Patents

Literature

52results about How to "Keep going" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

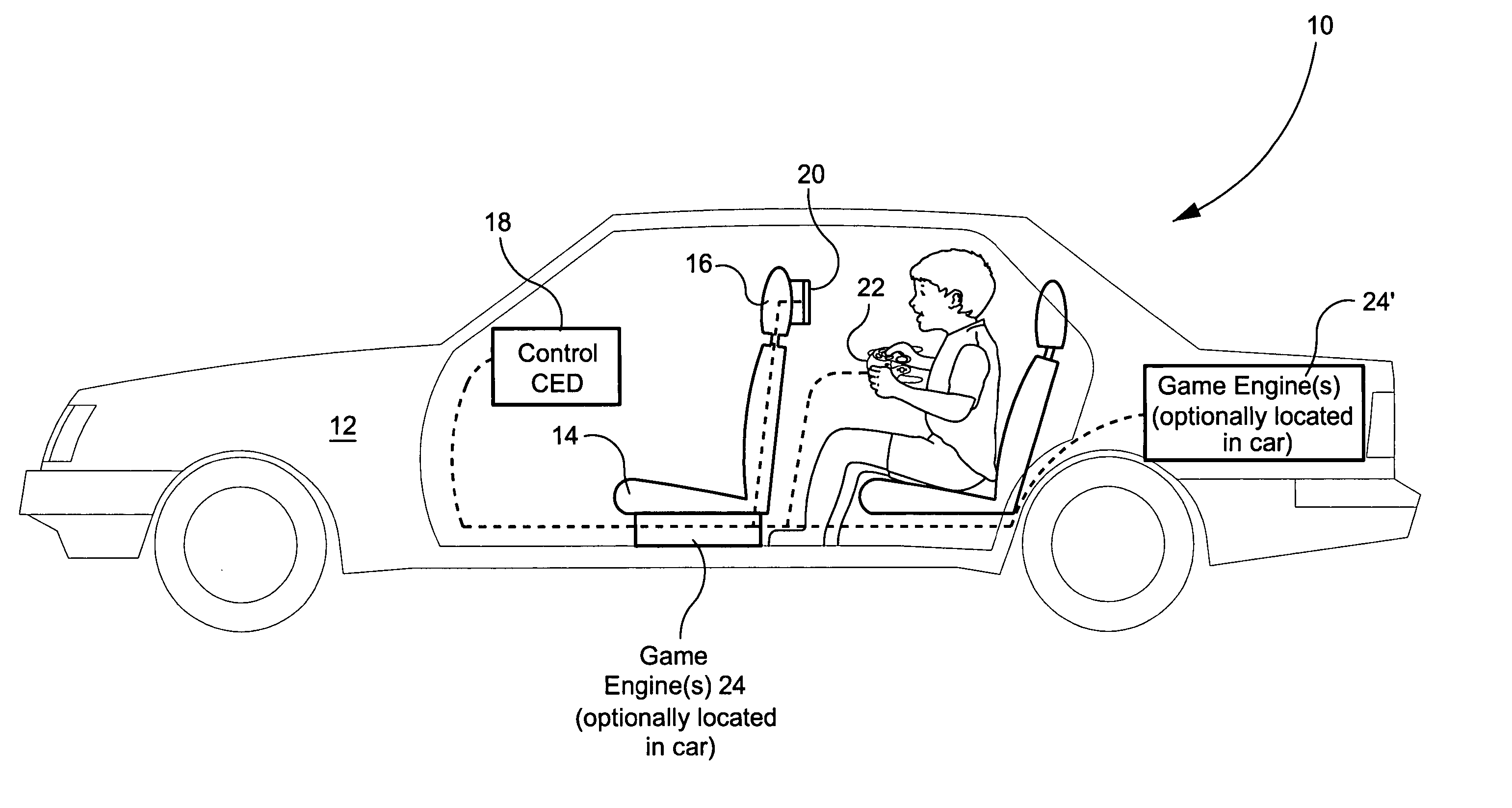

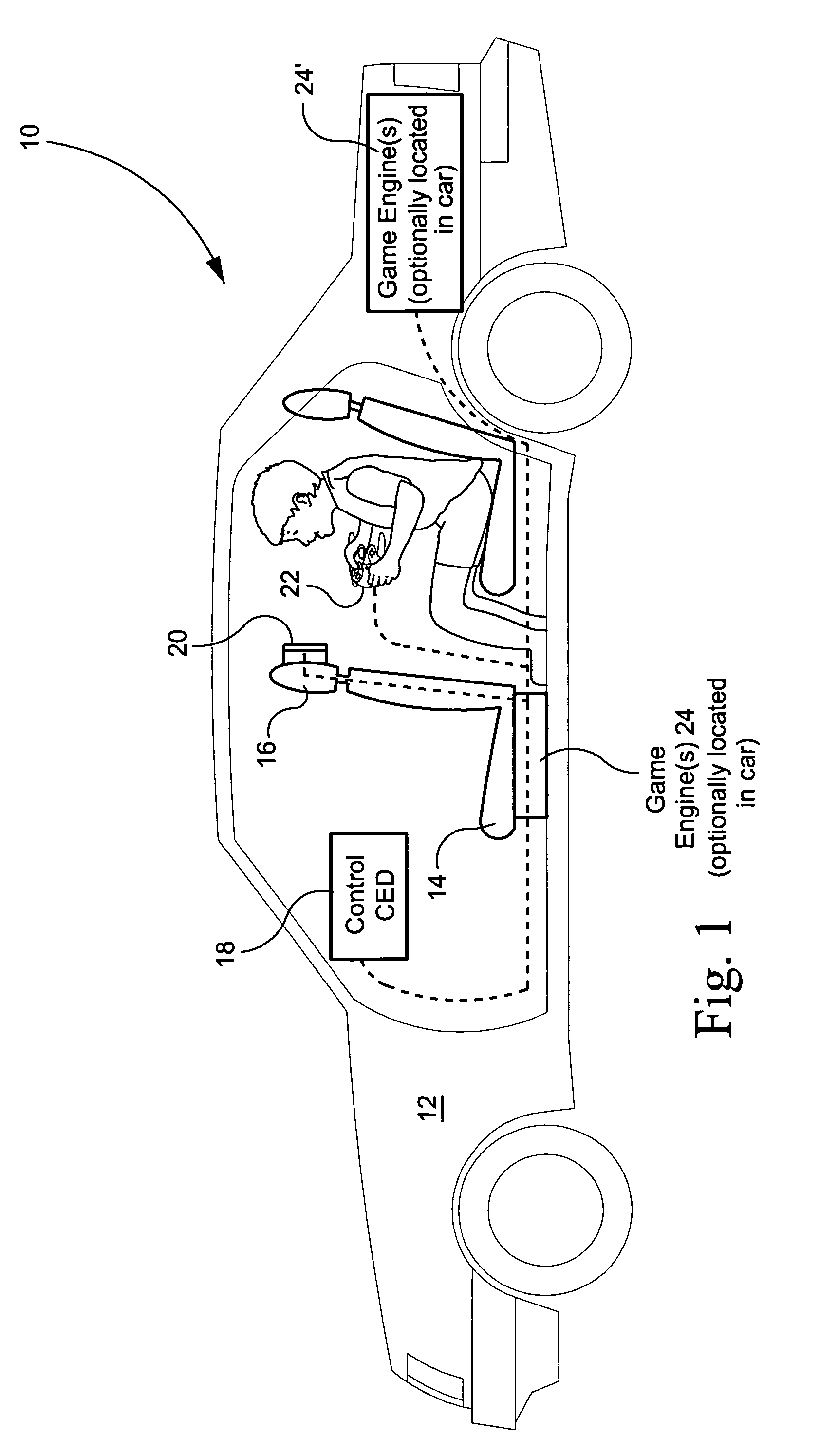

Car-based entertainment system with video gaming

InactiveUS20060009289A1Minimal costSimple methodVideo gamesSoftware simulation/interpretation/emulationArea networkDisplay device

A car area network is disposed in a car to enable communications between various devices in the car. An existing consumer electronics device (CED) coupled to the car area network (CAN) performs an existing consumer electronics device function. That existing (CED) is adapted to control various devices coupled to the CAN including video gaming devices. In one example, the adapted CED cooperates with a game server to effect game play. In another example, the adapted CED functions as a virtual video game platform to support play of video games. A multifunction controller transmits control information to the adapted CED via the car area network to permit a car occupant to control the adapted CED to permit the occupant to play a video game using the video game display. One or more audio and / or visual devices coupled to the CAN may also be controlled by commands transmitted from the adapted CED or from the multimedia controller over the CAN.

Owner:NINTENDO OF AMERICA

Composite coating with friction-decreasing function and biological-foul and seawater resistances and its production

InactiveCN101074331AImprove the protective effectResistant to microbial foulingAntifouling/underwater paintsPaints with biocidesComposite ceramicAlloy

A composite coating against biological fouling and seawater corrosion and its production are disclosed. The composition consists of oxide based-phase ceramic powder 80-95 wt% and powder against biological fouling 5-20 wt% with Cu, CuO or Cu2O powders. The composite coating comprises binding bottom layer, composite ceramic coating and surface sealing layer; ZnNi alloy powder is sprayed on metal substrate of binding bottom layer by supersonic flame; Composite ceramic power against biological fouling and sea-water corrosion is sprayed on bottom of composite ceramic coating by plasma; Inorganic or organic sealer with low surface energy is sprayed on surface sealing layer. An insulating ceramic transient layer is added between binding bottom layer and composite ceramic coating when Cu powder is adopted. It's simple and cheap and can be used for industrial production.

Owner:WUHAN UNIV OF TECH

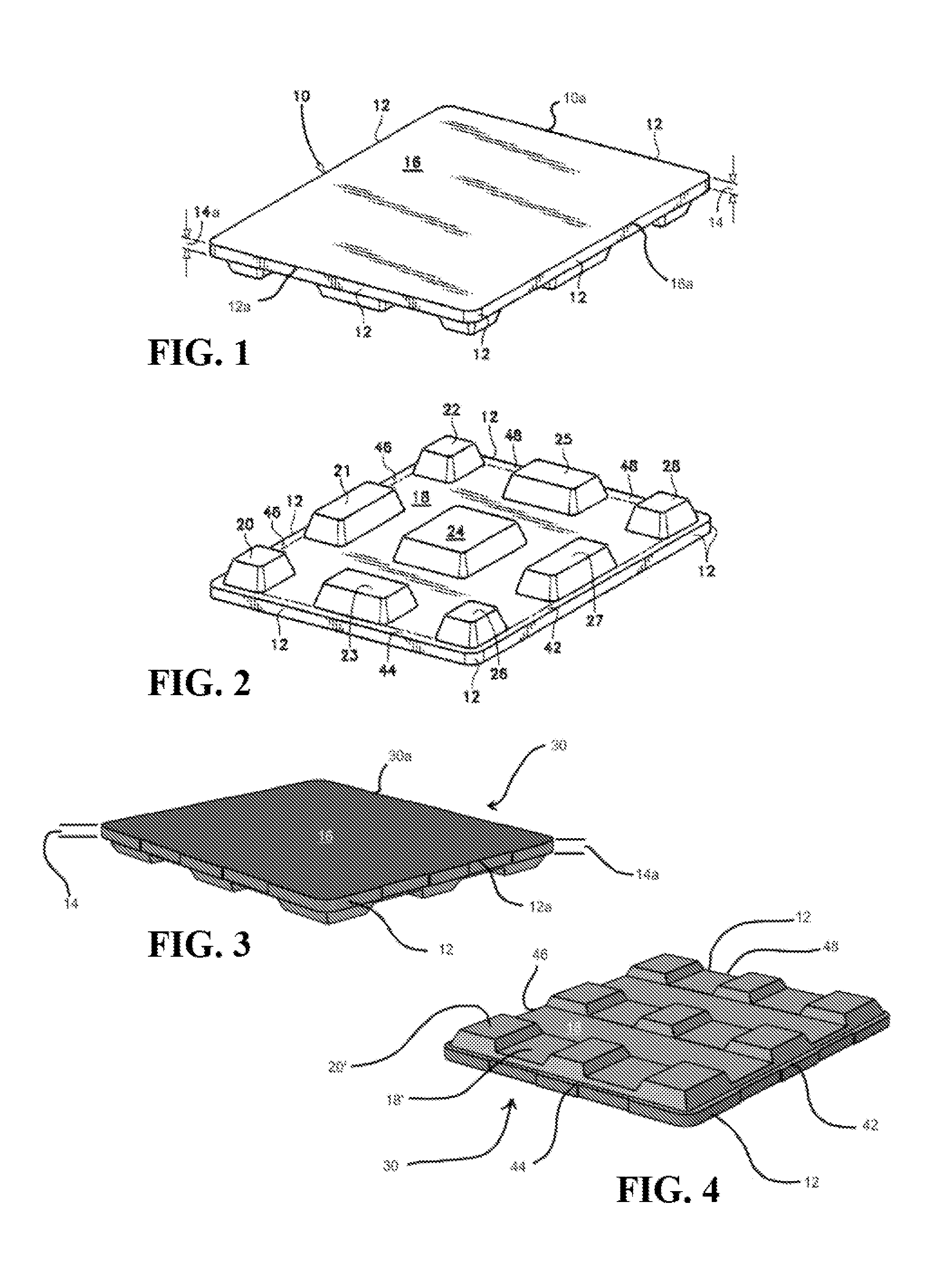

System for facilitating security check of shipment of cargo

InactiveUS20130015083A1Convenient security checkKeep goingSynthetic resin layered productsLarge containersCold chainFresh fish

The present invention provides a system for facilitating security check of cold-chain air freight cargo using a magnetic imaging scanner for shipping at the airport. Cold-chain material includes most perishables such as produce, fresh fish, biological parts, pharmaceuticals and similar that need to be kept at a lower temperature for preservation and freshness.

Owner:AIRDEX INT

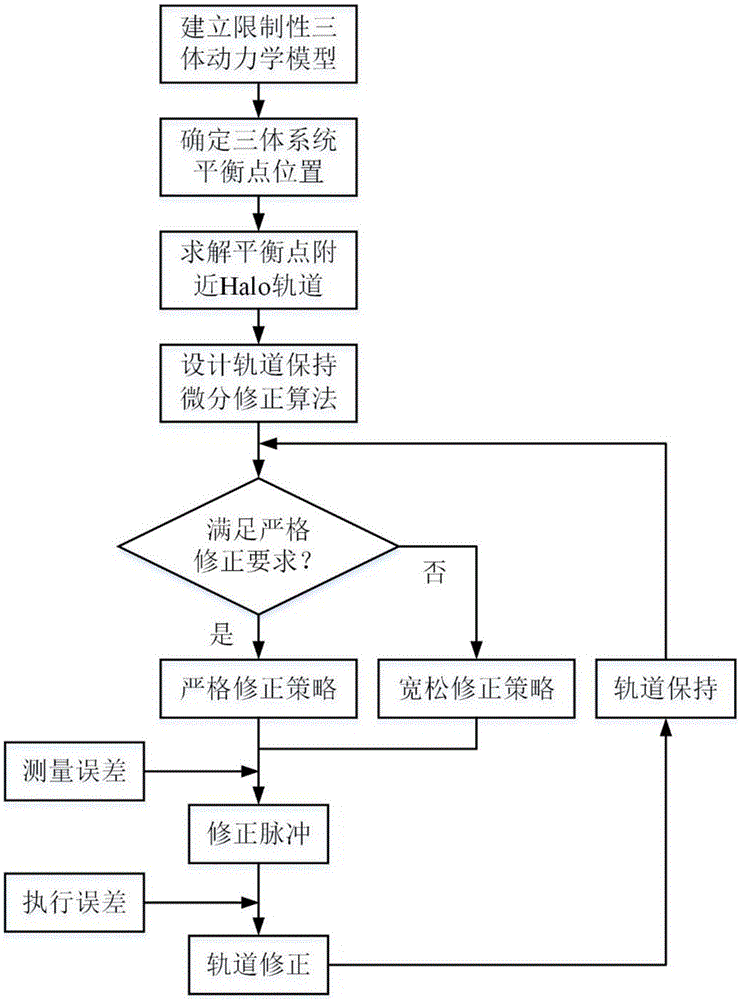

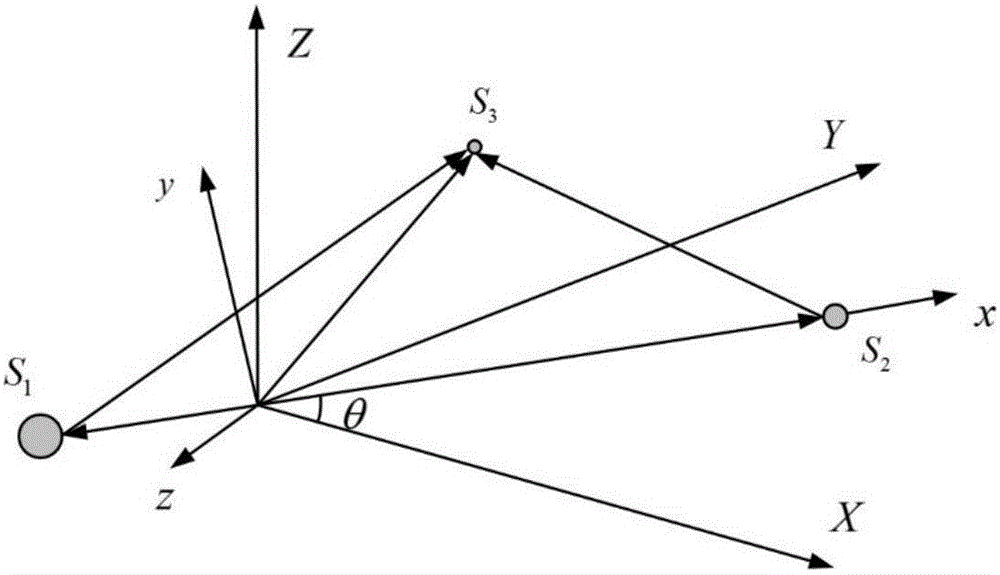

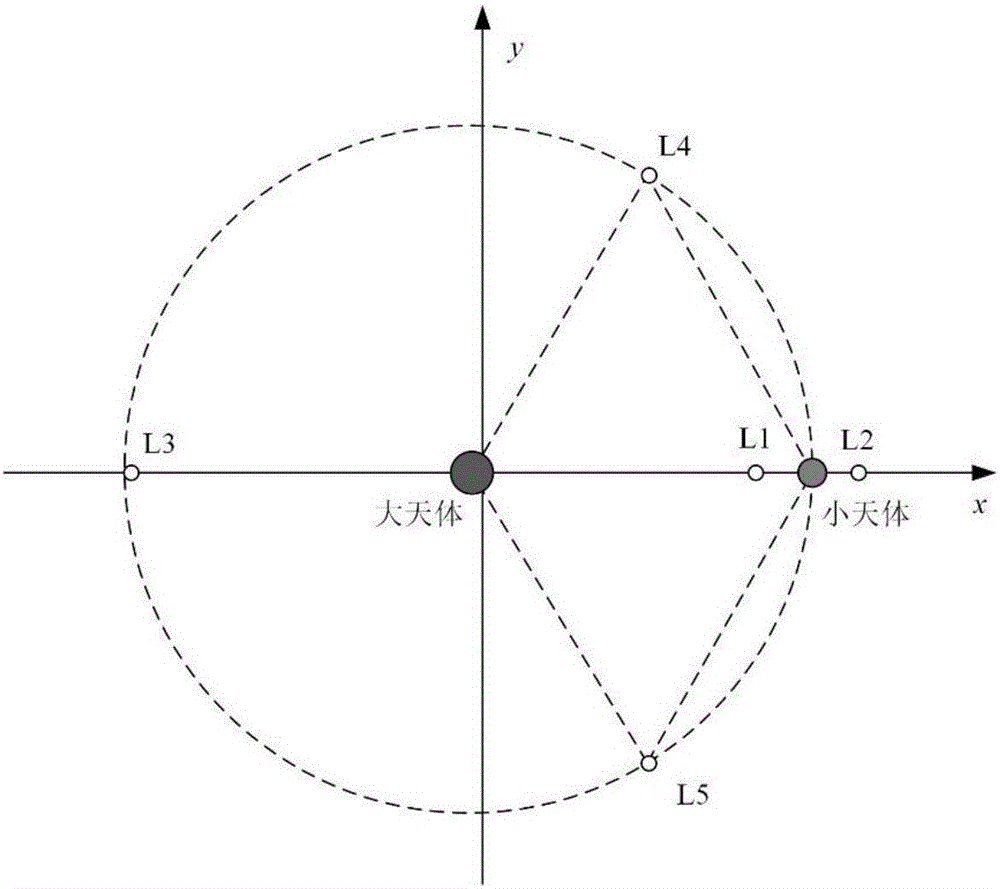

Halo orbit on-orbit keeping method considering amplitude constraint

InactiveCN106682274AStay fit in orbitSimple calculationCosmonautic condition simulationsDesign optimisation/simulationObservational errorAviation

The invention provides a Halo orbit on-orbit keeping method considering amplitude constraint, and belongs to the aerospace technology field. The method comprises the steps that by establishing a kinetic equation under a limited three-body model composed of two main celestial bodies and a detector, the position of a balance point of a three-body system composed of the two celestial bodies and the detector is determined; a Halo orbit, near the balance point, in the three-body system composed of the big and small celestial bodies and the detector is determined; a differential correction algorithm for Halo orbit keeping is designed according to the disturbance variable; a Halo orbit on-orbit keeping strategy is designed according to the differential correction algorithm; in a real ephemeris environment, measurement errors and execution errors are considered, the speed increment of each time of orbit correction is obtained according to the orbit keeping strategy through the differential correction algorithm, orbit correction control is conducted according to the speed increments. Accordingly, Halo orbit on-orbit keeping considering amplitude constraint can be achieved, and consumption of fuel needed in orbit keeping can be reduced as much as possible.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

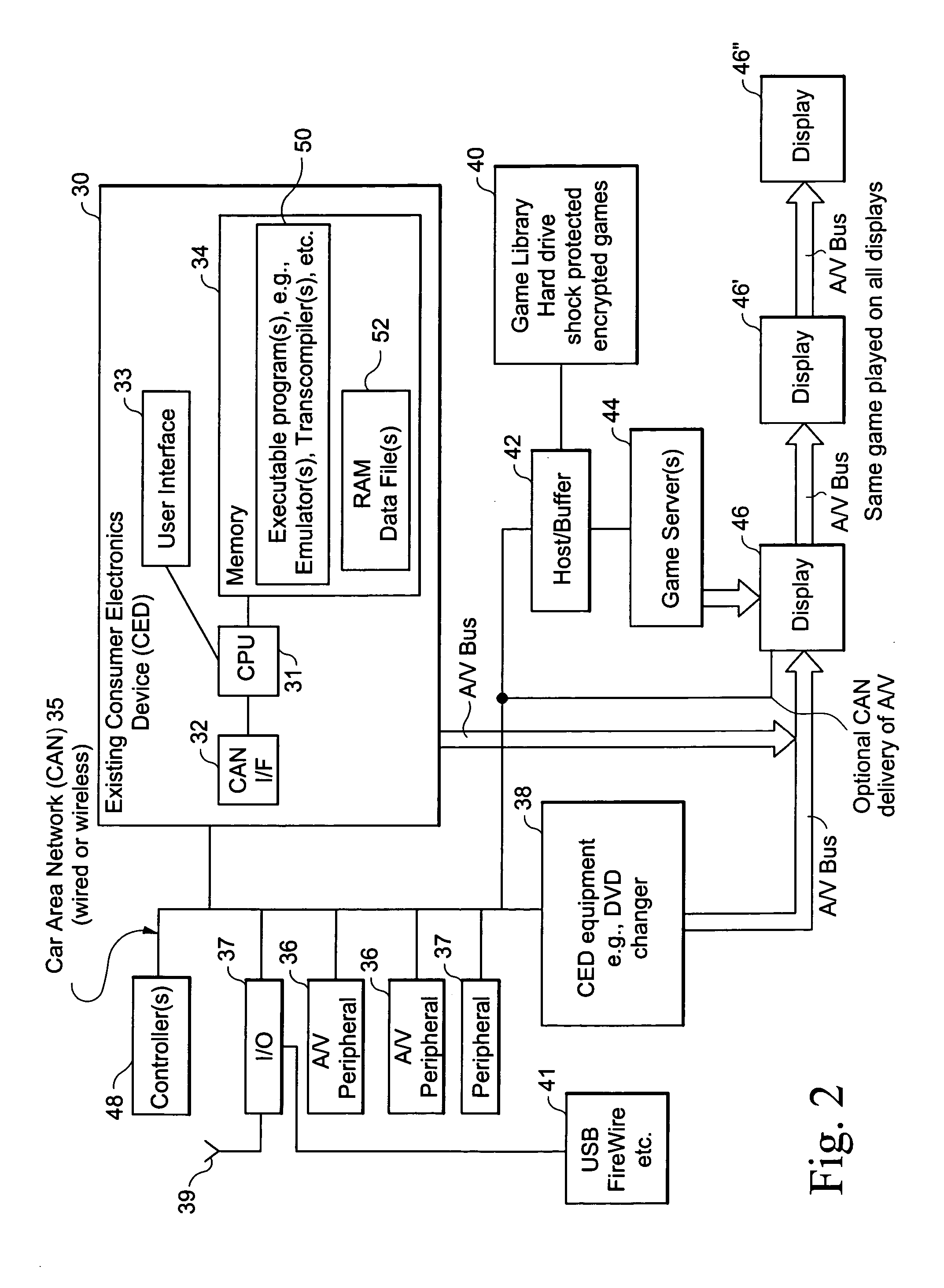

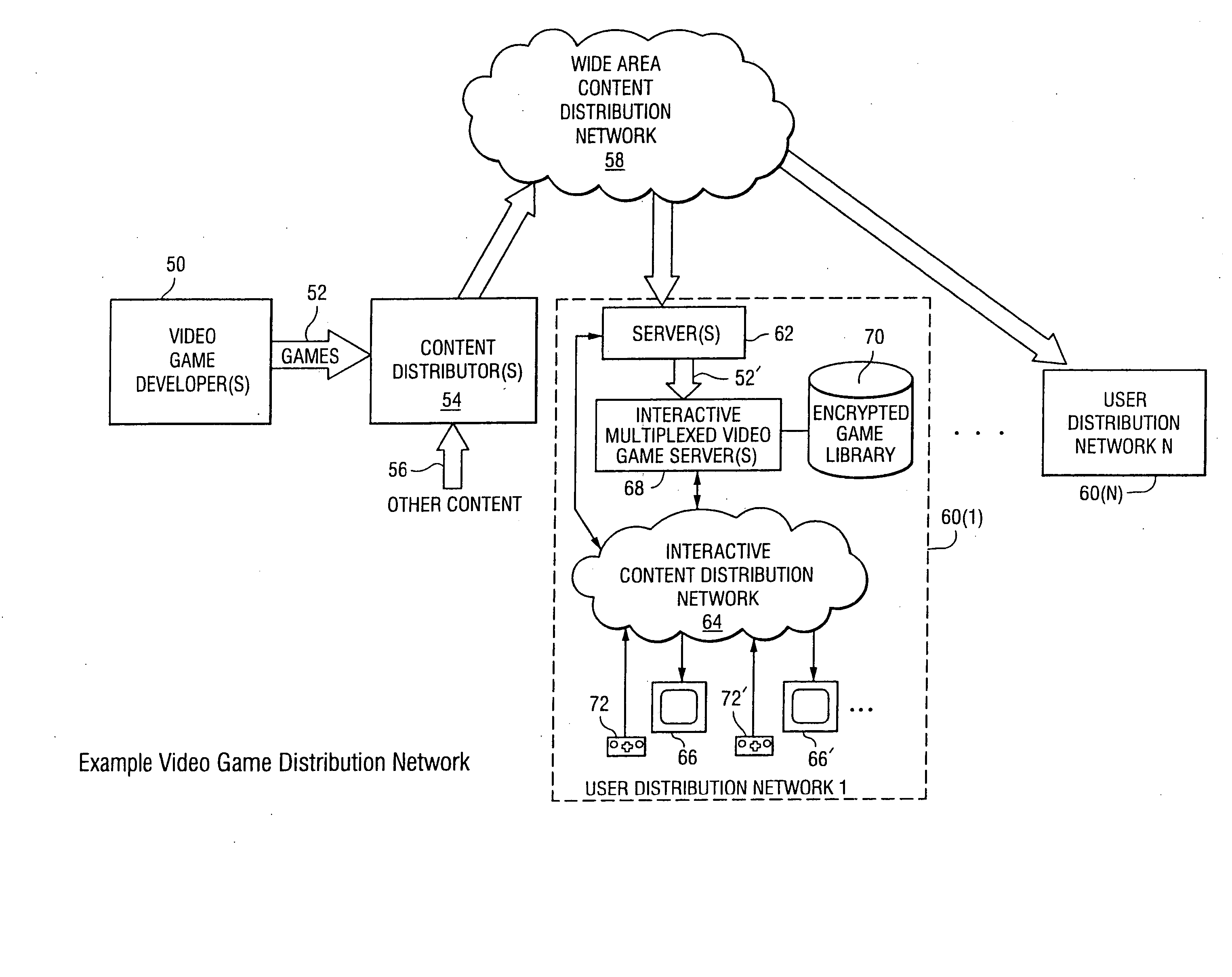

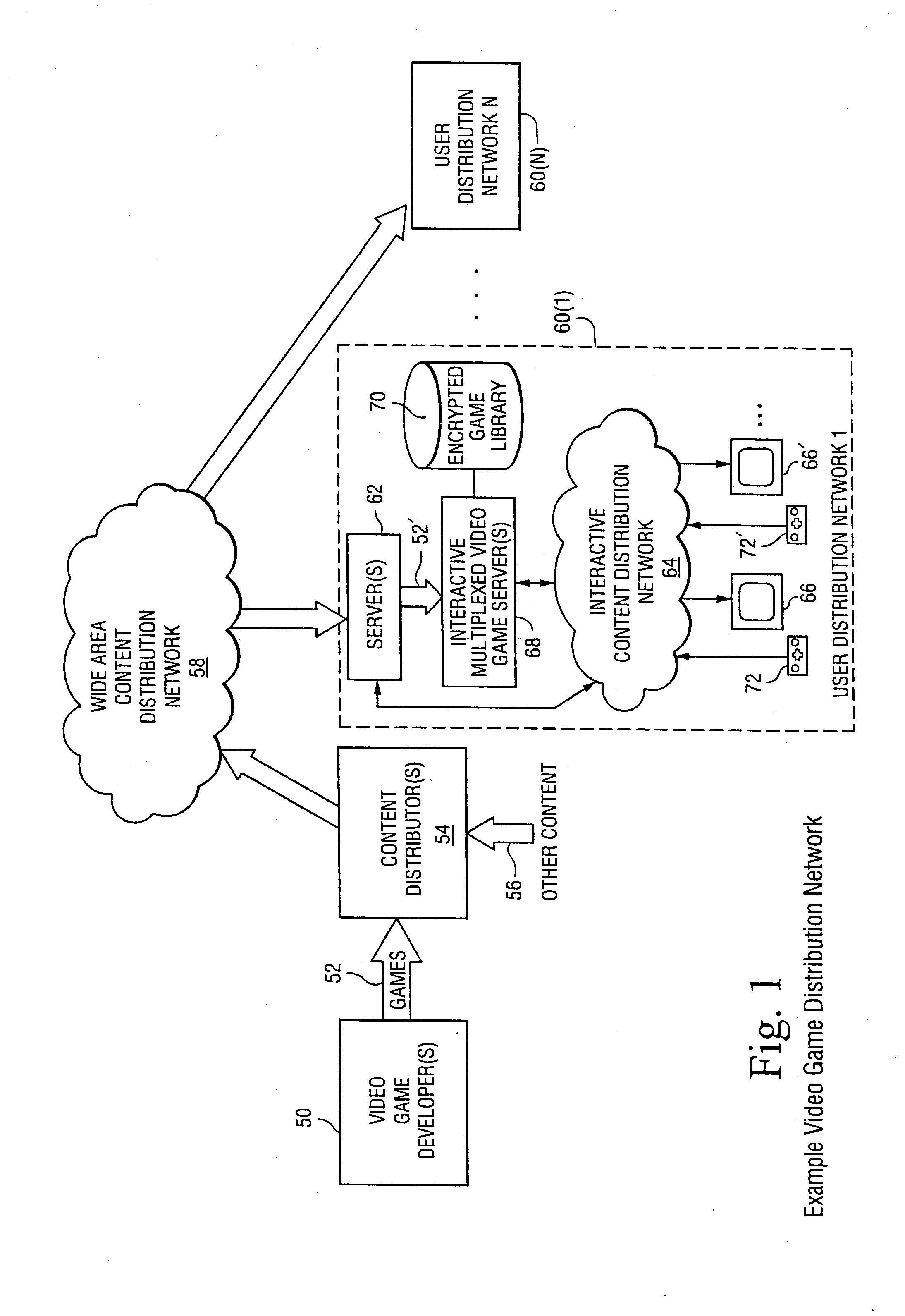

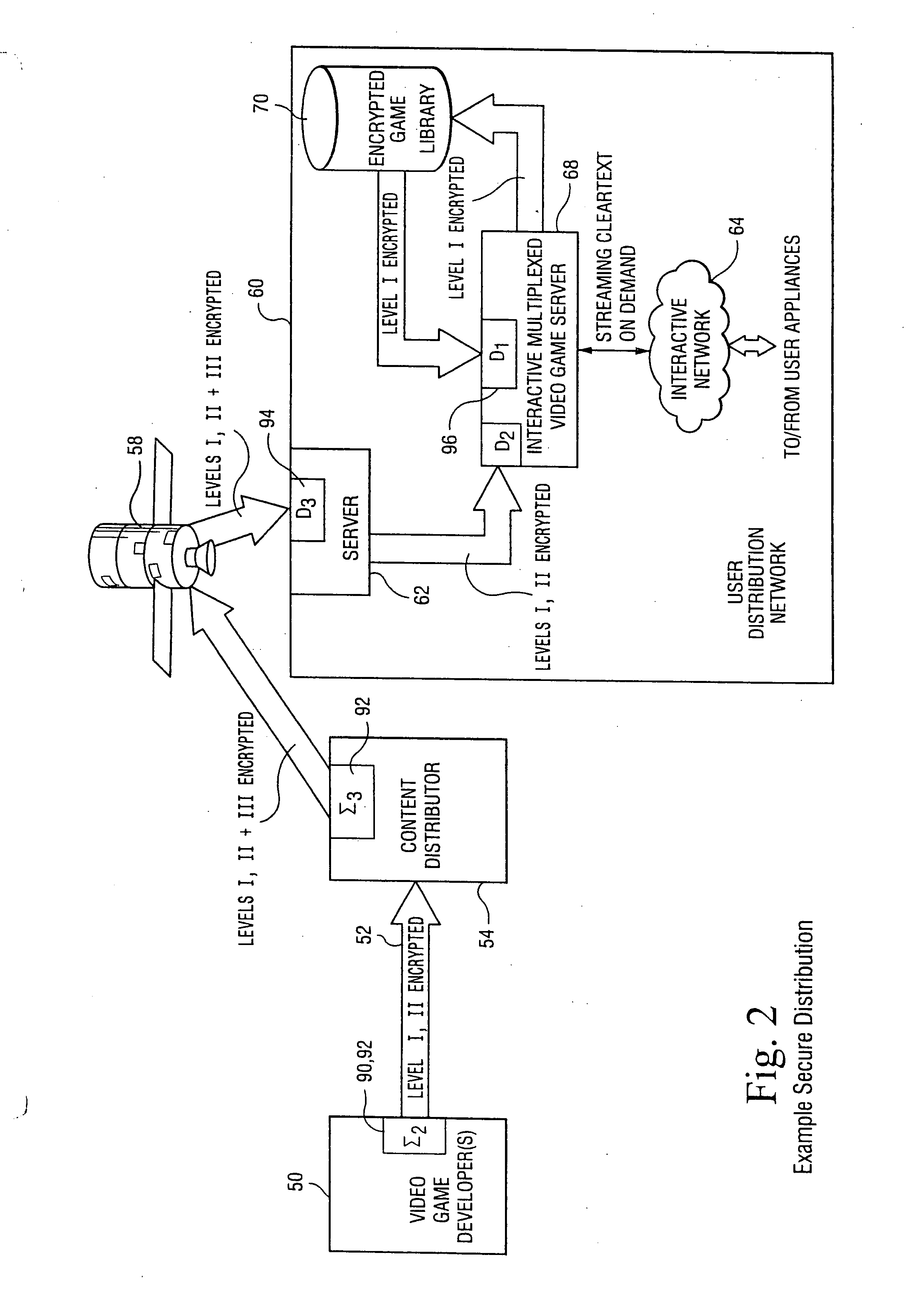

Multiplexed secure video game play distribution

ActiveUS20070275780A1Protected from riskMinimization requirementsVideo gamesSpecial data processing applicationsMultiplexingMass storage

Multiple video game players access an encrypted video game library stored on a shared mass storage device. A multiplexer multiplexes data read from the mass storage device to provide output streams to multiple video game playing units consuming video game instructions. A secure bus communicates video game instructions from the shared mass storage device to each of the video game playing units. Video game software or other entertainment content is distributed to the shared mass storage device via electronic download in multi-level encrypted form. Before being transported, the content is encrypted and then further encrypted. Once the content has been successfully transported, it is decrypted to remove the further encryption layer—leaving the first encryption layer intact for protecting the video game during storage on mass storage at the remote distribution location.

Owner:NINTENDO CO LTD

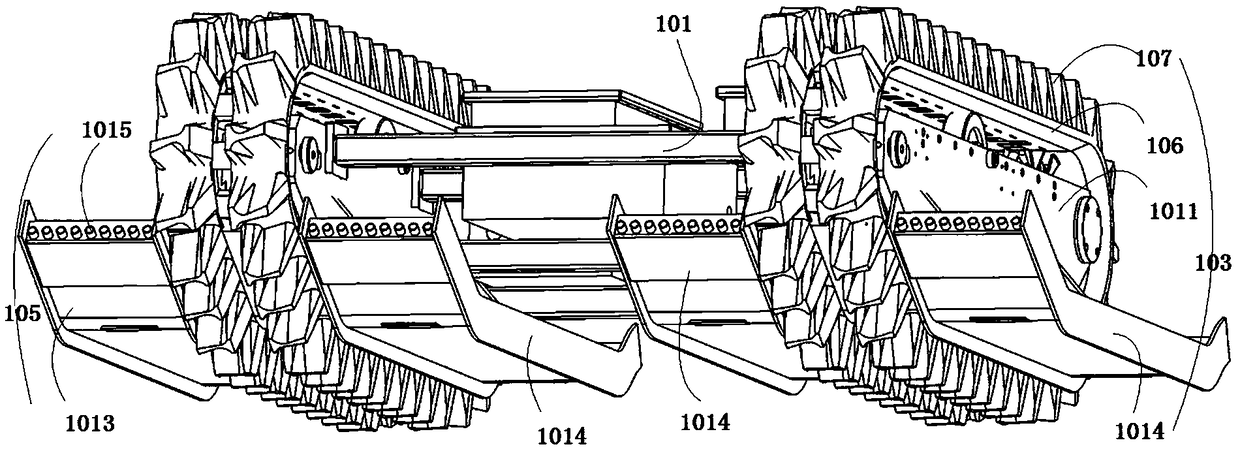

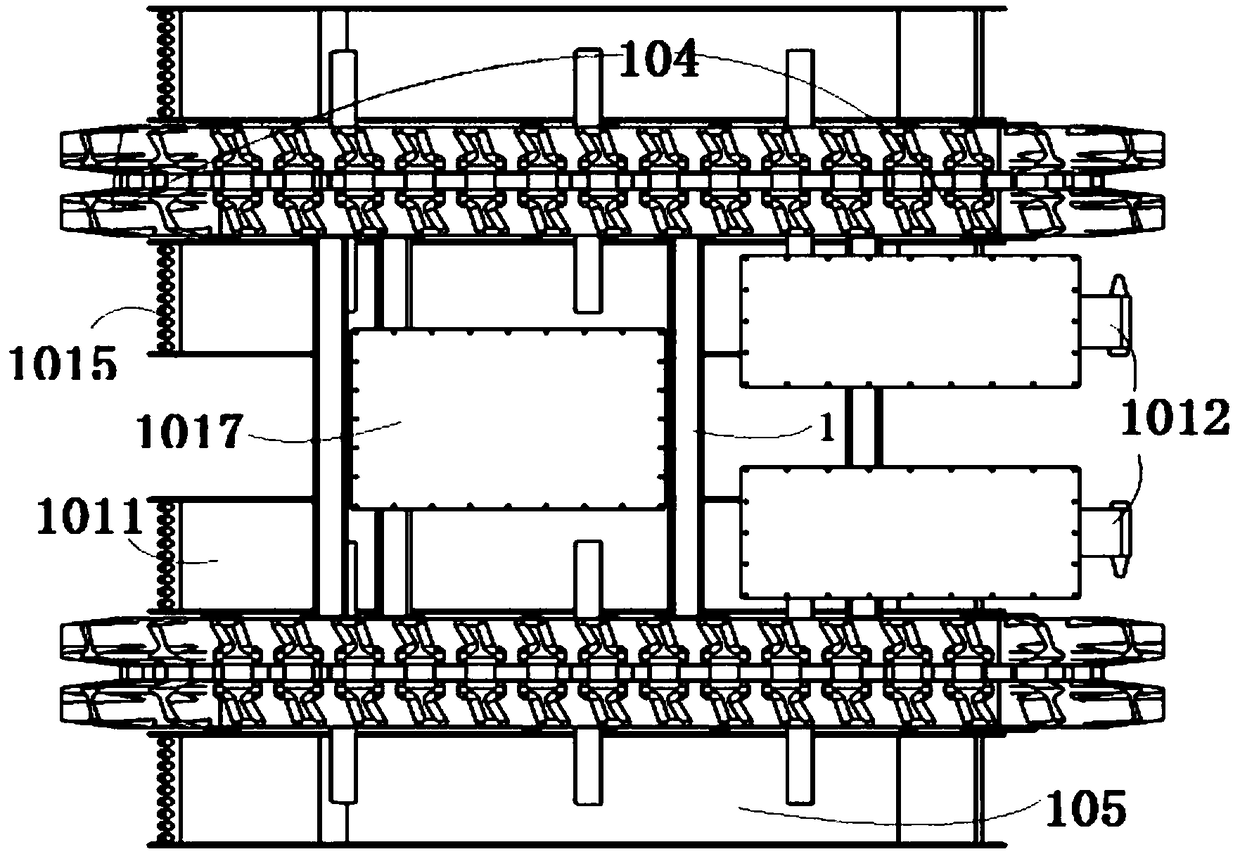

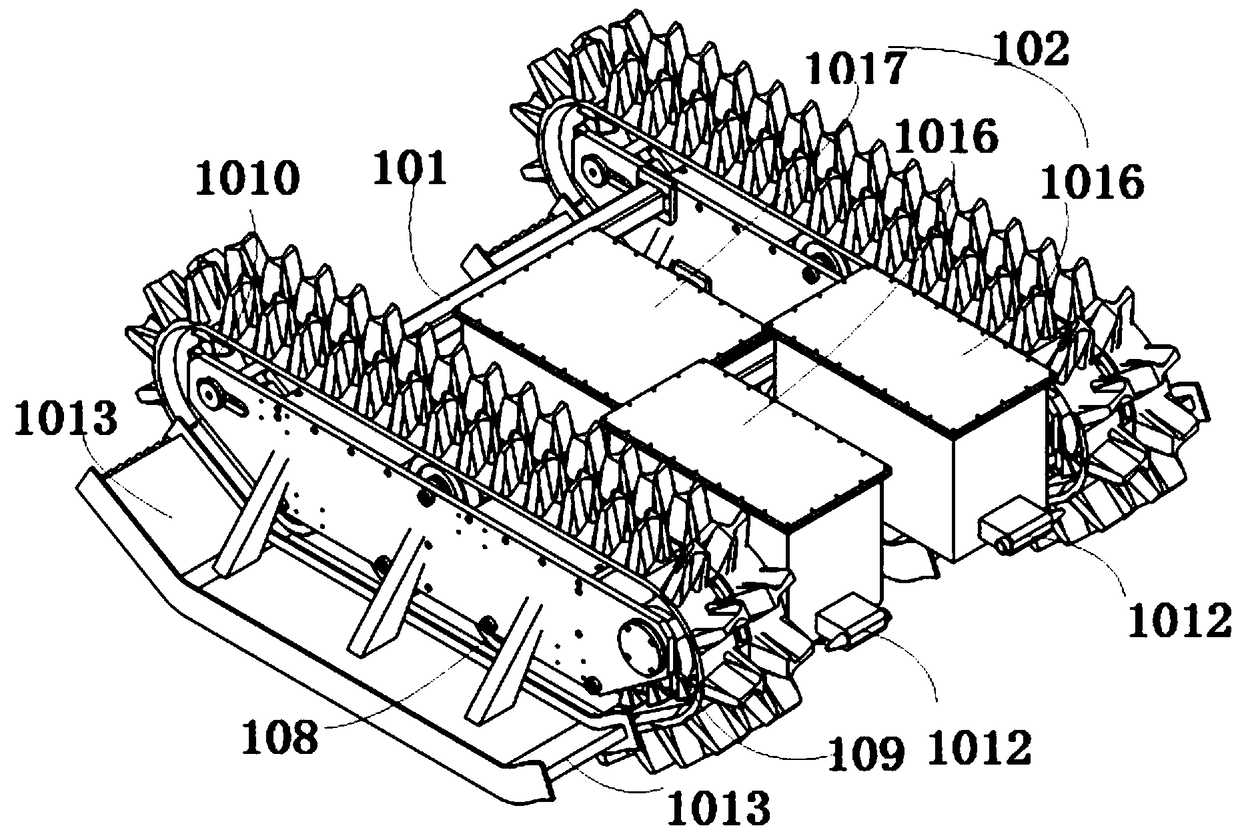

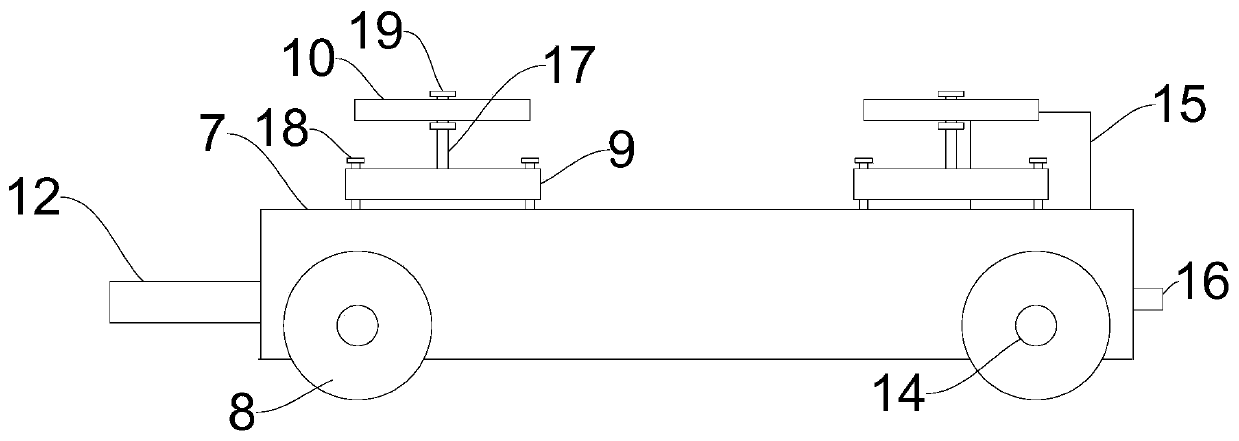

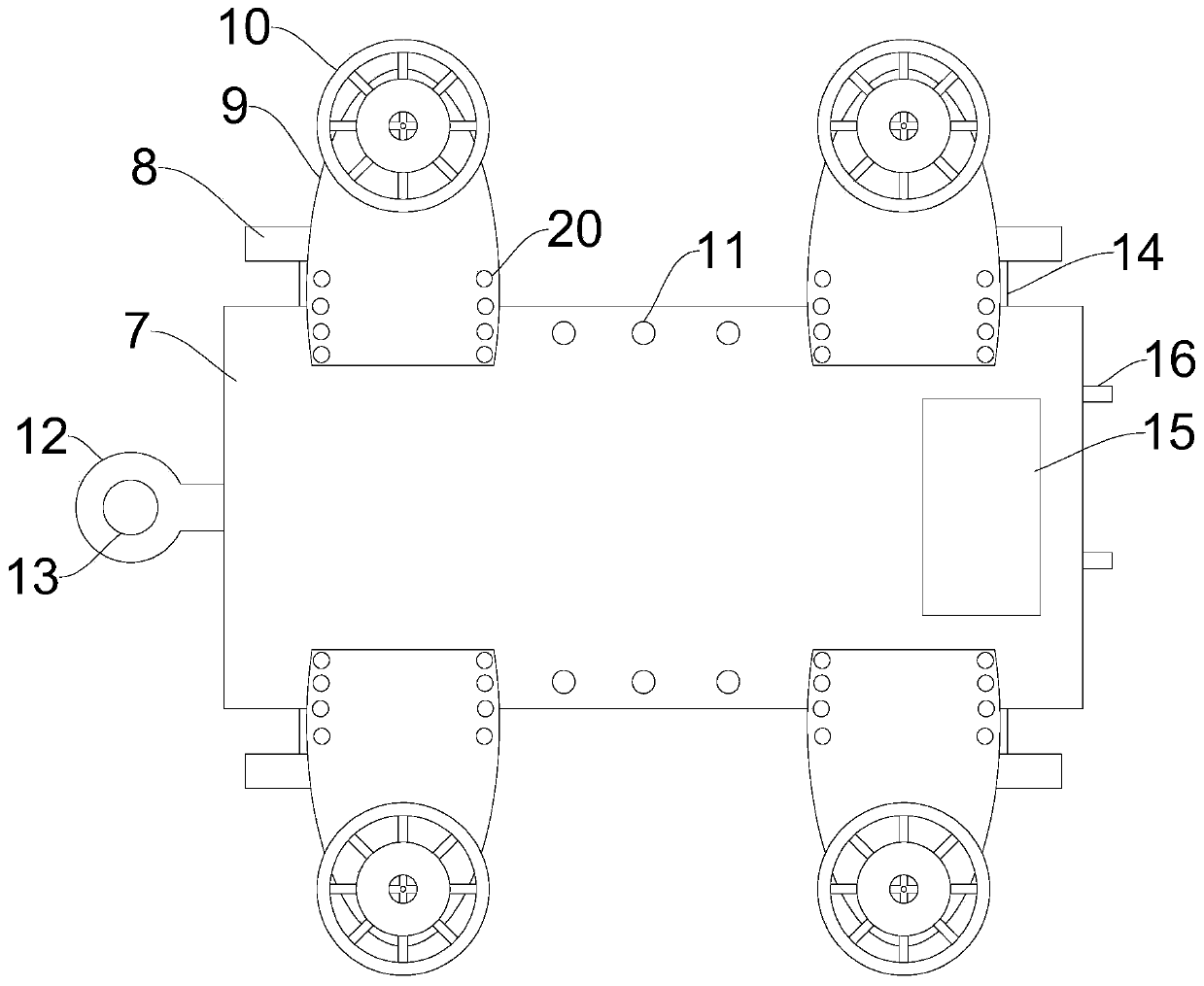

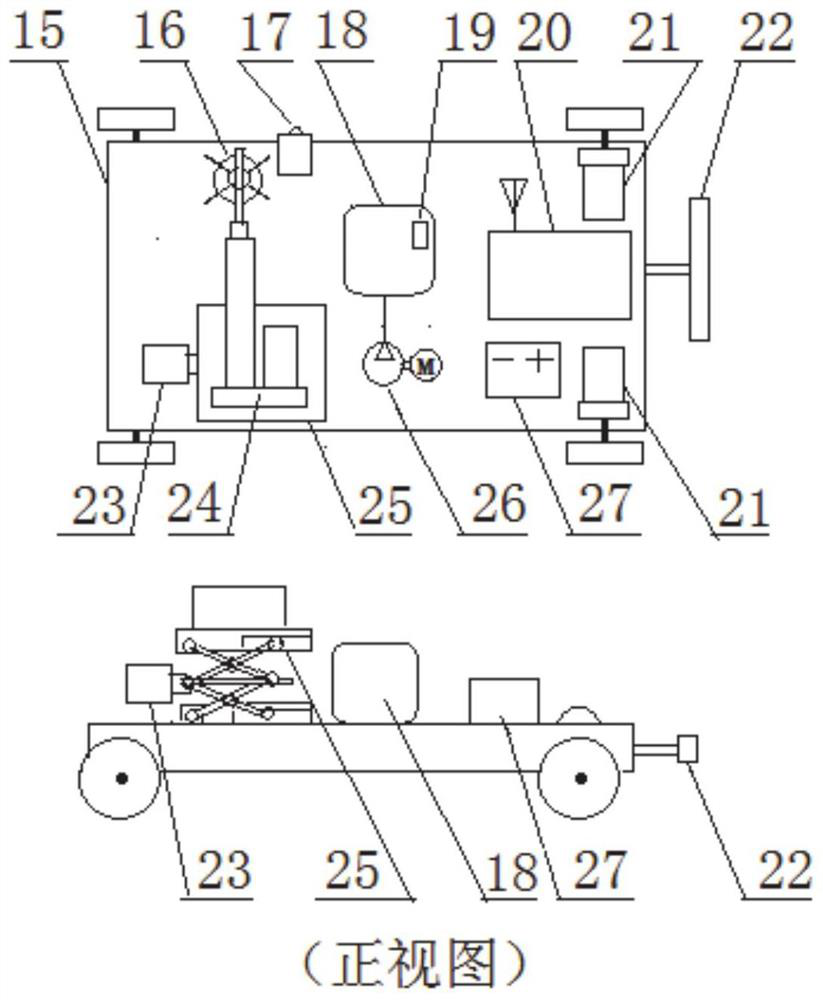

Floatable track type special underwater operation robot suitable for extremely soft geology

ActiveCN109291743AKeep goingGuaranteed smooth progressAmphibious vehiclesEndless track vehiclesOcean bottomHead pressing

Owner:SHANGHAI JIAO TONG UNIV

Manufacturing method of acrylic fiber and bamboo fiber blended water-repellent shell fabric

InactiveCN104562387AGuaranteed to be clean and sterileGood physical and mechanical propertiesFibre treatmentLiquid/gas/vapor removalPolyesterPolymer science

The invention discloses a manufacturing method of an acrylic fiber and bamboo fiber blended water-repellent shell fabric. The selected warp and weft materials comprise the following components in parts by mass: 40-90 parts of acrylic fibers, 20-45 parts of natural fibers, 6-12 parts of synthetic fibers, 8-15 parts of bamboo fibers, 60-95 parts of cotton fibers and 8-18 parts of super fine denier polyesters. According to the manufacturing method, water repellent finish is carried out between sizing operation and air injection by the following steps: padding a shell fabric in a water repellent finish liquid; taking out the shell fabric; and then carrying out electron radiation and drying treatment, wherein the water repellent finish liquid comprises 2-8% by mass of a water repellent; the drying treatment comprises first drying treatment and second drying treatment. According tothe manufacturing method of the acrylic fiber and bamboo fiber blended water-repellent shell fabric designed by the invention, the cohesive force between the fibers of the acrylic fiber and bamboo fiber blended water-repellent shell fabric can be enhanced, and the acrylic fiber and bamboo fiber blended water-repellent shell fabric has a good water-repellent antibacterial performance while having the advantages of high elasticity, high strength and heat and light resistance, and the washability and the softness of textile are improved.

Owner:SUZHOU CHENHENG WEAVING

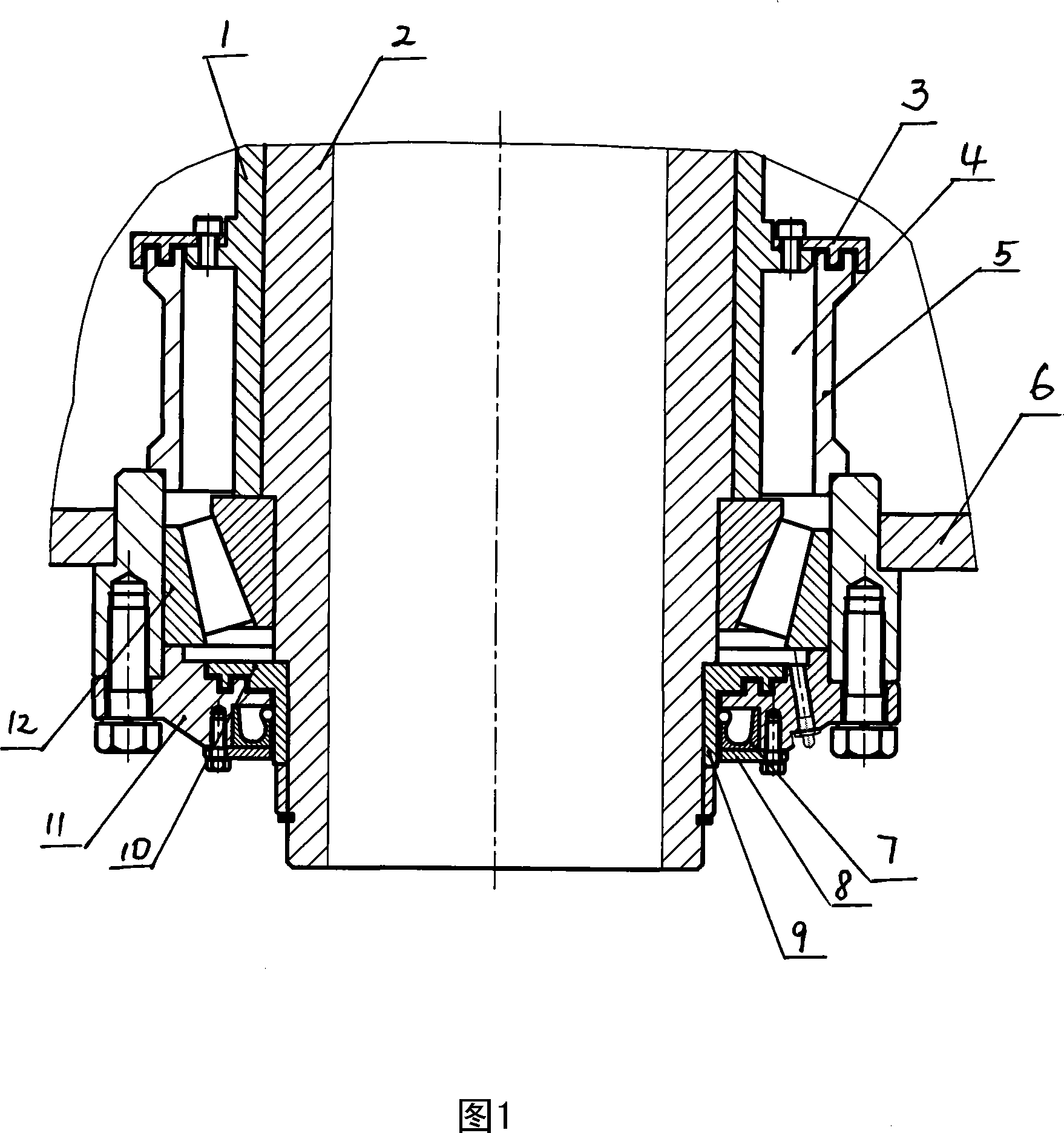

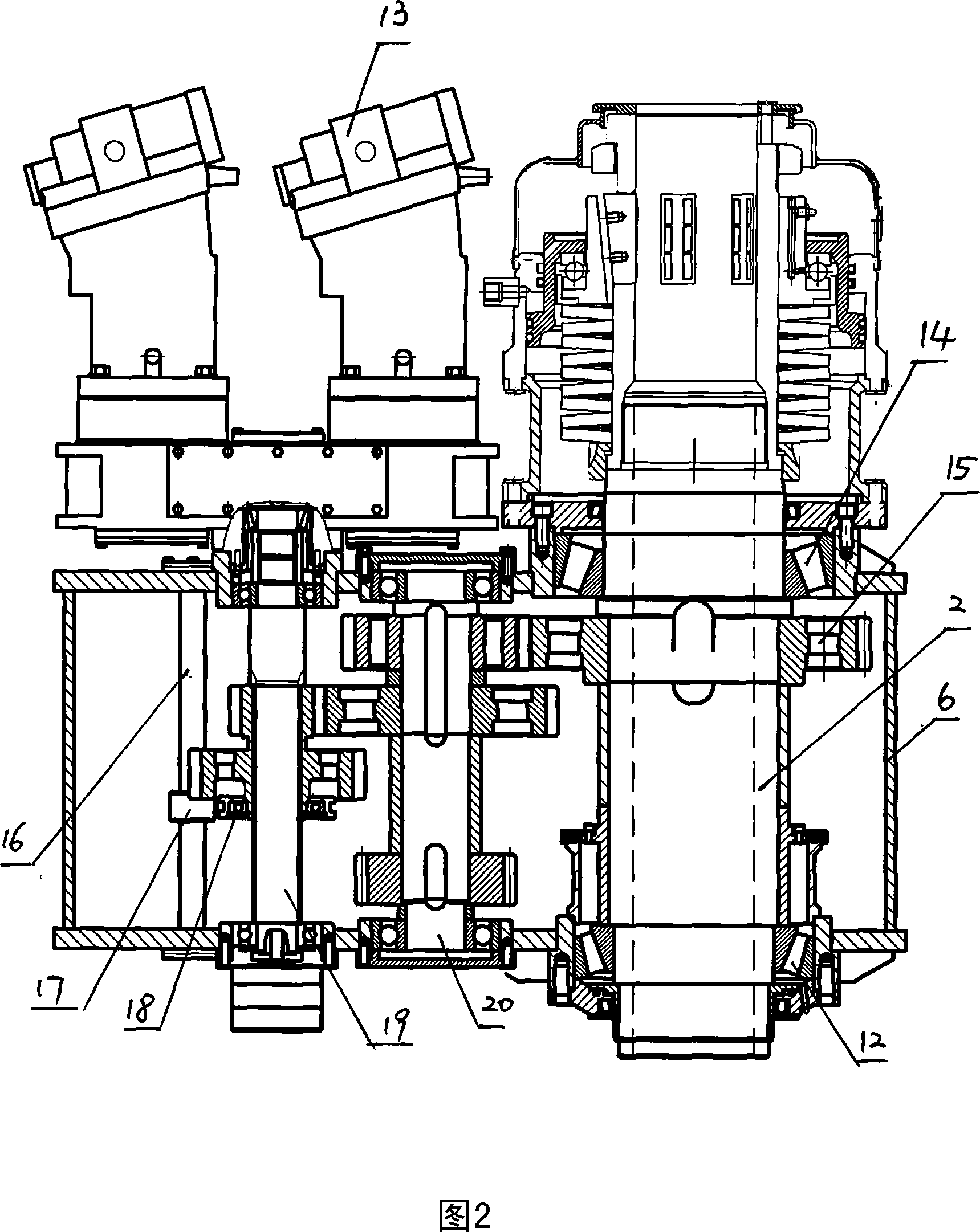

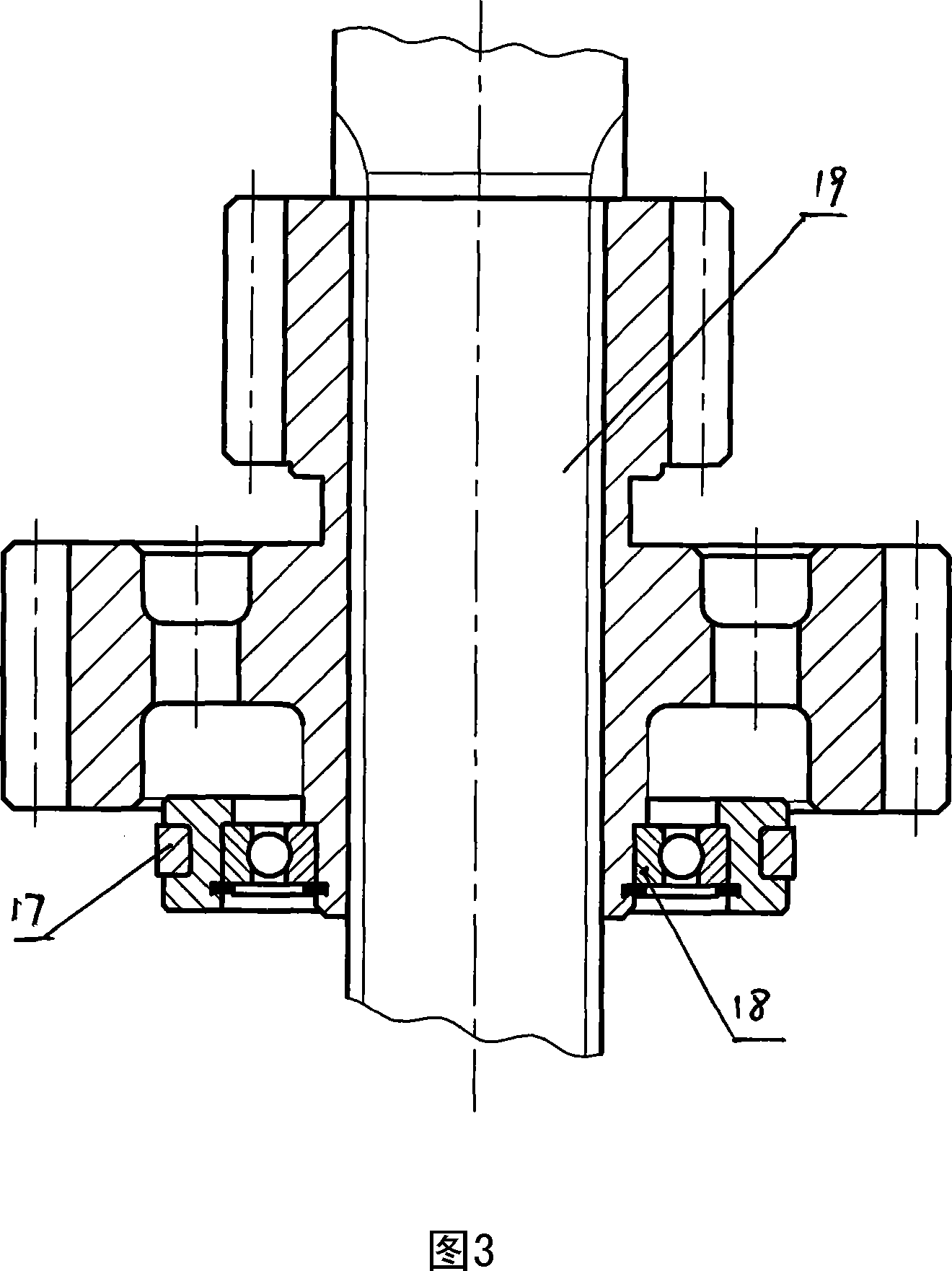

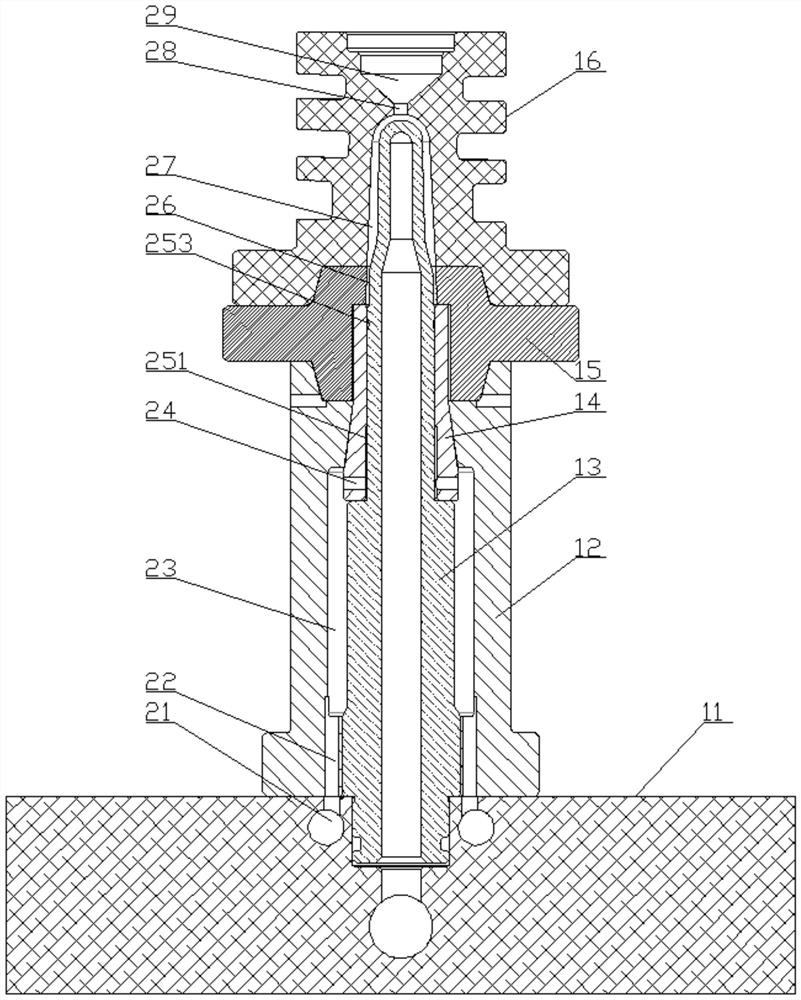

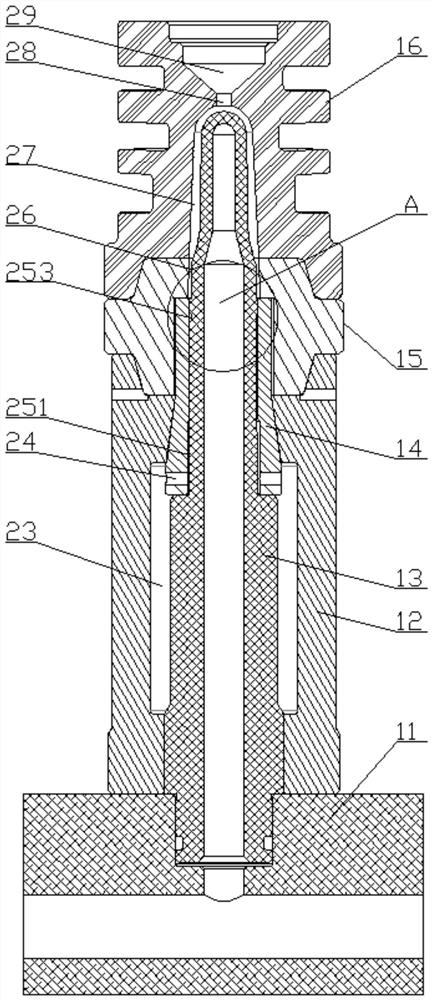

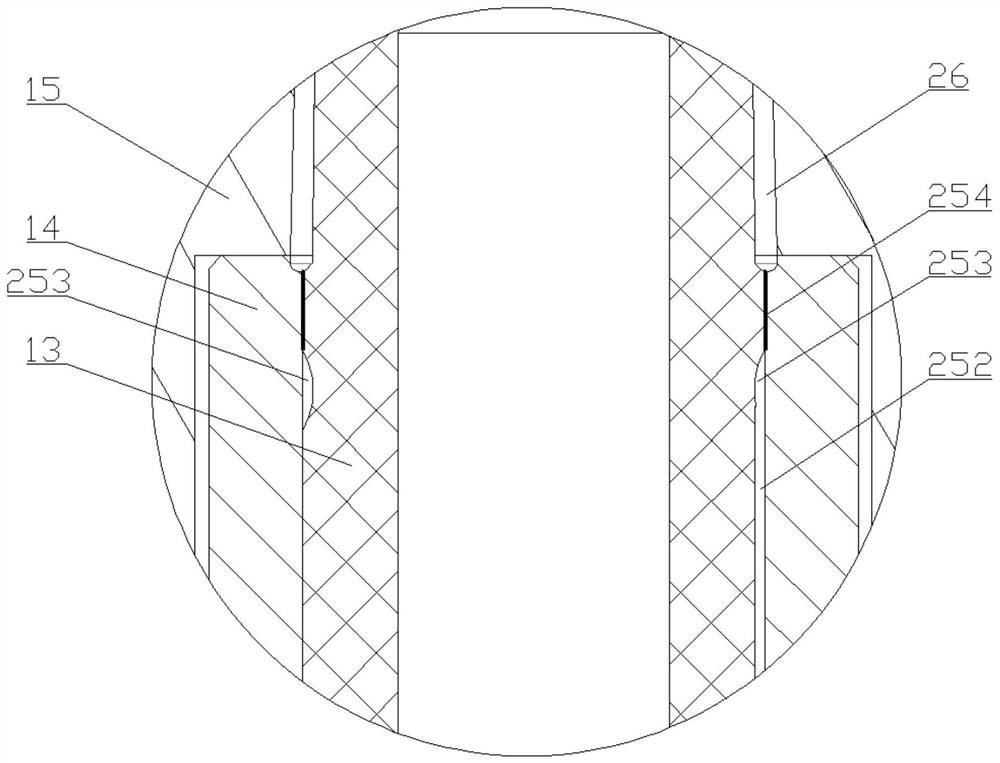

Full hydraulic rock core drilling machine unit head

InactiveCN101105112APrevent flowExtended service lifeConstructionsRotary drillingHydraulic motorGear drive

A power head for all-hydraulic operated drill is driven by double hydraulic motor and adopts the mode of power input, double-geared drive, hydraulic stepless speed regulation, hydraulic chuck clamping and long-travel feeding. A middle and lower labyrinth seals and a skeleton oil seal form a three-layer sealing device of a main shaft of the drill power head. The drill is lubricated by using mixed lubricating grease and thin oil. The middle part realizes labyrinth sealing by matching a supporting sleeve and a rotary plate, so as to provide a lower end bearing sufficient accumulated grease and heat dissipation space, guarantee the reliable lubrication and heat dissipation of the bearing, and increase secondary oil splashing and splash lubrication effect. The lower part realizes labyrinth sealing by matching an oil removal driving disk and an end cover, so as to effectively preserve and retain lubricating grease in the lower bearing box. The main shaft operates at high speed to cause temperature rising, and when the lubricating grease is diluted, its loss can be effectively prevented. The lower skeleton is oil sealed to prevent backflow and splashing of the drilling fluid, and further prevent the outer discharge of the lubricating grease when being diluted to take secondary protection effect.

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

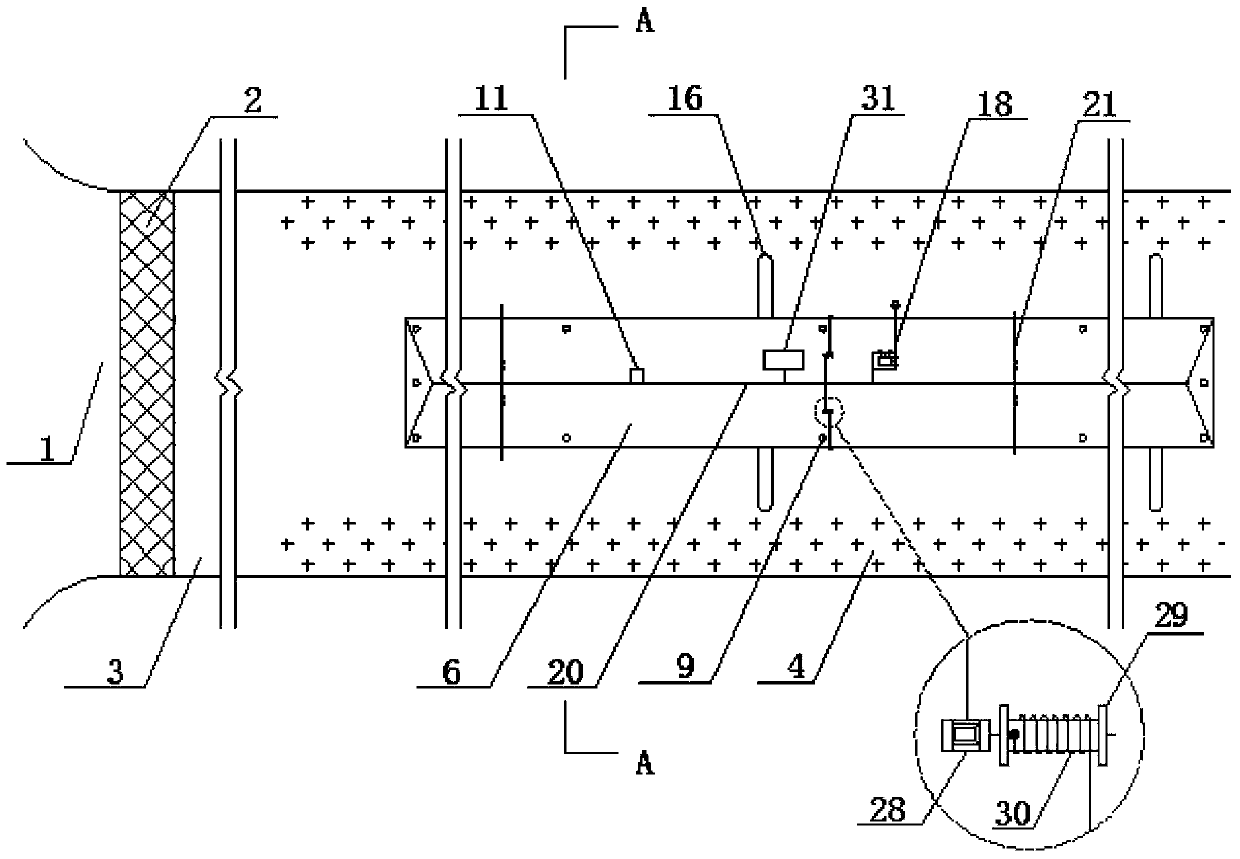

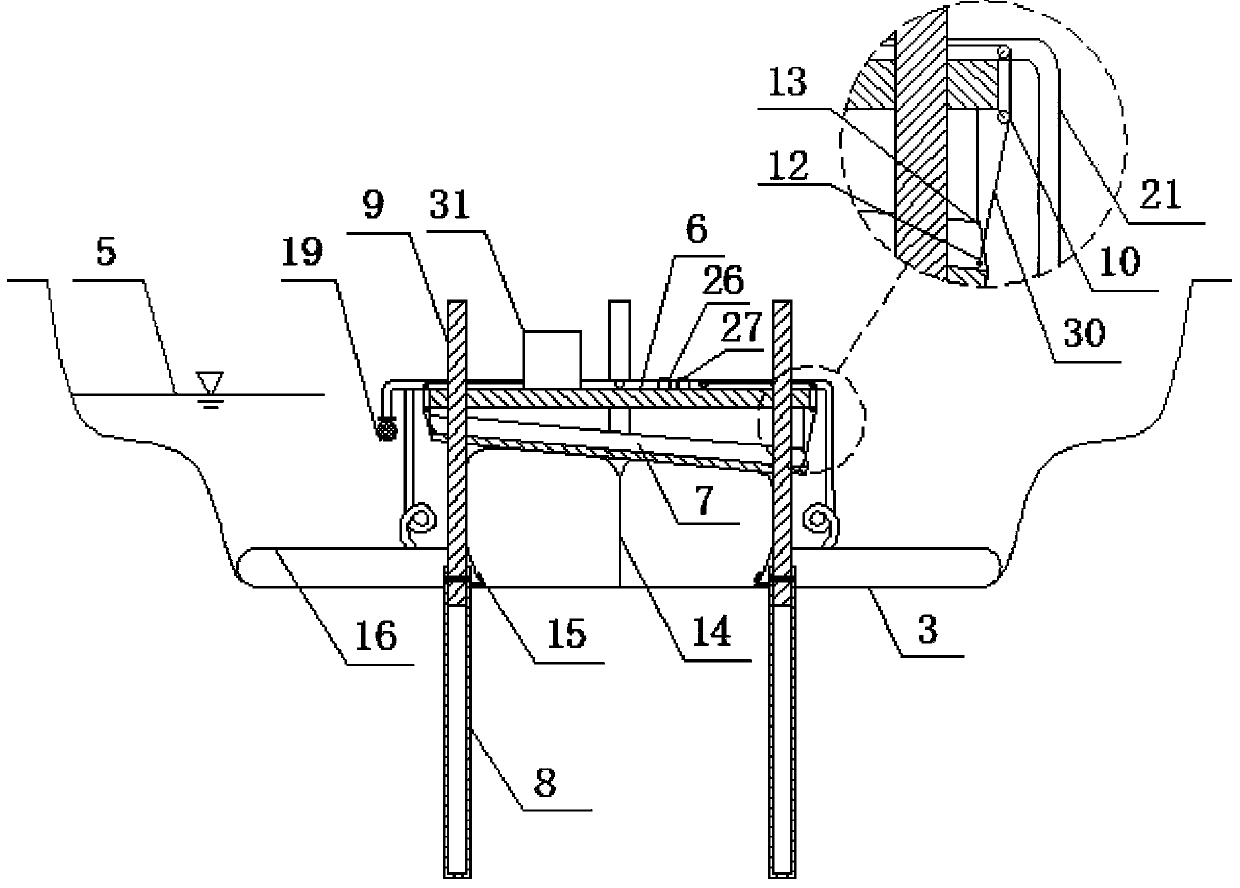

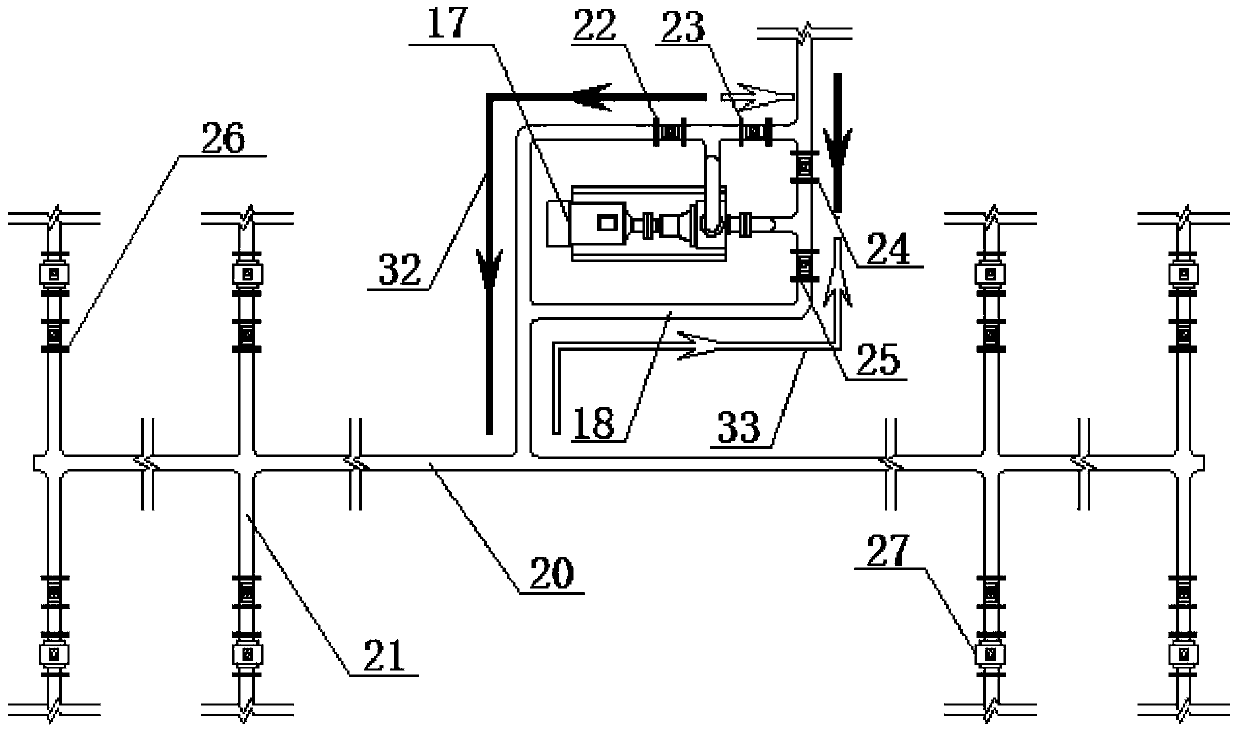

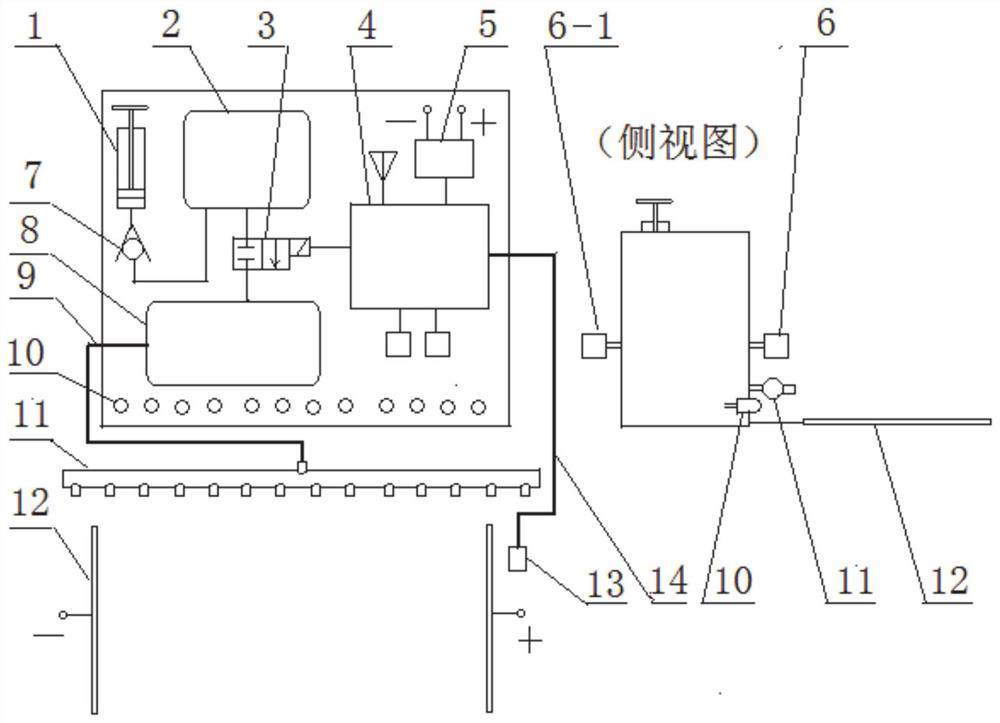

Device and method for regulating and controlling ecological water requirement in dry seasons of riverway bankside zone under dam

ActiveCN103741642ASatisfy the guarantee rate of ecological water demandWill not affect normal service functionClimate change adaptationHydraulic engineering apparatusDry seasonWater volume

The invention discloses a device and a method for regulating and controlling ecological water requirement in dry seasons of a riverway bankside zone under a dam. The device comprises an architecture device, a height adjustment device, a charge / discharge device, a pendulous device and a central control device. The invention also provides a method for regulating and controlling the ecological water requirement in dry seasons of the riverway bankside zone under the dam by using the device. The device is capable of running independently or running according to dispatching in combination with an upstream reservoir; the device does not increase, and even reduces the discharged volume under the dam in the dry seasons while meeting the basic requirements such as normal floodwater draw-off, shipping and upstream reservoir water supply, and therefore, effective regulation and control on the ecological water requirement of the bankside zone near the device can be realized; the water level of the riverway bankside zone under the dam can be remarkably banked up, and also the water level pulse amplitude of different areas can be flexibly controlled; and therefore, the assurance rate of the ecological water requirement in the dry seasons of the riverway bankside zone under the dam is achieved, and the uneven seasonal distribution problem of the water volume and the contradiction between the water conservancy project construction and the downstream ecological water requirement are solved.

Owner:HOHAI UNIV +1

Production method of copper ammonia/viscose/linen cotton fiber blended fabric

The invention discloses a production method of a copper ammonia / viscose / linen cotton fiber blended fabric. According to the production method, selected warp and weft materials are as follows in parts by mass: 30-50 parts of copper ammonia fibers, 15-25 parts of linen fibers, 40-90 parts of viscose fibers, 20-40 parts of combed cotton and 8-18 parts of ultrafine fine denier polyester. A step of slashing in the production process comprises the specific steps: (1) mixing size: adding water into a size mixing bucket and raising the temperature of the water to 50 DEG C, adding a pre-dyeing agent, wherein the adding mass of the pre-dyeing agent is 15-18% of that of water, starting a stirrer and adding solid PVA (Polyvinyl Acetate) at the mass ratio of the solid PVA to the water of (1-4) to 80, raising the temperature to 90 DEG C, and stirring and dissolving to prepare slurry; and (2) sizing: sizing by adopting a slashing machine, wherein size in a size tank does not need to be heated. The yarns of the sizing procedure are subjected to sizing by adopting the PVA with the concentration which is not higher than 4%; the sizing rate is low, size skins are not easy to form by a sizing agent and desizing is easy to carry out by post-finishing; and meanwhile, the sizing agent can be stored after being prepared and can be used at any time in future, and does not need to be prepared when being needed, so that the energy and time are saved.

Owner:SUZHOU CHENHENG WEAVING

Laser-Optical Position Detecting Module

ActiveUS20120224188A1Maintain accuracyKeep goingUsing optical meansInput/output processes for data processingLaser lightLaser optics

The present invention relates to a laser-optical position detecting module with a laser light source, comprising: laser mode conversing assembly, having a laser source capable of emitting a time-modulated laser beam; a laser mode conversing unit, used to expand the time-modulated laser beam to a two-dimension sensing plane; a drive control unit, adopted for driving the laser source to emit the time-modulated laser beam; and a detector matrix, used for detecting the. The laser mode conversing unit has a phase delay device and a passive optical device capable of reflecting the light; so that, through the laser mode conversing unit, the laser-optical position detecting module can expand the light emitted by the laser source to the two-dimension sensing plane without using any other mechanical scanning; moreover, it make the energy of the light emitted by the laser source not easily decays, so as to maintain the accuracy of light detection.

Owner:NATIONAL TSING HUA UNIVERSITY

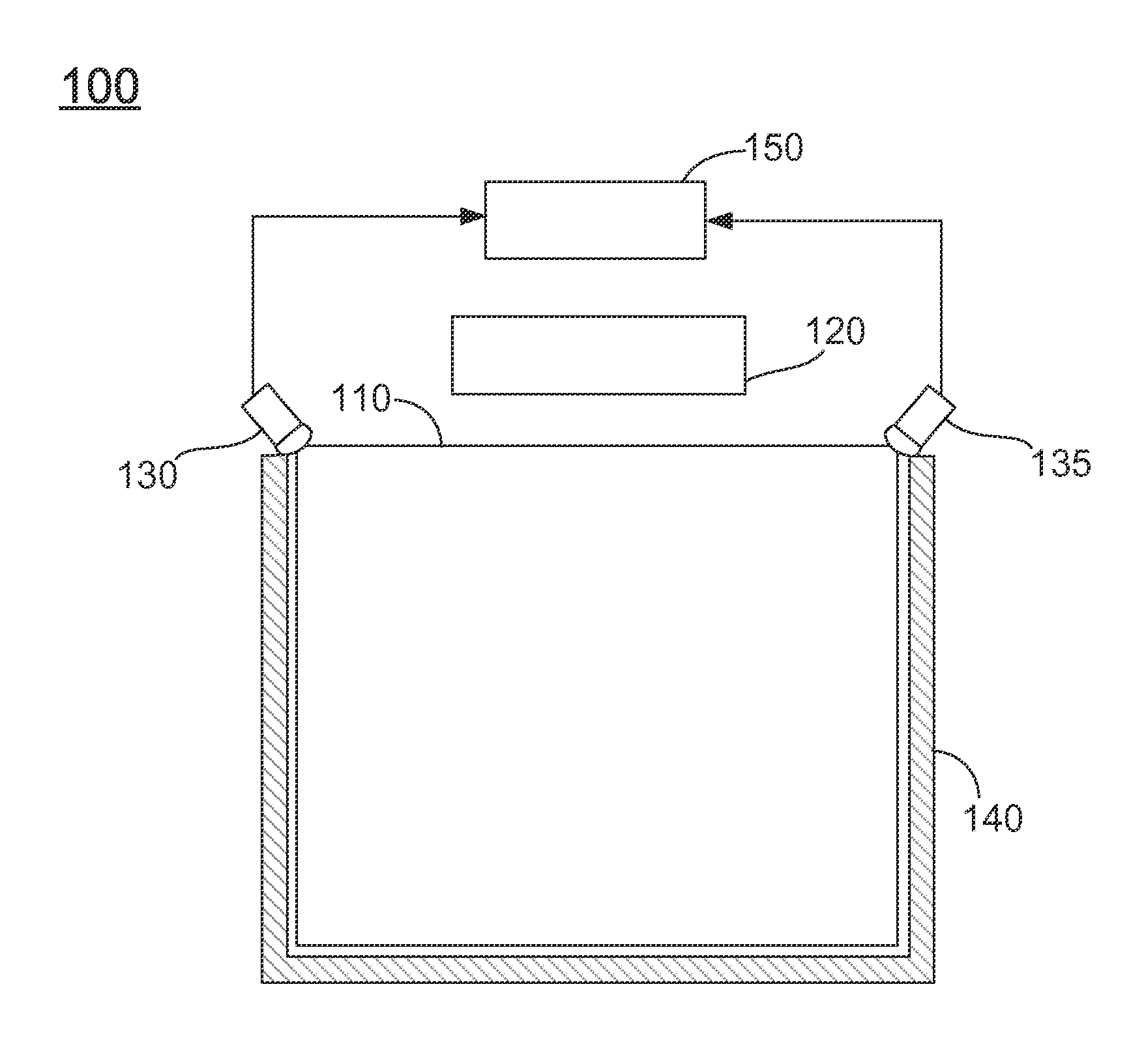

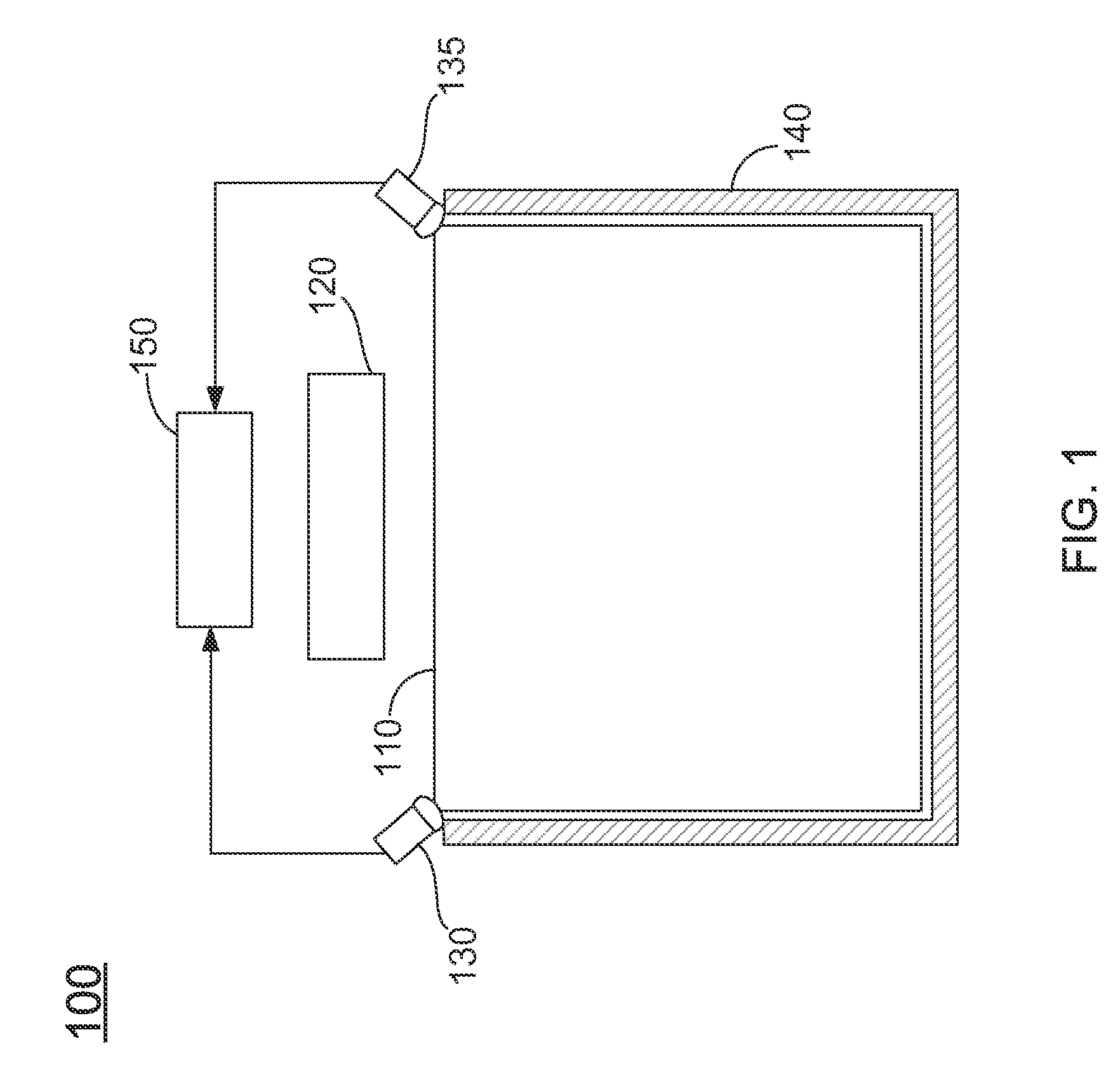

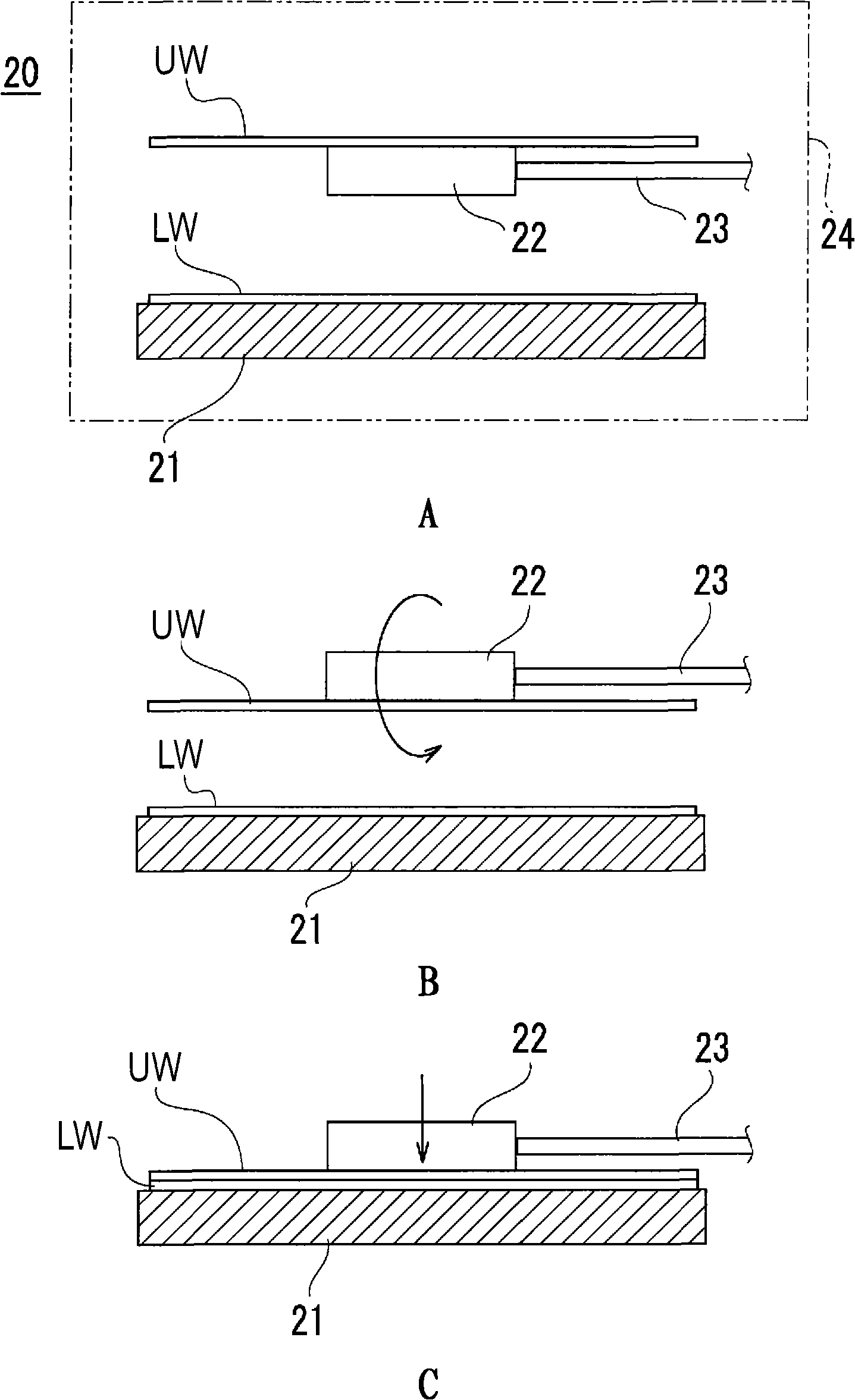

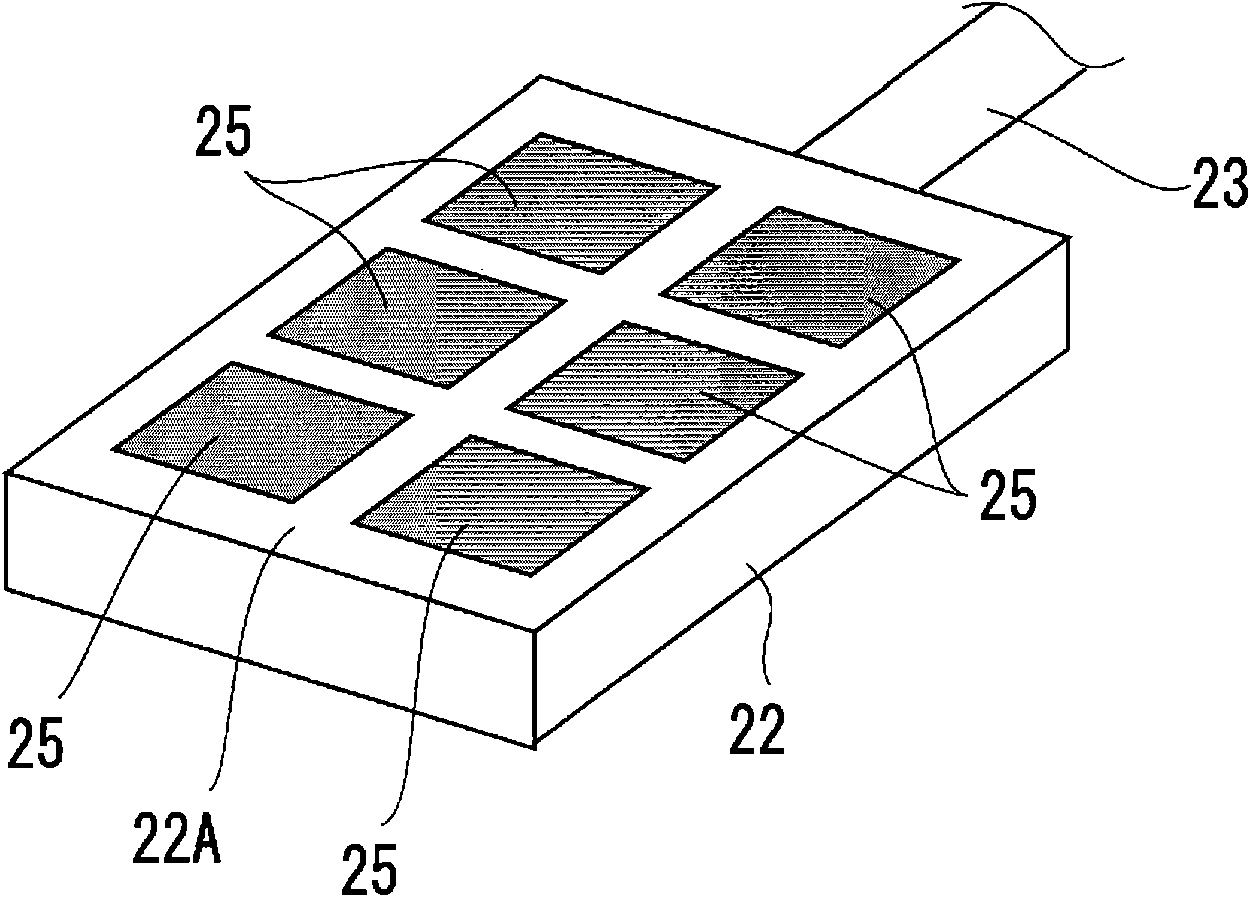

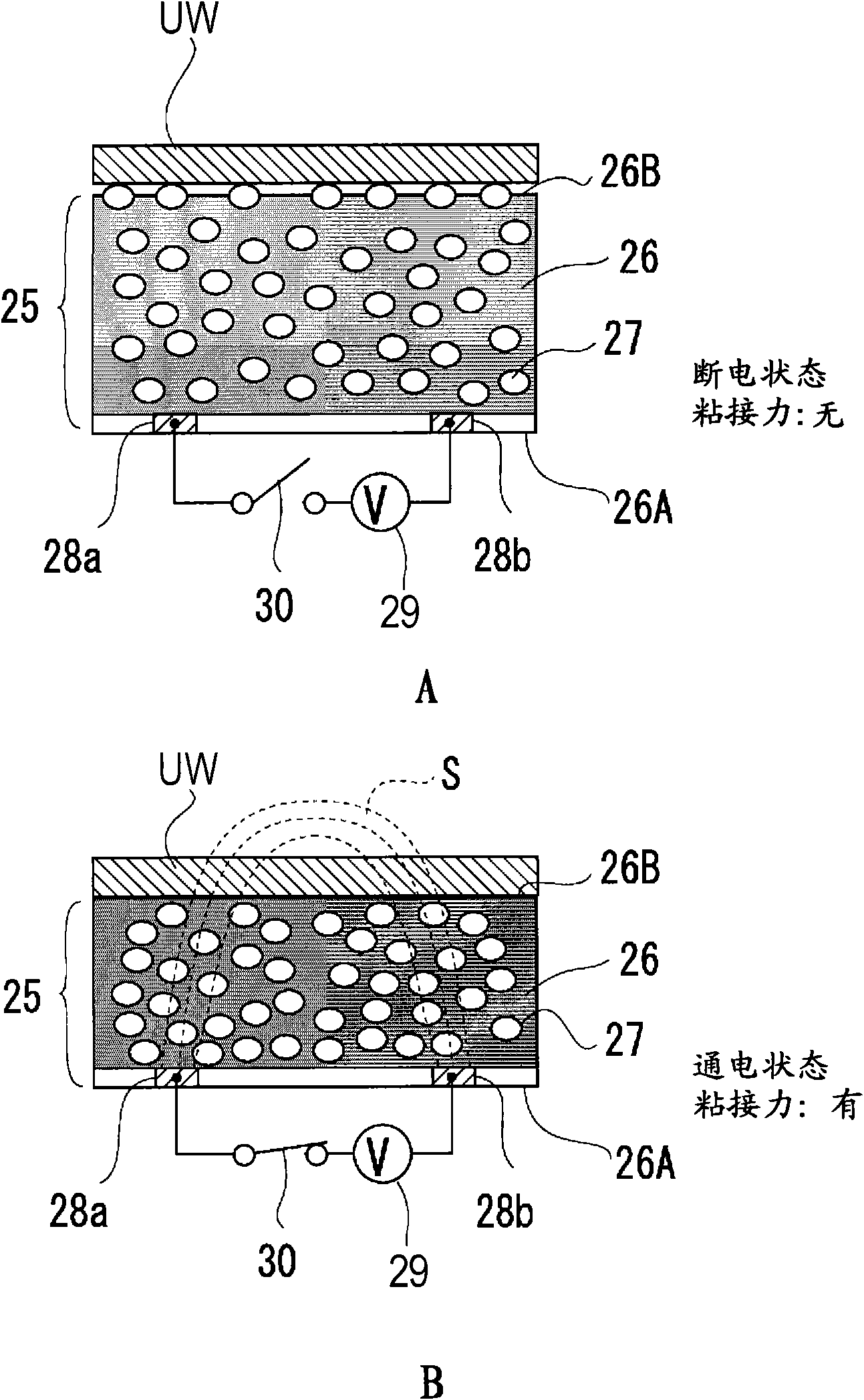

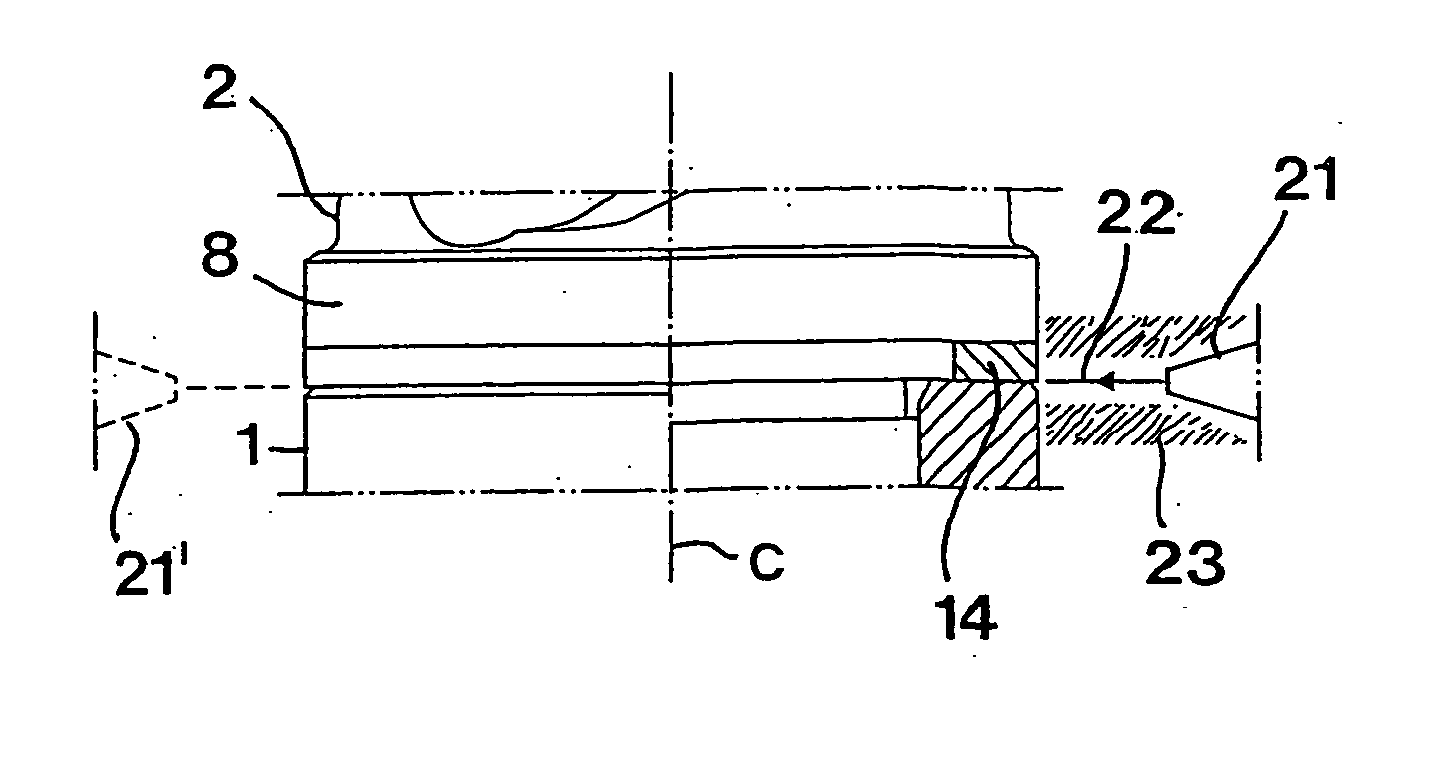

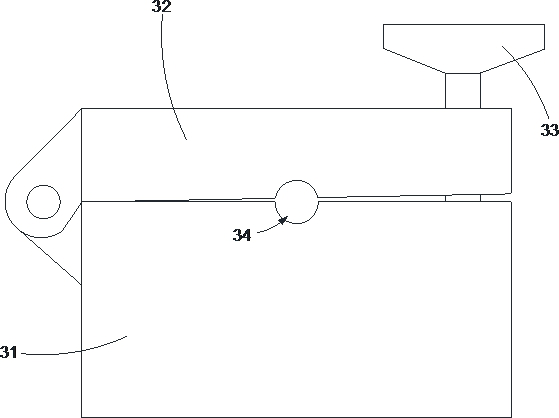

Substrate holding mechanism and substrate assembling apparatus provided with the same

ActiveCN101669199AKeep goingSimple structureConveyorsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A substrate assembling apparatus (20) is provided with a supporting table (21) and a holding mechanism (22). The supporting table (21) supports a lower substrate (LW). The holding mechanism (22) is provided with a holding surface and a functional element. The holding surface holds the upper surface of an upper substrate (UW). The functional element is arranged on the holding surface and varies a holding force by the level of a voltage. The holding mechanism makes the lower surface of the upper substrate (UW) face the upper surface of the lower substrate (22) supported by the supporting table (21). Thus, the force for holding the substrate (UW) can be electrically controlled, and the configuration of the holding mechanism is simplified. Furthermore, since the holding force of the substrate(UW) can be smoothly varied, the holding mechanism can always correctly hold and release even a thin substrate.

Owner:ULVAC INC

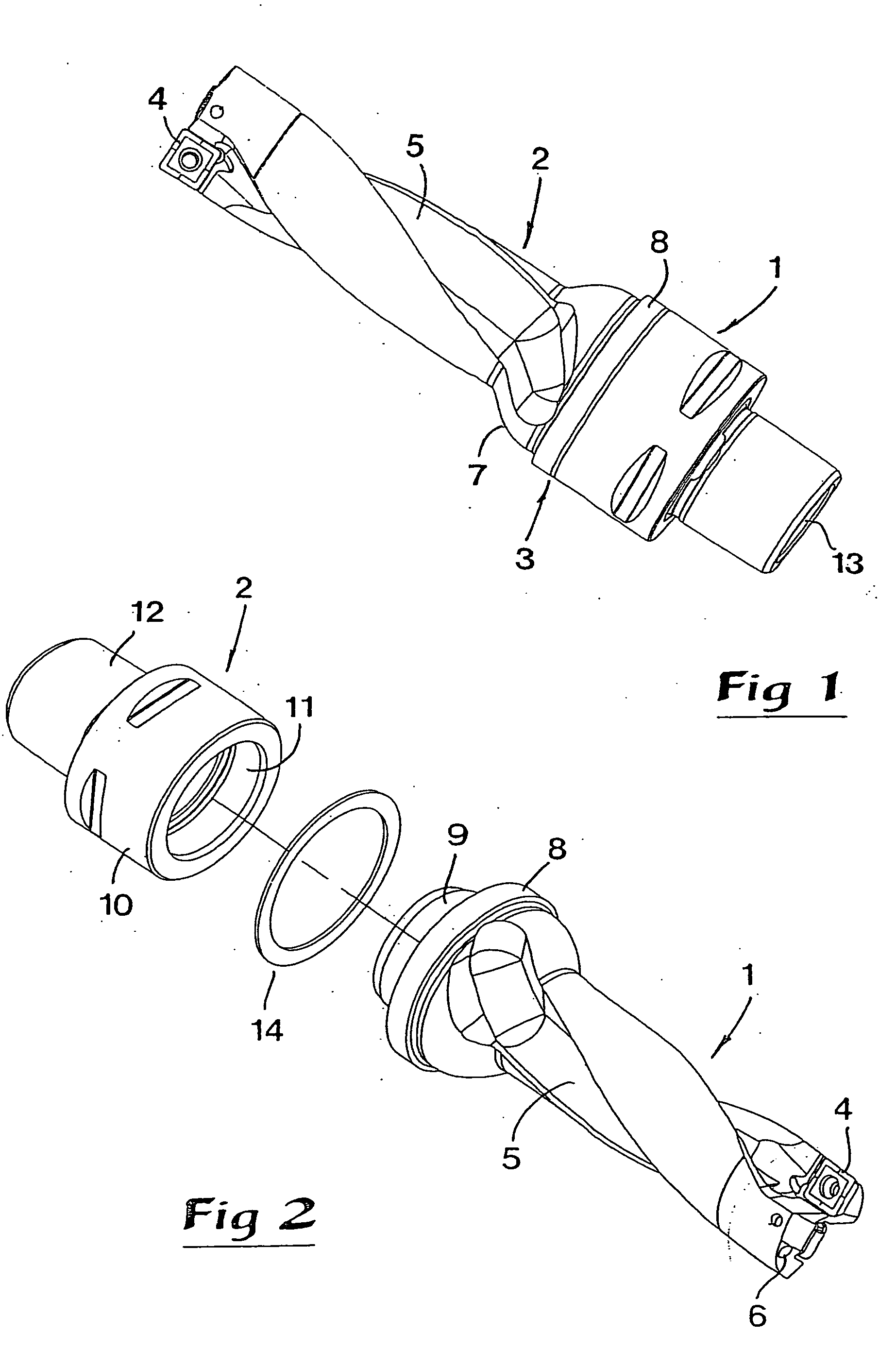

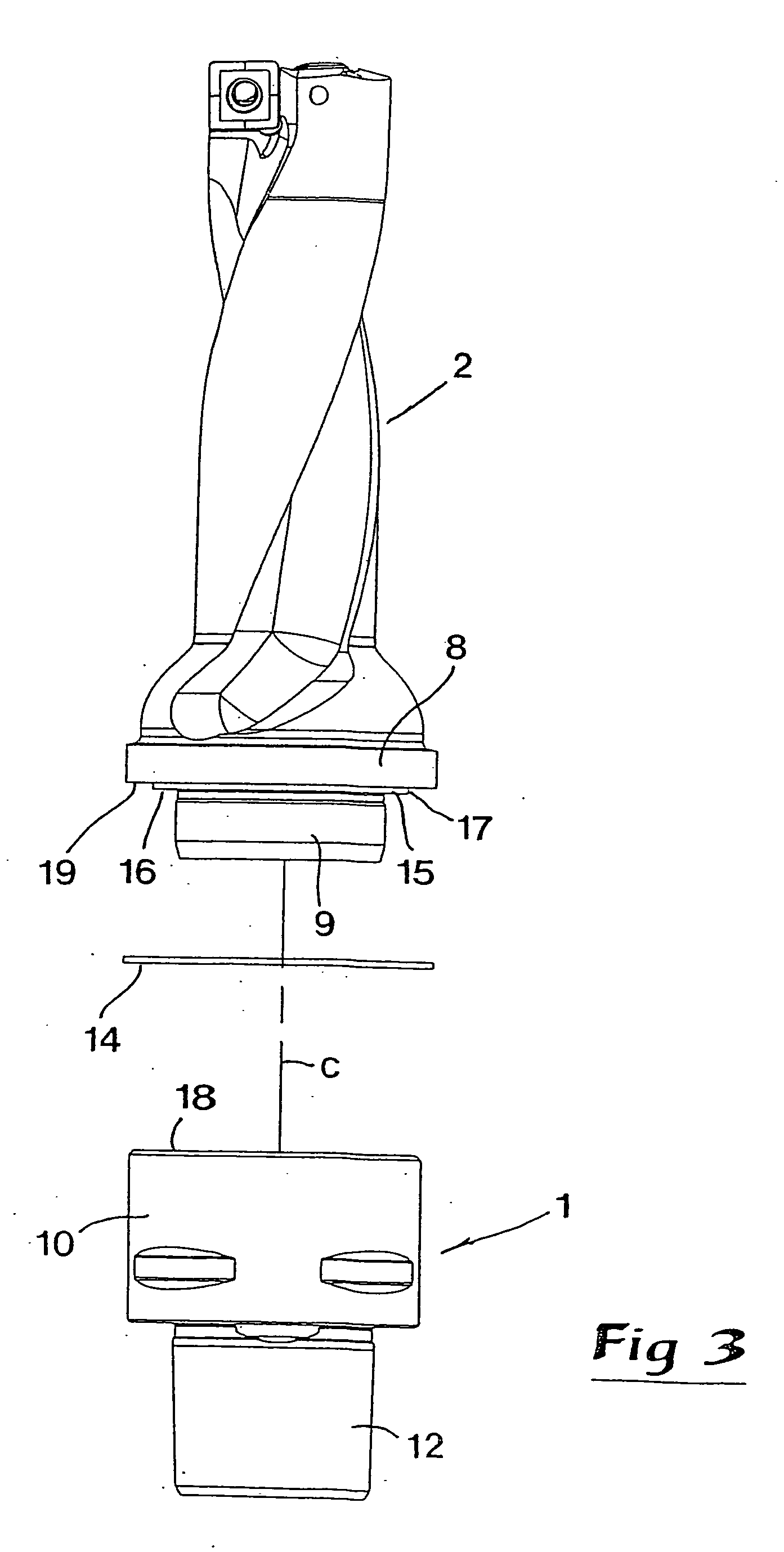

Cutting tool and a method for the manufacture thereof

InactiveUS20050133487A1Improve accuracyKeep goingDrill bitsTool workpiece connectionEngineeringMachining

A tool for chip-removing machining includes first and second metallic parts, and a metallic shim disposed within a gap between those parts. An outer periphery of the shim is exposed. A laser welding procedure is performed around the exposed outer periphery of the shim to weld the shim to the first and second parts. The procedure involves positioning a welder in a first position to weld the shim to one of the first and second parts, and then repositioning the welder to a second position to weld the shim to the other of the first and second parts.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

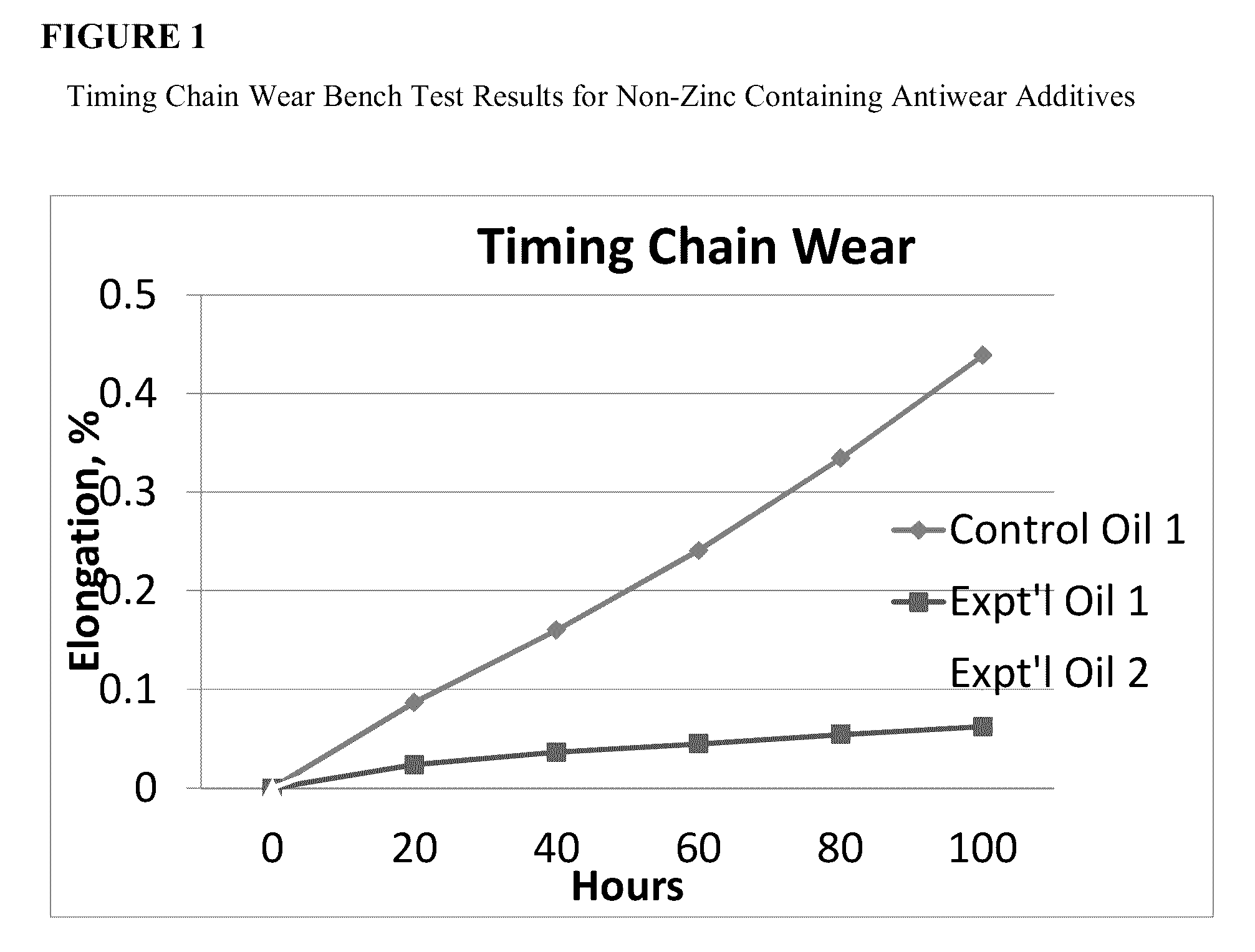

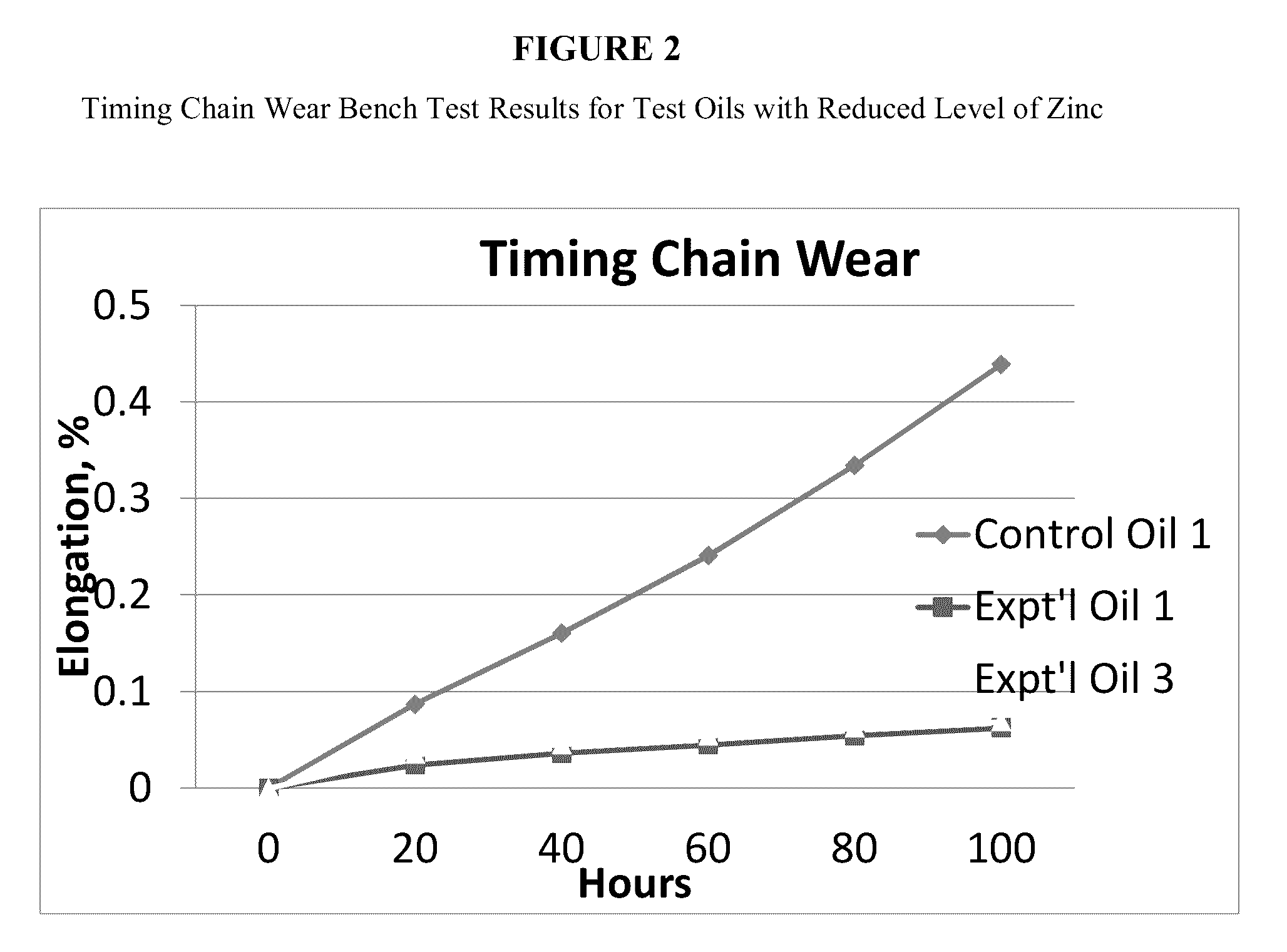

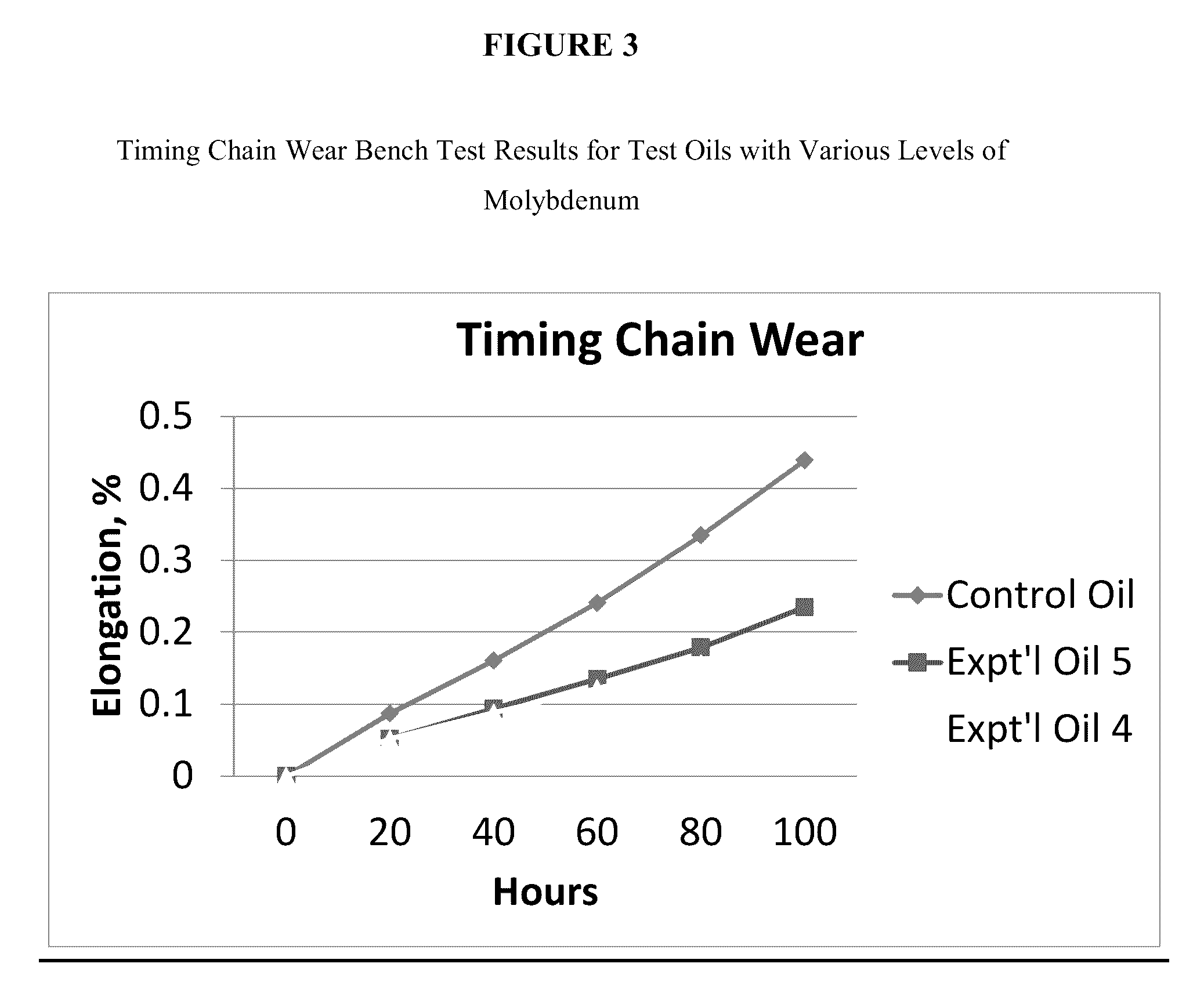

Lubricant additive for reducing timing chain wear

ActiveUS20160326451A1Impart antioxidant propertySufficient protectionAdditivesGearing detailsOrganophosphorous compoundsZinc

A lubricant composition is provided which mitigates the negative effect of zinc in ZDDP with respect to wear on timing chains by using in contact with the timing chain a lubricant composition comprising an ashless zinc-free organophosphorus compound and optionally zinc dialkyldithiophosphate, together providing about 50 to about 1000 ppm phosphorus, preferably about 300-800 ppm phosphorus, and more preferably about 500-750 ppm phosphorus; less than about 350 ppm to lower than <1 ppm zinc from ZDDP; and at least about 100 ppm molybdenum from an organomolybdenum compound (preferably molybdate ester); wherein the Mo:Zn ratio is at least about 0.2:1 and the Zn:P ratio is lower than or equal to about 1.1:1; or in the alternative an organomolybdenum compound providing between about 300-700 ppm molybdenum, in combination with ZDDP providing zinc between about 200-800 ppm zinc, wherein the ratio of Mo:Zn ratio is at least about 0.4:1 to about 3:1.

Owner:VANDERBILT CHEM LLC

Preparation method for acrylic fibers/regeneration, silkworm bamboo fiber blended washable fabrics

InactiveCN104695108AImprove washing strengthImprove the problem of not being washableBiochemical fibre treatmentLiquid/gas/vapor removalPolyesterPolymer science

The invention discloses a preparation method for acrylic fibers / regeneration, silkworm bamboo fiber blended washable fabrics. The selected warp and weft material comprises, by weight, 40-90 parts of acrylic fiber, 20-45 parts of natural fiber, 6-12 parts of synthetic fiber, 60-95 parts of cotton fiber, 8-18 parts of super fine denier polyester, 50-90 parts of regenerated bamboo fiber, 11-20 parts of mulberry fiber, 1-8 parts of corn protein fiber, 5-8 parts of fine staple cotton fiber and 5-10 parts of villus fiber, wherein washable treatment and water-repellency treatment are sequentially between the slashing operation and air injection operation. The washable treatment is: dipping the fabrics in the composite rare earth finishing agent for 45-60 minutes and finishing the dipped fabrics with complex enzyme after drying. Through the reasonable proportion of the composite rare earth finishing agent, the preparation method for the acrylic fibers / regeneration , silkworm bamboo fiber blended washable fabrics can improve the washing strength of the regenerated bamboo fiber, solves the problem that the regenerated bamboo fiber blended fabrics is not washable, and improves the wear-resisting property of the bamboo fiber blended fabrics.

Owner:SUZHOU CHENHENG WEAVING

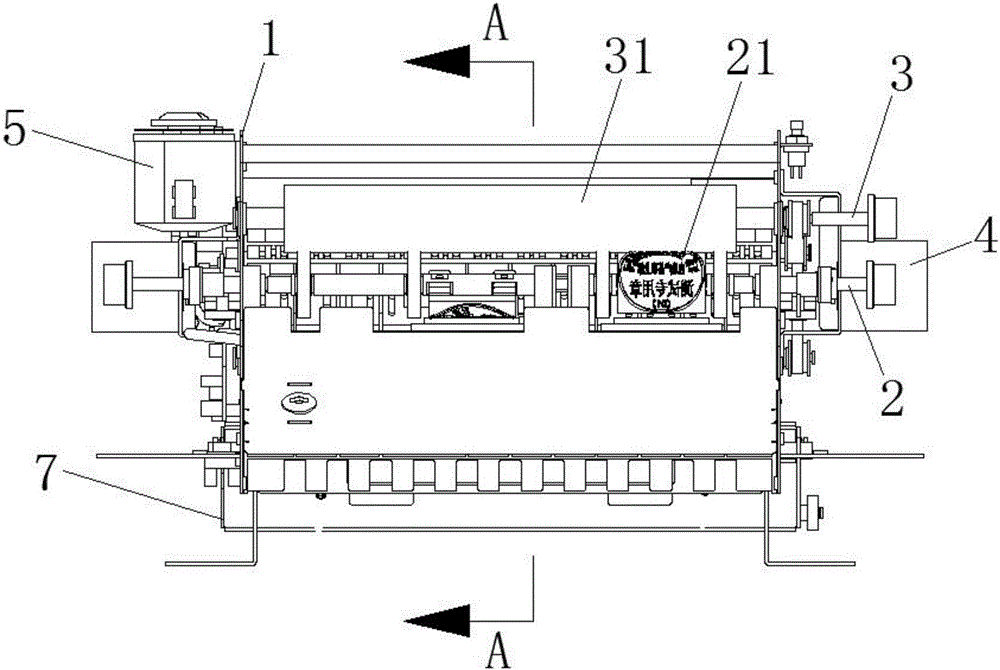

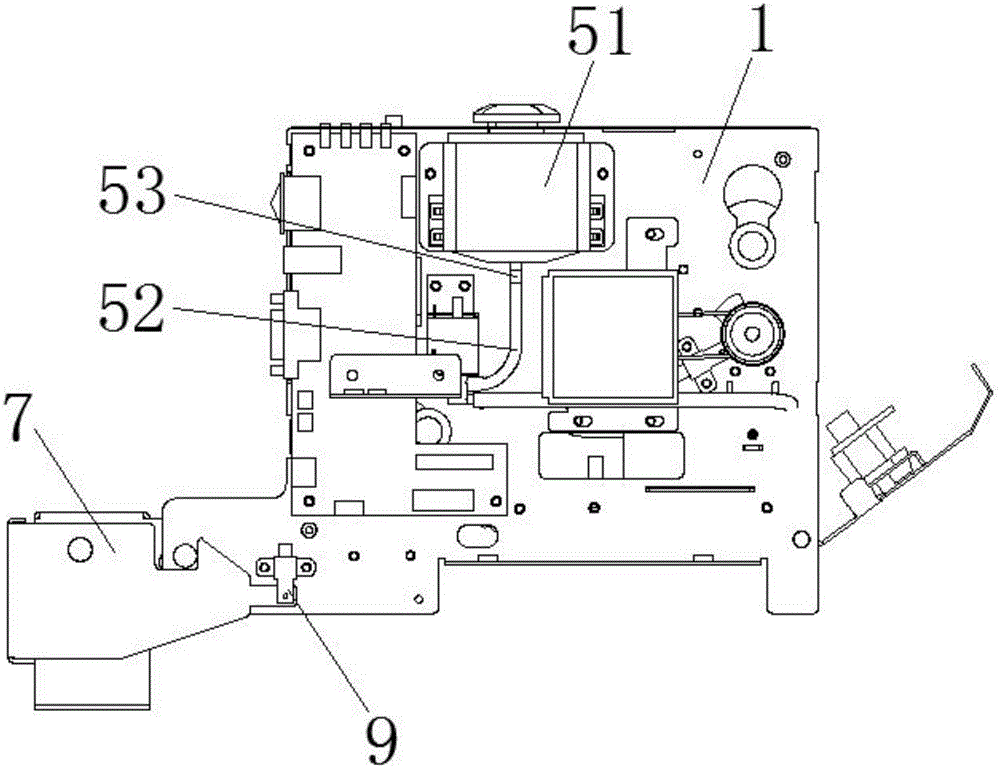

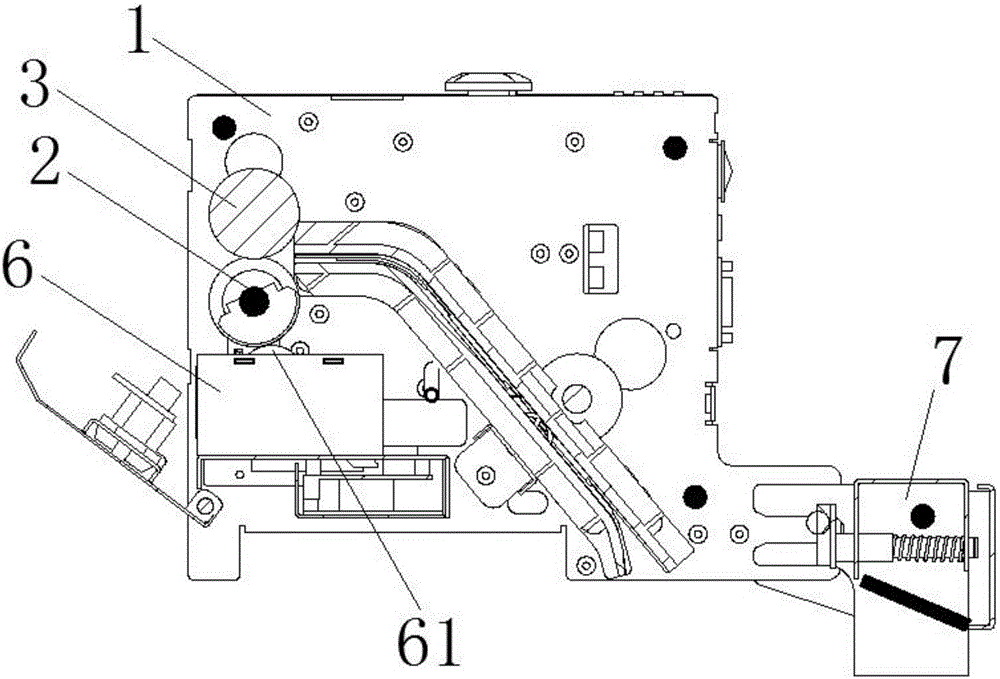

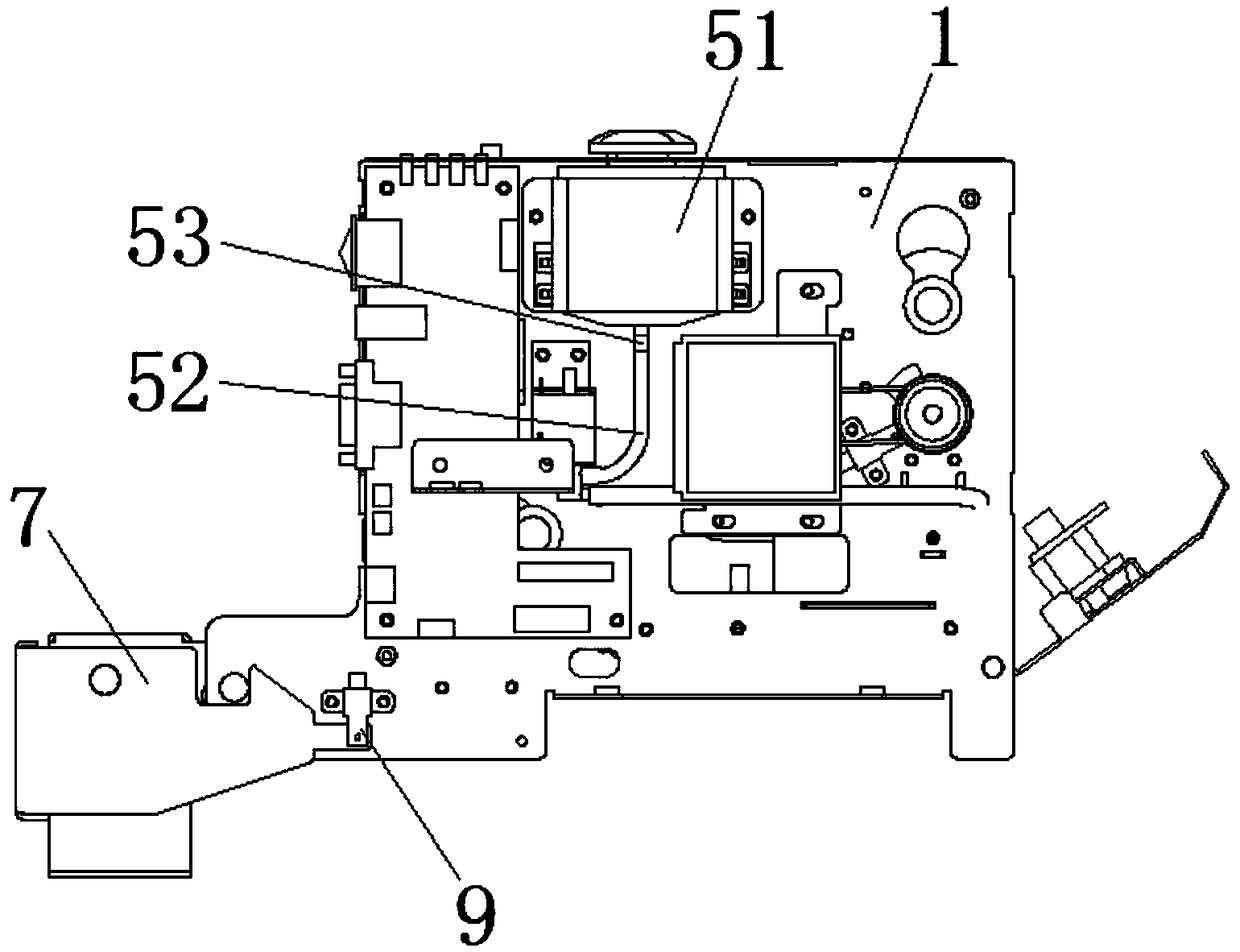

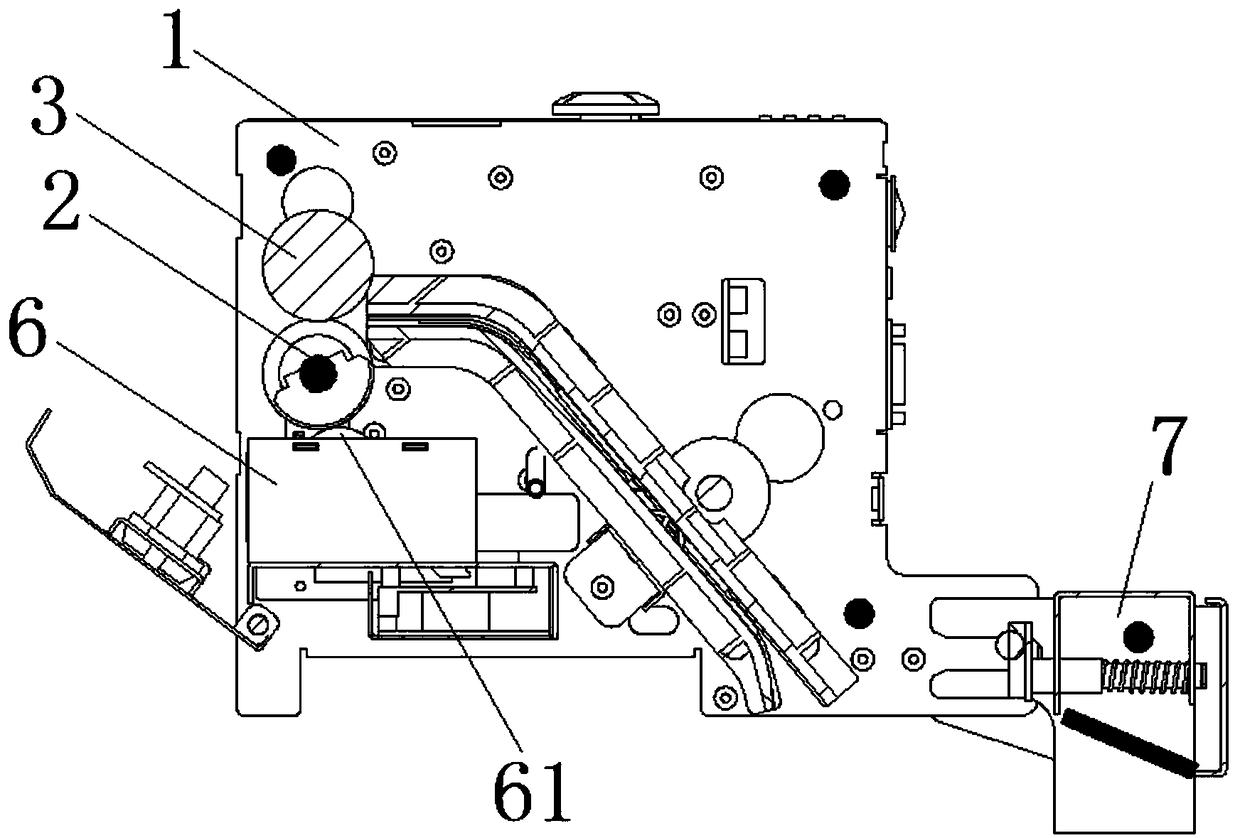

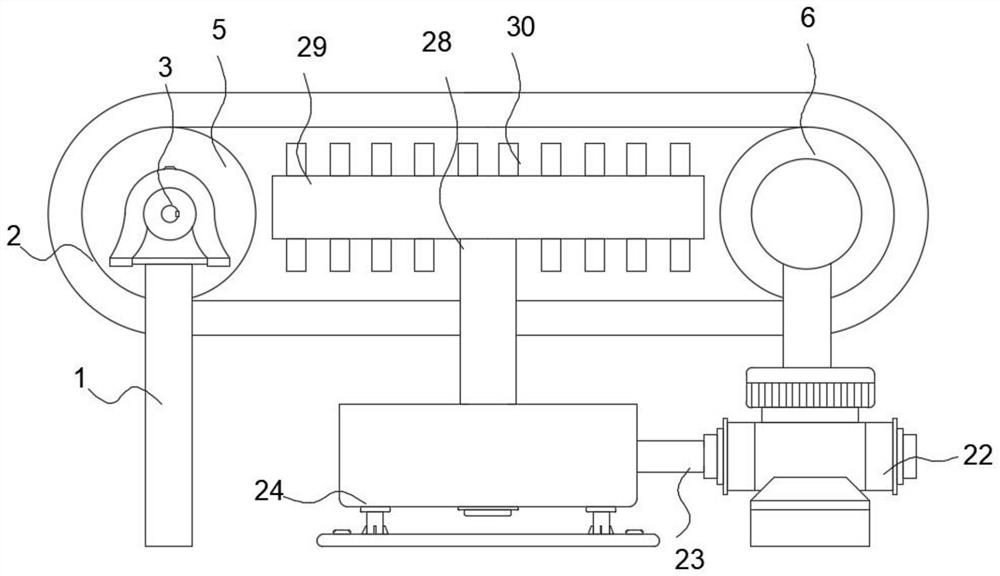

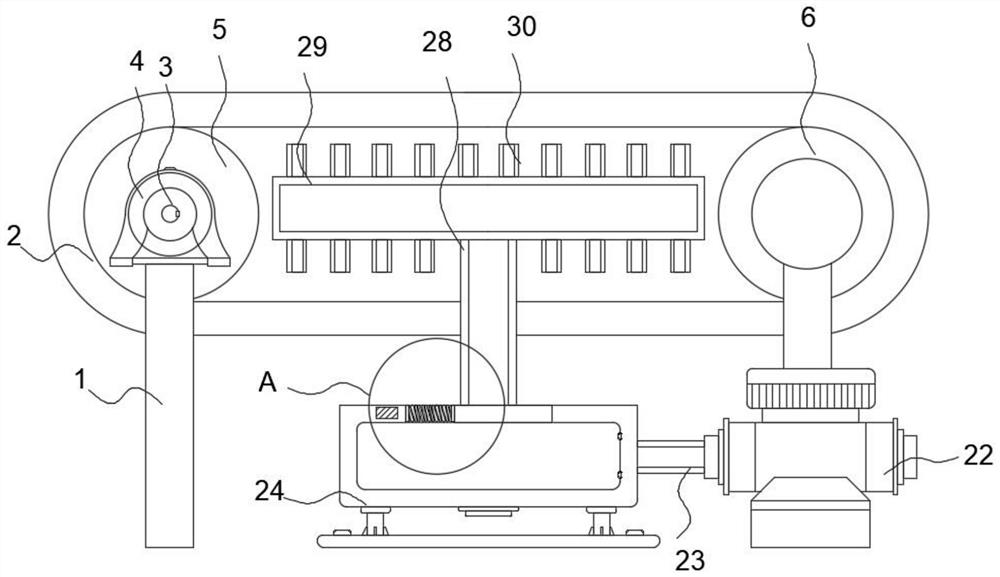

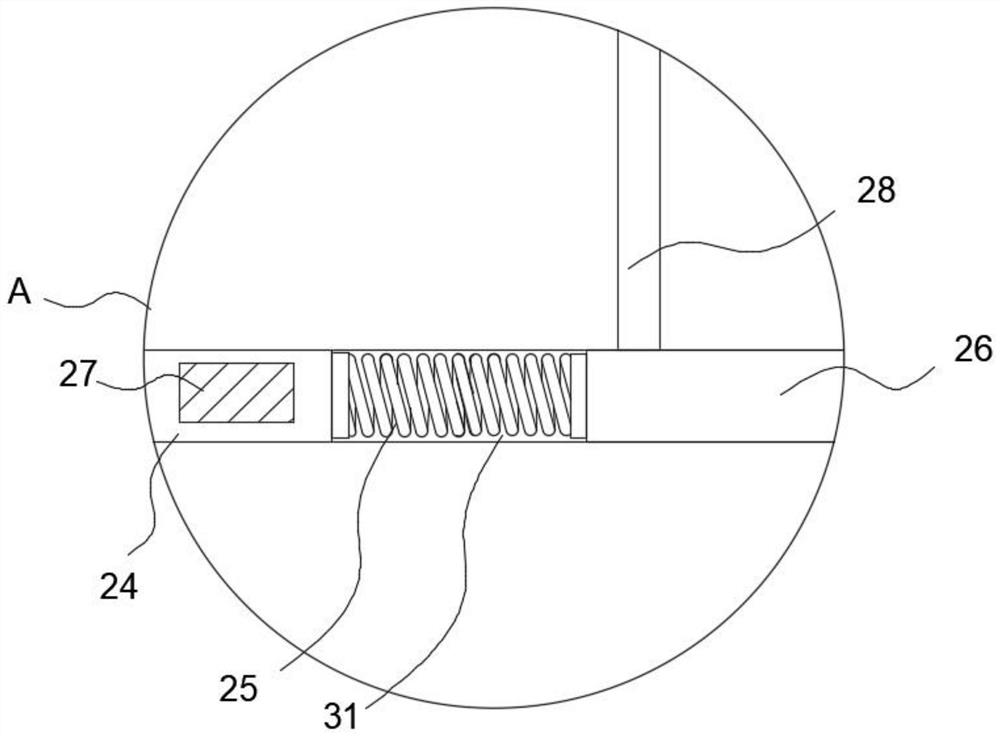

Automatic stamping machine

Disclosed is an automatic stamping machine. The automatic stamping machine comprises a machine frame, a stamp rotating shaft, a rolling rotating shaft, a driving mechanism, an automatic ink adding mechanism, a stamp ink box and a locating locking device. The stamp rotating shaft and the rolling rotating shaft are arranged on the machine frame in parallel in a rotating mode, and the stamp rotating shaft is located below the rolling rotating shaft. At least one rolling stamp is arranged on the stamp rotating shaft, and a rolling printing roller which corresponds to the rolling stamp in position is arranged on the rolling rotating shaft. The driving mechanism is installed on the machine frame and drives the stamp rotating shaft and the rolling rotating shaft to synchronously rotate in the opposite directions. The automatic ink adding mechanism automatically adds ink to the stamp ink box. First rolling wheel printing cotton which makes flexible contact with the rolling stamp is arranged in the stamp ink box. The machine frame and a printer are located and locked through the locating locking device. According to the automatic stamping machine, the relative position between the automatic stamping machine and the printer is accurately guaranteed through the innovative locating locking device, the probability of paper jams is reduced, and the stability and the reliability are improved. The first rolling wheel printing cotton makes flexible contact with the rolling stamp, and the service life is long. The automatic ink adding mechanism can achieve automatic and continuous ink addition.

Owner:GUOGUANG ELECTRONICS INFORMATION TECH

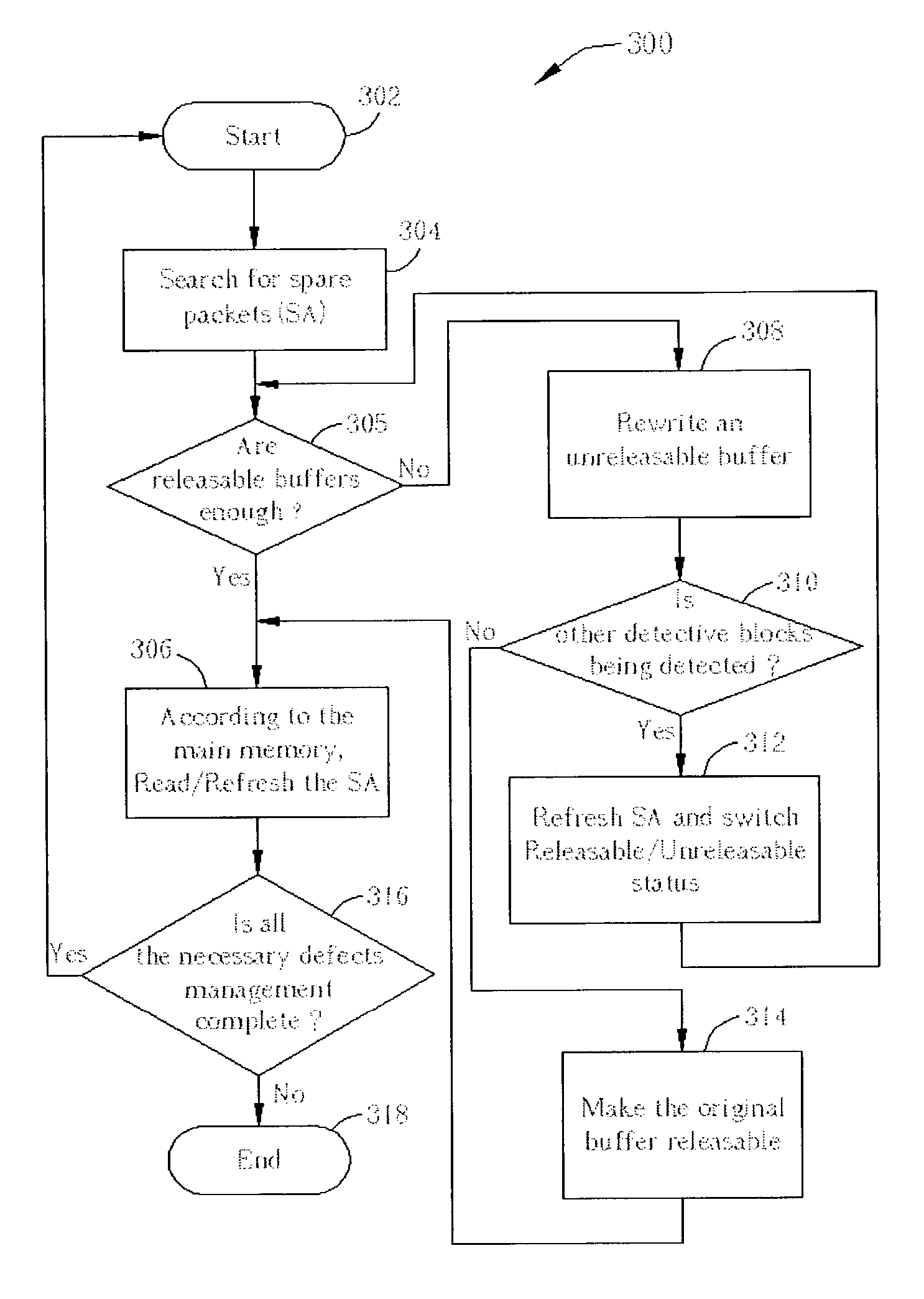

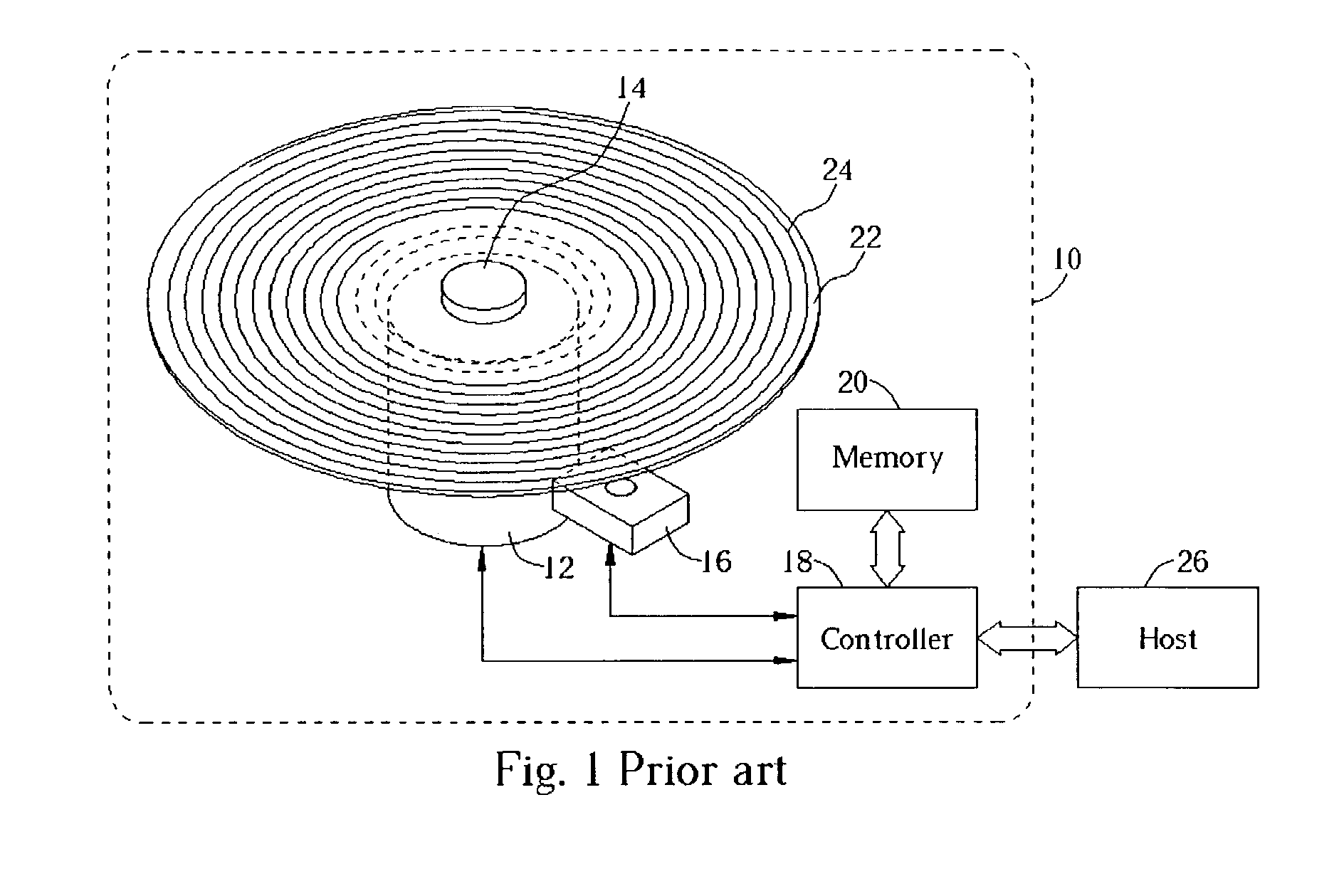

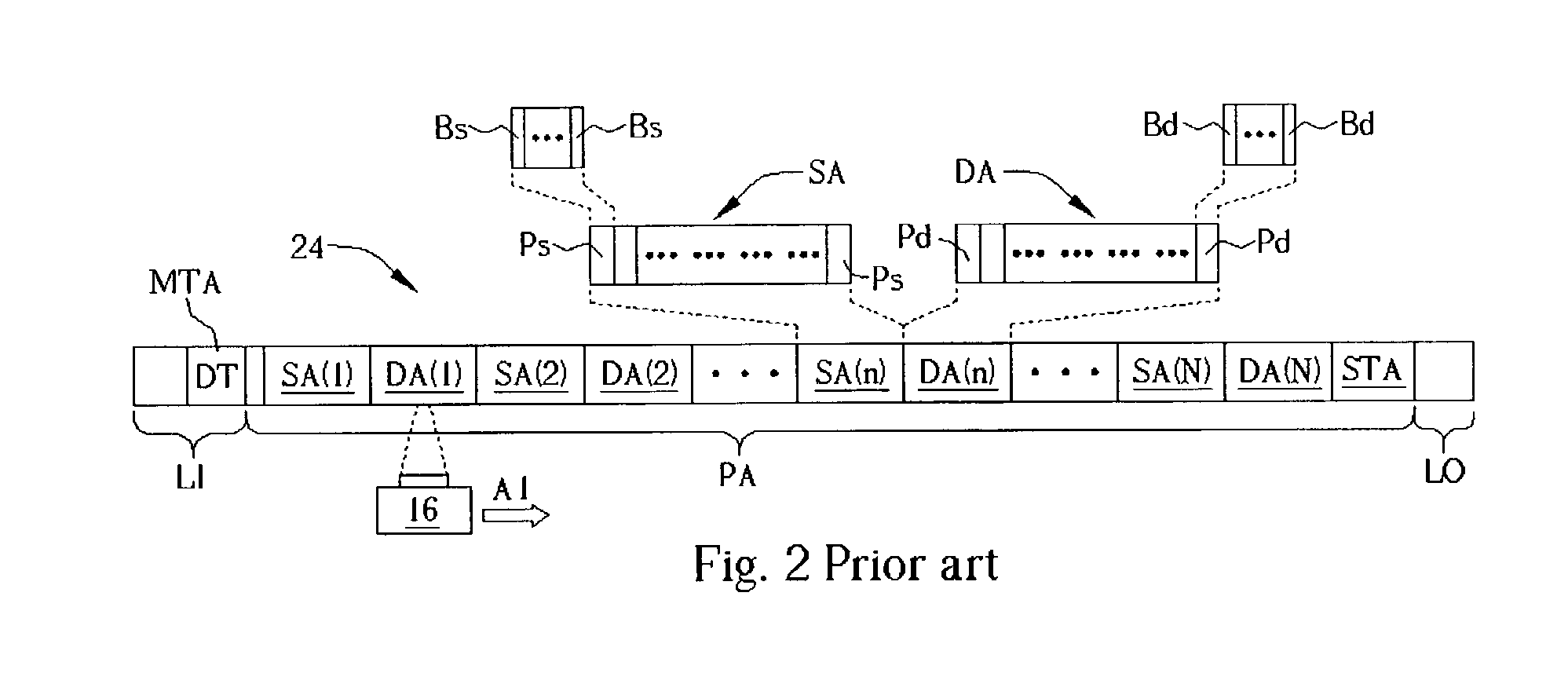

Method for managing defects of optical disk

InactiveUS7051232B2Easy to useSolve the real problemDisc-shaped record carriersData buffering arrangementsNetwork packetData buffer

A method for accessing data on an optical disk by a drive. The optical disk includes spare packets and data blocks. Each data block is for recording data written to the optical disk, and each spare packet has spare blocks for replacing defect blocks to record data. The drive has a memory allocated with buffers, and each buffer is for recording data of a spare packet. When writing data of a first buffer to a packet of the optical disk, if a plurality of first spare blocks are found defective, then searching a second spare packet which has spare blocks for replacing the first blocks. If the second spare packet is not read in a buffer, reading the second spare packet into a releasable buffer. After copying data written to the first spare blocks from the first buffer to the second buffer, making the first buffer releasable.

Owner:MEDIATEK INC

Composition and method for dust suppression wetting agent

ActiveUS20120000361A1Keep goingAvoid spreadingUsing liquid separation agentSeparation devicesParticulatesWater based

This disclosure teaches a composition and process which makes it possible to remove floating particulates or prevent the dissemination or particulates, by the misting of a solution that readily captures any particulate material in the air. More specifically, the present disclosure teaches the composition and use of aromatic compounds that are semi-volatile organic compounds (SVOCs) or slow evaporators in water-based carriers with surfactants as the misting / fogging agent for dust suppression. The particulate material is lowered to surfaces and removed by vacuuming, damp-wiping or using a dry cloth with a cationic charge (static cloth). This method can be achieved with neutral air pressure differentials in the work areas.

Owner:CASHMIR

PET bottle blank processing assembly and PET bottle blank processing method

The invention relates to a PET bottle blank processing assembly and a PET bottle blank processing method. The PET bottle blank processing assembly comprises a mold and a reverse blowing cleaning mechanism, wherein the reverse blowing cleaning mechanism is connected with the mold; an injection molding cavity is formed in the mold, a main air hole and an injection molding hole are formed in the positions, located at the two ends of the injection molding cavity, of the mold correspondingly, and the main air hole and the injection molding hole communicate with the injection molding cavity correspondingly to form a reverse blowing channel; the reverse blowing cleaning mechanism comprises a compressed air pipeline, a control air valve and a compressed air source; and the control air valve is installed on the compressed air pipeline, one end of the compressed air pipeline is installed and in communication with the main air hole, and the other end of the compressed air pipeline is connected with the compressed air source. The PET bottle blank processing assembly and the PET bottle blank processing method have the advantages of convenience in ash removal and rapidness.

Owner:GUANGZHOU HUAYAN PRECISION MACHINERY

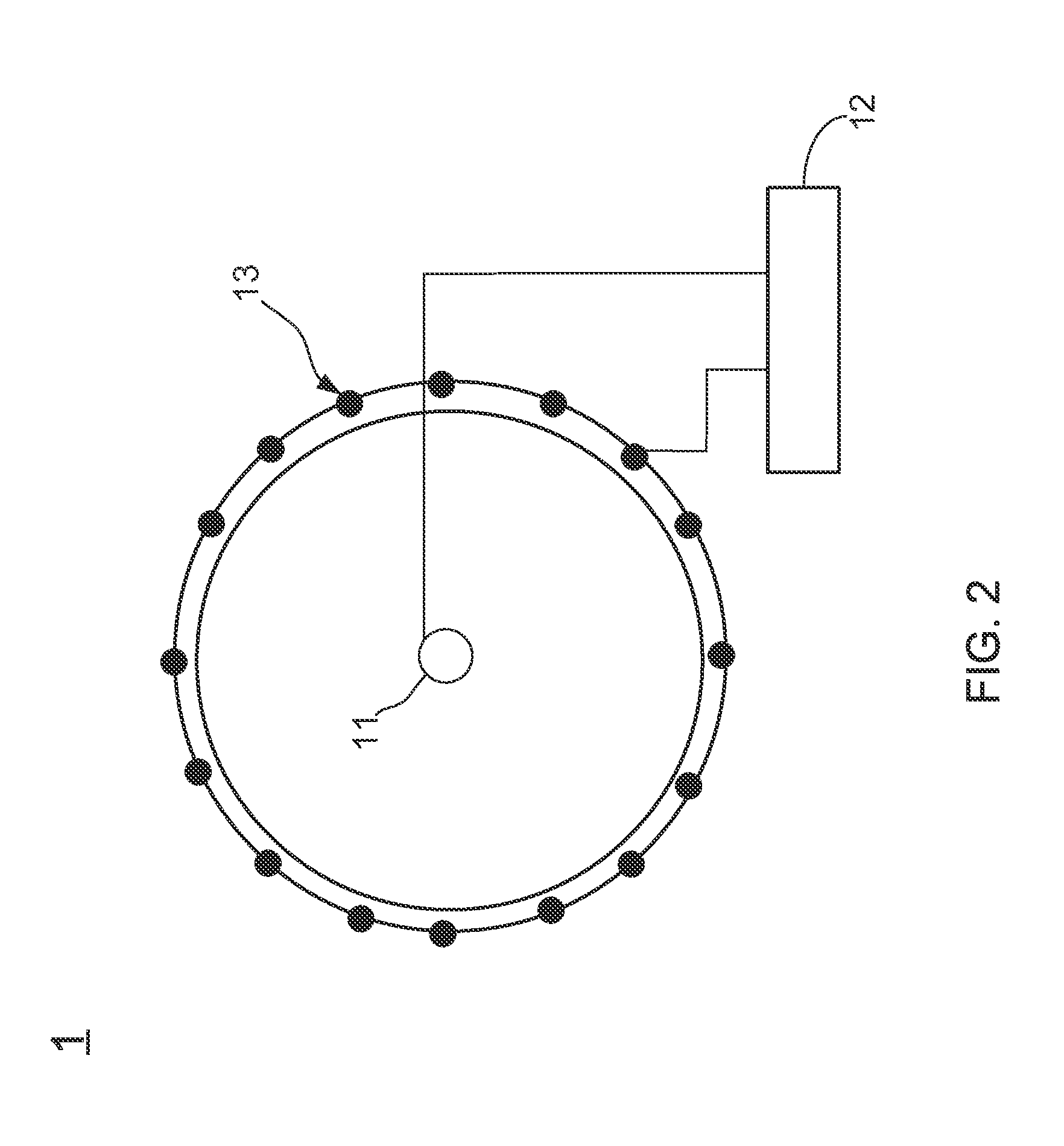

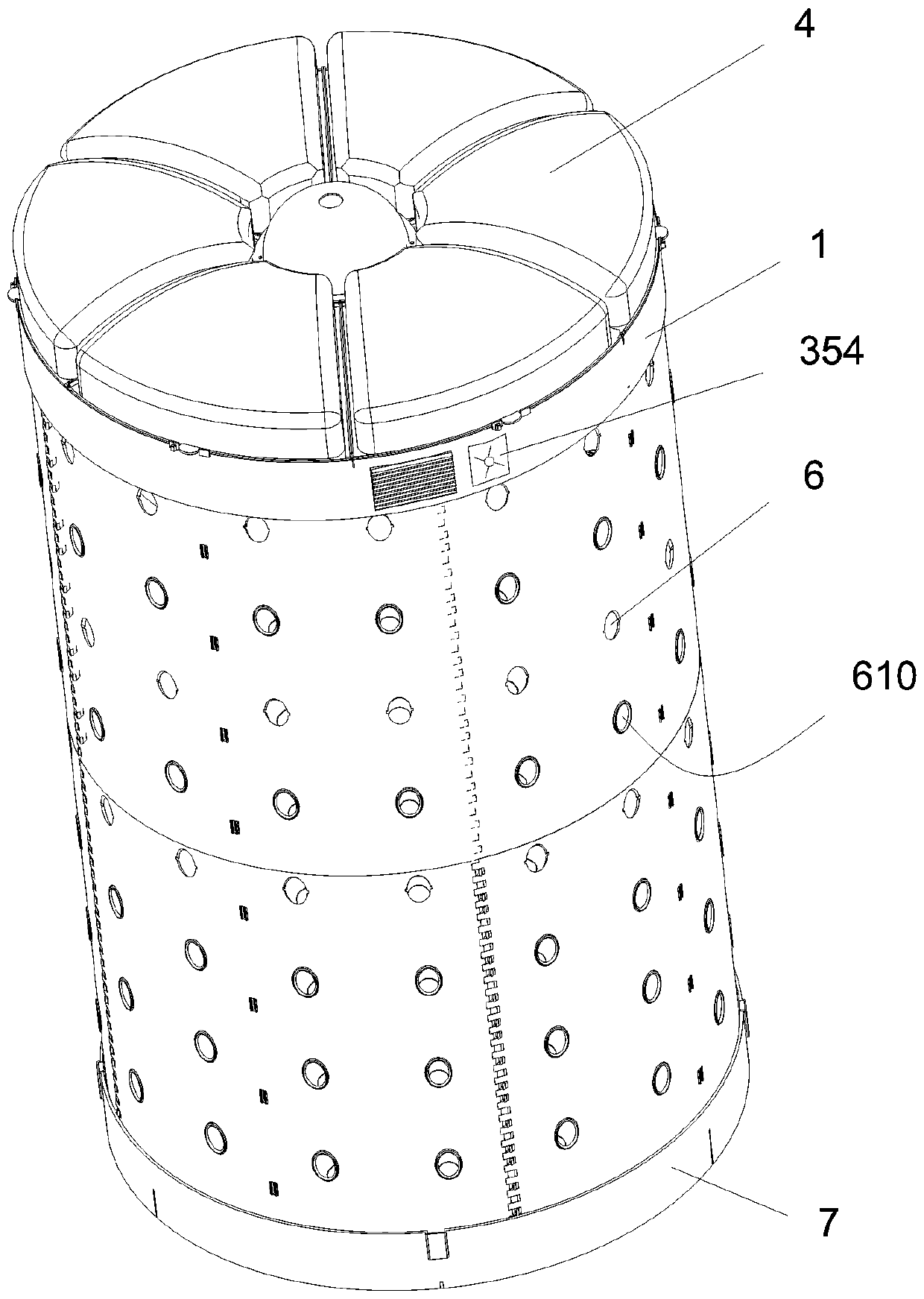

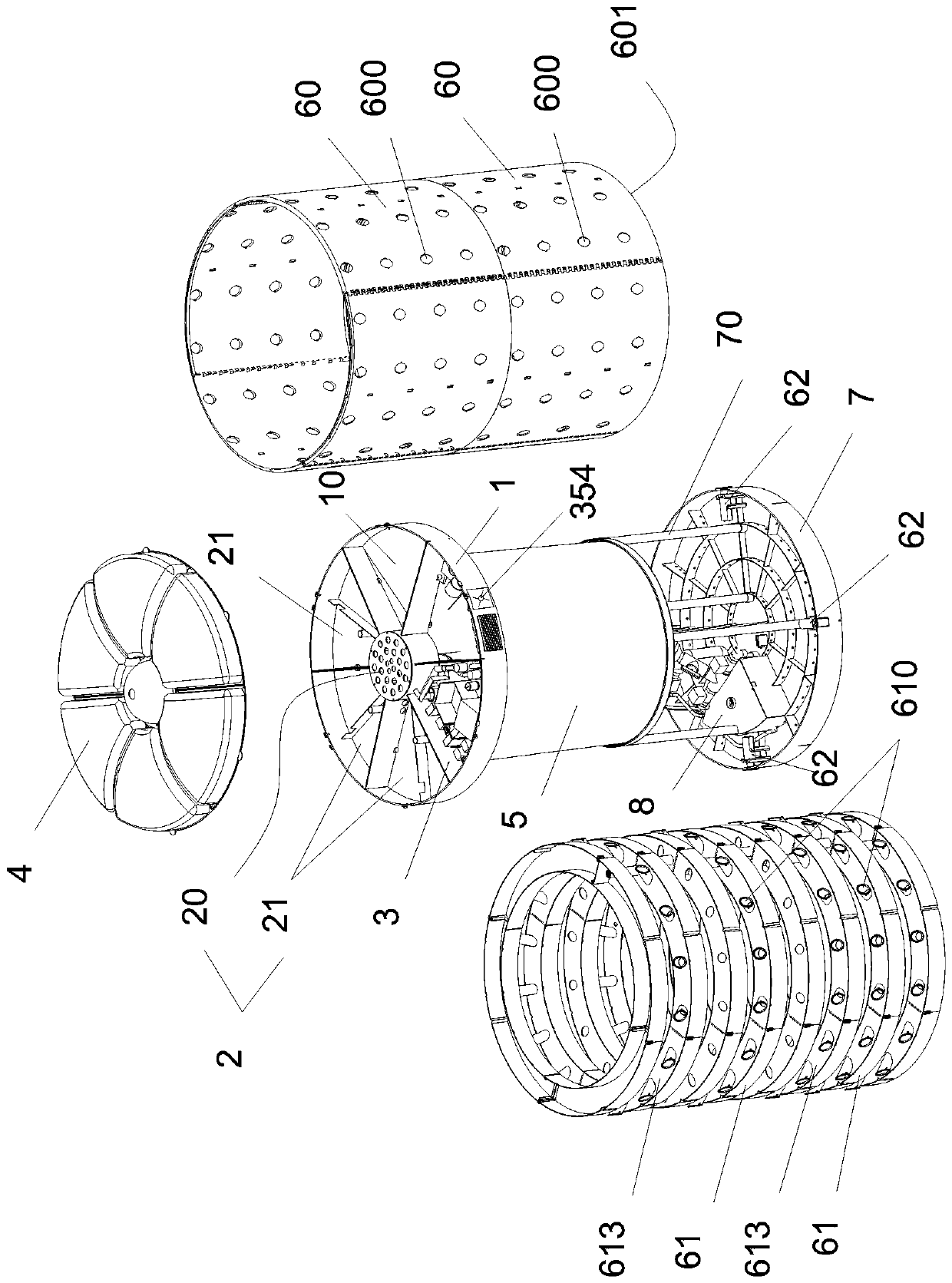

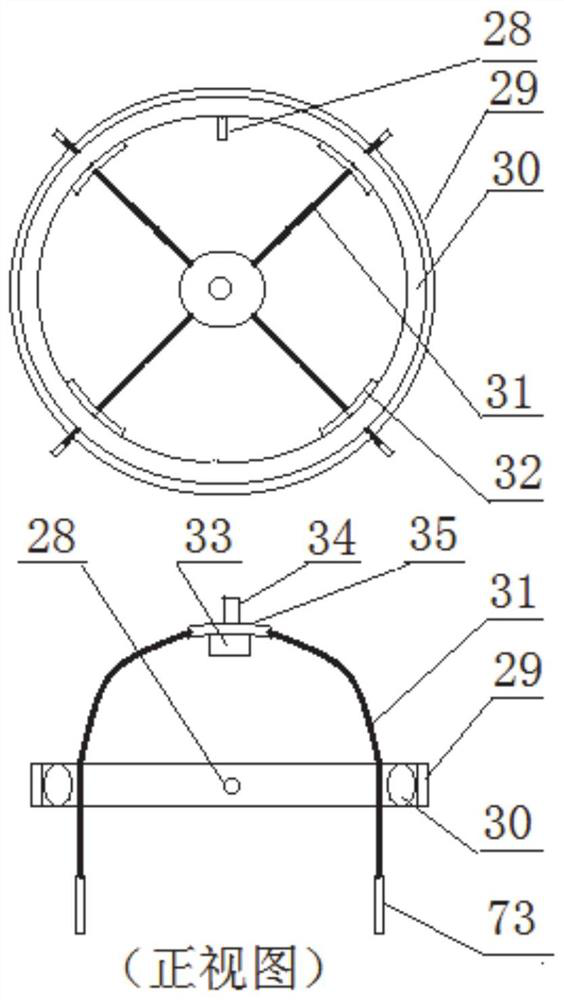

Controllable three-dimensional planting and breeding circulation machine

PendingCN111296106AGuaranteed oxygen contentImprove controllabilityBioreactor/fermenter combinationsBiological substance pretreatmentsTap waterFishery

The invention discloses a controllable three-dimensional planting and breeding circulation machine. The controllable three-dimensional planting and breeding circulation machine comprises the components of a disc body, an upper protective cover, a first breeding area, a rotatable water culture field planting device and a chassis, wherein the disc body is arranged at the upper part and used for arranging a water culture planting area, an electric control area, a quantitative feeding area and a fish taking observation area; the first breeding area and the rotatable water culture field planting device are arranged in the middle; the chassis is arranged at the lower part; a second breeding area, a dechlorination device for filtering tap water and a water suction pump body are arranged in the chassis; and the water culture field planting device comprises a plurality of field planting cylinders which are spliced with one another, a plurality of layers of annular water flowing grooves which communicate with one another, and a motor assembly for rotating the field planting cylinders. Space is fully utilized on the same occupied area, an upper vertical ecological system, a middle vertical ecological system and a lower vertical ecological system are formed through controllable design of physical conditions and microecology, the purpose of circular exchange of substances is achieved through water circulation design, and a water body has the self-purification capacity in the circulation machine, and the high-density planting and breeding requirements can be met.

Owner:黄炳南

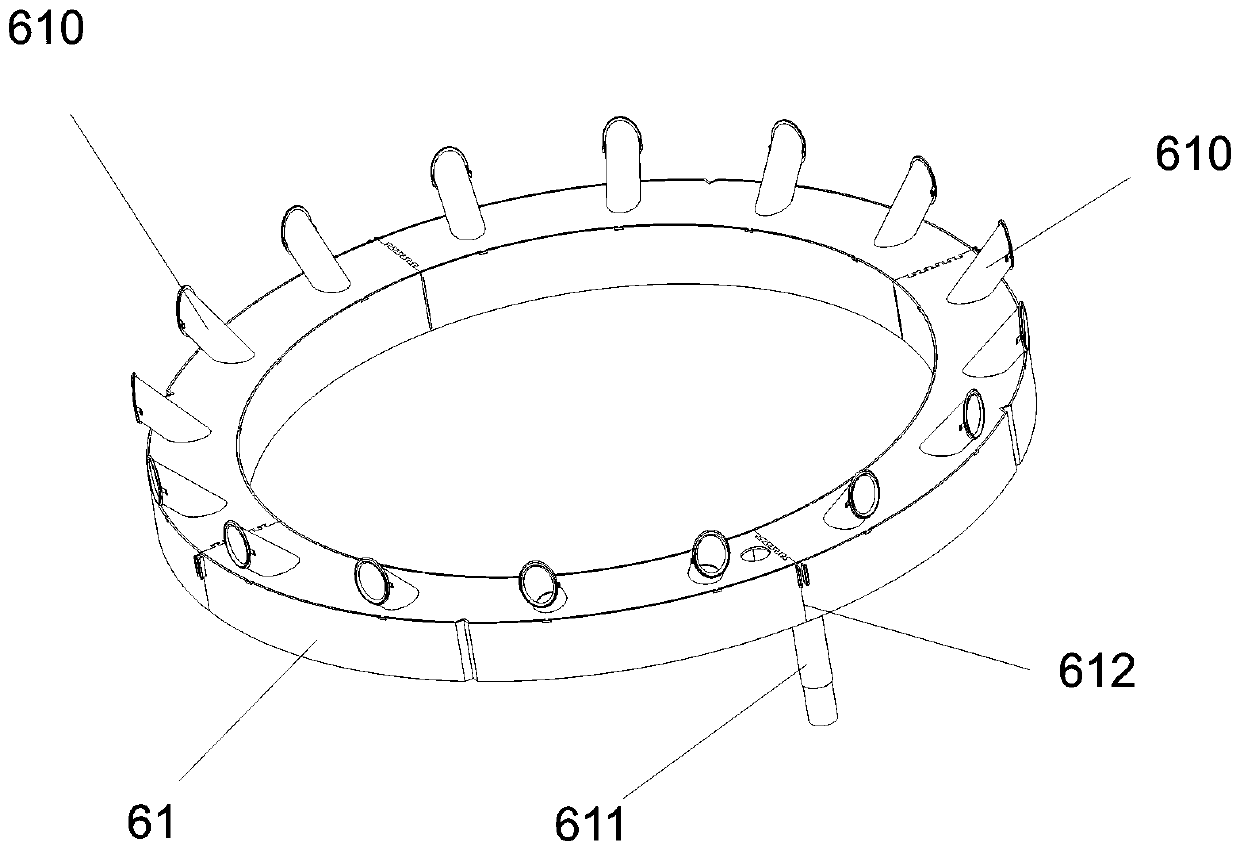

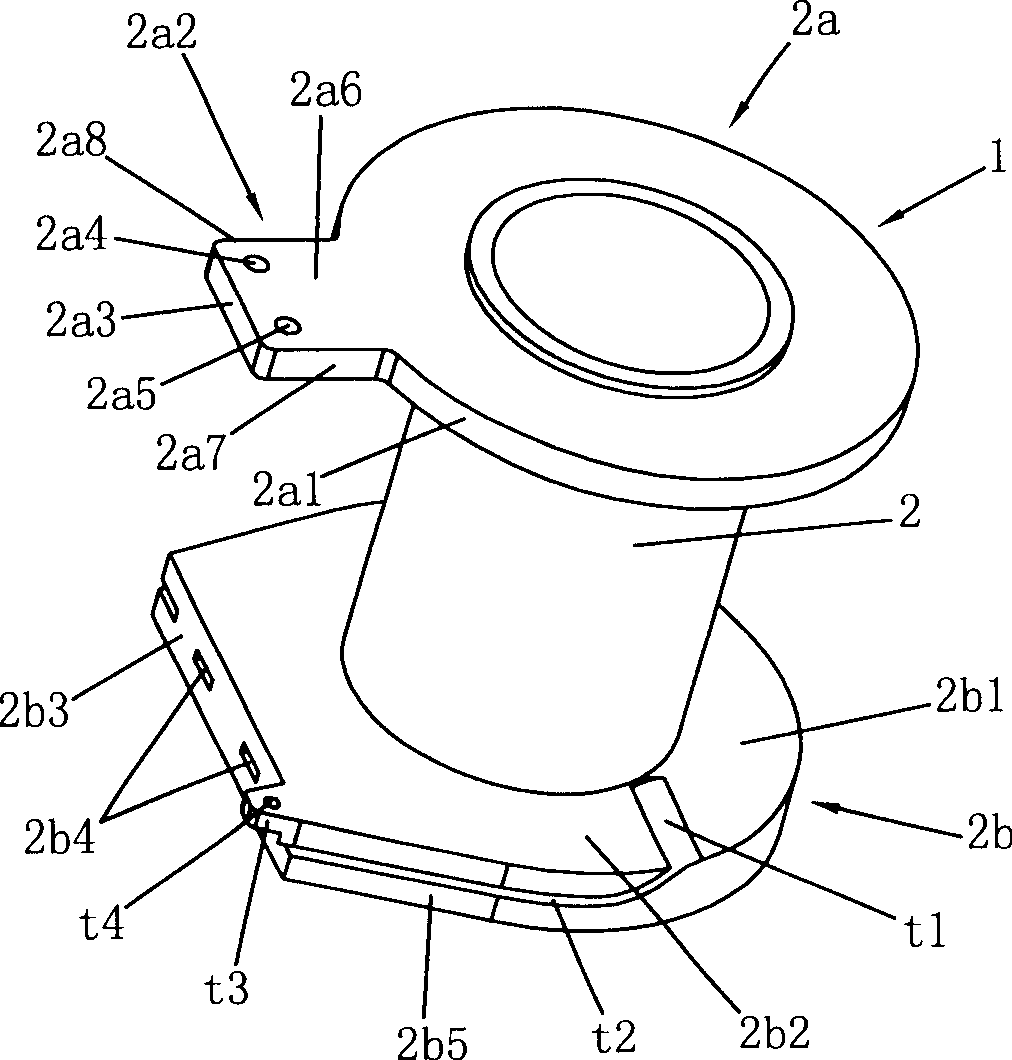

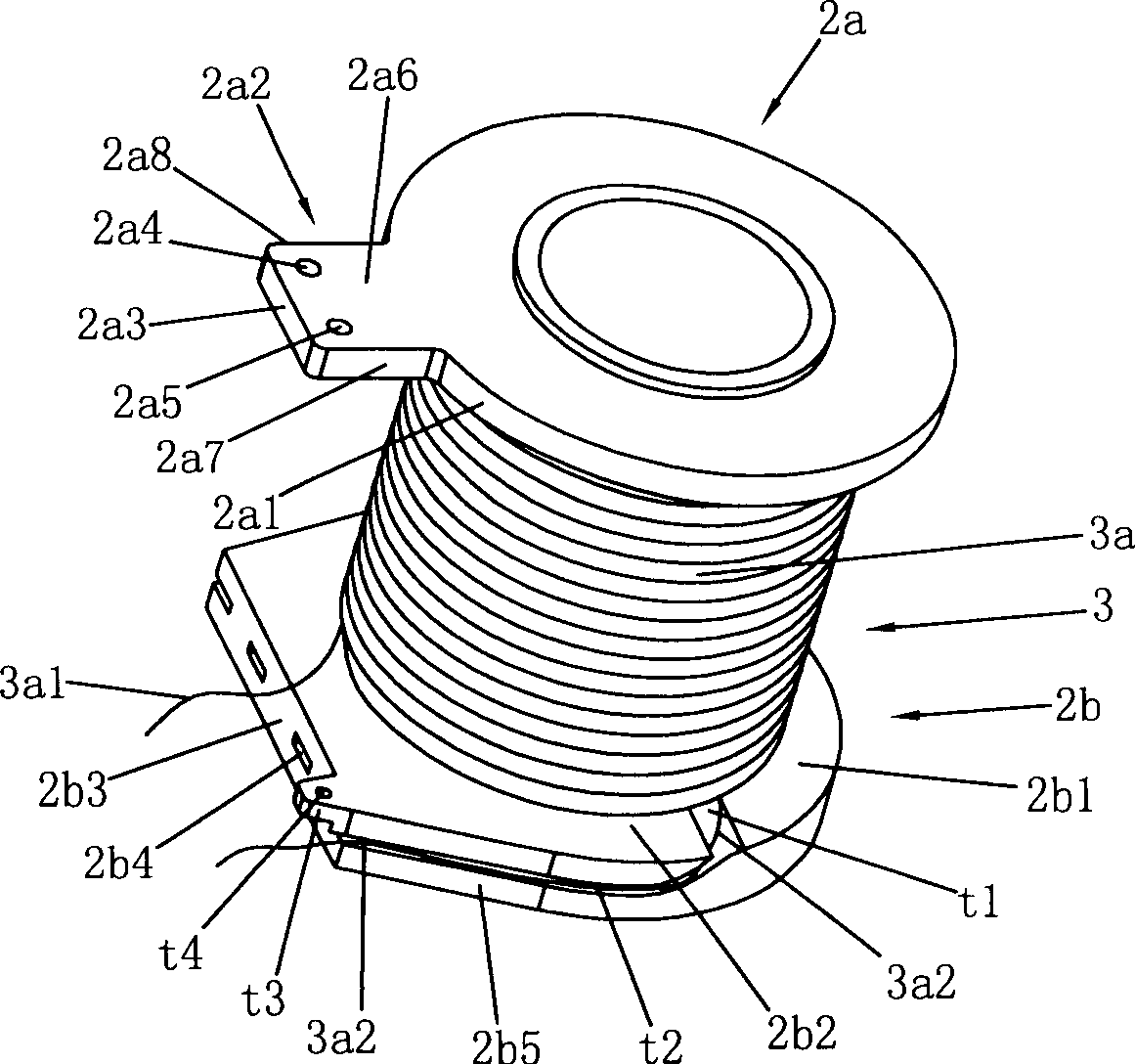

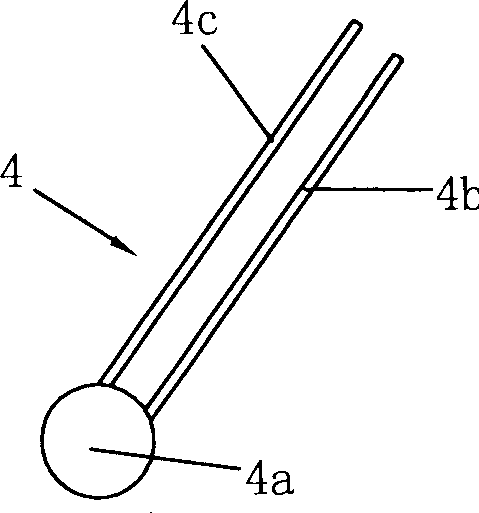

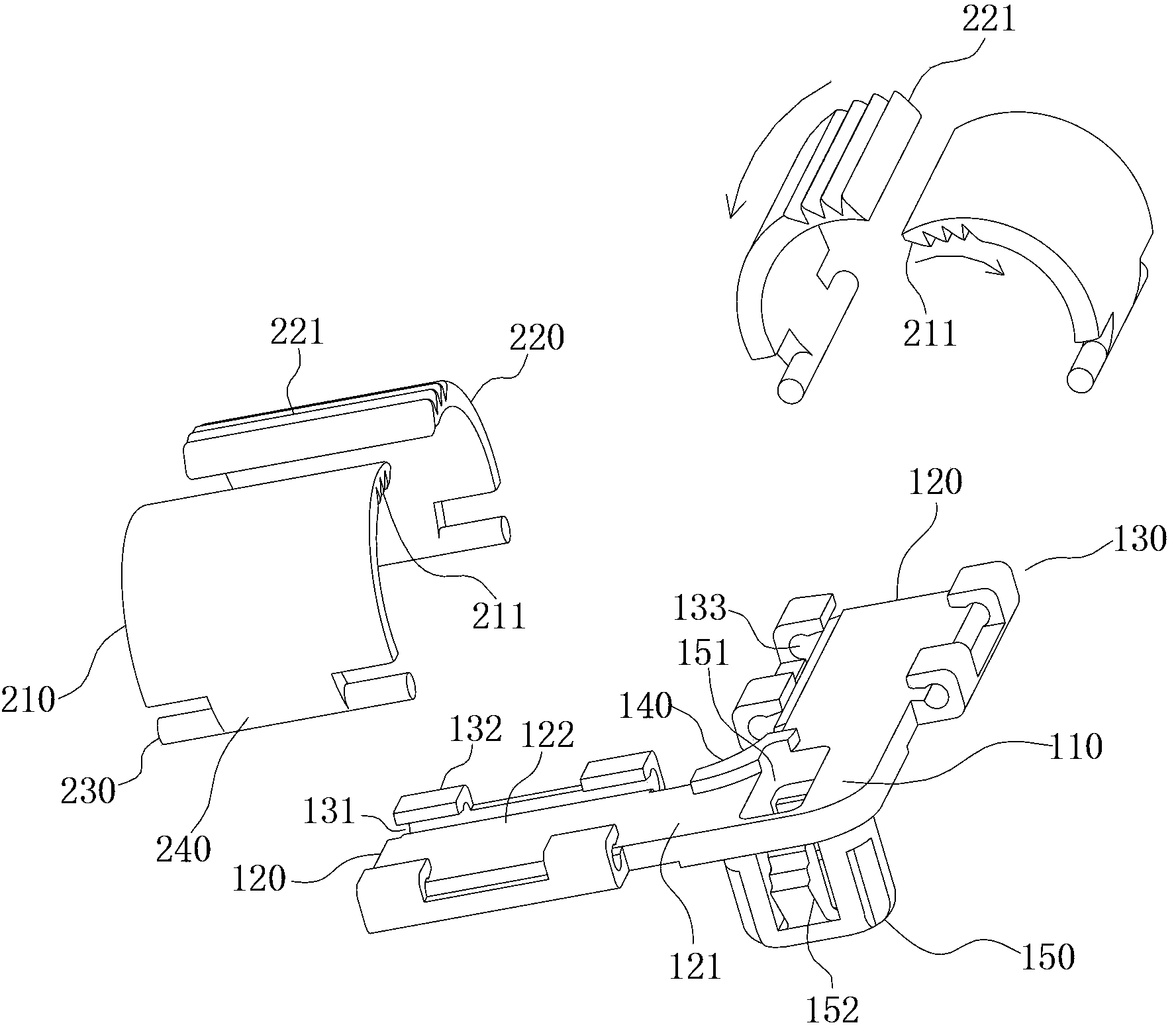

Coil framework and electromagnetic coil

ActiveCN101079345BEasy to placeEasy to fixOperating means/releasing devices for valvesTransformers/inductances magnetic coresConductor CoilSynthetic resin

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

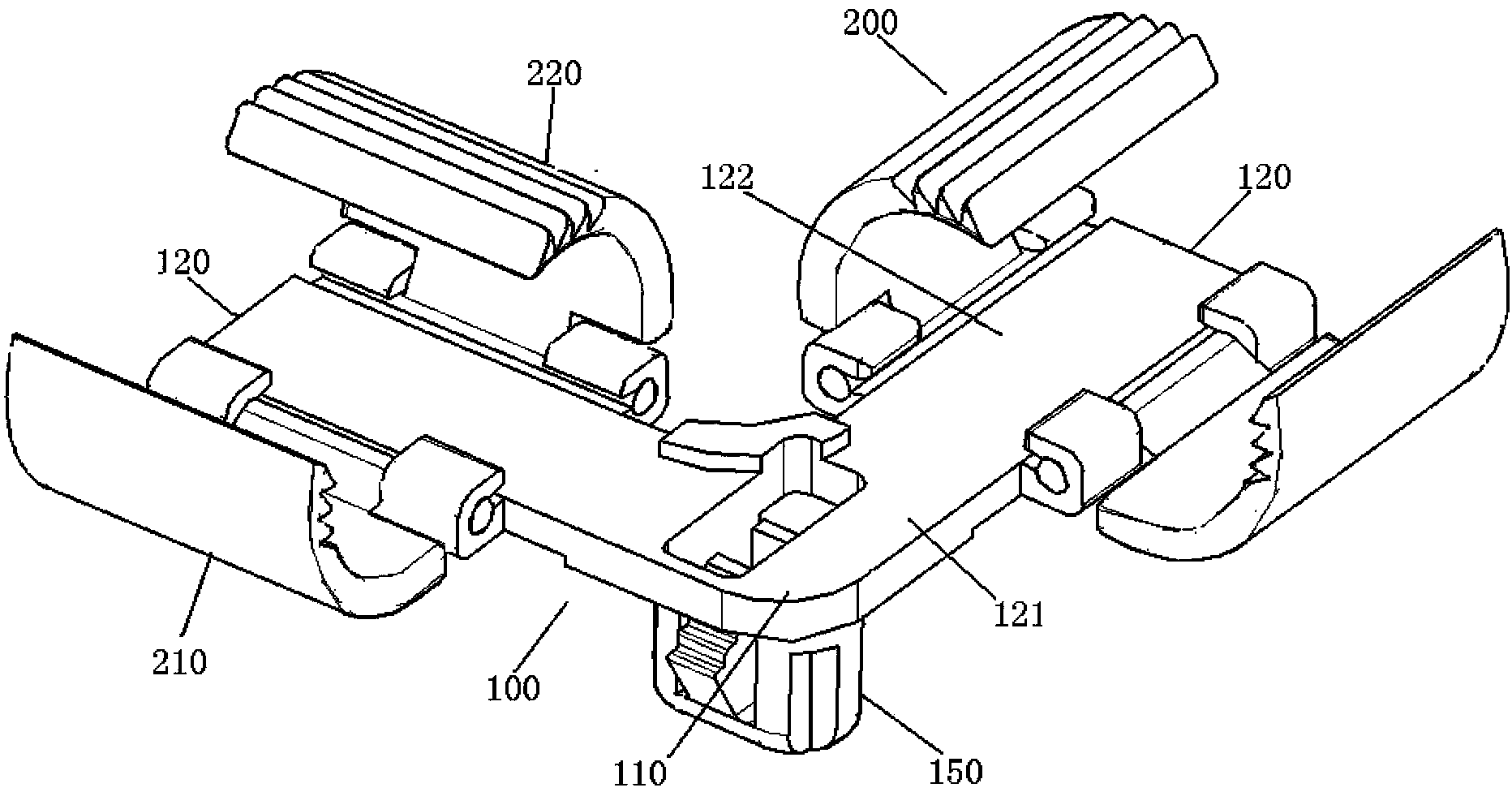

Bifurcated pipeline fixing device

ActiveCN104279371AKeep goingAchieve fixationPipe supportsElectrical apparatusMechanical engineeringEngineering

The invention relates to a pipeline fixing device, in particular to a bifurcated pipeline fixing device, which is used for fixing a bifurcated pipeline and can be used for ensuring the trend of each branch of the bifurcated pipeline. The device comprises a base and at least two buckles, wherein the base comprises at least two base support parts; the base support parts comprise connecting ends and buckling ends; the connecting ends of the base support parts are connected together; the base support parts are positioned on the same plane; an included angle between adjacent base support parts is greater than 0 degree; the buckles are arranged at the buckling ends of the base support parts respectively, and are used for buckling bifurcated pipeline branches carried on the base support parts. According to the bifurcated pipeline fixing device provided by the invention, a special structure in which the base is matched with the buckles is adopted, so that fixation of the bifurcated pipeline can be realized, and the trends of the branches of the bifurcated pipeline are effectively kept.

Owner:BEIQI FOTON MOTOR CO LTD

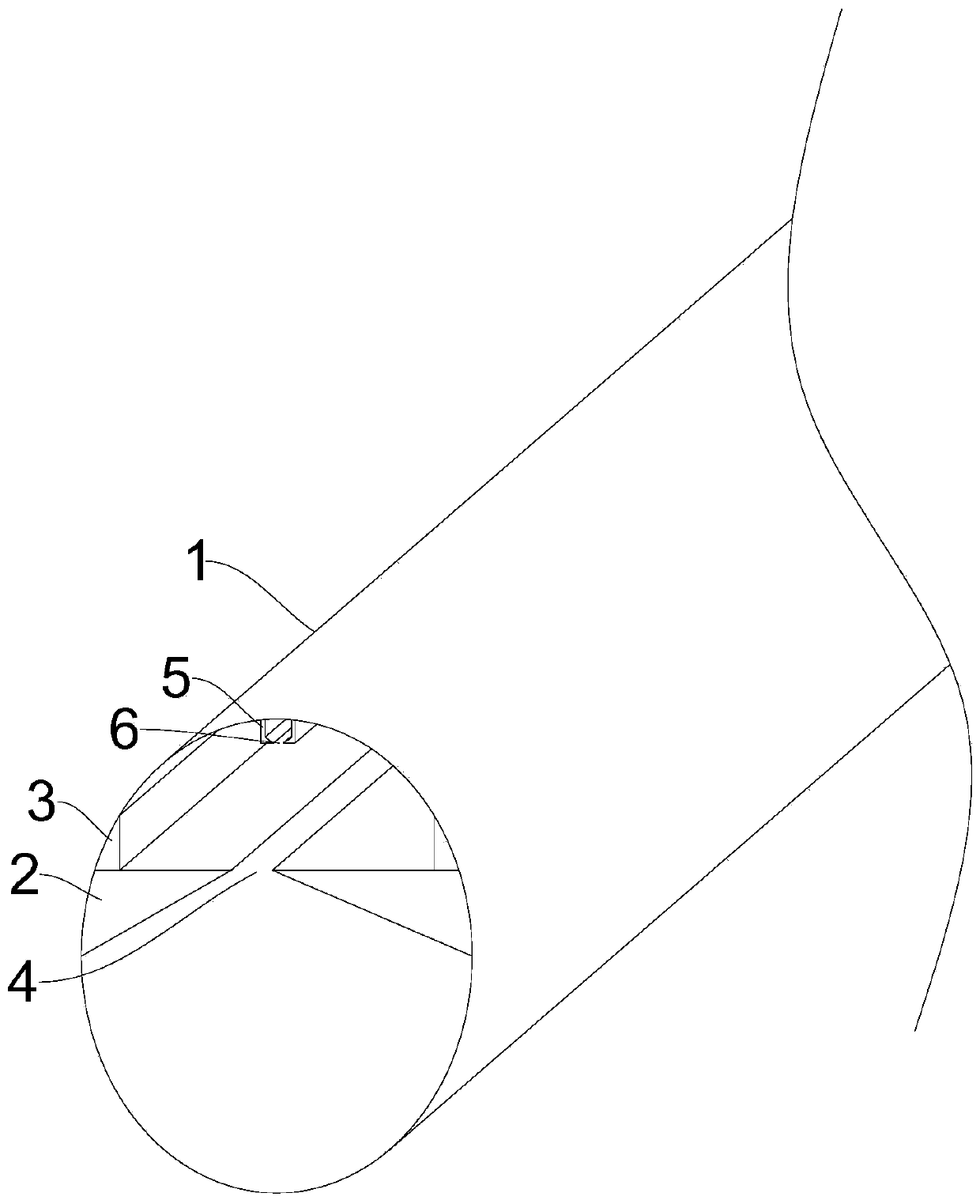

Spool for embedding cable and construction method for embedding cable

PendingCN110120649AEasy accessProtect the outer skinCable installations in underground tubesApparatus for laying cablesEngineeringBuilding construction

The invention discloses a spool for embedding a cable and a construction method for embedding the cable, and belongs to the technical field of cable construction. The spool comprises a pipe, and two oppositely arranged track tables extending in the length direction of the pipe are arranged in the pipe, wherein the two track tables are respectively and fixedly connected with the inner wall of the pipe, and a cable pay-off gap is arranged between the two track tables. The spool also comprises a traction trolley placed on the two track tables to travel, wherein one side of the traction trolley isfixedly connected with a cable traction hook, and the cable traction hook is arranged above the cable pay-off gap vertically. The invention has the beneficial effects that a cable can pass through the spool by using a small traction force, so that the cable embedding construction is more convenient, simpler and quicker, and a large amount of manpower resources are saved.

Owner:GUIZHOU MINZU UNIV

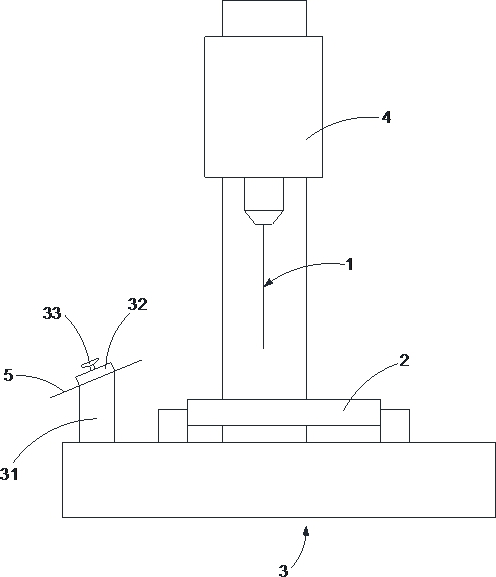

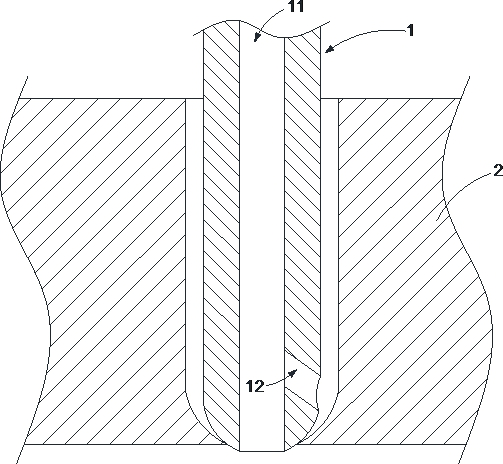

Electric spark punching rapid penetrating machining method and punching machine

InactiveCN114473098AKeep goingAvoid blockingMaintainance and safety accessoriesElectrical-based auxillary apparatusElectric dischargePunching

The invention relates to the technical field of fine hole electric discharge machines, in particular to an electric spark punching rapid penetrating machining method and a punching machine, and the punching machine is adopted for punching. The electrode wire is installed on the perforating machine, and the position of the electrode wire is adjusted through the perforating machine so that the workpiece can be perforated. The electrode wire is tubular, and a circulation hole is formed in the electrode wire in the length direction. A flow guide hole communicated with the circulation hole is formed in the outer side wall of the front end of the electrode wire. The flow guide hole is formed before the workpiece hole penetrates through the workpiece. And a punching electrode wire is arranged on a fixed part of the punching machine. The punching electrode wire and the workpiece are connected to the same electrode. The electrode wire is provided with the flow guide hole, so that when the tip end of the electrode wire penetrates through the workpiece, deionized water jetted by the flow guide hole can continue to wash the hole wall, and then the electrode wire can well complete the remaining punching action.

Owner:成都和鸿科技股份有限公司

A device, system and method for exterminating rodents in a planar current field

ActiveCN112970729BAuto clearImprove concealmentMeasurement devicesAnimal trapsTrappingSolenoid valve

The present disclosure provides a device, system and method for exterminating rodents in a planar current field, including a first control terminal, a spray tube, an electrode plate and a pyroelectric infrared sensing element; the spray tube is provided with a plurality of The through hole, the spray pipe is communicated with the liquid reservoir through the pipeline, the liquid reservoir is communicated with the gas storage bottle through the solenoid valve, the first control terminal is connected with the solenoid valve, and the pyroelectric infrared sensing element is connected with the first control terminal; the first control terminal is connected with the first control terminal. The control terminal is connected to the electrode plate through the power supply module, the electrode plate includes a positive electrode plate and a negative electrode plate, and the spray range of the spray pipe covers at least the area between the positive electrode plate and the negative electrode plate, and between the positive electrode plate and the negative electrode plate. A planar electric field for shocking mice is formed in the area of the present disclosure; the water film formed after spraying water on the ground of the present disclosure is no different from the natural environment, with strong concealment, and the mice cannot be identified, which improves the rat trapping efficiency; in addition, the rodent control system of the present disclosure The device is placed in a flexible place, and can automatically remove mouse carcasses, realizing continuous mouse capture.

Owner:山东师范大学附属中学

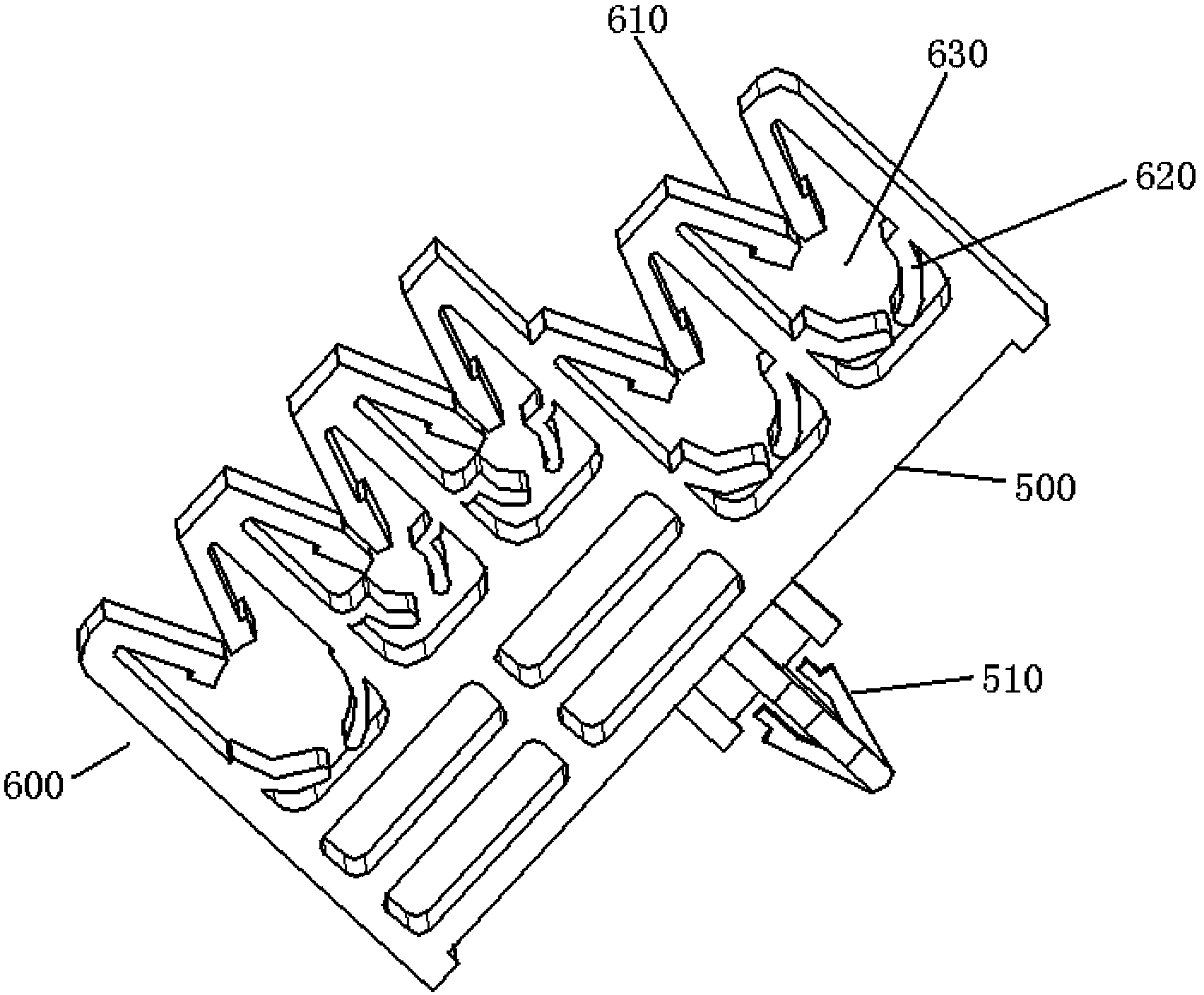

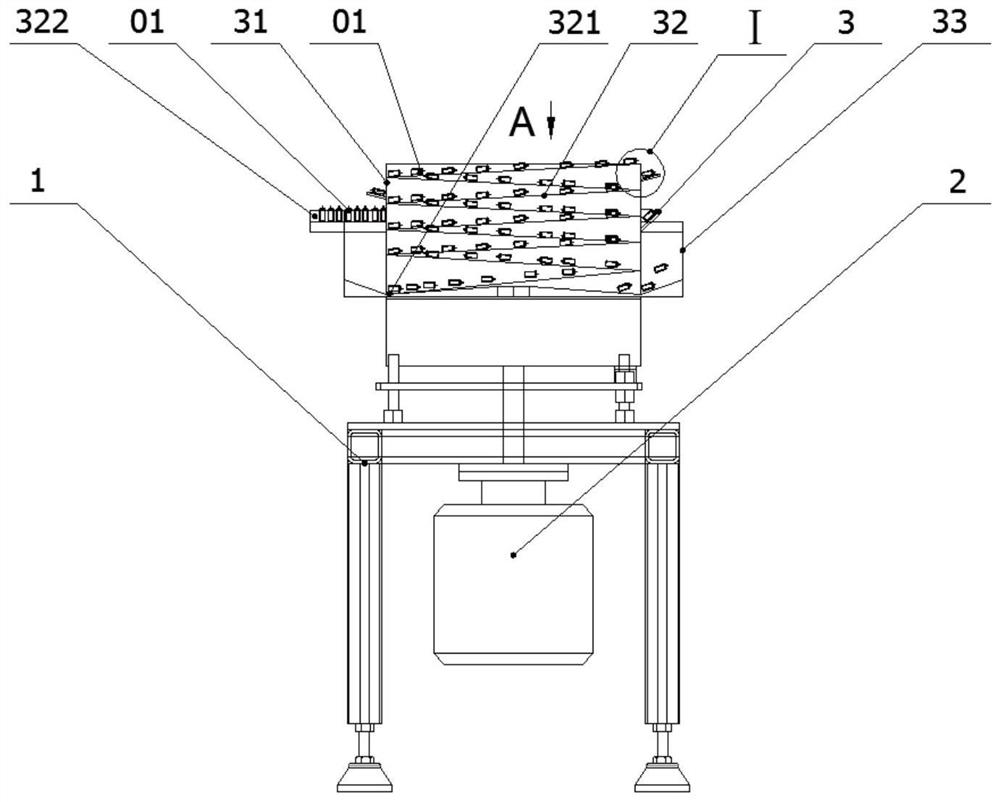

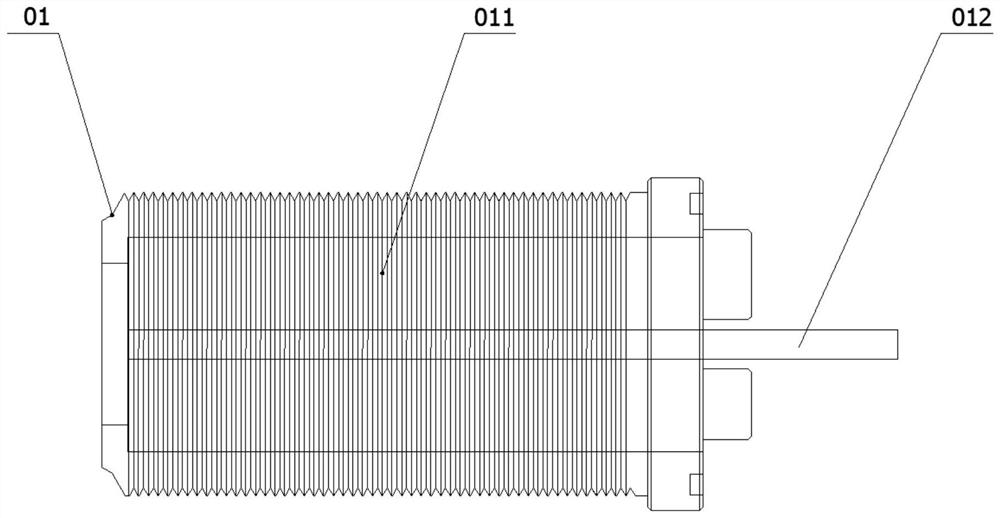

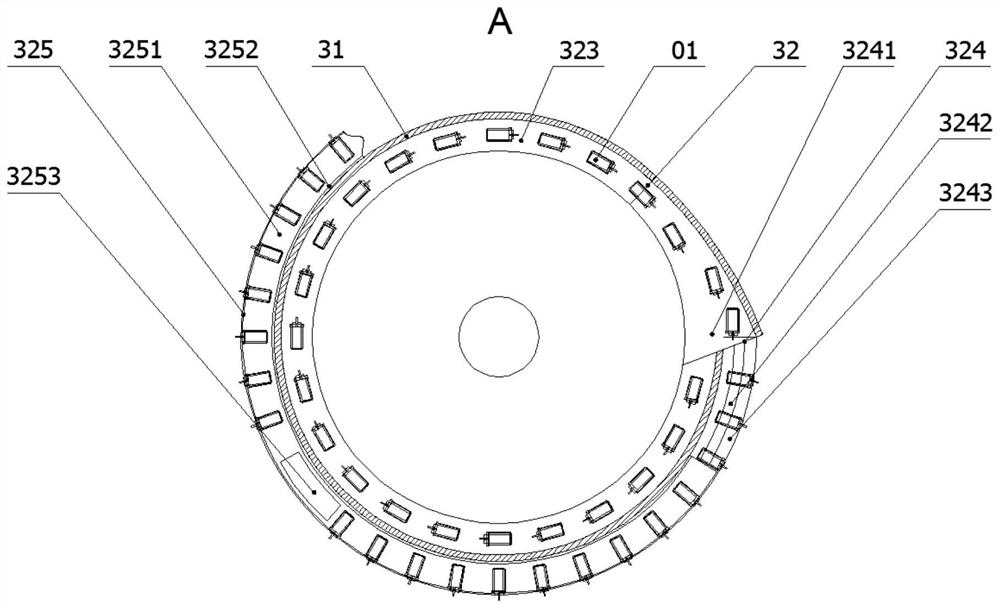

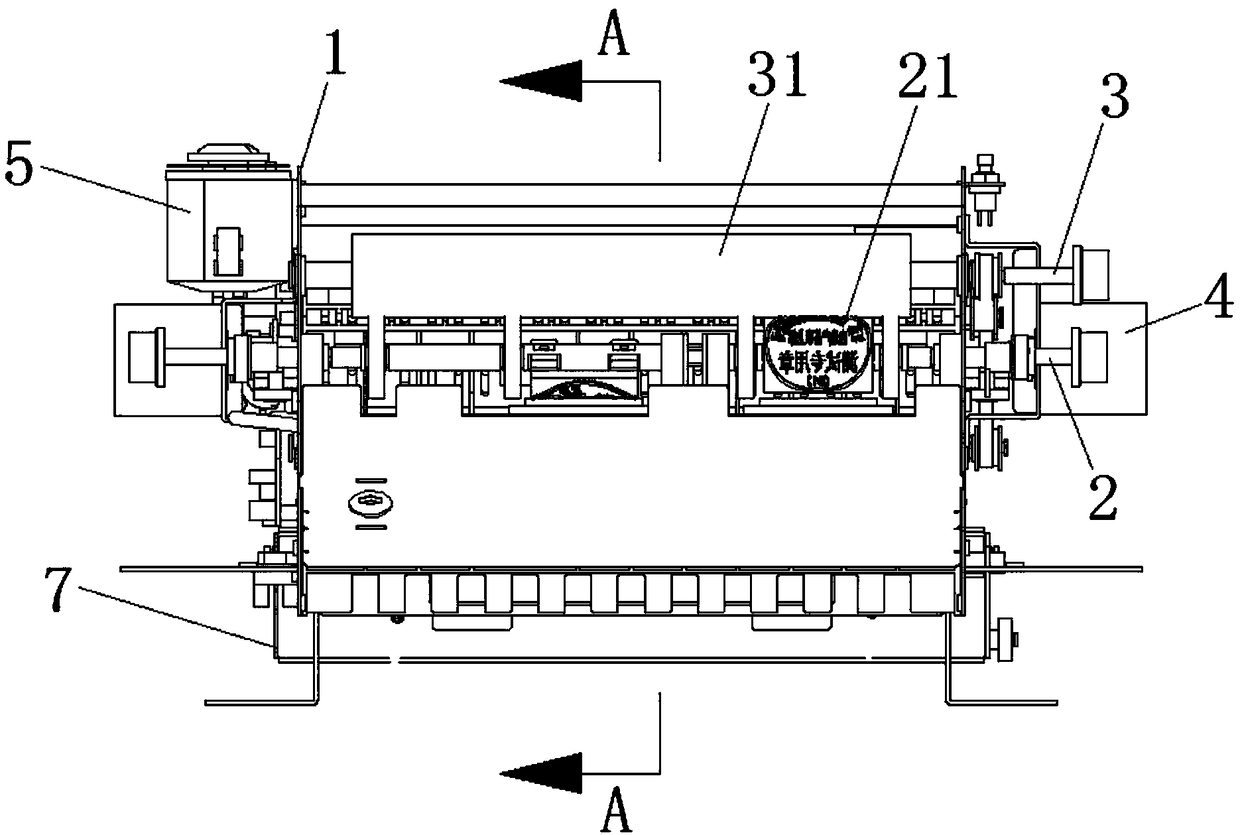

Feeding device for PIN folding machine and PIN folding machine

The invention discloses a feeding device for a PIN folding machine. The feeding device for the PIN folding machine comprises a frame body, a feeding driving unit and a feeding mechanism, the frame body is used for bearing the feeding mechanism and the feeding driving unit, and the feeding driving unit provides driving force for the feeding mechanism. The feeding mechanism is connected with the feeding driving unit and driven by the feeding driving unit to arrange disordered PINs into PINs in the same direction and output the PINs. Automatic feeding is carried out through cooperation of the feeding mechanism and the feeding driving unit, the feeding mechanism achieves on-demand arrangement in the PIN conveying process, finally PINs with the same PIN pointing direction are obtained, manual configuration is omitted, equipment is simple in configuration, the production efficiency is improved, and meanwhile, the cost can be effectively reduced. According to the technical scheme, the feedingdevice has practicability and economical efficiency.

Owner:CHERRY CHIEF PRECISION IND KUNSHAN

Preparation of polypropylene fiber fabric, and liquid all-in-one printing and dyeing pretreatment technology

InactiveCN104631148AIncrease elasticityHigh strengthHeating/cooling textile fabricsDyeing processPolyesterPolymer science

The invention discloses preparation of polypropylene fiber fabric, and a liquid all-in-one printing and dyeing pretreatment technology. The polypropylene fiber fabric is prepared from the following warp and weft materials in parts by weight: 40-90 parts of polypropylene fiber, 20-40 parts of combed cotton and 8-18 parts of superfine denier polyester; in the slashing working procedure, a liquid all-in-one auxiliary agent is fed into slurry, and the pH value of the liquid all-in-one auxiliary agent for dyeing is 2g / L: 8.5+ / -1; the auxiliary agent comprises the following components in parts by weight: 0.5-1.5 parts of sodium hydroxide, 0.2-0.5 part of a chelating agent and 0.2-1 part of sodium hexametaphosphate, wherein the ratio of the total mass of the sodium hydroxide, the chelating agent and the sodium hexametaphosphate to the mass of water is equal to 2:50; after the slashing technology is finished, heat preservation is carried out for 50-80 minutes according to the concentration of the material to be dyed of the fabric. After the preparation of the polypropylene fiber fabric is adopted, the fabric has the advantages of high elasticity, high strength, heat insulation, heat resistance and light resistance; furthermore, the dye liquor can rapidly permeate and diffuse into the fiber of the fabric in the subsequent dye liquor, so that the phenomena such as dye lot chromatism, dyeing defect, chromatic aberration and solid color spots can be effectively prevented in the printing and dyeing process.

Owner:SUZHOU CHENHENG WEAVING

An automatic stamping machine

Disclosed is an automatic stamping machine. The automatic stamping machine comprises a machine frame, a stamp rotating shaft, a rolling rotating shaft, a driving mechanism, an automatic ink adding mechanism, a stamp ink box and a locating locking device. The stamp rotating shaft and the rolling rotating shaft are arranged on the machine frame in parallel in a rotating mode, and the stamp rotating shaft is located below the rolling rotating shaft. At least one rolling stamp is arranged on the stamp rotating shaft, and a rolling printing roller which corresponds to the rolling stamp in position is arranged on the rolling rotating shaft. The driving mechanism is installed on the machine frame and drives the stamp rotating shaft and the rolling rotating shaft to synchronously rotate in the opposite directions. The automatic ink adding mechanism automatically adds ink to the stamp ink box. First rolling wheel printing cotton which makes flexible contact with the rolling stamp is arranged in the stamp ink box. The machine frame and a printer are located and locked through the locating locking device. According to the automatic stamping machine, the relative position between the automatic stamping machine and the printer is accurately guaranteed through the innovative locating locking device, the probability of paper jams is reduced, and the stability and the reliability are improved. The first rolling wheel printing cotton makes flexible contact with the rolling stamp, and the service life is long. The automatic ink adding mechanism can achieve automatic and continuous ink addition.

Owner:GUOGUANG ELECTRONICS INFORMATION TECH

Treatment water of lifestyle-related diseases and method of treating the lifestyle-related diseases

ActiveUS20180064756A1Keep goingImprove permeabilityHeavy metal active ingredientsDispersion deliveryTreatments waterDisease

To obtain a lifestyle-related disease therapeutic water which comprises a very small amount of anionized silver, nanosized gold, and 99.9% or more of water. A lifestyle-related disease therapeutic water comprising with respect to one liter of water (a), 3-15 mg in silver equivalent of thiosulfate silver ion (b), and 0.1-0.5 mg in gold equivalent of colloidal gold (c).

Owner:ICHIKAWA YOSHIO +2

High-temperature-resistant PVC conveying belt for food processing production line

PendingCN114408454AImprove stress resistanceImprove the temperature resistance coefficientConveyorsSynthetic resin layered productsFiberCarbon fibers

The invention discloses a high-temperature-resistant PVC conveying belt for a food processing production line, and relates to the technical field of food processing. The high-temperature-resistant PVC conveying belt for the food processing production line comprises a mounting bracket and a conveying belt body, a driving motor is mounted on the surface of the top end of the mounting bracket, a driving shaft is mounted on the surface of the outer side of the output end of the driving motor, and a driving roller shaft is mounted on the surface of the tail end of the driving shaft; and a driven roller shaft is mounted on the top end surface of the mounting bracket on one side of the driving motor, and a conveying belt body is jointly mounted on the outer side surfaces of the driving roller shaft and the driven roller shaft. The PVC base layer serves as a base structure of the conveying belt body, the compression resistance of the conveying belt body is enhanced through the carbon fiber supporting rods, so that the conveying belt body can transport objects with larger weight, and the overall temperature resistance coefficient of the conveying belt body is increased through the temperature resistance layer; and the antibacterial layer is added, so that the conveying belt body is more suitable for a food processing production line, and the safety coefficient is higher.

Owner:无锡铭成传动科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com