Patents

Literature

2270 results about "Cold chain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term cold chain or cool chain denotes the series of actions and equipment applied to maintain a product within a specified low-temperature range from harvest/production to consumption. A cold chain is a temperature-controlled supply chain. An unbroken cold chain is an uninterrupted series of refrigerated production, storage and distribution activities, along with associated equipment and logistics, which maintain a desired low-temperature range. It is used to preserve and to extend and ensure the shelf life of products, such as fresh agricultural produce, seafood, frozen food, photographic film, chemicals, and pharmaceutical drugs. Such products, during transport and when in transient storage, are sometimes called cool cargo. Unlike other goods or merchandise, cold chain goods are perishable and always en route towards end use or destination, even when held temporarily in cold stores and hence commonly referred to as cargo during its entire logistics cycle.

Method of recording the temperature of perishable products in cold chain distribution

InactiveUS6865516B1Easy selectionEasy to useThermometer detailsElectric signal transmission systemsCold chainEngineering

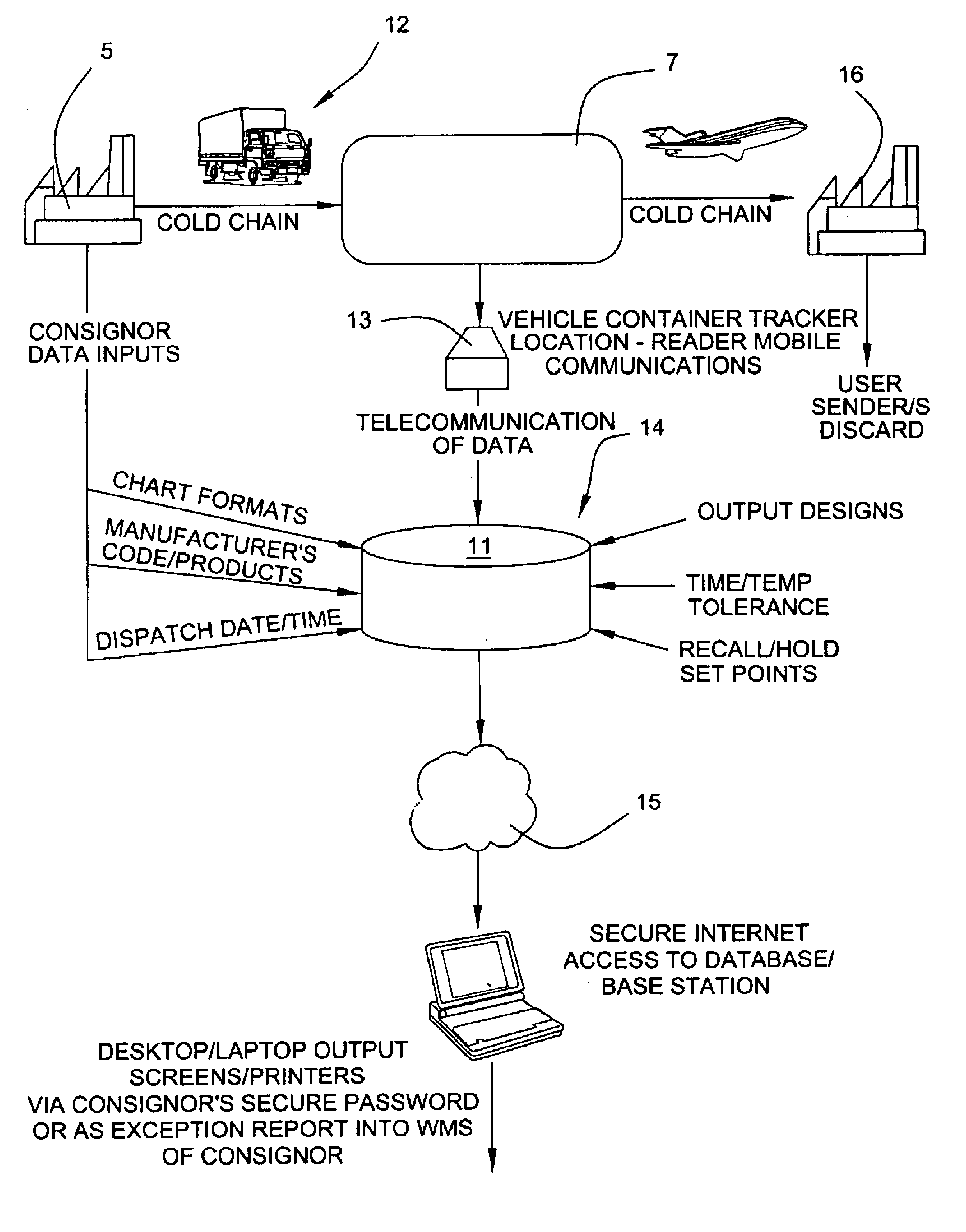

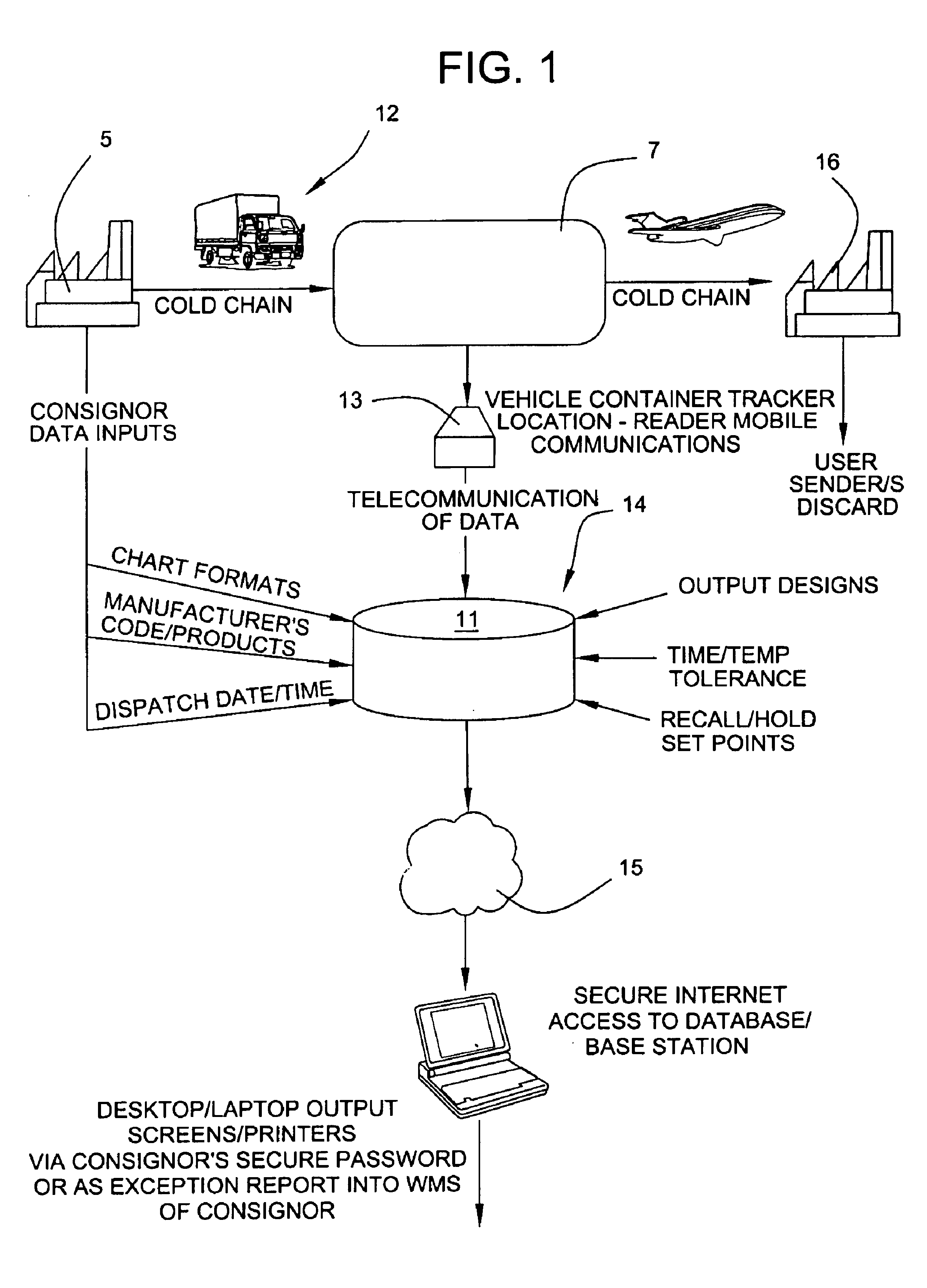

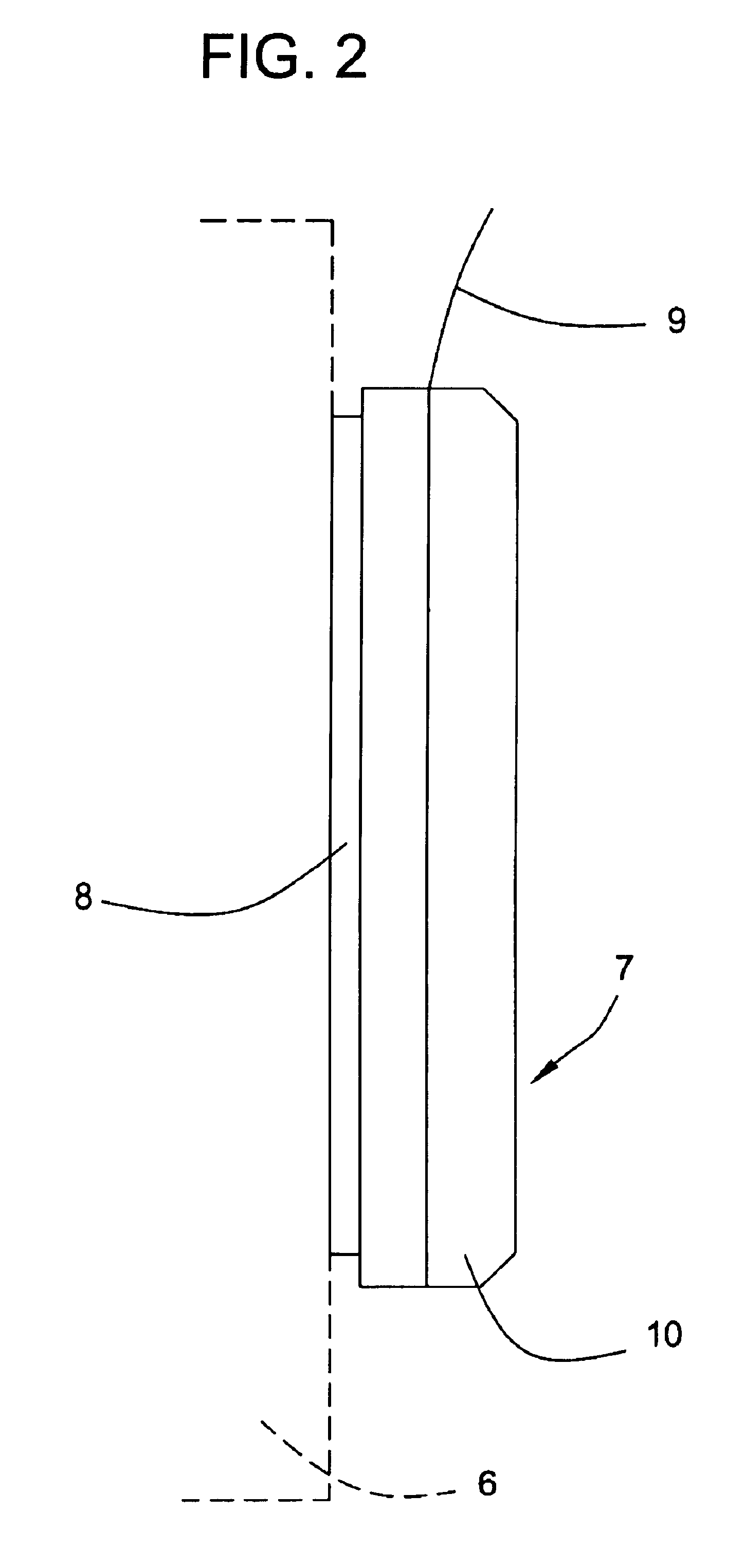

A method and apparatus for monitoring a consignment of goods including measuring a predetermined parameter or parameters of said consignment using a disposable device (7) attachable to said consignment; transmitting a signal containing data representative of the measured parameter to a central location (14) and maintaining a database (11) relating to said consignment at said central location (14), said database (11) including the data representative of said measured parameters. The database (11) may include temperature, time and location data associated with a consignment. The database (11) may be accessed remotely via a secure access link (15).

Owner:FRESH YES PTY LTD

Cold-chain logistics storage supervisory system and method

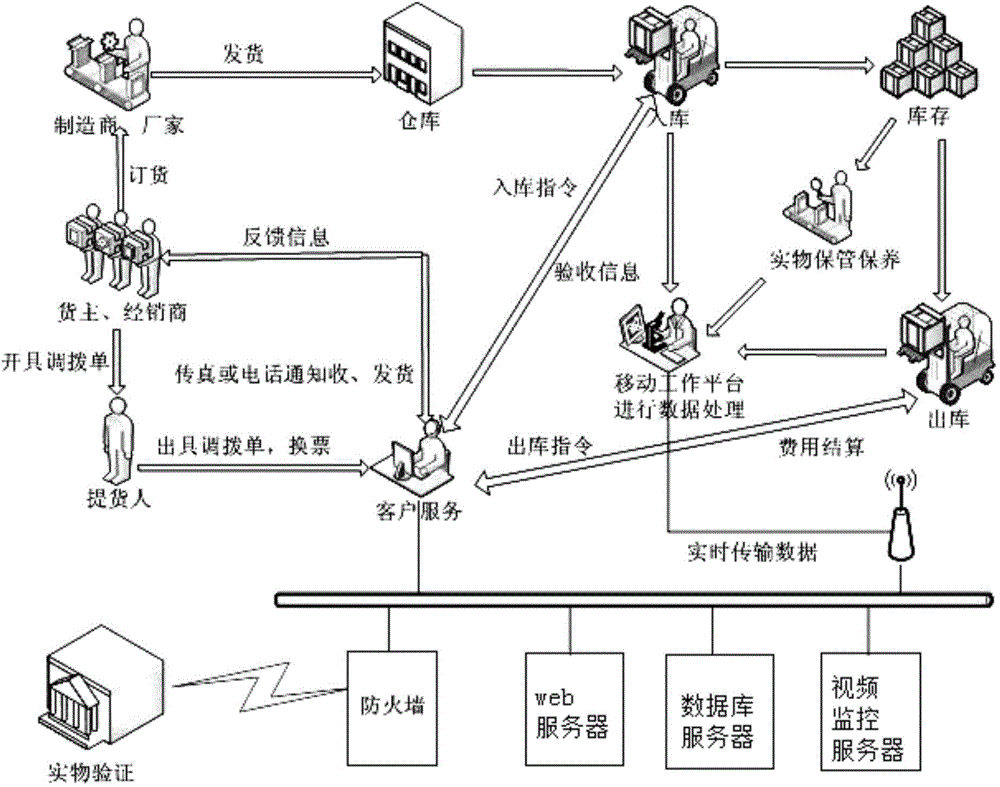

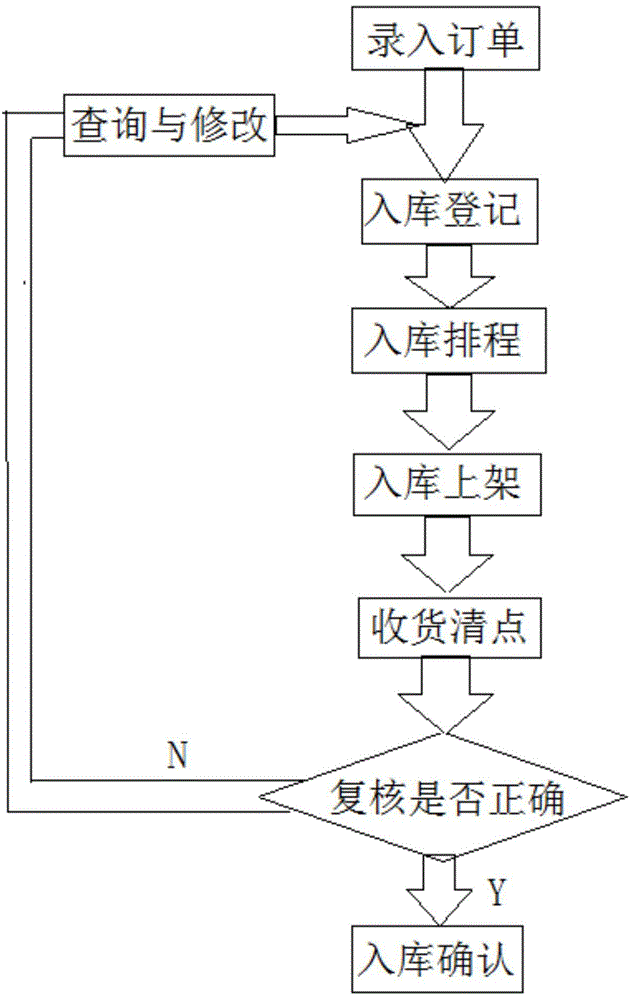

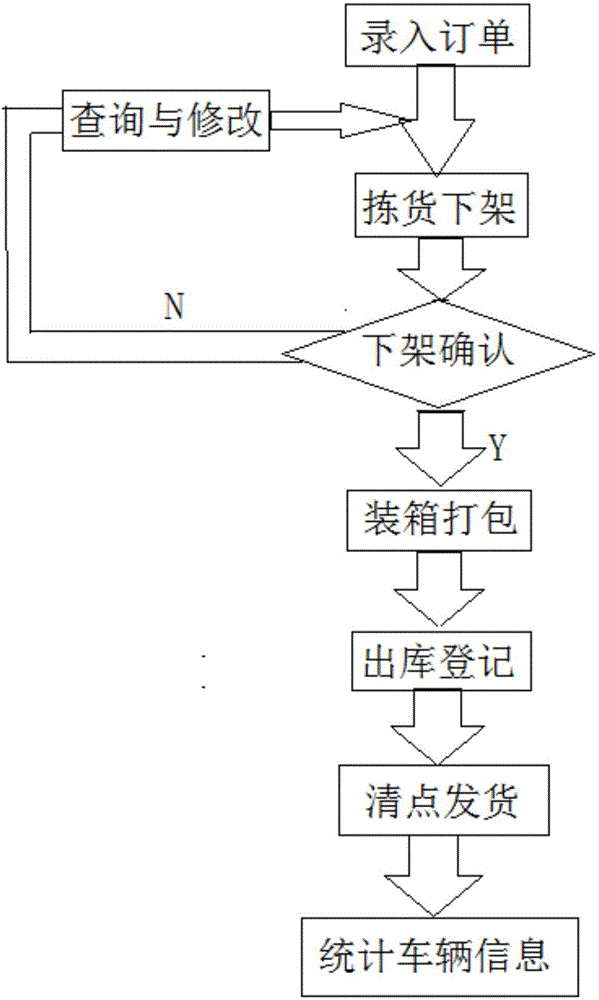

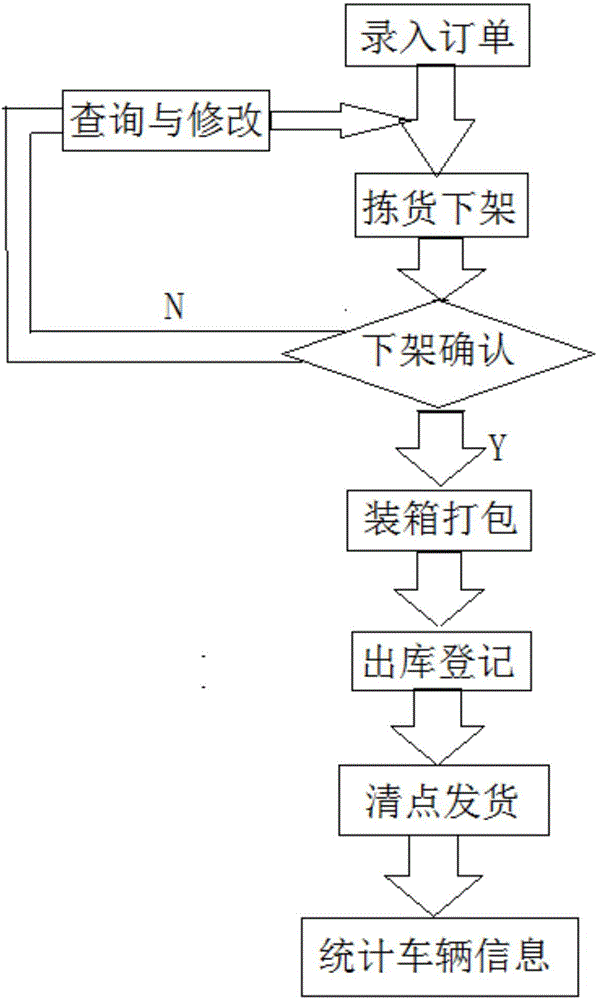

The invention discloses a cold-chain logistics storage supervisory system and method. The cold-chain logistics storage supervisory system includes a temperature monitoring module, a WMS (Warehouse Management System) management module, an order management module, an in-out stock monitoring module, a three-dimensional planning module, a processing module, an inventory management module and a locating and tracking module. The old-chain logistics storage supervisory system effectively organizes the staff, space and equipment by aid of the WMS for receiving, storing, picking and transporting goods, transporting raw materials and parts to manufacturing enterprises and conveying finished products to wholesalers, distributors and final customers. The main functions of the cold-chain logistics storage supervisory system are managing and controlling all in-out stock dynamic conditions of the warehouse and doing statistic analysis about inventory data, so decision makers can find problems timely, adopt corresponding measures to adjust the inventory structure, shorten the storage period, quicken capital turnover, and further to ensure smooth logistics in enterprise production.

Owner:临沂市义兰物流信息科技有限公司

Cold-chain logistic stowage intelligent recommendation method based on spectral cl9ustering

InactiveCN105654267AReduce the no-load ratioIncrease profit marginsCharacter and pattern recognitionLogisticsCold chainRating matrix

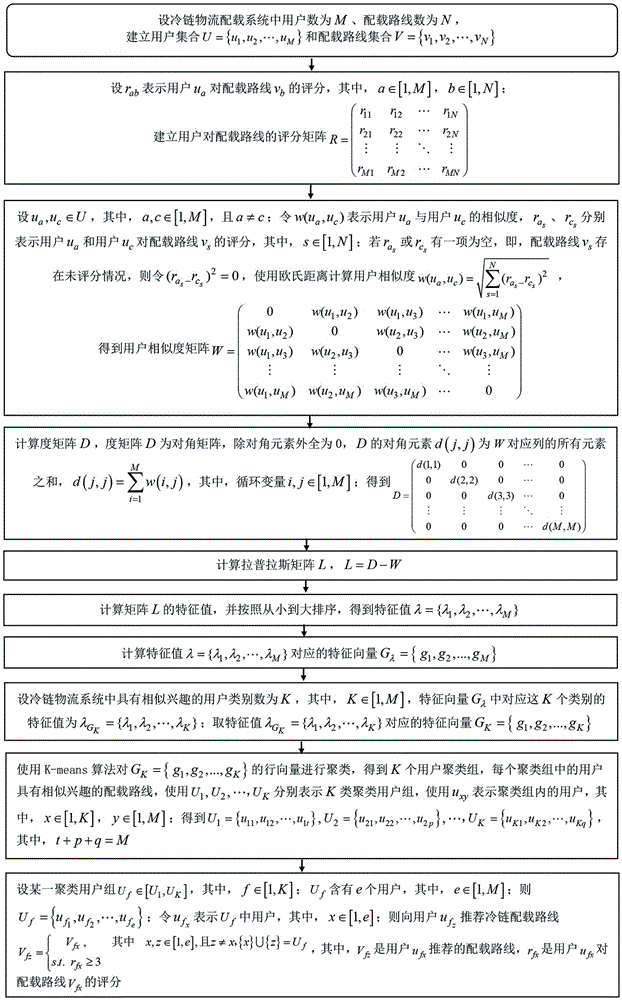

The invention discloses a cold-chain logistic stowage intelligent recommendation method based on spectral clustering. Scores of users for a stowage line are conveyed through a cold chain for cold-chain logistic stowage intelligent recommending, a score matrix is built, the Euclidean distance is used for calculating the user similarity, a degree matrix is used for calculating a Laplacian matrix, feature vectors are obtained by calculating feature values of the orderly Laplacian matrix, a K-means algorithm is used for clustering the feature values to obtain a user group with the similar interesting stowage line, and a stowage line is recommended inside the user group with the similar interesting stowage line, so that cold-chain logistic stowage intelligent recommending is achieved, the cold-chain logistic vehicle non-load ratio is lowered, and the profit rate of cold-chain logistic transport vehicles is increased.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

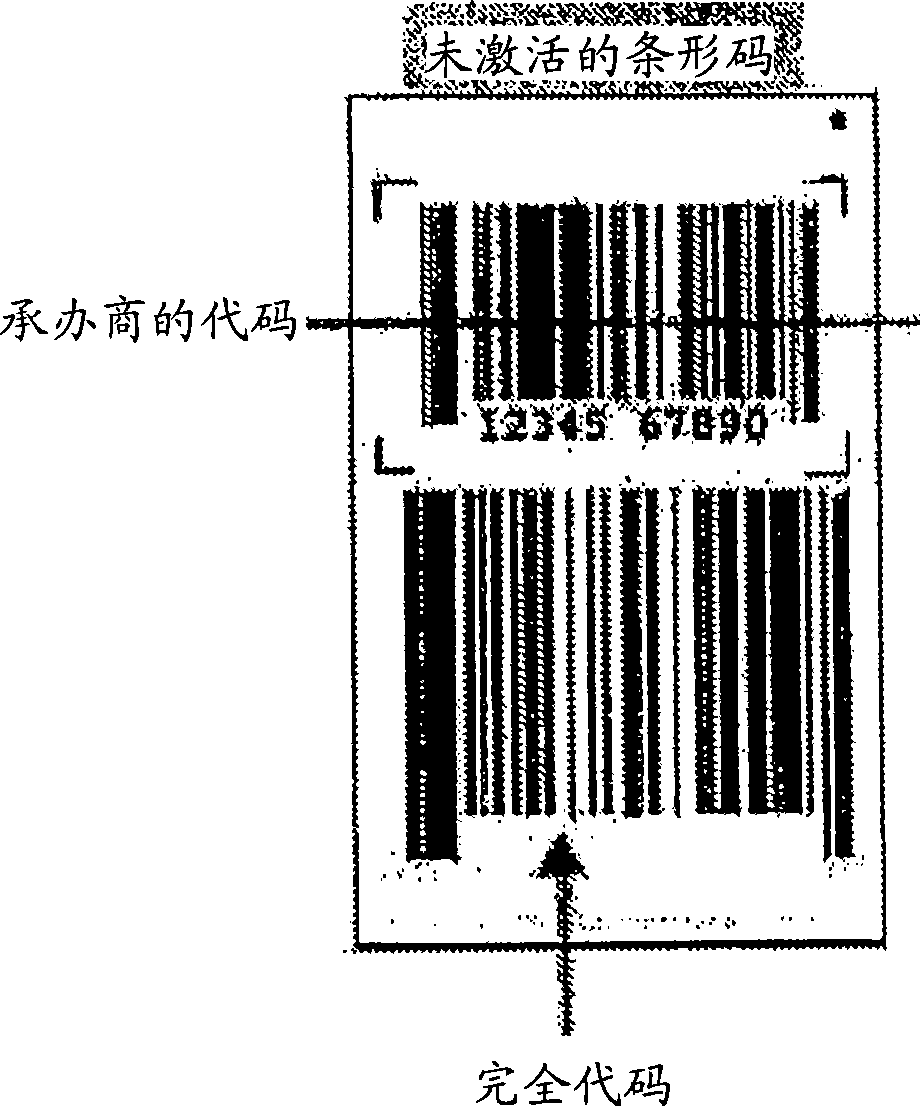

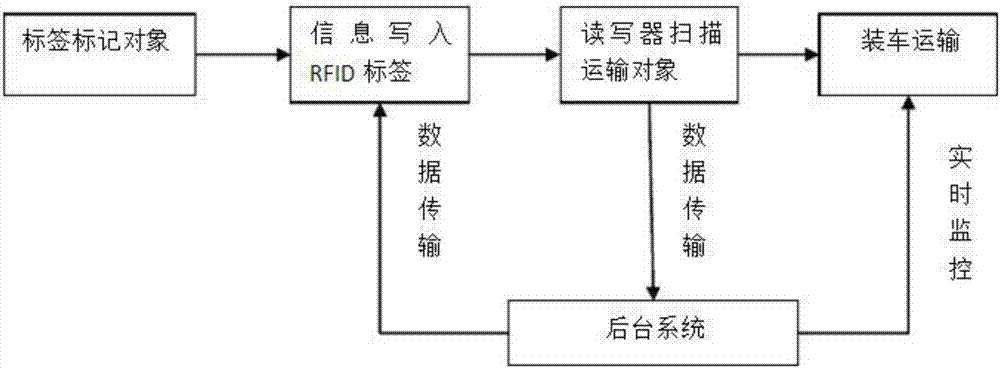

Aquatic product supply chain traceability system based on RFID and bar code technology and method thereof

InactiveCN101840538AHigh implementabilityAvoid defectsCo-operative working arrangementsResourcesCold chainVideo monitoring

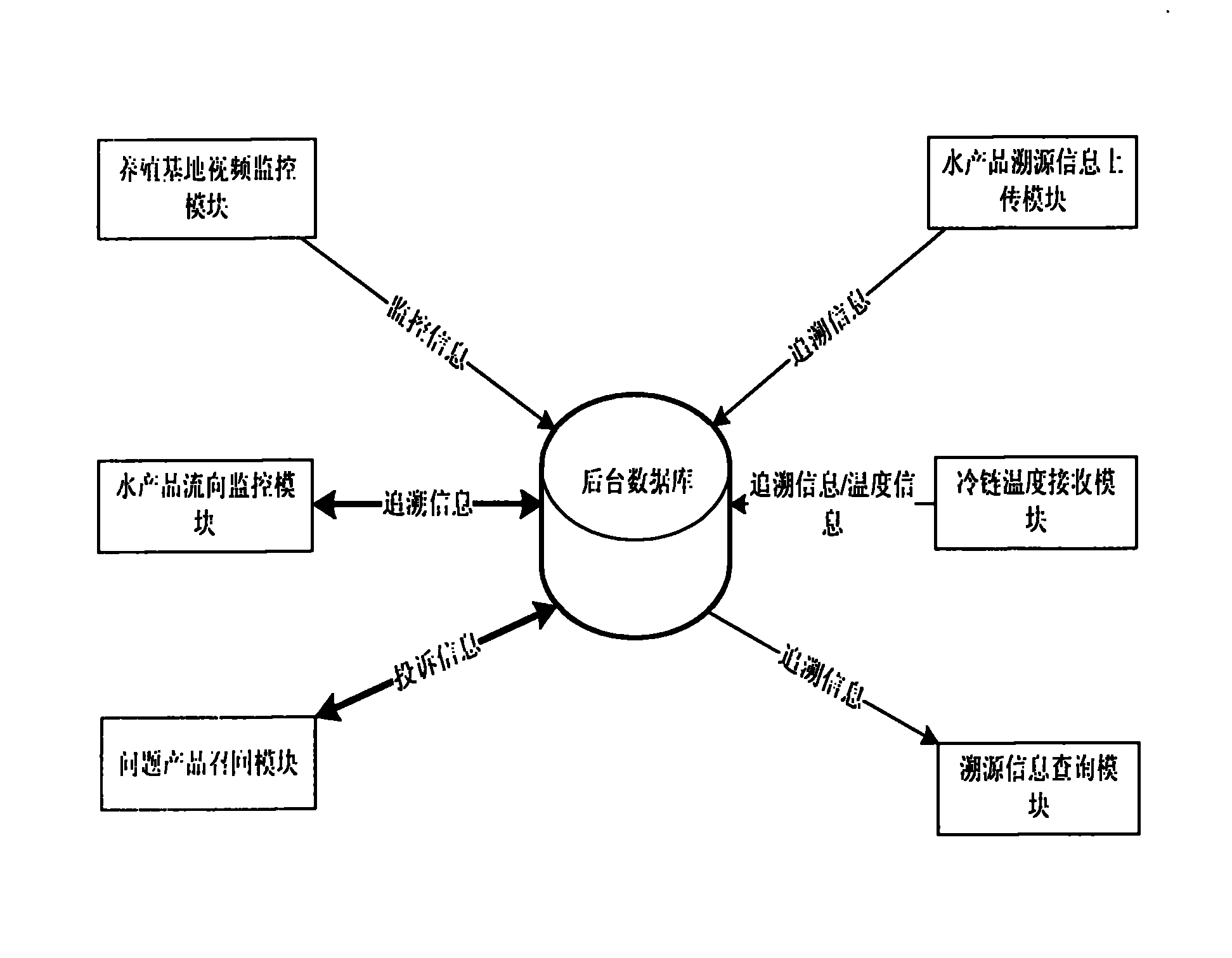

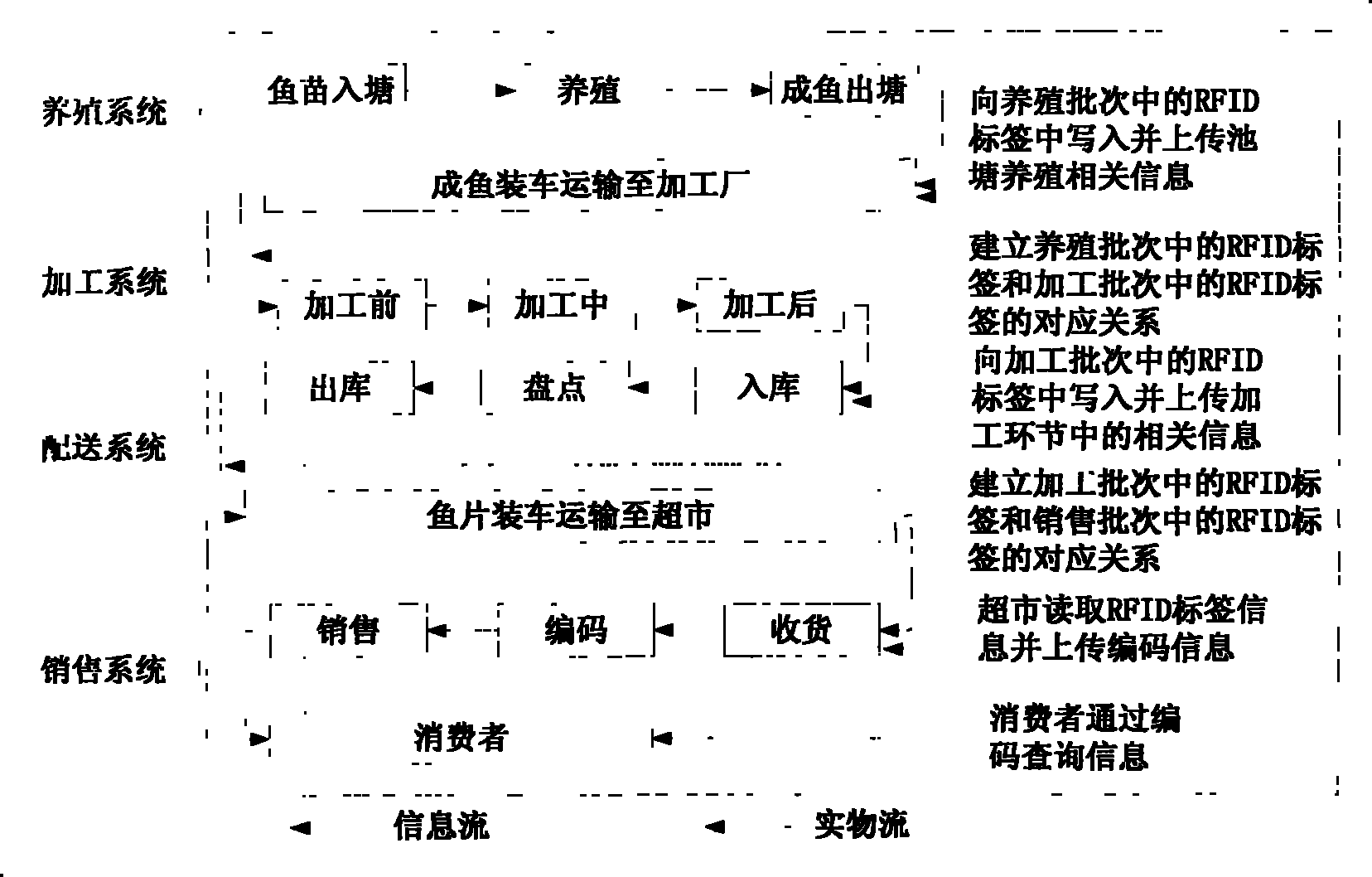

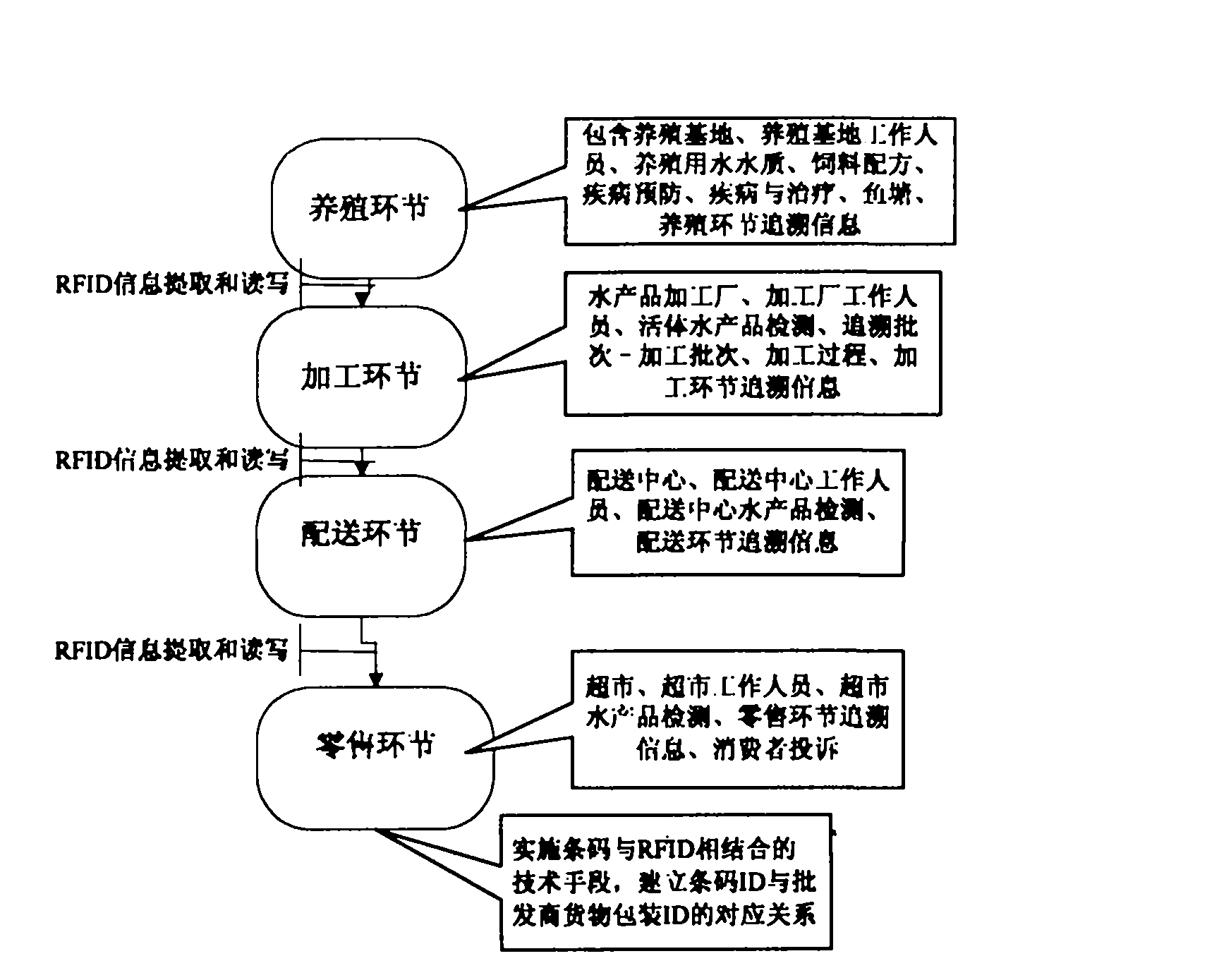

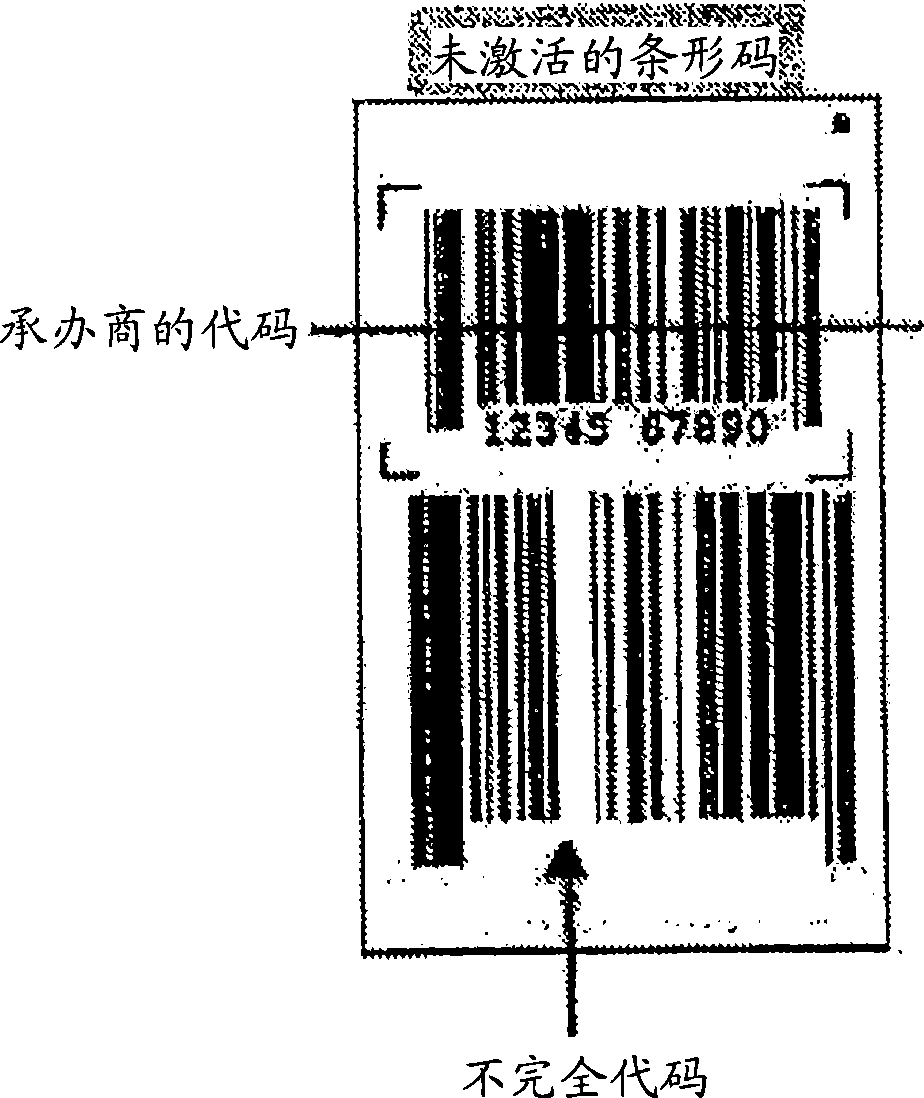

The invention discloses an aquatic product supply chain traceability system based on an RFID and bar code technology and a method thereof. The system comprises a background database, an aquaculture base video monitoring module, an aquatic product tracing information uploading module, an aquatic product flow-direction monitoring module, a cold chain temperature receiving module, a tracing information query module and an unqualified product recalling module. The specific method comprises four parts, i.e. an aquaculture section, a processing section, a delivery section and a retail section, after all processes are finished, the tracing information are uploaded to the background database, or is read from the background database, while the transfer of the tracing information on the supply chain can be realized among all the processes by batch information stored in an RFID electronic tag. By effective combination of the RFID tap and the bar code, the invention really realizes a management mode with descending tracking and ascending tracing and brings great convenience for consumers and enterprises.

Owner:SOUTH CHINA UNIV OF TECH

Identification and condition detection system

The present disclosure relates to a method for monitoring item sourcing and handling information. The present disclosure provides a device for tracking and tracing a product or item's source and handling history. The present disclosure may, for instance, be applied to any product that is packaged, distributed, shipped, or requiring or using cold chain distribution where a greater quality of freshness of a product is desired or where preventing distribution or removing from distribution of a product exposed to a preselected condition such as an undesirable environmental temperature is desired.

Owner:SIRA TECH

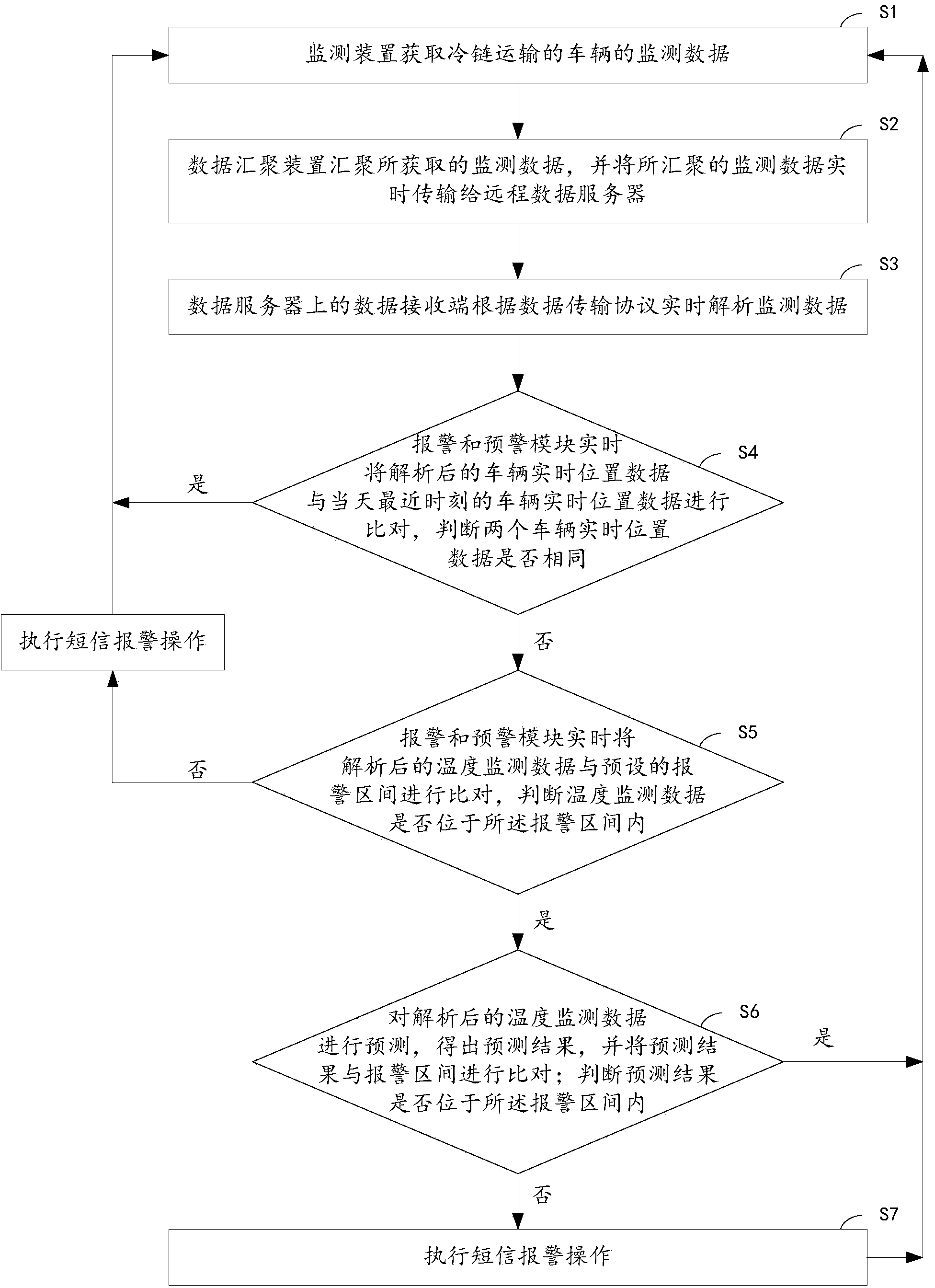

Cold-chain transport temperature monitoring and early warning method and system

InactiveCN104359565AEnsure safetyEmission reductionThermometer detailsTransmission systemsCold chainEarly warning system

The invention discloses a cold-chain transport temperature monitoring and early warning method and system. The cold-chain transport temperature monitoring and early warning method is characterized in that a wireless sensing network is established to acquire temperature data in carriers in real time by Zigbee, the temperature during cold-chain transport can be monitored and warned early, and an early model is learned from the historical temperature data acquired based on the BP neural network in real time. The cold-chain transport temperature monitoring and early warning system can analyze the monitored temperature data in real time by the aid of the early warning model, and can automatically warn by short messages if the predicted results exceed the set warning threshold, so that alarming and early warning of the cold-chain temperature can be realized.

Owner:CHINA AGRI UNIV

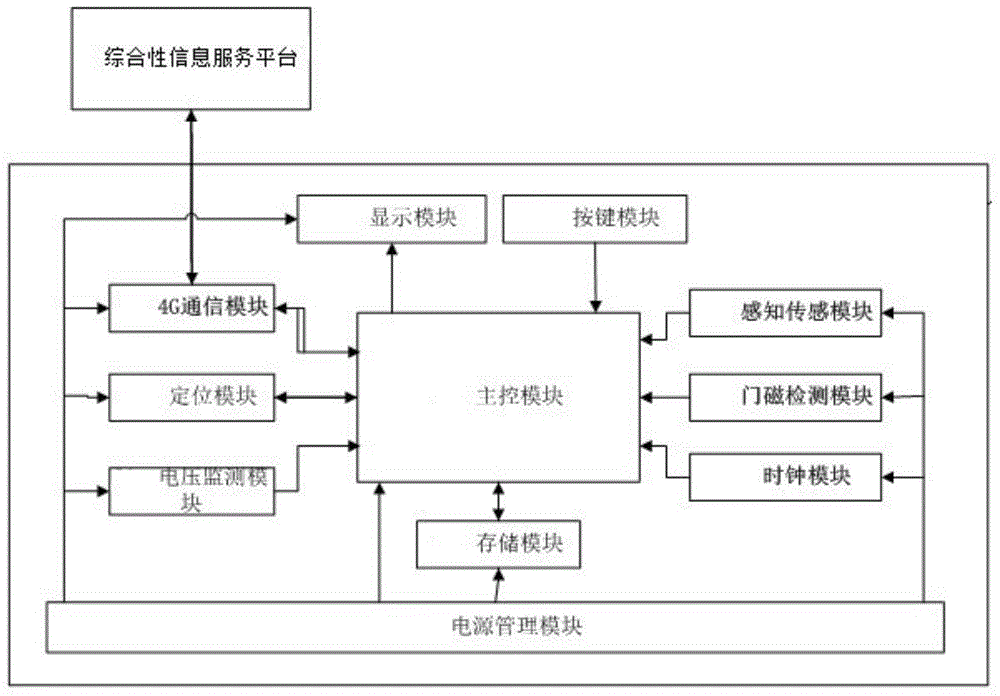

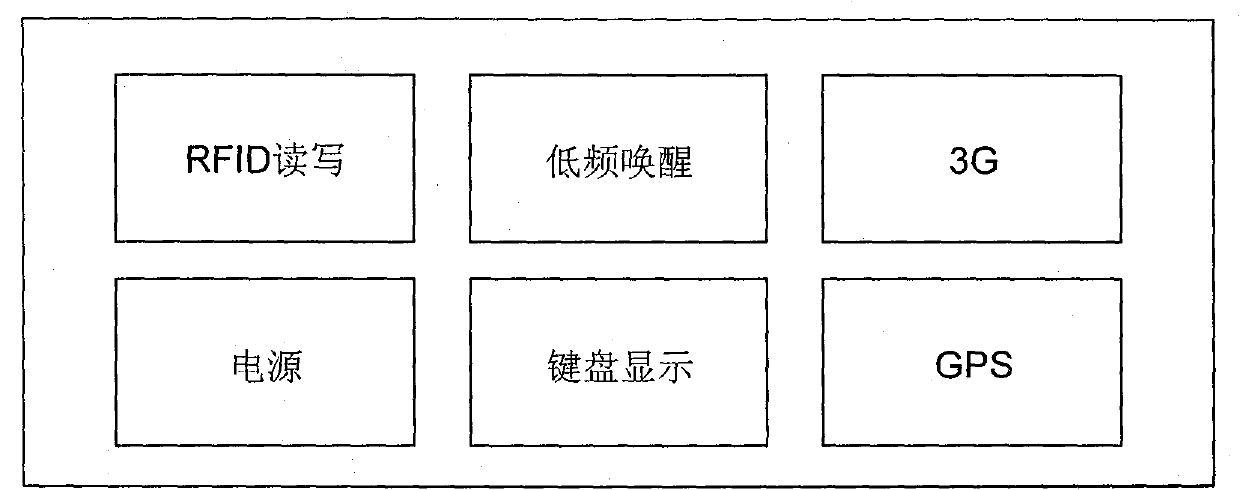

Cold chain monitor, cold chain monitoring system and control method of cold chain monitoring system

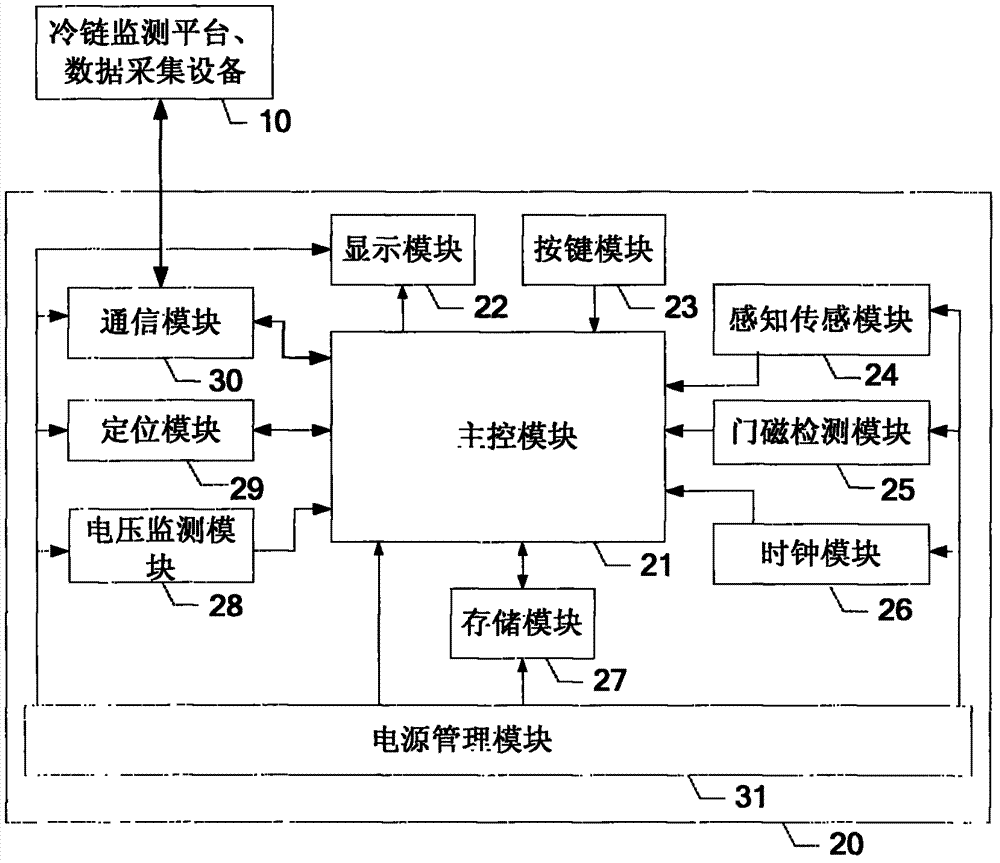

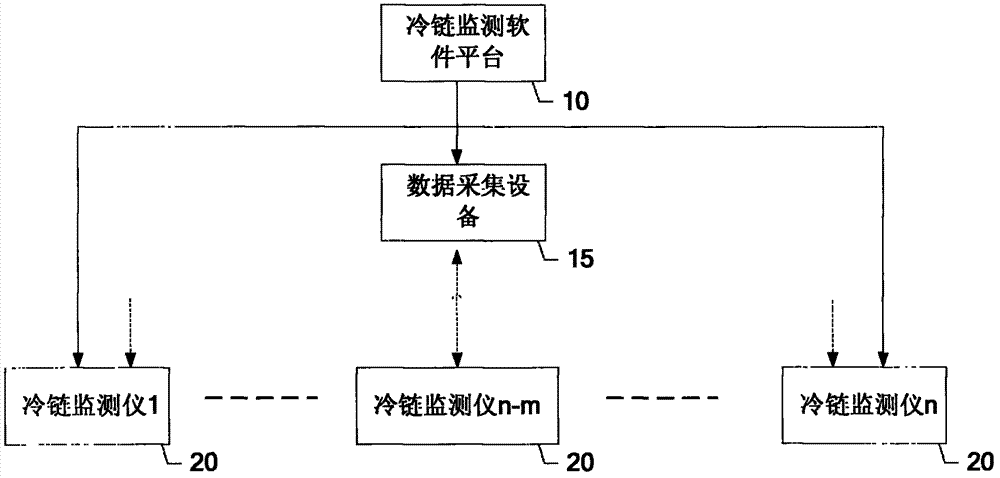

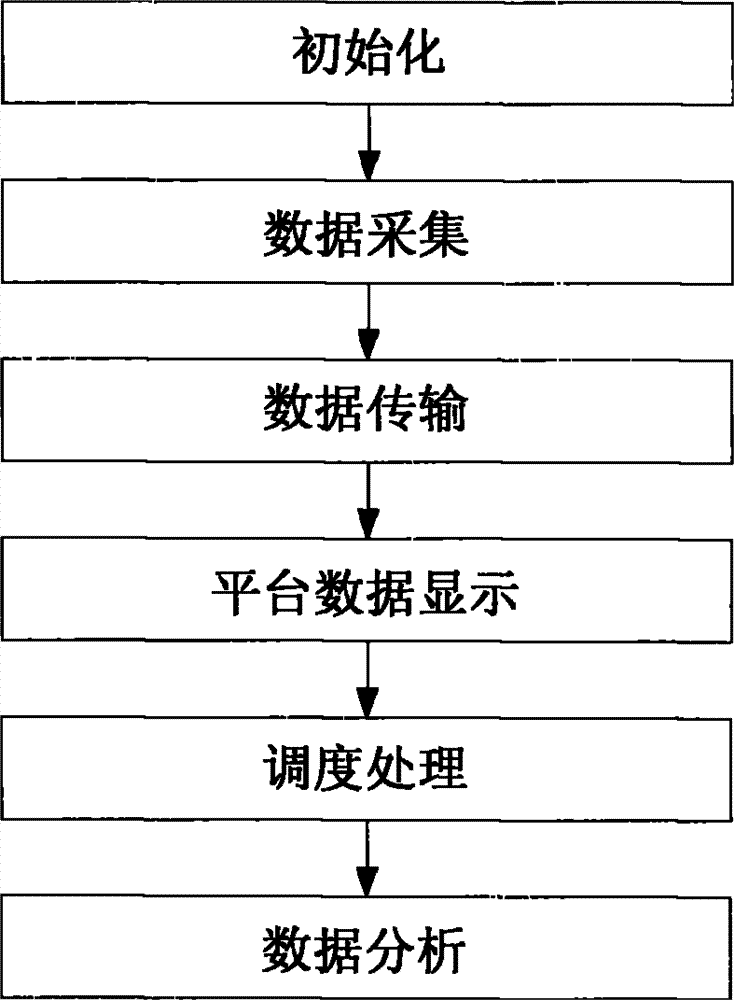

InactiveCN103197621AGuaranteed real-timeIntegrity guaranteedTotal factory controlProgramme total factory controlCold chainData display

The invention provides a cold chain monitor, a cold chain monitoring system and a control method of the cold chain monitoring system. The cold chain monitor comprises a master control module, a positioning module, an induction sensing module, a communication module, a door magnetism detection module, a voltage monitoring module, a data storage module, a clock module, a display module, a button module and a power supply module. The cold chain monitoring system comprises the cold chain monitor, a data collection device and a cold chain monitoring software platform. The control method of the cold chain monitoring system comprises the steps of initialization, data collection, data transmission, platform data display, scheduling processing and data analysis. By means of the cold chain monitor, the cold chain monitoring system and the control method of the cold chain monitoring system, the chain breaking problem in cold-chain logistics is solved, and the problems of temperature collection monitoring, data transmission, back-stage management and early-warning processing in the cold chain transportation process are especially solved.

Owner:李代万

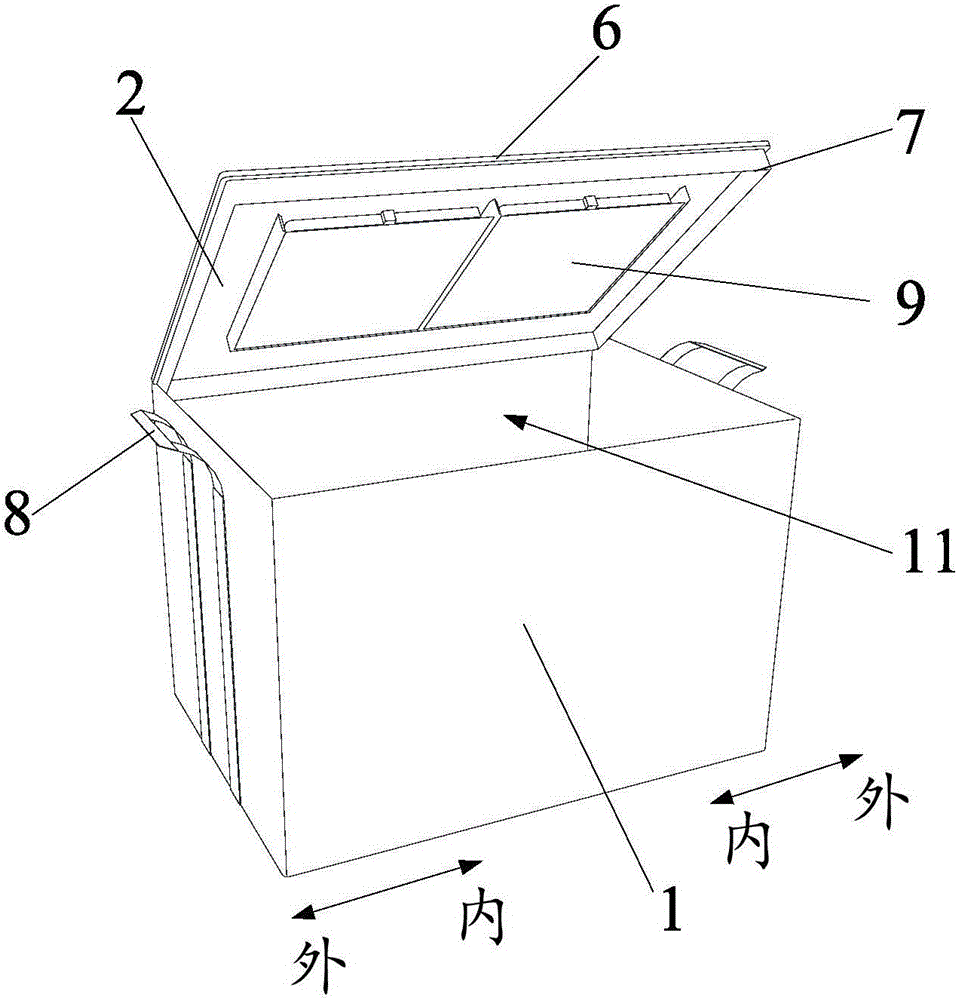

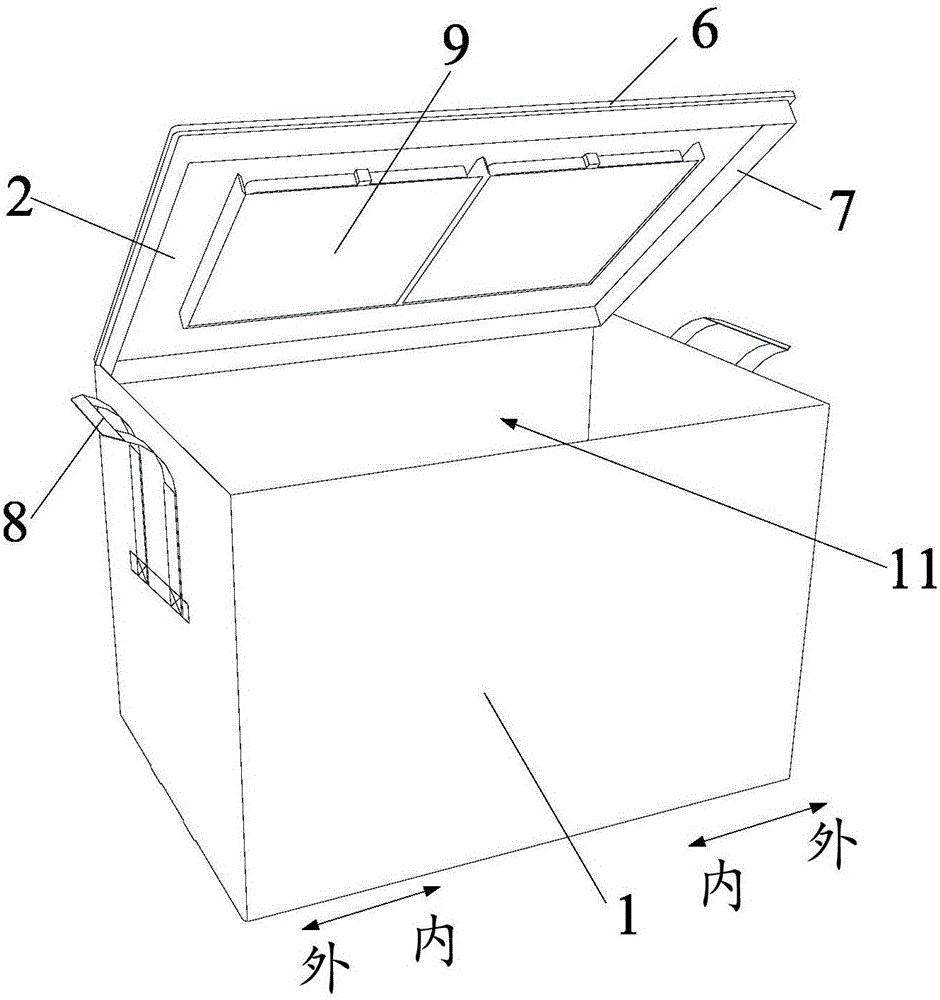

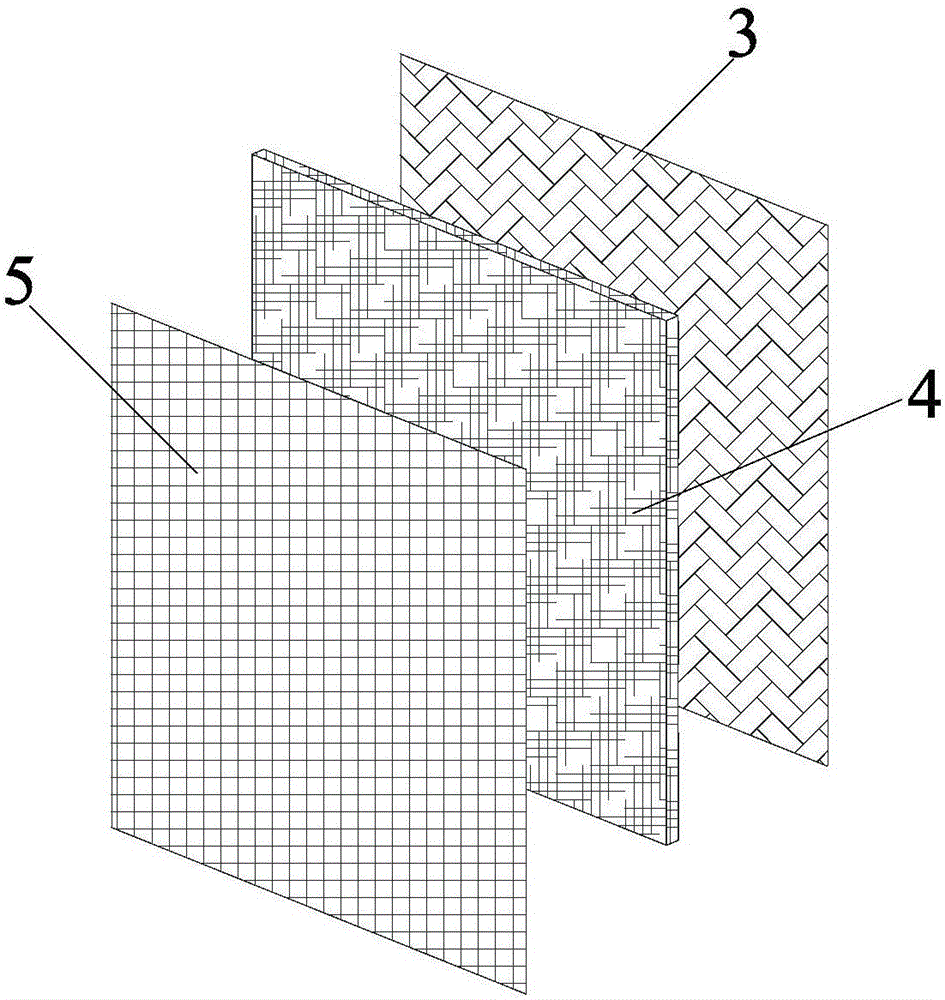

Cold-chain transportation cold preservation box and manufacturing method thereof

InactiveCN105819110AImprove waterproof performanceLow thermal conductivityDomestic cooling apparatusLighting and heating apparatusCold chainThermal insulation

The invention provides a cold-chain transportation cold preservation box and a manufacturing method thereof, wherein the cold-chain transportation cold preservation box comprises a box body and a box cover; the box body is provided with an opening, and each of the box body and the box cover comprises an outer layer, a thermal insulating layer and an inner layer; the box cover can be detachably connected with the box body and is used for closing the opening; and each thermal insulating layer is made of an aerogel thermal insulating material and is arranged between each outer layer and each inner layer. According to the cold-chain transportation cold preservation box provided by the invention, the thermal insulating layer made of the aerogel thermal insulating material has an ultralow thermal conductivity, is good in low-temperature stability and can keep cold preservation performance, favorable flexibility and non-cracking property for a long term at 270 DEG C below zero; compared with a thermal insulation box used for solving the problem of last kilometer transportation in the express industry at present, the cold-chain transportation cold preservation box has an ultrathin property and is better in cold preservation property, in addition, the thermal insulating layer is enabled to have better waterproofness; and the aerogel thermal insulating material has relatively good flexibility and can be made into a flexible box body together with the outer layer and the inner layer, so that the box body has the folding property, convenient and rapid and easy to operate.

Owner:SHENZHEN NANENG TECH CO LTD

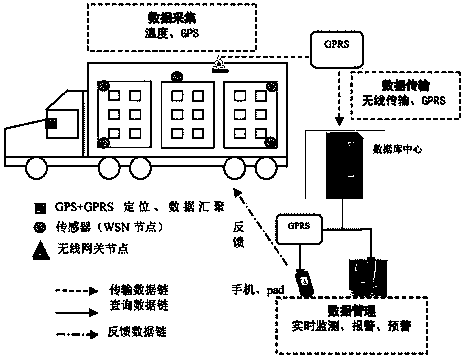

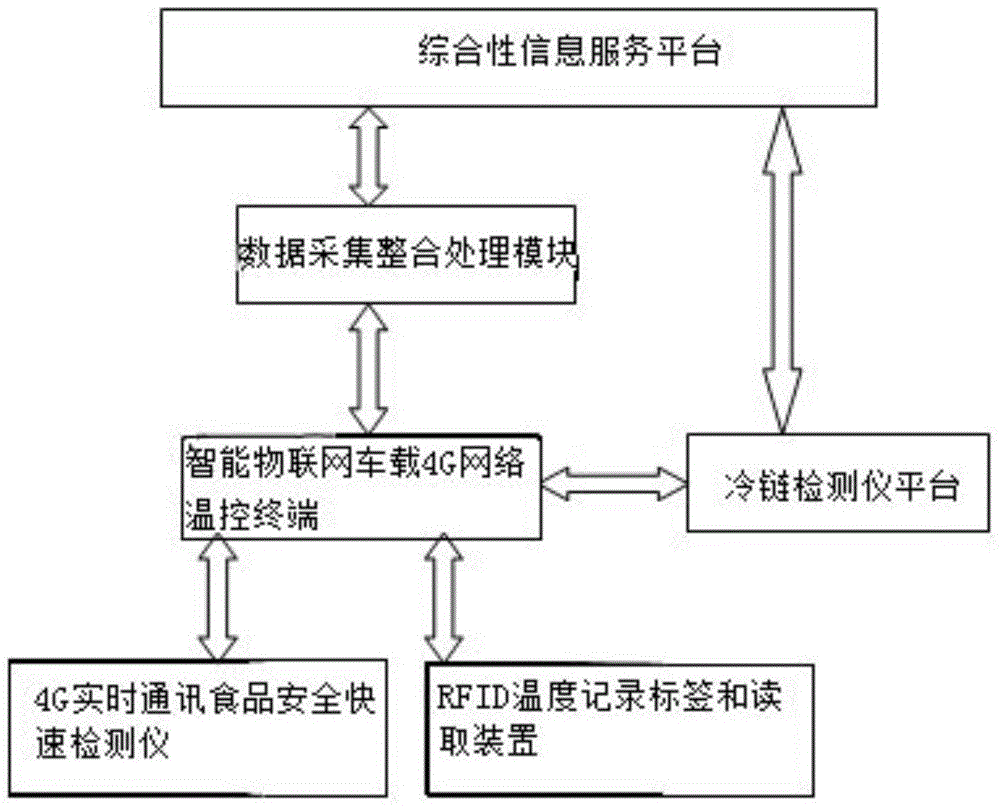

Cold chain transportation tracking system based on Internet of Things

InactiveCN105096073ATimely feedbackAccurate feedbackSensing record carriersTransmissionCold chainData acquisition

The invention aims to provide a cold chain transportation tracking system based on Internet of Things. The system can realize monitoring of a whole cold chain process and can realize traceable management and can perform centralized integration on all data in the cold chain transportation process. According to the invention, a comprehensive information service platform is connected with a data collection integration processing module and a cold chain detecting instrument platform electrically. The data collection integration processing module is connected with an intelligent IoT vehicle 4G network temperature control terminal electrically. The intelligent IoT vehicle 4G network temperature control terminal is connected with the cold chain detecting instrument platform, a 4G real-time communication food safety quick detecting instrument and an RFID temperature recording label / reading device electrically. By adopting the above technical scheme, monitoring of a whole cold chain process is realized and traceable management and centralized integration on all the data in the cold chain transportation process are achieved. Therefore, superiority of cold chain transportation is ensured and the system has a good application value in cold chain transportation industry.

Owner:QINGDAO YOUMING WEIYE INFORMATION TECH CO LTD

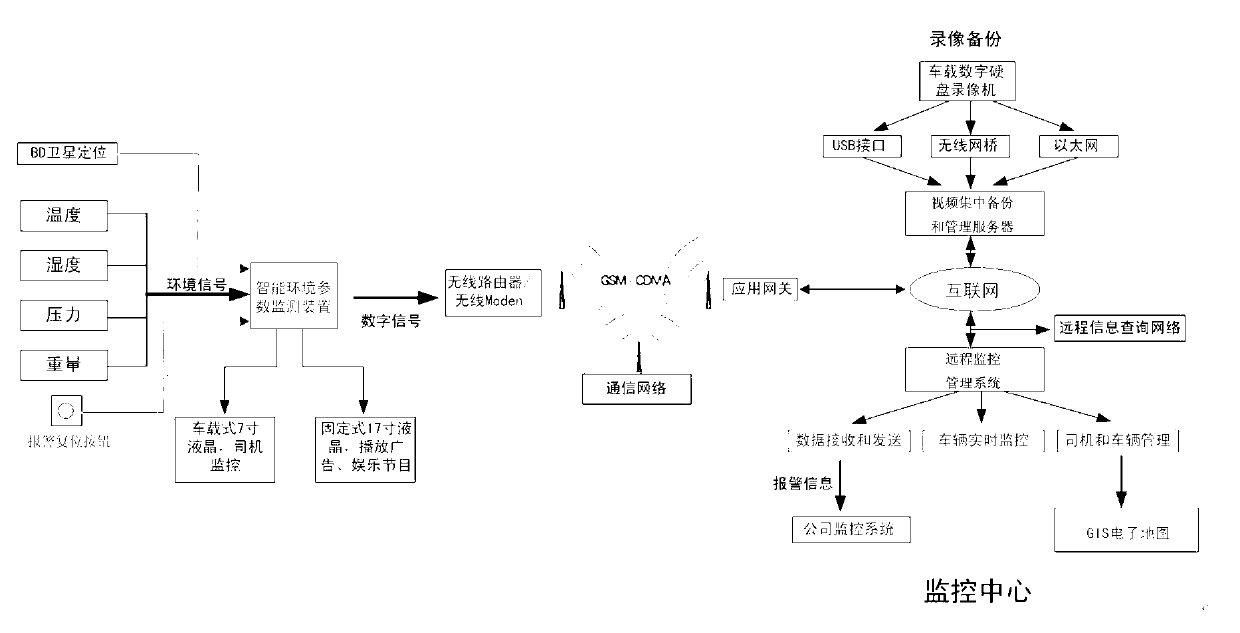

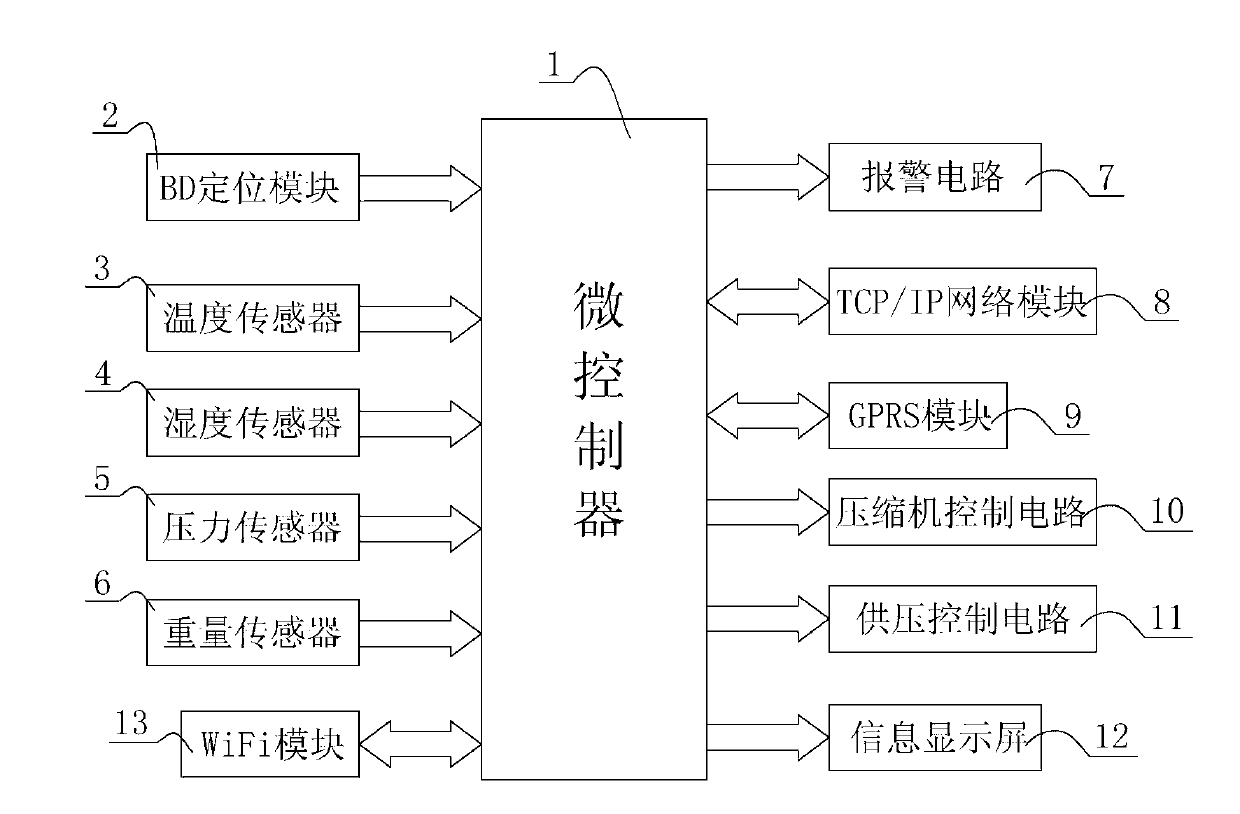

Green storage and transportation and cold-chain logistics monitoring system and method based on BeiDou system

ActiveCN103135640ARealize the function of intelligent controlRealize the warning effectLogisticsSimultaneous control of multiple variablesGeneral Packet Radio ServiceMicrocontroller

The invention provides a green storage and transportation and cold-chain logistics monitoring system based on the BeiDou system. The green storage and transportation and cold-chain logistics monitoring system based on the BeiDou system comprises an environment parameter monitoring device, a remote monitoring management system and a remote inquiring platform, and is characterized in that the environment parameter monitoring device comprises a BeiDou locating module, a temperature sensor, a humidity sensor, a pressure sensor and a weight sensor, the BeiDou locating module, the temperature sensor, the humidity sensor, the pressure sensor and the weight sensor are connected with a microcontroller, and an output end of the microcontroller is connected with an alarm circuit, a compressor control circuit, a pressure supply control circuit, a transmission control protocol (TCP) / internet protocol (IP) network module and a general packet radio service (GPRS) module. A control method for the environment parameter monitoring device comprises the steps of (a) collecting environment information, (b) uploading the information, (c) judging weight, (d) judging whether temperature reaches an alarm value, and (e) judging whether the temperature reaches an automatic cooling value. According to the green storage and transportation and cold-chain logistics monitoring system and the method based on the BeiDou system, the fact that agricultural products, aquatic products, foods and drinks are located in an optimum freshness retaining state in the process of freshness retaining, transportation and storage is ensured, original corruption and spoilage are prevented, and safety of stored and transported objects is ensured.

Owner:SHANDONG COMP SCI CENTNAT SUPERCOMP CENT IN JINAN

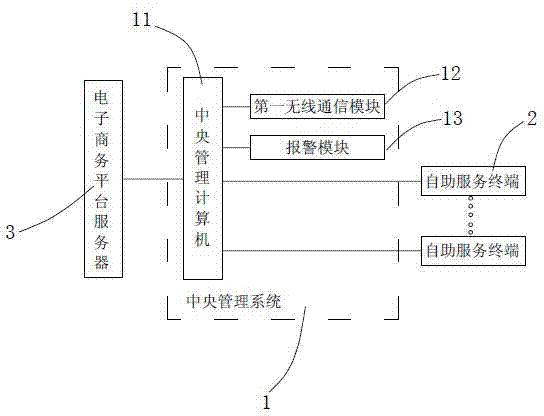

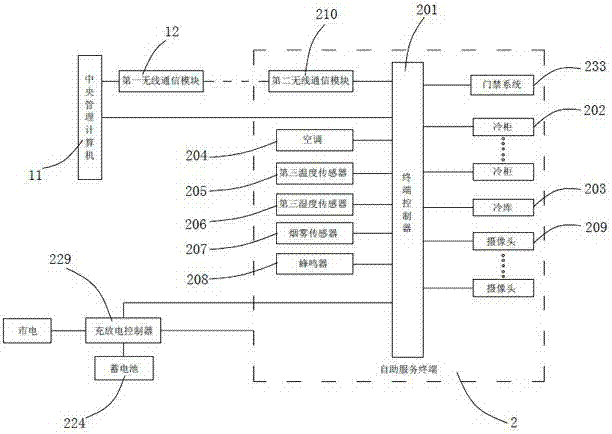

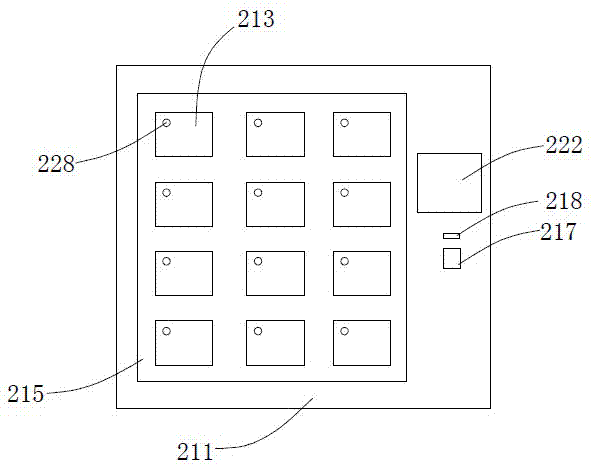

Cold chain distribution self-service system

InactiveCN103577954ARealize staggered time tradingImprove qualityApparatus for meter-controlled dispensingLogisticsElectricityCold chain

The invention discloses a cold chain distribution self-service system which comprises a central management system and self-service terminals which are arranged in communities. The central management system comprises a central management computer. Each self-service terminal comprises a terminal controller and multiple refrigerating cabinets. The refrigerating cabinets comprise refrigerating cabinet bodies, and refrigerating chambers and refrigerating devices are arranged in the refrigerating cabinet bodies. Multiple storage boxes are arranged in the refrigerating chambers. An electric control box door is arranged on each storage box. An electric control cabinet door is arranged on each cabinet body. A refrigerating cabinet controller, a first IC card reader and a first bar code reader are further arranged on each cabinet body. The refrigerating cabinet controllers are electrically connected with the refrigerating devices, the electric control box doors, the electric control cabinet doors, the first IC card readers, the first bar code readers and the terminal controllers respectively. The central management computer is electrically connected with the terminal controllers and an electronic business platform server respectively. According to the cold chain distribution self-service system, a delivery man and a buyer can perform trading at different time points, the waiting process between the delivery man and the buyer is eliminated, the distribution efficiency is improved and the distribution cost is reduced.

Owner:NINGBO SANZHANG GUIXIN BUSINESS

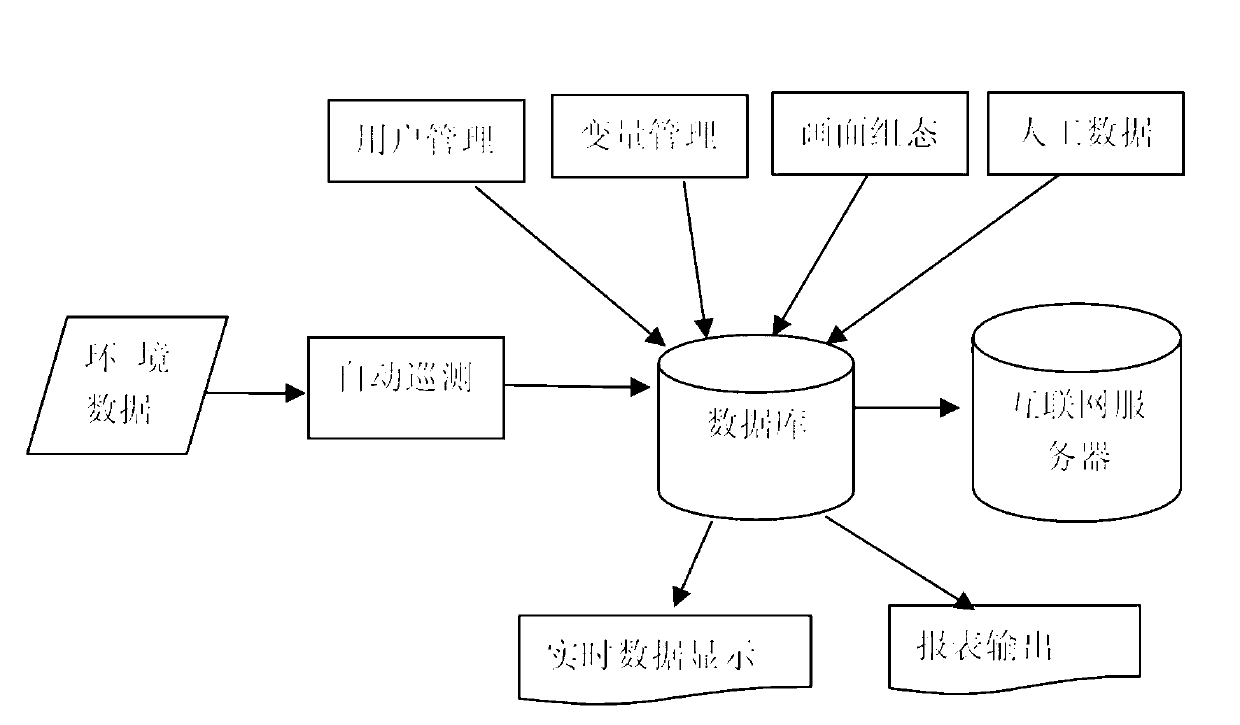

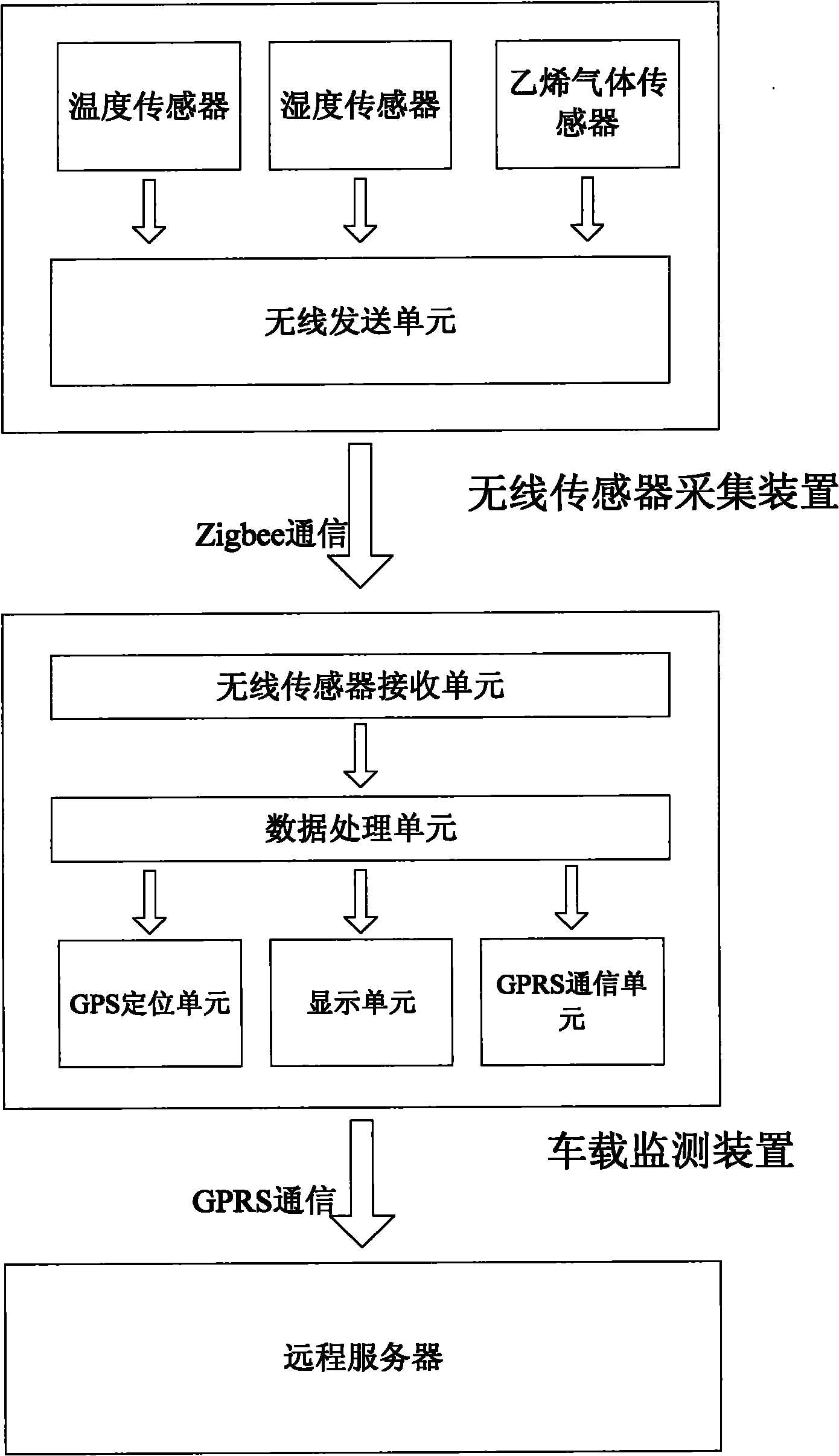

Cold chain transportation process information monitoring system and method

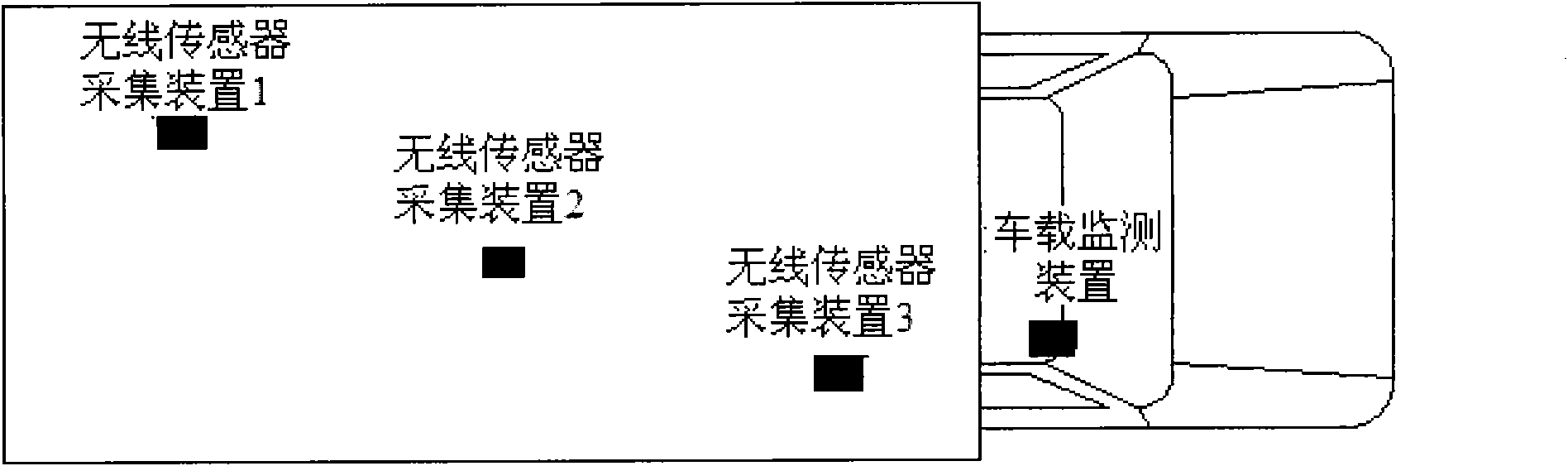

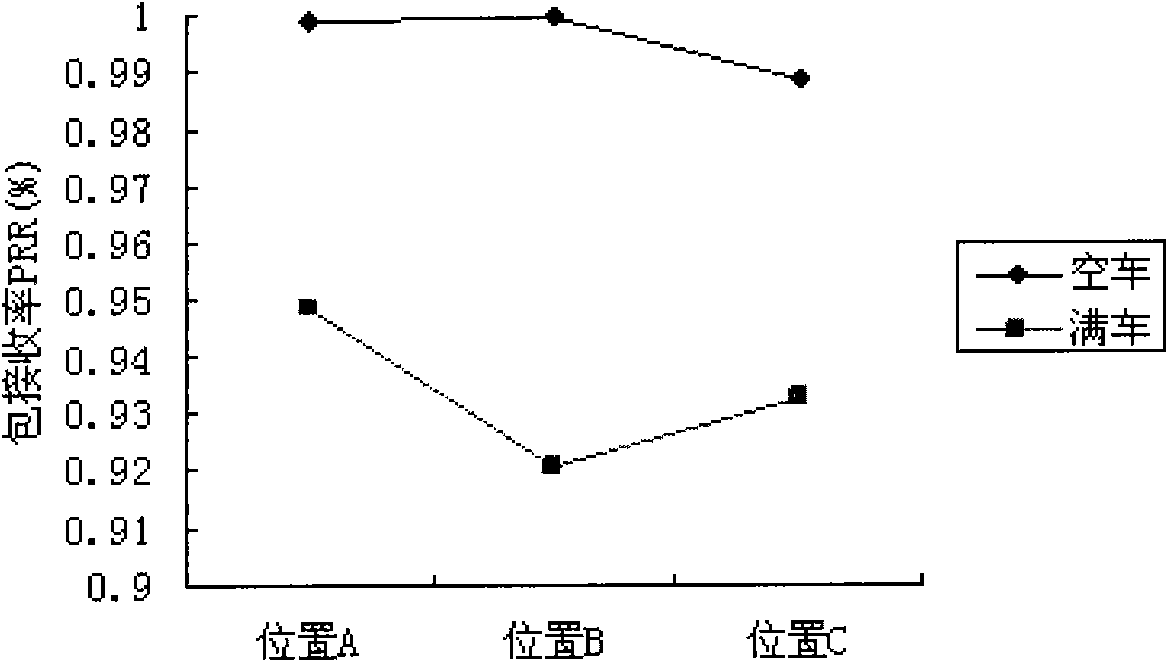

InactiveCN101853566AReal-time dual monitoringTransmission systemsRefrigerated goods vehicleCold chainBody compartment

The invention discloses a cold chain transportation process information monitoring system, comprising a wireless sensor acquisition device, a vehicle-bone monitoring device and a remote server; wherein the wireless sensor acquisition device is used for acquiring temperature, humidity and ethylene gas concentration information data in carriage in real time and transmitting the information data to the vehicle-bone monitoring device; and the vehicle-bone monitoring device is used for receiving and processing the information data transmitted by the wireless sensor acquisition device and transmitting the processed information to the remote server. The device and method of the invention can store the acquired information into the monitoring device, can transmit data to the remote server in real time and can realize real-time and whole course dual monitoring.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

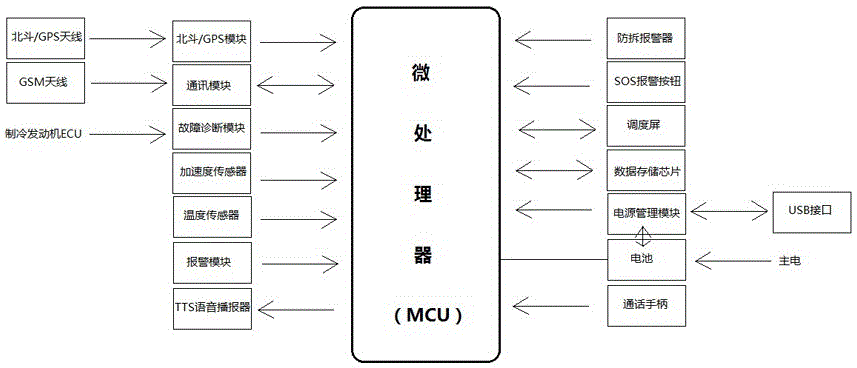

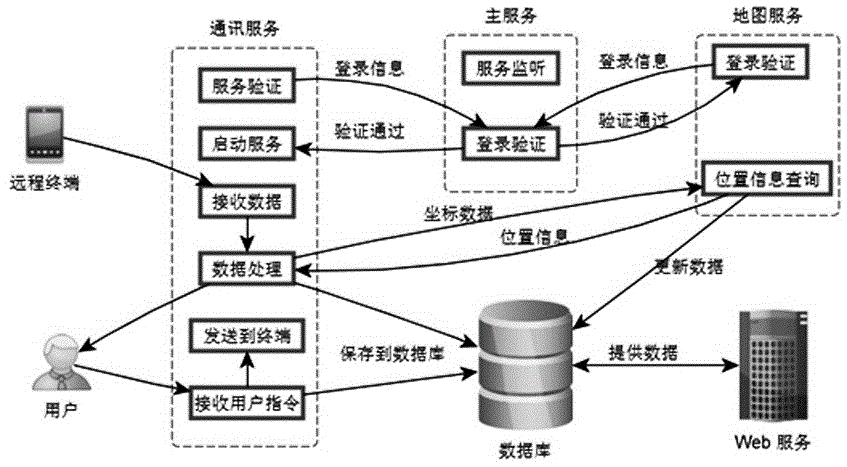

Cold chain transportation safety remote monitoring system

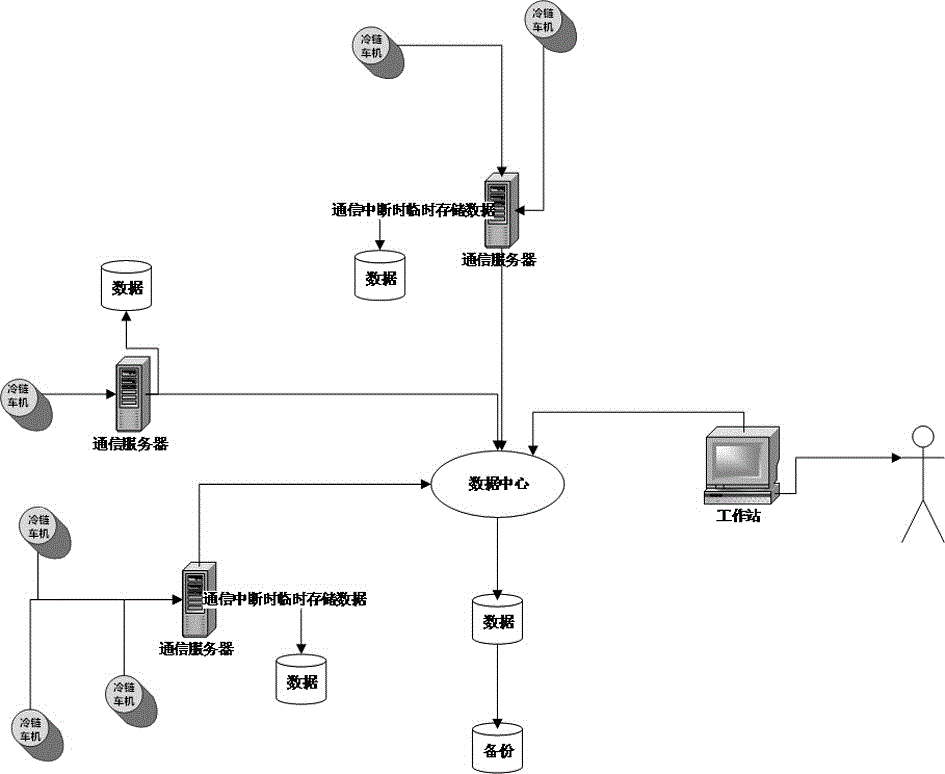

The invention discloses a cold chain transportation safety remote monitoring system which comprises a vehicle-mounted intelligent monitoring terminal, a central server, a client terminal and network equipment. The vehicle-mounted intelligent monitoring terminal comprises a microprocessor, a Beidou / GPS (global positioning system) positioning module, a communication module, a power source, a power source management module, an acceleration sensor, a data storage module, a diagnosis module and an anti-dismantle alarming module, the central server comprises a database server, a communication server, a backup server and a plurality of workstations, the client terminal is a PC or an intelligent phone, and the network equipment is used for forming an internal local network and a private wire network with mobile terminals. By the system, temperature and humidity of cold chain vehicles or cold chain transport cases conveying different preservation products are monitored in real time respectively on a same platform to control the temperature and the humidity within set temperature-humidity wave peak values, so that cold chain working effect is guaranteed.

Owner:南通启健物联科技有限公司

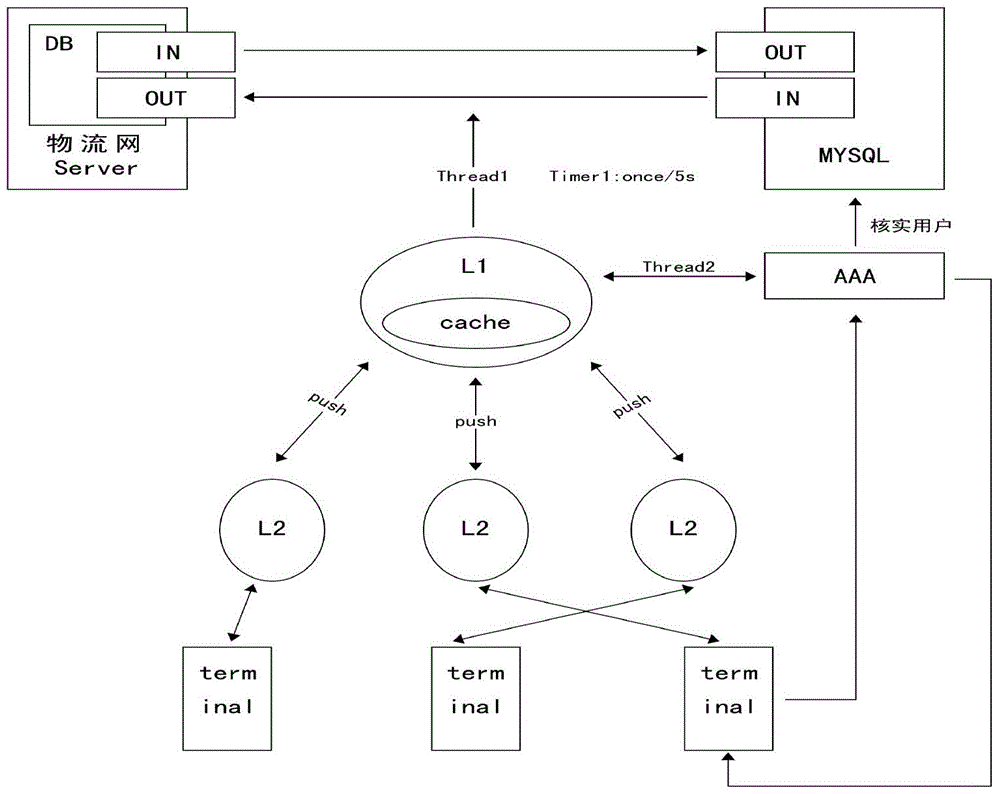

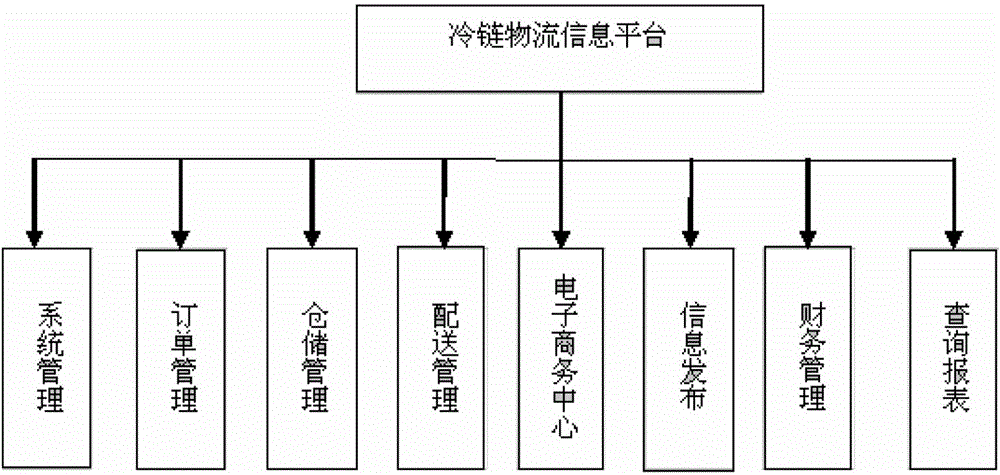

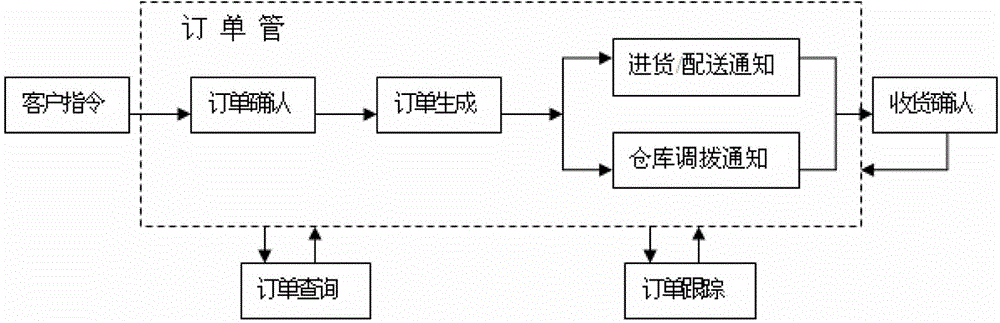

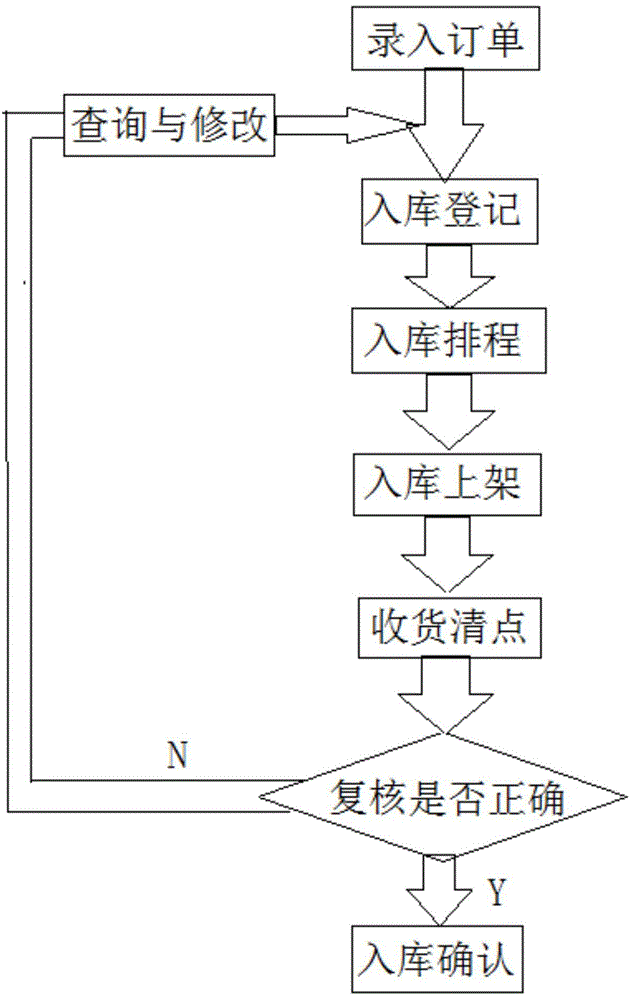

Cold-chain logistics information platform system

The invention discloses a cold-chain logistics information platform system. The cold-chain logistics information platform system is characterized by comprising a system management module, an order management module, a warehousing management module, a delivery control module, an e-commercial trade module, an information release platform, a financial management module and a report query module. The system management module is applicable to system-level operations such as maintenance of basic data, warehousing information and personnel information. The cold-chain logistics information platform system has the advantages that management efficiency is improved, information sharing is enhanced, and operating cost is lowered.

Owner:LIUZHOU TIANYU GERMANY REFRIGERATED TRANSPORT

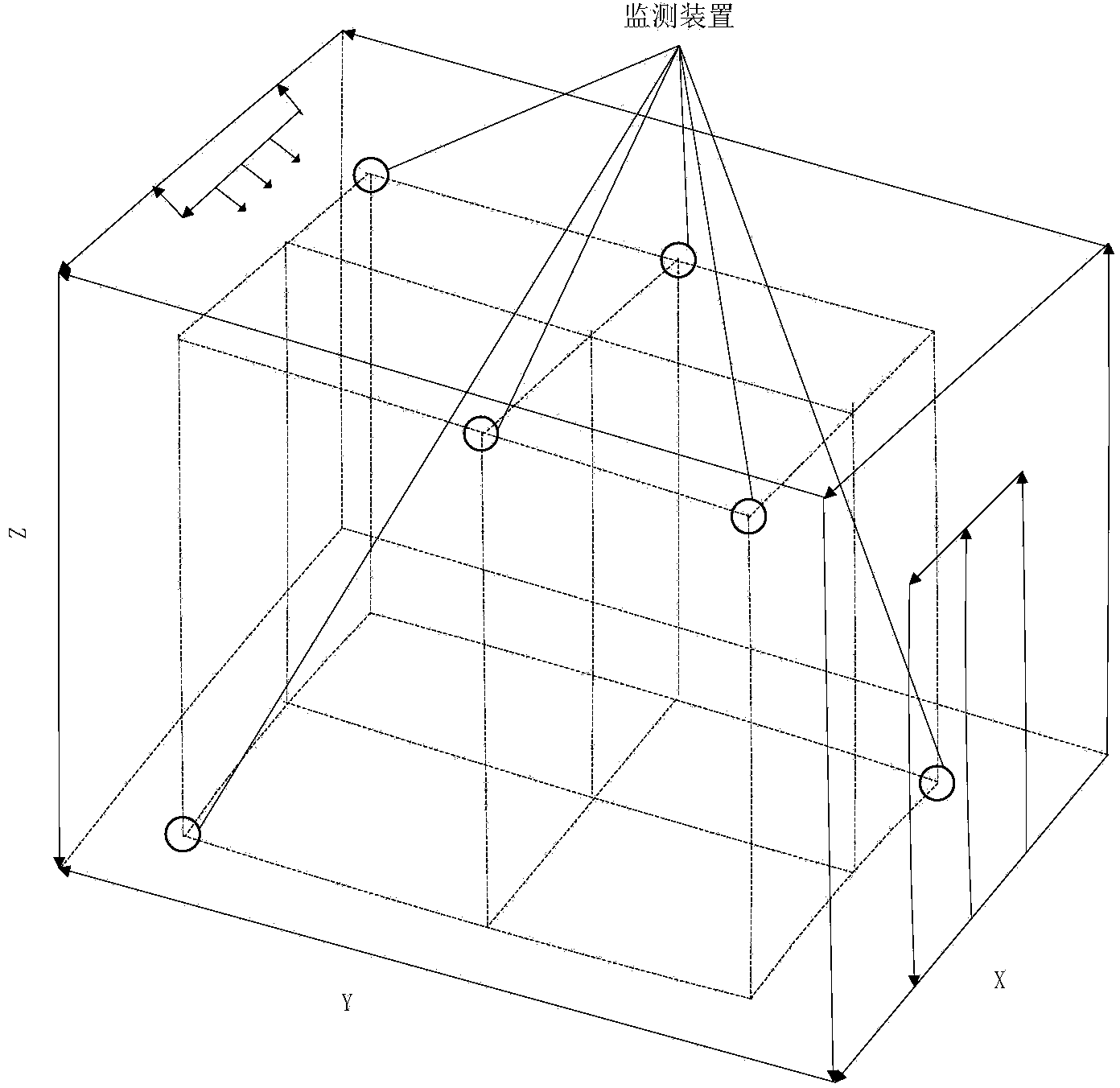

Cold-chain logistics visual monitoring system and method

ActiveCN104571044AReal-time grasp of temperature changesTimely responseTotal factory controlProgramme total factory controlCold chainTemperature control

The invention discloses a cold-chain logistics visual monitoring system and method. The system comprises a temperature control module, a control module, an order management module, a warehouse output and input monitoring module, a three-dimensional planning module and an inventory management module, wherein the temperature control module is used for measuring and monitoring the temperature in a warehouse and a transport vehicle and transmitting collected information to the control module; the control module is used for controlling the system to achieve visibility and control of all monitoring links; the order management module receives and records order information, establishes new orders of clients and tracks the state of each order; the warehouse output and input monitoring module is used for monitoring and positioning the output and input conditions of cargoes in real time, reading the states of the orders and judging whether warehouse output and input are normal operation or not and connected with the control module; the three-dimensional planning module is used for displaying a warehouse position plan three-dimensionally and reminding warehouse movement and cargo supplementation automatically; the inventory management module is used for displaying and updating the inventory of existing cargoes and connected with the control module. By means of the cold-chain logistics visual monitoring system and method, visibility of the whole process is achieved, and the clients can conveniently inquire about temperature and transport data in the whole transport process from picking-up of the cargoes to signing by a consignee at any time.

Owner:ROKIN LOGISTICS SUPPLY CHAIN

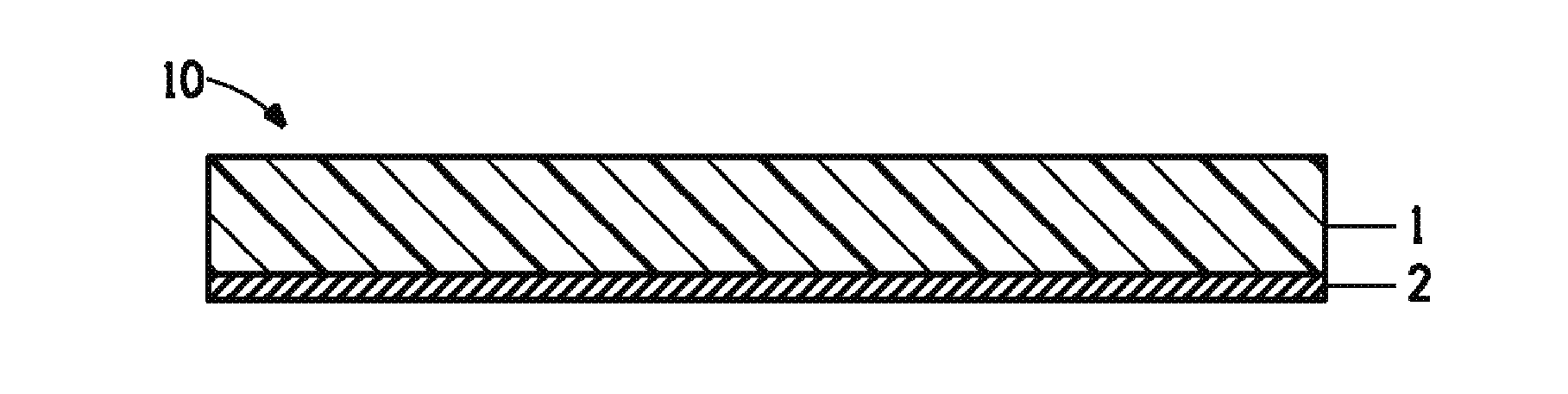

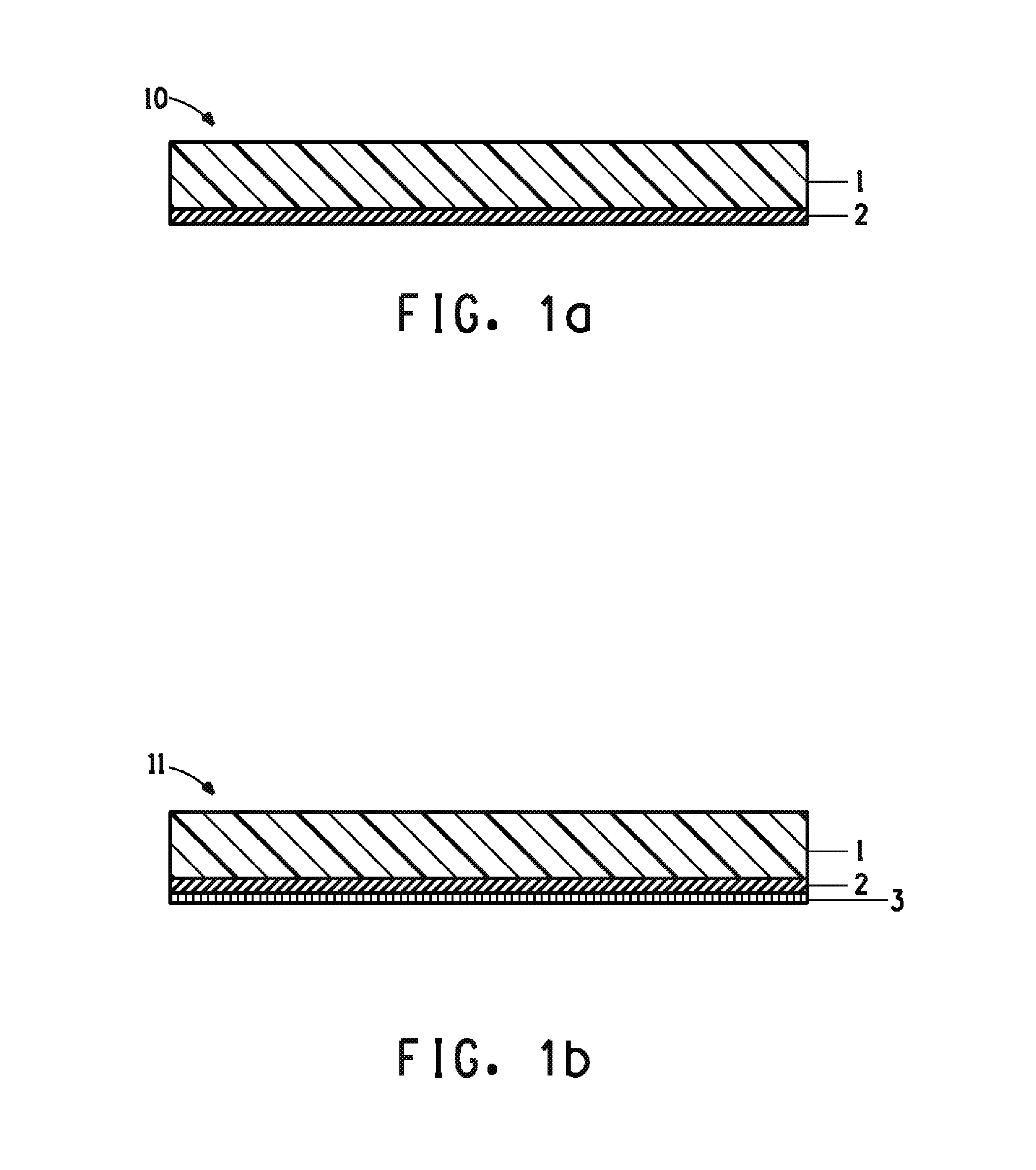

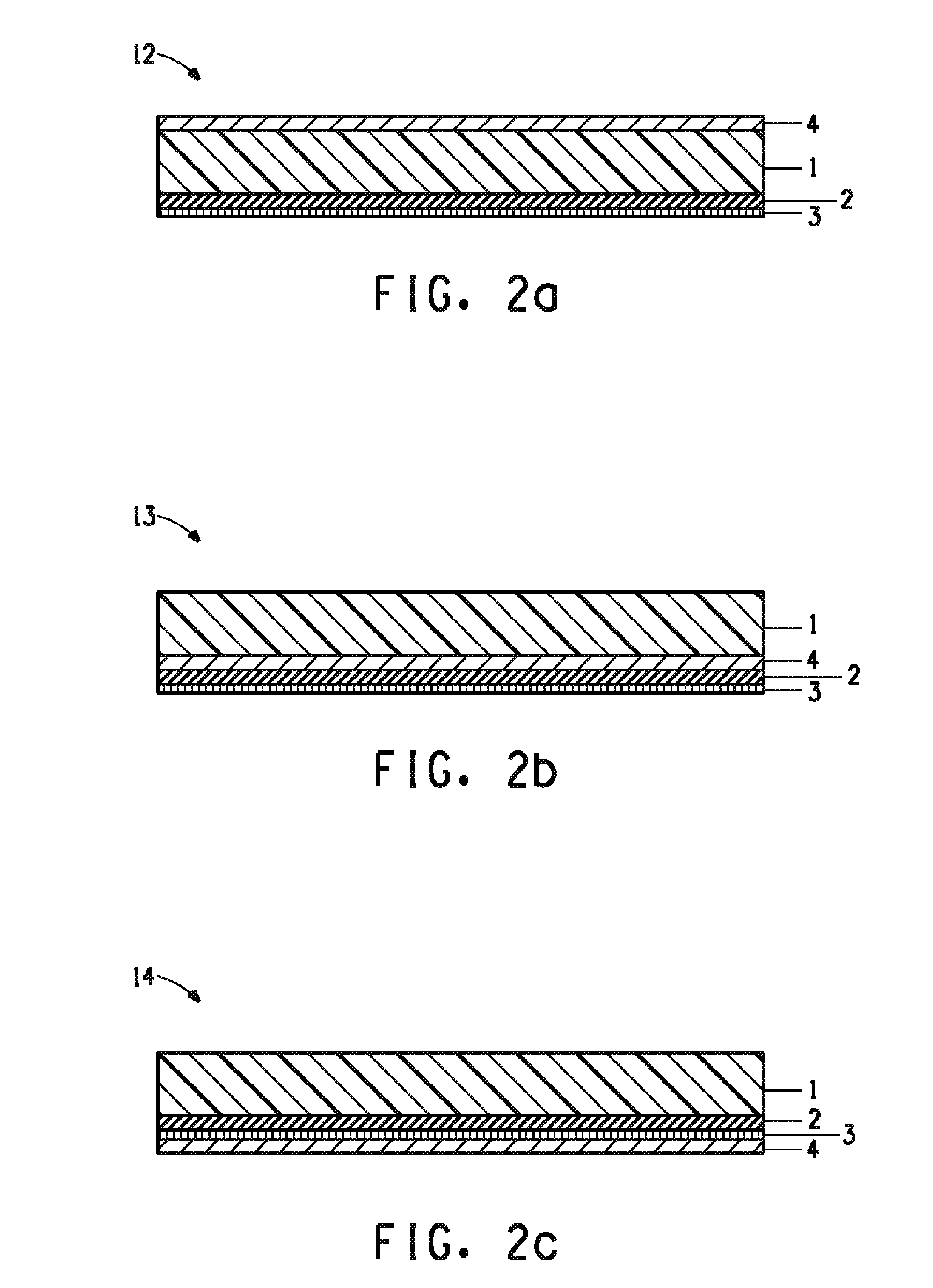

Breathable product for protective mass transportation and cold chain applications

ActiveUS20150053086A1Low emissivityImprove reflectivitySemi-permeable membranesLayered productsCold chainThermal insulation

The present invention concerns a breathable product for protective mass transportation and cold chain applications, in particular a reflective sheet for covering temperature sensitive products the reflective sheet having at least a first layer made of a highly reflective moisture vapor permeable substrate having an outer side and an inner side, wherein said inner side comprises in addition at least a metal layer deposited by a PVD process to provide a thermal insulation through high reflection low convection while providing controlled moisture vapor permeability.

Owner:DUPONT SAFETY & CONSTR INC

Time-temperature indicating device

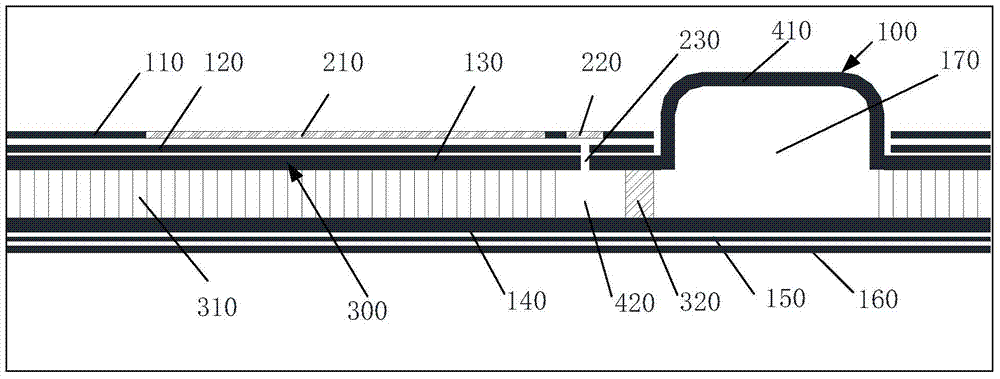

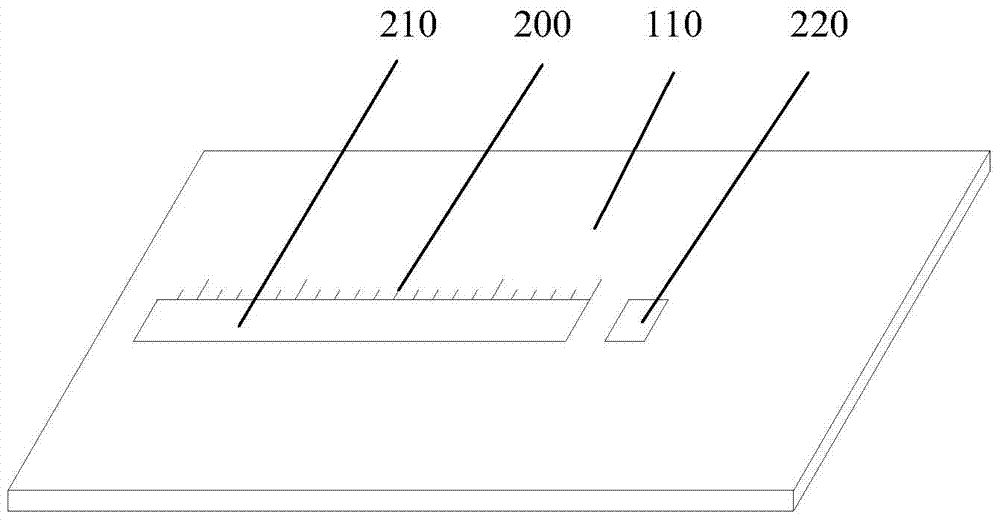

ActiveCN104501994AMaterial heat developmentThermometers using physical/chemical changesCold chainLiquid state

The invention discloses a time-temperature indicating device. The time-temperature indicating device comprises a starting part, a phase-change material, a movable medium, an activating display part and a time display part; the phase-change material is under a phase-change temperature and can enter the liquid state in case that the local environmental temperature is more than the phase-change temperature and enters the solid state in case that the local environmental temperature is less than the phase-change temperature; the starting part is used for pushing the phase-change material under the liquid state to move through an external force; when the phase-change material moves to reach a visual position on the activating display part and the environmental temperature is less than the phase-change temperature, the phase-change material is cured at the visual position on the activating display part and reminds of activating; the time display part is used for reminding of the deterioration time length of an article to be detected when the cured phase-change material enters the liquid state and moves along the movable medium. By adopting the time-temperature indicating device, the time that the environmental temperature of a cold chain system exceeds the upper critical temperature of the article to be detected can be monitored in the whole process, so as to remind a user of detecting whether the article to be detected deteriorates.

Owner:SHENZHEN NINE STARS PRINTING & PACKAGING GRP

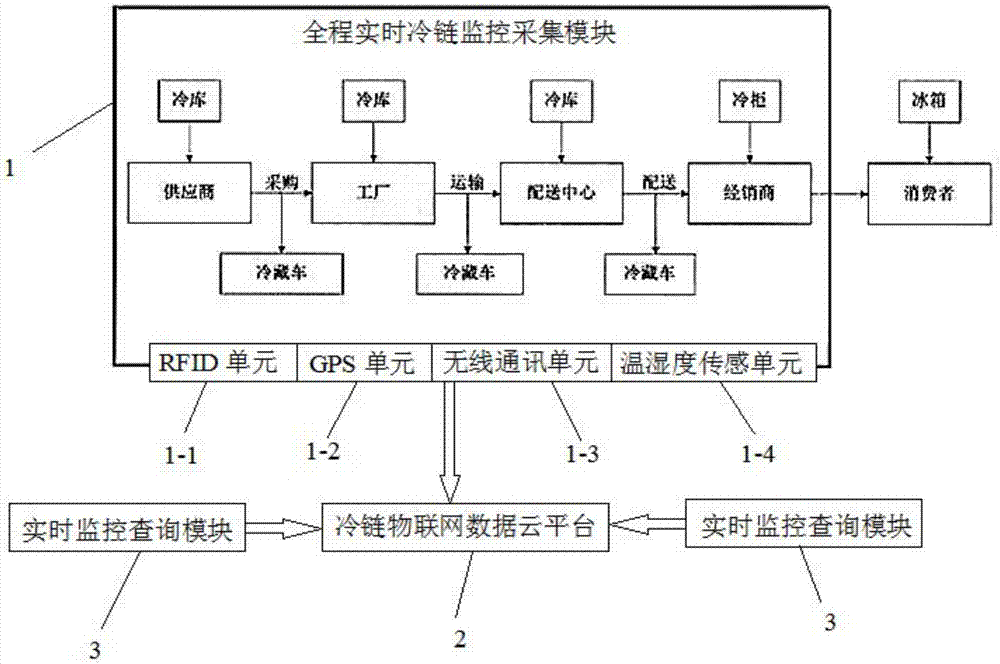

Hami melon cold-chain logistics control system and control method

InactiveCN107464078AReal-time acquisitionImplement queryCo-operative working arrangementsLogisticsCold chainAutomatic control

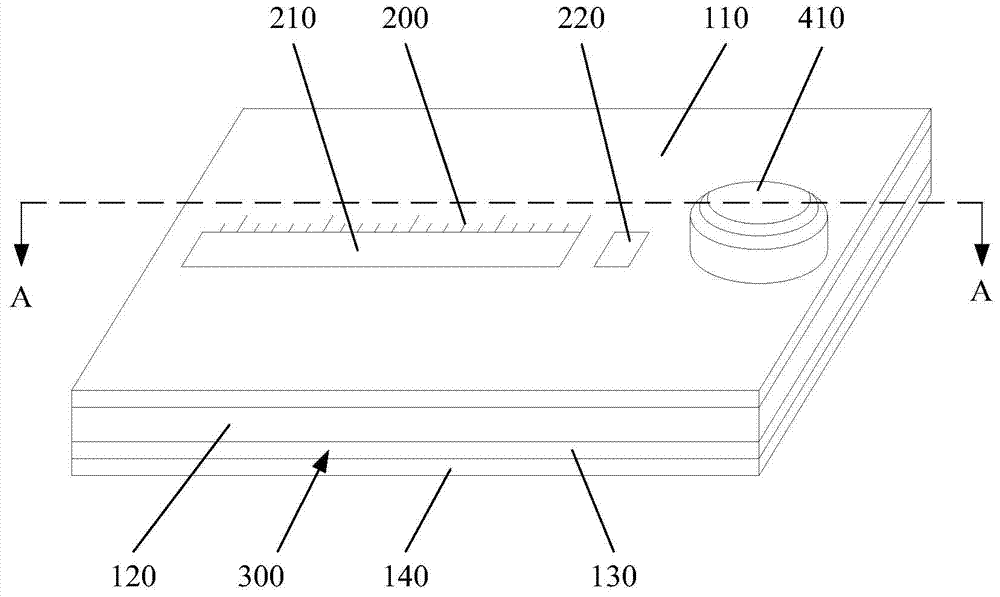

The invention belongs to the technical field of automatic control and discloses a Hami melon cold-chain logistics control system and control method. Through RFID, GPS, wireless communication and temperature-humidity sensing, temperature-humidity monitoring and goods and transport vehicle locating in cold-chain logistics are realized; an RFID unit directly reads data to a database and writes a logistics processing state in an electronic tag; an internal GPRS module, a temperature-humidity monitoring module and a video camera module are connected with a terminal of a mobile communication module; a cold-chain internet-of-things data cloud platform transmits locating data to a server in the Internet for performing storage; and information of the cold-chain internet-of-things data cloud platform is queried in the terminal to determine the temperature and humidity of a goods environment, the position of a transport vehicle and real-time video data of goods. The temperature-humidity monitoring and the goods and transport vehicle locating in the cold-chain logistics are realized; and the goals of logistics visualization, goods traceability and evidence-based supervision are really achieved.

Owner:新疆维吾尔自治区葡萄瓜果研究所

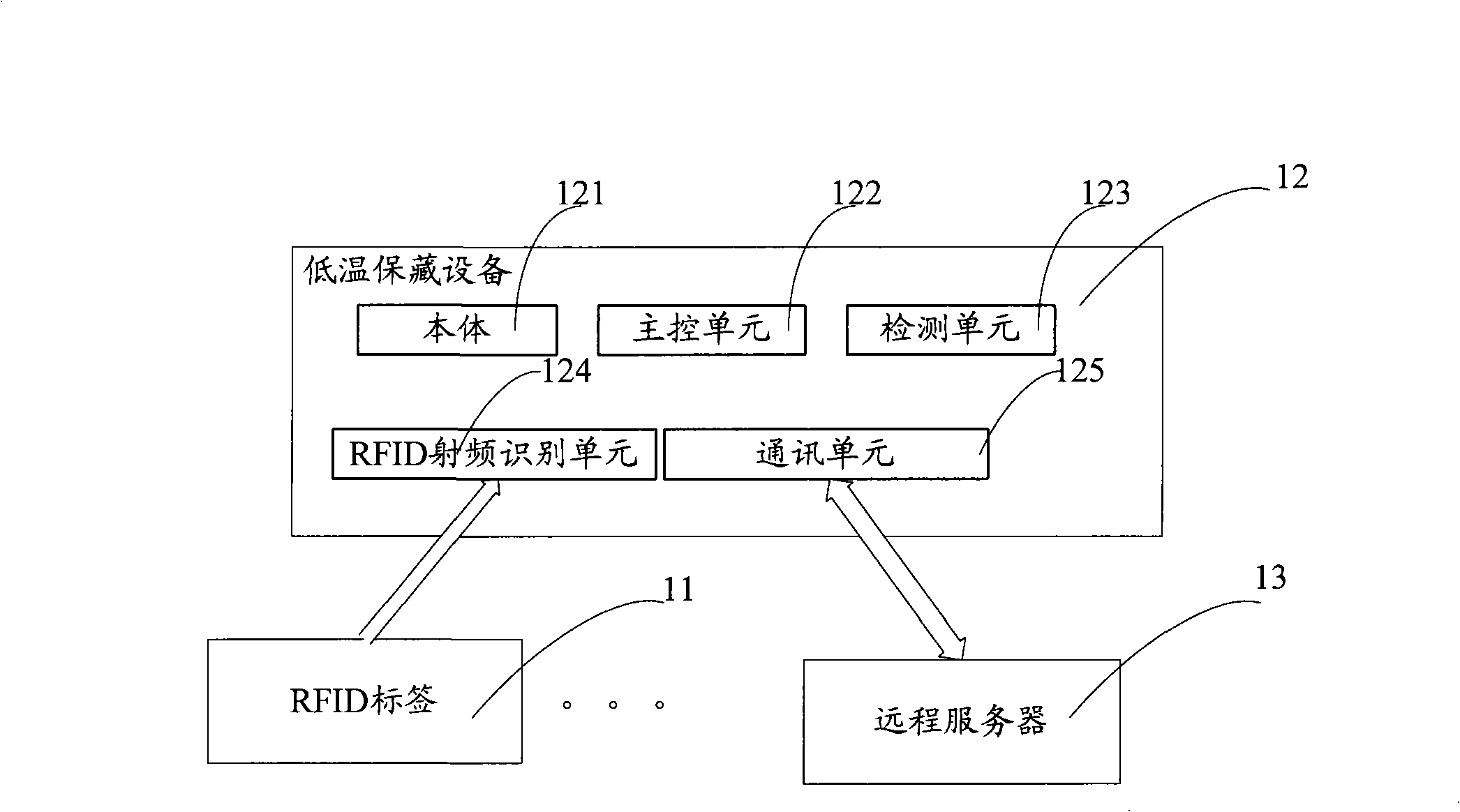

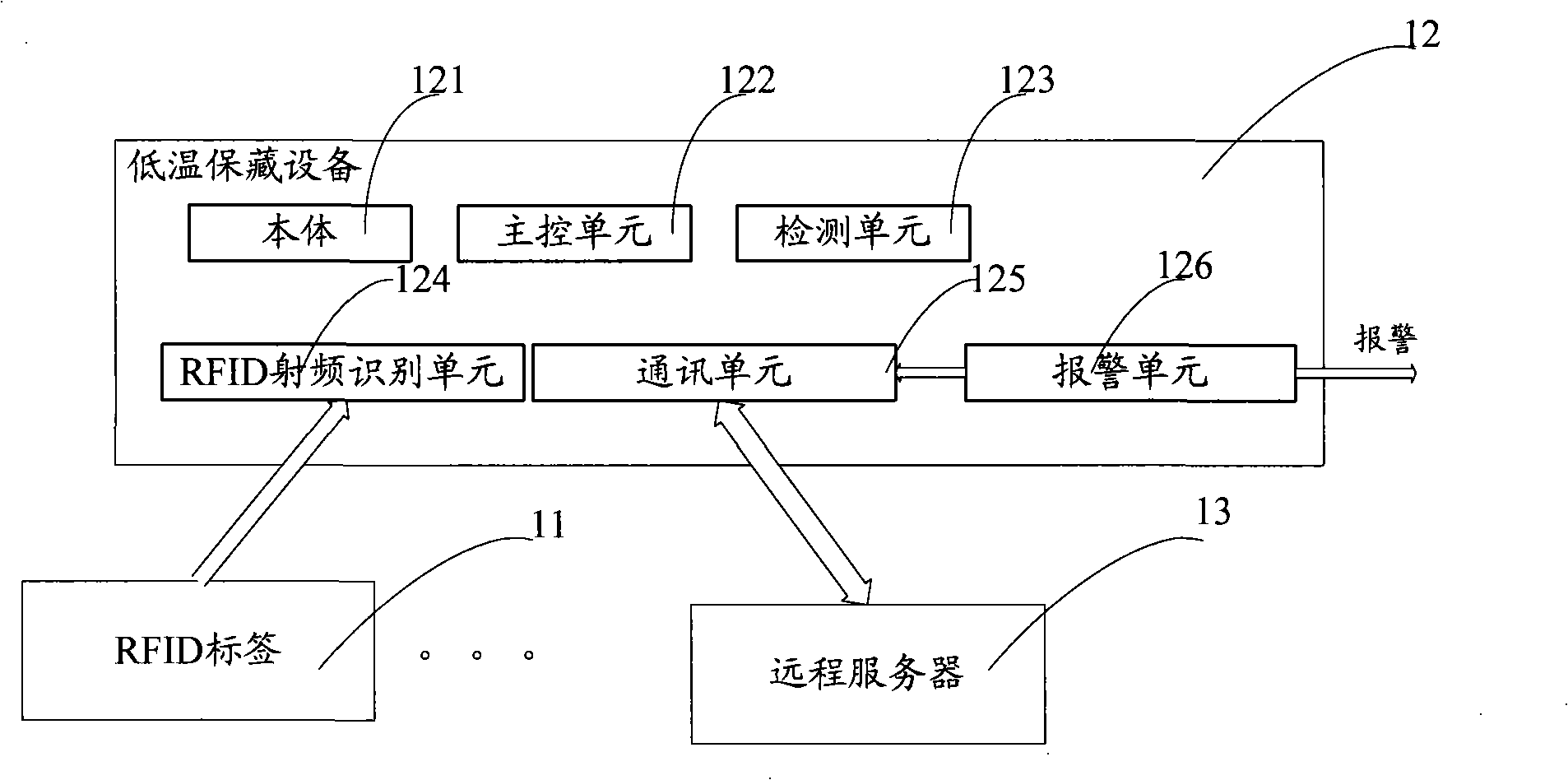

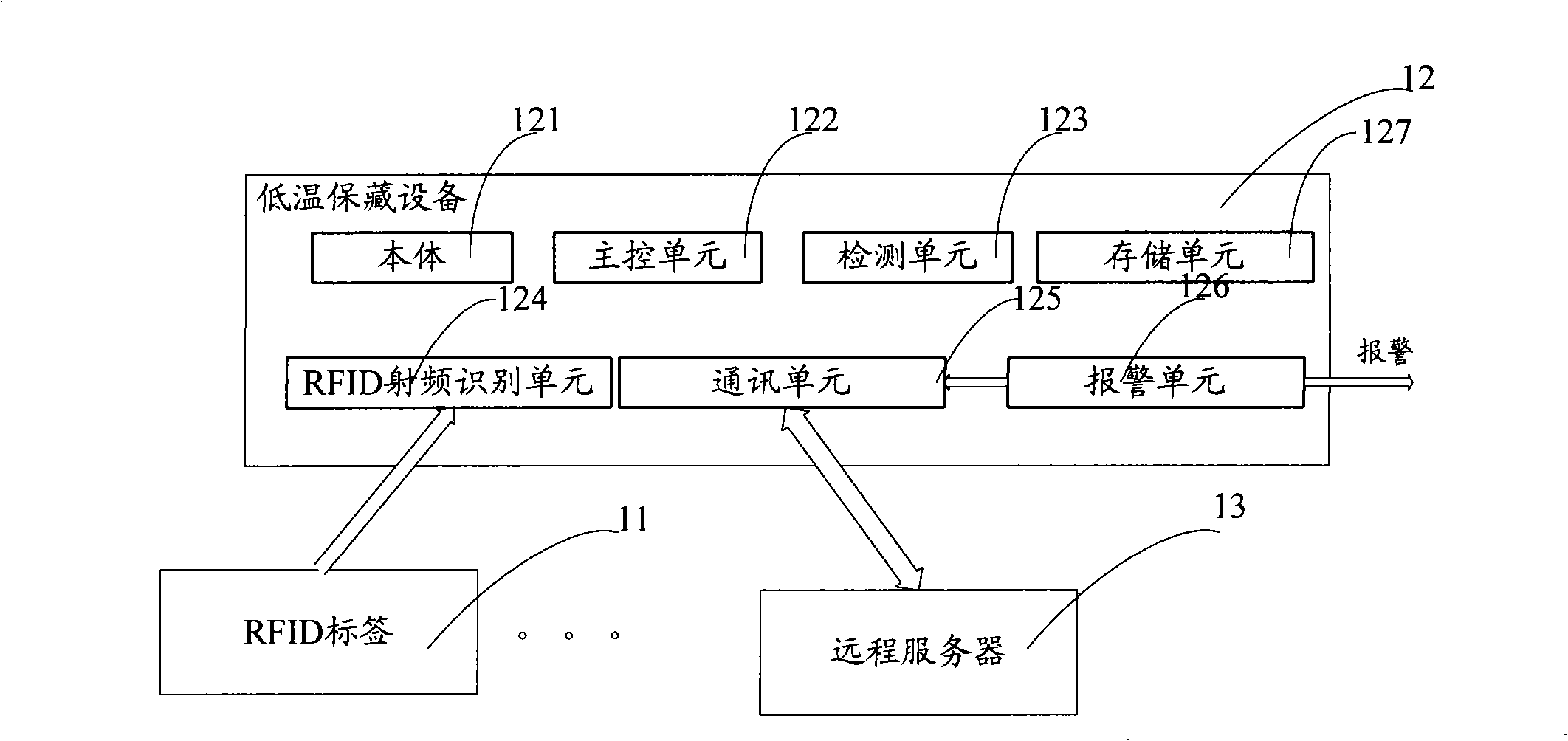

Cold chain monitoring system and refrigeration equipment

InactiveCN101334848AReduce lossesReal-timeDomestic cooling apparatusLighting and heating apparatusCold chainCommunication unit

The invention discloses a cold-chain monitoring system which comprises a RFID tag arranged correspondingly to each article unit in a cold chain and records the management information of the article unit, a Radio Frequency Identification( RFID) unit, a low-temperature preservation device of a communication unit, wherein, the Radio Frequency Identification( RFID) unit can read the management information stored in the RFID tag of each article unit in the low-temperature preservation device; the communication unit is used for sending information outwards, including the management information of the RFID tag of each article unit acquired by the Radio Frequency Identification( RFID) unit and the information of operational parameters of the low-temperature preservation device. The cold-chain monitoring system of the invention also comprises a remote server which is used for receiving the information sent by the low-temperature preservation device and saving the information in a database and monitoring and controlling such information. By adopting the cold-chain monitoring system of the invention, the complete information record of all article units in the cold chain during a cold-chain transferring process can be acquired. As a result, the source of the problem can be determined according to the information record when any problem occurs to the article in the cold chain.

Owner:HAIER GRP CORP +1

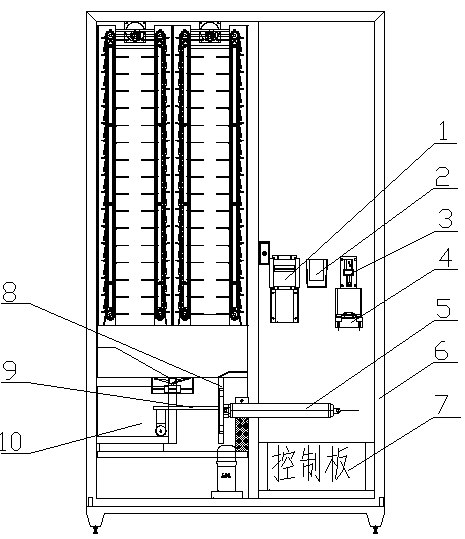

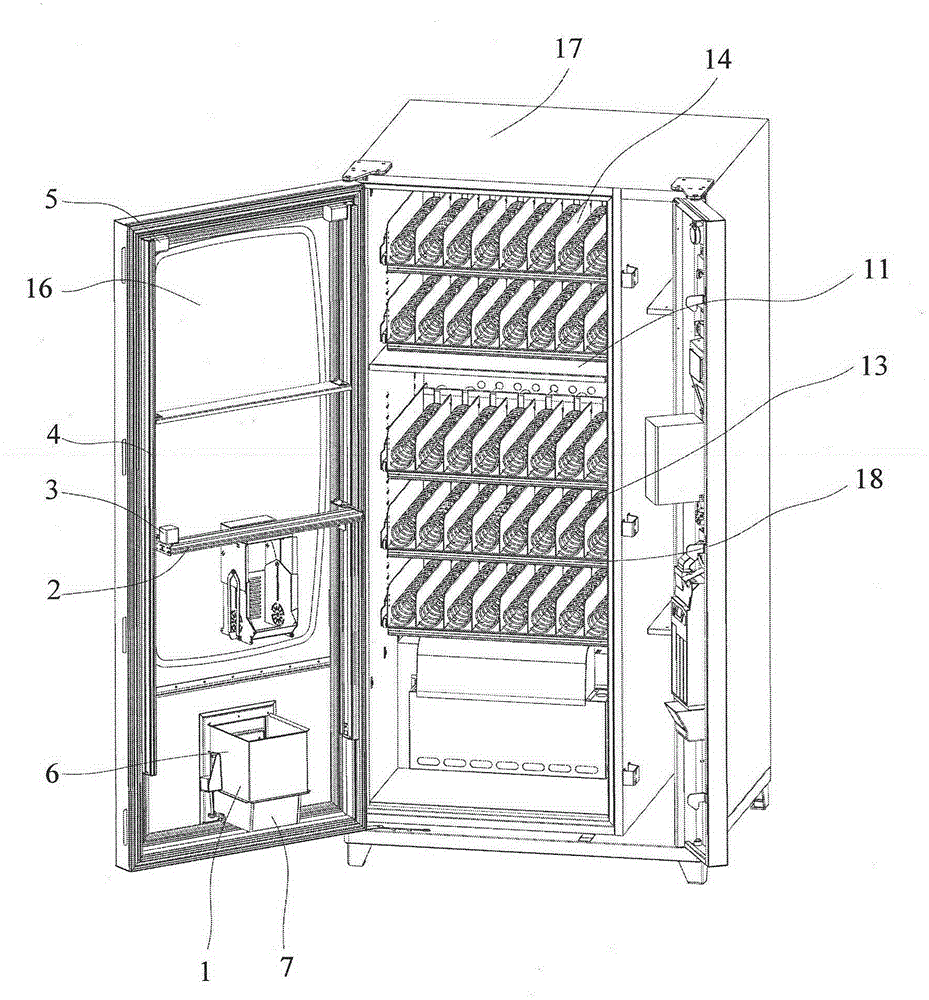

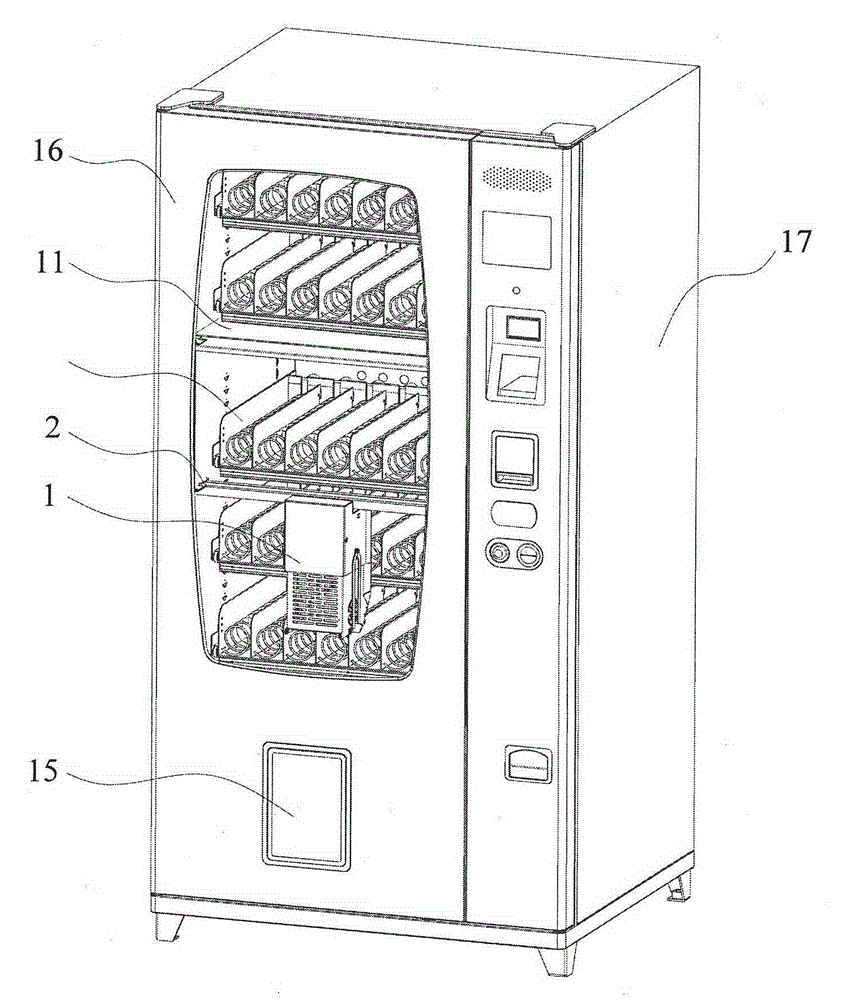

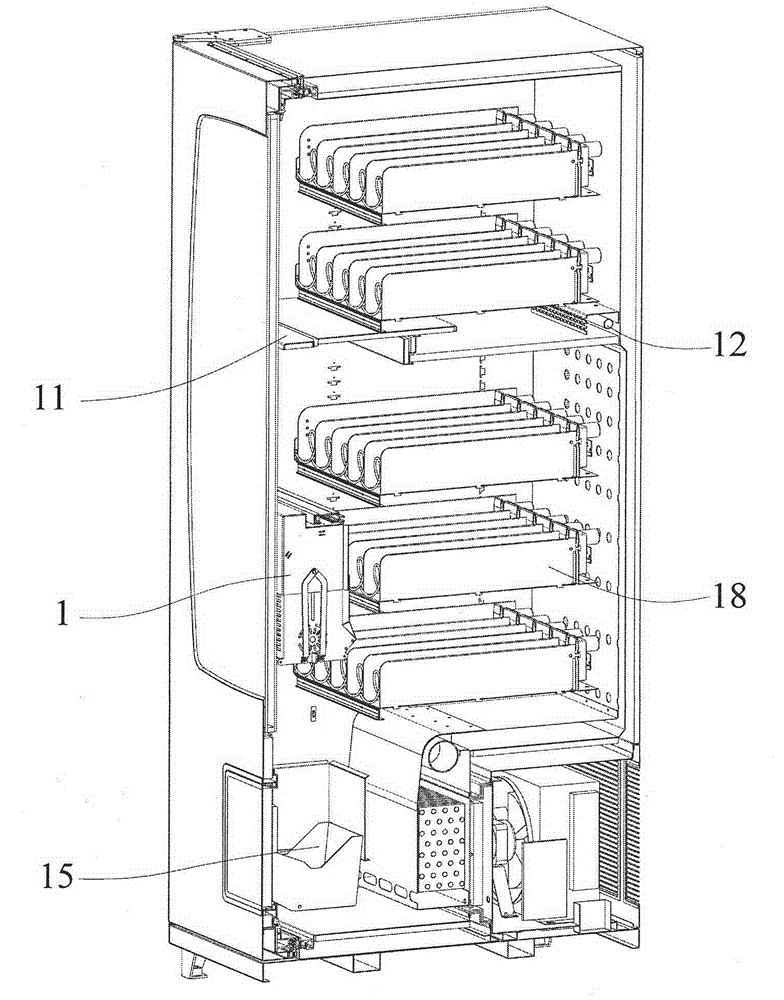

Intelligent efficient food and beverage vending machine

InactiveCN103413380AFast deliveryImprove efficiencyCoin-freed apparatus detailsApparatus for dispensing discrete articlesFood guideCold chain

The invention relates to an intelligent efficient food and beverage vending machine which comprises an ordering and fee charging operating system, an electronic control system, a refrigeration system, a constant temperature storage system, a heating system, a falling type output system and a cabinet, wherein in the falling type output system, shafts I and bevel gears I are fixed on a bracket, output ends of electrical motors are connected with bevel gears II, shafts II are connected with the bevel gears I, the shafts I are connected with the bevel gears I and chain wheels, and chains are connected with the chain wheels and support plates, so that an output mechanism which can continuously, rapidly and stably operate is constituted; a food taking window is fixed on a door leaf of the cabinet, a food guide plate is fixed below the output mechanism, and food can be taken when a box lunch arrives to the food taking window through the food guide plate; an electric push rod is connected with a microwave oven door and integrally fixed right below the food guide plate with a tray, and opening and closing actions of the microwave oven door are finished through stretching and retracting of the electric push rod. The intelligent efficient food and beverage vending machine is characterized in that with the adoption of a vertical top-to-down mechanical delivery manner, the intelligent efficient food and beverage vending machine is simple in structure, low in cost, few in fault, high in efficiency, convenient to maintain and capable of simultaneously performing hot chain food supply and cold chain food supply.

Owner:WUHAN CATELY ELECTROMECHANICAL ENG CO LTD

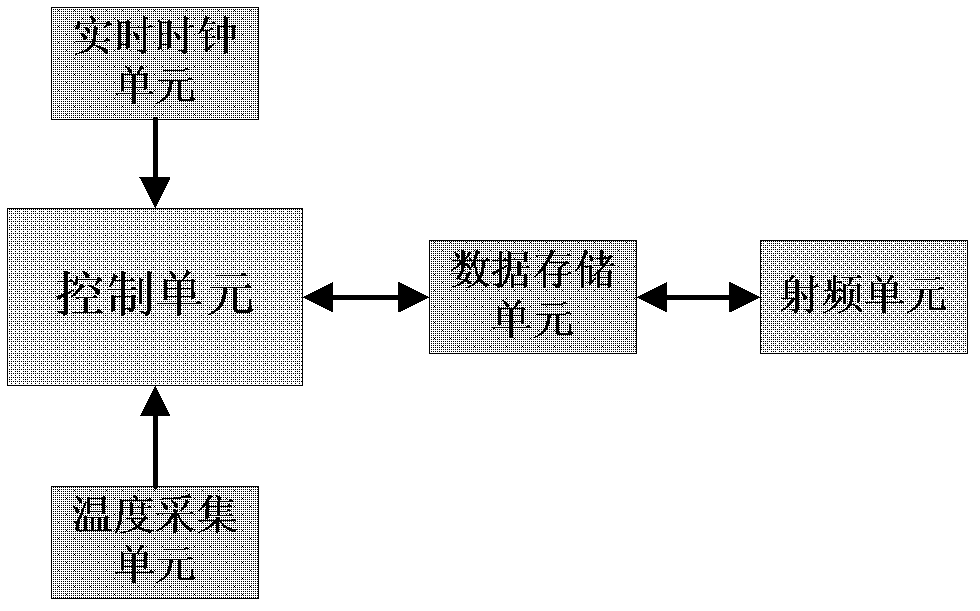

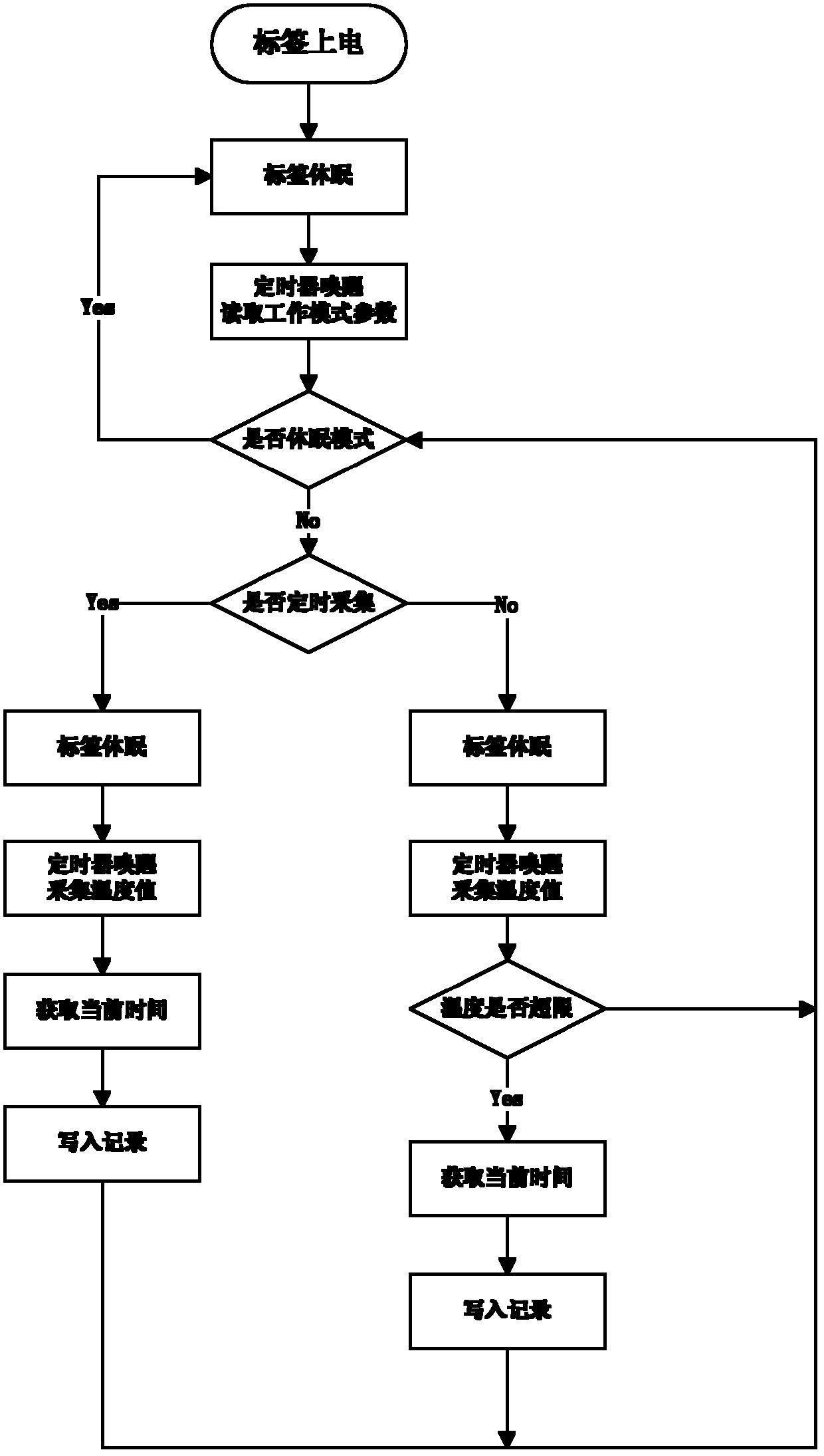

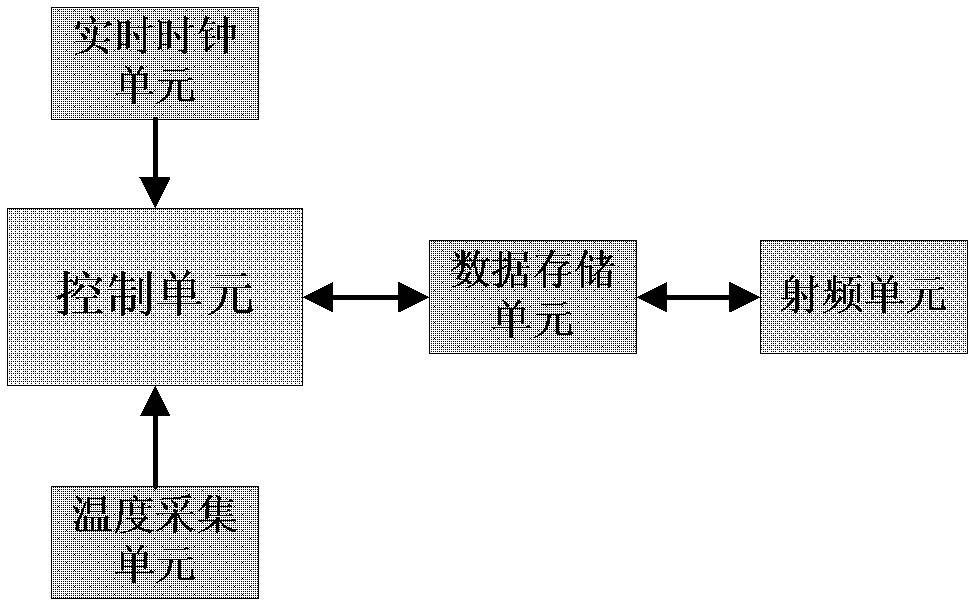

Cold chain RFID (Radio Frequency Identification Devices) temperature electronic label based on NFC (Near Field Communication)

InactiveCN102592165AEasy to readThe purpose of timely and simple traceabilityCo-operative working arrangementsNear-field systems using receiversCold chainReal-time clock

The invention discloses a cold chain RFID (Radio Frequency Identification Devices) temperature electronic label based on NFC (Near Field Communication). The cold chain RFID temperature electronic label comprises a radio frequency unit, a temperature collecting unit, a data storage unit, a real-time clock unit and a control unit. The temperature collecting unit and the real-time clock unit are respectively connected with the control unit; the control unit and the data storage unit are connected with each other and can be operated in double ways; and the data storage unit is simultaneously connected with the radio frequency unit. The data storage unit is supplied with power by a battery while being read and written by the control unit. The electronic label disclosed by the invention can be used for recording the temperature of a cold chain product by using a periodic or temperature overranging method, writing the temperature into a label memory, reading the temperature record in the later stage, determining the quality of the cold chain product and tracing the product problem link. The temperature can be very conveniently read by portable equipment, such as a mobile phone supporting NFC and the like; therefore, the temperature information of each link and period of the cold chain are clear at a glance and the purpose of tracing the cold chain product is simply achieved in time.

Owner:杭州物鼎传感技术有限公司

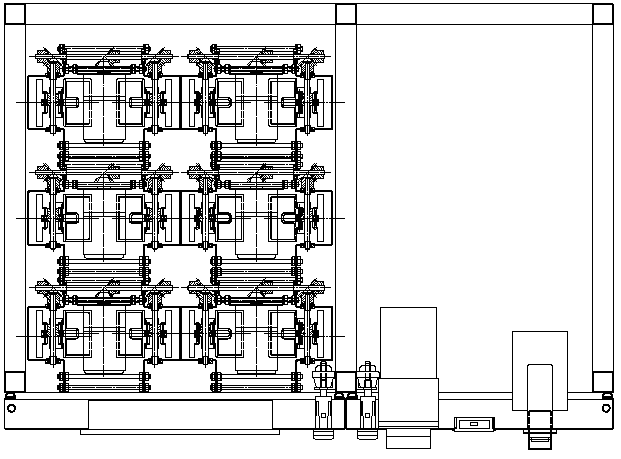

Material conveying device for automatic vending machine

InactiveCN106327691AEffective layoutCompact structureCoin-freed apparatus detailsApparatus for dispensing discrete articlesCold chainEngineering

The invention discloses a material conveying device for an automatic vending machine. The material conveying device comprises a transverse sliding rail device, a vertical sliding rail device and a goods fetching device. The transverse sliding rail device comprises a transverse guide rail and a transverse driving motor. The vertical sliding rail device comprises two sets of vertical guide rails and a vertical driving motor. The goods fetching device comprises a goods fetching hopper and a goods fetching motor. The vertical guide rails are arranged at two ends of a door body of the vending machine. The transverse guide rail is arranged between the two vertical guide rails in a sliding manner. The goods fetching hopper is arranged on the transverse guide rail. The goods fetching hopper comprises a fixed hopper and a movable hopper which communicate with each other. The movable hopper is hinged onto the fixed hopper and located below the fixed hopper and driven by the goods fetching motor to swing. The bottom of the movable hopper is provided with a movable door. The material conveying device for the automatic vending machine has the advantage that cold-chain fresh, heated and fragile goods can be sold at the same time.

Owner:CHANGSHA YANHA MECHANICAL & ELECTRICAL APPLIANCE MFG

Network of Participants In a Shipment Cold-Chain

ActiveUS20150039529A1Increase valueEasy to storeThermometers using mean/integrated valuesDomestic cooling apparatusCold chainComputer science

The invention relates to a network of participants connected through a website and thereby forming a virtual cold chain, and wherein the participants can make proposals and / or bids to shipment owners, shippers, receivers, and customers, to provide services or products to keep the shipment at desired conditions (especially, temperature conditions) during a period of the remaining shipment. The shipment can be monitored en route by agents acting for the website or by either the same participants making proposals, or other participants.

Owner:INTEGREON GLOBAL INC

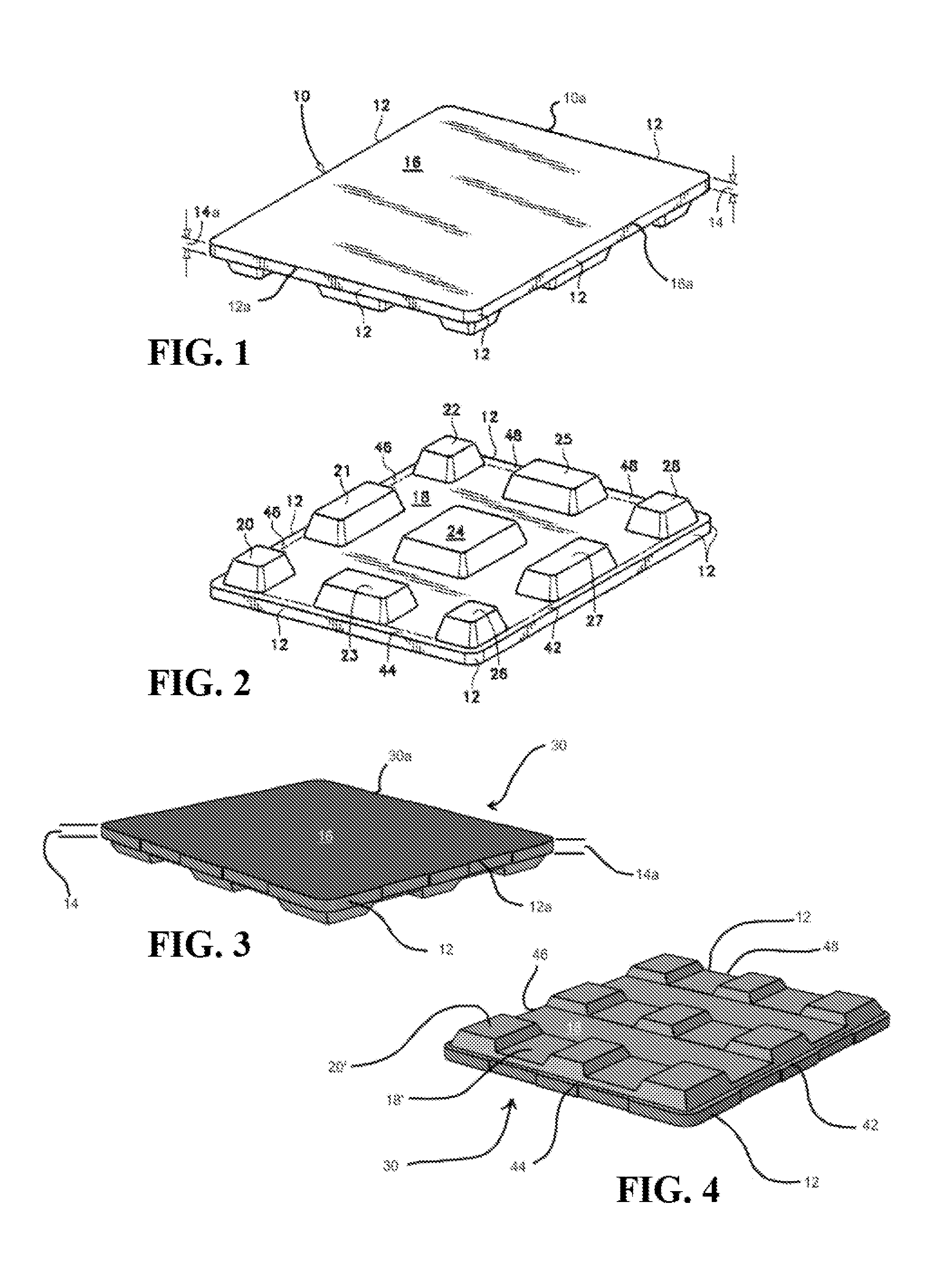

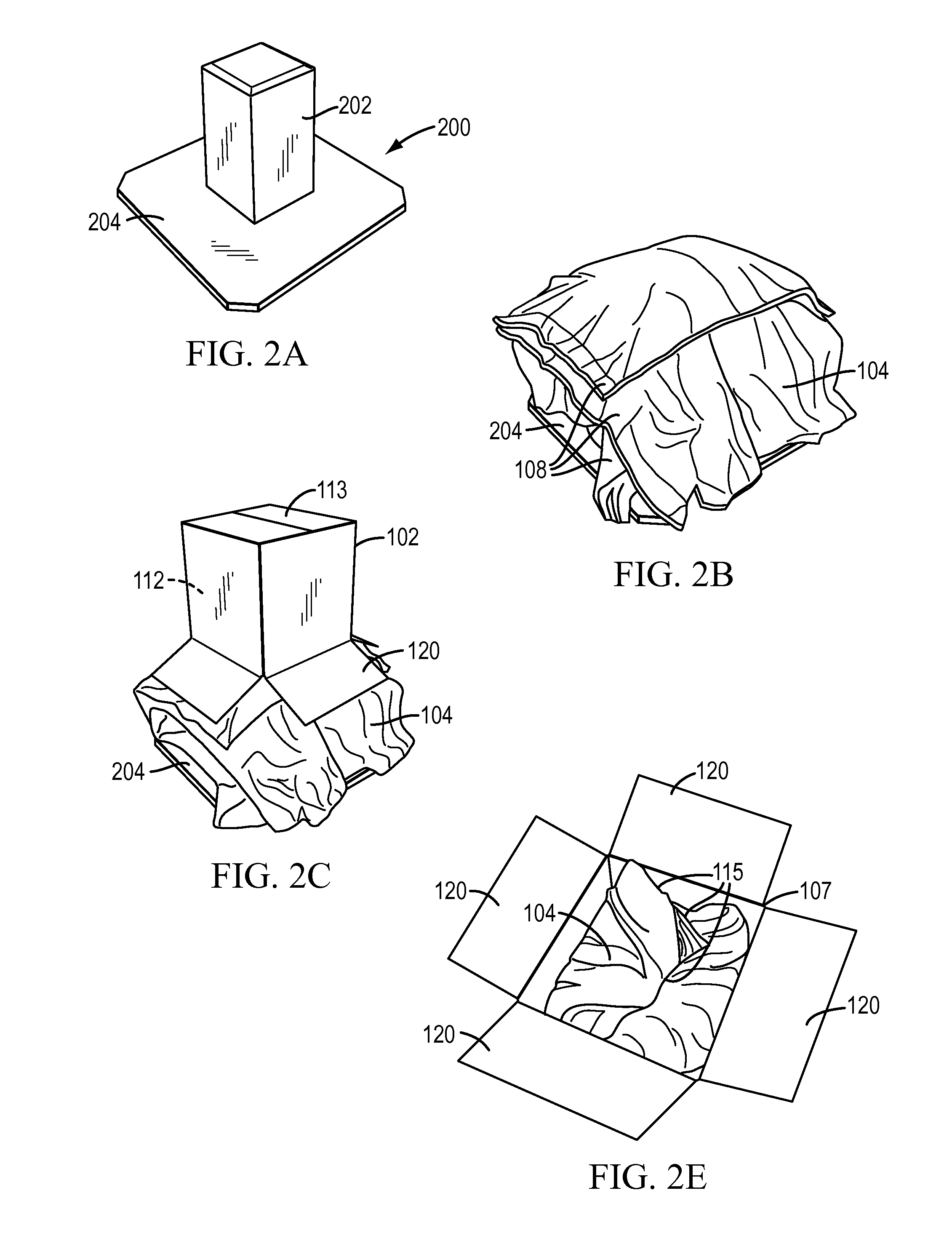

System for facilitating security check of shipment of cargo

InactiveUS20130015083A1Convenient security checkKeep goingSynthetic resin layered productsLarge containersCold chainFresh fish

The present invention provides a system for facilitating security check of cold-chain air freight cargo using a magnetic imaging scanner for shipping at the airport. Cold-chain material includes most perishables such as produce, fresh fish, biological parts, pharmaceuticals and similar that need to be kept at a lower temperature for preservation and freshness.

Owner:AIRDEX INT

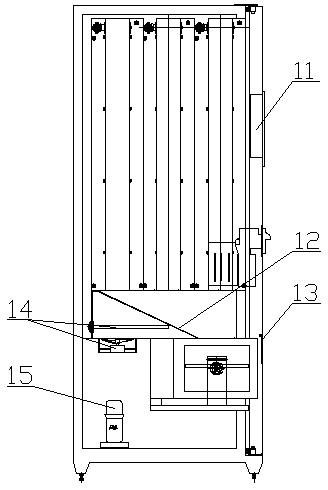

Low temperature storage system

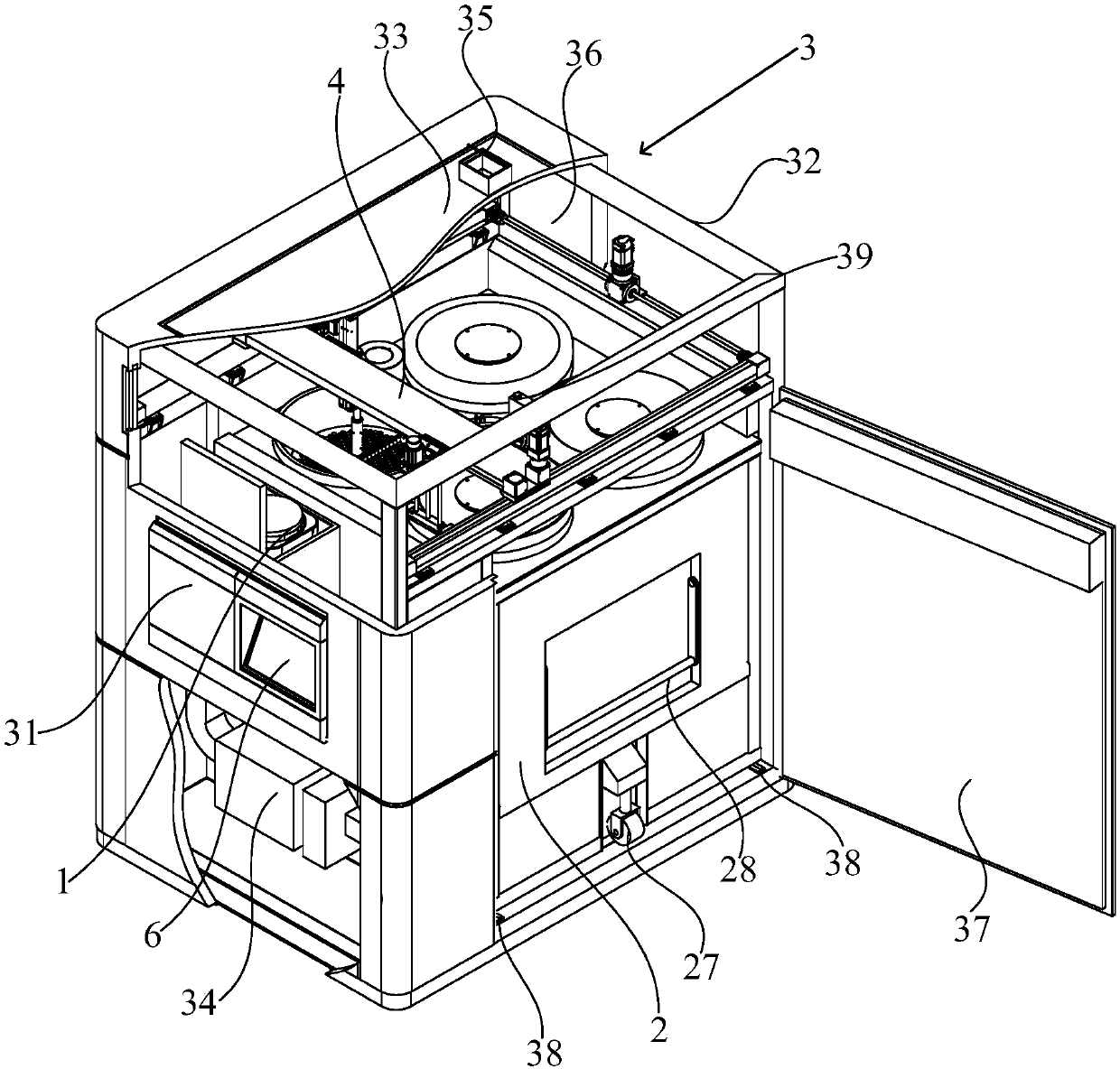

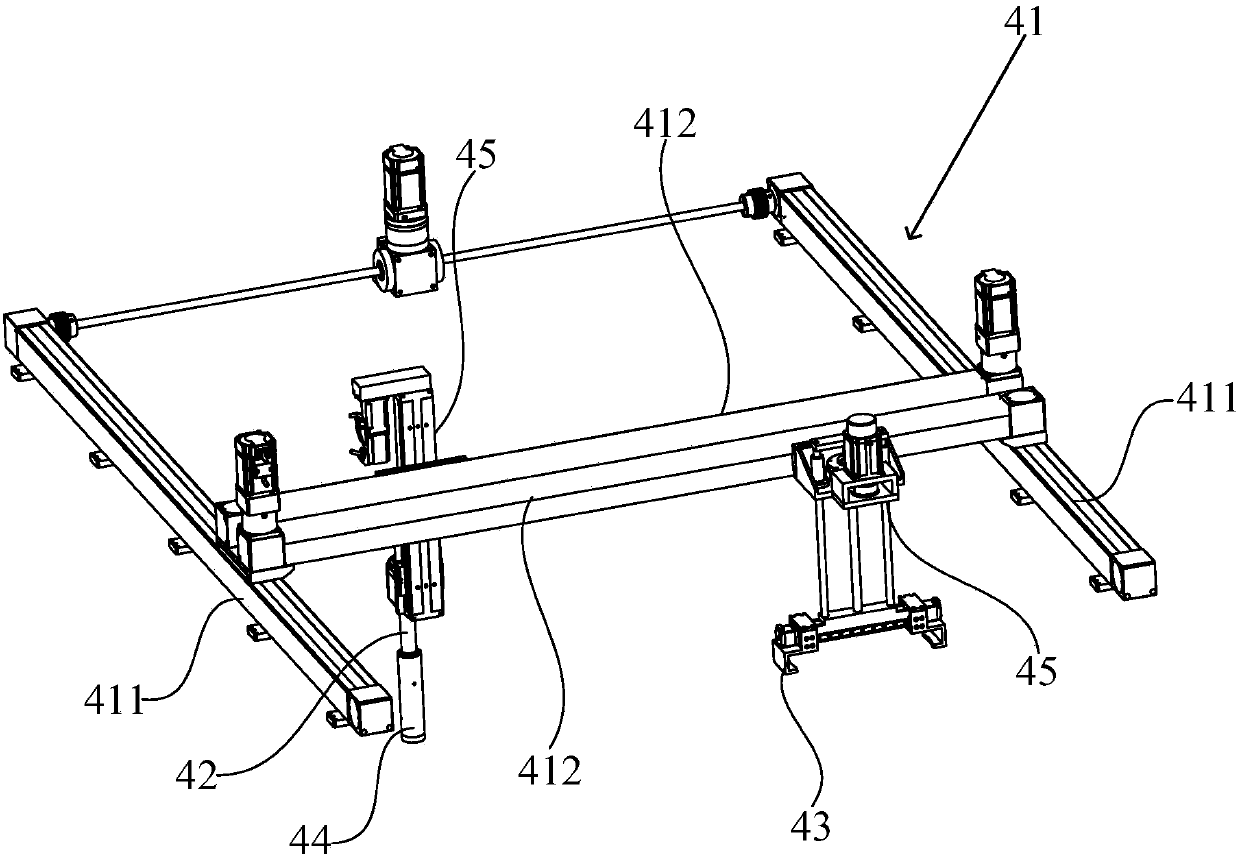

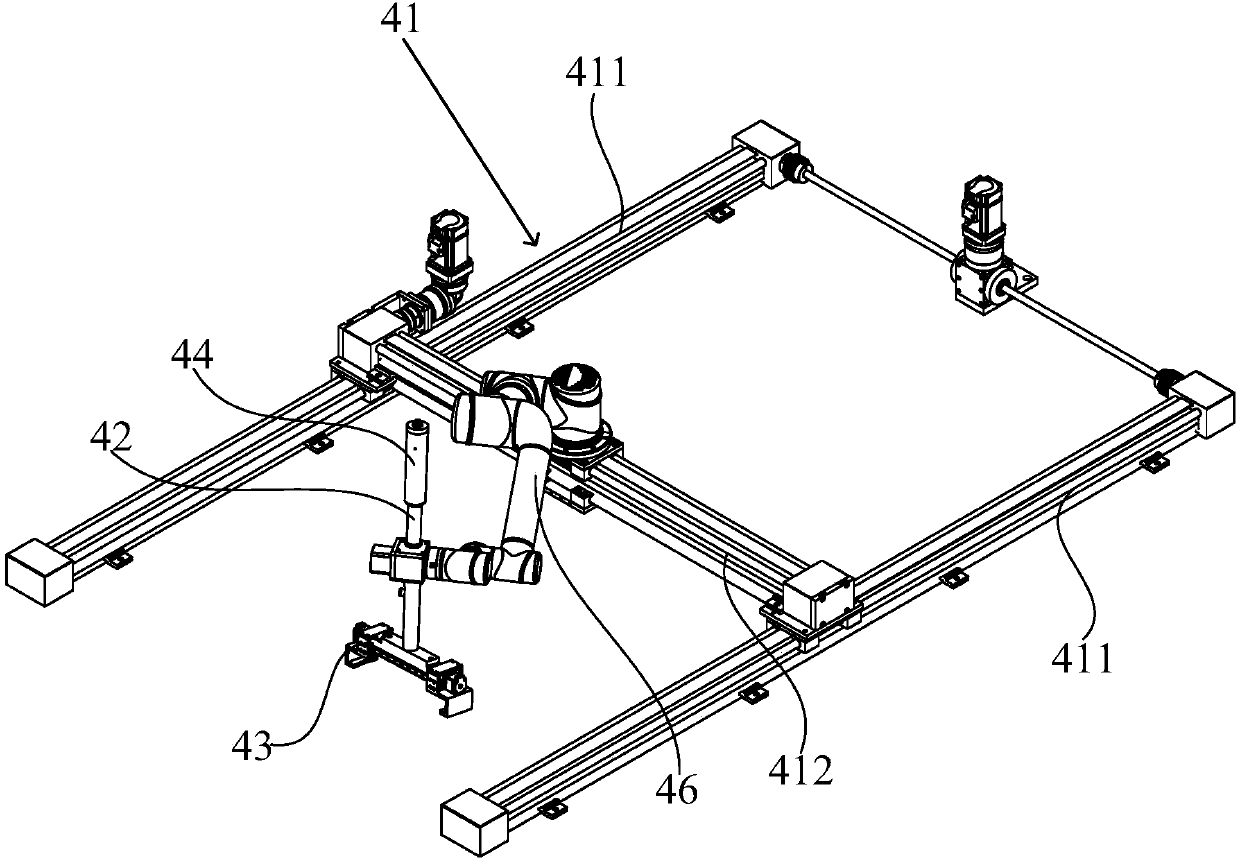

InactiveCN107624751AImprove reliabilityAvoid damageLighting and heating apparatusPreparing sample for investigationCold chainManufacturing cost reduction

The invention discloses a low temperature storage system. The system comprises a transit pot and a storage device, and both the transit pot and the storage device are used for storing biosample loadedcryopreservation tubes. The low temperature storage system also includes: a dry seal cavity, one side of which is provided with a transfer cabin for the transit pot to pass; and a low temperature transport device, which is located in the dry seal cavity together with the storage device, and is used for pick-and-place and freezing protection of the cryopreservation tubes. According to the low temperature storage system provided by the invention, the low temperature transport device is disposed in the dry seal cavity, thus lowering the manufacturing cost and difficulty, and improving the reliability performance of the low temperature transport device. Moreover, all links of biosample transfer are under total cold chain protection, thus avoiding biosample damage caused by repeated freezing and thawing.

Owner:SHANGHAI ORIGINCELL BIOLOGICAL CRYO EQUIP CO LTD

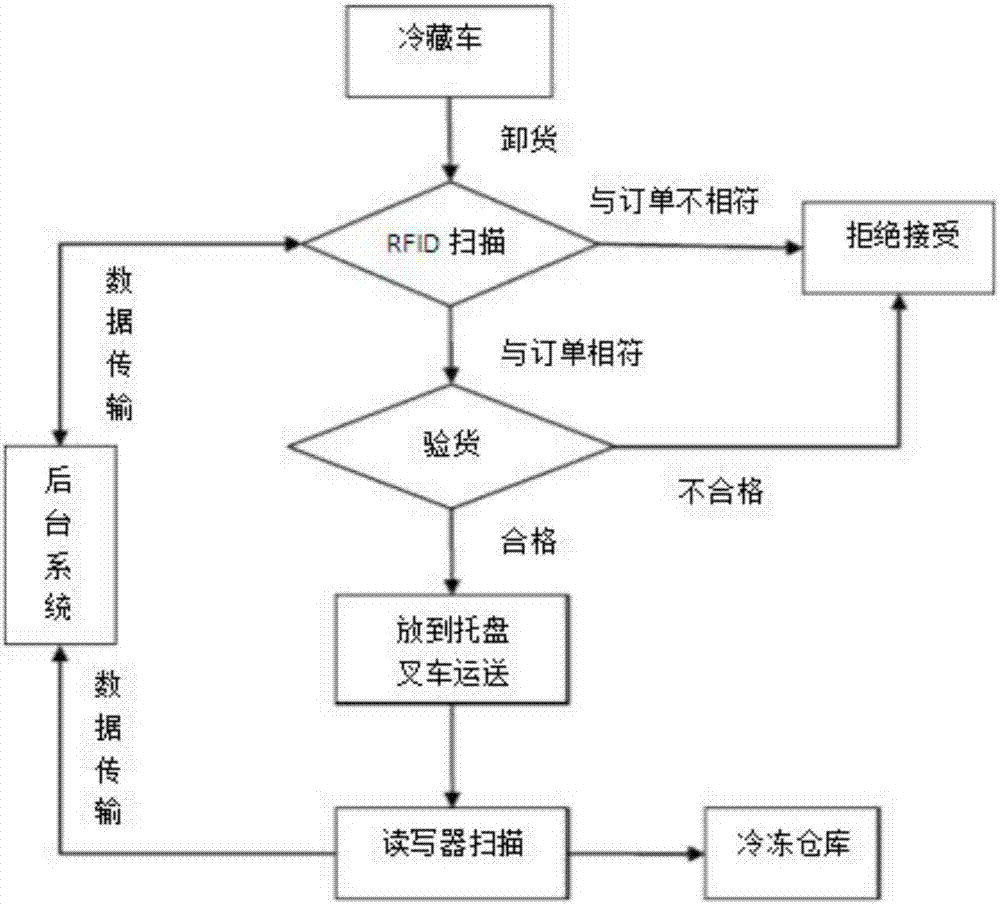

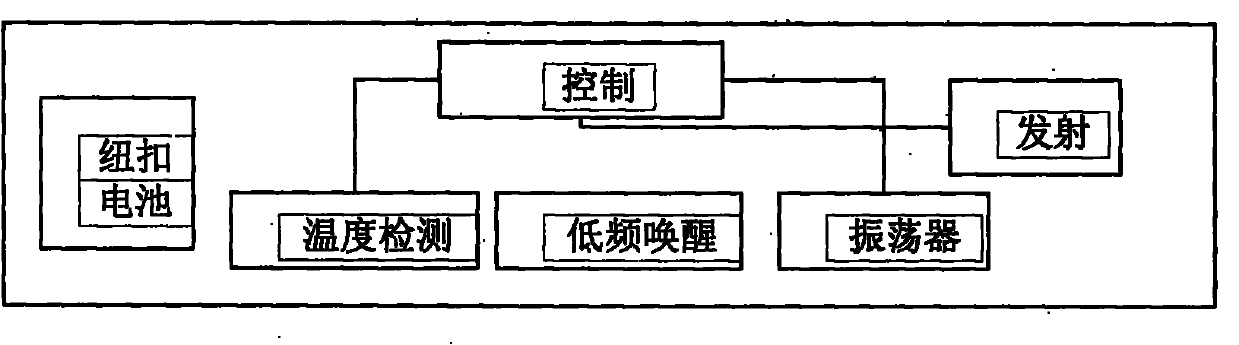

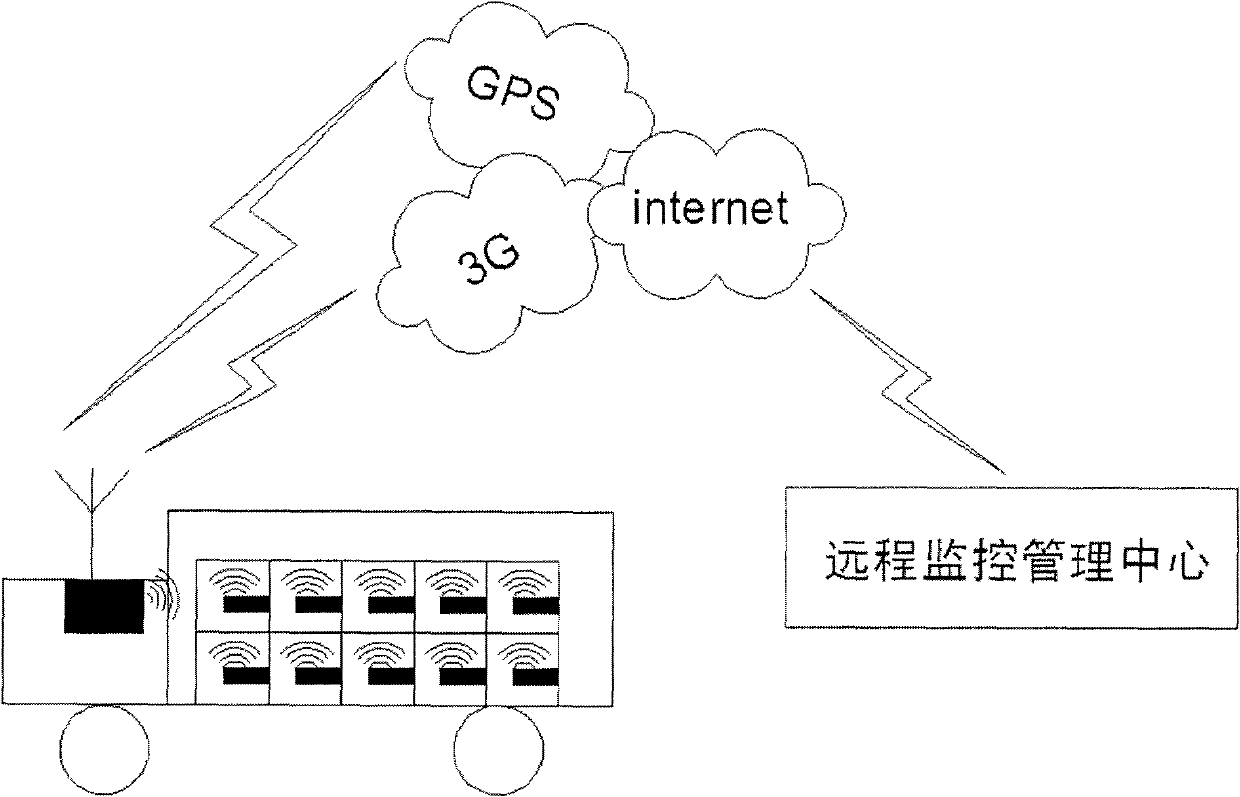

Medical medicine cold chain transportation monitoring method based on Internet of things

InactiveCN102005020AData processing applicationsCo-operative working arrangementsCold chainTemperature monitoring

The invention discloses a medical medicine cold chain transportation monitoring method based on an Internet of things, solving the problem that the traditional medical cold chain medicine transportation is difficult to monitor and manage in real time and having the characteristics of whole real-time temperature monitoring, positioning and controllable management of processes from disassembly, transportation, detection and storage of the cold chain medicines. The method comprises the steps of: putting an active RFID (Radio Frequency Identification Device) label provided with a temperature sensor and capable of being waken at low frequency in a cold chain medicine unit package, and installing an intelligent vehicle-mounted RFID reader-writer with low-frequency wakening and GPS (Global Position System) as well as 3G functions on a transportation vehicle. Meanwhile, the device has a recording display and alarm function, can monitor temperature conditions of the medicines in real time at a cold chain medical medicine management center background, and can immediately and automatically alarm and interfere when temperatures of monitored medicines are abnormal.

Owner:苏州世纪泰鼎电子科技有限公司

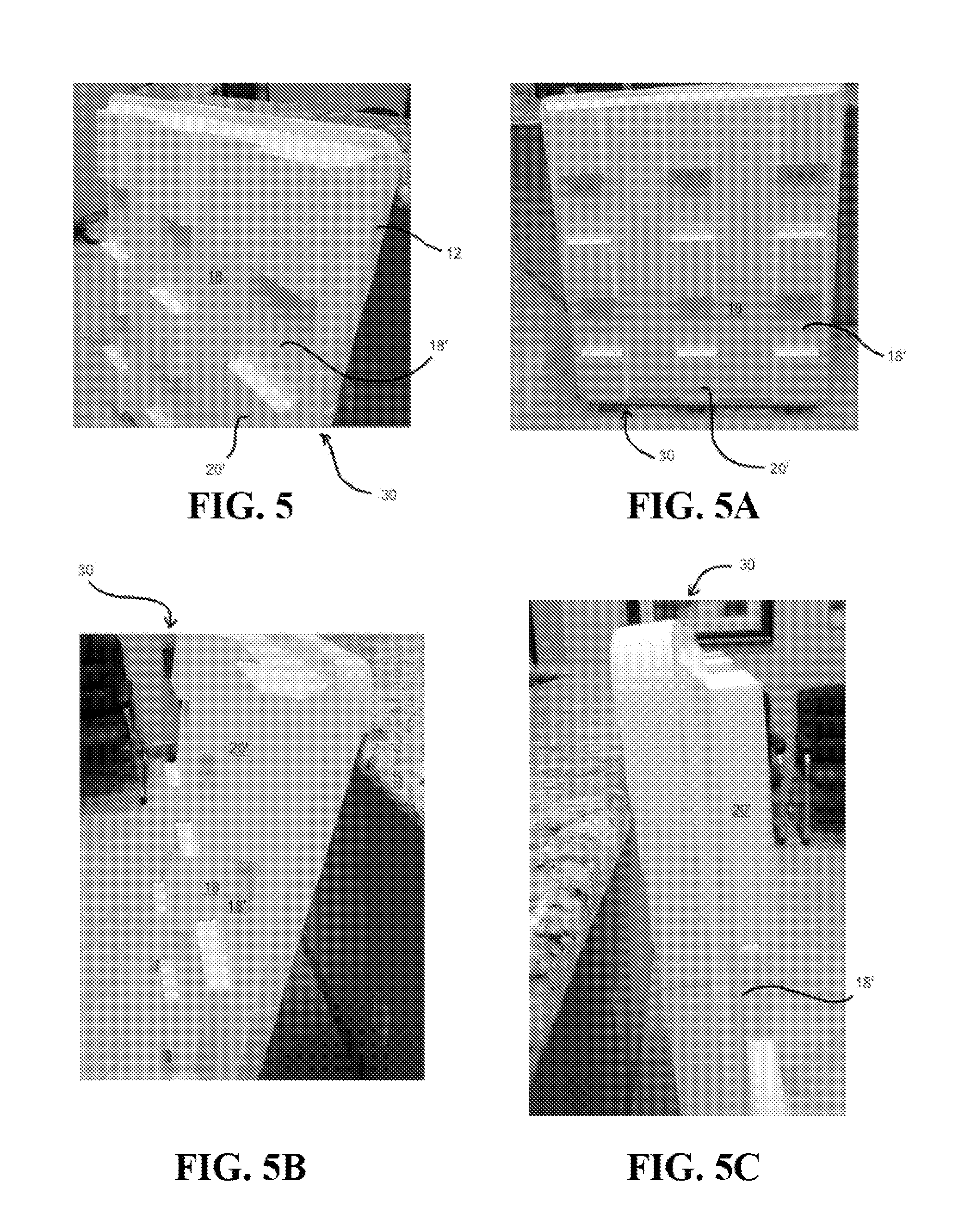

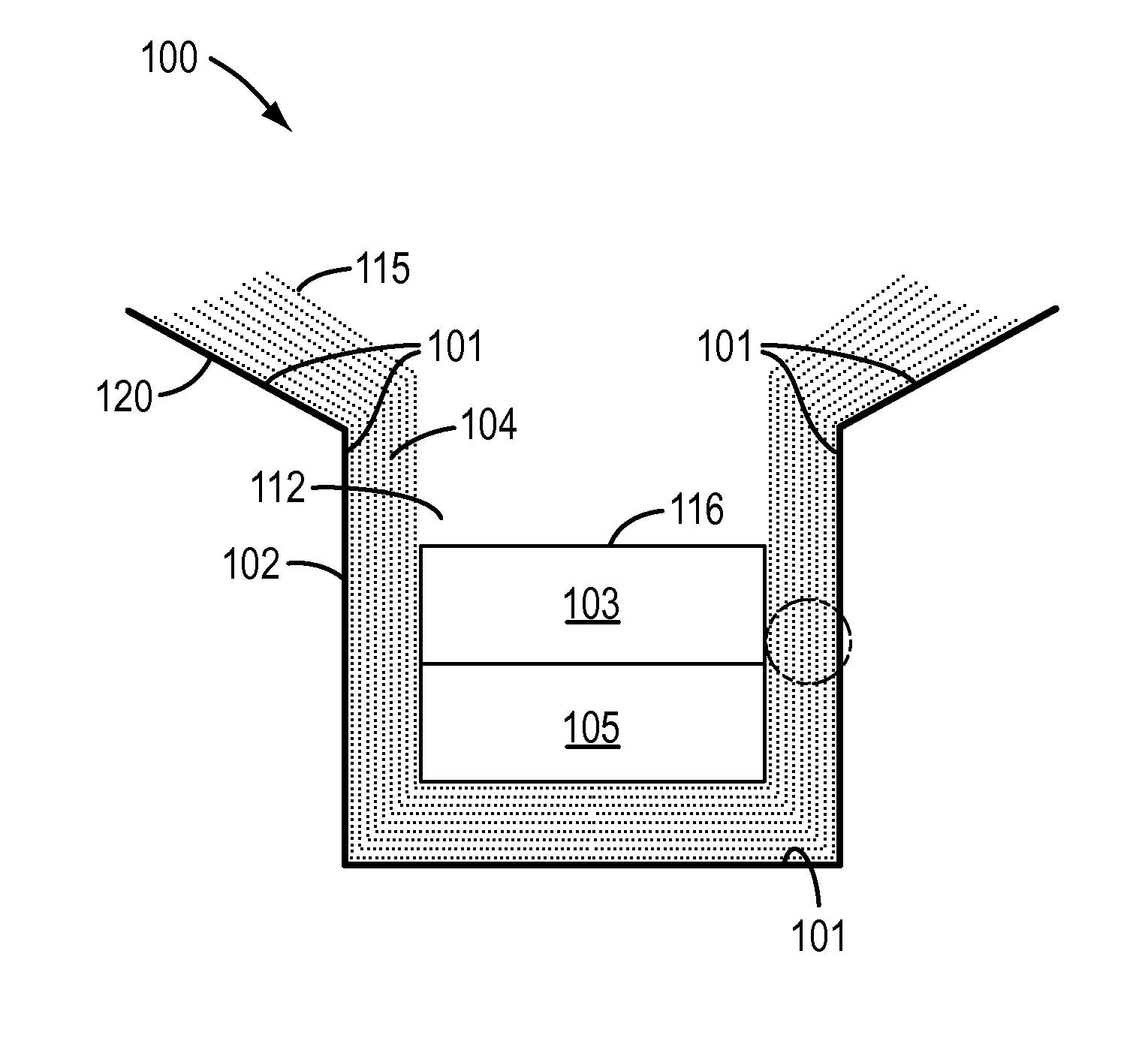

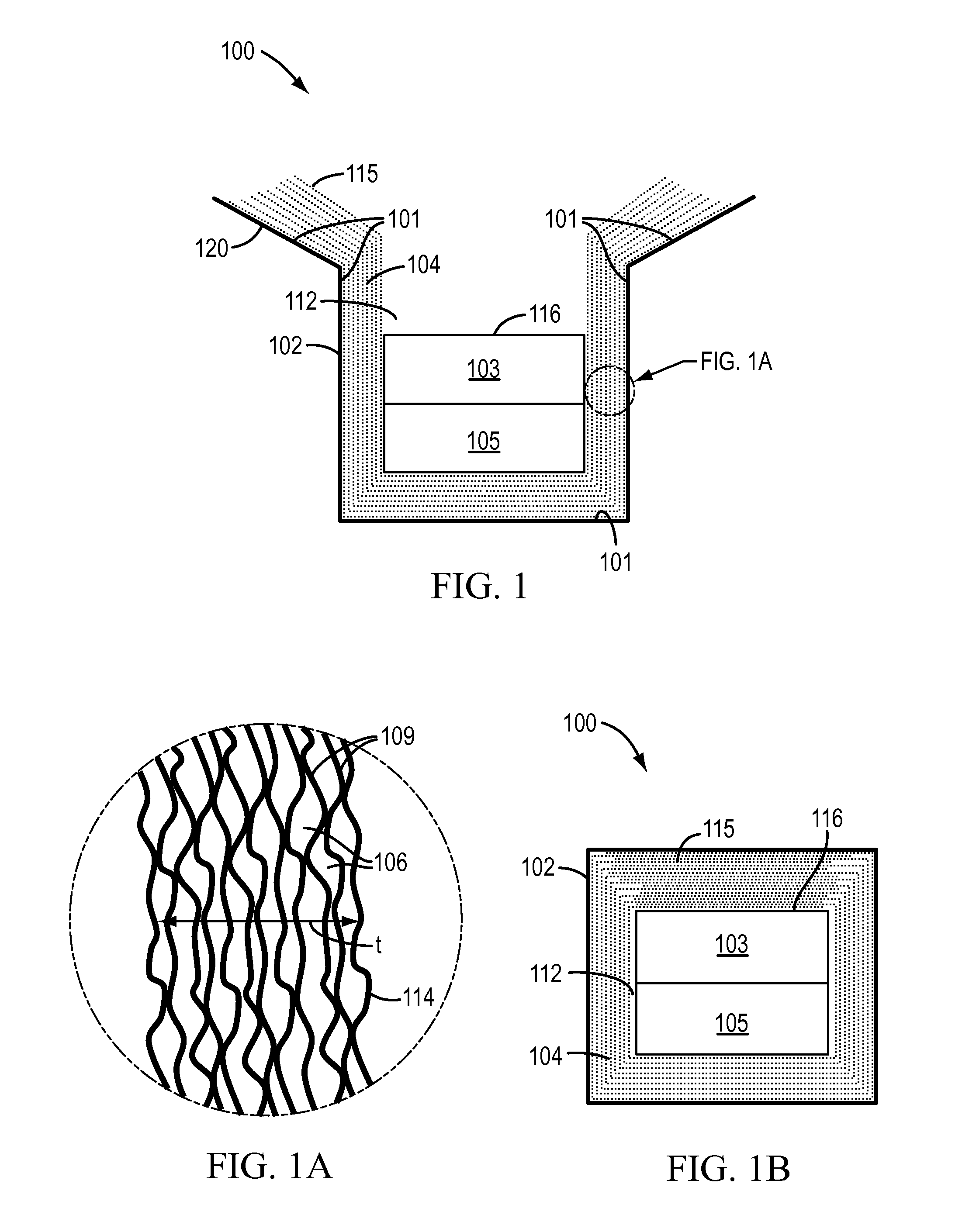

Packaging systems and methods for cold chain shipments

A packaging system for cold chain shipment may include a container having interior surface portions, a plurality of cellulose sheets disposed along the interior surface portions and defining a space configured to receive an item for cold chain shipment, and a cold source disposed within the space and configured to cool the container for cold chain shipment. The packaging system may further include a plurality of cellulose sheets, wherein adjacent sheets of the plurality of cellulose sheets define a plurality of pockets configured to trap air, and wherein the plurality of cellulose sheets are configured to insulate the space.

Owner:LIFE TECH CORP

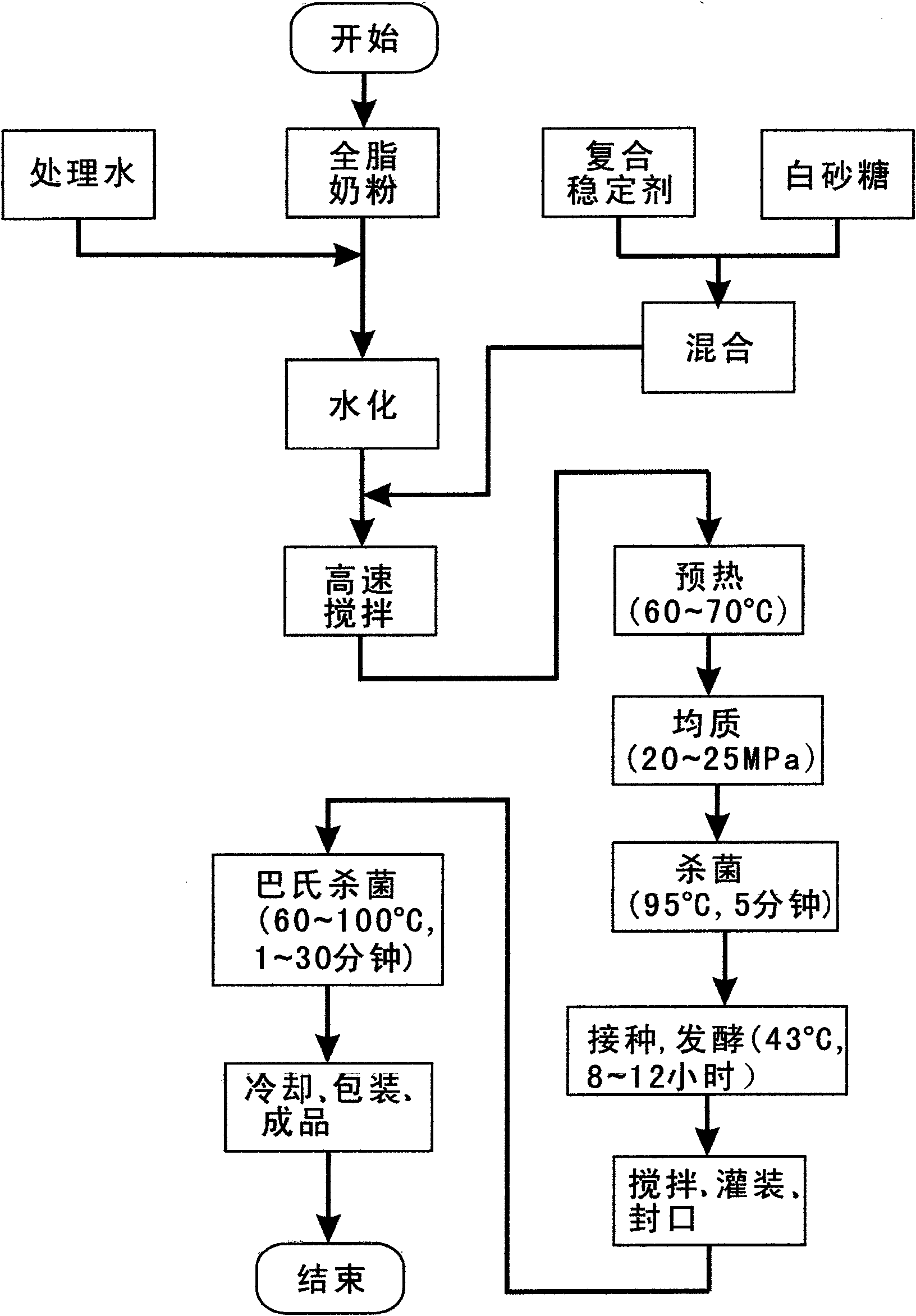

Preparation method and special yoghourt stabilizer of yoghourt with long shelf life

The invention discloses a preparation method and special yoghourt stabilizer of yoghourt with long shelf life. The method of the invention comprises the following steps: dissolving whole milk powder, stabilizer and sucrose; 2) preheating and homogenizing the materials; 3) sterilizing fluid milk at 90-95 DEG C for 5min, cooling; 4) inoculating, fermenting, breaking emulsion; 5) filling, sealing; 6) pasteuring; 7) cooling, packaging, and 8) inspecting and warehousing. In the method of the invention, the mixed yoghourt is creatively pasteurized, the flora in the yoghourt can be killed and the syneresis of protein resulting in precipitating large amount of whey can not be caused under the protection of the stabilizer; and after either stirred yoghurt or set yoghurt is pasteurized, the yoghourt stabilizer can realize the aims of preventing the precipitation of whey, improving mouthfeel and product quality and increasing product stability. The special yoghourt stabilizer of the invention can effectively prolong the shelf life of yoghourt without controlling the cold chain, and the product shelf life is up to six months under the room temperature.

Owner:DONG GUAN SHI LONG JIN WEI BEVERAGE & FOOD

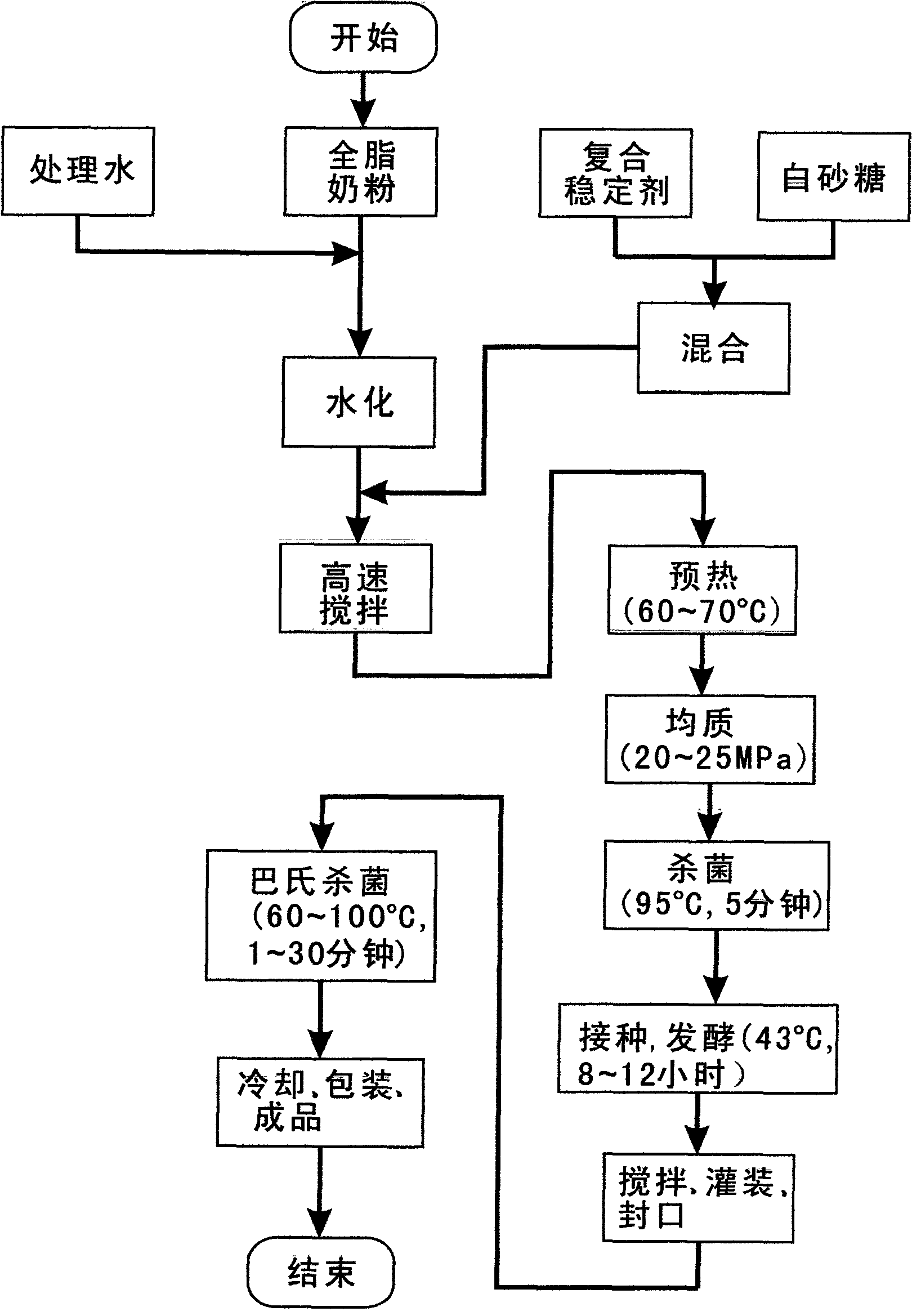

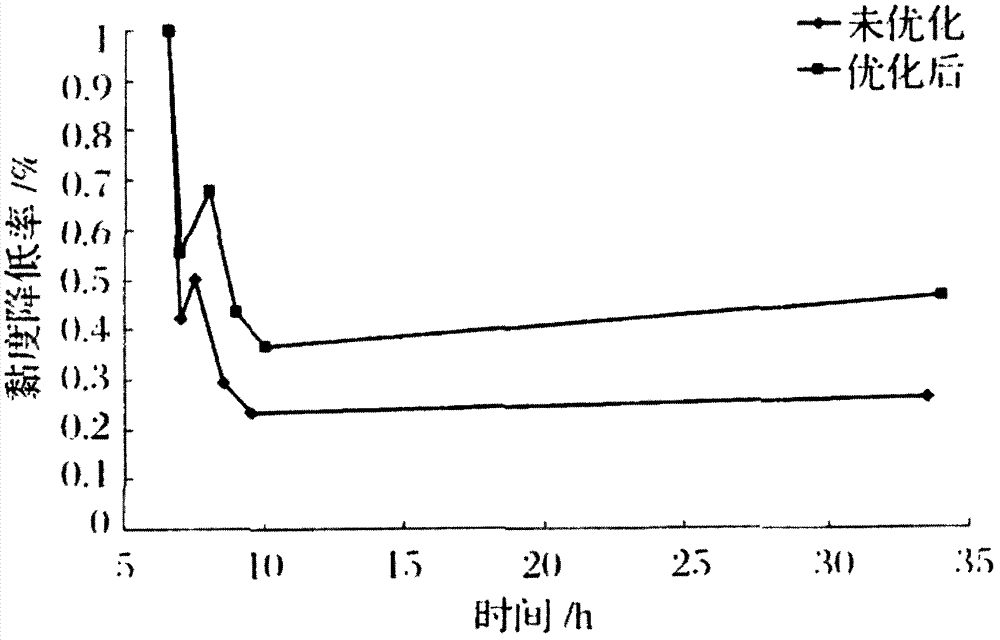

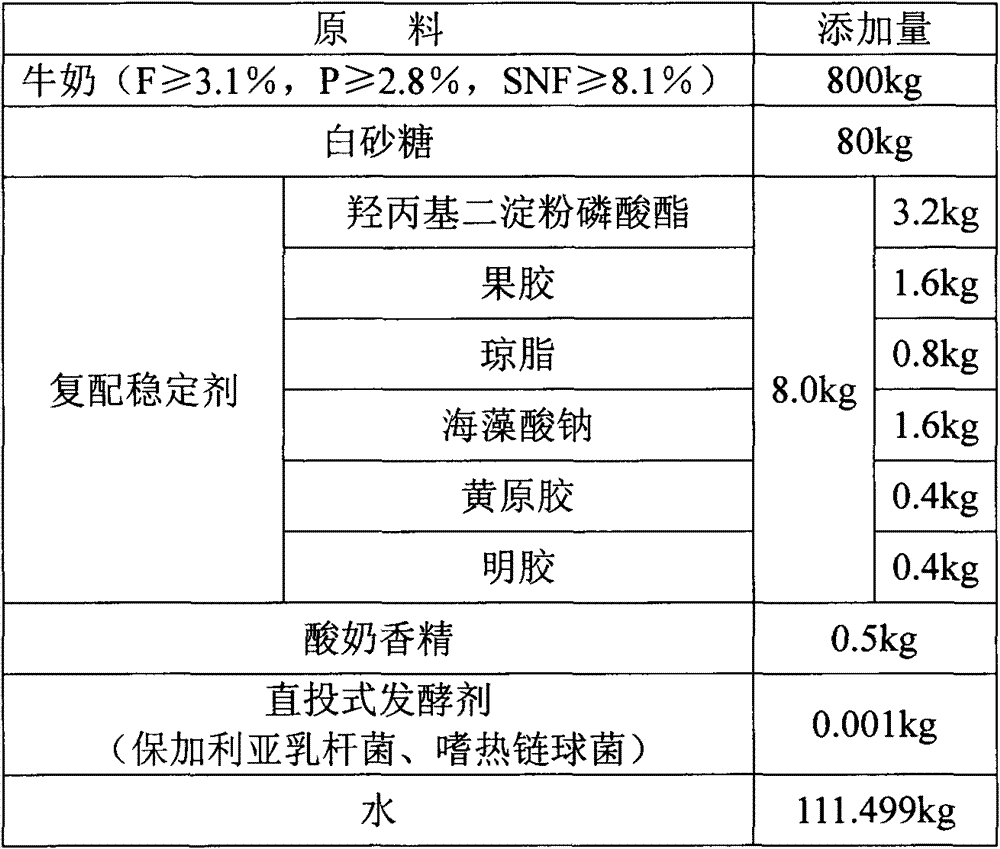

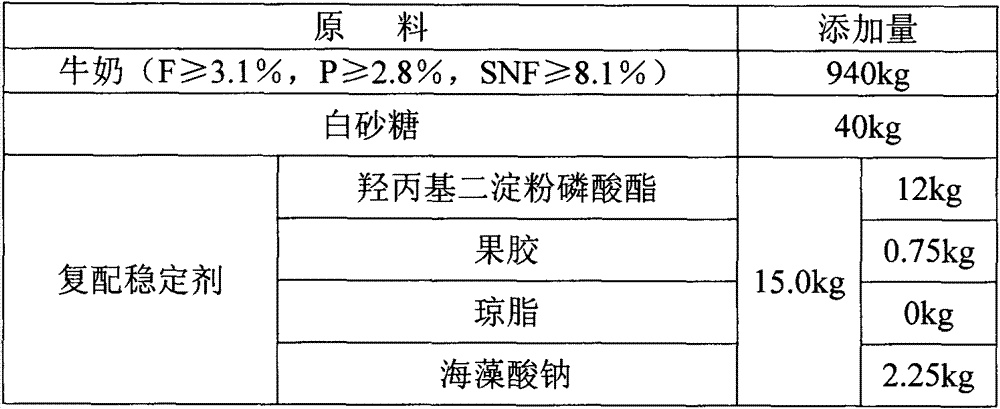

Compound stabilizing agent, fermented yogurt comprising compound stabilizing agent, and preparation method of fermented yogurt

ActiveCN103081995AImprove shear resistanceAchieve room temperature salesMilk preparationCold chainPasteurization

The invention discloses a compound stabilizing agent, a fermented yogurt comprising the compound stabilizing agent, and a preparation method of the fermented yogurt. The compound stabilizing agent provided by the invention comprises esterified starch, pectin, sodium alginate, agar, xanthan gum, and gelatin. The viscosity of the sodium alginate is 500mPa.s-1000mPa.s. The preparation method provided by the invention comprises the steps that: (1) the compound stabilizing agent provided by the invention, a sweetening agent, water, and pre-sterilized and preheated nonreactive milk are uniformly mixed; (2) homogenization is carried out; (3) pasteurization is carried out; (4) cooling is carried out, and a fermentation agent is added and fermentation is carried out; (5) jar turning is carried out; (6) pasteurization is carried out; and (7) rapid cooling is carried out, and sterile preservation is carried out. With the twice pasteurization technology and the sterile filling technology, physical and chemical stability and hygienic index stability of the fermented yogurt can be maintained after 3-6 months of storage under a normal temperature of 20-40 DEG C. Therefore, normal-temperature selling of fermented yogurt with a protein content no lower than 2.3% is realized, and the problem of long-distance selling of fermented yogurt due to cold chain restriction is solved.

Owner:BRIGHT DAIRY & FOOD

Long distance ice temperature live keeping transport case

InactiveCN104760785AQuality improvementEasy to buyLiving organism packagingLarge containersCold chainControl system

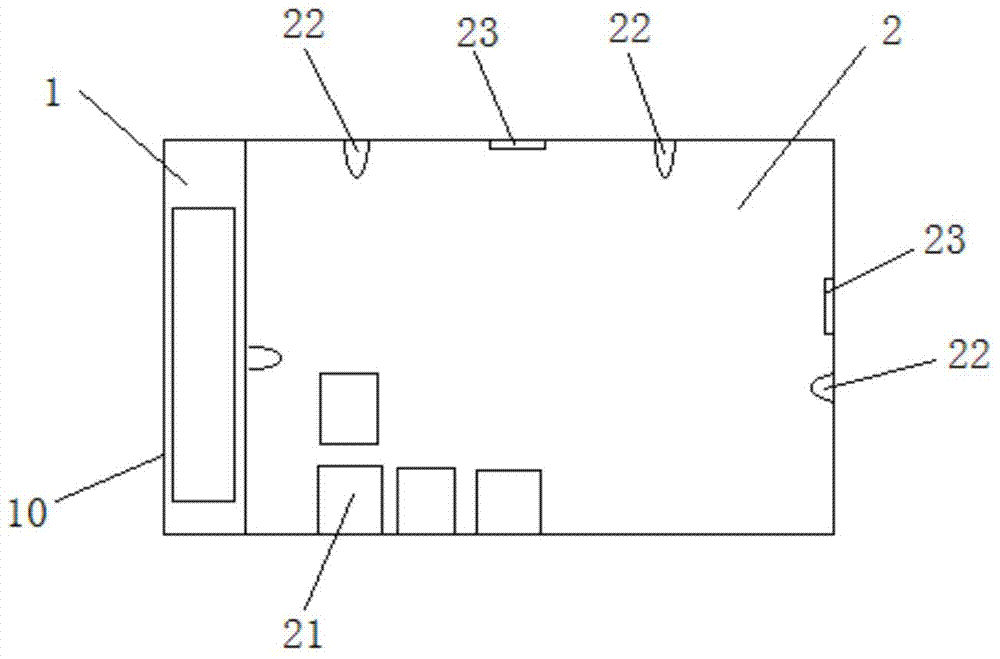

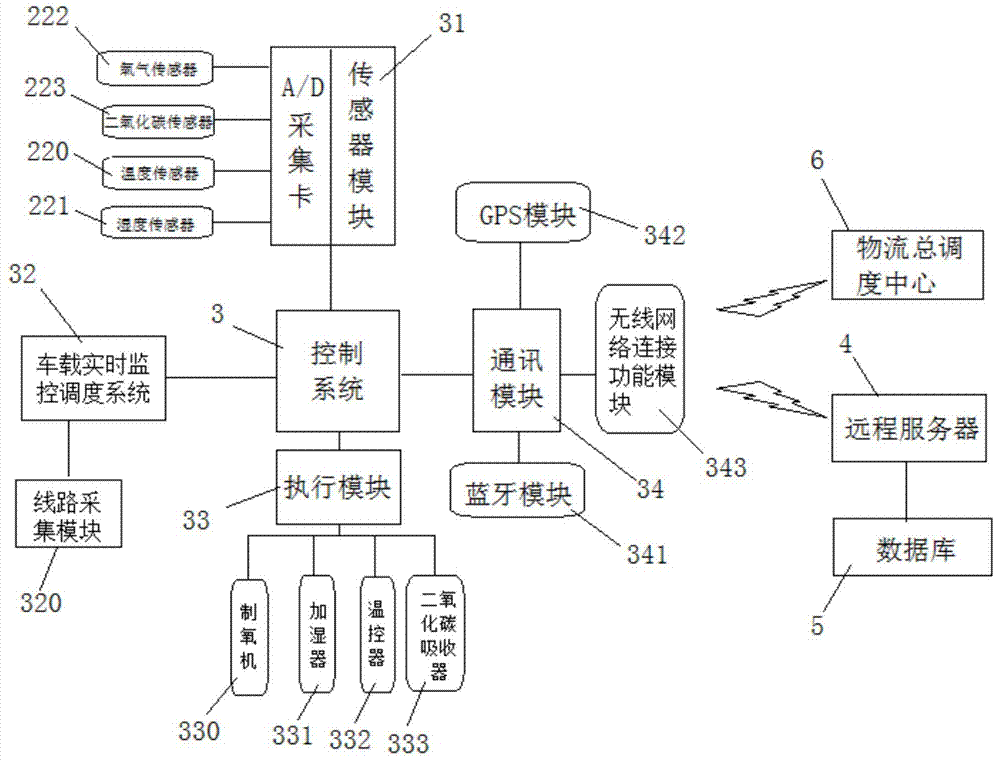

The invention discloses a long distance ice temperature live keeping transport case which comprises a control region and a storage region, wherein a control system is arranged in the control region; the storage region is used for positioning a fish box; a plurality of multifunction sensors are evenly arranged on the top and four walls of the storage region at interval; a temperature sensor, a humidity sensor, an oxygen sensor and a carbon dioxide sensor are arranged on each multifunction sensor, and each multifunction sensor is connected with the control system through the sensor module; a temperature controller, a draught fan, a humidifier, an oxygen generator, a GPS module, a communication module, a water pump and a warning device are arranged in the control region. The long distance ice temperature live keeping transport case can effectively improve freshness retaining quality of the long-distance transport aquatic product, improve transport amount and reduce the transport cost, the fresh and alive aquatic product can be transported and stored under ice temperature live keeping condition and the transparency, technicalization and integration of cold chain management can be promoted.

Owner:QINGDAO BEIDIAN HIGH TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com