Patents

Literature

1761 results about "Cap device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

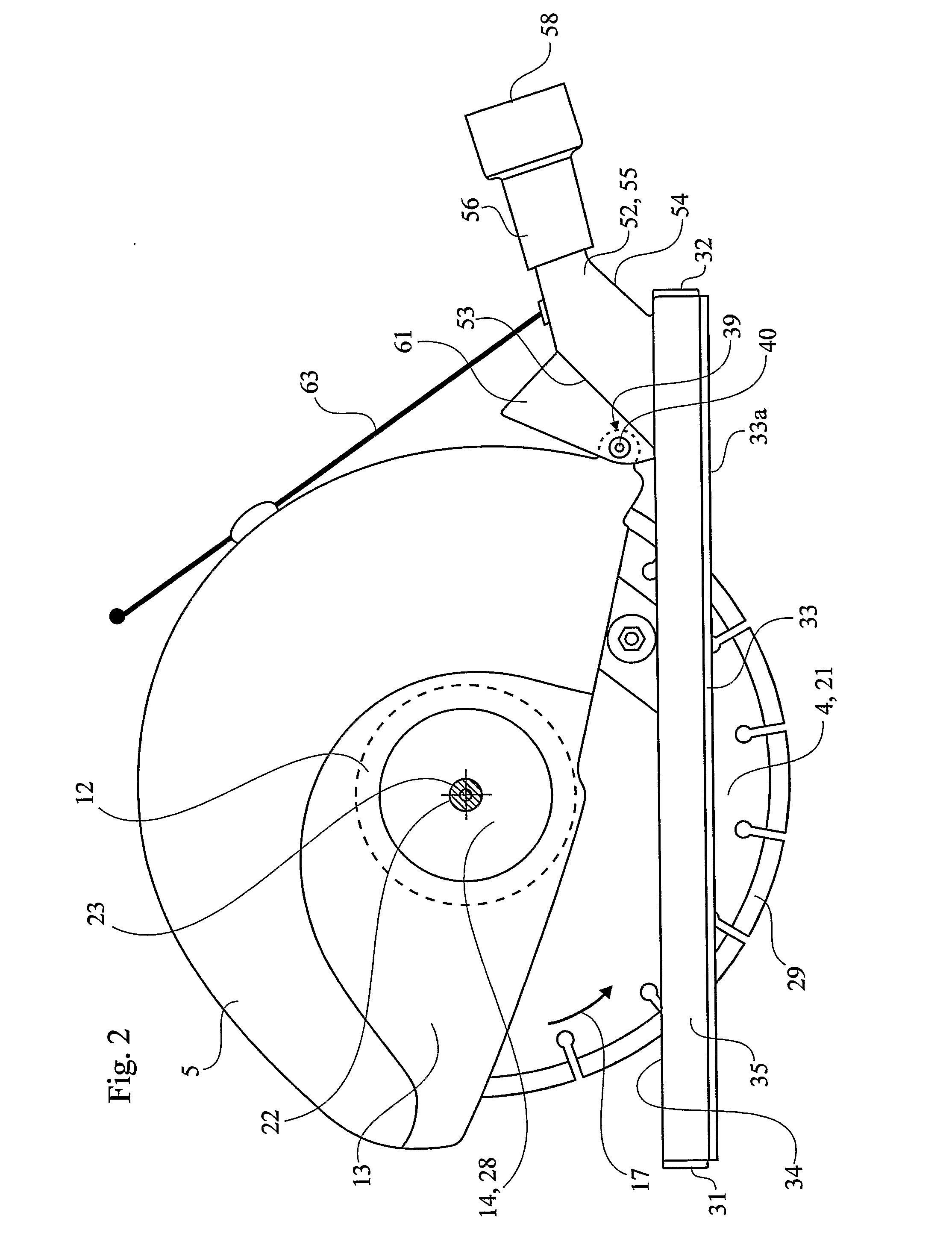

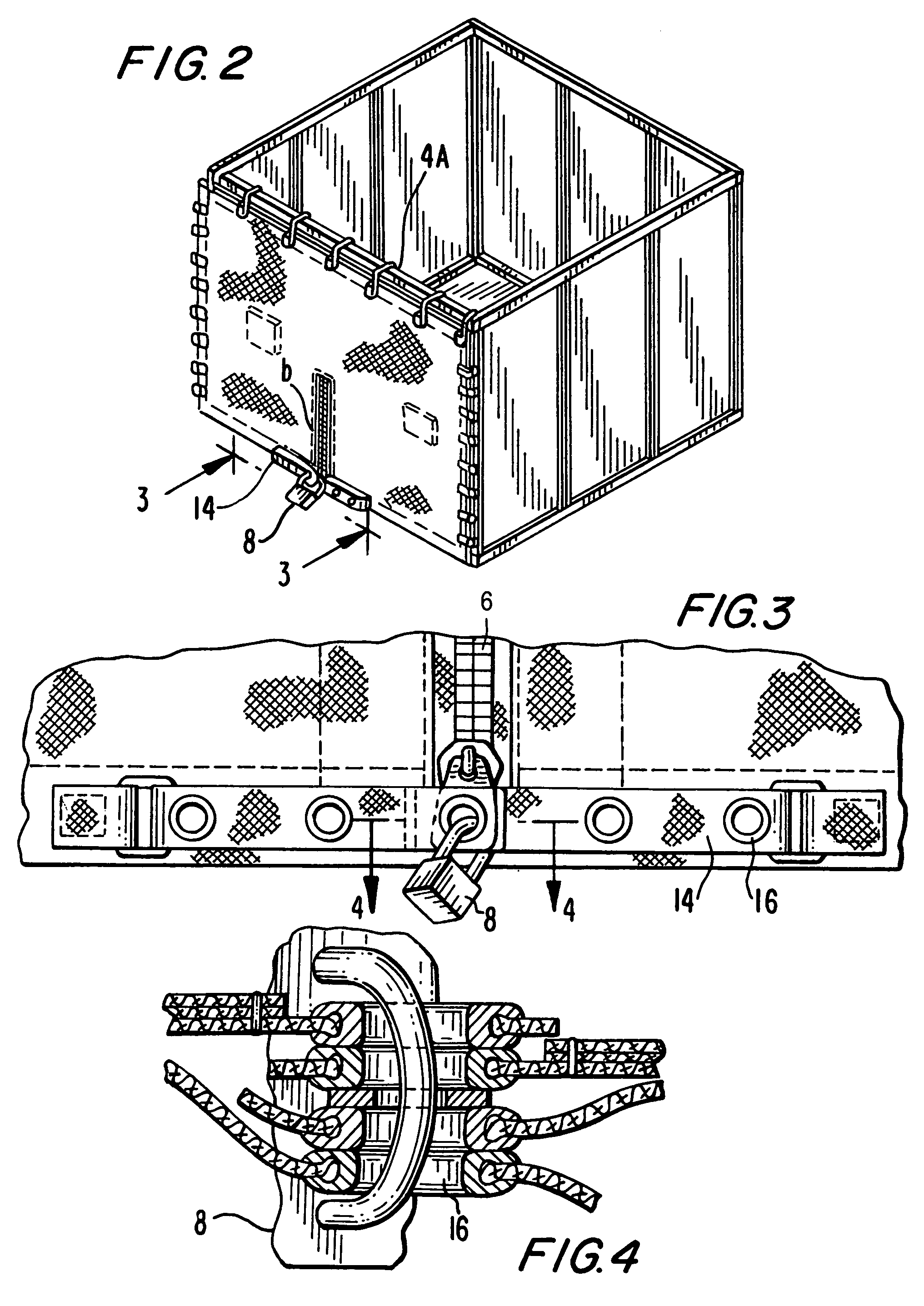

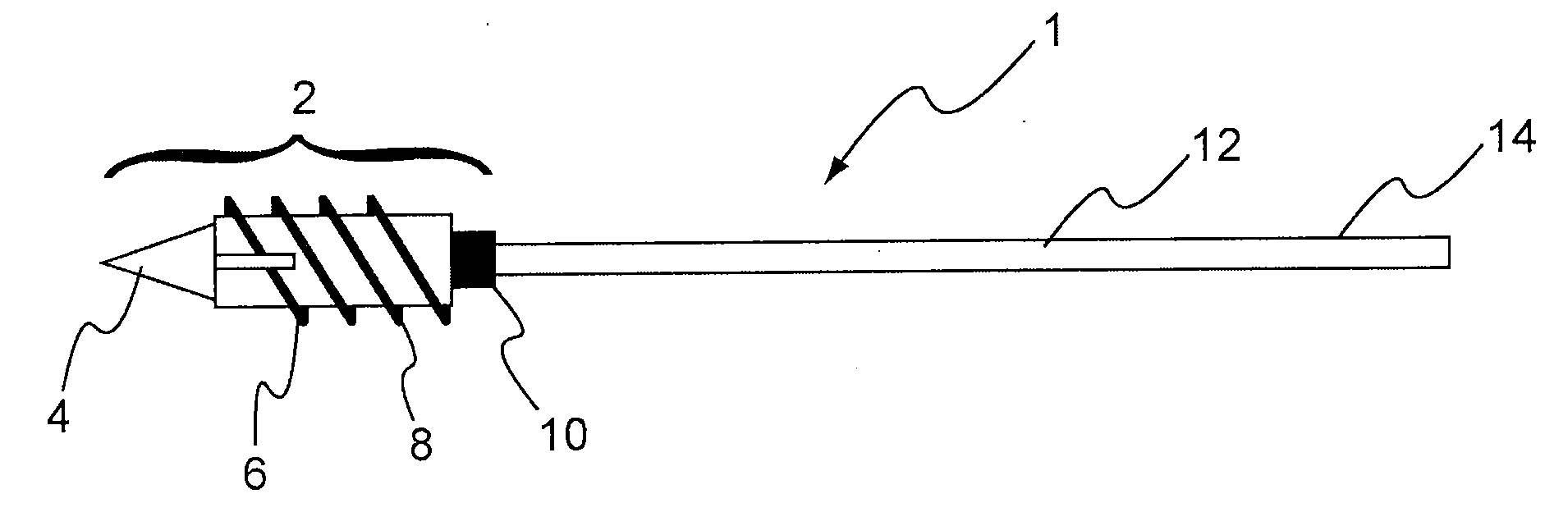

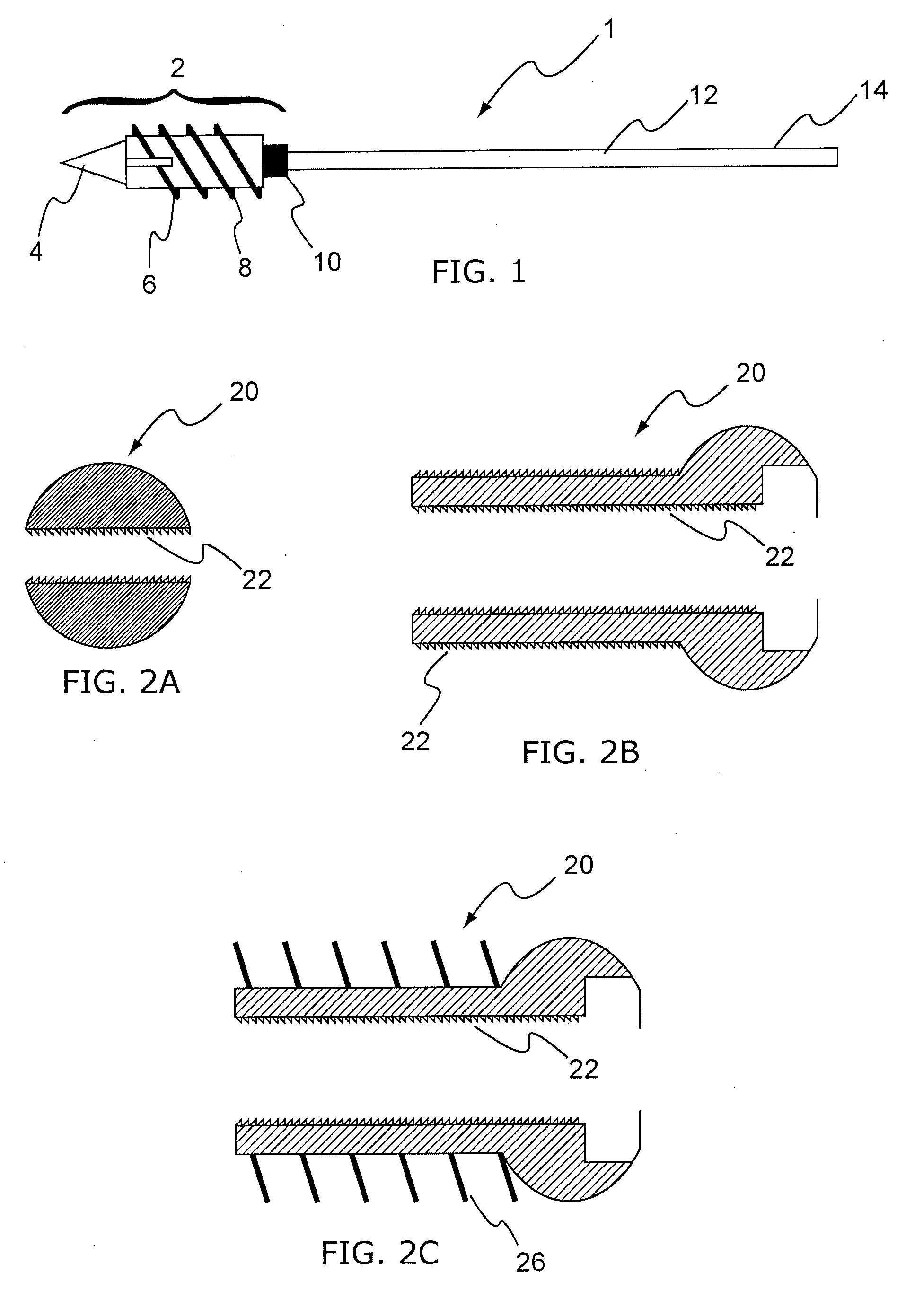

System and method for the fixation of bone fractures

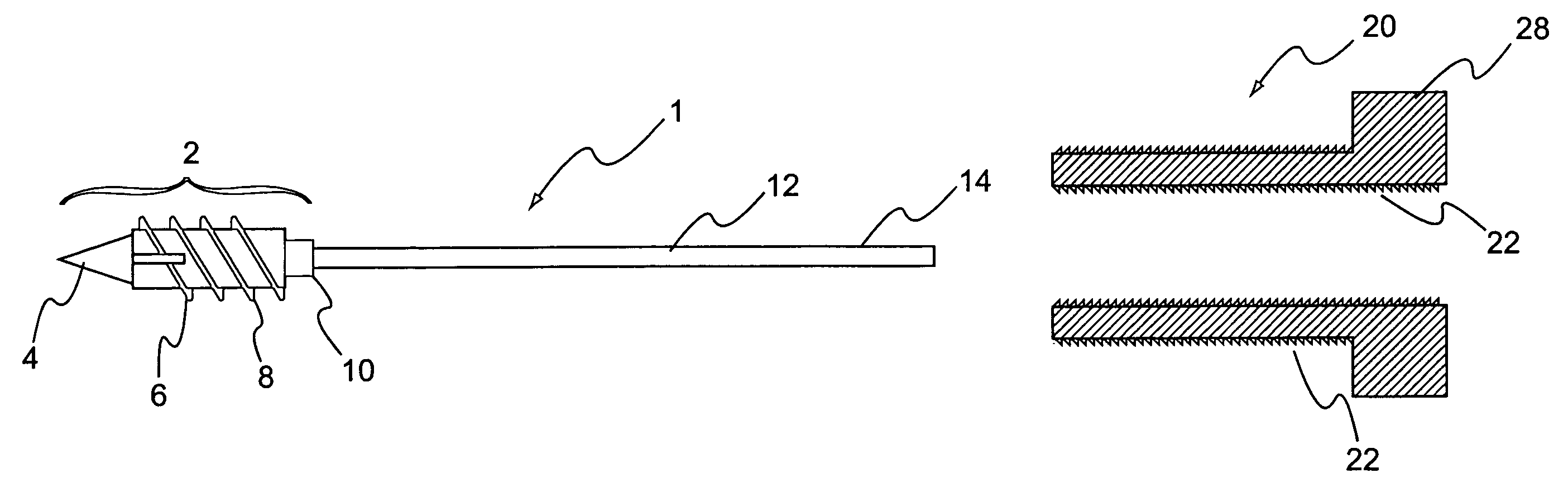

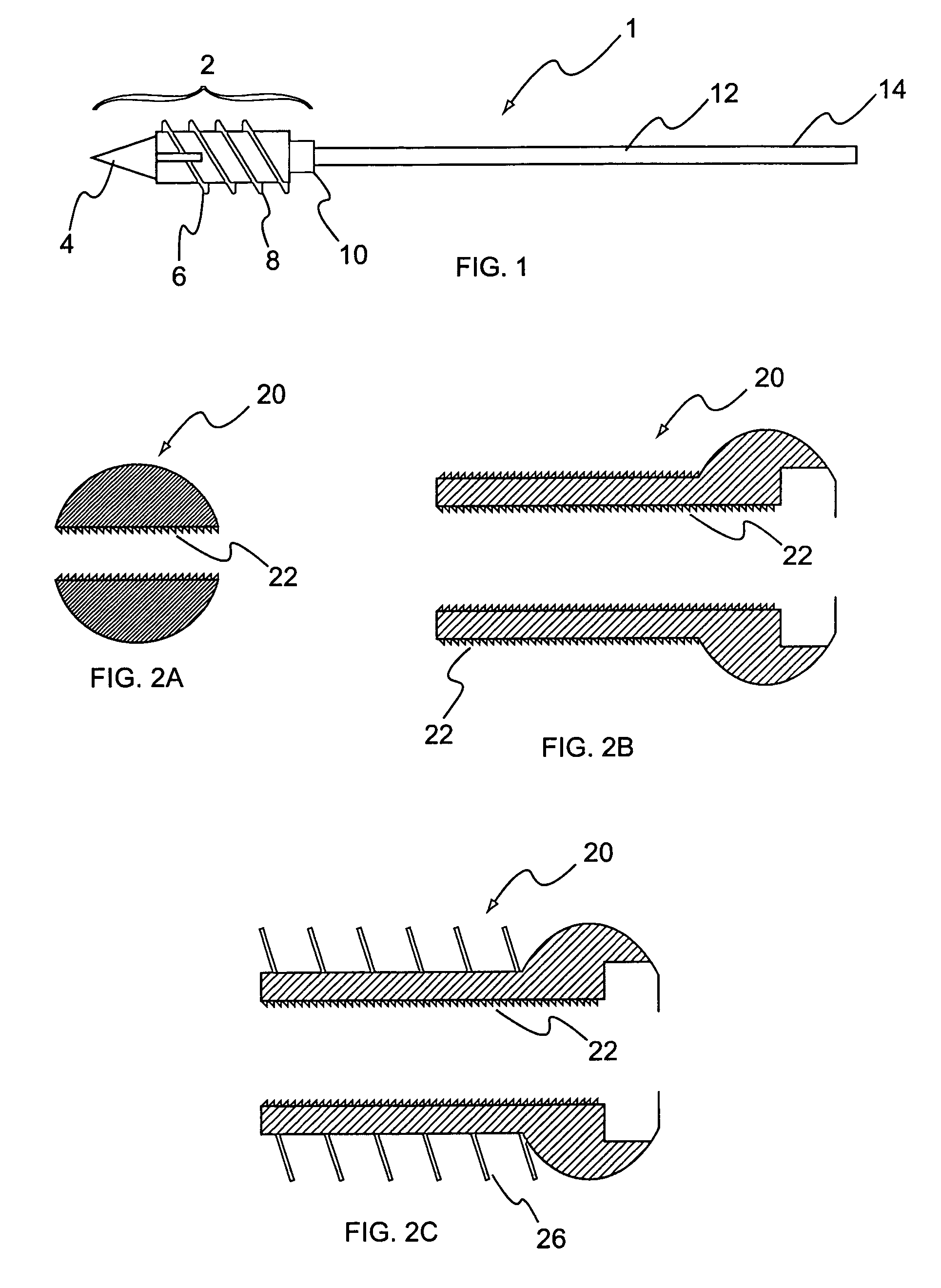

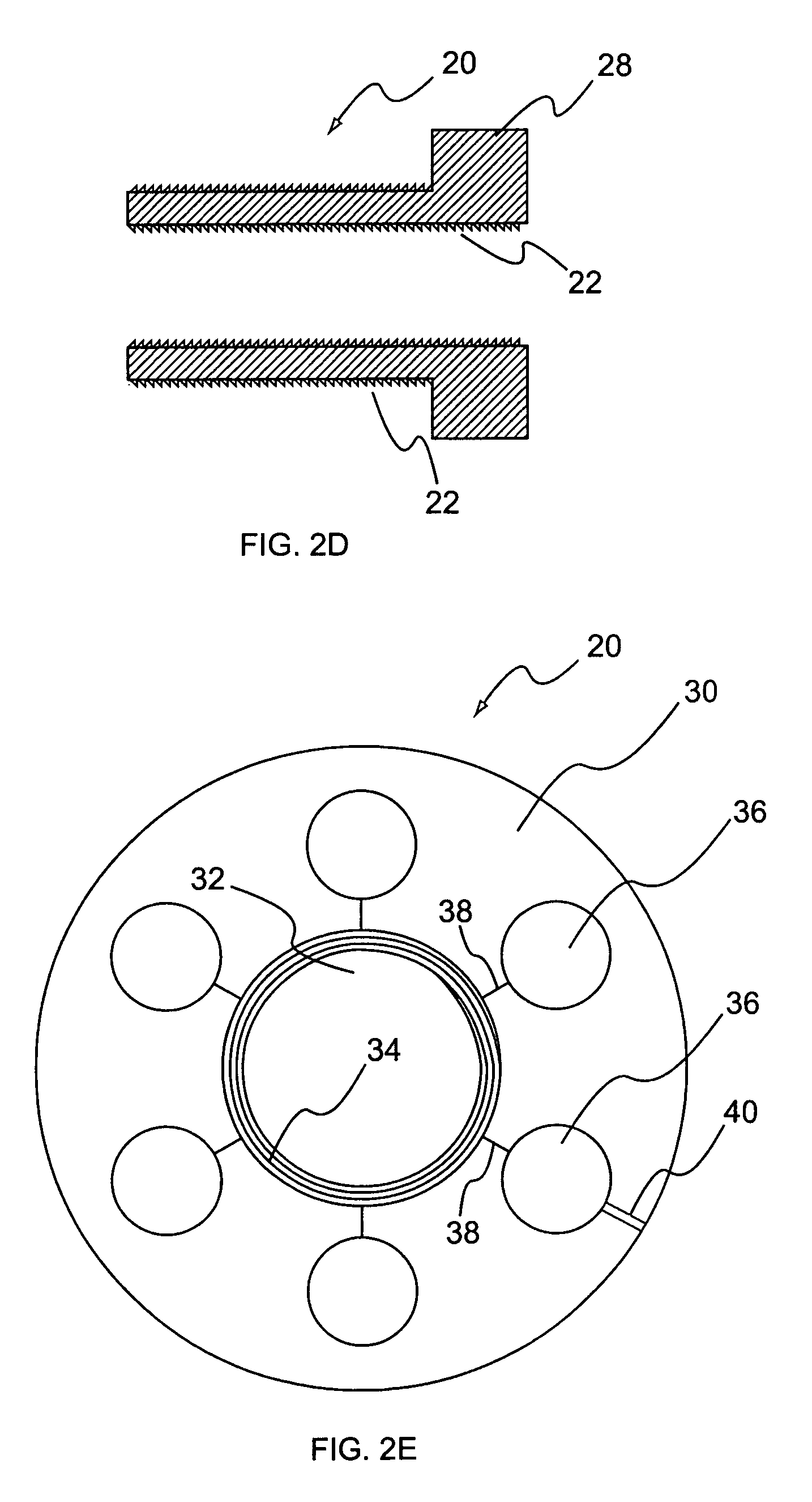

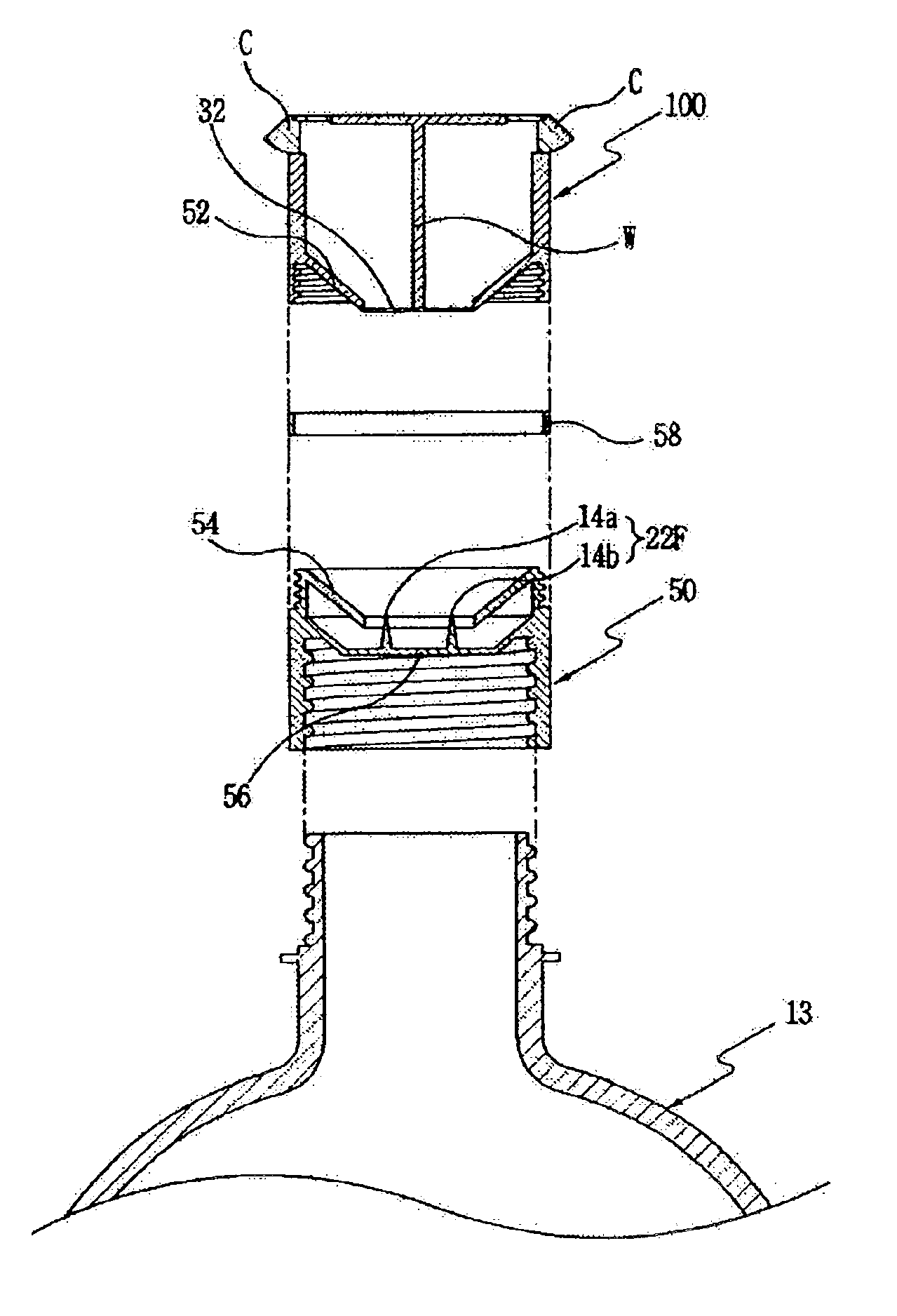

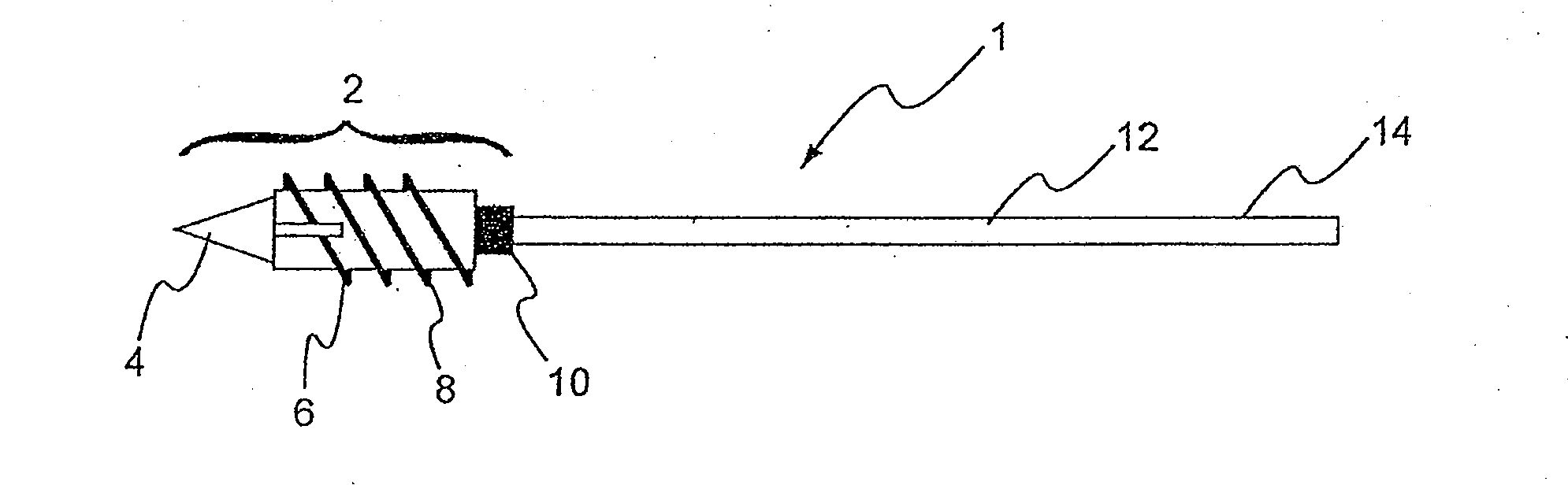

The invention facilitates the fixation of bone fractures. In a particular embodiment, the head component includes a tip, cutting threads and mating threads which are inserted into the far cortex of the bone. A wire extends from the head component and exits from the near cortex. A cap device having a sawtooth inner surface is threaded over the wire having an inverse sawtooth outer surface such that the cap is restricted from backwards movement. Tension is then applied to the wire while the cap is tightened against or within the bone surface to thereby apply an appropriate amount of pressure between the surfaces of the fracture. The excess wire beyond the cap can then be removed.

Owner:ORTHOIP

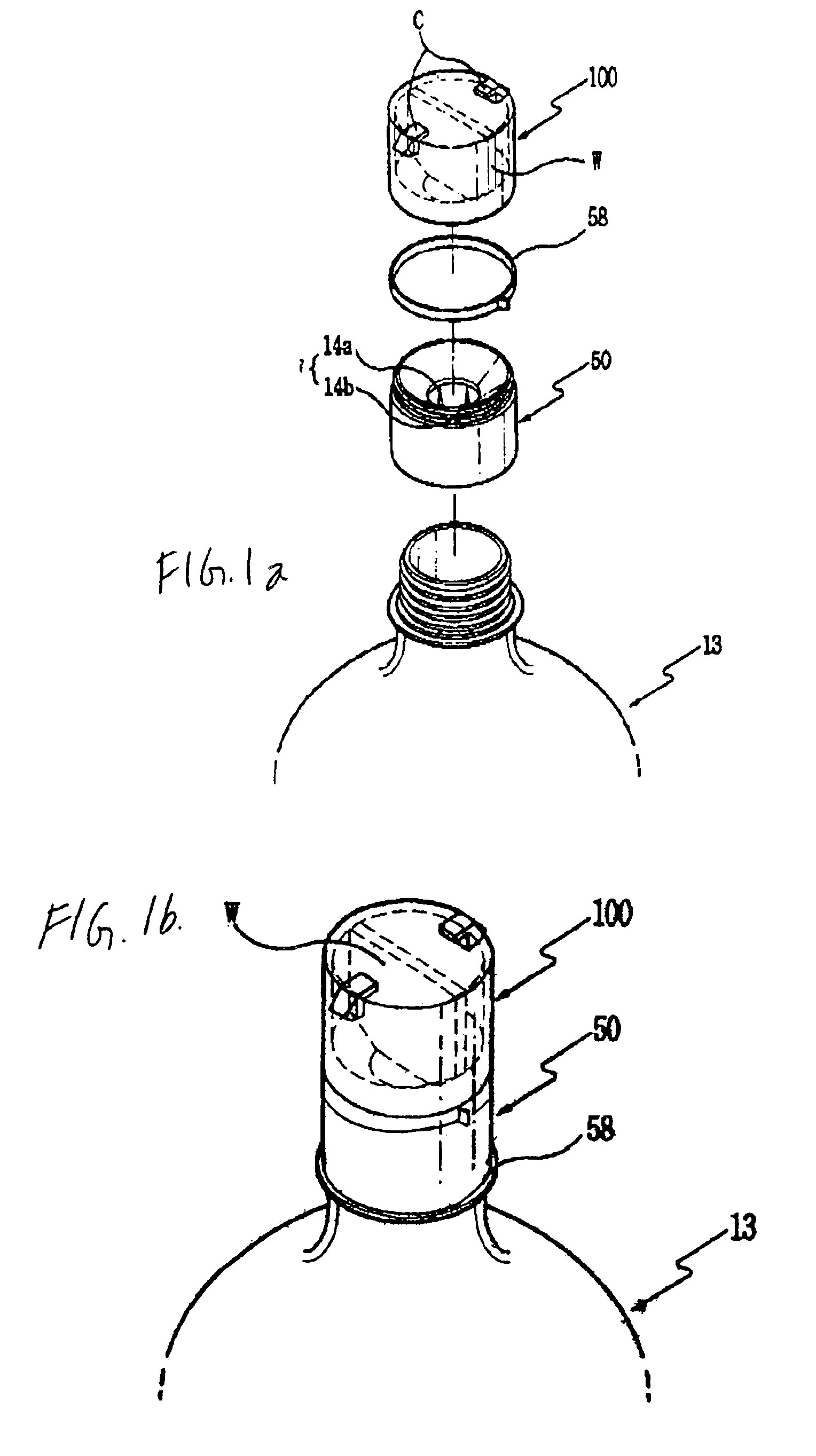

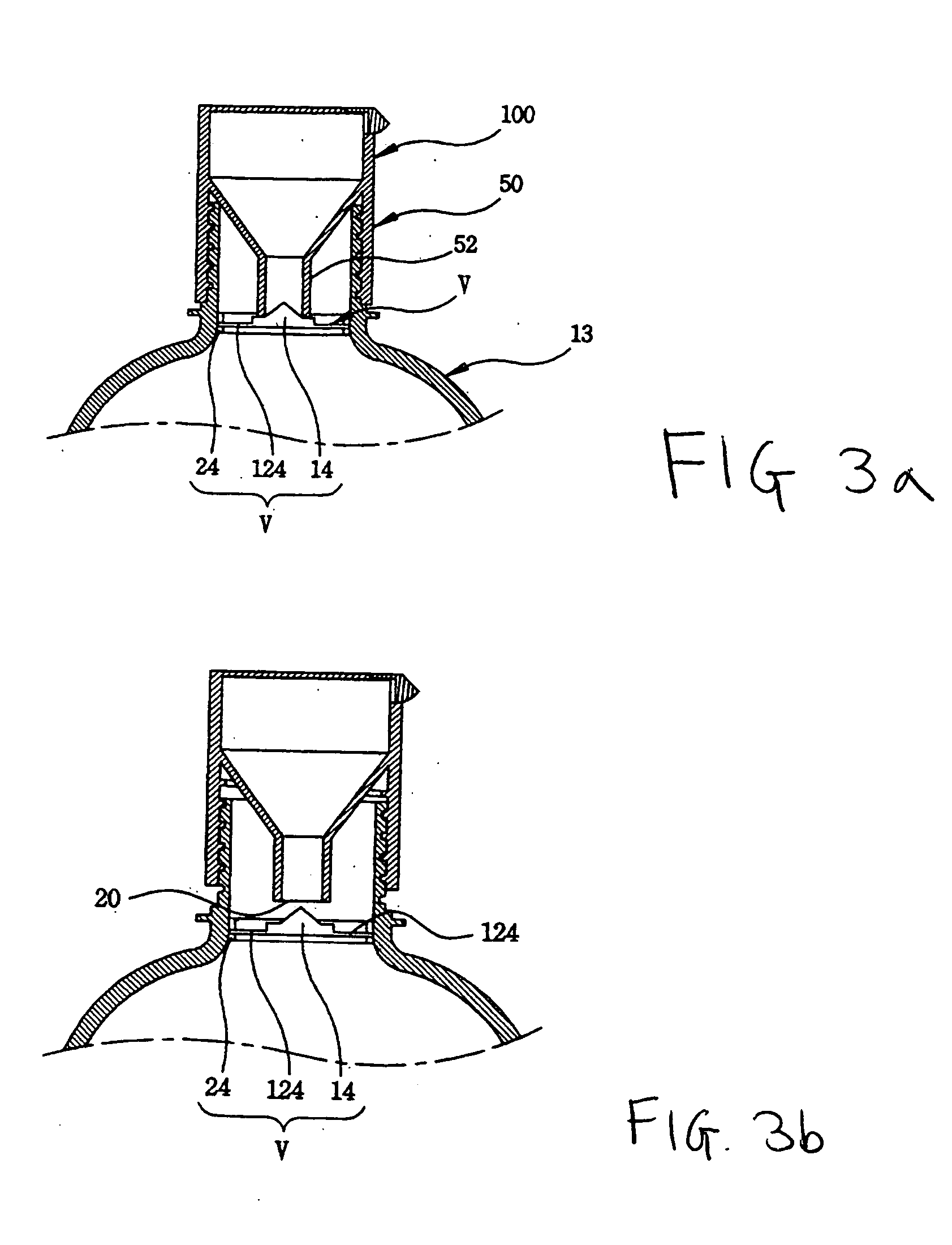

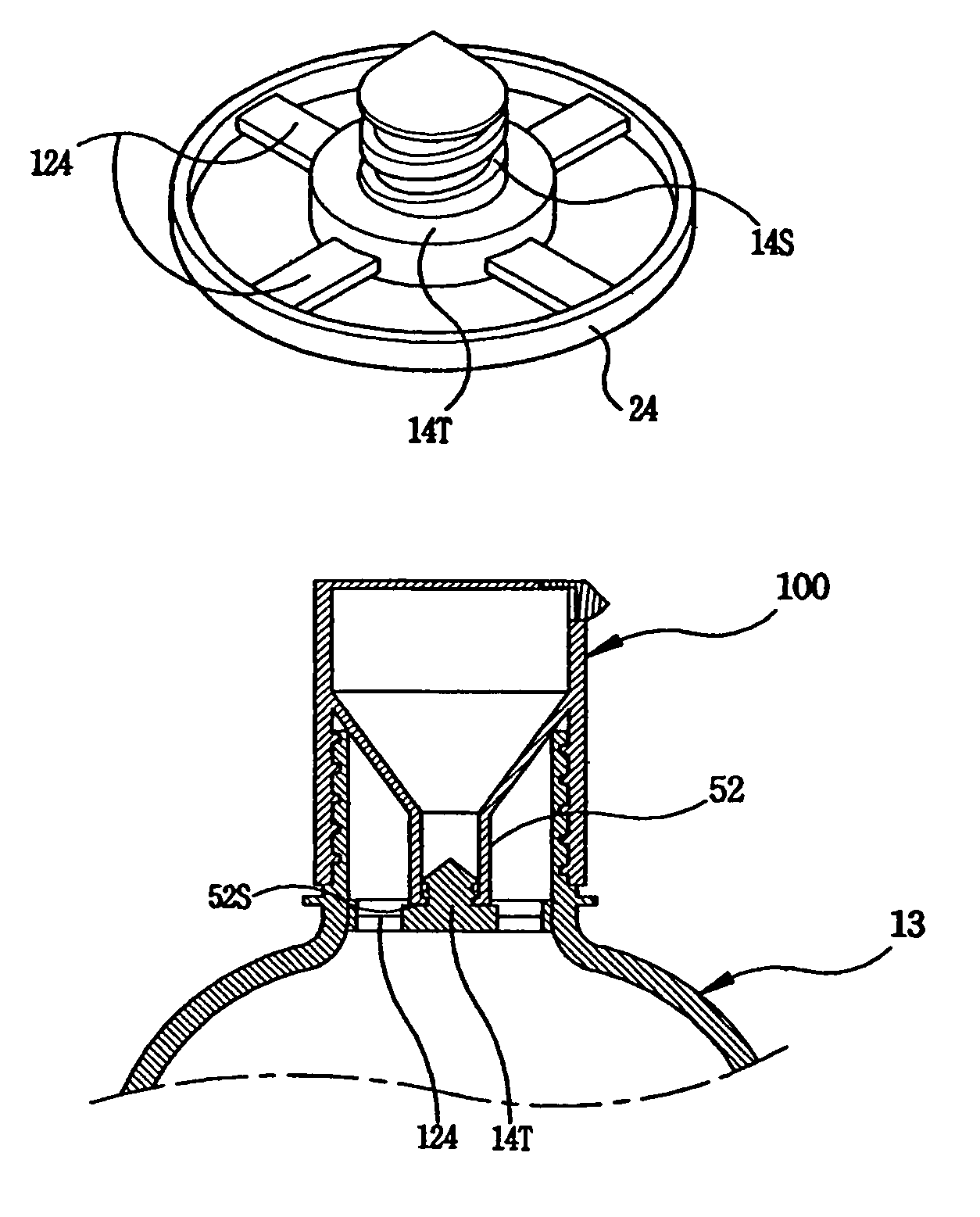

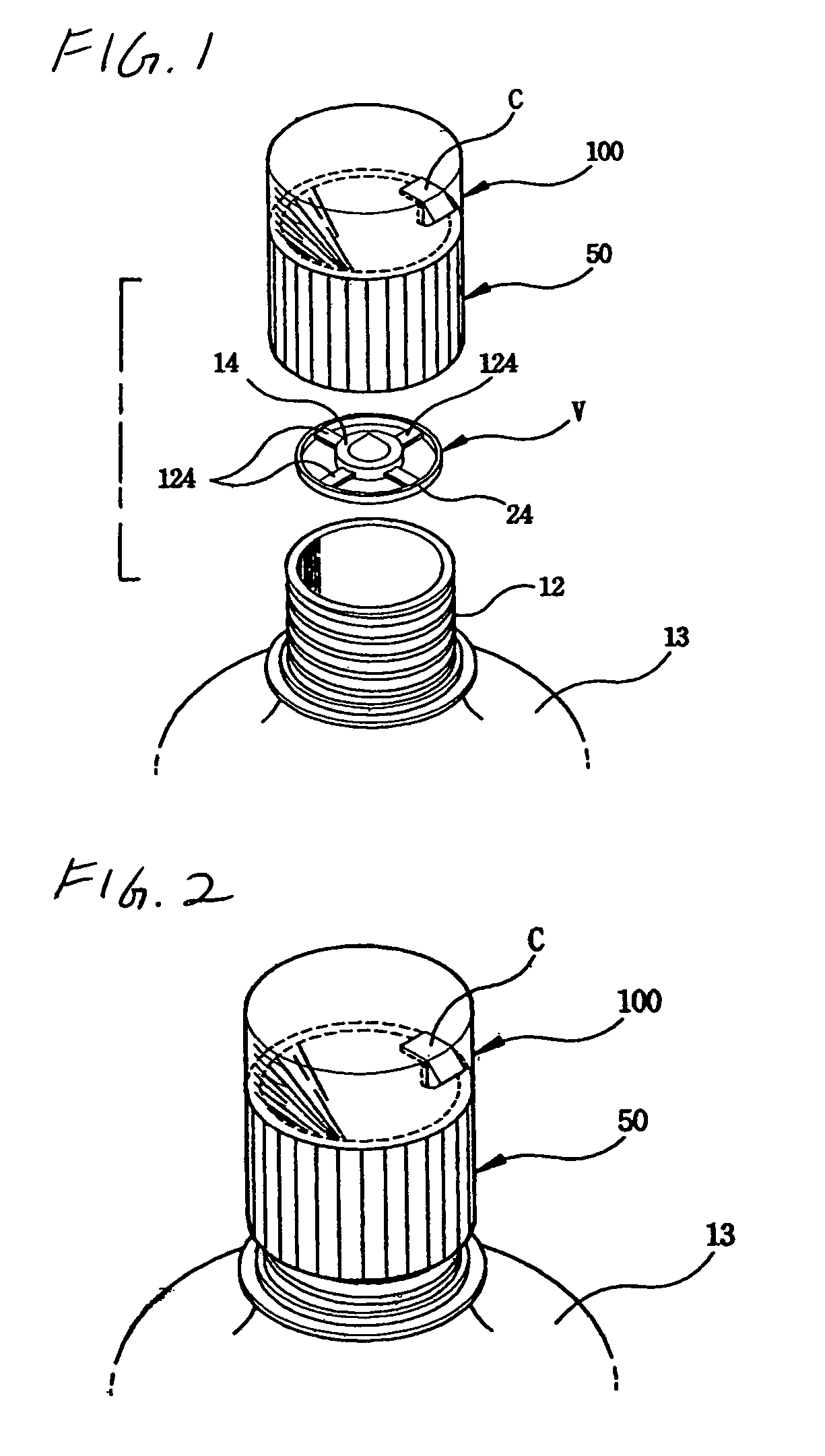

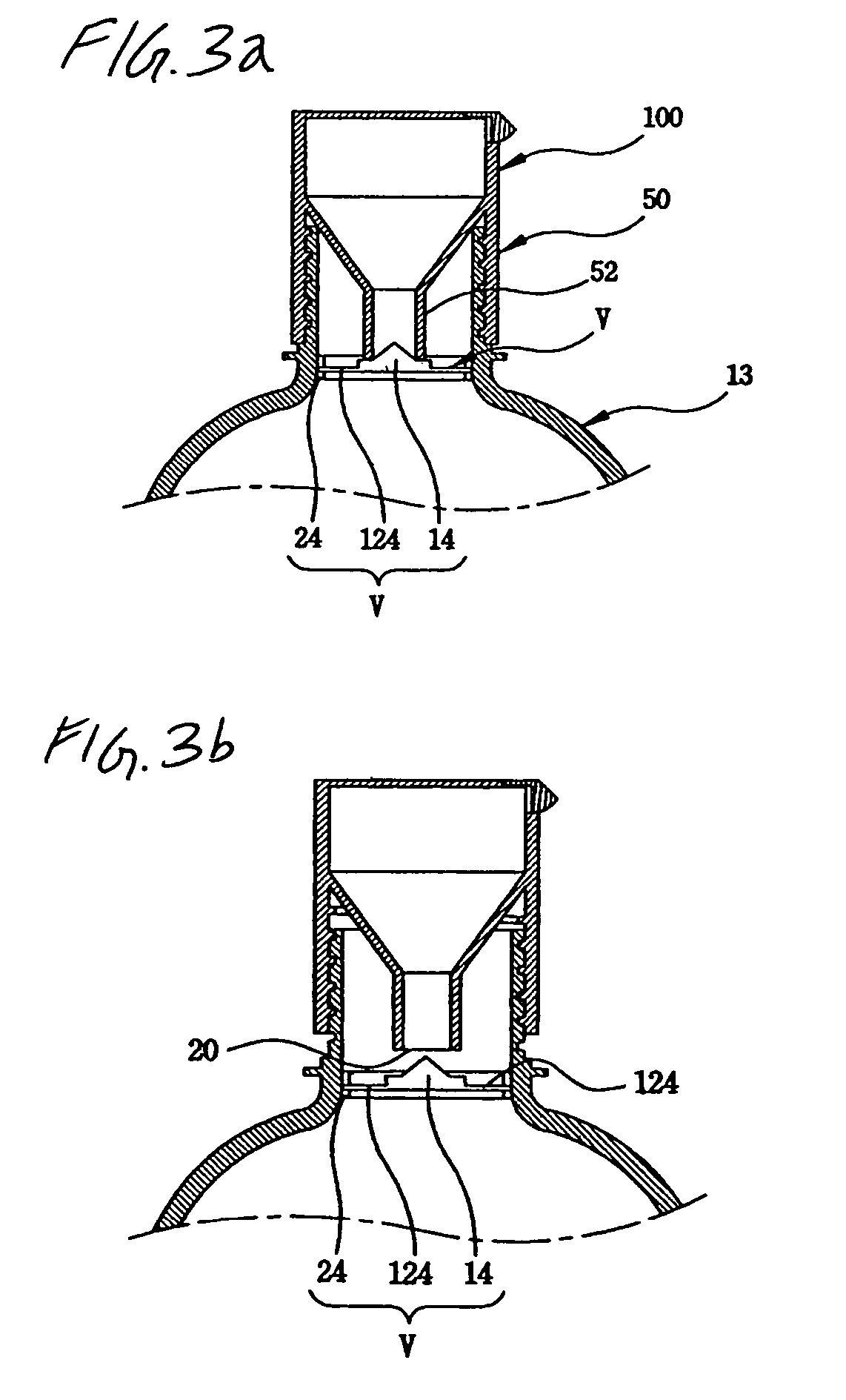

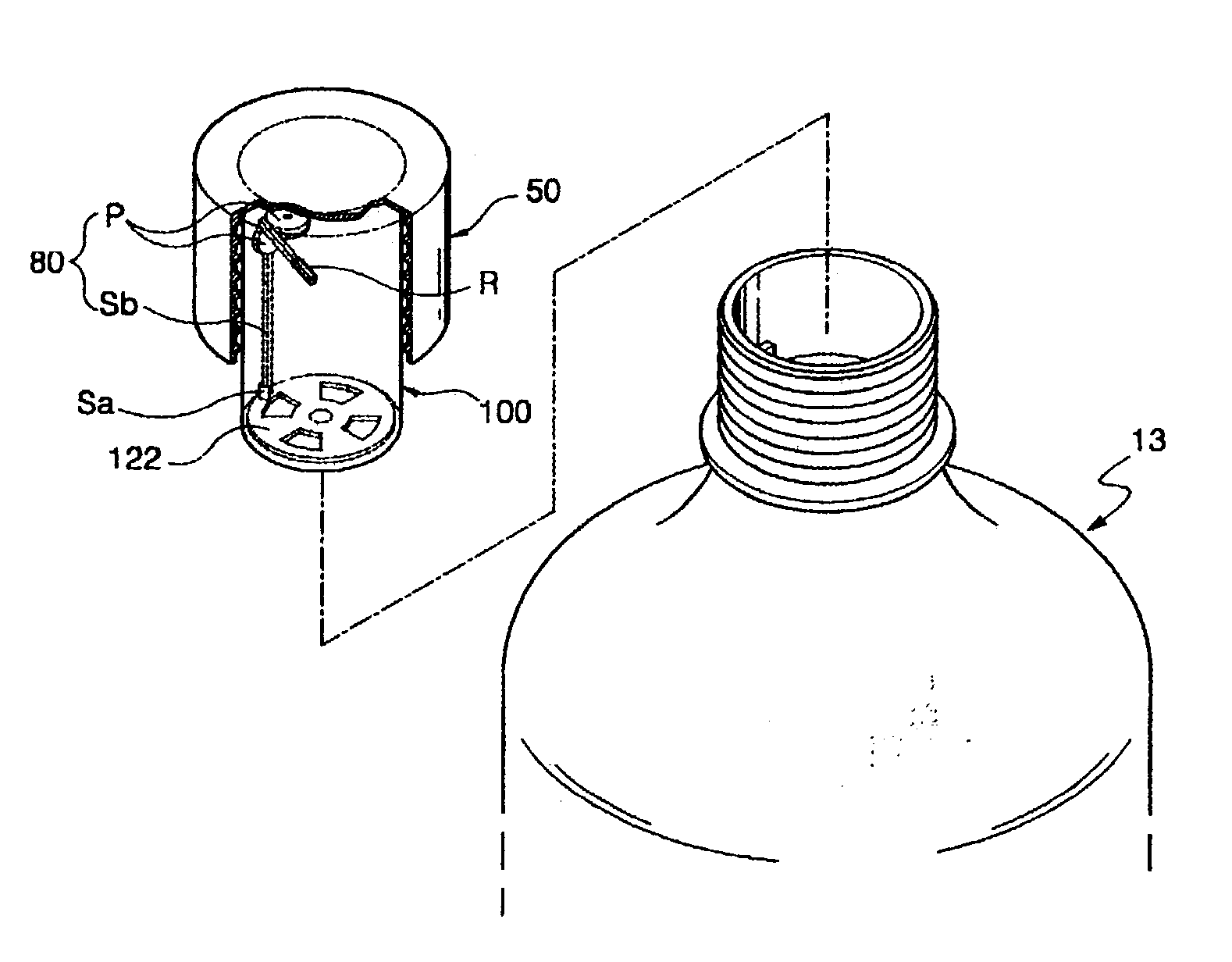

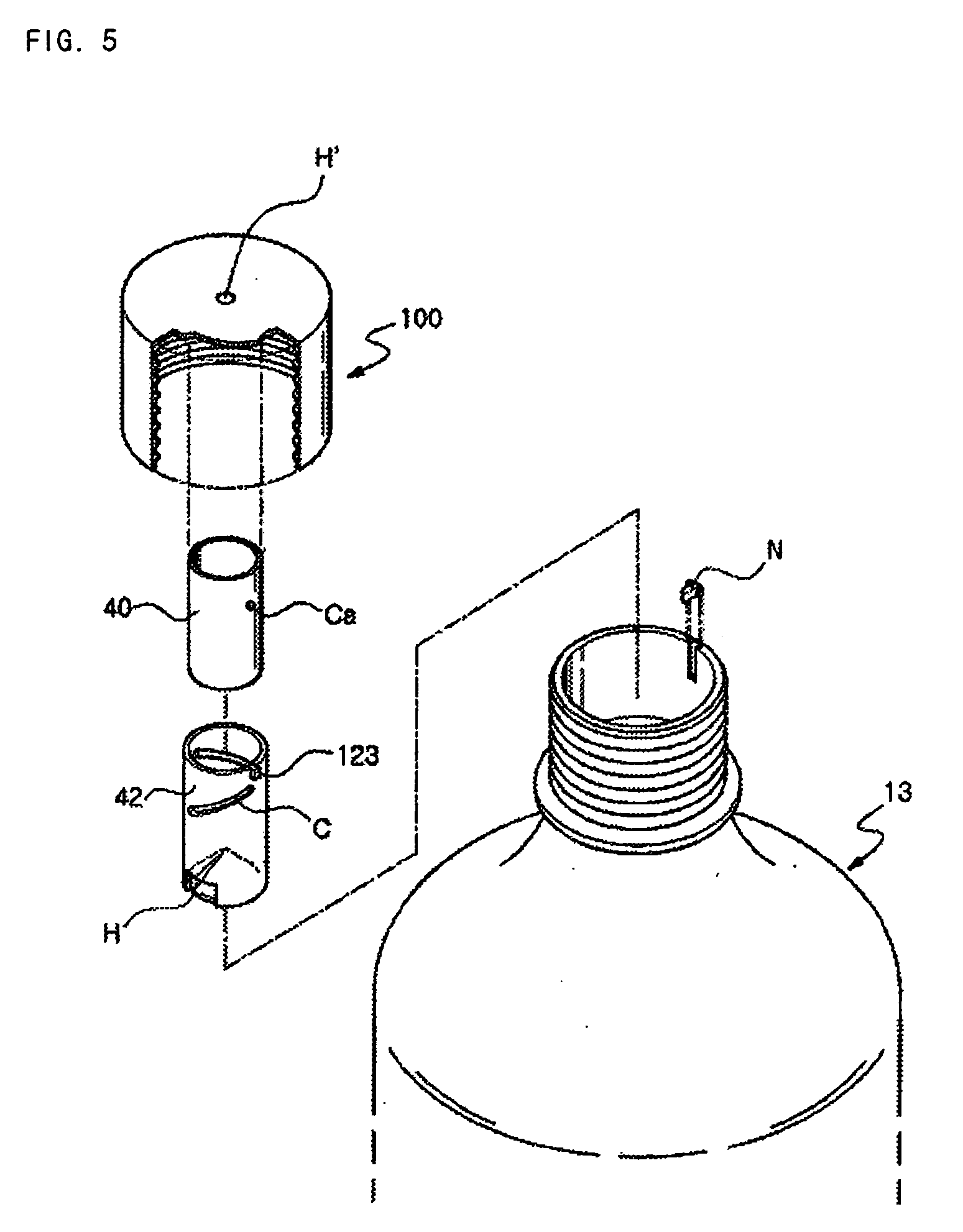

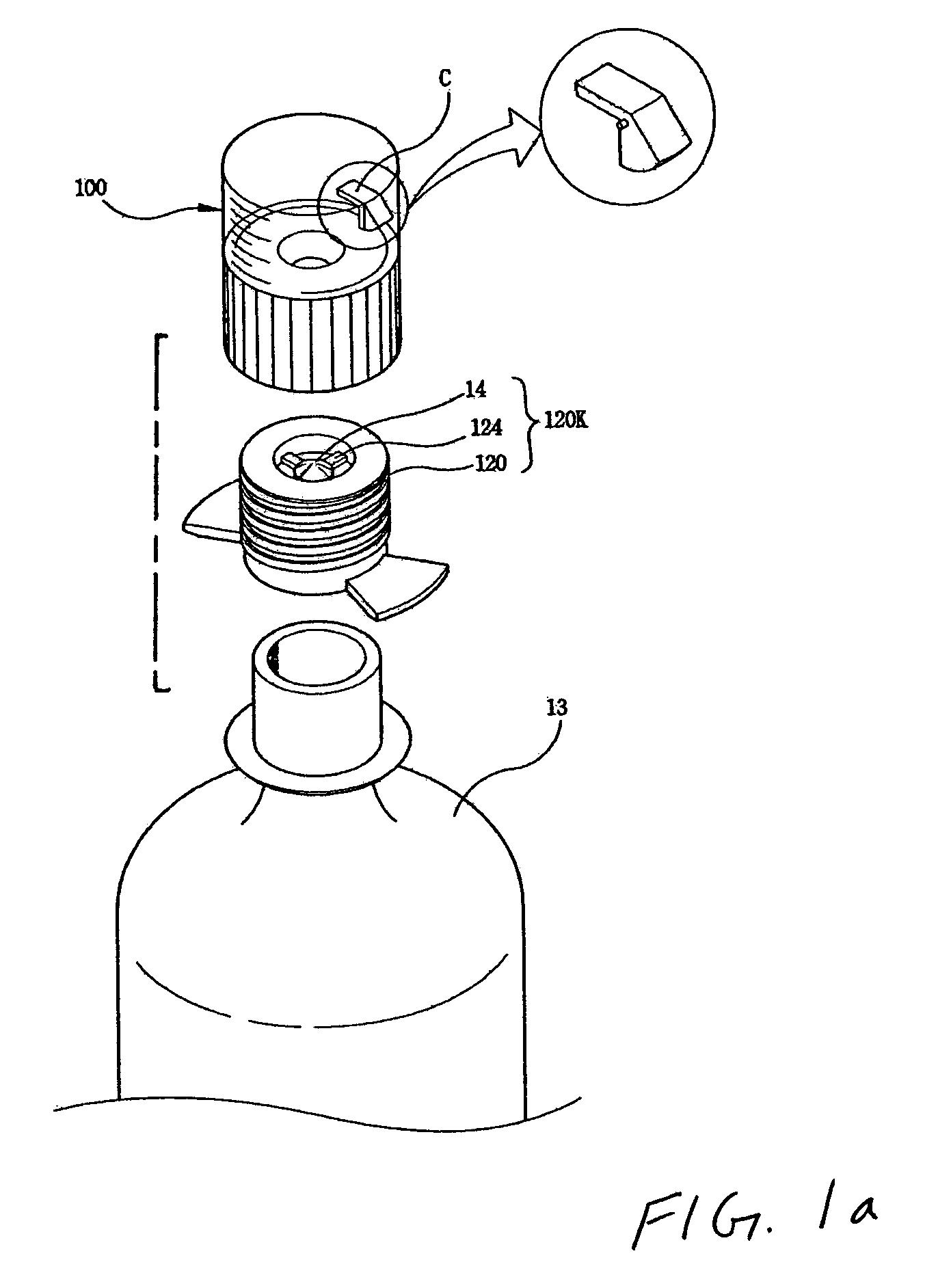

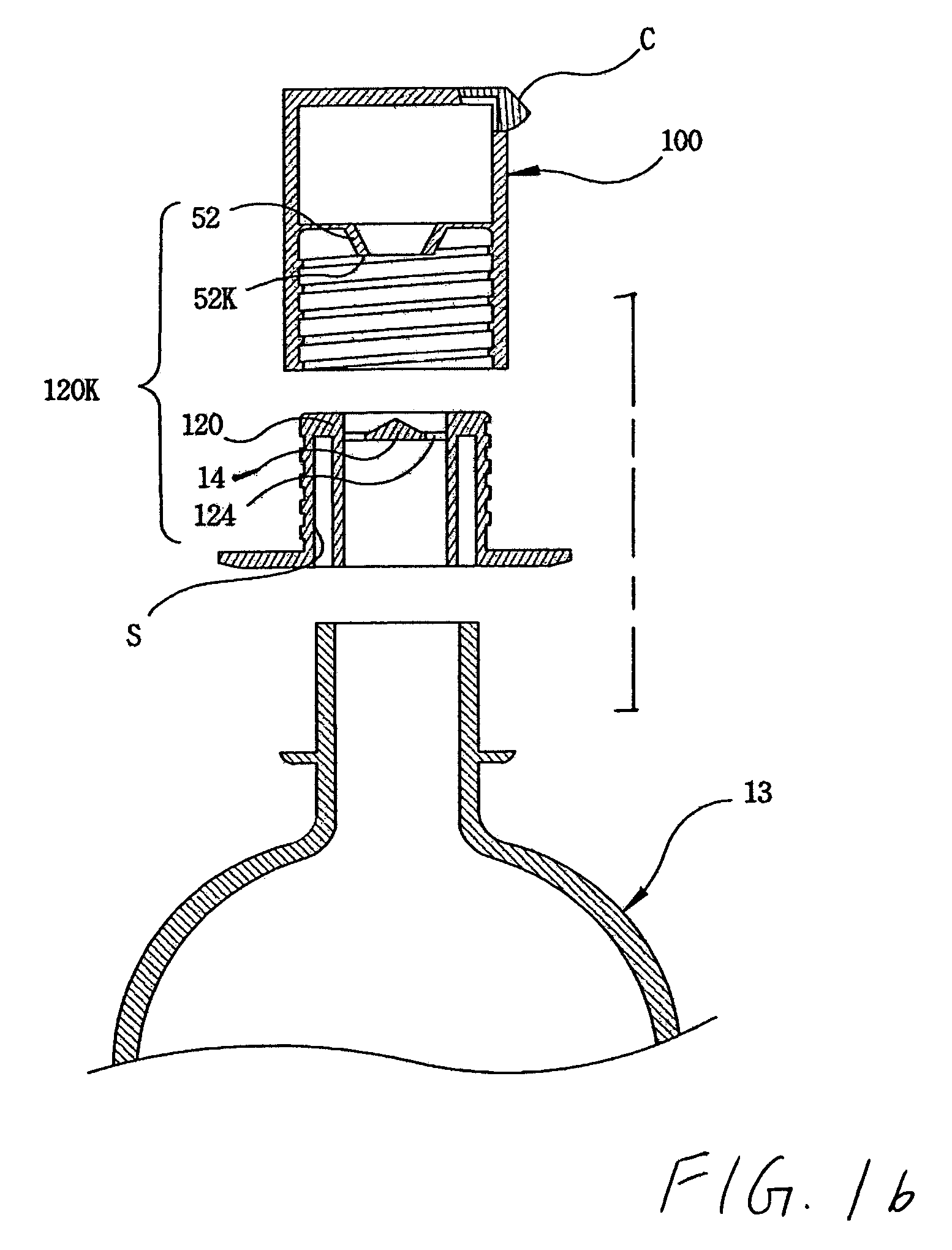

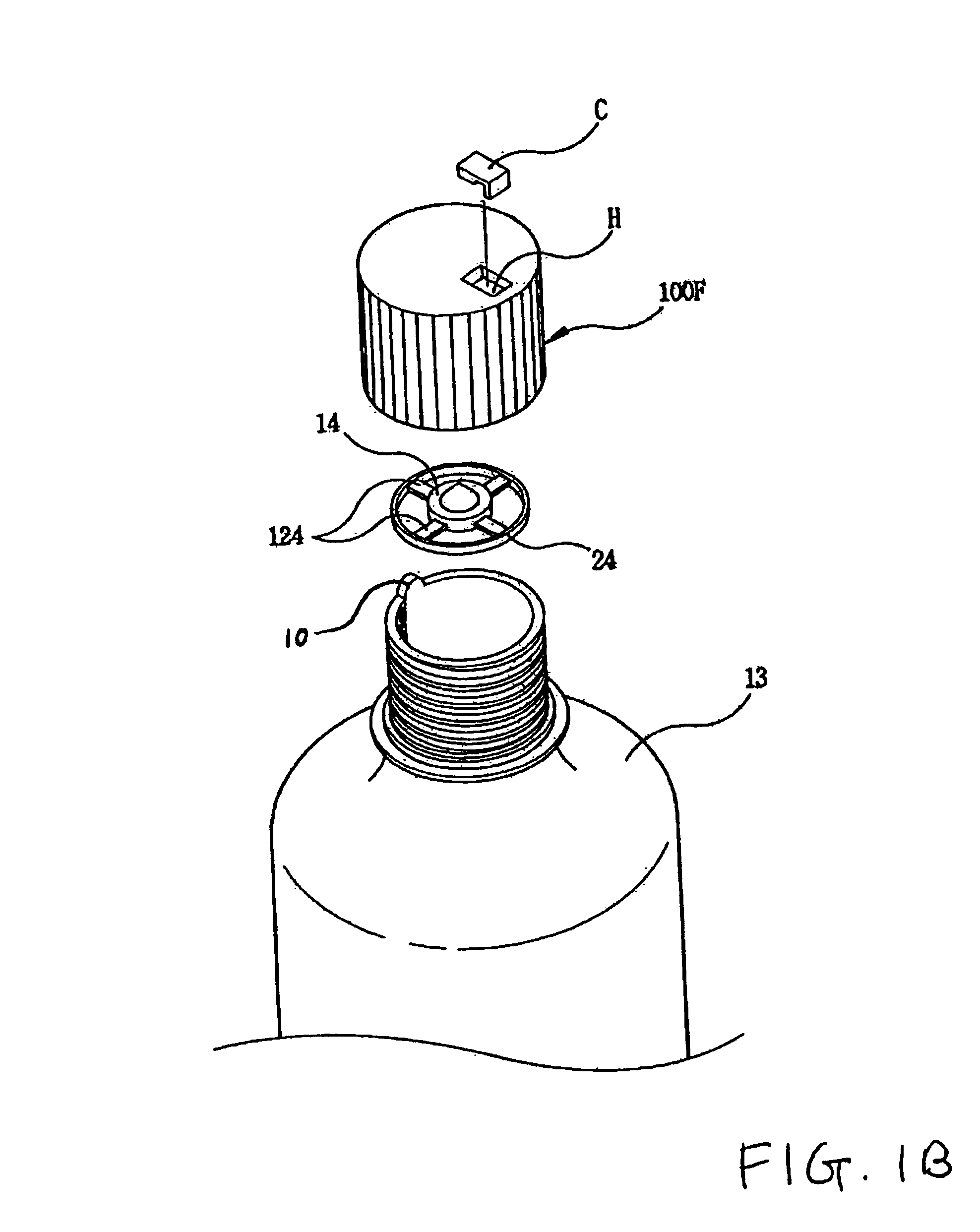

Cap device for mixing different kinds of materials separately contained therein and in bottle

InactiveUS6935493B2Easily brokenEasy to prepareLighting and heating apparatusBottlesEngineeringBottle

A cap device for bottles, which is capable of mixing two different additives separately contained therein with a material contained in a bottle to prepare a mixture in accordance with a simple rotating action of the cap device relative to the bottle, performed by a user, thus allowing the user to easily prepare the mixture just before drinking or using the mixture. The cap device has a cap cover acting as an additive containing part, and defining a cavity therein, with a partition wall provided in the cavity to divide the cavity into two chambers and to separately contain two different additives in the chambers; a first funnel part provided at a lower section of the cap cover; a breakable sheet having a structure to be easily broken by external impact provided at an open lower end of the first funnel part to close the open lower end of the first funnel part; a cap body assembled with a lower end of the cap cover externally tightened to an externally threaded mouth of a bottle; a second funnel part having the same shape as the first funnel part provided at an upper section of the cap body, such that the first and second funnel parts are spaced apart from each other or come into contact with each other; and a means for breaking the breakable sheet so as to open the lower end of the first funnel part.

Owner:CHO YOUNG KOOK

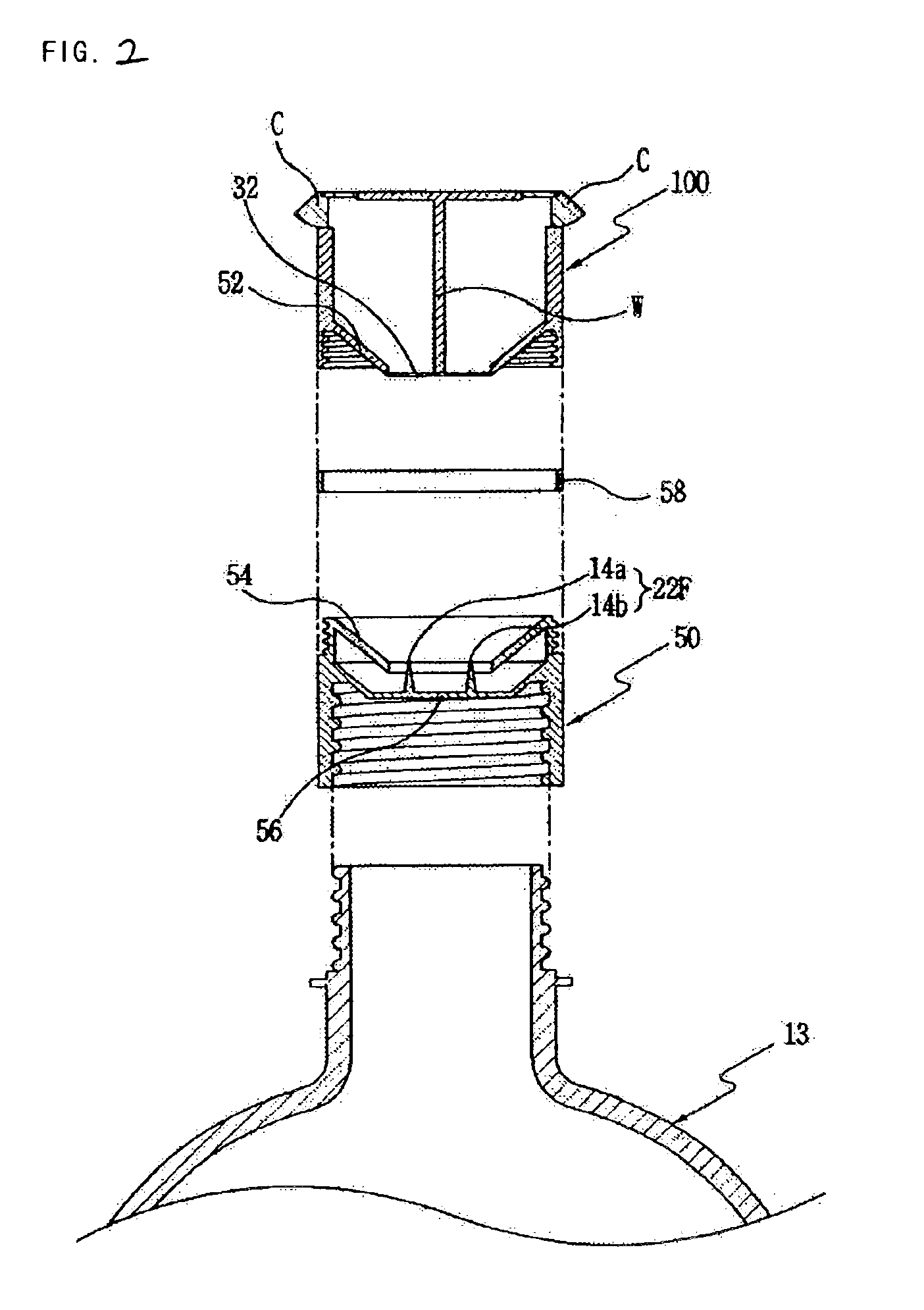

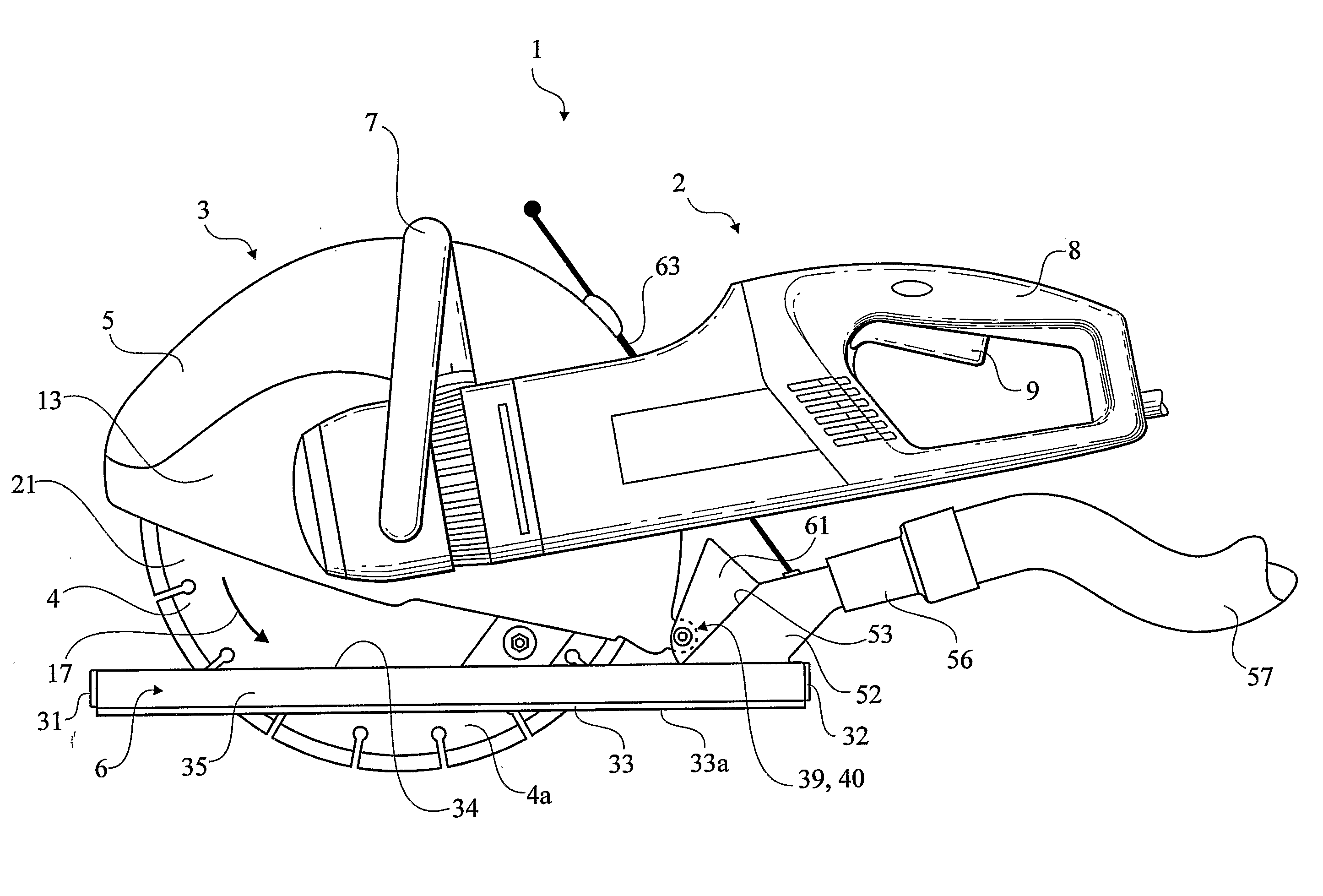

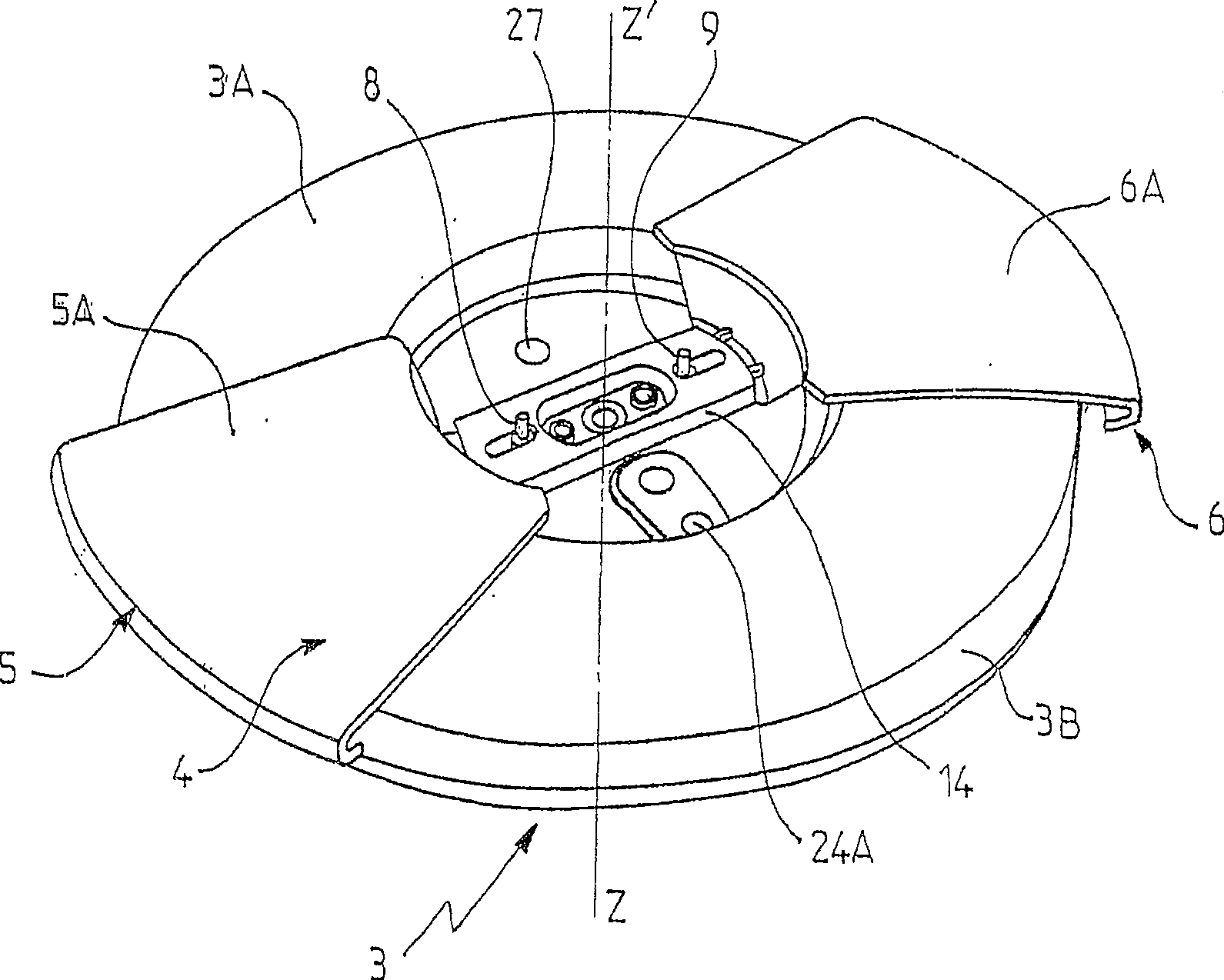

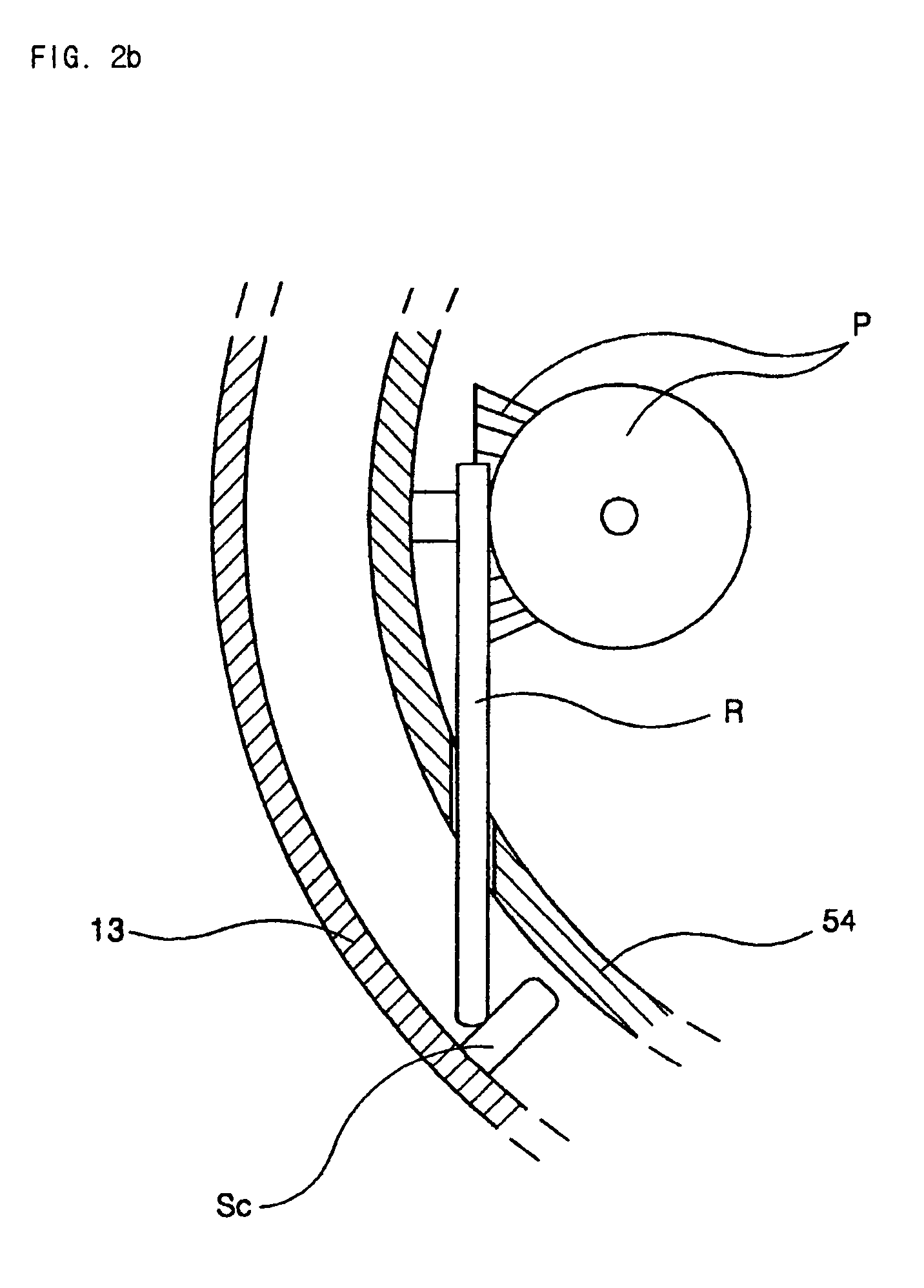

Cutting and Dust Collecting Assembly and Working Machine with Such Assembly

ActiveUS20080163492A1Avoid flyingEfficient collectionMetal sawing devicesMetal sawing accessoriesCircular sawDust control

A cutting and dust collecting assembly comprises a rotatable, circular saw blade (4) having a first side (20), a second side (21), and a cover device (6) with a terminal member (52). The bottom surface (36) of the cover device extends in a plane. A longitudinal passage (45, 46) for the saw blade extends through the cover device from its top surface to its bottom surface. The terminal member comprises a terminal chamber (60) having an inlet (45a), the mouth of which coincides with the plane of said bottom surface. An outlet (58) can be connected to a vacuum source. The direction of rotation of the operating blade is such that the rear part (4a) of the saw blade which has passed beyond the bottom surface of the cover device will move in a direction upwards-rearwards towards the bottom surface. The invention also concerns the cover device, a sealing body belonging to the cover device and a working machine which is provided with the cutting and dust collecting assembly.

Owner:HUSQVARNA AB

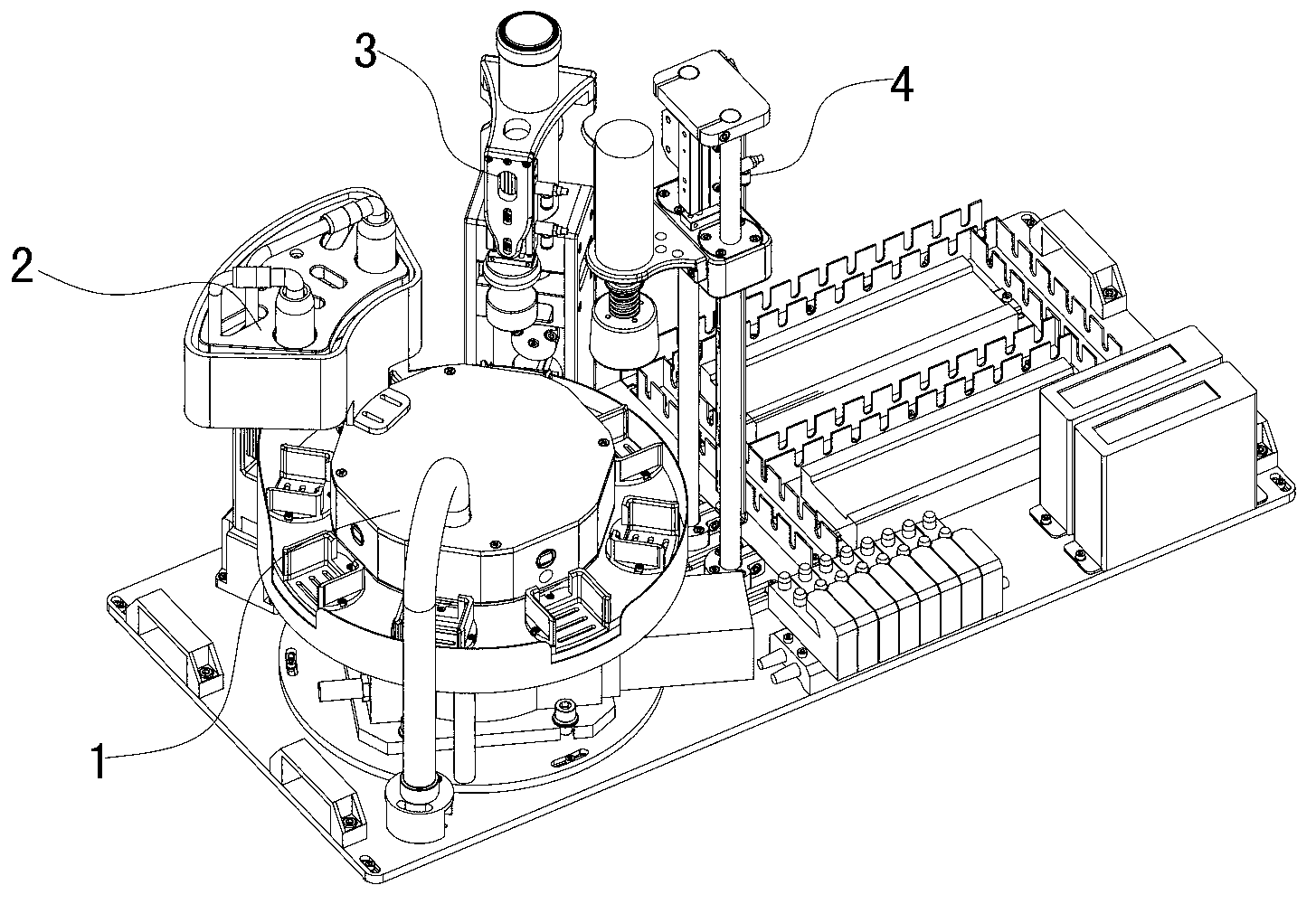

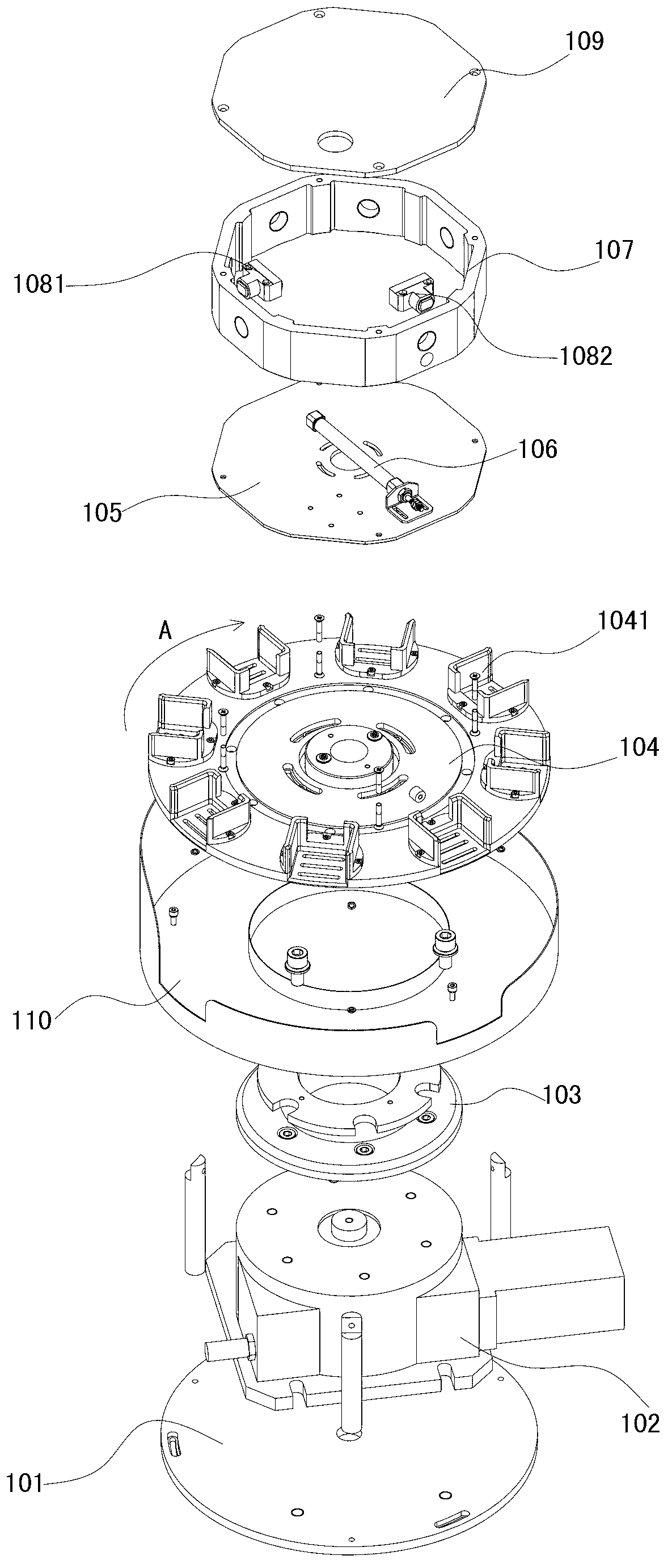

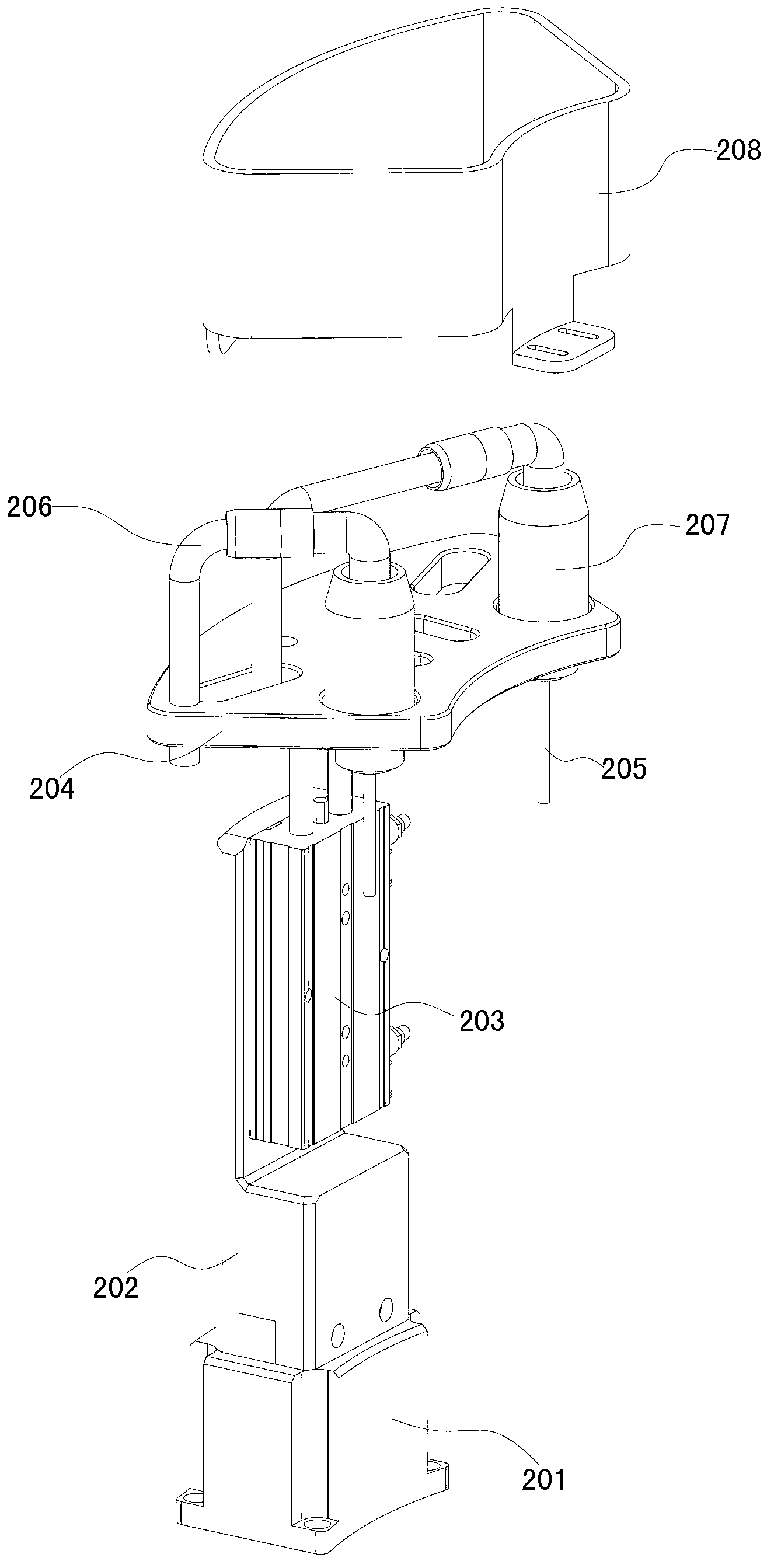

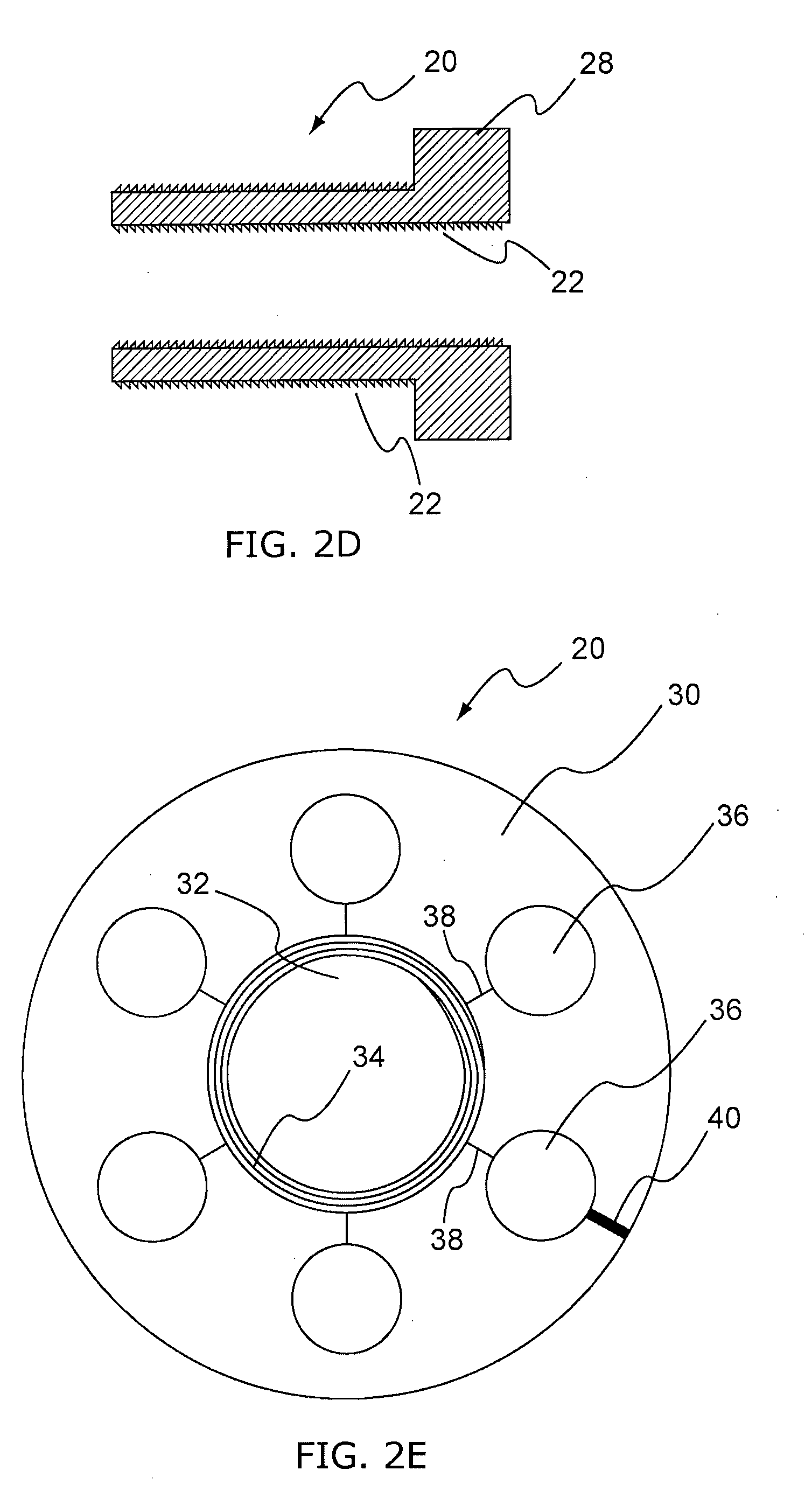

Filling capping device

ActiveCN102701127ALow costImprove space utilizationThreaded caps applicationLiquid fillingElectric machineryBottle cap

The invention discloses a filling capping device comprising a rotary disk component, a filling component, a cap pressing component and a screw capping component. The rotary disk component comprises a rotary disk and a pneumatic division plate which is used for driving the rotary disk to intermittently rotate; the filling component comprises a liquid injection needle, a liquid feeding pipe and a liquid injection lifting cylinder for driving the liquid injection needle to move up and down; the cap pressing component comprises a storage barrel, a transverse push cylinder and a cap pressing cylinder for pushing downwards a bottle cap to be added pushed by the transverse push cylinder; and the screw capping component comprises a screw capping motor, a screw capping lifting cylinder for driving the screw capping motor to move up and down and a rotating sleeve arranged at the free end of the screw capping motor, and a screw capping core arranged in the rotating sleeve. The filling capping device has a simple structure and is low in equipment cost; as the rotary disk is adopted to convey bottles, the volume of the entire device is reduced and subsequently the occupied area of the device is reduced; the filling capping device can be used for teaching demonstration; and furthermore, the space utilization rate of a workshop is improved.

Owner:广东三向智能科技股份有限公司

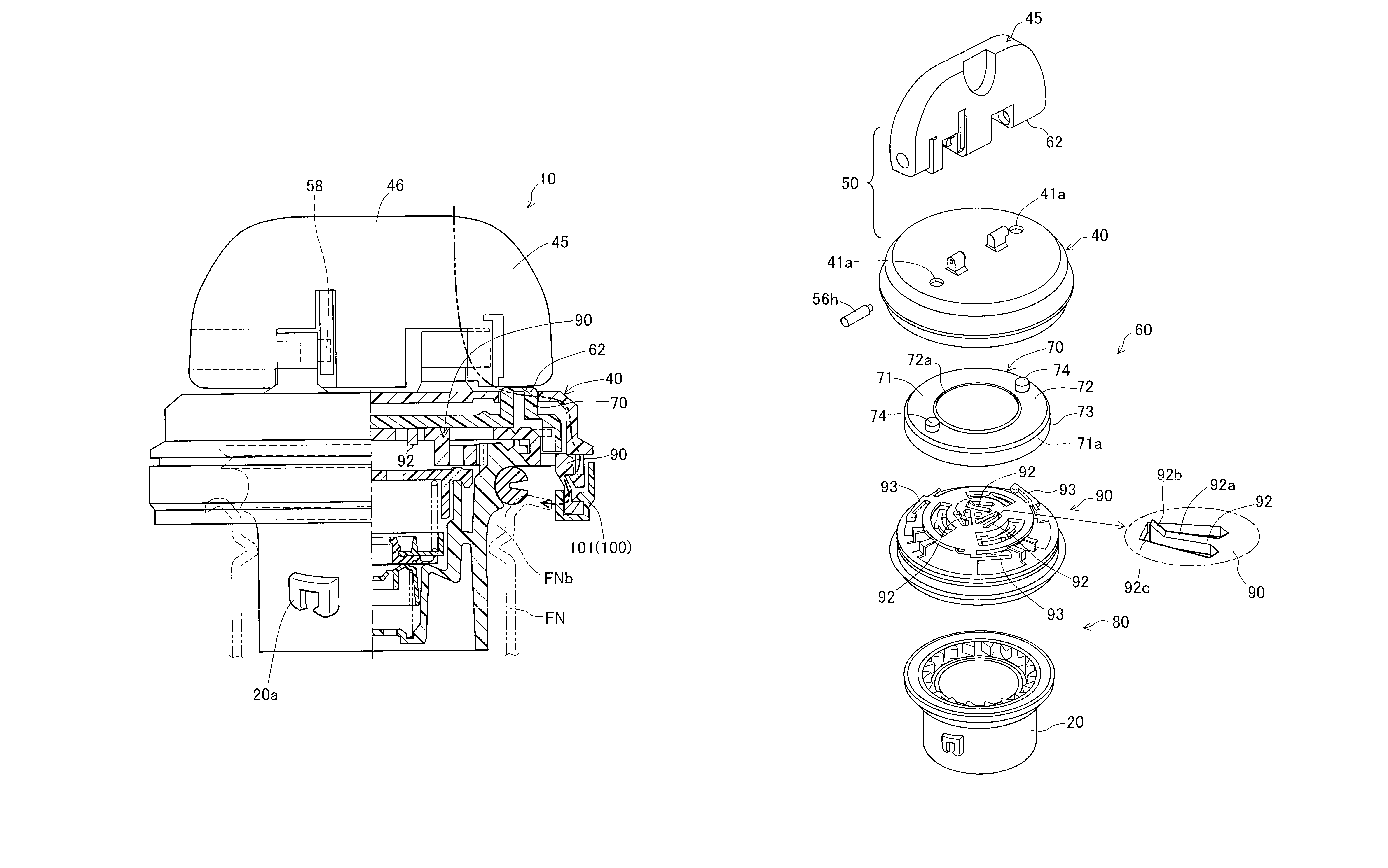

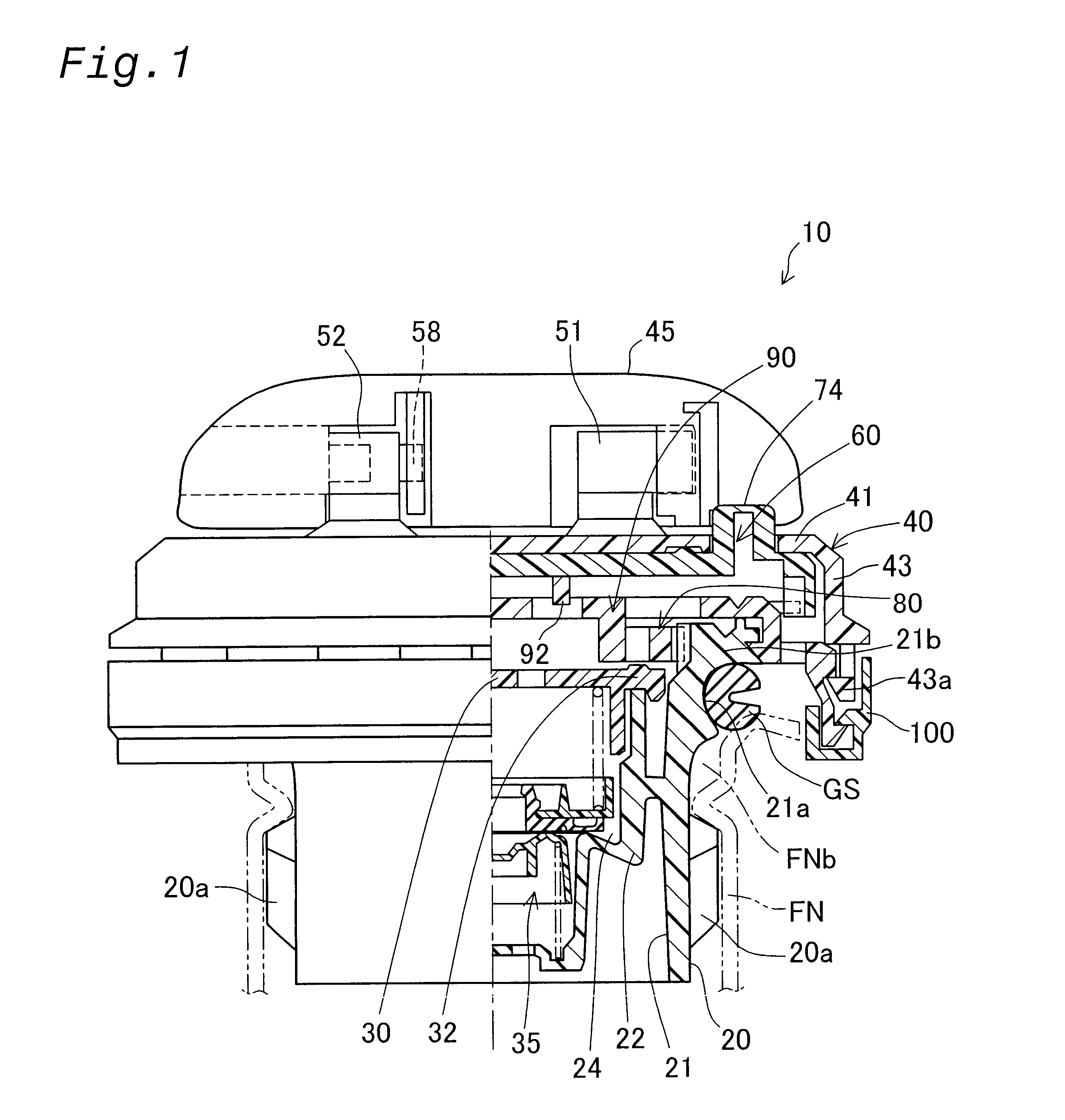

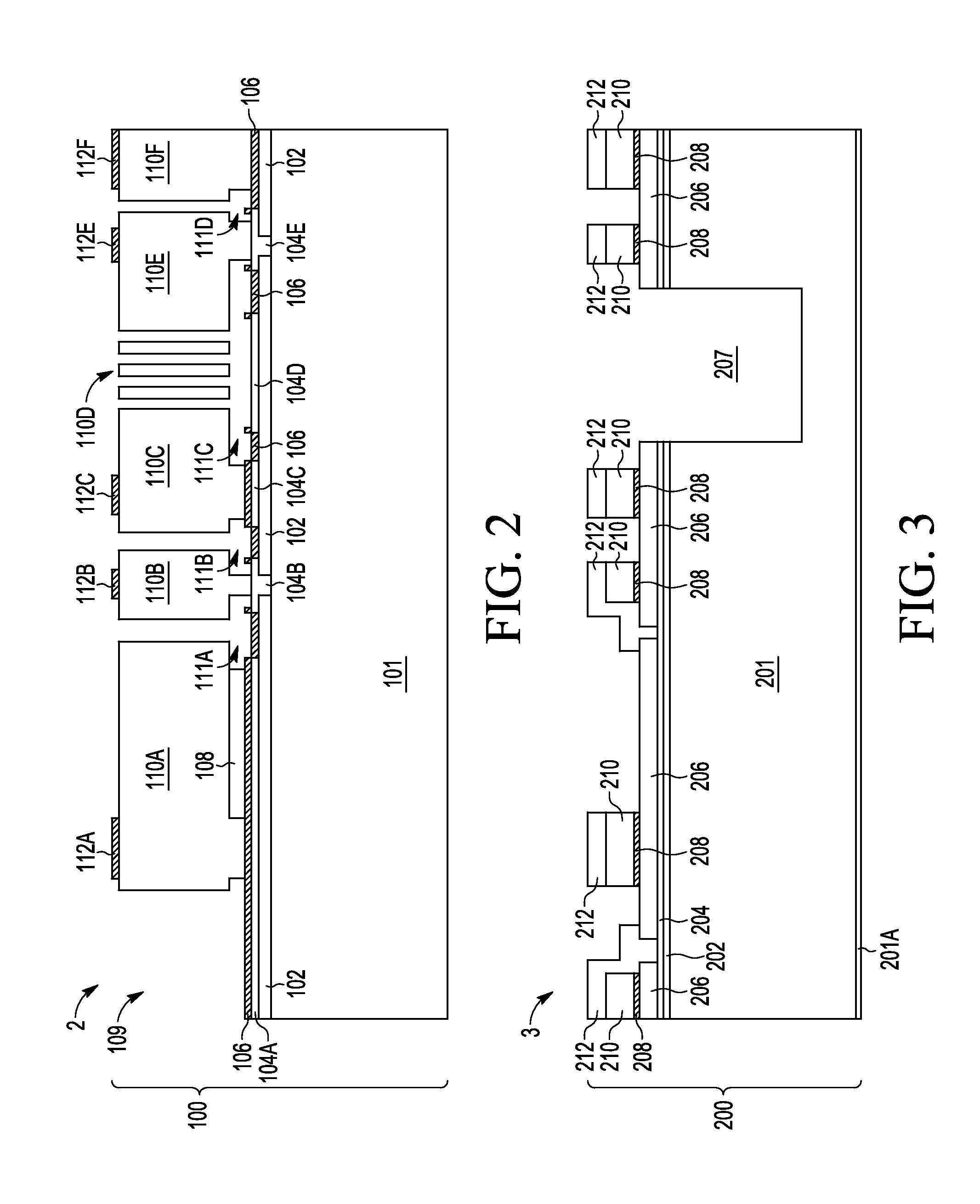

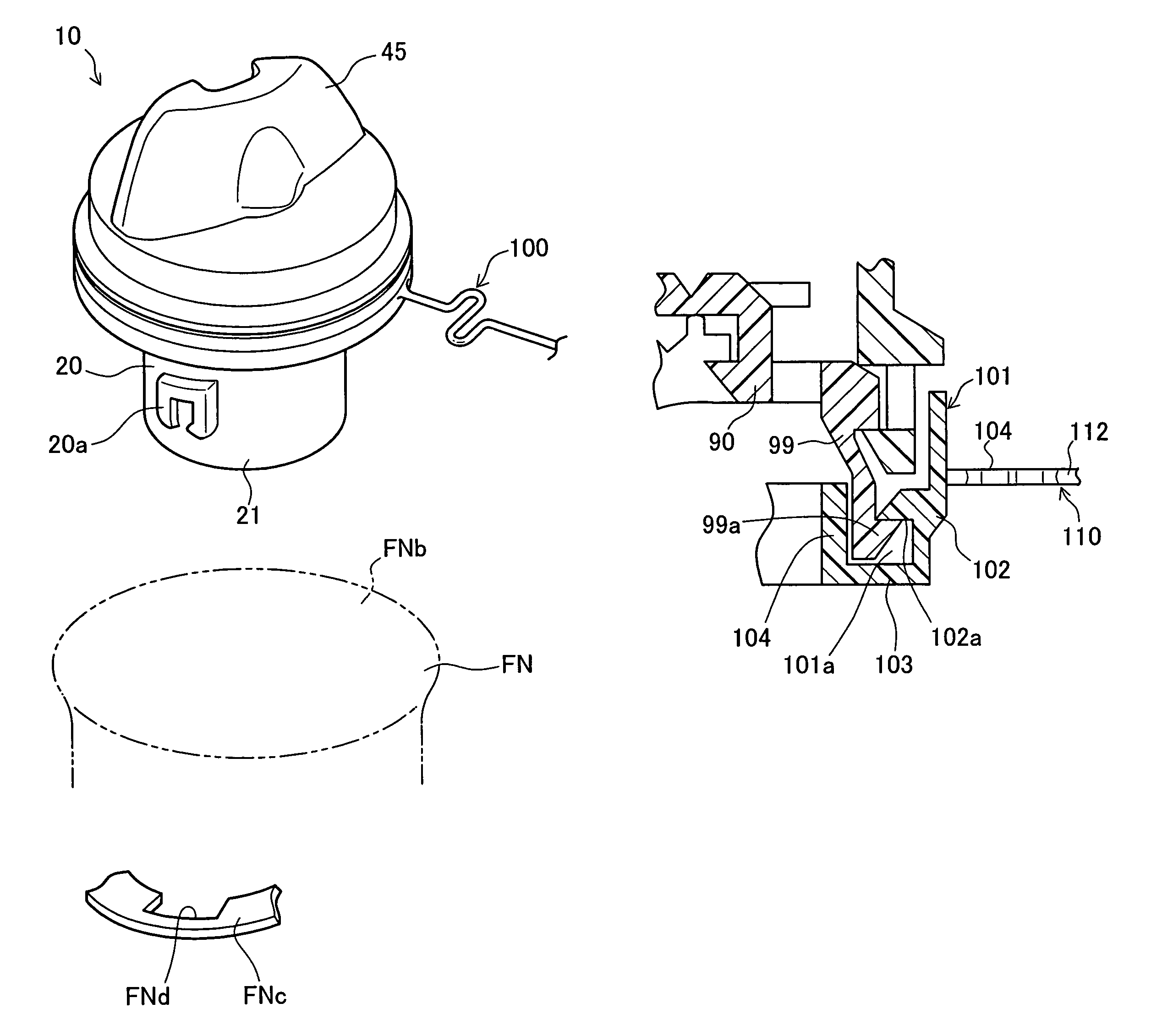

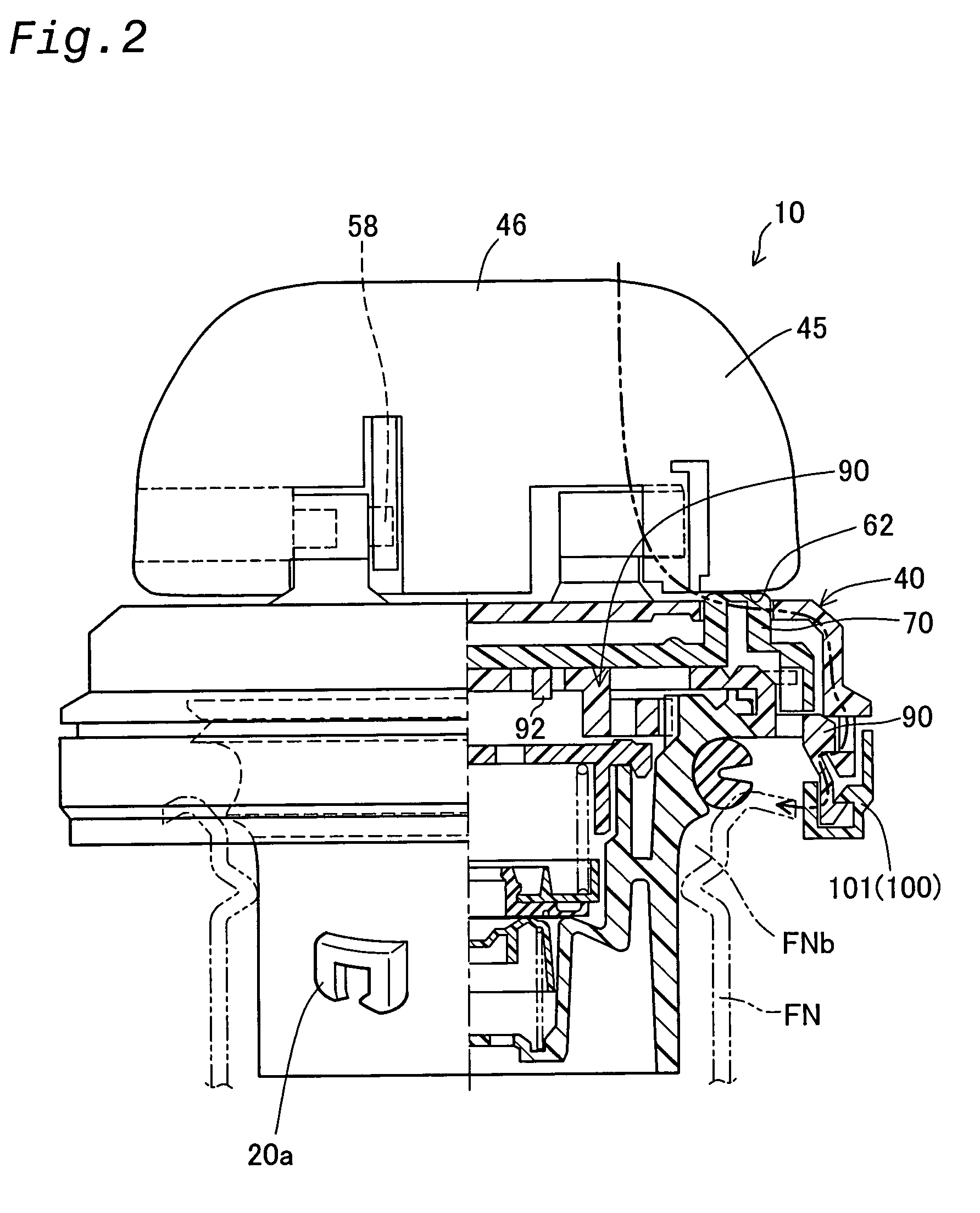

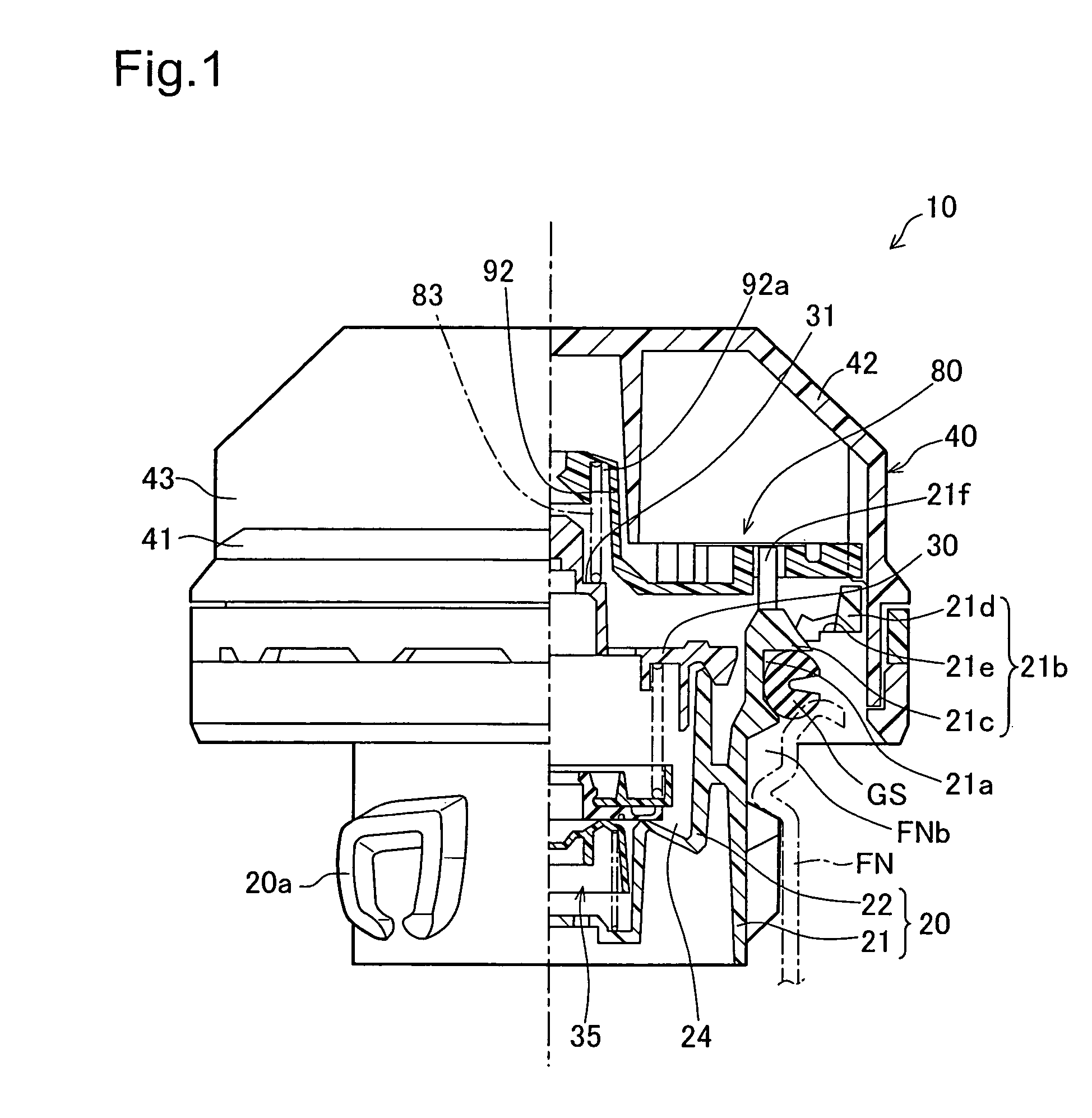

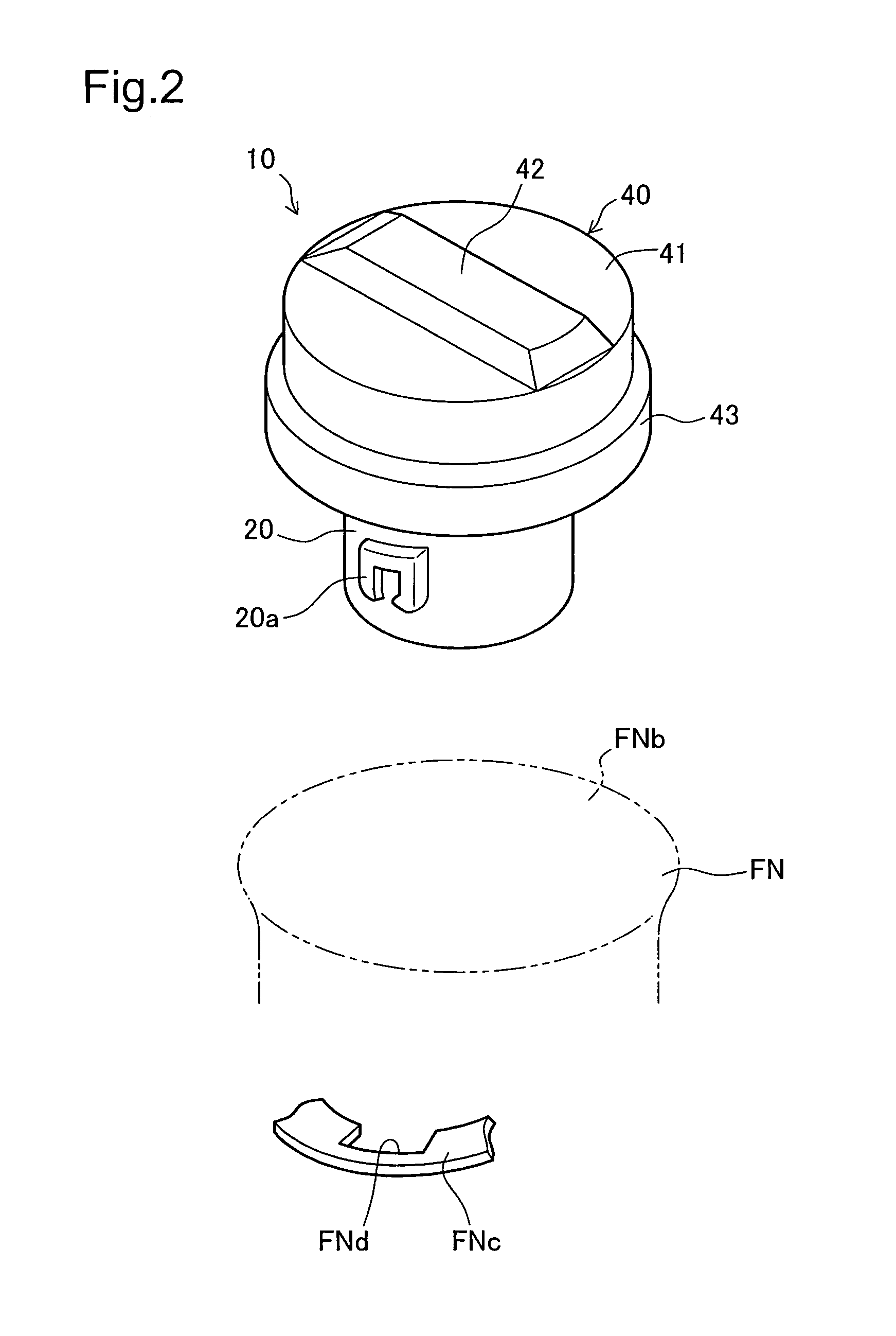

Cap device

InactiveUS6745914B2Easily transmittedReduce the number of partsCapsClosure capsTorque transmissionCap device

A fuel cap 10 maintains high sealing even when subjected to external force; is easy to operate; and requires minimal space for accommodation. The cap device comprises a casing body 20 for closing the filler opening FNb in a sealed condition, a cover 40, a handle 45, a clutch mechanism 60 and a torque transmission mechanism 80. By upraising the handle to the handling position and applying rotational torque, rotational torque is transmitted to the casing body 20 via the clutch mechanism 60 and the torque transmission mechanism 80, closing the filler opening FNb. The handle 45 lowers back to the retracted position when released, whereupon the clutch mechanism 60 assumes non-transmission mode wherein the cover 40 and the handle 45 rotate freely if subjected to external force such as in a collision.

Owner:TOYODA GOSEI CO LTD

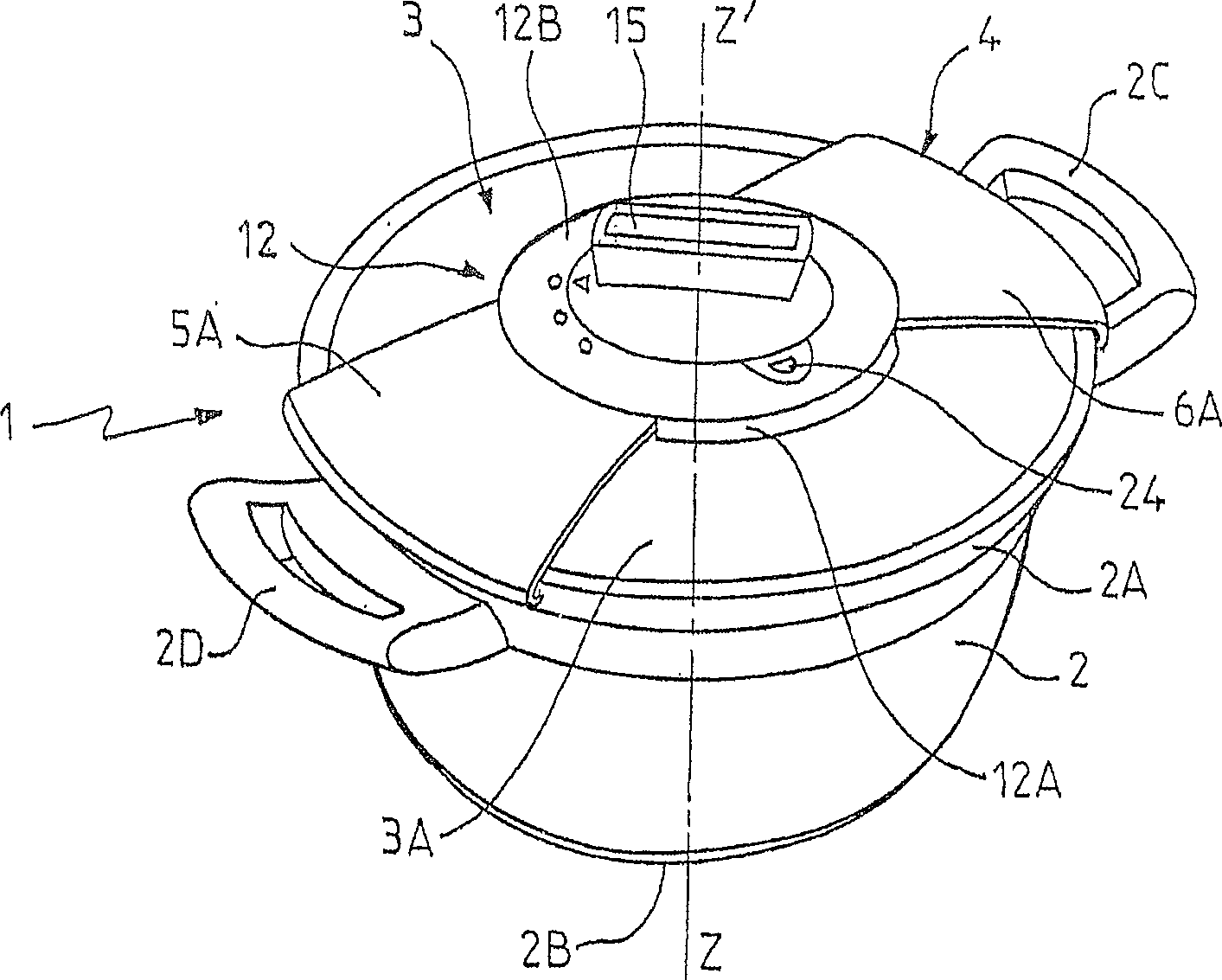

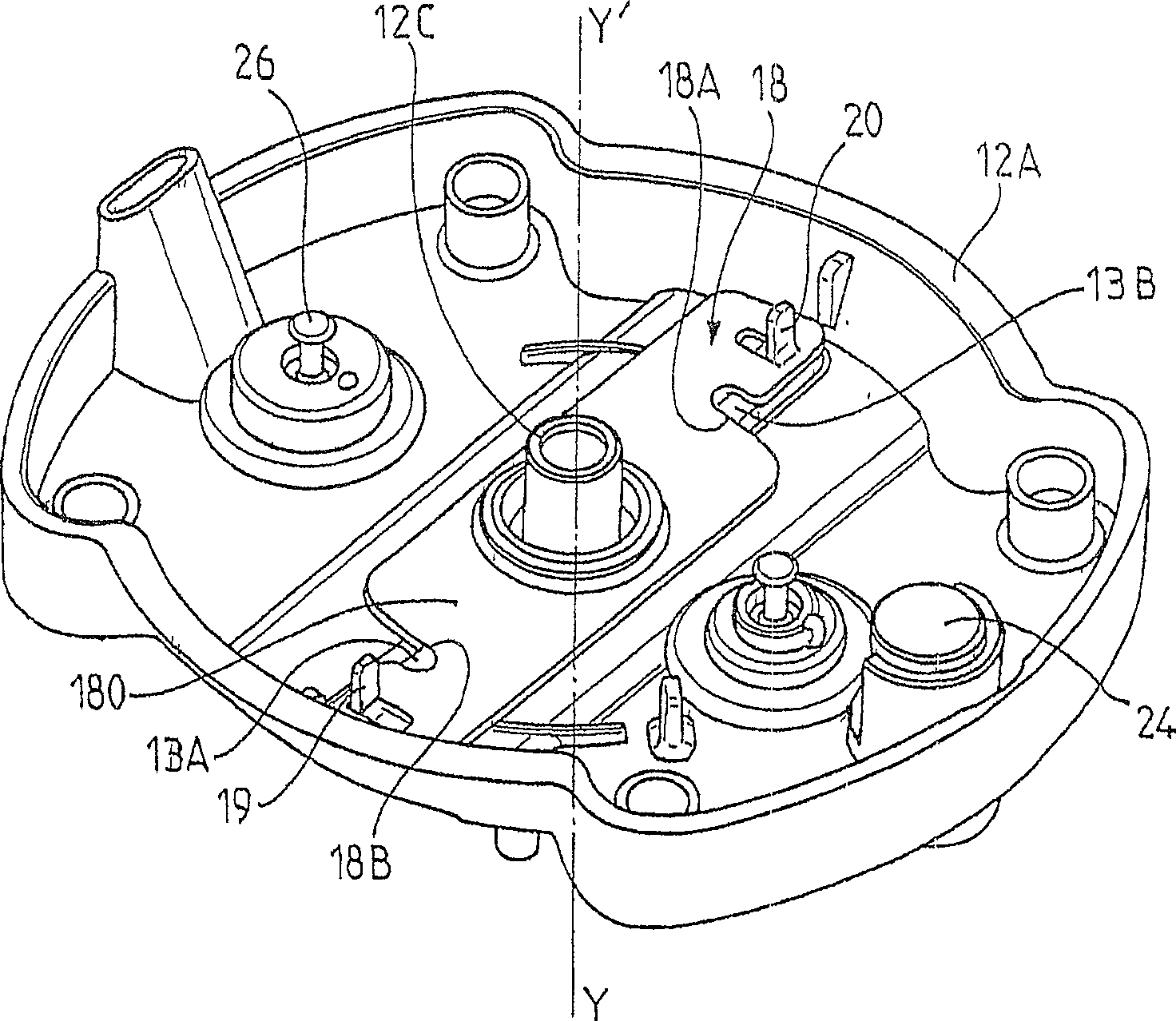

Pressure cooking appliance with improved safety system

The present invention provides a pressure cooking appliance with an improved safety system. The pressure cooking appliance (1) of the present invention includes: a bowl (2) and a lid (3); a device (4) for locking the lid (3) relative to the bowl (2) and is installed to movement between a locked position and an unlocked position; and a device (7) for controlling the movement of the locking / unlocking device (4) and mounted for movement between an open position and a closed position. The invention is characterized in that the appliance includes a blocking device (18) mounted movable between a position blocking the locking / unlocking device (4) and a position releasing the locking / unlocking device (4) . In addition, the blocking device (18) cooperates with the above-mentioned control device (7), so that when the control device (7) moves from the closed position to the open position, the blocking device (18) moves from the blocking position to the release position. .

Owner:SEB SA

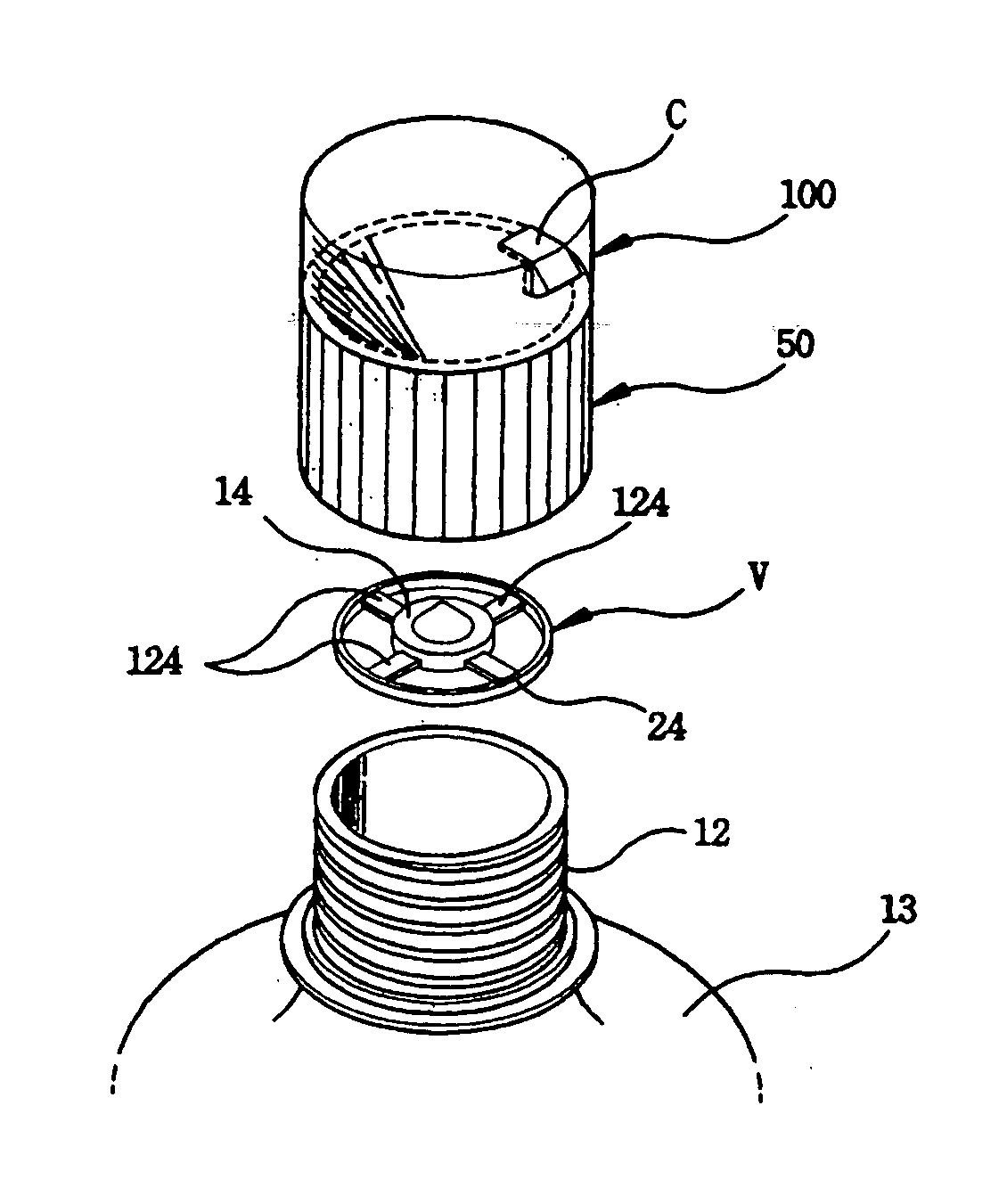

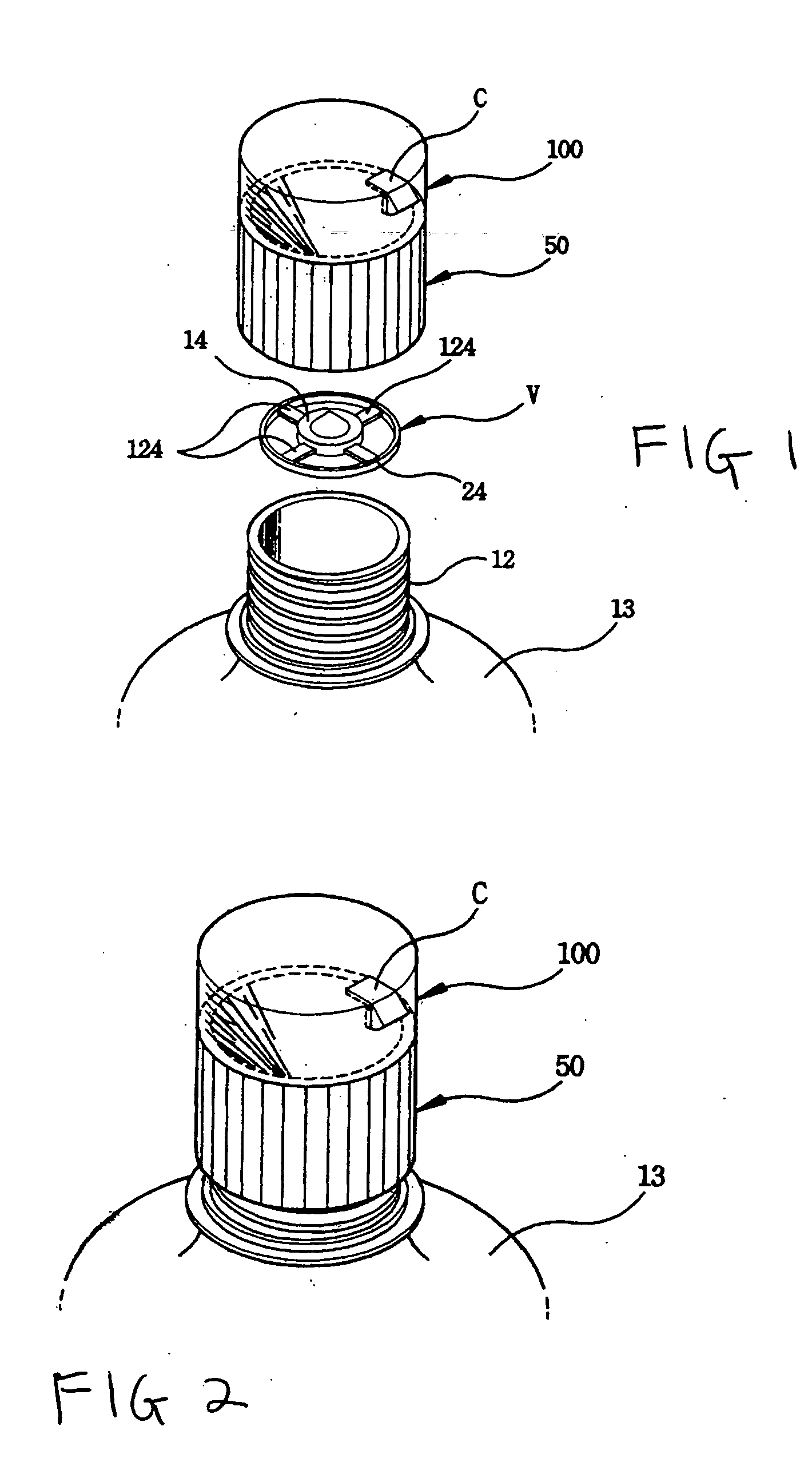

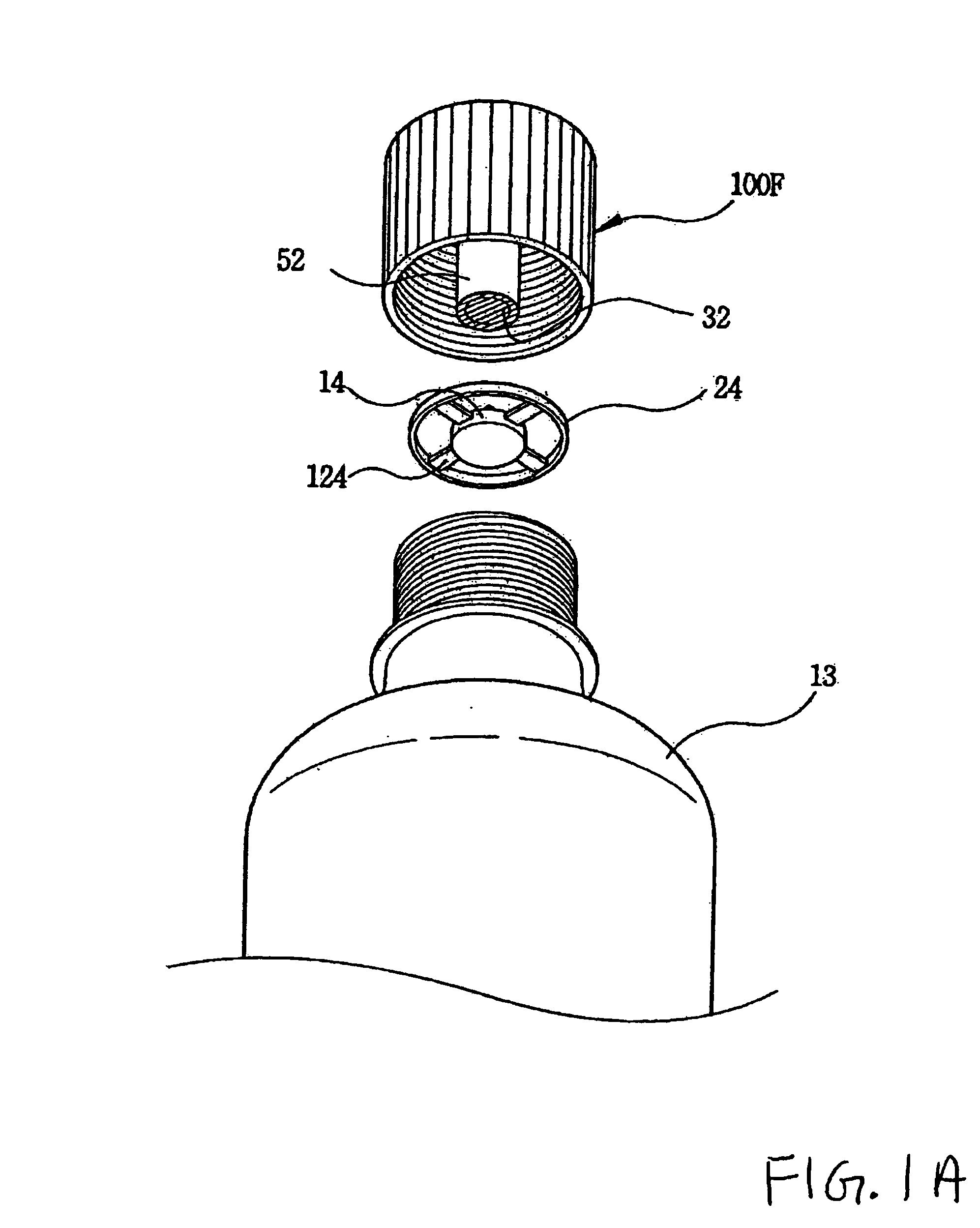

Cap device for mixing different kinds of materials separately contained therein and in bottle

InactiveUS20050115845A1Easy to preparePrevented from being prematurely addedClosure with auxillary devicesRigid containersEngineeringBottle

A cap device for bottles allows an additive and a material to be separately stored in the cap device and a bottle, thus preventing the additive from being undesirably added to the bottled material. Furthermore, the cap device may contain a semisolid additive therein, as desired, thus allowing a user to mix the semisolid additive with the bottled material to prepare a mixture. The cap device has a cap body tightened to a mouth or an open lower end of the bottle, with an additive discharging means provided in the cap body to discharge the additive from a space inside the cap body into the bottle. The cap device further has a valve means for opening or closing the discharging means, according to a rotating action of the cap device relative to the bottle. The valve means includes a valve part which is brought into close contact with or spaced apart from the discharging means, thus closing or opening the discharging means to allow the additive to be discharged into the bottle to prepare the mixture. The valve means further includes a plurality of radial or vertical ribs which are integrated with the valve part into a single structure.

Owner:CHO YOUNG KOOK

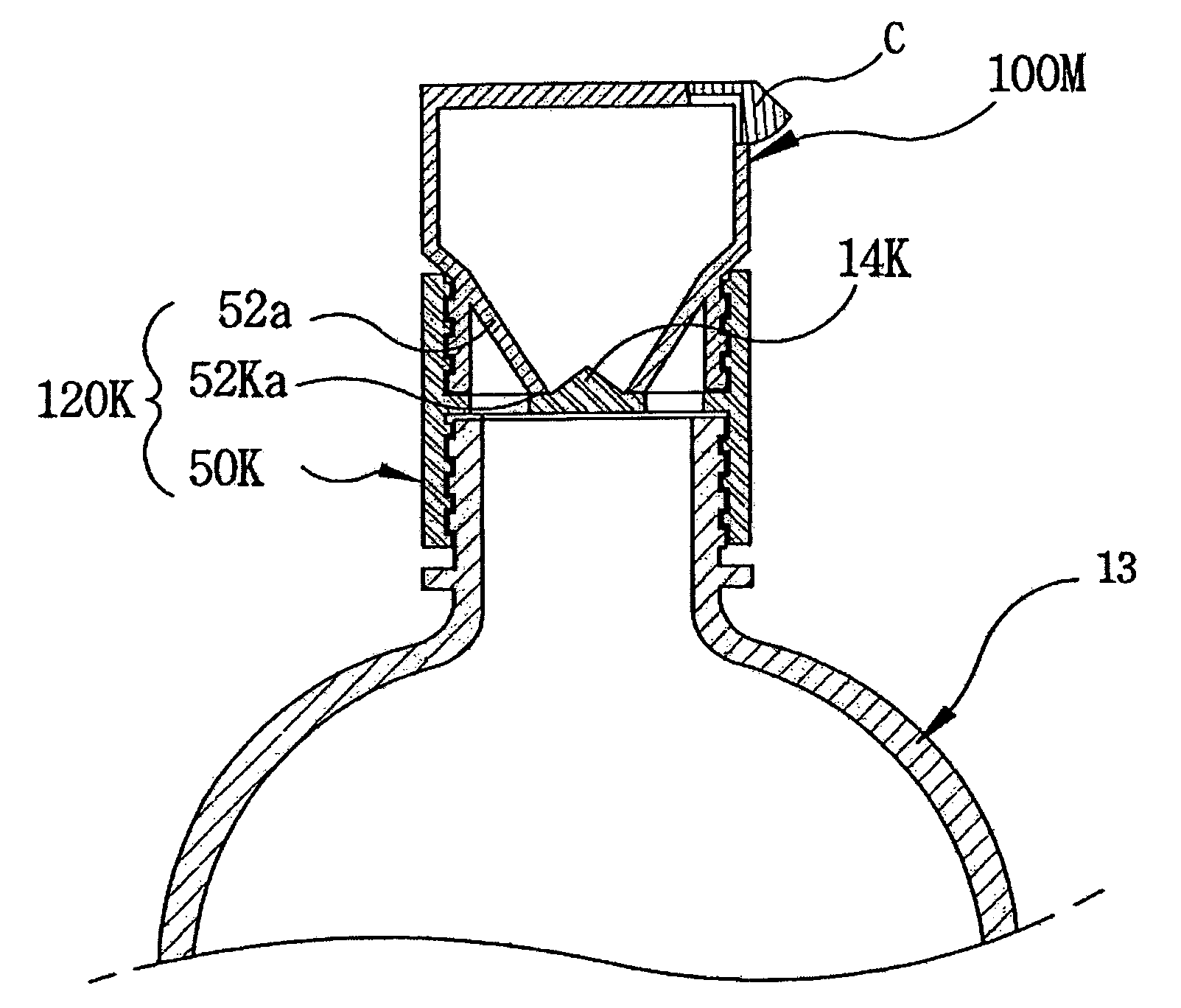

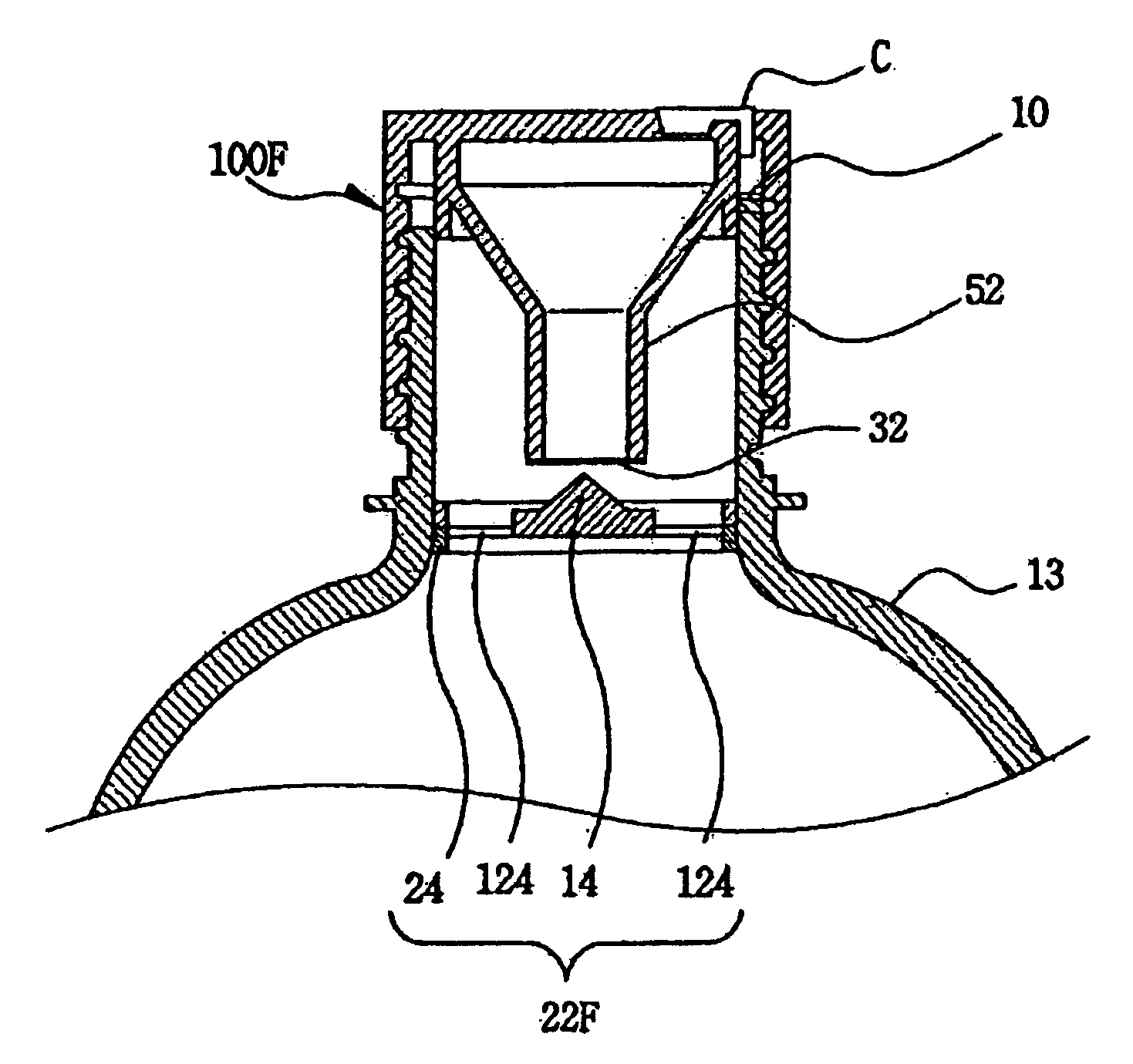

Cap device for mixing different kinds of materials separately contained therein and in bottle

A cap device for bottles, in which a valve means is stably placed at a desired position in a neck of the bottle, without being undesirably displaced, and which allows an additive and a material to be completely separately stored in the cap device and the bottle, respectively, such that the additive is not undesirably added to the bottled material. The cap device has a cap body tightened to an externally threaded mouth of a bottle, with a funnel part integrally formed in the cap body to discharge an additive from the cap body into the bottle through a lower end thereof. A cap cover is assembled with the cap body to cover an open upper end of the cap body while defining a cavity inside both the cap body and the cap cover to contain the additive in the cavity. The cap device also has a valve means for opening or closing the lower end of the funnel part of the cap body in accordance with a rotating action of the cap body relative to the externally threaded mouth of the bottle. The valve means comprises a valve member having a conical valve part to be brought into close contact with or spaced apart from the lower end of the funnel part of the cap body, thus closing or opening the lower end of the funnel part. A plurality of radial ribs extend outward from an external surface of the conical valve part in radial directions. A ring is integrated with outside ends of the radial ribs so as to be supported on an inner surface of a neck of the bottle.

Owner:CHO YOUNG KOOK

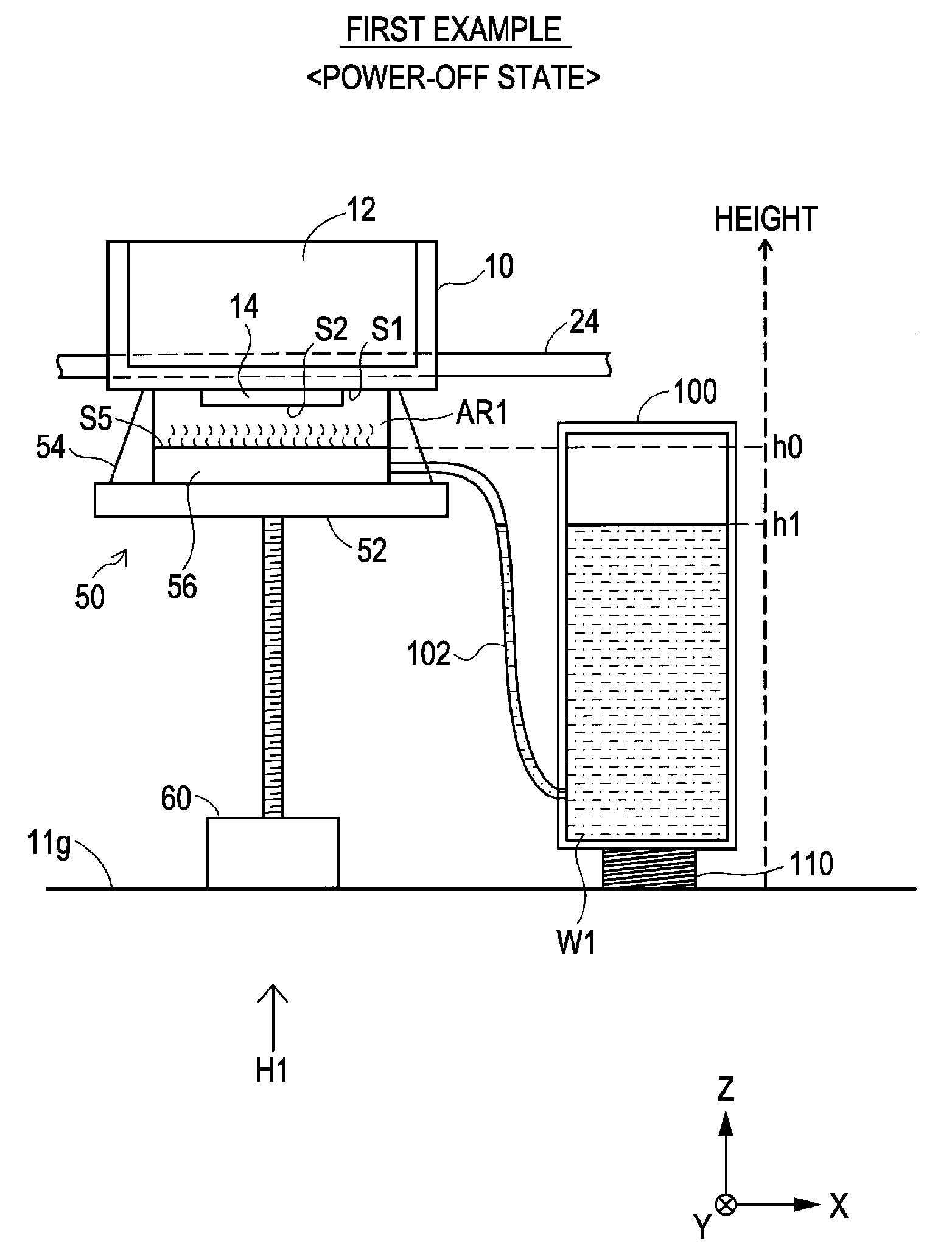

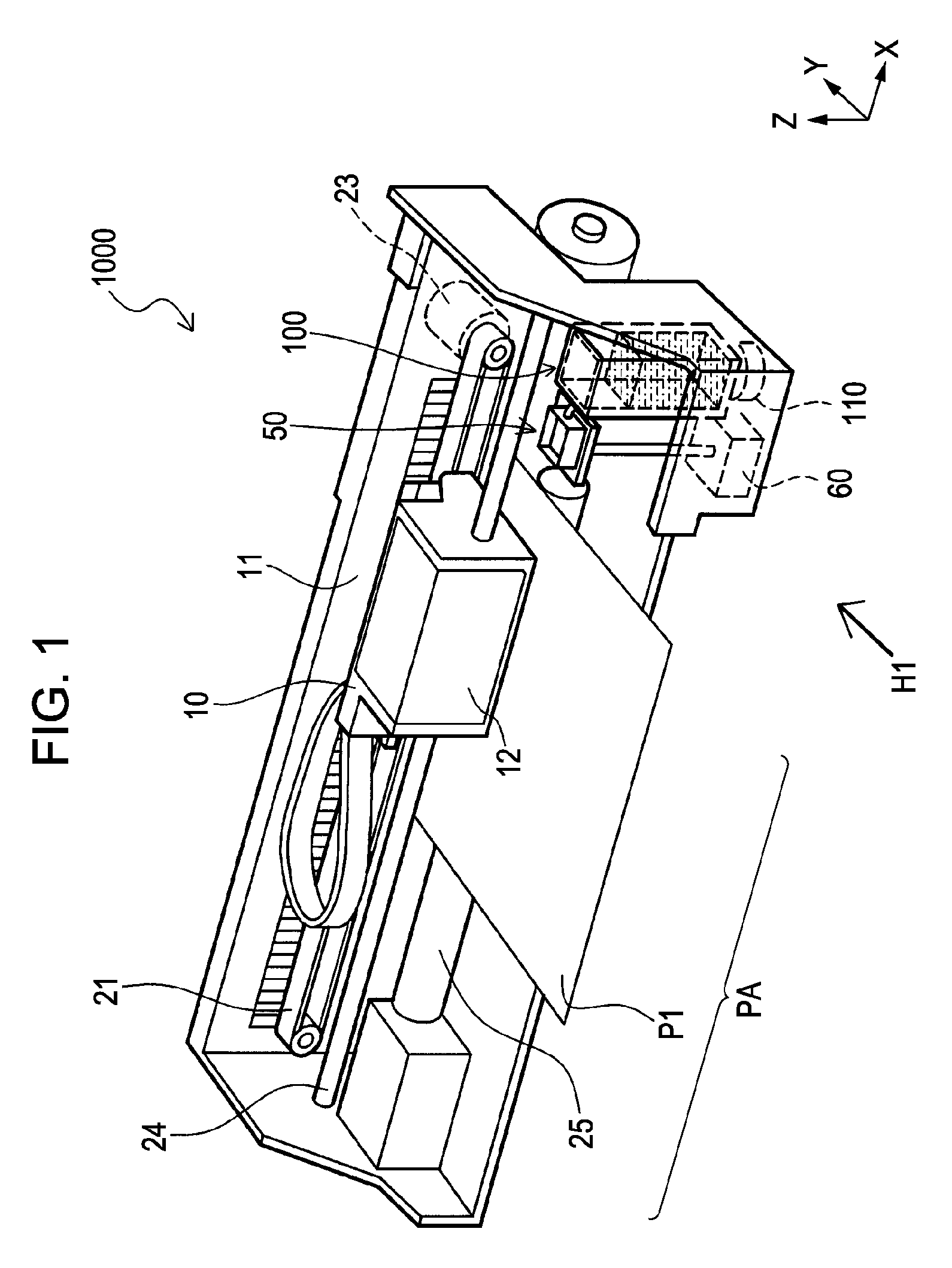

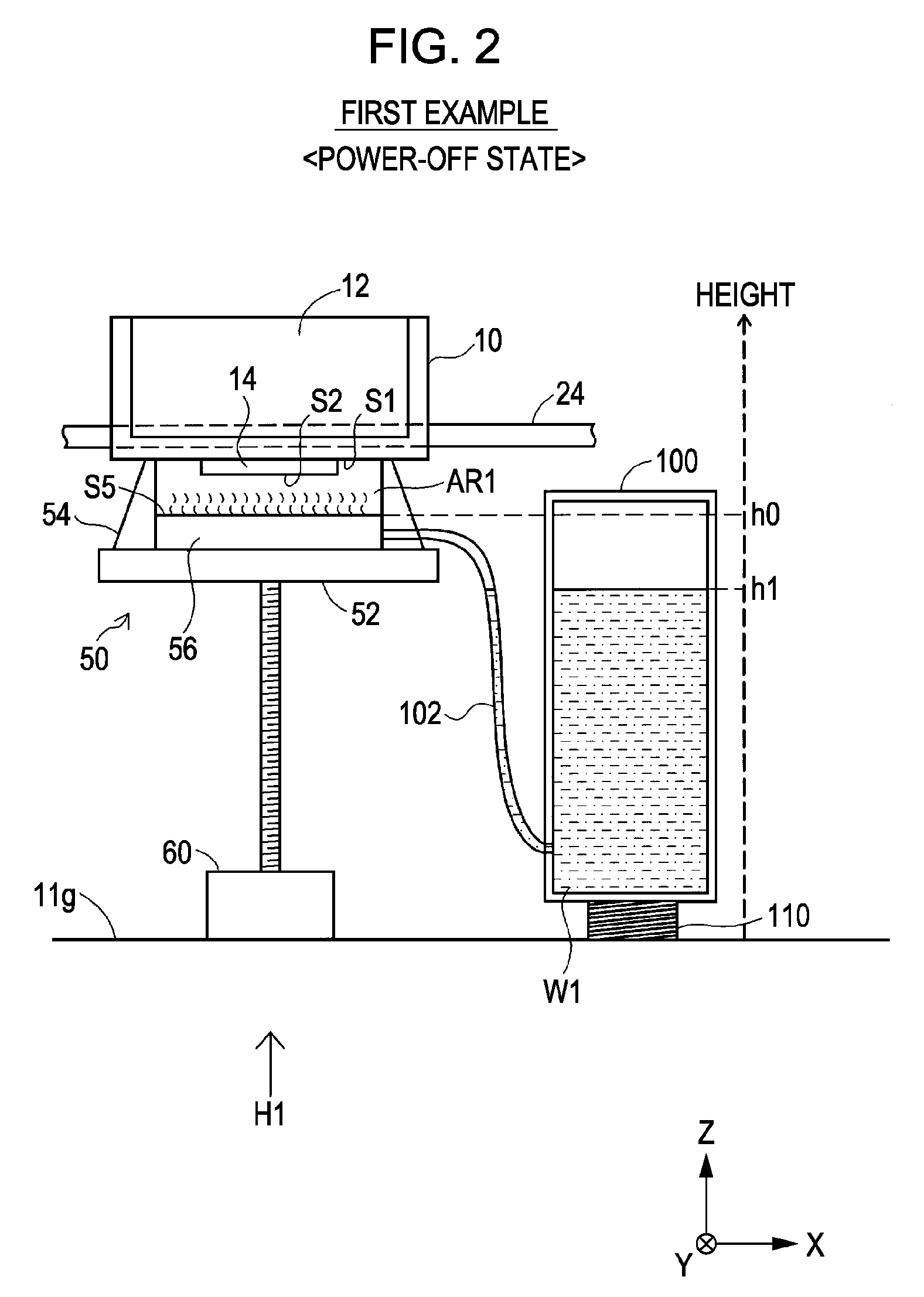

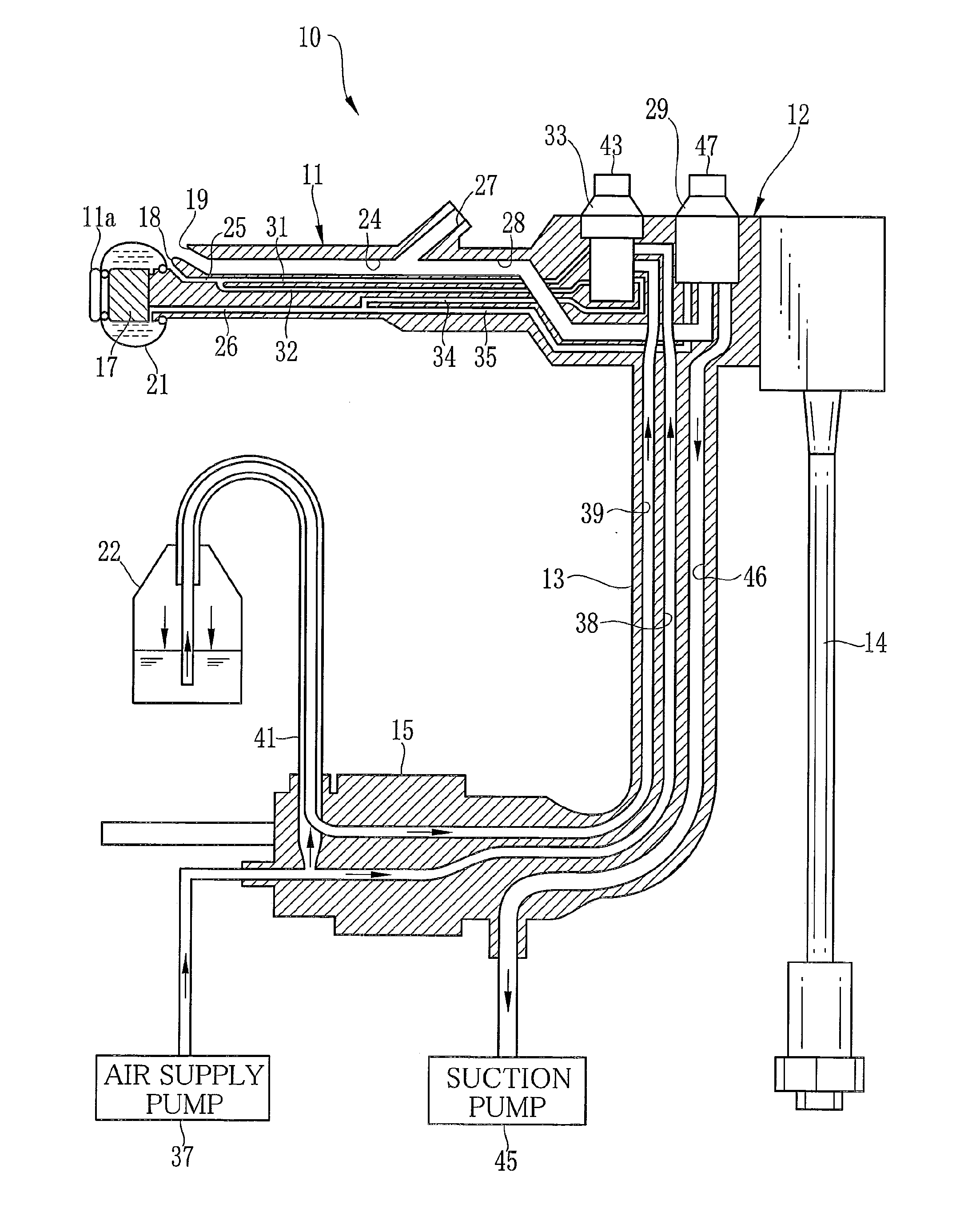

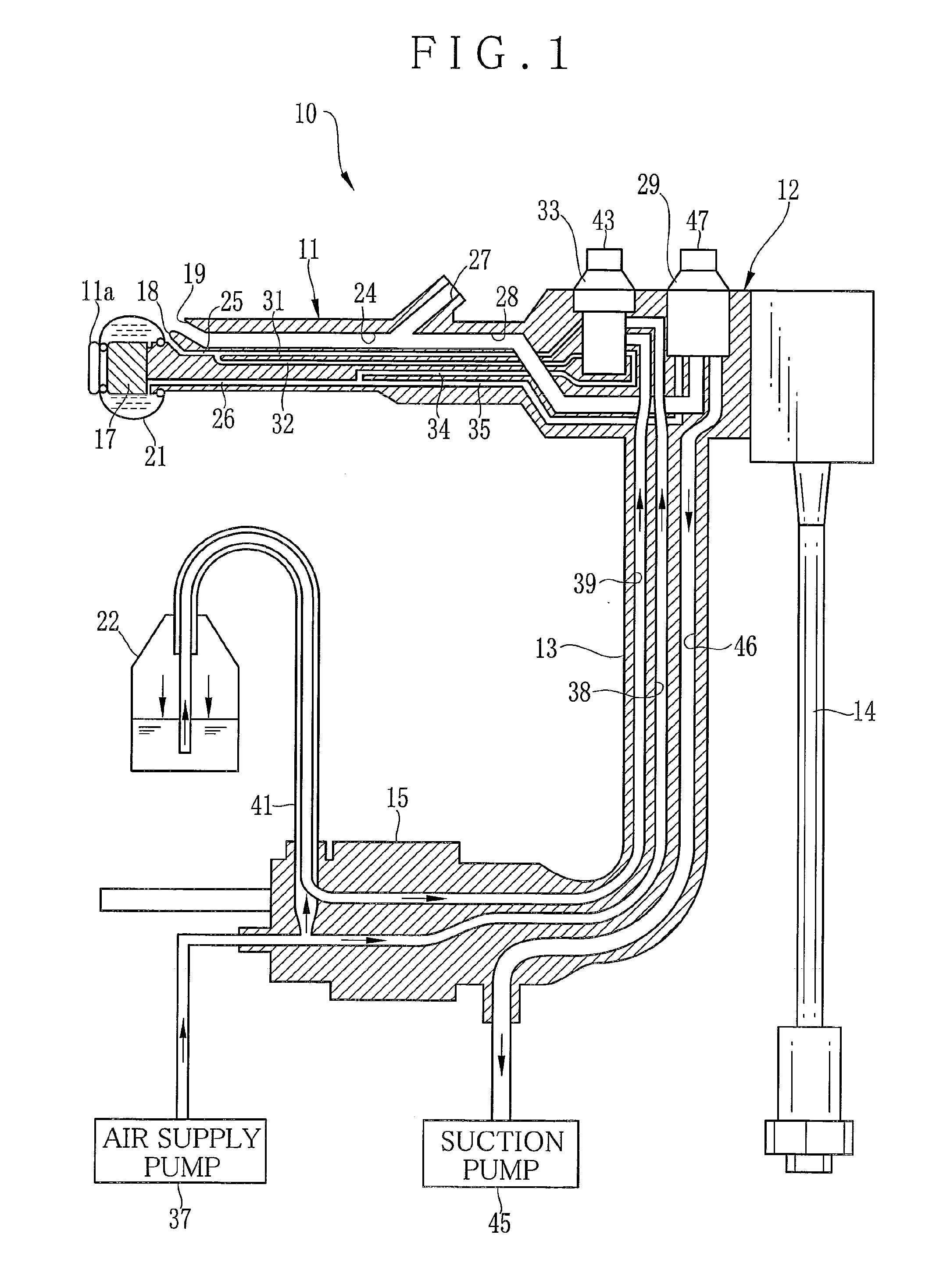

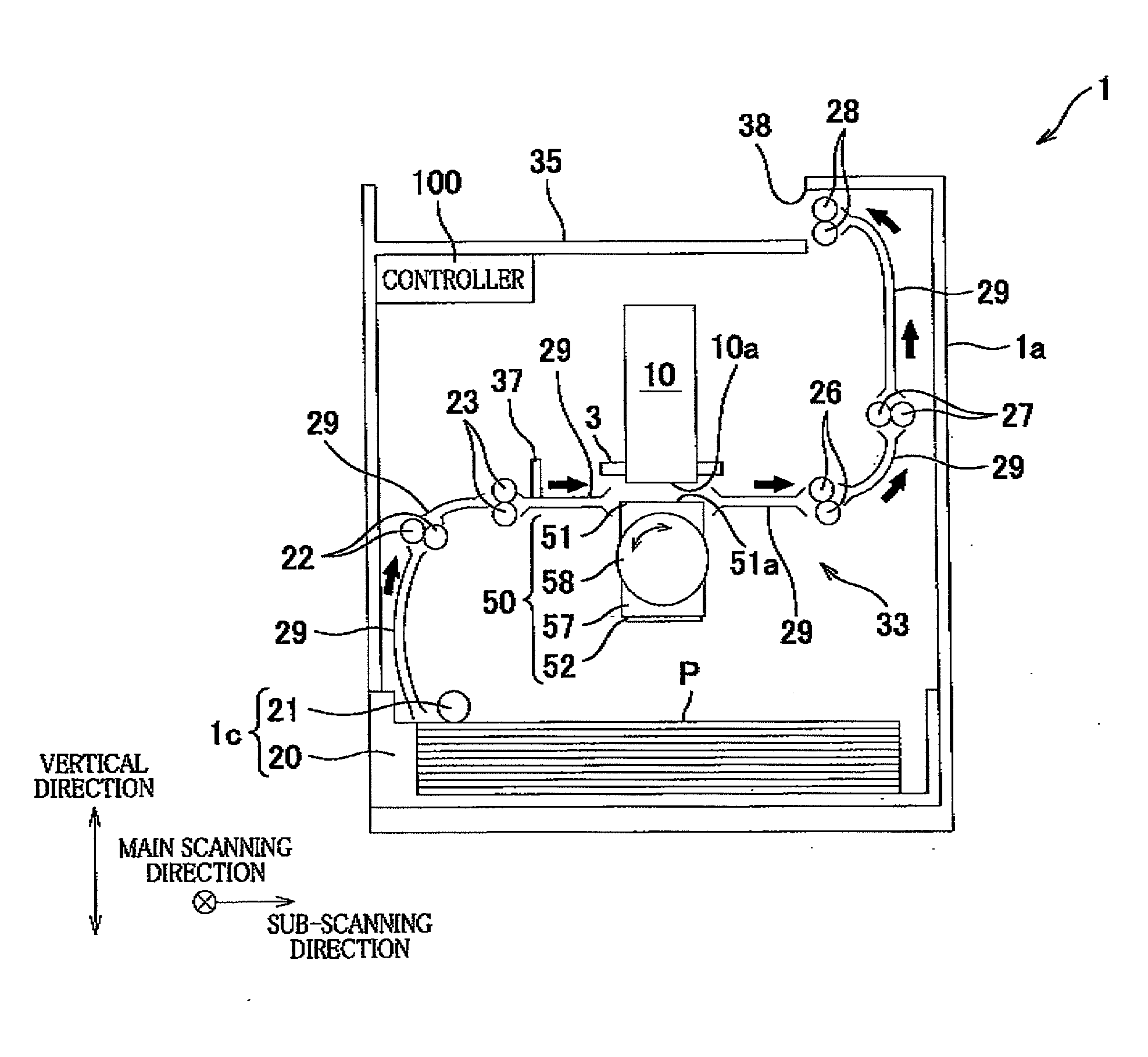

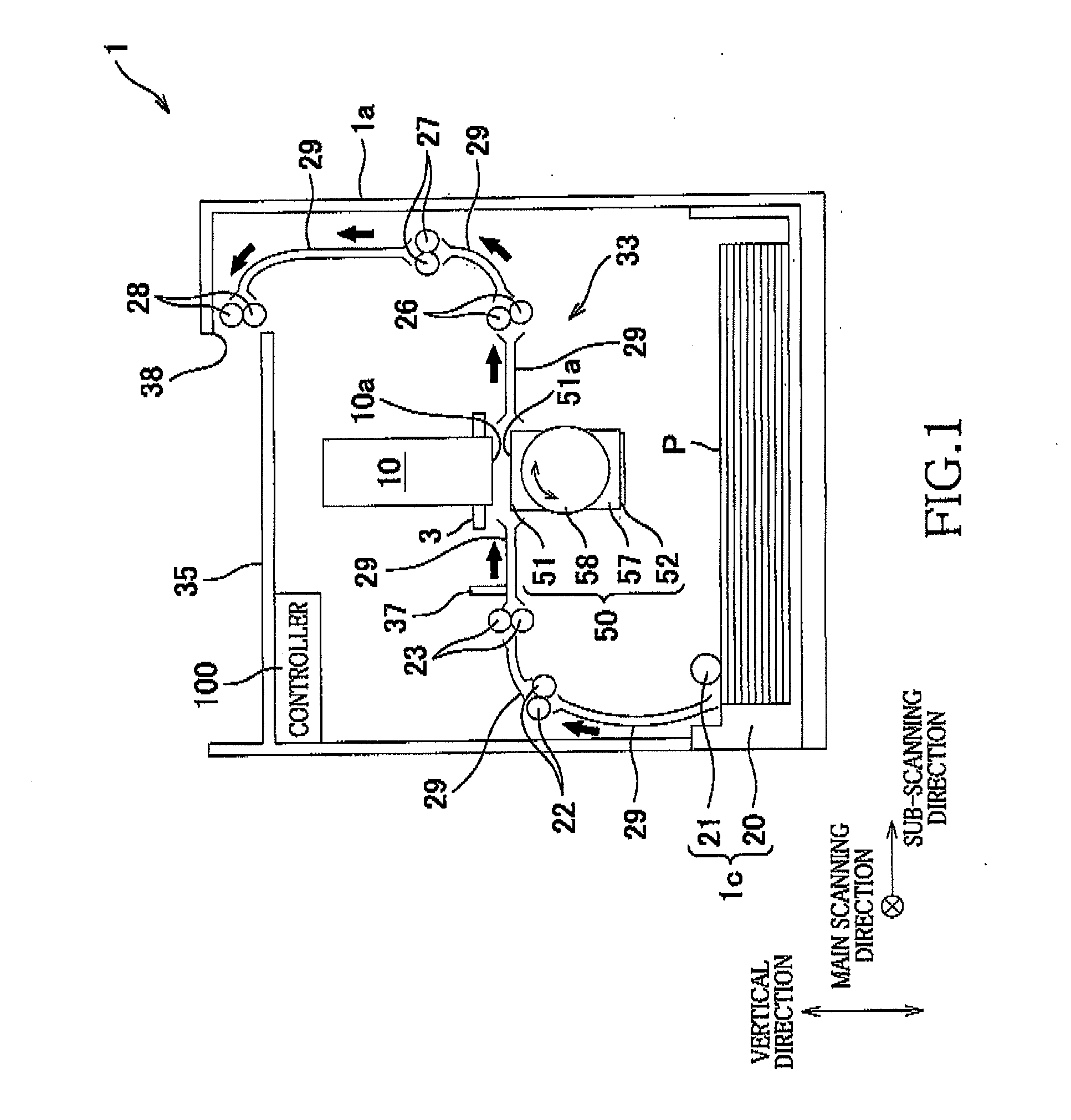

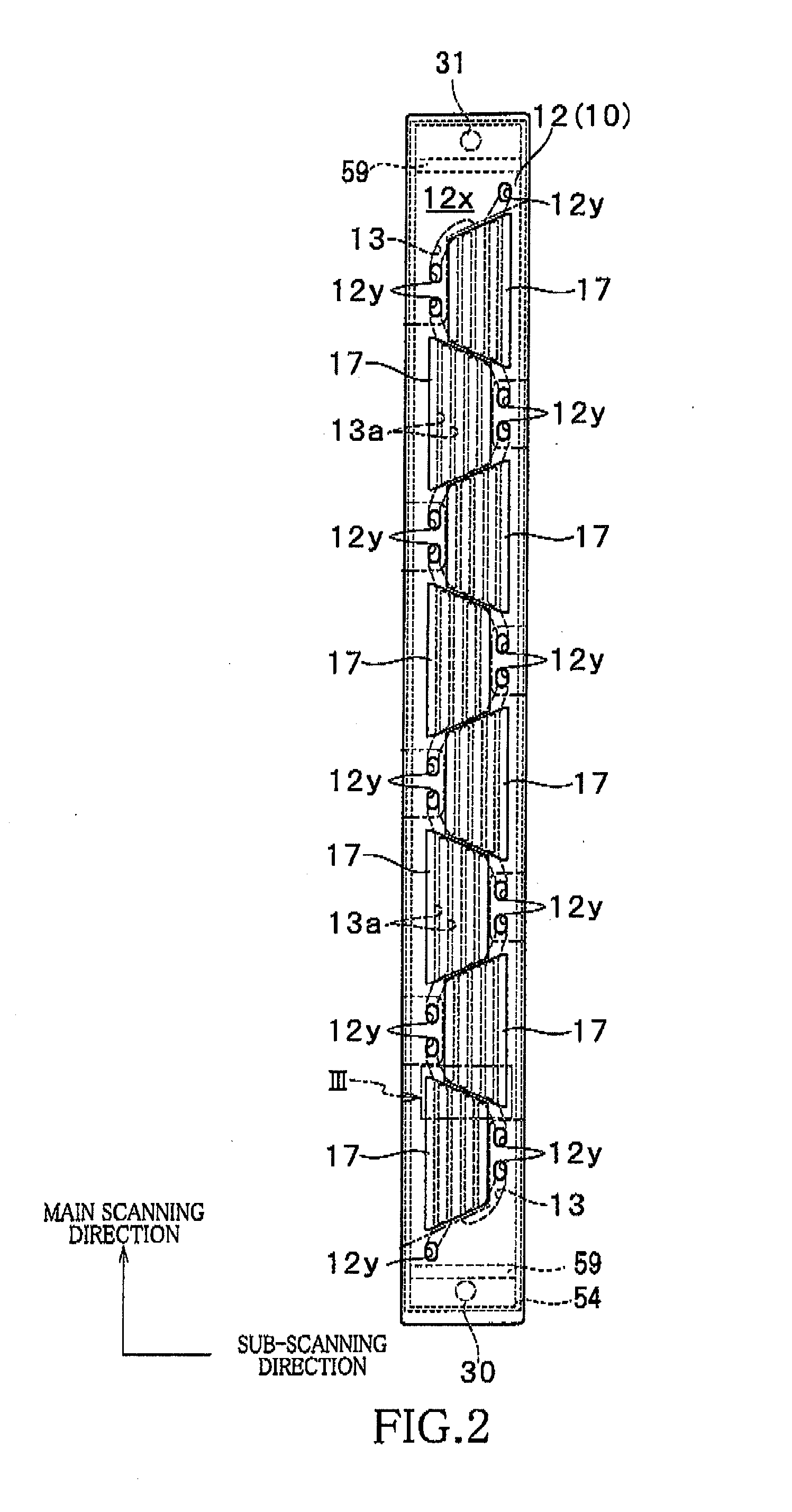

Fluid ejecting apparatus

A fluid ejecting apparatus that ejects a fluid includes a head that ejects the fluid, a first moisturizing cap device that covers the head to moisturize the head, and a first moisturizing liquid supply portion that supplies, to the first moisturizing cap device, a first moisturizing liquid for moisturizing the head when the first moisturizing cap device covers the head. The first moisturizing liquid supply portion has a first tank that stores the first moisturizing liquid. The first moisturizing cap device has a first moisturizing liquid storage portion that stores the first moisturizing liquid to be supplied from the first moisturizing liquid supply portion. The first moisturizing liquid supply portion supplies the first moisturizing liquid stored in the first tank to the first moisturizing cap device in accordance with a water head difference between the first moisturizing liquid stored in the first tank and the first moisturizing liquid storage portion.

Owner:SEIKO EPSON CORP

Fuel lid

InactiveUS20110140477A1Strong supporting structureImprove closing reliabilitySuperstructure subunitsClosures to prevent refillingEngineeringMechanical engineering

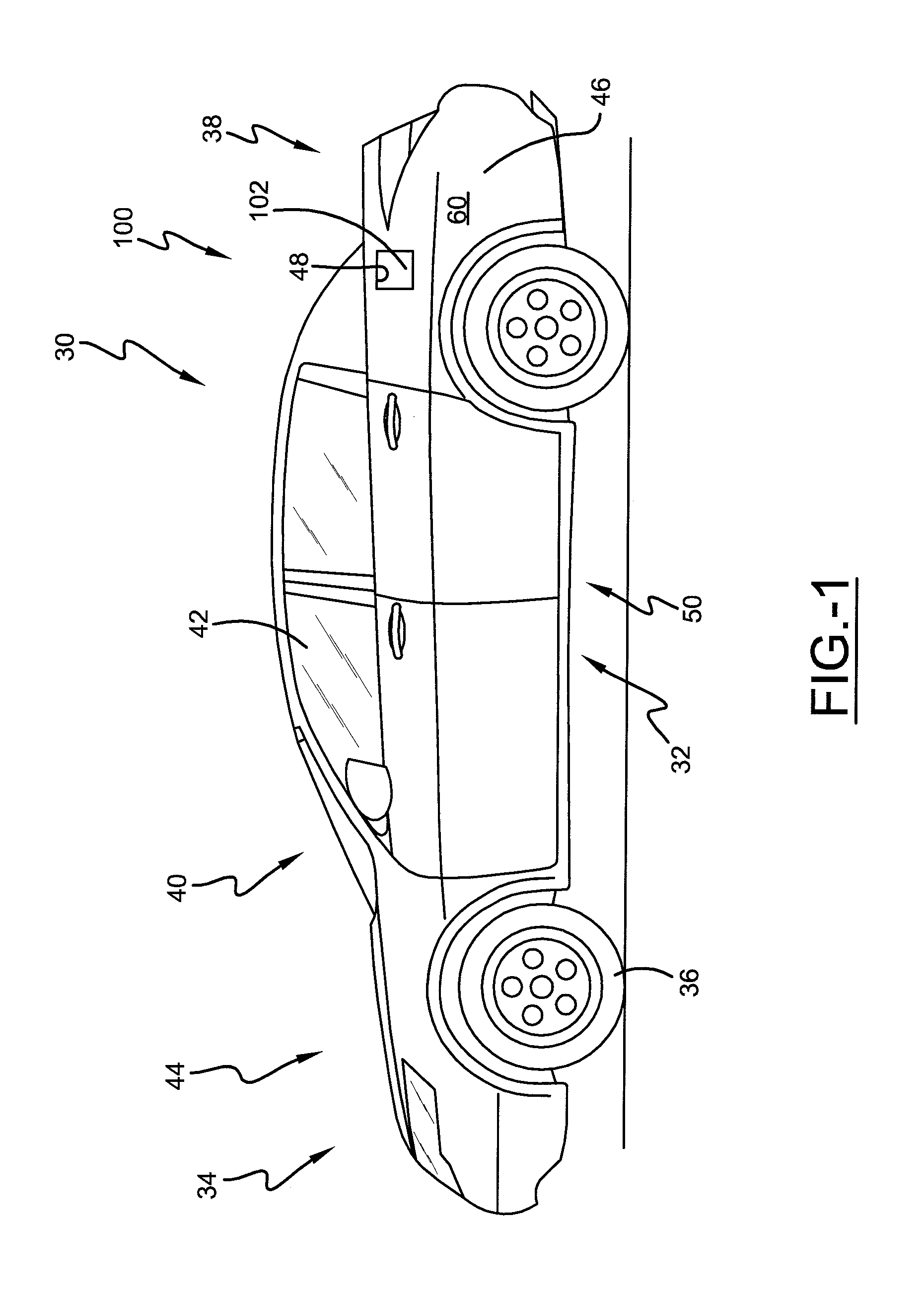

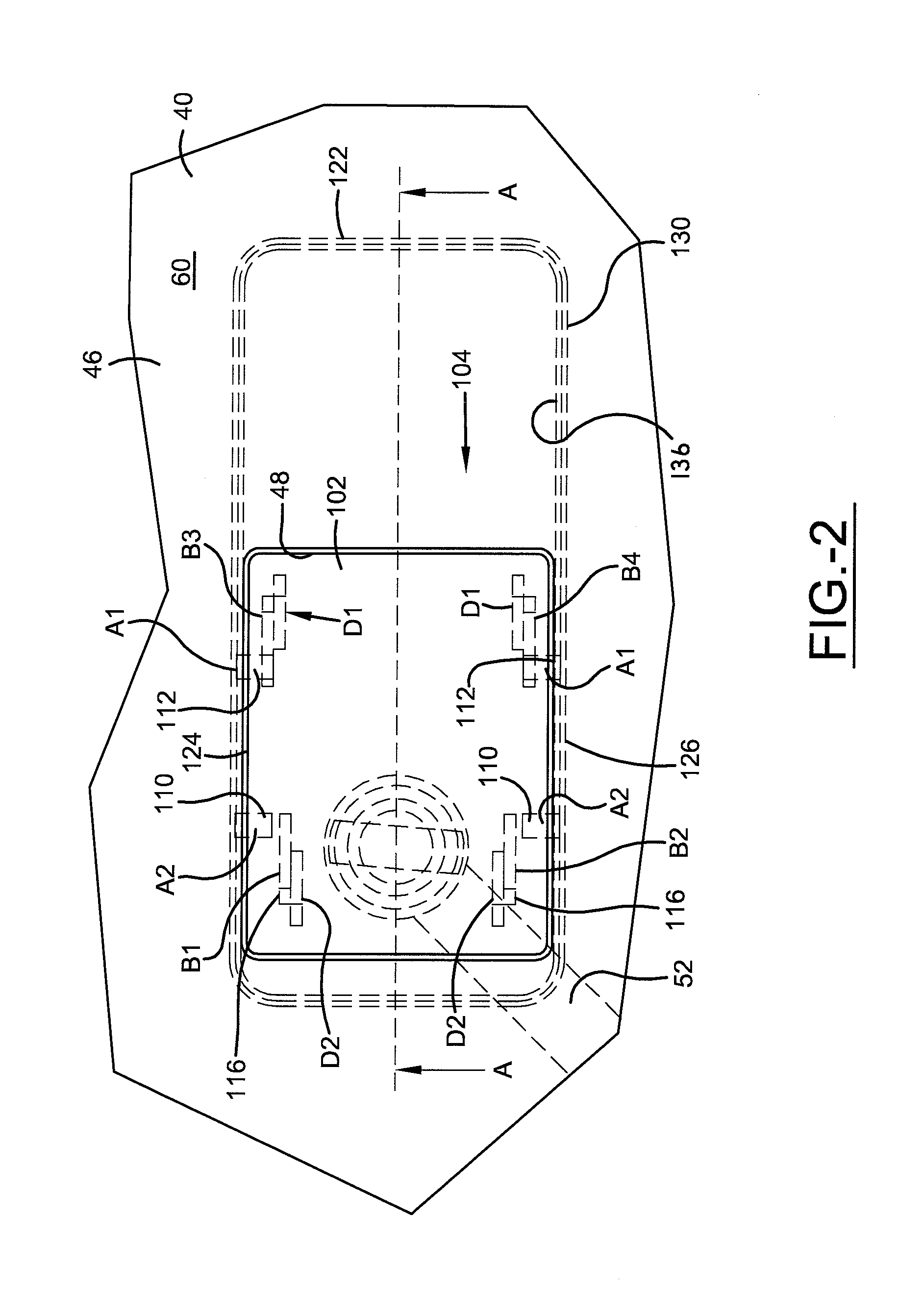

A vehicle fuel lid apparatus may include a lid and a linkage assembly that pivotally attaches the lid to the vehicle. The lid may be movable about the pivotal attachments between closed and open conditions.

Owner:HONDA MOTOR CO LTD

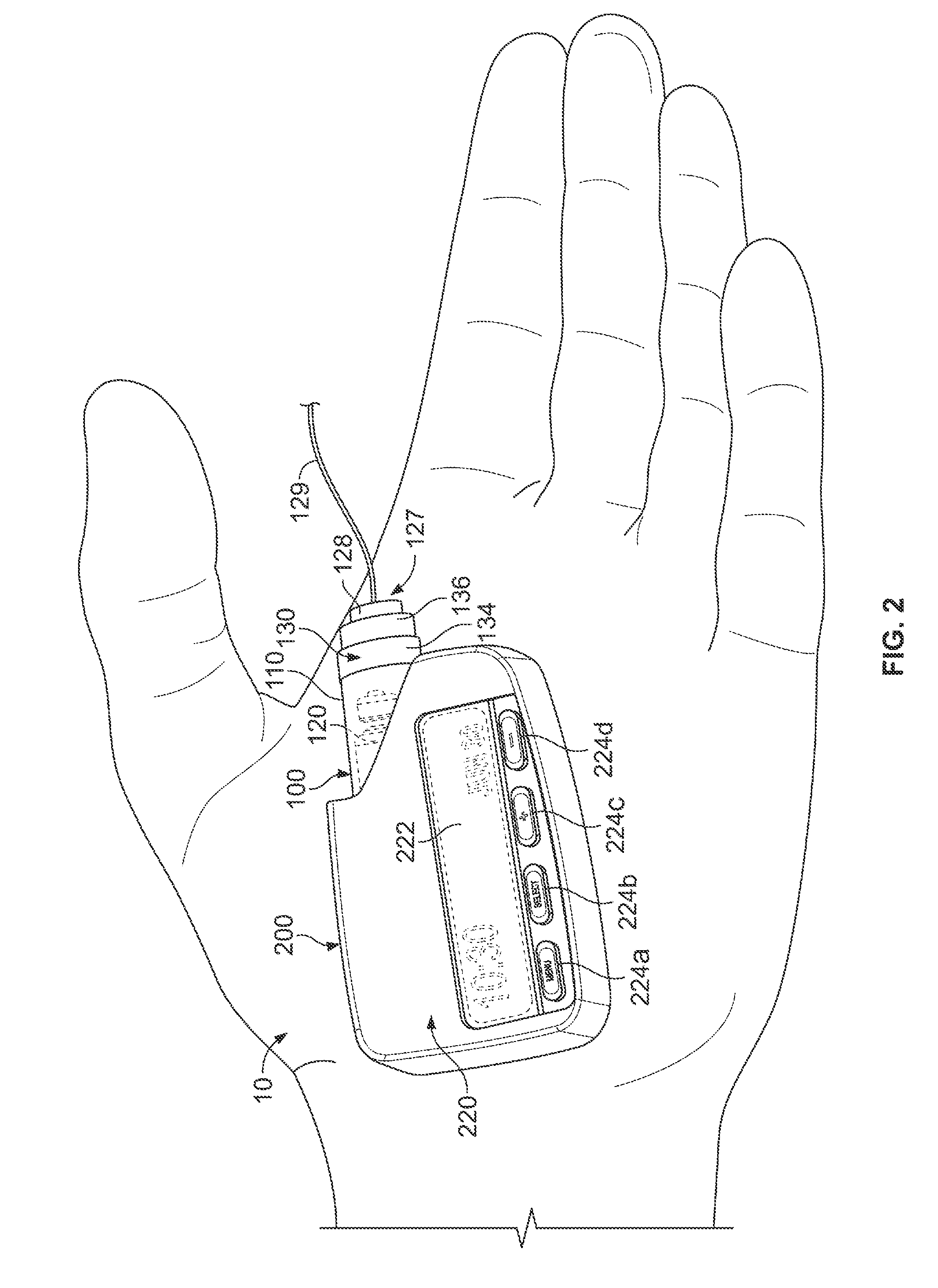

Dispensing Fluid from an Infusion Pump System

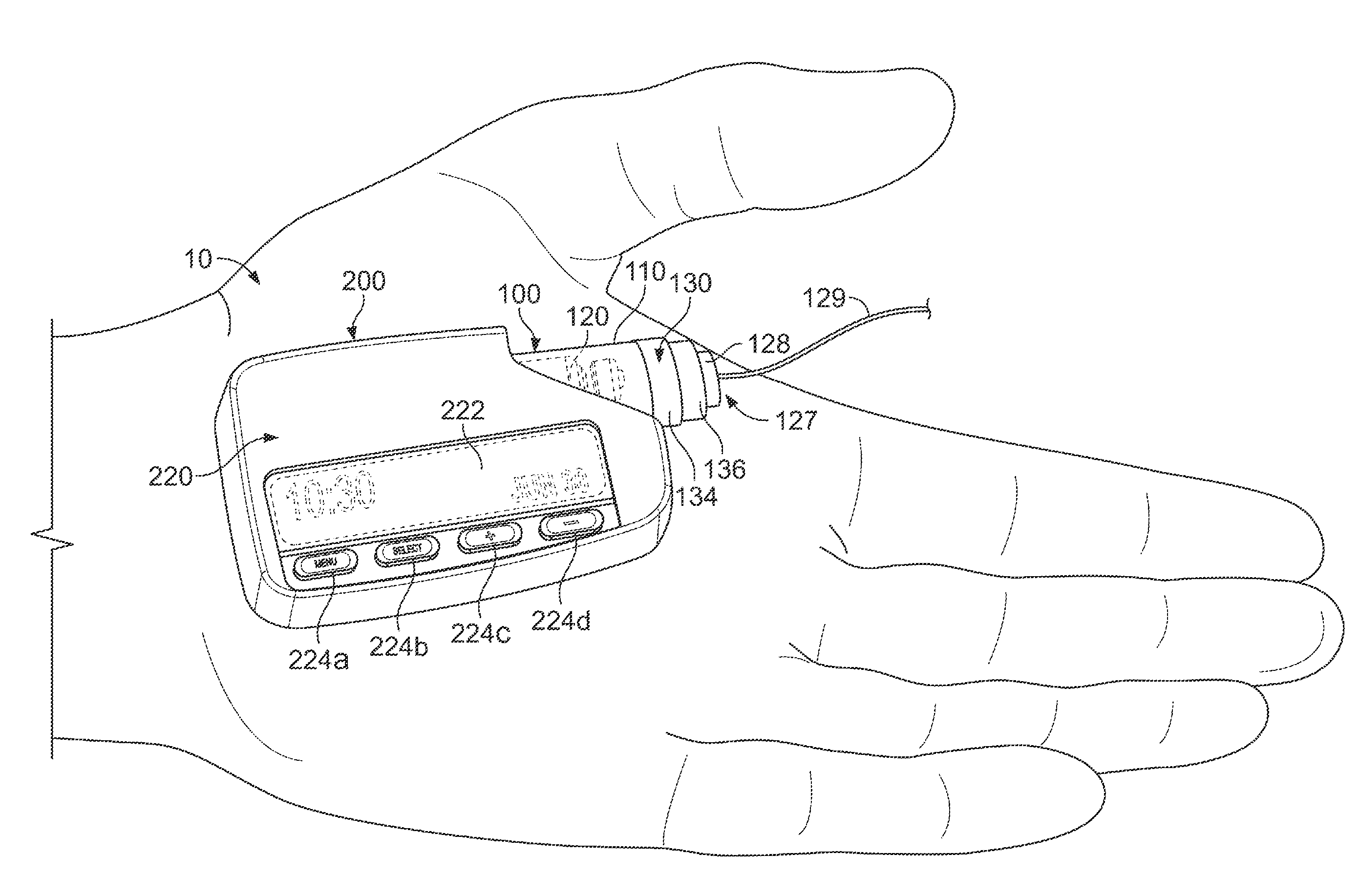

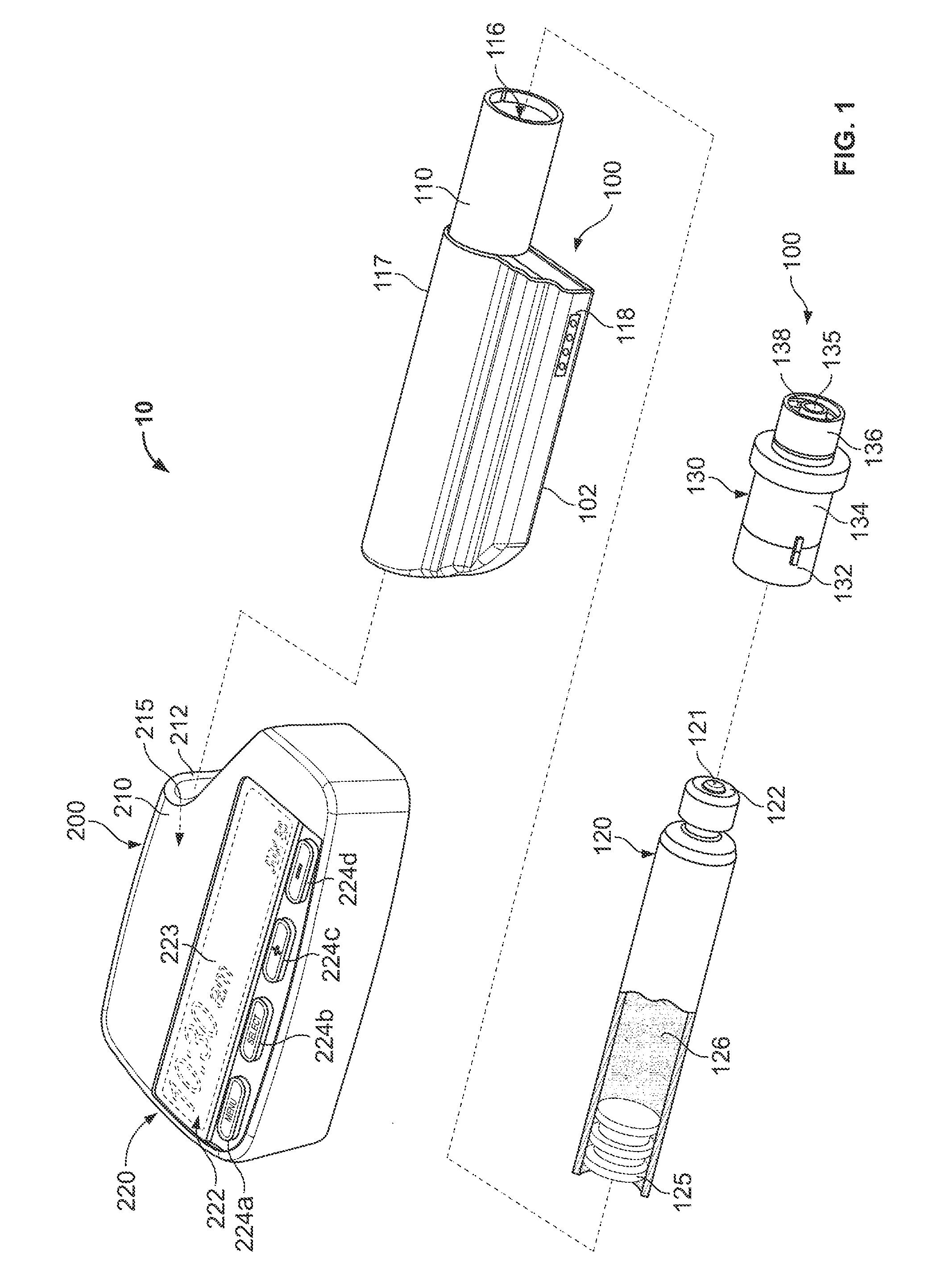

ActiveUS20120022496A1Easy to monitorEasy to wearMedical devicesPressure infusionInfusion pumpCap device

Some embodiments of a medical infusion pump system include a pump device having a cap device that mates with a pump housing to retain a medicine cartridge therein. In addition to retaining the medicine cartridge in the pump housing, the cap device may perform a number of preparatory functions or safety functions. In addition or in the alternative, some embodiments of the pump device may include a drive system that advances a piston rod to dispense medicine to the patient in a safe and energy efficient manner.

Owner:INSULET CORP

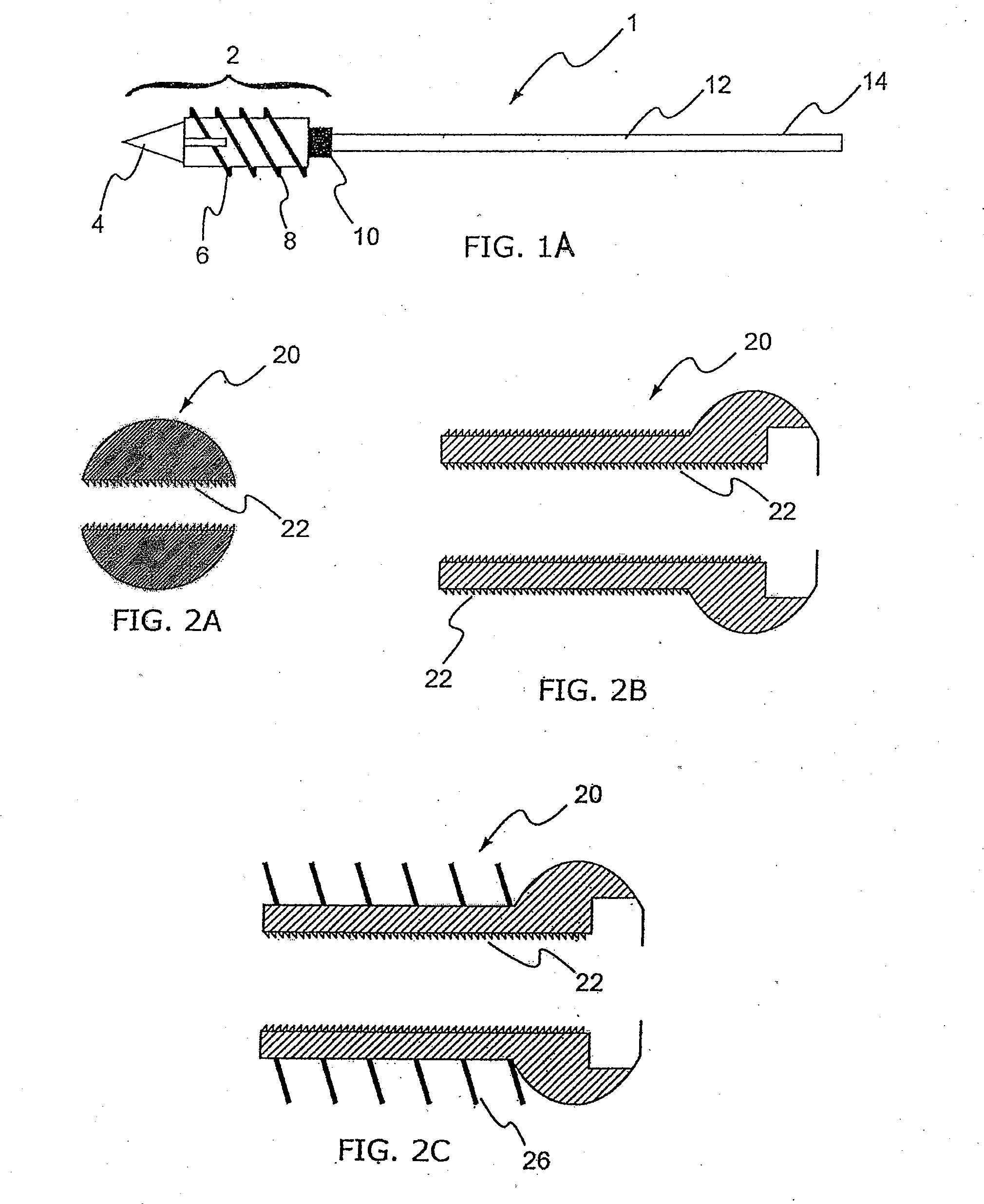

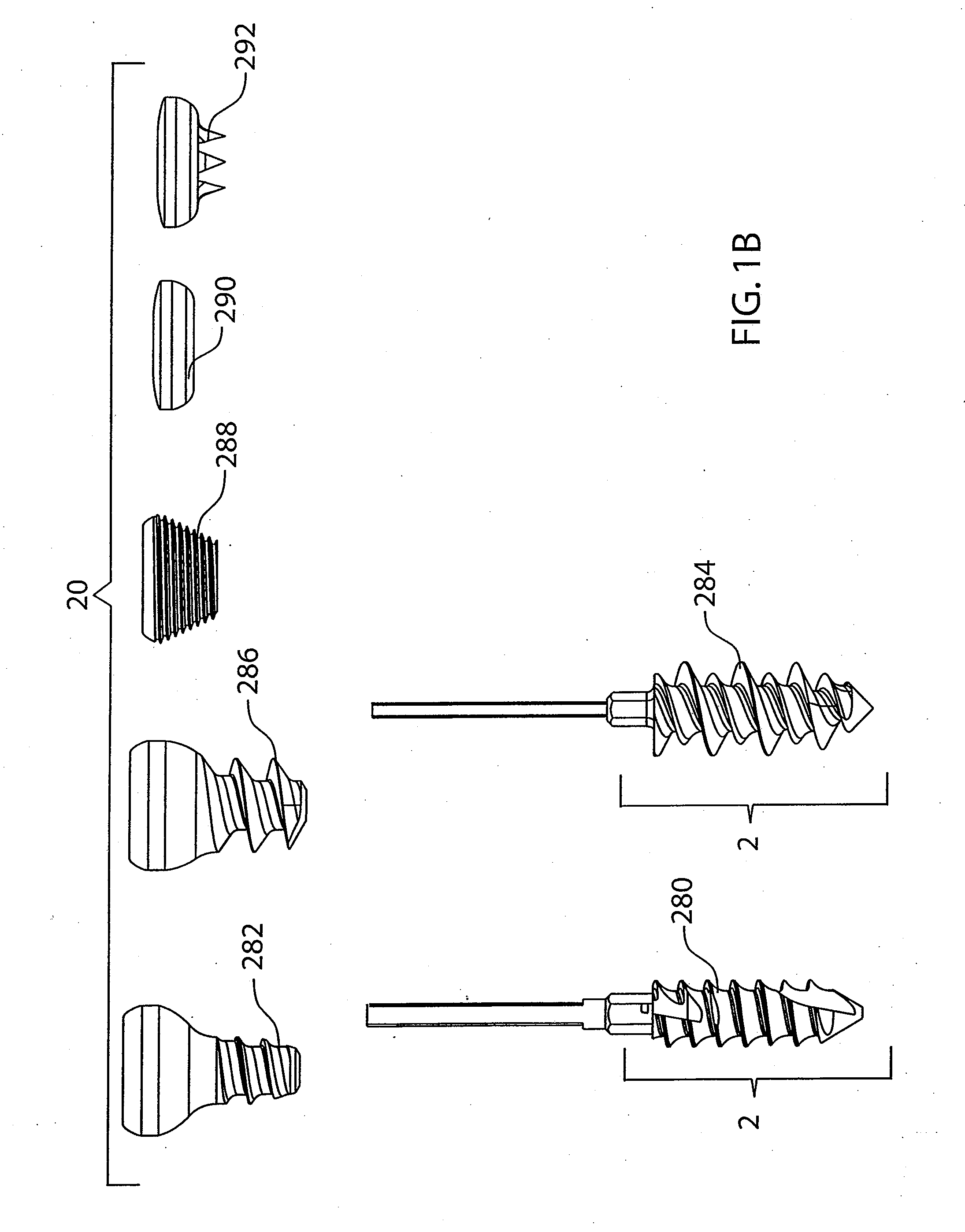

System and method for a cap used in the fixation of bone fractures

A system and method for facilitating the fixation of bone fractures is disclosed. The anchor component includes a tip, cutting threads and mating threads which are inserted into the far cortex of the bone. A wire extends from the anchor component and exits from the near cortex. A cap device includes a tension spring, a ratcheting mechanism, a lever clutch, and / or at least one wedge, wherein the tension spring, ratcheting mechanism, lever clutch, and / or at least one wedge is configured to assert friction against the wire when the cap is translated in one direction, but minimal friction against the wire when the cap is translated in the opposite direction. The cap is threaded over the wire such that the cap is restricted from backwards movement.

Owner:ORTHOIP

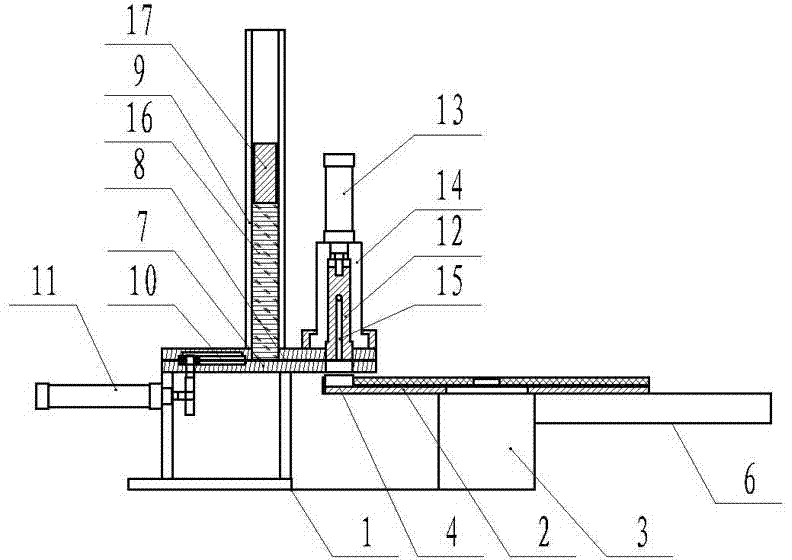

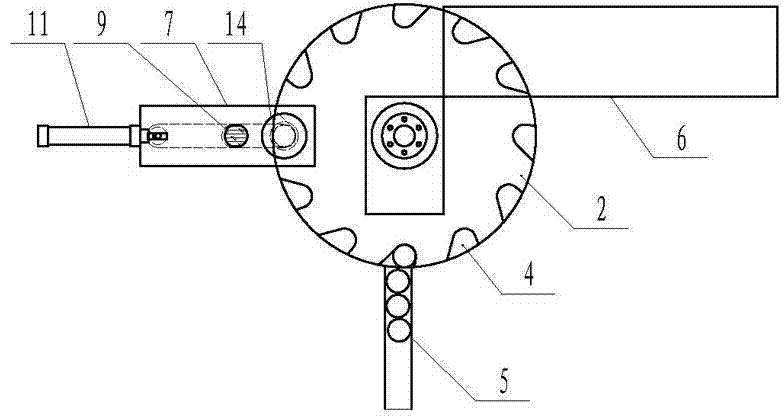

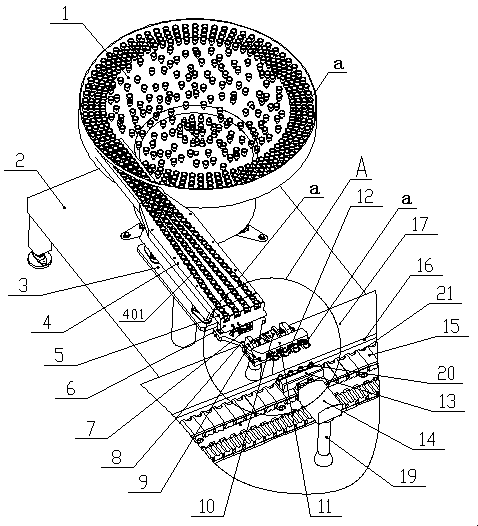

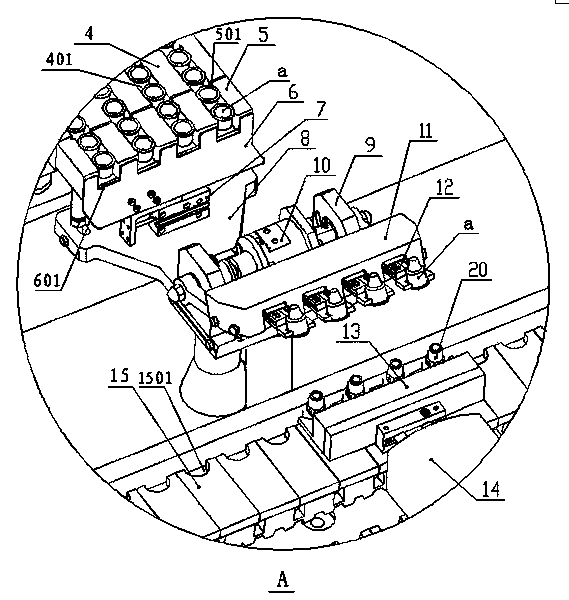

Gasket capping device

InactiveCN102962663ASimple structureHigh degree of automationMetal working apparatusDrive motorEngineering

The invention relates to a gasket capping device. The gasket capping device comprises a stand, wherein a worktable and a driving motor are arranged on the stand; a plurality of cap mounting grooves are uniformly formed in the worktable along the annular direction; and a cap feeding track, a sheeting device and a conveyor belt are sequentially arranged at the side part of the worktable along the rotating direction of the worktable. The sheeting device is structurally characterized in that the sheeting device comprises a sheet pushing track which is horizontally arranged on the stand; a gasket groove is formed in the sheet pushing track; a gasket library is arranged above the gasket track; the lower part of the gasket library is communicated with the gasket groove; a push rod and a gasket pushing air cylinder for driving the push rod to move are arranged in the gasket groove on one side of the sheet pushing track; a pressure lever and a pressure lever air cylinder for pushing the pressure lever to vertically move are arranged on the other side of the sheet pushing track; and the pressure lever is positioned above the cap mounting grooves. According to the gasket capping device disclosed by the invention, the traditional mode of manually placing the gasket into a bottle cap is replaced, so that the work efficiency is greatly increased; and in addition, the position of the gasket in the bottle cap can be kept consistent and the gasket is arranged to be in place, and thus the sealing effect is improved.

Owner:苏州天奇自动化机械制造有限公司

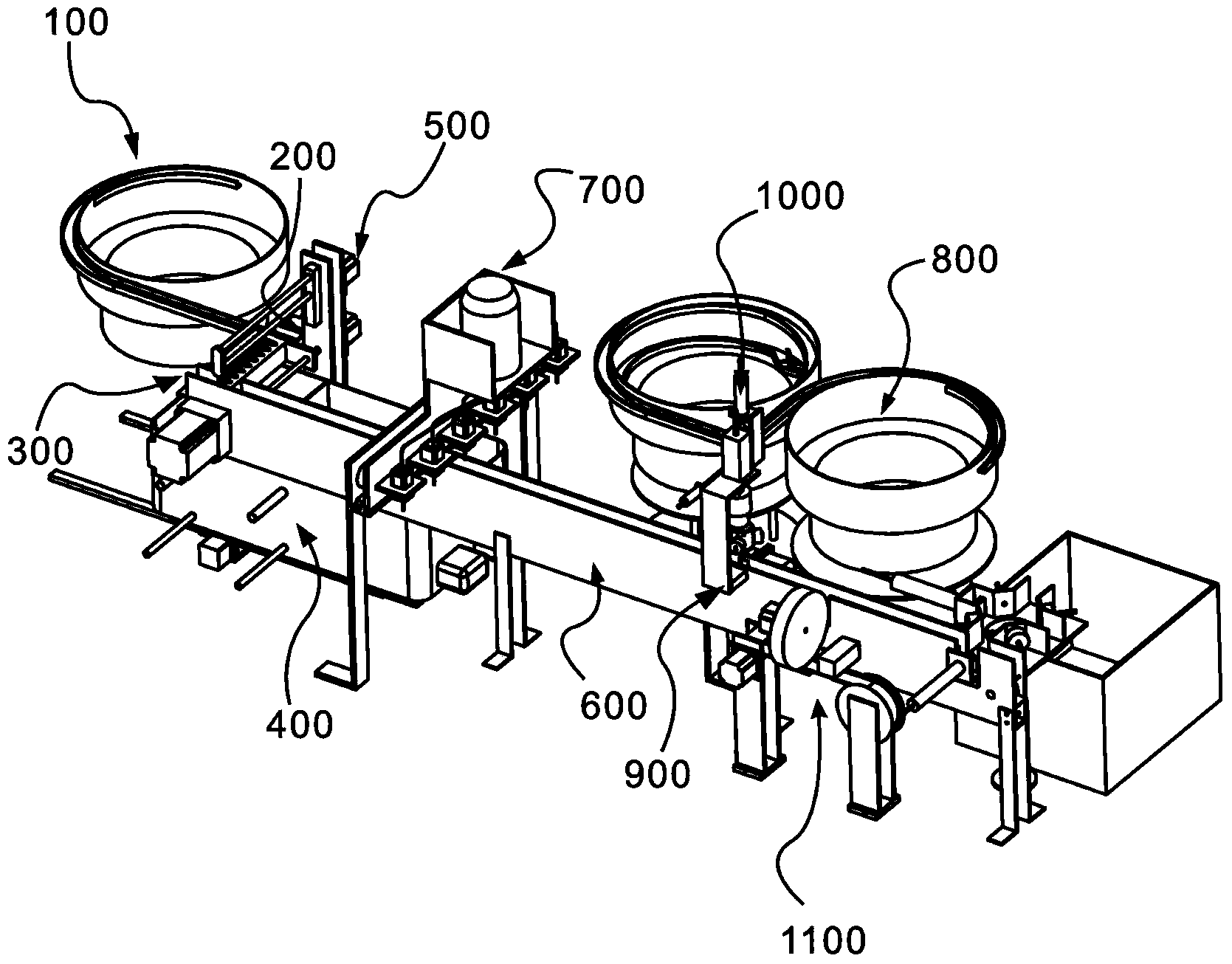

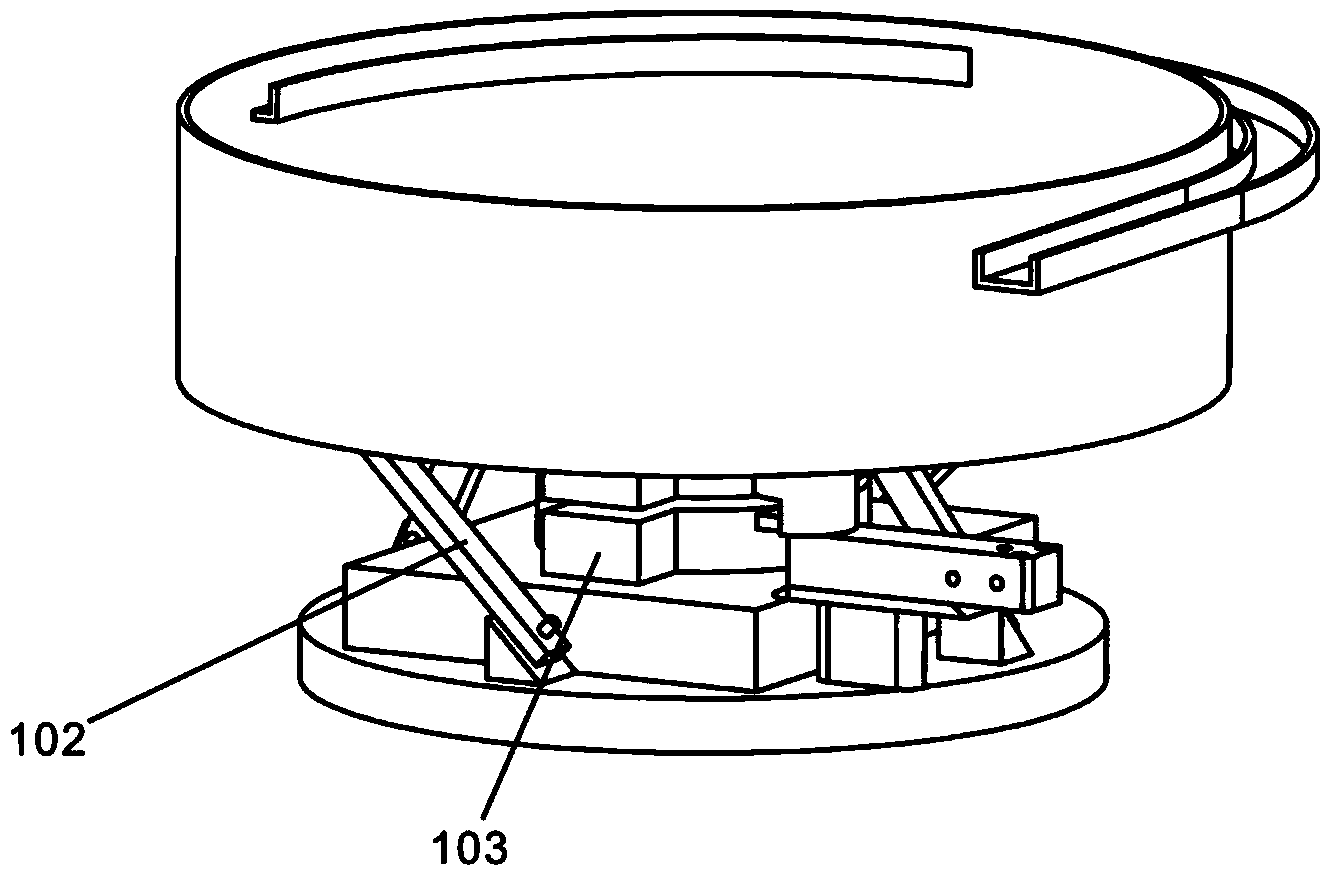

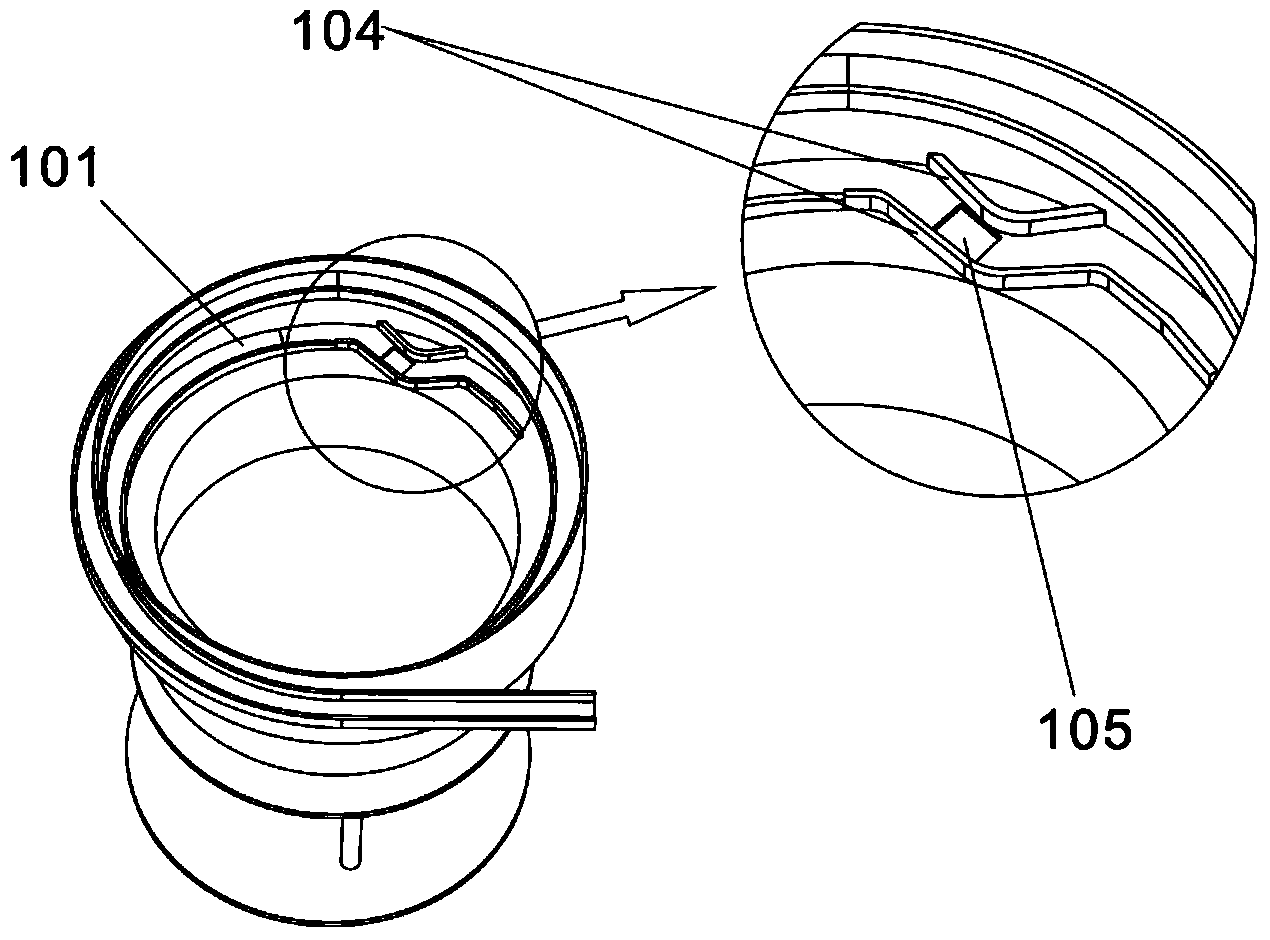

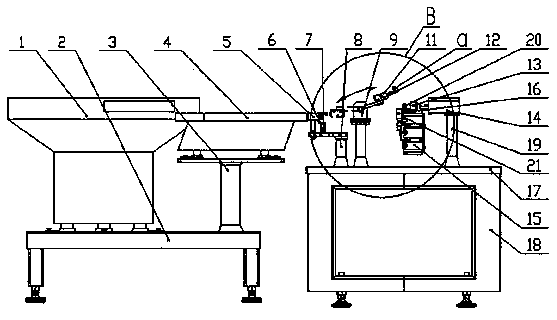

Filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system

ActiveCN104326431ASolve the problem of directional transportCapsThreaded caps applicationEngineeringBottle

The invention discloses a filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system which comprises a correcting device and a pushing device and also comprises a carrying device, a rinsing device, a progressive device, a conveying device, a filling device, a cover conveying device, an impact extrusion device, a cover screwing device and a labeling device, wherein the correcting device is a cavity of which one end is open; a material channel which spirally ascends is formed in the inner side wall of the cavity; and the pushing device comprises a pushing cylinder and a pushing platform. According to the system disclosed by the invention, the problem that the filling bottles cannot be directionally transported can be solved, and the problems that the filling bottles cannot be subjected to automatic progressive rinsing, conveying and filling, cover conveying, filling bottle cover impact extrusion and fixation, cover screwing and labeling and coding also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

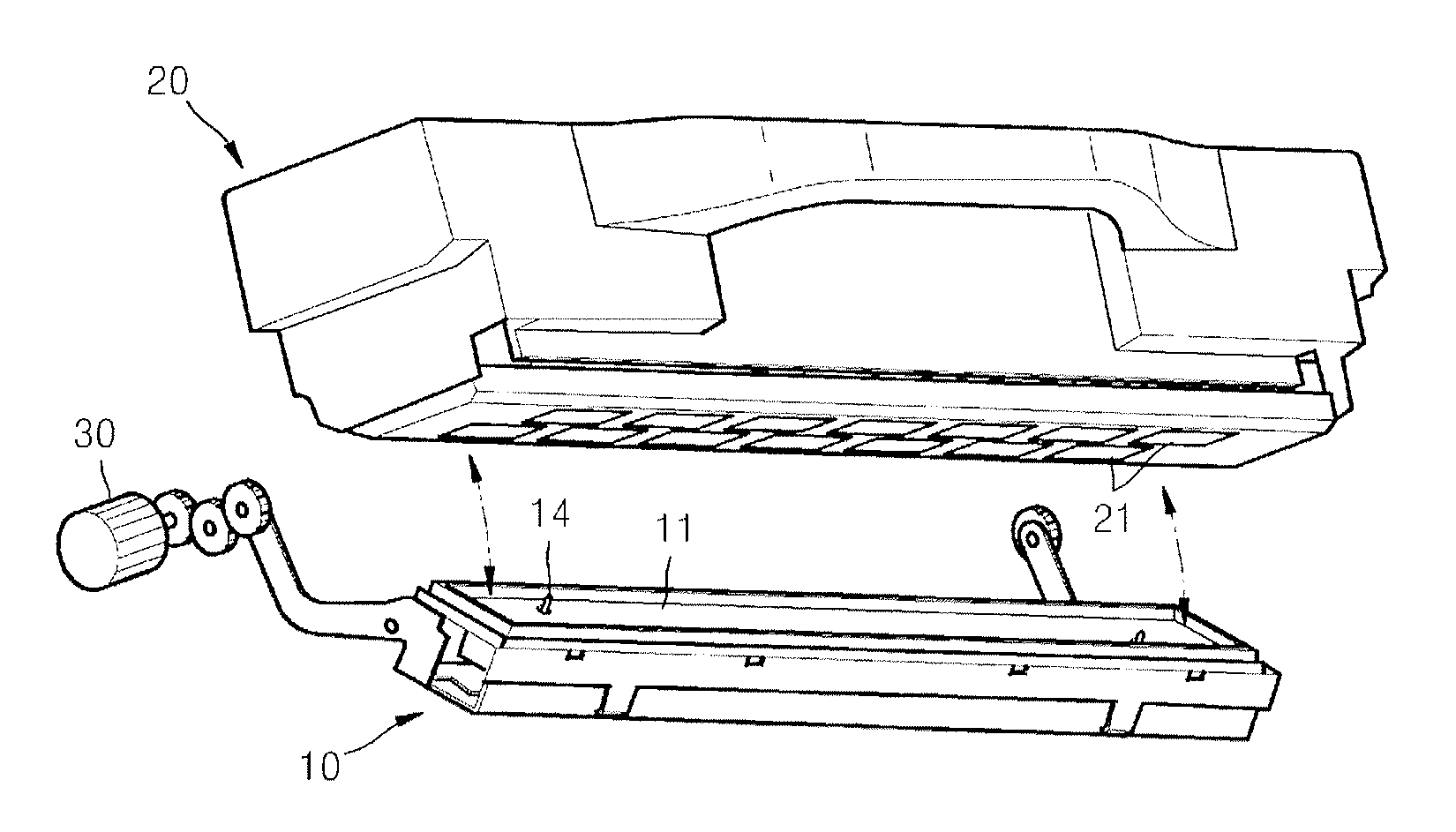

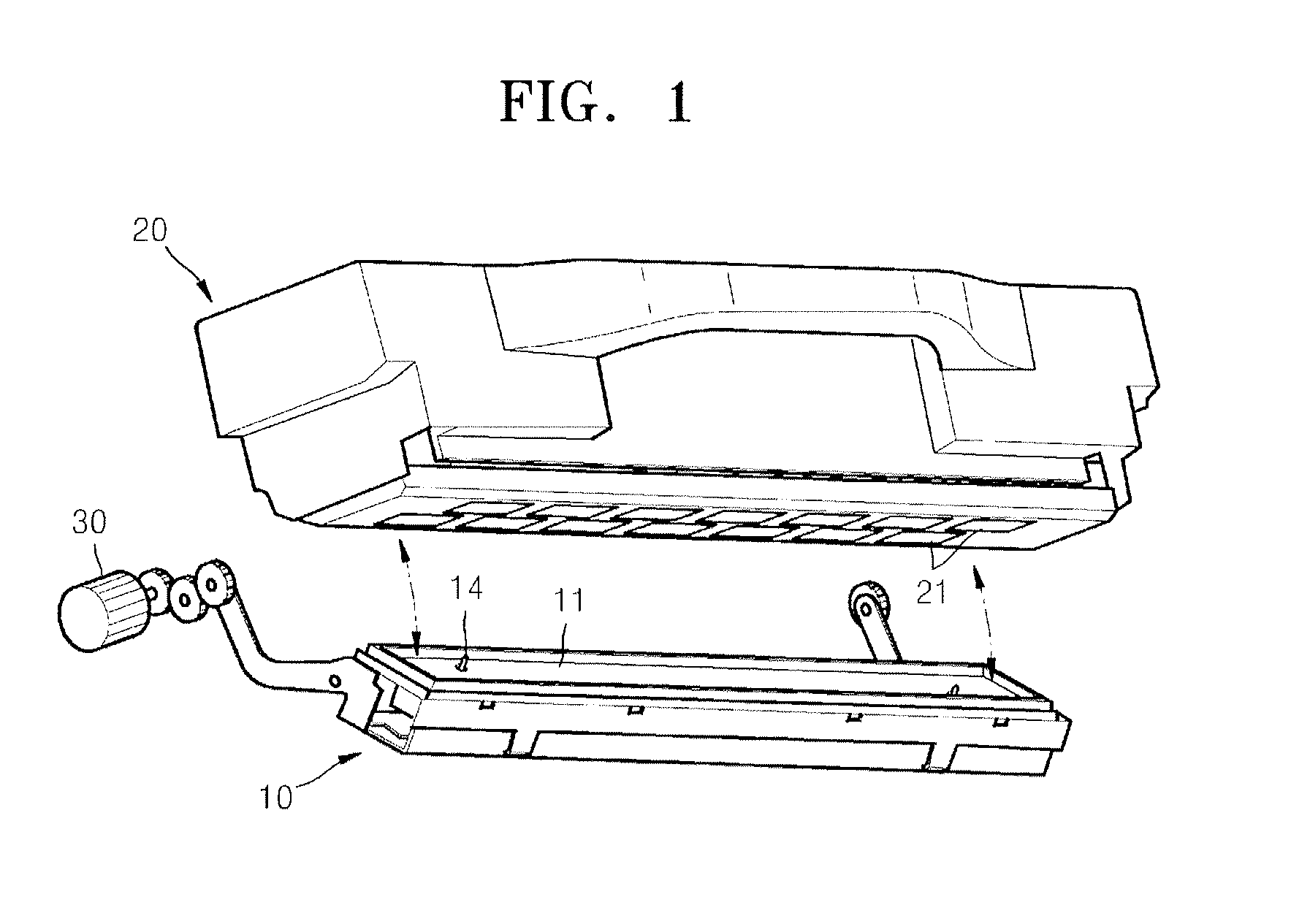

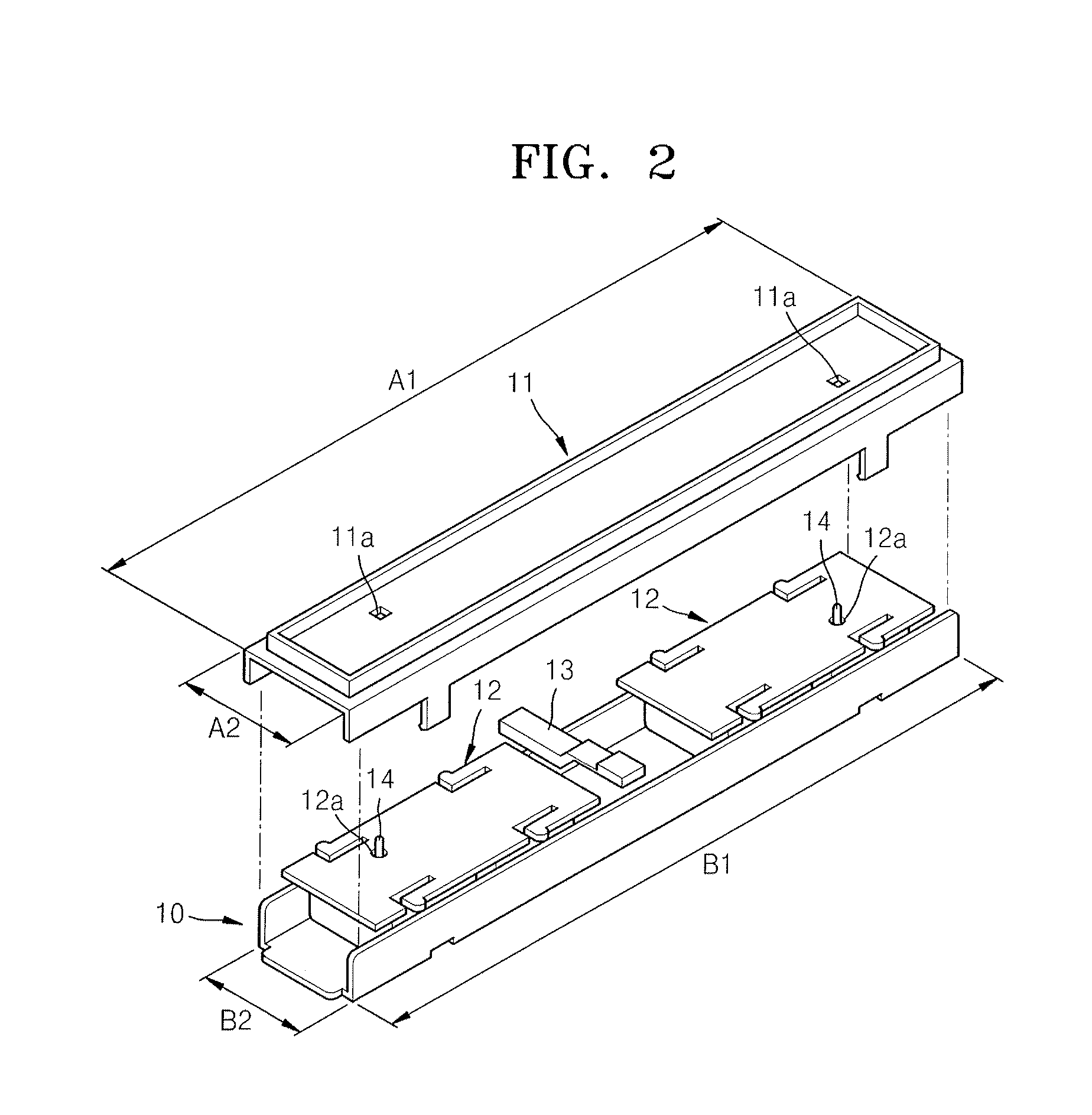

Carding machine with linearly movable casing

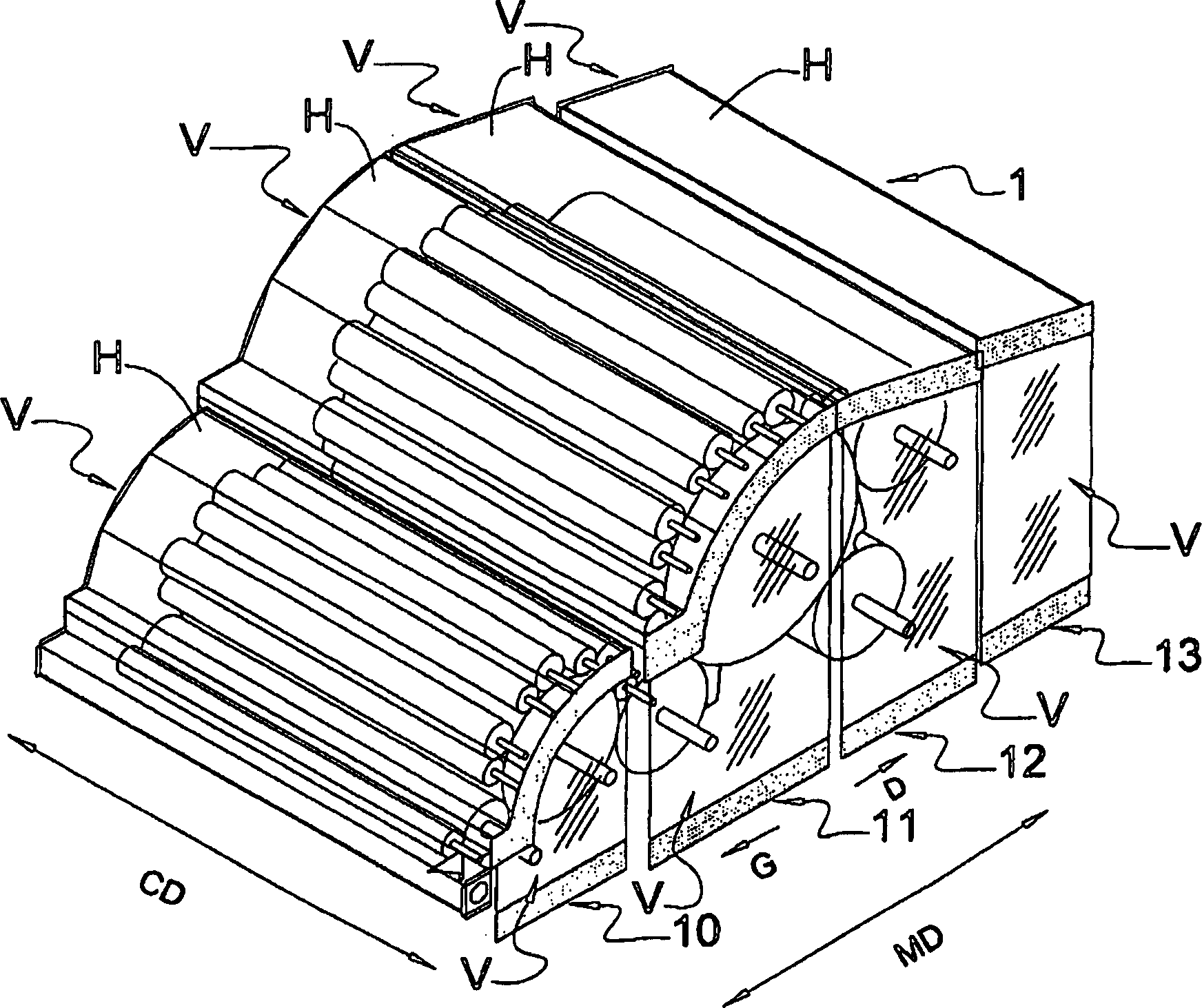

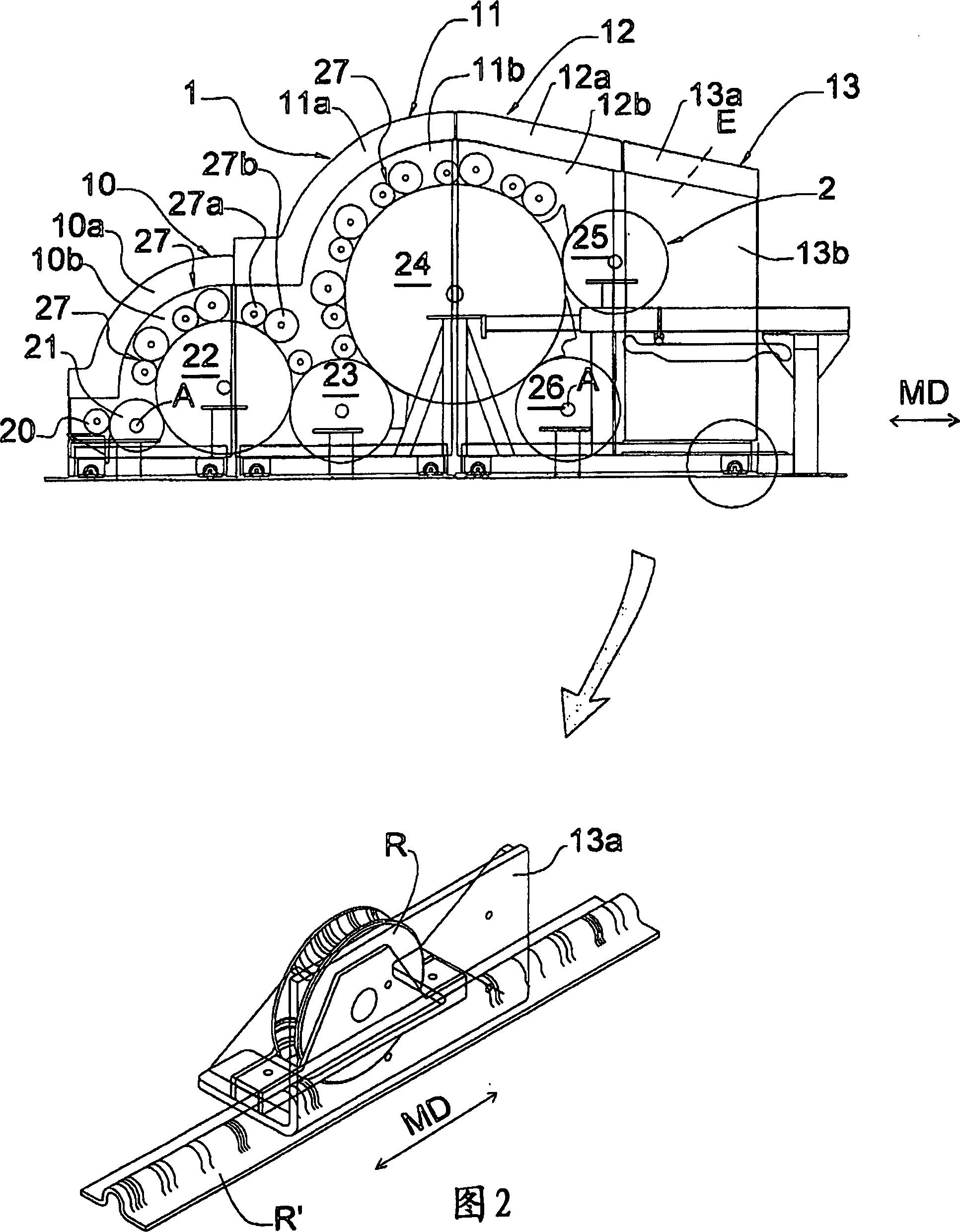

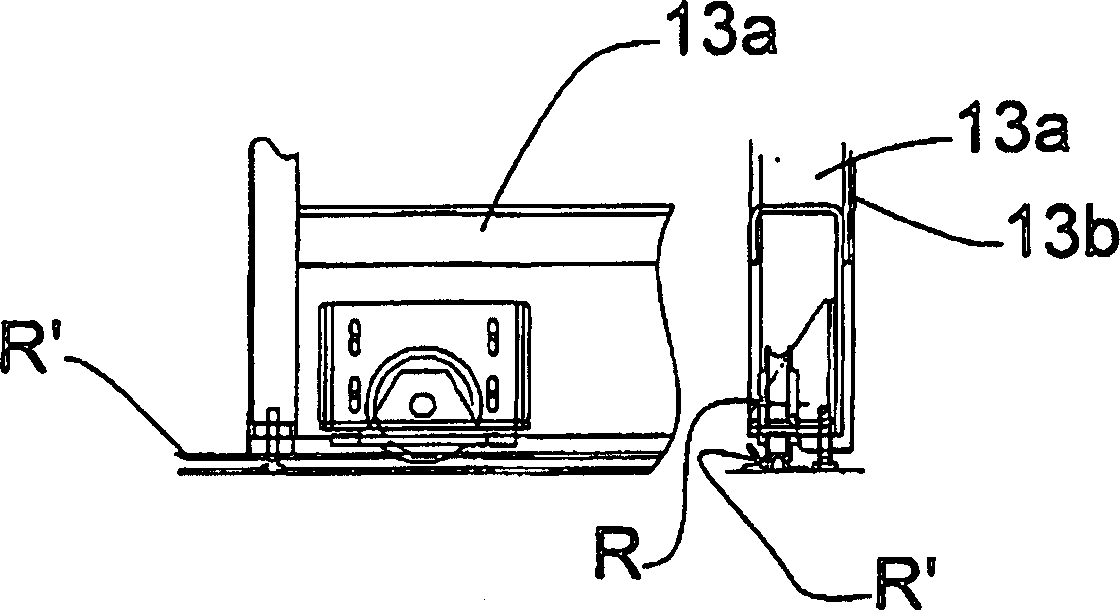

InactiveCN1811027AAddress accessibility issuesIncrease contactCarding machinesEngineeringMechanical engineering

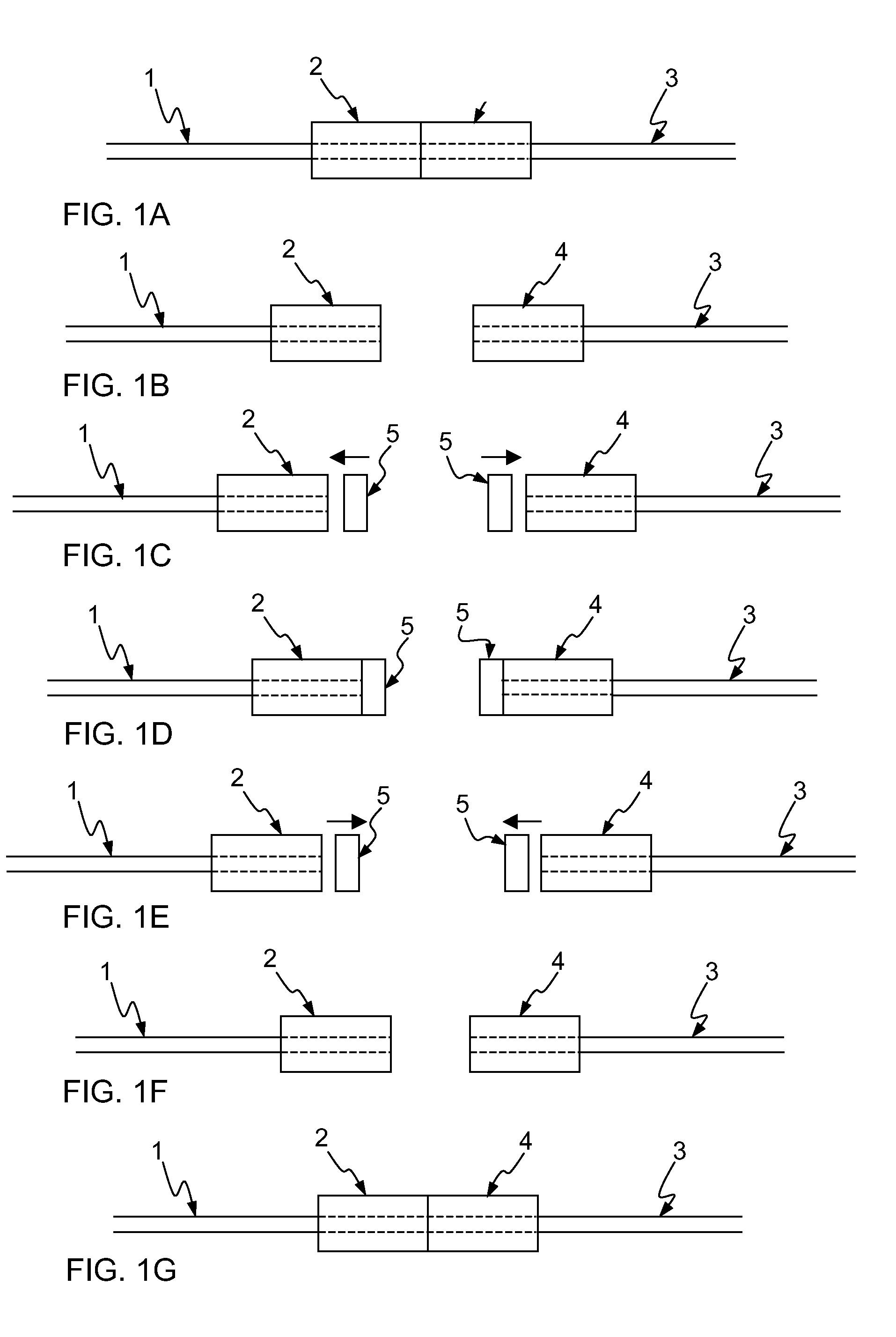

The invention relates to a carding machine which is provided with a plurality of drums (20,21,22 and so on) and a covering device, wherein the covering device (1) can form an encloser (E), and the drums of the carding machine is contained in the encloser. The covering device (1) is provided with at least a covering element (10, 11, 12, and 13), and the covering element is vertical to the vertical direction of the drums of the carding machine along a shaft line (MD) and can do translational motion between a covering position and an end portion opening position, the covering position exclusively belongs to the covering unit on the position, at least one portion of the drums of the carding machine is covered by the covering element, and the drums are not covered by the cover element on the end portion opening position.

Owner:ASSELIN THIBEAU

Maintaining sterile conditions in a fluid transportation system

ActiveUS20110165020A1Reduce riskEasy to handleMedical devicesCombustion enginesPeritoneal dialysisDisinfectant

A capping device is configured to terminate a connector while disconnected from another connector in a fluid transportation system, e.g., for peritoneal dialysis. The connector comprises an exposed surface portion that is enclosed when the connector is connected to the other connector. The capping device comprises a body defining a chamber with an opening, a liquid-containing disinfectant in the chamber, a sealing element arranged in the opening to form a sealed cavity retaining the disinfectant, and a structure for engaging and guiding the connector towards the body such that a portion of the connector displaces the sealing element into the chamber. The sealed cavity is configured such that a displacement of the sealing element into the chamber actively presses the disinfectant out of the sealed cavity, for disinfecting at least part of the exposed surface portion. The capping device may be manufactured by introducing the liquid-containing disinfectant into the chamber through the opening, and by arranging the sealing element in the opening to form the sealed cavity.

Owner:GAMBRO LUNDIA AB

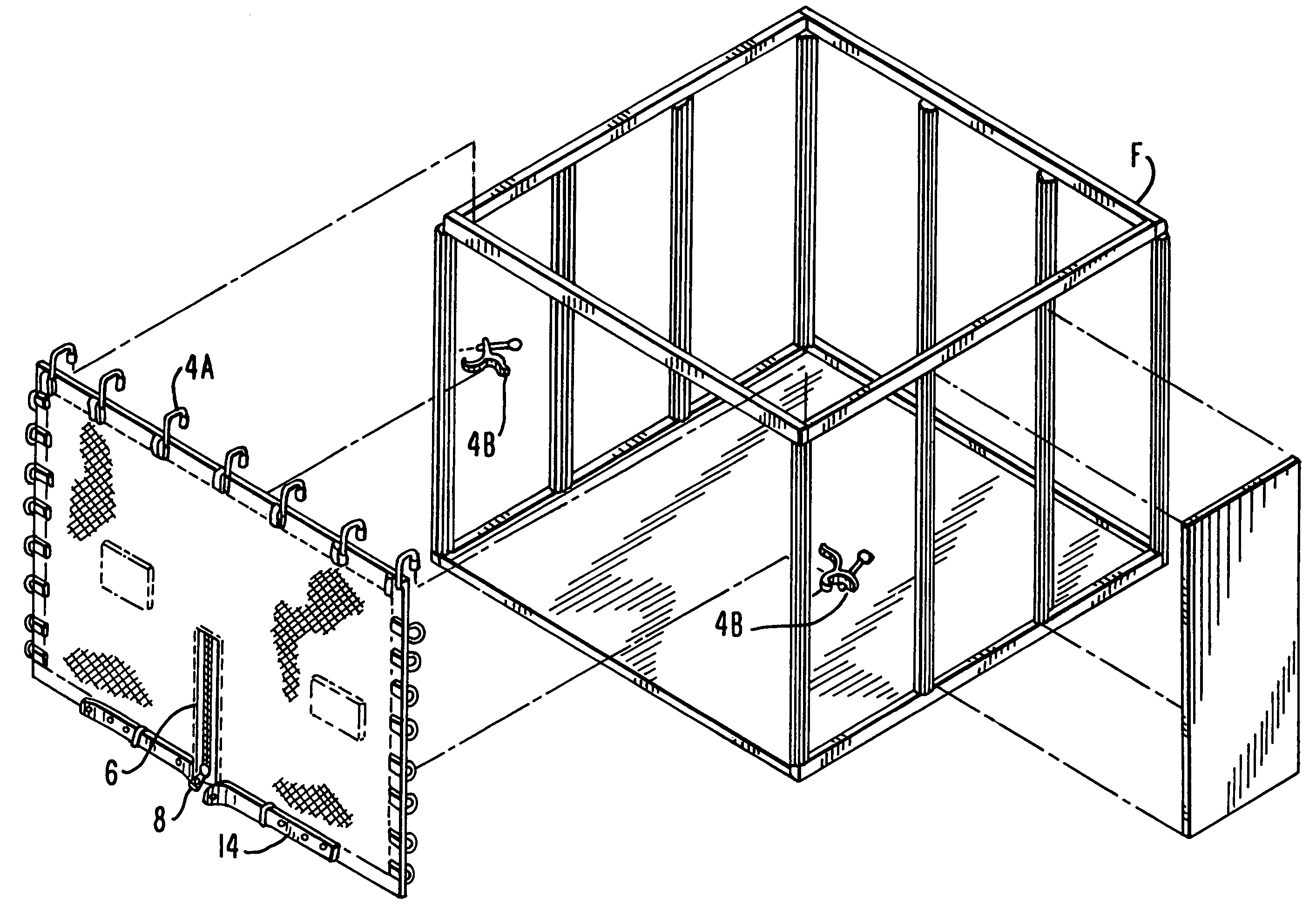

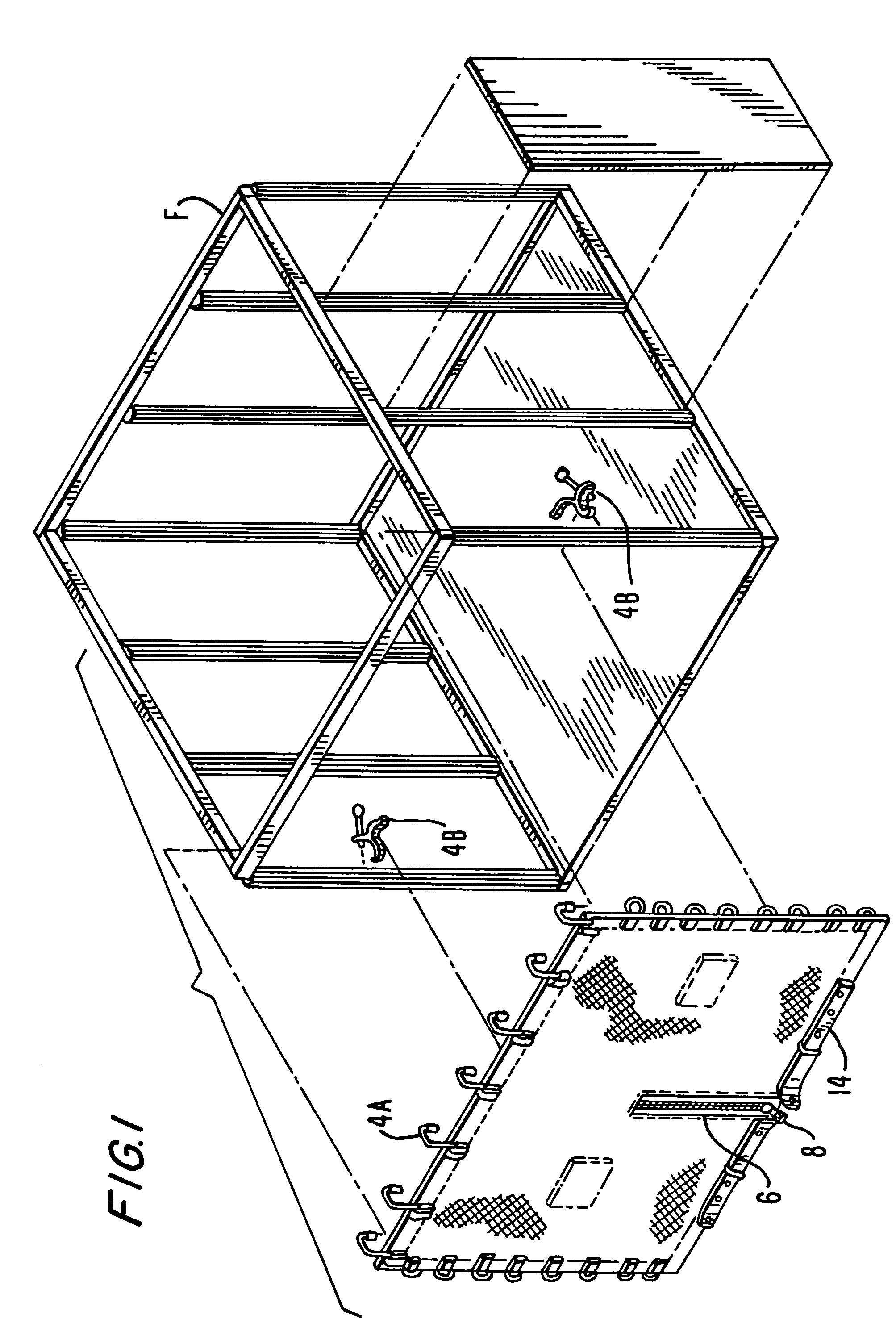

Securable cover apparatus for trade show booths

Owner:BOOTHSEAL

Cap device for mixing different kinds of substances separately kept therein within a container

InactiveUS20040149599A1Lighting and heating apparatusClosure with auxillary devicesCap deviceEngineering

A cap device having a cap member connected to a threaded outer surface of a neck portion of a container body and an additive containing member connected to one side of the cap member. A cylinder member is formed within the cap device as an integrated body having a space on a upper side of the cylinder member such that the cylinder member connects to the additive containing member. A plurality of first throughholes is formed in a fan shape are formed in the lower side of the cylinder member. A valve plate is rotatably positioned within the cylinder member, and the valve plate has a plurality of second throughholes corresponding in positions with the plurality of the first throughholes of the additive containing member based on a predetermined rotation of the valve plate to selectively open or close the plurality of first throughhole. An opening and closing means is installed and formed around the cylinder and the cap member and the neck portion of the container body so that the valve plate opens and closes the plurality of first throughholes of the cylinder member as the valve plate is rotated.

Owner:CHO YOUNG KOOK

Cap device for mixing different kinds of materials separately contained therein and in bottle

InactiveUS6974024B2Change colorConvenient for userLighting and heating apparatusClosure with auxillary devicesBottleCap device

A cap device for bottles, which is capable of mixing an additive contained therein with a material contained in a bottle to prepare a mixture in accordance with a simple rotating action of the cap device relative to the bottle, performed by a user, thus allowing the user to easily prepare the mixture just before drinking or using the mixture. The cap device also allows the mixture to be quickly discharged from the container. The cap device for bottles of the present invention includes a valve unit closely and removably fitted over a mouth of a bottle. An additive containing unit externally and removably engages with the valve unit, and the additive containing unit defines a cavity therein to contain an additive.

Owner:CHO YOUNG KOOK

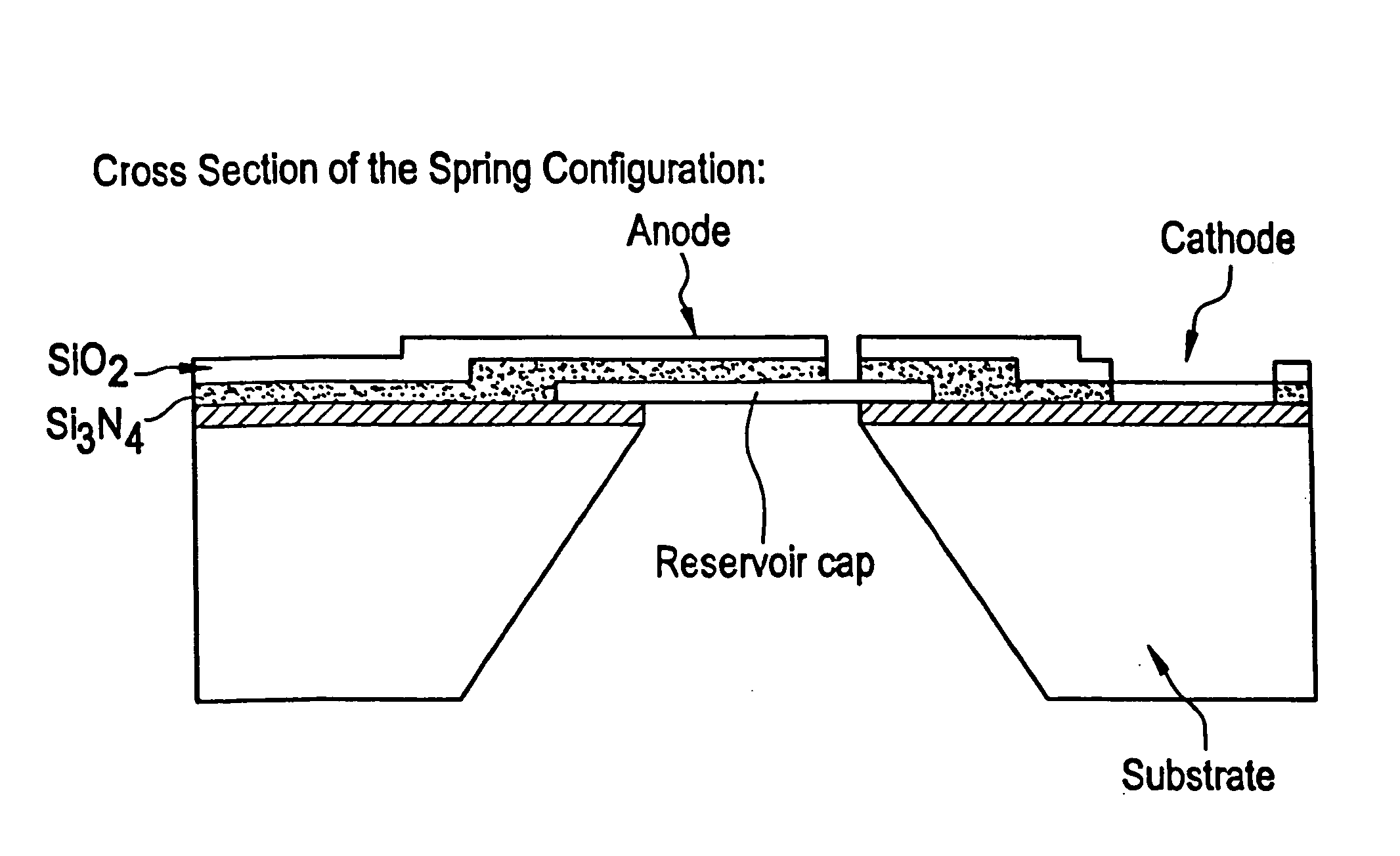

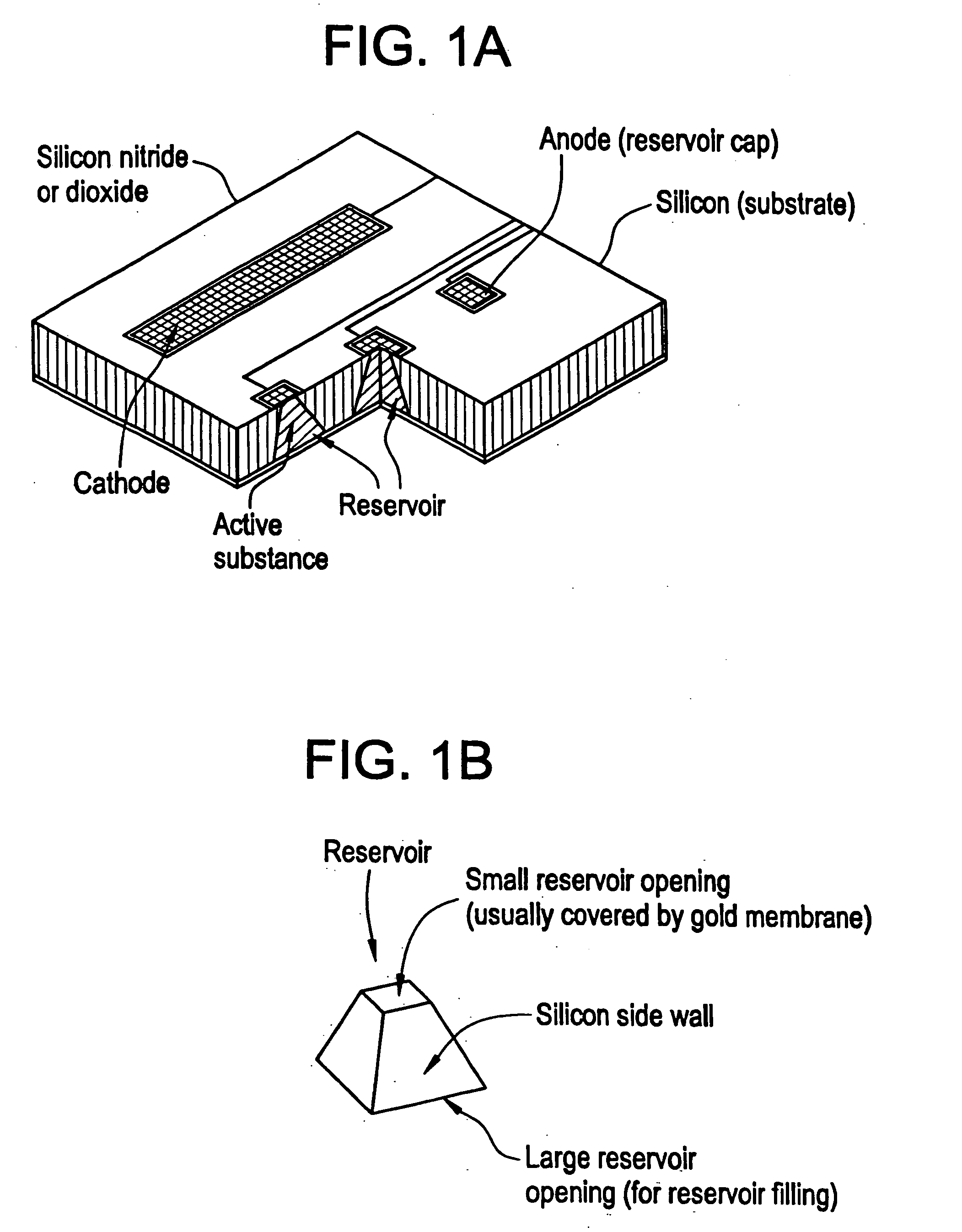

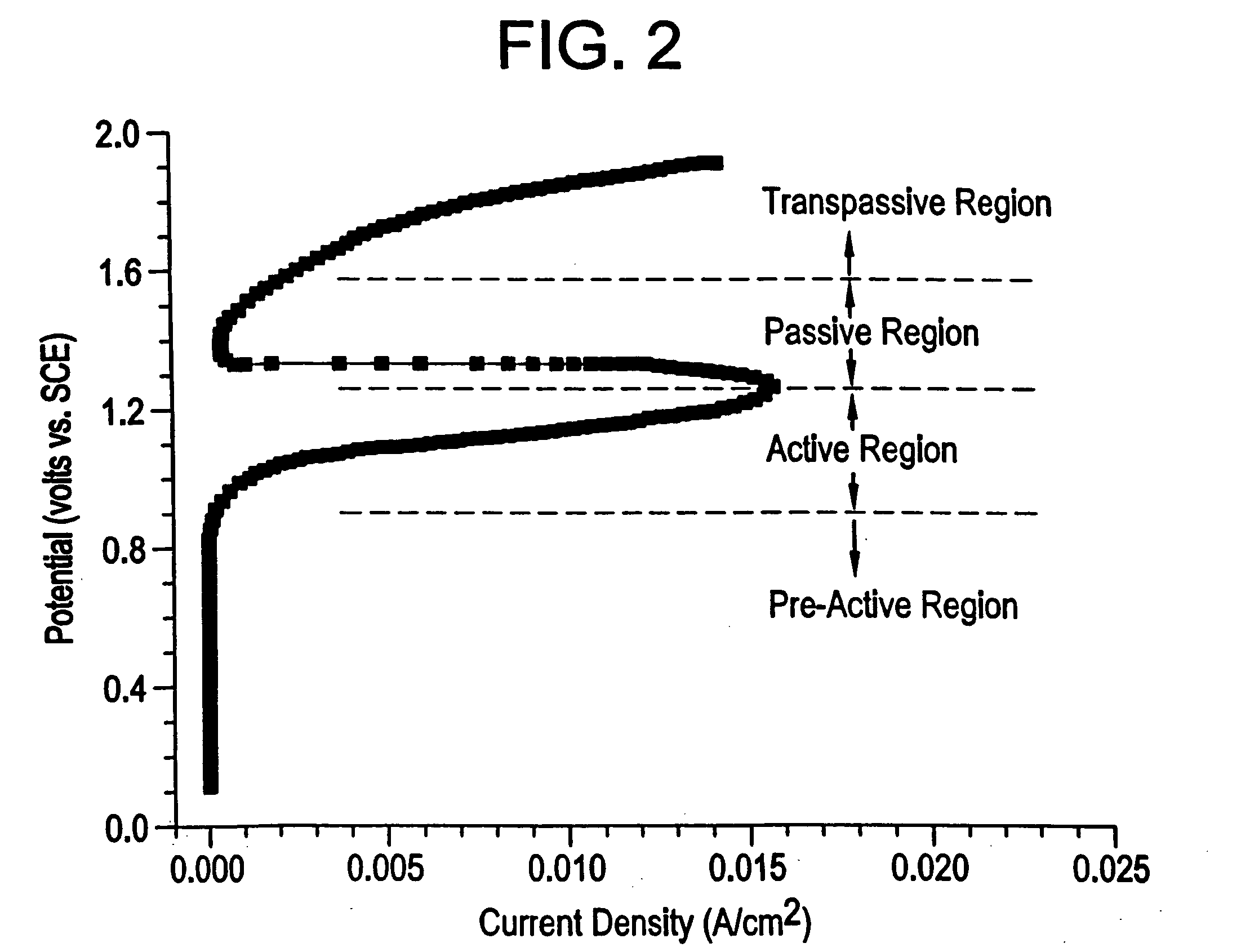

Device for controlled reservoir opening with reinforced reservoir caps

InactiveUS20050143715A1Increase uniformity and reliabilityGood disintegrationValve arrangementsMedical devicesControl releaseControl circuit

Owner:MASSACHUSETTS INST OF TECH

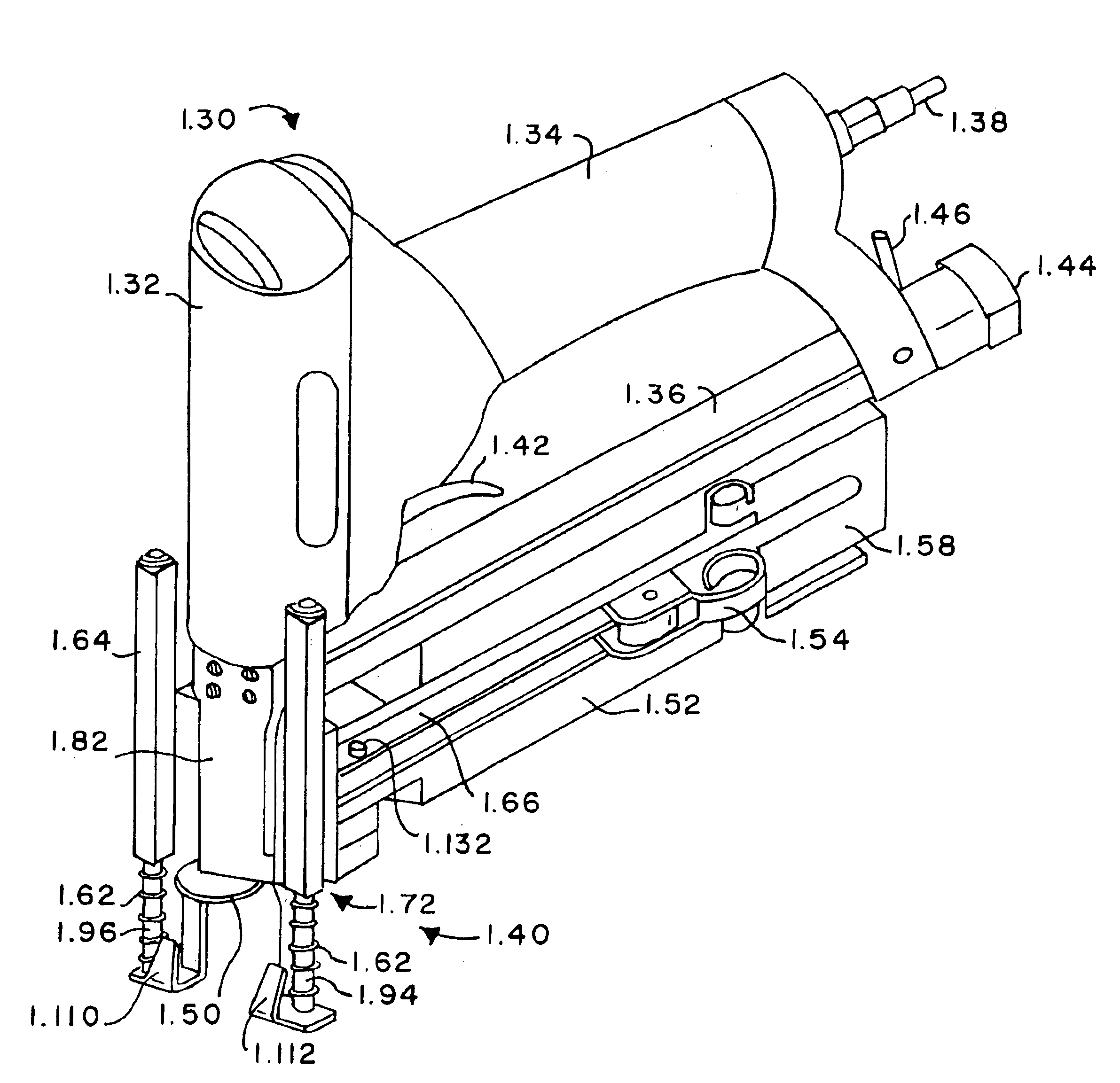

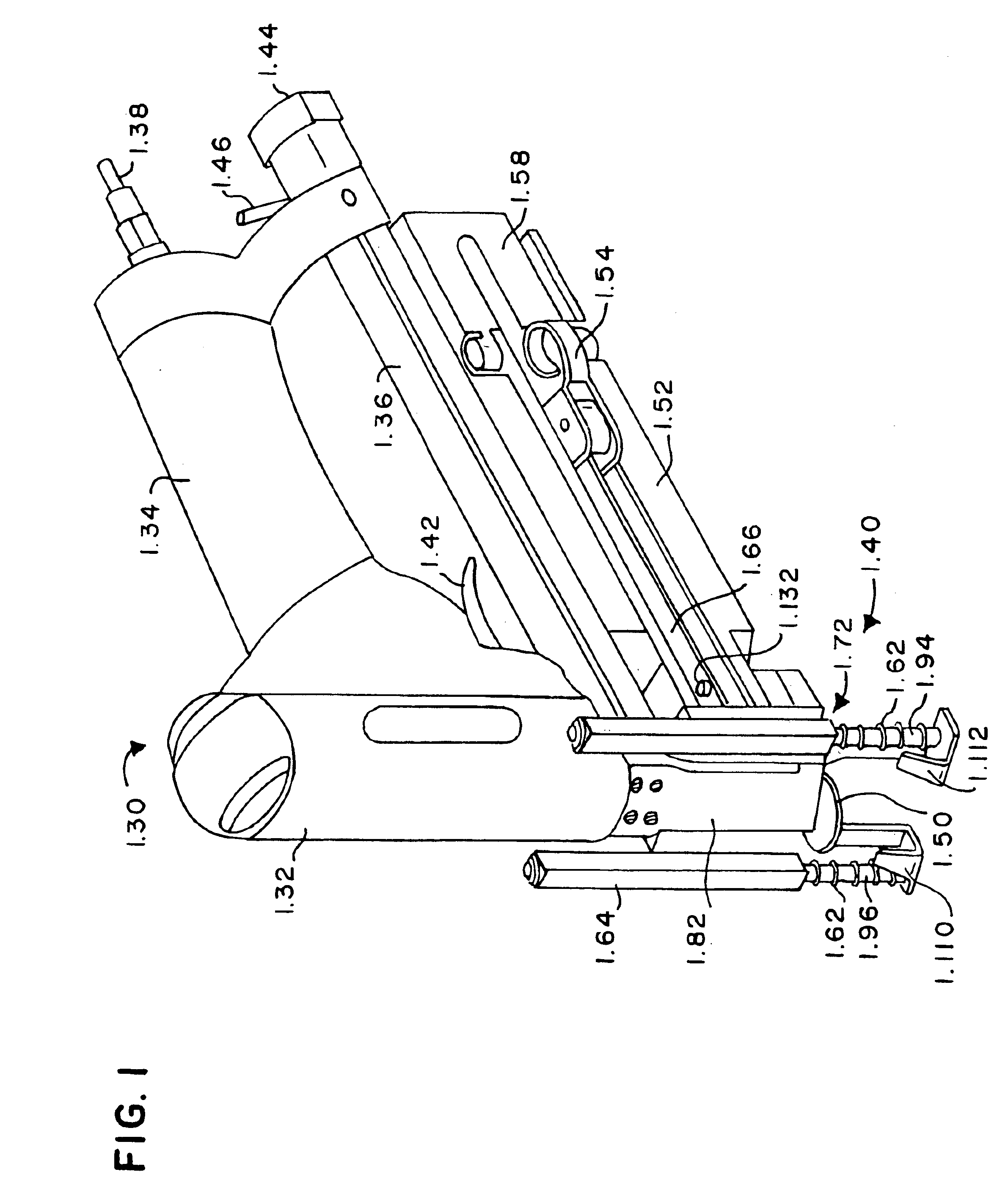

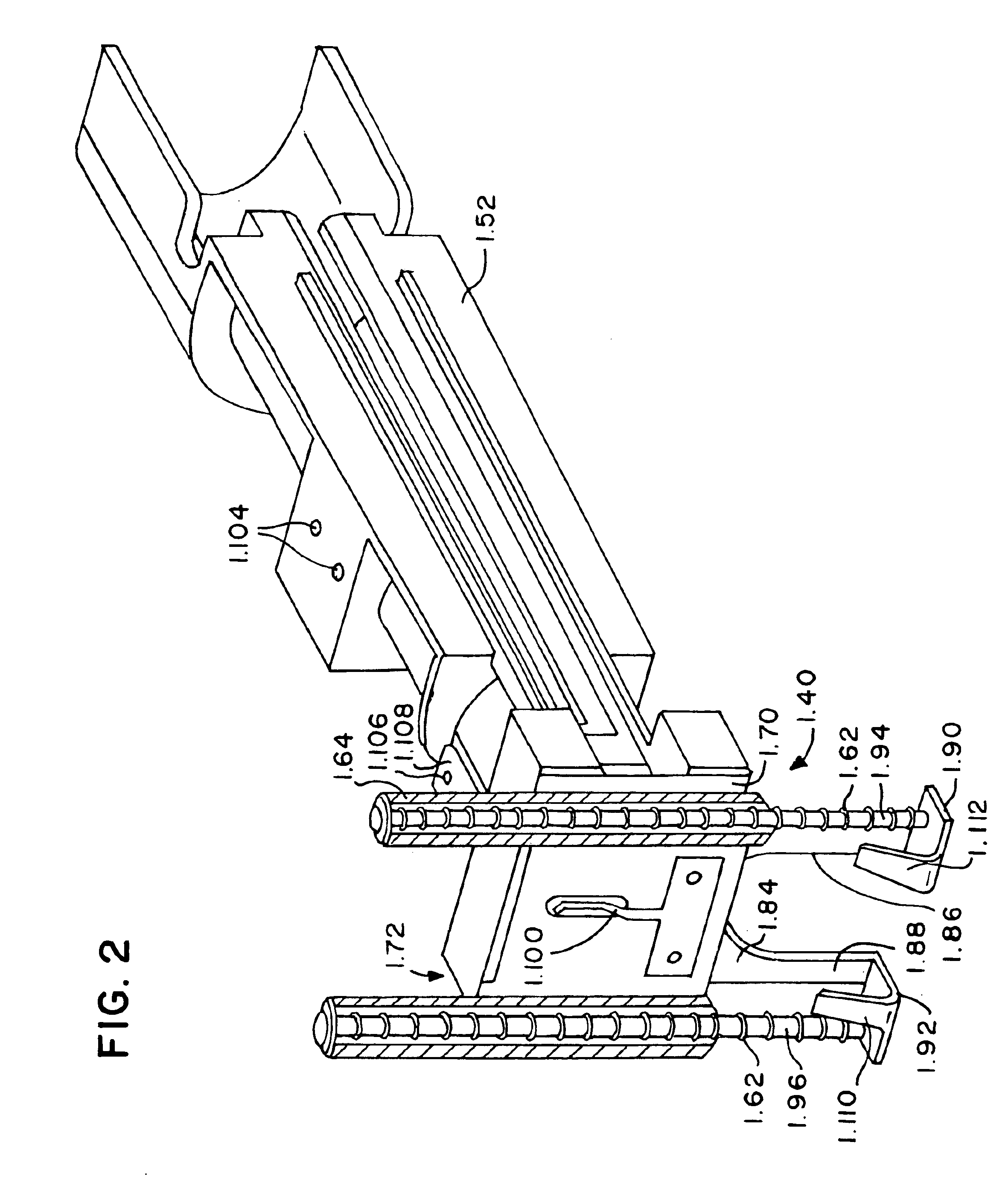

Cap feeding apparatus for a fastener gun

ActiveUS6837412B2Reduce the overall heightShort shuttle strokeStapling toolsBook coversEngineeringFastener

A construction tool and method of use for affixing holding cap washers to roofing paper and building wrap tar paper. The tool is a combination of a fastener-driving gun together with a feeding magazine holding a clip of plastic cap washers to be affixed, and the feed magazine feeds successive cap washers under the nose of the fastener-driving gun so that fasteners, such as nails or staples, can penetrate the cap washer and hold down the roofing paper or building wrap tar paper. As the cap approaches the nose of the gun, the cap feeder flips the cap ninety degrees along an axis transverse to the feed direction. A shortened shuttle is used with a spring arm holding one edge of the leading cap in the magazine and the rearward portion of the shuttle holding the other edge of the leading cap.

Owner:PNEUTOOLS

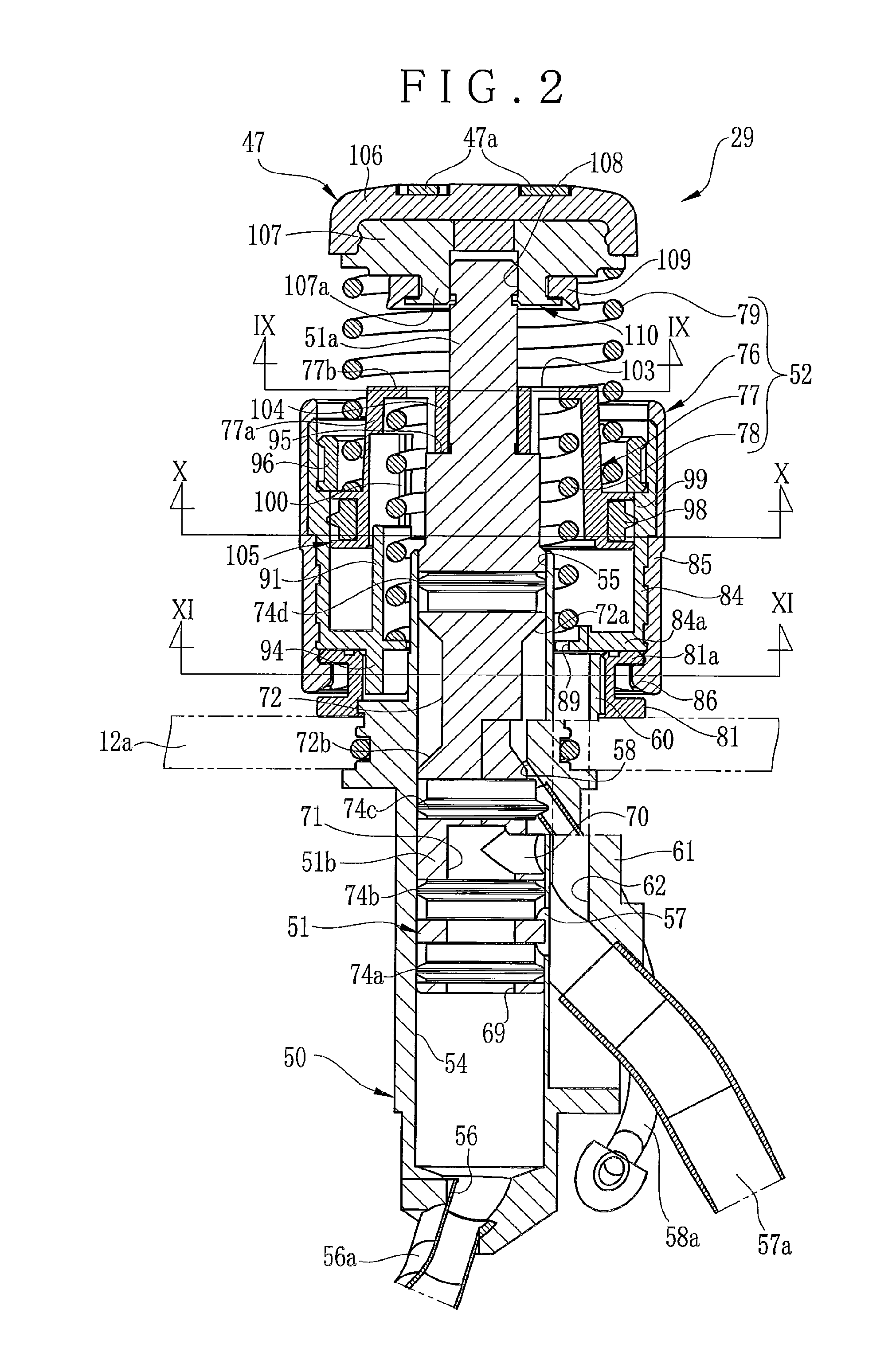

Switching valve assembly for endoscope

InactiveUS20120088975A1Prevent air leakageReliable preventionSurgeryEndoscopesCylinder headCoil spring

A switching valve assembly for an endoscope includes a cylinder, a piston unit, a button device, a flow channel in the piston unit, and plural flow openings. The piston unit changes over plural flow lines between communication and interruption by changing a combination of the flow openings with the flow channel for communication. The switching valve assembly includes a cylinder cap device and a slide device of a cup shape. An end ring keeps the slide device contained in the cylinder cap device. A first coil spring is disposed between the slide device and cylinder cap device, for biasing the slide device in an upward direction from the cylinder. A second coil spring is disposed between the button device and slide device, for biasing the button device in the upward direction with smaller force of bias than the first coil spring. The slide device includes an inner guide sleeve.

Owner:FUJIFILM CORP

Cap device for mixing different kinds of materials separately contained therein and in bottle

InactiveUS6908011B2Easy to prepareEliminate pressureLighting and heating apparatusClosure with auxillary devicesVacuum pressureStopcock

A cap device for bottles, which smoothly and naturally removes a vacuum pressure from a cavity containing an additive therein by opening a valve cock in response to a rotating action of a cap body. The cap device having a cap body provided with a cavity to contain an additive therein and tightened to an externally threaded mouth of a bottle. A funnel part being integrally formed in the cap body to discharge the additive from the cavity into the bottle through a lower end thereof. A small vent hole being formed at a top surface of the cap body. A breakable sheet being attached to the lower end of the funnel part to close the lower end of the funnel part. A valve cock being provided at the vent hole of the cap body to open or close the vent hole. A projection being provided at a predetermined position on a top edge of the mouth of the bottle to thrust and open the valve cock with downward rotation of the cap body. The cap device also has a valve having a structure capable of allowing a liquid to pass therethrough. The valve being placed in a neck of the bottle, such that the valve thrusts and breaks the breakable sheet when the cap body is rotated to move downward relative to the mouth of the bottle.

Owner:CHO YOUNG KOOK

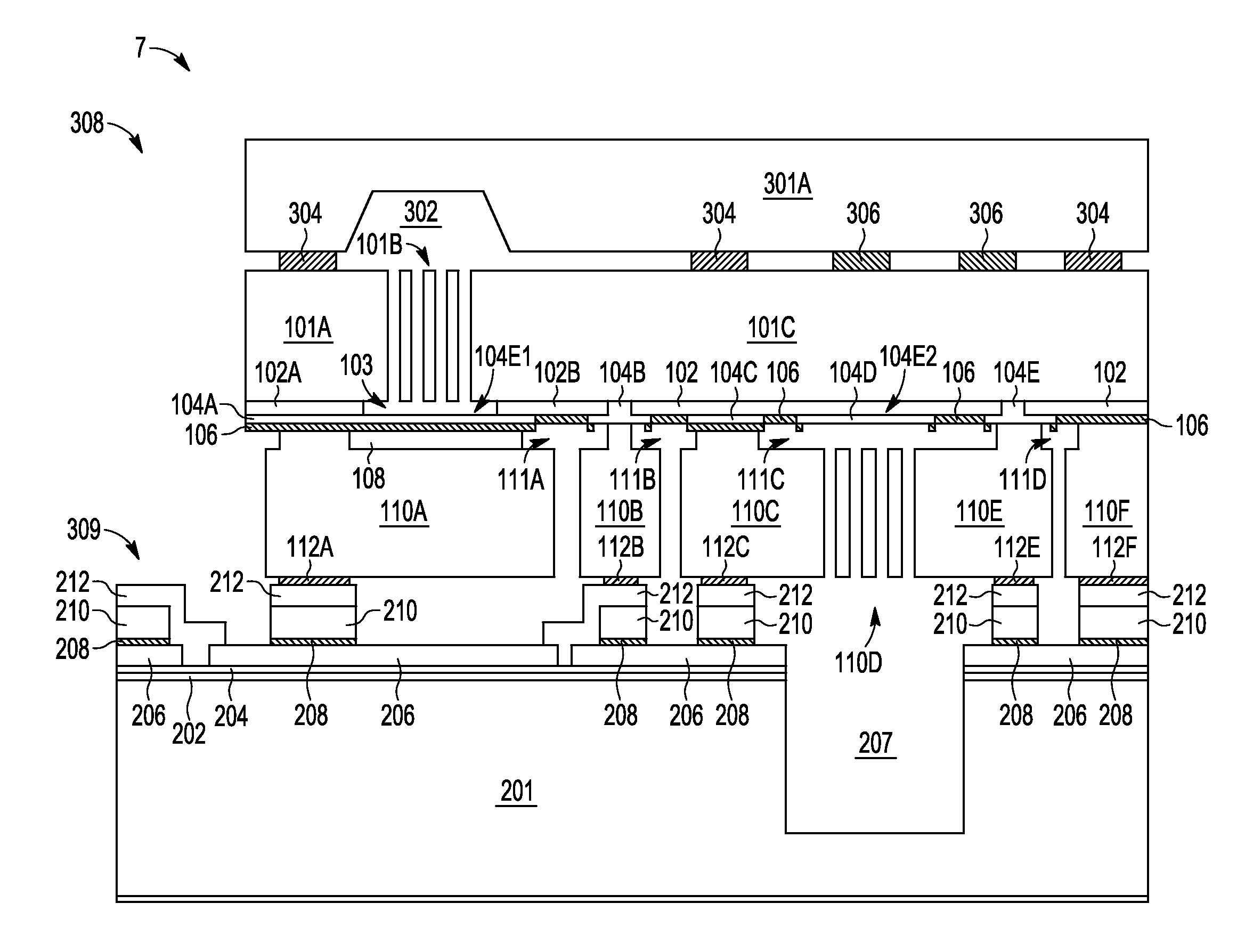

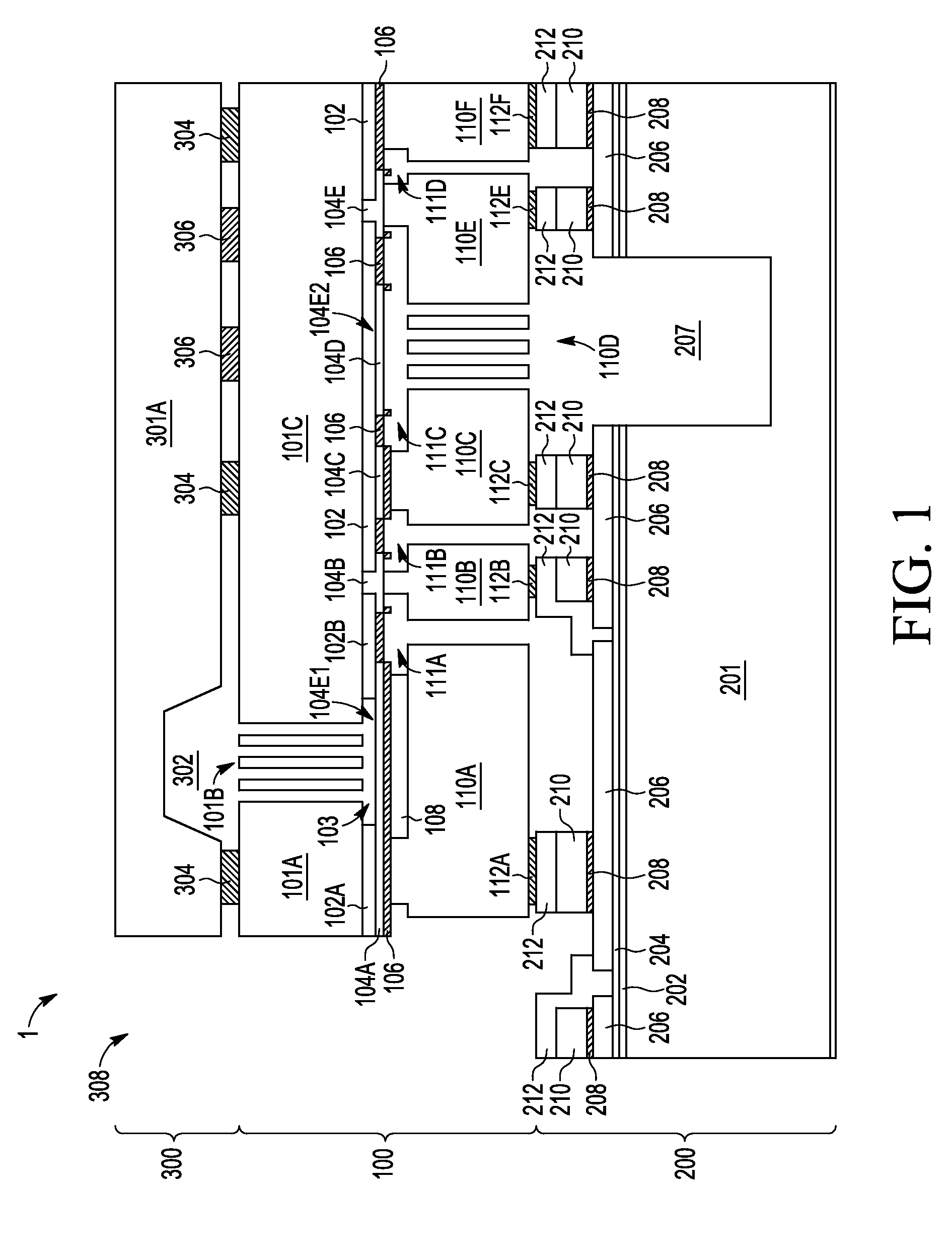

MEMS Fabrication Process with Two Cavities Operating at Different Pressures

ActiveUS20150375995A1Acceleration measurement using interia forcesTransducer detailsManufacturing technologySemiconductor structure

A method and apparatus are described for fabricating a high aspect ratio MEMS sensor device having multiple vertically-stacked inertial transducer elements (101B, 110D) formed in different layers of a multi-layer semiconductor structure (100) and one or more cap devices (200, 300) bonded to the multi-layer semiconductor structure (100) to protect any exposed inertial transducer element from ambient environmental conditions.

Owner:NXP USA INC

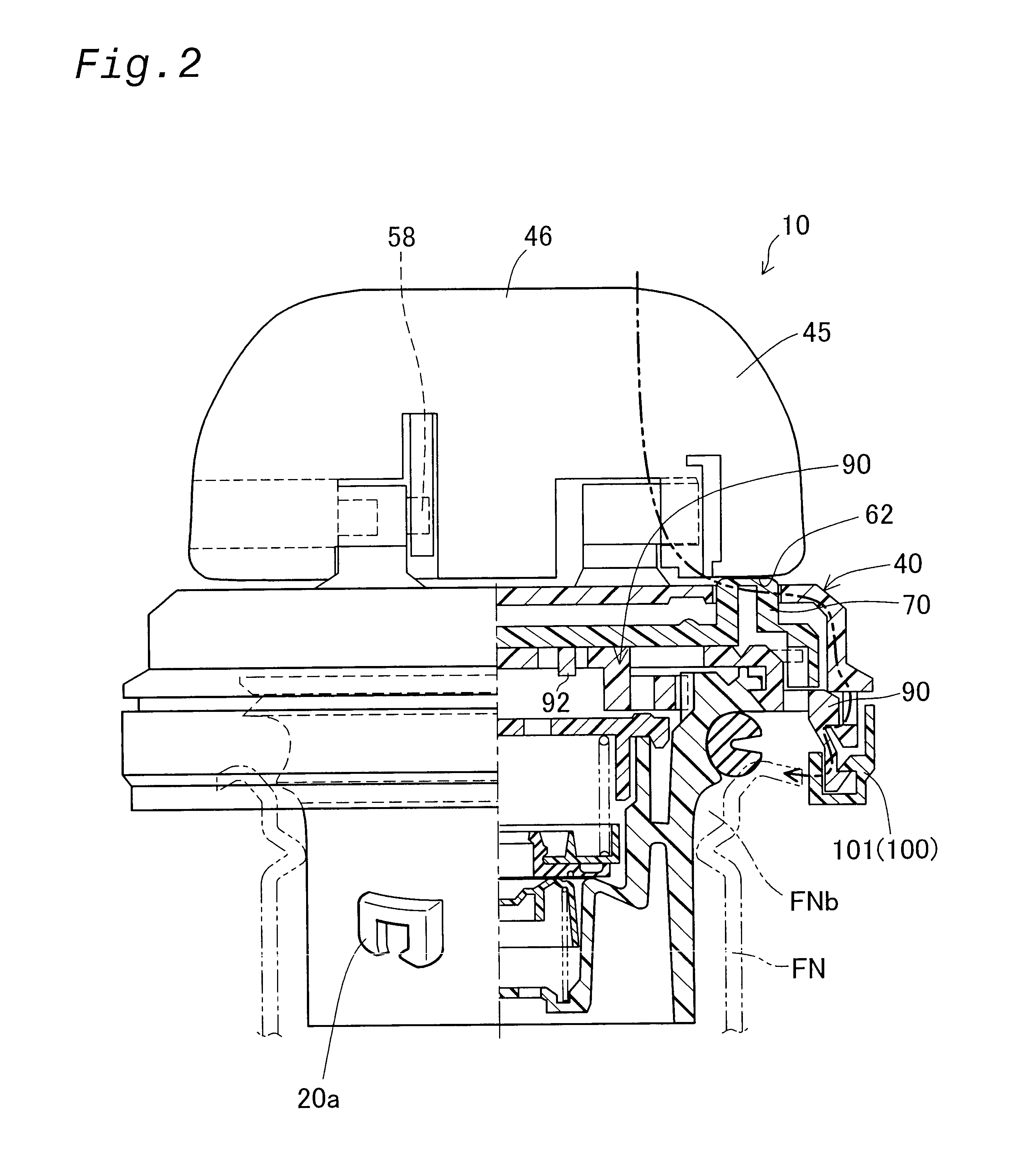

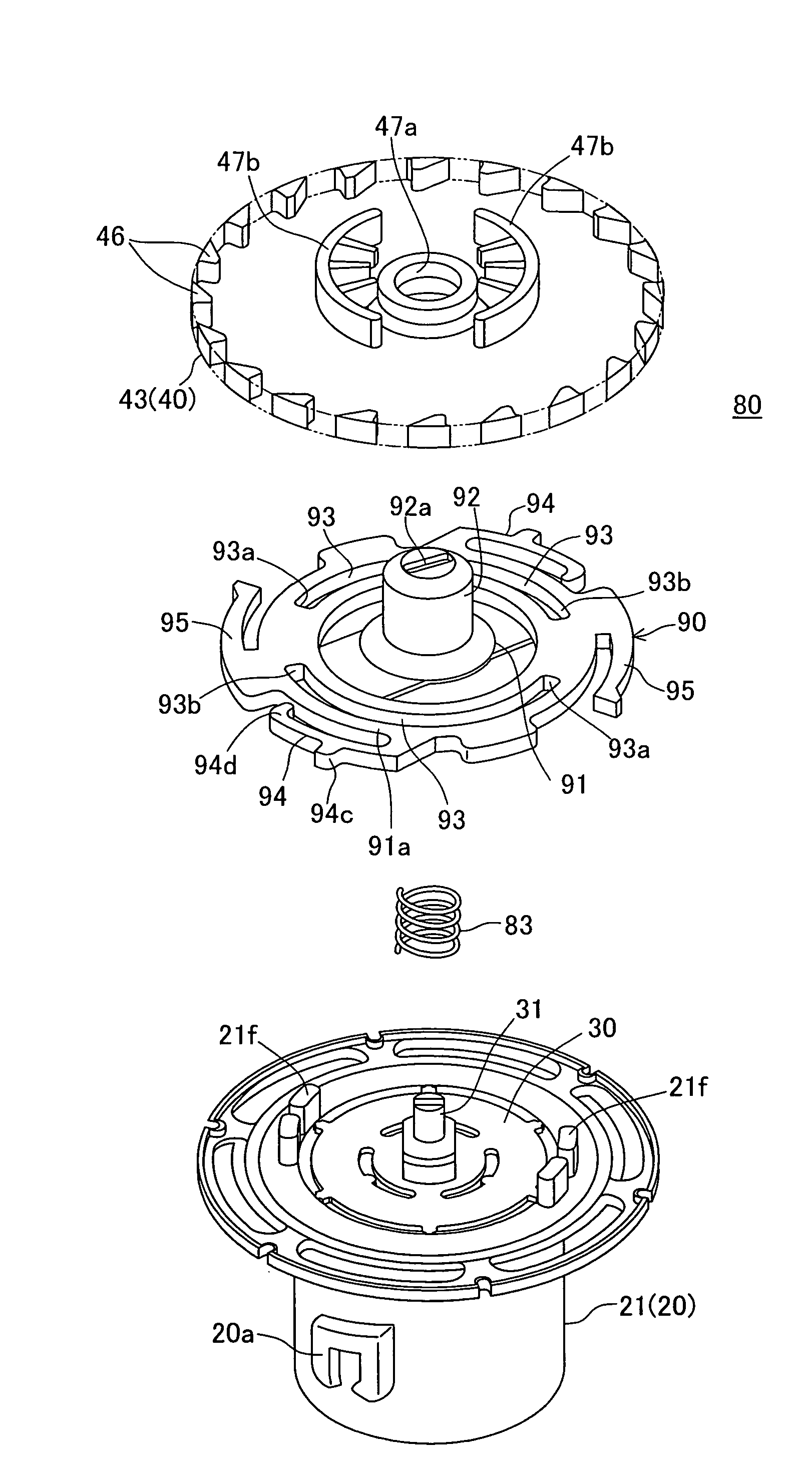

Cap device

InactiveUS7025222B2Not lower operatabilityAvoid missingRefuse receptaclesSealingFree rotationThermoplastic elastomer

A fuel cap has a torque member that is attached to a casing body in a freely rotatable manner. A tether mechanism is attached to the torque member and functions to link the fuel cap with a fuel lid. The tether mechanism includes a tether rotation support that is set on the torque member in a freely rotatable manner, and a connector member. The torque member is mainly composed of a resin material, for example, polyacetal, whereas the tether rotation support is mainly composed of a thermoplastic elastomer (TPEE). The resin material of the torque member has a liquid swelling property substantially equal to or less than that of the tether rotation support. This structure of the invention ensures the good operation ability of the fuel cap even in wet weather.

Owner:TOYODA GOSEI CO LTD

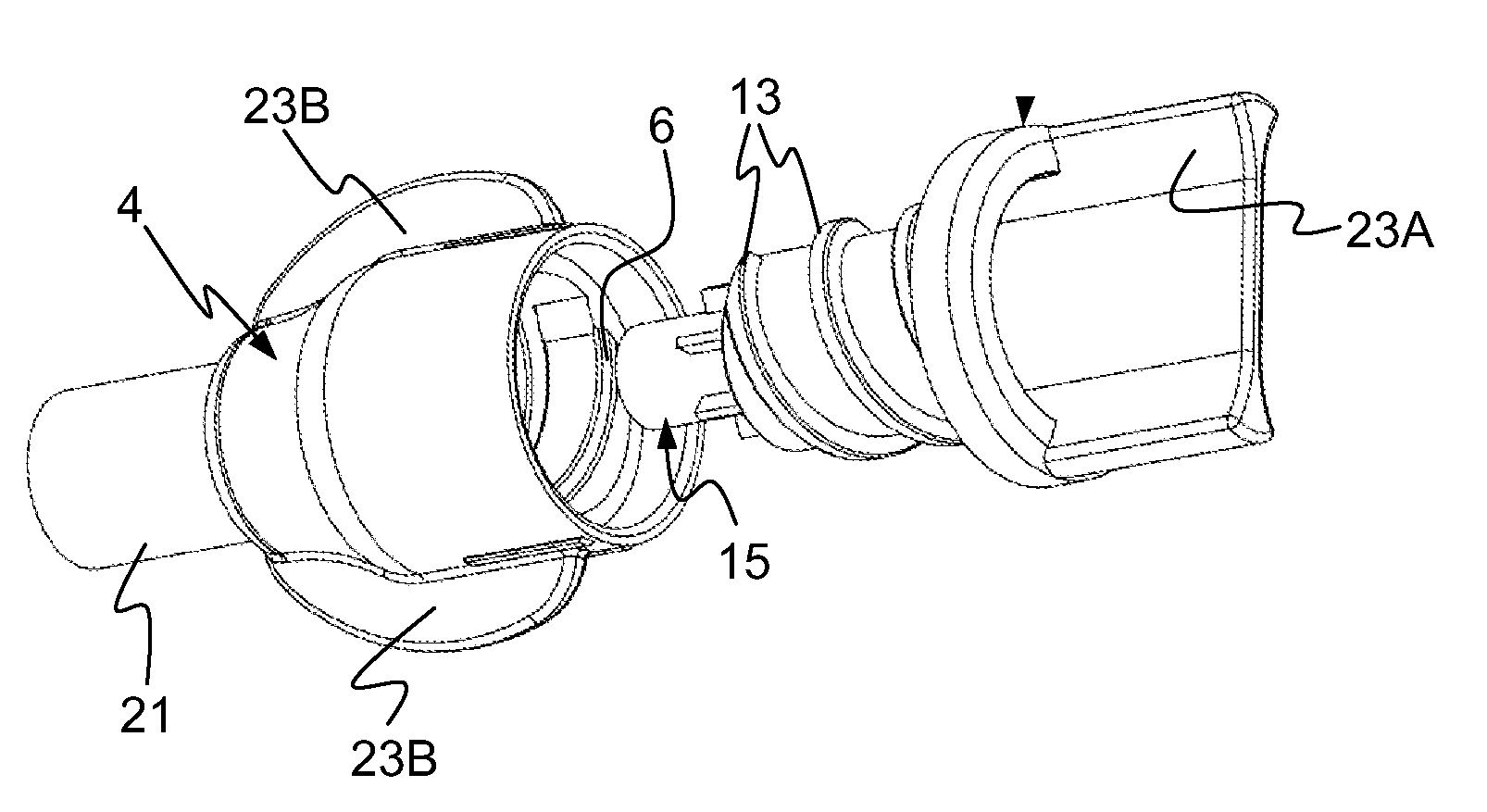

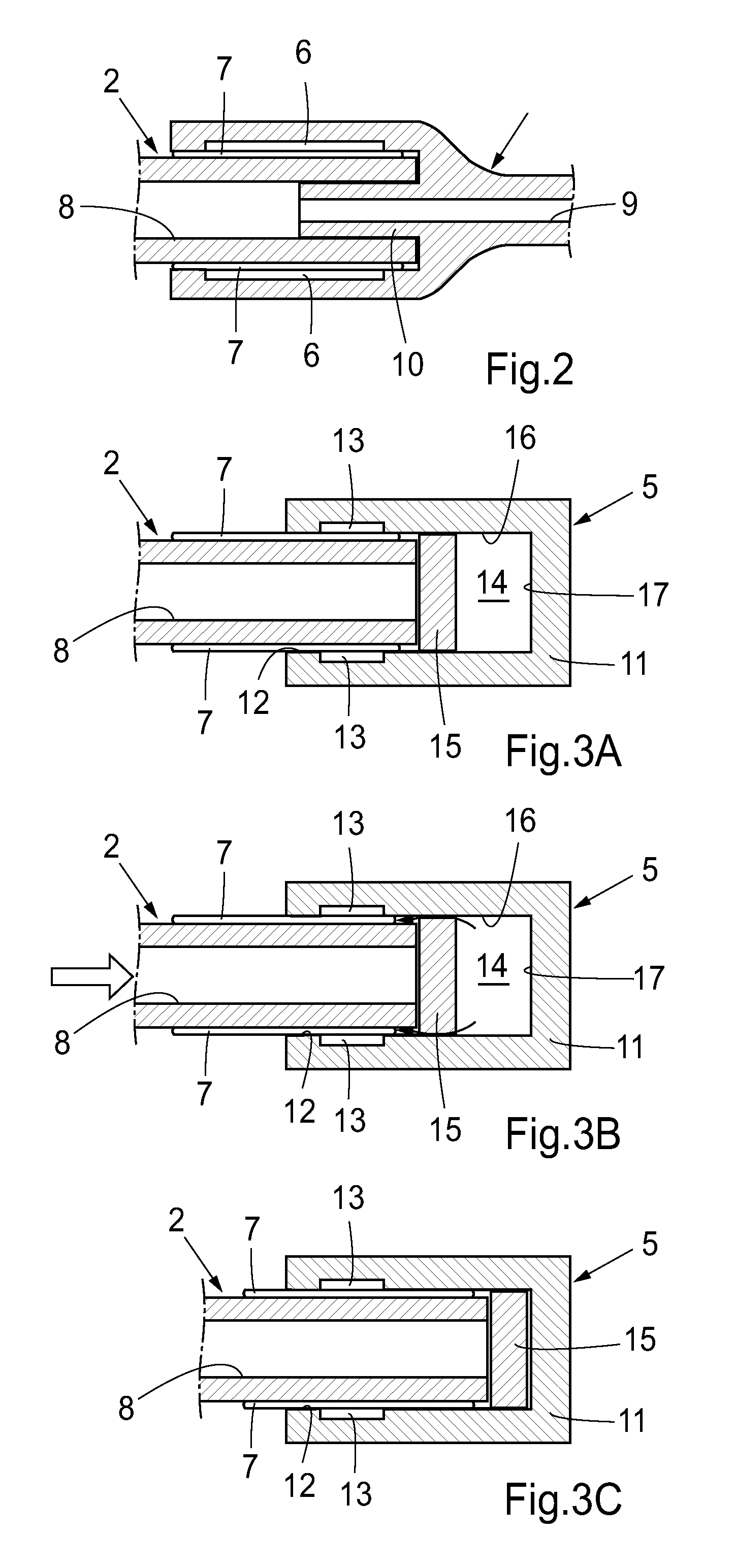

System and method for a cap used in the fixation of bone fractures

ActiveUS20070162026A1Easy to fixInternal osteosythesisExternal osteosynthesisEngineeringScrew thread

A system and method for facilitating the fixation of bone fractures is disclosed. The head component includes a tip, cutting threads and mating threads which are inserted into the far cortex of the bone. A wire extends from the head component and exits from the near cortex. A cap device includes a tension spring, wherein the tension spring is configured to assert friction against the wire when the cap is translated in one direction, but minimal friction against the wire when the cap is translated in the opposite direction. The cap is threaded over the wire such that the cap is restricted from backwards movement. Tension is then applied to the wire while the cap is tightened against or within the bone surface to apply an appropriate amount of pressure between the surfaces of the fracture. The excess wire beyond the cap can then be removed.

Owner:ORTHOIP

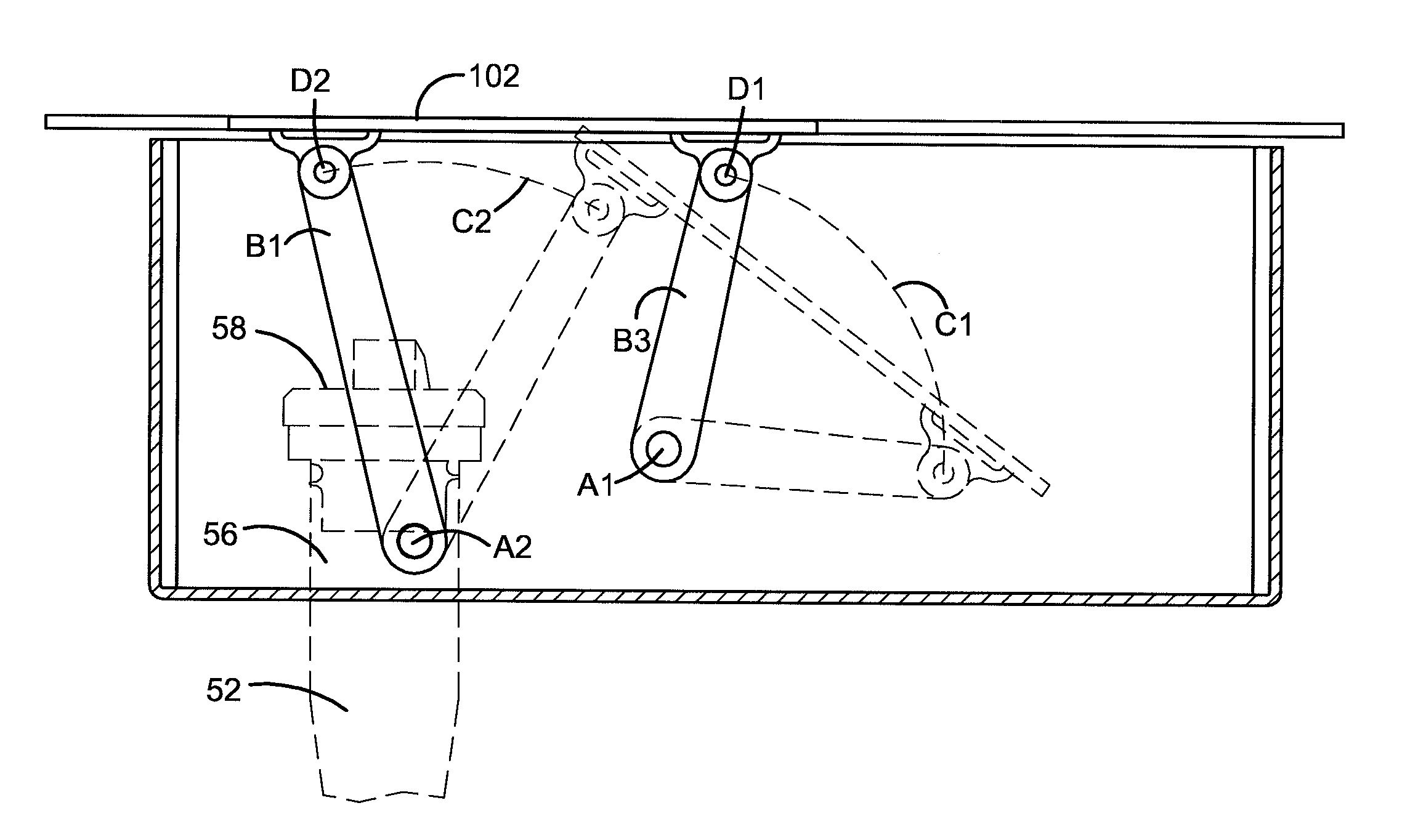

Liquid ejection apparatus

ActiveUS20120162311A1Performance can be restrained being deterioratedPrintingLiquid jetExterior space

A liquid ejection apparatus including: a liquid ejection head that ejects ink through liquid ejection openings in a liquid ejection surface of the head, a cap device that establishes a sealing state, such that an ejection space opposed to the liquid ejection surface is sealed from an exterior space by the cap device, an air introduction opening and an air discharge opening that are located in the cap device, and a humidifier that supplies an humidified air into the ejection space through the air introduction opening and that discharges an air from the ejection space through the air discharge opening. The air discharge opening opens in an area other than a liquid discharge area onto which the ejected liquid is to be discharged. The apparatus further includes a flow restrainer that restrains the liquid discharged onto the liquid discharge area, from flowing to the air discharge opening.

Owner:BROTHER KOGYO KK

Cap device

A fuel cap has a torque mechanism that transmits a rotational torque to a casing main body through engagement elements in response to rotation of a cover. When the rotational torque exceeds a predetermined level, the engagement is released to give a click. The first torque arm is constructed as a cantilever beam having a free end facing an arm support member across a preset gap. Under application of pressure, the first torque arm is deformed and transmits a rotational torque in the closing direction to the casing main body. This arrangement assures setting of the rotational torque of the torque mechanism to the predetermined level to apply a sufficient sealing stress to the fuel cap.

Owner:TOYODA GOSEI CO LTD

Overturning stopper adding and capping device for linear plastic bottle filling sealing machine

InactiveCN103832953AImprove general performanceCompact structureCapsClosure using stoppersReciprocating motionButt joint

The invention discloses an overturning stopper adding and capping device for a linear plastic bottle filling sealing machine. The overturning stopper adding and capping device comprises a feeding mechanism provided with a feeding groove, a material dividing mechanism in butt joint with the feeding mechanism, a clamping mechanism in butt joint with the material dividing mechanism, and a positioning mechanism corresponding to the clamping mechanism. The material dividing mechanism comprises a separation baffle movably arranged at the end of the feeding groove and moving in a reciprocating mode relative to the feeding groove. The separation baffle is provided with a notch corresponding to the feeding groove. The clamping mechanism comprises an overturning arm and a mechanical arm arranged on the overturning arm and corresponding to the end of the feeding groove. The overturning stopper adding and capping device is simple and compact in structure, easy to maintain, accurate and reliable in stopper adding and capping, high in production efficiency, high in universality of packaging materials, more clean in packaging process and capable of meeting the requirement for the new-edition GMP of pharmacy, and a relative friction movement component which may generate fine particles is not arranged above an opening of a packaging bottle in the stopper adding and capping process.

Owner:HUNAN YUHUAN INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com