Patents

Literature

1073 results about "Diamond-like carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diamond-like carbon (DLC) is a class of amorphous carbon material that displays some of the typical properties of diamond. DLC is usually applied as coatings to other materials that could benefit from some of those properties.

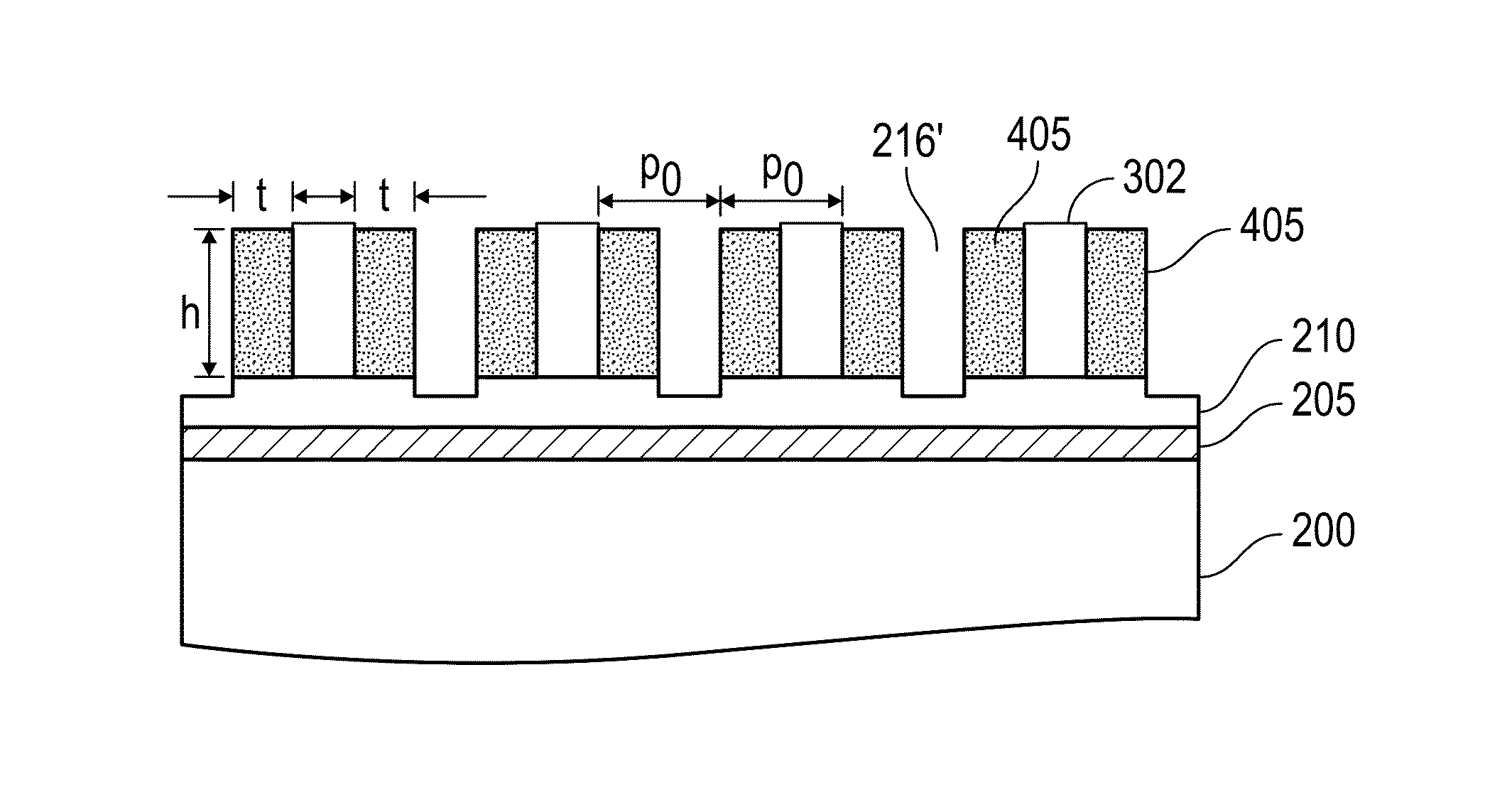

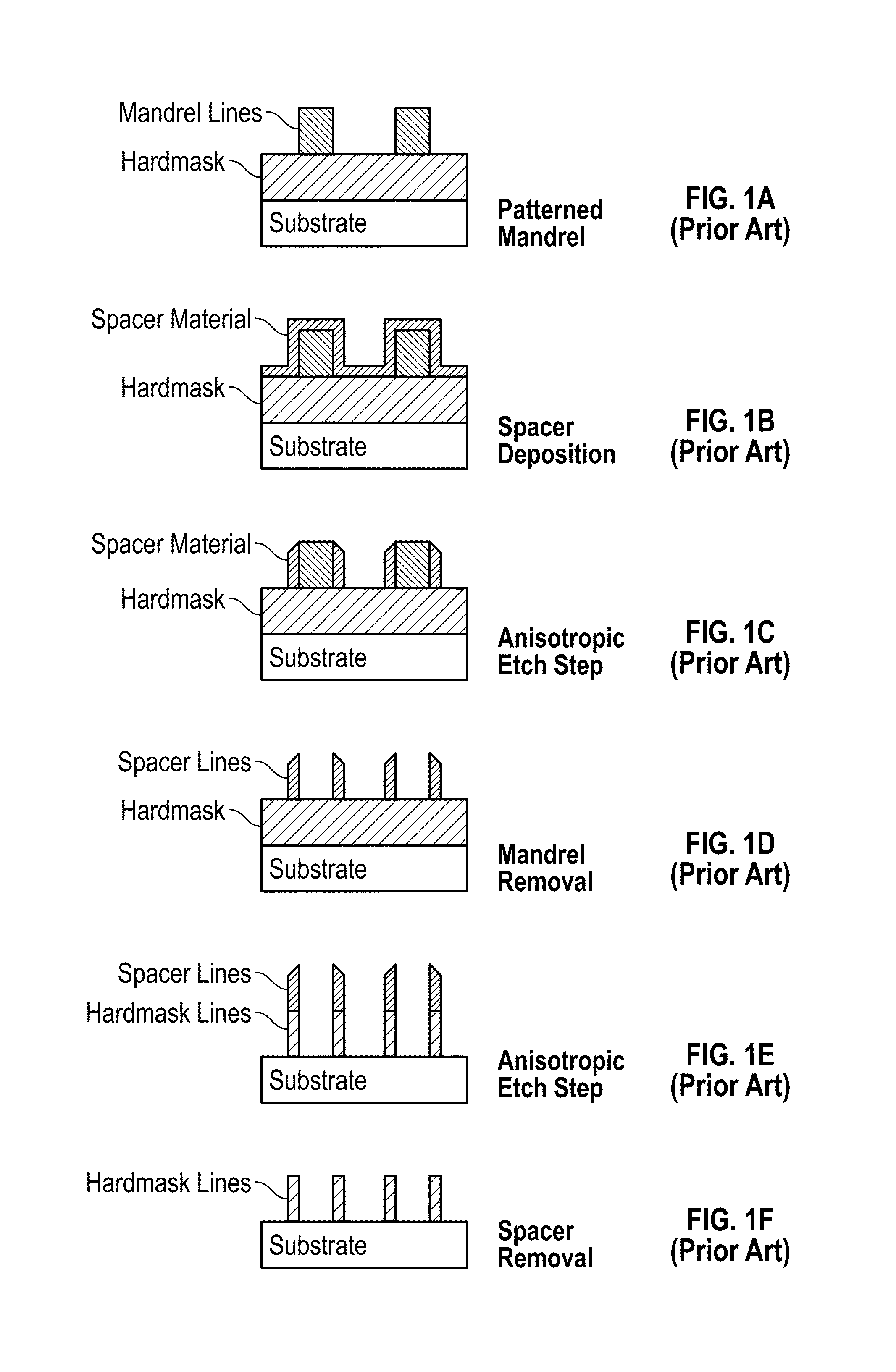

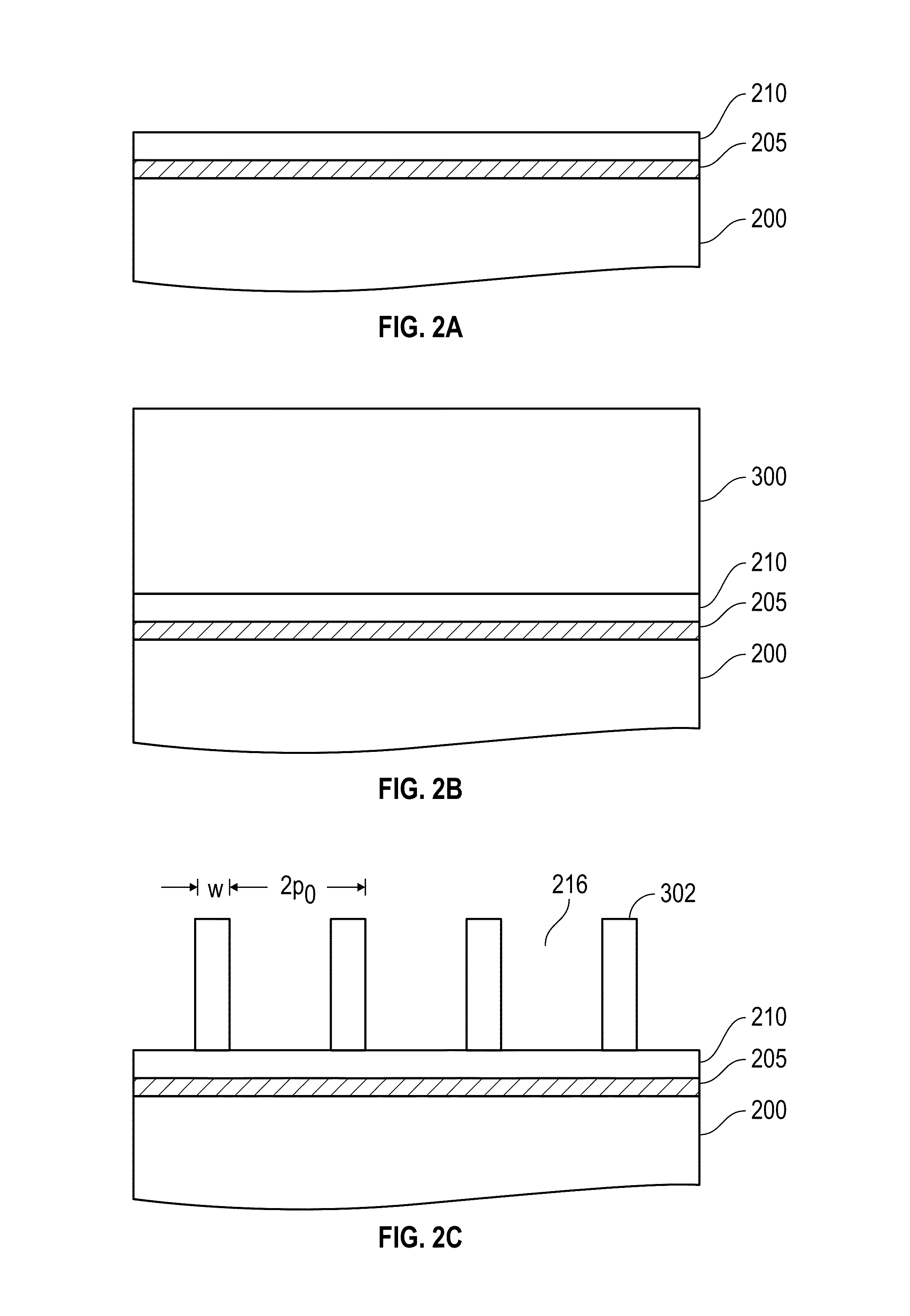

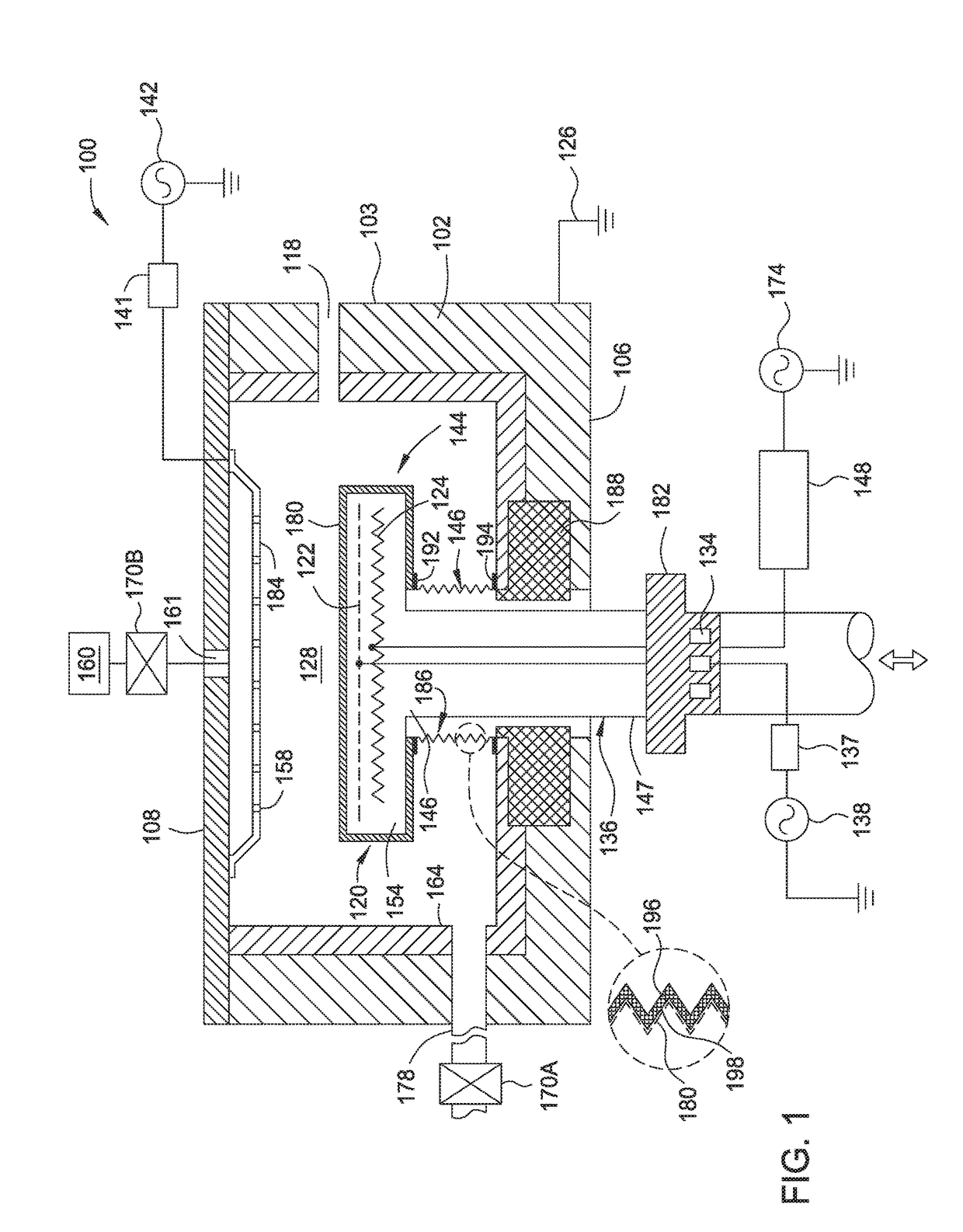

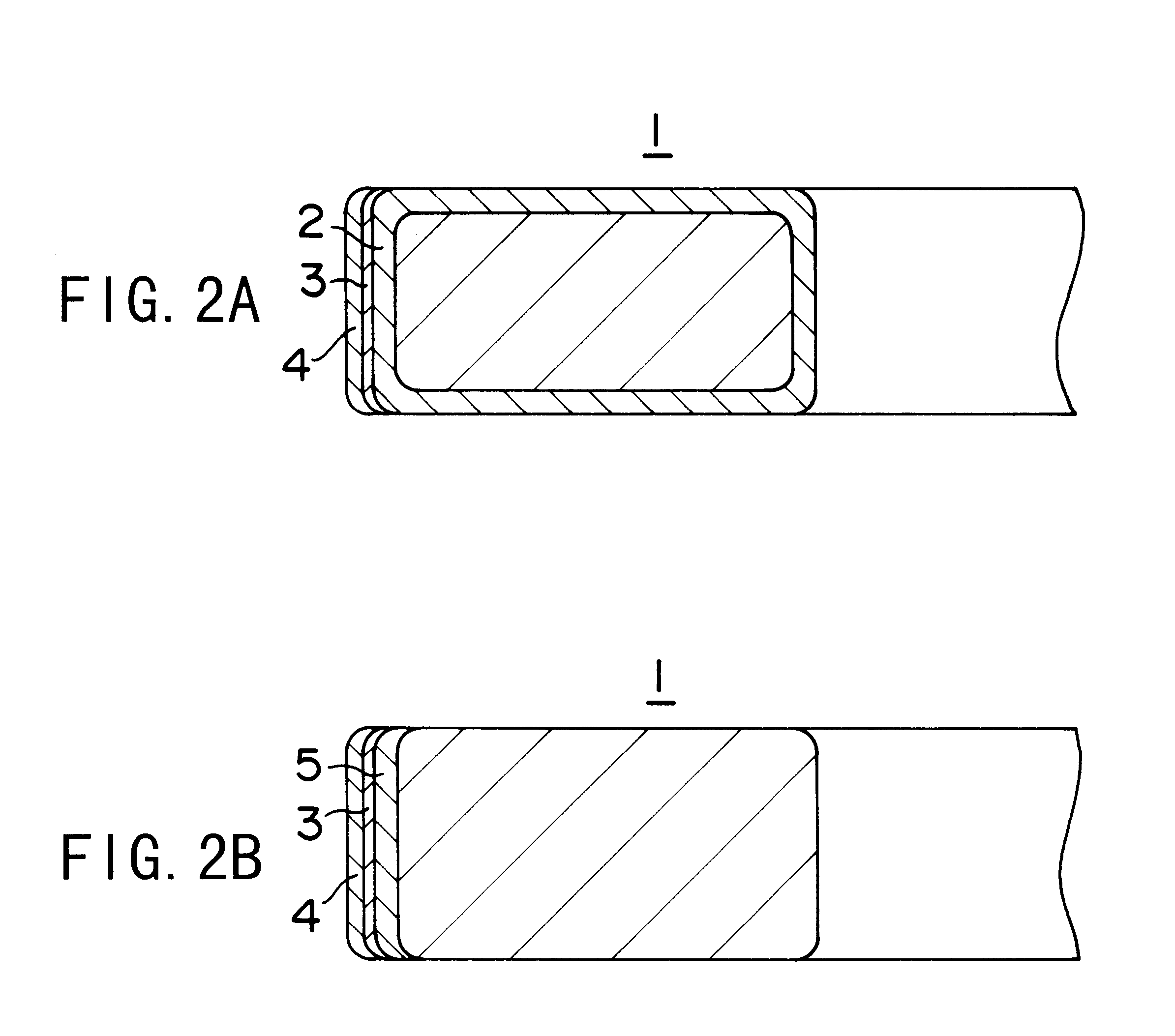

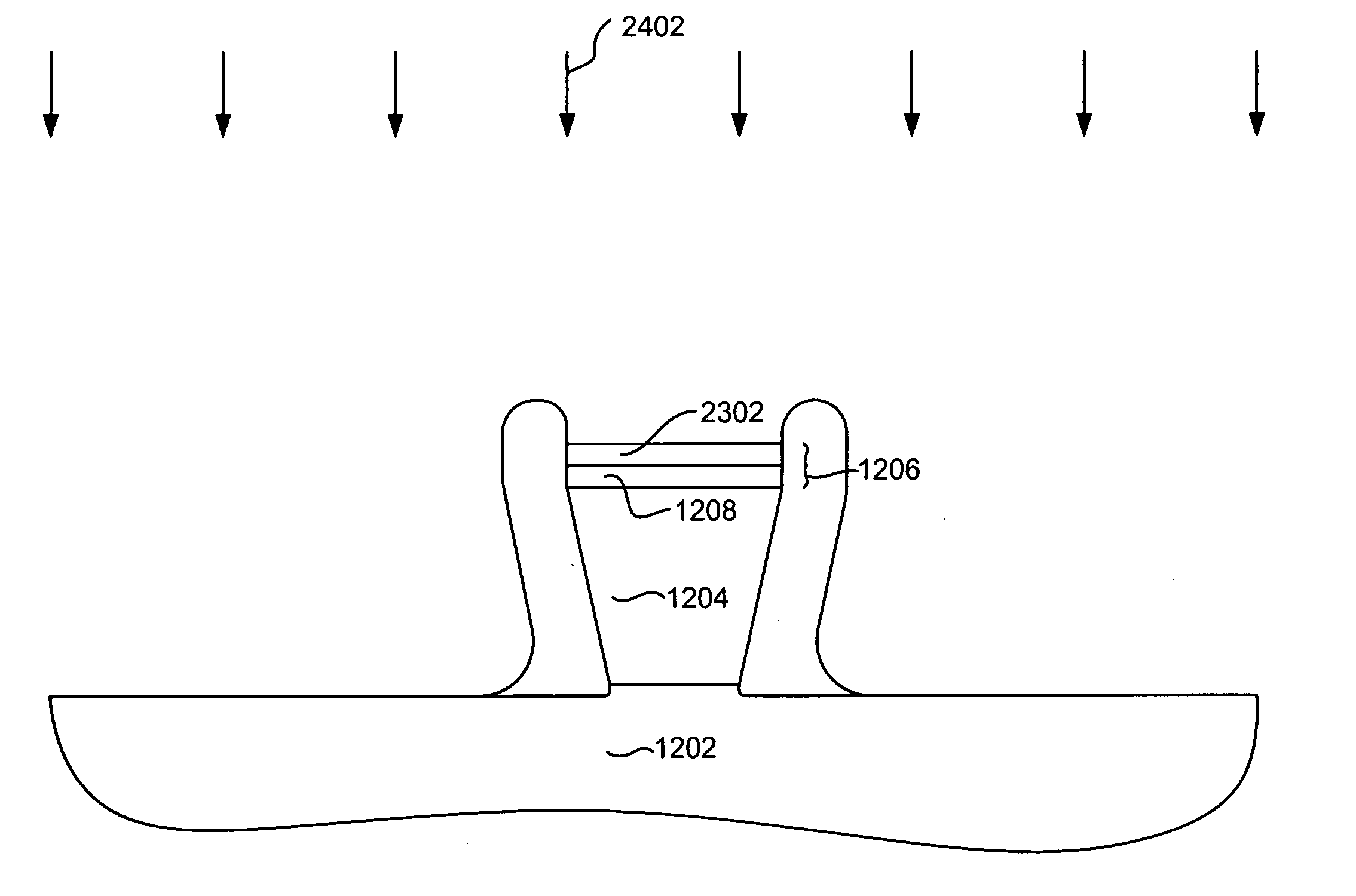

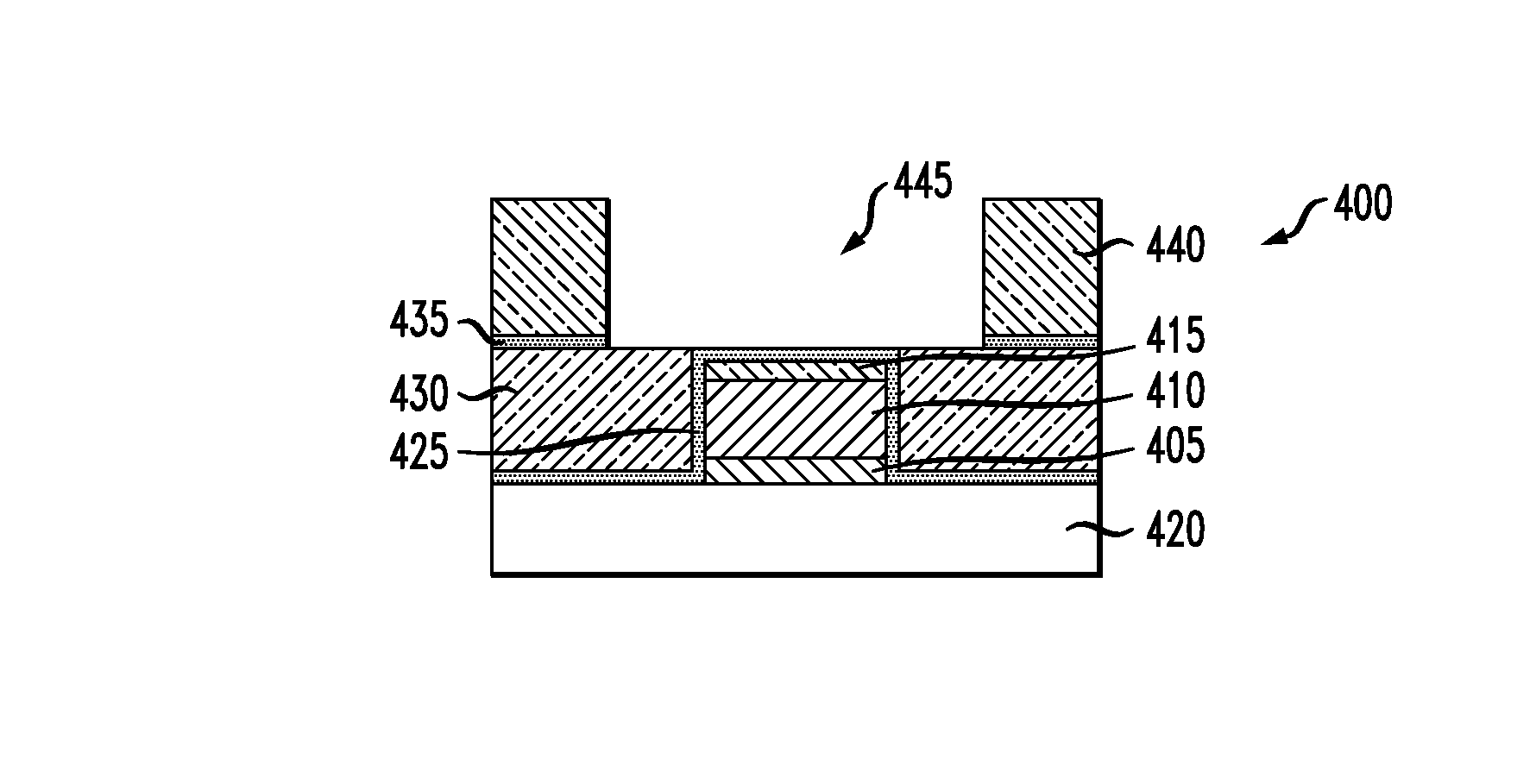

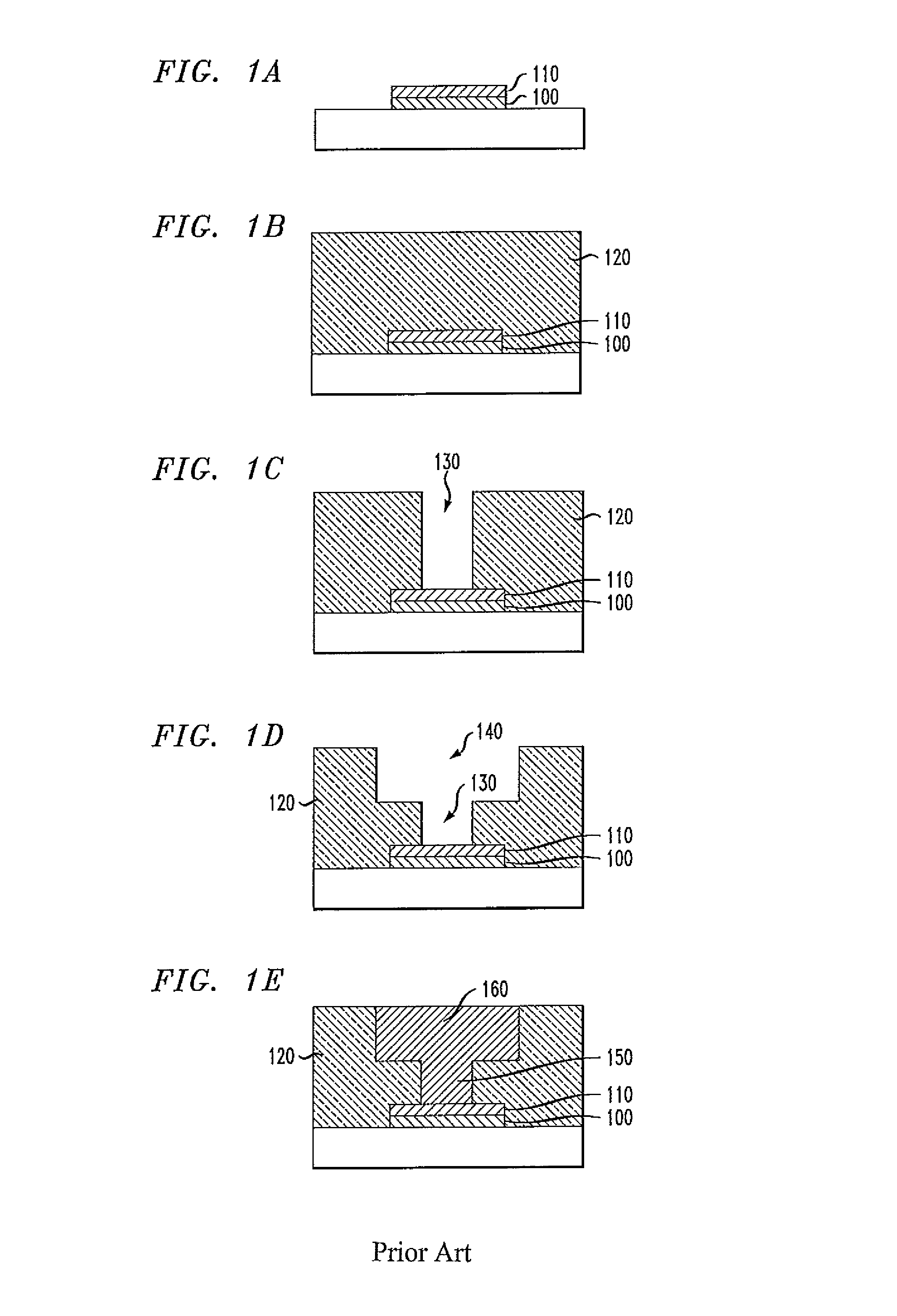

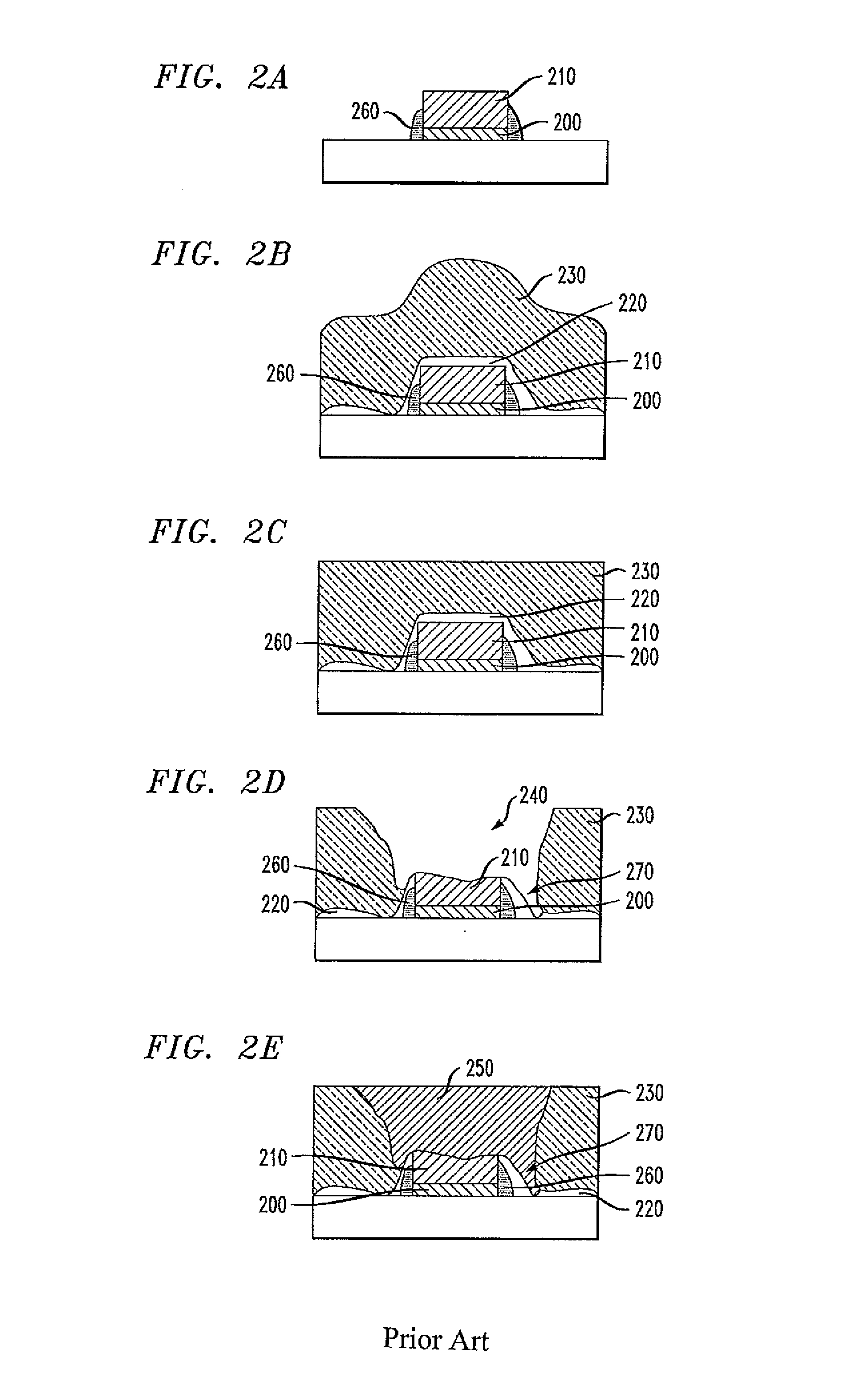

Method for sidewall spacer line doubling using atomic layer deposition of a titanium oxide

A method for sidewall spacer line doubling uses thermal atomic layer deposition (ALD) of a titanium oxide (TiOx) spacer layer. A hardmask layer is deposited on a suitable substrate. A mandrel layer of diamond-like carbon (DLC) is deposited on the hardmask layer and patterned into stripes with tops and sidewalls. A layer of TiOx is deposited, by thermal ALD without the assistance of plasma or ozone, on the tops and sidewalls of the mandrel stripes. Thermal ALD of the TiO2, without energy assistance by plasma or ozone, has been found to cause no damage to the DLC mandrel stripes. After removal of the TiOx from the tops of the mandrel stripes and removal of the mandrel stripes, stripes of TiO2 are left on the hardmask layer and may be used as an etch mask to transfer the pattern into the hardmask layer.

Owner:WESTERN DIGITAL TECH INC

Corrosion control for chamber components

Owner:APPLIED MATERIALS INC

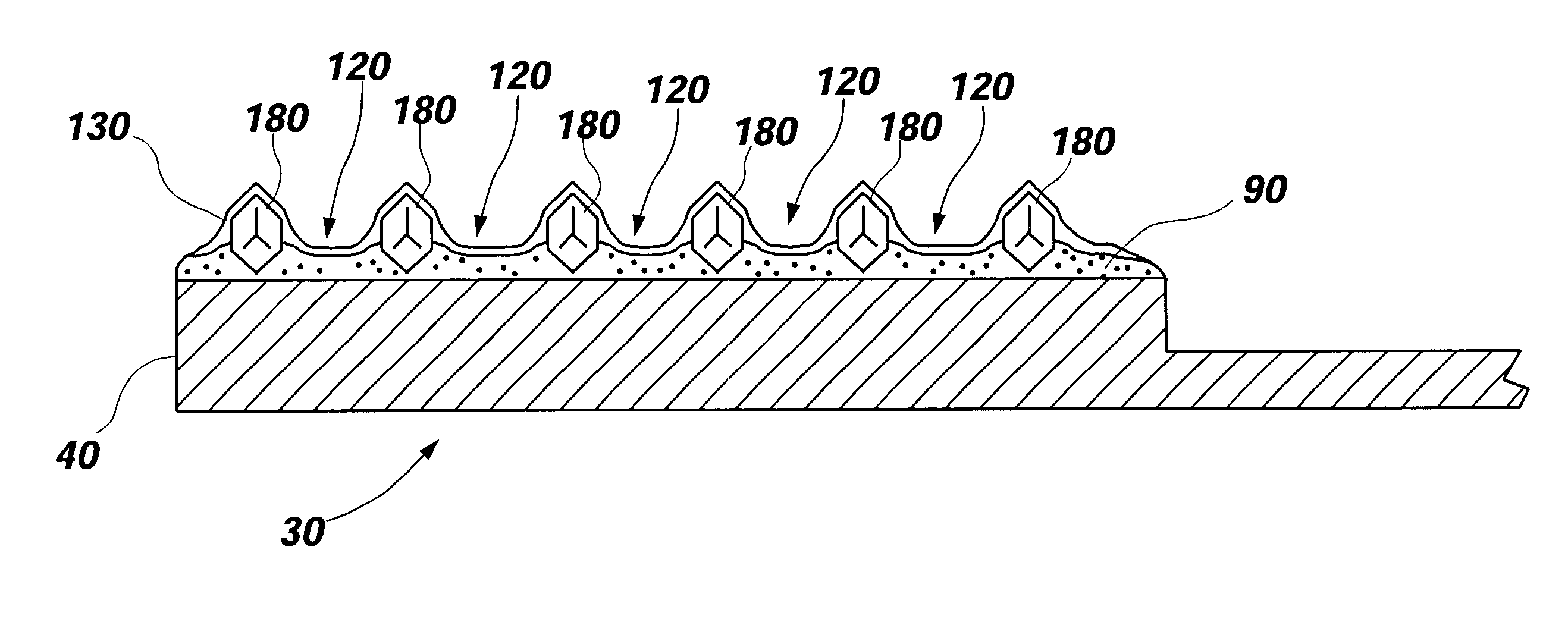

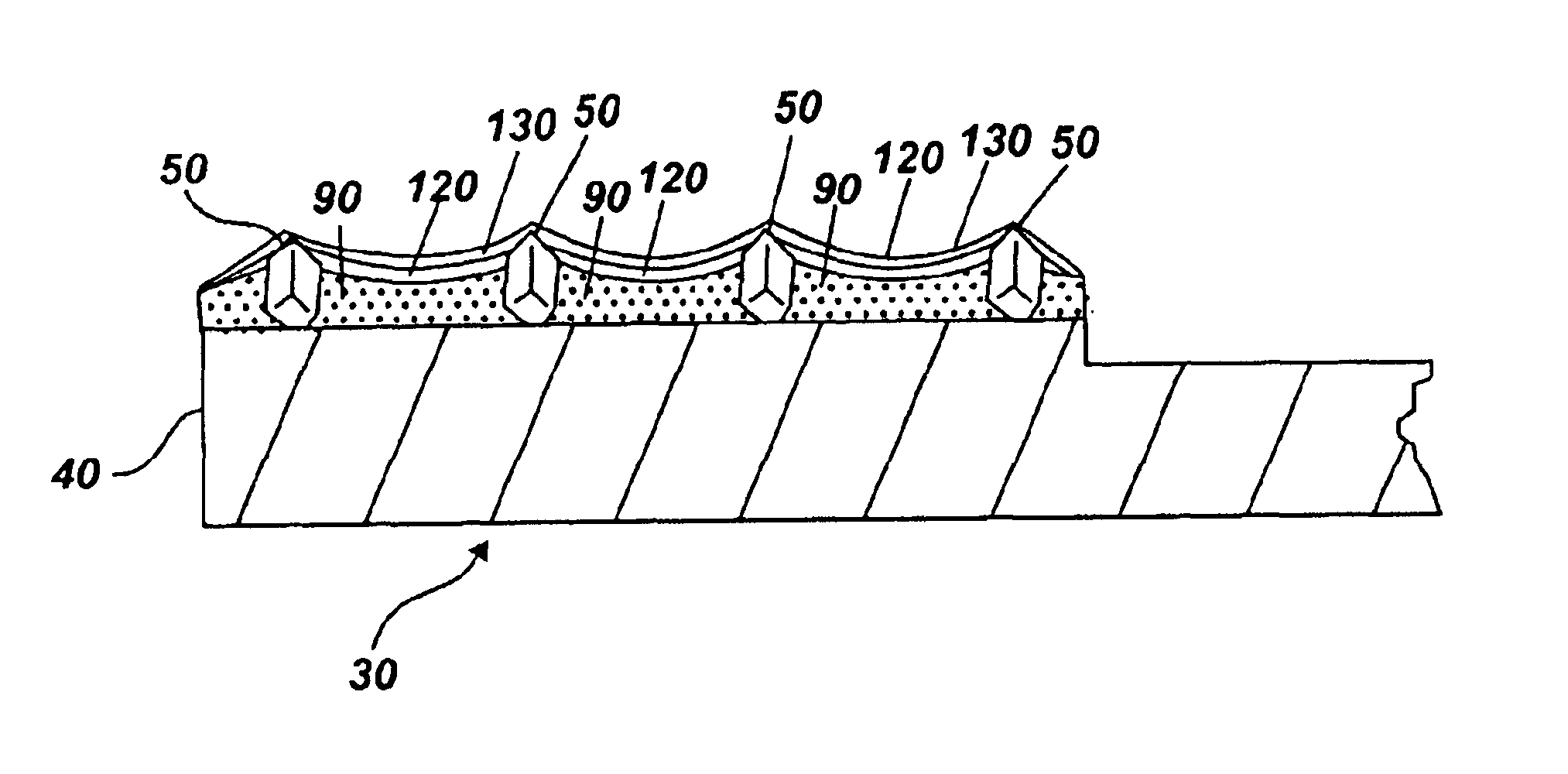

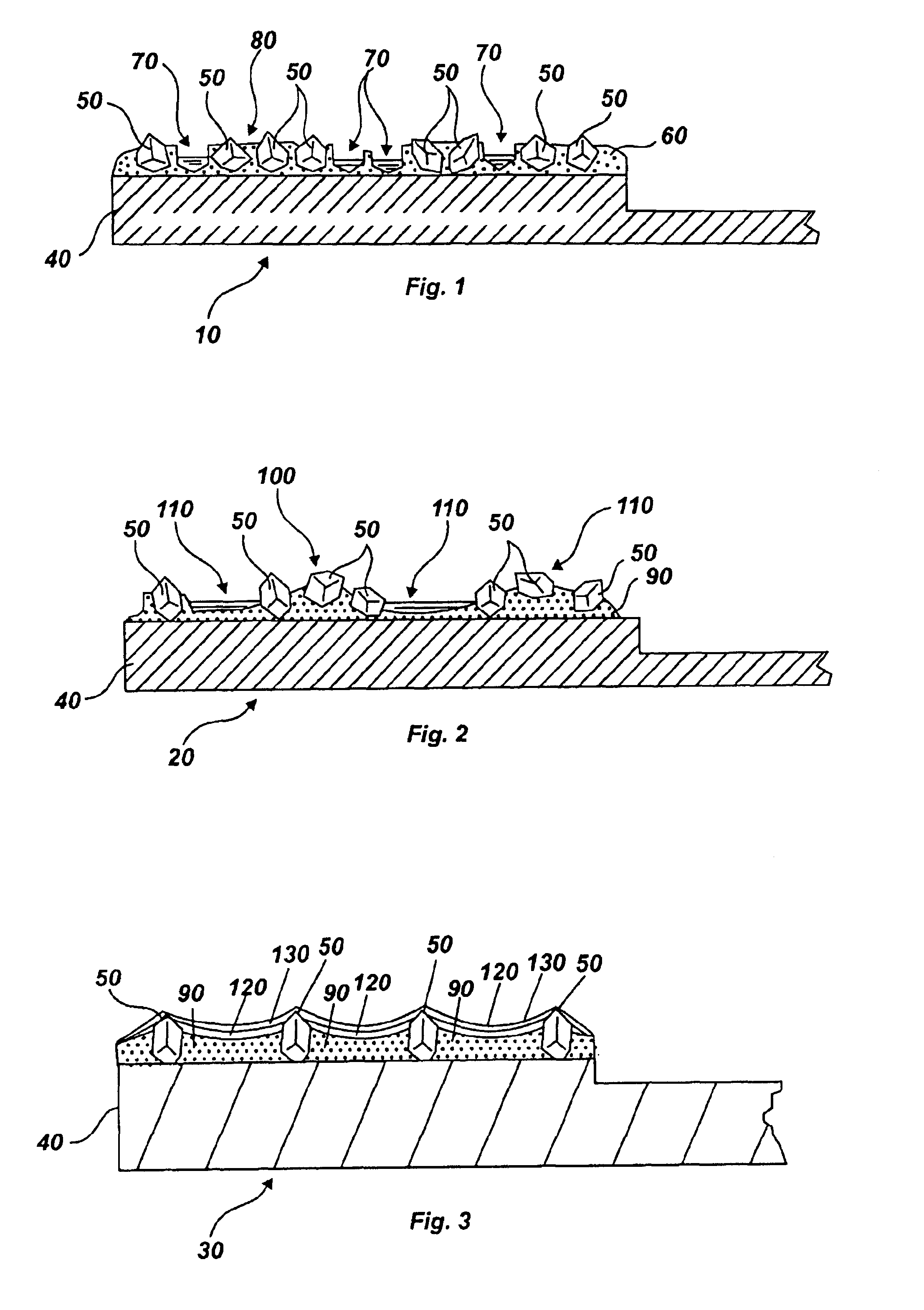

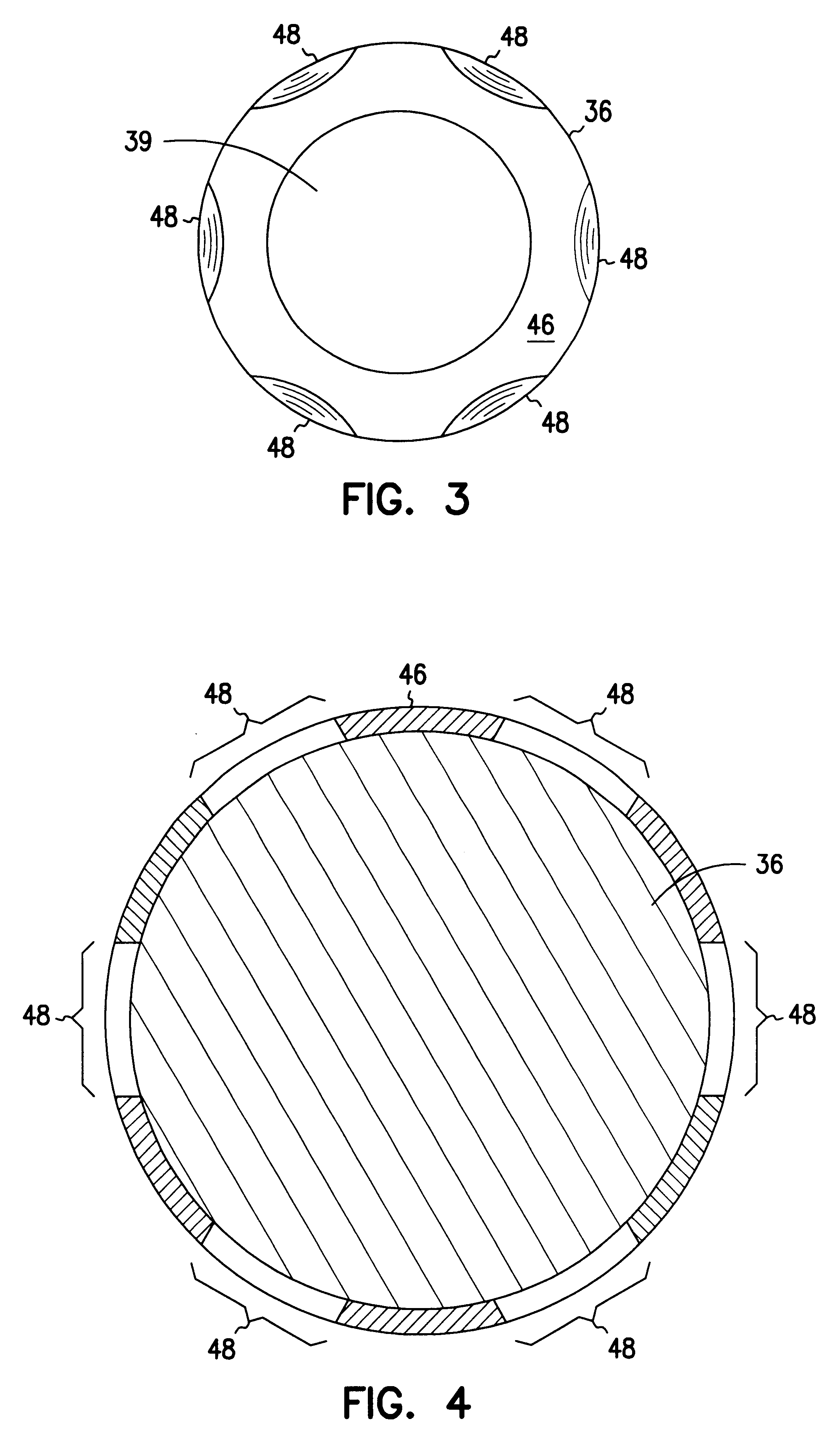

Diamond grid CMP pad dresser

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

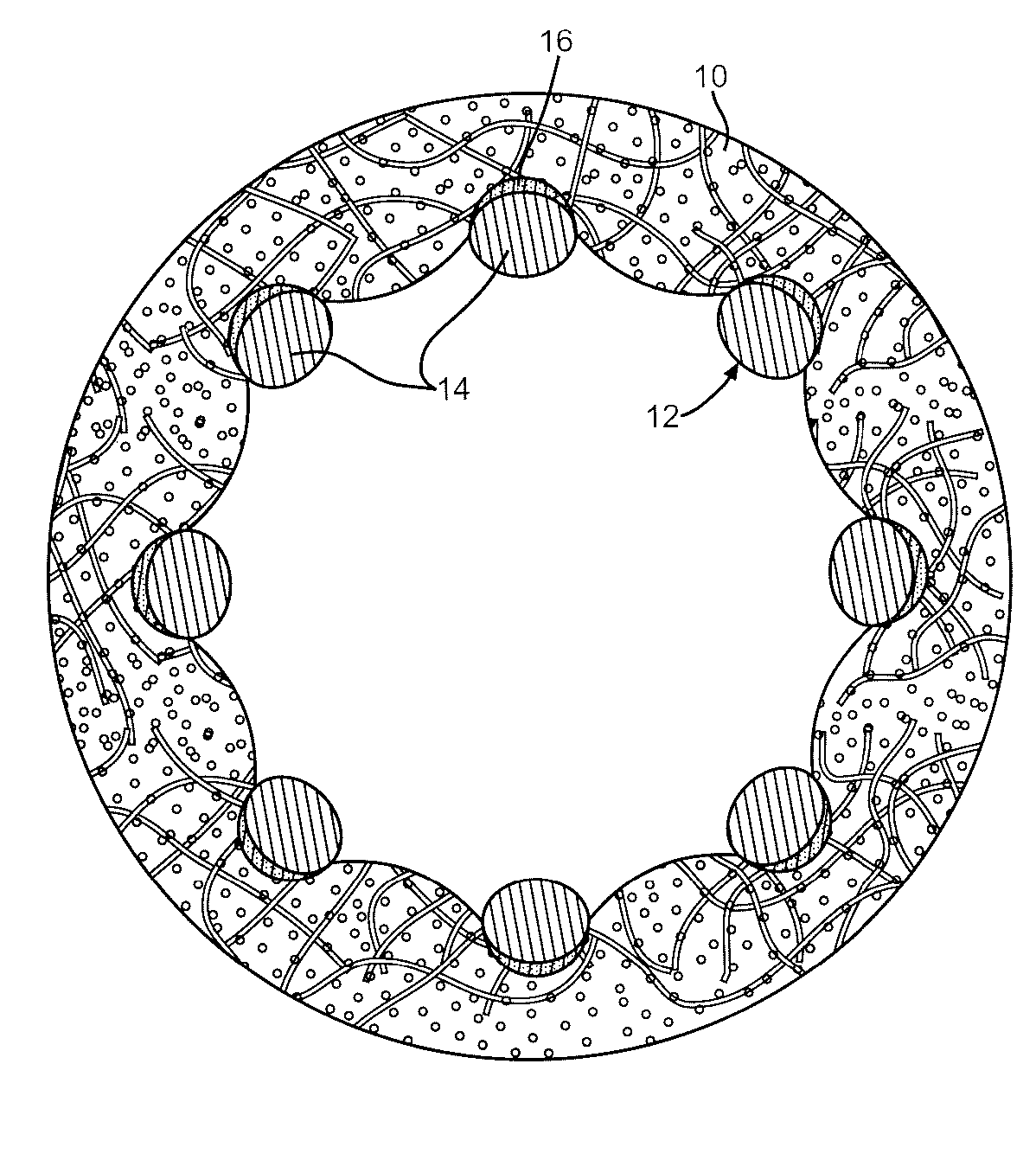

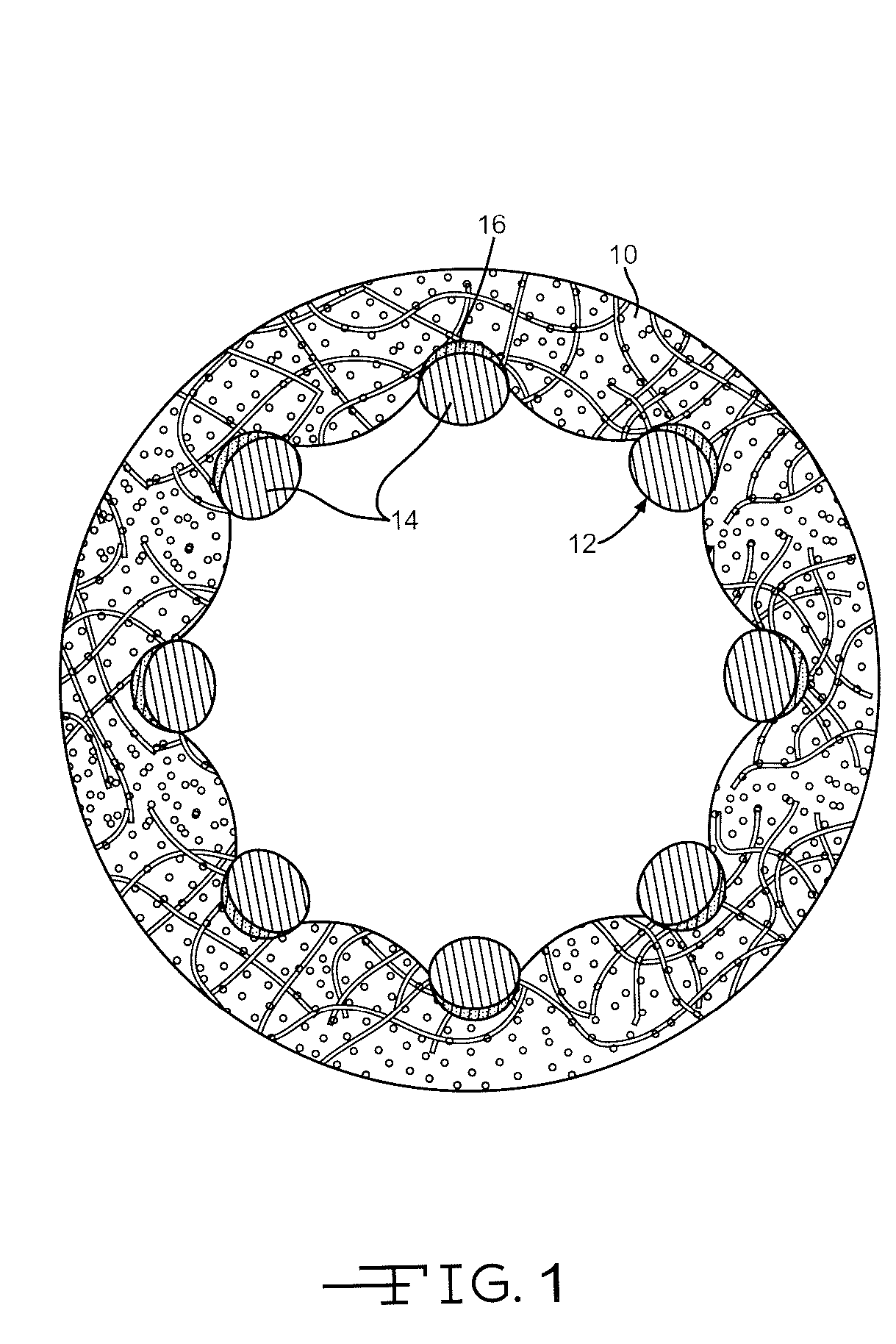

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

Corrosion control for chamber components

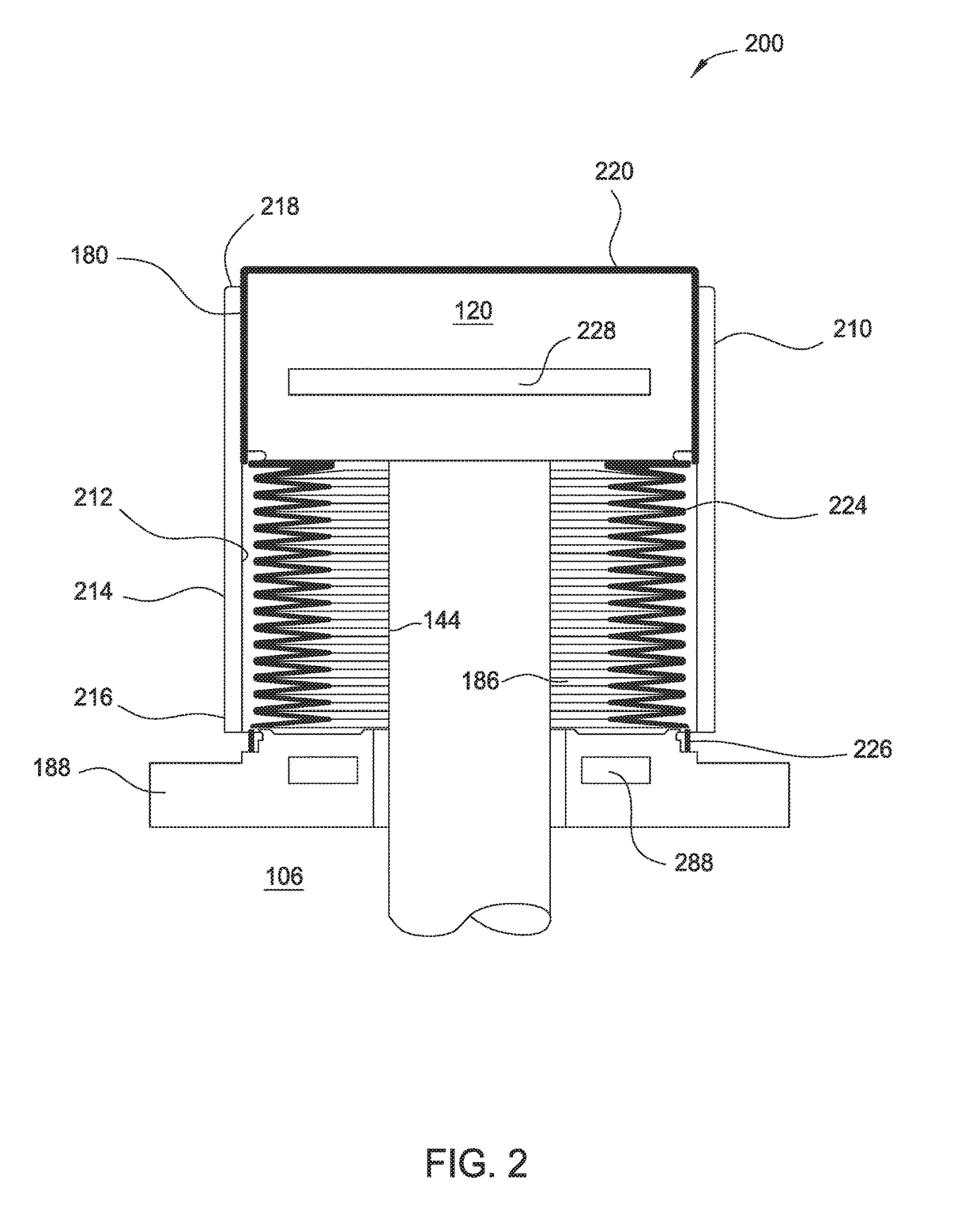

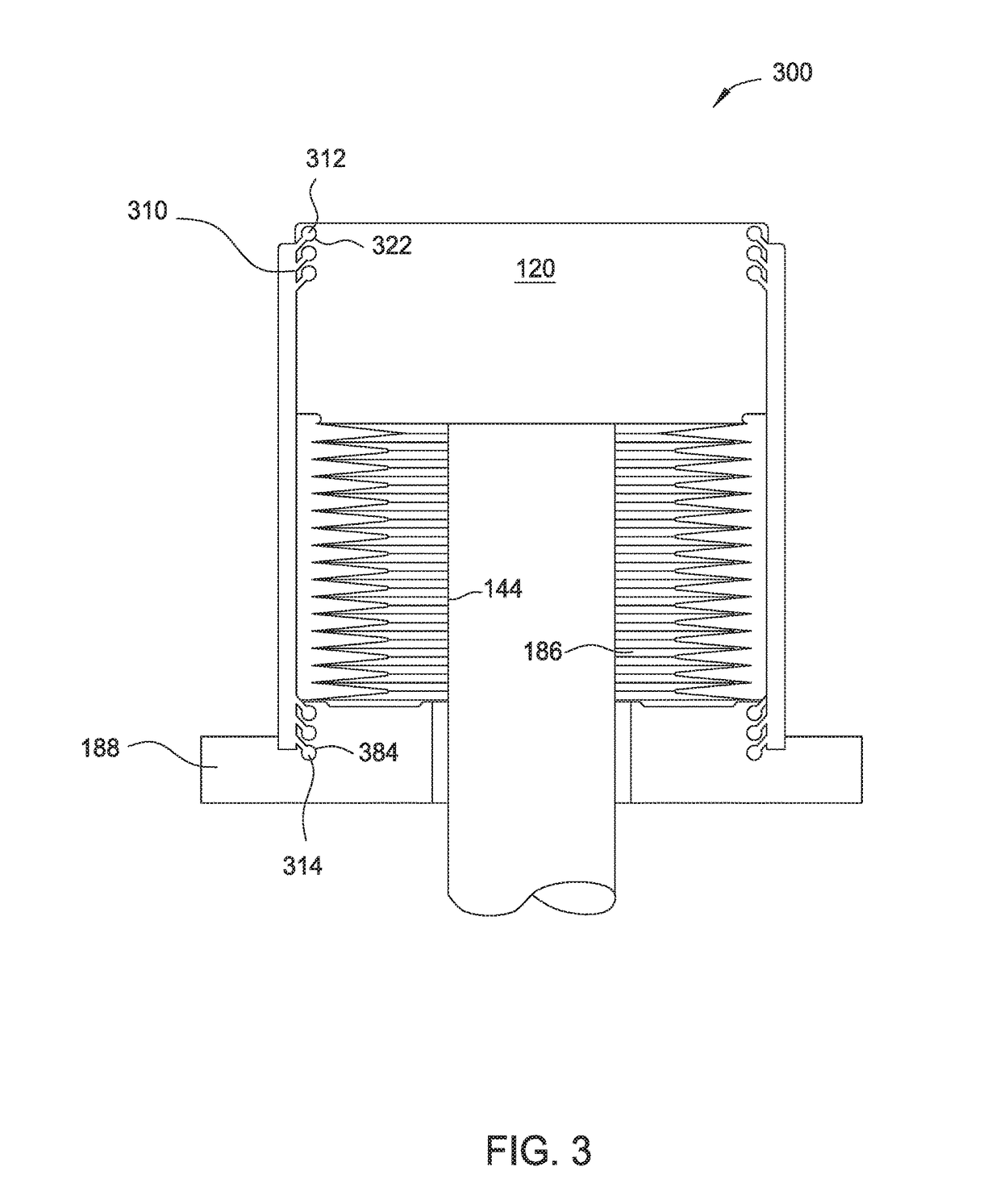

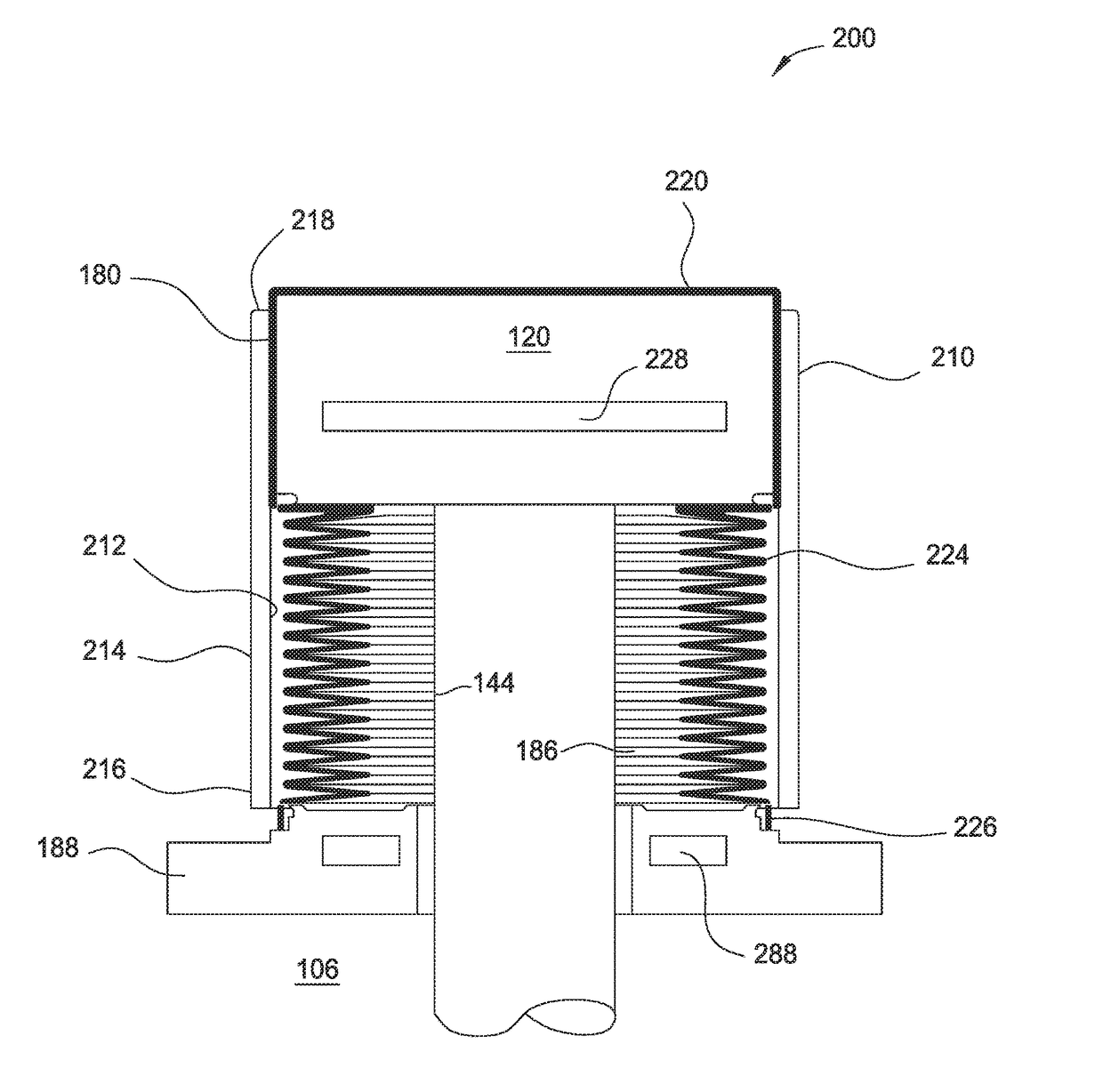

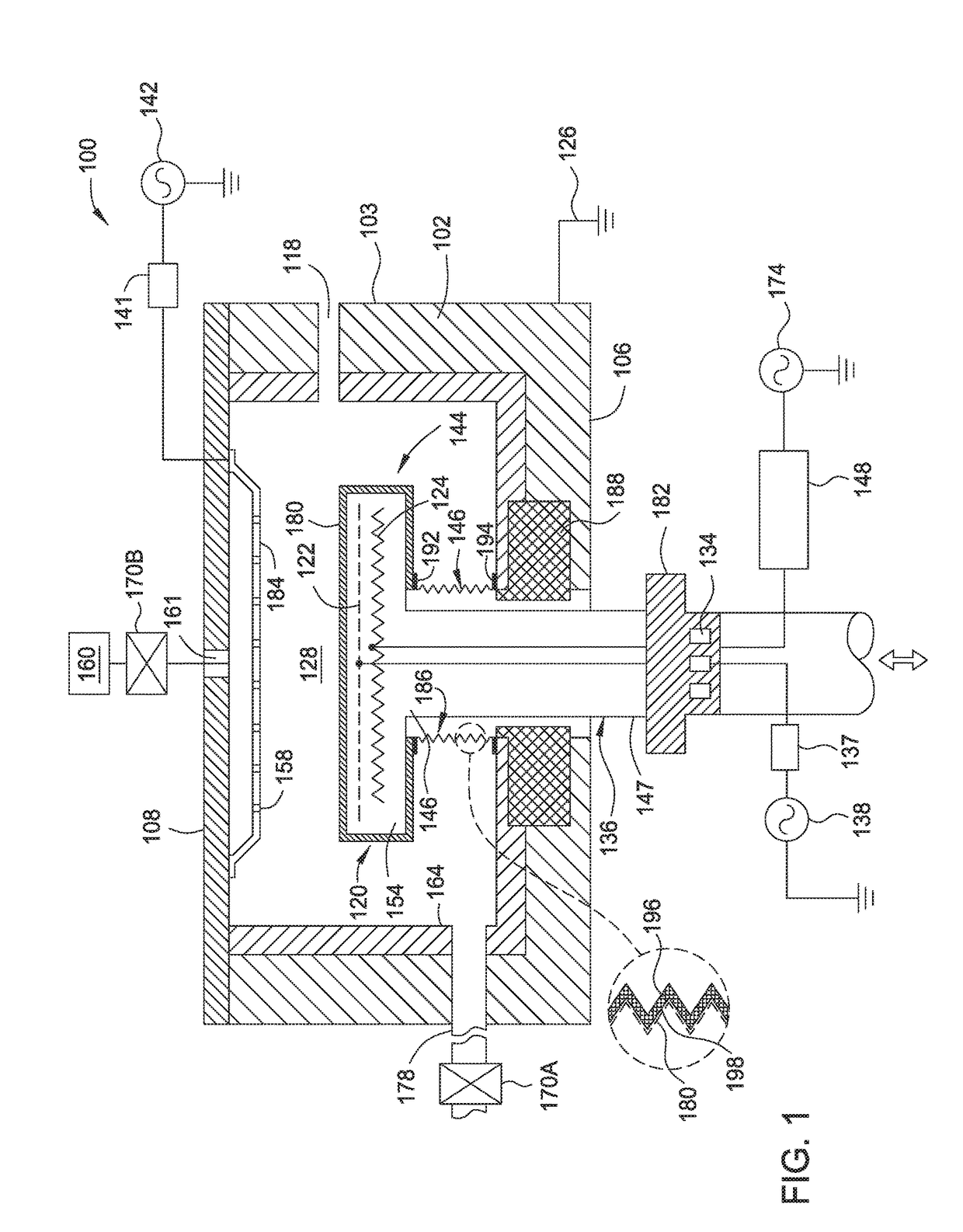

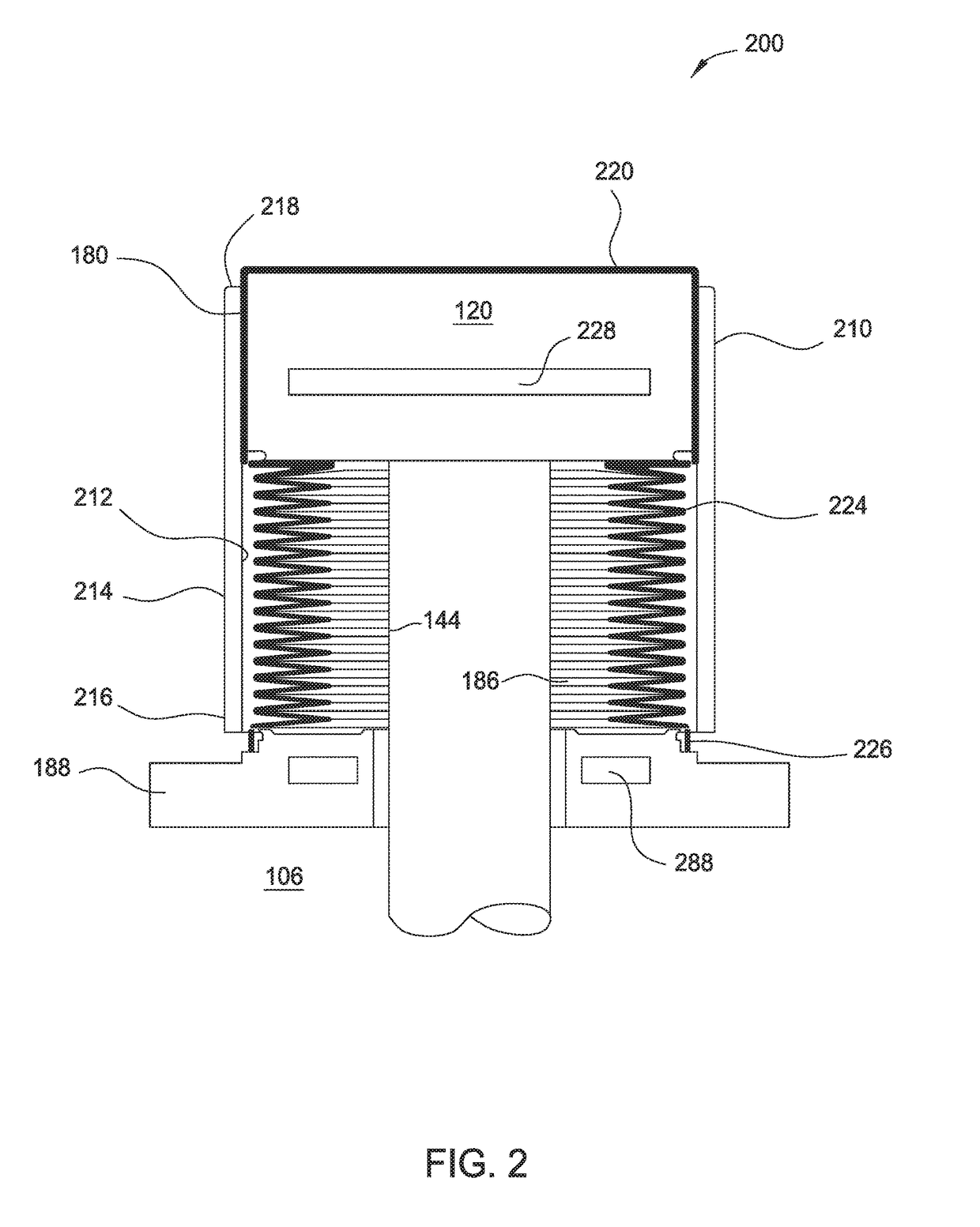

ActiveUS20170152968A1Protection cleanSpindle sealingsElectric discharge tubesParyleneDiamond-like carbon

Implementations described herein protect a chamber components from corrosive cleaning gases used at high temperatures. In one embodiment, a chamber component includes at least a bellows that includes a top mounting flange coupled to a bottom mounting flange by a tubular accordion structure. A coating is disposed on an exterior surface of at least the tubular accordion structure. The coating includes of at least one of polytetrafluoroethylene, parylene C, parylene D, diamond-like carbon (DLC), yttria stabilized zirconia, nickel, alumina, or aluminum silicon magnesium yttrium oxygen compound. In one embodiment, the chamber component is a valve having an internal bellows.

Owner:APPLIED MATERIALS INC

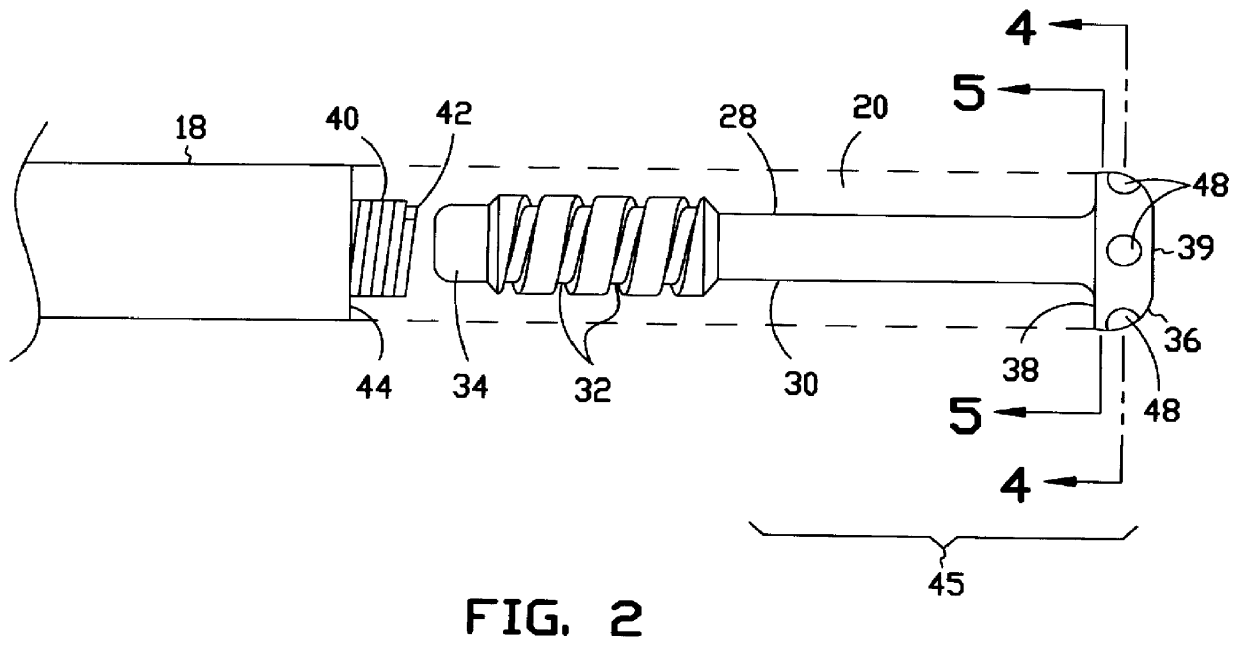

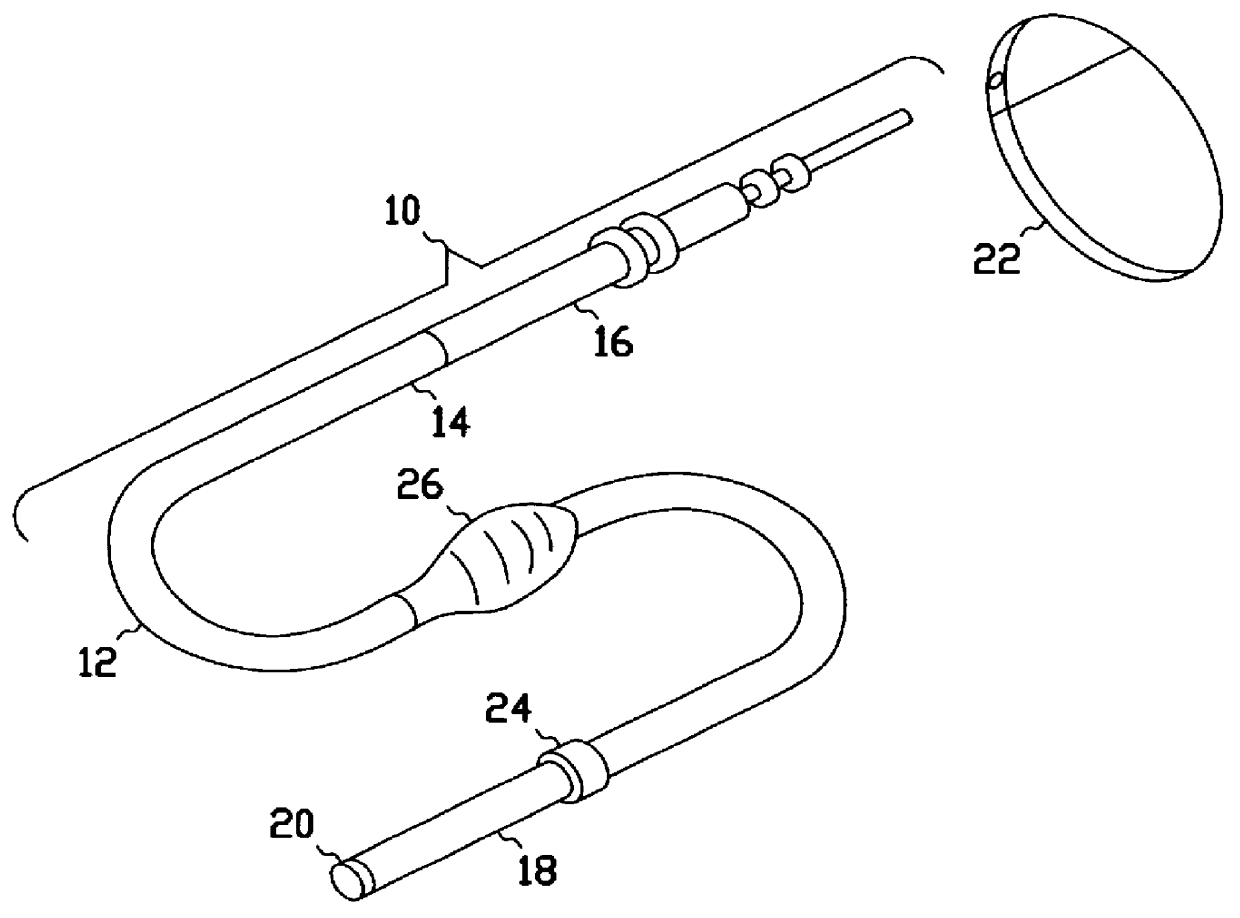

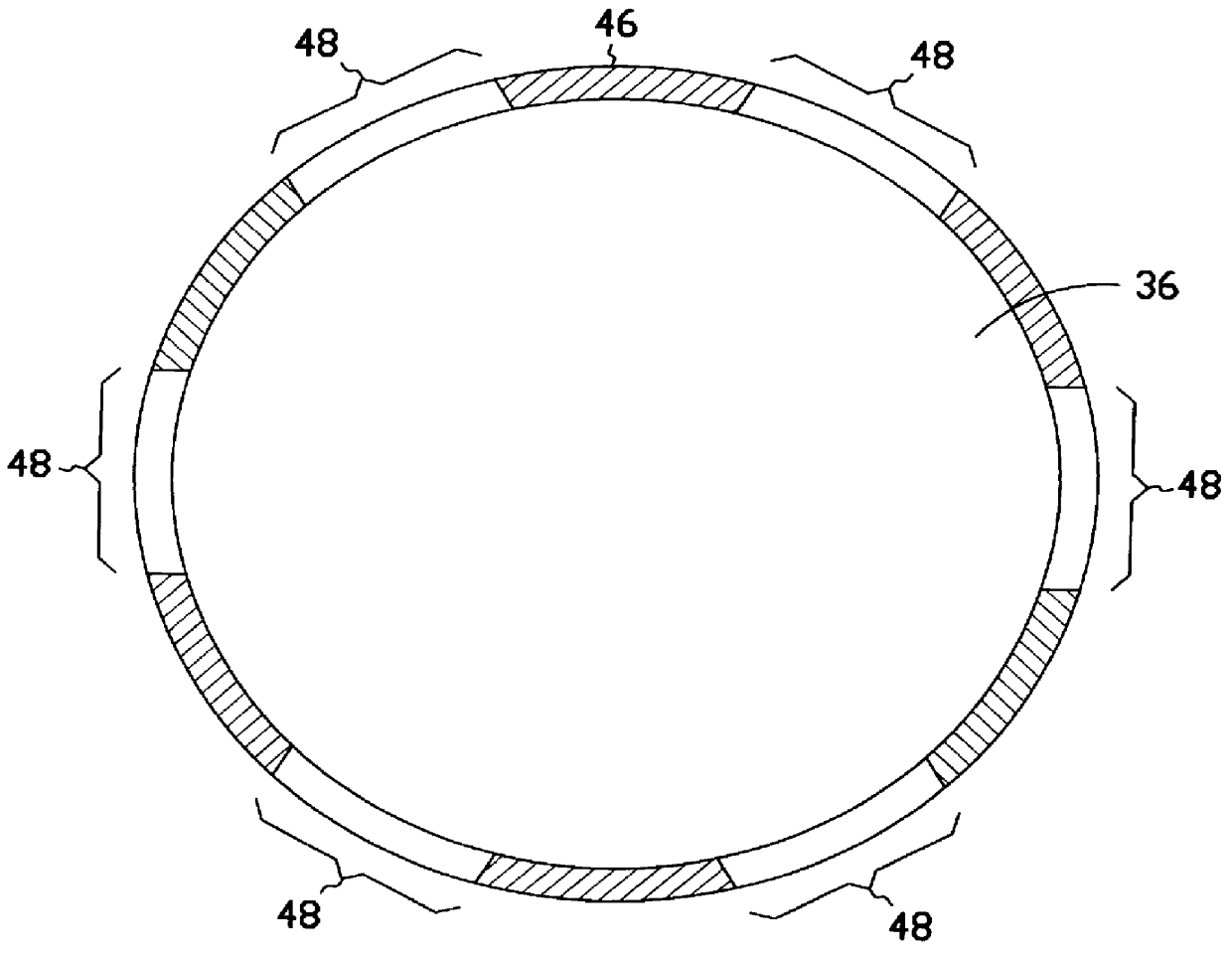

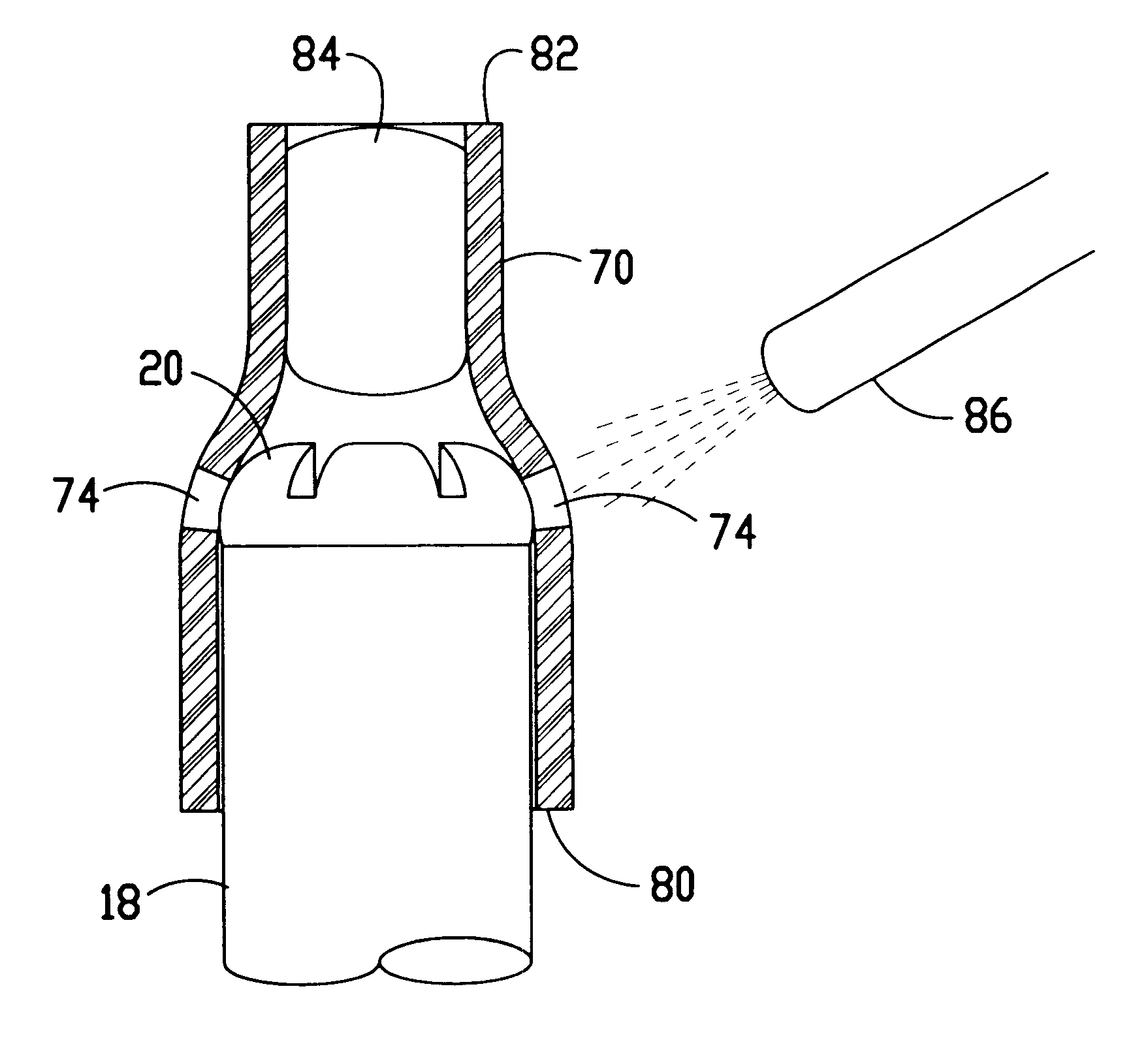

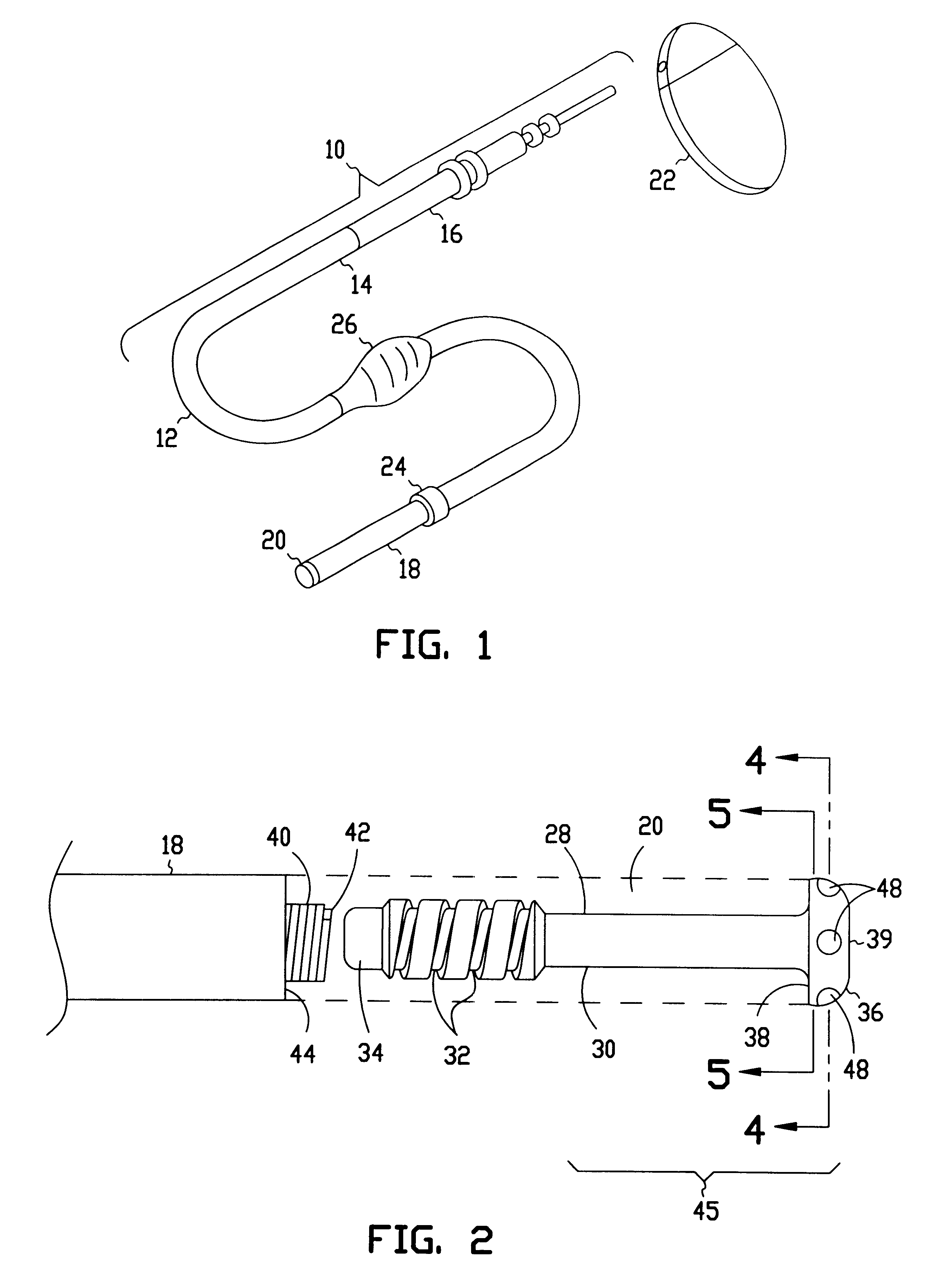

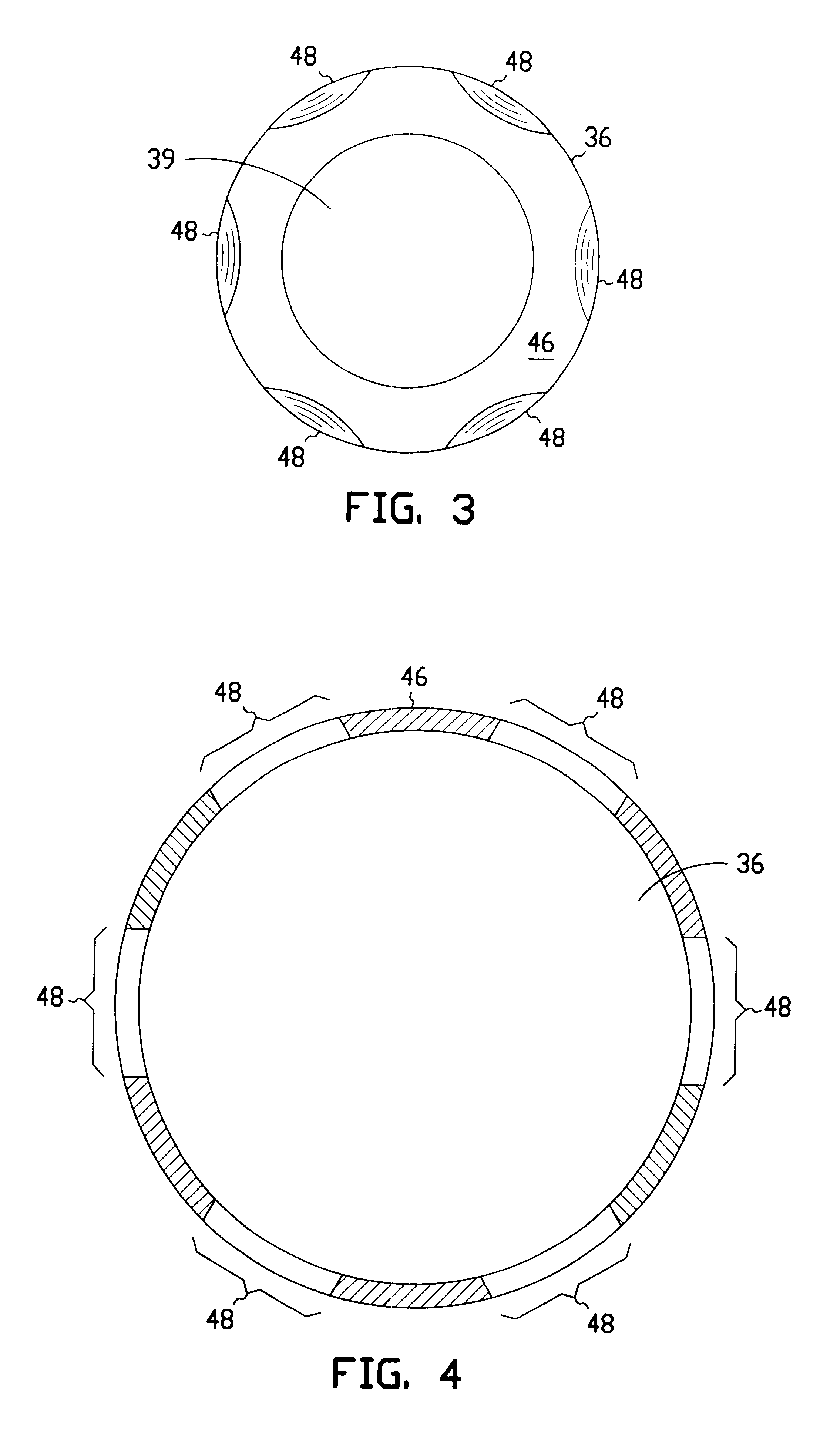

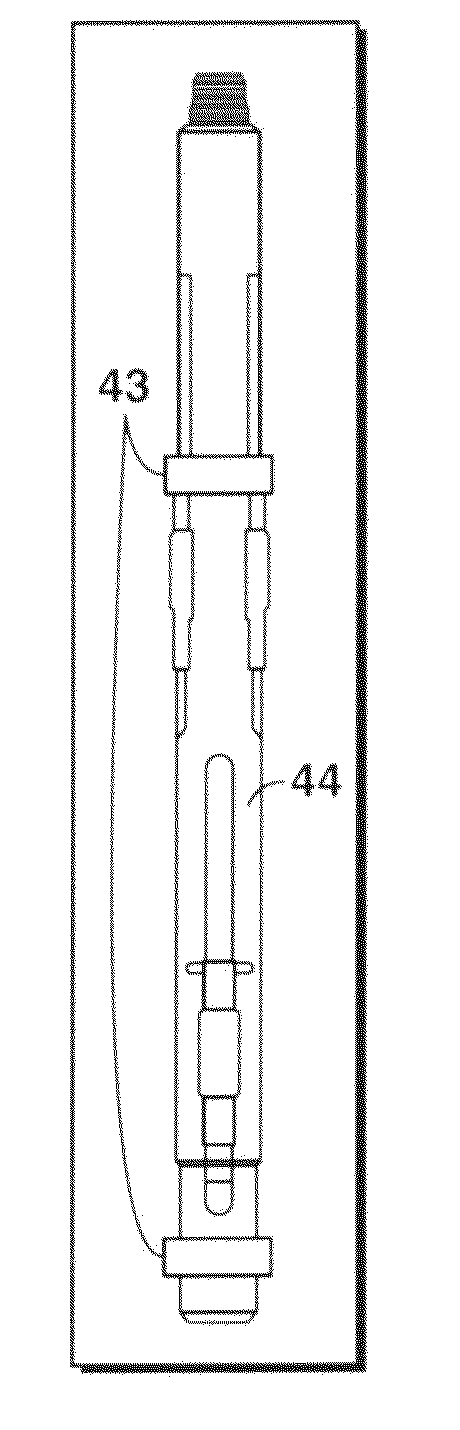

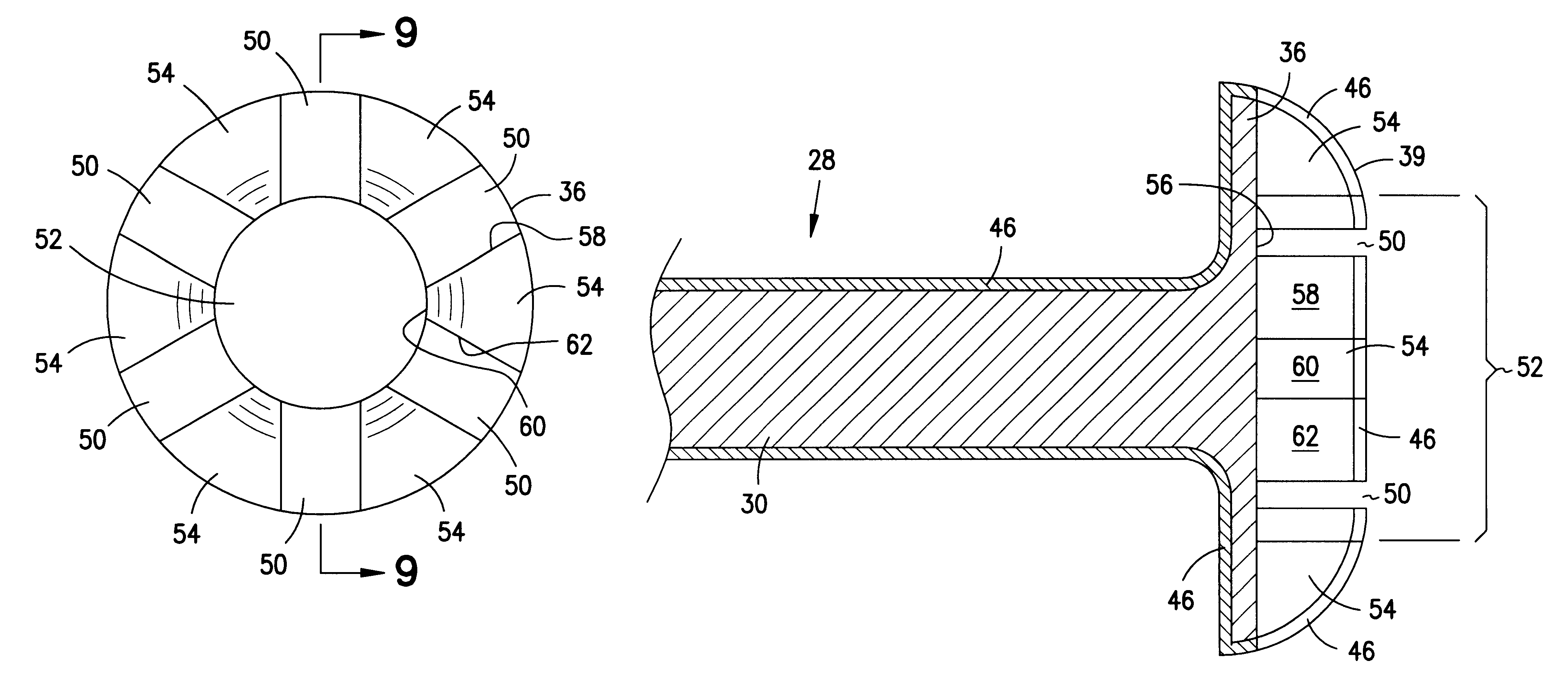

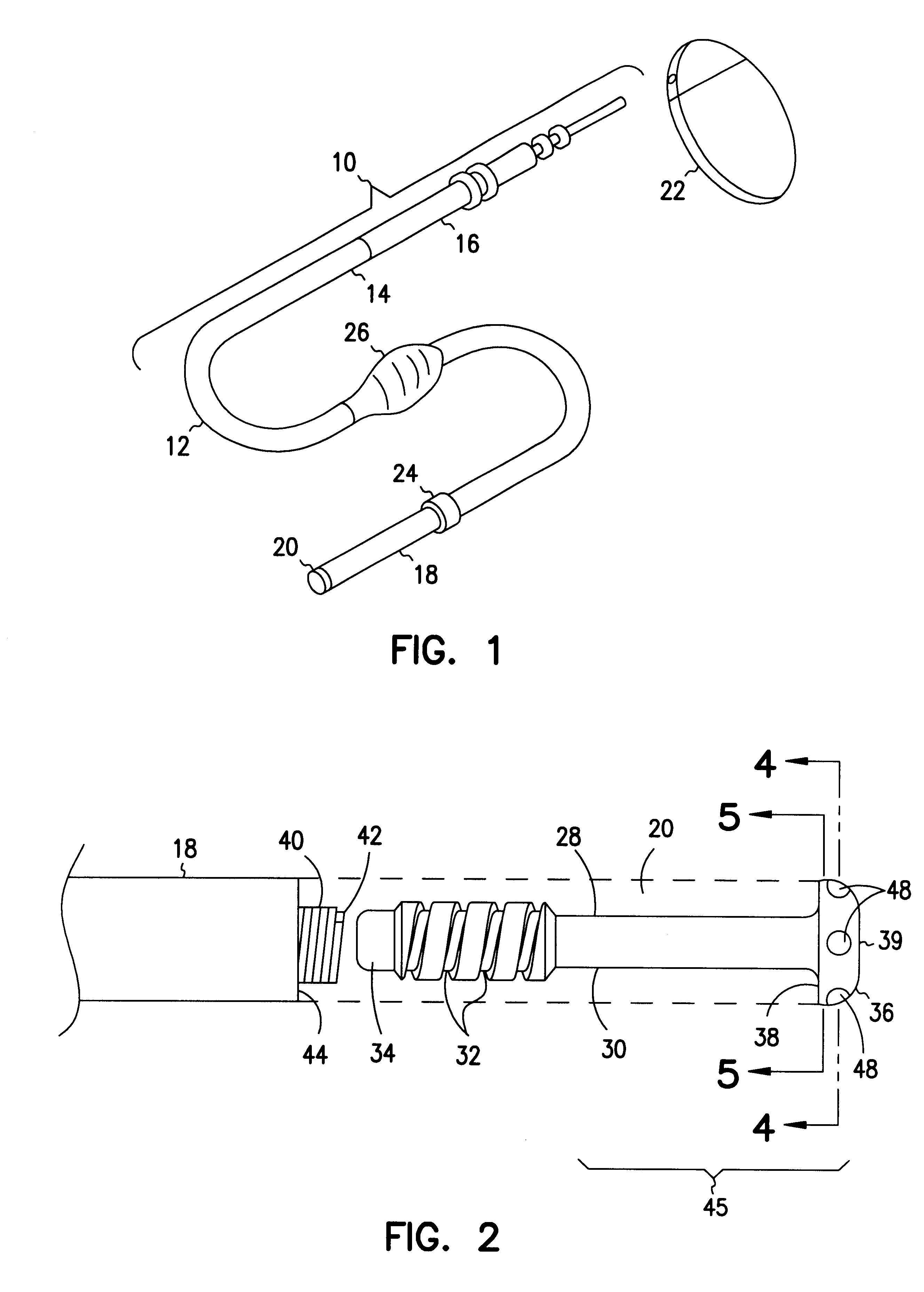

Method for making cardiac leads with zone insulated electrodes

An electrode for a cardiac lead and method of making the same are provided. The electrode includes an electrode member and a coating applied to the electrode member. A method of fabricating a high impedance cardiac lead electrode is provided. The method includes the steps of providing an electrode member and coating a first portion of the electrode member with an electrically insulating material and placing a tubular mask or shield over the electrode. Portions of the insulating material are removed to expose selected areas of the electrode. The second or exposed portion enhances the impedance of the electrode, resulting in power savings and extended life spans for implantable stimulation and sensing devices. Exemplary materials for the coating includes diamond-like carbon and sapphire.

Owner:INTERMEDICS

Method for making cardiac leads with zone insulated electrodes

InactiveUS6526321B1Internal electrodesDiagnostic recording/measuringDiamond-like carbonBiomedical engineering

An electrode for a cardiac lead and method of making the same are provided. The electrode includes an electrode member and a coating applied to the electrode member. A method of fabricating a high impedance cardiac lead electrode is provided. The method includes the steps of providing an electrode member and coating a first portion of the electrode member with an electrically insulating material and placing a tubular mask or shield over the electrode. Portions of the insulating material are removed to expose selected areas of the electrode. The second or exposed portion enhances the impedance of the electrode, resulting in power savings and extended life spans for implantable stimulation and sensing devices. Exemplary materials for the coating includes diamond-like carbon and sapphire.

Owner:INTERMEDICS

Piston ring

InactiveUS6325385B1Good sliding propertiesRelieve pressurePiston ringsBraking action transmissionCarbon filmDiamond-like carbon

Owner:TEIKOKU PISTON RING CO LTD

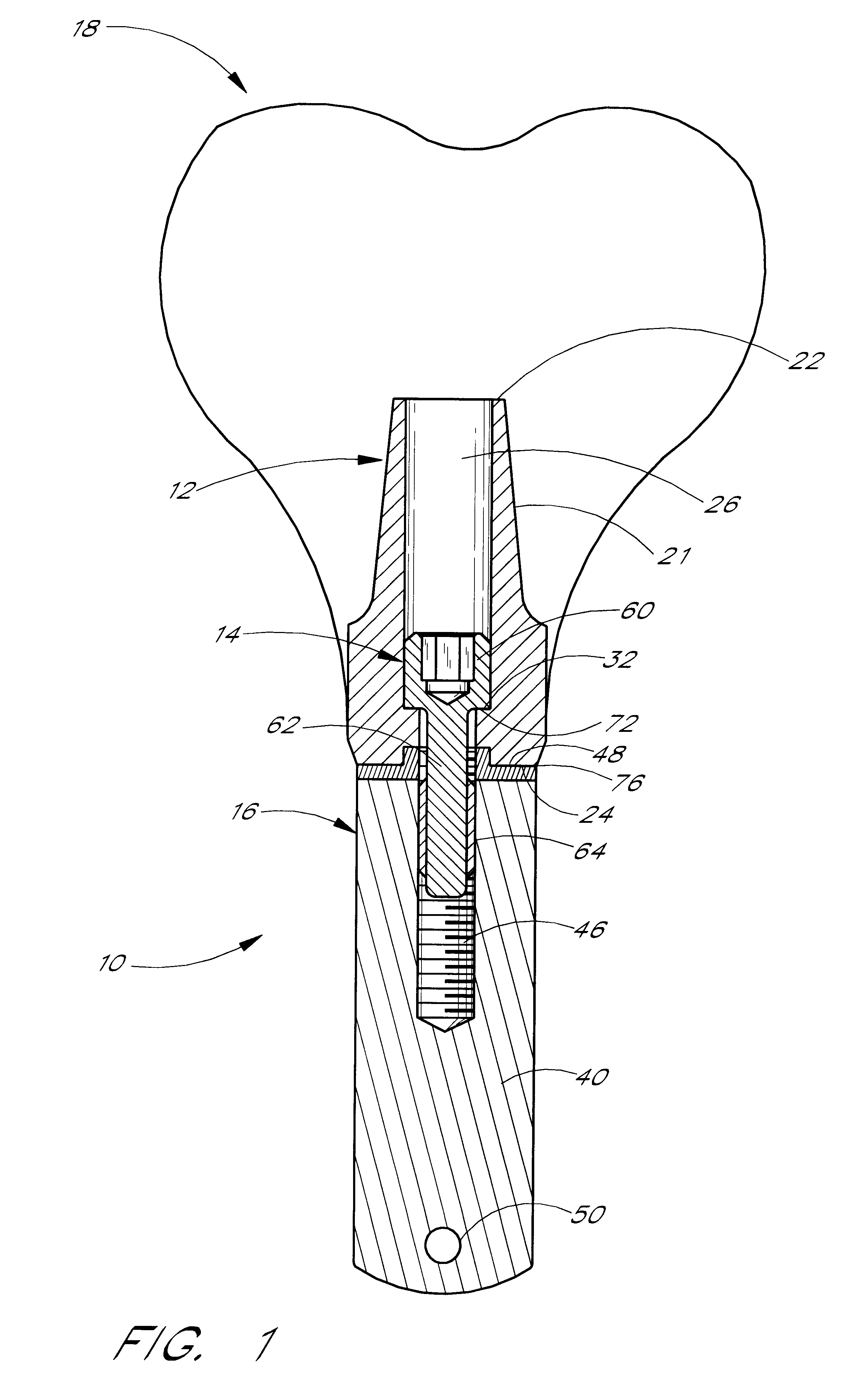

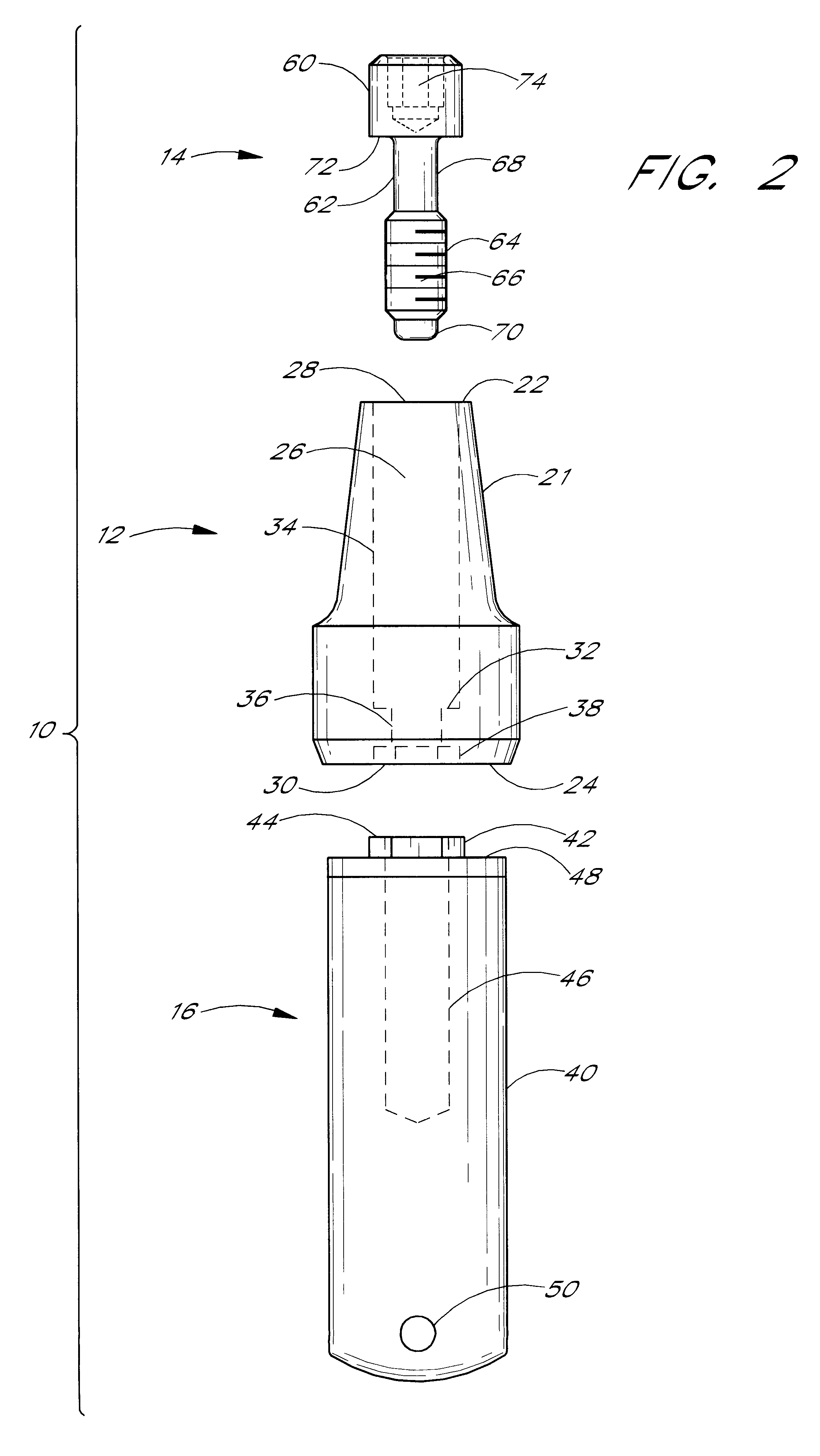

Diamond-like carbon coated dental retaining screws

The invention relates to a coated dental screw for retaining and securing components of a dental prosthetic implant stack. The screw is coated with a hard carbon coating / film to provide a low friction surface finish which advantageously results in improved preloading of the screw, and hence a high clamping force between the components of the dental prosthetic implant stack. The coating can comprise diamond-like carbon (DLC), amorphous diamond, crystalline diamond, or a combination thereof. The dental screw can include abutment retaining screws and prosthesis retaining screws. Other advantages provided by the hard carbon coating include high mechanical surface hardness, biocompatibilty, corrosion resistance, chemical inertness and low cost.

Owner:NOBEL BIOCARE SERVICES AG

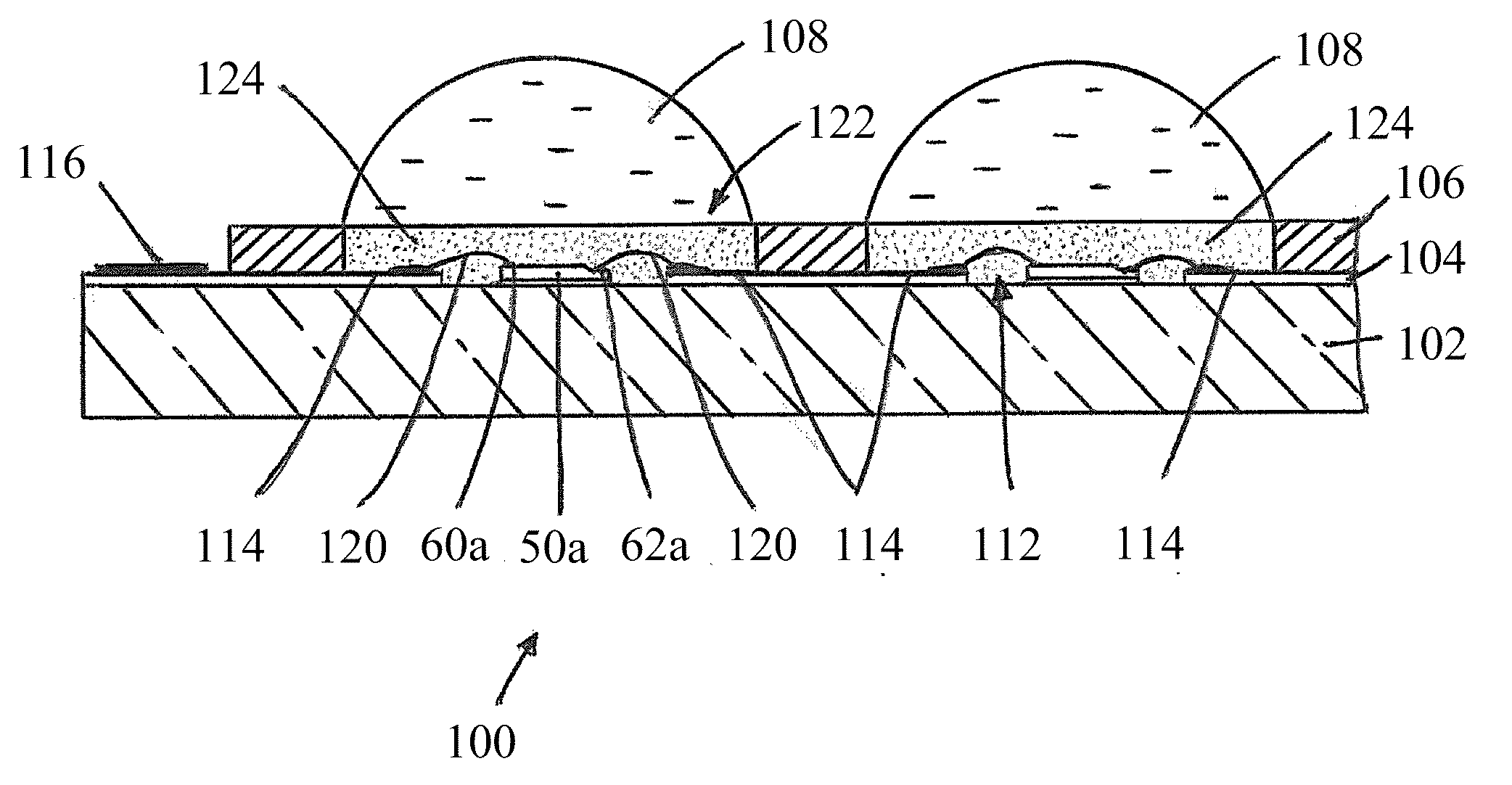

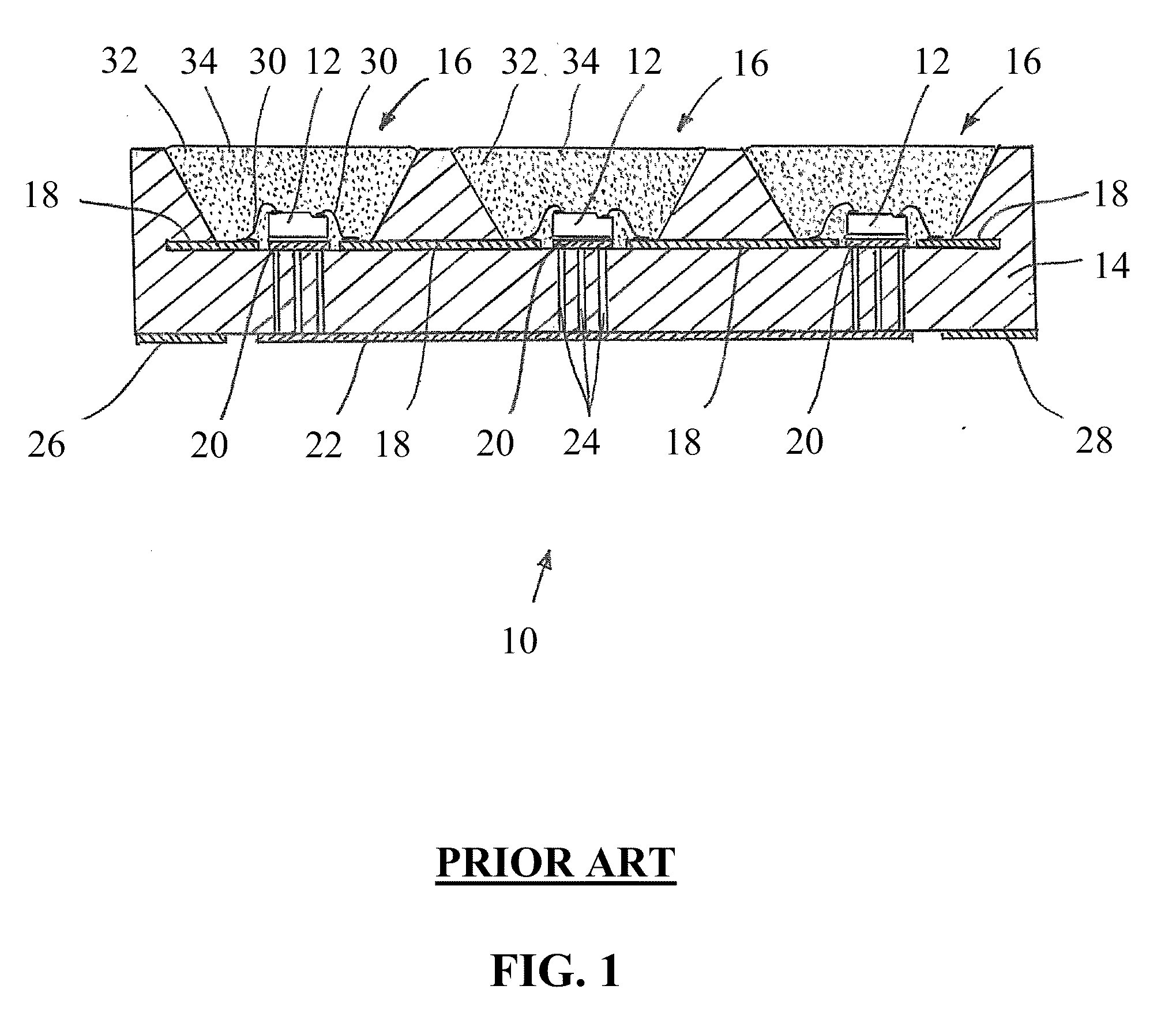

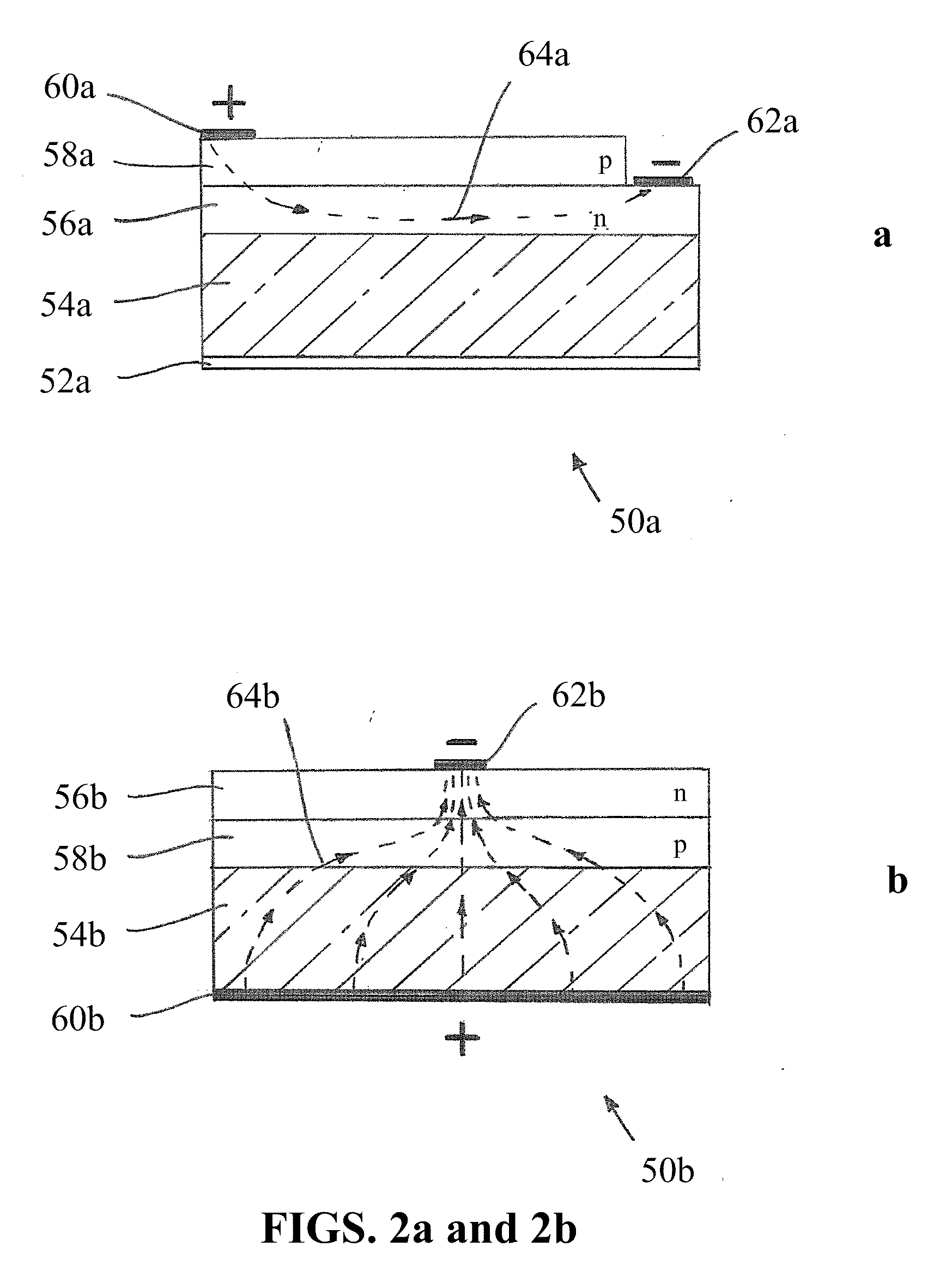

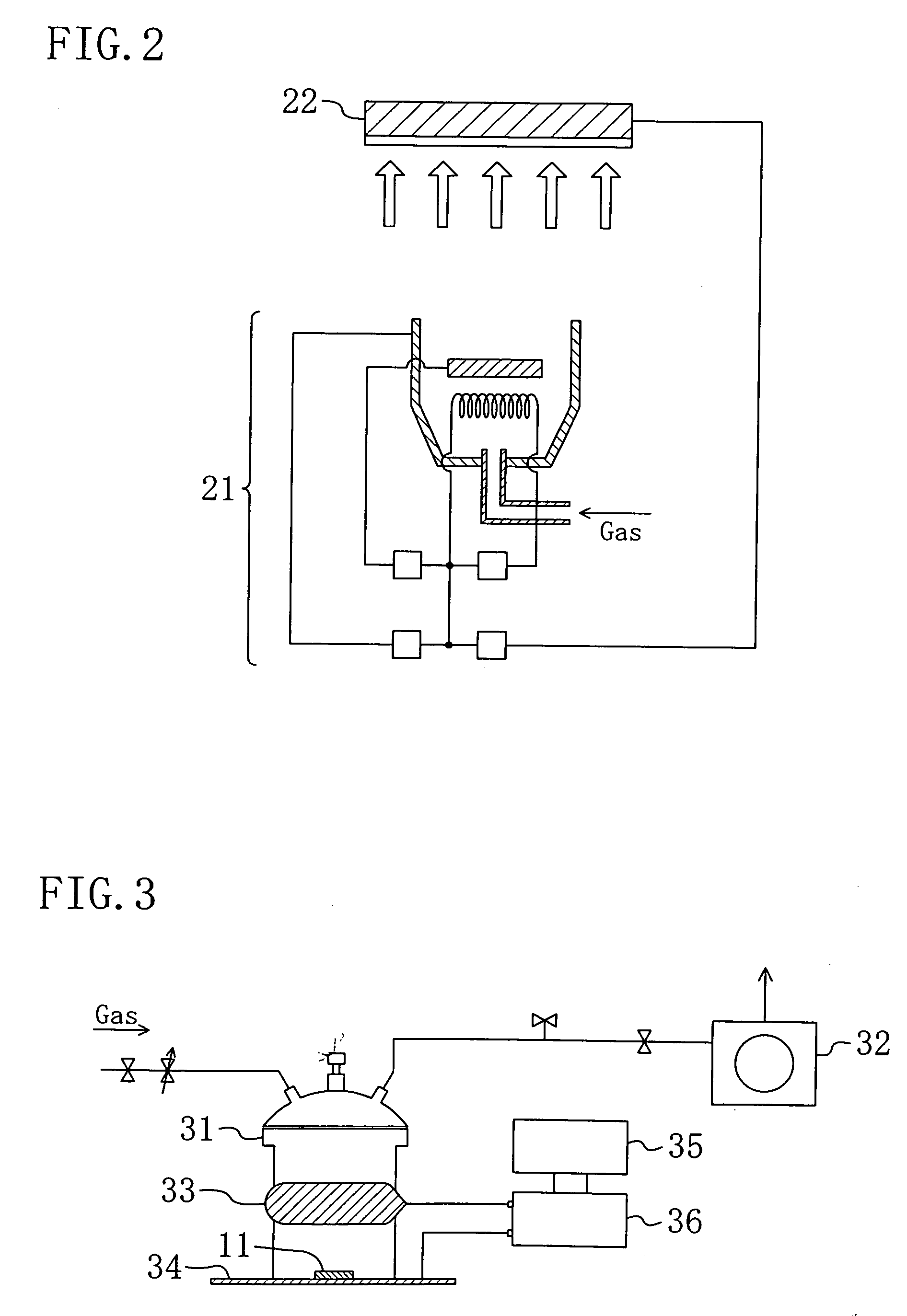

Light emitting device

ActiveUS20100295070A1Thermal resistance minimizationImprove cooling effectPrinted circuit aspectsSolid-state devicesCarbon filmDiamond-like carbon

A light emitting device comprises a plurality of LED chips (“lateral” or “vertical” conducting) operable to generate light of a first wavelength range and a package for housing the chips. The package comprises: a thermally conducting substrate (copper) on which the LED chips are mounted and a cover having a plurality of through-holes in which each hole corresponds to a respective one of the LED chips. The holes are configured such that when the cover is mounted to the substrate each hole in conjunction with the substrate defines a recess in which a respective chip is housed. Each recess is at least partially filled with a mixture of at least one phosphor material and a transparent material. In a device with “lateral” conducting LED chips a PCB is mounted on the substrate and includes a plurality of through-holes which are configured such that each chip is directly mounted to the substrate. For a device with “vertical” conducting LED chips the LED chips are mounted on a diamond like carbon film.

Owner:EPISTAR CORP

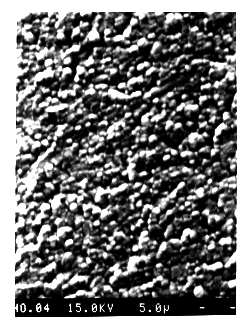

Method and system for coating internal surfaces of prefabricated process piping in the field

ActiveUS7300684B2Improve adhesionIncreases magnitudeLiquid surface applicatorsVacuum evaporation coatingHydrocarbon mixturesDiamond-like carbon

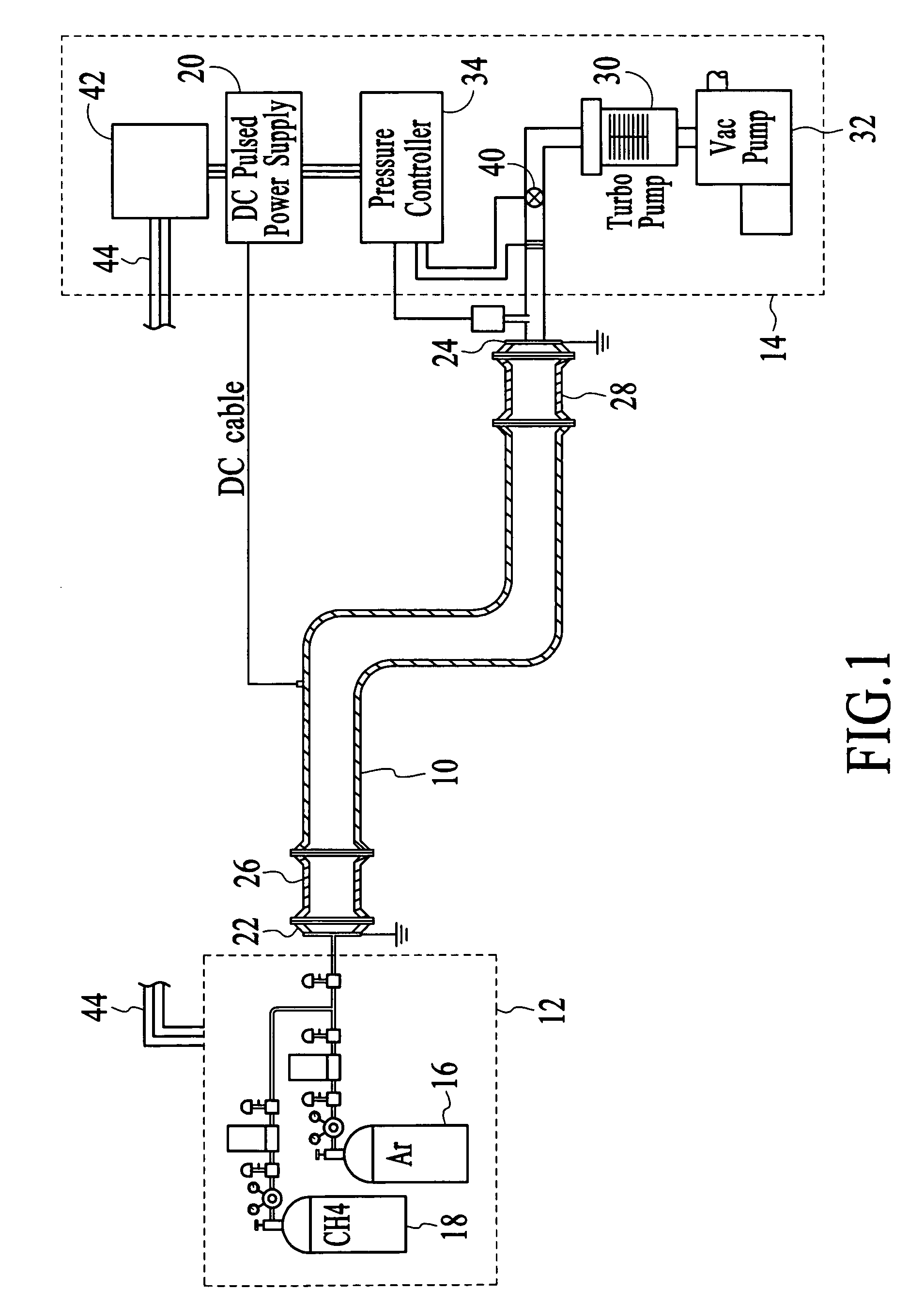

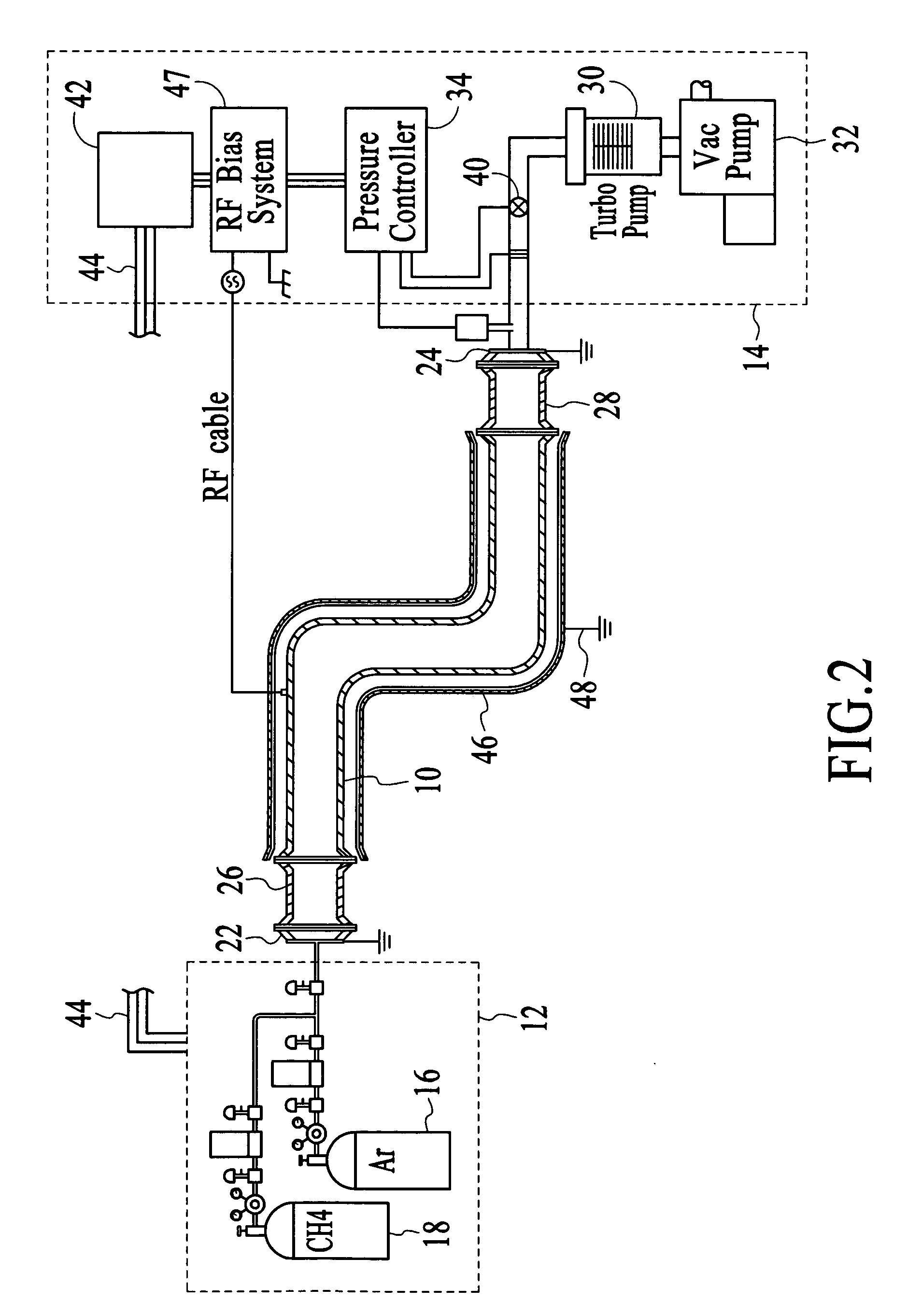

The coating of internal surfaces of a workpiece is achieved by connecting a bias voltage such that the workpiece functions as a cathode and by connecting an anode at each opening of the workpiece. A source gas is introduced at an entrance opening, while a vacuum source is connected at an exit opening. Pressure within the workpiece is monitored and the resulting pressure information is used for maintaining a condition that exhibits the hollow cathode effect. Optionally, a pre-cleaning may be provided by introducing a hydrocarbon mixture and applying a negative bias to the workpiece, so as to sputter contaminants from the workpiece using argon gas. Argon gas may also be introduced during the coating processing to re-sputter the coating, thereby improving uniformity along the length of the workpiece. The coating may be a diamond-like carbon material having properties which are determined by controlling ion bombardment energy.

Owner:AGM CONTAINER CONTROLS

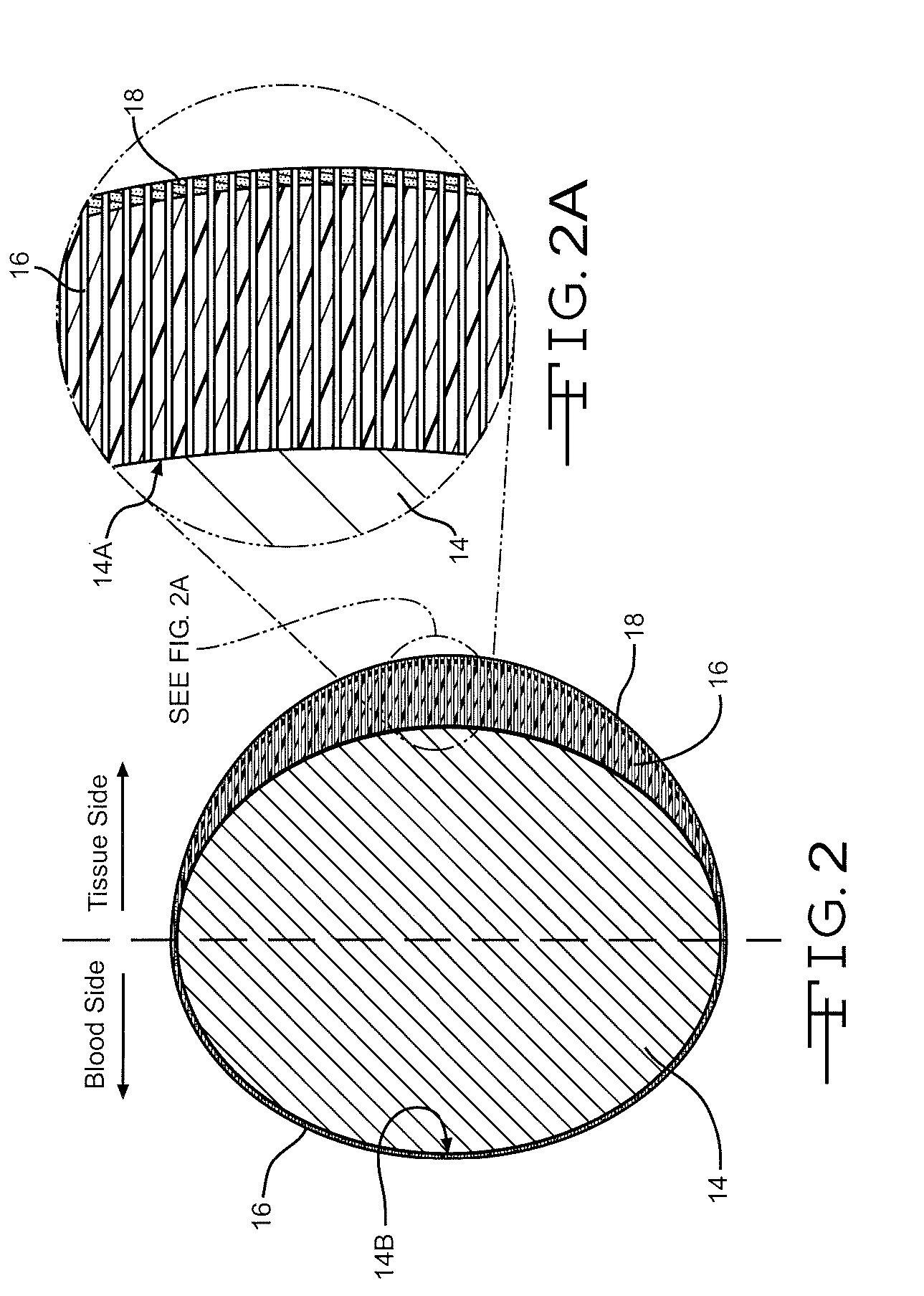

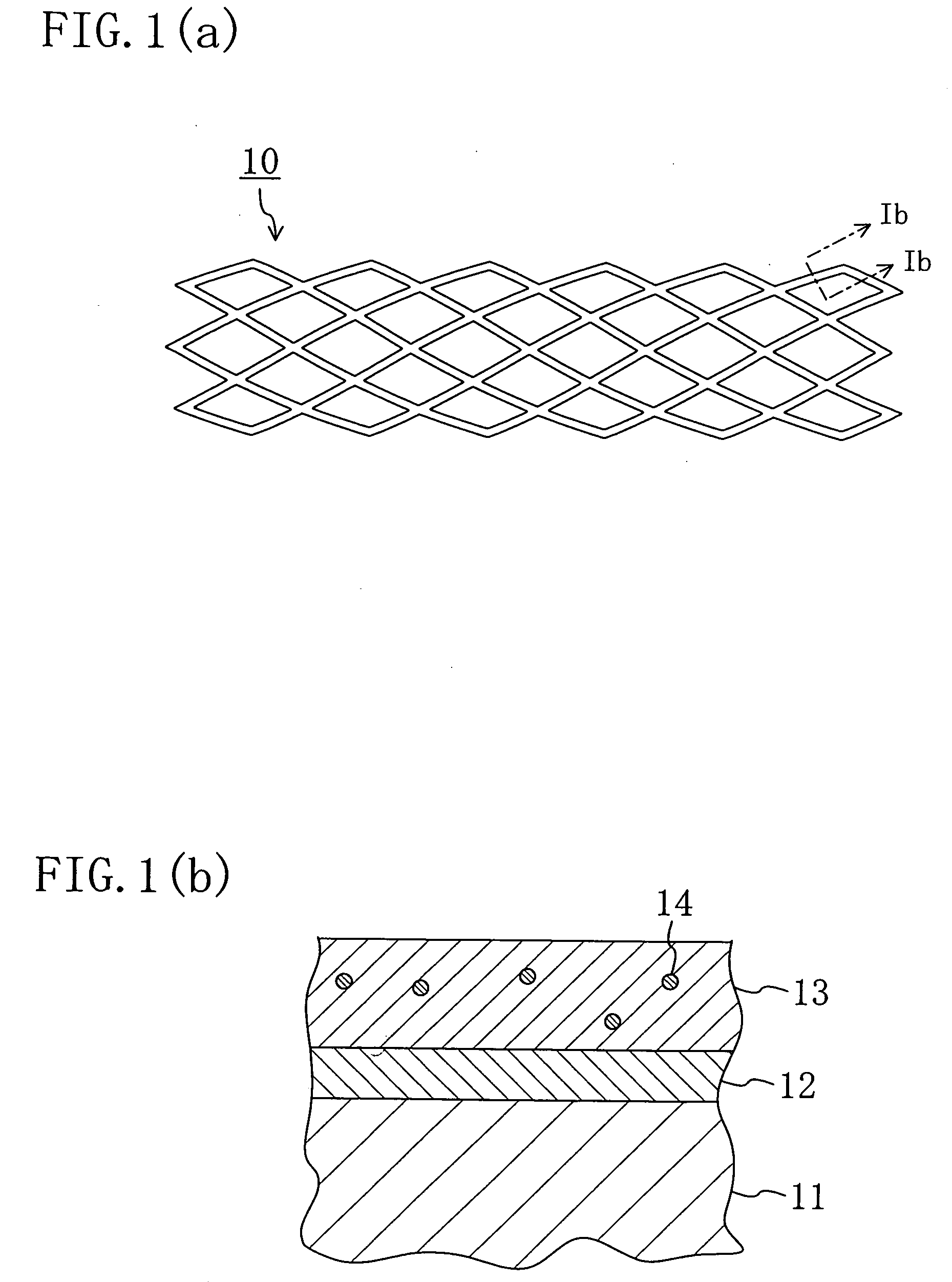

Stent Coating For Eluting Medication

InactiveUS20060200231A1Good biocompatibilityPrevention and therapyStentsSurgeryPorosityDiamond-like carbon

A vascular stent comprising a drug-eluting outer layer of a porous sputtered columnar metal having each column capped with a biocompatible carbon-containing material is described. This is done by placing the stent over a close-fitting mandrel and rotating the assembly in a sputter flux. The result is a coating that is evenly distributed over the outward-facing side of the stent's wire mesh while preventing the sputtered columnar coating from reaching the inward facing side where a smooth hemocompatible surface is required. The stent is then removed from the mandrel, exposing all surfaces, and finally coated with a layer of carbon such as amorphous carbon or diamond-like carbon. The carbonaceous coating enhances biocompatibility without preventing elutriation of a therapeutic drug provided in the porosity formed between the columnar structures. The result is a stent that is adapted to both the hemodynamic and the immune response requirements of its vascular environment.

Owner:WILSON GREATBATCH LTD

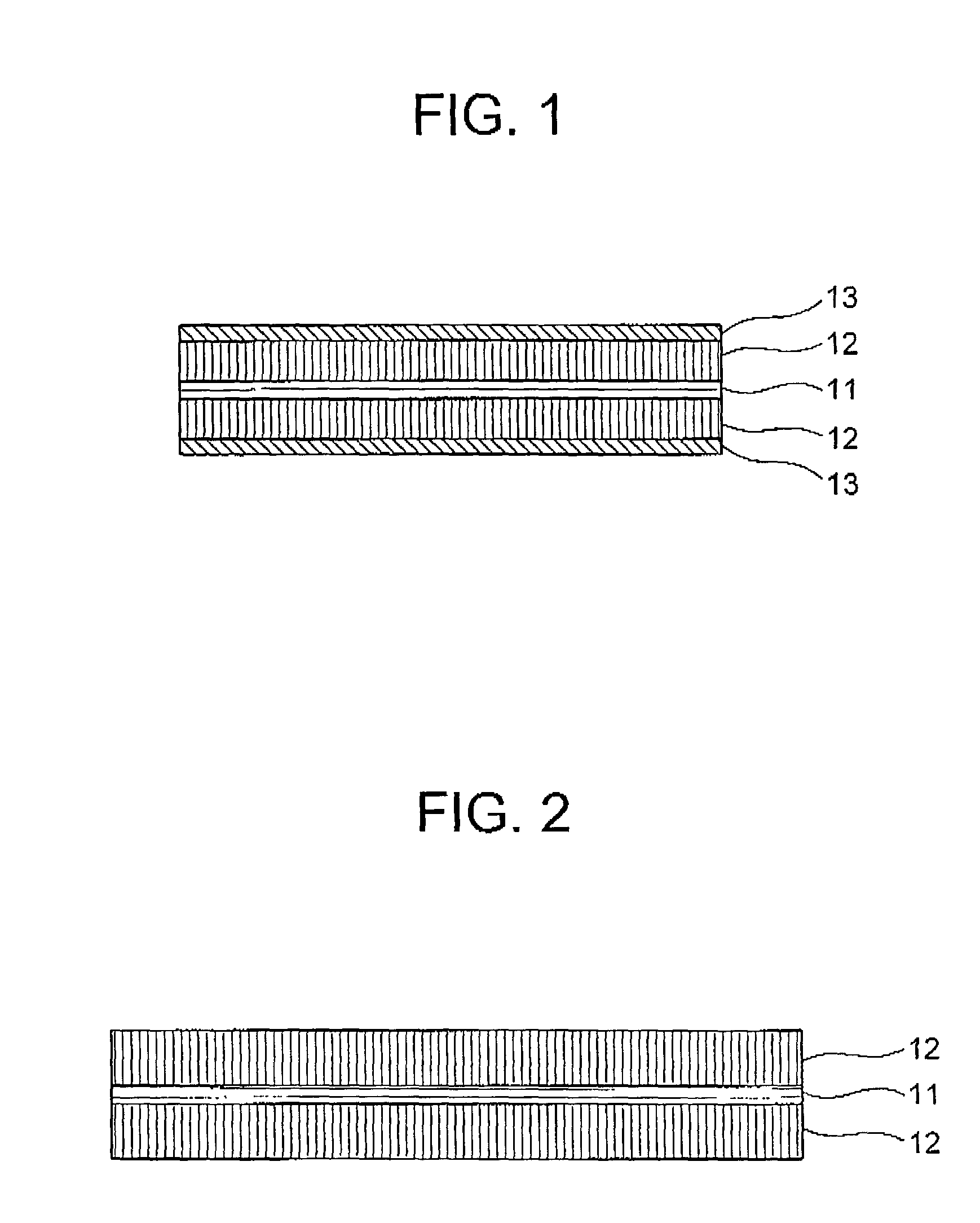

Anode for a secondary battery

InactiveUS20030129497A1Avoid it happening againPrevent degradationPrimary cell electrodesLi-accumulatorsCarbon filmDiamond-like carbon

An anode for use in a non-aqueous-electrolyte secondary battery includes an active material film for occluding and releasing lithium ions, and an amorphous carbon film or a diamond-like carbon film covering the active material film for suppressing growth of dendrite and degradation of the anode, thereby achieving improved cycle lifetime of the secondary battery.

Owner:NEC CORP

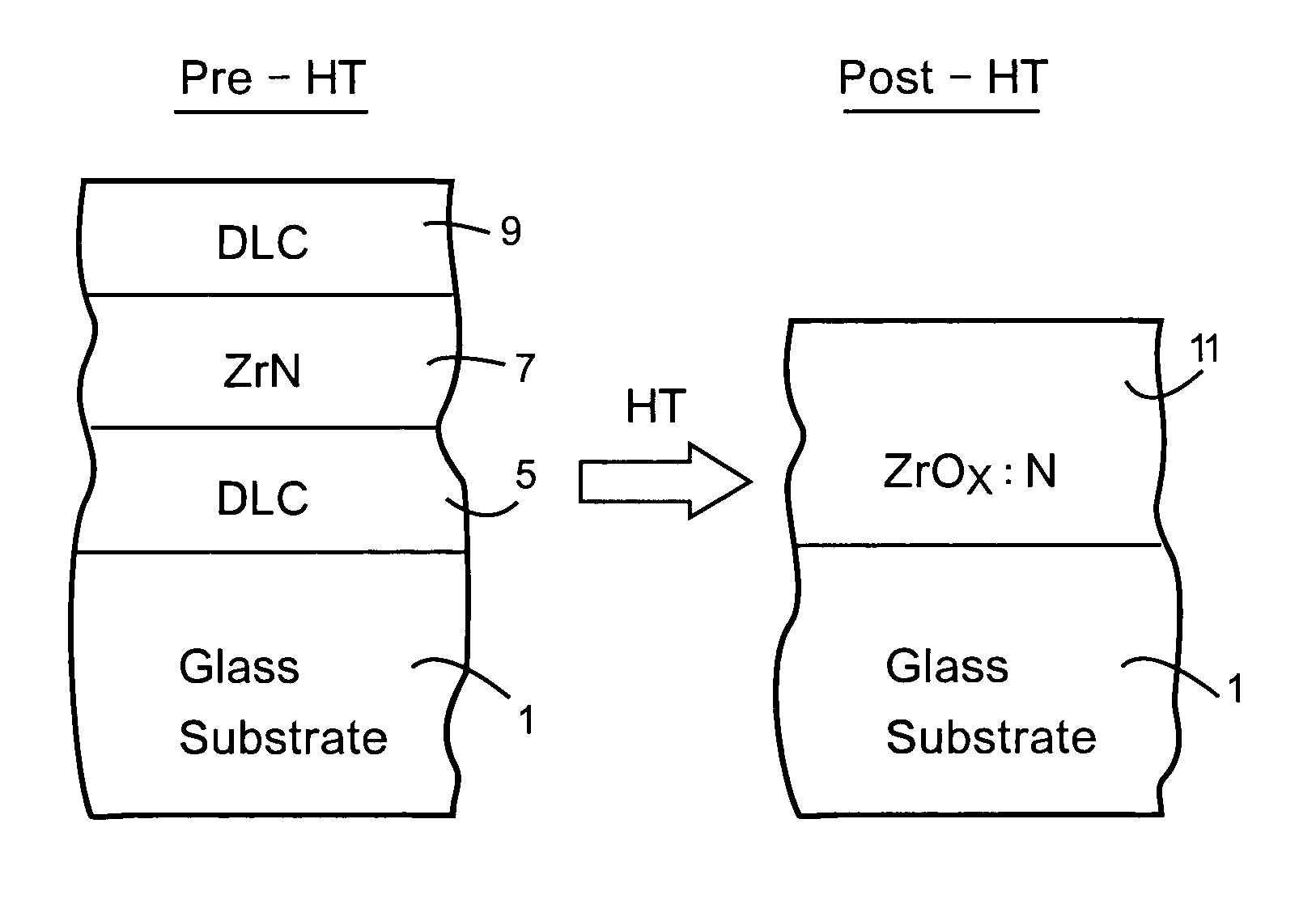

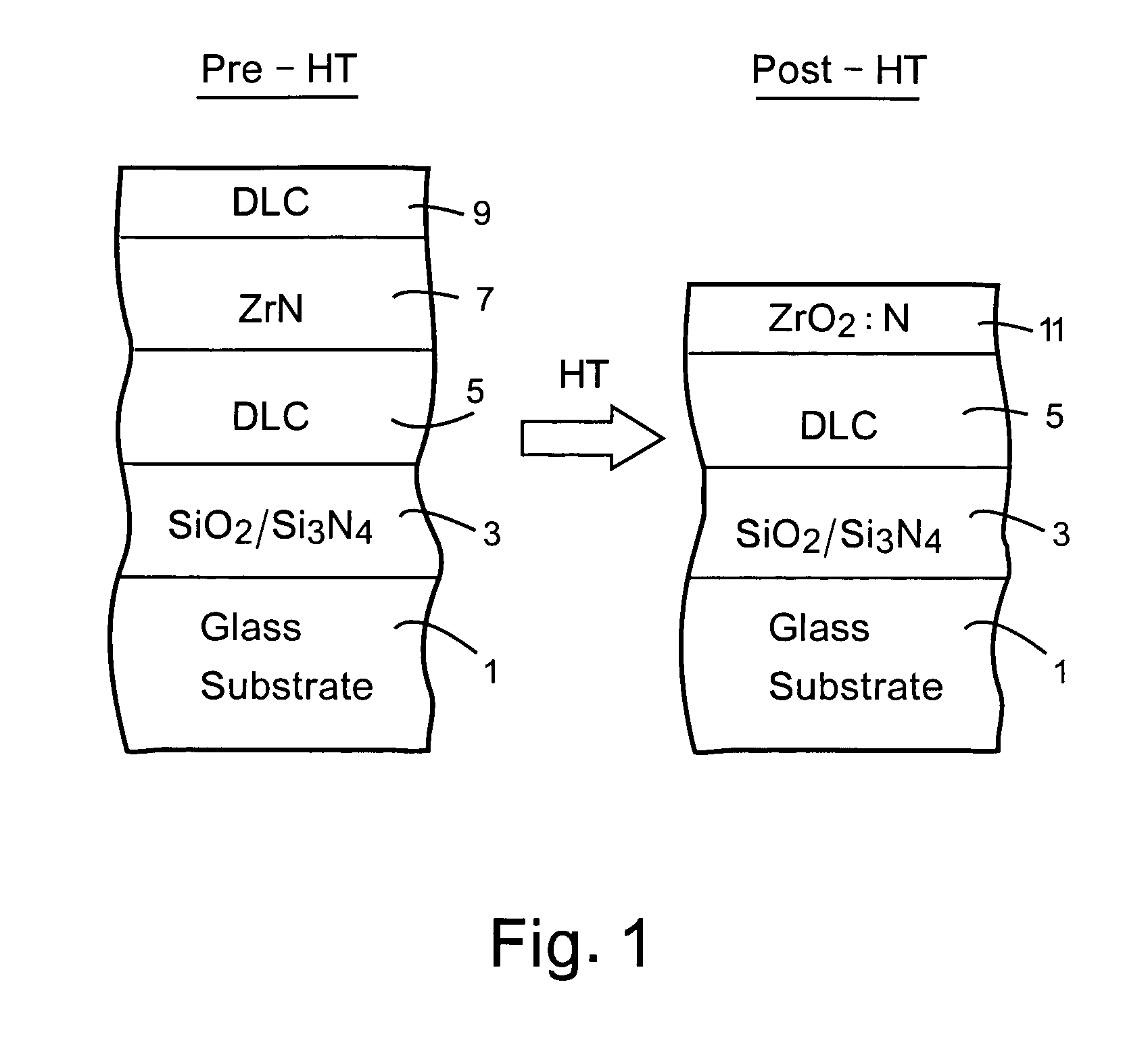

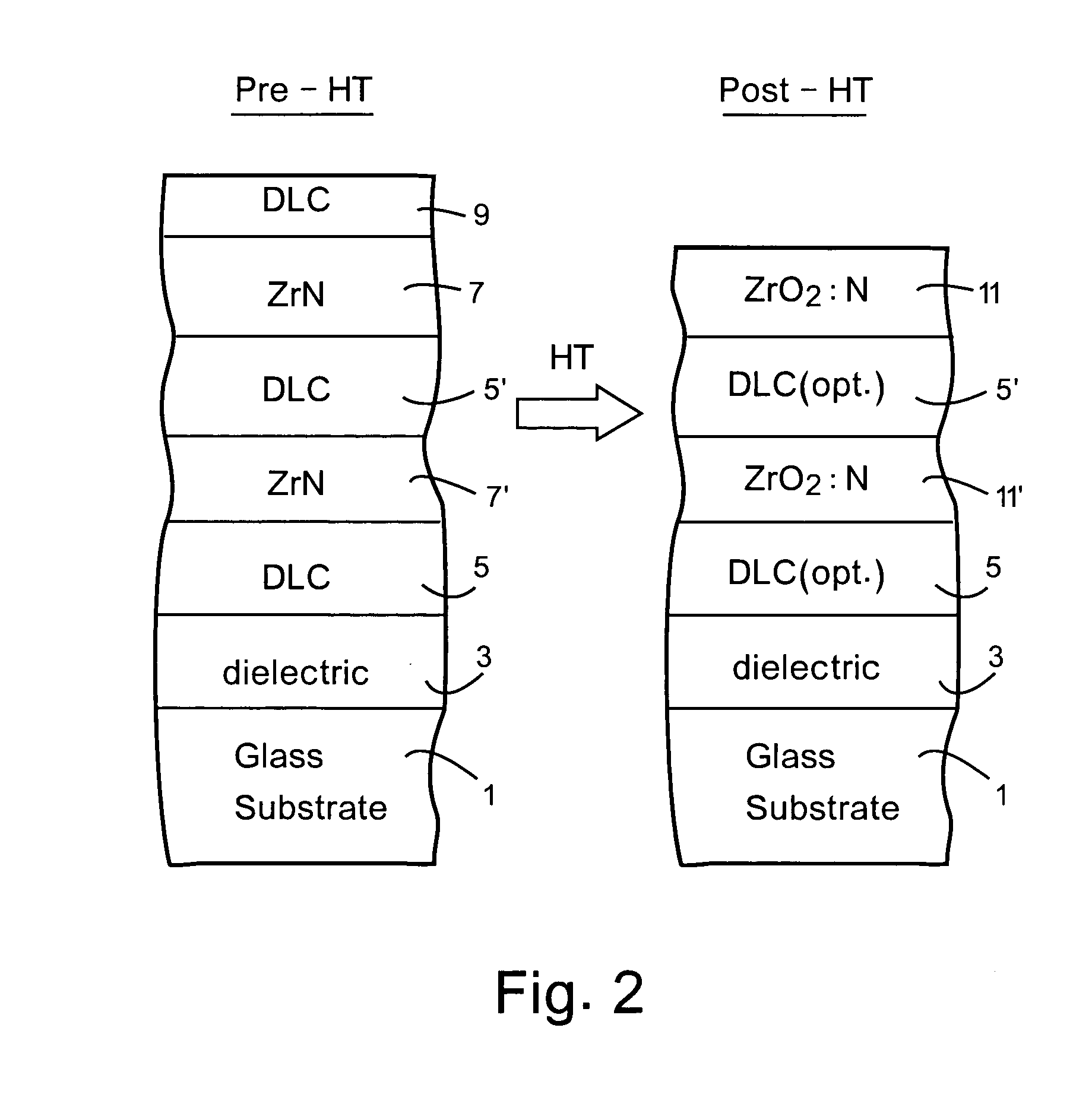

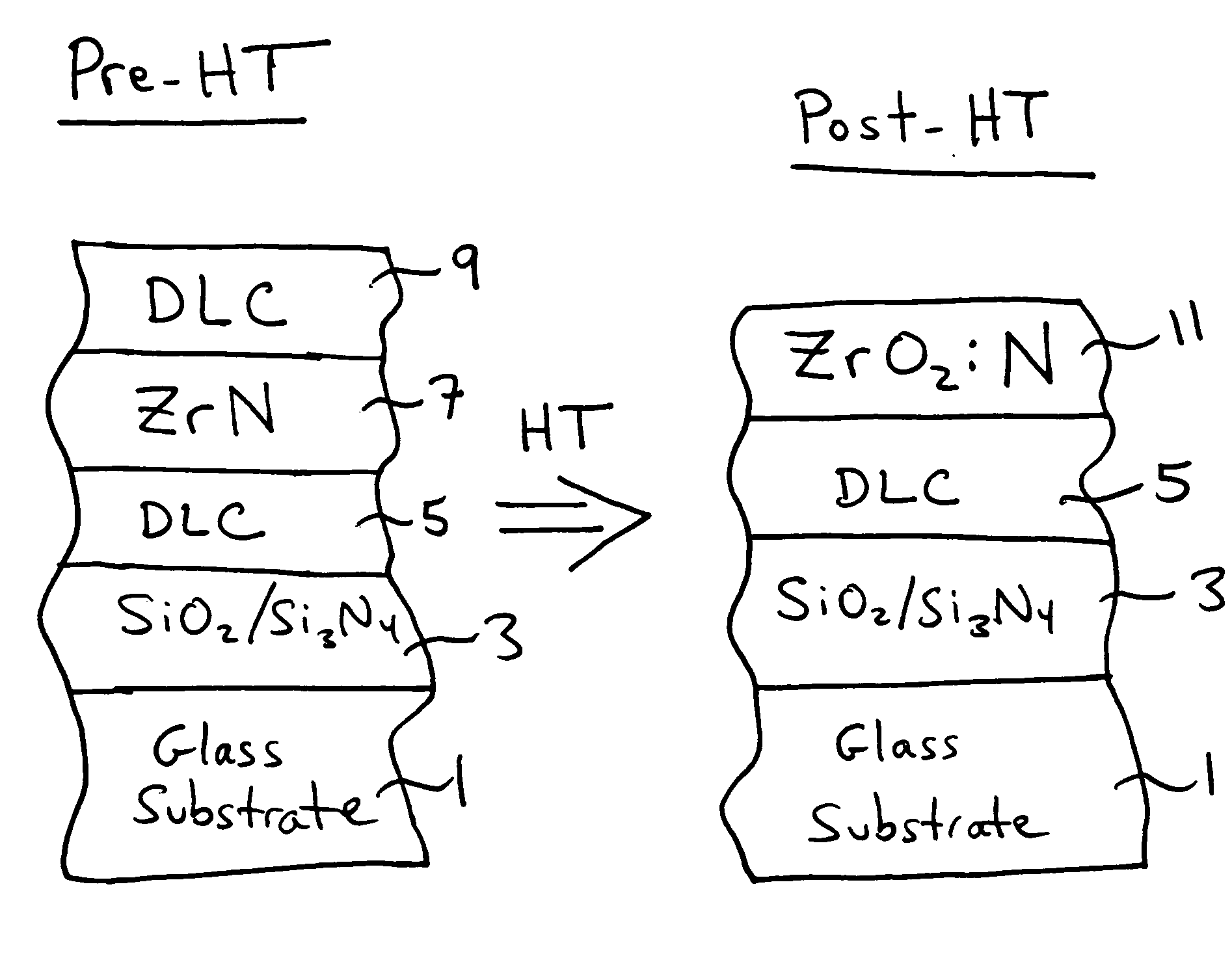

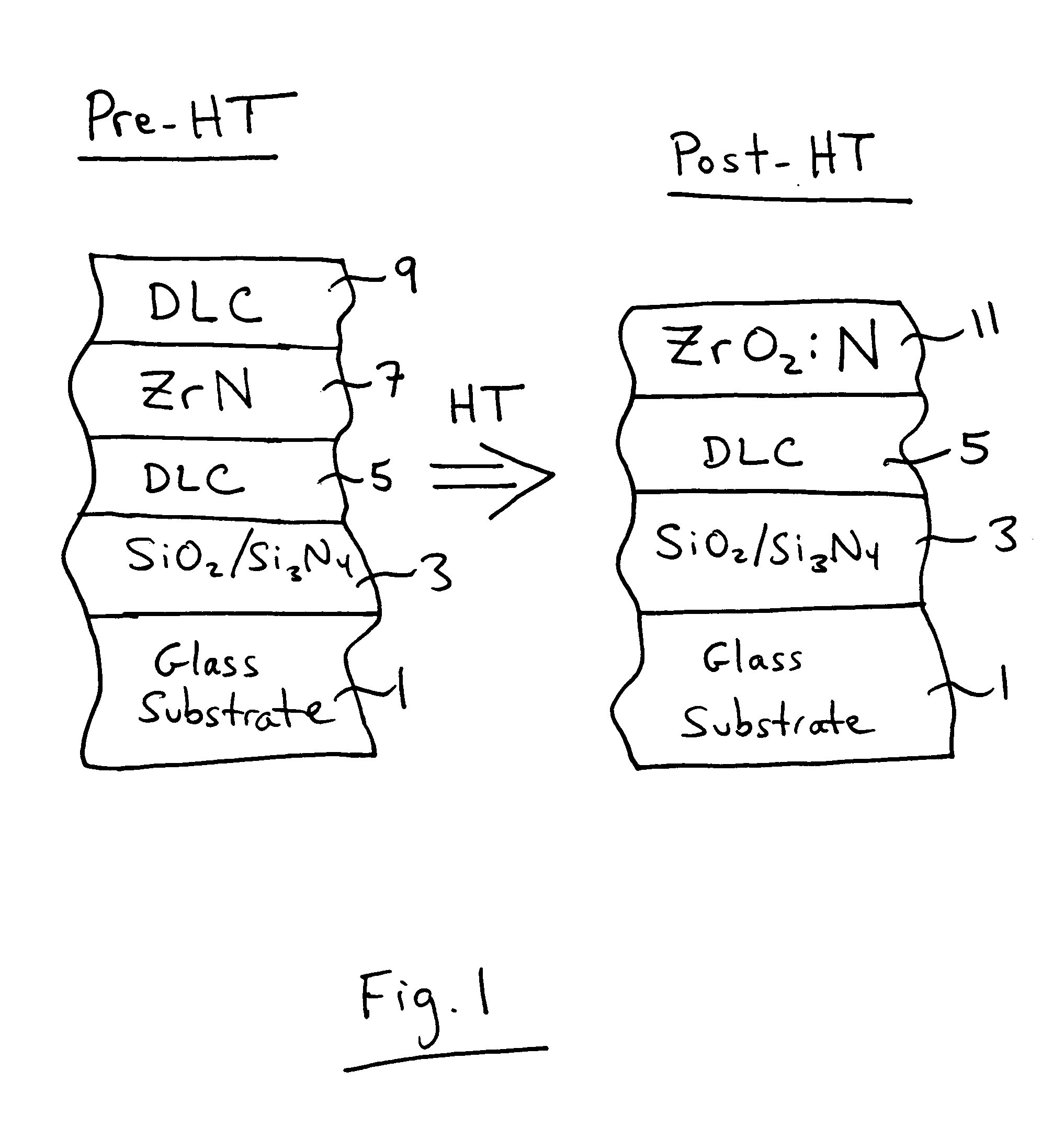

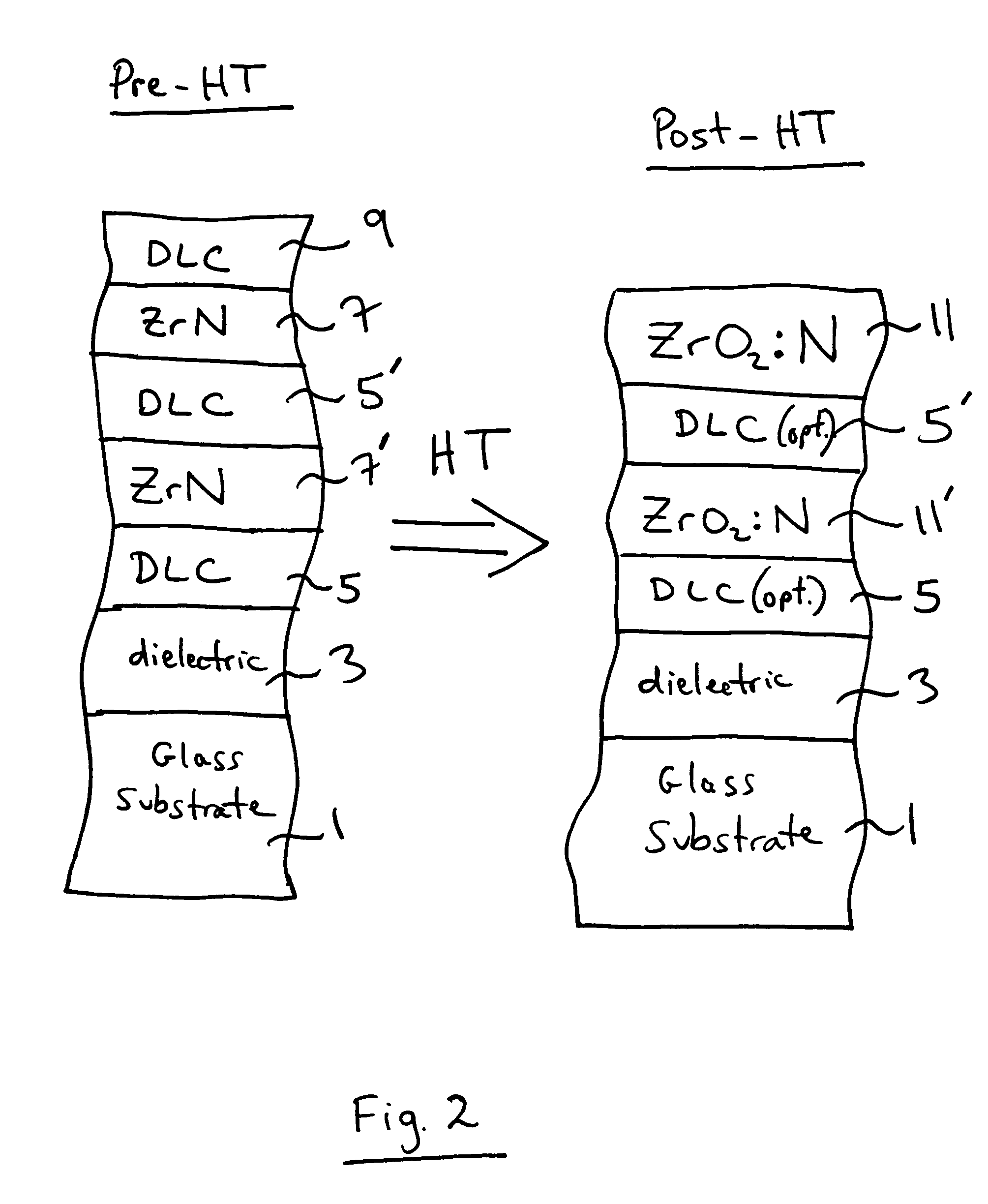

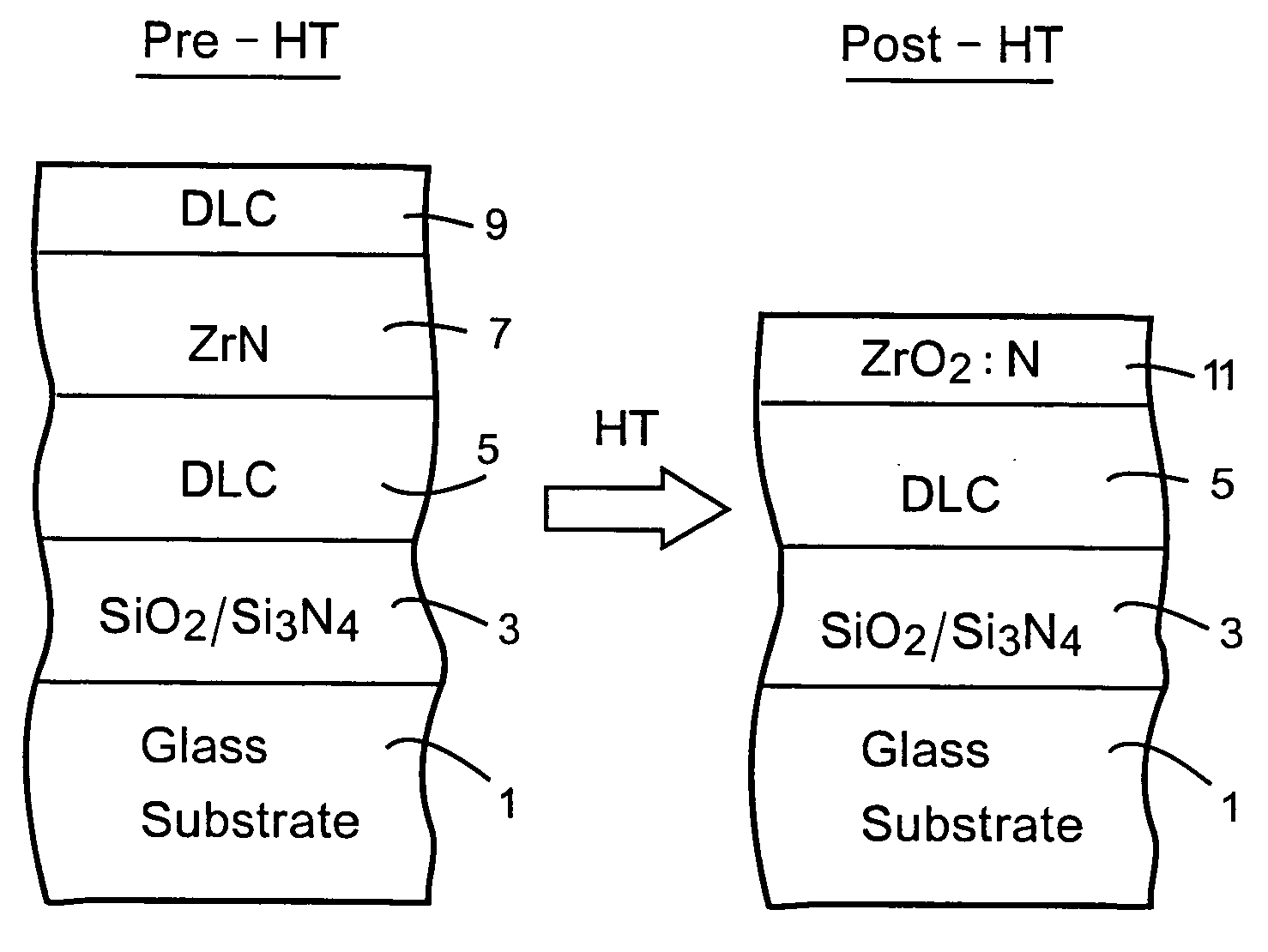

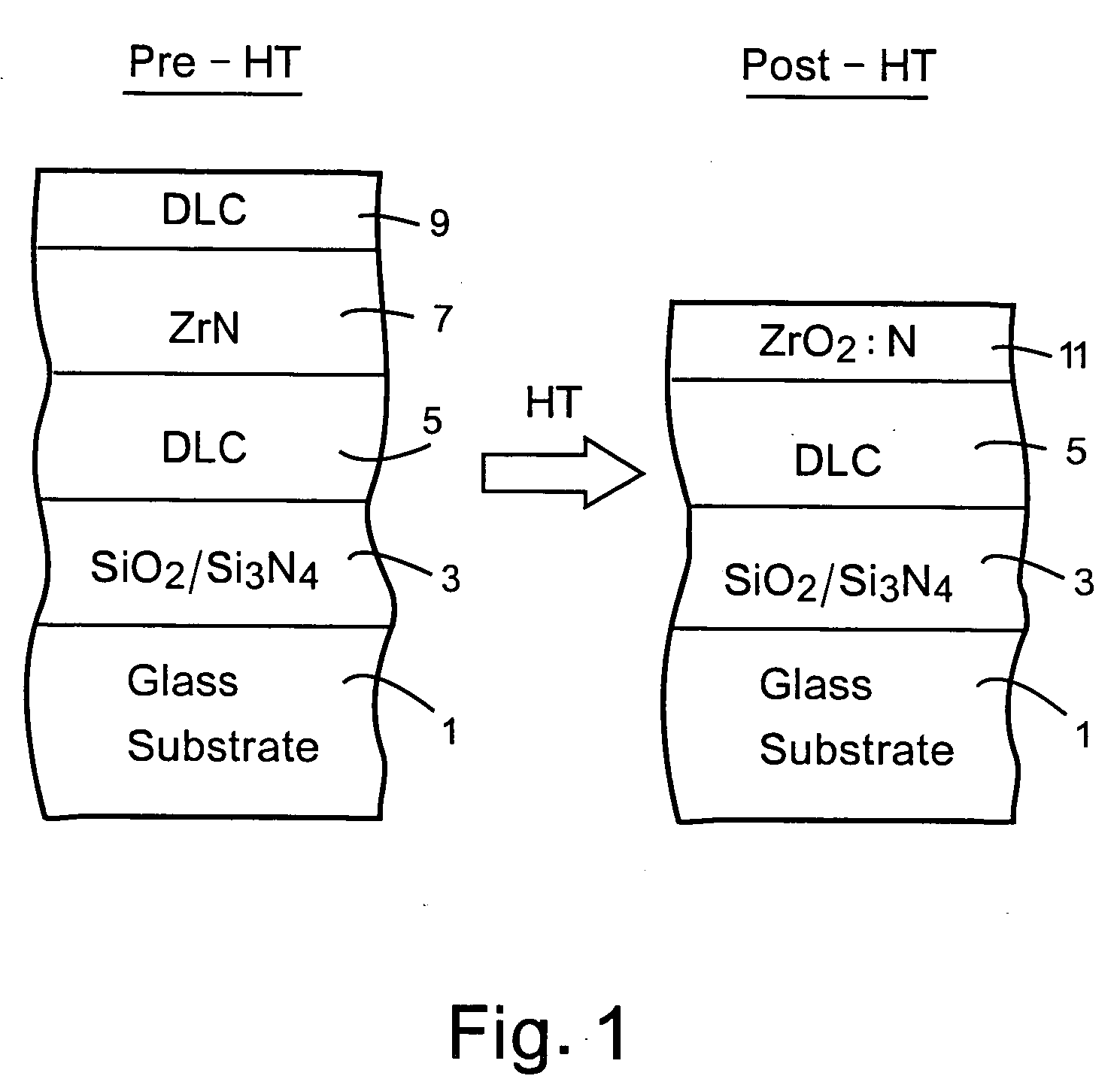

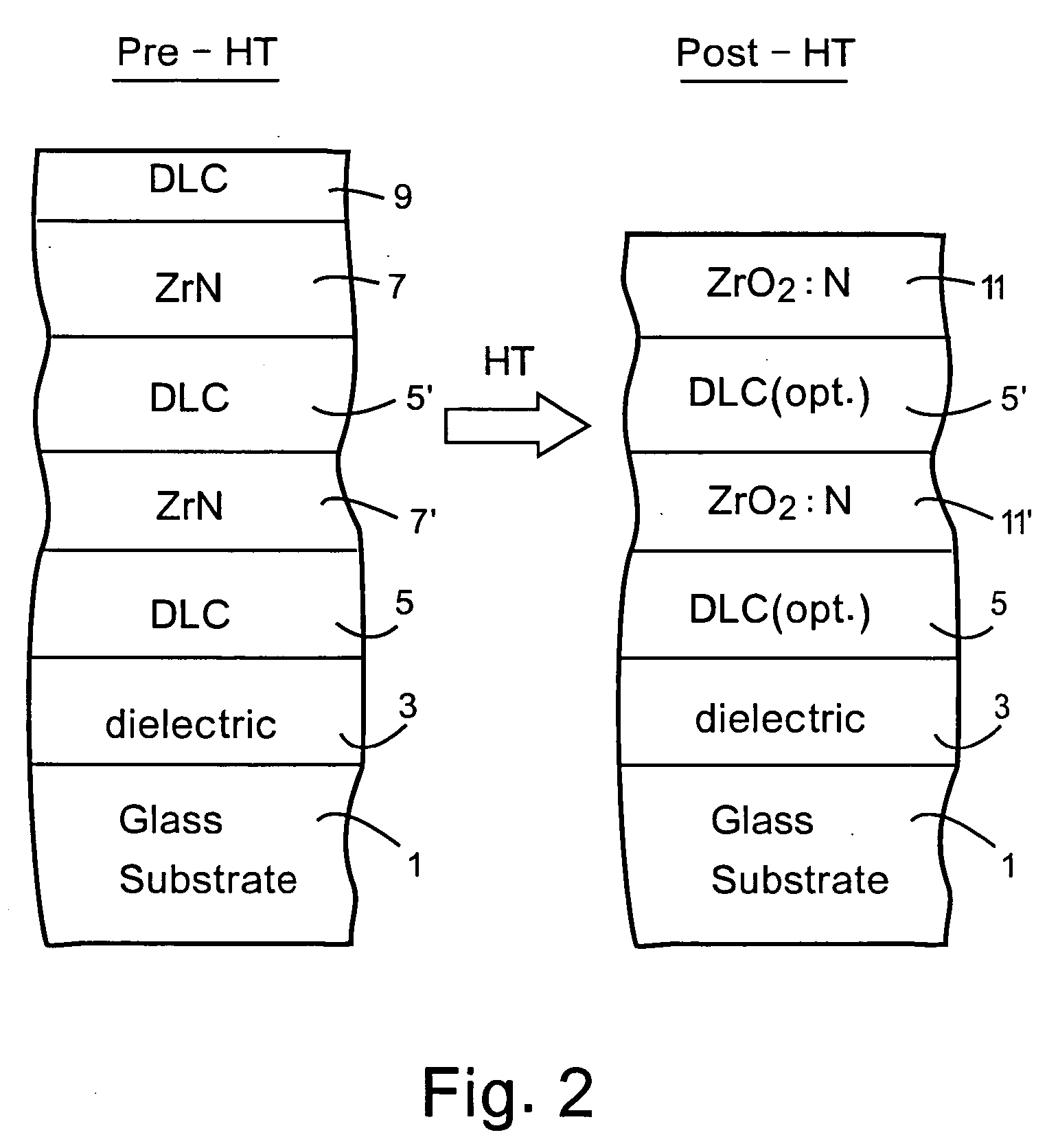

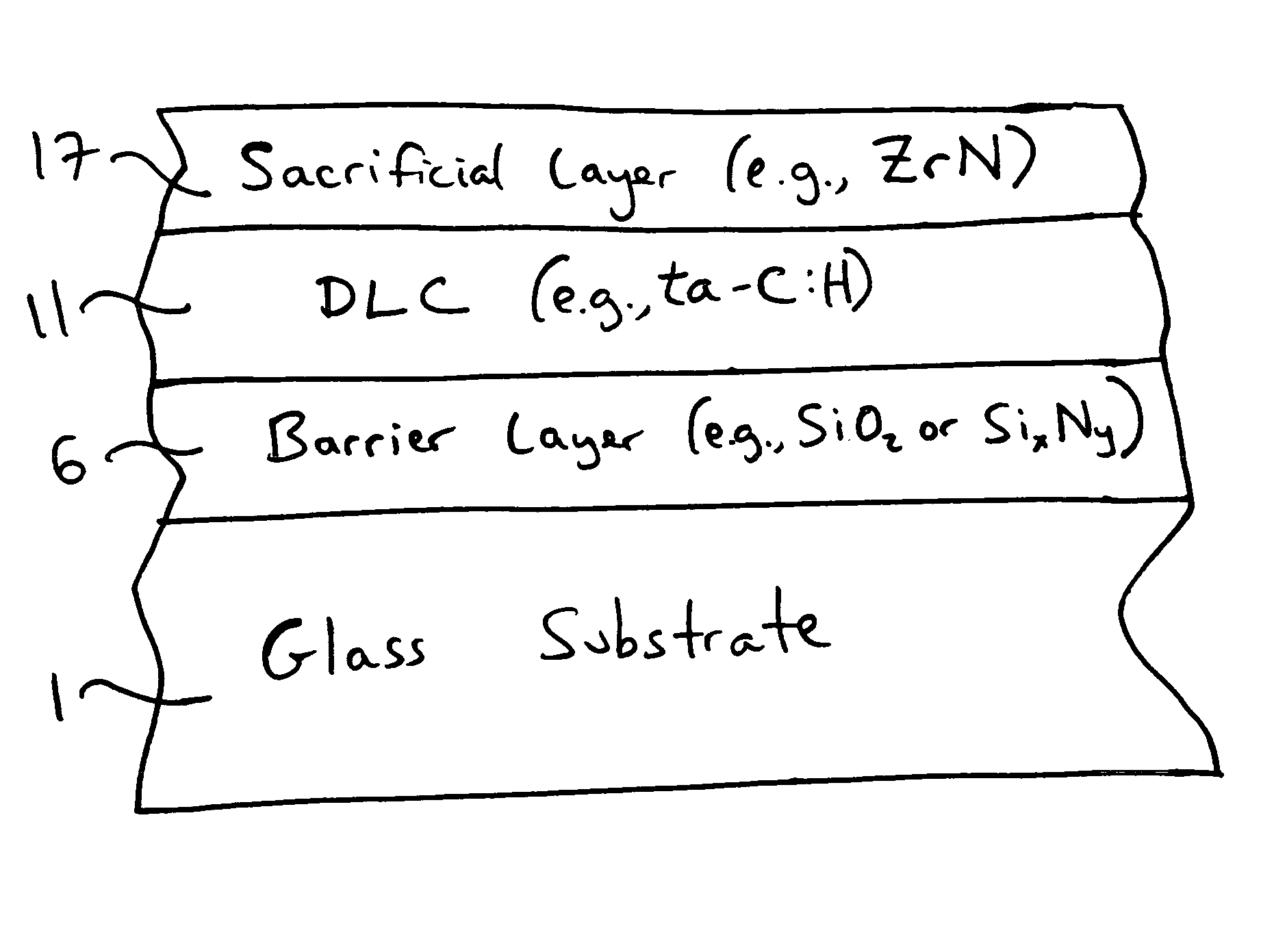

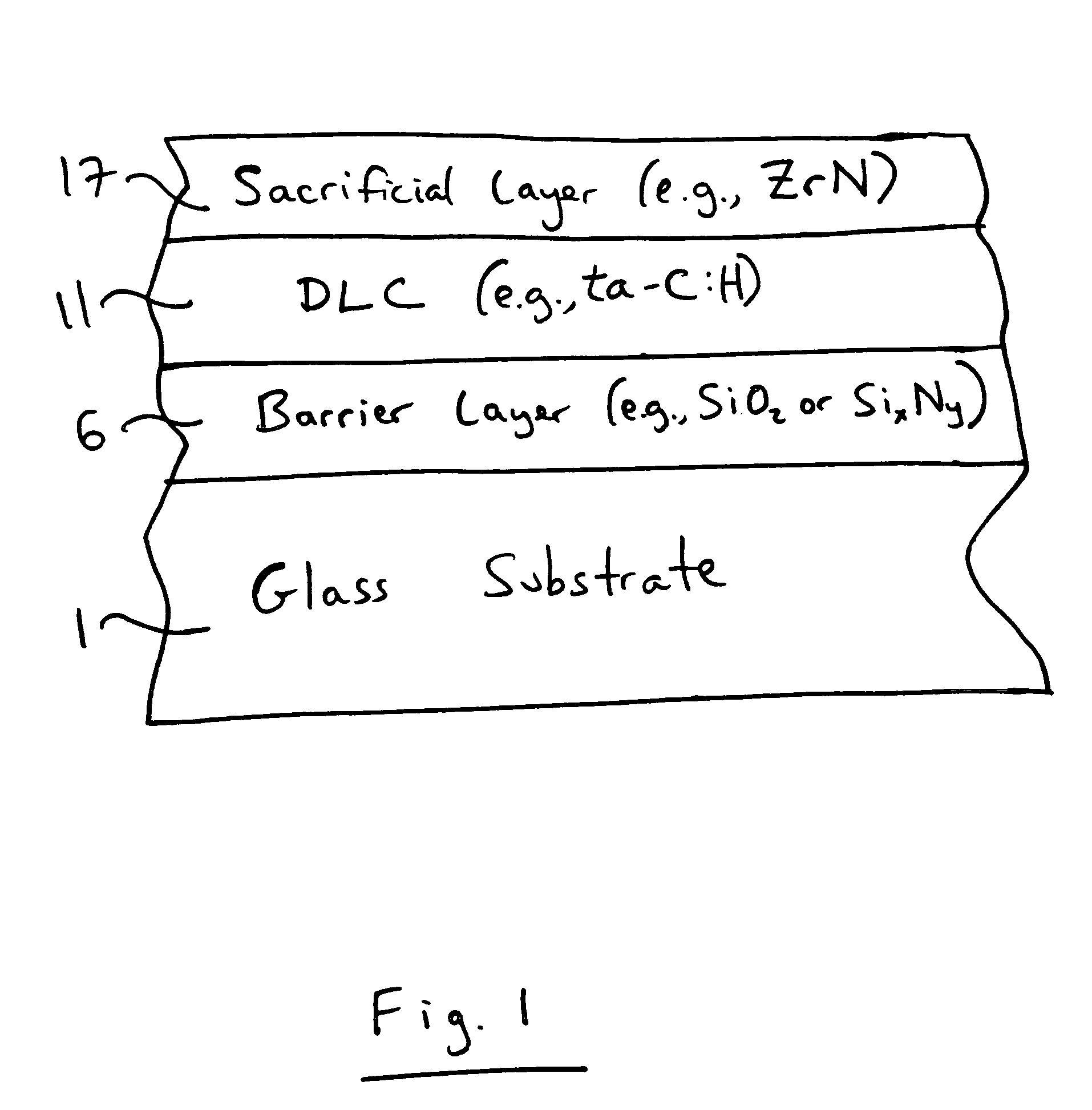

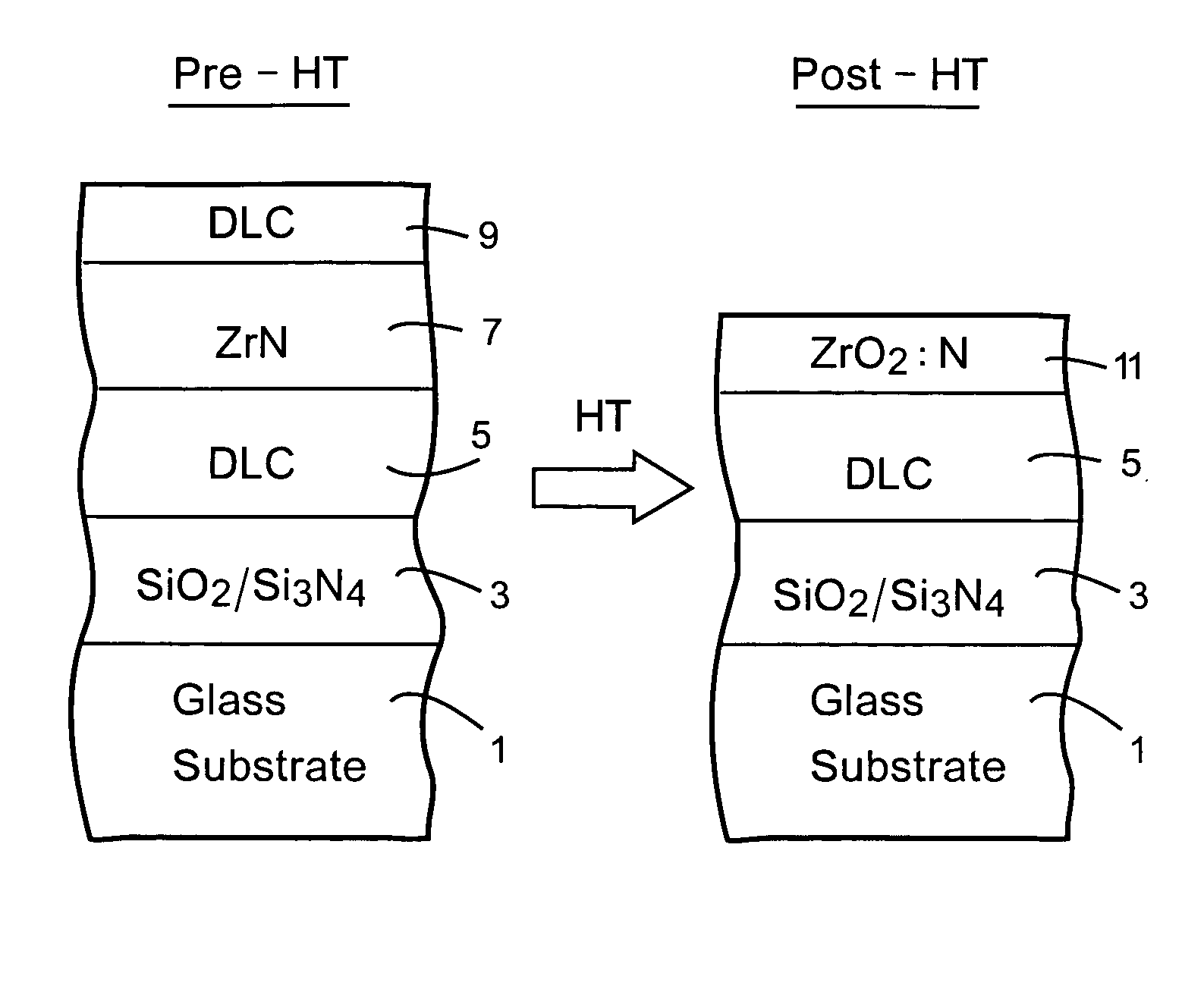

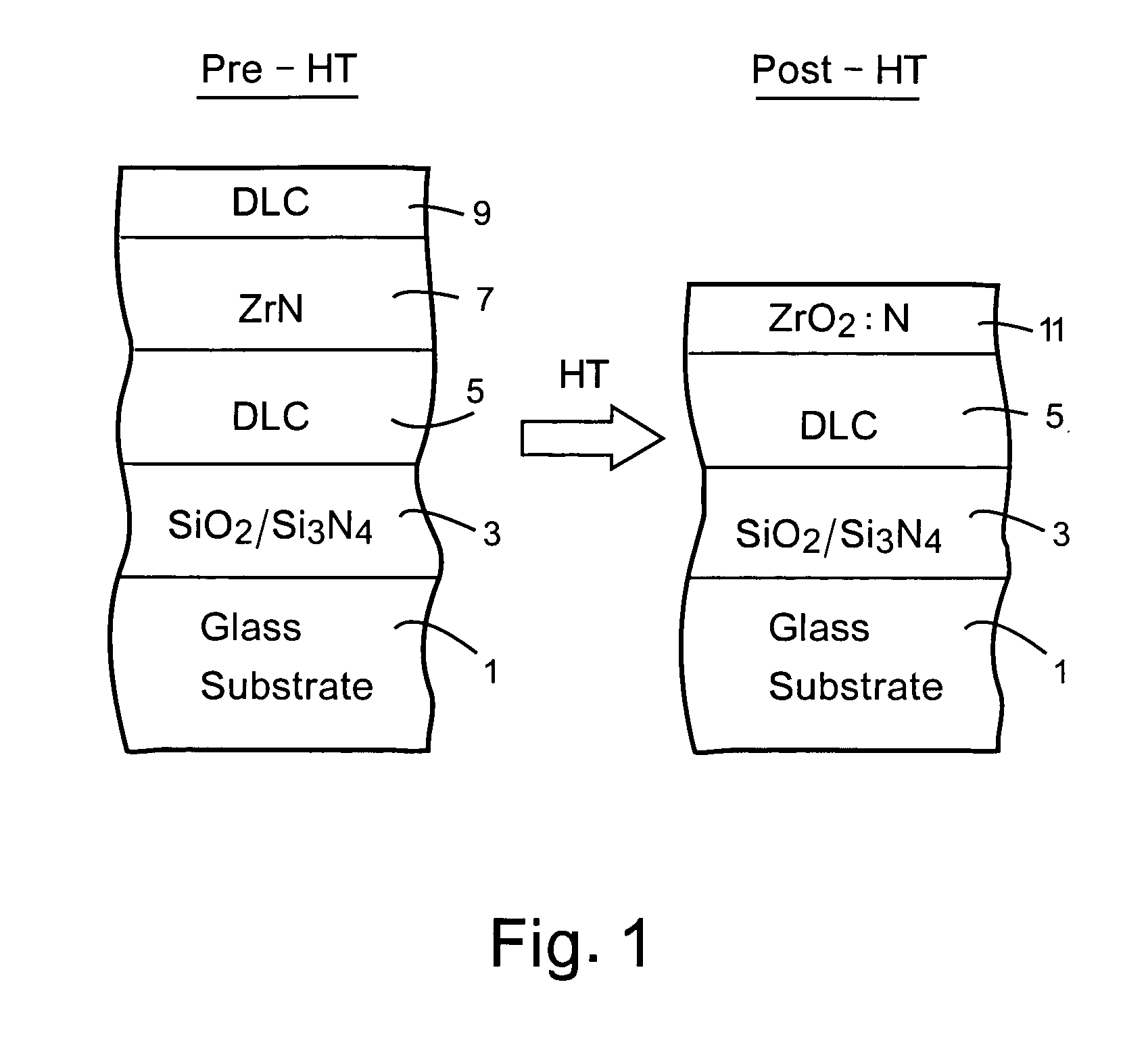

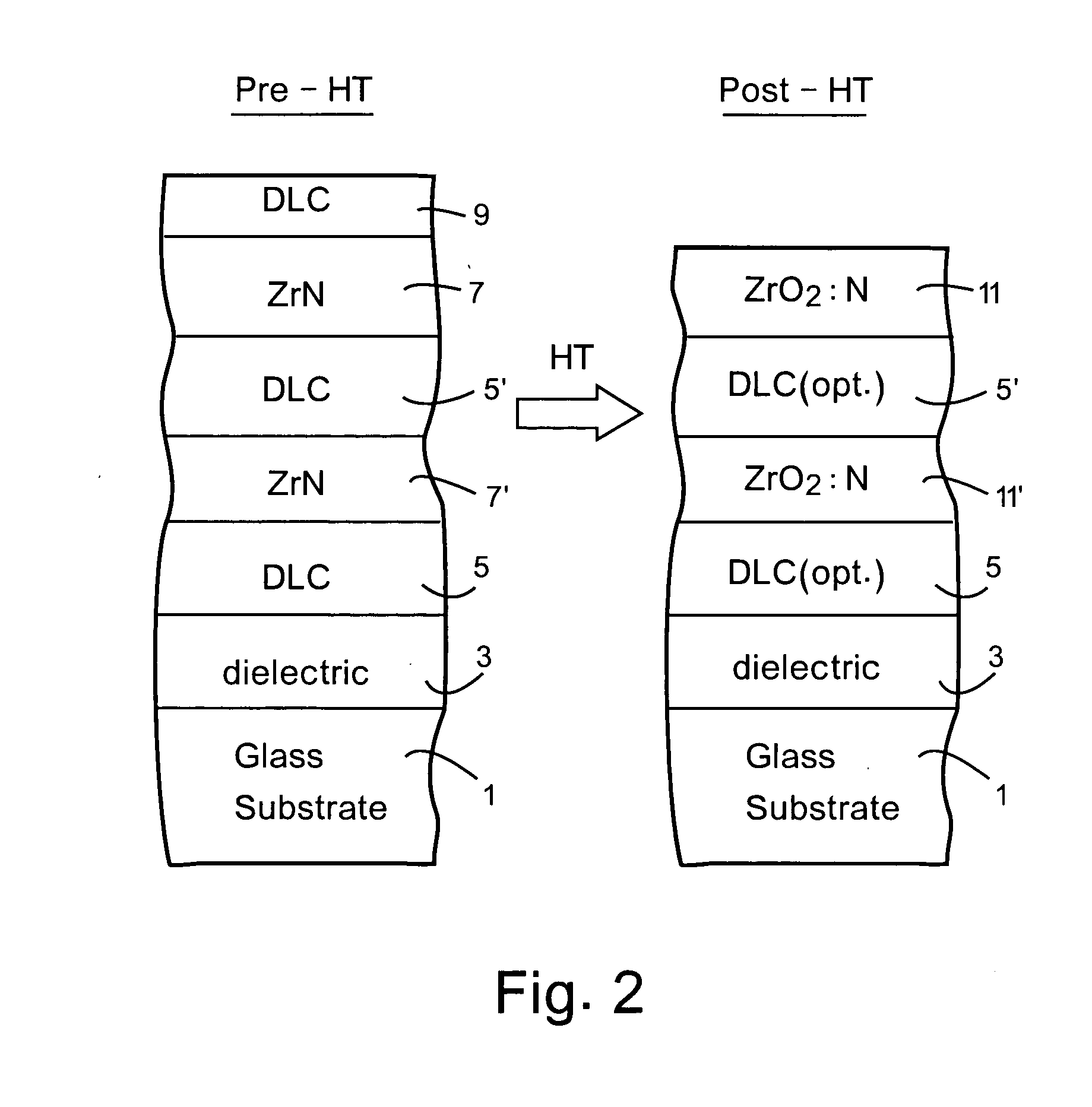

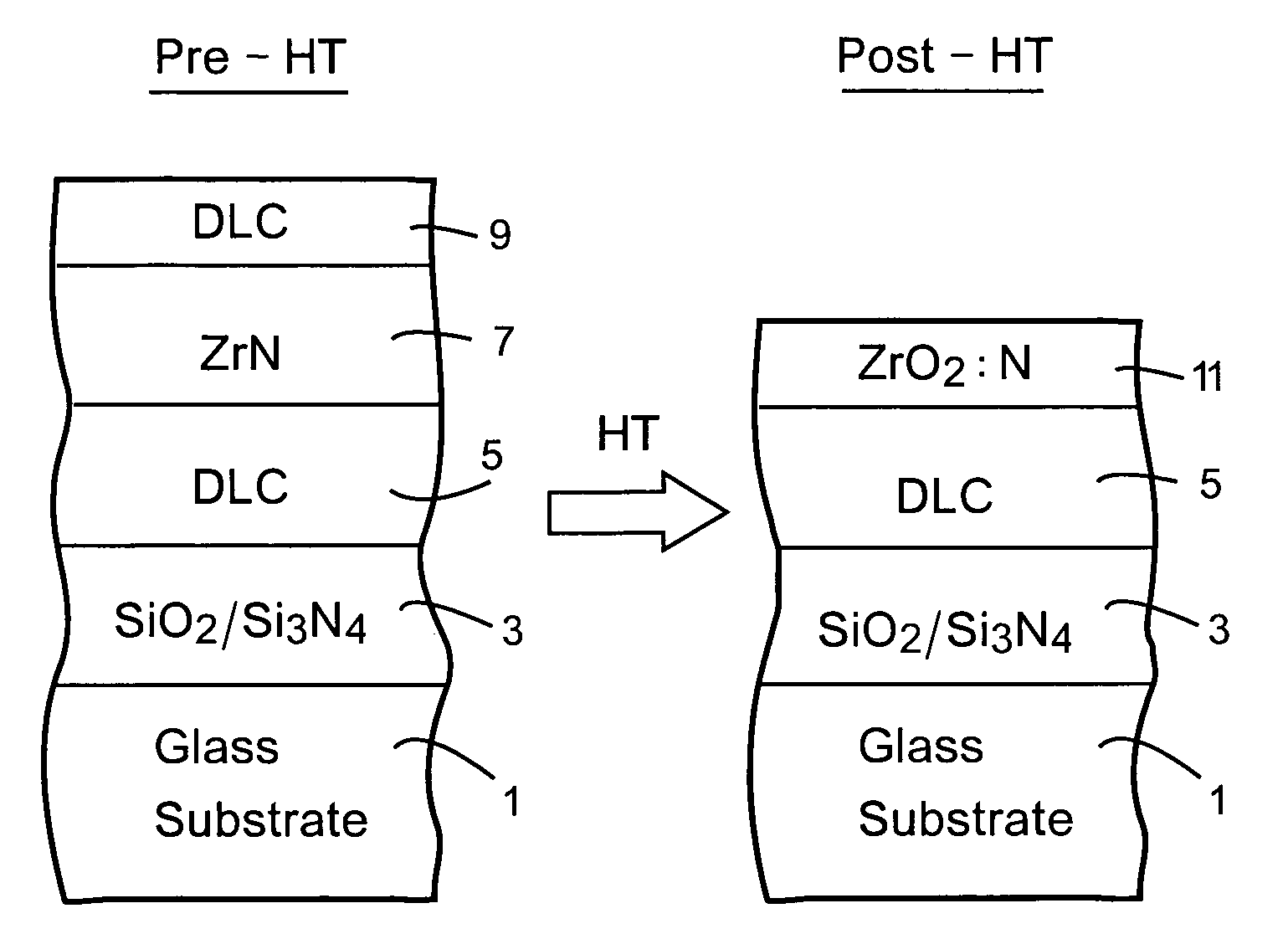

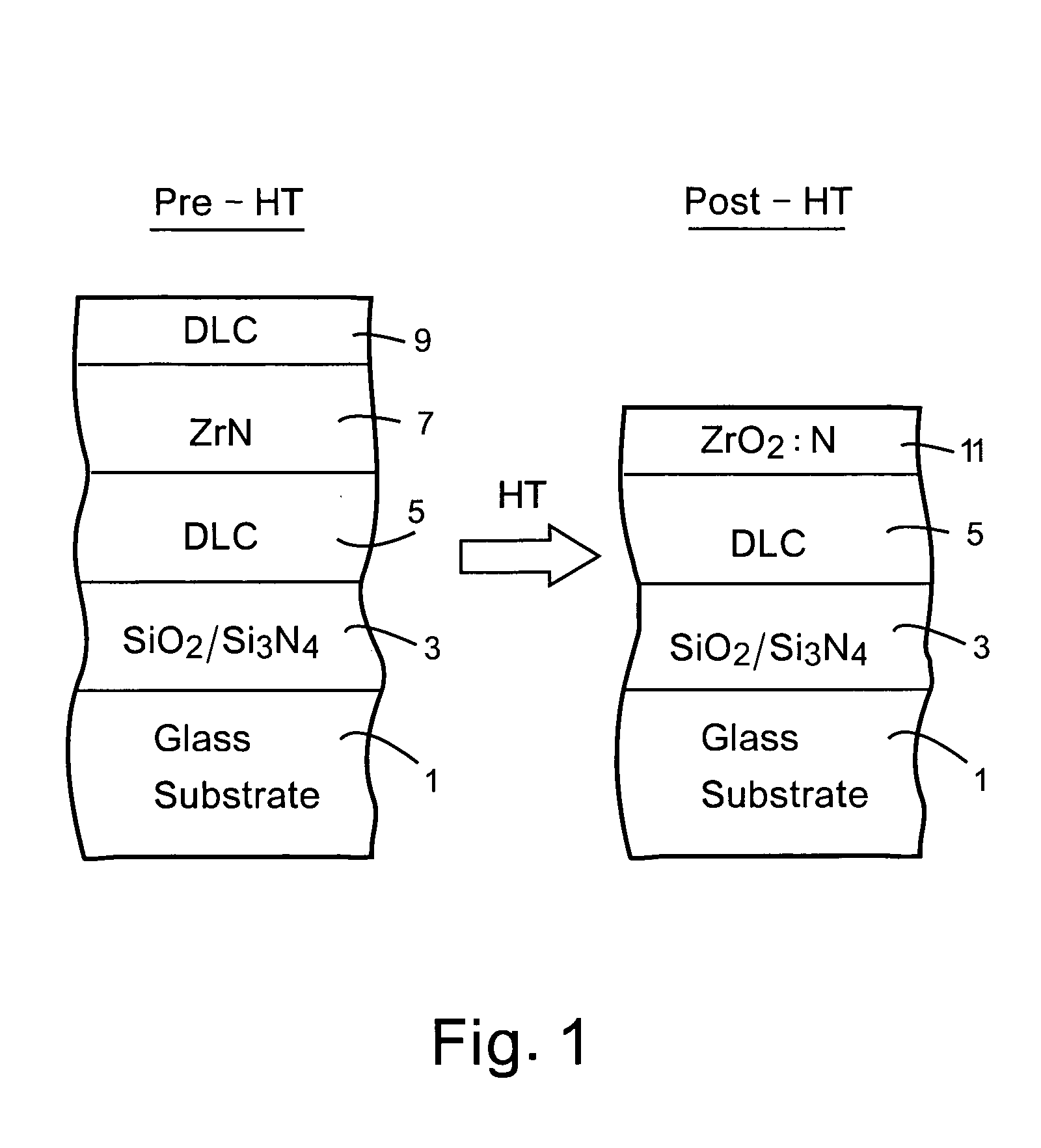

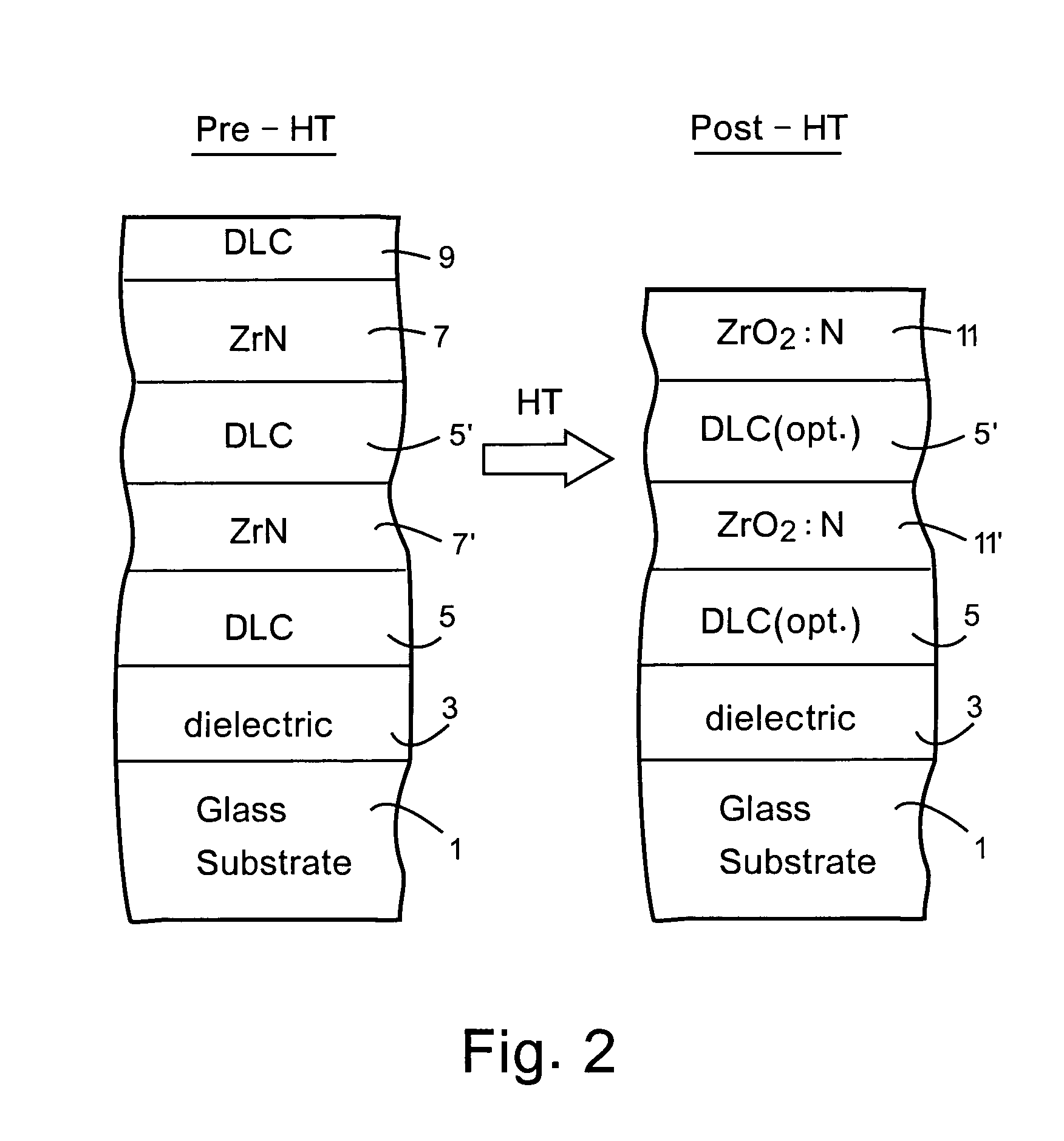

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

In certain example embodiments, a coated article includes respective layers including diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is scratch resistant and durable.

Owner:GUARDIAN GLASS LLC

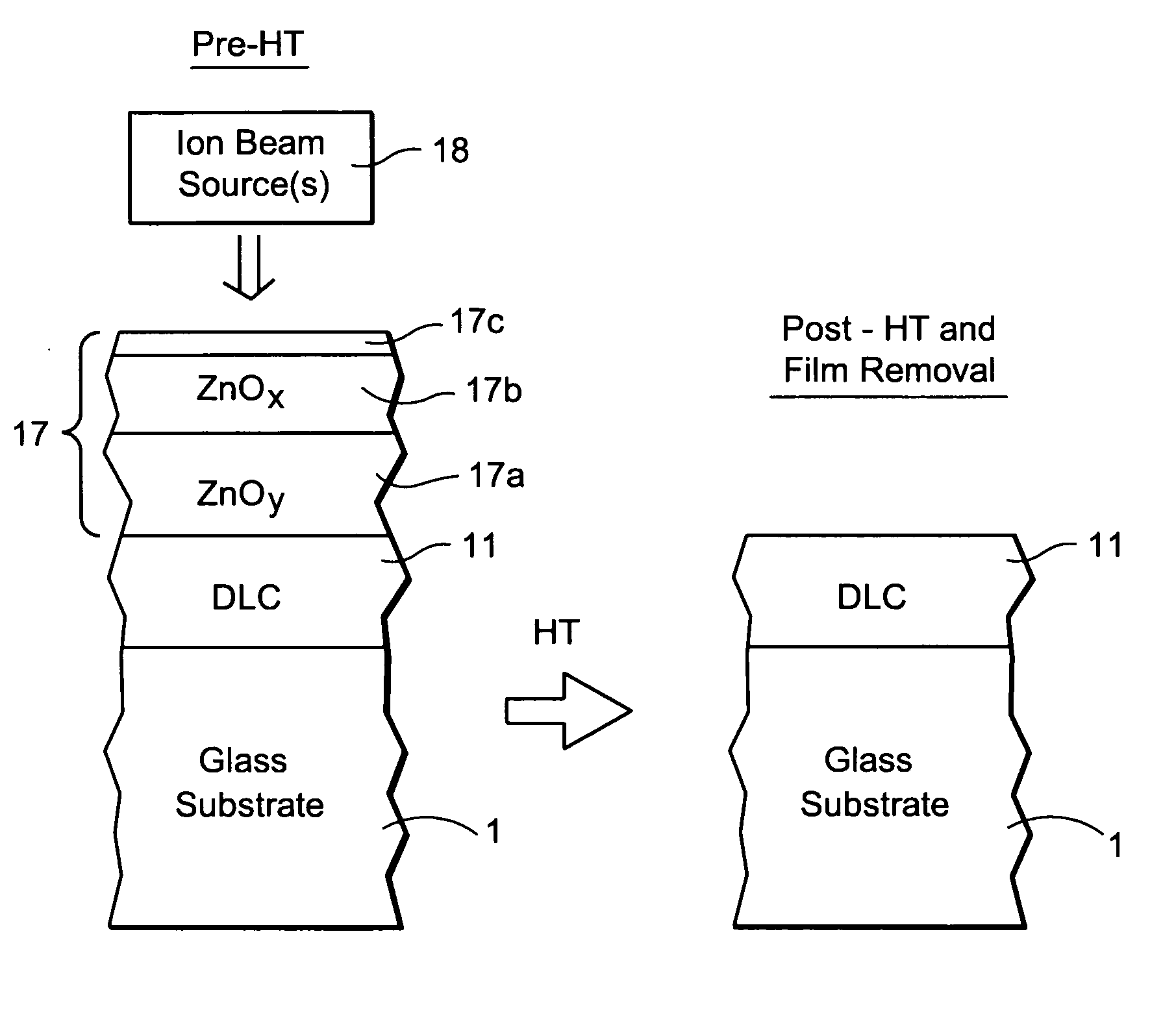

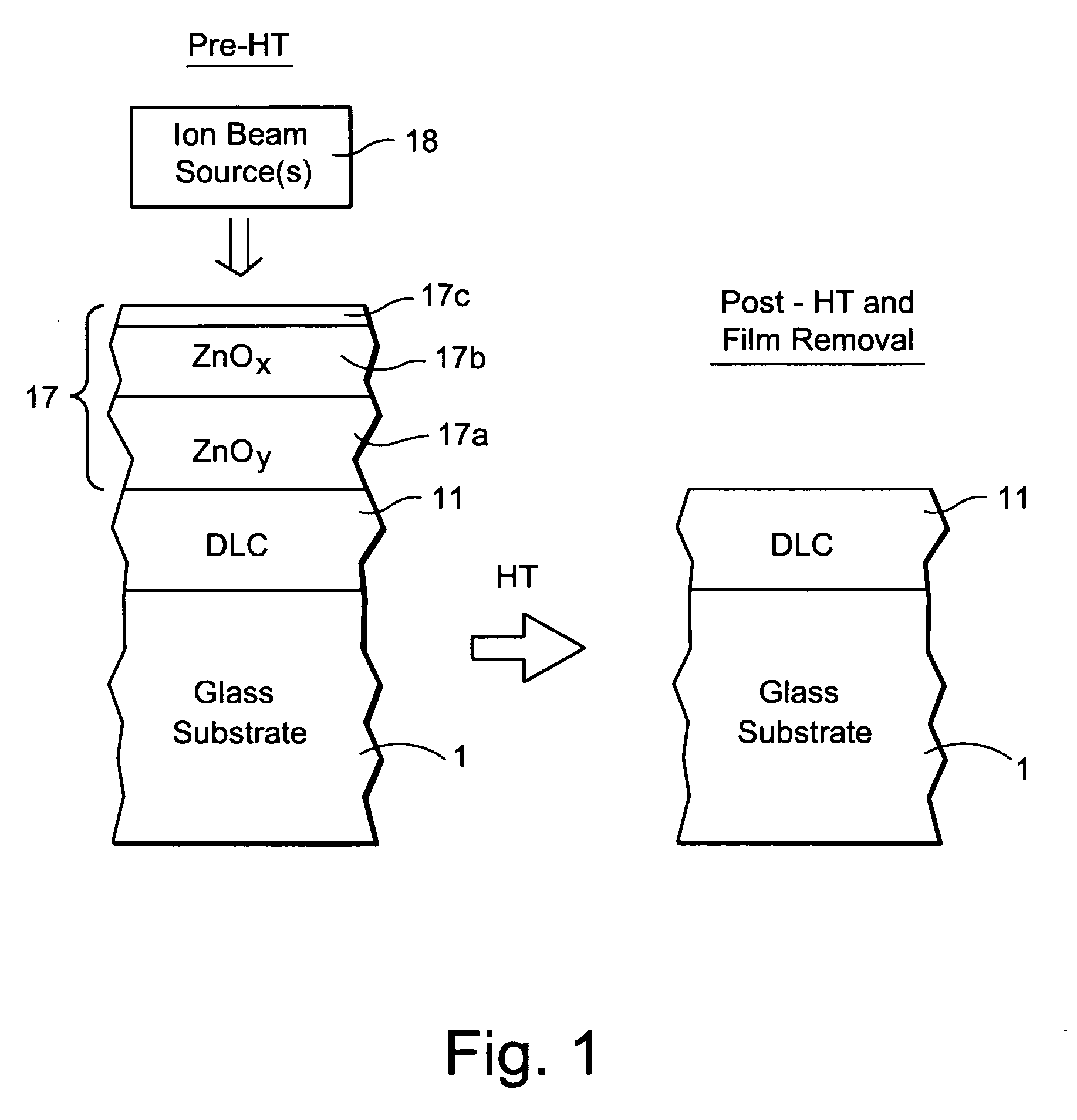

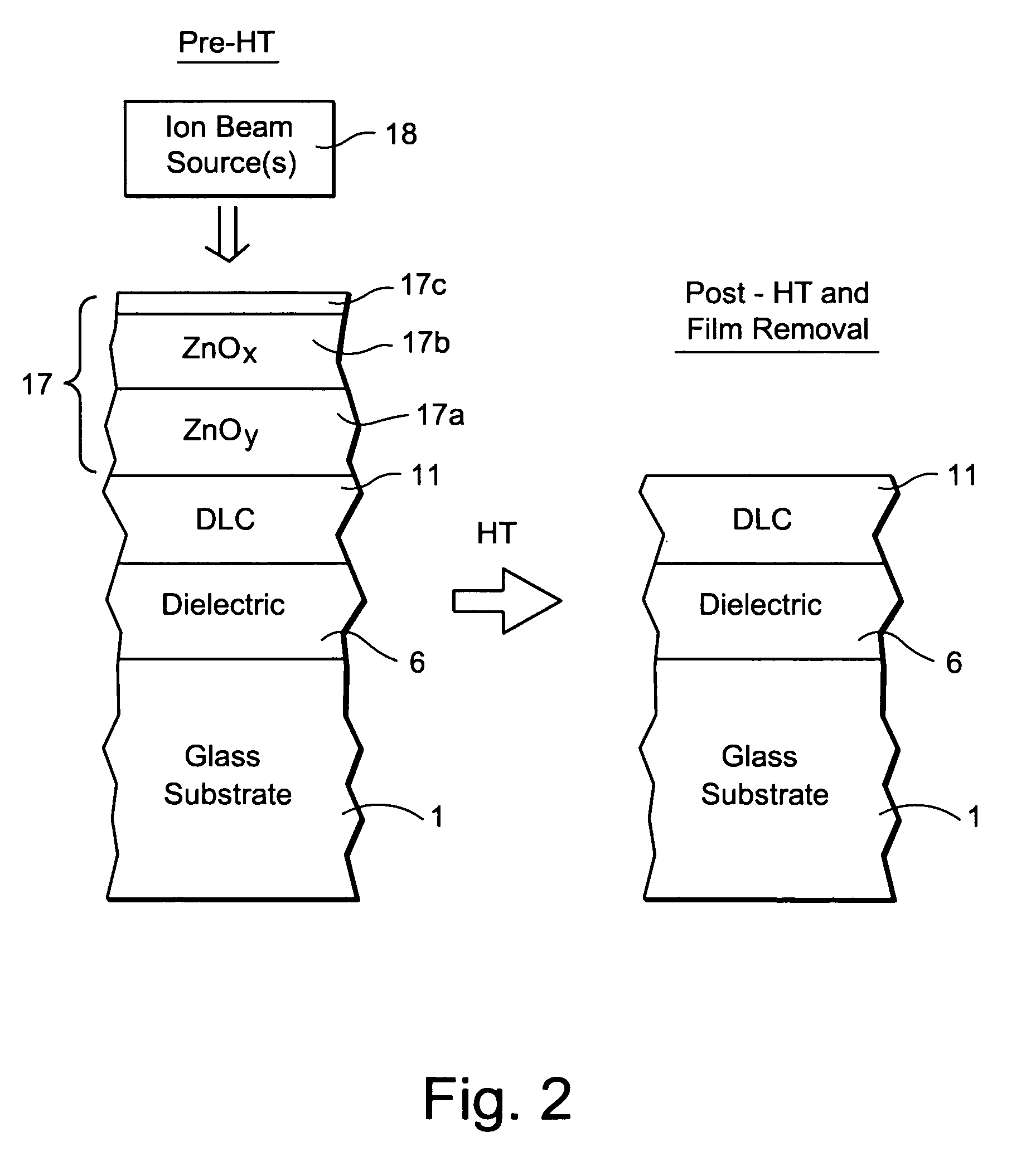

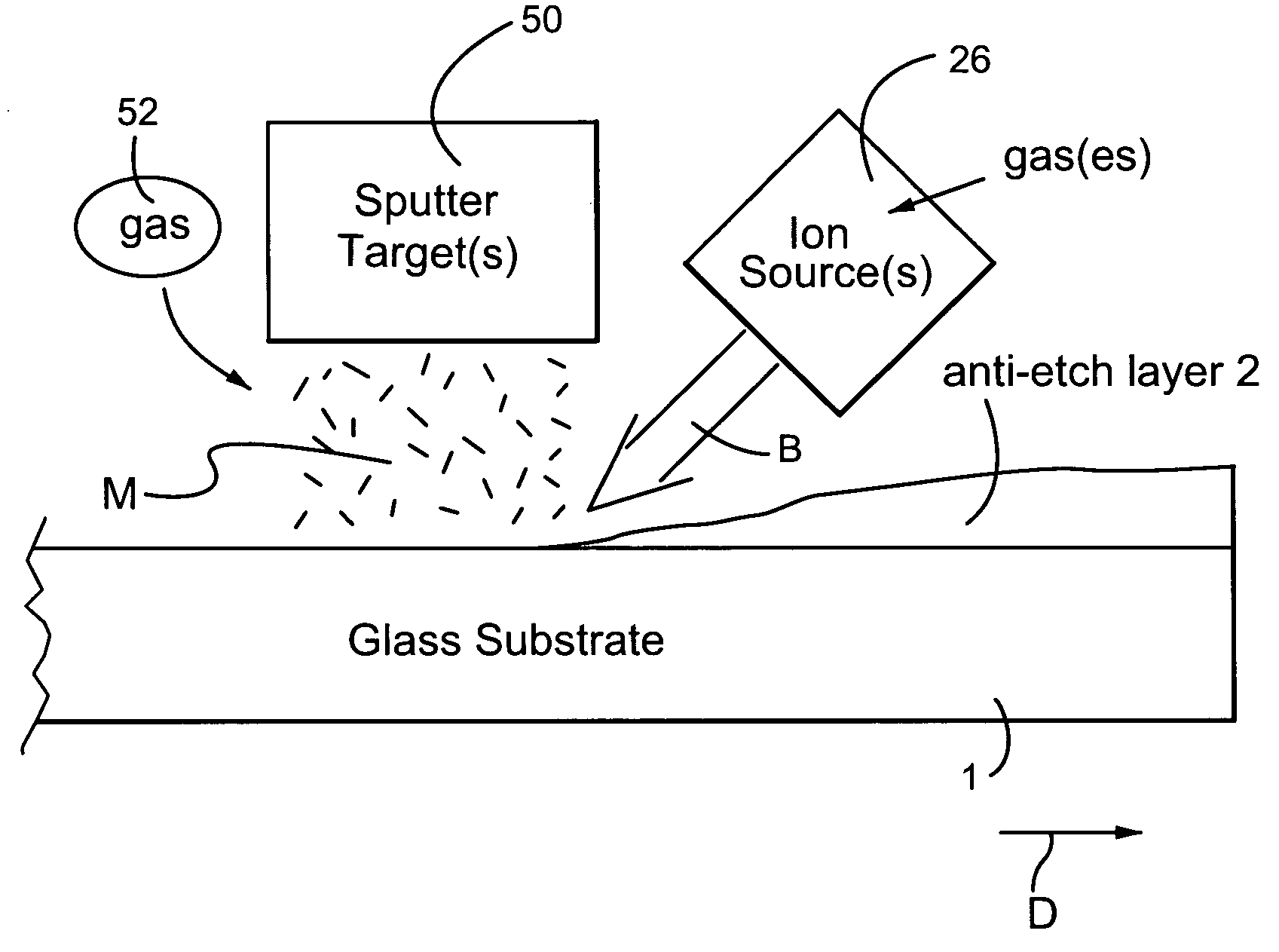

Method of making coated article including ion beam treatment of metal oxide protective film

There is provided a method of making a heat treated (HT) coated article to be used in shower door applications, window applications, or any other suitable applications where transparent coated articles are desired. For example, certain embodiments of this invention relate to a method of making a coated article including a step of heat treating a glass substrate coated with at least a layer of or including diamond-like carbon (DLC) and an overlying protective film (e.g., of or including zinc oxide) thereon. In certain example embodiments, the protective film may be ion beam treated with at least carbon ions. It has been found that the ion beam treatment improves the shelf-life of the product prior to HT. Following and / or during heat treatment (e.g., thermal tempering, or the like), the protective film may be removed.

Owner:GUARDIAN GLASS LLC

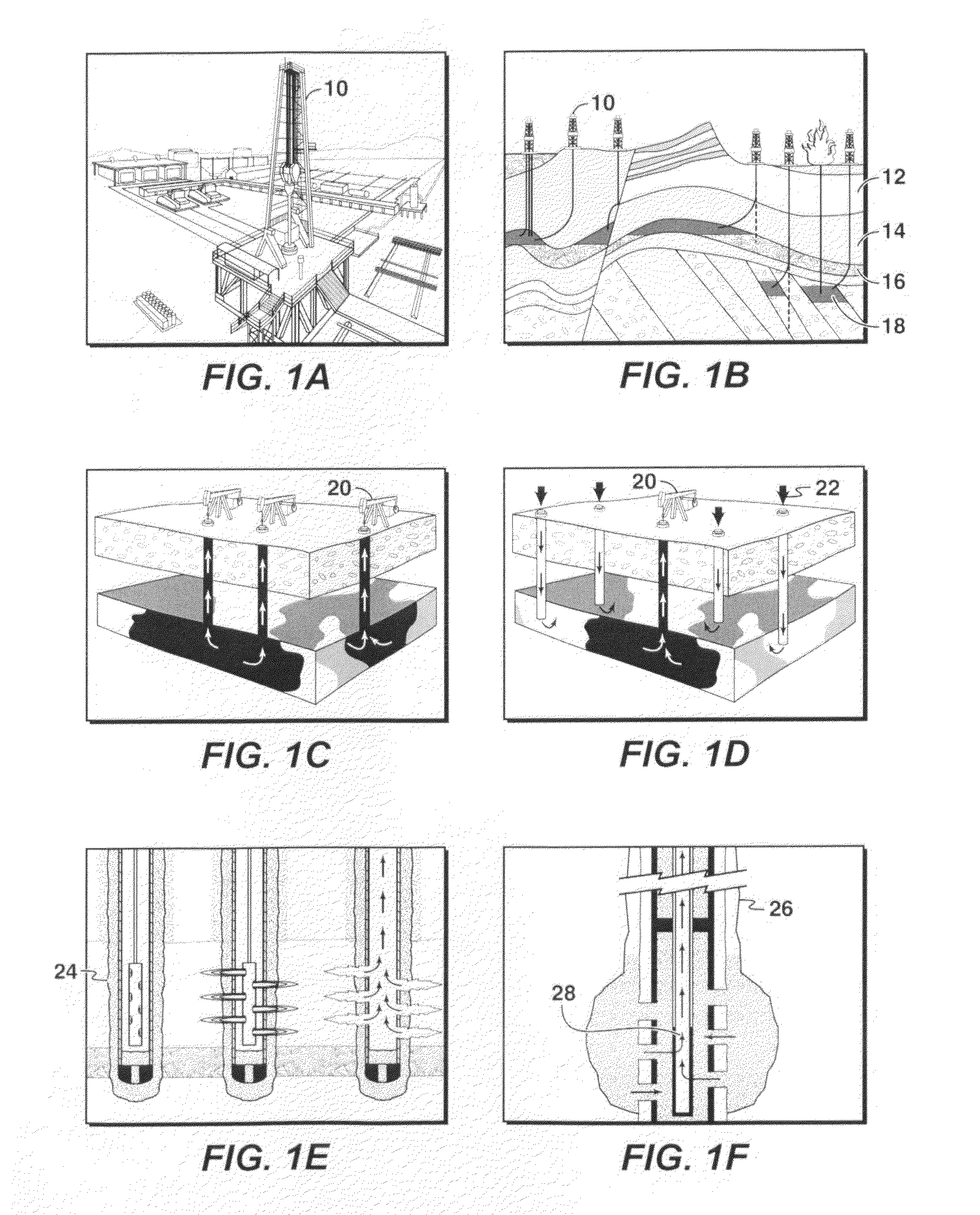

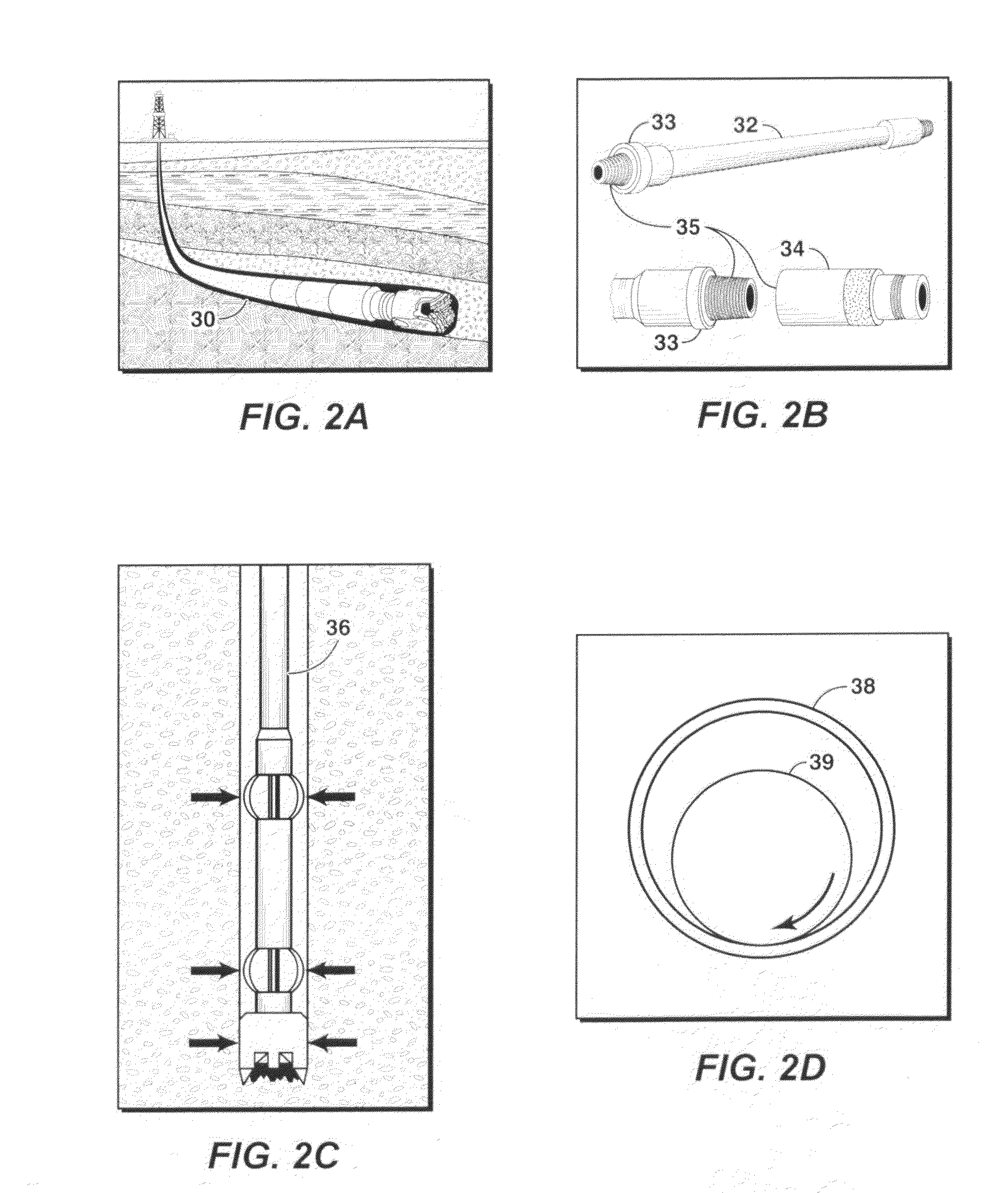

Coated sleeved oil and gas well production devices

Provided are coated sleeved oil and gas well production devices and methods of making and using such coated sleeved devices. In one form, the coated sleeved oil and gas well production device includes an oil and gas well production device including one or more bodies and one or more sleeves proximal to the outer or inner surface of the one or more bodies, and a coating on at least a portion of the inner sleeve surface, outer sleeve surface, or a combination thereof, wherein the coating is chosen from an amorphous alloy, a heat-treated electroless or electro plated based nickel-phosphorous composite with a phosphorous content greater than 12 wt %, graphite, MoS2, WS2, a fullerene based composite, a boride based cermet, a quasicrystalline material, a diamond based material, diamond-like-carbon (DLC), boron nitride, and combinations thereof. The coated sleeved oil and gas well production devices may provide for reduced friction, wear, erosion, corrosion, and deposits for well construction, completion and production of oil and gas.

Owner:EXXONMOBIL UPSTREAM RES CO

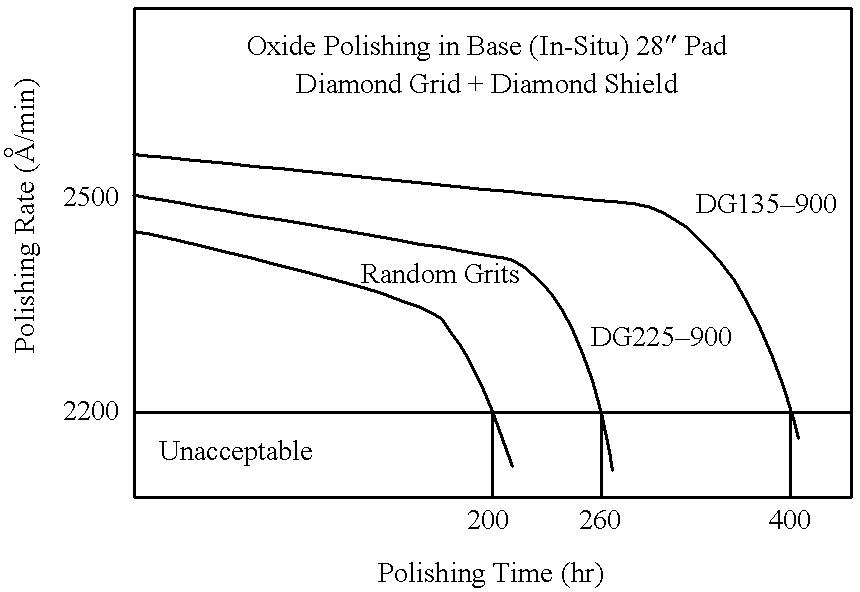

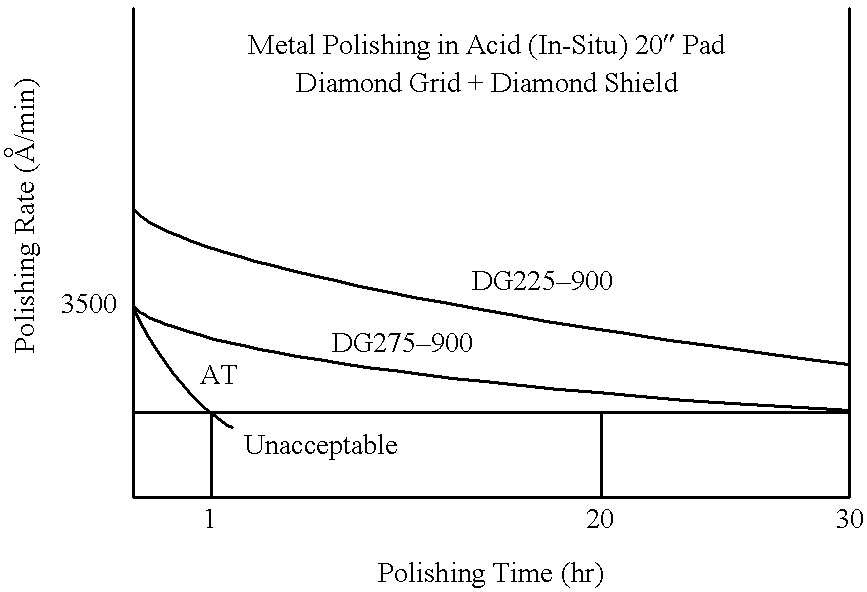

Diamond grid CMP pad dresser

InactiveUS6884155B2Easy to monitorUniform sizePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

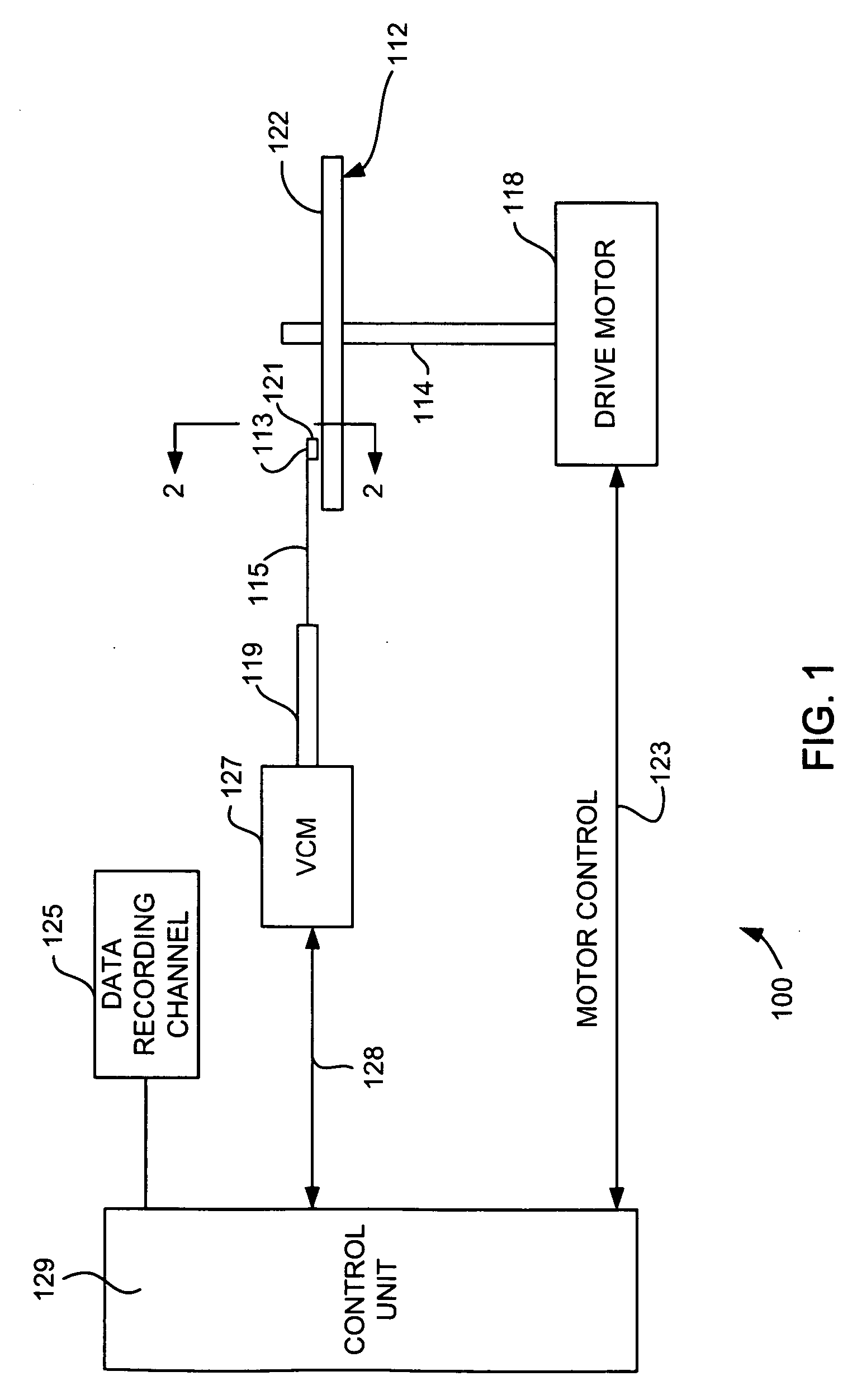

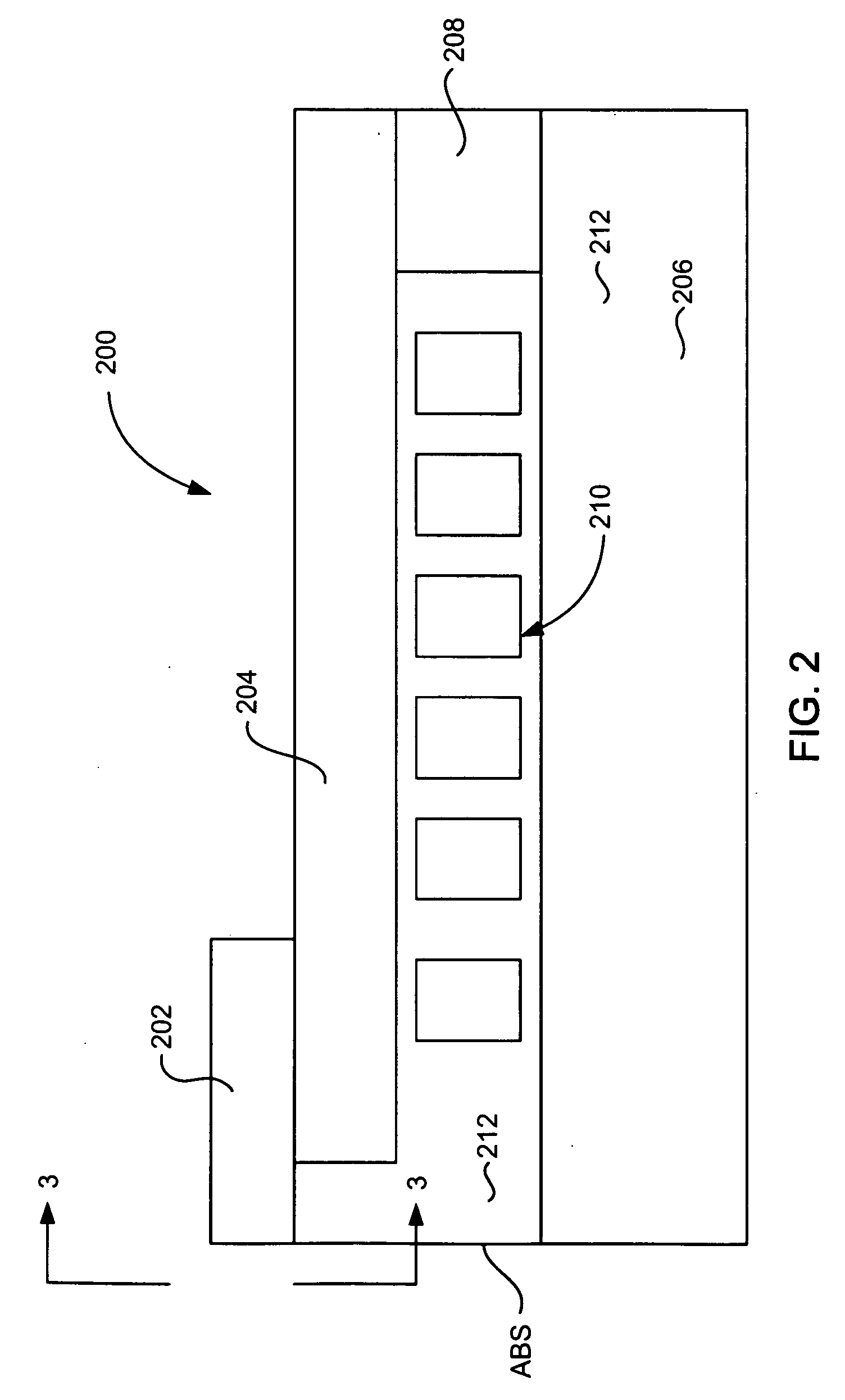

High milling resistance write pole fabrication method for perpendicular recording

InactiveUS20060174474A1Well-defined shapeExcellent track width controlElectrical transducersManufacture head surfaceDiamond-like carbonImage transfer

A mask structure for fabricating a write pole for a perpendicular write head. The mask structure includes a first and second hard mask structures separated by an image transfer layer, such as DURAMIDE®. The first mask structure may be a bi-layer mask structure that functions as a CMP stop as well as a hard mask for ion milling. The first hard mask is chosen to have a desired resistance to removal by ion milling to maintain excellent track width control during an ion milling process used to form the write pole. Therefore, the first hard mask may be comprises of two layers selected from the group consisting of Rh, alumina, and diamond like carbon (DLC). The second hard mask is constructed of a material that functions as a bottom antireflective coating as well as a hard mask.

Owner:WESTERN DIGITAL TECH INC

Cardiac lead with zone insulated electrodes

An electrode for a cardiac lead and method of making the same are provided. The electrode includes an electrode member and a coating applied to the electrode member. The coating is composed of an electrically insulating material and covers a first portion of the exterior of the electrode member while leaving a preselected second portion thereof exposed. The second or exposed portion enhances the impedance of the electrode, resulting in power savings and extended life spans for implantable stimulation and sensing devices. Exemplary materials for the coating includes diamond-like carbon and sapphire.

Owner:INTERMEDICS

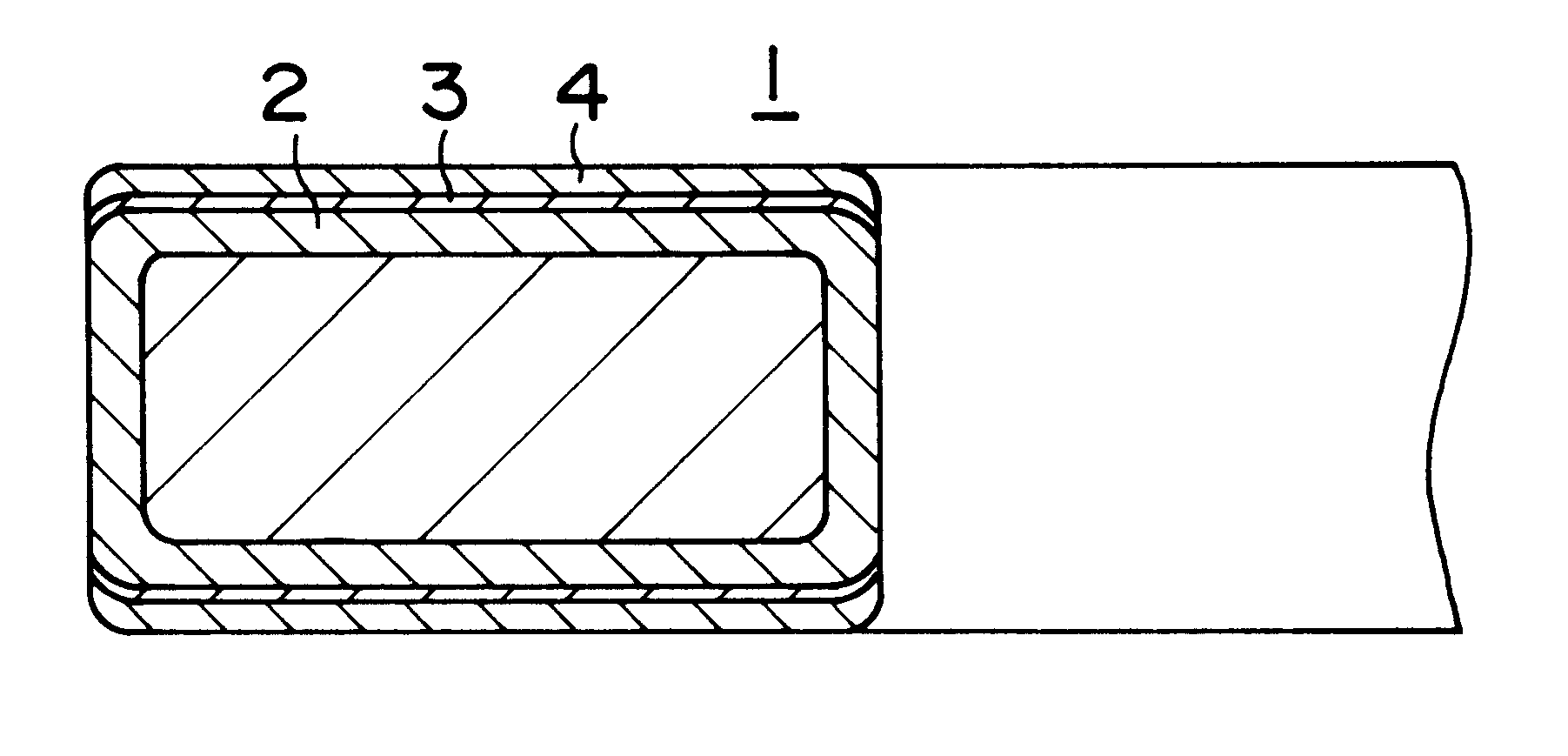

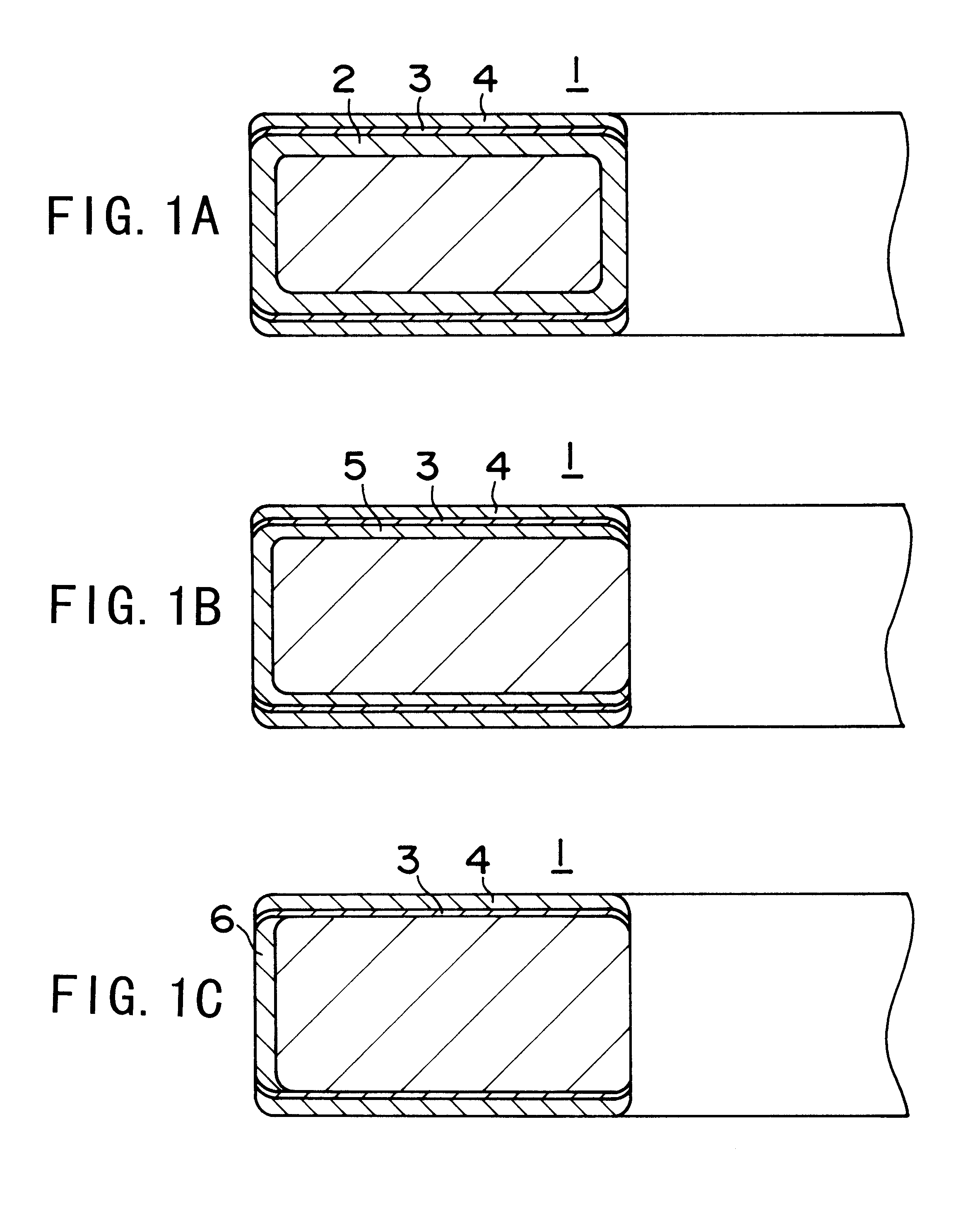

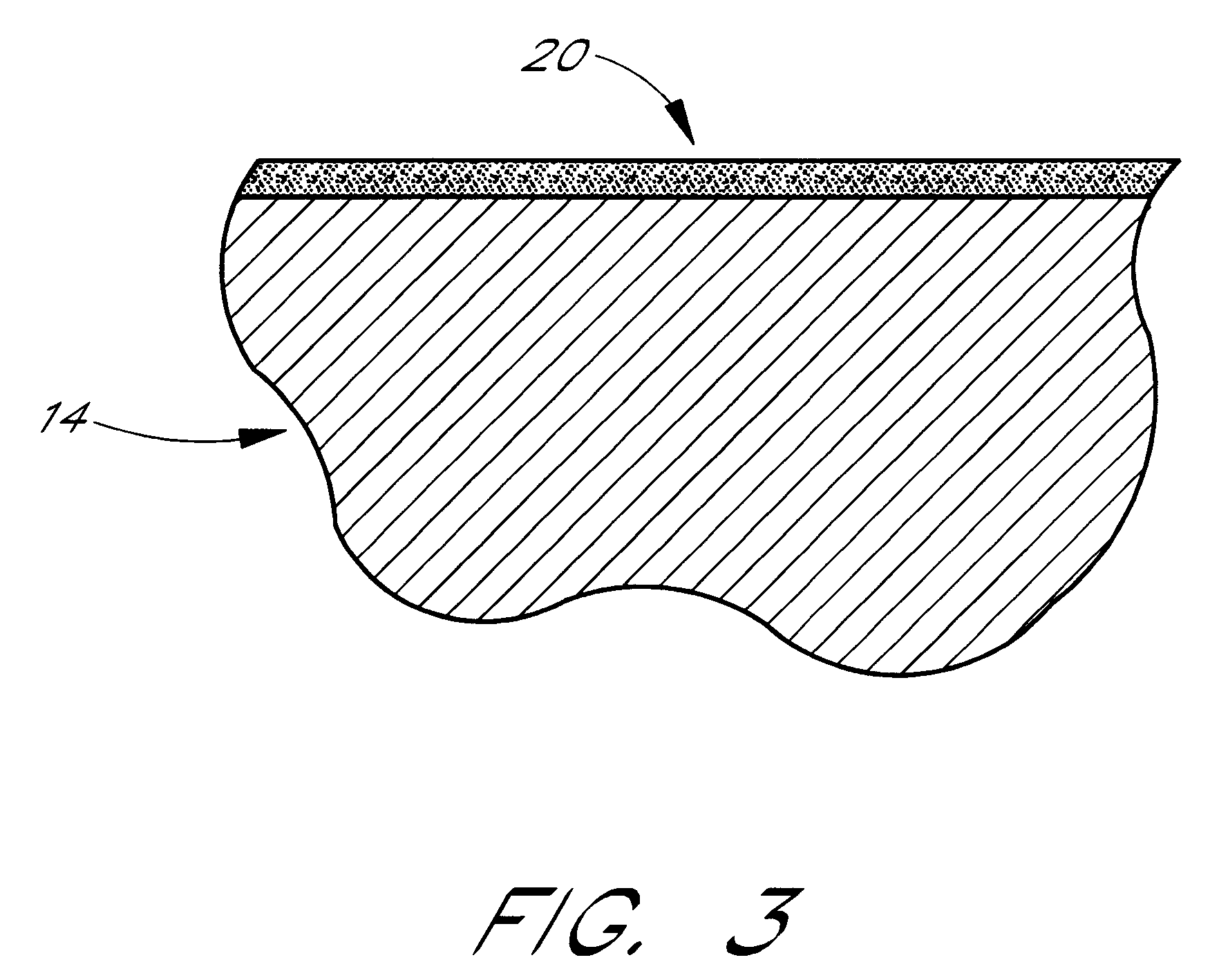

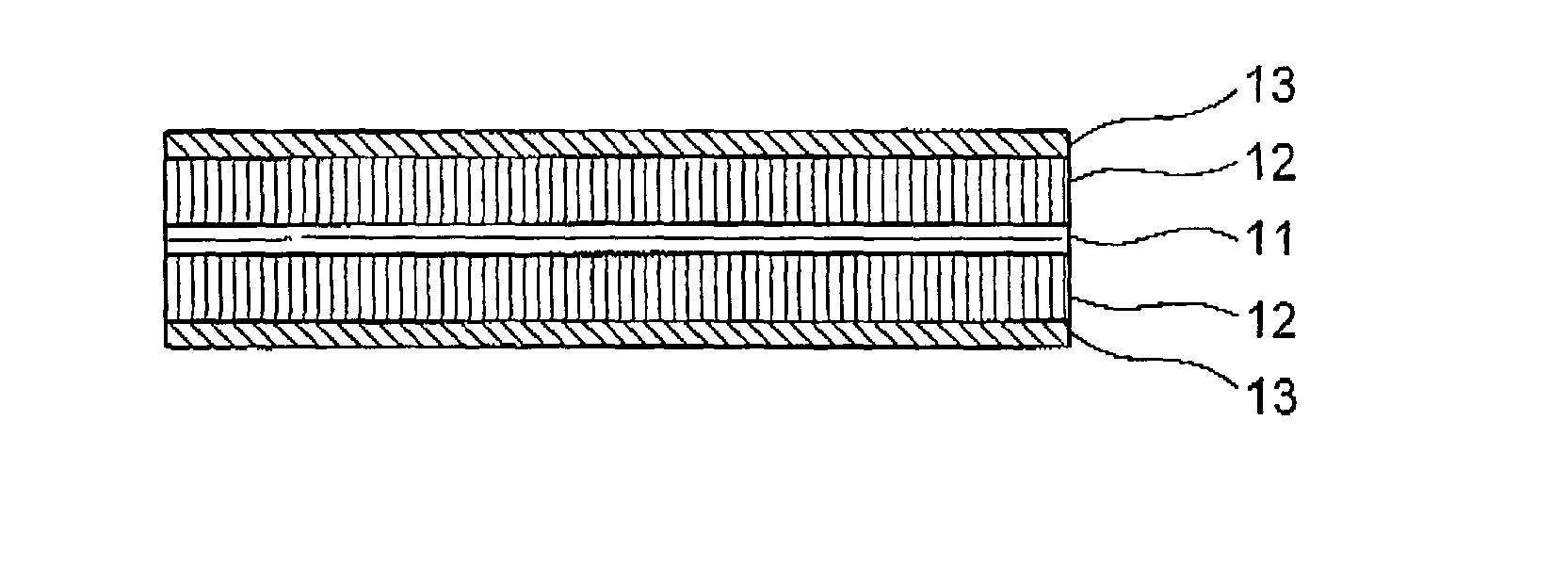

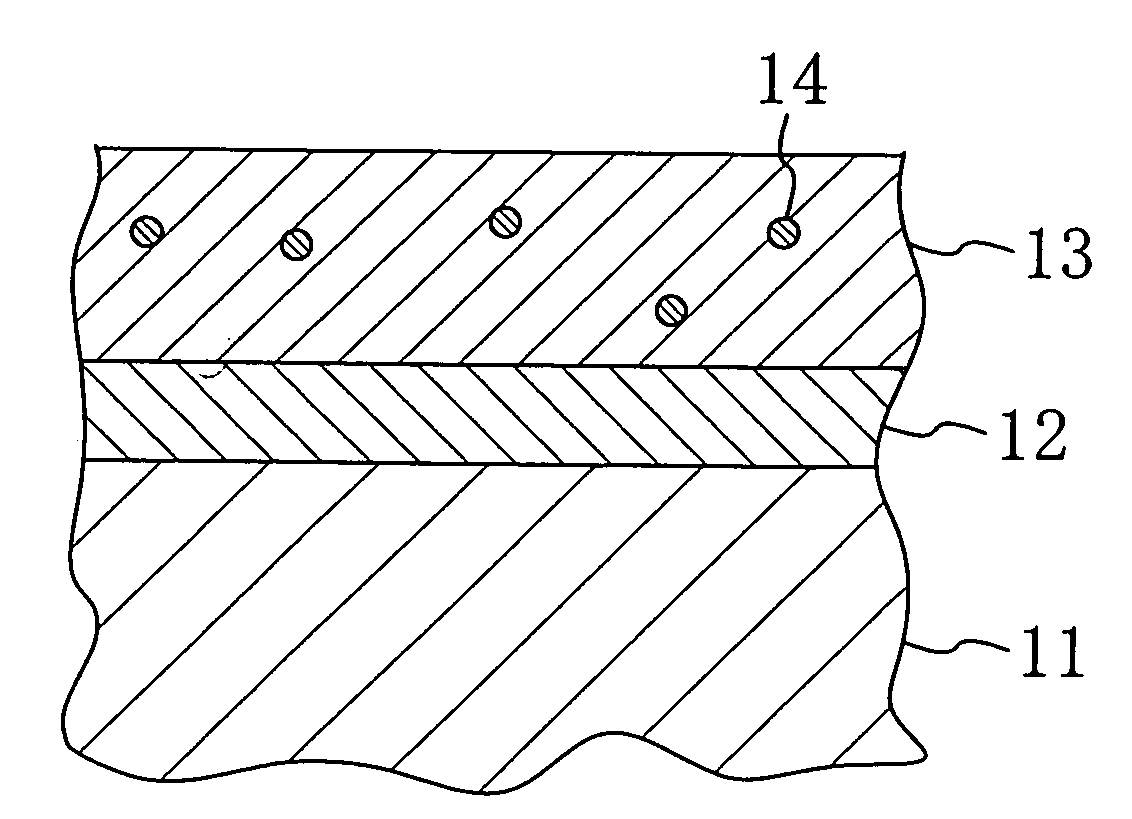

Stent and Method For Fabricating the Same

A stent includes a tubular stent body 11, a diamond-like carbon film 12 formed on the surface of the stent body 11 and having an activated surface, and a polymer layer 13 immobilized on the surface of the diamond-like carbon film. The polymer layer 13 contains a drug 14 having an effect to prevent restenosis, and the drug 14 is gradually released from the polymer layer 13.

Owner:TOYO ADVANCED TECH CO LTD +1

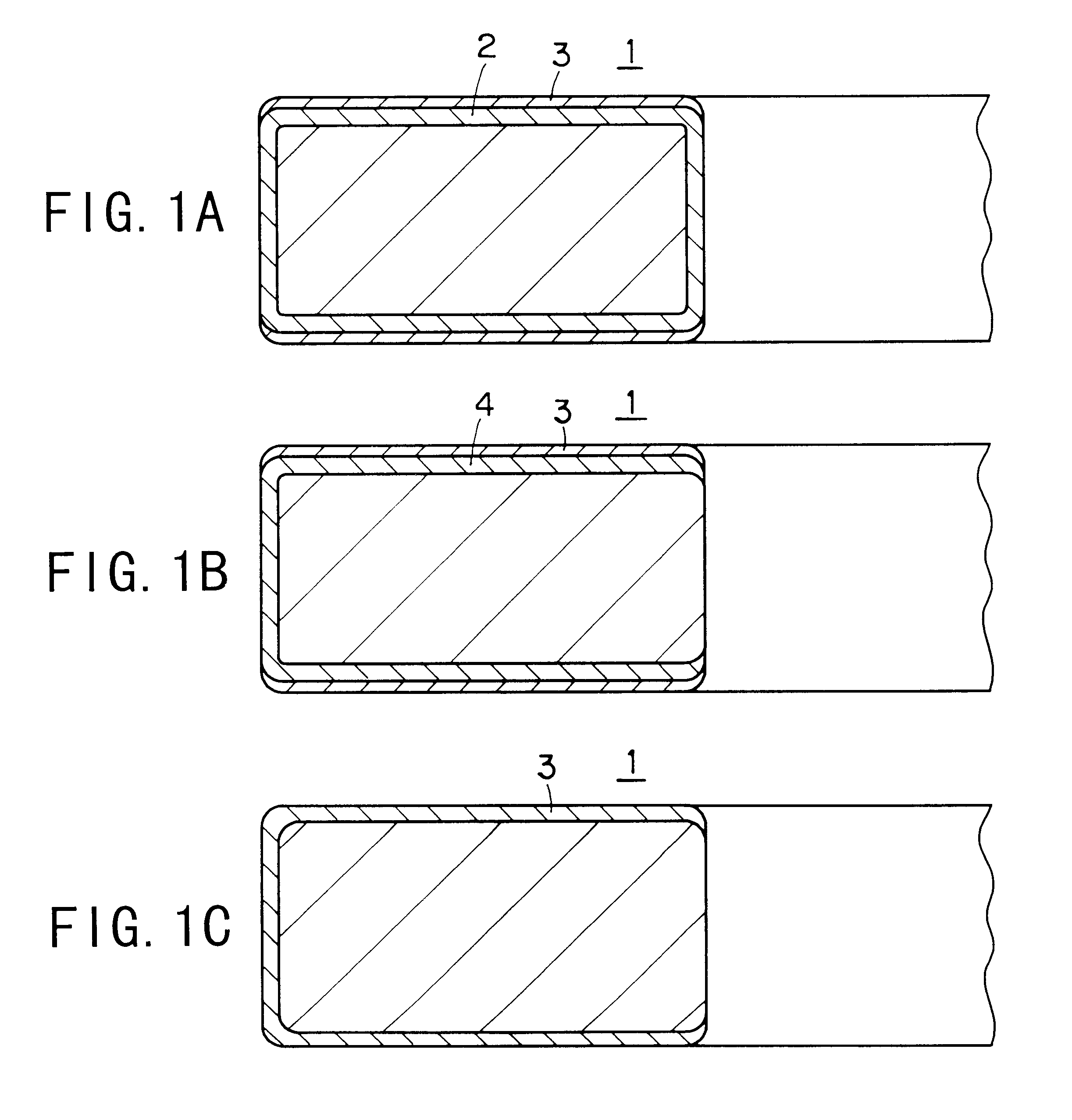

Sliding member and manufacturing method thereof

InactiveUS6279913B1Improve the immunityHigh bonding strengthPiston ringsBraking action transmissionCarbon filmDiamond-like carbon

A piston ring is formed over the entire surface with a gas nitrided layer. A diamond-like carbon film is formed in a thickness of 0.5 to 30 micrometers over the gas nitrided layer at the upper and lower surfaces. The diamond-like carbon film has a surface structure in which diamond-like carbon has been deposited in nodular shapes in sizes of 0.5 to 5 micrometers. The diamond-like carbon is configured with any one of an amorphous carbon structure, an amorphous carbon structure having partly a diamond structure, or an amorphous carbon structure having partly a graphite structure.

Owner:TEIKOKU PISTON RING CO LTD

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

In certain example embodiments, a coated article includes respective layers including hydrogenated diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is very scratch resistant and durable.

Owner:GUARDIAN GLASS LLC

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

InactiveUS20050191494A1Scratch resistantPretreated surfacesGlass/slag layered productsDiamond-like carbonOxygen

In certain example embodiments, a coated article includes respective layers including diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is scratch resistant and durable. In certain example embodiments, the zirconium nitride and / or zirconium oxide may be doped with F and / or C.

Owner:GUARDIAN GLASS LLC

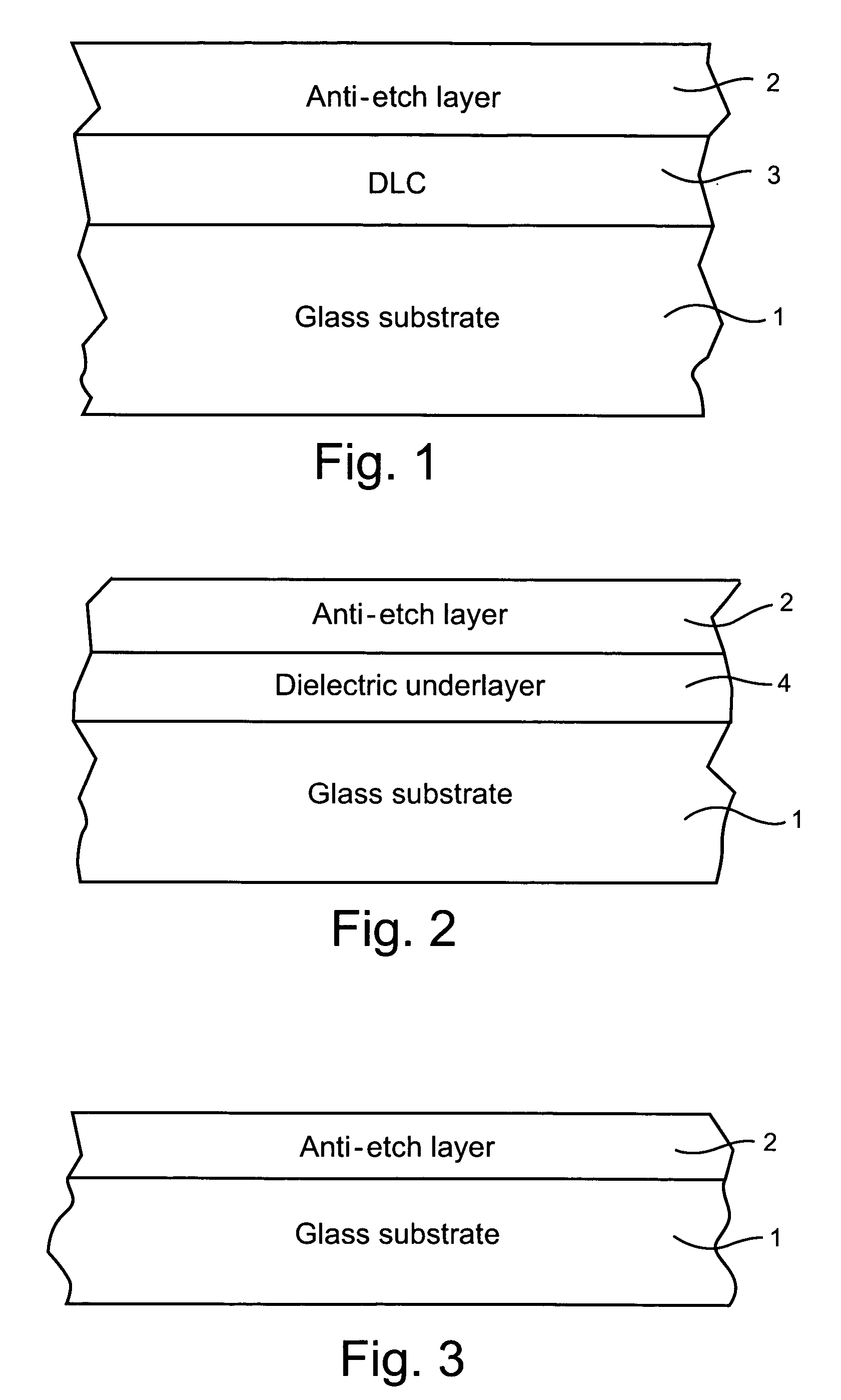

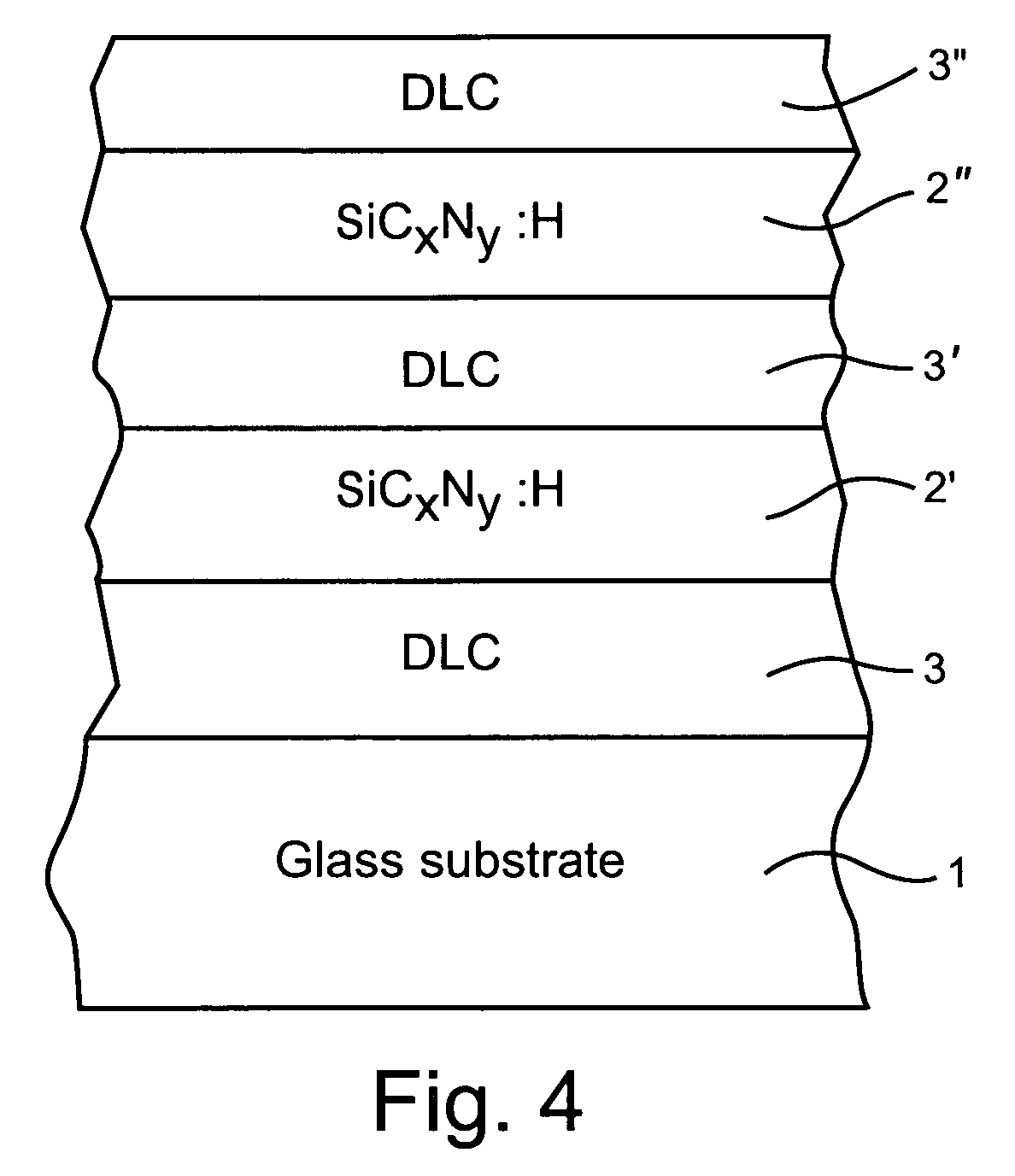

Method of making scratch resistant coated glass article including layer(s) resistant to fluoride-based etchant(s)

A method is provided for making a coated article including an anti-etch layer(s) that is resistant to attacks by at least some fluoride-based etchant(s) for at least a period of time. In certain example embodiments, an anti-etch layer(s) is provided on a glass substrate in order to protect the glass substrate from attacks by fluoride-based etchant(s). In certain example embodiments, the anti-etch layer(s) is formed using at least one ion beam (possibly in combination with at least one sputtering target). In certain embodiments, a diamond-like carbon (DLC) inclusive layer(s) may be provided over and / or under the anti-etch layer.

Owner:HER MAJESTY THE QUEEN AS REPRESENTED BY THE MINIST OF NAT DEFENCE OF HER MAJESTYS CANADIAN GOVERNMENT +1

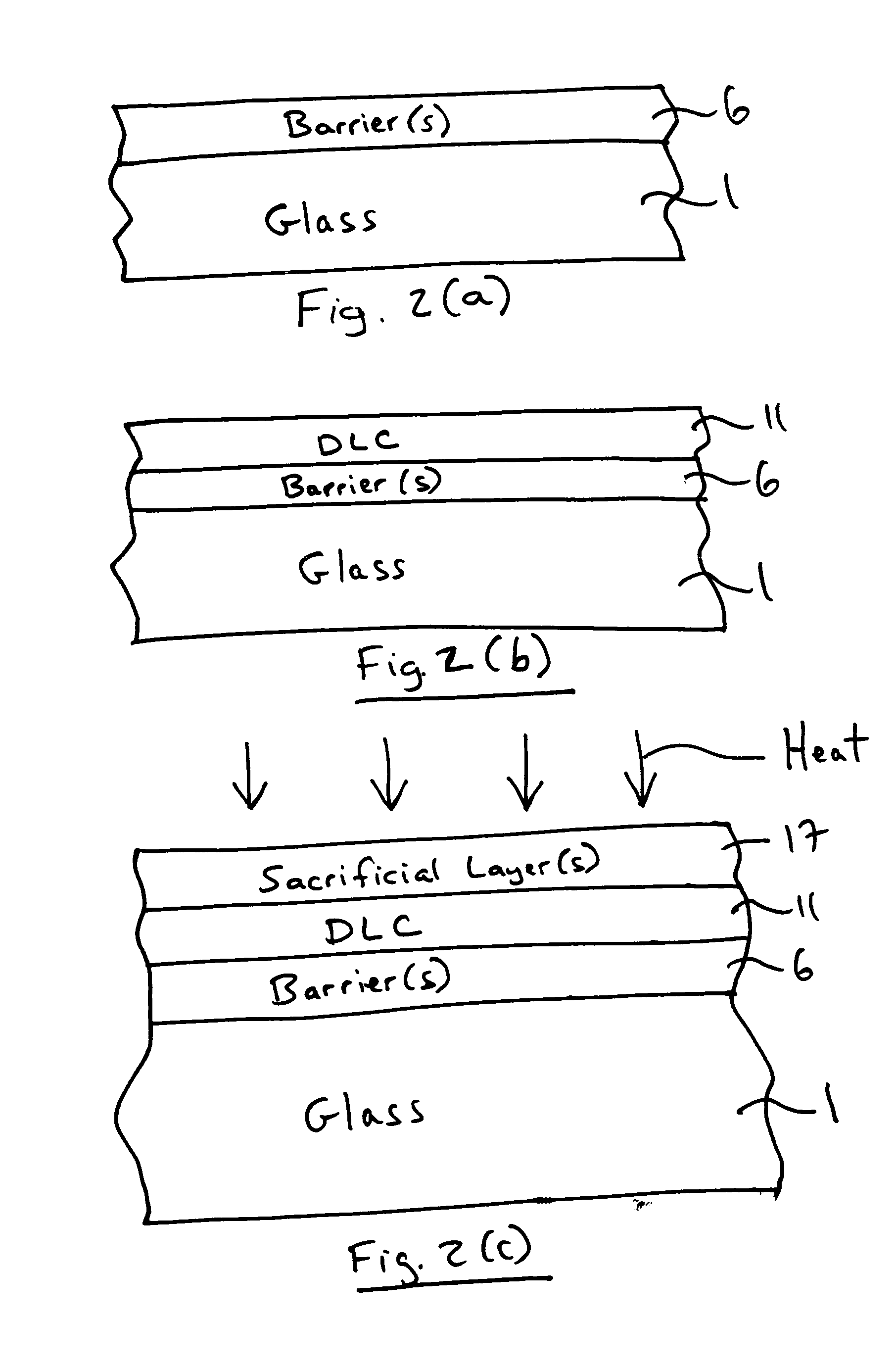

Heat treatable coated article with diamond-like carbon (DLC) coating

InactiveUS20050048284A1Vacuum evaporation coatingPretreated surfacesDiamond-like carbonProtection layer

A method of making a coated article (e.g., window unit), and corresponding coated article are provided. A layer of or including diamond-like carbon (DLC) is formed on a glass substrate, preferably over at least one barrier layer. Then, a protective layer is formed on the substrate over the DLC inclusive layer. During heat treatment (HT), the protective layer prevents the DLC inclusive layer from significantly burning off. Thereafter, the resulting coated glass substrate may be used as desired, it having been HT and including the protective DLC inclusive layer. The protective layer may be removed after HT.

Owner:GUARDIAN GLASS LLC

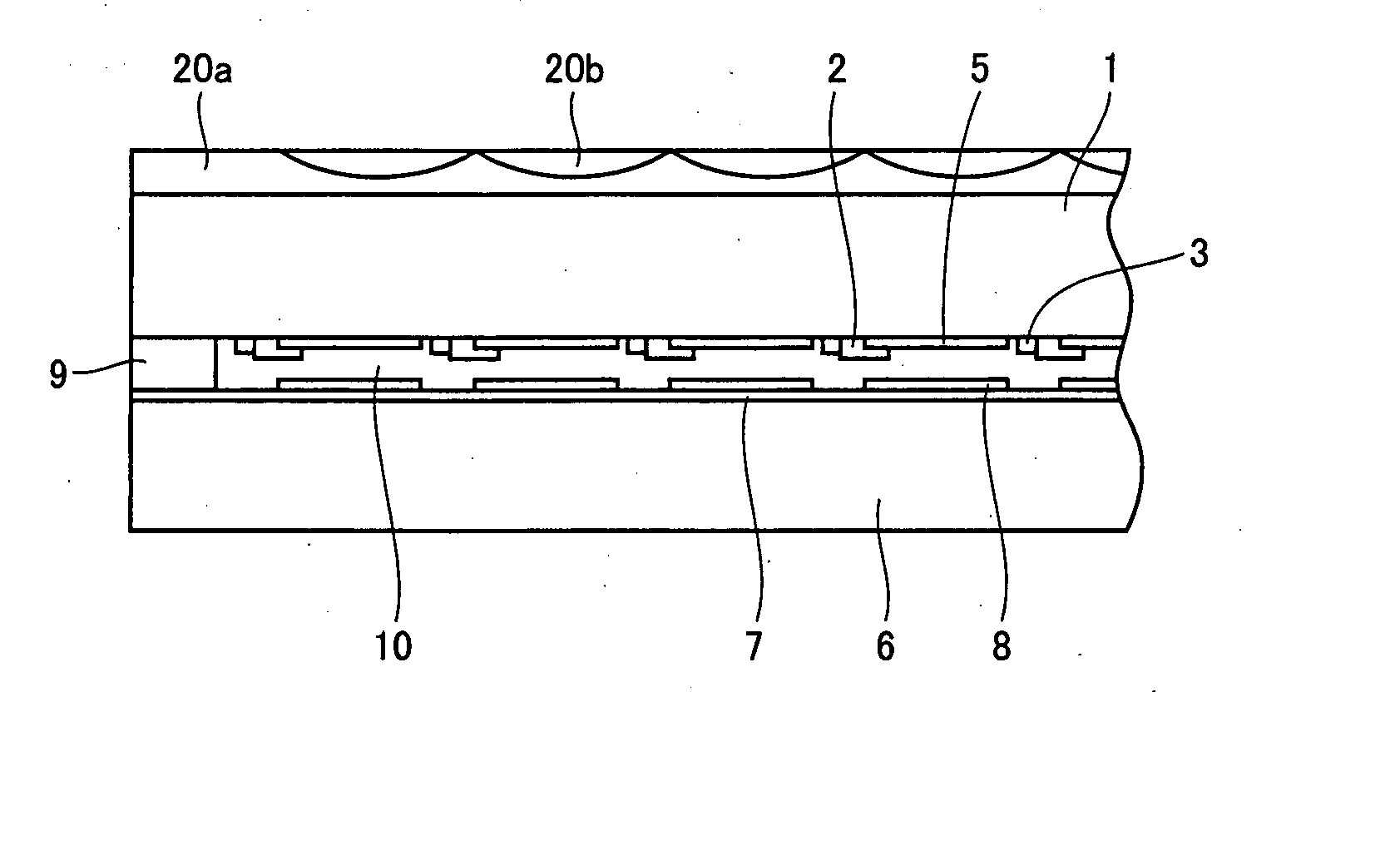

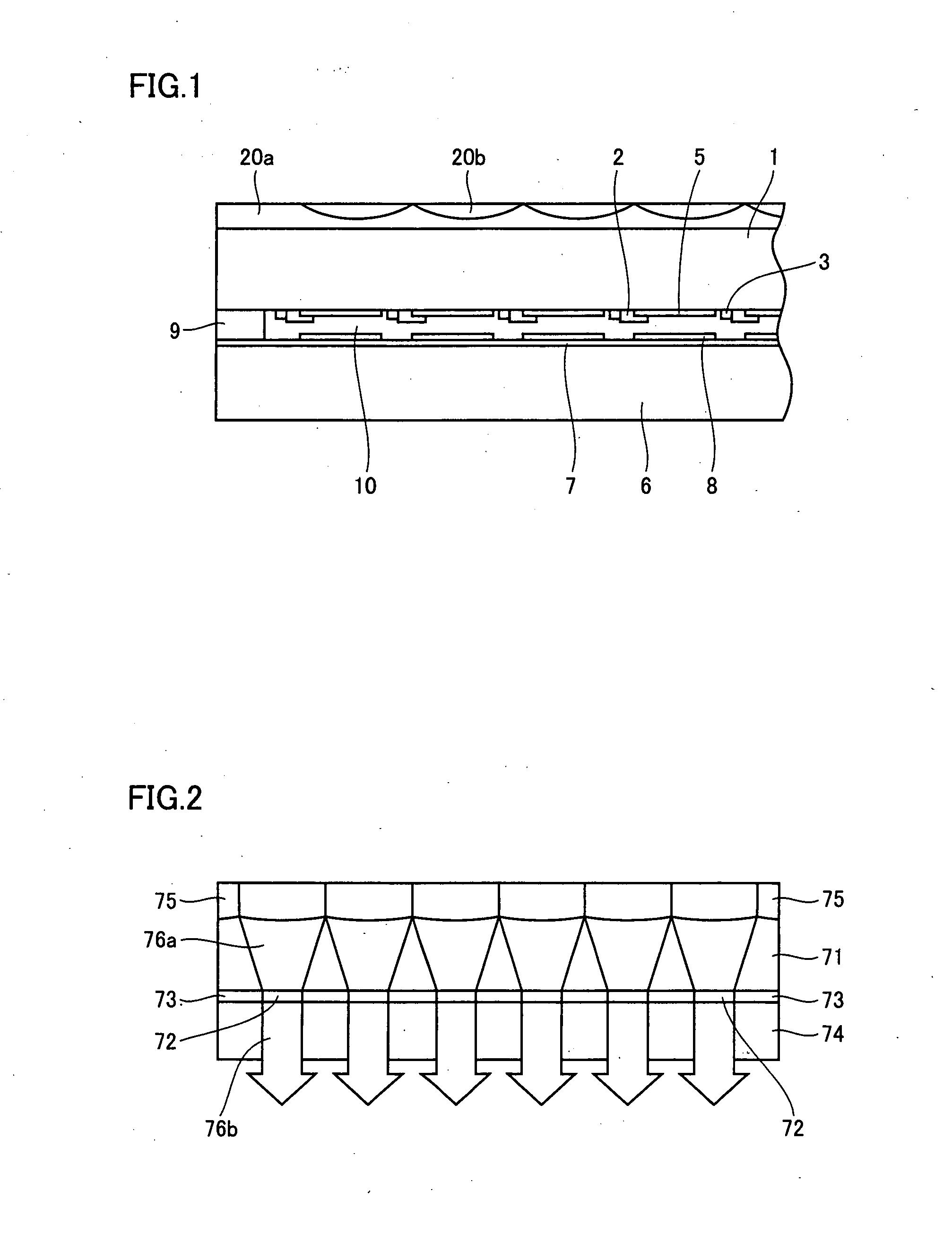

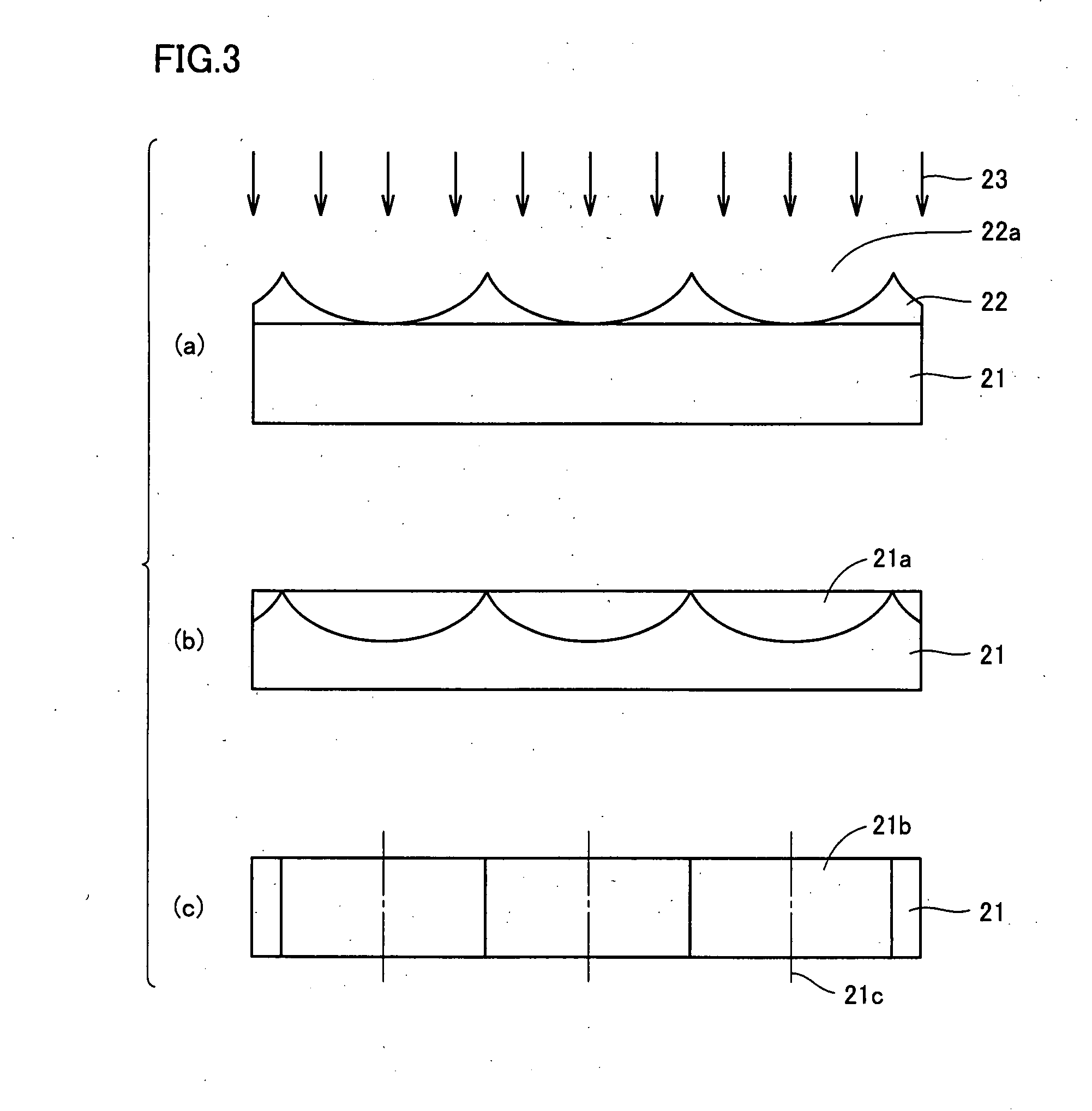

Transmission-Type Display Panel and Method of Manufacturing the Same

InactiveUS20080094716A1Low costIncrease display brightnessGlass making apparatusProjectorsLiquid-crystal displayDiamond-like carbon

A transmission-type display panel according to the present invention includes a plurality of transparency control regions arranged in an array, a non-transparent border region existing around each of the transparency control regions, and a microlens array including a plurality of microlenses arranged in an array so as to correspond to the plurality of transparency control regions. Each of the microlenses serves to converge incident light, which is about to advance straight to the non-transparent border region, into corresponding one of the transparency control regions. The microlens array is formed by use of a transparent diamond-like carbon (DLC) film. The DLC film includes a region having its refractive index modulated corresponding to each of the microlenses, and produces a light convergence effect when light flux passes through the region having its refractive index modulated. By applying the microlens array in the DLC film to a transmission-type display panel (e.g., a liquid crystal display panel), it is possible to provide a transmission-type display panel having improved display brightness, in a simple manner and at a low cost.

Owner:SUMITOMO ELECTRIC IND LTD

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

In certain example embodiments, a coated article includes respective layers including diamond-like carbon (DLC) and zirconium nitride before heat treatment (HT). During HT, the hydrogenated DLC acts as a fuel which upon combustion with oxygen produces carbon dioxide and / or water. The high temperature developed during this combustion heats the zirconium nitride to a temperature(s) well above the heat treating temperature, thereby causing the zirconium nitride to be transformed into a new post-HT layer including zirconium oxide that is scratch resistant and durable.

Owner:GUARDIAN GLASS LLC

Heat treatable coated article with diamond-like carbon (DLC) and/or zirconium in coating

InactiveUS20060057294A1Scratch resistantPretreated surfacesGlass/slag layered productsDiamond-like carbonHeat treated

In certain example embodiments, a coated article includes a zirconium nitride inclusive layer before heat treatment (HT). The coated article is heat treated sufficiently to cause the zirconium nitride based layer to transform into a zirconium oxide based layer that is scratch resistant and / or durable. In certain example embodiments, the zirconium nitride and / or zirconium oxide may be doped with F and / or C.

Owner:GUARDIAN GLASS LLC

Methods for fabricating contacts to pillar structures in integrated circuits

InactiveUS8008095B2Improve scalabilitySemiconductor/solid-state device manufacturingDigital storageDiamond-like carbonConductive materials

Owner:GLOBALFOUNDRIES INC

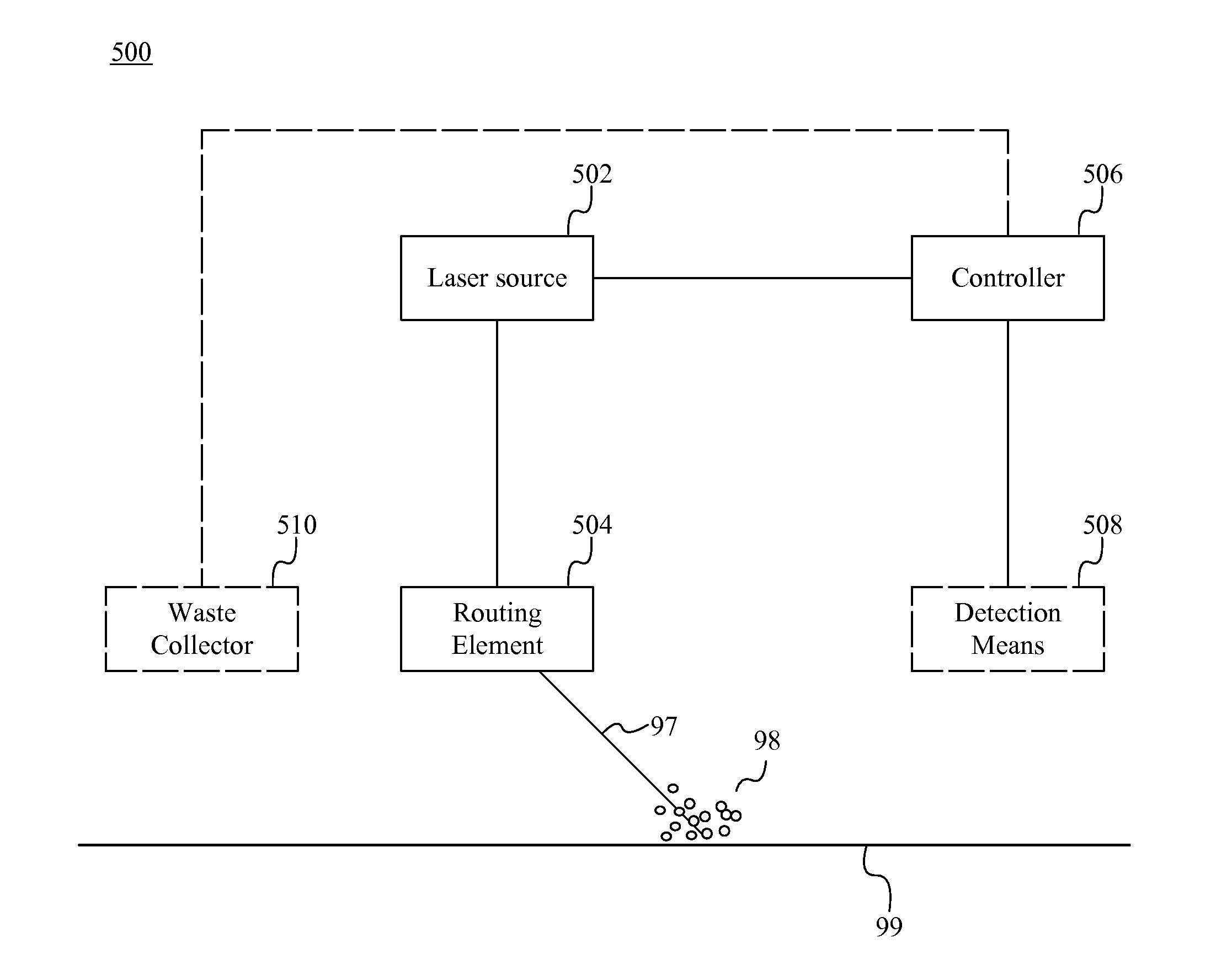

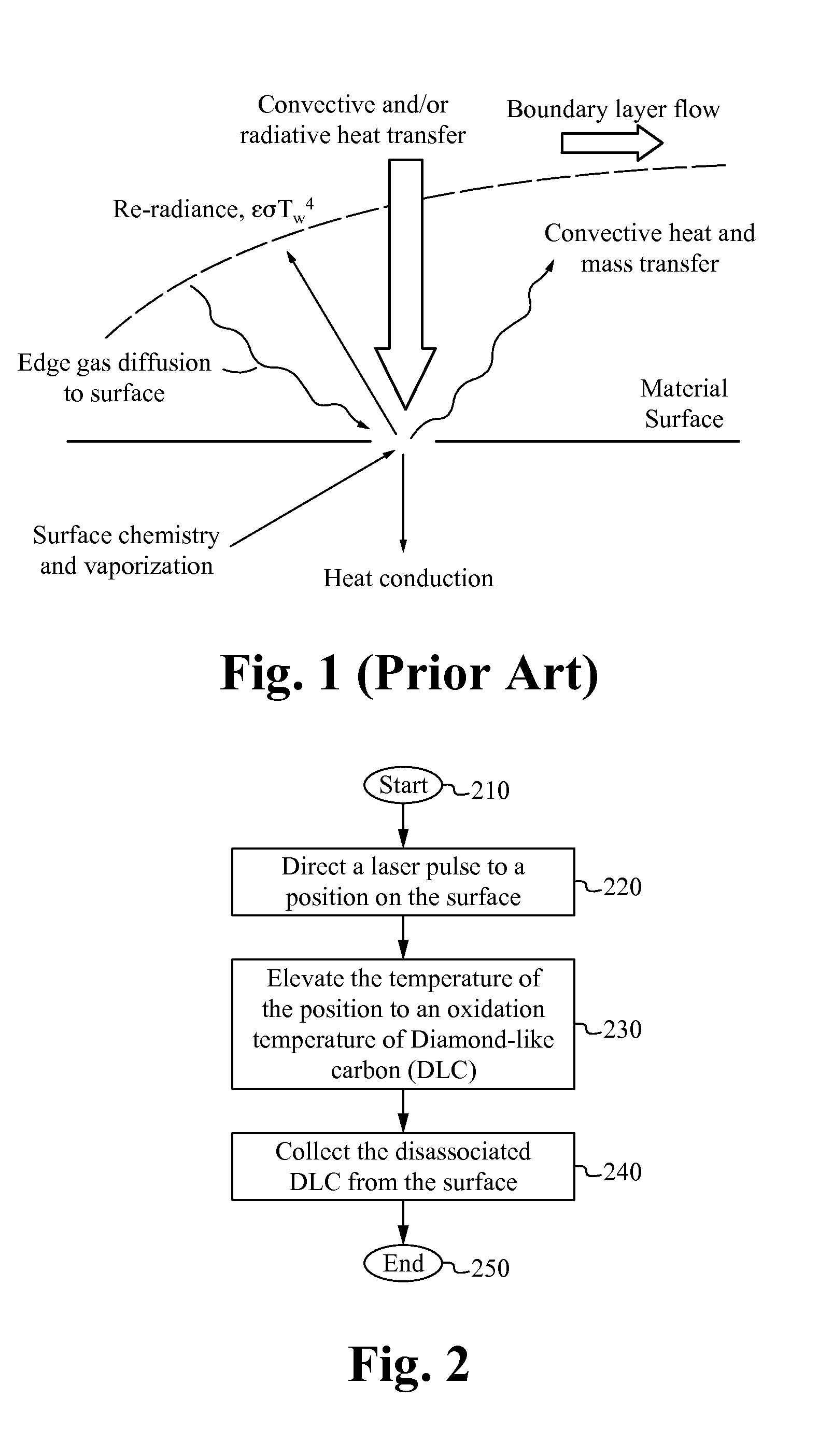

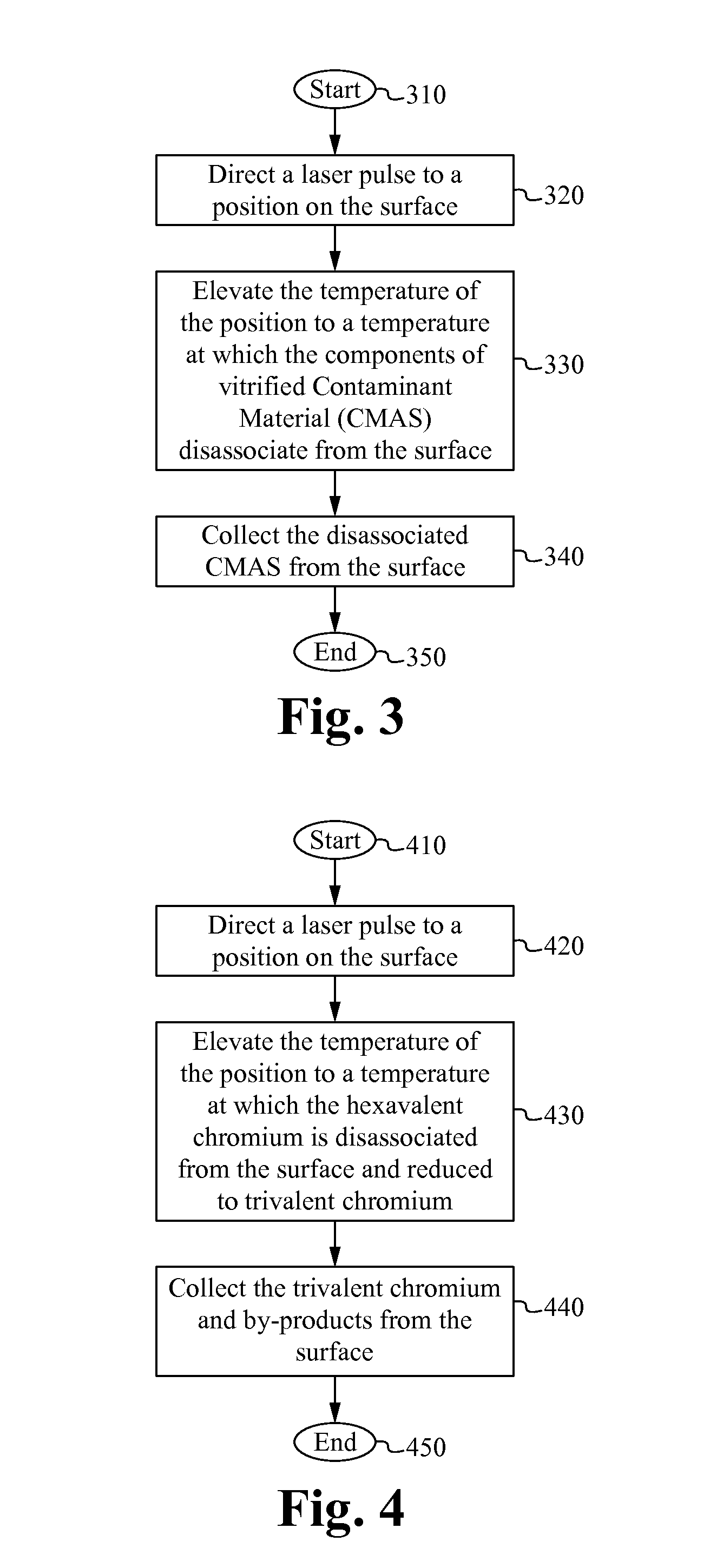

Laser ablation for the environmentally beneficial removal of surface coatings

ActiveUS20130220982A1Safe disposalMetal working apparatusLaser beam welding apparatusDiamond-like carbonMaterials science

A laser-based method of removing a coating from a surface comprises directing a laser pulse to a first position on the surface, removing the coating from the first position by rapidly elevating a surface temperature of the first position using the laser pulse and thereby disassociating the coating from the surface and collecting the disassociated coating. In some embodiments, the coating comprises an environmentally harmful substance such as Hexavalent Chromium. In some embodiments, the coating comprises Diamond-Like Carbon (DLC), Vitrified Contaminant Material (CMAS). The disassociated coating is collected by a waste collector.

Owner:GEN LASERTRONICS

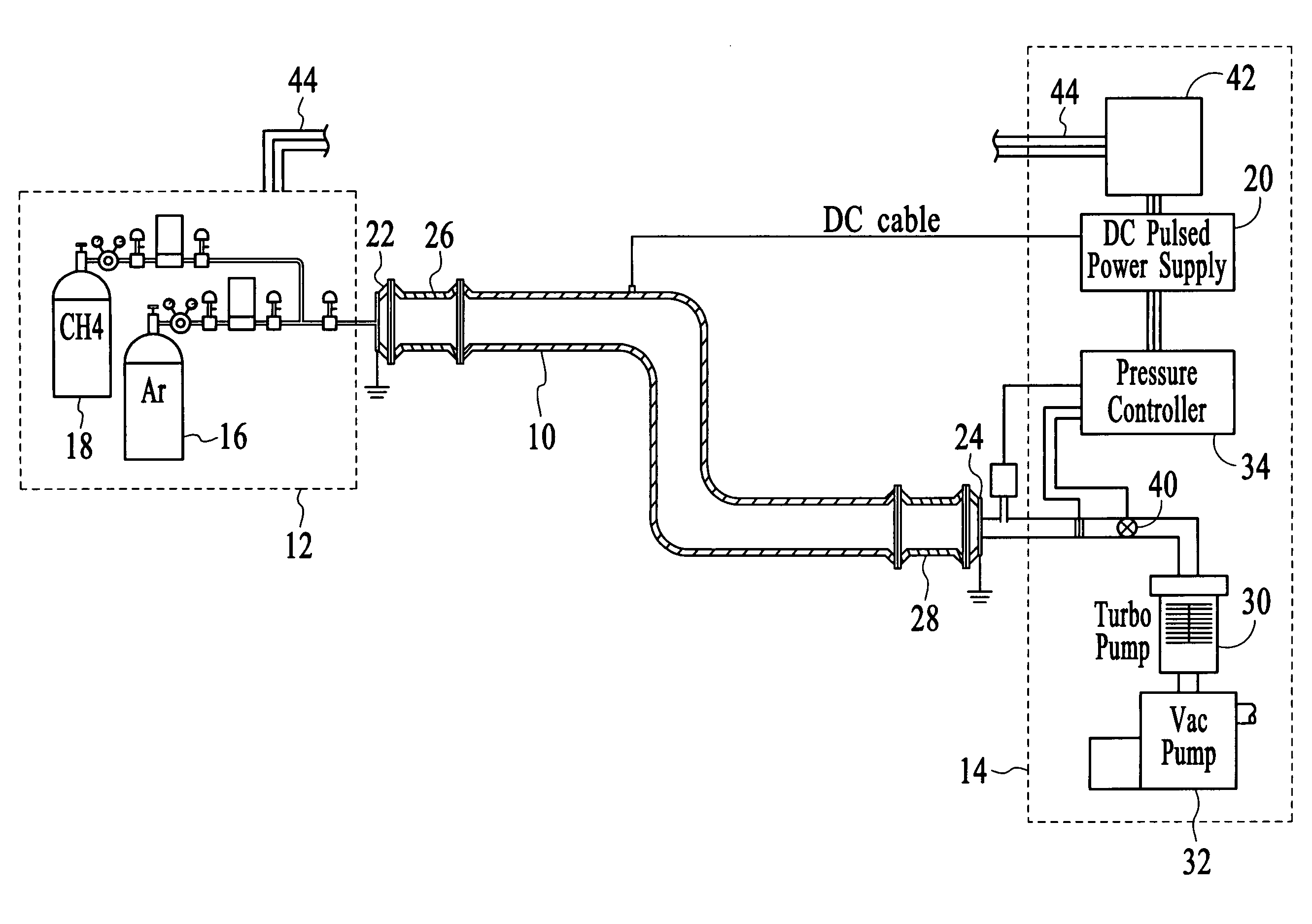

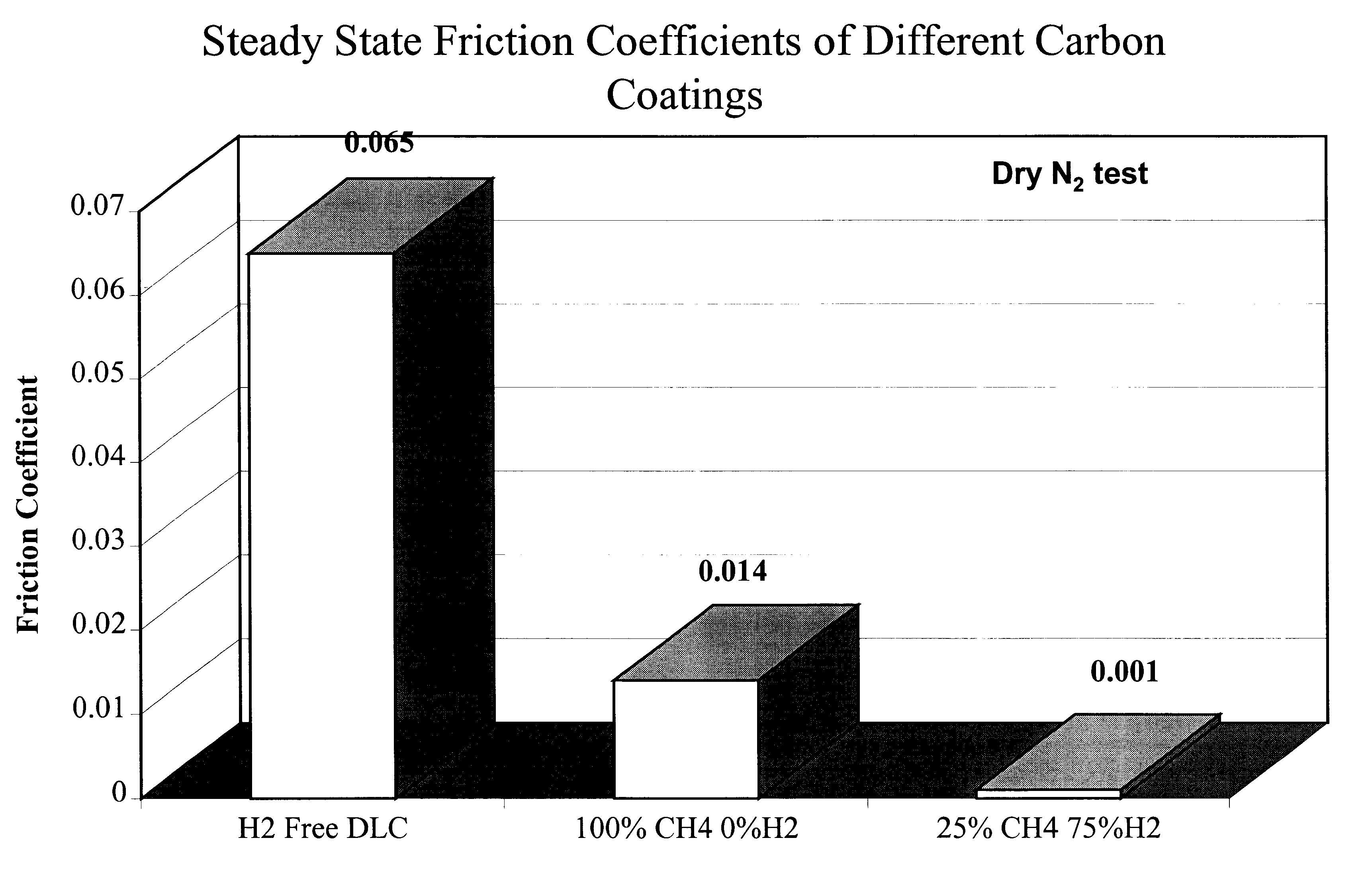

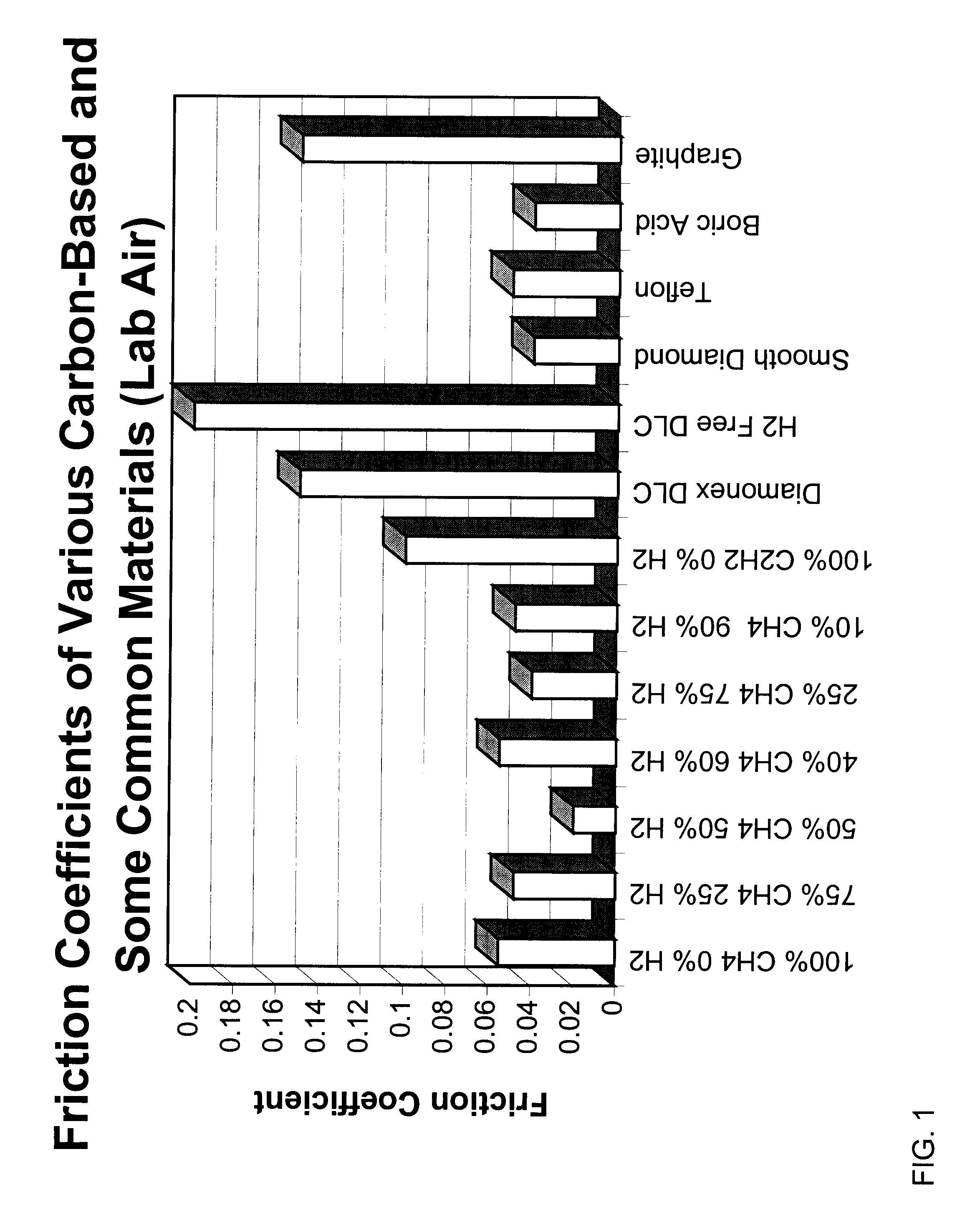

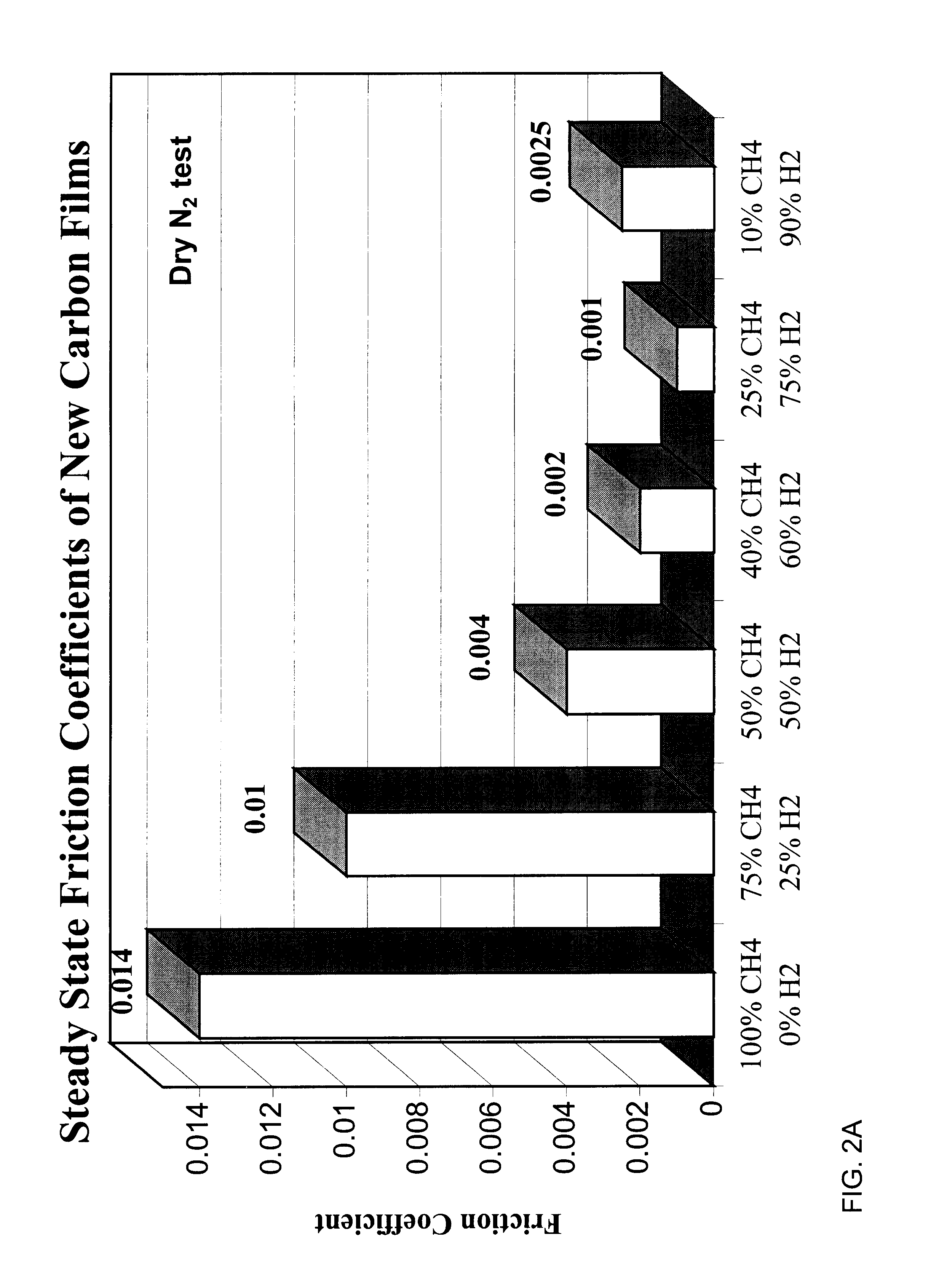

Method of produce ultra-low friction carbon films

InactiveUS6548173B2Friction wearWear propertiesLiquid surface applicatorsRecord information storageCarbon filmDiamond-like carbon

Owner:UCHICAGO ARGONNE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com