Patents

Literature

53results about How to "Solve the problem of directional transport" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system

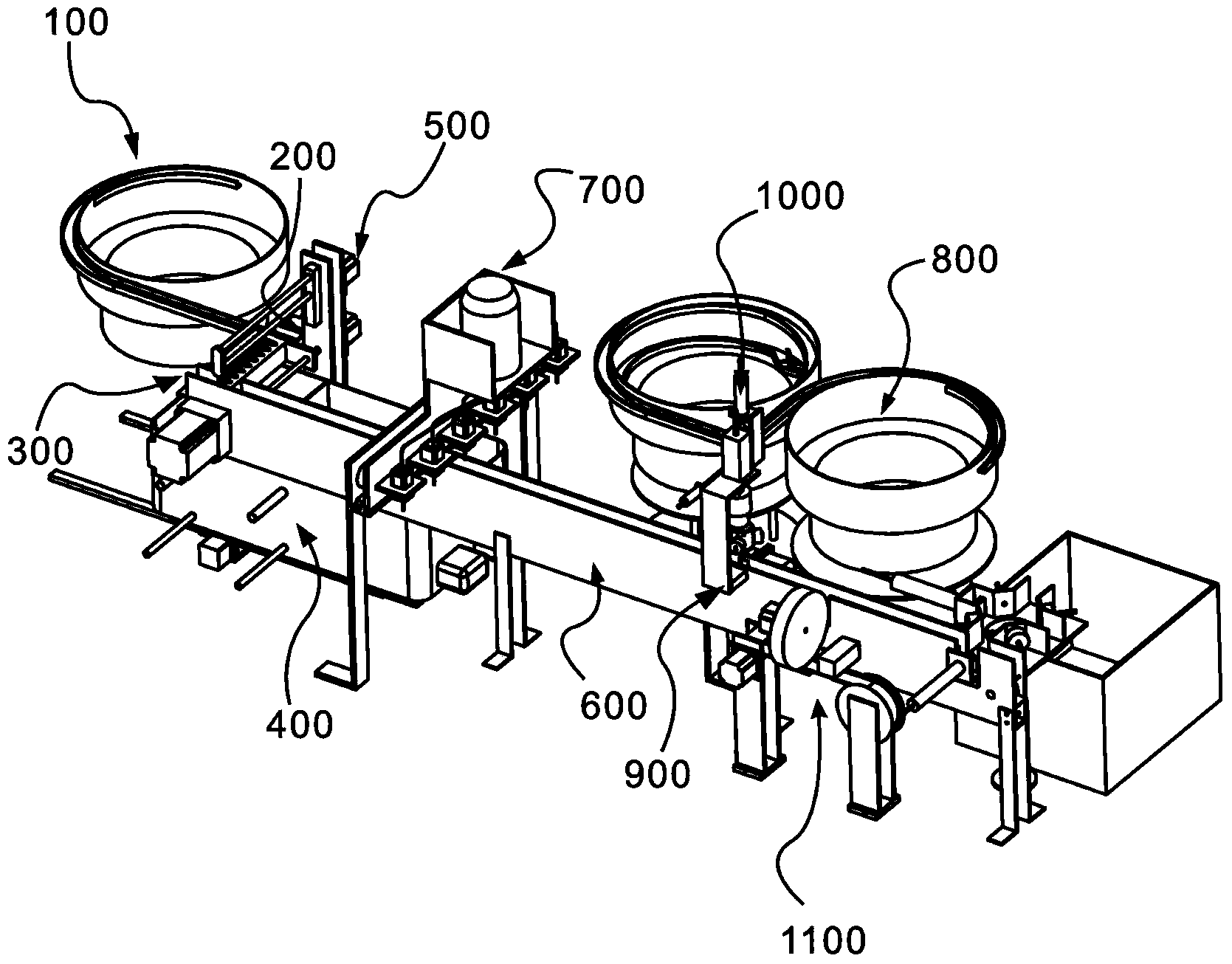

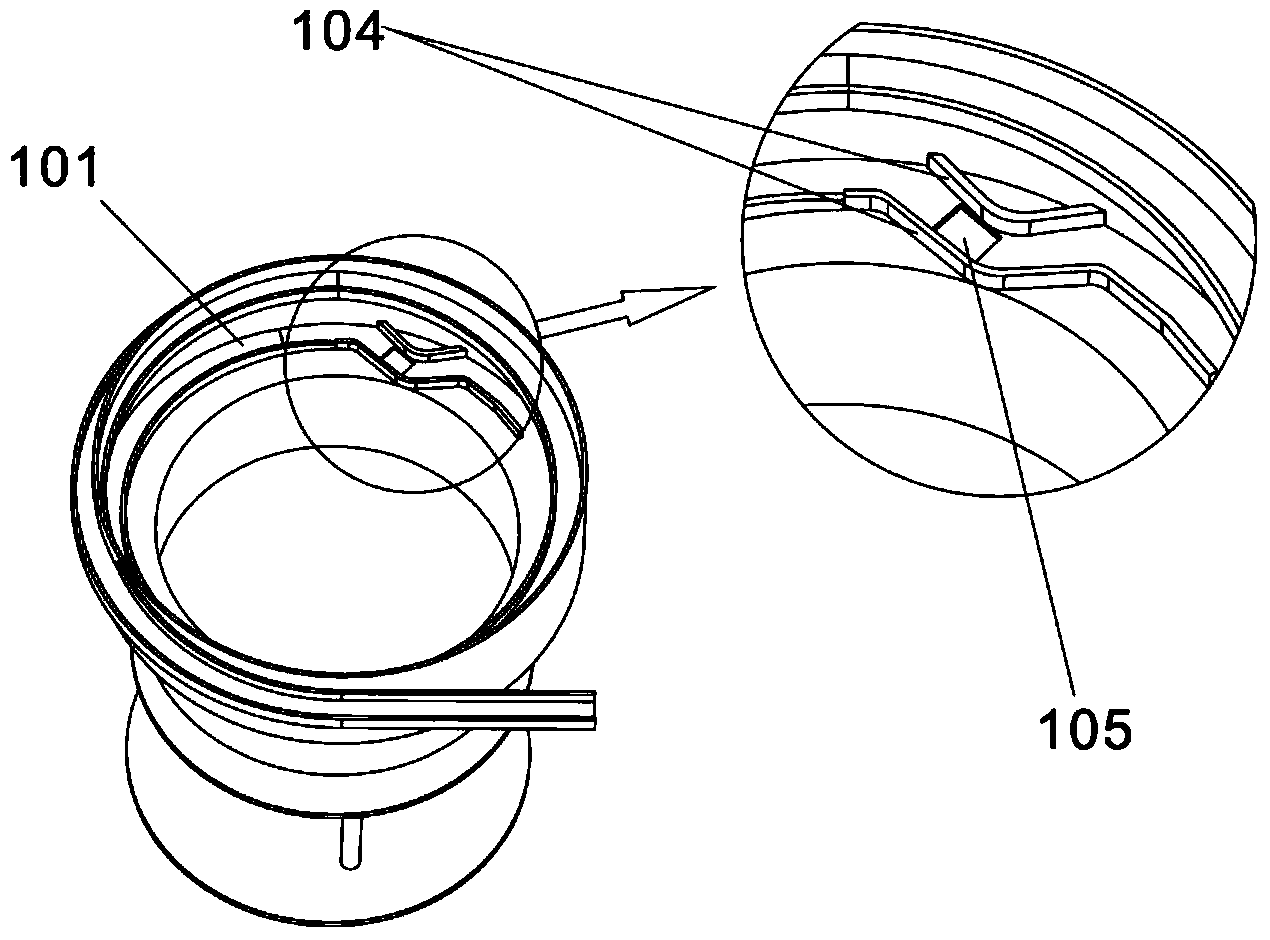

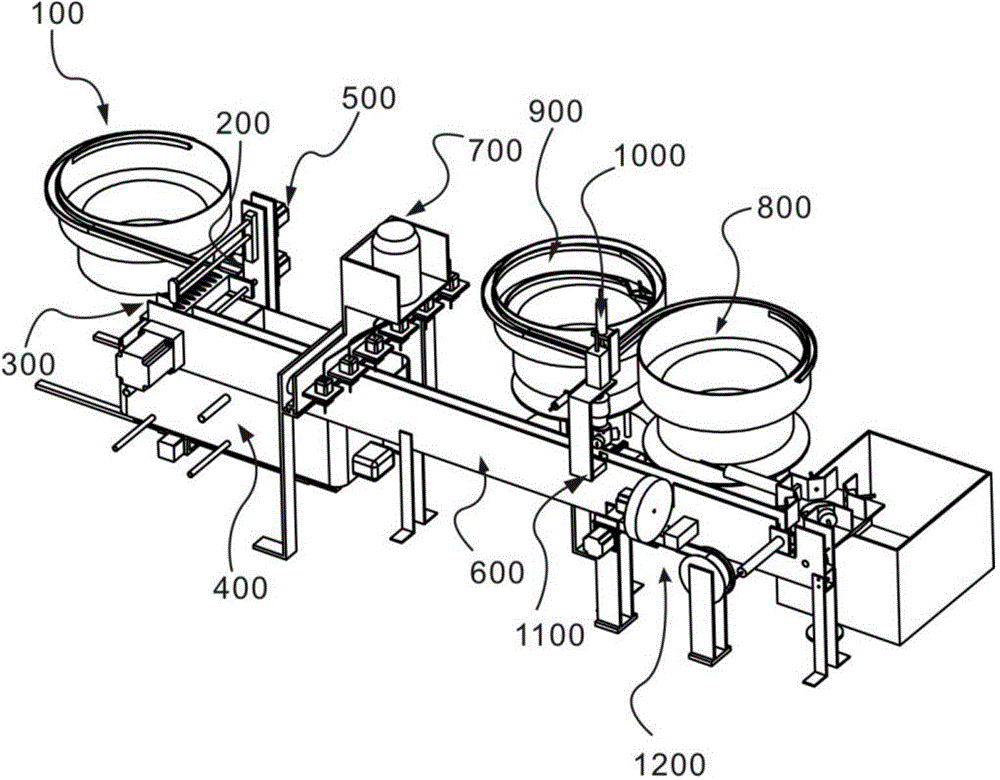

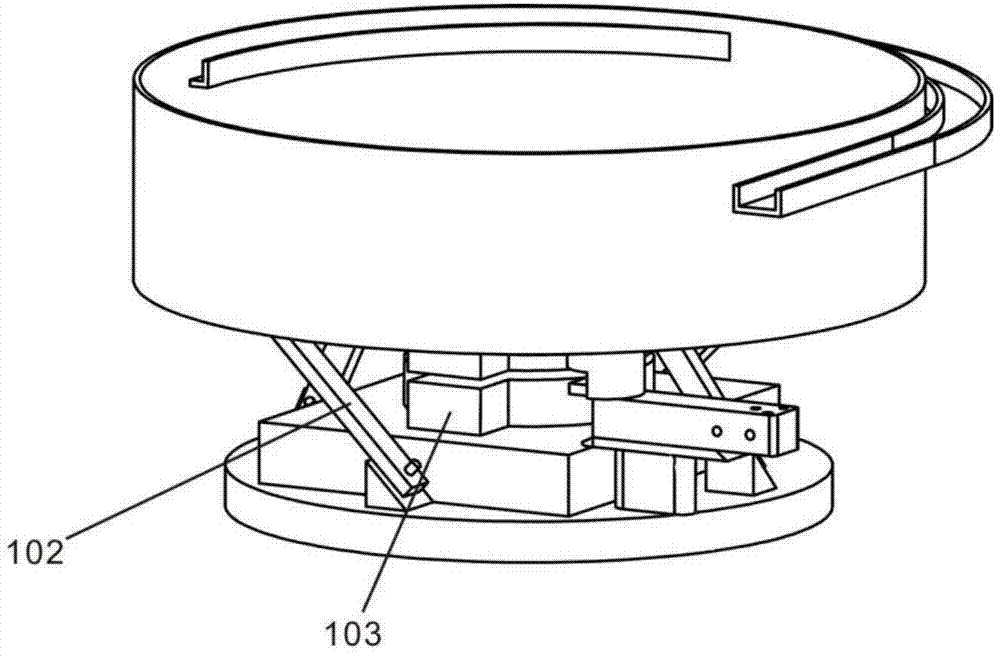

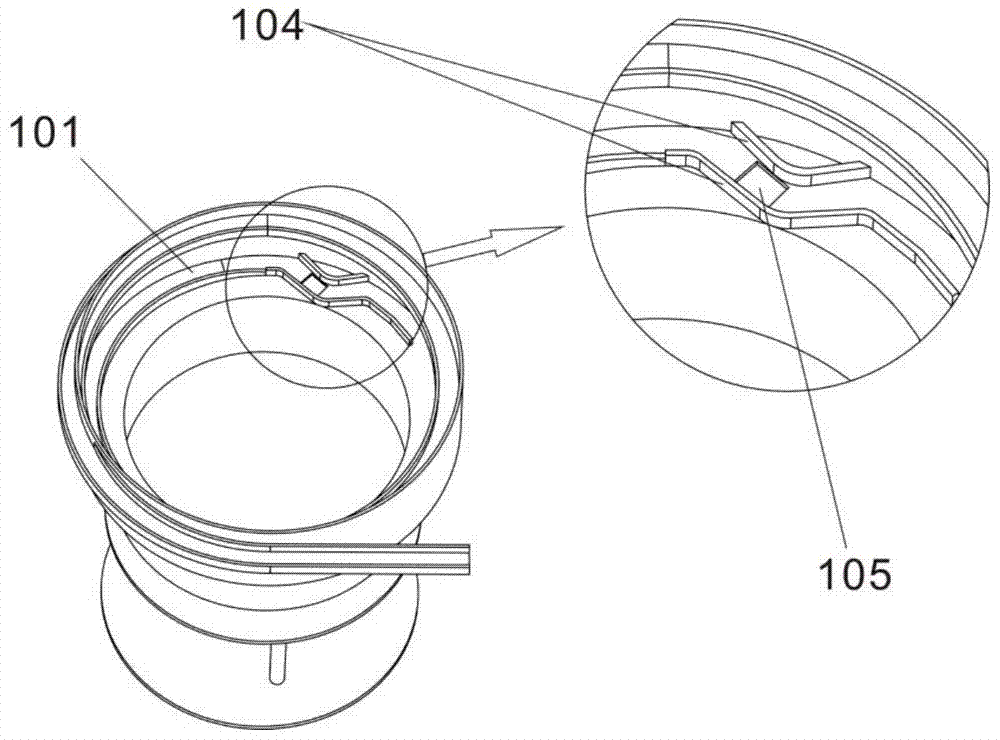

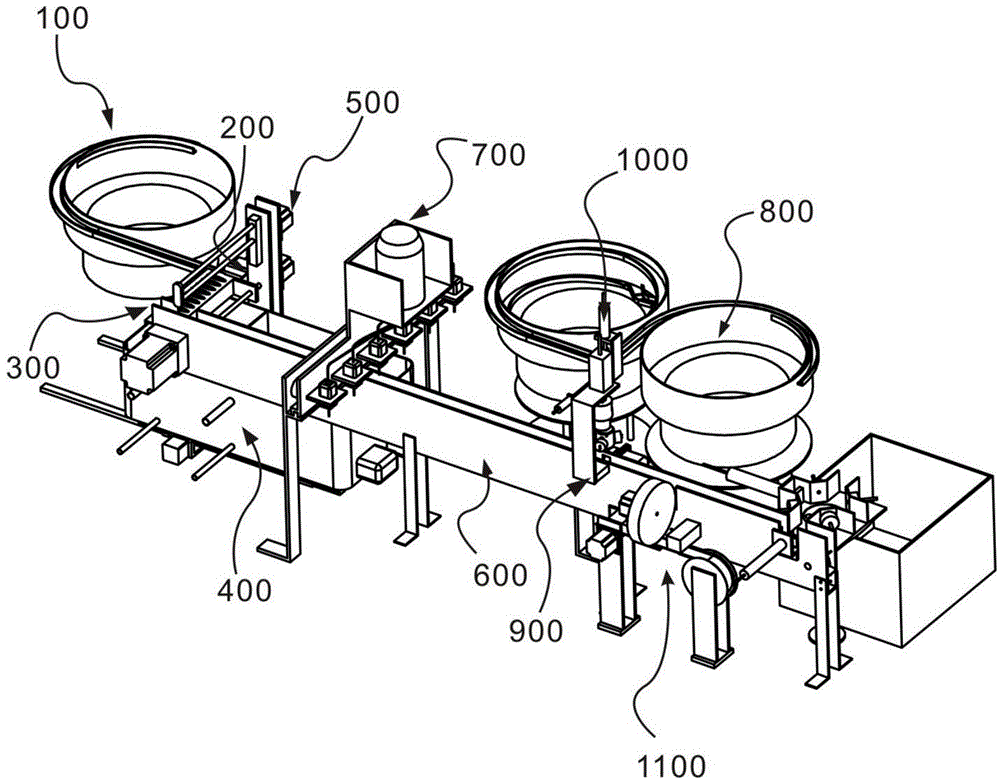

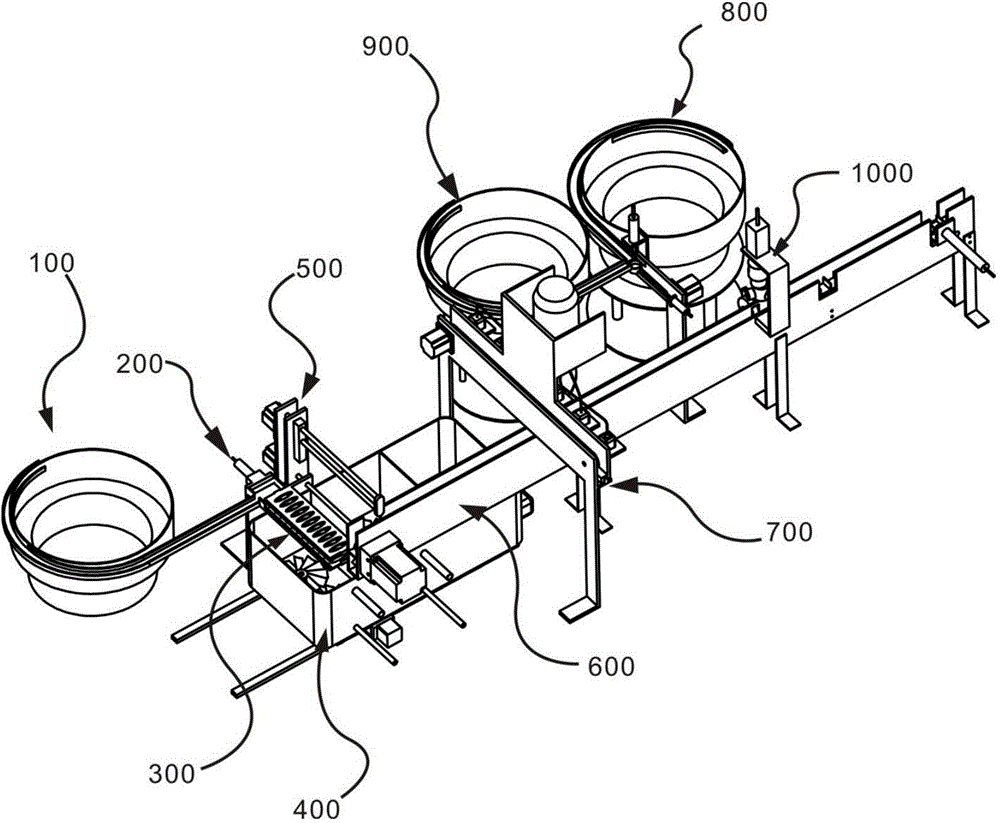

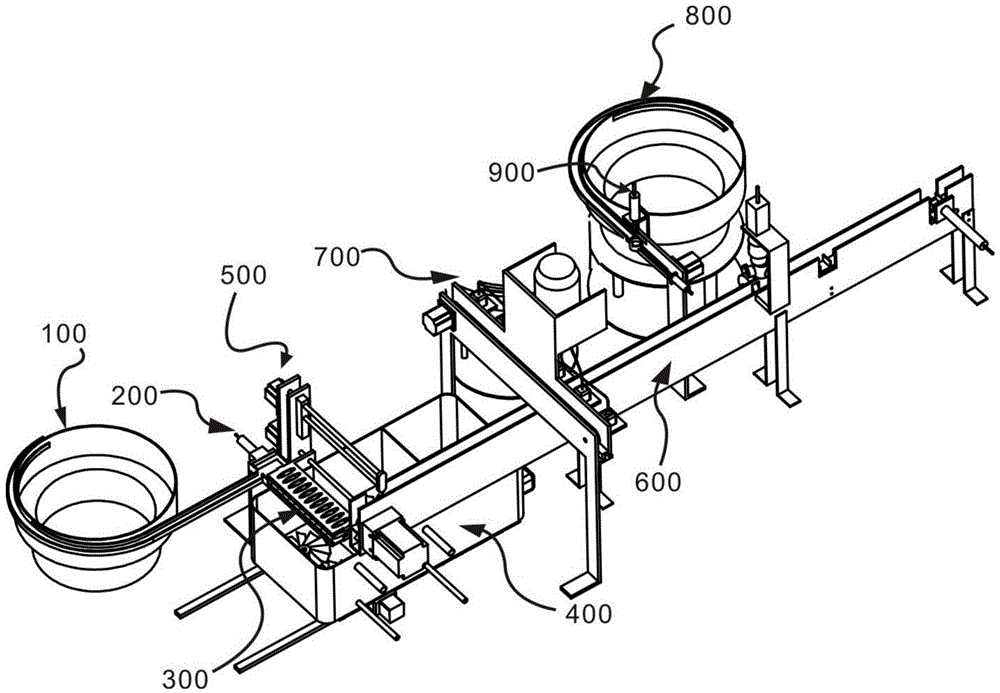

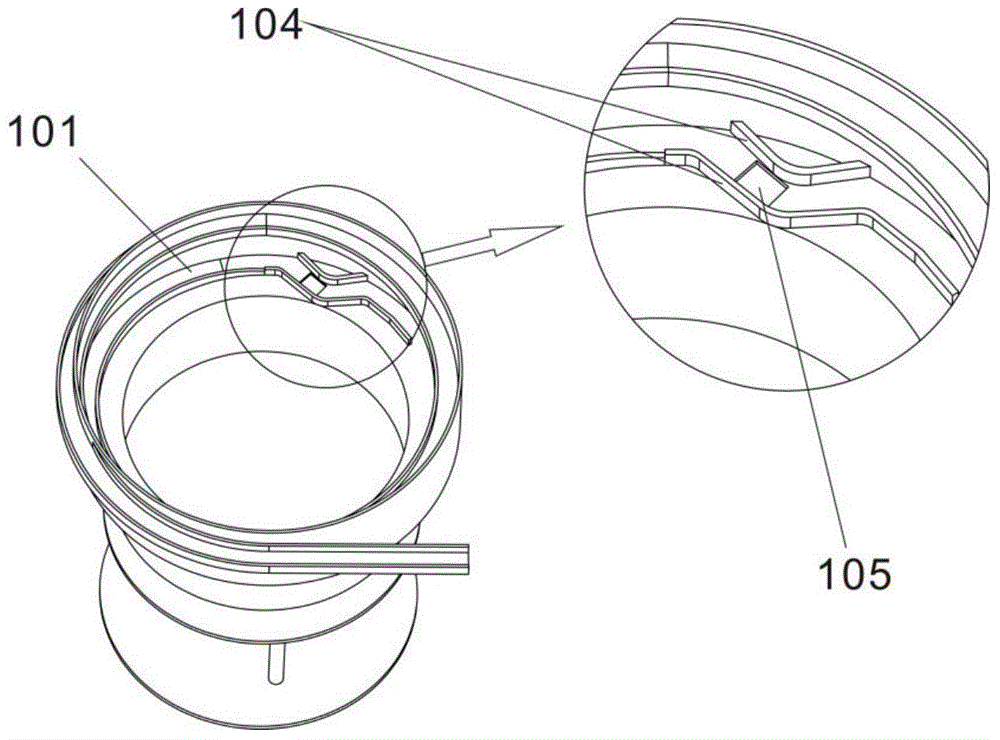

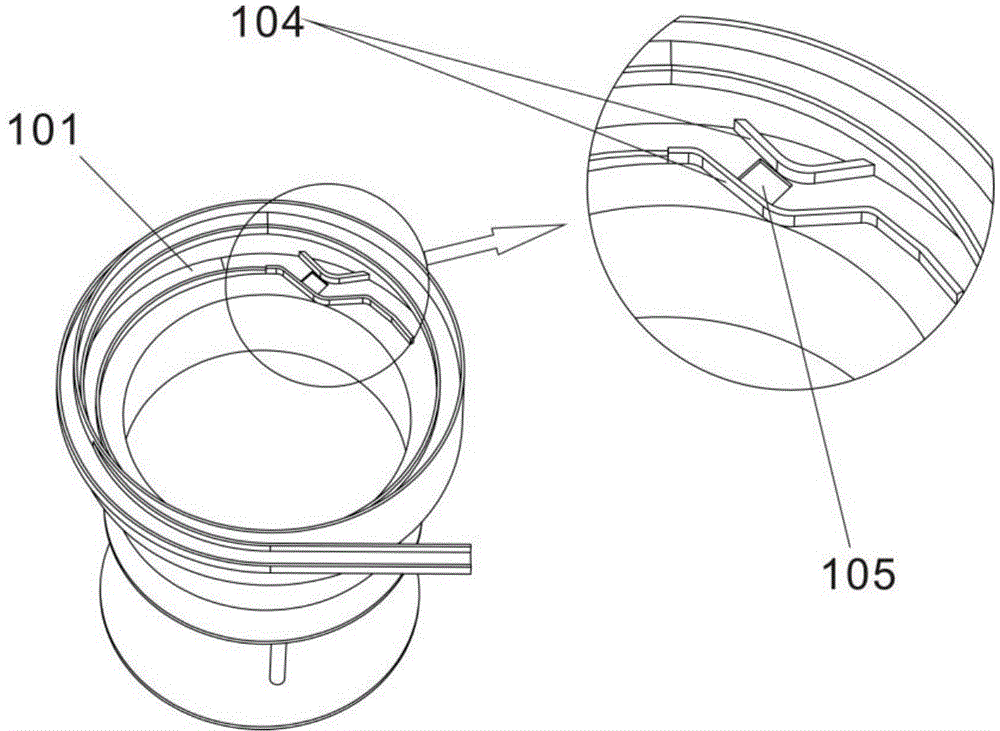

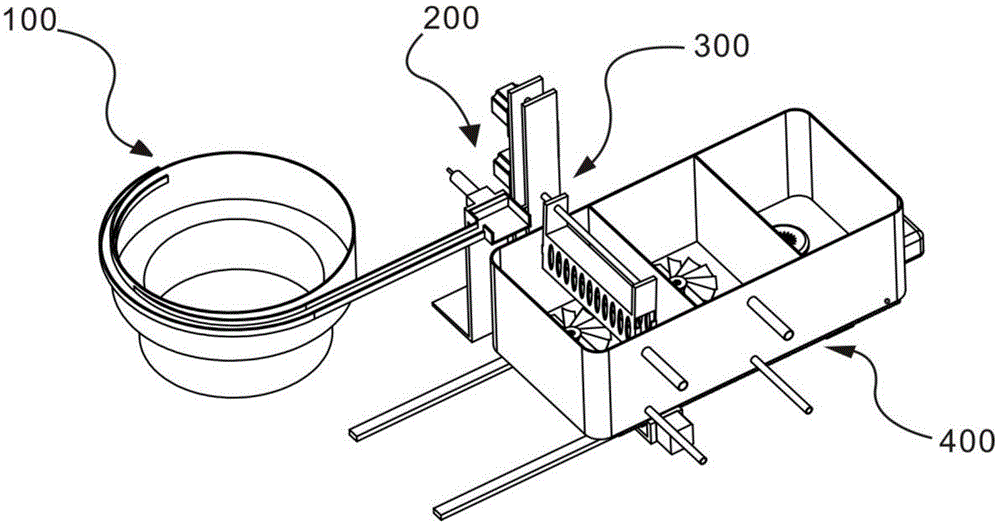

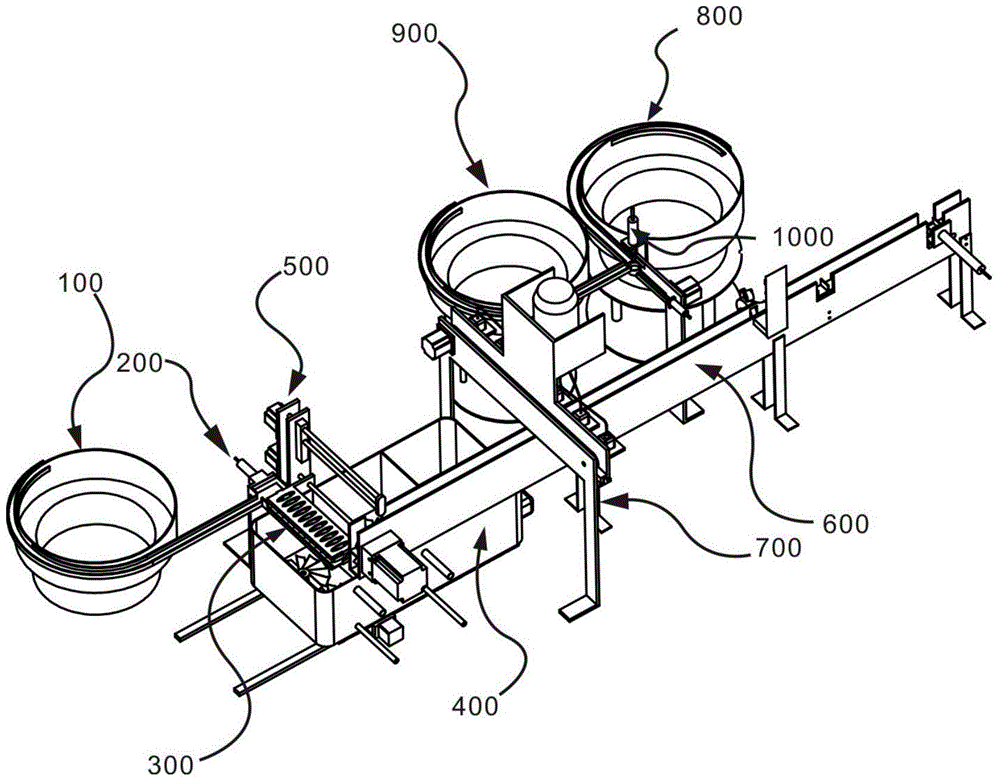

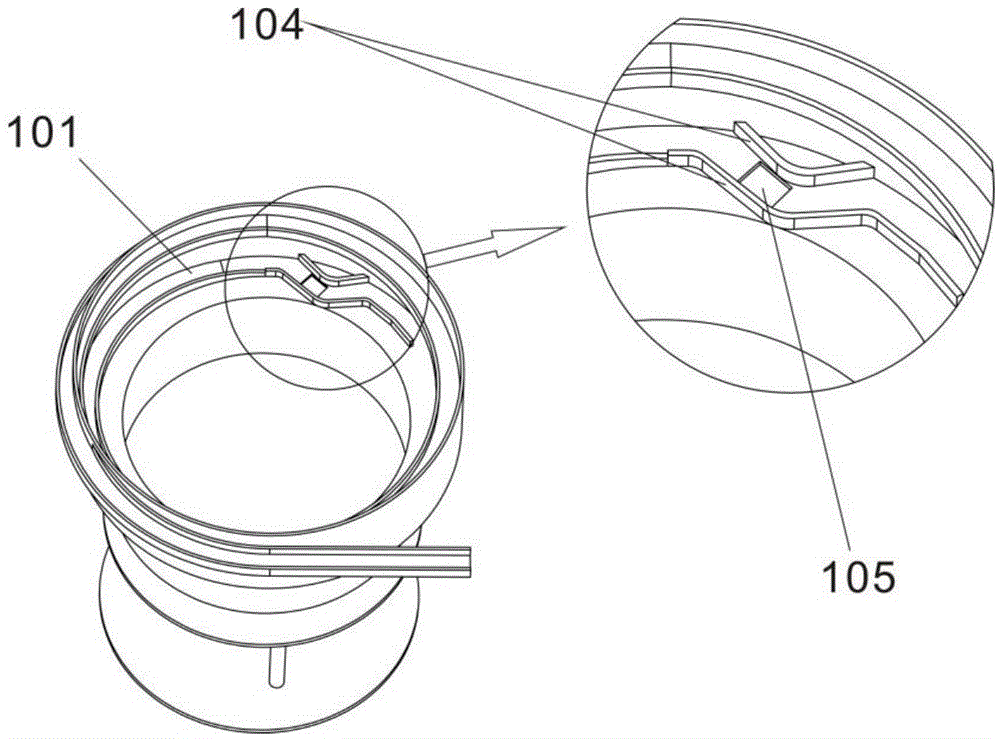

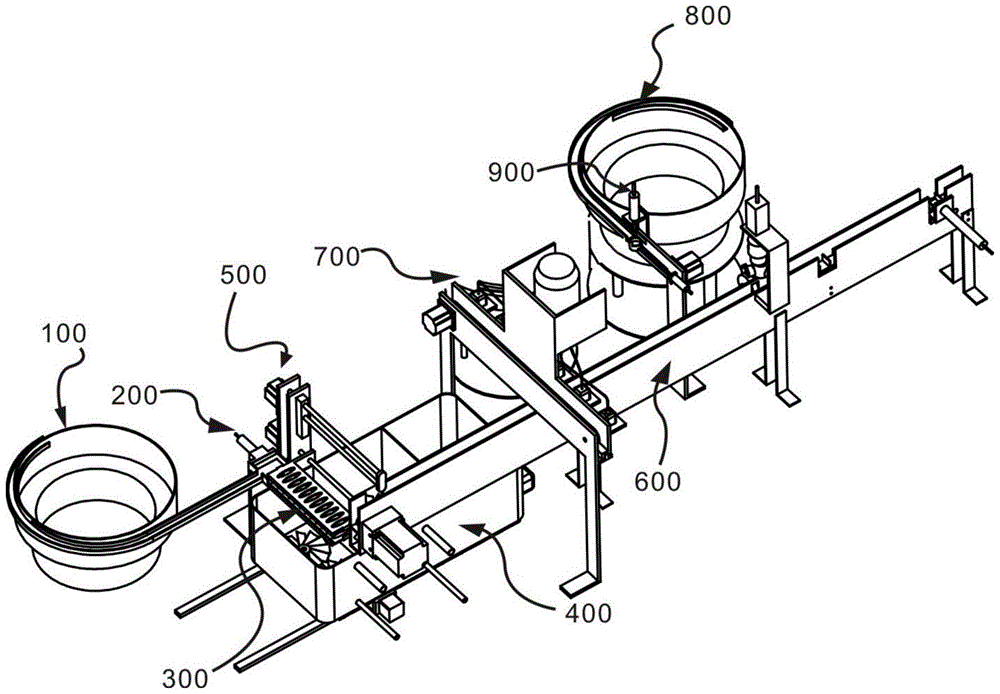

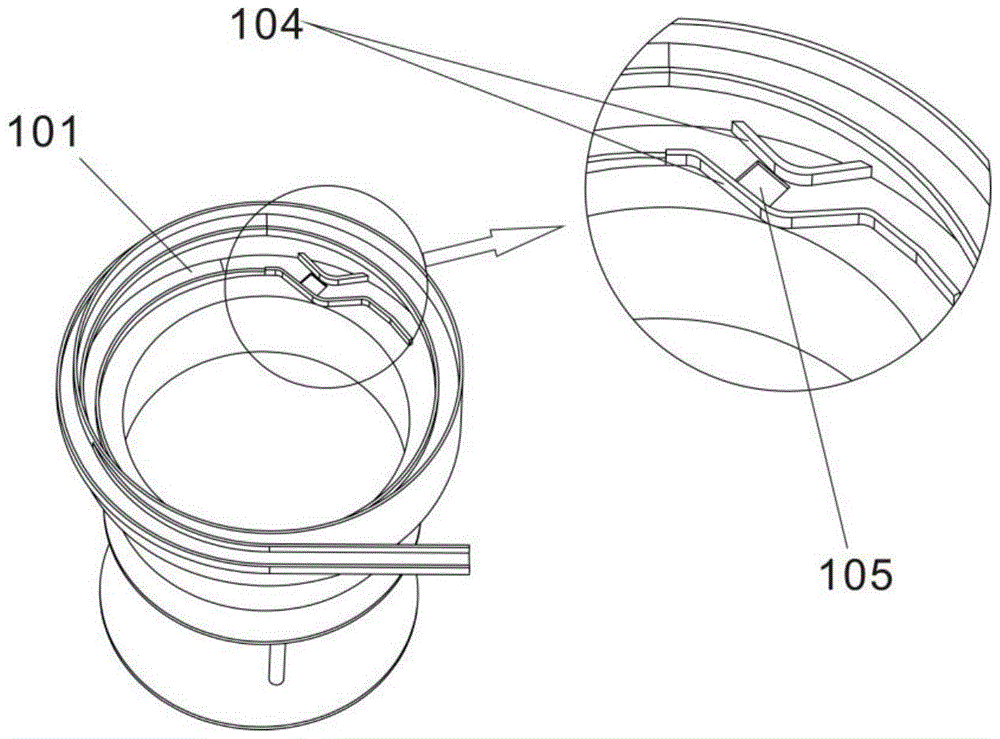

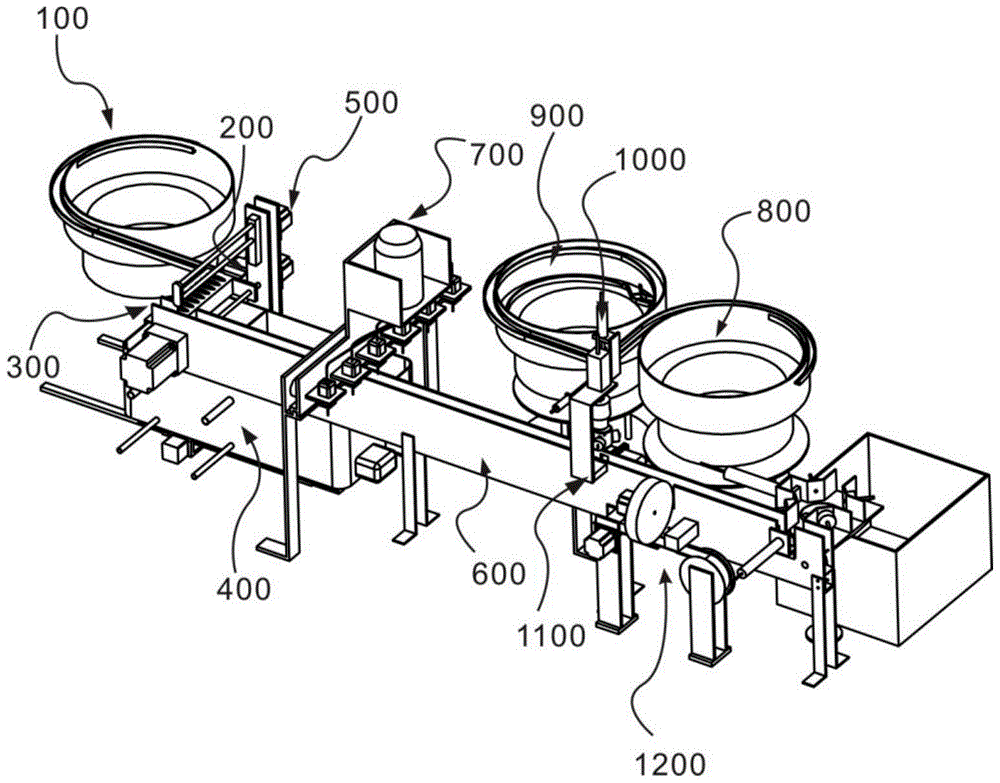

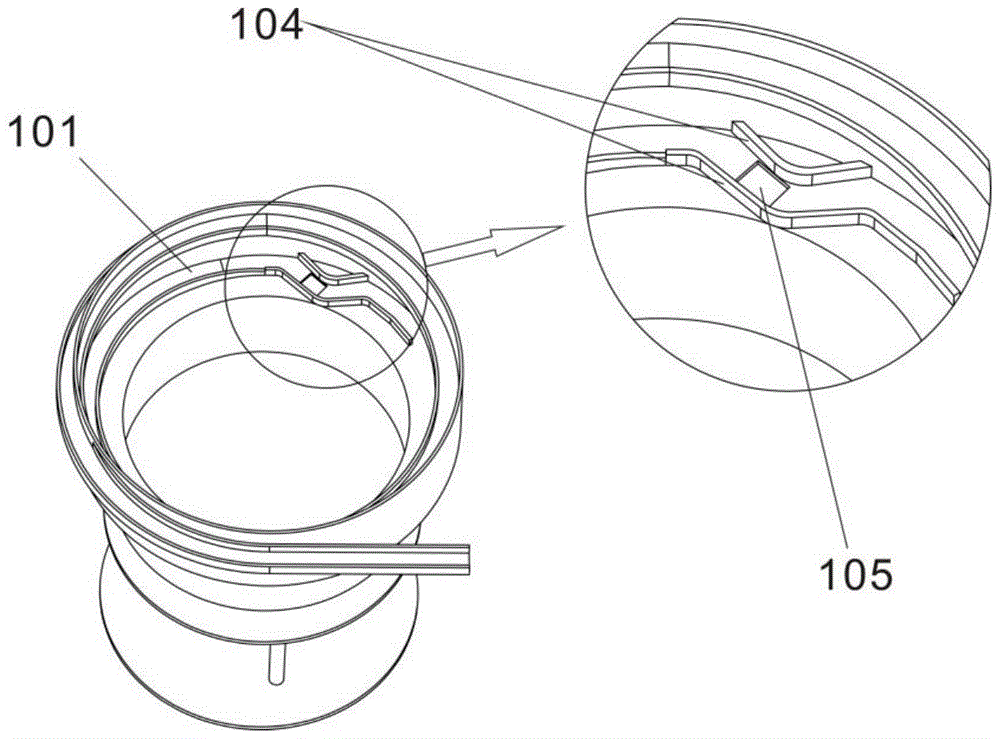

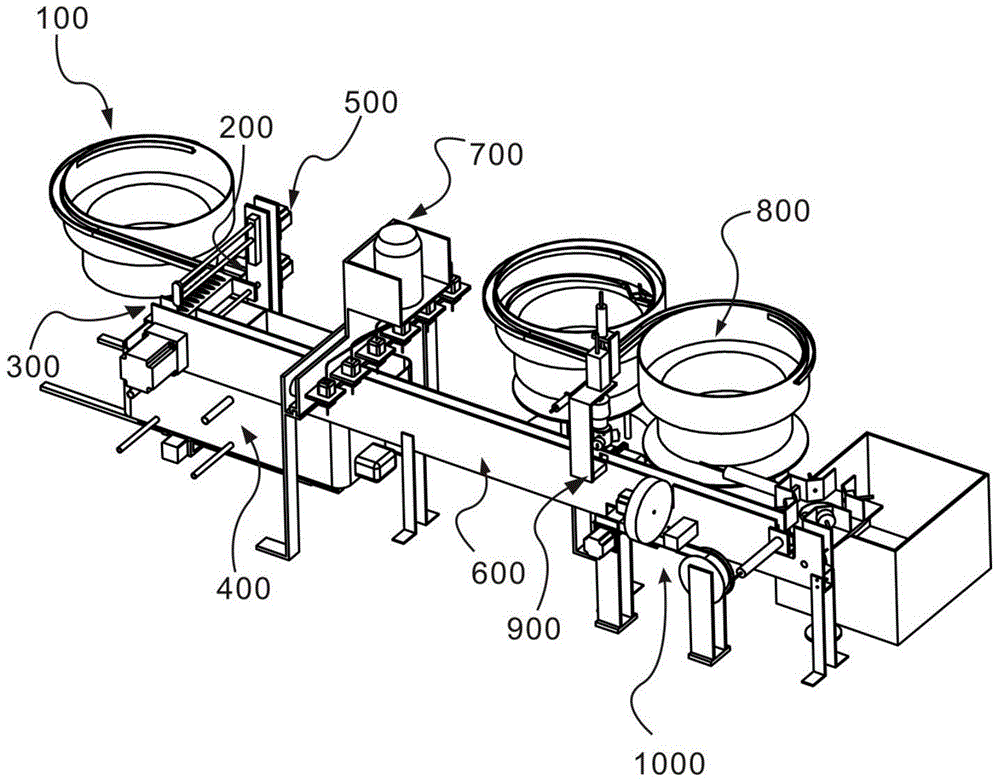

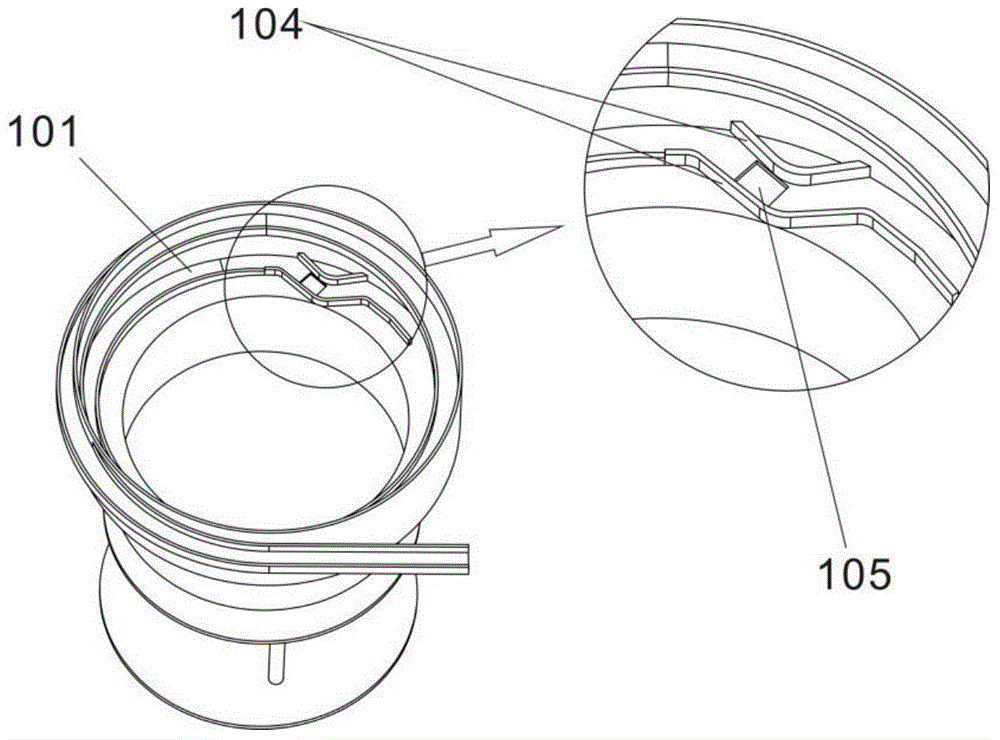

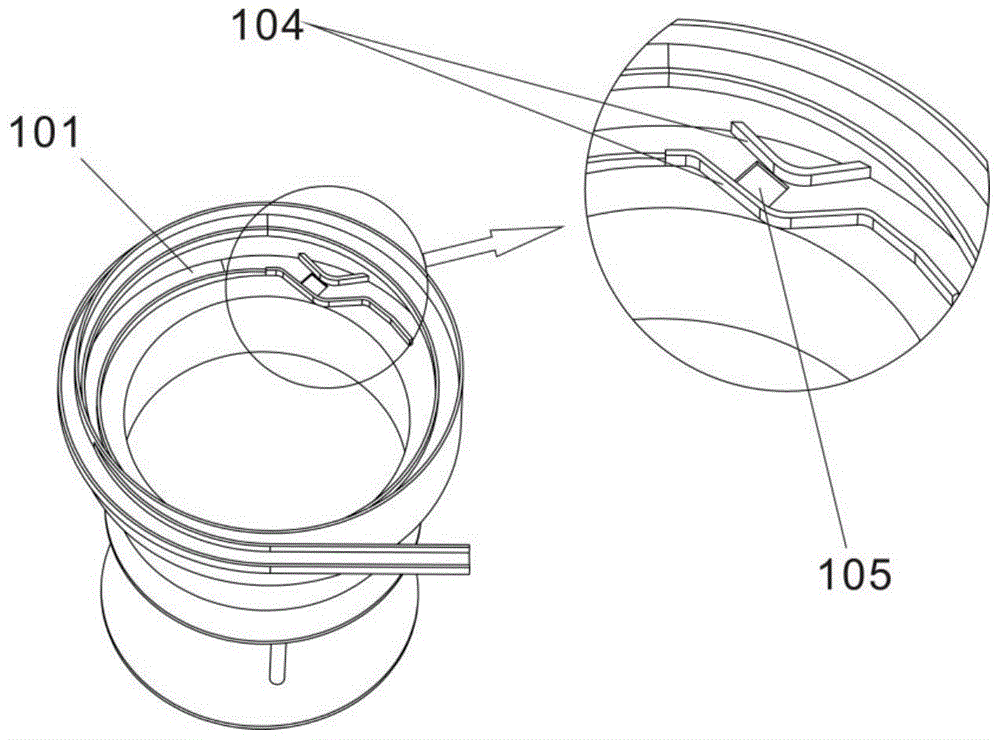

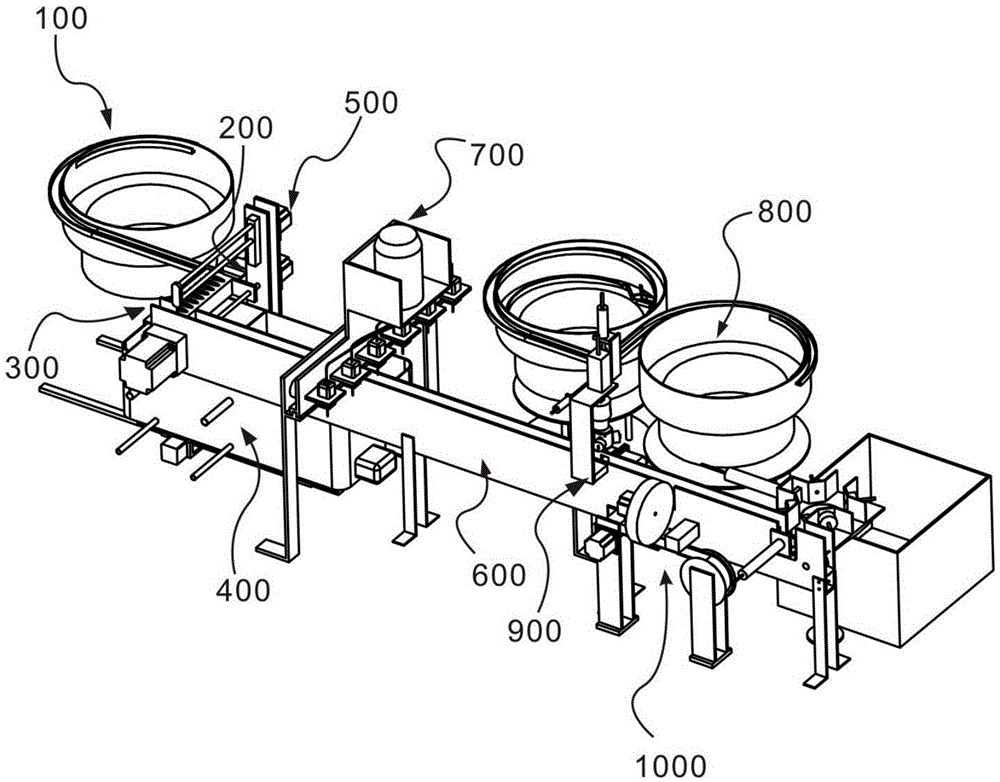

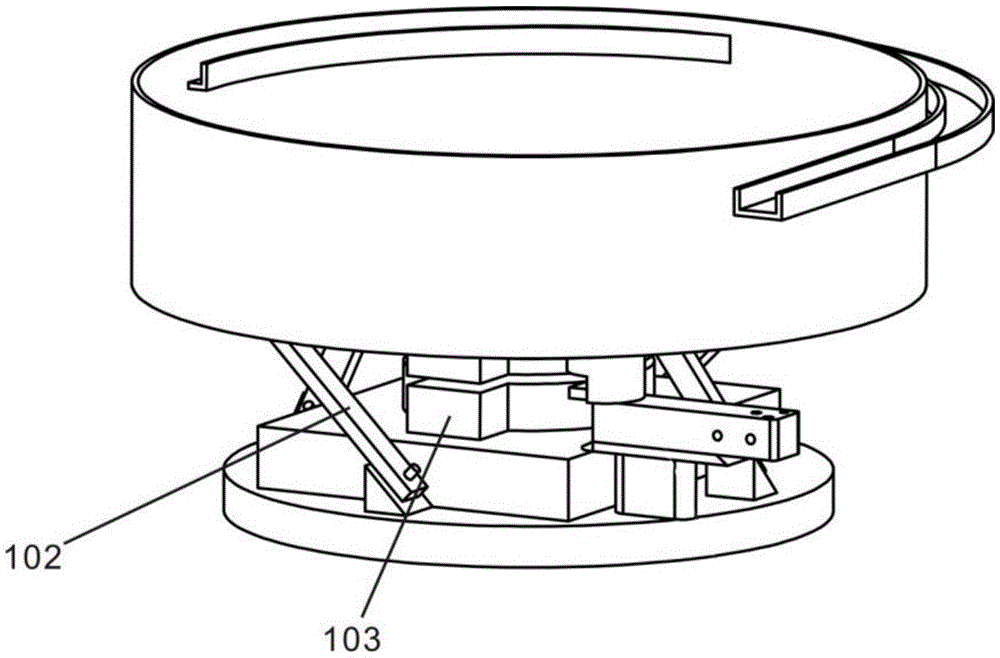

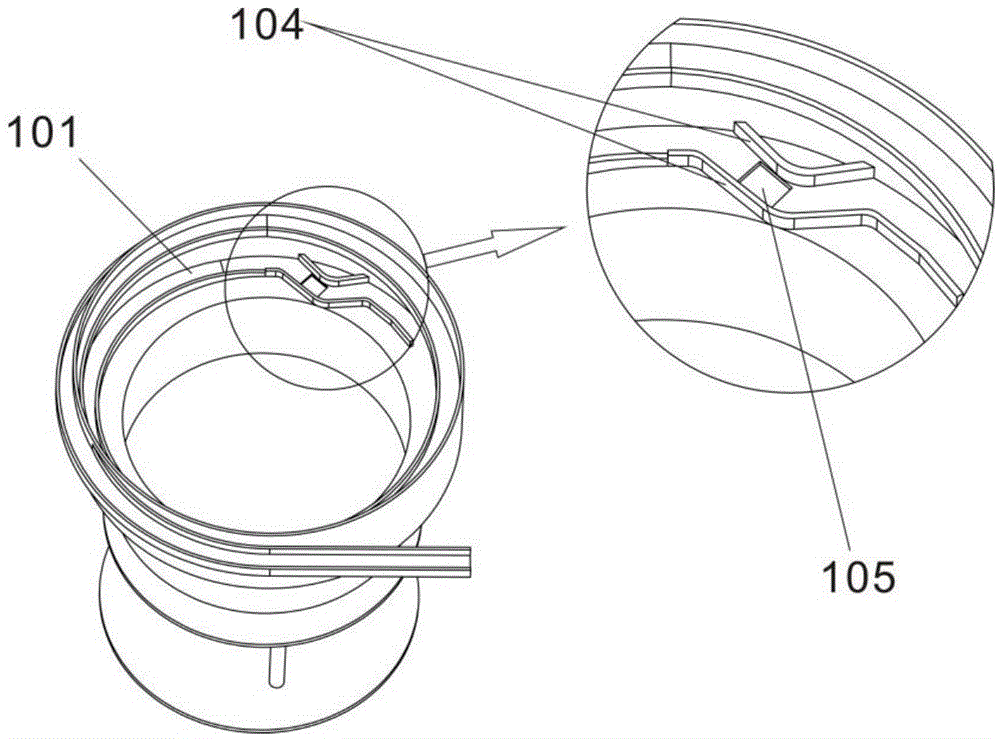

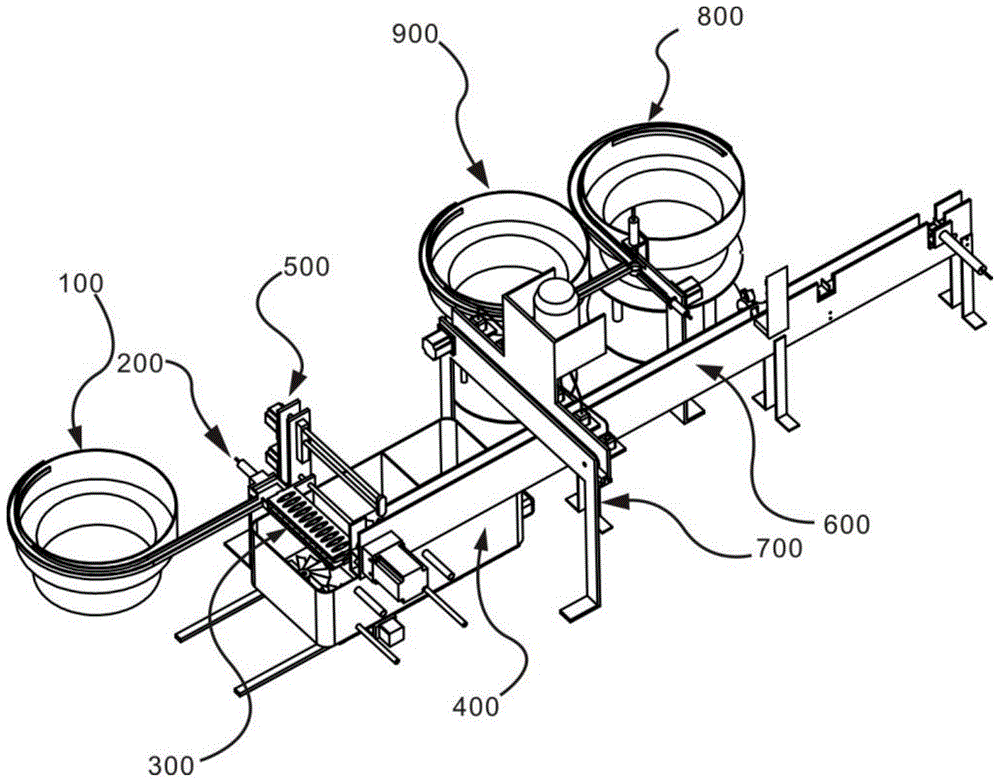

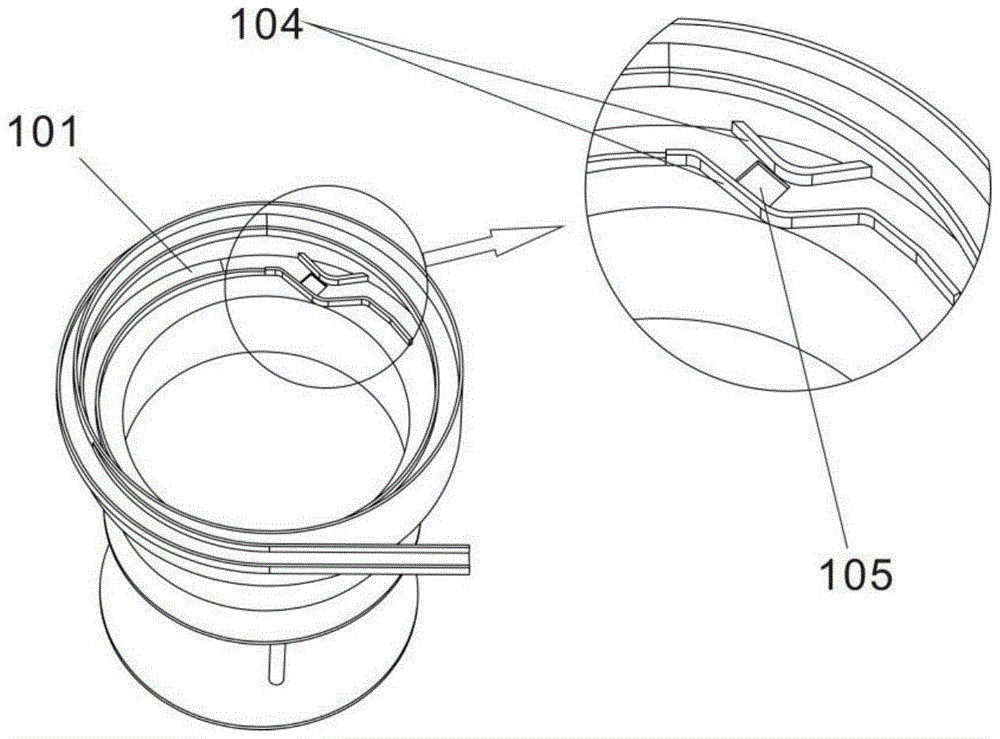

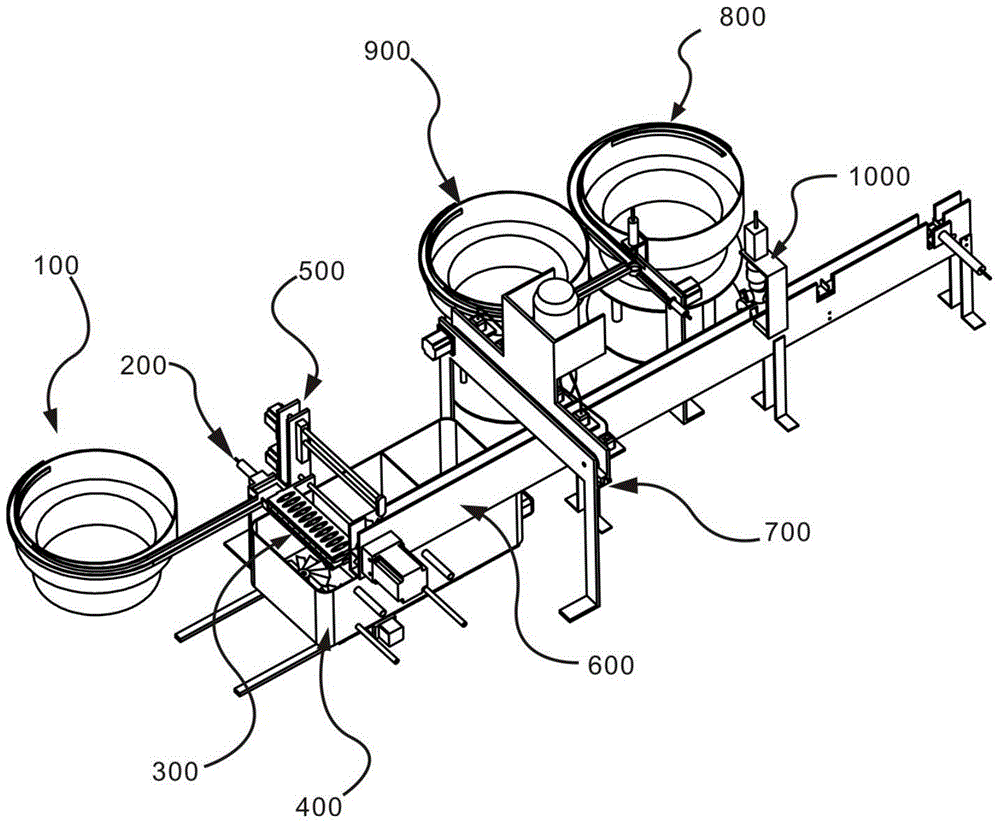

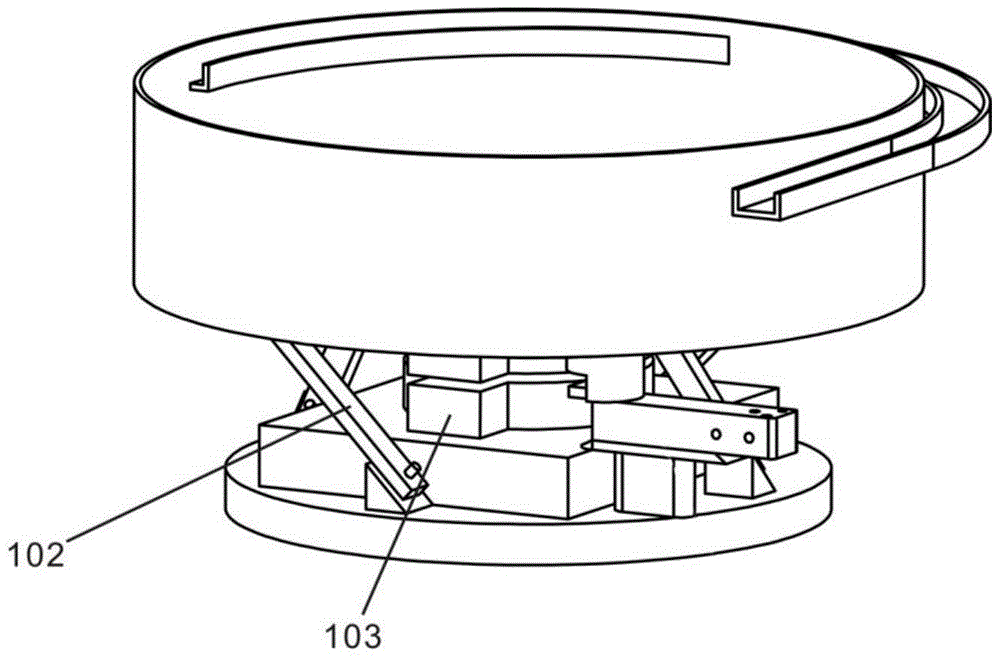

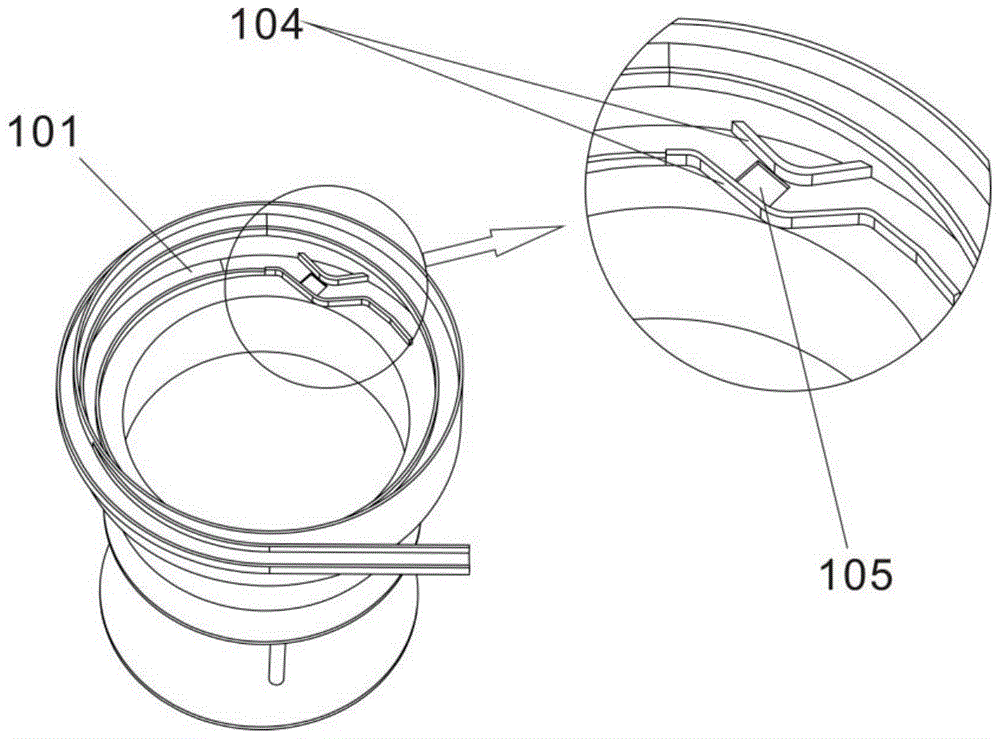

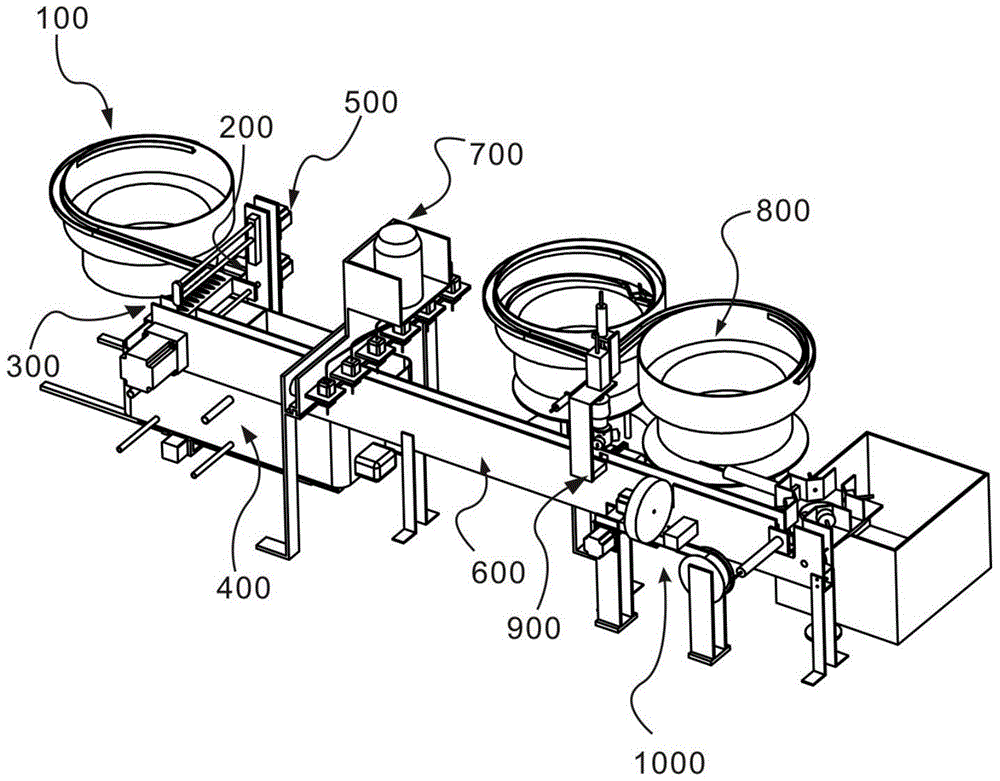

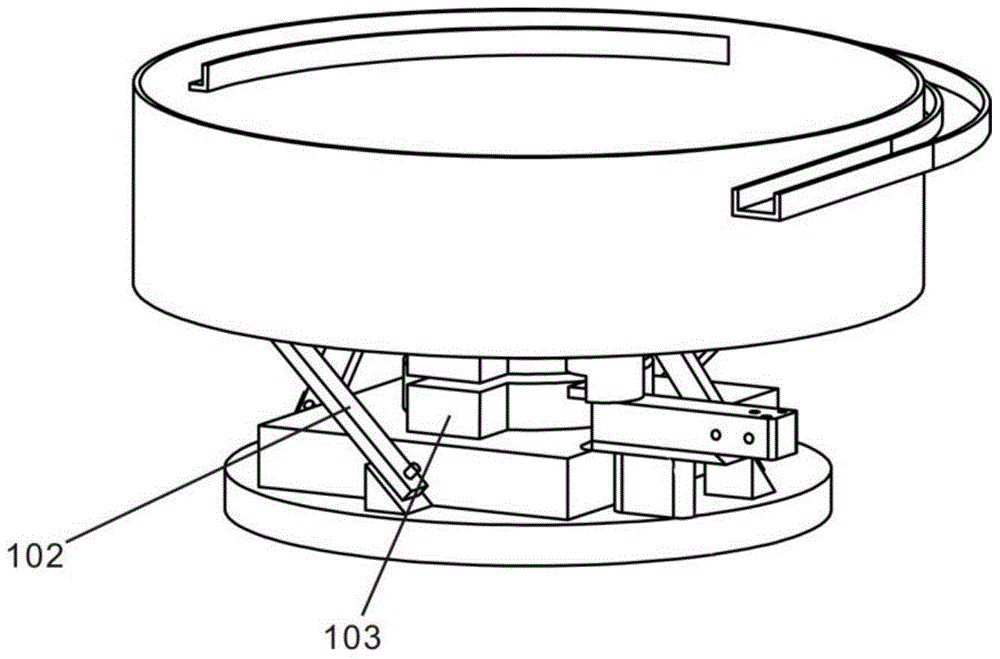

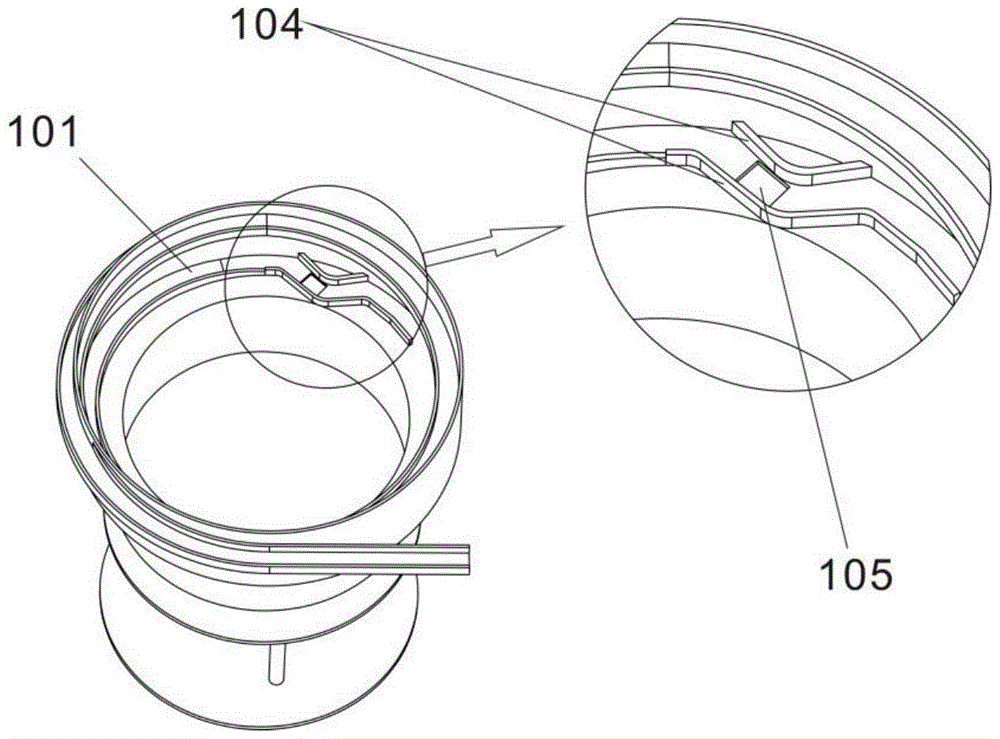

ActiveCN104326431ASolve the problem of directional transportCapsThreaded caps applicationEngineeringBottle

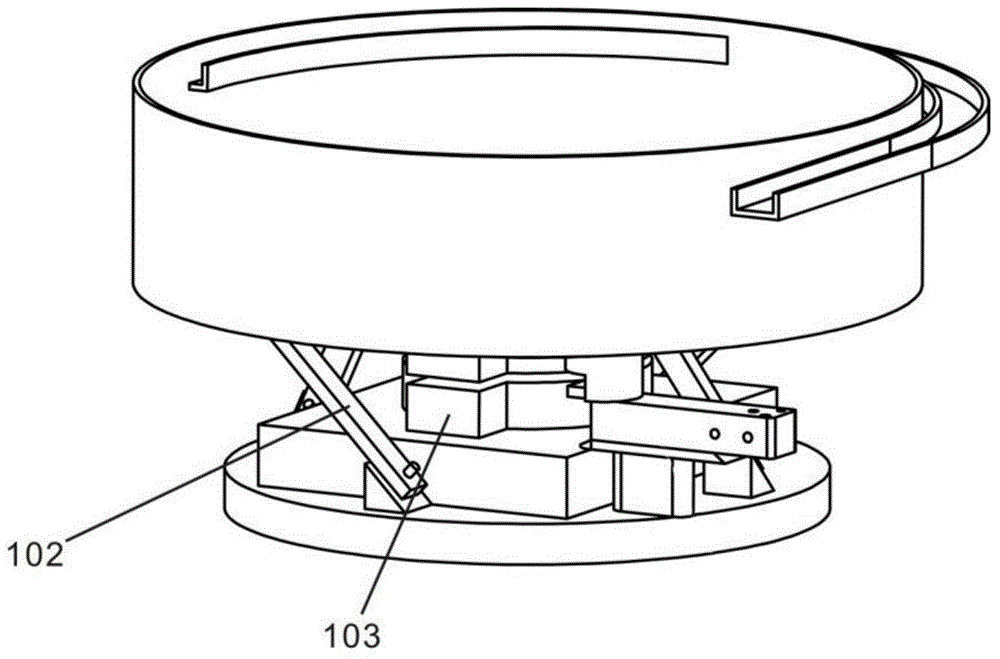

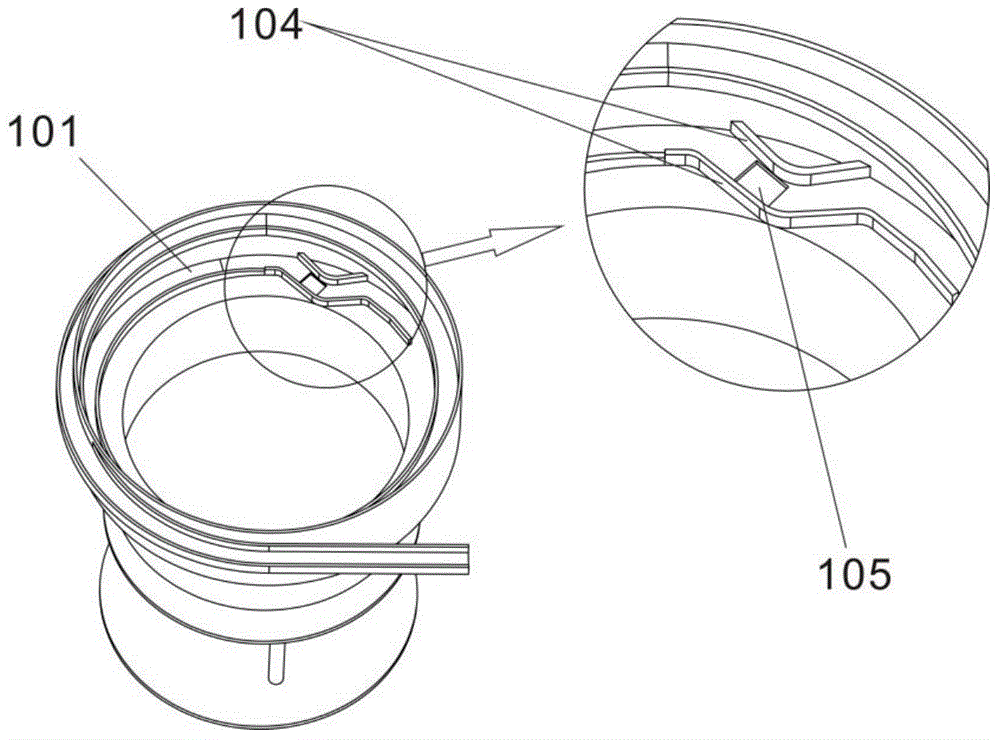

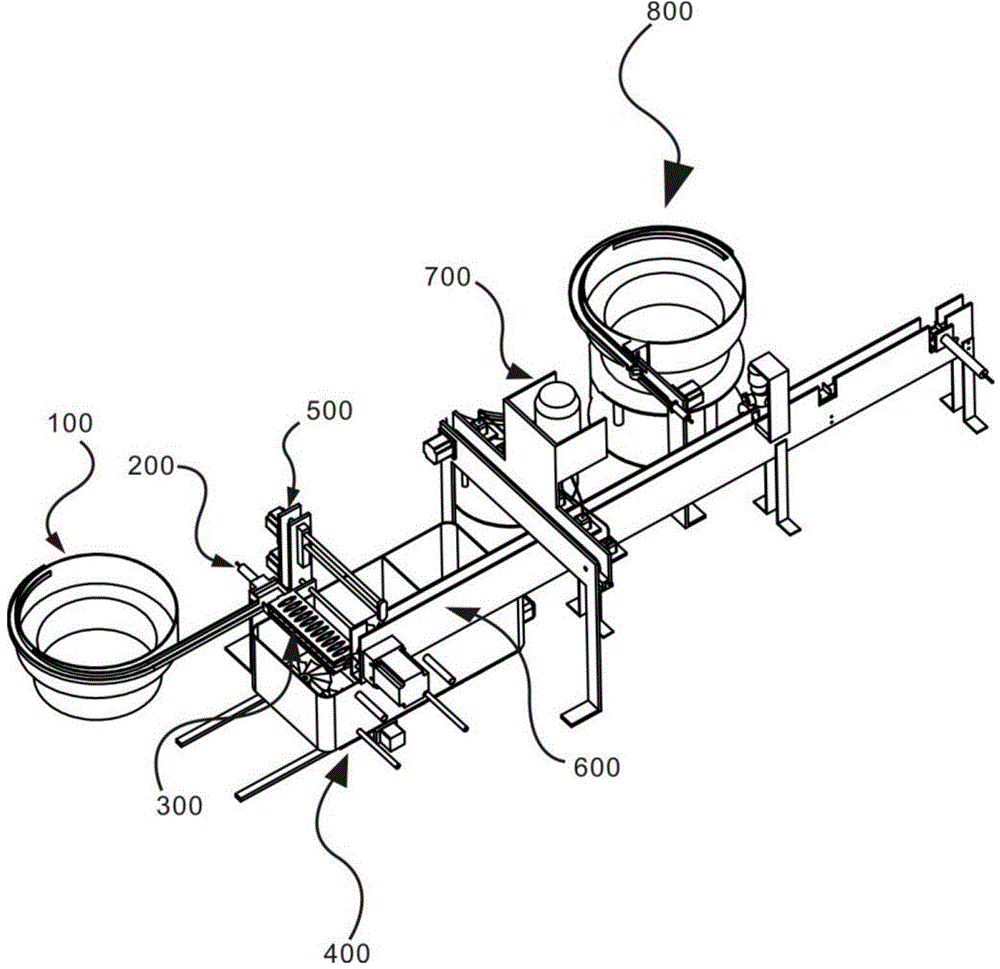

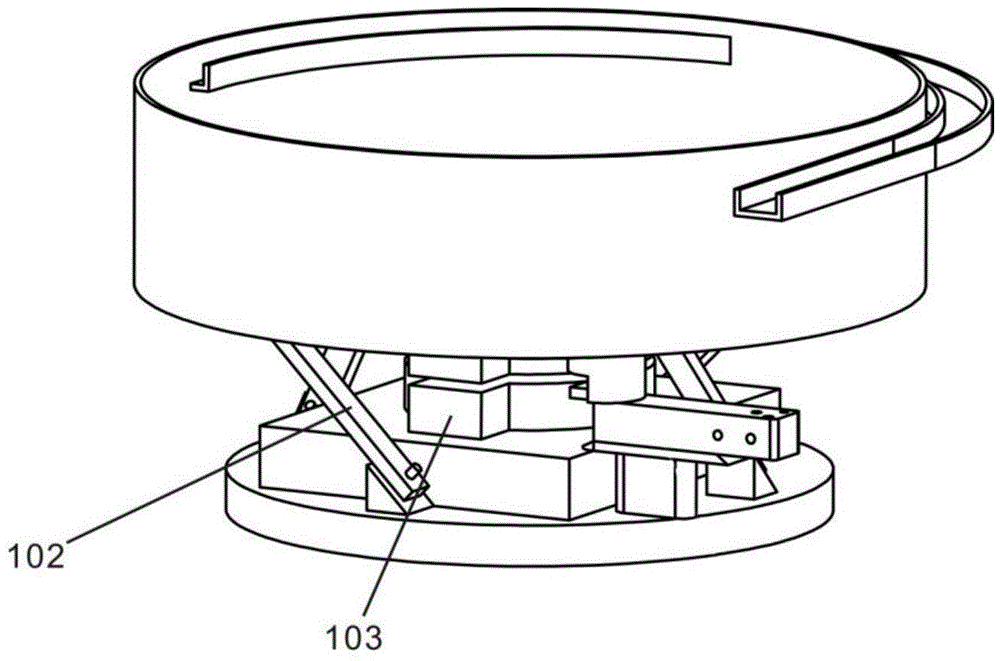

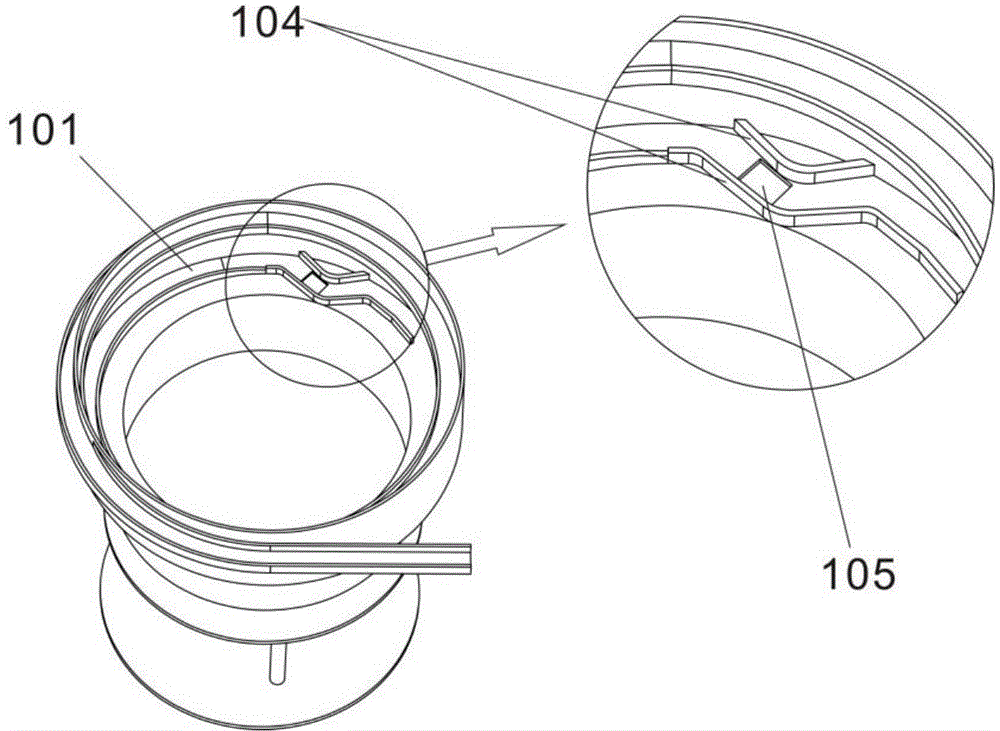

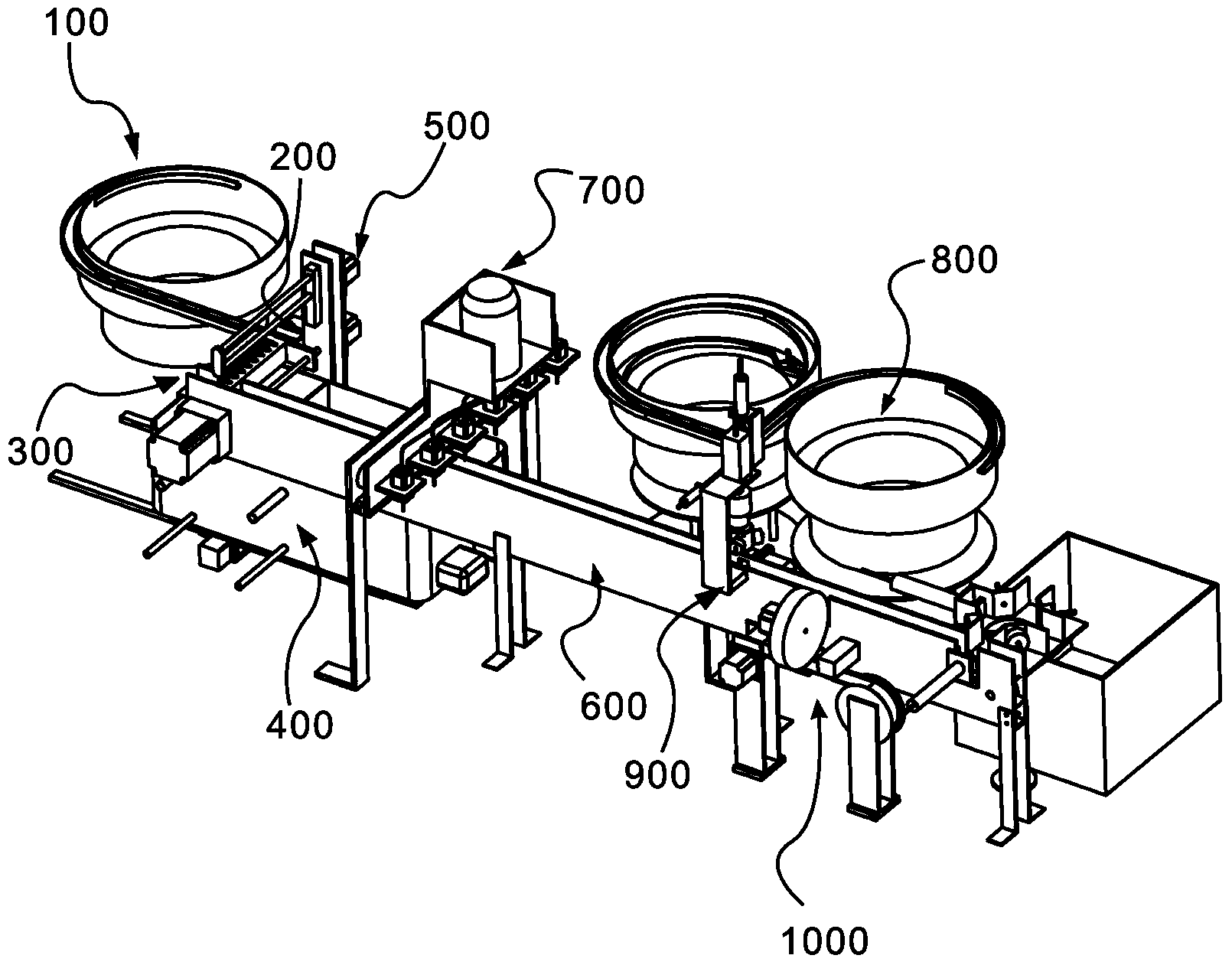

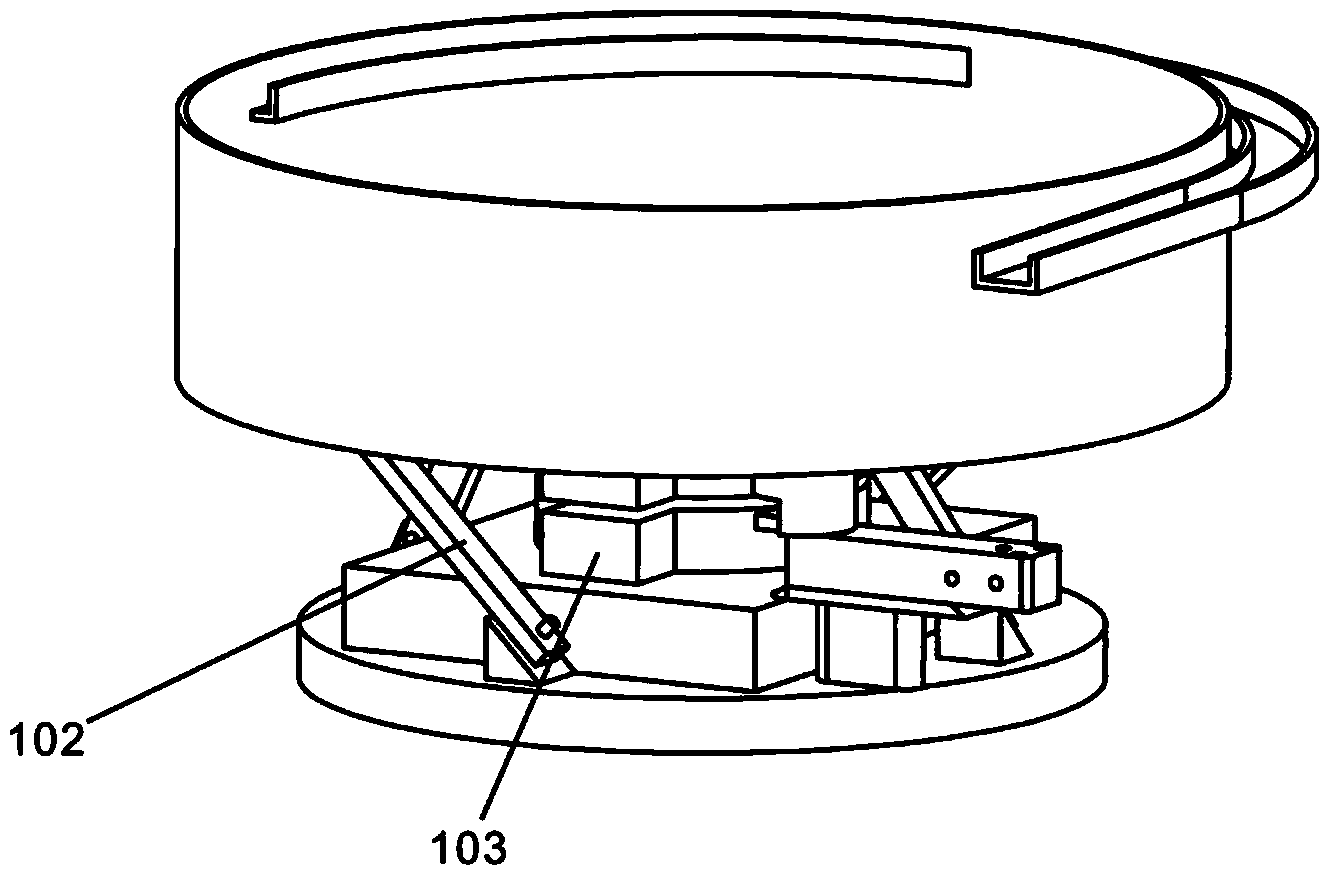

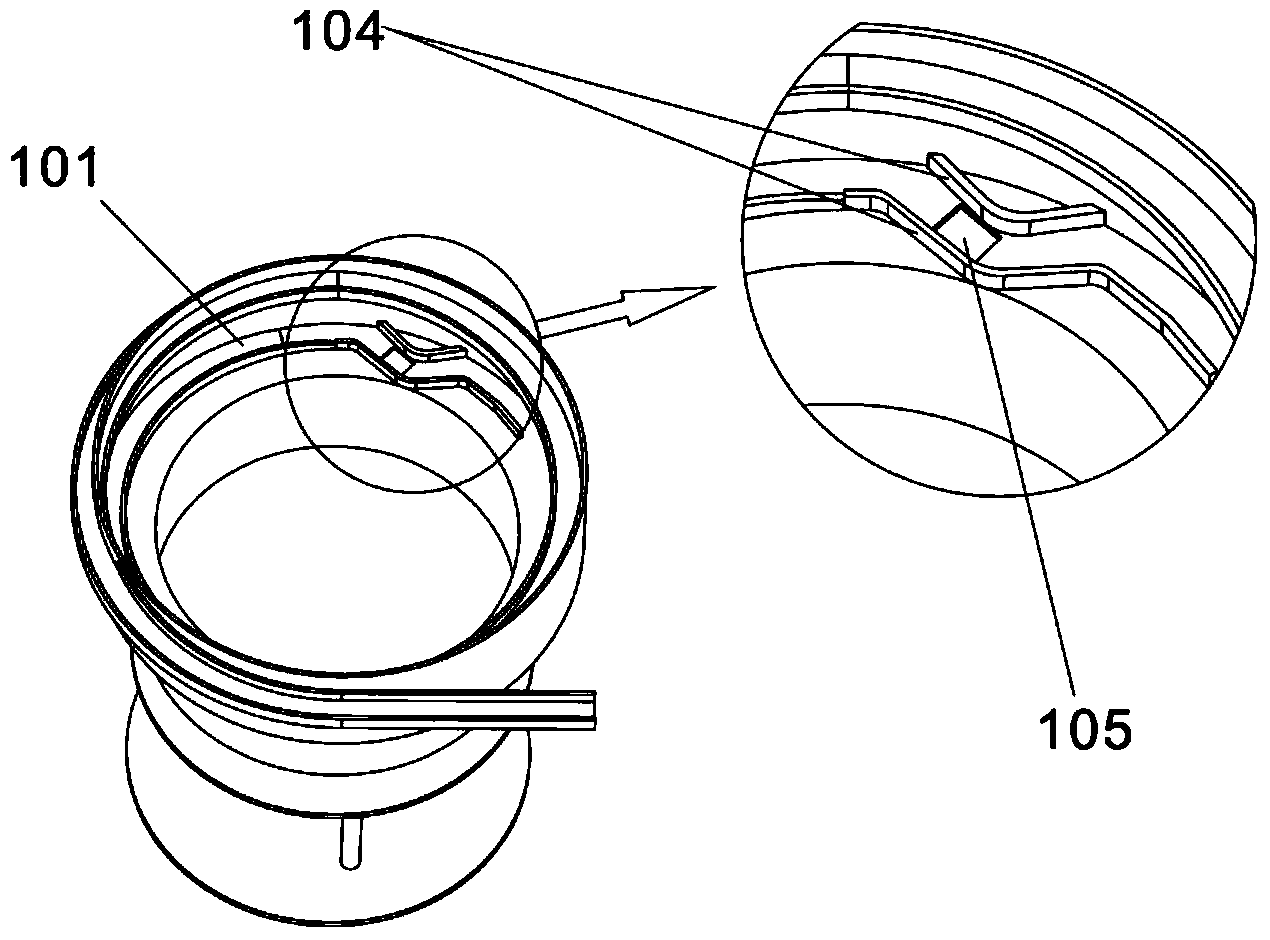

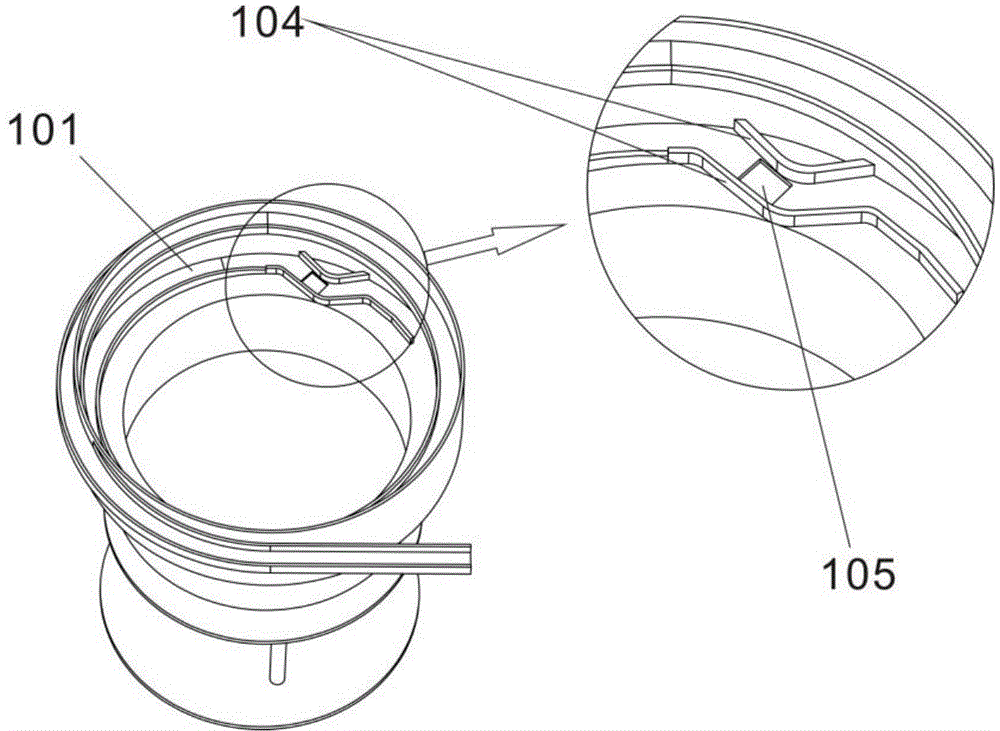

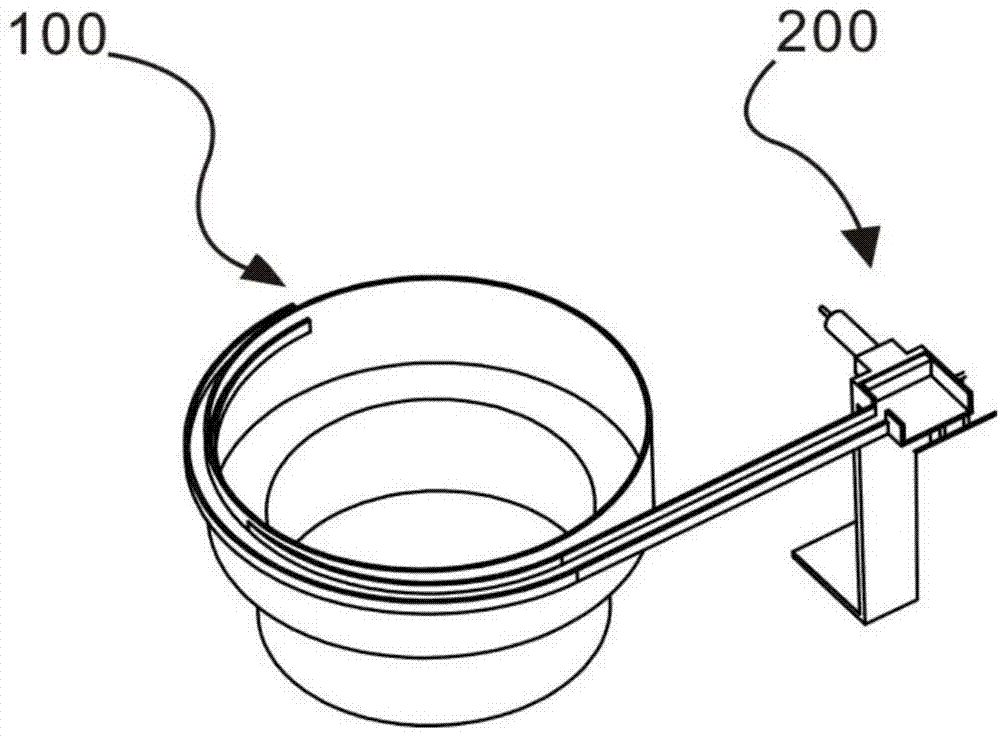

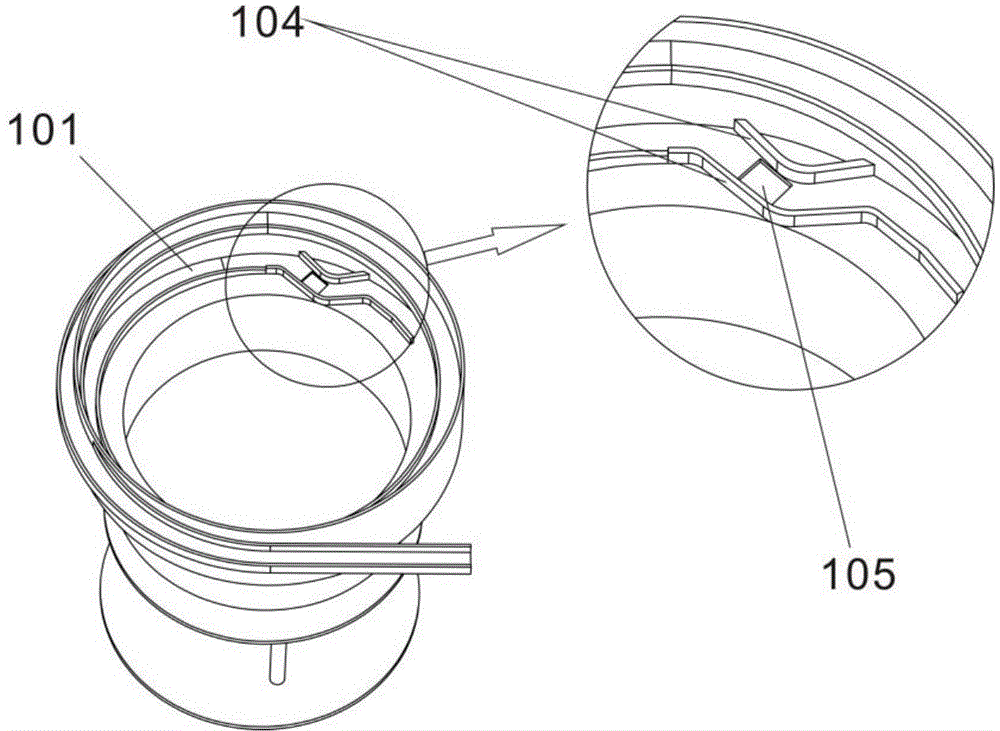

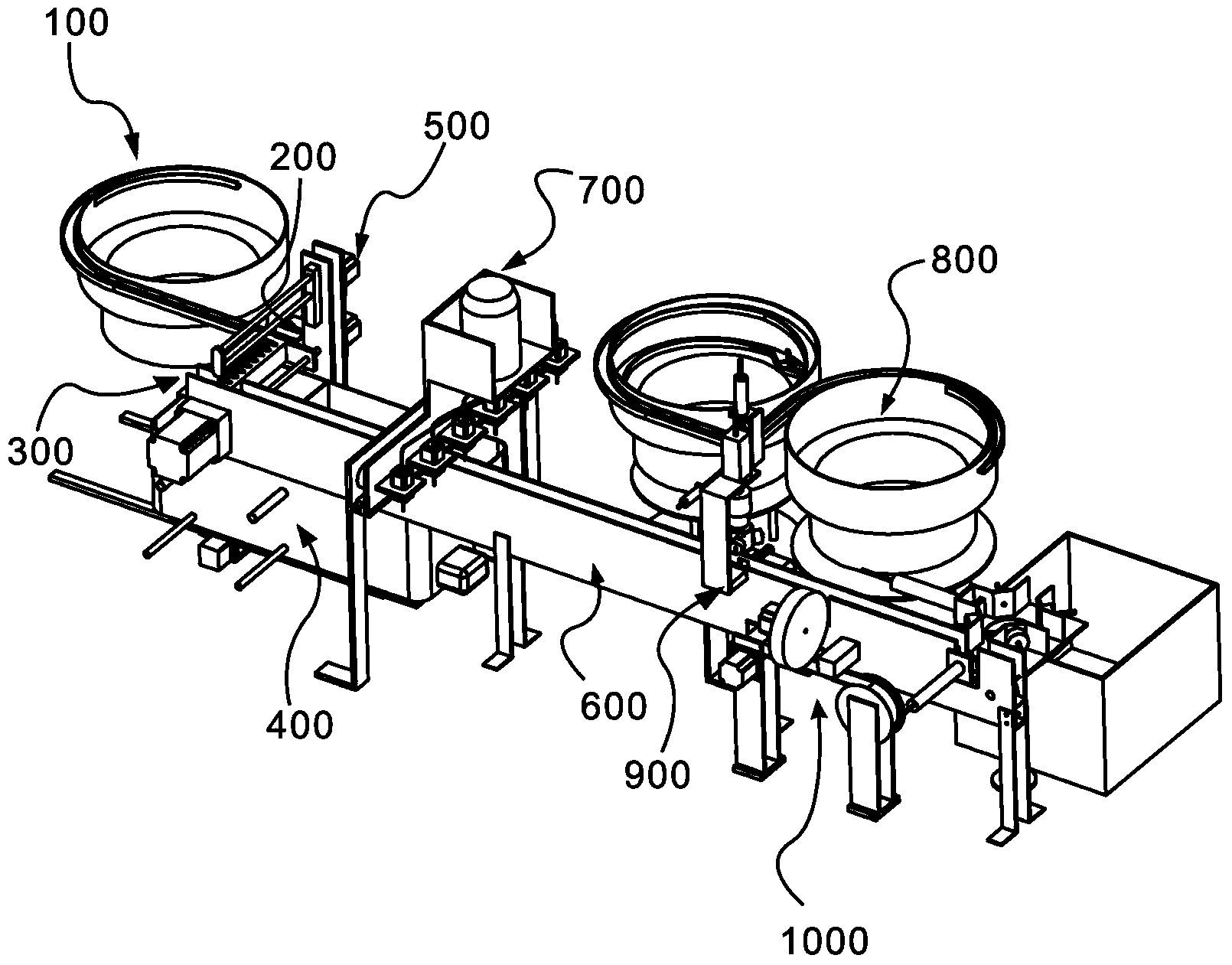

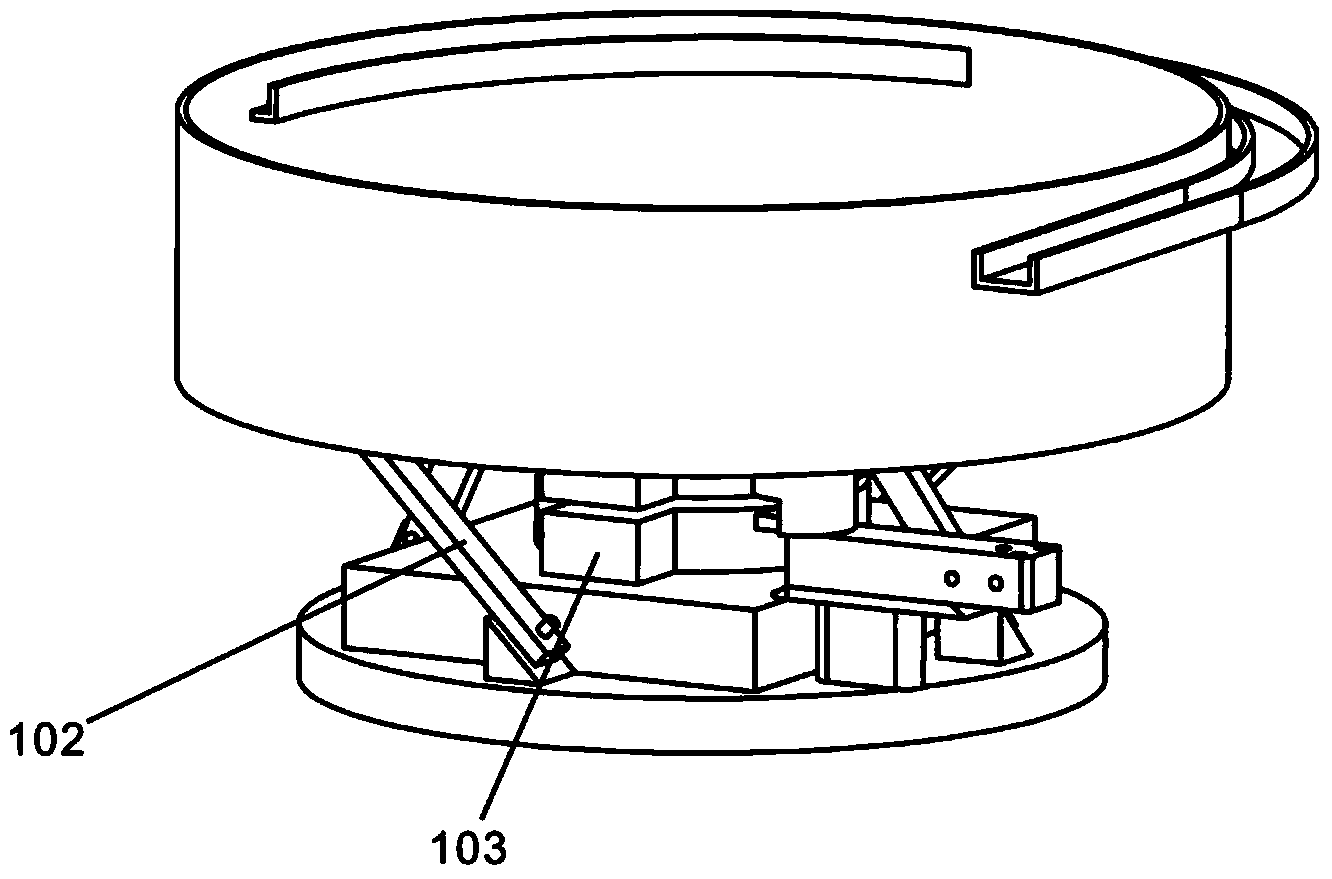

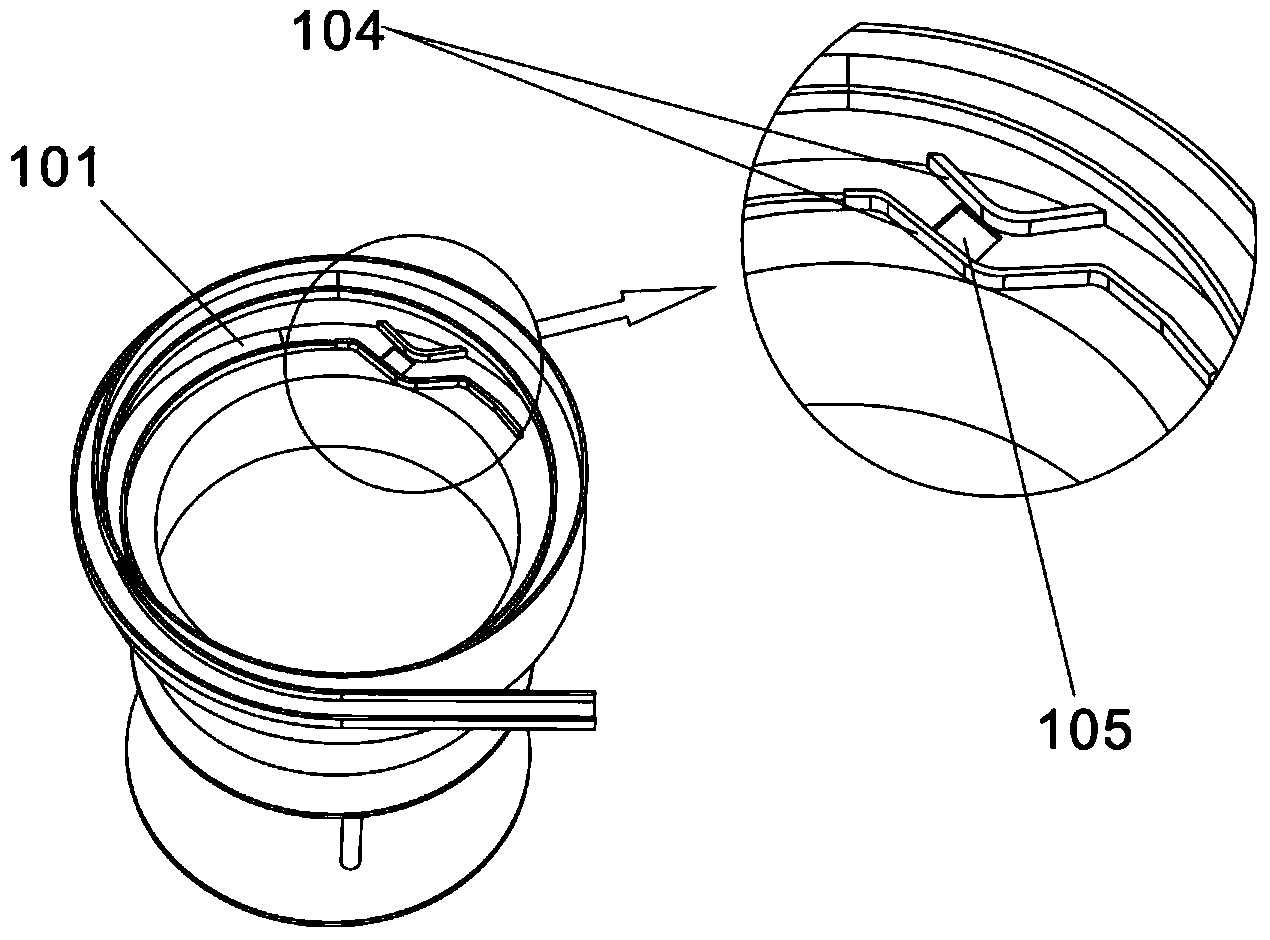

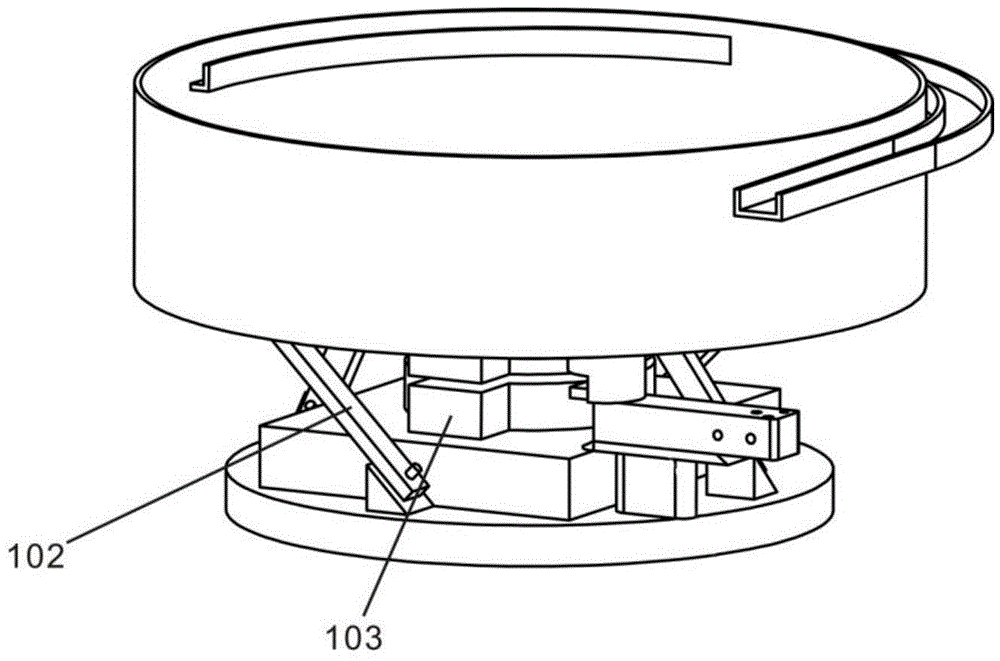

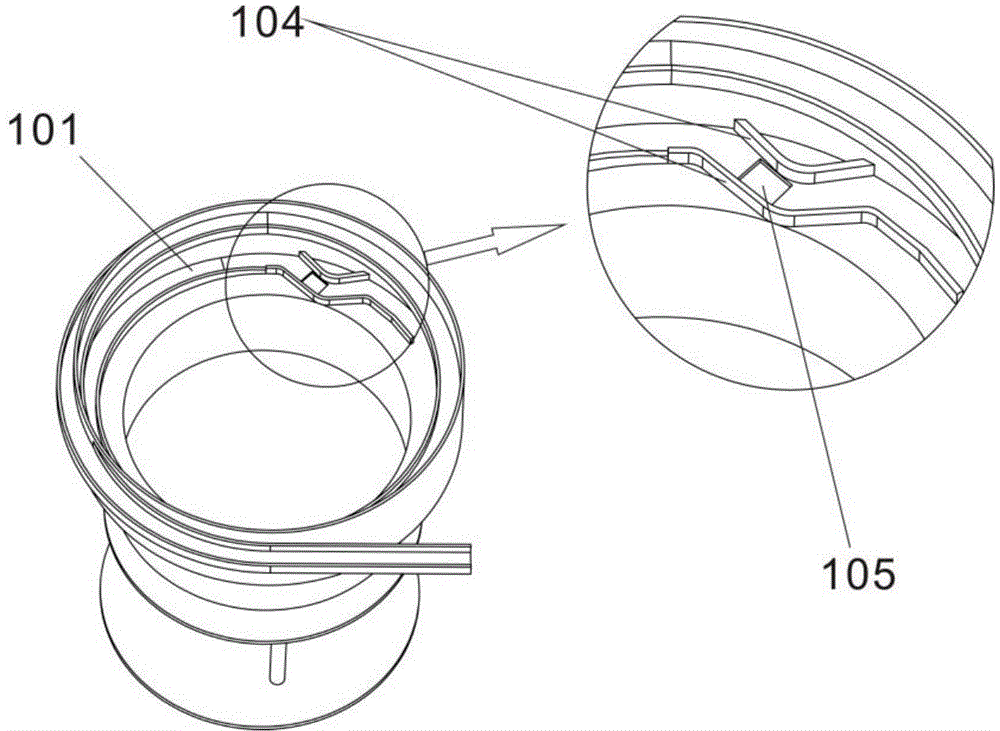

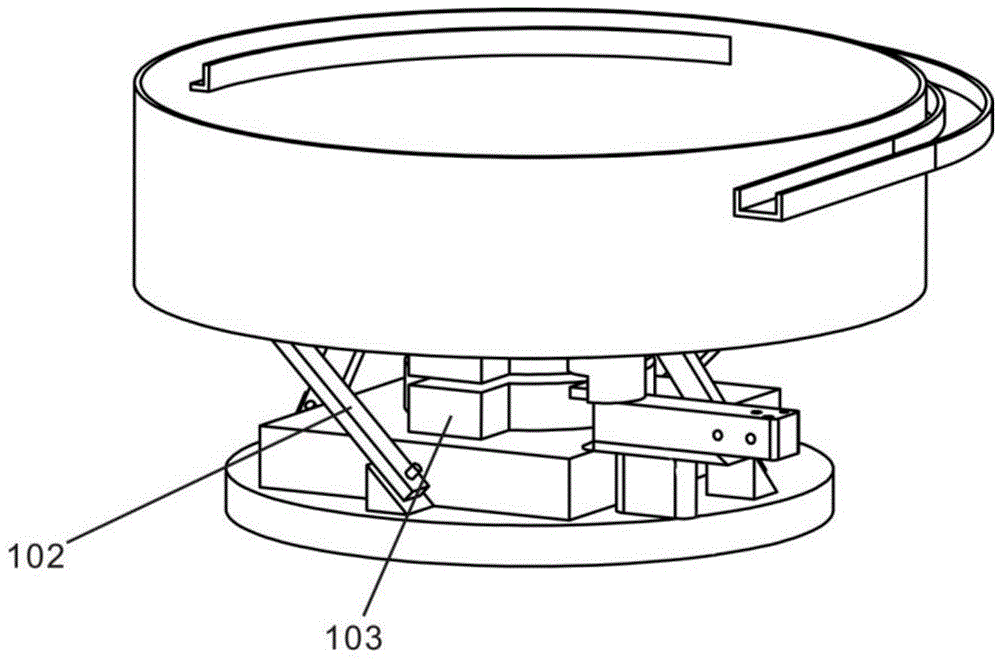

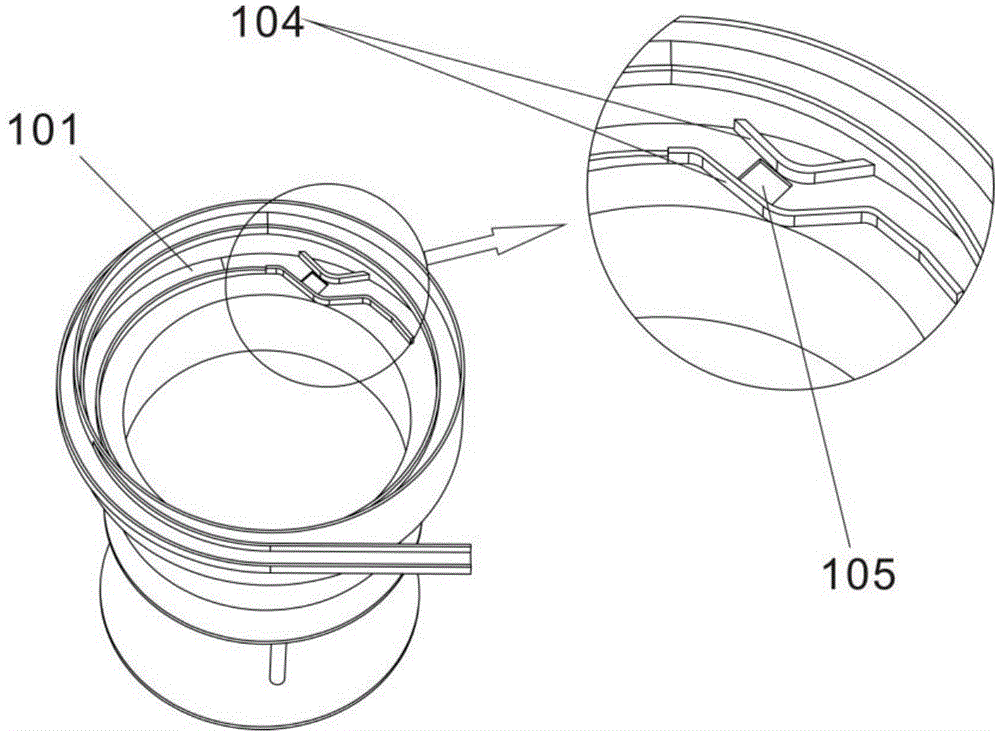

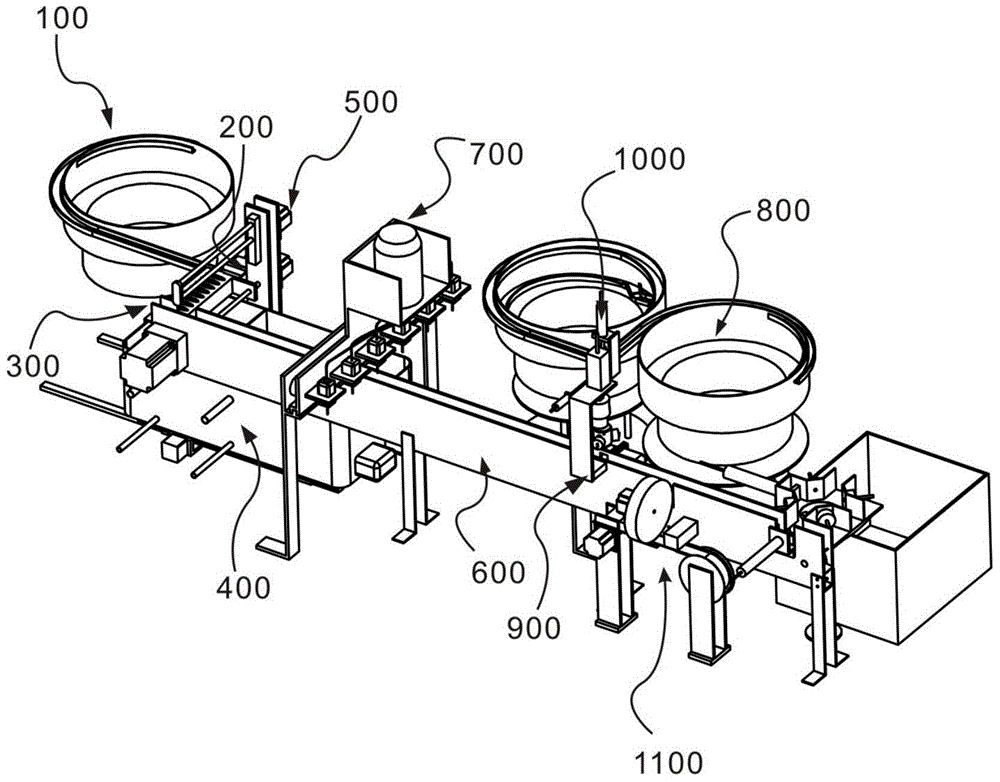

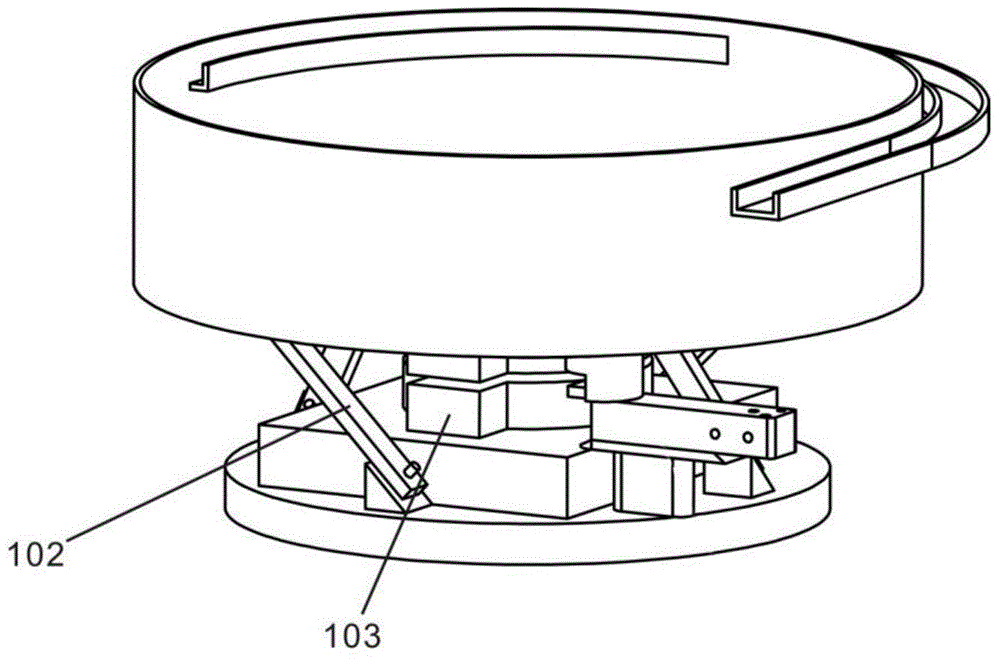

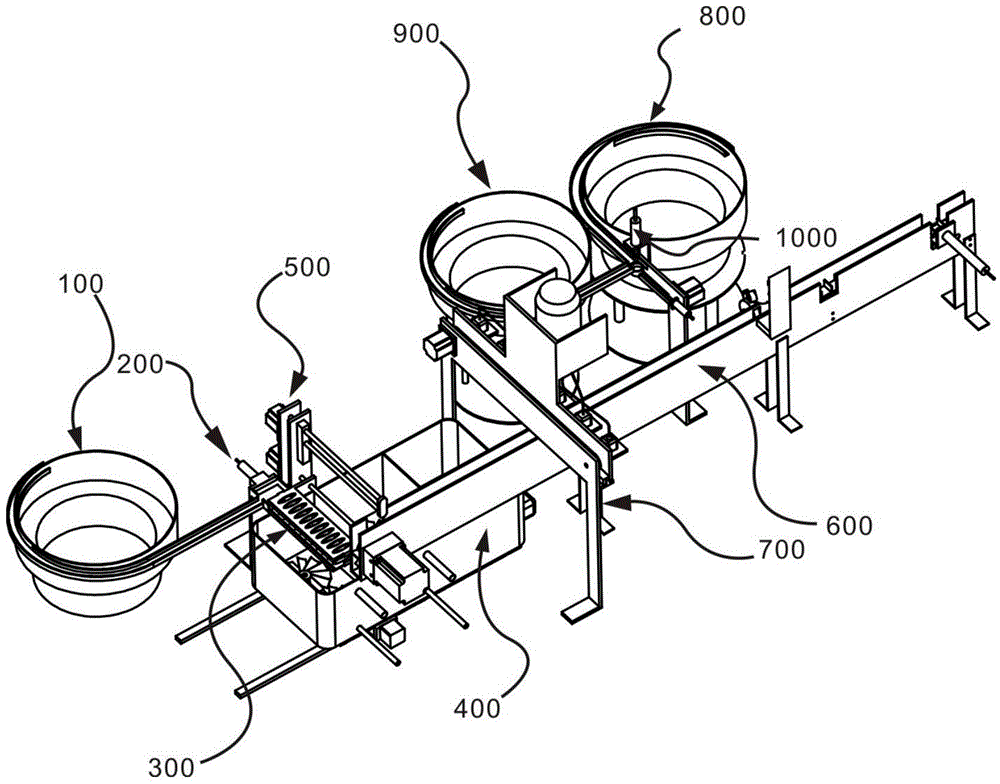

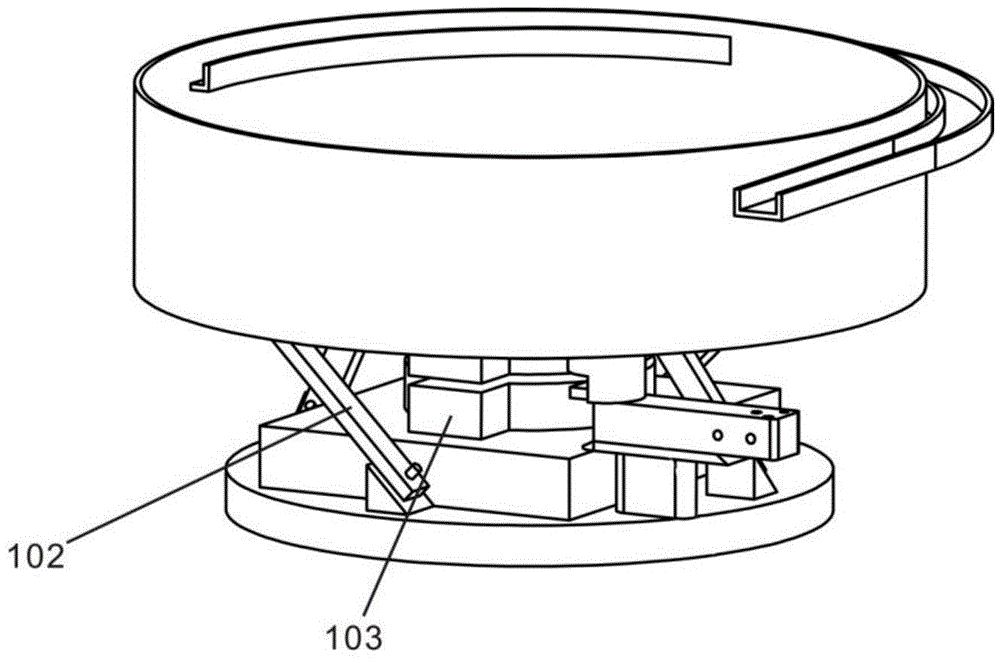

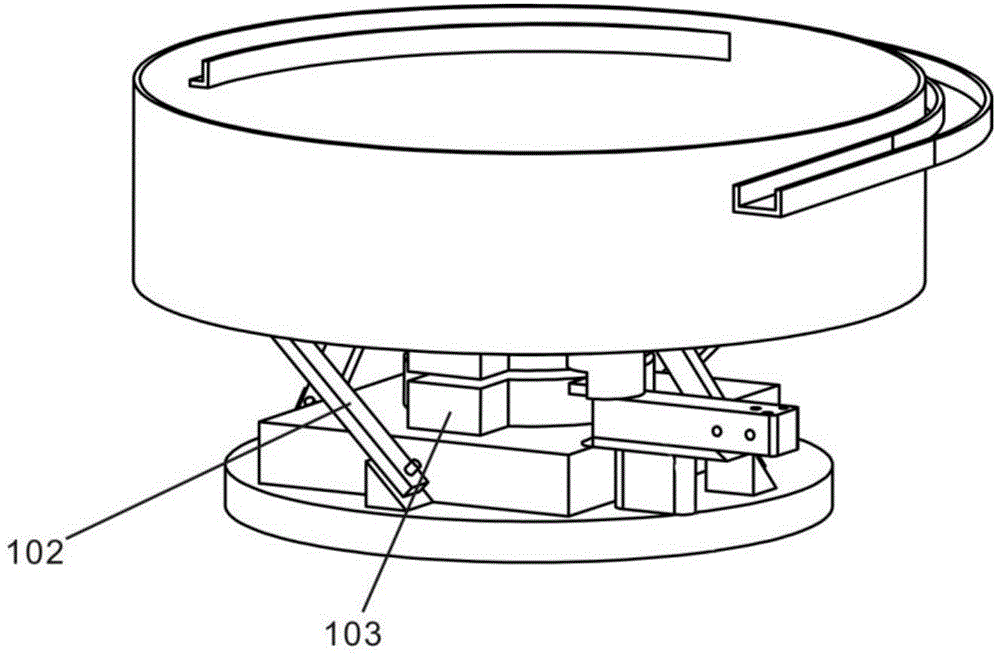

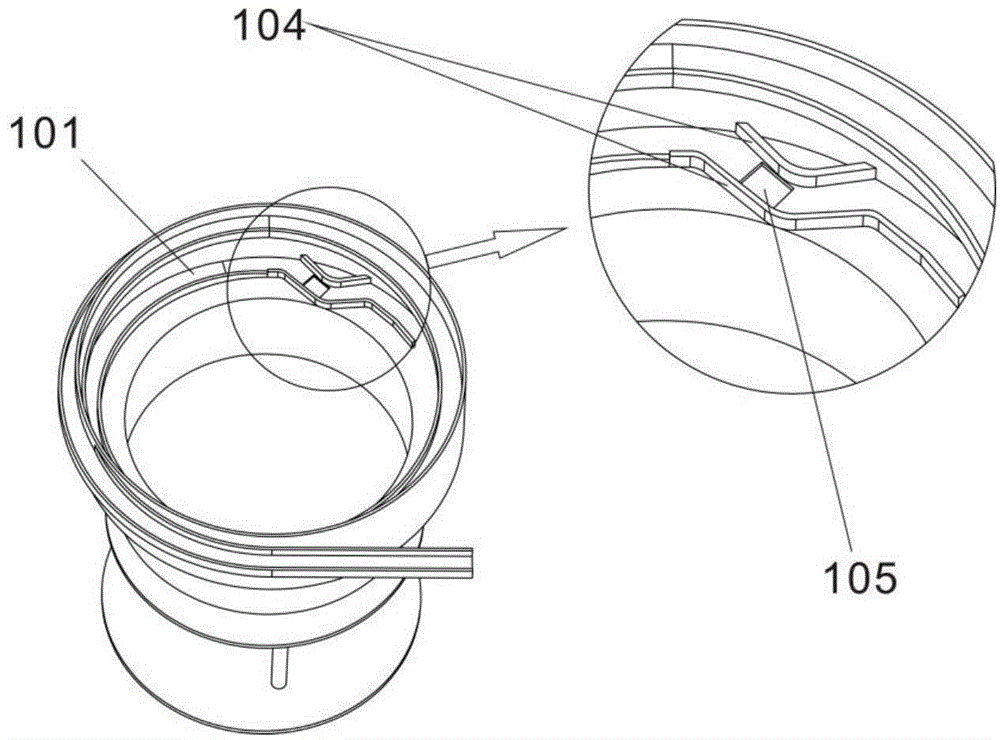

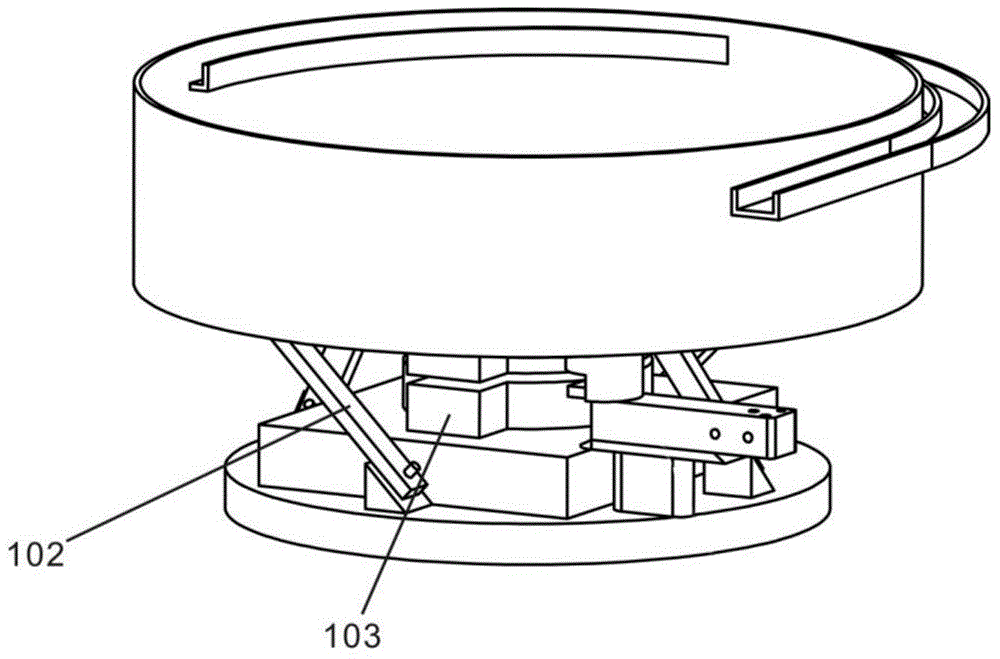

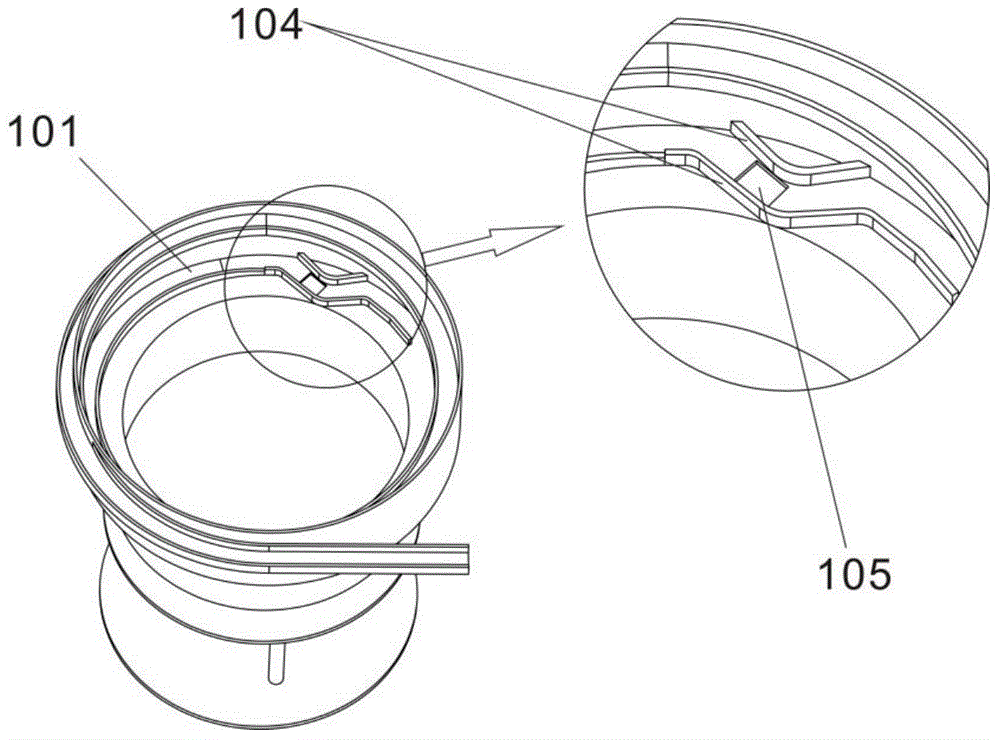

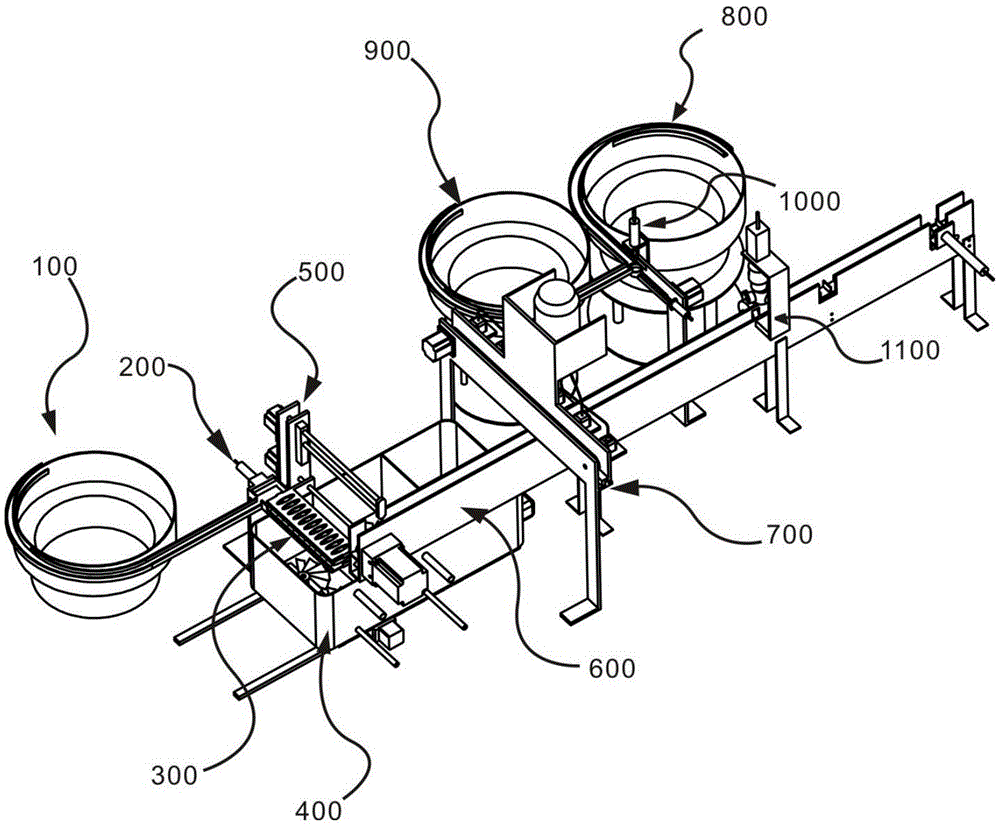

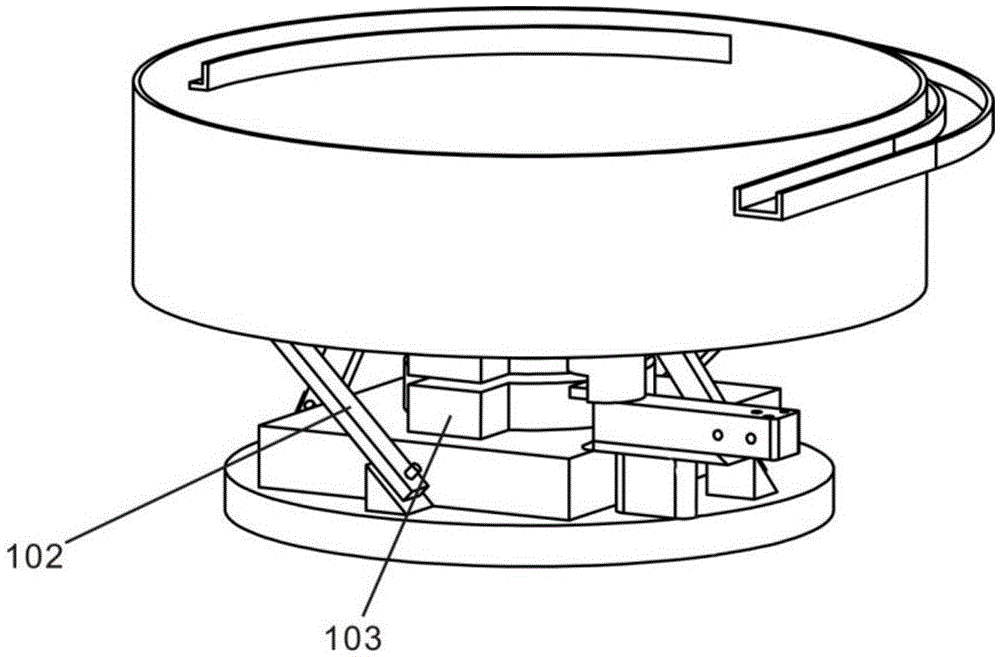

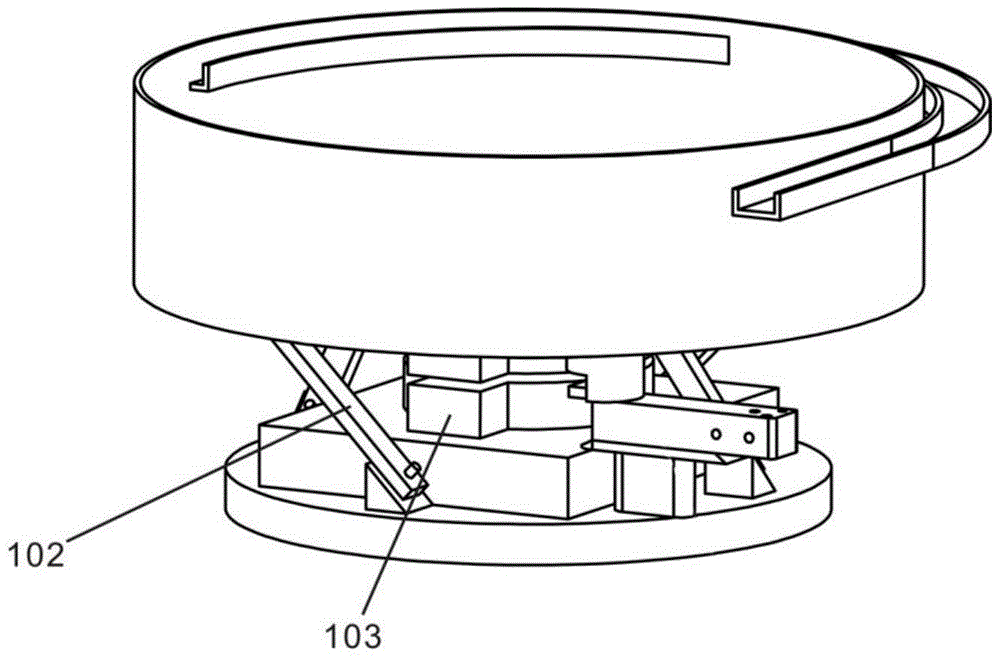

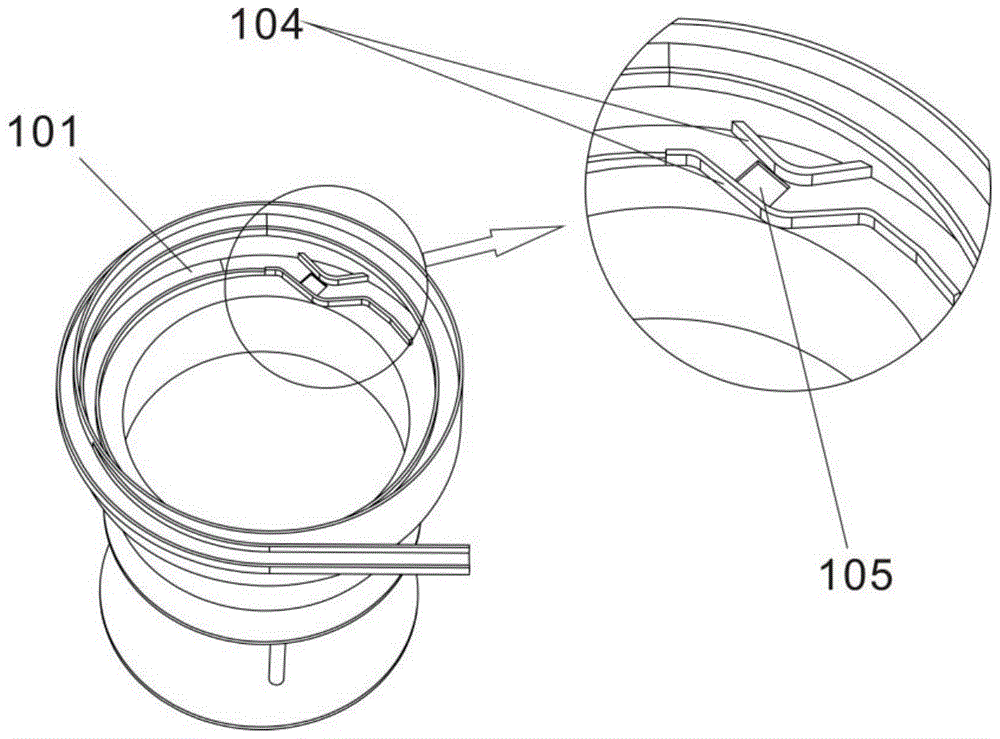

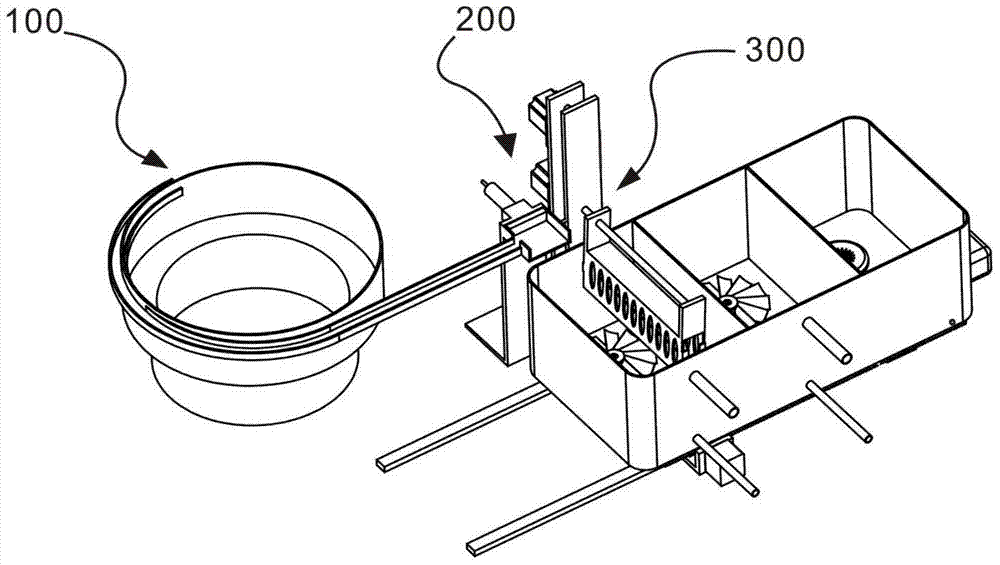

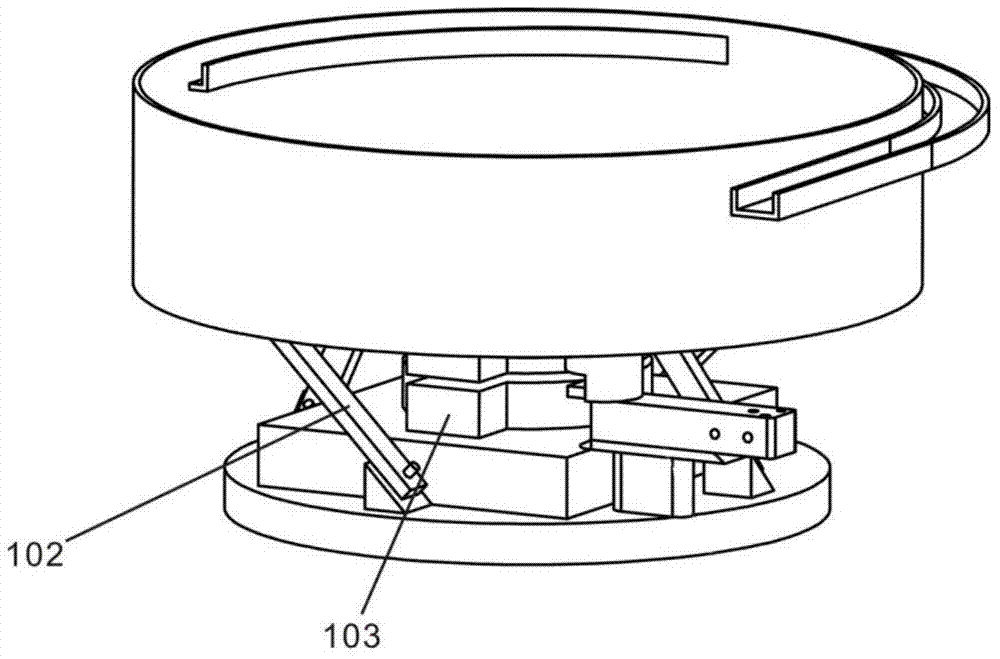

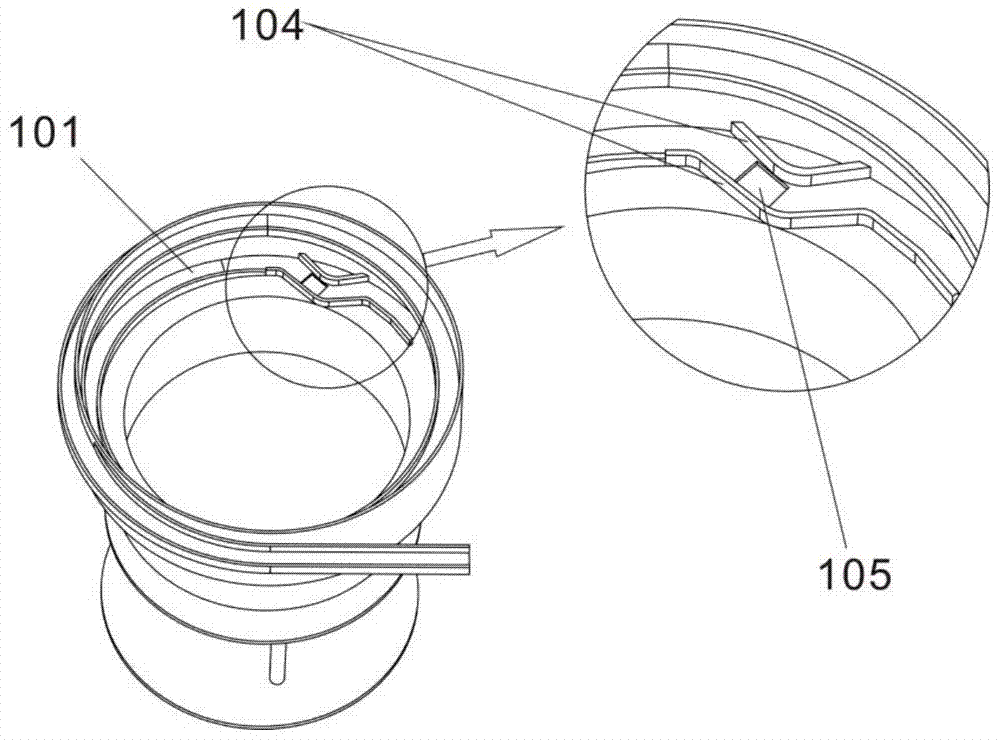

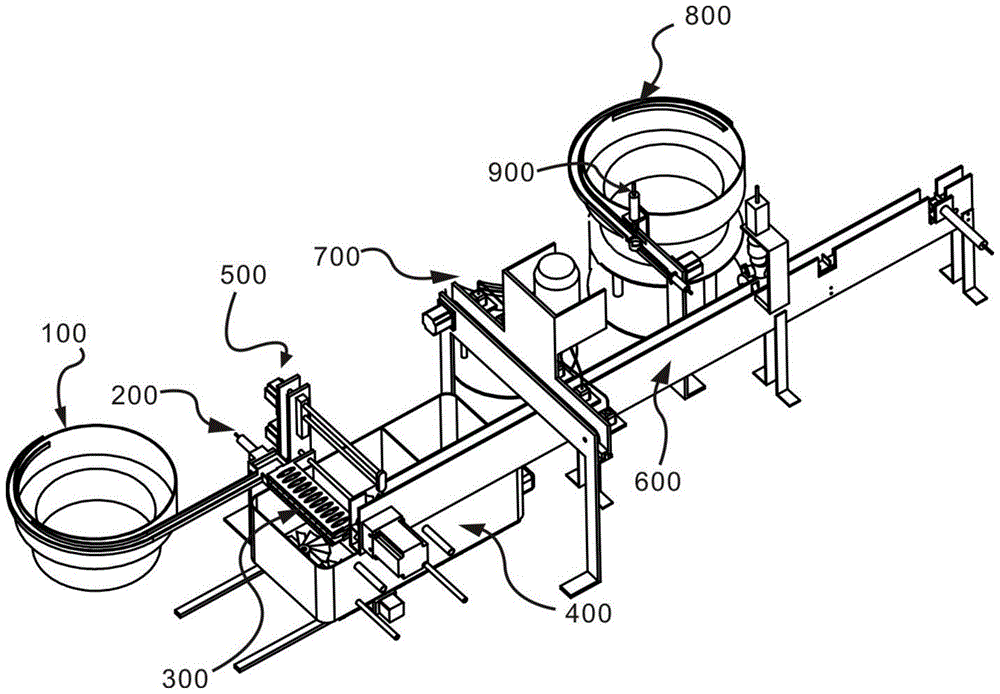

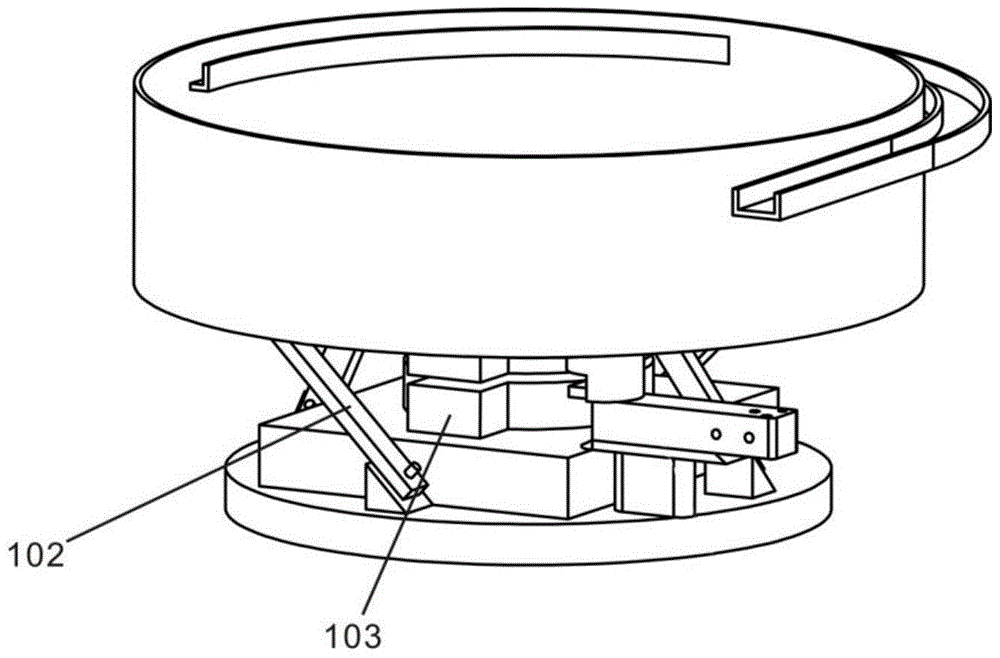

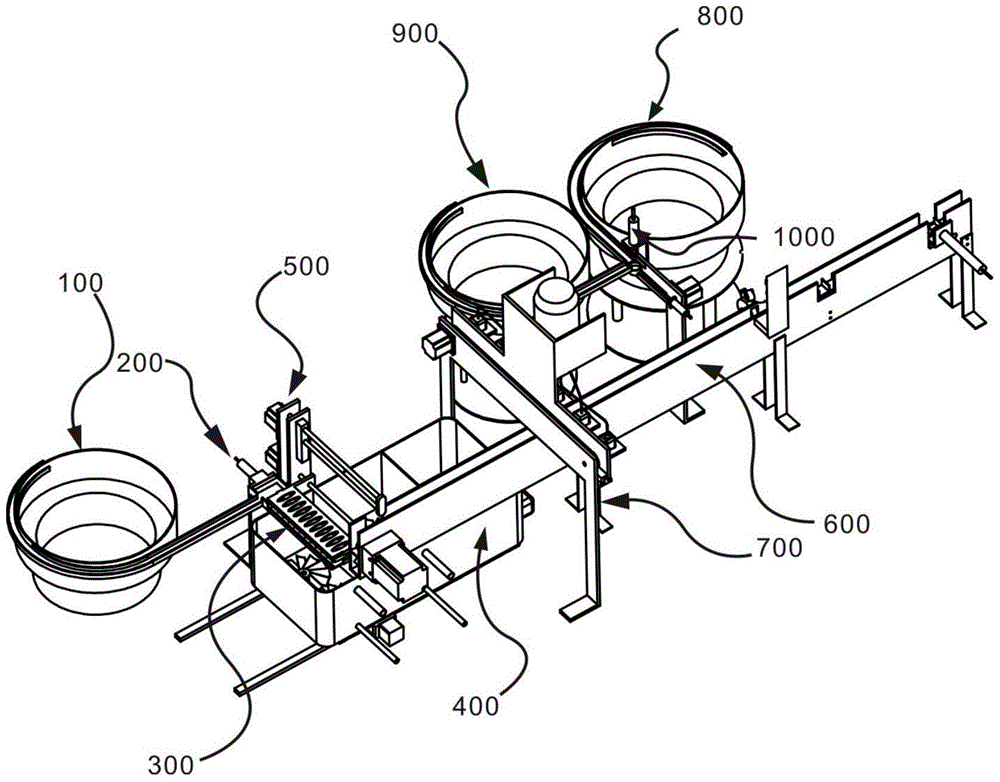

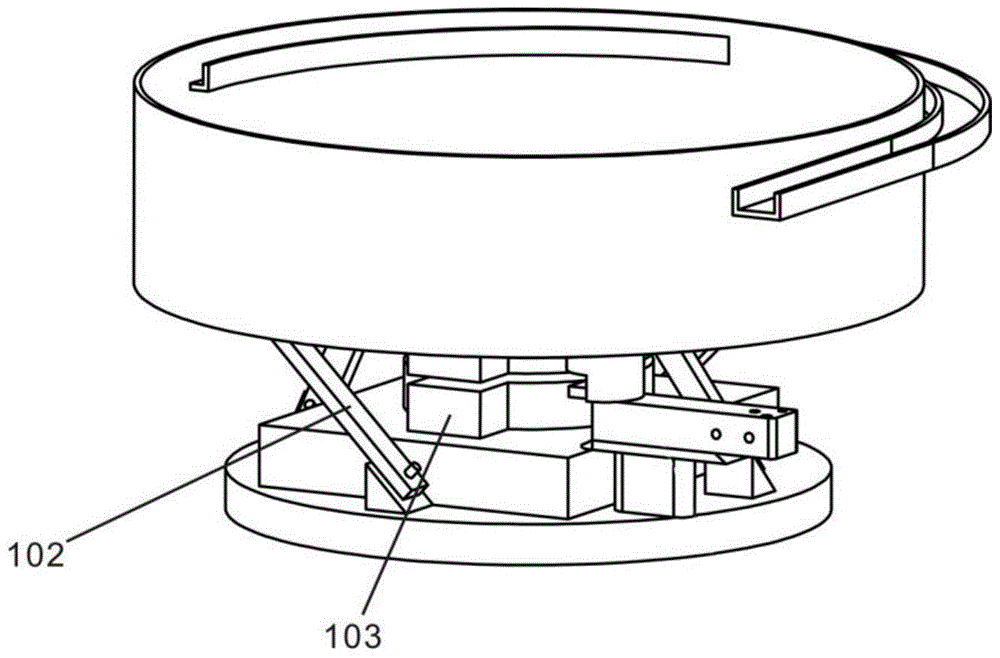

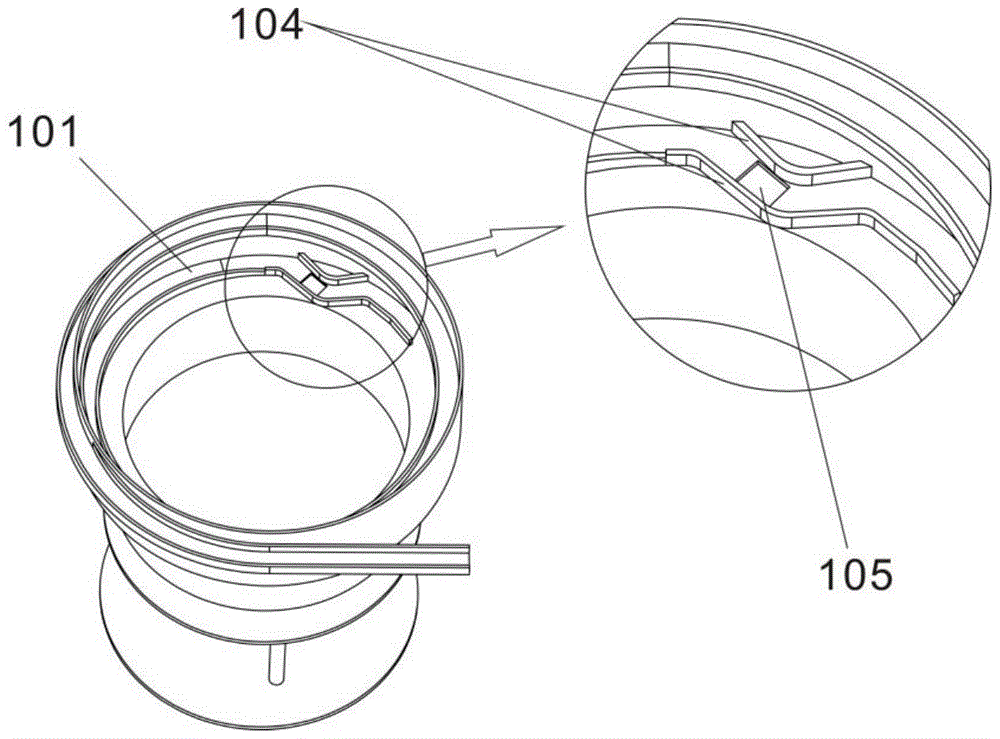

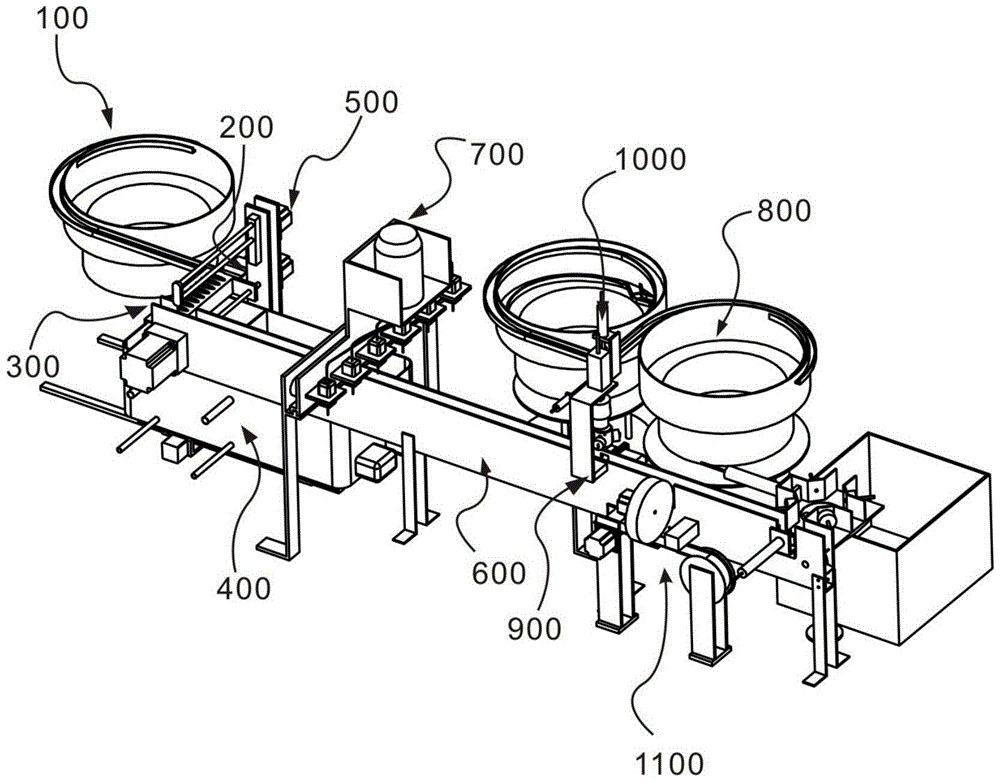

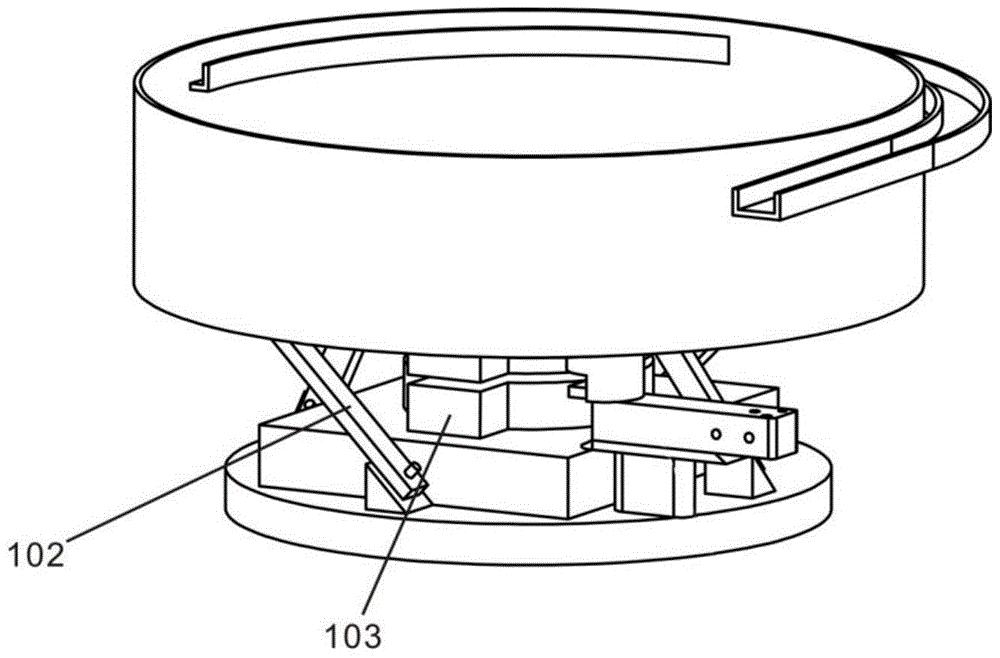

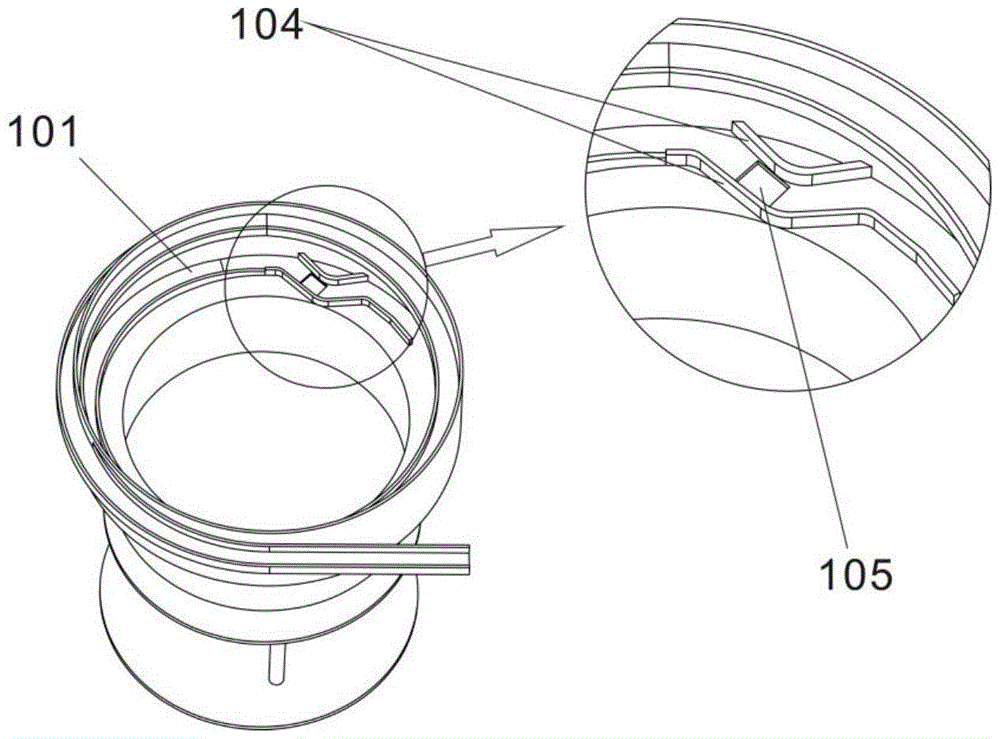

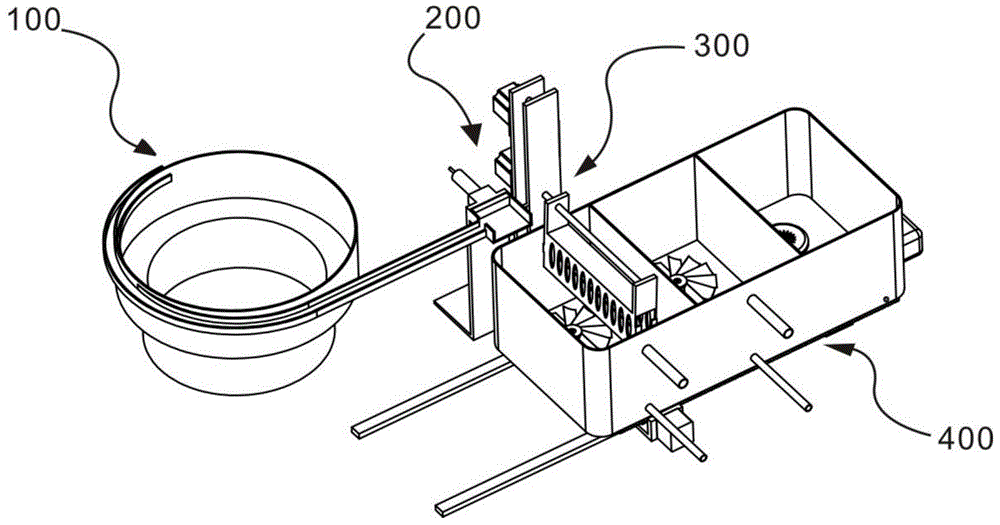

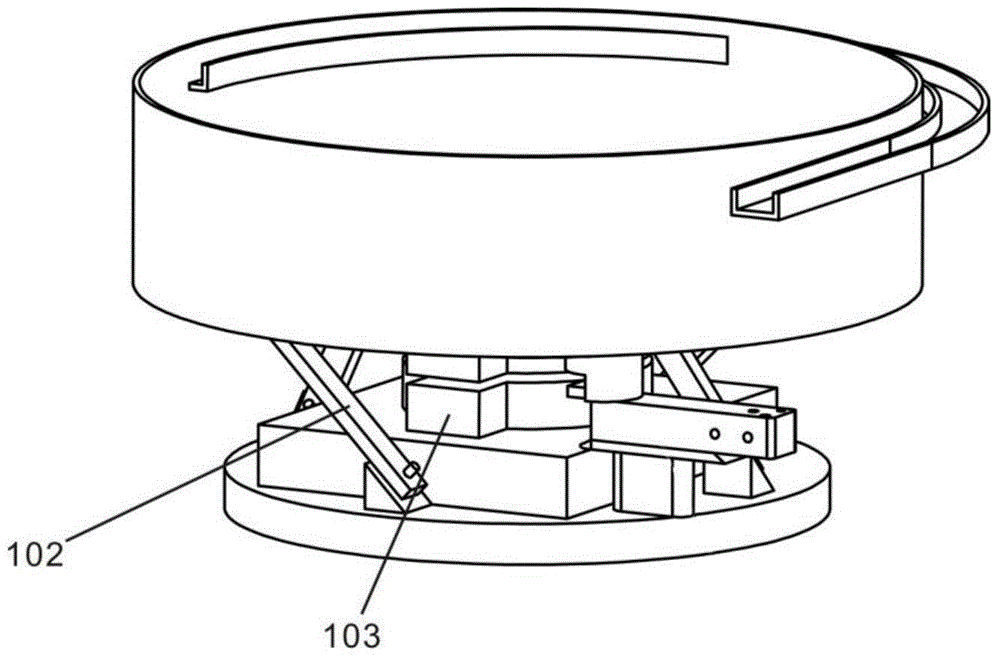

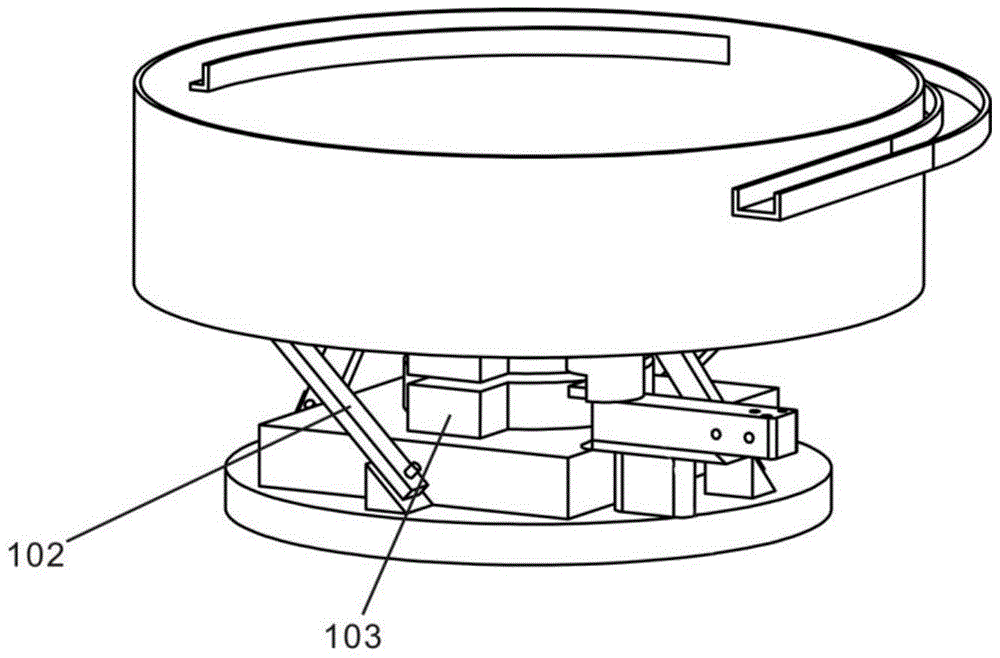

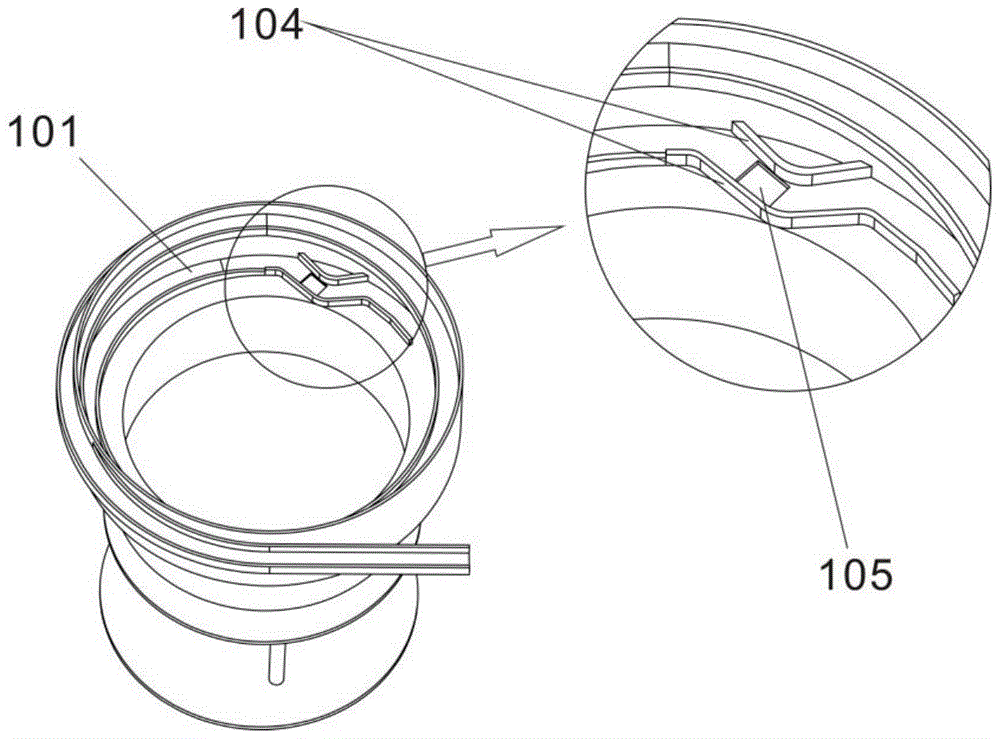

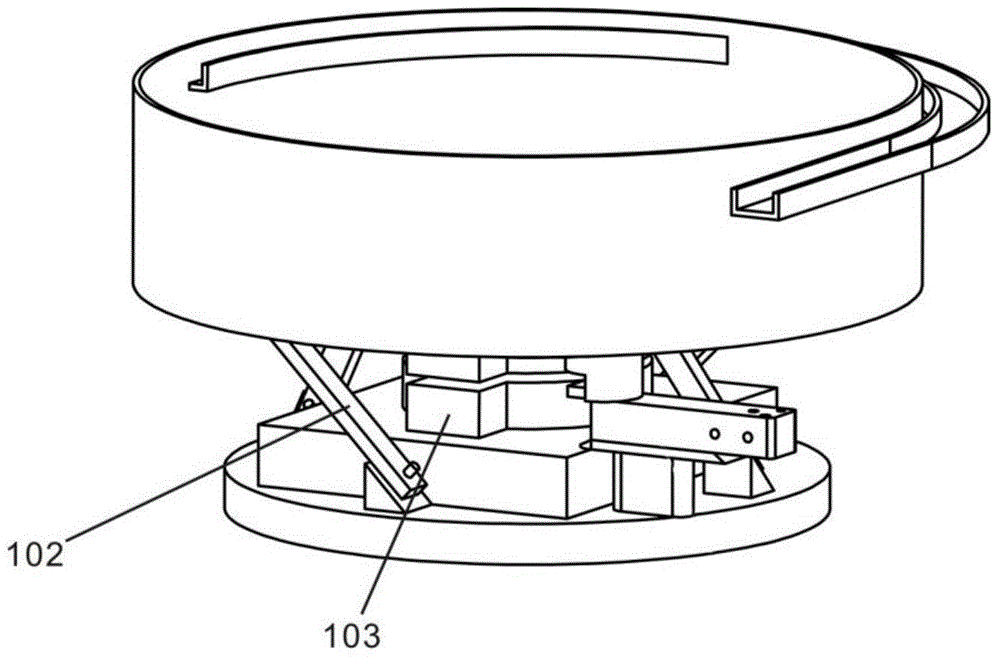

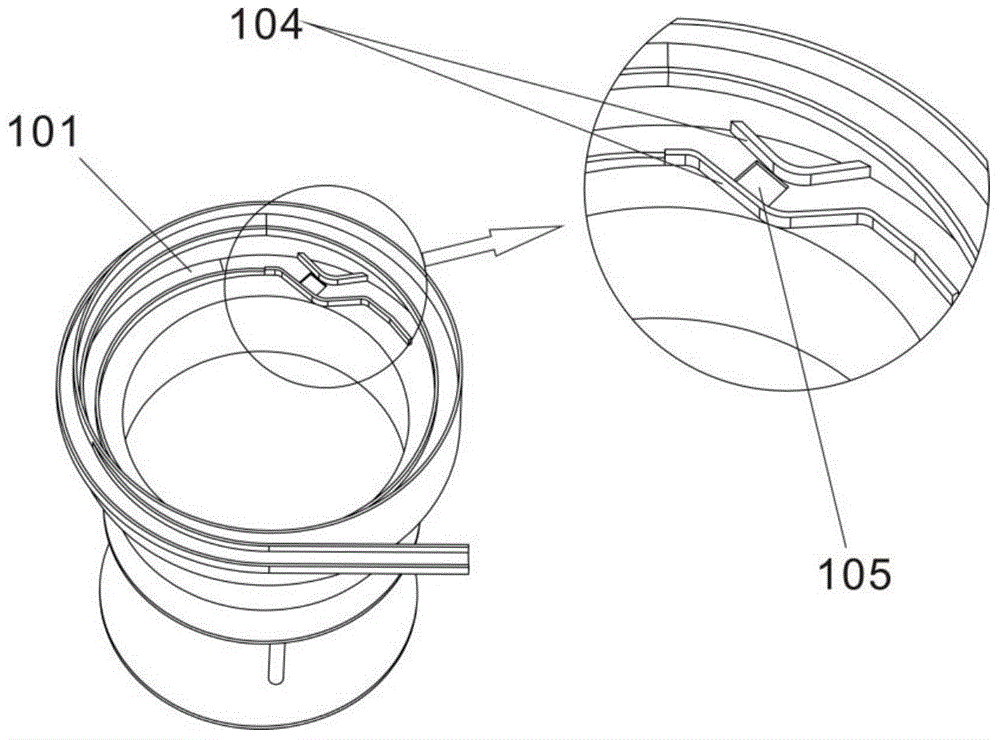

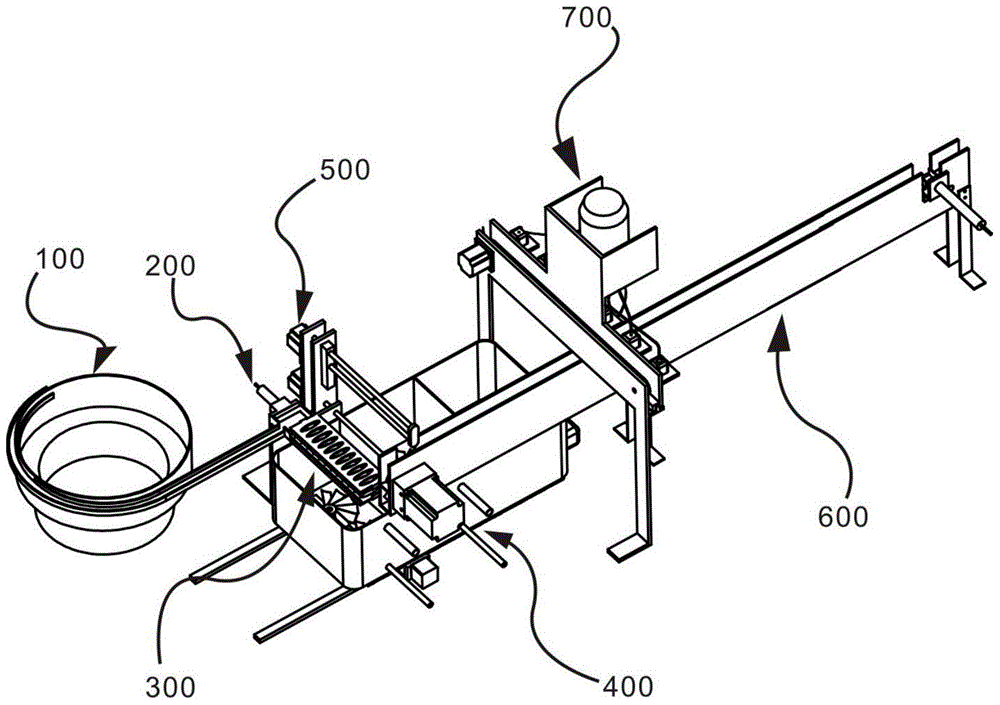

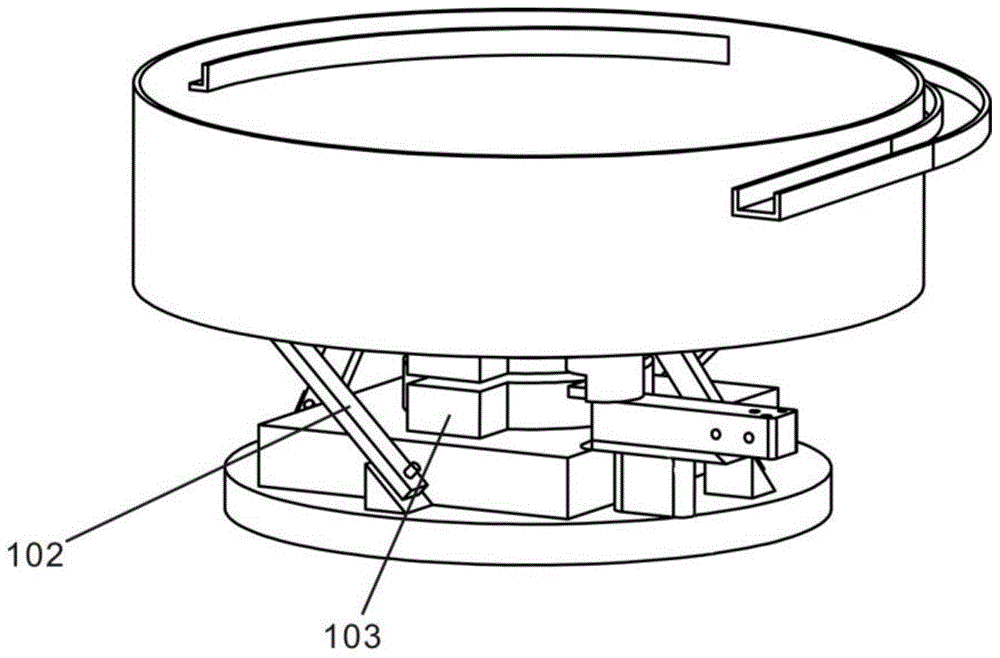

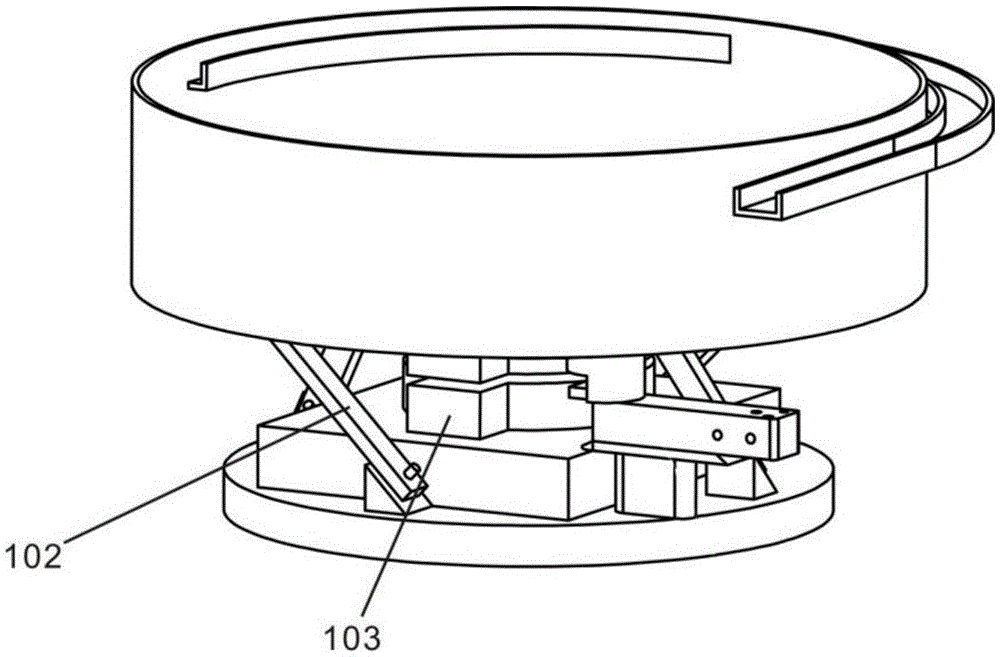

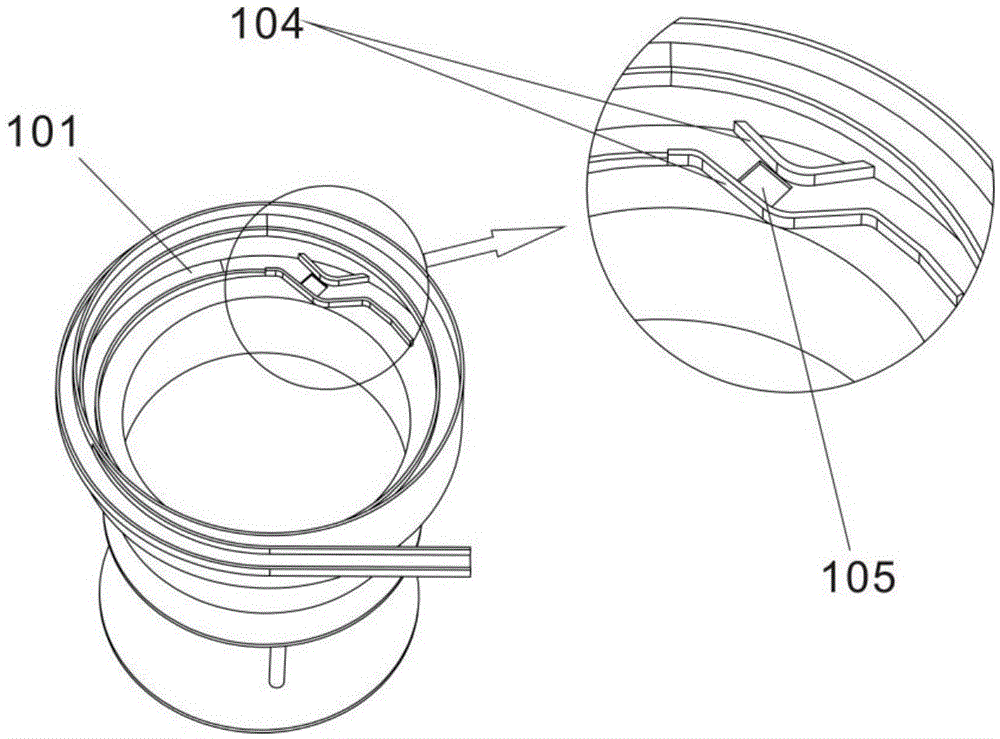

The invention discloses a filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system which comprises a correcting device and a pushing device and also comprises a carrying device, a rinsing device, a progressive device, a conveying device, a filling device, a cover conveying device, an impact extrusion device, a cover screwing device and a labeling device, wherein the correcting device is a cavity of which one end is open; a material channel which spirally ascends is formed in the inner side wall of the cavity; and the pushing device comprises a pushing cylinder and a pushing platform. According to the system disclosed by the invention, the problem that the filling bottles cannot be directionally transported can be solved, and the problems that the filling bottles cannot be subjected to automatic progressive rinsing, conveying and filling, cover conveying, filling bottle cover impact extrusion and fixation, cover screwing and labeling and coding also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

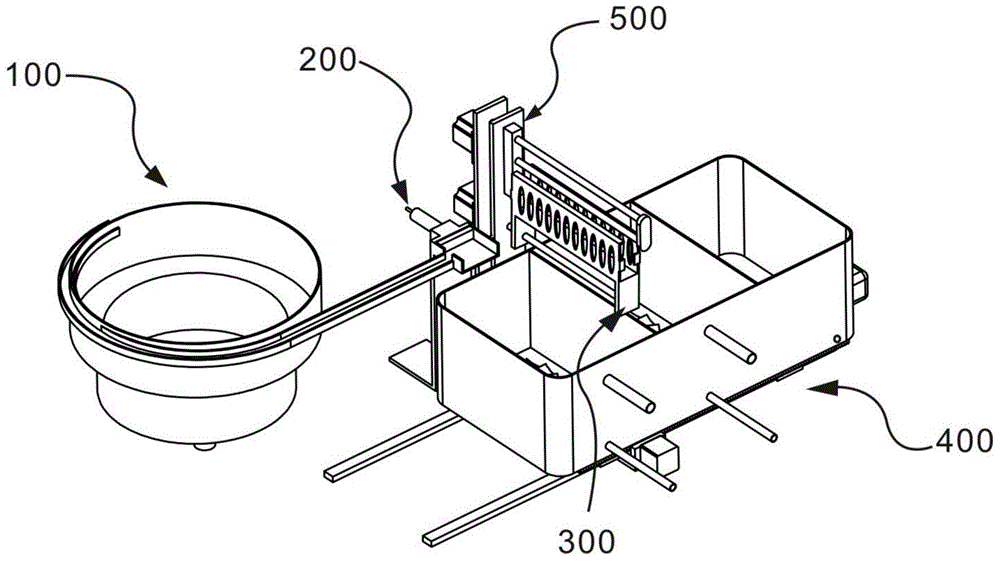

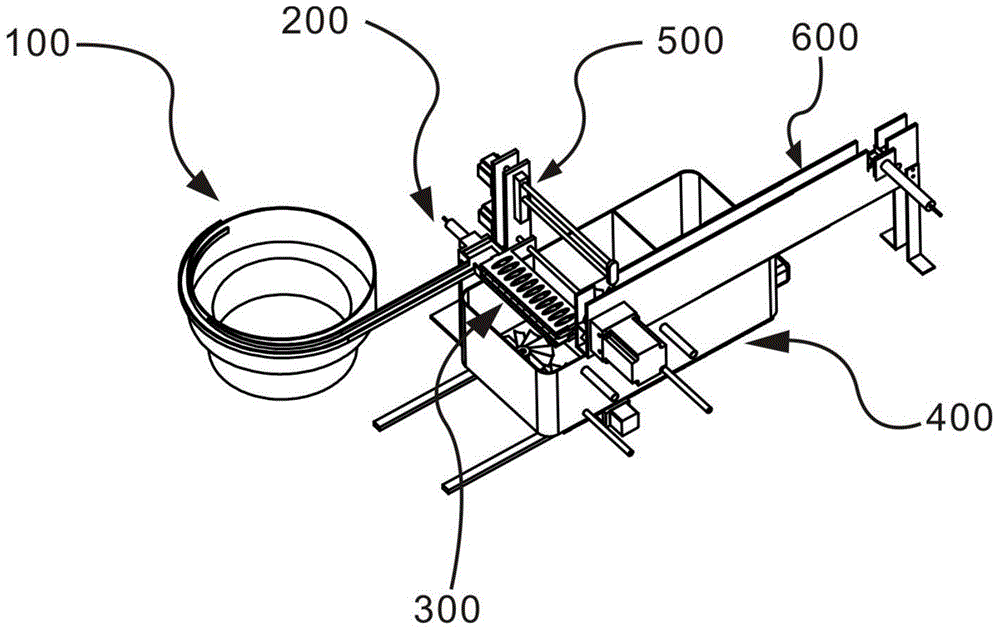

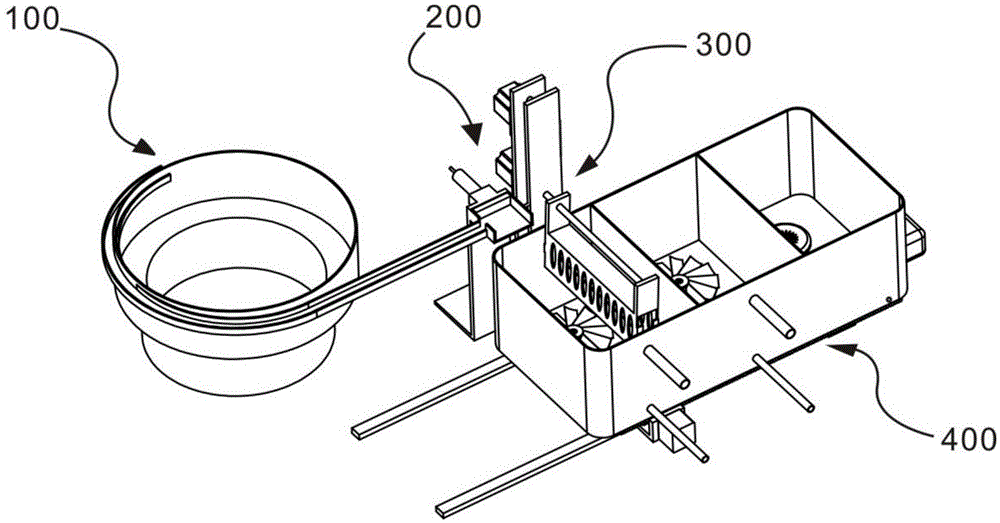

System for correcting, pushing, rinsing and progressively forwarding filling bottles

ActiveCN104445007ASolve the problem of directional transportSolve the problem of automatic rinsing progressHollow article cleaningBottle-handling machinesEngineeringBottle

The invention discloses a system for correcting, pushing, rinsing and progressively forwarding filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device and a progressively forwarding device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved, and the problems in automated rinsing and progressively forwarding of the filling bottles also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

System for correcting, pushing, rinsing, progressively forwarding, conveying, filling and cover transporting of filling bottles

ActiveCN104445008ASolve the problem of directional transportThreaded caps applicationHollow article cleaningEngineeringBottle

The invention discloses a system for correcting, pushing, rinsing, progressively forwarding, conveying, filling and cover transporting of filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device and a cover transporting device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved and meanwhile the problems in automated rinsing, progressively forwarding, conveying, filling and cover transporting of the filling bottles also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

Method for performing correction, pushing, rinsing, delivery, conveying, filling, cover conveying, cover screwing and labeling on filling bottle

InactiveCN104326429ASolve the problem of directional transportCapsThreaded caps applicationBottleFill device

The invention discloses a method for performing correction, pushing, rinsing, delivery, conveying, filling, cover conveying, cover screwing and labeling on a filling bottle. The method is based on a system for performing correction, pushing, rinsing, delivery, conveying, filling, cover conveying, cover screwing and labeling on the filling bottle. The system comprises a correction device and a pushing device, wherein the correction device is a cavity with an opening in one end; a spirally rising material channel is arranged on the inner side wall of the cavity; the pushing device comprises a pushing cylinder and a pushing platform. The system further comprises a carrying device, a rinsing device, a delivery device, a conveying device, a filling device, a cover conveying device, a cover screwing device and a labeling device. The method can be used for realizing directed transportation of the filling bottle, and automatic rinsing and delivery, conveying, filling, cover conveying, cover screwing and labeling on the filling bottle can be also realized.

Owner:全智机械科技南通有限公司

System for correcting, pushing, rinsing, conveying, filling, impact extrusion, cover screwing and labeling of filling bottles

ActiveCN104445025ASolve the problem of directional transportSolve the problem of easy falling offCapsThreaded caps applicationEngineeringBottle cap

The invention discloses a system for correcting, pushing, rinsing, conveying, filling, impact extrusion, cover screwing and labeling of filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device, a pad transporting device, an impact extrusion device and a labeling device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved, meanwhile the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting and seal pad transporting of the filling bottles can be solved, and the problem of easy falling of seal pads during rotary arrangement of filling bottle covers and the seal pads of the filling bottle covers as well as problems in cover screwing and labeling of the filling bottles can be solved.

Owner:启东市富晨天然气有限公司

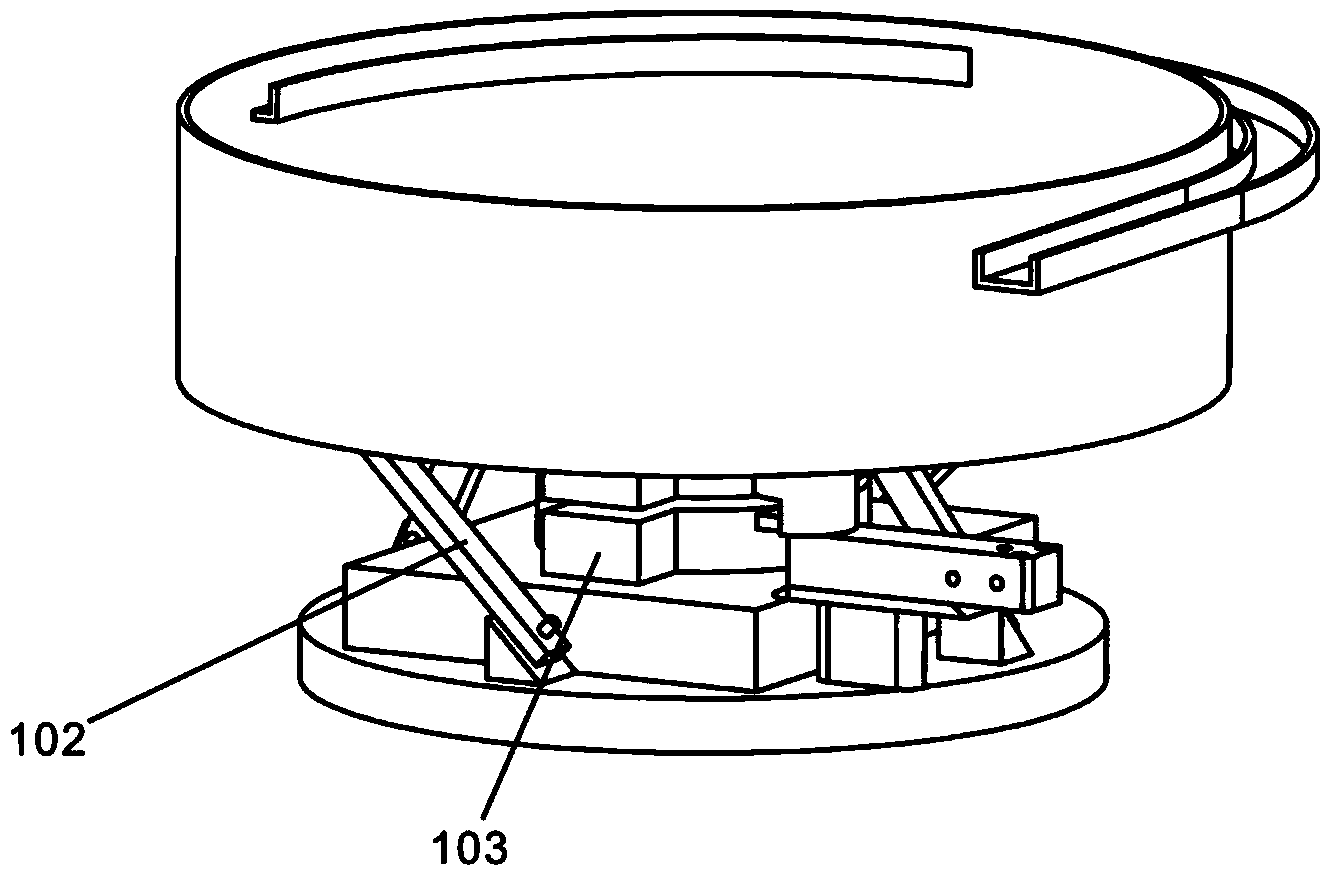

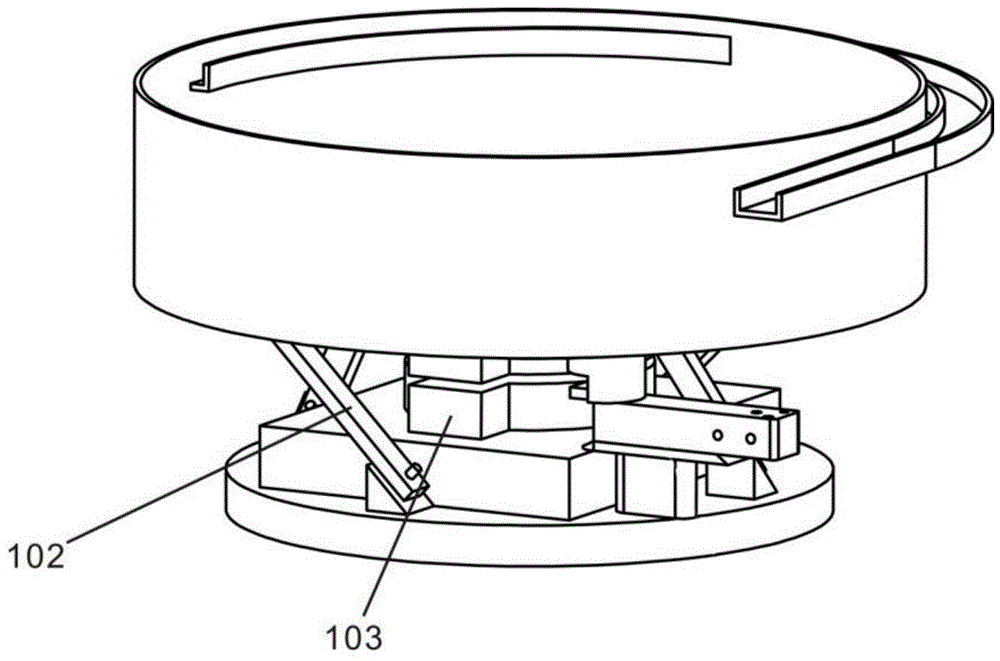

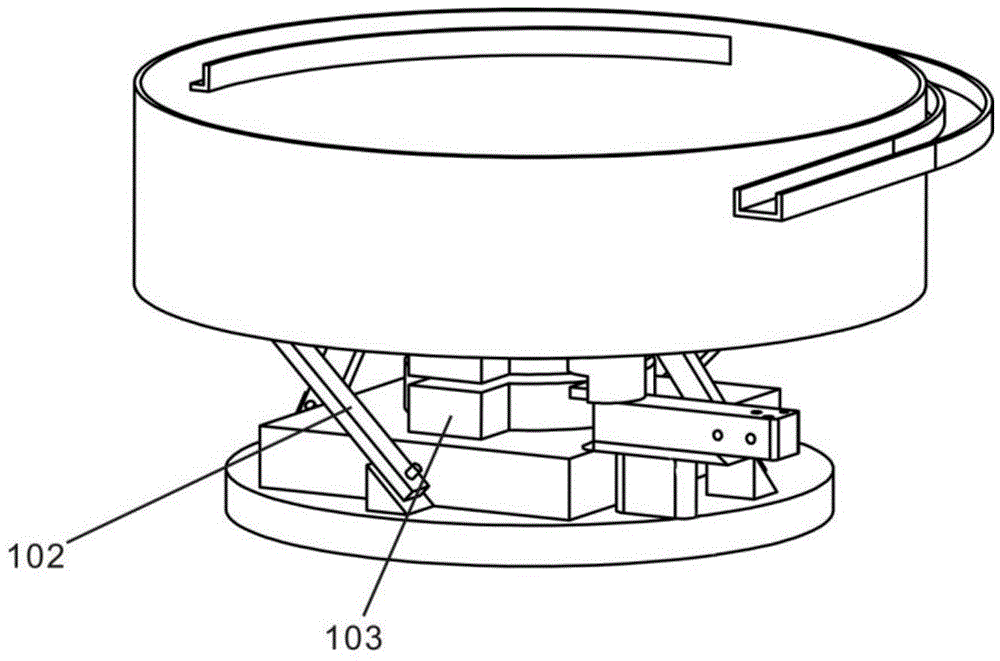

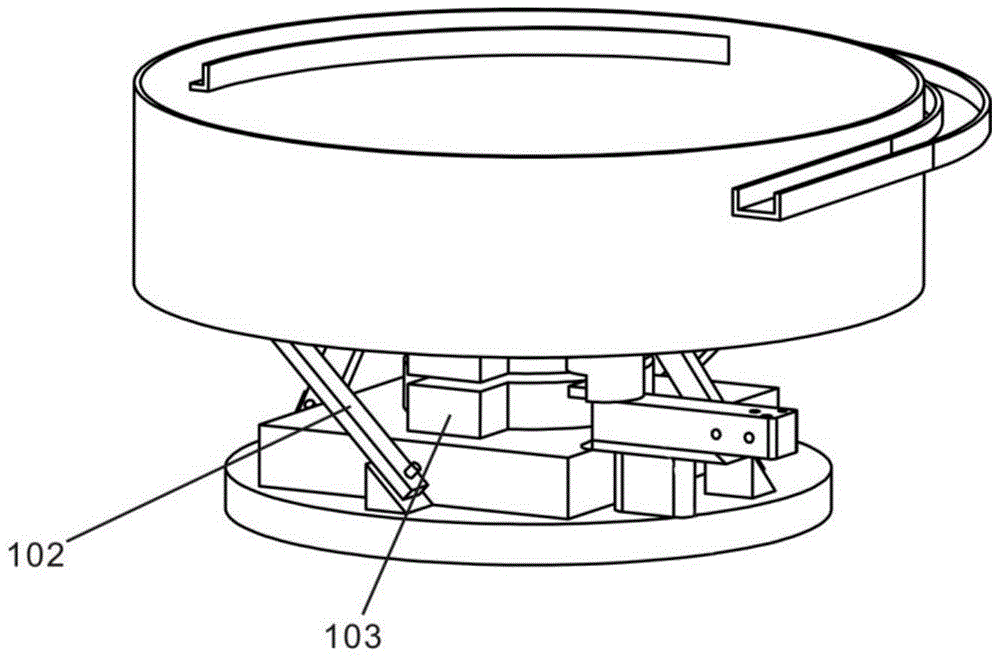

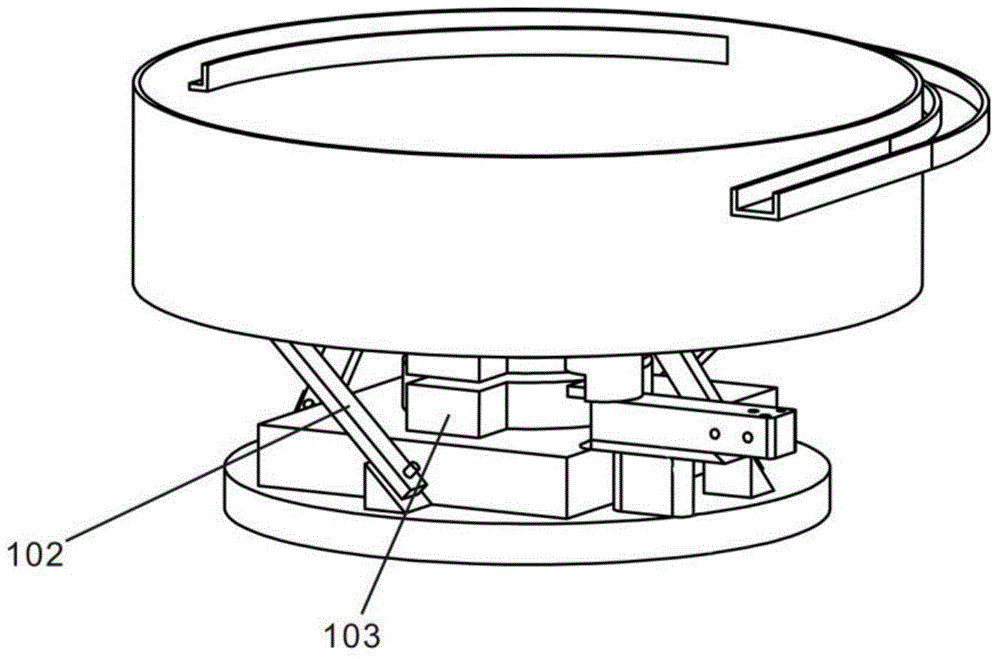

Filling bottle correcting and pushing system

The invention discloses a filling bottle correcting and pushing system comprising a correcting device and a pushing device. The correcting device is a cavity with one end open, the inner side wall of the cavity is provided with a spiral rising material passage, and the pushing device comprises a pushing cylinder and a pushing platform. By the system, directional conveying of filing bottles as well as automatic direction correction and pushing of the filling bottles can be achieved.

Owner:盐城康鼎机械有限公司

System for rectifying, pushing, rinsing, conveying, filling, cap-transferring, extruding, capping and labeling of filling bottle

InactiveCN104555859ASolve the problem of directional transportThreaded caps applicationSynchronising machinesEngineeringBottle cap

The invention discloses a system for rectifying, pushing, rinsing, conveying, filling, cap-transferring, extruding, capping and labeling of a filling bottle. The method depends on the system for rectifying, pushing, rinsing, conveying, filling, cap-transferring, extruding, capping and labeling of the filling bottle. The system comprises a rectifying device, a pushing device, a carrying device, a rinsing device, a progression device, a conveying device, a filling device, a cap transferring device, an extruding device, a capping device and a labeling device, wherein the rectifying device is a cavity body with an opening in one end; a material channel which ascends in a spiral manner is formed in the inner side wall of the cavity body; and the pushing device comprises a pushing cylinder and a pushing platform. According to the system disclosed by the invention, the problem of directional conveying of the filling bottle can be solved; and meanwhile, the problems of automatic rinsing, progressing, conveying, filling and cap transferring of the filling bottle, and extruding, fixing, capping and labeling of a filling bottle cap can be solved.

Owner:镇江市顶智微电子科技有限公司

Method for performing correction, pushing, rinsing, delivery, conveying, filling, cover conveying, cover screwing and labeling coding on filling bottle

ActiveCN104326430ASolve the problem of directional transportCapsThreaded caps applicationEngineeringBottle

The invention discloses a method for performing correction, pushing, rinsing, delivery, conveying, filling, cover conveying, cover screwing and labeling coding on a filling bottle. The method is based on a system for performing correction, pushing, rinsing, delivery, conveying, filling, cover conveying, cover screwing and labeling coding on the filling bottle. The system comprises a correction device and a pushing device, wherein the correction device is a cavity with an opening in one end; a spirally rising material channel is arranged on the inner side wall of the cavity; the pushing device comprises a pushing cylinder and a pushing platform. The system further comprises a carrying device, a rinsing device, a delivery device, a conveying device, a filling device, a cover conveying device, a cover screwing device and a labeling coding device. The method can be used for realizing directed transportation of the filling bottle, and automatic rinsing and delivery, conveying, filling, cover conveying, cover screwing and labeling coding on the filling bottle can be also realized.

Owner:NANTONG SNT PACKING MACHINERY

Method for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting, pad transporting and cover screwing of filling bottles

ActiveCN104445022ASolve the problem of directional transportThreaded caps applicationHollow article cleaningEngineeringBottle

The invention discloses a method for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting, pad transporting and cover screwing of filling bottles. The method is based on a system for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting, pad transporting and cover screwing of the filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device, a pad transporting device and a cover screwing device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the method, the problem in directional transportation of the filling bottles can be solved, and the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting, seal pad transporting and cover screwing of the filling bottles also can be solved.

Owner:启东市富晨天然气有限公司

System for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting and impact extrusion of filling bottles

ActiveCN104445017ASolve the problem of directional transportSolve the problem of flushing and fixingThreaded caps applicationSynchronising machinesEngineeringBottle

The invention discloses a system for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting and impact extrusion of filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device and an impact extrusion device, wherein the correcting device is a cavity body with an open end; a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved, and the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting and cover impact extrusion fixation of the filling bottles also can be solved.

Owner:启东翔龙旅游开发有限公司

Method for correcting, pushing, rinsing, conveying, filling, cover transporting, cover screwing and labeling and coding of filling bottles

ActiveCN104445015ASolve the problem of directional transportThreaded caps applicationManual label dispensersBottleImpact extrusion

The invention discloses a method for correcting, pushing, rinsing, conveying, filling, cover transporting, cover screwing and labeling and coding of filling bottles. The method is based on a system for correcting, pushing, rinsing, conveying, filling, cover transporting, cover screwing and labeling and coding of the filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device, an impact extrusion device, a cover screwing device and a labeling device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the method, the problem in directional transportation of the filling bottles can be solved, and the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting, cover impact extrusion fixation, cover screwing and labeling and coding of the filling bottles also can be solved.

Owner:启东市富晨天然气有限公司

System for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting, pad transporting and impact extrusion of filling bottles

InactiveCN104445023ASolve the problem of directional transportSolve the problem of easy falling offThreaded caps applicationSynchronising machinesEngineeringImpact extrusion

The invention discloses a system for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting, pad transporting and impact extrusion of filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device, a pad transporting device and an impact extrusion device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved, meanwhile the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting and seal pad transporting of the filling bottles can be solved, and the problem of easy falling of seal pads during rotary arrangement of filling bottle covers and the seal pads of the filling bottle covers can be solved.

Owner:黎明

System for correcting, pushing and rinsing filling bottles

ActiveCN104445009ASolve the problem of directional transportSolve the problem of automatic washingSynchronising machinesHollow article cleaningEngineeringBottle

The invention discloses a system for correcting, pushing and rinsing filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device and a rinsing device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved, and the problem in automated rinsing of the filling bottles also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

Method for performing correction, pushing, rinsing, feeding, conveying and loading on loading bottle, conveying cover, conveying gasket, and performing impact extrusion

ActiveCN104528619ASolve the problem of directional transportSolve the problem of easy falling offThreaded caps applicationSynchronising machinesImpact extrusionBottle

The invention discloses a method for performing correction, pushing, rinsing, feeding, conveying and loading on loading bottle, conveying cover, conveying gasket, and performing impact extrusion. The method depends on a system for performing correction, pushing, rinsing, feeding, conveying and loading on loading bottle, conveying cover, conveying gasket, and performing impact extrusion. The system comprises a correction device, a pushing device, a carrying device, a rinsing device, a feeding device, a conveying device, a loading device, a cover-conveying device, a gasket-conveying device and an impact extrusion device; the correction device is a chamber with an opened end, and the inner side wall of the chamber is provided with a spirally-ascended material channel; and the pushing device comprises a pushing cylinder and a pushing platform. The method is capable of solving the orientated conveying problem of the loading bottle, also is capable of solving the problems of automatically rinsing, feeding, conveying and loading the loading bottle, conveying the cover and conveying the gasket, and also is capable of solving the problems that the sealing gasket is easy to fall off when the loading bottle cover and the sealing gasket are put in a rotation way.

Owner:SHIJIAZHUANG JIUDING ANIMAL PHARMA CO LTD

A method for correcting, pushing, rinsing, conveying, filling, transporting, capping, transporting mat, punching, squeezing and screwing a filling bottle

ActiveCN104326428BSolve the problem of directional transportSolve the problem of easy falling offCapsThreaded caps applicationPunchingEngineering

The invention discloses a method applied to correcting, pushing, rinsing, conveying, filling, cap transporting, cushion transporting, punching, extruding and cap screwing of filling bottles. The method is constructed based on a system applied to the correcting, pushing, rinsing, conveying, filling, cap transporting, cushion transporting, punching, extruding and cap screwing of the filling bottles. The system comprises a correcting device, a pushing device, a carrying device, a rinsing device, a propelling device, a conveying device, a filling device, a cap transporting device, a cushion transporting device and a punching and extruding device, wherein the correcting device is a cavity with an opening in one end; the inside wall of the cavity is provided with a material channel which rises spirally and upwards; the pushing device comprises a pushing air cylinder and a pushing platform. By virtue of the method, the problem of oriented transportation of the filling bottles can be solved; meanwhile, the problems of automatic rinsing, propelling, conveying, filling, cap transporting and sealing cushion transporting of the filling bottles can be solved; furthermore, the problems that sealing cushions are easy to fall off and caps are screwed when the bottle caps and the sealing cushions of the filling bottles are rotatably placed can be solved.

Owner:NANTONG SNT PACKING MACHINERY

A method of correcting, pushing, rinsing, progressively conveying, filling, transporting and capping for filling bottles

ActiveCN104445012BSolve the problem of directional transportSolve the problem of flushing and fixingThreaded caps applicationHollow article cleaningEngineeringBottle

The invention discloses a method for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting and impact extrusion of filling bottles. The method is based on a system for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting and impact extrusion of the filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device and an impact extrusion device, wherein the correcting device is a cavity body with an open end; a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the method, the problem in directional transportation of the filling bottles can be solved, and the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting and cover impact extrusion fixation of the filling bottles also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

A Filling Bottle Correction, Pushing, Washing, Conveying, Filling, Squeezing, Capping, and Labeling System

ActiveCN104445025BSolve the problem of directional transportSolve the problem of easy falling offCapsThreaded caps applicationBottle capImpact extrusion

The invention discloses a system for correcting, pushing, rinsing, conveying, filling, impact extrusion, cover screwing and labeling of filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device, a pad transporting device, an impact extrusion device and a labeling device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved, meanwhile the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting and seal pad transporting of the filling bottles can be solved, and the problem of easy falling of seal pads during rotary arrangement of filling bottle covers and the seal pads of the filling bottle covers as well as problems in cover screwing and labeling of the filling bottles can be solved.

Owner:启东市富晨天然气有限公司

Filling bottle correcting, pushing and carrying method

InactiveCN104495316ASolve the problem of directional transportSolve automation to correct directionConveyor partsBottleEngineering

The invention discloses a filling bottle correcting, pushing and carrying method. The method depends on a filling bottle correcting, pushing and carrying system which comprises a correcting device, a pushing device and a carrying device. The correcting device is a cavity with one end open, the inner side wall of the cavity is provided with a spiral rising material passage, and the pushing device comprises a pushing cylinder and a pushing platform. By the method, directional conveying of filing bottles as well as automatic direction correction and pushing and carrying of the filling bottles can be achieved.

Owner:镇江市顶智微电子科技有限公司

A kind of filling bottle corrective push rinsing progressive conveying filling transport cap flushing system

ActiveCN104445017BSolve the problem of directional transportSolve the problem of flushing and fixingThreaded caps applicationSynchronising machinesEngineeringMechanical engineering

The invention discloses a system for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting and impact extrusion of filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device and an impact extrusion device, wherein the correcting device is a cavity body with an open end; a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved, and the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting and cover impact extrusion fixation of the filling bottles also can be solved.

Owner:启东翔龙旅游开发有限公司

System for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting, cover screwing and labeling and coding of filling bottles

ActiveCN104445026ASolve the problem of directional transportThreaded caps applicationManual label dispensersEngineeringFill device

The invention discloses a system for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting, cover screwing and labeling and coding of filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device, a cover screwing device and a labeling and coding device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved, and the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting, cover screwing and labeling and coding of the filling bottles also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

A kind of filling bottle corrective pushing and rinsing progressive conveying system

InactiveCN104445023BSolve the problem of directional transportSolve the problem of easy falling offThreaded caps applicationSynchronising machinesBottleImpact extrusion

The invention discloses a system for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting, pad transporting and impact extrusion of filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device, a pad transporting device and an impact extrusion device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved, meanwhile the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting and seal pad transporting of the filling bottles can be solved, and the problem of easy falling of seal pads during rotary arrangement of filling bottle covers and the seal pads of the filling bottle covers can be solved.

Owner:黎明

A method for correcting, pushing, rinsing, conveying, filling, capping, capping, labeling and coding for filling bottles

ActiveCN104445015BSolve the problem of directional transportThreaded caps applicationManual label dispensersEngineeringBottle cap

The invention discloses a method for correcting, pushing, rinsing, conveying, filling, cover transporting, cover screwing and labeling and coding of filling bottles. The method is based on a system for correcting, pushing, rinsing, conveying, filling, cover transporting, cover screwing and labeling and coding of the filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device, an impact extrusion device, a cover screwing device and a labeling device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the method, the problem in directional transportation of the filling bottles can be solved, and the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting, cover impact extrusion fixation, cover screwing and labeling and coding of the filling bottles also can be solved.

Owner:启东市富晨天然气有限公司

Method for correcting, pushing and rinsing filling bottles

ActiveCN104445018ASolve the problem of directional transportSolve the problem of automatic washingHollow article cleaningBottle-handling machinesEngineeringBottle

The invention discloses a method for correcting, pushing and rinsing filling bottles. The method is based on a system for correcting, pushing and rinsing the filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device and a rinsing device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the method, the problem in directional transportation of the filling bottles can be solved, and the problem in automated rinsing of the filling bottles also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

A method of correcting, pushing, rinsing, progressive conveying, filling, capping, capping, labeling and coding for filling bottles

ActiveCN104326430BSolve the problem of directional transportCapsThreaded caps applicationEngineeringMechanical engineering

Owner:NANTONG SNT PACKING MACHINERY

A method of correcting, pushing, rinsing, and progressively conveying, filling, capping, and cushioning for filling bottles

ActiveCN104528620BSolve the problem of directional transportThreaded caps applicationSynchronising machinesEngineeringBottle

The invention discloses a method for performing correction, pushing, rinsing, feeding, conveying and loading on a loading bottle, conveying a cover and conveying a gasket. The method depends on a system for performing correction, pushing, rinsing, feeding, conveying and loading on a loading bottle, conveying a cover and conveying a gasket. The system comprises a correction device, a pushing device, a carrying device, a rinsing device, a feeding device, a conveying device, a loading device, a cover-conveying device and a gasket-conveying device; the correction device is a chamber with an opened end, and the inner side wall of the chamber is provided with a spirally-ascended material channel; and the pushing device comprises a pushing cylinder and a pushing platform. The method is capable of solving the orientated conveying problem of the loading bottle, and also is capable of solving the problems of automatically rinsing, feeding, conveying and loading the loading bottle, conveying the cover and conveying the gasket.

Owner:启东翔龙旅游开发有限公司

Method for correcting, pushing, rinsing, progressively forwarding and conveying filling bottles

InactiveCN104444995ASolve the problem of directional transportSolve the automatic rinsing progressHollow article cleaningCleaning using liquidsEngineeringBottle

The invention discloses a method for correcting, pushing, rinsing, progressively forwarding and conveying filling bottles. The method is based on a system for correcting, pushing, rinsing, progressively forwarding and conveying the filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device and a conveying device, wherein the correcting device is a cavity body with an open end; a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the method, the problem in directional transportation of the filling bottles can be solved, and the problems in automated rinsing, progressively forwarding and conveying of the filling bottles also can be solved.

Owner:珠海市卓伟化妆品有限公司

A method for correcting, pushing, rinsing, progressive conveying and filling of filling bottles

ActiveCN104445027BSolve the problem of directional transportSynchronising machinesHollow article cleaningEngineeringBottle

The invention discloses a method for correcting, pushing, rinsing, progressively forwarding, conveying and filling filling bottles. The method is based on a system for correcting, pushing, rinsing, progressively forwarding, conveying and filling the filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device and a filling device, wherein the correcting device is a cavity body with an open end; a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the method, the problem in directional transportation of the filling bottles can be solved, and the problems in automated rinsing, progressively forwarding, conveying and filling of the filling bottles also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

A filling bottle corrective pushing, rinsing, progressive conveying, filling, capping, cushioning, cushioning and capping system

InactiveCN104445016BSolve the problem of directional transportThreaded caps applicationHollow article cleaningEngineeringBottle

The invention discloses a system for correcting, pushing, rinsing, progressively forwarding, conveying, filling, cover transporting, pad transporting and cover screwing of filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device, a pad transporting device and a cover screwing device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved, and the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting, seal pad transporting and cover screwing of the filling bottles also can be solved.

Owner:全智机械科技南通有限公司

A method of correcting, pushing, rinsing, progressively conveying, filling, transporting, capping and labeling of filling bottles

InactiveCN104326429BSolve the problem of directional transportCapsThreaded caps applicationEngineeringBottle

The invention discloses a method for performing correction, pushing, rinsing, delivery, conveying, filling, cover conveying, cover screwing and labeling on a filling bottle. The method is based on a system for performing correction, pushing, rinsing, delivery, conveying, filling, cover conveying, cover screwing and labeling on the filling bottle. The system comprises a correction device and a pushing device, wherein the correction device is a cavity with an opening in one end; a spirally rising material channel is arranged on the inner side wall of the cavity; the pushing device comprises a pushing cylinder and a pushing platform. The system further comprises a carrying device, a rinsing device, a delivery device, a conveying device, a filling device, a cover conveying device, a cover screwing device and a labeling device. The method can be used for realizing directed transportation of the filling bottle, and automatic rinsing and delivery, conveying, filling, cover conveying, cover screwing and labeling on the filling bottle can be also realized.

Owner:全智机械科技南通有限公司

A method for correcting pushing and rinsing of filling bottles

ActiveCN104445018BSolve the problem of directional transportSolve the problem of automatic washingHollow article cleaningBottle-handling machinesEngineeringBottle

Owner:NANTONG SNT PACKING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com