Method for preparing fluorescent carbon quantum dots by laser irradiation

A technology of carbon quantum dots and laser irradiation, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as pollution, complex preparation process, and low efficiency of quantum dots, achieve good controllability, and solve photoluminescence difficulties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

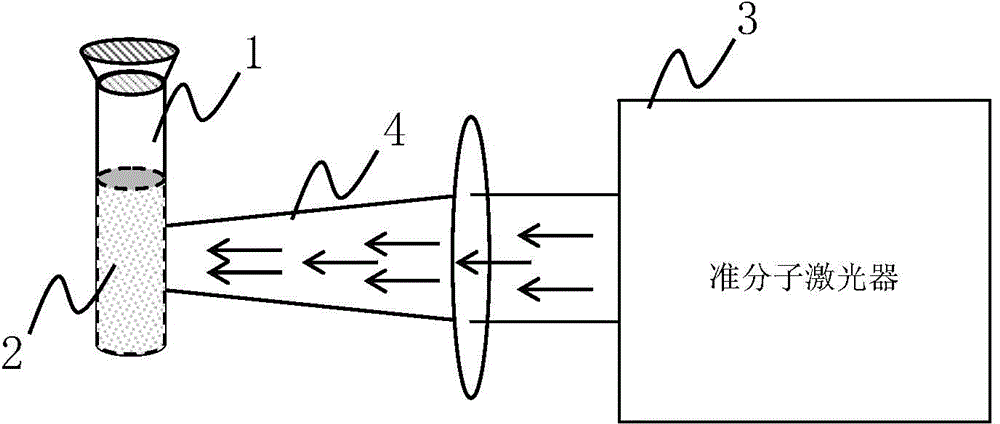

[0029] This example uses toluene as a carbon source to prepare fluorescent carbon quantum dots. For the preparation method, see figure 1 ,Specific steps are as follows:

[0030] (1) At room temperature, clean the quartz test tube 1 with ultrasonic waves, and after airtight drying, add 4ml of toluene as the carbon source 2, fill the test tube with argon protection and seal it;

[0031] (2) Select excimer laser 3 as ultraviolet light with a laser wavelength of 248nm, select single pulse power as 130mJ, select operating frequency as 5Hz, and irradiate in a non-focused manner for 10 minutes. See optical path 4. figure 1 The light yellow-green liquid in the resulting quartz test tube is the toluene solution of fluorescent carbon quantum dots;

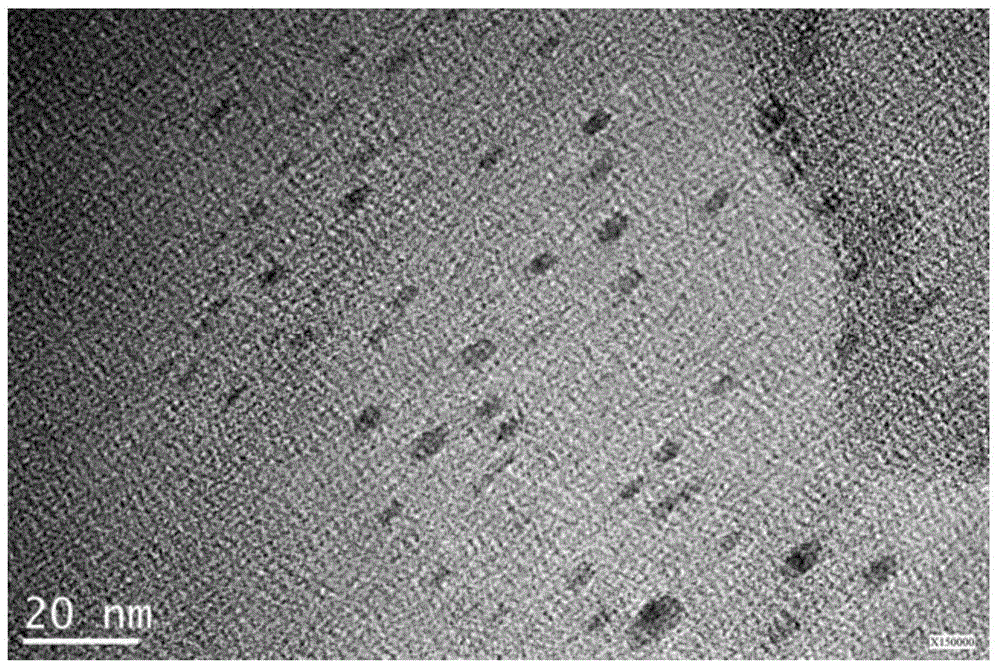

[0032] Use the Japan Electronics JEM-2100F transmission electron microscope to scan the morphology of the fluorescent carbon quantum dots in this example, the results are as follows figure 2 As shown, it can be seen that most of the carbo...

Embodiment 2

[0036] In this example, benzene is used as a carbon source to prepare fluorescent carbon quantum dots. For the preparation method, see figure 1 ,Specific steps are as follows:

[0037] (1) At room temperature, clean the quartz test tube with ultrasonic waves, and after airtight drying, add 4ml of benzene, fill the test tube with argon protection and seal it;

[0038] (2) The laser wavelength of the excimer laser is selected to be ultraviolet light of 248nm, the single pulse power is selected to be 147mJ, the working frequency is selected to be 10Hz, and irradiated in a non-focused manner for 10 minutes;

[0039] (3) light yellow-green liquid in the gained quartz test tube is the benzene solution of fluorescent carbon quantum dots;

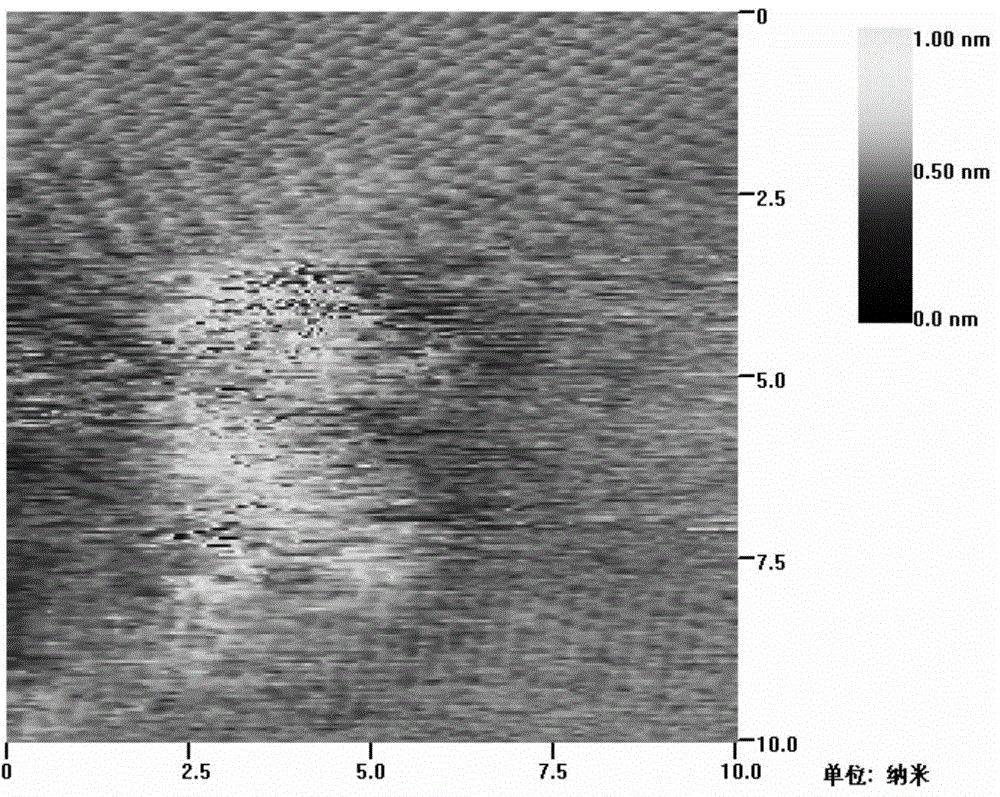

[0040] The morphology of the fluorescent carbon quantum dots in this example was scanned using Shanghai Aijian Nano AJ-I Scanning Tunneling Microscope (STM), and the results are as follows Figure 5 As shown, it can be seen that the particle size...

Embodiment 3

[0043] In this embodiment, solid dimethylnaphthalene was used as a carbon source to prepare a solution of dimethylnaphthalene in ethanol, wherein the mass concentration of dimethylnaphthalene was 5%, and ethanol was 95%, as the carbon source solution. Specific steps are as follows:

[0044] (1) At room temperature, the quartz test tube was cleaned by ultrasonic waves, after airtight drying, 4ml of carbon source solution was added, and the test tube was filled with argon gas for protection and then sealed;

[0045] (2) The laser wavelength of the excimer laser is selected to be ultraviolet light of 248nm, the single pulse power is selected to be 195mJ, the working frequency is selected to be 5Hz, and the irradiation is performed in a non-focused manner for 20 minutes;

[0046] (3) transparent liquid in the gained quartz test tube is the ethanol solution of fluorescent carbon quantum dots;

[0047] The experimental results show that the carbon quantum dots exhibit good fluoresc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com