Patents

Literature

38 results about "Air freight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cargo airlines (or airfreight carriers, and derivatives of these names) are airlines mainly dedicated to the transport of cargo by air. Some cargo airlines are divisions or subsidiaries of larger passenger airlines.

System for facilitating security check of shipment of cargo

InactiveUS20130015083A1Convenient security checkKeep goingSynthetic resin layered productsLarge containersCold chainFresh fish

The present invention provides a system for facilitating security check of cold-chain air freight cargo using a magnetic imaging scanner for shipping at the airport. Cold-chain material includes most perishables such as produce, fresh fish, biological parts, pharmaceuticals and similar that need to be kept at a lower temperature for preservation and freshness.

Owner:AIRDEX INT

Box type freight unmanned aerial vehicle, matching system thereof and application

PendingCN107444643APackage structure is simpleQuick dockingRemote controlled aircraftLogisticsAviationManufacturing technology

The invention discloses a box type freight unmanned aerial vehicle, a matching system thereof and application. unmanned aerial vehicle freight, a standard cargo box generally adopted by cities or a national standard tricycle express distribution mode are combined, the box type freight unmanned aerial vehicle covers technologies such as cargo box standard, cargo bin structures, unmanned aerial vehicle navigation and flight control which are suitable for high attendance rate and low altitude flight, low altitude links and navigation monitoring systems and updating and development of a whole industry value chain such as corresponding airworthiness standard and authorized regulations, flight space managing regulations, operator training methods, unmanned aerial vehicle system design and manufacturing technology, flight application and business models. Design of box type freight of an unmanned aerial vehicle adopts carriage national standard of an express tricycle, express cargo automatic sorting engineering matching is facilitated, one-stop automatic sorting and box dividing transportation are achieved, a combined transport mode of air freight and urban express is established, time and cost of airport loading and unloading links are reduced, and development of automatic equipment of express delivery industry is promoted.

Owner:陶文英

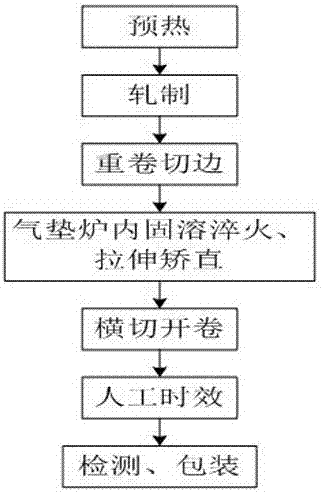

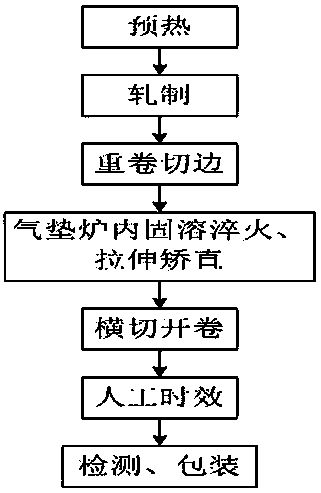

Manufacturing method for ultra-wide aluminum alloy thin plate for air freight

The invention discloses a manufacturing method for an ultra-wide aluminum alloy thin plate for air freight. The manufacturing method comprises the following steps of: (1) preheating; (2) rolling; (3) re-coiling and trimming; (4) solid-solution quenching and stretching-stretching; (5) cross-cutting and coiling; (6) artificial aging; and (7) detecting and packaging. The manufacturing method disclosed by the invention is fewer in processes, is short in production period, is lower in cost, is higher in yield and is higher in production efficiency; and the produced plate is low in residual stress, is high in dimension precision and is relatively good in surface quality, and meets the use requirements of relatively low unevenness of the aluminum alloy thin plate for air freight.

Owner:广西南南铝加工有限公司

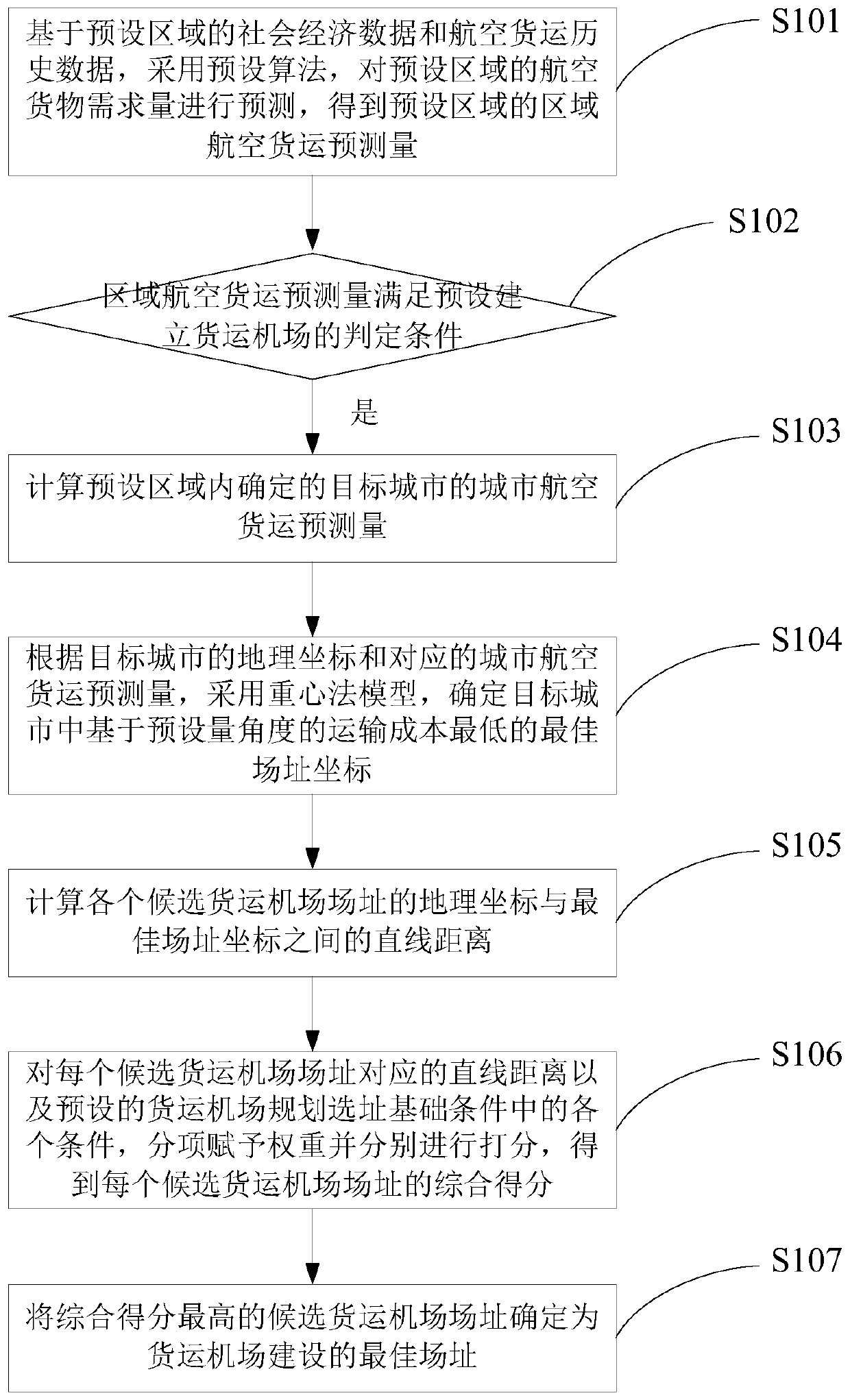

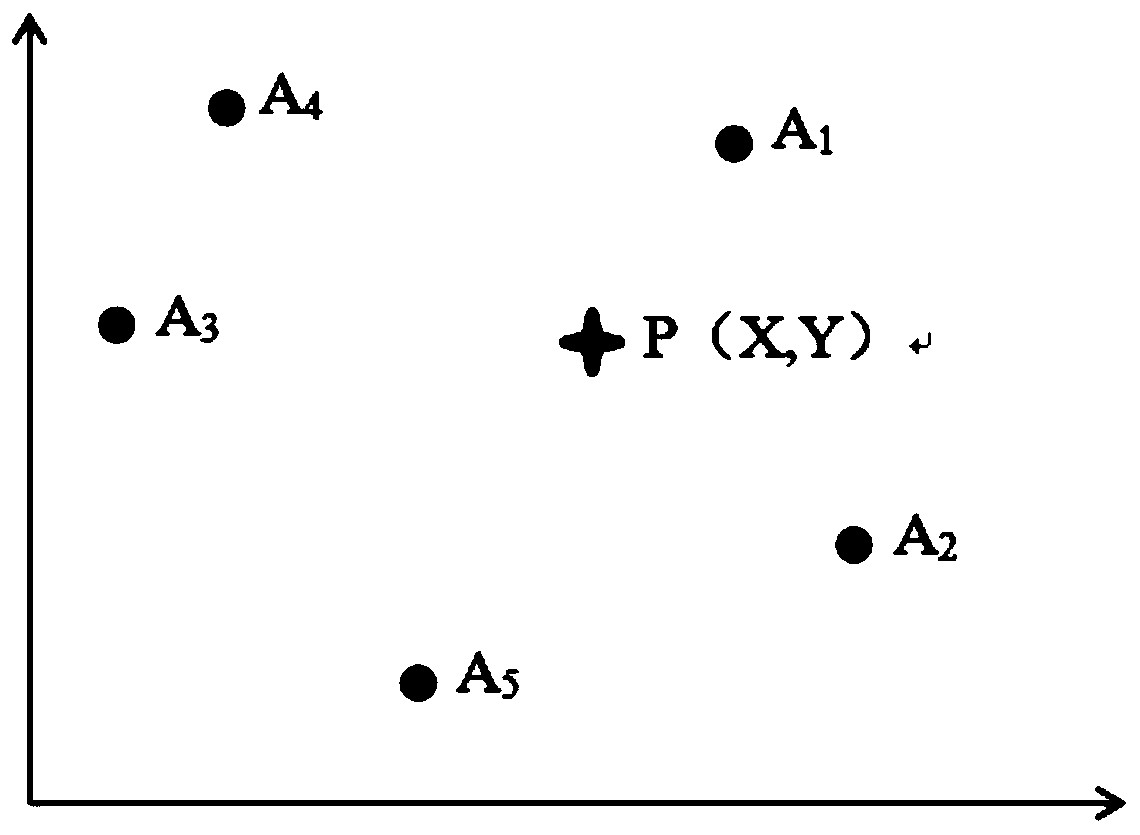

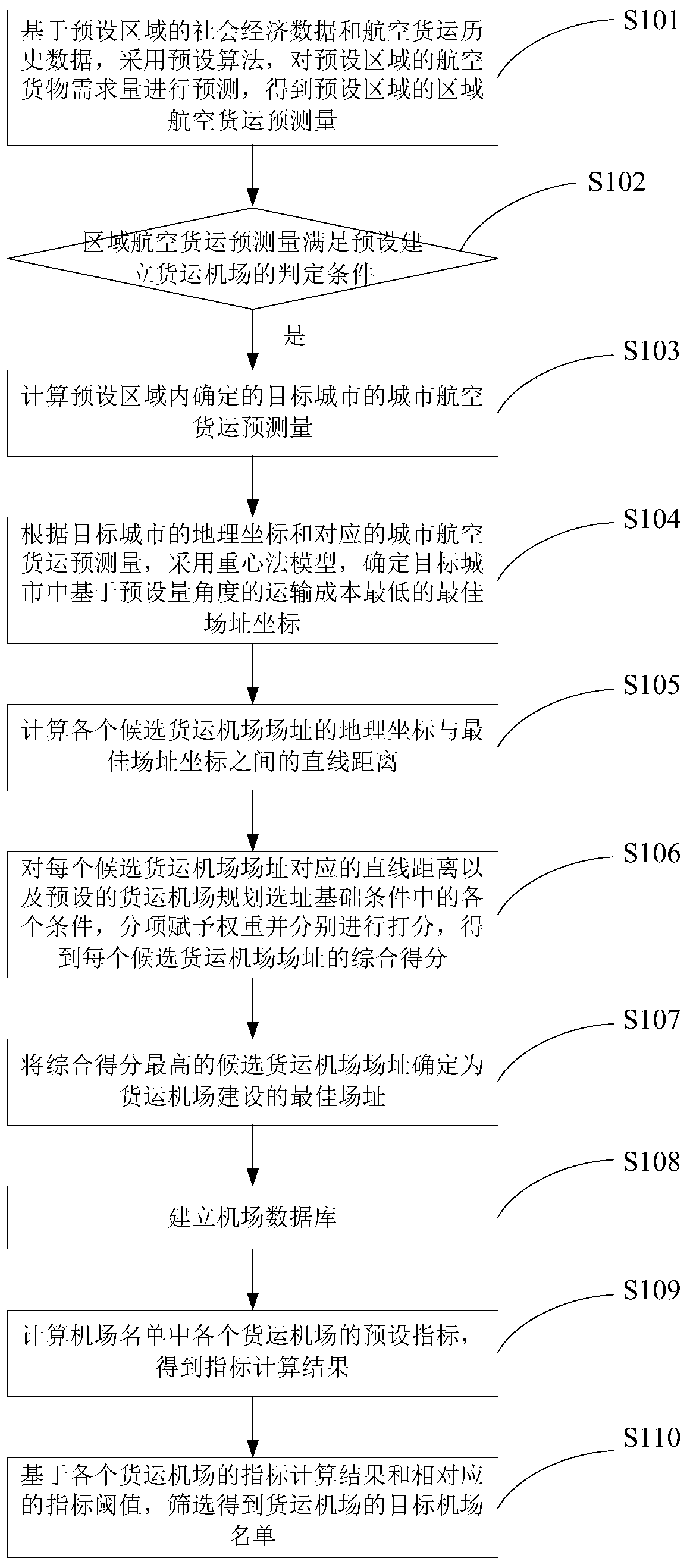

Planning and site selection method and system for freight airport

PendingCN110990789AAddressing under-researched issuesComplex mathematical operationsMarket data gatheringSocio economic dataGravity center

The invention discloses a planning and site selection method and system for a freight airport. According to the method, a preset algorithm is adopted to obtain the regional air freight prediction quantity of a preset region on the basis of the social and economic data and air freight historical data of the preset region, so that the urban air freight prediction quantity of a target city in the preset region is determined; the optimal site coordinates of the target city are determined by adopting a gravity center method model according to the geographic coordinates of the target city and the corresponding city air freight prediction quantity; linear distances between the geographic coordinates of each candidate freight airport site and optimal site coordinates and each condition in preset freight airport planning and site selection basic conditions are weighted and scored; the comprehensive score of each candidate freight airport site is obtained; and the candidate freight airport sitewith the highest comprehensive score is determined as an optimal site for freight airport construction. With the method and system adopted, quantitative deep research on the planning and site selection of freight airports is realized, and the problem of insufficient research on the planning and site selection of the freight airports at the present stage is solved.

Owner:中国民航工程咨询有限公司

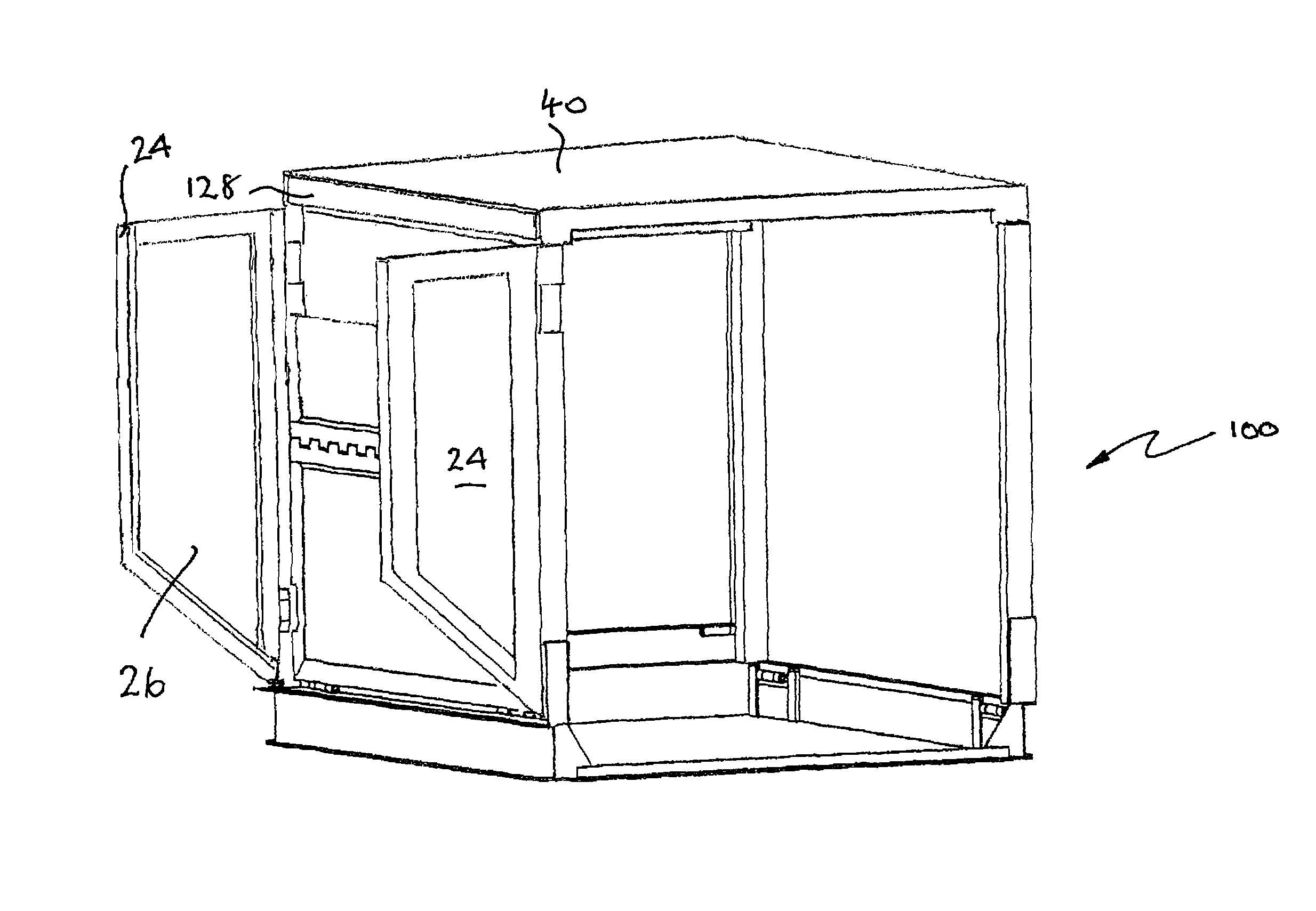

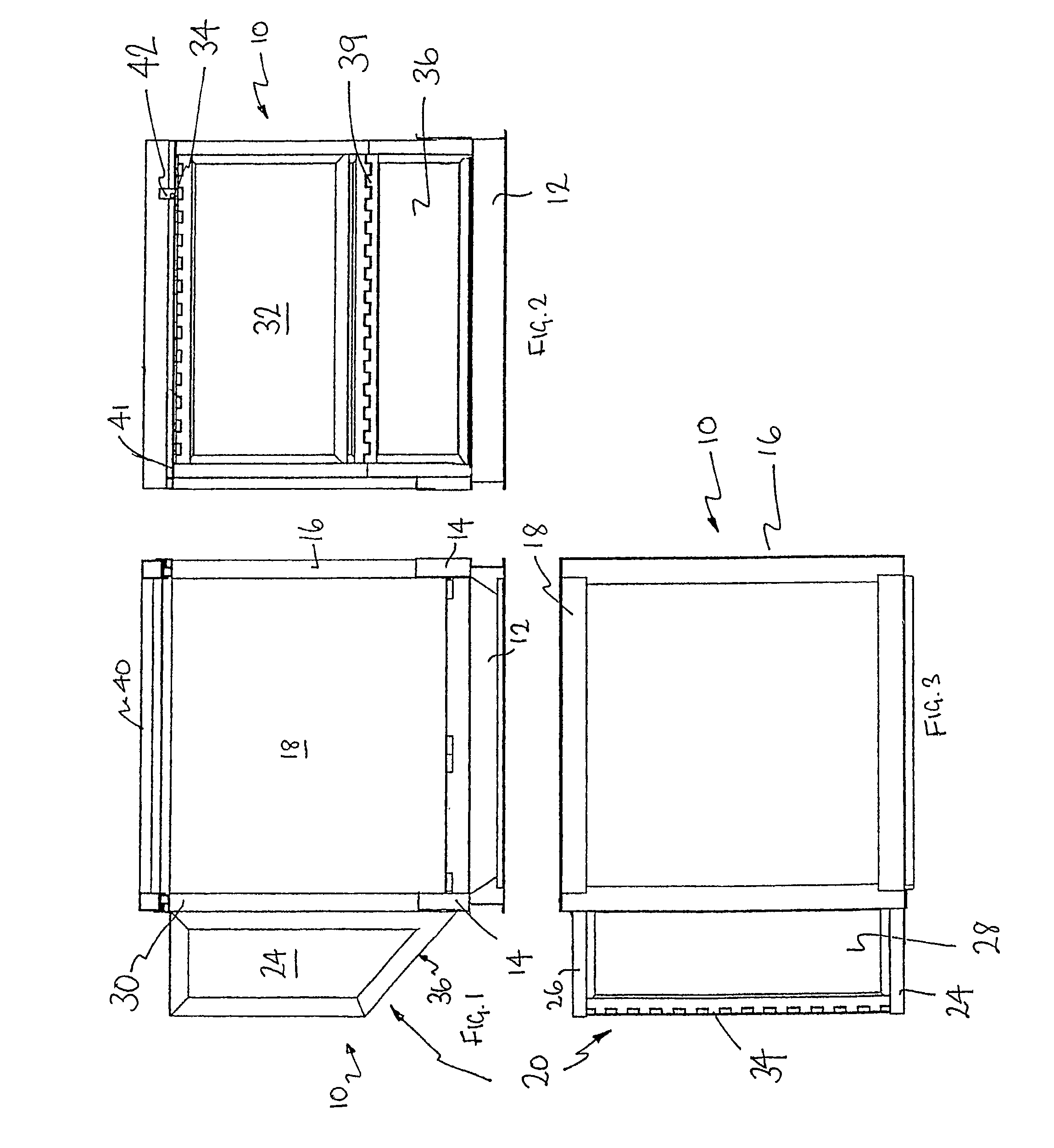

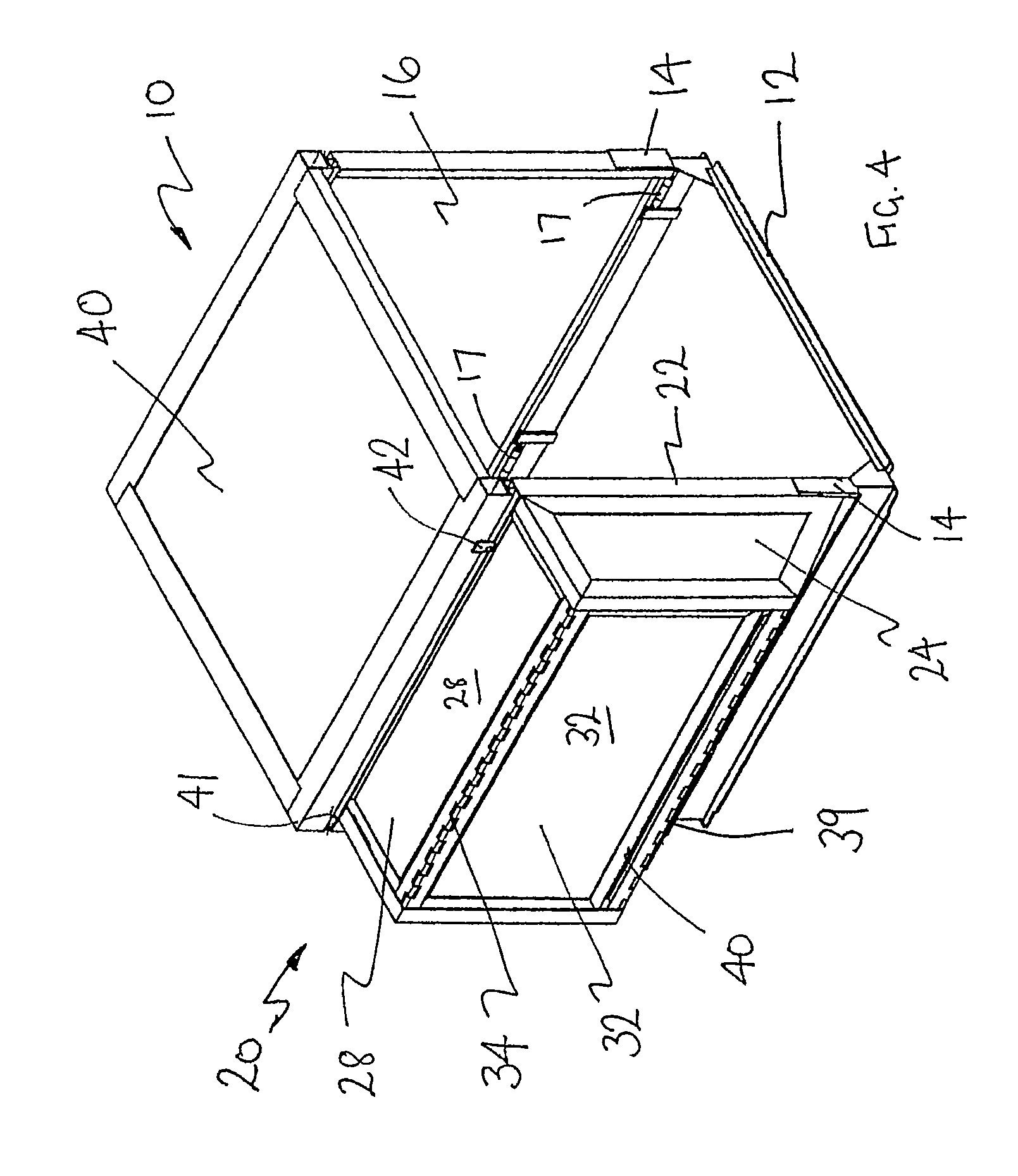

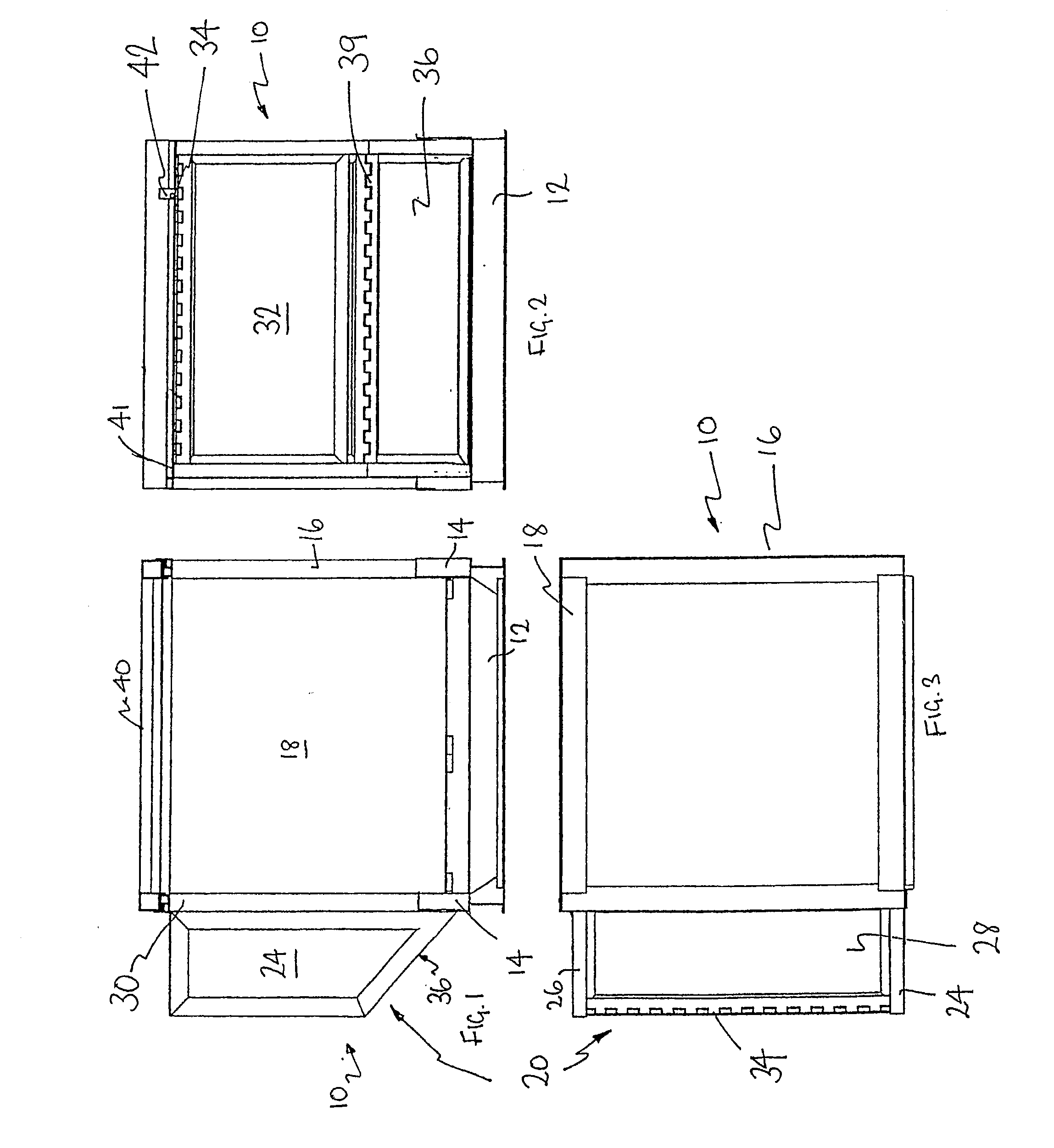

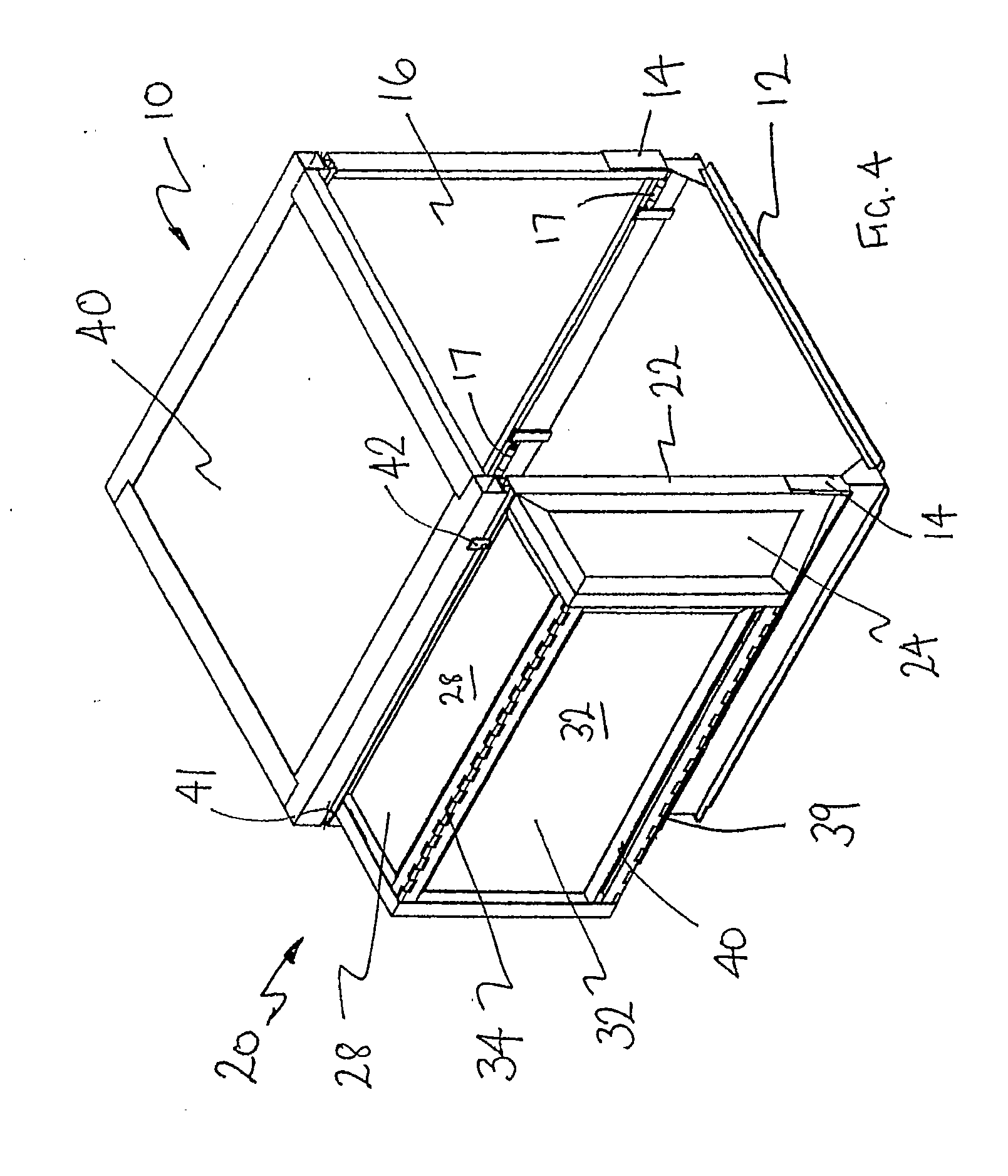

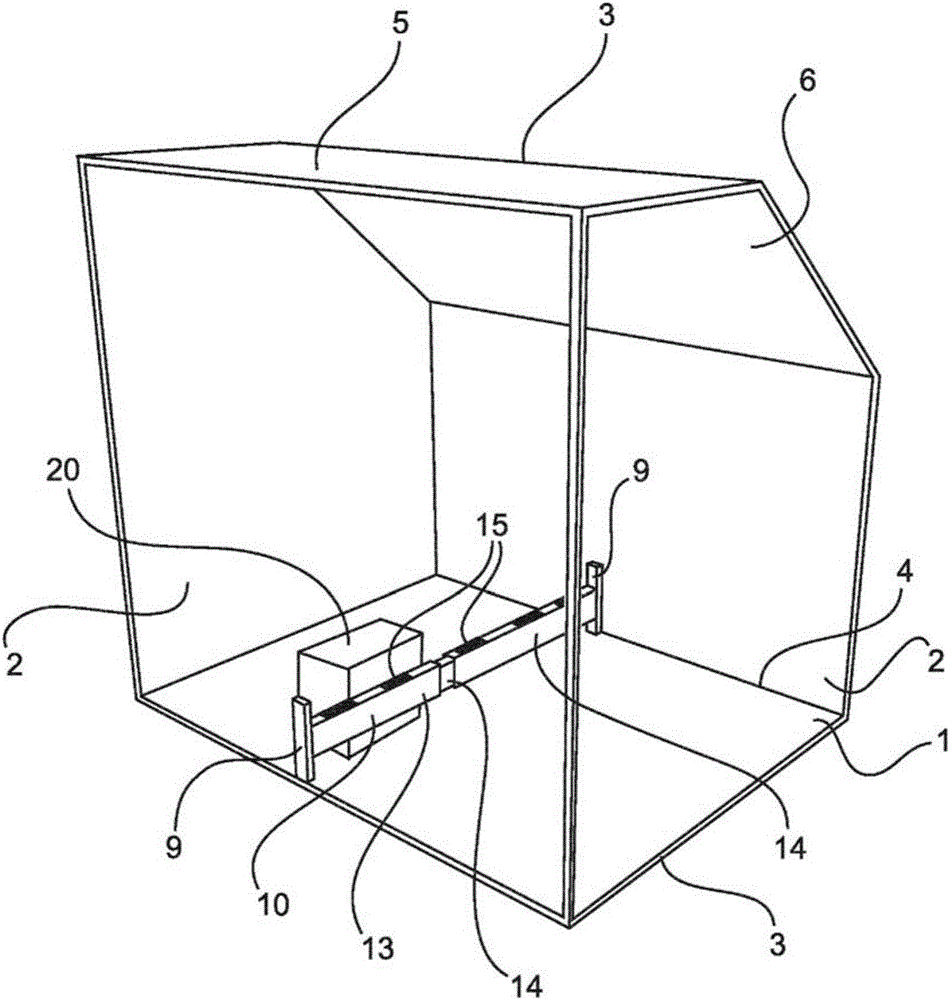

Folding containers

InactiveUS8261924B2Improve stacking characteristicMinimal amountLarge containersRigid containersEngineeringMechanical engineering

A collapsible air freight container (10) comprises a standard base (12), a side panel (16) slideably hinged to the base and a back panel (18) which is hinged to the base which interlocks with the side panel. There is a side extension (20) which is generally trapezoidal to roughly conform to the shape of a side wall of a plane's cargo hold. A lid is slideably mounted on top of the container so that it can be slid relative to the back panel. The lid is arranged so that when fully retracted to the back of the container relative to the back panel, it may pivot to overlay the back panel. The container may be collapsed by retracting and pivoting the lid to overlie the back panel (18), folding the side extension (20), folding and sliding the side panel (16) into the base (12) and lowering the folded side extension (20) and then the back panel (18) and lid (40) into the base.

Owner:TECHNOSEARCH

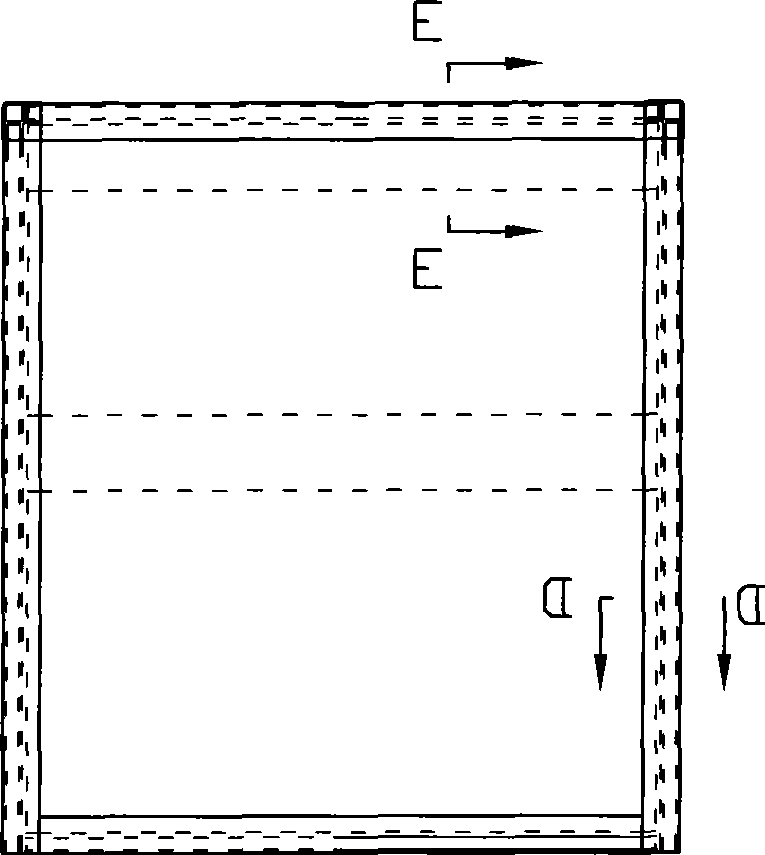

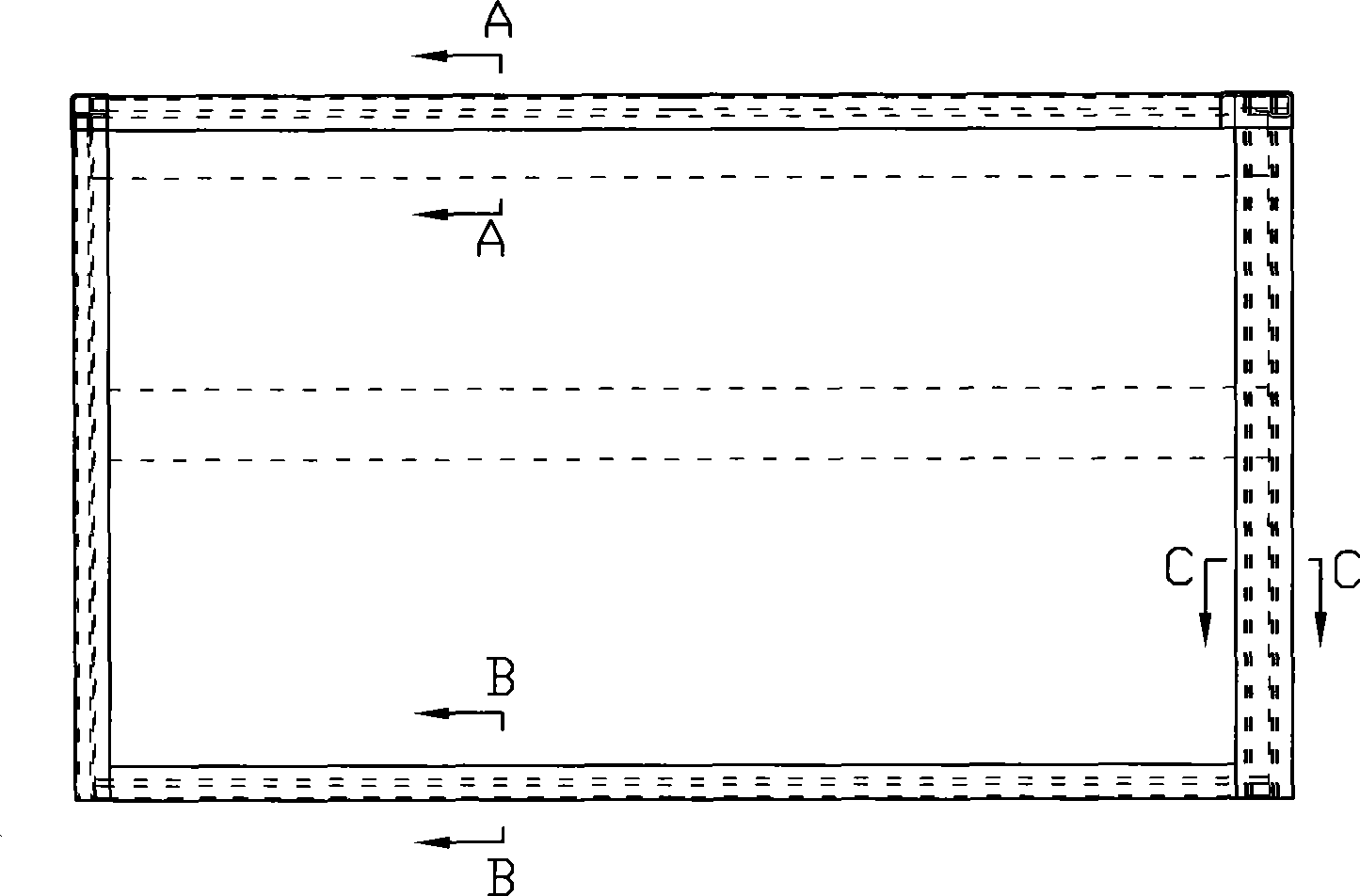

Splicing pair and splicing box body

InactiveCN101434265AHigh strengthIncrease stiffnessVehicle with living accommodationSuperstructure connectionsEngineeringMechanical engineering

The invention discloses a plug pair and a plug container body. The plug pair comprises a connecting angle part and a plug groove; the connecting angle part comprises two grooves; teeth are arranged in one groove of the connecting angle part; teeth are arranged on the outer side of the plug groove; and when the plug groove is plugged into the teeth groove of the connecting angle part, the teeth on the plug groove is meshed with the teeth on the connecting angle part. The container body is provided at least a group of adjacent boards connected with the plug pair. The invention can realize the quick mounting of a container body so as to bring convenience for the export by SKD air freight or shipping and largely reduce the shipping cost. The plug pair is provided with a simple structure and can connect all the boards in the container body with distinct effect. Therefore, the container is provided with better rigid, strength and sealing performance; and the mounting can be realized quickly so as to bring convenience for the bulk assembling manufacturing.

Owner:JINAN BULLEX IND & TRADE

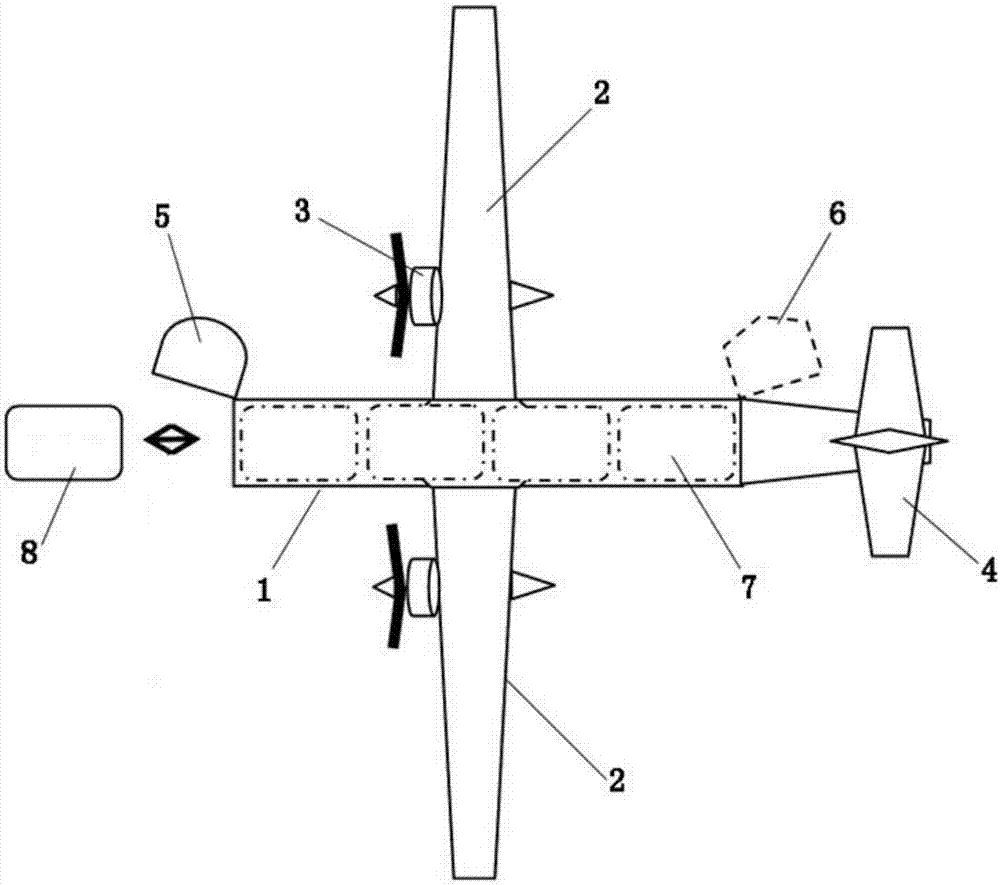

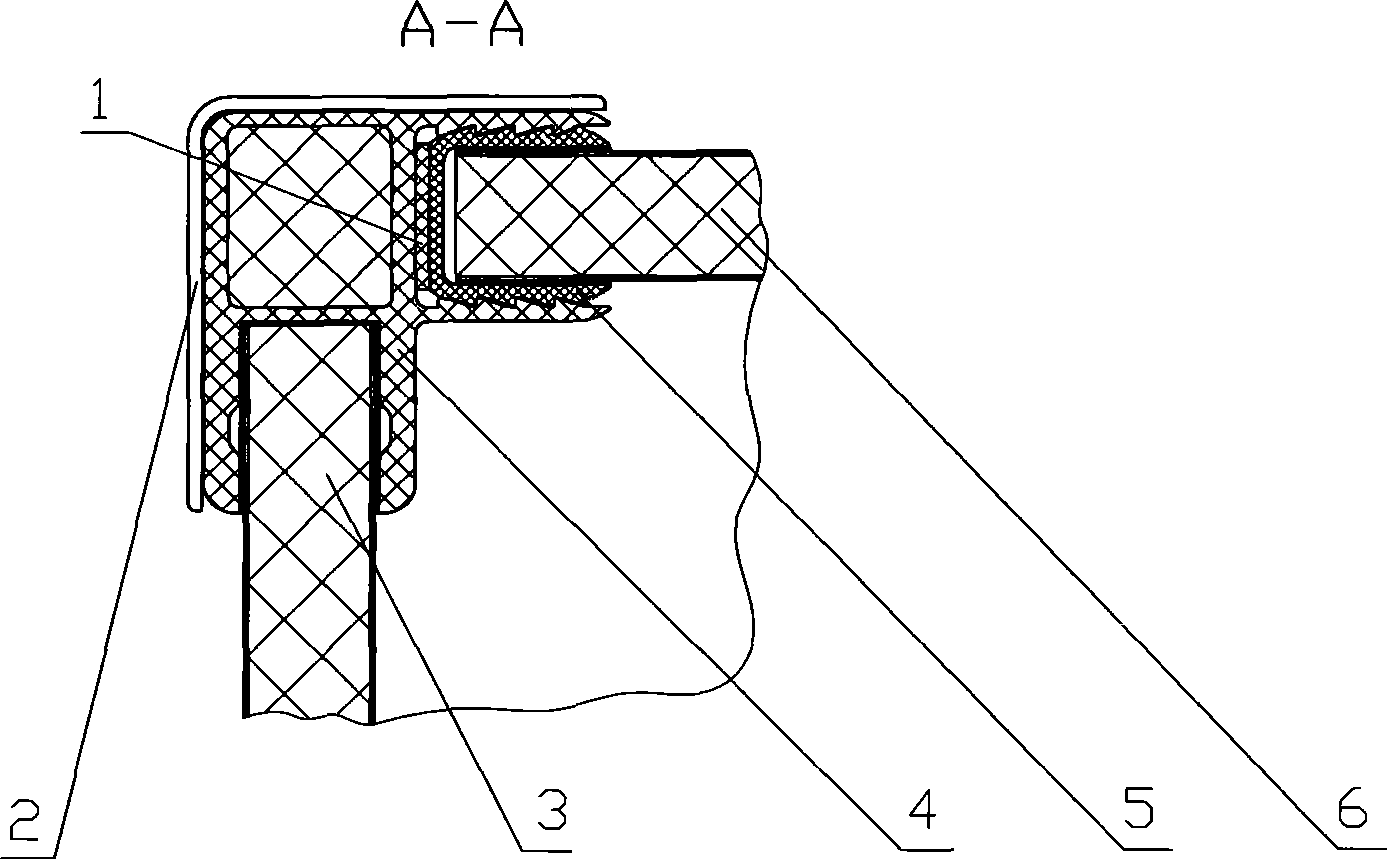

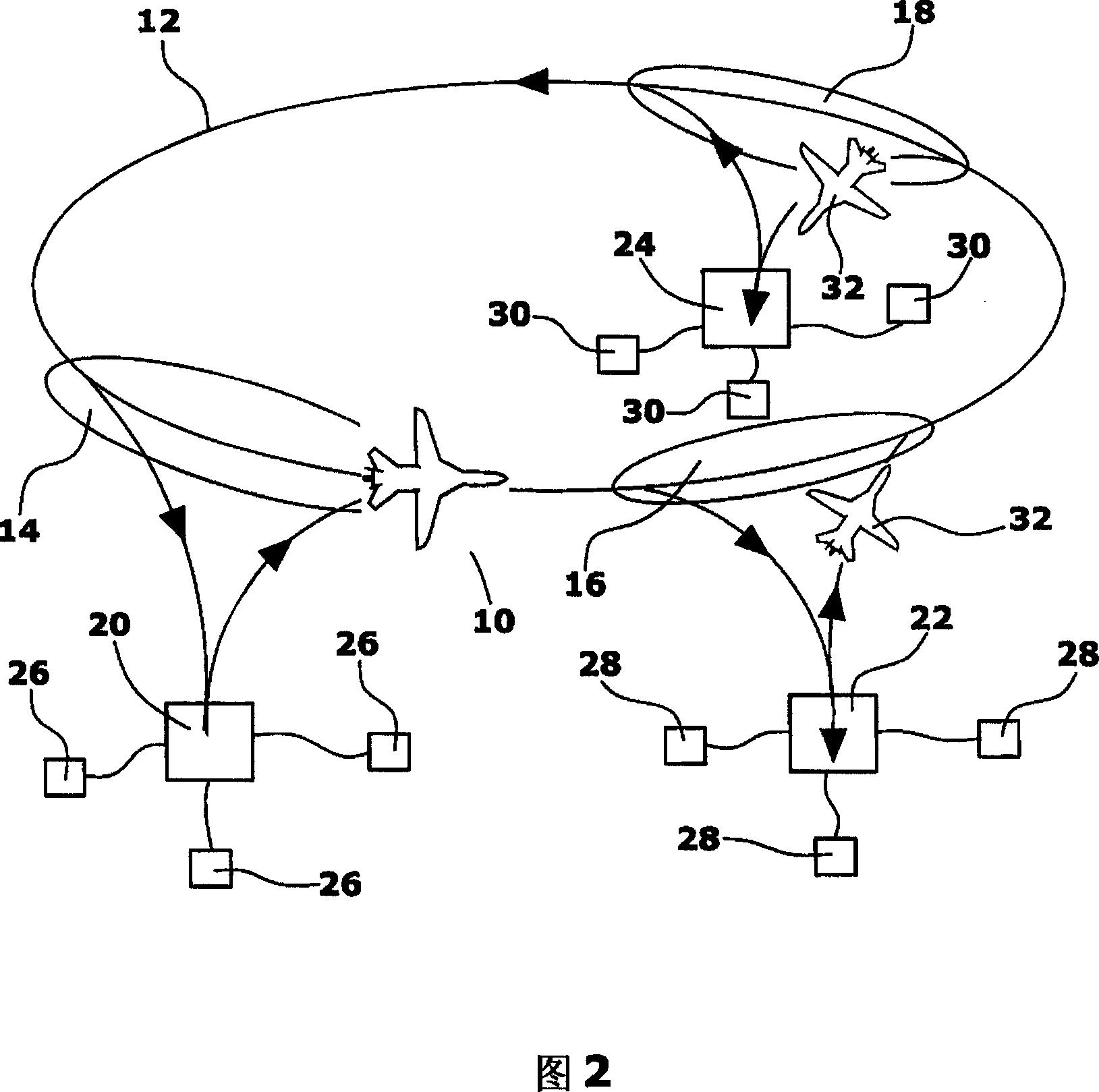

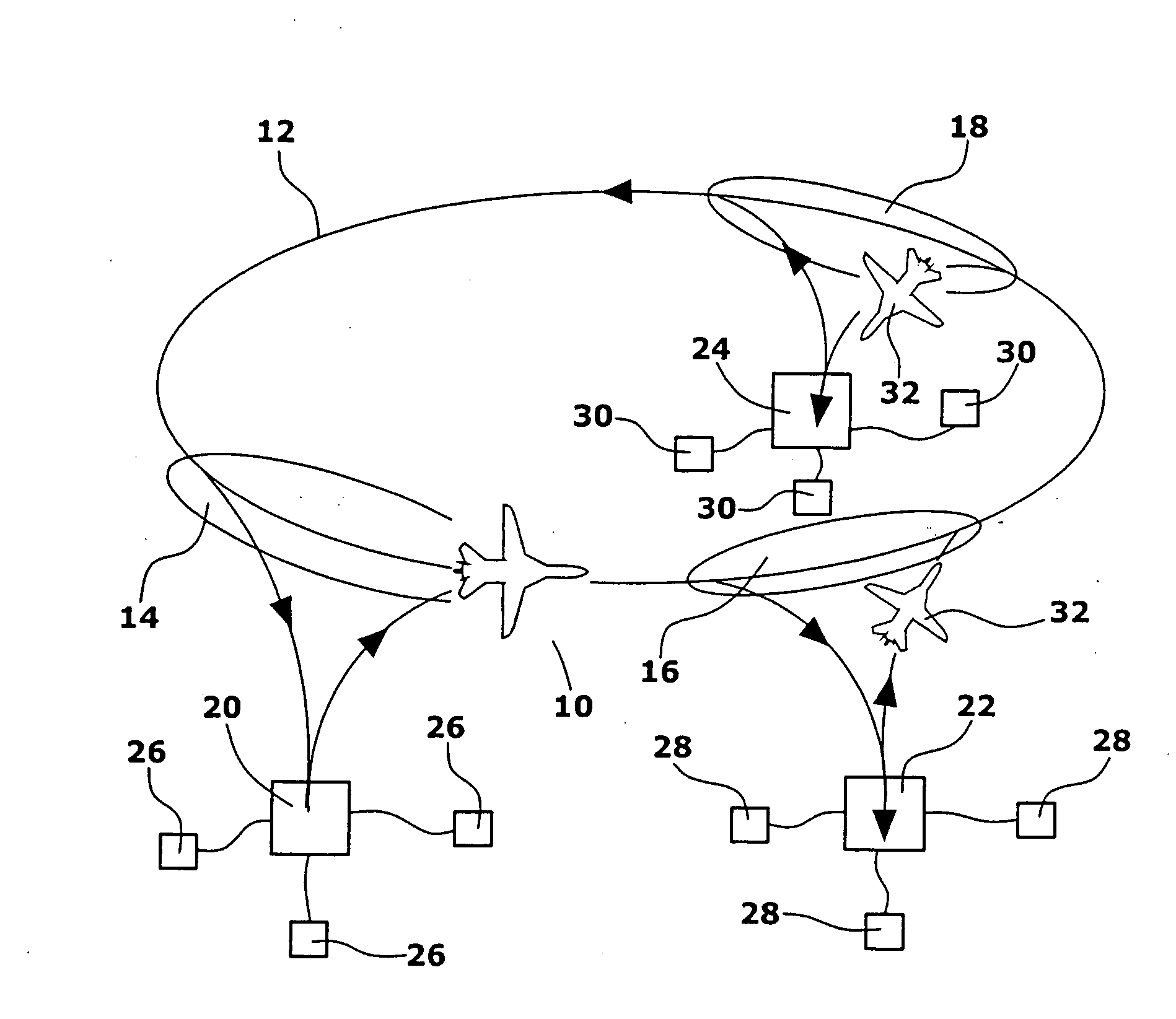

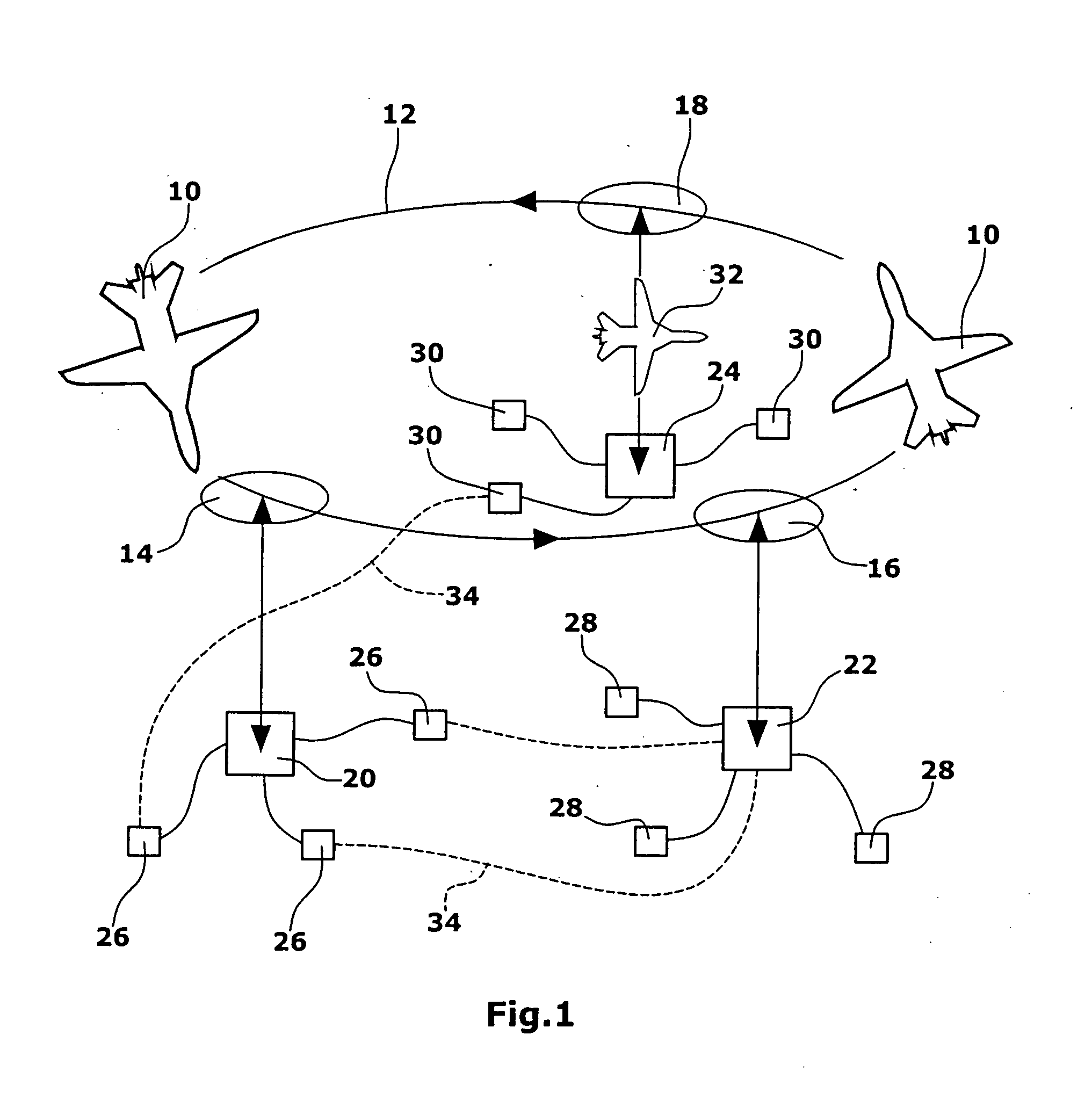

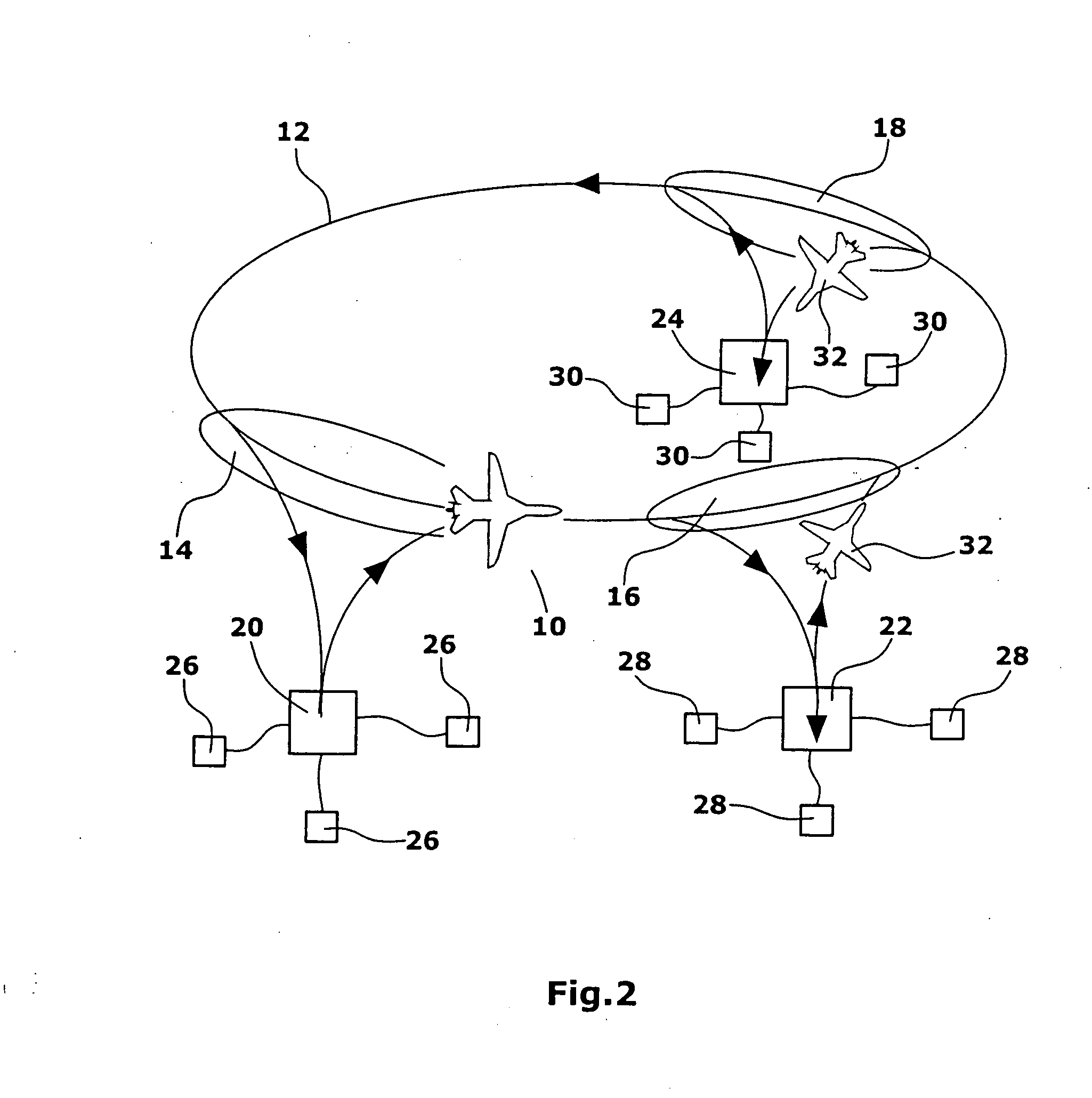

Air freight transport method, transport aeroplane and air freight transport system

InactiveCN1960910AExtended use timeImprove transportation efficiencyConvertible aircraftsFreight handlingTransport systemAir freight

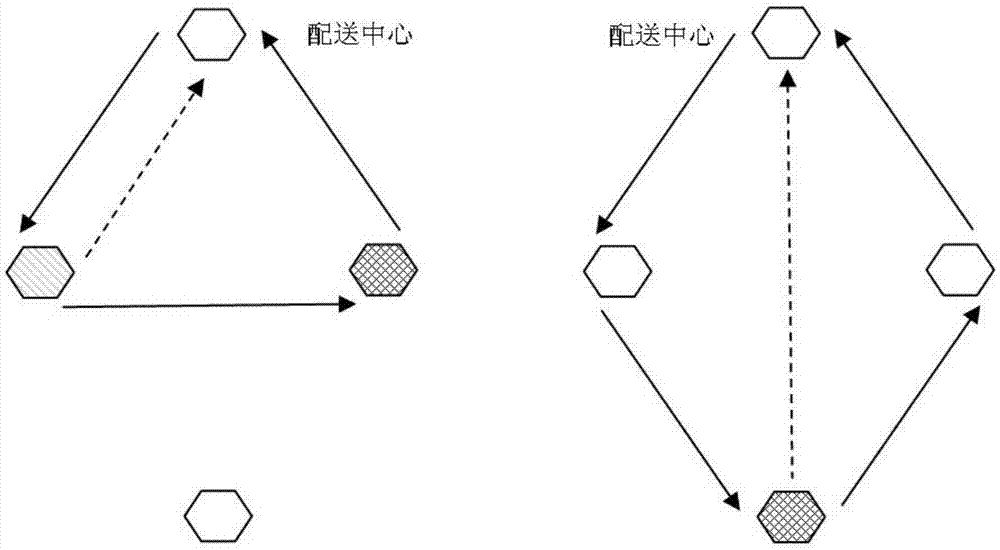

The invention relates to an air freight transport system which is used to transport various freights to different destinations (26, 28, 30). According to the invention, a transport aeroplane (10), which crosses through at least three air zones (14, 16, 18) associated with one station (20, 22, 24), is prepared. The aeroplane can not land on one of the stations (20, 22, 24). Transportation of the freight between the transport aeroplane (10) and one of the stations (20, 22, 24) occurs with the help of feeder planes (32), whereby transfer of the freight between the feeder plane (32) and the transport plane (10) takes place in the air. The transport plane (10) and two feeder planes (32) form the inventive air freight transport system and the transport aeroplane (10) can comprise two feeder planes (32) which are connected together. The inventive air freight transport method improves the charge of the transport aeroplanes (10). Additionally, the transport paths for individual freights can be shortened thus making said method more economical.

Owner:加比·特劳特·赖因哈特

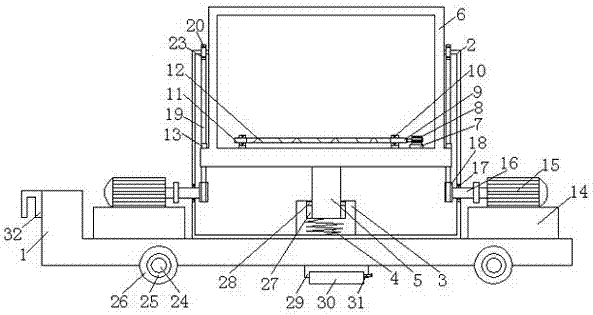

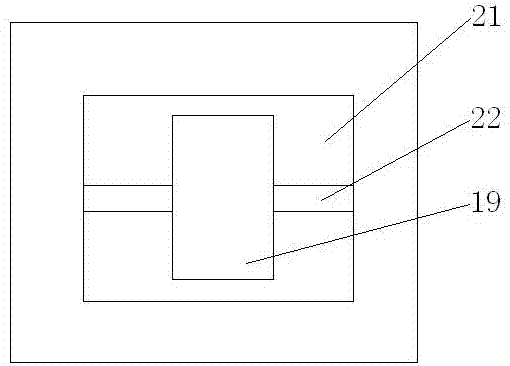

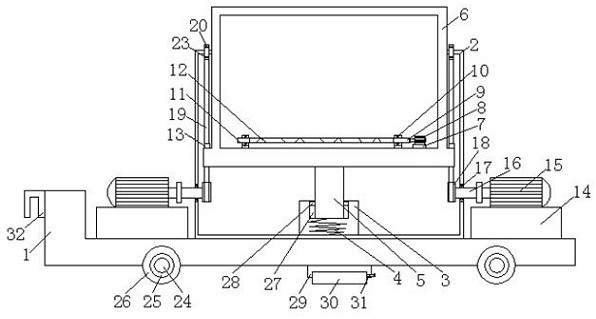

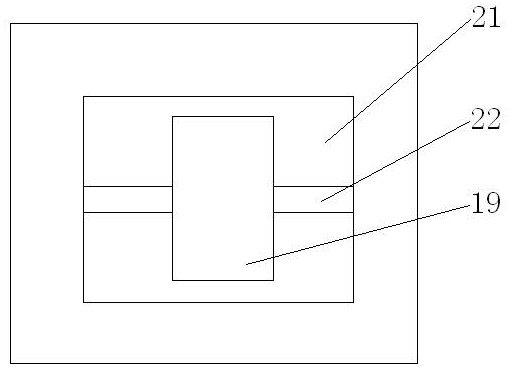

Air freighting lifting equipment

ActiveCN107323683APrevent slidingSolve the problem of high ground clearance and difficulty in moving goodsLifting framesFreight handling installationsMotor driveAir freight

The invention discloses air freighting lifting equipment. The air freighting lifting equipment comprises a trailer plate. An outer box is fixedly connected to the surface of the trailer plate. A telescopic pipe is fixedly connected to the inner wall of the outer box, a spring is fixedly connected to the inner wall of the telescopic pipe, a telescopic rod is fixedly connected to one end of the spring, and the inner wall of the outer box is in sliding connection with an inner box. The surface of the inner box is in sliding connection with the surface of the telescopic rod. The inner wall of the inner box is fixedly connected with a conveying motor base. The surface of the conveying motor base is fixedly connected with a conveying motor. According to the air freighting lifting equipment, when cargo is elevated and lowered, lifting motors are started, the lifting motors drive first lifting rotation shafts to rotate, the first lifting rotation shafts rotate and drive rollers to rotate, second lifting rotation shafts support lifting belts, the rollers rotate for elevating and lowering of one ends of the lifting belts, one end of each lifting belt is elevated and lowered, the inner box is elevated and lowered through pull buckles, and the effect of inner box ascending and descending is achieved; and accordingly the problem that in the air freighting process, due to the fact that a cabin leaves the ground by a large height, cargo carrying is difficult is effectively solved.

Owner:于浩

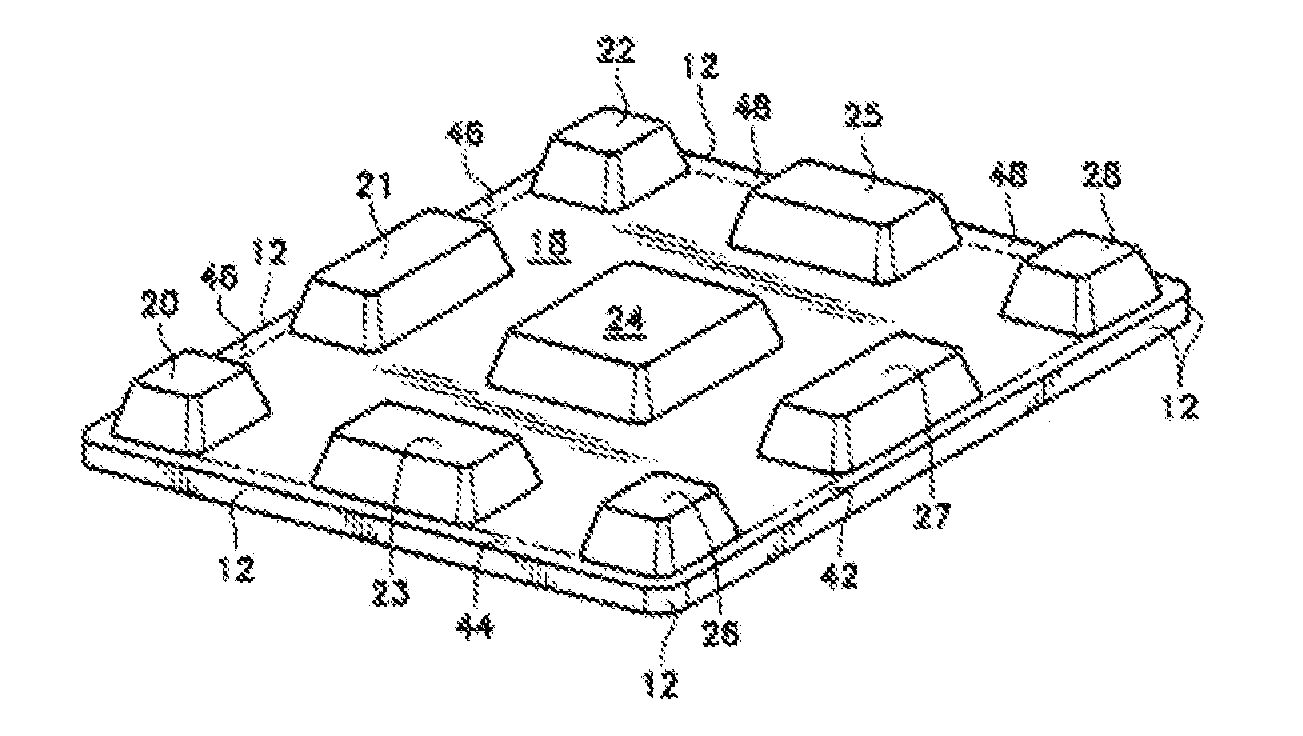

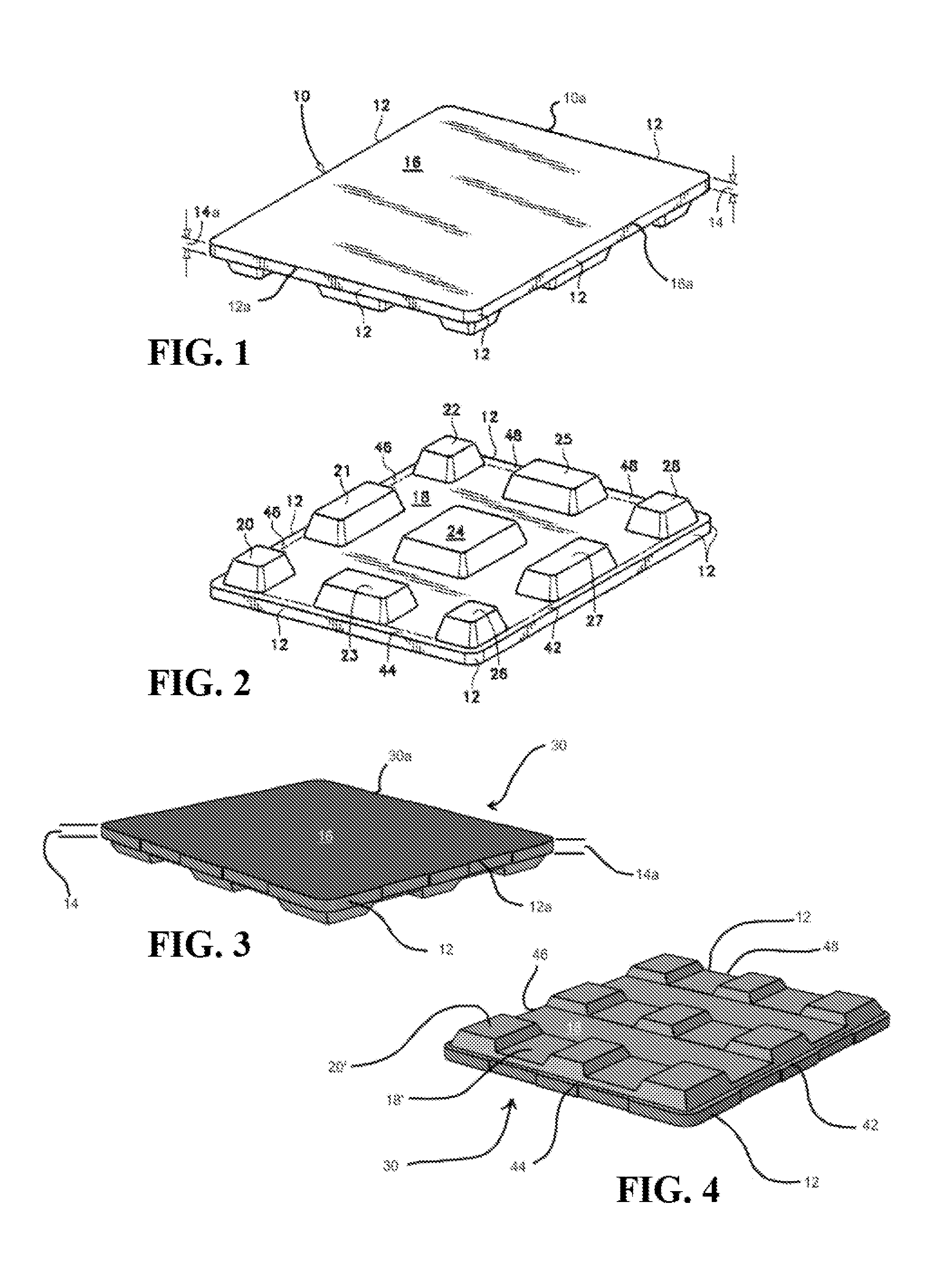

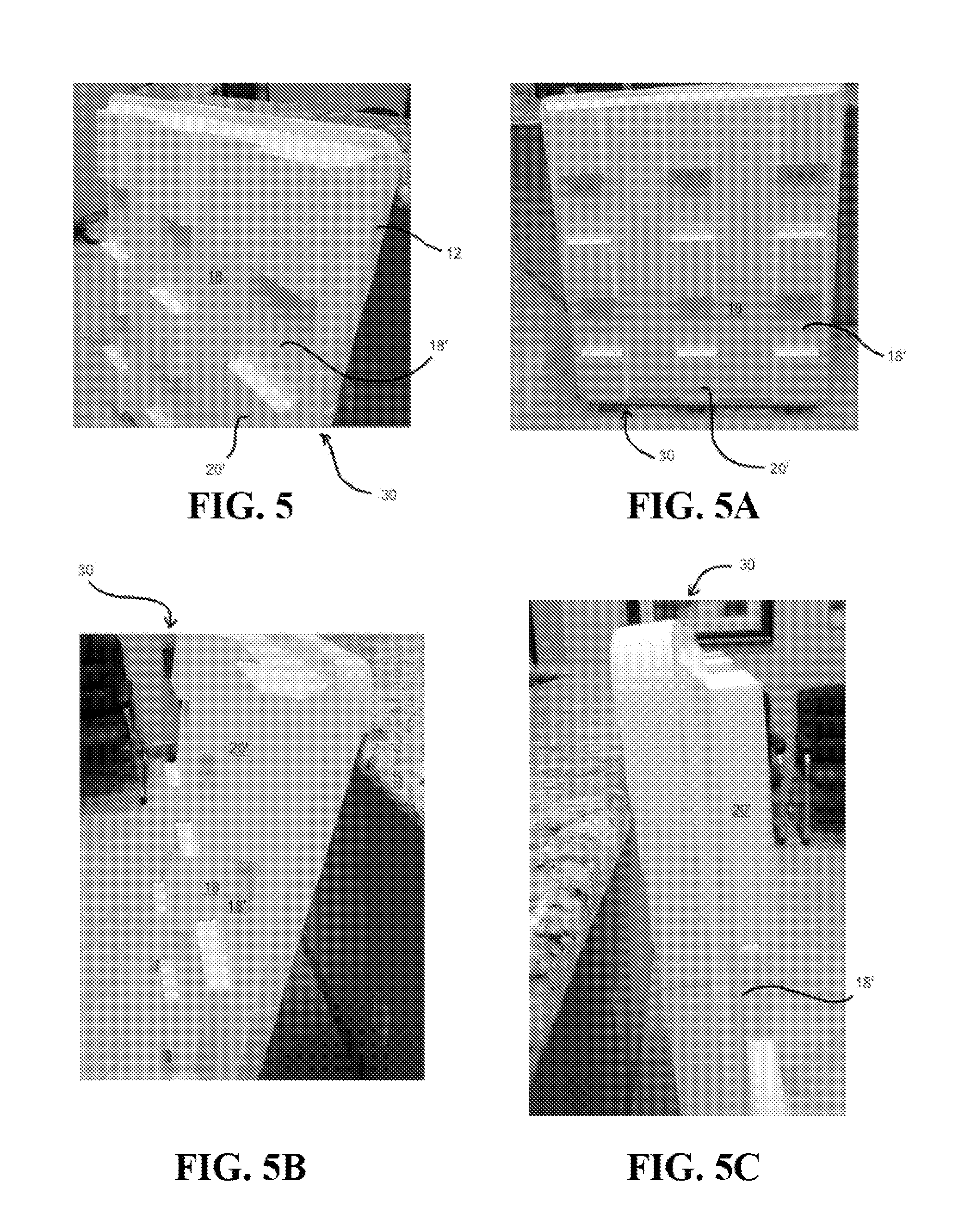

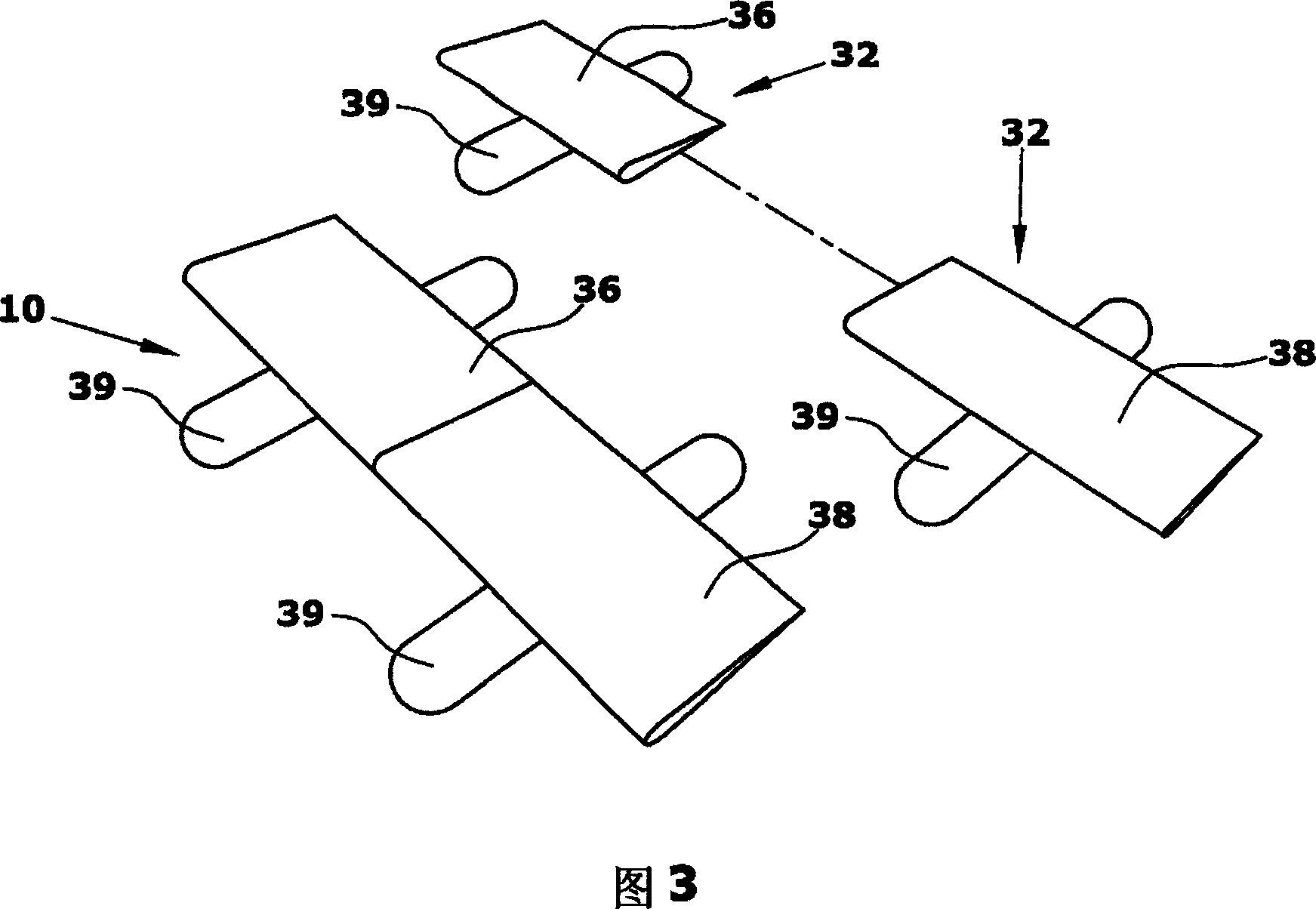

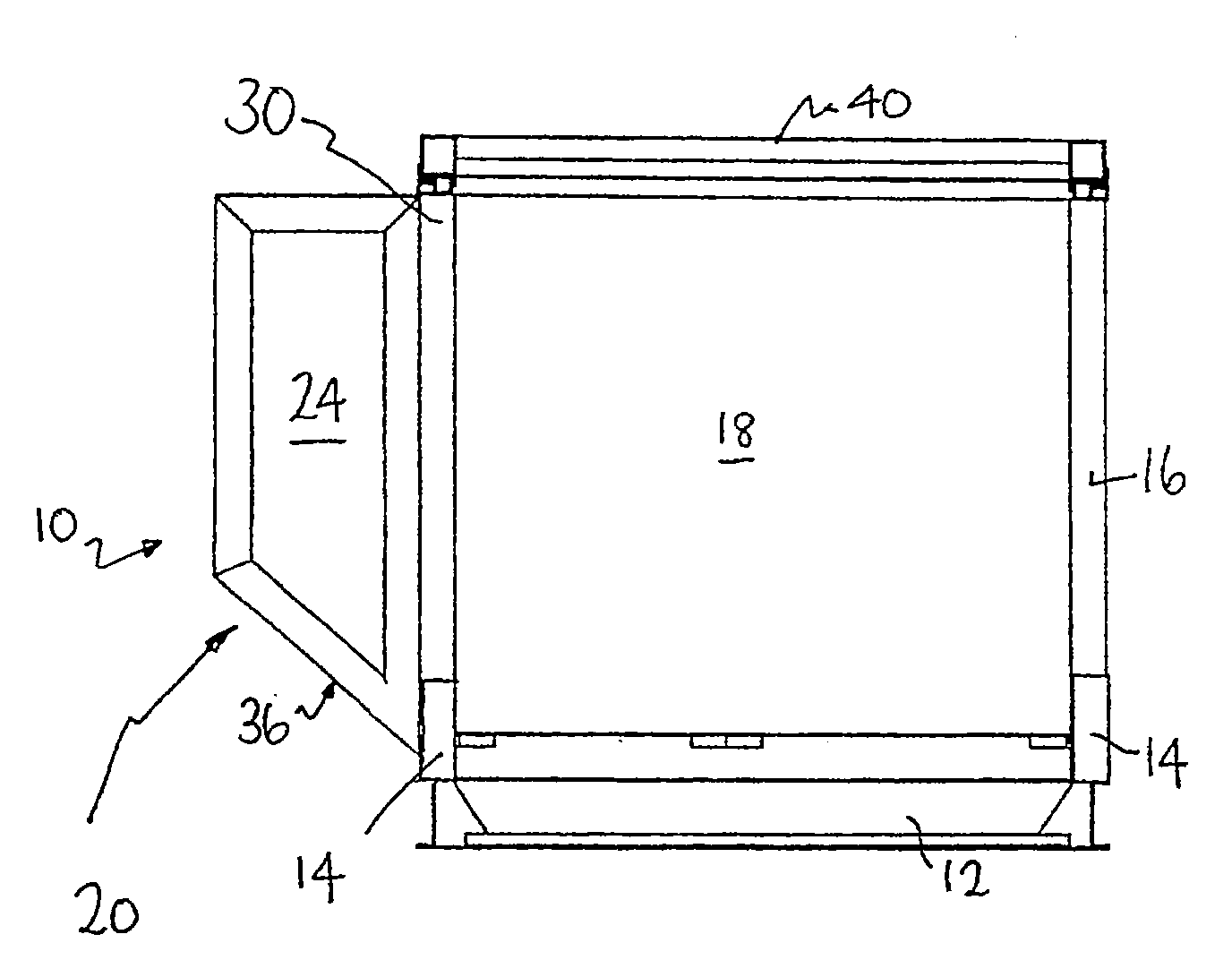

Folding containers

InactiveUS20100187228A1Improve stacking characteristicMinimal amountLarge containersRigid containersUnit load deviceUnit device

A collapsible air freight container (10) also known as a unit load device, comprises a standard base (12), commonly used on unit load devices, a side panel (16) slideably hinged to the base and a back panel (18) which is hinged to the base which interlocks with the side panel. There is a side extension (20) which is generally trapezoidal to roughly conform to the shape of a side wall of a plane's cargo hold. The side extension (20) includes a frame which (22) is hinged to the base and two trapezoidal (front and rear) panel extensions (24, 26) hinged to the frame. The side extension (20) is completed by a lid (28) and side wall panel (32) connected together by a hinge (34) with the lid (28) being hinged to a top of the frame, and by a sloping bottom panel (36) and relatively short side wall panel (40) hingedly connected to each other with the bottom panel (36) also being hinged to a bottom member of the frame. A lid is slideably mounted on top of the container so that it can be slid relative to the back panel. The lid is arranged so that when fully retracted to the back of the container relative to the back panel, it may pivot to overlay the back panel. As is typical of unit load devices the front of the container is open but may be covered by a flexible curtain or the like. The container may be collapsed by retracting and pivoting the lid to overly the back panel (18), folding the side extension (20) within the frame (22), folding and sliding the side panel (16) into the base (12) and lowering the folded side extension (20) and then the back panel (18) and lid (40) into the base.

Owner:TECHNOSEARCH

RFID tag case and production and application methods thereof

InactiveCN101558934AEasy to drop and wearEasy to use for a long timeStampsChecking apparatusMethods of productionEmbedded system

The invention provides an RFID tag case, which comprises a case and an RFID tag; and the RFID tag records production information of the case, and is buried in fabric, a handle, various plastic accessories or a draw bar of the case. The invention also provides a production method and an application method in production, storage or sale, airport field and exhibitions. The RFID tag is buried in the case, so that the RFID tag has the characteristics of concealment, safety and suitability for long-term use; man-made links are reduced through information reading and recording in the processes of production, storage and sale, so convenience, accuracy and economy are provided; when applied in the airport field and anti-terrorism, the RFID tag case can be identified, transported by air-freight service quickly and accurately, tracked and searched and the like; and in large exhibitions, the RFID tag case is effectively identified in real time to improve checking efficiency and safety.

Owner:上海新顶箱包有限公司

Air Freight Transport Method, Transport Aeroplane and Air Freight Transport System

InactiveUS20080296428A1Few or no effectsReduce loadConvertible aircraftsEfficient propulsion technologiesTransport systemMode of transport

An air cargo transportation method, a transport plane and an air cargo transport system. In the air cargo transportation method for the transport of various cargoes to different destinations, a transport plane is provided first that flies through at least three air regions respectively associated to a station. The transport plane does not land at one of the stations. Instead, the cargo is transported between the transport plane and one of the stations by an airworthy feeders, the cargo being transferred between the feeder and the transport plane while in the air. The transport plane and two feeders form the air cargo transport system, wherein the transport plane may comprise two interconnected feeders. With the air cargo transportation method, the utilization of the transport plane is enhanced. Further, the transport ways for individual cargo items can be shortened so that the efficiency is improved.

Owner:GABY TRAUTE REINHARDT

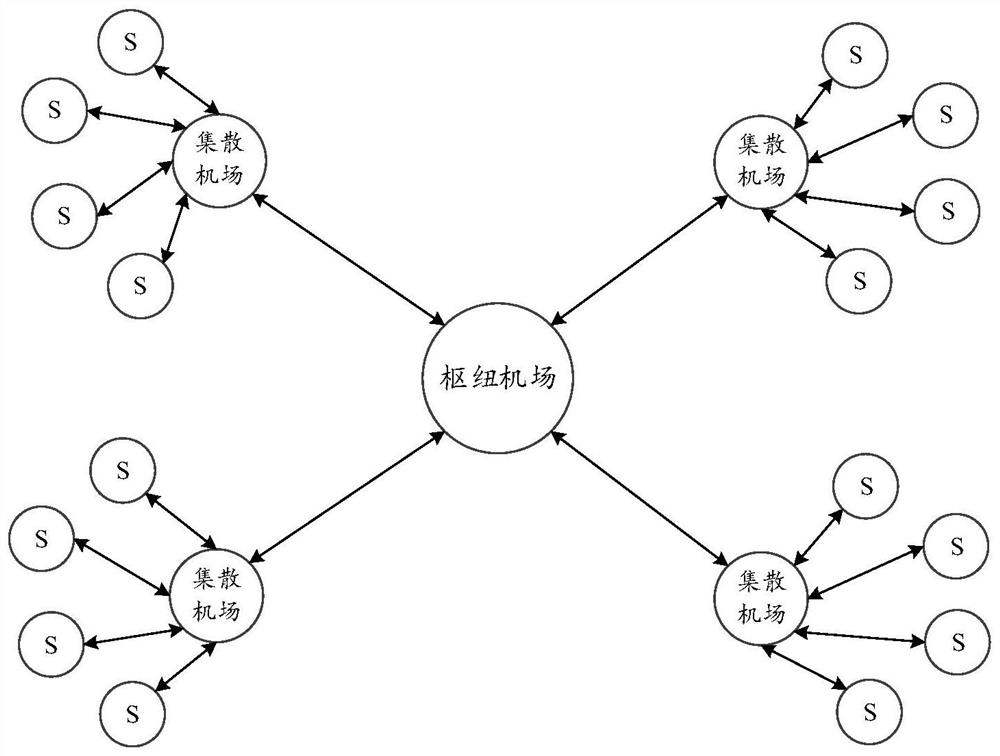

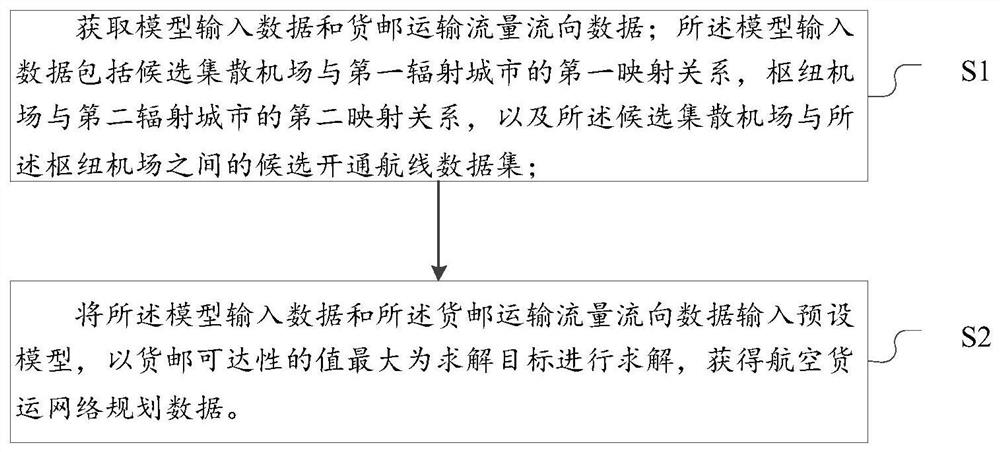

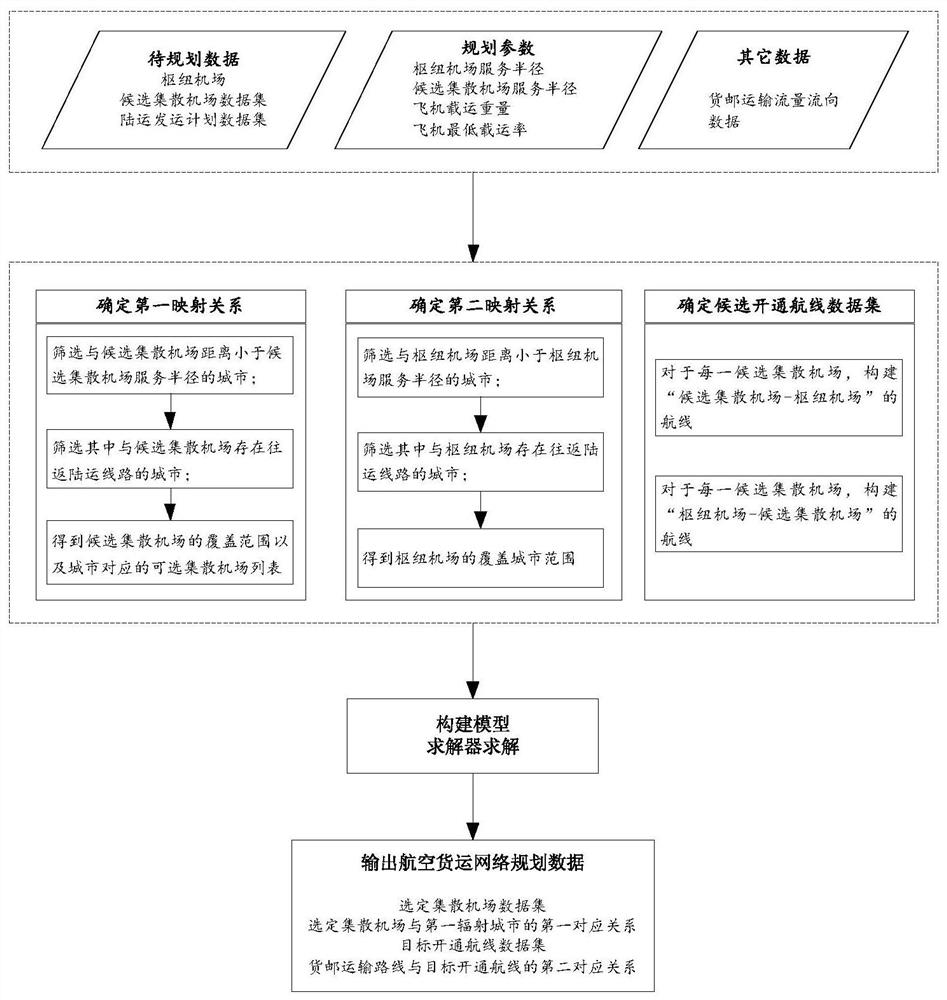

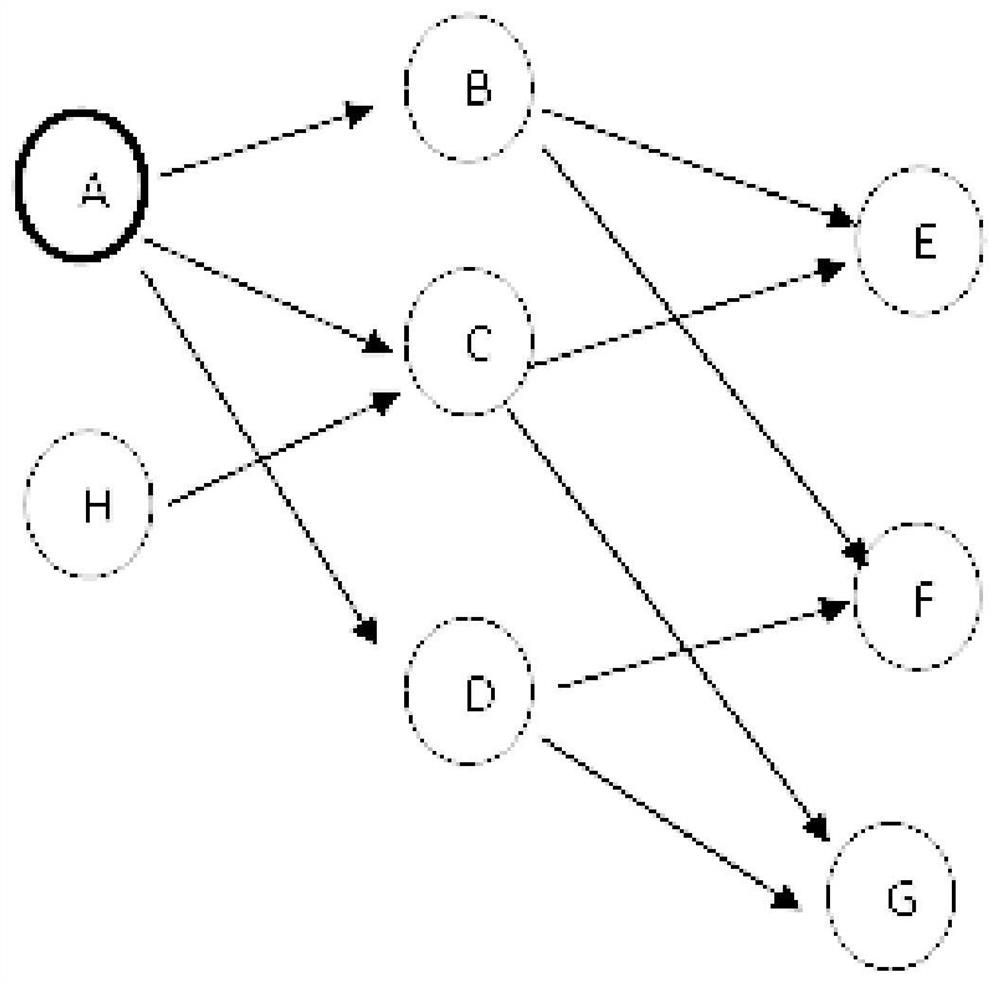

Planning method and system of air freight network, electronic equipment and storage medium

The invention discloses a planning method of an air freight network. The method comprises the following steps: acquiring model input data and mail transportation flow direction data; enabling the model input data to comprise a first mapping relation between the candidate collecting and distributing airports and a first radiation city, a second mapping relation between the hub airport and a second radiation city, and a candidate opening airline data set between the candidate collecting and distributing airports and the hub airport; inputting the model input data and the mail transportation flow and flow direction data into a preset model, and solving by taking the maximum value of the mail accessibility as a solving target to obtain air freight network planning data; and enabling the air freight network planning data to comprise a selected collection and distribution airport data set, a first corresponding relation between the selected collection and distribution airport and a first radiation city, a target opening route data set, and a second corresponding relation between the mail route and the target opening route. The invention can improve the overall freight efficiency and service range of the air freight network.

Owner:杉数科技(北京)有限公司 +3

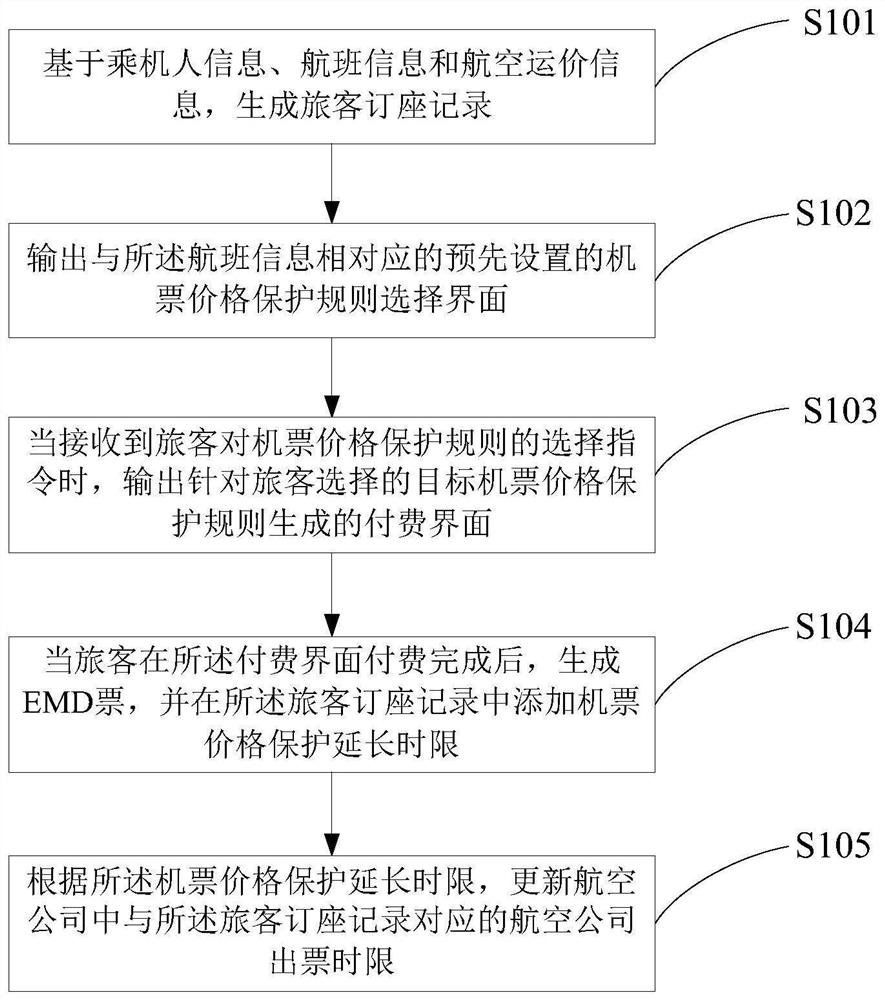

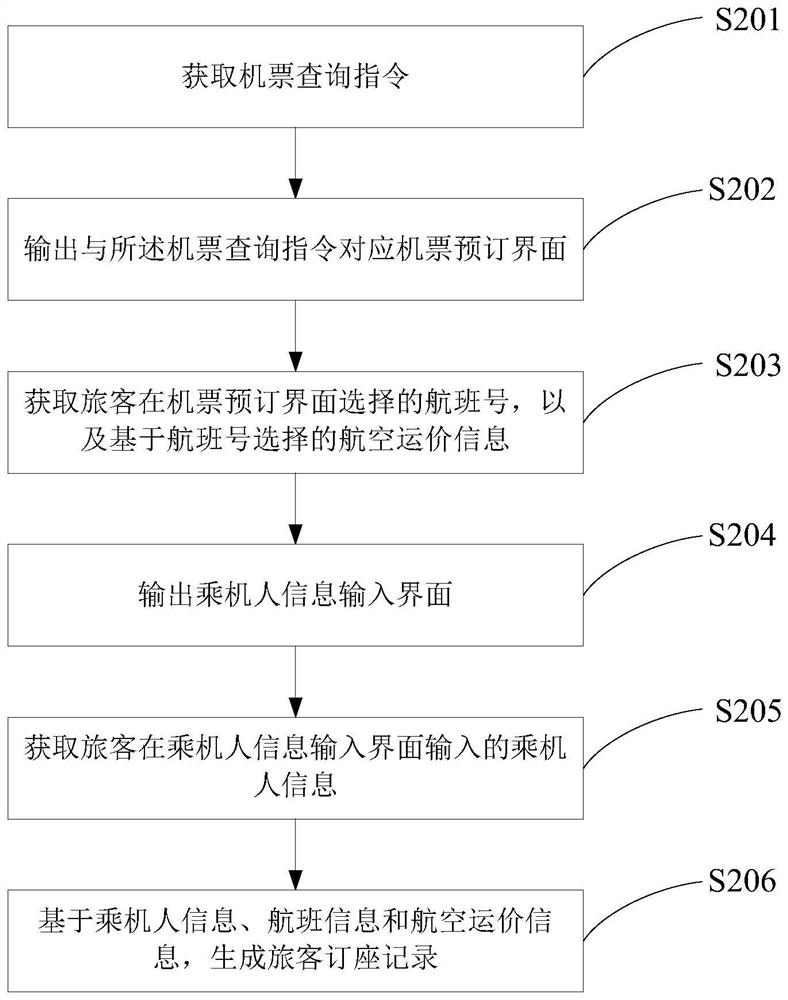

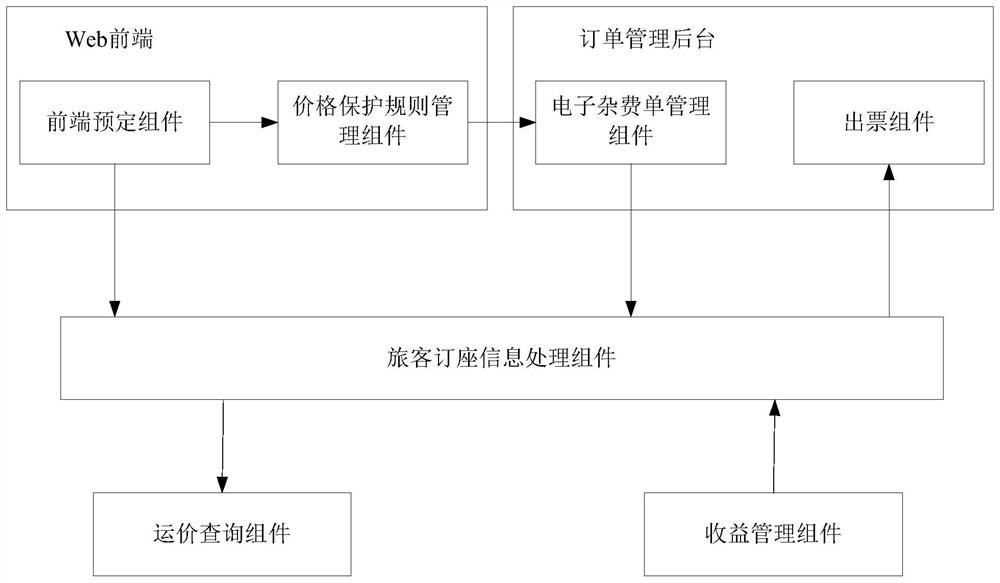

Airline ticket booking method and device

PendingCN111898781AImprove experienceExtended consideration timeReservationsBuying/selling/leasing transactionsAviationAir freight

The invention discloses an airline ticket booking method and device. Based on passenger information, flight information and air freight rate information, passenger booking records are generated, an airline ticket price protection rule selection interface corresponding to the flight information is outputted. When a passenger needs to protect the current airline ticket price, the passenger selects an airline ticket price protection rule and pays correspondingly to generate an additional service ticket, adds an airline ticket price protection extension time limit in the passenger booking record,and updates the airline ticket issuing time limit corresponding to the passenger booking record in the airline company. By protecting the air ticket price is protected. time for the passenger to purchase the special-price airline ticket or not is prolonged is considered. For the passenger, although additional service fees need to be paid additionally for airline ticket price protection rules, thepassenger can still enjoy the special-price airline tickets during traveling, and even if the passenger do not travel, the passenger lose only the acceptable additional service fees, so that the experience of purchasing the special-price airline tickets by the passenger is improved to a certain extent.

Owner:TRAVELSKY

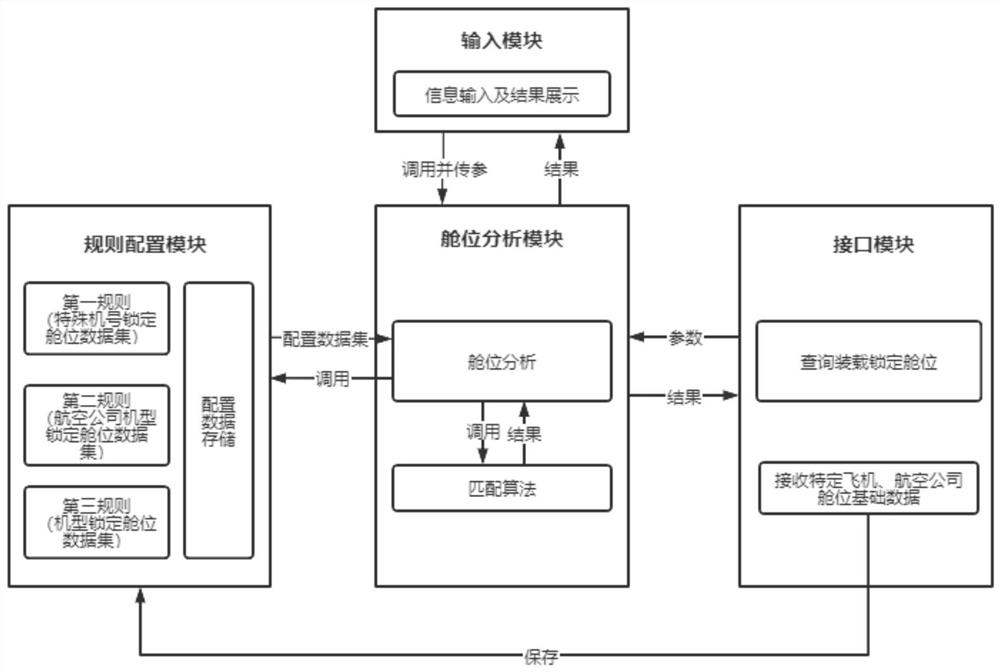

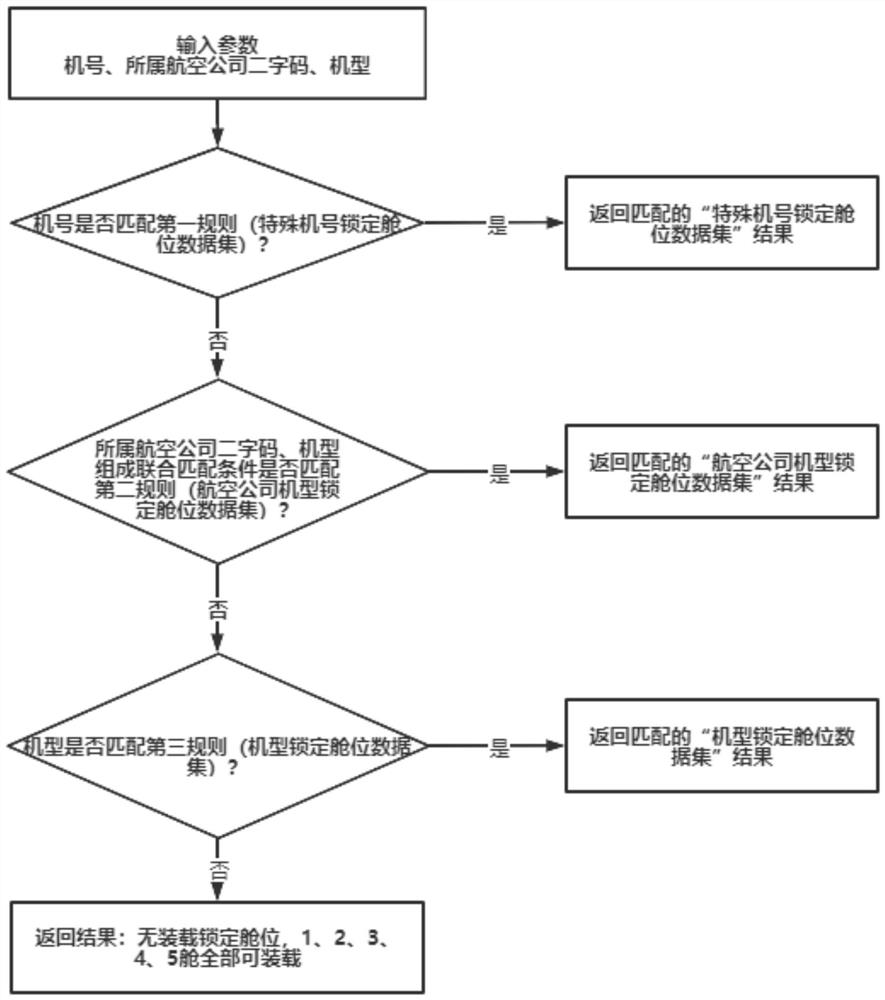

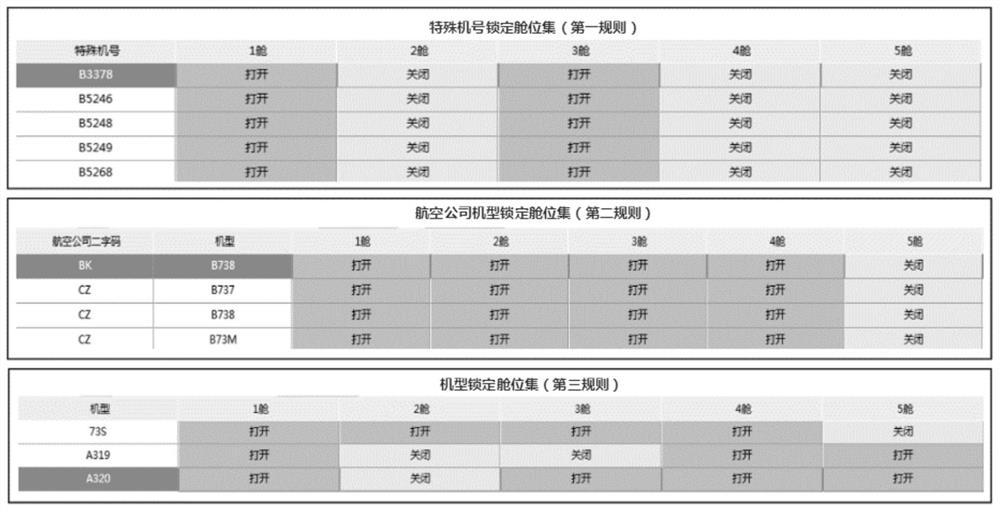

System and method for judging and locking shipping space in air freight

The invention discloses a system and a method for judging and locking a shipping space in air freight. Configuration data stored in a rule configuration module and a matching algorithm of a shipping space analysis module jointly form a calculation model for locking shipping space data analysis; and the shipping space analysis module starts to traverse from a first rule, analyzes whether the currently traversed rule is matched by combining the calculation parameters, enters the rule if the currently traversed rule is matched, locates corresponding data, returns a data result to an interface module or an input module to be displayed, jumps out of the rule if the currently traversed rule is not matched , and continues to traverse to the next rule. In the invention, a user or an external system only needs to input relevant parameters, the system can automatically carry out recognition and calculation, feed back the loadable shipping space of an airplane, load locked shipping space data andenable the locked shipping space not to load goods and luggage, shipping space loading information is prevented from being reported or input mistakenly, and transportation safety is guaranteed.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

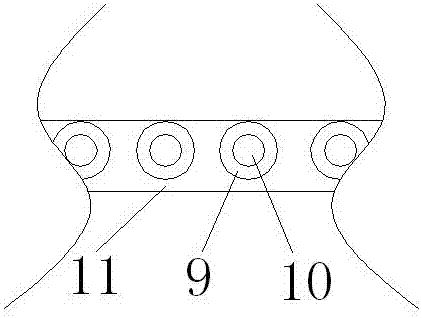

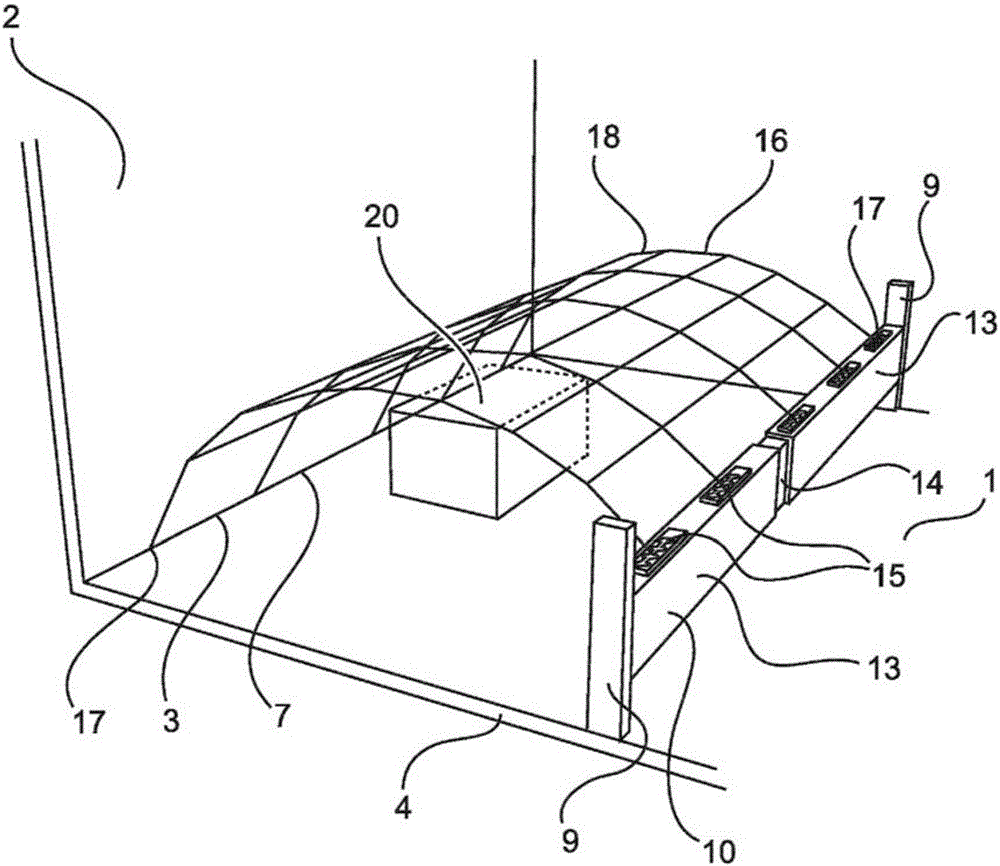

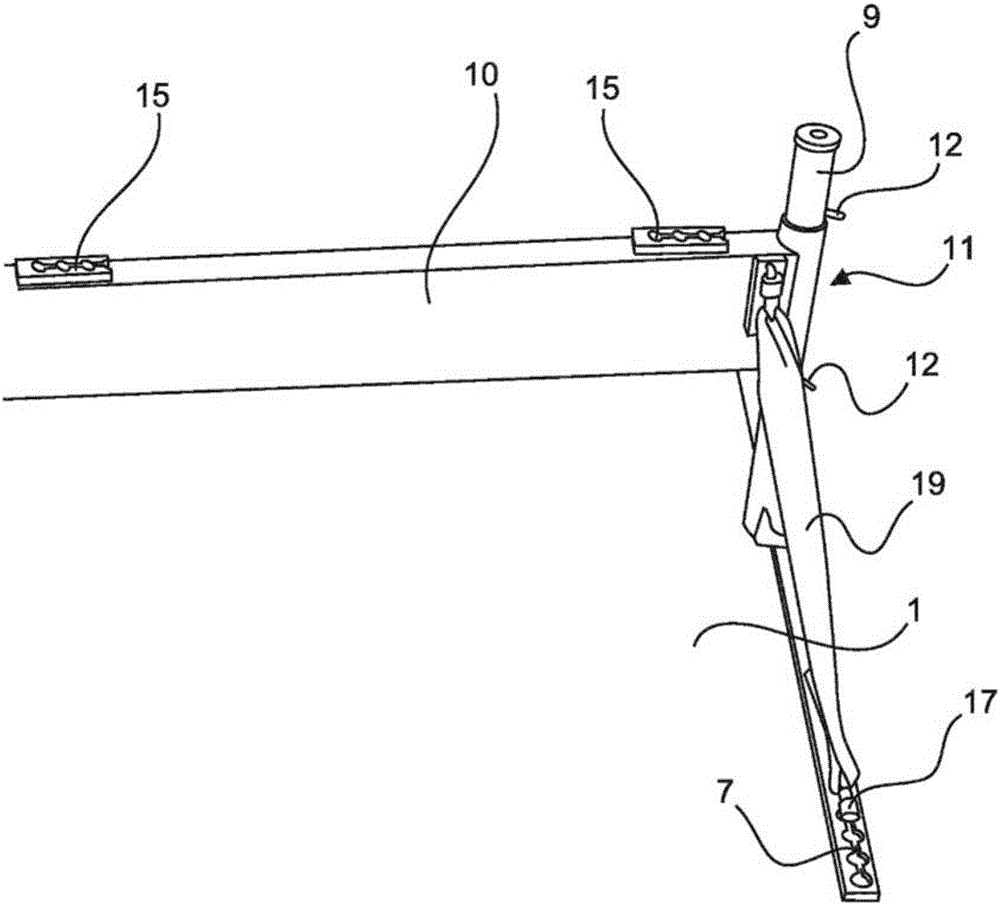

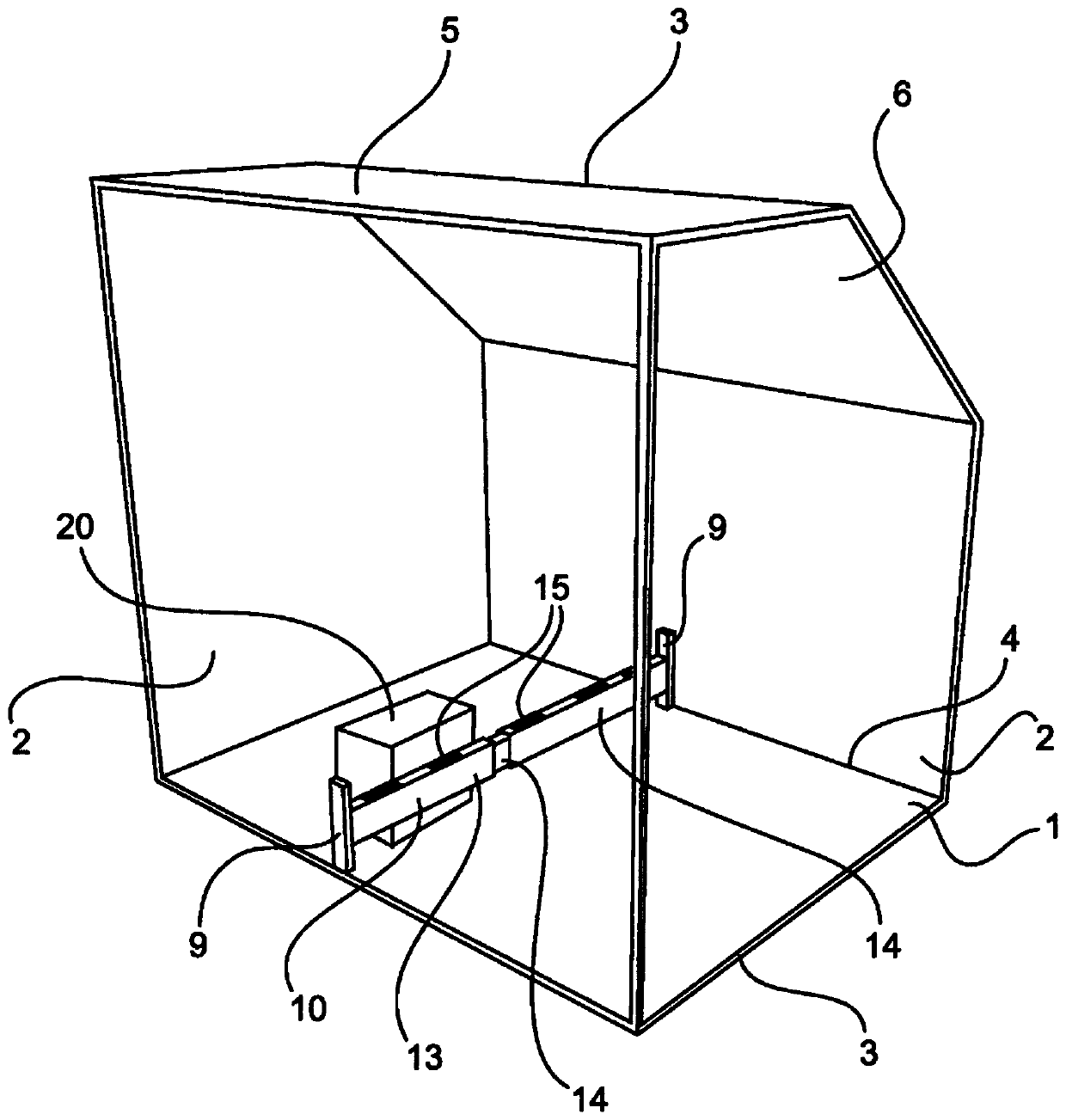

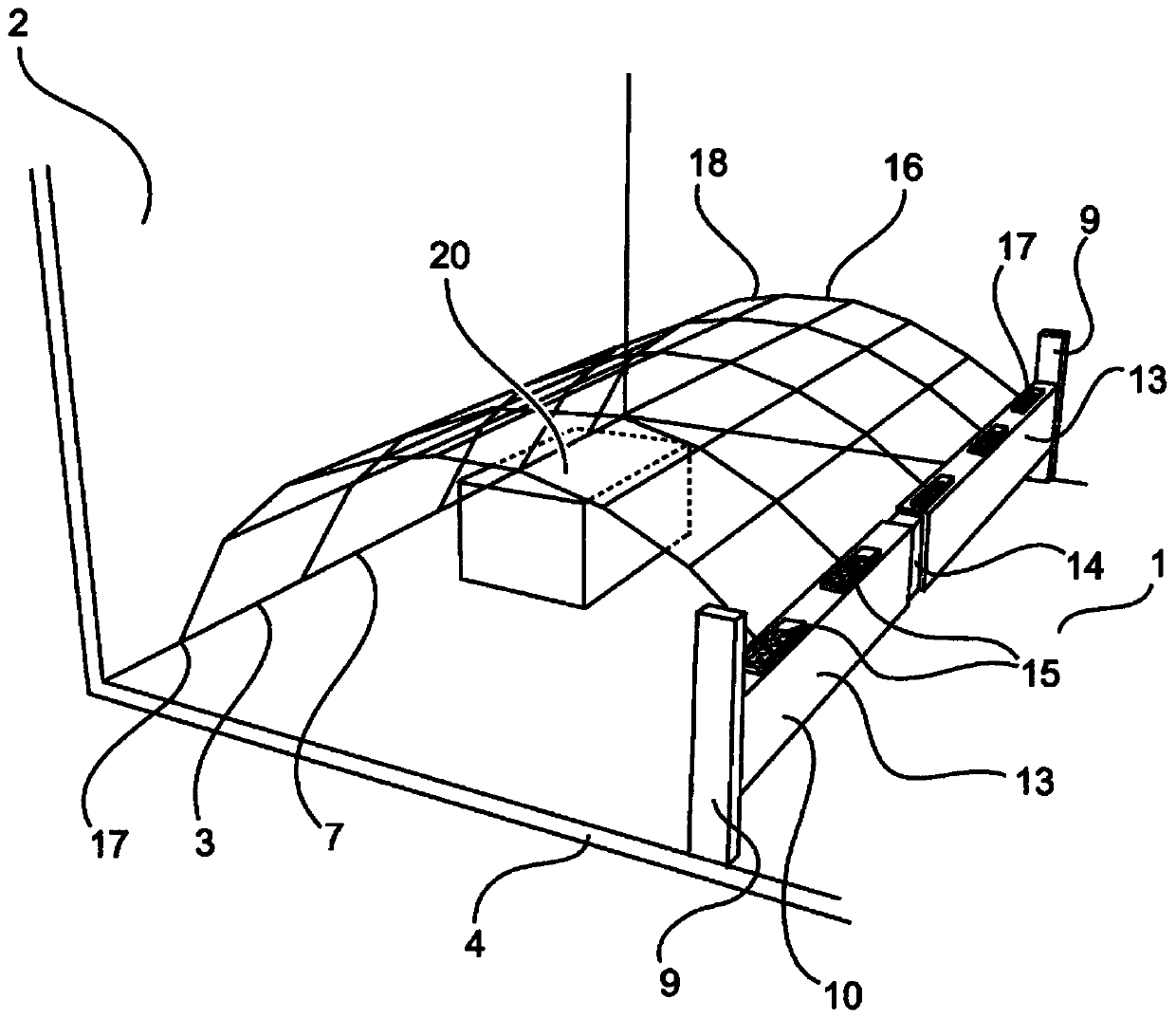

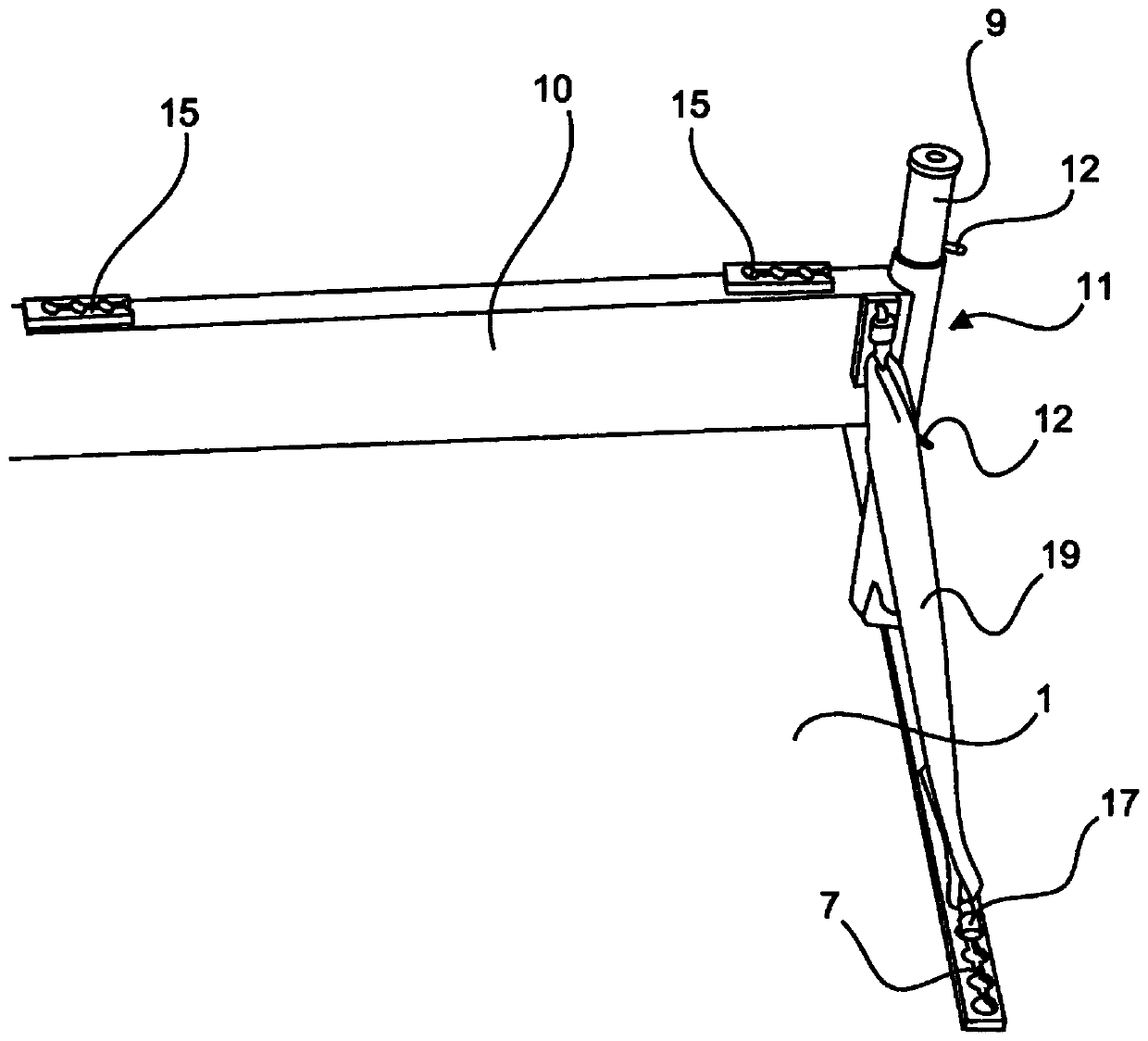

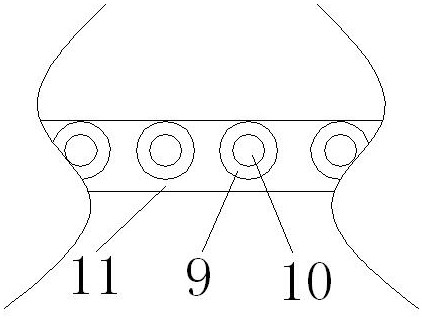

Air freight container and/or air freight pallet

ActiveCN106536380AReduce the ratioReduced compensationLarge containersRigid containersAir cargoSubject matter

The subject matter of the invention is an air freight container and / or air freight pallet with a planar bottom wall and / or side wall (1, 2), at least two guide devices (7) arranged on the bottom wall and / or side wall (1, 2), two connecting elements (9), wherein a fastening region (11) assigned to a first end of the connecting element (9) in each case extends over part of the connecting element (9), and a securing element (10) for securing an item (20) transportable by means of the air freight container and / or air freight pallet, wherein the securing element (10) is connected at the first end thereof to the fastening region (11) of the one connecting element (9) and at the second end thereof opposite the first end to the fastening region (11) of the other connecting element (9), the connecting elements (9) each have, at a second end arranged opposite the first end, a latching device (8) designed for latching into the respective guide device (7), and at least one guide device (7) is configured in such a manner that the latching device (8) can be latched into the guide device (7) at different, respectively spaced-apart positions along the planar extent of the bottom wall and / or side wall (1, 2).

Owner:DEUT POST AG

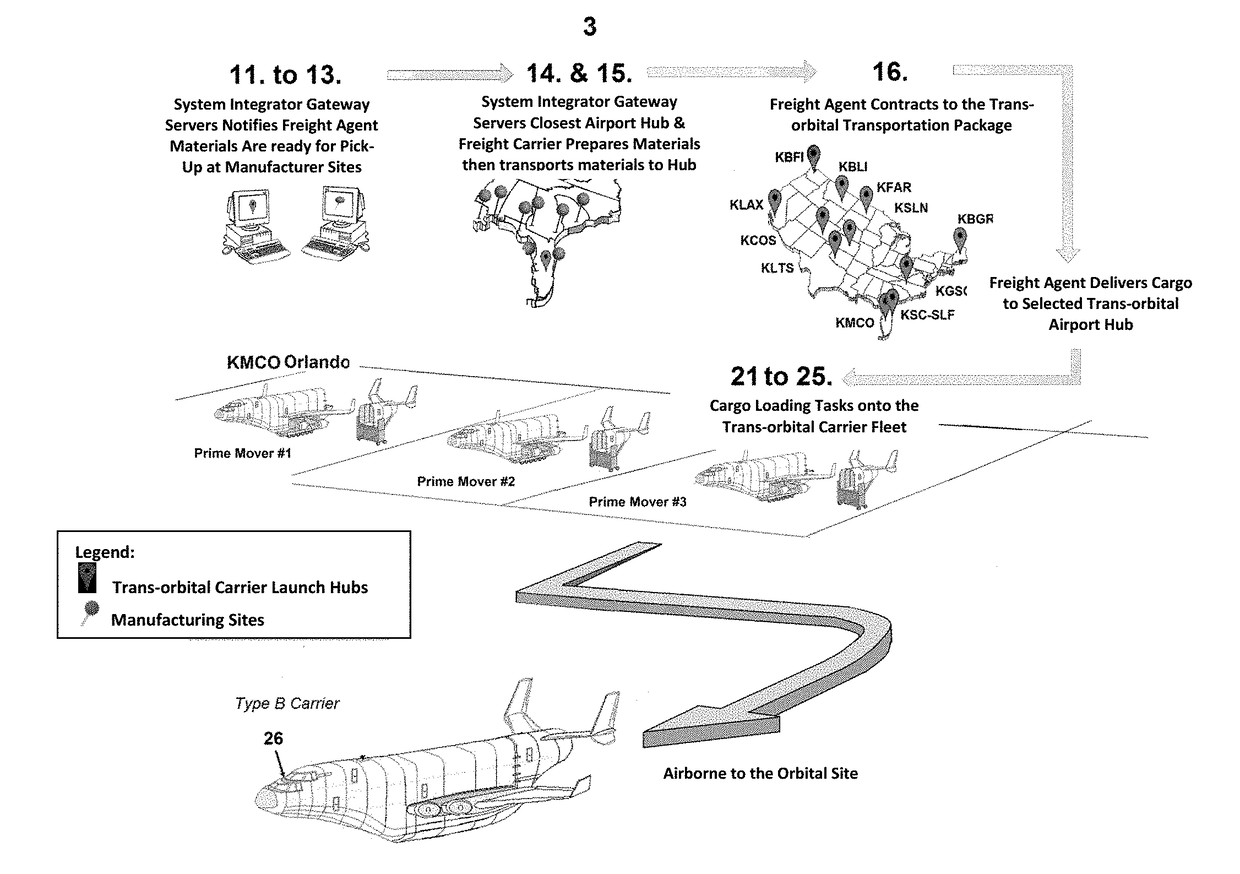

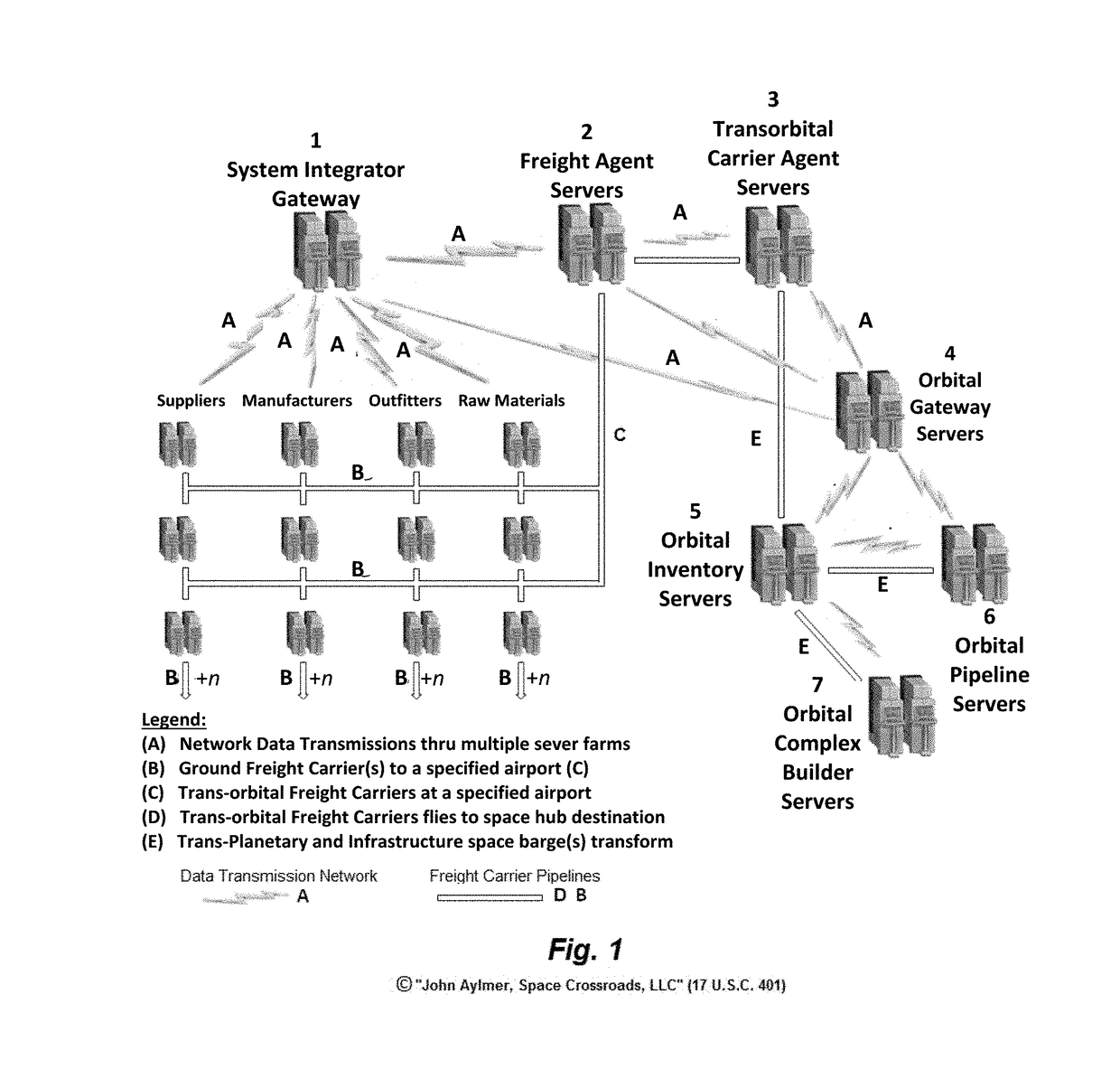

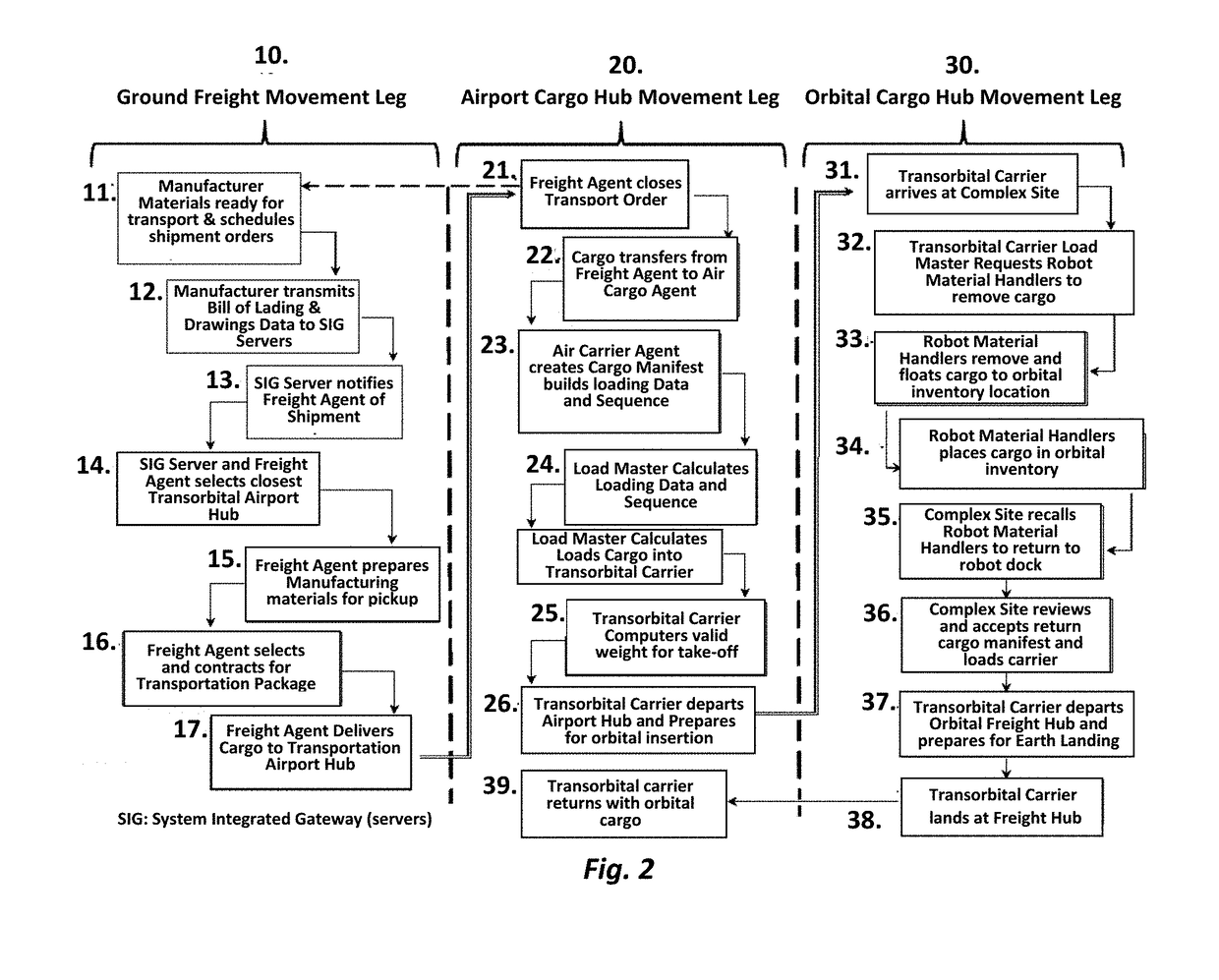

Methods of orchestrating ground to trans-orbital pipelines connecting to orbital freight management hubs to create and sustain any orbital heavy industry.

At the time of this invention, parallel efforts by military and government agencies in conjunction with the mushrooming commercial space flight industry are reaching for a everyday, reliable, and profitable solution to making Space and Planetary development an advantageous business venture. To date, their solutions still have major shortfalls originating from the missing link of not providing for a highly profitable routine round trip utilizing trans-orbital, extremely heavy-lift freight carrier operation of greater than 60 tons which is modeled after typical air freight operations similar to UPS or FedEx.

Owner:AYLMER JOHN

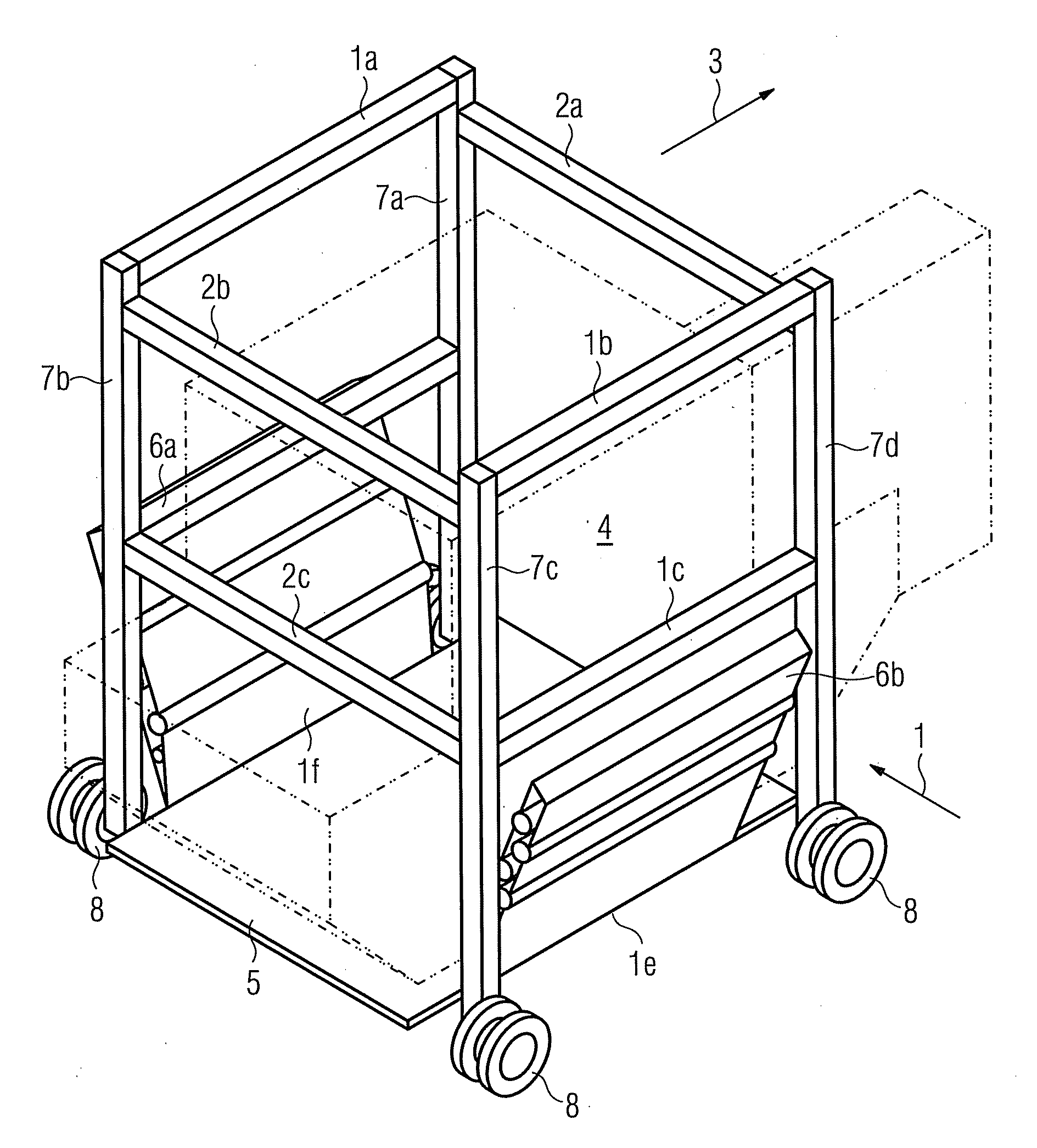

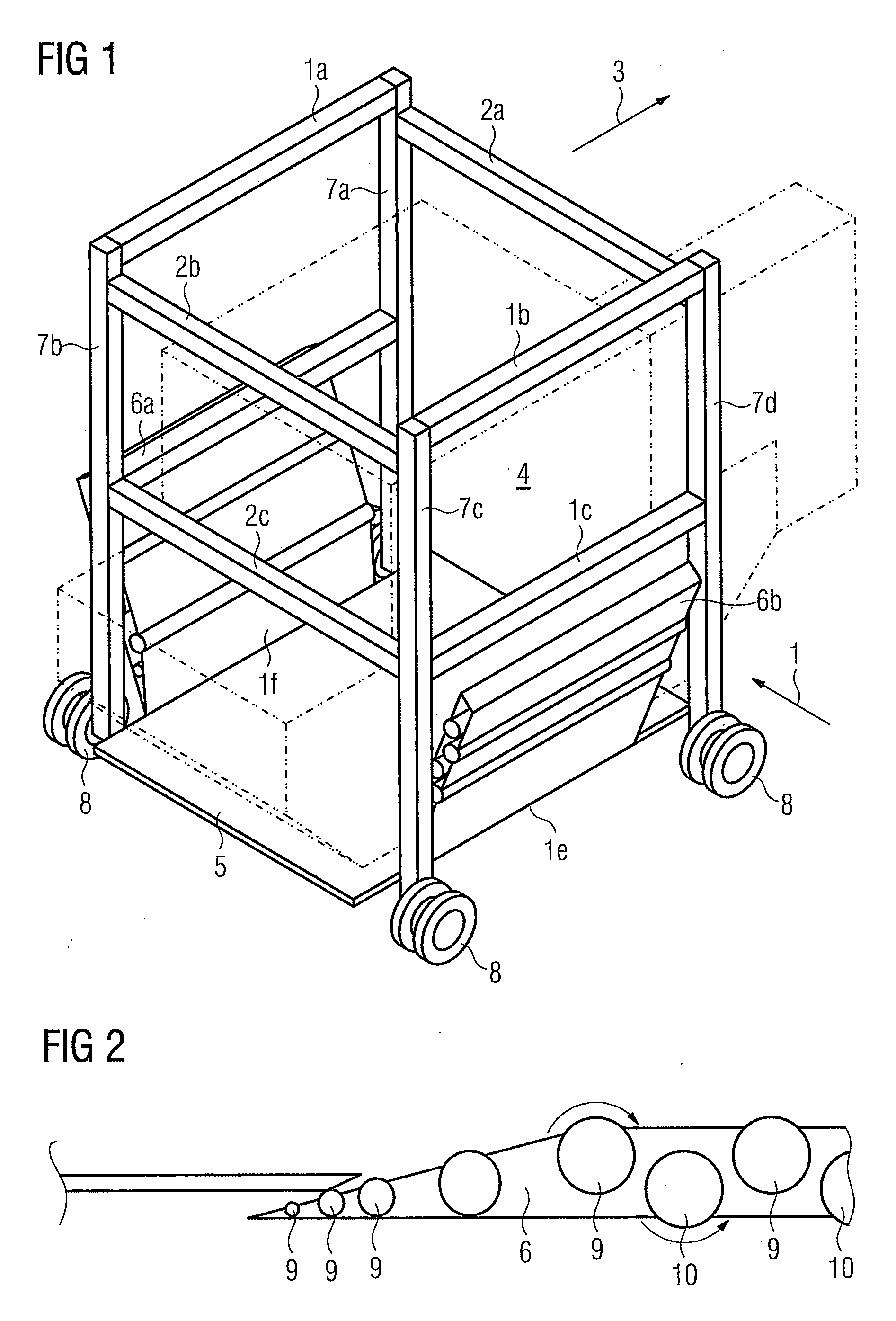

Transport vehicle for raising and transporting ULDs and cargo pallets

InactiveUS20100003116A1Laborious and and disadvantageous in of economyReduce operating costsRefuse receptaclesFreight handling installationsBraced frameAir freight

A transport vehicle is provided for raising and transporting ULDs and cargo pallets used in the air freight sphere, with a supporting frame which fits over the ULD or the cargo pallet and with driven and steerable wheels for the free movement of the transport vehicle on the ground. In order to simplify the complicated reloading of transport units onto auxiliary pallets, it is proposed according to the invention that the transport vehicle is movable over the ULD or the cargo pallet at least in one direction, that supporting devices arranged on both sides of the frame of the transport vehicle are movable at the same time in the opposite direction under the ULD or the cargo pallet, and that, in the process, the ULD or the cargo pallet is raisable with the aid of the supporting devices.

Owner:SIEMENS AG

Air Containers and/or Air Pallets

The subject of the invention is an air freight container and / or air freight pallet having a flat bottom wall and / or side walls (1, 2), at least two / or guides (7) on the side walls (1, 2), two connecting elements (9), and fixings (20) for fixing items transportable by means of the air cargo container and / or air pallet Element (10), wherein the fastening region (11) assigned in each case to the first end of the connecting element (9) extends over a part of the connecting element (9), wherein the fixing element (10 ) is connected at its first end to the fastening region (11) of one connecting element (9) and at its second end opposite the first end to the fastening region of the other connecting element (9) (11), the connecting elements (9) each have, at a second end opposite to the first end, a latching device (8) designed for latching into the corresponding guide (7), and at least A guide (7) is configured in such a way that the latch (8) can be latched to the bottom and / or side walls (1, 2) at different respective spaced apart positions along the planar extent of the bottom and / or side walls (1, 2). in the guide (7).

Owner:DEUT POST AG

A kind of preparation method of air cargo ultra-wide aluminum alloy sheet

The invention discloses a manufacturing method for an ultra-wide aluminum alloy thin plate for air freight. The manufacturing method comprises the following steps of: (1) preheating; (2) rolling; (3) re-coiling and trimming; (4) solid-solution quenching and stretching-stretching; (5) cross-cutting and coiling; (6) artificial aging; and (7) detecting and packaging. The manufacturing method disclosed by the invention is fewer in processes, is short in production period, is lower in cost, is higher in yield and is higher in production efficiency; and the produced plate is low in residual stress, is high in dimension precision and is relatively good in surface quality, and meets the use requirements of relatively low unevenness of the aluminum alloy thin plate for air freight.

Owner:广西南南铝加工有限公司

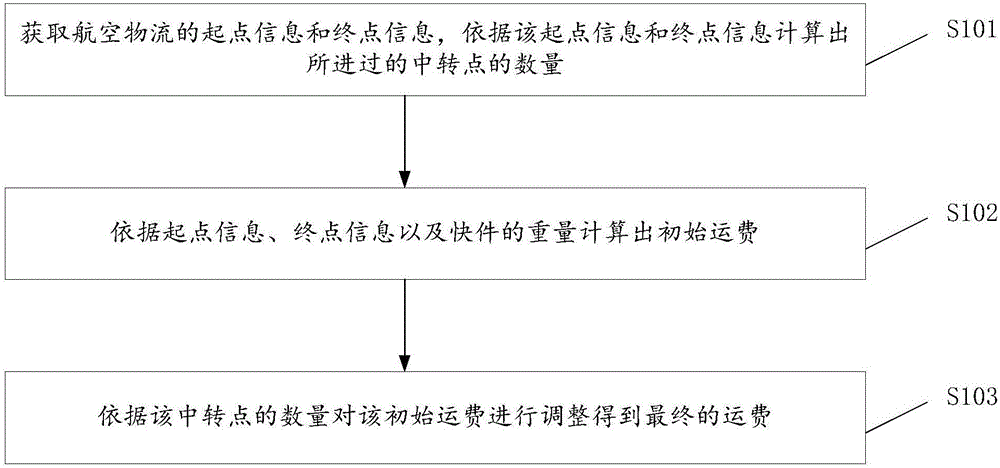

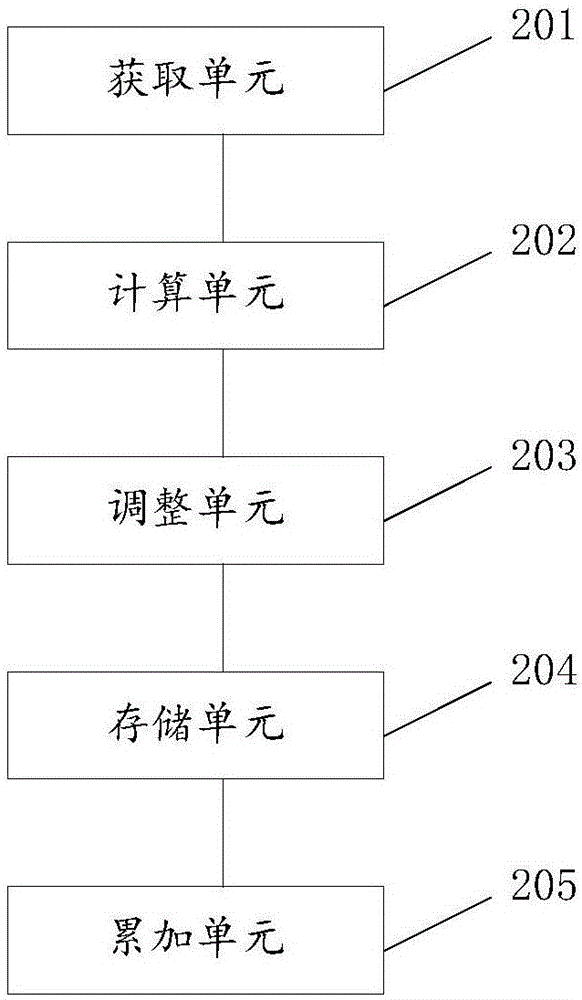

Method and system for calculating air freight

The present invention provides a method and system for calculating air freight. The method comprises the following steps of: acquiring the starting point information and terminal point information of aviation logistics, and calculating the number of passed transit points according to the starting point information and the terminal point information; calculating initial freight according to the starting point Information, terminal point information and the weight of a parcel; adjusting the initial freight according to the number of transit points to get the final freight. The method and system provided by the invention has advantages of accurate freight calculation.

Owner:石莉

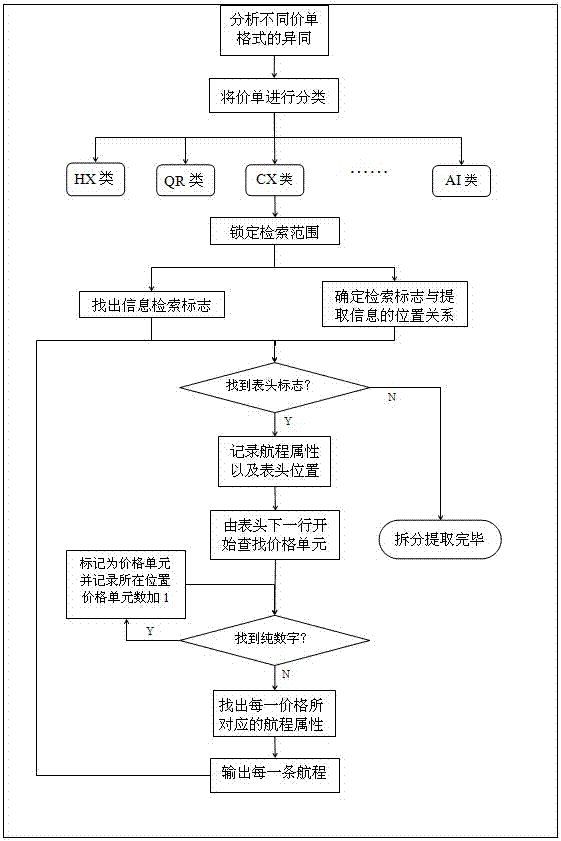

A method for intelligently parsing international air ticket tariffs in excel format

ActiveCN104133861BImprove retrieval speedSpecial data processing applicationsComputer scienceAir freight

The invention discloses a method for intelligently resolving excel format international air ticket freight rate lists. According to the method, general characteristics are analyzed from different freight rate lists in different formats, and different information retrieval extraction rules are analyzed and concluded for different freight rate information, so the required freight rate information is extracted. The freight rate information mainly includes freight rate list basic information, air range information, air range freight rate, additional freight rate and the like. Finally, the freight rate lists are split into a plurality of pieces of air range information according to differences of departure places, transit stations, destinations, single-trip or round-trip modes, cabins and the like, and are stored into a unified format. The method provided by the invention has the advantage that the unified air range information can be accurately and fast extracted from the freight rate lists.

Owner:SOUTH CHINA UNIV OF TECH

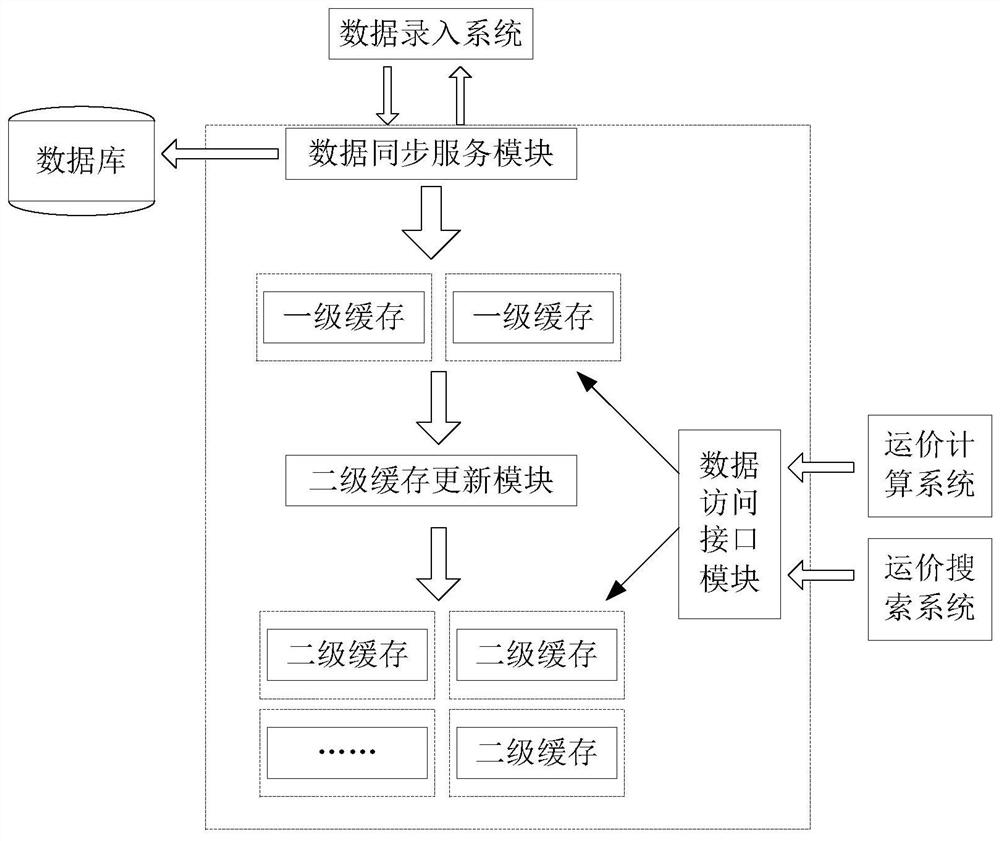

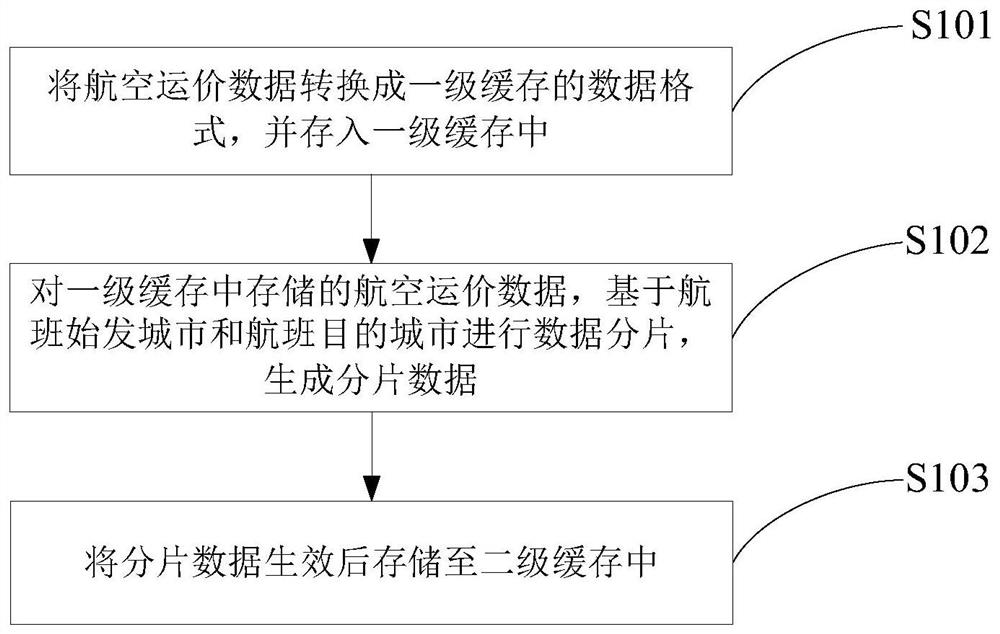

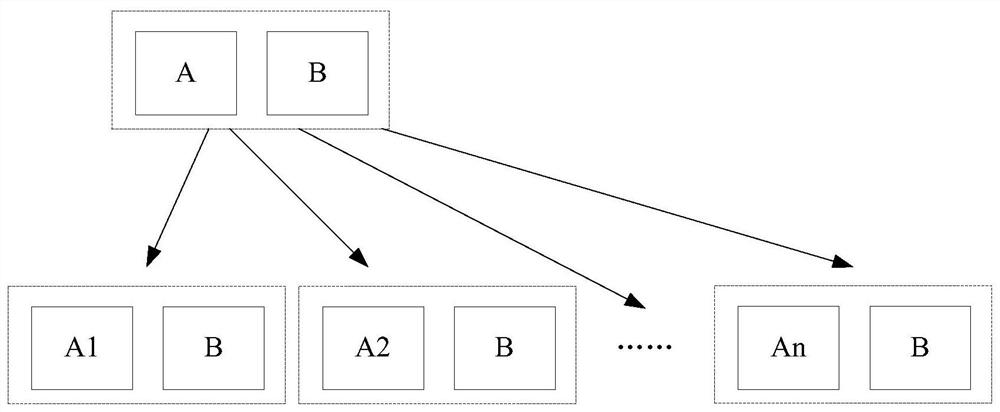

A caching method and system for air freight rate data

ActiveCN110309184BImprove horizontal scalabilityDatabase management systemsReservationsAviationComplete data

The invention discloses a caching method and system for air freight rate data. Firstly, the air freight rate data is converted into the data format of the first-level cache, and stored in the first-level cache, and then the air freight rate data stored in the first-level cache is , based on the flight departure city and the flight destination city, the fragmented data is generated by data fragmentation. Each data node of the fragmented data contains a copy of the complete data set of the air freight rate data for which the fragmentation algorithm is not available and a copy of the available fragmentation algorithm. The data subsets of air freight rate data, each data subset constitutes the data set of air freight rate data that can be fragmented, and the fragmented data is stored in the secondary cache after it takes effect. Since each data node of the fragmented data cached to the secondary cache only contains part of the air freight data available with the fragmentation algorithm, the present invention improves the It improves the horizontal expansion capability of the cache system.

Owner:TRAVELSKY

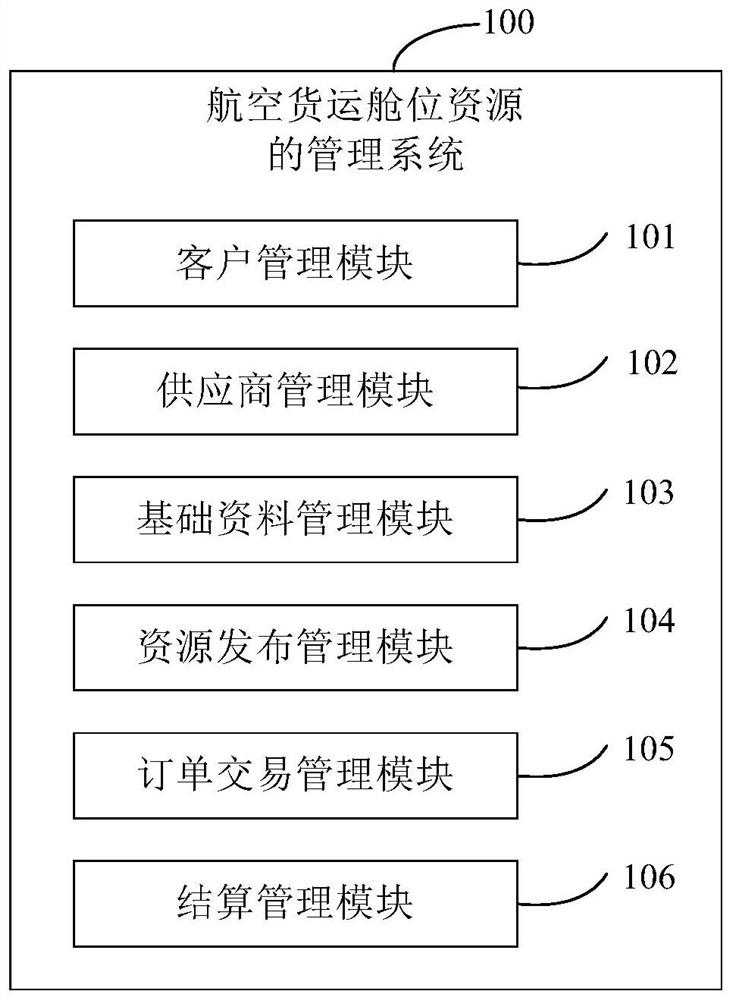

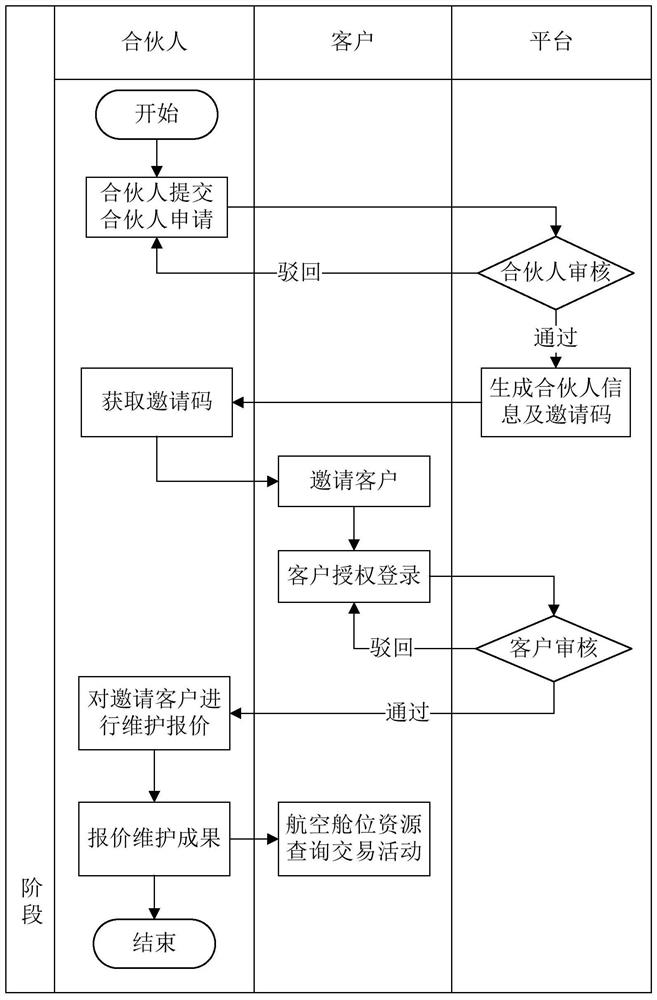

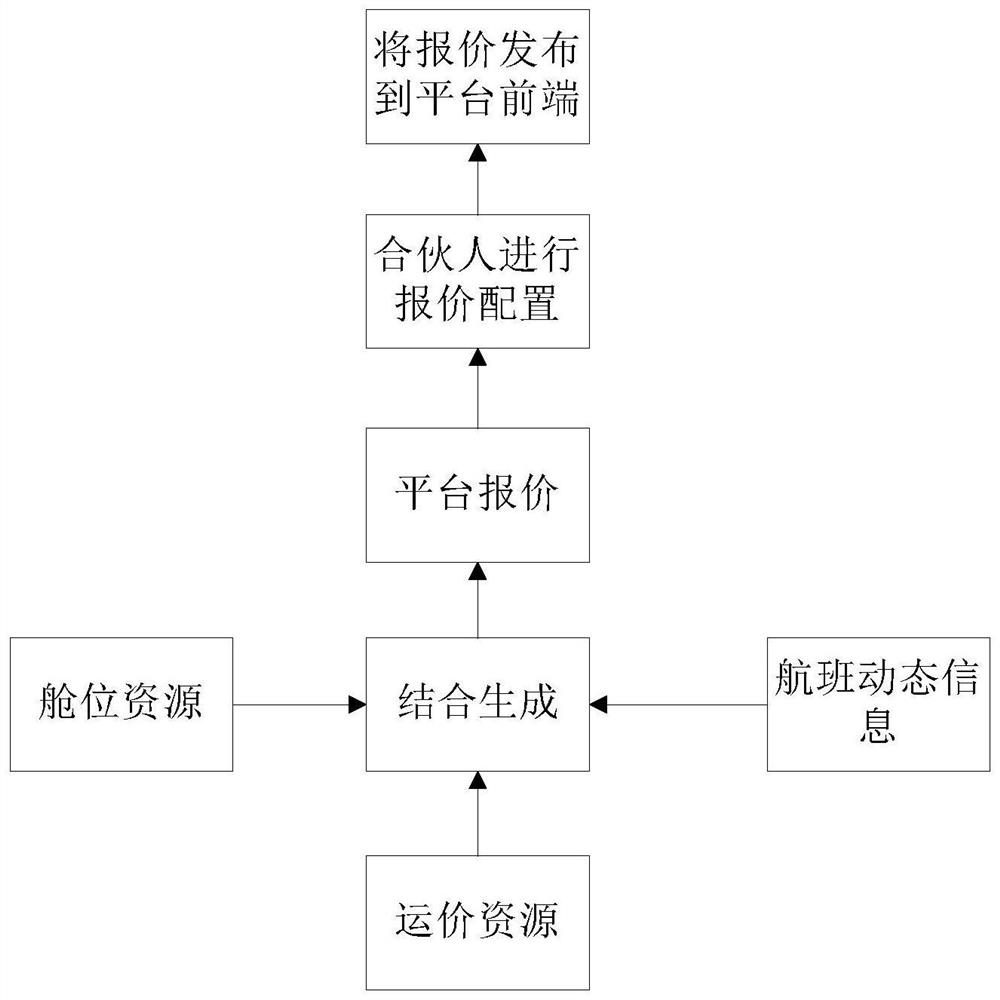

Management system for air freight shipping space resources

PendingCN113610395ASolve the problem of reducing costsReservationsPre-payment schemesAviationTransaction management

The invention discloses a management system for air freight shipping space resources, and relates to the technical field of computers. The system comprises a client management module used for managing partners and clients registered in the system; a supplier management module used for managing suppliers entering the system, wherein the suppliers provide freight services for customers; a basic data management module used for managing basic data information stored in the system; a resource release management module used for managing release operation of resources, wherein the release operation comprises on-shelf operation and off-shelf operation; an order transaction management module used for splitting and segmenting the order according to the service type of the order; and a settlement management module used for carrying out expense settlement on the order. According to the implementation mode, the problem of how to reduce the cost is solved for cargo owners, and meanwhile, customer channels are expanded for airlines.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

An air cargo lifting device

ActiveCN107323683BAchieve the effect of lifting the inner boxAchieve the desired effectLifting framesFreight handling installationsAviationAir cargo

The invention discloses air freighting lifting equipment. The air freighting lifting equipment comprises a trailer plate. An outer box is fixedly connected to the surface of the trailer plate. A telescopic pipe is fixedly connected to the inner wall of the outer box, a spring is fixedly connected to the inner wall of the telescopic pipe, a telescopic rod is fixedly connected to one end of the spring, and the inner wall of the outer box is in sliding connection with an inner box. The surface of the inner box is in sliding connection with the surface of the telescopic rod. The inner wall of the inner box is fixedly connected with a conveying motor base. The surface of the conveying motor base is fixedly connected with a conveying motor. According to the air freighting lifting equipment, when cargo is elevated and lowered, lifting motors are started, the lifting motors drive first lifting rotation shafts to rotate, the first lifting rotation shafts rotate and drive rollers to rotate, second lifting rotation shafts support lifting belts, the rollers rotate for elevating and lowering of one ends of the lifting belts, one end of each lifting belt is elevated and lowered, the inner box is elevated and lowered through pull buckles, and the effect of inner box ascending and descending is achieved; and accordingly the problem that in the air freighting process, due to the fact that a cabin leaves the ground by a large height, cargo carrying is difficult is effectively solved.

Owner:于浩

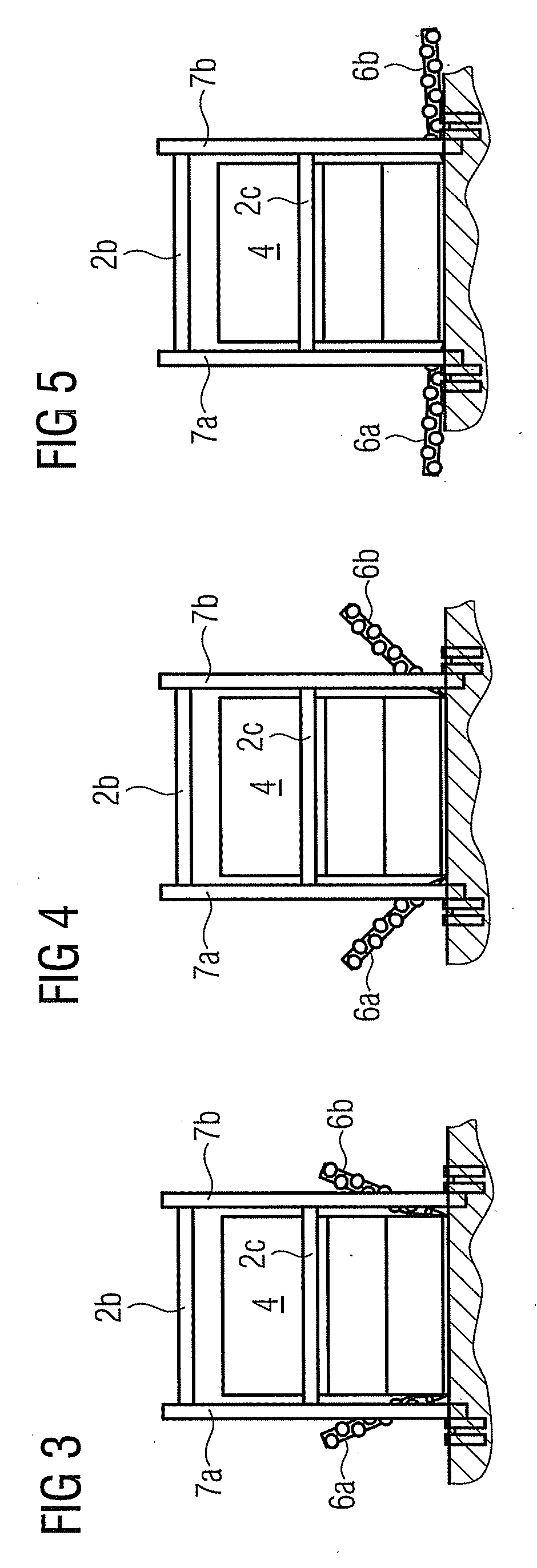

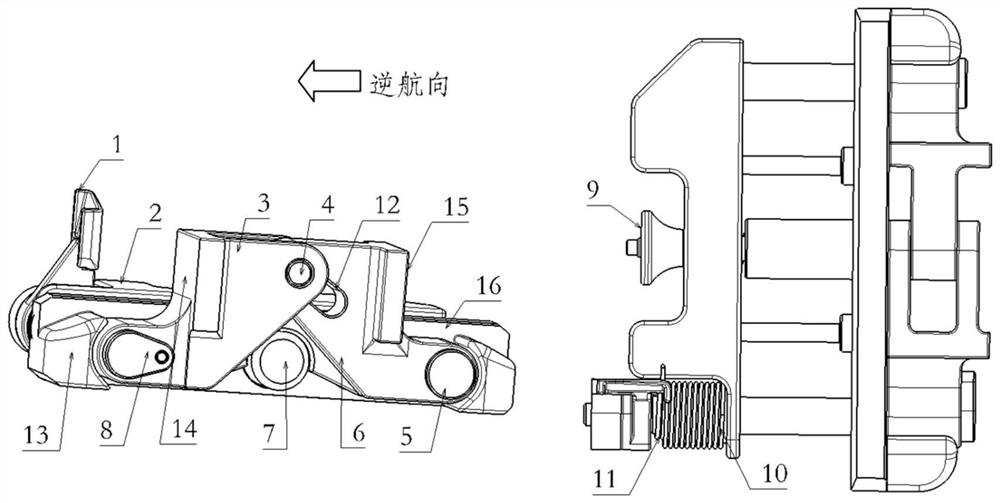

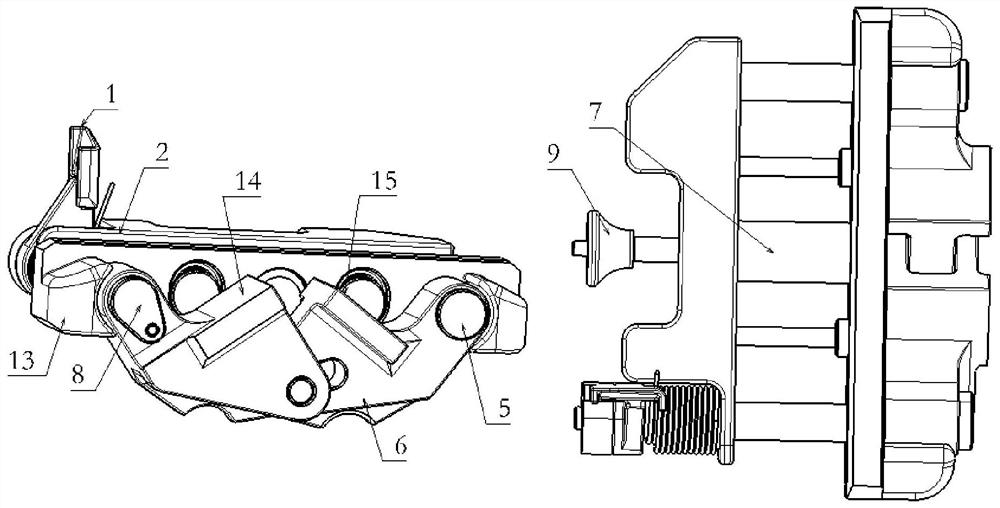

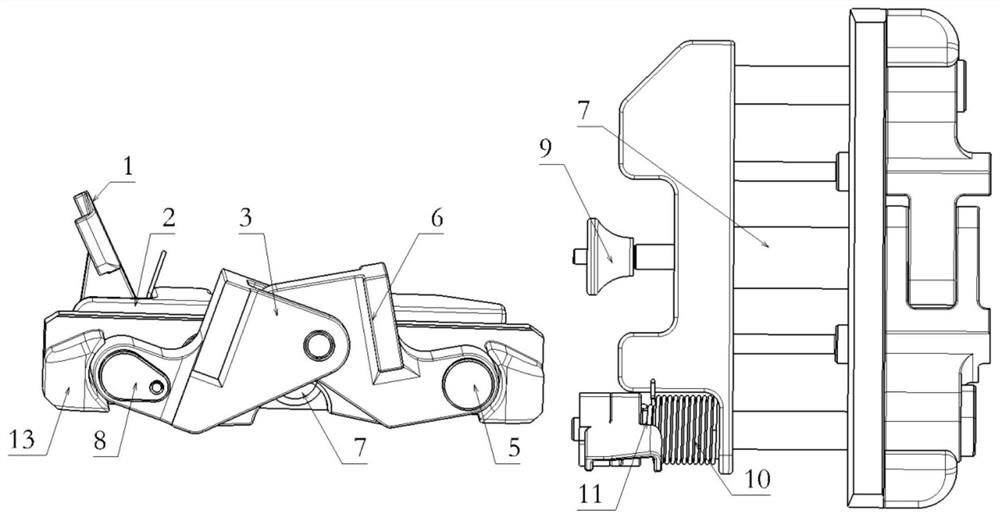

Device for realizing two-way movement limiting of packaging unit for aircraft packaging type freight transport system

PendingCN114104257AIncreased load rangeFast installation/removalFreight handlingAircraft floorsAviationTransport system

The invention belongs to the professional field of air freight, and particularly relates to a device for achieving bidirectional movement limiting of a container unit of a container type freight system of a civil aircraft. The device comprises a spring bolt I (6), a spring bolt II (3), a fixed support (16) and a limiting pin (7), the spring bolt I (6) and the spring bolt II (3) are rotationally connected with the fixed support (16) respectively; the spring bolt I (6) is rotationally connected with the spring bolt II (3); the limiting pin (7) is connected to the fixed support (16) and is telescopic; when the limiting pin (7) extends out relative to the fixed support (16), the limiting pin (7) is located below the spring bolt I (6) and the spring bolt II (3) and used for limiting rotation of the spring bolt I (6) and the spring bolt II (3). And the spring bolt I (6) or the spring bolt II (3) is used for bearing goods.

Owner:QINGAN GRP

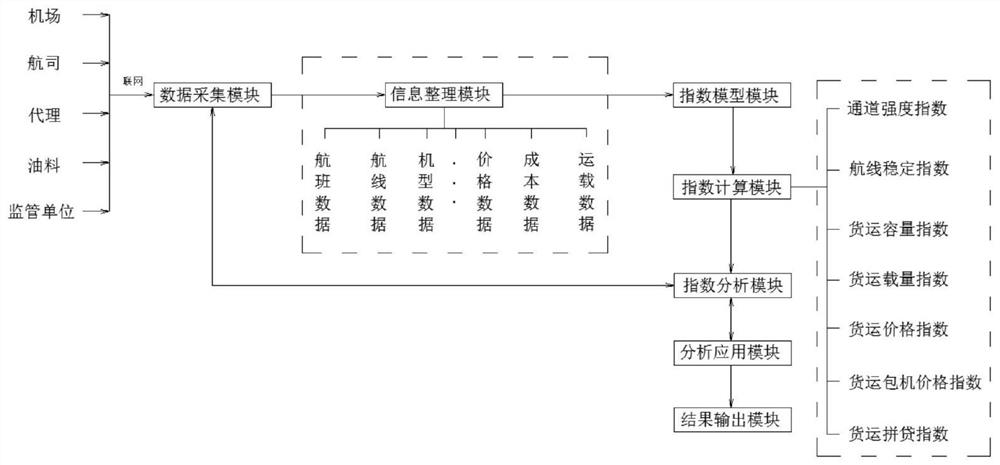

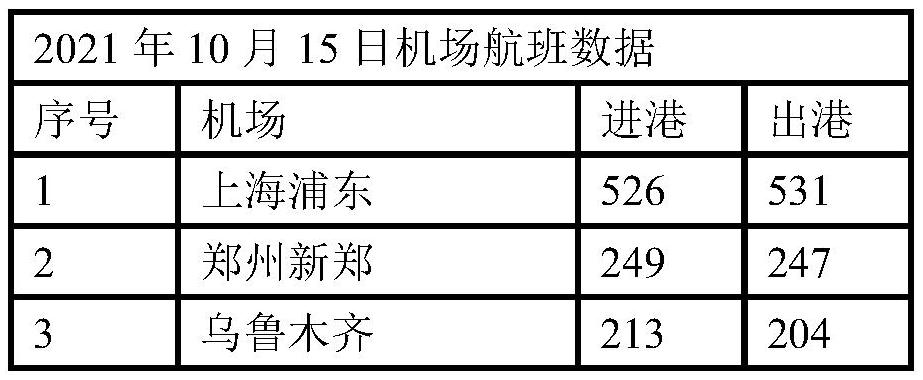

System and method for measuring, calculating and analyzing digital application index based on air freight

PendingCN114493447AImprove Freight UtilizationOptimize layoutResourcesLogisticsAviationDigital analysis

The invention discloses an index measurement and analysis system and method based on air freight digital application, and belongs to the field of aviation, and the system comprises a data collection module, an information arrangement module, an index model module, an index calculation module, an index analysis module, an analysis application module and a result output module, the data acquisition module is connected with the index model module through the information arrangement module, the index model module is connected with the index analysis module through the index calculation module, and the index analysis module is connected with the analysis application module. And the analysis application module is connected with the data acquisition module and the result output module. Through the indexed analysis and application of the air freight data, the accuracy and convenience of air freight data analysis are optimized, the combined application with the actual operation of freight is increased, and the advantages and actual effects of digital analysis can be exerted from the integrity and continuity of the air freight data.

Owner:行空载物航空货运服务(上海)有限公司

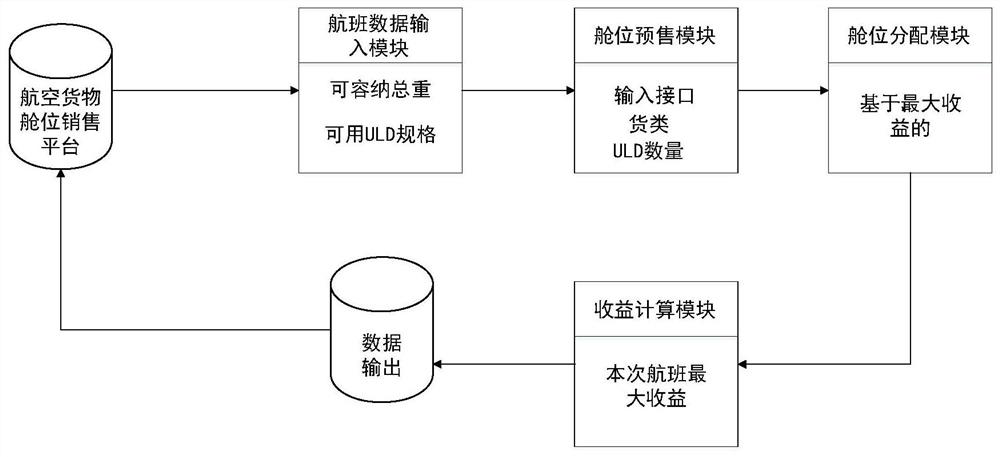

Air freight shipping space distribution method and system

The invention relates to the field of air transportation, and aims to solve the problems that in the prior art, a sales method rarely considers various types of goods, and a sales strategy is too simple and cannot be practically applied. Therefore, the technical scheme adopted by the invention is as follows: the air freight shipping space distribution method comprises the following steps: step 1,determining a flight freight shipping space pricing standard and shipping space capacity; 2, constructing a model by adopting a dynamic planning concept and taking the highest total income as a target; and 3, carrying out optimization solution on the maximum expected revenue expression of the shipping space distribution system obtained in the step 2, and outputting a shipping space distribution decision scheme under the condition of the maximum expected revenue. The method and system are mainly applied to air transportation cargo shipping space distribution occasions.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

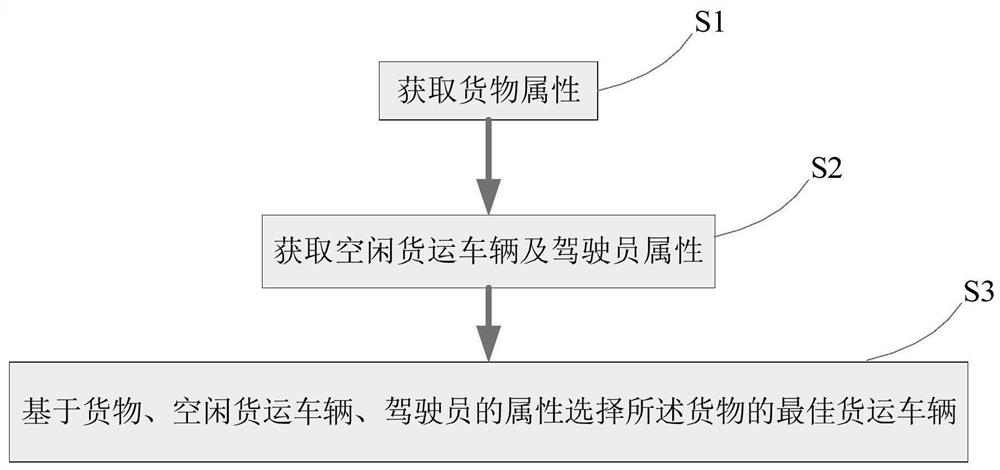

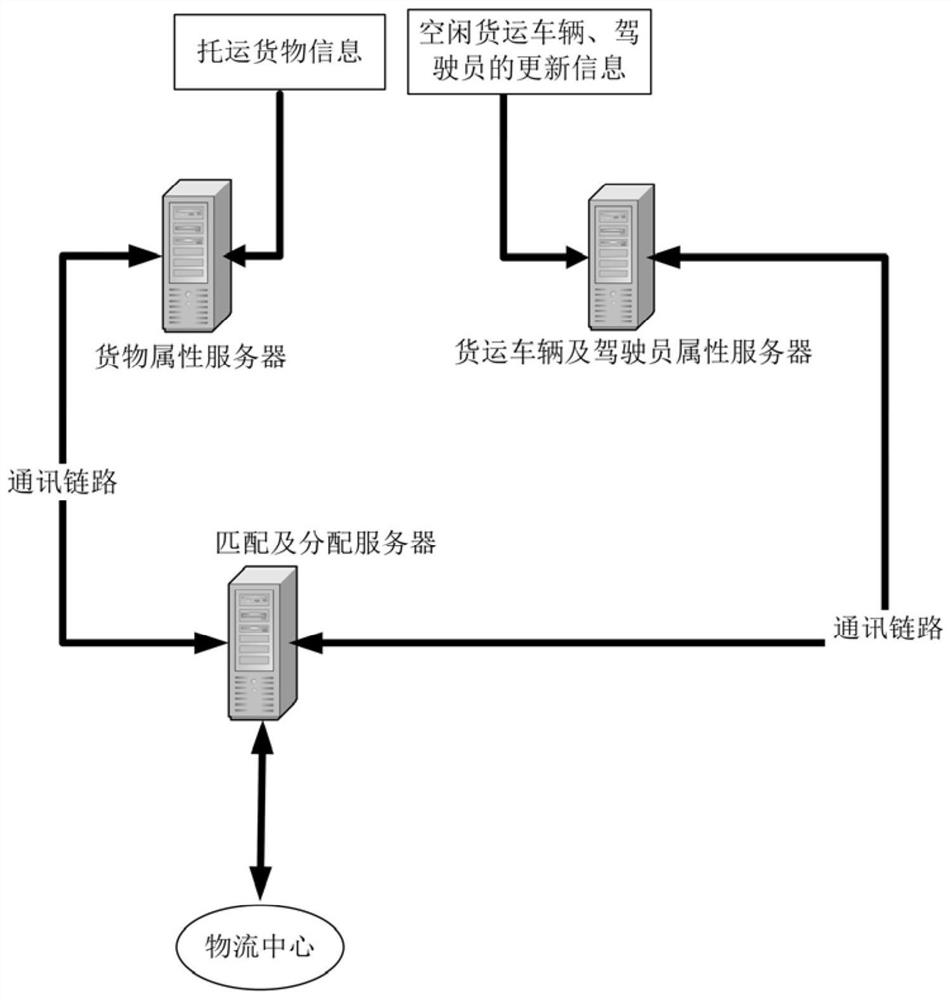

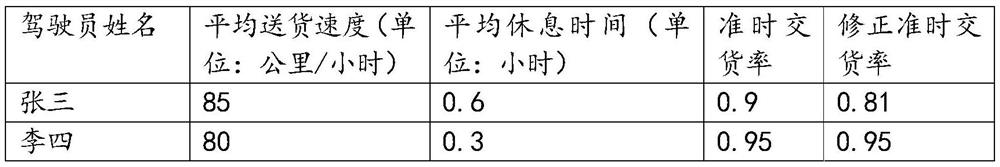

A method and system for deploying safe freight vehicles

ActiveCN108549978BImprove securityDevelop safe driving habitsResourcesDriver/operatorVehicle driving

The invention discloses a method for allocating safe freight vehicles, which includes acquiring the attributes of goods; acquiring the attributes of idle freight vehicles and drivers; and selecting the best freight vehicles for the goods based on the attributes of goods, idle freight vehicles and drivers. The method for dispatching freight vehicles based on driver behavior proposed by the present invention can effectively improve the transportation safety of the dispatched freight vehicles.

Owner:WELLONG ETOWN INT LOGISTICS

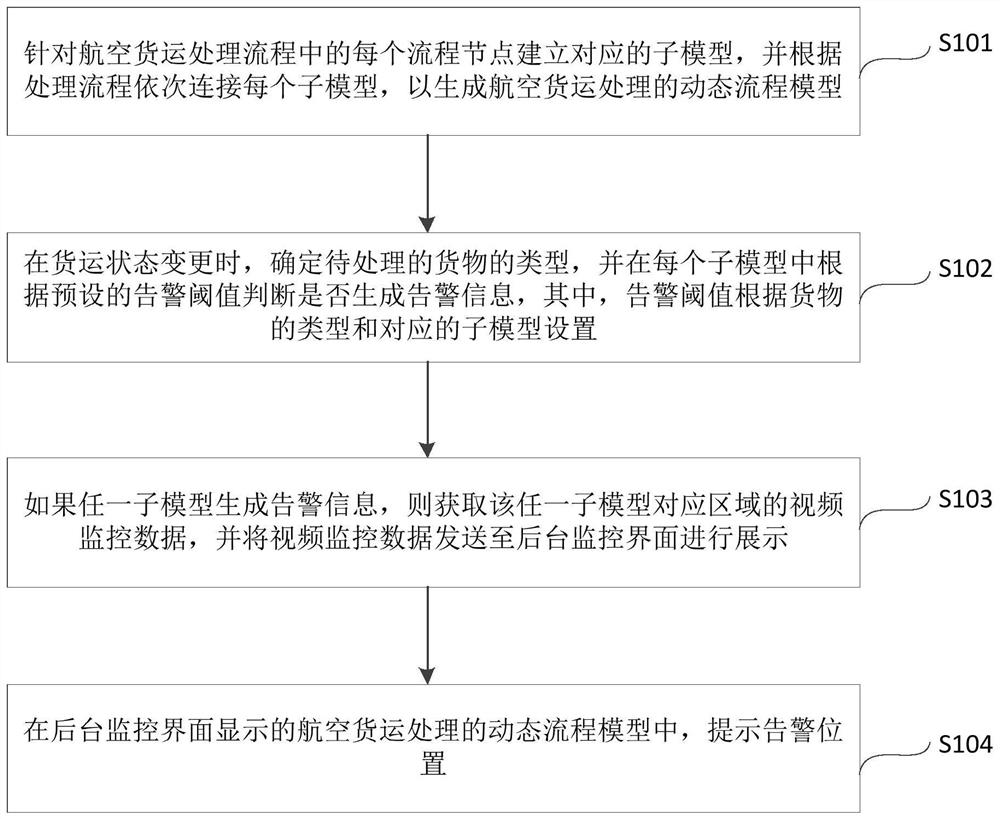

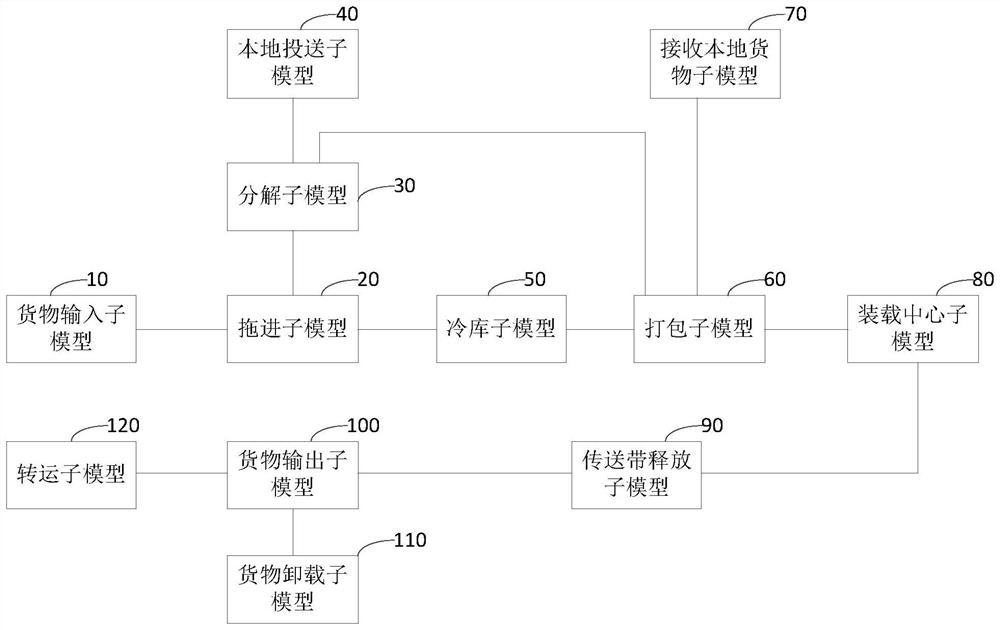

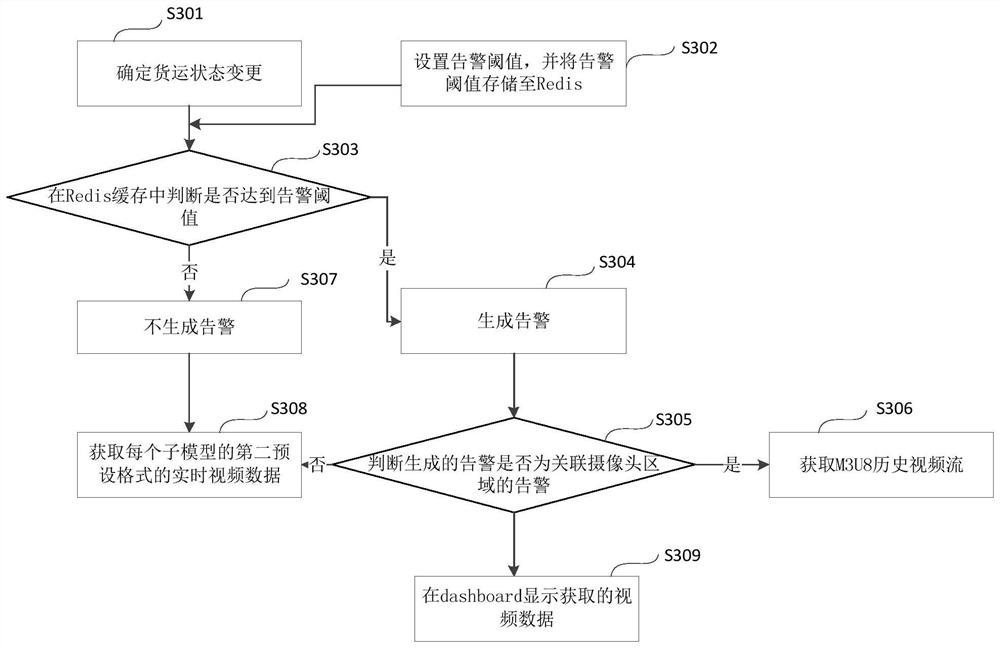

Freight management method and system based on dynamic process model and video monitoring

PendingCN114783153AOptimize the alarm handling processLow costClosed circuit television systemsFlight plan managementVideo monitoringComputer science

The invention provides a freight management method and system based on a dynamic process model and video monitoring, and the method comprises the steps: building a corresponding sub-model for each process node in an air freight processing process, sequentially connecting the sub-models according to the processing process, and generating a dynamic process model of air freight processing; the type of the goods to be processed is determined, whether alarm information is generated or not is judged in each sub-model according to a preset alarm threshold value, and the alarm threshold value is set according to the type of the goods and the corresponding sub-model; if any sub-model generates alarm information, video monitoring data of a corresponding area of any sub-model is acquired, and the video monitoring data is sent to a background monitoring interface for display; and prompting an alarm position in the dynamic process model of the air freight processing displayed on the background monitoring interface. According to the method, the air freight process is modeled, and freight warning and video monitoring are combined, so that the intelligence of video monitoring is improved, and the freight warning processing efficiency is improved.

Owner:TSINGHUA UNIV +2

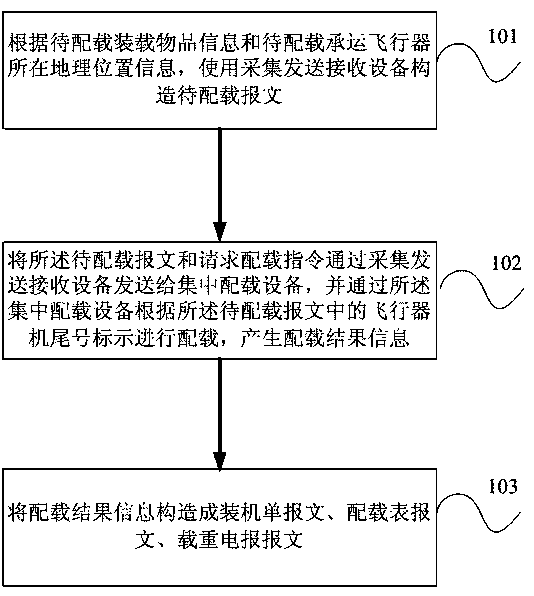

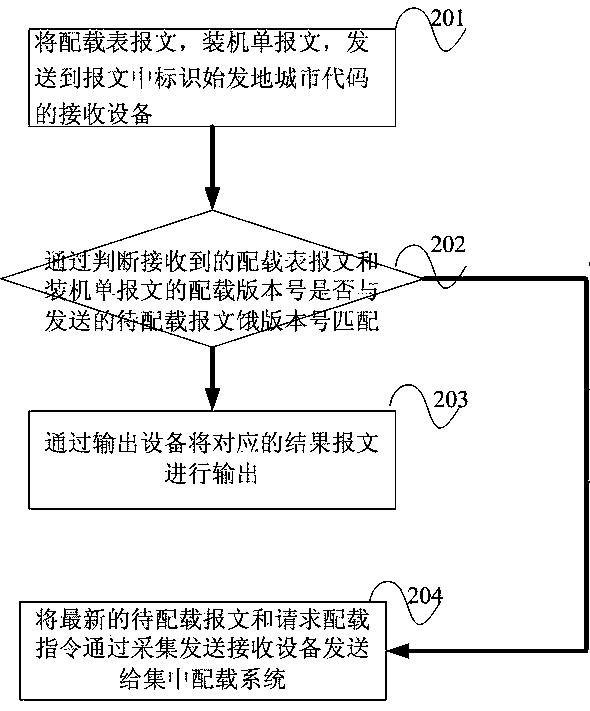

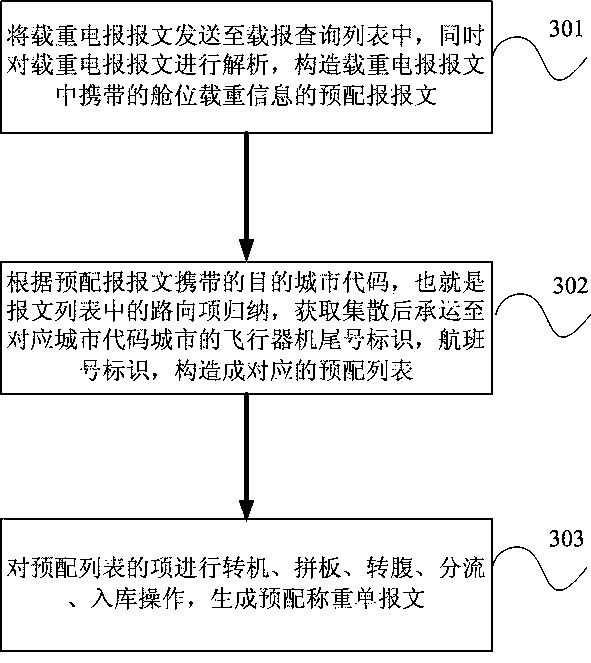

Remote centralized stowage method and system for distributed cargo aviation

InactiveCN103295177BReduce security risksEnsure safetyData processing applicationsAviationJet aeroplane

The invention relates to a centralized-distributed type freight transportation aerial remote centralized stowage method, equipment and system which can collect stowage information through wireless data and can send stowage results to off-plane personnel through wireless data transmission. The stowage method comprises the steps of constructing message to be transported according to information of transported articles to be transported and geographical location information of transporting carriage airplanes, sending the message to be transported and request stowage orders through a sending device to centralized stowage equipment, generating stowage result information through the centralized stowage equipment according to tail number signs of the airplanes in the message to be transported, constructing the stowage result information into stowage table message, constructing the stowage result information into loading table message, and sending the loading table message to city code receiving equipment at the positions of the airplanes. The centralized-distributed type freight transportation aerial remote centralized stowage method solves the problems that stowage standard is inaccurate, manual information transmission is long in time, the requirements for airworthiness of using airborne equipment to transmit information are high, data link cost is high, and personnel of a collecting and distributing center only can obtain stowage information on flights to carry out collection and distribution after the flights arrive at the collection and distribution center to cause airplane delay, long collection and distribution time and safety hazards in the prior art.

Owner:杨光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com