Patents

Literature

88 results about "Amorphous diamond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An amorphous diamond is a simulated diamond that is created by a completely unique process. This stone is composed of millions of tiny diamond crystals that are bonded or aligned together. ... The amorphous diamond is non-porous and resembles the mined diamond in this characteristic. This makes the surface of the mined diamond and the amorphous diamond more slippery than cubic zirconia.

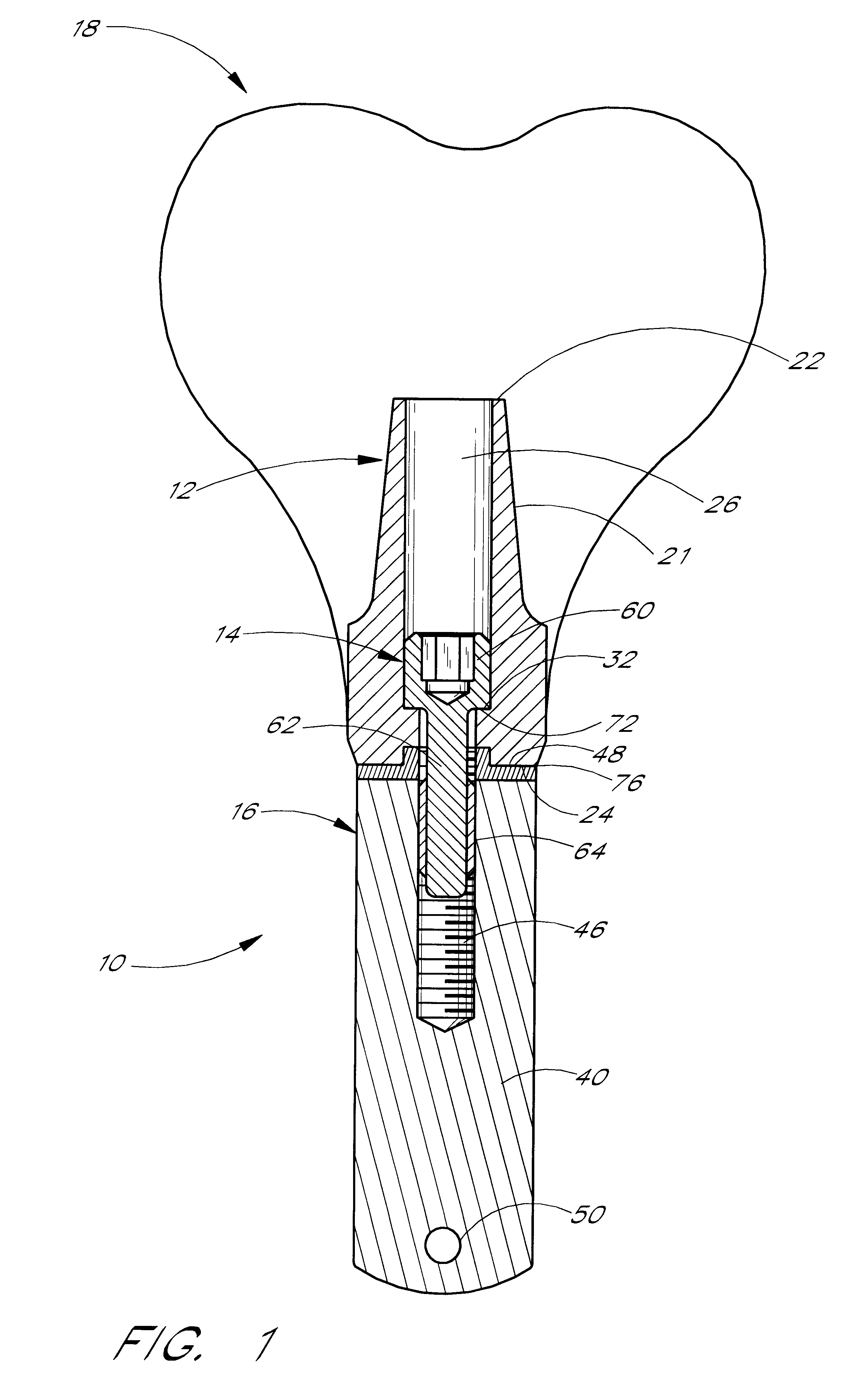

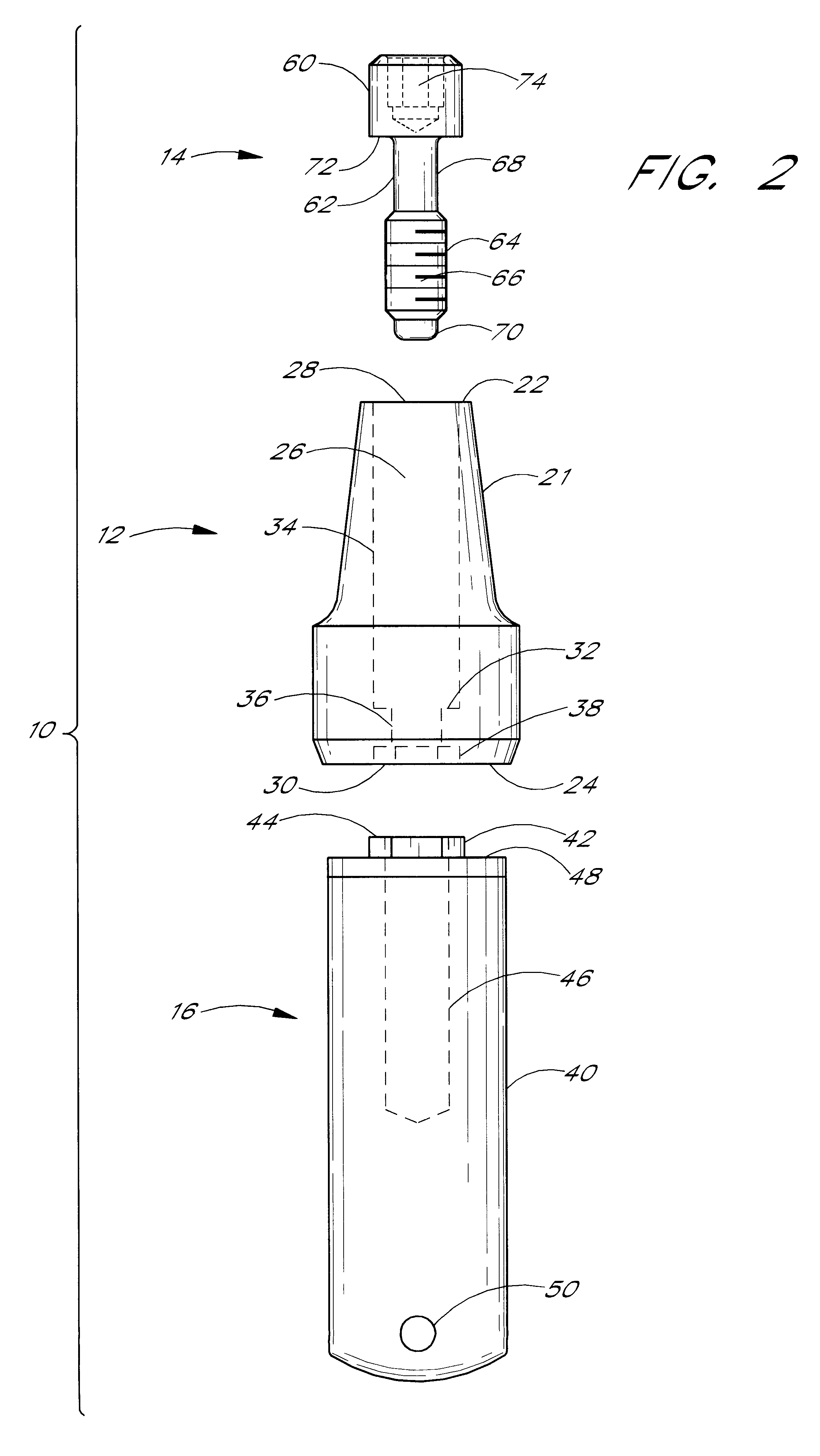

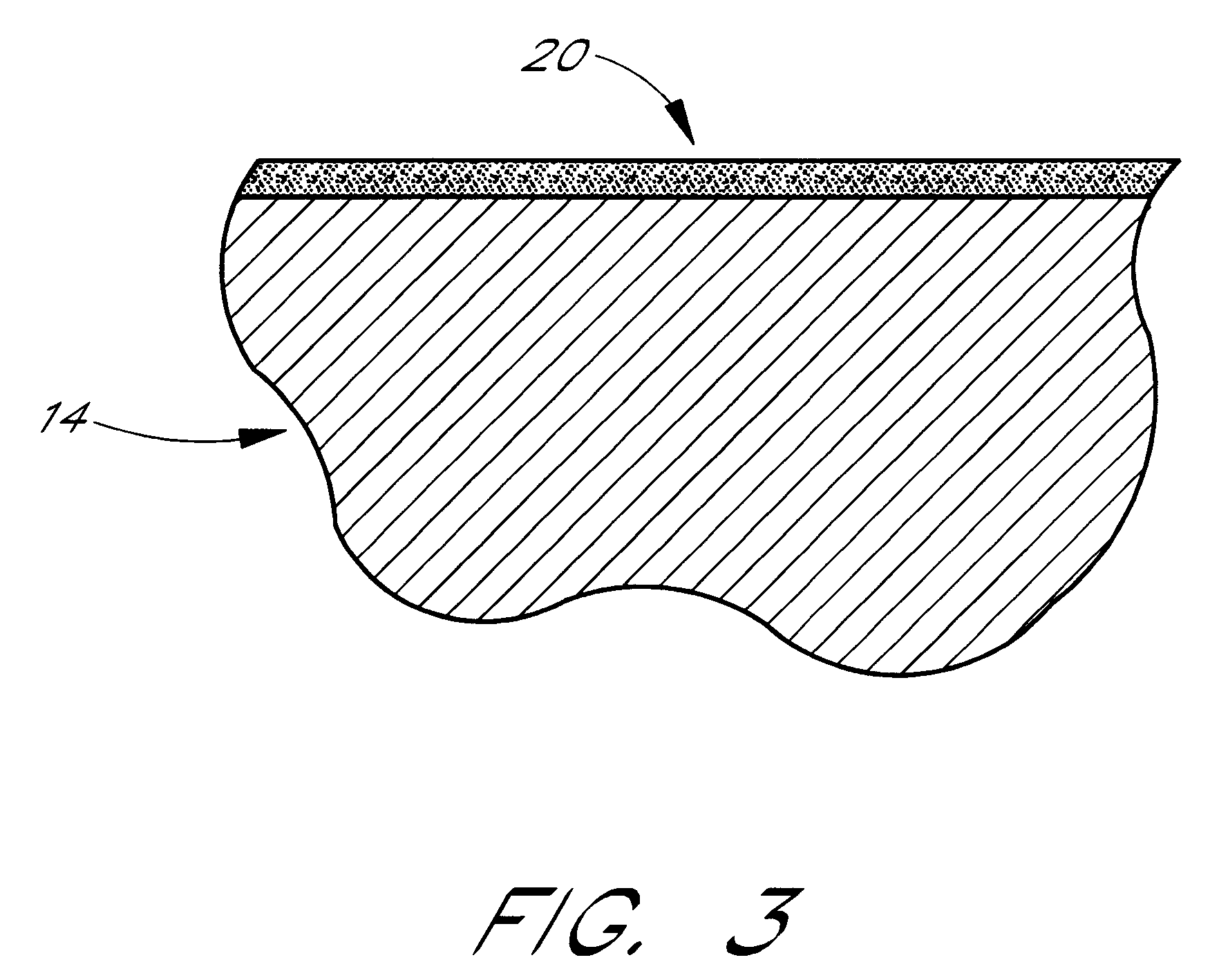

Diamond-like carbon coated dental retaining screws

The invention relates to a coated dental screw for retaining and securing components of a dental prosthetic implant stack. The screw is coated with a hard carbon coating / film to provide a low friction surface finish which advantageously results in improved preloading of the screw, and hence a high clamping force between the components of the dental prosthetic implant stack. The coating can comprise diamond-like carbon (DLC), amorphous diamond, crystalline diamond, or a combination thereof. The dental screw can include abutment retaining screws and prosthesis retaining screws. Other advantages provided by the hard carbon coating include high mechanical surface hardness, biocompatibilty, corrosion resistance, chemical inertness and low cost.

Owner:NOBEL BIOCARE SERVICES AG

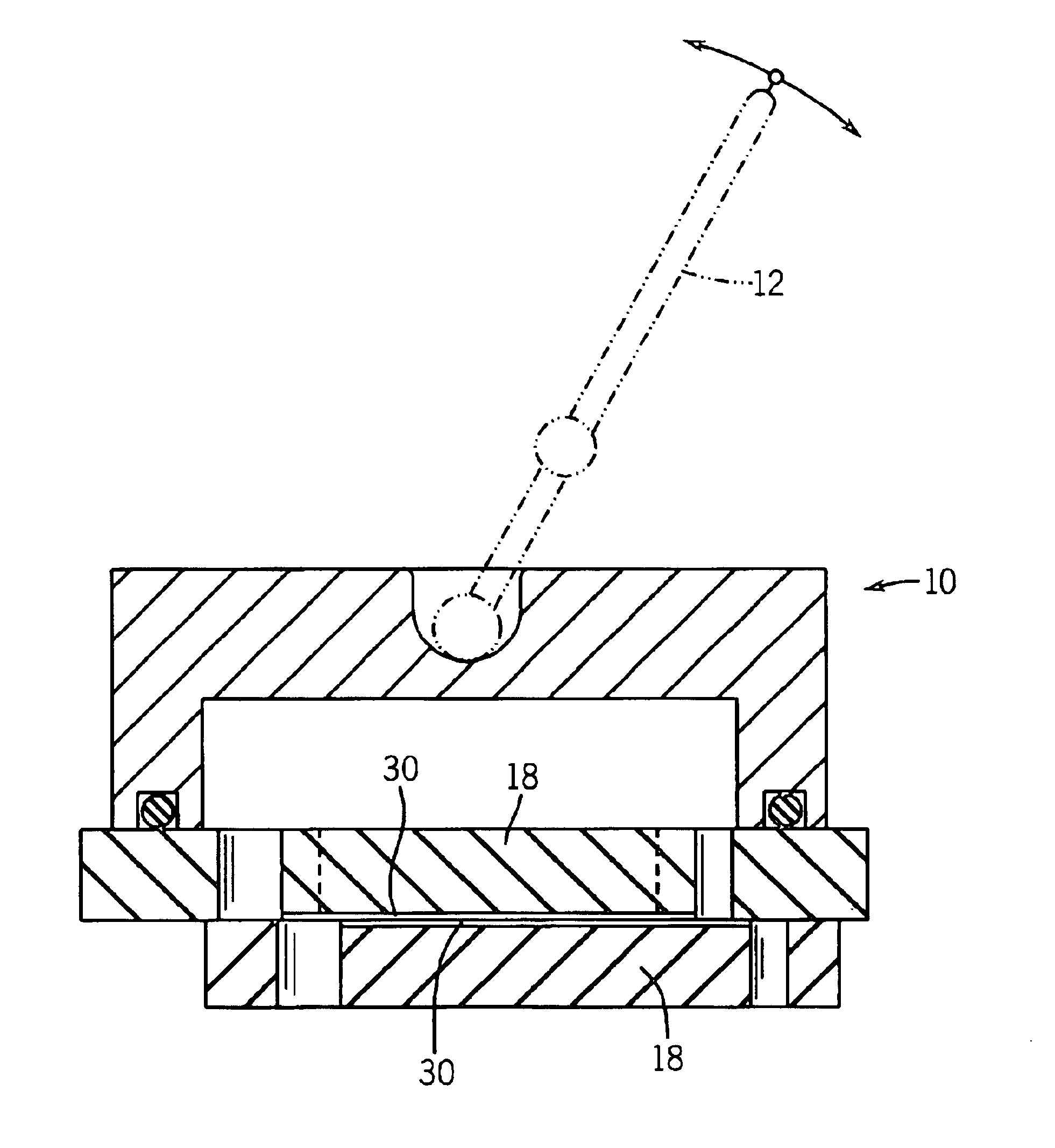

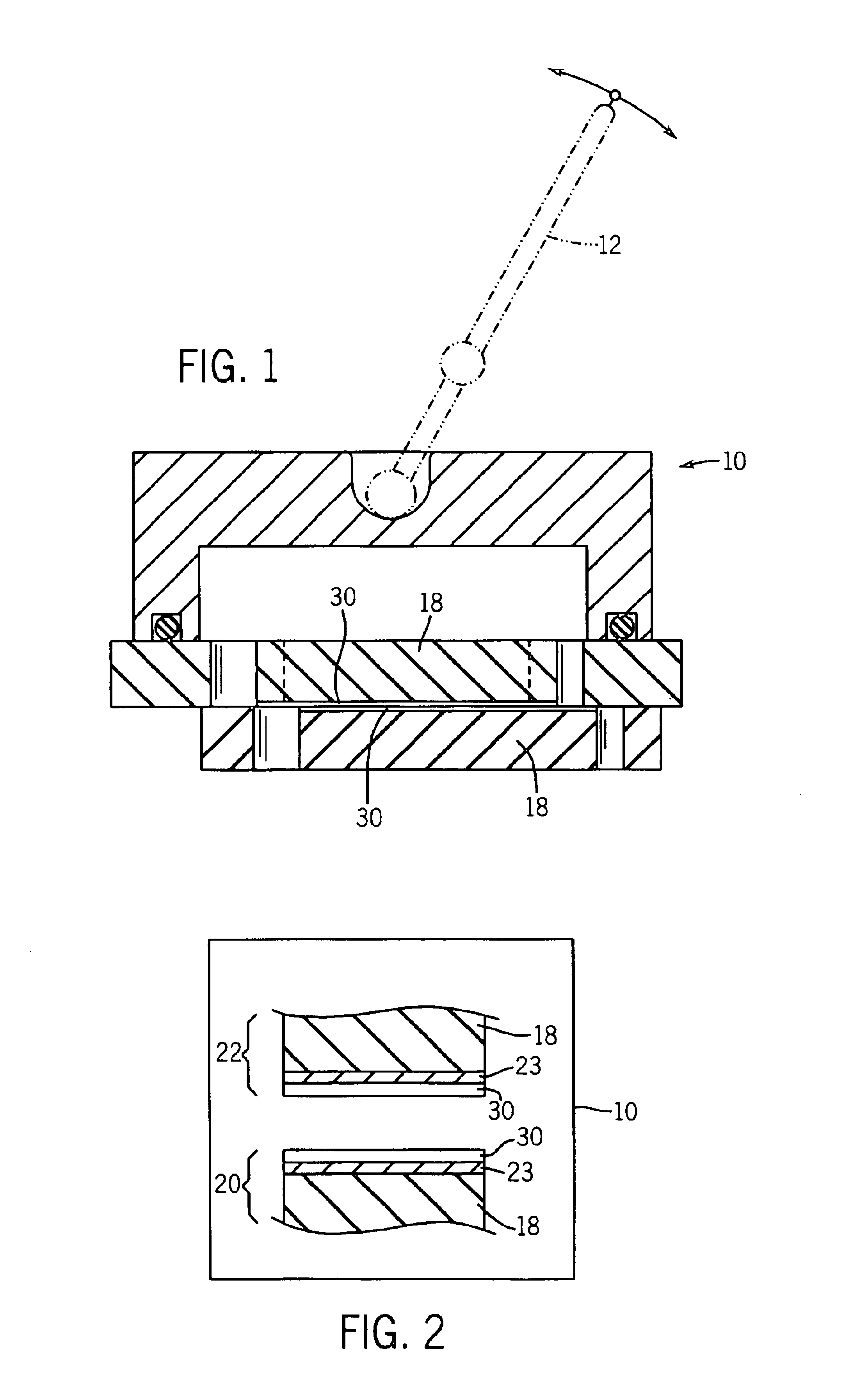

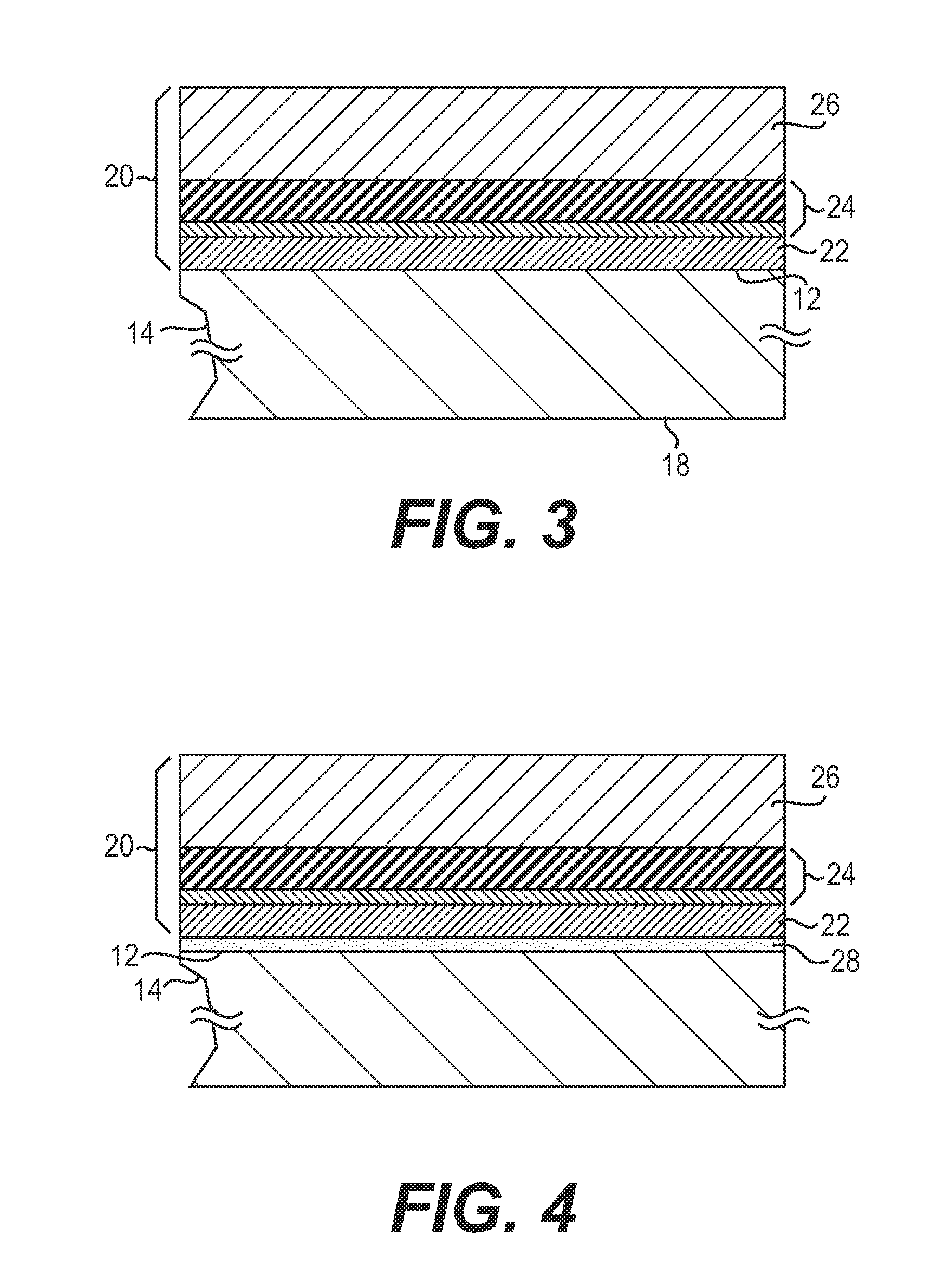

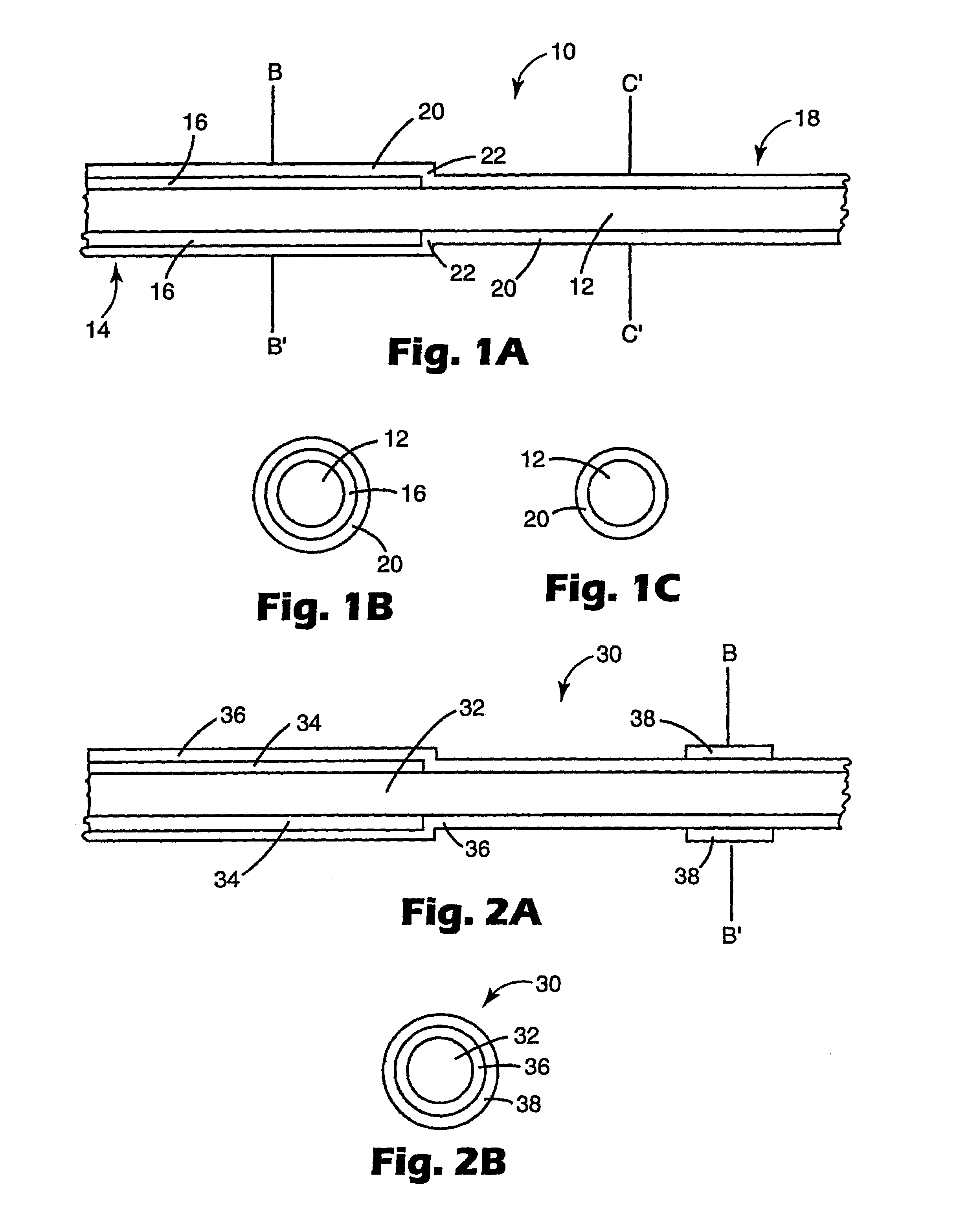

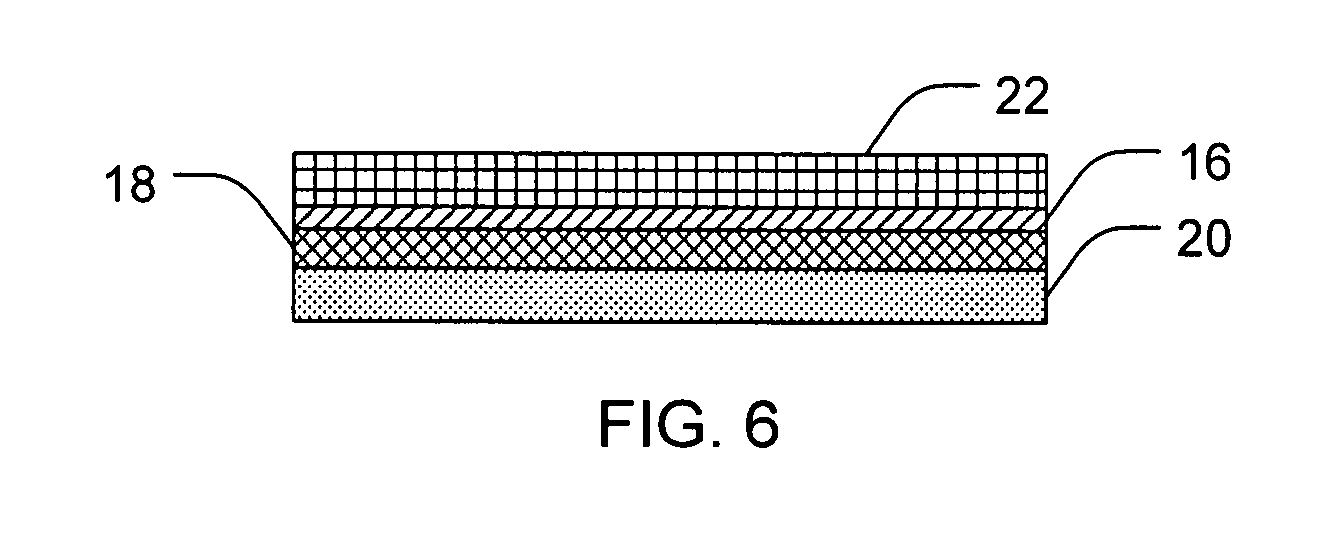

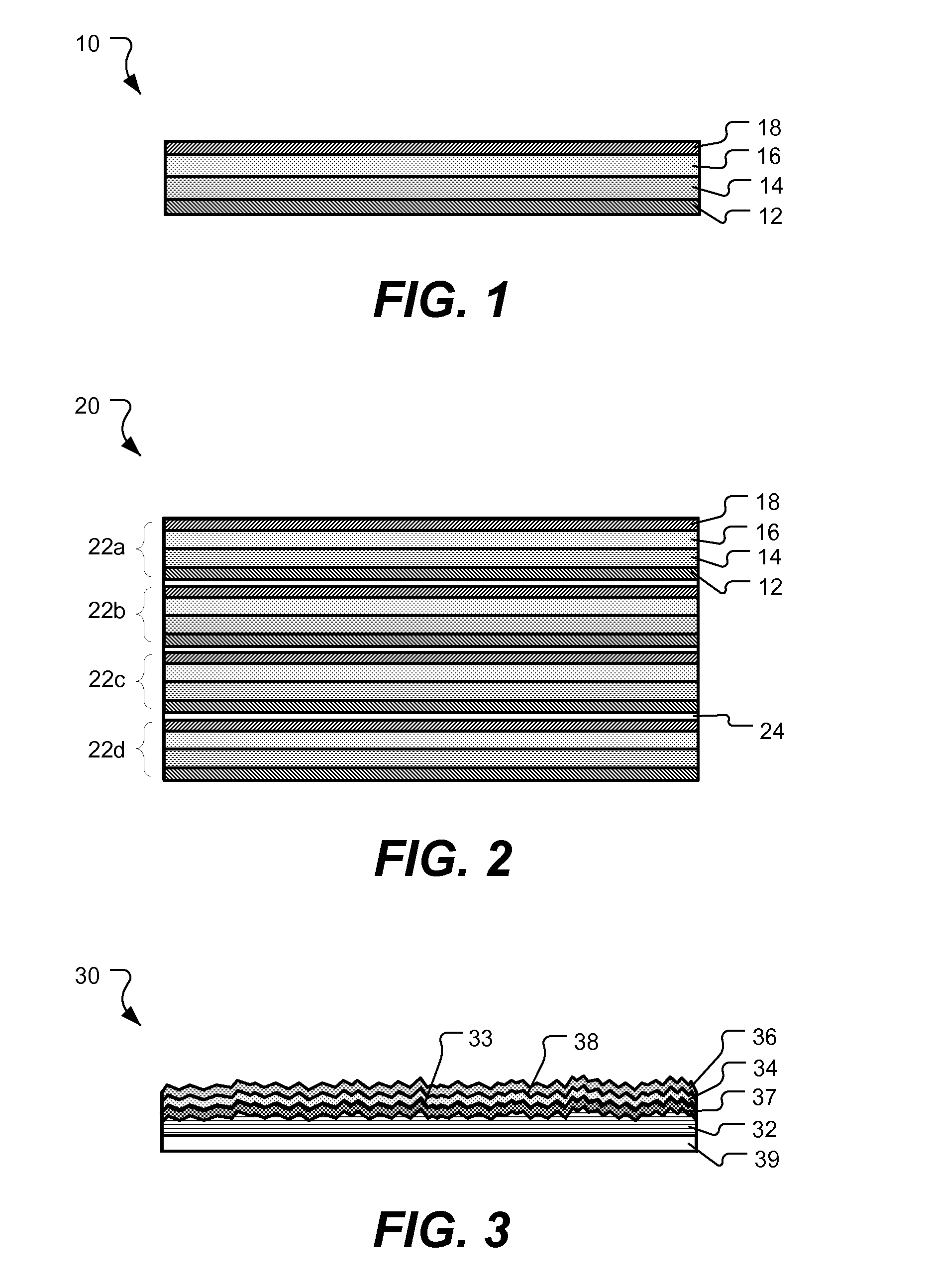

Valve component with multiple surface layers

InactiveUS6904935B2High hardnessExcellent abrasion resistancePipe supportsMultiple way valvesCircular discSurface layer

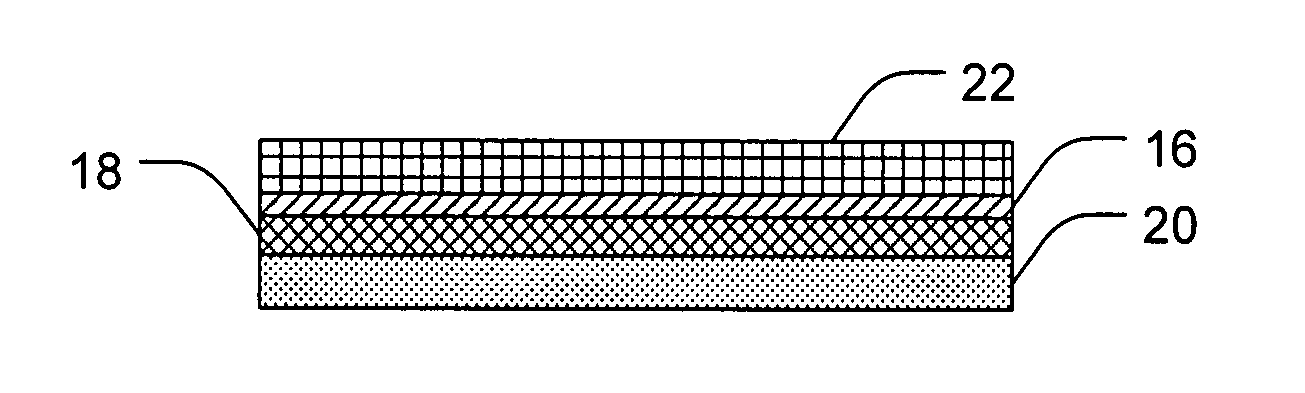

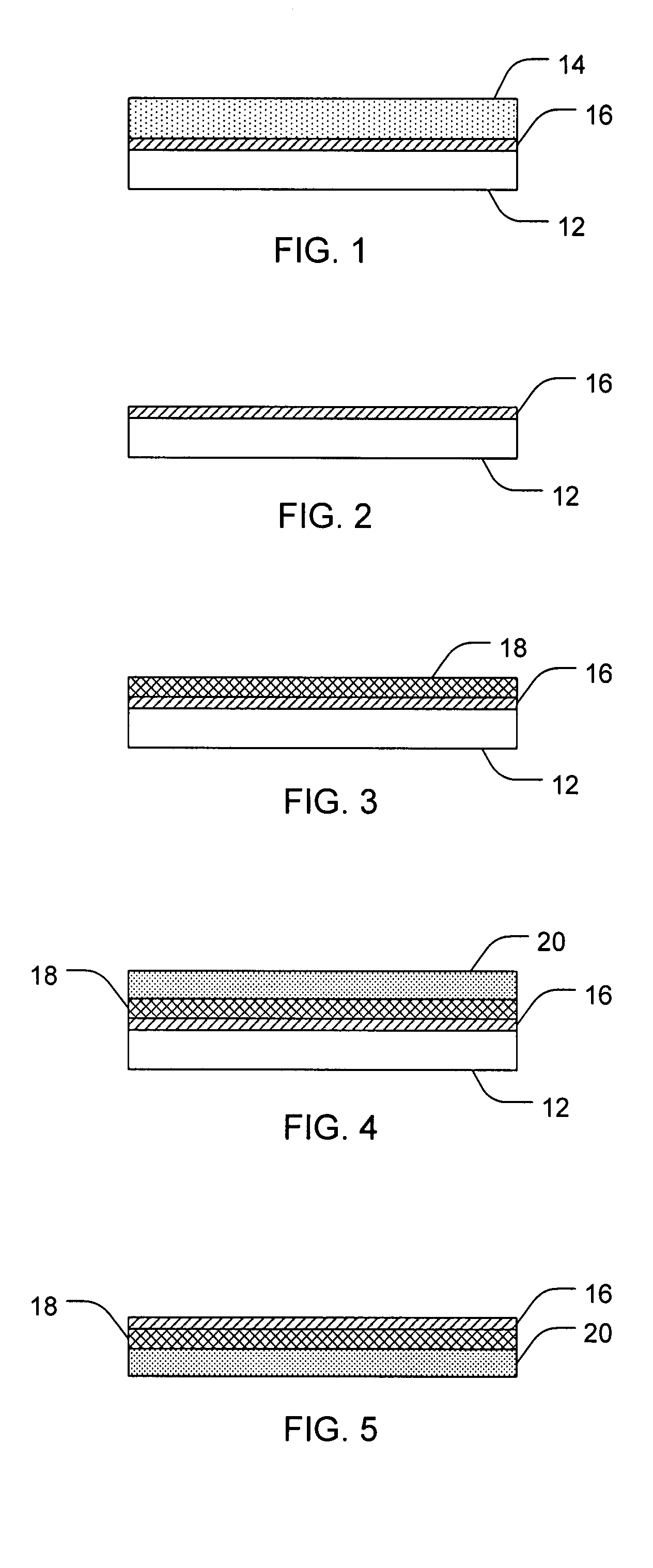

A sliding component, particularly a disk valve plate. The sliding component includes a multi-layer surface structure comprising a strengthening layer harder than the substrate material, and an amorphous diamond top layer.

Owner:DELTA FAUCET COMPANY

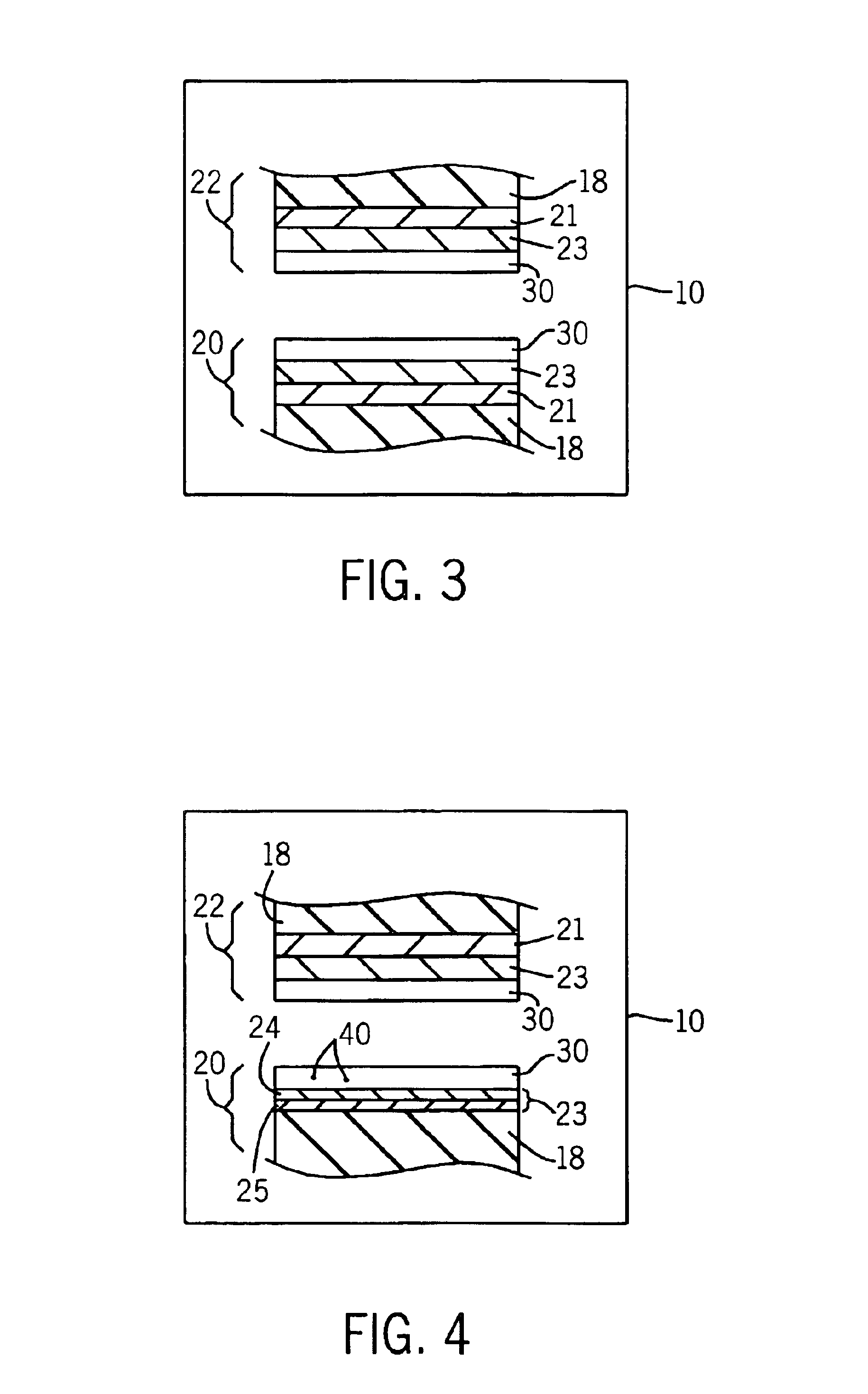

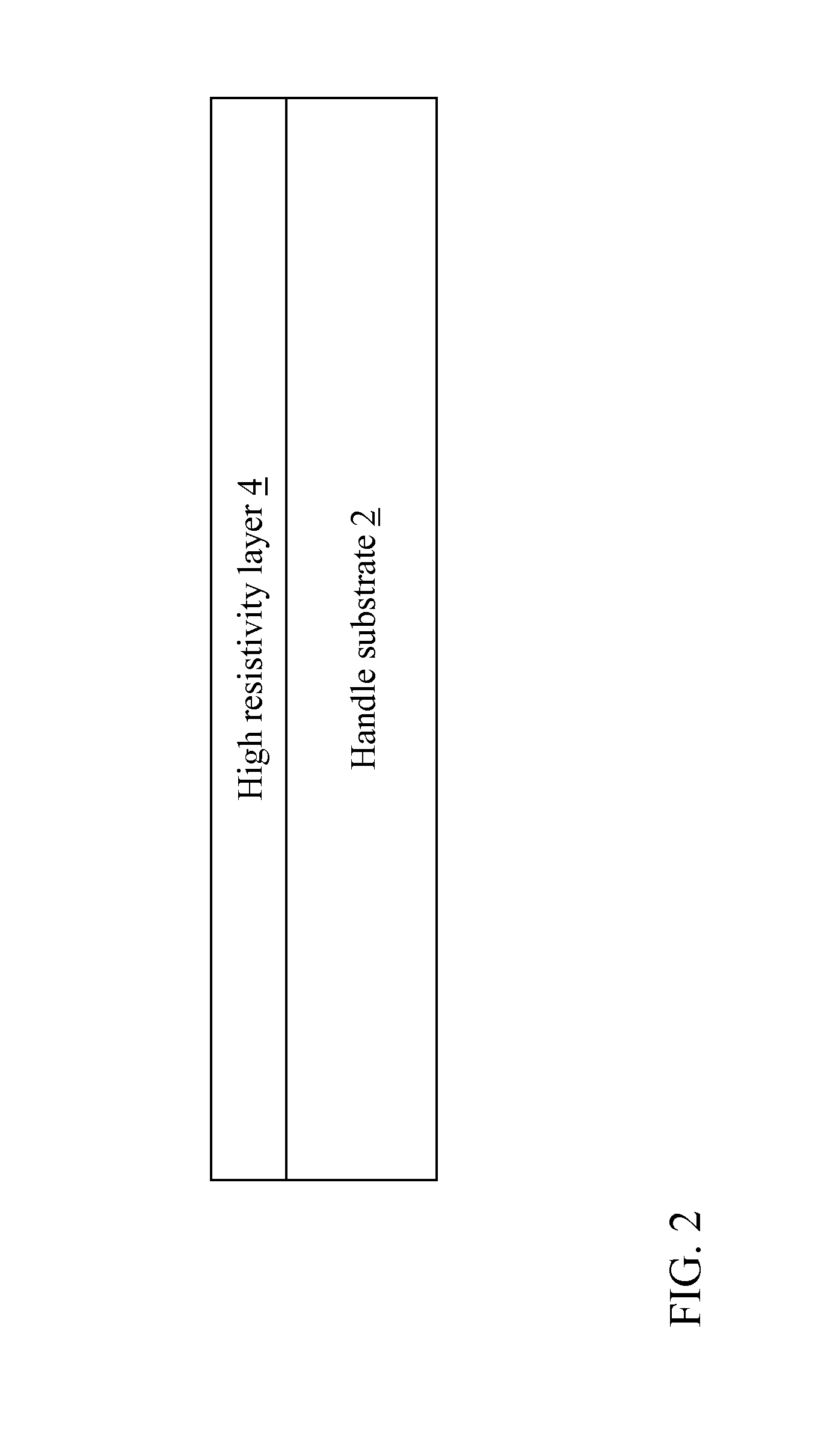

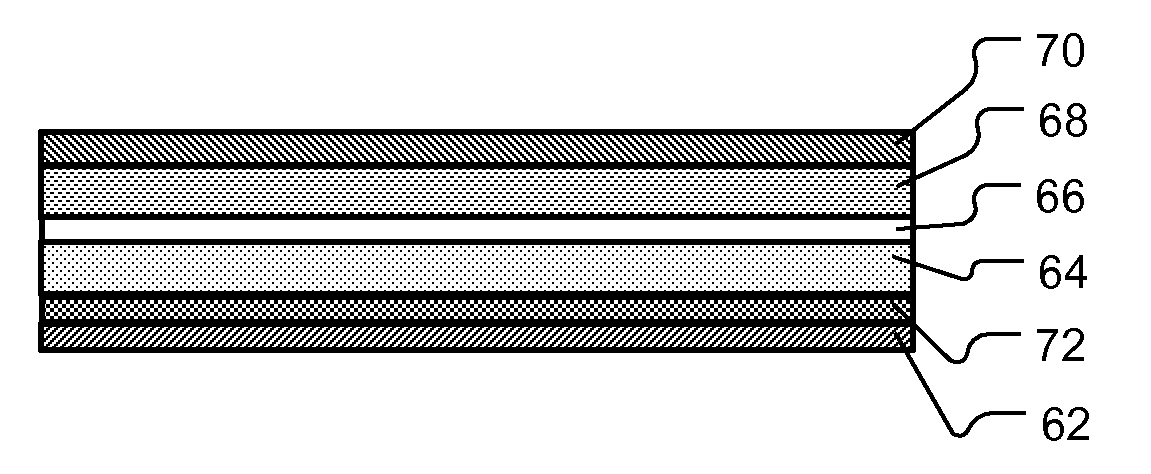

High resistivity silicon-on-insulator substrate and method of forming

InactiveUS20140124902A1Semiconductor/solid-state device detailsSolid-state devicesWaferingSemiconductor structure

A semiconductor structure and a method of forming the same. In one embodiment, a method of forming a silicon-on-insulator (SOI) wafer substrate includes: providing a handle substrate; forming a high resistivity material layer over the handle substrate, the high resistivity material layer including one of an amorphous silicon carbide (SiC), a polycrystalline SiC, an amorphous diamond, or a polycrystalline diamond; forming an insulator layer over the high resistivity material layer; and bonding a donor wafer to a top surface of the insulator layer to form the SOI wafer substrate.

Owner:GLOBALFOUNDRIES INC

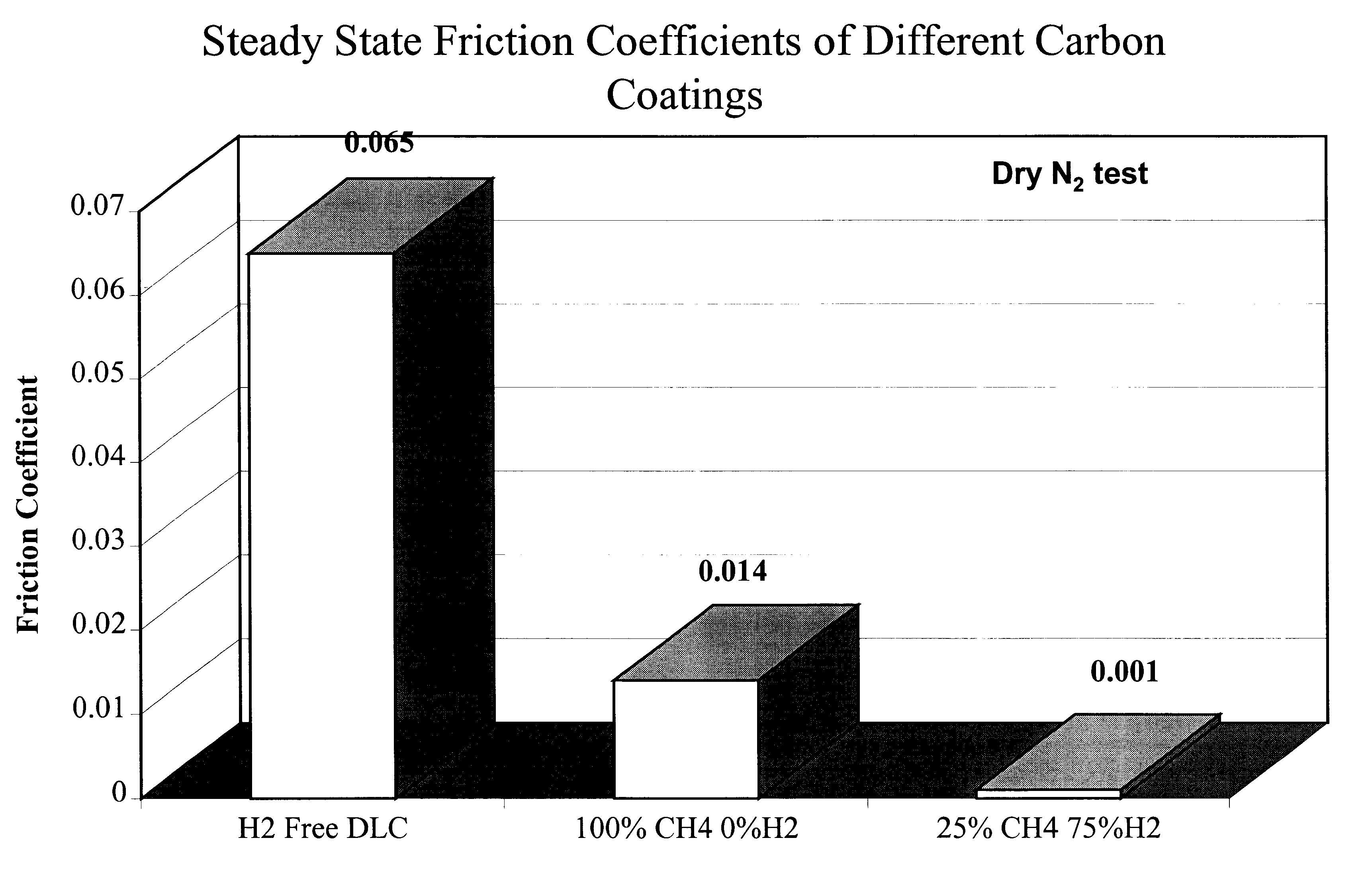

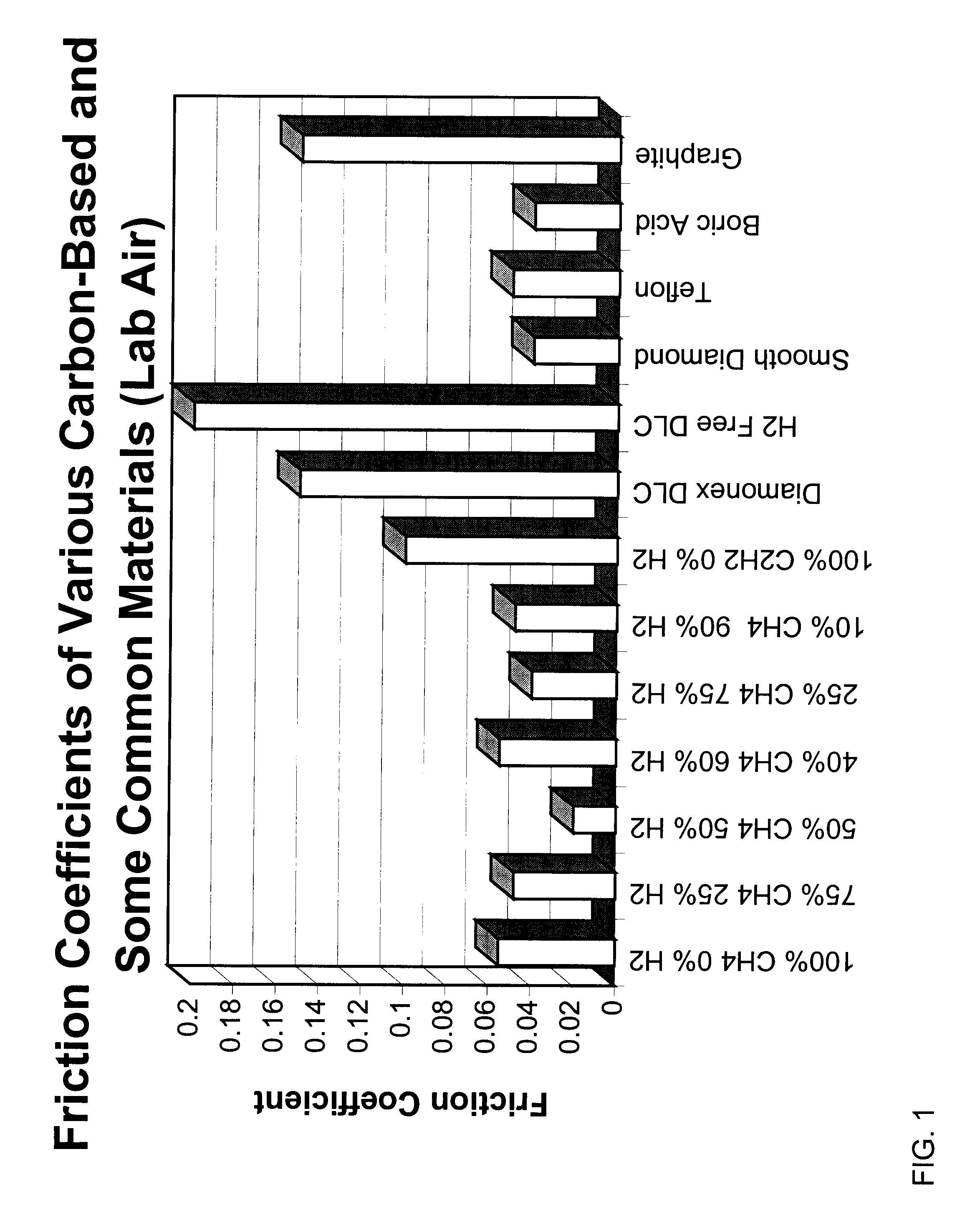

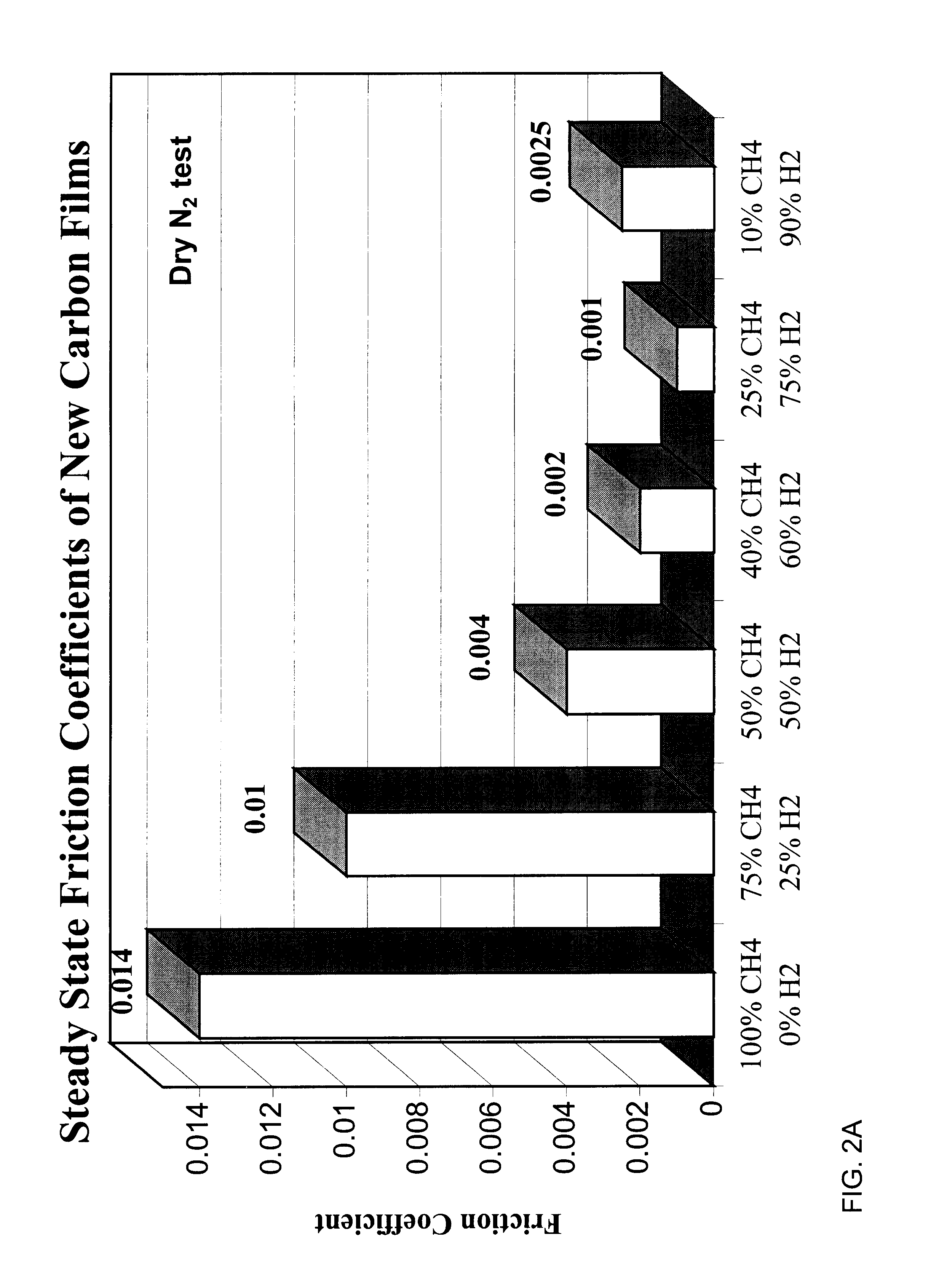

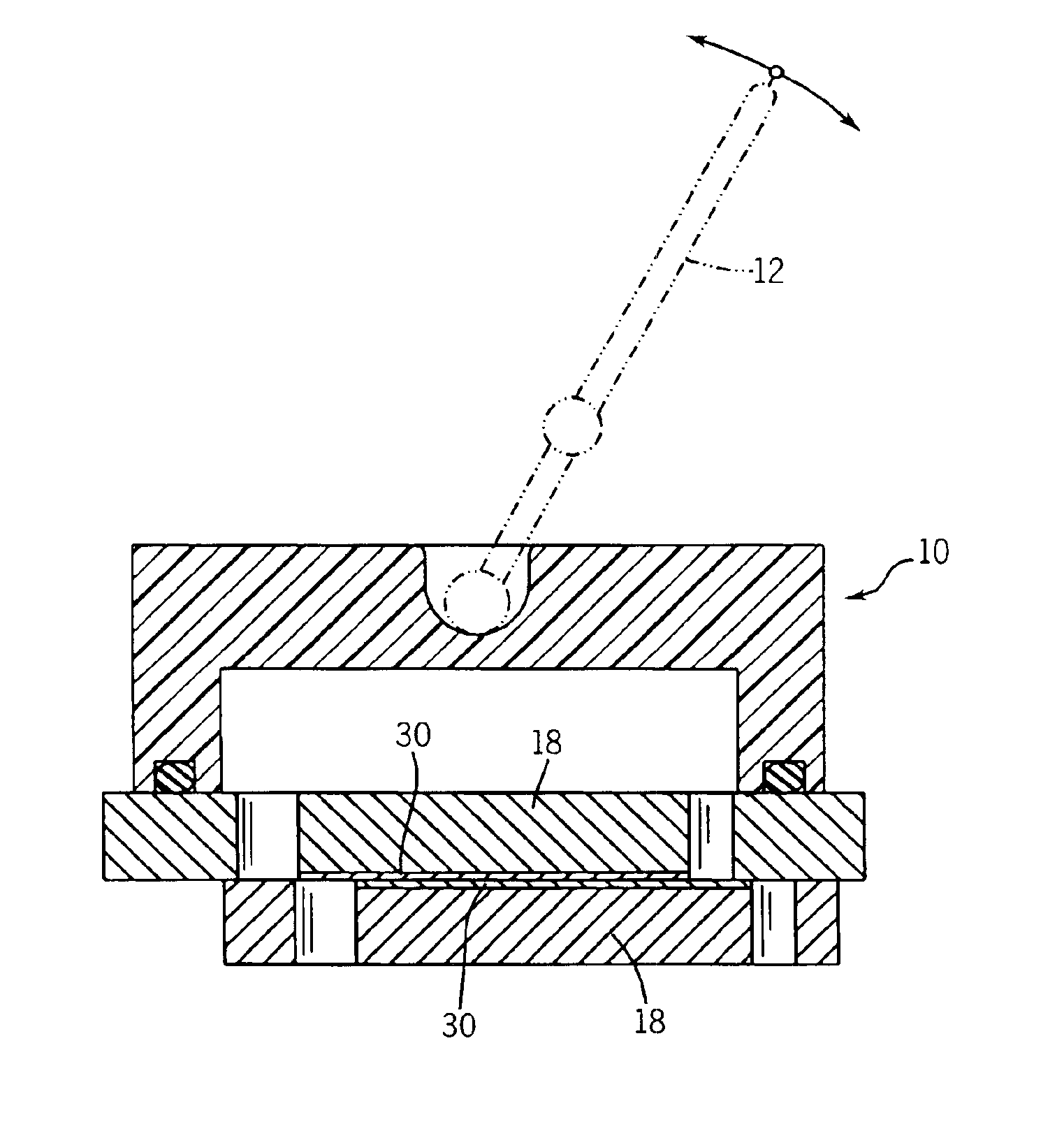

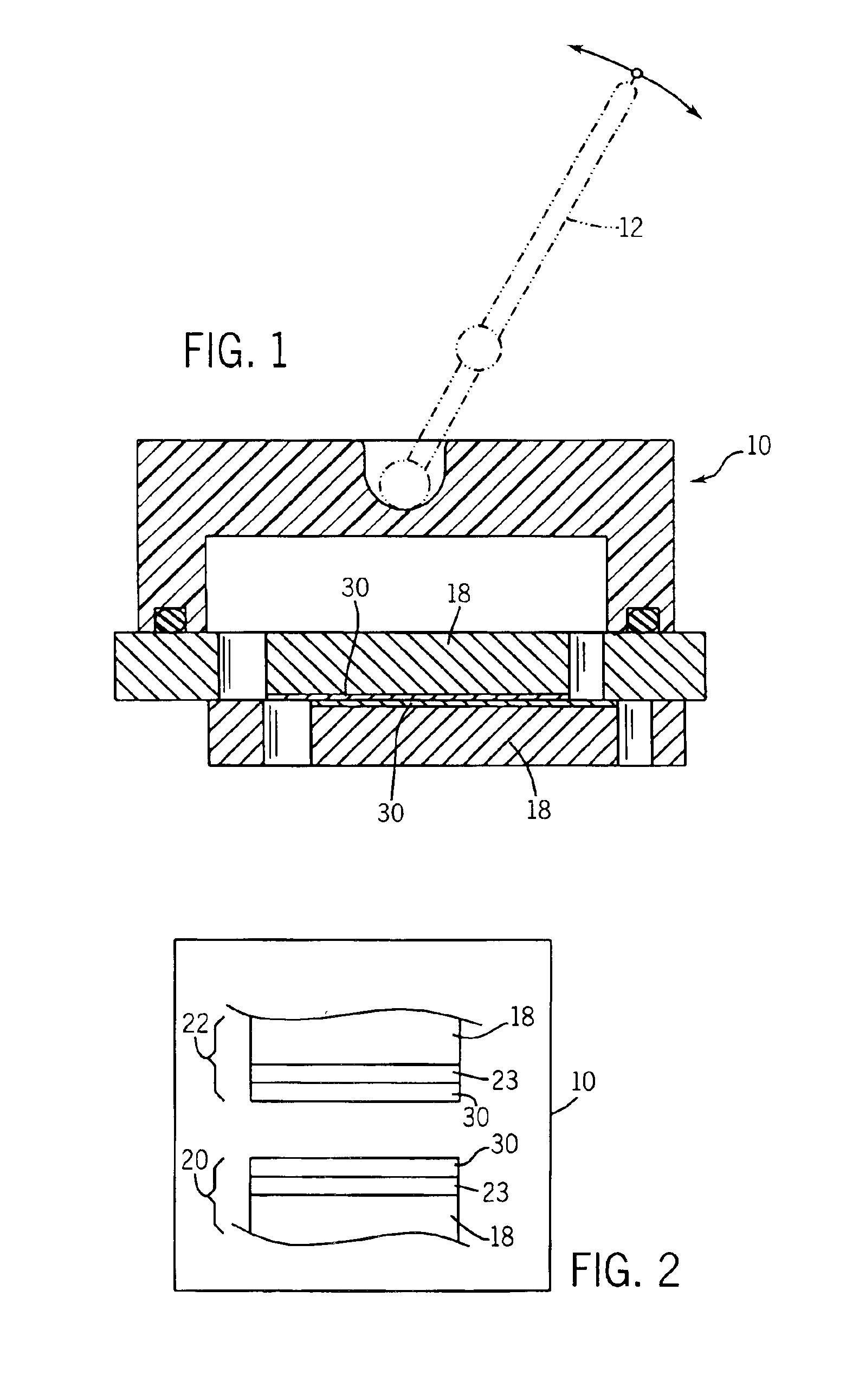

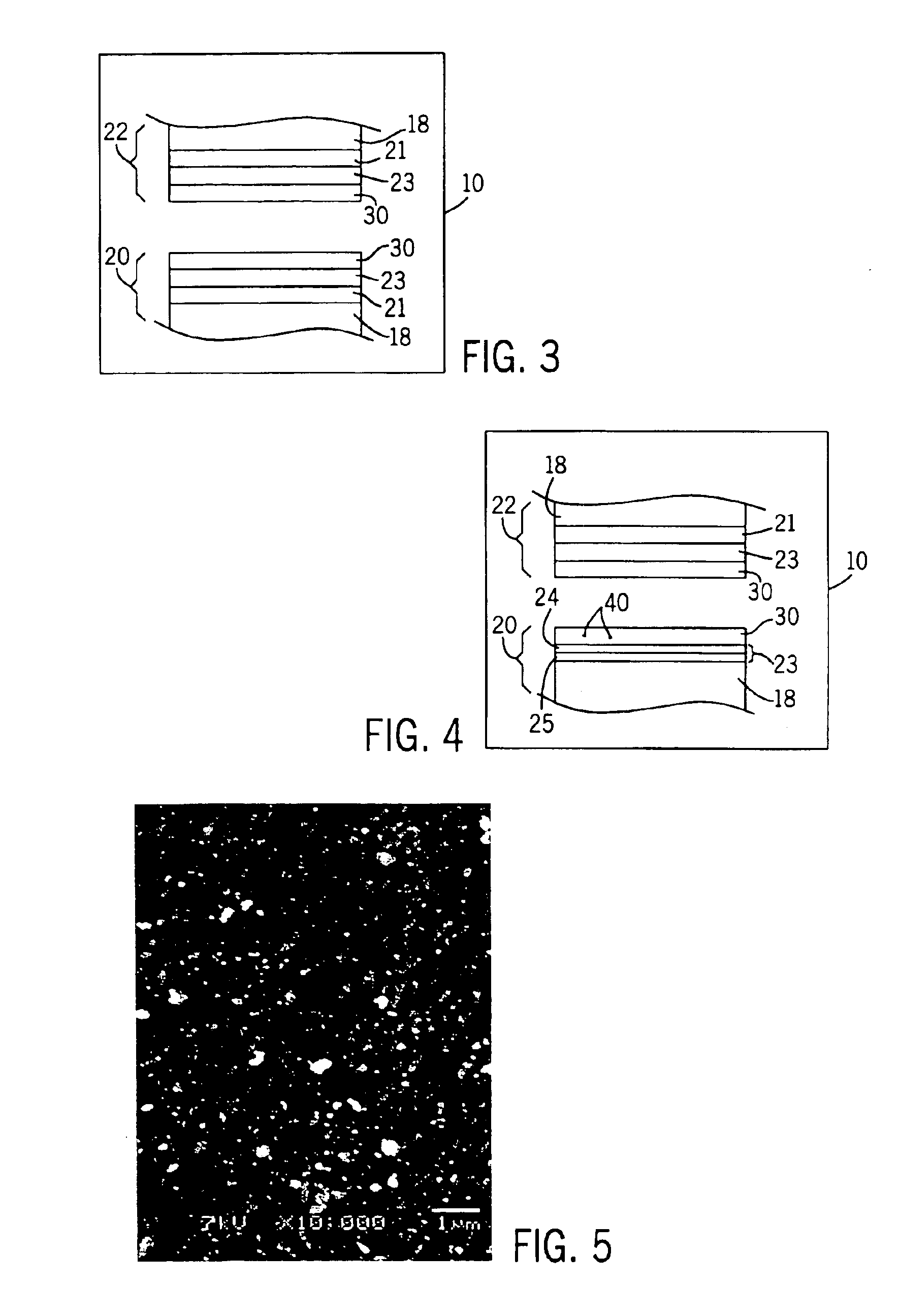

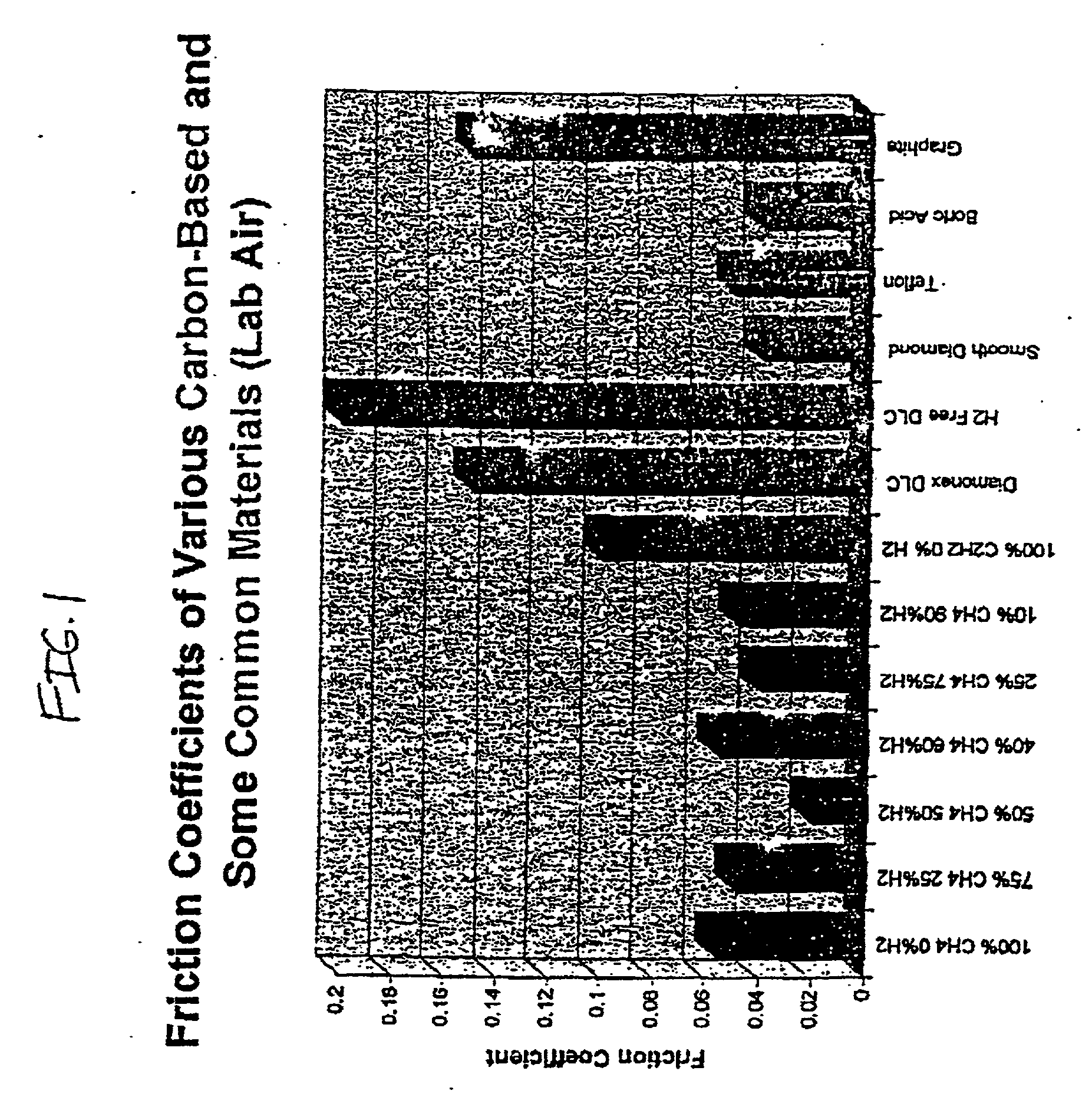

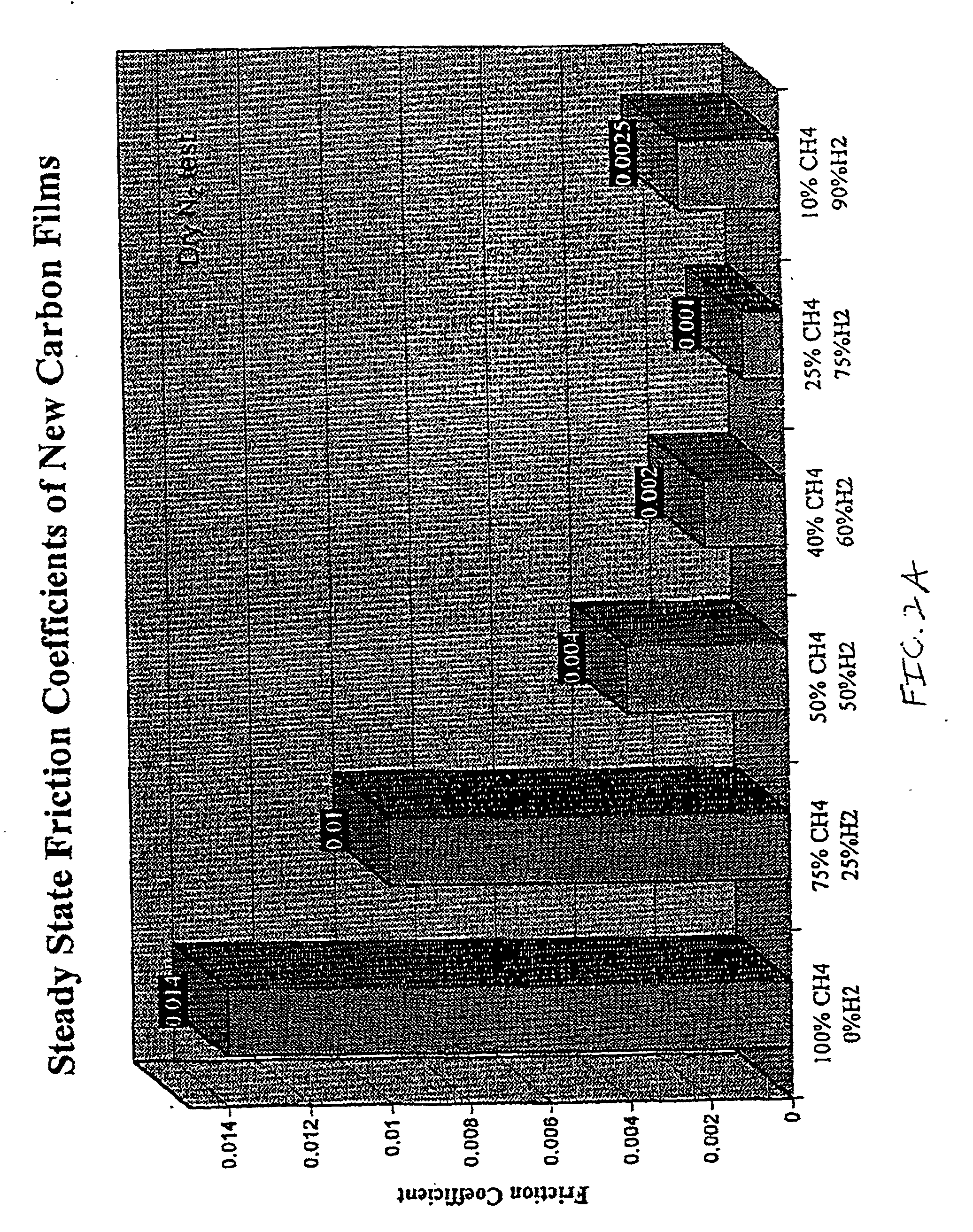

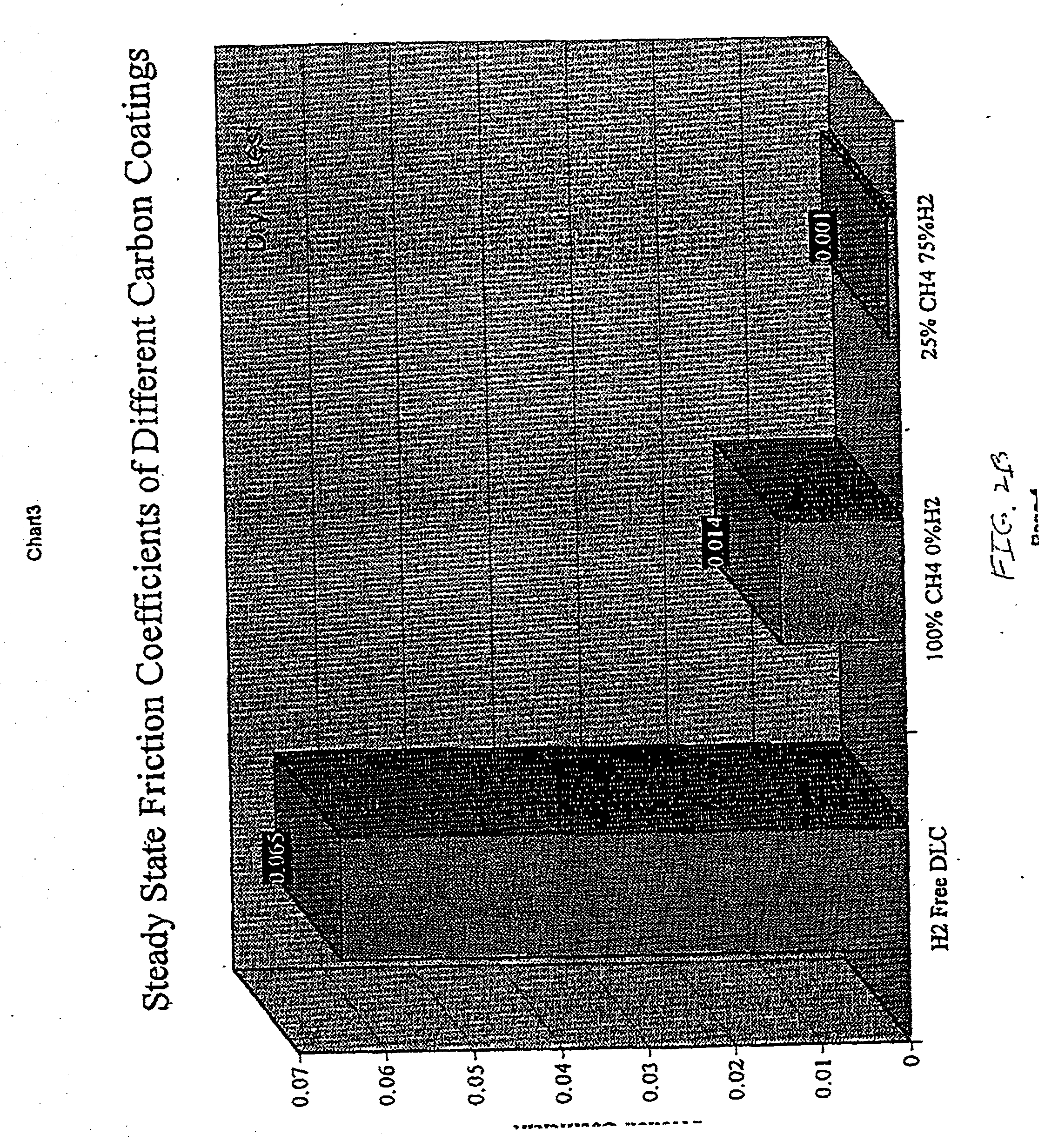

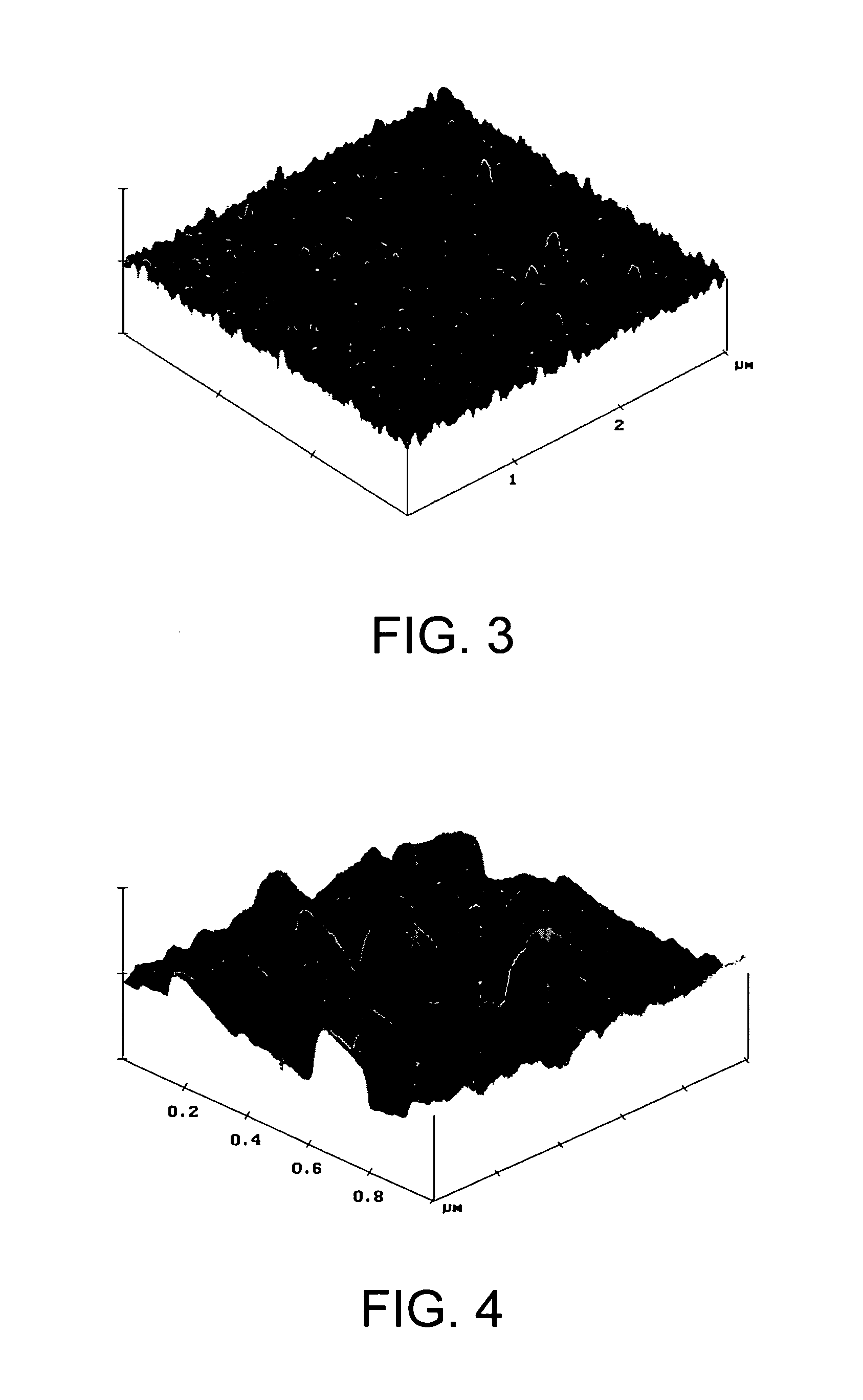

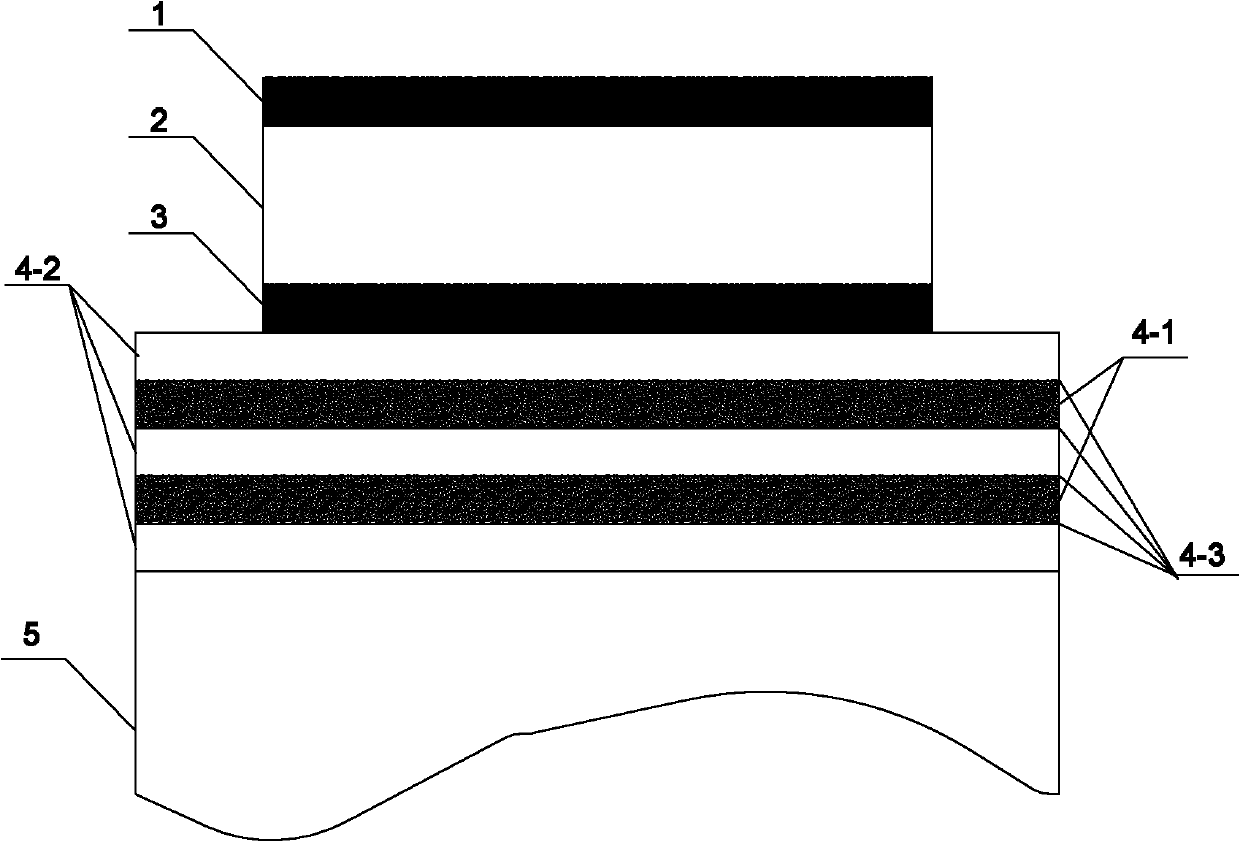

Method of produce ultra-low friction carbon films

InactiveUS6548173B2Friction wearWear propertiesLiquid surface applicatorsRecord information storageCarbon filmDiamond-like carbon

Owner:UCHICAGO ARGONNE LLC

Valve component with multiple surface layers

InactiveUS6935618B2High hardnessIncrease resistanceOperating means/releasing devices for valvesMultiple way valvesSurface layerAmorphous diamond

A sliding component, particularly a disk valve plate. The sliding component includes a multi-layer surface structure comprising a strengthening layer harder than the substrate material, and an amorphous diamond top layer.

Owner:DELTA FAUCET COMPANY

Method to produce ultra-low friction carbon films

InactiveUS20020041930A1Ultra-low frictionUltra-low wear propertyLiquid surface applicatorsRecord information storageCarbon filmDiamond-like carbon

A method and article of manufacture of amorphous diamond-like carbon. The method involves providing a substrate in a chamber, providing a mixture of a carbon containing gas and hydrogen gas with the mixture adjusted such that the atomic molar ratio of carbon to hydrogen is less than 0.3, including all carbon atoms and all hydrogen atoms in the mixture. A plasma is formed of the mixture and the amorphous diamond-like carbon film is deposited on the substrate. To achieve optimum bonding an intervening bonding layer, such as Si or SiO2, can be formed from SiH4 with or without oxidation of the layer formed.

Owner:UCHICAGO ARGONNE LLC

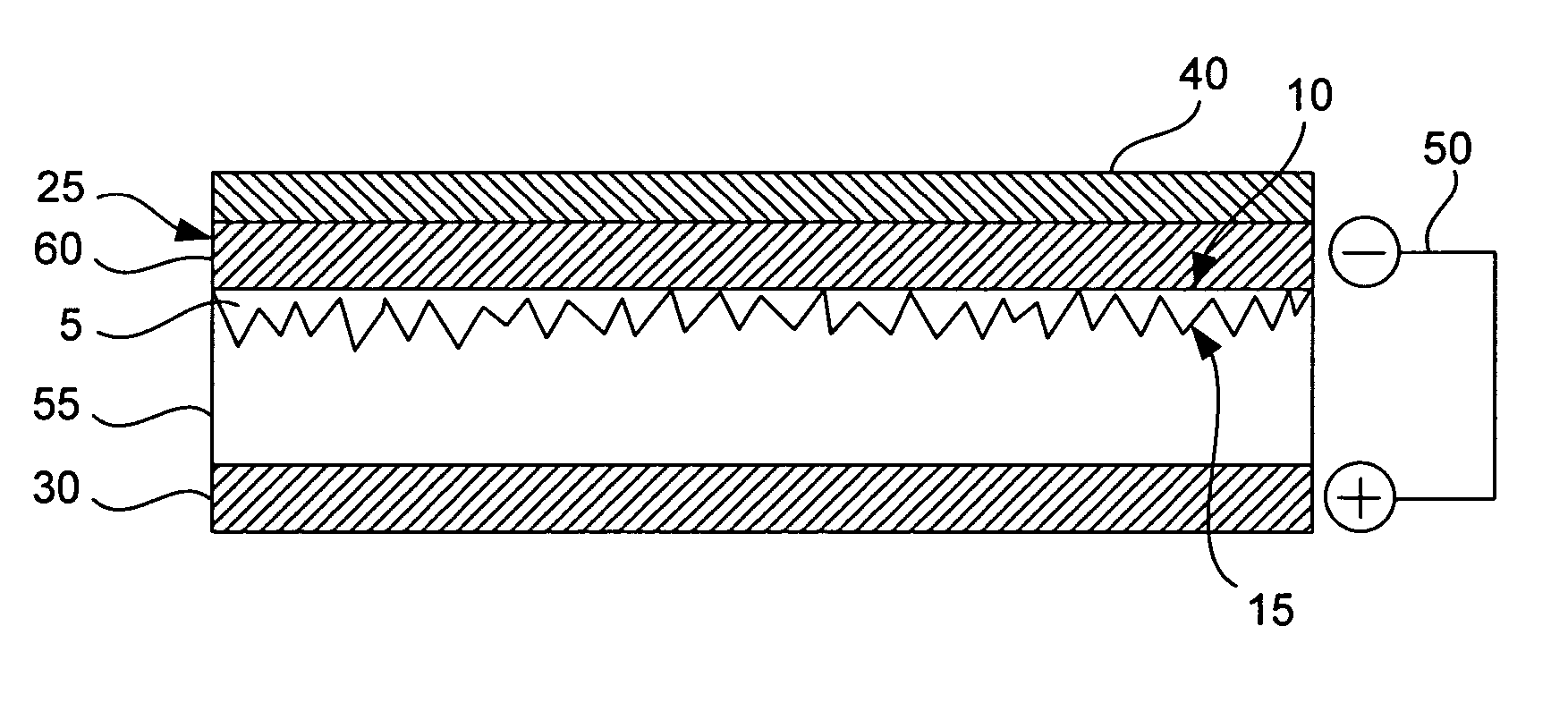

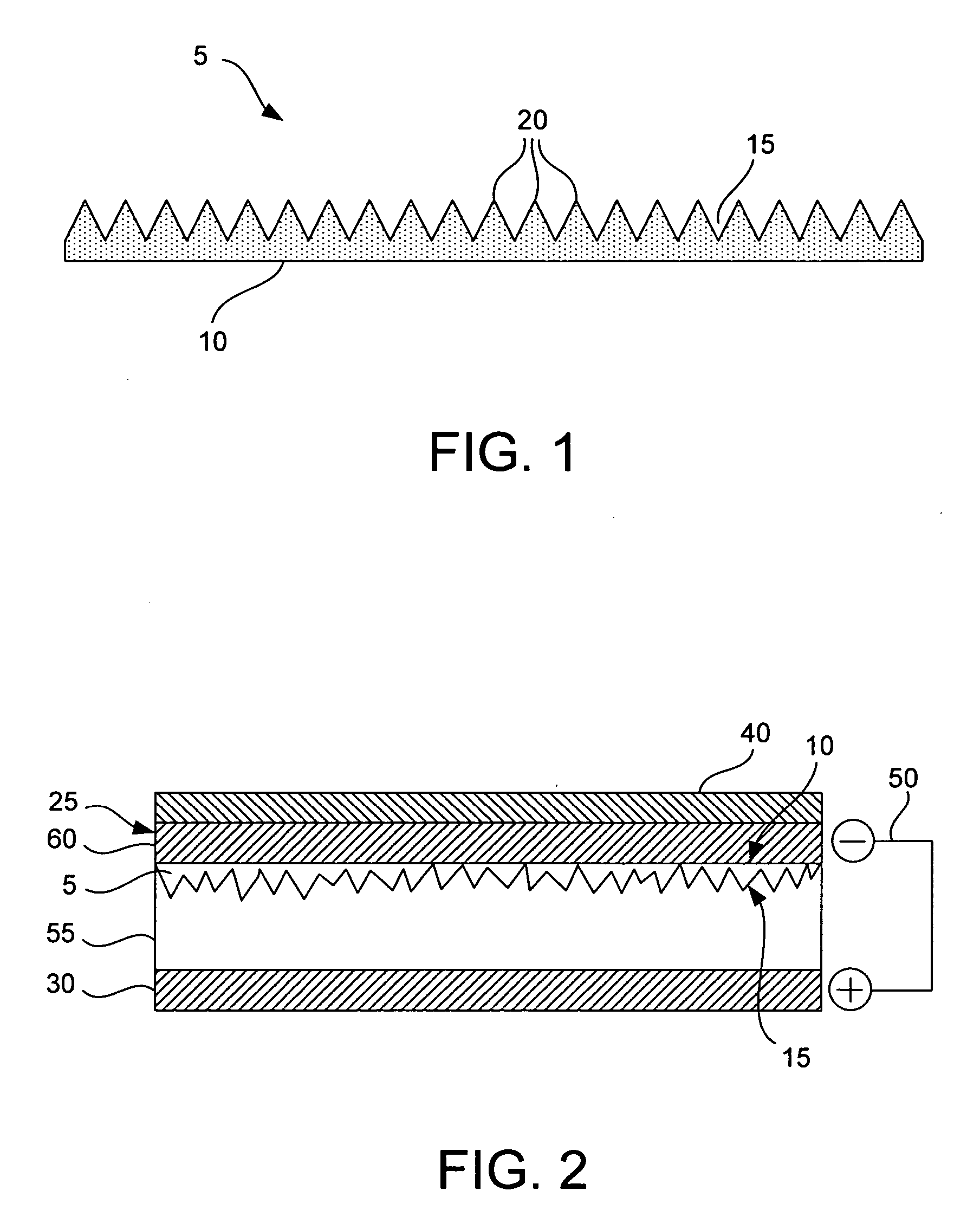

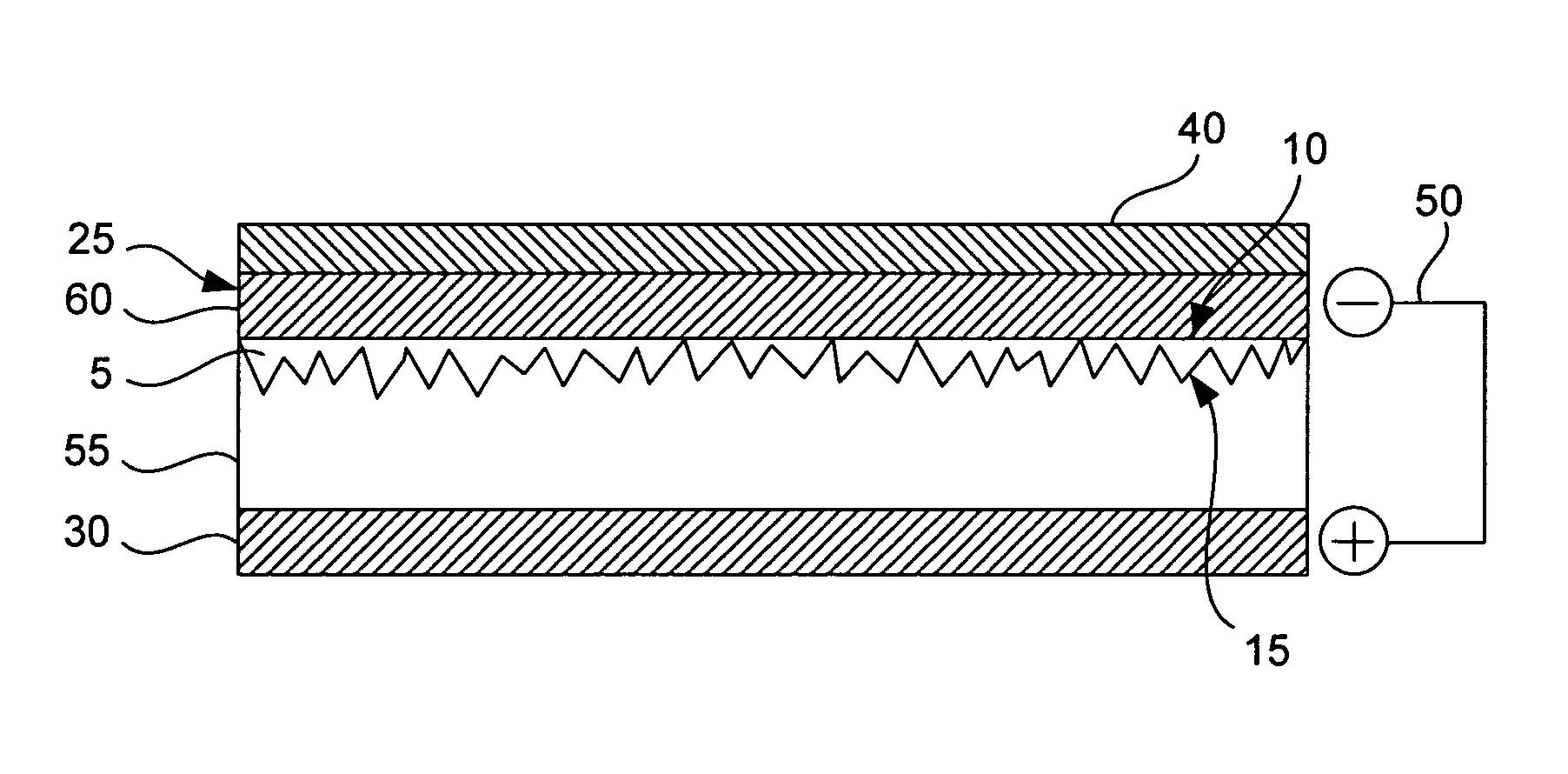

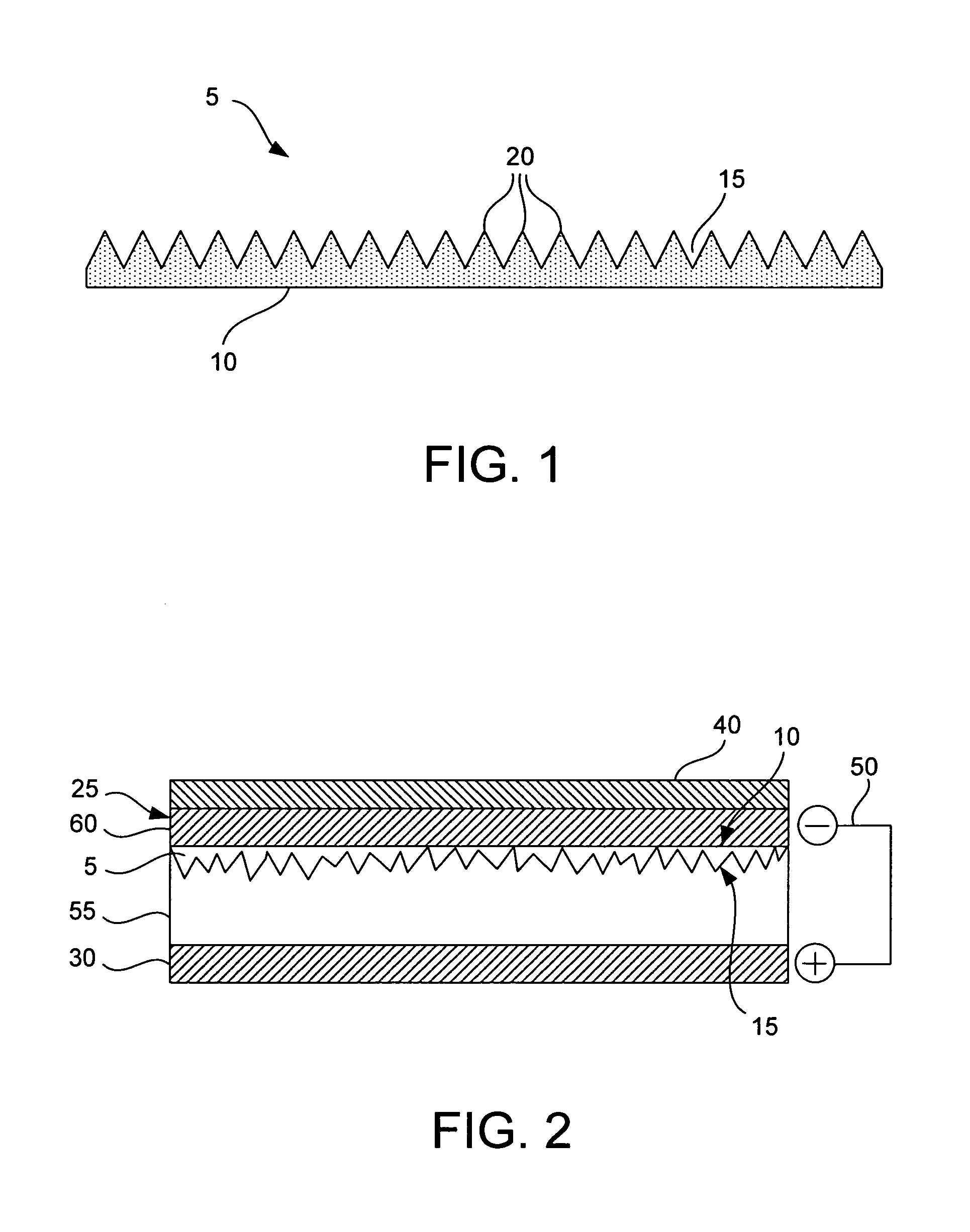

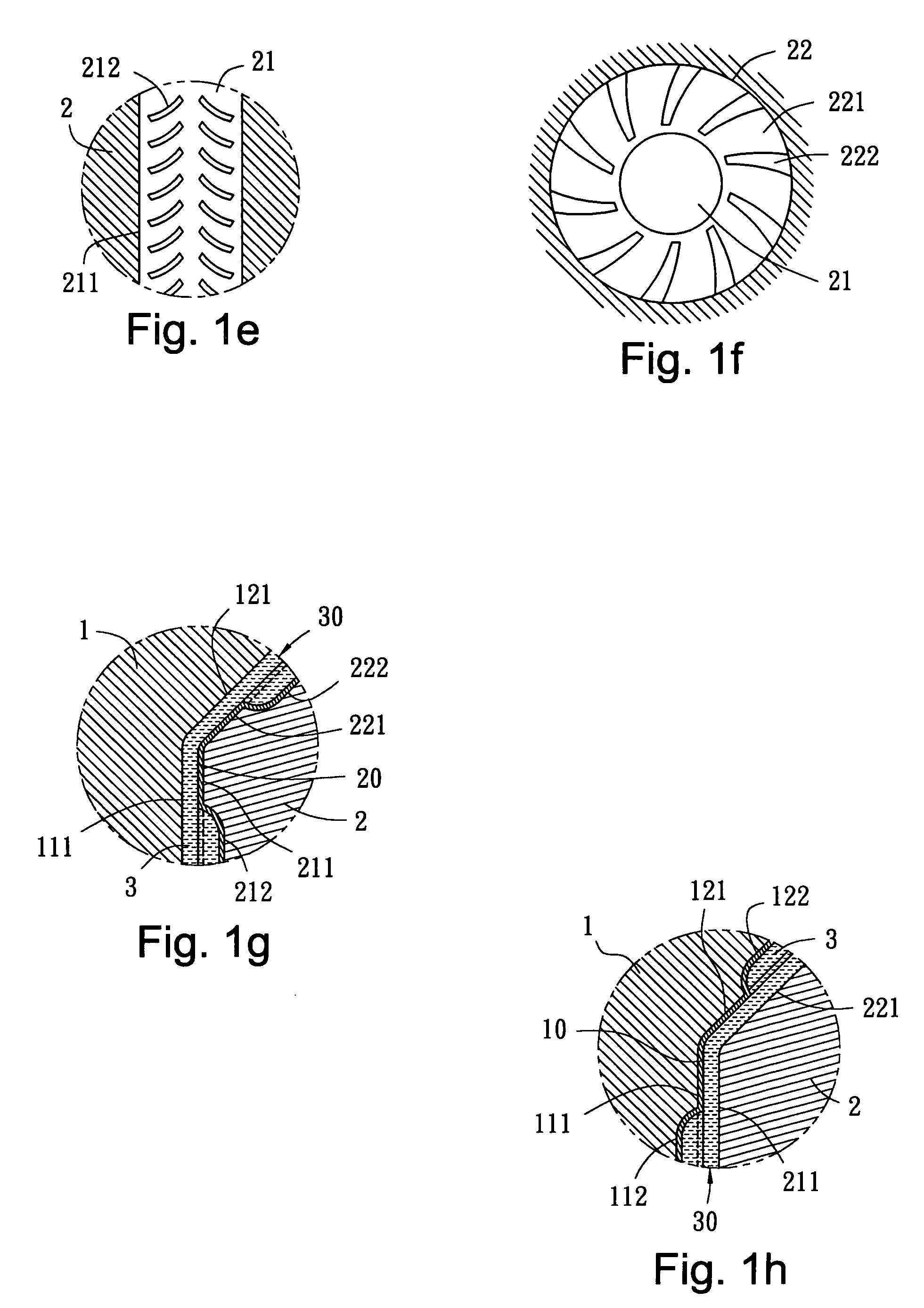

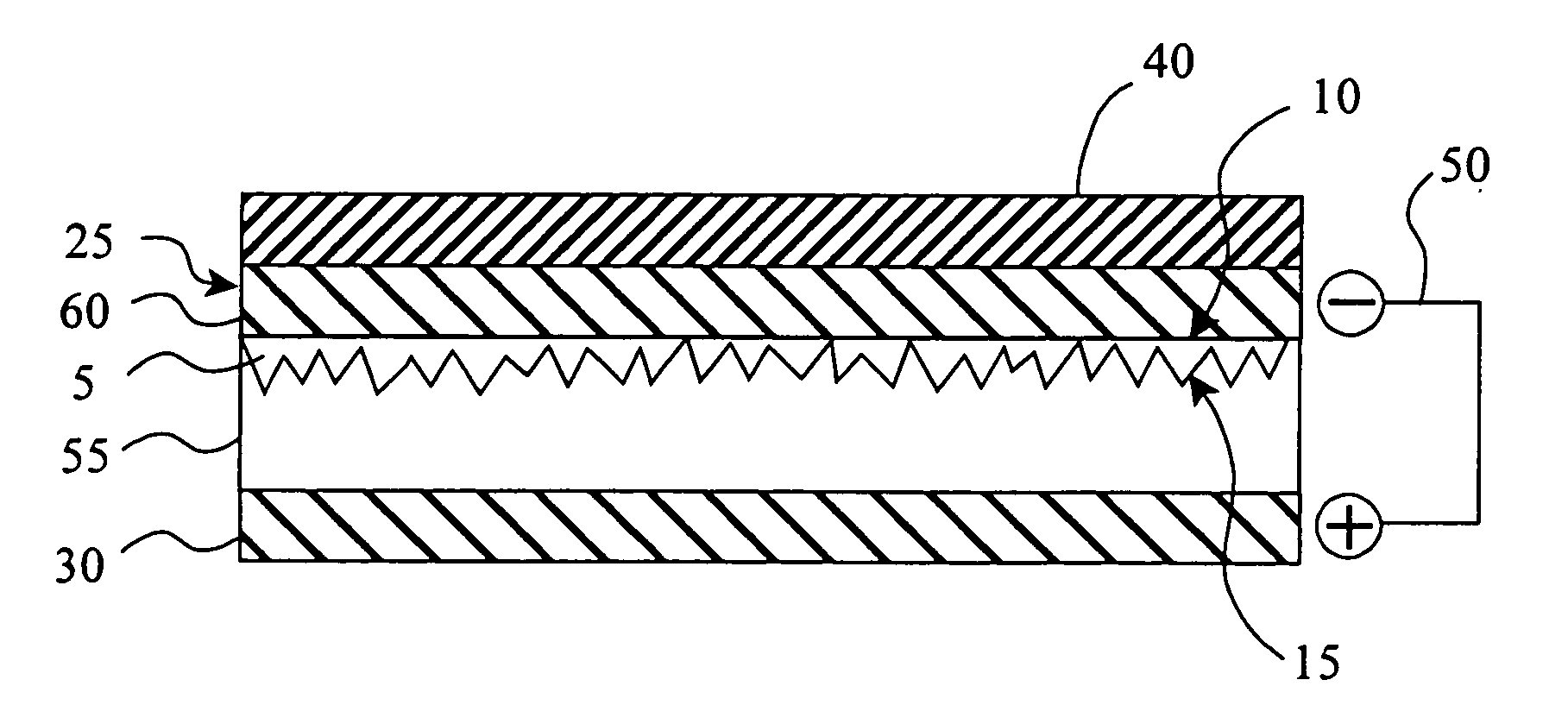

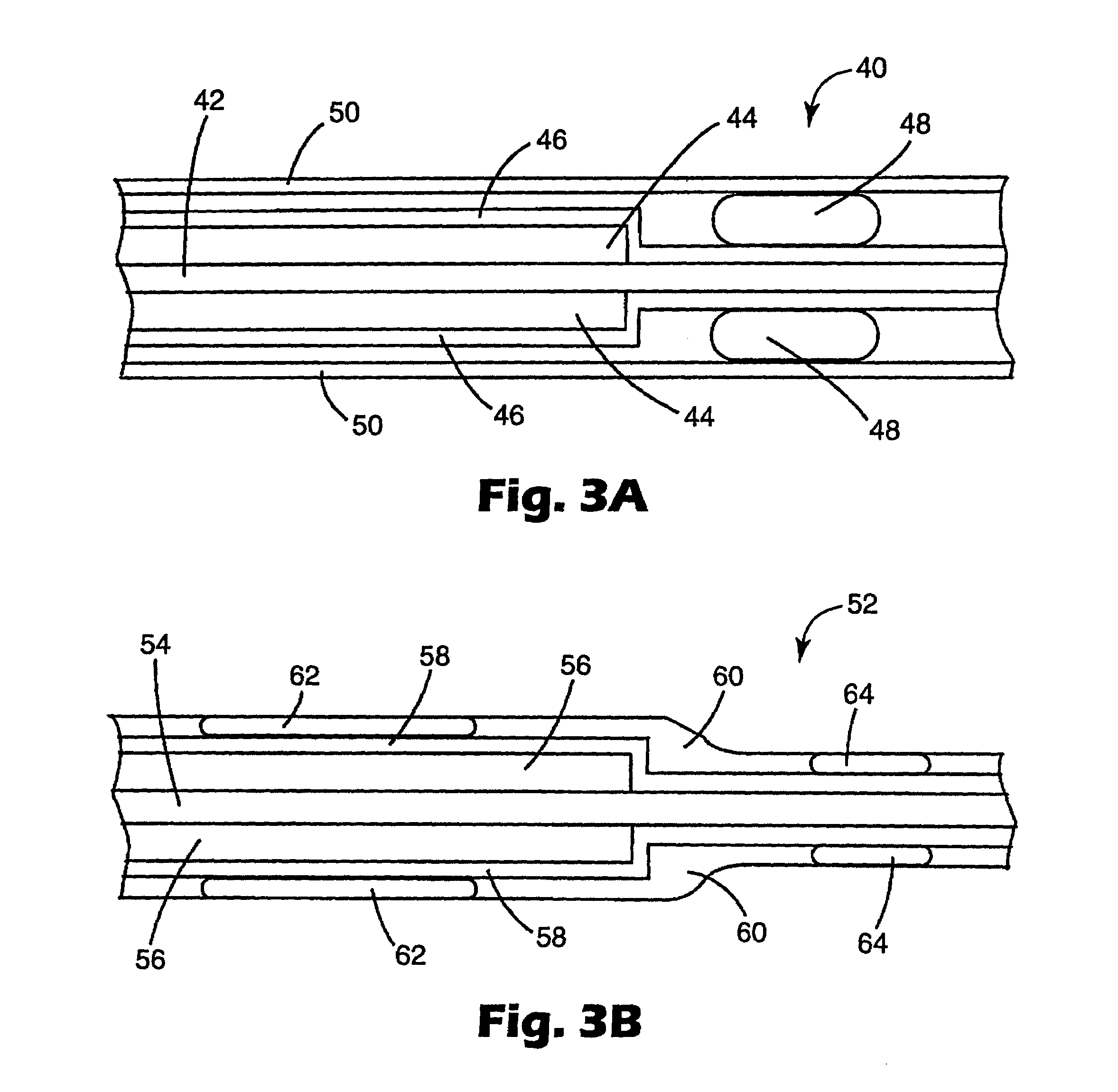

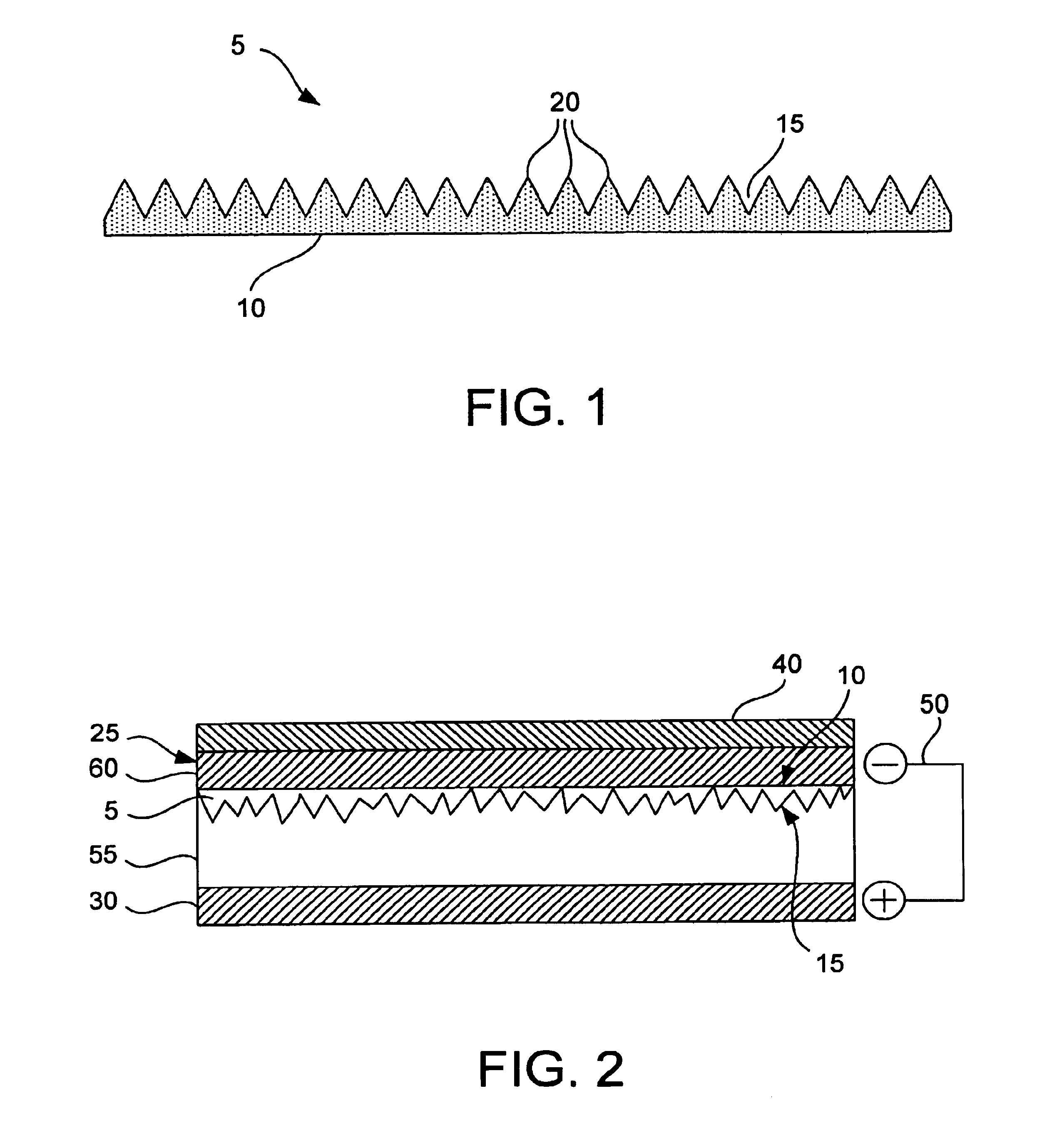

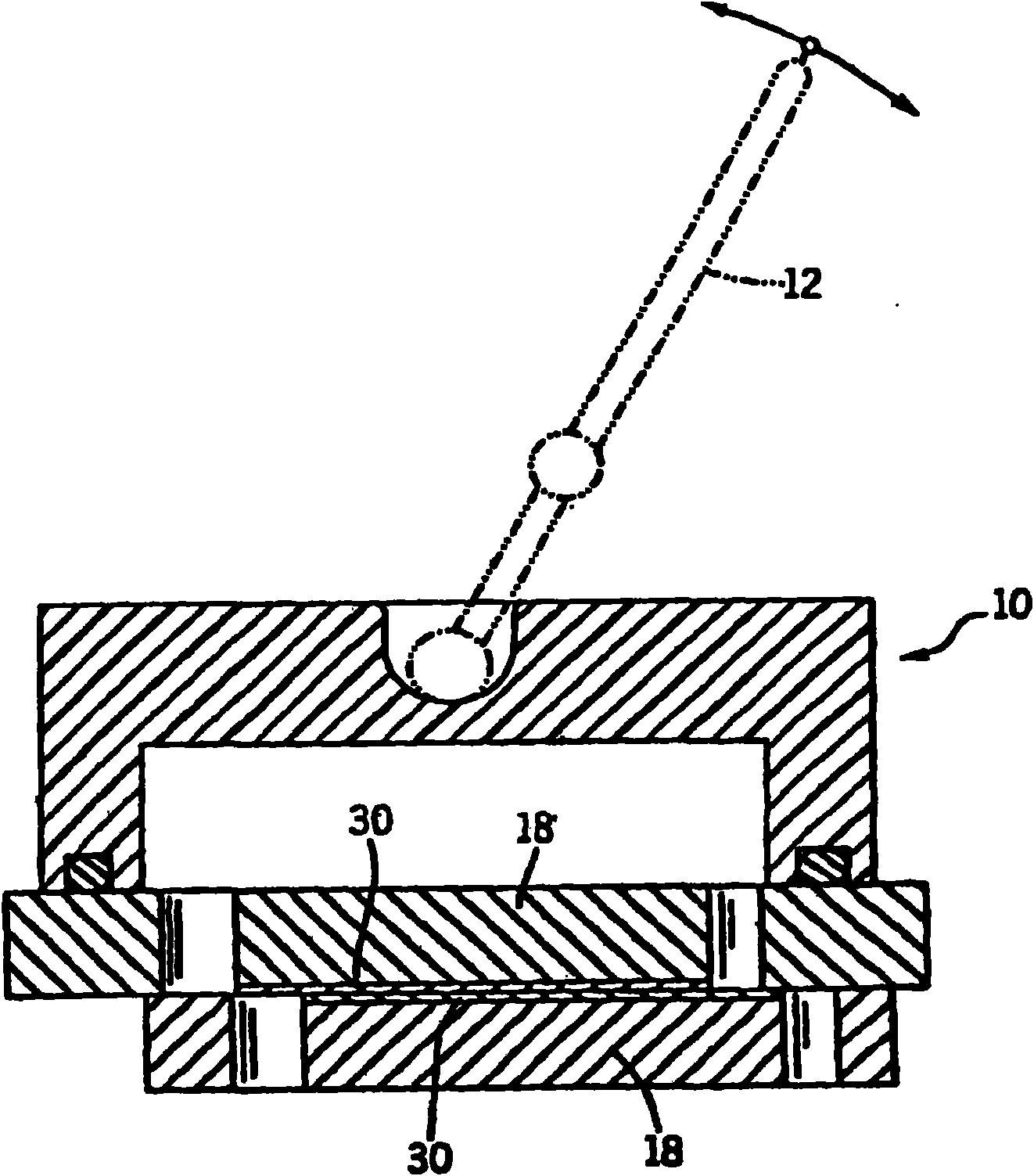

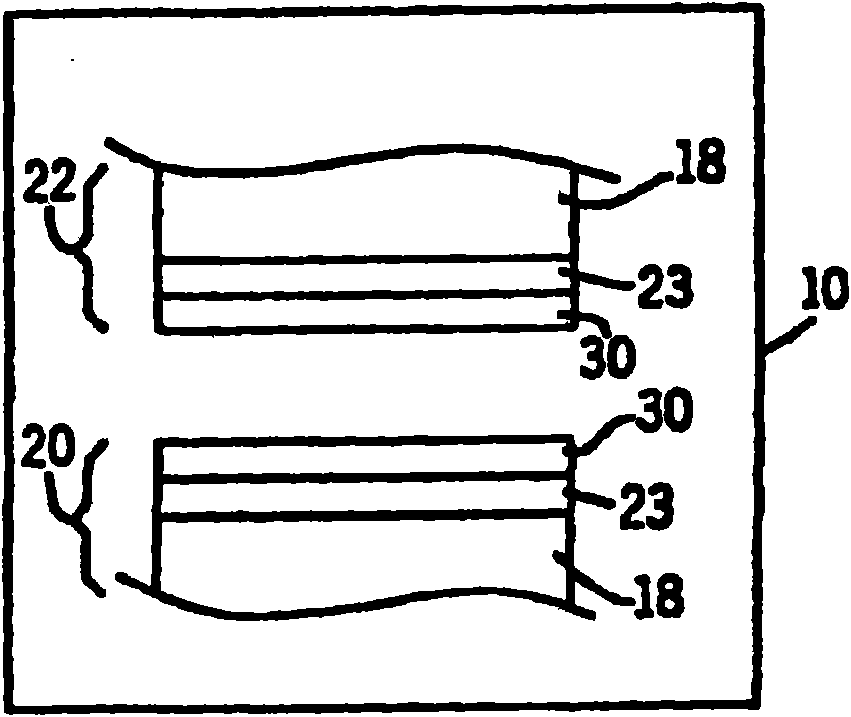

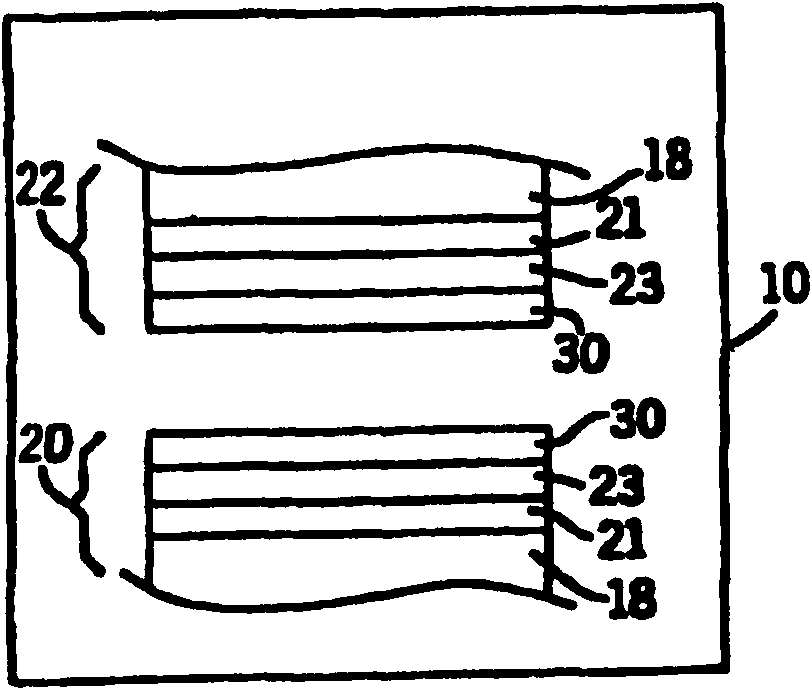

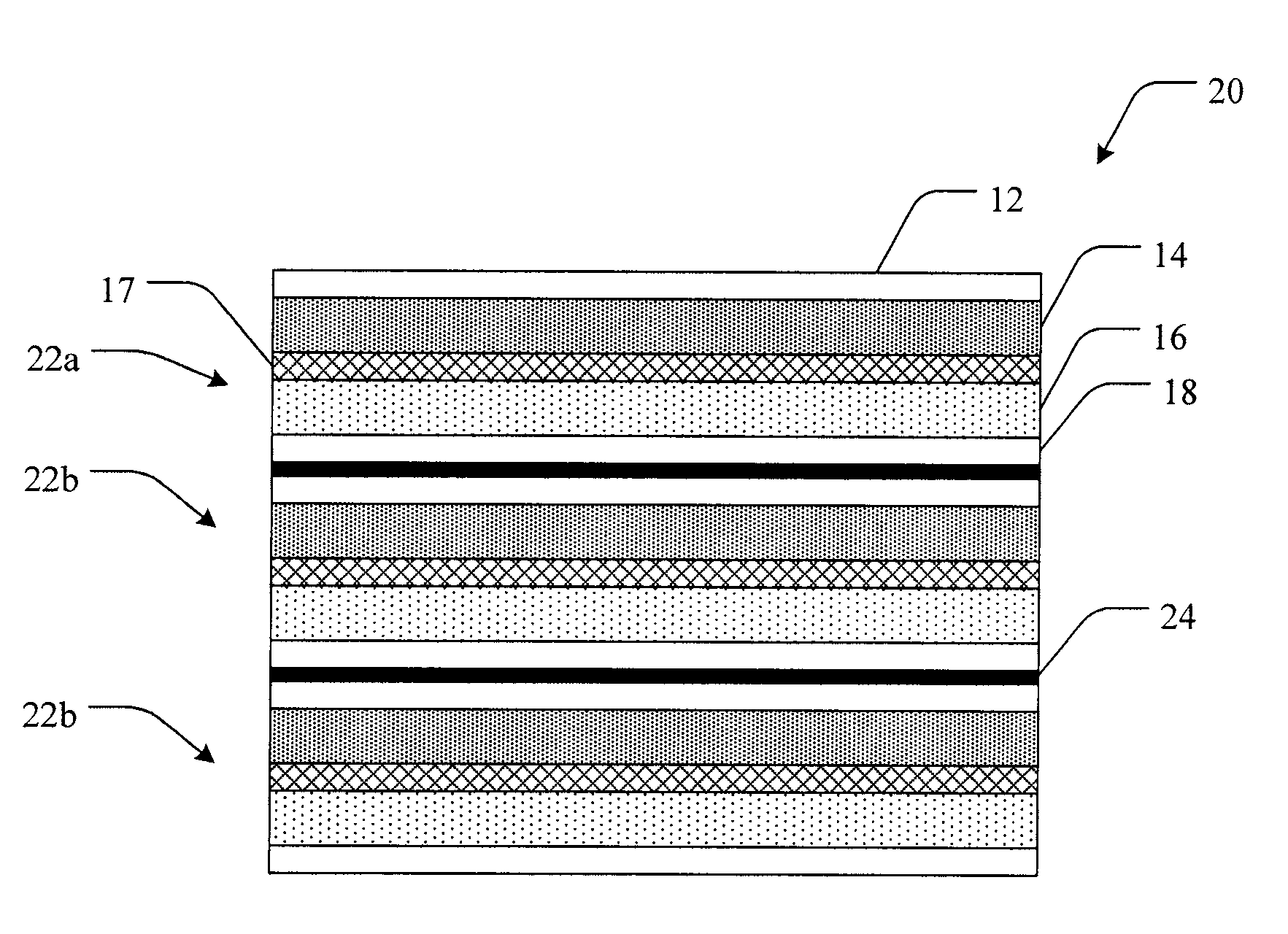

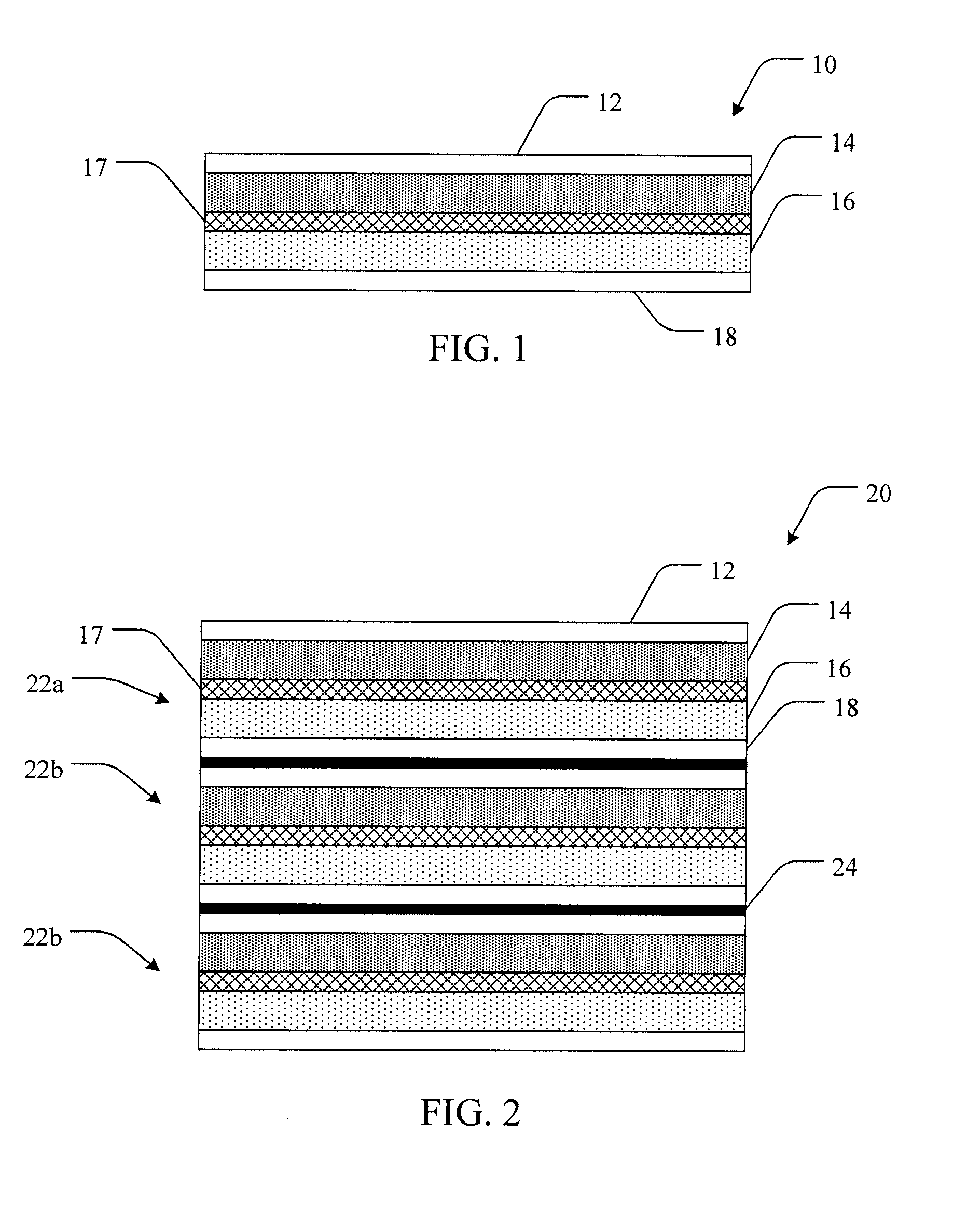

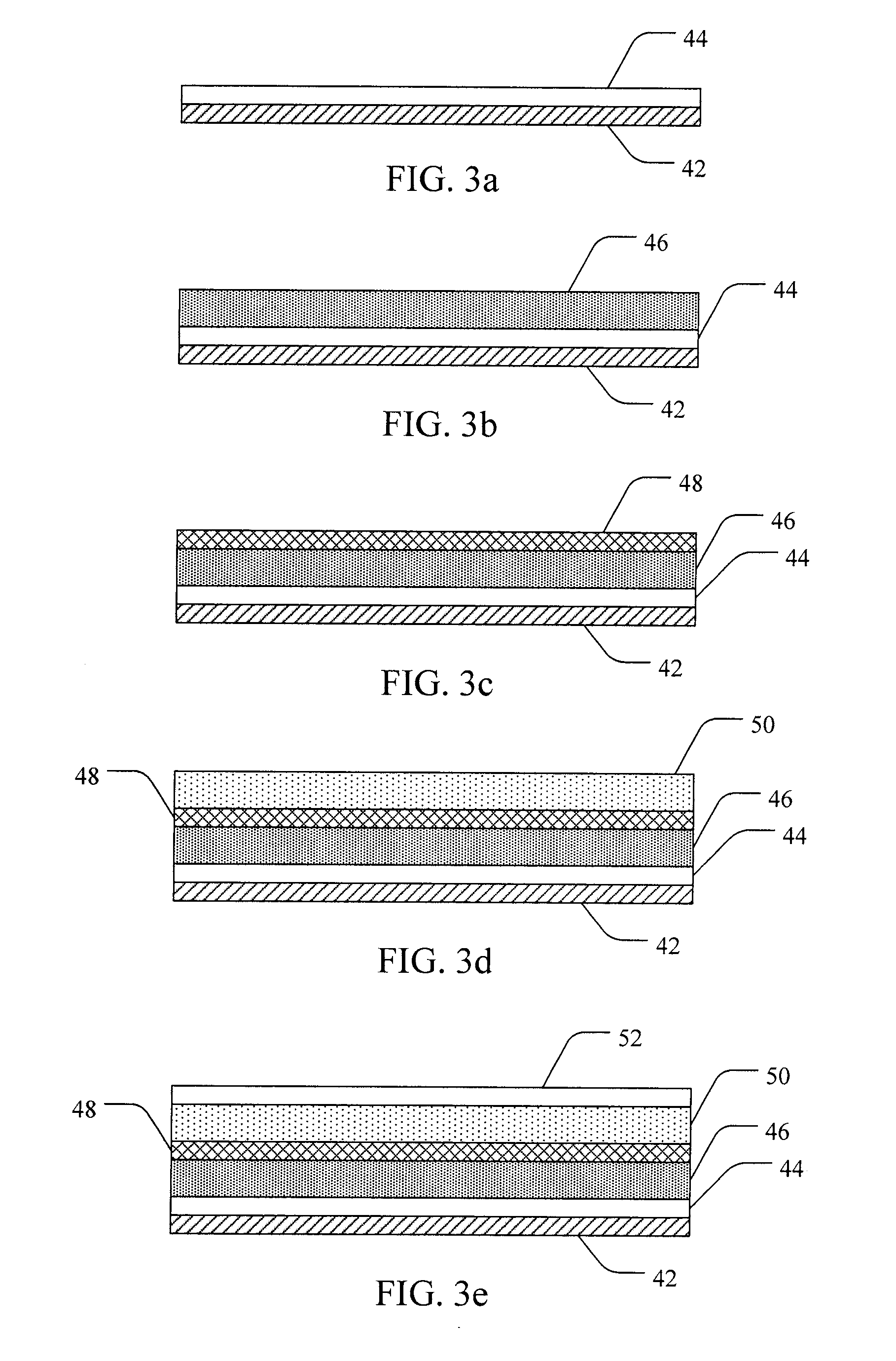

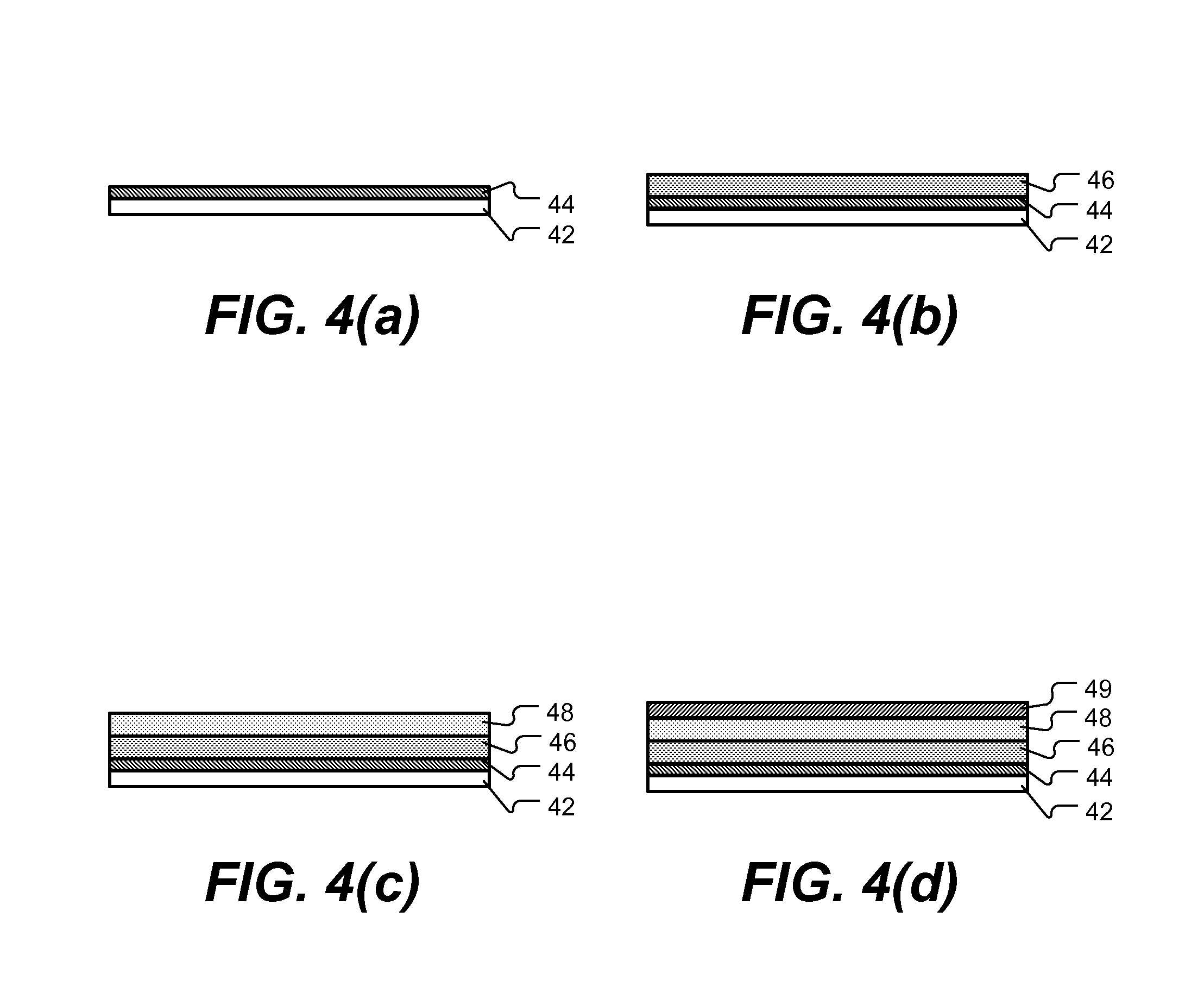

Diamond-like carbon thermoelectric conversion devices and methods for the use and manufacture thereof

InactiveUS20050275330A1Conveniently formedLow costThermionic cathodesDischarge tube solid thermionic cathodesElectricityDiamond-like carbon

Diamond-like carbon based thermoelectric conversion devices and methods of making and using the same which have improved conversion efficiencies and increased reliability. The device can include a cathode having a base member with a layer of diamond-like carbon material such as amorphous diamond coated over the cathode. A dielectric intermediate member can be electrically coupled between the diamond-like carbon material and an anode. Various additional layers and configurations can allow for improved performance such as multiple cathode layers and / or multiple intermediate layers. The thermoelectric conversion devices can be configured as an electrical generator and / or a cooling device and can be conveniently formed. In addition, the devices of the present invention do not require formation of a vacuum space and are typically completely solid throughout. As a result, the devices of the present invention are susceptible of mass production at reduced costs and have improved conversion efficiencies and reliability.

Owner:SUNG CHIEN MIN

Diamond-like carbon thermoelectric conversion devices and methods for the use and manufacture thereof

InactiveUS20080029145A1Conveniently formedLow costCathode ray tubes/electron beam tubesThermoelectric device manufacture/treatmentElectricityDiamond-like carbon

Diamond-like carbon based thermoelectric conversion devices and methods of making and using the same, which have improved conversion efficiencies and increased reliability. The device can include a cathode having a base member with a layer of diamond-like carbon material such as amorphous diamond coated over the cathode. A dielectric intermediate member can be electrically coupled between the diamond-like carbon material and an anode. Various additional layers and configurations can allow for improved performance such as multiple cathode layers and / or multiple intermediate layers. The thermoelectric conversion devices can be configured as an electrical generator and / or a cooling device and can be conveniently formed. In addition, the devices of the present invention do not require formation of a vacuum space and are typically completely solid throughout. As a result, the devices of the present invention are susceptible to mass production at reduced costs and have improved conversion efficiencies and reliability.

Owner:SUNG CHIEN MIN

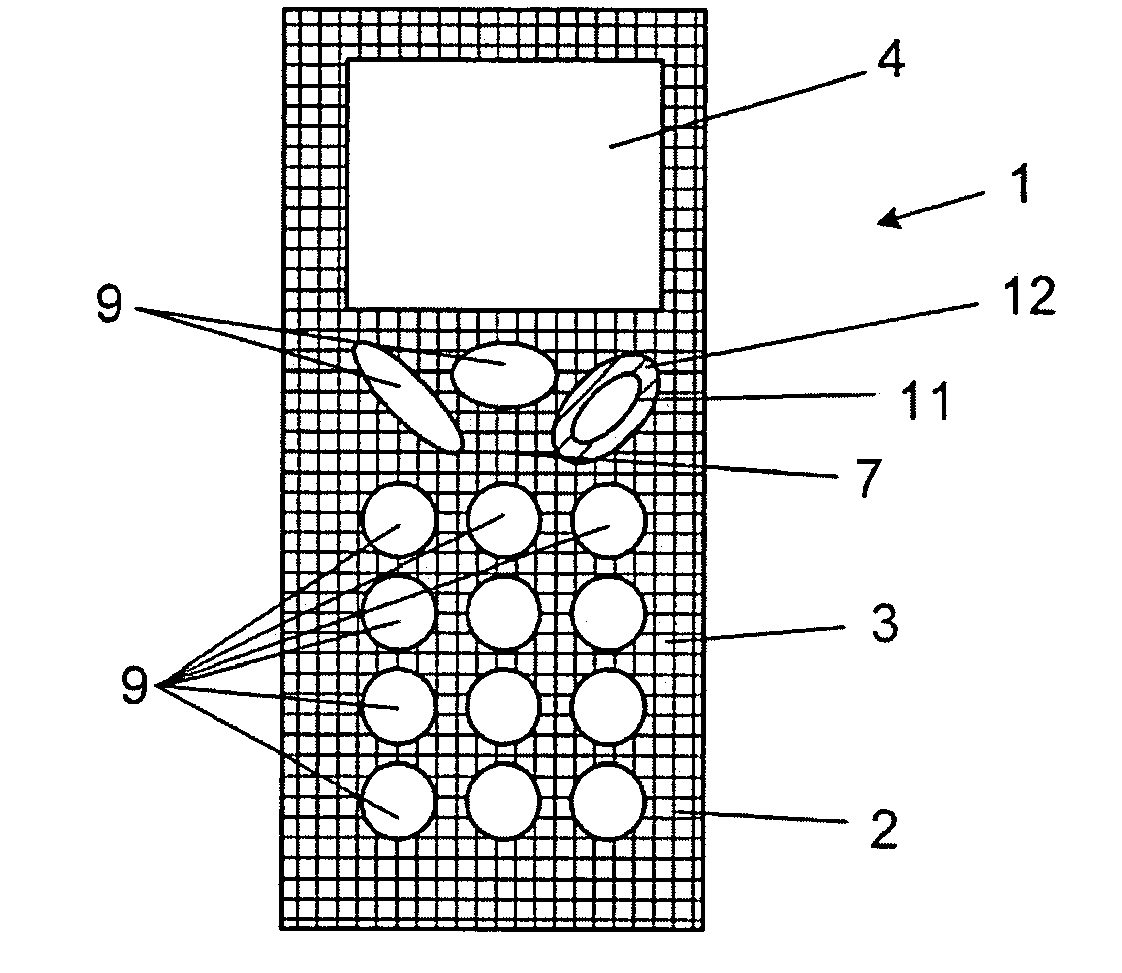

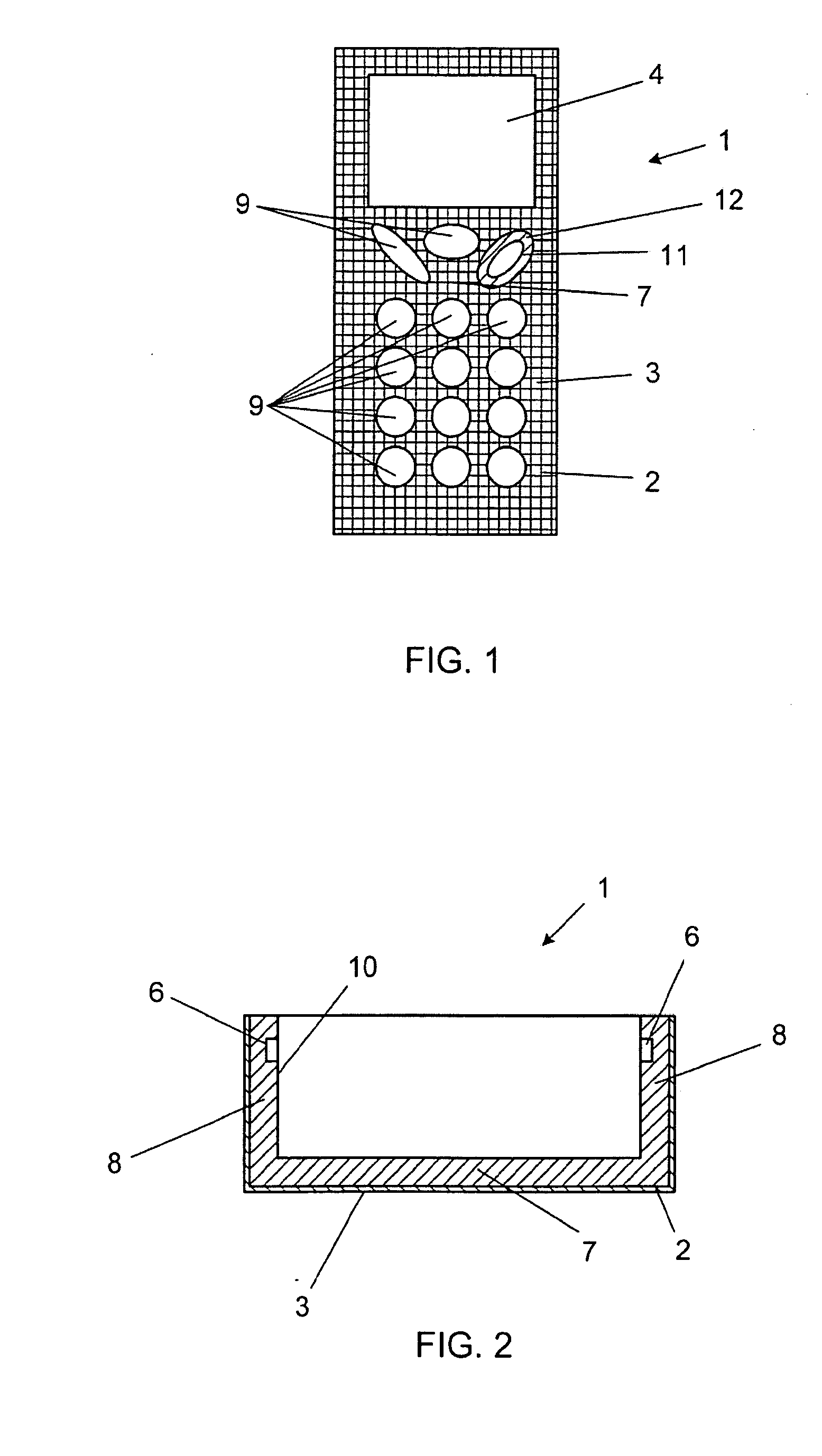

Cover, mobile communications apparatus and method for producing a coated cover

InactiveUS20060240260A1Special visual functionSimply and inexpensively achievedLayered productsVacuum evaporation coatingDlc coatingAmorphous diamond

The invention relates to a cover, a mobile communications apparatus and a method for producing a coated cover for an electronic apparatus. According to the invention at least a part of the cover is coated with a DLC-coating, also called an amorphous diamond coating.

Owner:SPYDER NAVIGATIONS L L C

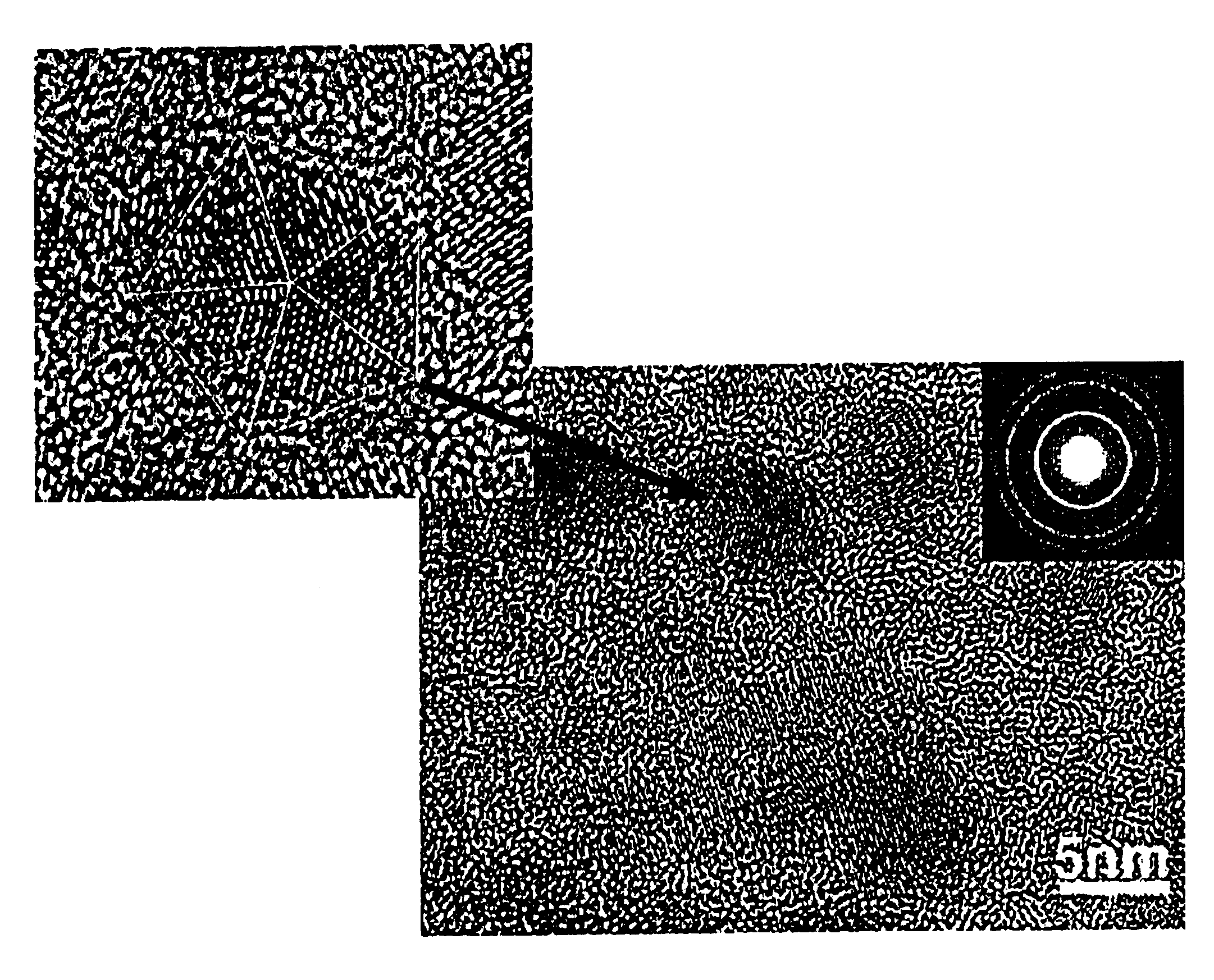

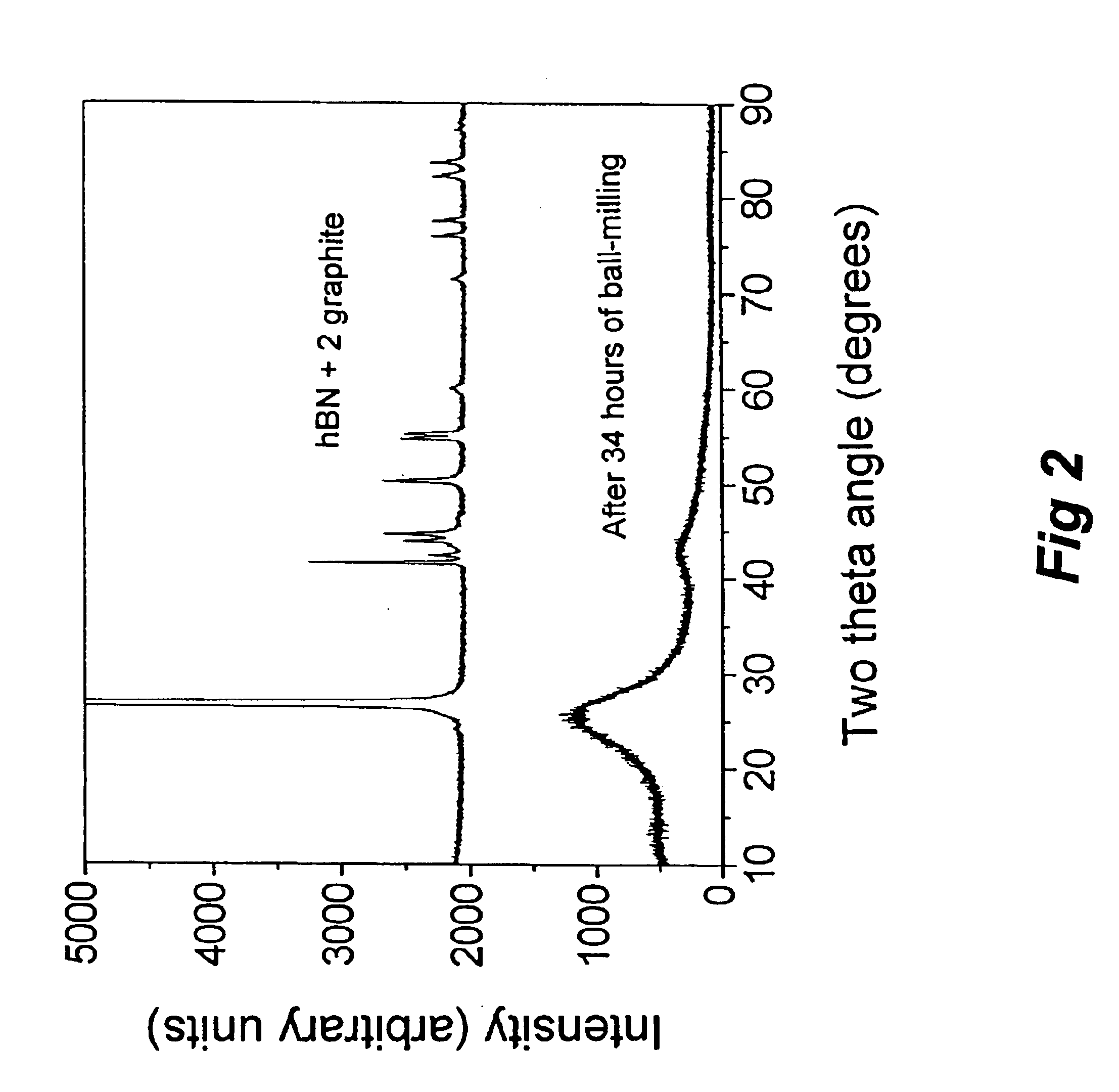

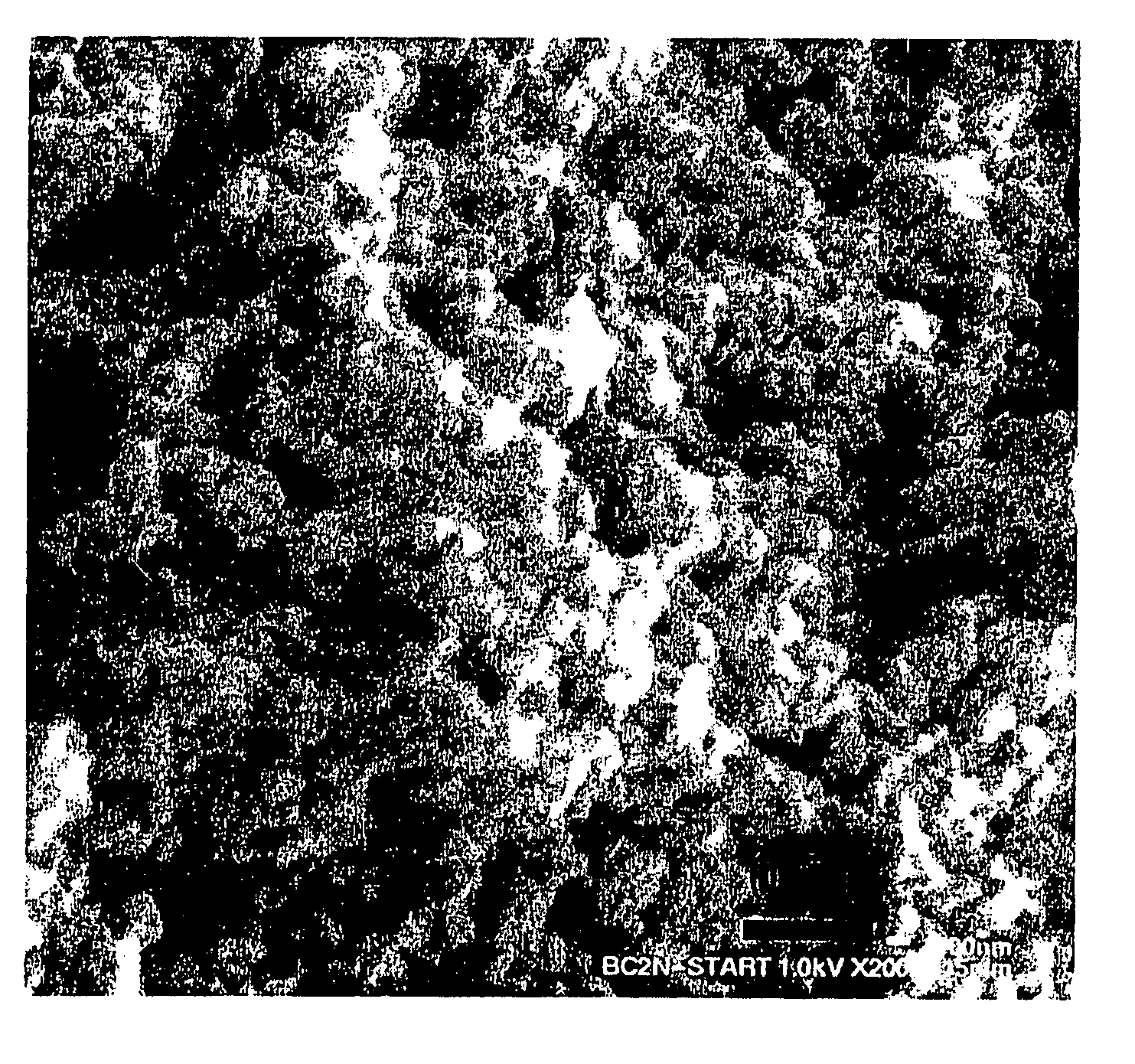

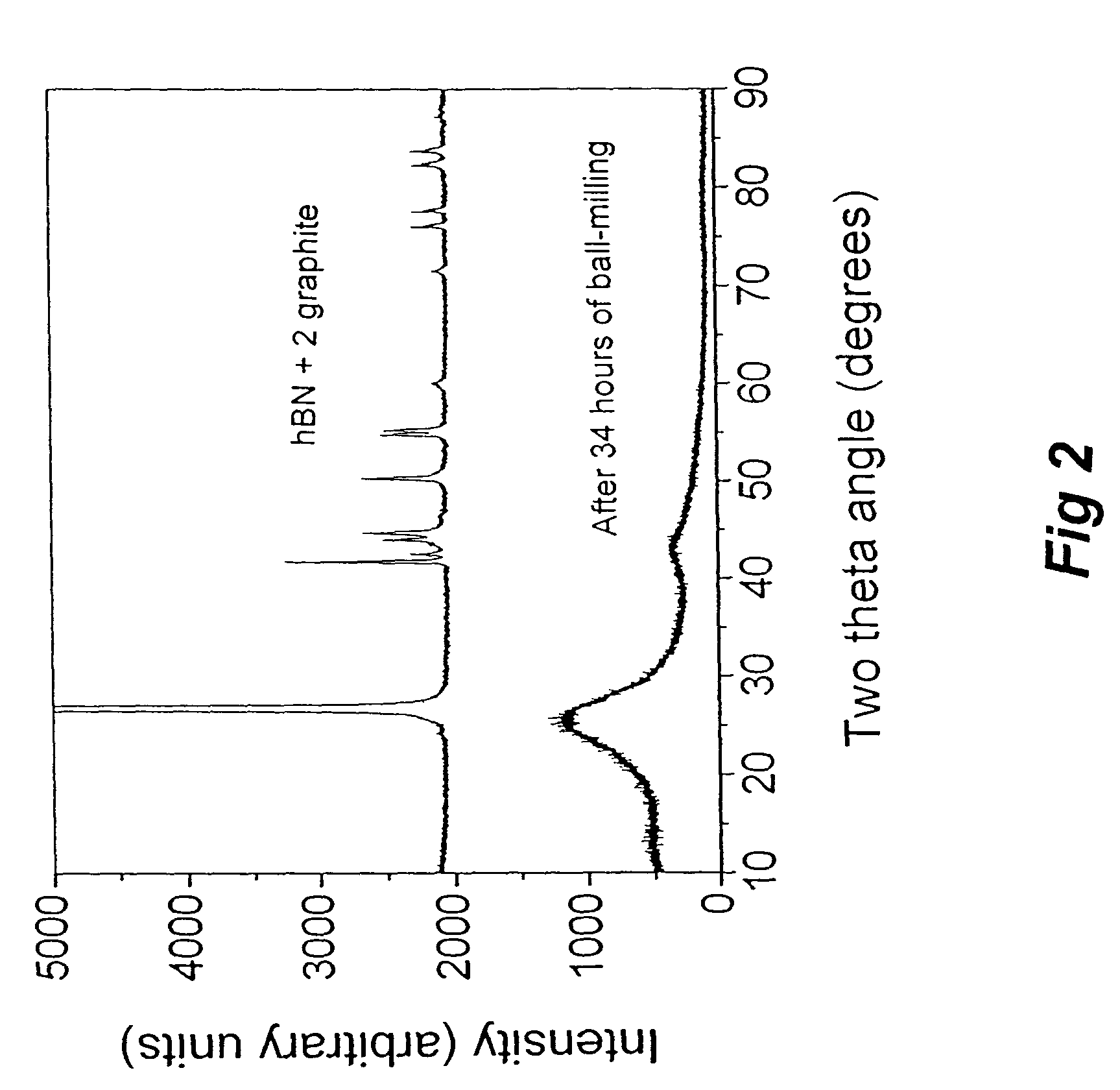

Bulk superhard B-C-N nanocomposite compact and method for preparing thereof

InactiveUS6759128B1Material nanotechnologyCeramic layered productsDiamond-like carbonHexagonal boron nitride

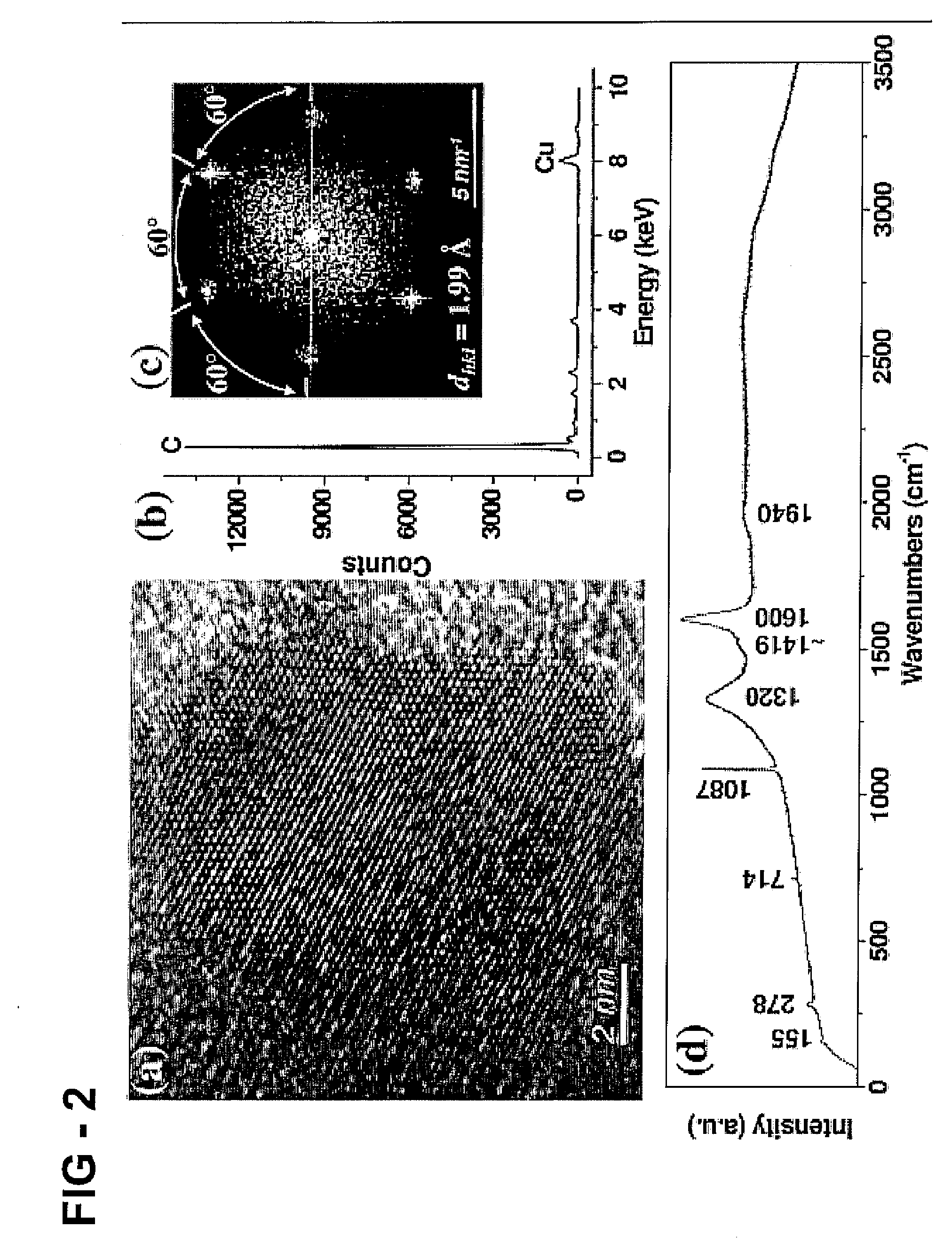

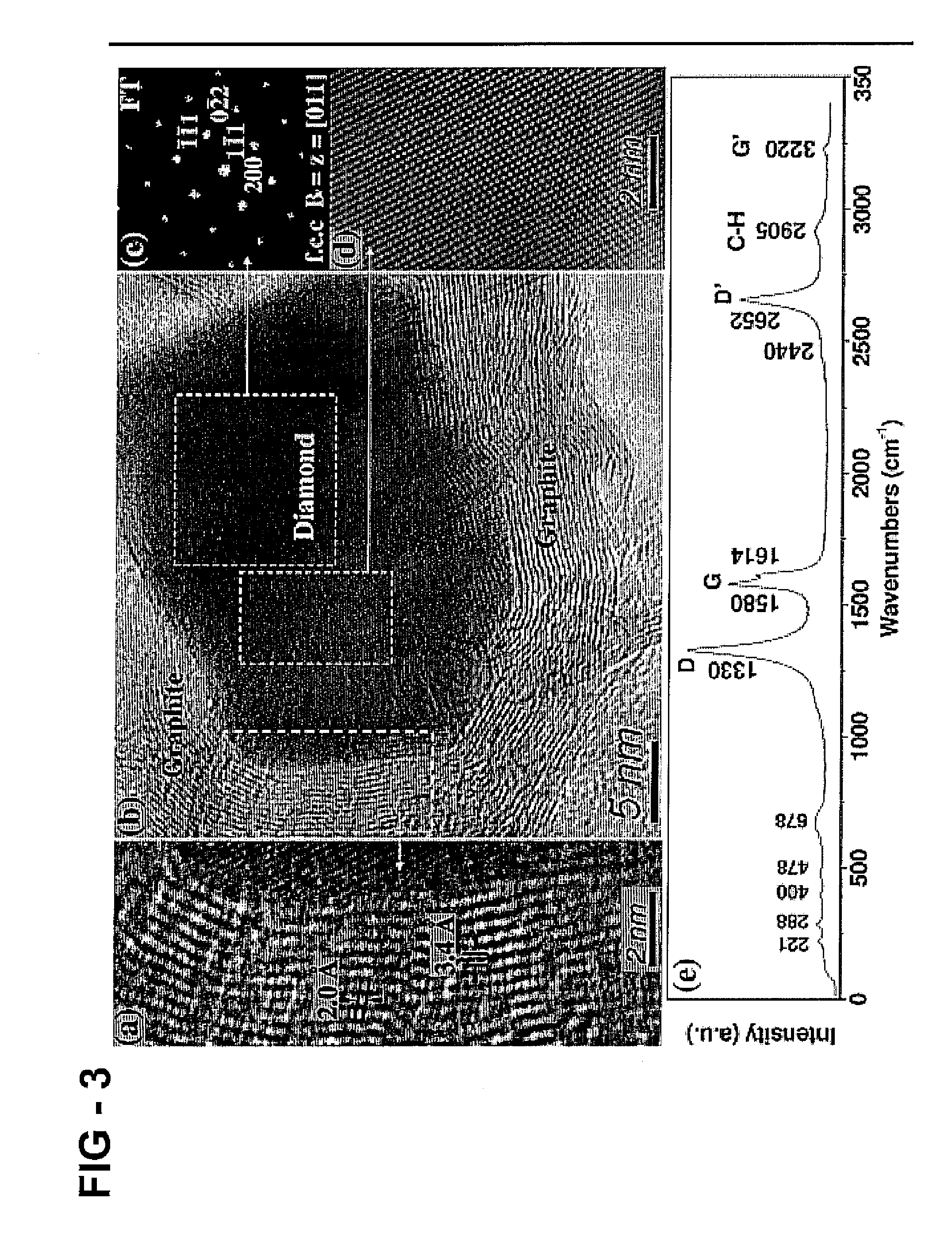

Bulk, superhard, B-C-N nanocomposite compact and method for preparing thereof. The bulk, superhard, nanocomposite compact is a well-sintered compact and includes nanocrystalline grains of at least one high-pressure phase of B-C-N surrounded by amorphous diamond-like carbon grain boundaries. The bulk compact has a Vicker's hardness of about 41-68 GPa. It is prepared by ball milling a mixture of graphite and hexagonal boron nitride, encapsulating the ball-milled mixture, and sintering the encapsulated ball-milled mixture at a pressure of about 5-25 GPa and at a temperature of about 1000-2500 K.

Owner:LOS ALAMOS NATIONAL SECURITY

Diamond-like carbon thermoelectric conversion devices and methods for the use and manufacture thereof

InactiveUS7235912B2Improve conversion efficiencyImprove reliabilityThermionic cathodesDischarge tube solid thermionic cathodesElectricityDiamond-like carbon

Diamond-like carbon based thermoelectric conversion devices and methods of making and using the same which have improved conversion efficiencies and increased reliability. The device can include a cathode having a base member with a layer of diamond-like carbon material such as amorphous diamond coated over the cathode. A dielectric intermediate member can be electrically coupled between the diamond-like carbon material and an anode. Various additional layers and configurations can allow for improved performance such as multiple cathode layers and / or multiple intermediate layers. The thermoelectric conversion devices can be configured as an electrical generator and / or a cooling device and can be conveniently formed. In addition, the devices of the present invention do not require formation of a vacuum space and are typically completely solid throughout. As a result, the devices of the present invention are susceptible of mass production at reduced costs and have improved conversion efficiencies and reliability.

Owner:SUNG CHIEN MIN

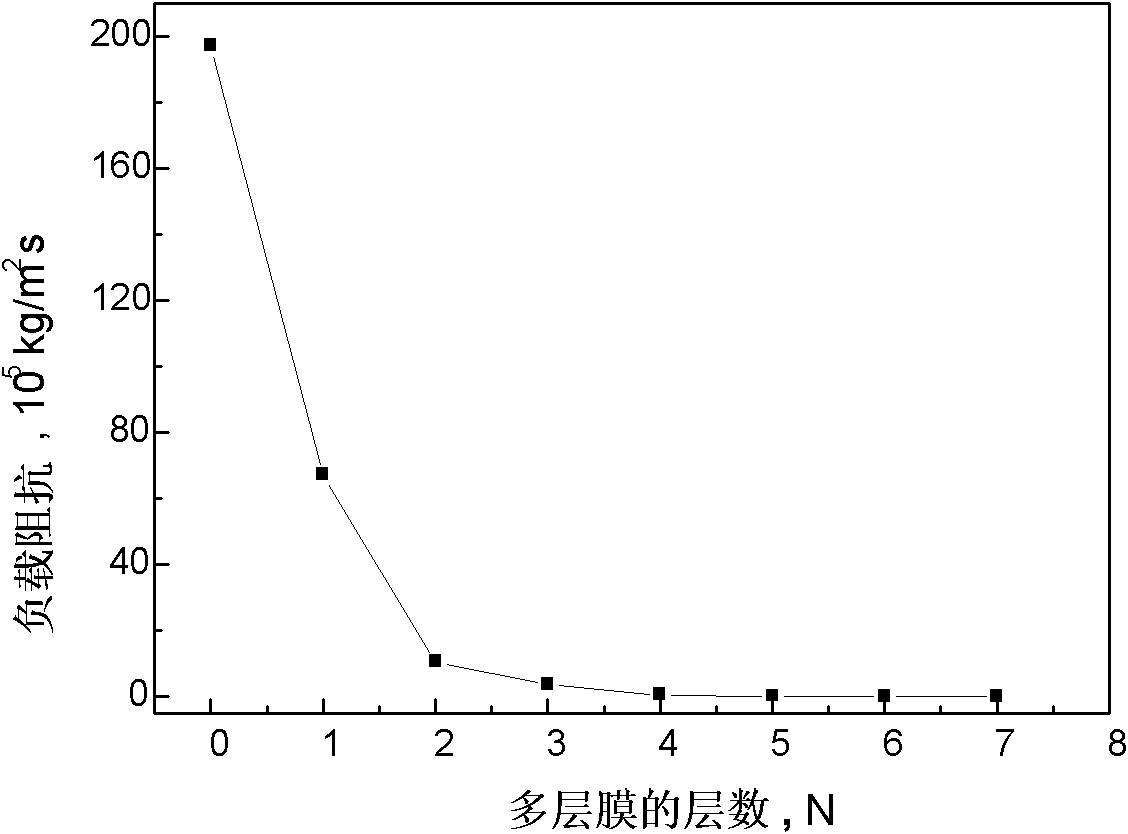

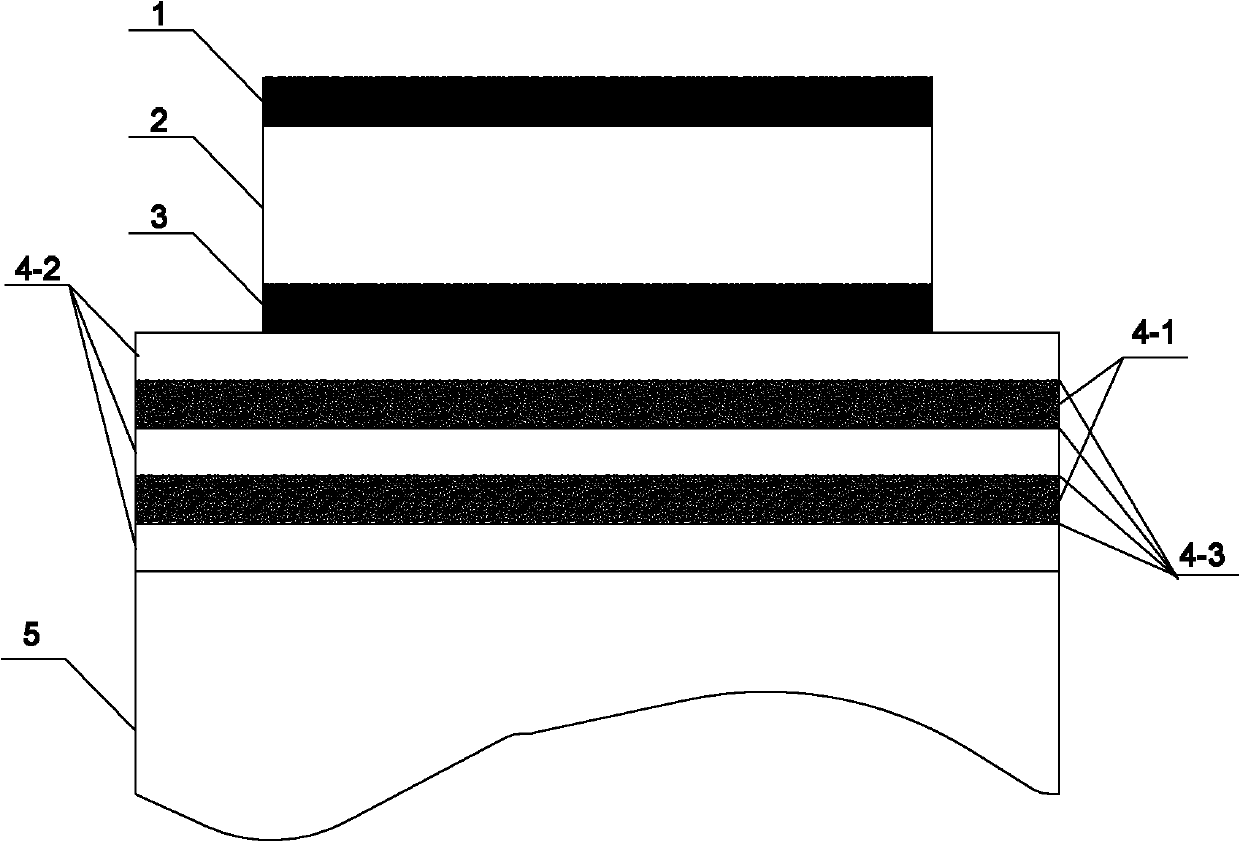

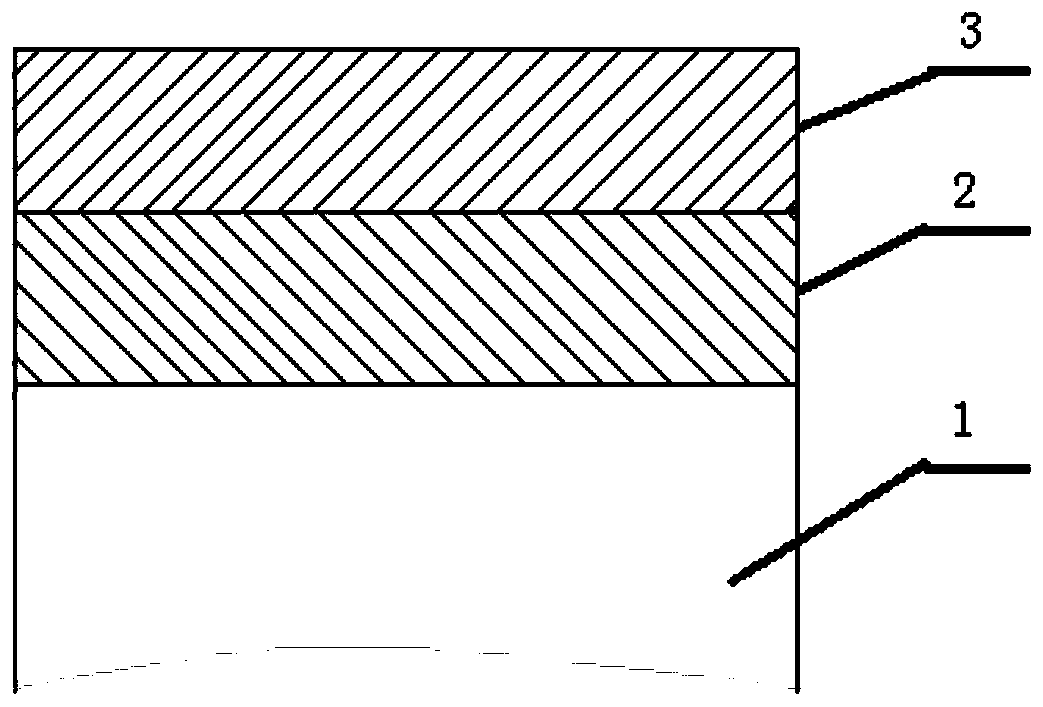

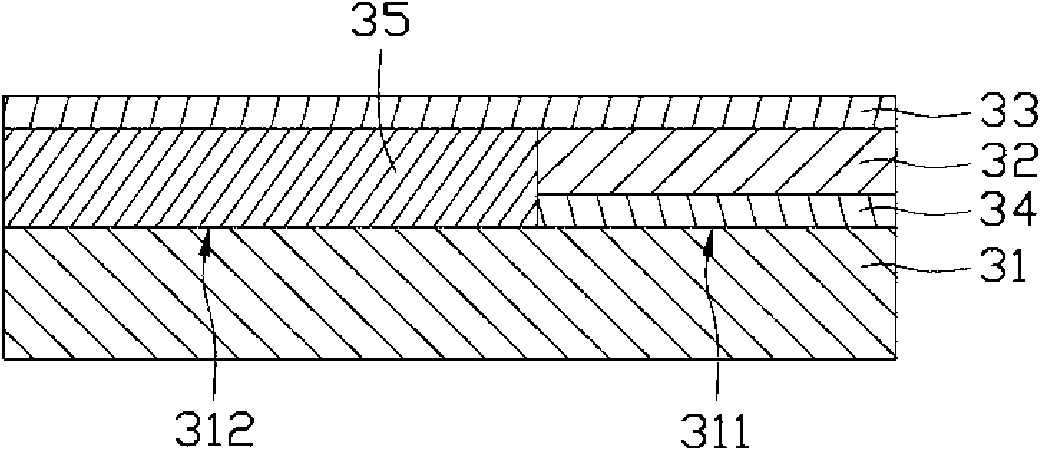

Solidly mounted film bulk acoustic resonator and method for preparing fully insulated Bragg reflecting grating thereof

InactiveCN101997512AExcellent sound reflection effectGood sound reflectionImpedence networksThin-film bulk acoustic resonatorGrating

The invention relates to provides a solidly mounted film bulk acoustic resonator (SMR-FBAR) and a method for preparing a fully insulated Bragg reflecting grating thereof. The invention solves the problem that parasitic capacitance exists in application of the existing SMR-FBAR, so that the electroacoustic performance of the device is substantially reduced and unstable. The resonator is characterized in that a piezoelectric oscillation pile of sandwich structure, which is formed by upper and lower electrodes and a piezoelectric film, is directly grown on the fully insulated Bragg reflecting grating; and the fully insulated Bragg reflecting grating is formed by alternating 3-7 groups of high / low impedance film layers. The method comprises the following steps: 1. designing a system; 2. cleaning a substrate; 3. depositing a first low impedance SiO2 film layer; 4. depositing silicon as an adhesive layer; 5. depositing a first high impedance amorphous diamond film layer; 6. depositing silicon film as an adhesive layer; and 7. depositing a second low impedance SiO2 film layer. The invention is suitable for the application fields requiring stable electroacoustic performance.

Owner:HARBIN INST OF TECH

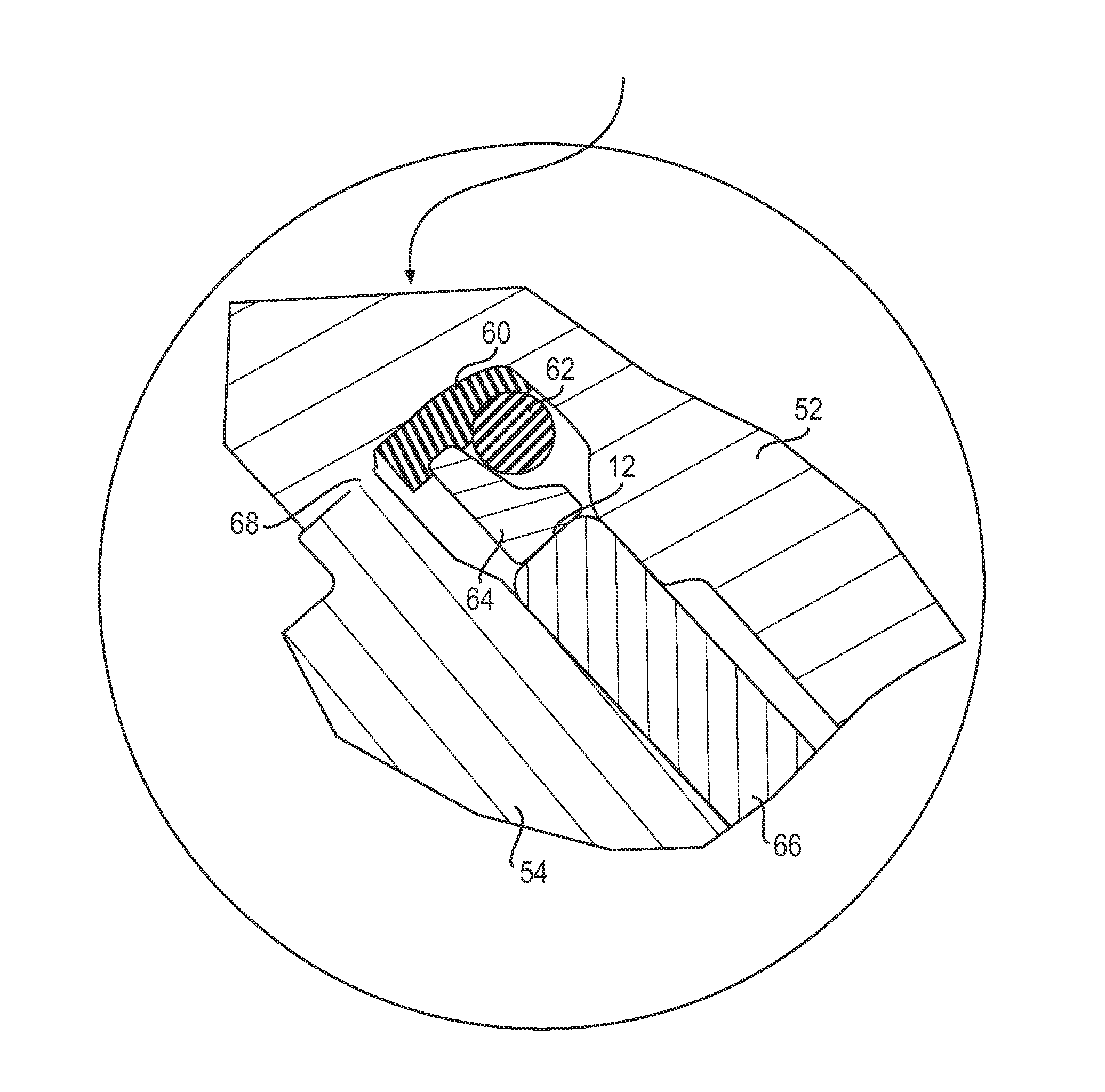

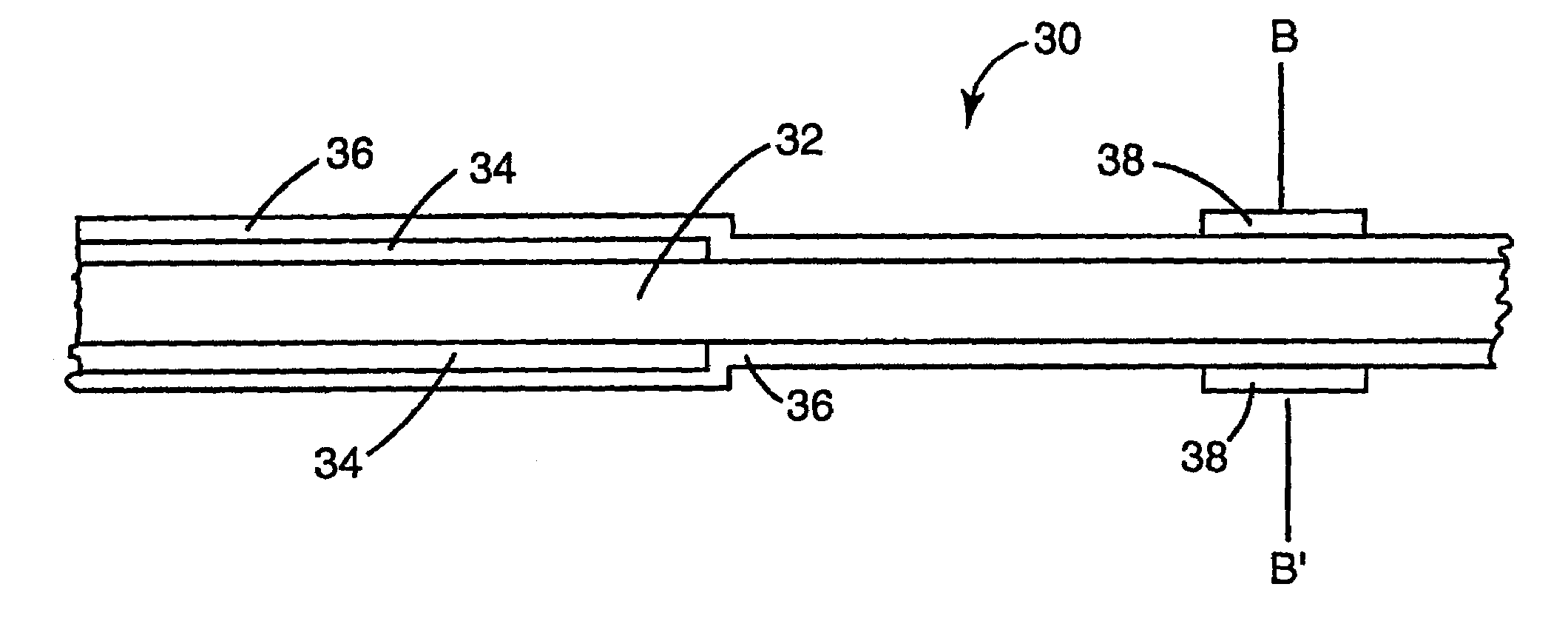

Thin film coating on mechanical face seals

A seal is disclosed. The seal has a first surface and a second surface disposed in a plane generally parallel to the first surface. At least one of the first surface and the second surface is at least partially coated with a film that includes an adhesion layer, a transition layer, and an amorphous diamond-like (a-DLC) layer.

Owner:CATERPILLAR INC

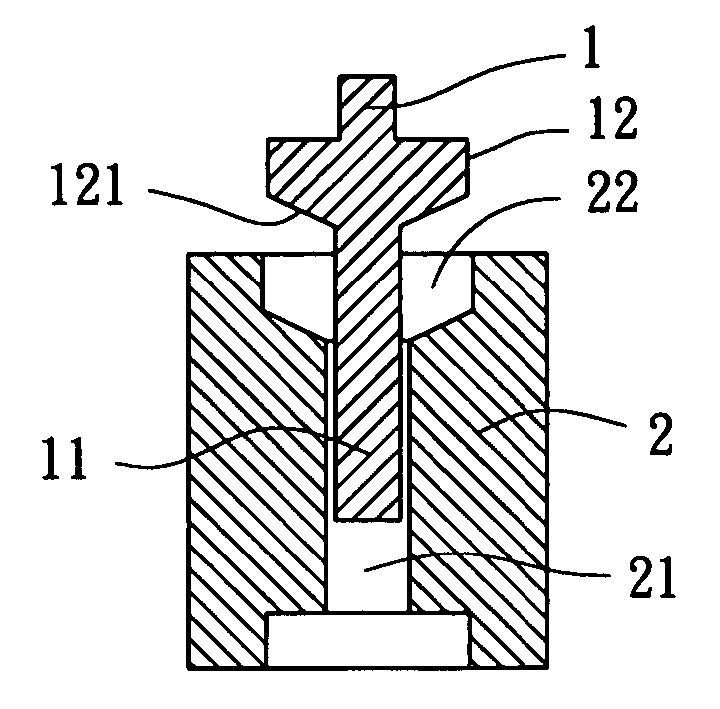

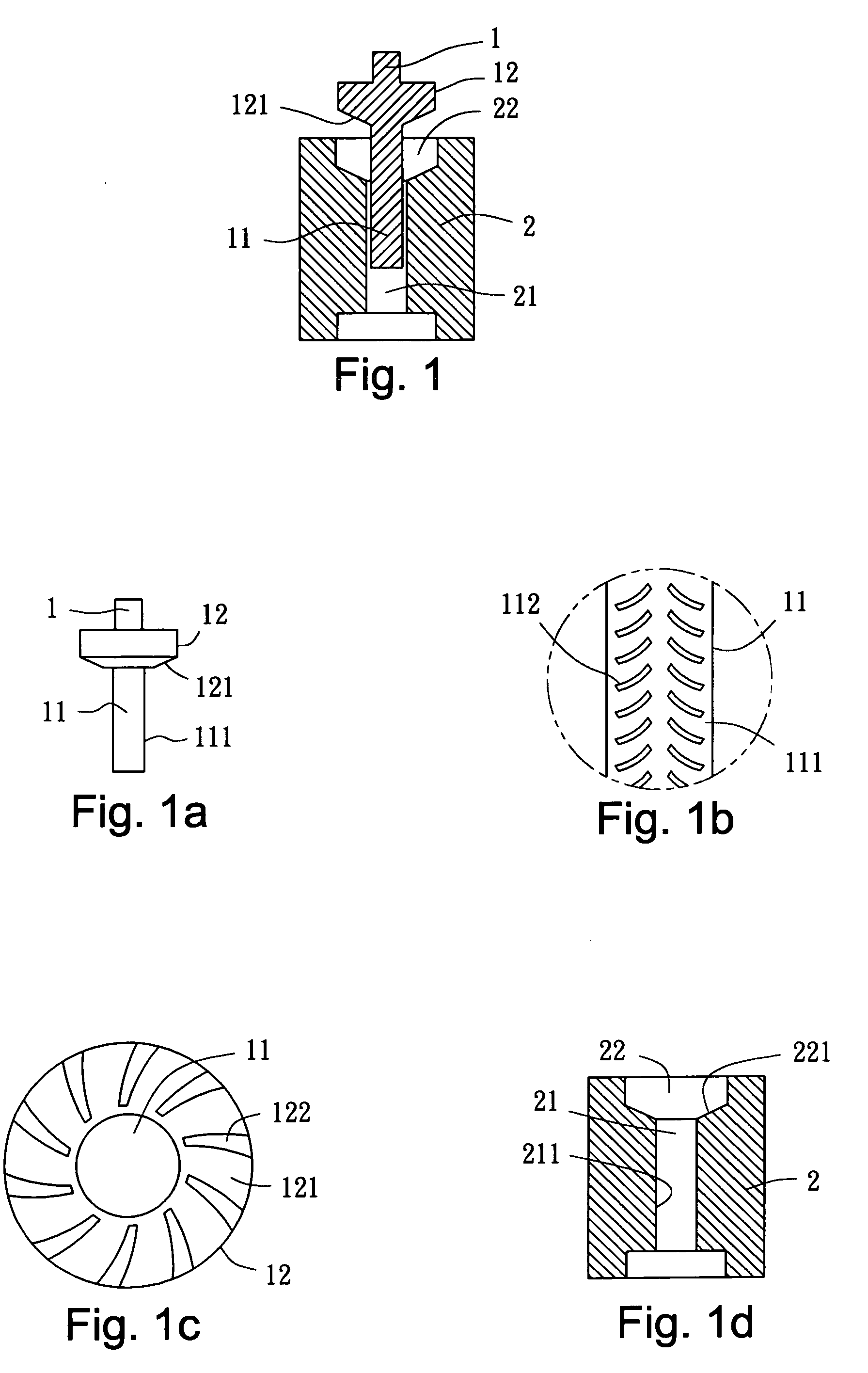

Method for producing a dynamic fluid bearing with high rotation precision and high hardness

InactiveUS20060059688A1High precisionHigh hardnessMetal-working apparatusVacuum evaporation coatingSurface patternGas phase

A method for manufacturing bearing components of high precision and hardness supporting fluid dynamic-pressure comprises the steps of: (1) selecting at least one rotary component provided with a predetermined surface pattern for supporting a distribution of fluid dynamic-pressure; (2) forming an opaque and hard amorphous diamond (DLC, a-D) film (or nano-crystalline diamond film) on the pivotal surface of the component by physical vapor deposition (PVD). Thereby the pivotal surfaces of the rotary component and the pattern thereon can have excellent hardness, wearing resistance, rotational stailbity and durability under repeated urging of dynamic fluid pressure.

Owner:HUNG CHIN CHU +5

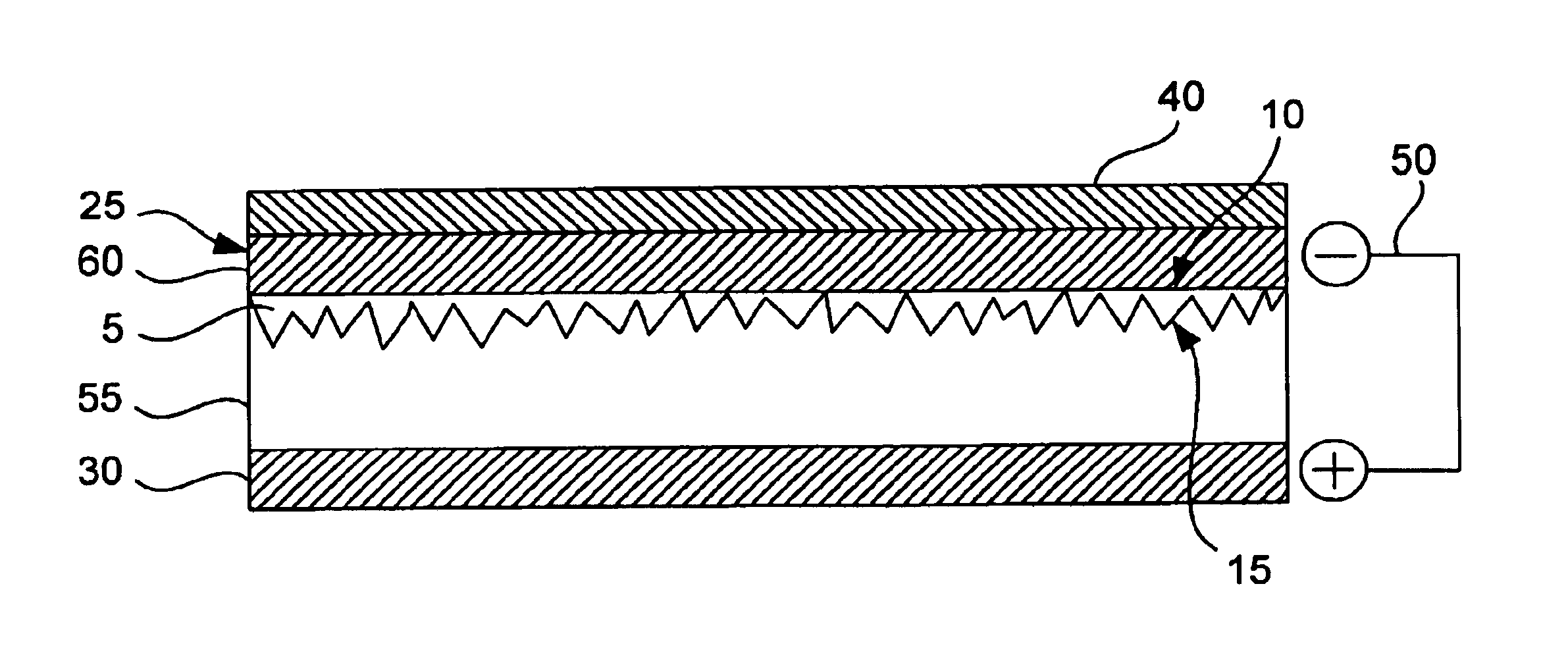

Amorphous diamond materials and associated methods for the use and manufacture thereof

InactiveUS20050151464A1Luminance is optimizedSufficient amountDischarge tube luminescnet screensCathode ray tubes/electron beam tubesCarbon layerDiamond-like carbon

An electroluminescence device having improved luminescence per volt input is provided. The device can include a first electrode, a second electrode, a diamond-like carbon layer electrically coupled to at least one of the first electrode or the second electrode, and a luminescent material electrically coupled to the diamond-like carbon layer, to the first electrode, and to the second electrode, such that upon receiving electrons from the diamond-like carbon layer, the luminescent material luminesces. The diamond-like carbon layer and the luminescent material can be separated by a dielectric material. As the frequency of an introduced alternating current is increased, the level of luminosity of the luminescent material increases, and the voltage required to generate similar levels of luminosity decreases.

Owner:SUNG CHIEN MIN

Optical and optoelectronic articles

InactiveUS7106939B2Improve high temperature stabilityImprove propertiesGlass optical fibreOptical fibre with multilayer core/claddingHydrogenOxygen

Optical and optoelectronic articles incorporating an amorphous diamond-like film are disclosed. Specifically, the invention includes optical or optoelectronic articles containing an amorphous diamond-like film overlying two or more proximate substrates, and to methods of making optical and optoelectronic articles. In certain implementations, the film comprises at least about 30 atomic percent carbon, from about 0 to about 50 atomic percent silicon, and from about 0 to about 50 atomic percent oxygen on a hydrogen-free basis. Another embodiment includes optical or optoelectronic articles containing an amorphous diamond-like film that is further coated with a metallic or polymeric material for attachment to a device package.

Owner:3M INNOVATIVE PROPERTIES CO

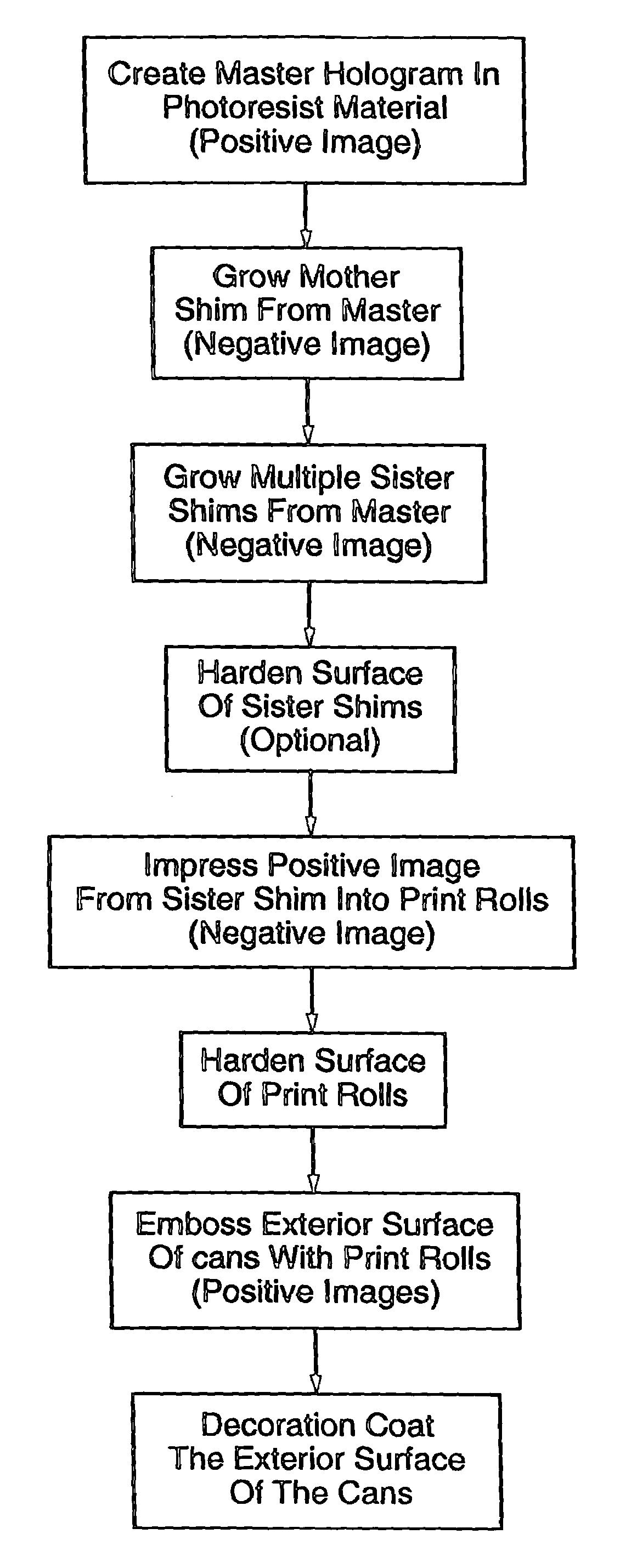

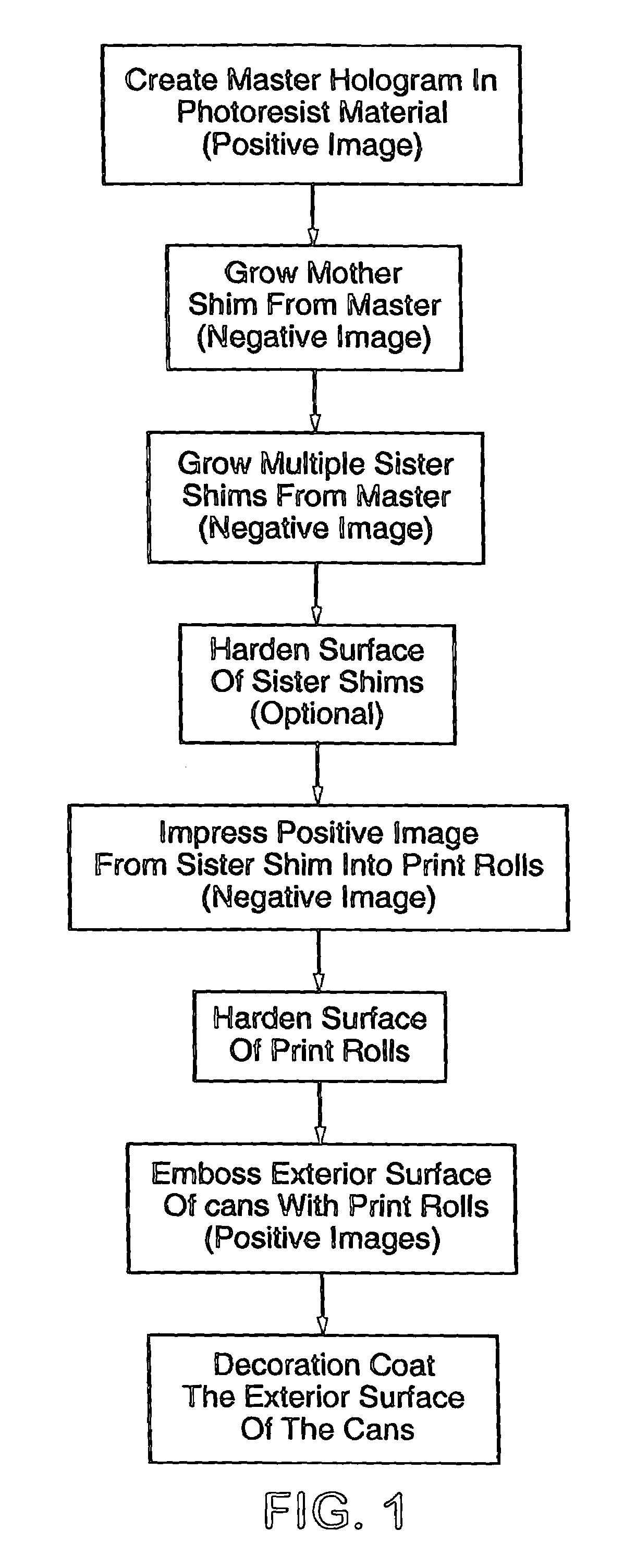

Methods for transferring holographic images into metal surfaces

InactiveUS7094502B2Quality improvementEconomical for mass marketingMechanical working/deformationDecorative surface effectsMetal foilCLARITY

A method for impressing holographic images or holograms in the surface of metal objects such as aluminum cans, sheet metal or metal foil. The surfaces of metal shims and print rolls bearing holograms are hardened as by coating them with thin amorphous diamond coatings or diamond like coatings so the holograms can be embossed into many thousands of metal objects with clarity and consistency.

Owner:SEAGATE TECH INC +1

Aluminum-containing diamond-like carbon film and method for preparing same

InactiveCN101665904AImprove adhesionSolve Adhesion ProblemsVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

The invention discloses an aluminum-containing diamond-like carbon film and a method for preparing the same. The film adopts a diamond-like structure and comprises 3 to 20 percent of metal aluminum and the balance of carbon; the metal aluminum is dispersed in the amorphous diamond-like carbon film in an atomic state and is not bonded with the carbon, and the thickness of the film is between 500 and 5,000 nanometers. The aluminum containing diamond-like carbon film has the advantages of lower internal stress, higher hardness, good film-substrate bonding force and good abrasion proof property.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

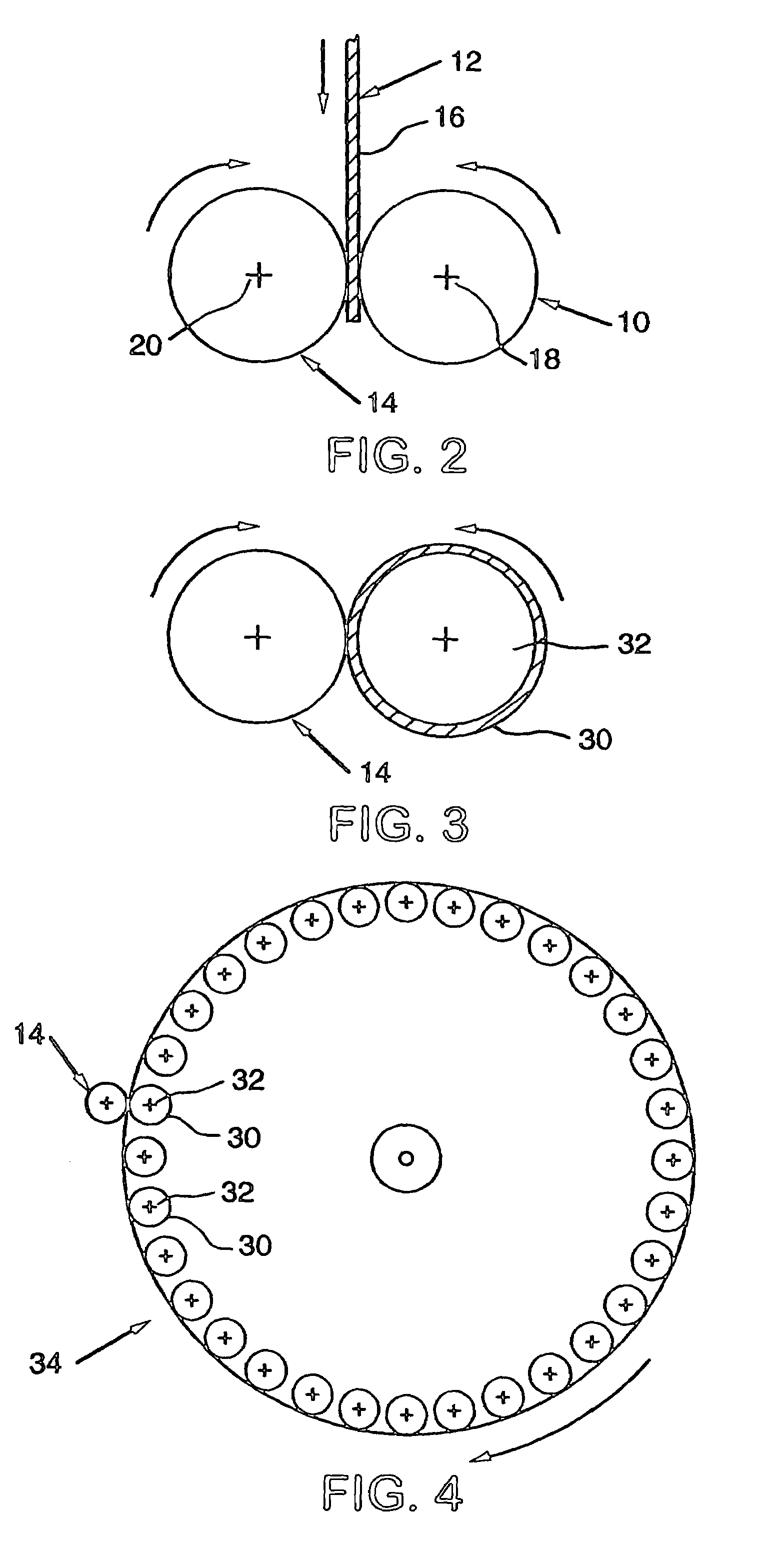

Lower pressure synthesis of diamond material

InactiveUS20070148080A1Increase kinetic energyMaterial nanotechnologyPolycrystalline material growthDiamond-like carbonHigh energy

Methods of synthesizing a diamond material, particularly nanocrystalline diamond, diamond-like carbon and bucky diamond are provided. In particular embodiments, a composition including a carbon source, such as coal, is subjected to addition of energy, such as high energy reactive milling, producing a milling product enriched in hydrogenated tetrahedral amorphous diamond-like carbon compared to the coal. A milling product is treated with heat, acid and / or base to produce nanocrystalline diamond and / or crystalline diamond-like carbon. Energy is added to produced crystalline diamond-like carbon in particular embodiments to produce bucky diamonds.

Owner:PENN STATE RES FOUND

Single crystal silicon carbide layers on diamond and associated methods

ActiveUS7799599B1Change thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesCarbideSingle crystal

Semiconductor-on-diamond devices and methods for making such devices are provided. In one aspect, for example, a method for making a semiconductor-on-diamond substrate is provided, including depositing a conformal amorphous diamond layer on a single crystal Si base layer, thereby forming in situ a single crystal SiC layer therebetween, removing the amorphous diamond layer to expose the SiC layer, and epitaxially depositing a single crystal diamond layer on the SiC layer.

Owner:SUNG CHIEN MIN

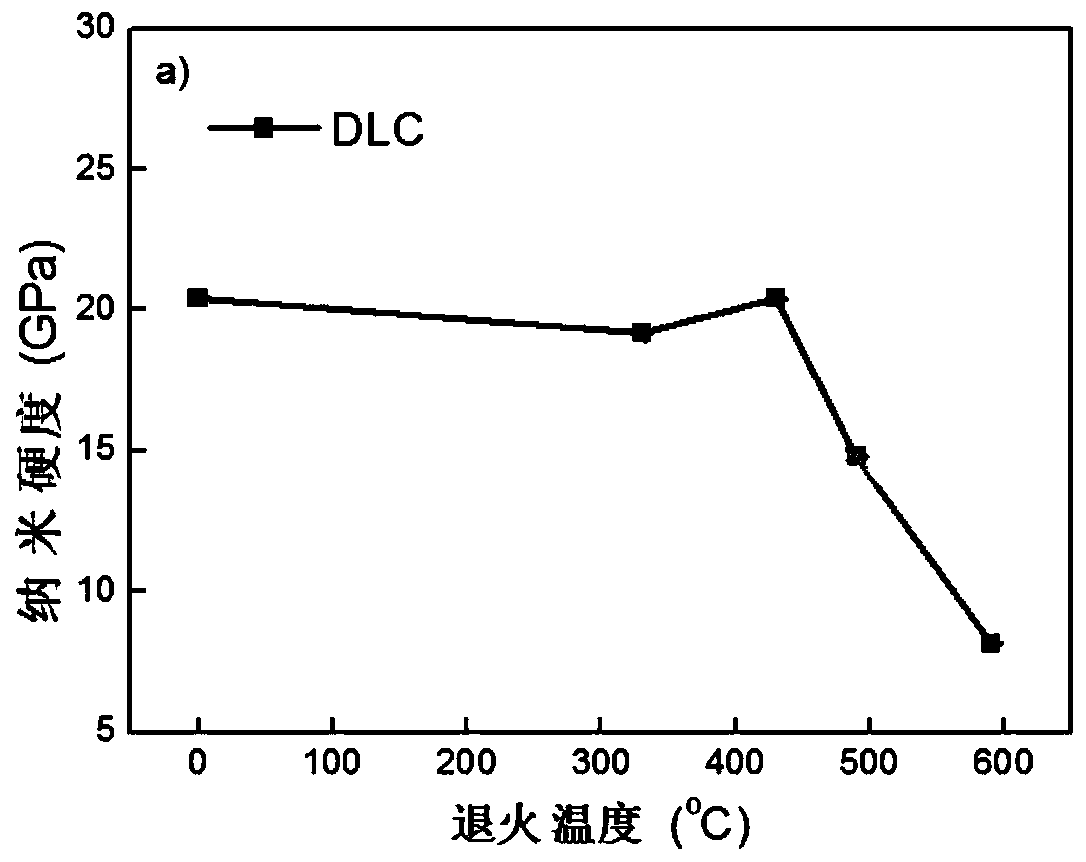

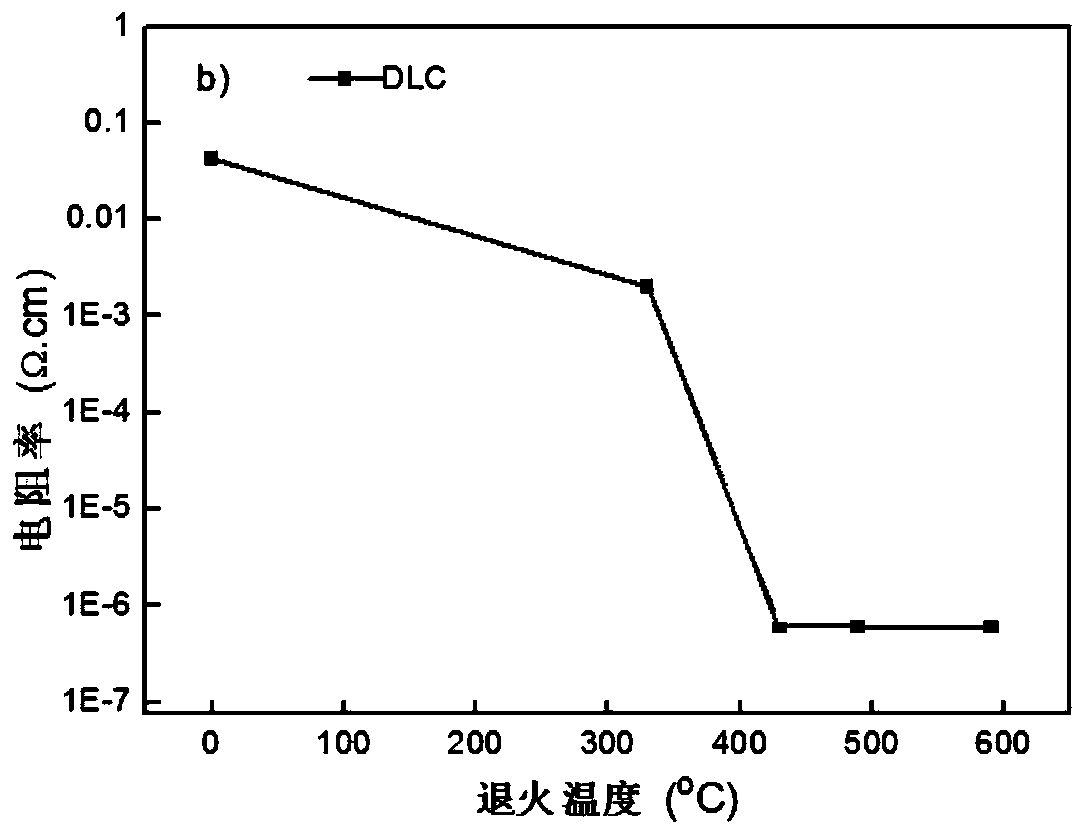

Preparation method of high-hardness conductive carbon-based thin film

ActiveCN109943824AHardness is not weakImprove bindingVacuum evaporation coatingSputtering coatingDlc coatingEtching

The invention discloses a preparation method of a high-hardness conductive carbon-based thin film. The preparation method of the high-hardness conductive carbon-based thin film comprises the steps ofplacing an ultrasonically cleaned conductive metal workpiece in a vacuum chamber of a vacuum coating device, and carrying out ion etching and activating; then adopting a bipolar pulse direct-current power supply, sequentially passing through a Cr metal target and a WC target, and forming a Cr-WC transition layer; preparing a hydrogen-containing amorphous diamond-like coating on the Cr-WC transition layer; and rising the temperature to 430 to 600 DEG C in a heat treatment device, preserving heat, and obtaining the high-hardness conductive carbon-based thin film. According to the preparation method of the high-hardness conductive carbon-based thin film provided by the invention, in the diamond-like coating (DLC), the content of sp3C-C is high, high hardness is obtained, meanwhile, the conductivity is reduced, and the diamond-like coating / carbon-based thin film with high adhesion, high hardness and conductivity equivalent to graphite is obtained.

Owner:SOUTH CHINA UNIV OF TECH

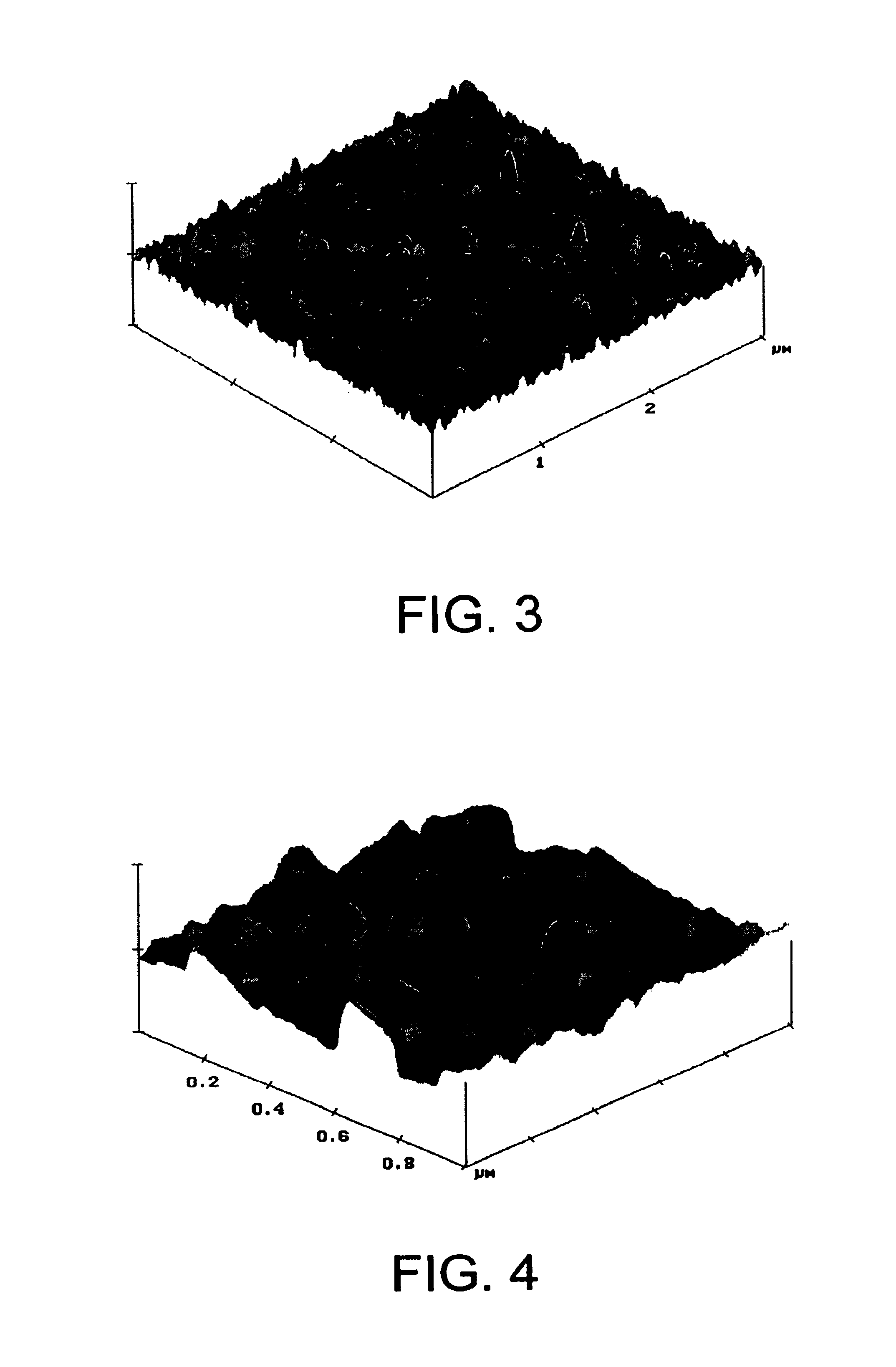

Amorphous diamond materials and associated methods for the use and manufacture thereof

InactiveUS6949873B2Improved Energy HarvestingLamp incadescent bodiesThermionic cathodesThermionic emissionAmorphous diamond

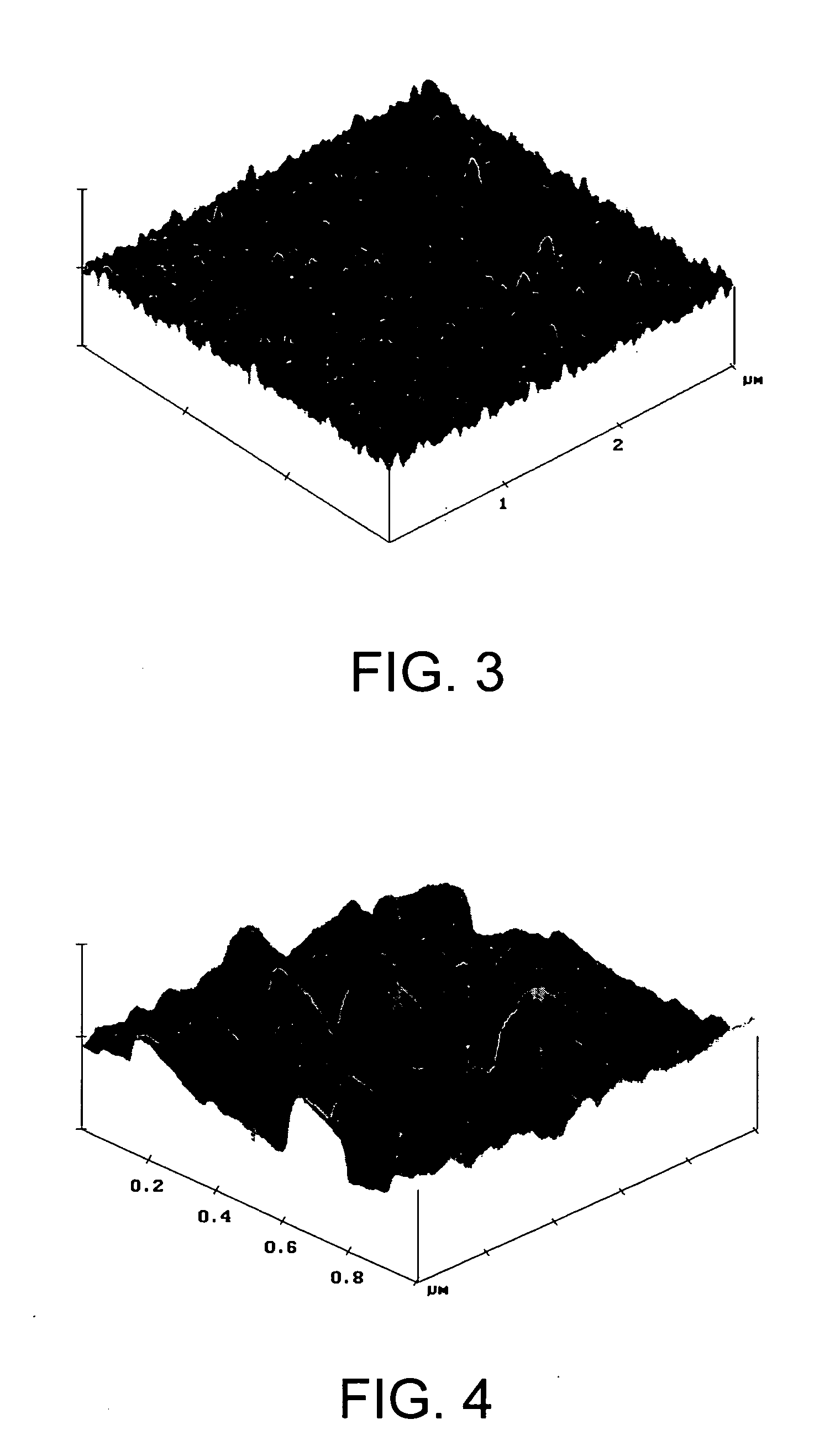

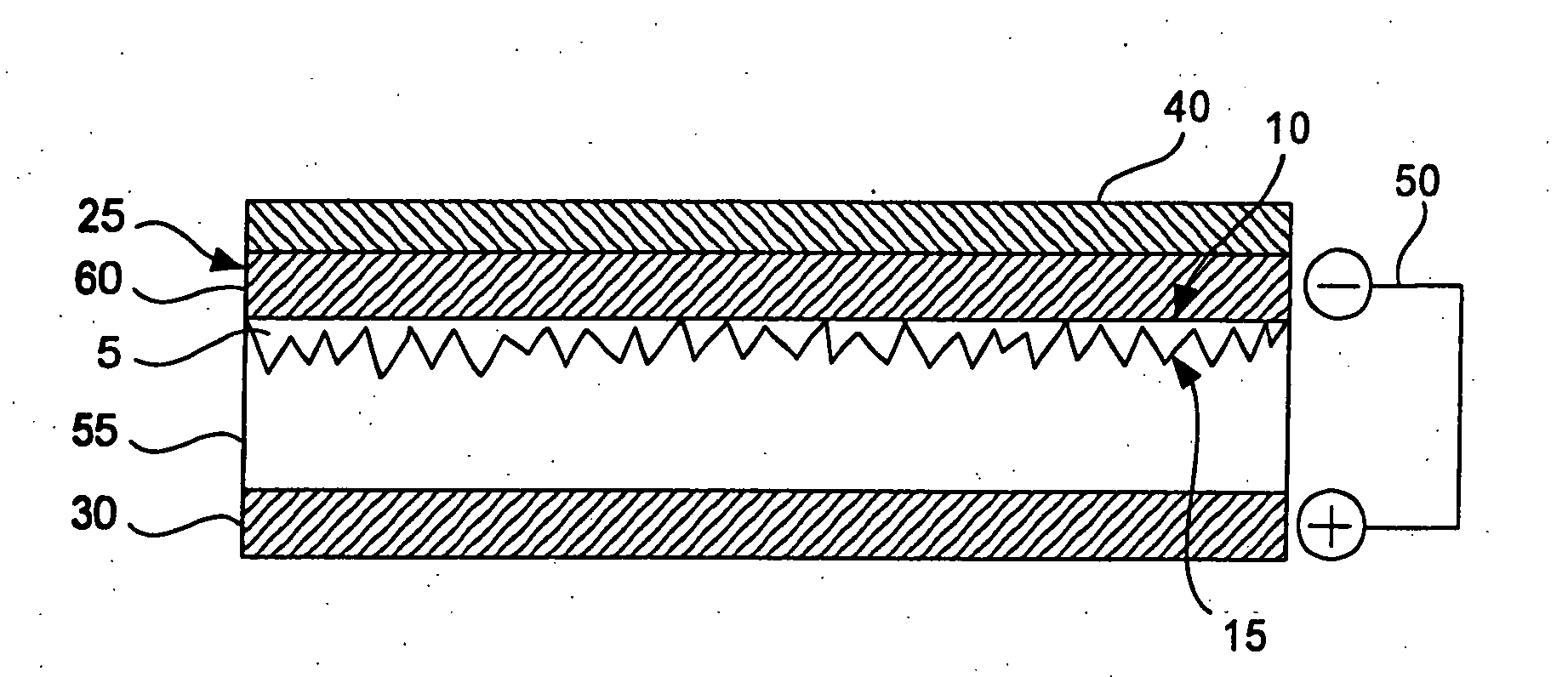

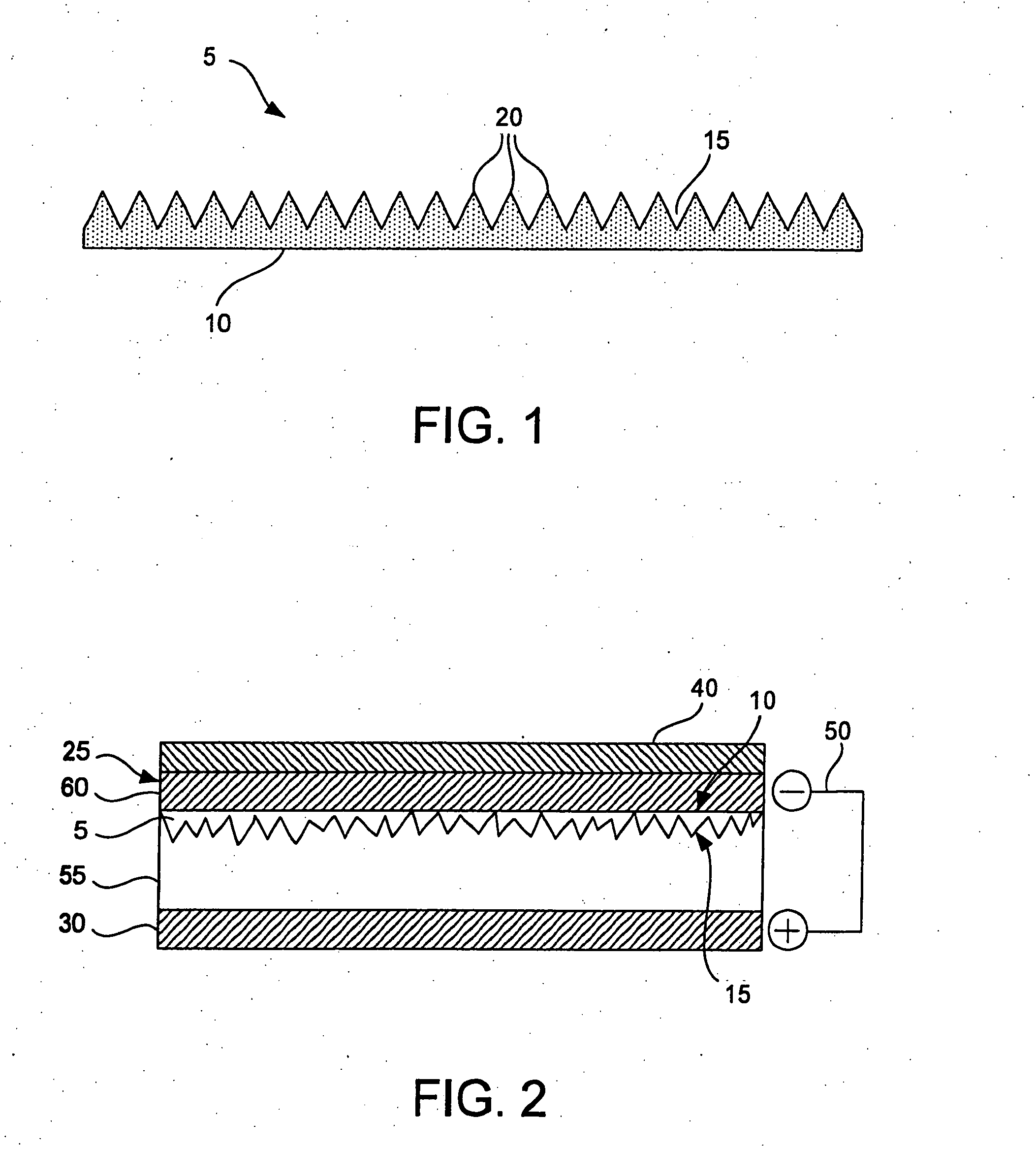

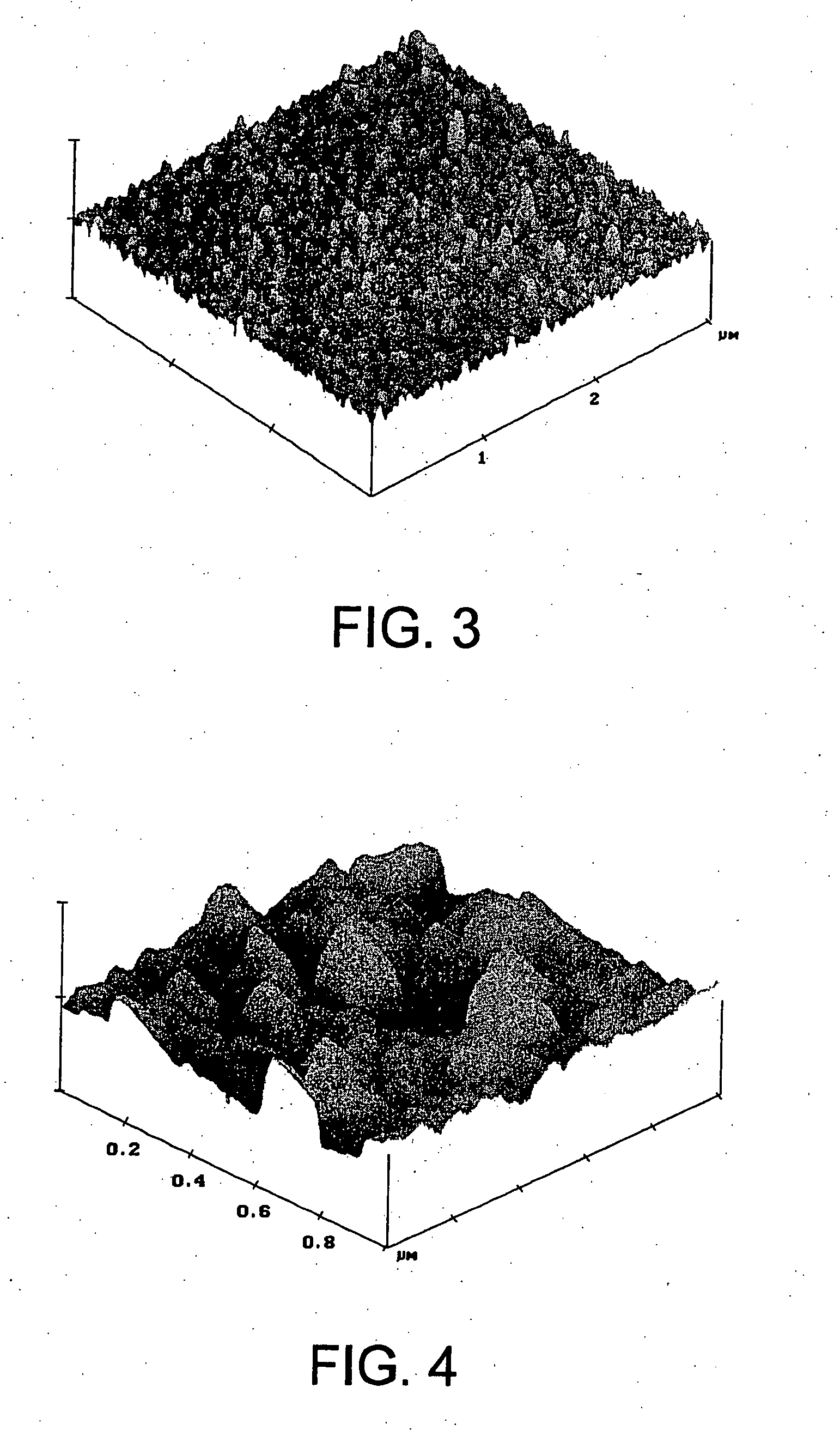

An amorphous diamond electrical generator having a cathode at least partially coated with amorphous diamond material and an intermediate member coupled between the cathode and an anode. The amorphous diamond material can have at least about 90% carbon atoms with at least about 20% of the carbon atoms bonded in a distorted tetrahedral coordination. The amorphous diamond coating has an energy input surface in contact with a base member of the cathode and an electron emission surface opposite the energy input surface. The electron emission surface can have an asperity height of from about 10 to about 1,000 nanometers and is capable of emitting electrons upon input of a sufficient amount of energy. The intermediate member can be coupled to the electron emission surface of the amorphous diamond coating such that the intermediate member has a thermal conductivity of less than about 100 W / mK and a resistivity of less than about 80 μΩ-cm at 20° C. The amorphous diamond electrical generator is a thermionic emission device having improved electron emission properties.

Owner:SUNG CHIEN MIN

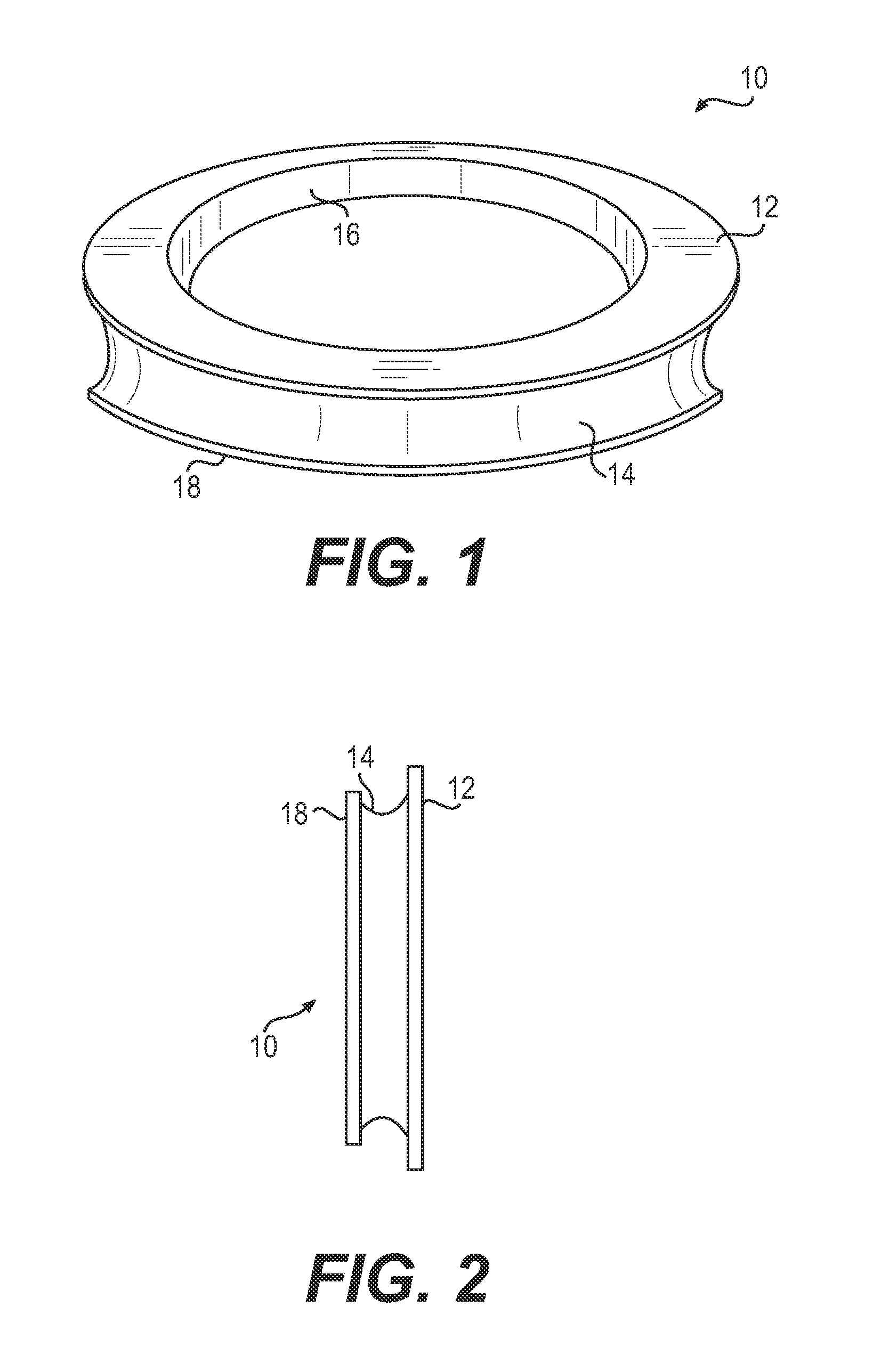

Faucet

The present invention relates to an article with cross-slip components, more concretely, discloses a faucet including a first valve plate comprising a base material and a strengthening layer provided above the base material. An amorphous diamond material is provided above the strengthening layer. The amorphous diamond material has a coefficient of friction that is lower than that of diamond-like carbon and has a hardness that is greater than that of diamond-like carbon.

Owner:DELTA FAUCET COMPANY

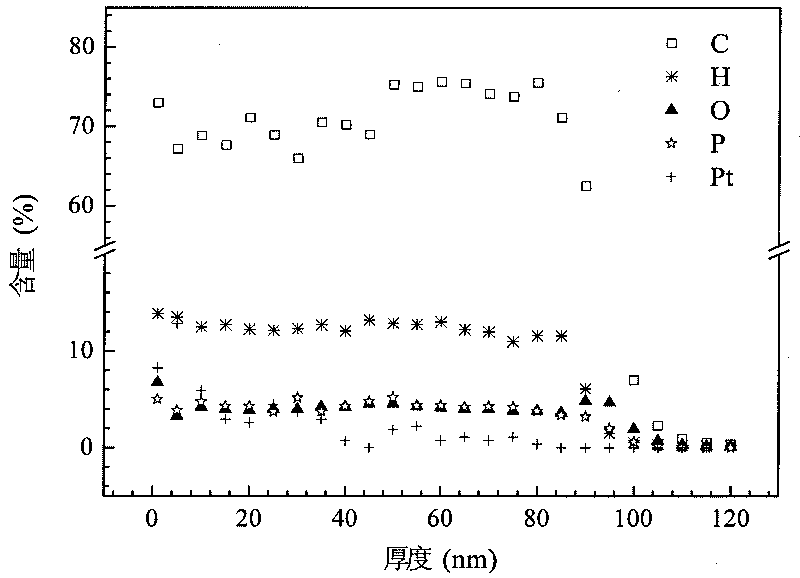

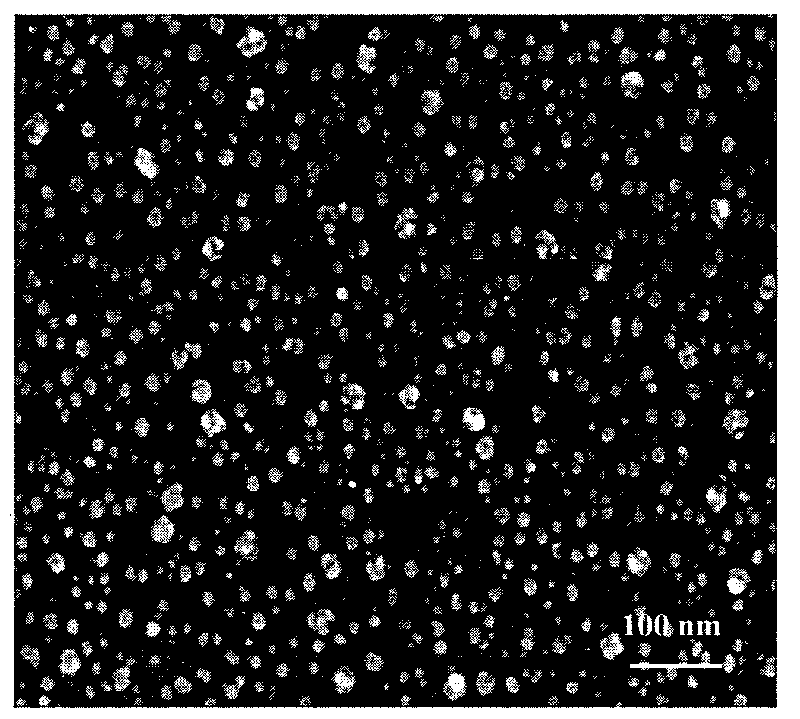

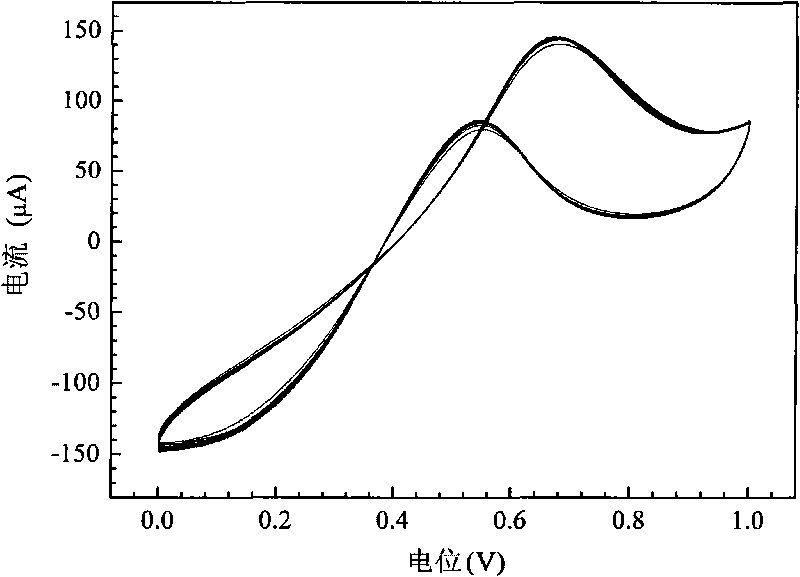

Metal particle-amorphous diamond composite anode for fuel cell and preparation method thereof

InactiveCN101740787AImprove catalytic abilityEasy to prepareCell electrodesAlcohol fuelMetal particle

The invention discloses a metal particle-amorphous diamond composite anode for a fuel cell and a preparation method thereof. In the anode, a doped amorphous diamond film and metal nanoparticles are deposited on a substrate of the anode in sequence from bottom to top, wherein the doped amorphous diamond film contains carbon, hydrogen, oxygen and a current carrier doping agent; the current carrier doping agent is any one of boron, nitrogen or phosphorus; the metal nanoparticles are any one or any more than two alloys of platinum, ruthenium or palladium; and the composite anode comprises the following components in percentage by mass: 58.7 to 77.5 percent of carbon, 0 to 14.0 percent of hydrogen, 6.4 to 15.3 percent of oxygen, 1.7 to 8.5 percent of current carrier doping agent, and 3.2 to 13.4 percent of metal nanoparticles. The metal particle-amorphous diamond composite anode has simple preparation technology, can be used as an anode material of alcohol fuel cells, and has good catalytic capability.

Owner:ZHEJIANG SCI-TECH UNIV

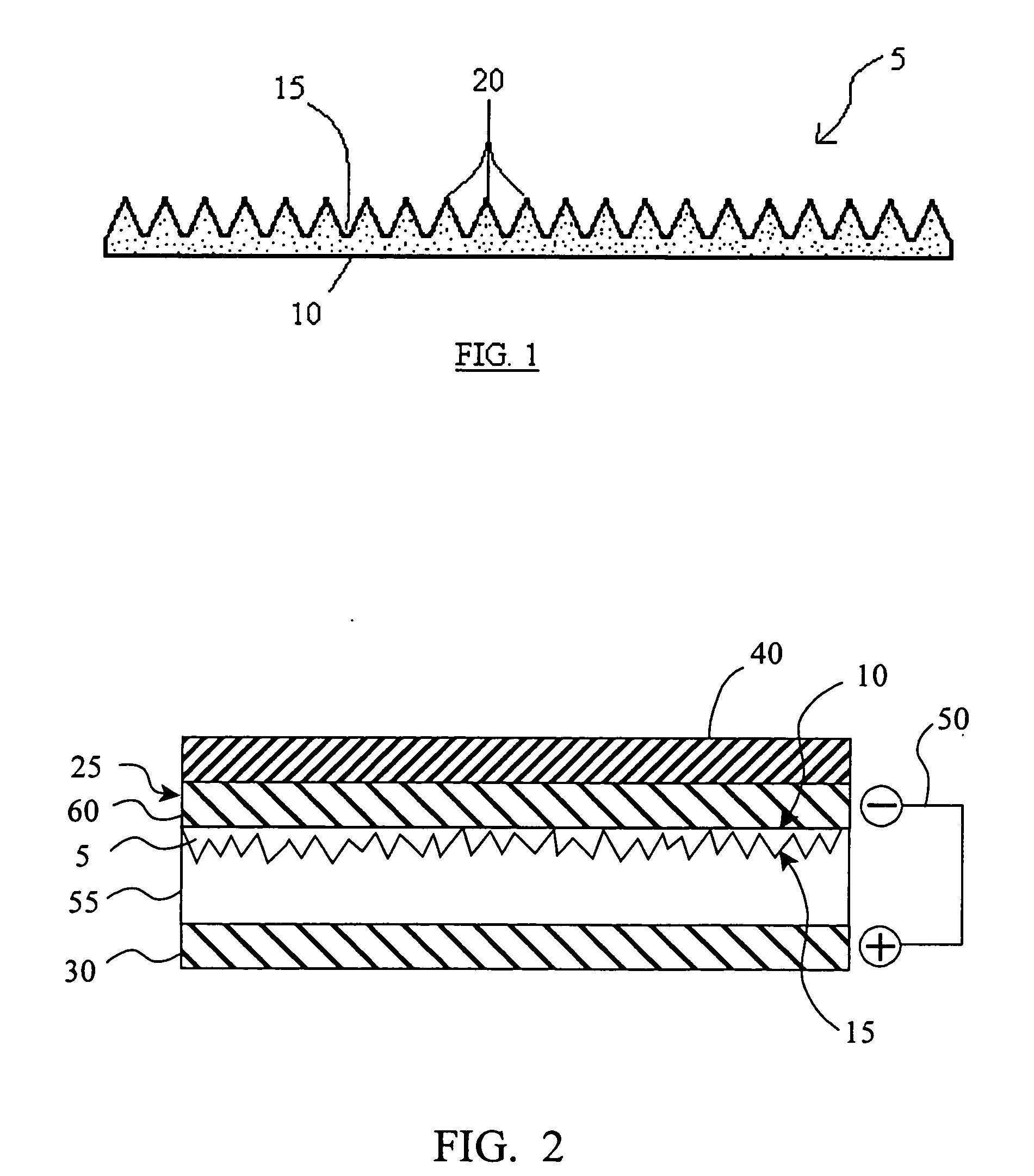

Solar cell having nanodiamond quantum wells

InactiveUS20100147369A1Improve energy conversionGreat contributionFinal product manufactureSemiconductor/solid-state device manufacturingElectrical conductorProviding material

The present invention provides materials, devices, and methods for generation of electricity from solar power. In one aspect, the present invention includes a solar cell, including a first conductor, a doped silicon layer in electrical communication with the first conductor, a nanodiamond layer in contact with the doped silicon layer, a doped amorphous diamond layer in contact with the nanodiamond layer, and a second conductor in electrical communication with the doped amorphous diamond layer.

Owner:SUNG CHIEN MIN

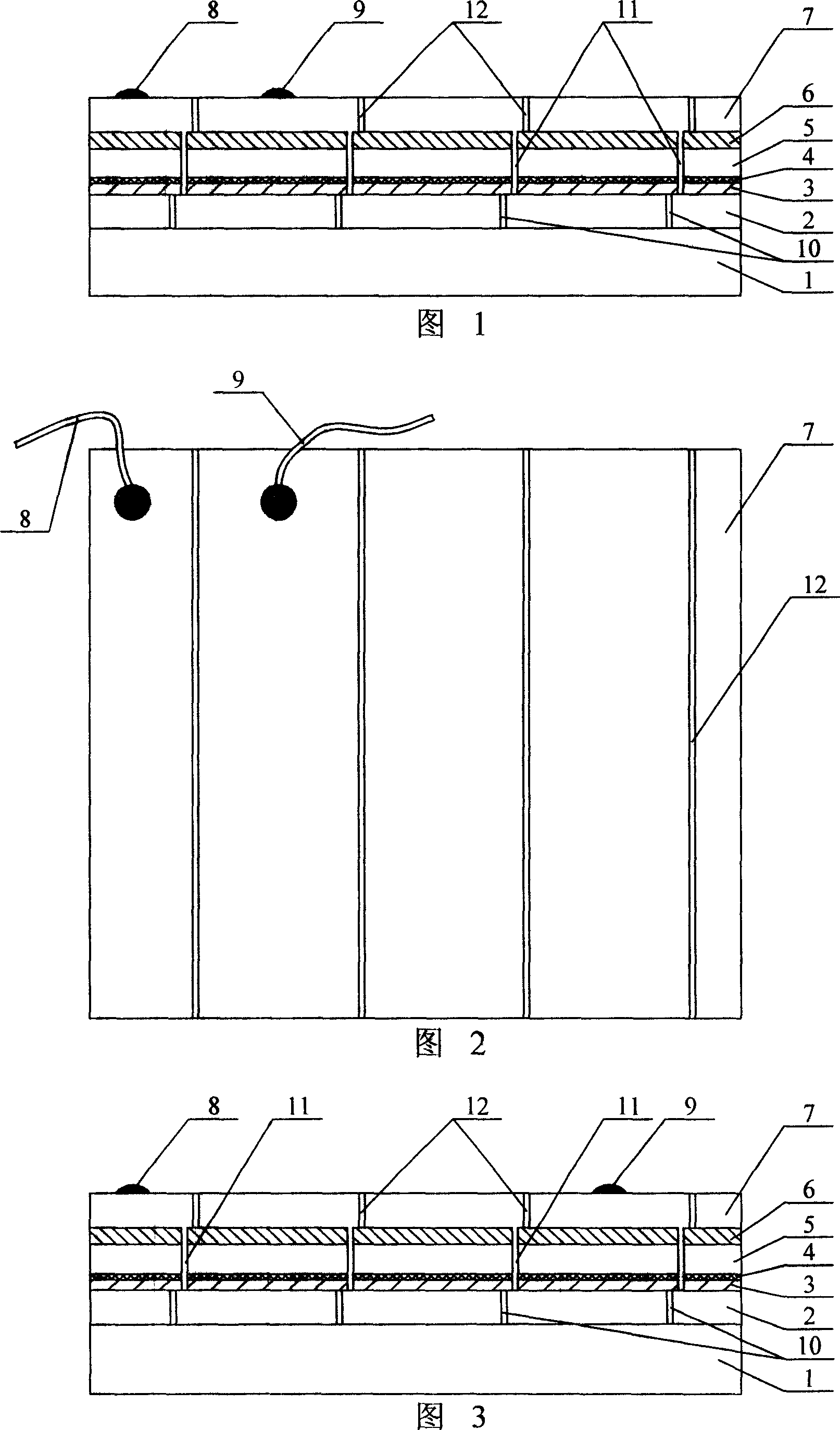

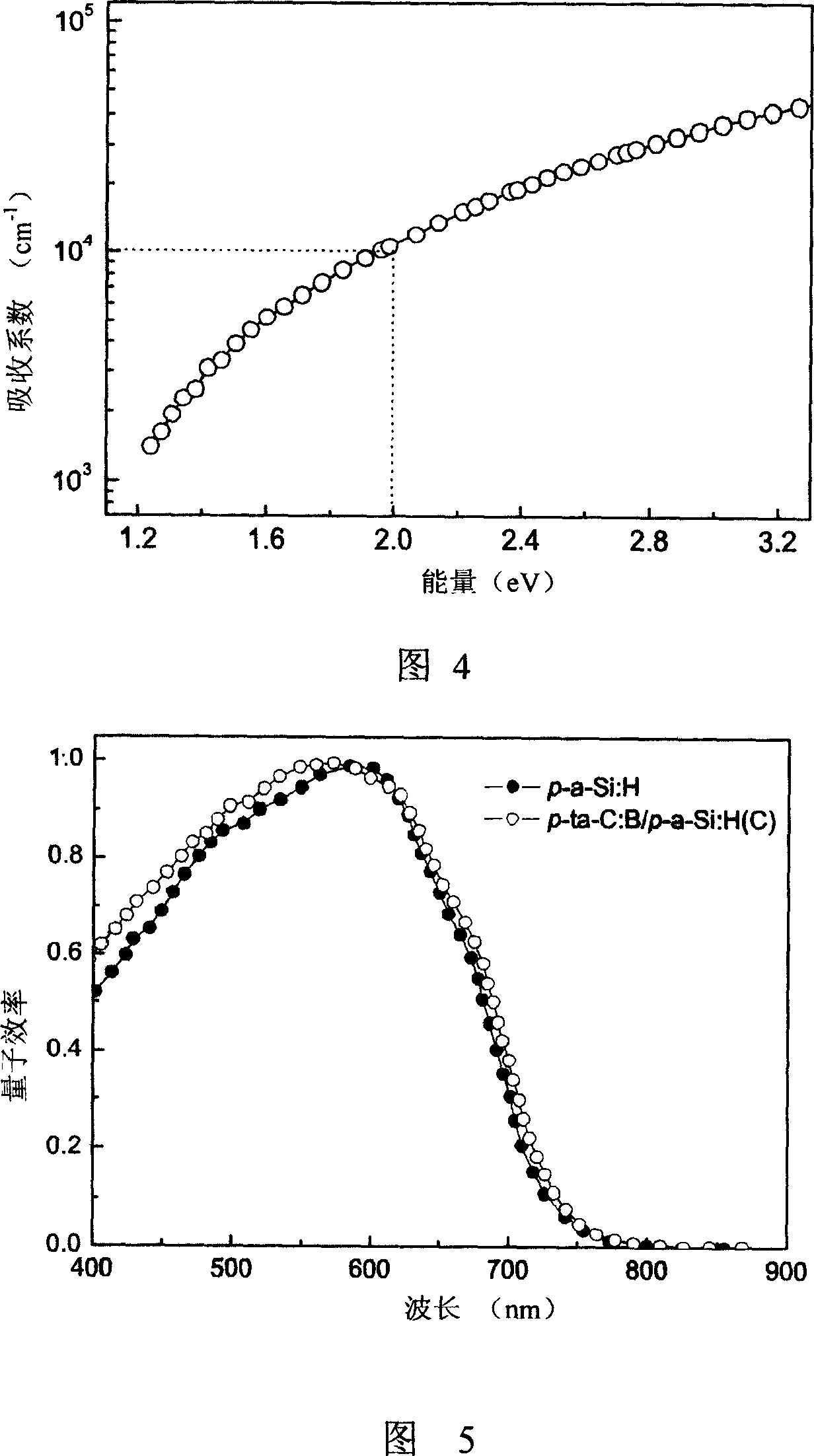

An a-Si:H solar battery with the boron mixing non-crystal diamond film as the window layer and its making method

InactiveCN101009337AHigh hardnessHigh modulusFinal product manufacturePhotovoltaic energy generationEvaporationAmorphous silicon

The a-Si:H solaode and preparing method which regards the boron-doping amorphous diamond film as window layer, it relates to a amorphous silicon solaode and preparing method. It resolves the problems of low transform efficiency of current p type amorphous silicon solaode. The upper surface of the corning glass (1) is connected with the lower surface of the SnO2:F conducting film (2), the upper surface of the SnO2:F conducting film (2) is connected with the lower surface of the p-ta-C:B film (3), the upper surface of the p-ta-C:B film (3) is connected with the lower surface of the transition p-a-Si:H(C) film (4), the upper surface of the transition p-a-Si:H(C) film (4) is connected with the lower surface of the i-a-Si:H film (5), the upper surface of the i-a-Si:H film (5) is connected with n-a-Si:H film (6). The method of the invention possesses following steps: a. depositing the SnO2:F conducting film, b. scoring with laser, c. depositing p-ta-C:B film, d. depositing transition p-a-Si:H(C) film, i-a-Si:H film and n-a-Si:H film, e. scoring with silicon firstly, f. evaporation of aluminum, g. scoring with silicon secondly. The invention possesses advantages of increasing transform efficiency of battery.

Owner:HARBIN INST OF TECH

Non-conductive plastic member with metal texture

InactiveCN101890828ARich choiceDoes not affect wireless transmissionMagnetic/electric field screeningScreening apparatusCarbon filmDiamond-like carbon

The invention relates to a plastic member comprising a polymer substrate. A metal texture film and a diamond-like carbon film, the metal texture film is selected from silicon nitride, silicon carbide, titanium carbide and a mixture thereof; the diamond-like carbon film is selected from a hydrogenated amorphous diamond-like carbon film or a nitriding amorphous diamond-like carbon film, and the thickness of the class diamond carbon film is between 5 and 50 nanometers. Because the metal texture film and the diamond-like carbon film both are not conducted, wireless transmission is not influenced when the plastic member is used as a shell of an electronic product having a wireless communication function, and the plastic member has the luster of the metal so that people has richer choices on the appearance of the electronic product.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Preparation of bulk superhard B-C-N nanocomposite compact

InactiveUS7938997B2Pigmenting treatmentMaterial nanotechnologyDiamond-like carbonHexagonal boron nitride

Owner:TRIAD NAT SECURITY LLC

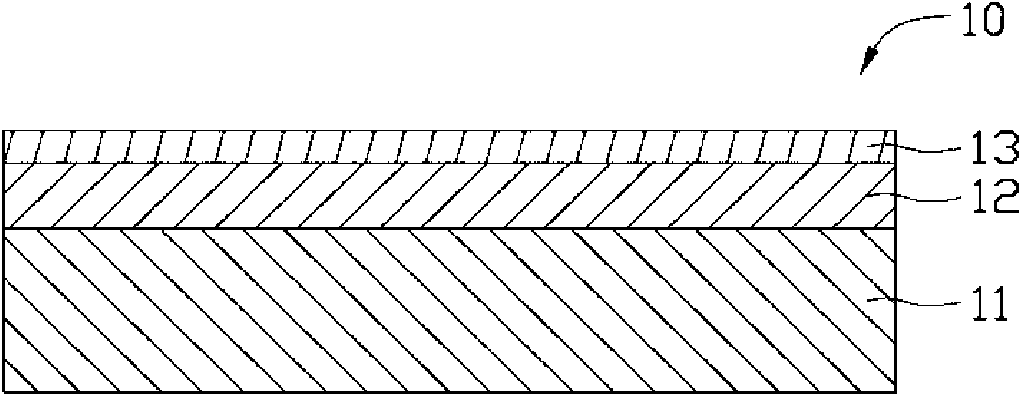

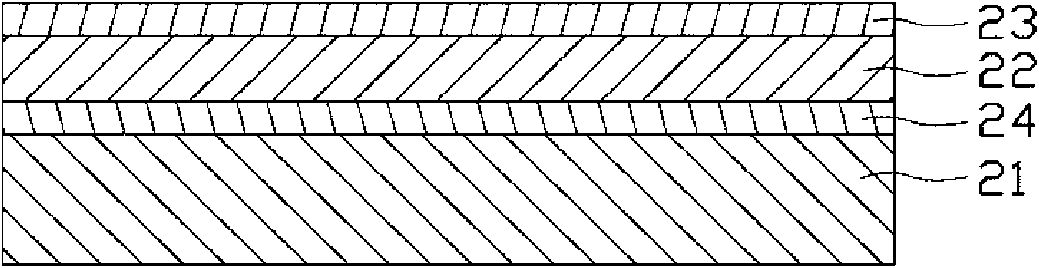

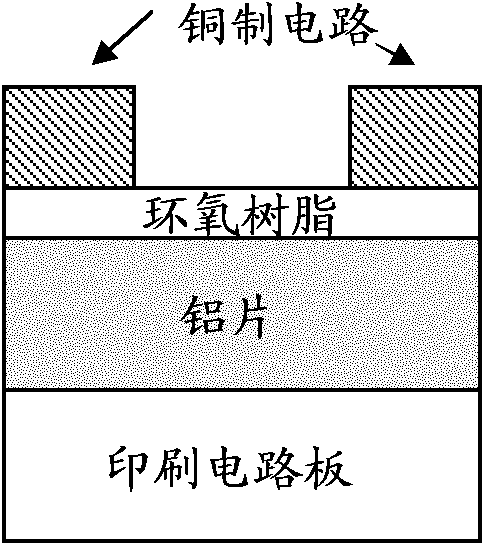

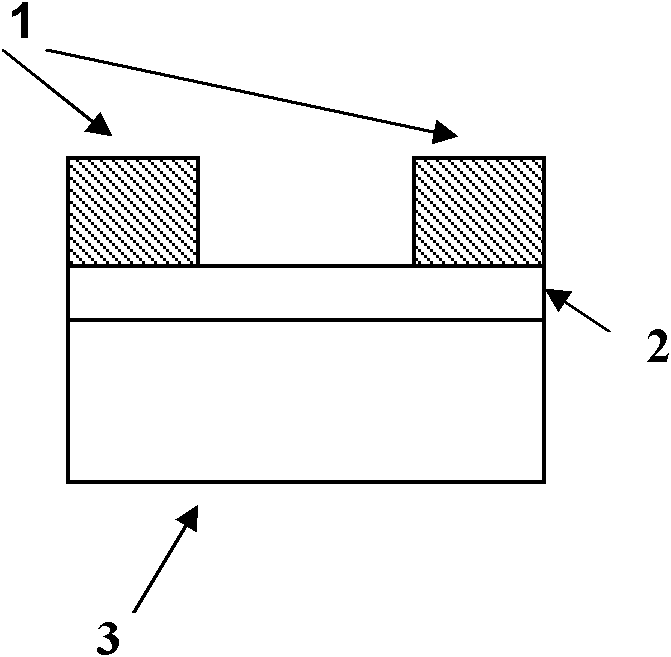

LED printed circuit board and preparation method of amorphous diamond heat dissipation and insulation film layer thereof

InactiveCN101998758ASimple processIncrease brightnessPoint-like light sourcePrinted circuit detailsElectricityEngineering

The invention relates to a light-emitting diode (LED) printed circuit board and a preparation method of an amorphous diamond heat dissipation and insulation film layer thereof, in particular to an LED printed circuit board and a preparation method of a heat dissipation and insulation dual-efficacy film layer thereof. In the invention, the problem of poor heat dissipation effect of the existing LED printed circuit board because the hard-and-fast requirement of electric insulation is limited is solved, and an LED printed circuit board and a preparation method of an amorphous diamond heat dissipation and insulation film layer thereof are provided. The circuit board is formed by adding the amorphous diamond heat dissipation and insulation film layer between a printed circuit board and a copper circuit. The preparation method comprises the following concrete steps: (1) cleaning: cleaning the LED printed circuit board by deionized water, and blow-drying the LED printed circuit board; (2) etching: etching the amorphous diamond depositing surface of the LED printed circuit board by a Kaufman ion gun; and (3) depositing: alternately depositing carbon ions by adopting different negative bias to gradually form the heat dissipation and insulation dual-efficacy film layer of an amorphous diamond film formed by alternately constructing a sub-film layer with low stress and a sub-film layer with high sp3 hybridization content. The invention is suitable for printed circuit boards.

Owner:HARBIN INST OF TECH

Solar cell having improved electron emission using amorphous diamond materials

InactiveUS20090065052A1Reducing back conversionFacilitate up of electron energyFinal product manufactureSemiconductor/solid-state device manufacturingField electron emissionThin layer

Solar cells and related methods using thin layers of amorphous diamond. A thin layer of amorphous diamond is in electrical communication with a conductor. The use of a thin layer of amorphous diamond helps to reduce back conversion of excited electrons to heat. Reduced back conversion in turn can provide an increase in the efficiency of solar cells using the presently disclosed techniques.

Owner:SUNG CHIEN MIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com