Patents

Literature

5617results about How to "Easily broken" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

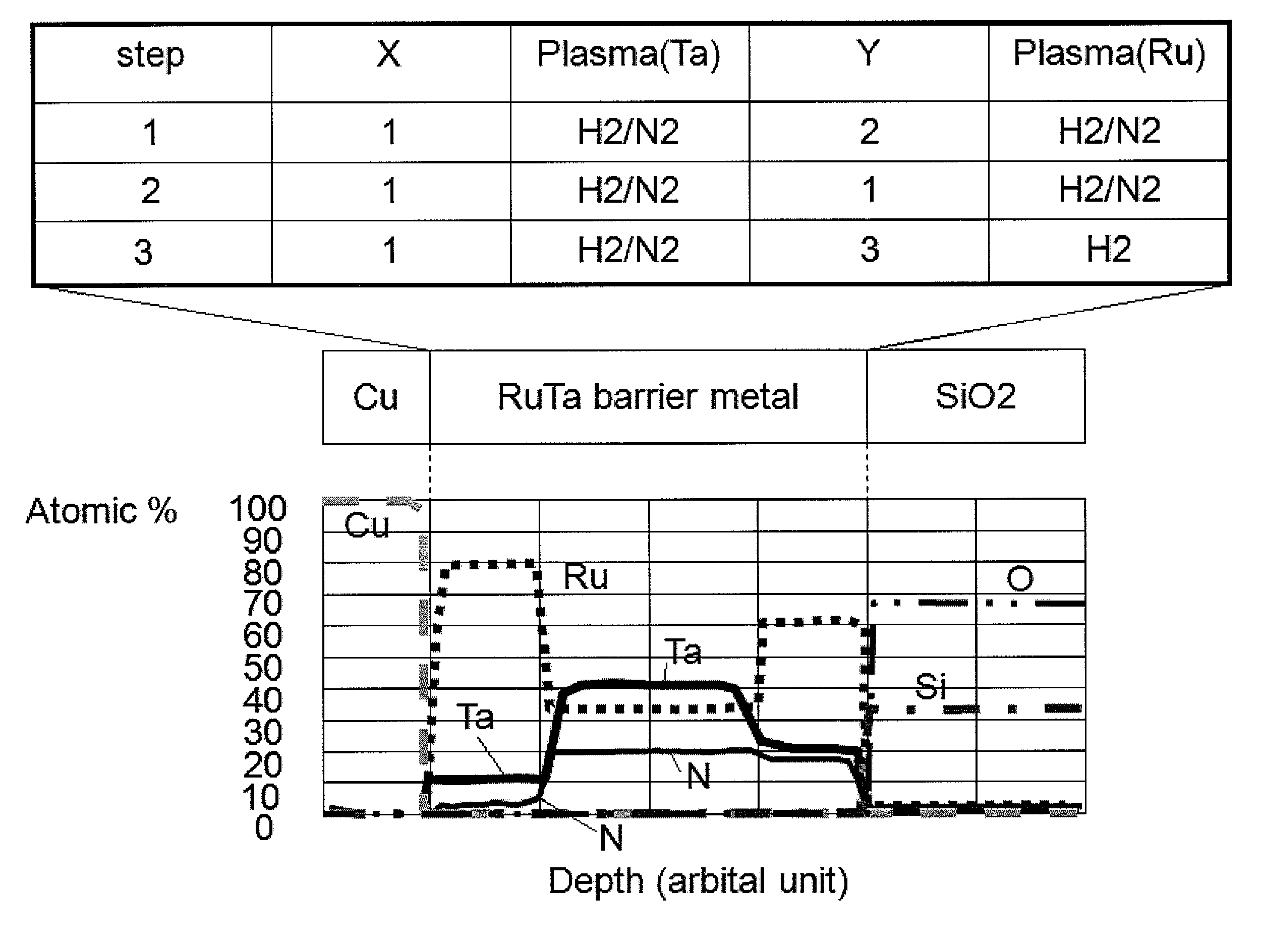

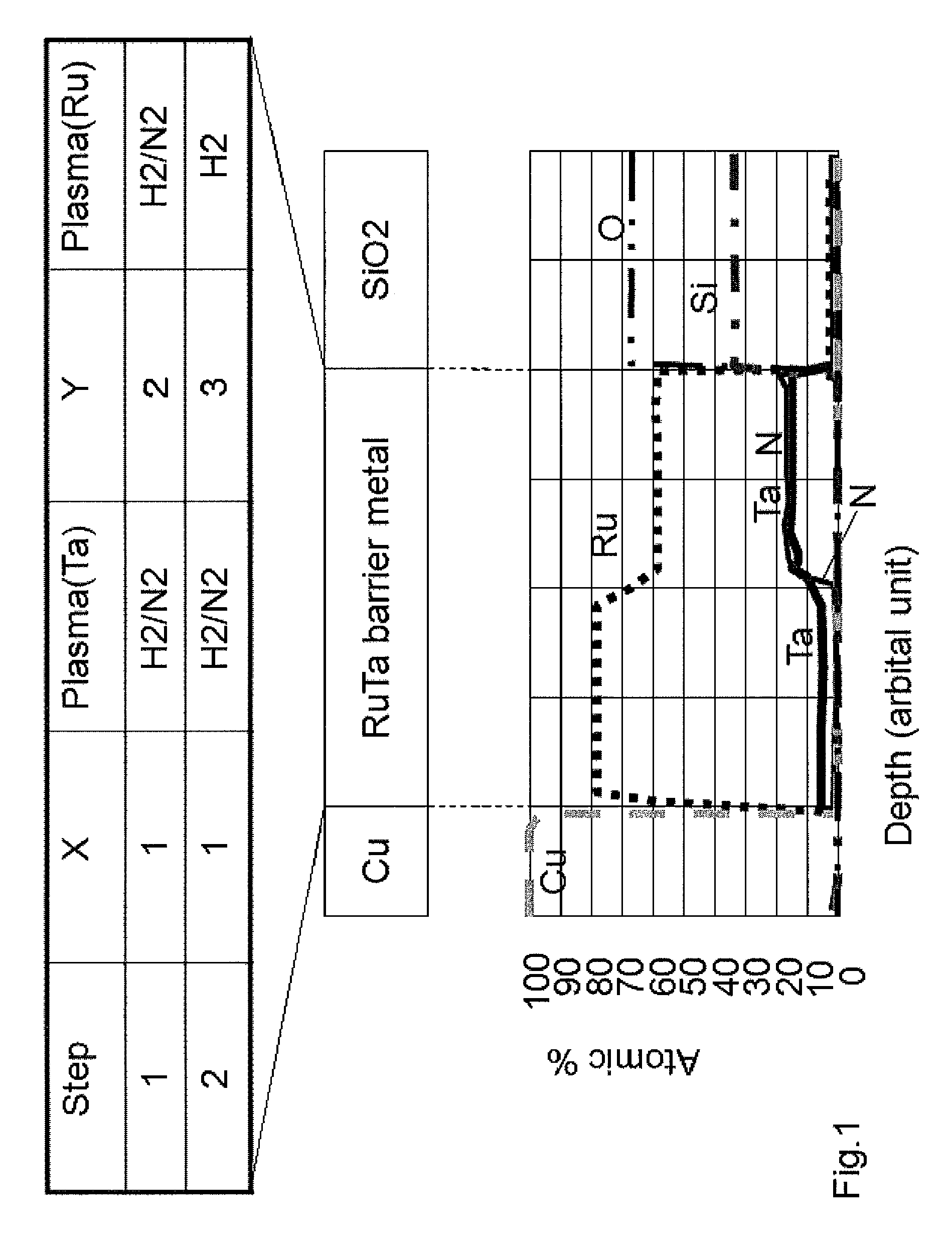

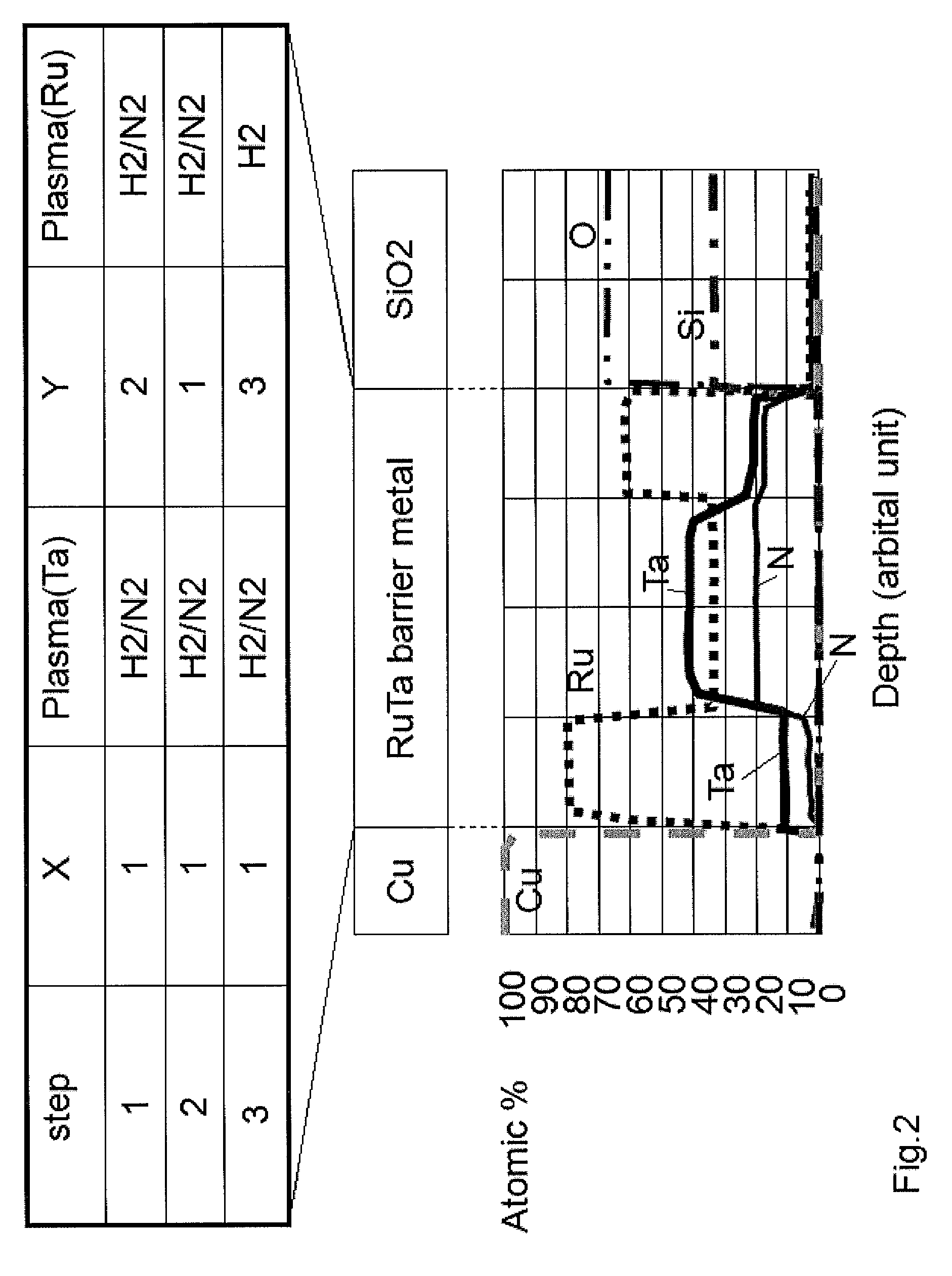

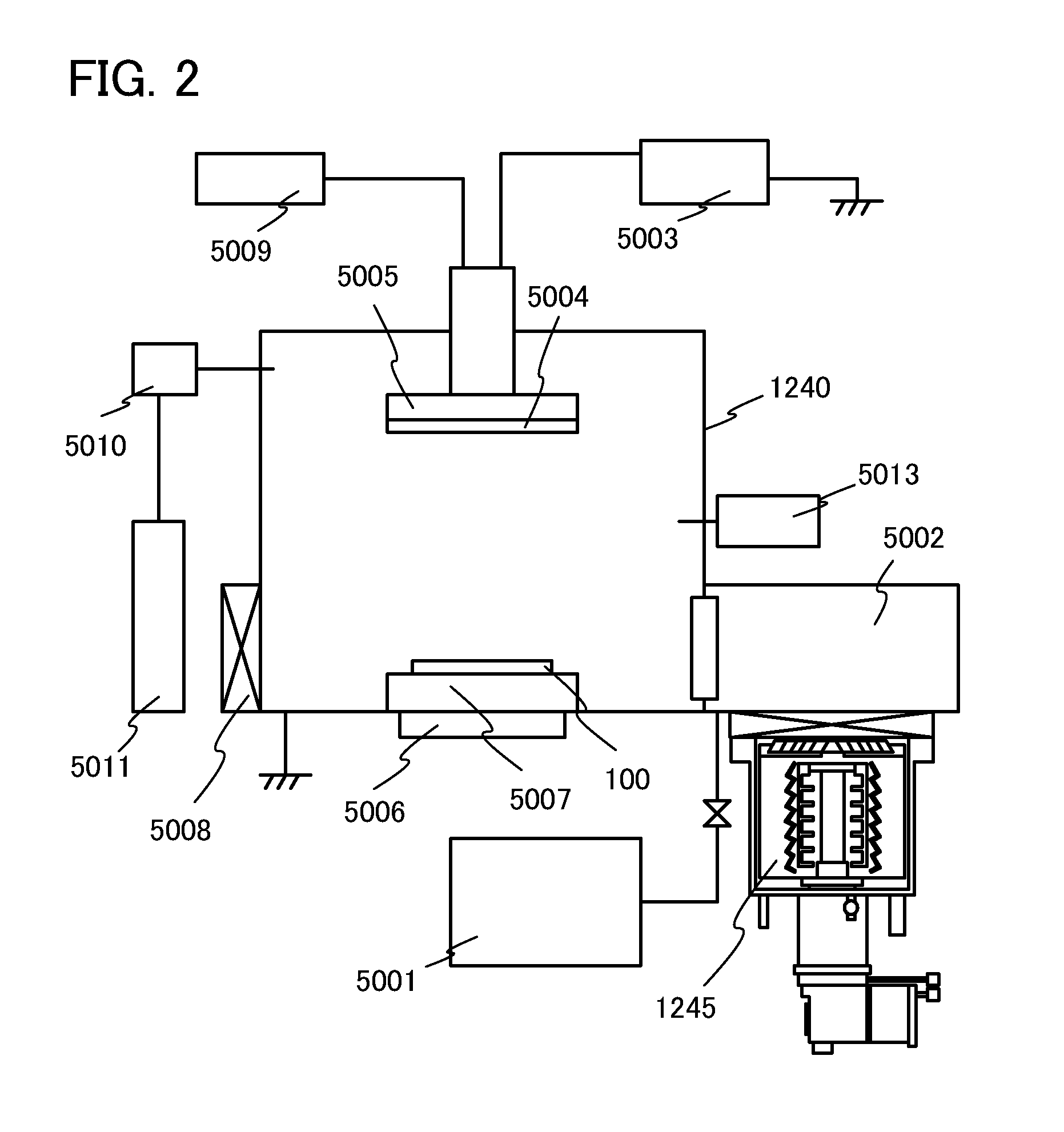

Atomic composition controlled ruthenium alloy film formed by plasma-enhanced atomic layer deposition

ActiveUS8084104B2Reduce resistanceLow densitySemiconductor/solid-state device detailsSynthetic resin layered productsRutheniumAlloy

A metal film composed of multiple atomic layers continuously formed by atomic layer deposition of Ru and Ta or Ti includes at least a top section and a bottom section, wherein an atomic composition of Ru, Ta or Ti, and N varies in a thickness direction of the metal film. The atomic composition of Ru, Ta or Ti, and N in the top section is represented as Ru(x1)Ta / Ti(y1)N(z1) wherein an atomic ratio of Ru(x1) / (Ta / Ti(y1)) is no less than 15, and z1 is 0.05 or less. The atomic composition of Ru, Ta or Ti, and N in the bottom section is represented as Ru(x2)Ta / Ti(y2)N(z2) wherein an atomic ratio of Ru(x2) / (Ta / Ti(y2)) is more than zero but less than 15, and z2 is 0.10 or greater.

Owner:ASM JAPAN

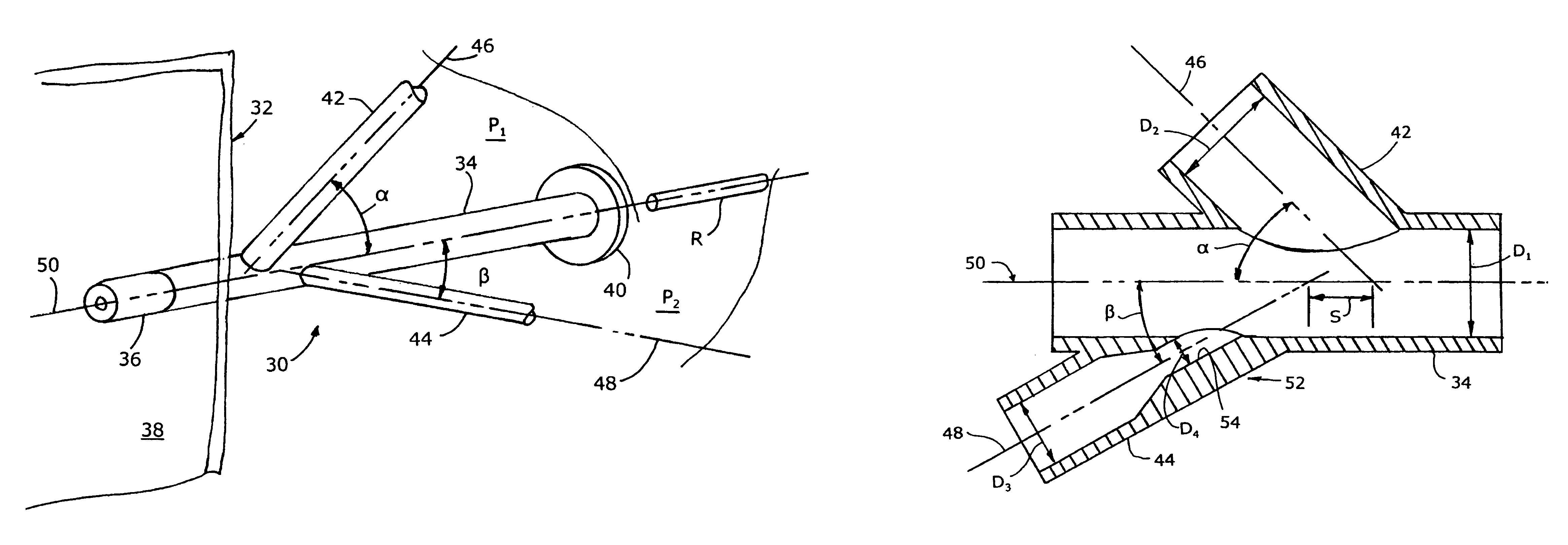

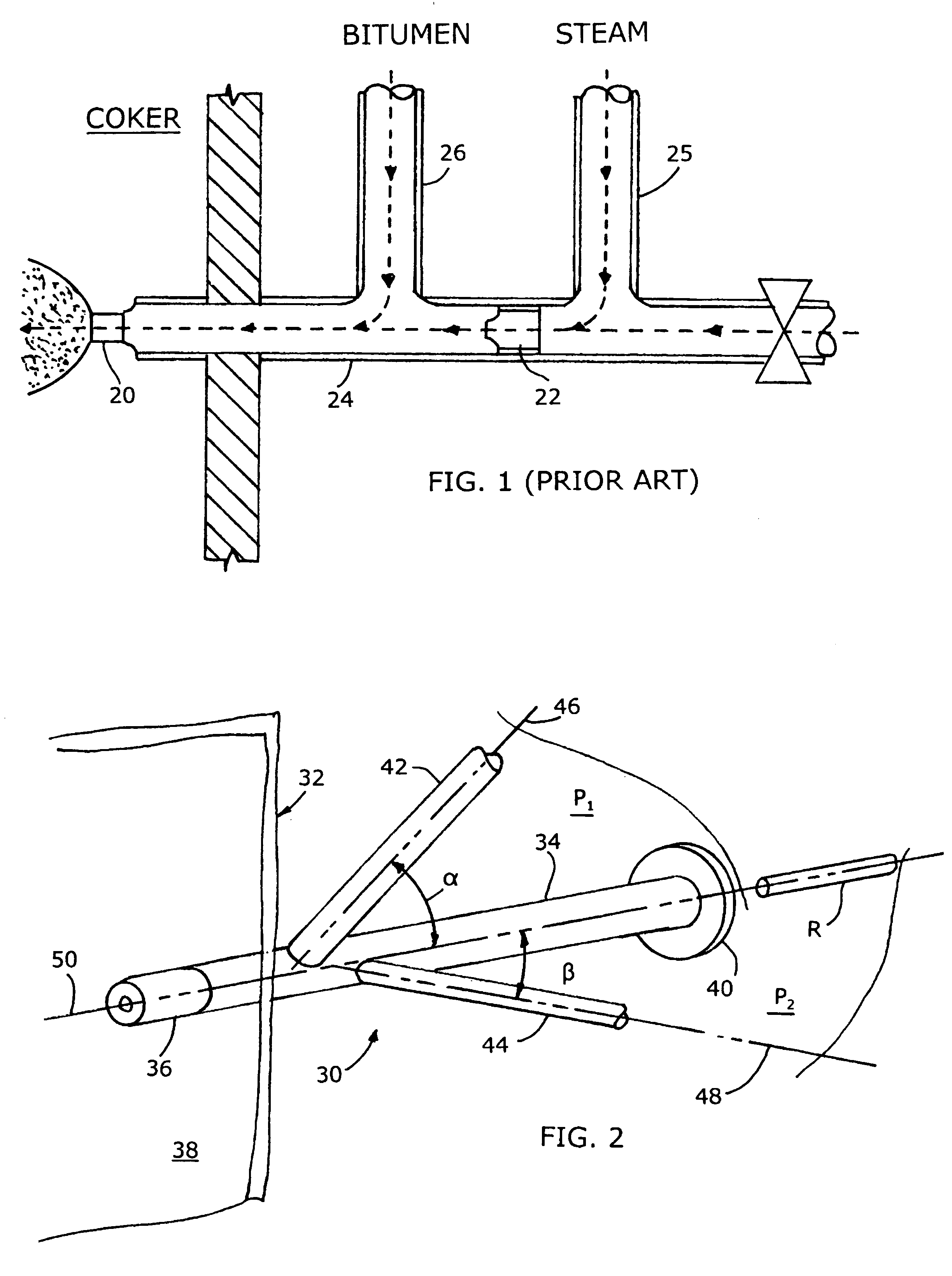

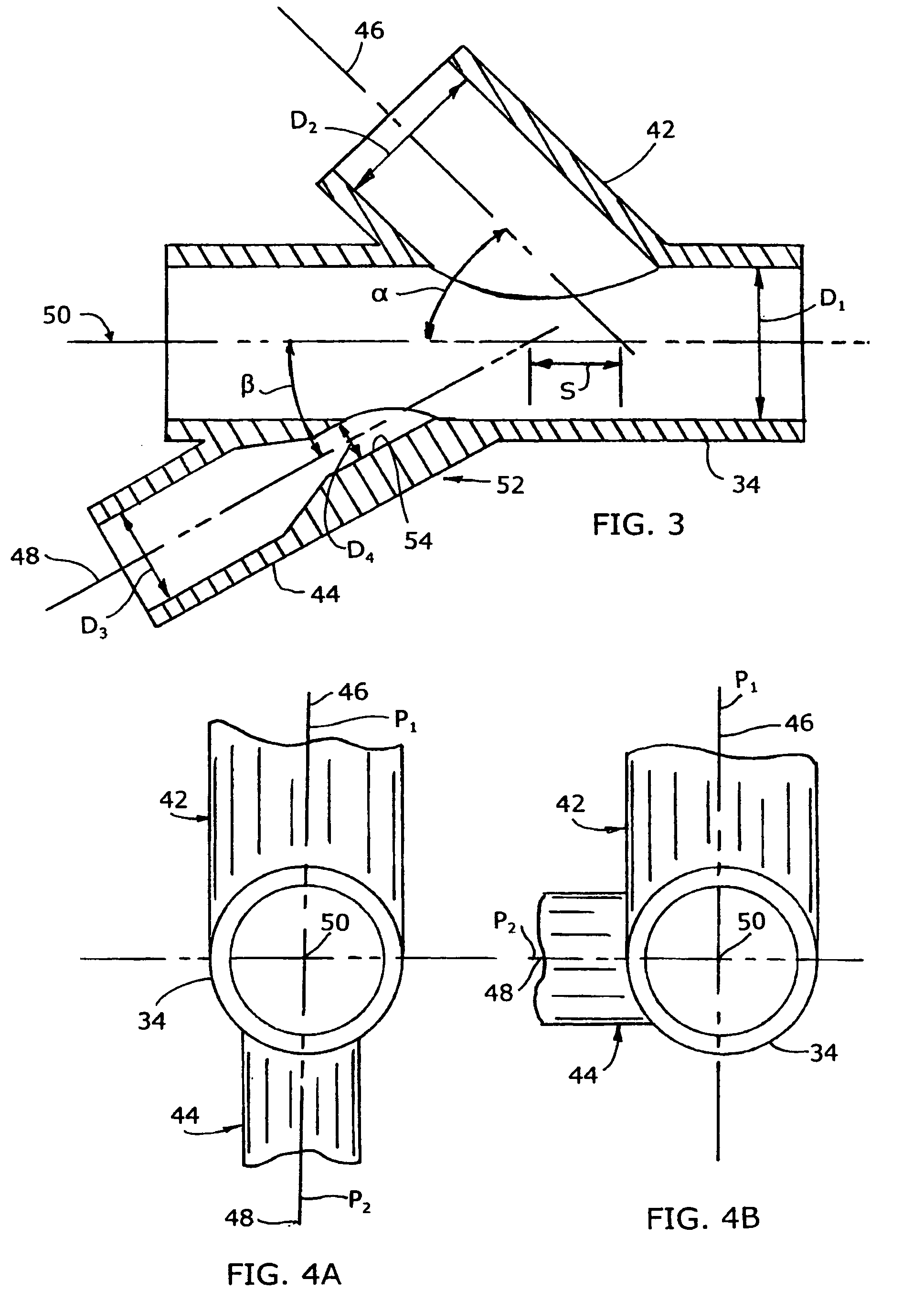

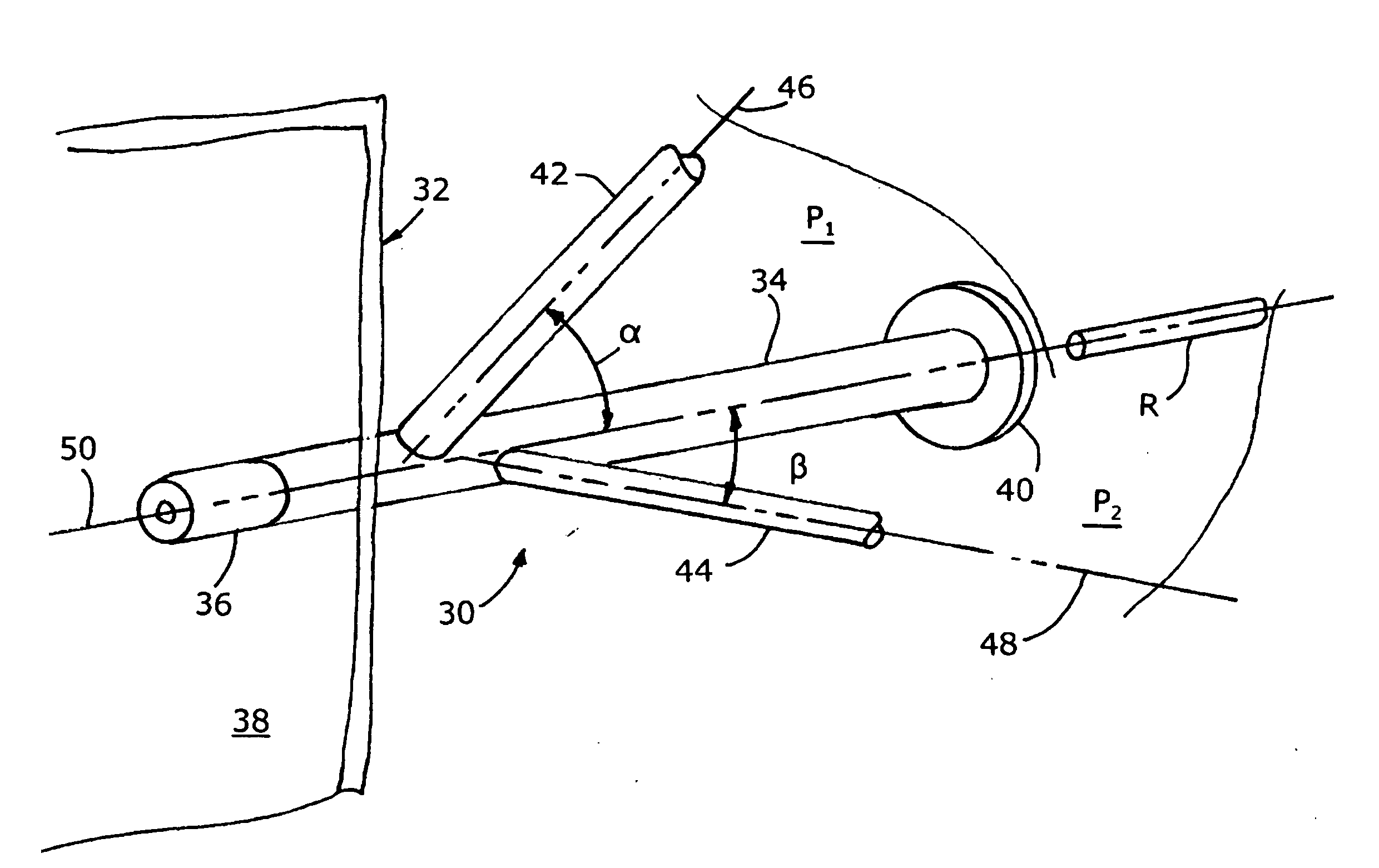

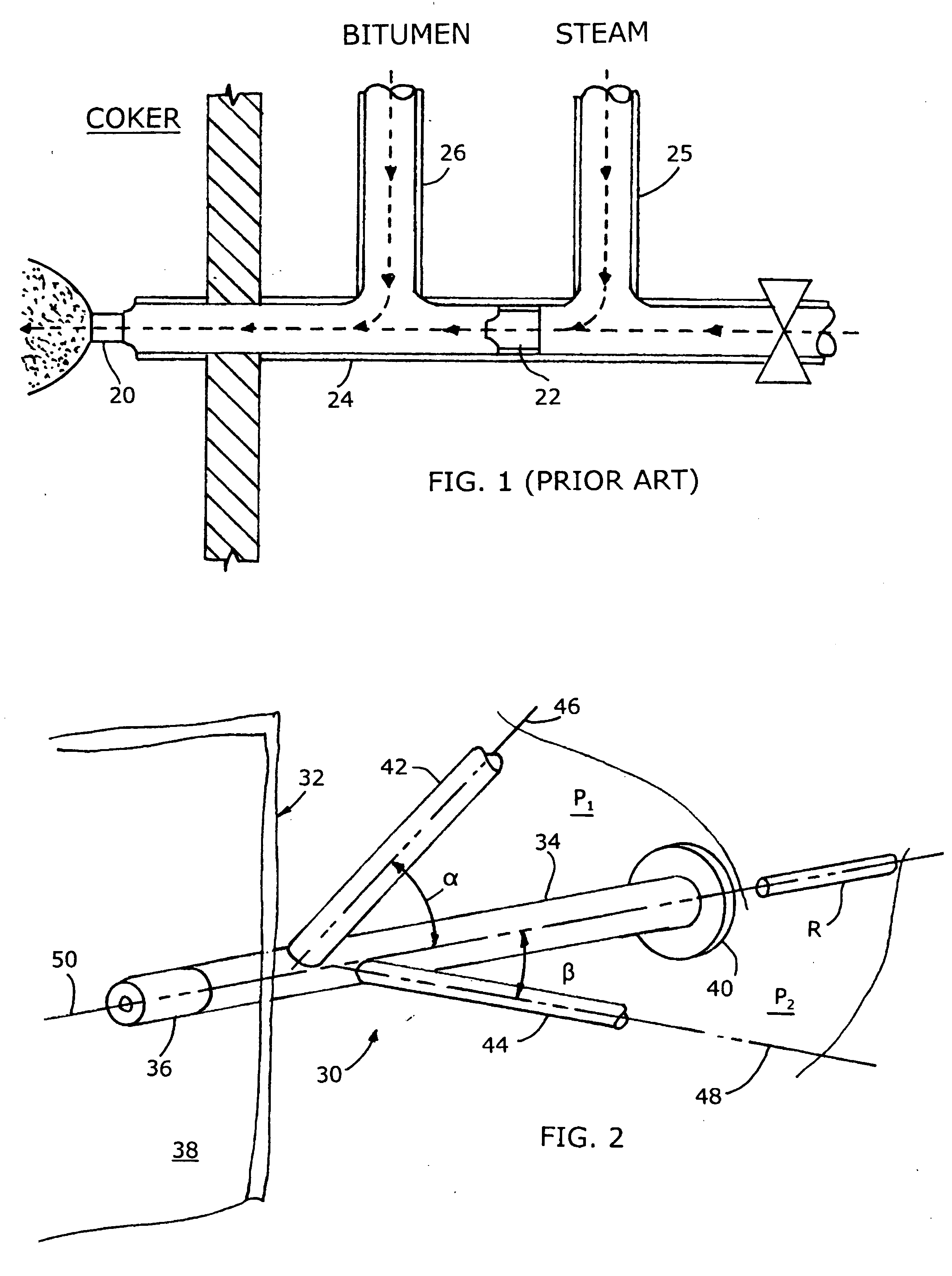

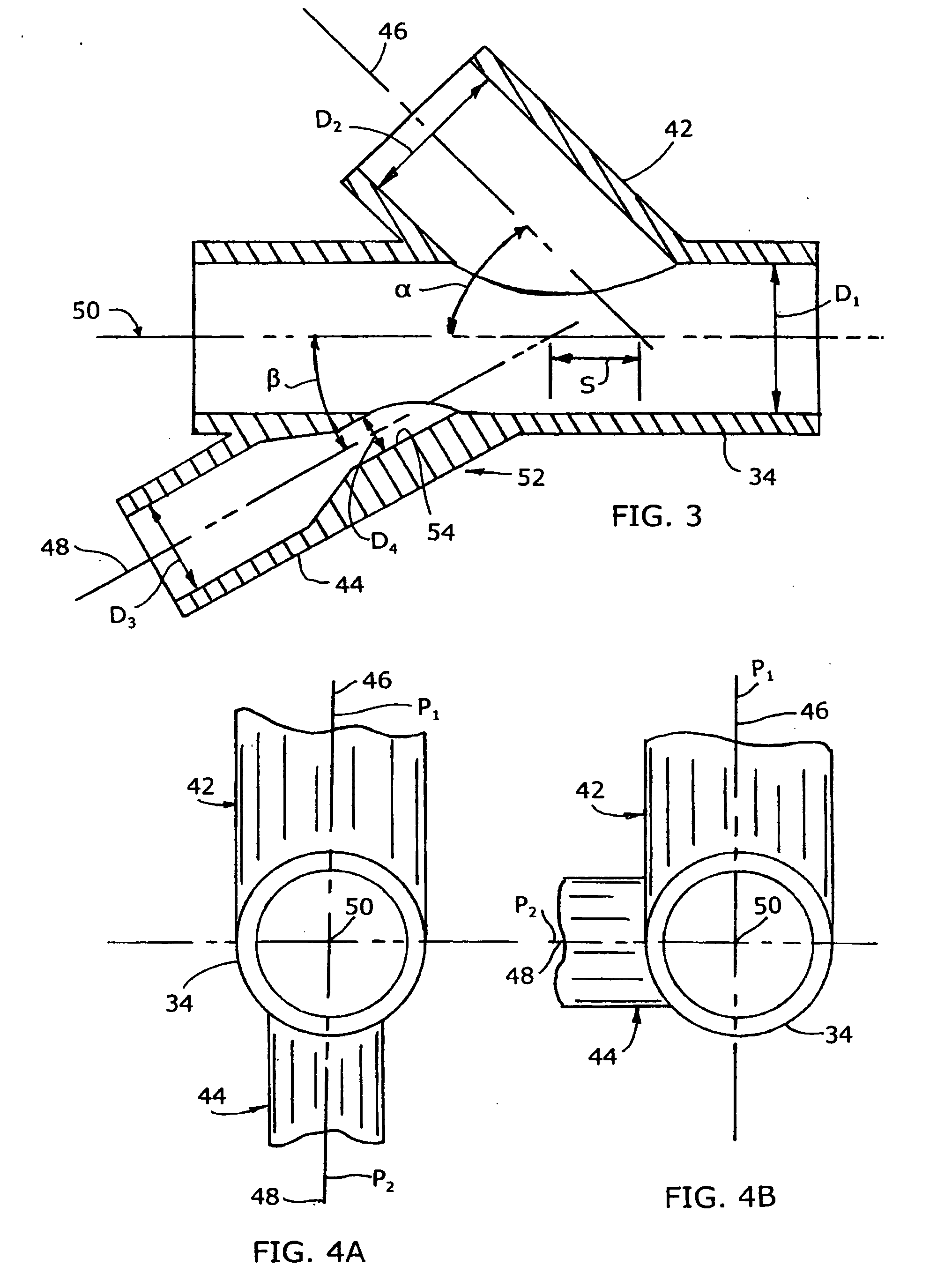

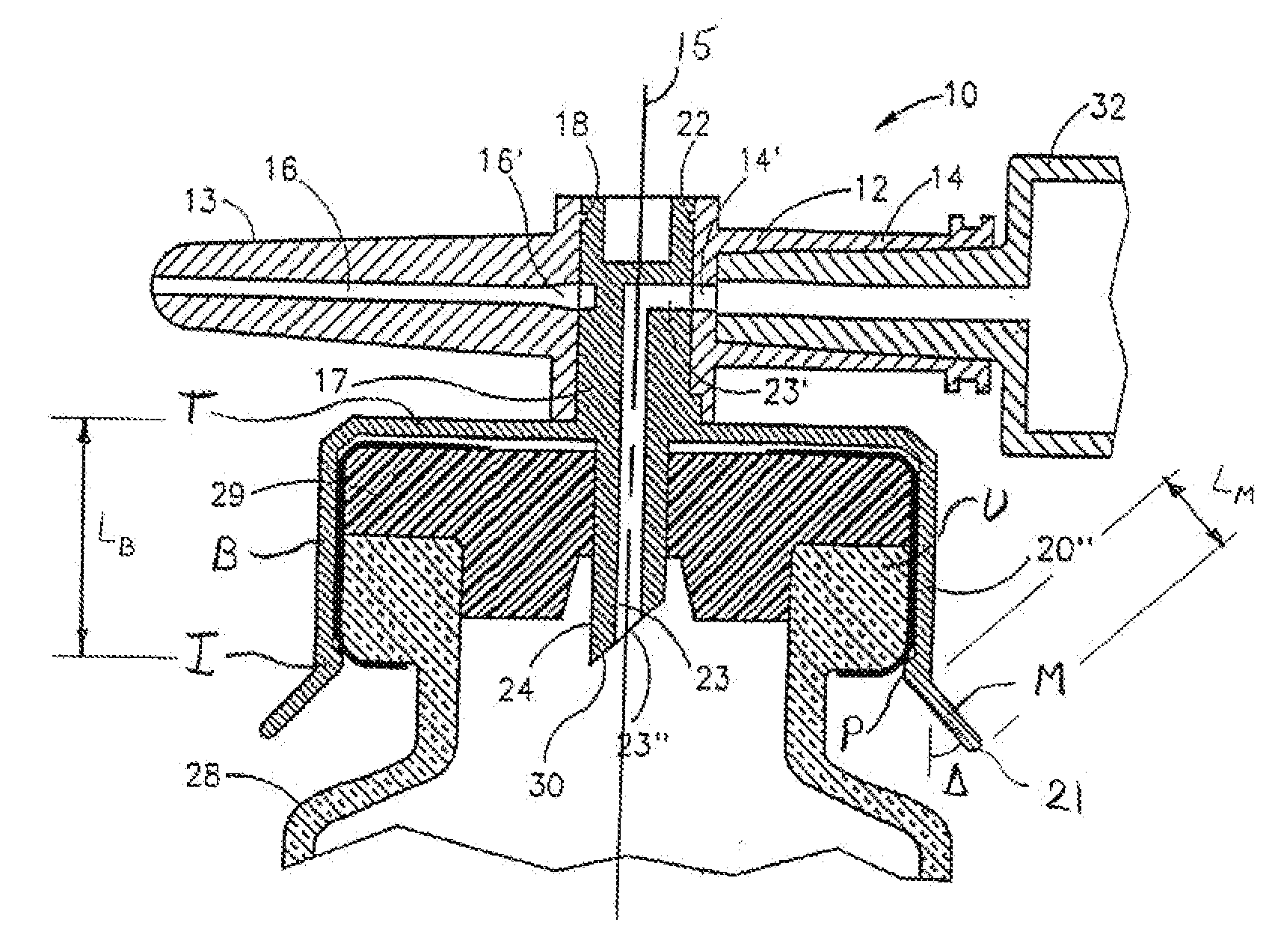

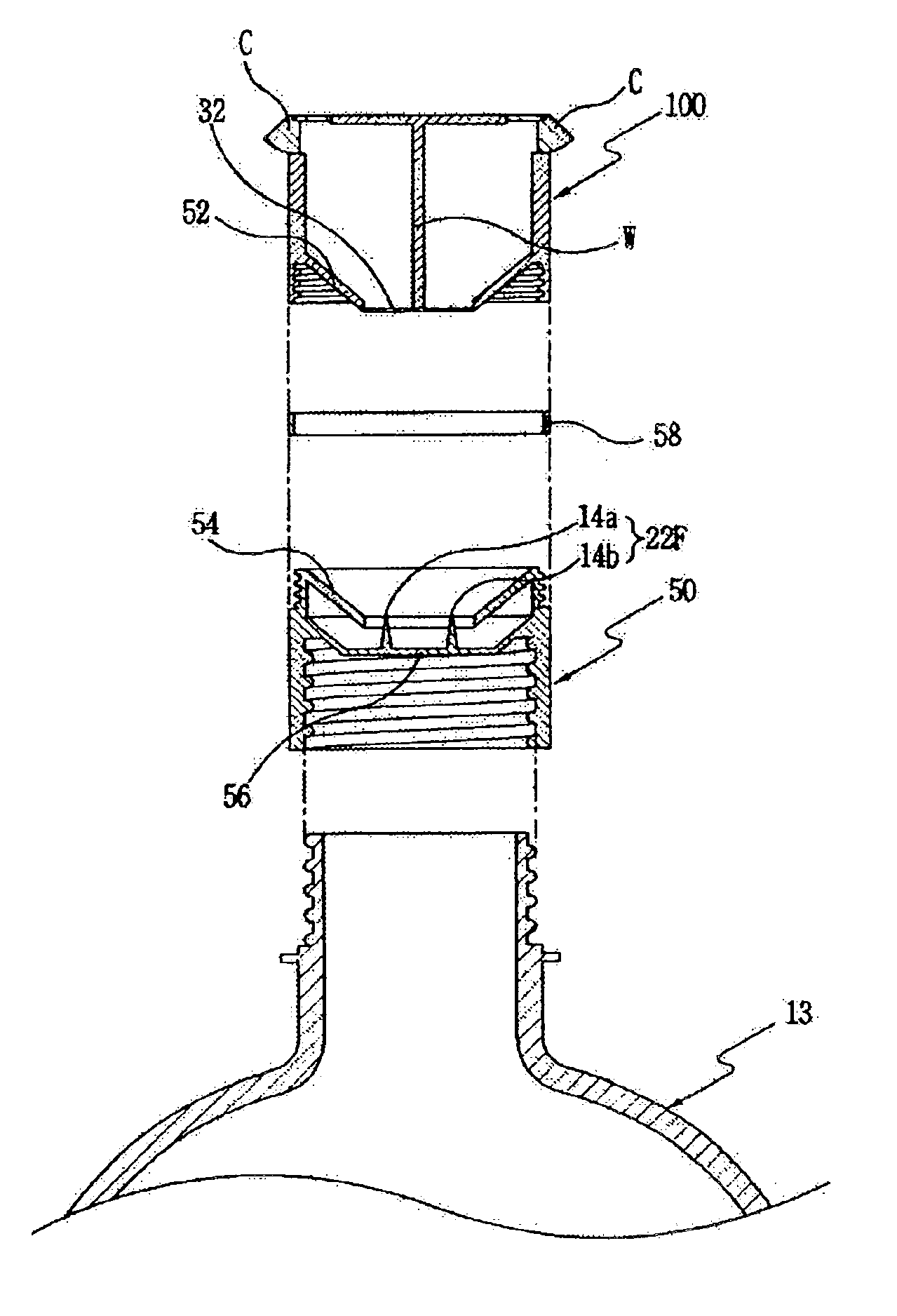

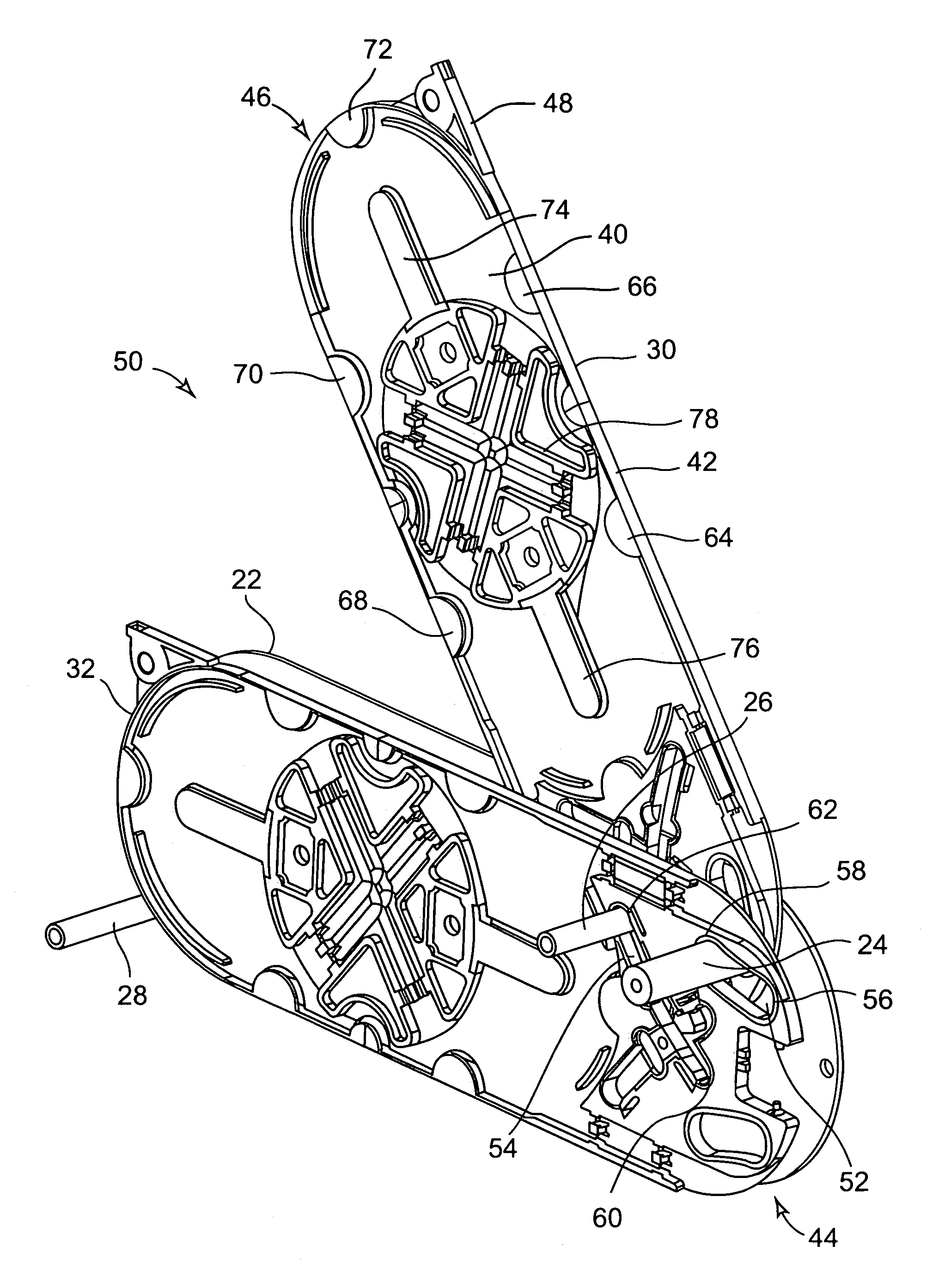

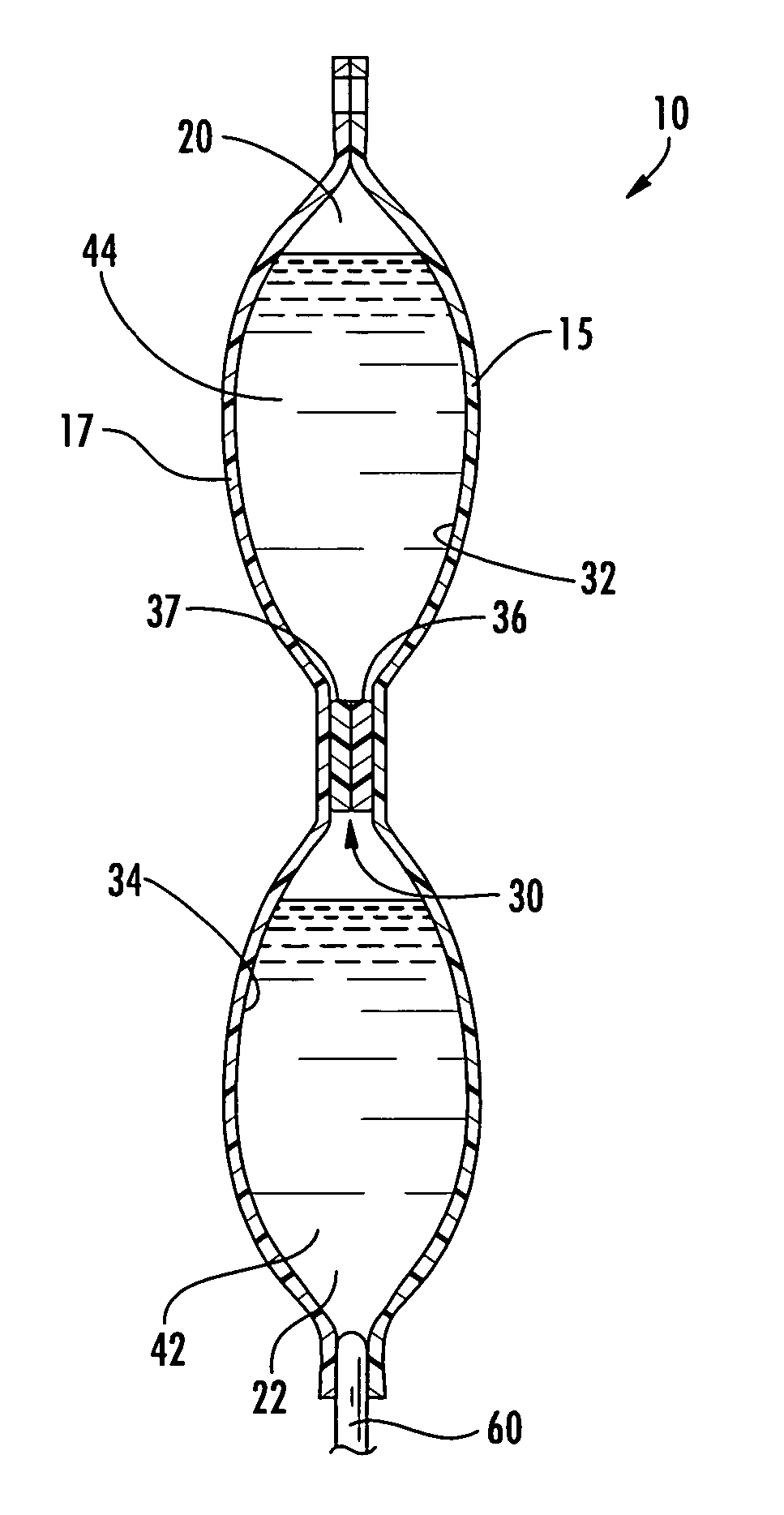

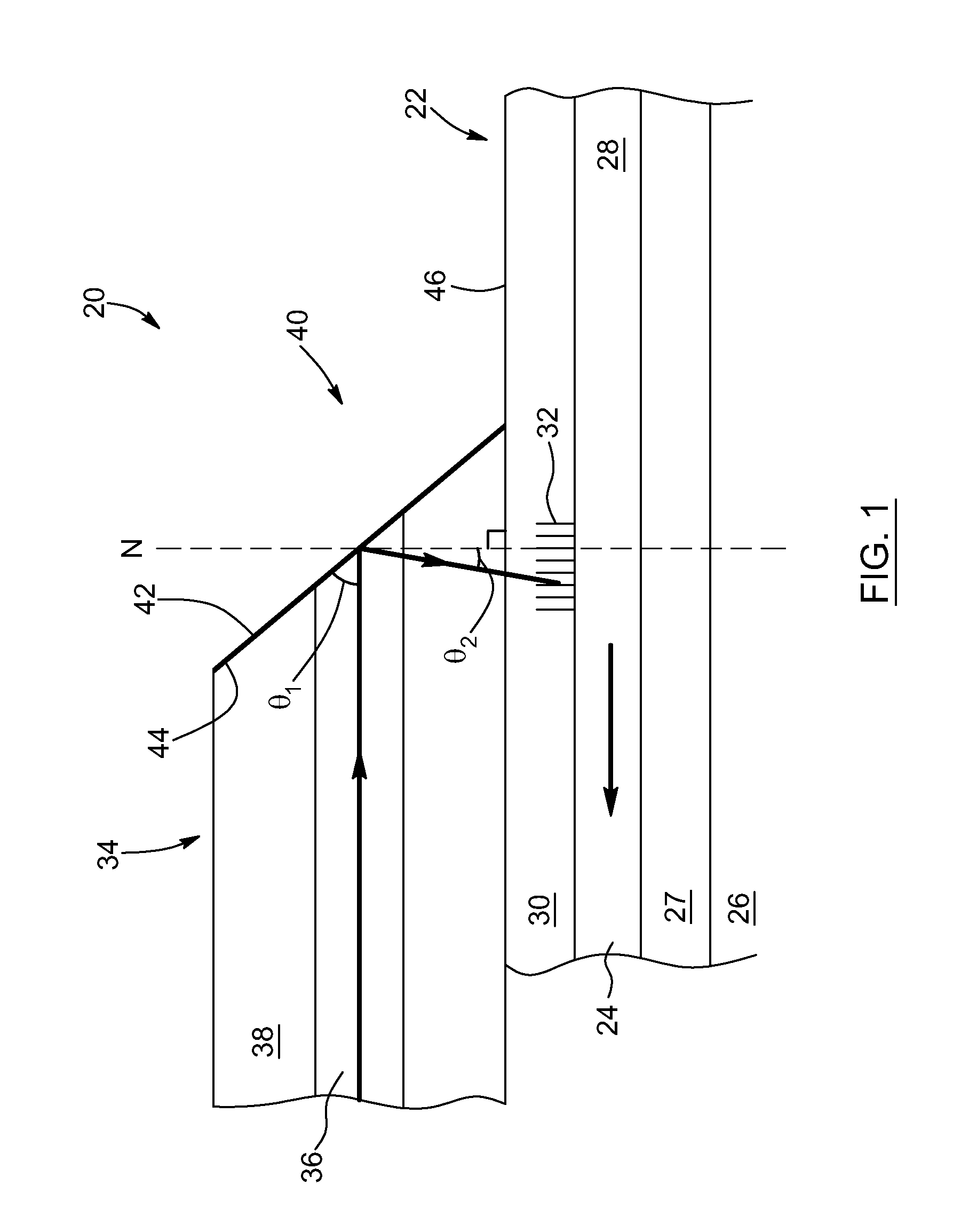

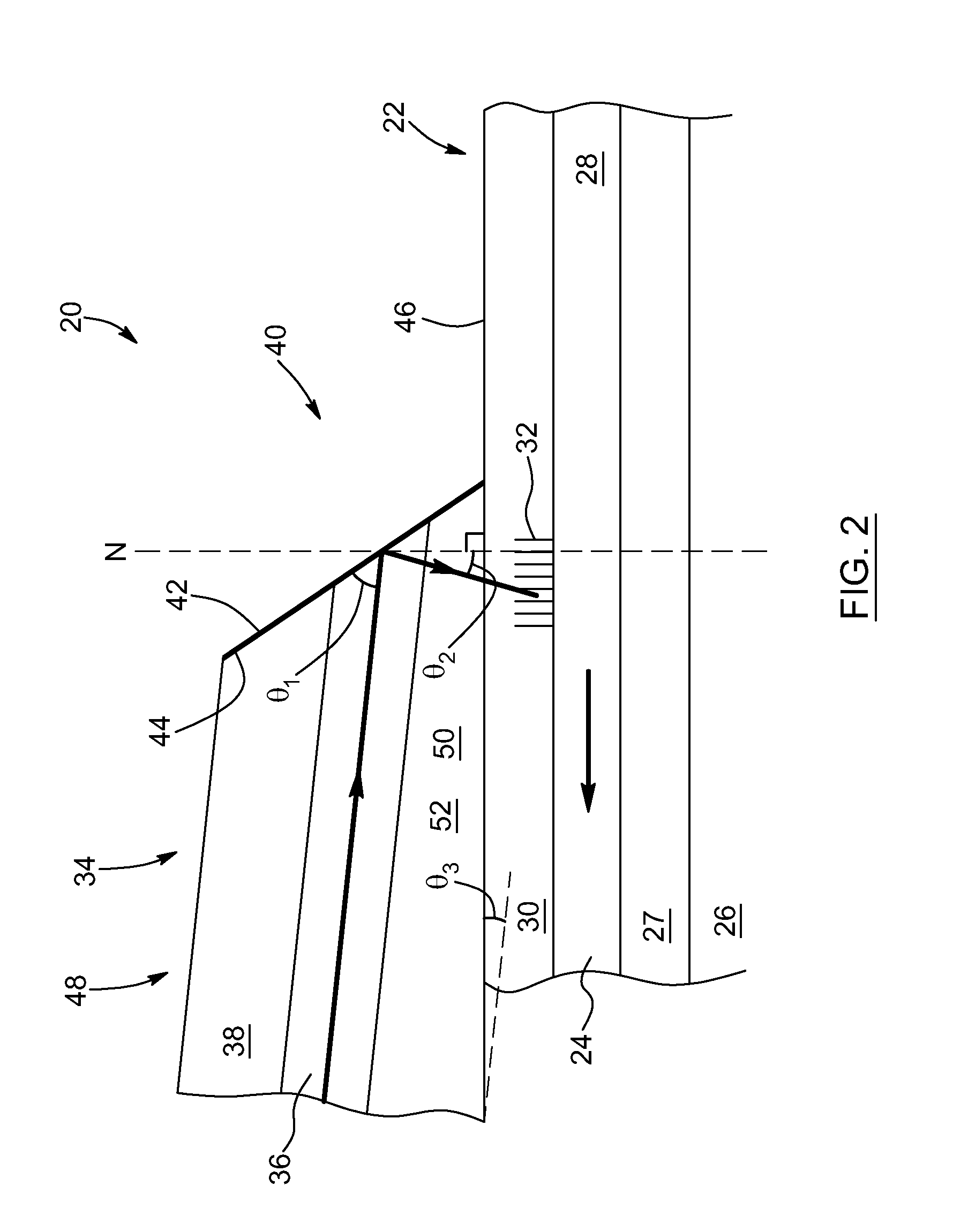

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS7140558B2Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned upstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

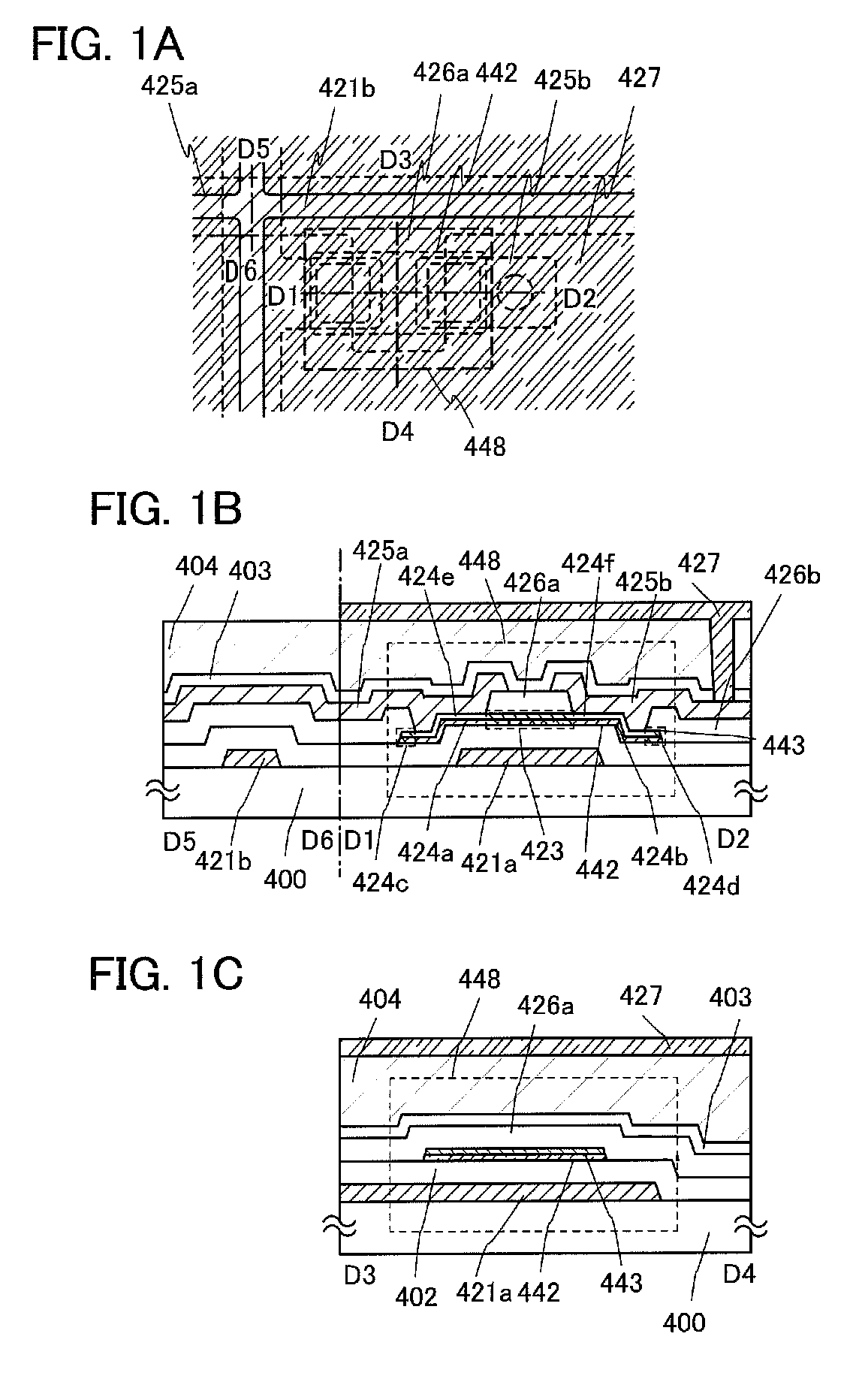

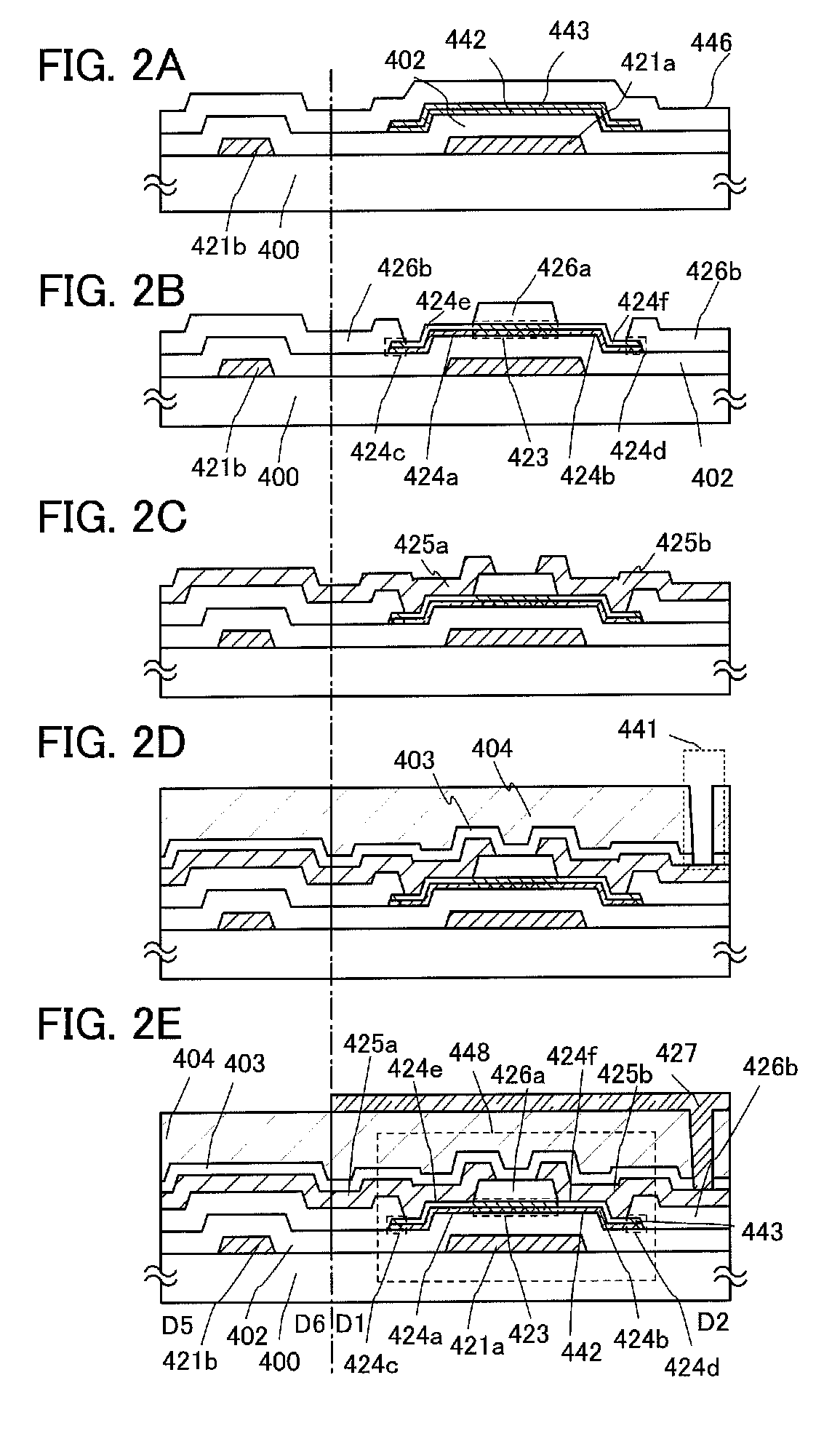

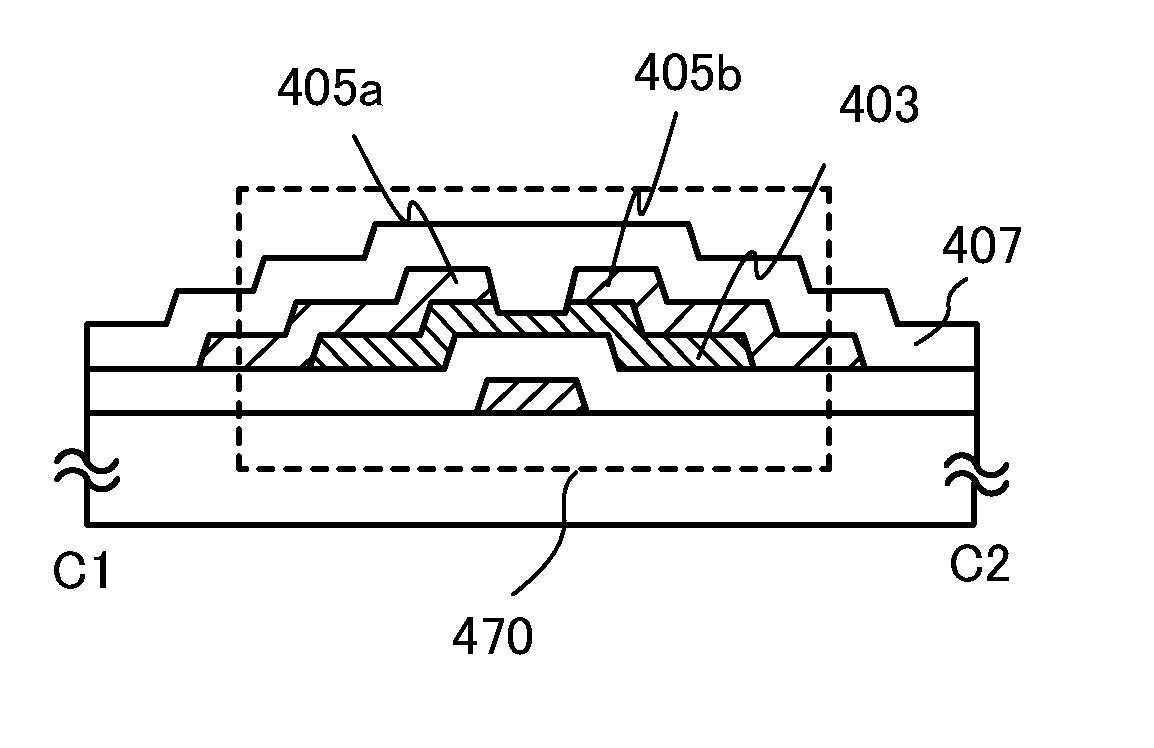

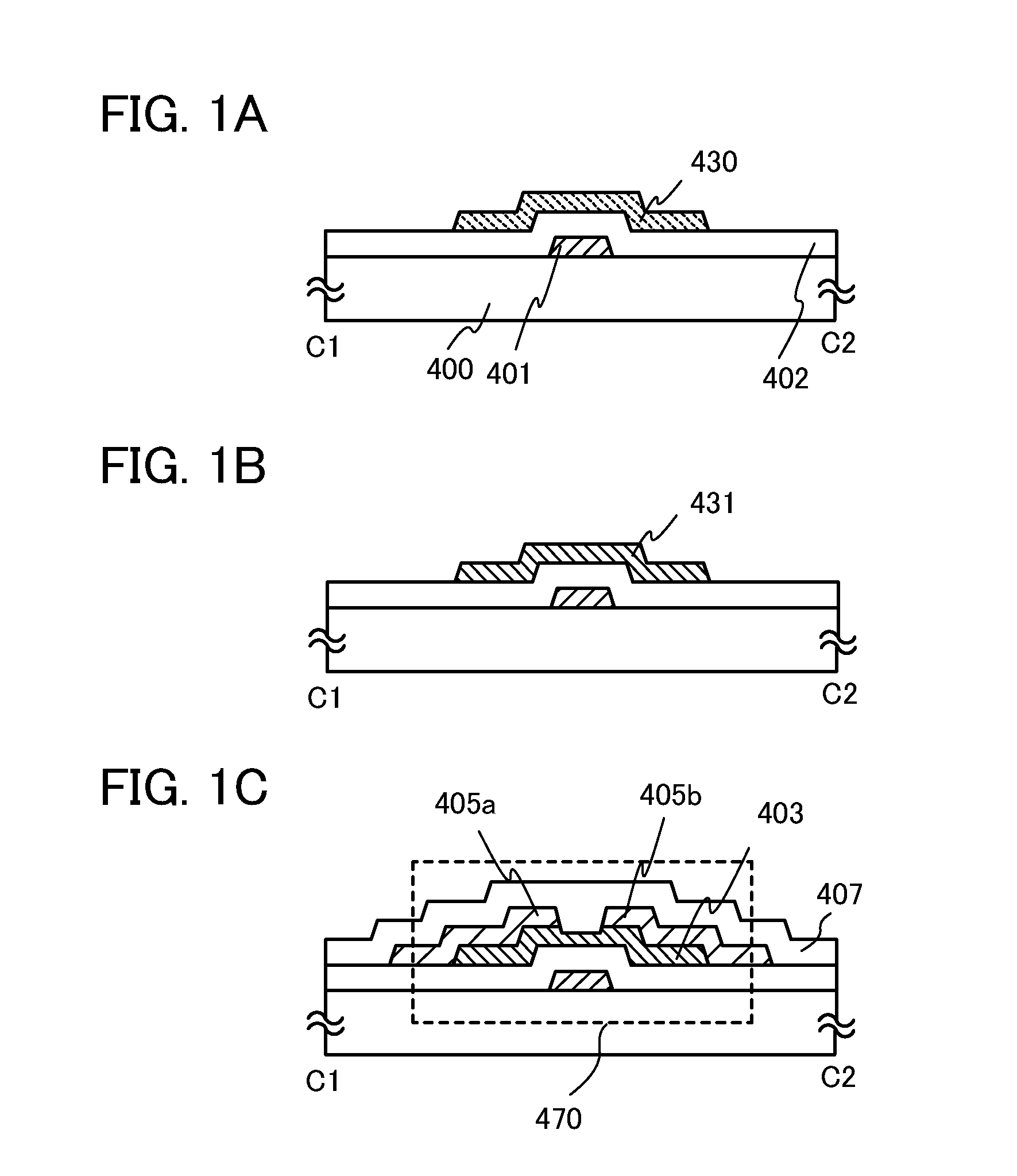

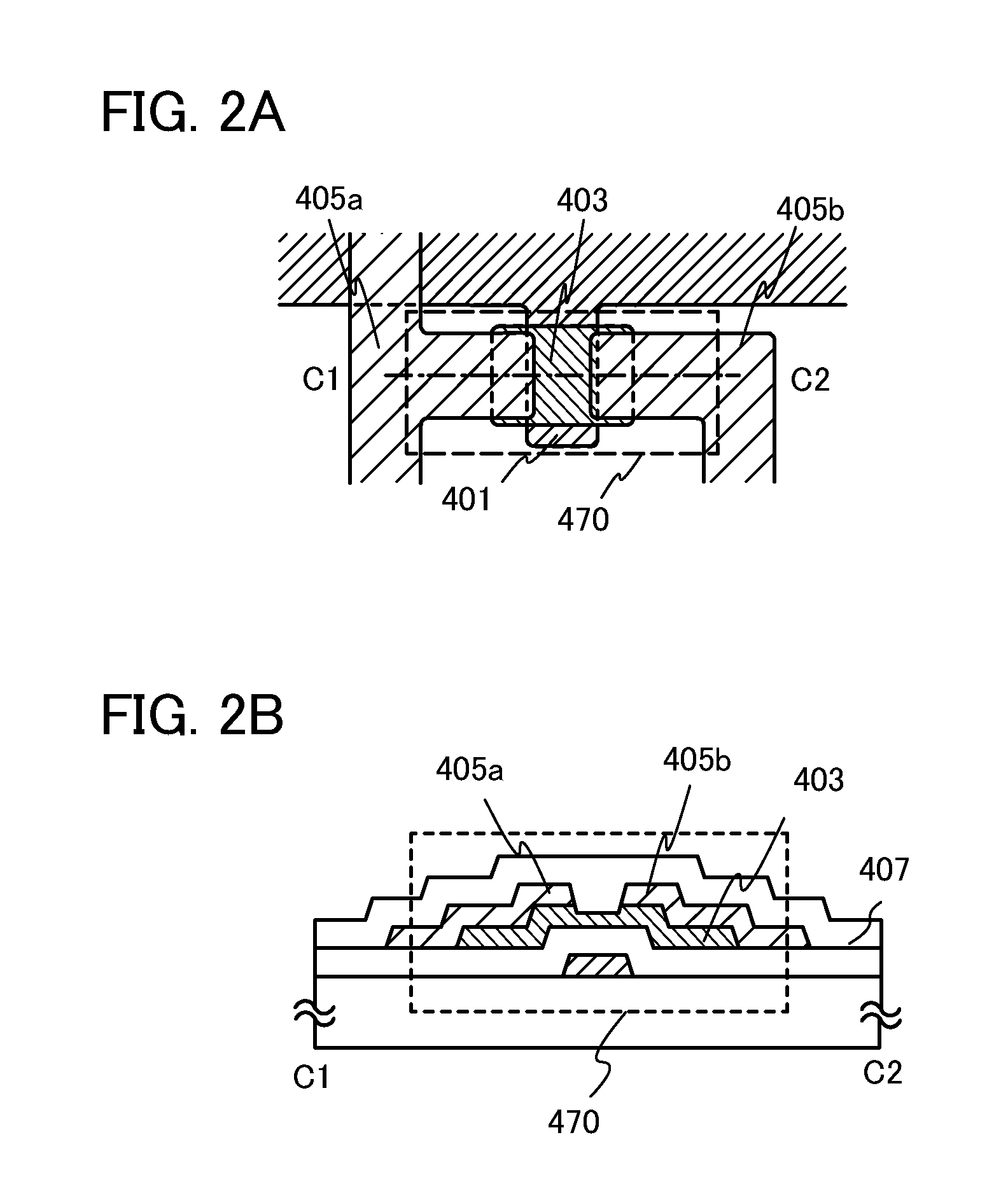

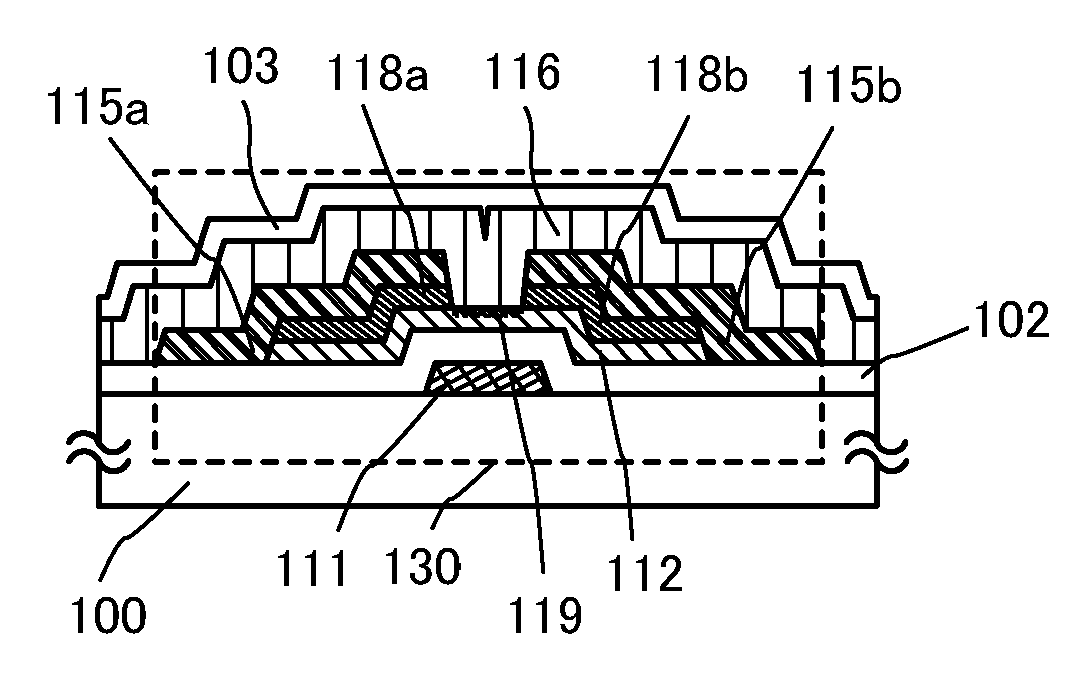

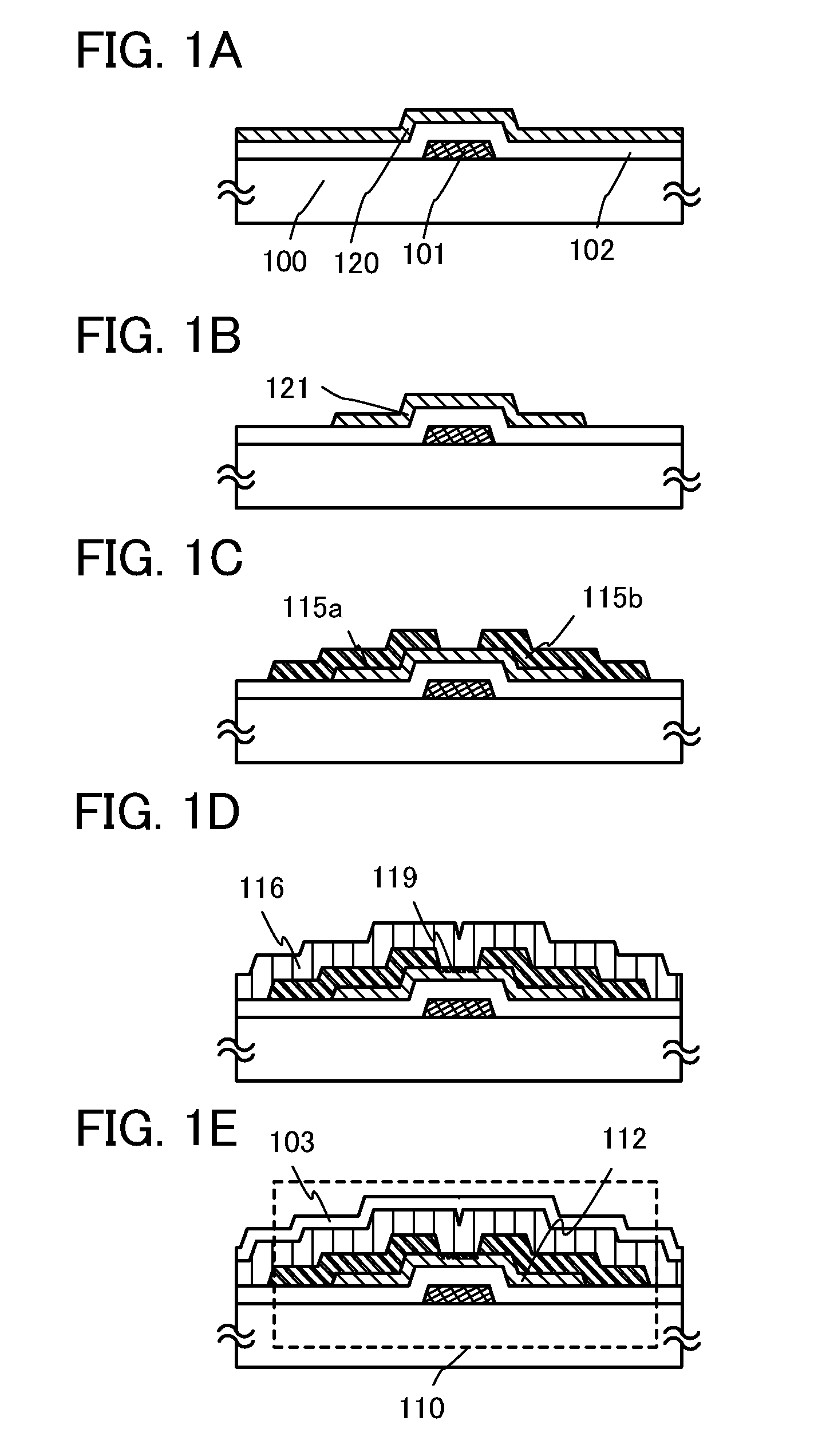

Semiconductor device and manufacturing method thereof

ActiveUS20110024751A1Reduce manufacturing costEasily brokenTransistorSolid-state devicesBottom gateSemiconductor

In a bottom-gate thin film transistor using the stack of the first oxide semiconductor layer and the second oxide semiconductor layer, an oxide insulating layer serving as a channel protective layer is formed over and in contact with part of the oxide semiconductor layer overlapping with a gate electrode layer. In the same step as formation of the insulating layer, an oxide insulating layer covering a peripheral portion (including a side surface) of the stack of the oxide semiconductor layers is formed.

Owner:SEMICON ENERGY LAB CO LTD

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS20050001062A1Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned downstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit. The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

Curvilinear LED light source

ActiveUS20060028837A1Avoid easy installationEasily brokenLighting support devicesPoint-like light sourceMulti materialLight guide

An LED system that simulates bare or exposed neon in appearance. The curvilinear LED light source comprises a rigid, formable light guide having a generally circular cross-section and a flexible LED light engine. The light guide is made of a material or materials that can be heated and formed into a desired shape. The light guide retains the desired shape upon cooling. The flexible light engine is inserted into a groove in the light engine.

Owner:GE LIGHTING SOLUTIONS LLC

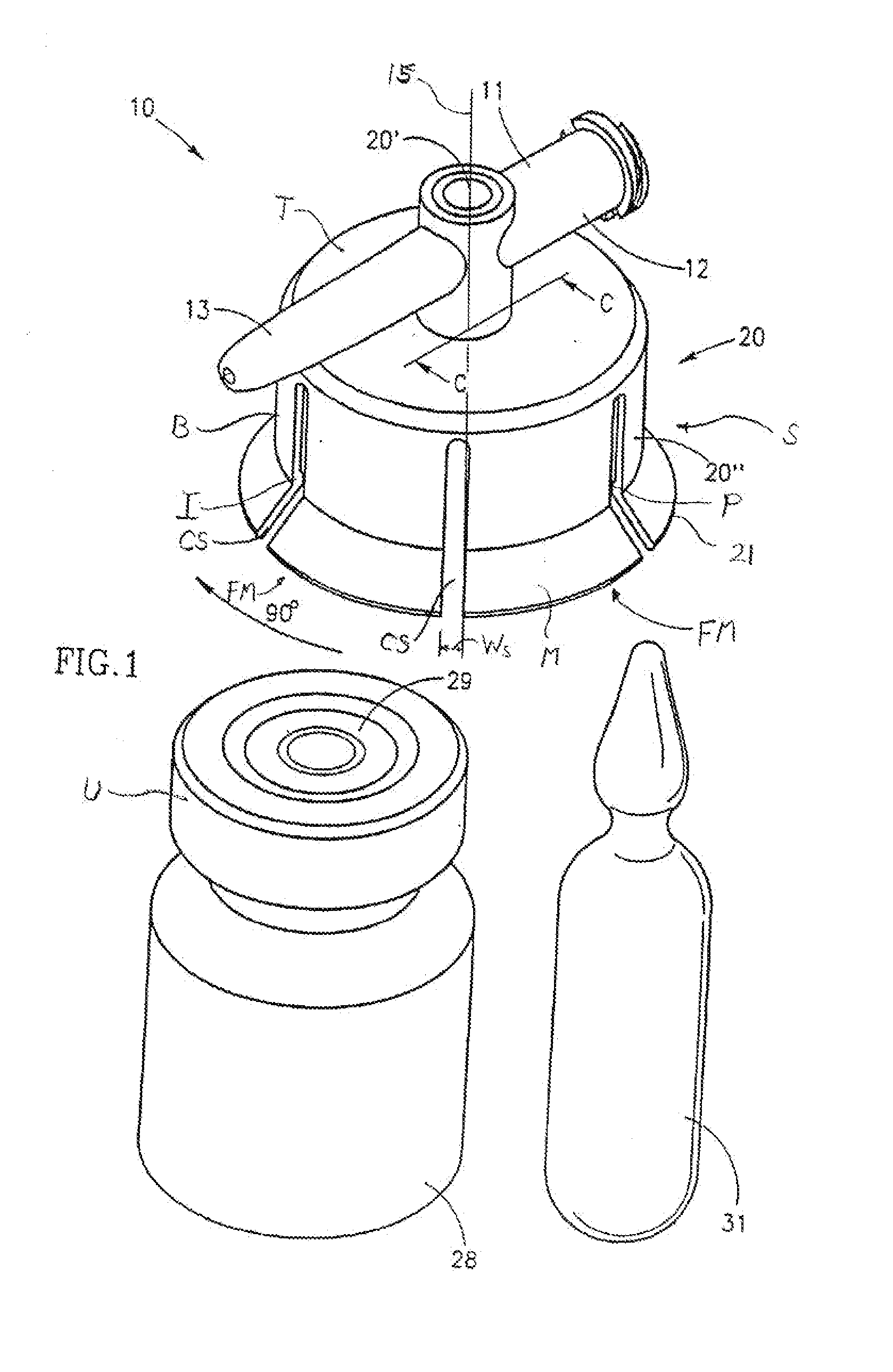

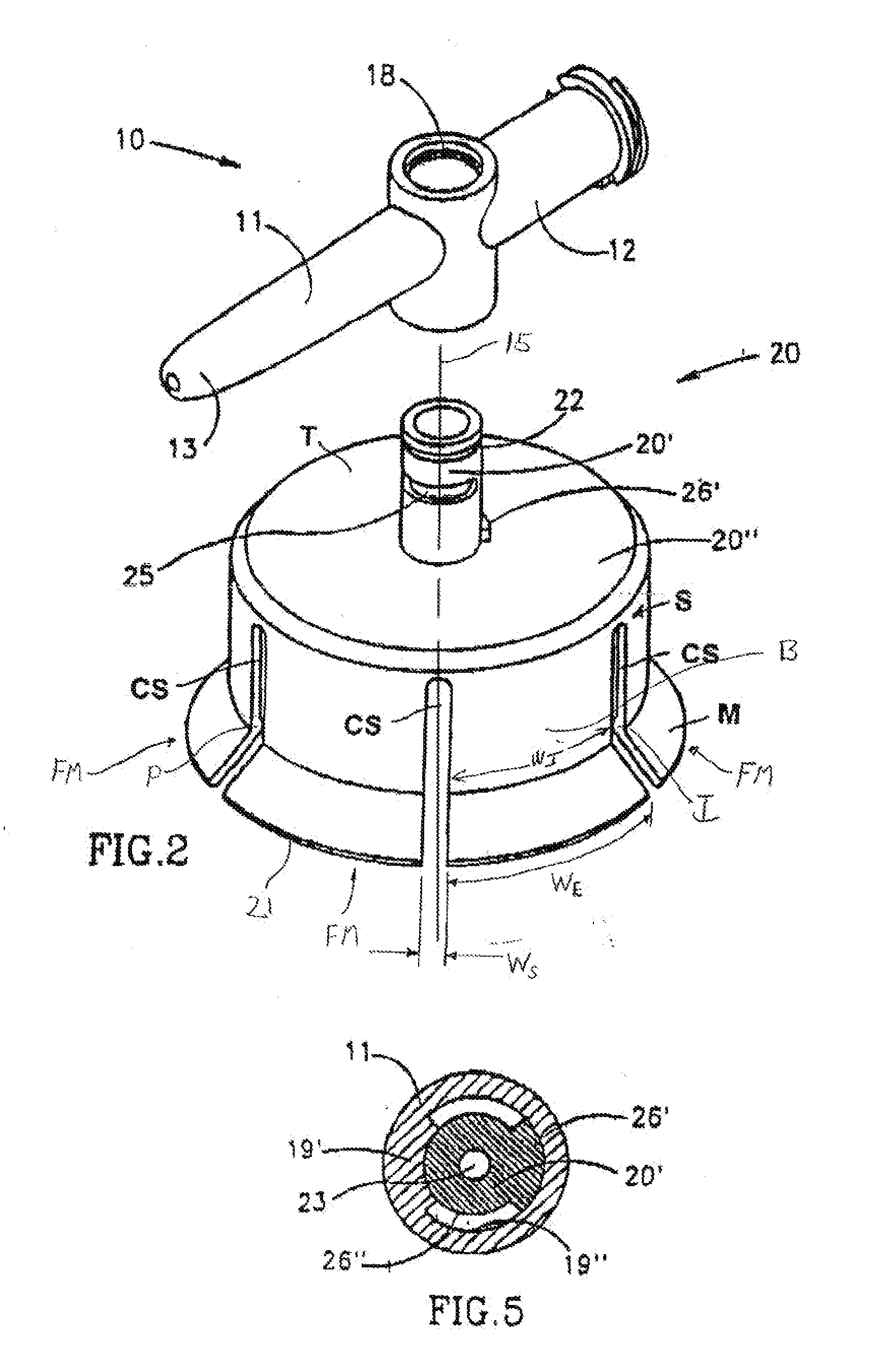

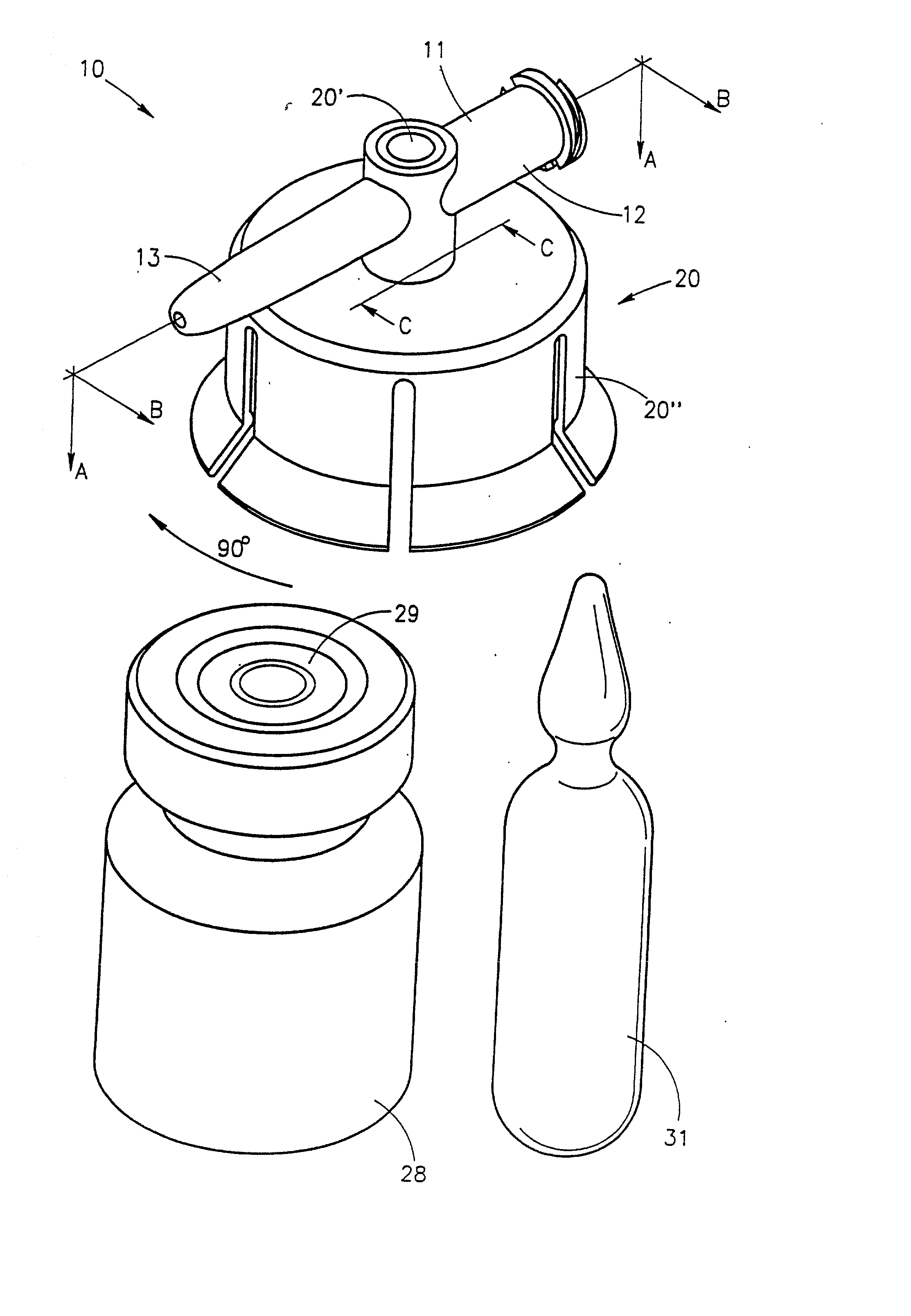

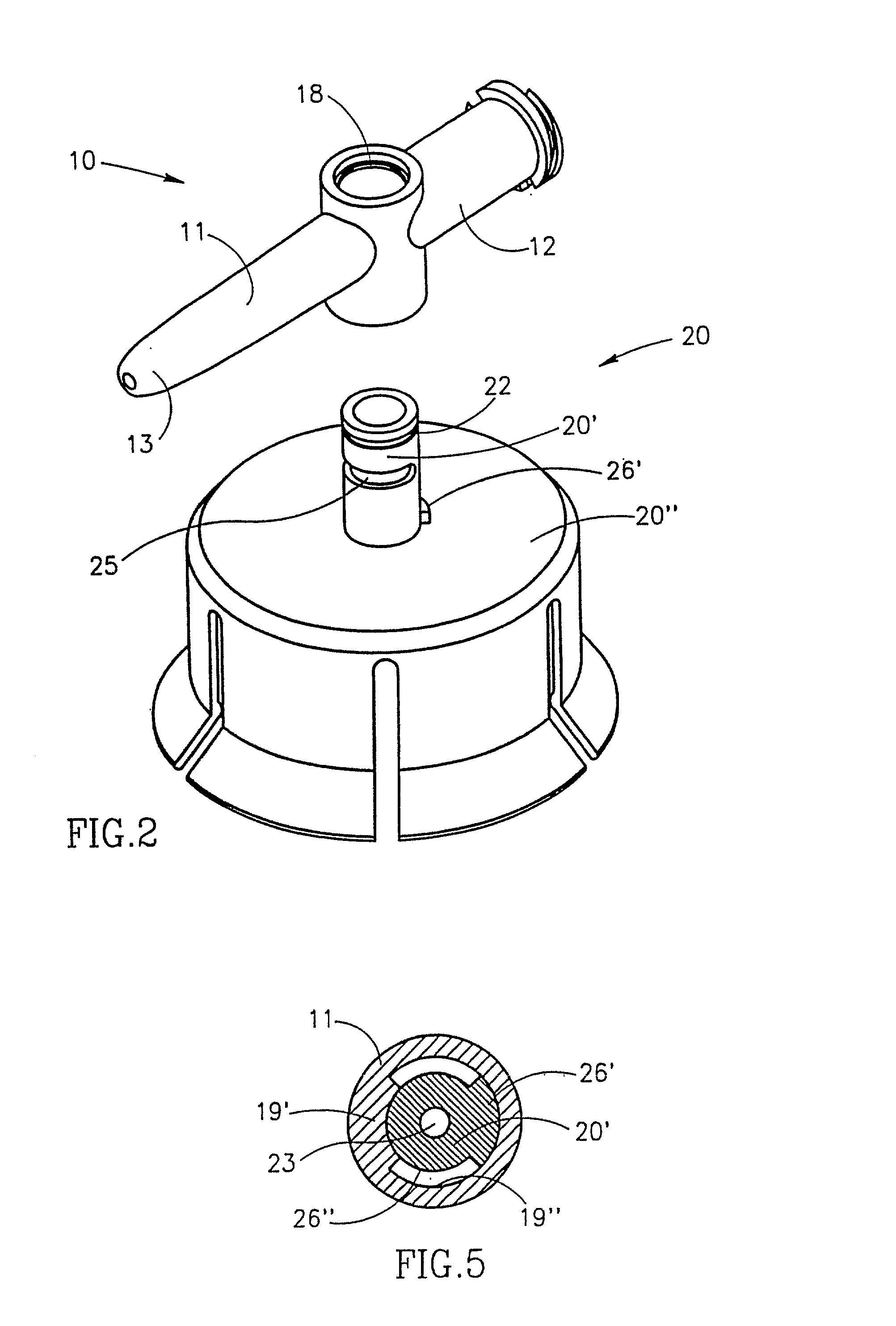

Fluid transfer device

A fluid ducting assembly for enabling flow communication between a syringe and either one of a vessel and a dispenser for dispensing a fluid contained, a priori in the syringe or in the vessel. The fluid ducting assembly includes a base having a first member, a second member, and a third member for connection to and providing flow communication with the syringe, the vessel and the dispenser, respectively. The fluid ducting assembly further includes a flow controller within the base enabling any one of a flow path between the first member and the second member and a flow path between the first member and the third member. The flow controller has either a first operative position in which the flow path between the first member and the second member in enabled or a second operative position in which the flow path between the first member and the third member is enabled. The flow controller being readily switchable from its first operative position to its second operative position but not readily switchable form its second operative position to its first operative position.

Owner:MEDIMOP MEDICAL PROJECTS

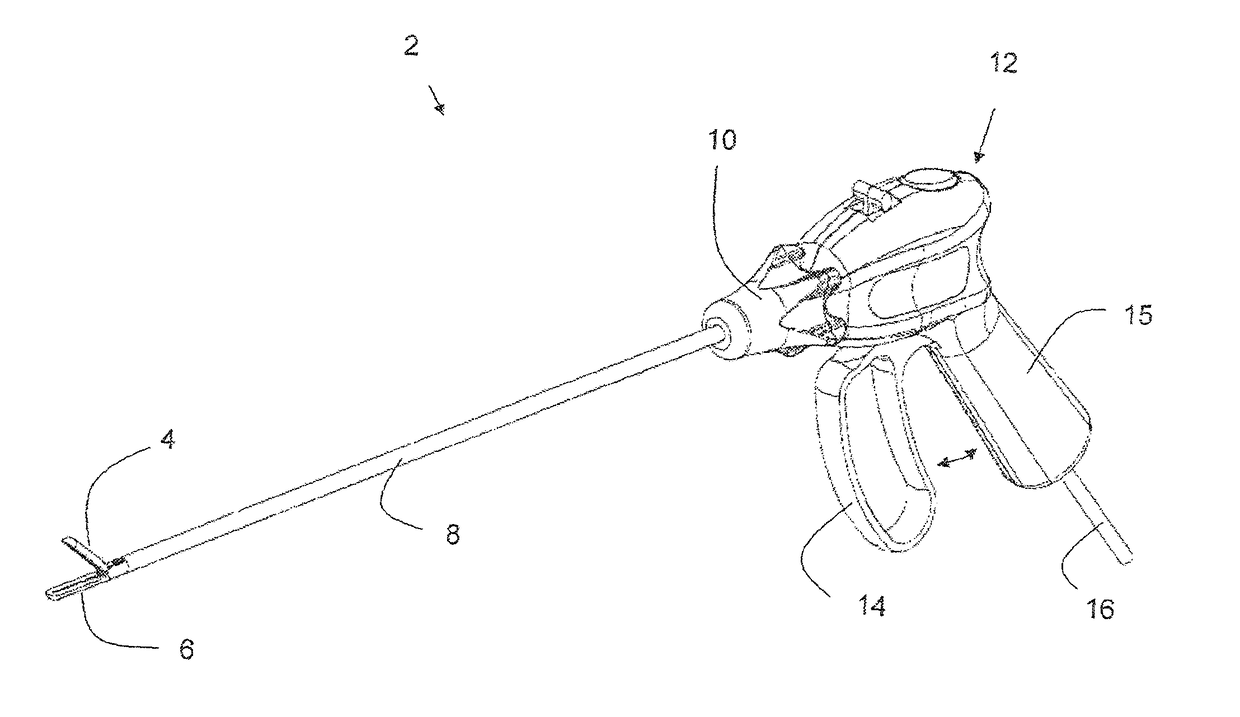

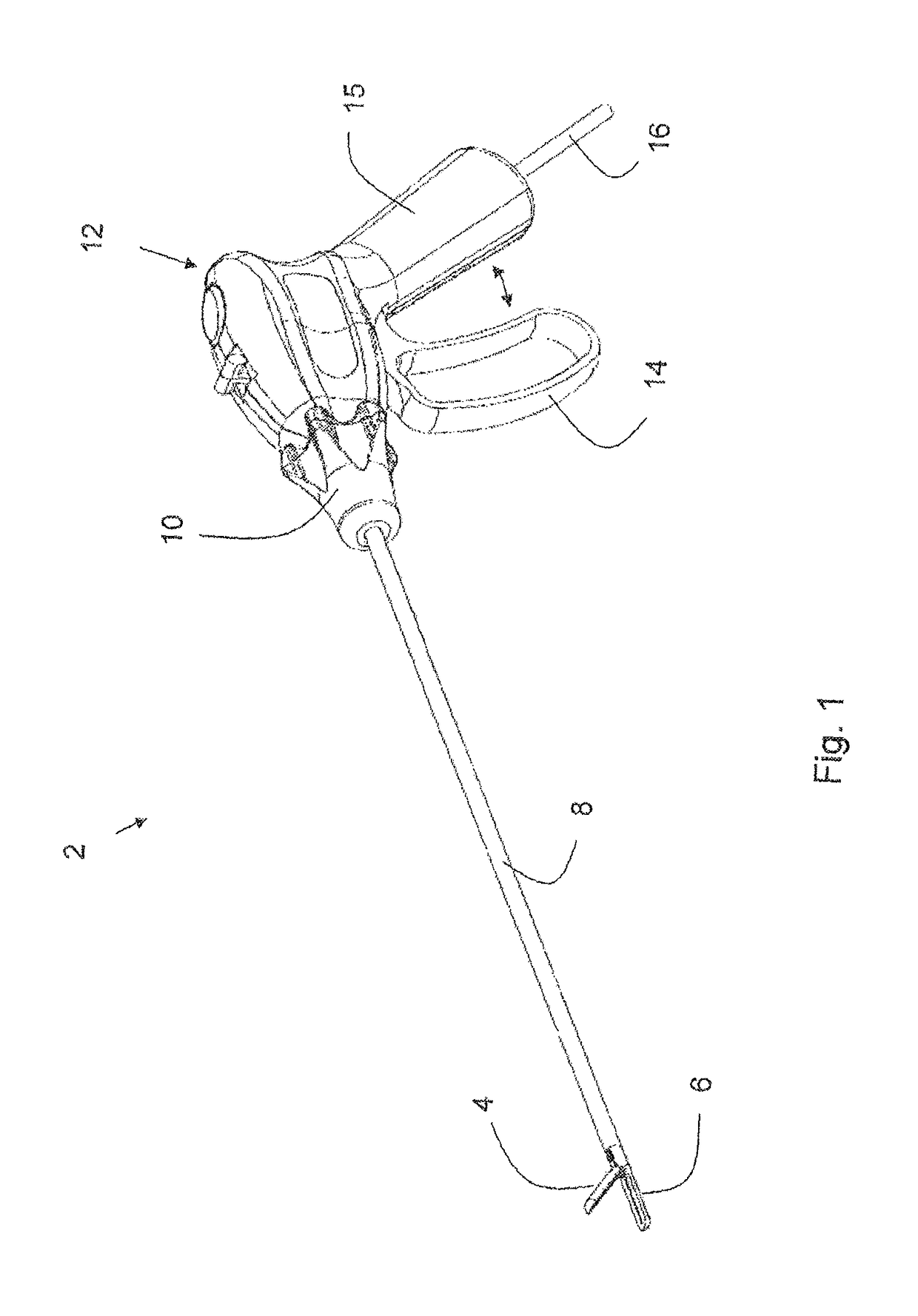

Electrosurgical instrument and jaw part therefor

ActiveUS10092350B2Easily brokenReduce negative impactDiagnosticsSurgical instruments for heatingAbutmentConductive materials

Owner:AESCULAP AG

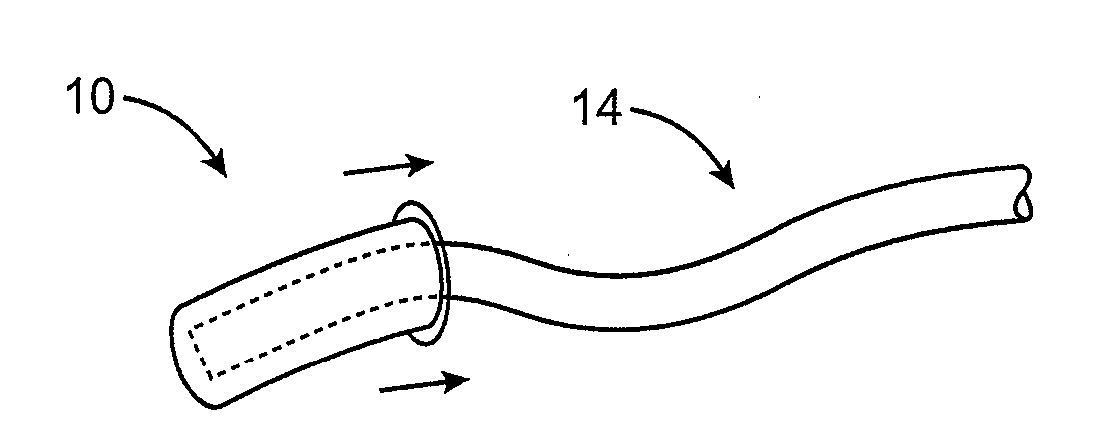

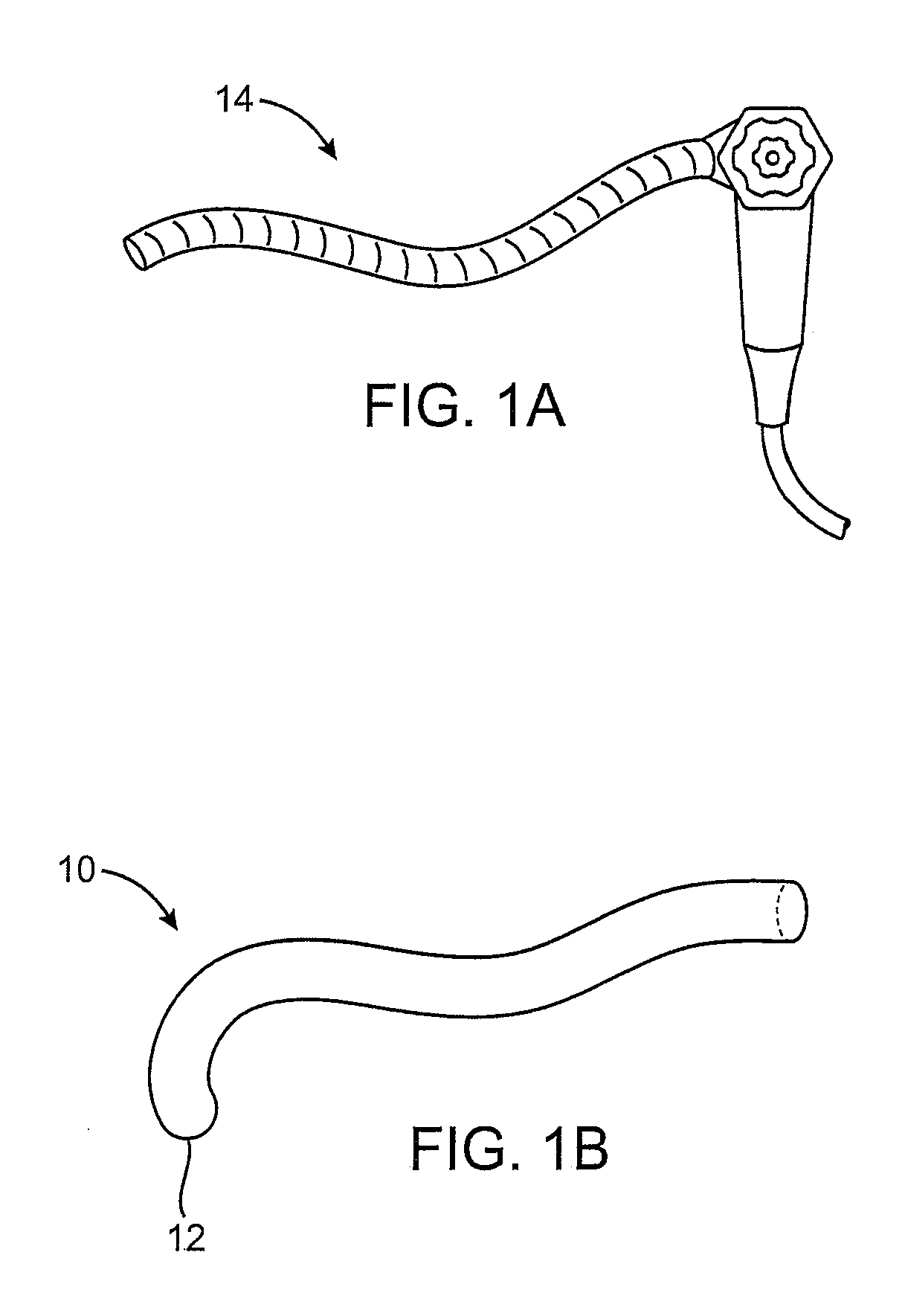

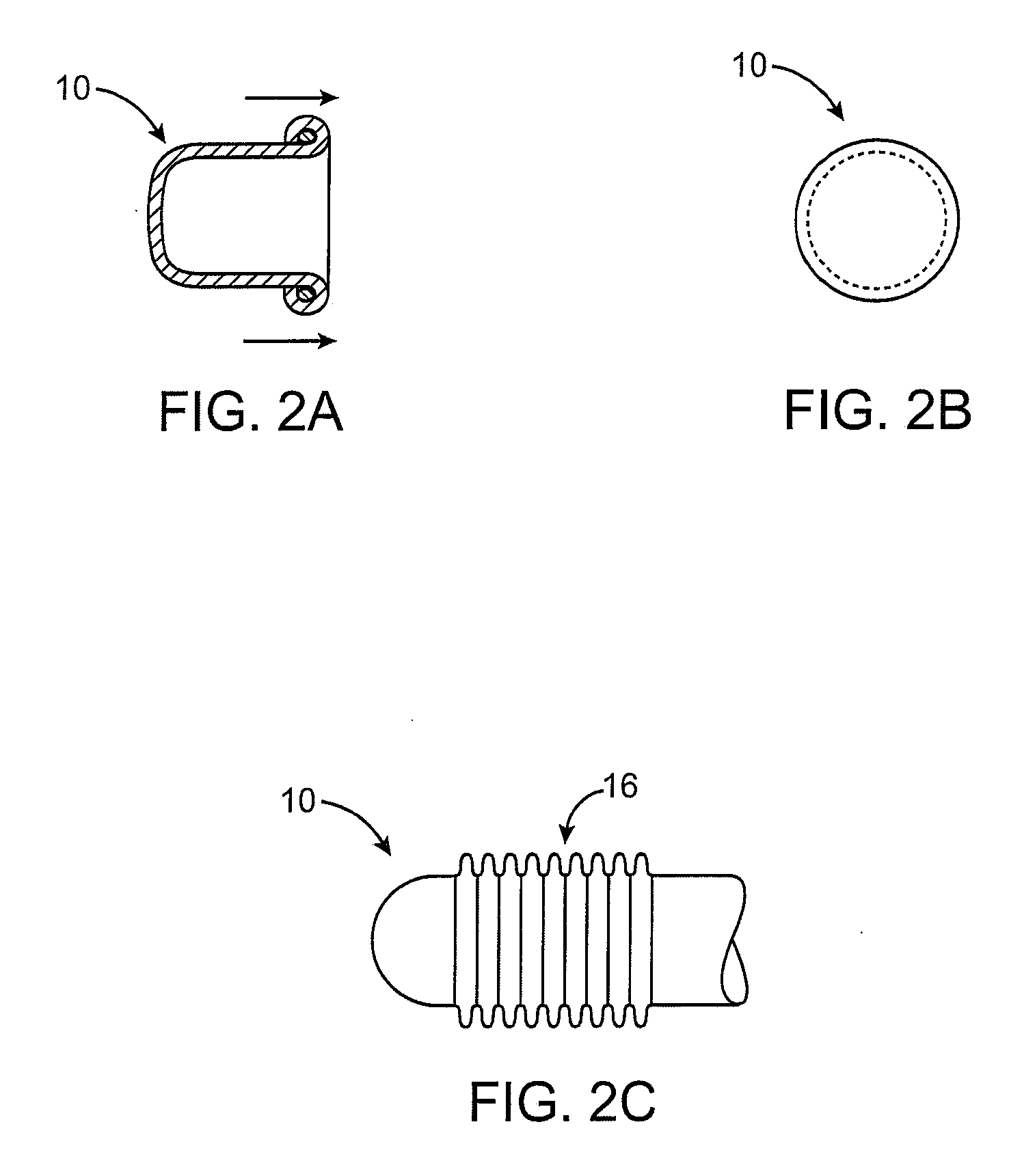

Methods and apparatus for maintaining sterility during transluminal procedures

InactiveUS20060258909A1Improve permeabilityMaintain normalSuture equipmentsCannulasEndoscopeInstrumentation

Methods and apparatus for maintaining sterility during transluminal procedures are described. The sterility is achieved by making use of a membrane in either the form, e.g., of a sheath, cap or umbrella to keep the instruments (endoscopes, overtubes, etc.) sterile while being advanced through lumens in the body and into the various cavities. Methods, such as vacuum acquisition, mechanical tissue anchoring, etc., of the underlying tissue followed by incision of the tissue with, e.g., a needle knife, can be utilized to gain access to the various cavities. It is expected that this procedure will provide the desired level of sterility for transluminal procedures.

Owner:USGI MEDICAL

Fluid control device

A fluid ducting assembly for enabling flow communication between a syringe and either one of a vessel and a dispenser for dispensing a fluid contained, a priori in the syringe or in the vessel. The fluid ducting assembly includes a base having a first member, a second member, and a third member for connection to and providing flow communication with the syringe, the vessel and the dispenser, respectively. The fluid ducting assembly further includes a flow controller within the base enabling any one of a flow path between the first member and the second member and a flow path between the first member and the third member. The flow controller has either a first operative position in which the flow path between the first member and the second member is enabled or a second operative position in which the flow path between the first member and the third member is enabled. The flow controller being readily switchable from its first operative position to its second operative position but not readily switchable from its second operative position to its first operative position.

Owner:MEDIMOP MEDICAL PROJECTS

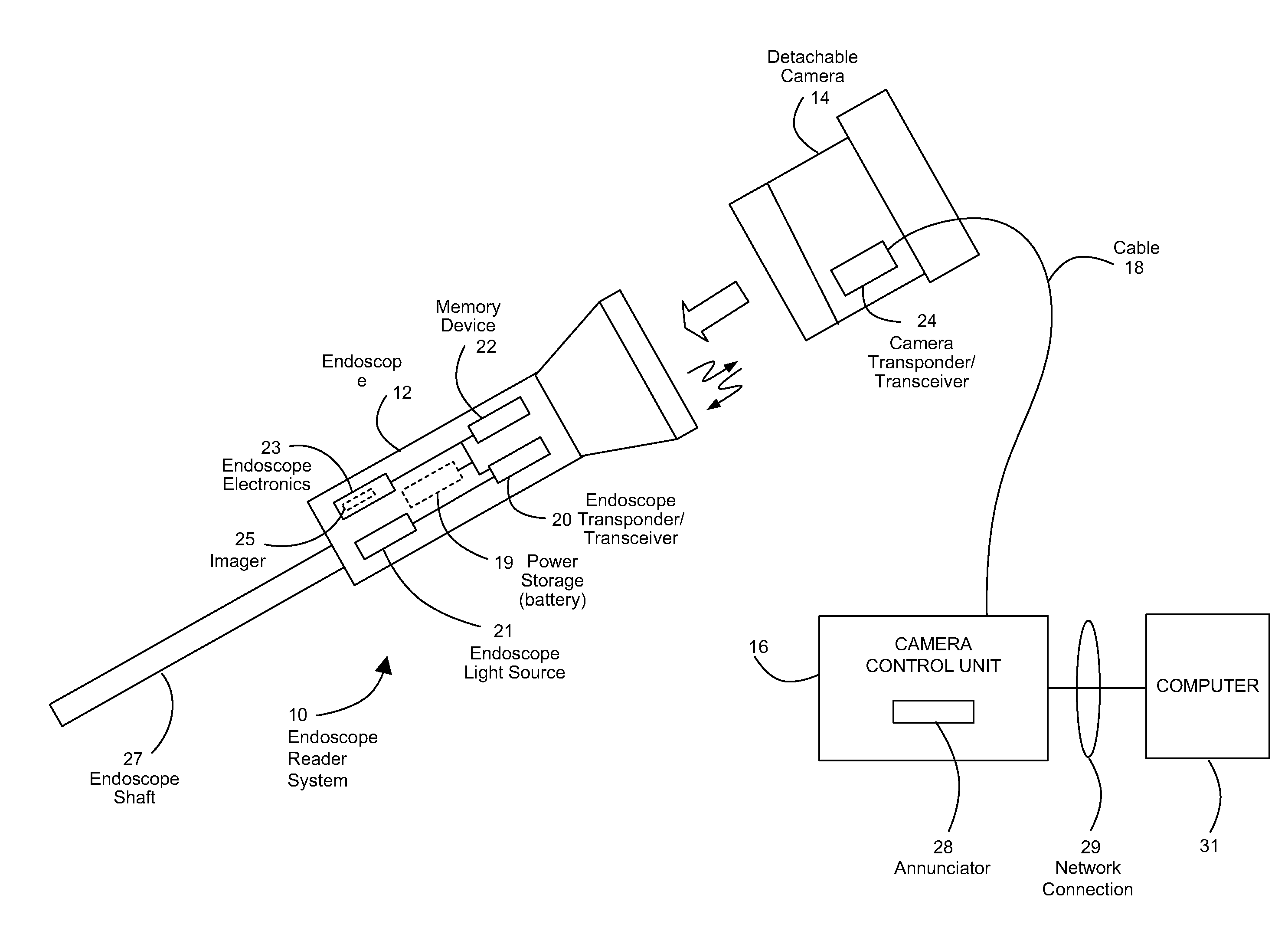

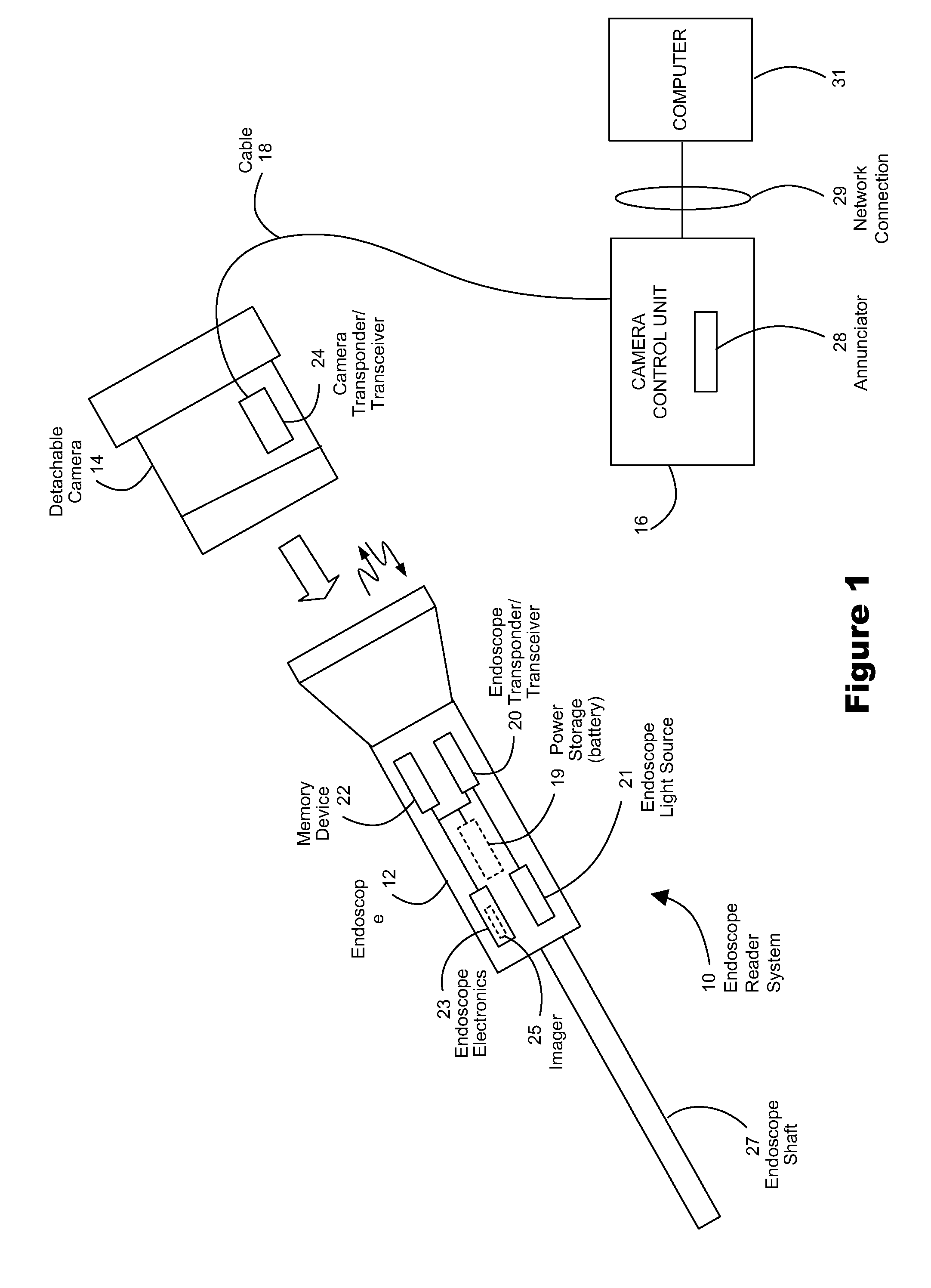

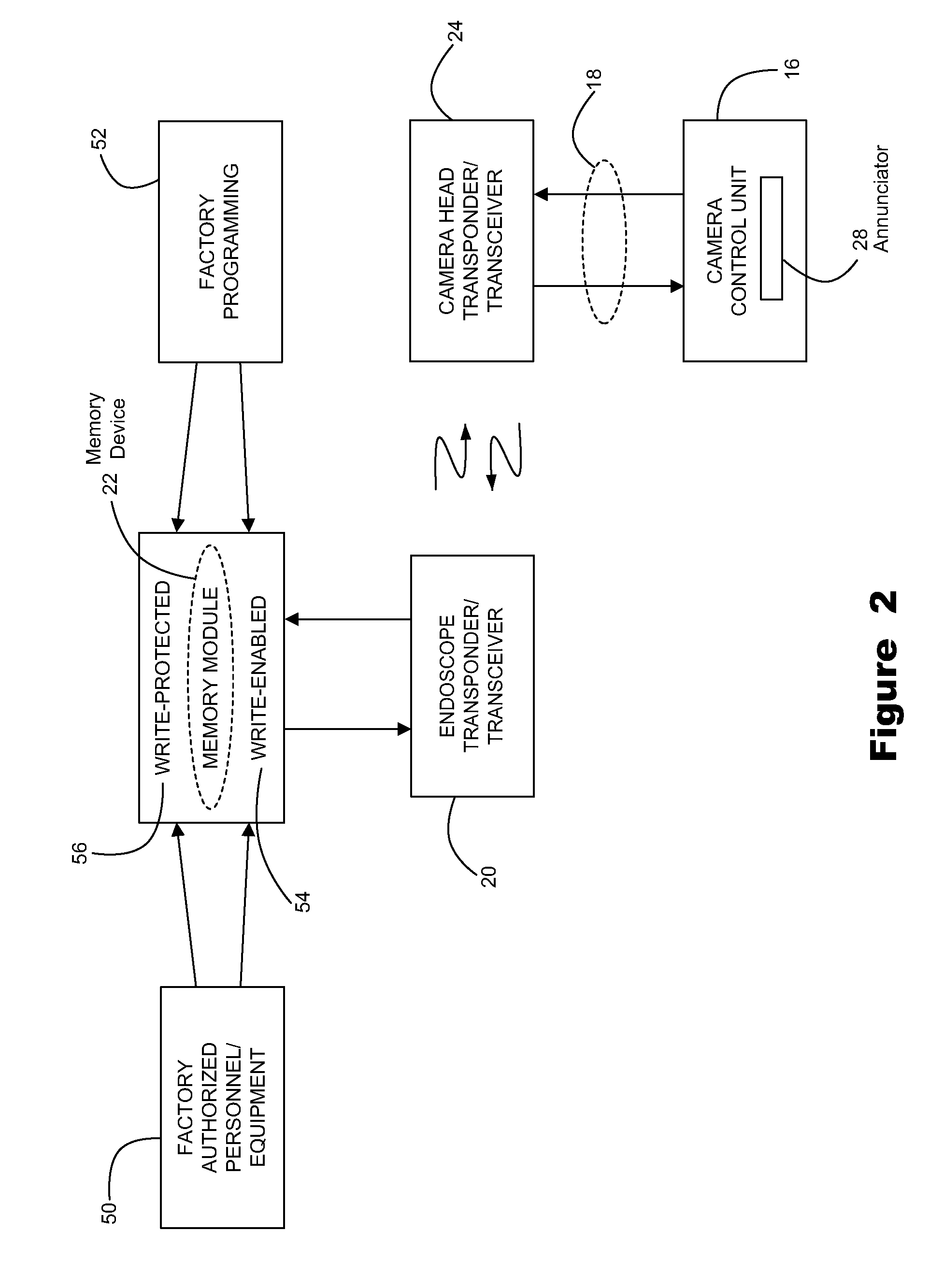

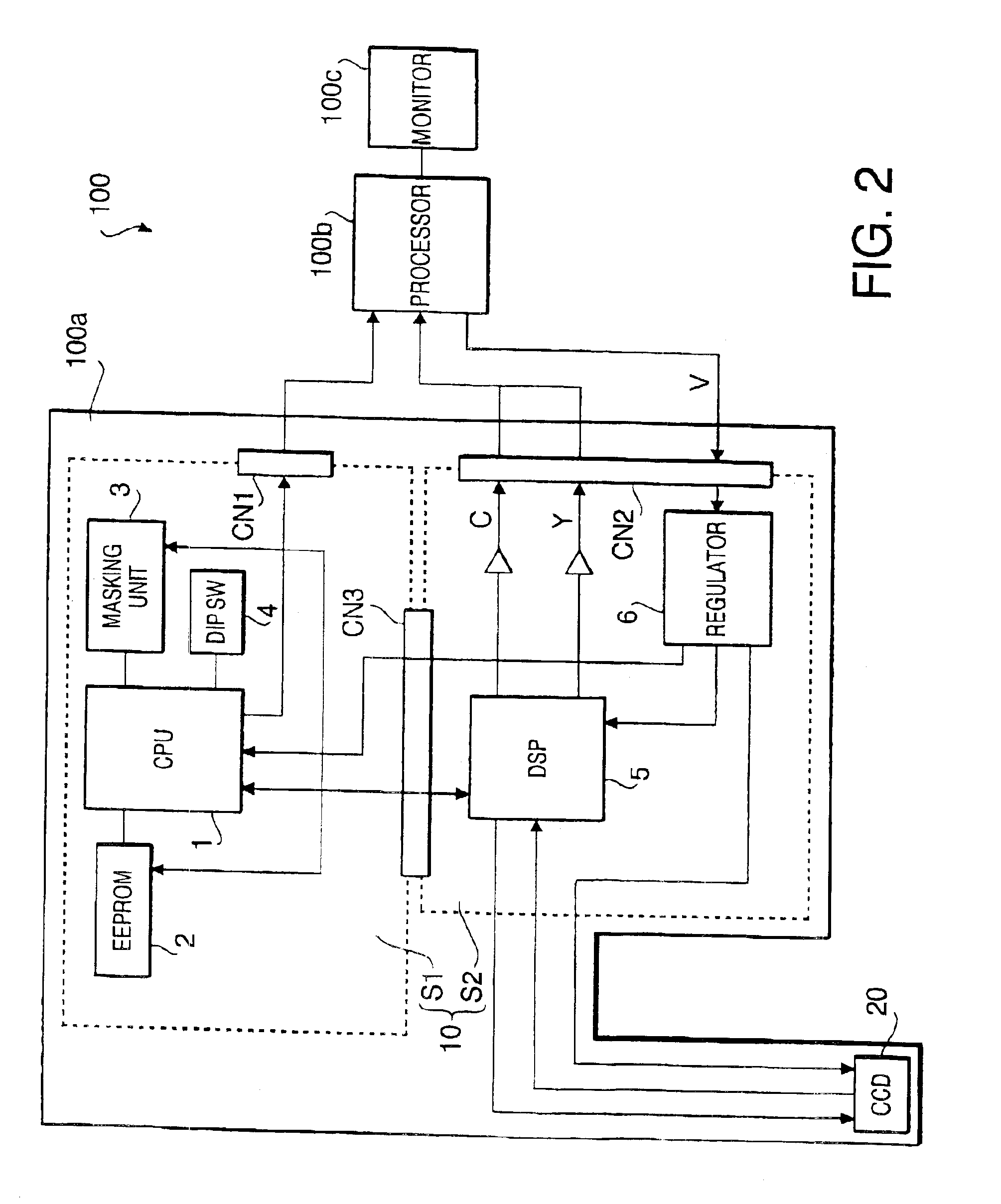

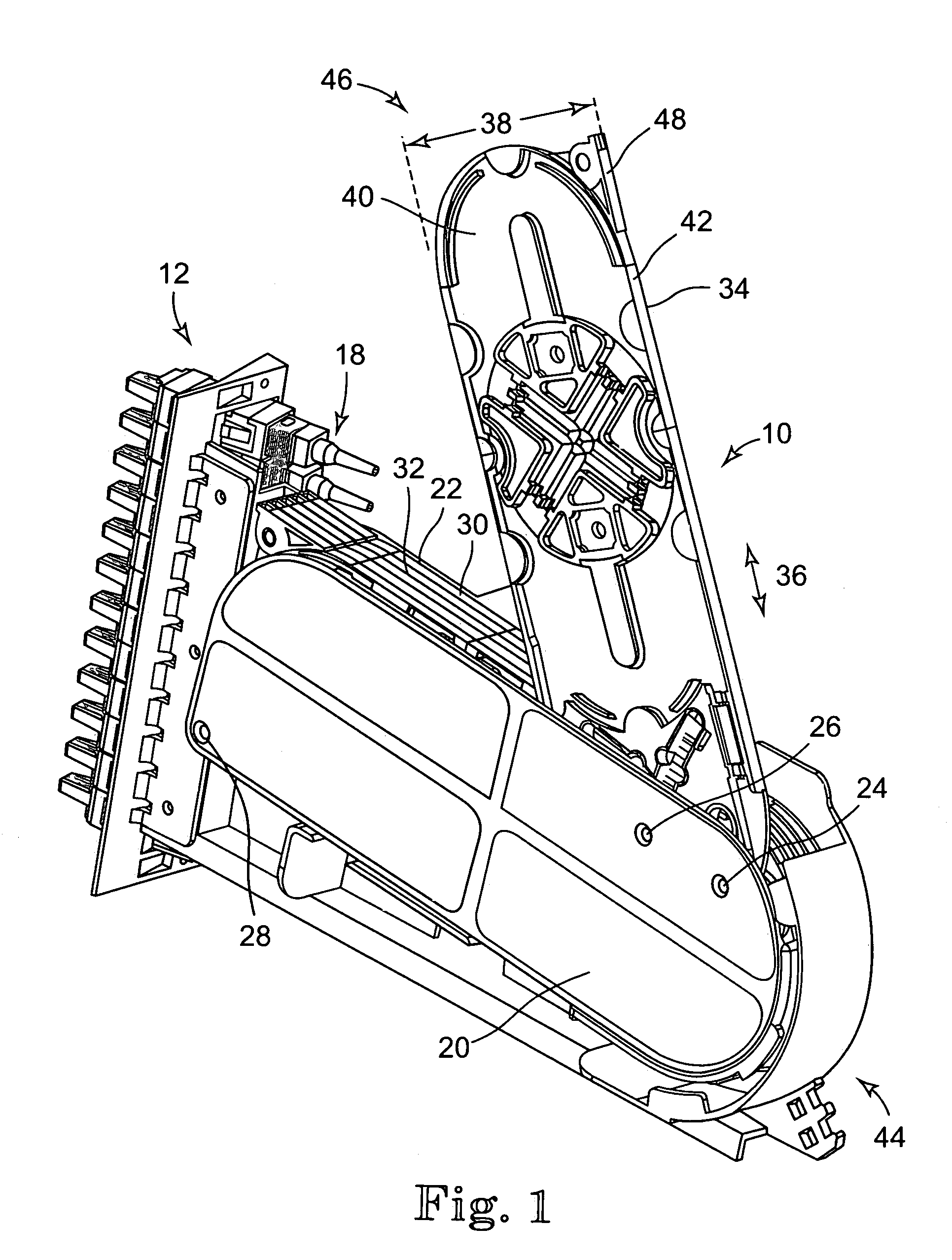

Wireless Camera Coupling With Rotatable Coupling

ActiveUS20110193948A1Easy and quick switchingEasy to repairTelevision system detailsSurgeryQuality assuranceData transmission

A system for wirelessly powering various devices positioned on an endoscope, including, for example, a light source, various electronics including an imager and / or a memory device. The endoscope is coupled to a camera where the endoscope may be rotated relative to the camera when coupled thereto. The system is further provided such that video signal processing parameters are automatically set for an endoscopic video camera system based upon characteristics of an attached endoscope, with reduced EMI and improved inventory tracking, maintenance and quality assurance, and reducing the necessity for adjustment and alignment of the endoscope and camera to achieve the data transfer.

Owner:KARL STORZ IMAGING INC

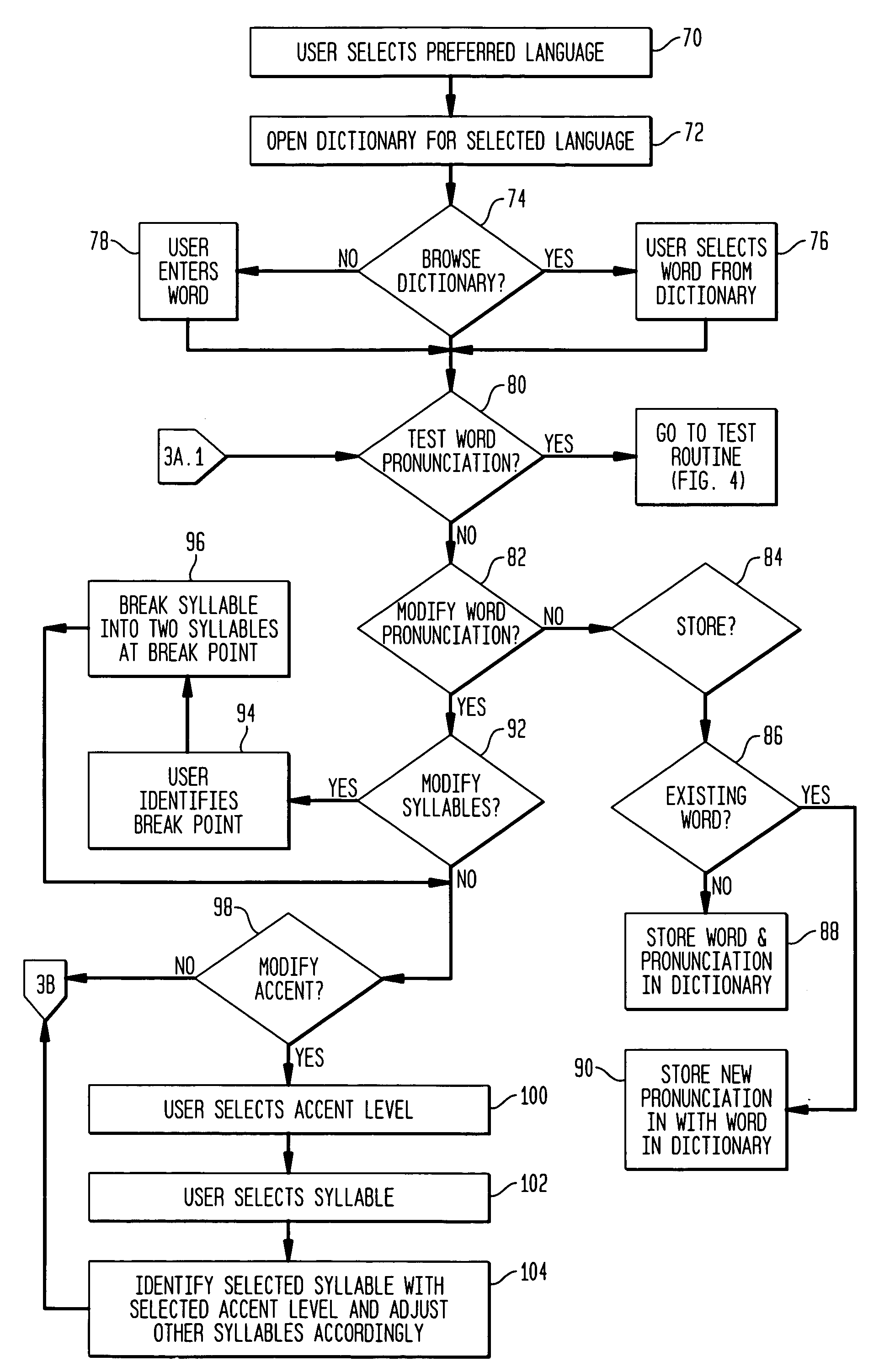

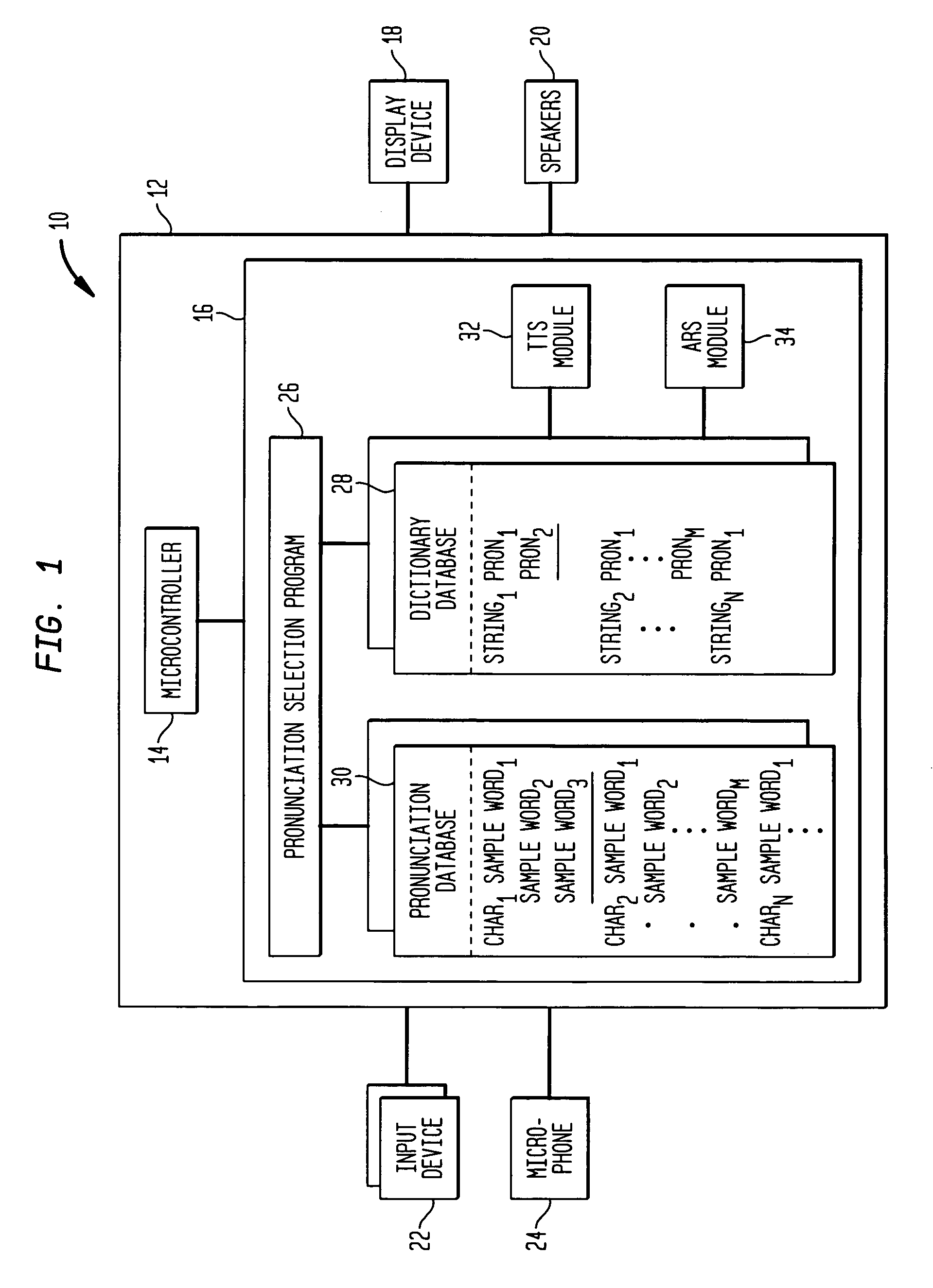

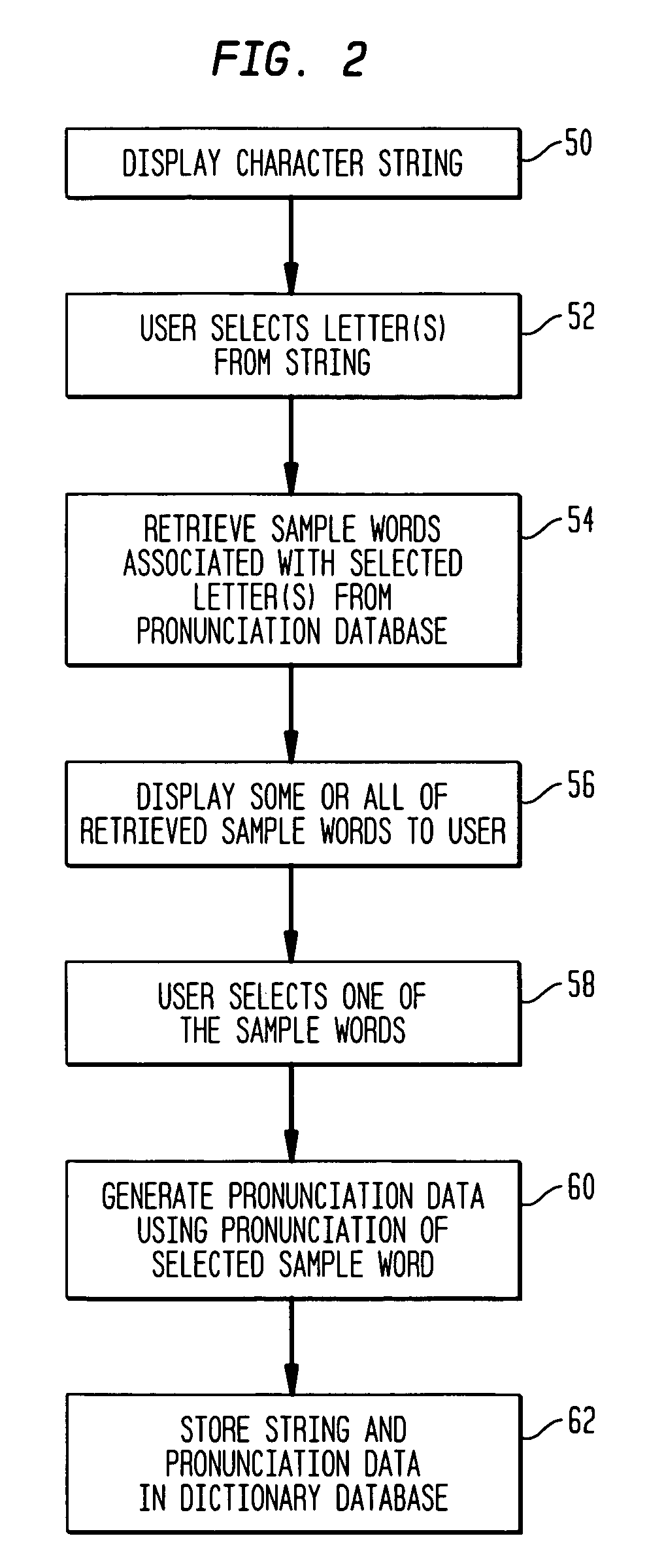

Graphical user interface and method for modifying pronunciations in text-to-speech and speech recognition systems

InactiveUS7292980B1Easily brokenSimple and intuitive user interfaceSound input/outputSpeech recognitionSpeech identificationGraphical user interface

A method and user interface which allow users to make decisions about how to pronounce words and parts of words based on audio cues and common words with well known pronunciations. Users input or select words for which they want to set or modify pronunciations. To set the pronunciation of a given letter or letter combination in the word, the user selects the letters and is presented with a list of common words whose pronunciations, or portions thereof, are substantially identical to possible pronunciations of the selected letters. The list of sample, common words is ordered based on frequency of correlation in common usage, the most common being designated as the default sample word, and the user is first presented with a subset of the words in the list which are most likely to be selected. In addition, the present invention allows for storage in the dictionary of several different pronunciations for the same word, to allow for contextual differences and individual preferences.

Owner:SOUND VIEW INNOVATIONS

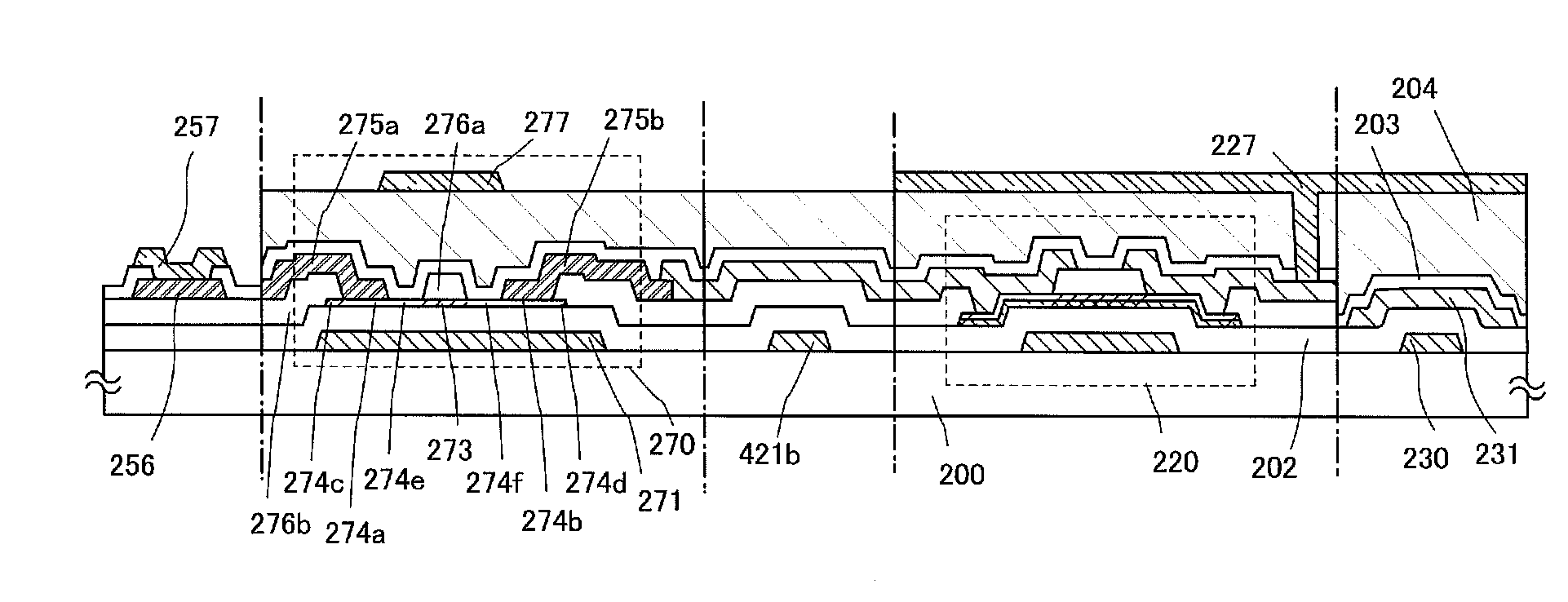

Semiconductor device and method for manufacturing the same

ActiveUS20110006302A1Easily brokenIncrease opening ratioTransistorSolid-state devicesDisplay deviceMoisture

It is an object to manufacture and provide a highly reliable display device including a thin film transistor with a high aperture ratio which has stable electric characteristics. In a manufacturing method of a semiconductor device having a thin film transistor in which a semiconductor layer including a channel formation region is formed using an oxide semiconductor film, a heat treatment for reducing moisture and the like which are impurities and for improving the purity of the oxide semiconductor film (a heat treatment for dehydration or dehydrogenation) is performed. Further, an aperture ratio is improved by forming a gate electrode layer, a source electrode layer, and a drain electrode layer using conductive films having light transmitting properties.

Owner:SEMICON ENERGY LAB CO LTD

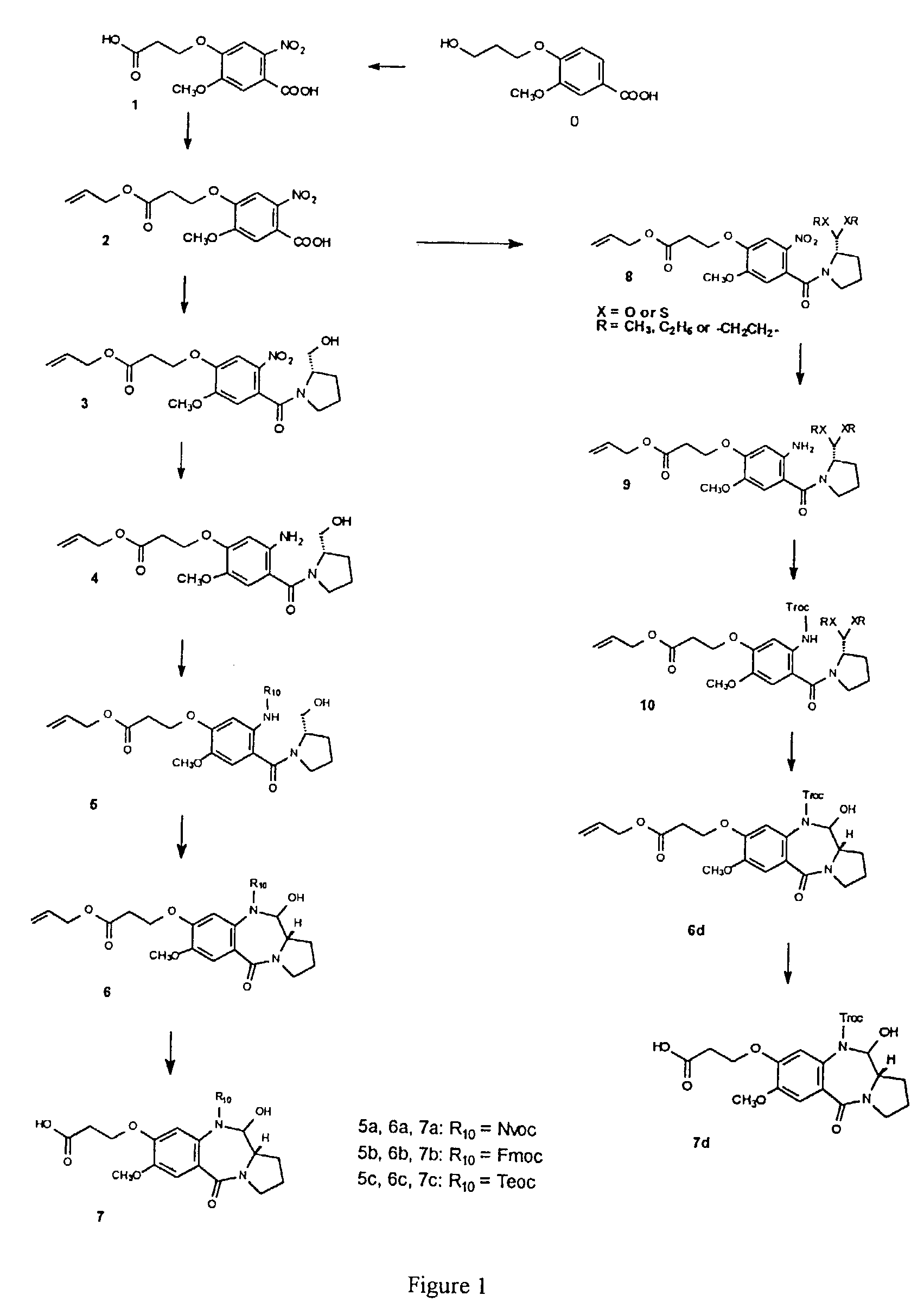

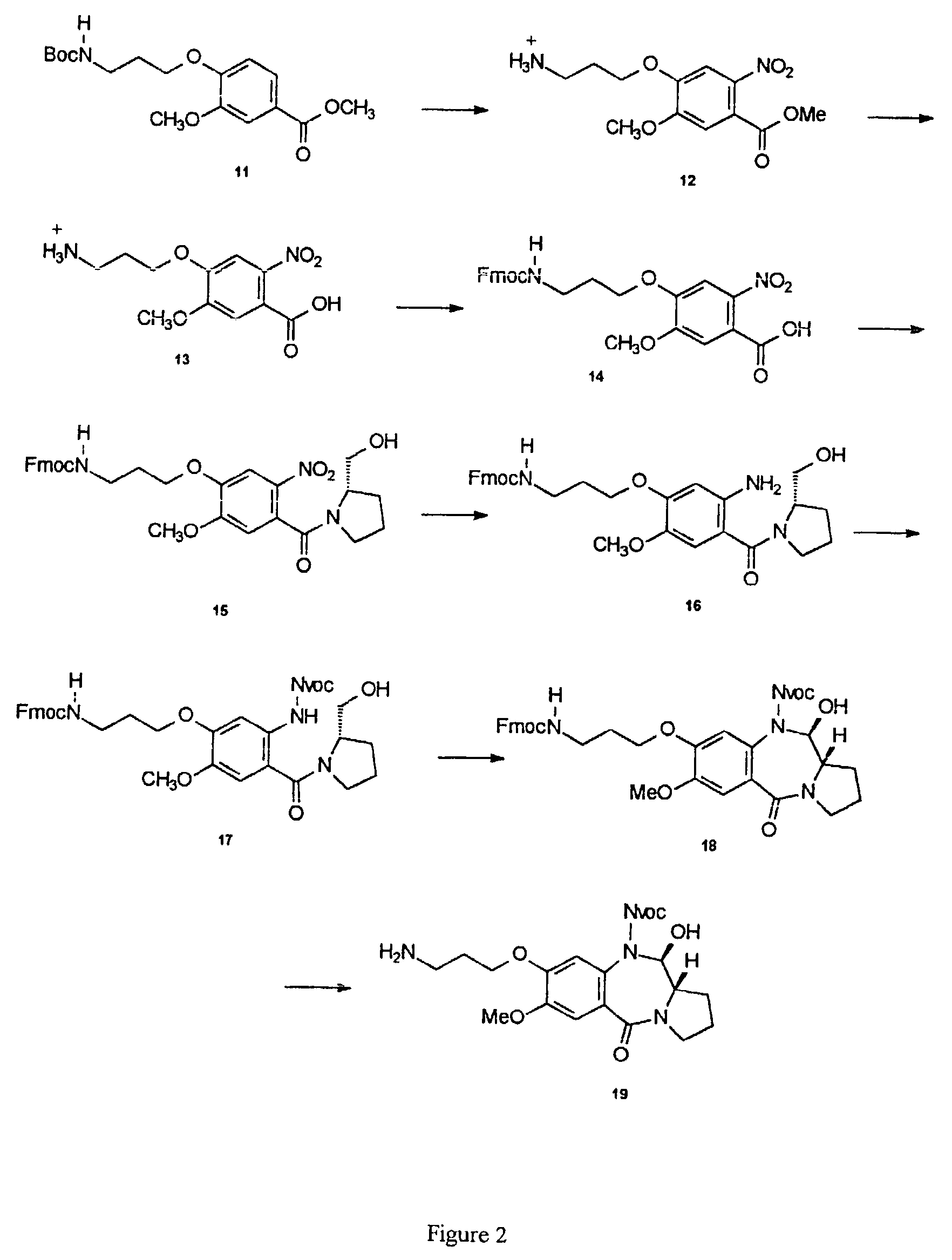

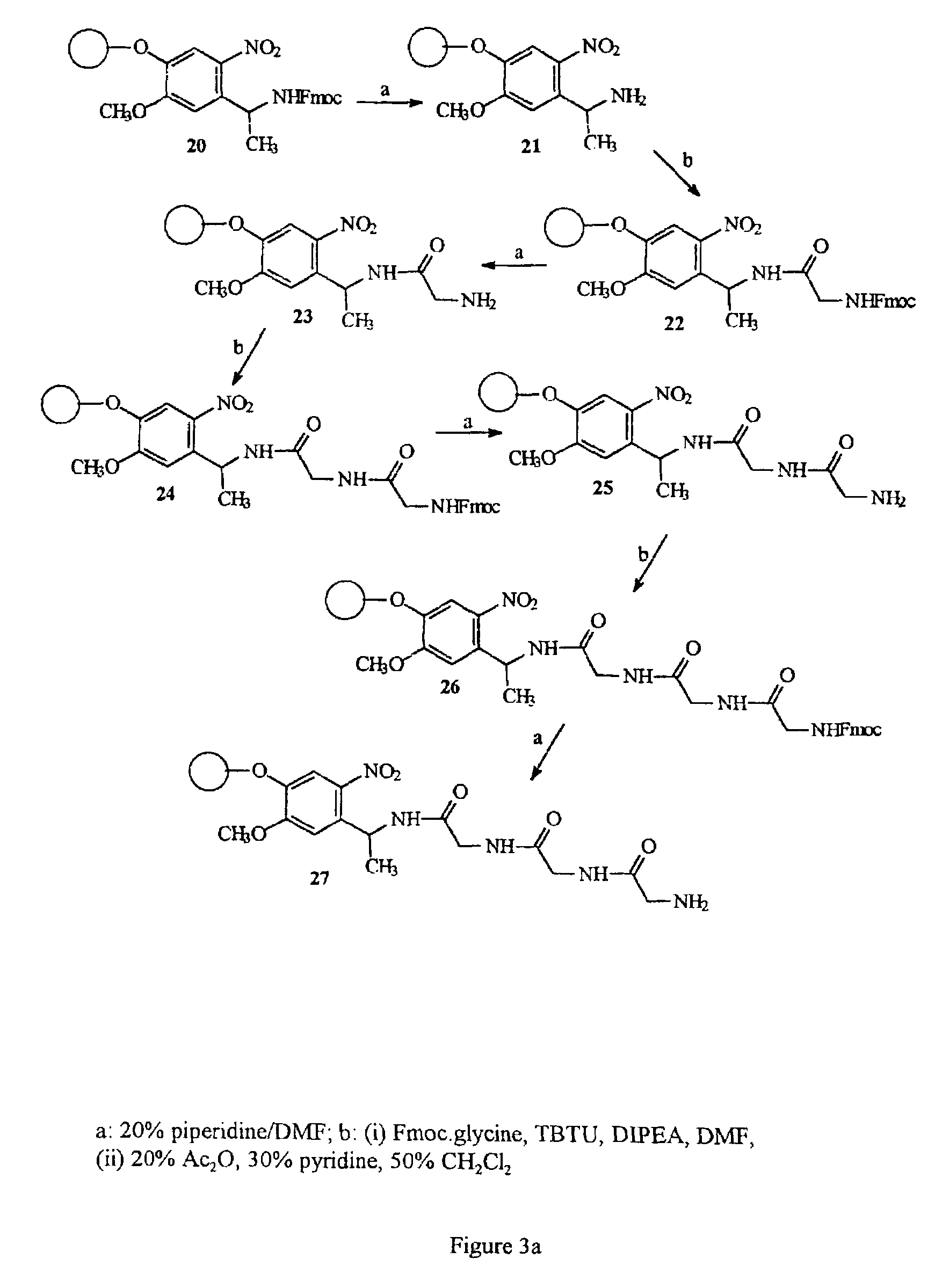

Library of compounds comprising pyrrolobenzodiazepine moieties

InactiveUS7704924B2Easily brokenPrevent premature cleavageAntibacterial agentsOrganic active ingredientsNitrogenDouble bond

A compound of formula (IV): O is a solid support; L is a linking group or a single bond; X′ is selected from CO, NH, S, or O; A is O, S, NH, or a single bond; R2 and R3 are independently selected from: H, R, OH, OR, ═O, ═CH—R, ═CH2, CH2—CO2R, CH2—CO2H, CH2—SO2R, O—SO2R, CO2R, COR, CN and there is optionally a double bond between C1 and C2 or C2 and C3; R6, R7, and R9 are independently selected from H, R, OH, OR, halo, nitro, amino, Me3Sn; R11 is either H or R; Q is S, O or NH; R10 is a nitrogen protecting group; and Y is a divalent group such that HY═R, and other related compounds and collections of compounds.

Owner:MEDIMMUNE LTD

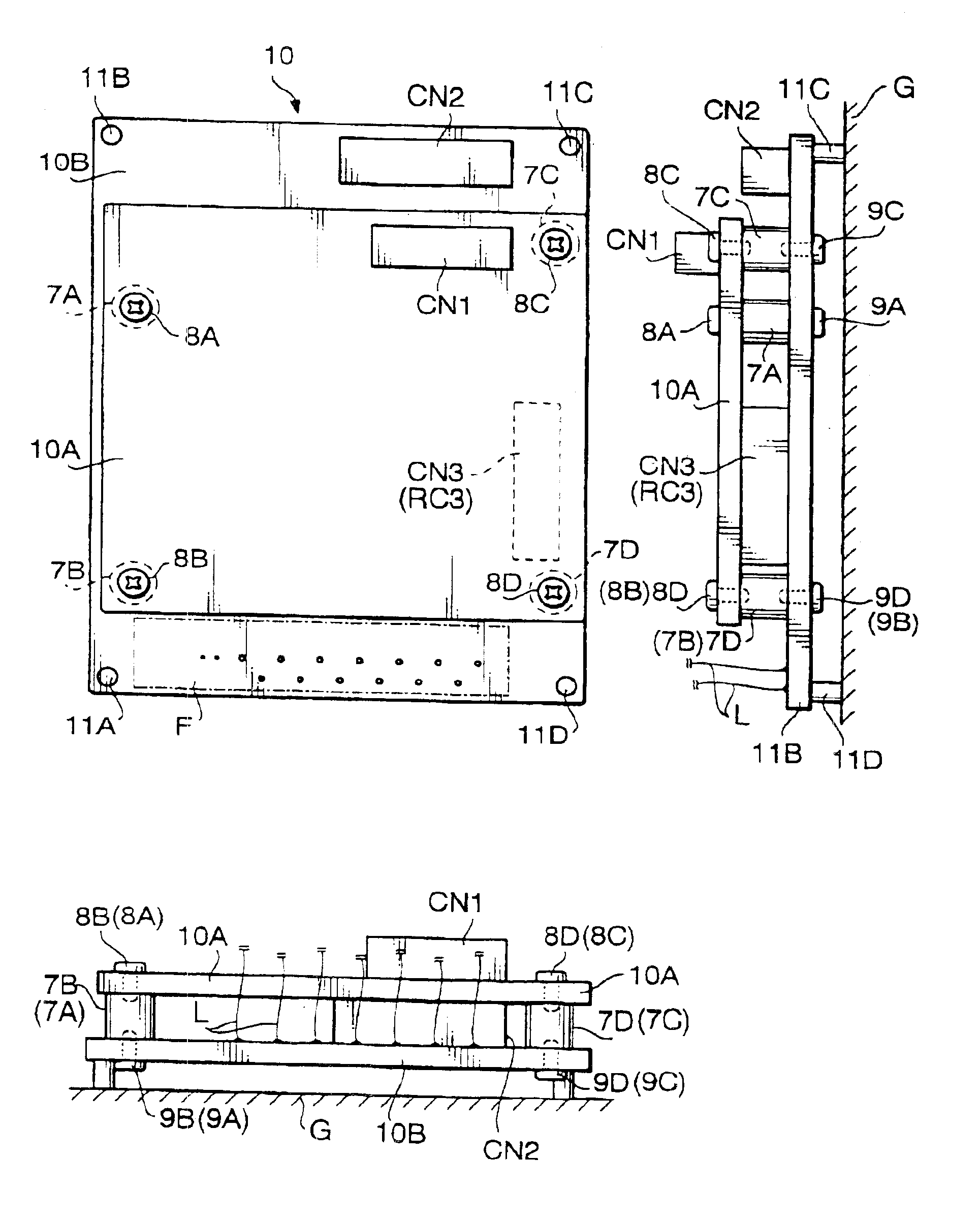

PCB structure for scope unit of electronic endoscope

InactiveUS6898086B2Simple structureElectrical connectionTelevision system detailsEndoscopesEngineeringBoard structure

A printed circuit board structure for a scope unit of an electronic endoscope system, which is provided with a first printed circuit board formed with a first circuit section, and a second printed circuit board formed with a second circuit section. The first printed circuit board is piled on the second printed circuit board. The second printed circuit board having an area covered with the first printed circuit board and at least one area which is not covered with the first circuit board. The at least one area is used for electrically connecting the second circuit section with an electrical unit other than the second circuit section.

Owner:ASAHI KOGAKU KOGYO KK

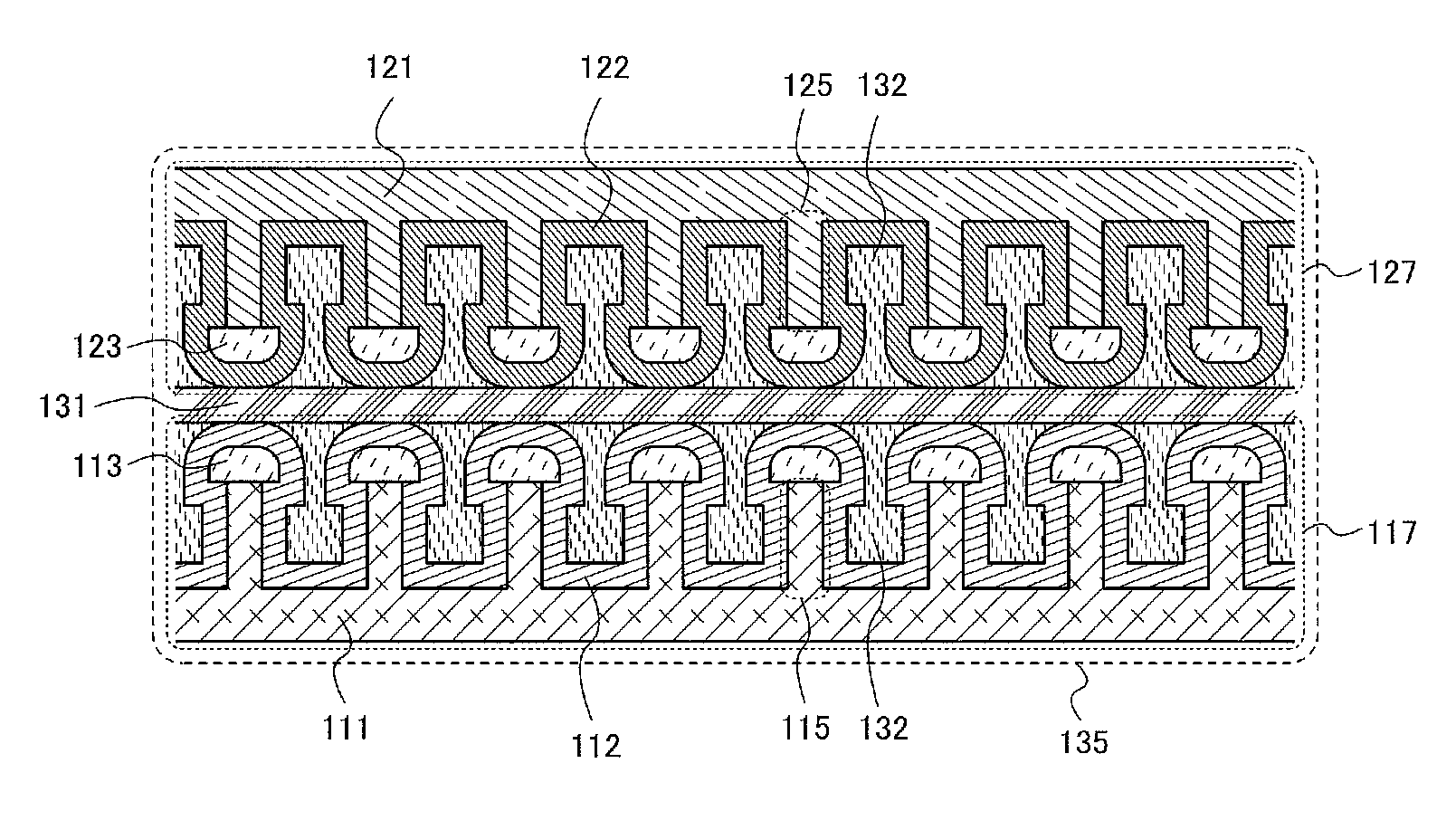

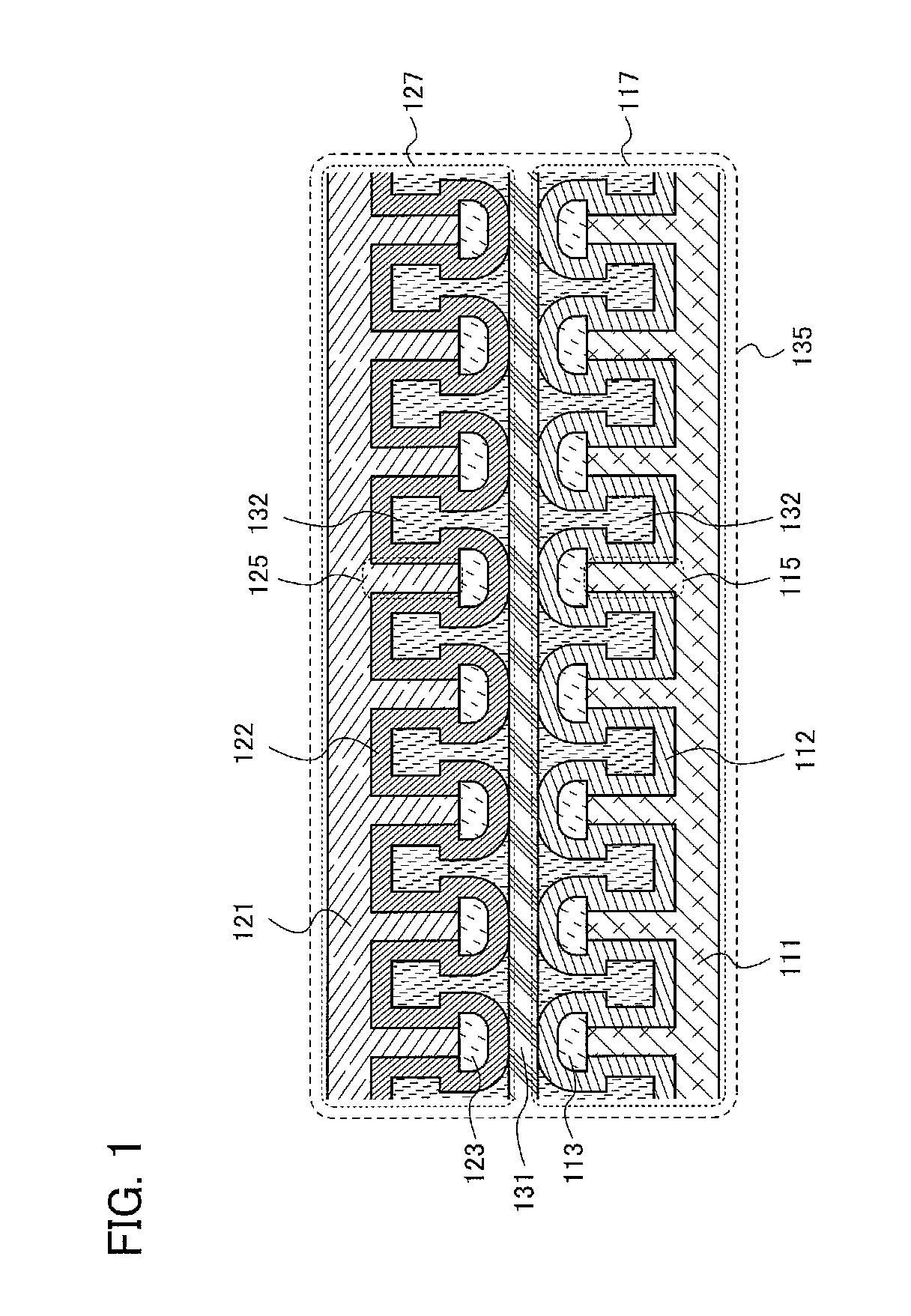

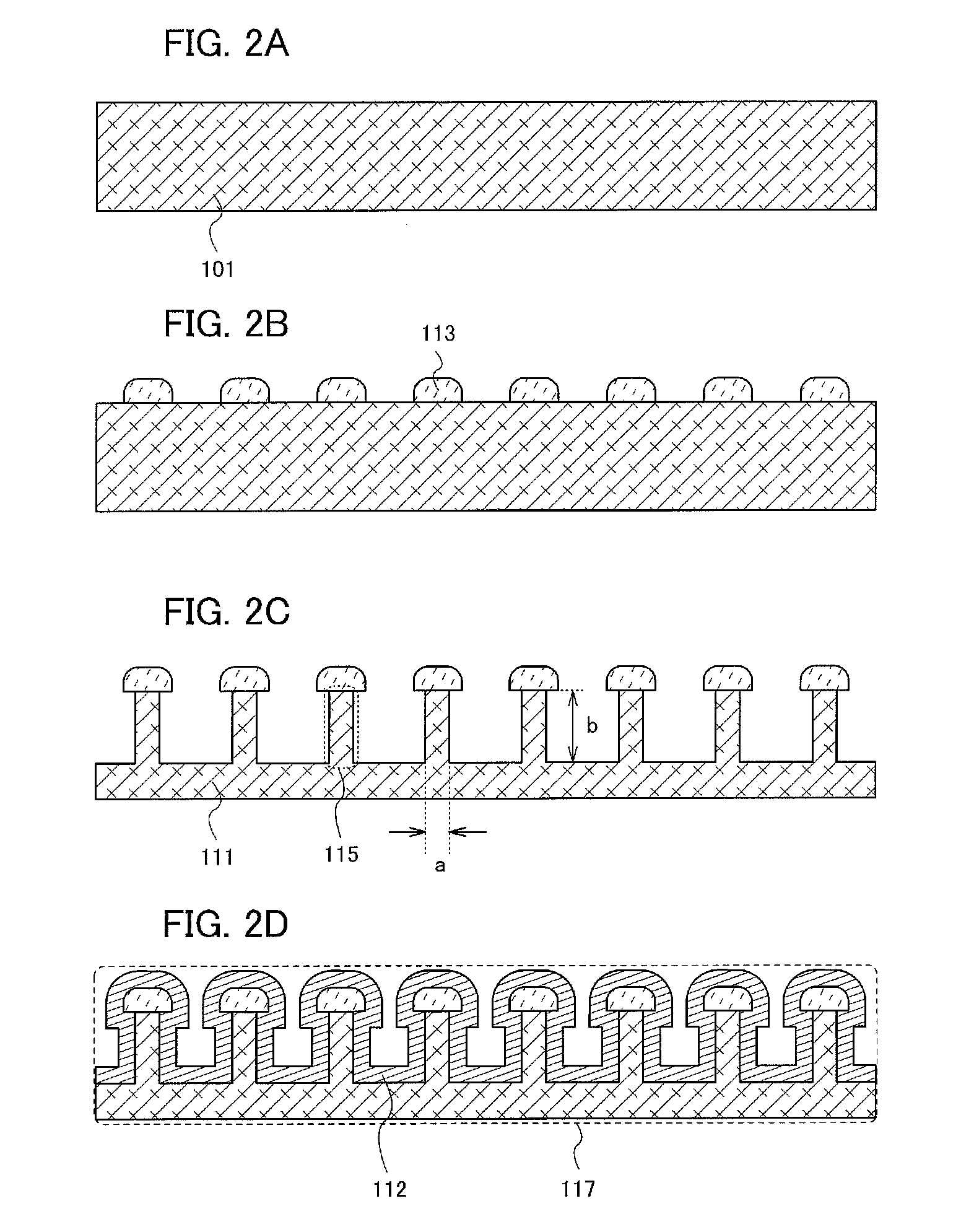

Power Storage Device

ActiveUS20100209784A1Large capacityIncrease surface areaHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersIonPower storage

An embodiment of the present invention relates to a power storage device which includes a positive electrode having a positive-electrode current collector with a plurality of first projections, a first insulator provided over each of the plurality of first projections, and a positive-electrode active material provided on a surface of the first insulator and the positive-electrode current collector with the plurality of first projections; a negative electrode having a negative-electrode current collector with a plurality of second projections, a second insulator provided over each of the plurality of second projections, and a negative-electrode active material provided on a surface of the second insulator and the negative-electrode current collector with the plurality of second projections; a separator provided between the positive electrode and the negative electrode; and an electrolyte provided in a space between the positive electrode and the negative electrode and containing carrier ions.

Owner:SEMICON ENERGY LAB CO LTD

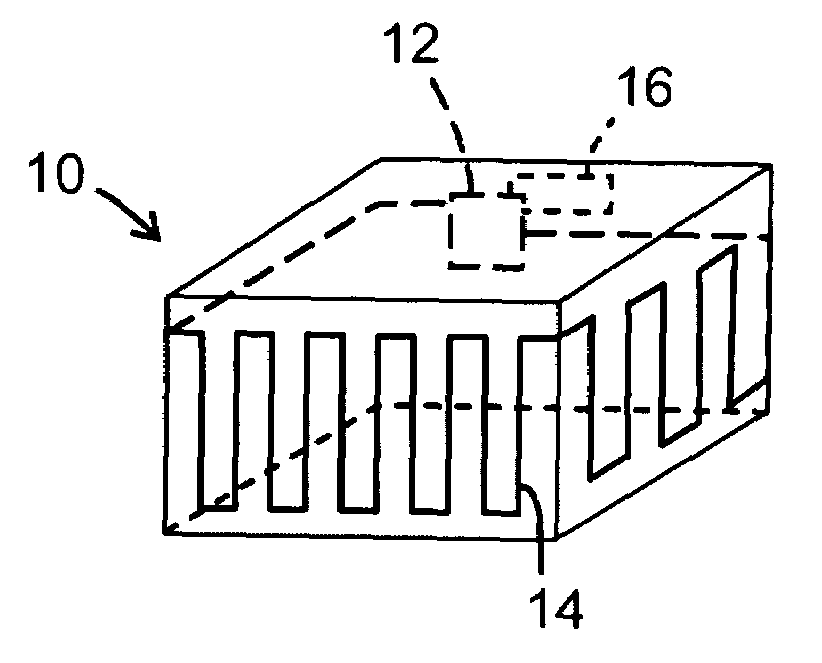

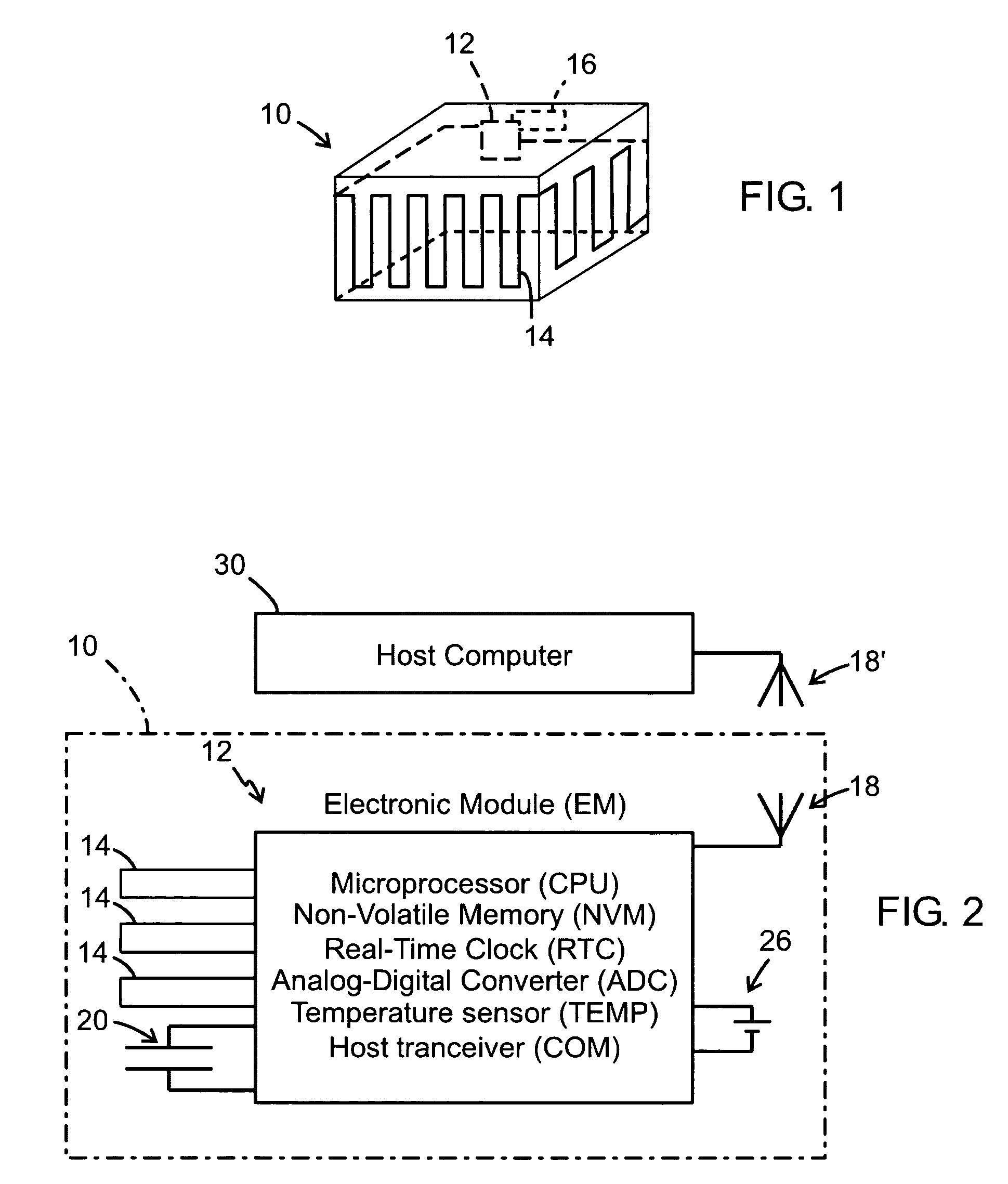

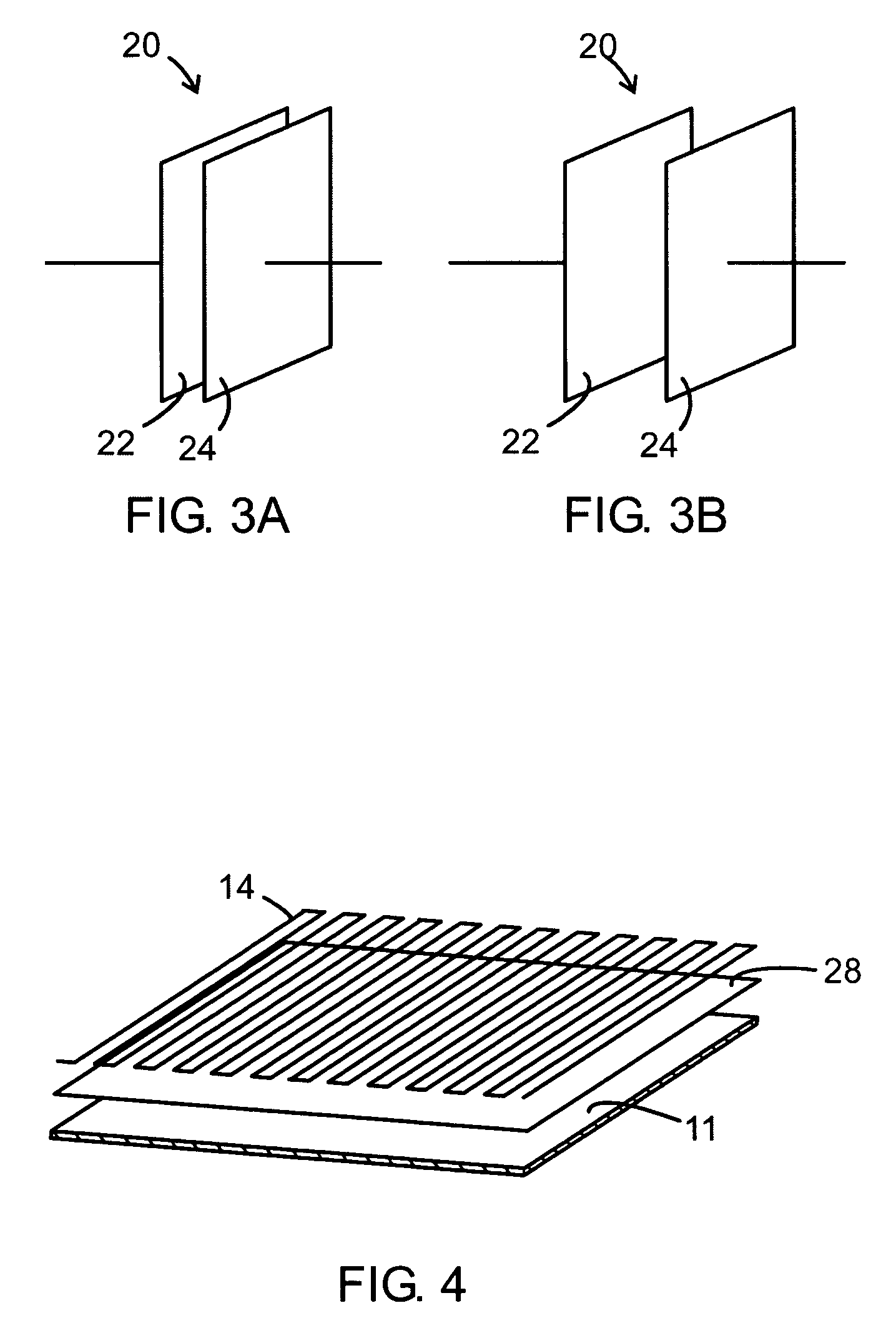

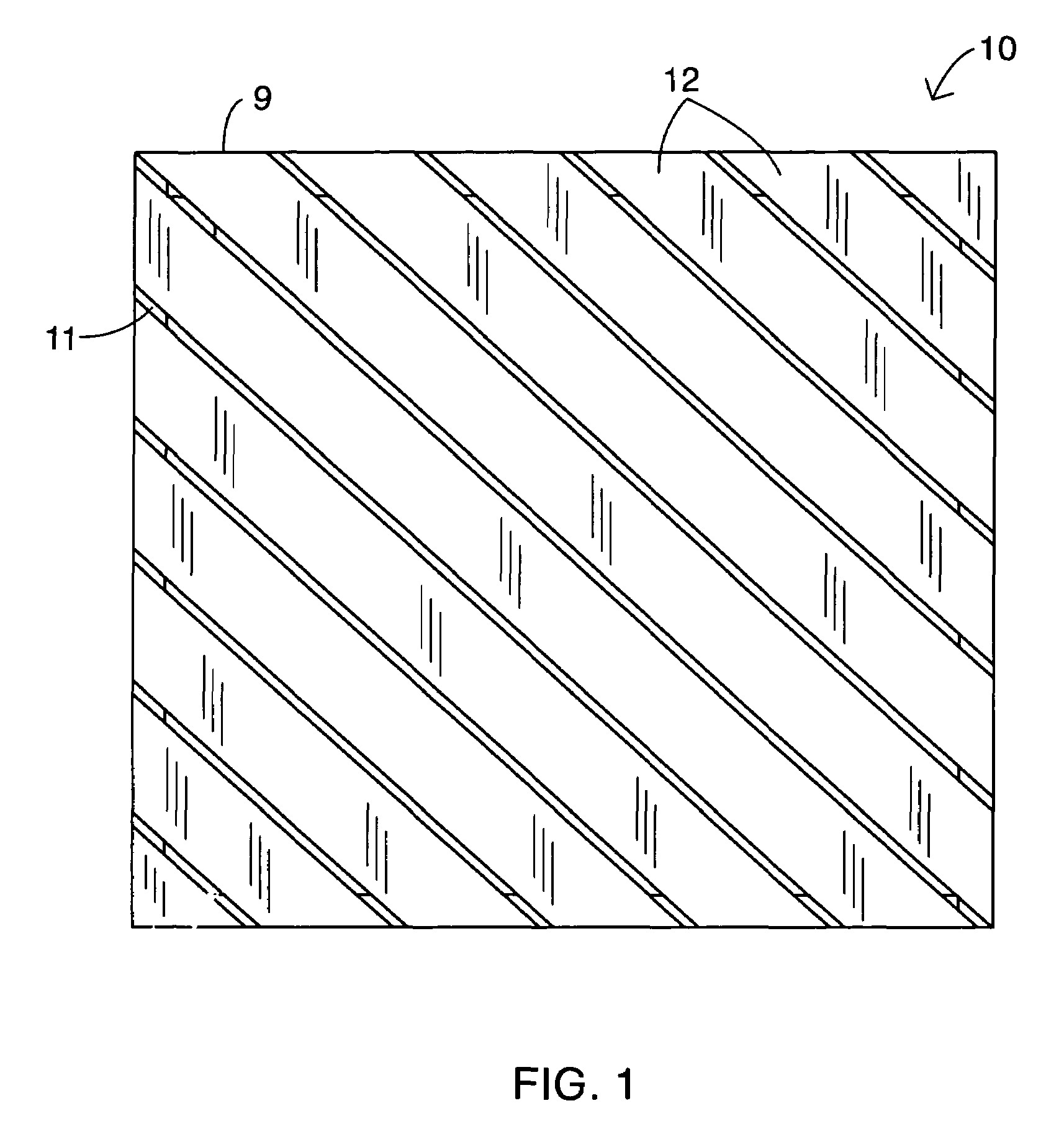

Tamper evident packaging

ActiveUS7170409B2Risk minimizationLess secureElectric/electromagnetic visible signallingPackagingLogistics managementTransceiver

A packaging and a method for monitoring a packaging (10) of a disposable material in a chain of logistics. As an integral part of the packaging, the packaging has an electronic module (12) comprising electric energy supply means, data processing means, data storage nonvolatile memory means for storing information related to the packaging, time keeping means, and data transceiver means for transmitting and receiving said information in communication with a host computer (30). The electronic module also has sensor means (14, 20) for detecting a changed physical condition of the packaging and for signaling information representing said changed physical condition to the electronic module (12) to be stored in the memory means together with a notation of time from the time keeping means.

Owner:SONY CORP

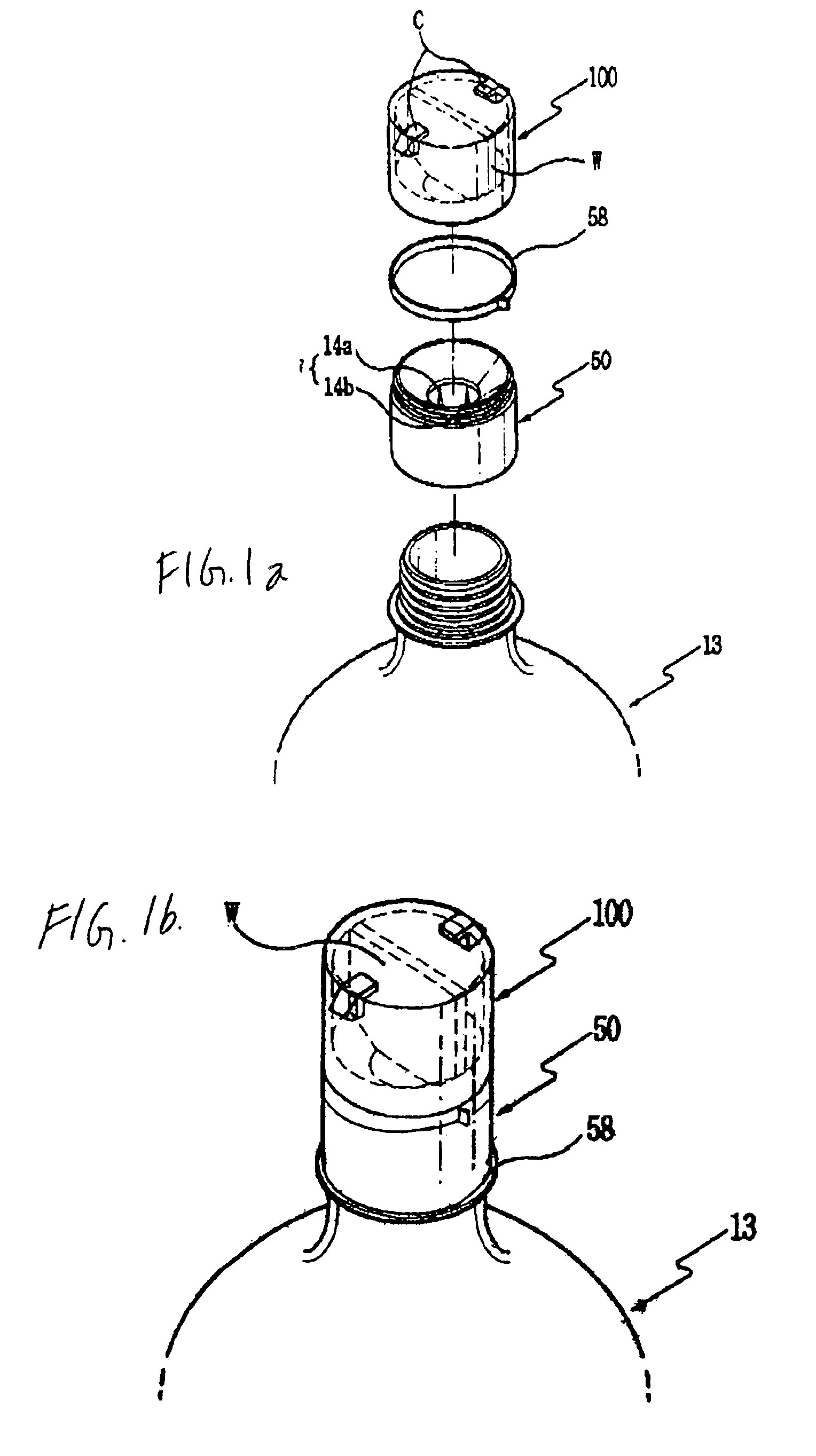

Cap device for mixing different kinds of materials separately contained therein and in bottle

InactiveUS6935493B2Easily brokenEasy to prepareLighting and heating apparatusBottlesEngineeringBottle

A cap device for bottles, which is capable of mixing two different additives separately contained therein with a material contained in a bottle to prepare a mixture in accordance with a simple rotating action of the cap device relative to the bottle, performed by a user, thus allowing the user to easily prepare the mixture just before drinking or using the mixture. The cap device has a cap cover acting as an additive containing part, and defining a cavity therein, with a partition wall provided in the cavity to divide the cavity into two chambers and to separately contain two different additives in the chambers; a first funnel part provided at a lower section of the cap cover; a breakable sheet having a structure to be easily broken by external impact provided at an open lower end of the first funnel part to close the open lower end of the first funnel part; a cap body assembled with a lower end of the cap cover externally tightened to an externally threaded mouth of a bottle; a second funnel part having the same shape as the first funnel part provided at an upper section of the cap body, such that the first and second funnel parts are spaced apart from each other or come into contact with each other; and a means for breaking the breakable sheet so as to open the lower end of the first funnel part.

Owner:CHO YOUNG KOOK

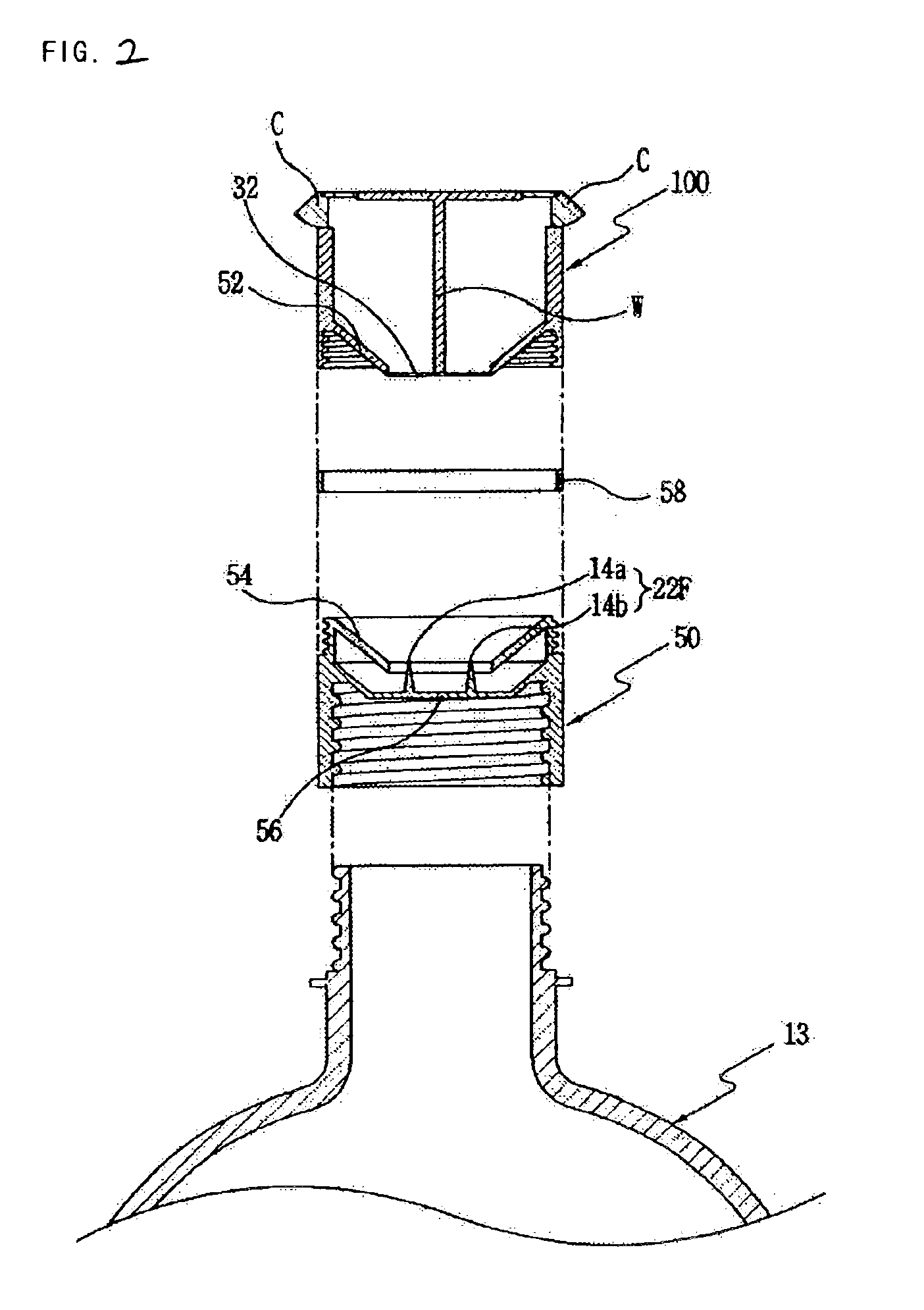

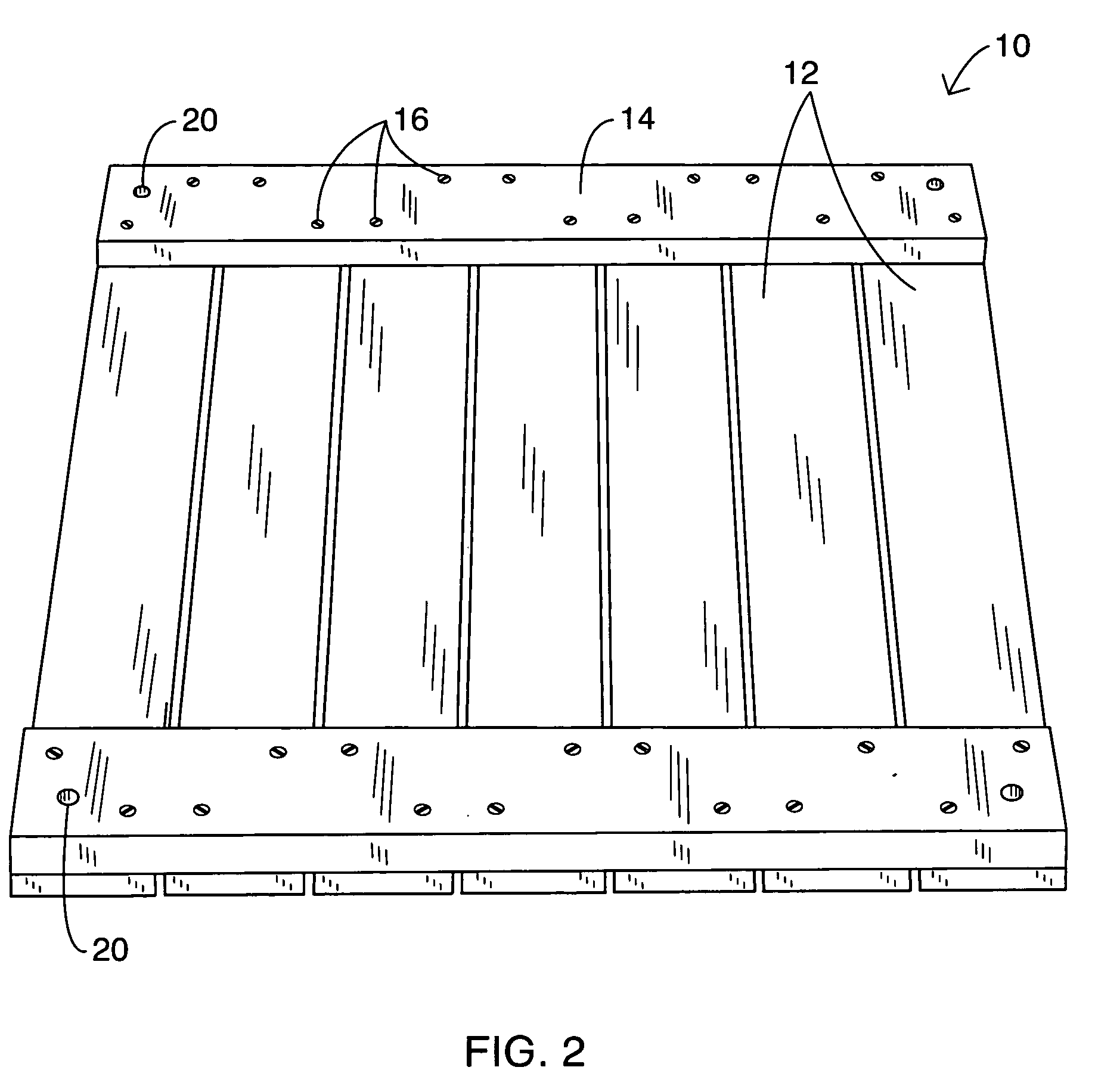

System for installation of decking tiles

Materials for use in installing a deck include a plurality of decking tiles, each of the tiles having an outside corner angle with a hole at a predetermined location with respect to the corner and a plurality of decking tile connectors. Each of the connectors includes a plate, spacer flanges upstanding from the plate arranged to divide the plate into quadrants defined by angles that are the same as the corner angles of the tiles, and Christmas tree fasteners upstanding in the quadrants at locations to align with the holes in the tiles.

Owner:DALHOFF LARSEN & HORNEMAN

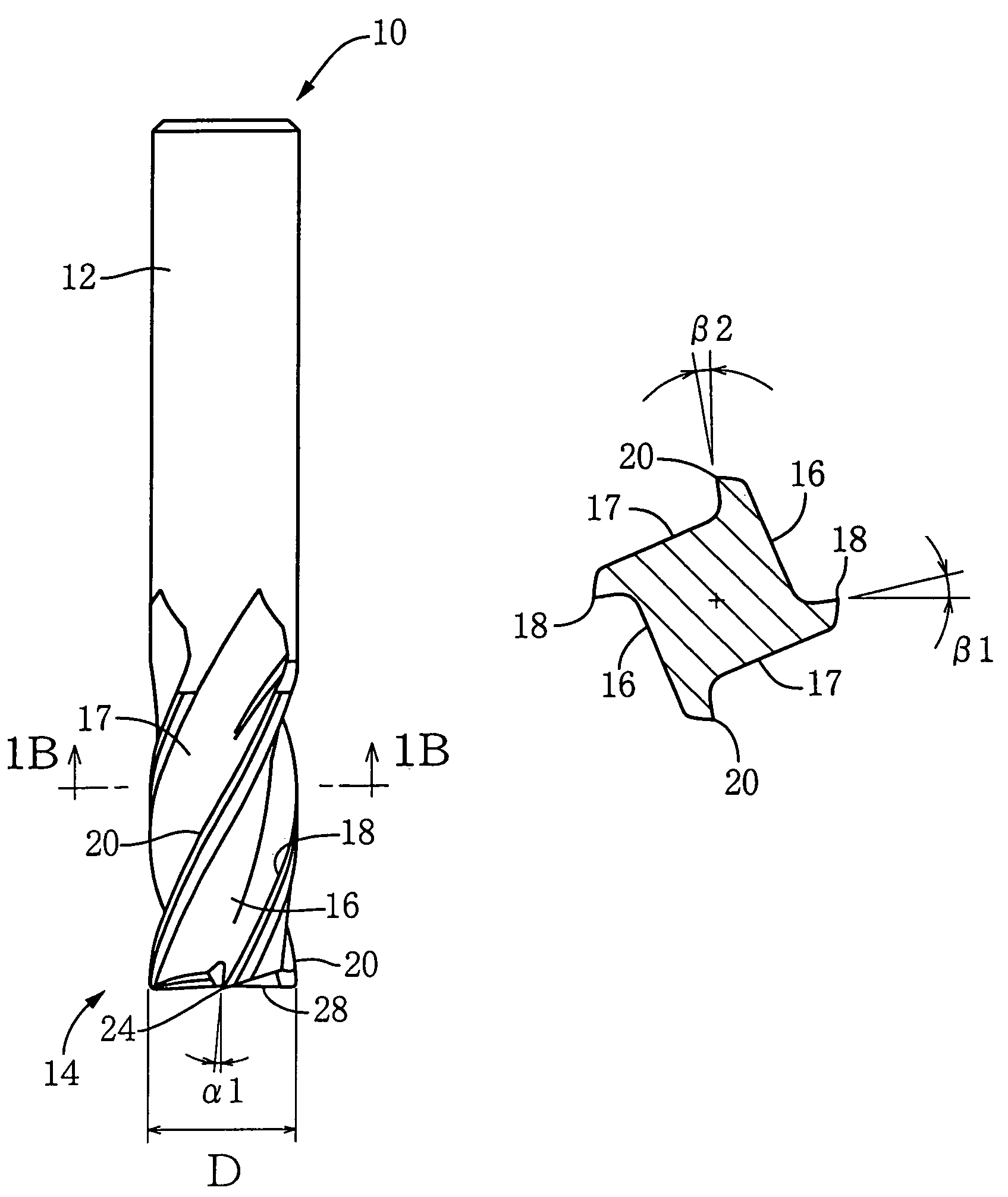

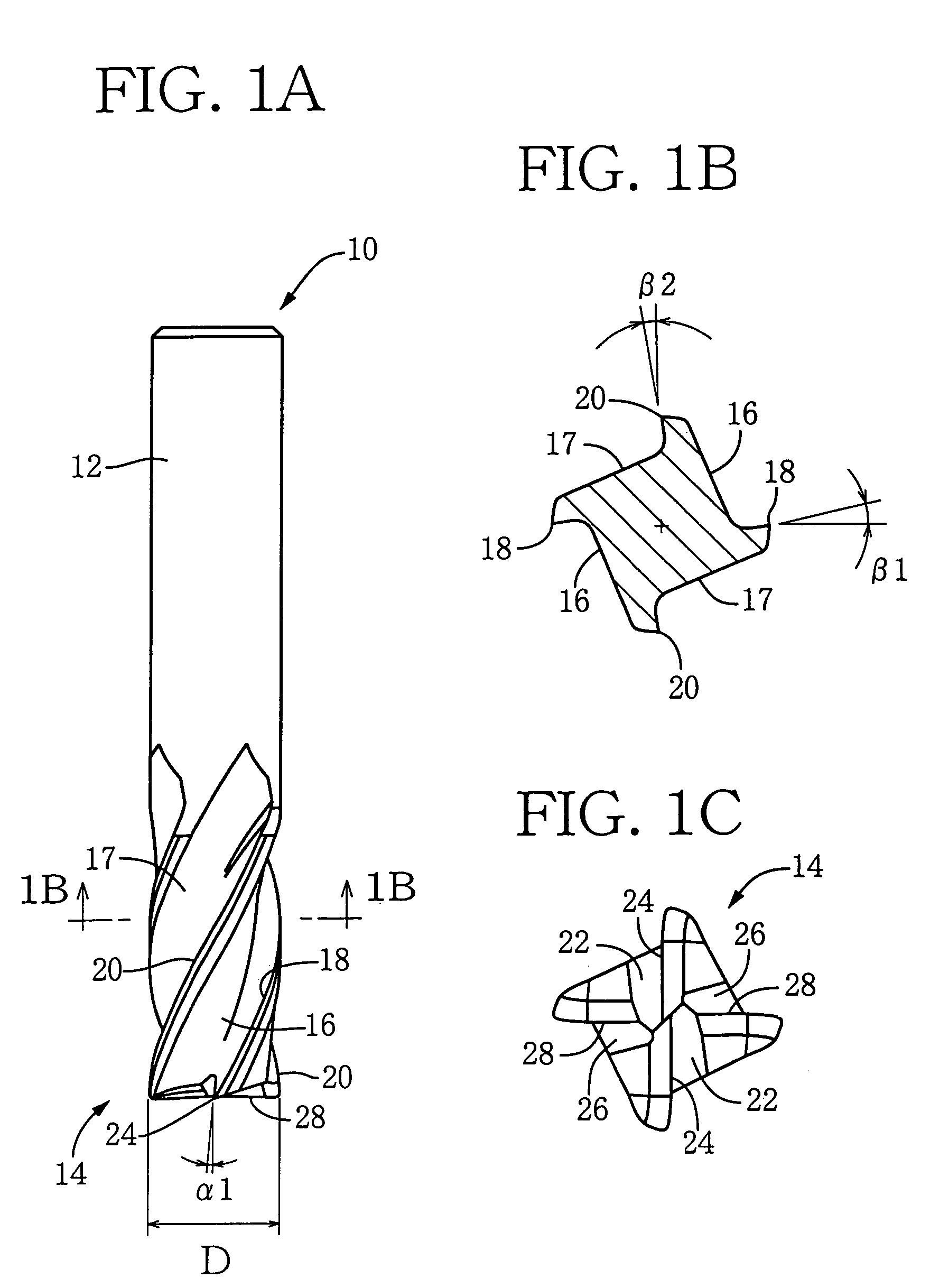

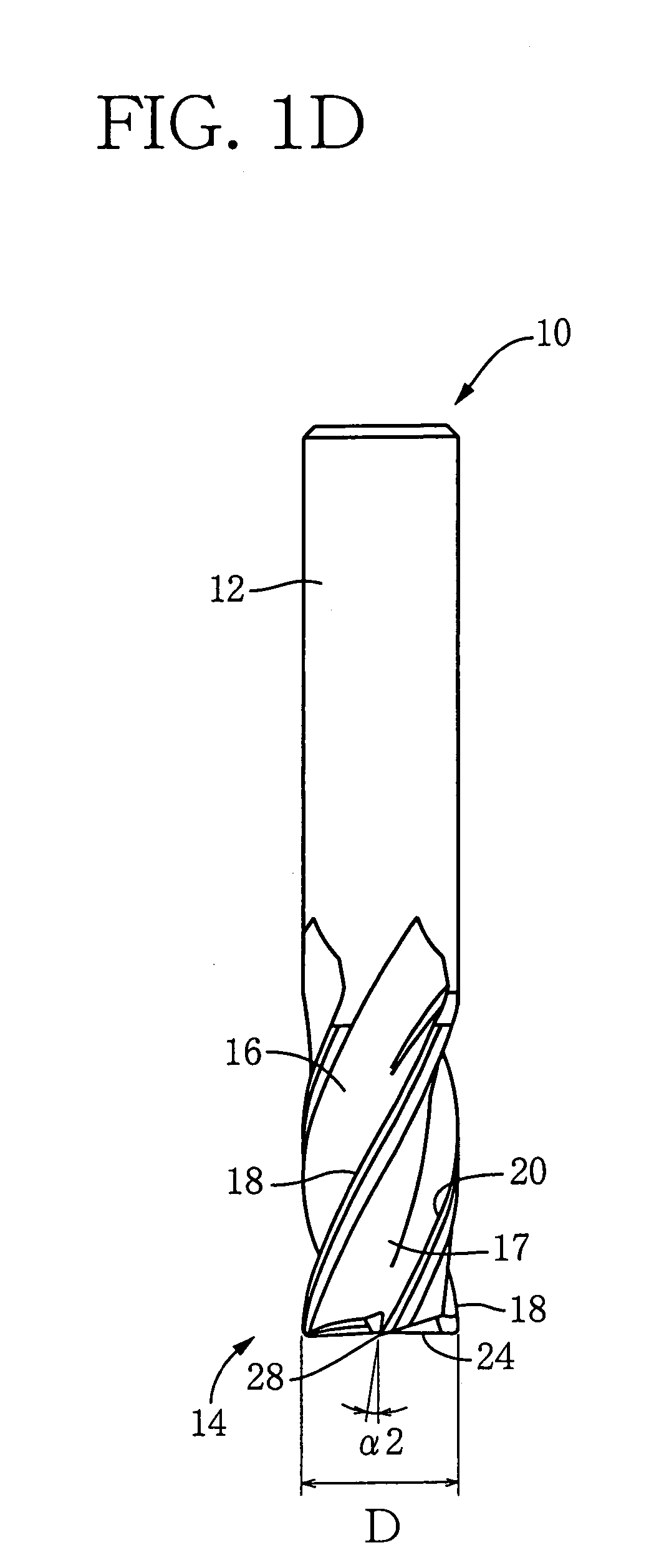

End mill having different axial rake angles and different radial rake angles

ActiveUS6997651B2High degree of durabilityPrevent chatterMilling cuttersShaping cuttersFluteEngineering

An end mill including a cylindrical body having (a) flutes each formed in the cylindrical body and each extending from an axially distal end of the cylindrical body toward an axially proximal end of the cylindrical body, (b) peripheral cutting edges each provided by one of widthwise opposite edges of a corresponding one of the flutes, and (c) end cutting edges each located at the axially distal end of the cylindrical body and contiguous to a corresponding one of the peripheral cutting edges. The end cutting edges include first and second end cutting edges, while the peripheral cutting edges include first and second peripheral cutting edges which are contiguous to the first and second end cutting edges, respectively. A first axial rake angle of the first end cutting edge is smaller than a second axial rake angle of the second end cutting edge, while a first radial rake angle of the first peripheral cutting edge is larger than a second radial rake angle of the second peripheral cutting edge.

Owner:OSG

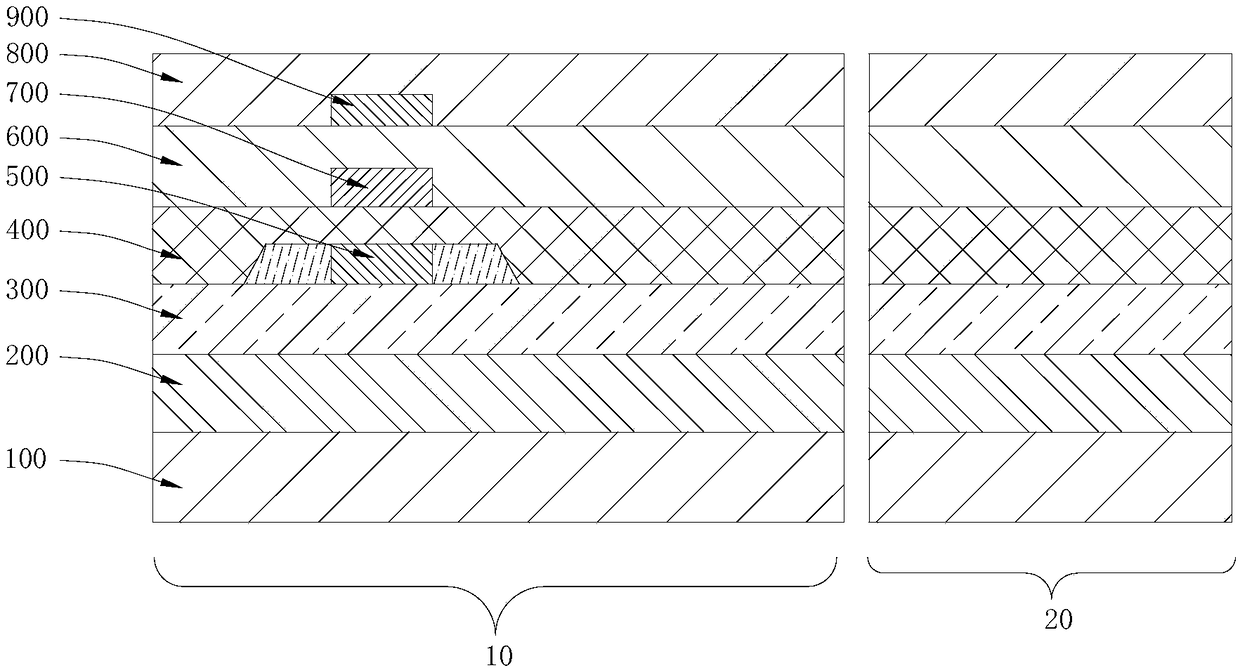

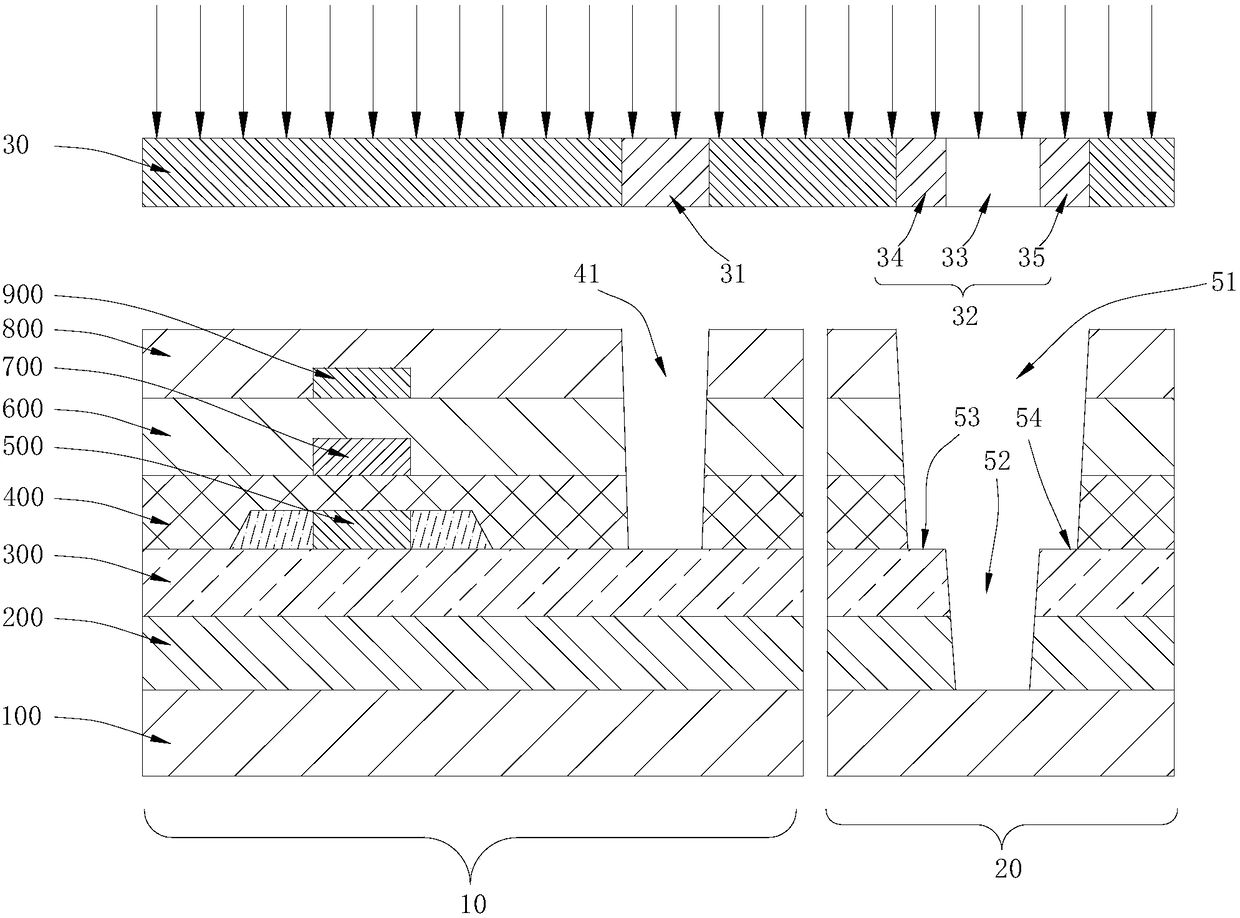

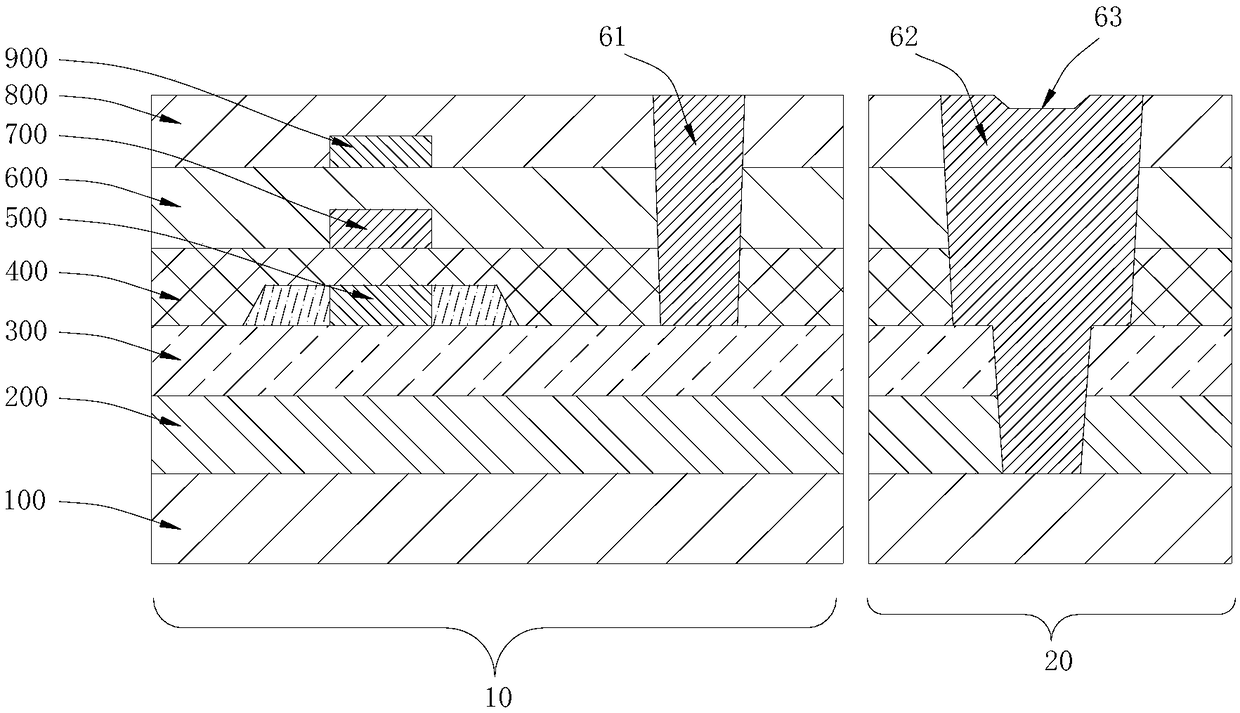

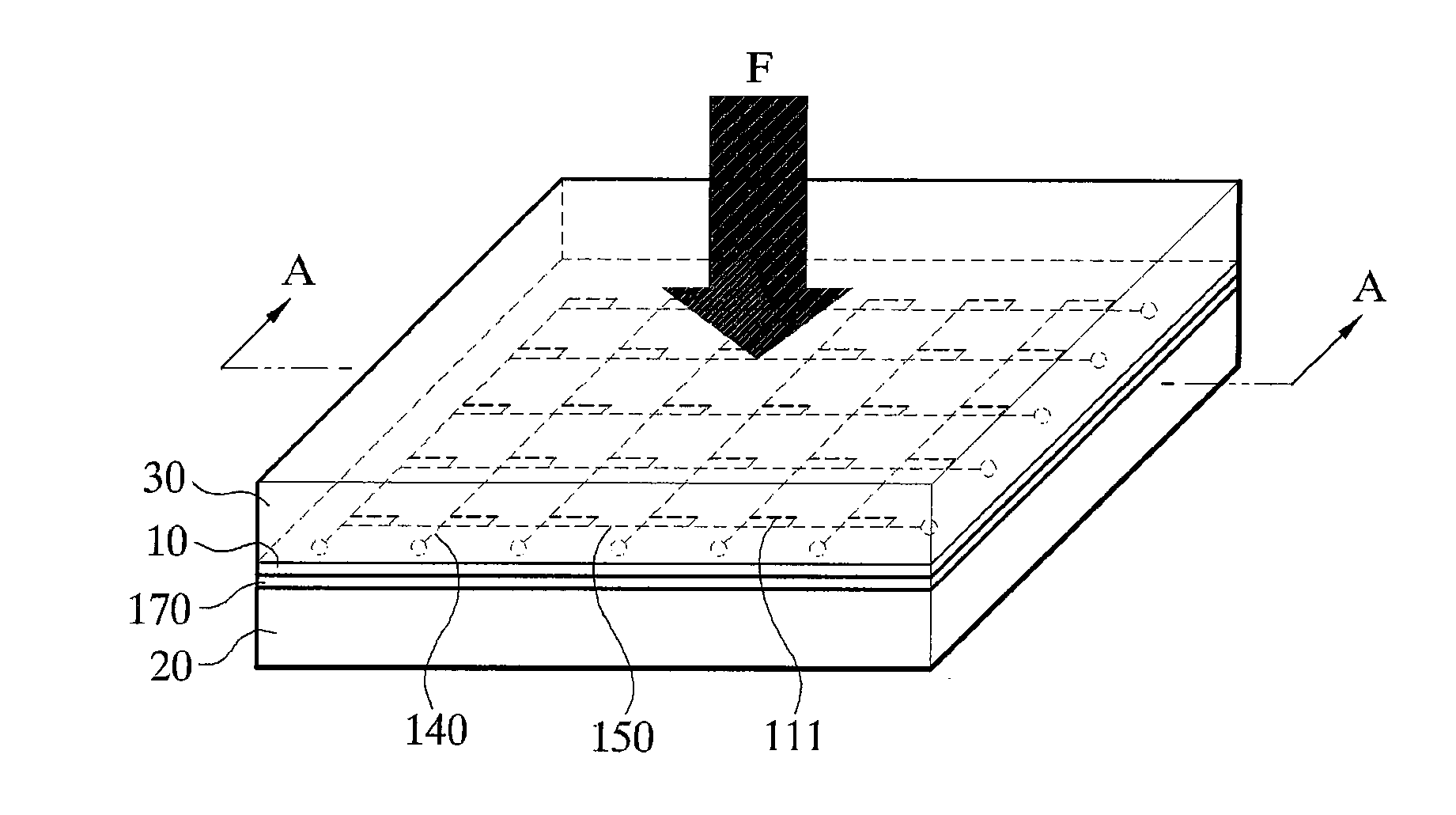

Flexible display panel and manufacturing method thereof

ActiveCN108288637AReduce bendingEasily brokenFinal product manufactureSolid-state devicesEngineeringFlexible display

The invention provides a manufacturing method of a flexible display panel. The manufacturing method comprises the following steps of providing an array substrate, wherein the array substrate comprisesa semiconductor layer, the flexible display panel is divided into adjacent pixel region and bending region, and the pixel region comprises the semiconductor layer; digging a second groove in the bending region, wherein the second groove forms a stage structure in the array substrate, and the stage structure extends from the interior of the array substrate to a direction opposite to the inner wallof the second groove; filling the second groove with an organic material, and an inwardly concave conical groove is formed in the surface, flush with the array substrate, of the organic material filled in the second groove; and manufacturing a source, a drain and source and drain routing lines on the array substrate, wherein the source and the drain are connected to the semiconductor layer, and the source and drain routing lines cover the conical groove. By virtue of the above-mentioned setting, the bending degree of the source and drain routing lines in the position of the conical groove canbe lowered, thereby effectively relieving the problem of cracking of the source and drain routing lines in the position of the conical groove. The invention also provides the flexible display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

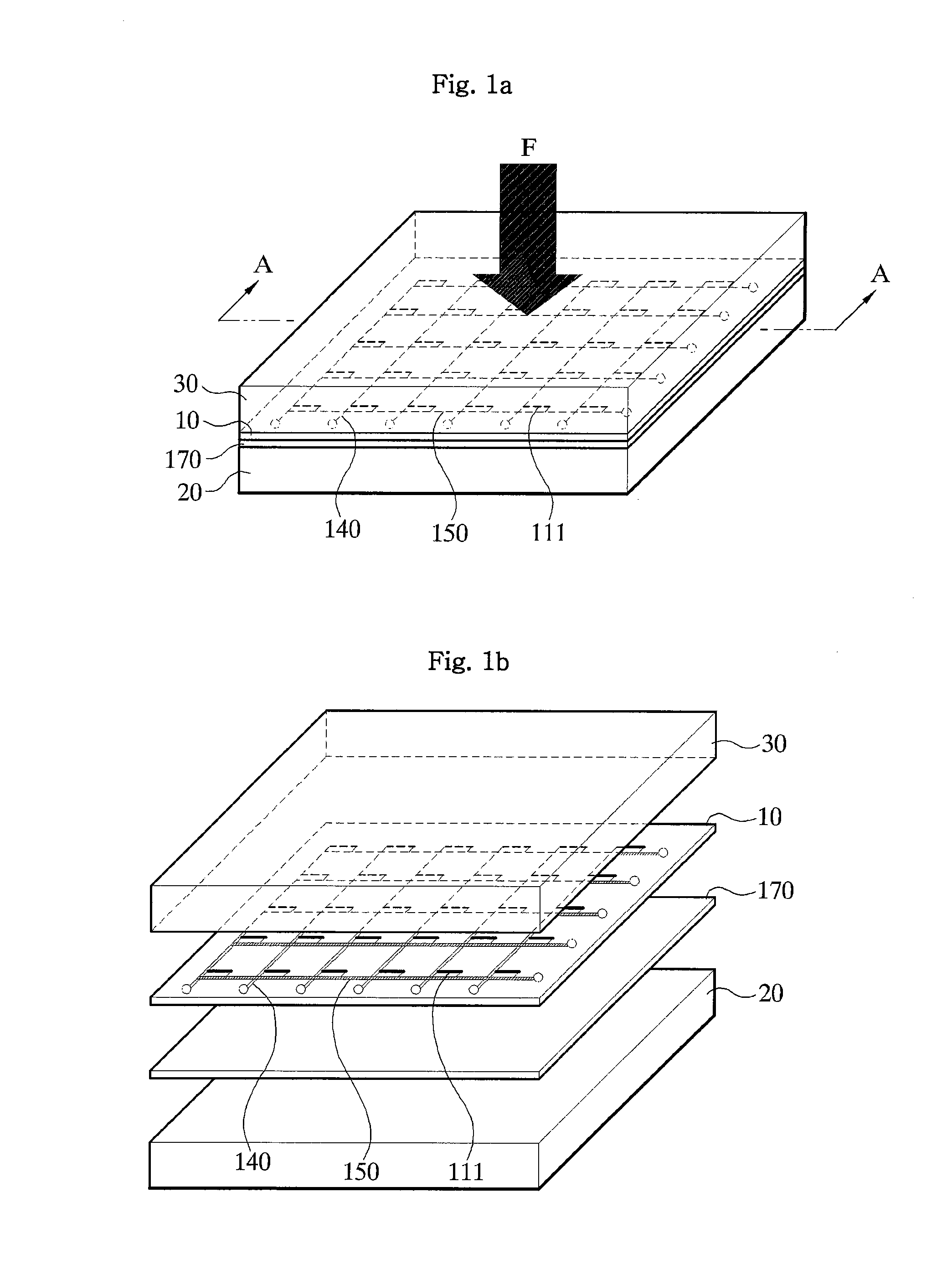

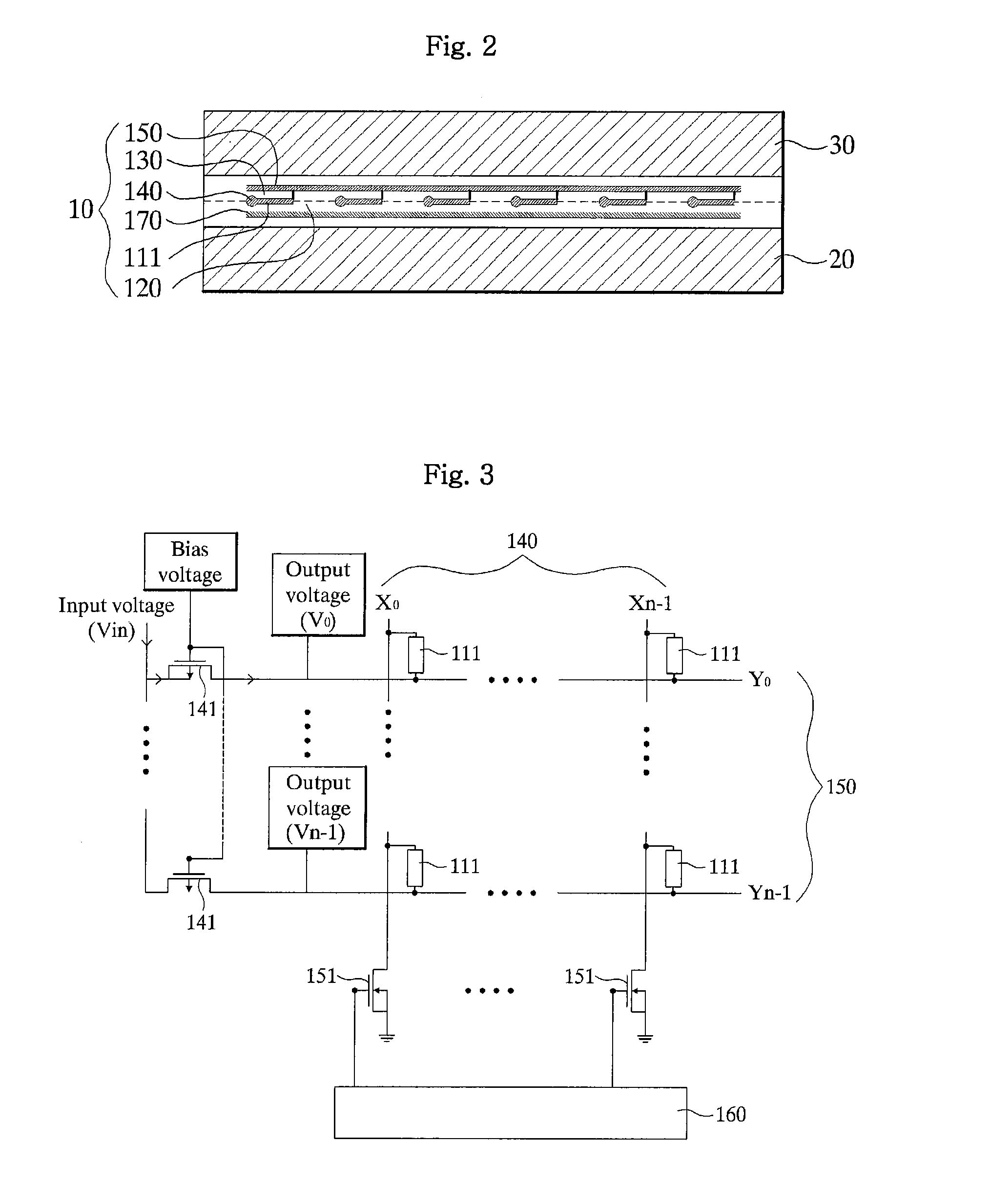

Flexible force or pressure sensor array using semiconductor strain gauge, fabrication method thereof and measurement method thereof

ActiveUS20110226069A1Simple and robust structureIncrease strainForce measurementSemiconductor/solid-state device manufacturingSensor arrayElastomer

The force or pressure sensor array of the present invention effectively has both flexibility and elasticity. Since the substrate itself is a kind of a polymer material, the substrate can be bent or expanded. Although silicon, which is a material of the semiconductor strain gauge, is easily broken and solid, mechanical flexibility can be secured if it is fabricated extremely thin. To this end, particularly, disclosed is a flexible force or pressure sensor array using semiconductor strain gauges 110, the sensor array comprising: a substrate 10 including: the semiconductor strain gauges 110 in which a plurality of elements formed in a certain array pattern is deformed by force or pressure, a pair of polymer film layers 120 and 130 having film surfaces contacted facing each other and containing the semiconductor strain gauge 110 between the film surfaces contacted with each other, and a pair of signal line layers formed on top and bottom surfaces of an insulating layer using either of the pair of polymer film layers 120 and 130 as the insulating layer and connected to the elements 111 of the array pattern to form electrodes, for fetching deformation signals outputted due to deformation of the elements 111 to outside; and a pair of elastomer layers 20 and 30 formed on both sides of the substrate 10 to contain the substrate 10 inside.

Owner:KOREA RES INST OF STANDARDS & SCI

Array of fiber optic splicing cassettes

InactiveUS7110654B2Easily break-offEasily brokenOptical fibre/cable installationFibre mechanical structuresFiberMechanical engineering

An array of fiber optic splicing cassettes. The array has first and second side plates connected to one another by first and second axes. The fiber optic splicing cassettes each have a base and first and second curved slots in the base. Each of the first slots is moveably engaged on the first axis, and each of the second slots is moveably engaged on the second axis. In this way each of the cassettes may be moved between an open position and a closed position by simultaneously moving the first and second slots in one of the cassettes relative to the first and second axes.

Owner:3M INNOVATIVE PROPERTIES CO

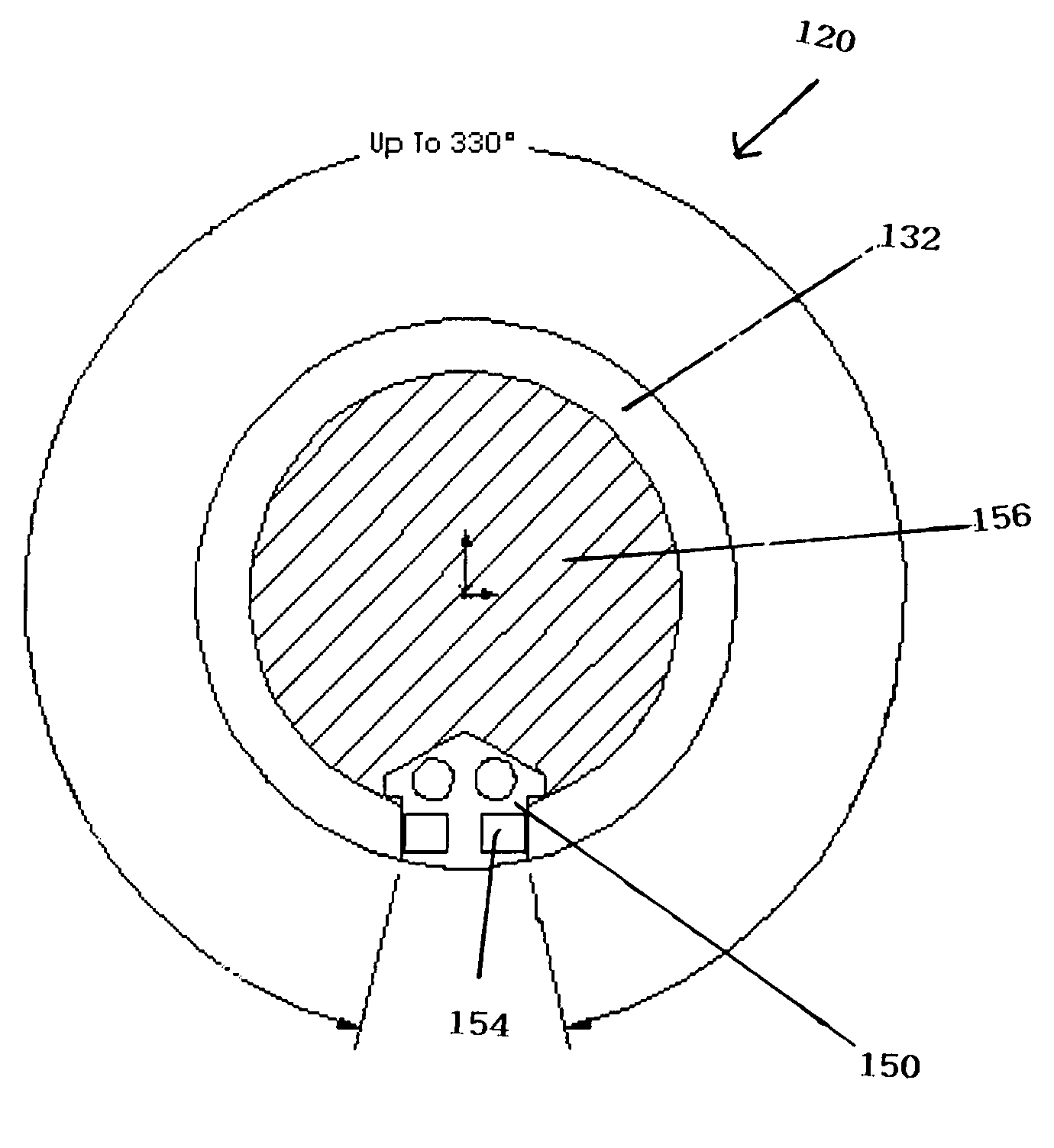

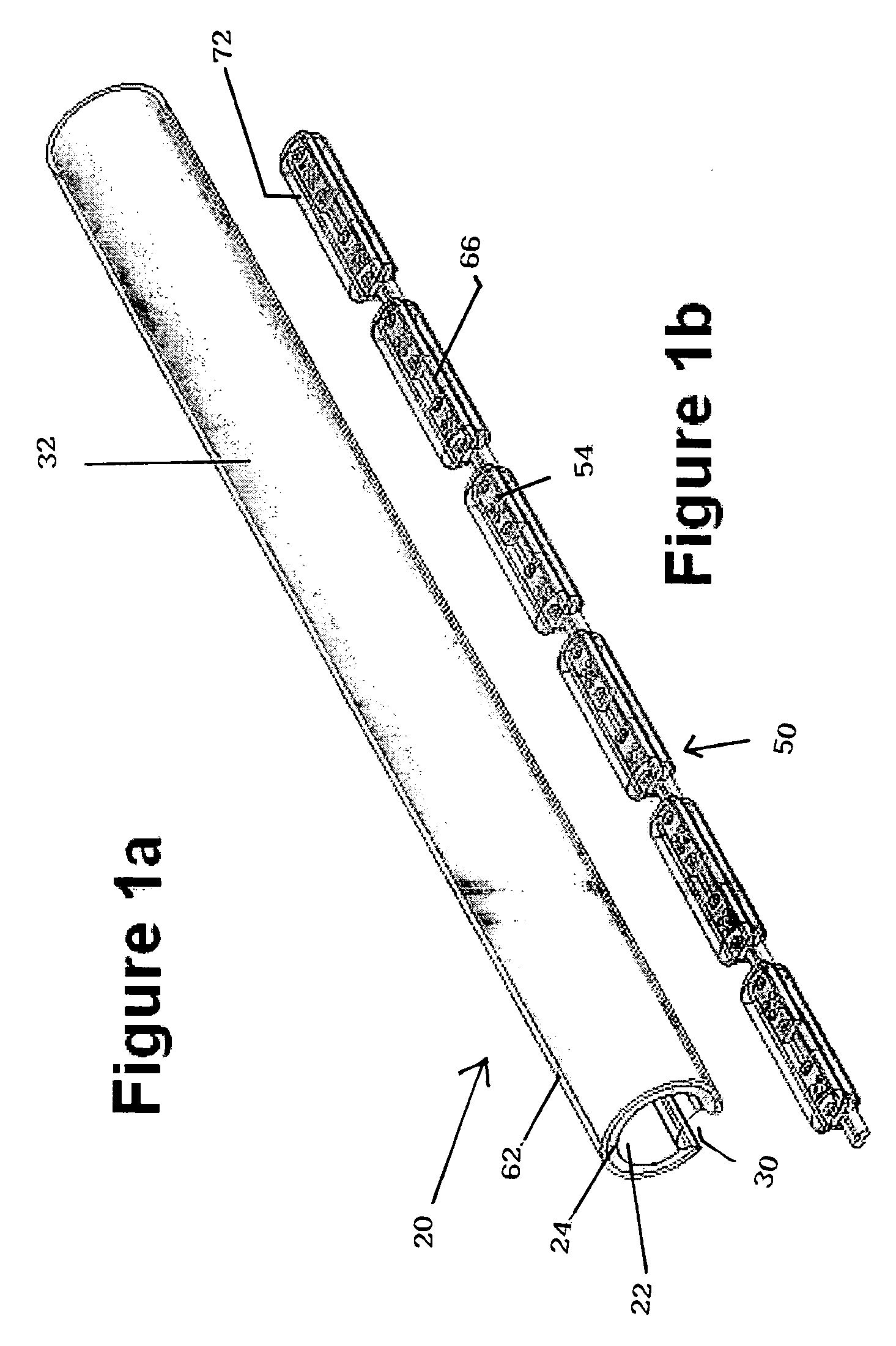

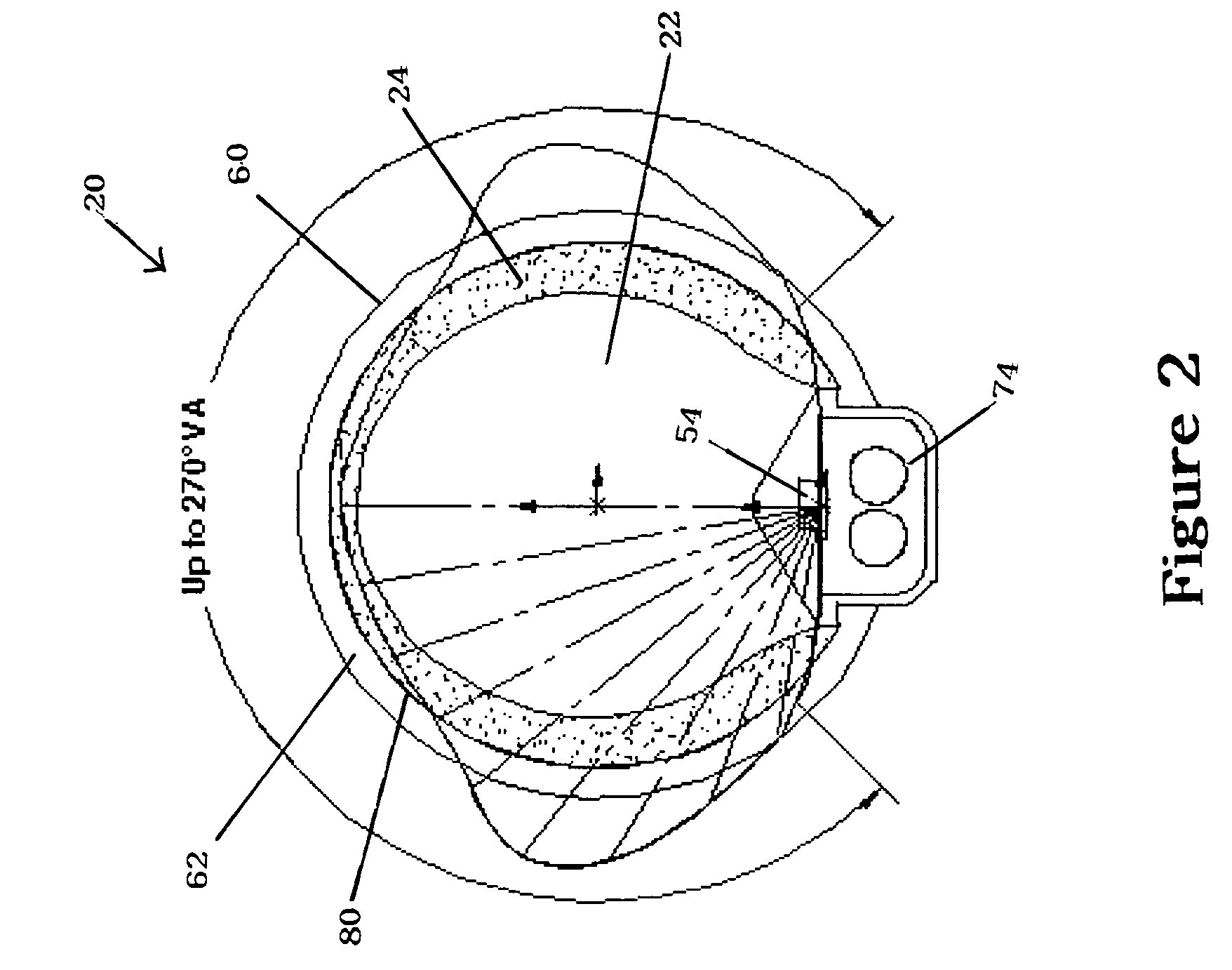

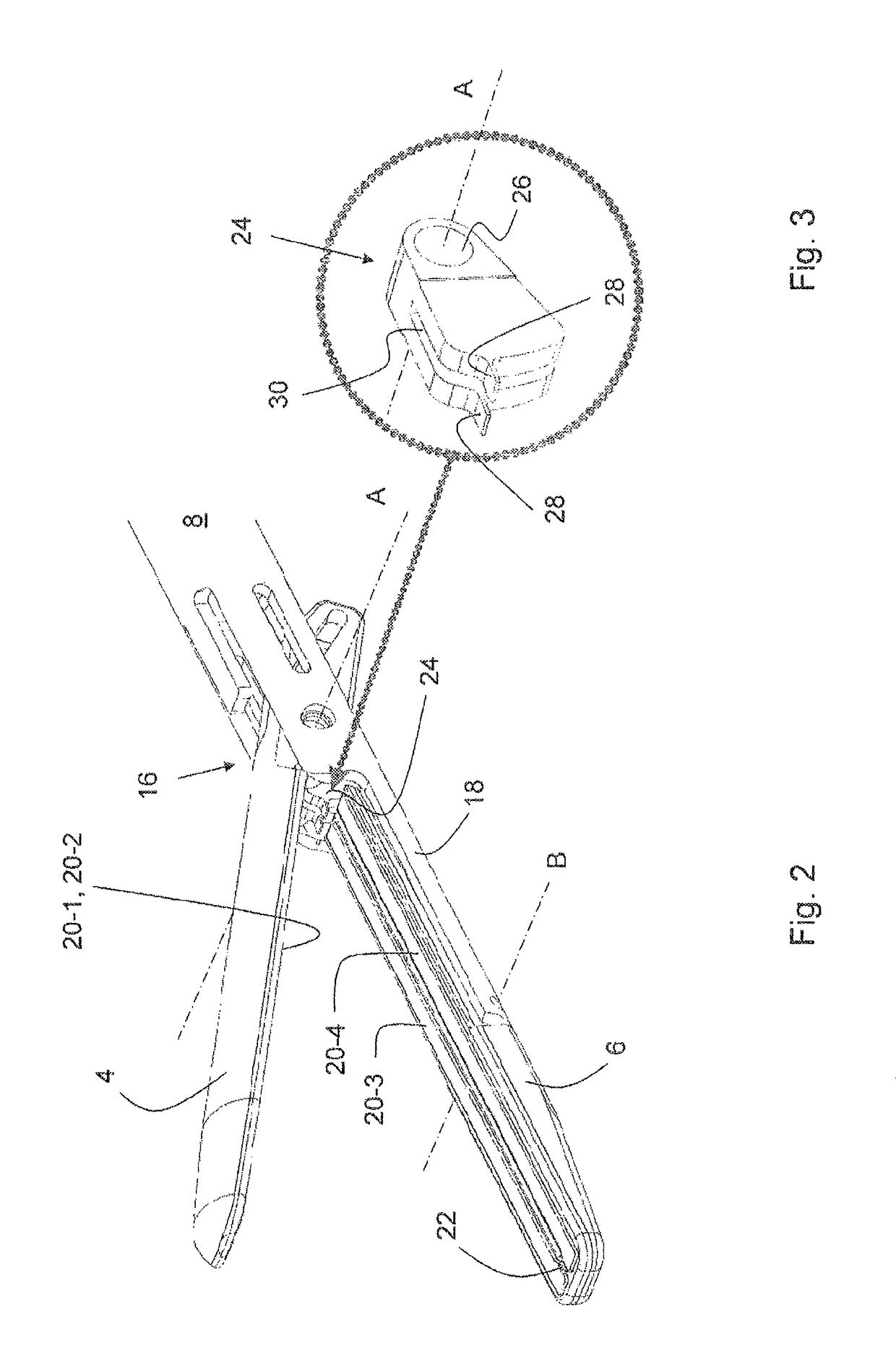

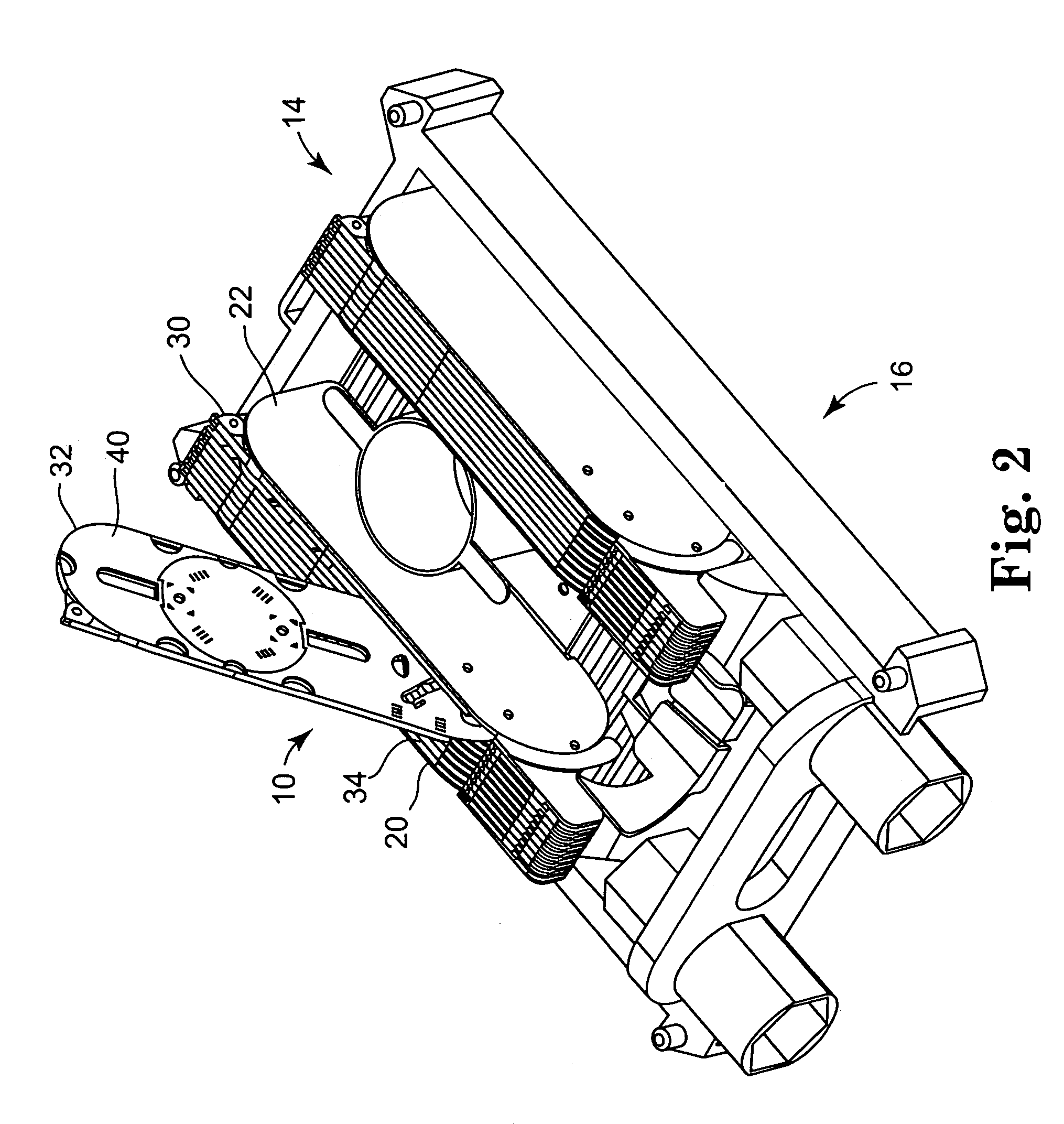

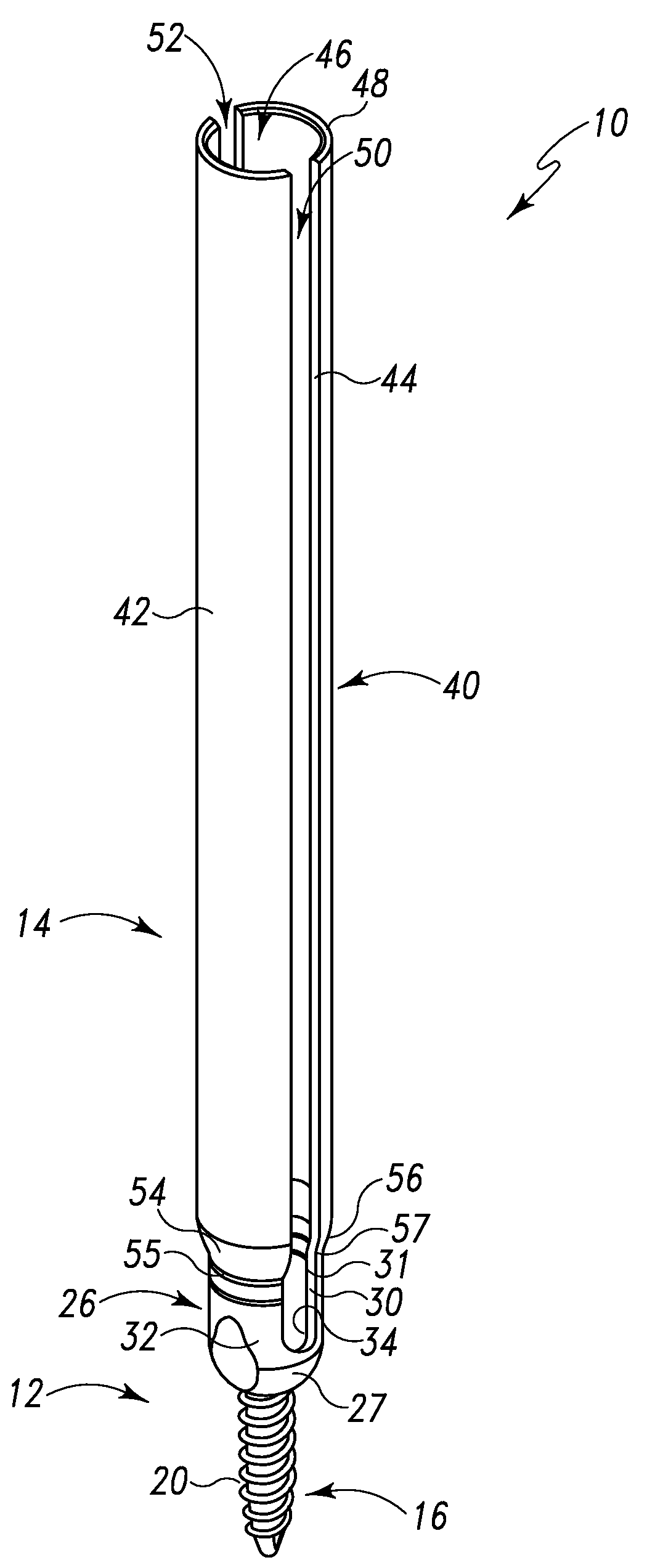

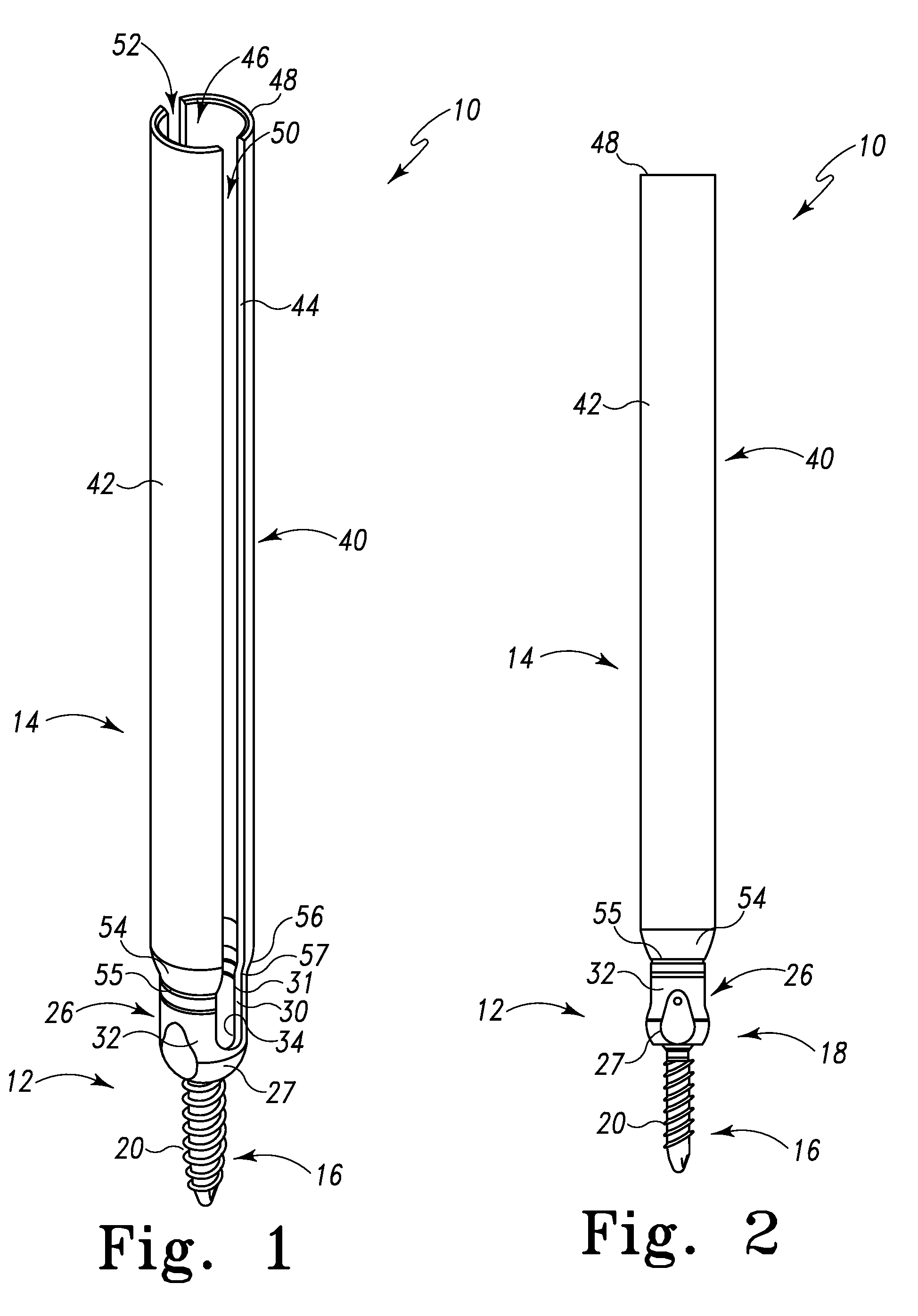

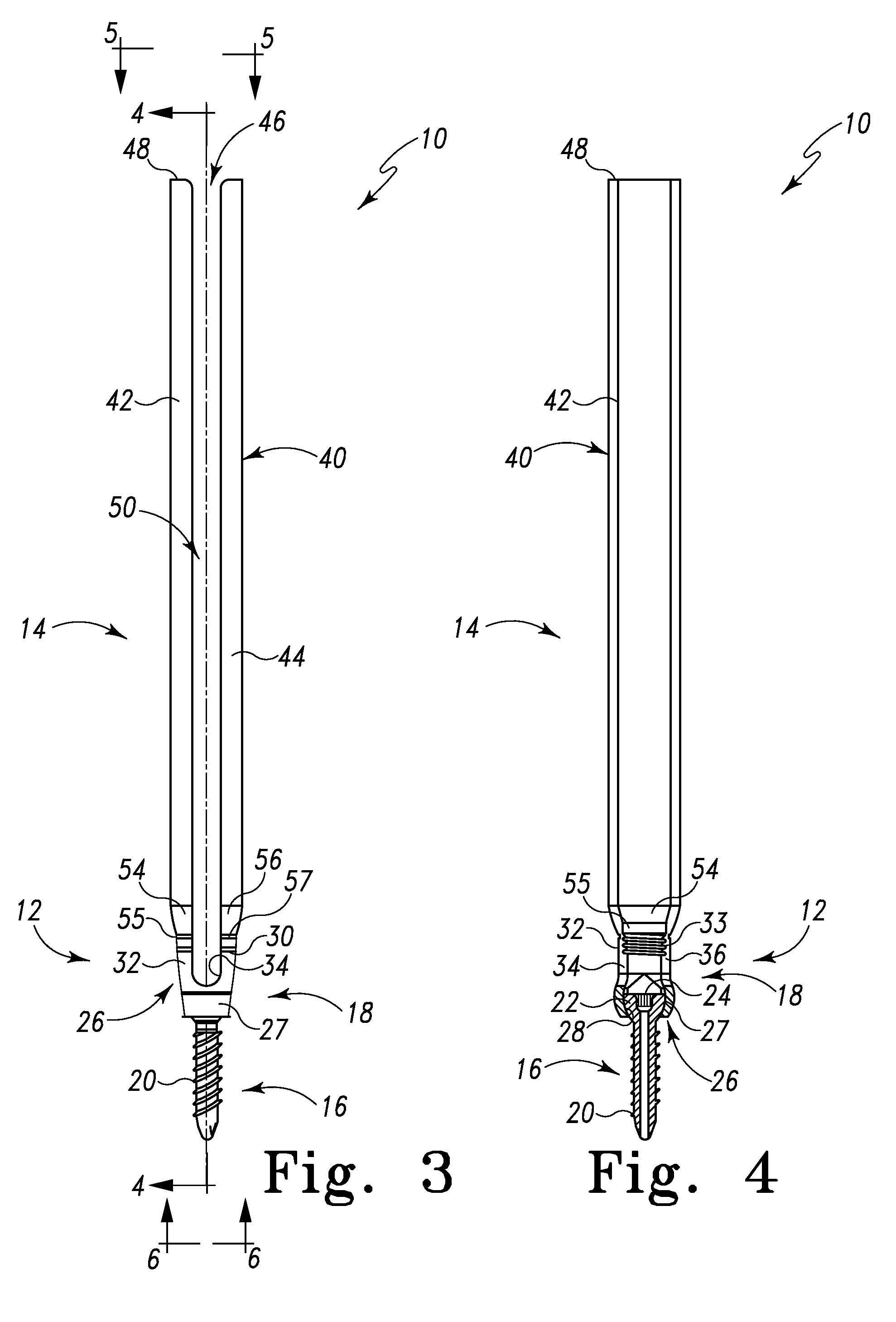

Spinal Rod Guide For A Vertebral Screw Spinal Rod Connector Assembly

ActiveUS20090240292A1Easy to placeAccurate guideInternal osteosythesisNon-surgical orthopedic devicesVertebral boneDirect communication

A spinal rod guide and / or guide assembly is provided for mounting a spinal rod onto a spinal rod holder / connector of a vertebral bone screw. The spinal rod guide is configured to extend between an opening in a patient's body and the spinal rod holder of the vertebral bone screw assembly, to receive a spinal rod therein, and thereafter accurately guide the spinal rod into the spinal rod holder. The spinal rod guide is defined by a first elongated arc portion and a second elongated arc portion to define a guide tube for the introduction and placement of additional spinal rod components onto the spinal rod connector, particularly, but not necessarily, for securing the spinal rod into the spinal rod connector. The elongated arc portions are mountable or initially attached onto a top of a spinal rod holder of a spinal rod bone screw assembly. The elongated arc portions (tube) define first and second longitudinal slots extending from a top of the elongated arc portions to a bottom of the elongated arc portions. The two longitudinal slots are situated such as to be diametrically opposite one another. Each longitudinal slot aligns with a spinal rod slot of the spinal rod holder to thereby allow easy placement of the spinal rod into the spinal rod holder. Thereafter, the defined elongated tube provides direct communication and alignment with the top of the spinal rod holder in order to receive a spinal rod connector drive screw for securing the spinal rod into the spinal rod holder.

Owner:LIFE SPINE INC

Semiconductor device and manufacturing method thereof

ActiveUS20110079778A1Easily brokenEasy to spreadElectroluminescent light sourcesSolid-state devicesHydrogen atomSilicon oxide

An object is to provide a semiconductor device with stable electric characteristics in which an oxide semiconductor is used. The impurity concentration in the oxide semiconductor layer is reduced in the following manner: a silicon oxide layer including many defects typified by dangling bonds is formed in contact with the oxide semiconductor layer, and an impurity such as hydrogen or moisture (a hydrogen atom or a compound including a hydrogen atom such as H2O) included in the oxide semiconductor layer is diffused into the silicon oxide layer. Further, a mixed region is provided between the oxide semiconductor layer and the silicon oxide layer. The mixed region includes oxygen, silicon, and at least one kind of metal element that is included in the oxide semiconductor.

Owner:SEMICON ENERGY LAB CO LTD

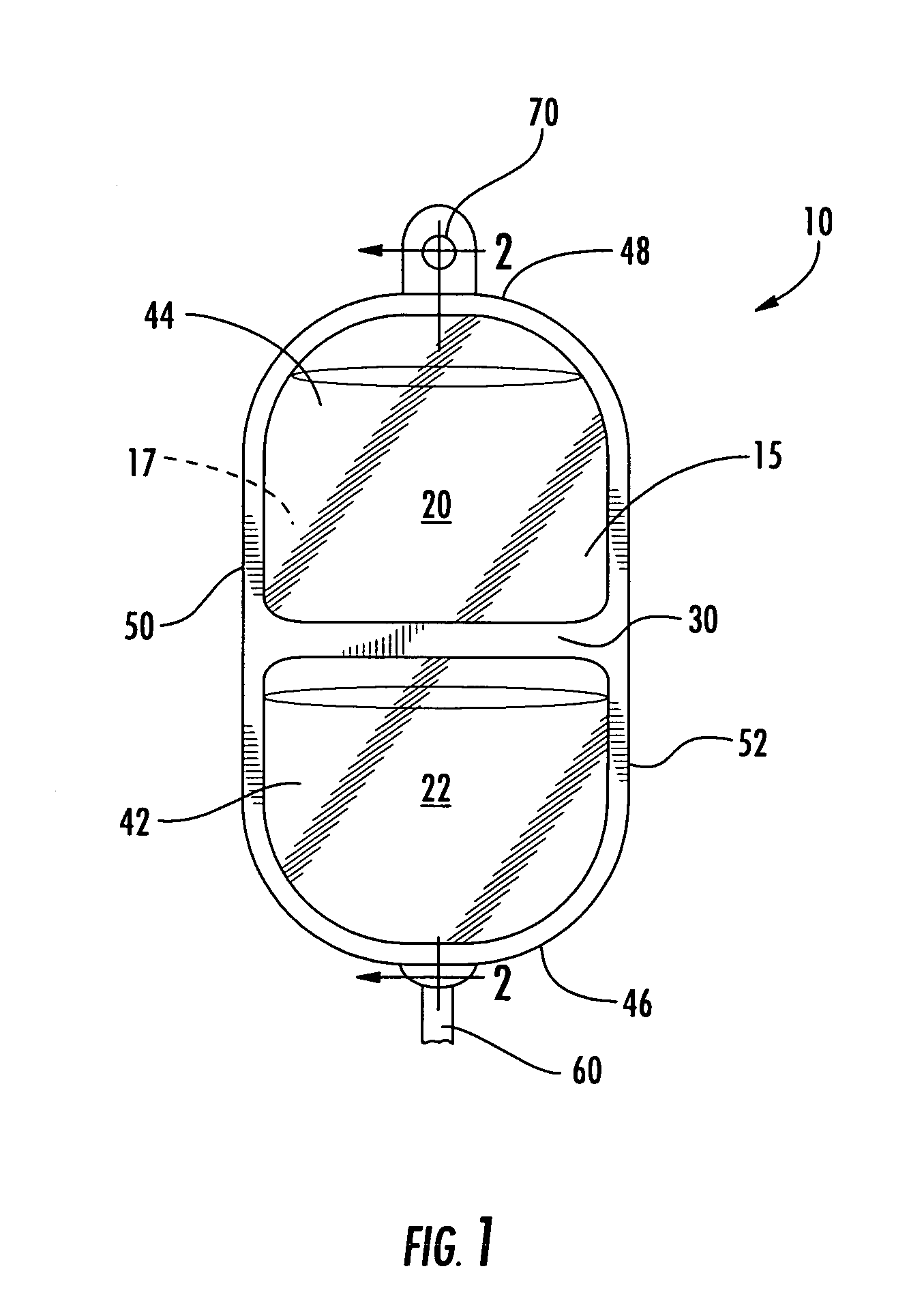

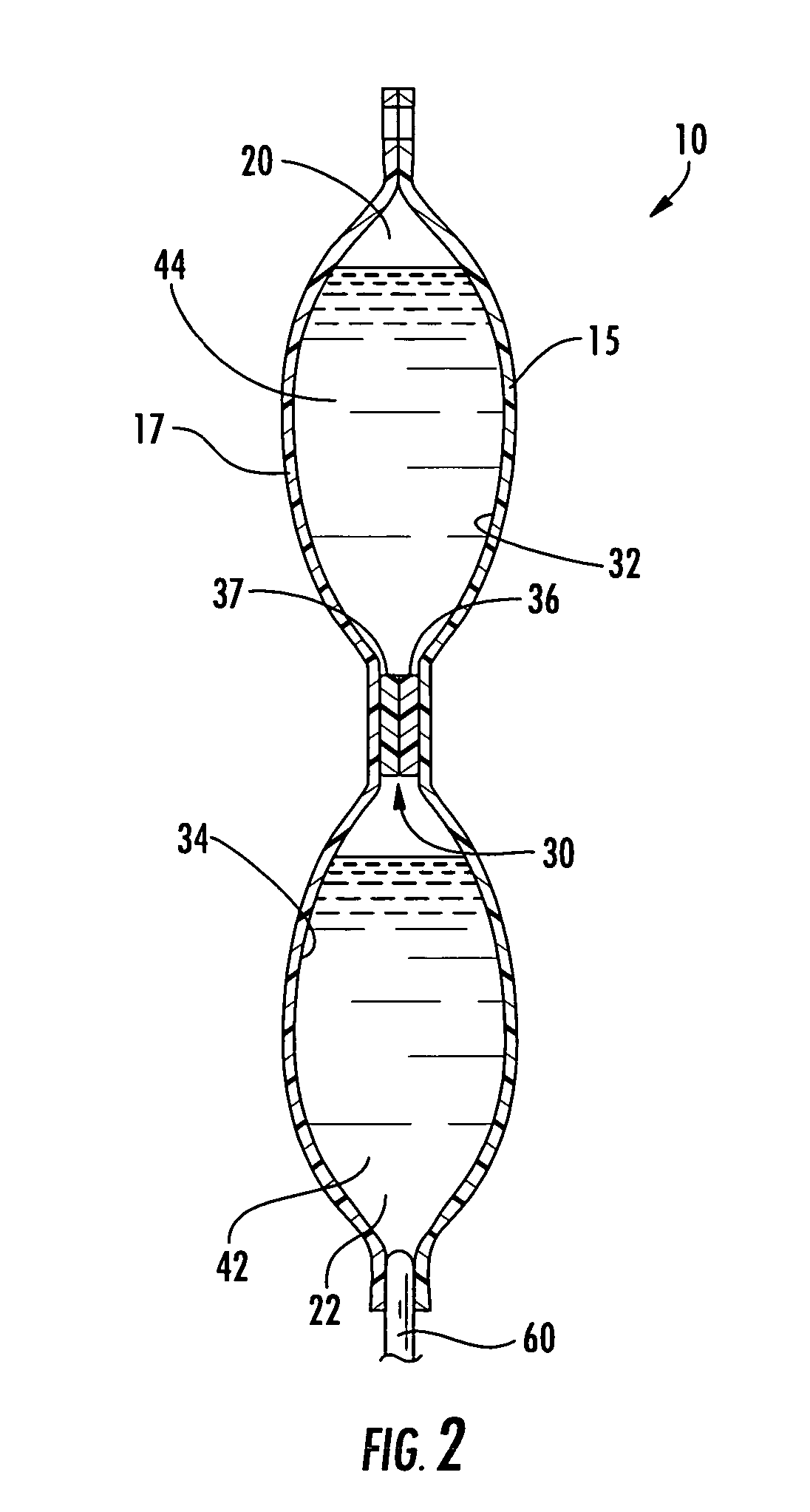

Multi-compartment pouch having a frangible seal

InactiveUS20060093765A1Easily brokenBroken with effortSynthetic resin layered productsPharmaceutical containersEngineeringUltimate tensile strength

The invention provides a pouch having a frangible seal comprised of two strips of thermoplastic material that are disposed in the interior of the pouch, and sealed to each other in a face-to face orientation. A first strip of thermoplastic material is sealed to an interior surface of one side of the pouch, and the second strip of thermoplastic material is sealed to an interior surface of the opposite side of the pouch. The strips of thermoplastic material are adapted to form stronger bonds with the front and rear sheets than they are with each other. As a result, the strength of the seal between the two strips of material may be controlled to produce a frangible seal that can be broken with minimal effort and without having to sacrifice the desired heat sealing properties of the film forming the pouch.

Owner:SEALED AIR U S

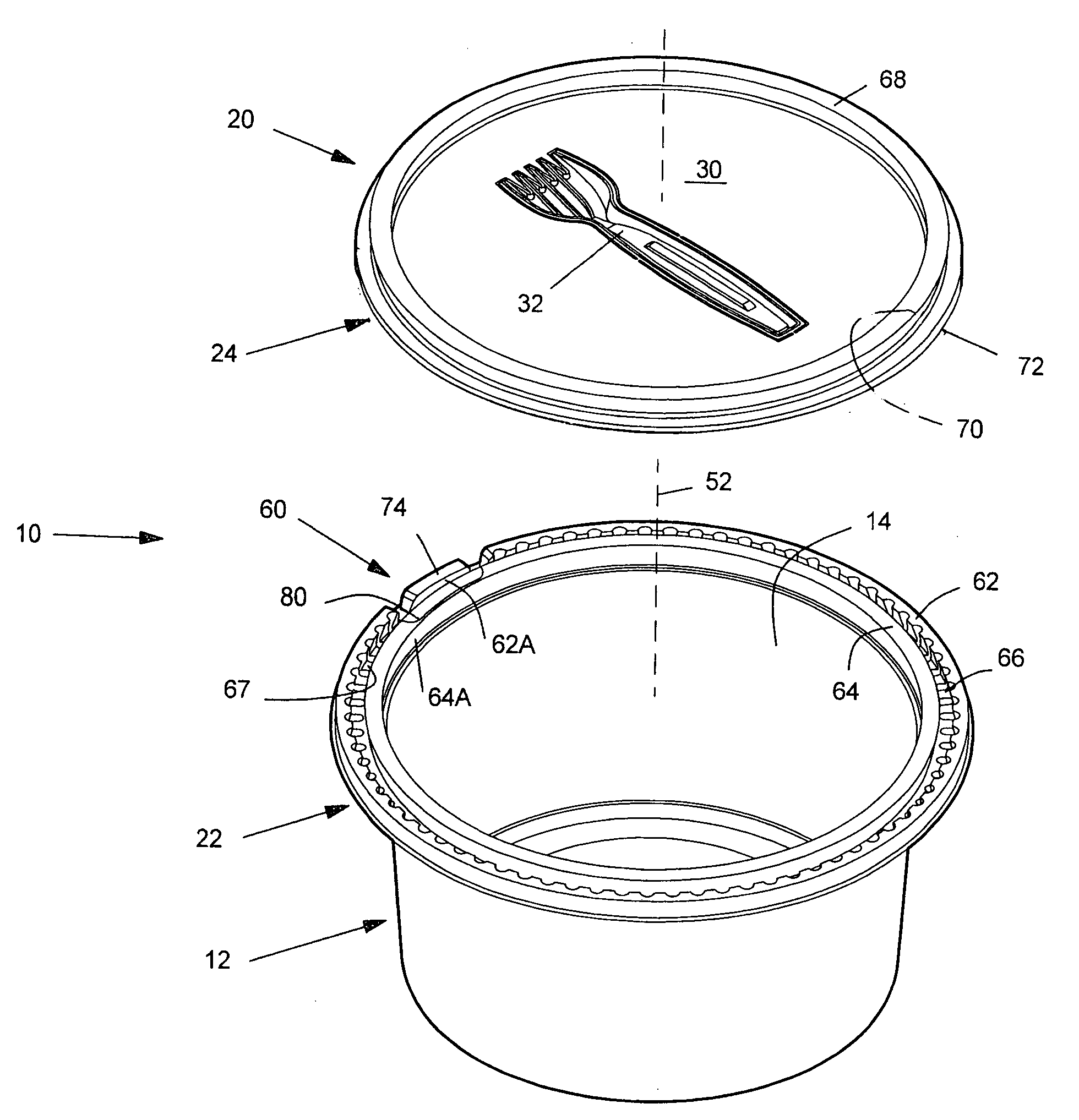

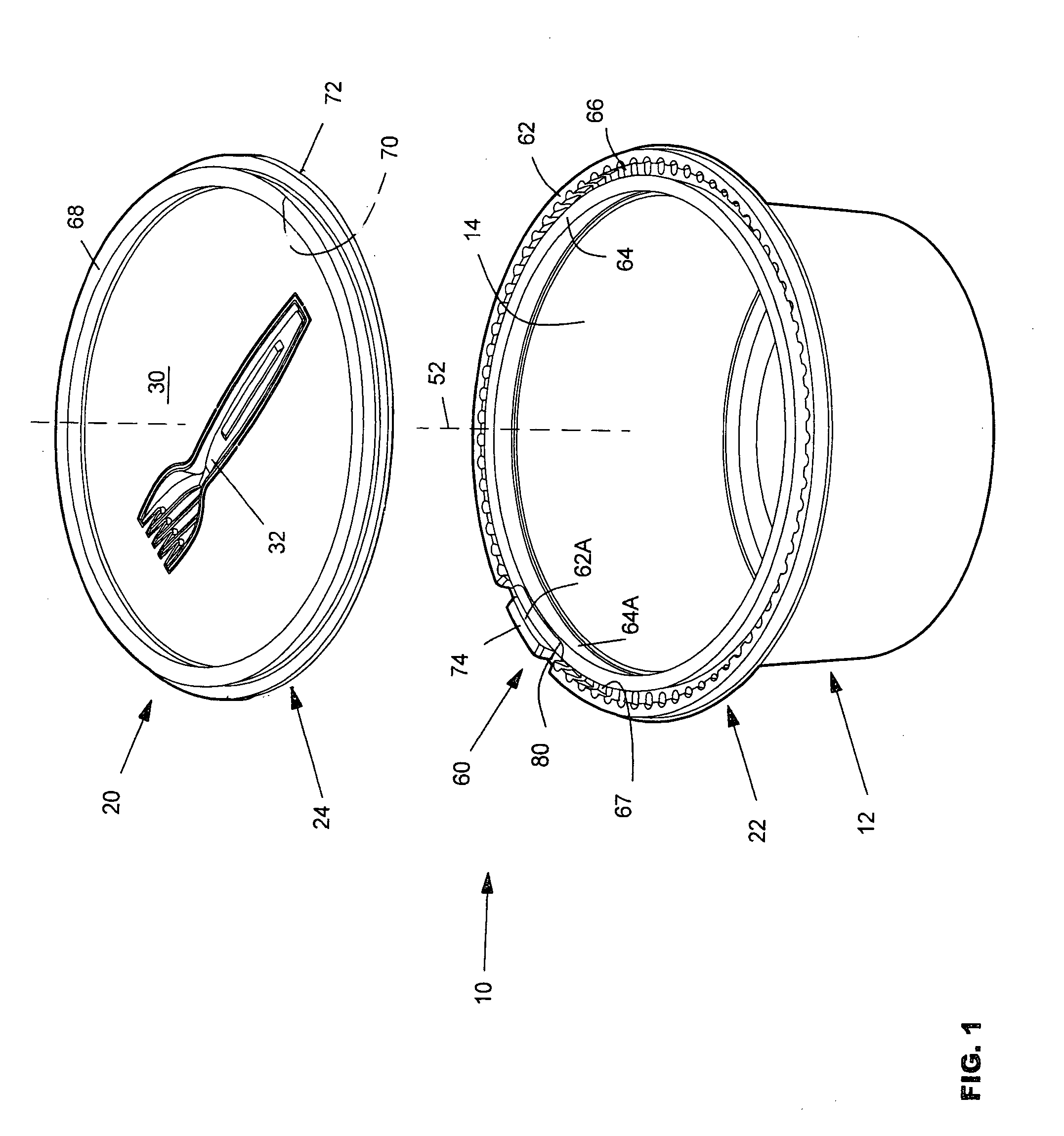

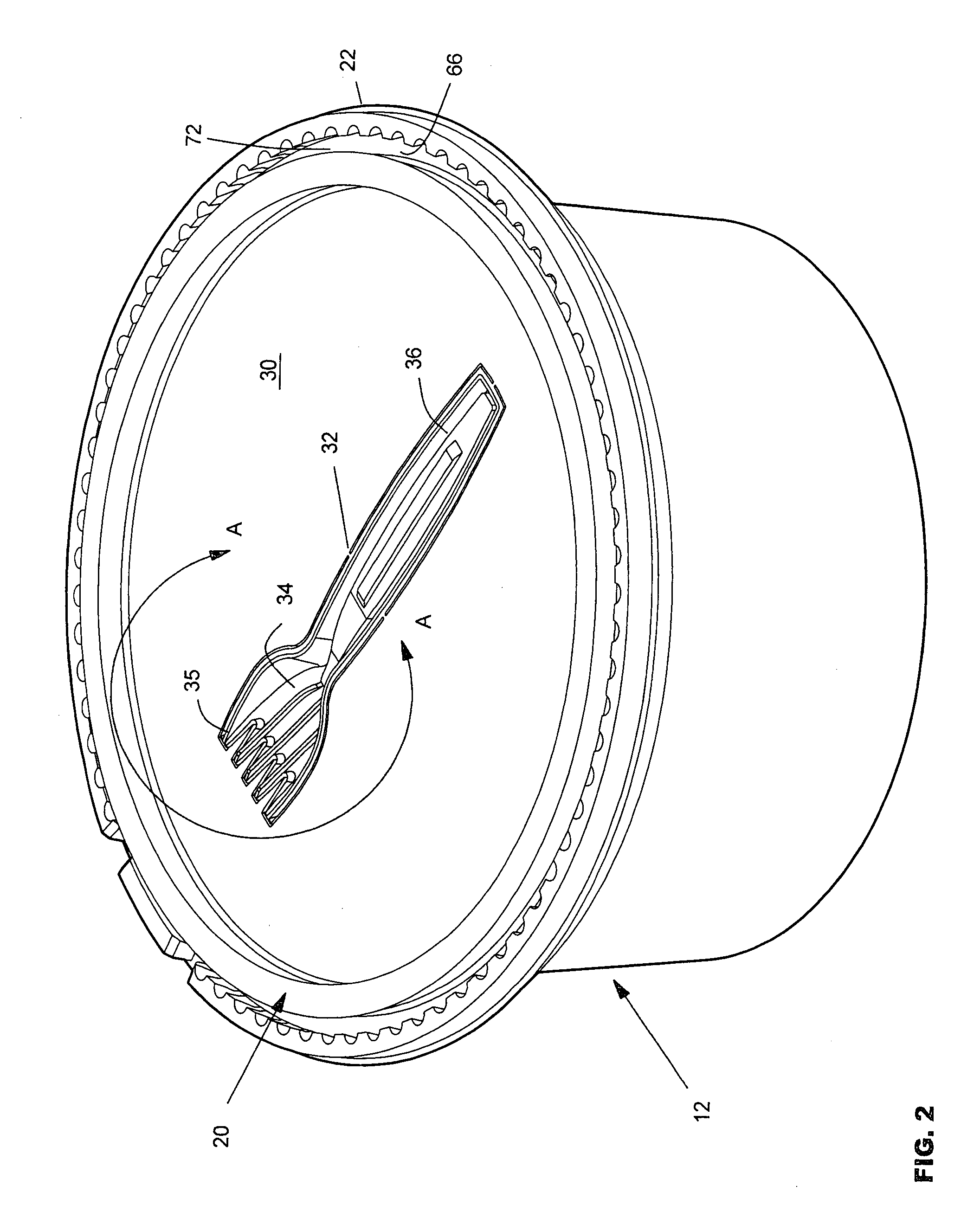

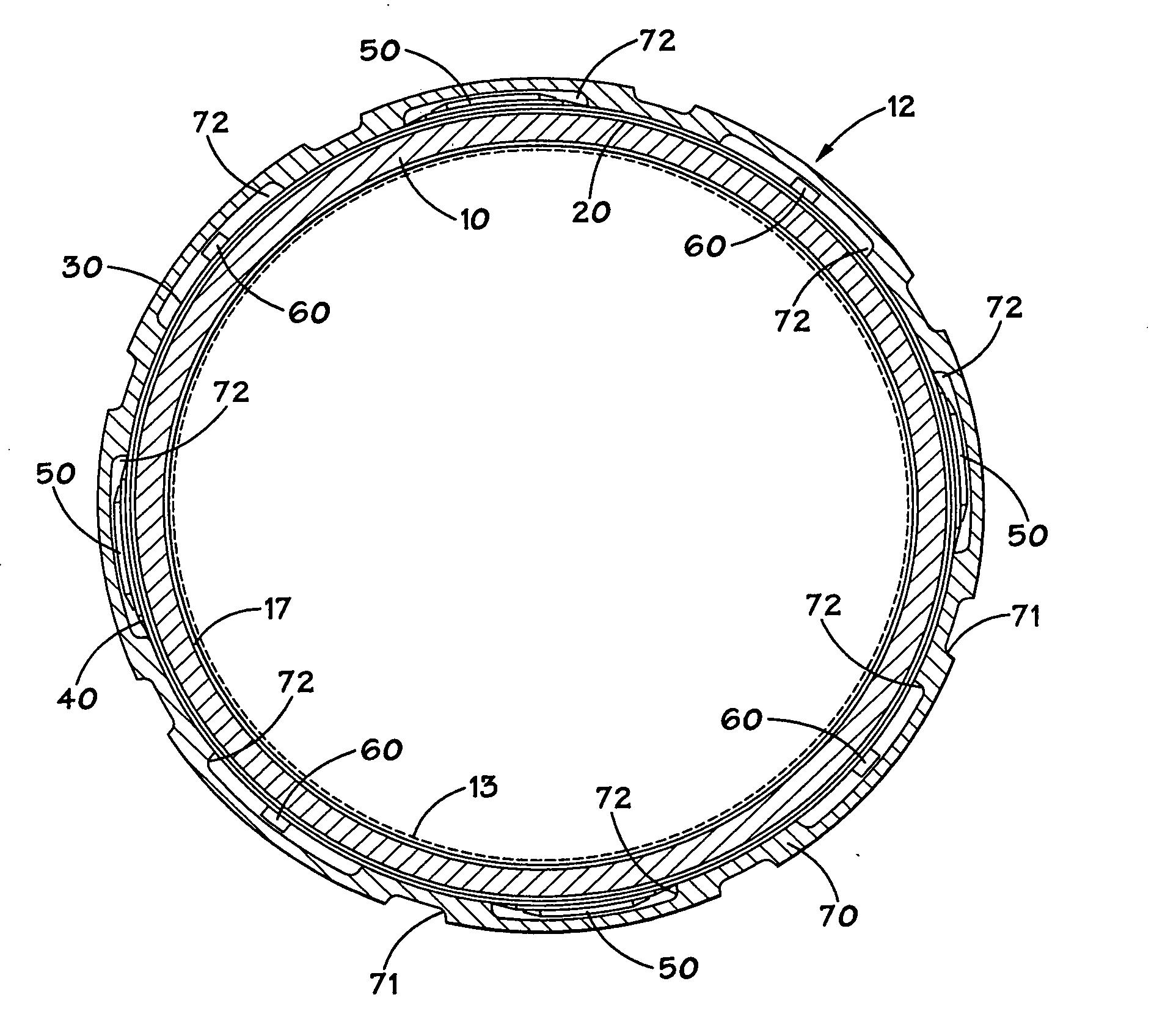

Convenient food container

A food container includes a base (12) with a food-holding cavity (14) and a lid (20) that closes the cavity, each formed of plastic sheeting. The lid defines an eating utensil (32) such as a fork, by a breakaway line that extends around the utensil and that can be easily broken to remove the utensil. The base has radially inner and outer upstanding flanges (64, 62) and an upwardly-opening base groove (66) between them that receives a lid lip (72). At an initial opening section (60) that occupies less than one-fifth of the container perimeter, a section (62A) of the outer base flange is partially separated from the rest of the base by a cut (80) extending along the base groove and by opposite breakable lines. At that section, the inner base flange (64A) is of reduced width to provide more room for a person to grasp the lid, and there is also a smaller interference fit between the base inner flange with walls of the lid groove.

Owner:PWP INDS

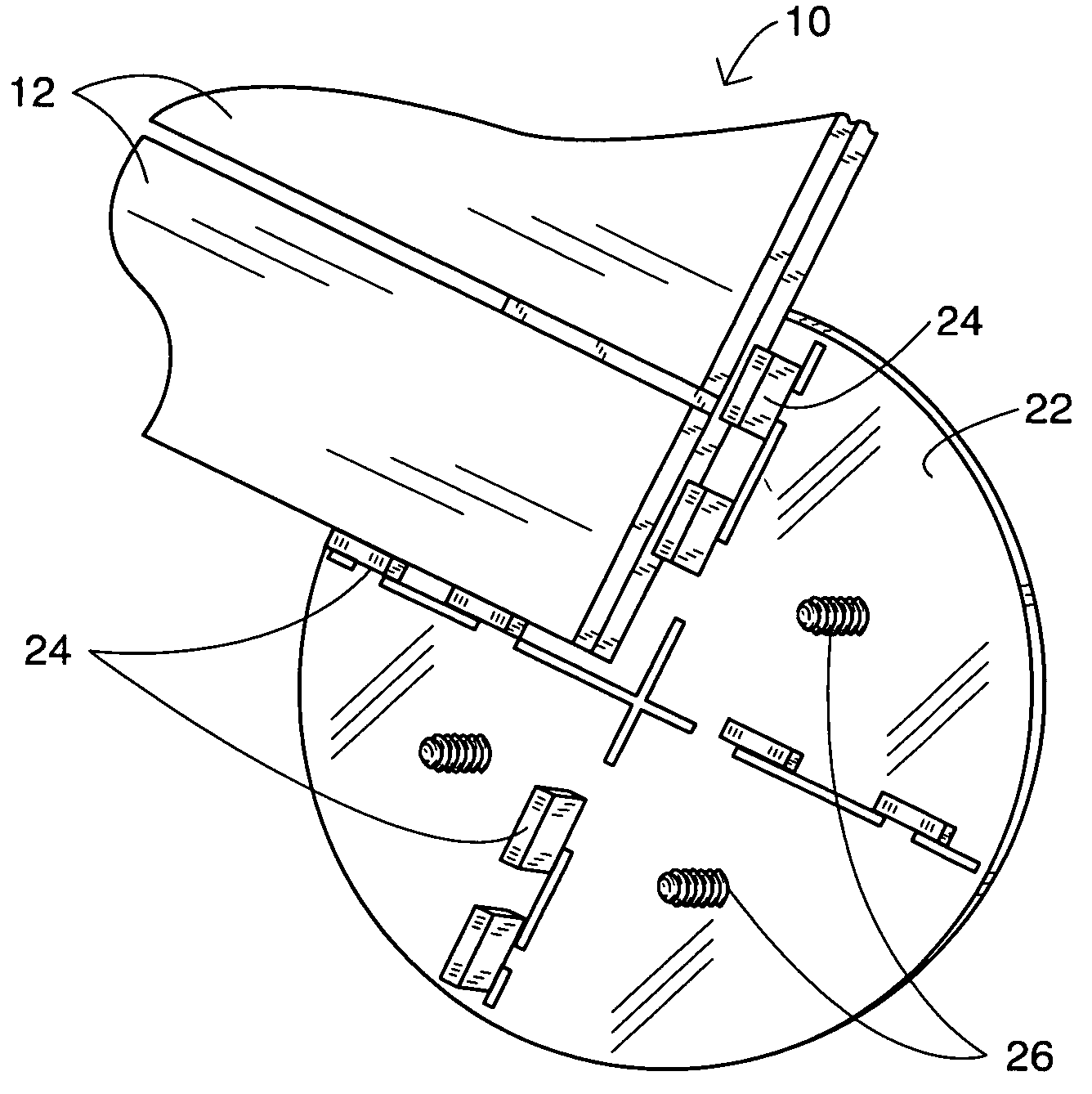

Methods and systems for in situ manufacture and installation of non-metallic high pressure pipe and pipe liners

ActiveUS20090308475A1% coveragePrevent intrusionPipe elementsFlexible pipesNuclear engineeringSubject matter

Pipe with a liner or core pipe and a liner or core pipe which is insertable into a host pipe, the liner or core pipe including, in certain aspects, a pipe made of temperature-resistant non-metallic corrosion-resistant material; first and second strengthening wraps around the pipe; a plurality of spaced-apart axial strength members or pulling tapes on the pipe; and a protective outer wrap on the pipe. This abstract is provided to comply with the rules requiring an abstract which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure and is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims, 37 C.F.R. 1.72(b).

Owner:SMART PIPE COMPANY

Method for preparing liquid seaweed fertilizer

InactiveCN104447008AReduce moistureEasy to breakOrganic fertilisersLiquid fertilisersBULK ACTIVE INGREDIENTHigh activity

The invention discloses a method for preparing a liquid seaweed fertilizer. The seaweeds serve as raw materials, and the method sequentially comprises the following steps: pulping and crushing fresh seaweeds or soaking and swelling dried seaweeds for pulping and crushing, performing ultrasonic extraction, performing solid-liquid separation, performing alkaline extraction on solid seaweeds, compounding the seaweed extraction solution and common fertilizers, thereby obtaining the liquid seaweed fertilizer. According to the method disclosed by the invention, the extraction efficiency of active ingredients in the seaweeds can be obviously improved, and compared with a traditional chemical extraction method, the method disclosed by the invention has the advantages that because a mild method is adopted, for example, ultrasonic extraction and relatively low temperature and dilute acid / dilute alkali assisted ultrasonic extraction are adopted, and the alkali extraction time is obviously shortened. According to the process technology, the activity of the active ingredient can be obviously preserved in the extraction process, so that high-activity seaweed extract and products thereof are obtained.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI +1

Fiber Coupling Technique on a Waveguide

ActiveUS20130022316A1Easy to manufactureReduce the difficulty of polishingCoupling light guidesTip positionOptical coupling

An optical coupling assembly for coupling light from an optical fiber including an angled tip into a planar waveguide via a waveguide coupling element is provided. In one embodiment, the optical fiber extends along the planar waveguide with the angled tip positioned such that light propagating in the optical fiber is coupled by the waveguide coupling element to propagate in the planar waveguide in counter propagation with respect to a fiber propagation direction. In another embodiment, the optical fiber includes a tapered peripheral portion tapering toward the angled tip and is disposed over the planar waveguide with the tapered peripheral portion extending therealong such that light propagating in the optical fiber is coupled to propagate in the planar waveguide with either forward or counter propagation. Embodiments of the present invention may be part of various photonic integrated circuits and may be manufactured more easily than known optical coupling assemblies.

Owner:CIENA

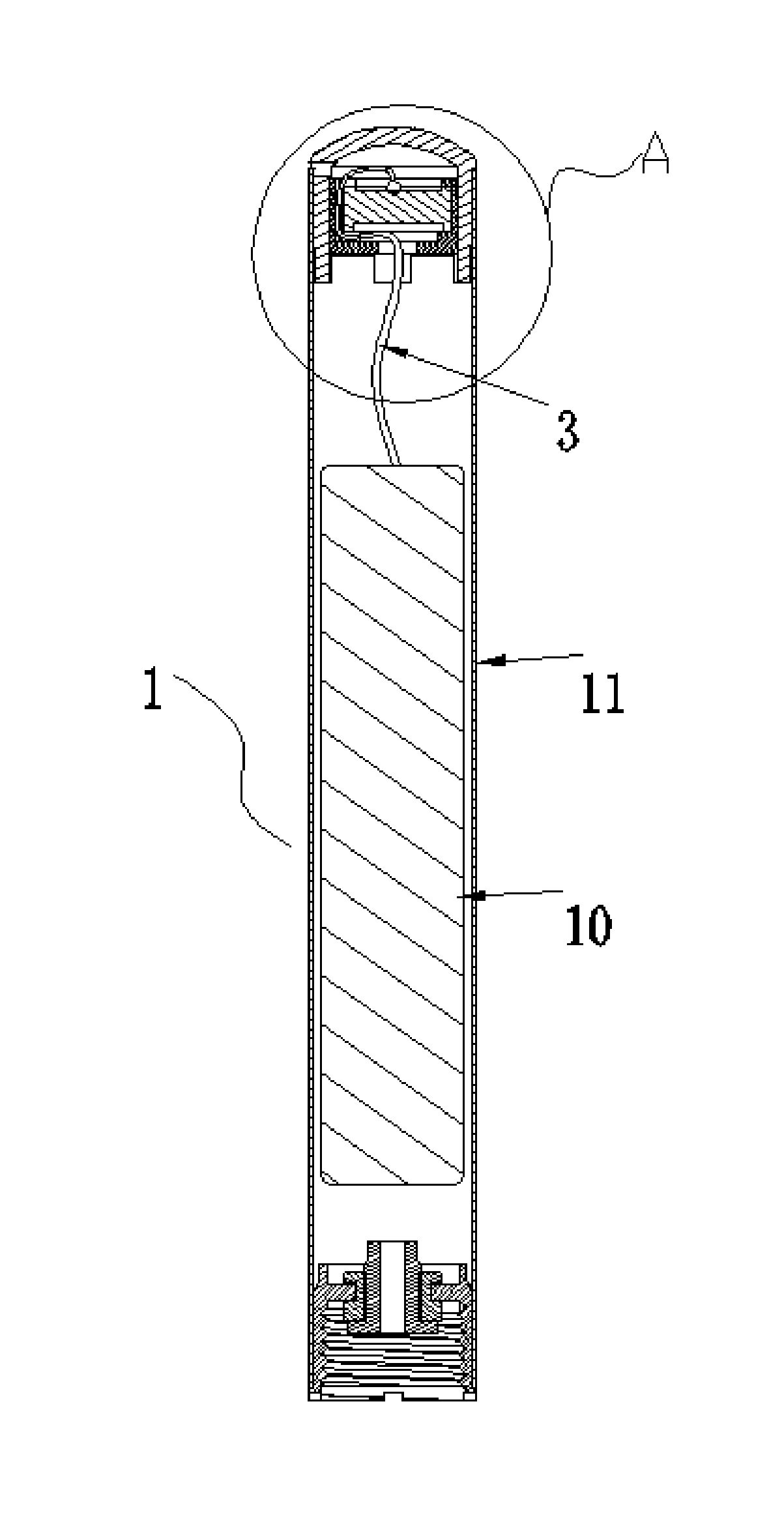

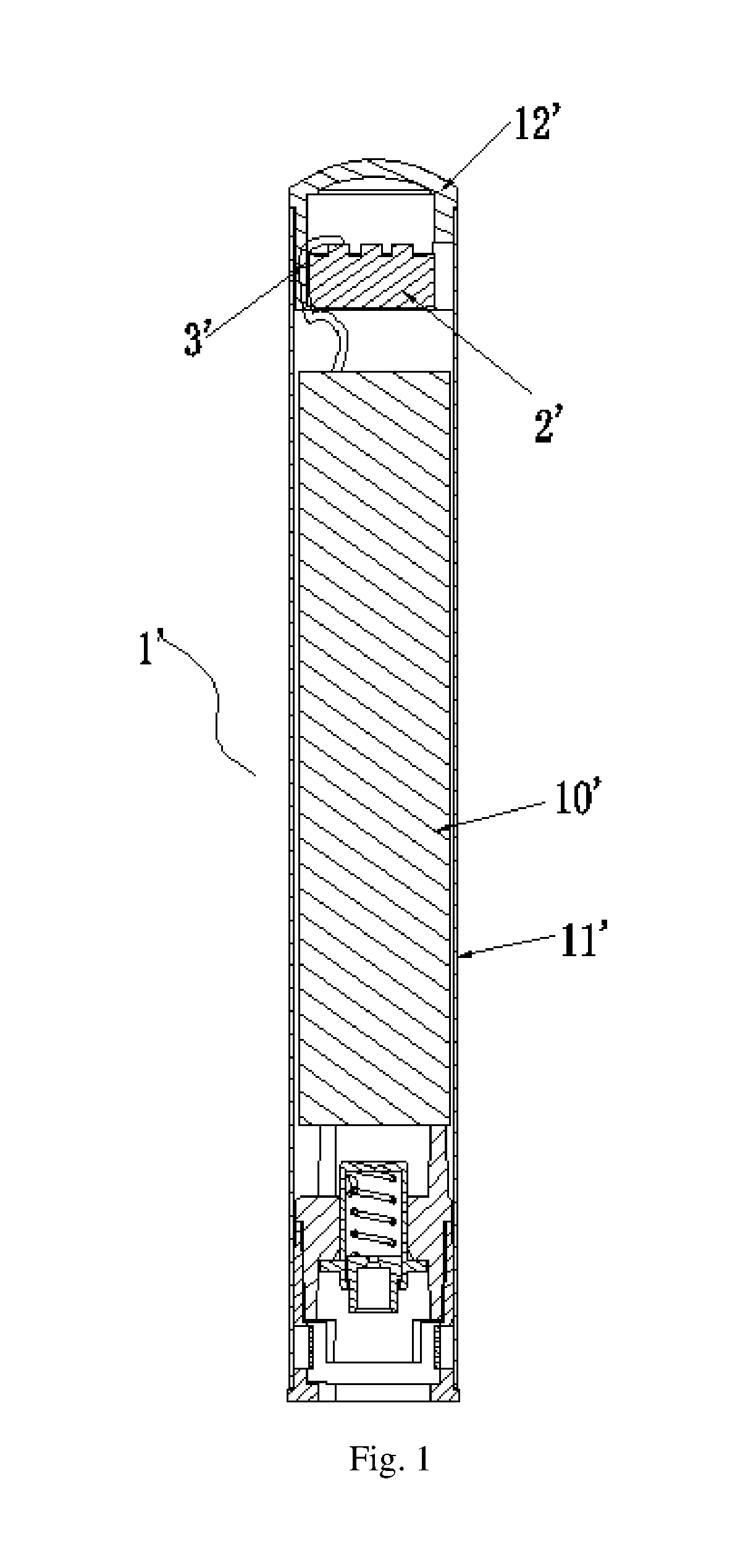

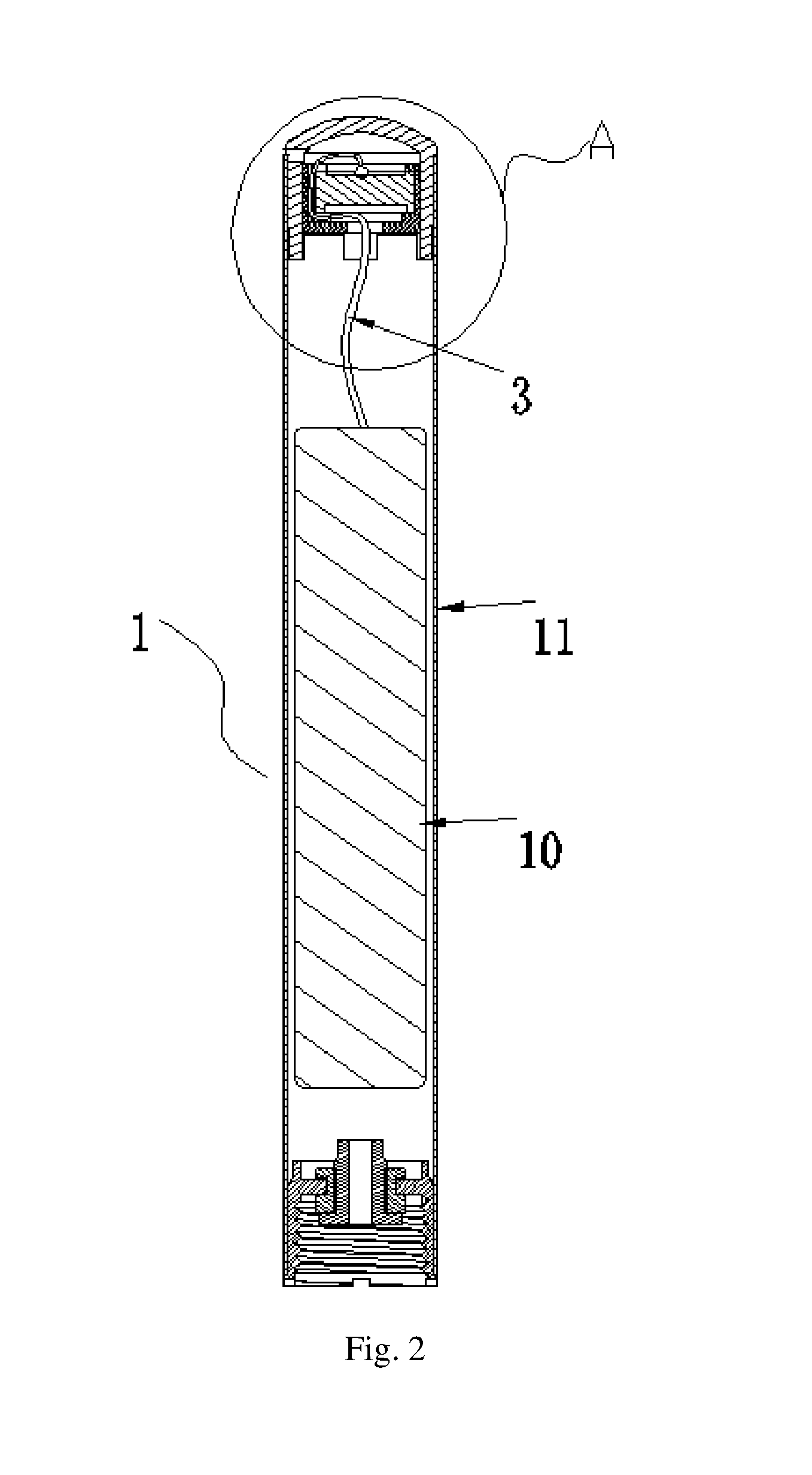

Battery stick, electronic cigarette, and method for assembly of battery stick

InactiveUS20170006919A1Improve sealingEasy to assembleRespiratorsTobacco treatmentElectrical batteryComputer module

A battery rod, an electronic cigarette, and a method for assembling the battery rod, the battery rod comprises a battery casing, a battery, a control module and an end cover; the control module comprises wires and an airflow sensor; the end cover comprises a cover body and a connecting sleeve which is embedded in an elastic installation base; the control module is embedded on the elastic installation base; an outer peripheral surface of the elastic installation base flexibly abuts an inner wall of the connecting sleeve, and an inner peripheral surface of the elastic installation base flexibly abuts an outer peripheral surface of the control module; the wires are flexibly pressed between the control module and the elastic installation base. The elastic installation base is used to ensure the battery rod is airtight and the air flow sensor has a high sensitivity, preventing the wires from damaging the control module.

Owner:HUIZHOU KIMREE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com