Patents

Literature

165results about How to "Improve lubricating properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

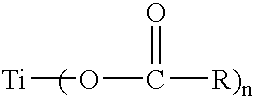

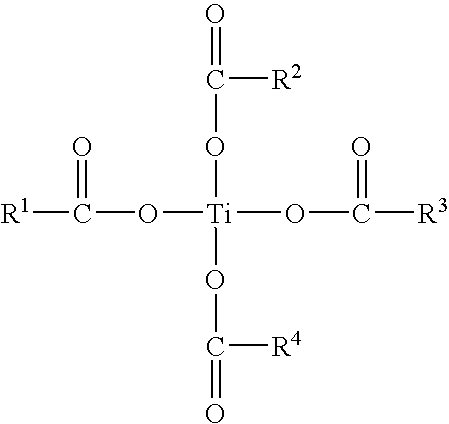

Titanium-containing lubricating oil composition

ActiveUS20070111908A1Improved performance characteristicsImprove featuresMixingAdditivesImideMolybdenum compounds

A fully formulated lubricating oil, lubricated surface, and lubricant additive concentrates for lubricants providing reduced sludge formation. The fully formulated lubricating oil composition has therein at least one succinimide dispersant derived from a polyalkylene compound having from about 50 to about 85% vinylidene double bonds in the compound, a metal containing detergent, at least one wear reducing agent, at least one antioxidant, and a hydrocarbon soluble titanium compound as a friction modifier. The lubricating oil composition is also substantially free of molybdenum compounds.

Owner:AFTON CHEMICAL

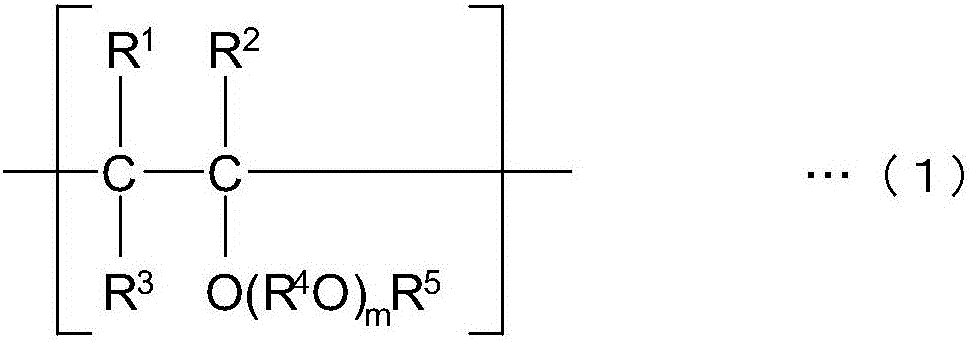

Grease composition

ActiveUS20110195880A1Reduce frictionImprove lubricating propertiesThickenersAdditivesUnsaturated hydrocarbonBase oil

A grease composition for use in resin lubrication wherein at least one amine salt of an unsaturated or saturated fatty acid is incorporated in a grease base material which includes a base oil and a thickener, preferably wherein at least one fatty acid amine salt of the following general formula (1) is incorporated: RCOO−R′NH3′ wherein either (i) R is an unsaturated by hydrocarbon group having from 15 to 21 carbon atoms, and R′ is a saturated or unsaturated linear or branched hydrocarbon group having from 8 to 22 carbon atoms; or (ii) R is a linear saturated hydrocarbon group having from 5 to 21 carbon atoms, and R′ is an unsaturated hydrocarbon group having from 16 to 18 carbon atoms. The grease composition of the- present invention improves the lubricity between resin and resin or resin. and another material such as a metal.

Owner:SHELL USA INC

Pantograph sliding plate of assorted fibre reinforced composite material and preparing method thereof

InactiveCN1719549AImprove lubricating propertiesImprove conductivityNon-insulated conductorsMetal/alloy conductorsSlide plateFiber-reinforced composite

This invention relates to a hybrid fiber reinforcement compound material pantograph slide plate with lamination used in railway electric locomotives and its preparation method, which takes a metal net and hybrid fiber reinforcement compound material as the backing of said slide plate and makes them distribute in lamination, among which, phenolic resin is taken as the matrix, hybrid fiber as the reinforcement agent, rubber, graphite, copper powder, baritite and at least three kinds in SiO2 as the friction performance modifiers of the compound material to be mixed fully to be hot-pressed with the metal net to form a pantograph slide plate.

Owner:SHANDONG UNIV

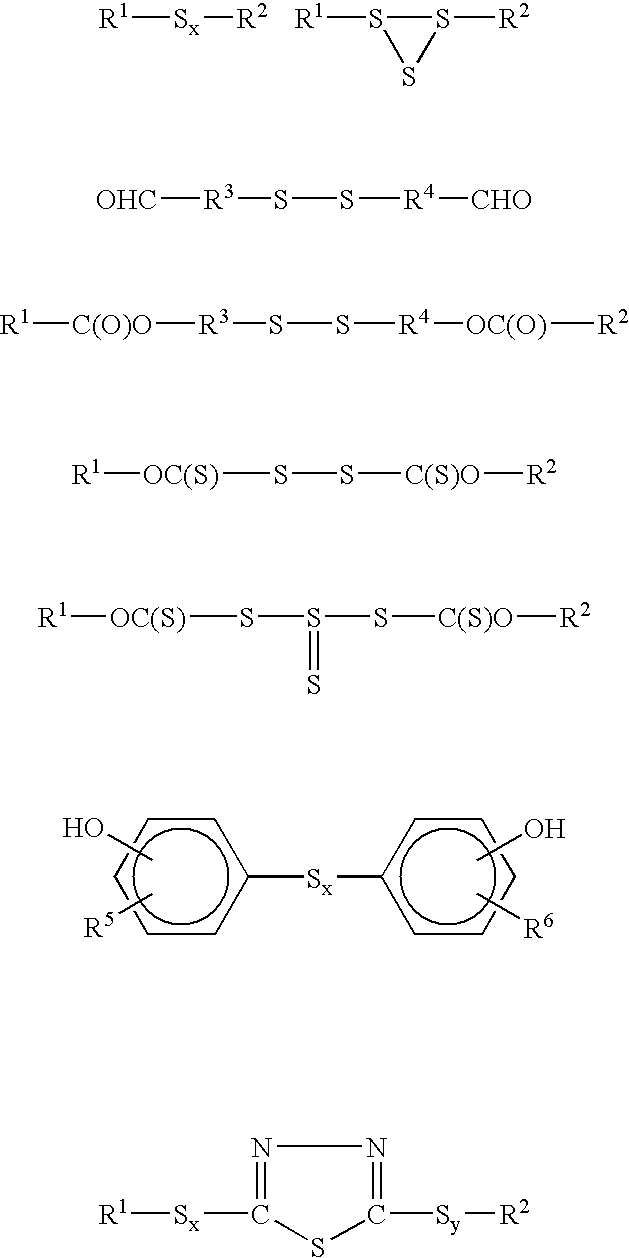

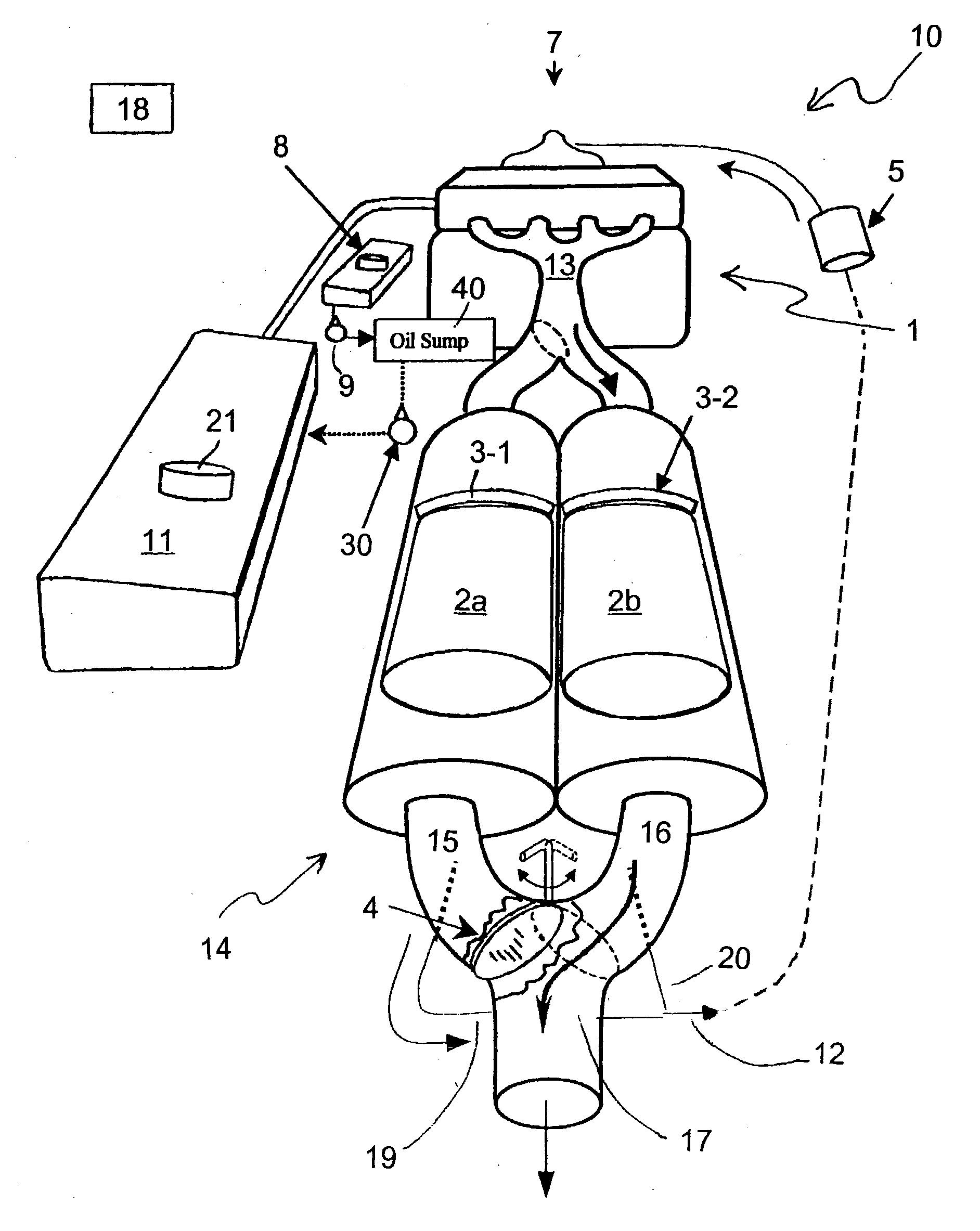

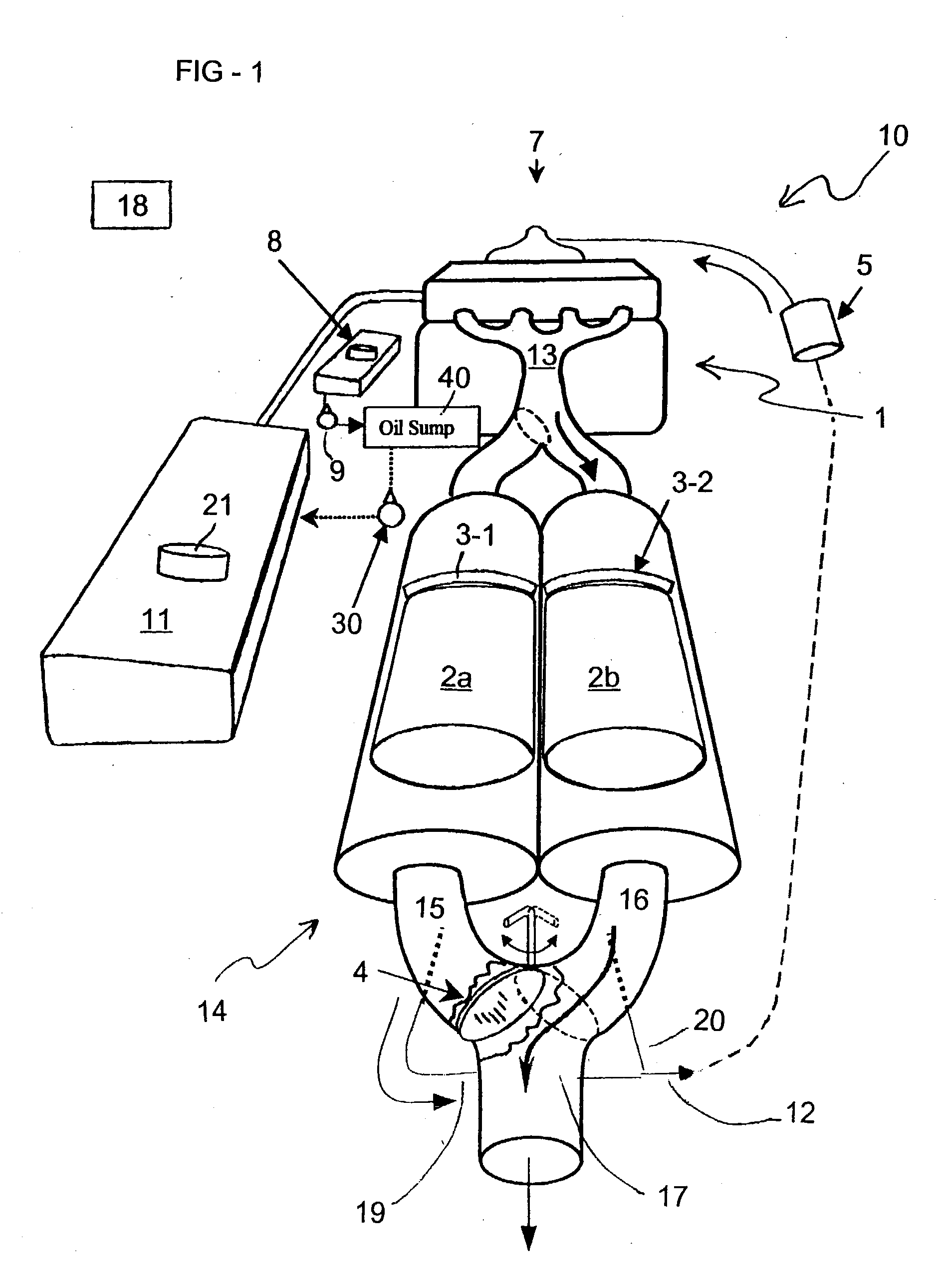

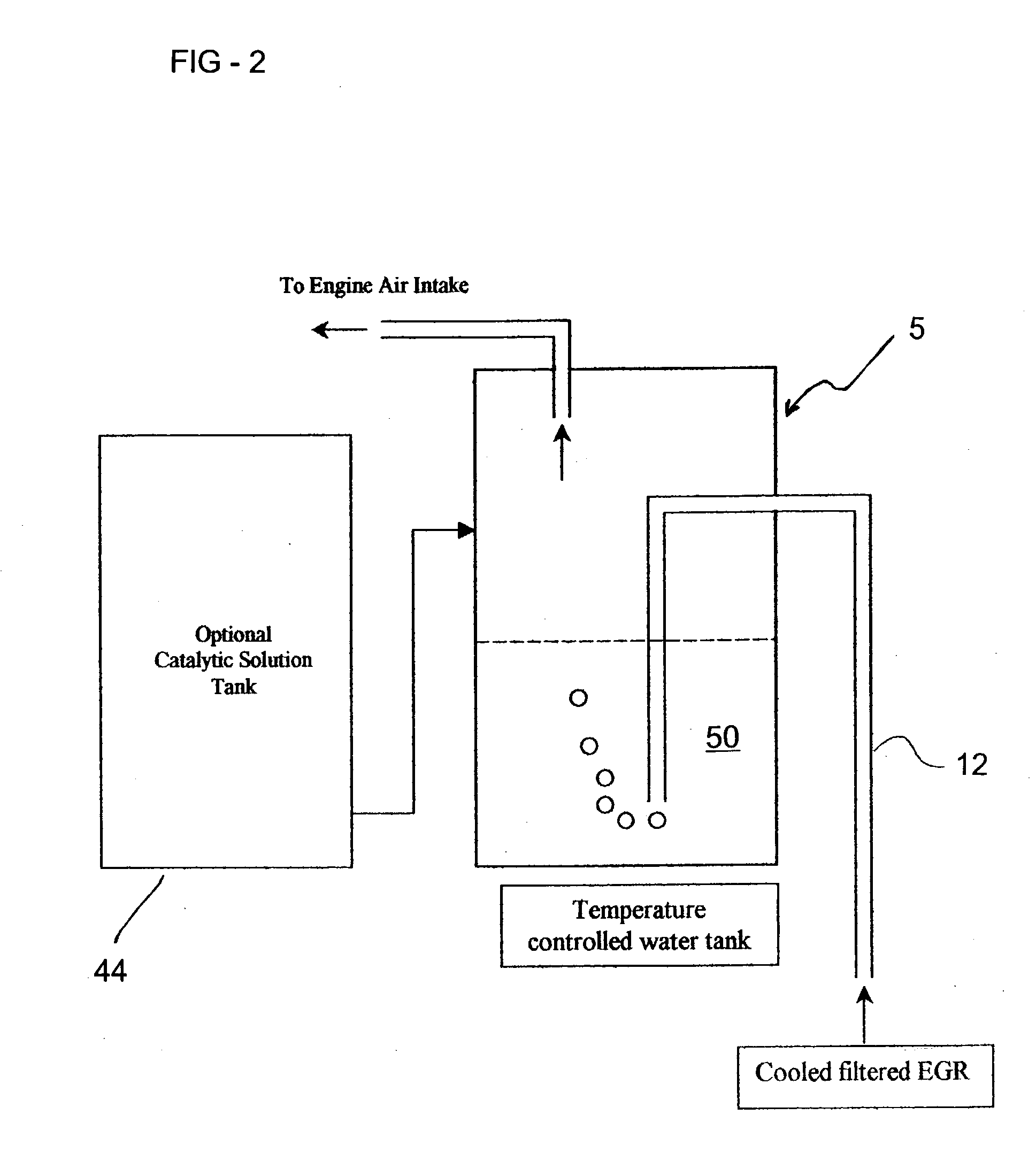

System for and methods of operating diesel engines to reduce harmful exhaust emissions and to improve engine lubrication

InactiveUS20040194454A1Facilitates DPF regenerationAnti-wear propertyInternal combustion piston enginesNon-fuel substance addition to fuelOil additiveExhaust gas emissions

A Diesel engine anti-wear lubricant oil additive composition that includes organo-metallic compounds of Cu, Ce, etc., is used to catalytically bum-off diesel particulate matter (PM) collected by diesel particulate filter (DPF). A fuel borne catalyst (FBC) of Cu,Ce,Fe etc., required for regenerating the DPF is made by blending a predetermined quantity of used engine oil, removed from the engine crankcase oil system, with fuel in the fuel tank of a diesel engine equipped with DPF and EGR systems. A method of fumigating water and catalytic compounds of Cu, Fe, Ce, etc., into the air-intake system of a diesel engine in the EGR gases from the DPF or air, to reduce both PM and NOx emissions from a diesel engine, with improved engine lubrication performance, is also disclosed.

Owner:RIM JULIUS J

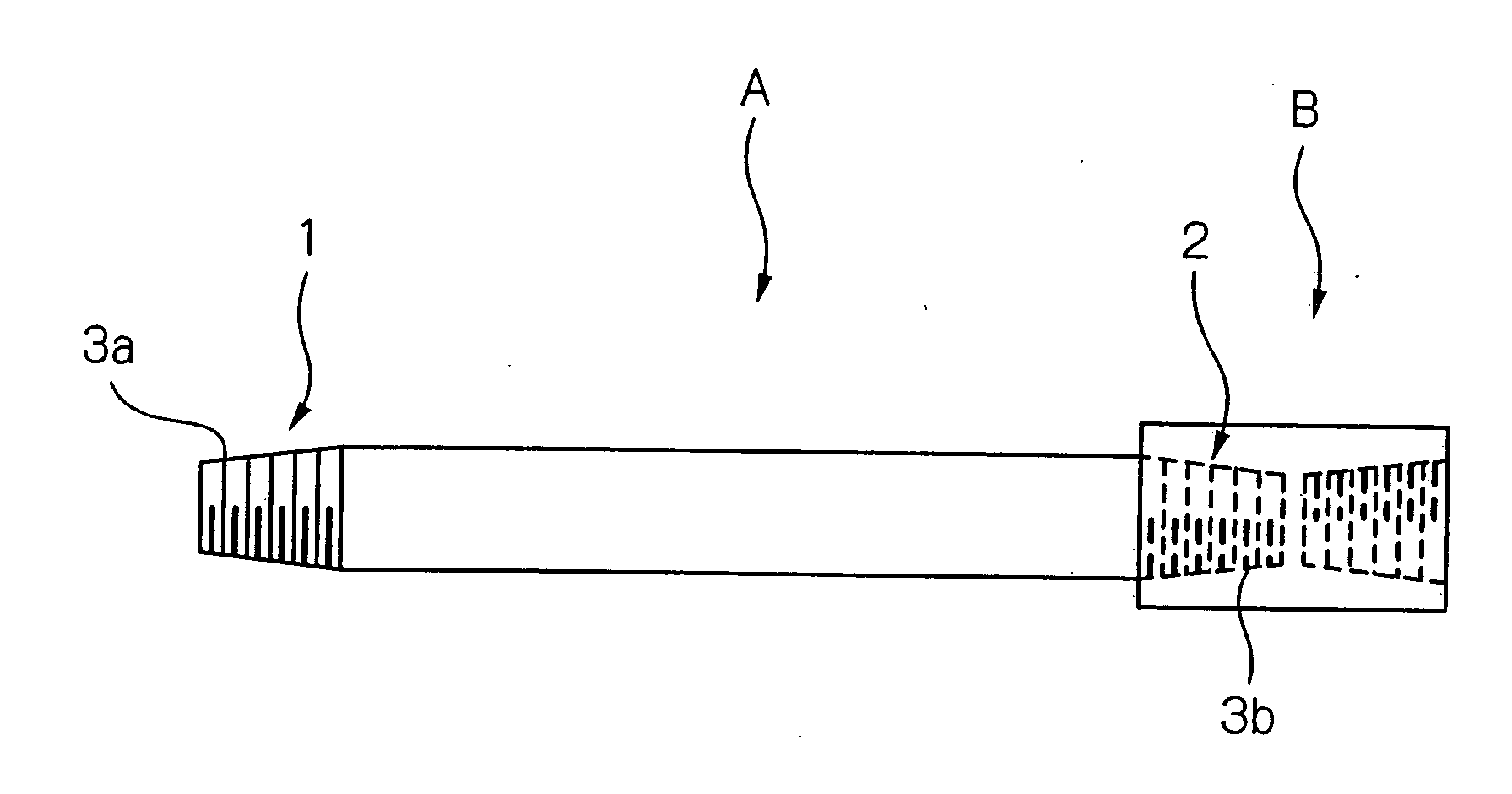

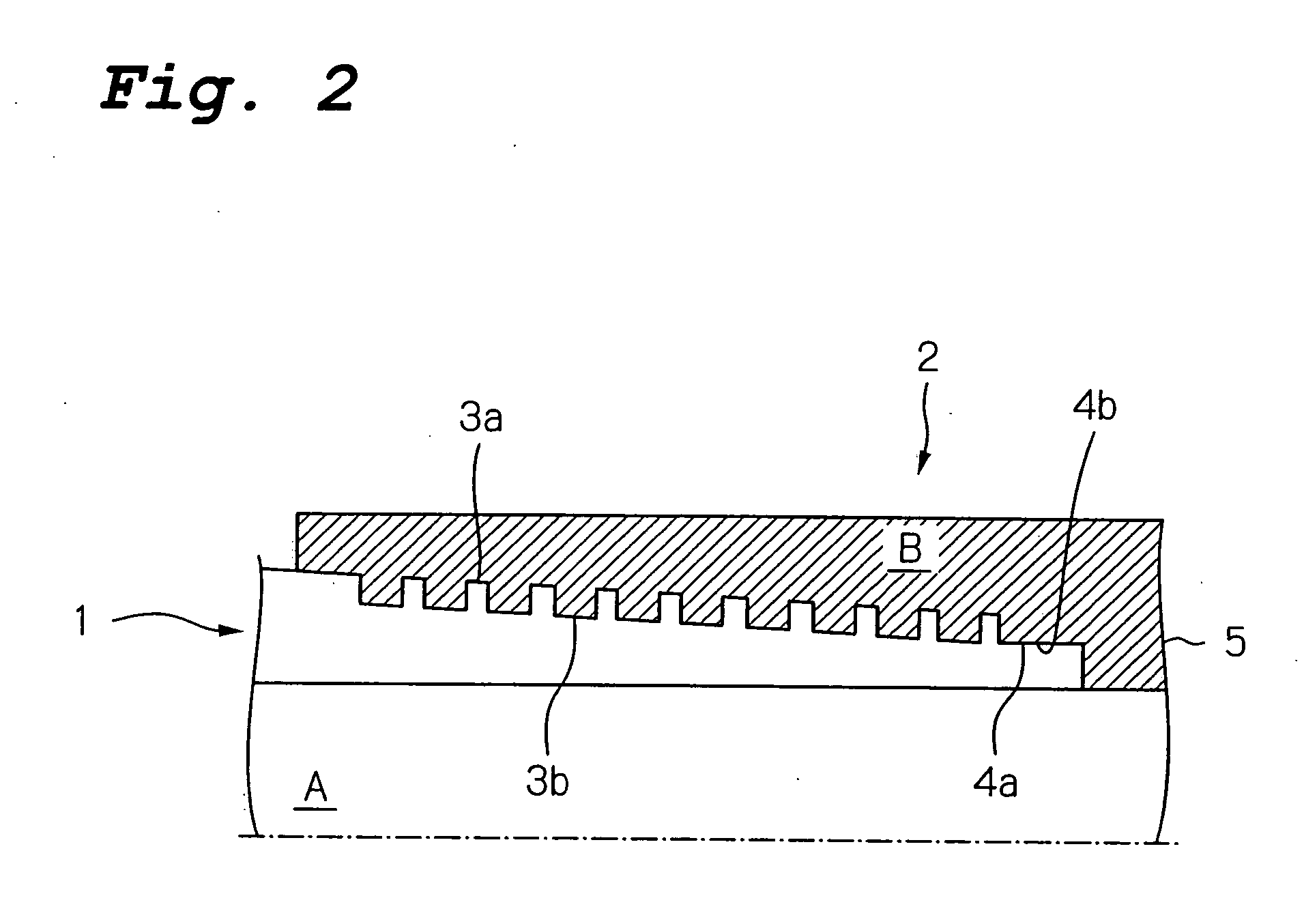

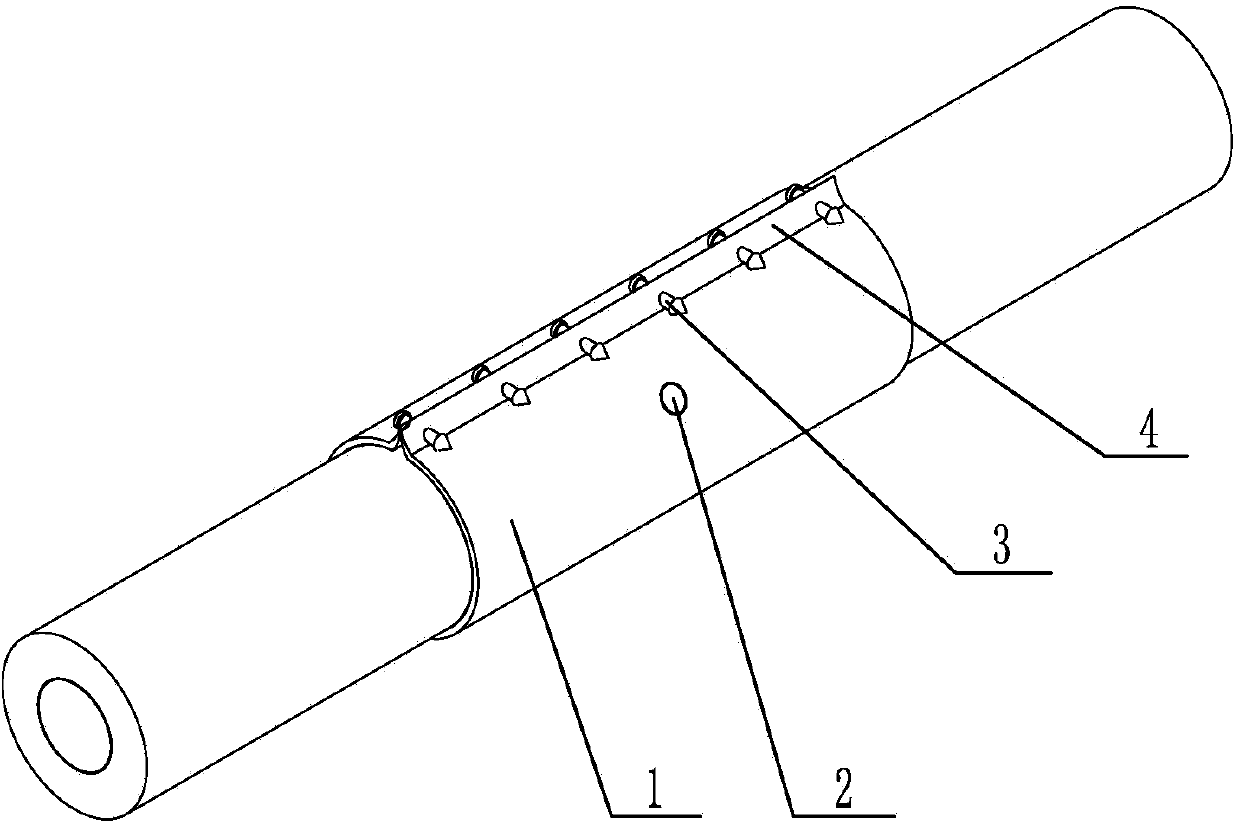

Threaded joint for steel pipes

InactiveUS20060197343A1Improve adhesionImprove the immunitySleeve/socket jointsPipe supportsEpoxyEngineering

A threaded joint for steel pipes comprises a pin (1) and a box (2) each having a threaded portion (3a or 3b) and an unthreaded metal-to-metal contact portion (4a or 4b) as contact surfaces which contact each other when the joint is fastened. The contact surfaces (3a and 4a and / or 3b and 4b) of at least one of the pin (1) and the box (2) are coated with a lower layer of a solid lubricating coating containing a solid lubricating powder (e.g., molybdenum disulfide, tungsten disulfide, or graphite) and a binder (e.g., an epoxy or other organic resin) and an upper layer of a solid corrosion protective coating formed by an organic resin which does not contain solid particles.

Owner:NIPPON STEEL CORP

Method for producing concrete mixture by using machine-made sand to substitute natural sand

The invention relates to a production method of a concrete mixture, in particular to a method of producing concrete mixture by using machine-made sand instead of natural sand. The machine-made sand and gravel after being measured are fed into a stirrer to be stirred uniformly, then 70-80 percent of water of the total water is added into the mixture, which is stirred again so as to lead the mixture to become wet; measured cementing materials are put into the stirrer, and the residual water of the total water and concrete additive are added into the stirrer to be stirred uniformly. The concrete mixture prepared by the invention overcomes the defects existed in the concrete mixture which is prepared by employing machine-made sand instead of natural sand with the existing traditional technology, thus improving the property of the concrete mixture which is produced by adopting machine-made sand.

Owner:CHONGQING DAYE CONCRETE

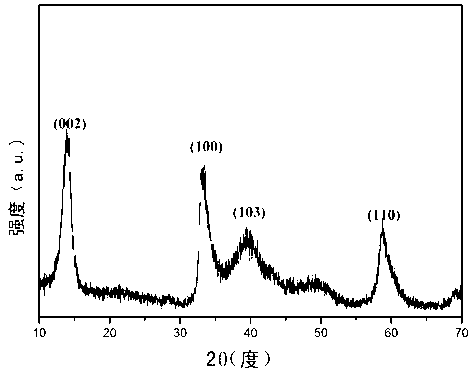

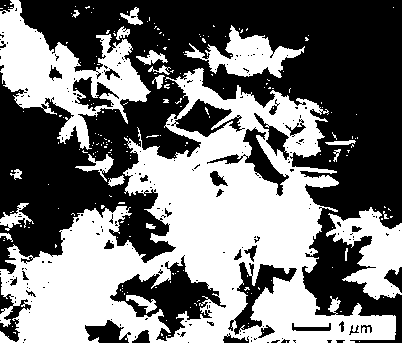

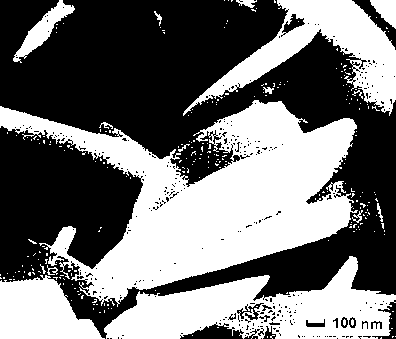

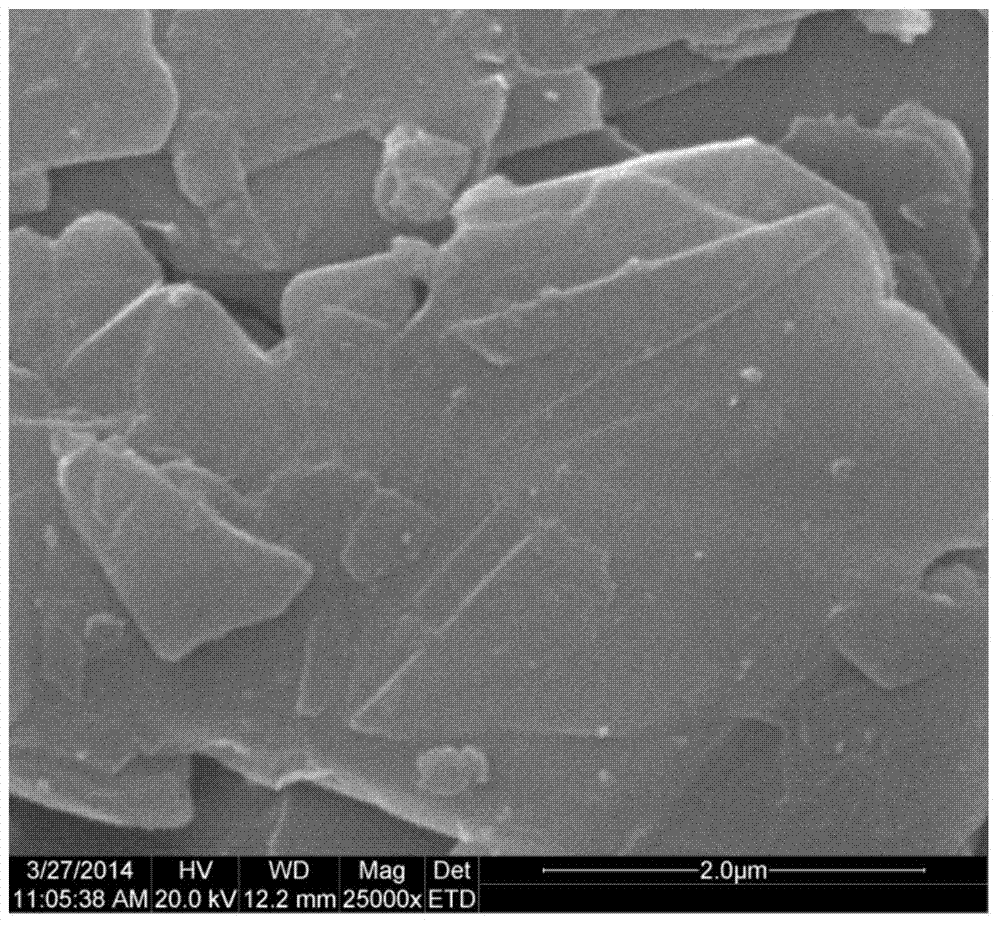

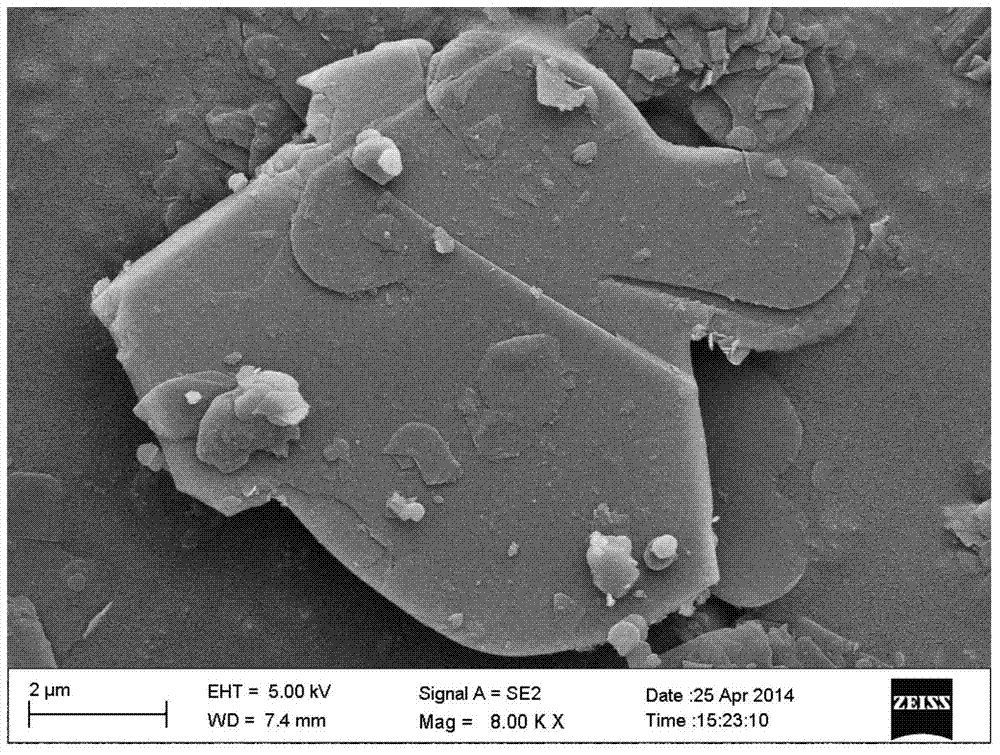

Method for preparing hexagonal molybdenum disulfide nanosheet as anti-friction additive

ActiveCN103073060AReduce manufacturing costThe production process is simple and easy to controlMaterial nanotechnologyMolybdenum sulfidesTube furnaceHydrothermal synthesis

The invention discloses a method for preparing a hexagonal molybdenum disulfide nanosheet as an anti-friction additive. An additive-assistant hydrothermal synthesis method is adopted. The preparation method comprises the following steps: synthesizing a carbon ball from a high molecular compound as a carbon source by a Stober method; dissolving Na2MO4, Na2S and NH2OH.HCl in water to obtain a solution; adding the prepared nano carbon ball and uniformly dispersing the nano carbon ball in the solution by centrifugal stirring; adjusting the pH value of the solution to 6 to 8 with acid, and stirring the obtained solution and then moving the solution to a stainless steel reaction kettle for thermostatic reaction to obtain a reaction product; and separating the reaction product and annealing the product in a tube furnace of 400 to 600 DEG C to obtain the hexagonal molybdenum disulfide nanosheet. The preparation method is simple in process, and the prepared product is high in purity and yield, and excellent in antifriction and anti-wearing and lubricating property, and can serve as the anti-friction additive of lubricating oil and fat.

Owner:苏州惠丰润滑材料有限公司

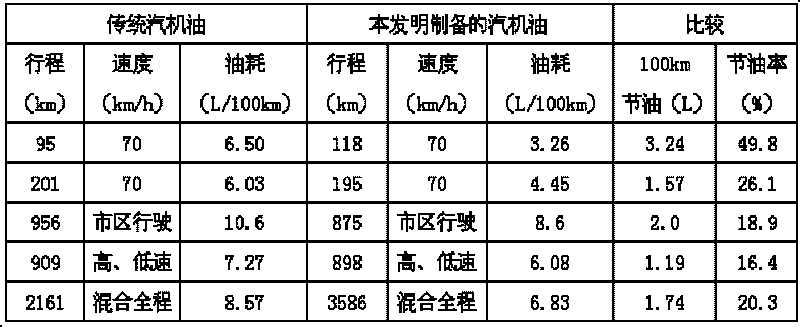

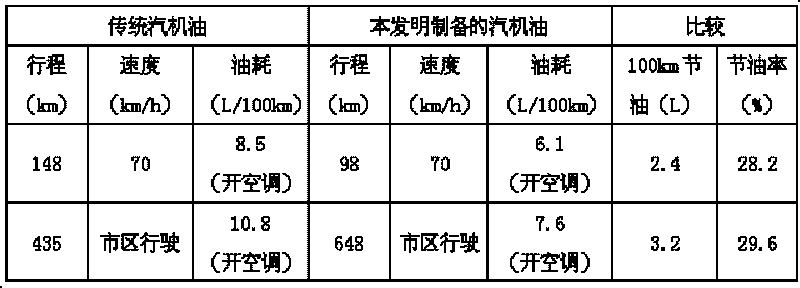

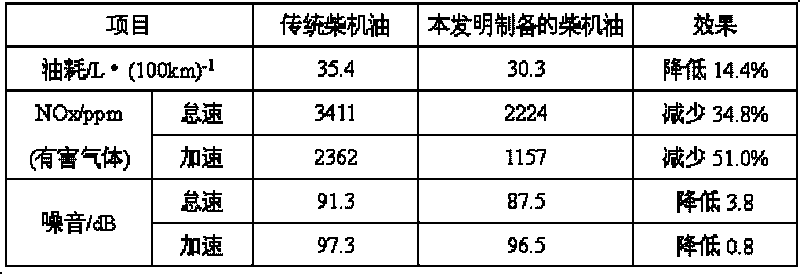

Vehicle engine oil additive and engine oil

The invention provides a vehicle engine oil additive and engine oil. The additive comprises the following components: 15 to 34 weight percent of nano WS2 powder, 0 to 24 weight percent of nano MoS2 powder, 20 to 20.5 weight percent of dispersant, 0 to 0.5 weight percent of antioxidant, 0 to 1 weight percent of metal passivant and the balance of base oil, wherein the kinematic viscosity of the base oil at 40 DEG C is 70 to 190mm2 / s, and the kinematic viscosity of the base oil at 100 DEG C is 12 to 20mm2 / s. The engine oil of the invention comprises 5 to 20 weight percent of additive and 80 to 95 weight percent of petrolic oil or comprises 15 to 25 weight percent of additive and 75 to 85 weight percent of diesel engine oil. The engine oil can improve the service life of engine, reduce oil consumption and has obvious energy-saving and emission-reducing effects and other effects.

Owner:CENT SOUTH UNIV

Conveyor lubricants for use in the food and beverage industries

InactiveUS20040167044A1Provide compatibilityAvoid formingOrganic chemistryLiquid carbonaceous fuelsCarboxylic saltEther

A lubricant concentrate comprising an effective lubricating amount of at least one ether carboxylate and at least one foam destabilizer, and methods of using the same. The lubricant concentrate may be diluted with water prior to use.

Owner:ECOLAB USA INC

Flame-proof abrasion-resistant semi-fragrant polyamide composition

The present invention discloses one kind of fire retardant antiwear semi-aromatic polyamide composition, which consists of semi-aromatic polyamide 40-55 wt%, polyamide 6 or polyamide 66 5-15 wt%, magnesium hydroxide 20-30 wt%, zinc borate 1-8 wt%, ultrahigh molecular weight polyethylene 5-15 wt%, unsaturated carboxylic acid or carboxylic anhydride grafted high density polyethylene 2-8 wt%, molybdenum disulfide 0.5-3 wt%, and coupling agent 0.2-0.5 wt%. The fire retardant antiwear semi-aromatic polyamide composition has high fire retarding property, high wear resistance, excellent high temperature rigidity and high size stability and low friction noise. It may be used in making various kinds of antiwear parts, such as lining, guide rail, piston ring, gear, slide block, etc.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

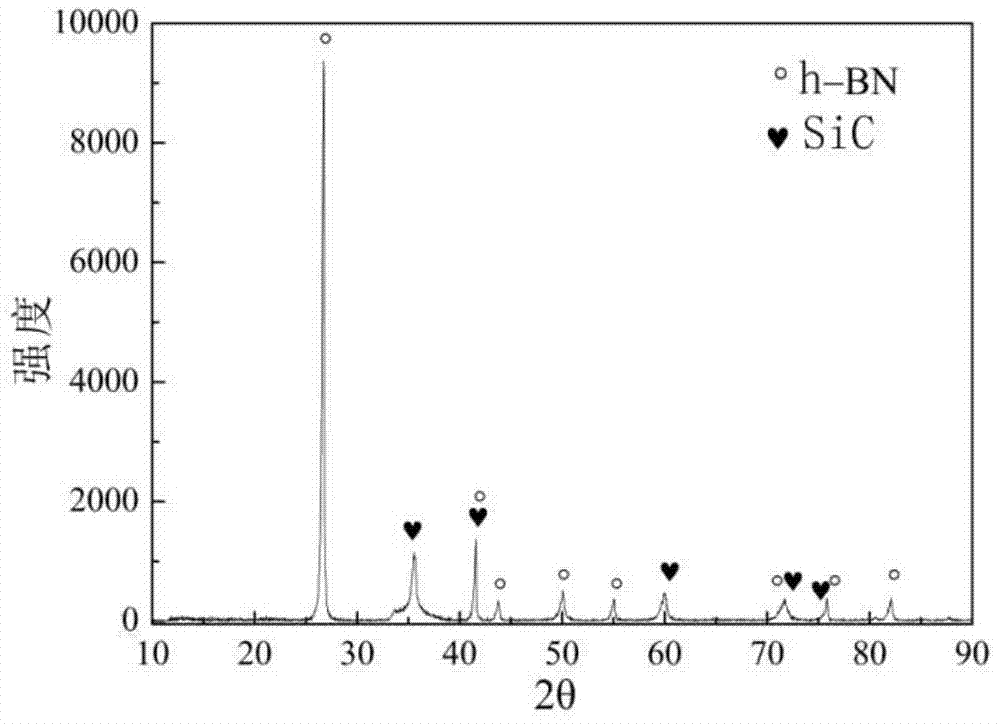

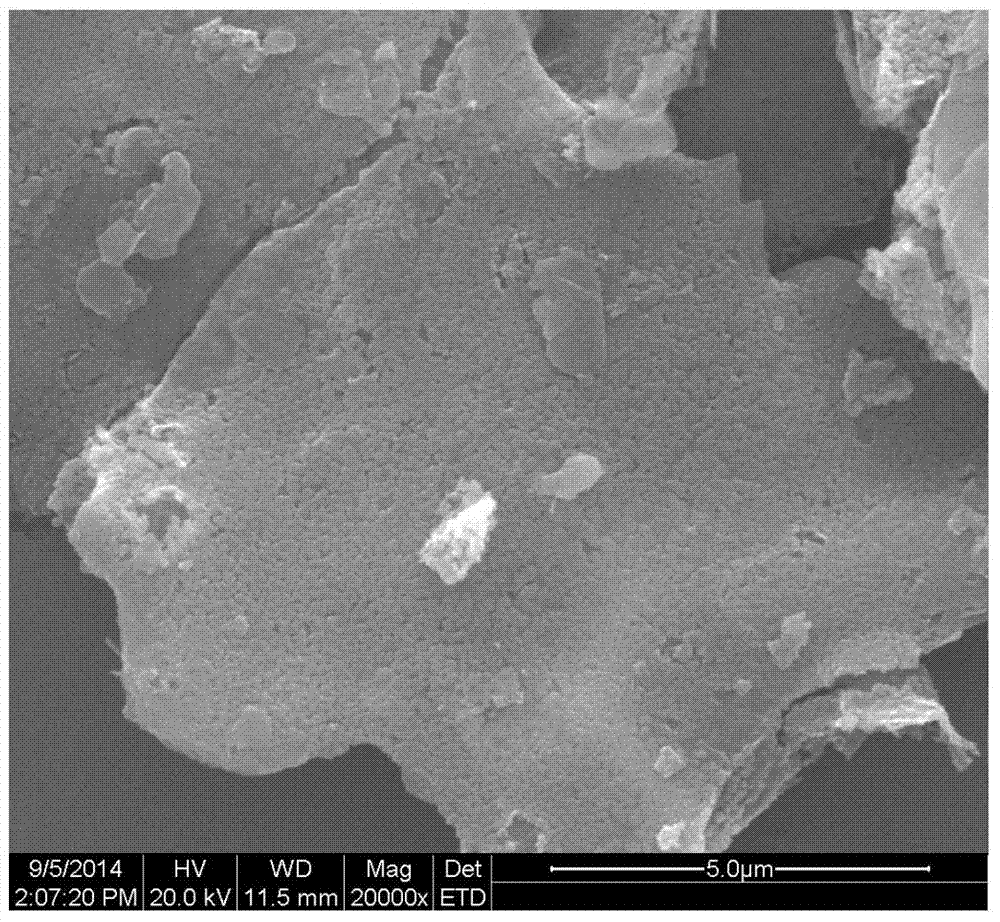

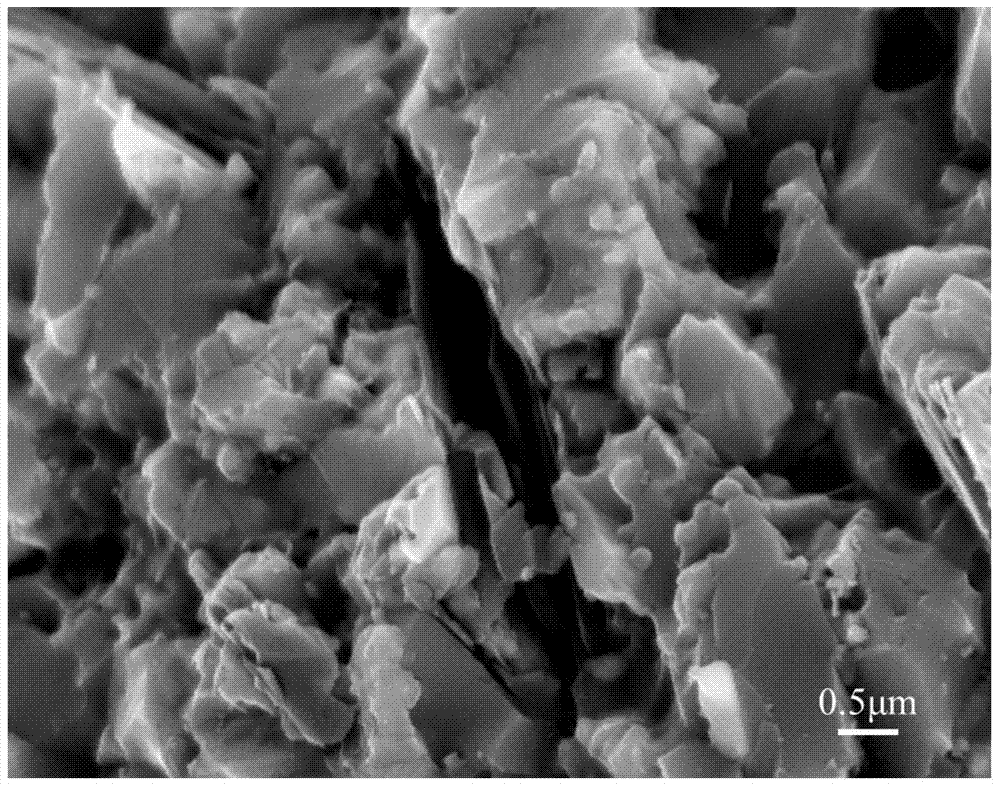

SiC-coated hexagonal boron nitride composite powder modified self-lubricating ceramic cutter material and preparation method thereof

ActiveCN104844225ASmall mechanical propertiesReduce adverse effectsHexagonal boron nitrideTitanium carbide

The invention relates to a SiC-coated hexagonal boron nitride composite powder modified self-lubricating ceramic cutter material and a preparation method thereof. The ceramic cutter material is prepared from the following raw materials in percentage by volume: 20-80% of aluminum oxide, 10-80% of titanium carbide, 1-20% of SiC-coated hexagonal boron nitride composite powder and 0.2-5% of magnesium oxide serving as a sintering aid. The invention further provides the preparation method of the ceramic cutter material; since the surface of hexagonal boron nitride composite powder is coated with SiC, the mechanical property of the material can be enhanced and the wettability of h-BN and a substrate can be improved and therefore agglomeration can be reduced.

Owner:QILU UNIV OF TECH

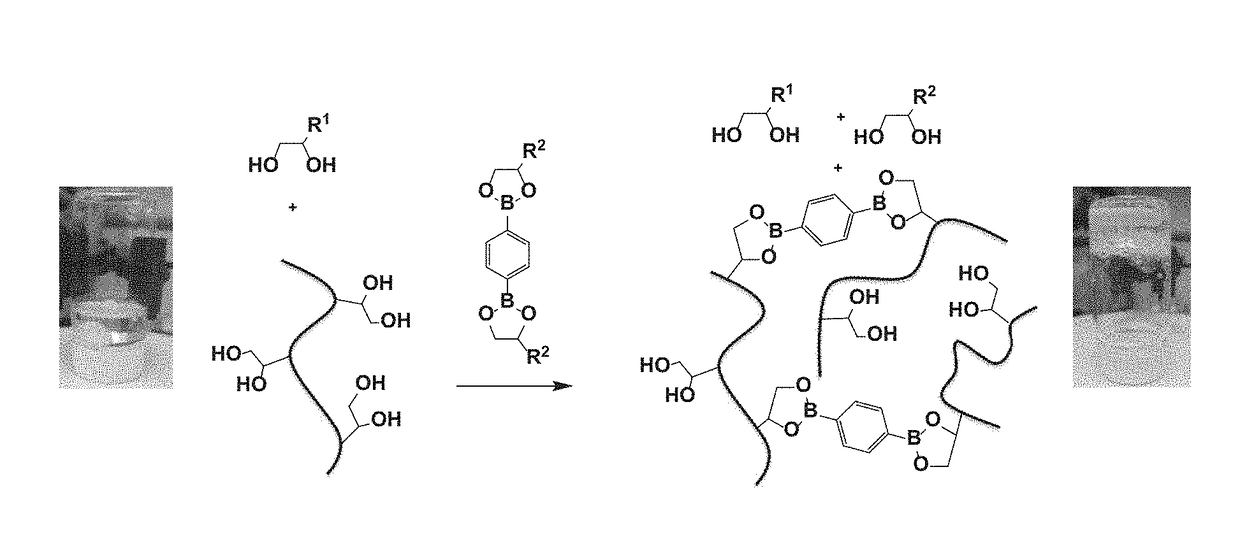

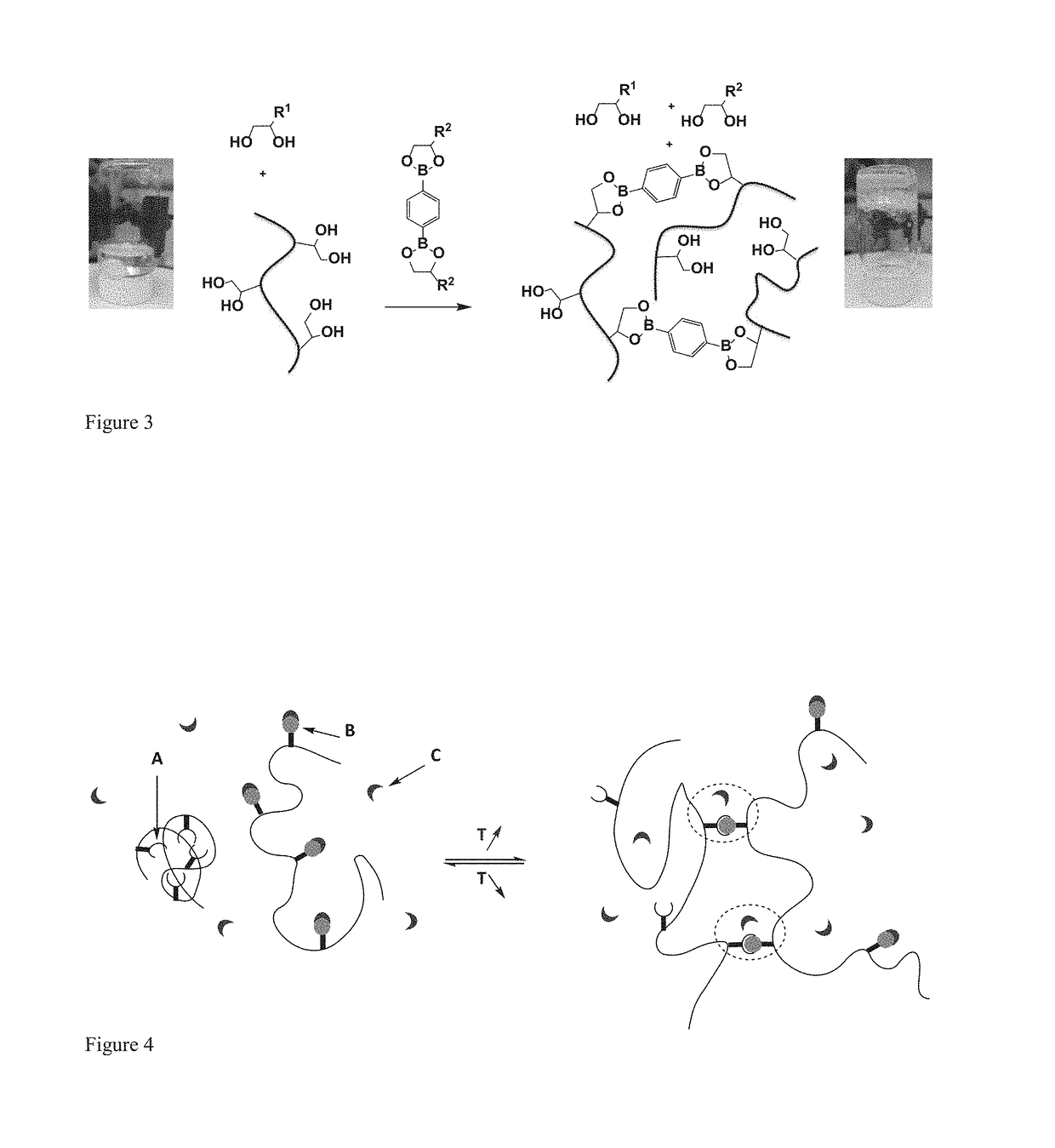

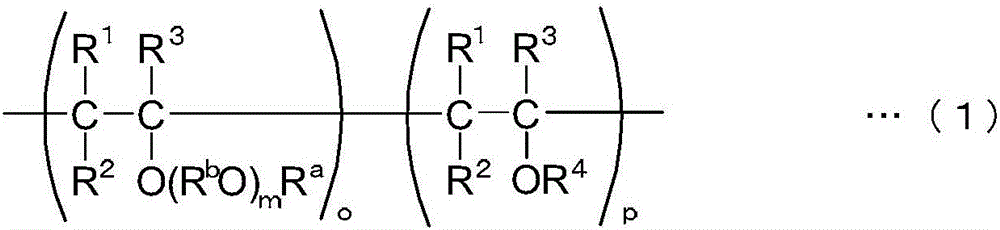

Compositions of thermoassociative additives with controlled association and lubricant compositions containing them

The present disclosure relates to novel compositions of additives that result from mixing at least two thermoassociative and exchangeable copolymers and at least one compound for controlling the association of these two copolymers. A lubricant composition results from mixing at least one lubricating base oil, at least two thermoassociative and exchangeable copolymers and at least one compound for controlling the association of these two copolymers. The present disclosure also relates to a process for modulating the viscosity of a lubricant composition that results from mixing at least one lubricating base oil, at least two thermoassociative and exchangeable copolymers; as well as the use of a diol compound for modulating the viscosity of a lubricant composition.

Owner:CENT NAT DE LA RECHERCHE SCI +2

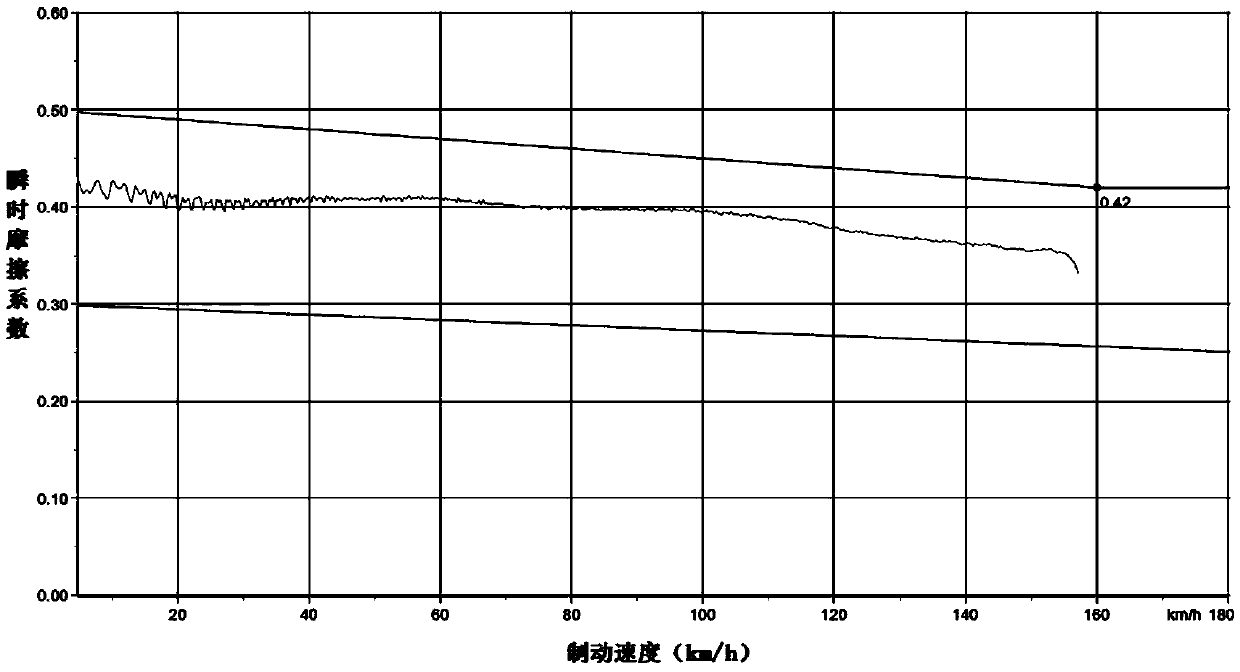

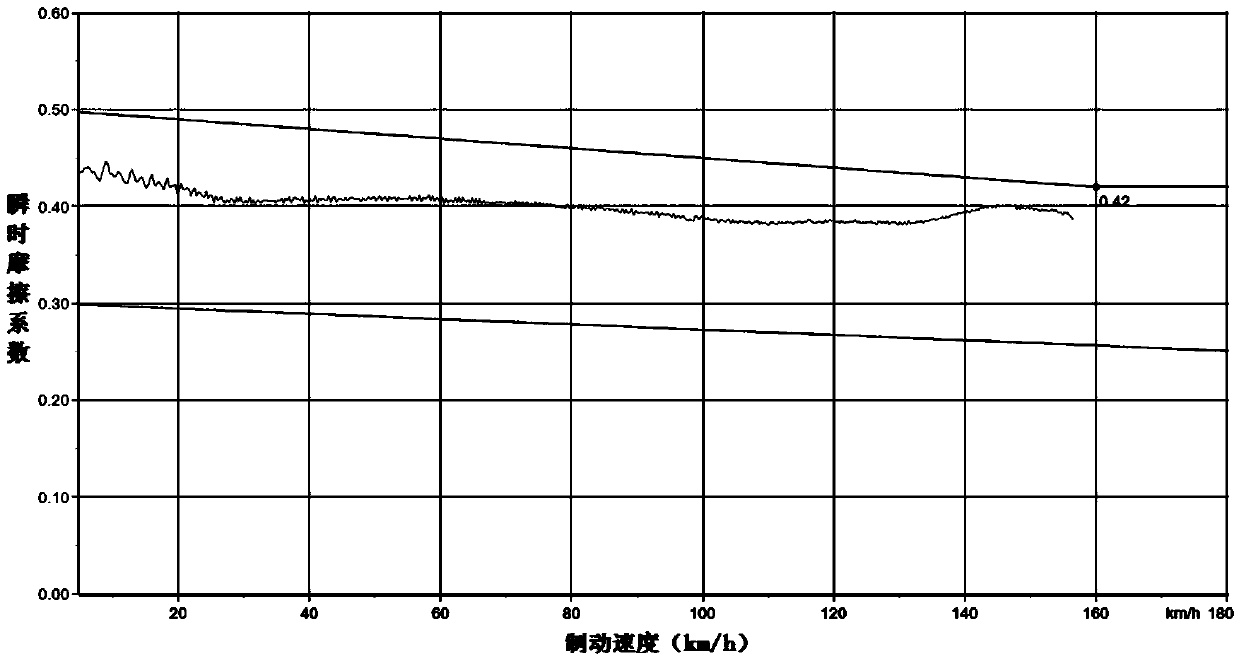

Powder metallurgy brake pad friction material and preparation method thereof

The invention relates to a powder metallurgy brake pad friction material and a preparation method thereof. The preparation method comprises the following specific steps: (A) raw materials are weighed, and include the following components in percentage by mass: 46-56% of copper, 25-35% of ferrochrome, 8-18% of graphite and 4-7% of silicon carbide; (B) the raw materials are fully mixed; (C) the raw materials are molded by pressing; and the pressing pressure is 15-20 MPa; and (D) the pressurization and the sintering are performed; the sintering temperature is 950-1050 DEG C; the sintering time is 7-15 h; and the sintering pressure is 0.5-3 MPa. The prepared powder metallurgy brake pad friction material is high in purity, excellent in friction performance and lower in cost.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

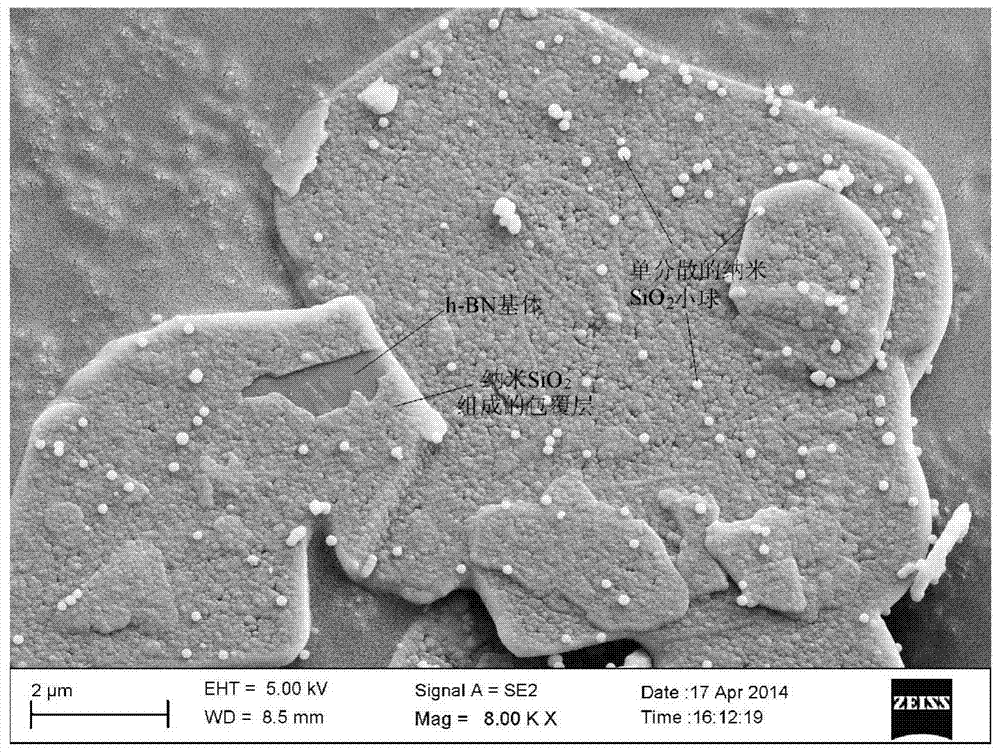

Preparation method of self-lubricating ceramic cutting tool material comprising spherical nanometer silicon dioxide coated hexagonal boron nitride composite powder

ActiveCN104844178AImprove mechanical propertiesTightly boundHexagonal boron nitrideCeramic cutting tool

The invention relates to a preparation method of self-lubricating ceramic cutting tool material comprising spherical nanometer silicon dioxide coated hexagonal boron nitride composite powder. The self-lubricating ceramic cutting tool material comprises the following raw material components in percentage by volume: 15-75% of TiC, 2-20% of h-BN@SiO2, 0.2-2.5% of MgO and the balance of Al2O3, wherein the h-BN@SiO2 is the spherical silicon dioxide coated hexagonal boron nitride composite powder which is obtained by dispersing h-BN powder in absolute ethyl alcohol and dropwise adding tetraethyl orthosilicate at the temperature of 30-70 DEG C. The invention also provides the preparation method of the self-lubricating ceramic cutting tool material. The added h-BN@SiO2 can improve the wettability of h-BN@SiO2 and a matrix and the mechanical property of the cutting tool material when the excellent lubricating property of the cutting tool material is remained, and reduce the agglomeration of air holes and the h-BN@SiO2 and the negative influence of the added h-BN on the mechanical property of the self-lubricating ceramic cutting tool material. The self-lubricating ceramic cutting tool material is suitable for application in manufacturing of self-lubricating ceramic cutting tools and can also be used for manufacturing ceramic molds, bearings and other wear-resisting anti-corrosion components and parts.

Owner:QILU UNIV OF TECH

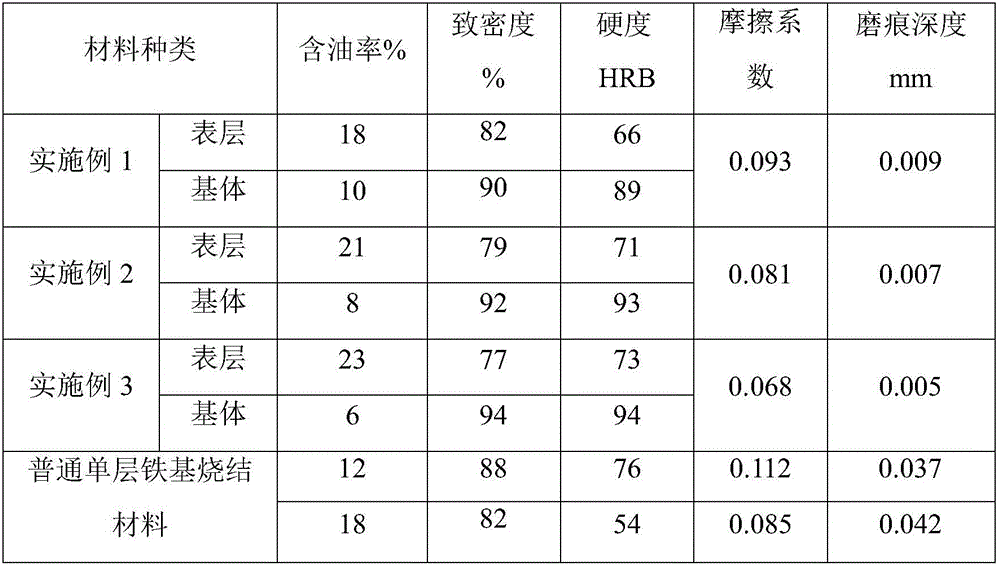

High-strength antifriction double-layered iron base powder metallurgy material and preparation method thereof

ActiveCN106041099AImprove carrying capacitySpeed up the flowTransportation and packagingMetal-working apparatusSurface layerHardness

The invention discloses a high-strength antifriction double-layered iron base powder metallurgy material and a preparation method thereof. The preparation method comprises the following steps that a densification enhancer is mixed in a matrix, so that a matrix material is dense and high in strength; a compound pore-forming agent is mixed in a surface layer to enable a surface layer material to be porous and oil-bearing, and besides, the requirements on the hardness and the wear resistance of the surface layer are met, and the contact interface and the lubricating condition of a friction pair are kept stable, so that the novel high-strength antifriction double-layered iron base powder metallurgy material is prepared. The bearing property, the wear resistance and the antifriction anti-seizing property of the iron base powder metallurgy material are improved remarkably, and high strength and a high lubricating property are effectively combined.

Owner:HEFEI UNIV OF TECH

Diamond grinding paste

ActiveCN104017499AImprove lubricating propertiesExtended service lifeOther chemical processesPolishing compositions with abrasivesDispersityAqueous medium

The invention relates to a diamond grinding paste and belongs to the technical field of grinding materials. The diamond grinding paste comprises the following raw materials in parts by weight: 20-50 parts of water, 5-30 parts of glycerin, 0.5-10 parts of Teflon micro powder and 10-20 parts of diamond micro powder. The diamond grinding paste is capable of improving dispersity of diamond micro powder and guaranteeing the grinding effect of special-type ceramic, and is applicable in oil and water mediums.

Owner:贵州荣清工具有限公司

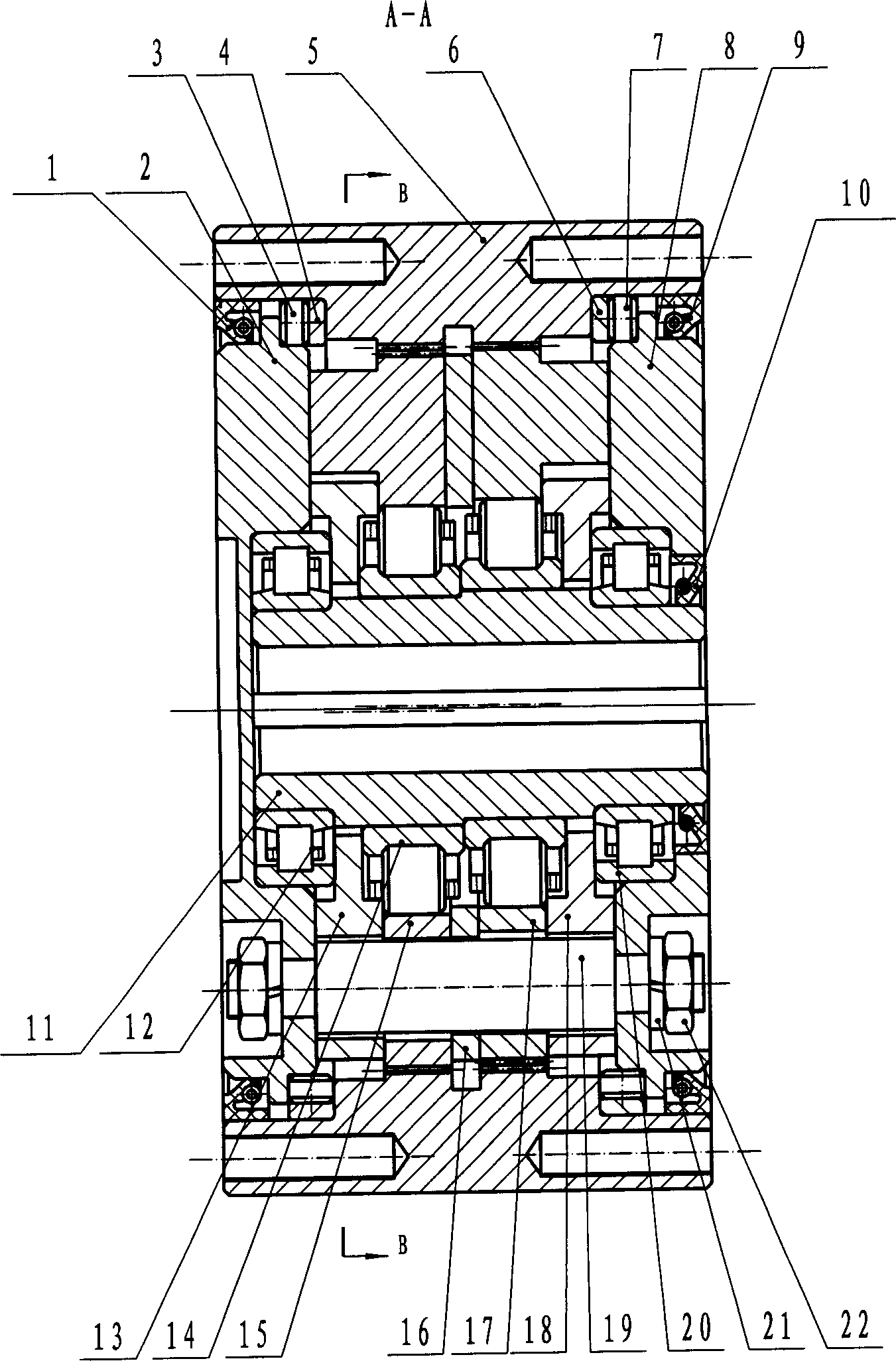

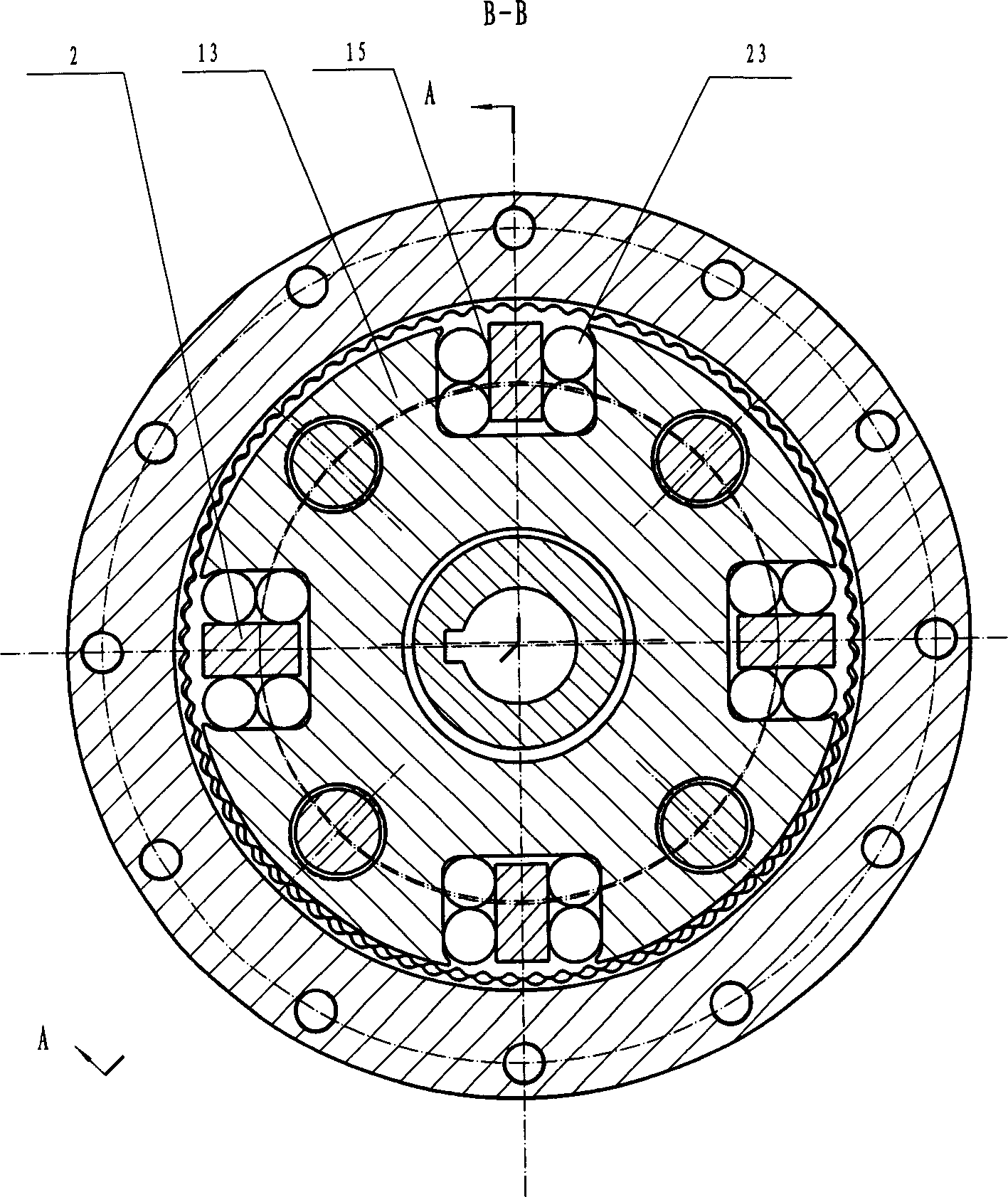

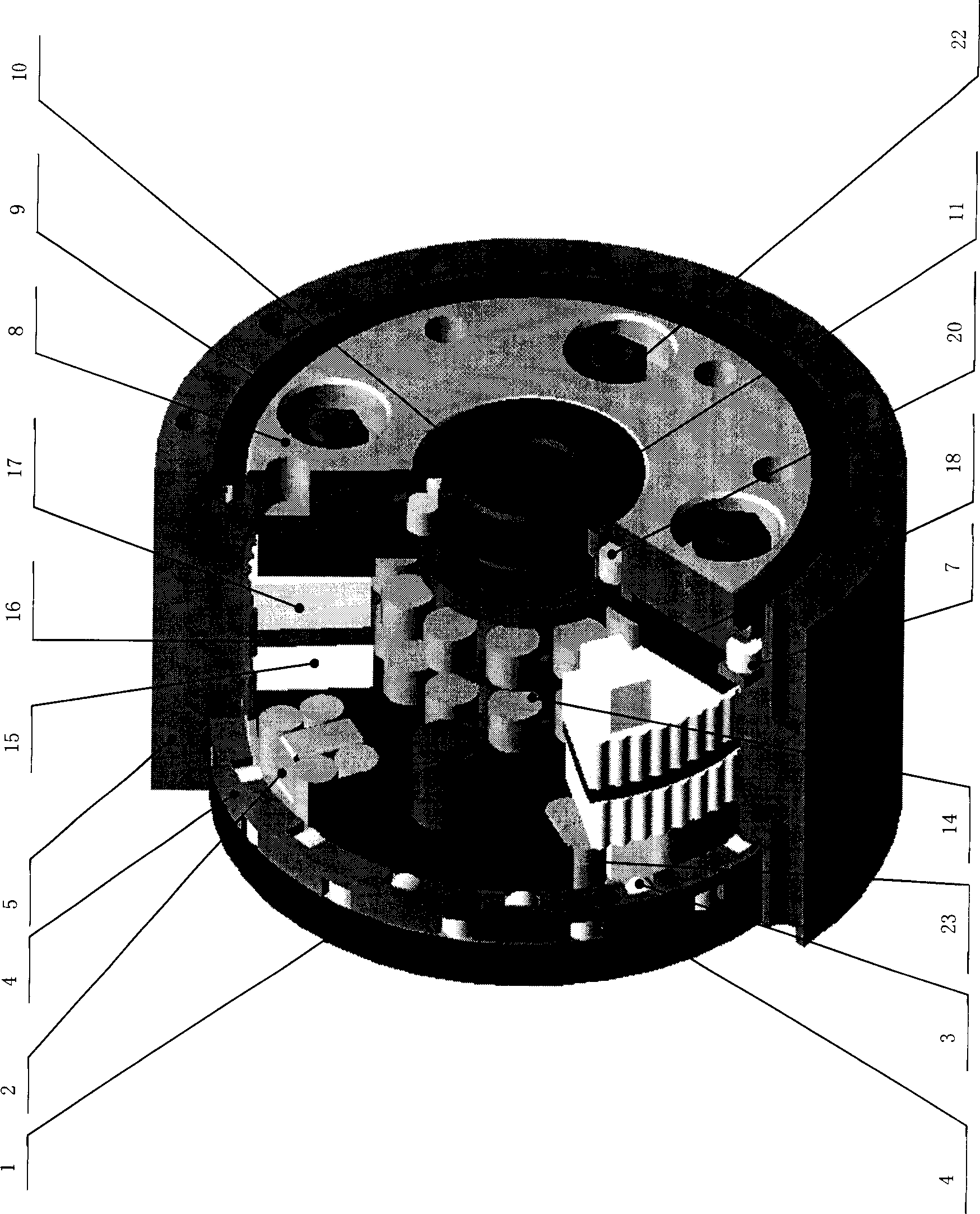

Secondary envelope cycloid planet driving device

ActiveCN1844704AImprove carrying capacityImprove lubricating propertiesToothed gearingsSmall teethEngineering

The invention discloses a secondary enveloped cycloid planet transmission device, belonging to the technique of the planet speed reducer with small tooth difference. It can solve the problems of present cycloid planet transmission that single-line contact and larger reverse-force of bearing. The invention comprises an input axle, left and right discs, a cycloid wheel, an inner gear wheel, a connecting axle, a rolling groove float disc output device and a bearing. Wherein, the inner gear wheel is enveloped by the planet motion of cycloid wheel; the tooth of cycloid wheel and the tooth of inner gear wheel form the conjugated meshed couple; the left and right float discs between the left disc and the left cycloid wheel and between the right cycloid wheel and the right disc form a output device while they are connected by rolling side groove; the rolling elements arranged axially and radially are filled into a support to form a radial / axial special bearing. The invention has dual-line connection, to improve the bearing ability and the lubricant property, to improve the transmission accuracy and prolong the service life.

Owner:CHONGQING UNIV

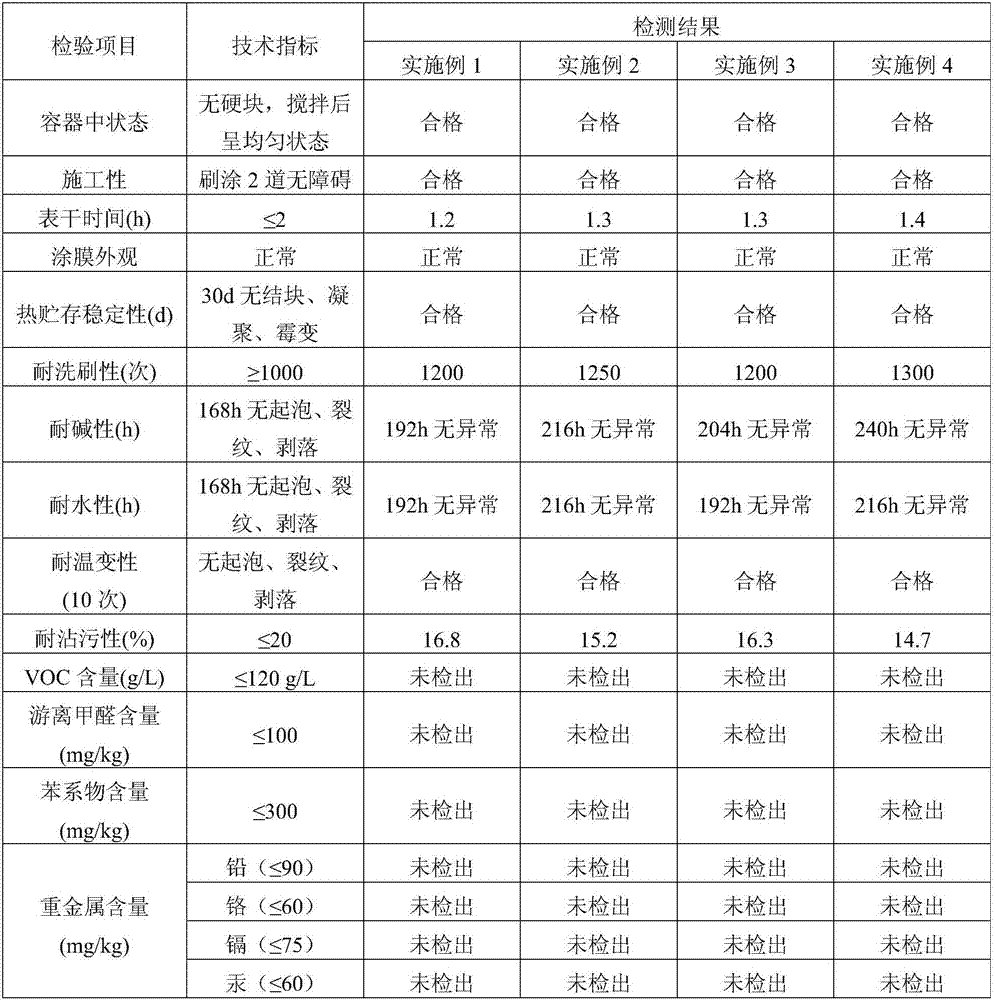

Novel environment-friendly waterborne inorganic paint and preparation method thereof

InactiveCN107266944AFire retardantAntibacterial and antifungalFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholFire resistance

The invention discloses novel environment-friendly waterborne inorganic paint and a preparation method thereof. The novel environment-friendly waterborne inorganic paint is prepared from, by weight, 55-65 parts of kaolin, 12-20 parts of sodium silicate, 20-30 parts of titanium dioxide, 1-5 parts of nano zinc oxide, 5-10 parts of ultrafine wollastonite powder, 1-10 parts of nano calcium carbonate, 1-5 parts of ultrafine white mica powder, 7-15 parts of polyvinyl alcohol, 1-4 parts of ultrafine molybdenum disulfide powder, 2-10 parts of nano silicon dioxide, 2-12 parts of nano magnesium oxide, 2-12 parts of nano aluminum oxide, 1-3 parts of magnesium chloride, 1-3 parts of a sodium silicate hardening accelerator, 2-5 parts of a pH value regulating agent, 1-8 parts of a waterproof agent, 6-10 parts of an antifoaming leveling agent, 1-3 parts of a thickening anti-settling agent and 280-310 parts of water. The novel environment-friendly waterborne inorganic paint which is environment-friendly waterborne inorganic paint for buildings is high in storage stability, excellent in water resistance and alkali resistance, strong in adhesion, high in fire resistance, high in strength and hardness, resistant to scratching and contamination, excellent in corrosion resistance and antibacterial property, free of formaldehyde, benzene compounds, VOC (volatile organic compounds) and heavy metal elements, completely environmental friendly and nontoxic, suitable for industrial production, easy for painting and convenient and quick in construction.

Owner:CHENGDU POLYTECHNIC

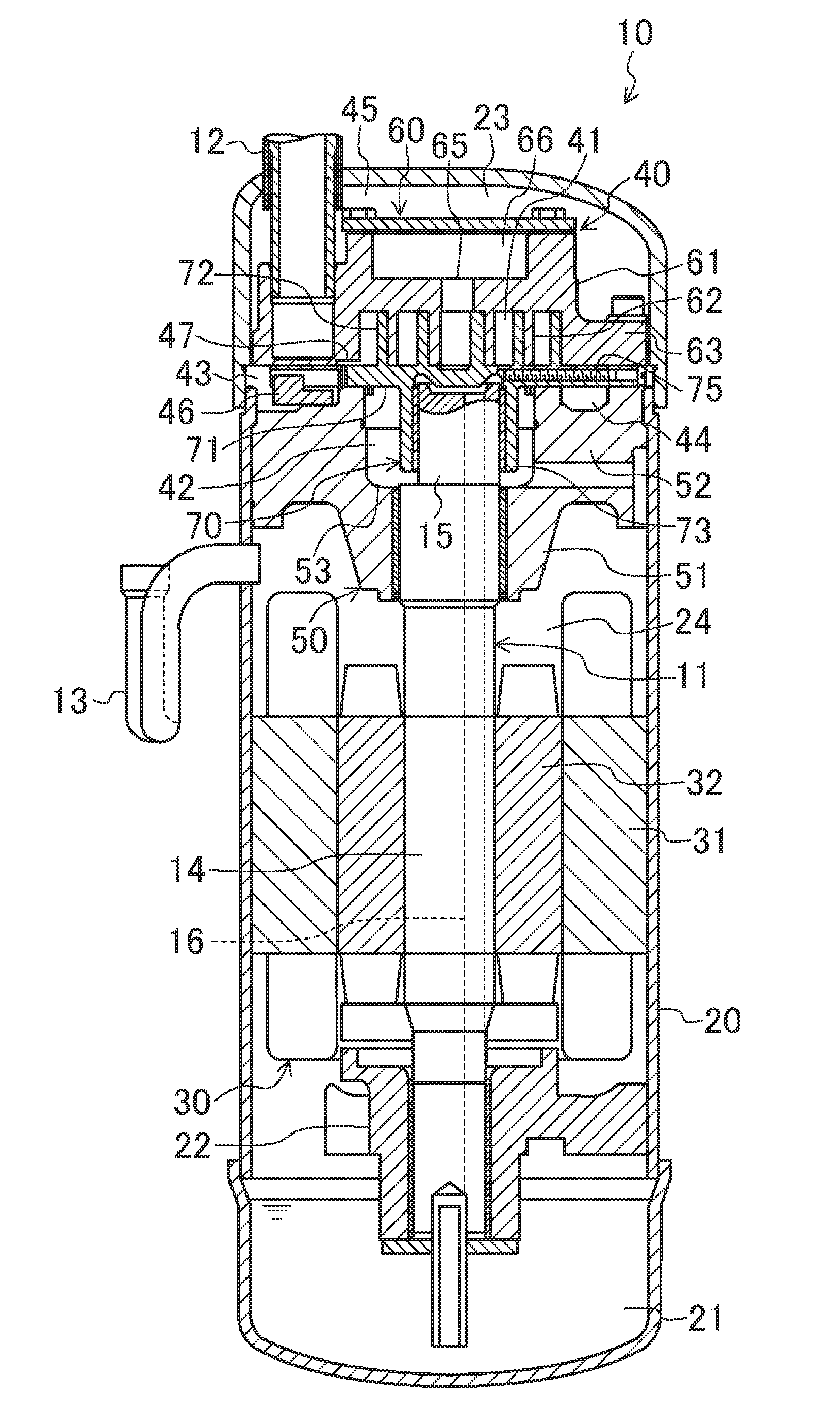

Screw compressor

ActiveUS20140010694A1Reduce leakageIncrease lubrication areaRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringHigh pressure

A scroll compressor includes a compression mechanism having a fixed scroll and an orbiting scroll. The fixed scroll includes a first end plate, an outer peripheral wall extending from an edge of first end plate, a first oil groove, and a first wrap inside of the outer peripheral wall. The orbiting scroll includes a second end plate in sliding contact with an end of the first wrap and an end of the outer peripheral wall, a second oil groove, and a second wrap. The first oil groove is disposed on a surface of the outer peripheral wall, extends along an inner periphery of the outer peripheral wall, and is configured to receive lubricating oil at a high pressure corresponding to a discharge pressure of the compression mechanism. The second oil groove is disposed on a surface of the second end plate, and is communicatable with the first oil groove.

Owner:DAIKIN IND LTD

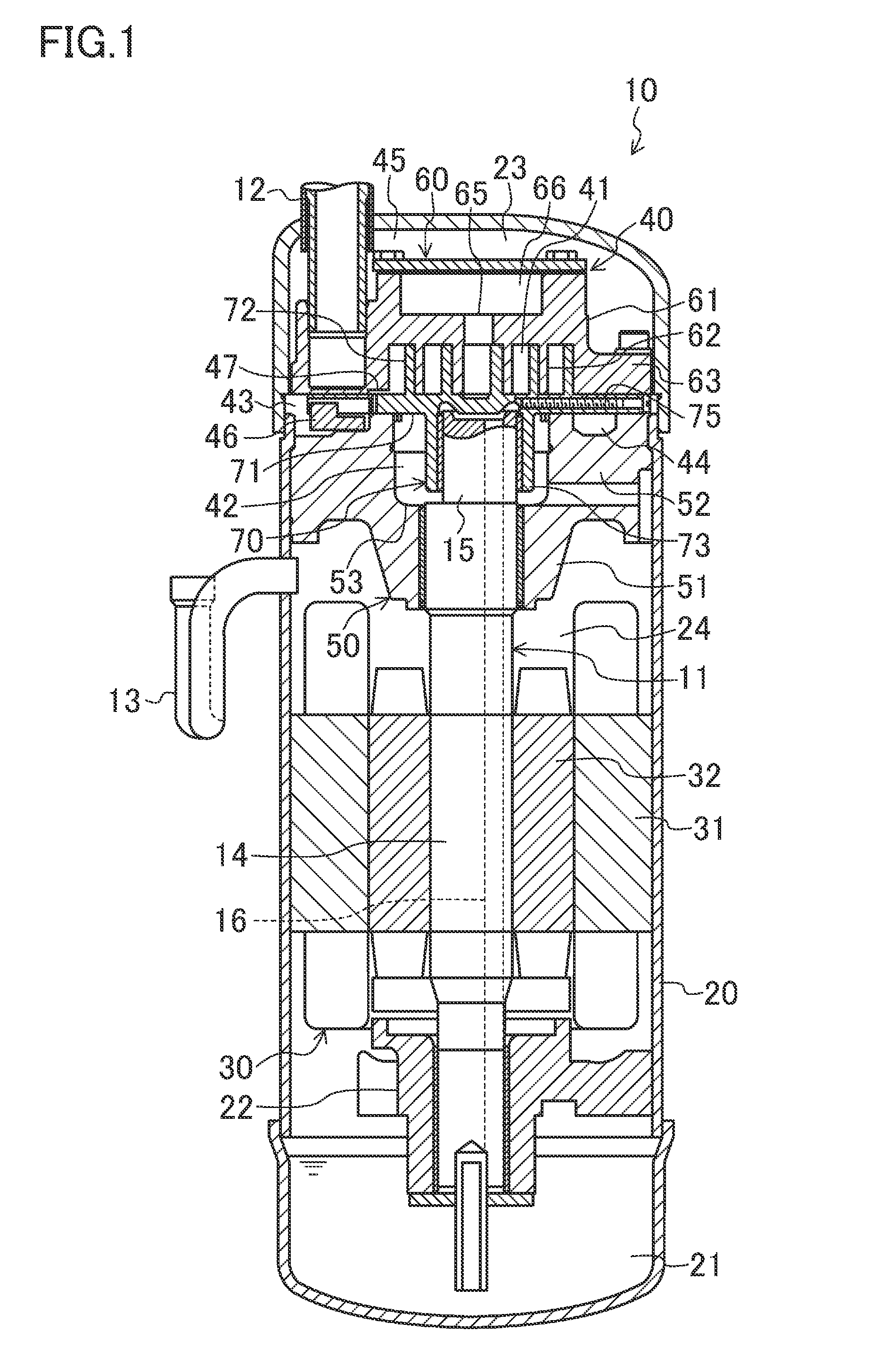

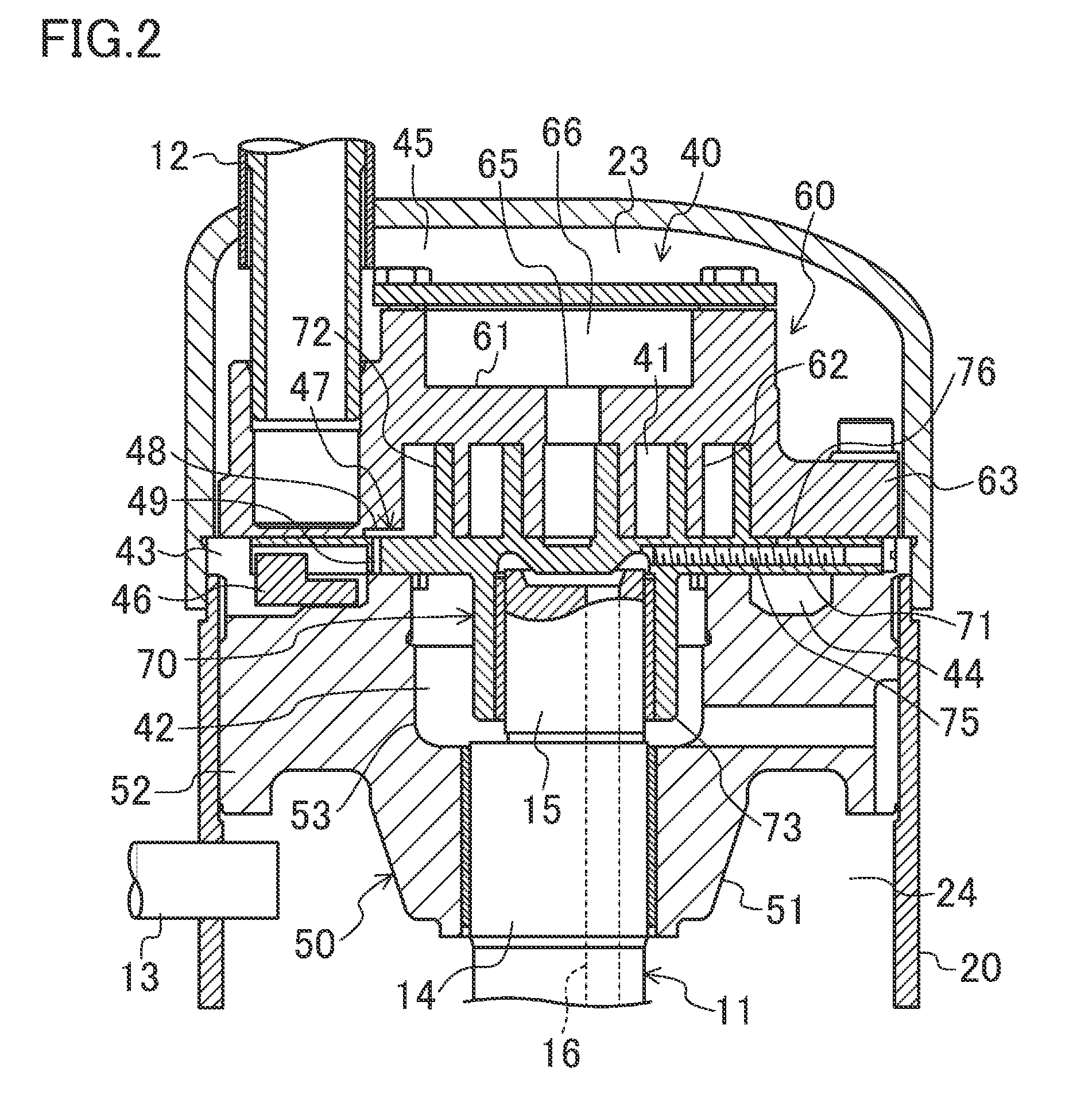

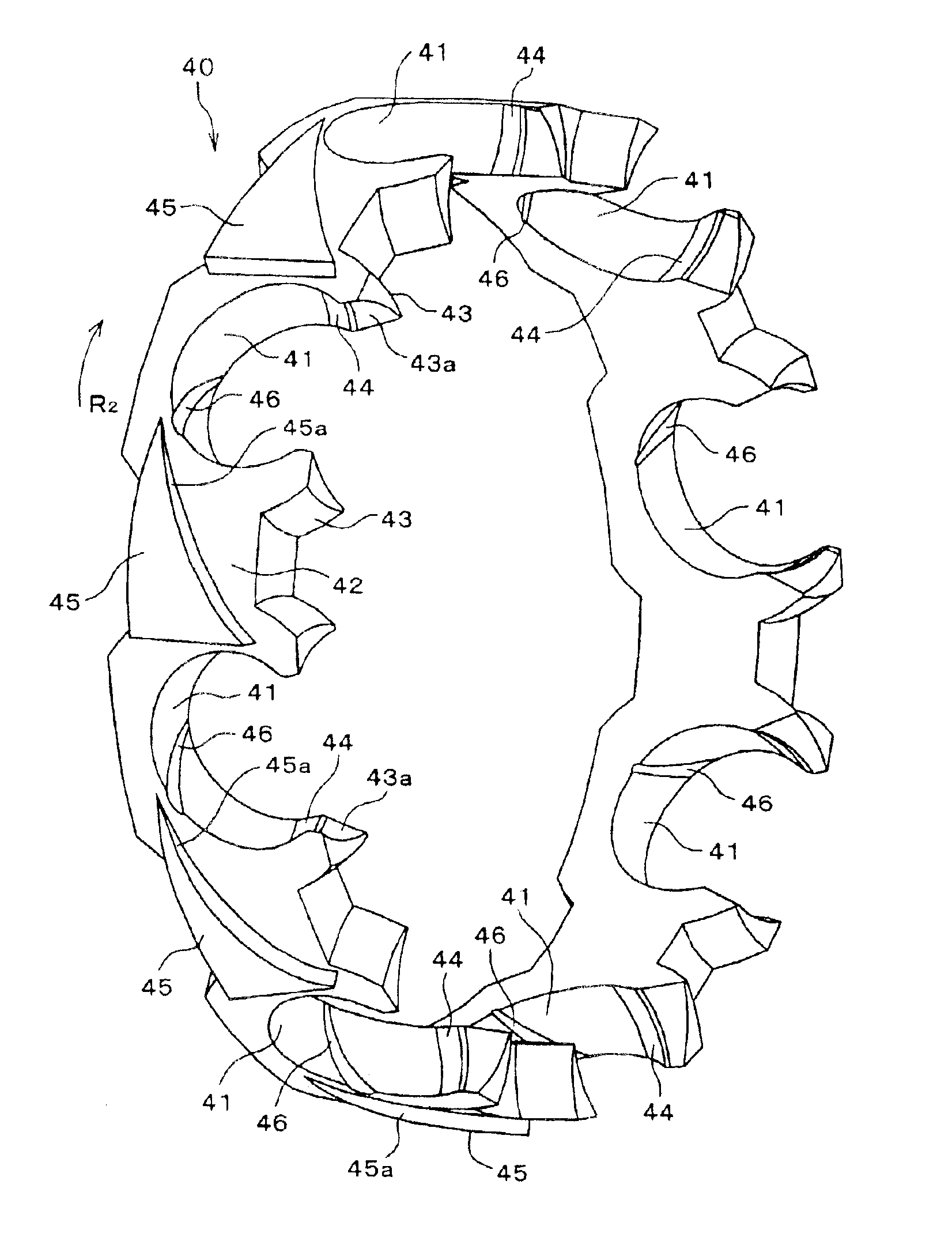

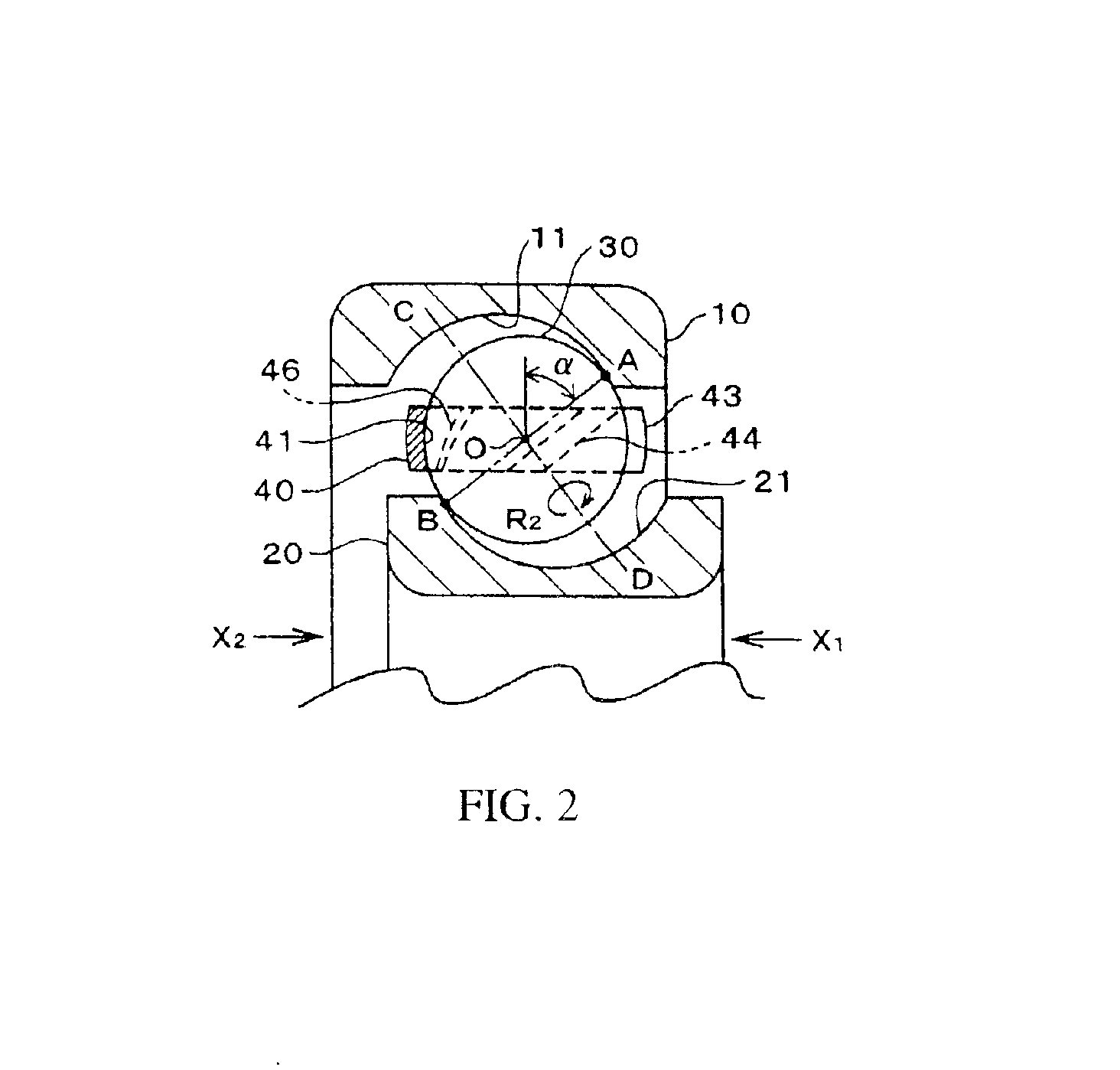

Radial ball bearing retainer

InactiveUS6890105B2Improve lubricating propertiesReduce rotation torqueShaftsBall bearingsLeading edgeBall bearing

A deep channel type of radial ball bearing having a retainer. The bearing has an outer ring and an inner ring. Running channels are formed on the mutually opposing orbiting surfaces of the outer ring and inner ring. A specified number of balls are fit into the running channels. The retainer having pockets is placed between the outer ring and the inner ring. Each ball is captured in one of the pockets. A ball contact surface is formed on the inner surface of each edge on the opening side of the pockets. A curved ridge line forms the boundary between the inner surface of the pocket and the contact surface. This curved ridge line that forms the boundary is substantially parallel to the direction of rotation of the balls. A channel is formed at the bottom surface of the pocket. The channel extends from the inner perimeter to the outer perimeter of the retainer. The lubricating oil on the bottom surface of the pocket flows through the channel by virtue of the rolling of the balls and is guided to the outer perimeter side. A triangle-shaped fin having an inclined surface is integrally formed between the adjacent pockets on the outer perimeter surface. The inclined surface is formed on the trailing side of pocket with respect to the retainer direction of rotation. Lubricating oil directed from the above-described channel to the outer perimeter surface by the rolling of the ball is received at the inclined surface of the fin and is supplied to the vicinity of the leading edge of the pocket that is located behind the fin by the rotation of the retainer.

Owner:MINEBEAMITSUMI INC

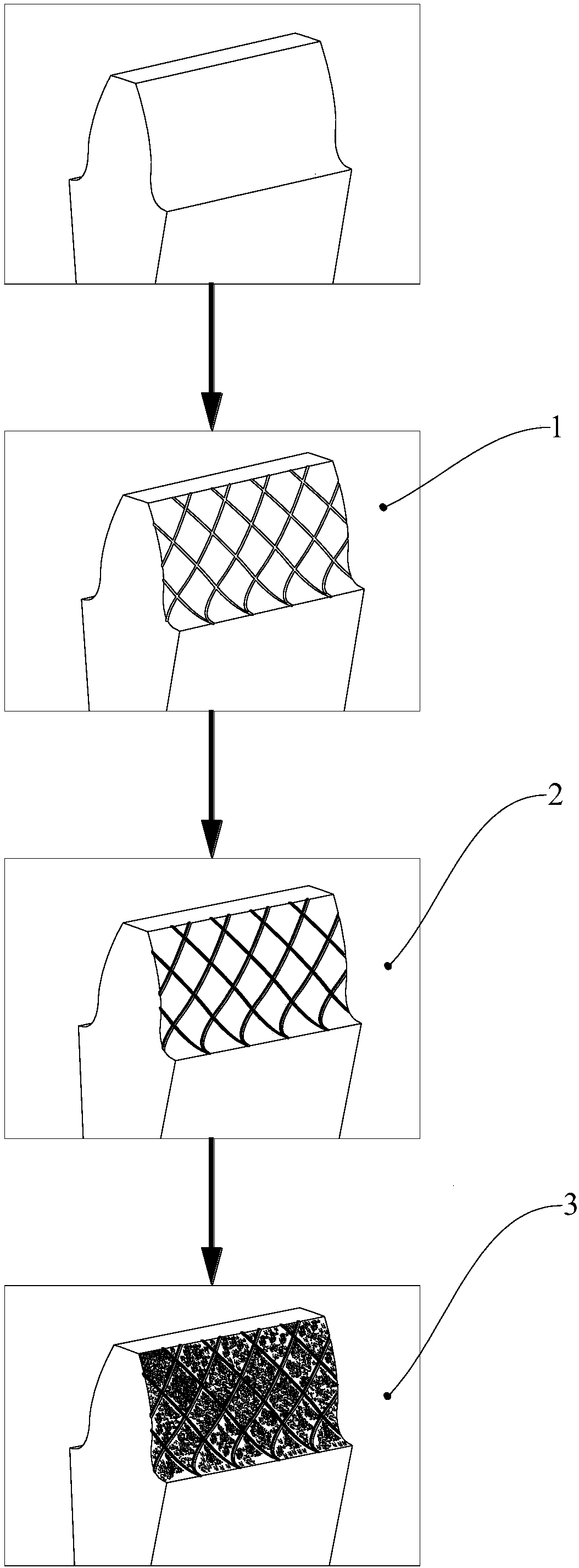

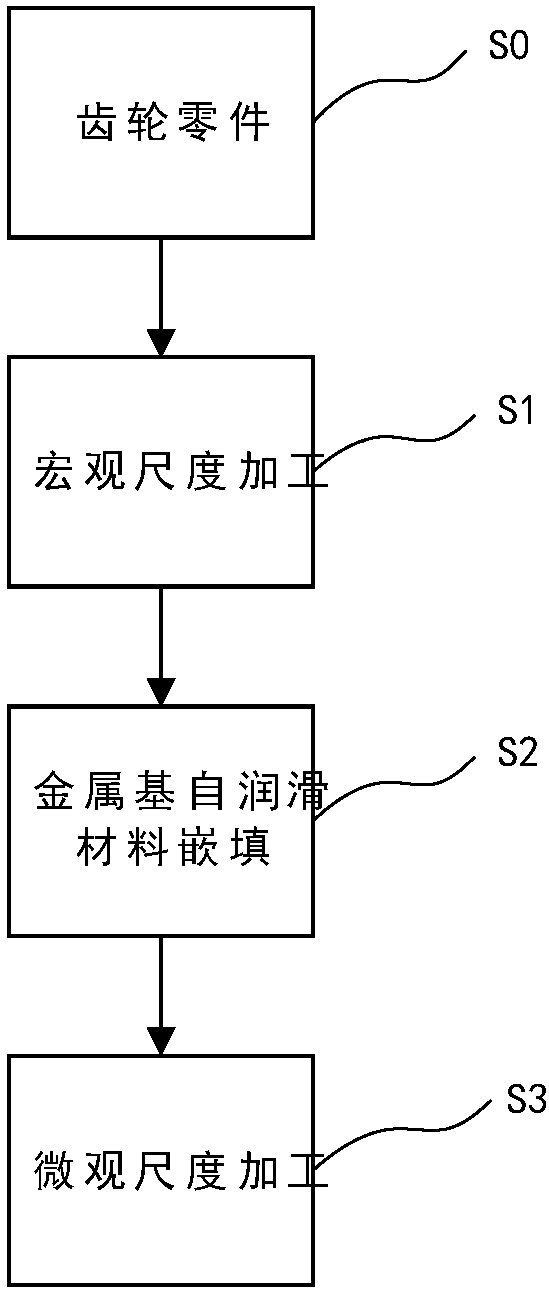

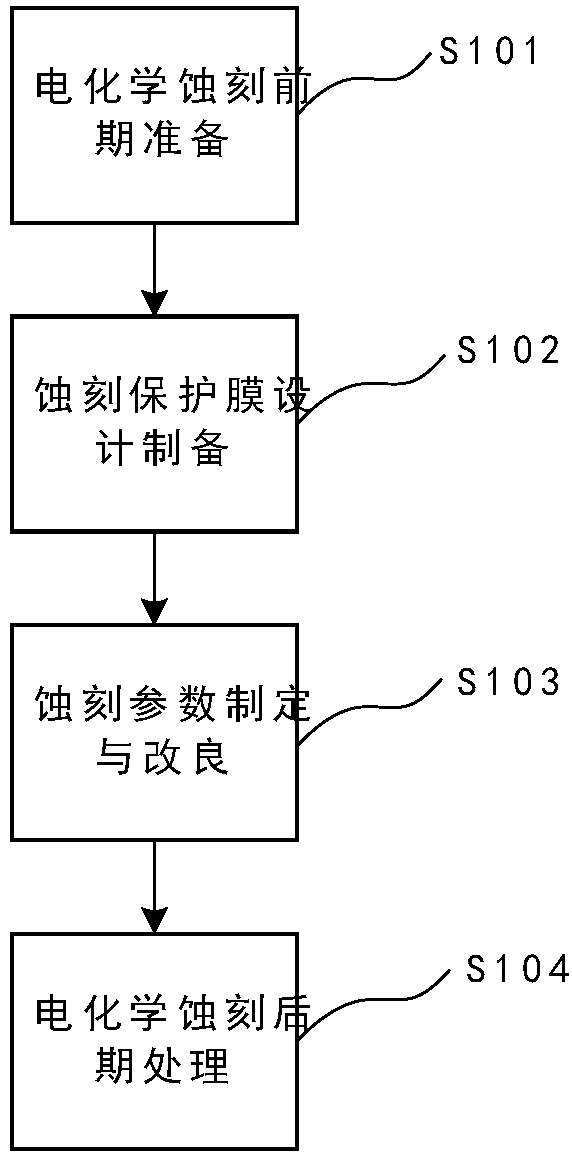

Machining method for cross-scale staggered embedded type self-lubricating gear surface

InactiveCN108406016AImprove lubricating propertiesEasy to processMetallic material coating processesElectrochemical machining apparatusSurface grindingHardness

The invention relates to a machining method for a cross-scale staggered embedded type self-lubricating gear surface. The machining method comprises the four main machining steps of macro-scale machining, self-lubricating material embedded filling, gear surface grinding machining and micro-scale machining. According to the machining method, a cross-scale self-lubricating interface is formed on thegear surface by arranging the interface according to a certain rules and combining the characteristics of a self-lubricating material through an electrochemical machining method, a laser cladding technology and a laser microtexture technology, the lubricating requirement of a gear under the oil-free or oil-lack condition is met, and the gear surface has the enough hardness and smoothness. According to the machining method for the cross-scale staggered embedded type self-lubricating gear surface, a common gear can be machined into a cross-scale staggered embedded type self-lubricating gear, anda foundation is laid for practical application of the self-lubricating gear.

Owner:HEFEI UNIV OF TECH

Aerial insulation wire electrification repairing method

ActiveCN104009421ANon-stickReduce the temperatureApparatus for repairing insulation/armouring cablesSilicone tapeElectrical tape

The invention relates to an aerial insulation wire electrification overhauling method, in particular to an aerial insulation wire electrification repairing method. The method comprises the steps that polyimide adhesive tape is wrapped on the exposed part of an aerial insulation wire through a half fold packaging method, the outer side of the exposed part wrapped by the polyimide adhesive tape is coated with a layer of teflon coating film, an injection hole is formed in the middle of the teflon coating film, and a spray gun sprays a polyurethane foam joint mixture to the position between the teflon coating film and the polyimide adhesive tape through the injection hole for joint filling. According to the aerial insulation wire electrification repairing method, the problems that the insulation performance of the aerial wire is lowered, and a grounded short circuit accident is caused due to the facts that the aerial wire is exposed and the insulation adhesive tape is aged, unglued and chapped are effectively prevented, large-area power failure is avoided, power supply reliability is provided for reducing interphase short circuits and ground faults, and hidden dangers existing when workers work are avoided.

Owner:STATE GRID CORP OF CHINA +1

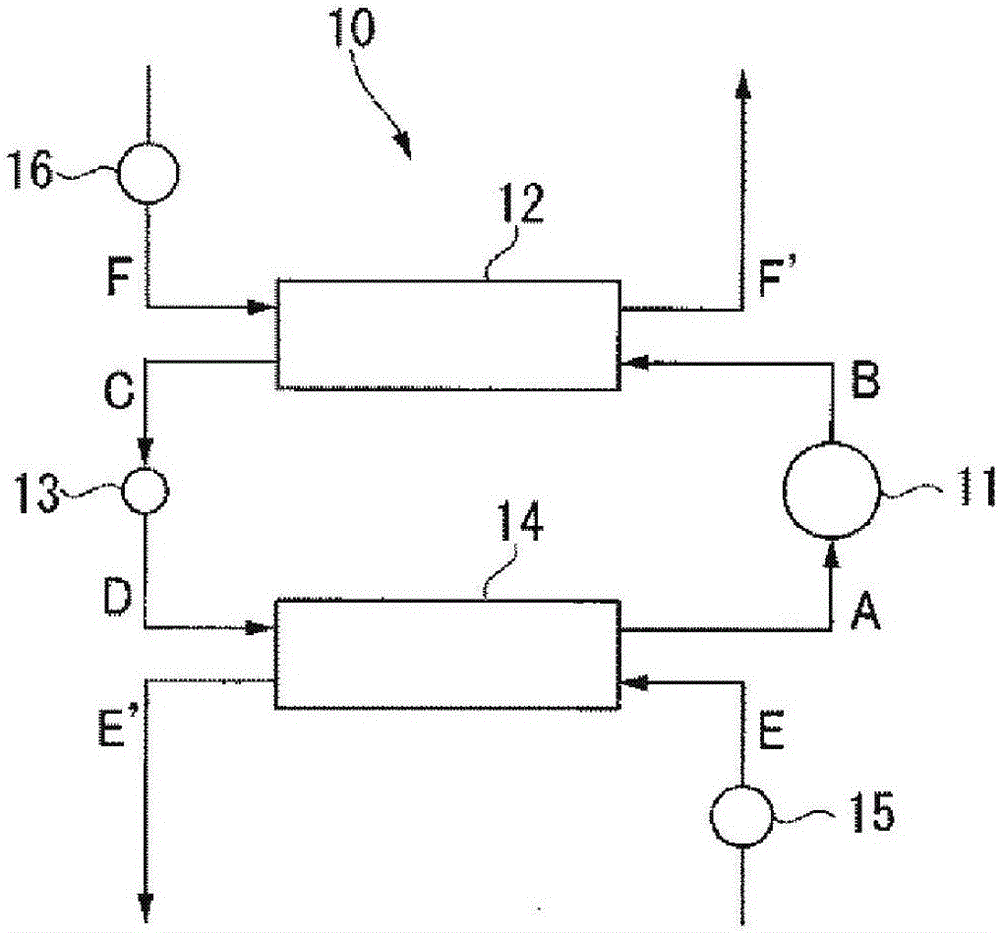

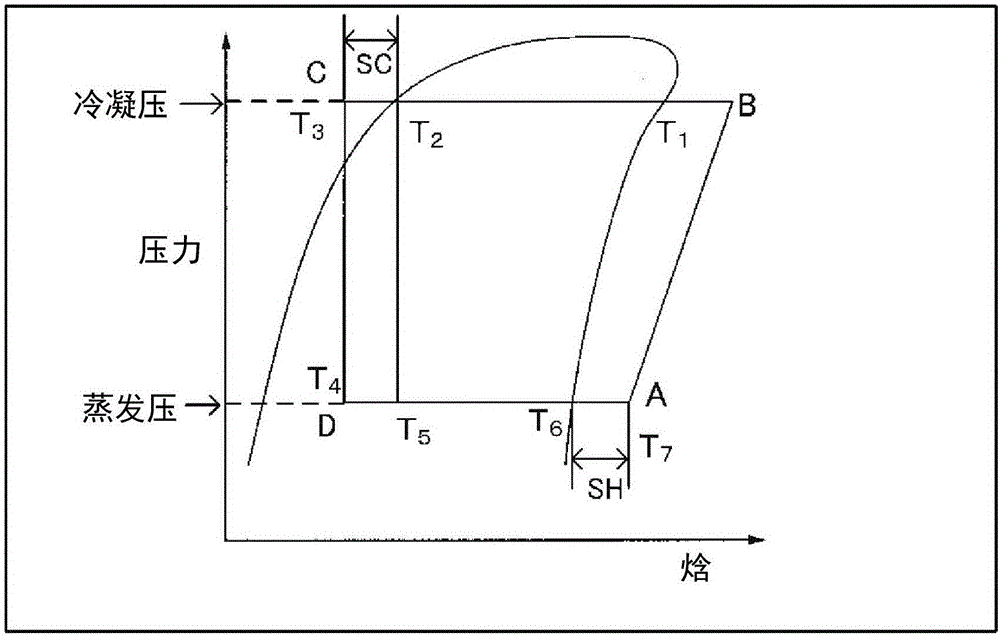

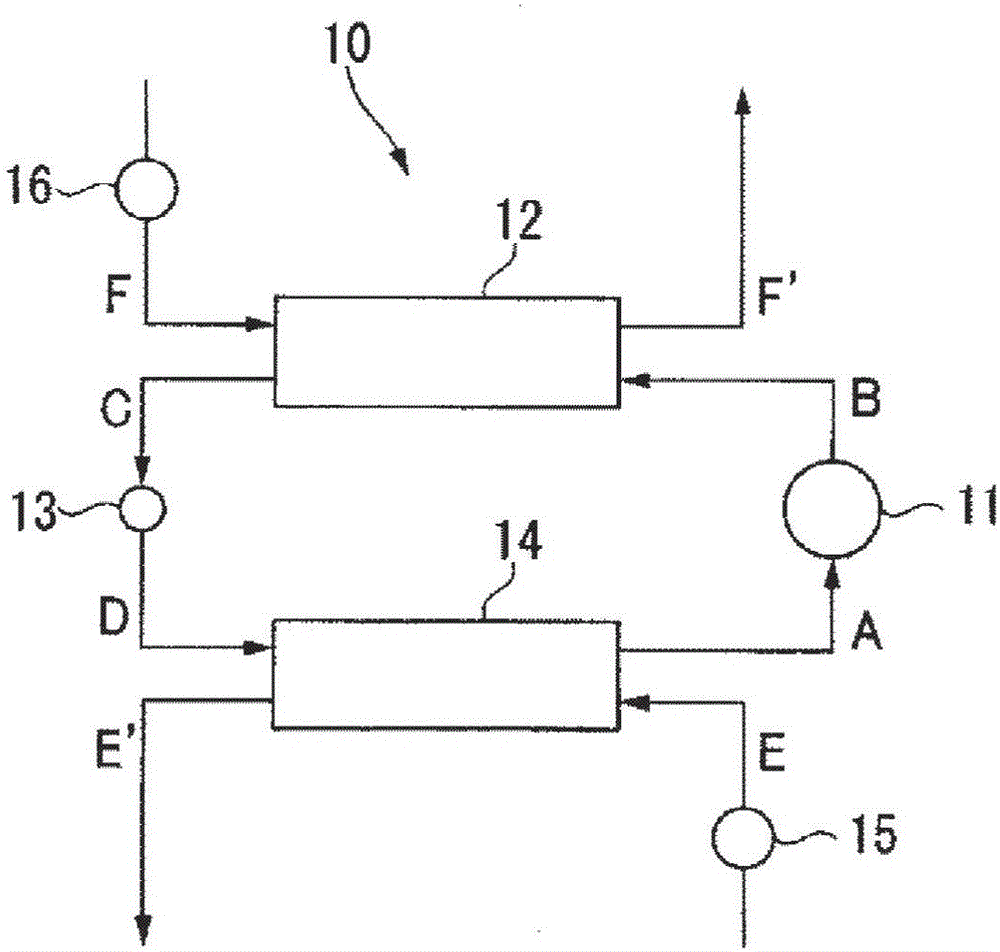

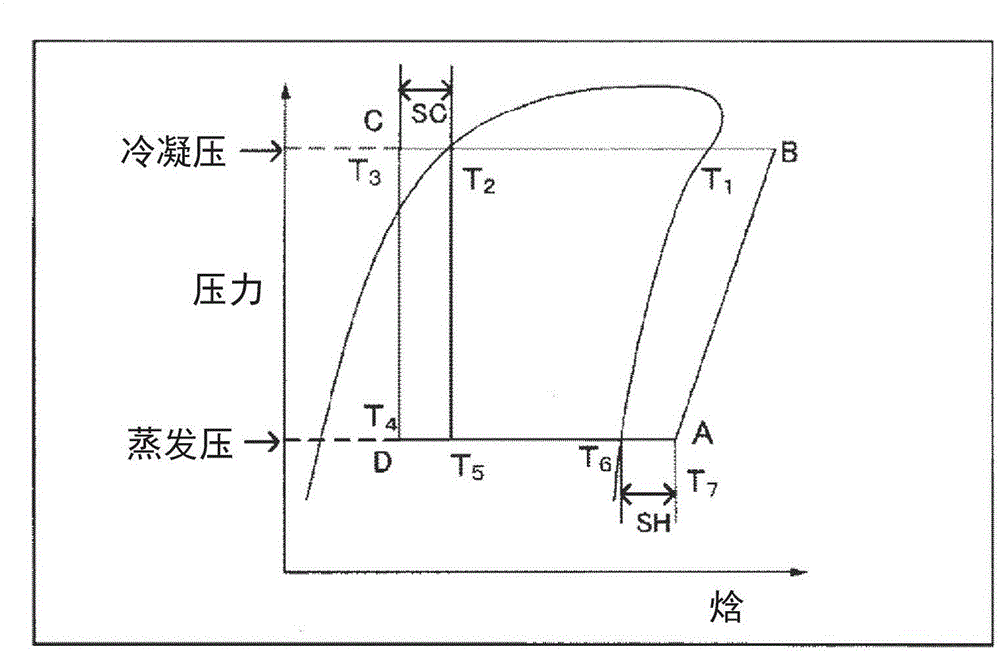

Composition for heat cycle system, and heat cycle system

ActiveCN106029853AImprove the lubrication effectGive full play to the low greenhouse effect coefficientHeat-exchange elementsCompression machines with reversible cycleProcess engineeringHydroxyl value

A composition for a heat cycle system which has excellent lubrication properties and which contains a heat cycle working medium usable as a substitute for R410A and having a low global warming potential, and a heat cycle system using said composition are provided. This composition for a heat cycle system contains a heat cycle working medium that contains an unsaturated fluorinated hydrocarbon compound of a specific structure, and a refrigerant oil which has an insulation breakdown voltage of 25kV or greater and a hydroxyl value of 0.1mgKOH / g or less, and for which the lowest temperature on the high temperature side of the phase separation temperature for separation from the heat cycle working medium is 35 DEG C or higher, and the highest temperature on the low temperature side is -60 DEG C or lower; this heat cycle system uses the aforementioned composition for a heat cycle system.

Owner:ASAHI GLASS CO LTD

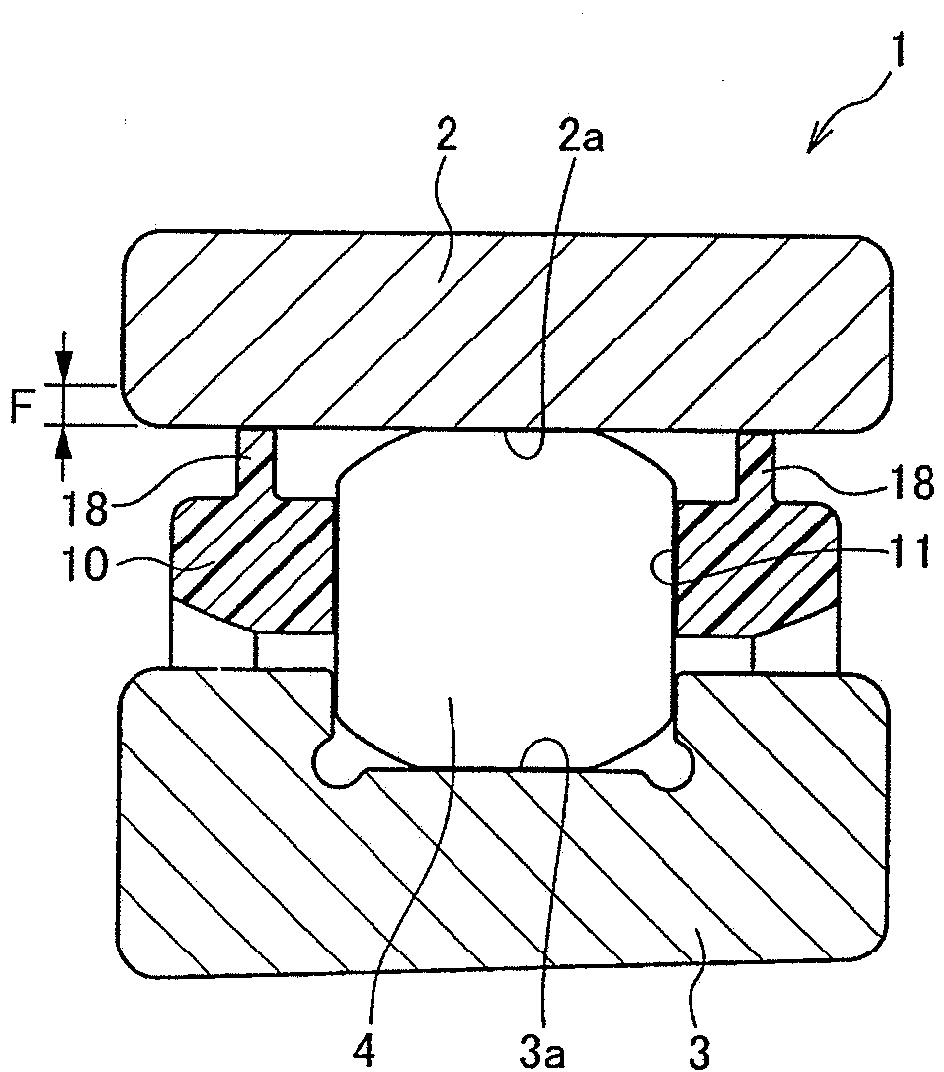

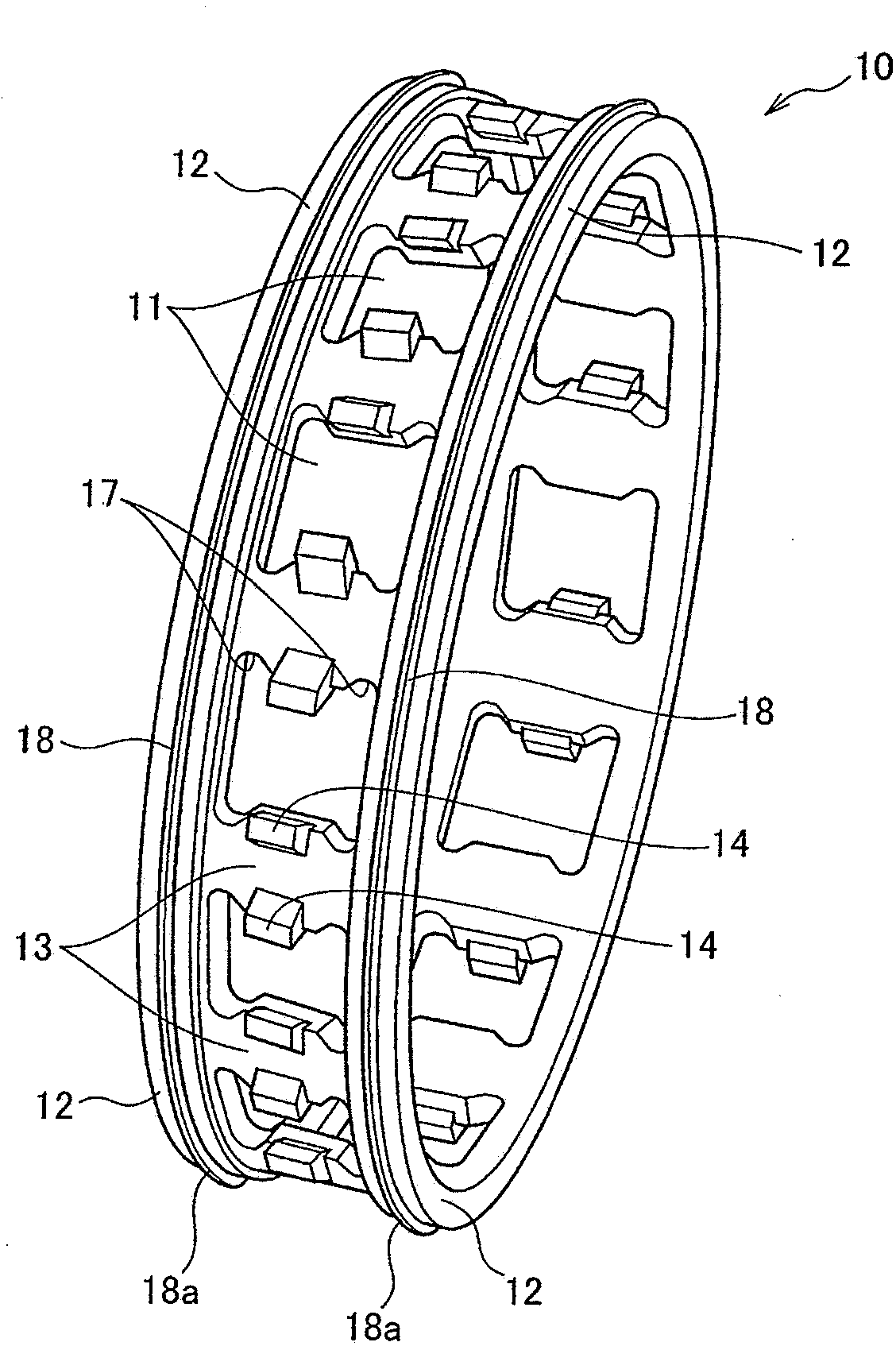

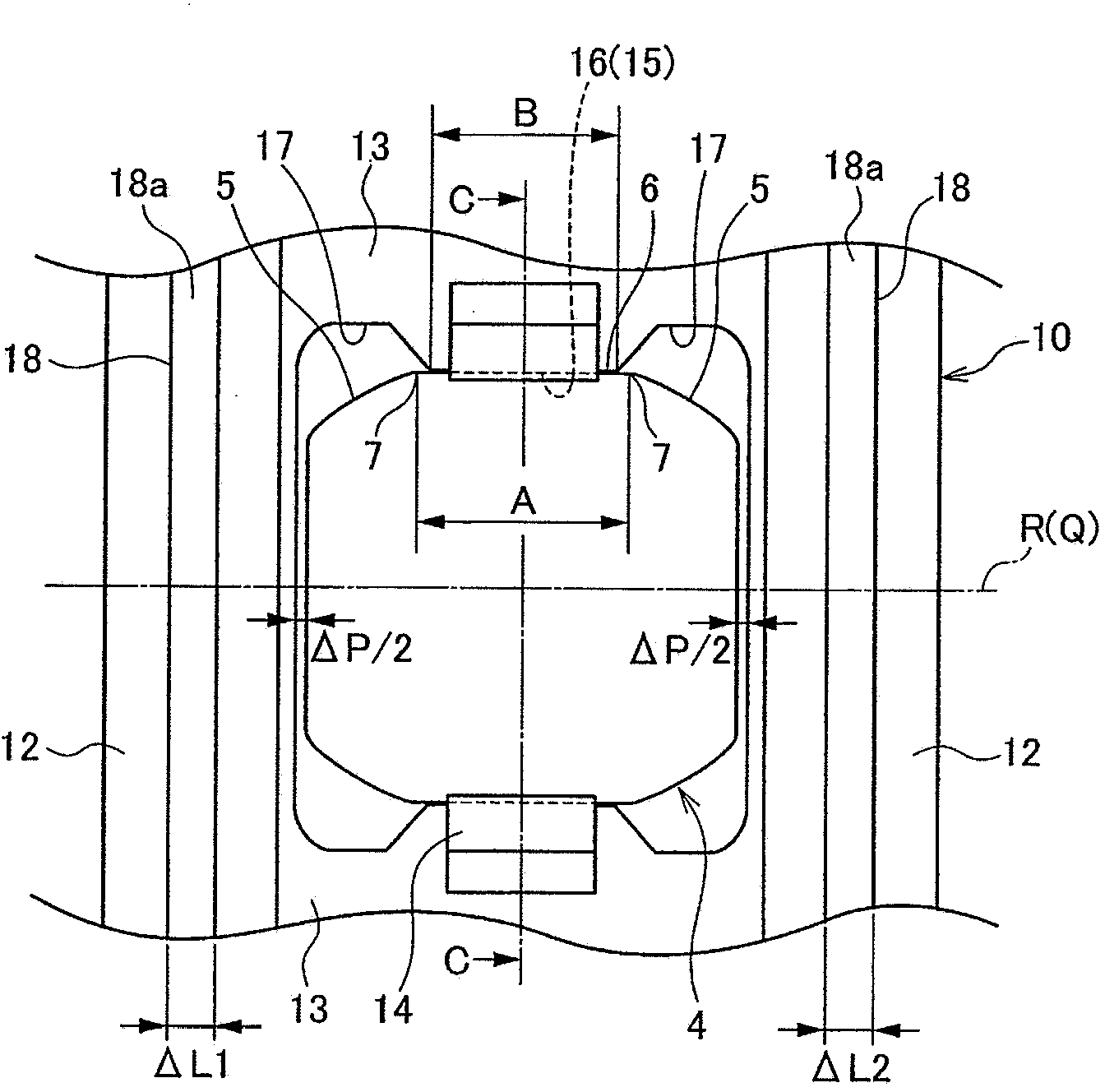

Rolling bearing, and spindle device for machine tool

InactiveCN103732933APrevent seizingIncreased longevityRoller bearingsShaftsRolling-element bearingEngineering

A rolling bearing (1) is provided with an outer ring (2), an inner ring (3), rollers (4) which are provided in a rollable manner between the outer ring (2) and the inner ring (3), and a retainer (10) which has pockets (11) formed at predetermined intervals in the circumferential direction and respectively retaining the rollers (4). The retainer (10) is of the outer ring guide type or the inner ring guide type. The retainer (10) has retainer guide surfaces on one axial side and the other axial side, respectively, of each of the rollers (4). If the width of the retainer guide surface on the one axial side is DeltaL1, the width of the retainer guide surface on the other axial side is DeltaL2, and the gap of an axial pocket is DeltaP, the rolling bearing (1) satisfies the expressions of DeltaP<= DeltaL1<= 4*DeltaP and DeltaP <= DeltaL2 <= 4*DeltaP.

Owner:NSK LTD

Composition for heat cycle system and heat cycle system

InactiveCN106414682AImprove the lubrication effectPromote circulationCompressorCompression machines with non-reversible cycleEtherProcess engineering

Provided are a composition for a heat cycle system having good lubricating properties including a working medium for the heat cycle having a low global warming potential that can be substituted for R410A, and a heat cycle system using this composition. A composition for a heat cycle system including a working medium for the heat cycle including 1,2-difluoroethylene, oxygen-containing synthetic oil (ester refrigeration oil, ether refrigeration oil, or the like), and refrigeration oil such as hydrocarbon refrigeration oil or the like, and a heat cycle system using this composition for a heat cycle system.

Owner:ASAHI GLASS CO LTD

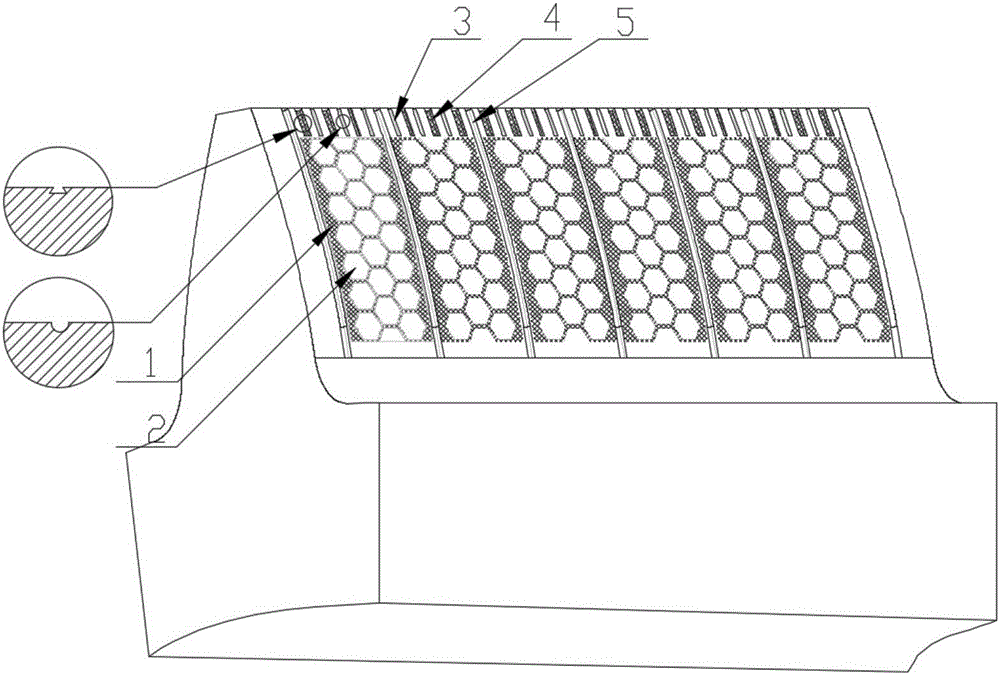

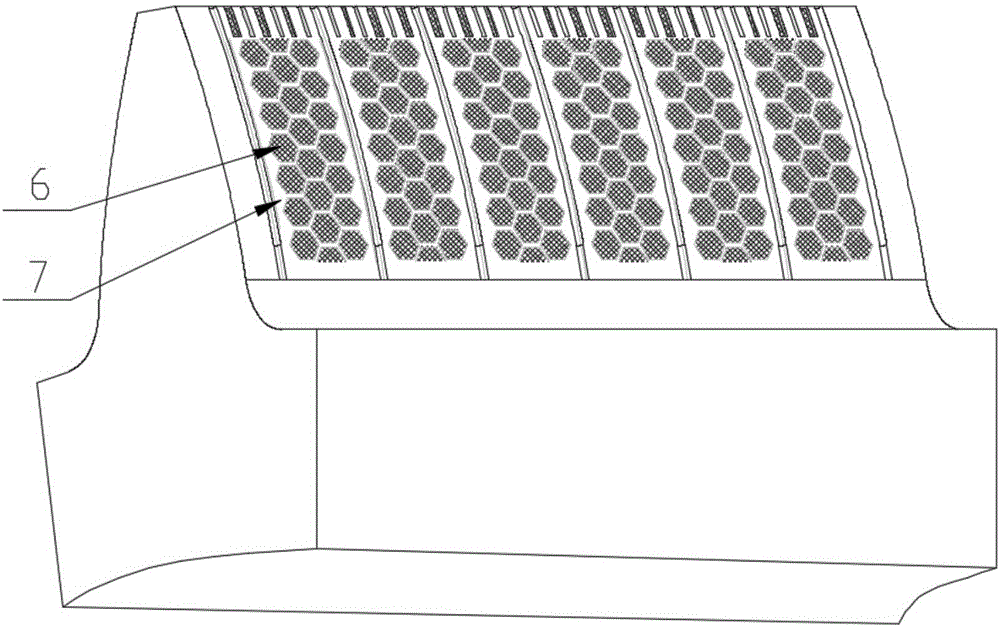

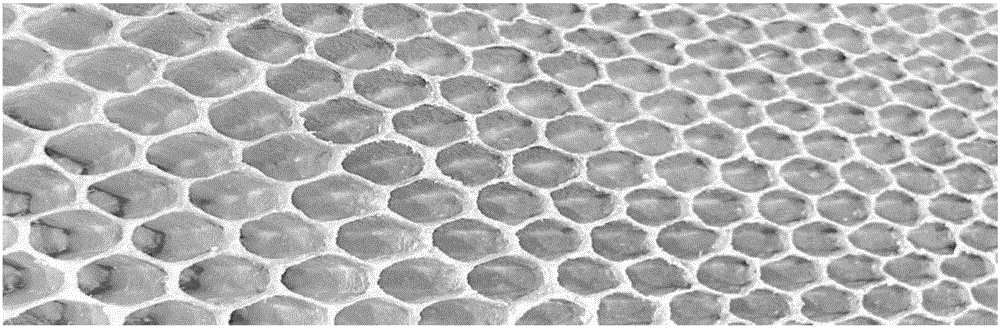

Honeycomb-shaped polygonal self-lubricating gear

InactiveCN106763649AReduce usageGuaranteed StrengthPortable liftingGearing elementsHoneycombEngineering

The invention relates to a honeycomb-shaped polygonal self-lubricating gear. Honeycomb-shaped grooves, strip-shaped grooves, middle strip-shaped chip grooves and top strip-shaped chip grooves are processed in a tooth surface of the honeycomb-shaped polygonal self-lubricating gear; the honeycomb-shaped grooves are positioned in the middle of the tooth surface, and are filled with self-lubricating materials; the strip-shaped grooves are positioned in the top of the tooth surface, and are filled with the self-lubricating materials; and the middle strip-shaped chip grooves and the top strip-shaped chip grooves separately penetrate through the whole tooth surface and are formed in the top of the tooth surface, are distributed in a spaced mode, and are beneficial for chip removal. The invention discloses the honeycomb-shaped polygonal self-lubricating gear which is inspired by a honeycomb shape based on the bionic idea; compared with an existing gear, the honeycomb-shaped polygonal self-lubricating gear has self-lubricating characteristics, does not need to additionally add media such as lubricating oil and lubricating grease, enriches a gear lubricating mode, and can meet normal operation when the gear is under extreme working conditions such as an oil-free working condition and an oil-lack working condition.

Owner:HEFEI UNIV OF TECH

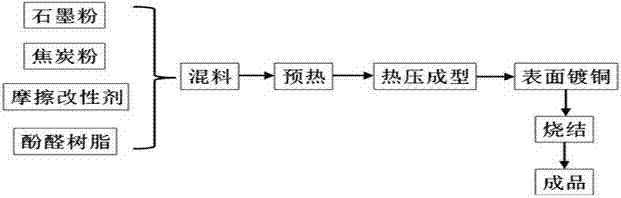

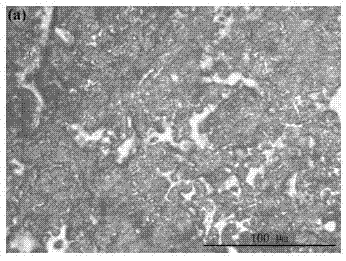

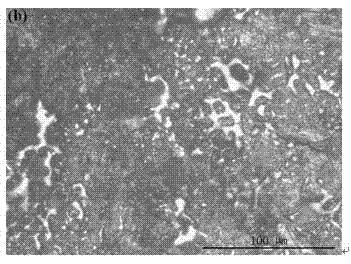

Carbon based sliding plate material of high speed railway pantograph and preparation method thereof

The invention provides a carbon based sliding plate material of a high-speed railway pantograph and a preparation method thereof. The carbon based sliding plate material is composed of graphite, powdered coke, thermosetting phenol resins, aluminum oxide and glass powder. The preparation method of the carbon based sliding plate material comprises the steps of mixing the materials in a dry basis state, wherein a base body is formed by the graphite and the powdered coke, the thermosetting phenol resins serve as binders, and the mixture of the aluminum oxide and the glass powder serves as friction modifier; performing hot press molding; plating copper on the surface of the base body in an electric spark mode under the nitrogen atmosphere; and performing high-temperature diffusion in a plasma vacuum sintering device to obtain the carbon based sliding plate material with a surface modified layer. The carbon based sliding plate material has good lubricating performance of a pure carbon sliding plate and good conductivity of a pure metal sliding plate, and is low in cost, less in consumed energy, simple in preparation process, short in production period and suitable for manufacturing a slide plate of an electric locomotive pantograph of a high-speed railway.

Owner:TAIYUAN UNIV OF TECH

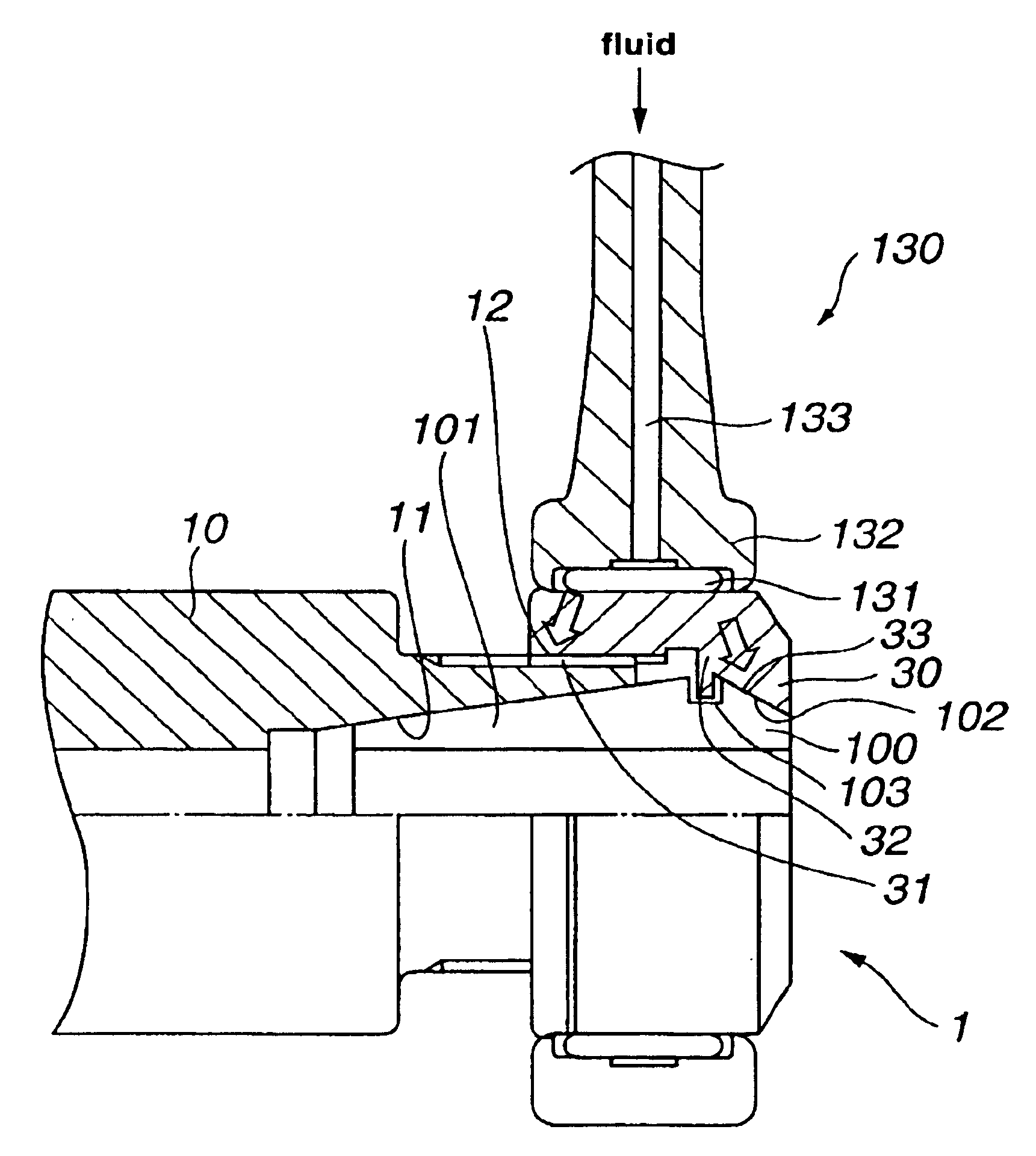

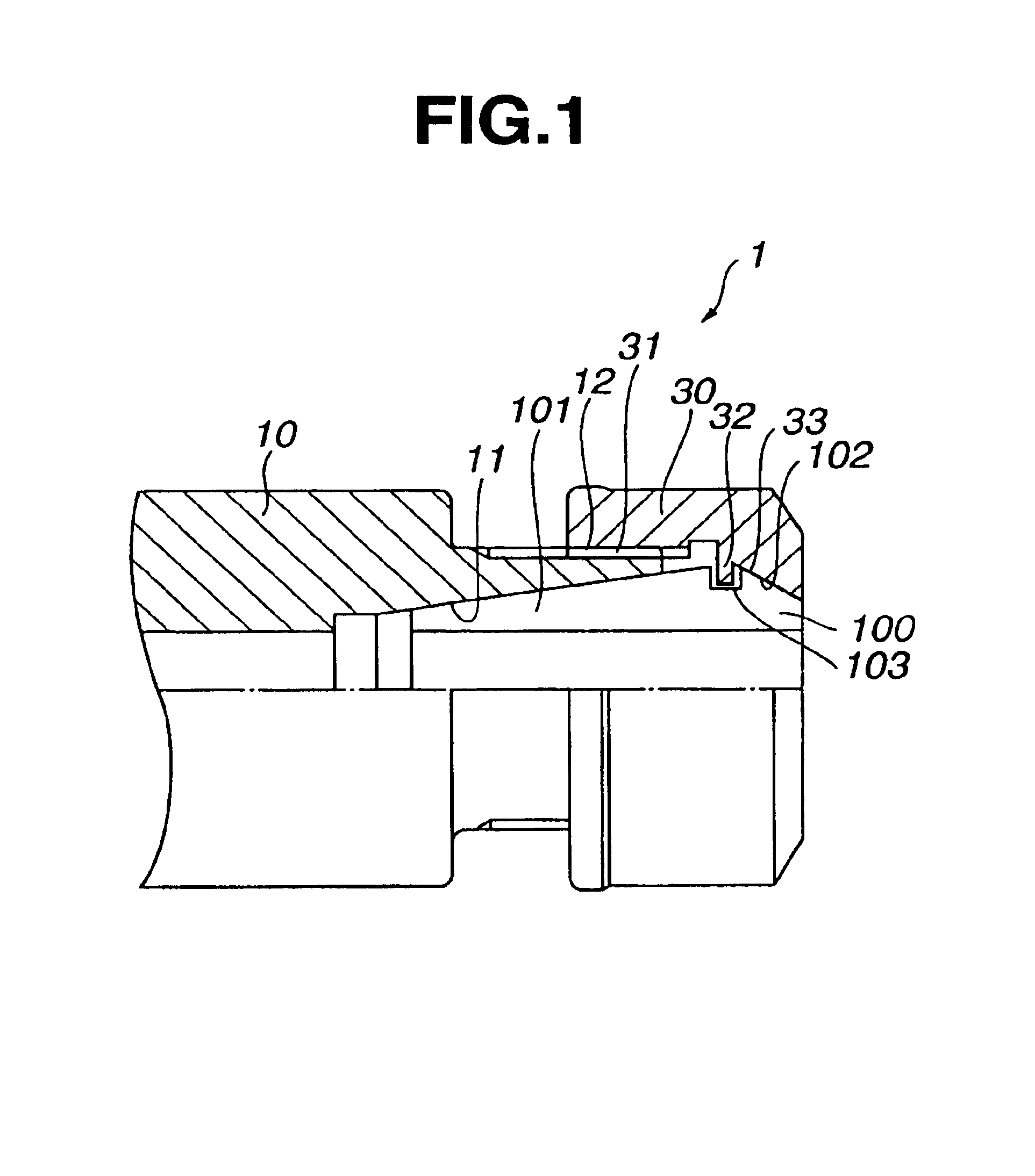

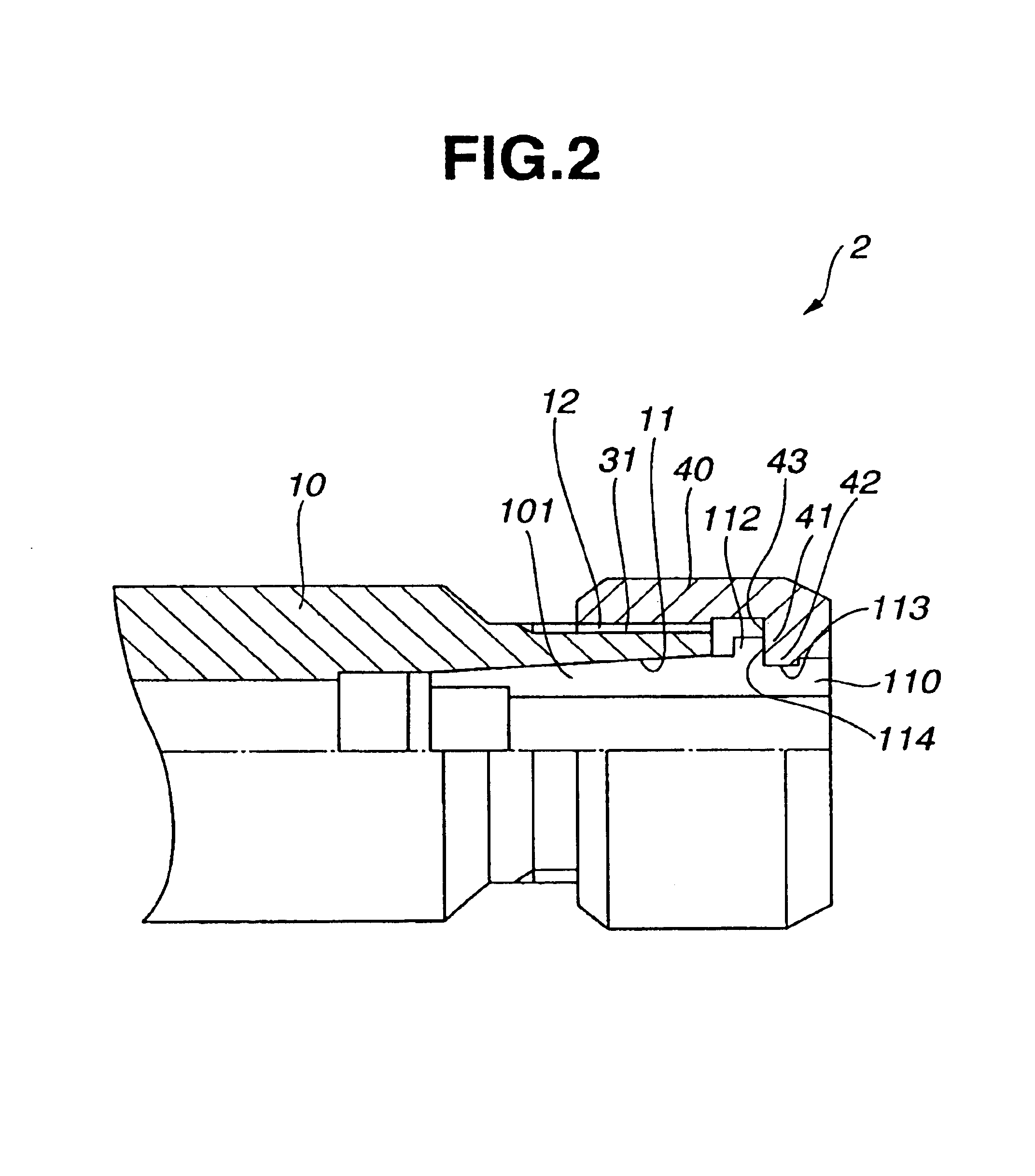

Clamp nut and collet chuck

InactiveUS6886835B2Improve lubricating propertiesReduce coefficient of frictionSleeve/socket jointsFace lathesEngineeringCollet

The present invention enhances the lubricating property of the sliding surfaces of a clamp nut and a collet, reduces a friction coefficient, prevents the occurrence of seizure, and enhances durability. Accordingly, it is possible to rotate the clamp nut and the collet without causing vibrations due to imbalance. Moreover, this invention provides a clamp nut that can maintain tool-mounting accuracy for a long period of time even in the case of high-speed rotation, and also provides a collet chuck including such clamp nut. Concerning the clamp nut which is mounted on a collet chuck body for holding tools in the collet and which clamps the collet chuck body and the collet together, at least a part of the clamp nut which comes in contact with the collet is made of oil-bearing metal.

Owner:BIG ALPHA CO LTD

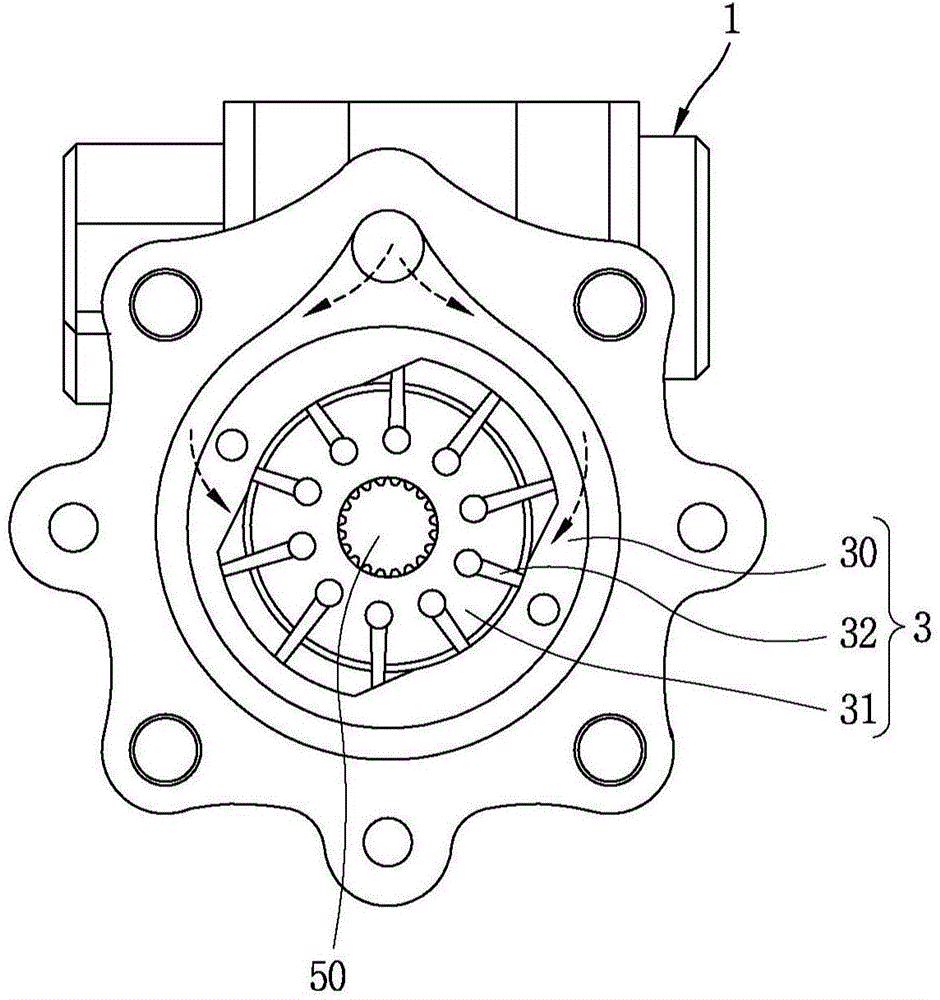

Vane Pump

InactiveCN104033380ASimple materialWear minimizationRotary piston pumpsRotary piston liquid enginesDuctile ironMechanical engineering

The invention relates to a vane pump. According to an embodiment of the invention, a vane pump is provided. The vane pump includes: a rotor having a plurality of slots formed on an outer circumferential surface thereof; vanes slidably inserted into each of the slots; and a cam ring having the rotor therein and having a inner circumferential surface in contact with an end portion of the vane, wherein the rotor is formed of nodular graphite cast iron, the vanes are formed of high speed tool steel, and the cam ring is formed of alloy cast iron.

Owner:LG ELECTRONICS INC

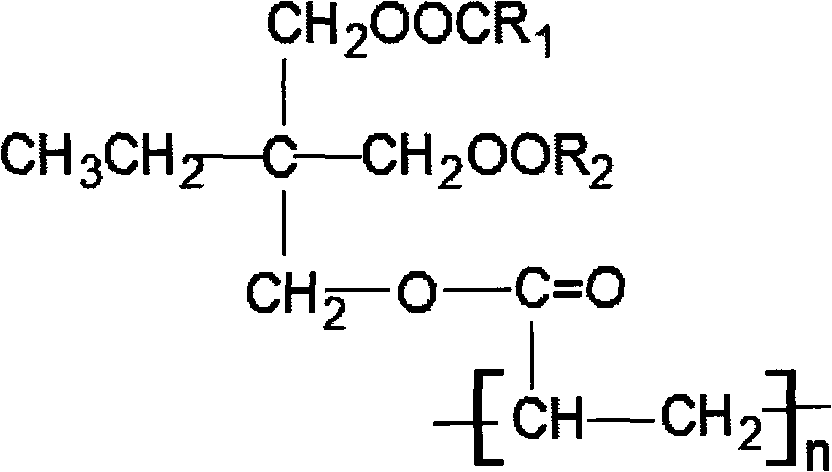

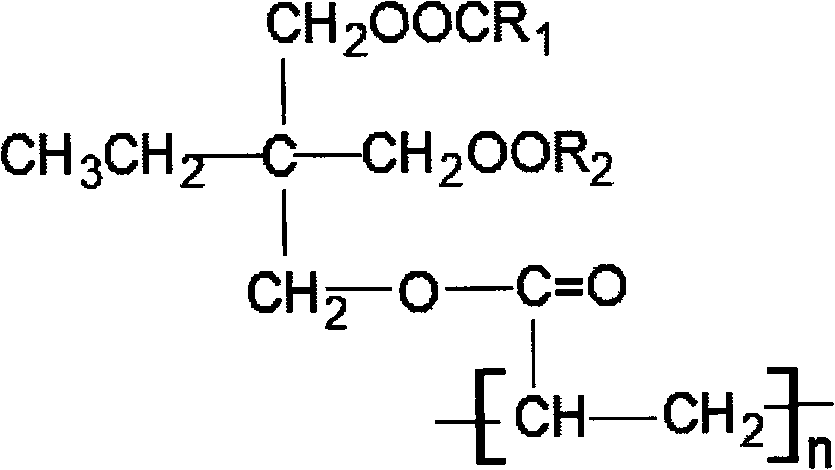

Trimethylolpropane-acrylic ester-based polyester and preparation method of polyester

ActiveCN102603947AGood lubricating propertiesImprove lubricating propertiesBase-materialsPolyesterFatty acid ester

The invention relates to trimethylolpropane-acrylic ester-based polyester and a preparation method of the trimethylolpropane-acrylic ester-based polyester. The method comprises the steps of taking trimethylolpropane, acrylic ester and aliphatic monocarboxylic acid as raw materials, synthesizing trimethylolpropane-acrylic ester containing mono-aliphatic ester, and conducting polymerization reaction to form the polyester. The polyester obtained by the method has good lubricating performance and can be taken as lubrication base oil for use.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com