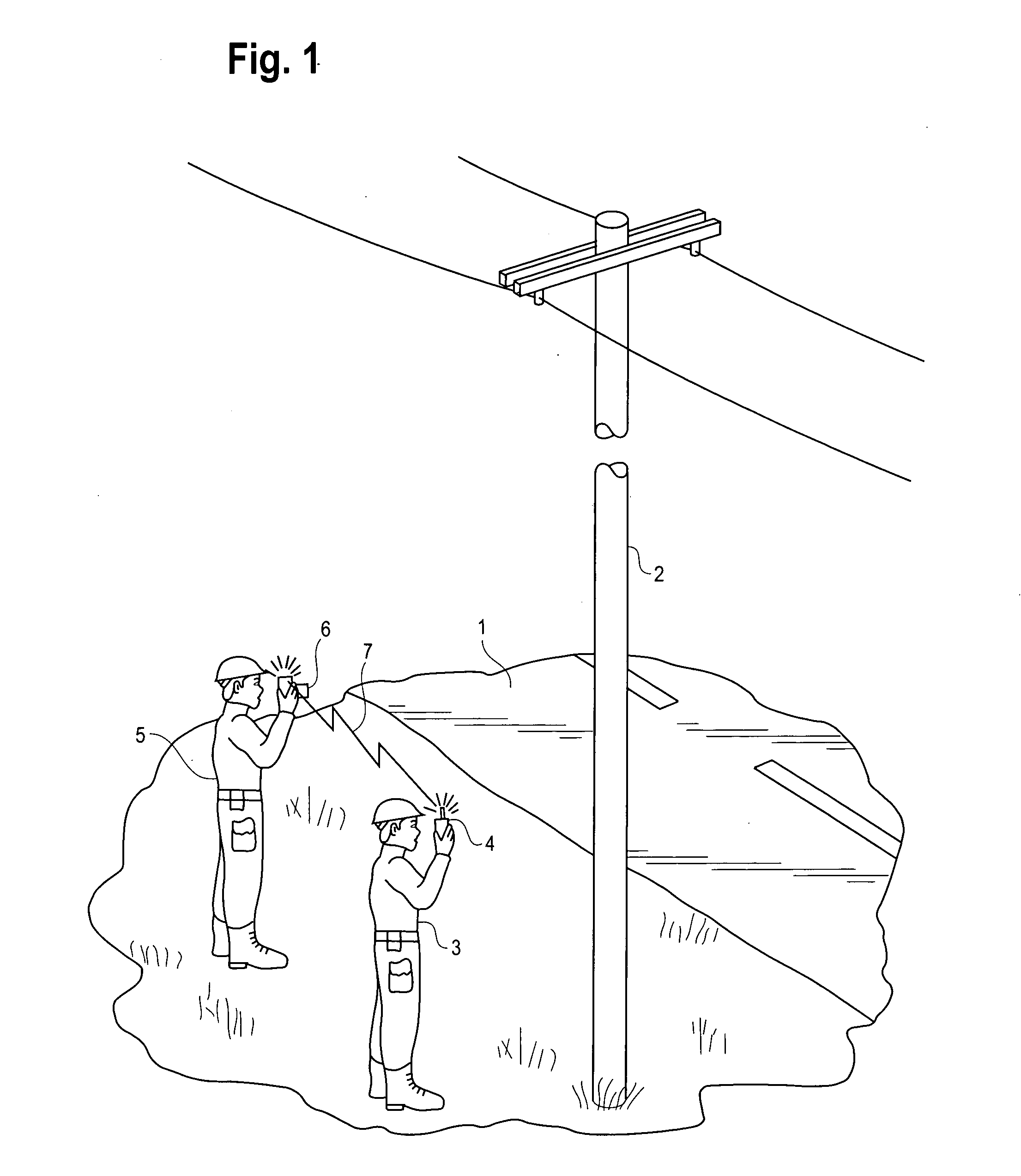

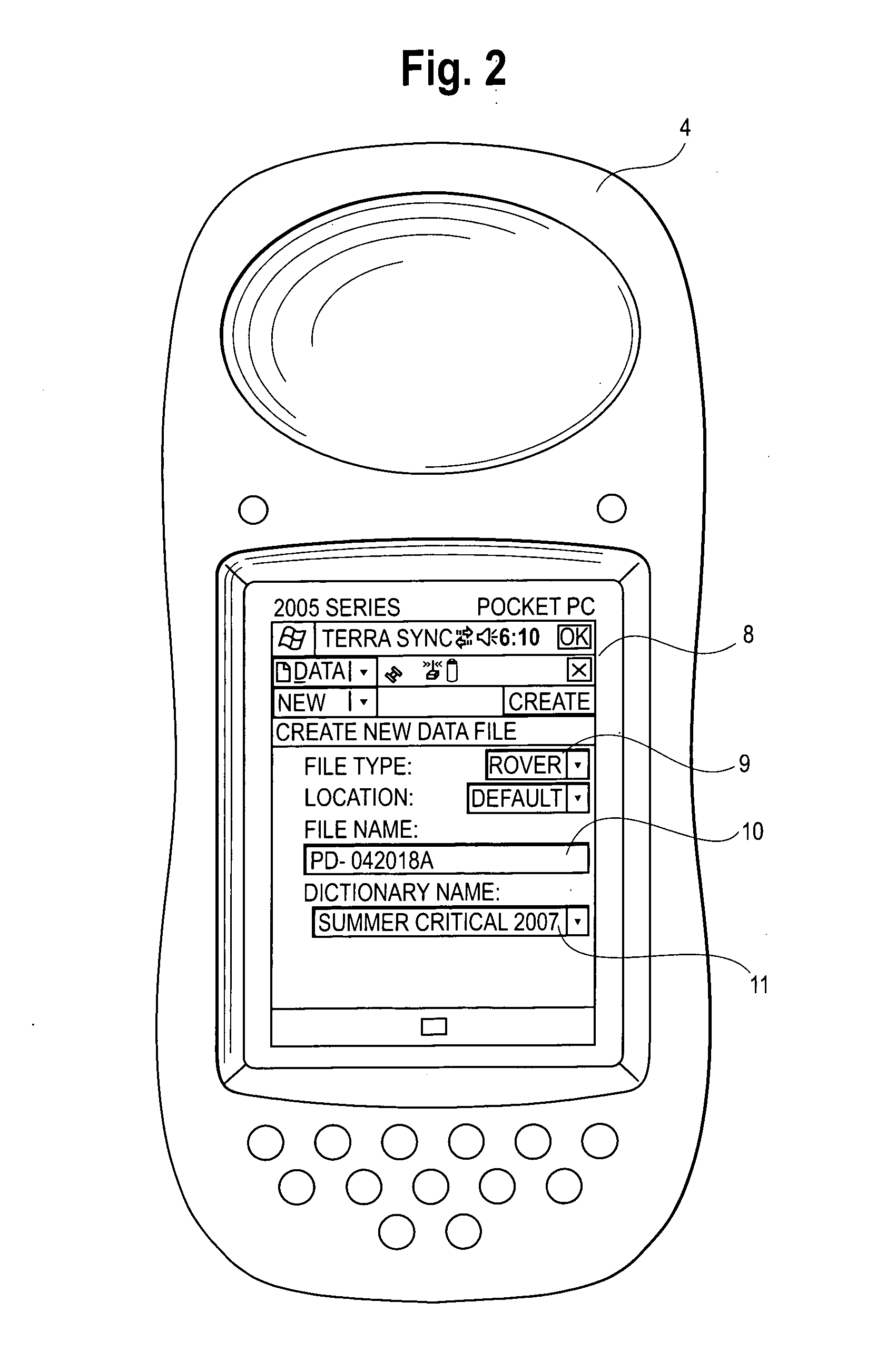

Field site data gathering and reporting system and method

InactiveUS20080120122A1Improve accuracyEasy to carrySurveying instrumentsResourcesAviationWeb service

A system and method of reporting and displaying field survey data related to particular features located at remote sites that includes generating GPS data related to a feature with a handheld device, generating at least one image of the location, entering text data related to the location on the handheld device, and uploading the GPS data, image and text data into a database located at a central location. The photograph can be optionally transferred wirelessly from a camera to the handheld device. In particular, the transfer can be on a wireless network (WiFi). Data can be post-processed at the database location before entry into the database. GIS maps and reports can be made from the processed data for use in a project. These maps and reports can be placed on a web server for access by authorized personnel. The maps can contain an aerial photograph of the remote sites with symbols representing features overlaid on the aerial photograph. Each feature on the map can be linked to the GPS data, image data and text data related to that feature.

Owner:UTILITECH SOLUTIONS

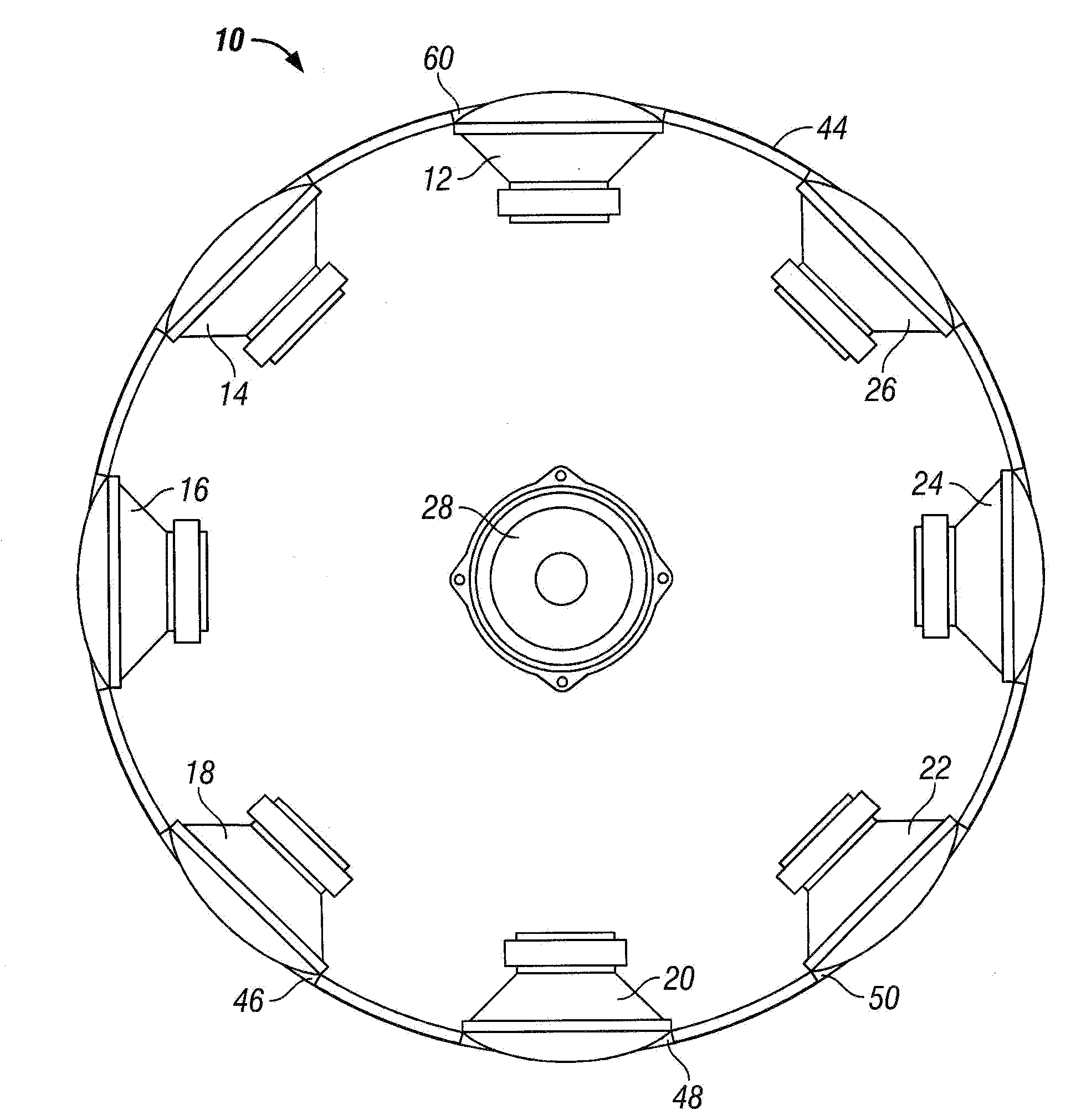

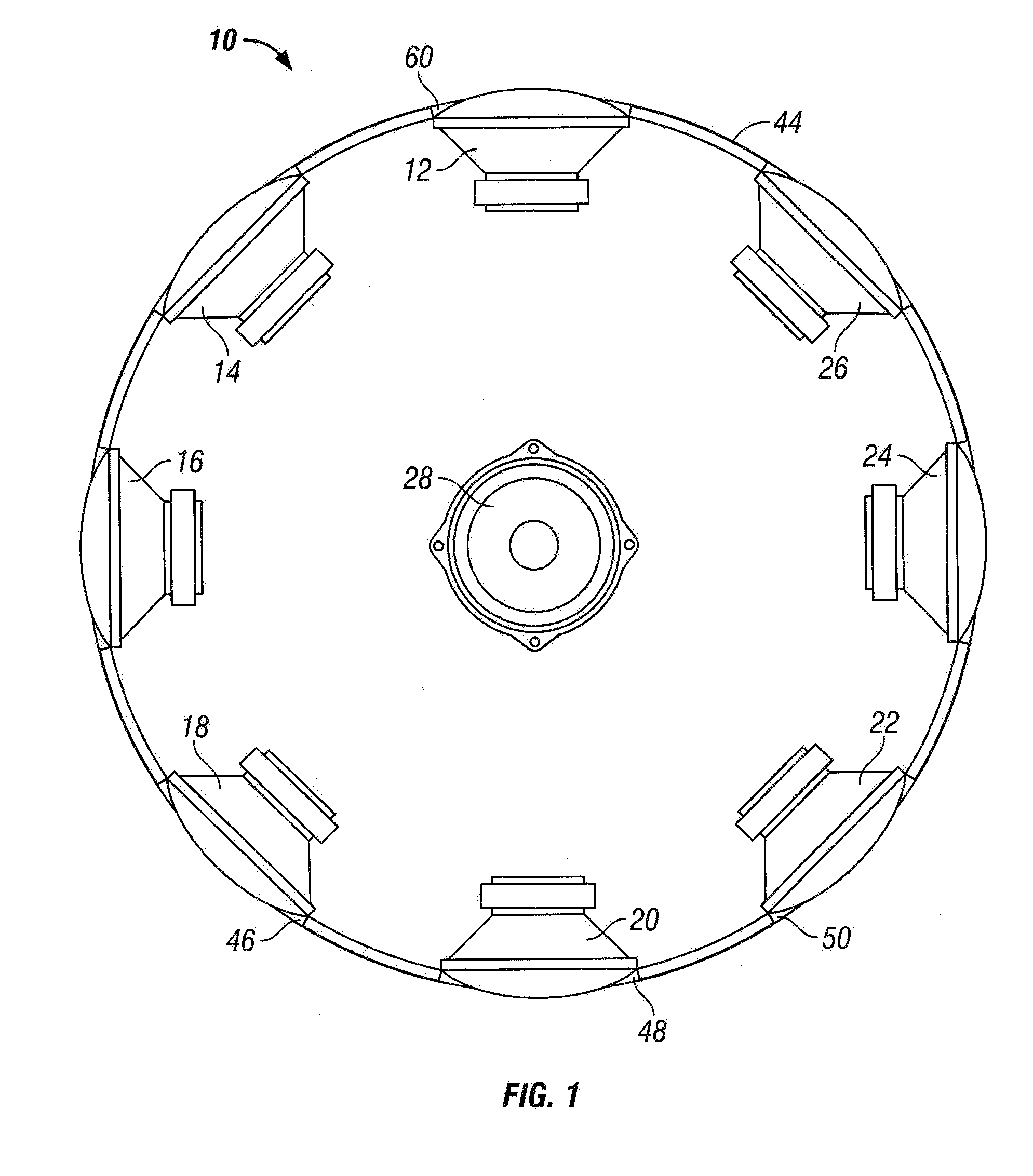

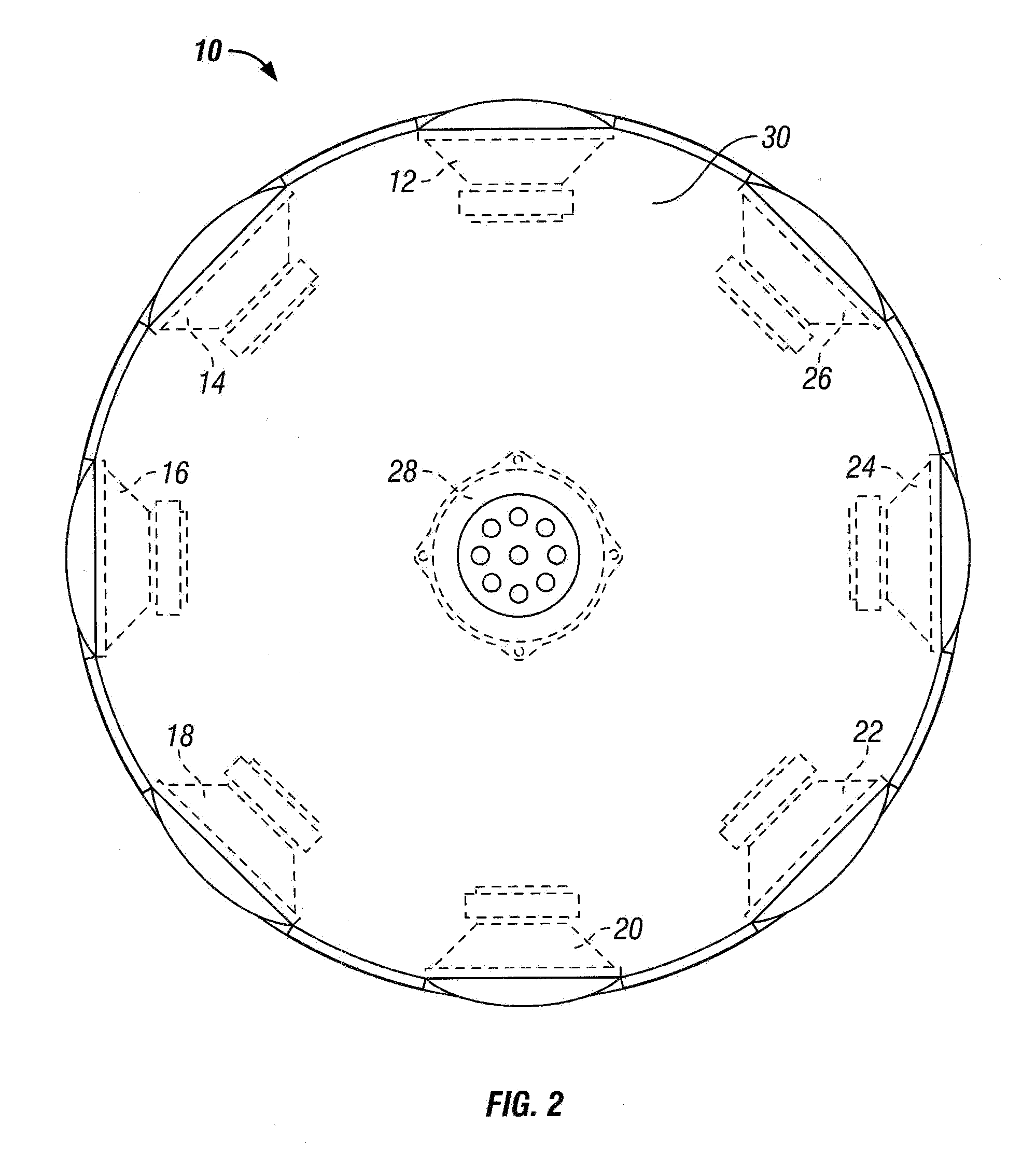

Quickly Installed Multiple Speaker Surround Sound System and Method

InactiveUS20070041599A1Quick installationConveniently formedTransducers for sound channels pluralityTransducer detailsEngineeringSurround sound

A surround sound speaker system is provided whereby multiple speakers that broadcast acoustic signals representative of sound from different directions may be mounted in one speaker housing rather than in separate speaker housings that are positioned at separate positions within the room. Thus, the present invention eliminates the need to mount and run wiring to separate speakers in the room. Because the number of speakers within the speaker housing can be relatively easily increased, the surround sound speaker system can be utilized to implement even highly complicated surround sound systems such as surround sound system 9.1, which is otherwise very difficult and expensive for the average consumer to install or have installed.

Owner:GAUTHIER LLOYD M +1

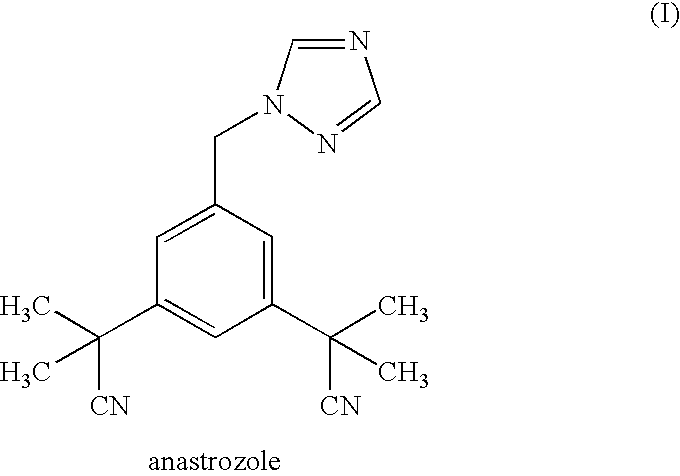

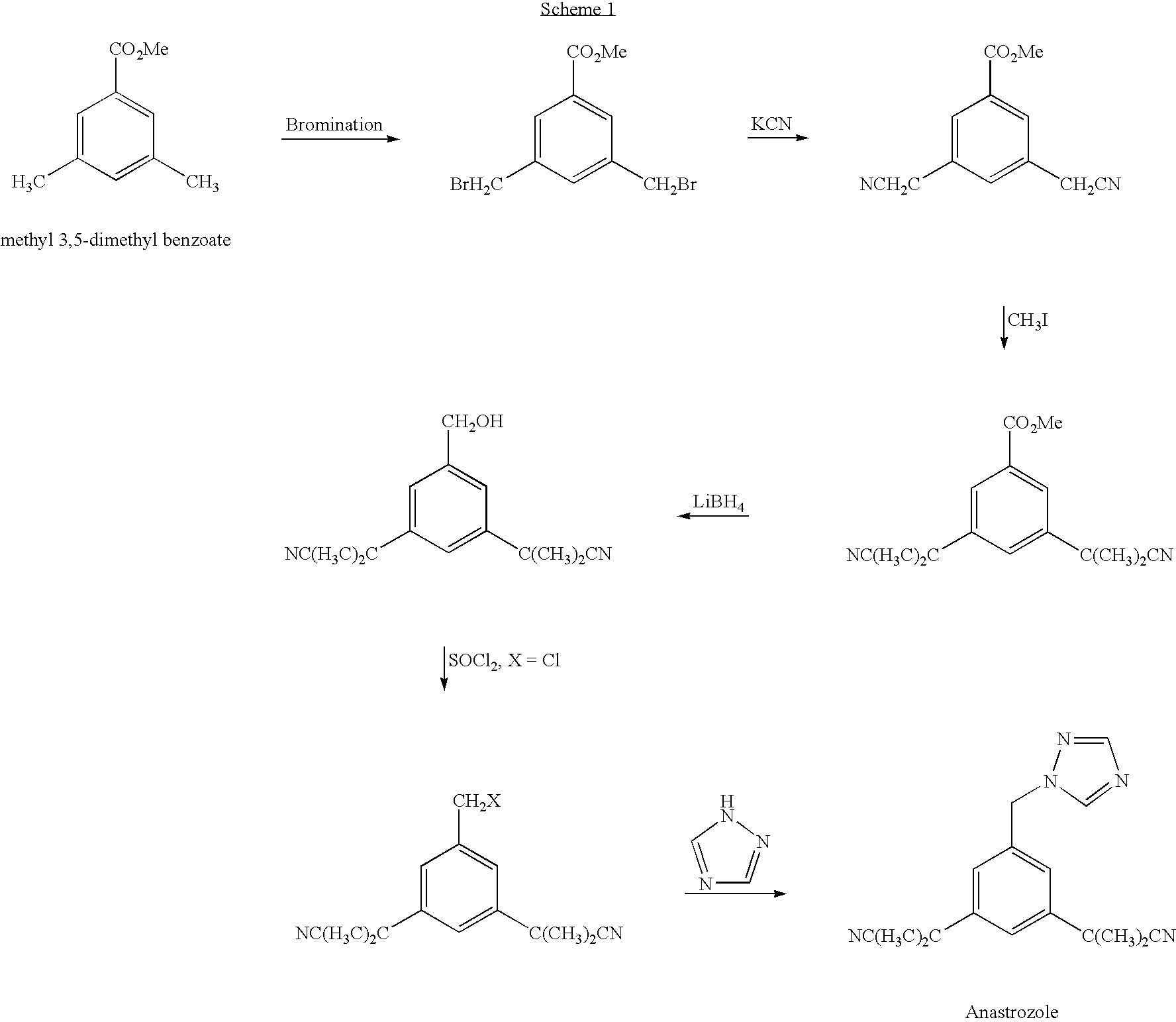

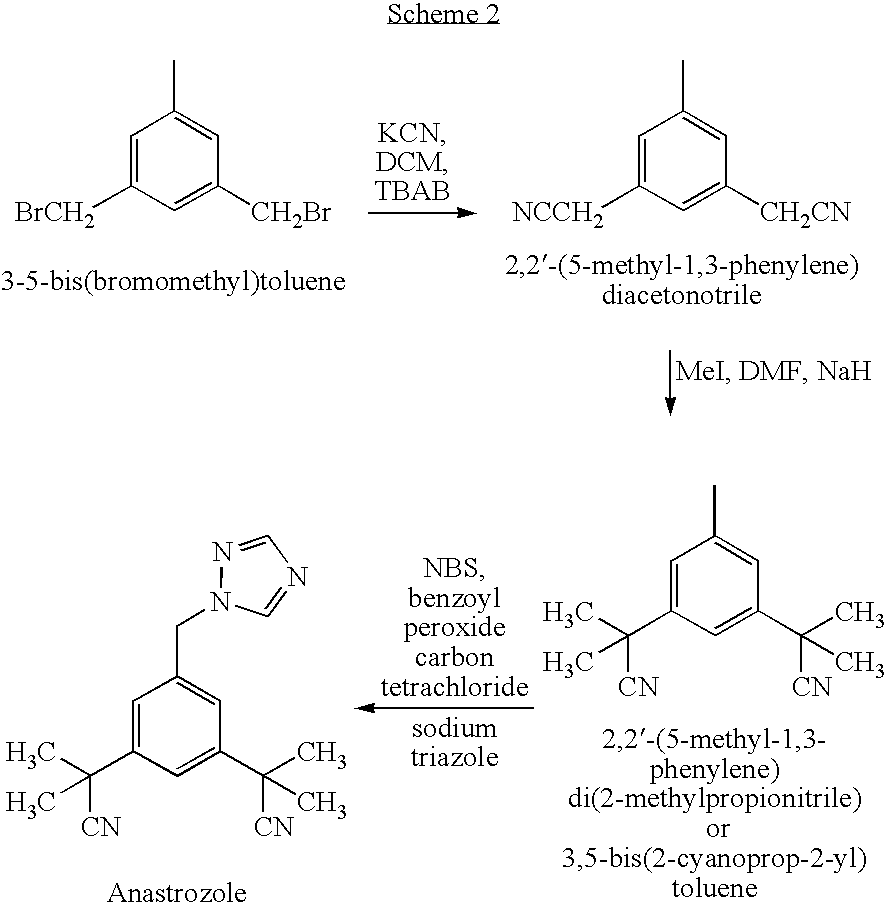

Novel processes for preparing substantially pure anastrozole

InactiveUS20060035950A1Straightforward and more purificationReduce in quantityBiocideCarboxylic acid nitrile preparationAnastrozoleSolvent

The present invention provides novel processes for purifying anastrozole, devoid of using liquid chromatography. The purification processes are via the isolated anastrozole salt forms, either by crystallization or by selective acidic extractions, and optionally in both cases, converting the purified anastrozole salt to anastrozole base. Also provided is an improved process for the synthesis of anastrozole, which is obtained by alkylating the isolated and purified starting material 3,5-bis(2-cyanoprop-2-yl)benzylbromide, the process being devoid of using toxic, hazardous and environmental unfriendly solvents and reagents.

Owner:CHEMAGIS

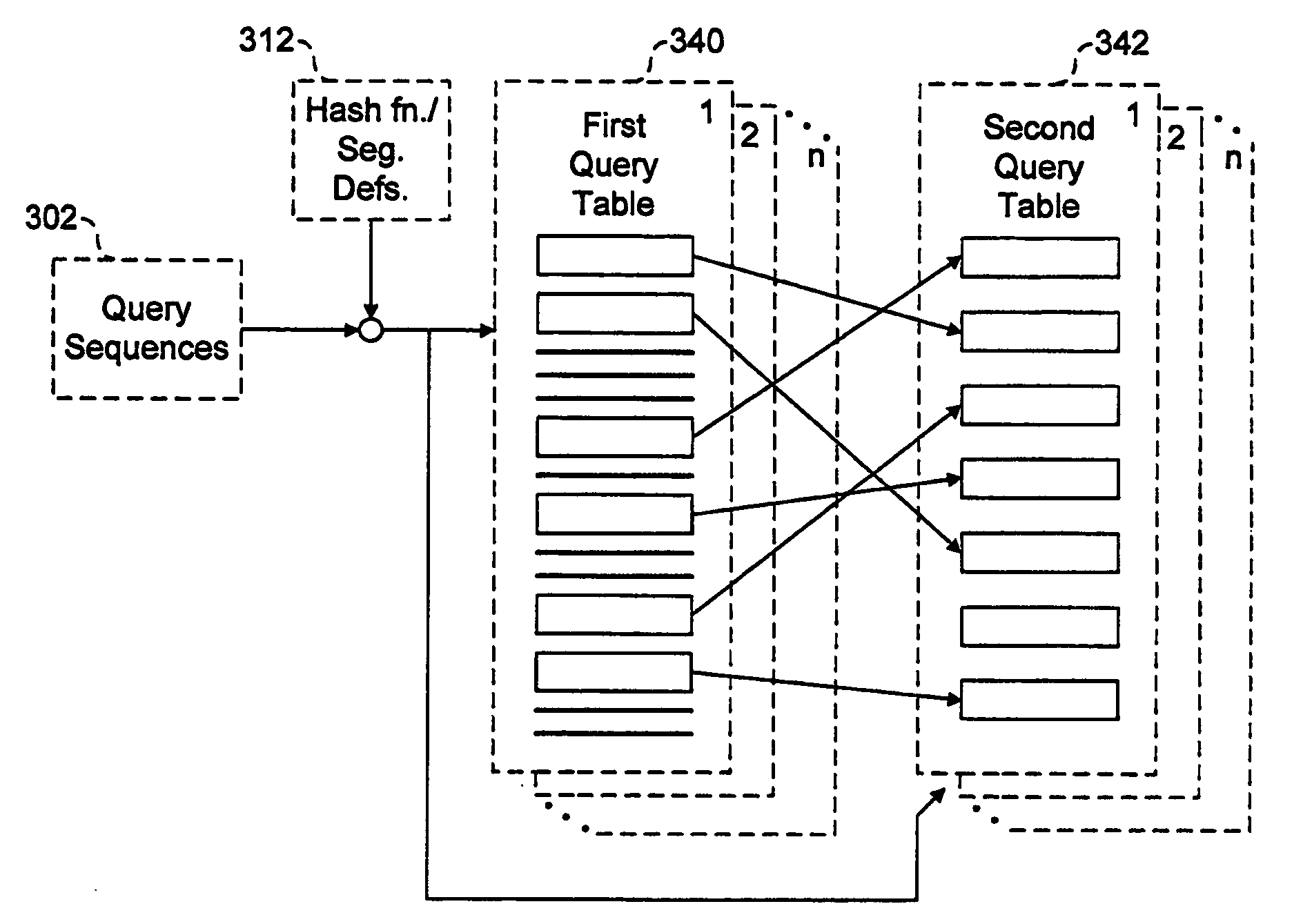

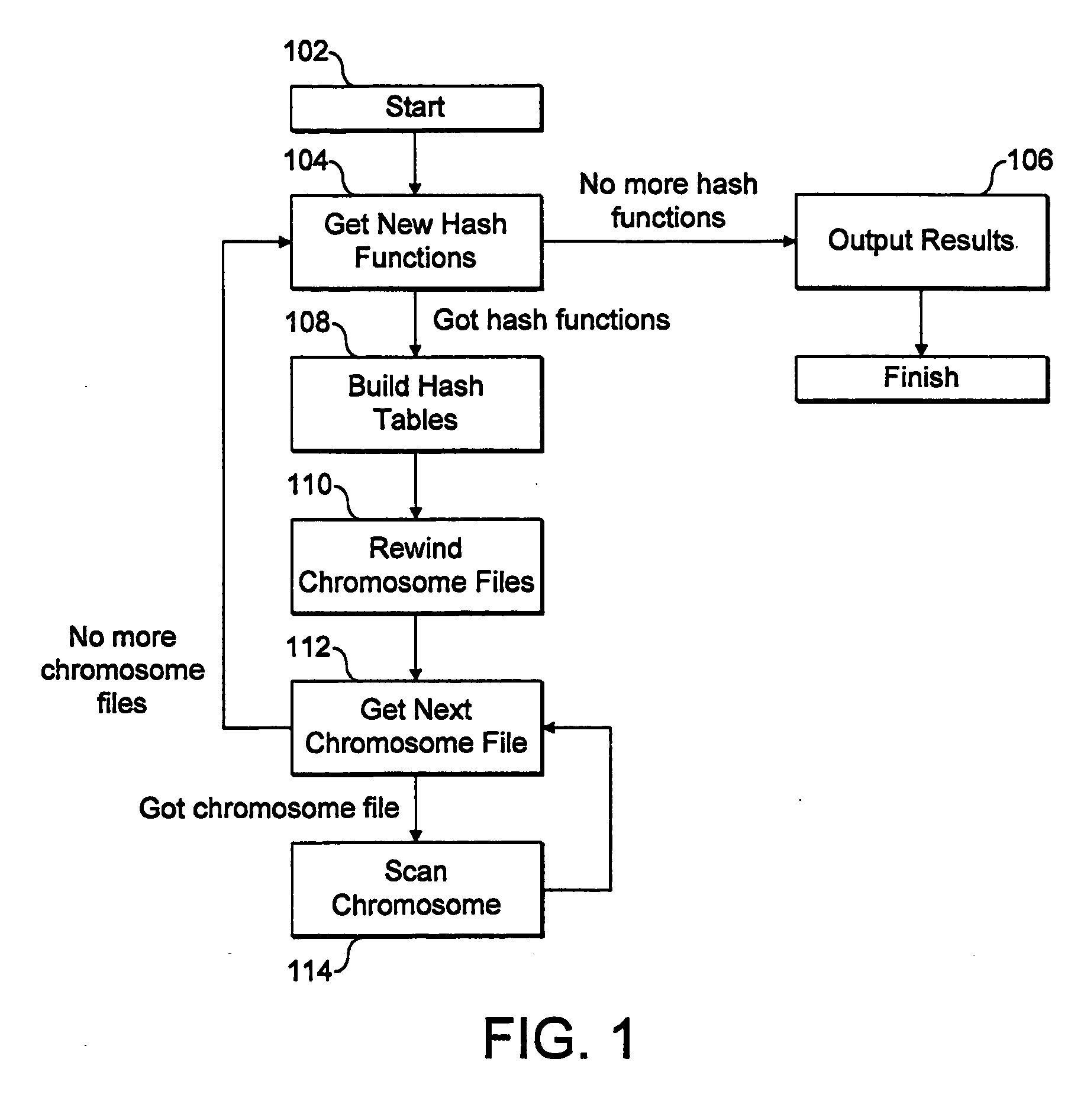

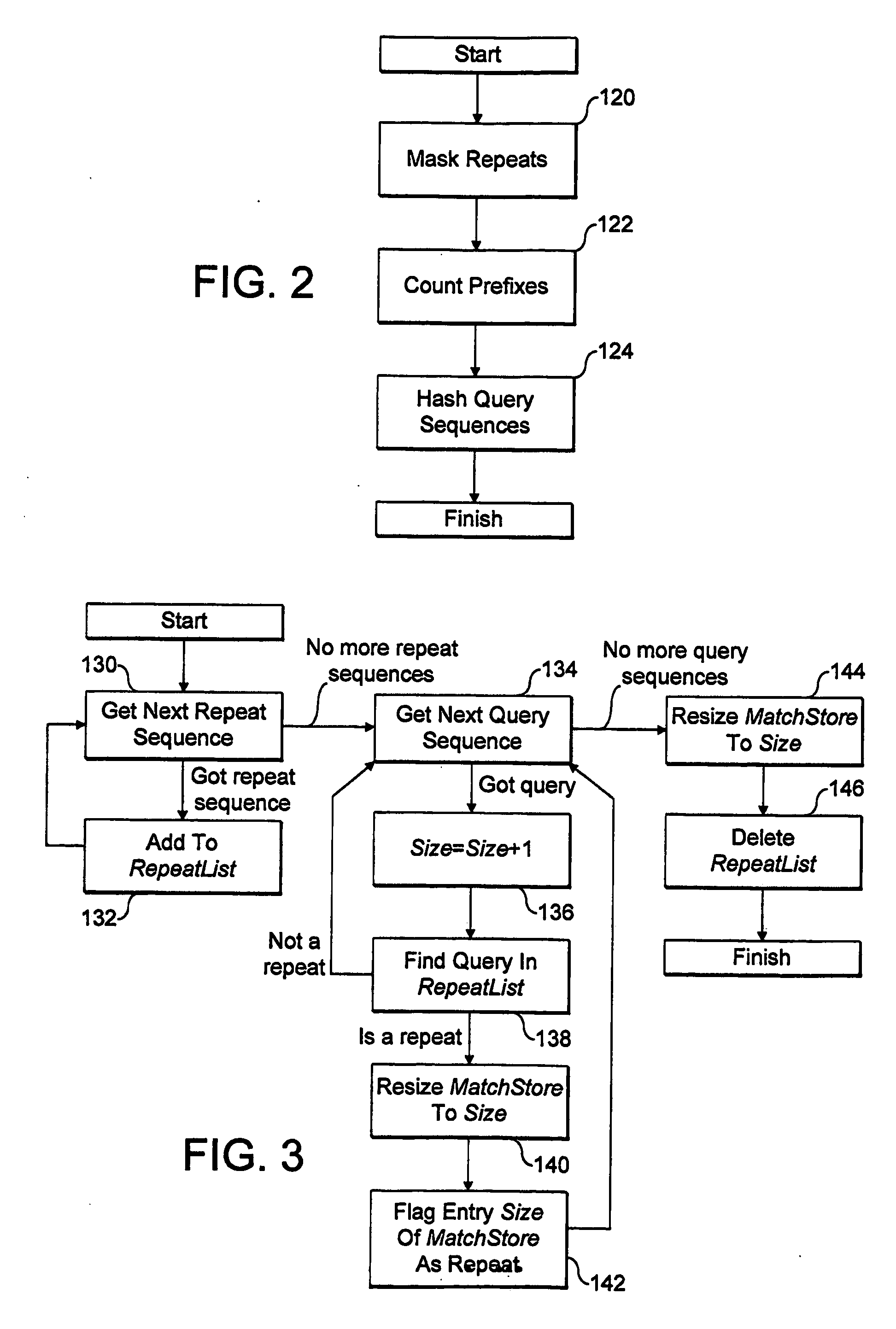

Apparatus and Method for Searching for Multiple Inexact Matching of Genetic Data or Information

InactiveUS20080222094A1Efficient executionEasy to handleDigital data processing detailsSequence analysisComputer scienceTarget groups

A computer implemented method of searching genetic data or information for a plurality of query sequences in a set of target sequence fragments, allowing for mismatches at up to n sequence positions, including dividing each query sequence of the plurality of query sequences into n+1 query sequence segments and dividing each target fragment of the target sequence fragments into at least n+1 target sequence fragment segments, for each query sequence, constructing a first query group and a second query group by distributing query sequence segments there between such that at least n query sequence segments are contained in the second query group, constructing from each target fragment a first target group having a same distribution as the first query group, and for each query sequence, comparing the first query group with each first target group to identify potential matching target fragments.

Owner:ILLUMINA CAMBRIDGE LTD

Patterning crystalline compounds on surfaces

InactiveUS20070190783A1Block compoundImprove throughputMaterial nanotechnologyNanoinformaticsCompound (substance)Organic semiconductor

A method of patterning the surface of a substrate with at least one organic semiconducting compound, comprising the steps of: (a) providing a stamp having a surface including a plurality of indentations formed therein defining an indentation pattern, said indentations being contiguous with a stamping surface and defining a stamping pattern, (b) coating said stamping surface with at least one compound (C1) capable of binding to the surface of the substrate and of binding at least one organic semiconducting compound (S), (c) contacting at least a portion of the surface of a substrate with said stamping surface to allow deposition of said compound (C1) on the substrate, (d) removing said stamping surface to provide a pattern of binding sites on the surface of the substrate, (e) applying a plurality of crystallites of the organic semiconducting compound (S) to the surface of the substrate to enable at least a portion of the applied crystallites to bind to at least a portion of the binding sites on the surface of the substrate.

Owner:BASF AG +1

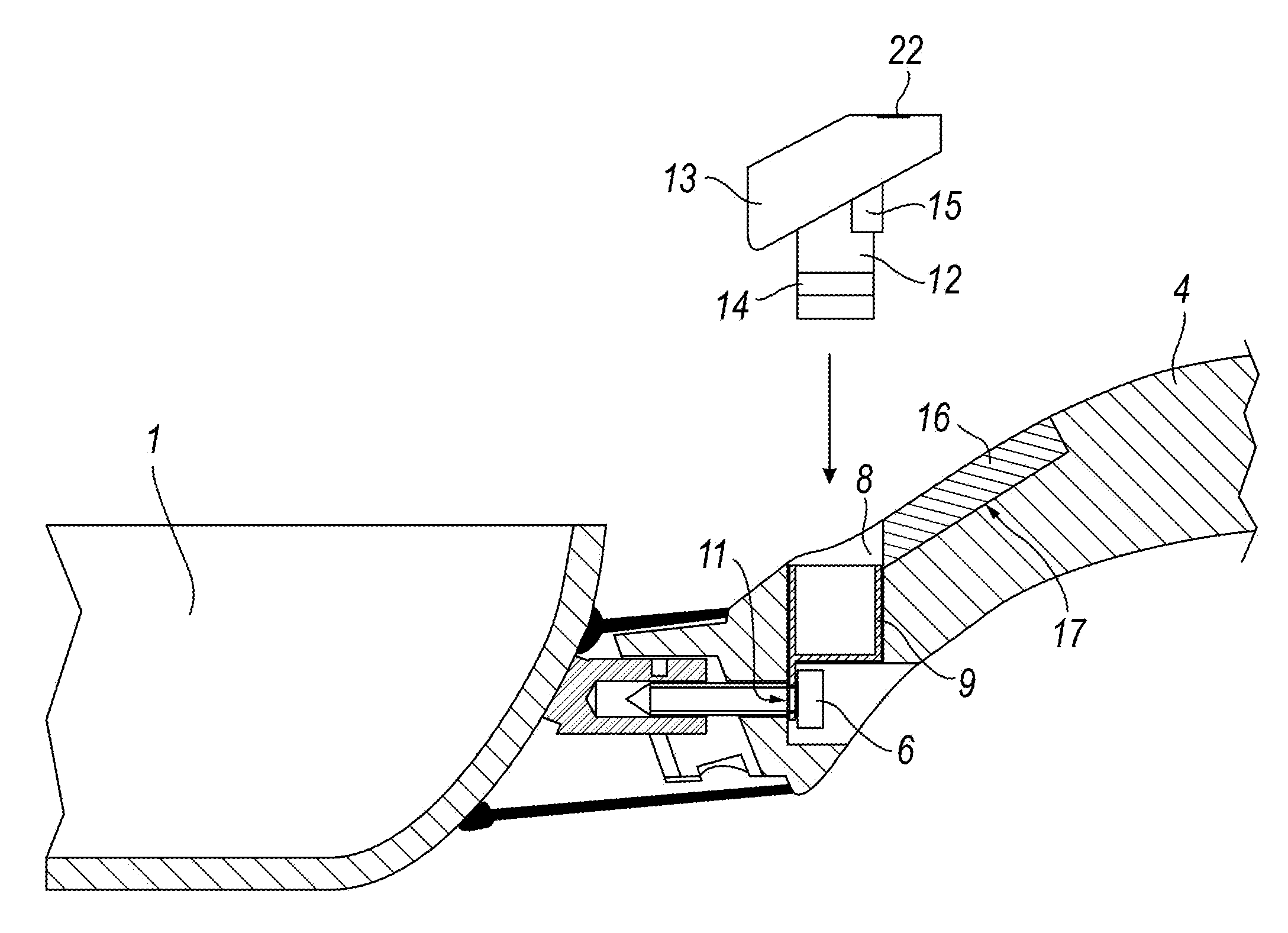

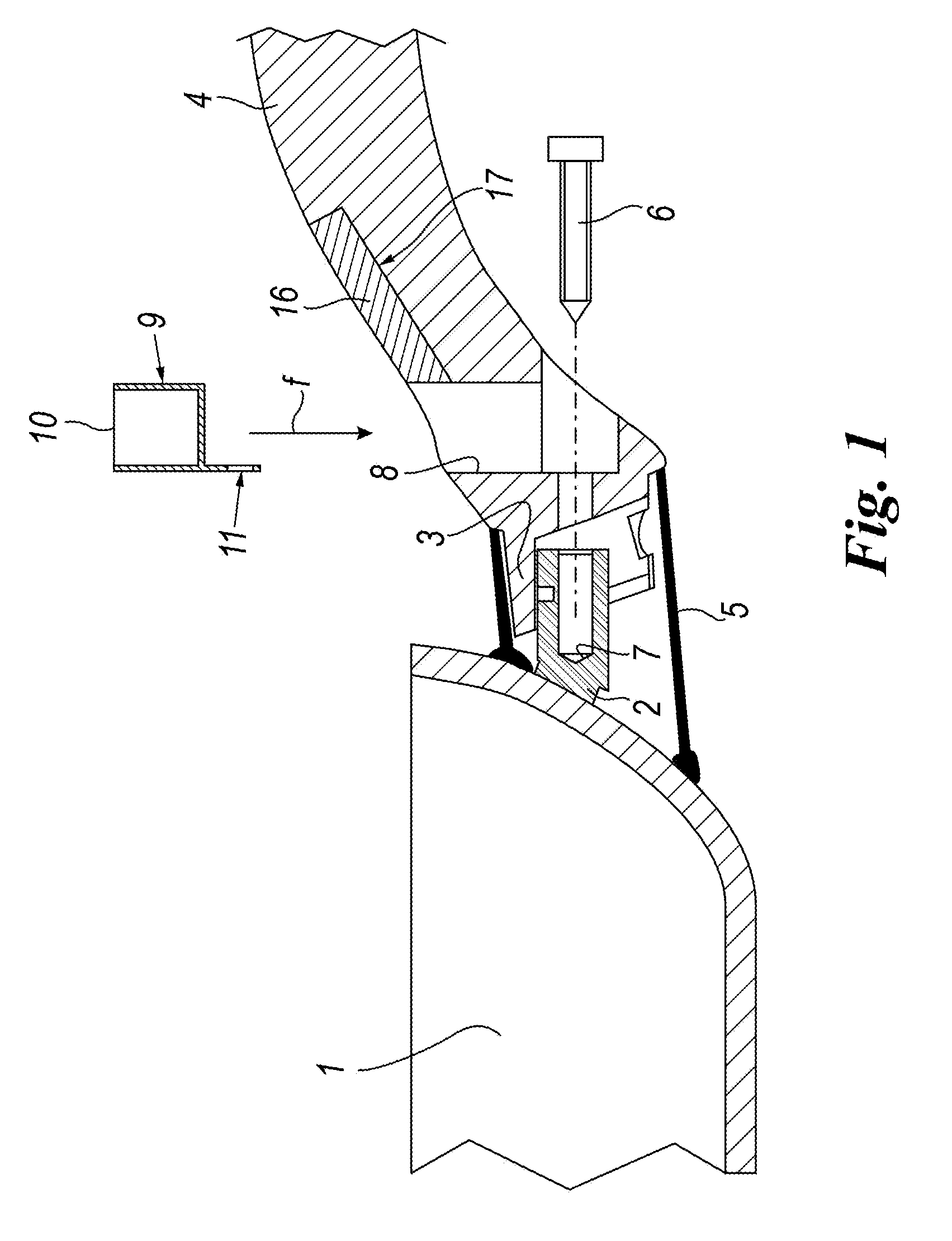

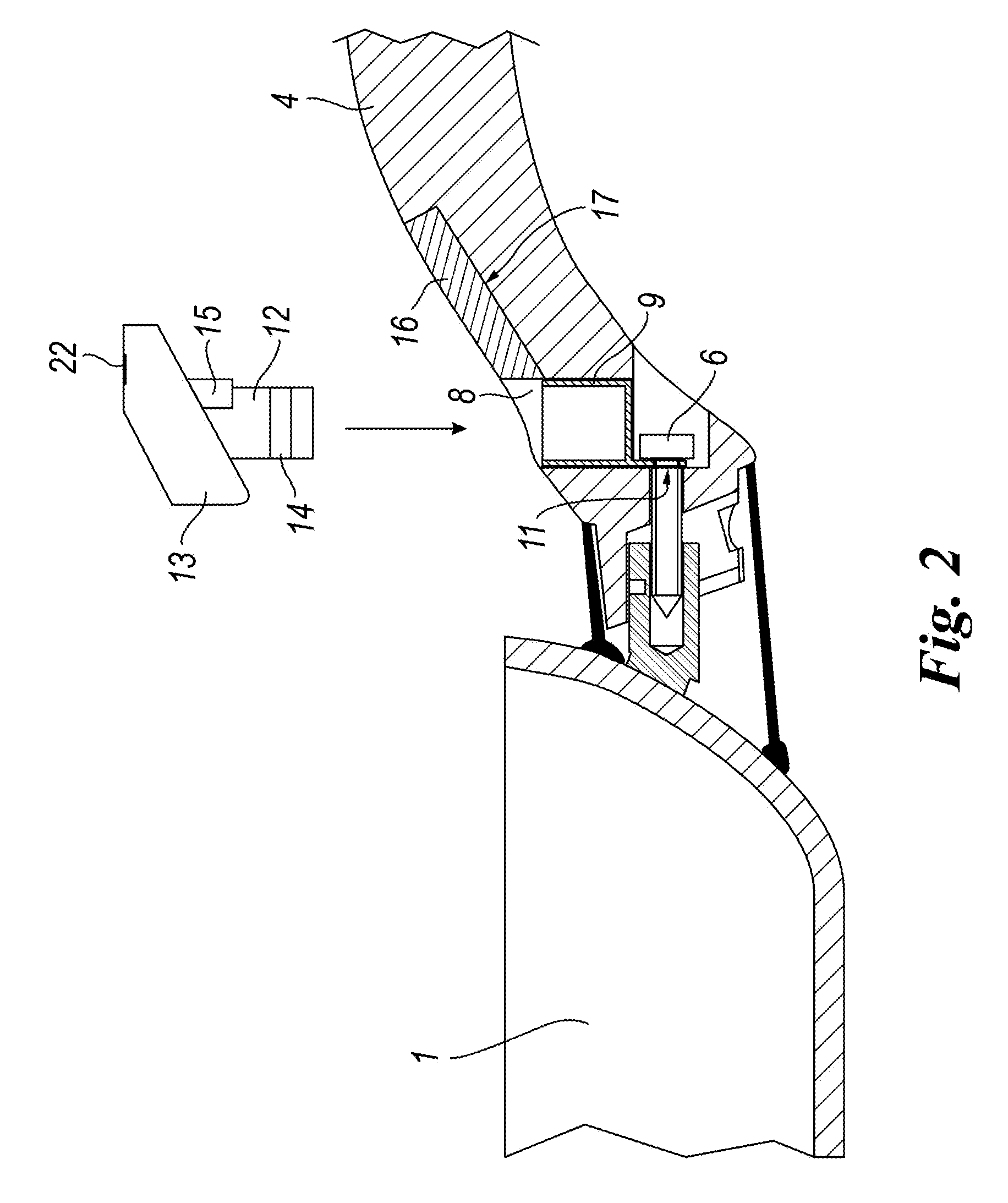

Methods and apparatus for forming anastomotic sites

InactiveUS20040215233A1Conveniently formedAvoid interferenceSuture equipmentsSurgical veterinaryEnd to side anastomosisThree vessels

Apparatus and methods are provided for forming a working space on the interior wall of a blood vessel, such as the aorta. The working space is isolated from blood flow and permits creation of an anastomotic hole and subsequent suturing of the hole to form an end-to-side anastomosis, even while the heart is beating. The apparatus comprises tools including inflatable barriers, such as cup-shaped balloons, which engage the inner wall of the blood vessel with minimum trauma and maximum sealing. In a first embodiment, the inflatable barrier is introduced through a penetration at the site of the anastomotic attachment. In a second embodiment, the inflatable barrier is introduced through a second penetration axially spaced-apart from the site of the anastomotic attachment.

Owner:MAGENTA MEDICAL CORP

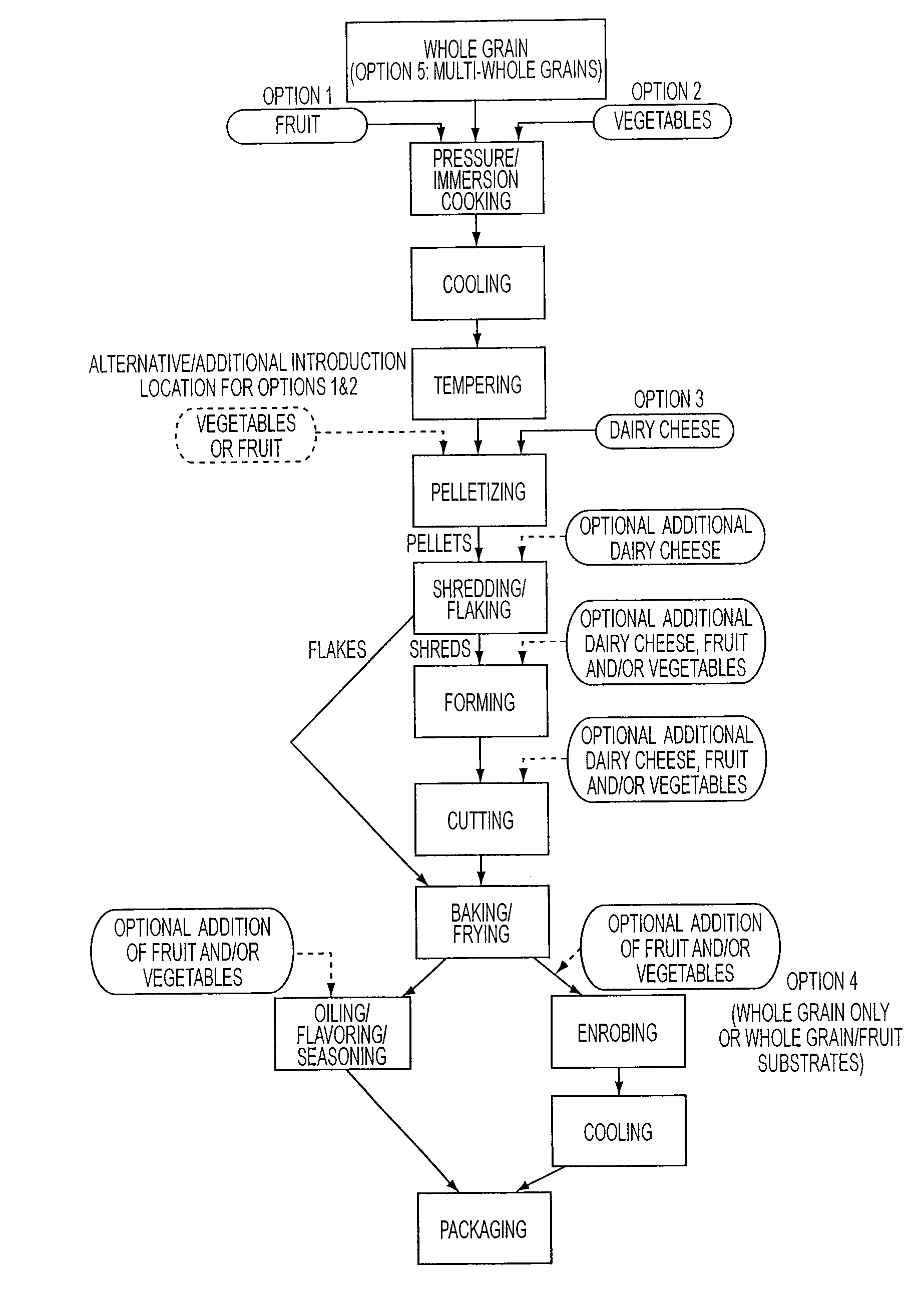

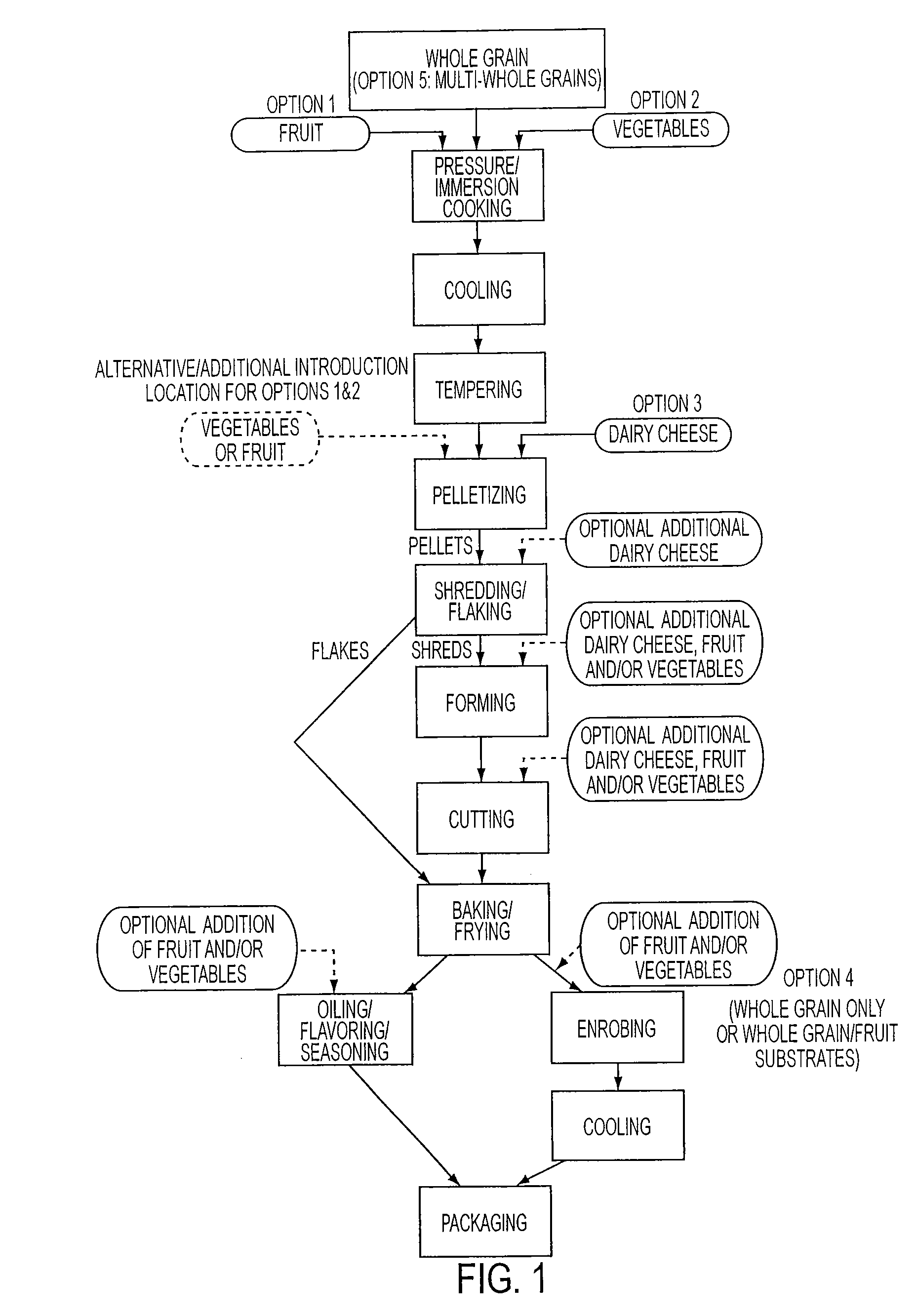

Production of shredded or flaked whole grain-containing composite food products

ActiveUS20060246202A1Eliminating and minimizing problemConveniently formedCocoaBakery productsBiotechnologySweetness

Shredded or flaked whole grain-containing composite food products, such as ready-to-eat cereals, and sweet and savory snacks, are continuously produced by pelletizing cooked, tempered, whole cereal grain particles in the presence of vegetables, fruit, or dairy cheese. In another aspect, an enrobing coating containing chocolate is applied to a baked shredded laminate product of the pelletization, wherein the shredded product may further optionally include fruit added and present during pelletization.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

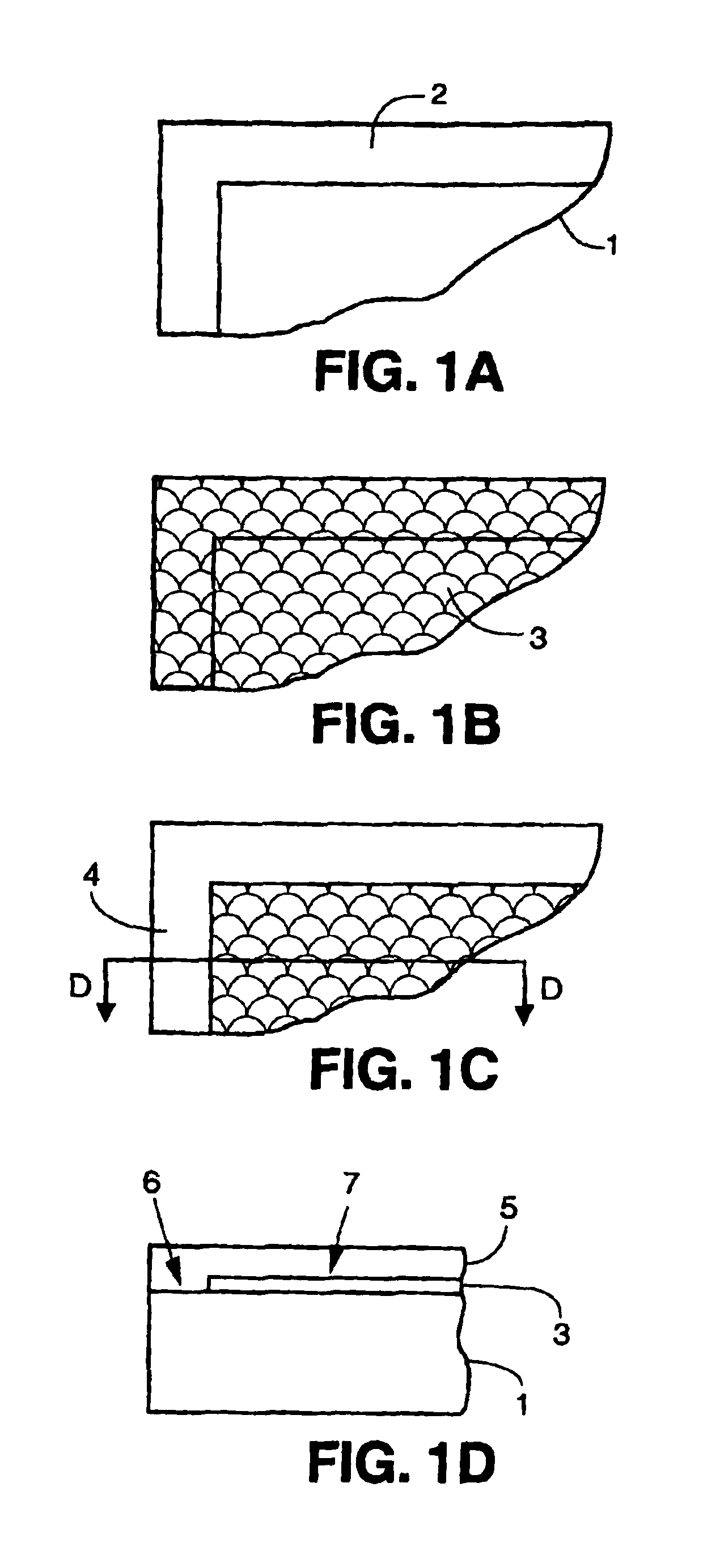

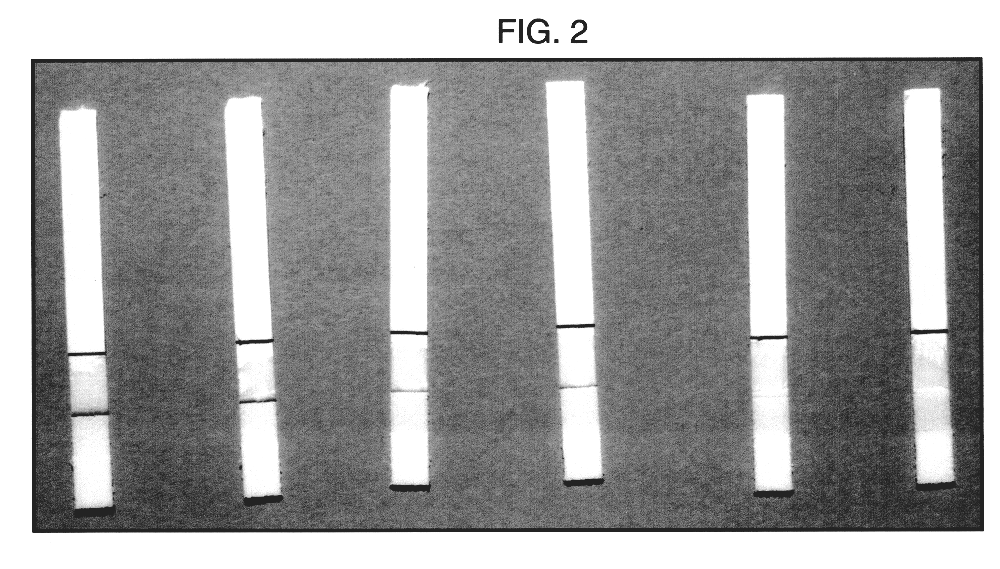

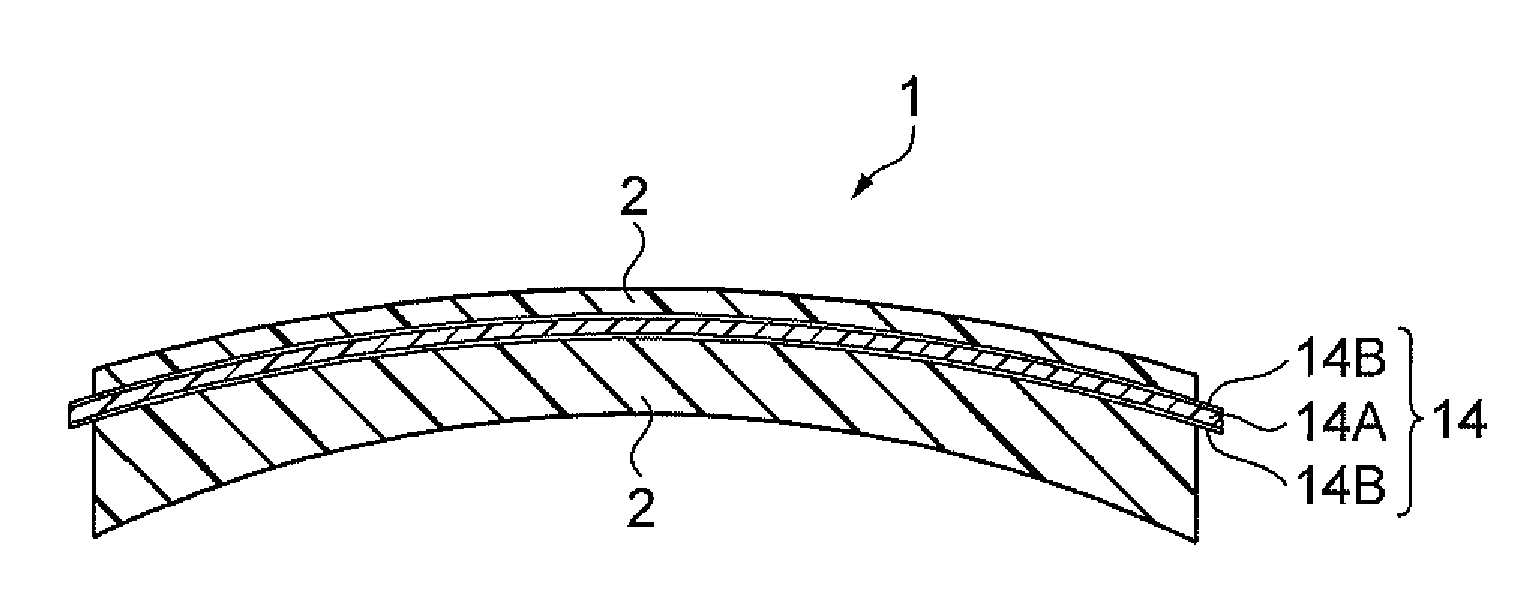

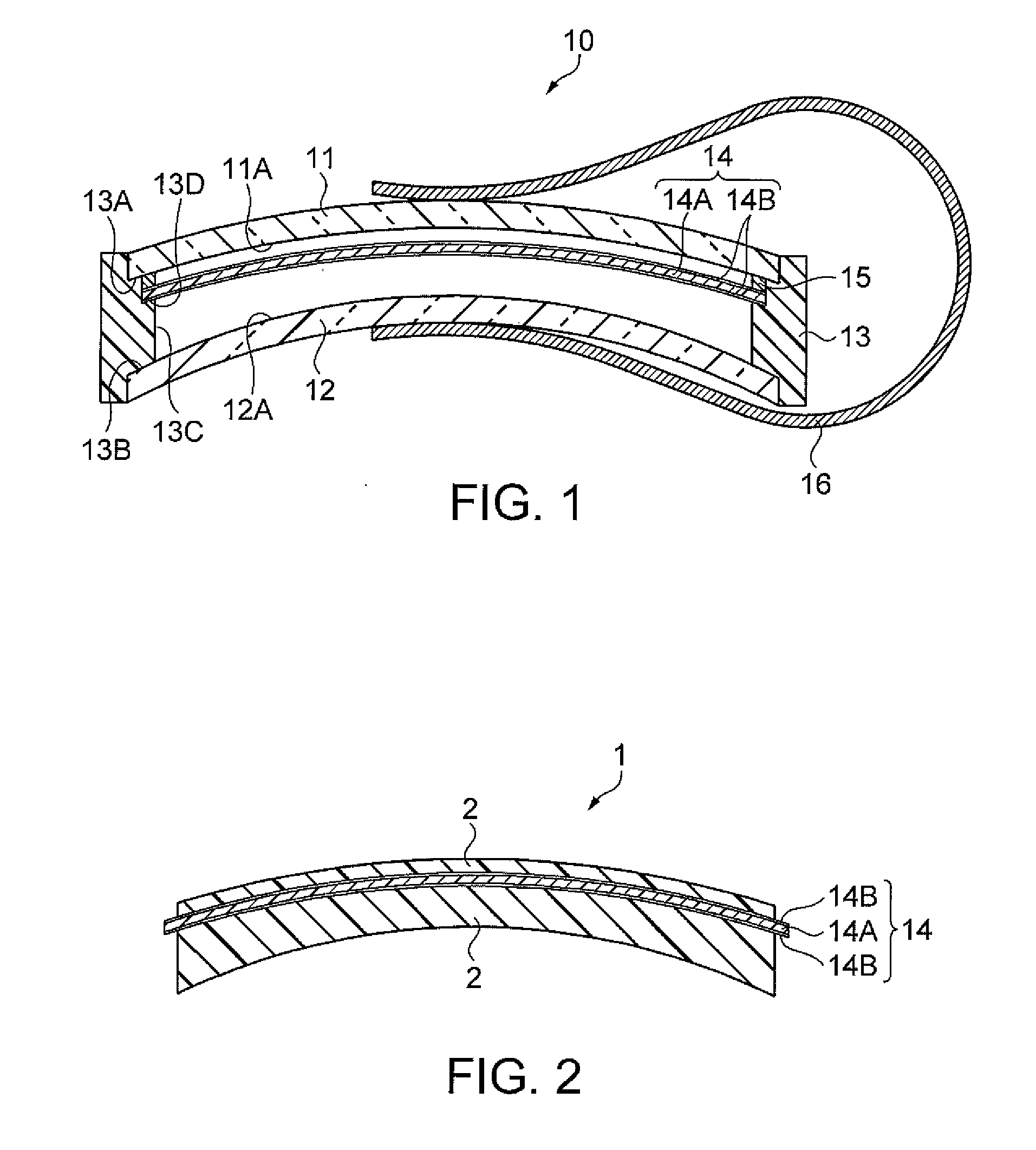

Plastic Polarized Lens

InactiveUS20090091825A1High refractive indexGood lookingPolarising elementsCoatingsRefractive indexLens plate

A plastic polarized lens 1 contains a lens substrate 2, which is obtained by curing through polymerization a polymerization composition having a refractive index of 1.60 or more containing a thiourethane polymerization composition or a thioepoxy polymerization composition, having embedded therein a polarized film 14, which is obtained by forming antireflection layers 14B having a five-layer structure of Al2O3 ZrO2 accumulated alternately on both surfaces of a polarized film substrate 14A obtained by curving an iodine polarized film to a prescribed curvature, followed by cutting into a circular outer shape. According to the constitution, such a plastic polarized lens can be obtained that is reduced in reflection on the surface of the polarized film embedded in the polymerization composition and has good polarizing capability.

Owner:SEIKO EPSON CORP

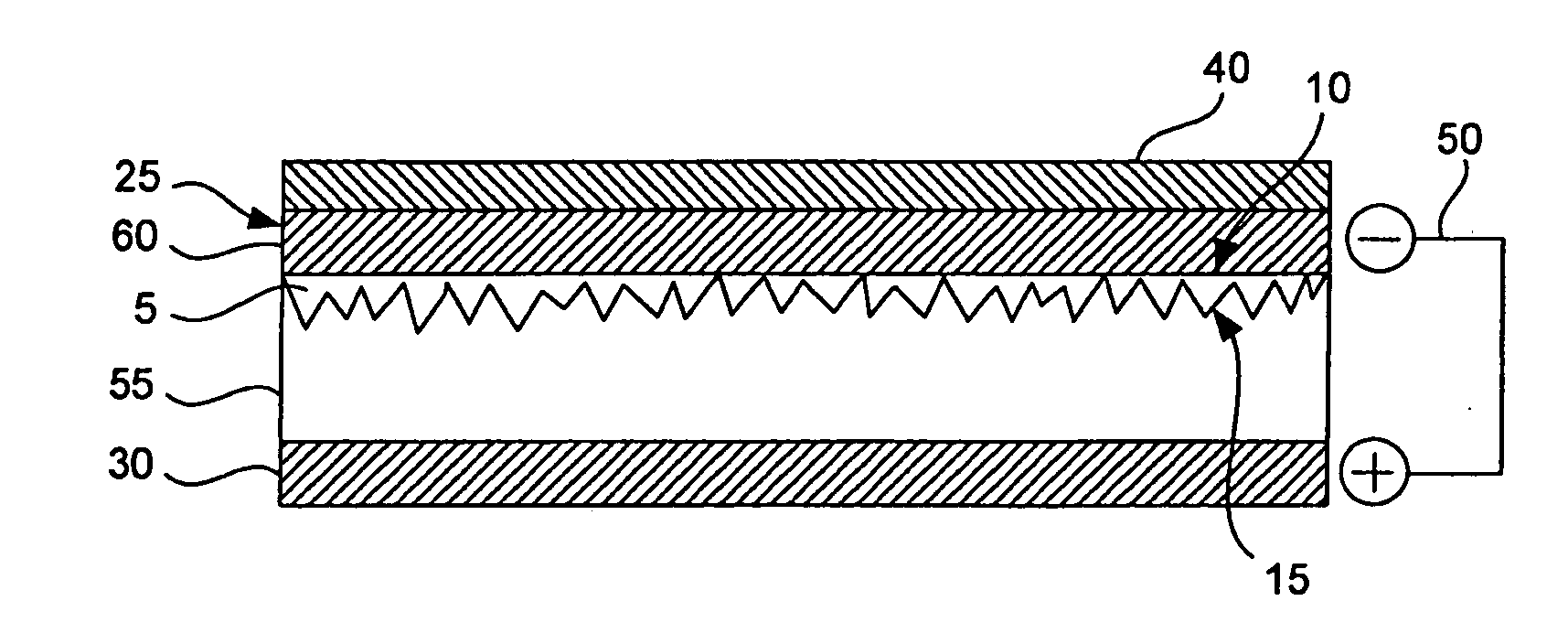

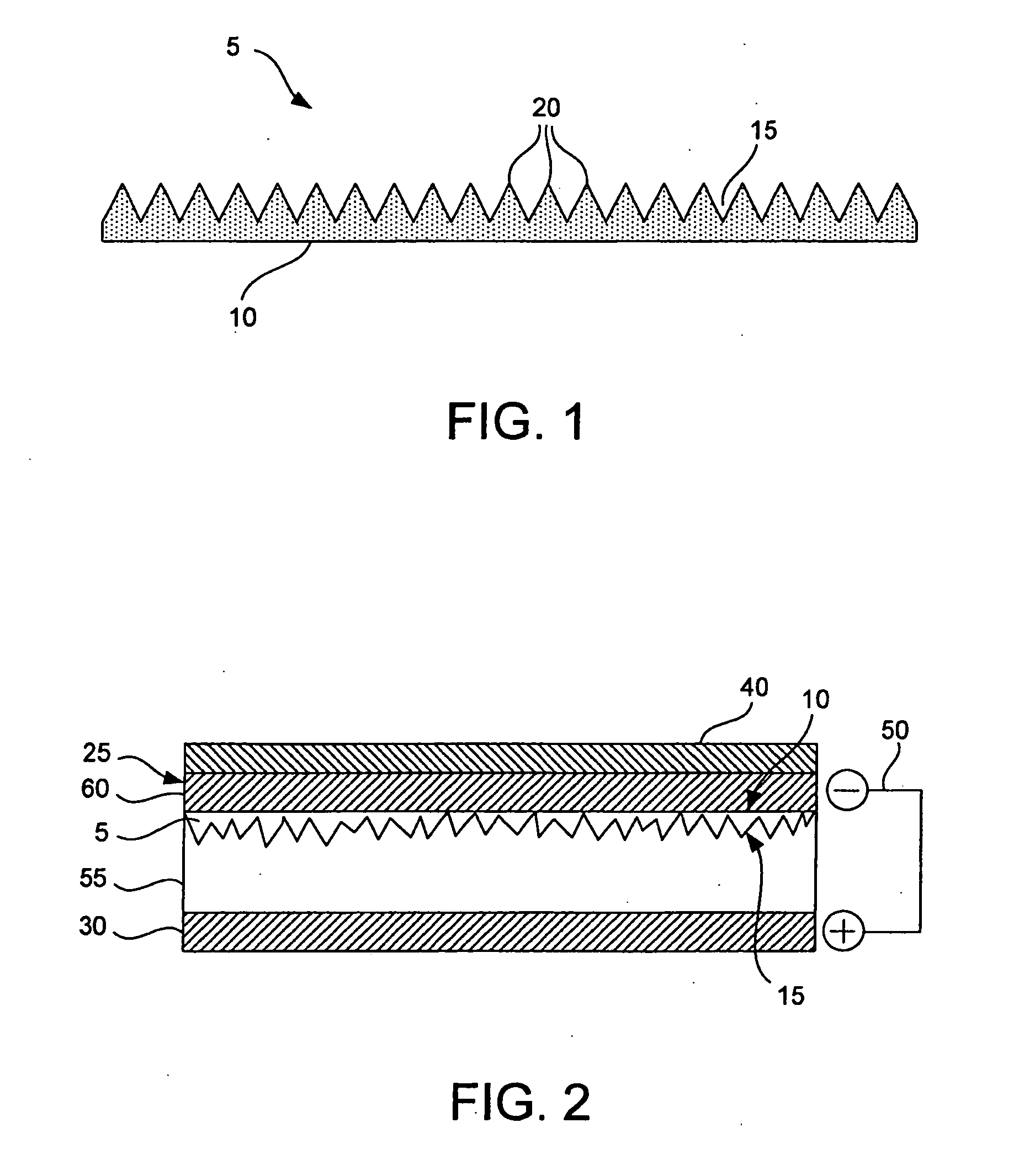

Diamond-like carbon energy conversion devices and methods thereof

InactiveUS20070042667A1Conveniently formedLow costElectric discharge tubesDischarge tube/lamp detailsDiamond-like carbonMaterials science

Diamond-like carbon based energy conversion devices and methods of making and using the same which have improved conversion efficiencies and increased reliability. Such a device may include a cathode having a base member with a layer of diamond-like carbon material coated over at least a portion thereof, an intermediate member electrically coupled to the diamond-like carbon material, the intermediate member including a plurality of carbon structures coated with a layer of an insulating material, and an anode electrically coupled to the intermediate member opposite the diamond-like carbon material.

Owner:SUNG CHIEN MIN

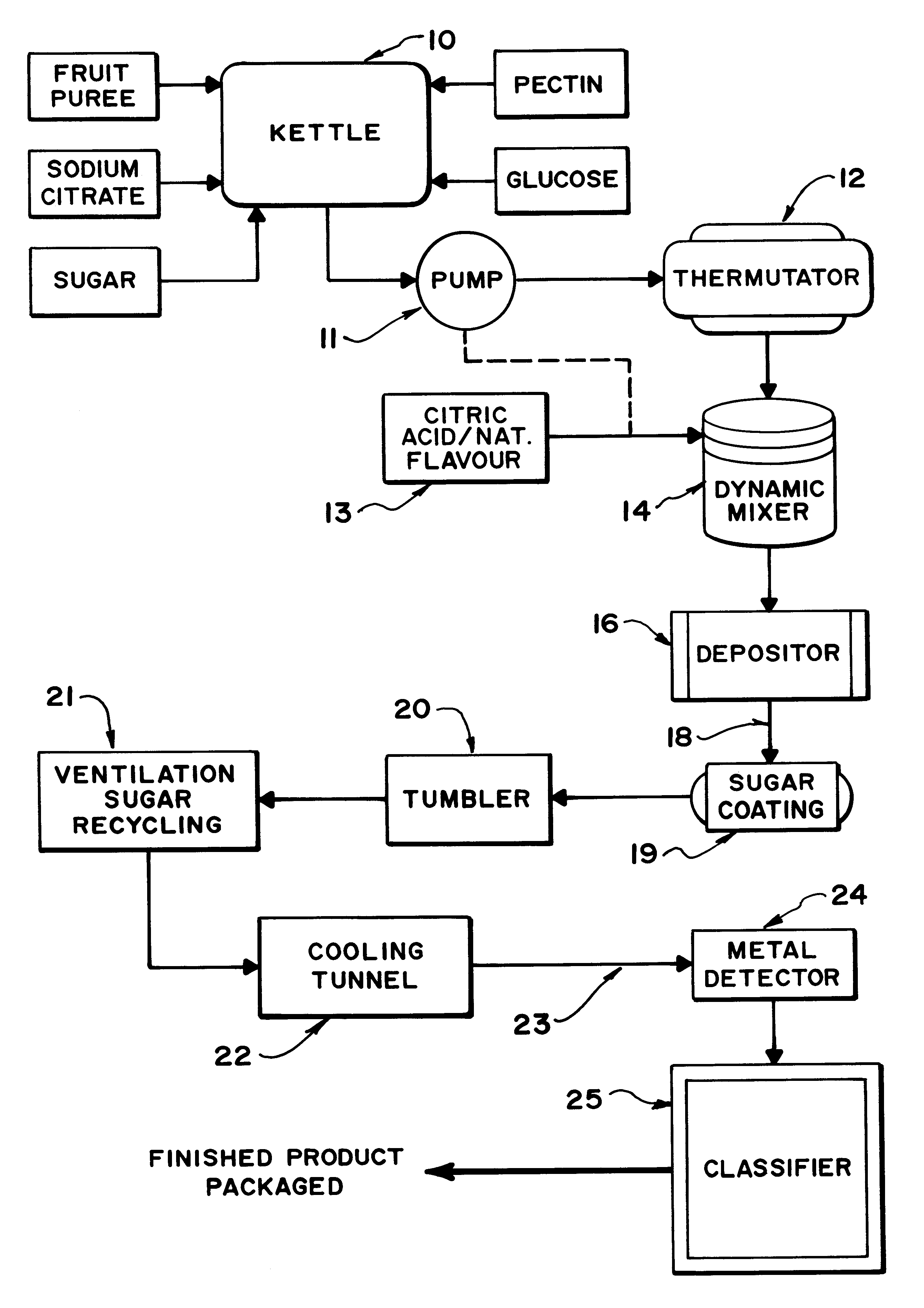

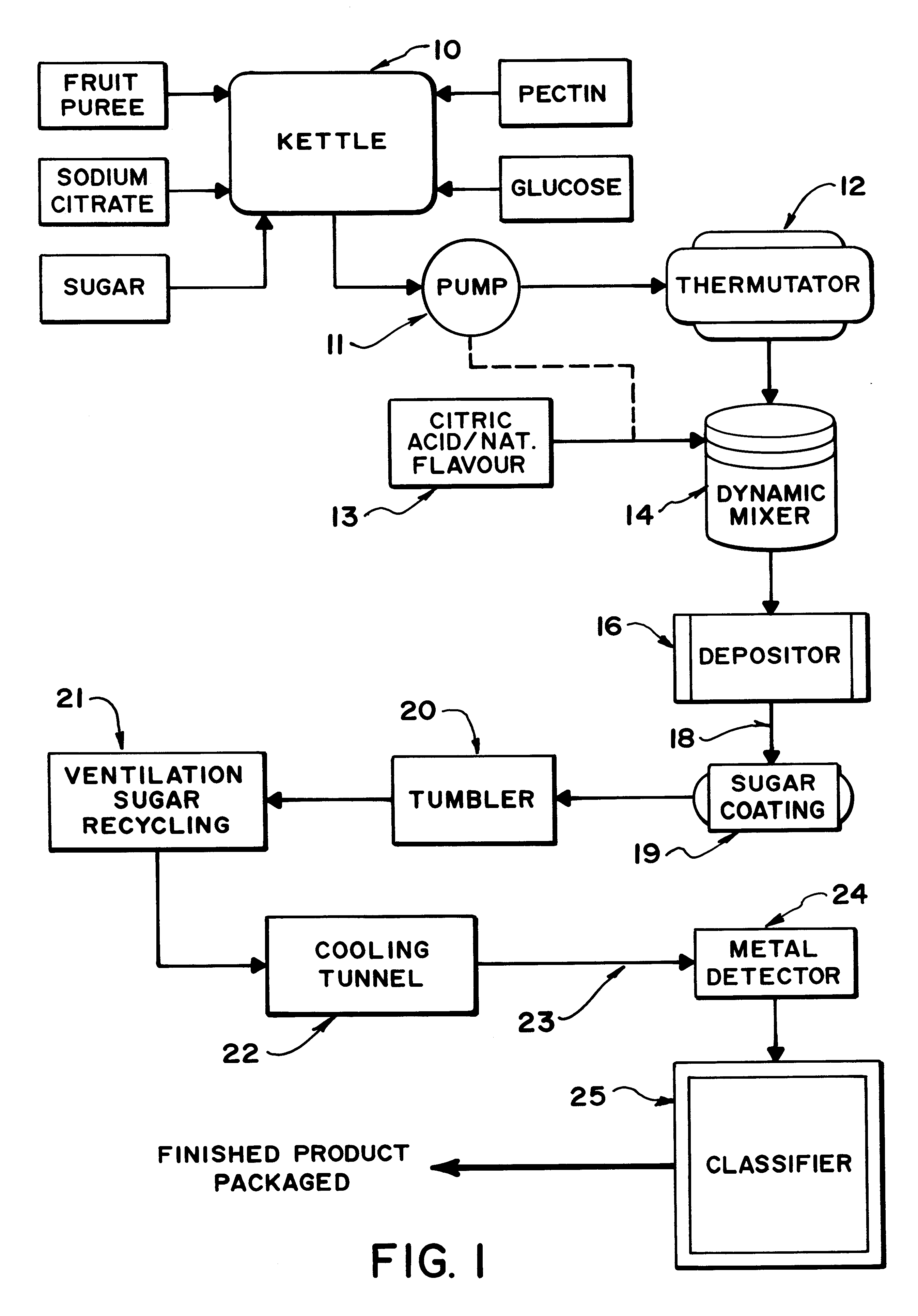

Particulate natural fruit product and method of making same

InactiveUS6251466B1Conveniently formedNatural flavorMilk treatmentCheese manufactureParticulatesNatural product

The present invention relates to a novel method of making a non-liquid fruit product (fruit chip) which has a natural fruit flavor and which can be formed in desired individual or discrete configurations and sizes. A method of making a dry particulate natural fruit chip product comprising: (a) adding a fruit ingredient and water to a heated kettle; (b) adding buffer, sugar and pectin to the fruit ingredient and water; (c) boiling the buffer, sugar and pectin fruit ingredient and water mixture to hydrate the pectin; (d) adding liquid sugar to the mixture and continuing to boil the mixture until excess water is boiled away; (e) adding sugar to the mixture in the kettle to reduce the temperature of the mixture and increase solids concentration; (i) transporting the mixture from the kettle through a heat exchanger to raise the temperature of the mixture; (g) adding acid and flavoring mix to the mixture and mixing the acid / flavour into the mixture; (h) passing the mixture into a heated depositor and dispensing the mixture onto a surface in the form of discrete fruit chips; (i) retaining the fruit chips on the surface until they lose heat and form a stable gel; (j) transporting the gelled fruit chips through a zone to remove excess moisture and enhance gel strength of the fruit chips; and (k) transporting the fruit chips through a cooling zone so that the fruit chips lose further heat and reach ambient temperature.

Owner:BROOKSIDE FOODS

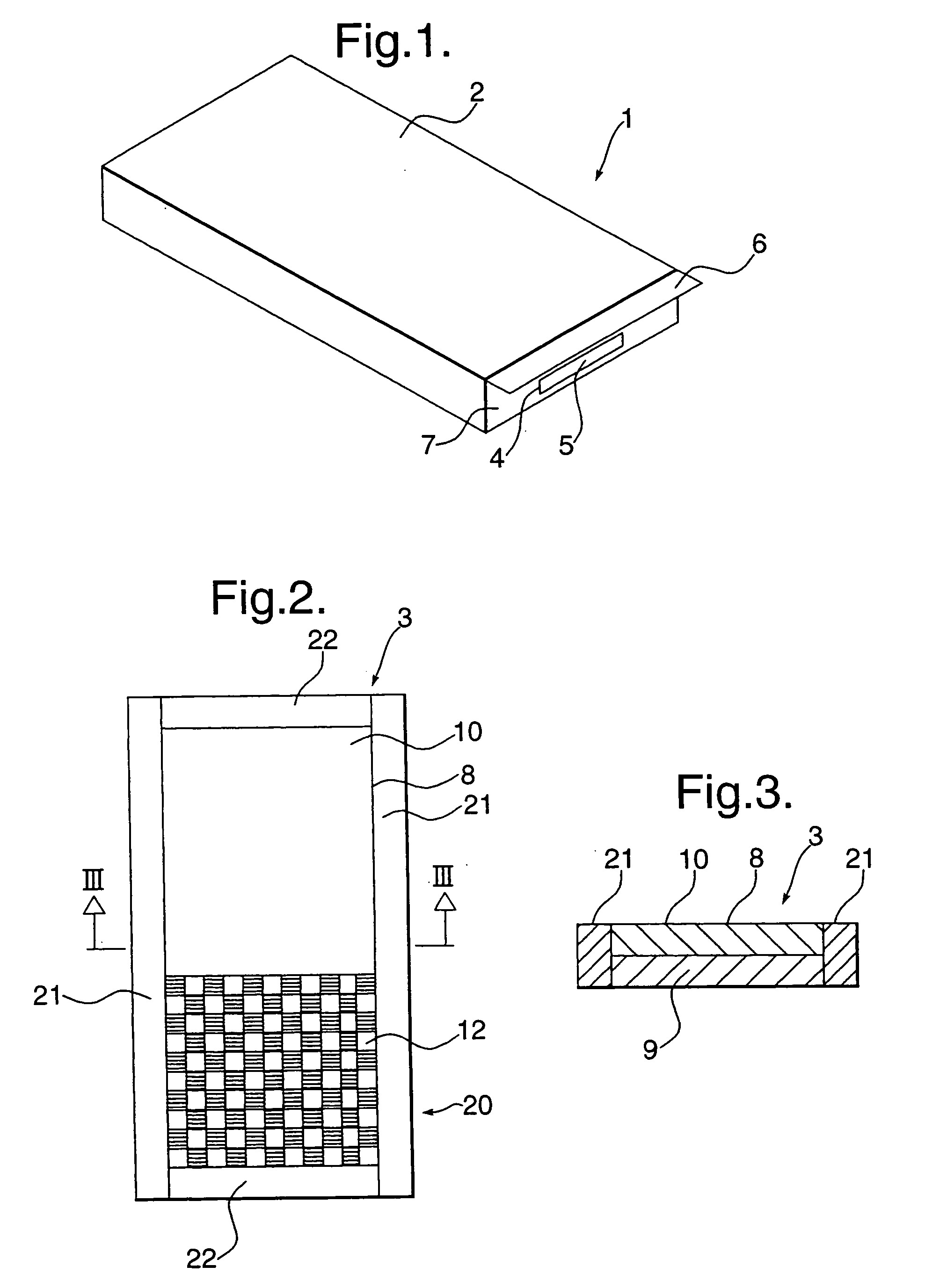

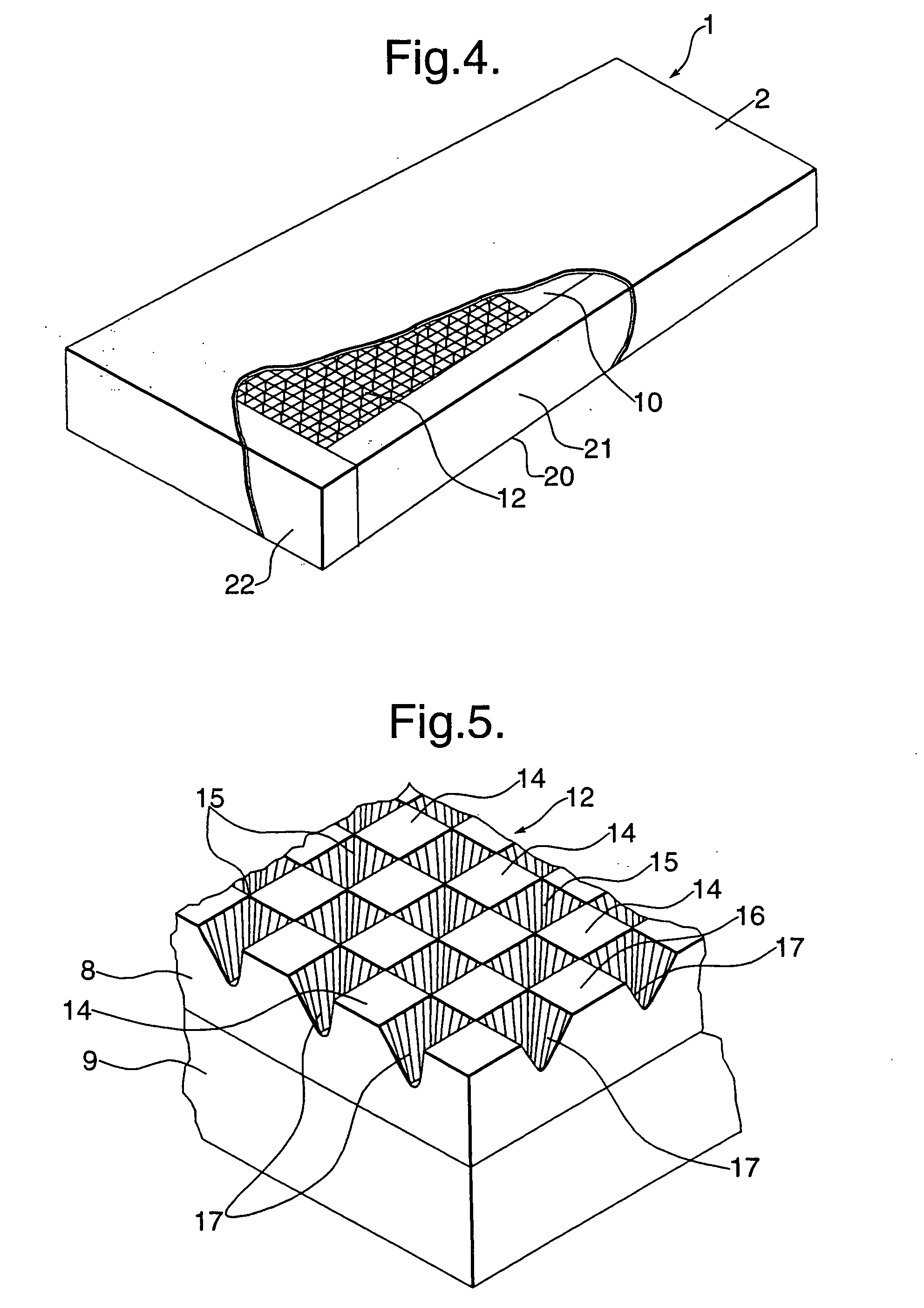

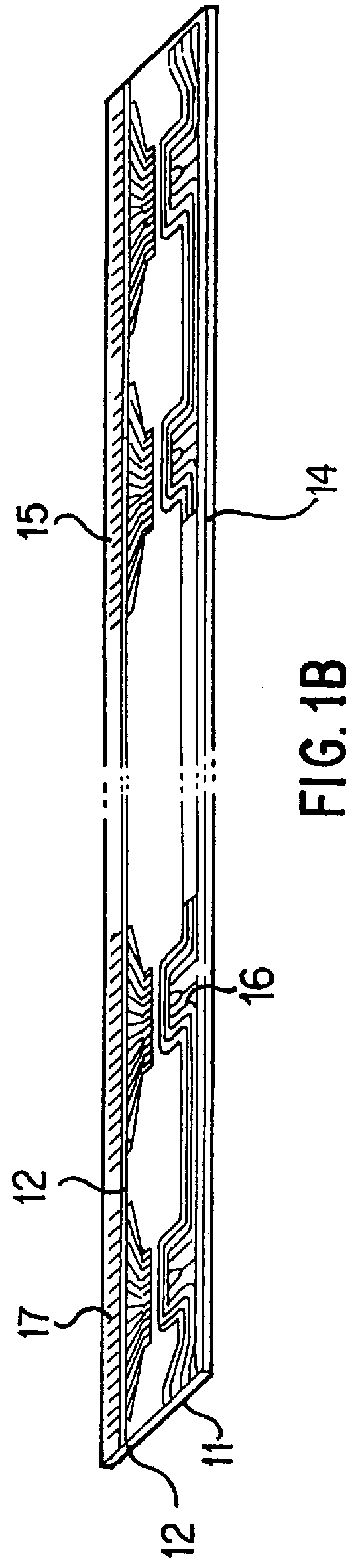

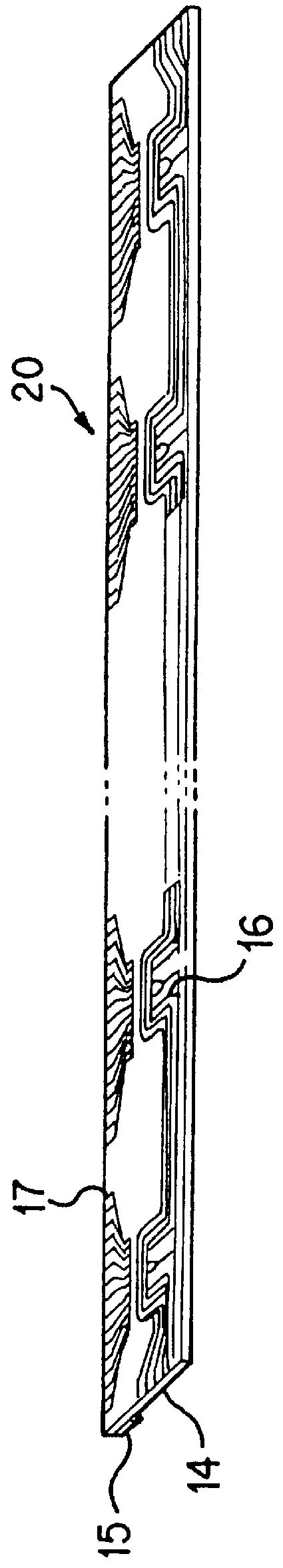

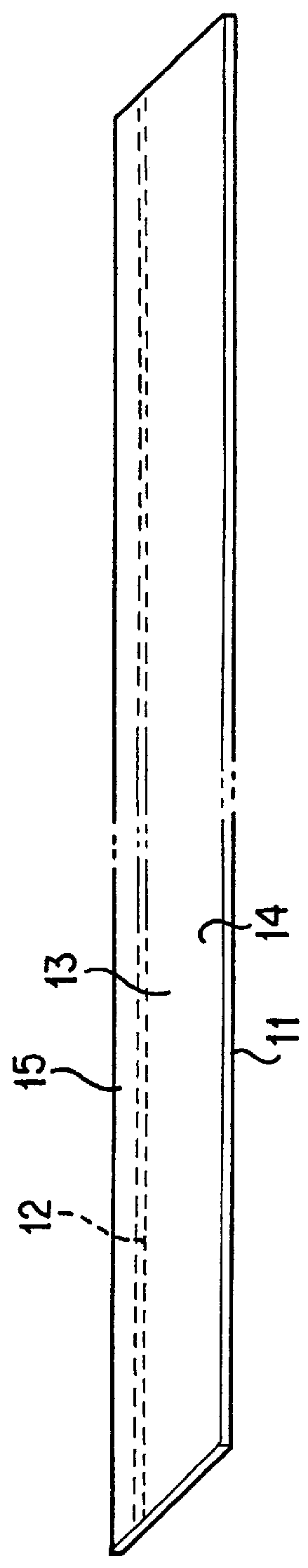

Printed wiring board and its manufacturing method, and electronic apparatus

InactiveUS6121988AReduce manufacturing costSimple designPrinted circuit assemblingSemiconductor/solid-state device detailsLiquid-crystal displayElectrical conductor

PCT No. PCT / JP95 / 01941 Sec. 371 Date Mar. 27, 1997 Sec. 102(e) Date Mar. 27, 1997 PCT Filed Sep. 26, 1995 PCT Pub. No. WO96 / 10326 PCT Pub. Date Apr. 4, 1996A cutout portion 12 is formed by partially cutting out a board along a predetermined fold and a first portion 14 and a second portion 15 partitioned along the fold are folded and attached together into a unitary body by a bonding agent or thermal fusing. Formed on a surface of the printed wiring board 11 is a conductor pattern 17 that continuously runs across the fold at the cutout portion between the first portion and the second portion, and thus the conductor pattern assuring continuity between both sides of a printed wiring board 20 results without the need for providing through-holes. By employing such a printed wiring board, a compact and low-cost feature can be implemented into electronic apparatuses or portable information apparatuses, such as liquid crystal display devices or electronic printers, through a miniature, light-weight and flat design effort.

Owner:BOE TECH GRP CO LTD

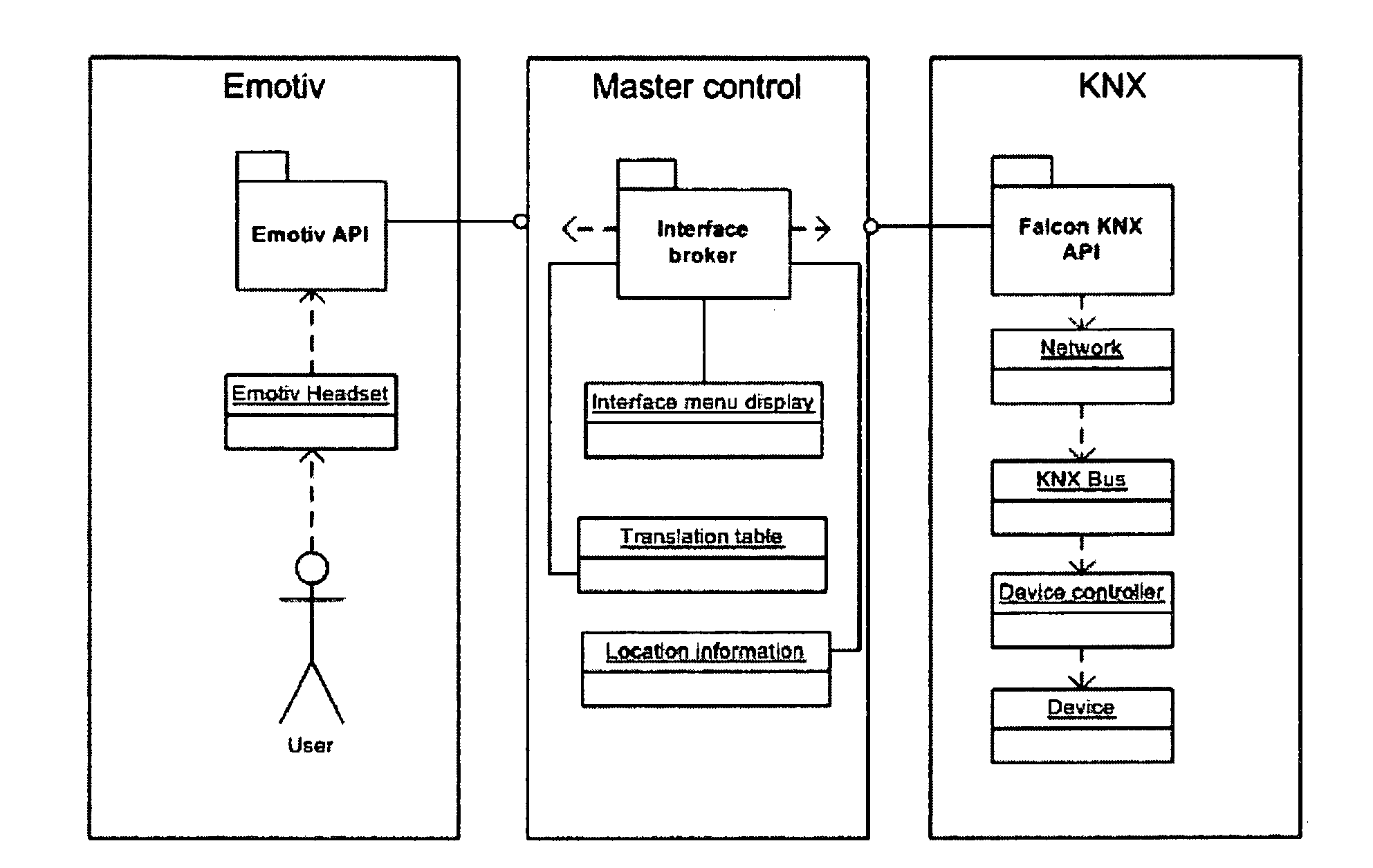

Environmental control method and system

InactiveUS20120296476A1Easy to operateGuaranteed to workSampled-variable control systemsComputer controlUser inputComputer science

The invention relates to an environment management system method and apparatus used to manage the environment within a structure. When implemented within a system the invention includes a plurality of peripheral devices distributed within the structure where operation of a peripheral device modifies the environment of at least one region of the structure associated with the peripheral device. The system also includes at least one network which connects the plurality of devices, and at least one controller arranged to receive signals from one or more peripheral device and to transmit a command to one or more peripheral devices using this network. The system of the invention also includes a user input system interfaced with the at least one controller where this user input system is arranged to use at least one user neural signal to provide a user command to one or more controllers.

Owner:CALE RICHARD JOHN +1

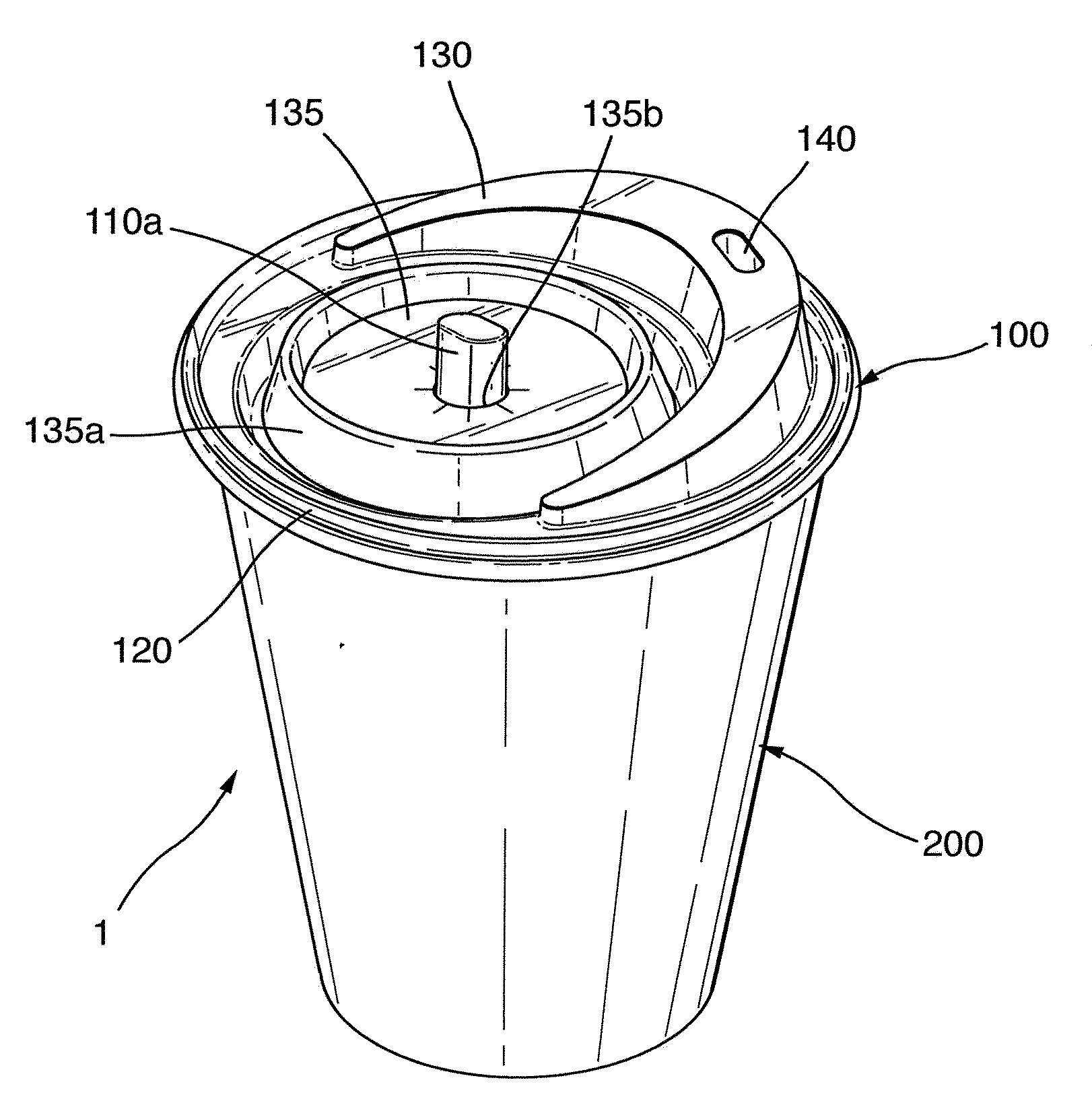

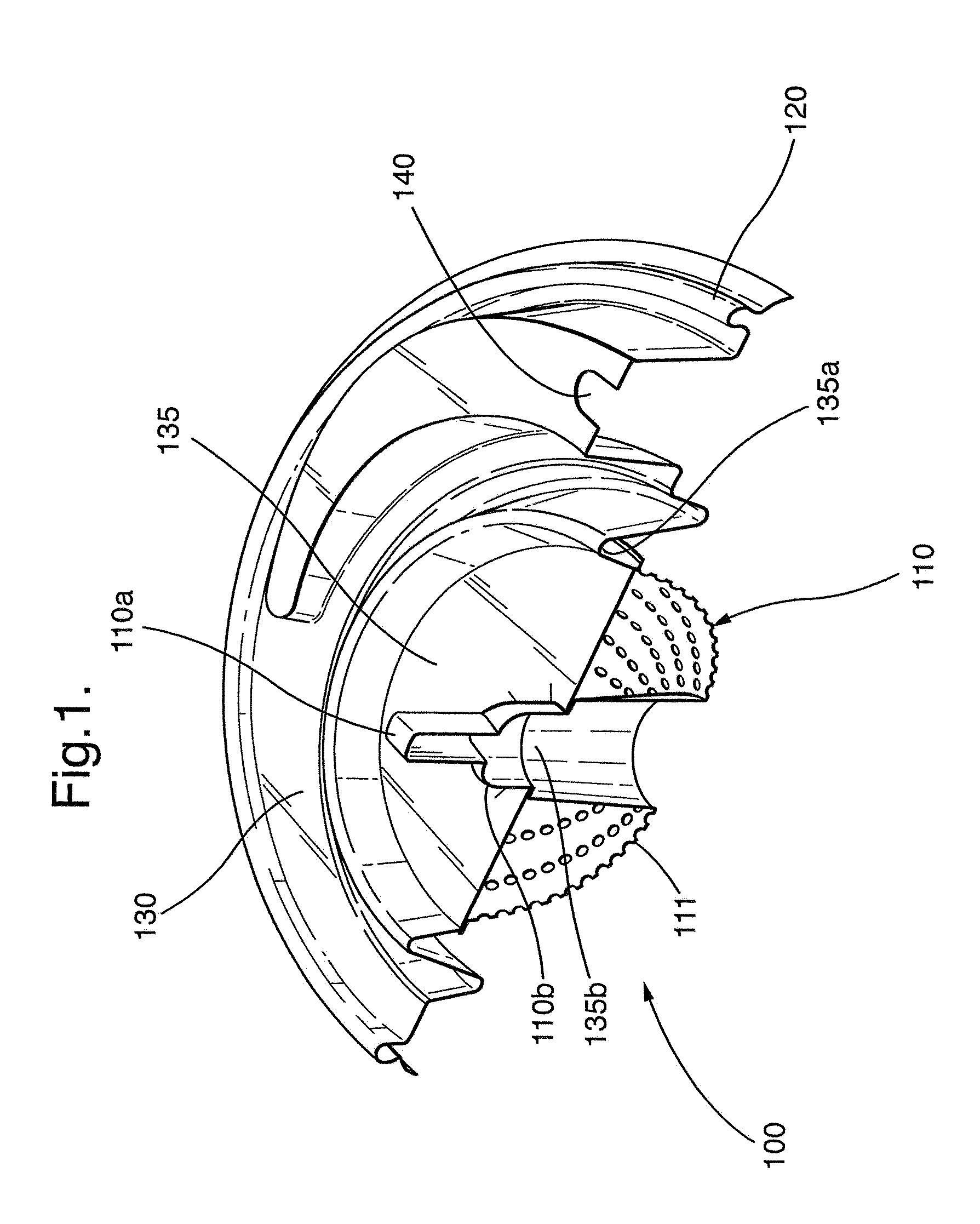

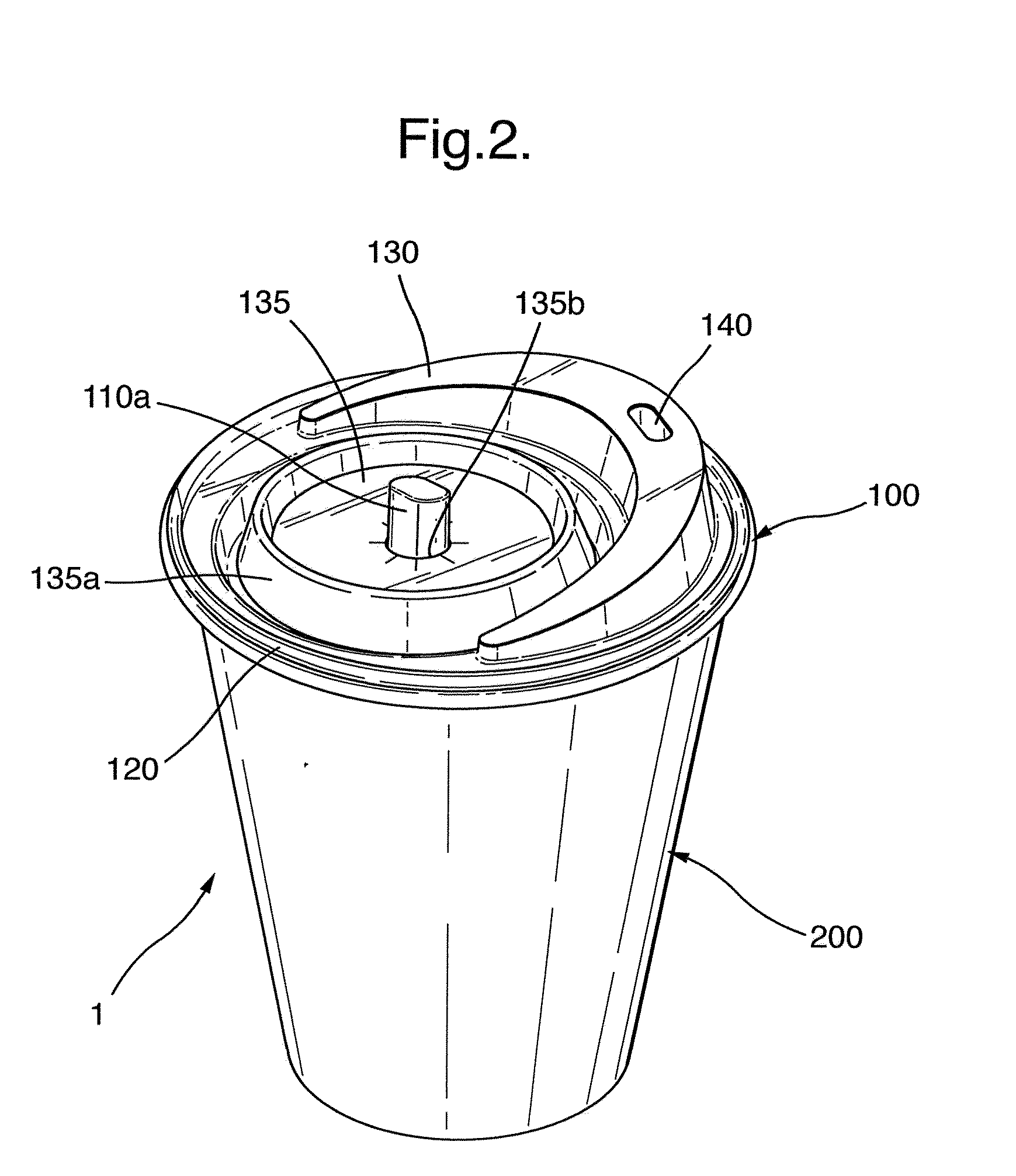

Lid, in particular for a disposable cup

InactiveUS20100037780A1Stop infusion processTranslational movementCapsLarge containersDisposable cupSurgery

Disclosed is a lid (100), in particular for a disposable cup. The lid comprises an infusion chamber (110) having at least one water-permeable wall (111) and comprising an infusible substance; a flange (120) for attaching the lid to the rim (210) of a cup (200); and a body section (130) comprising a moveable portion (135). The infusion chamber (110) is attached to the moveable portion (135) and with the lid (100) fitted to the cup (200), the moveable portion (135) is reversibly translatable between a raised and a lowered position in a direction (A) substantially perpendicular to the plane of the rim (210).

Owner:CONOPCO INC D B A UNILEVER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com