Patents

Literature

338results about How to "Improve thermal stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

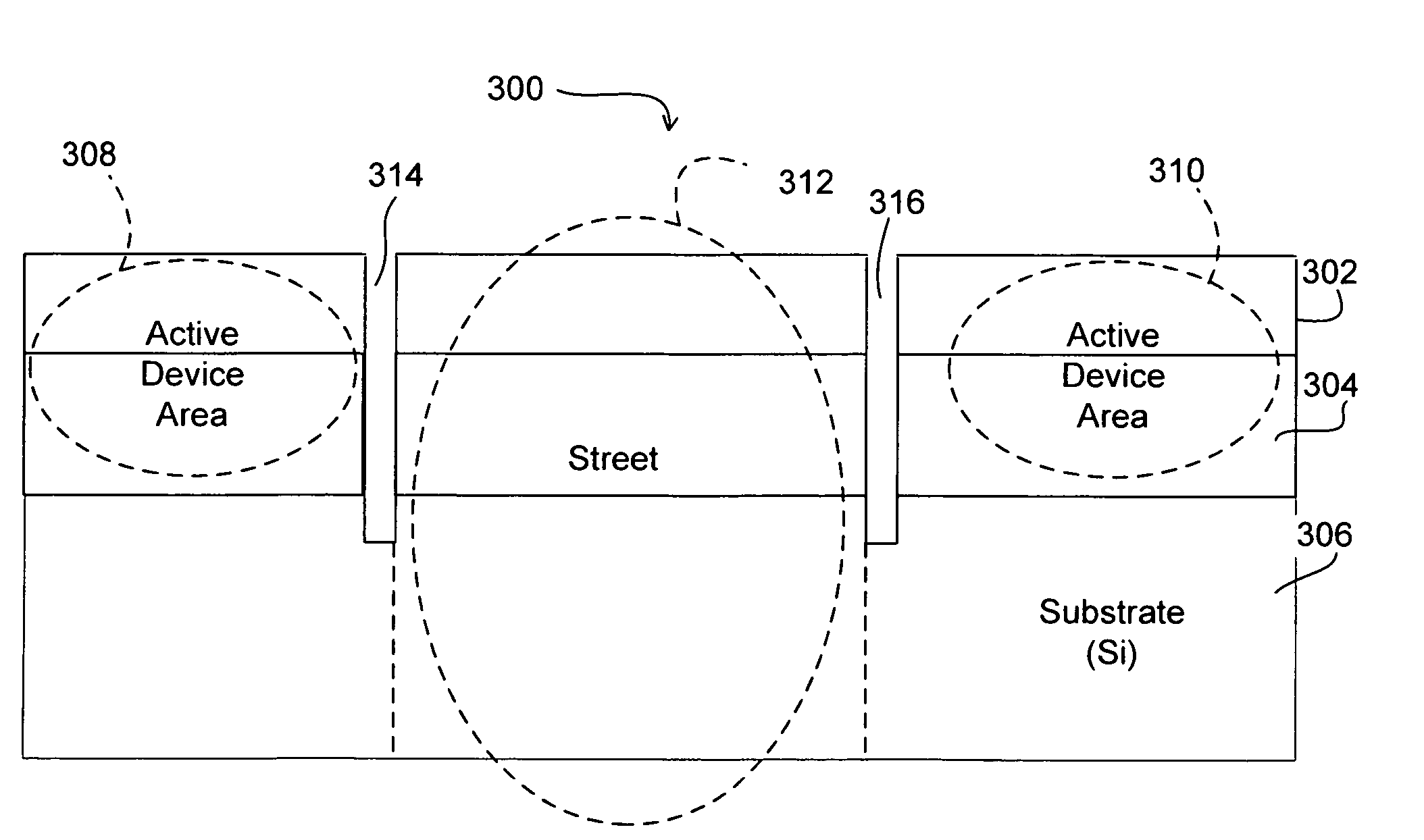

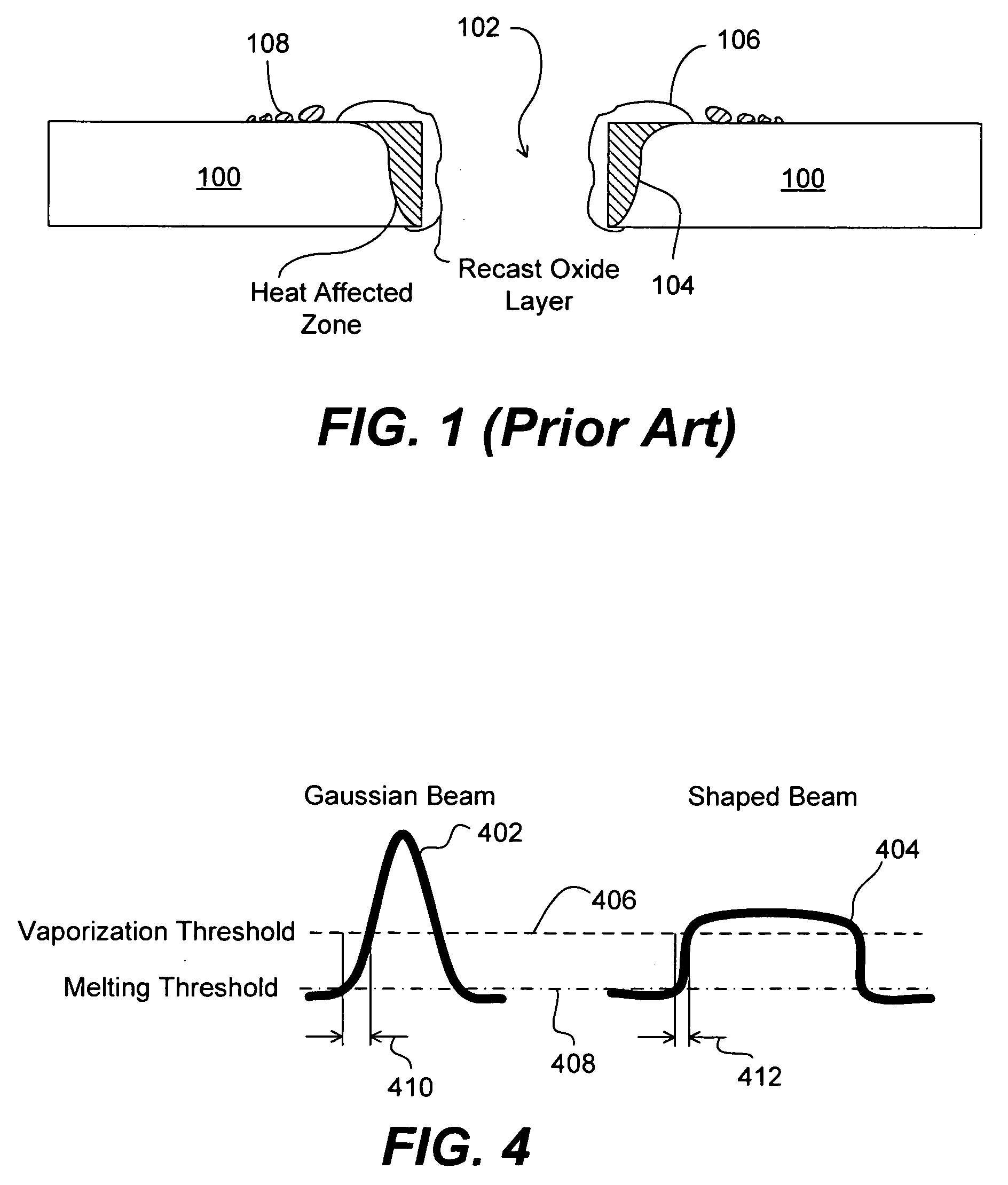

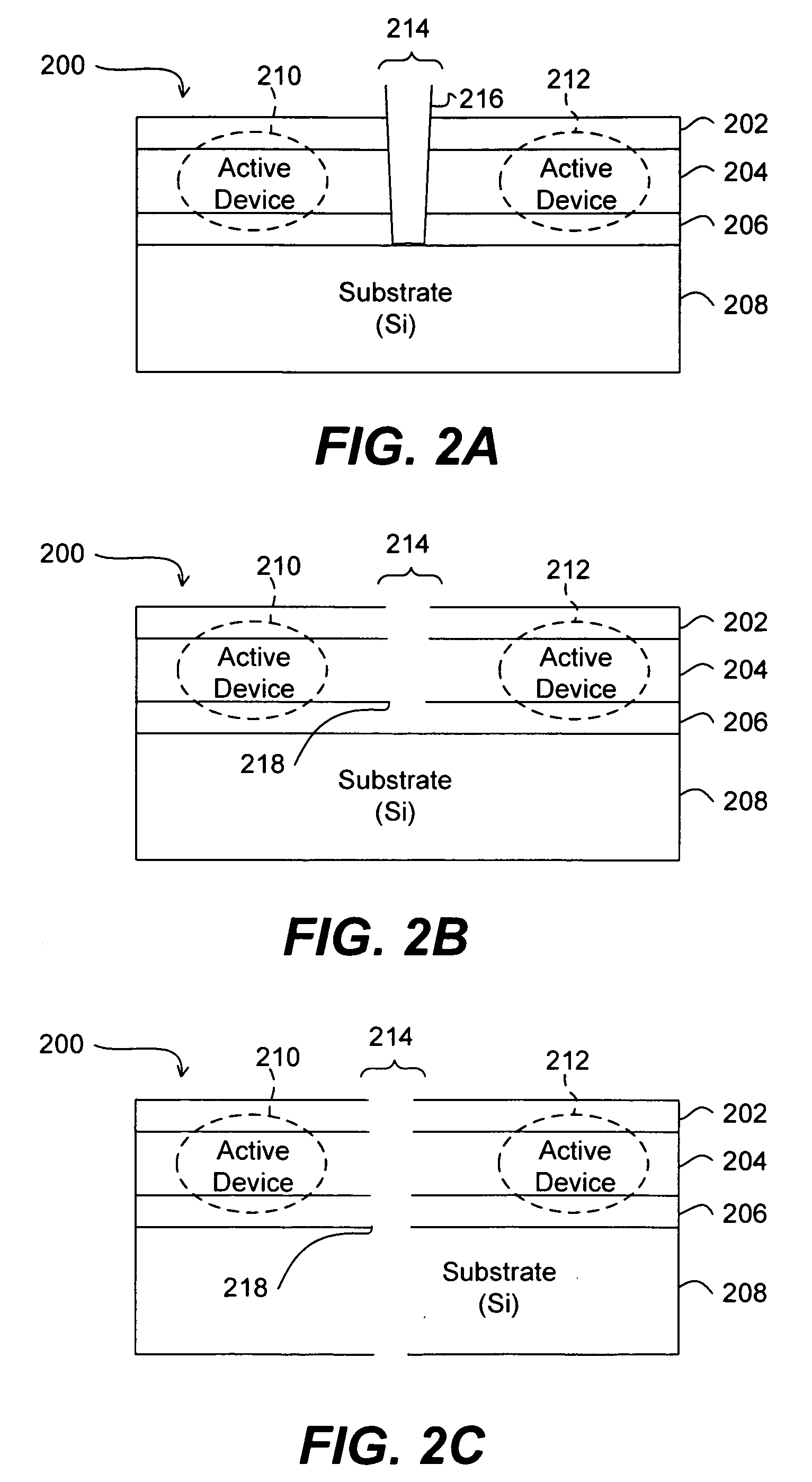

Ultrashort laser pulse wafer scribing

InactiveUS20070272668A1Improve mechanical stressImprove thermal stressSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLight beamOptoelectronics

Systems and methods are provided for scribing wafers with short laser pulses so as to reduce the ablation threshold of target material. In a stack of material layers, a minimum laser ablation threshold based on laser pulse width is determined for each of the layers. The highest of the minimum laser ablation thresholds is selected and a beam of one or more laser pulses is generated having a fluence in a range between the selected laser ablation threshold and approximately ten times the selected laser ablation threshold. In one embodiment, a laser pulse width in a range of approximately 0.1 picosecond to approximately 1000 picoseconds is used. In addition, or in other embodiments, a high pulse repetition frequency is selected to increase the scribing speed. In one embodiment, the pulse repetition frequency is in a range between approximately 100 kHz and approximately 100 MHz.

Owner:ELECTRO SCI IND INC

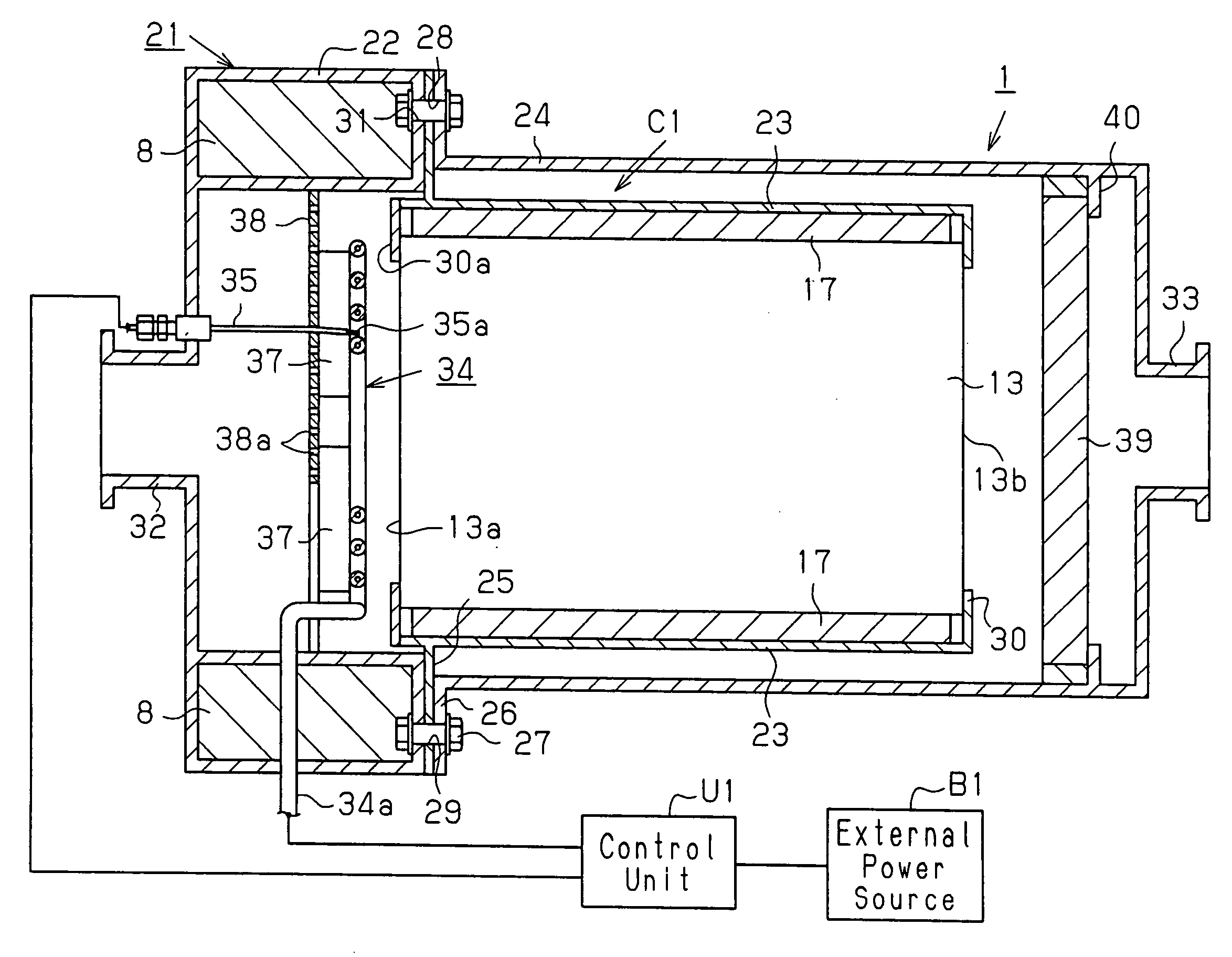

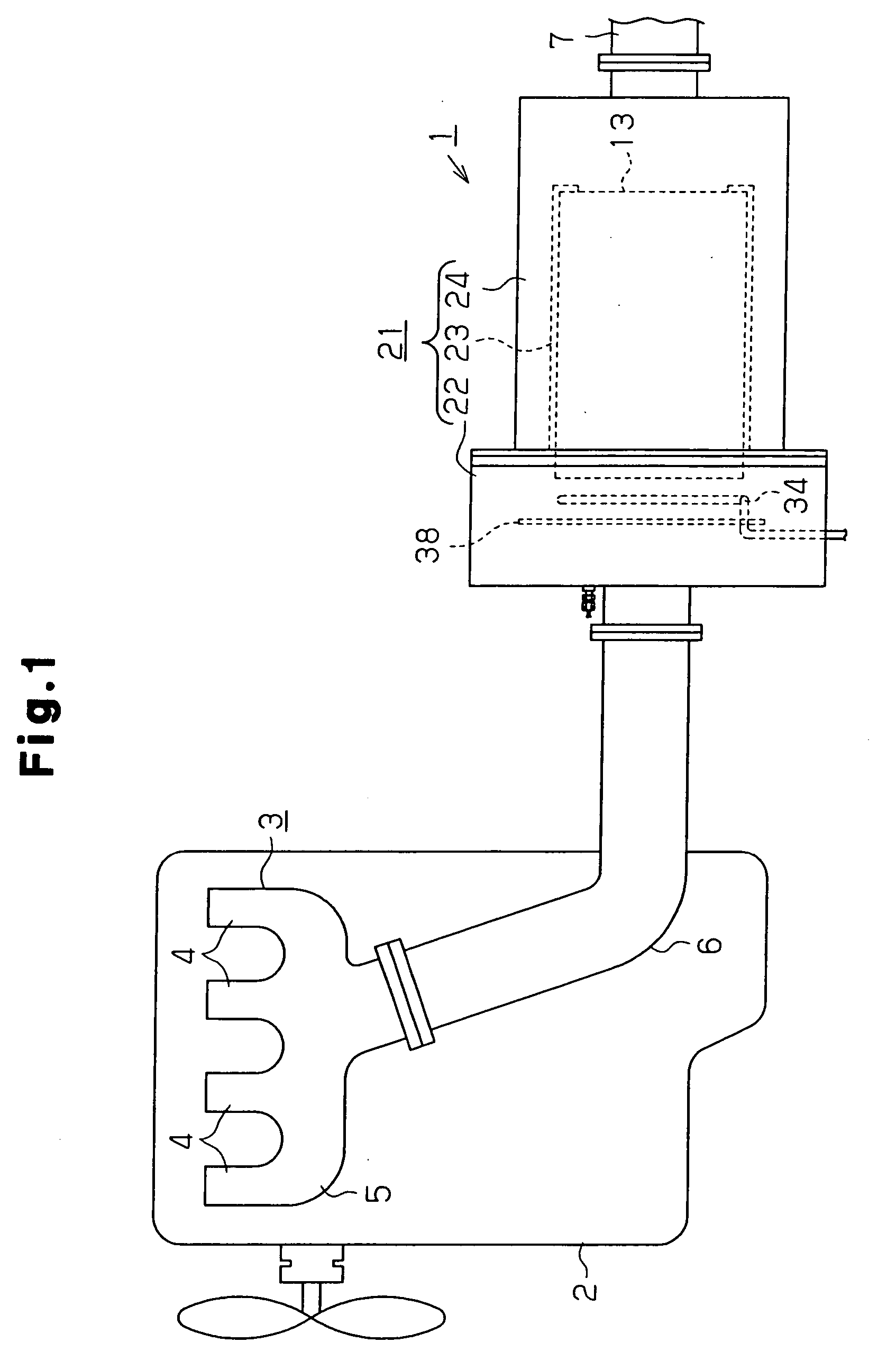

Exhaust emission control device and casing structure of the control device

InactiveUS20050115224A1Reduce energy lossLow costInternal combustion piston enginesDispersed particle filtrationParticulatesEngineering

An exhaust gas purifying device includes a tubular casing arranged in exhaust passages of an internal combustion engine. A filter is held in the casing. The filter collects and burns particulates contained in the exhaust gas discharged by the internal combustion engine. The casing has a double structure including an inner case supporting an outer peripheral surface of the filter and an outer case arranged around the inner case. The inner and outer cases are spaced from each other with a clearance defined between the cases.

Owner:IBIDEN CO LTD

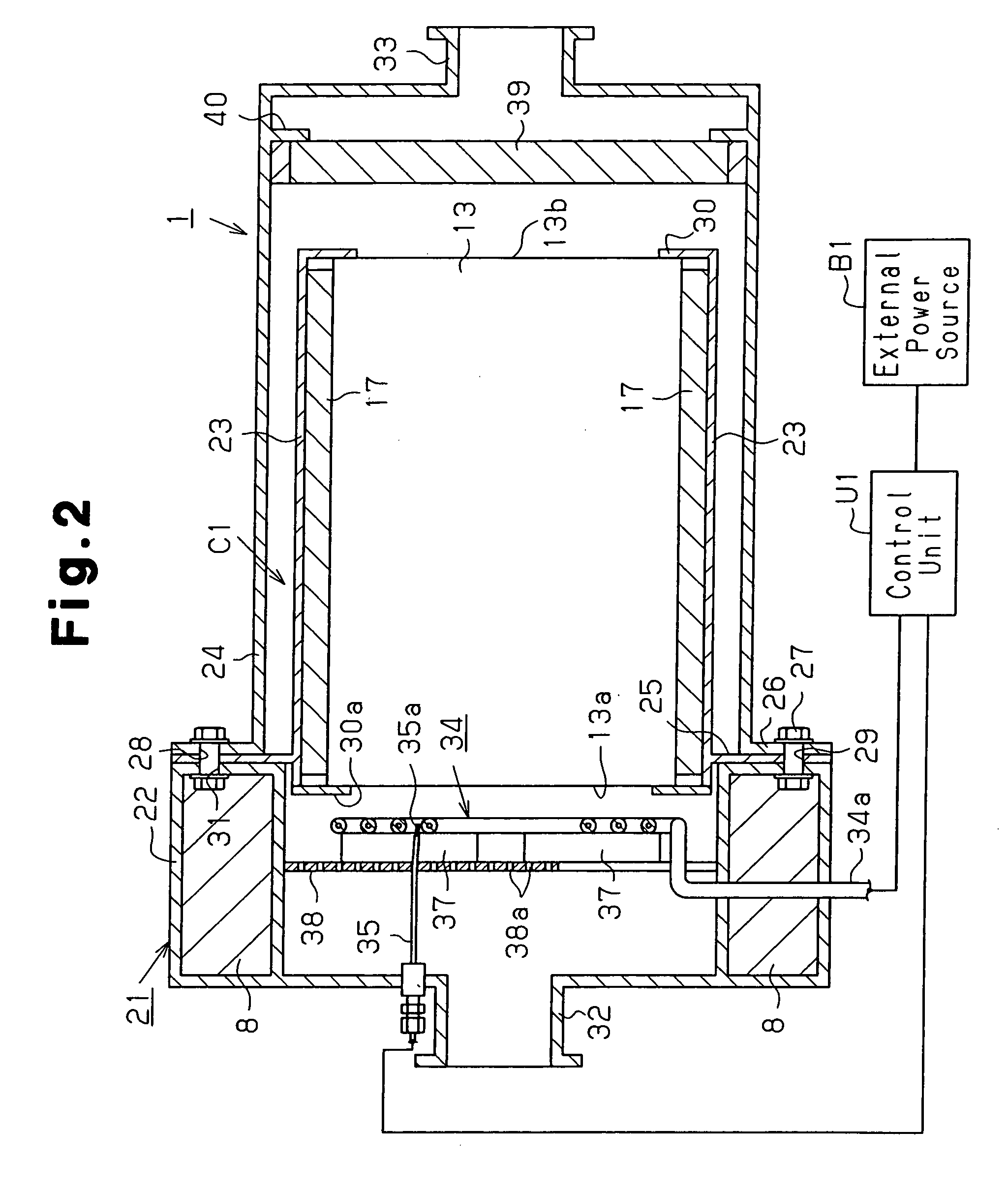

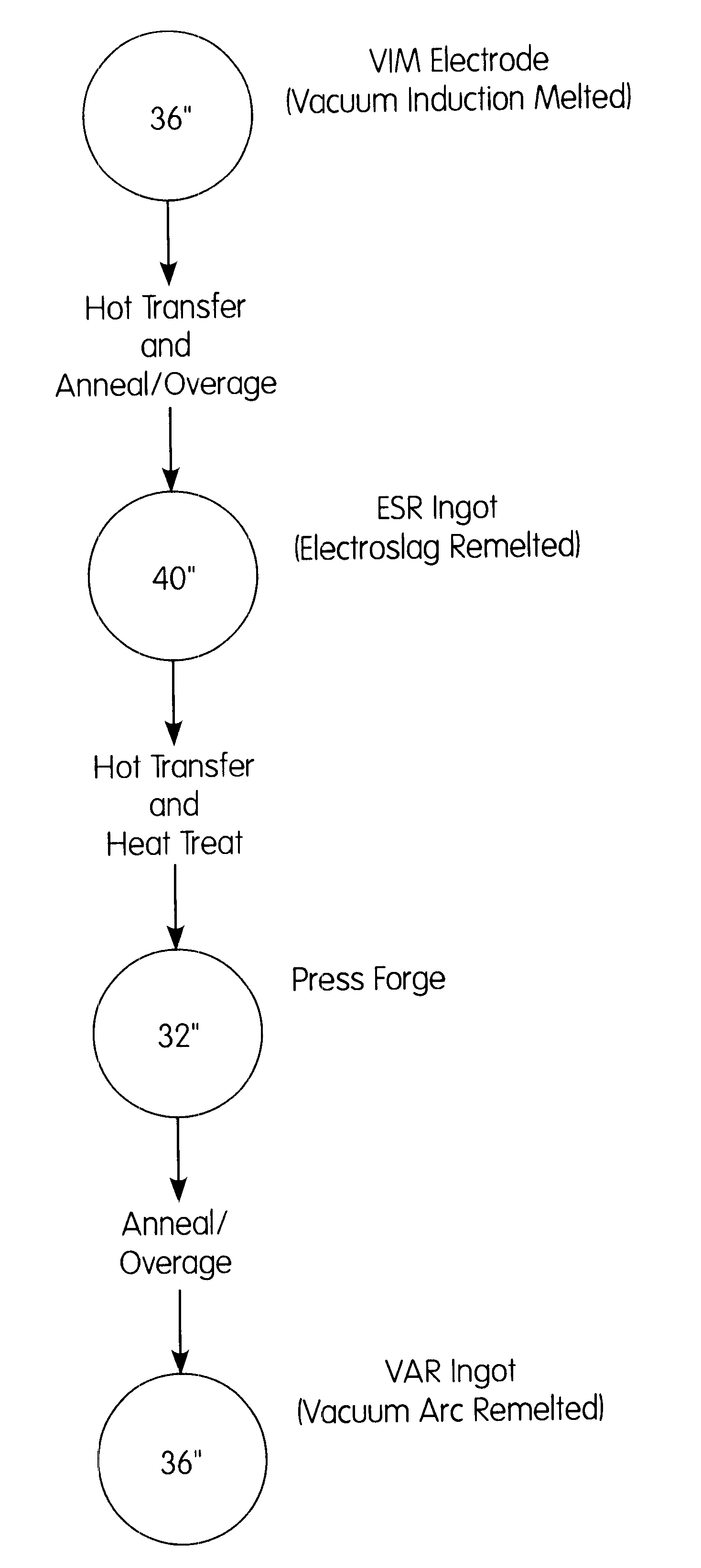

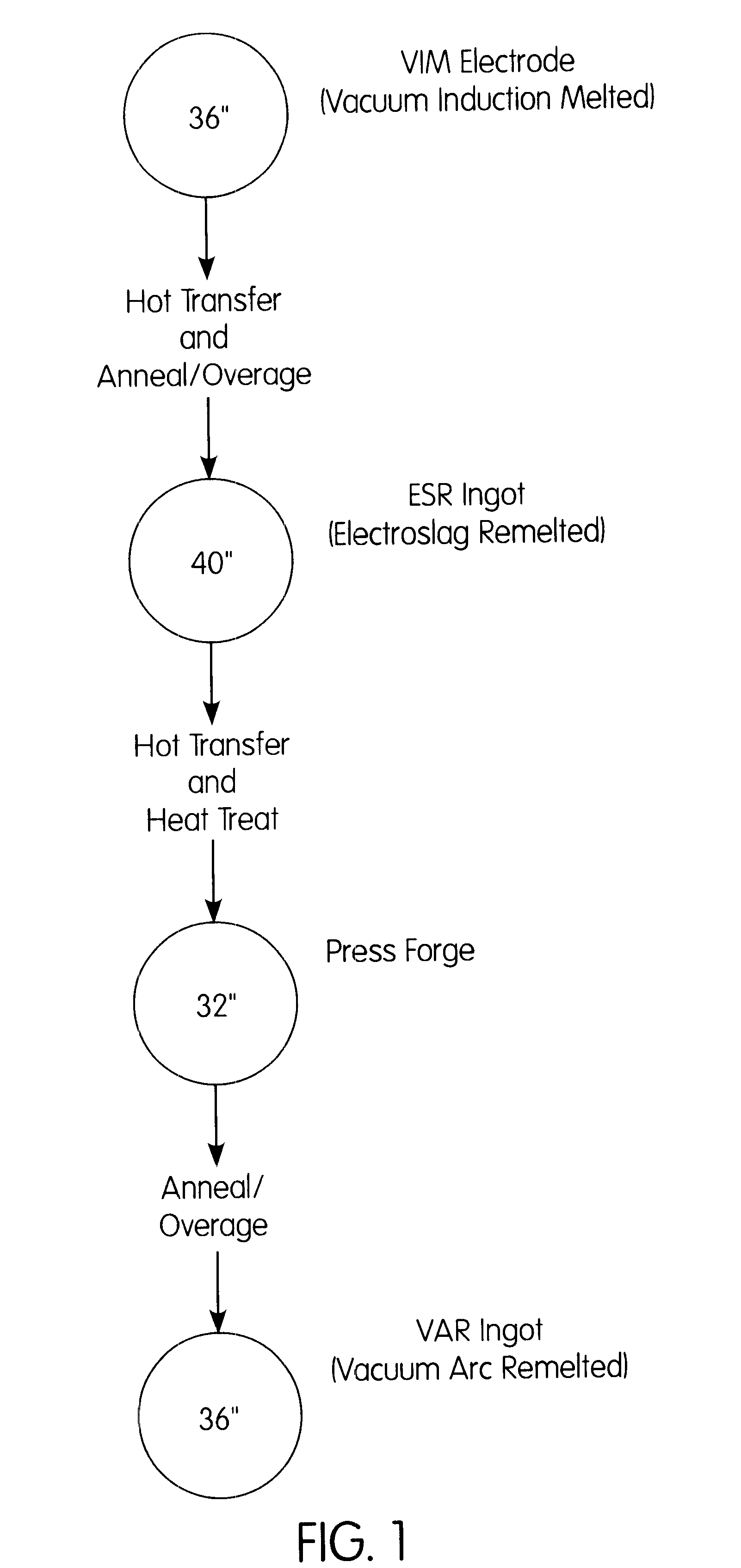

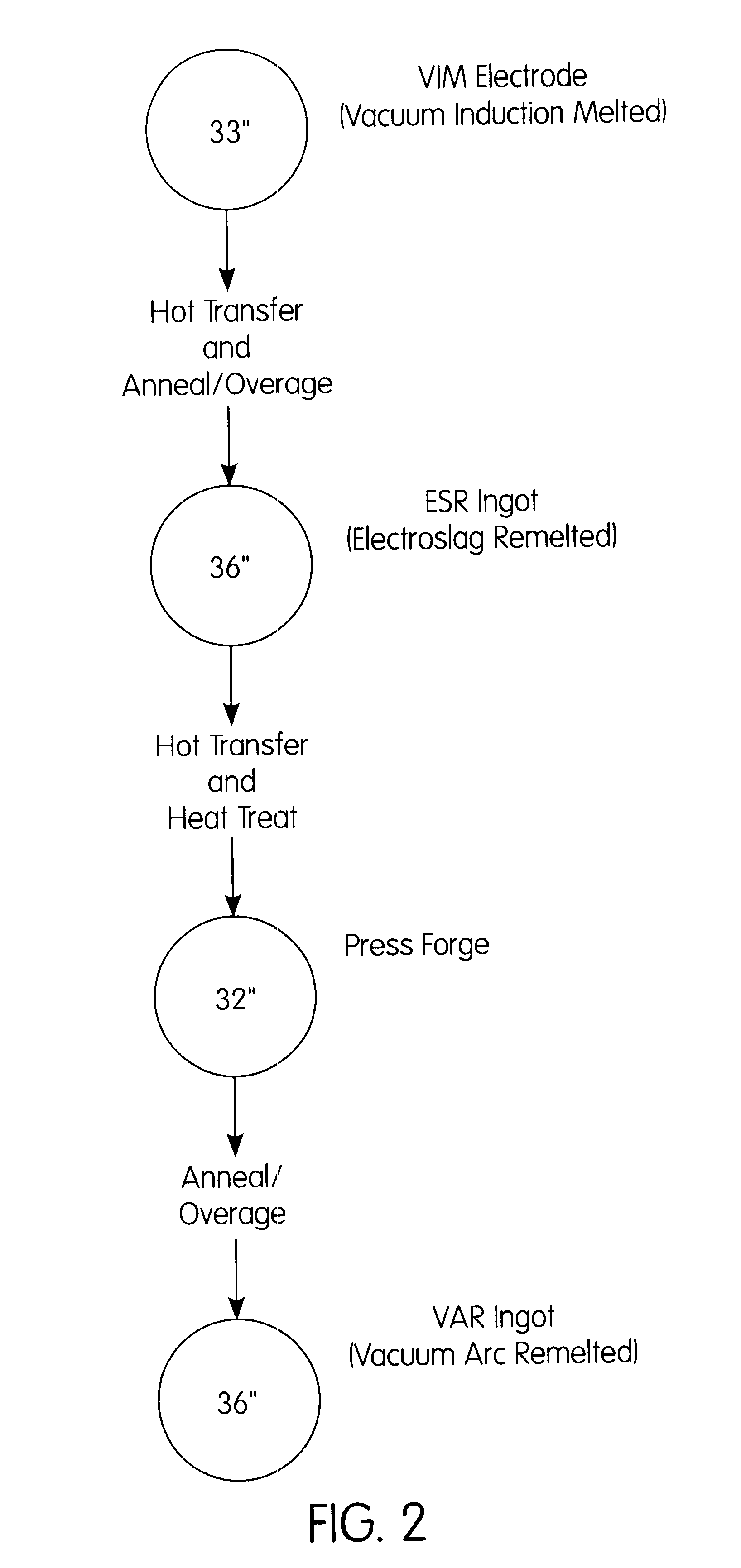

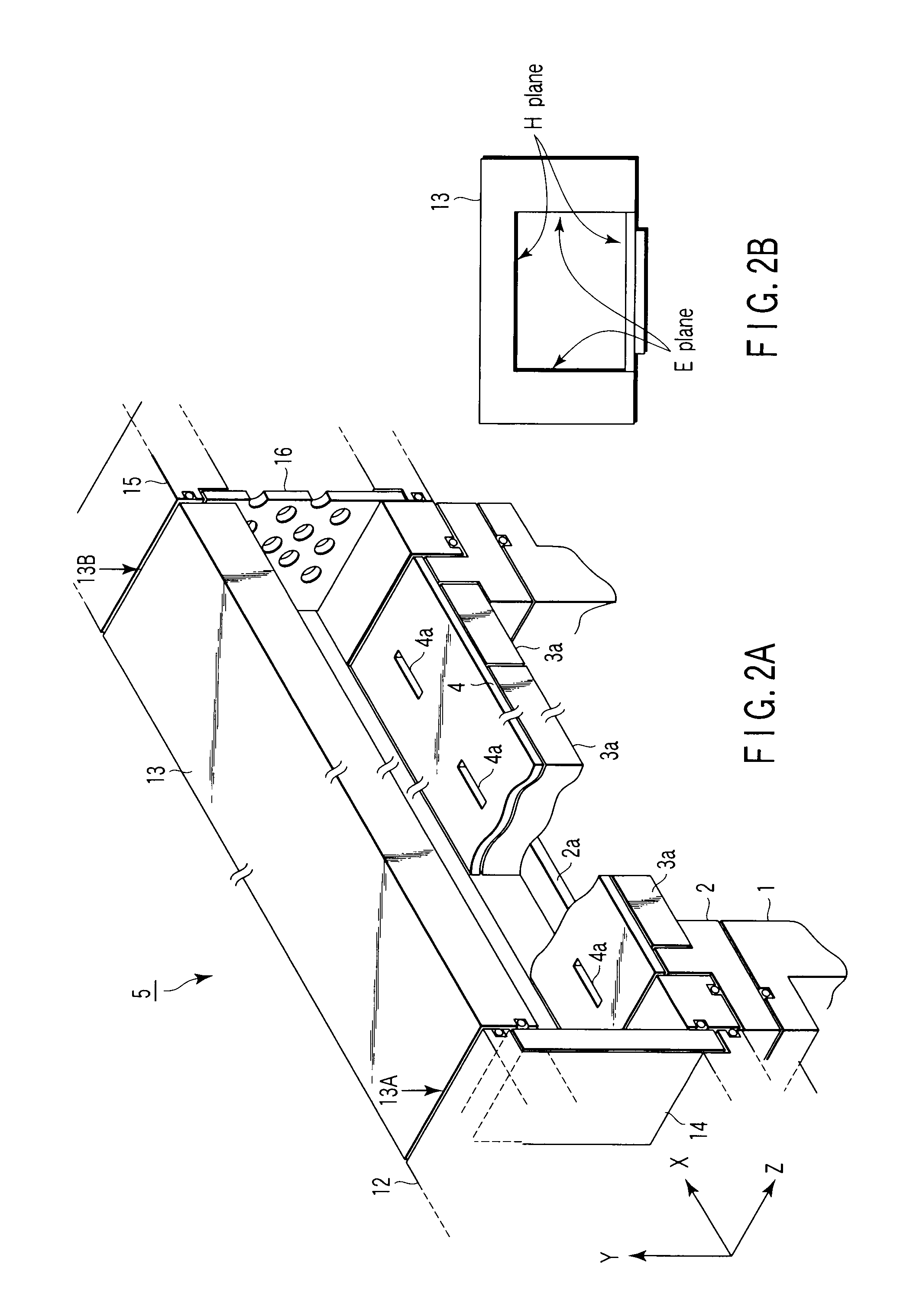

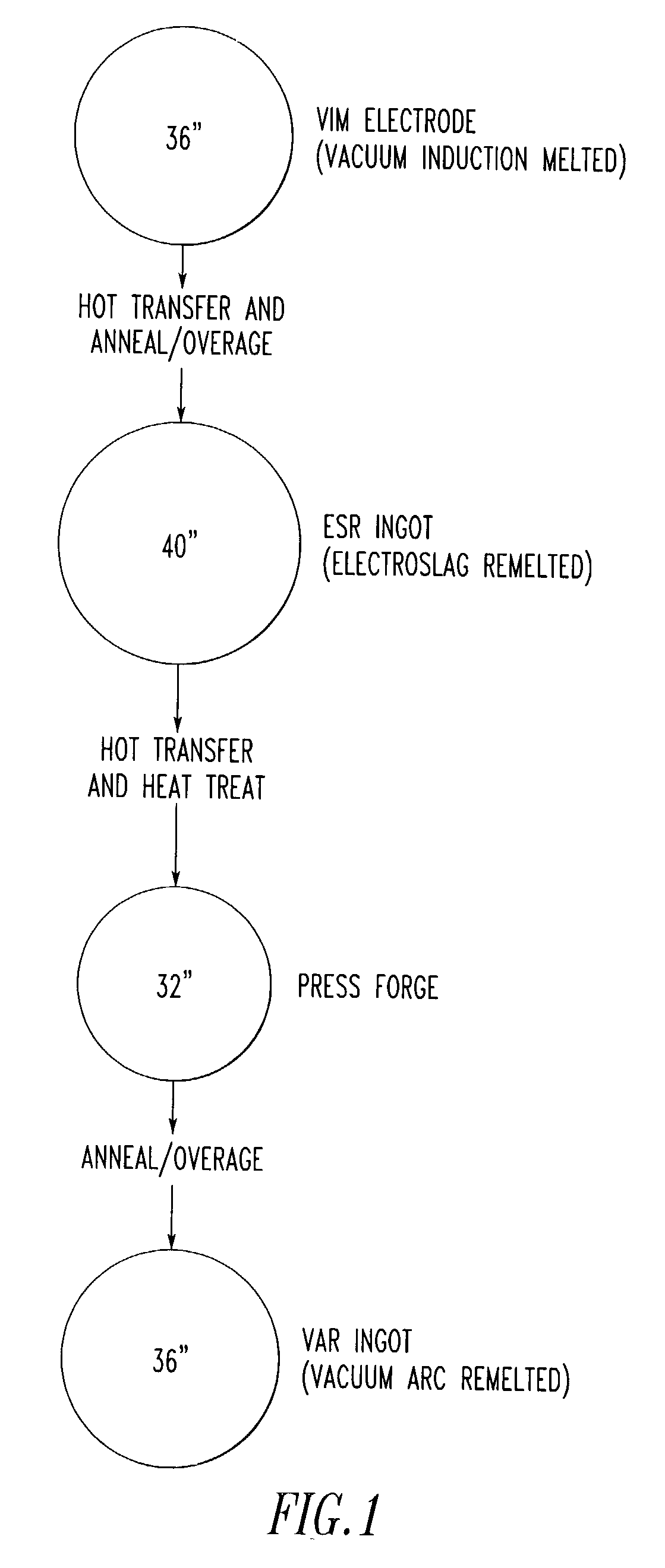

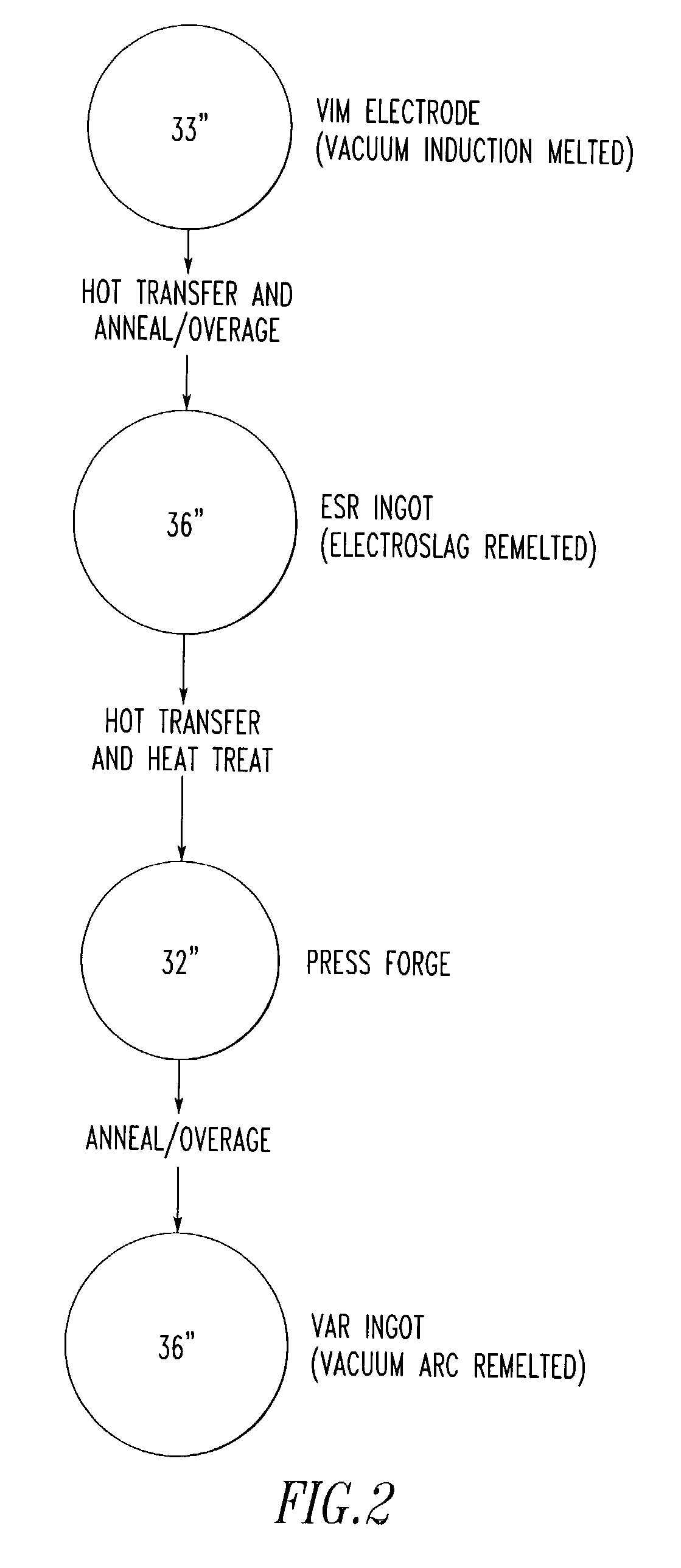

Method for producing large diameter ingots of nickel base alloys

InactiveUS6416564B1Inhibit thermal stressLarge caliberWelding/cutting media/materialsElectric furnaceCasting moldHeating furnace

A method of producing a nickel base alloy includes casting the alloy within a casting mold and subsequently annealing and overaging the ingot at at least 1200° F. (649° C.) for at least 10 hours. The ingot is electroslag remeelted at a melt rate of at least 8 lbs / min (3.63 kg / mm.), and the ESR ingot is then transferred to a heating furnace within 4 hours of complete solidification and is subjected to a novel post-ESR heat treatment. A suitable VAR electrode is provided form the ESR ingot, and the electrode is vacuum arc remelted at a melt rate of 8 to 11 lbs / minute (3.63 to 5.00 kg / minute) to provide a VAR ingot. The method allows premium quality VAR ingots having diameters greater than 30 inches (762 mm) to be prepared from Alloy 718 and other nickel base superalloys subject to significant segregation on casting.

Owner:ATI PROPERTIES

Process for producing sterile suspensions of slightly soluble basic peptide complexes, sterile suspensions of slightly soluble basic peptide complexes, pharmaceutical formulations containing them, and the use thereof as medicaments

InactiveUS20060135405A1High viscosityAssist resuspendabilityNervous disorderPeptide/protein ingredientsParenteral Dosage FormPharmaceutical formulation

The present invention provides a novel process for producing sterile suspensions of slightly soluble basic peptide complexes. The present invention further provides a novel process for producing sterile lyophilizates of slightly soluble basic peptide complexes. In addition, a novel process for producing sterile suspensions suitable for the parenteral administration of slightly soluble basic peptide complexes is provided. The invention moreover provides sterile suspensions and sterile lyophilizates of slightly soluble basic peptide complexes, and pharmaceutical formulations comprising them. The provided sterile suspensions, sterile lyophilizates and pharmaceutical formulations comprising them are particularly suitable for use in a parenteral dosage form as medicaments for the treatment and prophylaxis of diseases and pathological states in mammals, especially in humans.

Owner:ZENTARIS GMBH

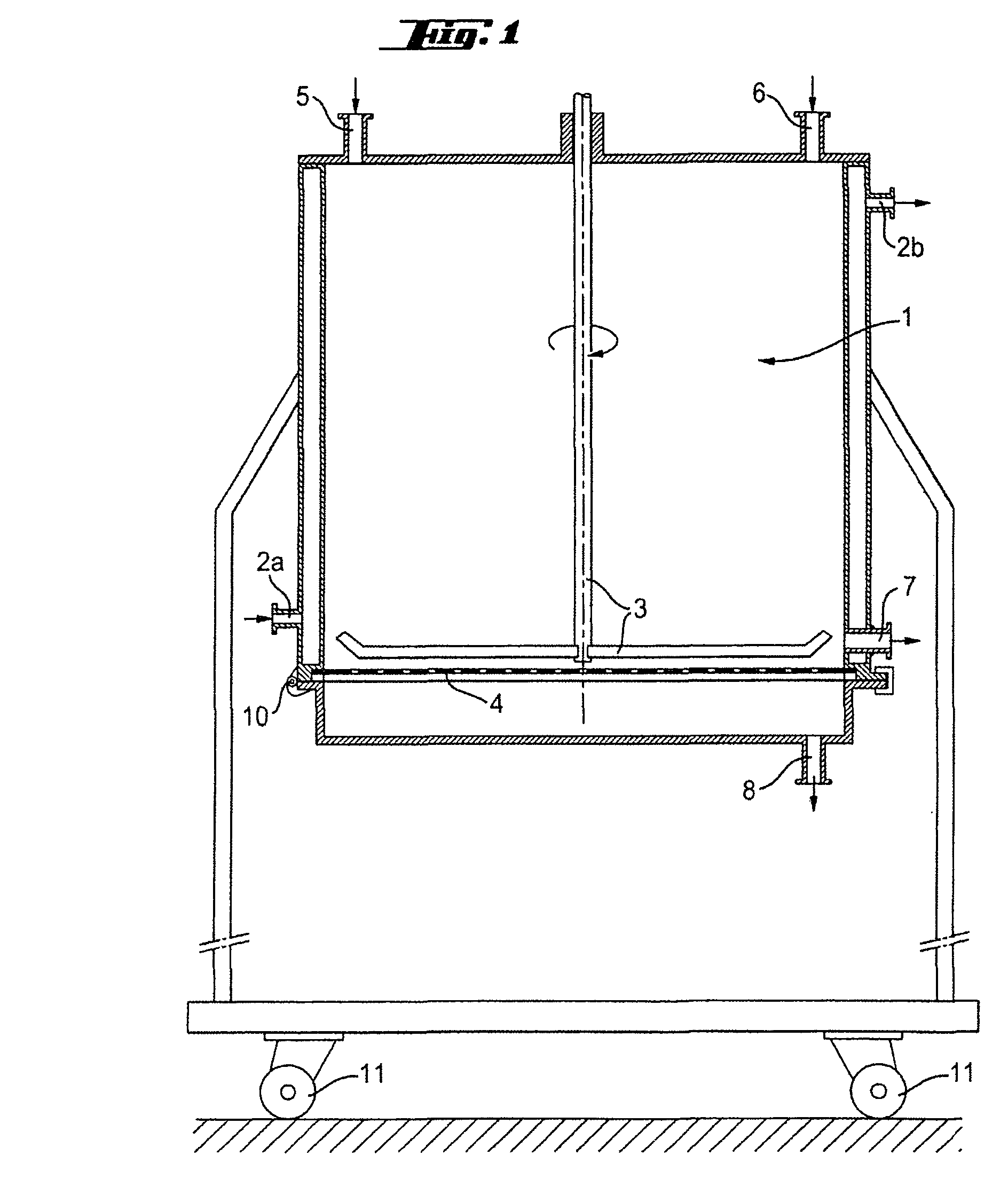

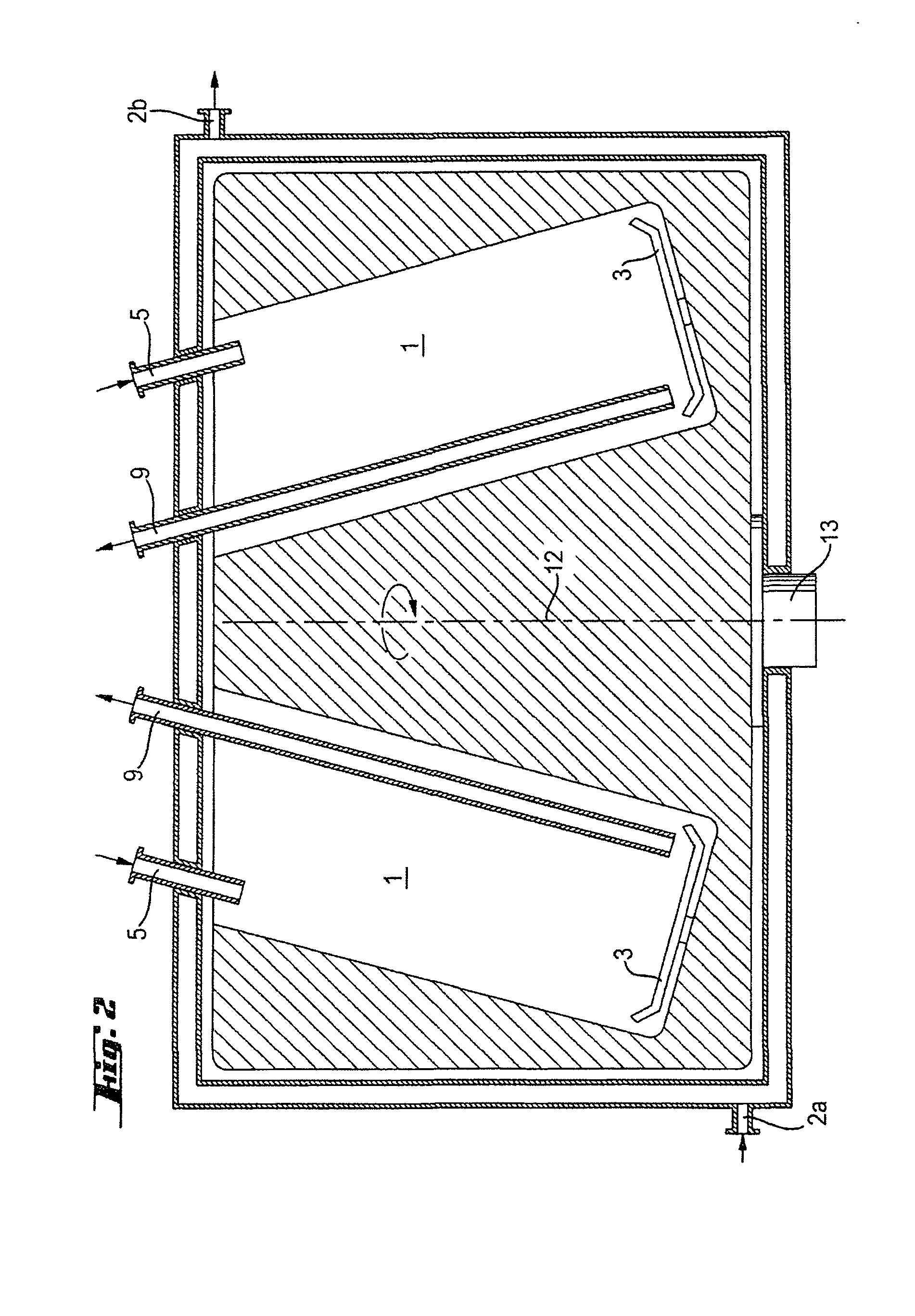

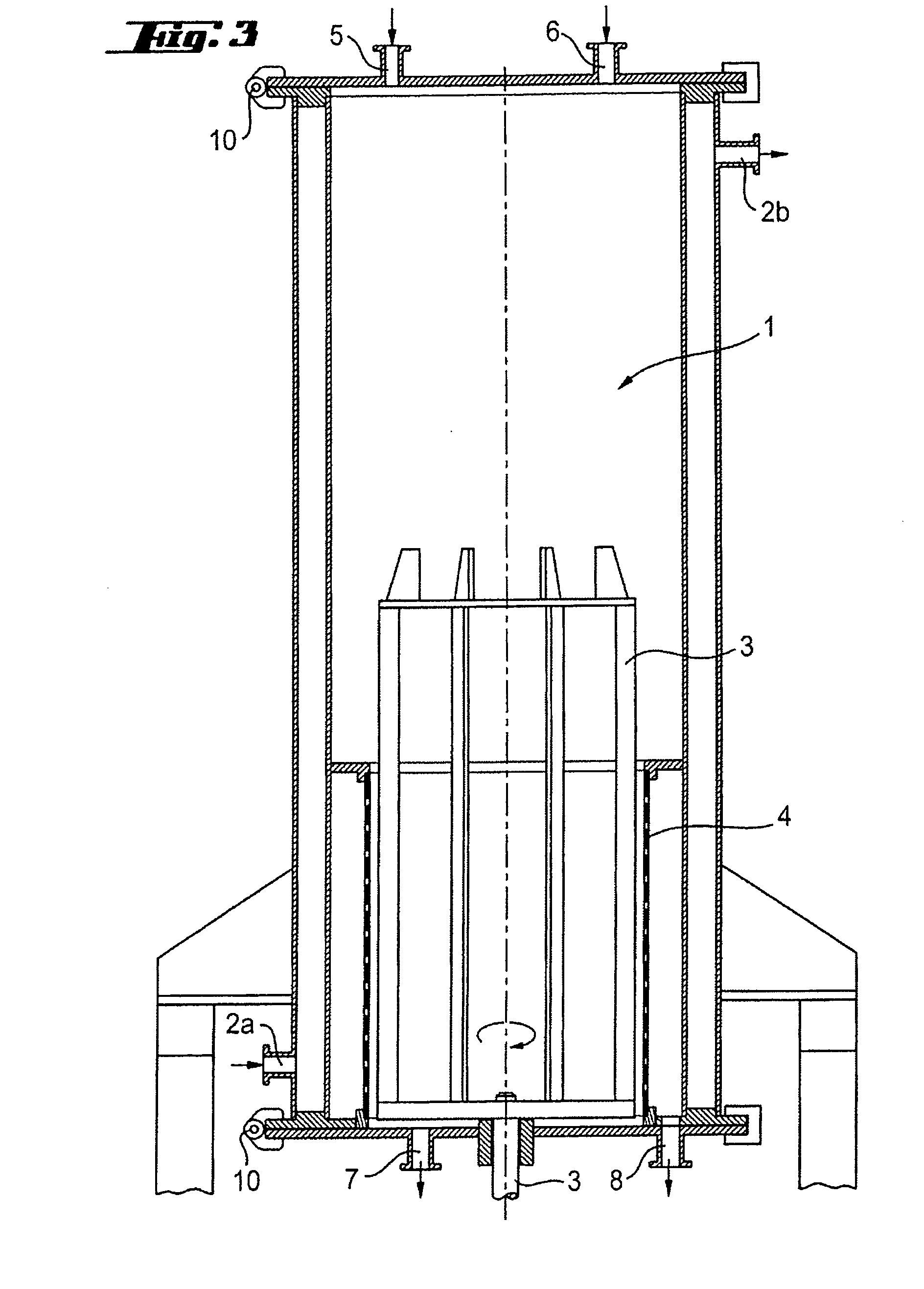

Steam generator of annealing furnace and control method thereof

InactiveCN101871043AEasy to passNot easy to crack and leakSteam generation heating methodsFurnace typesElectric energyElectric heating

The invention relates to the technical field of steam generators, in particular to a steam generator of an annealing furnace and a control method thereof. The steam generator of the annealing furnace comprises an electric heating device twisted with resistance wires, a built-in dry combustion liner, a PLC controller, a water supply device, a thermocouple, and a steam distributor communicated with an inner chamber of a steam oven. The steam generator of the annealing furnace can better utilize heat brought by wires, avoids the waste of water and electric energy caused by overflow, improves the stability of steam, simplifies structure, is easy to operate, and reduces manufacturing cost and maintenance cost.

Owner:东莞市康汇聚线材科技有限公司

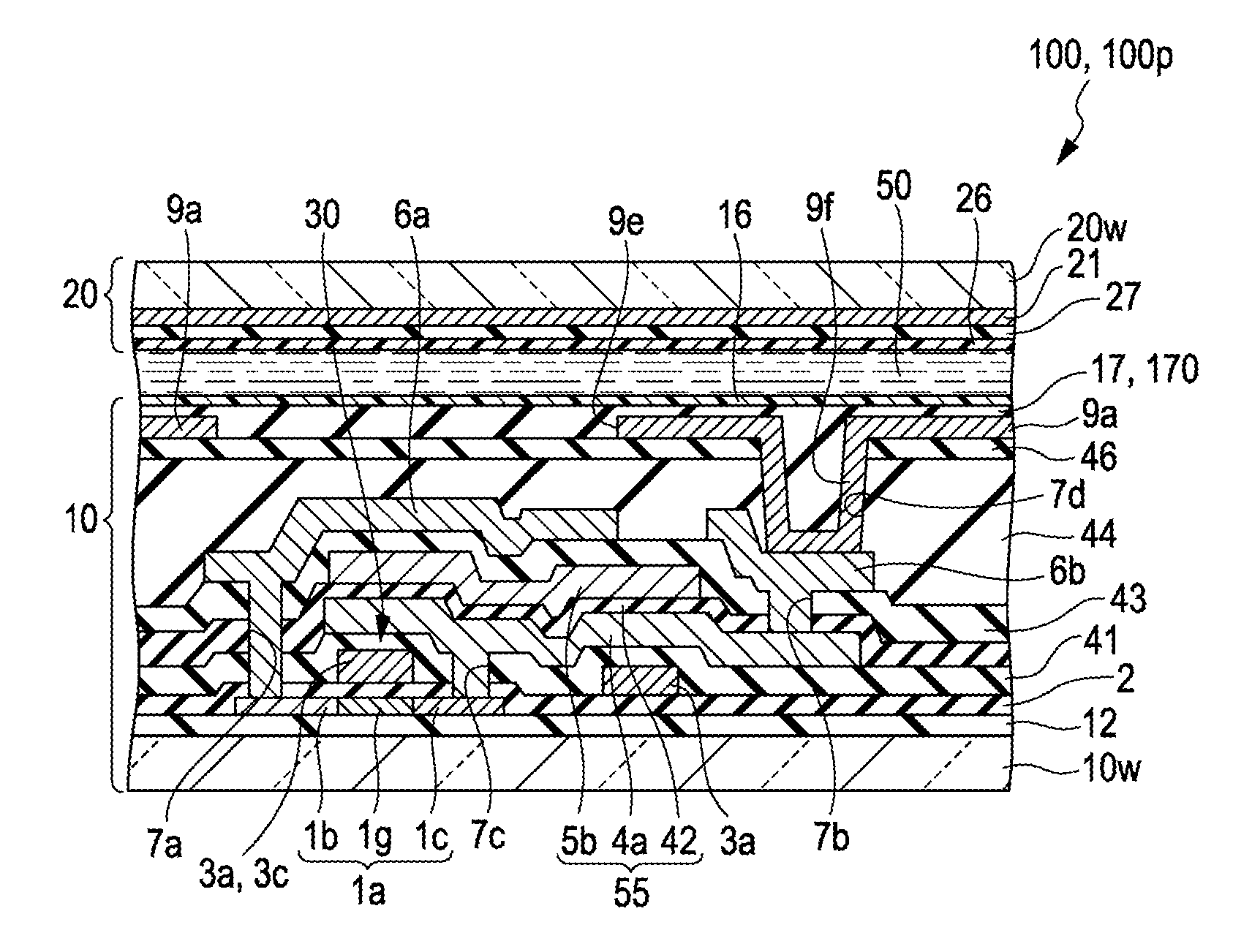

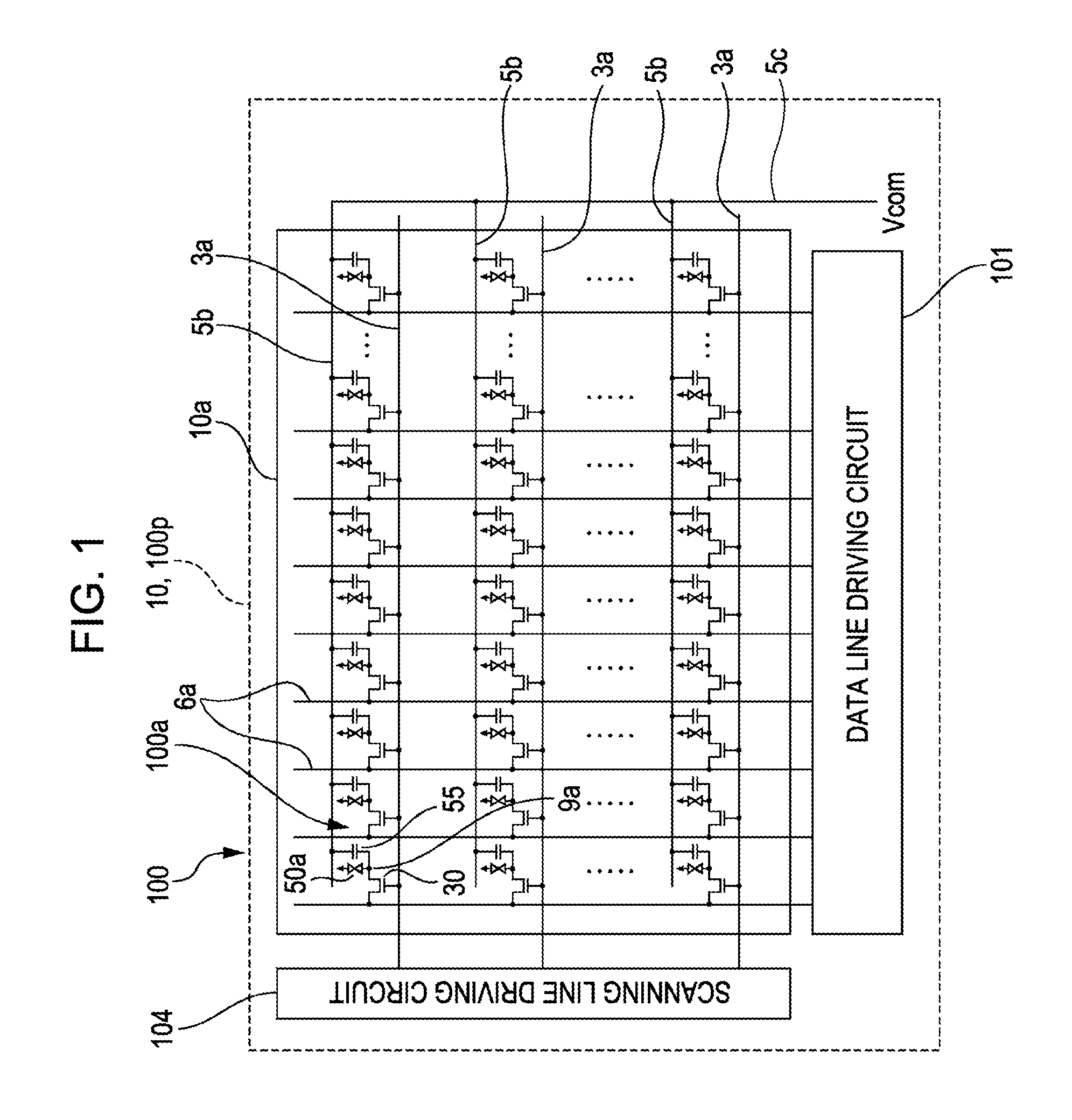

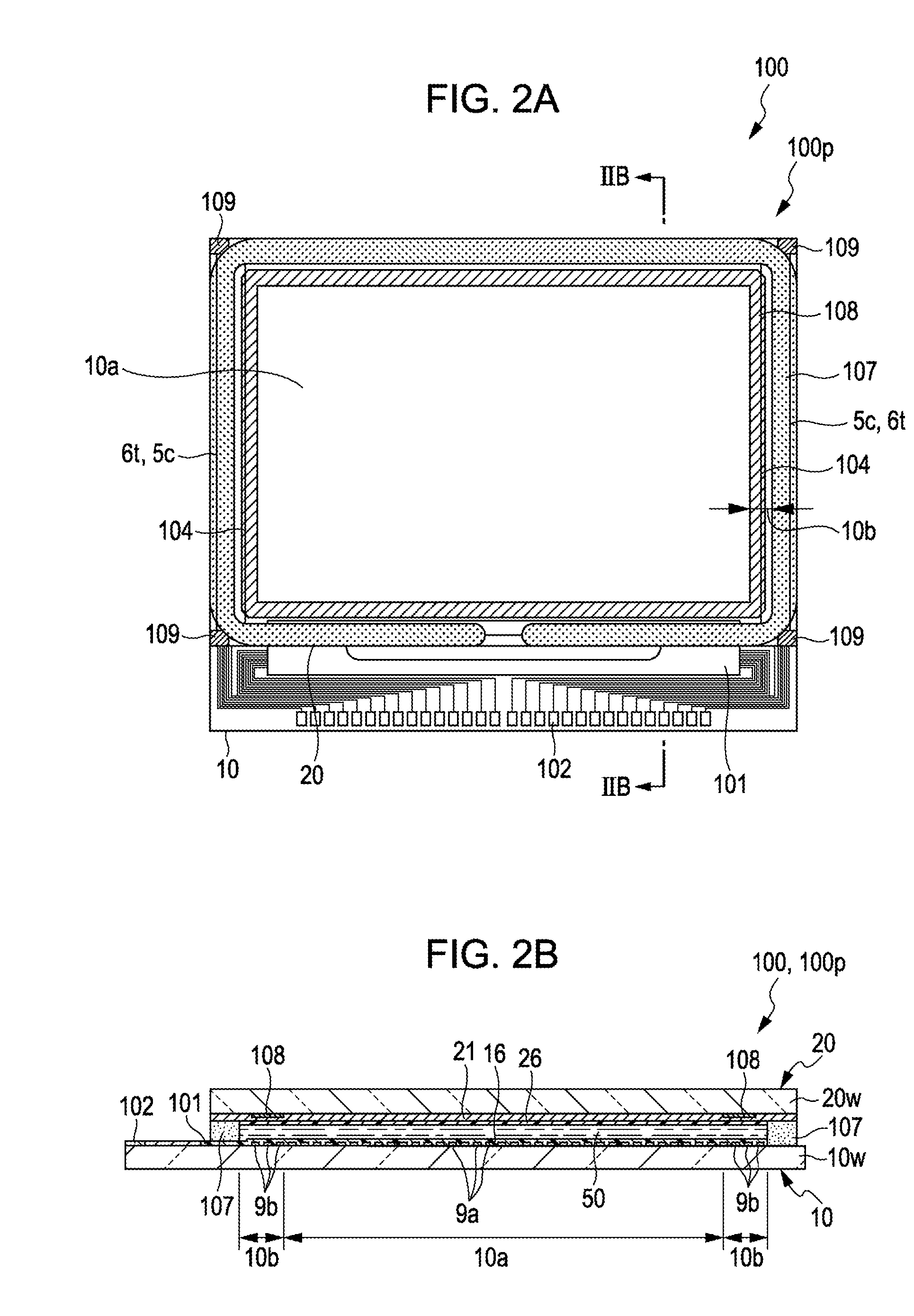

Electro-optic device and projection-type display apparatus

ActiveUS20120120357A1Preventing a defect such as hillockReduce generationNon-linear opticsStress relievingSilicon oxide

An electro-optic device is provided with an substrate, in which a stress relieving film formed of a doped silicon oxide film is formed between a third interlayer insulating film formed of a non-doped silicon oxide film and a pixel electrode formed of an aluminum film or the like. The stress relieving film is formed of the doped silicon oxide film, has a thermal expansion coefficient different from that of the third interlayer insulating film, comes in contact with the third interlayer insulating film, has a thermal expansion coefficient different from that of the pixel electrode, and comes in contact with the pixel electrode. The thermal expansion coefficients are in the following relation of Third Interlayer Insulating Film<Stress relieving Film<Pixel Electrode.

Owner:SEIKO EPSON CORP

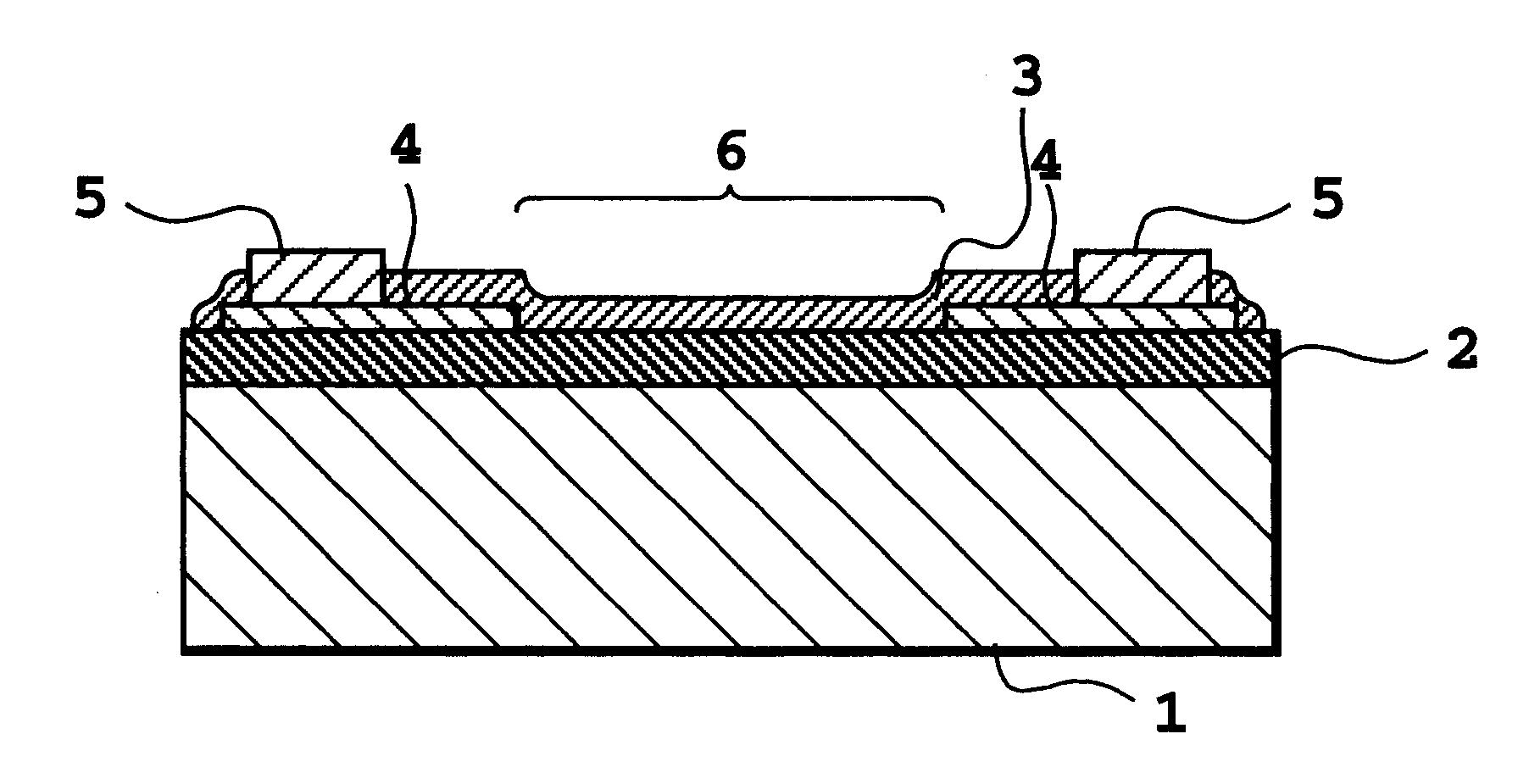

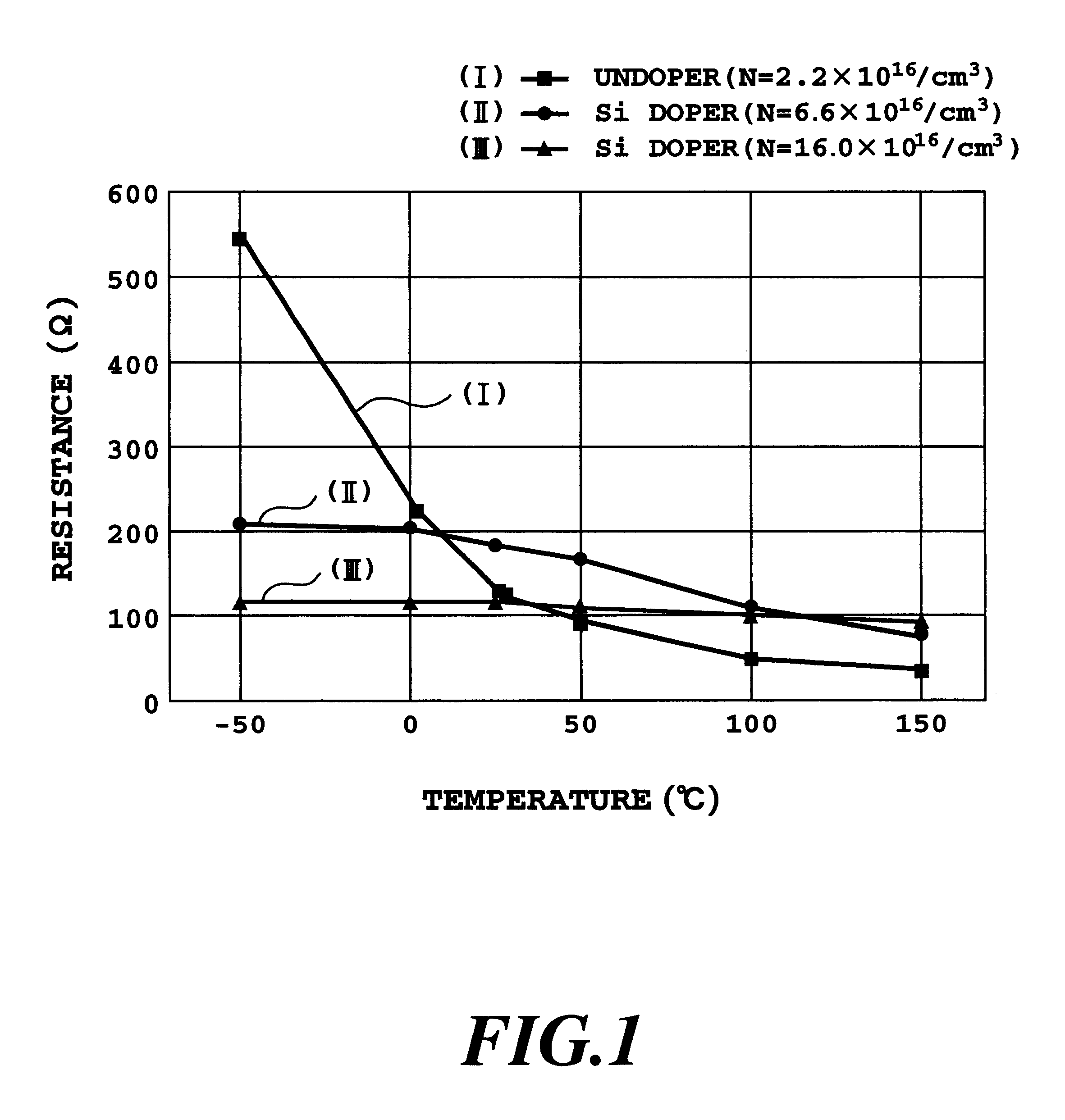

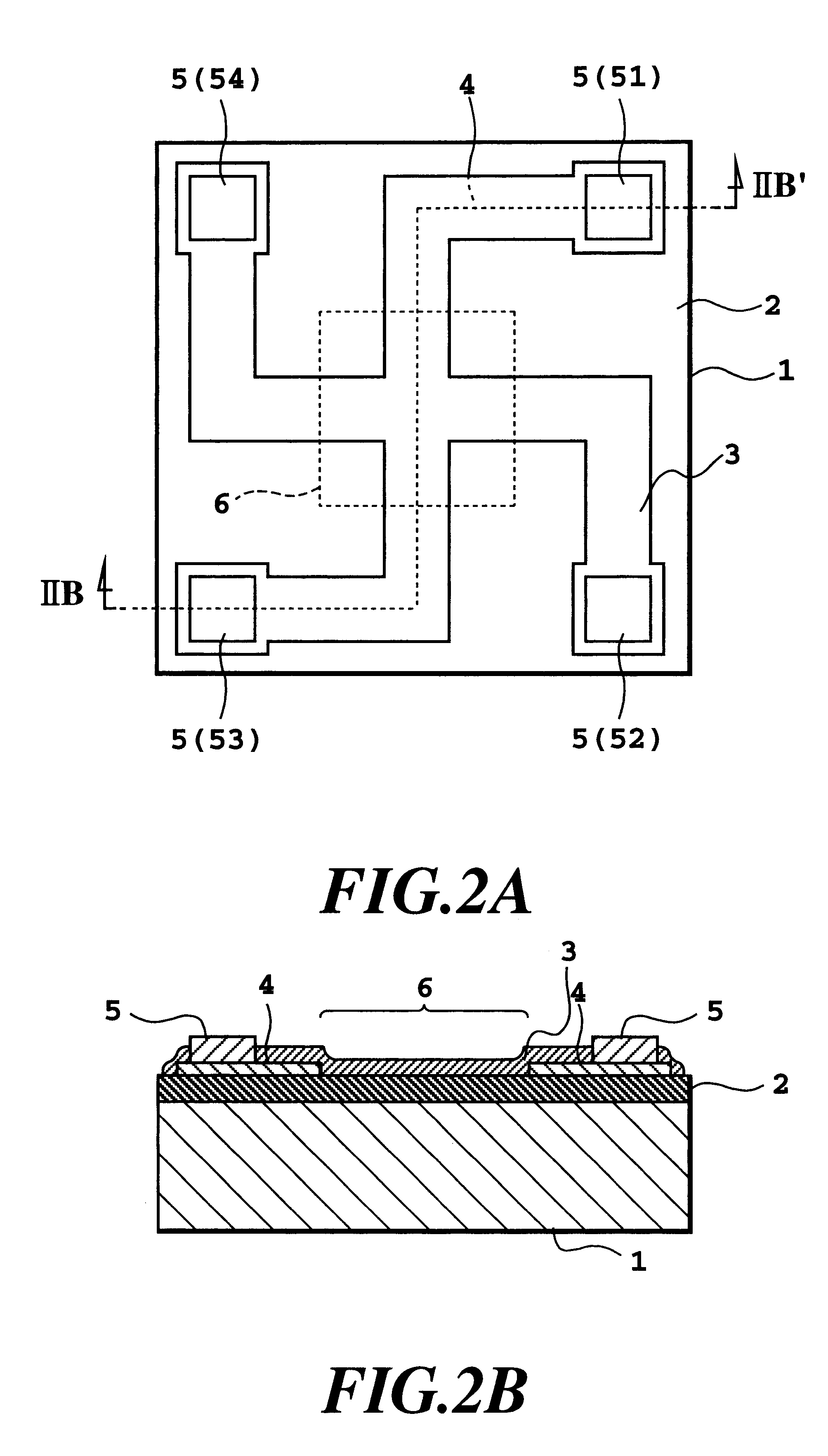

Magnetic sensor, magnetic sensor apparatus, semiconductor magnetic resistance apparatus, and production method thereof

InactiveUS6590389B1Improve reliabilityImprove thermal stressMagnetic-field-controlled resistorsSolid-state devicesElectricityDielectric substrate

An InxGa1-xAsySb1-y (0<x<=1, 0<=y<=1) thin film of an electron concentration of 2x1016 / cm3 or more is formed on a dielectric substrate. Temperature dependence of resistance is controlled by composition setting or donor atom doping of the thin film to reduce the temperature dependence. As a result, a magnetic sensor of small temperature dependence of device resistance and high sensitivity can be provided.

Owner:ASAHI KASEI KK +1

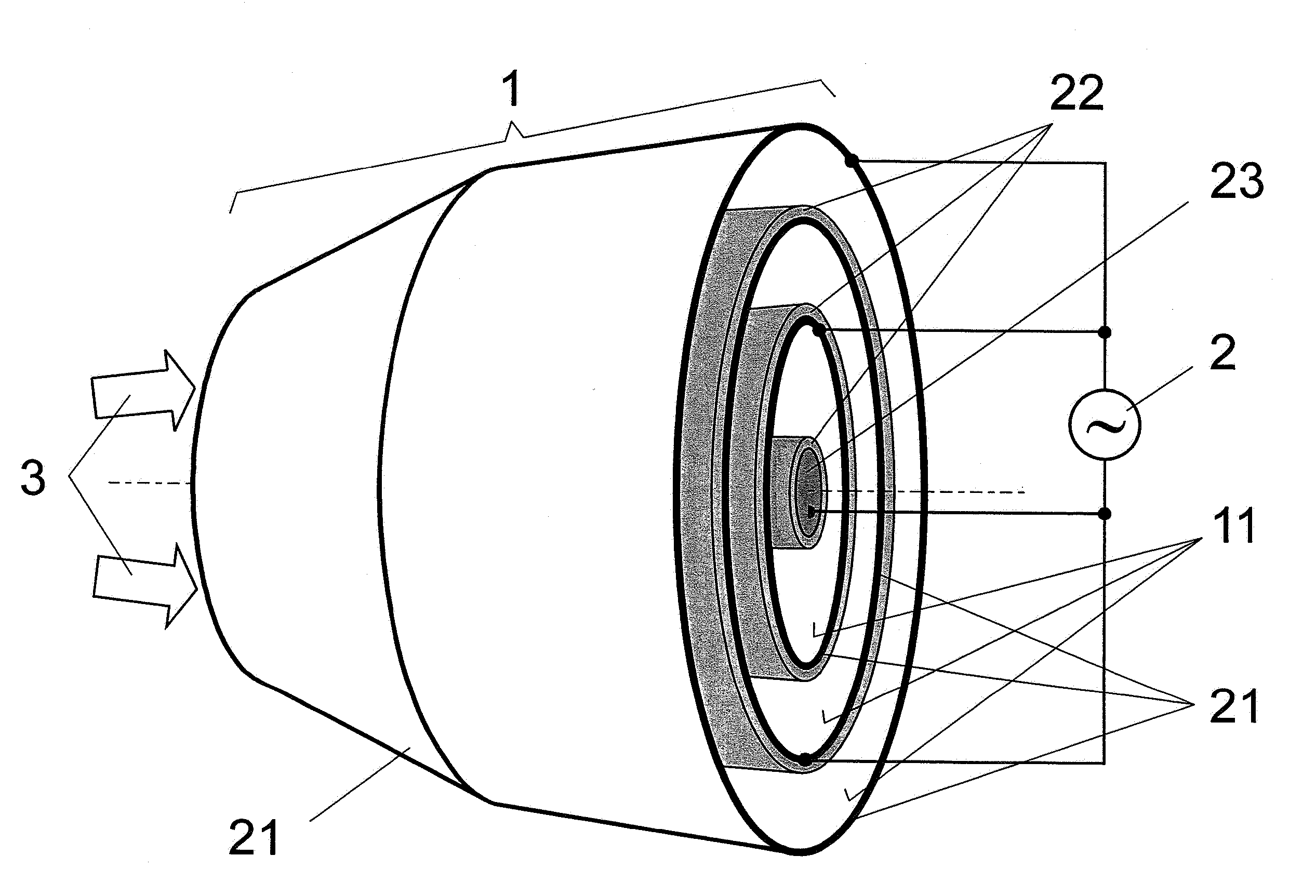

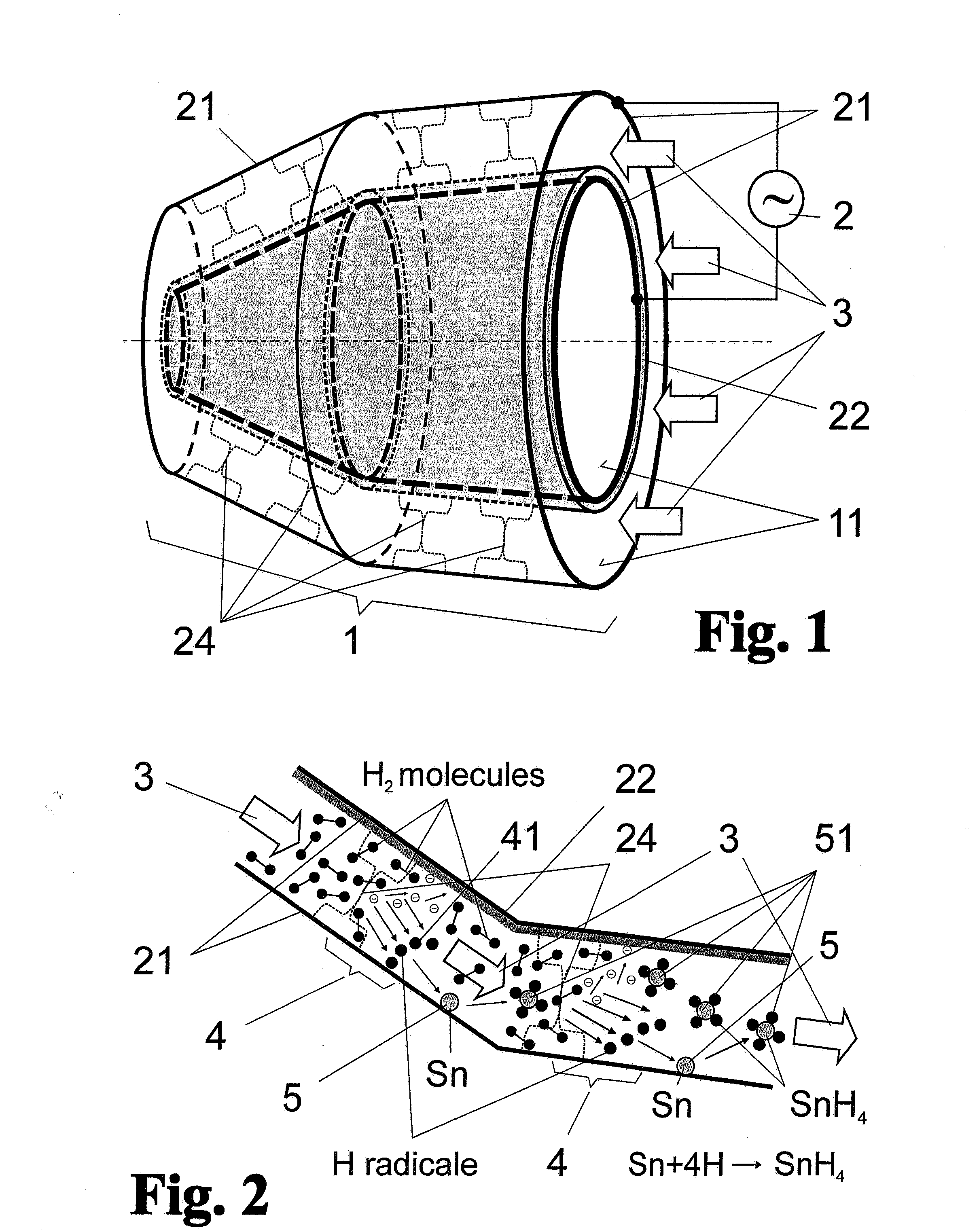

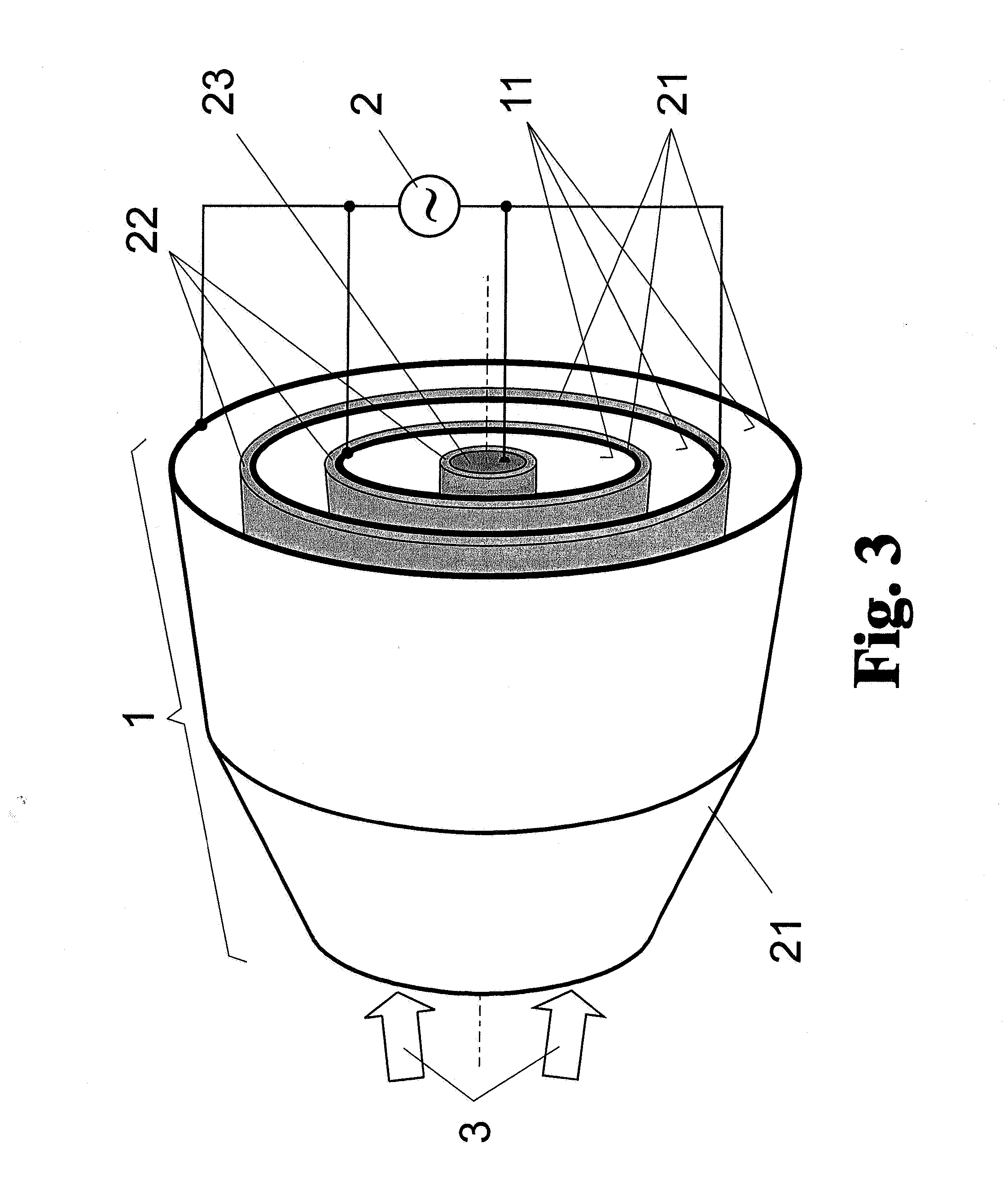

Method and arrangement for cleaning optical surfaces in plasma-based radiation sources

ActiveUS20090014027A1Meet growth requirementsImprove thermal stressElectric discharge tubesDecorative surface effectsDebris particleSurface electrode

The invention is directed to a method and an arrangement for cleaning optical surfaces of reflection optics which are arranged in a plasma-based radiation source or exposure device arranged downstream and contaminated by debris particles emitted by a hot plasma of the radiation source. It is the object of the invention to find a novel possibility for in-situ cleaning of the optical surfaces of reflection optics which are contaminated by debris in plasma-based radiation sources so as to allow an integrated generation of known gas radicals and the isotropic distribution thereof on the contaminated optical surfaces. According to the invention, this object is met in that the gas radicals are generated by dielectrically impeded discharge between two surface electrodes along the entire optical surface. The gas radicals are generated almost exclusively by electron transfer on at least one barrier layer which covers the entire surface of at least one of the surface electrodes, an AC voltage in the Hz to kHz range is applied to the surface electrodes for periodically eliminating the charge polarization at the barrier layer so that a cold plasma is generated continuously and the deposited debris particles are removed as gaseous reaction products by the gas flow guided over the optical surface.

Owner:USHIO DENKI KK

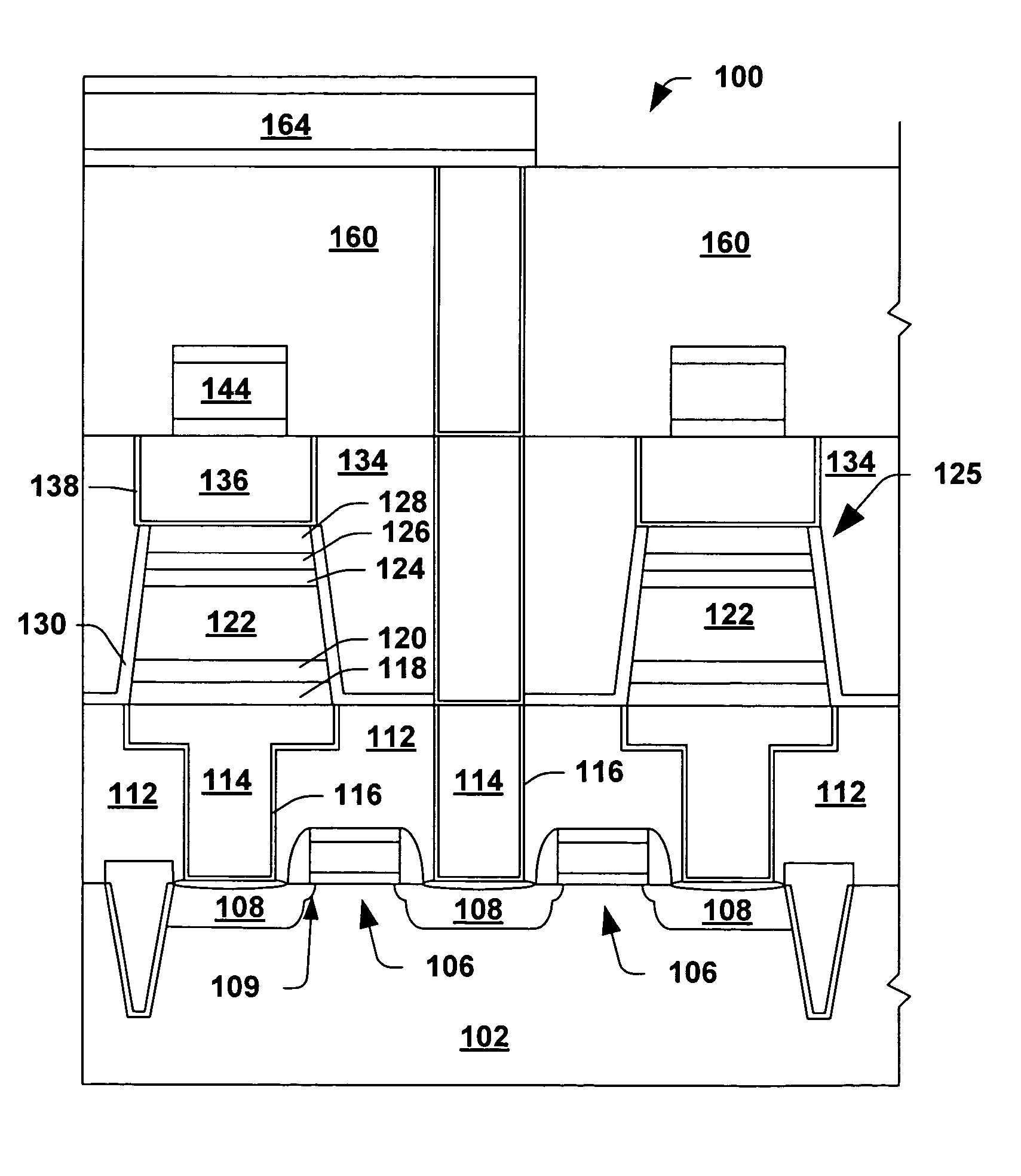

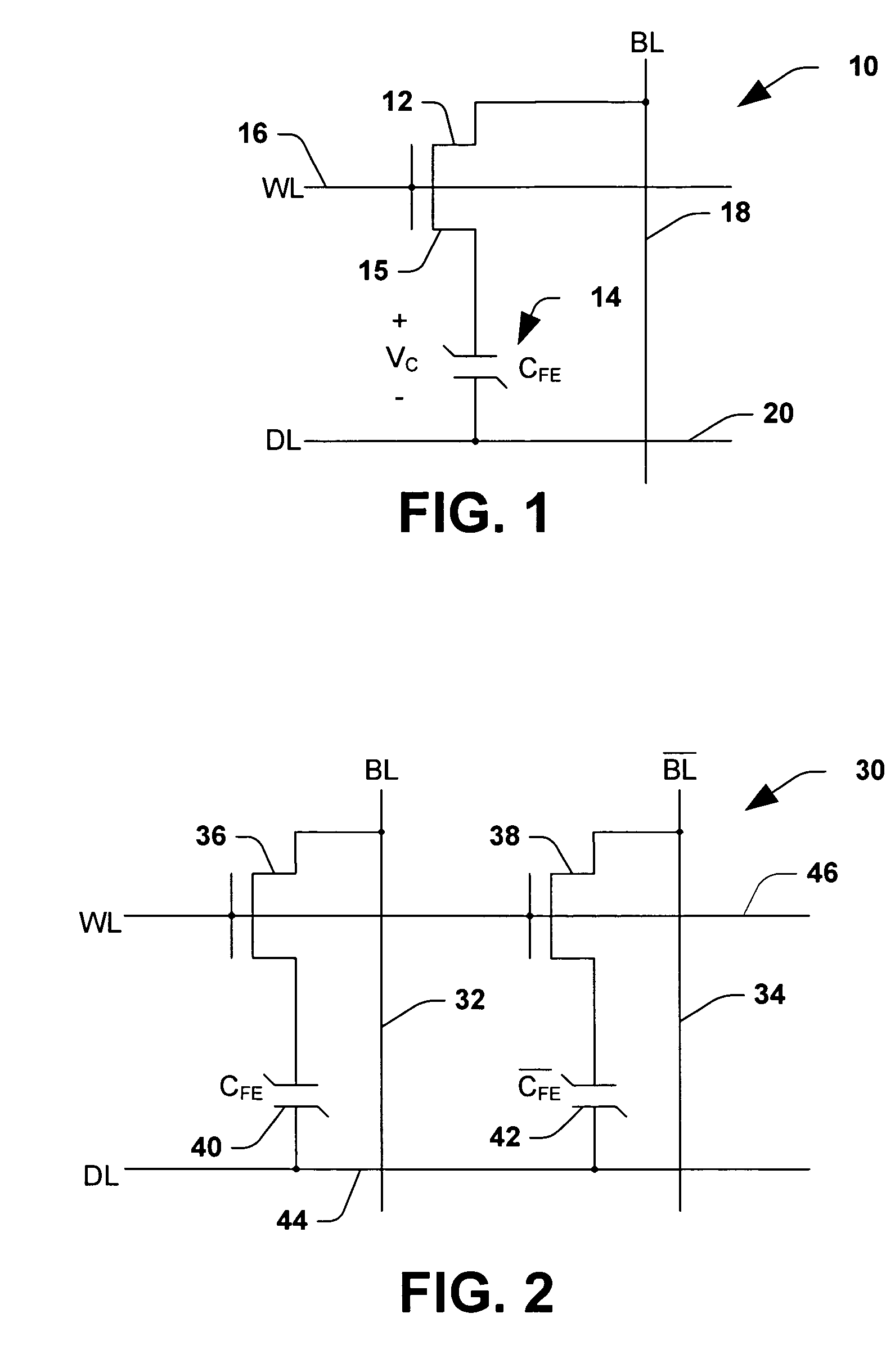

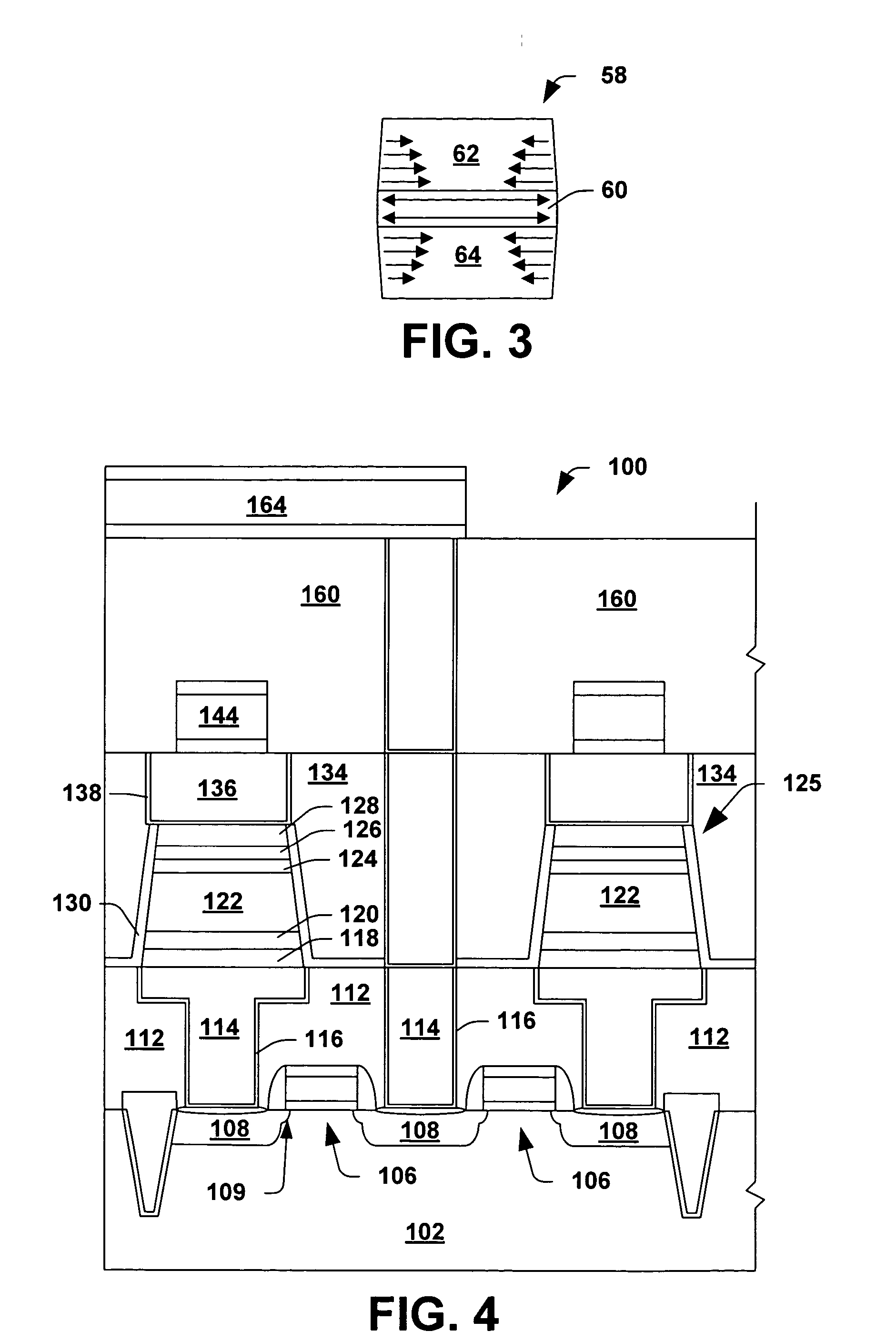

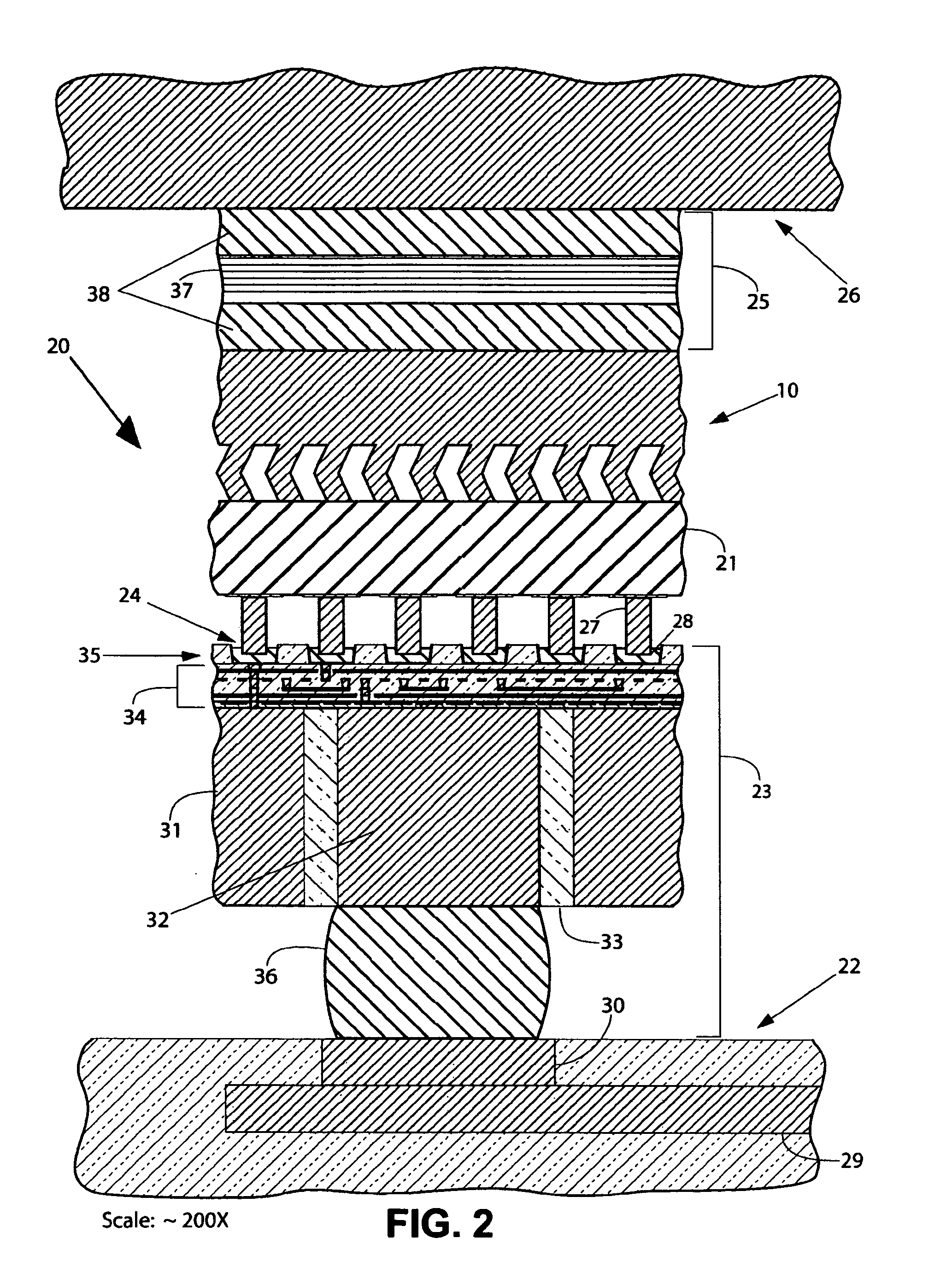

High polarization ferroelectric capacitors for integrated circuits

InactiveUS20050145908A1High switched polarizationSpontaneous polarizationSolid-state devicesSemiconductor/solid-state device manufacturingRoom temperatureCurie temperature

One aspect of the invention relates to a method of manufacturing an integrated circuit comprising forming an array of ferroelectric memory cells on a semiconductor substrate, heating the substrate to a temperature near a Curie temperature of the ferroelectric cores, and subjecting the substrate to a temperature program, whereby thermally induced stresses on the ferroelectric cores cause a switched polarization of the cores to increase by at least about 25% as the cores cool to about room temperature. Embodiments of the invention include metal filled vias of expanded cross-section above and below the ferroelectric cores, which increase the thermal stresses on the ferroelectic cores during cooling.

Owner:TEXAS INSTR INC

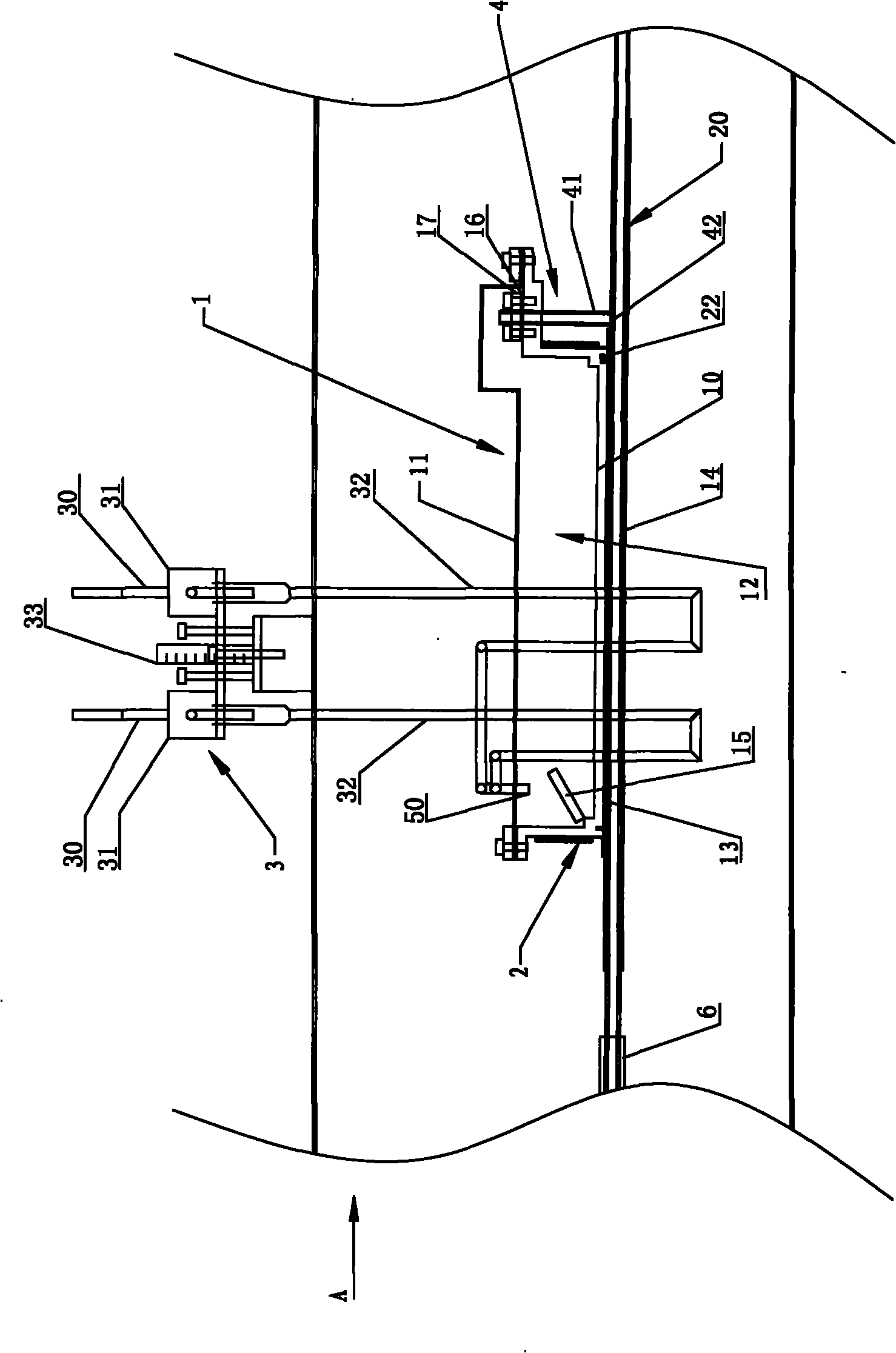

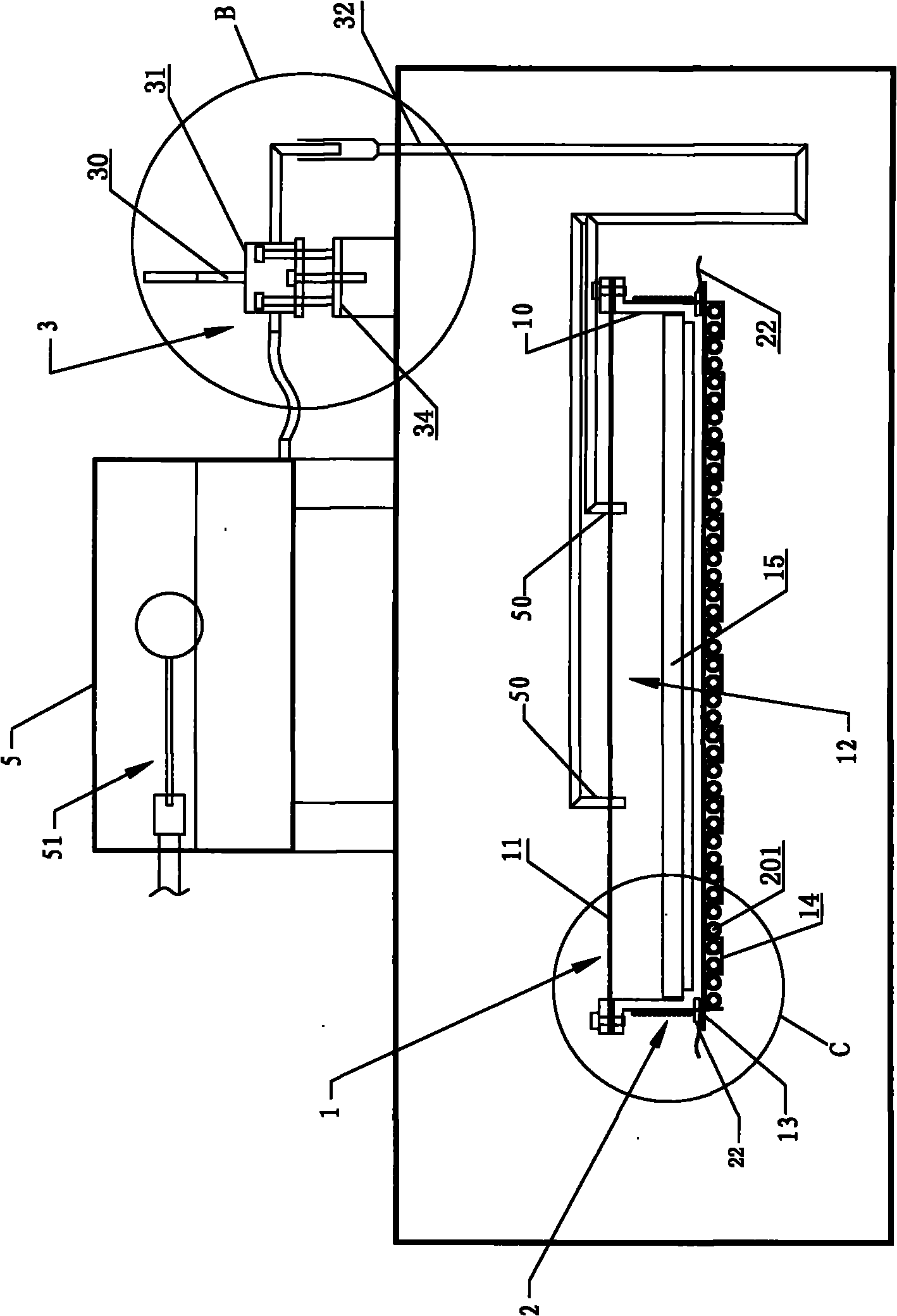

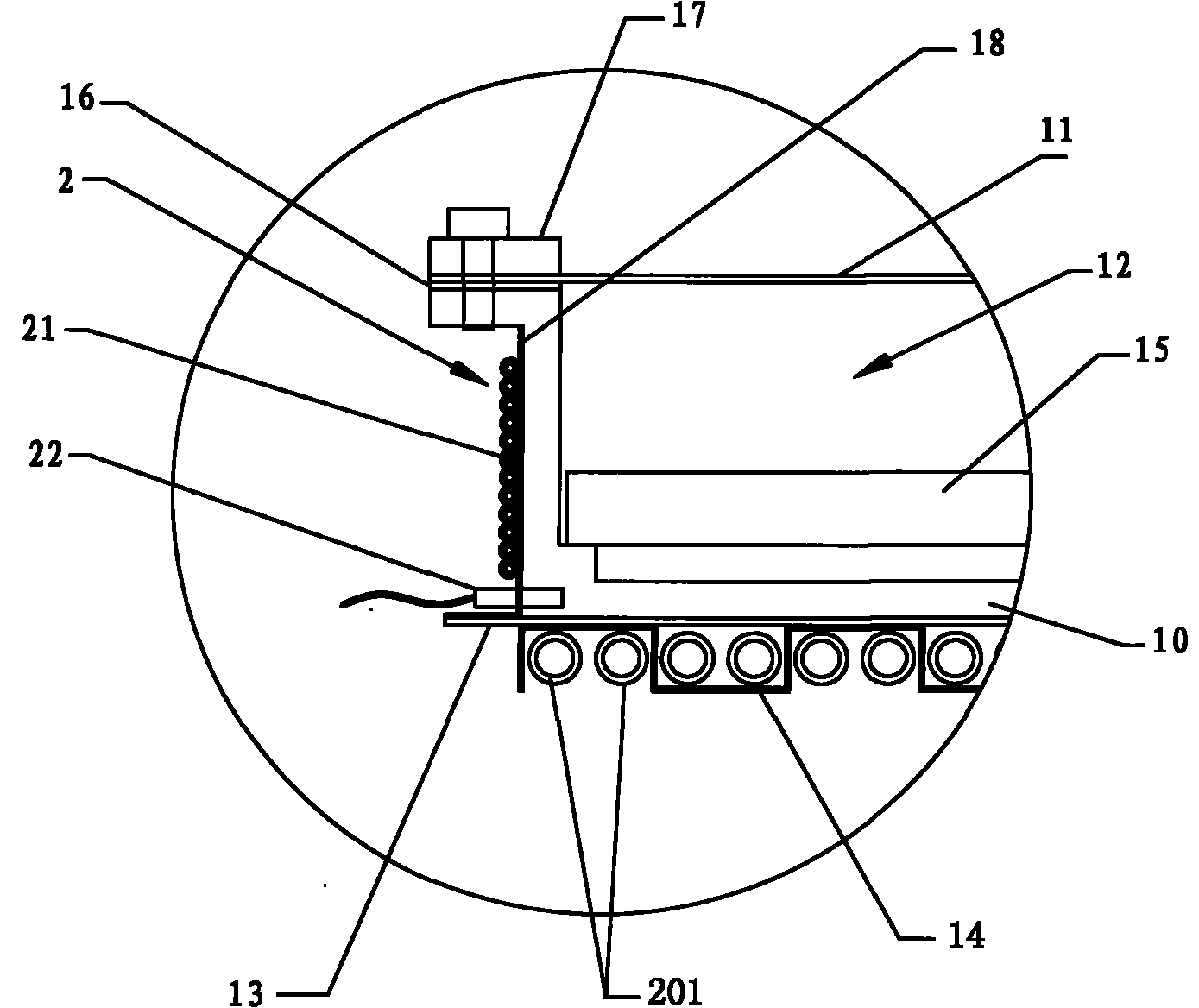

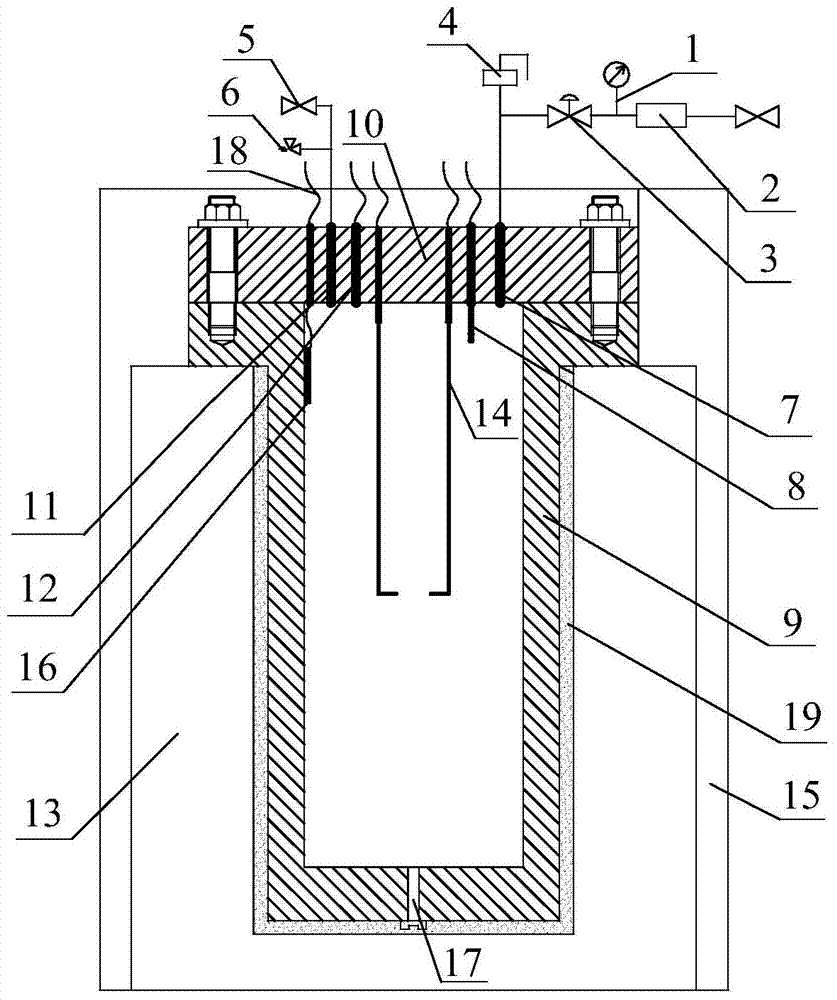

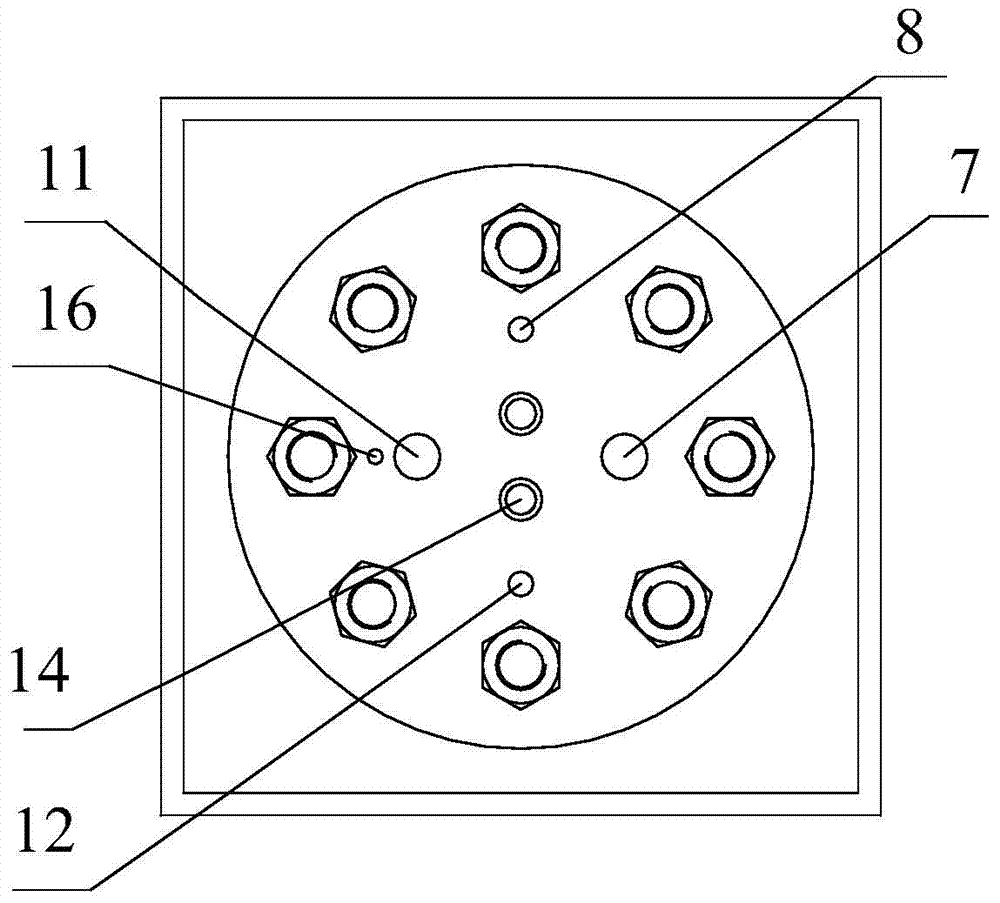

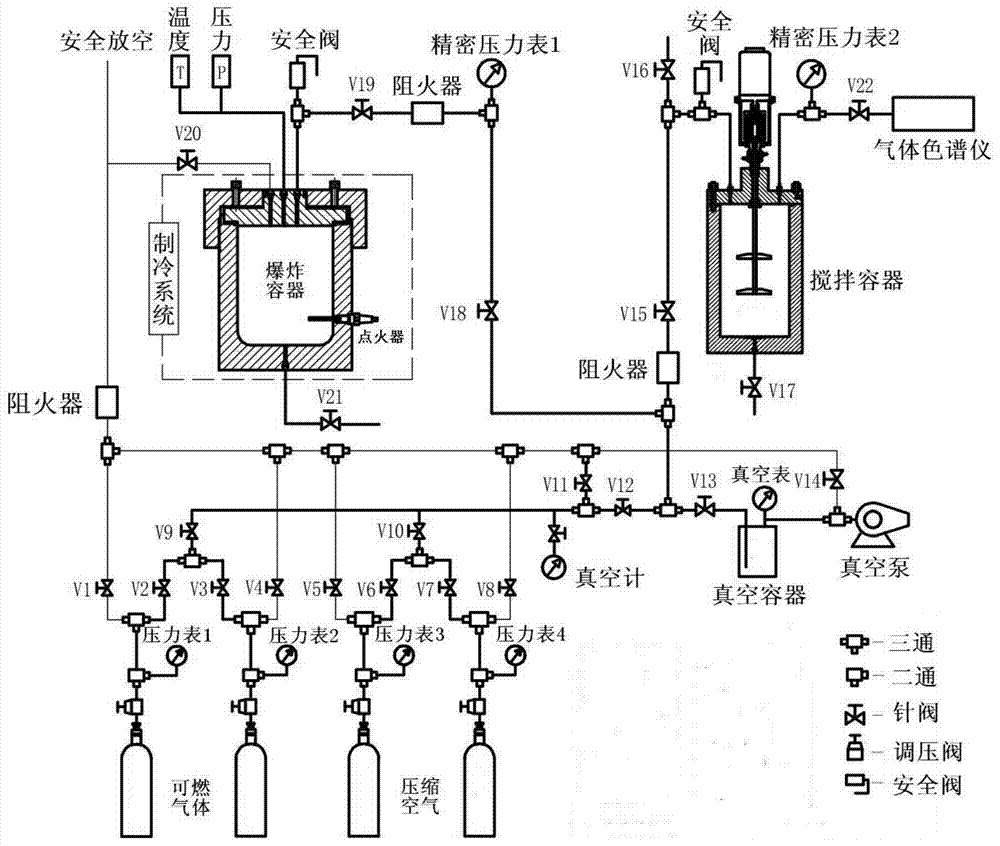

Device and method for testing explosion properties of flammable gases at ultralow temperature

ActiveCN104749218AEasy temperature controlAvoid risks and excessive heat stressMaterial exposibilityStrain gaugeFlammability limit

The invention relates to a device and a method for testing the explosion properties of flammable gases at ultralow temperature. The device comprises a refrigerating device, an explosion vessel with a length-diameter ratio of 3 to 1 is arranged in an inner cavity of the refrigerating device, a gap is formed between the explosion vessel and the inner cavity of the refrigerating device, and a heat conducting material by which the temperatures of the explosion vessel and gas in the explosion vessel are reduced to an experimental temperature is added in the gap; the top of the explosion vessel is sealed by a blind flange, two ignition electrodes connected with an ignition energy console are arranged in the explosion vessel, the bottom of the explosion vessel is provided with a liquid outlet for implementing the cleaning of deposited carbon in the explosion vessel, and a strain gage for carrying out real-time monitoring on heat stress produced in the process of explosion is attached to the inner wall of the explosion vessel; and the blind flange is provided with a temperature sensor, a pressure sensor, a gas inlet and a gas outlet, and the gas inlet and the gas outlet are communicated with the inside of the explosion vessel. The device disclosed by the invention can be used for eliminating the trouble that the application amount of liquid nitrogen in liquid-nitrogen refrigerating is huge, and avoiding the occurrence of risks and ultra-high heat stress caused by the rapid evaporation of liquid nitrogen due to heat produced by explosion; and the device is high in refrigeration efficiency, and can meet the requirements on minimum ignition energy and explosion limit tests.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

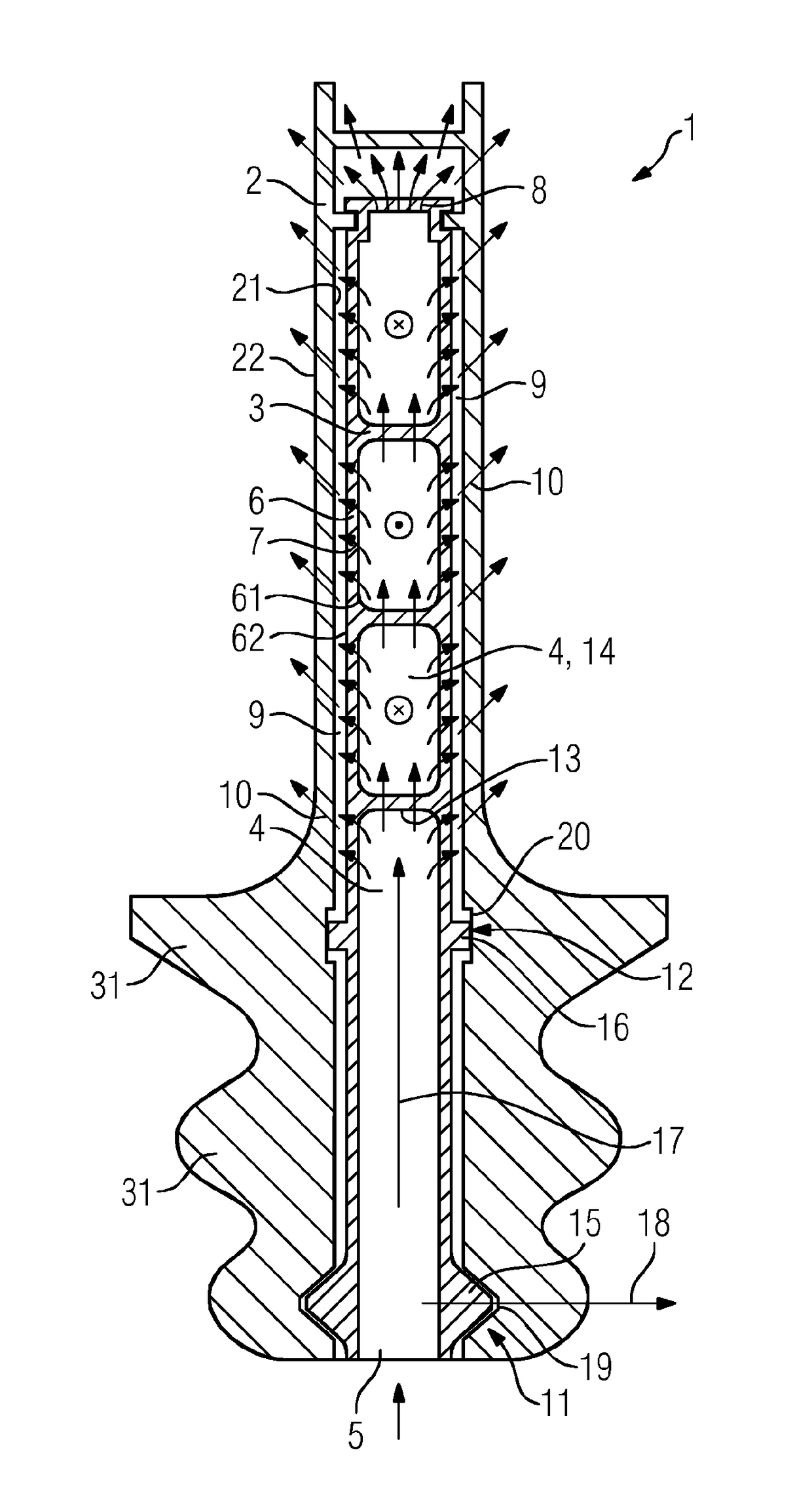

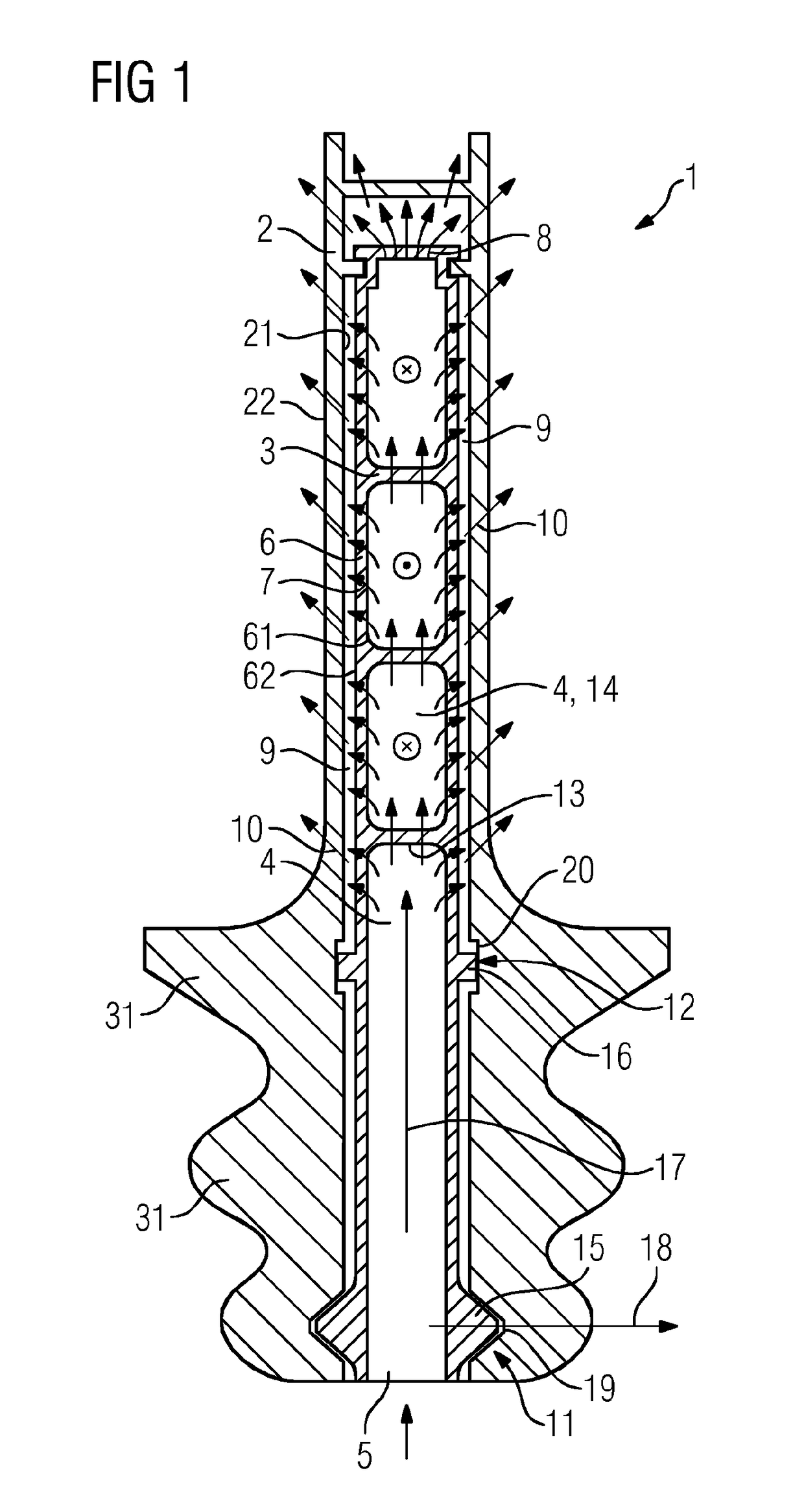

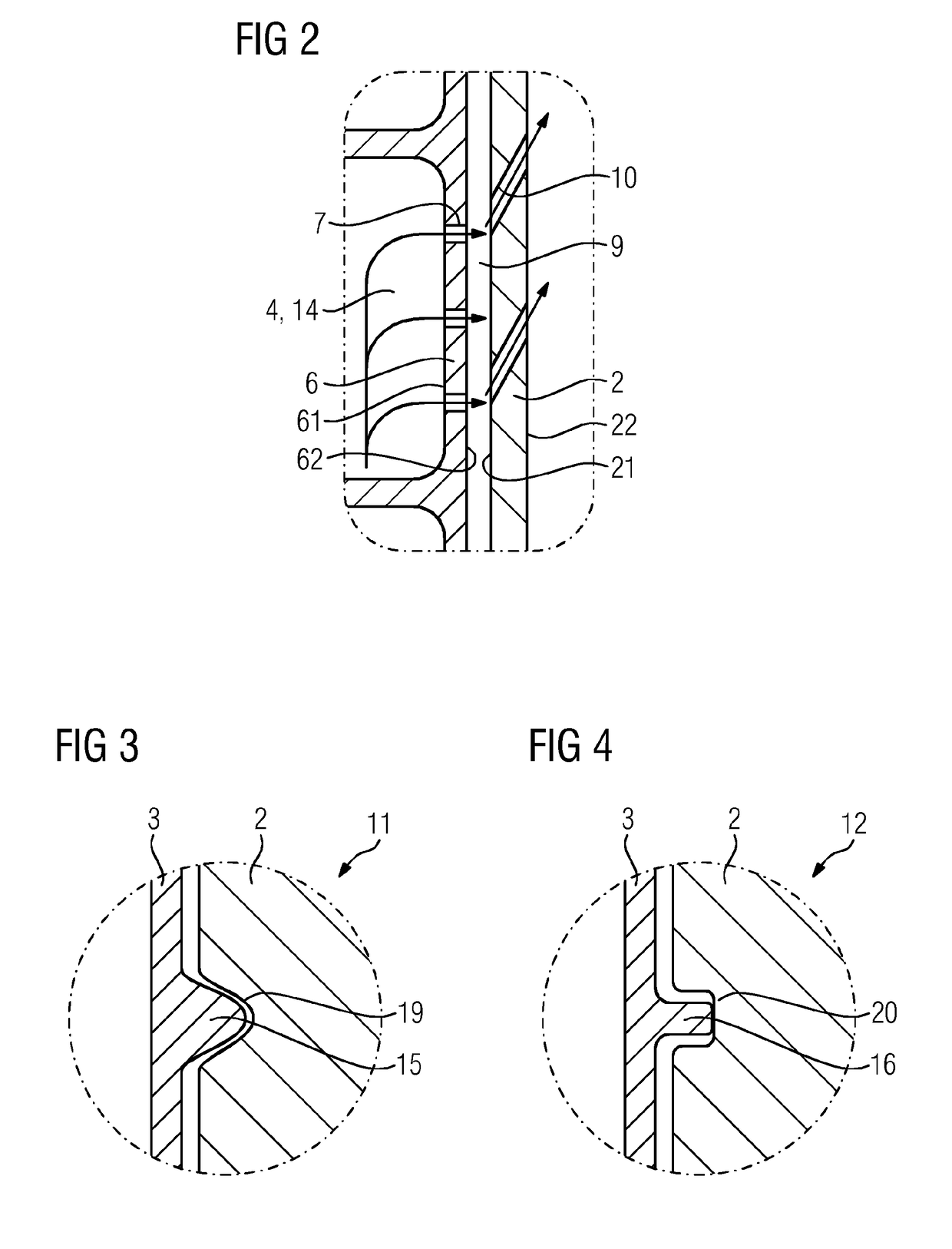

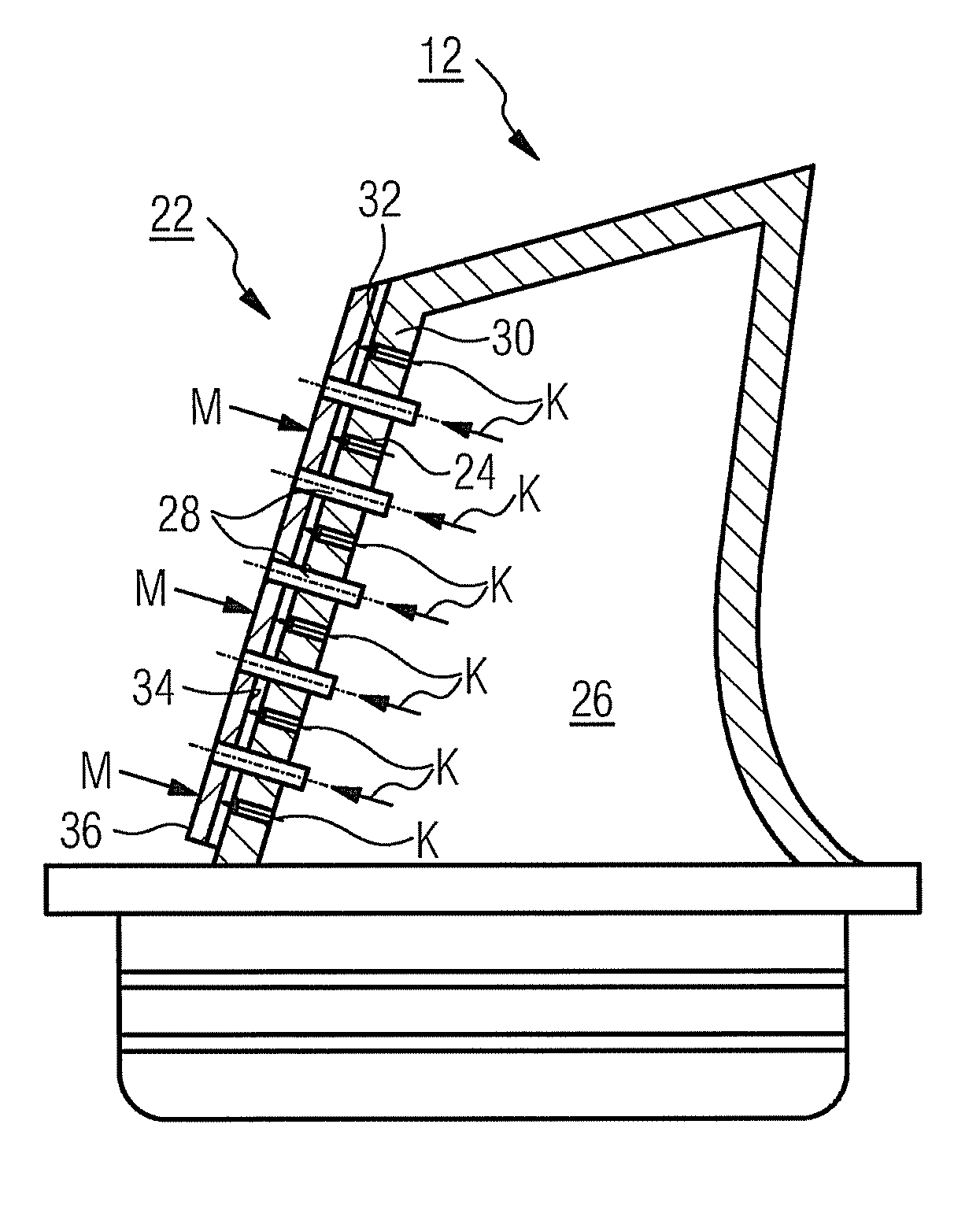

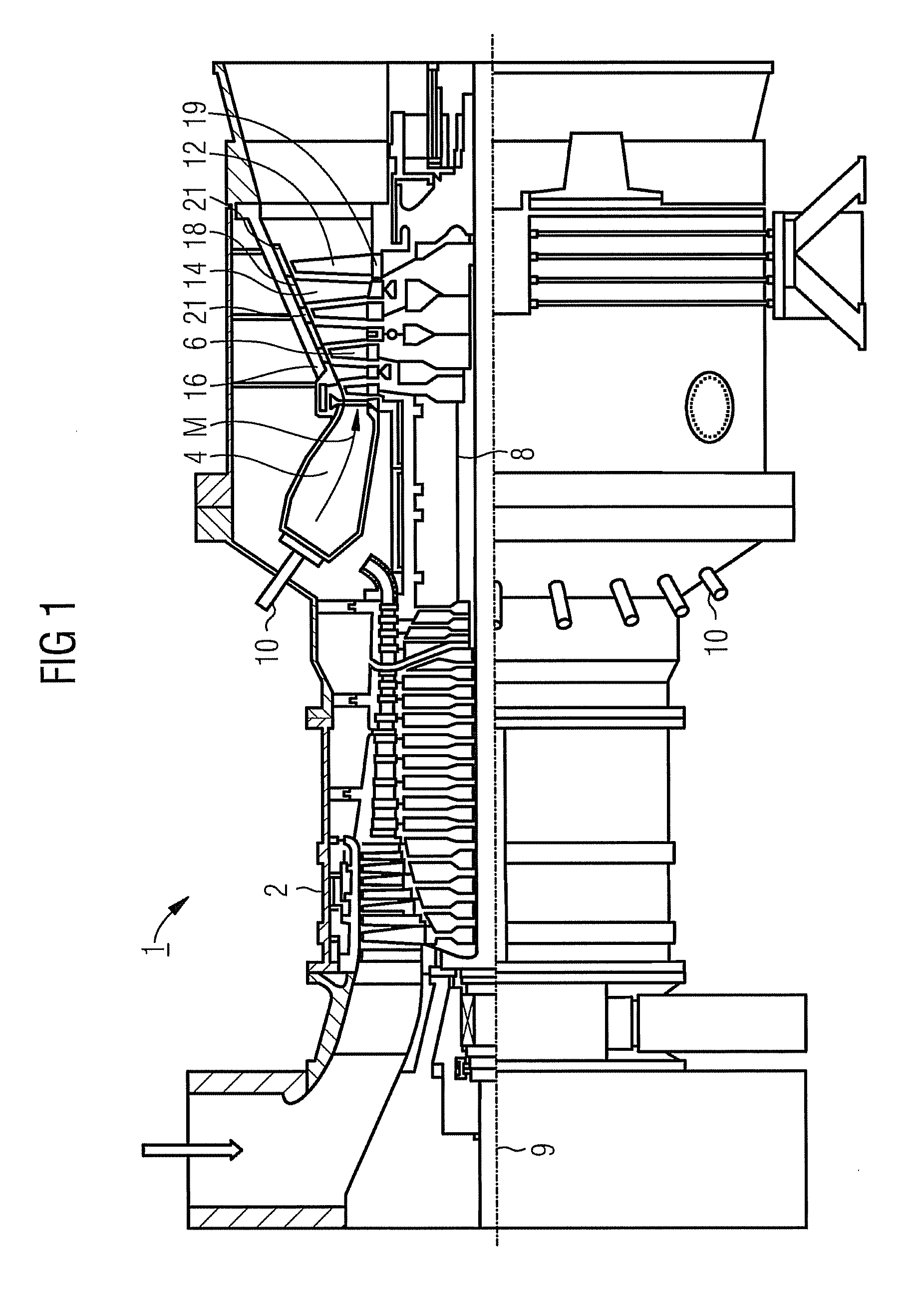

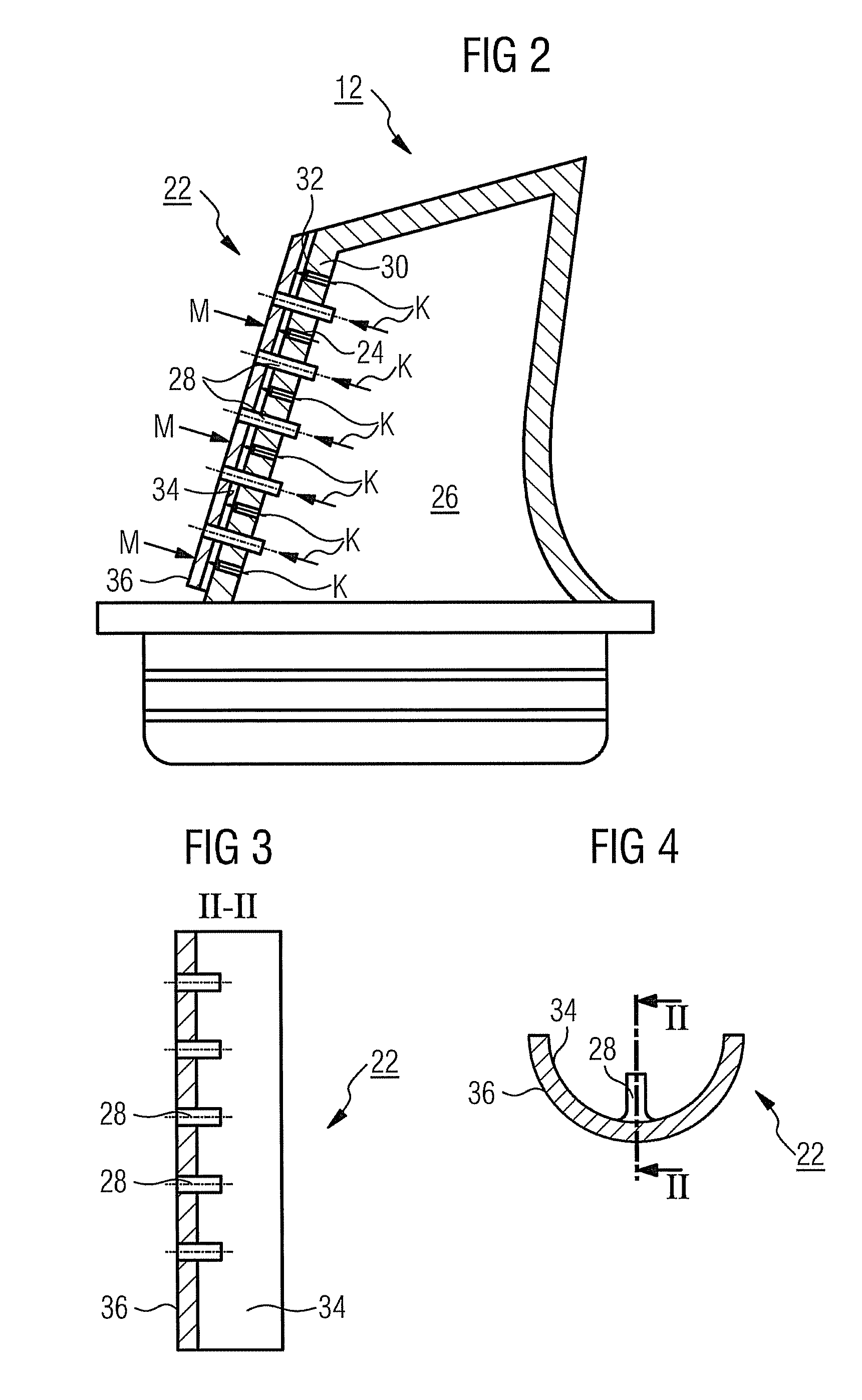

Turbine blade having an inner module and method for producing a turbine blade

InactiveUS20170306766A1Improve thermal stressCooling and structural functions can be decoupledTurbinesAdditive manufacturing apparatusTurbine bladeAerospace engineering

A turbine blade having a casing and having an inner module, wherein a cooling medium can flow through the inner module both in a longitudinal direction and in a radial direction, and the inner module is attached to the casing by fixed bearings and floating bearings. A method for producing a turbine blade having an inner module and having a casing is produced by selective laser melting.

Owner:SIEMENS AG

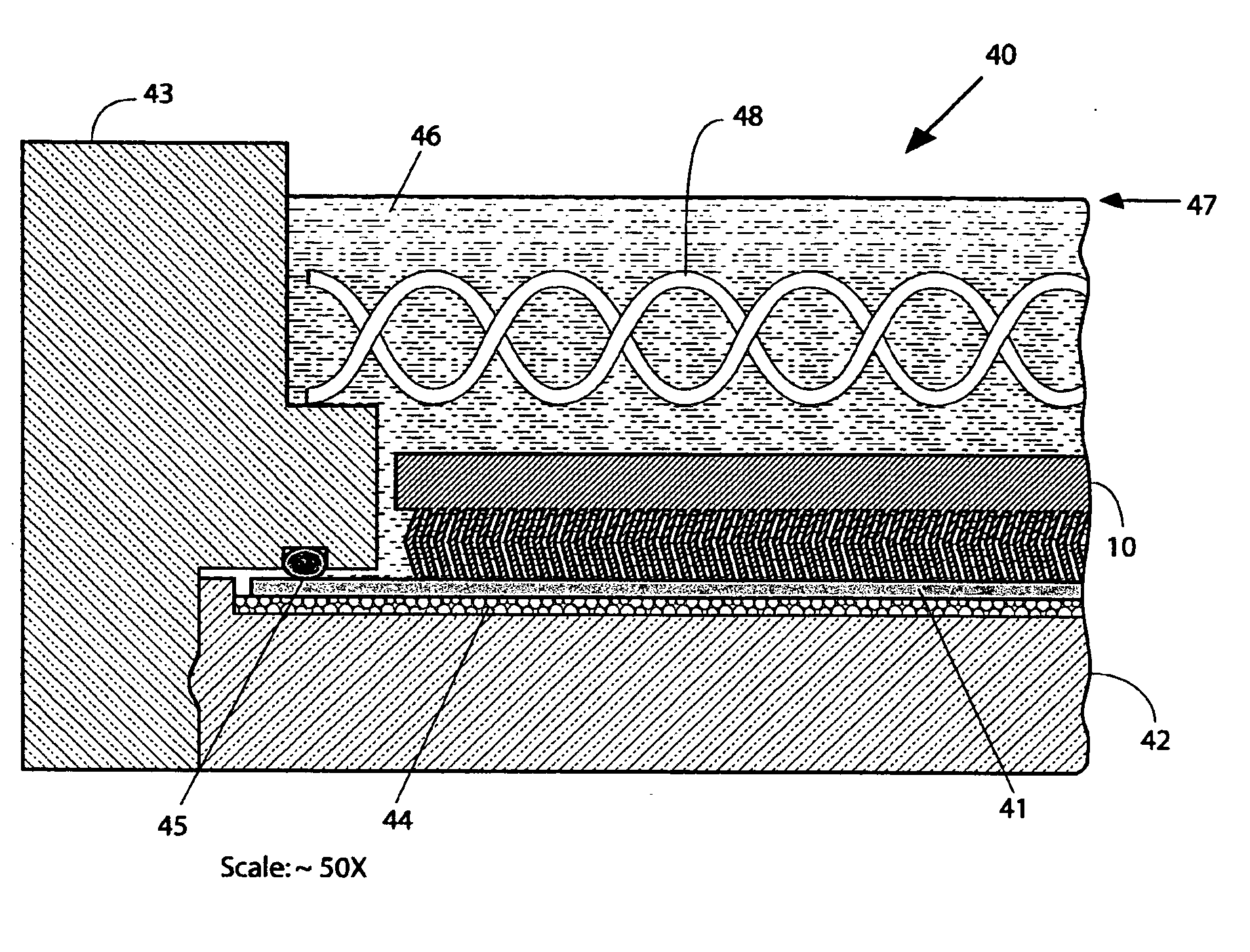

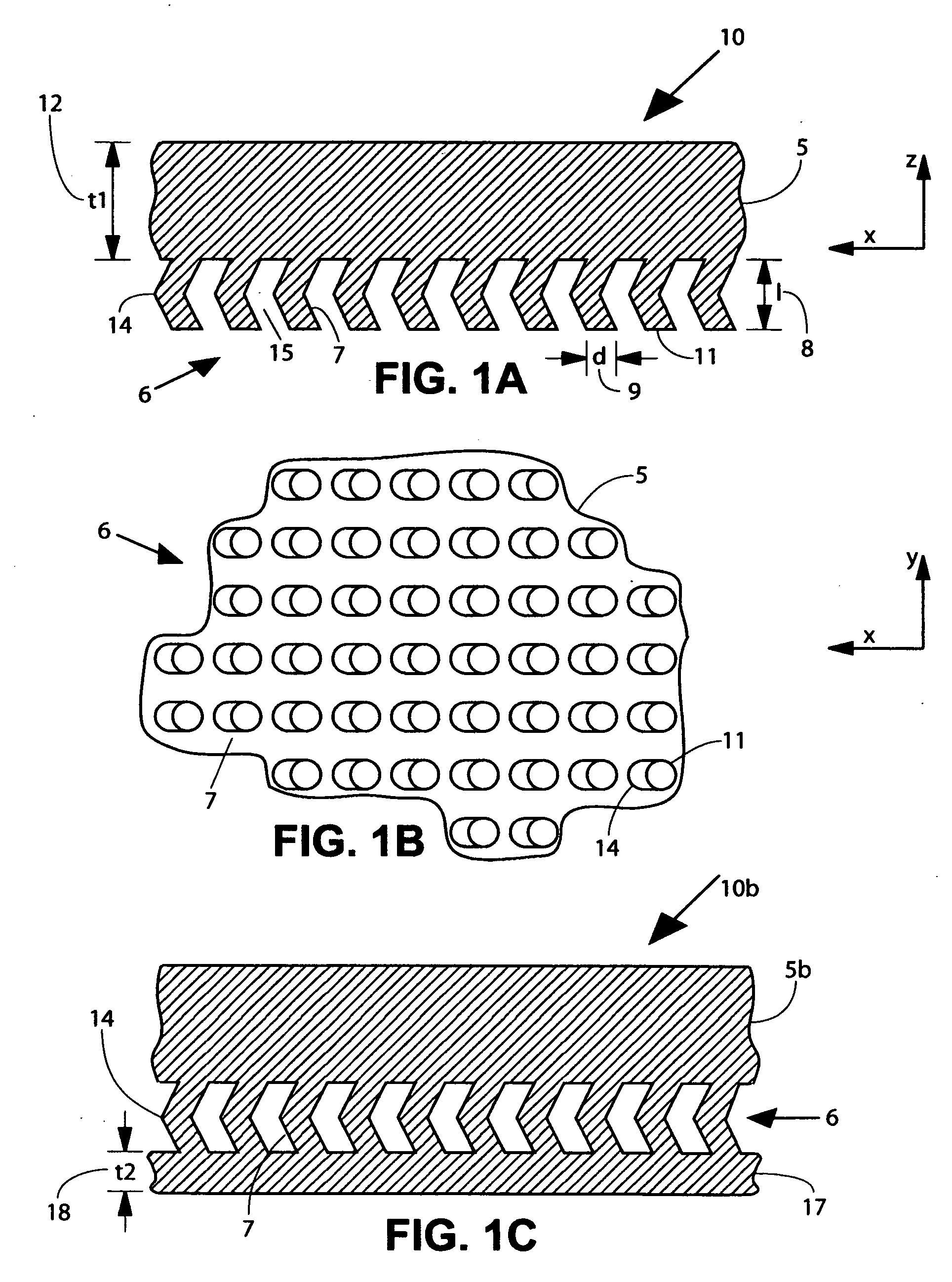

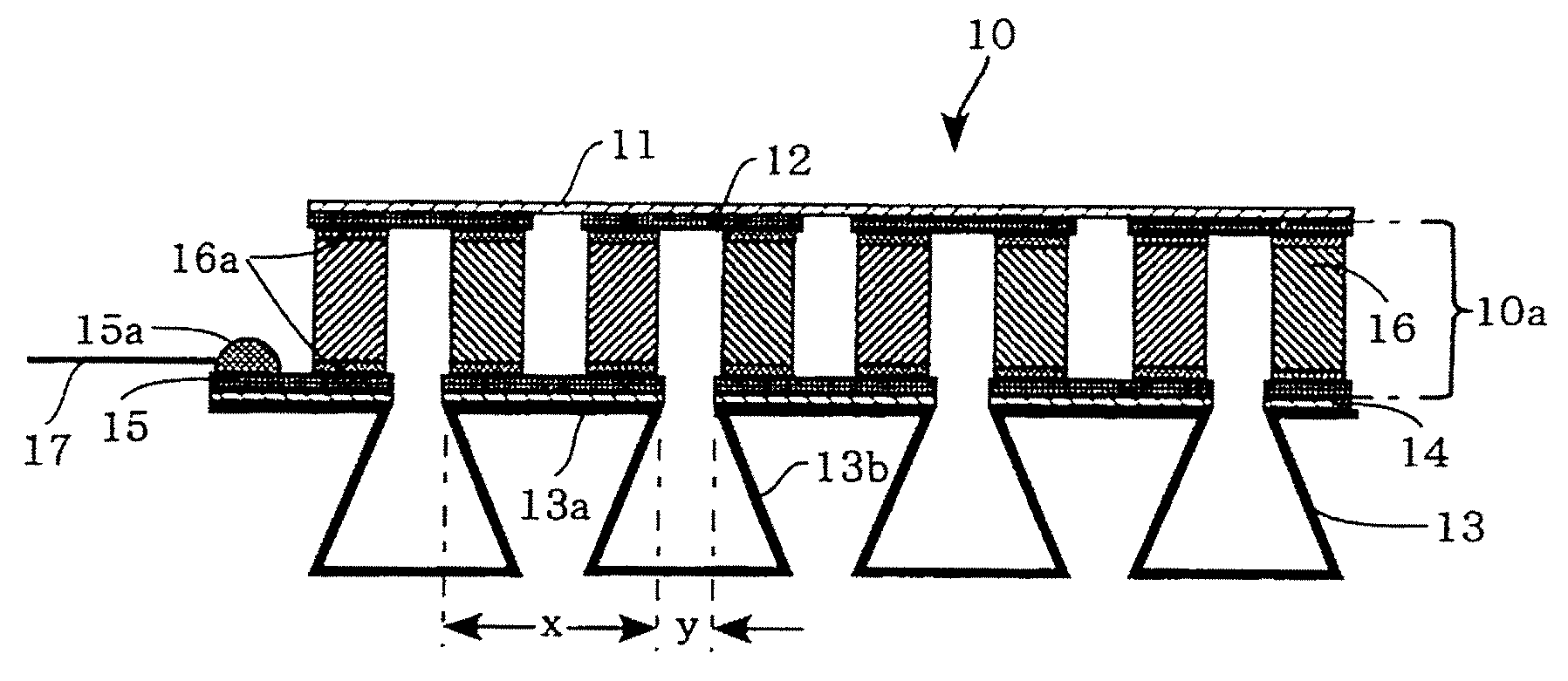

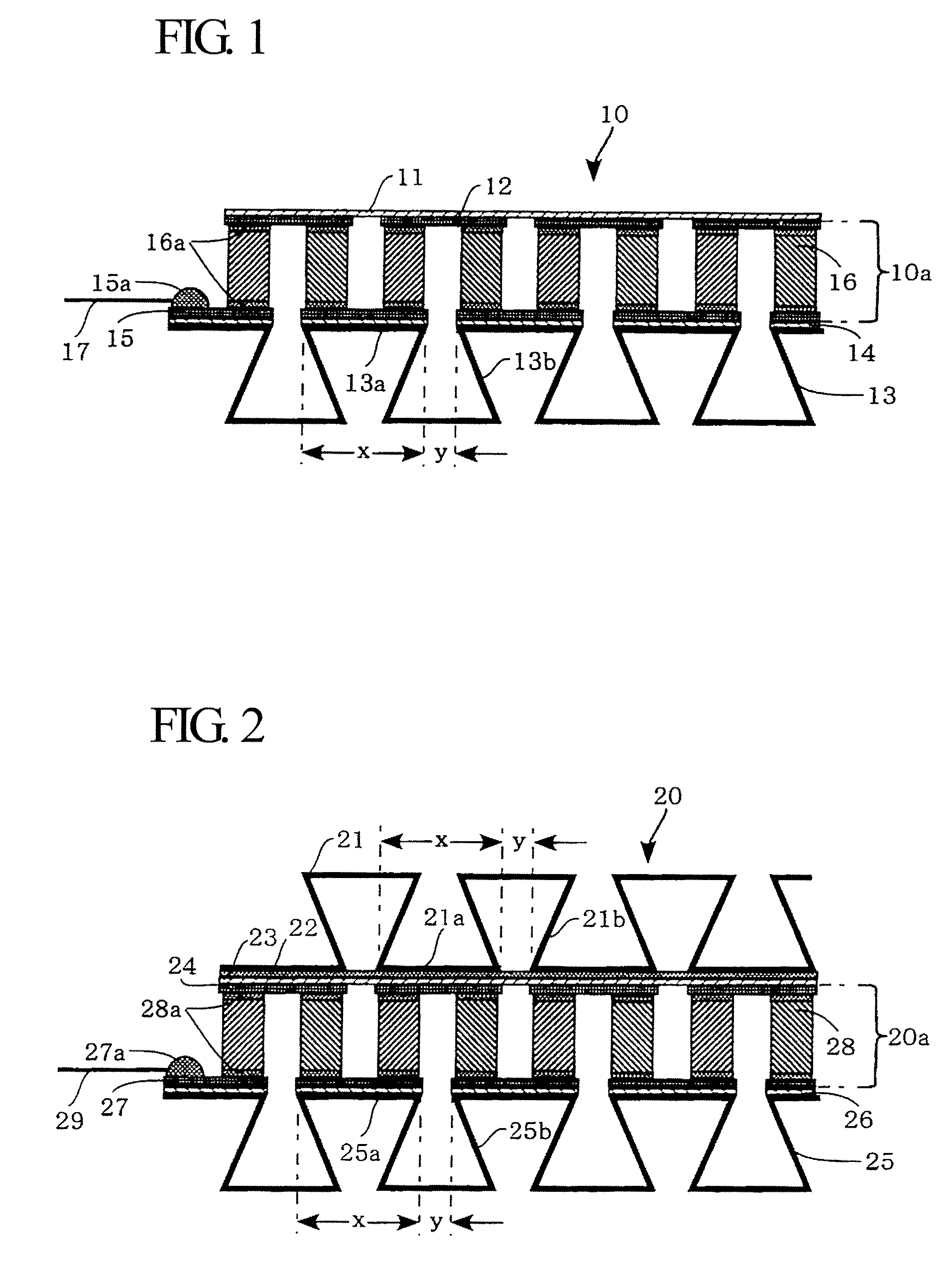

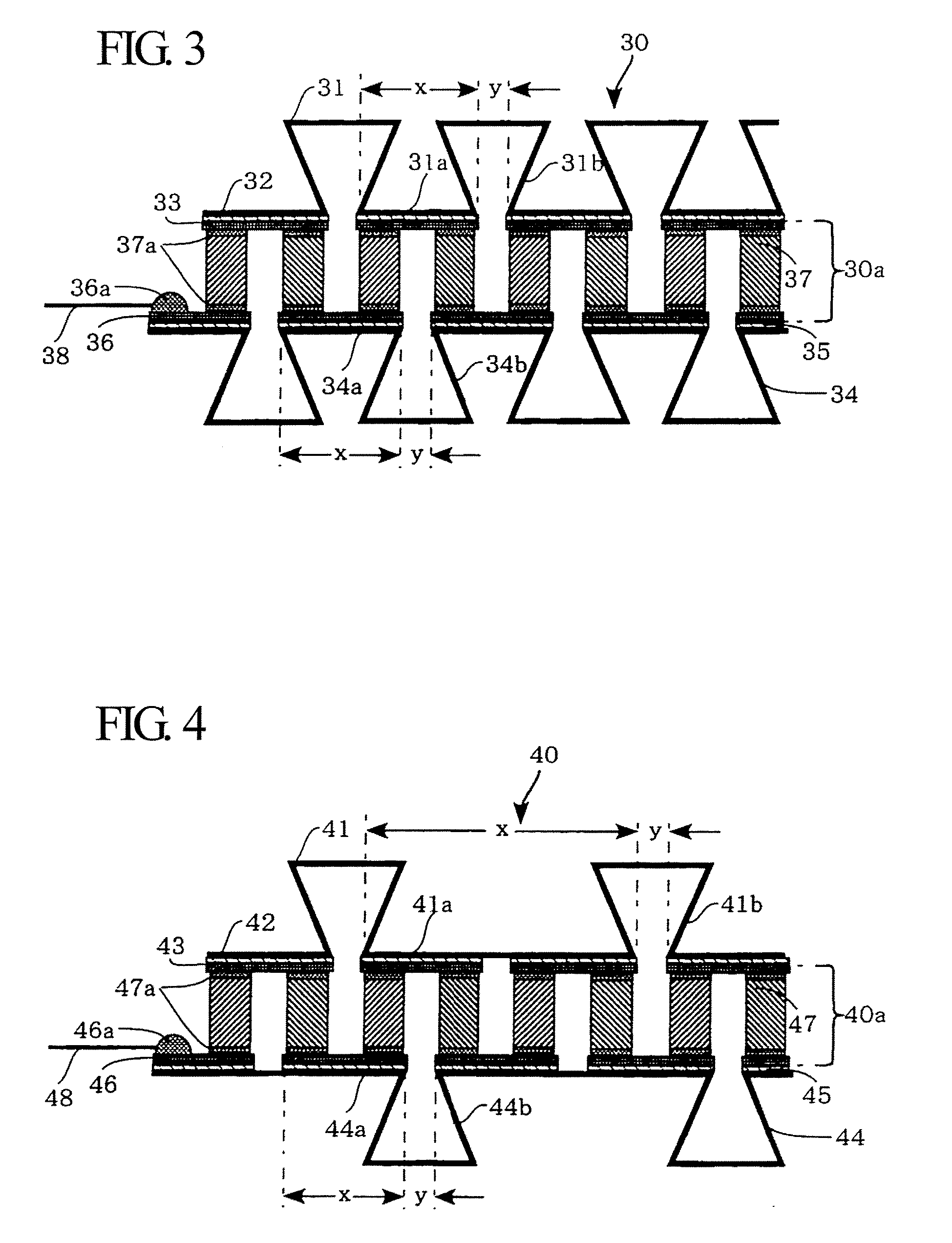

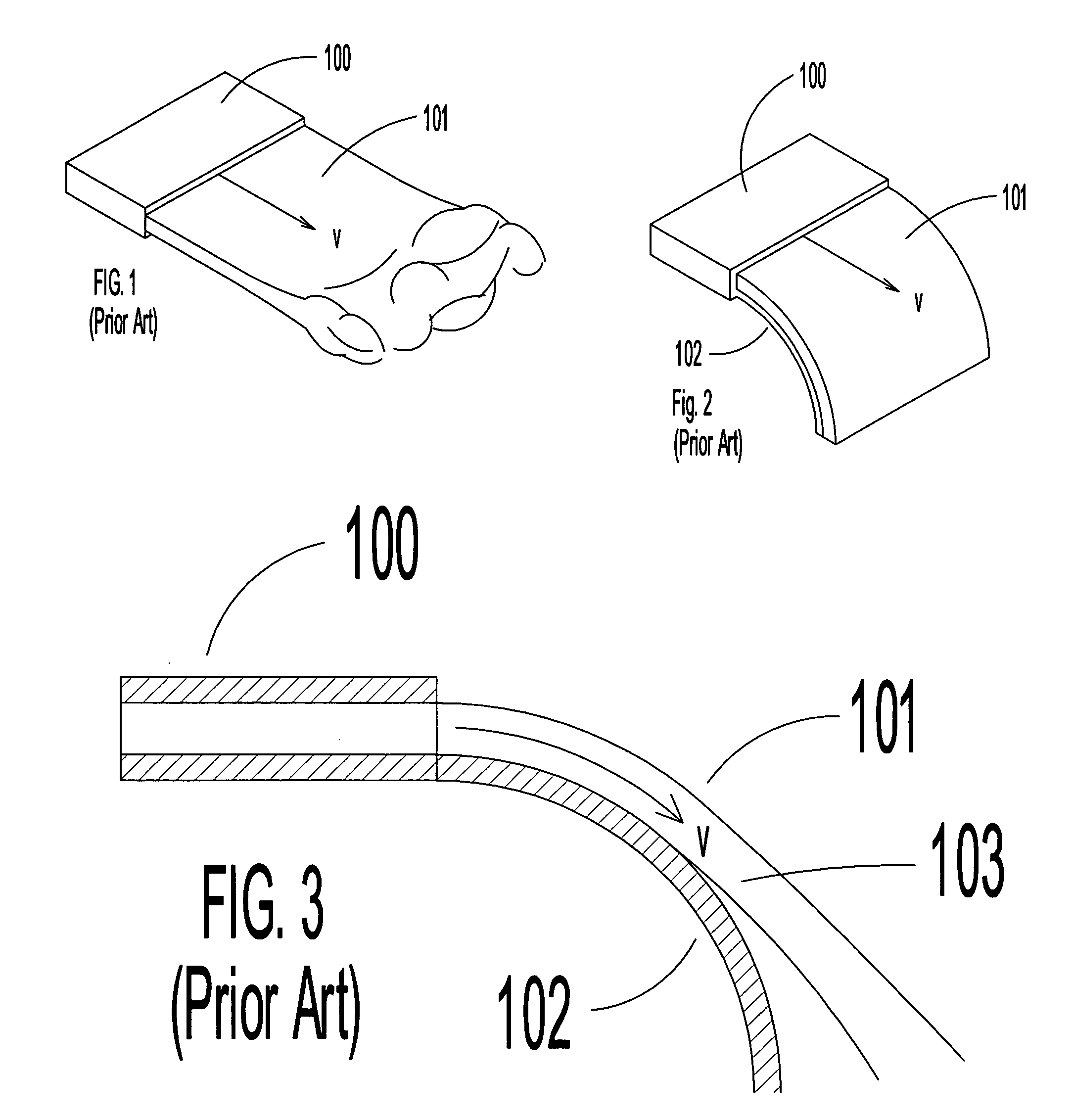

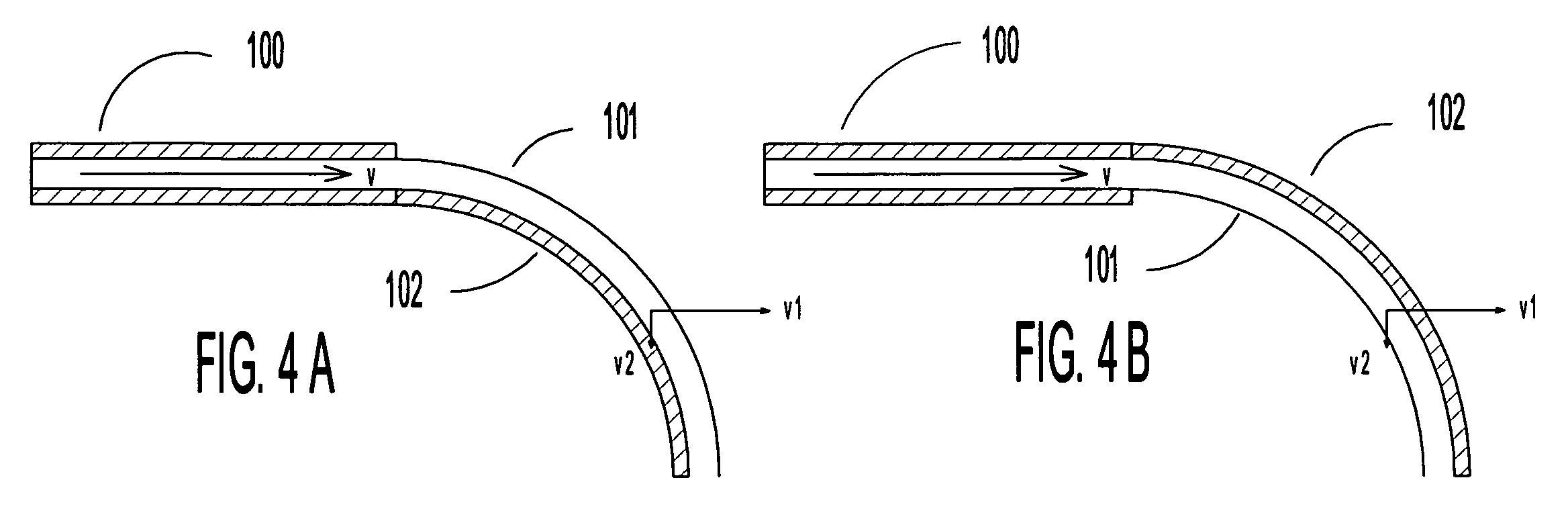

Adaptive interface using flexible fingers

InactiveUS20060077638A1Ease mechanical stressEase thermal stressSemiconductor/solid-state device detailsSolid-state devicesThermal greaseSemiconductor chip

A multi-function interface adaptor comprises a base layer and flexible fingers extending from it. The interface adaptor is interposed between two objects to provide a mechanical and / or thermal interface with stress relief or shock absorption. Using bent fingers operating like springs, shocks and distributed stresses can be relieved in the plane of the adaptor, as well as normal to the plane. A preferred embodiment is an Interface Adaptor that replaces thermal grease between a semiconductor chip and its associated heat sink.

Owner:PETER C SALMON LLC A CALIFORNIA LIMITED LIABILITY

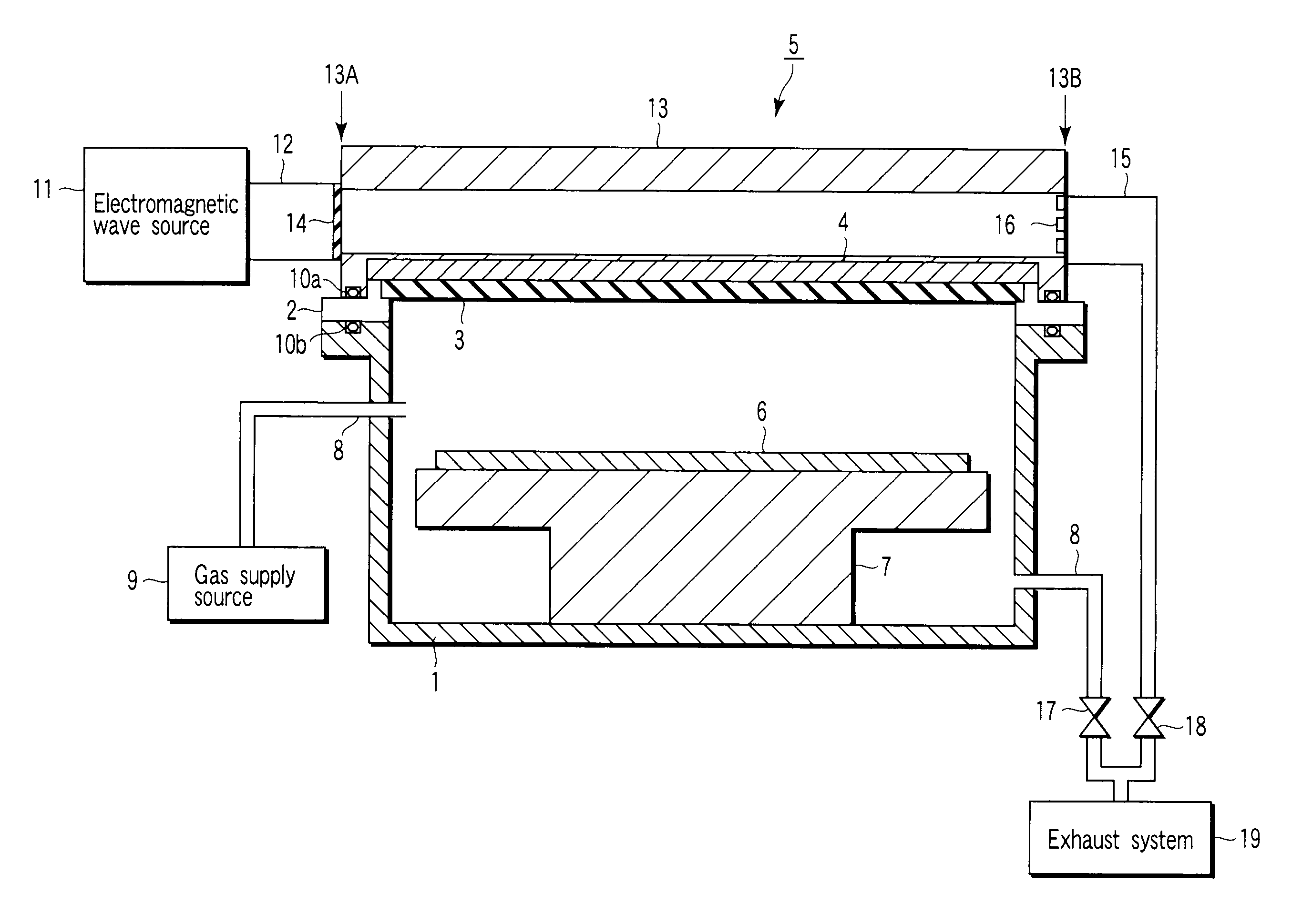

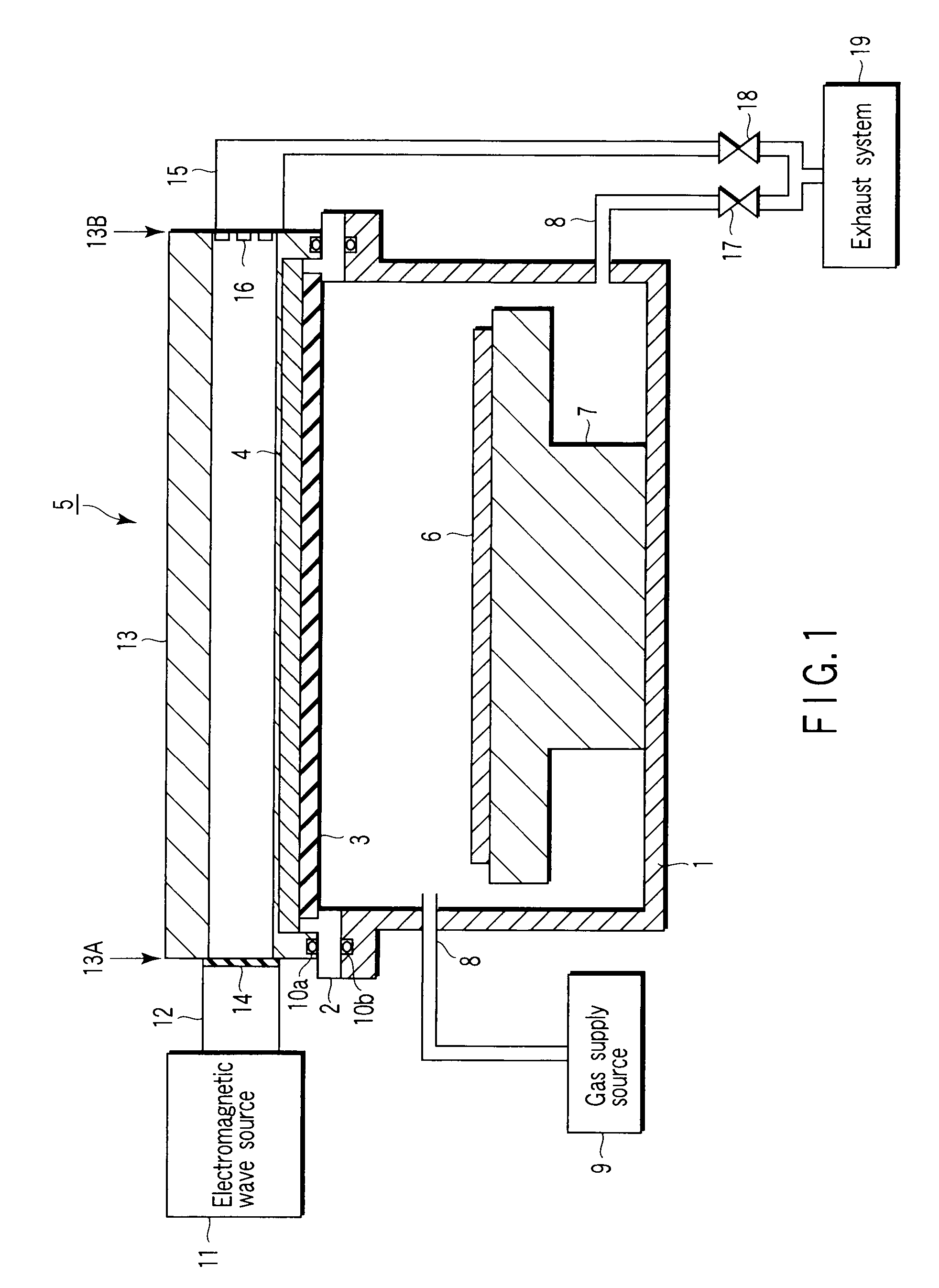

Plasma processing device and plasma processing method

InactiveUS20080105650A1Improve thermal stressReduce thicknessElectric discharge tubesDecorative surface effectsMicrowaveSurface plasmon

A plasma processing device reduces the pressure inside a vacuum waveguide which propagates microwave to a vacuum of a high degree, thereby preventing abnormal discharge in the vacuum waveguide and around a slot plate, and reduces the difference in pressure between the processing chamber and the vacuum waveguide, thereby lowering the stress applied on the slot plate and a dielectric member for generating surface plasma, thus carrying out high-quality plasma processing.

Owner:SHARP KK

Large diameter ingots of nickel base alloys

InactiveUS20020170386A1Difficult to extractIncrease the diameterWelding/cutting media/materialsElectric furnaceCasting moldHeating furnace

A method of producing a nickel base alloy includes casting the alloy within a casting mold and subsequently annealing and overaging the ingot at at least 1200° F. (649° C.) for at least 10 hours. The ingot is electroslag remelted at a melt rate of at least 8 lbs / min. (3.63 kg / min.), and the ESR ingot is then transferred to a heating furnace within 4 hours of complete solidification and is subjected to a novel post-ESR heat treatment. A suitable VAR electrode is provided form the ESR ingot, and the electrode is vacuum arc remelted at a melt rate of 8 to 11 lbs / minute (3.63 to 5.00 kg / minute) to provide a VAR ingot. The method allows premium quality VAR ingots having diameters greater than 30 inches (762 mm) to be prepared from Alloy 718 and other nickel base superalloys subject to significant segregation on casting.

Owner:ATI PROPERTIES

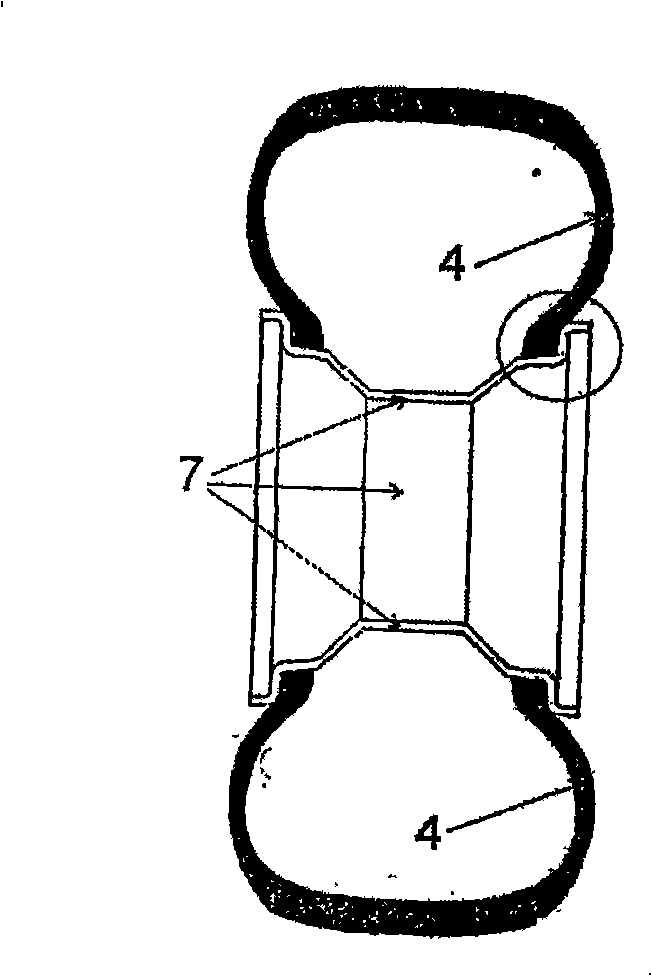

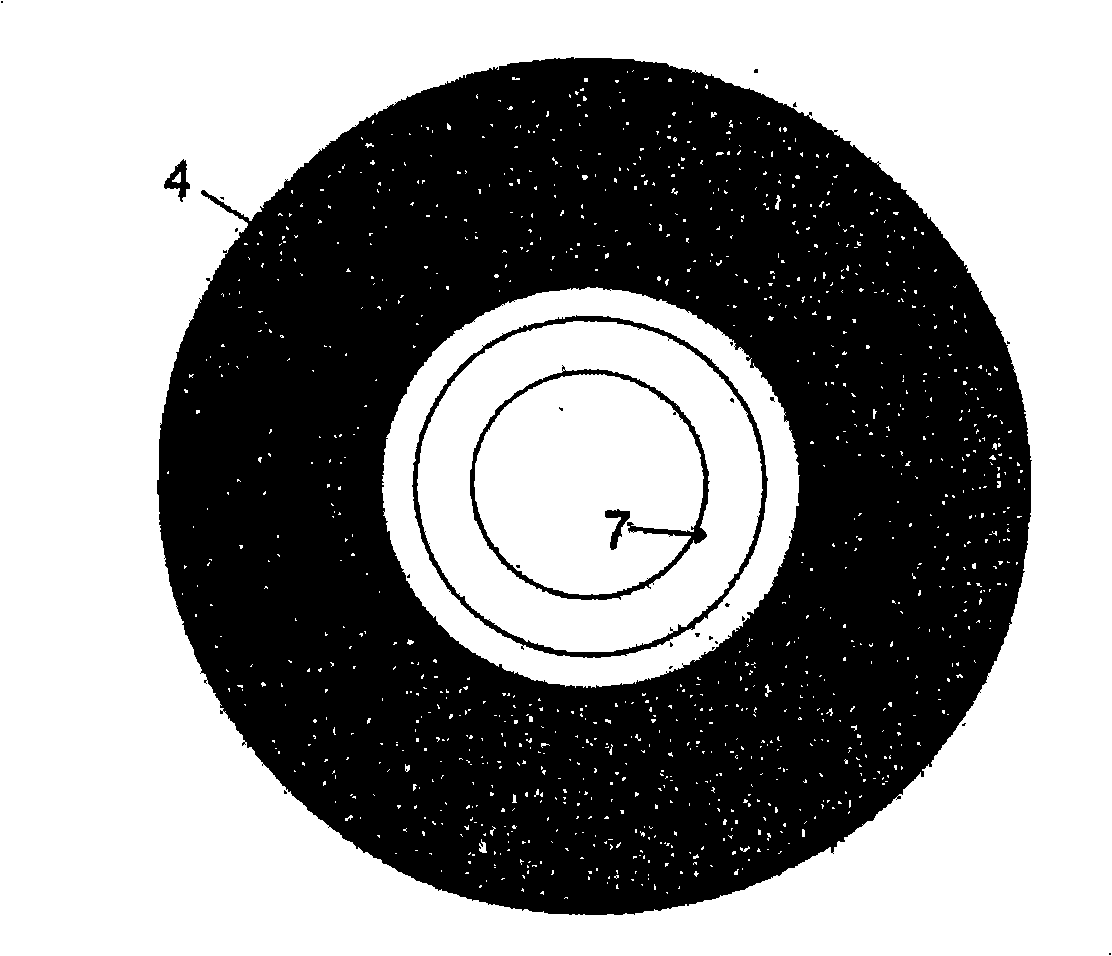

A chamber of a peristaltic pump for tire pressure adjustment

InactiveCN101495331AEasy to modifyComplete structureTyre beadsTyre measurementsPeristaltic pumpTire bead

A chamber (1) that works as a peristaltic pump for the pressure correction in the tire (4), which is a part of the tire (4) or of an ancillary structure (6) placed between the rim (7) and the tire bead (4) and is connected with the tire (4) internal space at one end and with the external environment at the other end. The chamber (1) is in the shape of a curved hollow channel, where at least one enclosing wall is at least partially formed by at least a pair of surfaces (10) coplanar with the longitudinal direction of the chamber (1). When the tire is mounted on the rim, the pair of surfaces (10) are pressed together thus hermetically closing the chamber (1). When the chamber (1) is closed during rotation of the wheel, the surfaces (10) can slightly slide on one another taking internal wall tensions onto themselves thus decreasing the possibility of wall damage through ripping. A method of producing the chamber (1) is also disclosed.

Owner:哥达发展公司

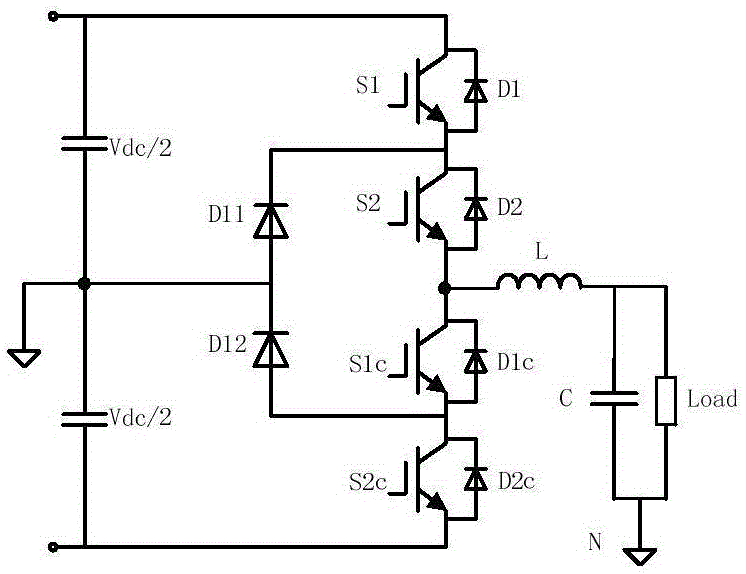

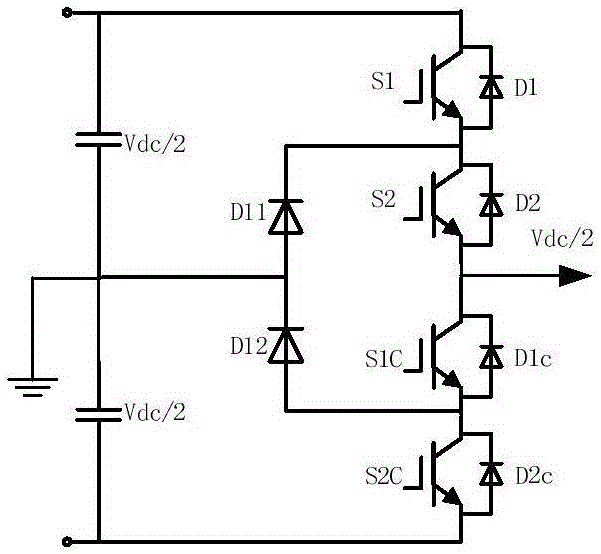

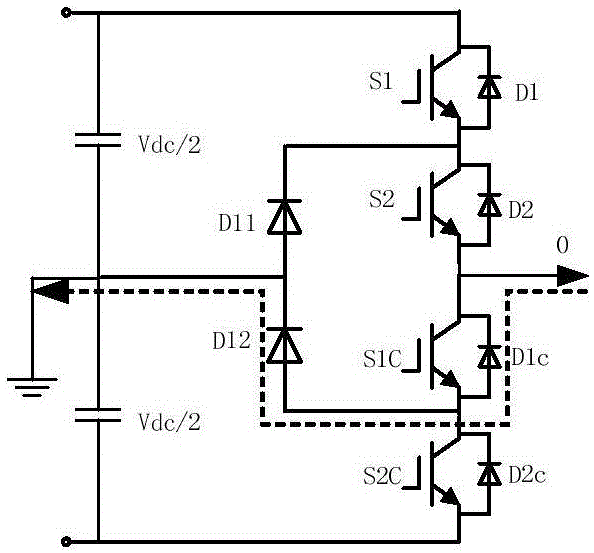

Three-level inverter

ActiveCN106655853AImprove conversion efficiencyReduce thermal stressAc-dc conversionMOSFETReverse recovery

The invention discloses a three-level inverter, comprising a first direct current source, a second direct current source, a first switch tube, a second switch tube, a third switch tube, a fourth switch tube, a fifth switch tube, and a sixth switch tube. The first switch and the fourth switch are high-speed IGBTs. The second switch tube, the third switch tube, the fifth switch tube and the sixth switch tube are low-speed IGBTs. The beneficial effects of the invention are that through the configuration of the IGBTs of different switching characteristic parameters, system losses are reduced, and the conversion efficiency of the inverter is improved; and in addition, the outer tube adopts the MOSFET to withstand the main switching losses, thereby increasing the switching speed and reducing the switching losses, and the problem of poor reverse recovery characteristics of a MOSFET built-in body diode is solved through an additional diode.

Owner:EMERSON NETWORK POWER CO LTD

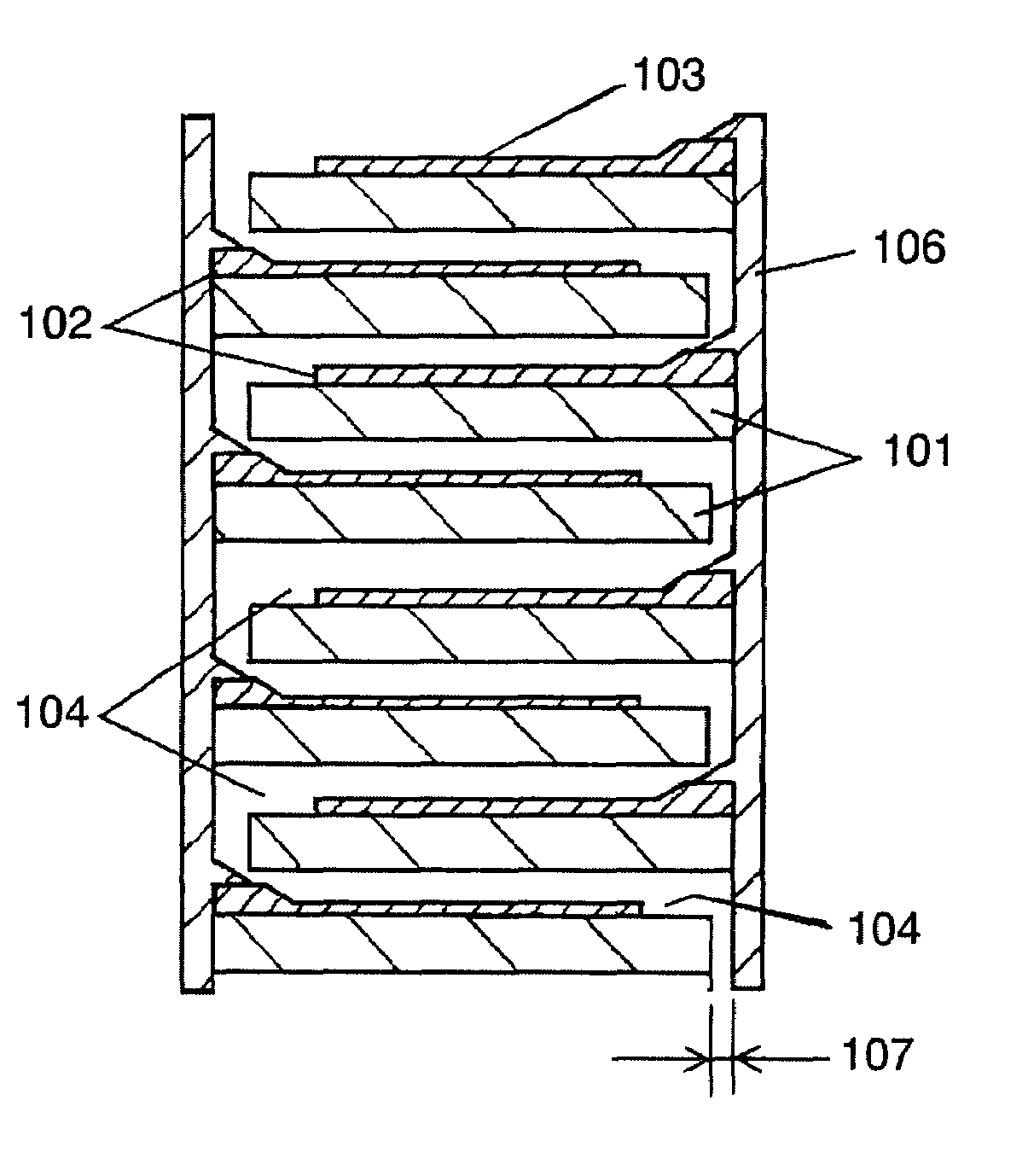

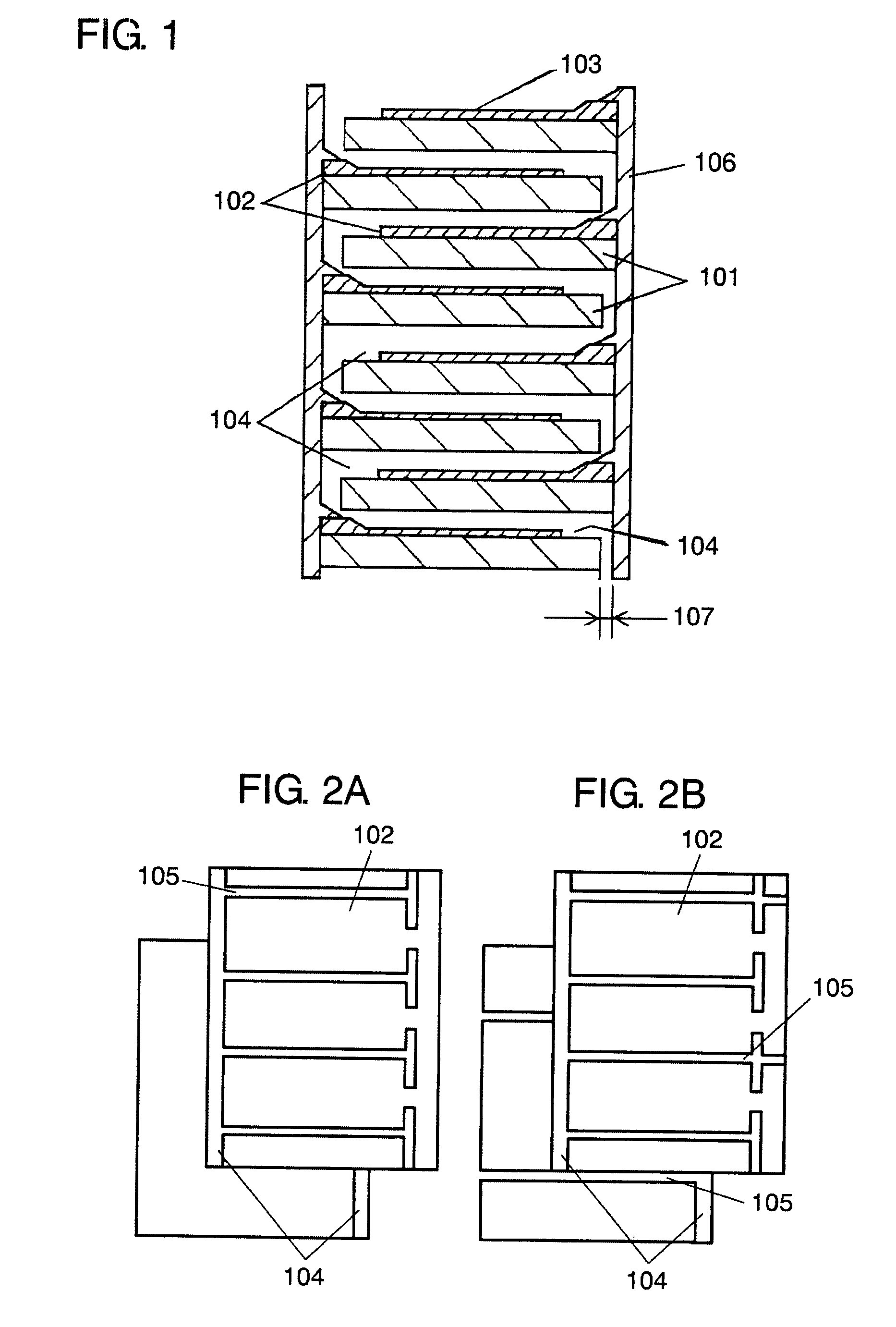

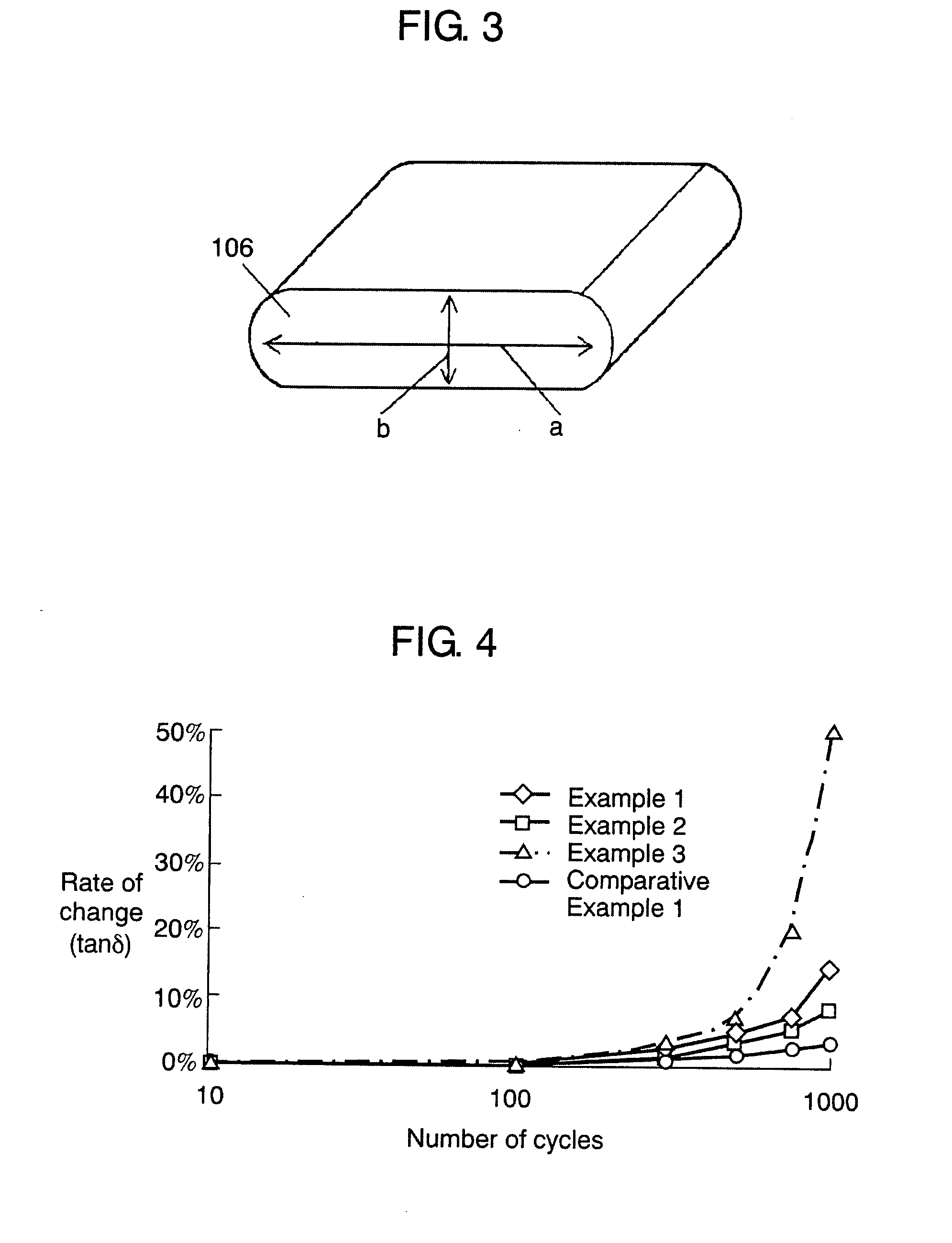

Metalized Film Capacitor, Case Mold Type Capacitor Using the Same, Inverter Circuit, and Vehicle Drive Motor Drive Circuit

ActiveUS20080310075A1Large capacitySmall and thin sizeFixed capacitor electrodesFixed capacitor dielectricDrive motorMetallised film

A metalized film capacitor capable of exhibiting stable performance in a wide temperature range is provided. The metalized film capacitor has an elliptical cross sectional shape having a major axis of 60 mm or above. In this capacitor, offset for shifting in the width direction of a pair of metalized film is set to 1.2 mm or above. Since the bonding state between metal vapor-deposited electrode and metal sprayed electrode formed on the end surface is stable, a stable contact between metal sprayed electrode and dielectric film is maintained, thereby preferably maintaining tan σ and exhibiting excellent performance even if the use temperature range is increased and the thermal stress is increased.

Owner:PANASONIC CORP

Welding deformation control aid of large-size stainless steel cylinder and welding deformation control method

ActiveCN101797671AAvoid mechanical propertiesAvoid thermal shaping processWelding/cutting auxillary devicesAuxillary welding devicesDirect observationFree state

The invention relates to a welding deformation control aid of a large-size stainless steel cylinder, comprising an inner arc flat panel, an outer arc flat panel and jack screws, wherein the inner arc flat panel and the outer arc flat panel are flat panels one side of which is an arc side, and the arc radiuses of the arc sides are the same as that of the cylinder; the jack screws are fixedly connected to both sides of points of the plat panels opposite to a longitudinal welding line of the cylinder; and the top ends of the jack screws face towards the arc sides of the plat panels. When in use, the assembly datum lines of the inner circumference and the outer circumference of the cylinder are drawn out on a welding platform, and the arc segment of the cylinder is hung on the platform and takes the places according to the datum lines; the lengths and the angles of a non-line length segment at both sides of the longitudinal line under a free state are measured, and the aid is selected according to the non-line lengths and the angles; the aid is spot welded on the cylinder, and the longitudinal line of the cylinder is alternately welded; and the welding order and the jack screws on the aid are adjusted according to the deformation condition of the longitudinal line. The invention has the advantages that the working procedures of mechanical shape correction and the hot shape correction after welding of the cylinder are avoided; the deformation in a welding process can be directly observed and regulated by taking technical measures; and the aid has simple structure and use method.

Owner:CHINA FIRST HEAVY IND +1

Turbine Blade

InactiveUS20100068069A1Stay in shapeExtended service lifeBlade accessoriesMachines/enginesLeading edgeTurbine blade

A turbine blade, having a plurality of auxiliary cooling channels which branch off from a main cooling channel, formed within a blade body, is provided. The plurality of auxiliary cooling channels open into outlet openings in the leading edge region of the blade body. A heat shield element is attached to the blade body in the leading edge region at a predefined spacing, wherein the heat shield element has a number of outlet channels which are arranged behind one another in the longitudinal direction and extend from the main cooling channel to the outer wall face of the heat shield element.

Owner:SIEMENS AG

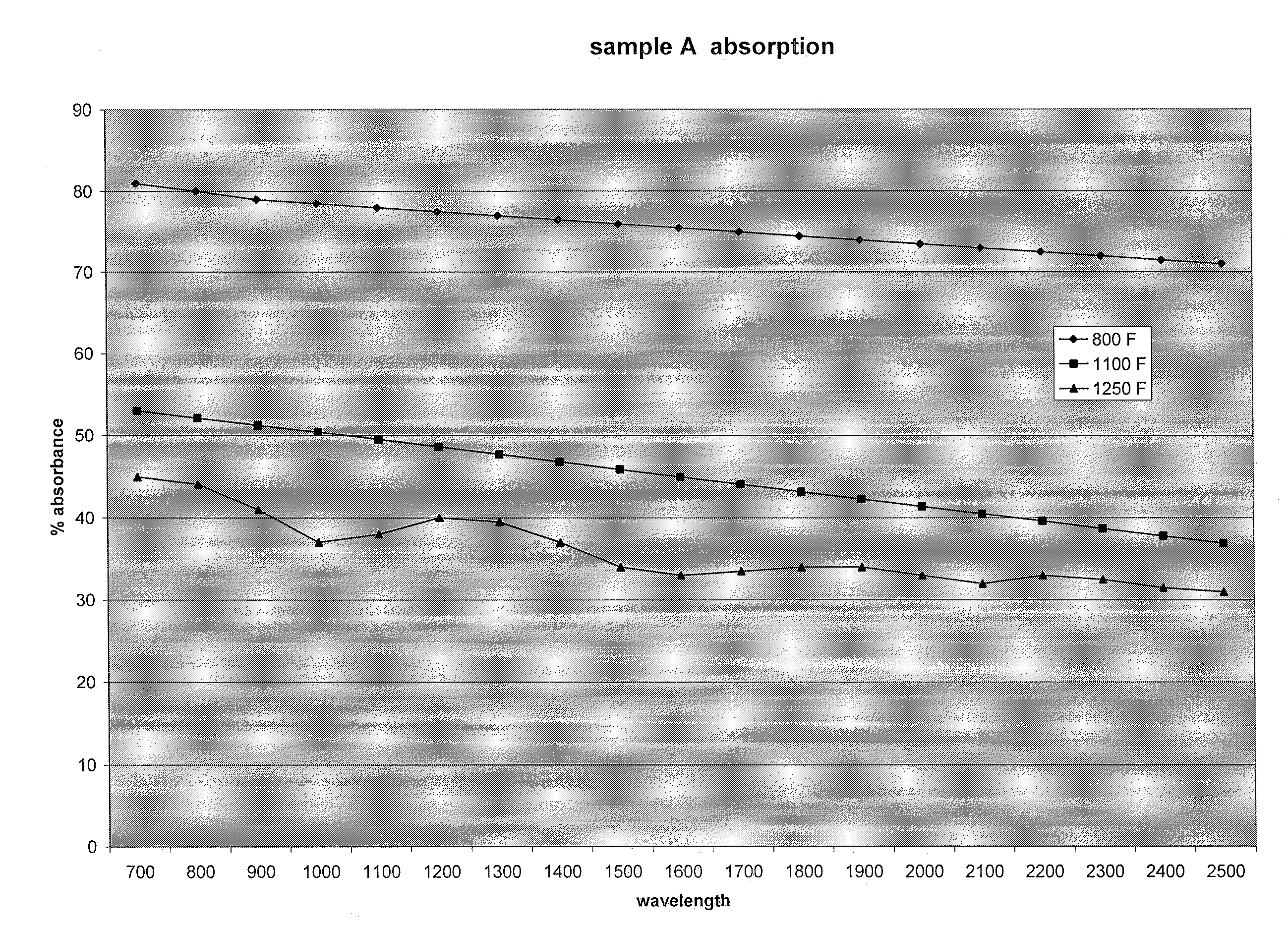

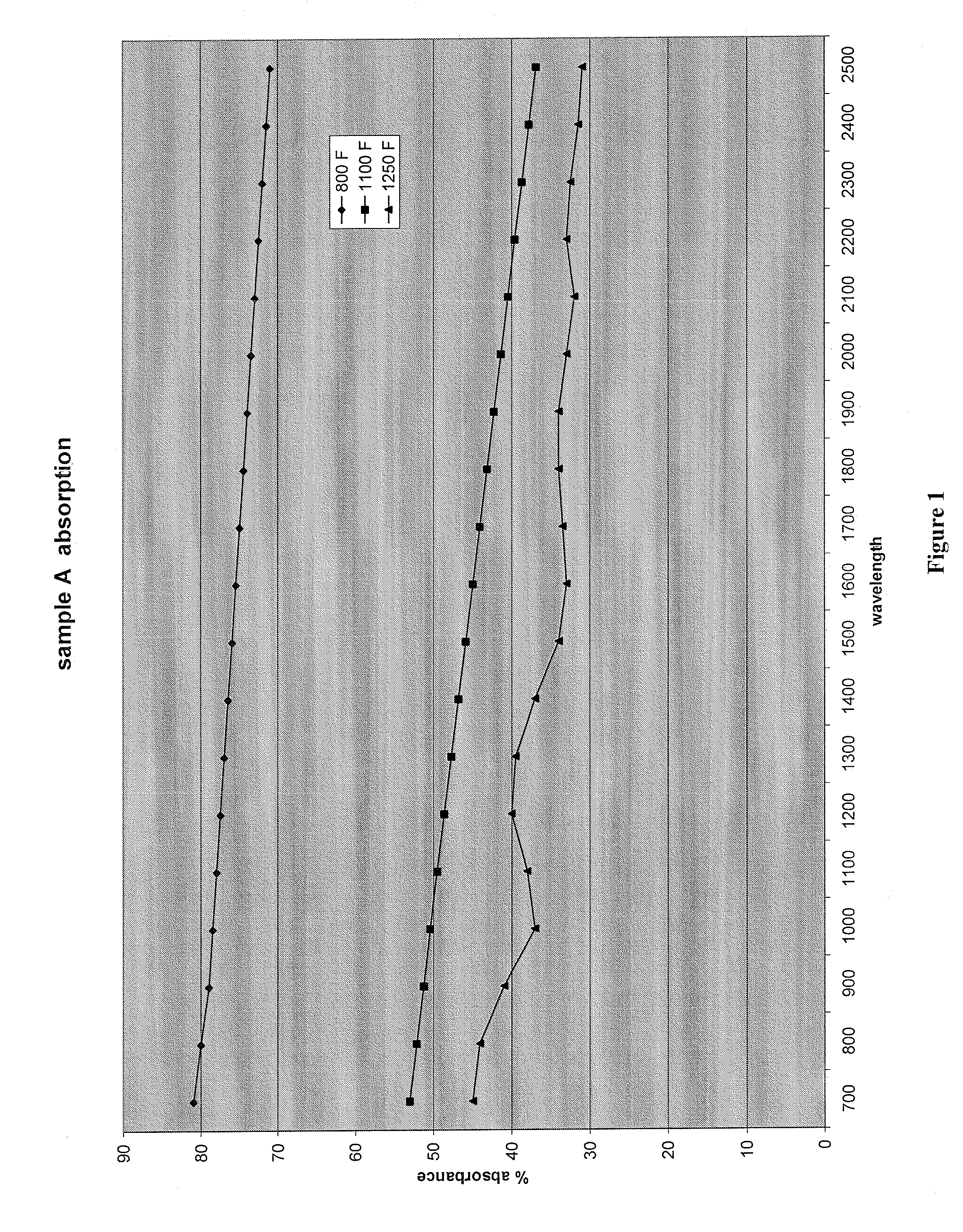

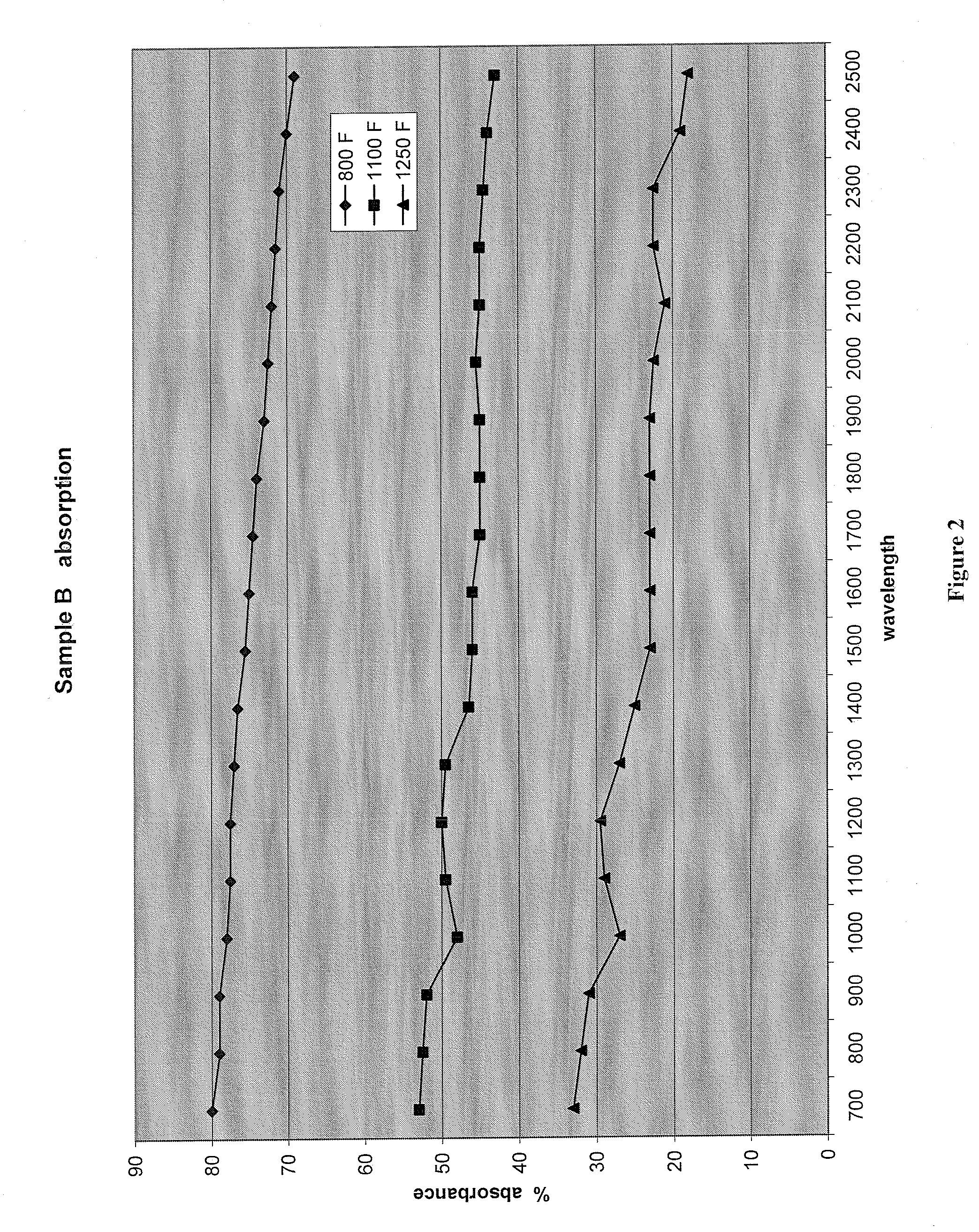

Ultra Low-Emissivity (Ultra Low E) Silver Coating

ActiveUS20090029057A1Improve adhesionImprove thermal stressConductive materialMetal-working apparatusDecompositionAdditive ingredient

A silver conductive coating possessing infrared absorbing properties is disclosed. The coating is made from a blend of one or more micron size silver powders and / or flakes together with carbon black, inorganic pigment, glass frit, and powdered selenium or bismuth metal. The foregoing dry ingredients are pasted with an organic vehicle, applied to a substrate, and fired at a temperature of up to 1400° F. The coating absorbs infrared radiation beyond the decomposition of carbon black, thus allowing higher firing temperatures and hence shorter firing times.

Owner:FERRO CORP

Heat exchange device

InactiveUS20090236087A1Increase heat absorptionReduce thermal resistanceThermoelectric device with peltier/seeback effectHeat exchange apparatusEpoxyEngineering

A heat exchange device includes a heat exchanger disposed in connection with at least one of a heat-dissipation electrode and a heat-absorption electrode, between which a plurality of thermoelectric elements is connected in series, via an insulating resin layer, which is composed of an epoxy resin or polyimide resin doped with fillers having high thermal conductivity, without intervention of a substrate. The heat exchanger corresponds to a plurality of corrugated fins which are constituted of a plurality of joint regions joining with one of the heat-dissipation electrode and heat-absorption electrode and a plurality of non-joint regions projecting externally from a plurality of gaps formed between the joint regions adjacently aligned together, wherein the joint regions and non-joint regions are alternately aligned. Thus, it is possible to achieve high reliability by reducing thermal resistance and thermal stress while increasing the maximum heat absorption coefficient (Qmax).

Owner:YAMAHA CORP

Fluidic barrier

InactiveUS20070272244A1Provide goodMaximum comfortRespiratorsChemical protectionParticulatesFluidics

The invention relates to a method for providing a mini / microenvironment, separating a determined zone from a surrounding space while providing said zone a window access opening without loss of protection against hazardous agents either entering or leaving the protected zone. More particularly, an embodiment describes personal respiratory protection provided against hazardous airborne particulates and pathogens without the requirement of a solid barrier over the oral-nasal portion of the face. High breathing resistance, impaired voice communication, thermal stress, and uncomfortable straps holding a mask tightly over the mouth and nose are eliminated. Thereby, considerable increased comfort during long-term use is realized without compromising protection.

Owner:WITMER WARNER HARRY

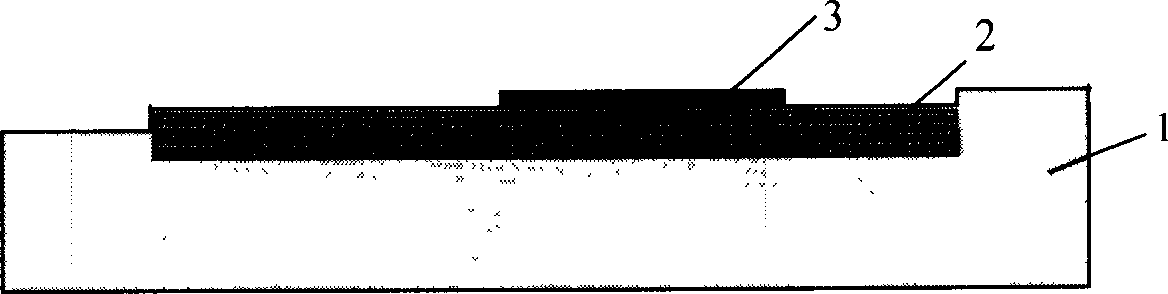

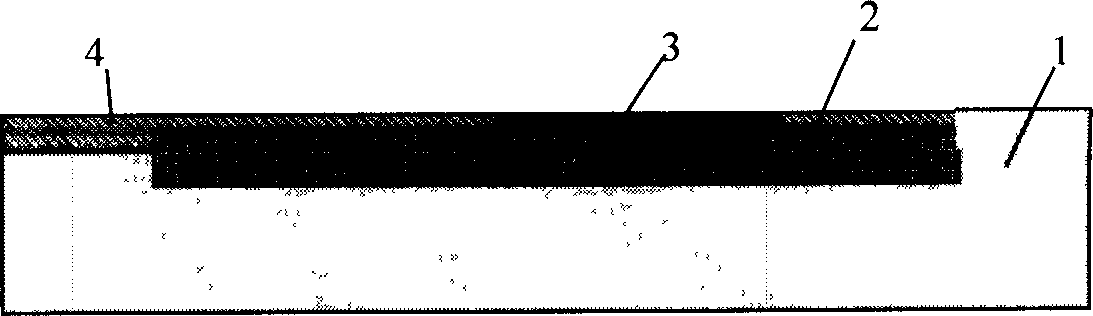

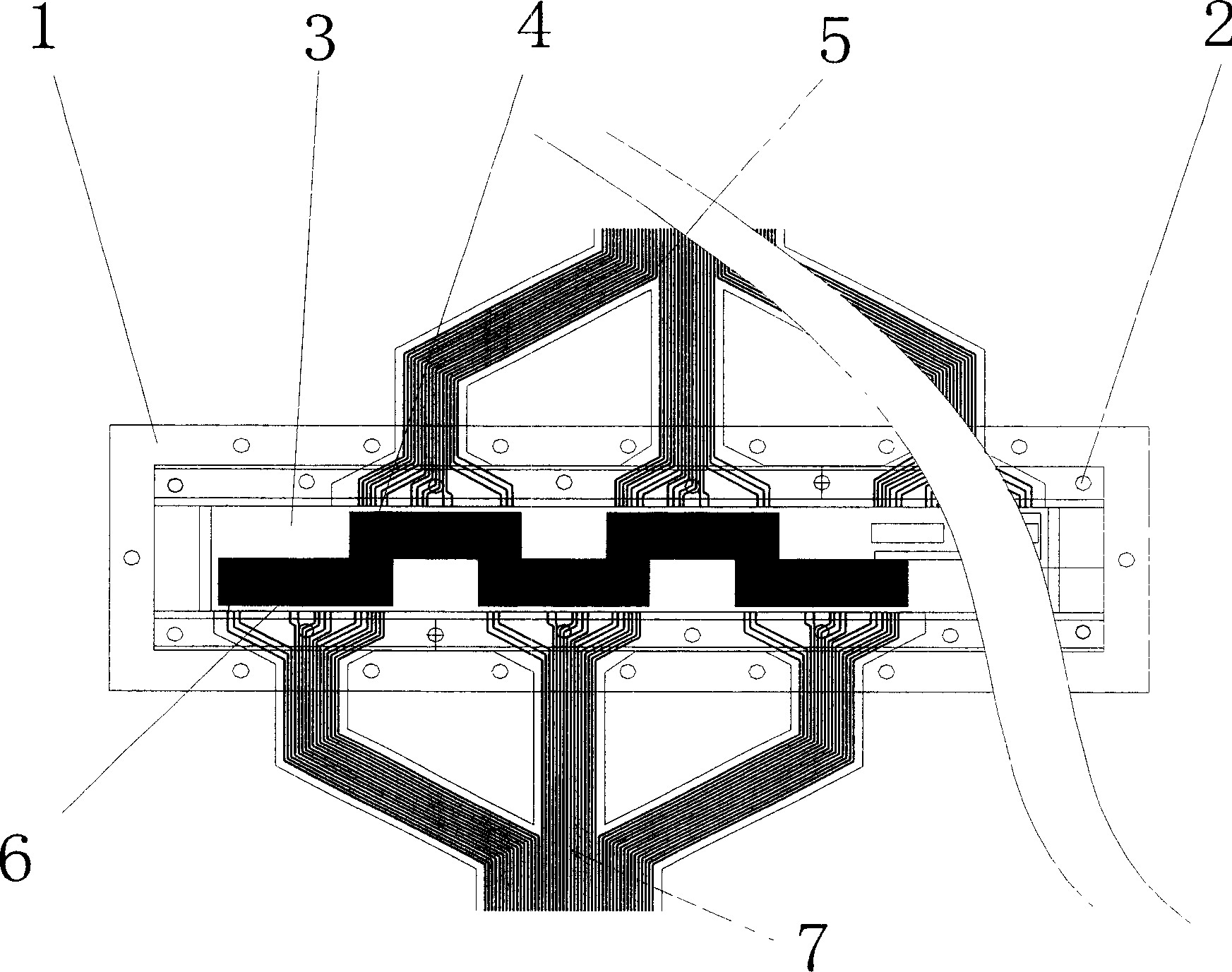

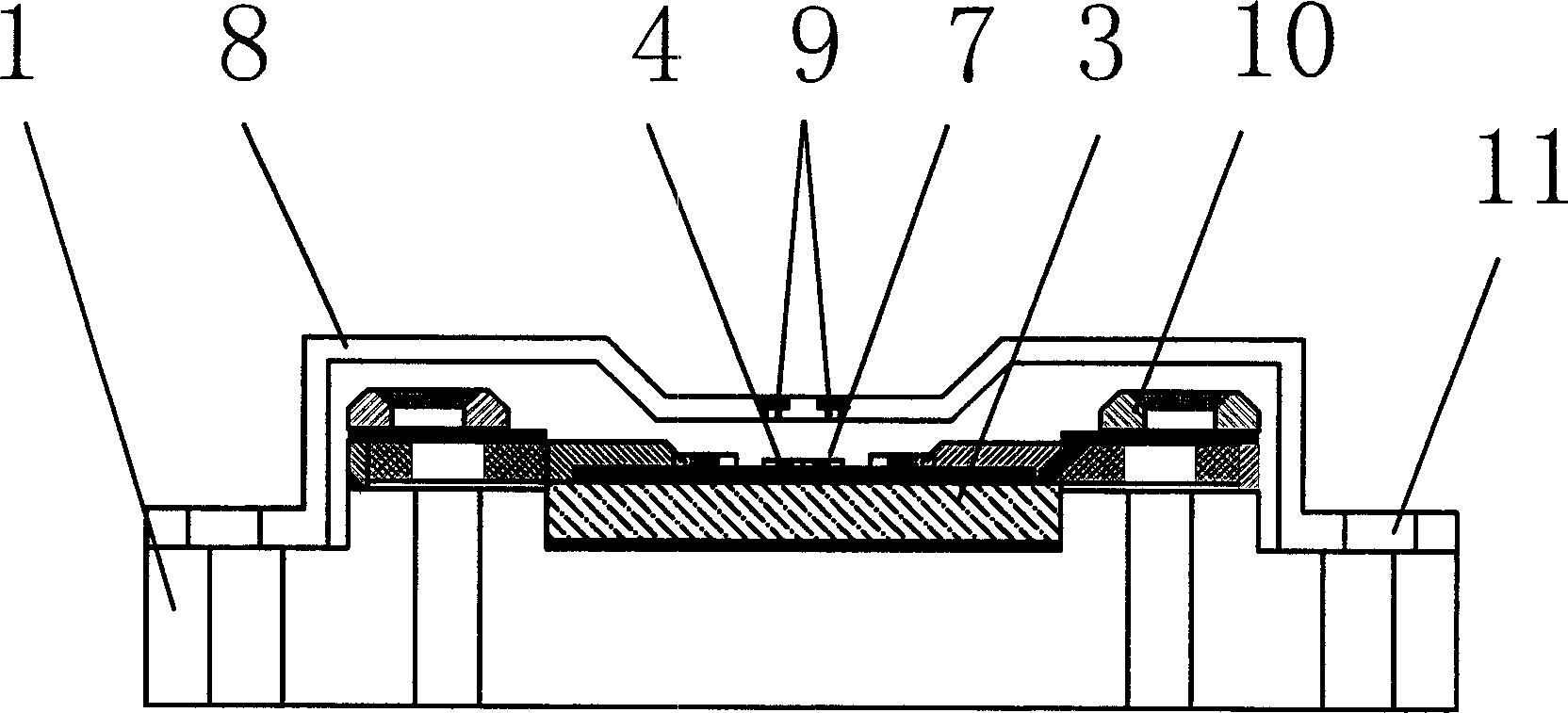

Method for preparing focal plane of quantum trap infrared detecter

InactiveCN1787234ALower resistanceReduce inductanceFinal product manufactureSemiconductor devicesIntegrated circuitCompound (substance)

The invention is a method for preparing focal plane (FPA) of a quantum well infrared probe (QWIP), starting with two heterogeneous wafers, silicon wafer and GaAs wafer, where the silicon wafer and the GaAs wafer are made with a silicon-base read integrated circuit, and terminating layer, lower electrode layer, quantum well layer, upper electrode layer, and 2D grating, respectively; firstly using the chemical-mechanical flattening process to make the surface of the silicon wafer smooth, flat and clean and then aligning the upper electrodes of the smooth, flat and clean GaAs wafer with the corresponding metallic electrodes on the silicon wafer, using low-temperature heterogeneous wafer bonding method to bond the two wafers and make low-temperature thermal treatment until they are bonded together, then thinning the substrate of the GaAs wafer, selectively eating off the residual substrate, using corrosive solution to eat off the terminating layer, and finally completing the connection between the QWIP and the corresponding electrodes of the silicon-base read integrated circuit to obtain the productí¬FPA of QWIP. The method has the advantages of low cost, strong mechanical strength and good reliability.

Owner:EAST CHINA NORMAL UNIVERSITY +1

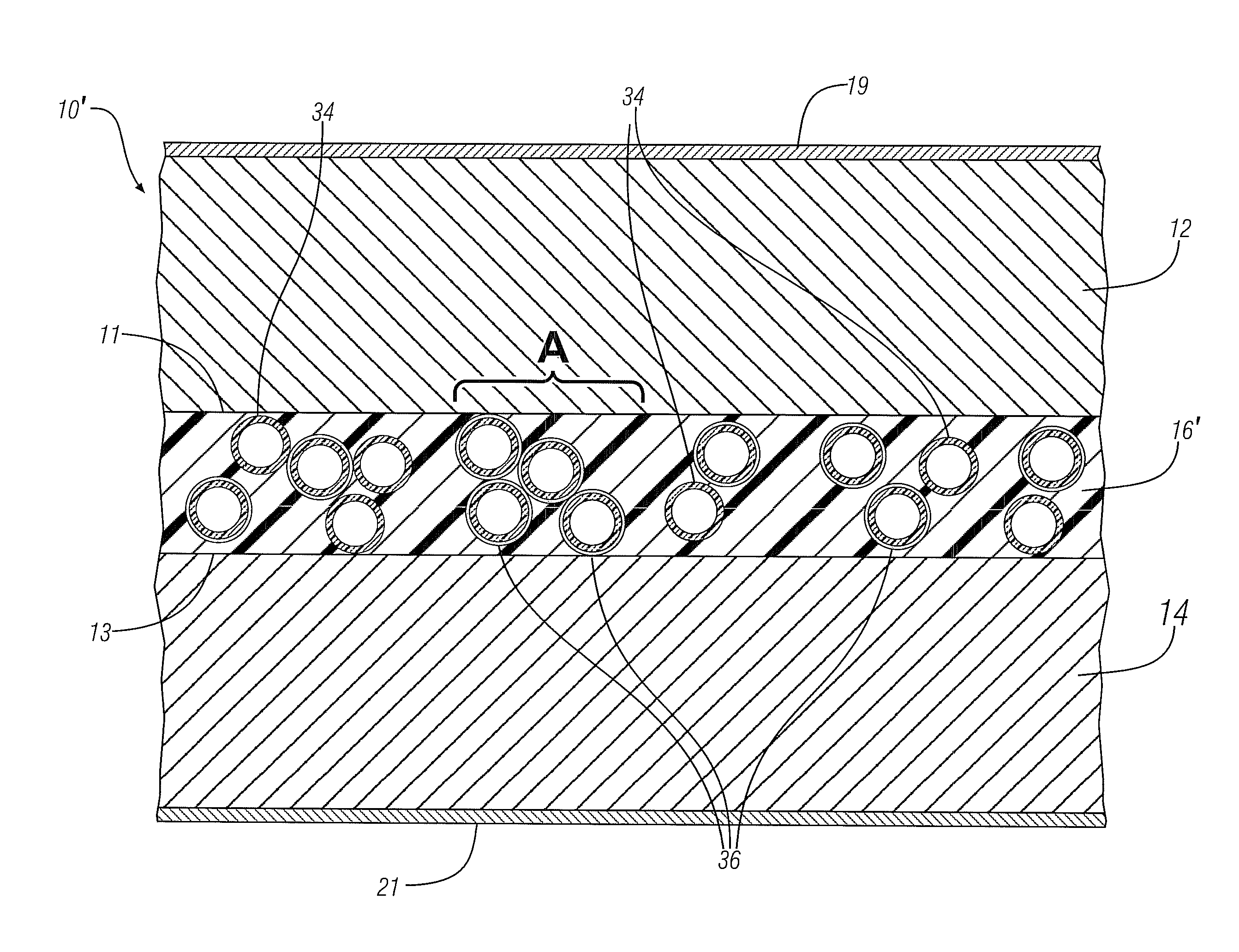

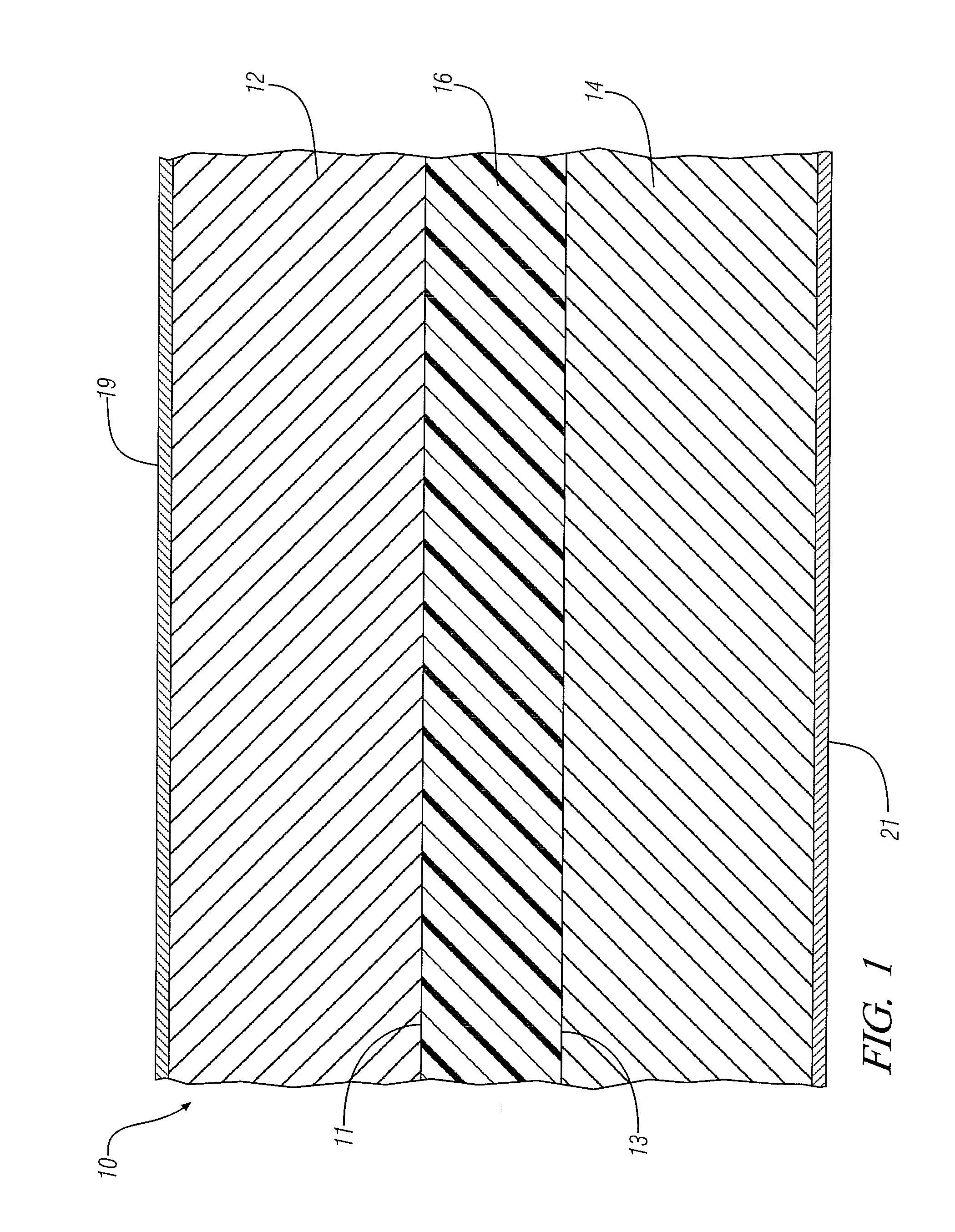

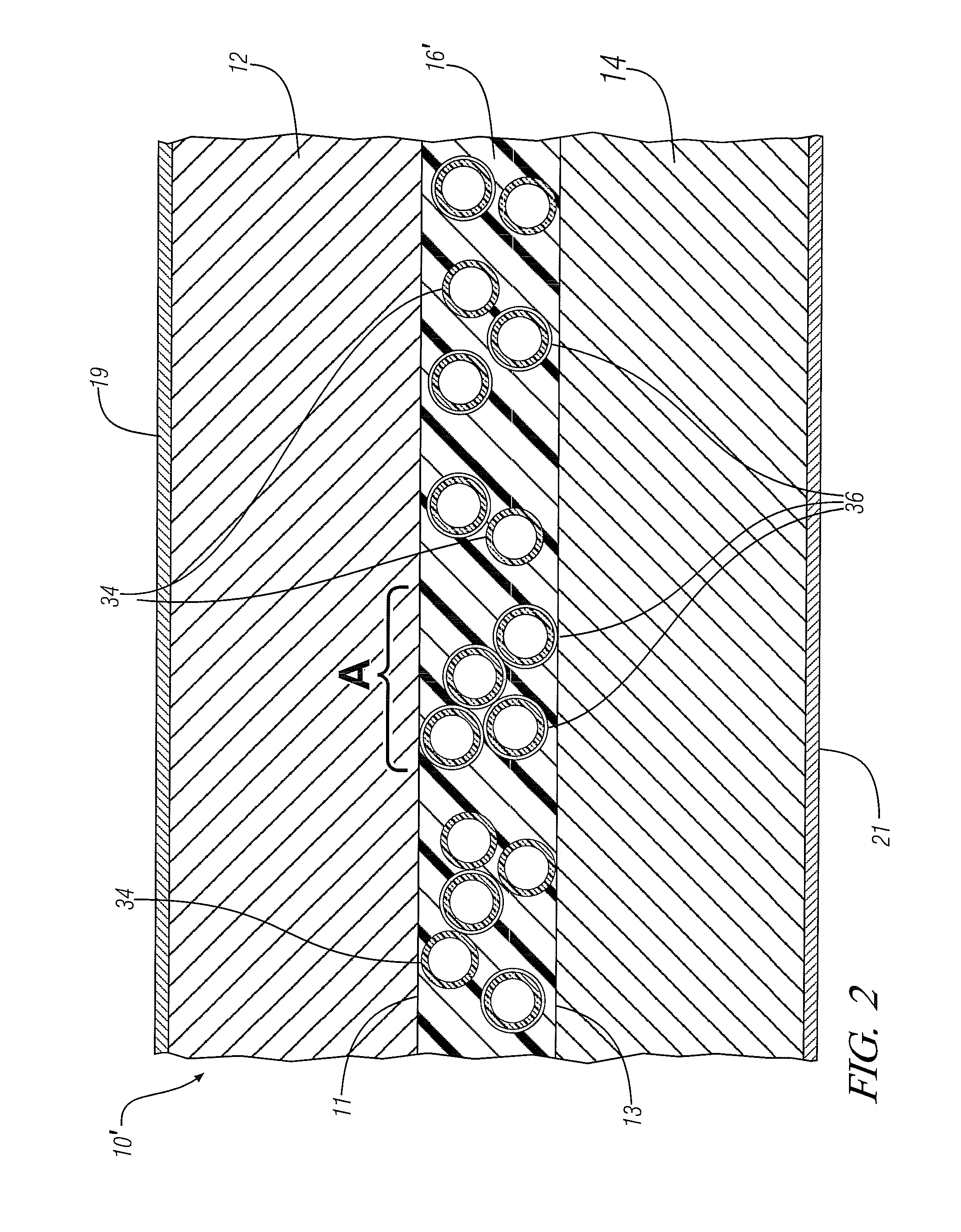

Laminated steel with compliant viscoelastic core

InactiveUS8328971B2Reduce impactImprove thermal stressSynthetic resin layered productsLaminationElectrical resistance and conductanceMetallurgy

Laminated metallic sheets which comprise an interior layer of a viscoelastic polymeric compound sandwiched between outer layers of metallic sheet may exhibit enhanced properties through modification of the viscoelastic phase. In a first embodiment the elastic modulus of the viscoelastic polymeric compound may be reduced by incorporating voids, bubbles or pores within the compound. These voids which may be introduced by introduction of polymeric microspheres are effective in reducing the internal stresses induced in the laminate by temperature changes. In a second embodiment, coating the microspheres with an electrically-conductive layer may be effective in enabling resistance spot welding of such laminated materials.

Owner:GM GLOBAL TECH OPERATIONS LLC

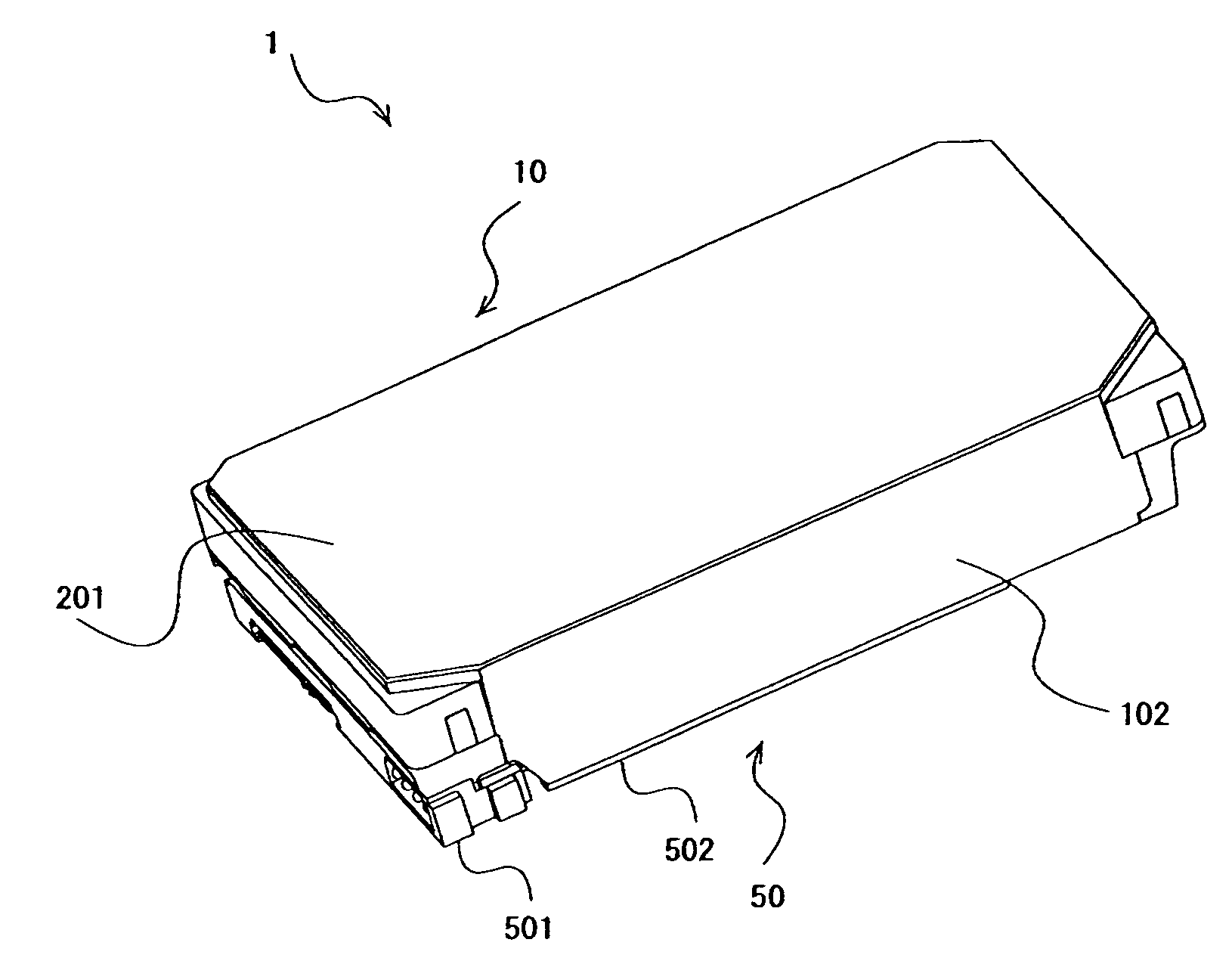

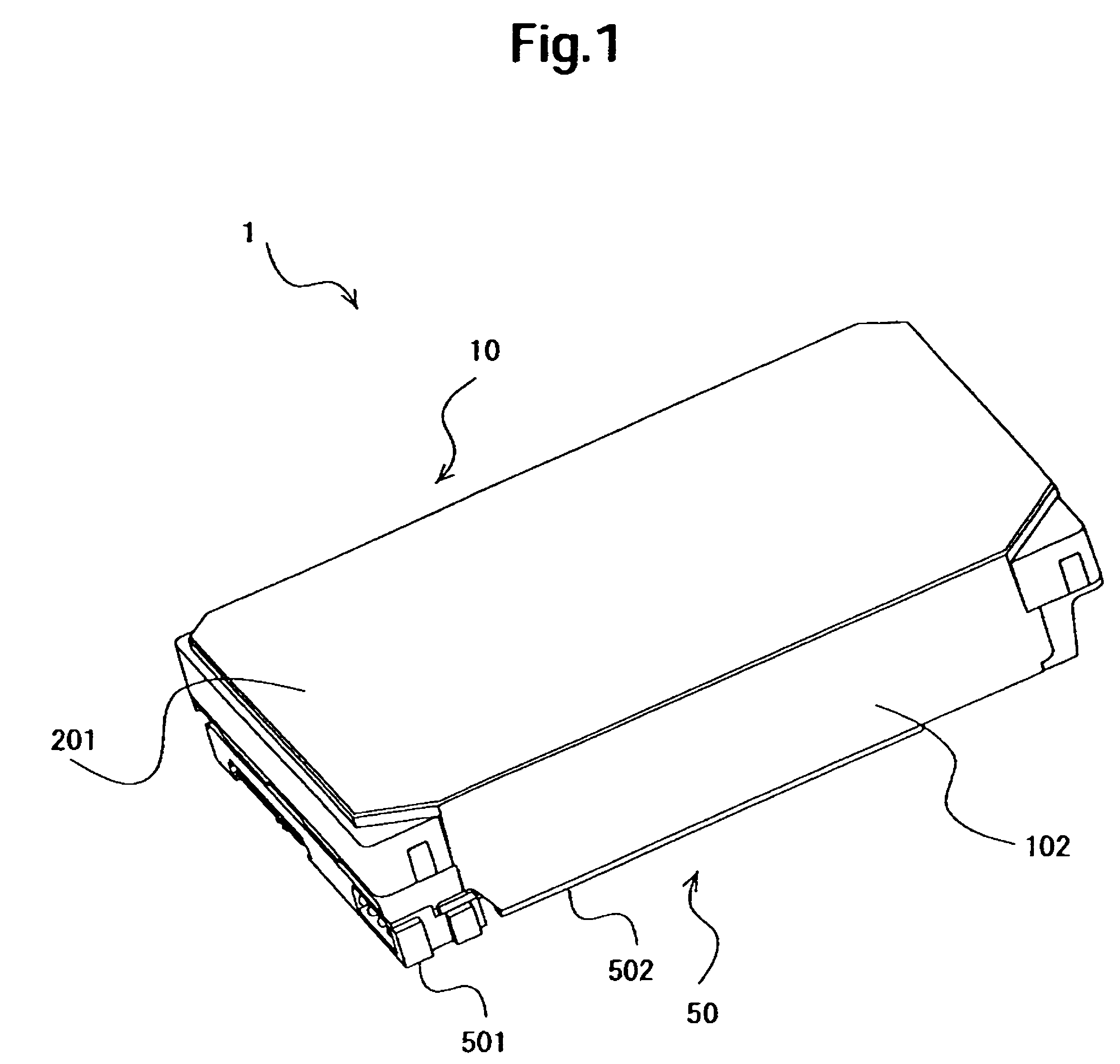

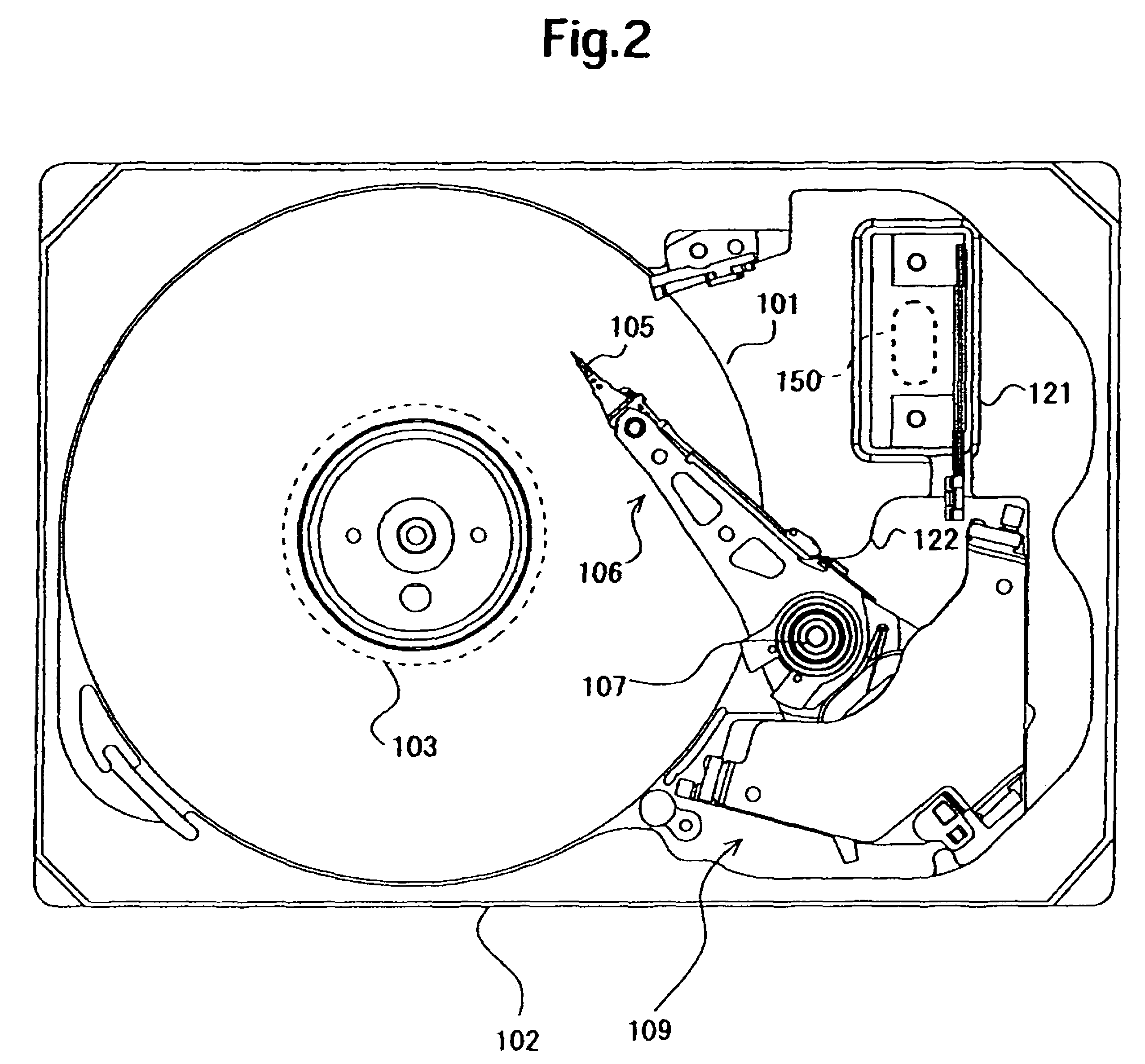

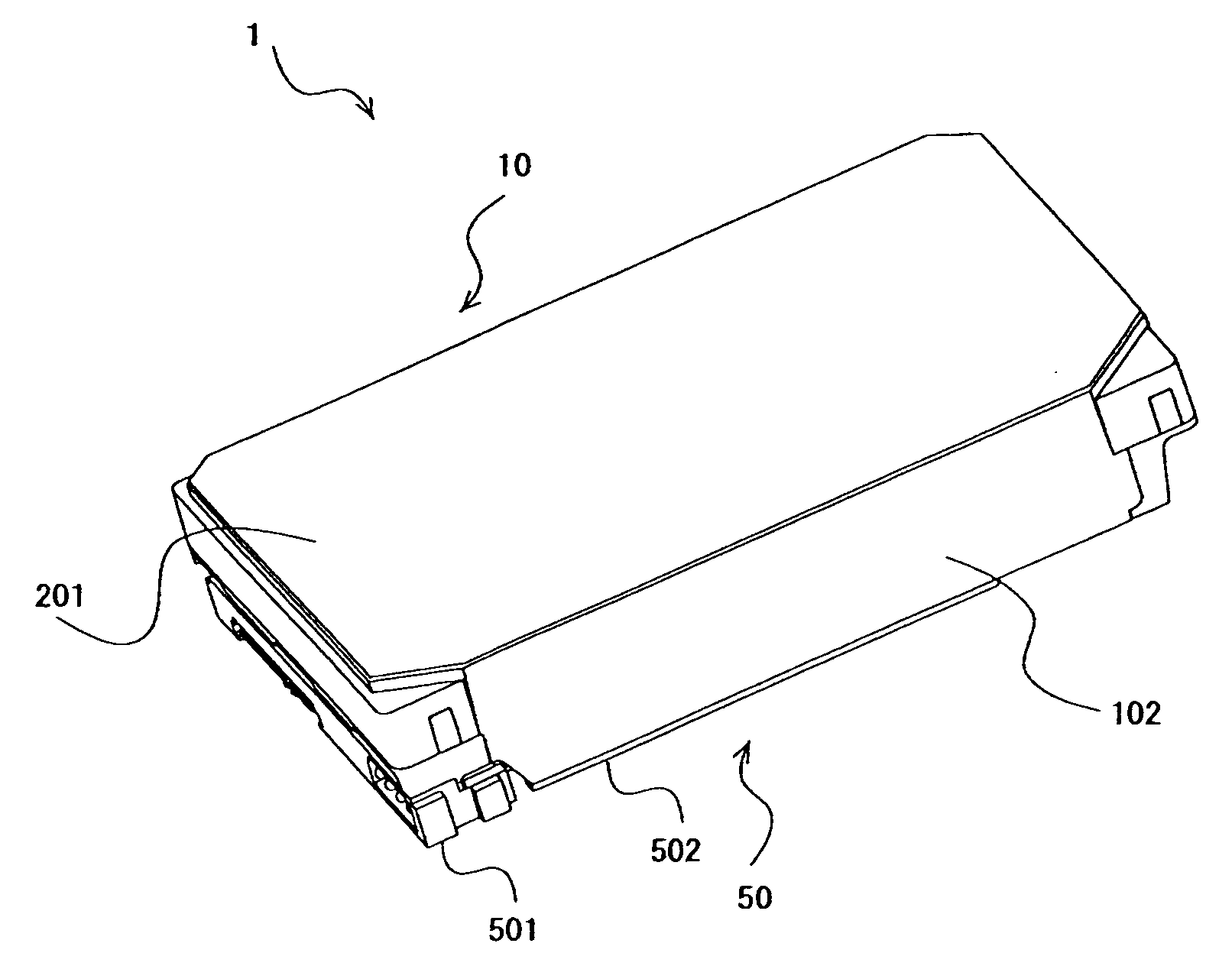

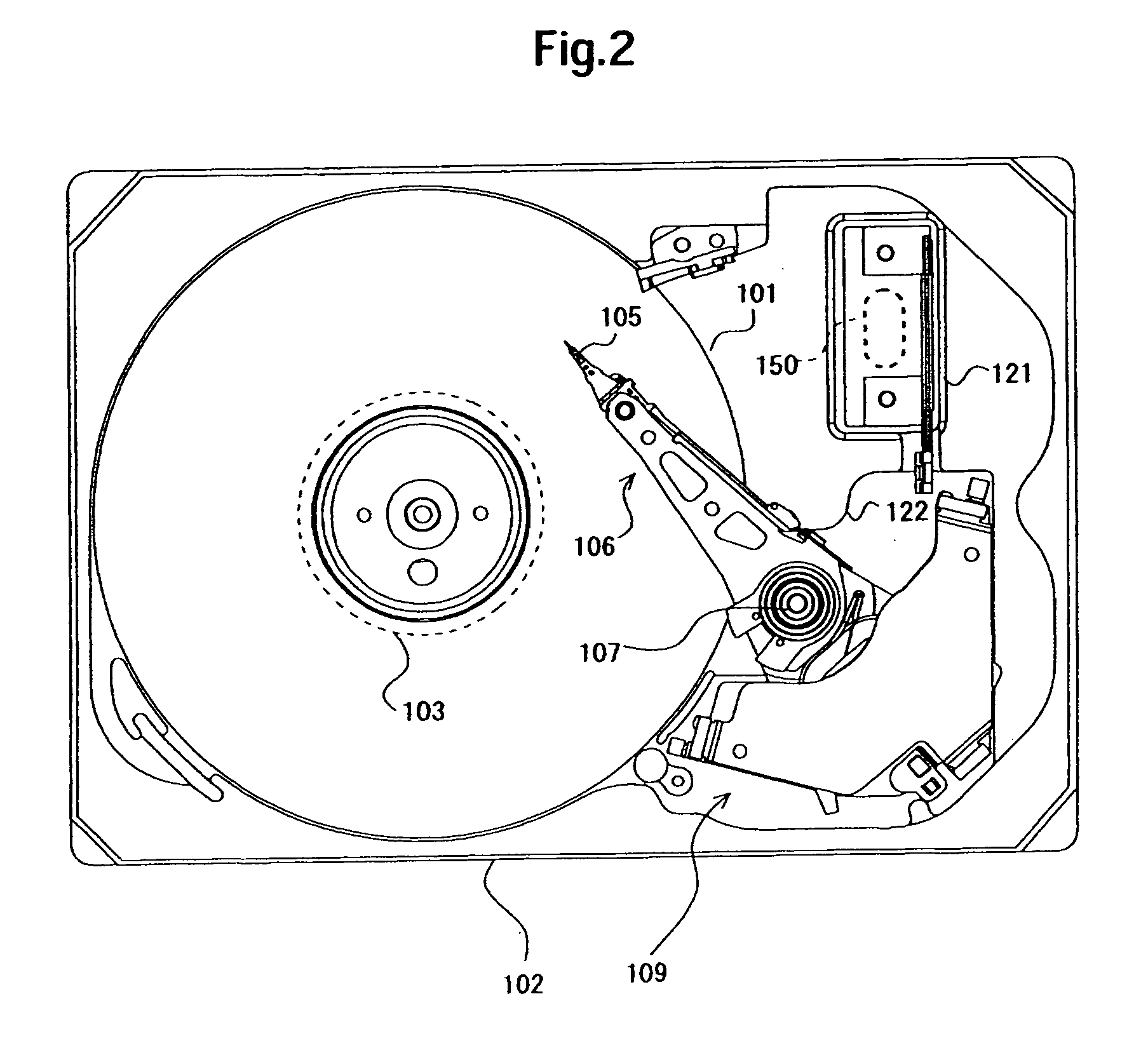

Disk drive device

ActiveUS7872836B2Improve joint reliabilityImprove thermal stressUndesired vibrations/sounds insulation/absorptionRecord information storageInterior spaceEngineering

In a disk drive device in which low-density gas is sealed, embodiments of the present invention help to improve joint reliability at a solder joint section between a feedthrough and an enclosure with respect to stress applied by deformation due to changes in temperature environment in use. According to one embodiment, helium gas is sealed in an interior space of an HDD. A feedthrough is solder jointed to a feedthrough mounting surface of a base. At a part with relatively large thermal stress, a width of the feedthrough mounting surface is increased, and at a part with relatively small thermal stress, a width of the feedthrough mounting surface is decreased. This prevents a crack penetrating path from being generated at the solder joint section due to the thermal stress and prevents the solder joint section from contacting pins.

Owner:WESTERN DIGITAL TECH INC

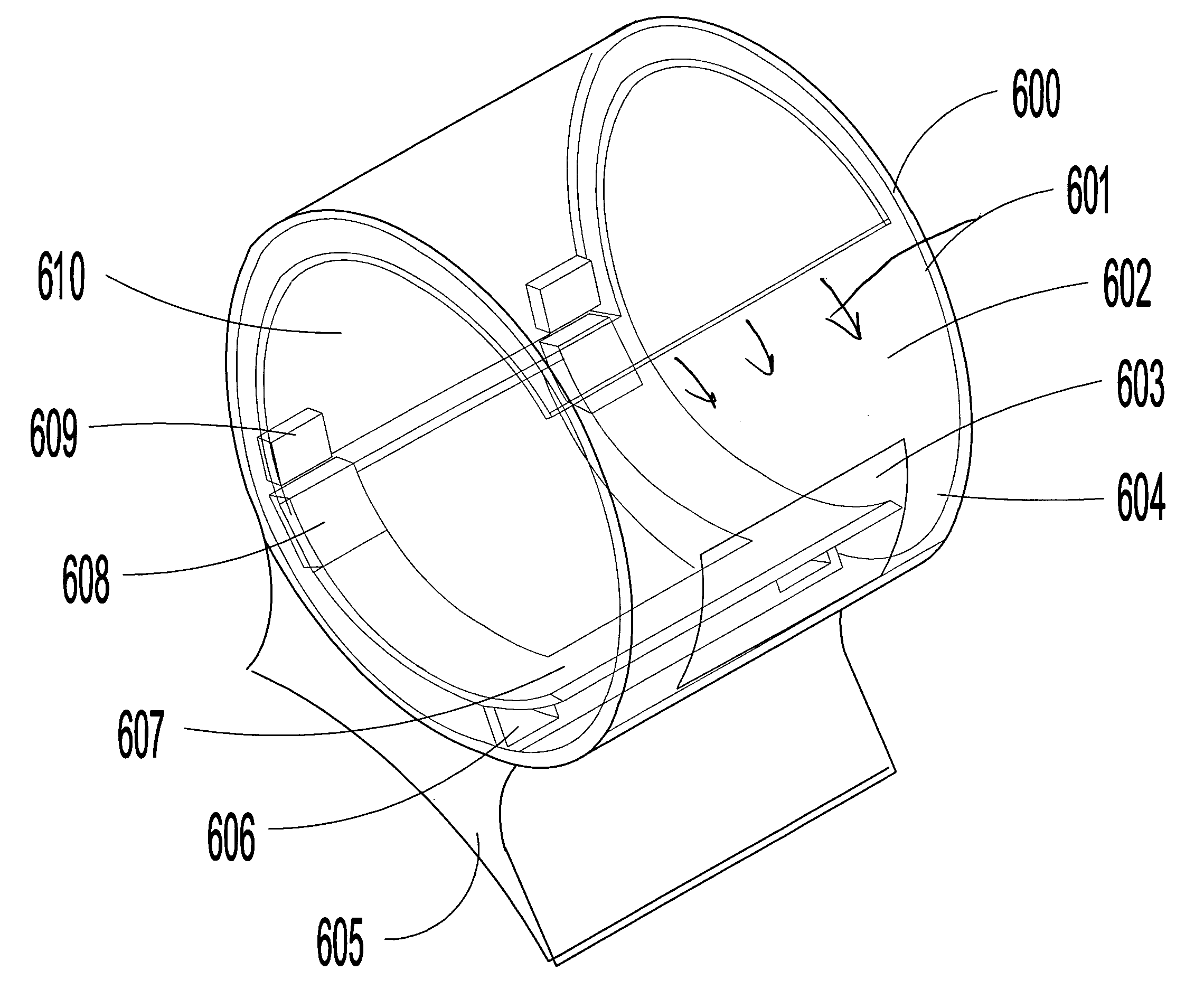

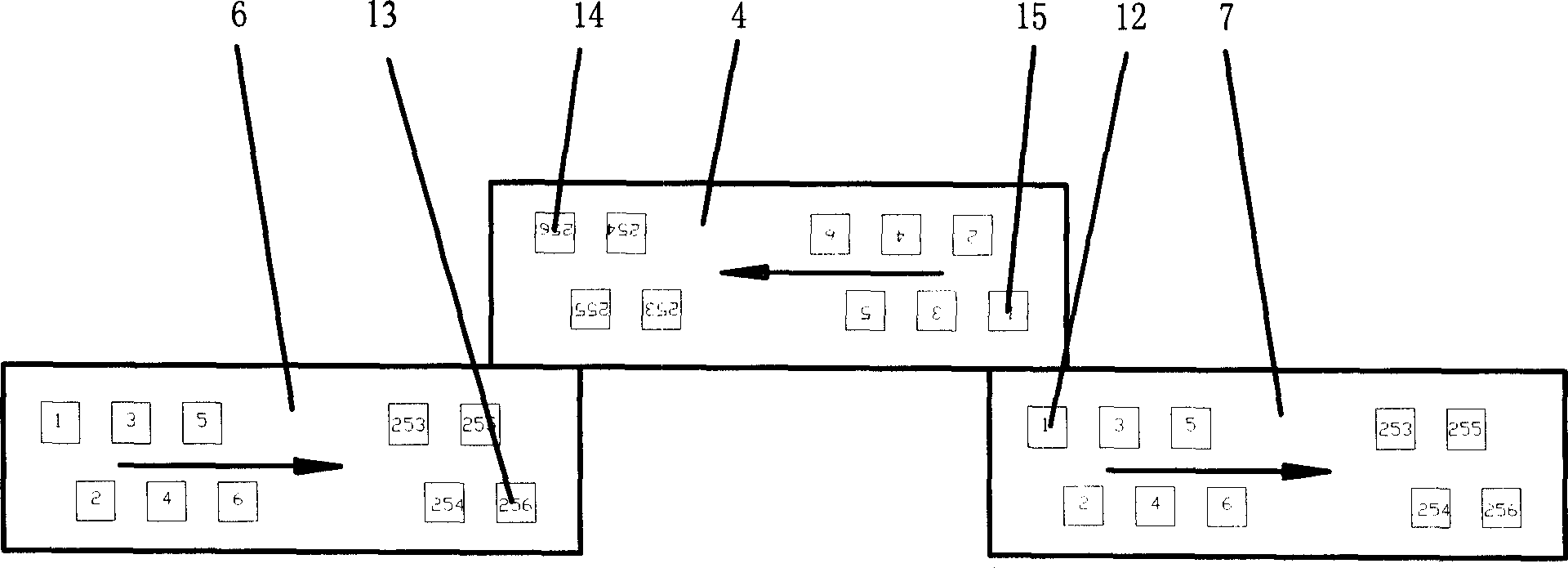

Super long alignment infrared focus plane detector

ActiveCN1858906AEasy to installEasy to debugSemiconductor/solid-state device detailsSolid-state devicesWave bandFocal plane detector

This invention discloses a super long line infrared focal plane detector, which is formed by rotating multiple sub-modules to be crossly fixed on a spliced base plate to form the splice without leakage, in which, the sub-modules are small line infrared focal plane detectors of 256x1 or 512x1, which can be either single wave band or double wave band.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Disk drive device

ActiveUS20080165449A1Improve joint reliabilityIncrease widthUndesired vibrations/sounds insulation/absorptionRecord information storageInterior spaceEngineering

In a disk drive device in which low-density gas is sealed, embodiments of the present invention help to improve joint reliability at a solder joint section between a feedthrough and an enclosure with respect to stress applied by deformation due to changes in temperature environment in use. According to one embodiment, helium gas is sealed in an interior space of an HDD. A feedthrough is solder jointed to a feedthrough mounting surface of a base. At a part with relatively large thermal stress, a width of the feedthrough mounting surface is increased, and at a part with relatively small thermal stress, a width of the feedthrough mounting surface is decreased. This prevents a crack penetrating path from being generated at the solder joint section due to the thermal stress and prevents the solder joint section from contacting pins.

Owner:WESTERN DIGITAL TECH INC

A machining process of a large screen sapphire mobile-phone panel

ActiveCN104536602AImprove thermal stressImprove appearance cleanlinessTelephone set constructionsInput/output processes for data processingScreen printingLarge screen

The invention discloses a machining process of a large screen sapphire mobile-phone panel. The machining process of the large screen sapphire mobile-phone panel comprises the steps of 1) blanking sapphire of a bar material and forming a sheet material; 2) contouring a sapphire panel by adopting a CNC, machining hole sites at surfaces of the sapphire panel by adopting laser, and machining and shaping arc edges by adopting a diamond grinding wheel; 3) executing double-sided grinding and polishing on the sapphire panel by adopting a double-sided copper disc machine, to realize thinning; 4) executing double-sided polishing on the sapphire panel; and 5) executing film coating or silk-screen printing on the surfaces of the sapphire panel. According to the machining process of the large screen sapphire mobile-phone panel, the large screen panel is machined with respect to the material of sapphire, such that the machining efficiency is high, the appearance quality is good, and the steps of the process are practicable, thus being suitable for batch machining production by an enterprise.

Owner:LENS TECH CHANGSHA

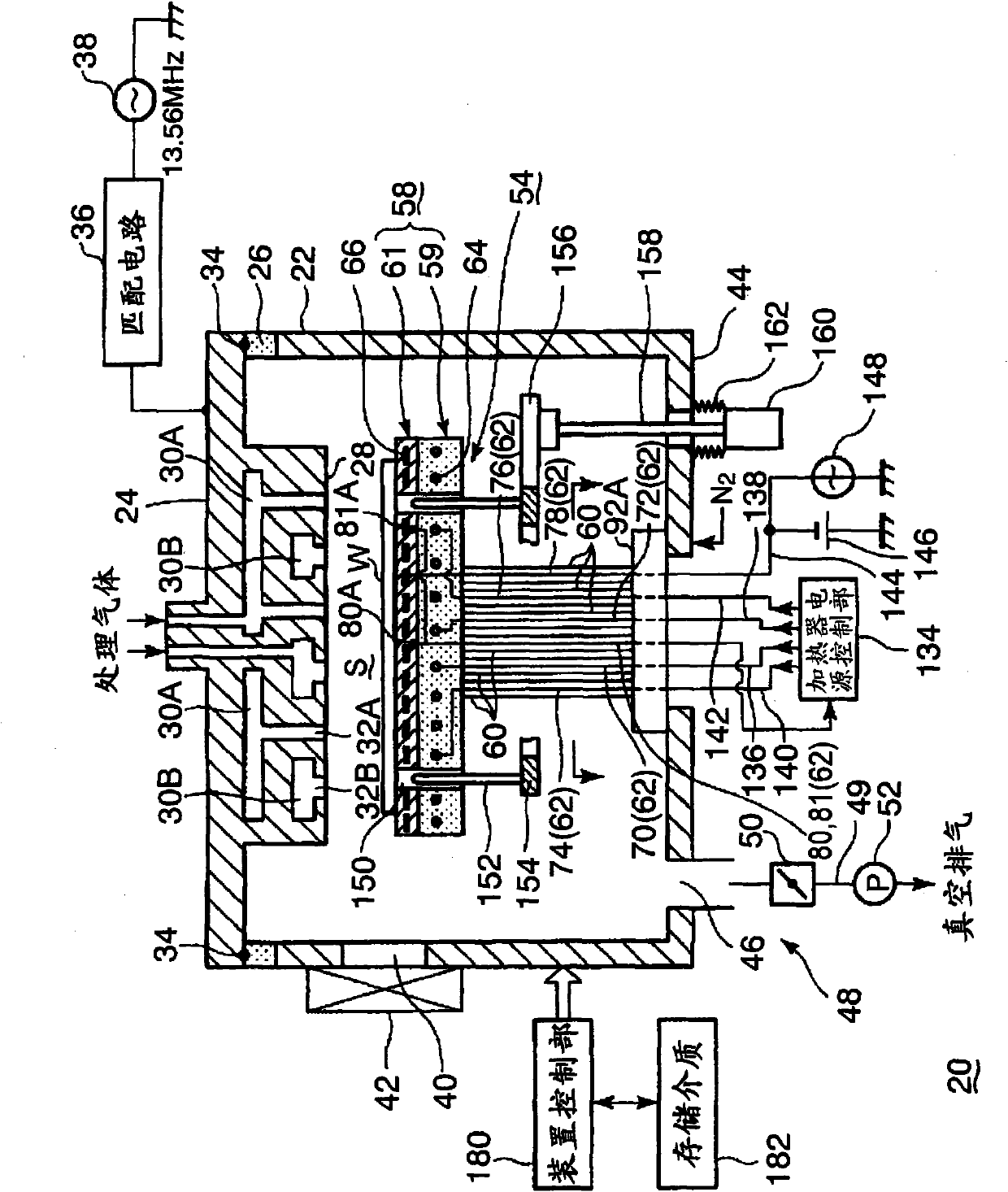

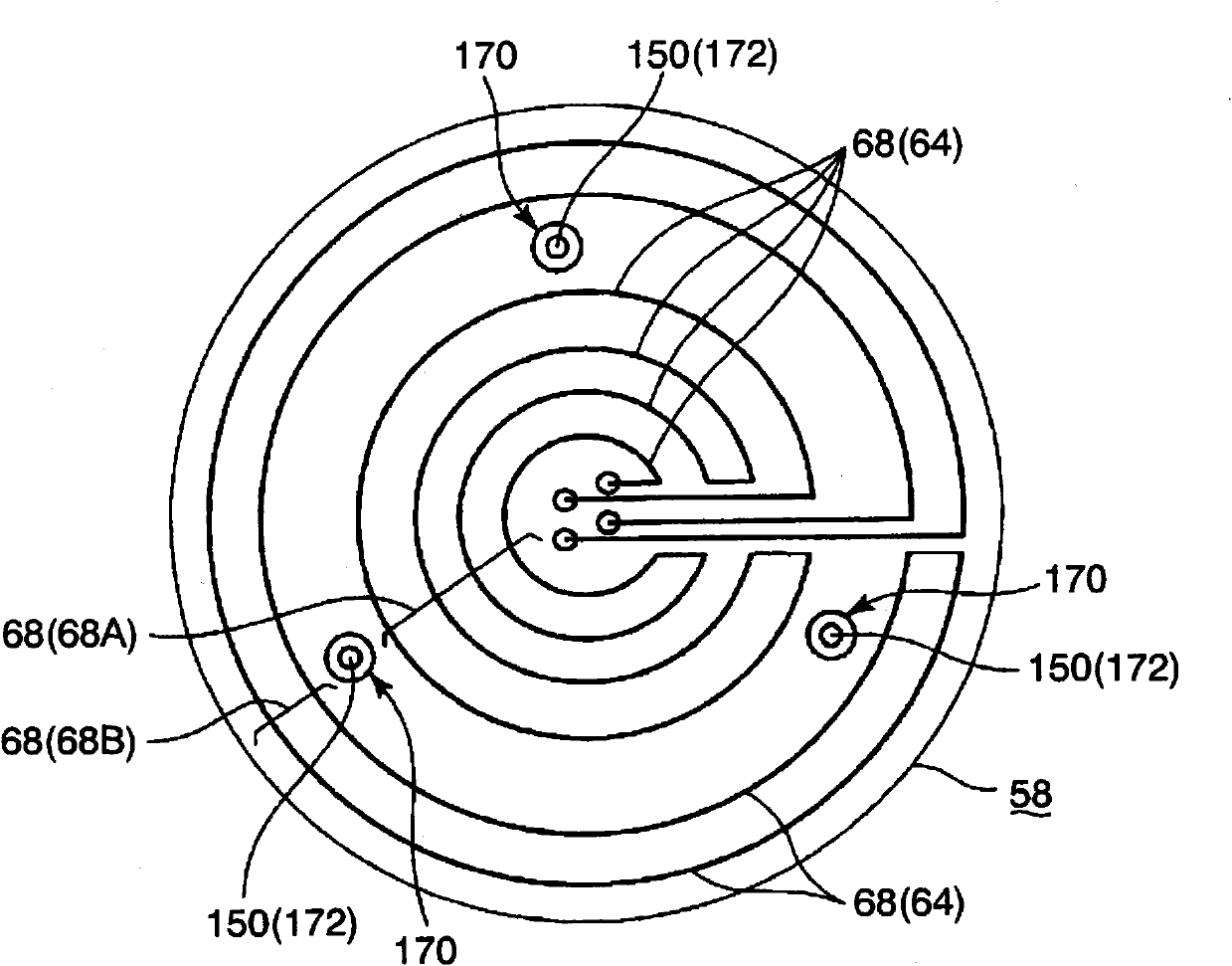

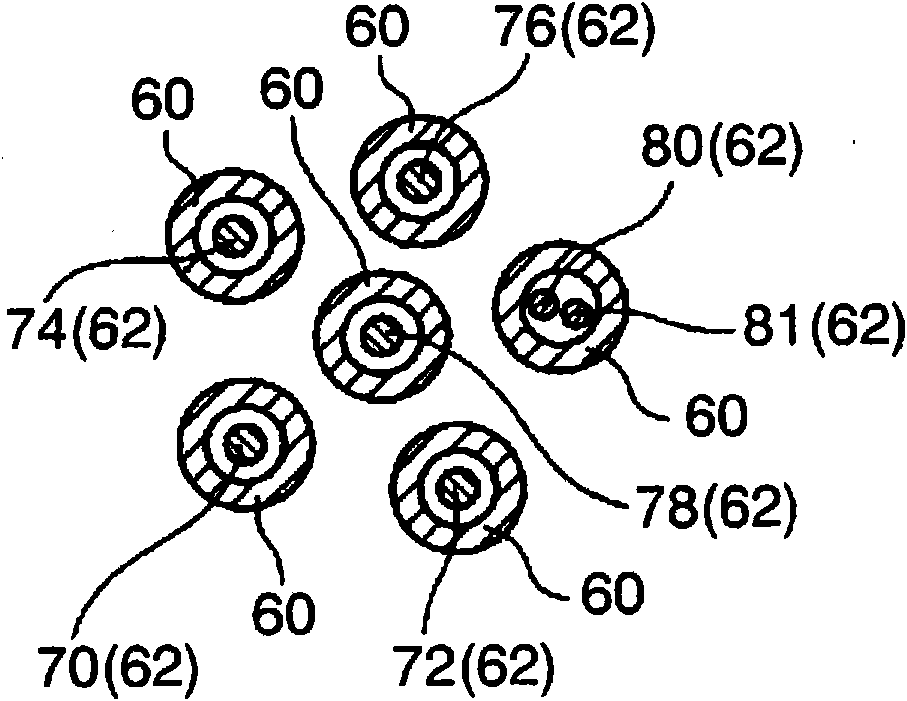

Loading table structure and processing device

InactiveCN101772837AImprove thermal stressAvoid breakingSemiconductor/solid-state device manufacturingDielectricEngineering

Owner:TOKYO ELECTRON LTD

Low-temperature glass solder bonding and encapsulating method based on disc level glass micro-chamber

InactiveCN101497422AGuaranteed reliabilityLower packaging costsTelevision system detailsPrecision positioning equipmentCMOSFritted glass

The invention discloses a low-temperature glass solder bonding and packaging method based on wafer-level glass microcavities, which comprises the following steps: firstly, utilizing a silk-screen printing process to coat low-temperature glass solder on a packaging contact part of a Pyrex7740 glass substrate provided with a microcavity structure, preliminarily drying the low-temperature glass solder, and making the low-temperature glass solder be cured and cling to the Pyrex7740 glass substrate provided with the microcavity structure; secondly, aligning a Pyrex7740 glass packaging wafer which is cured with the low-temperature glass solder and a silicon substrate wafer comprising an MEMS device or a CMOS circuit, and making the microcavity structure on the Pyrex7740 glass substrate correspond to the position of the MEMS device or the CMOS circuit to be packaged of a silicon substrate; and thirdly, using a clamper to firmly clamp the two aligned wafers, applying the pressure, sintering the glass solder in a specified packaging atmosphere, and cooling the glass solder. The whole process is based on integral processing of the silicon wafer and the Pyrex7740 glass wafer, belongs to a process for manufacturing and packaging a wafer-level MEMS, and has the characteristics of simple method, adjustable packaging space and low cost.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com