Patents

Literature

313results about How to "Avoid heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

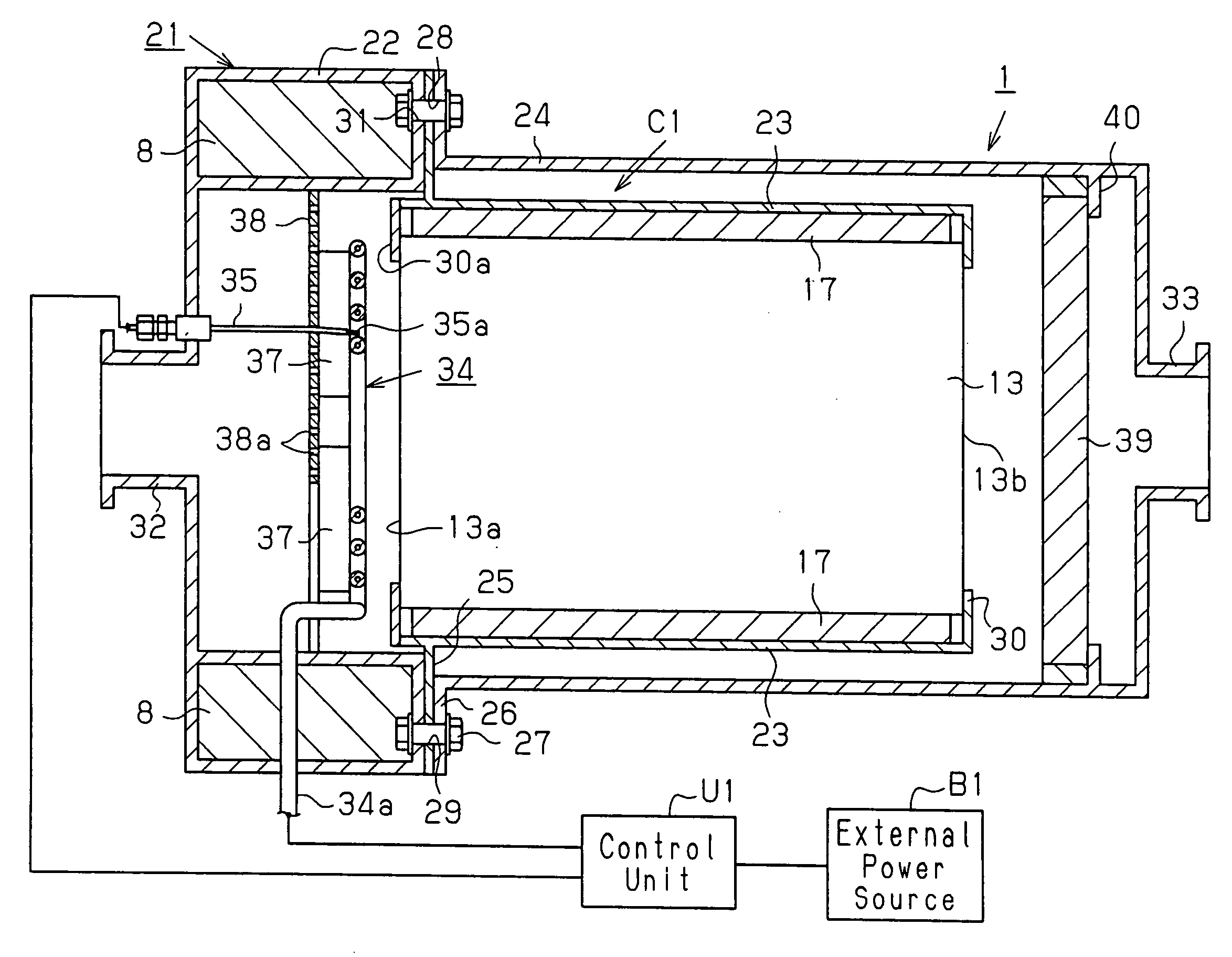

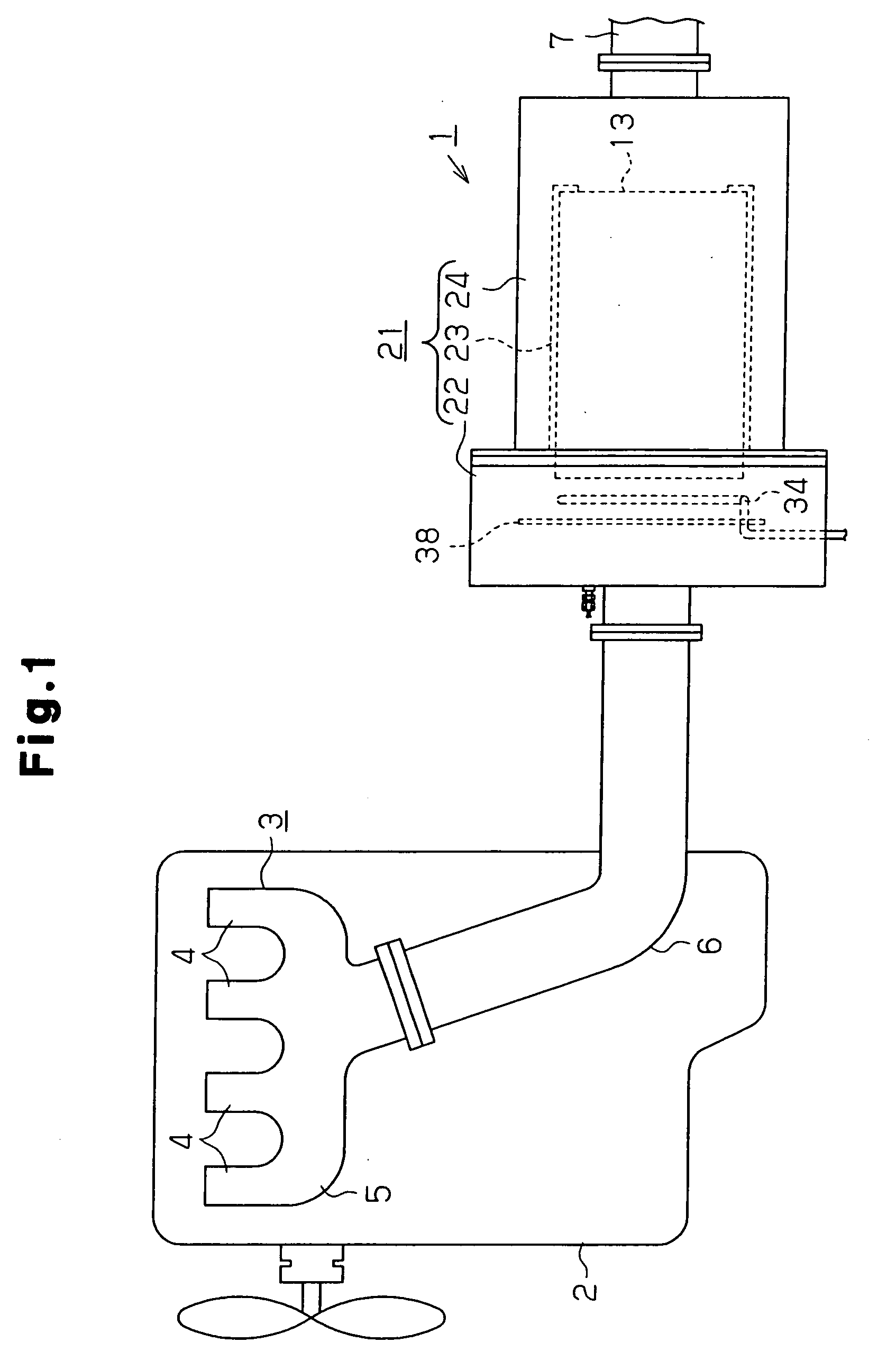

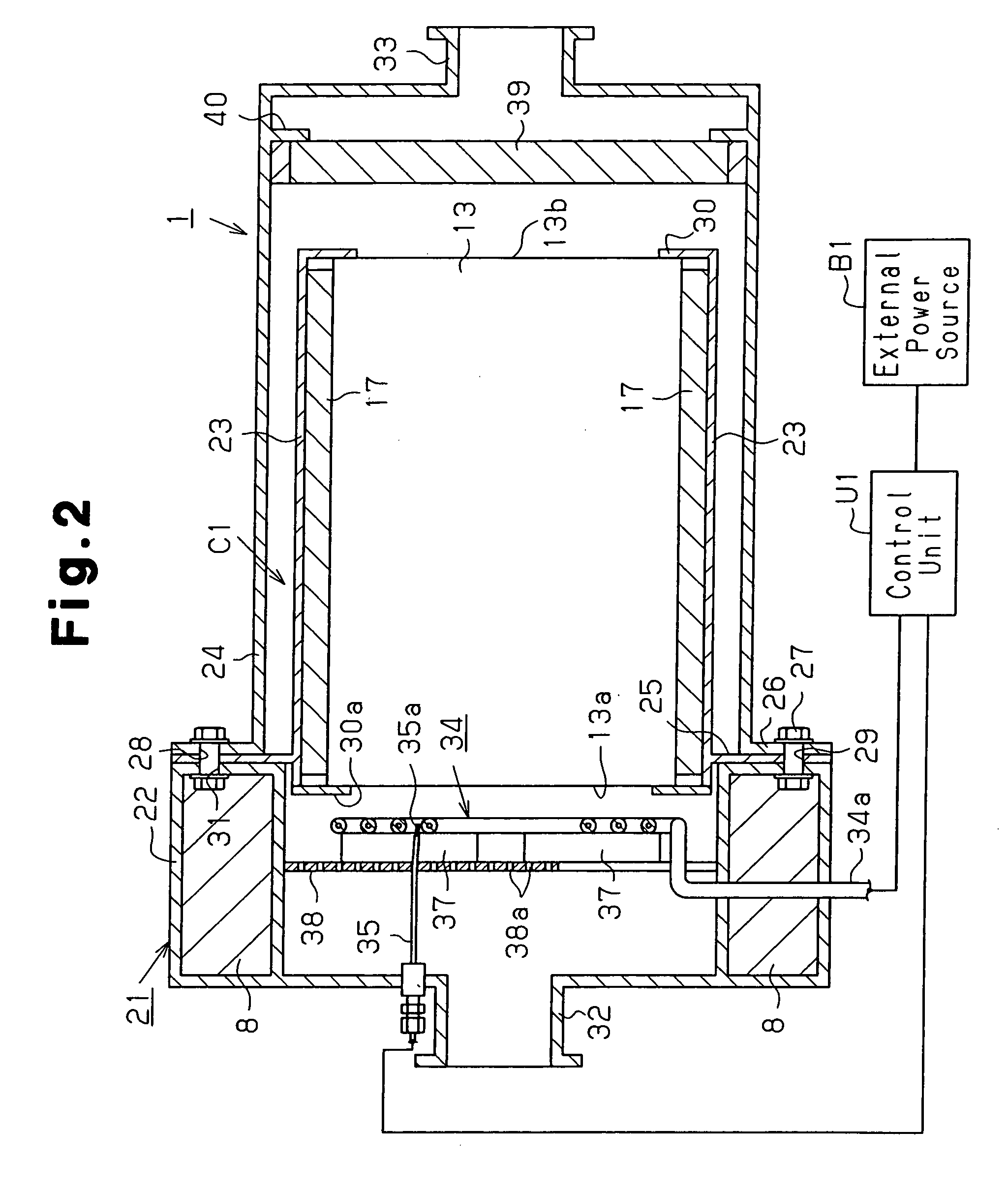

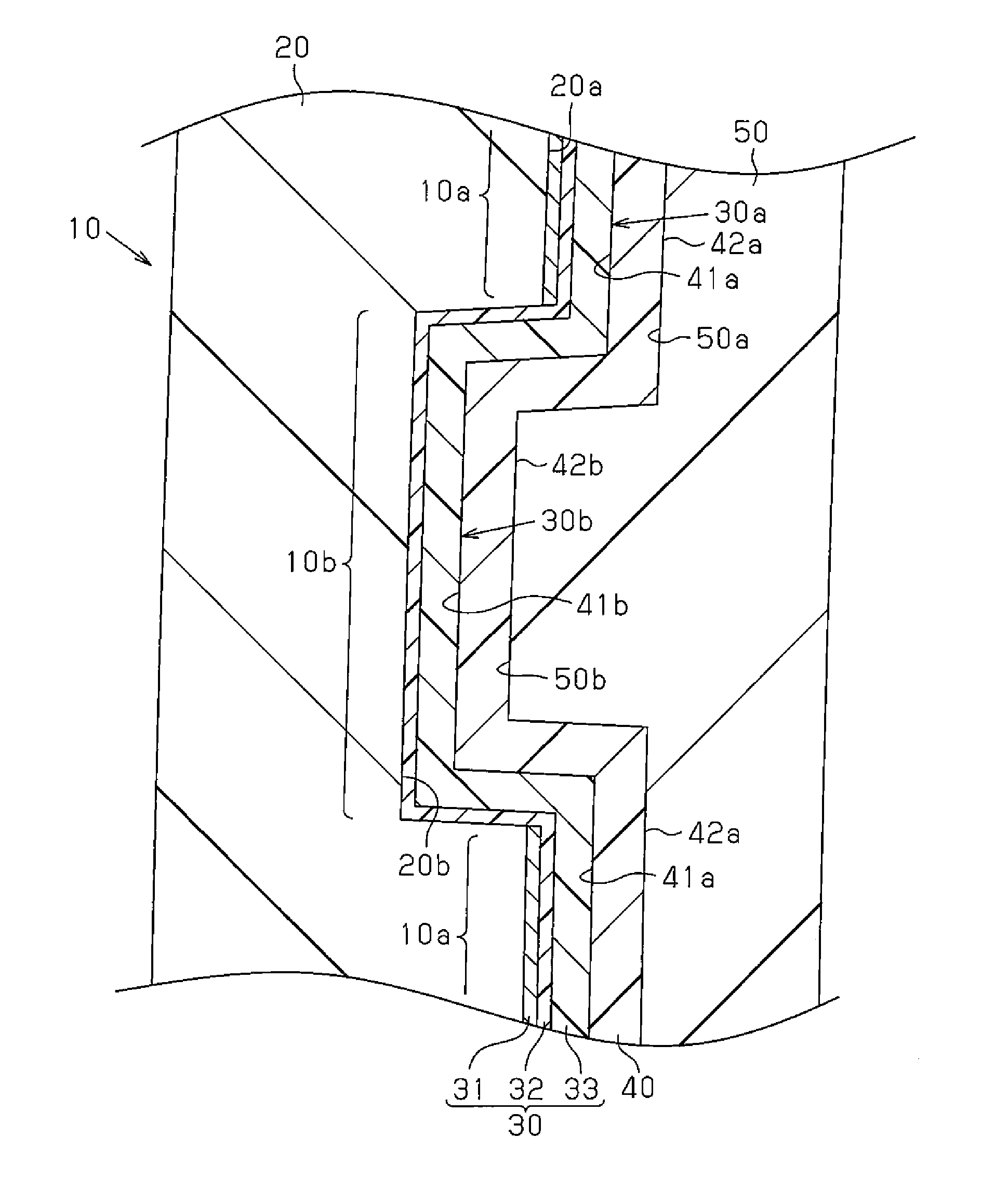

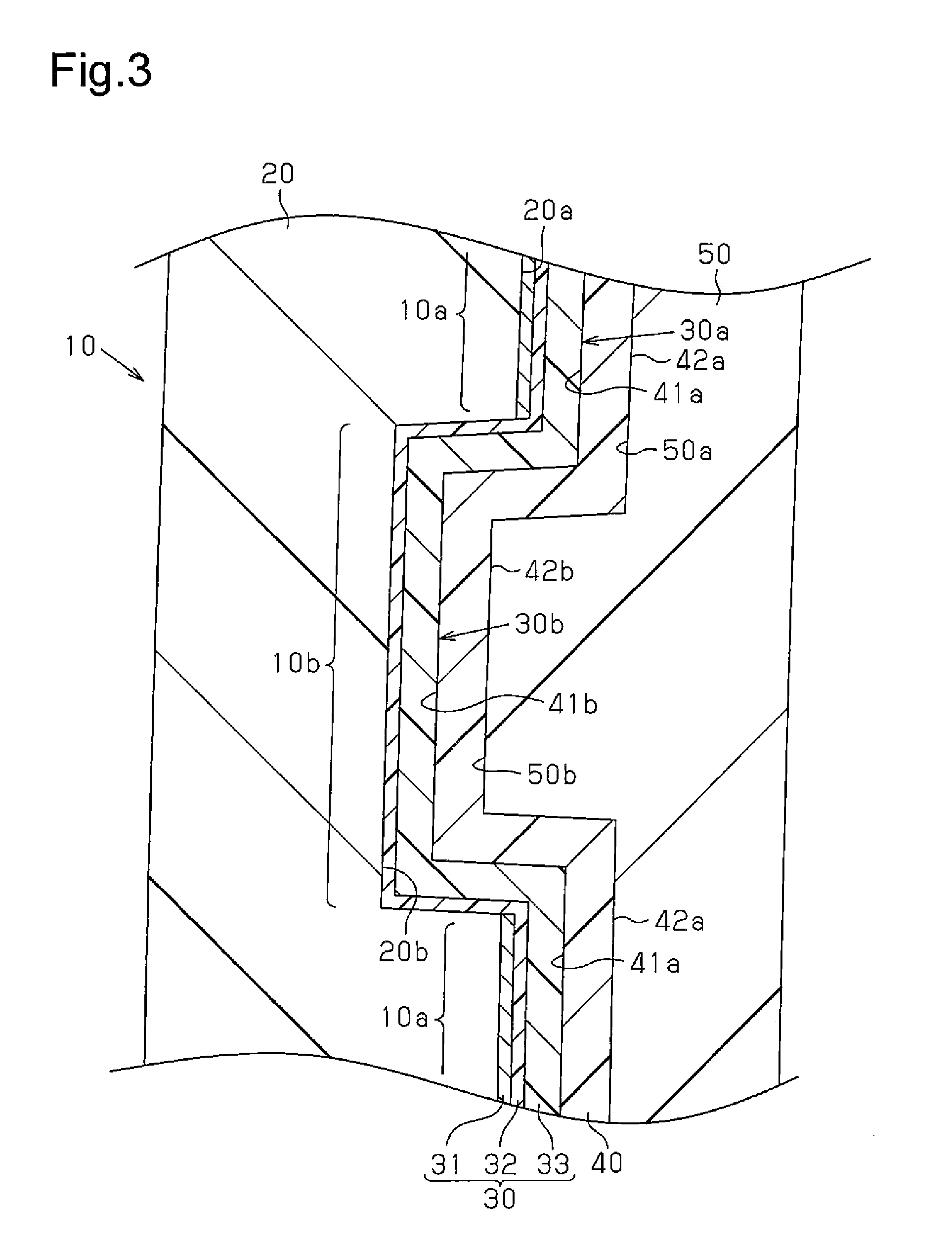

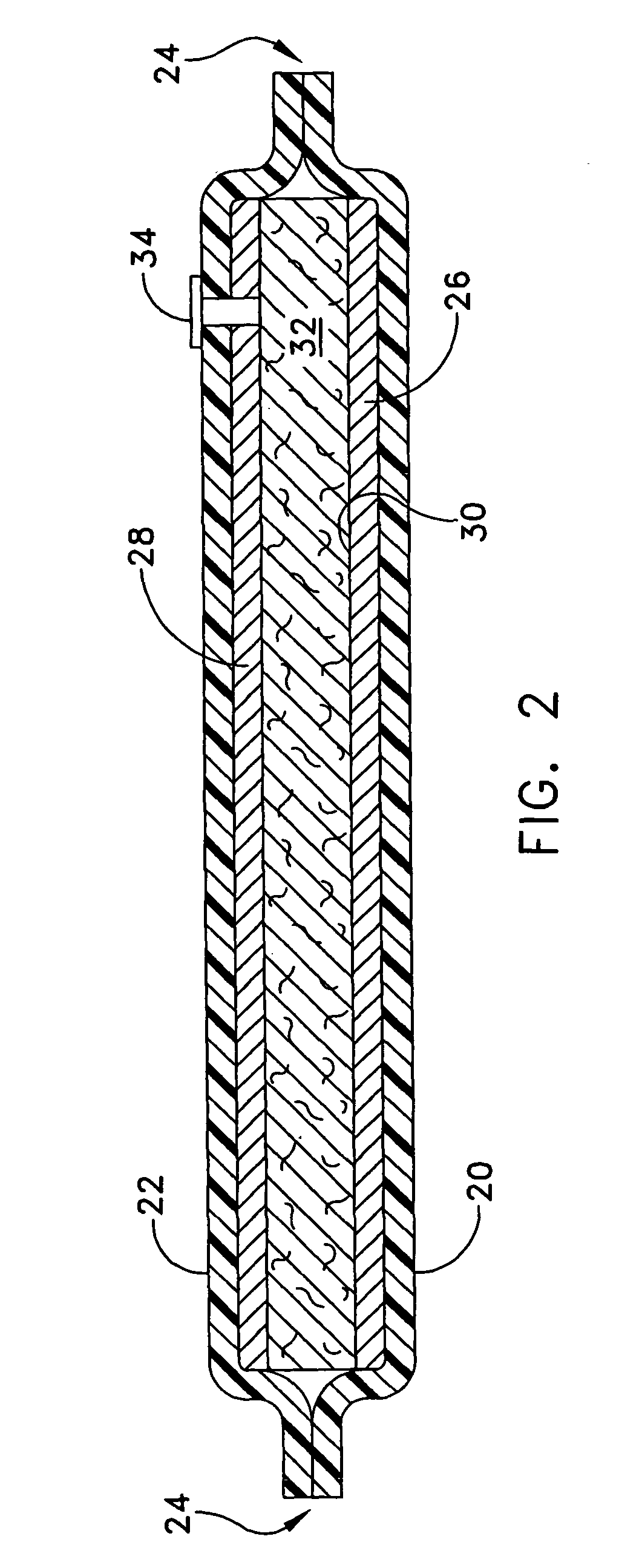

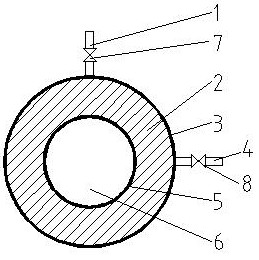

Exhaust emission control device and casing structure of the control device

InactiveUS20050115224A1Reduce energy lossLow costInternal combustion piston enginesDispersed particle filtrationParticulatesEngineering

An exhaust gas purifying device includes a tubular casing arranged in exhaust passages of an internal combustion engine. A filter is held in the casing. The filter collects and burns particulates contained in the exhaust gas discharged by the internal combustion engine. The casing has a double structure including an inner case supporting an outer peripheral surface of the filter and an outer case arranged around the inner case. The inner and outer cases are spaced from each other with a clearance defined between the cases.

Owner:IBIDEN CO LTD

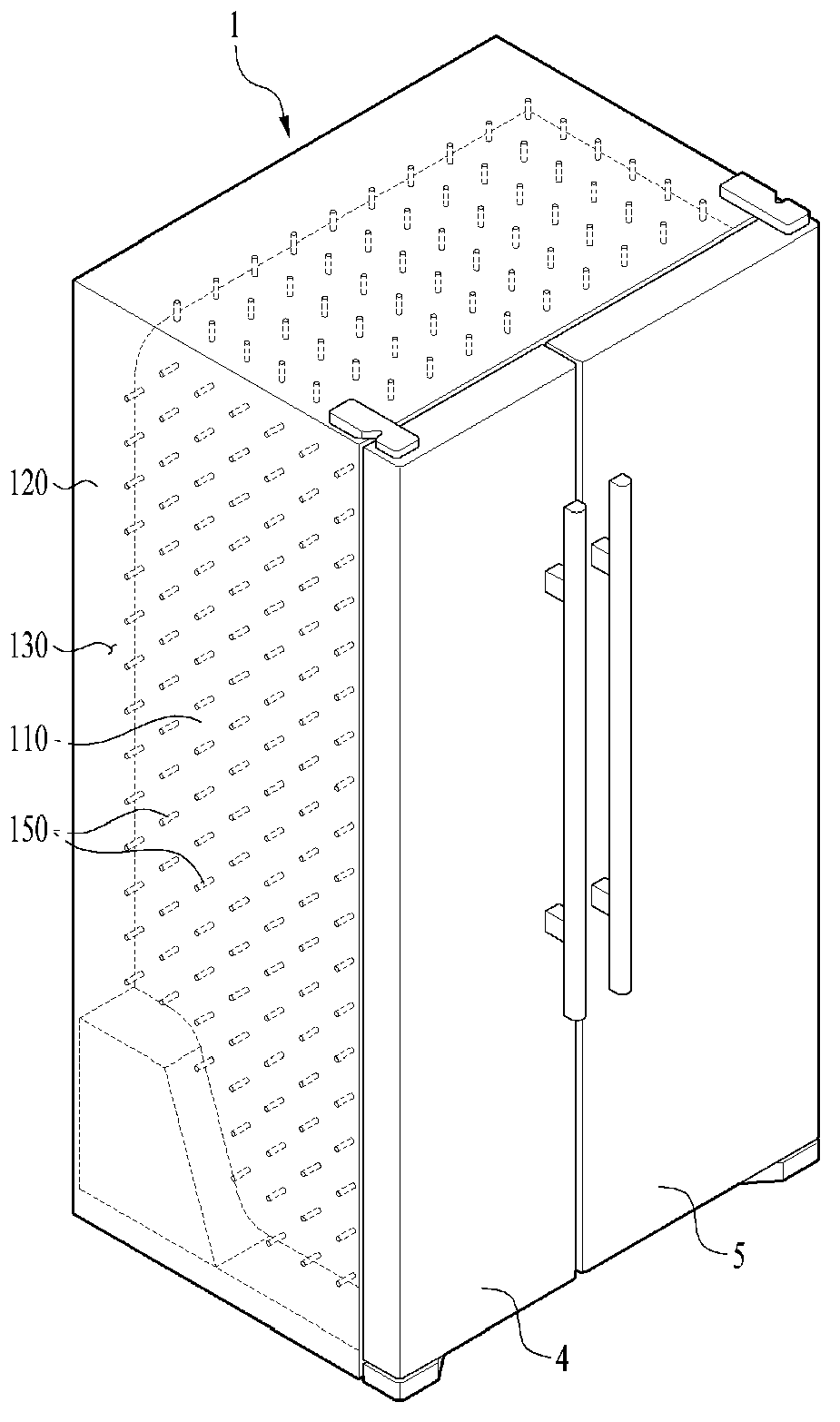

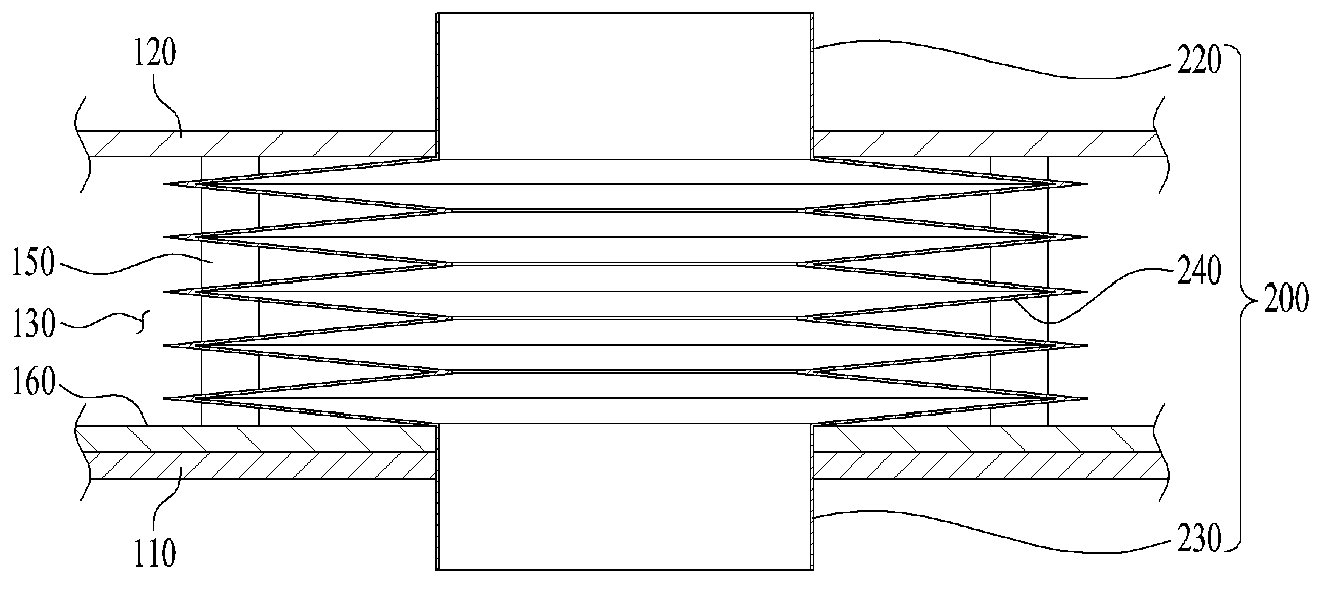

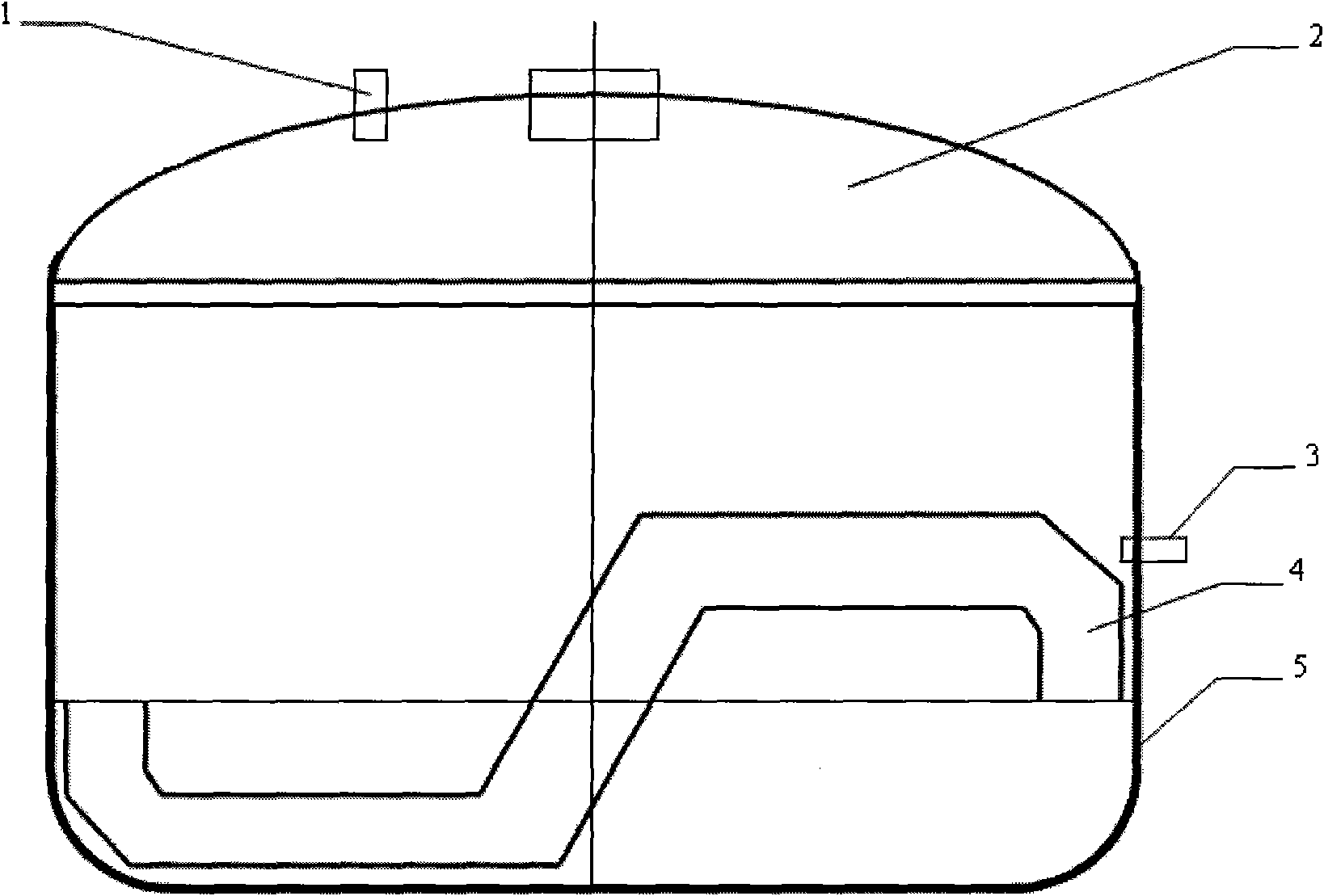

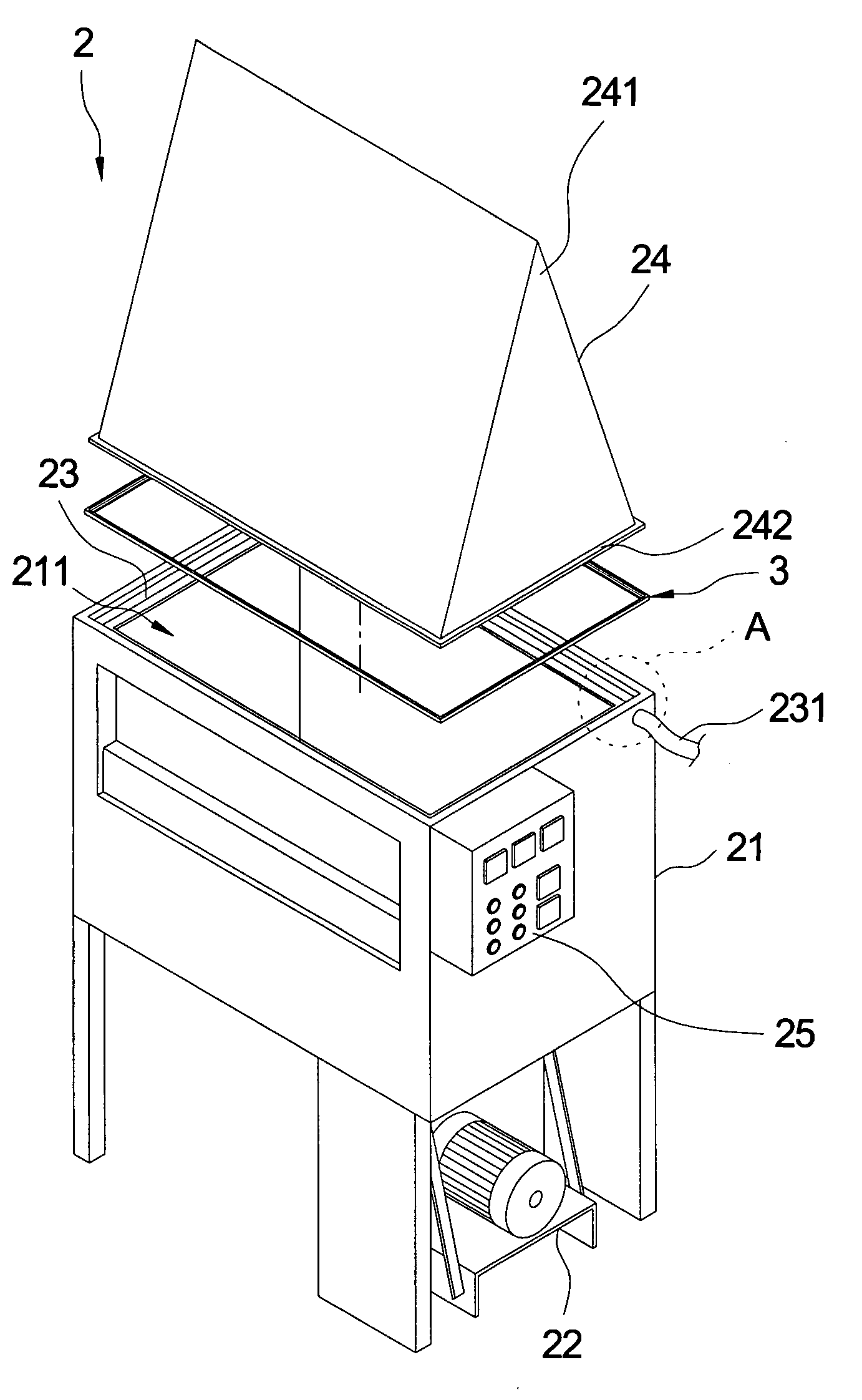

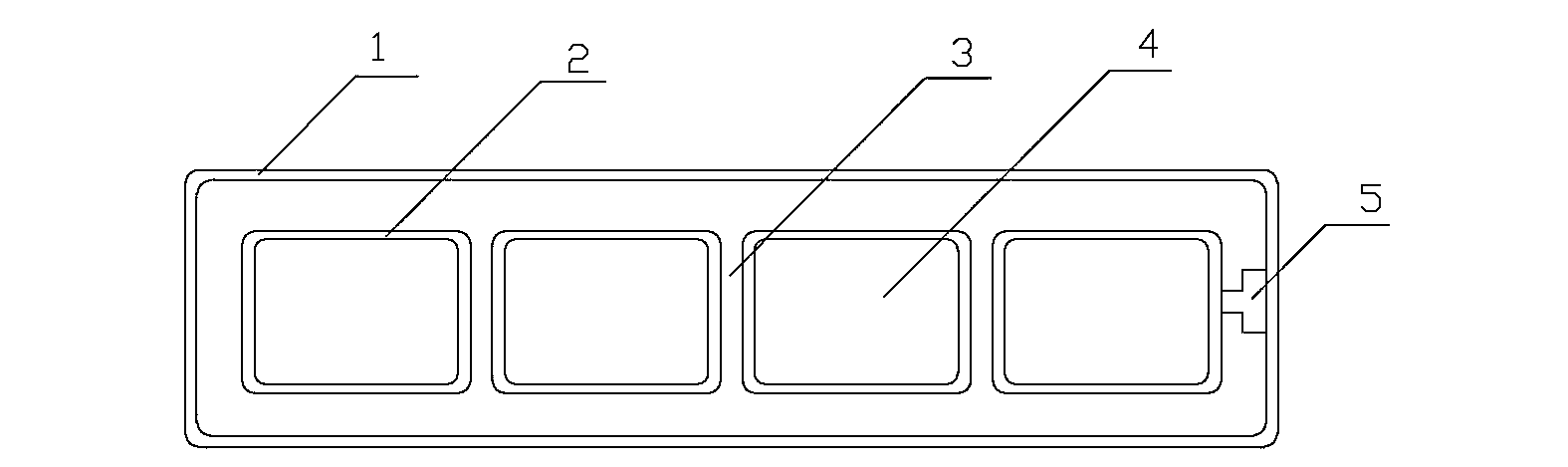

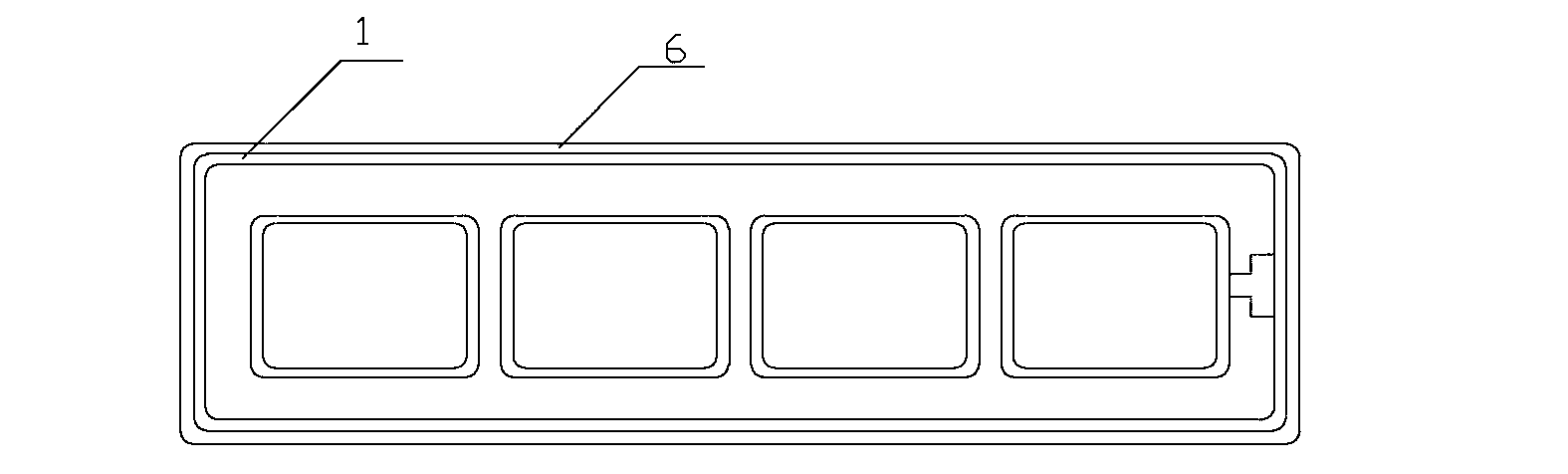

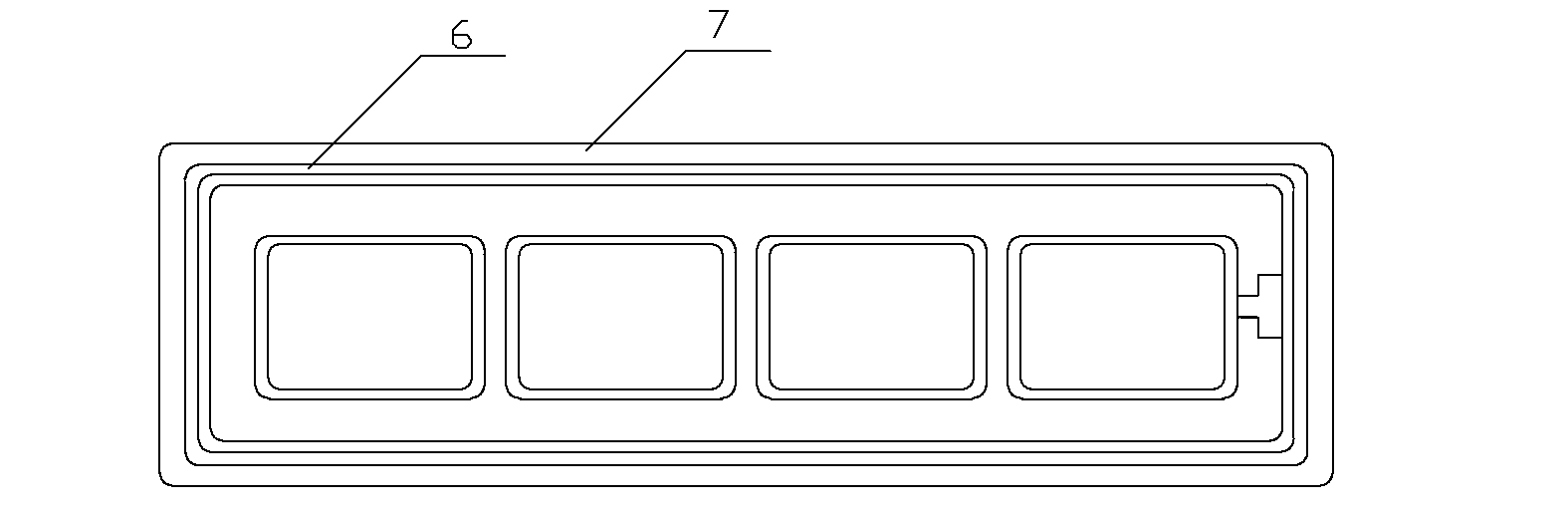

Refrigerator

ActiveCN103090615AAvoid heat transferGood heat insulationThermal insulationDomestic refrigeratorsEngineeringRefrigerated temperature

There is disclosed a refrigerator including an inner case that defines an exterior appearance of a storage space, with a communication hole formed therein, an outer case spaced apart a predetermined distance from the inner case, with a communication hole formed at a position corresponding to the communication hole of the inner case, a vacuum space provided between the inner case and the outer case, with being maintained vacuum, to insulate the inner case from the outer case, and a connection pipe passing through the vacuum space, to connect the communication hole of the inner case and the communication hole of the outer case with each other.

Owner:LG ELECTRONICS INC

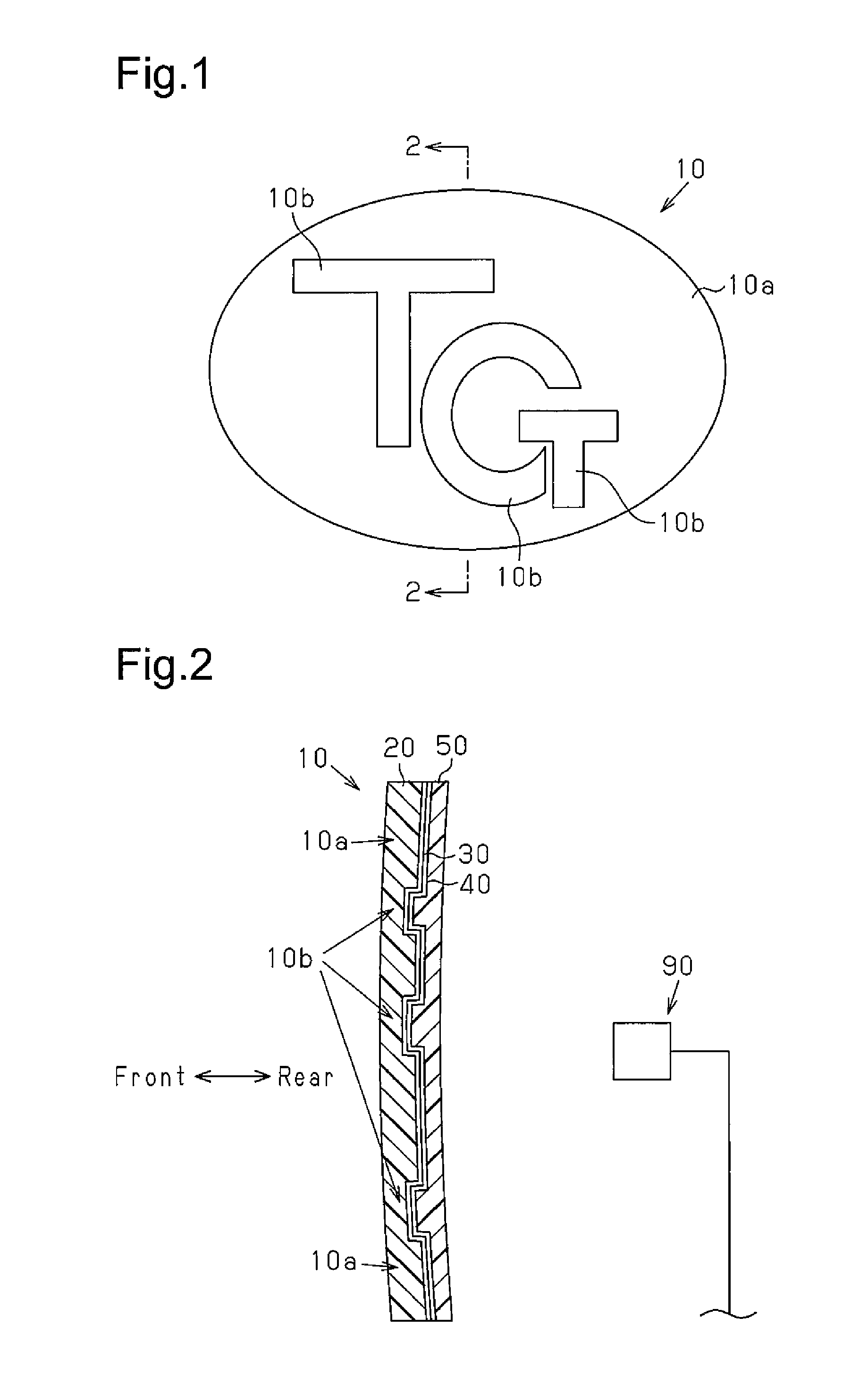

Radio-wave transparent cover and method for manufacturing radio-wave transparent cover

InactiveUS20150140259A1Shorten the timeInhibitionMouldsSynthetic resin layered productsRadarEngineering

A radio-wave transparent cover is adapted to be arranged on a radio wave path of a radar device. The radio-wave transparent cover includes a transparent member, a decorative layer, a base, and a suppression member. The transparent member is formed of a first resin material. The decorative layer is formed on the rear surface of the transparent member. The base is formed of a second resin material and arranged behind the decorative layer. The suppression member is formed of a third resin material and molded in advance. The suppression member is arranged on the decorative layer to cover the rear surface of the decorative layer. The suppression member suppresses heat transfer to the transparent member when the base is insert-molded.

Owner:TOYODA GOSEI CO LTD

Food cooking control method and device

InactiveUS20090324785A1Easy to controlSimple designThermometer detailsTemperature measurement in household appliancesEngineeringCooking process

Owner:POINTJUST

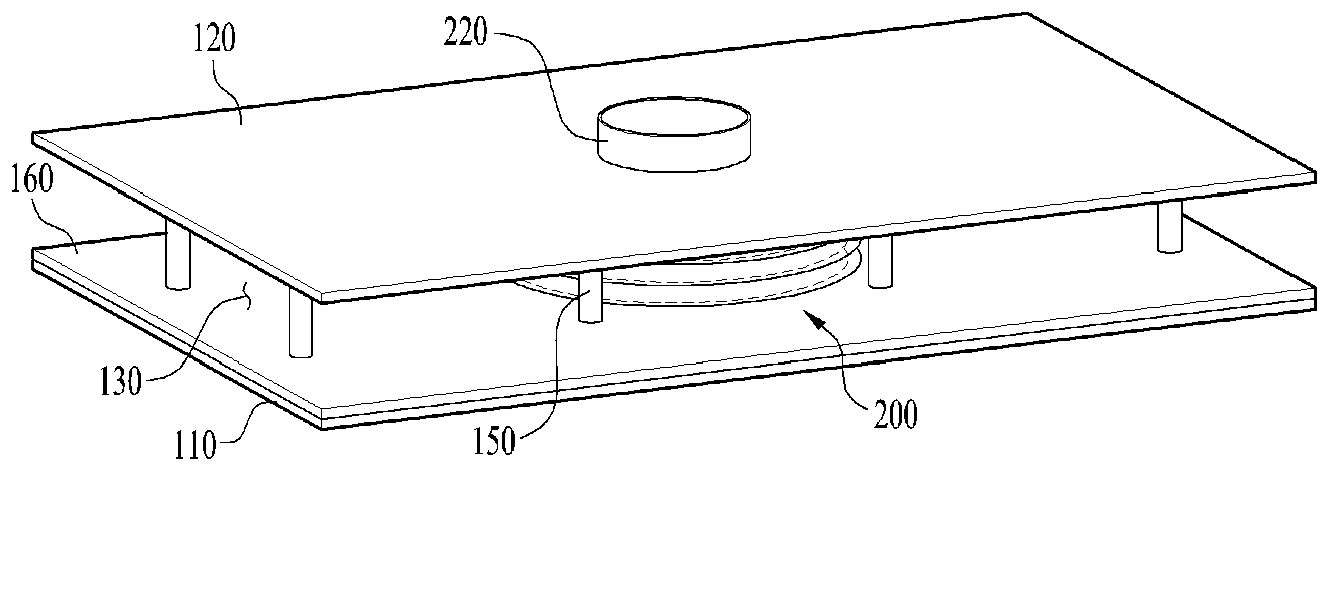

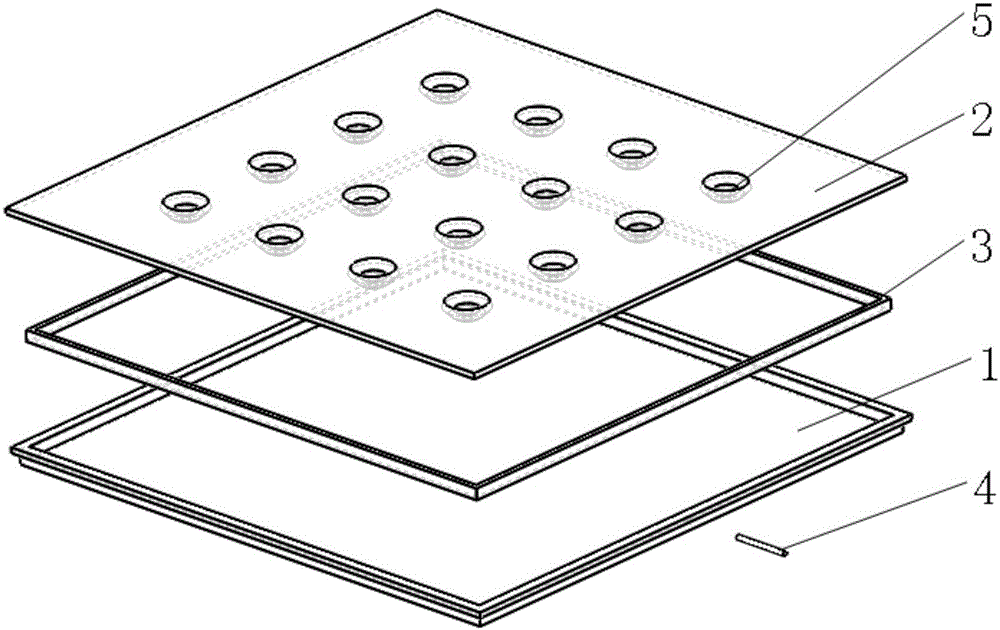

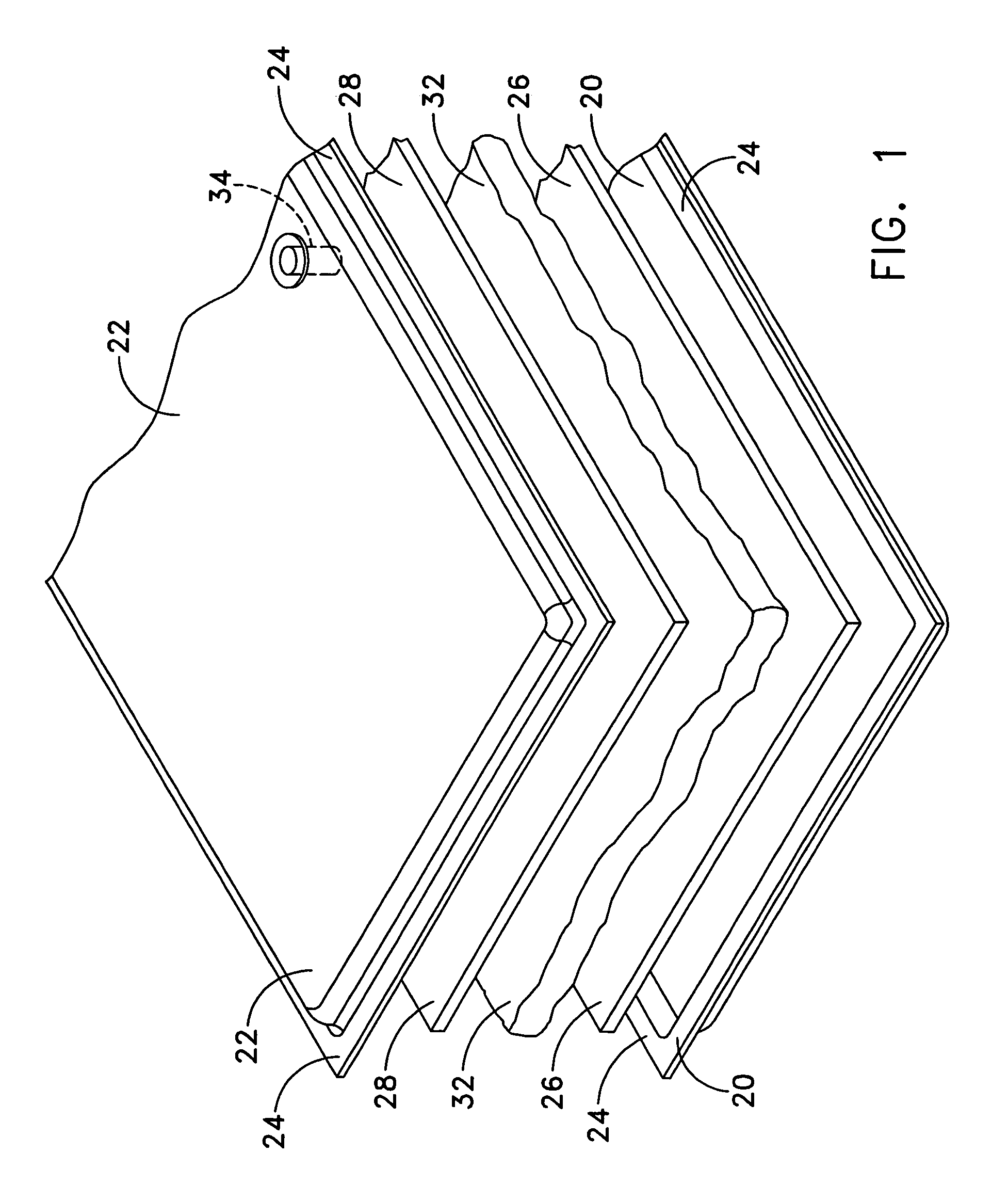

Flat plate heat pipe and manufacturing method thereof

ActiveCN106091765AExert heat soaking characteristicsImprove performanceIndirect heat exchangersEvaporationThin layer

The invention provides a flat plate heat pipe. The flat plate heat pipe comprises an evaporation cover plate, a condensation cover plate, a liquid filling pipe and liquid absorption cores. The evaporation cover plate is of a concave table structure. A connection belt is arranged around the periphery of the top end of the concave table structure of the evaporation cover plate. The liquid absorption cores of a porous capillary structure are formed in the periphery of the inner side of the top end of the concave table structure of the evaporation cover plate, and a hydrophilic thin layer is compounded to the bottom face of the inner side of the top end of the concave table structure of the evaporation cover plate. A plurality of convex plates are arranged on the side, in contact with the evaporation cover plate, of the condensation cover plate. A hydrophobic thin layer is compounded to the positions, except for the positions with the convex tables, of the side, in contact with the evaporation cover plate, of the condensation cover plate. A through hole is formed in the outer side of the evaporation cover plate, and the liquid filling pipe is arranged in the through hole. The evaporation cover plate and the condensation cover plate are connected in a sealed mode to form a closed cavity. Through modification of the hydrophilic property of the evaporation cover plate of the flat plat heat pipe and the hydrophobic property of the condensation cover plate, and through the supporting convex plates machined on the condensation cover plate, the heat exchange capacity and stability of the flat plate heat pipe are improved.

Owner:GUANGDONG UNIV OF TECH

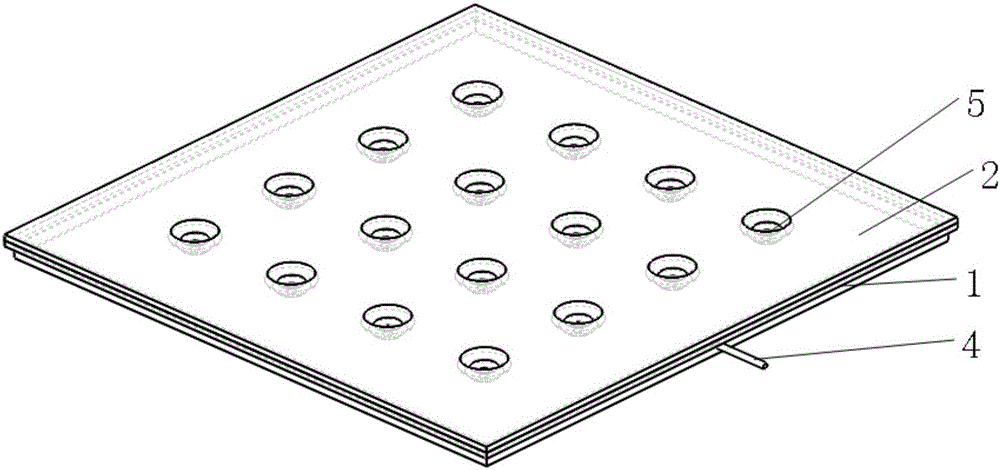

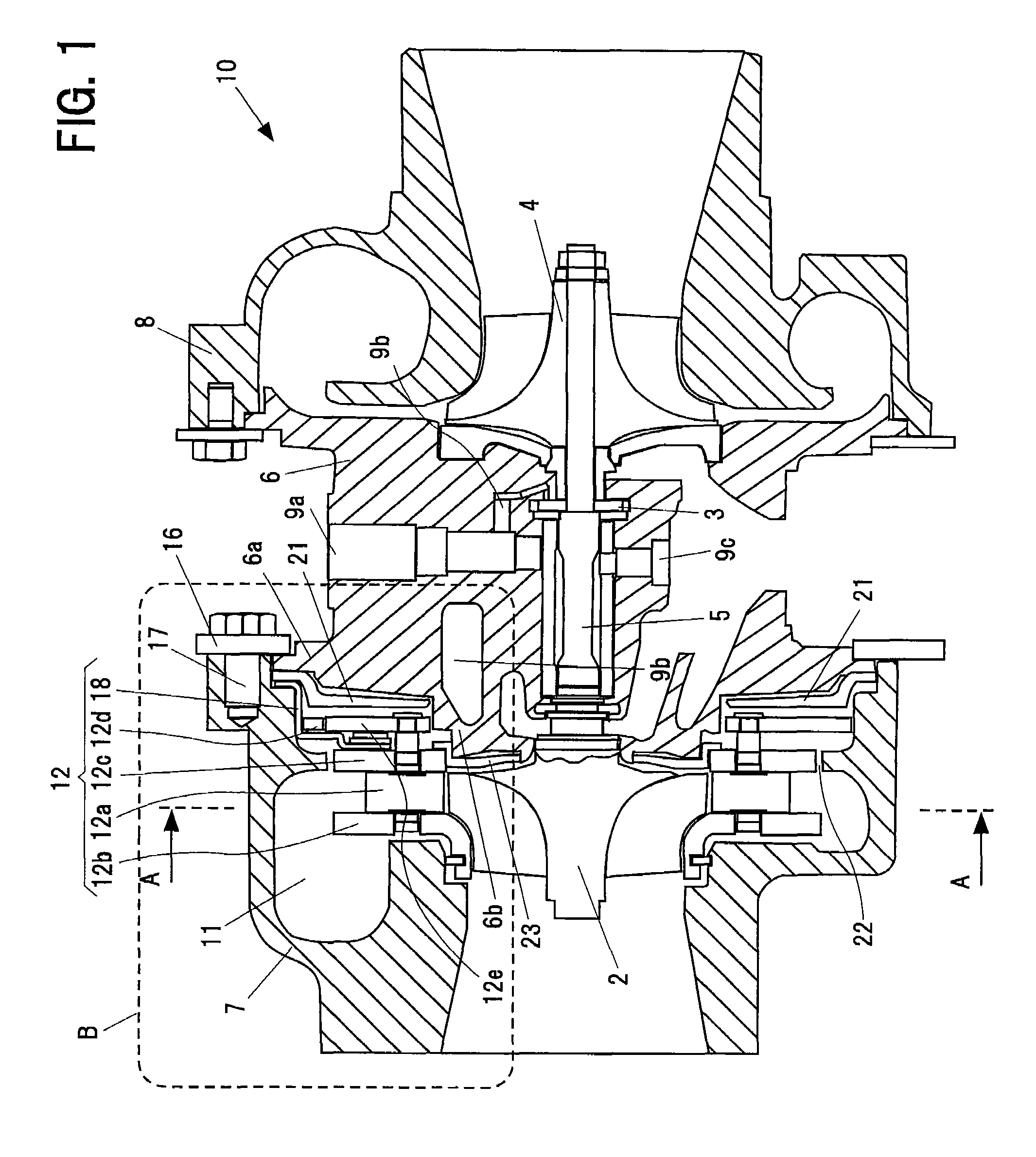

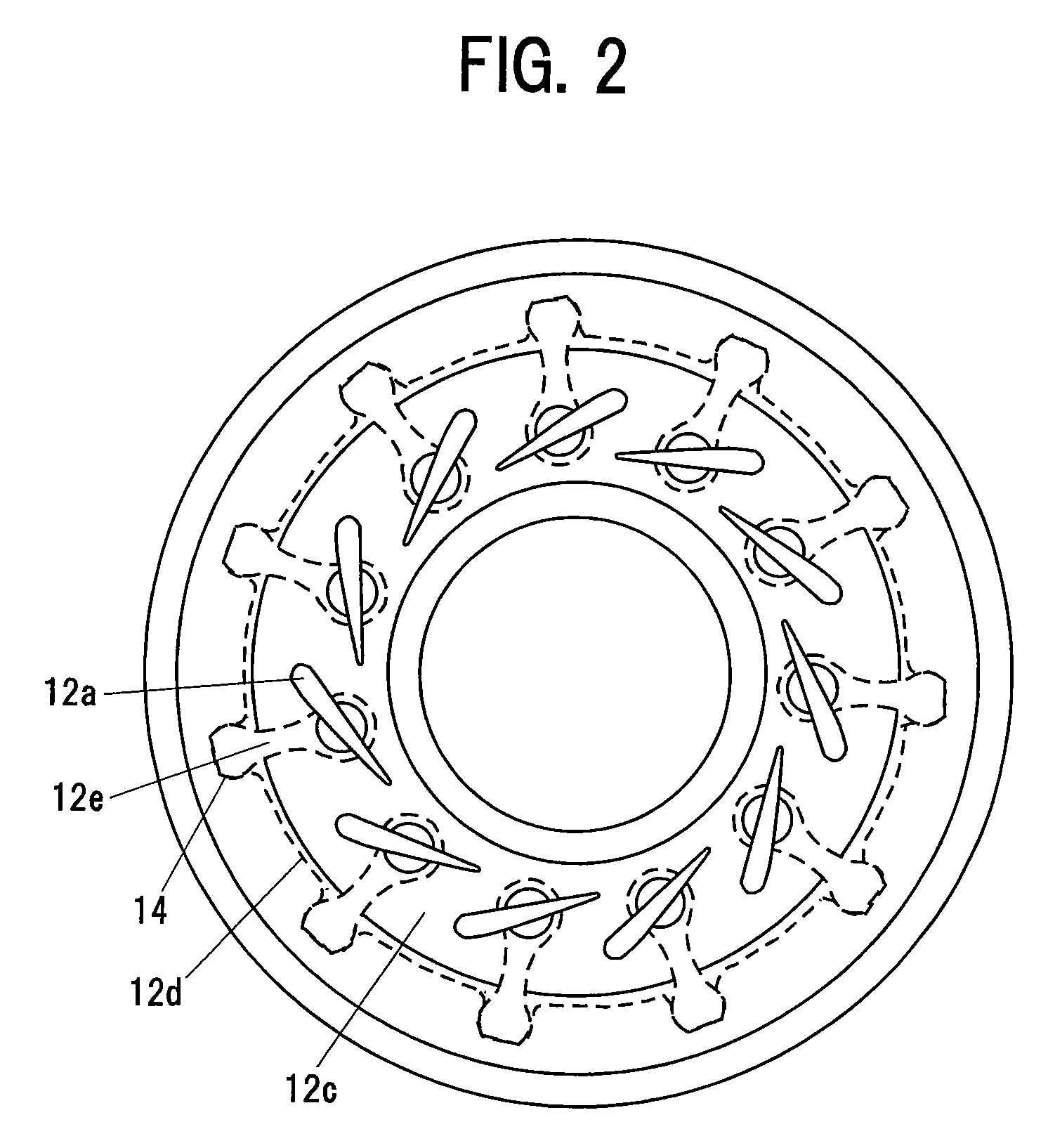

Turbocharger with variable nozzle

ActiveUS7509804B2Avoid heat transferIncrease in sizePump componentsWind motor controlImpellerTurbine wheel

A turbocharger with a variable nozzle has a turbine impeller, a compressor impeller, a shaft coupling the turbine impeller and the compressor impeller, a bearing housing rotatably supporting the shaft, and a turbine housing accommodating the turbine impeller. The turbocharger further includes a variable nozzle mechanism, provided in a compressor impeller side in a radial-direction outer side of the turbine impeller, for adjusting a flow rate of an exhaust gas directed to the turbine impeller. The bearing housing has a radially expanded portion that extends to a radial-direction outer side to be coupled to the turbine housing at a radial-direction outer side portion thereof such that the variable nozzle mechanism is accommodated between the turbine housing and the radially expanded portion. Between the variable nozzle mechanism and the radially expanded portion, a heat shield plate is provided for preventing a heat transmission between them.

Owner:IHI CORP

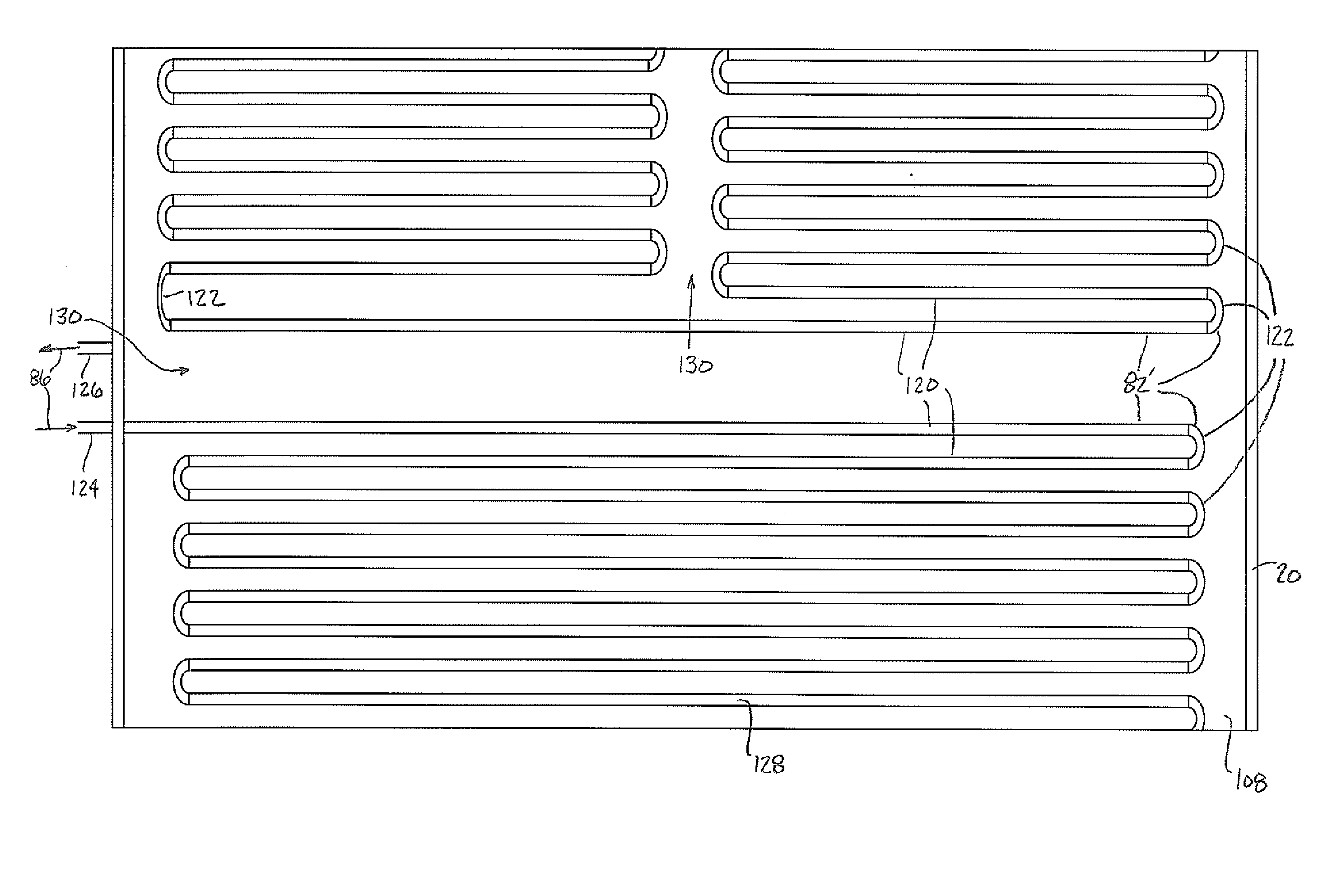

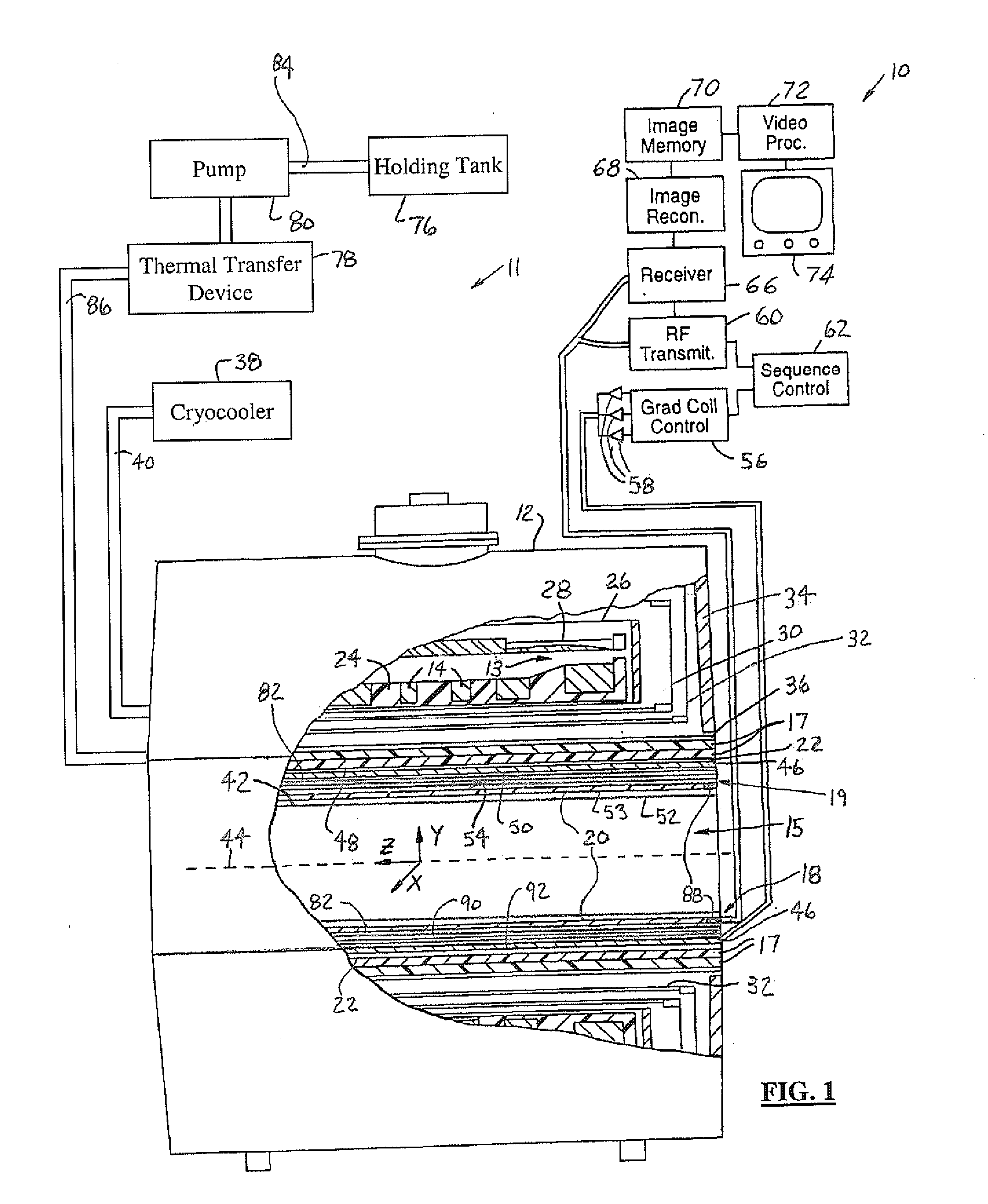

MRI system with liquid cooled RF space

InactiveUS20050179512A1Low cooling temperatureAvoid heat transferTransformers/inductances casingsSuperconducting magnets/coilsThermal energyEnergy transfer

A radio frequency space cooling system (11) for a magnetic resonance imager system (10) includes a thermal energy transfer device (78). The energy transfer device (78) reduces the temperature of a cooling fluid (86) within the cooling system (11). A cooling element (82) is coupled to the energy transfer device (78) and extends along a patient bore (15) between a radio frequency shield (22) and a radio frequency coil (20) of the magnetic resonance imager system (10). The cooling element (82) has a channel (90) for passage of the cooling fluid (86).

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

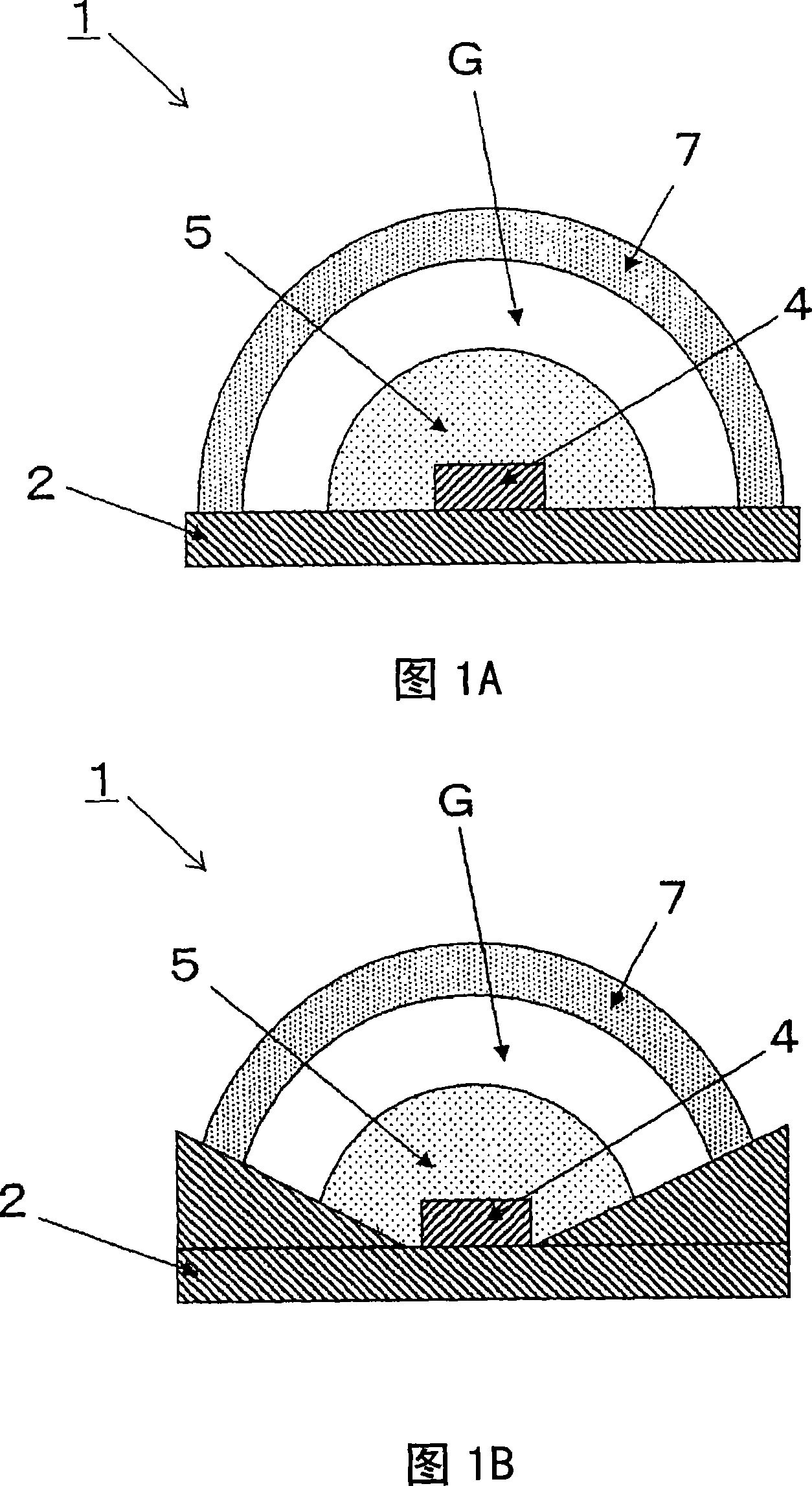

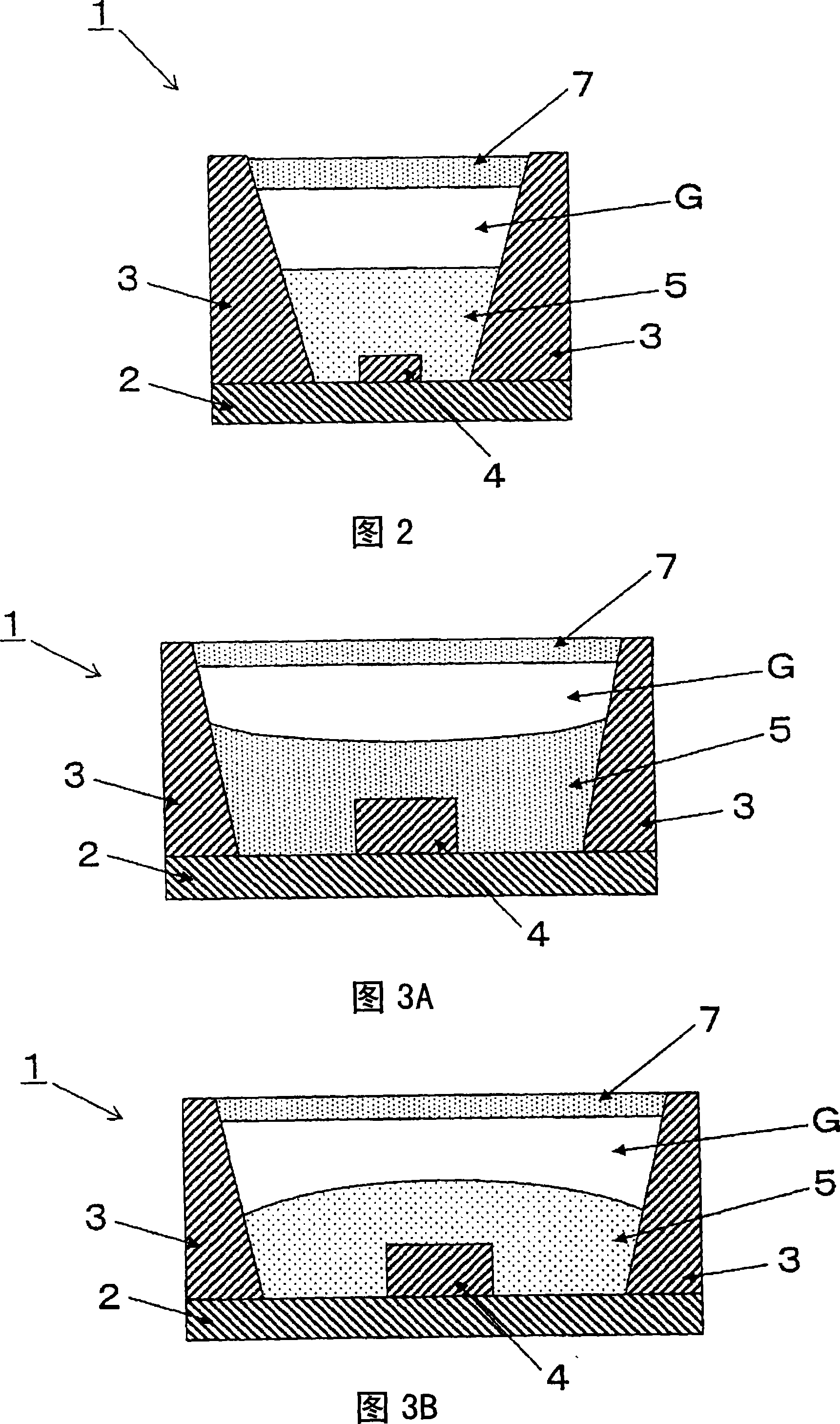

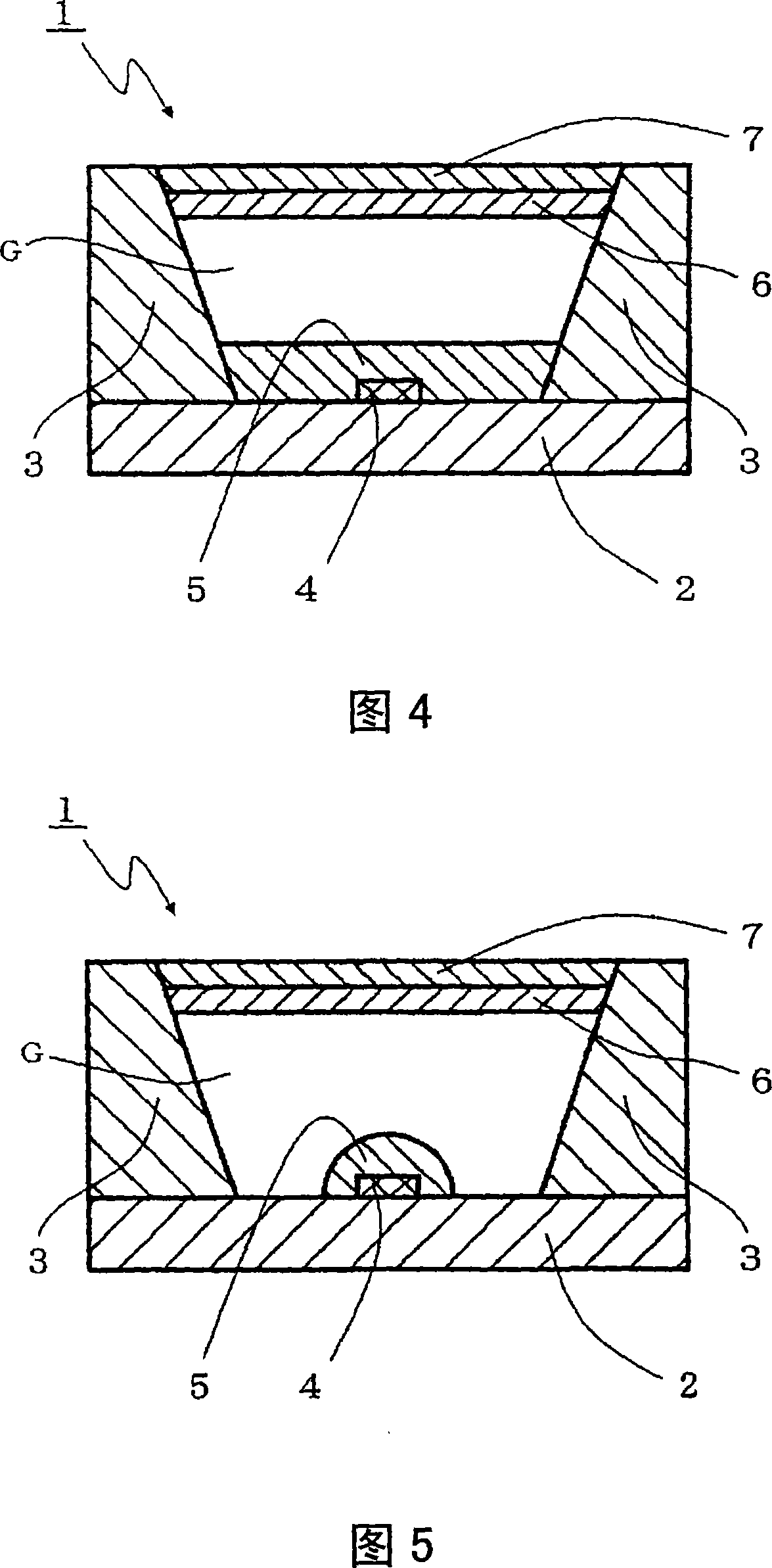

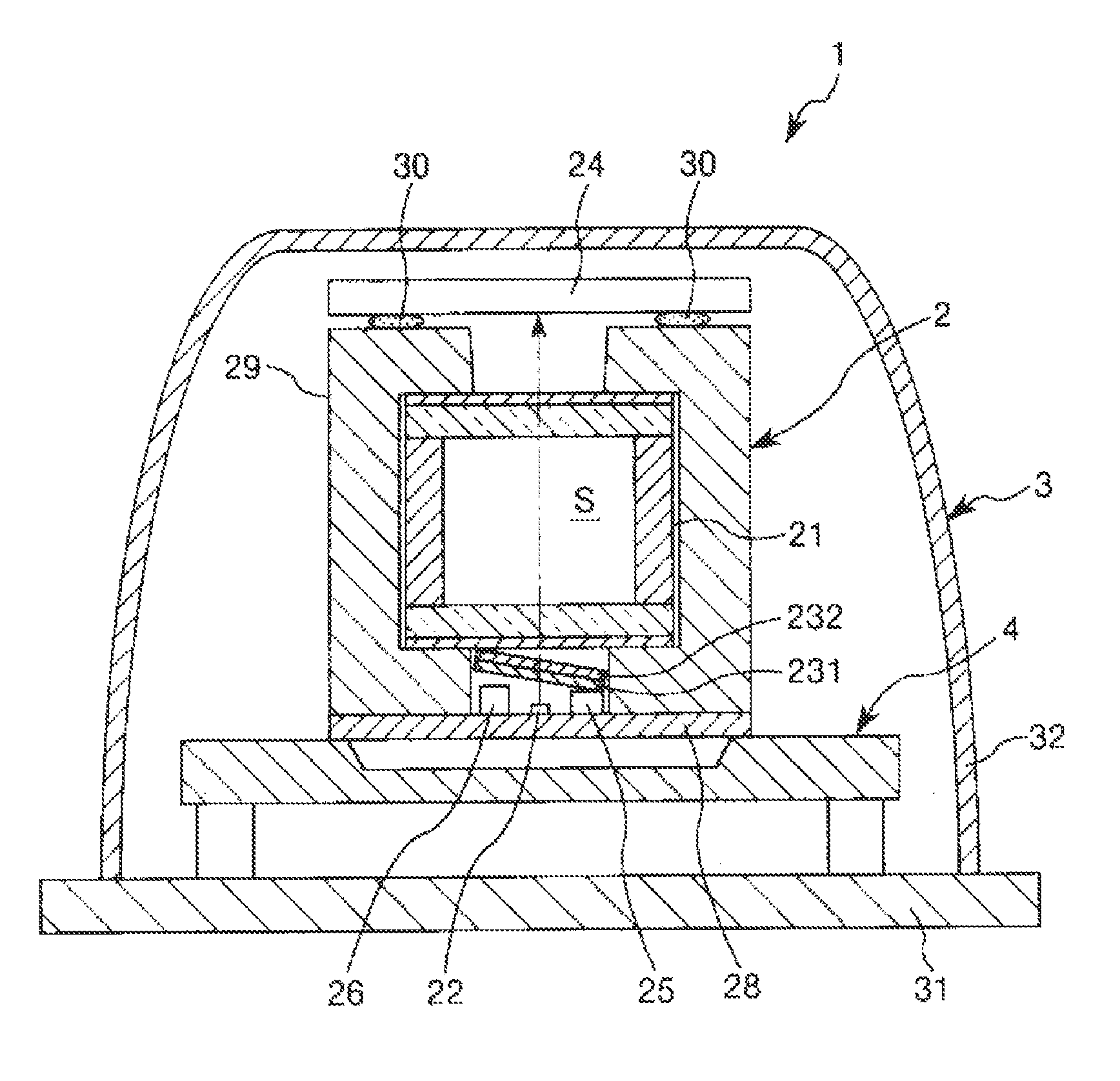

Light-emitting device and illuminating device

InactiveCN101124683AHigh intensity of emitted lightInhibit deteriorationSolid-state devicesSemiconductor devicesElectrical conductorPhosphor

A light-emitting device comprises a base where a wiring conductor is formed over the top to bottom surfaces or over the top to side surfaces, a light-emitting element mounted on the top surface of the base and electrically connected to the wiring conductor, a first light-transmitting section covering the light-emitting element, a second light-transmitting section disposed over the first light-transmitting section, covering the first light-transmitting element, and made of a light-transmitting material containing a phosphor for converting the wavelength of the light emitted from the light-emitting element and a third light-transmitting section interposed between the first and second light-transmitting sections. The following relations are satisfied: n3 H01L 33 / 00 9 29 2 2005 / 7 / 27 101124683 2008 / 2 / 13 000000000 Kyocera Corp. Japan Tabuchi Tomoya Miyake Akira Sakumoto Daisuke lixiang lan 11021 The Patent Agency of the Chinese Academy of Sciences Inside the Chinese Academy of Sciences, No.52 Sanlihe Road, Fuwai, Beijing 100864 Japan 2004 / 12 / 24 375037 / 2004 Japan 2005 / 1 / 24 016054 / 2005 2007 / 8 / 17 PCT / JP2005 / 013749 2005 / 7 / 27 WO2006 / 067885 2006 / 6 / 29 Japanese

Owner:KYOCERA CORP

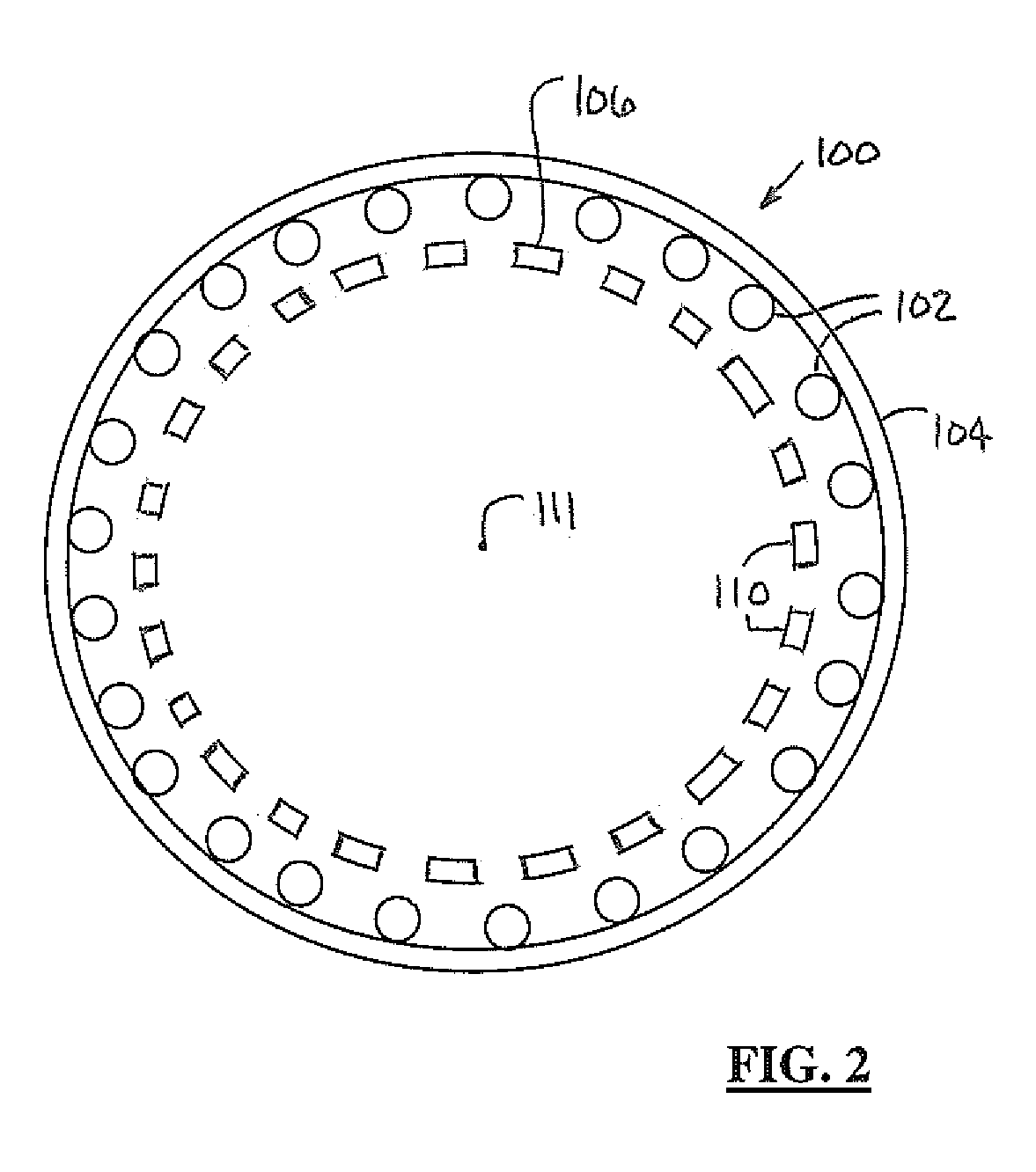

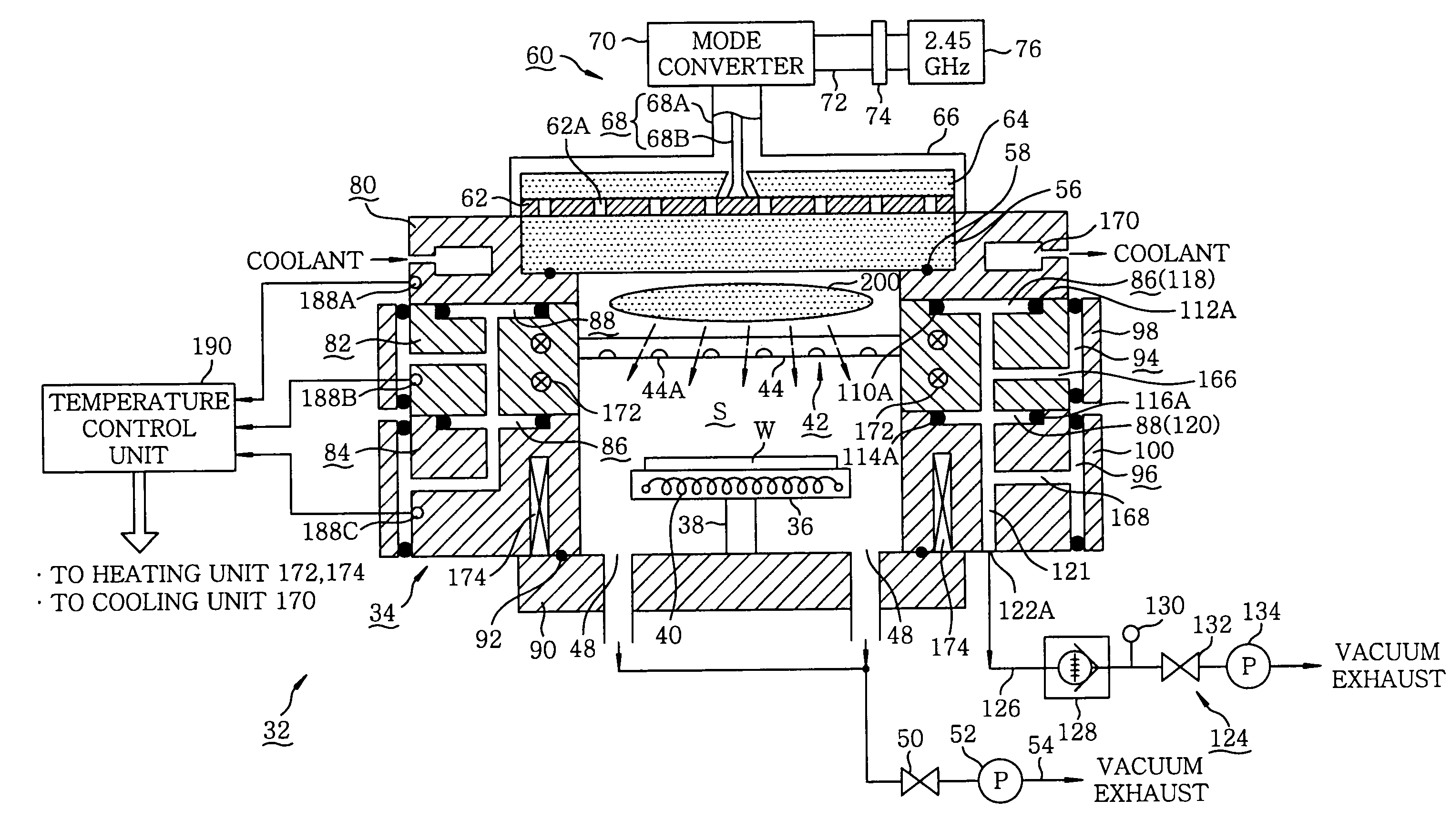

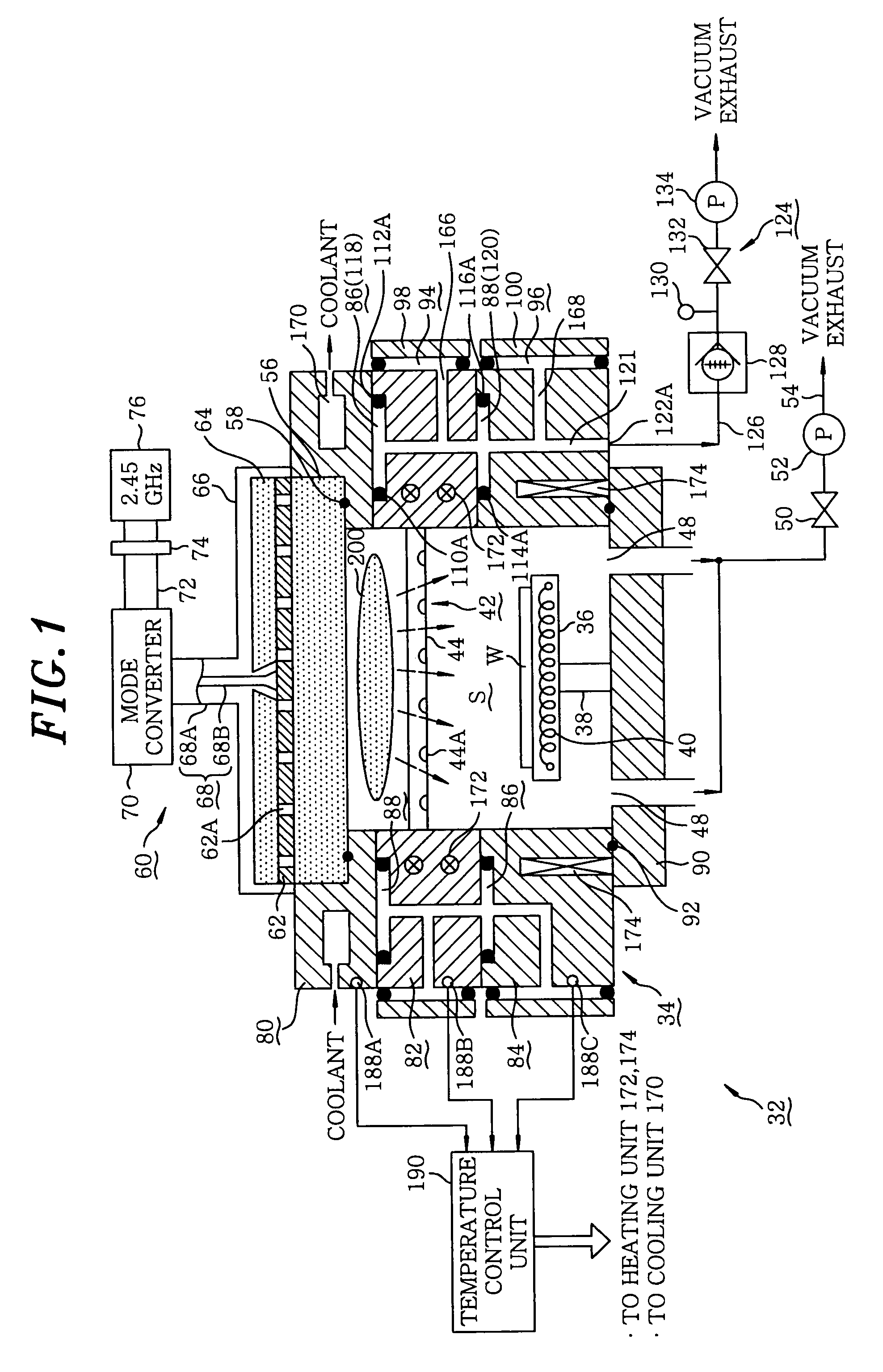

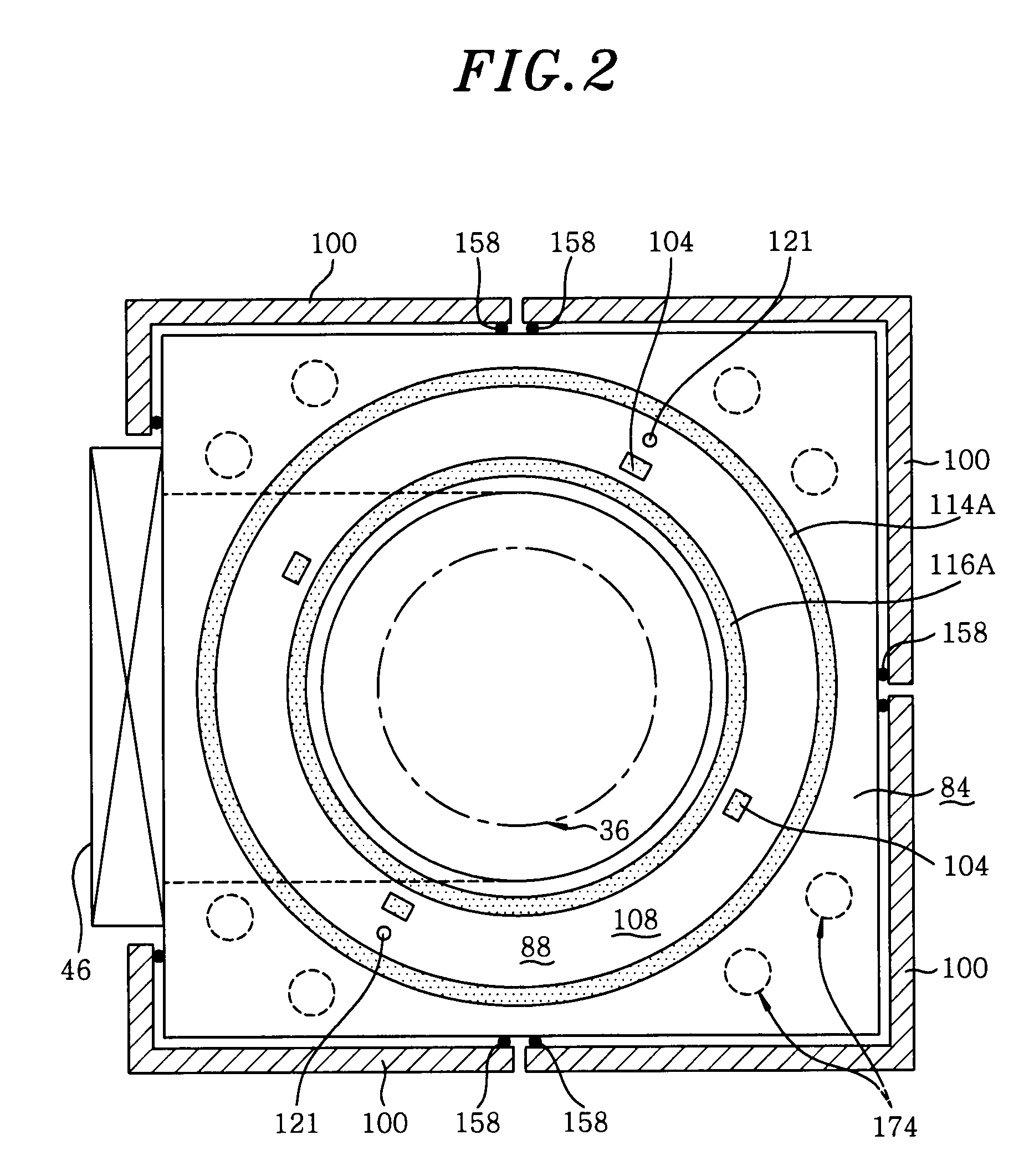

Processing apparatus

InactiveUS20090133835A1Improve energy efficiencyAvoid heat transferLiquid surface applicatorsElectric discharge tubesEngineeringSemiconductor

Provided is a structure of an improved processing vessel for a processing apparatus which processes a target object, such as a semiconductor wafer, which is heated in the metal cylindrical shaped processing vessel by using a processing gas. The processing vessel (34) is composed of a plurality of block bodies (80, 82, 84) mutually connected by being stacked in the vertical direction. Heat insulating vacuum layers (86, 88) are arranged between the adjacent block bodies. Thus, heat transfer between block bodies is suppressed, so that temperature of each block body can be separately controlled, thereby improving energy efficiency.

Owner:TOKYO ELECTRON LTD

Cooling apparatus

ActiveCN106233083AIncrease temperatureQuick freezeLighting and heating apparatusDomestic refrigeratorsEvaporatorHeating element

Cooling apparatus (1), in particular a chest freezer (2), having a cooling circuit (3), a compressor (4), at least one evaporator (5) and a condenser (44), and a closable cooling chamber (6) with a plurality of cooling chamber side walls (7), a cooling chamber floor (8), at least one cooling element (9) and an insulating container (10). In the cooling apparatus (1), the evaporator (5) and the cooling element (9) are arranged within the cooling chamber (6) in such a way that the rear side of the cooling element (11) bears at least partially against the evaporator (5), and the front side of the cooling element (12) faces the insulating container (10), and the insulating container (10) is closed at least towards the at least one cooling element (9) and forms a chilled goods chamber (13). That rear side of the cooling element (11) which bears against the evaporator (5) has at least one cut-out (14), into which at least one removable refrigeration accumulator (15) can be inserted. At least one heating element (17) and at least one accumulator element (18) are preferably arranged in the region of the downwardly pointing end (16) of the insulating container (10).

Owner:DOMETIC SARL LU

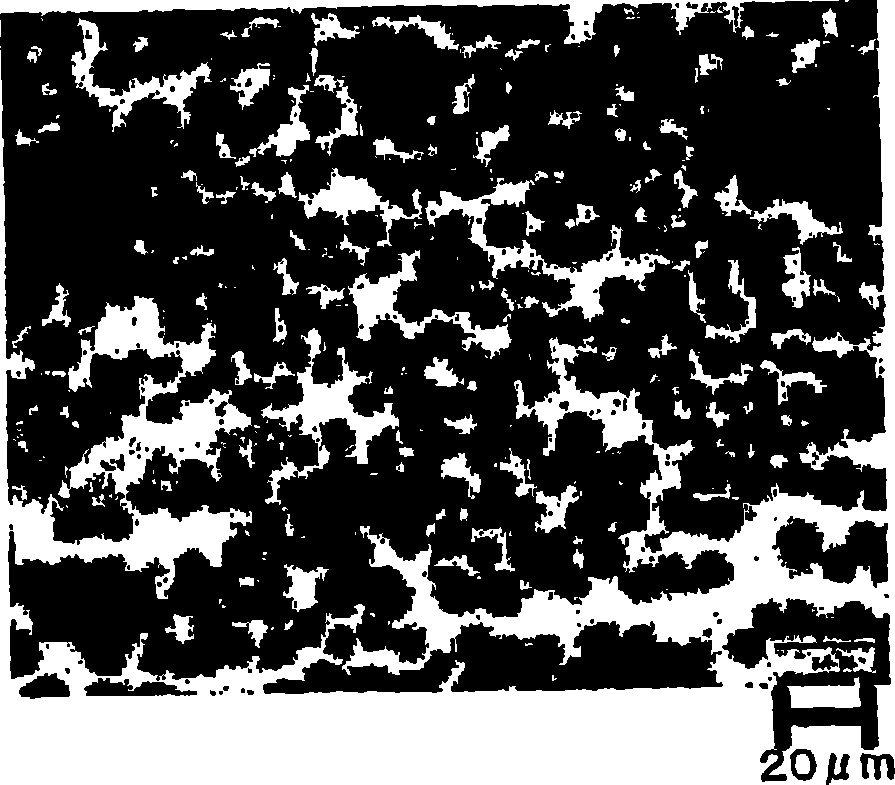

Metal-based carbon fiber composite material and method for producing the same

InactiveCN1894435AReduce weightHigh thermal conductivityMaterial nanotechnologySemiconductor/solid-state device detailsMetal fiberHeat flow

A method is provided for producing a metal-based carbon fiber composite material lightweight, high in the thermal conductivity and also capable of controlling the direction of heat flow, while inhibiting metal carbide formation. The method for producing the metal-based carbon fiber composite material comprises the steps of: obtaining a metal fiber mixture by physically mixing carbon fiber with metal powder; filling the metal fiber mixture into a jig, while the metal fiber mixture is aligned; and setting the jig in an air, vacuum or inert gas atmosphere and directly supplying pulse electric current to the metal fiber mixture, with applying a pressure, to effect sintering by the heat generated therefrom. Here, the composite material contains 10 to 80 % by weight of carbon fiber based on a total weight of the composite material and is sintered at 70% or more of ideal density.

Owner:岛根县

Thermal Type Flow Sensor

InactiveUS20070251315A1Prevent heat transferEliminate pollutionVolume/mass flow by thermal effectsControl circuitResistor

A flow rate measuring element of a thermal type flow sensor is placed in the fluid to be measured. The element includes: a first heating resistor for measuring a flow rate; a second heating resistor for heating a support for the first heating resistor; and current control circuits and which control heating resistor supply current so that the temperature of the second heating resistor is higher than the temperature of the first heating resistor.

Owner:HITACHI LTD

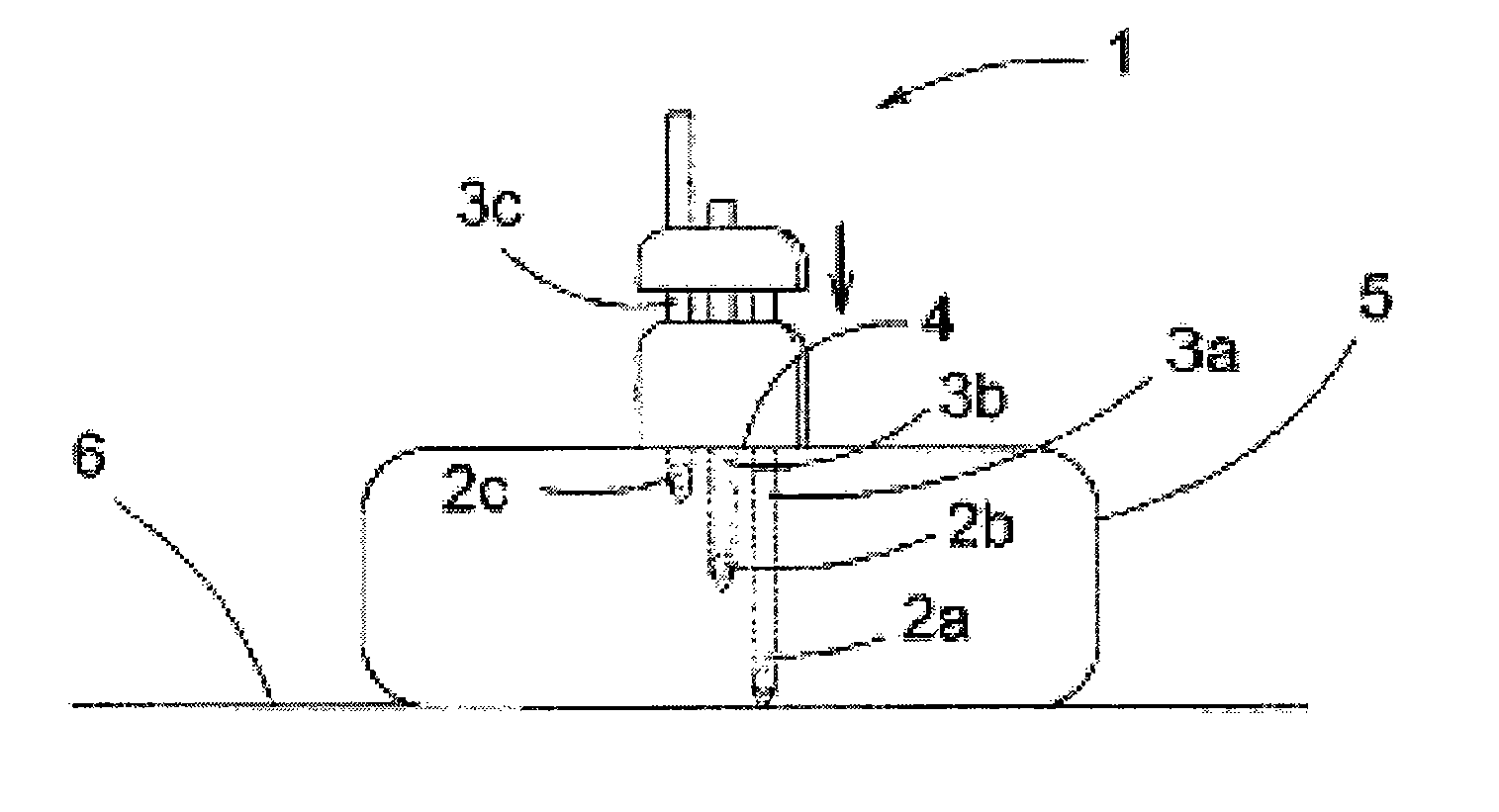

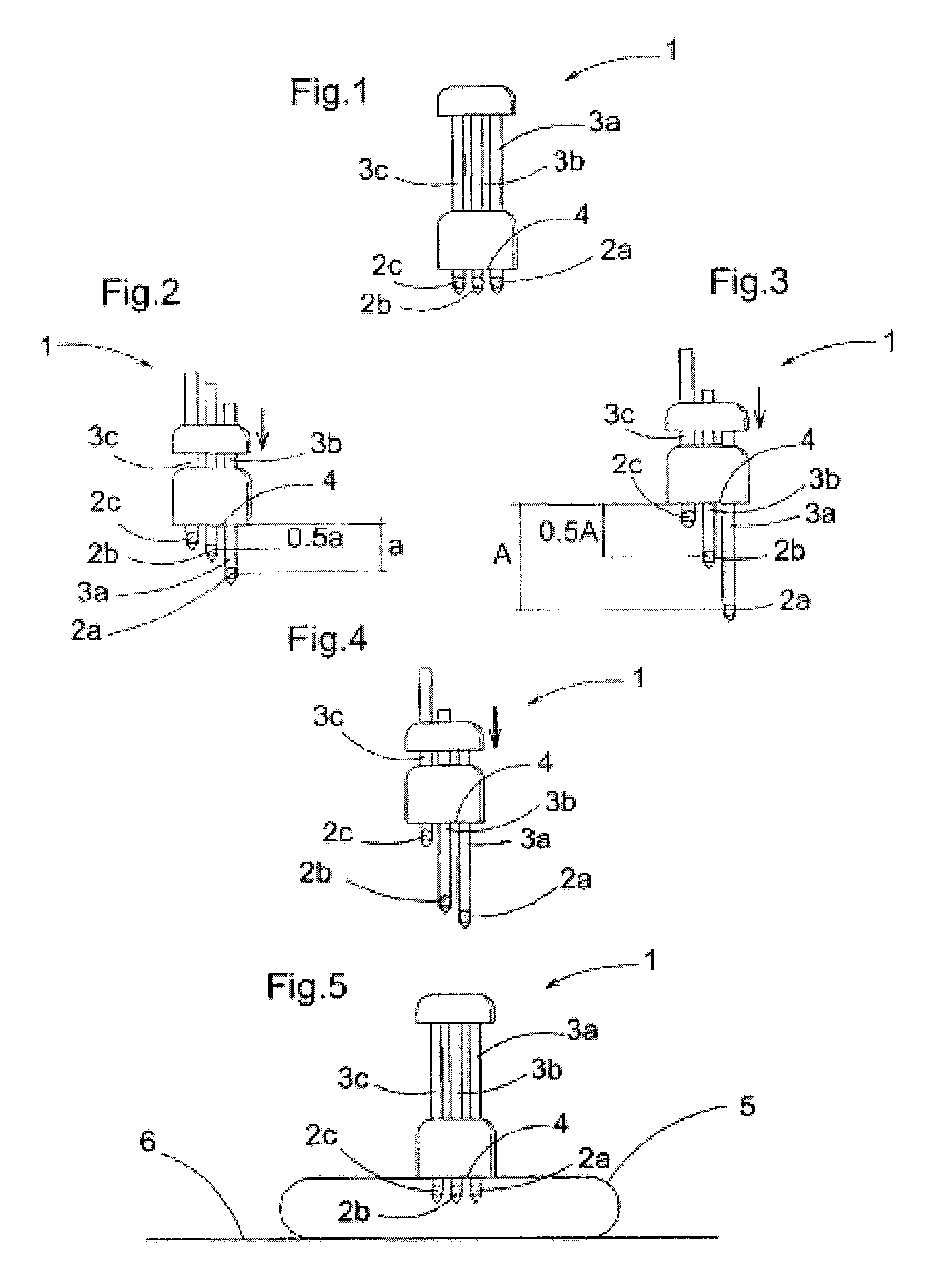

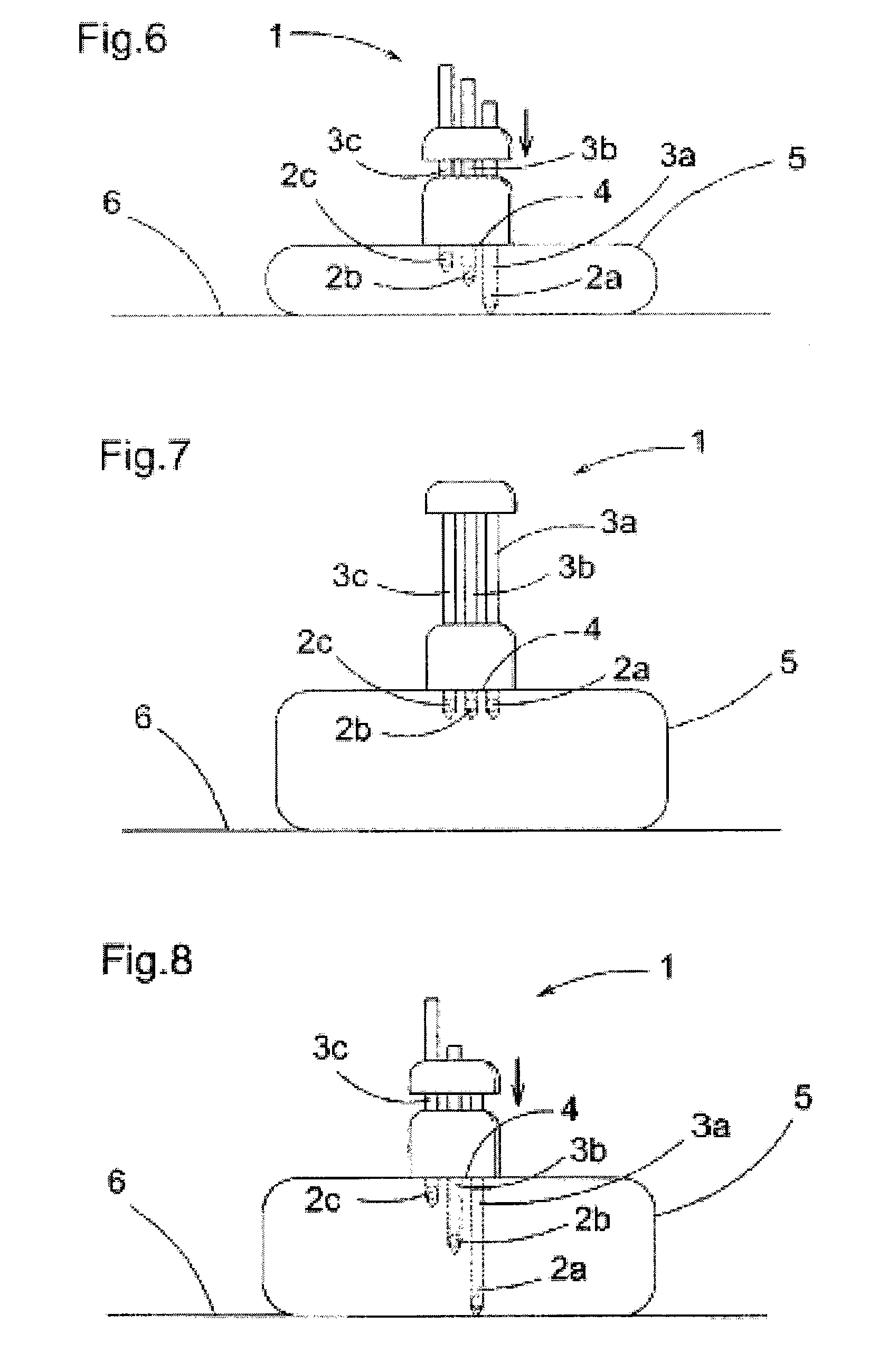

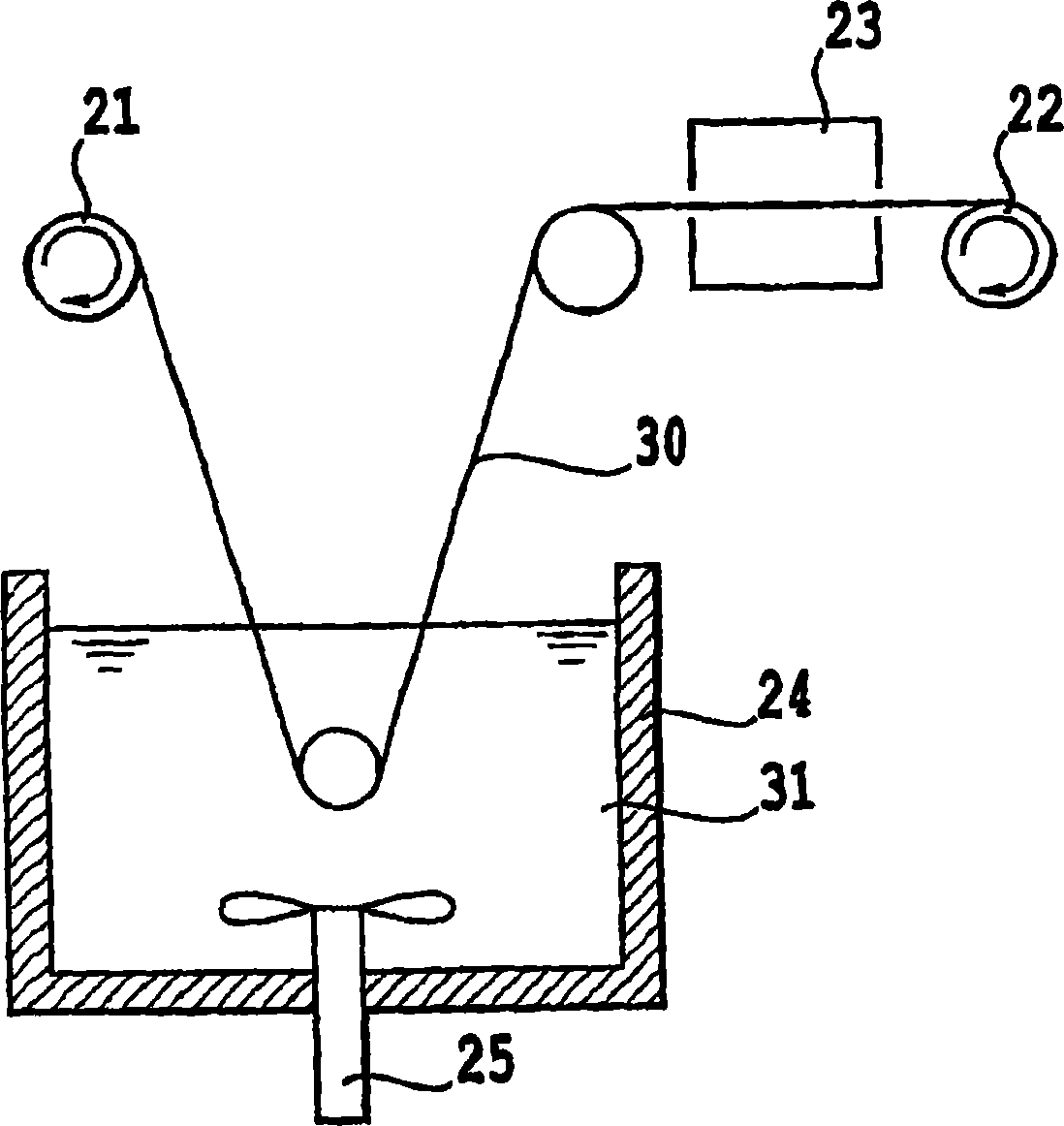

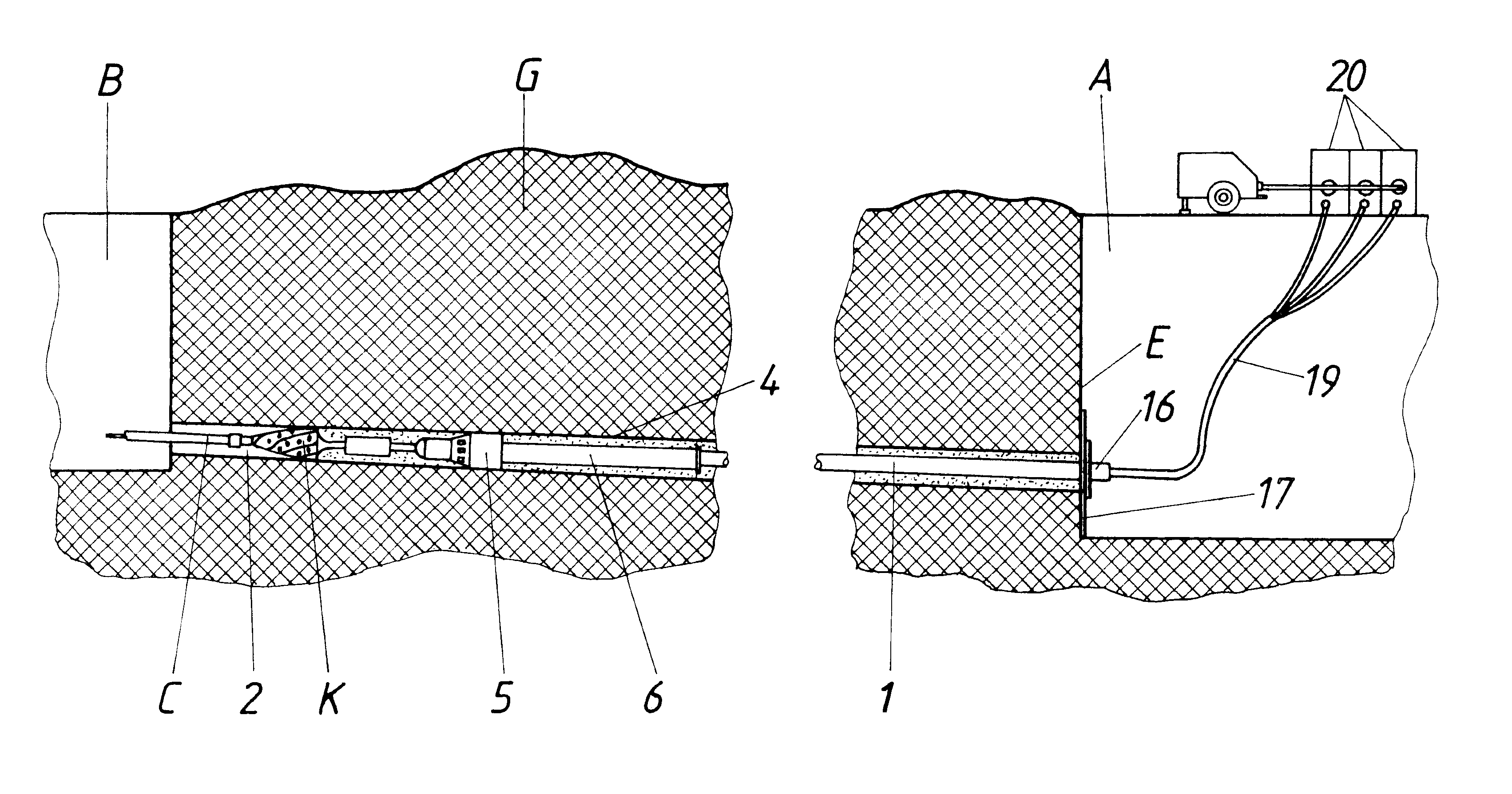

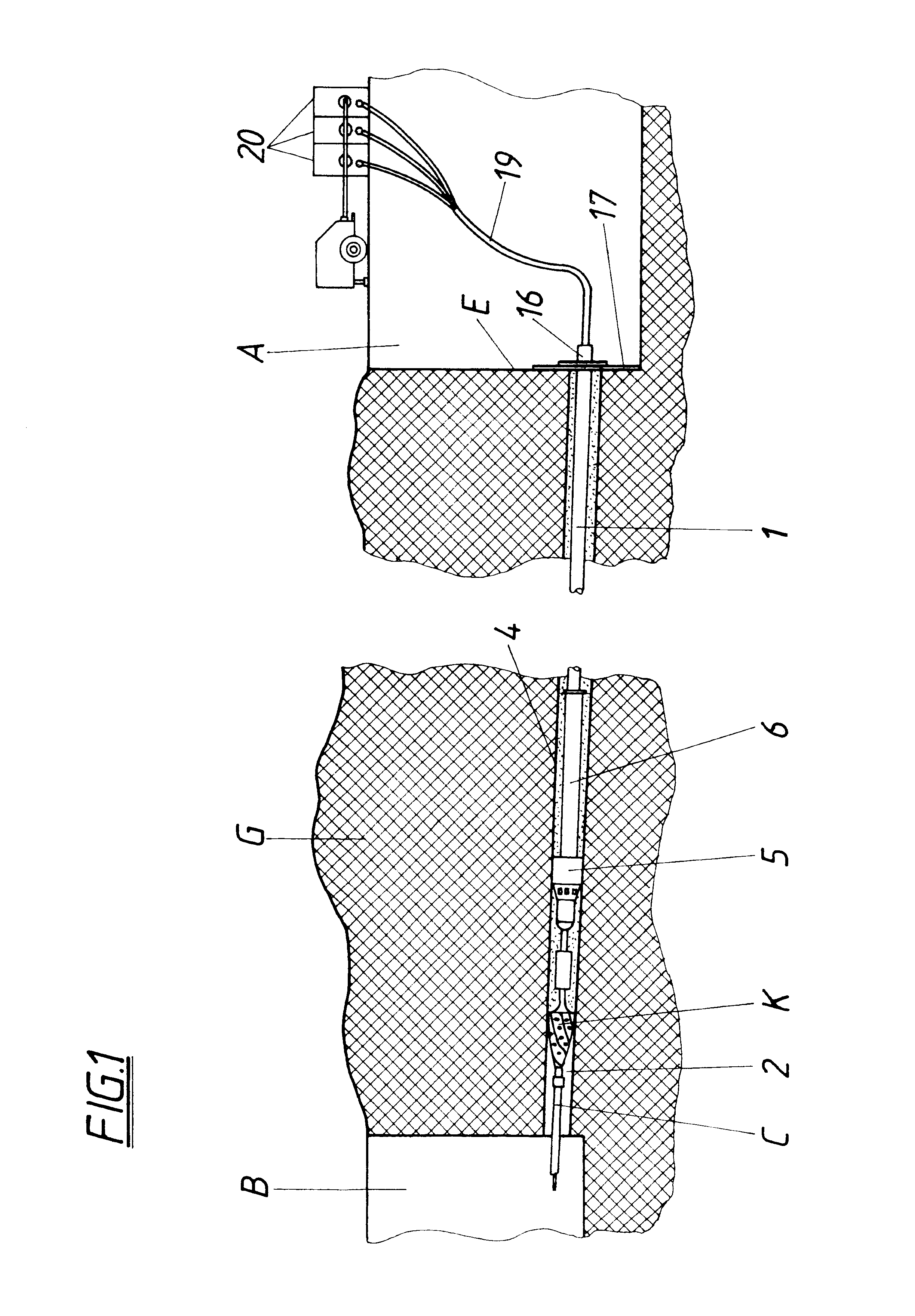

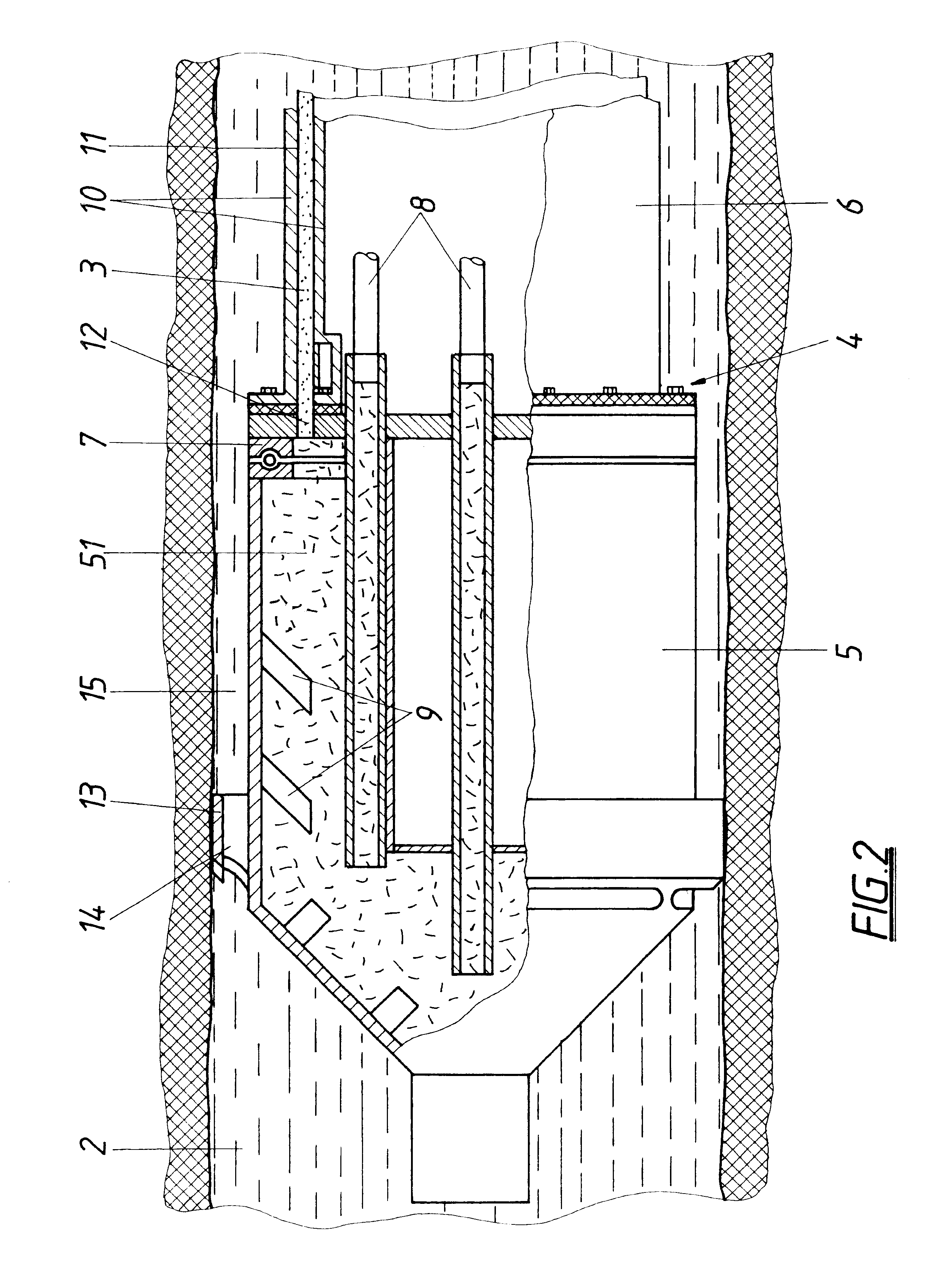

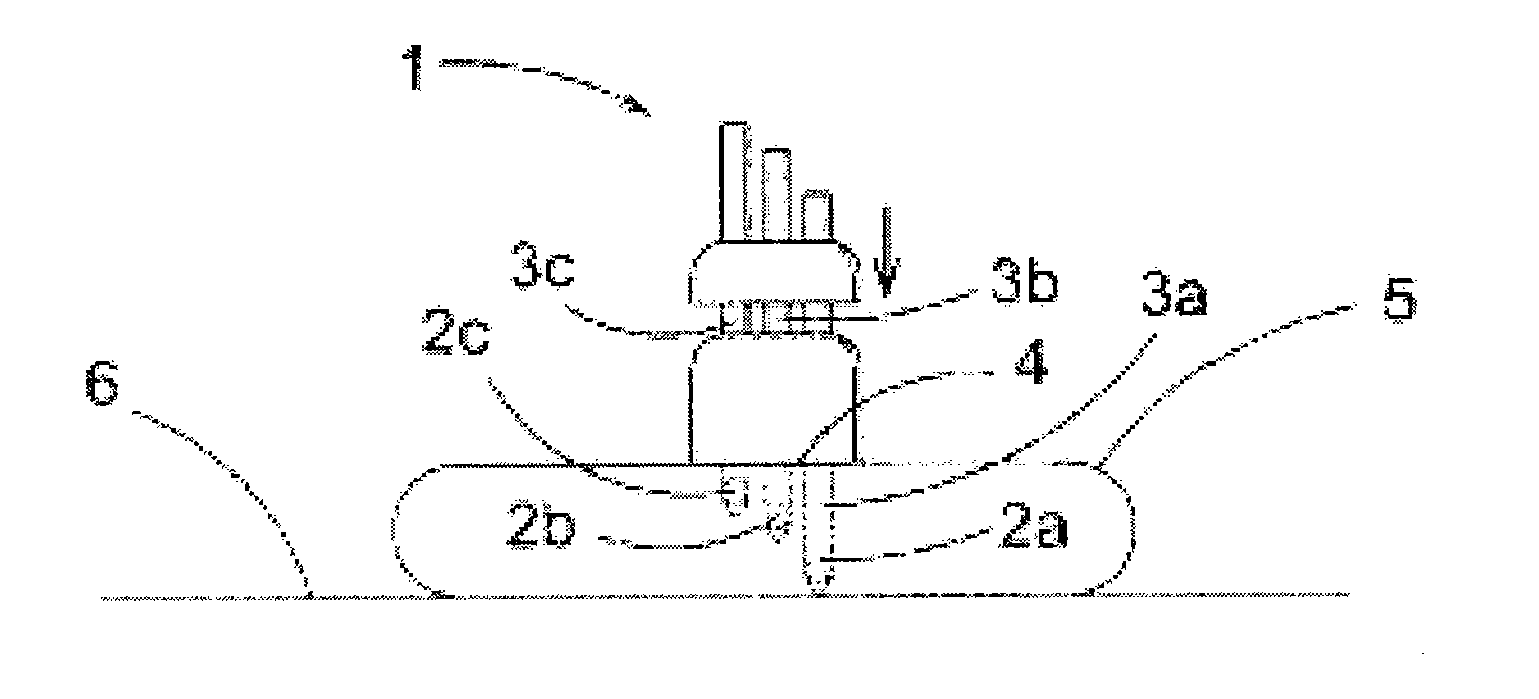

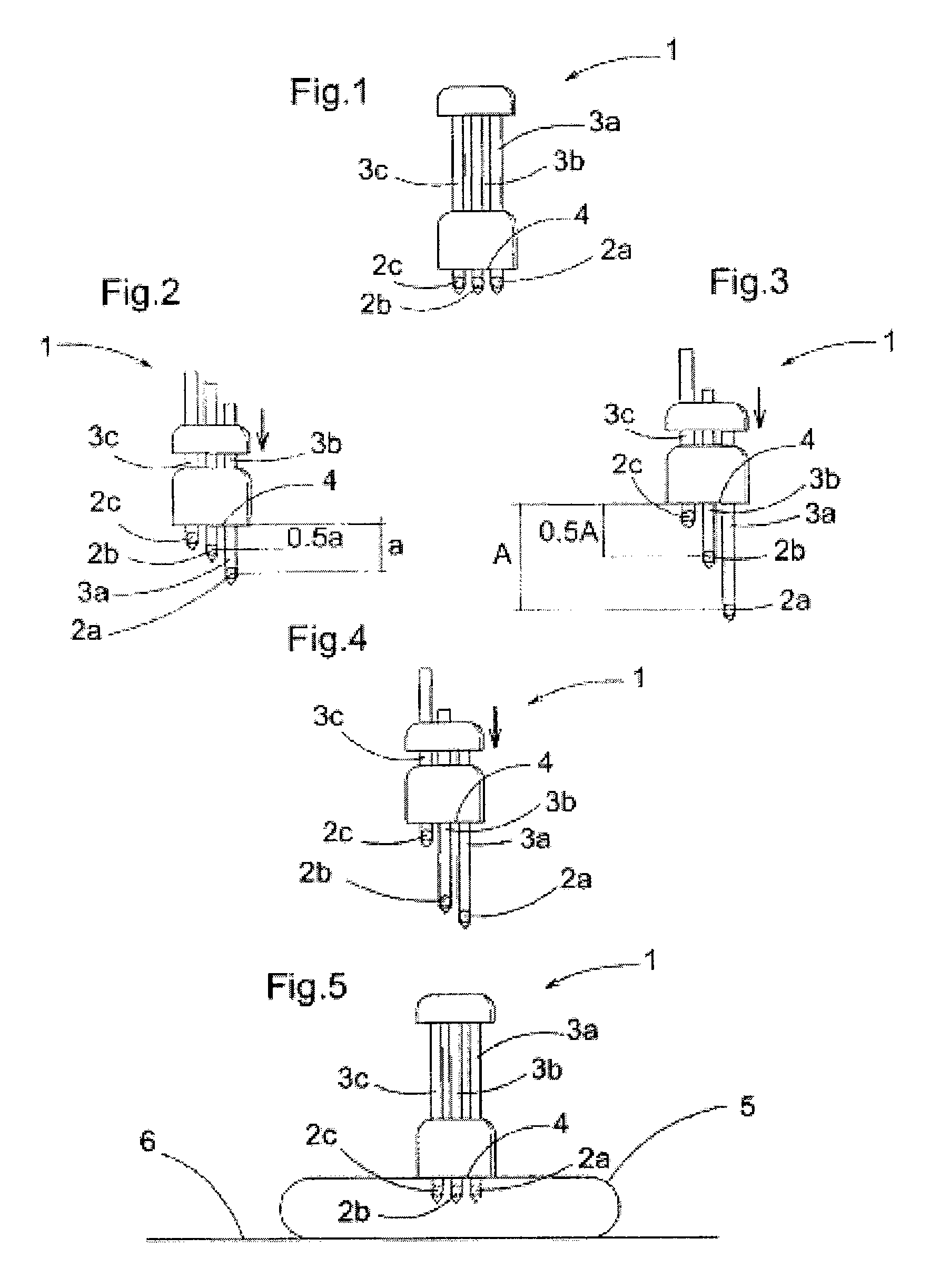

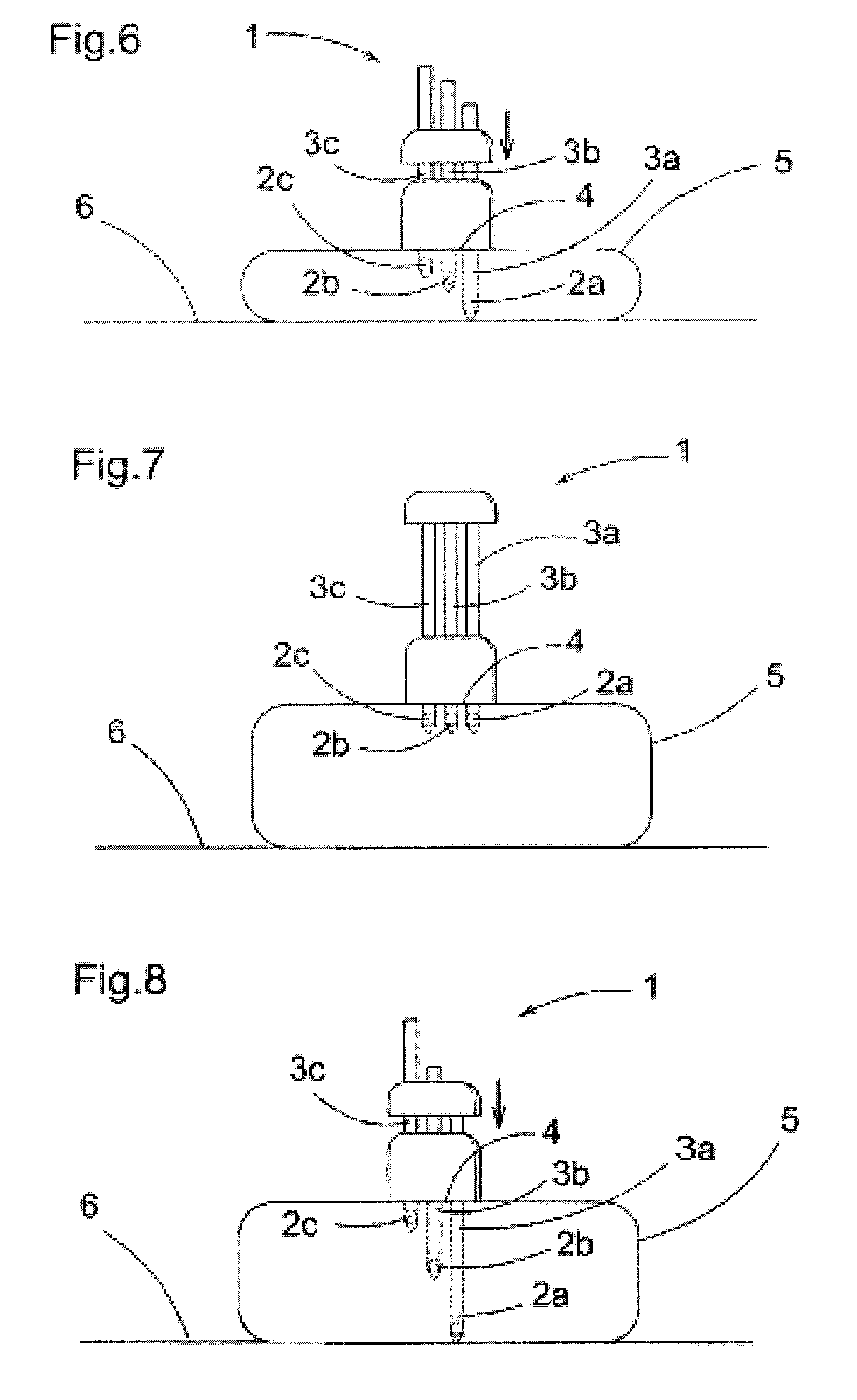

Method and device for laying an underground duct made of a plastic material

InactiveUS6565285B1Increase spacingEfficient executionPipe laying and repairUnderground chambersPlastic materialsSynthetic substance

For laying synthetic underground piping (1) a ground channel (2) is first bored and the piping (1) is introduced into the ground channel (2). To facilitate laying an underground pipe length particularly effectively, the pipe length (1) comprising a hardening synthetic mass is manufactured at the same time as it is introduced into the ground channel (2) by the prepared synthetic mass being formed continuously inside the ground channel (2) as a run of piping (3) and left to harden. A reactor (4) which can be drawn through the ground channel (2) and comprising a front reactor drum (5) and a rear double-sheathed calibrating cylinder (6) is provided for this purpose, whereby reactor drum (5) and calibrating cylinder (6) are arranged coaxially to one another and relatively rotatably and lines (8) for supply of constituents terminate in the reactor chamber (51) of the reactor drum (5) and the reactor chamber (51) is connected by way of a nozzle ring (12) to the calibrating space, open from below and formed from the double mantle (10) of the calibrating cylinder (6).

Owner:LANDRICHTER WOLFGANG

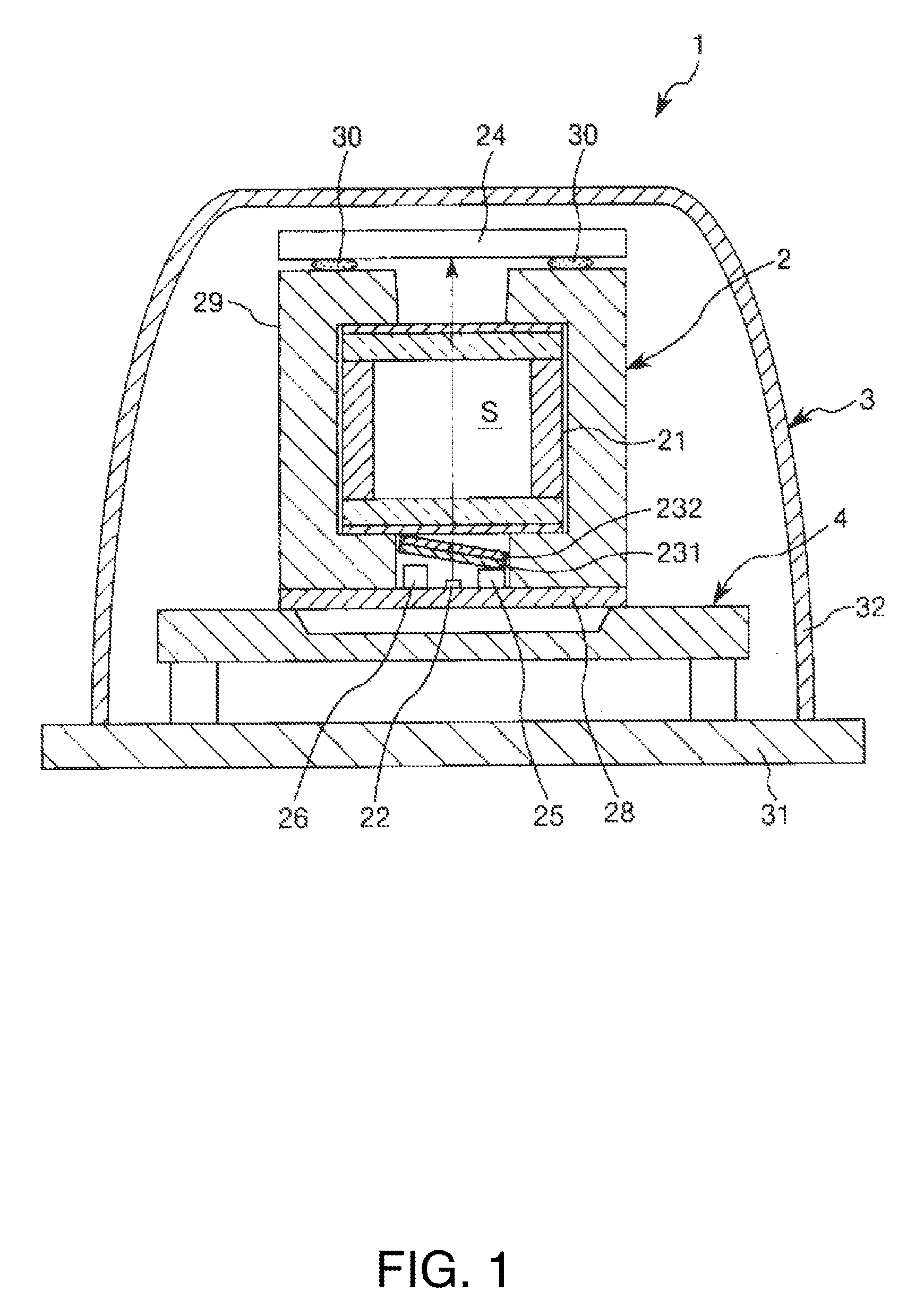

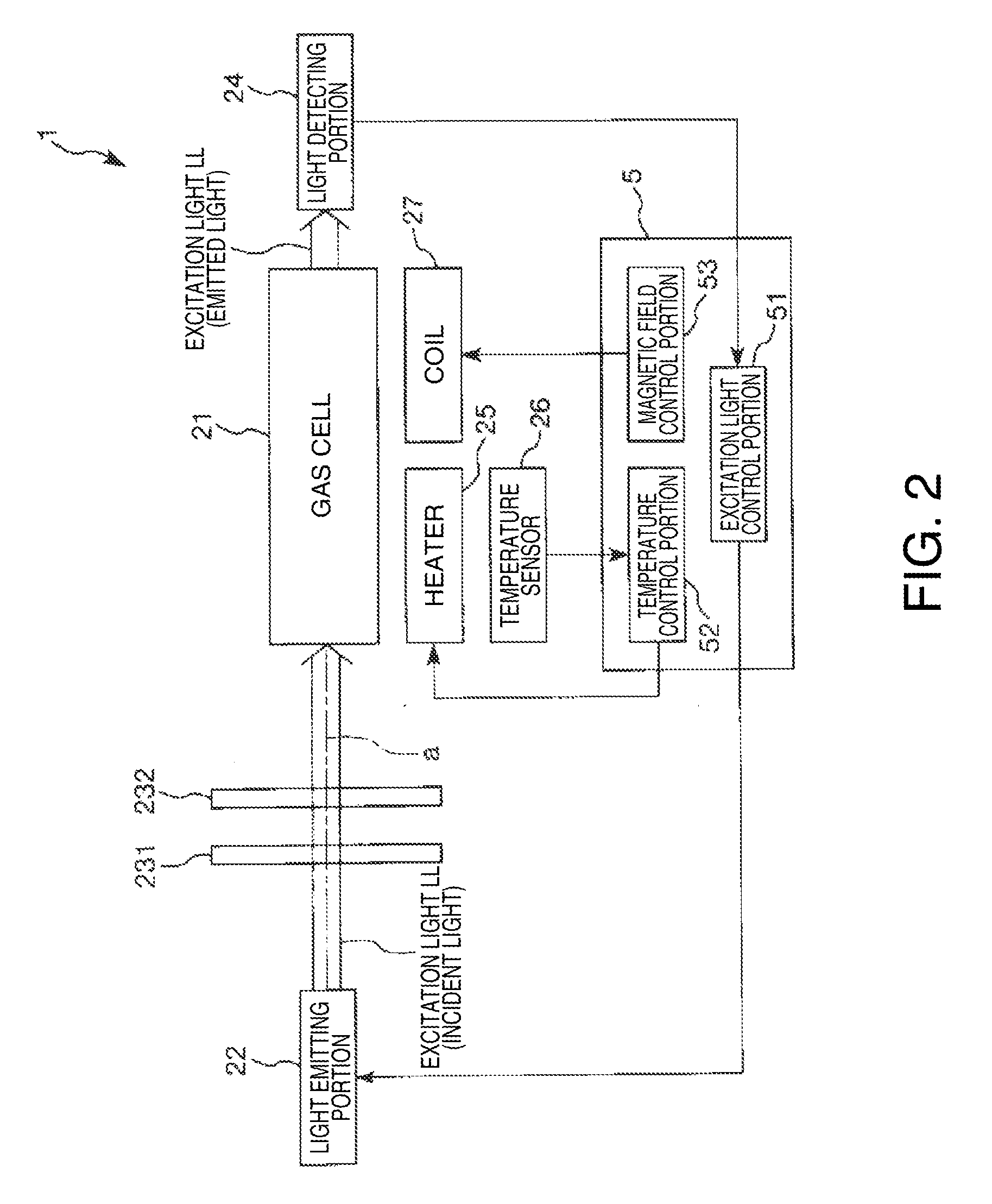

Quantum interference device, atomic oscillator, and moving object

ActiveUS20140232478A1Excellent reliabilityAvoid heat transferPulse automatic controlGaseous masersEngineeringQuantum

An atomic oscillator includes a base, a unit portion including a gas cell and the like, and a support member that supports the unit portion against the base. The support member includes a plurality of leg portions and a connecting portion that connects the plurality of leg portions to each other. A connection portion between each leg portion and the base is separated from the unit portion in plan view from a direction in which the base and the unit portion overlap each other.

Owner:MICROCHIP TECH INC

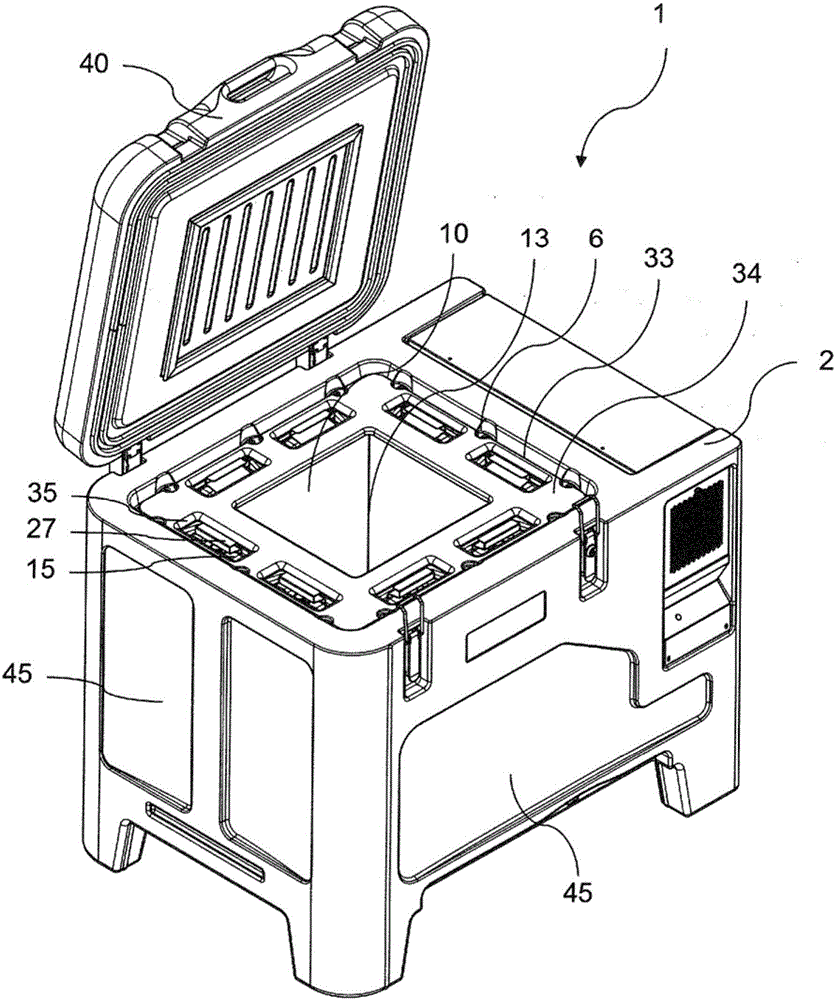

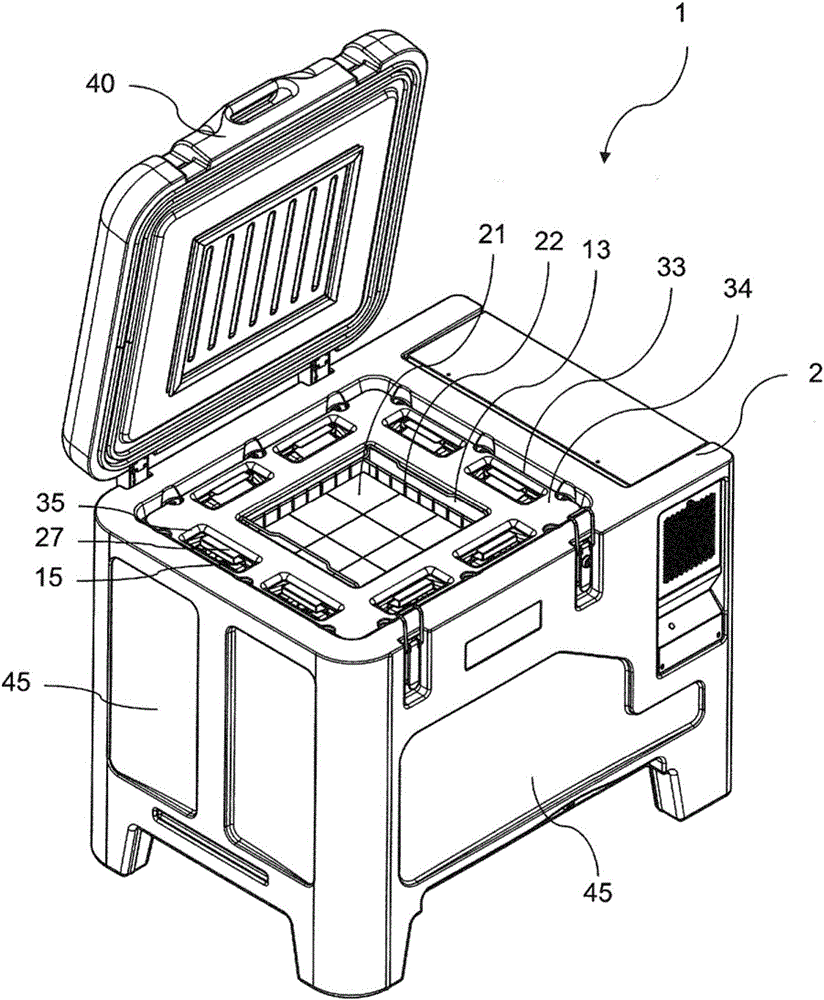

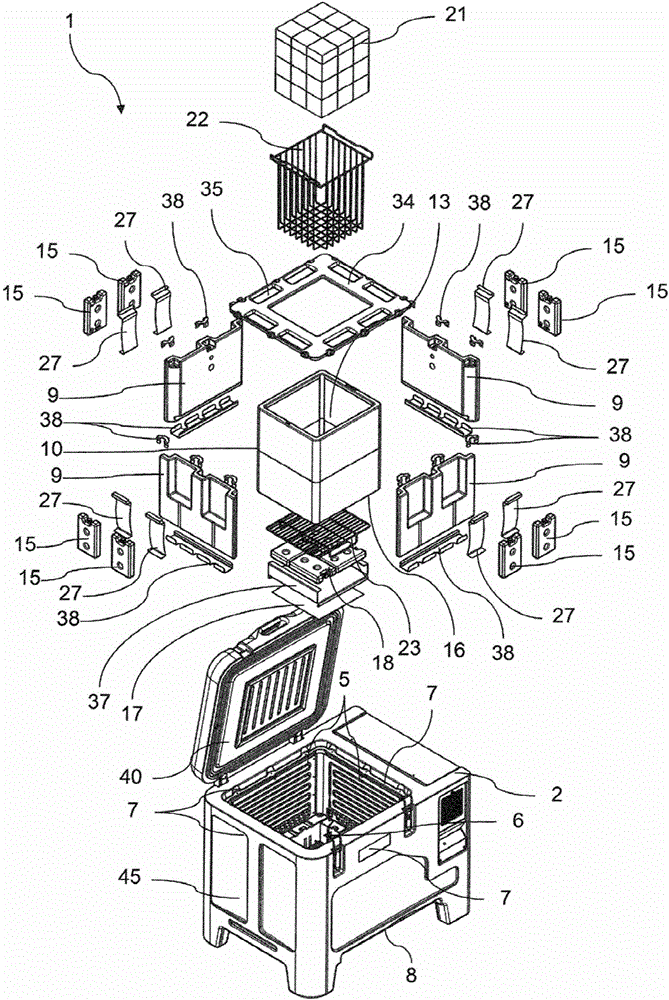

Cold-chain logistics heat preservation box and preparation method thereof

InactiveCN105819107AHigh strengthReduce wall thicknessDomestic cooling apparatusLighting and heating apparatusCold chainLogistics management

The invention discloses a cold chain logistics incubator and a preparation method thereof. The incubator includes an outer box, a middle box and an inner box nested sequentially from outside to inside, the outer box includes an outer box body and an outer box cover, and the outer box body Both the inner box and the outer box cover are made of corrugated board structure; the middle box includes the middle box body and the middle box cover, and the middle box body and the middle box cover are both made of vacuum insulation board structure; the inner box includes the inner box body and the inner box cover, the inner box body and the inner box cover. The inner box cover adopts the cold storage plate structure, and the cold storage liquid is arranged in the cold storage plate. The heat preservation box has the advantages of simple structure, convenient use, low cost, high effective volume ratio and long heat preservation time. The preparation method of the cold chain logistics incubator has the advantages of simple process and high degree of standardization.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Food cooking control method and device

InactiveUS8609168B2Easy to controlSimple designThermometer detailsBoiling over preventionEngineeringCooking process

Owner:POINTJUST

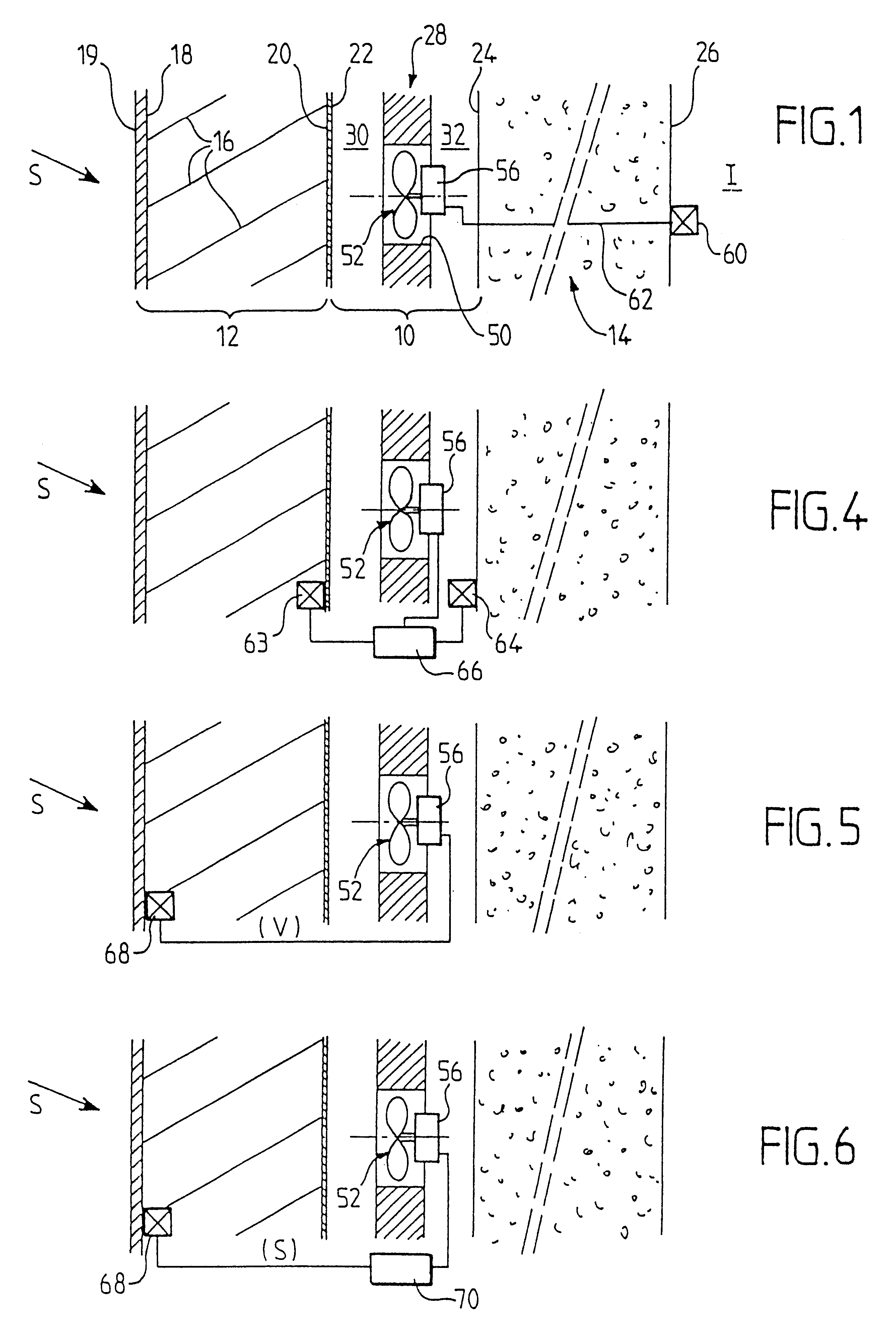

Device for transferring heat between a panel heated by solar radiation and a wall

InactiveUS6494200B1Avoid draftsAvoid heat transferRoof covering using slabs/sheetsSolar heating energyInterior spaceAir cycle

A device for transferring heat between a panel heated by solar radiation and a wall surface, including an insulating plate mounted parallel between the panel and the wall surface, to define a closed external space between the panel and the insulating plate, and a closed internal space between the insulating plate and the wall. An air circulator is interposed between the external space and the internal space and can be put selectively in an open state allowing circulation of air between the external space and the internal space, and thus allowing thermal transfer between the panel and the wall, and a closed state preventing circulation of air between the external space and the internal space, and thus preventing thermal transfer between the panel and the wall.

Owner:RYLEWSKI EUGENIUSZ

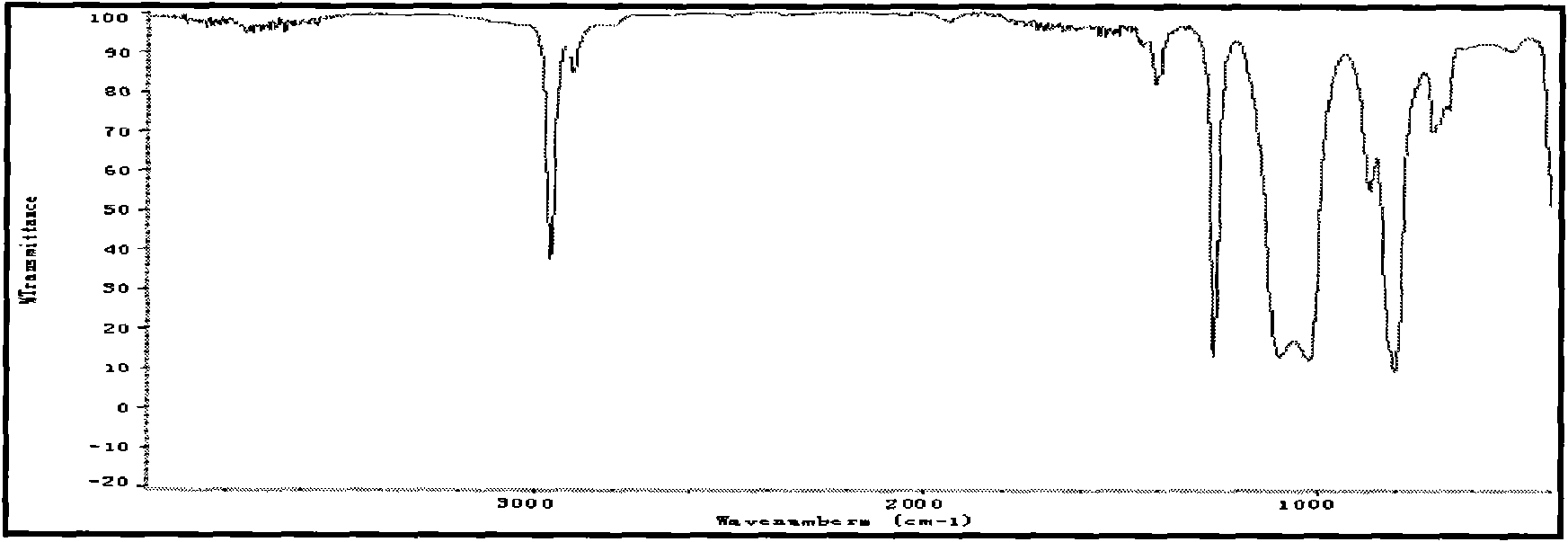

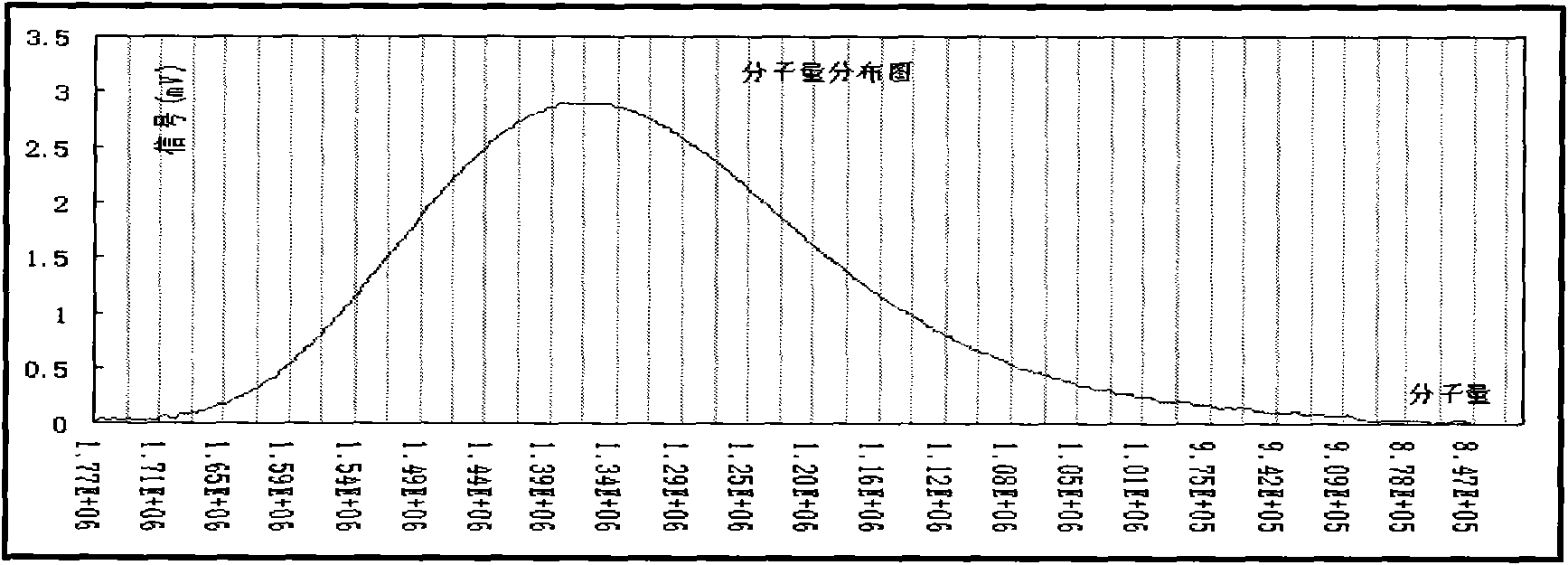

Preparation method for polysiloxane with extra high molecular weight

The invention discloses a preparation method for polysiloxane with extra high molecular weight, comprising the steps of (1) adding dimethyl siloxane or alpha, omega-dihydroxy polydimethylsiloxane intoa reactor, stirring, controlling the rotating speed being 30 to 60 revolutions per minute, heating up to 90-160 DEG C., adding catalyzer which occupies 0.001% to 0.1% by weight of raw materials and reacting for 2.0 to 6.0 hours at constant temperature, (2) at constant temperature, vacuum-pumping for 1.0 to 4.0 hours, and controlling the vacuum degree being -0.080 to -0.10 MPa, and (3) adding neutralizing agent which occupies 0 to 0.1% by weight of raw materials, heating up to 170-180 DEG C., introducing nitrogen, vacuum-pumping for 2.0 to 6.0 hours, stopping heating, stirring, discharging after cooling to room temperature to obtain the blocky or granular hydroxyl silicone oil products with extra high molecular weight. The invention can prepare the polysiloxane with molecular weight more than 1000000.

Owner:GUANGZHOU TINCI MATERIALS TECH

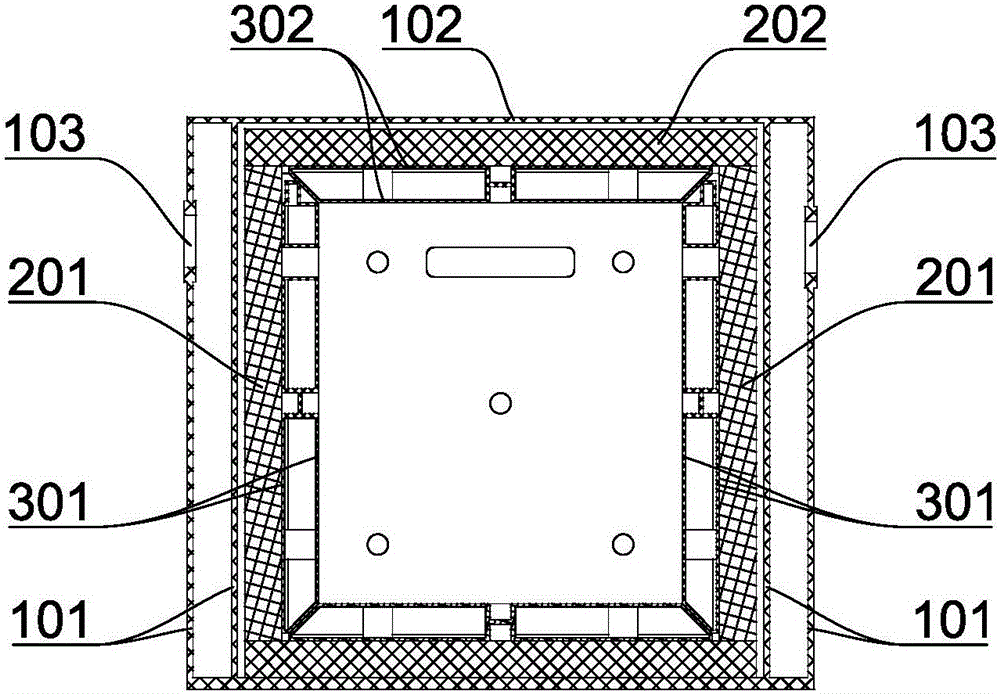

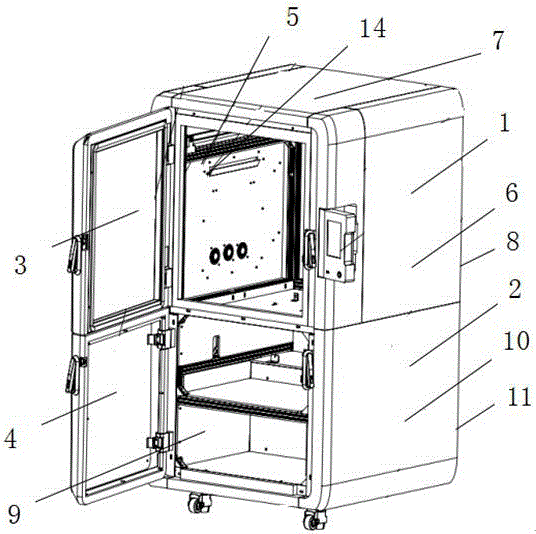

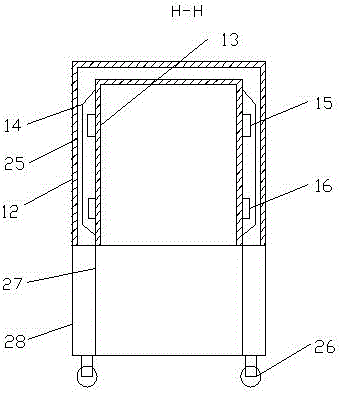

FDM 3D printer with heating thermal insulation property

InactiveCN106003736ABeautiful structureLow priceAdditive manufacturing apparatusThermal insulationFlue

The invention discloses a FDM3D printer with heating and heat preservation performance, which comprises a casing, the casing includes a lower casing and an upper casing fixedly connected above the lower casing; an upper front door is installed directly in front of the upper casing, and the lower casing The lower front door is installed directly in front of the front; the upper shell and the lower shell are set as a rectangular parallelepiped structure without a front face; The double-layer structure, the double-layer structure includes the outer sheet metal shell and the inner sheet metal plate; the double-layer structure on the upper left side and the upper right side is equipped with an air duct; the upper end of the air duct is equipped with a heater, and the lower end is It is equipped with a turbo fan; it reduces the heat exchange between the printer's printing chamber and the outside air, so that the hot air in the printer is not easy to flow out from the sheet metal gap; and heats the air in the upper casing, and makes the printing chamber reach the preset goal After the temperature value, it is in a state of constant temperature and uniformity.

Owner:JIANGSU OURING THREE DIMENSIONAL SCI & TECH CO LTD

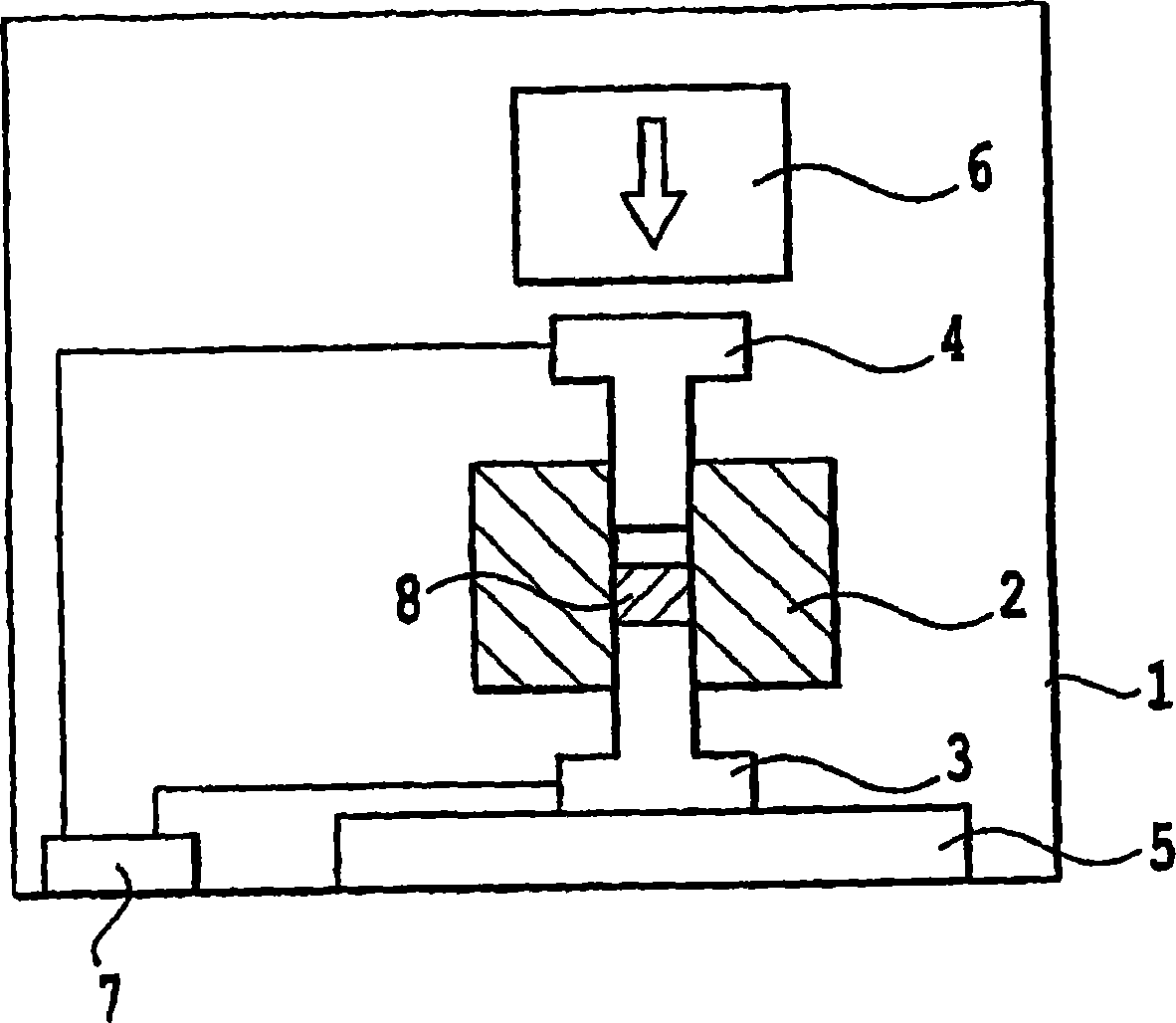

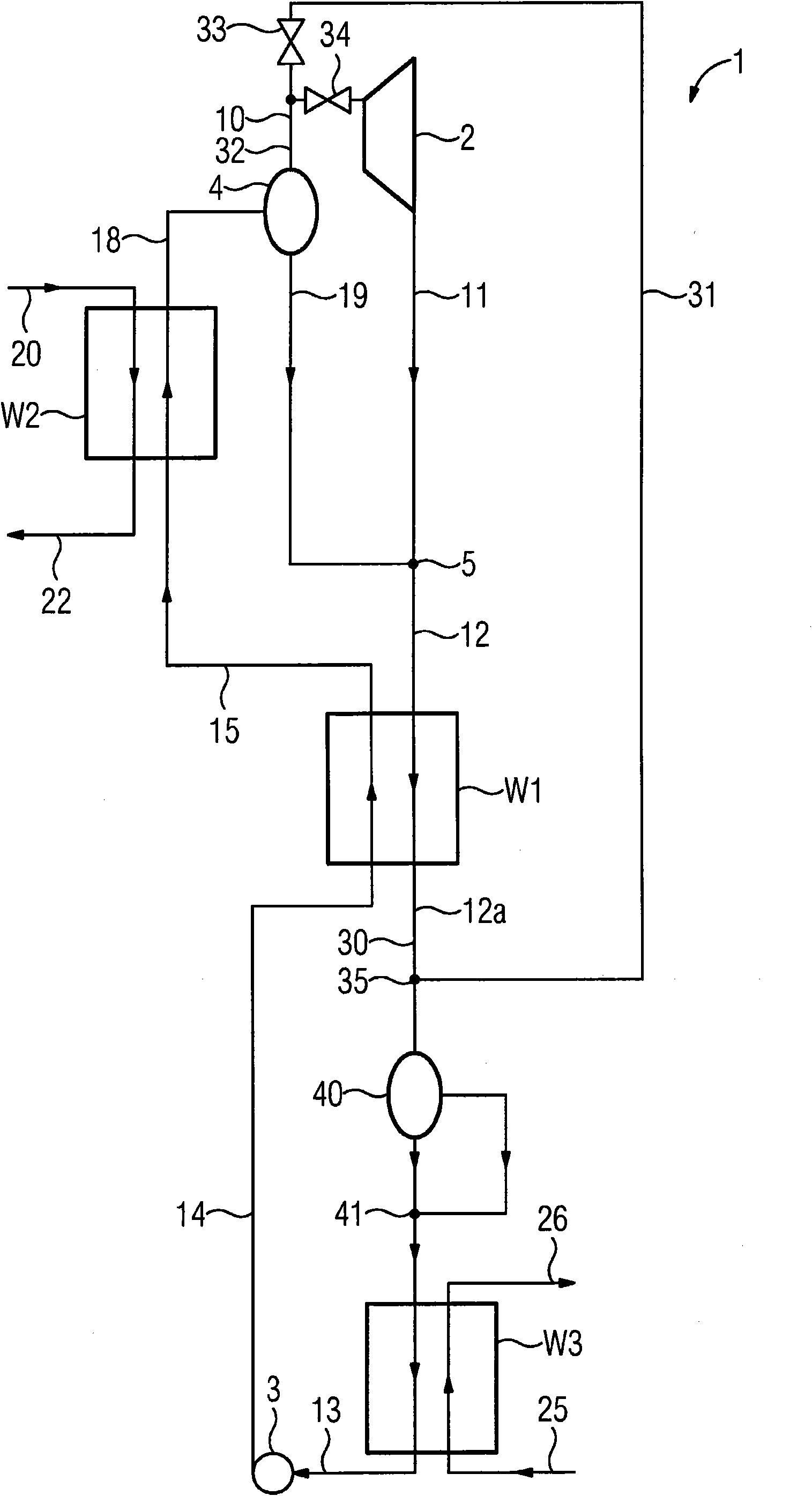

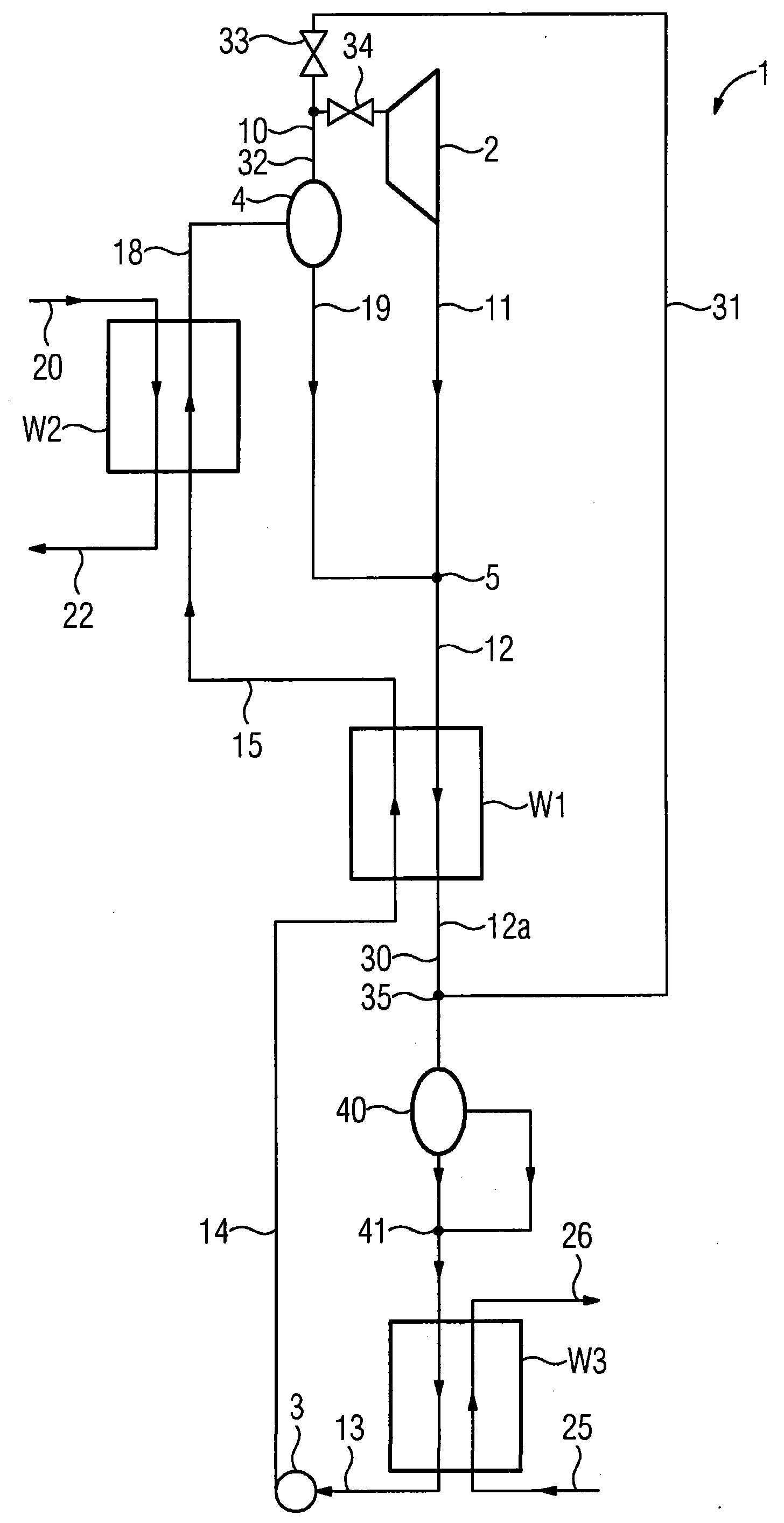

Method for operating a thermodynamic cycle, and thermodynamic cycle

ActiveCN102084093AEfficient cyclePrevent heat inputSteam engine plantsCombined combustion mitigationHeat transmissionEngineering

The invention relates to a thermodynamic cycle (1) with at least: - one first heat exchanger (W1) for creating a first heated or partially evaporated working medium flow (15) by heating or partially evaporating a liquid working medium flow (14) by heat transmission from an expanded working medium flow (12); - a second heat exchanger (W2) for creating a second at least partially evaporated working medium flow (18); - a separator (4) for separating a liquid phase (19) from a vaporous phase (10) of the second working medium flow (18); - an expansion device (2) for creating an expanded vaporous phase (10). According to the invention, pressure pulsations are prevented during the start-up of the cycle in that the vaporous phase (10) separated by the separator (4) is conducted past the expansion device (2) and the first heat exchanger (W1). The liquid phase (19) separated by the separator (4) is cooled in the first heat exchanger (W1) by heat transfer to the liquid working medium flow (14). After the first heat exchanger (W1), the cooled, separated, liquid phase and the separated vaporous phase (10) are brought together.

Owner:KALINA POWER LTD

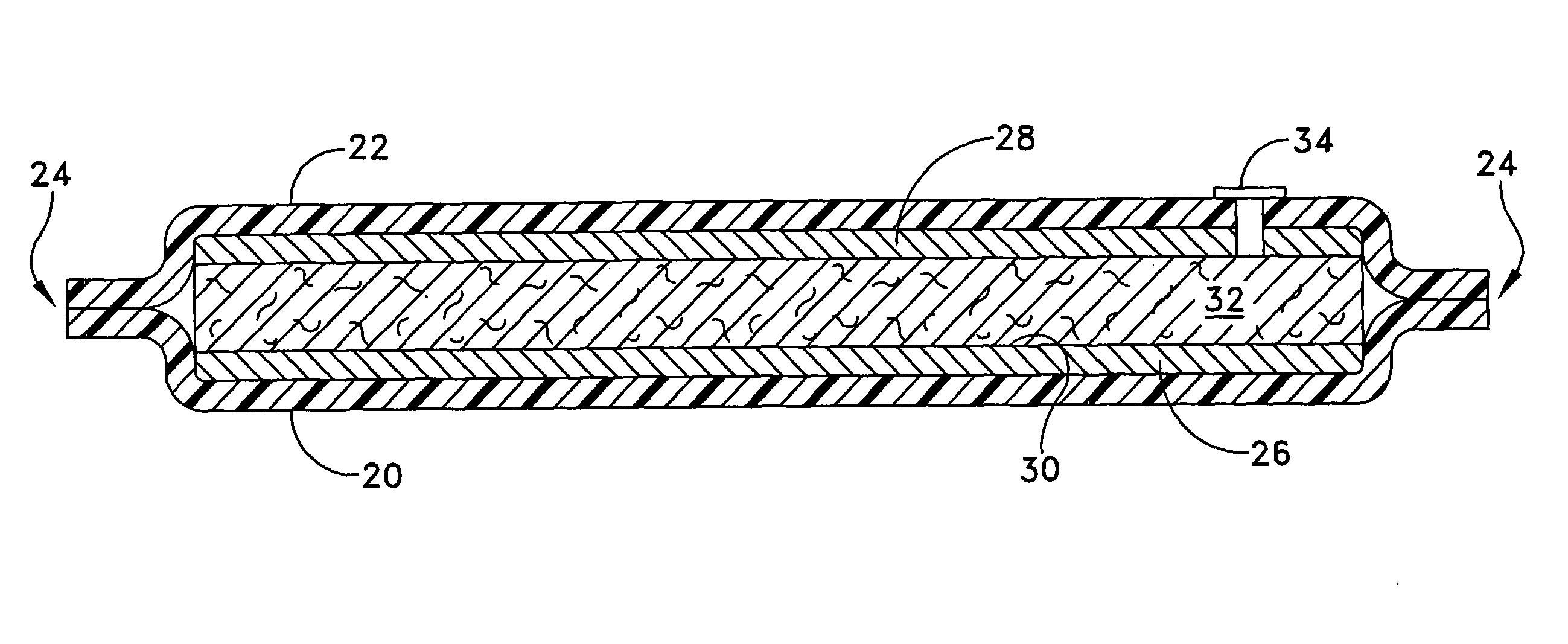

Thermal barrier fabric

InactiveUS7977261B2Restricting freedom of movementPrevent heat transferDomestic containersCoatingsThermal energyReflective layer

A thermal barrier fabric includes an inner impermeable material layer, an outer impermeable material layer, a spacer material disposed between the inner and outer impermeable material layers, and a reflective layer of material disposed between the spacer and a selected one of the inner impermeable material layer and the outer impermeable material layer. The inner and outer impermeable material layers are bound to each other along portions thereof outboard of the spacer material and the reflective layer of material to define a closed compartment. The compartment is under a vacuum, such that the reflective layer of the fabric reflects thermal energy back toward the source thereof and the vacuum substantially prevents thermal energy transfer through the compartment.

Owner:ARMY USA AS REPRESENTED BY THE SEC OF THE

Dryer

InactiveUS20080022549A1Reduce the required powerAvoid environmentDrying using combination processesDrying solid materials with heatEngineering

Owner:LEE SHING HONG

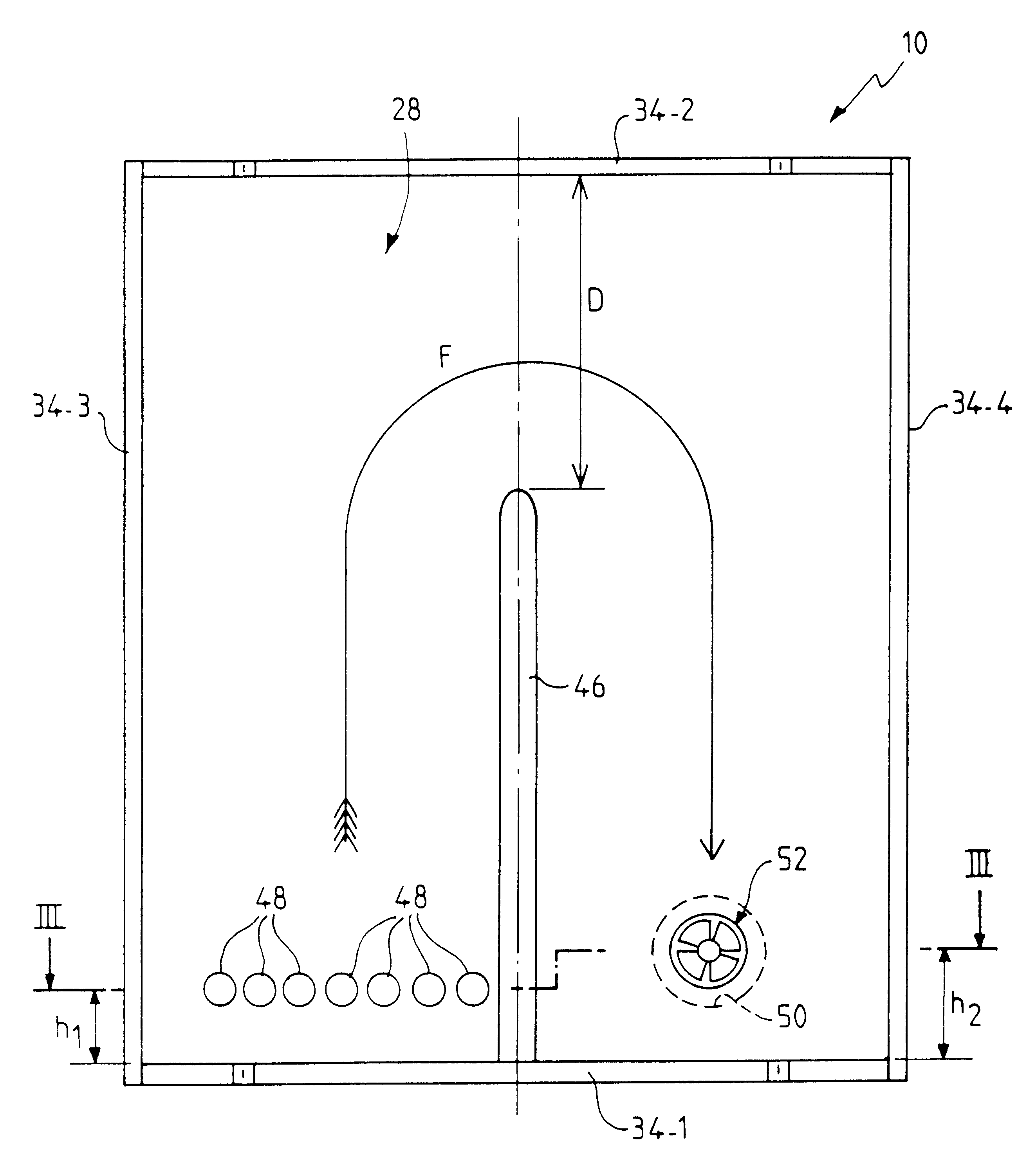

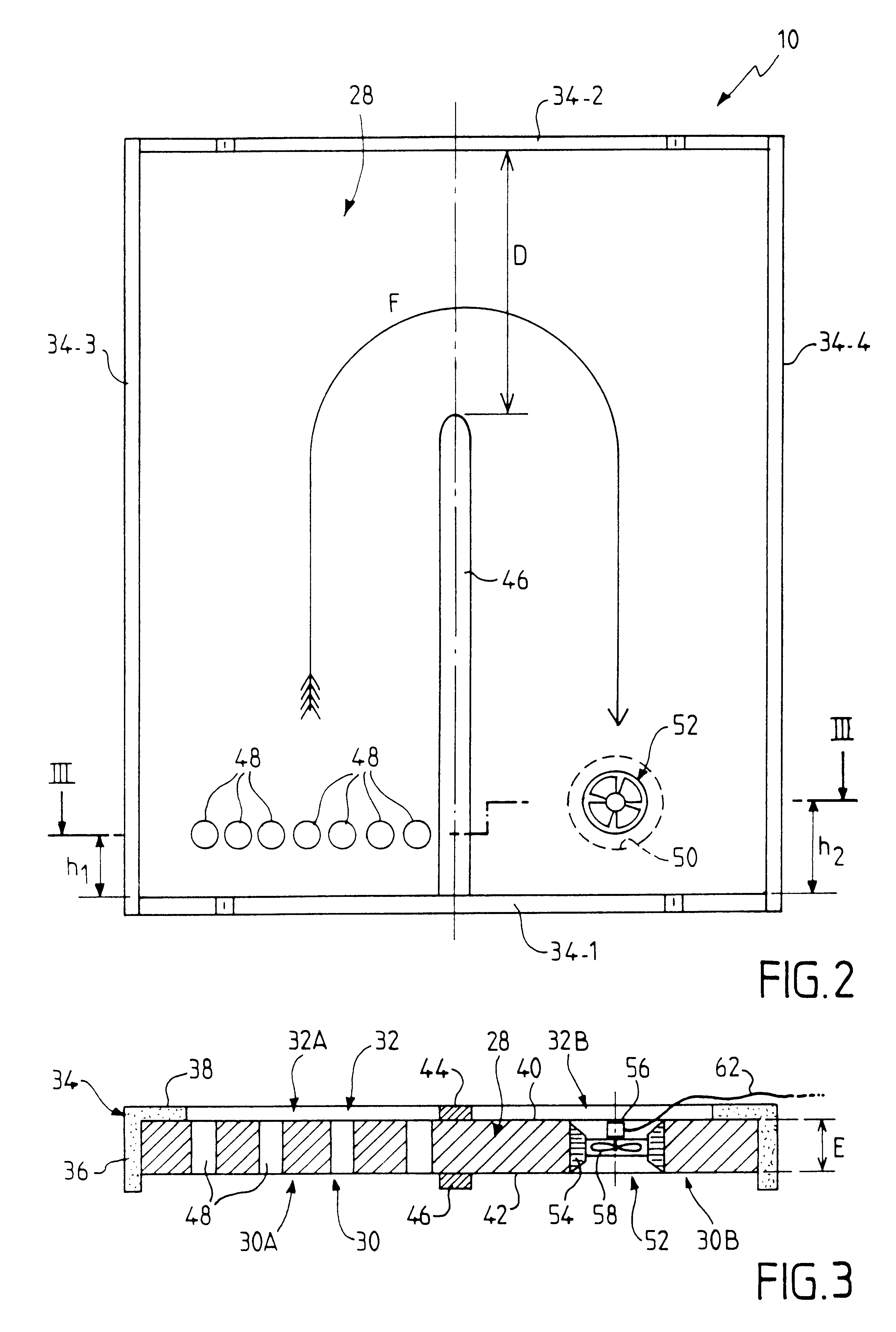

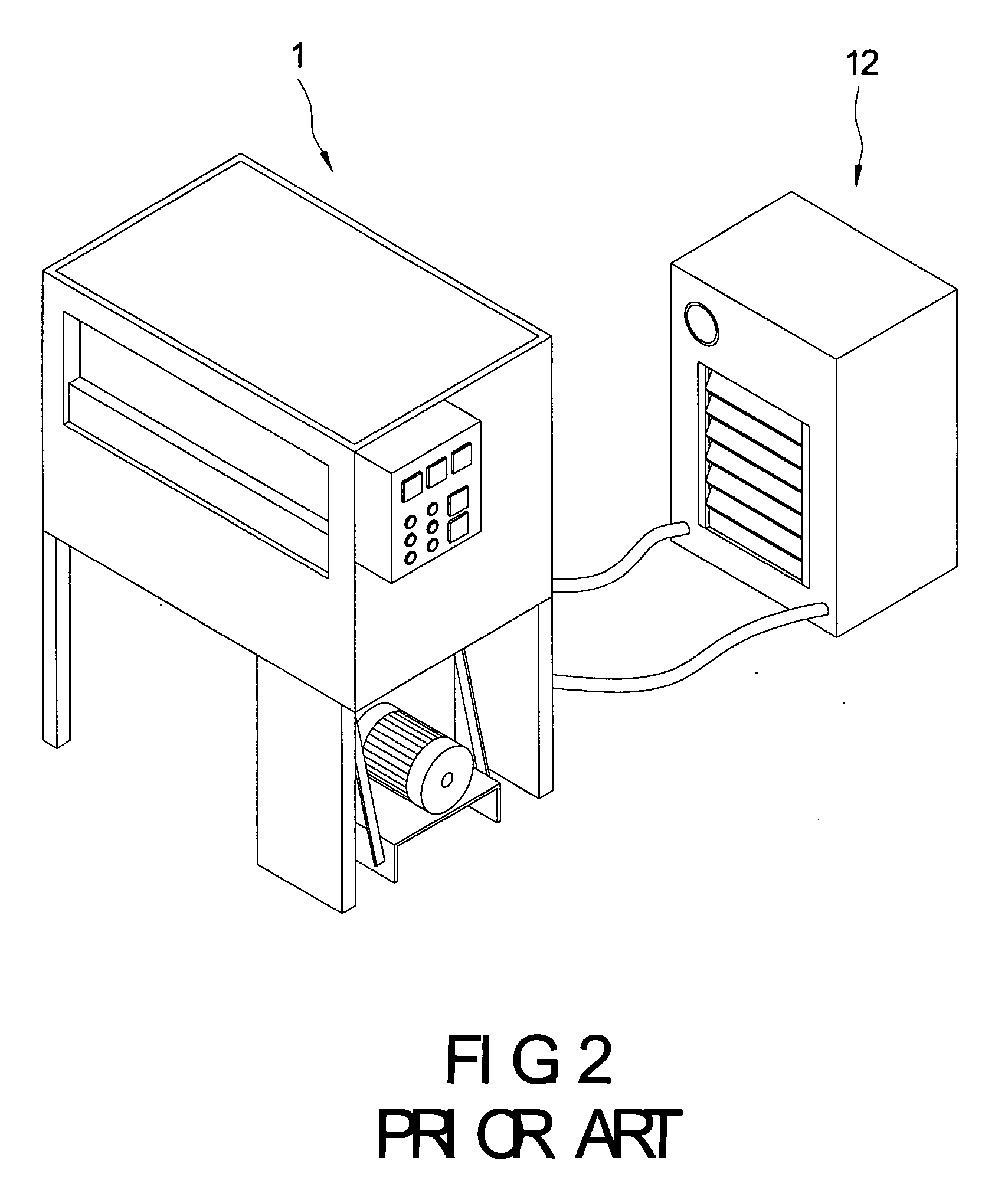

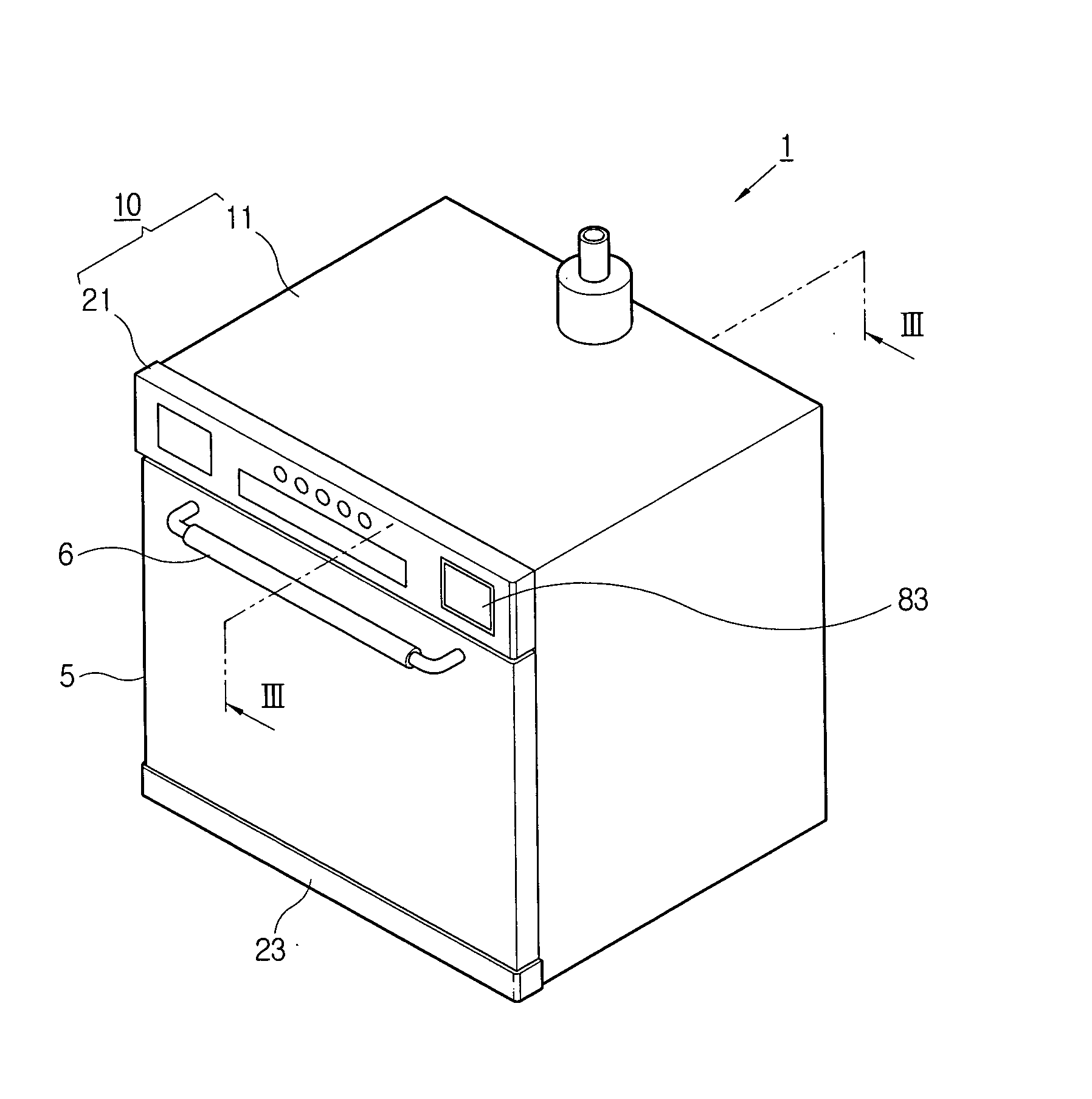

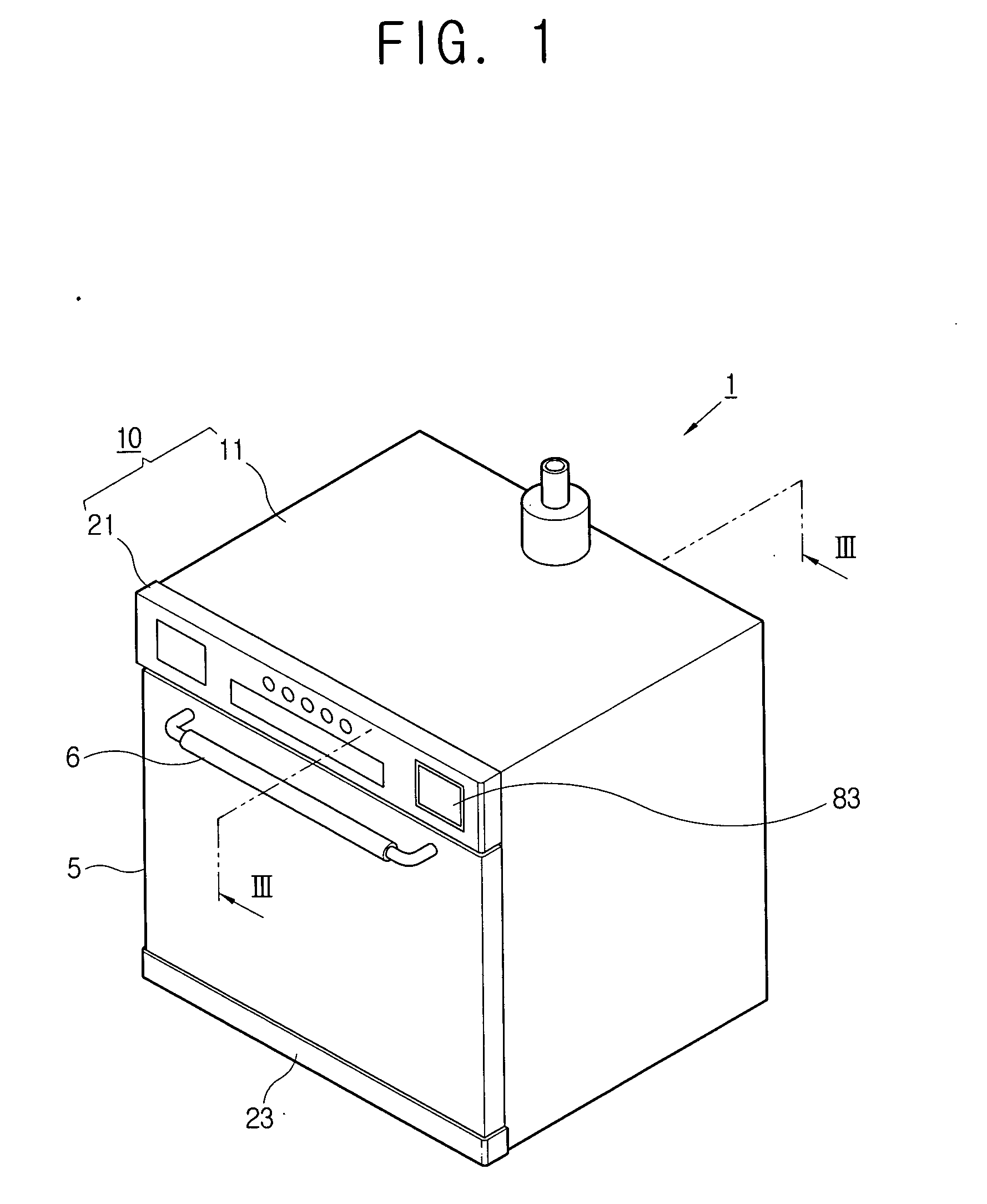

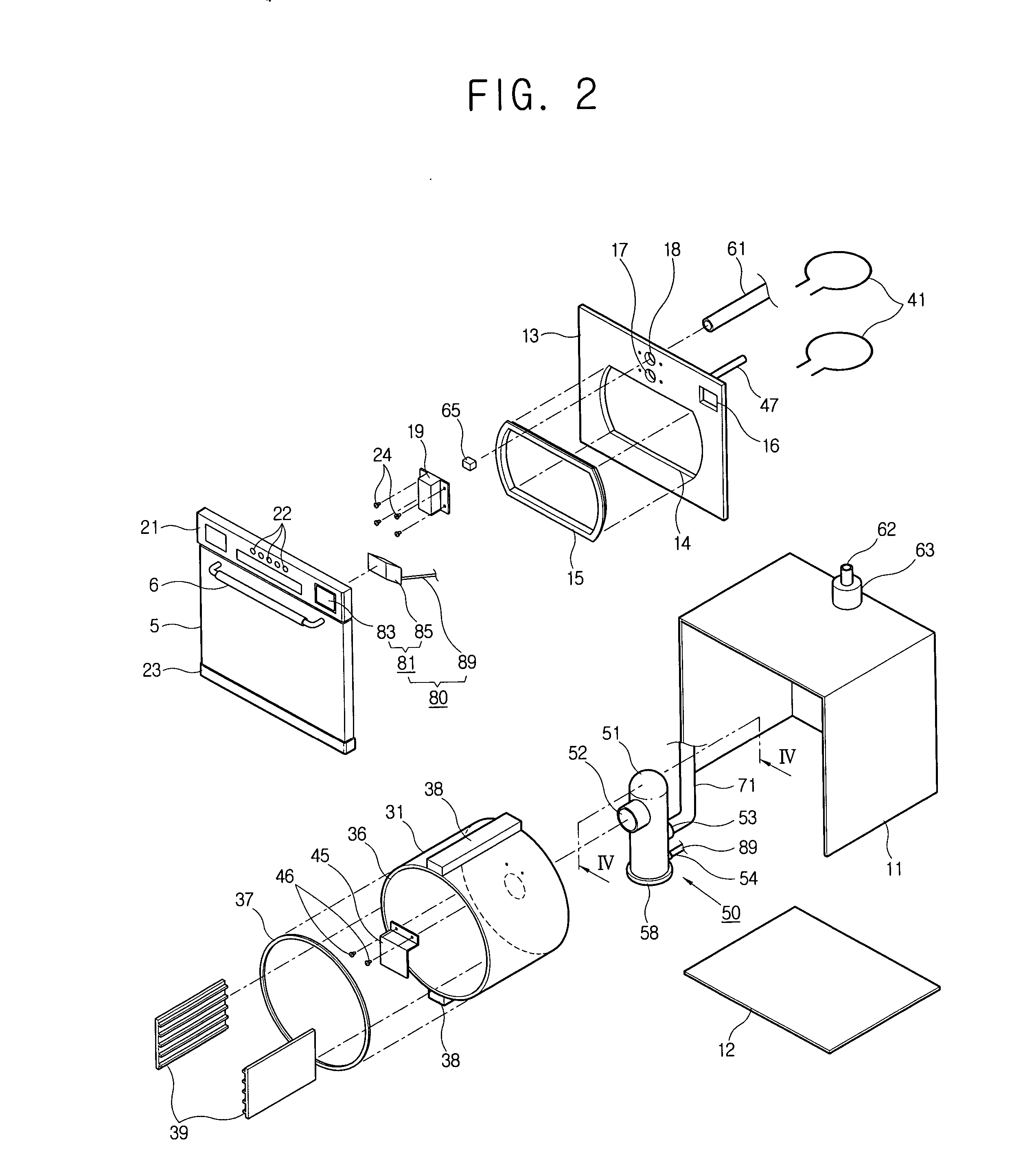

Overheat steam cooker

InactiveUS20070006864A1Avoid radiationSimple configurationDoors for stoves/rangesDomestic stoves or rangesEngineeringSuperheated steam

An overheat steam cooker includes a cooker cabinet having a heating housing forming therein a food accommodating space; an overheated steam generator generating overheated steam to be supplied into the heating housing; a water supplying device including a water injecting part provided to the cooker cabinet, through which water is injected, and a water supplying pipe provided between the water injecting part and the overheated steam generator, supplying the water injected from the water injecting part to the overheated steam generator; an exhaust device including an exhaust pipe, discharging the steam supplied to the heating housing; and an exhaust circulating device including an exhaust circulating pipe to supply the steam discharged to the exhaust pipe to the overheated steam generator, and a flow selection part provided between the exhaust pipe and the exhaust circulating pipe, selectively discharging the steam to the outside or guiding it to the exhaust circulating pipe.

Owner:SAMSUNG ELECTRONICS CO LTD

Vacuum insulation plate and manufacturing method thereof

InactiveCN103306388AGood insulation performanceExtended service lifeClimate change adaptationInsulation improvementVacuum pressureSelf weight

The invention discloses a vacuum insulation plate and a manufacturing method thereof. The vacuum insulation panel comprises a closed hollow cavity body which is formed by casting a material slurry, wherein the interior of the cavity body is hollow; an airtight layer is arranged on the inner wall or / and the outer wall of the cavity body. After the cavity body is vacuumized, convective heat transfer caused by air movement can be avoided, so that the thermal insulation is excellent; the vacuum insulation plate is formed by casting concrete or the material slurry, so that the vacuum insulation plate is firm and reliable; a basic material adopts the concrete or the material slurry with high strength, and the strength is high enough to bear long-term effects of a vacuum pressure, a wind load, self weight and a temperature deformation stress; more than 90% of the plate structure is made of cement and other inorganic materials, so that the long service life of the vacuum insulation plate can be ensured; the vacuum insulation plate mainly uses vacuum, the cement, pottery sand and other low-cost materials, so that the cost of the vacuum insulation plate disclosed by the invention is only 1 / 3 that of the conventional vacuum insulation plate; 90% of the plate structure is made of the cement and the pottery sand, so that the fire-proof performance is class A; the vacuum insulation plate is applicable to external wall insulation and roof insulation for buildings with a shear wall structure, a framework structure and a steel structure.

Owner:许浒

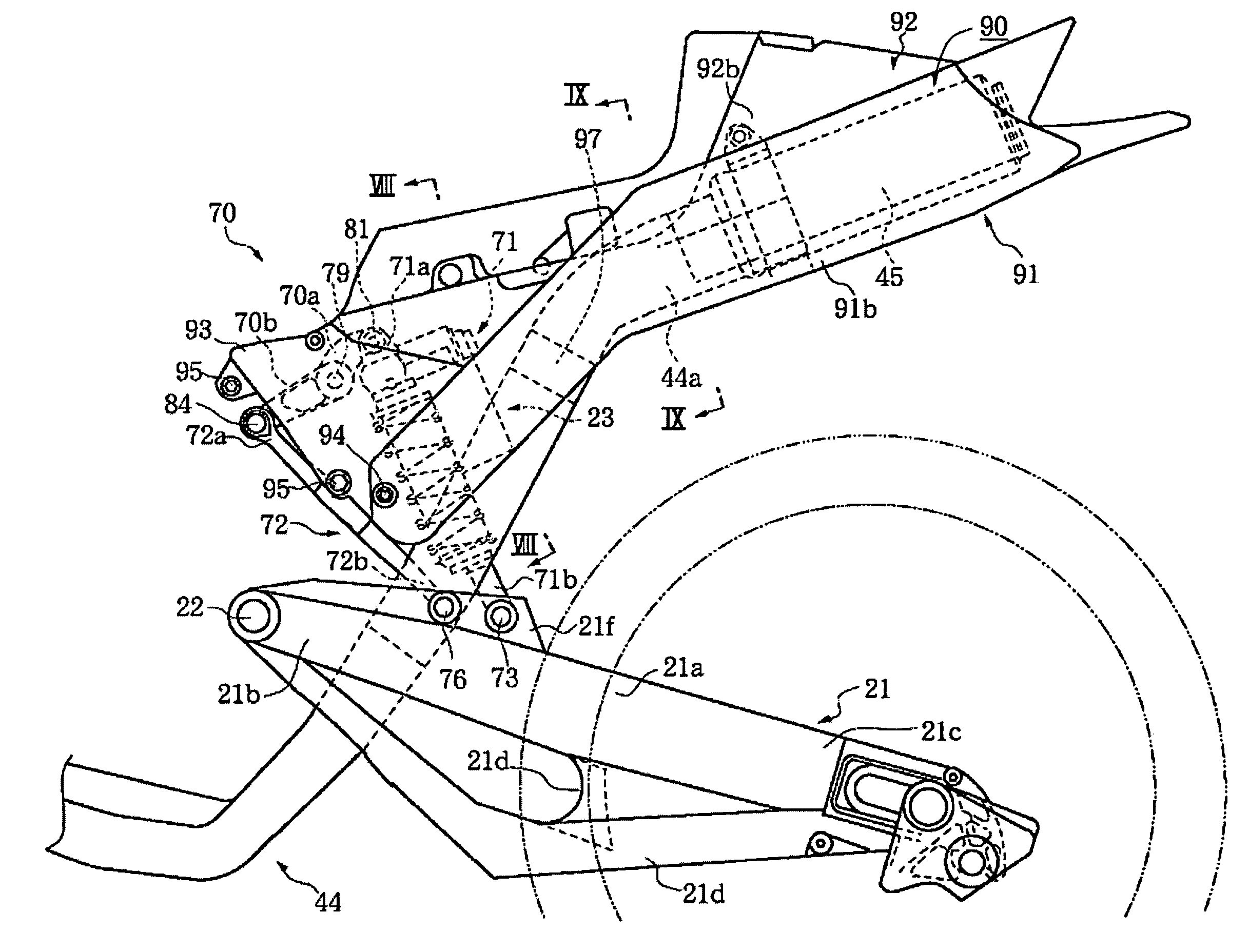

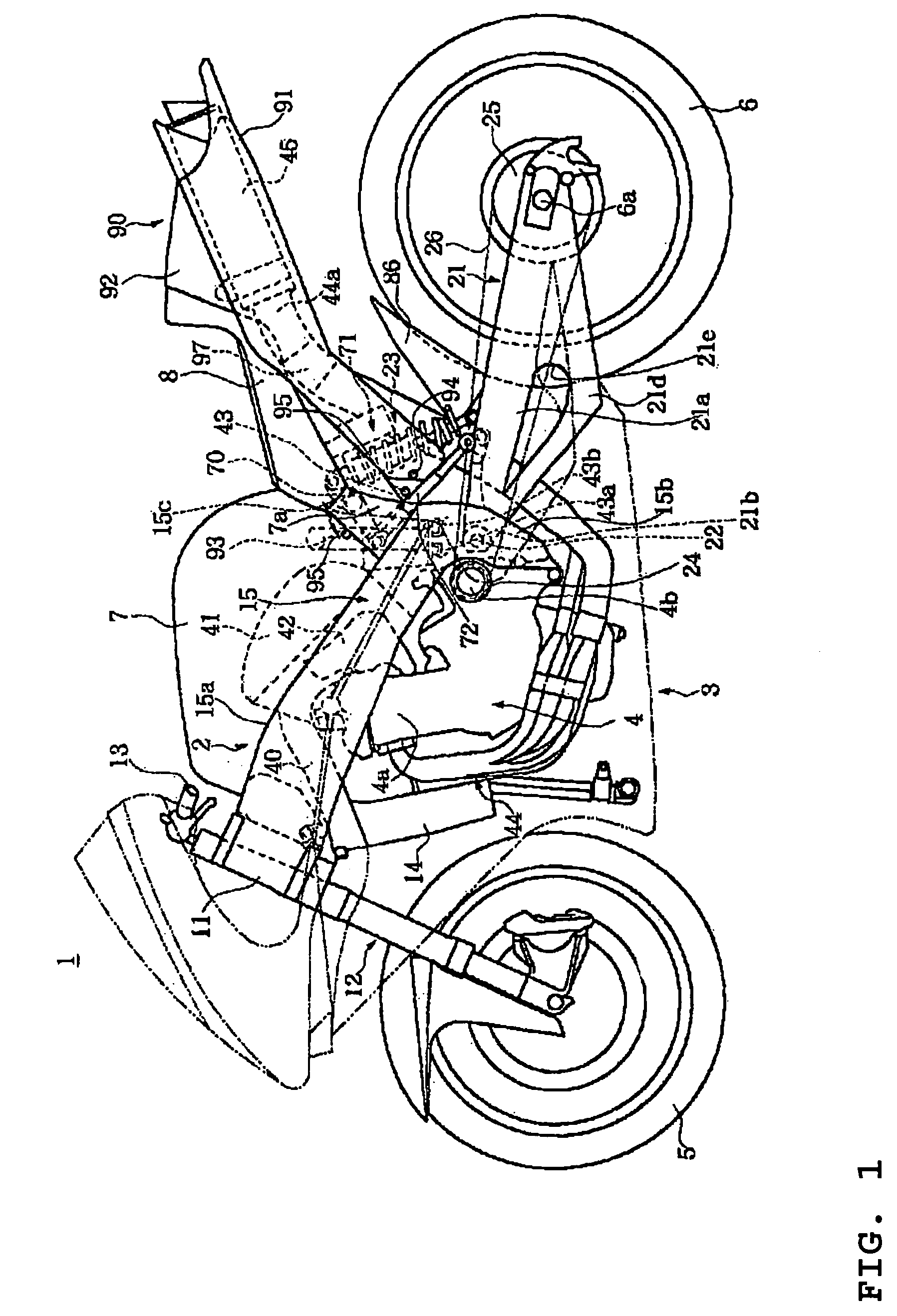

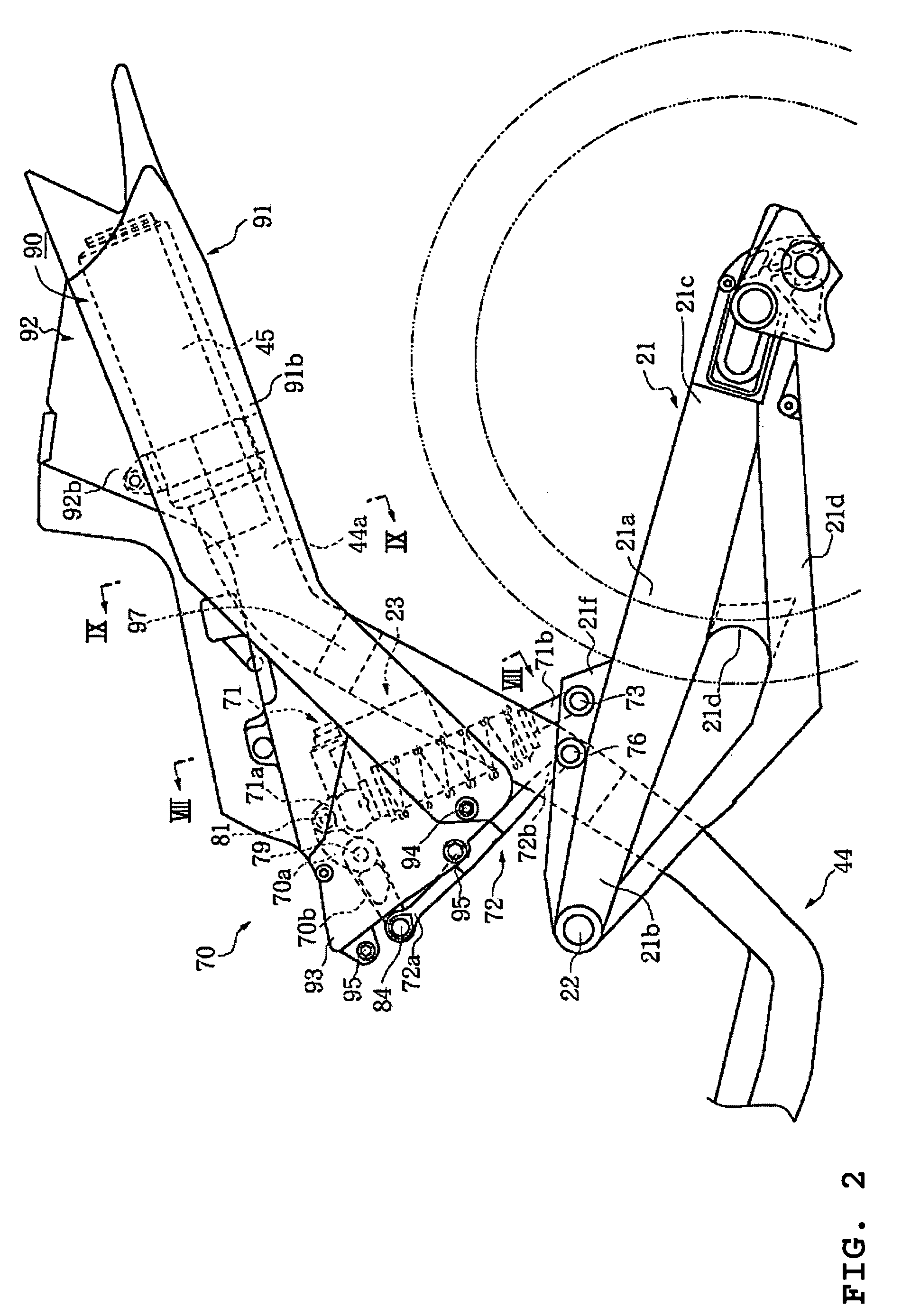

Motorcycle

InactiveUS7156199B2Simple structureReduce heat transferExhaust apparatusSilencing apparatusMechanical engineeringExhaust pipe

A motorcycle includes a seat supporting member provided extending in a rearward direction from a body. The seat supporting member includes an upper seat supporting member with a seat in place and a lower seat supporting member connected to and separated in a downward direction from the upper seat supporting member. The lower seat supporting member is configured as a plate-like member in a shape to cover a region above at least an exhaust pipe.

Owner:YAMAHA MOTOR CO LTD

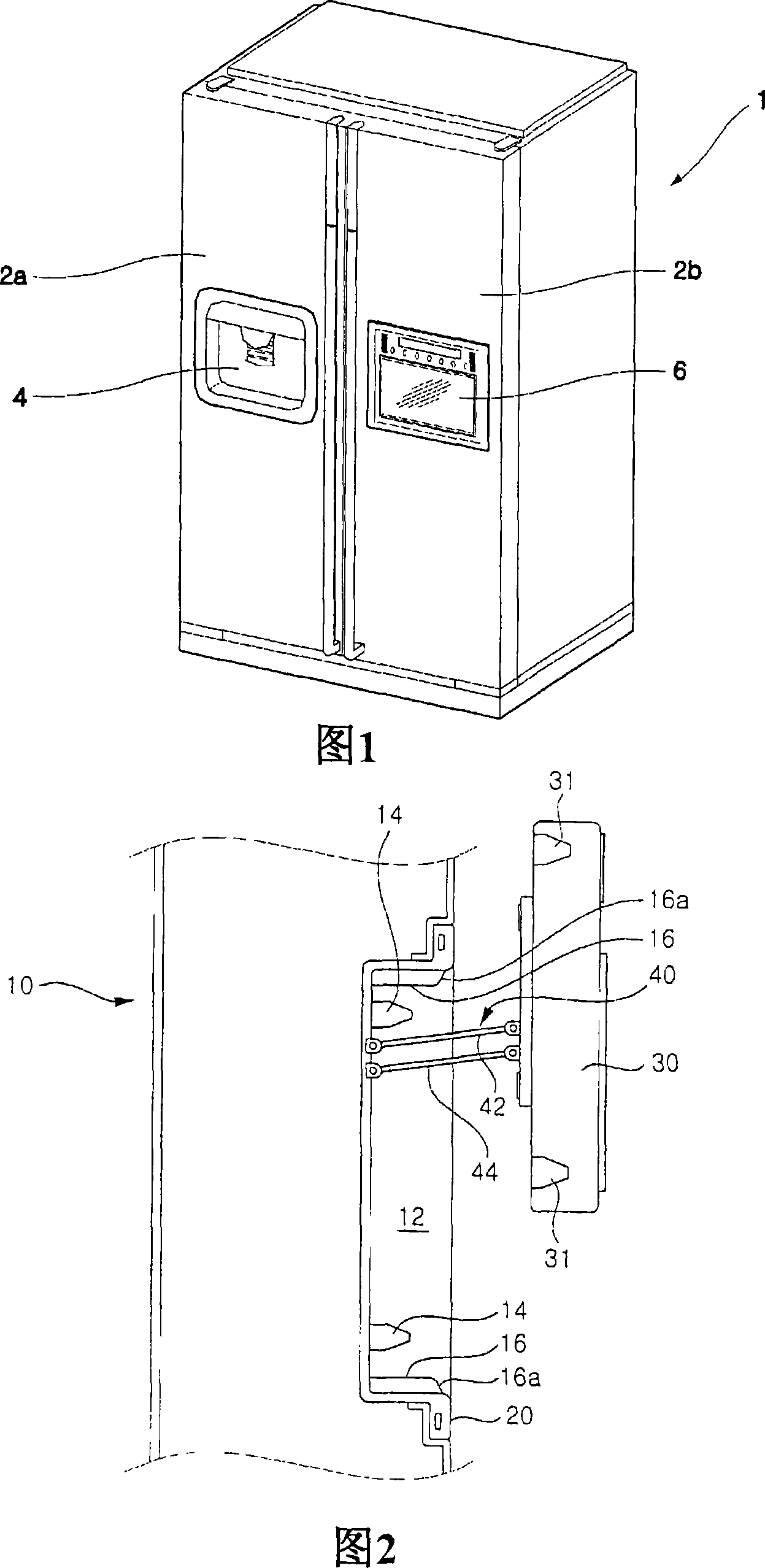

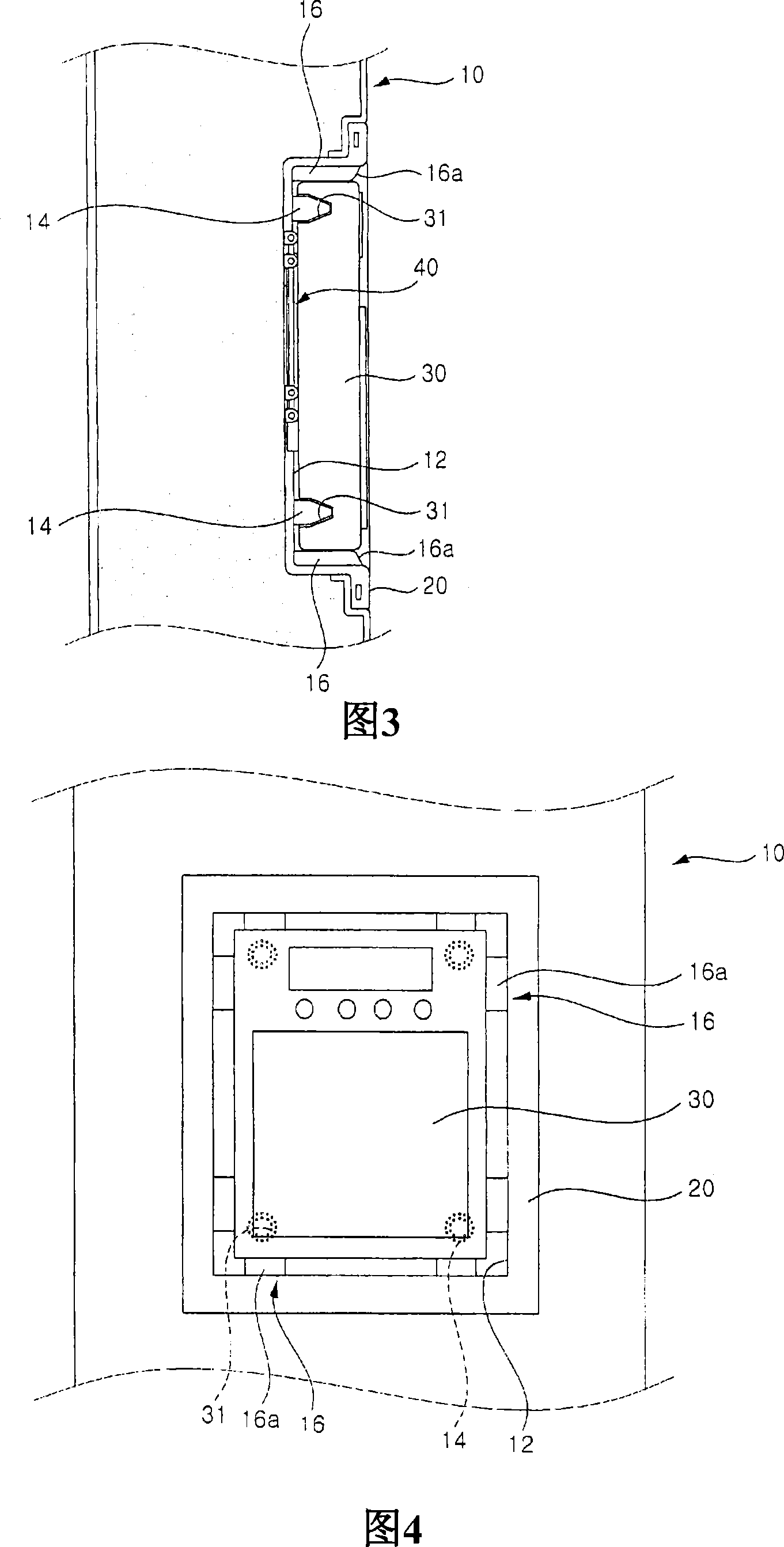

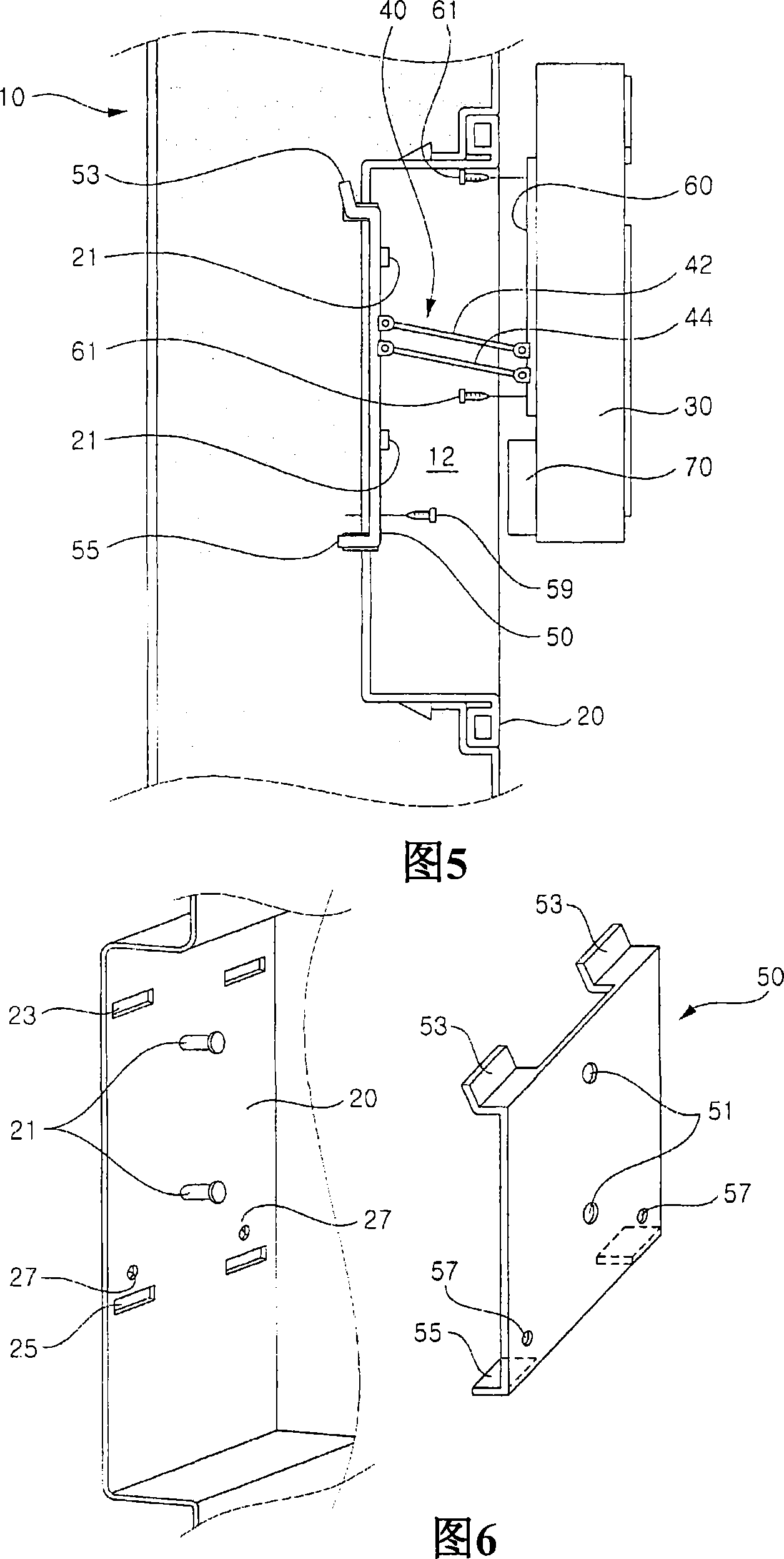

Display unit installing structure for refrigerator

InactiveCN101087983AImprove heat radiation efficiencyAvoid heat transferTelevision system detailsLighting and heating apparatusEngineeringRefrigerated temperature

The present invention relates to a display unit installing structure for a refrigerator. The present invention comprises an accommodating unit which is formed by depressing a portion on a front surface of a door and in which a display unit for displaying a variety of information thereon and inputting operating signals are retractably installed; a link mechanism for guiding accommodation and withdrawal of the display unit and tiltably supporting the display unit withdrawn from the accommodating unit at a predetermined angle; and a locking means for preventing the display unit from being inadvertently escaping from the accommodating unit. According to the present invention, there is an advantage in that the display unit can be retractably installed on the front surface of the refrigerator door.

Owner:LG ELECTRONICS INC

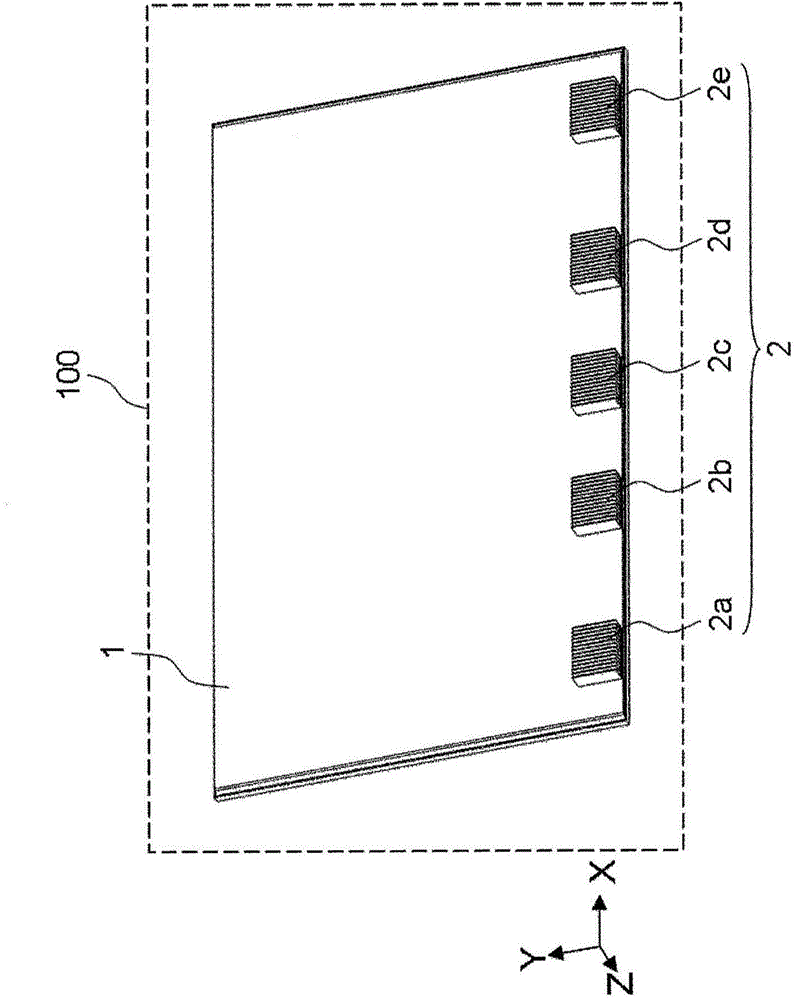

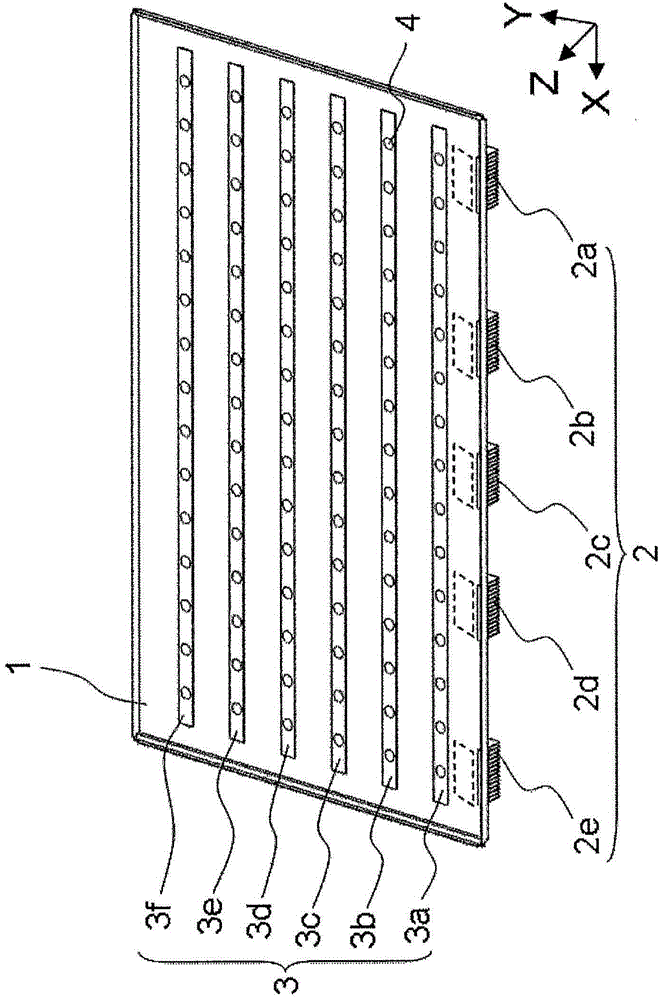

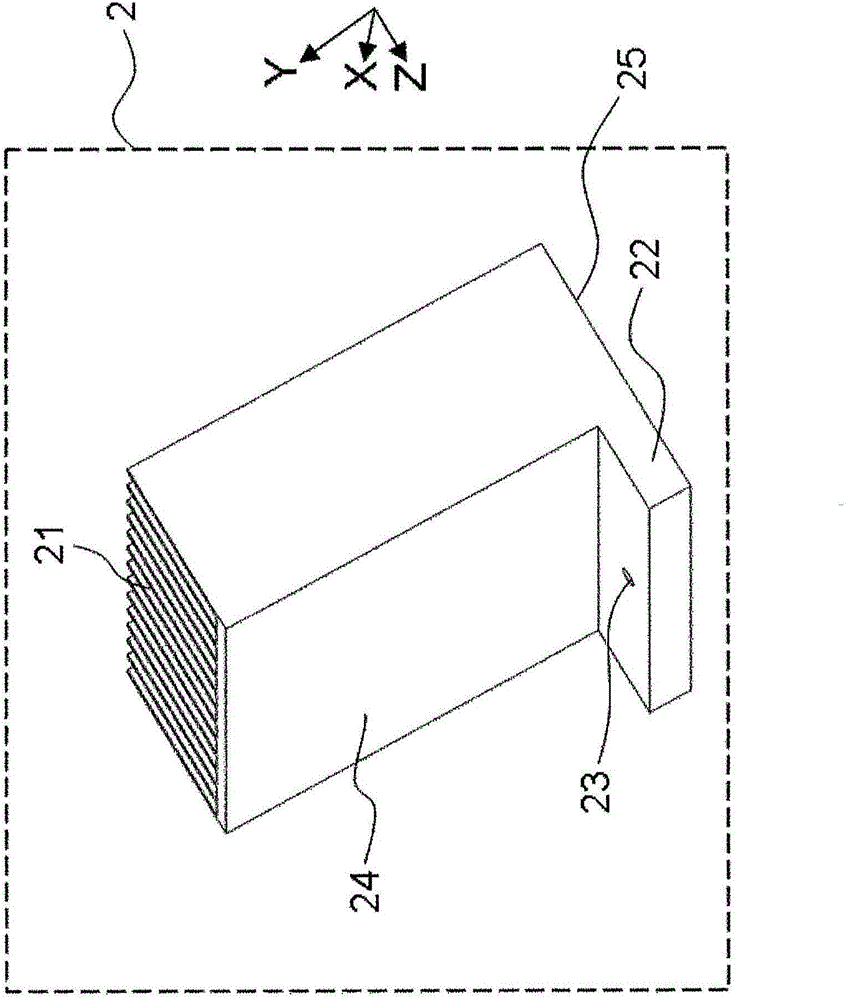

Liquid crystal display

InactiveCN104487763AAvoid heat transferPoint-like light sourceLighting heating/cooling arrangementsLaser lightLiquid-crystal display

A liquid crystal display (100) is provided with a laser light source (5), an LED light source (4), and a radiator (2). The laser light source (5) emits laser light (51). The LED light source (4) emits LED light (41). The radiator (2) holds the laser light source (5), and transmits heat produced by the laser light source (5) and releases said heat in the air. The laser light source (5) is positioned lower than the LED light source (4). The liquid crystal display (100) prevents heat from the LED light source (4), which is not easily affected by heat, from being transferred to the laser light source (5), which is easily affected by heat.

Owner:MITSUBISHI ELECTRIC CORP

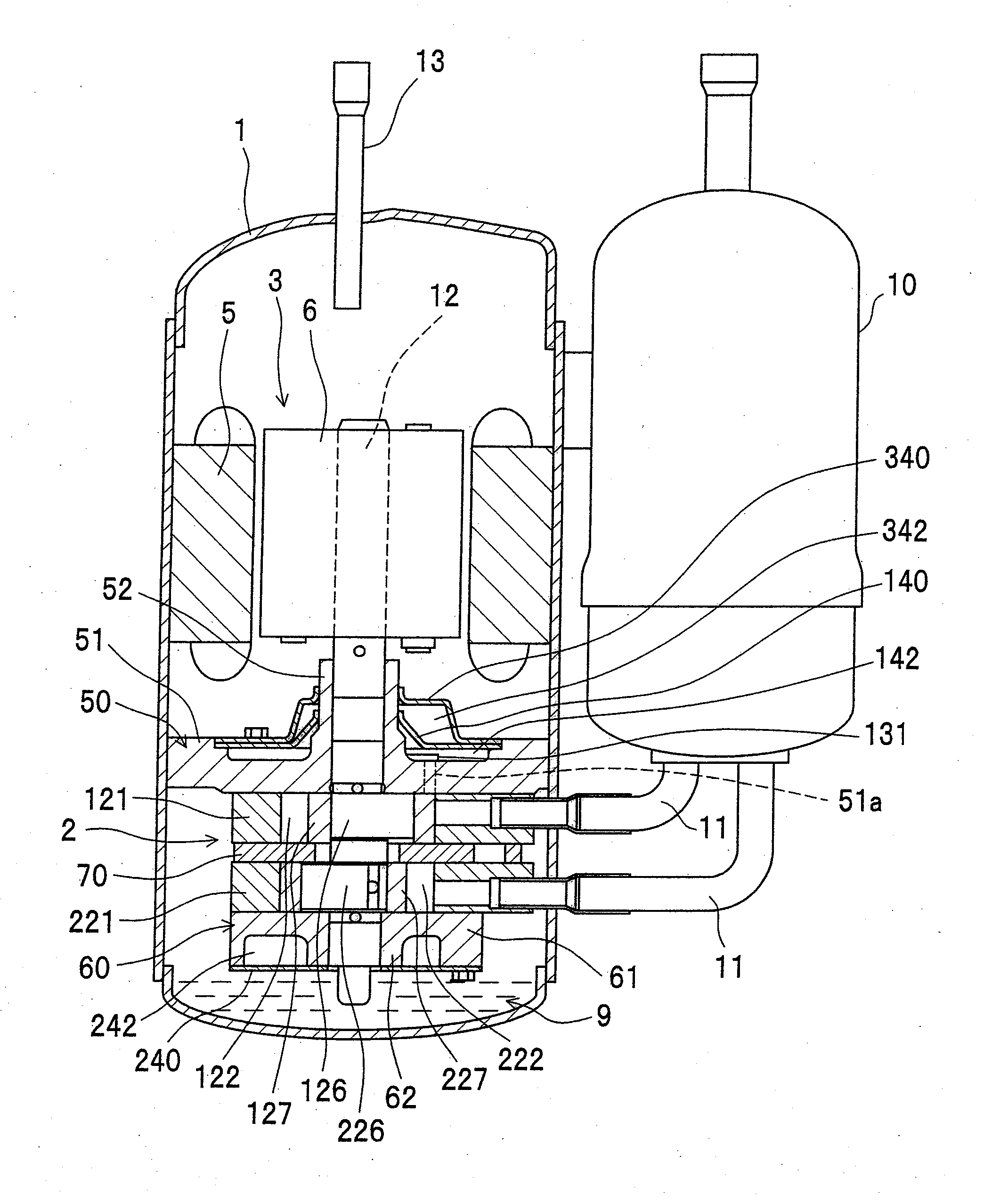

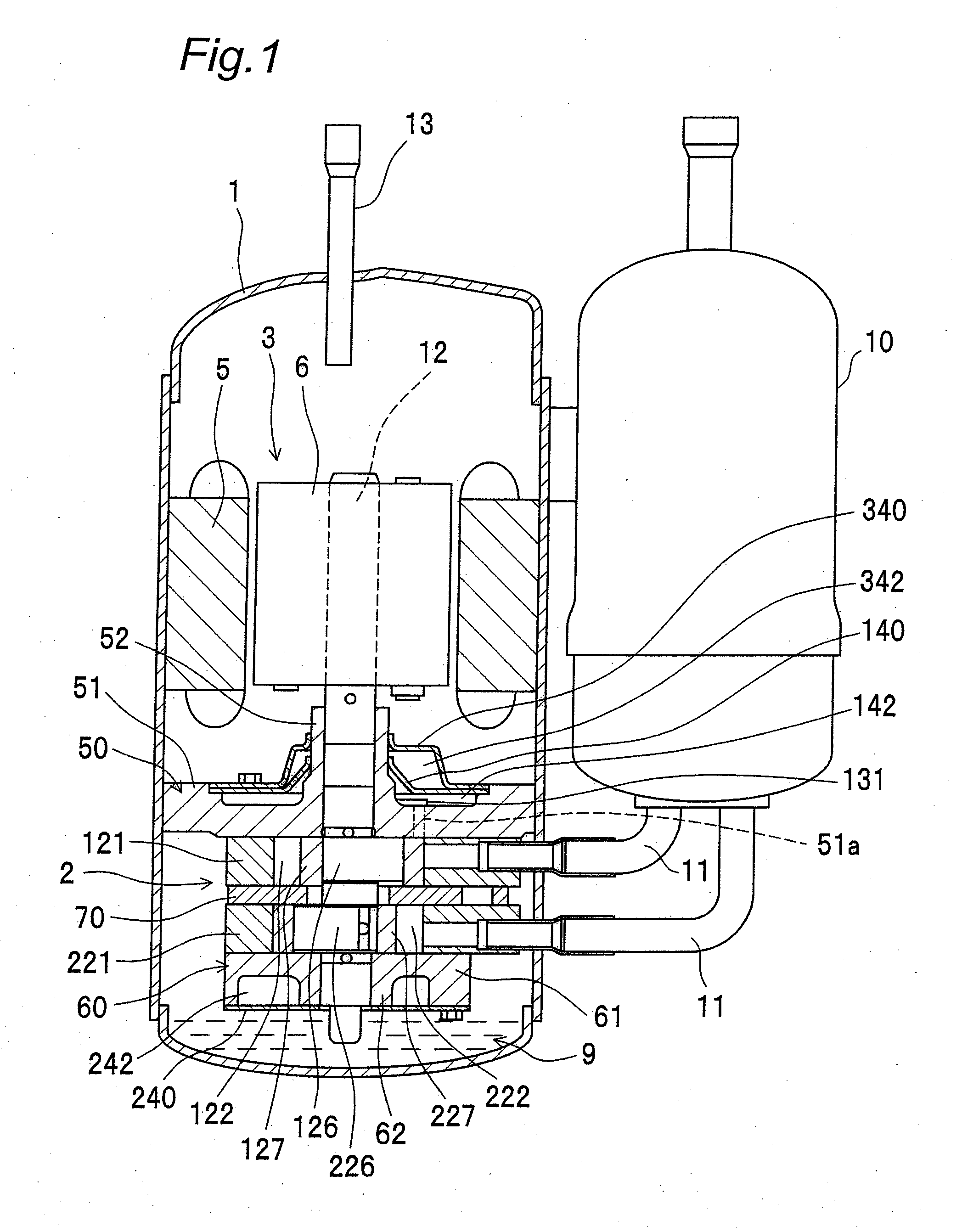

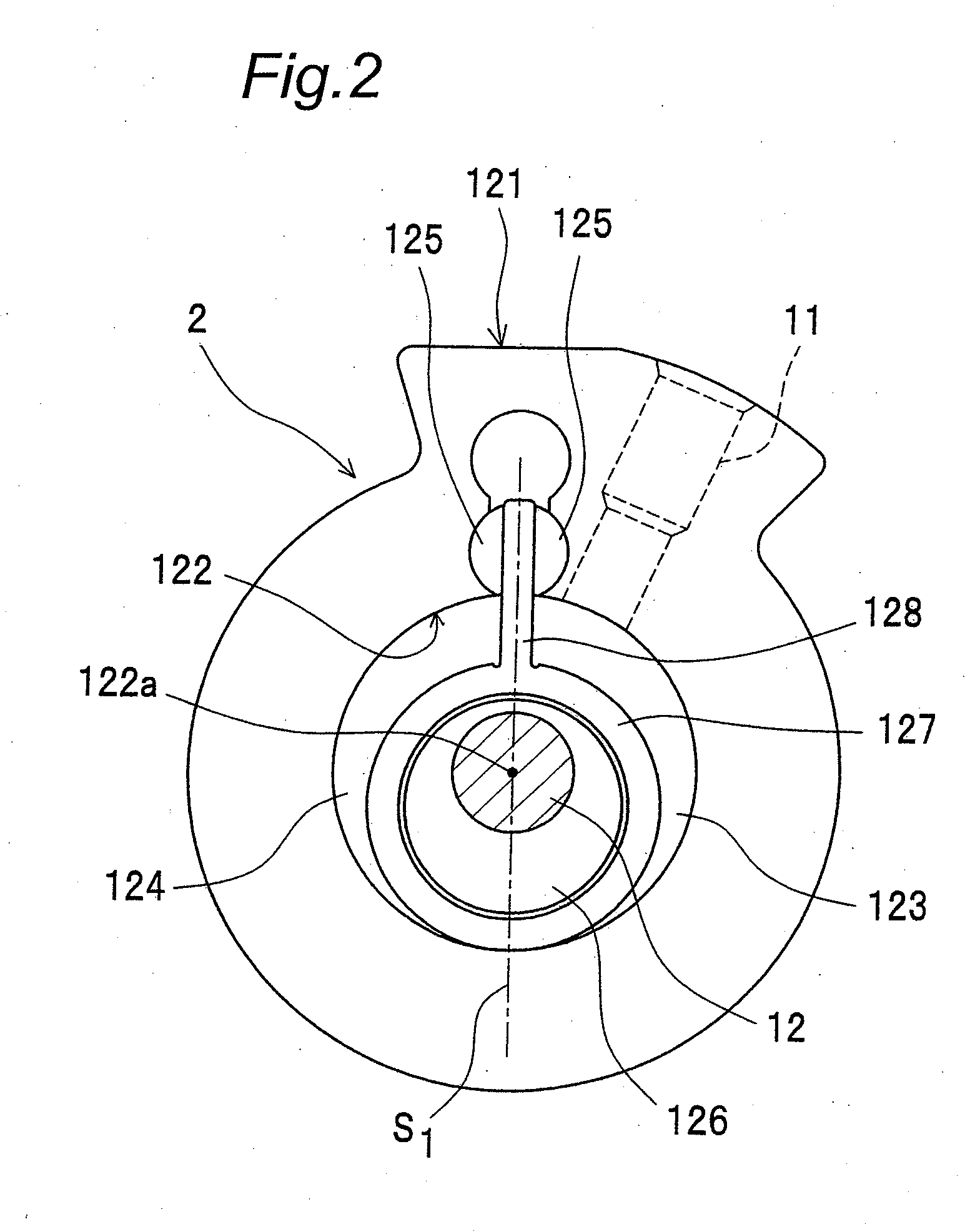

Rotary compressor

ActiveUS20100226796A1High strengthImprove compression efficiencyRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsHigh pressureRefrigerant

A stagnation space defined by barriers is provided in a first muffler chamber communicating with a first cylinder chamber. The stagnation space overlaps with a refrigerant-gas inlet side of the first cylinder chamber, the inlet side being bordered by a center plane as viewed in a direction of a center axis of the first cylinder chamber. In the first muffler chamber, the high-temperature, high-pressure refrigerant gas is unlikely to enter into the stagnation space, so that heat is less absorbed to the inlet side of the first cylinder chamber.

Owner:DAIKIN IND LTD

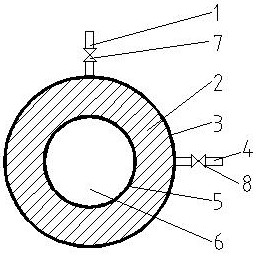

Vacuum insulation pipe filled with inert gas

InactiveCN102003596ABlock collisionImprove insulation effectThermal insulationPipe protection by thermal insulationFiberKrypton

The invention relates to a vacuum insulation pipe filled with inert gas, wherein, an ultrafine particle (fiber) insulation material is filled between an inner pipe and an outer pipe; the ultrafine particle (fiber) insulation material is filled with low-thermal conductivity inert gas maintained in a vacuum state such as argon, krypton, xenon and the like; and the vacuum absolute pressure of the inert gas in the ultrafine particle (fiber) insulation material is 10-15000Pa, and better insulation effect can be obtained under lower pressure. In the invention, the adopted low-thermal conductivity inert gas has better thermal insulation property than that of air, and the ultrafine particle (fiber) insulation material prevents collision of gas molecules so as to hinder heat conduction; the ultrafine particle (fiber) insulation material also prevents heat transfer caused by convection and irradiation; and the radiating loss of the vacuum insulation pipe is about 2.5%-25% of that of the conventional insulation pipe with the same thickness and the same material and is only 50% of that of the common vacuum insulation pipe (not filled with inert gas) under the same vacuum degree.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

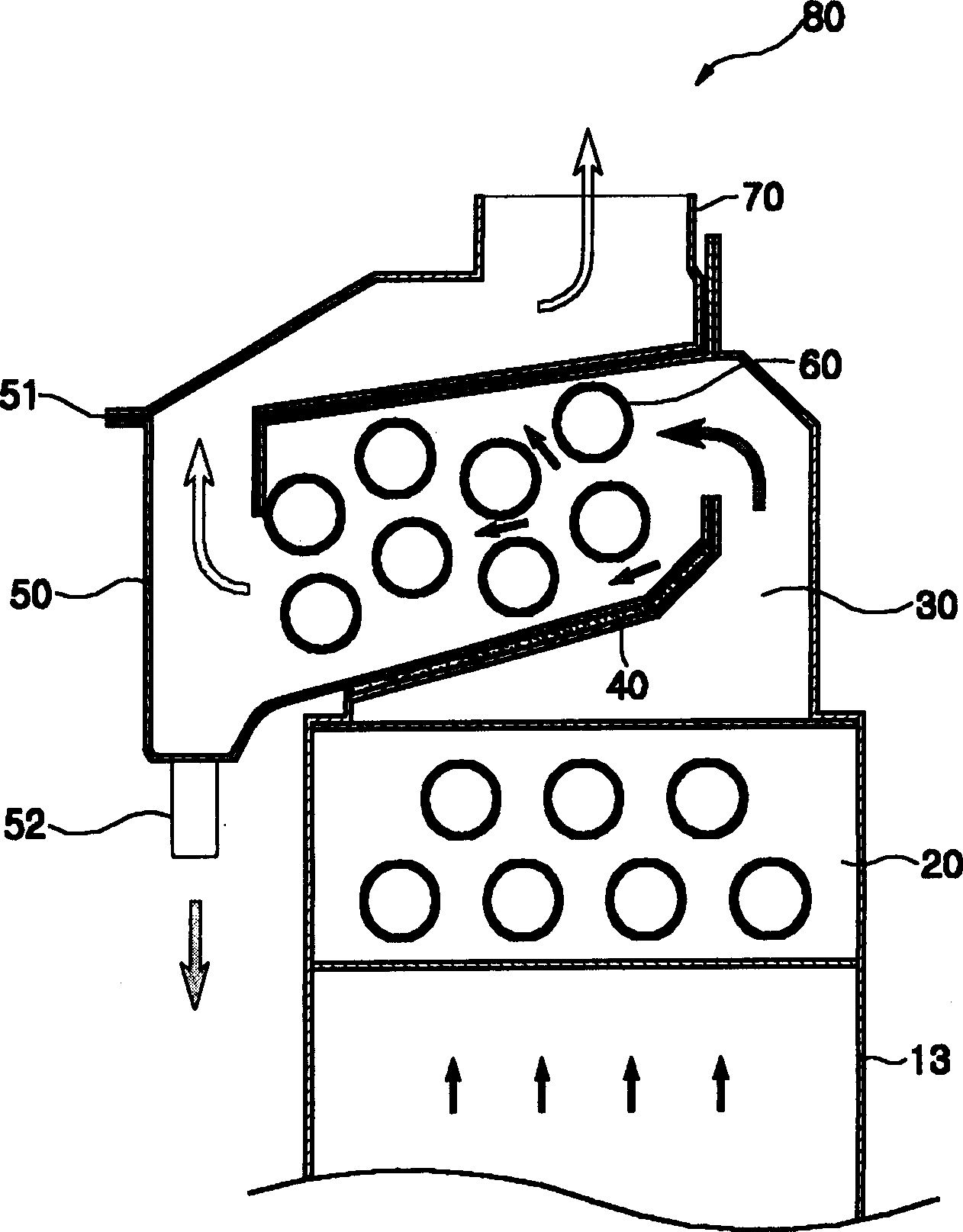

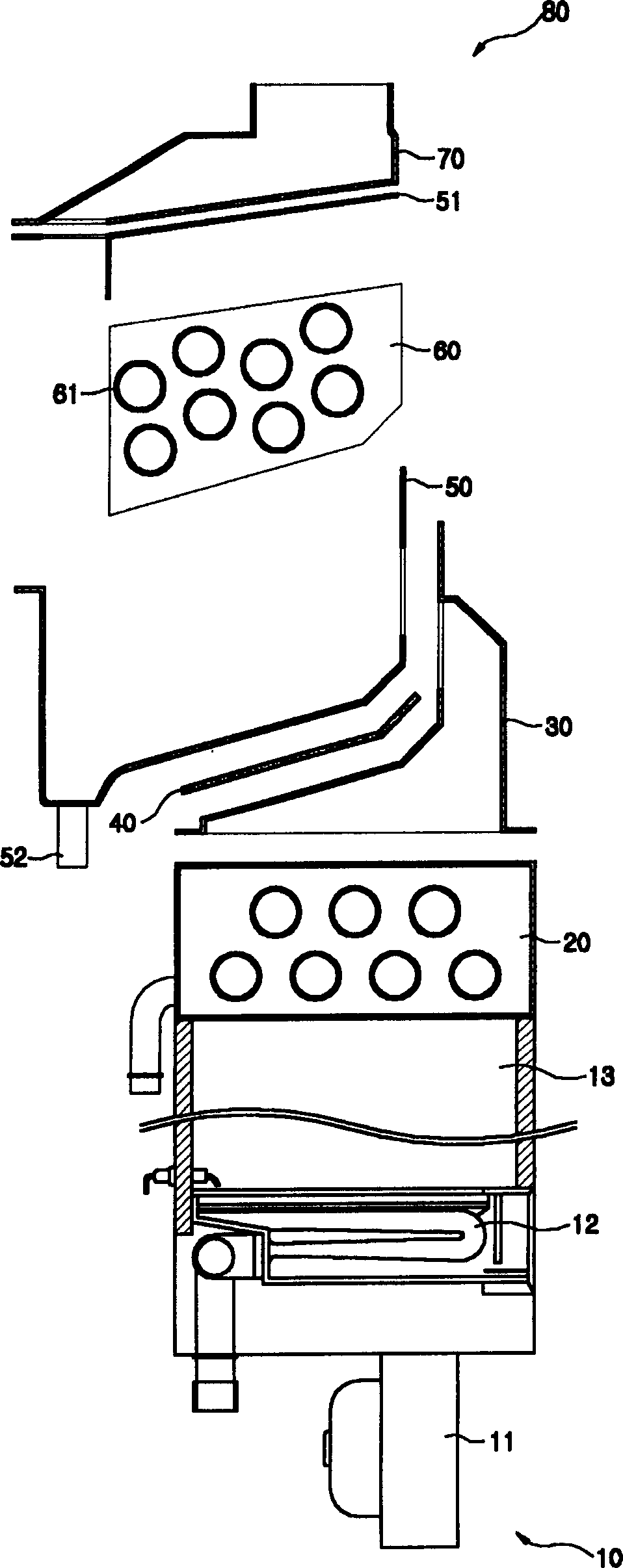

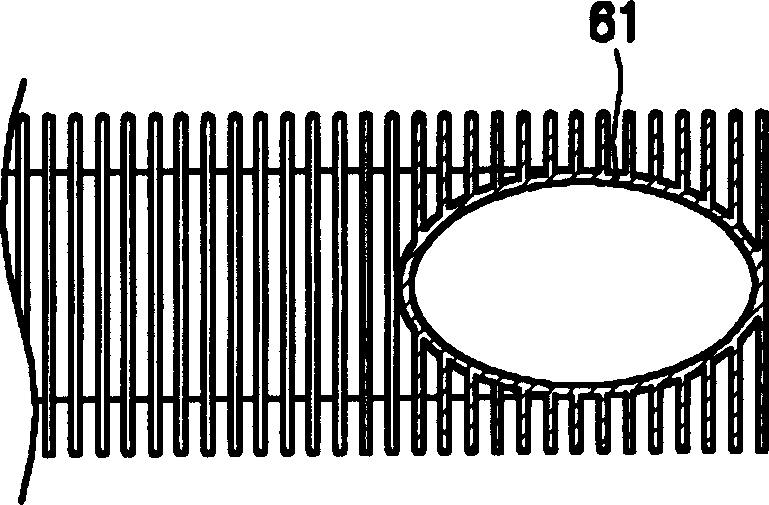

Latent heat absorbing apparatus for gas boiler

The invention discloses a latent heat absorbing device for a gas boiler. Said gas boiler comprises a latent heat exchanger installed in the chamber such that the latent heat exchanger is separated from the sensible heat exchanger and also separated from the exterior of the gas boiler. The invention prevents heat transfer between the heat exchangers and also prevents condensate from dripping onto the elements of the gas boiler. In addition, at the first channel communicating with both the combustion chamber and the chamber above, the exhaust gas can also maintain a smooth flow in an accelerated state.

Owner:TAISEI SANGYO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com