LED printed circuit board and preparation method of amorphous diamond heat dissipation and insulation film layer thereof

A technology of printed circuit board and amorphous diamond, which is applied in the direction of printed circuit manufacturing, printed circuit, printed circuit parts, etc., can solve the problems of poor heat dissipation effect of the electrical insulation layer, achieve improved heat dissipation effect, simplify the process, and simplify the process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

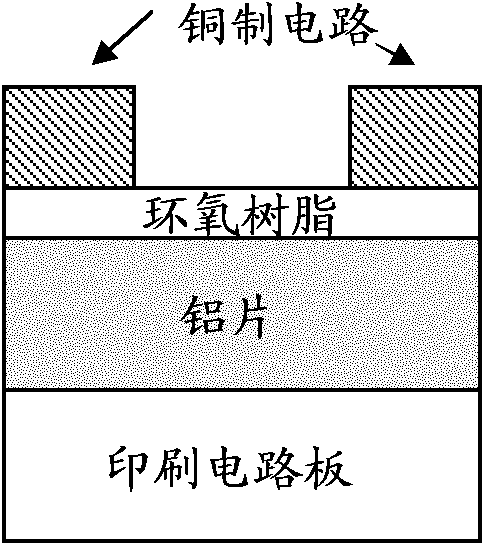

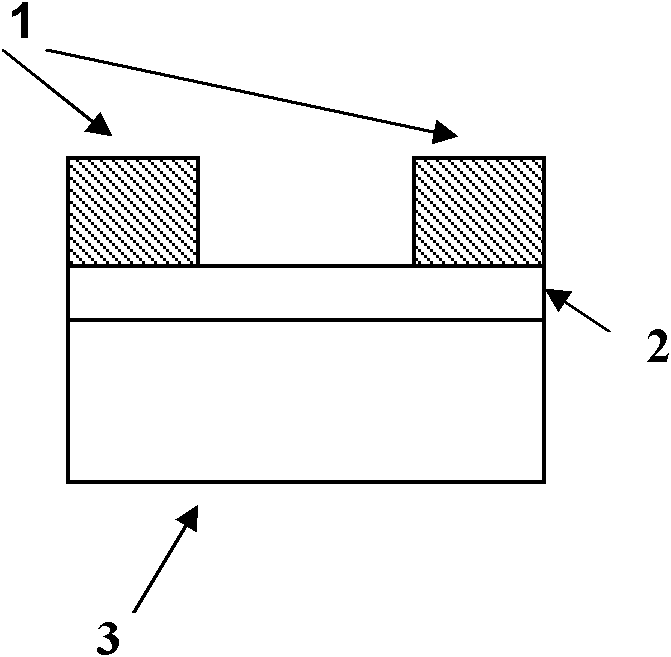

[0014] Specific implementation mode 1. Combination figure 2 Describe this embodiment mode, LED printed circuit board, it comprises printed circuit board 1, amorphous diamond heat dissipation insulating film layer 2, copper circuit layer 3, adds amorphous diamond heat dissipation between printed circuit board 1 and copper circuit layer 3 Insulation film layer 2.

specific Embodiment approach 2

[0015] Specific embodiment 2. This embodiment is a further description of specific embodiment 1. The amorphous diamond heat-dissipating insulating film layer 2 is sp rich sp deposited on the surface of the printed circuit board by using the filtered cathode vacuum arc system. 3 Hybrid amorphous diamond films.

specific Embodiment approach 3

[0016] Specific Embodiment 3. This embodiment is a further description of Specific Embodiment 1 or 2. The thickness of the amorphous diamond heat-dissipating insulating film layer 2 is 0.5-2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com