Full hydraulic rock core drilling machine unit head

A technology of core drilling rig and power head, which is applied in the direction of rotary drilling rig, drilling equipment, earthwork drilling and production, etc. It can solve the problems of not being able to work continuously for a long time, the skeleton oil seal is easy to wear, and the drilling rig cannot work, so as to reduce pitting corrosion , Good heat dissipation effect, prevent backflow and splashing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

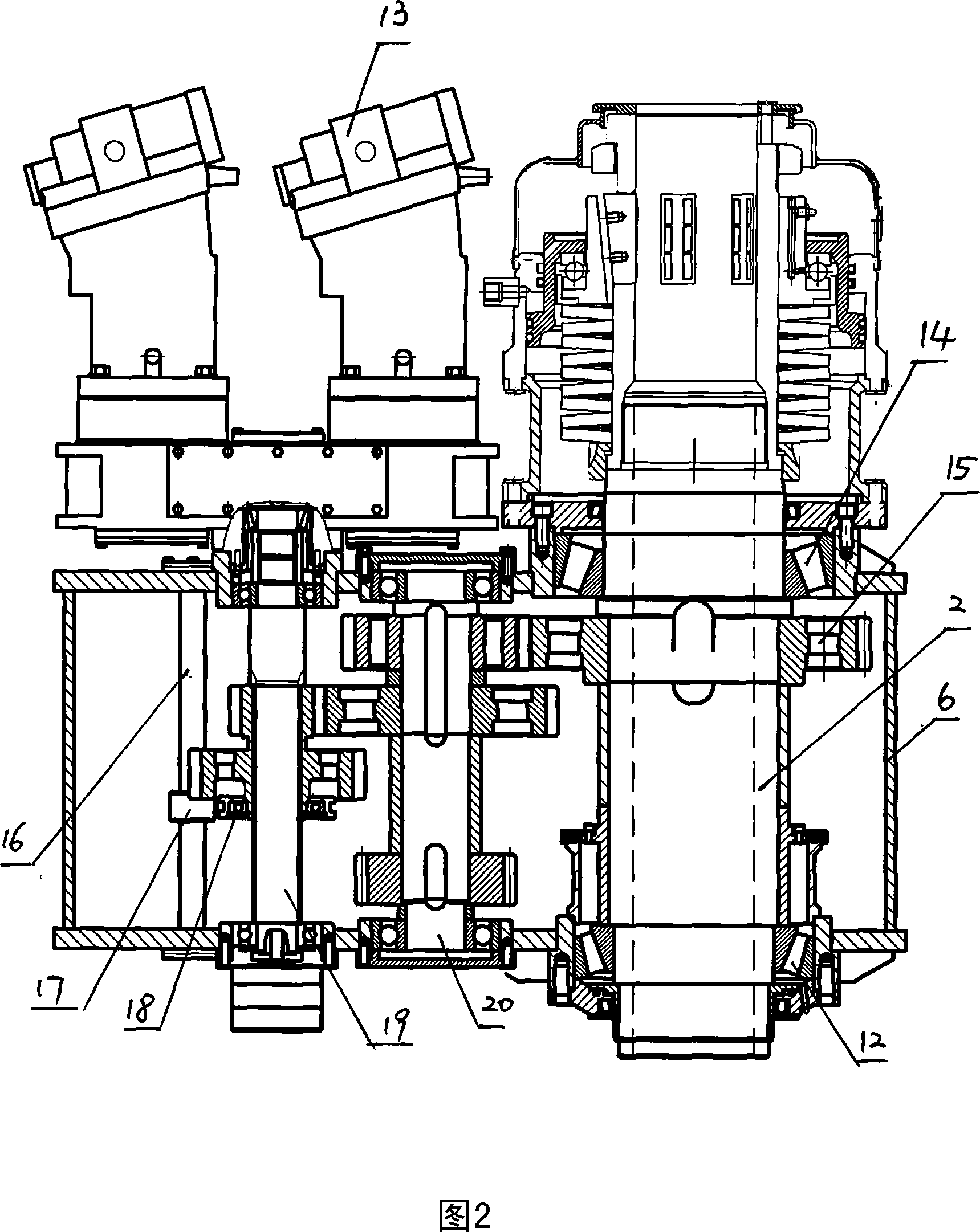

[0014] A fully hydraulic core drilling rig power head, driven by dual hydraulic motors, parallel power input, two-stage gear transmission, hydraulic stepless speed regulation, hydraulic chuck clamping and long stroke feed mode.

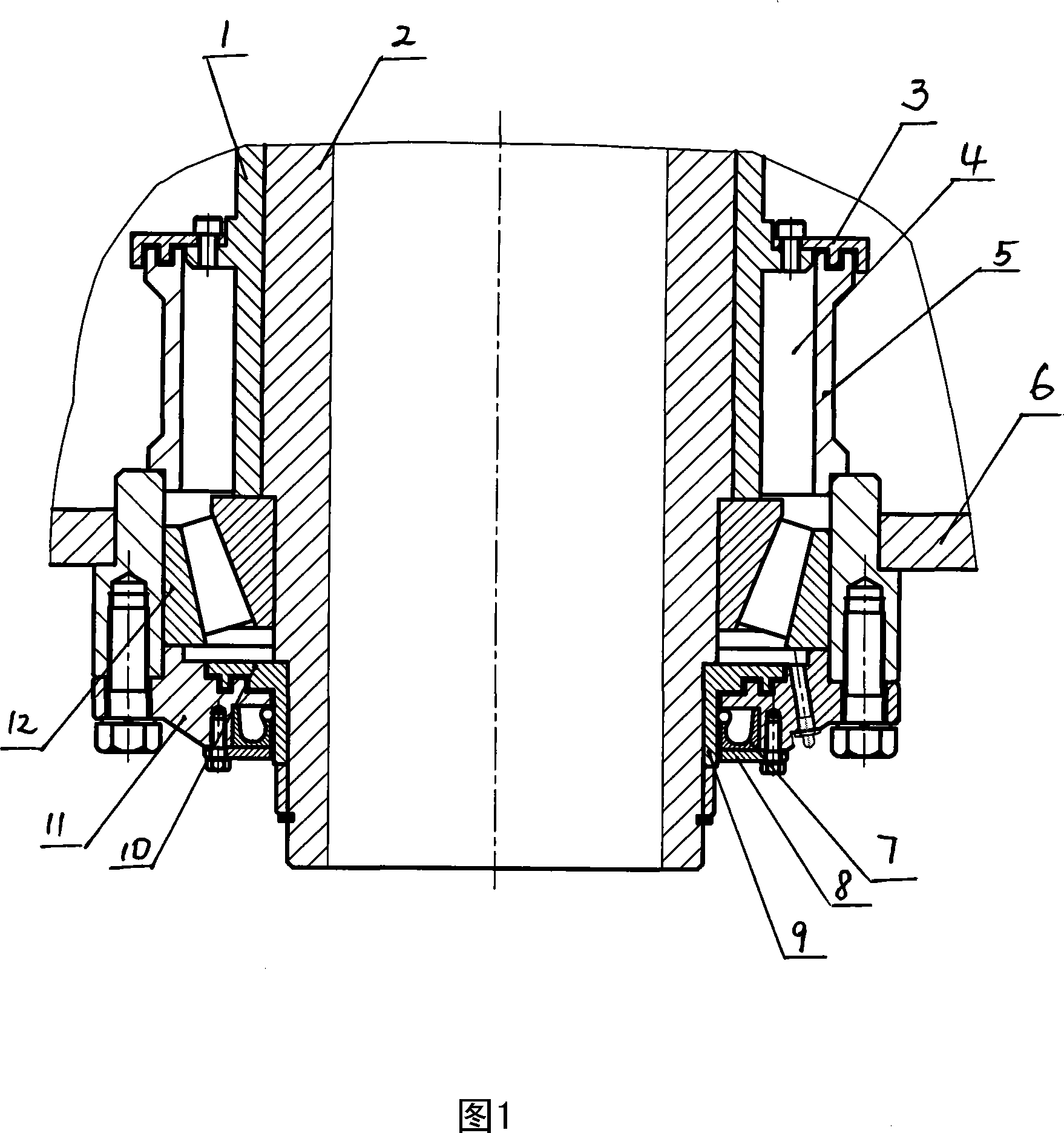

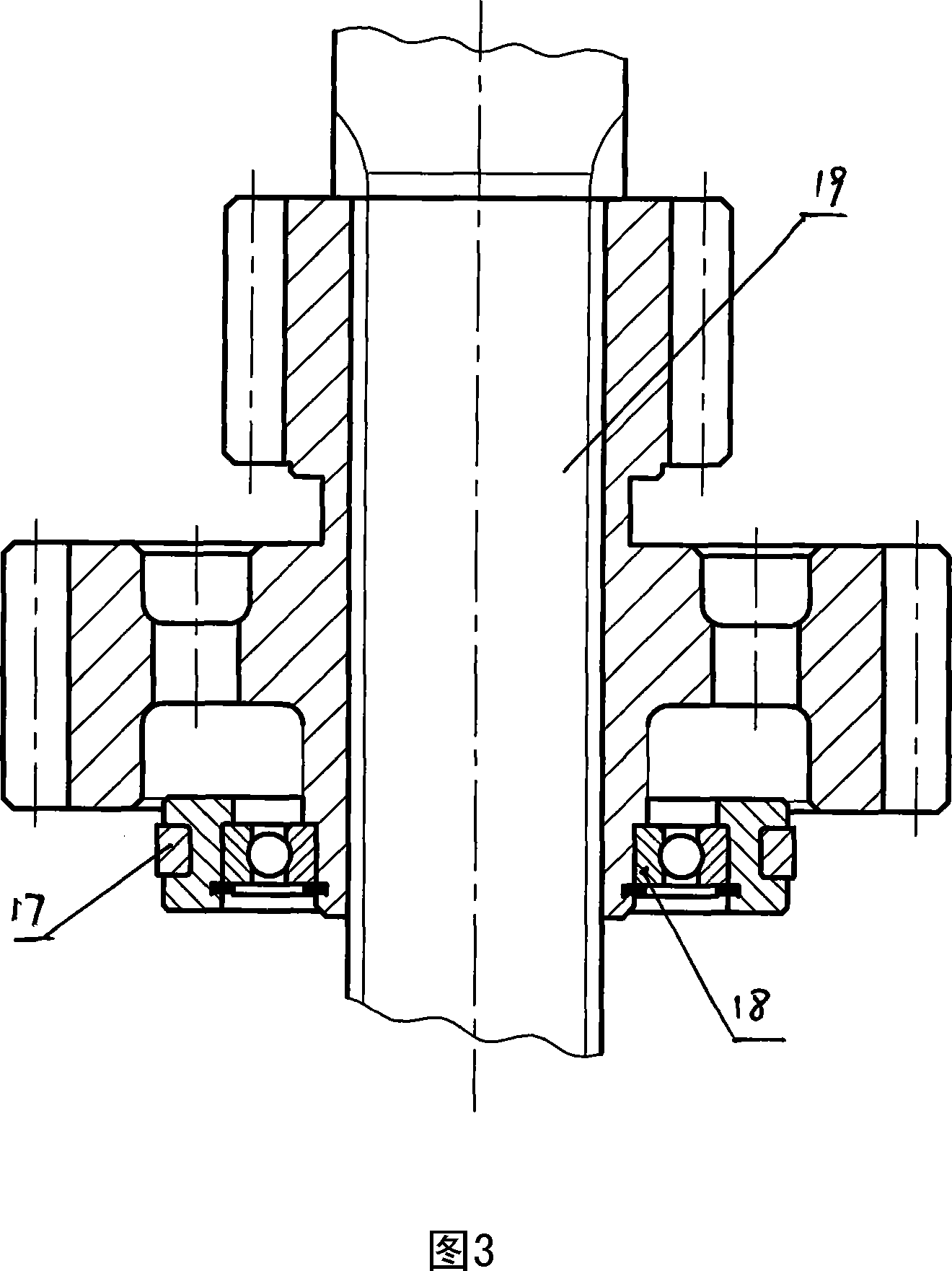

[0015] It is equipped with a power head box 6, the main shaft 2 is vertically arranged at the front of the box body 6, and double hydraulic motors 13 are used for parallel power input. A variable speed transmission mechanism is provided between the motor 13 and the main shaft 2. The transmission transmission mechanism is provided with a transmission shaft 19 and an intermediate shaft 20 arranged vertically side by side. The hydraulic motor 13 is connected to the upper end of the transmission shaft 19. A pair of constant meshing gears are used to drive between them. The transmission shaft 19 is equipped with a two-stage speed change dual gear, and the intermediate shaft 20 is equipped with a fixed gear that cooperates with the transmission shaft dual ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com