Non-conductive plastic member with metal texture

A technology of metal texture and plastic parts, applied in the direction of electrical components, metal layered products, instrument parts, etc., can solve the problems of unsatisfactory bonding between the film layer and the non-conductive metal film layer, and is not environmentally friendly, so as to achieve rich choices , the effect of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The plastic part provided by the technical solution and the preparation method thereof will be further described in detail below in conjunction with the accompanying drawings and embodiments.

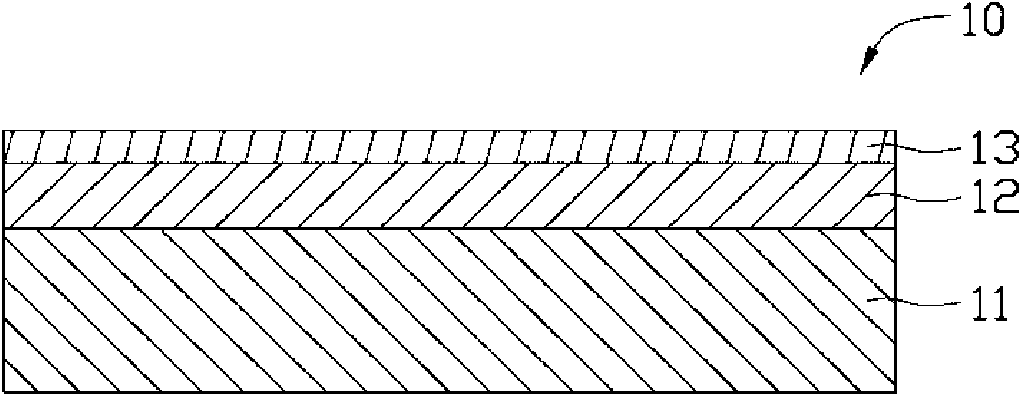

[0013] refer to figure 1 The plastic part 10 provided by the first embodiment includes a polymer substrate 11 and a metallic film 12 and a diamond-like carbon film 13 sequentially formed on the polymer substrate. The polymer substrate may be selected from polycarbonate (PC), polypropylene (PP), acrylonitrile-styrene-butadiene copolymer (ABS), polymethylmethacrylate (PMMA), PC+ABS mixture. The metal texture film 11 is selected from silicon nitride, silicon carbide, titanium carbide and mixtures thereof, and its thickness is 50 nm to 1000 nm. The diamond-like carbon film 13 is selected from a hydrogenated amorphous diamond-like carbon film or a nitrided amorphous diamond-like carbon film, and its thickness is 5 nm to 50 nm. The metal texture film 11 has metallic luster, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com