Preparation method of high-hardness conductive carbon-based thin film

A high-hardness, carbon-based technology, applied in the direction of ion implantation plating, gaseous chemical plating, coating, etc., can solve the problems that do not meet the requirements of electrical conductivity and wear resistance of the brush surface, loose and not dense coating, etc., and achieve excellent Comprehensive mechanical properties and solid lubricating properties, improve the interface state, and enhance the effect of bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

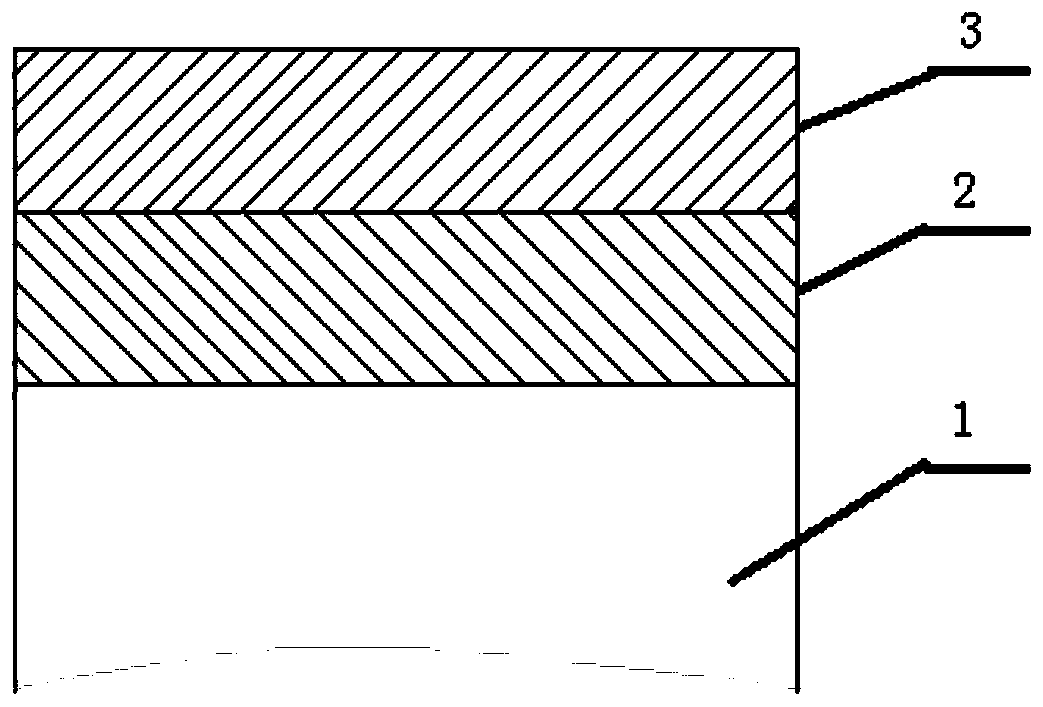

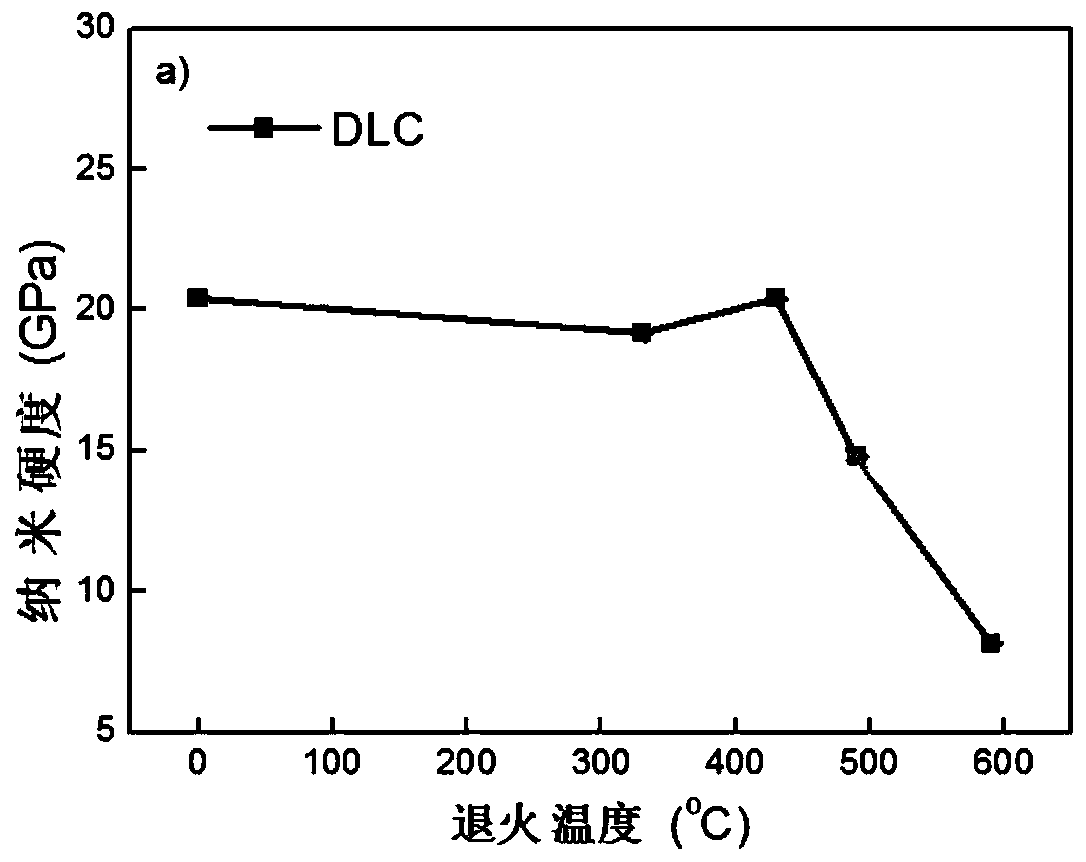

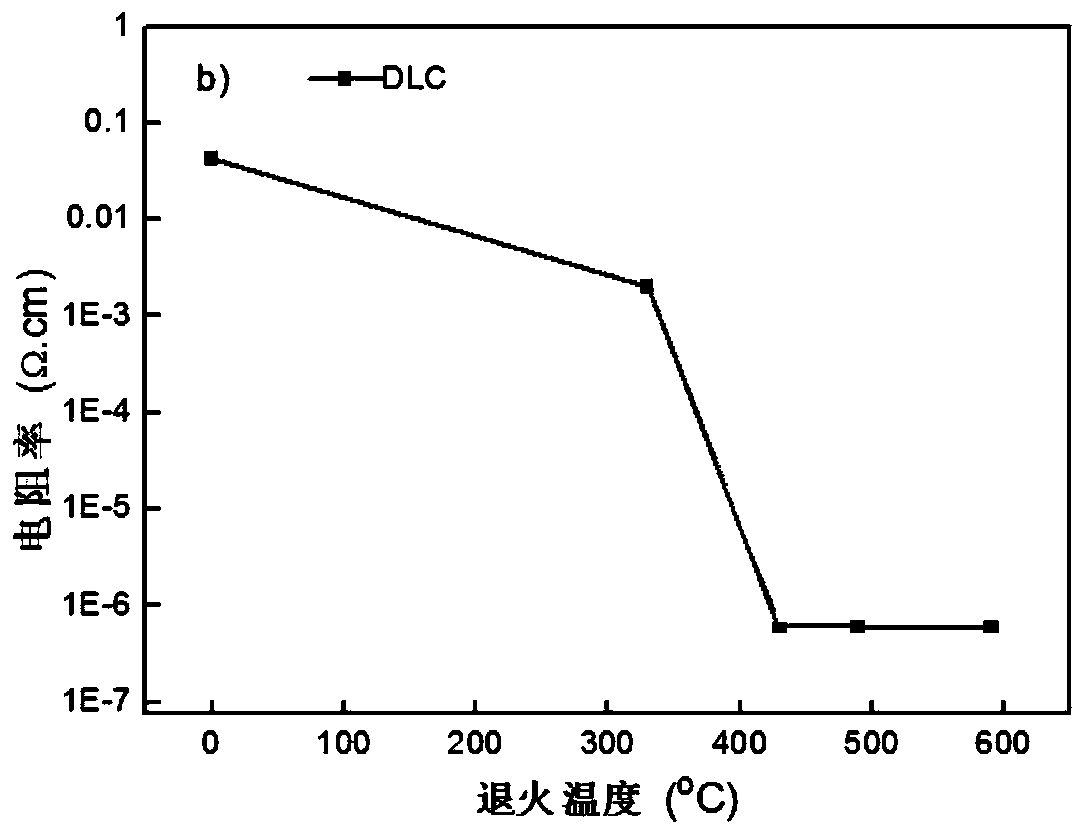

Image

Examples

Embodiment 1

[0040] A method for preparing a high-hardness conductive carbon-based film, comprising the steps of:

[0041] Step 1: The square copper alloy (T2) sample with a size of 20x20x5mm is cleaned in the GT-Cleaning system cleaning line to make the surface clean, then dried with oil-free compressed air, hung on the fixture and placed in the Hauzer flexcoat 850 vacuum coating device, And start the workpiece bracket to rotate; the Hauzer flexcoat 850 vacuum coating device is a magnetron sputtering device driven by an auxiliary ion source, a bipolar pulse bias power supply, an auxiliary strong electromagnetic DC coil forming a closed magnetic field in the vacuum chamber, and a bipolar pulse DC power supply. The vacuum coating system of the device; the plasma formed by the carbon source gas discharge enhances the collision probability and improves the ionization efficiency of the plasma under the action of the auxiliary closed strong magnetic field.

[0042] Step 2: Etch activation: The ...

Embodiment 2

[0052] Step 1: After cleaning the square Ti6Al4V titanium alloy test piece with a size of 20x20x5mm in the cleaning line to make the surface clean, dry it with oil-free compressed air, hang it on the jig and put it into a machine containing a low-voltage DC arc plasma source and magnetron sputtering. Vacuum coating system, and drive the workpiece bracket to rotate;

[0053] Step 2: The vacuum chamber is evacuated to a back vacuum below 5x10 -3 After Pa, argon gas was introduced through the ion source to maintain the pressure of the vacuum chamber at 0.05 Pa, and the ion source was turned on to bombard and clean the test piece to apply a workpiece bias of 250V; during this period, the DC arc current was maintained at 15A. Adjust the bias voltage of the workpiece to -80V after ion bombardment cleaning for 60 minutes;

[0054] While etching was activated, the heating power was turned on to heat the sample to 240°C, and the temperature was maintained until the coating was deposit...

Embodiment 3

[0061] Step 1: After cleaning the square 316L test piece with a size of 20x20x5mm in the GT-Cleaning system cleaning line to make the surface clean, dry it with oil-free compressed air, hang it on the fixture, put it into the Hauzer flexcoat 850 vacuum coating device, and start it Workpiece holder rotation;

[0062]Step 2: The vacuum chamber is evacuated to a back vacuum below 5x10 -3 After Pa, argon gas was introduced through the ion source to maintain the pressure of the vacuum chamber at 0.15 Pa, and the ion source was turned on to bombard and clean the test piece to apply a workpiece bias of 150V; during this period, the DC arc current was maintained at 25A. Adjust the bias voltage of the workpiece to -150V after ion bombardment cleaning for 30 minutes;

[0063] At the same time of etching activation, turn on the heating power supply to heat the sample to 300 °C, and this temperature is maintained until the coating deposition is completed.

[0064] Step 3: Preparation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com