Aerial insulation wire electrification repairing method

A technology for overhead insulated wires and insulated wires, which is applied in the direction of insulation/armoured cable repair equipment, etc., which can solve problems such as difficult identification, reduced insulation performance, and wire core corrosion, so as to reduce phase-to-phase short circuits and ground faults, and avoid hidden dangers , the effect of high lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

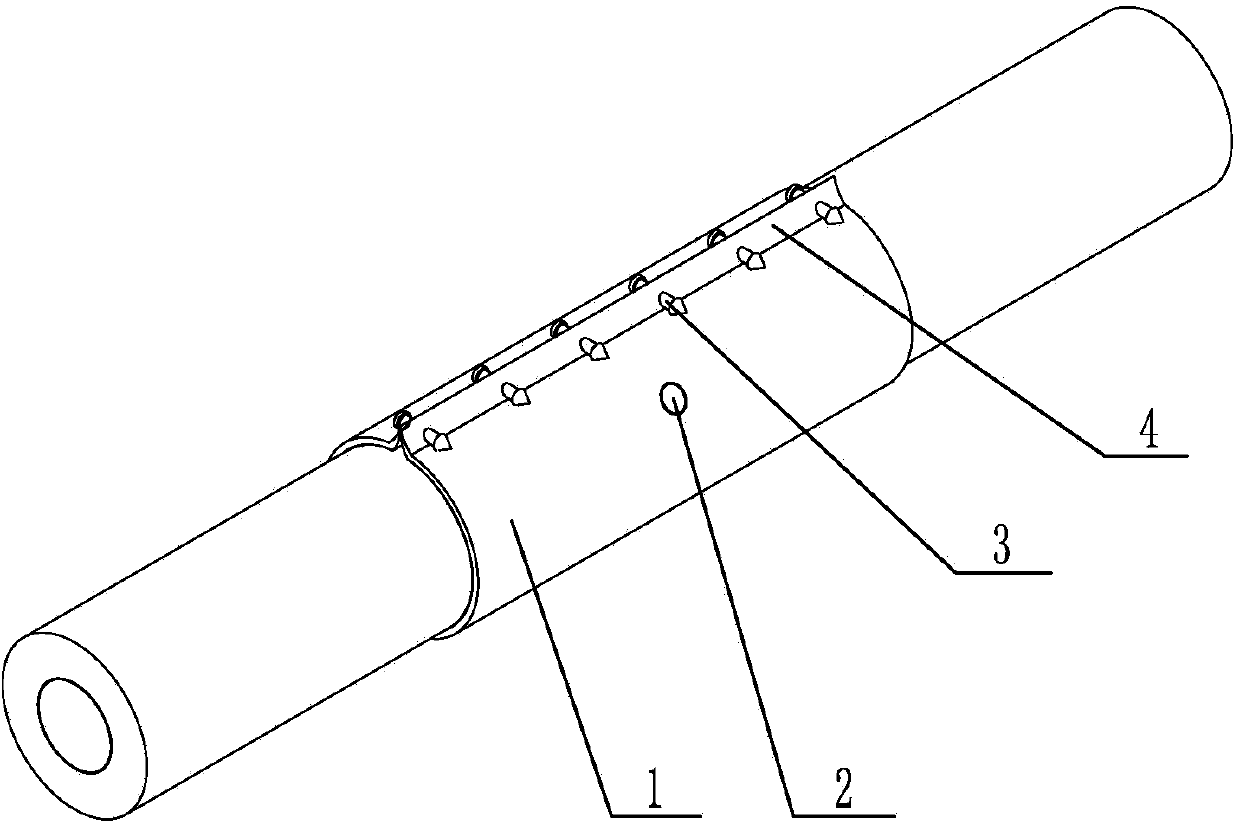

[0028] Such as figure 1 As shown, the overhead insulated conductor live repair method described in the present invention comprises the following steps:

[0029] First of all, the exposed part of the overhead insulated conductor is wrapped with a 0.1mm thick polyimide tape by the half-folding method. Polyimide has a high breakdown strength, and the 0.1mm thick polyimide tape can withstand Under the voltage of 10kV-19kV; Among them, the semi-folding method means that half of the tape on the back layer is pressed on the tape on the front layer to increase the sealing effect.

[0030] Secondly, wrap the white polytetrafluoroethylene covering film 1 with a thickness of 1 mm on the outside of the polyimide tape. The length of the polytetrafluoroethylene covering film 1 is 40 mm longer than the bare part of the wire, which can completely wrap the Cover the bare part, put the polytetrafluoroethylene coating film 1 on the bare part of the wire, so that the coating film larger than the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com