Hydraulic engineering sludge separation device

A separation device and water conservancy engineering technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, sludge treatment, etc., can solve problems such as equipment damage, and achieve the effect of avoiding residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

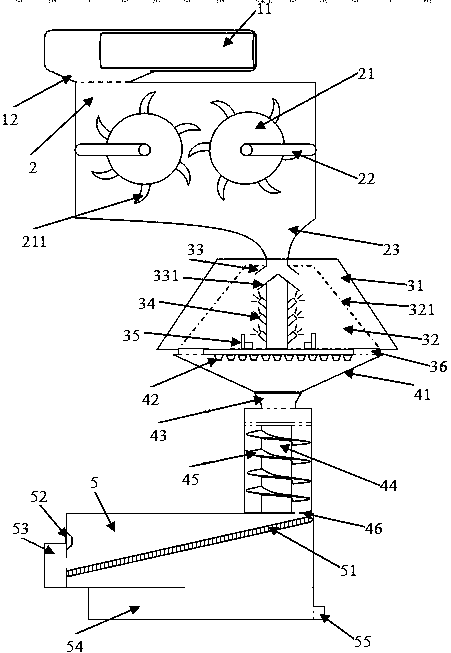

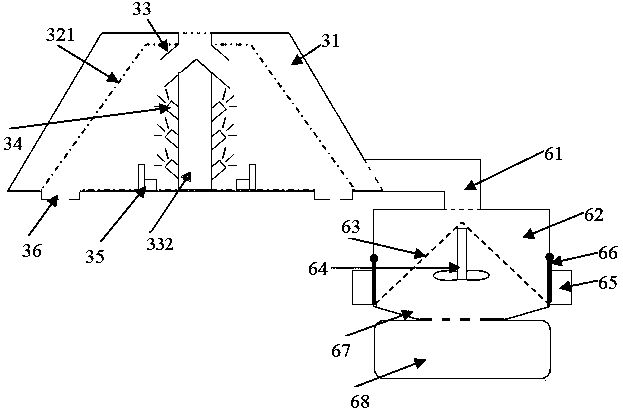

[0031] Such as figure 1 with figure 2 Shown: a water conservancy project sludge separation device, including a mud suction chamber, a crushing chamber, a separation chamber, a stirring and pushing chamber, a stone removal chamber and a sewage treatment chamber.

[0032] The suction chamber includes a suction chamber casing, a suction pump and an outlet of the suction chamber; the casing of the suction chamber is arranged in a transverse cylindrical structure, and a suction pump is arranged at one end inside it, and a suction pump is arranged at the lower part of the other end. Mud room egress.

[0033] The crushing chamber includes a crushing chamber shell, two crushing roller assemblies, an inlet of the crushing chamber and an outlet of the crushing chamber; the crushing roller assembly includes a crushing roller, crushing teeth arranged on the crushing roller and a support frame for fixing the crushing roller , the crushing teeth are arranged on the outer surface of the c...

Embodiment 2

[0046] A water conservancy project sludge separation device comprises a mud suction chamber, a crushing chamber, a separation chamber, a stirring and pushing chamber, a stone removal chamber and a sewage treatment chamber.

[0047] The suction chamber includes a suction chamber casing, a suction pump and an outlet of the suction chamber; the casing of the suction chamber is arranged in a transverse cylindrical structure, and a suction pump is arranged at one end inside it, and a suction pump is arranged at the lower part of the other end. Mud room egress.

[0048] The crushing chamber includes a crushing chamber shell, 3 groups of 6 crushing roller assemblies, the crushing chamber inlet and the crushing chamber outlet; the crushing roller assembly includes crushing rollers, crushing teeth arranged on the crushing rollers and a bracket for fixing the crushing rollers. The supporting frame, the crushing teeth are arranged in a half-crescent shape on the outer surface of the crus...

Embodiment 3

[0059] A water conservancy project sludge separation device comprises a mud suction chamber, a crushing chamber, a separation chamber, a stirring and pushing chamber, a stone removal chamber and a sewage treatment chamber.

[0060] The suction chamber includes a suction chamber casing, a suction pump and an outlet of the suction chamber; the casing of the suction chamber is arranged in a transverse cylindrical structure, and a suction pump is arranged at one end inside it, and a suction pump is arranged at the lower part of the other end. Mud room egress.

[0061] The crushing chamber includes a crushing chamber shell, three crushing roller assemblies, a crushing chamber inlet and a crushing chamber outlet; the crushing roller assembly includes a crushing roller, crushing teeth arranged on the crushing roller and a support frame for fixing the crushing roller , the crushing teeth are arranged on the outer surface of the crushing roller in a half-crescent shape, and the crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com