Patents

Literature

2180 results about "Pantograph" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pantograph (Greek roots παντ- "all, every" and γραφ- "to write", from their original use for copying writing) is a mechanical linkage connected in a manner based on parallelograms so that the movement of one pen, in tracing an image, produces identical movements in a second pen. If a line drawing is traced by the first point, an identical, enlarged, or miniaturized copy will be drawn by a pen fixed to the other. Using the same principle, different kinds of pantographs are used for other forms of duplication in areas such as sculpture, minting, engraving, and milling.

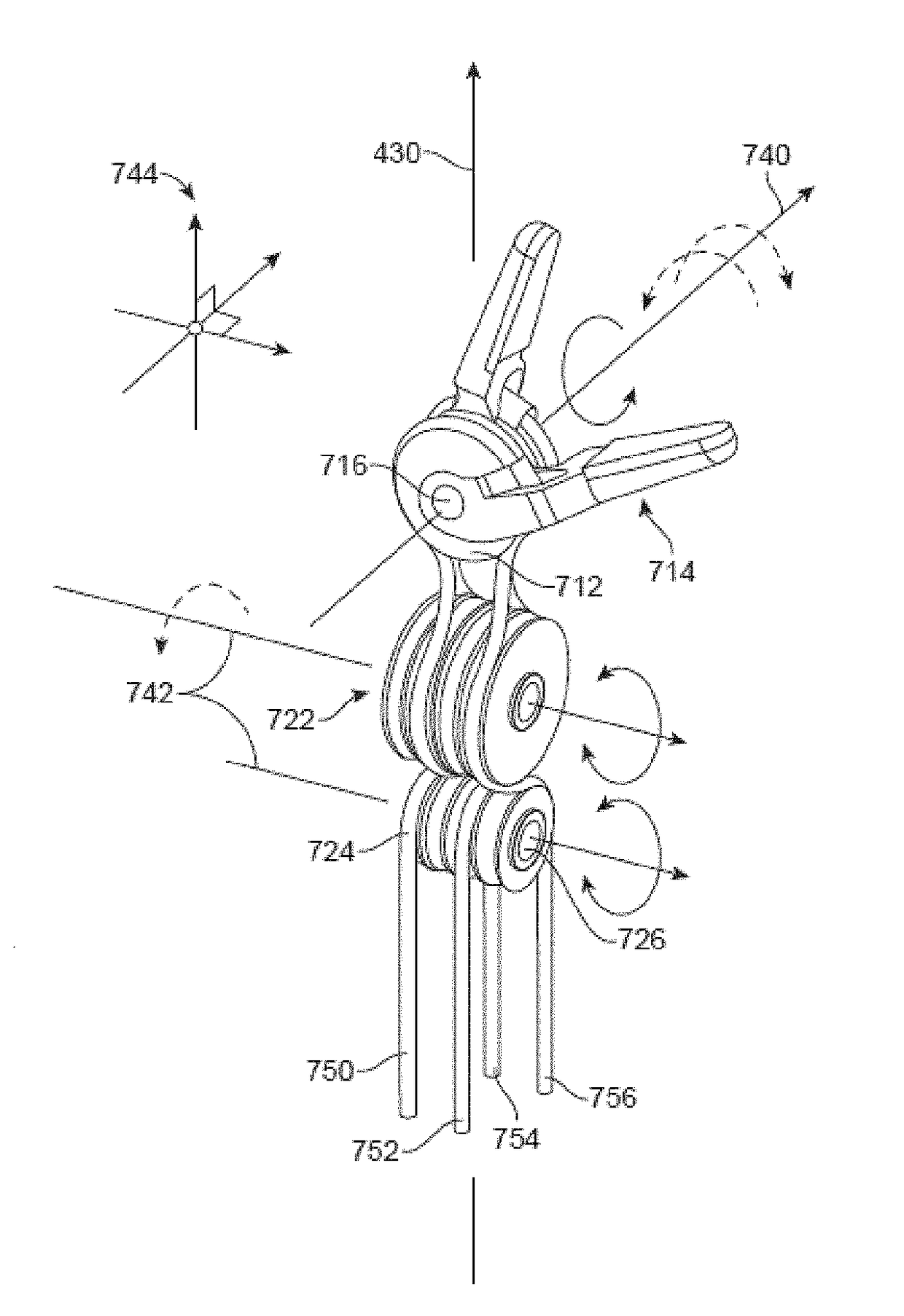

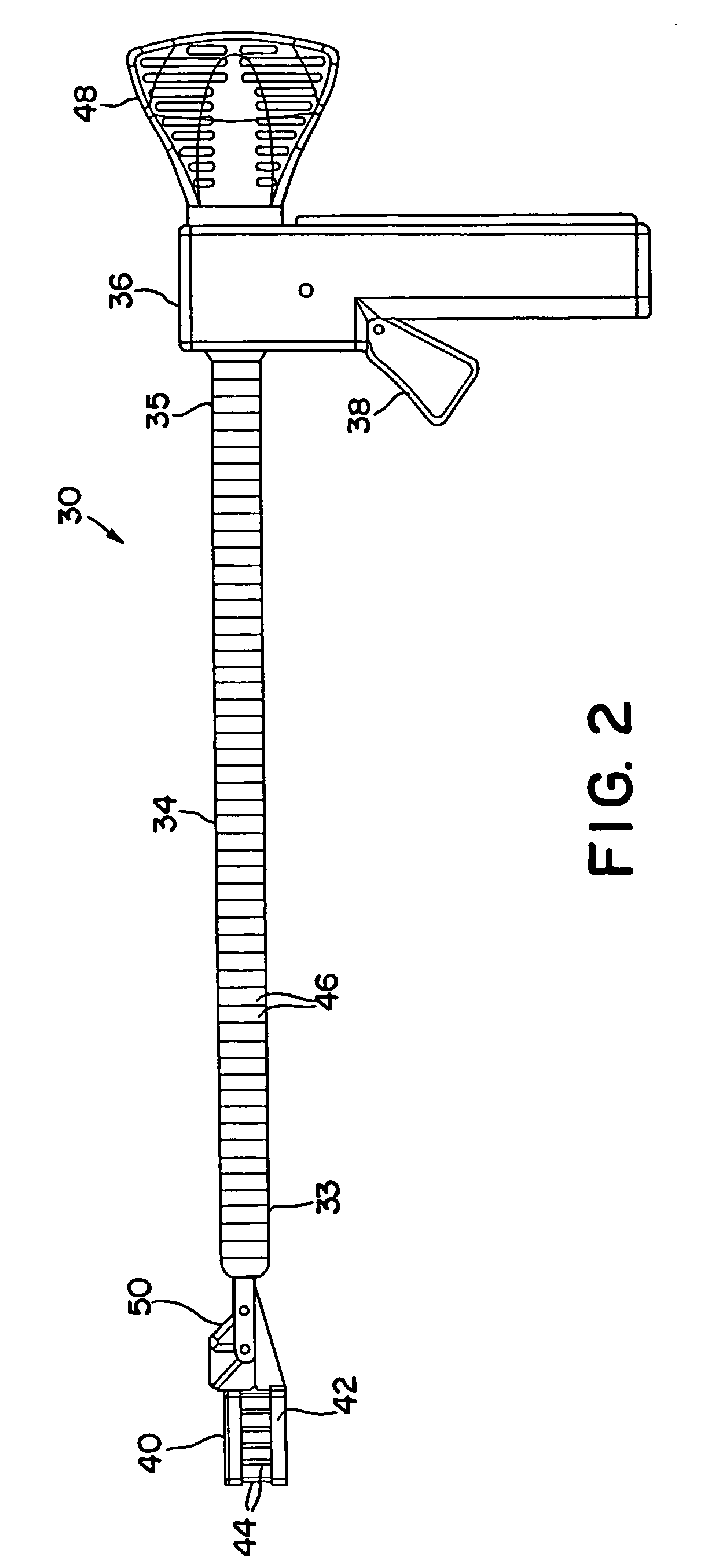

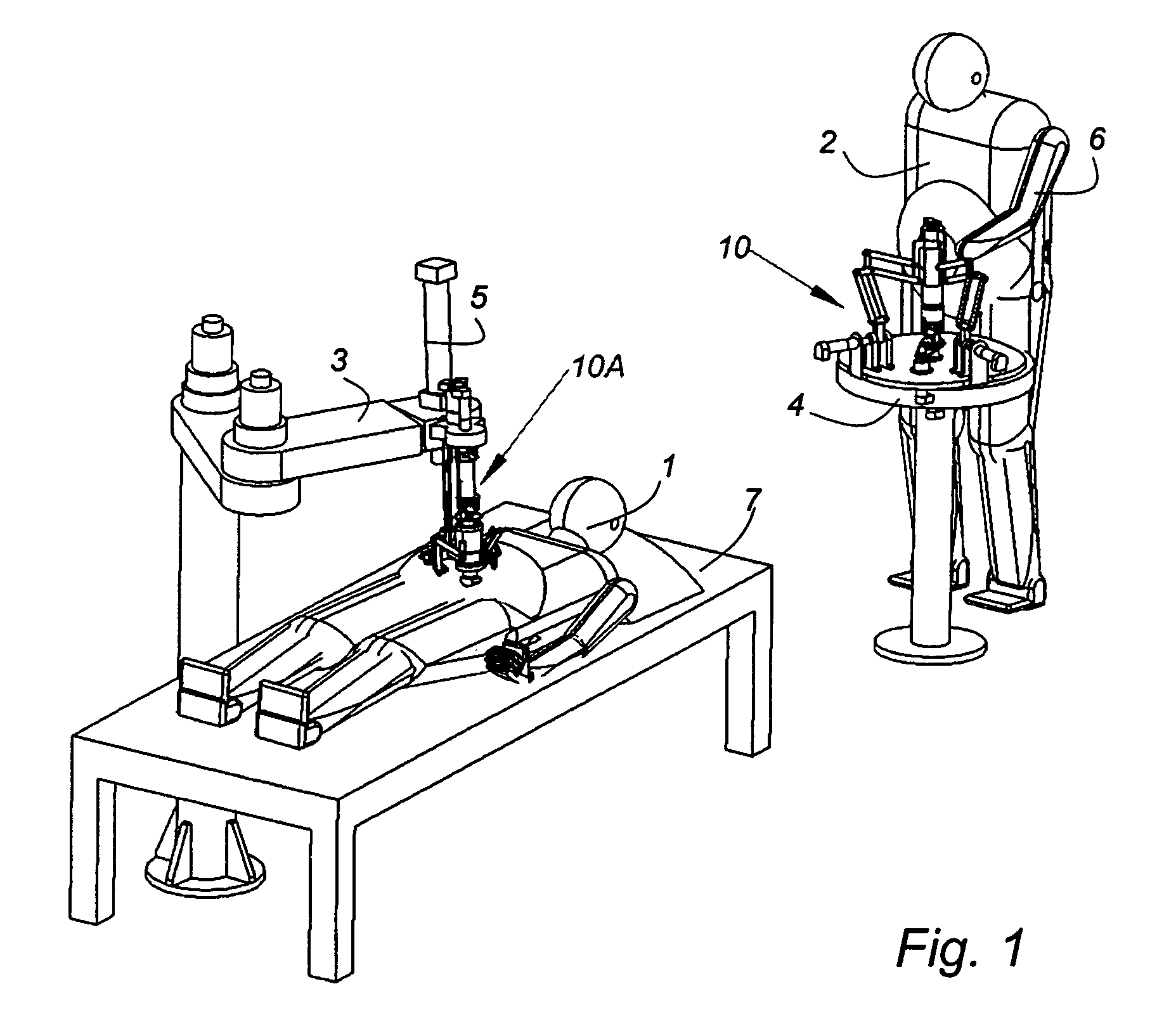

Length conservative surgical instrument

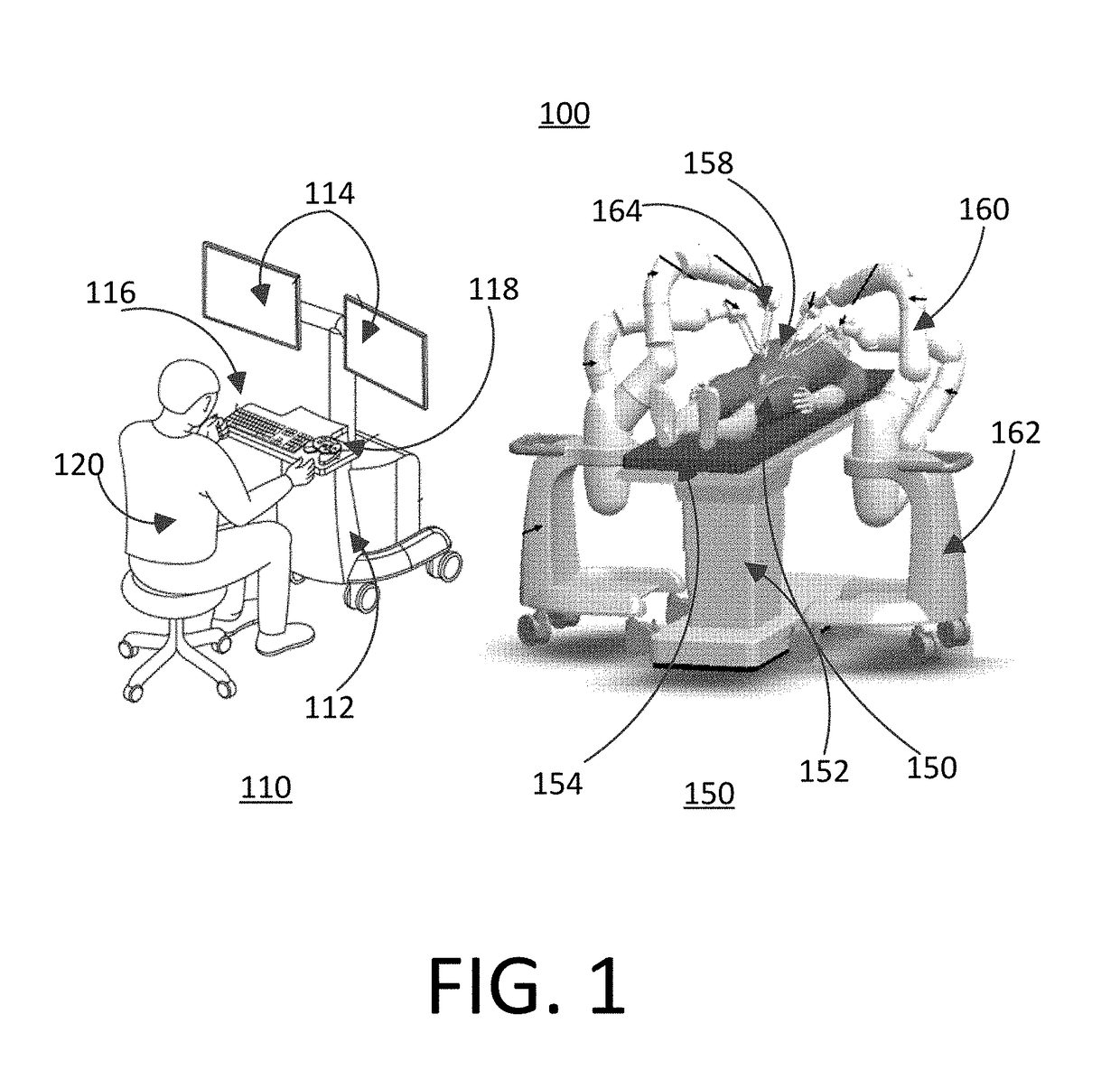

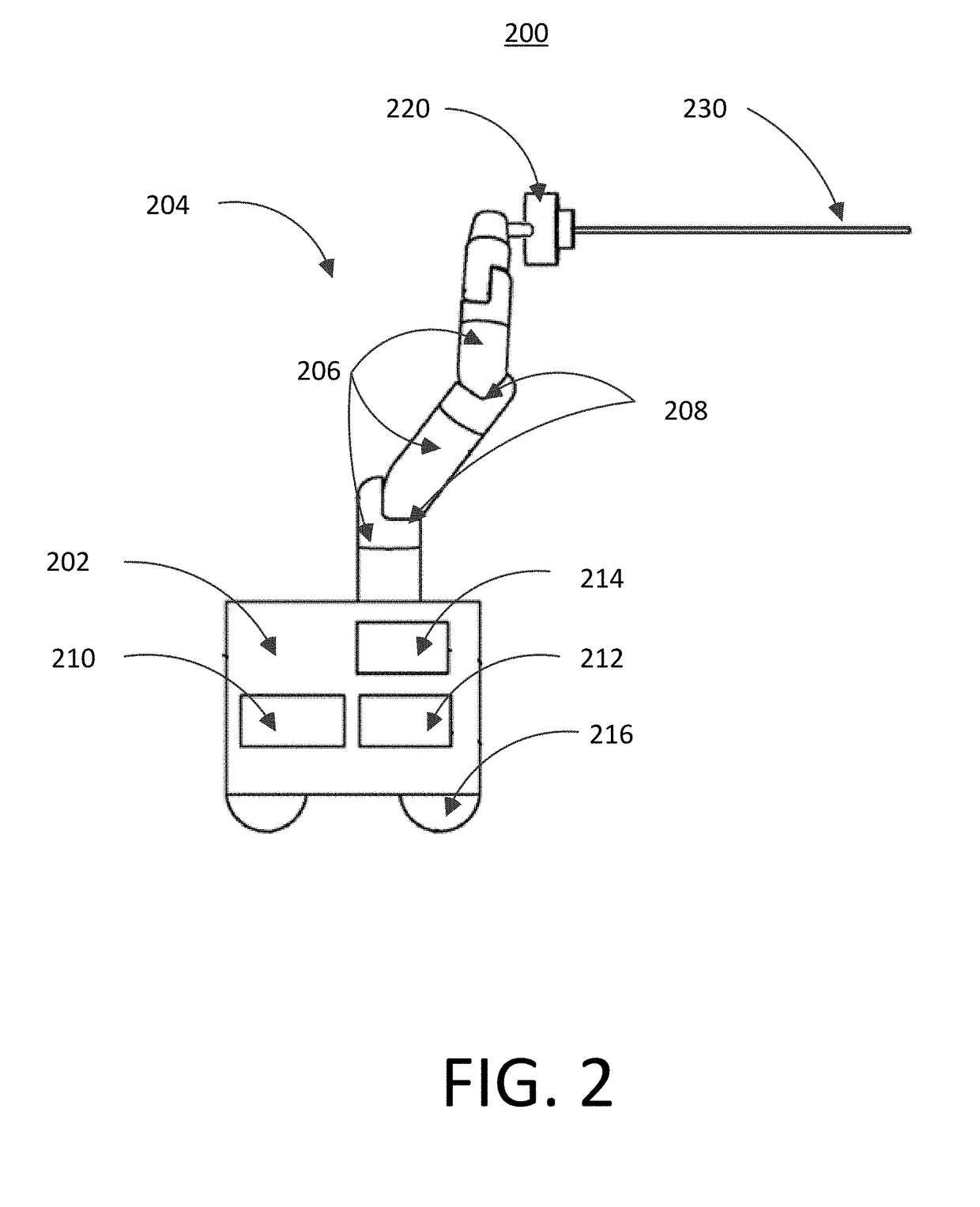

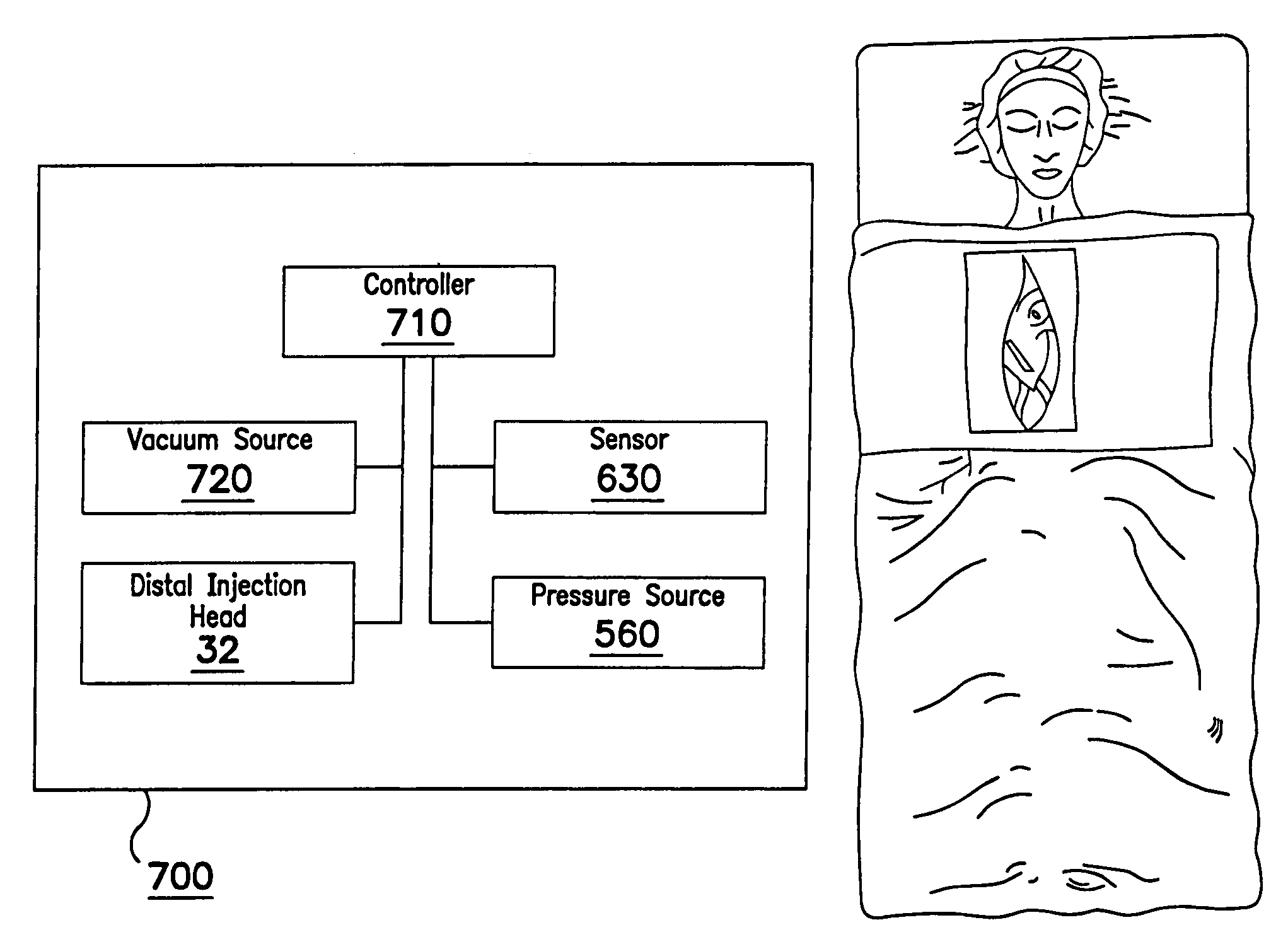

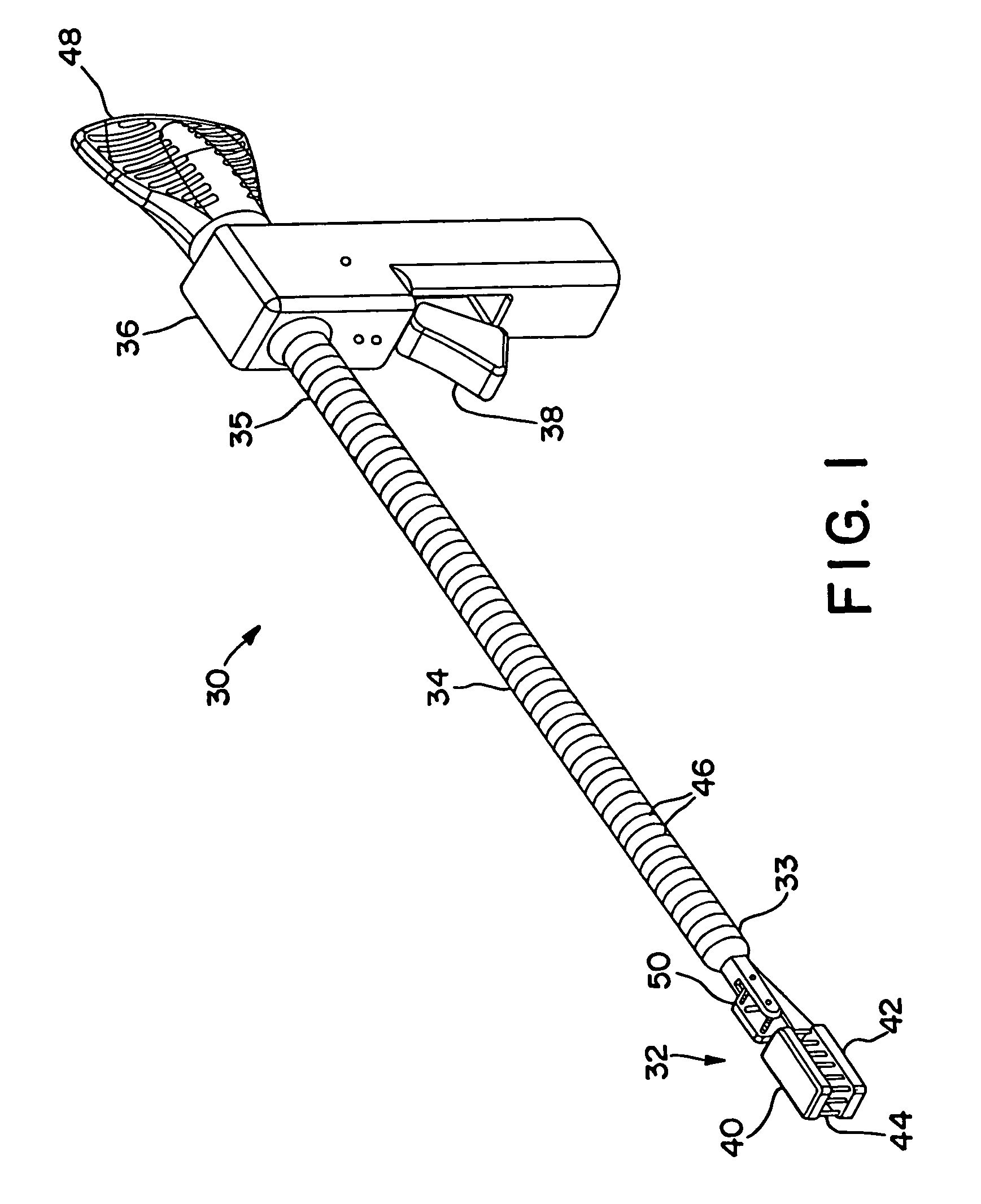

ActiveUS9962228B2Programme-controlled manipulatorSurgical manipulatorsSurgical siteDegrees of freedom

A surgical instrument is described that includes a surgical effector moving with N degrees of freedom for manipulation of objects at a surgical site during surgical procedures. The N degrees of freedom are manipulated by N+1 input controllers and a plurality of cables, the controllers and cables coupled to the surgical effector and configured to change the orientation of the surgical effector about the N degrees of freedom when actuated. In some embodiments, the N+1 input controllers and plurality of cables are further coupled to a pantograph, the pantograph configured to move in a reciprocal manner to the surgical effector when the input controllers and cables are actuated.

Owner:AURIS HEALTH INC

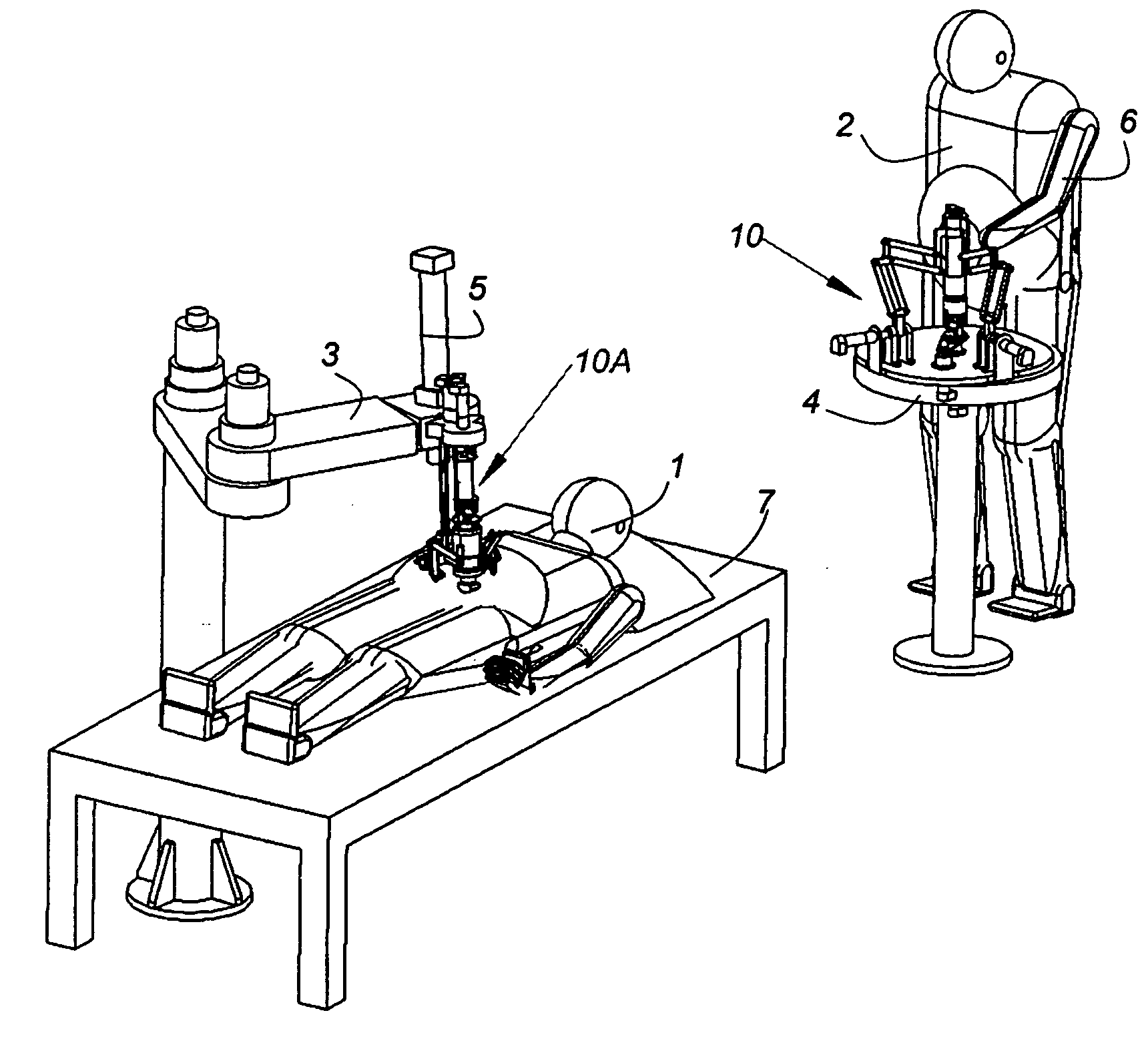

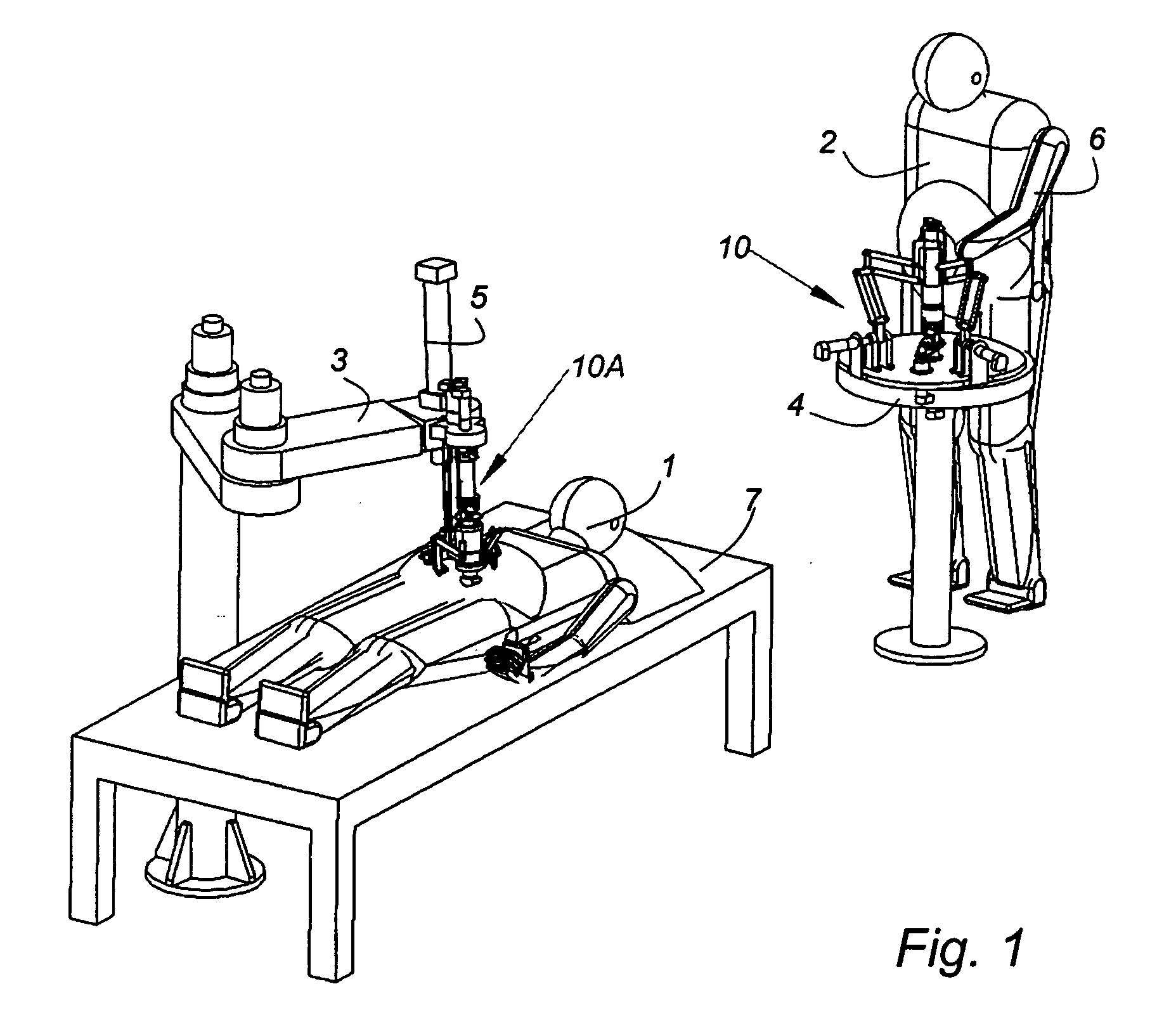

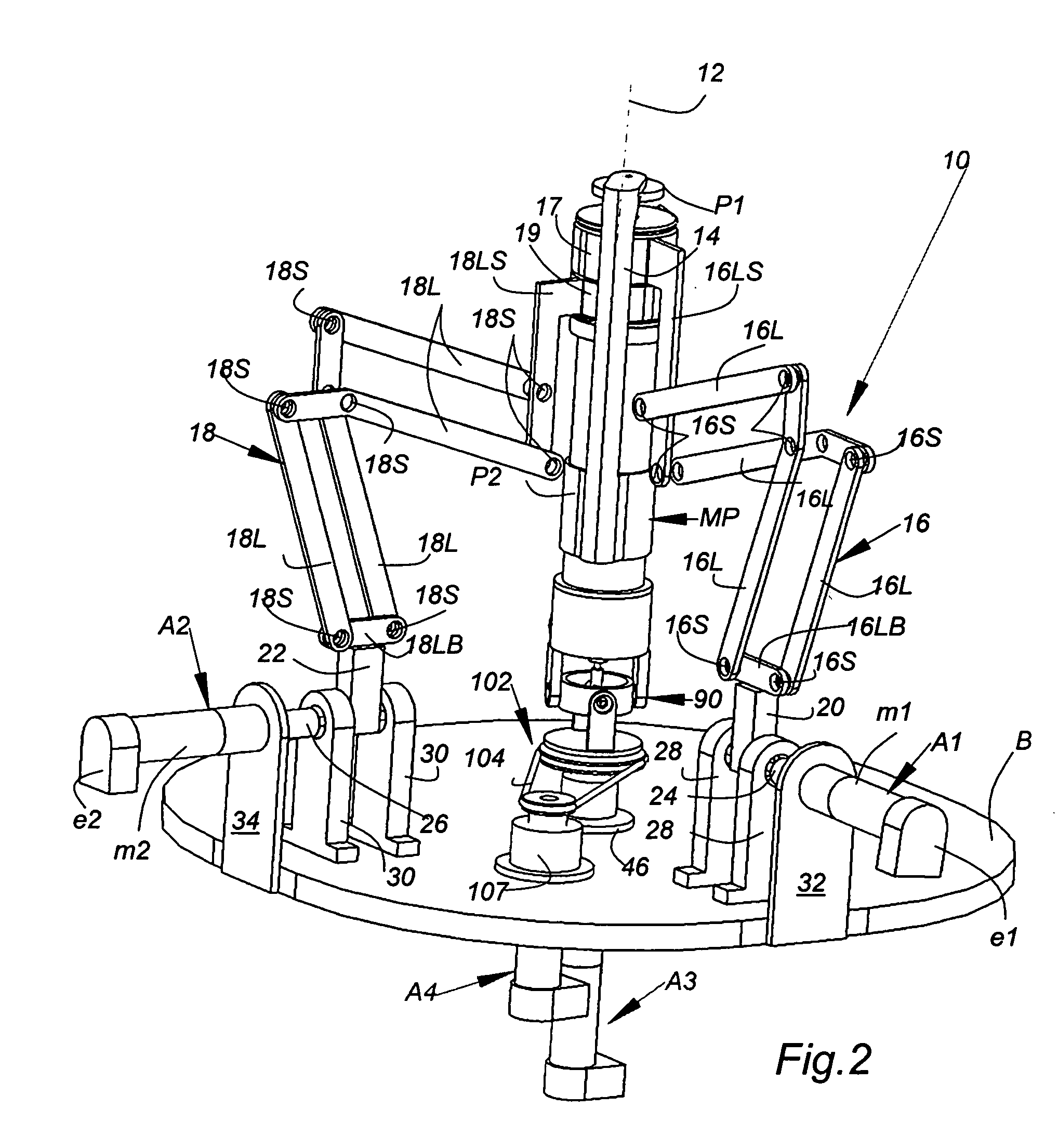

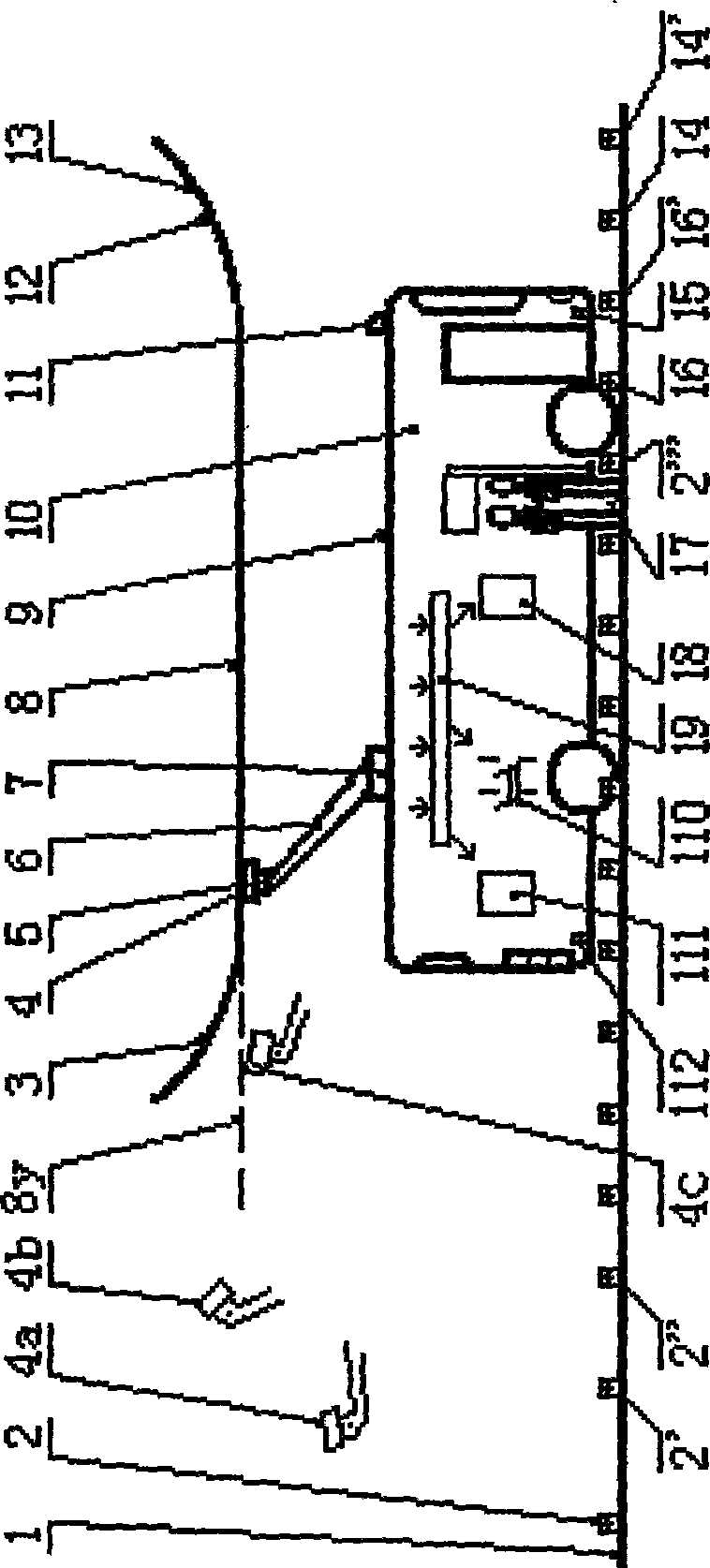

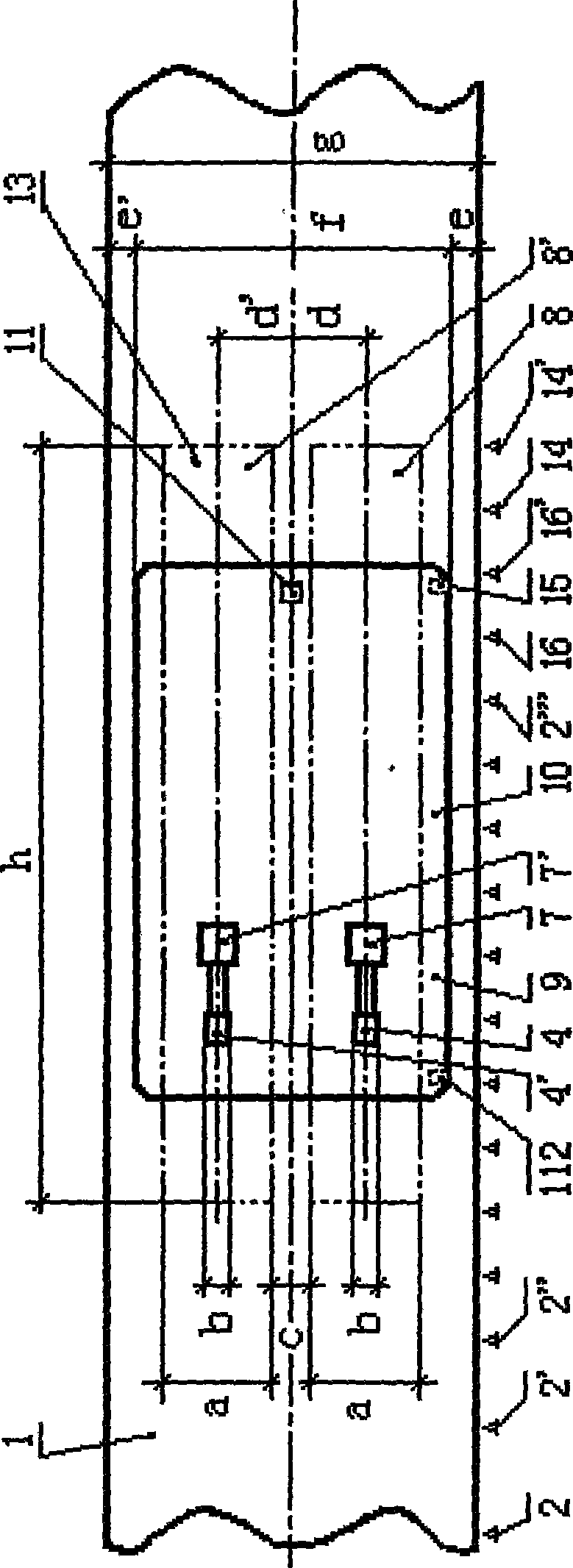

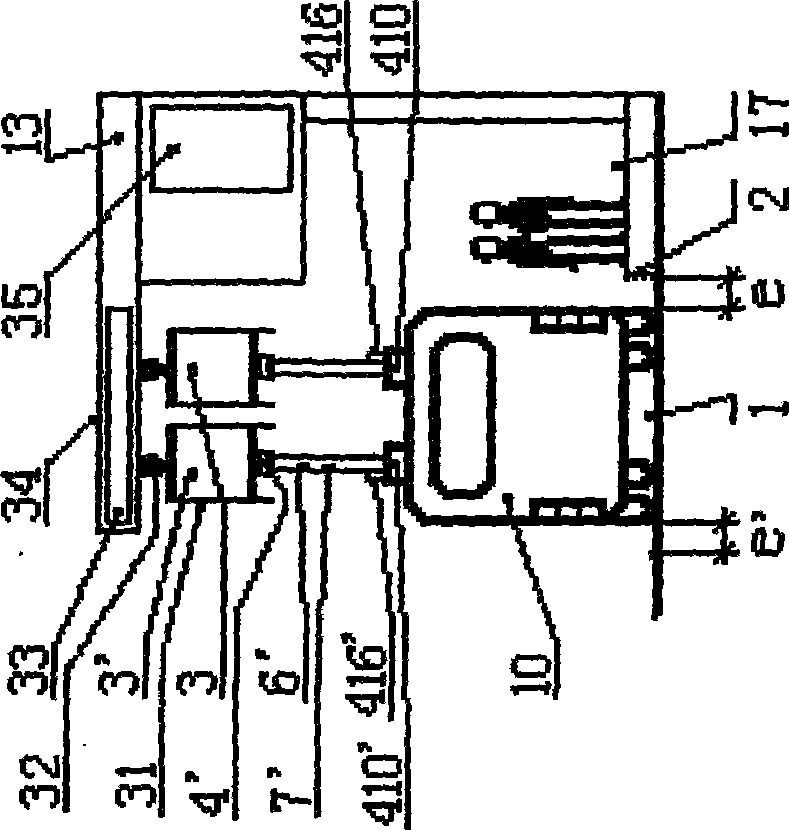

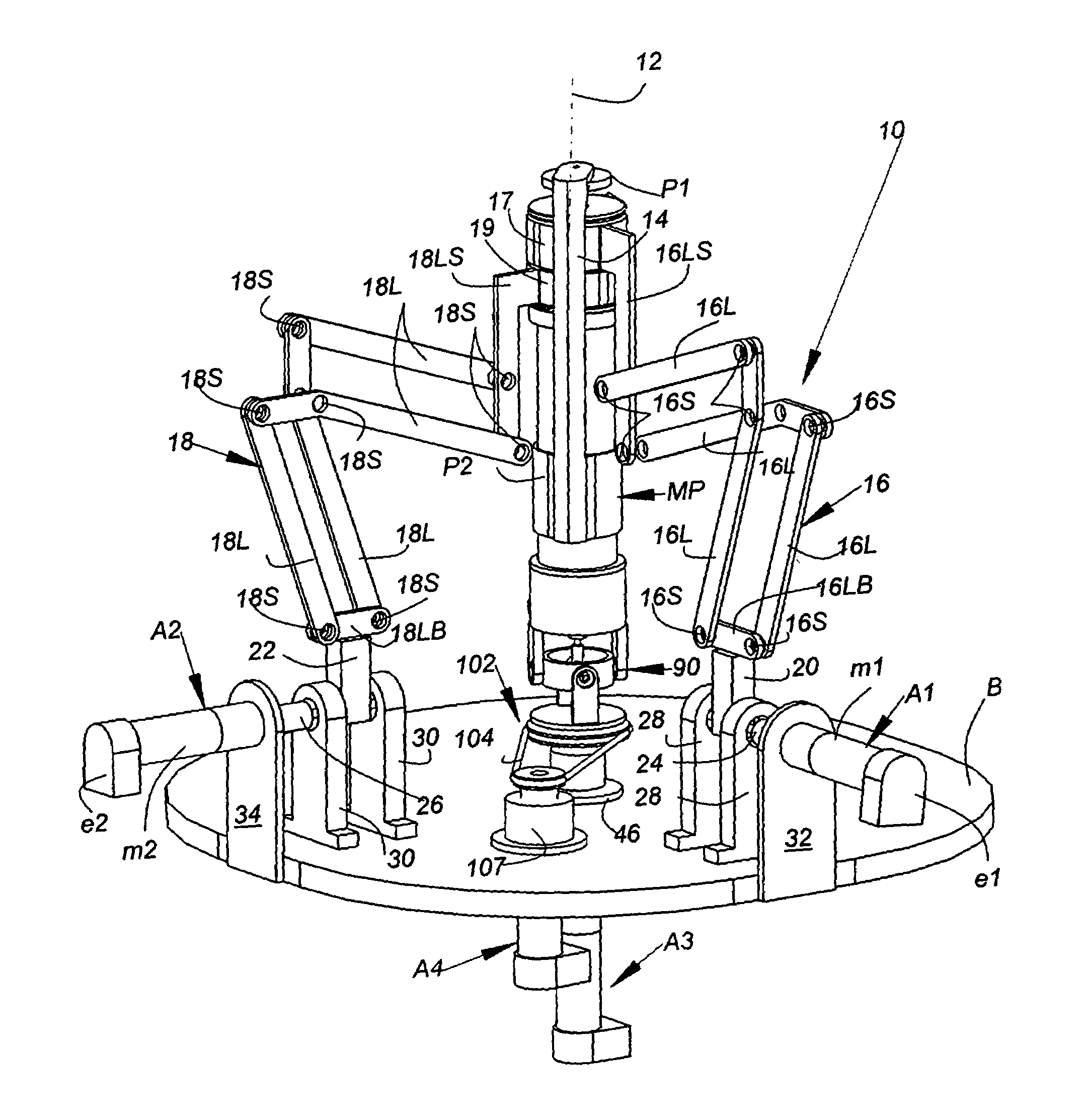

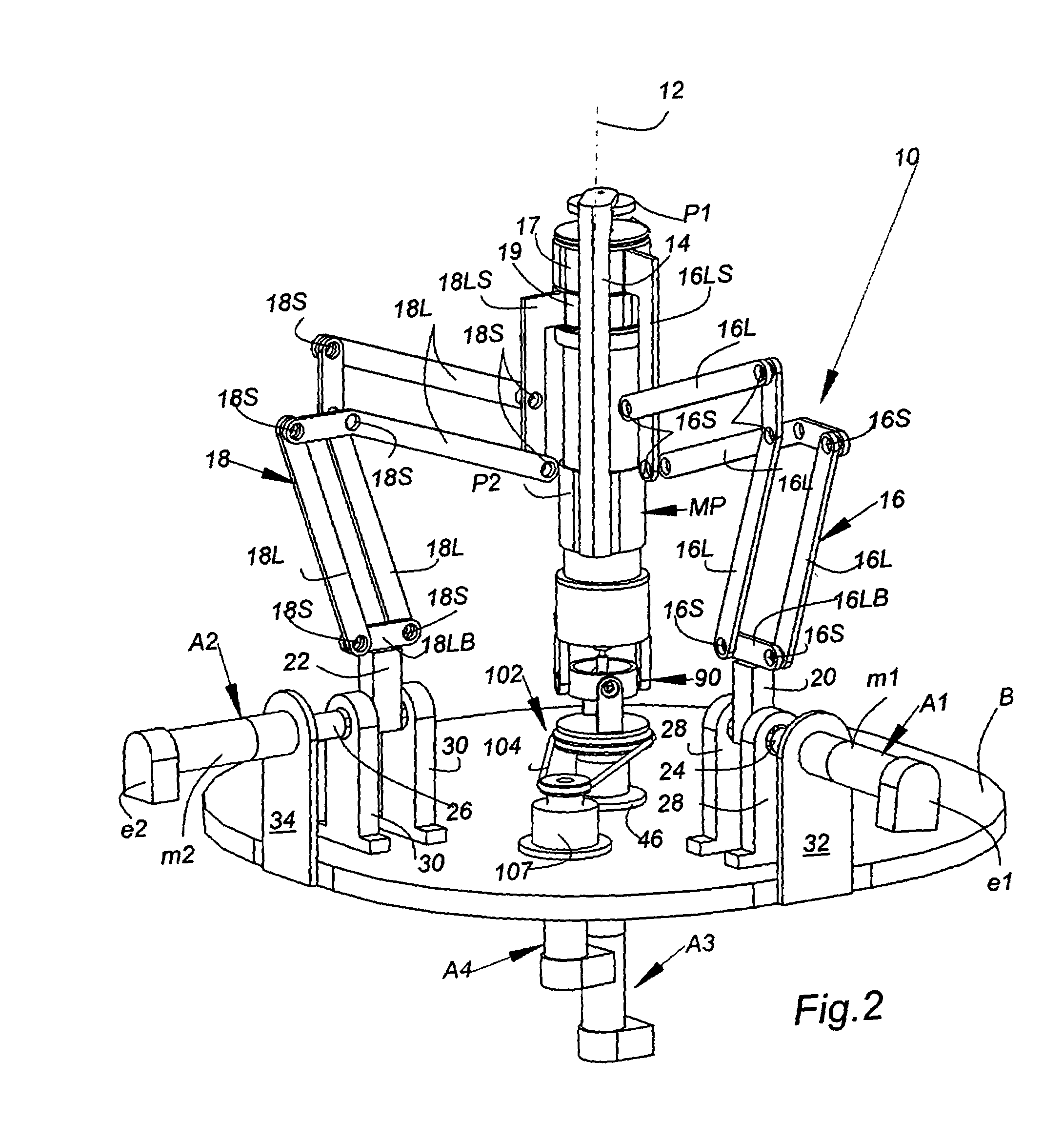

Hand controller and wrist device

InactiveUS20050183532A1Zero backlashEasy to measureMechanical apparatusJointsWorkspaceSingularity free

A compact four degrees of freedom parallel mechanism suitable for use as a hand control or wrist is provided that has backdrivability, is singularity free and has a large workspace and a large force reflecting capability. The structure is light but rigid, and the electric actuators are all placed on the ground or base and provide independent control of each degree of freedom. Each degree of freedom is connected to an actuator either directly or through a cable drive system. The first two degrees of freedom are created by two identical pantographs pivoted together on pivoted joints to define a hemispherical motion of an object (end point) about a center point (hemisphere center). The third and fourth degrees of freedom represent rotation and sliding motions of the object around and along the radius of the created hemisphere, respectively. The axes of these latter degrees of freedom are concentric, and these axes intersect with the axis of the pantographs pivoted joints at the hemispheric center.

Owner:UNIVERSITY OF MANITOBA

Length conservative surgical instrument

ActiveUS20180055583A1Programme-controlled manipulatorSurgical manipulatorsSurgical siteDegrees of freedom

A surgical instrument is described that includes a surgical effector moving with N degrees of freedom for manipulation of objects at a surgical site during surgical procedures. The N degrees of freedom are manipulated by N+1 input controllers and a plurality of cables, the controllers and cables coupled to the surgical effector and configured to change the orientation of the surgical effector about the N degrees of freedom when actuated. In some embodiments, the N+1 input controllers and plurality of cables are further coupled to a pantograph, the pantograph configured to move in a reciprocal manner to the surgical effector when the input controllers and cables are actuated.

Owner:AURIS HEALTH INC

Pantograph type current collector of electric automobile and automatic rapid charging station

InactiveCN101531141AEasy to introduceGuaranteed contactCharging stationsElectric vehicle charging technologyElectricityGas cylinder

The invention provides a pantograph type current collector of electric automobile and an automatic rapid charging station. Two pantograph type current collectors are parallel installed on the electric automobile top which has a single main shaft driven by gas cylinder or hydraulic pressure cylinder, and can act local arc movement, a gimbal is installed on the current collector end, a current slide block is fixed on the gimbal; an output end of the electric automobile charging station is two parallel contact plates on the automobile road upper part, two ends of the contact plate has introduce arc and educe arc; the electric automobile runs over the automobile charging station with standard speed along the road under control by relative sensing, detecting and controller which can complete whole process of collecting bow, charging, de-charging and depressing bow automatically.

Owner:田耕

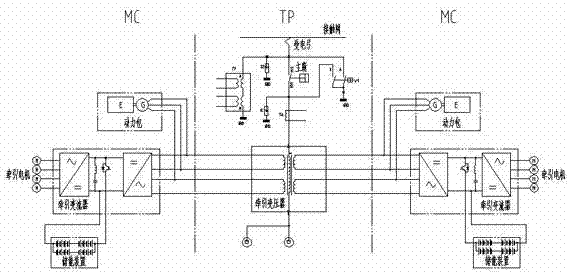

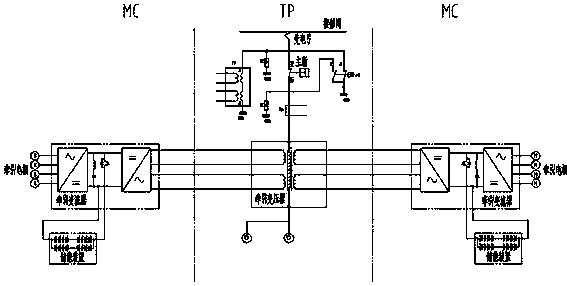

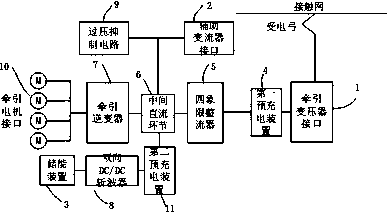

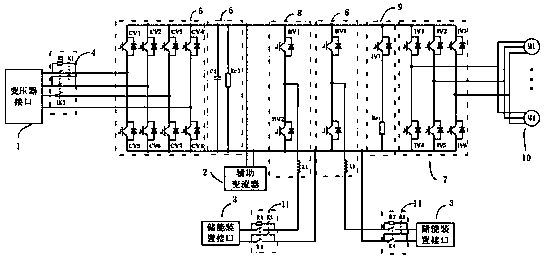

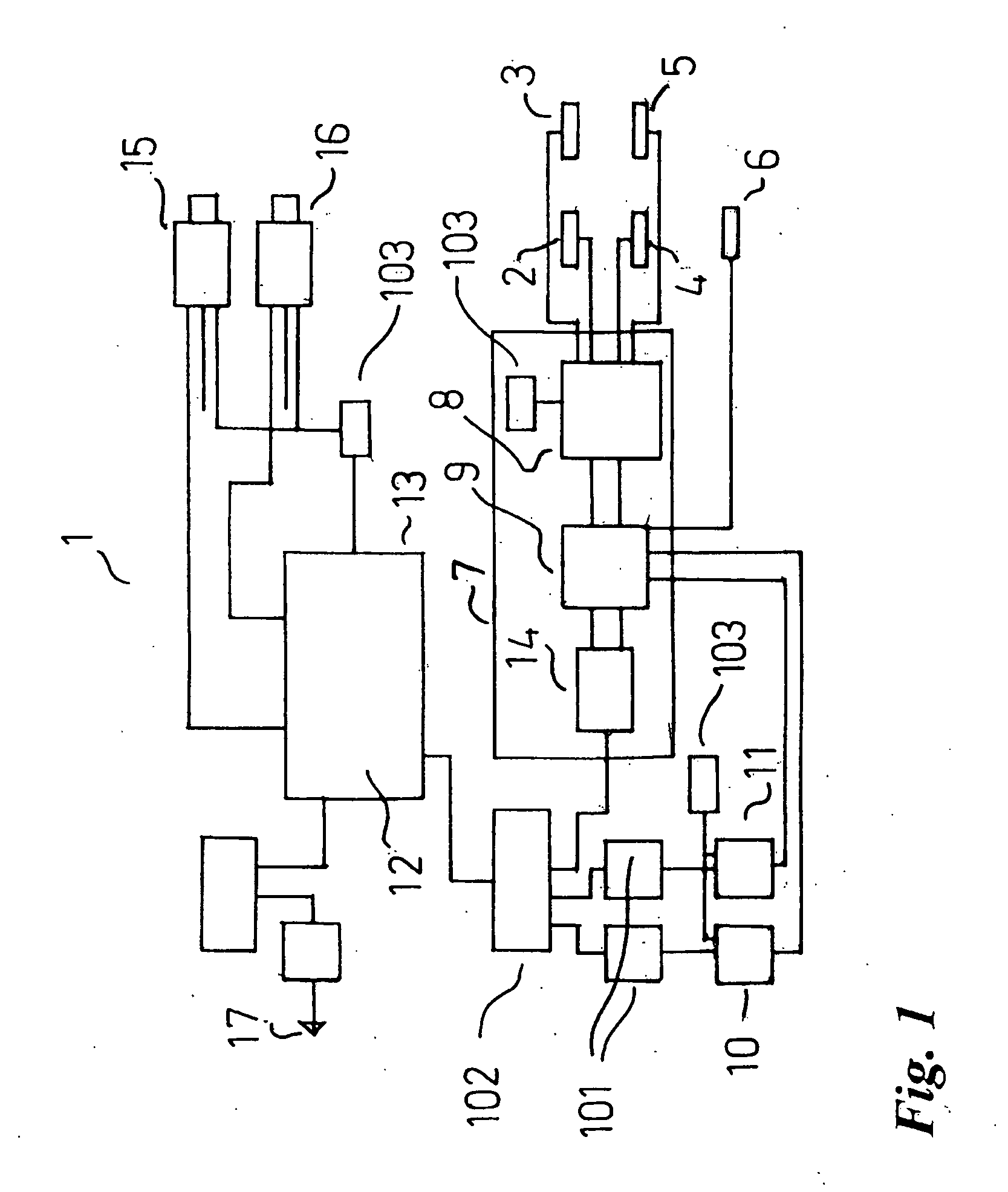

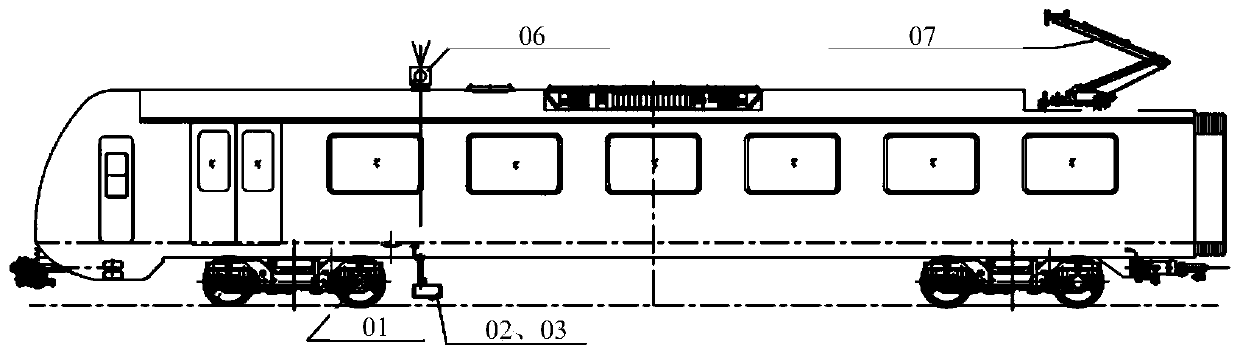

Contact system, power pack and energy storage device hybrid-powered CRH train traction system

ActiveCN103481787ARun across the lineAdapt to different transportation needsRailway vehiclesPropulsion by batteries/cellsTraction transformerConductor Coil

The invention relates to a contact system, power pack and energy storage device hybrid-powered CRH train traction system, which is characterized by mainly comprising a traction transformer, a power pack, an energy storage device, a traction converter and a traction motor, and a contact system is connected with the primary side of the traction transformer through a pantograph, and the two secondary windings of the traction transformer are directly connected with the traction converter; the traction converter is connected with the traction motor, and a diesel engine and a generator form the internal combustion power pack; and the three-phase output of the generator is directly connected with the traction inverter, and the energy storage device is connected with the intermediate DC bus of the traction converter. The traction system can run simultaneously on electrified and non-electrified lines, and can rescue self through power supplied by the power pack and the energy storage device.

Owner:CHINA RAILWAYS CORPORATION +1

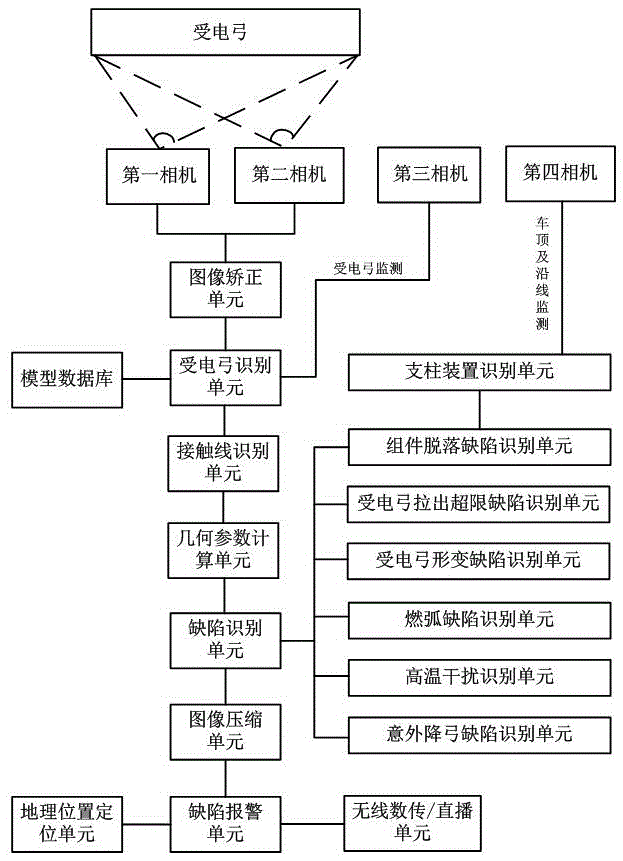

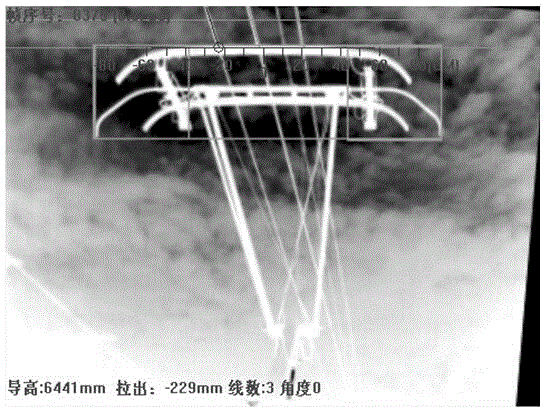

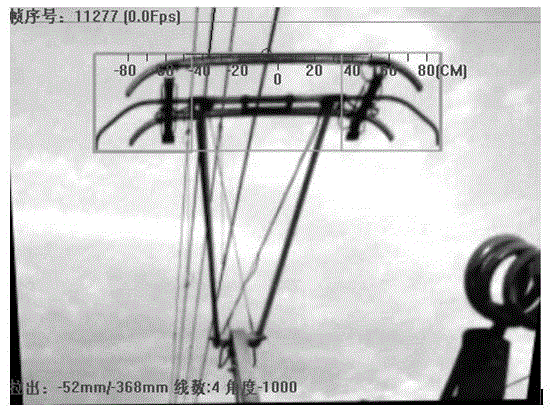

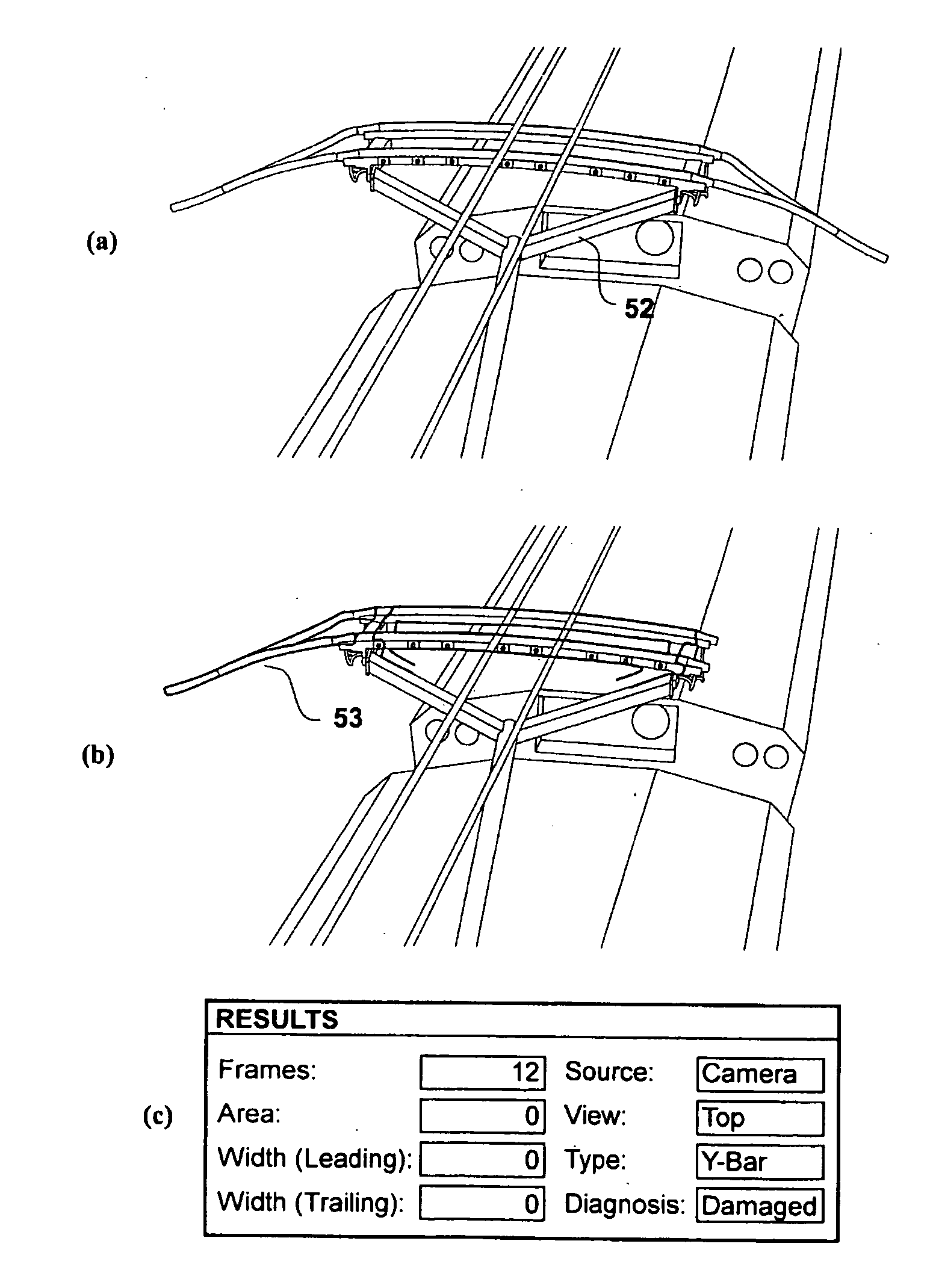

Safety monitoring analysis system for contact net running state

ActiveCN105652154ATimely detection of abnormal defectsFast online monitoringFault location by conductor typesElectricityContact line

The invention discloses a safety monitoring analysis system for contact net running state. The safety monitoring analysis system for contact net running state comprises a first camera, a second camera, an image rectification unit, a pantograph recognition unit, a contact line recognition unit, a model database, a geometrical parameter calculation unit and a defect recognition unit, wherein the defect recognition unit comprises a pantograph deformation defect recognition unit, a component fall-off defect recognition unit, a pantograph pull-out overrun defect recognition unit, an arcing defect recognition unit, a high temperature interference recognition unit and an accident pantograph falling-down defect recognition unit. The safety monitoring analysis system for contact net running state can detect and recognize defects, comprising contact net defect, pantograph defect and pantograph-net relationship defect, existing in the contact net in real time according to pantograph recognized by the pantograph recognition unit, a contact line recognized by the contact line recognition unit and / or geometrical parameters output by the geometrical parameter calculation unit. The safety monitoring analysis system for contact net running state can carry out online monitoring on the pantograph-net relationship without interfering transportation order of operating vehicles and timely find out abnormal defects existing in the pantograph and contact net.

Owner:CHENGDU NAT RAILWAYS ELECTRICAL EQUIP

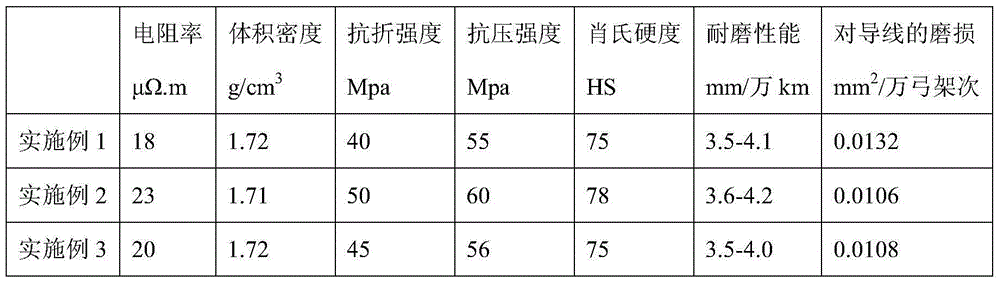

Carbon contact strip of pantograph and manufacturing method thereof

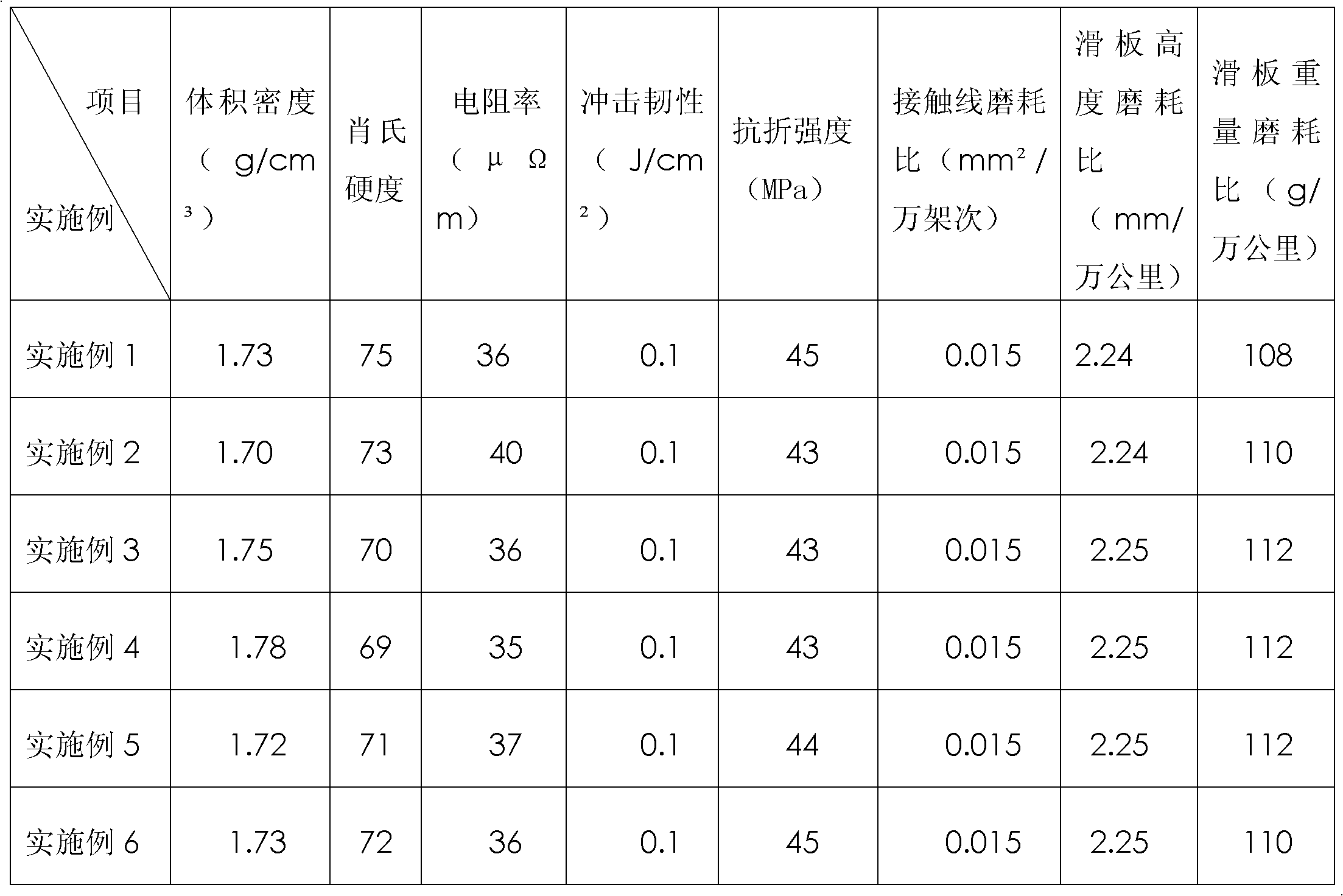

The invention discloses a carbon contact strip of a pantograph and a manufacturing method thereof. The carbon contact strip is prepared from following raw materials, by weight, 28-43 parts of petroleum coke powder, 25-28 parts of asphalt coke powder, 10-12 parts of sprayed carbon black, 2-5 parts of sulfur, 3-5 parts of boron nitride, 5-8 parts of carbon fiber, 4-6 parts of natural graphite, 5-7 parts of artificial graphite, 1-3 parts of calcium chloride powder and 30-35 parts of modified asphalt. The carbon contact strip is high in mechanical strength, is good in self-lubricating performance and electric arc resistance and is wear-resistant. The carbon contact strip can be not only used in various locomotives in railway main lines with speed per hour being 120-250 km / h, but also used in motor train units and high-speed trains with speed per hour being higher than 250 km / h. The carbon contact strip is free of limit of environment and climate conditions.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

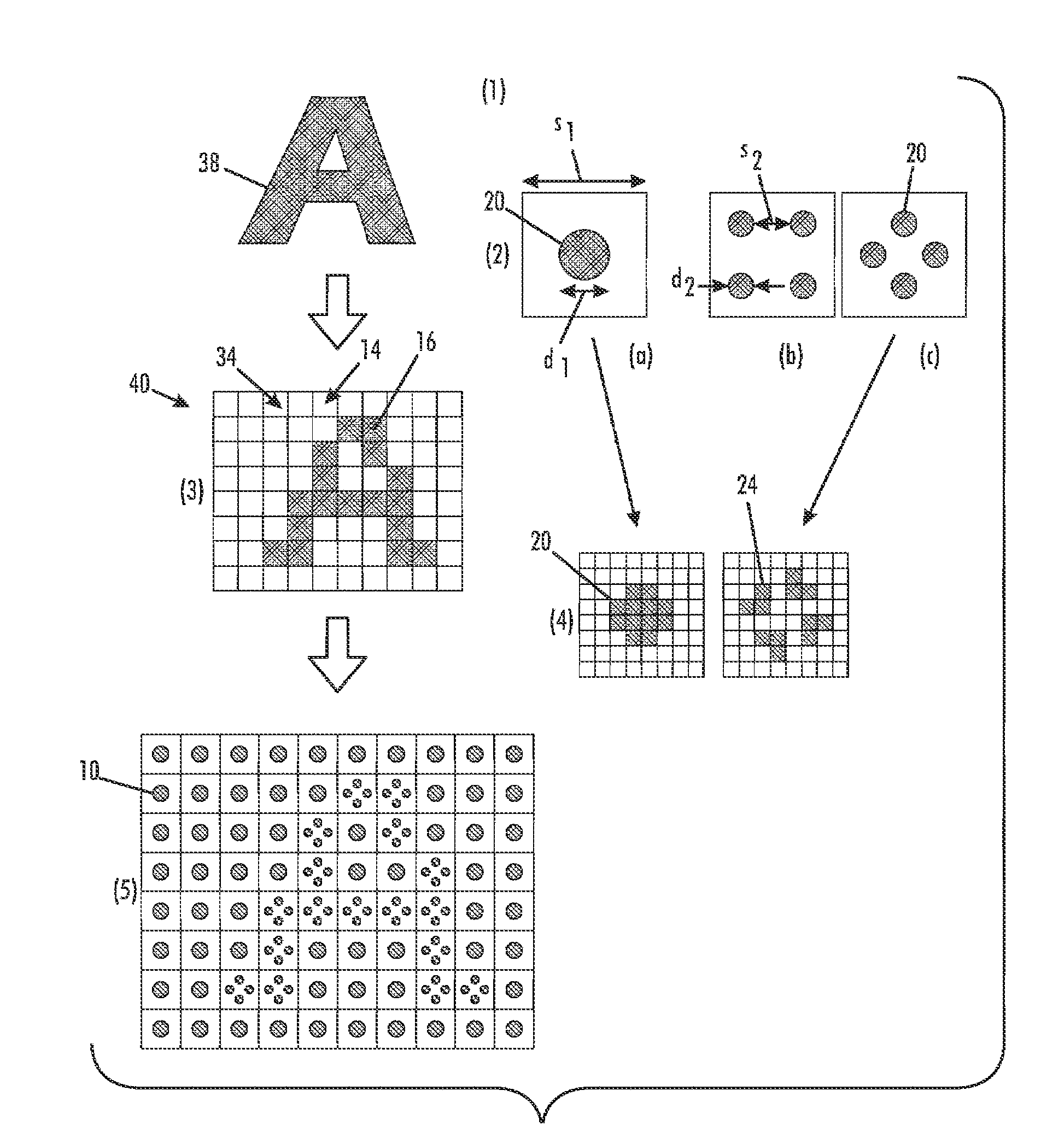

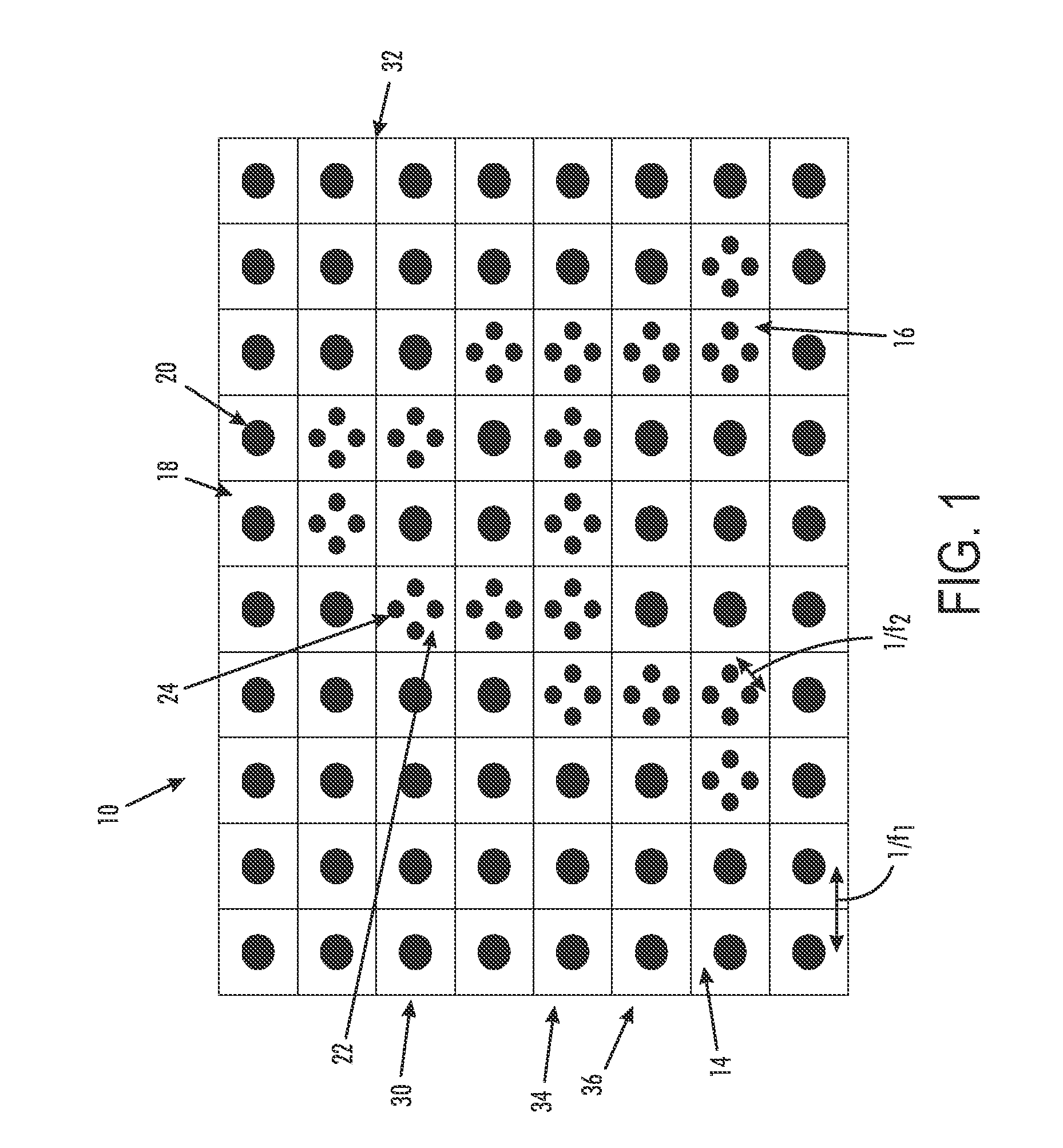

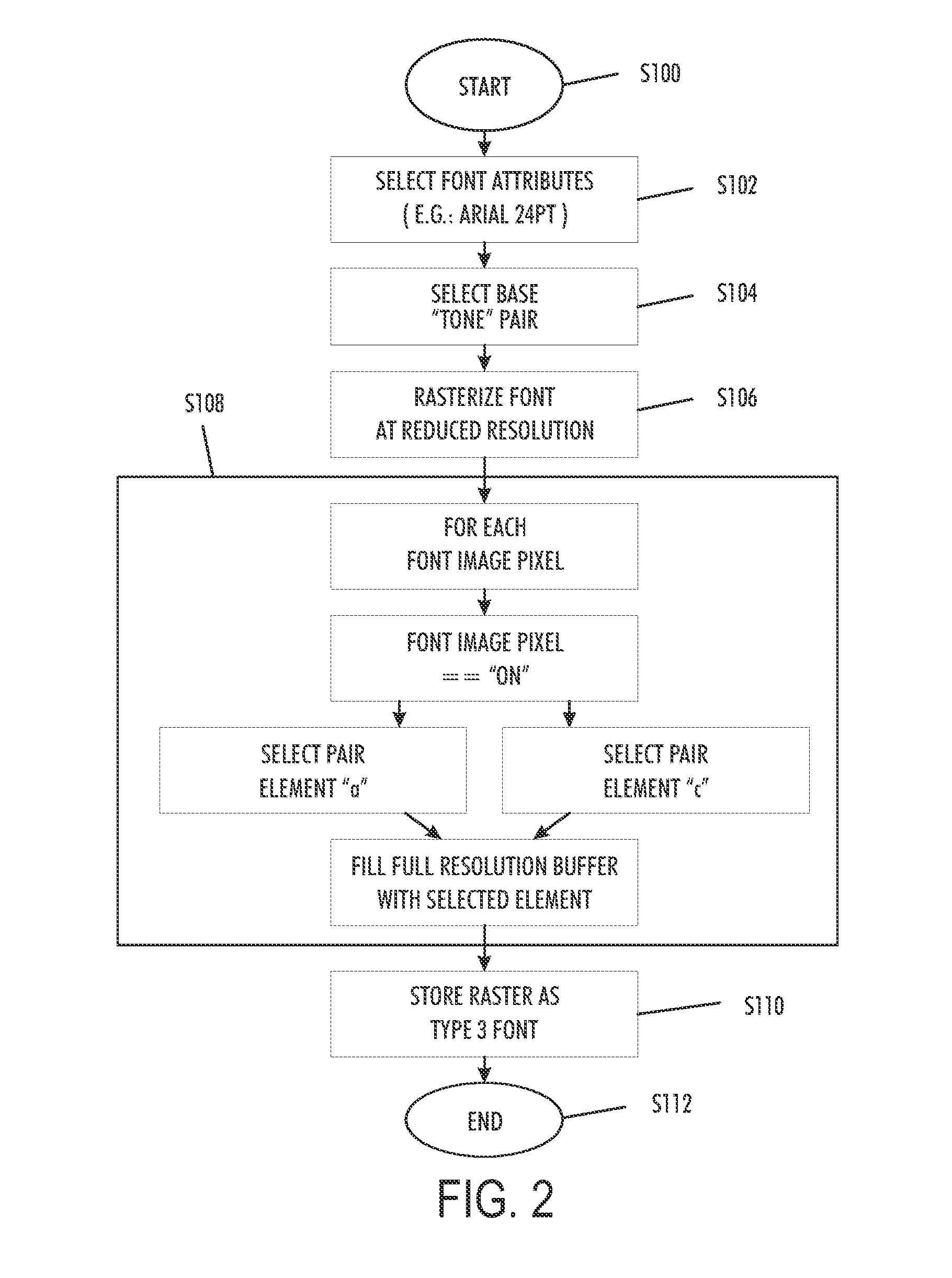

Variable data digital pantographs

InactiveUS20090207433A1Reduce resolutionNatural language data processingVisual representation by electrographic printingComputer graphics (images)Documentation

A variable data pantograph is formed by receiving a variable data string and retrieving at least one character representation from a vocabulary of character representations stored in memory. The retrieved at least one character representation corresponds to the variable data string. Each of the character representations in the vocabulary include a foreground region including a character shape and a background region suitably sized and arranged for encompassing the foreground region. The background region incorporates a first pattern of elements and the foreground region incorporates a second pattern of elements. The retrieved at least one character representation is assembled to form a variable data pantograph, whereby when the variable data pantograph is rendered in an original document, the foreground and background regions are similar in tone, the foreground and background regions being substantially less similar in tone in a copy of the original document to render the character visible.

Owner:XEROX CORP

Electric locomotive pantograph copper-soaking carbon contact strip producing method

ActiveCN104774012AImprove conductivityHigh mechanical strengthPower current collectorsShock resistanceNitrogen gas

The invention discloses an electric locomotive pantograph copper-impregnated carbon contact strip producing method. The method comprises the steps that 1, pitch coke powder, graphite powder, siliconized graphite powder and high temperature pitch are mixed according to the proportion to be ground into powder; the mixed powder is prepressed into a stage stock column, and then the stage stock column is solidified and squeezed to be molded and roasted, so that a composite carbon contact strip is obtained; 2, the composite carbon contact strip is cleaned and dried, then is cooled and placed into a graphite crucible, and is placed in an electric furnace at temperature of 1300-1400 DEG C to be preheated; copper liquid is poured into the crucible to soak the composite carbon contact strip, then the crucible is placed in an oil press cover, nitrogen is led in, heat preservation is kept for 3-5 min under the specific intensity of pressure, and finally cooling is carried after pressure releasing. According to the electric locomotive pantograph copper-impregnated carbon contact strip producing method, the electroconductibility of the copper-impregnated carbon contact strip is improved, the electrical resistivity is lowered, the mechanical strength of the carbon contact strip and copper impregnated angle can be increased, then the carbon contact strip abrasive resistance and self-lubrication are improved, the copper-impregnated carbon contact strip is more resistant to abrasion, main line damage and block dropping are avoided, the shock resistance is high, and the service life of the copper-impregnated carbon contact strip is prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

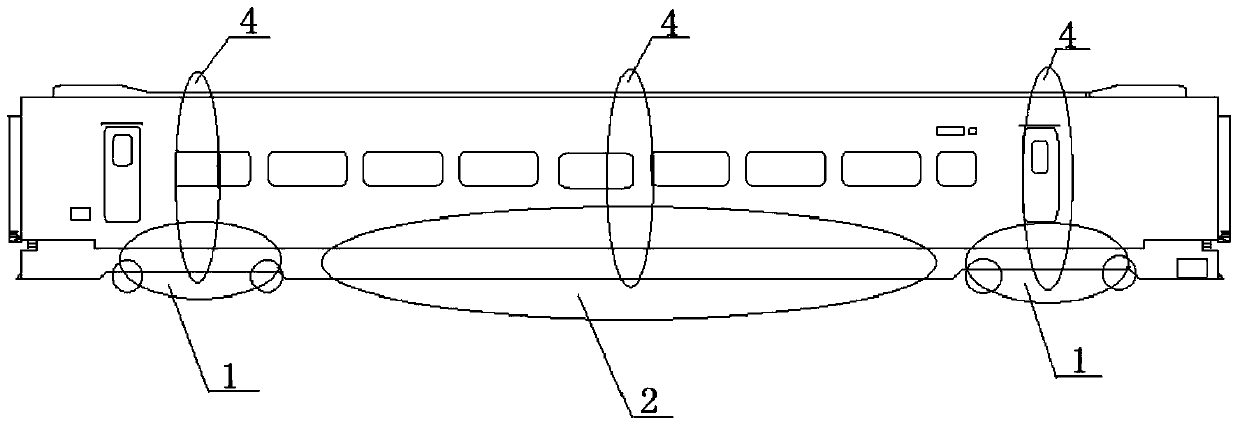

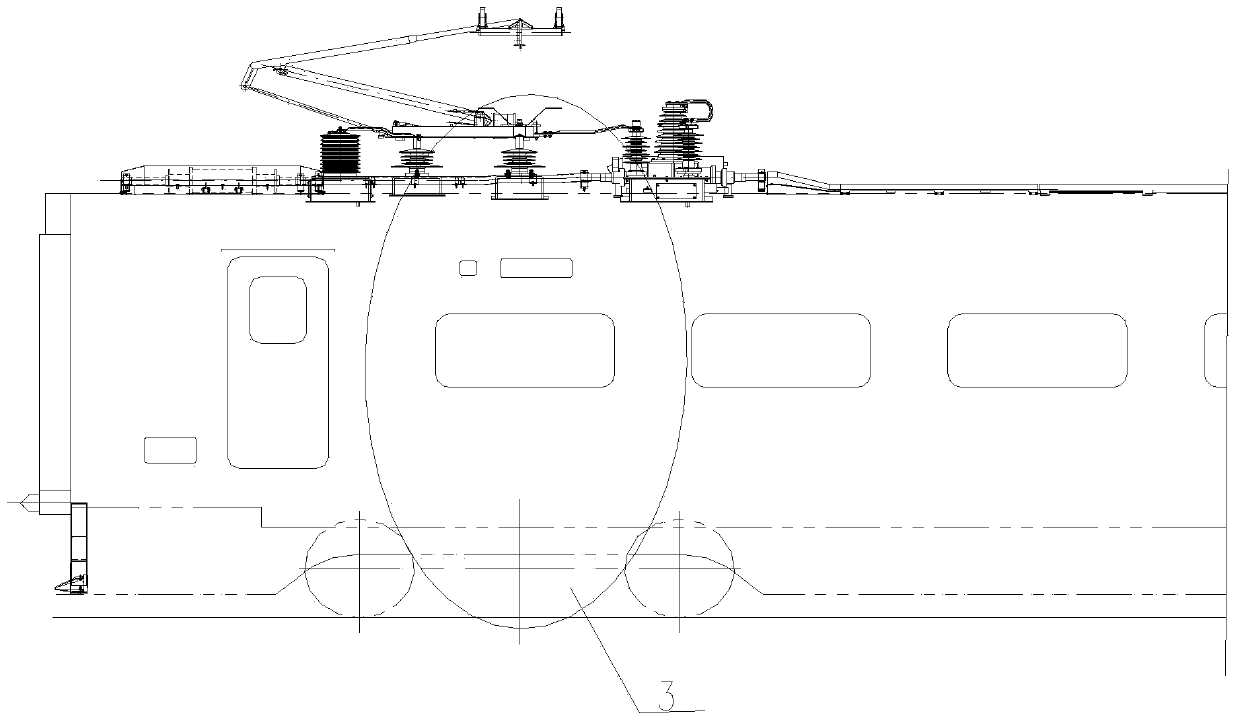

Noise source identifying and testing method for high speed train

ActiveCN103630232ARealize sound source controlImplement path controlSubsonic/sonic/ultrasonic wave measurementBogieSound sources

The invention relates to a noise source identifying and testing method for high speed train. The method comprising the following steps: partitioning noise sources into a steering frame wheel track noise testing area, an equipment noise testing area, a pantograph noise testing area and a pneumatic noise testing area; distributing testing points respectively according to the transmission paths of air sound and structure sound in each area; acquiring testing point data; analyzing through sound and vibration transmission paths; separating the air sound from the structure sound; calculating the contribution of each noise source to interior noise. According to the noise source identifying and testing method, sound sources and vibration sources causing interior noise of the high speed train can be identified, the contribution of each noise source and each vibration source to the interior noise is determined, sound source control and path control of the interior noise are realized fundamentally, and a scientific basis is laid for the vibration and noise reduction structural design of the high speed train.

Owner:CRRC QINGDAO SIFANG CO LTD

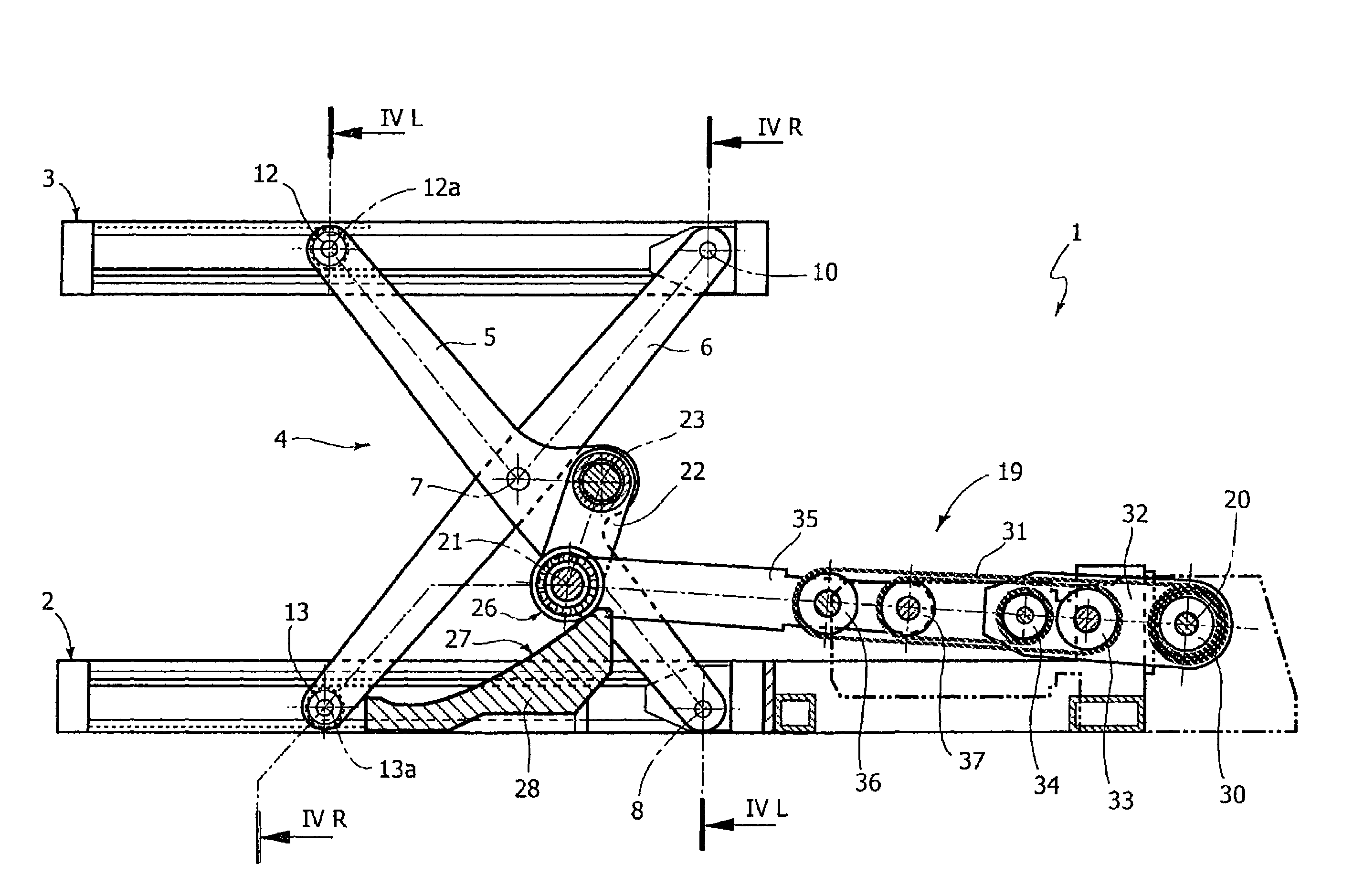

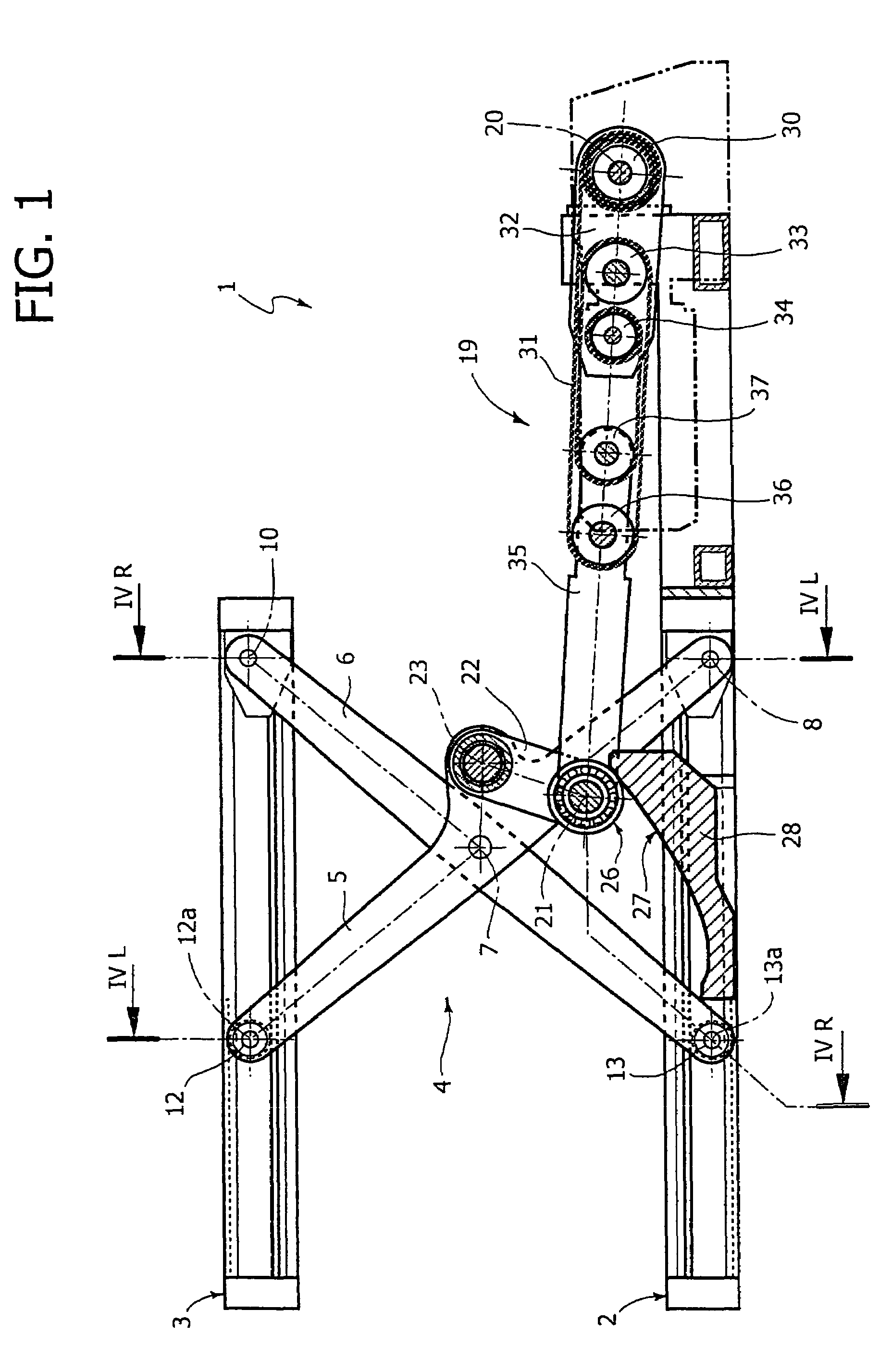

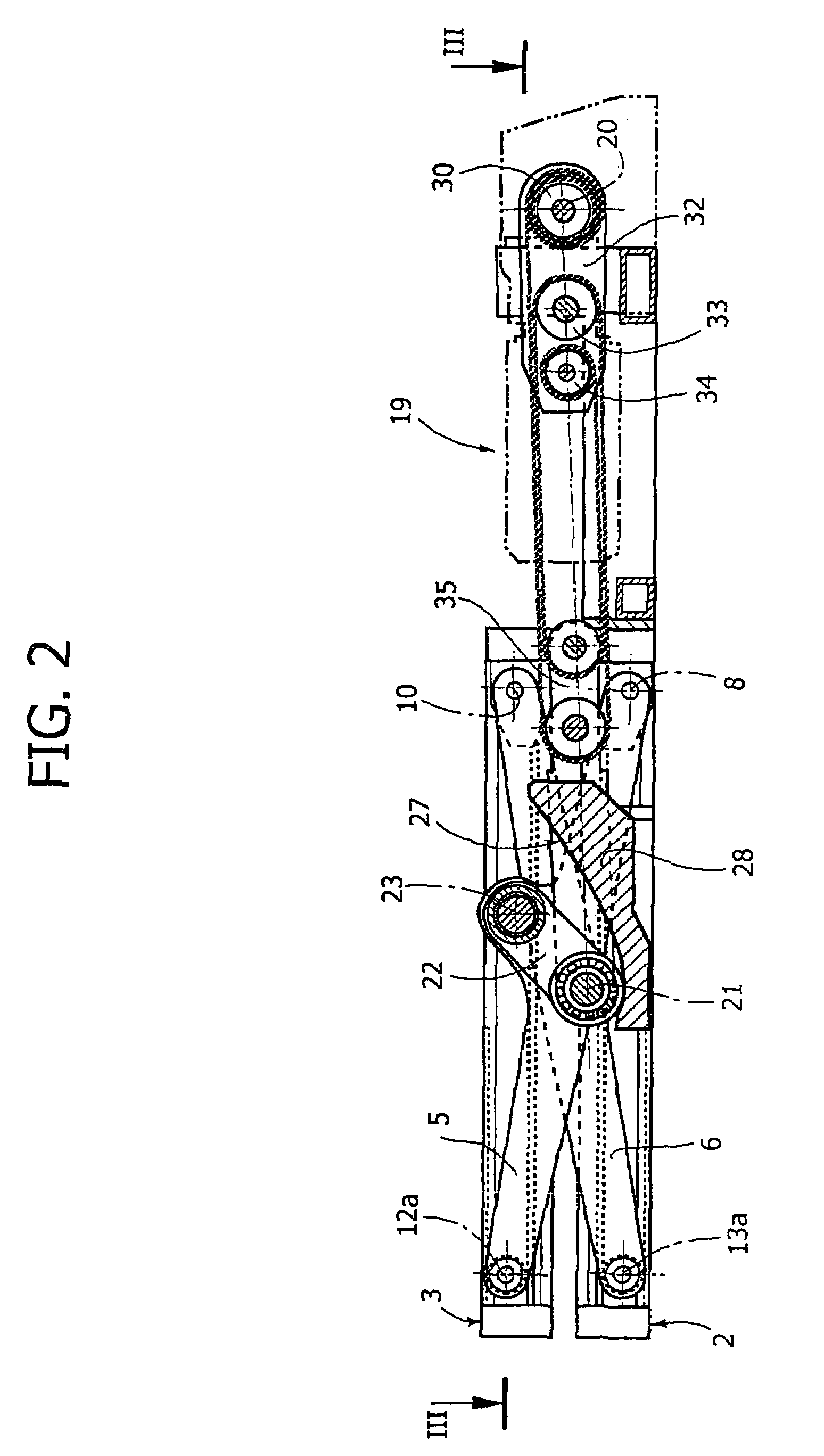

Load lifting device

A load lifting device includes a lower structure, an upper structure movable with respect to the lower structure between a lowered position and a raised position, a scissors-like pantograph, including at least two arms mutually articulated according to an X-shape, connecting the upper structure to the lower structure, and an actuator device controlling the position of a connecting element which connects the actuator to one arm of the pantograph and having a cam-following element cooperating with a fixed cam. The actuator is articulated to the connecting element around an axis which is located below the articulation axis of the connecting element to the arm of the pantograph, in such a way that, when the actuator is activated to cause the lifting movement of the device, the connecting element acts as a pushing strut subjected substantially to compression between the cam and the articulated arm. Preferably the actuator includes a hoist device with a belt, cord, or chain engaging a number of pulleys.

Owner:COMAU SPA

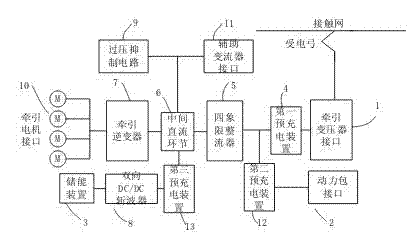

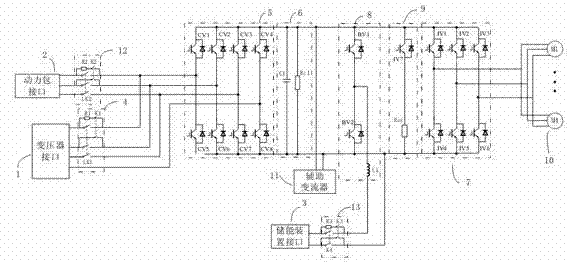

Motor train unit traction system adopting catenary and energy storing devices for hybrid power supply

ActiveCN103350647ARun across the lineAdapt to different transportation needsRailway vehiclesAc-ac conversionTraction systemEmergency rescue

A motor train unit traction system adopting a catenary and energy storing devices for hybrid power supply is characterized by mainly comprising a traction transformer, the energy storing devices, traction converters and traction motors, wherein the catenary is connected with a primary side of the traction transformer through a pantograph, and two secondary side windings of the traction transformer are directly connected with the traction converters which are connected with the traction motors; and the energy storing devices are connected with direct current buses in the middles of the traction converters. The motor train unit traction system can simultaneously operate on an electrification line and a non-electrification line, and the braking energy is absorbed through the energy storing devices under the working condition without the catenary, so that cyclic utilization of the energy is realized, and a green energy saving idea is reflected. Under special rainy or snowy weather or when the catenary is damaged, the motor train unit traction system has emergency rescue and readiness functions, and the energy storing devices can also be used as portable power sources.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Pantograph damage and wear monitoring system

InactiveUS20100322465A1Long exposure timeIncrease gain valueImage analysisRailway vehiclesMonitoring siteElectricity

A system for evaluating the condition of a pantograph, the system comprising: a track-side pantograph monitoring station that captures one or more images of a pantograph, while a locomotive comprising the pantograph is in normal service; a station management system that analyses one or more images captured at the monitoring site and determines the condition of the pantograph; and a user interface that controls the system and presents the results of the analysis to the user. A user may control the track-side monitoring station and station management system remotely.

Owner:QUEENSLAND RAIL LIMITED

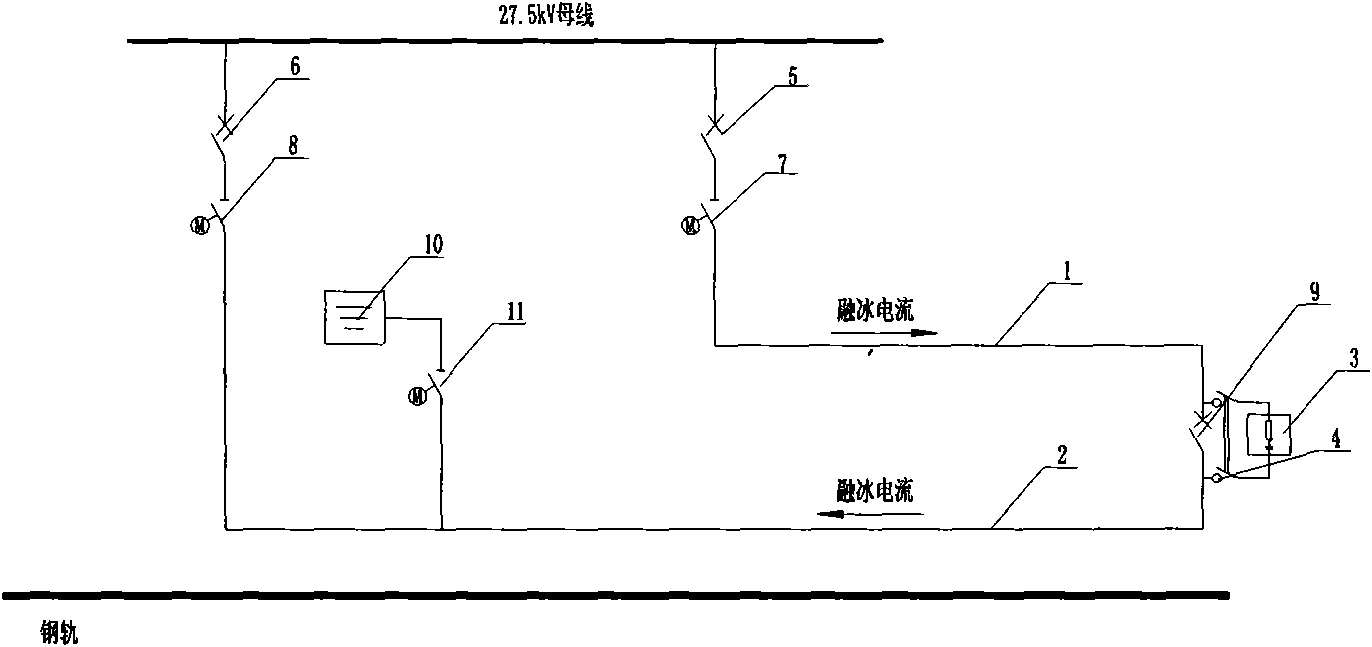

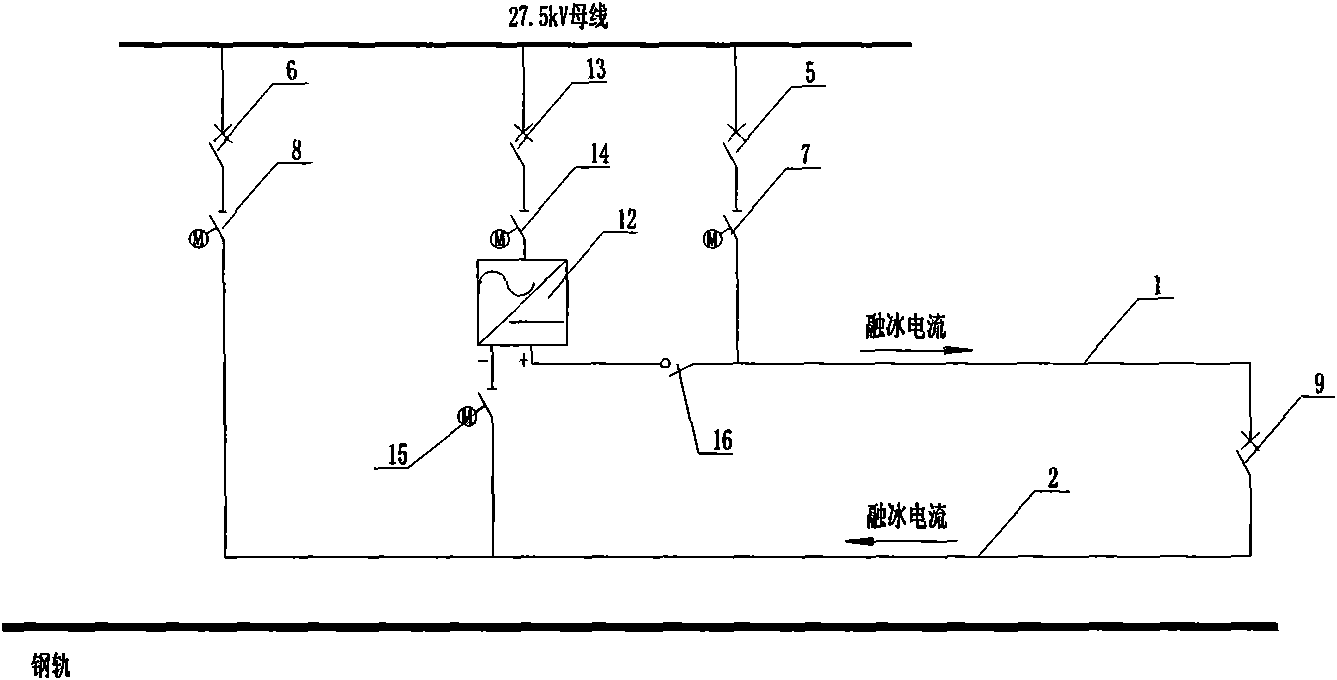

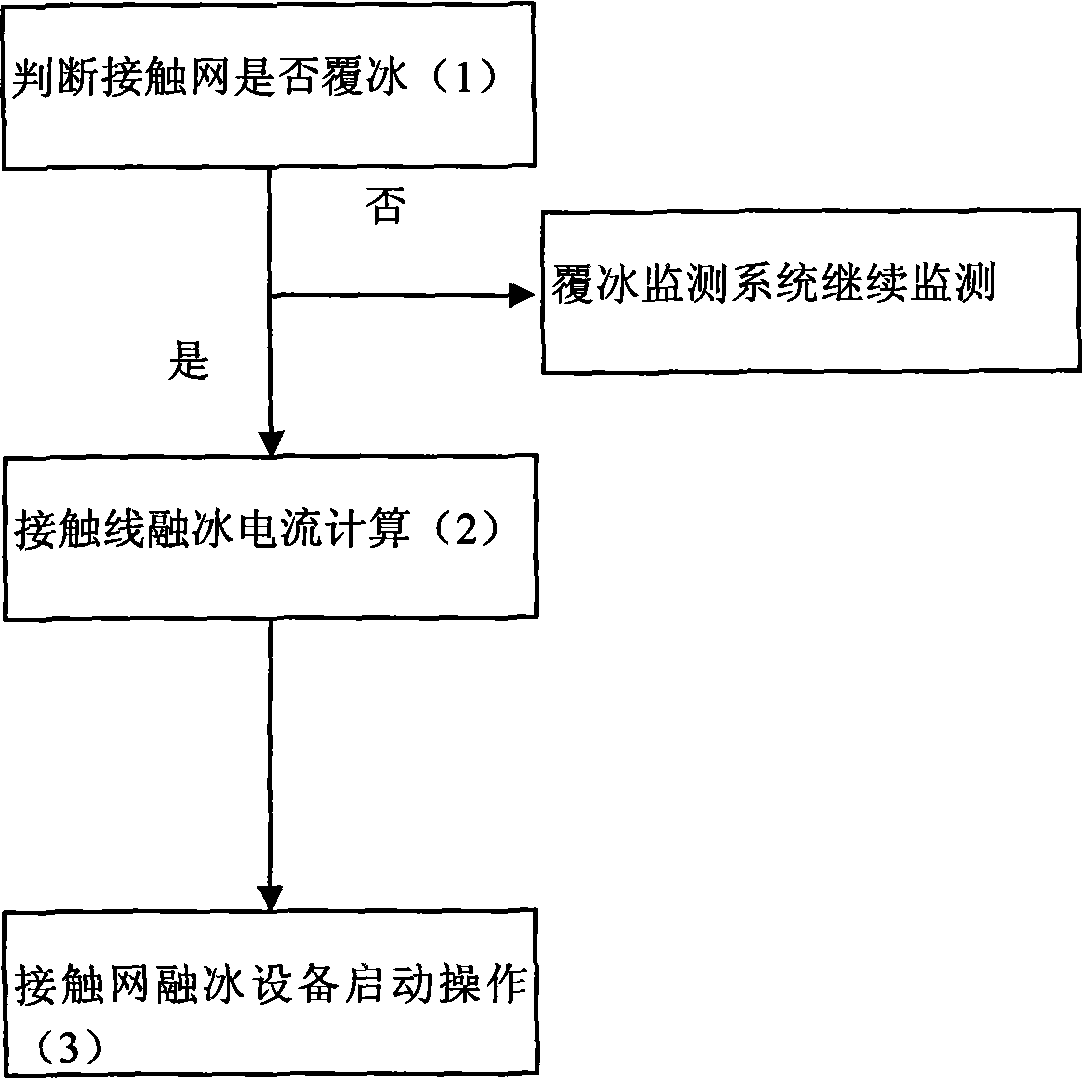

Ice melting method for overhead contact system of electrified railway and ice melting system thereof

InactiveCN101640400AEliminate damageReduce the impactOverhead installationTrolley linesEngineeringContact line

The invention relates to an ice melting method for overhead contact system of an electrified railway and an ice melting system thereof. Major hazards of ice coating of the overhead contact system include accidents that pantograph of electric locomotives can not contact with a contact line to obtain current, contact system brandishes, even falls of piles and collapses, and the like. In the ice melting method and the ice melting system thereof, an upper overhead contact system and a lower overhead contact system are connected in series to form a circuit by a section post, AC or DC ice melting current is input at the head end of the circuit, ice coating thickness and safe ice melting current value are obtained by analyzing meteorological and overhead contact system parameters with an ice coating data processing and control module, and then the ice melting system is controlled to output the ice melting current at the end of the circuit, thus ice is molten by Joule heat generated by the current. In the ice melting method and the ice melting system thereof, ice attached to the contact line is molten by joule heat, and compared with the deicing modes of artificial knock and the like of operation departments, the ice melting method and the ice melting system thereof greatly improve deicing efficiency, thus reducing the effect on railway transport, and eliminating damages of external force on the contact line.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

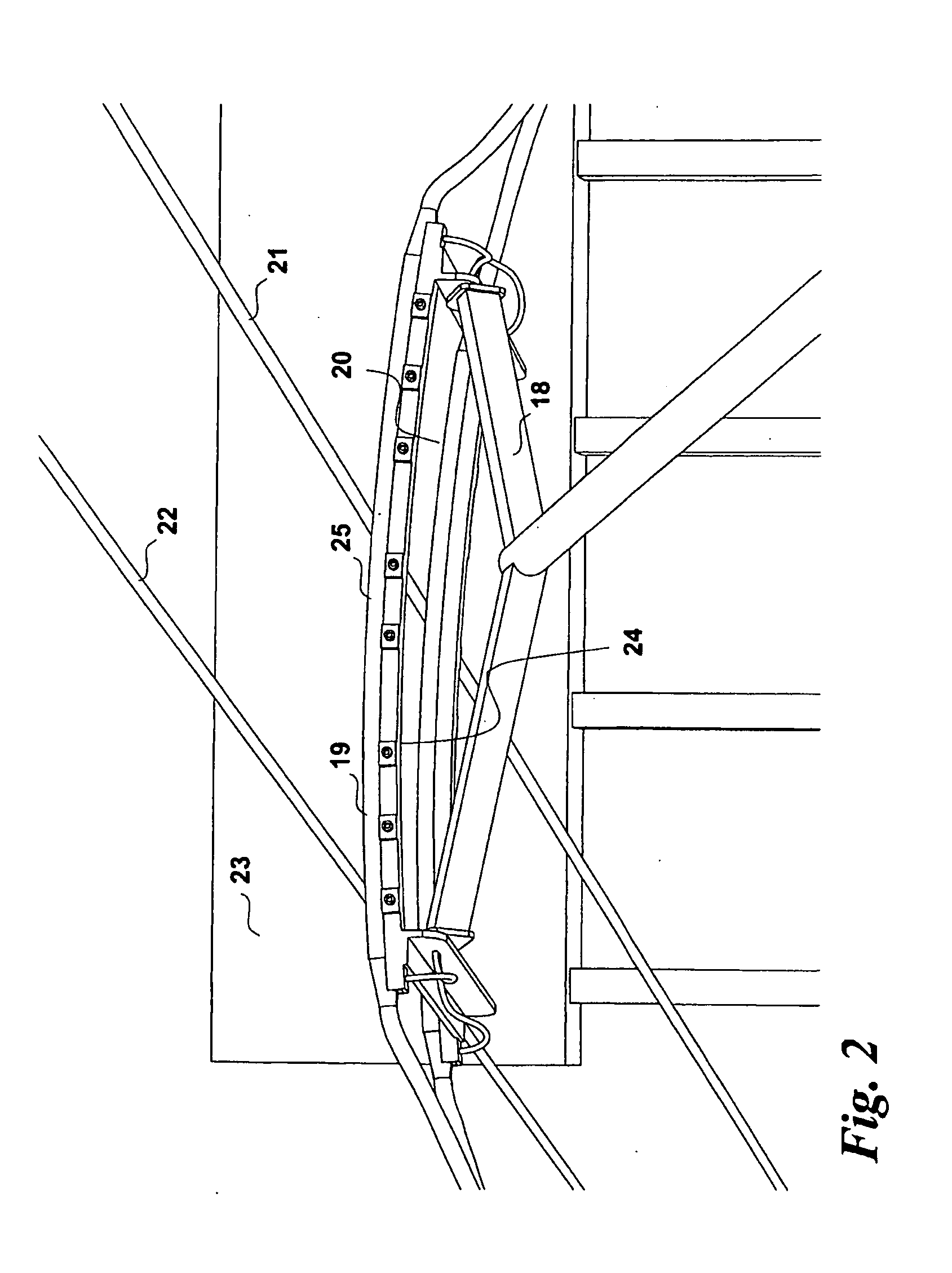

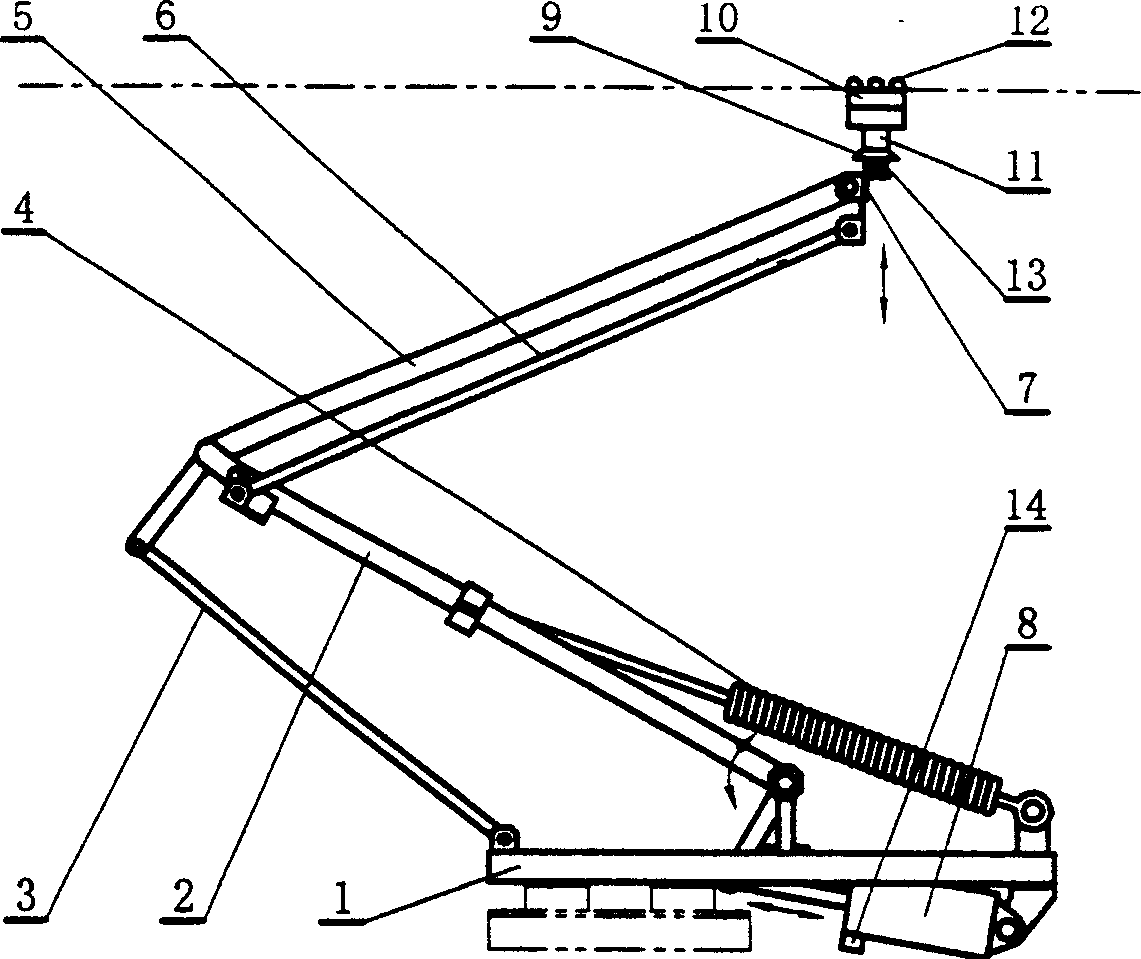

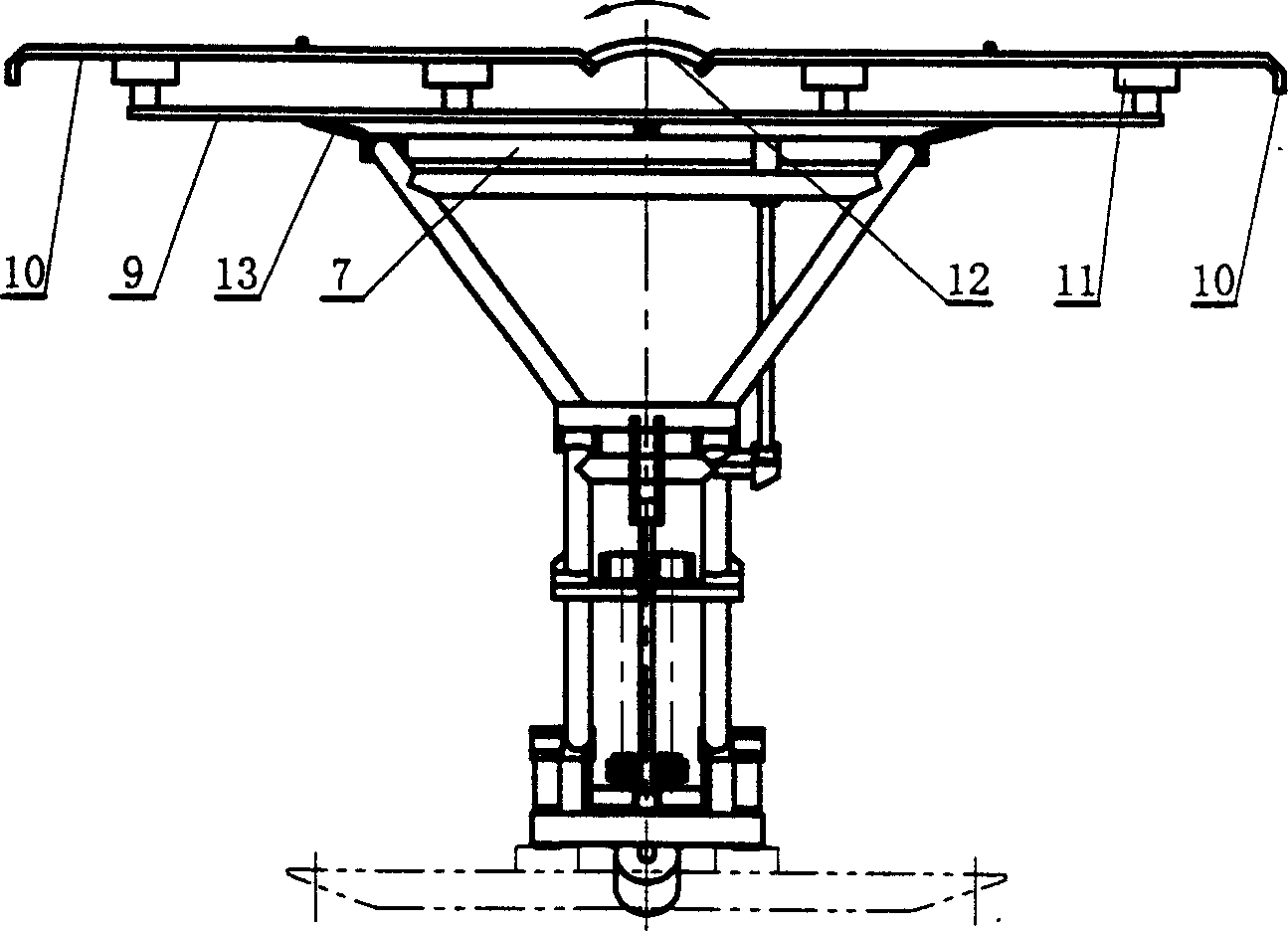

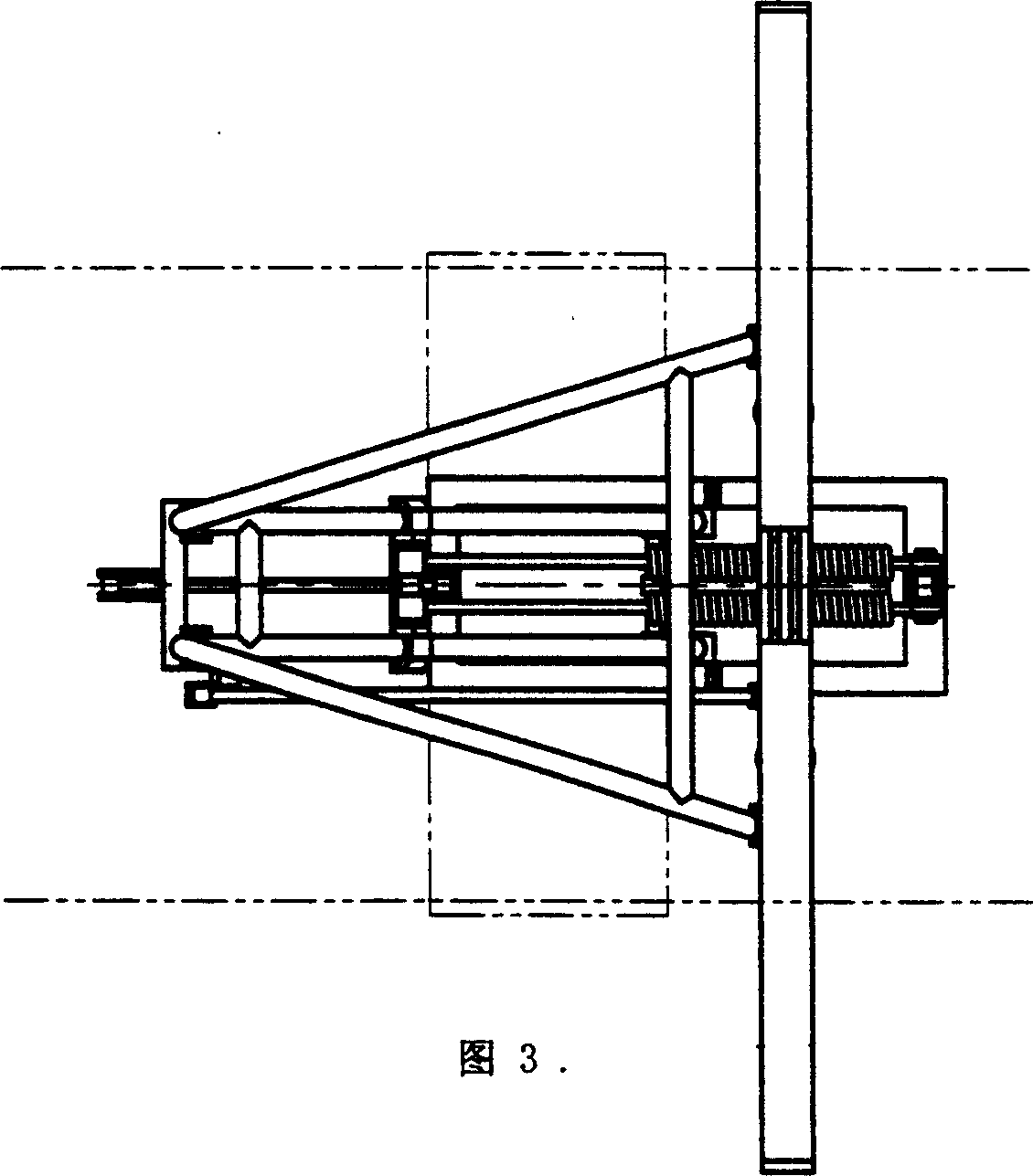

Double-wire powering trolleybus pantograph

InactiveCN1486887ASolve the problem of network access difficultiesIncrease contactPower current collectorsEngineeringSlide plate

The double-wire powering trolleybus bow collector used in city public traffic includes bottom frame, lower arm rod, pull rod, bow raising spring, upper arm rod, balance rod, head seat cross rod, cylinder, top cross rod, electrically conducting top sliding board, insulating seat, insulating rod and top spring. The six parts including bottom frame, lower arm rod, pull rod, upper arm rod, balance rod and head seat cross rod constitute two duplex planar quadric crank mechanisms with rods connected flexibly. The electrically conducting top sliding board is separated by the middle insulating rod into two current collectors fixed via the insulating seat on the top cross rod; and the top cross rod is connected flexibly to the head seat cross rod, with two ends being connected via the top spring. When the low arm rod is oscillated by the cylinder on the bottom frame and the bow raising spring, the electrically conducting top sliding board will ascend or descent. The present invention has good contact performance, etc.

Owner:SHANGHAI JIAO TONG UNIV

Hand controller and wrist device

InactiveUS7204168B2Zero backlashEasy to measureManual control with multiple controlled membersMechanical apparatusWorkspaceSingularity free

A compact four degrees of freedom parallel mechanism suitable for use as a hand control or wrist is provided that has backdrivability, is singularity free and has a large workspace and a large force reflecting capability. The structure is light but rigid, and the electric actuators are all placed on the ground or base and provide independent control of each degree of freedom. Each degree of freedom is connected to an actuator either directly or through a cable drive system. The first two degrees of freedom are created by two identical pantographs pivoted together on pivoted joints to define a hemispherical motion of an object (end point) about a center point (hemisphere center). The third and fourth degrees of freedom represent rotation and sliding motions of the object around and along the radius of the created hemisphere, respectively. The axes of these latter degrees of freedom are concentric, and these axes intersect with the axis of the pantographs pivoted joints at the hemispheric center.

Owner:UNIVERSITY OF MANITOBA

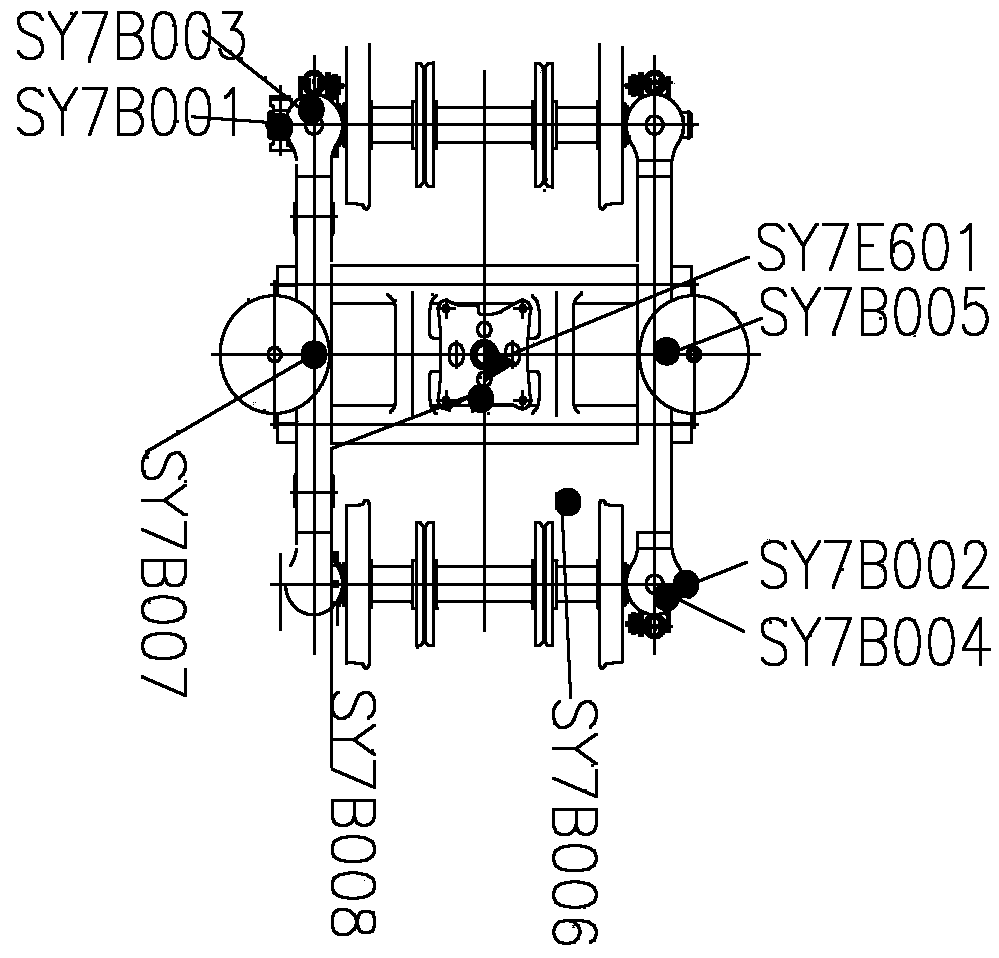

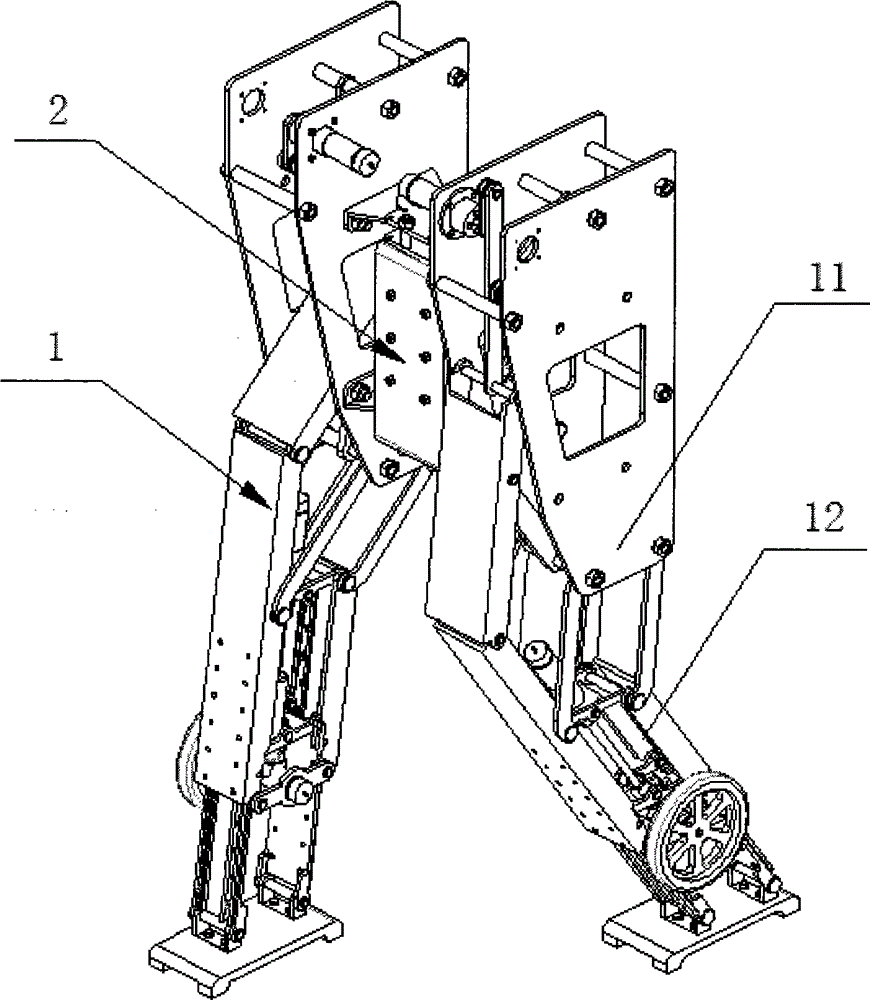

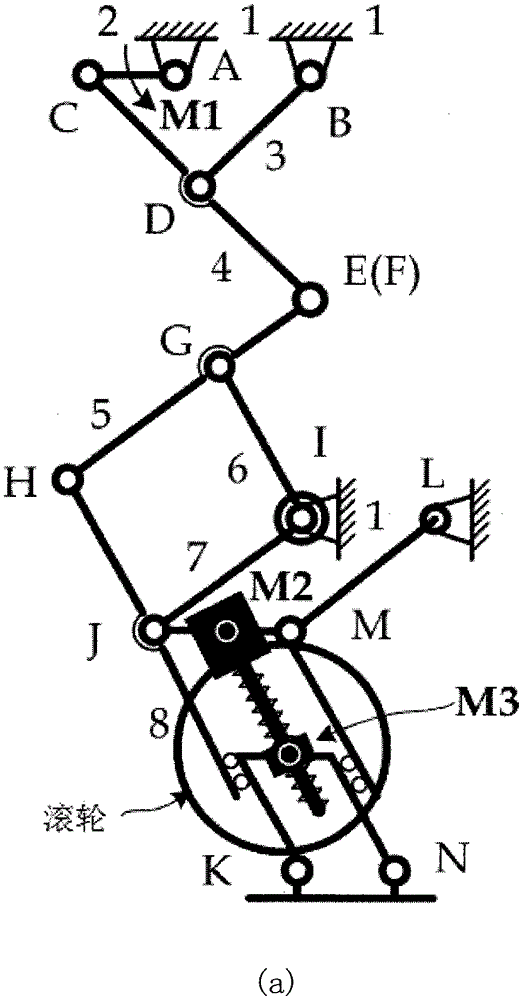

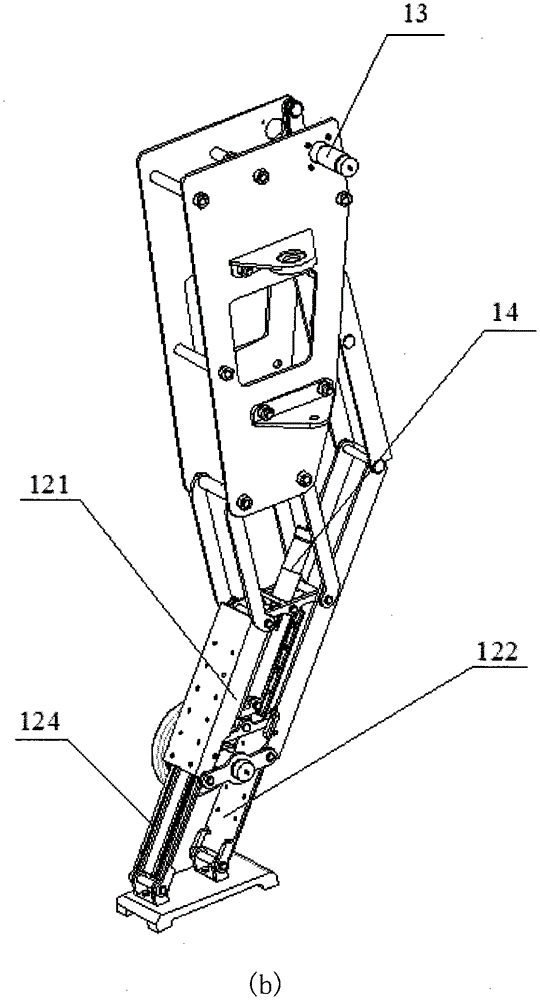

Double-foot robot walking mechanism

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

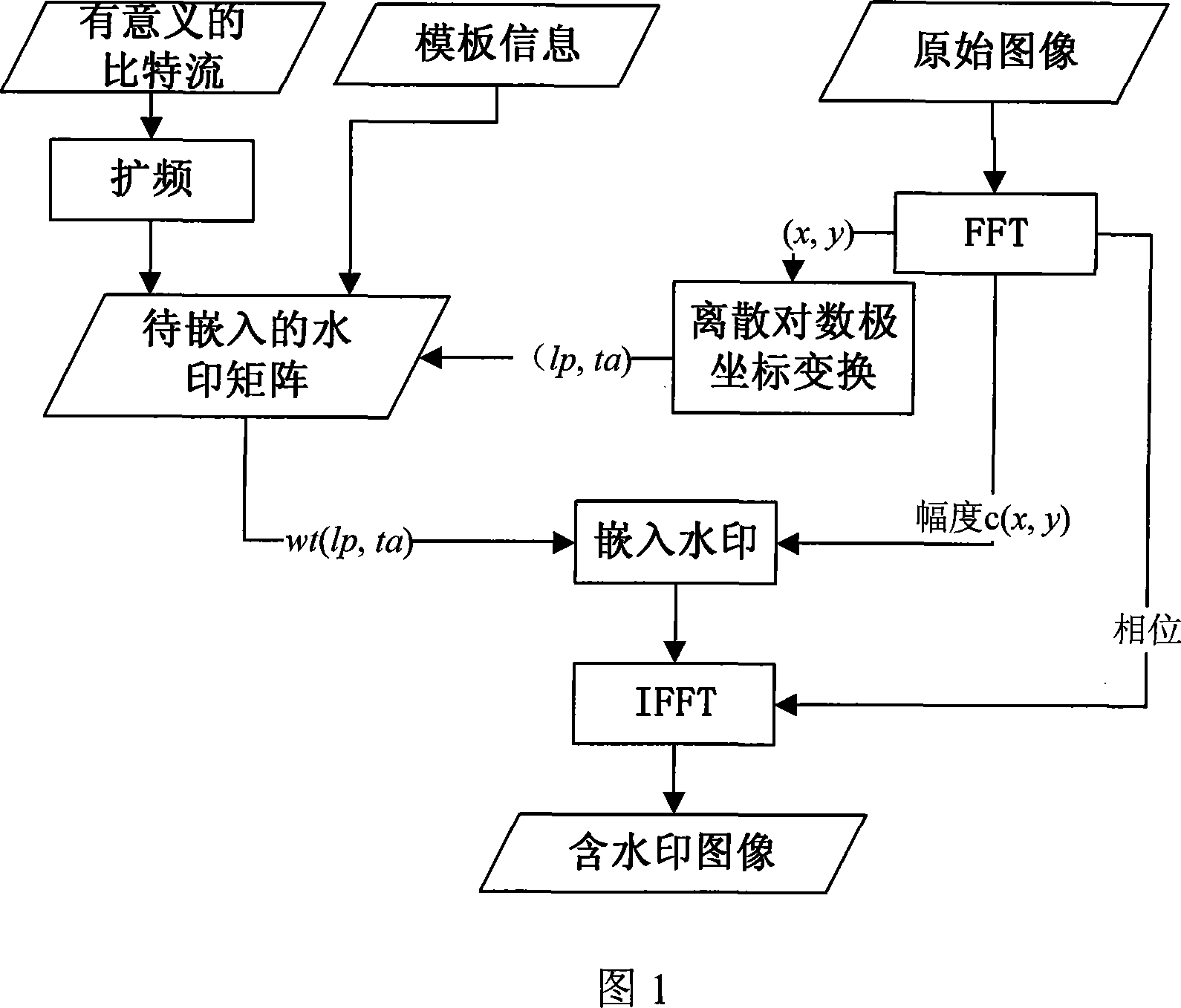

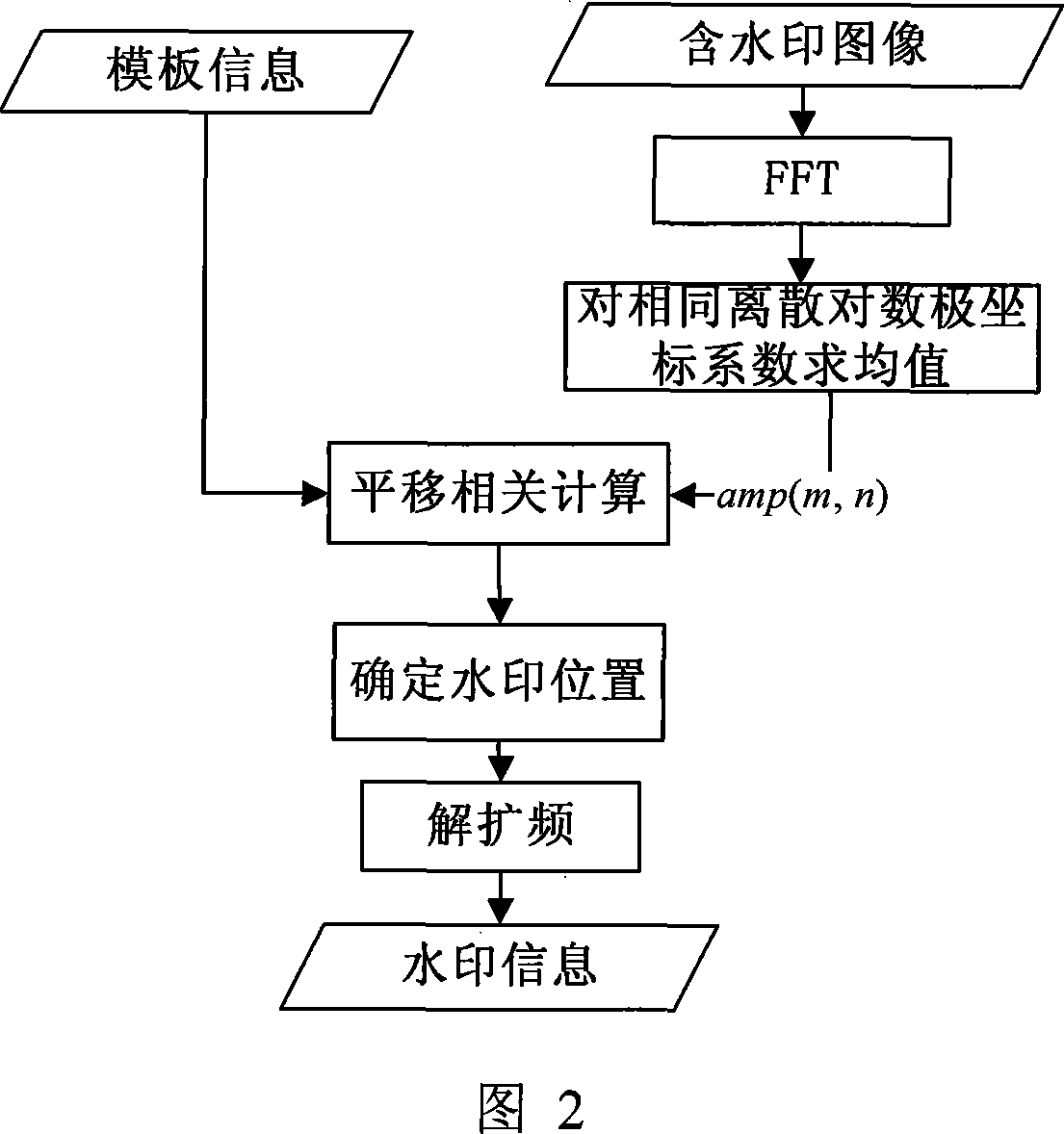

Multiple bit digital watermark method capable of resisting printing, scanning and geometric transformation

The invention discloses a multi-bit digital watermark method against the print scanning and the geometric transformation, which comprises the following steps: embedding the watermark in dispersion Fourier amplitude coefficient of the image; determining which Fourier amplitude coefficient every watermark bit embeds in according to the dispersion logarithmic polar coordinate of the Fourier amplitude coefficient; making the watermark detecting and extracting out-of-step when the image is carried out the geometric transformation of the pantographic rotating or the print scanning; synchronizing the information watermark according to the relation of the original mode and embedded mold when the watermark is detected and extracted because the pantograph and the rotating of the image corresponds with the translation of the Fourier logarithmic polar coordinate field at the radial and angel direction; extracting the meaning watermark information bit string; introducing the real interpolation and saving the time because the watermark embedding and detecting process doesn' t need the image interpolation arithmetic for the image and the Fourier amplitude coefficient; protecting the embedded mode. The invention can apply to the copyright protection of the digital image and video, false proof of the file and evidence, the monitoring of video broadcast.

Owner:SUN YAT SEN UNIV

Preparation method of pantograph carbon contact strip material

The invention relates to the field of carbon materials, in particular to a preparation method of a pantograph carbon contact strip material. The preparation method comprises mixing kneading, molding, first roasting, impregnating and secondary roasting. During mixing kneading, the aggregate is electrolytic graphene with a particle size of 30-45nm, semi-reinforcing carbon black with a particle size of 40-55nm and needlelike petroleum coke. The binder is medium temperature pitch, and the impregnating agent is impregnating pitch. Specifically, the particle size of the electrolytic grapheme is preferably 35-45nm, more preferably 36-42nm, and most preferably 40nm; and the particle size of the semi-reinforcing carbon black is preferably 50-65nm, more preferably 55-62nm, and most preferably 60nm. The carbon contact strip material prepared by the method provided by the invention has physico-chemical performance indexes comparable to other carbonaceous materials, can replace other carbonaceous materials to produce pantograph carbon contact strip materials, and has the advantages of wide raw material sources, low price, relatively simple preparation process, low technical difficulty, low production cost, and high product performance.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Carbon fiber reinforced slide plate for pantograph of electric locomotive and its manufacture

The present invention relates to vehicle fittings. The carbon fiber reinforced slide plate for pantograph of electric locomotive is manufactured with graphite, electrolytic copper powder / copper fiber as conducting stuffing, carbon fiber as reinforcing material and heat resisting modified phenolic resin as adhesive and through hot pressing. It has excellent friction performance, long service life, few wear of contacted wire, excellent mechanism performance and impact strength as high as ten times that of metal soaked carbon slide plate. The manufacture process has low cost, low power consumption and short period. The carbon fiber reinforced slide plate may be used in pantograph for rail transportation.

Owner:YIXING CITY YIYANG MEXICAN ROOTS MATERIALS

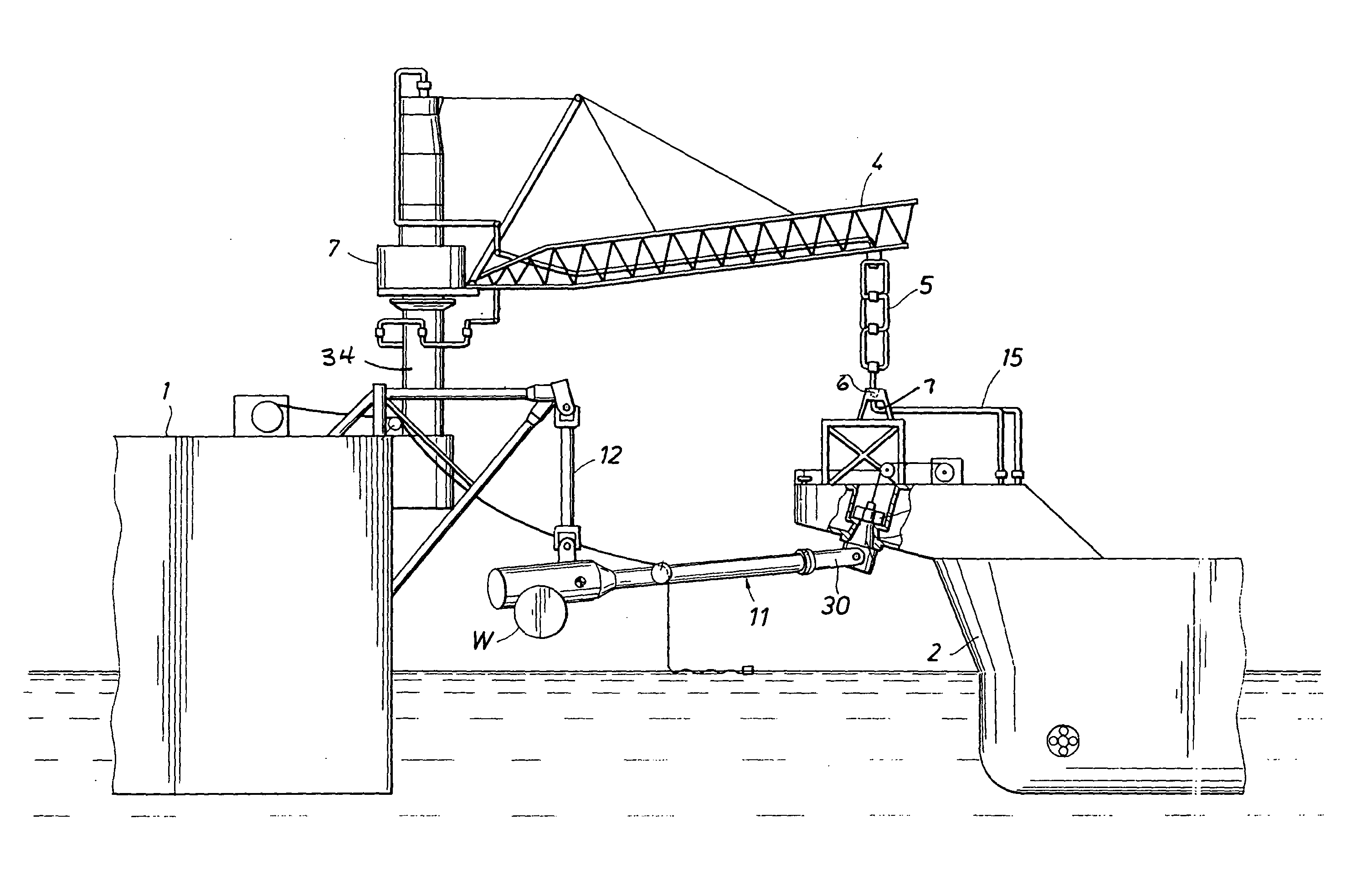

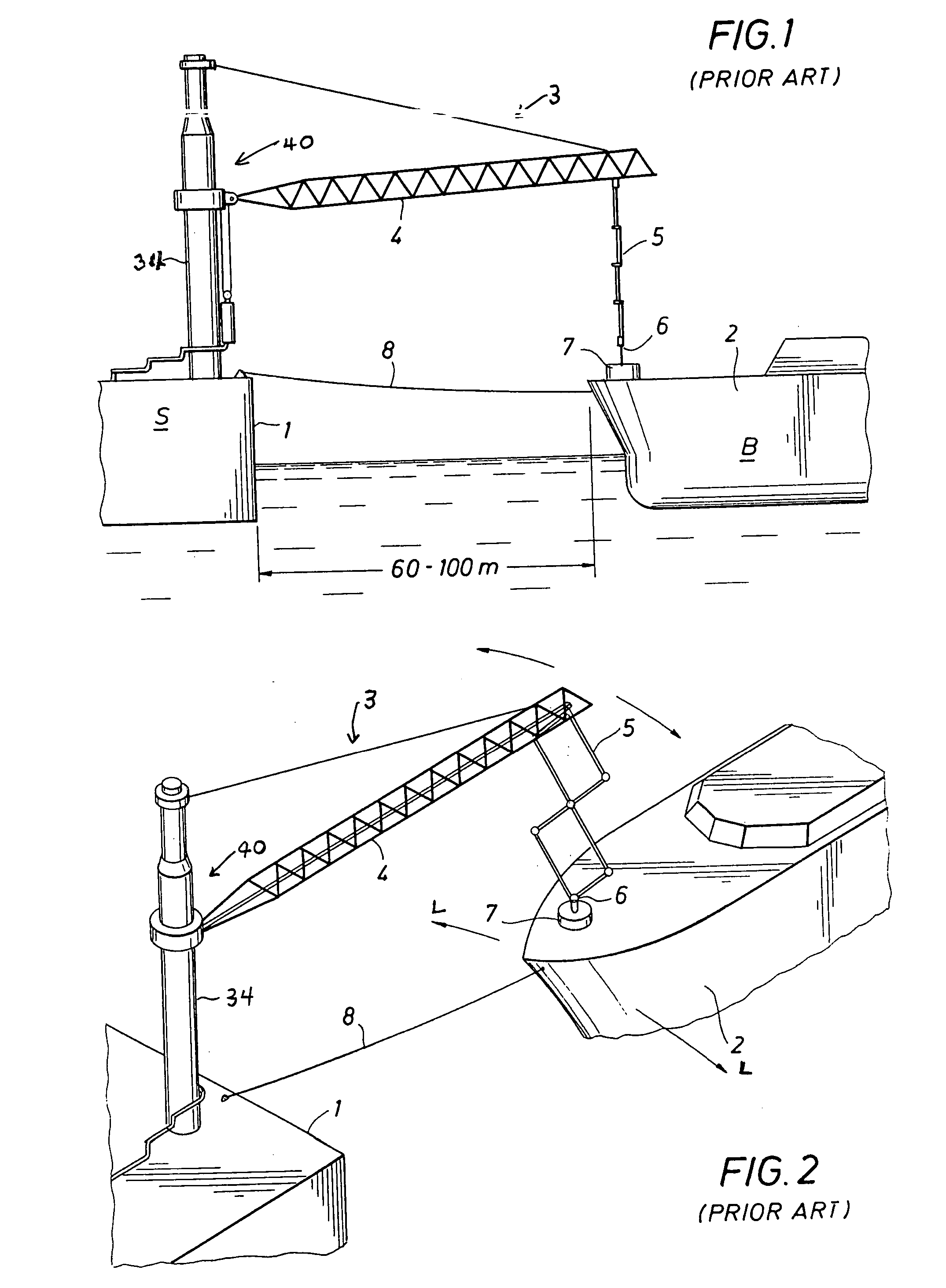

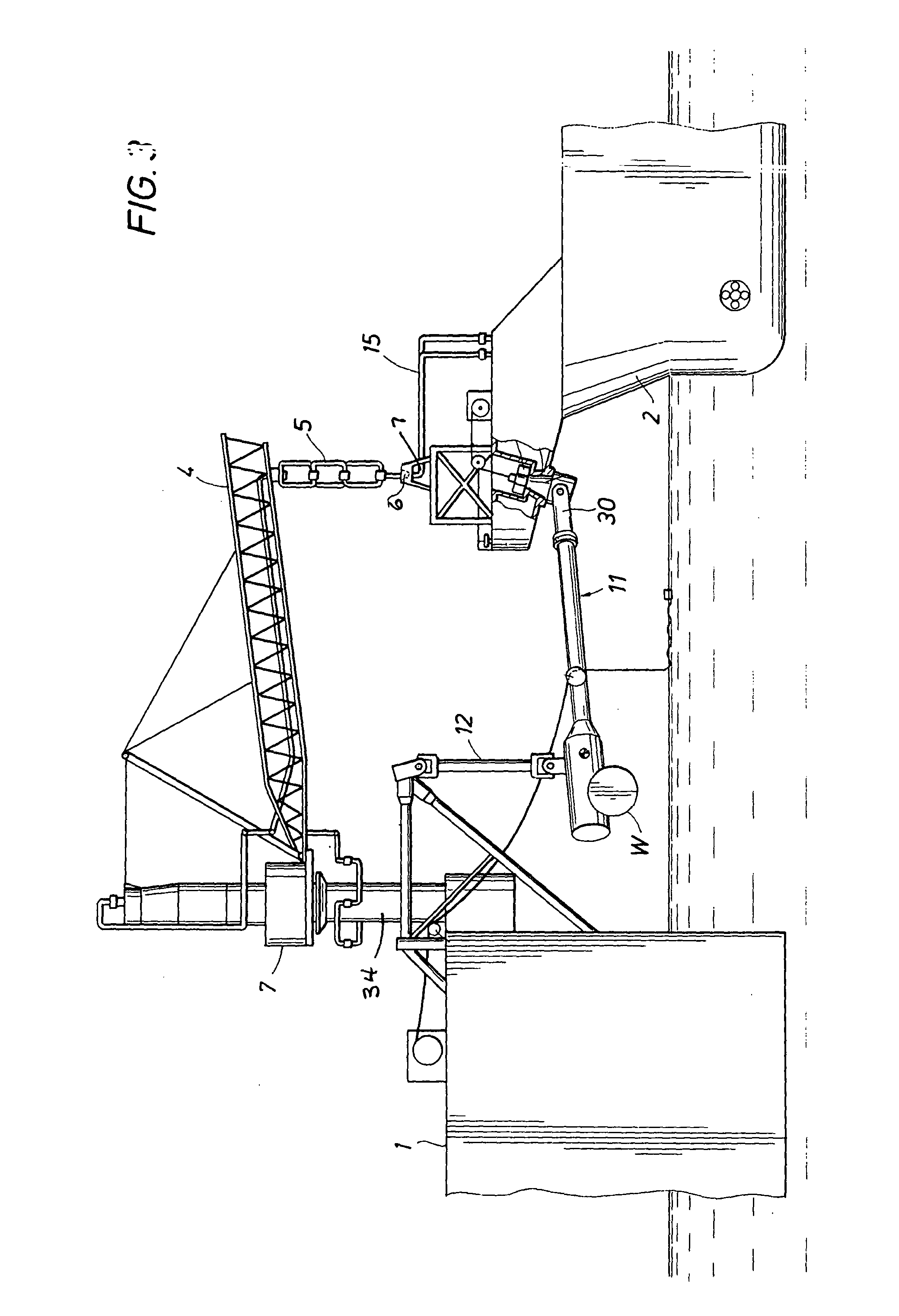

Duplex yoke mooring system

ActiveUS20040025772A1Improve reliabilityImprove securityCargo handling apparatusPassenger handling apparatusElectricityTransverse force

An offshore offloading system for hydrocarbon products from a storage station such as an LNG / FPSO to a shuttle vessel. The system includes a yoke mooring arrangement having a yoke and a connection assembly. One end of the yoke is selectively disconnectable to the shuttle vessel, while the other end of the yoke is rotatably connected to an end of the connection assembly which has its other end rotatably connected to a frame which extends from an end of the storage station. The yoke and connection assembly are arranged such that a transverse force in the lateral or y-direction moves the end of the yoke less than twice the movement of the yoke in response to an x-direction force. The system also includes arrangements for providing a hydrocarbon fluid flow path from the storage station to the shuttle vessel when the shuttle vessel is disconnectably moored to the storage station. A first fluid flow path arrangement includes a crane / boom arrangement mounted on a frame extension of the storage station so that a crane slewing arc radius of the transfer system is not larger than one half the separation distance between the storage station and a forward perpendicular of the shuttle vessel. A second arrangement includes a fixed frame with a piping pantograph mount at its end. A trolley and service platform suspended therefrom move between an operational position away from the pantograph and a service position beneath the pantograph when it is folded into a storage position.

Owner:SOFEC

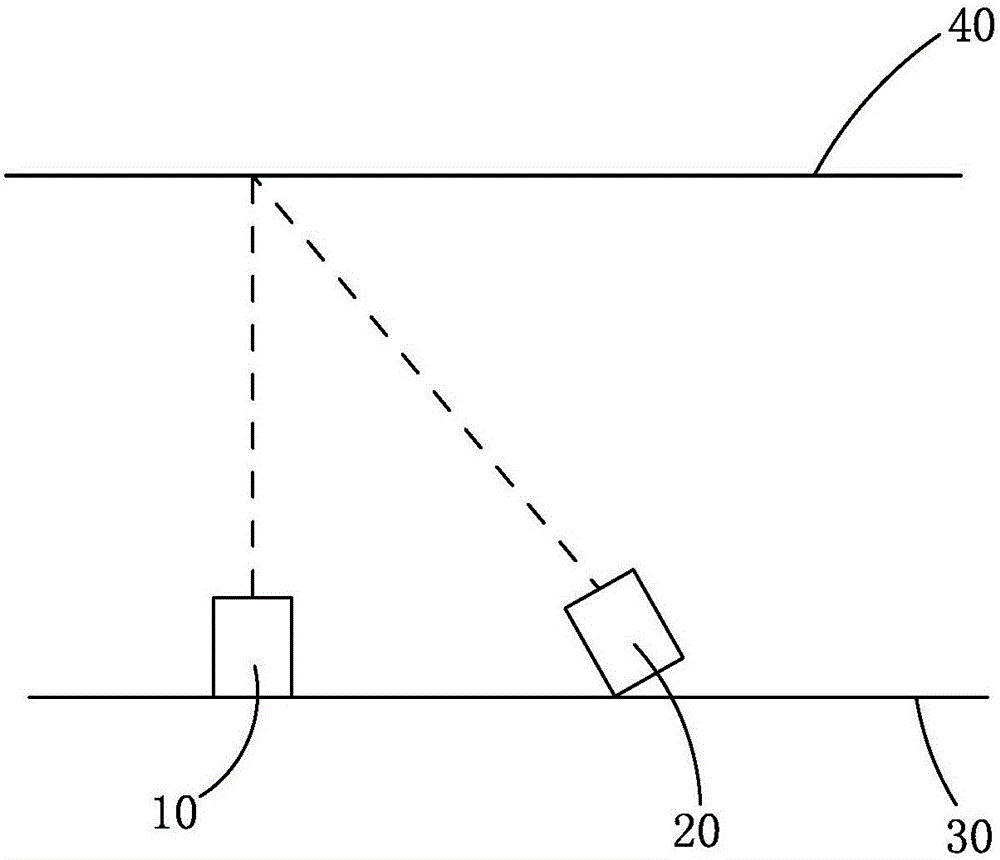

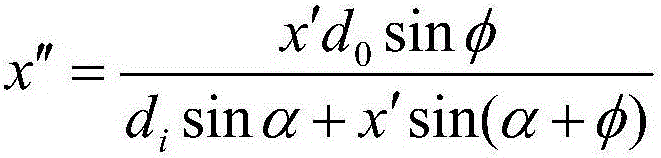

Catenary geometrical parameter dynamic detection method based on triangulation

ActiveCN105674896ASimple structureComprehensive measurement dataUsing optical meansIncline measurementTriangulationDynamic monitoring

The invention provides a catenary geometrical parameter dynamic detection method based on triangulation, and the method is applied to a vehicle-mounted pantograph catenary dynamic monitoring system or a hand-push type catenary patrol detection vehicle. The method comprises the following steps: 1) obtaining pixel coordinates (xPixel, yPixel) of a catenary in an image and angle change (xAngle, yAngle) of a detection device; 2) carrying out data processing: dividing the whole test range into N sections, and carrying out calibration on each section to enable each section to form a group of camera calibration parameters, judging and obtaining the calibration height section of each pixel coordinate according to the pixel coordinates obtained in the step 1), and obtaining stagger value and height value according to the camera calibration parameters of the height section; 3) carrying out data correction: through correction conversion, obtaining actual stagger value and height value of the catenary; and 4) carrying out slope calculation. The method, based on the triangulation principle, can effectively detect the height, stagger value, distance between two lines and slope of the catenary, thereby ensuring measurement accuracy in the whole range, and eliminating large-range error.

Owner:DONGGUAN NANNAR ELECTRONICS TECH

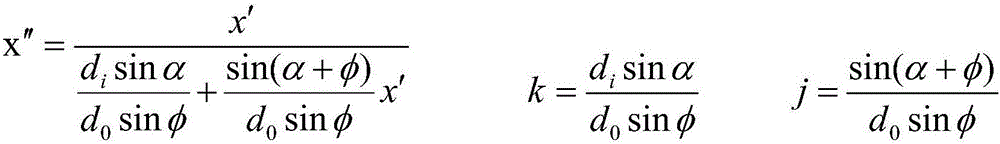

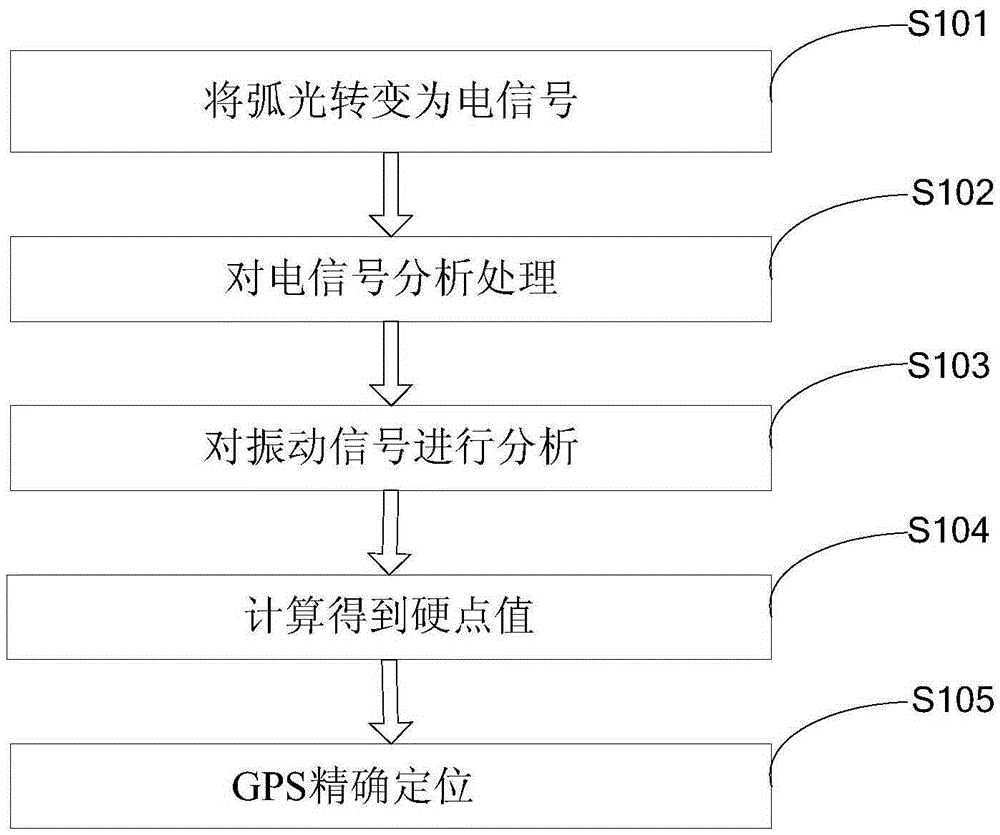

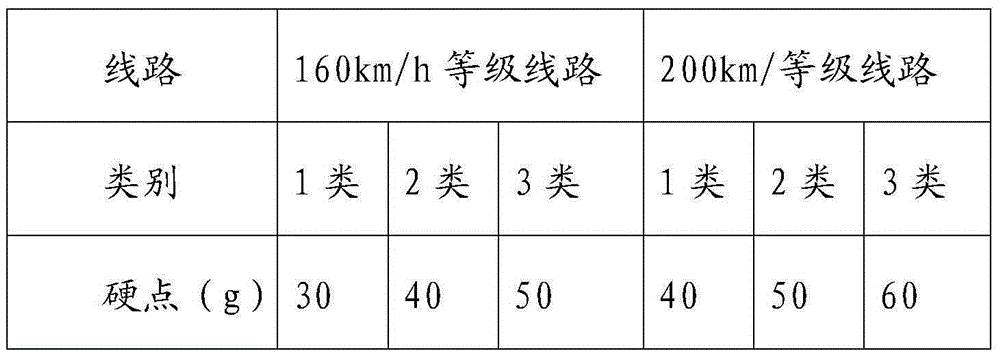

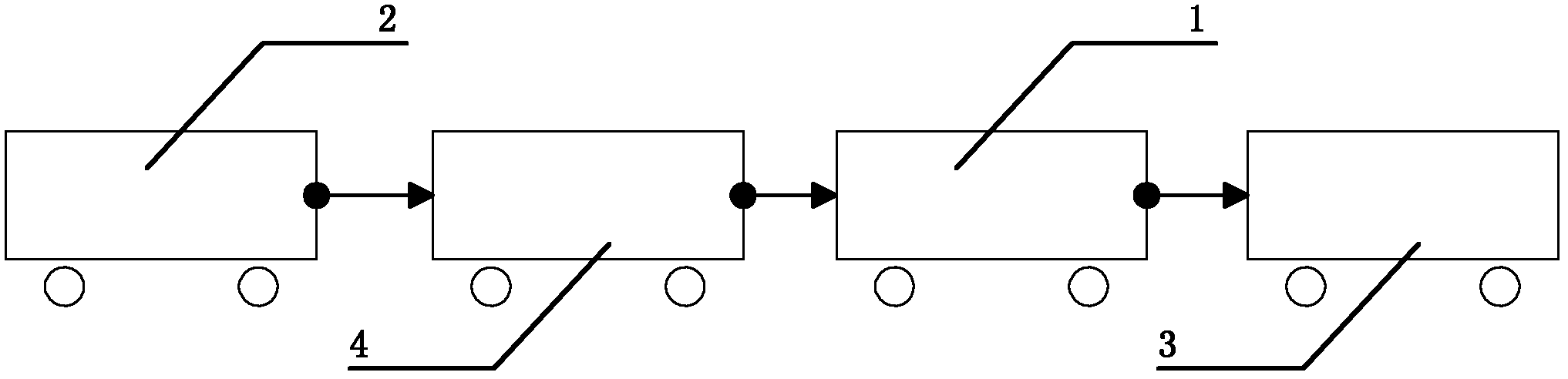

Locomotive pantograph-catenary hard point photoelectric vibration comprehensive detection and GPS positioning method and system

InactiveCN105403242APrecise positioningAccurate discriminationMeasurement devicesSignal conditioningGps positioning system

The invention provides a locomotive pantograph-catenary hard point photoelectric vibration comprehensive detection and GPS positioning method. The method includes steps: conversion from arc light to electric signals, analysis and processing of the electric signals, analysis of vibration signals, obtaining of a hard point value via calculation, and GPS accurate positioning. A locomotive pantograph-catenary hard point photoelectric vibration comprehensive detection and GPS positioning system mainly comprises a photoelectric sensor, an acceleration sensor, a signal conditioning device, an isolation transformer, an acquisition card, a control computer, a display, a memory, and a GPS positioner. According to the method and the system, acceleration detection of the hard point and photoelectric detection of the hard point are effectively combined, more accurate discrimination of the hard point can be made via double discrimination, accurate positioning of the hard point of a contact system is realized by employing an advanced GPS positioning module, the search and maintenance of faults are simple, and failure to adapt to the development requirement of high-speed rails and false and missed judgments can be avoided.

Owner:EAST CHINA JIAOTONG UNIVERSITY +1

Pantograph sliding plate of assorted fibre reinforced composite material and preparing method thereof

InactiveCN1719549AImprove lubricating propertiesImprove conductivityNon-insulated conductorsMetal/alloy conductorsSlide plateFiber-reinforced composite

This invention relates to a hybrid fiber reinforcement compound material pantograph slide plate with lamination used in railway electric locomotives and its preparation method, which takes a metal net and hybrid fiber reinforcement compound material as the backing of said slide plate and makes them distribute in lamination, among which, phenolic resin is taken as the matrix, hybrid fiber as the reinforcement agent, rubber, graphite, copper powder, baritite and at least three kinds in SiO2 as the friction performance modifiers of the compound material to be mixed fully to be hot-pressed with the metal net to form a pantograph slide plate.

Owner:SHANDONG UNIV

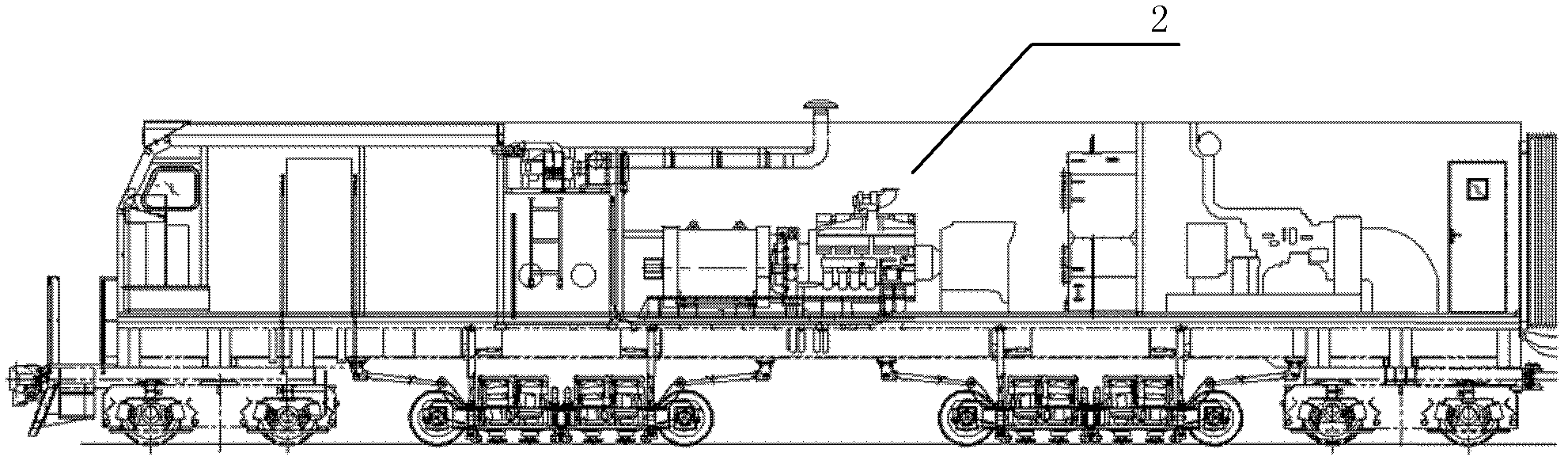

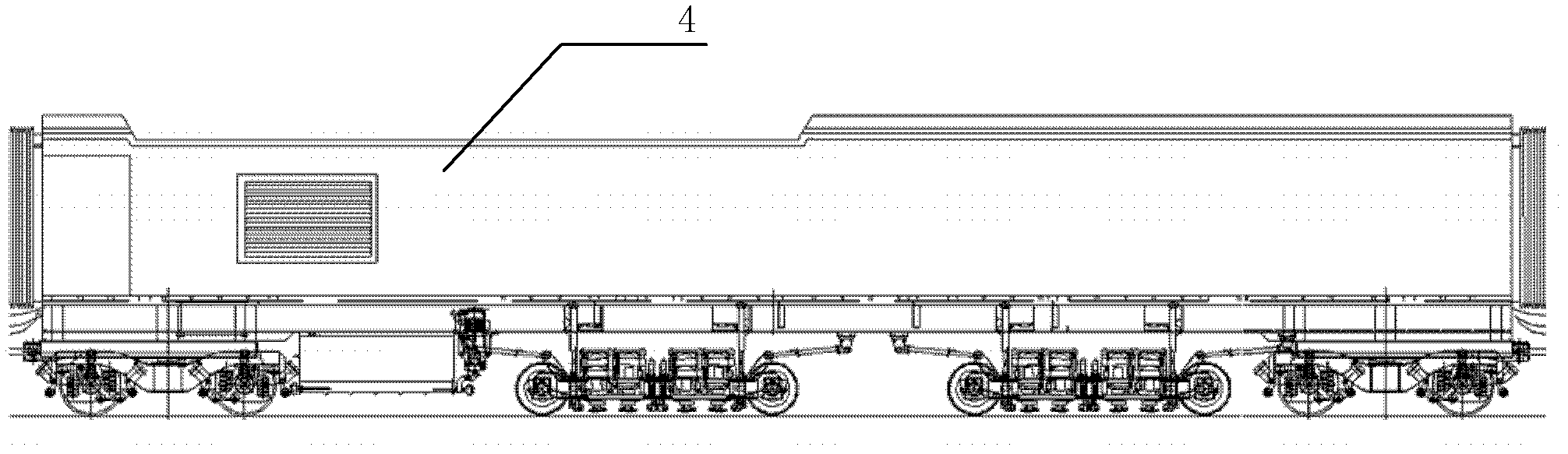

Hybrid rail grinding wagon

ActiveCN102535280AWith hybrid power sourceWork seamlesslyRailway track constructionCombustionTransformer

The invention discloses a hybrid rail grinding wagon, which is applied to operation of hybrid rail grinding trains in the field of large-sized track engineering. The hybrid rail grinding wagon comprises an internal-combustion engine driven power car, an electrically driven power car and more than one trailer, wherein a grinding device is mounted on each trailer. When the hybrid rail grinding wagon is operated in a power accessible area or tunnel area, power is taken from a contact system through a pantograph of the electrically driven power car, subjected to voltage reduction with a transformer, and subjected to rectification and inversion with an inverter to generate three-phase variable-frequency variable-voltage alternating current, which is supplied as power required by a tractor motor and the grinding devices. The hybrid rail grinding wagon switches to the internal-combustion engine and generator combined mode in the power inaccessible area, so that power required by travelling and the grinding devices of the hybrid rail grinding wagon is supplied. The technical problem that existing grinding wagons are low in operation and combustion efficiency, severe in emission pollution and high in use and maintenance cost is solved, and the hybrid rail grinding wagon can achieve full-section seamless operation in the power accessible or in accessible area and the tunnel area.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

Carbon fiber reinforced pantograph carbon sliding plate and manufacturing method thereof

The invention discloses a carbon fiber reinforced pantograph carbon sliding plate and a manufacturing method thereof. The carbon fiber reinforced pantograph carbon sliding plate contains intercalation graphite. The carbon fiber reinforced pantograph carbon sliding plate comprises the following materials in percentage by weight: 30-60% of intercalation graphite, 8-32% of petroleum coke, 2-16% of carbon fiber, and 15-35% of medium temperature asphalt. Compared with the prior art, the carbon fiber reinforced pantograph carbon sliding plate disclosed by the invention has the advantages of low electrical resistivity, high mechanical strength, good comprehensive properties such as electrical conductivity, abrasion resistance and self-lubricating property and the like; through test, the carbon fiber reinforced pantograph carbon sliding plate comes up to the foreign advanced technical level; according to the invention, the manufacturing method is simple, and the properties of the product are stable, therefore, the large-scale production can be realized.

Owner:湖北东南佳特碳新材料有限公司

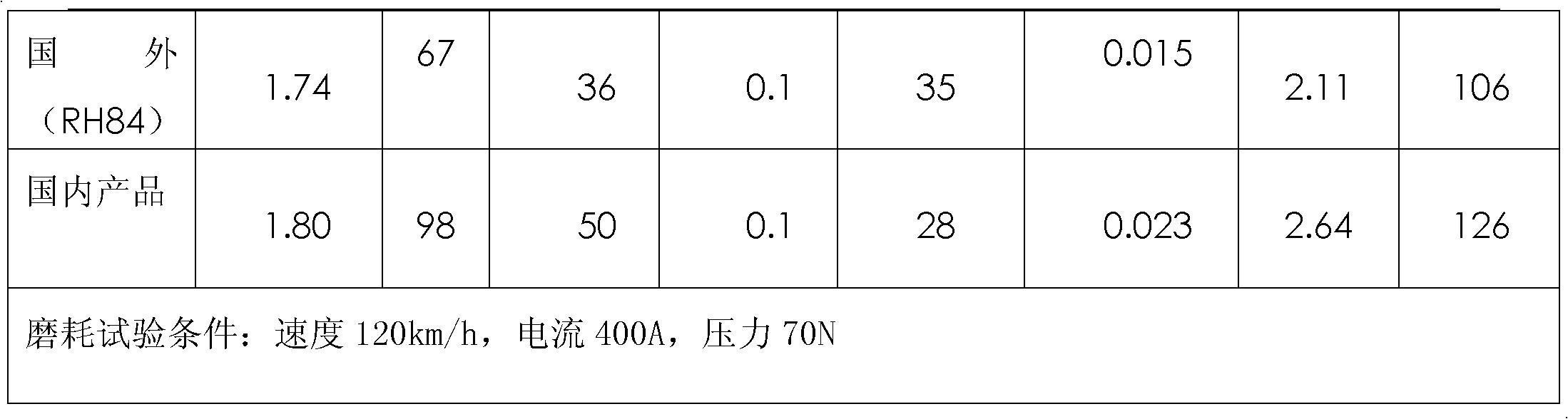

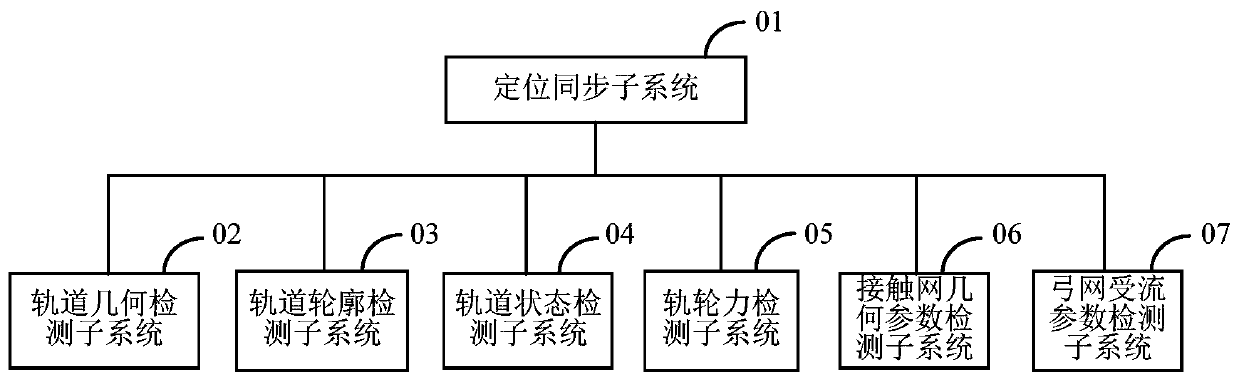

Railway infrastructure detection system

InactiveCN110588709AReduce operation and maintenance costsRealize synchronous acquisitionMeasurement devicesRailway auxillary equipmentOperation modeUrban rail

The invention discloses a railway infrastructure detection system. The system involves a positioning synchronization subsystem, and a rail geometry detection subsystem, a rail contour detection subsystem, a rail state detection subsystem, a rail wheel force detection subsystem, a catenary geometric parameter detection subsystem, a pantograph-catenary current collection parameter detection subsystem which are in communication with the positioning synchronization subsystem. According to the system, on the basis of the structural characteristics and operation modes of urban rail transit infrastructure, the plurality of detection subsystems are integrated on a urban rail transit electric bus, rail geometric parameters, rail contour abrasion, rail state information, rail wheel interaction force, catenary geometric parameters and pantograph-catenary current collection parameters of the urban rail transit infrastructure are synchronously collected and accurately measured, the detection efficiency is improved, the urban rail transit operation maintenance cost is reduced, and the system can be widely applied to urban rail traffic construction and operation and maintenance.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +2

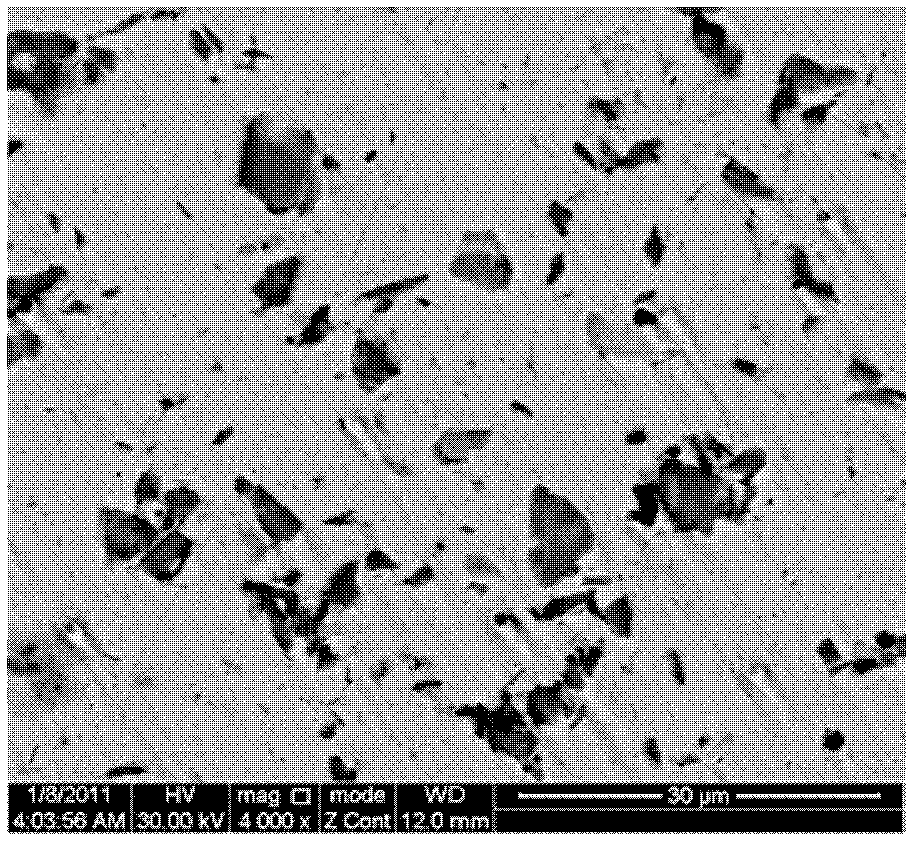

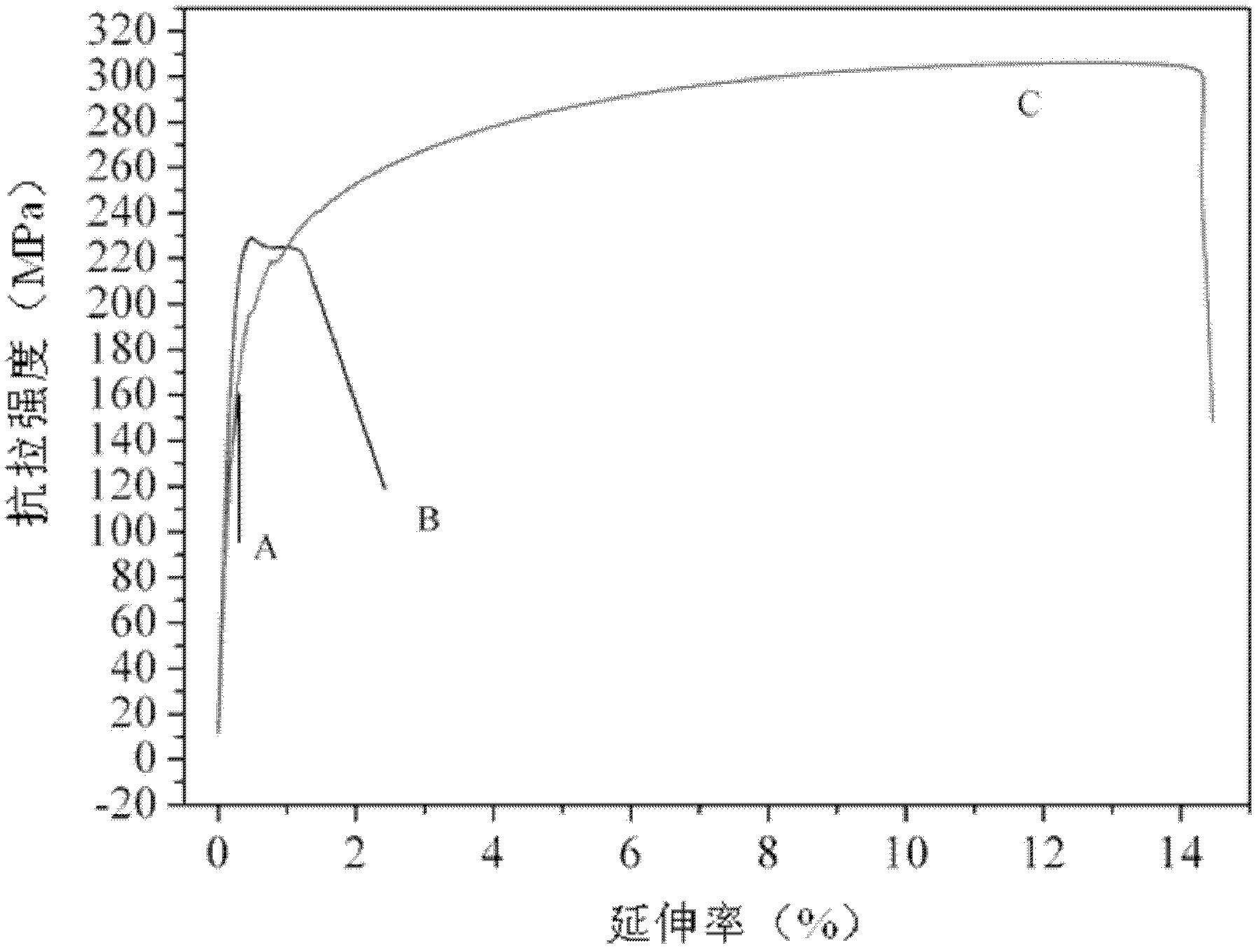

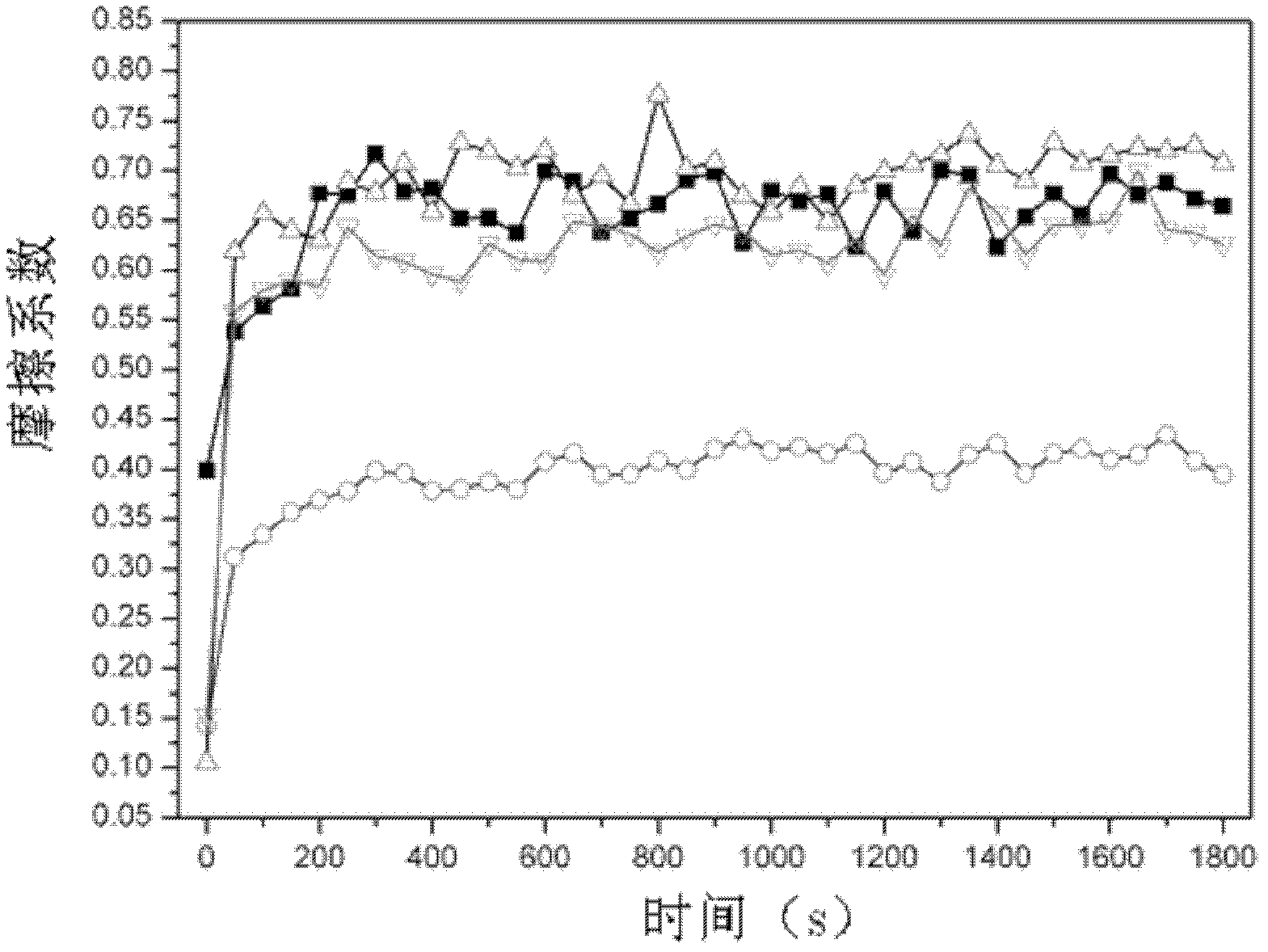

Pantograph slide composite material and preparation method thereof

InactiveCN102206771AHigh tissue densityEnhanced interface bindingLiquid/solution decomposition chemical coatingMixed materialsHardness

A pantograph slide composite material and a preparation method thereof relate to a copper-based pantograph slide composite material and a preparation method thereof. The invention solves the problems of poor interfacial wettability and low interfacial bonding strength between a ceramic reinforced phase and coppor in existing copper-based pantograph slide composite materials. The composite material of the invention is prepared by copper powder and ceramic particles, wherein the surface of the ceramic particle has a chemical copper plate layer. A mixed material is obtained by mixing the ceramic particles with chemical copper plate layers on the surfaces and the copper powder, and then the mixed material is processed by a hot-pressing sintering process or a combined process of hot-pressing sintering and hot extrusion. The Ti3AlC2 ceramic particles inside the composite material have uniform distribution, high structure density, good interfacial bonding performance, and good mechanical properties; the density is up to 99.86%-100.79%; the hardness is up to 92.3-93.3 HB; the tensile strength is up to 230-300 MPa; and the friction coefficient is 0.15-0.4.

Owner:HARBIN INST OF TECH

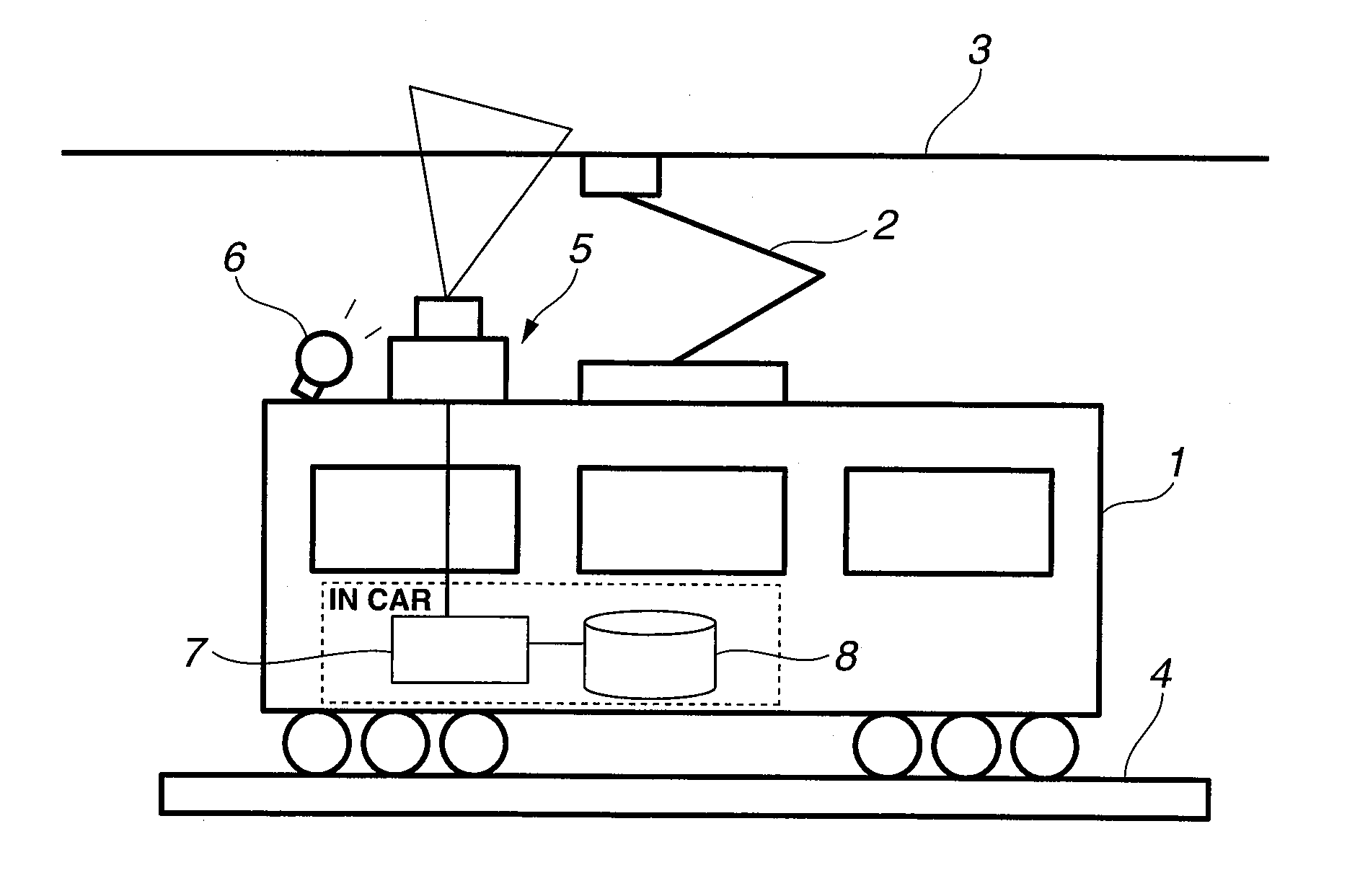

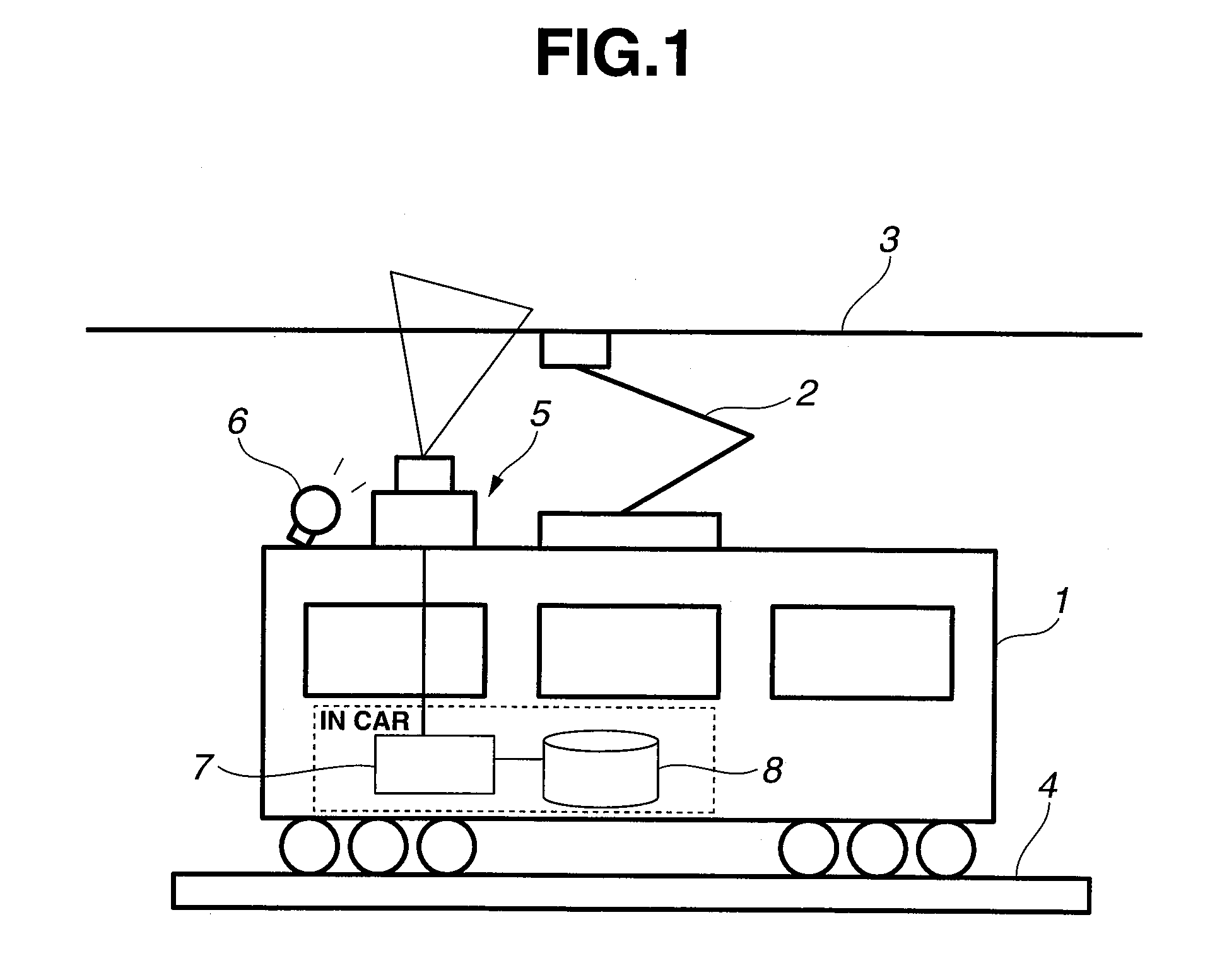

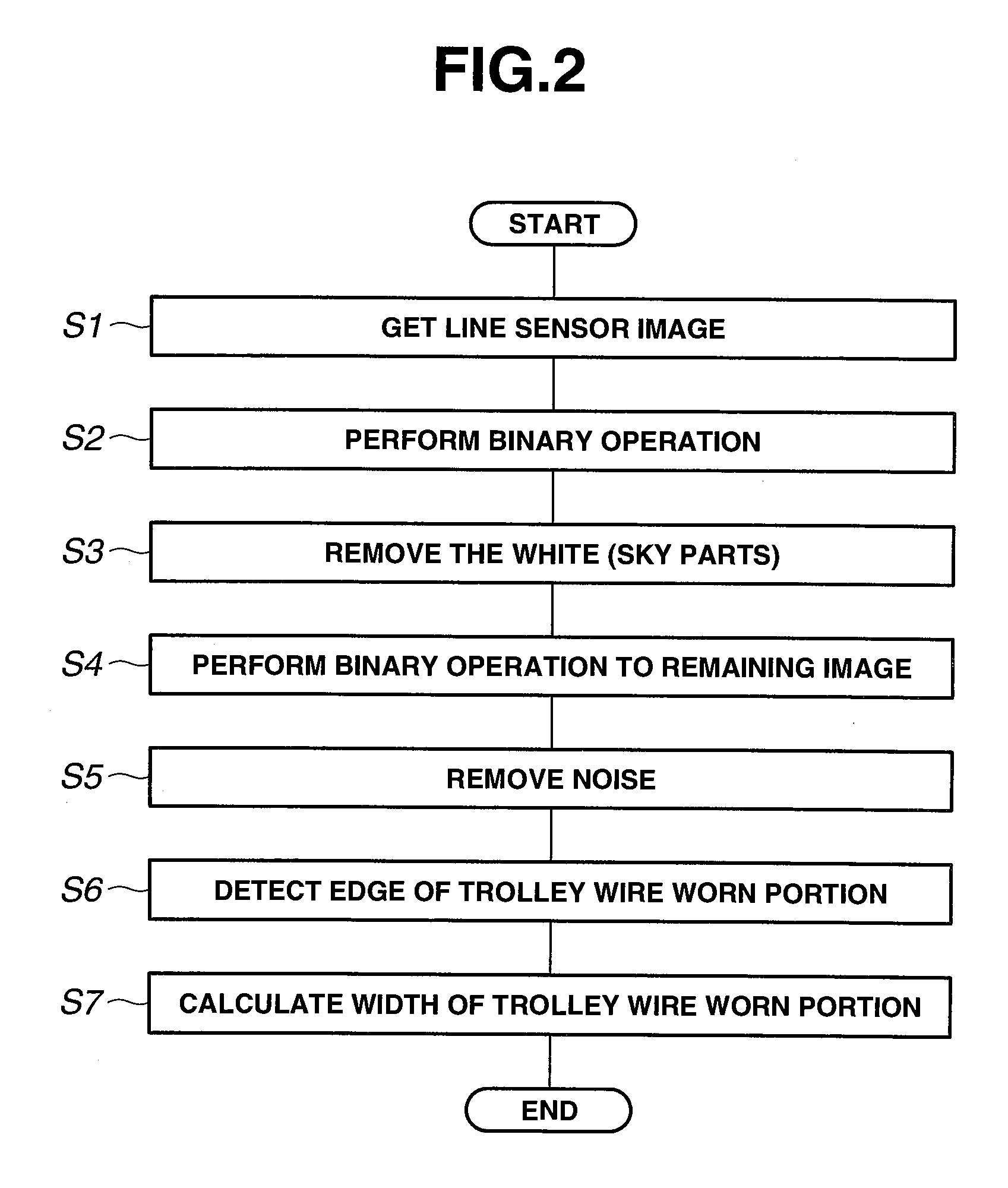

Trolley wire wear measuring device

ActiveUS20090320554A1Facilitates wear measurementMeasurement is performedSolid-state devicesInvestigating moving sheetsLine sensorSky

[Object] To ensure a wear measurement over an entire section of a trolley wire and to facilitate the wear measurement, and also to perform the measurement during daytime, without being affected by structures existing around the trolley wire.[Means to solve] A line sensor 5 and an illumination lamp 6, which are placed in a direction of a scanning line perpendicular to a laying direction of a trolley wire, are mounted on a test car 1. The line sensor 5 shoots a pantograph contact surface of the trolley wire by the running of the test car, and this image signal is saved in a recording device 8 through a measurement computer 7. The measurement computer 7 arranges luminance signals of scanning lines, obtained by the line sensor 5, in time series, and creates a line sensor image. The measurement computer 7 gets a binary operated line sensor image from this line sensor image. The measurement computer 7 further removes sky parts from this binary operated line sensor image and detects edges of a trolley wire worn portion, then determines a width of the trolley wire worn portion through an overall width of the trolley wire and a height, viewed from the line sensor, of the trolley wire.

Owner:MEIDENSHA ELECTRIC MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com