Patents

Literature

132 results about "Impact extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

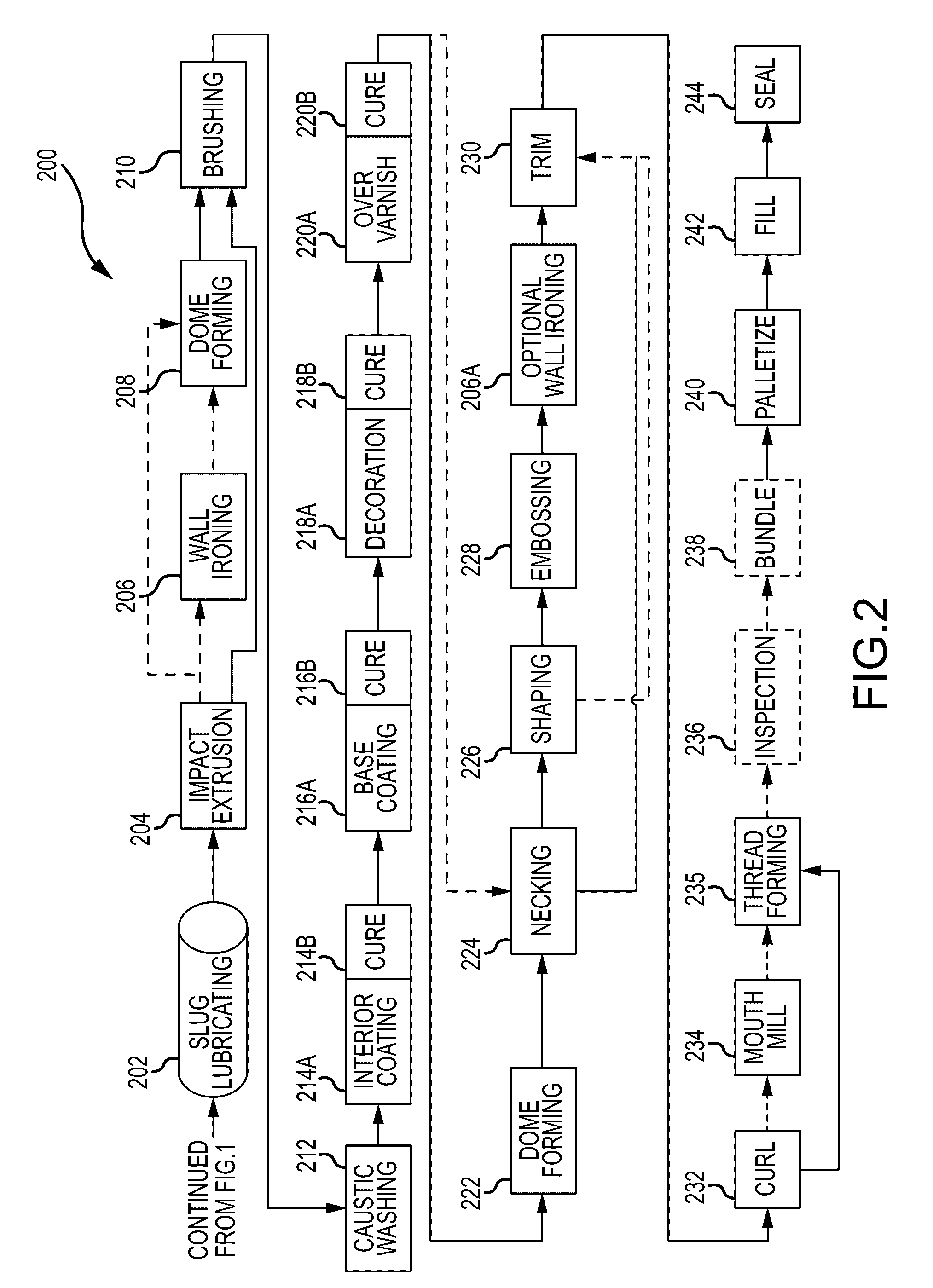

Impact extrusion is a manufacturing process similar to extrusion and drawing by which products are made with a metal slug. The slug is pressed at a high velocity with extreme force into a die or mold by a punch.

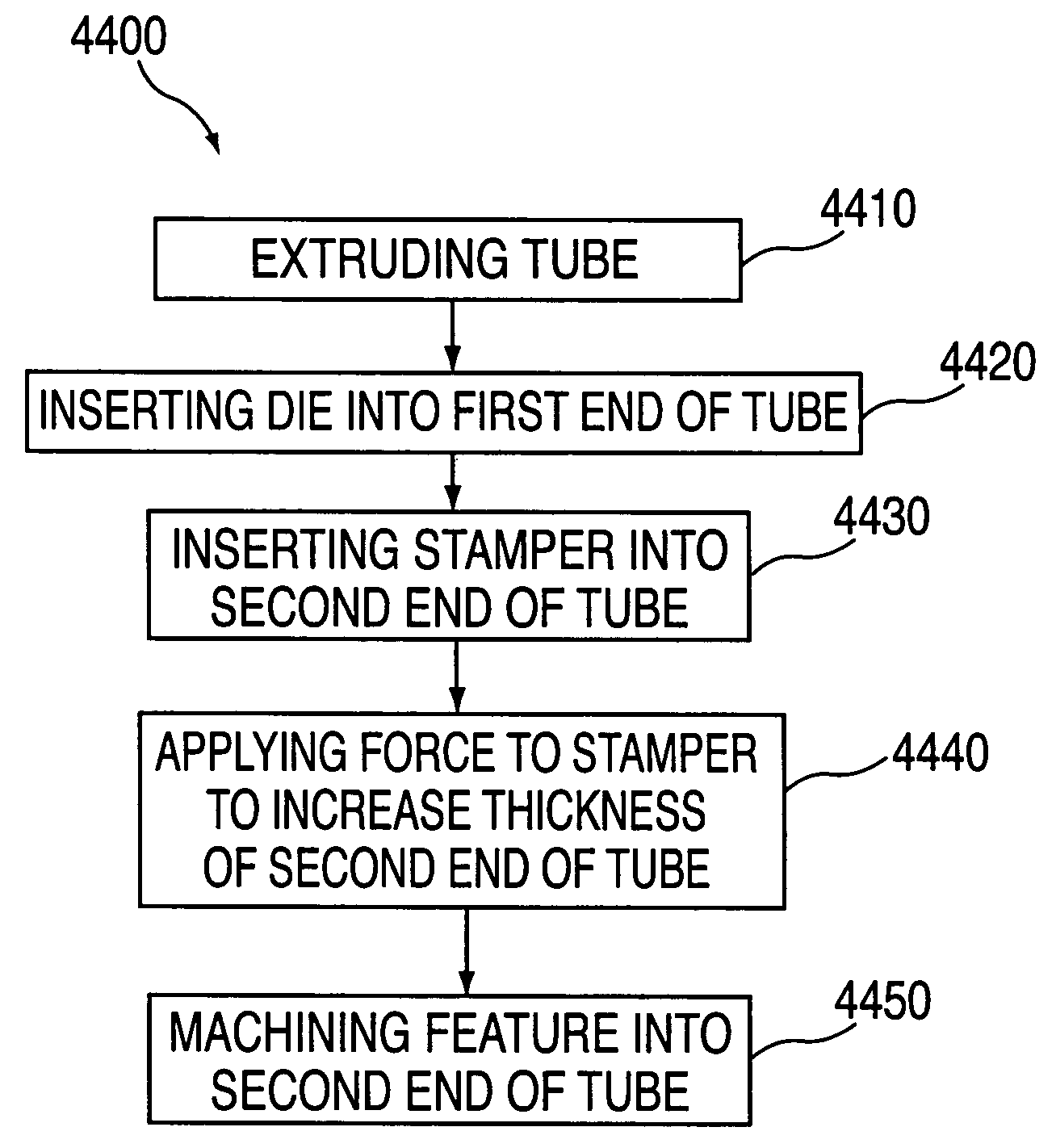

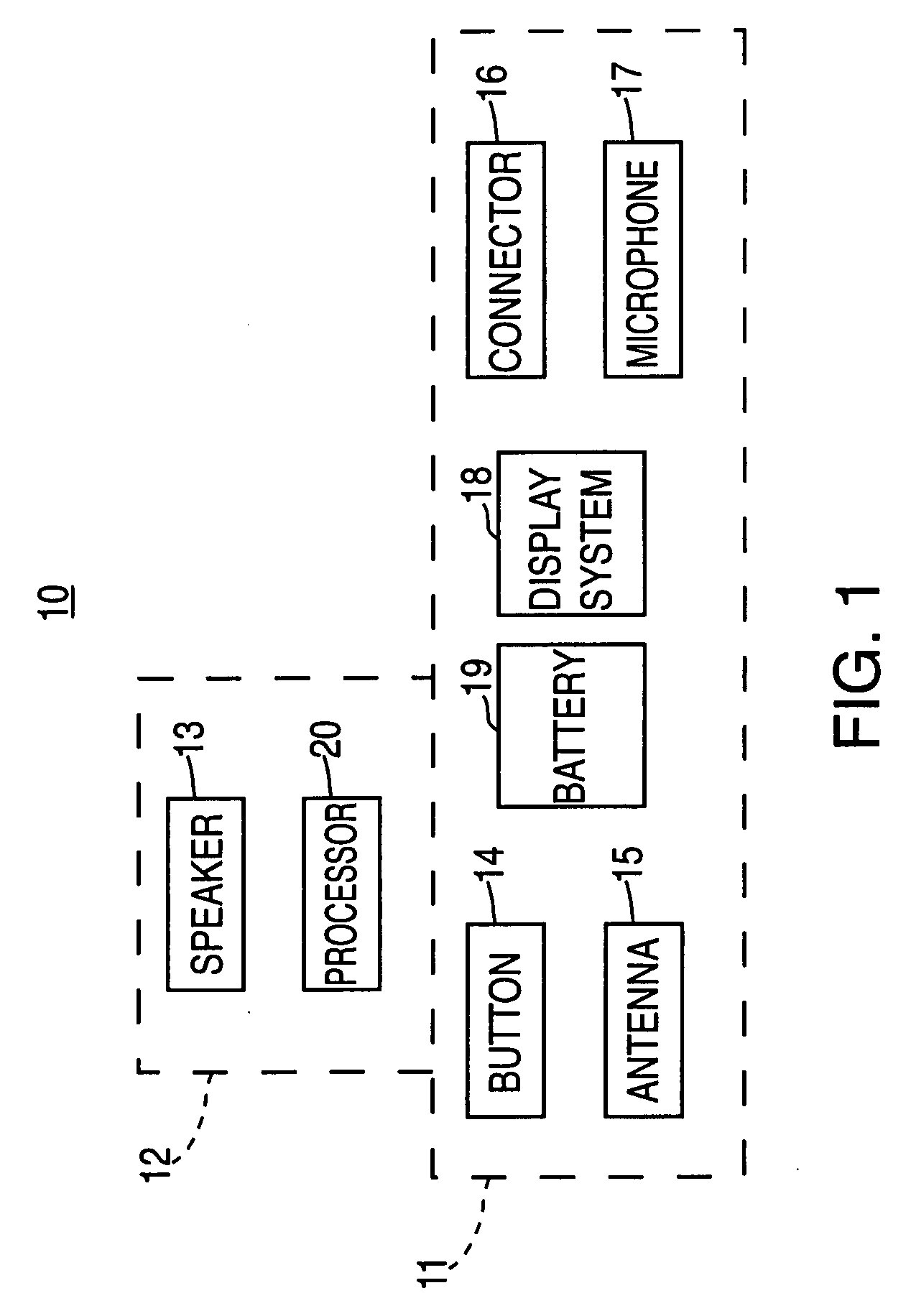

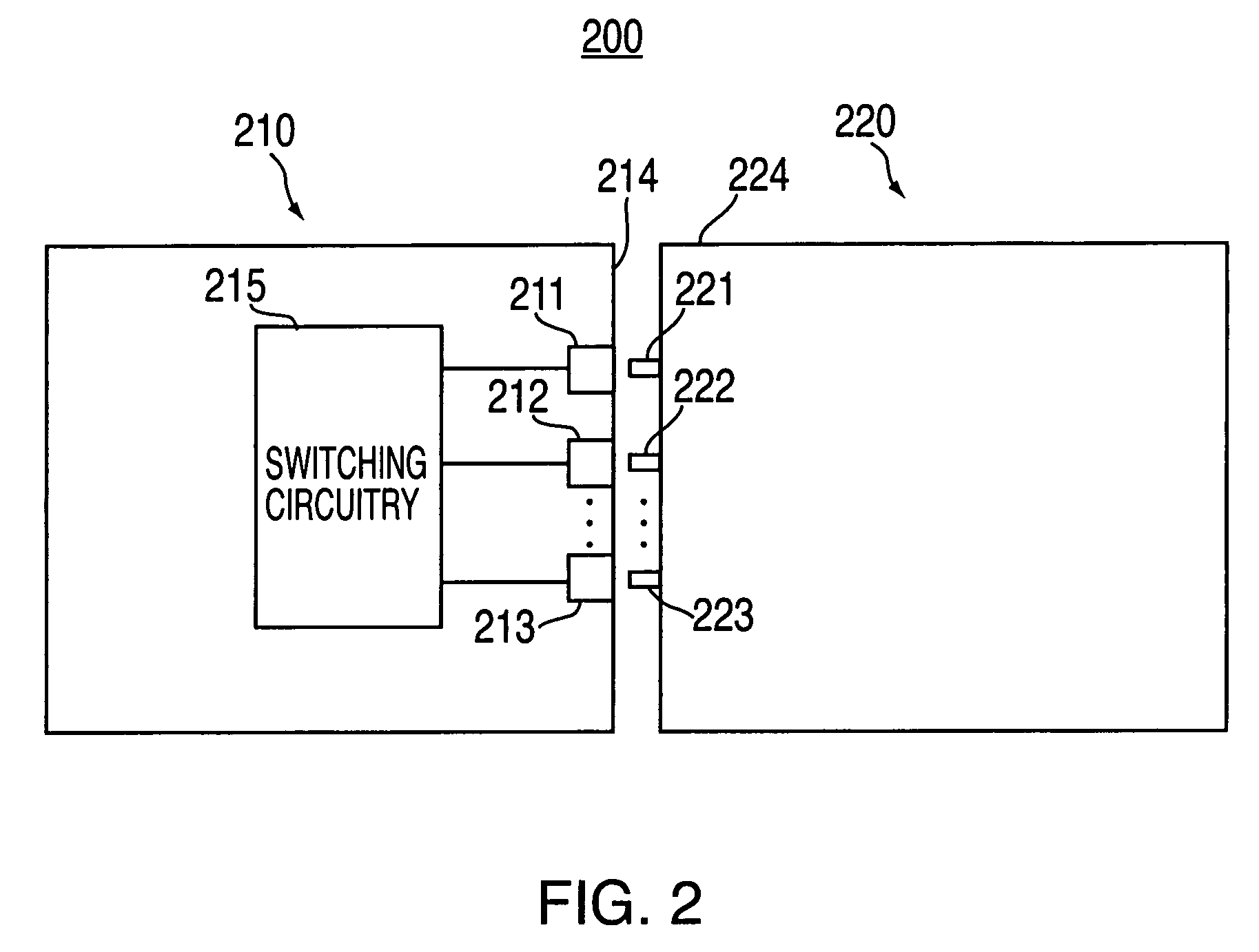

Compact tube with internal features and methods for fabricating the same

InactiveUS20080163663A1Filament/thread formingBattery overcurrent protectionMechanical engineeringSingle impact

Methods for forming a tube that includes a feature extending from an inner surface of the tube are provided. The methods can include using a die and stamper, single impact extrusion, double impact extrusion, and progressive deep draw process.

Owner:APPLE INC

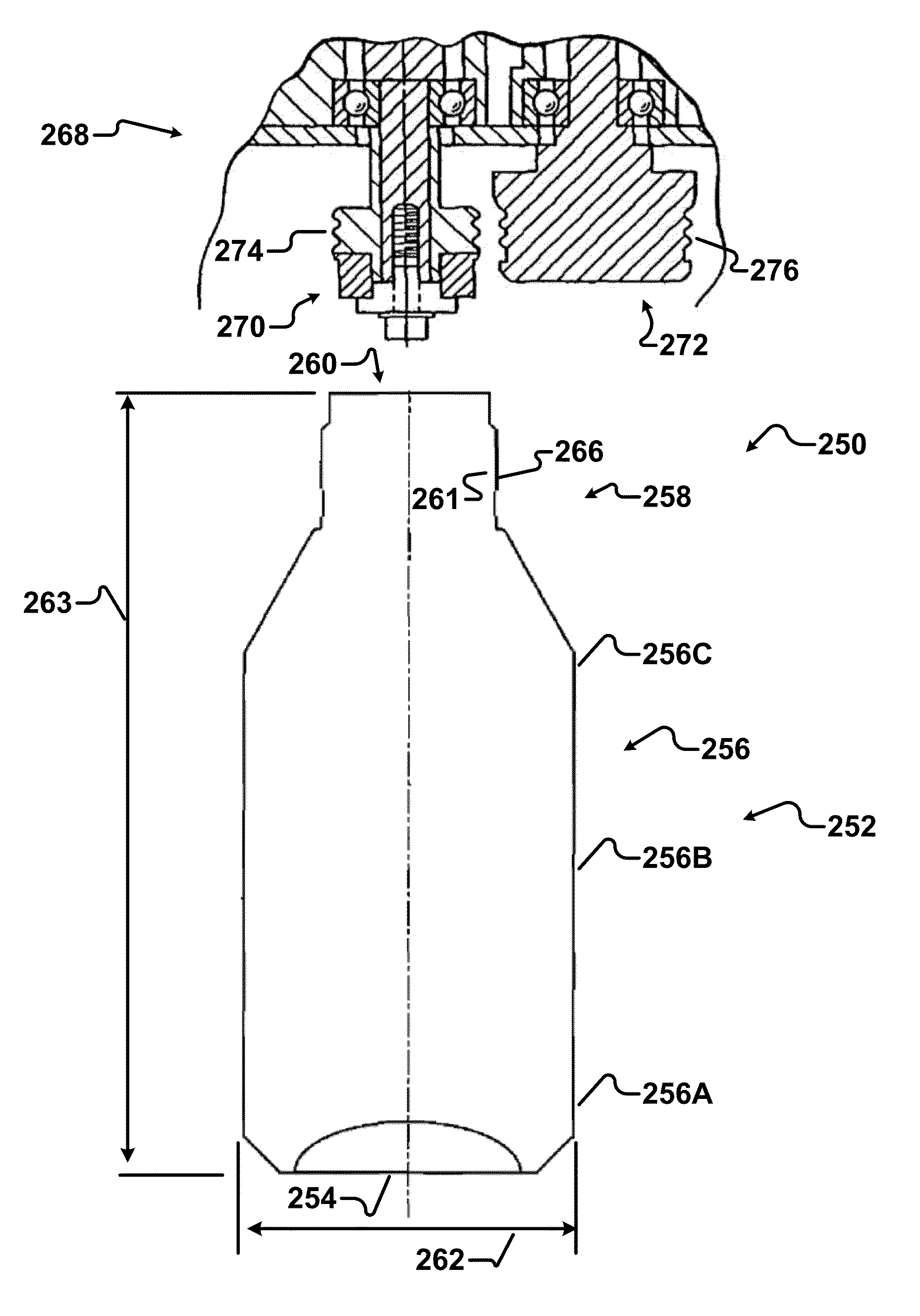

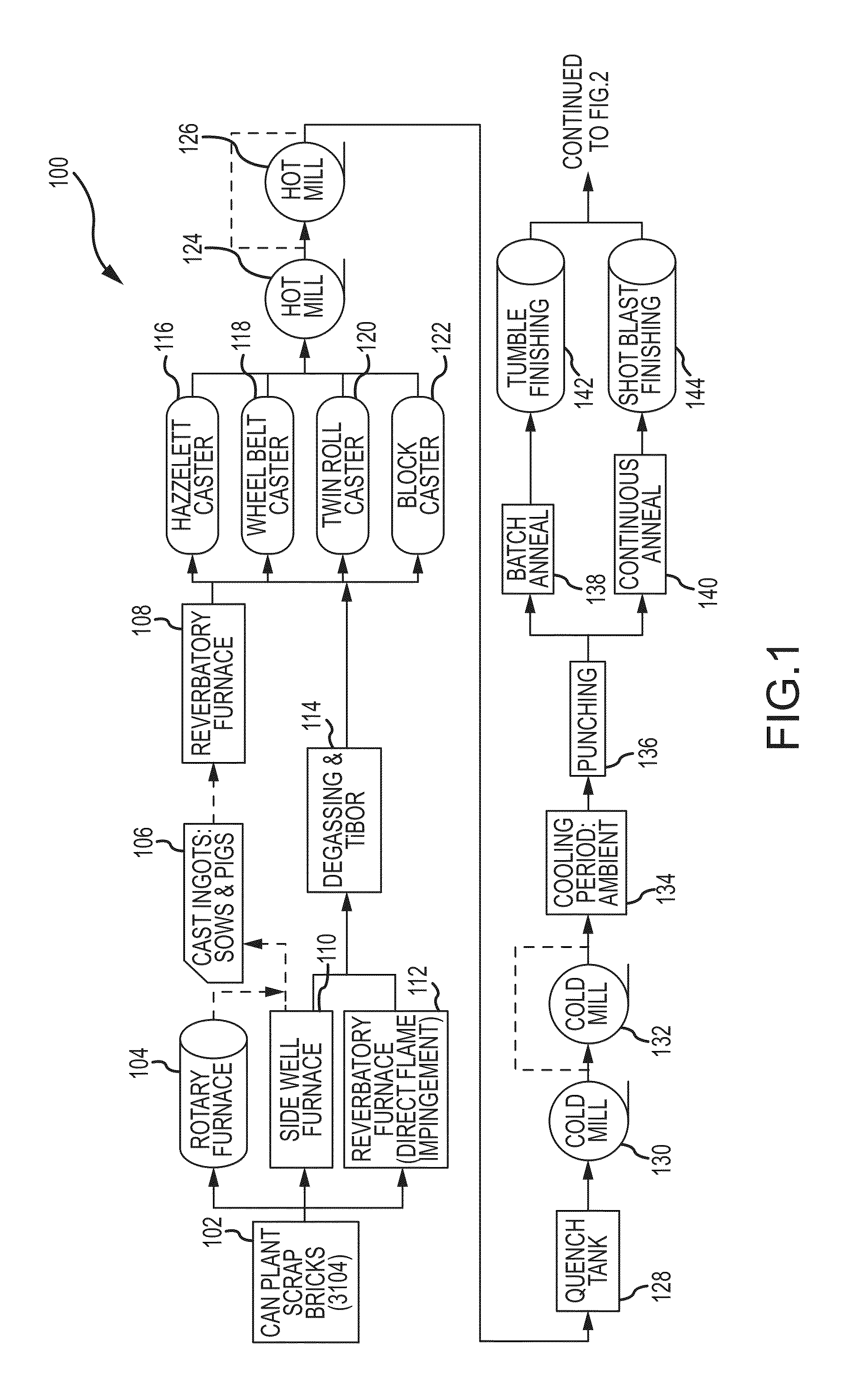

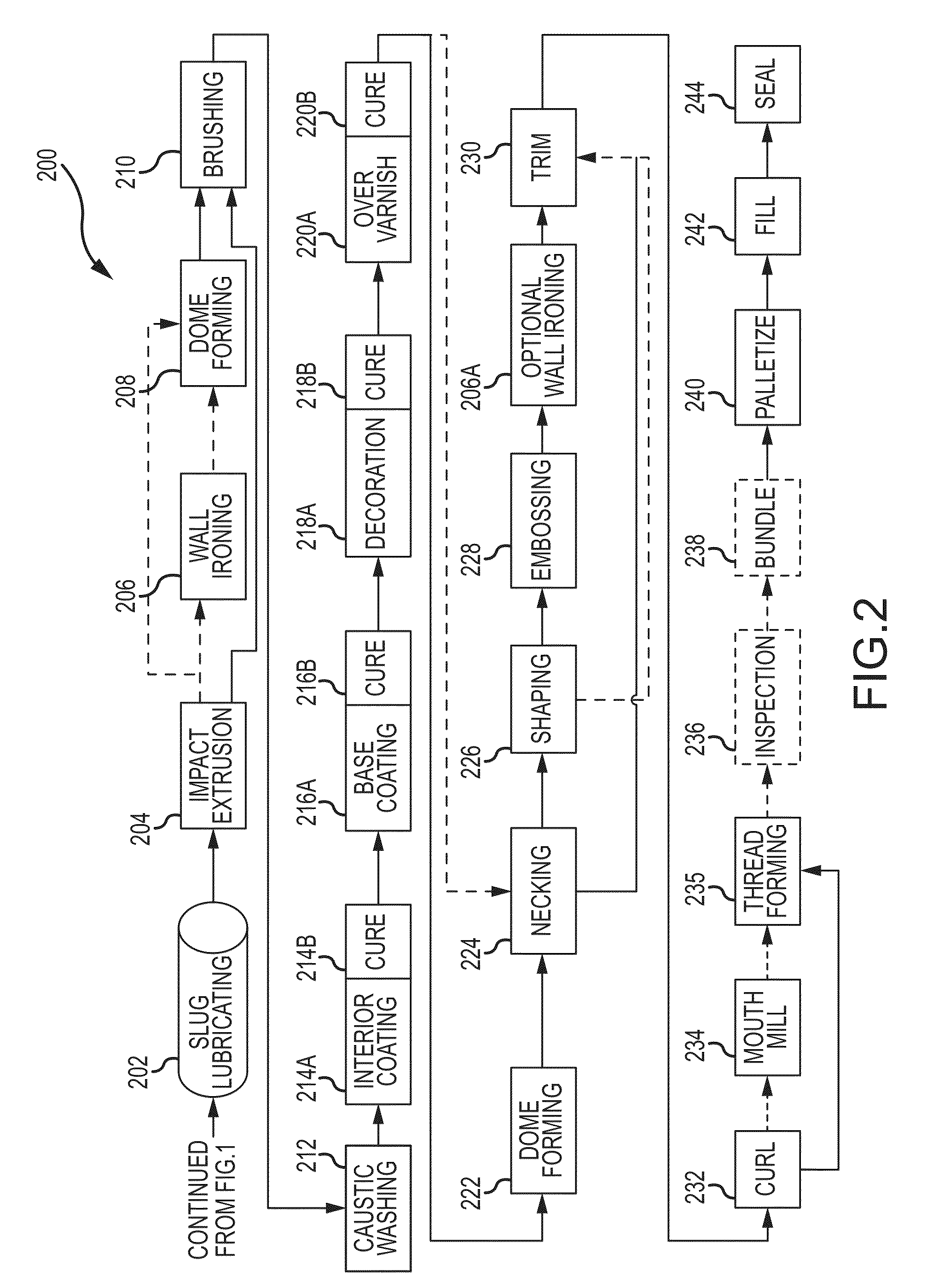

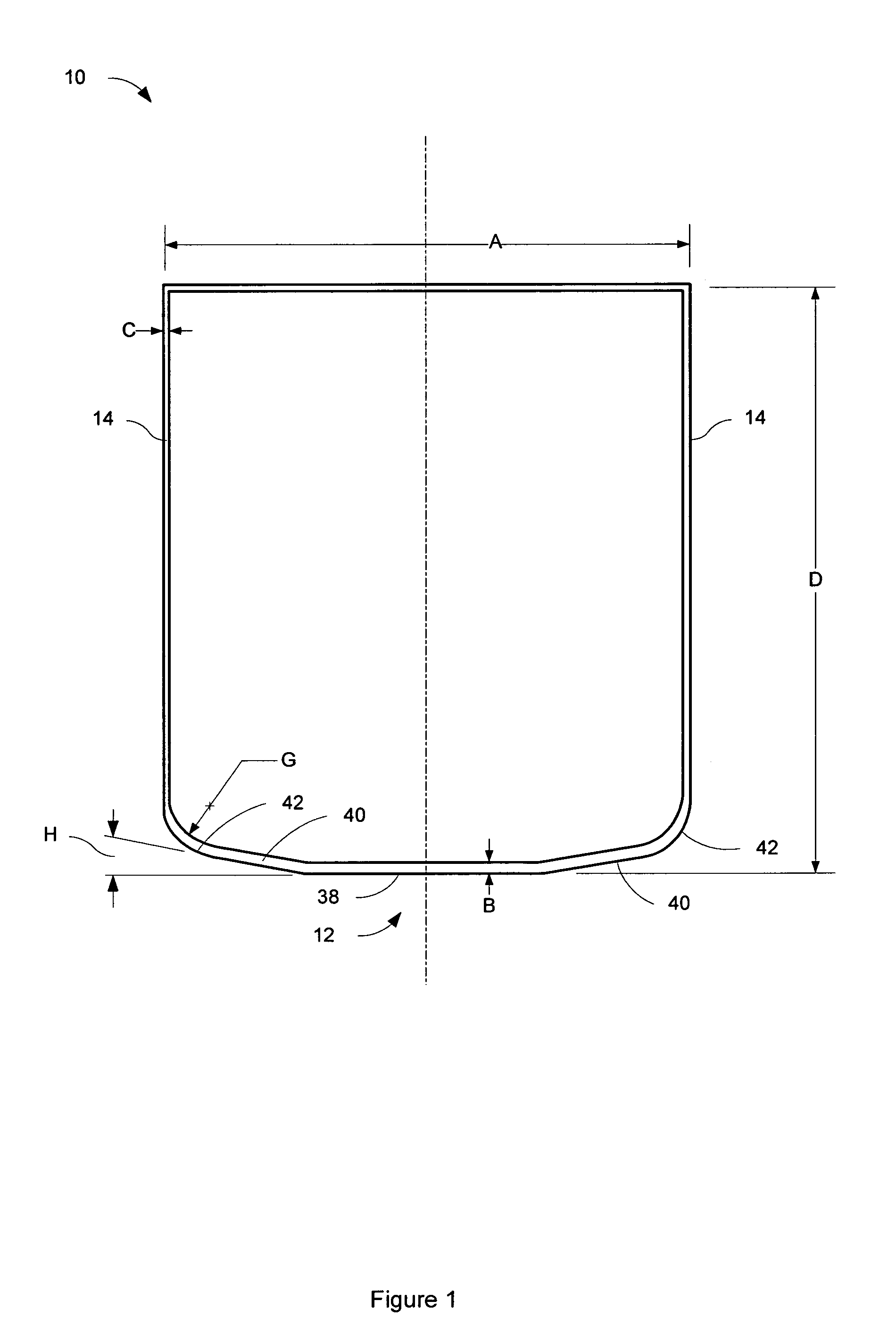

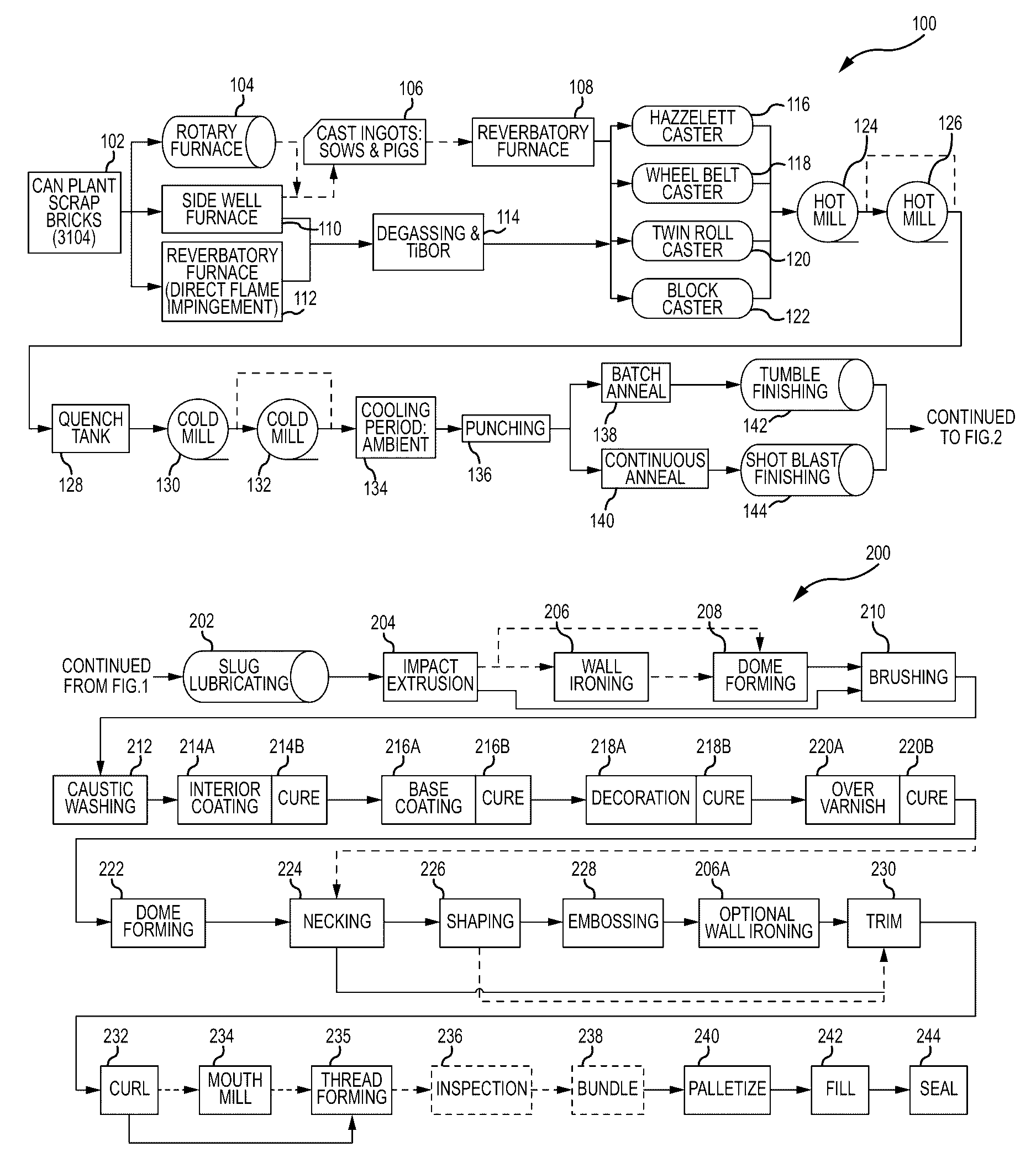

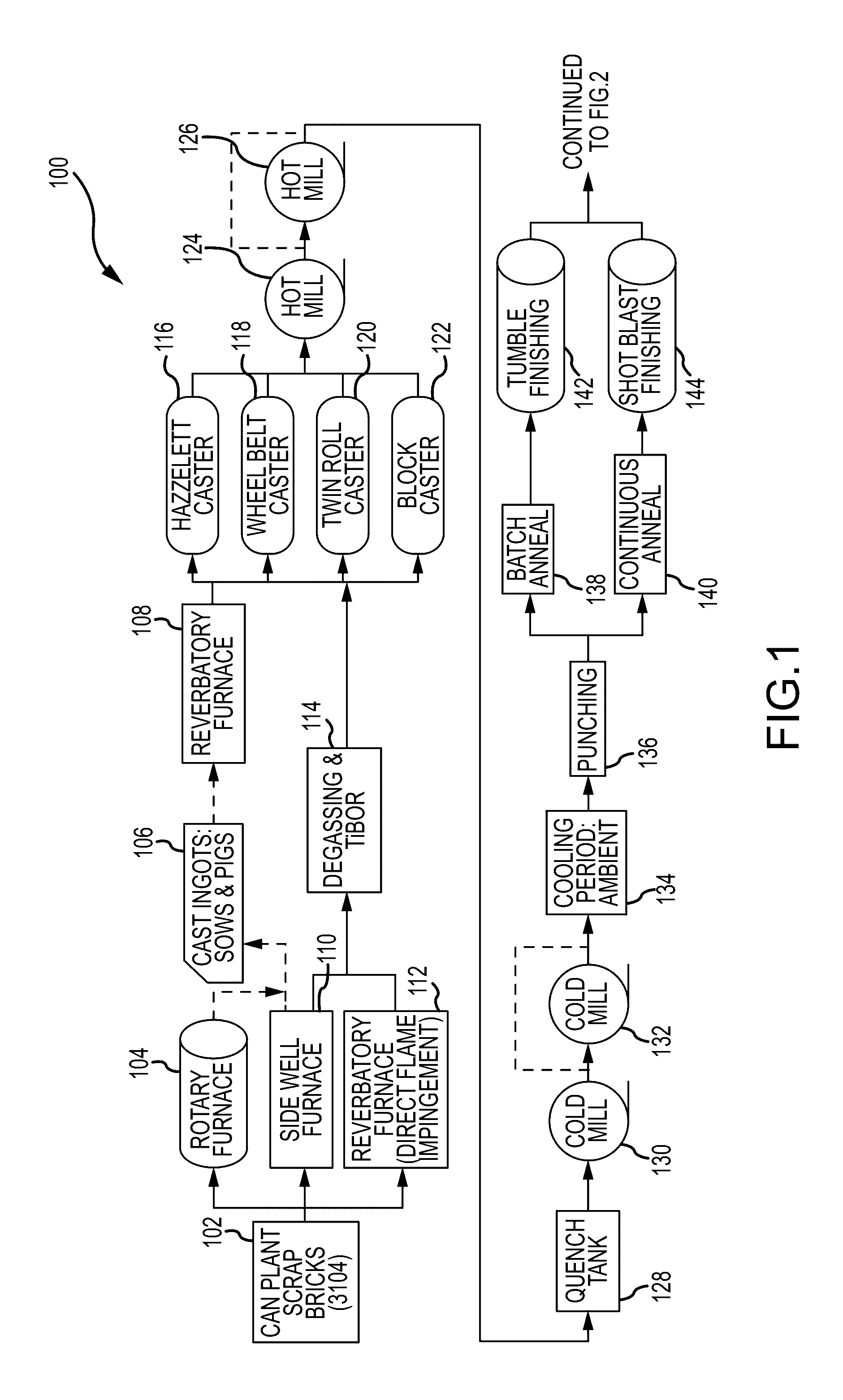

Aluminum impact extruded bottle with threaded neck made from recycled aluminum and enhanced alloys

ActiveUS20140298641A1High mechanical strengthLow costMetal rolling stand detailsClosure capsBottleUltimate tensile strength

The present invention relates generally to forming a threaded neck in a metal bottle manufactured by a process known as impact extrusion. More specifically, the present invention relates to methods, apparatus and alloy compositions used in the impact extrusion manufacturing of containers and other articles with sufficient strength characteristics to allow threading the container necks to receive a threaded closure on the threaded neck.

Owner:BALL CORP

Method of making metal containers

InactiveUS6945085B1Large caliberReduce the overall diameterMetal-working apparatusHollow articlesMetal alloyEngineering

Lightweight metal containers are formed from high-strength metal alloys by impact extrusion of a cup-shaped container having a substantially larger diameter than the finished container, drawing and wall ironing the extruded container to reduce its diameter and wall thickness while increasing the height of the container to the appropriate diameter, wall thickness and height.

Owner:CCL CONTAINER HERMITAGE

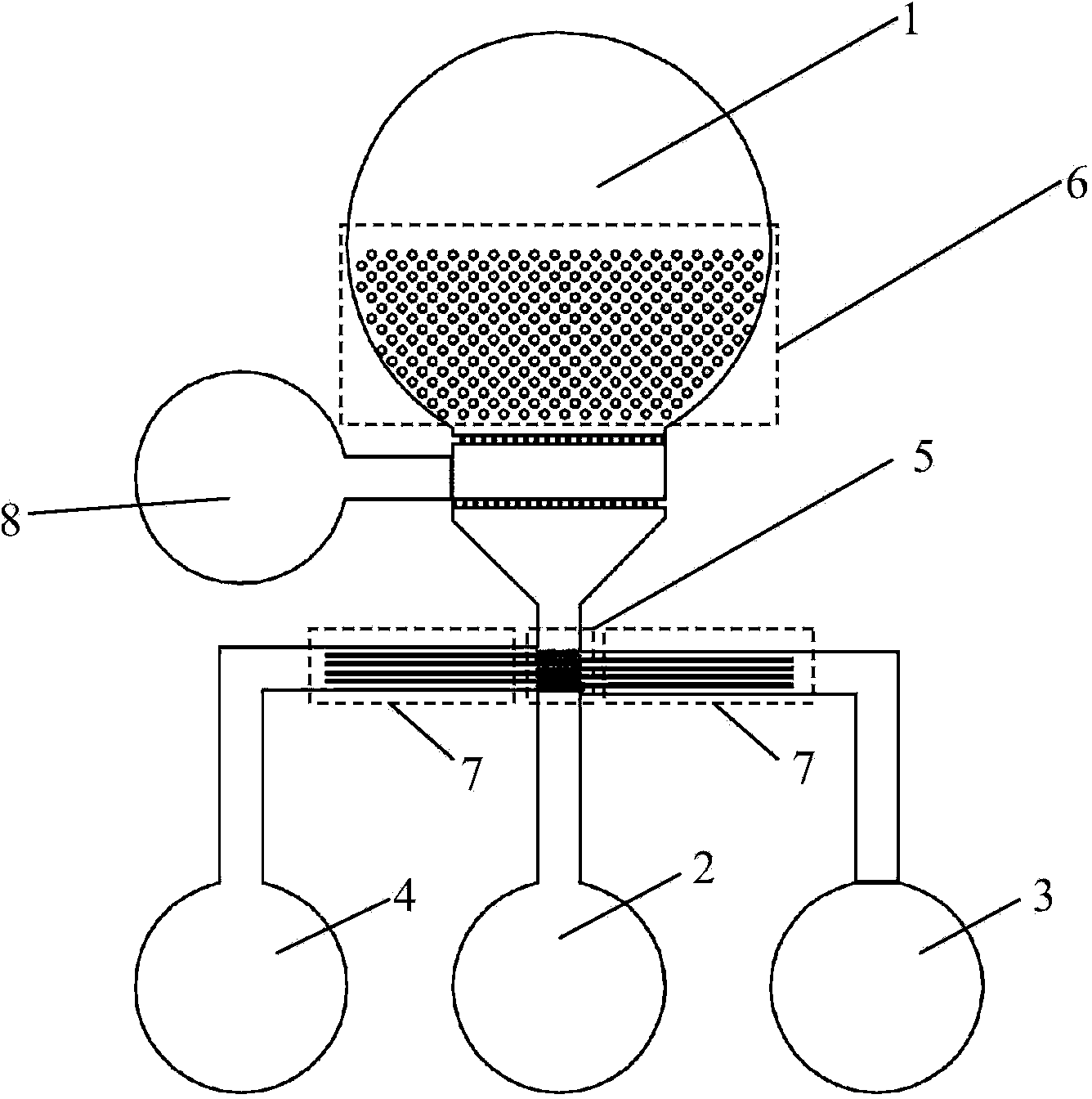

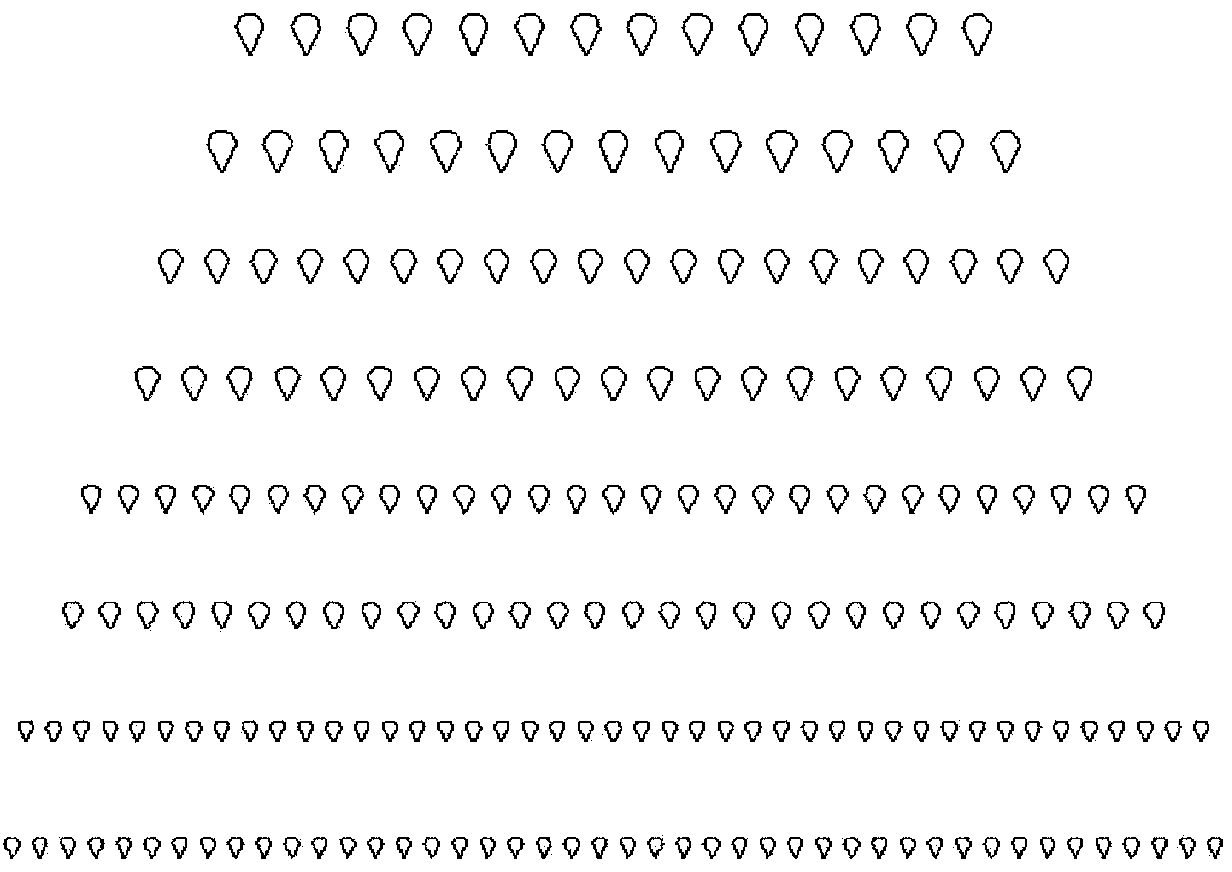

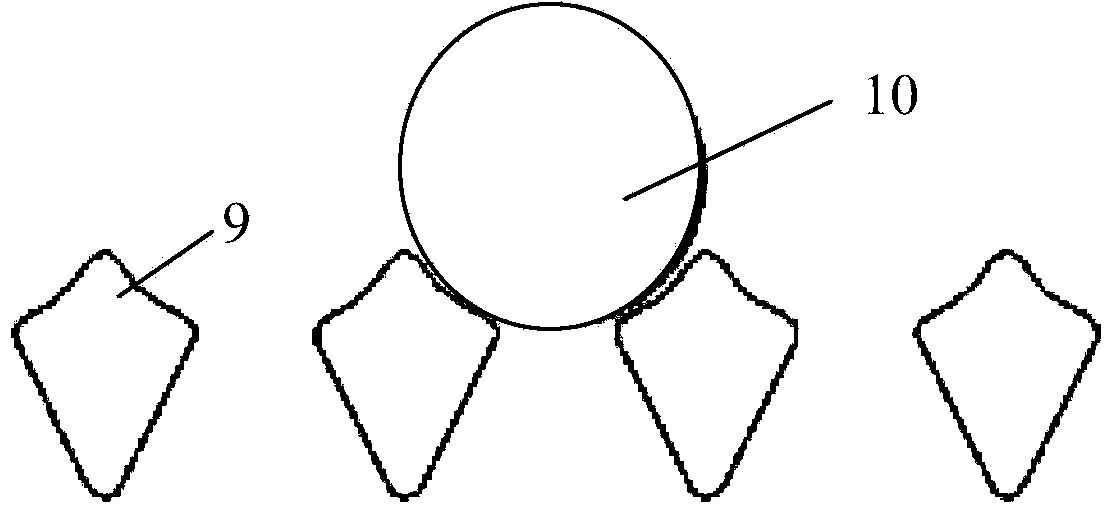

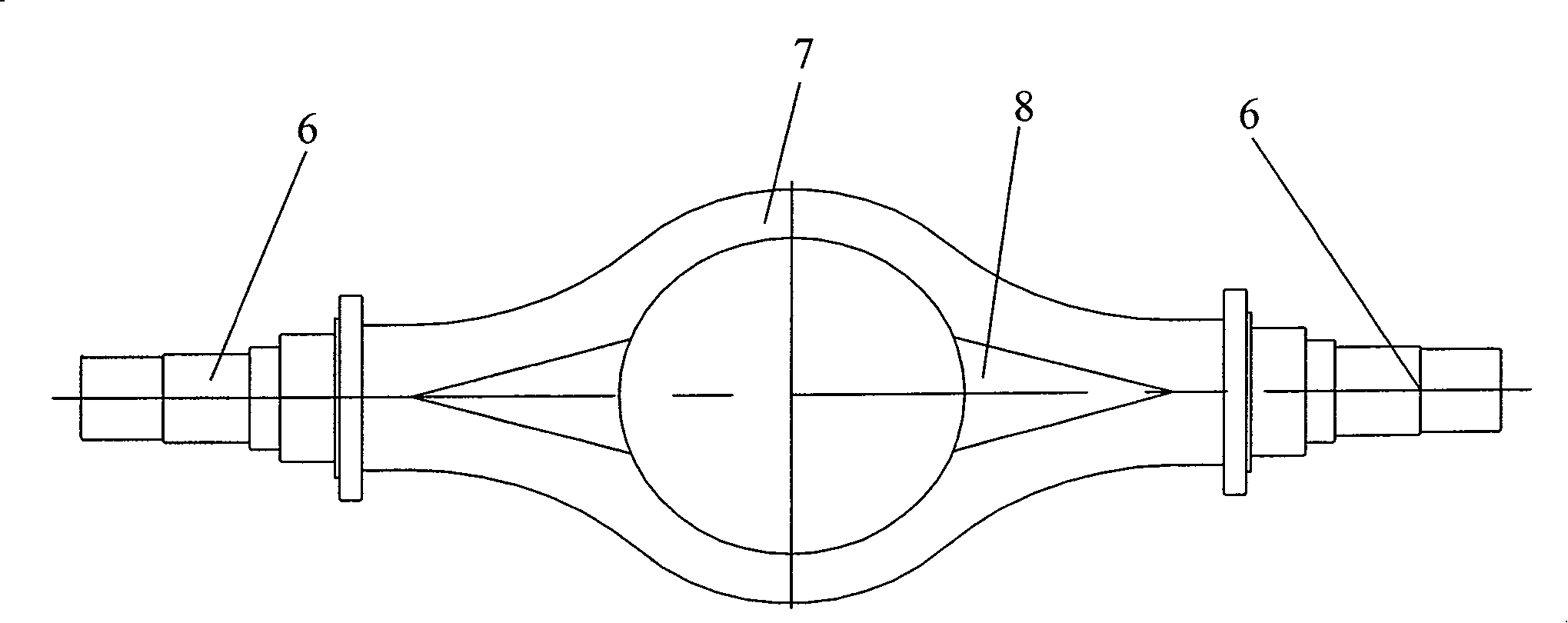

Cell separating micro-structural system

InactiveCN104073428ASimple separation and enrichmentRapid separation and enrichmentBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringCell separation

The invention relates to the technical field of biological and medical in vitro detection, and discloses a cell separating micro-structural system. The cell separating micro-structural system comprises a microfluidic chip, wherein the microfluidic chip comprises a sample inlet, a sample outlet, a cell capturing region, a side flushing inlet, a recycling outlet and a cleaning inlet; a plurality of microcolumns are formed inside the cell capturing region to form a microcolumn array; the microcolumn array is distributed in a gradient manner, thus showing microcolumn distance gradient change and microcolumn dimension gradient change; each layer of the microcolumn array is distributed in the form of a regular trapezoid gradually dispersing from the top layer to the bottom layer; the horizontal cross section shape of each microcolumn is divided into an upper part and a lower part; the upper part close to the sample inlet is similar to a normal isosceles triangle, wherein the two isosceles sides are in an symmetrical inner-concave circular arc shape; and the lower part close to the sample outlet is in an inverted isosceles triangle shape. The cell separating micro-structural system disclosed by the invention is used for separating, gathering, counting and recycling CTC or UETC, wherein detecting efficiency exceeds 90%; and moreover, damages of the microcolumn array on captured cells when a fluid impacts the captured cells are lowered.

Owner:PEKING UNIV

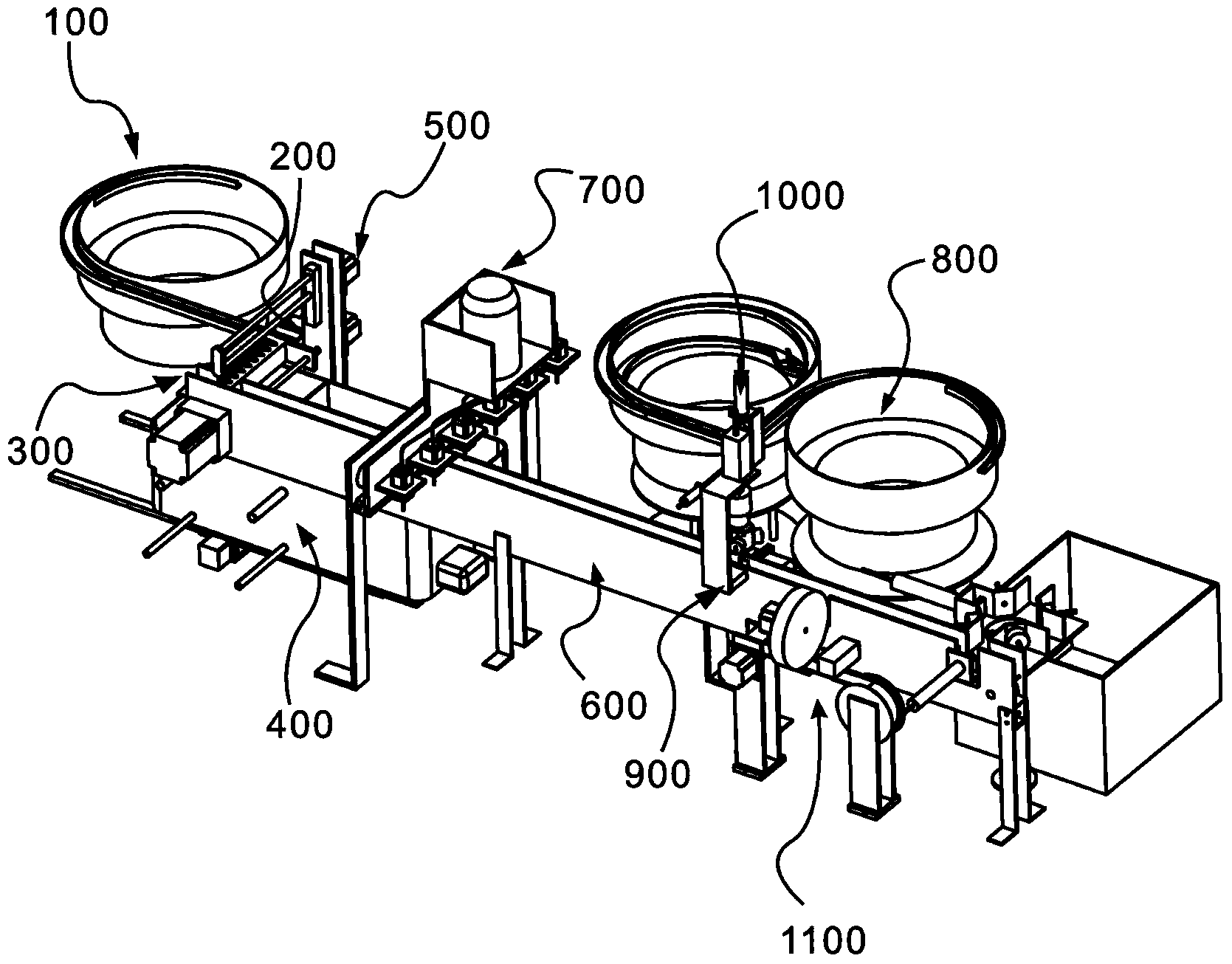

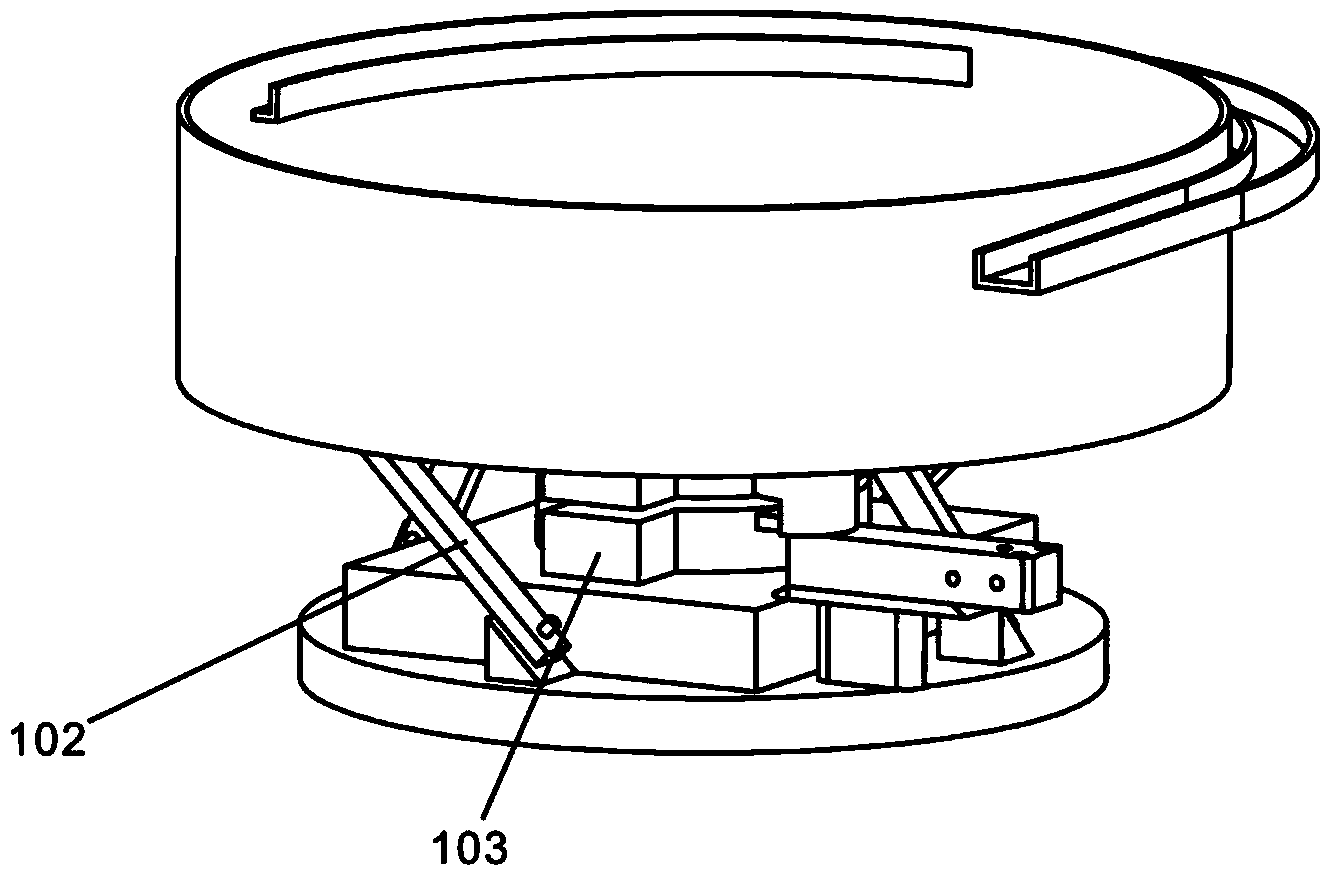

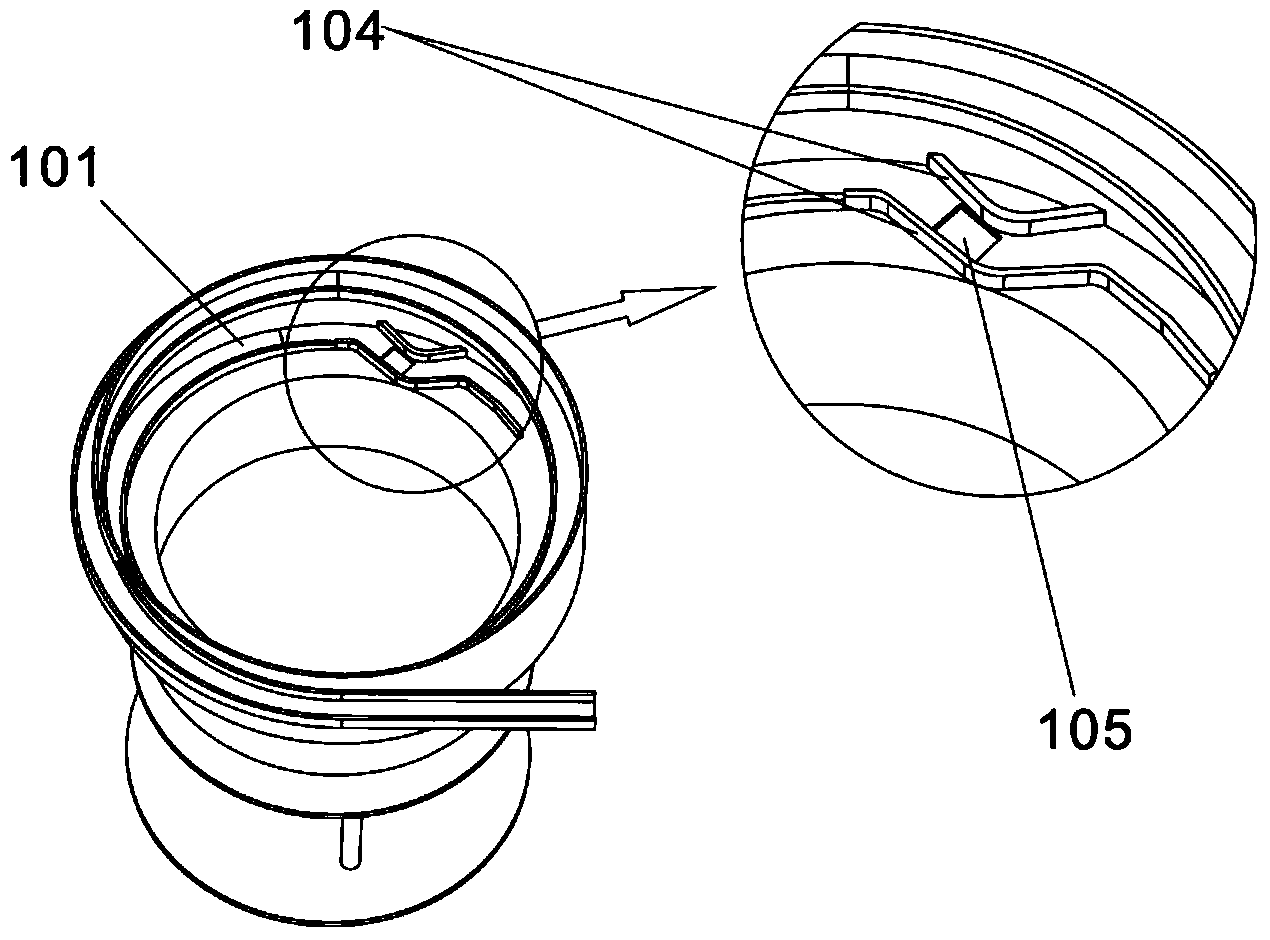

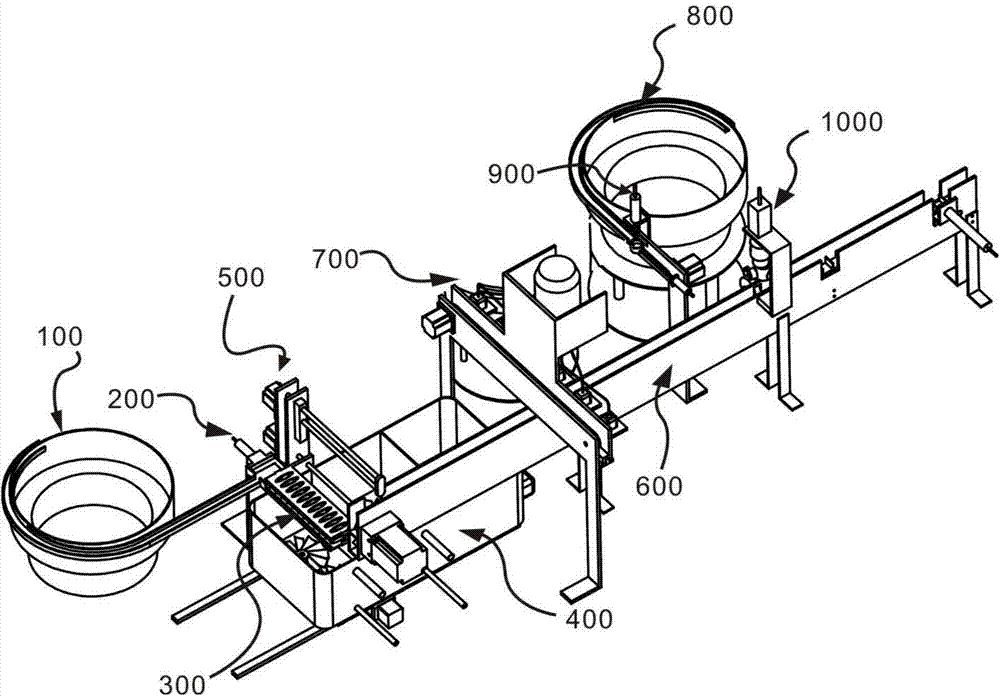

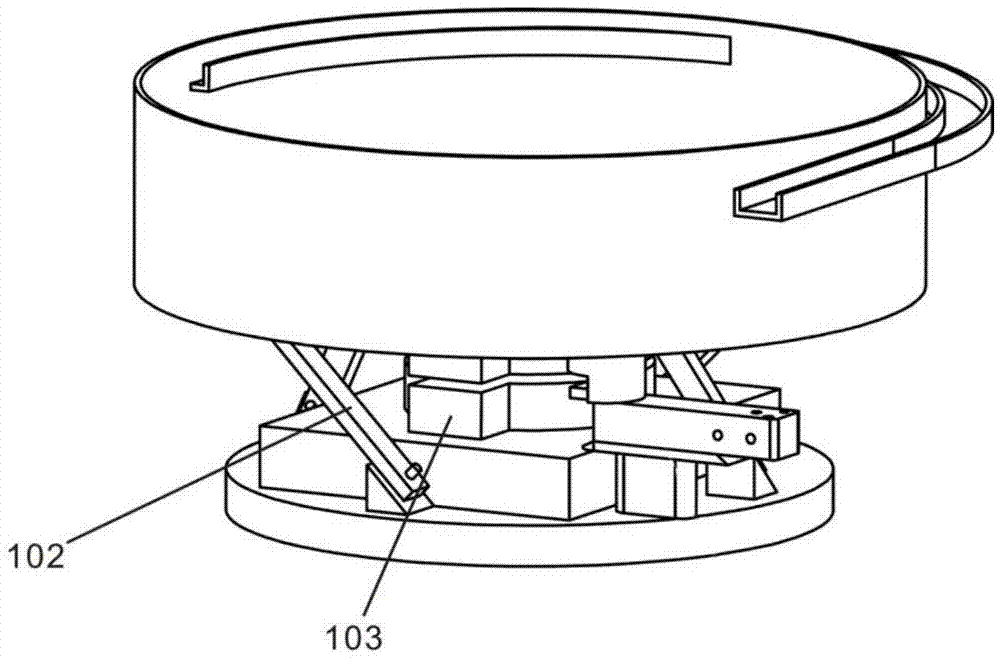

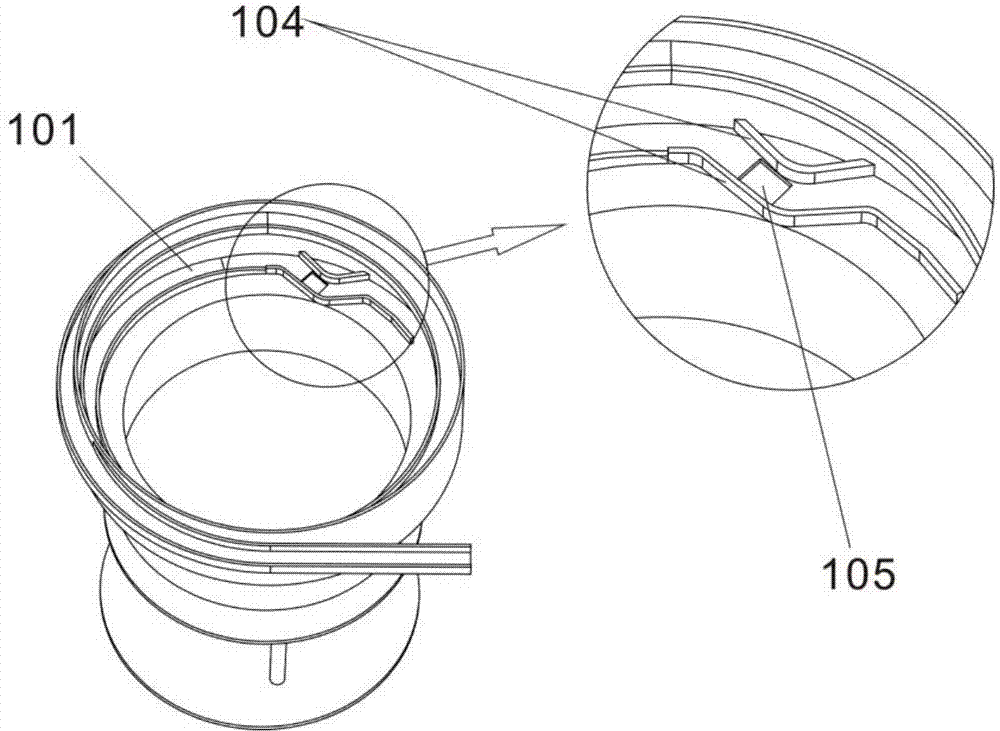

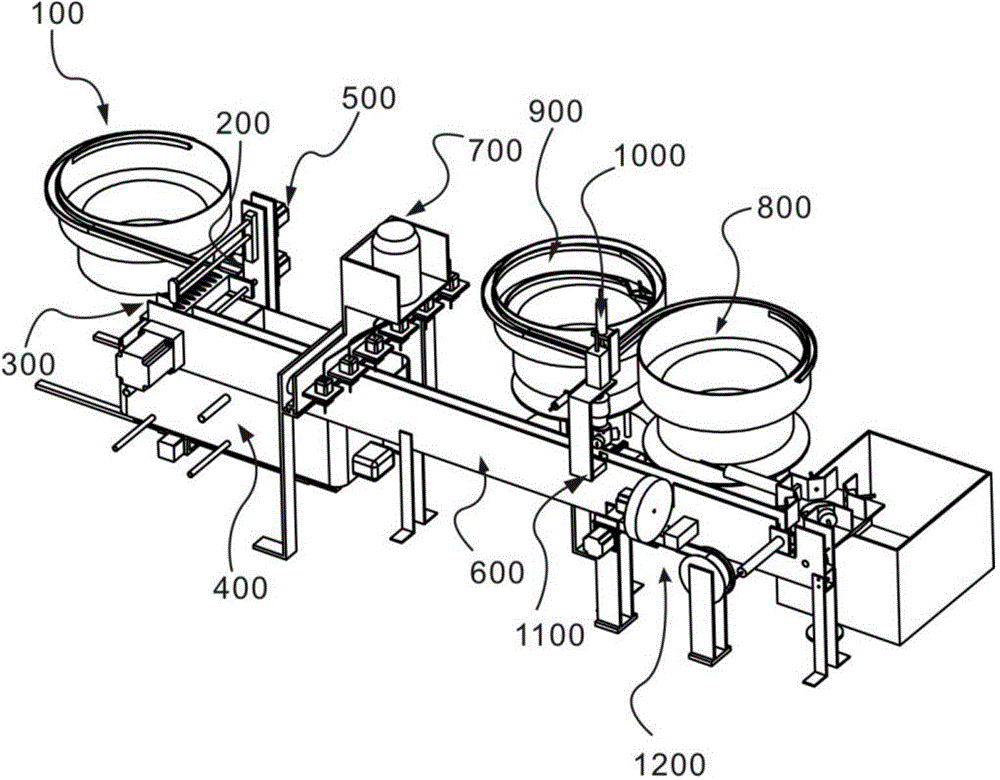

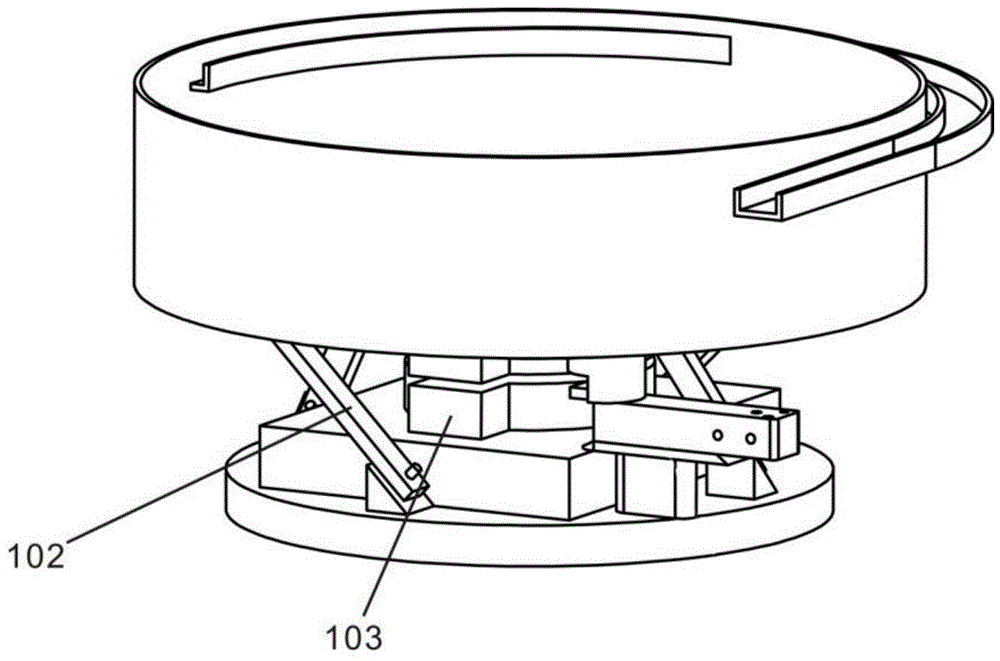

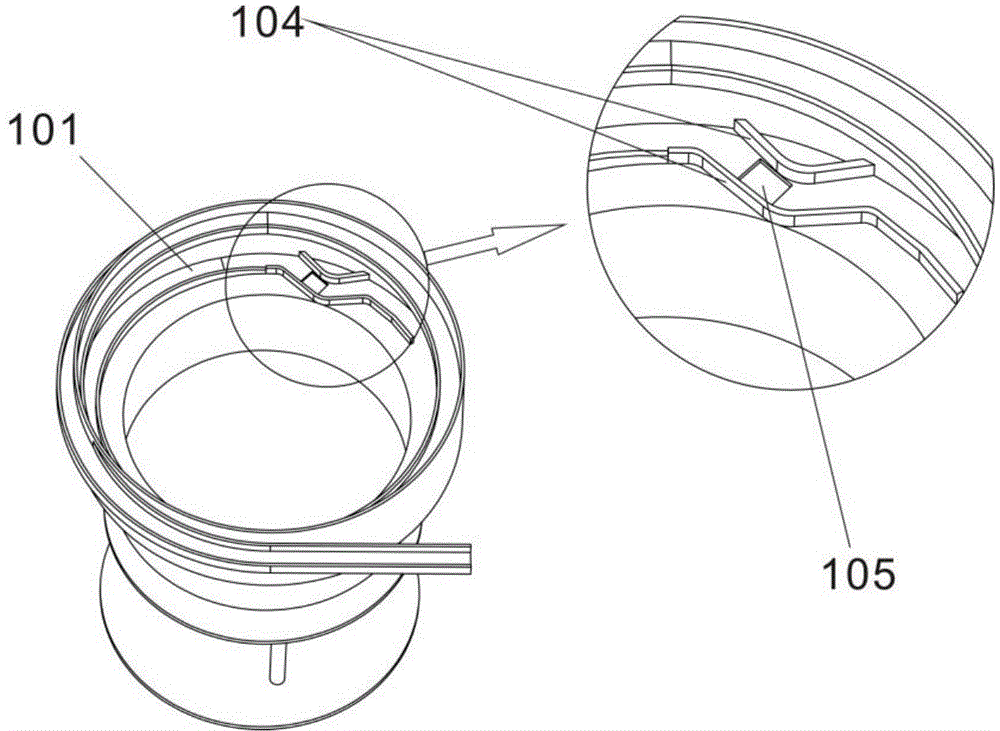

Filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system

ActiveCN104326431ASolve the problem of directional transportCapsThreaded caps applicationEngineeringBottle

The invention discloses a filling bottle correcting, pushing, rinsing, conveying, filling, cover conveying and screwing labeling and coding system which comprises a correcting device and a pushing device and also comprises a carrying device, a rinsing device, a progressive device, a conveying device, a filling device, a cover conveying device, an impact extrusion device, a cover screwing device and a labeling device, wherein the correcting device is a cavity of which one end is open; a material channel which spirally ascends is formed in the inner side wall of the cavity; and the pushing device comprises a pushing cylinder and a pushing platform. According to the system disclosed by the invention, the problem that the filling bottles cannot be directionally transported can be solved, and the problems that the filling bottles cannot be subjected to automatic progressive rinsing, conveying and filling, cover conveying, filling bottle cover impact extrusion and fixation, cover screwing and labeling and coding also can be solved.

Owner:NANTONG SNT PACKING MACHINERY

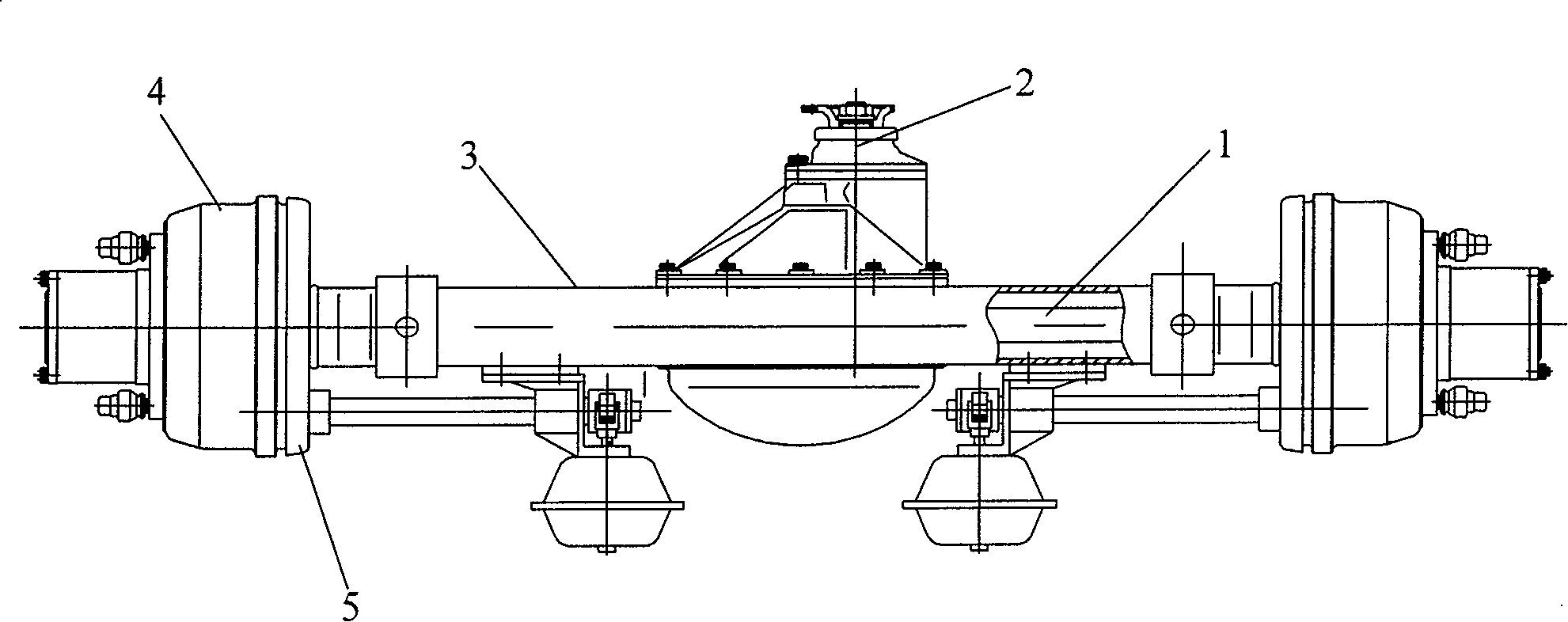

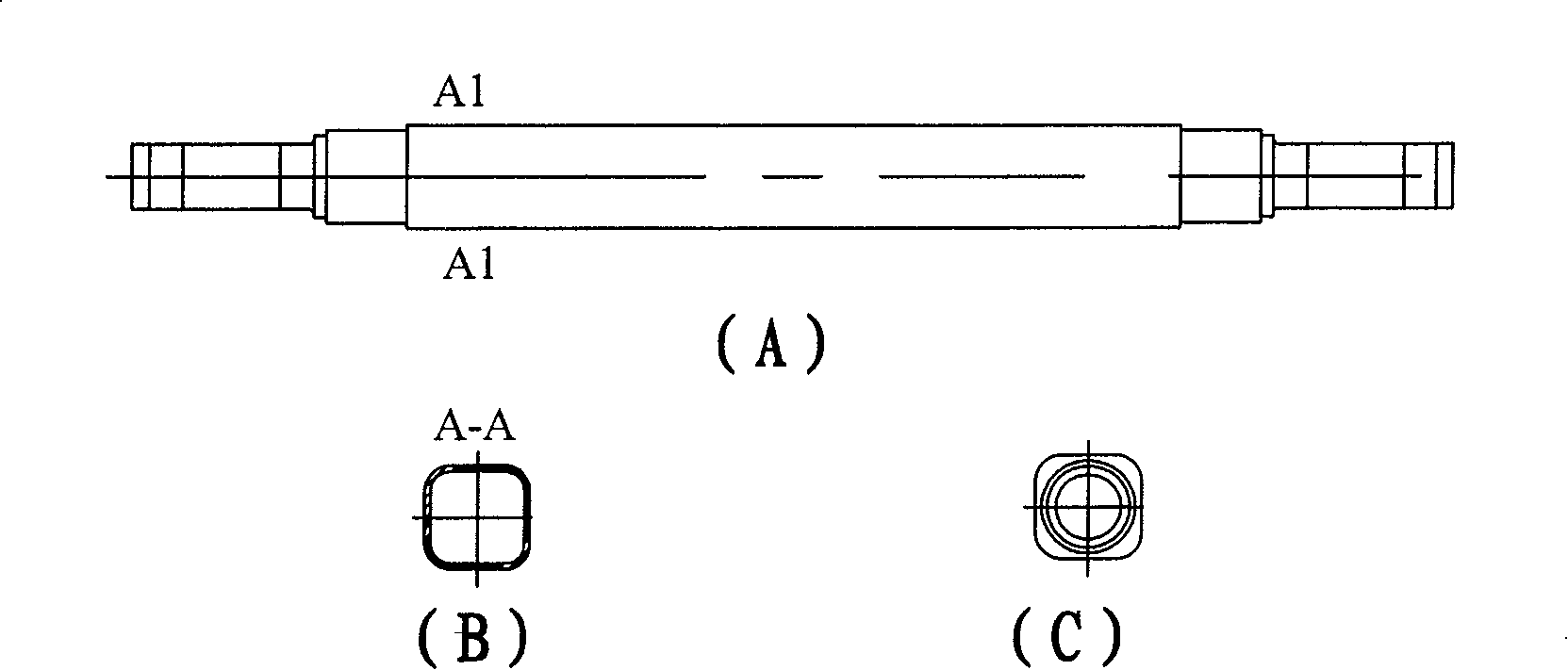

Roll type cold pressing processing method and device for vehicle driving axle housing

InactiveCN101185946ASimple structureHigh mechanical strengthExtrusion control devicesRams/plungersAxial pressureEngineering

Owner:梅利红

Aluminum impact extruded bottle with threaded neck made from recycled aluminum and enhanced alloys

The present invention relates generally to forming a threaded neck in a metal bottle manufactured by a process known as impact extrusion. More specifically, the present invention relates to methods, apparatus and alloy compositions used in the impact extrusion manufacturing of containers and other articles with sufficient strength characteristics to allow threading the container necks to receive a threaded closure on the threaded neck.

Owner:BALL CORP

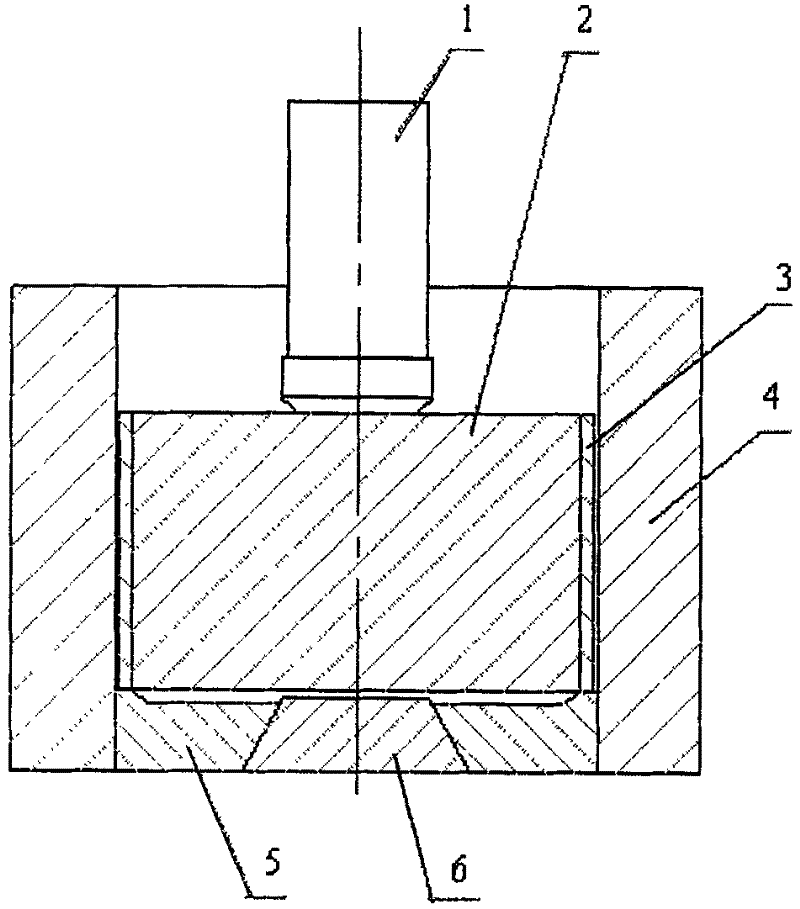

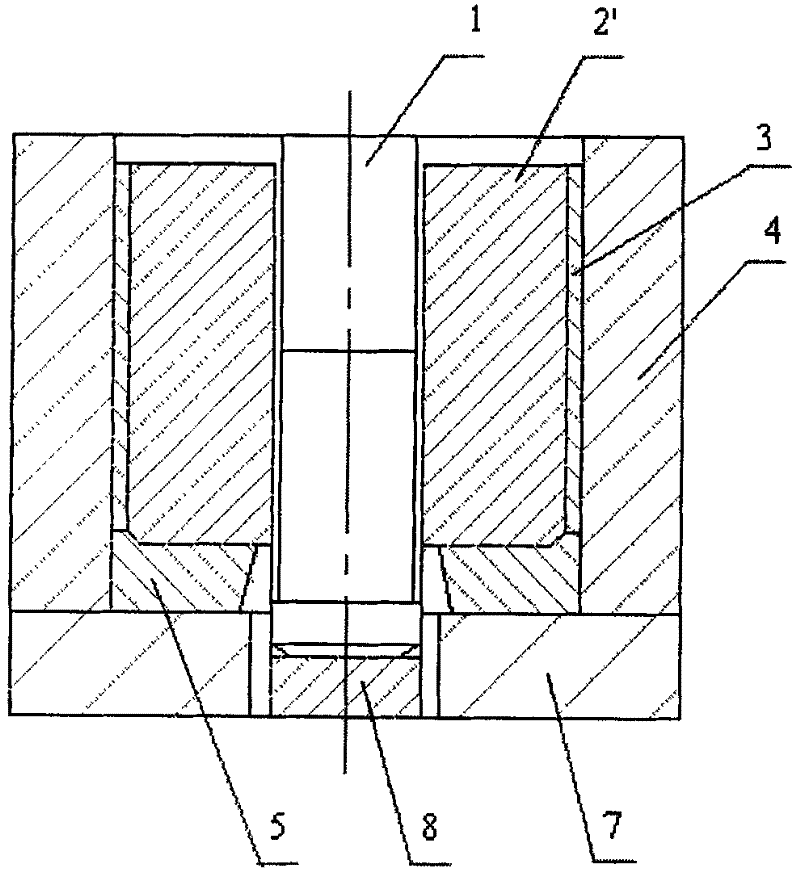

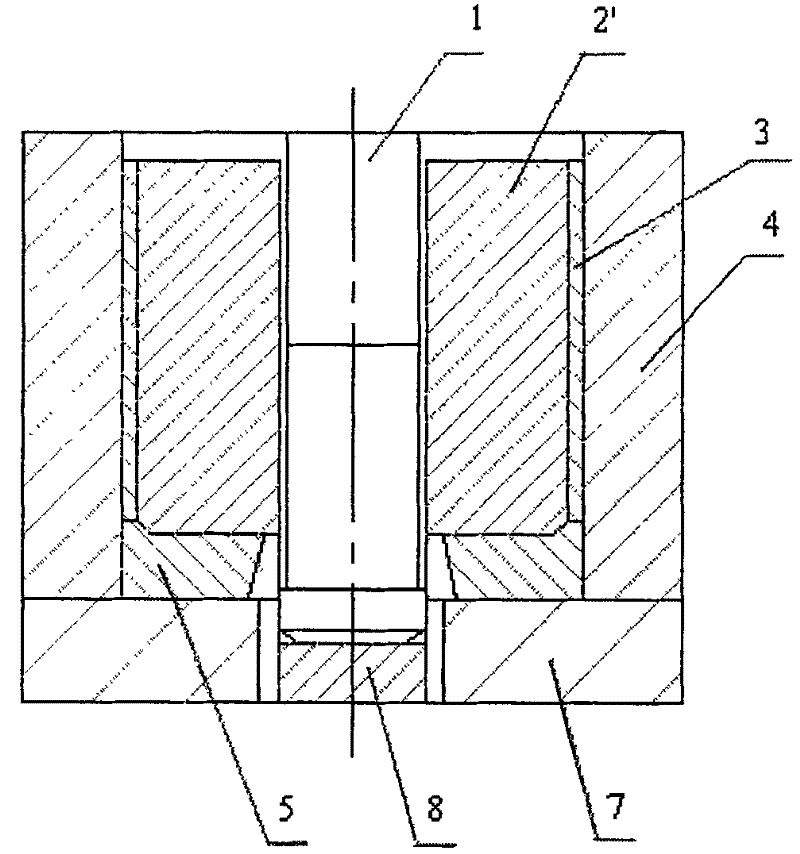

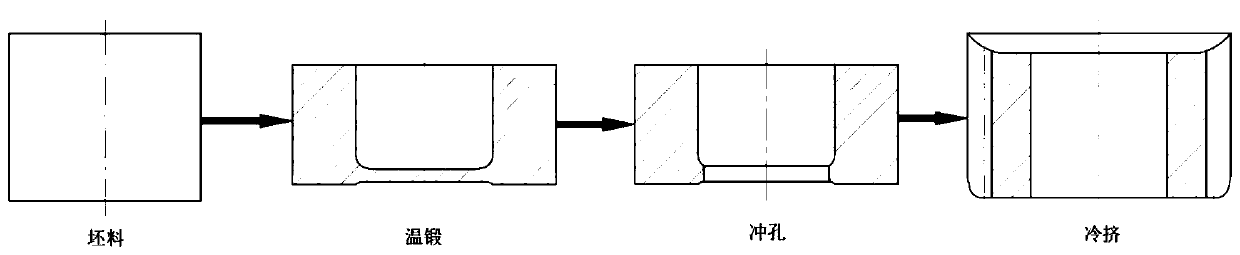

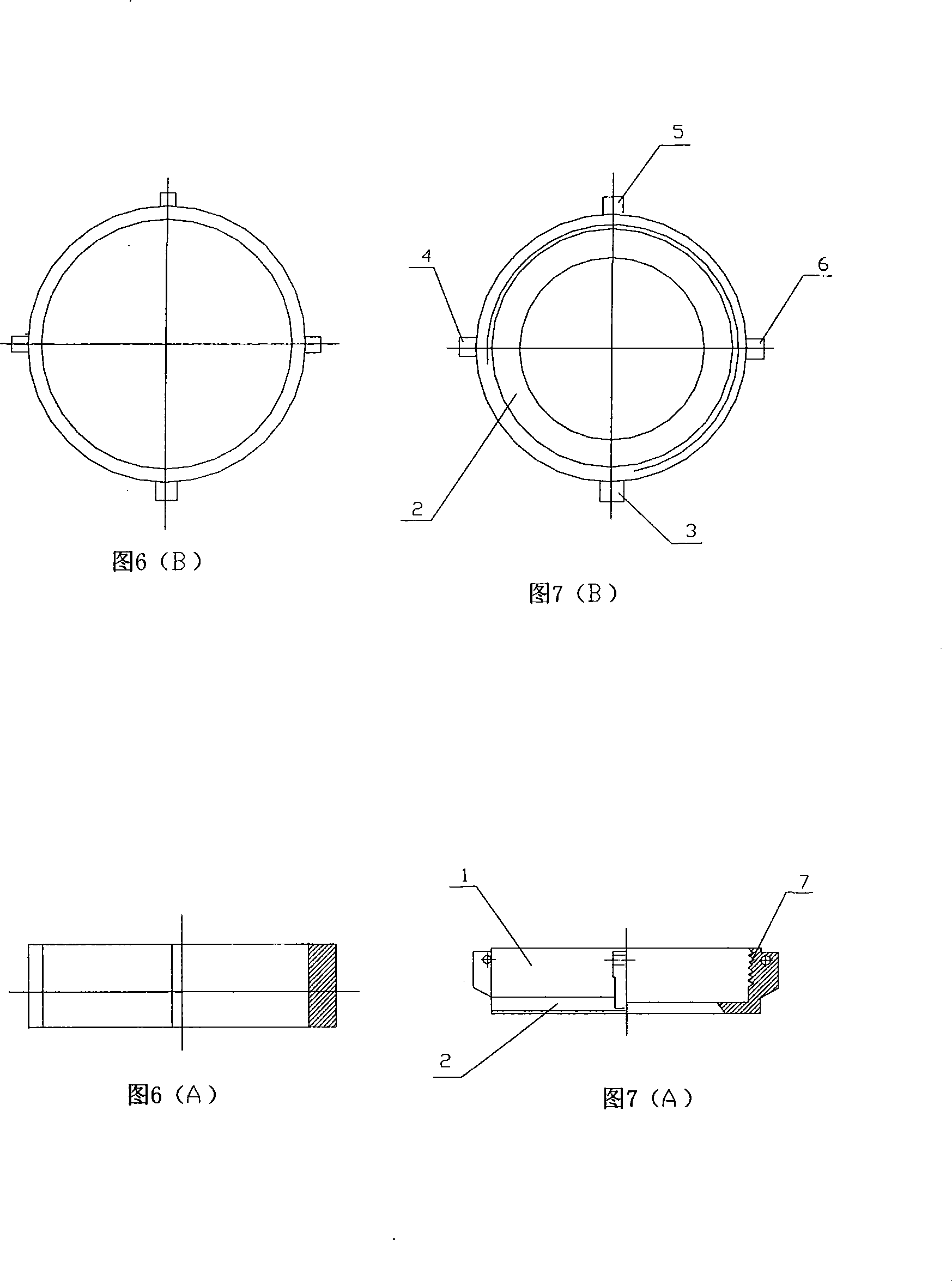

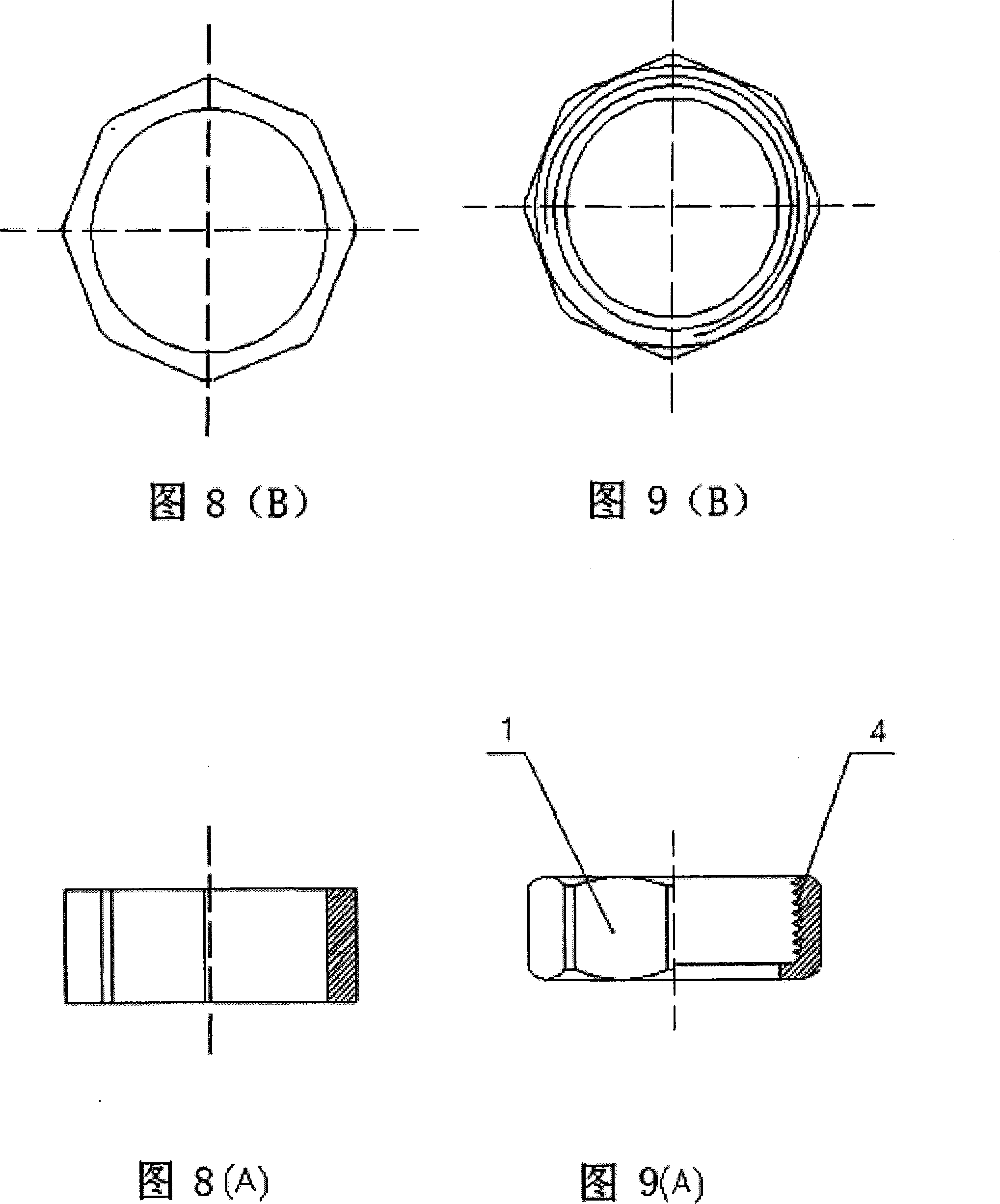

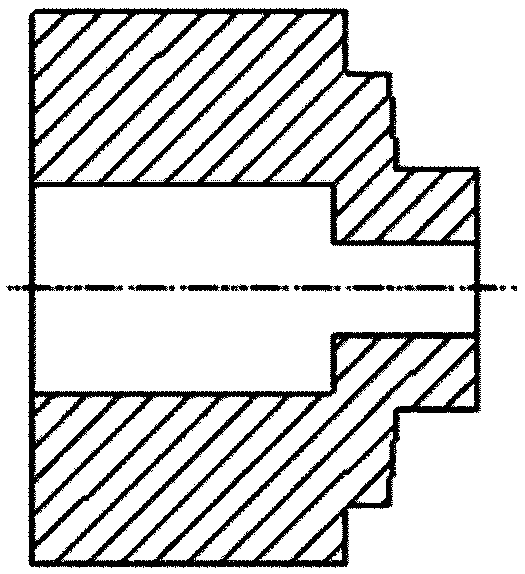

Hot impact extrusion process and device for large annular barrel type forged piece

ActiveCN101537438ASolve process problemsImprove uniformityExtrusion containersRams/plungersImpact extrusionLubricant

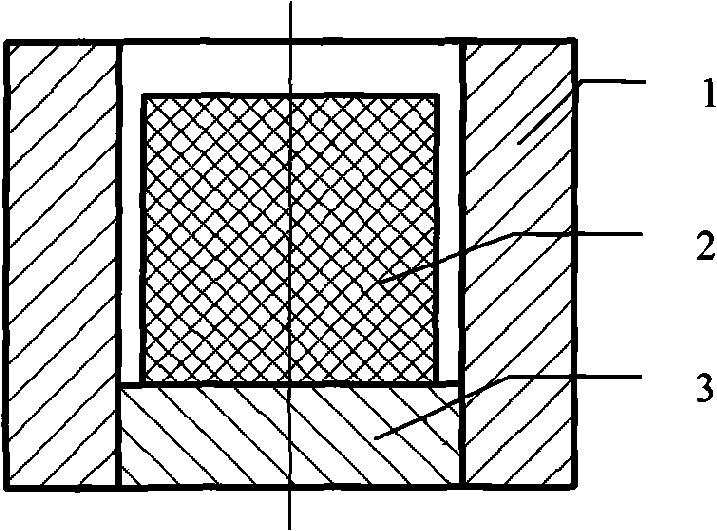

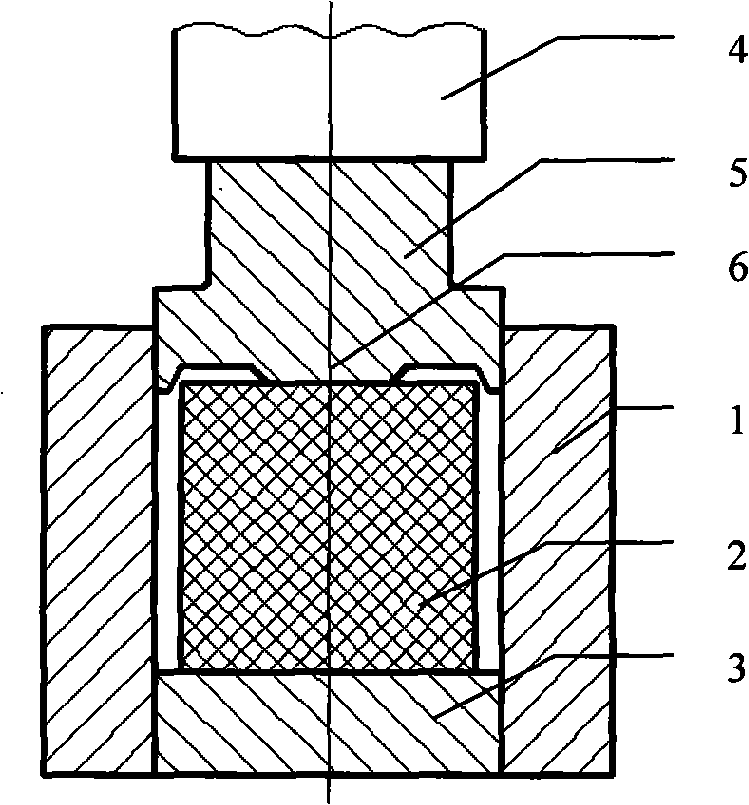

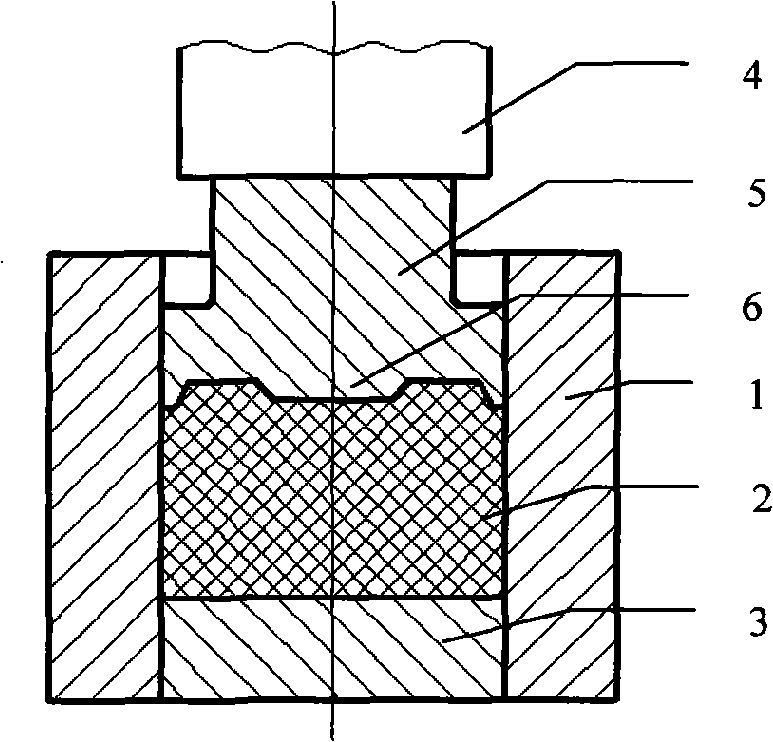

The invention relates to a hot impact extrusion process and a device for a large annular barrel type forged piece, which belongs to the technical field of hot forming of a large hollow forged piece. The process comprises the following steps: firstly, an extrusion cushion is placed on a press platform; secondly, the blanks to be heated are put on the extrusion cushion; thirdly, an extrusion cylinder is sleeved on the extrusion cushion; fourthly, a profiling punch is applied with force so that a mold cavity is filled with the blanks; fifthly, the lubricant is added; sixthly, a solid punch is applied with force so that the blanks are extruded to the set position of the process; seventhly, a hollow punch is sleeved on the solid punch and applied with pressure, so that the blanks are extruded to the set positioned of the process; eighthly, the extrusion cushion is taken out and a bottom flushing drain cap is replaced; and ninthly, the core material at the bottom is flushed out through the hollow punch. The devices required for finishing the process comprise an extrusion cylinder, an extrusion cushion, a profiling punch, a solid punch, a hollow punch, a solid extension rod, a hollow extension rod and a bottom flushing drain cap. The invention solves the difficult problems existing in the large annular barrel forged piece of long process flow of free forging, more forging times and large reverse extrusion molding for die forging and improves the utilization ratio of the material and the molding quality of the forged piece.

Owner:NANJING DEV ADVANCED MFG

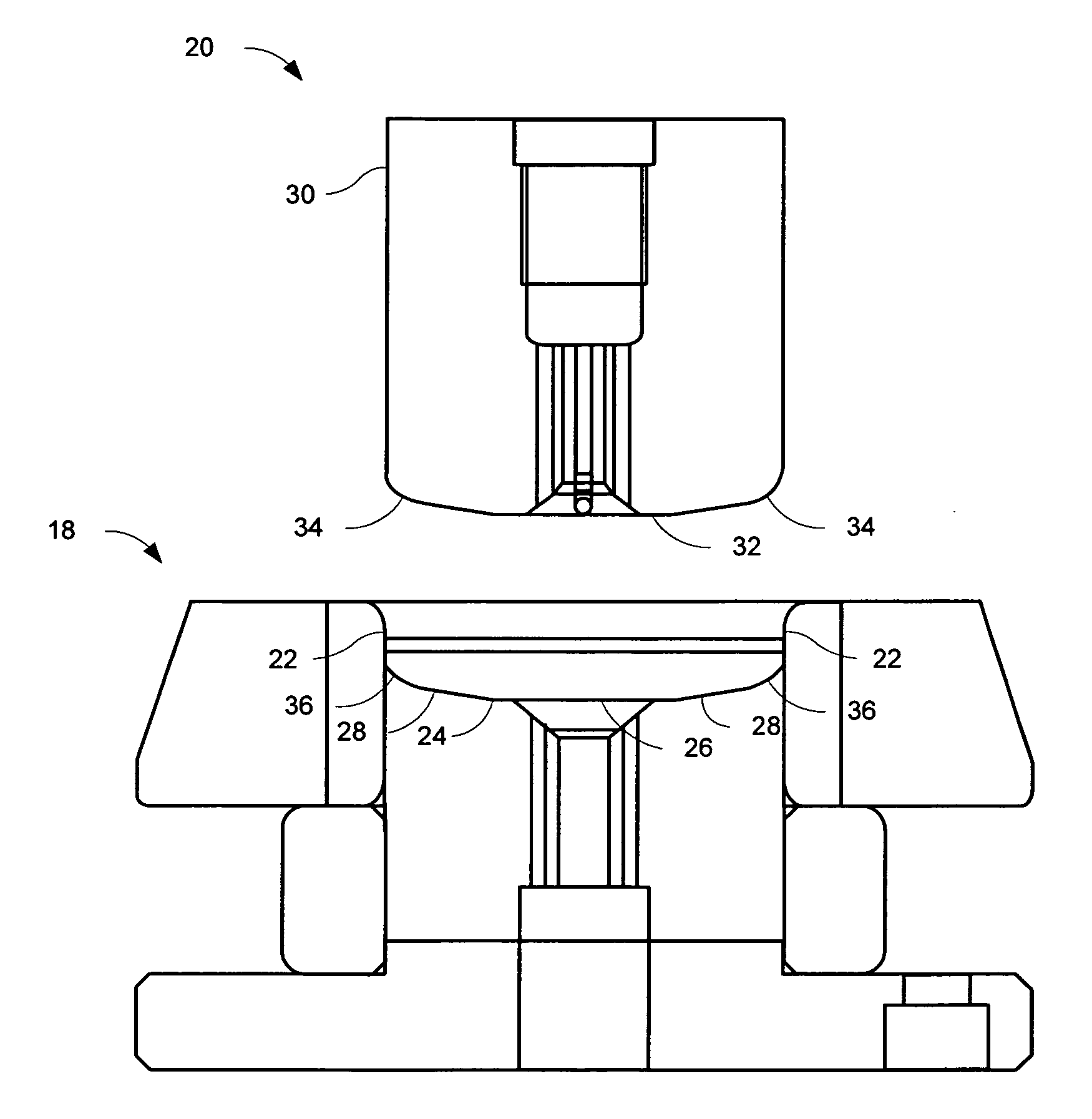

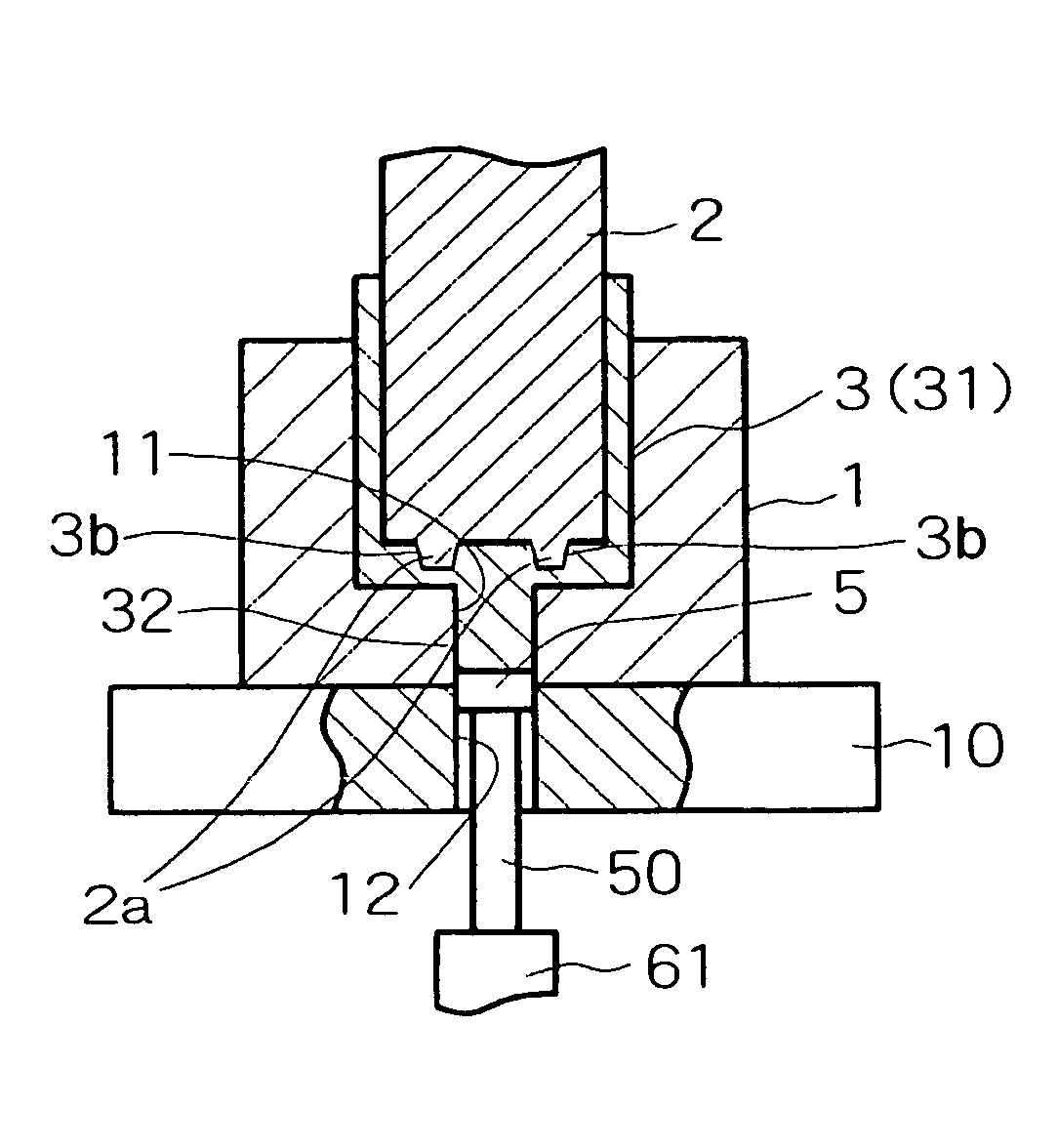

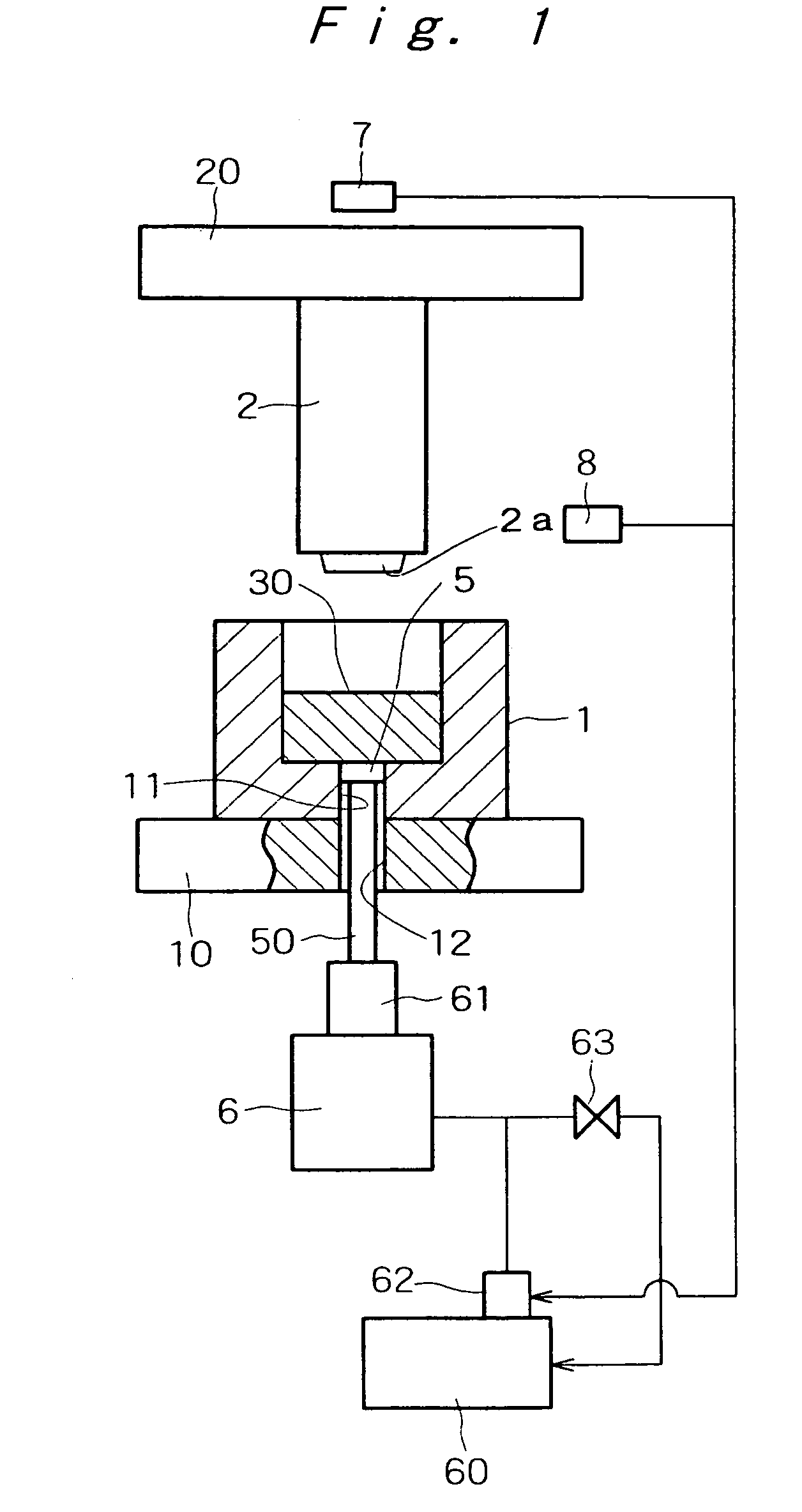

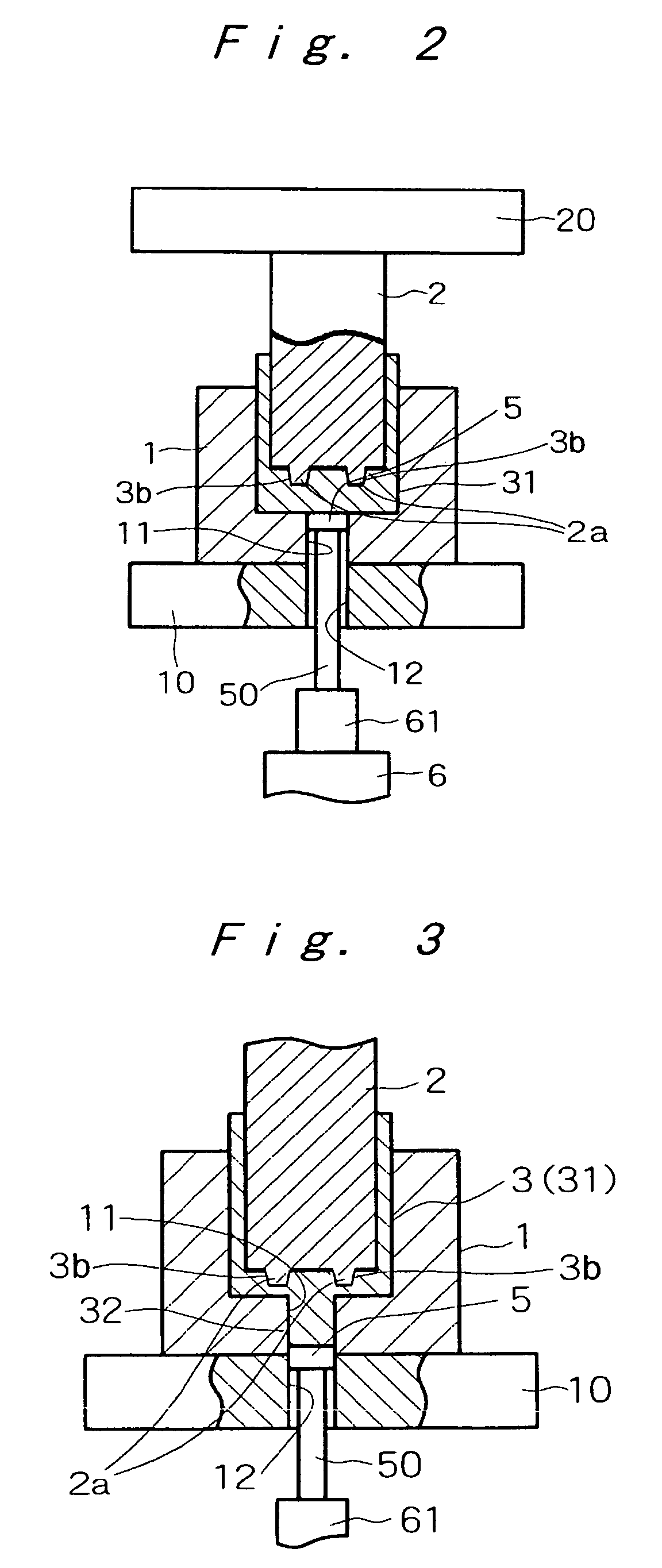

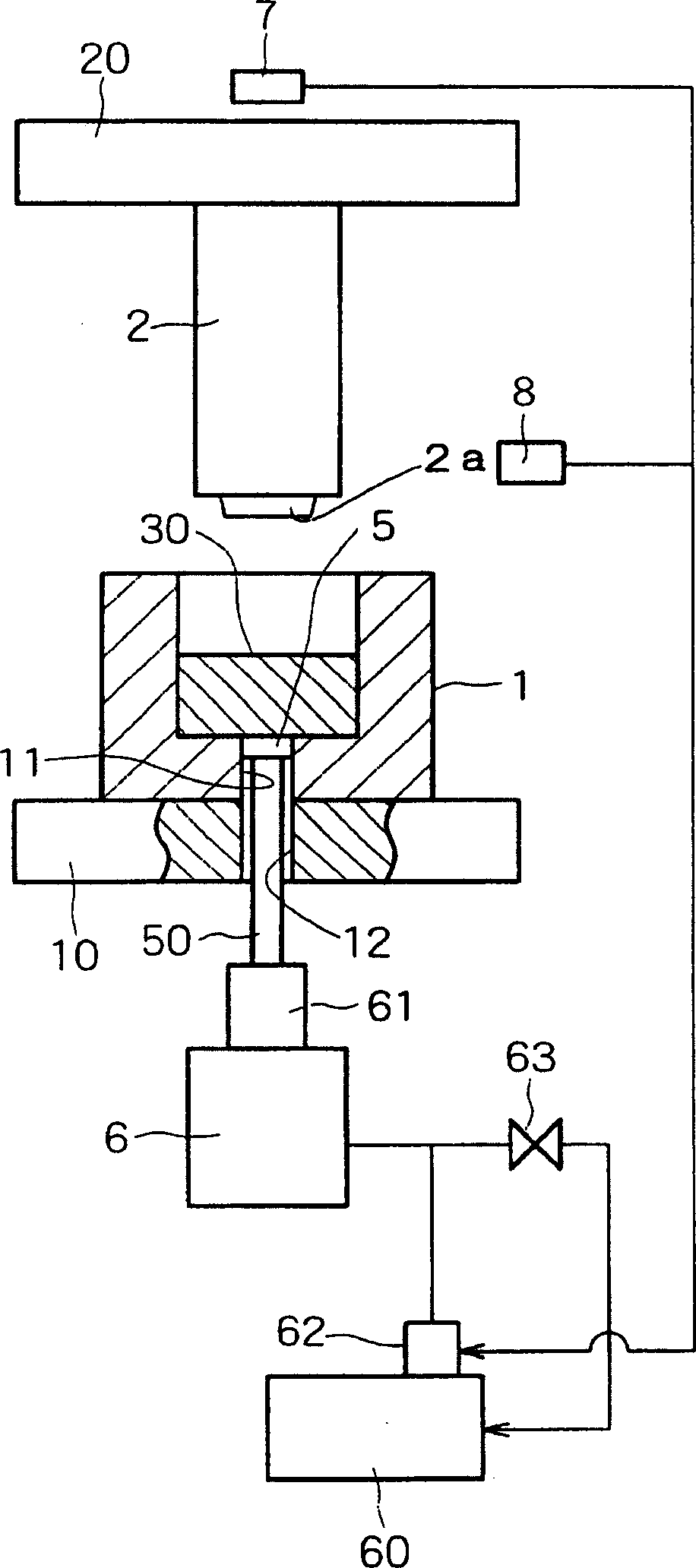

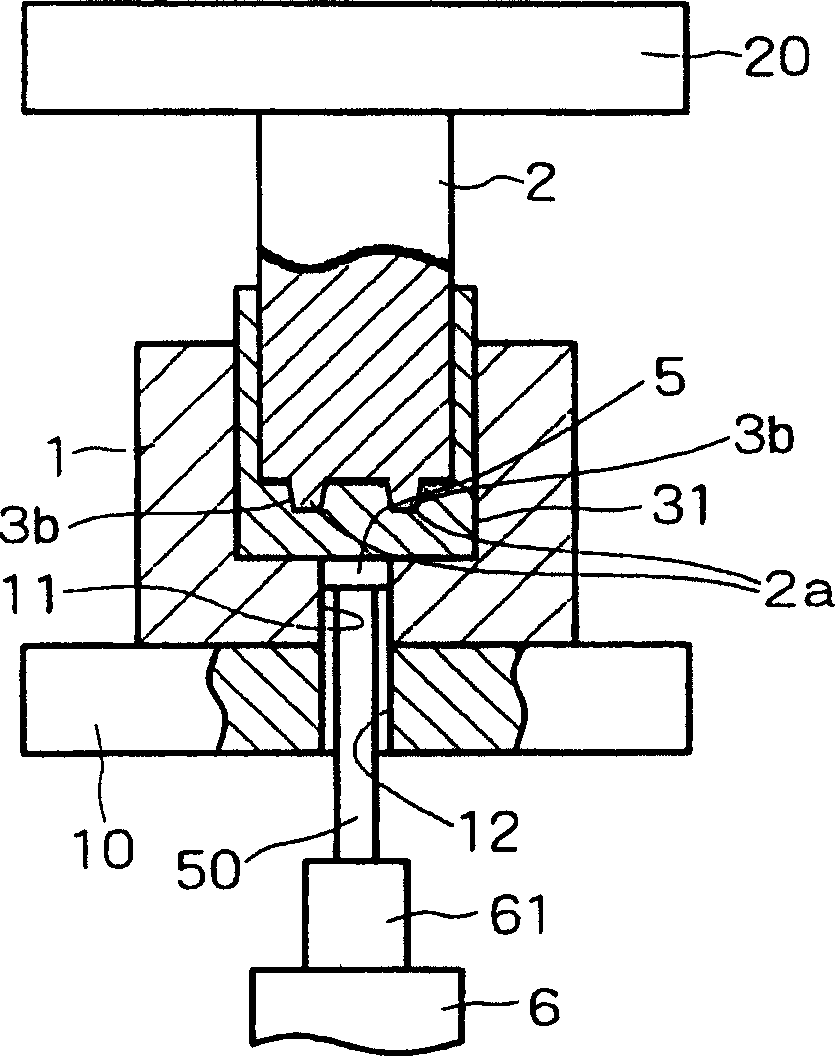

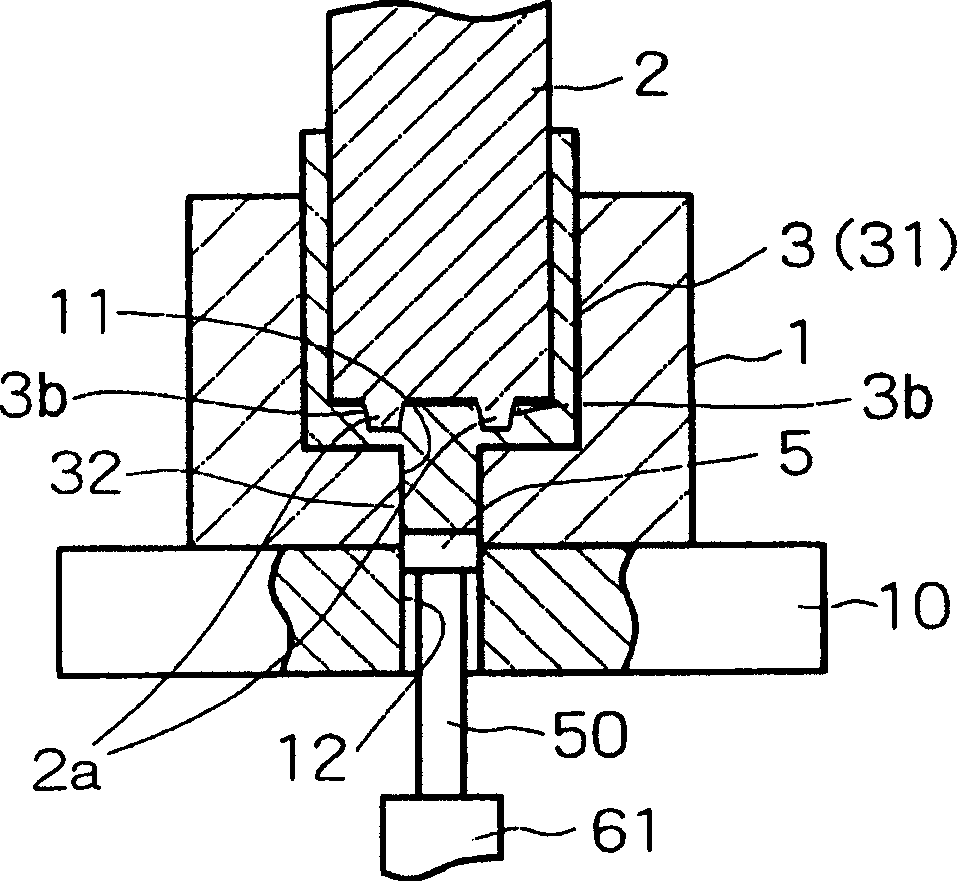

Impact extrusion molded article, and impact extrusion molding method, and an impact extrusion molding apparatus

An impact extrusion molded article that is molded while the metal-flow from a bottom of a slug set in a dice toward the side of the molded product article is suppressed; an impact extrusion molding method for manufacturing the impact extrusion molded article, and an impact extrusion molding apparatus used for the impact extrusion molding method, are provided.

Owner:FURUKAWA SKY ALUMINUM CORP

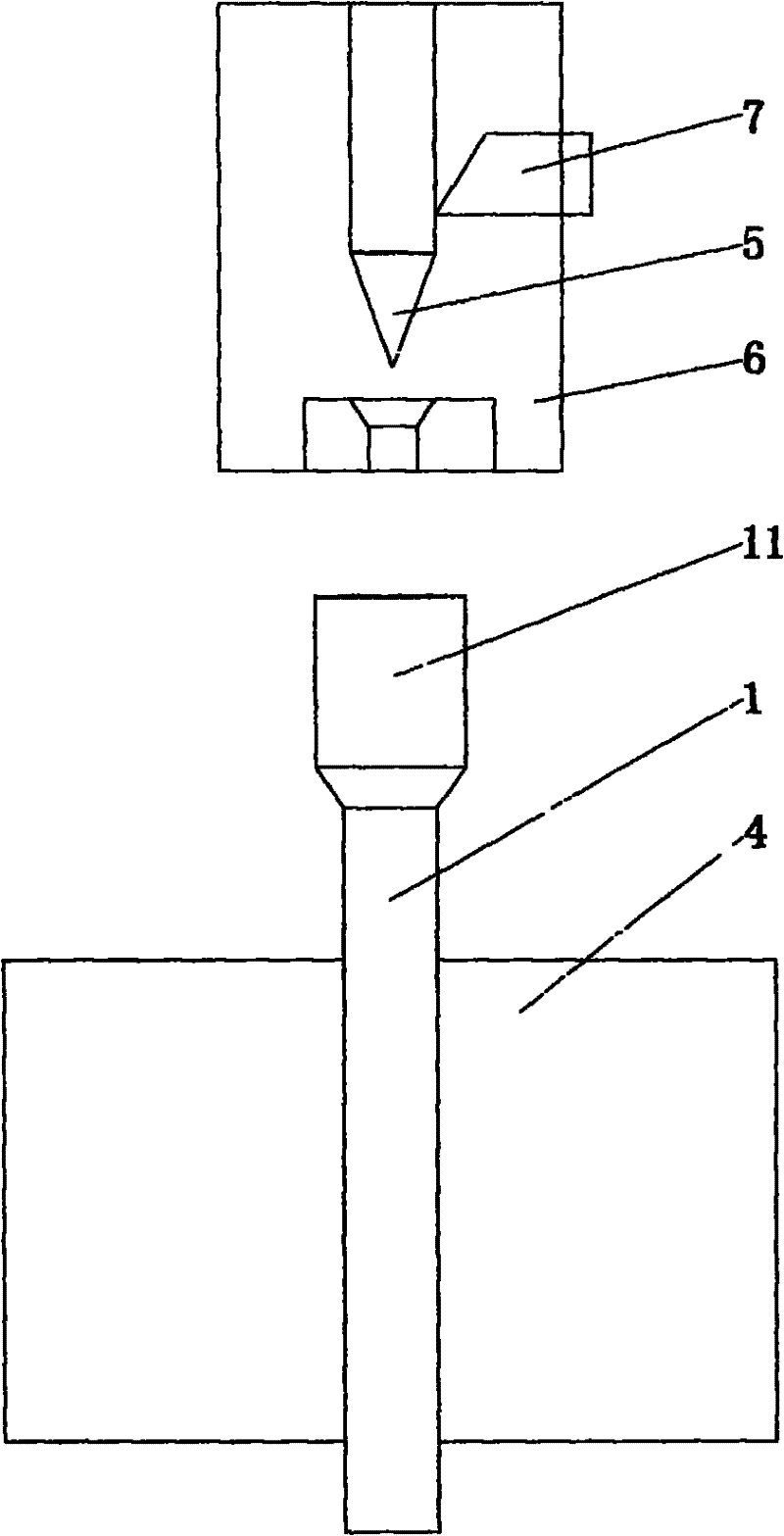

A forging method for preventing cracks in hot forging of mn18cr18n steel retaining ring

The invention relates to a forging method for preventing cracks from being generated by the hot forging of a Mn18Cr18N steel protecting ring, which belongs to the technical field of the hot-forging formation of alloy steel. Used devices comprise a boss, a bottom die, a cylinder die, a punching head and a leaking disk. The forging method for preventing the cracks from being generated by the hot forging of the Mn18Cr18N steel protecting ring is characterized in that the forging method comprises the following steps: (1) placing the boss in a conical hole of the bottom die and placing the boss and the bottom die at the inner bottom of the cylinder die together; (2) sleeving a wrapping sleeve outside a blank tightly and heating the wrapping sleeve and the blank to 950 to 1200 DEG C together; (3) placing the blank and the wrapping sleeve which are heated in the cylinder die, and carrying out impact extrusion on the blank from the top by using the punching head so as to reach the designed depth, wherein the difference delta of the outer diameter of the wrapping sleeve and the inner diameter of the cylinder die is equal to 0.03D to 0.10D; (4) removing the boss and replacing by the leakingdisk; (5) stamping the blank continuously by using the punching head, and stamping off burrs at the bottom of the blank; and (6) quitting the punching head and taking out an annular forged piece so as to finish the operations of punching and forming. The forging method for preventing the cracks from being generated by the hot forging of the Mn18Cr18N steel protecting ring has the following advantages that: (1) a clearance is remained between the wrapping sleeve and the cylinder die, so that the cracks generated at the surface of the forged piece can be prevented, and the tonnage of required equipment can also be decreased; and (2) crystal grains inside the forged piece can be thinned.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

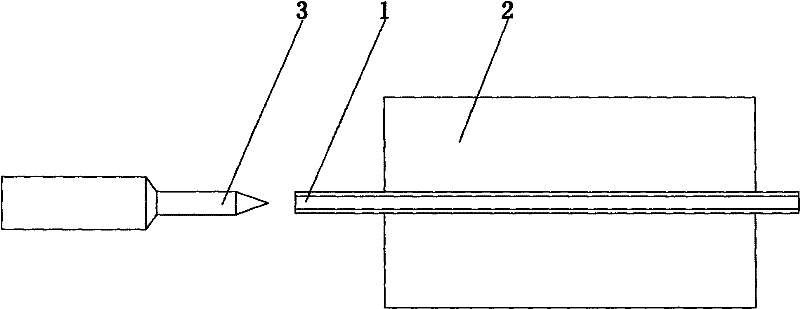

Method for machining reduced copper capillary tube used in air conditioner

The invention relates to a method for machining a reduced copper capillary tube used in an air conditioner. The method comprises the following steps of: 1) horizontally putting a copper capillary tube blank into a tensioning tooling of a hydraulic clamping device, carrying out impact extrusion on one end of the copper capillary tube by using a flaring punch in a flaring device for the first-time flaring; and 2) leading the flared end of the copper capillary tube to face upwards, vertically placing the copper capillary tube in a tensioning tooling of a pneumatic clamping device, carrying out impact extrusion on the flared end of the copper capillary tube by a flaring punch in a spinning flaring device for the second-time flaring; and simultaneously, cutting residual part of the copper capillary tube by utilizing a turning tool additionally arranged on a seat sleeve of the spinning flaring device, thus obtaining a reduced copper capillary tube with a set dimension. The machining method is adopted to directly flare the copper capillary tube to obtain the product, so that the production efficiency is high, the yield rate is high and the production cost is low. The reduced copper capillary tube manufactured by adopting the machining method is even in wall thickness, and excellent in linearity, and has smooth and round internal and external surfaces.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP +1

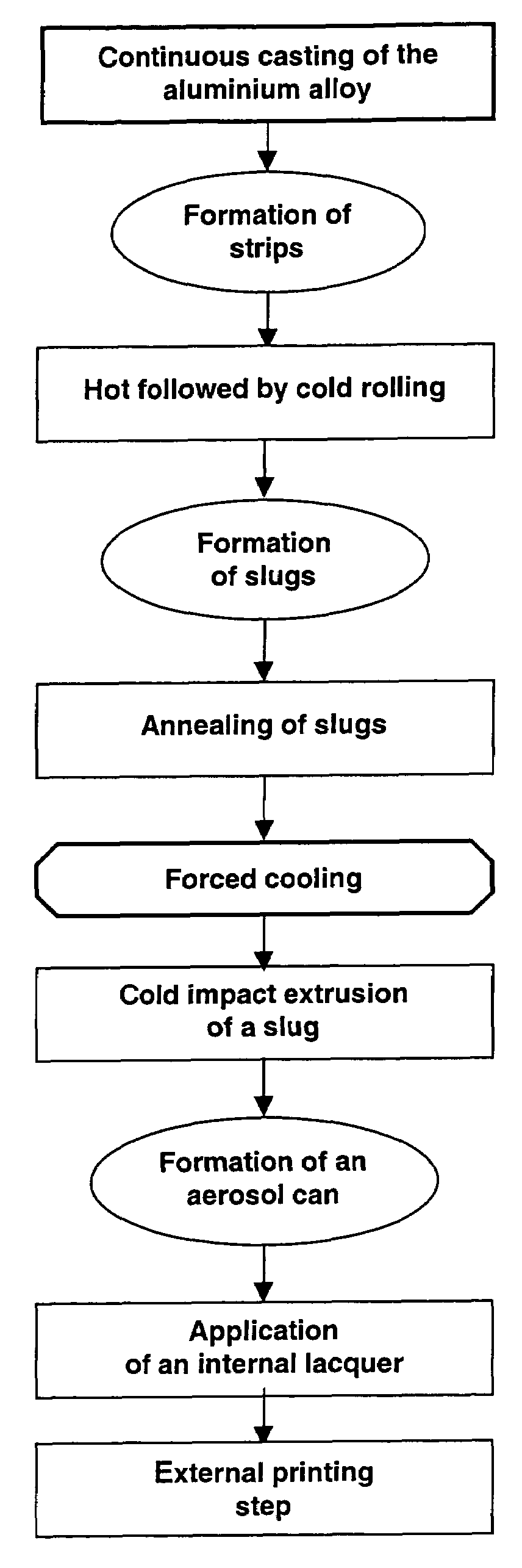

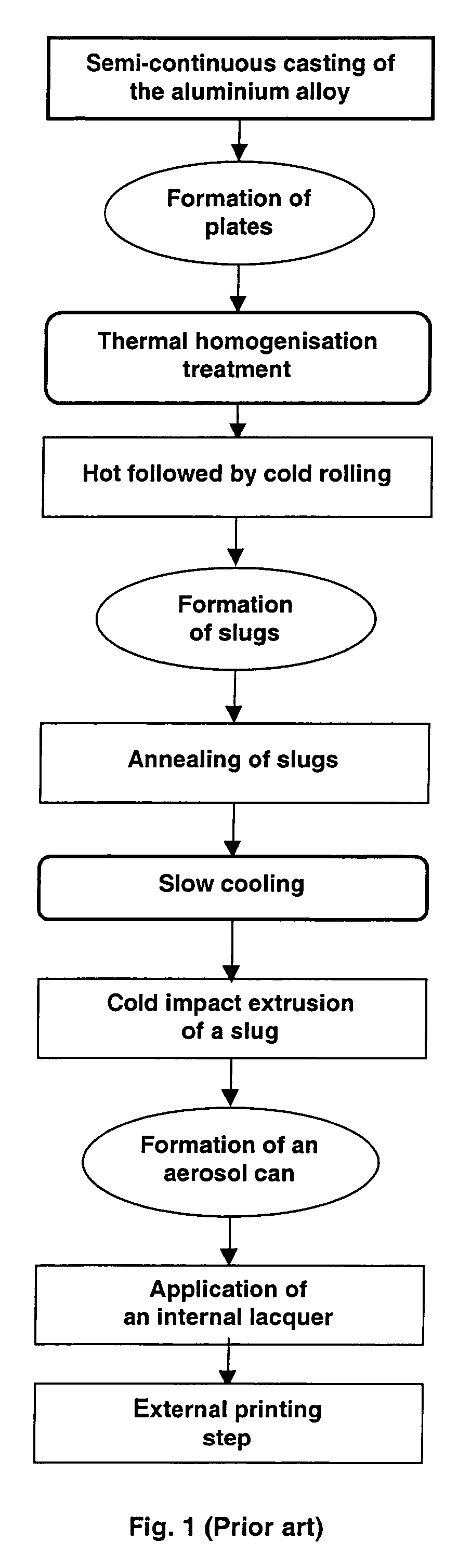

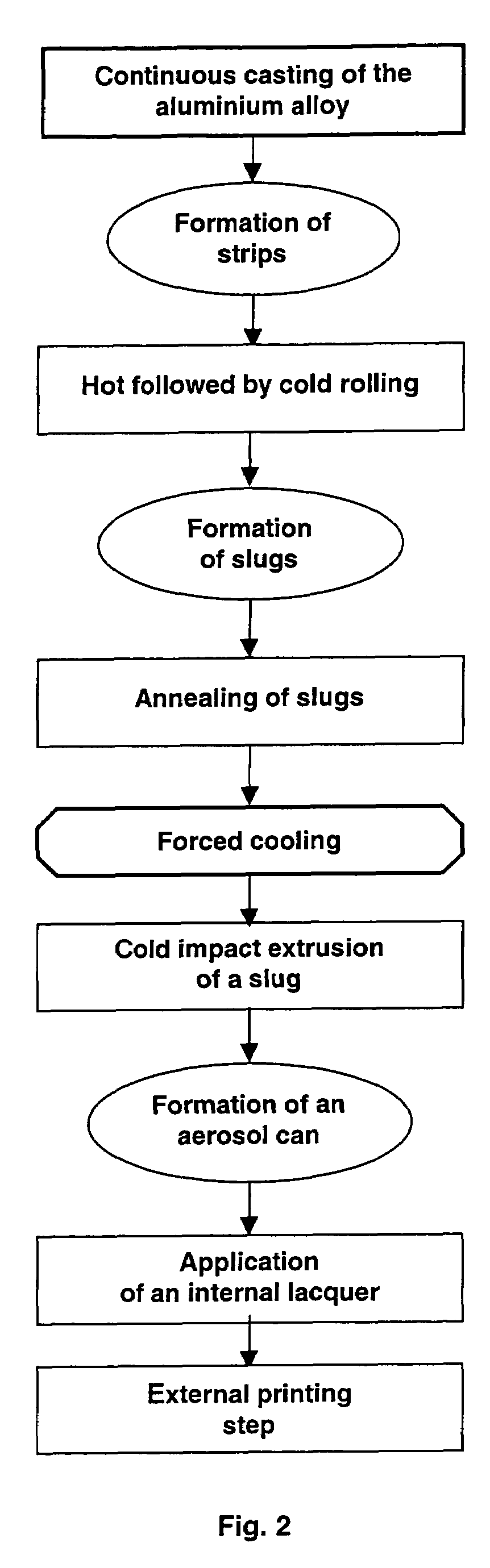

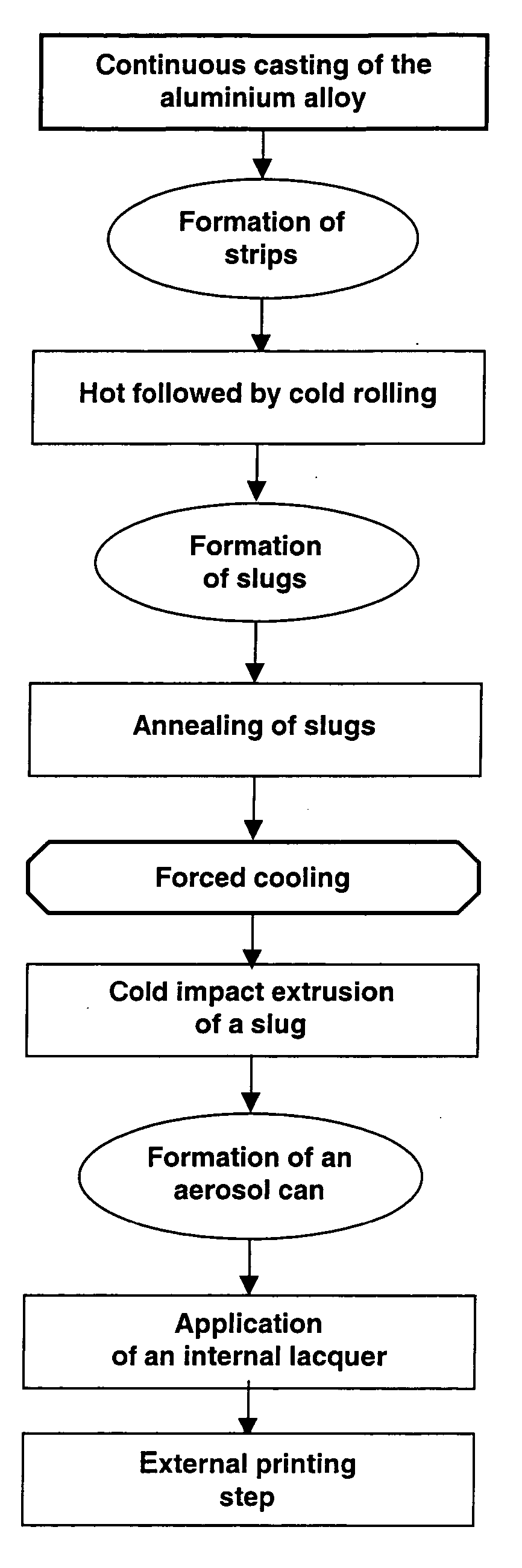

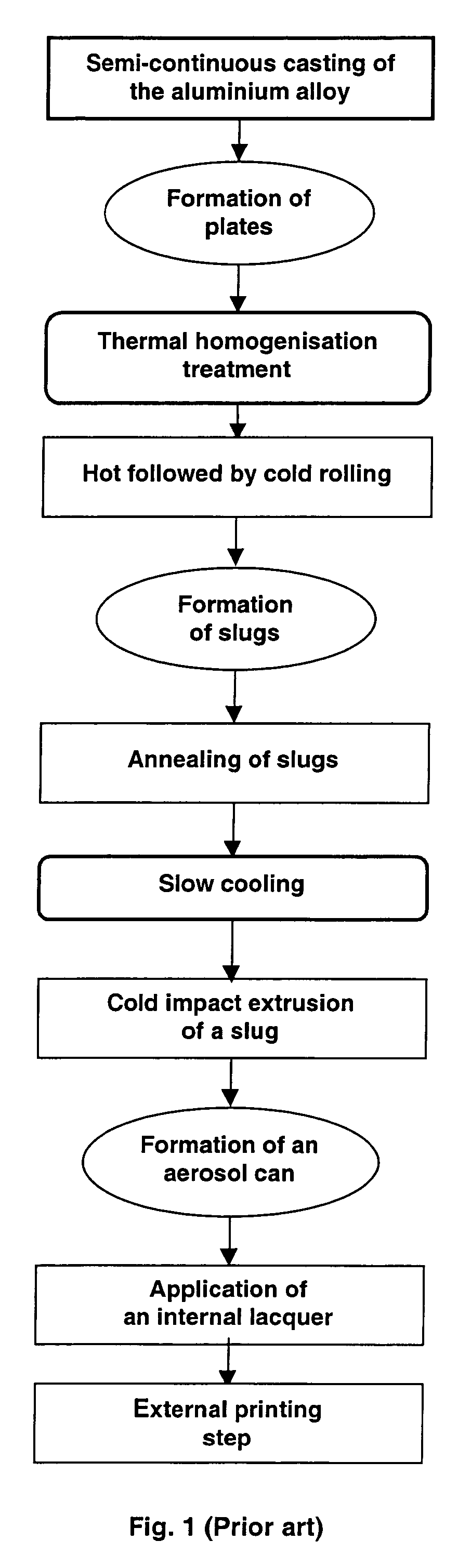

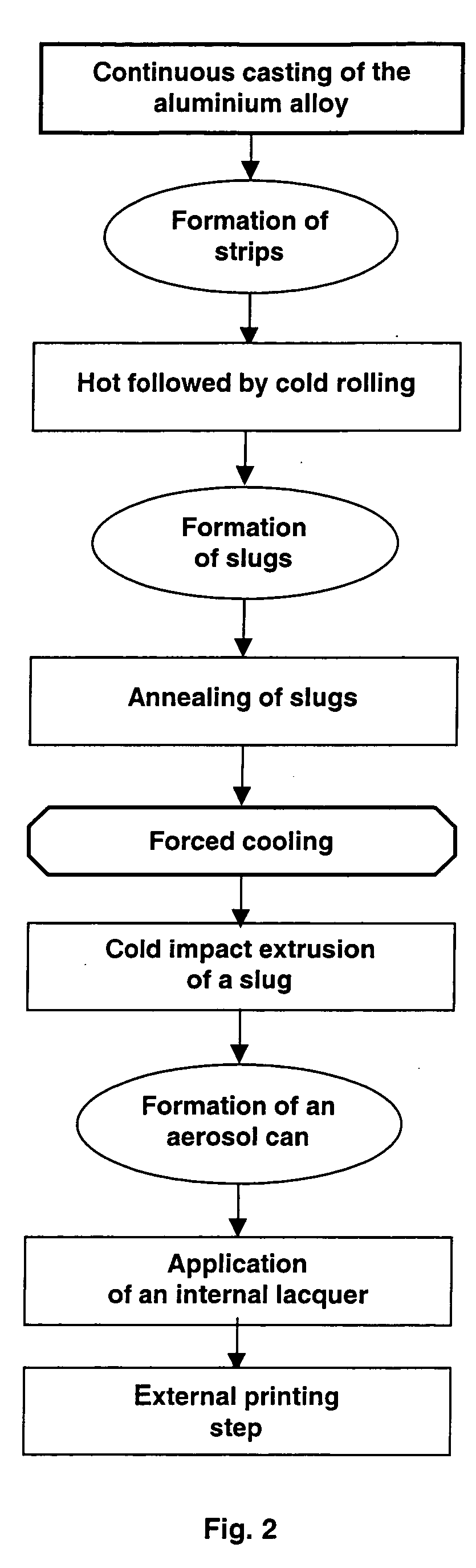

Aerosol can fabrication process

ActiveUS7520044B2Improve mechanical propertiesEasy to implementMetal rolling stand detailsWork treatment devicesAlloyThermal treatment

An aerosol can fabrication process comprises the following steps:formation of slugs from an aluminium-based alloy having the following composition, in weight percentage:Si0.35-0.45Mg0.25-0.40Mn0.05-0.15Fe0.12-0.20Total of minor elements≦0.15%AlBalance.thermal treatment of the slugs,forced cooling of the slugs,cold impact extrusion of a slug so as to form a can,applying a lacquer inside the can.

Owner:BOXAL FRANCE SA

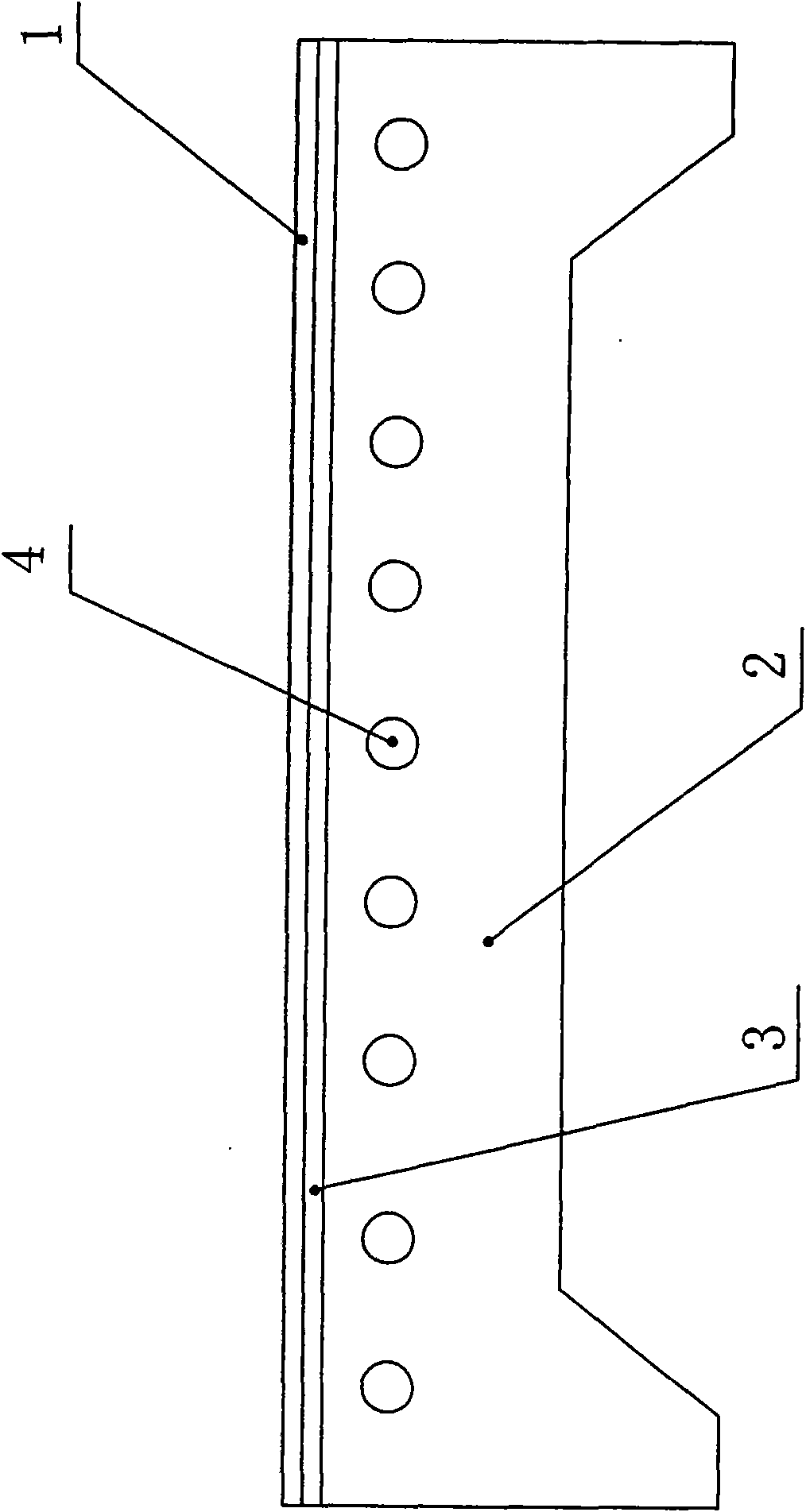

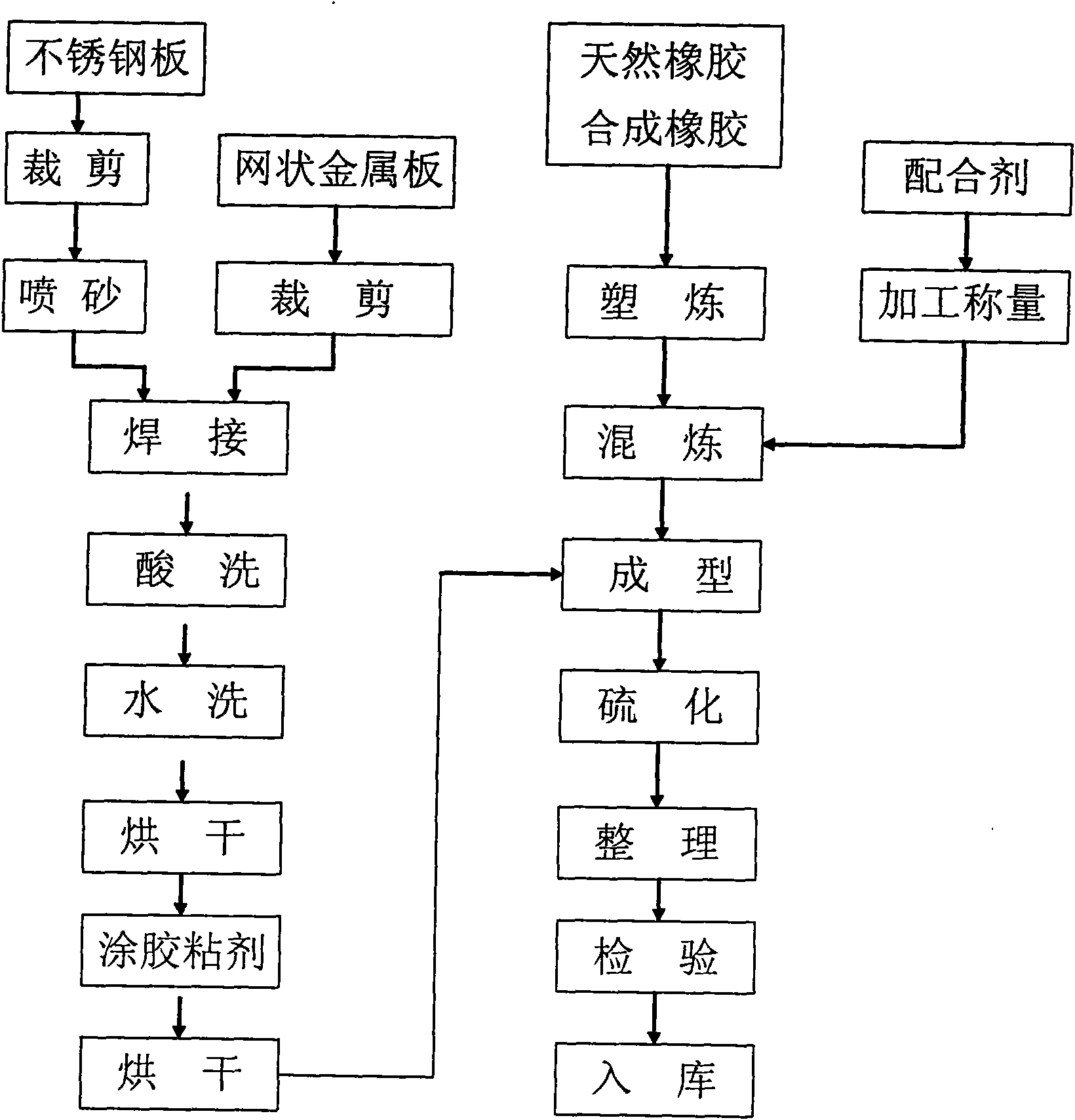

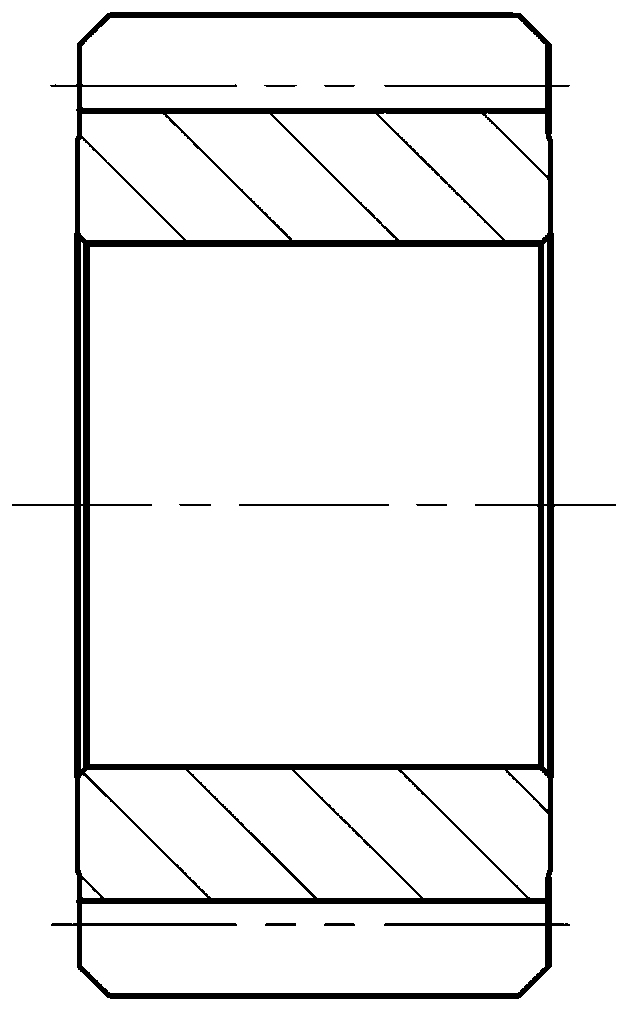

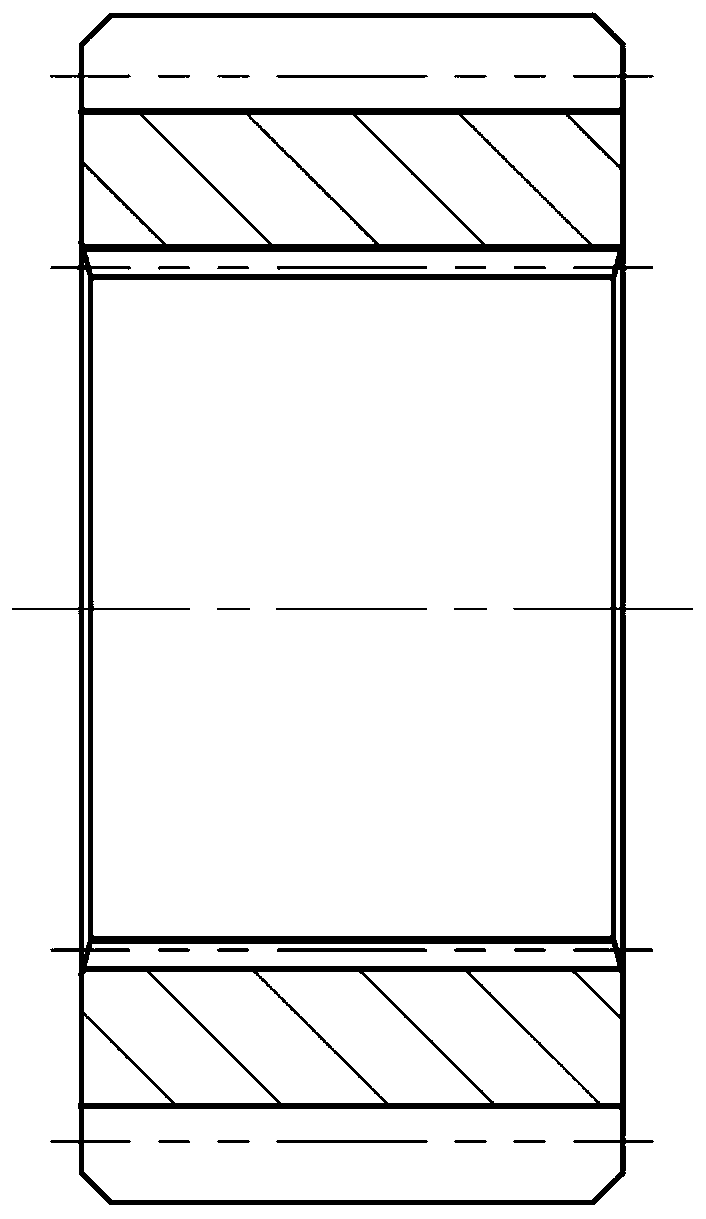

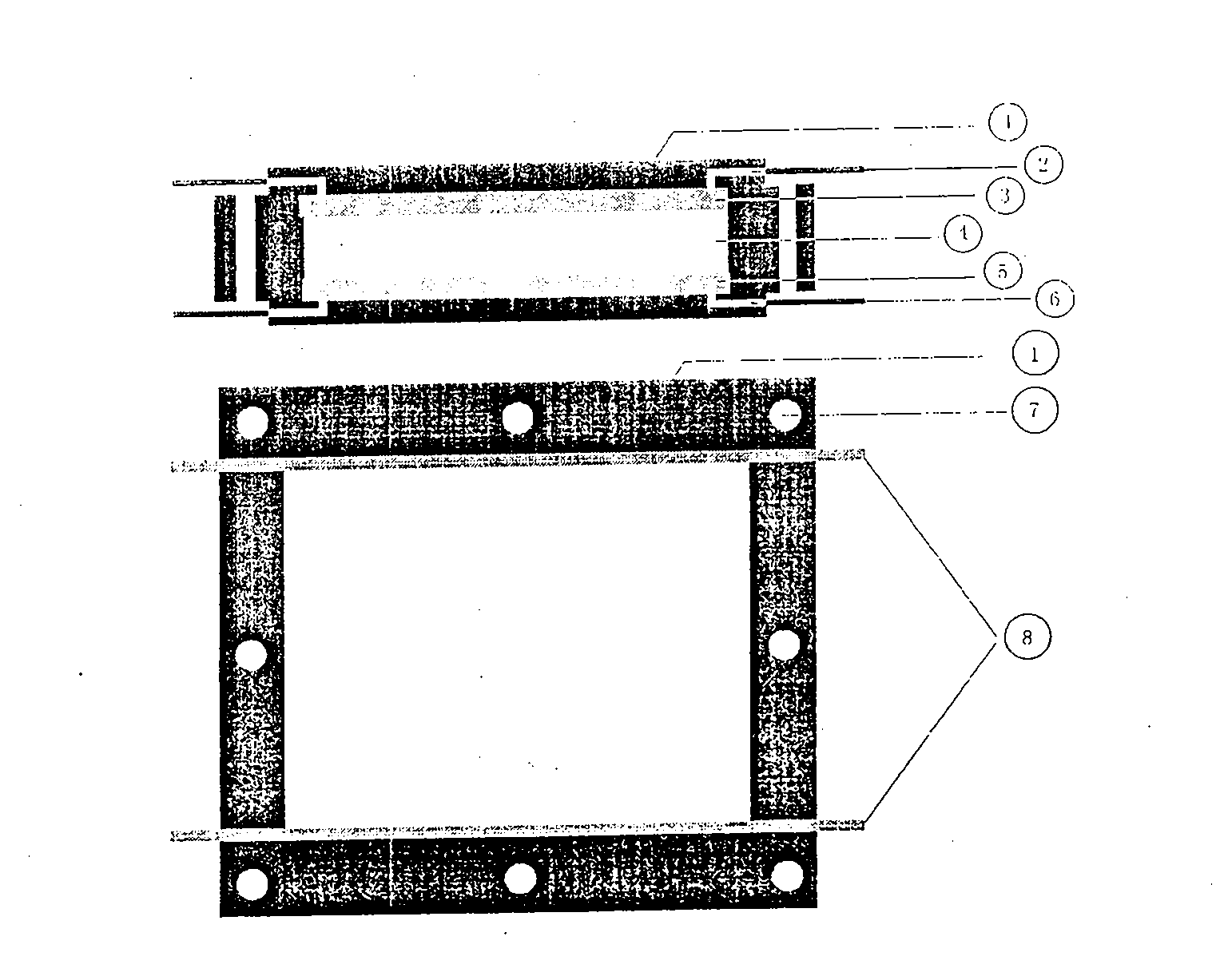

Vibration damping composite rubber mat plate used under railway rail and preparation method thereof

InactiveCN101555674AAvoid aestheticsImprove adhesionRail fastenersResistance welding apparatusAgricultural engineeringRubber sheet

The invention relates to a vibration damping composite rubber mat plate used under a railway rail and a preparation method thereof. The rubber mat plate comprises a stainless steel plate (1) and a rubber plate (2), wherein, the stainless steel plate (1) is stuck on the upper surface of the rubber plate (2); the rubber mat plate is characterized in that the lower surface of the stainless steel plate (1) is welded with a metal screen plate (3), and the stainless steel plate (1) and the metal screen plate (3) are connected on the upper surface of the rubber plate (2). The stainless steel plate of the composite rubber mat plate is stuck and integrated with the rubber plate by the metal screen plate, so that the aesthetic property of the stainless steel surface is ensured, and the adhesive attraction between the stainless steel plate and the rubber can be greatly improved; therefore, the stainless steel plate and the rubber are well stuck with each other and not easy to deglue, the service life is prolonged, and the preparation process is simpler. The rubber mat plate can be used for buffering the high speed vibration and impact extrusion force which are generated when vehicles pass through the steel rail, thus protecting a roadbed and a rail bearing of the steel rail and making electric insulation for a signal system.

Owner:刘浩杰

Cold extrusion process of planet gear sun gear of transmission of heavy-load truck

The invention provides a cold extrusion process of a planet gear sun gear of a transmission of a heavy-load truck. The cold extrusion process includes the following steps that a raw material bar is saw-cut into a specified size; the saw-cut bar is rapidly heated to 950 DEG C + / - 20 DEG C, upsetting and inner hole impact extrusion are completed, a cup-shaped blank is formed, and forging waste heatis saved; spheroidizing annealing treatment of a forging blank is completed, and the hardness of the blank is reduced to be smaller than or equal to 120 HB; punching is completed, and an annular blankis formed; polymer lubricant soaking treatment is carried out after turning is completed, and the blank is air-dried and then prepared for extrusion; tooth form cold extrusion forming is completed; an inner hole and the two end faces of a cold extrusion part are turned, a tooth form is chamfered so that burrs can be removed, an internal spline of the sun gear is broached, and part machining before heat treatment is completed; carburizing and quenching treatment is carried out, carbon potential is controlled at 1% at a strong carburizing stage, the carbon potential is controlled at 0.8% at a diffusion stage, and the surface hardness, the core hardness, the carburized layer depth and the grain size of the quenched part meet the technical requirements; and after a tooth surface is ground, the design requirements are met. The cold extrusion process is low in machining cost and environmentally friendly, and the abrasion resistance is improved.

Owner:DONGFENG COMML VEHICLE CO LTD

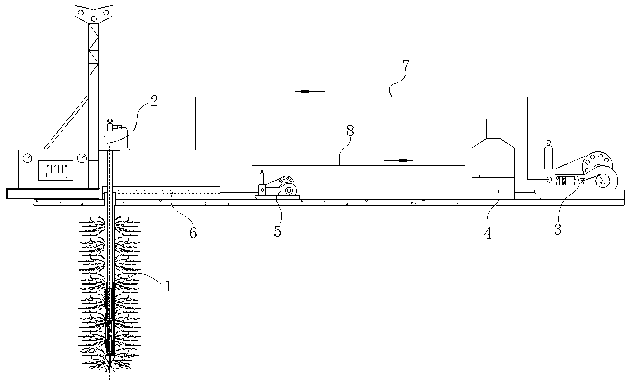

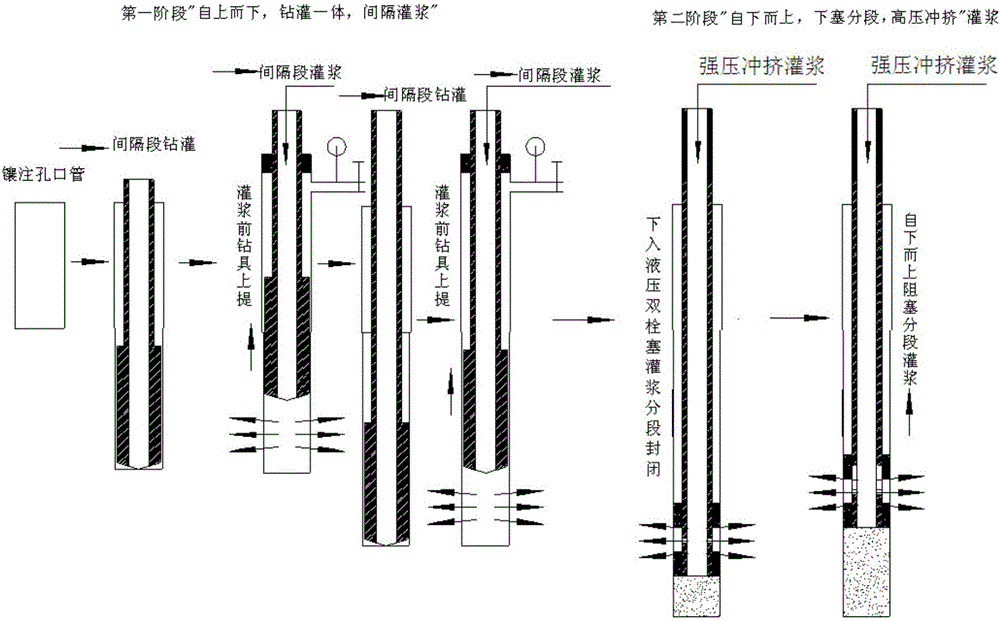

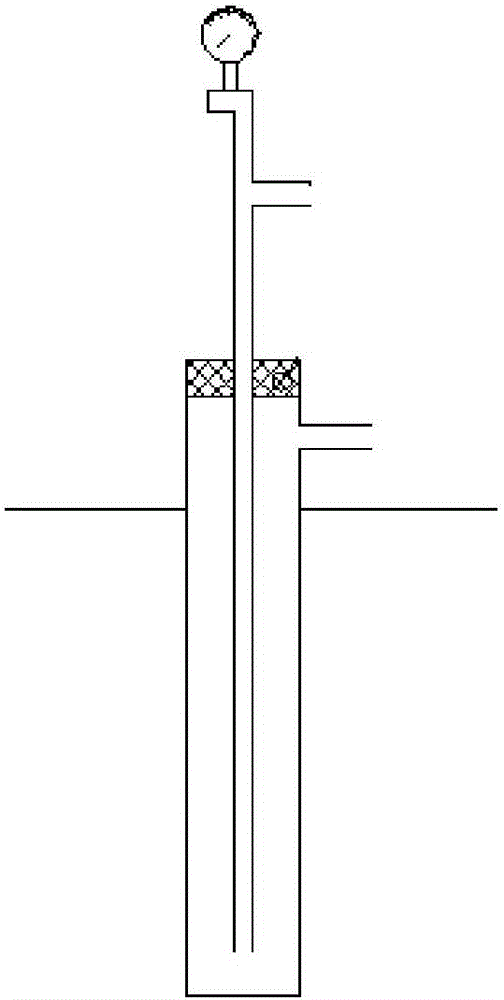

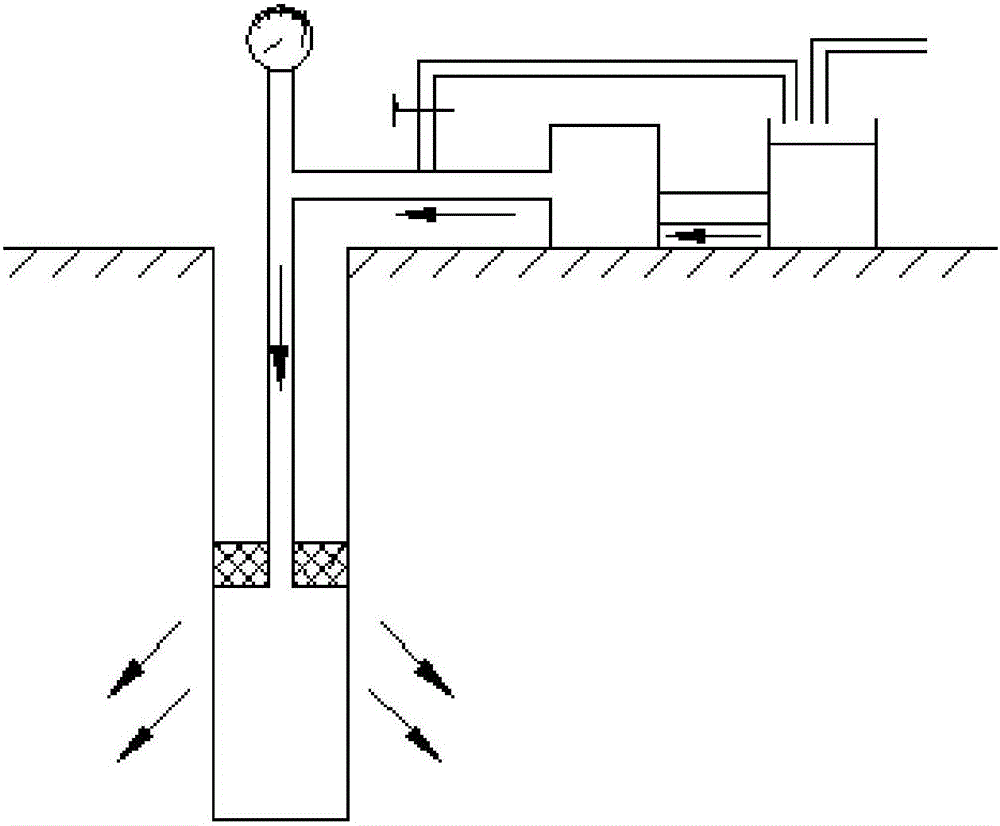

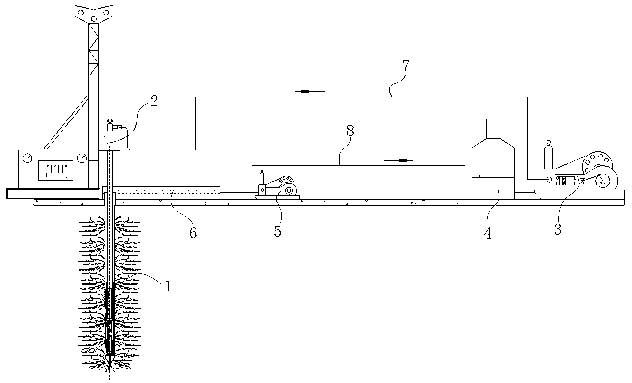

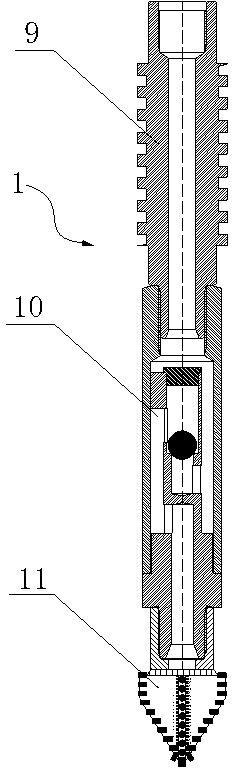

Drilling and grouting integrated top-down high-pressure impact extrusion grouting method

The invention discloses a drilling and grouting integrated top-down high-pressure impact extrusion grouting method, which is mainly applicable to conduct foundation strengthening and anti-seepage grouting treatment on poor geologic bodies with loose and weak structures. A spiral sealing high-pressure impact extrusion grouting head is adopted according to the specification of a drilling and grouting hole; grouting liquid is adopted as flushing liquid; pulse mud jacking is conducted at the bottom of the hole by a grouting pump; drilling and grouting integrated top-down high-pressure impact extrusion grouting is conducted on a stratum by the action of the spiral sealing high-pressure impact extrusion grouting head, and slag can be discharged and a drill hole wall can be protected while the grouting is conducted. According to the grouting method, the whole grouting hole is continuous and uniform, the technological operation is simple and convenient, and the grouting method is economical and environmental-friendly. Hole arrangement methods with different hole pitches can be adopted according to different engineering requirements, so as to achieve an ideal grouting quality effect.

Owner:POWERCHINA ZHONGNAN ENG

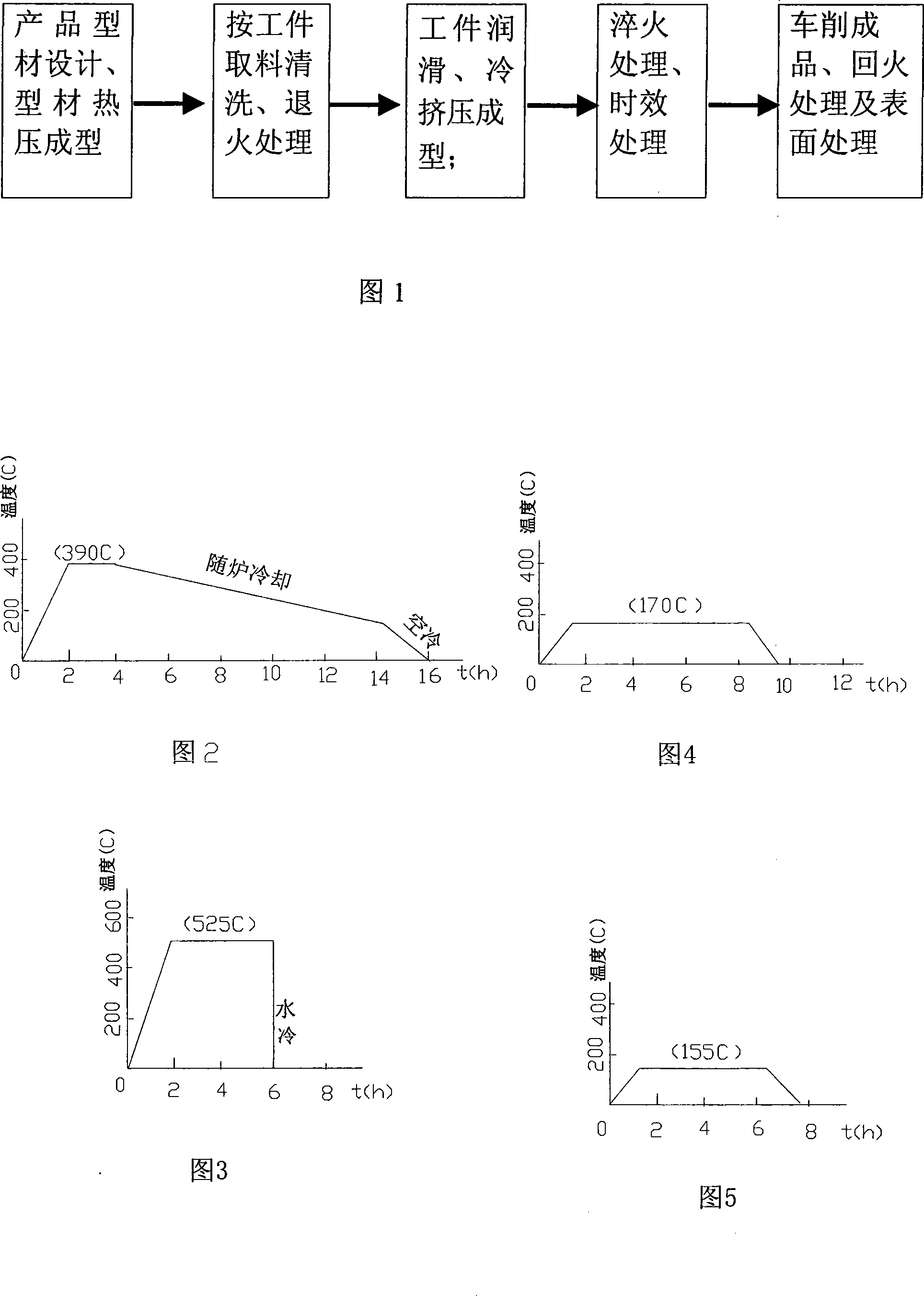

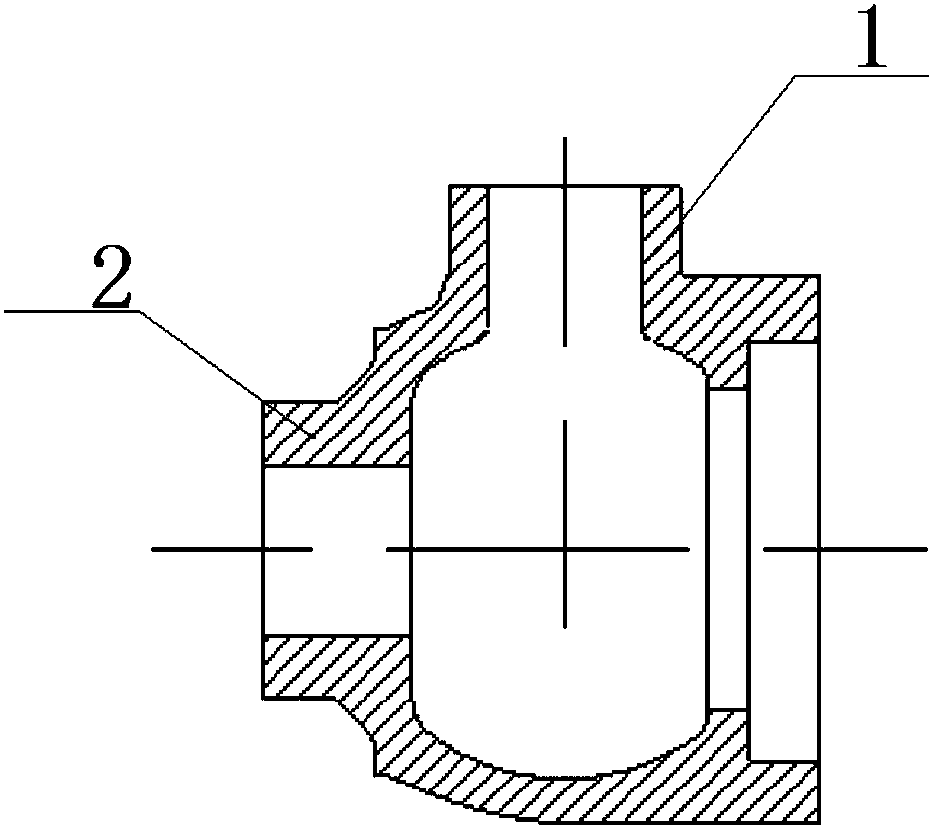

Impact extrusion forming technology for aluminum alloy water heating parts and products thereof

InactiveCN101224542AReduce hardnessImprove mechanical propertiesExtrusion diesExtrusion control devicesUltimate tensile strengthImpact extrusion

The invention relates to the water heating equipment field, in particular to a cold extrusion forming technique of an aluminium alloy water heating part and the water heating part product. The invention solves the problems that the existing product which takes the cast iron as the raw material is rough, has poor mechanical performance, low yield strength, and comparatively large brittleness, is easy to be broken during the construction installation and cracked during chilliness, and is not easy to resist the chilliness; furthermore, the product which takes the copper material as the raw material has high price, low mechanical performance and is not easy to resist the chilliness, and the cold extrusion technique of the aluminium alloy material can not be well formed; the detailed method of the invention can be seen in a manual; the product which is produced by the invention has the advantages of excellent mechanical performance, high hardness and tensile strength, high yield strength beyond comparison, comparatively small specific gravity, reducing the weight of the single part, beautiful appearance, no rust, no cracks, resisting the chilliness, long service life, high yield of the aluminium alloy cold extrusion forming product, and low cost of the products.

Owner:宁波炜兴特种铝制品有限公司

Lubrication impact extrusion forming method of nickel titanium-base shape memory alloy tubing glass

This invention relates to impact cover extrusion forming method with nickel-tantalum based shape memory alloy pipe glass lubrication with the technical steps: 1) forge or roll to nickel-tantalum based shape memory alloy bar, process blind core bar and hole pipe billet with block end of cone; 2) heat pipe billet, core bar, extrusion pad and mould to 200Degí‚10Deg, spray lubricant agent separately, insert the core bar into pipe billet to make the integer with back end of extrusion pad, heat integrally to 830Deg~880Deg; 3) heat mould to 400Deg~550Deg; 4) put the integer and its extrusion pad into mould to impact and break; 5) move away the extrusion pad, cut the back integer end to present core bar, and heat integer to 800Deg~850Deg; 6) draw the core bar plastically to reduce its diameter and take out from pipe billet. This invention saves labor and time, and has low cost.

Owner:JIANGSU FASTEN TECH DEV CENT

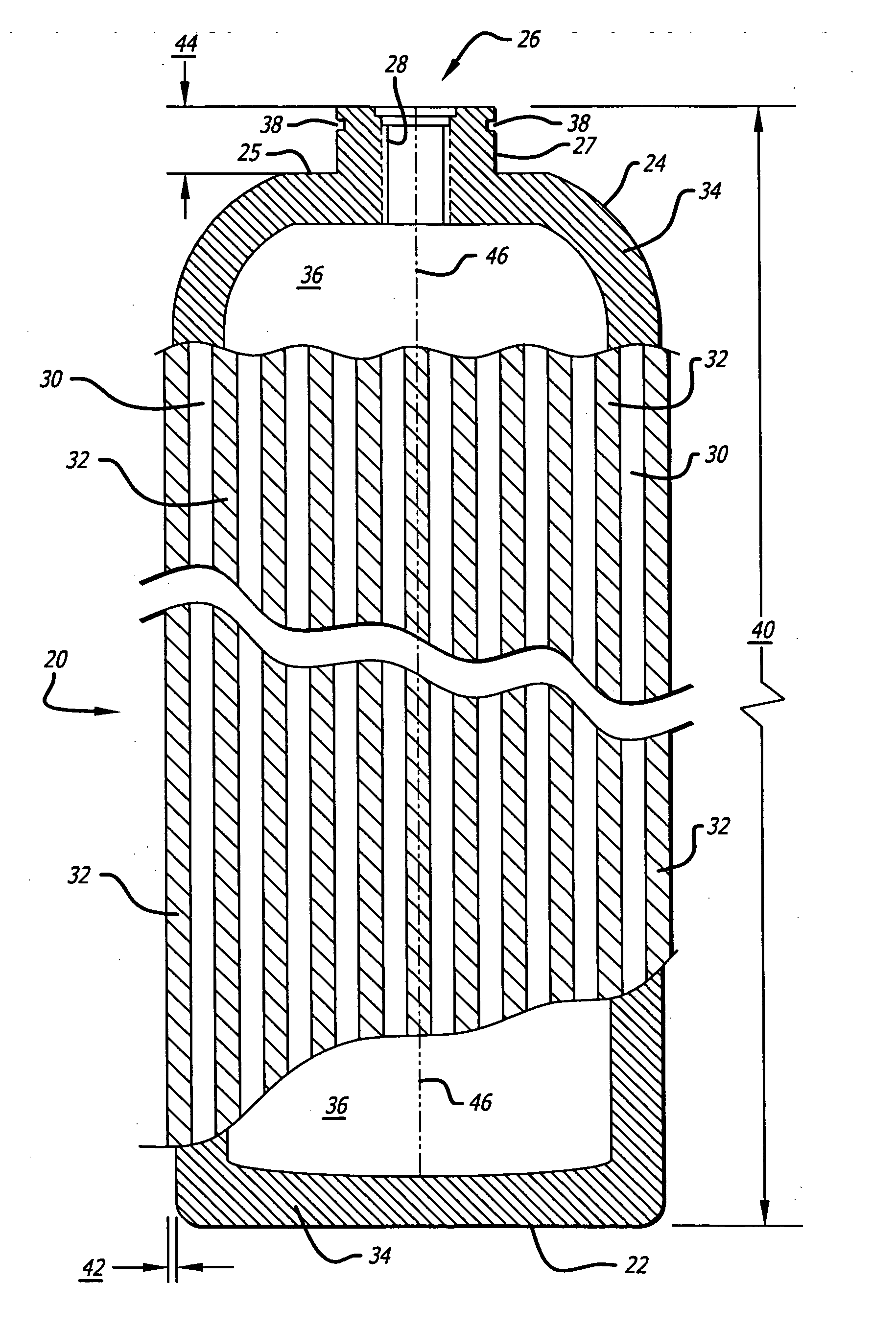

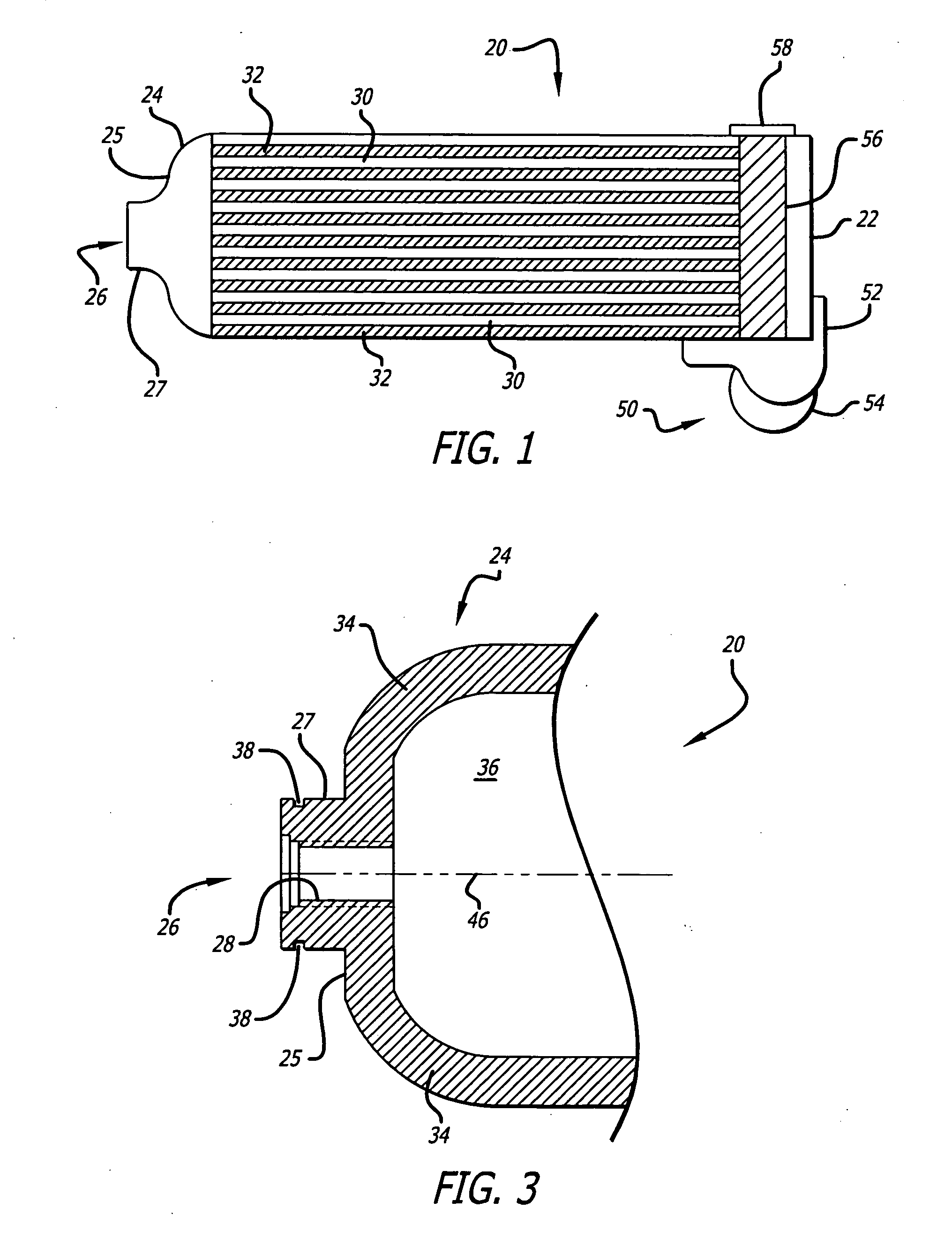

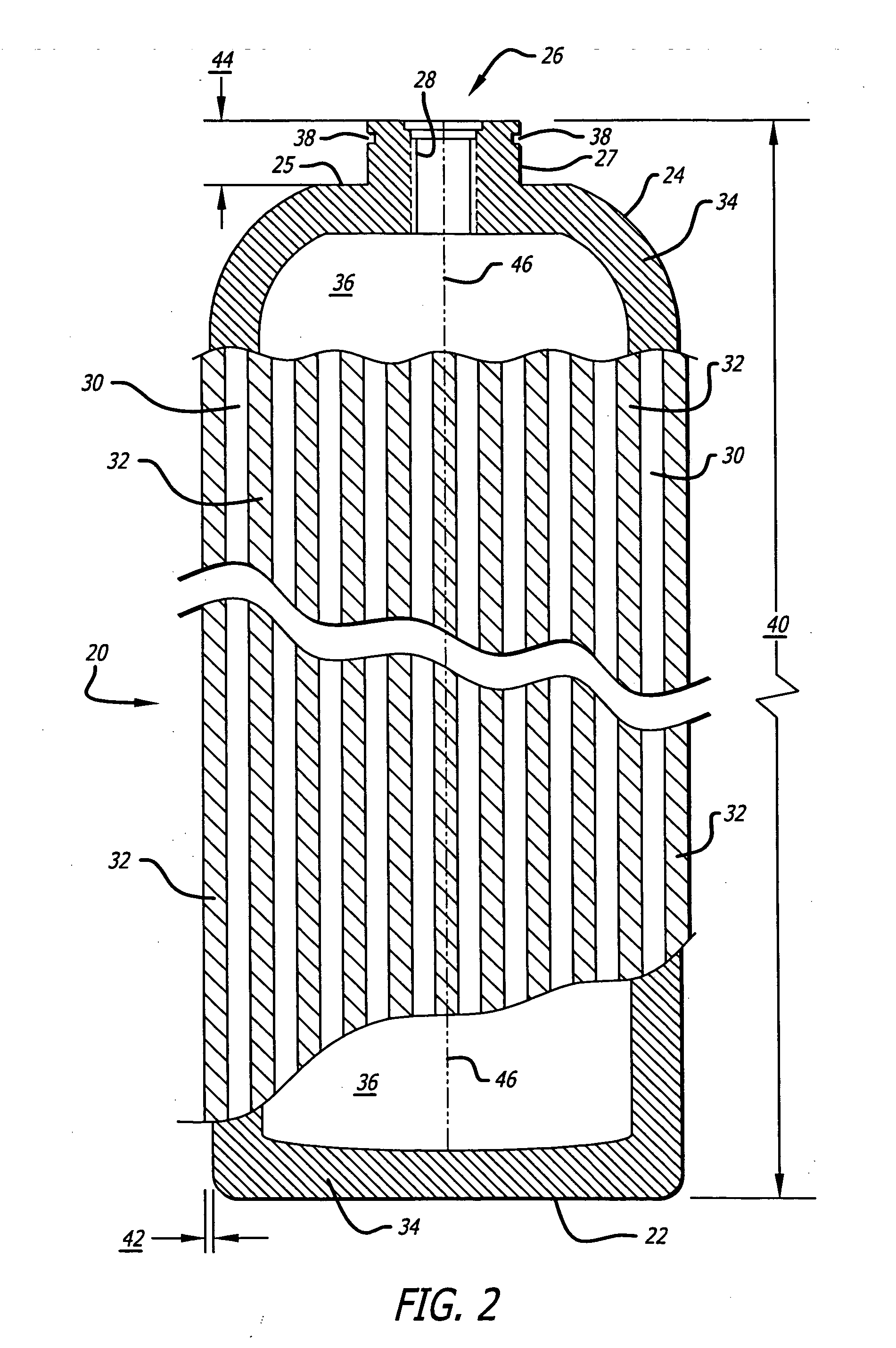

Gas cylinder

InactiveUS20050284873A1Simple structural designImprove securityVessel mounting detailsVessel geometry/arrangement/sizeGas cylinderEngineering

A gas cylinder, such as a scuba tank, is formed with raised ribs that extend longitudinally from near the top of the cylinder to near the bottom of the cylinder. The longitudinal ribs may be arcuate and equally spaced along the outside circumference of the cylinder so as to protect the body of the cylinder from damage. The gas cylinder may be made from steel or an aluminum alloy, such that the longitudinal ribs are formed by backward impact extrusion. The gas cylinder may be configured with a cylindrical neck at the top of the body so as to house a valve and valve stem. The gas cylinder may be transported using a wheeled pedestal having an adjustable strap for securing the cylinder to the pedestal. A valve protector with an optional handle and retaining clip is provided.

Owner:ALBERT IAN

Aerosol can fabrication process

ActiveUS20060021415A1Improve mechanical propertiesEasy to implementMetal rolling stand detailsWork treatment devicesLacquerAlloy

An aerosol can fabrication process comprises the following steps: formation of slugs from an aluminium-based alloy having the following composition, in weight percentage: <tables id="TABLE-US-00001" num="1"> <tgroup align="left" colsep="0" rowsep="0" cols="3"> <colspec colname="OFFSET" colwidth="35PT" align="left" / > <colspec colname="1" colwidth="77PT" align="left" / > <colspec colname="2" colwidth="105PT" align="center" / > <ROW> <ENTRY / > <ENTRY / > < / ROW> <ROW> <ENTRY / > <entry namest="OFFSET" nameend="2" align="center" rowsep="1" / > < / ROW> <ROW> <ENTRY / > <ENTRY>Si< / ENTRY> <ENTRY>0.35-0.45< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Mg< / ENTRY> <ENTRY>0.25-0.40< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Mn< / ENTRY> <ENTRY>0.05-0.15< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Fe< / ENTRY> <ENTRY>0.12-0.20< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Total of minor elements< / ENTRY> <ENTRY><=0.15%< / ENTRY> < / ROW> <ROW> <ENTRY / > <ENTRY>Al< / ENTRY> <ENTRY>Balance.< / ENTRY> < / ROW> <ROW> <ENTRY / > <entry namest="OFFSET" nameend="2" align="center" rowsep="1" / > < / ROW> < / TGROUP> < / TABLES> thermal treatment of the slugs, forced cooling of the slugs, cold impact extrusion of a slug so as to form a can, applying a lacquer inside the can.

Owner:BOXAL FRANCE SA

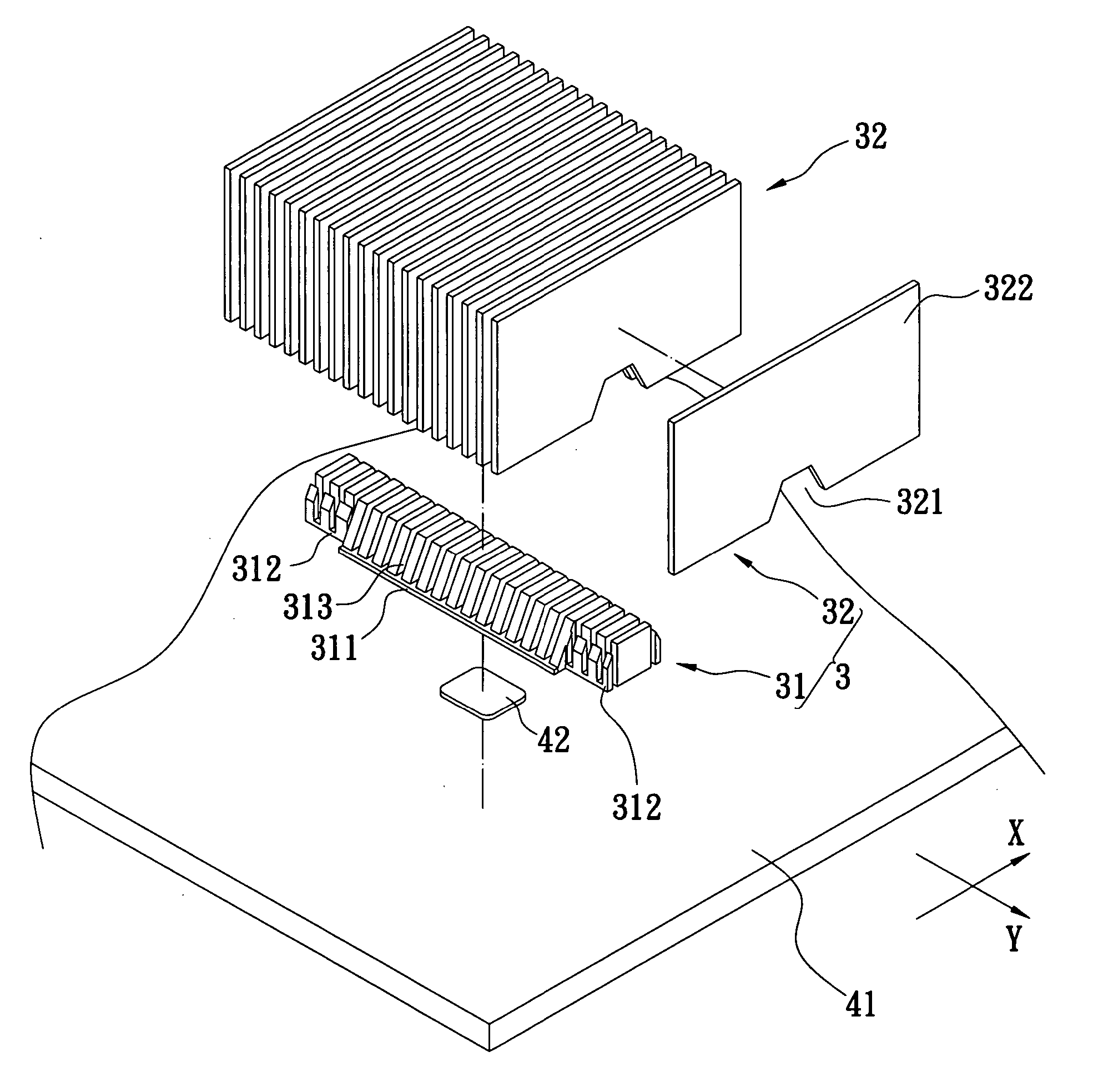

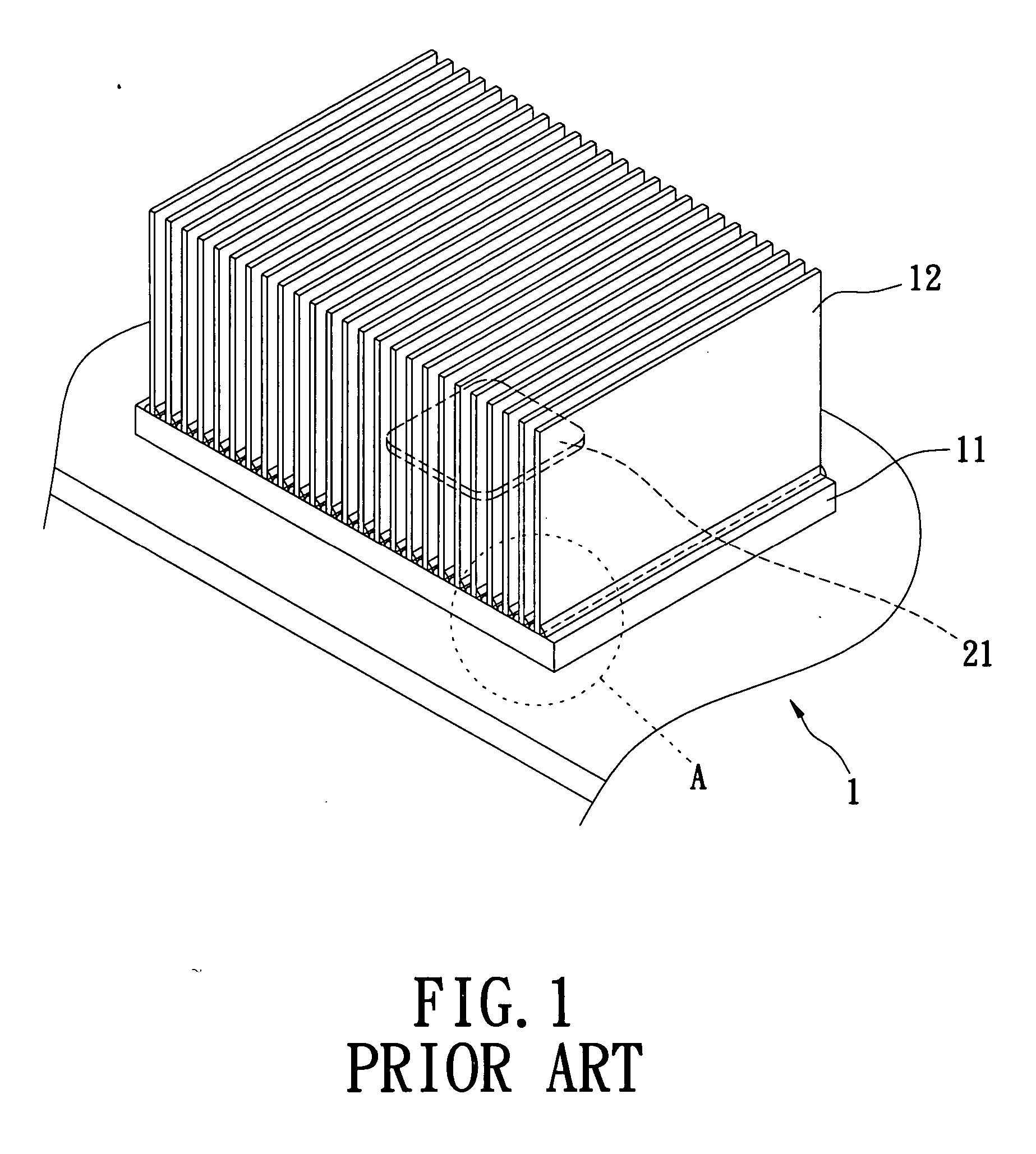

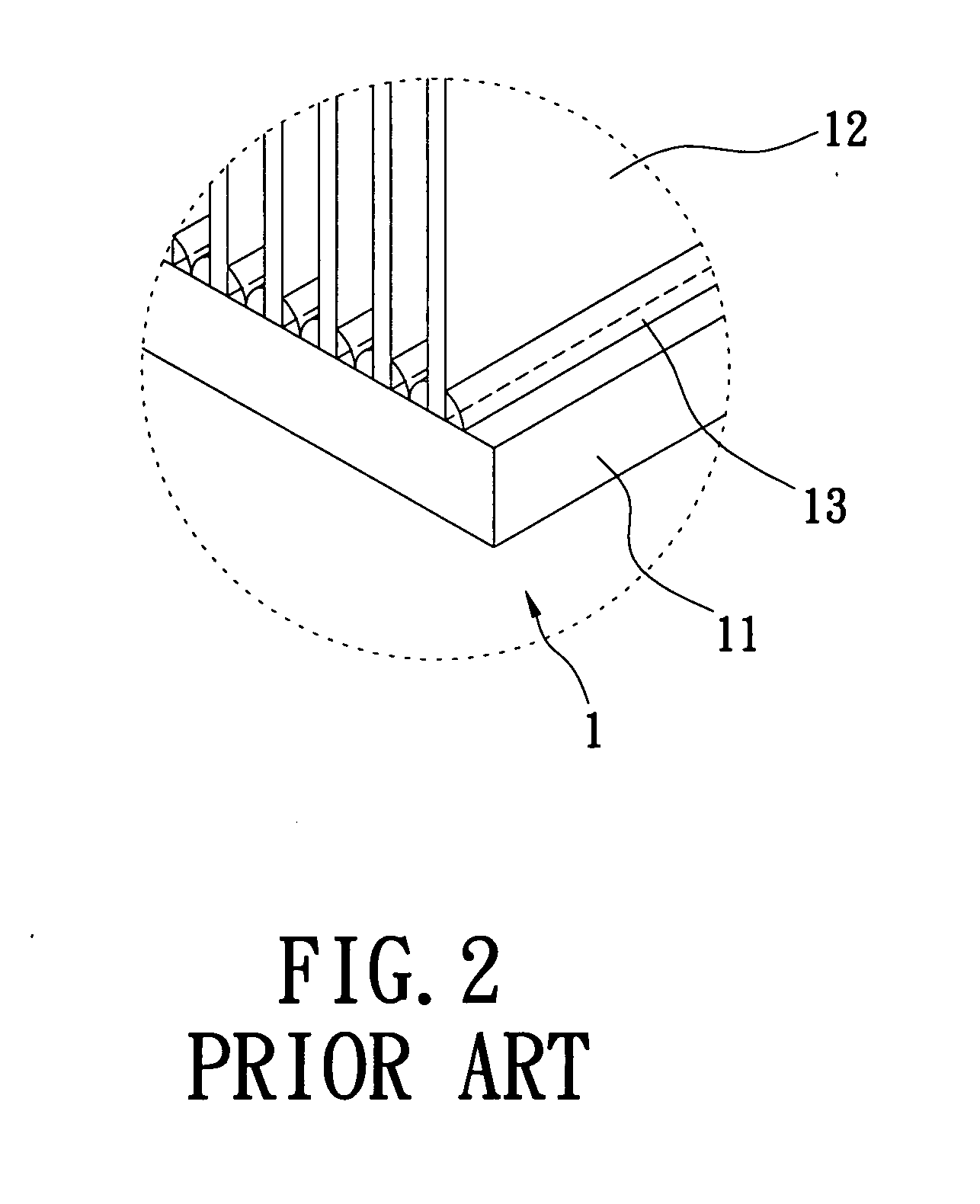

Heat sink and method for manufacturing the same

InactiveUS20050150633A1Easy to manufactureEfficient heat dissipationSemiconductor/solid-state device detailsSolid-state devicesProcess engineeringImpact extrusion

A heat sink and a method for manufacturing a heat sink are described. A plate-like base is manufactured with a plurality of parallel grooves and a plurality of fins by an impact extrusion process. A high temperature heat treatment is performed to soften the plate-like base. The fins are positioned in corresponding grooves and an equal force is applied to both ends of the plate-like base so that the grooves are deformed and the fins are fixedly positioned. The method is simpler and significantly cheaper than that for conventional heat sinks.

Owner:THERMAL TECH

Unfavorable geologic body grouting method under pressure-bearing seepage conditions

The invention discloses an unfavorable geologic body grouting method under pressure-bearing seepage conditions. The unfavorable geologic body grouting method under the pressure-bearing seepage conditions comprises the following stages that I, a drilling and grouting process of integrated drilling and grouting, operation from top to bottom and high-pressure impact extrusion is adopted, and effective hole fixation and water-stop grouting are conducted on an unfavorable geologic body grouting hole section under the pressure-bearing seepage conditions; and II, a grouting process of operation from bottom to top, plug closing and high-pressure impact extrusion is adopted, and uniform effective high-pressure extrusion splitting, pressing seepage and infiltration grouting are conducted on an unfavorable geologic body under the pressure-bearing seepage conditions. Through the unfavorable geologic body grouting method, hole fixation, water-stop and high-pressure impact extrusion grouting can be effectively conducted on unfavorable geologic body grouting under the pressure-bearing seepage conditions, meanwhile, effective epoxy slurry seepage infiltration solidification can be conducted on unfavorable geology by means of the secreting action of high-pressure impact extrusion grouting composite slurry carrier epoxy.

Owner:POWERCHINA ZHONGNAN ENG

Tube nozzle forging method and nuclear main pump shell profiled forging process

The invention relates to the field of forging, and discloses a tube nozzle forging method and a nuclear main pump shell profiled forging process. The tube nozzle forging method comprises the followingsteps: forging of a first tube nozzle: processing a positioning hole in a barrel blank; locally heating the positioning hole; placing the barrel blank on a lower die, arranging a guide column which is matched with the positioning hole in a flute of the lower die, and enabling the guide column to penetrate through the positioning hole to position the barrel blank; carrying out pre-punching in thebarrel blank by using a first punch, forming a first guide hole which corresponds to the guide column in the first punch, inserting the guide column into the first guide hole to form a cavity in the barrel blank, and carrying out impact extrusion in the barrel blank by using the first punch, wherein the diameter of the second punch is smaller than that of the first punch; and forming a second guide hole which corresponds to the guide column in the second punch, and inserting the guide column into the second guide hole during impact extrusion to form a first tube nozzle. The utilization rate ofmaterials can be increased, the machining amount is reduced, the deformation degree of forge pieces is large, the quality of the forge pieces is good, and the performance is excellent.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

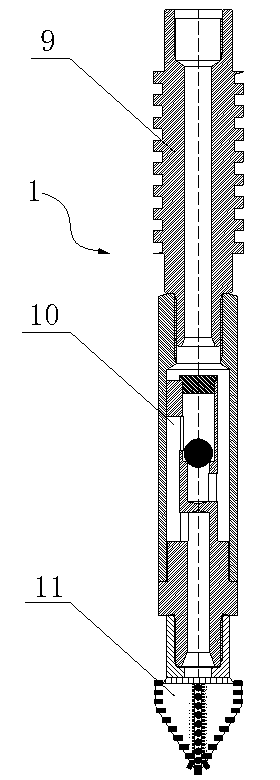

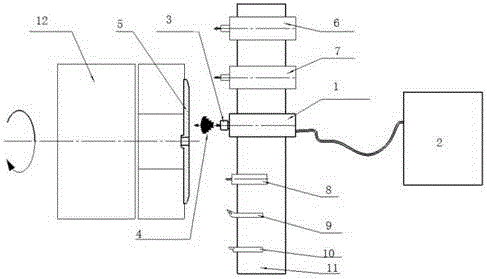

Integral drilling and filling top-bottom high-pressure impact extrusion grouting system

The invention discloses an integral drilling and filling top-bottom high-pressure impact extrusion grouting system, which is mainly applicable to the foundation reinforcement and anti-seepage grouting treatment on poor geologic bodies with loose and weak structures and the like. The grouting system comprises a drilling machine, a drilling rod and a high-pressure impact extrusion grouting head, wherein the drilling rod is connected onto a vertical shaft of the drilling machine, the high-pressure impact extrusion grouting head is connected onto the drilling rod and is used for hole drilling and grouting from top to bottom, a water faucet arranged at the upper part of the drilling rod connected onto the vertical shaft of the drilling machine is connected with a grouting pump through a drilling and filling slurry inlet pipe, the hole opening position of a drilling hole is provided with a hole opening return slurry collecting and settling device, and the return slurry after settlement treatment in the hole opening return slurry collecting and settling device is conveyed into a grouting slurry storage barrel through a drilling and filling slurry returning pipe via a mud pump for cyclic use. The grouting system has the advantages that the grouting full holes are continuous and uniform, the process operation is simple and convenient, and economy and environment protection are realized. The ideal grouting quality effect can be reached by adopting different hole array pitch hole distribution modes according to different engineering requirements.

Owner:POWERCHINA ZHONGNAN ENG

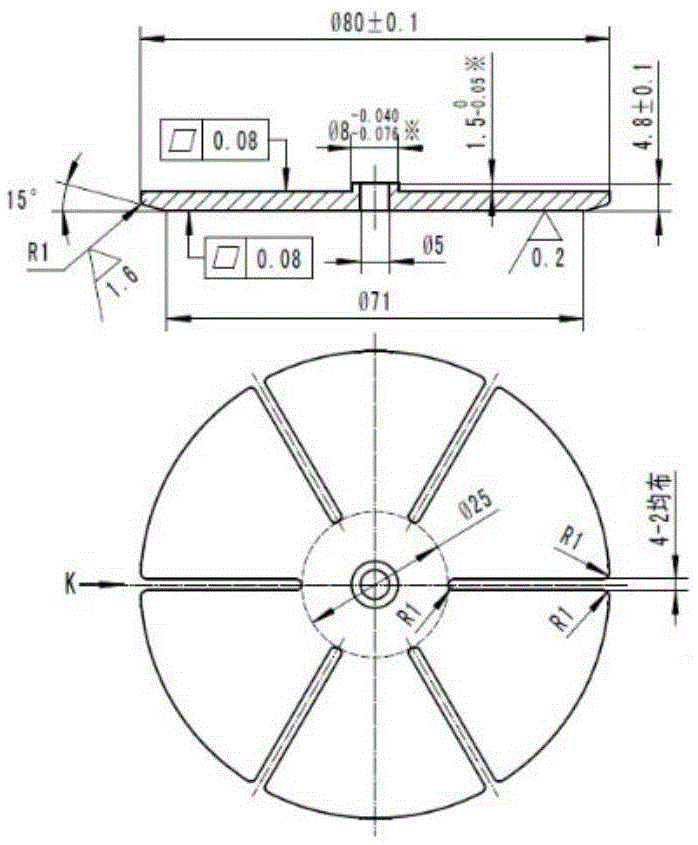

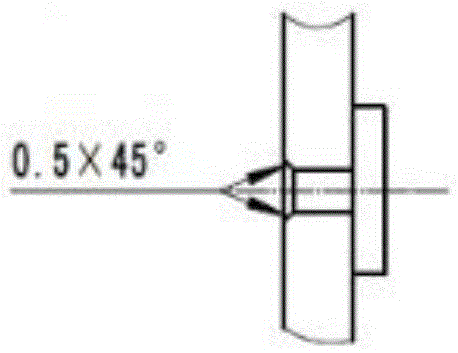

CuCr contact surface finishing equipment and method

The invention relates to CuCr contact surface finishing equipment and method. The equipment is a turning and milling composite machine tool additionally provided with a Hawking tool assembly directly installed on a machine tool row tool support plate of the turning and milling composite machine tool. The method comprises steps including blank preparation, turning I, turning II, Hawking finishing, milling of six grooves, cleaning and drying, turning III, appearance treatment, final inspection and vacuum packaging. Micro impact extrusion deformation is formed on contact surfaces under the combined action of high-frequency vibration impact energy and Hawking energy of Hawking metal machining equipment, so that the surface roughness of a CuCr contact material can be increased to Ra2.0 or below, the mirror effect can be realized, and the requirement of special use occasions of the CuCr contact material for working surface Ra2.0 or below is met.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Impact extrusion formed article, impact extrusion forming method, and impact extrusion forming device

Provided are a press molded product which is molded while suppressing the flow of metal from the bottom of a blank set in a die to the side of the molded product; and a press forming method for manufacturing A stamping molded product, and a stamping forming apparatus suitable for the stamping forming method.

Owner:FURUKAWA SKY ALUMINUM CORP

Hydraulic power generation technique by utilizing piezoelectricity principle

InactiveCN101924492ASimple structureRealize large-scale industrial productionPiezoelectric/electrostriction/magnetostriction machinesElectric power systemEngineering

The invention relates to a hydraulic power generation technique by utilizing piezoelectricity principle. According to the principle of piezoelectric generation, the generating unit of the invention is made of a piezoelectric material; and the piezoelectric material in the generating unit should have the effects of high pressure resistance, shock resistance and corrosion resistance. The generating unit is installed underwater, and used for receiving the flow speed, fall impact and depth pressure of water. When the generating unit is subjected to the actions of flow speed, fall impact and depth pressure of water, the piezoelectric material is subjected to impact extrusion to continuously generate electric power. The electric power can be delivered to places in need of electric power through the electric power conversion and storage (delivery) circuit system. The invention can be widely used in places in contact with water, such as in riverbeds, ducts, channels, oceans, ship bottoms (sea gauge positions) and the like.

Owner:周维武

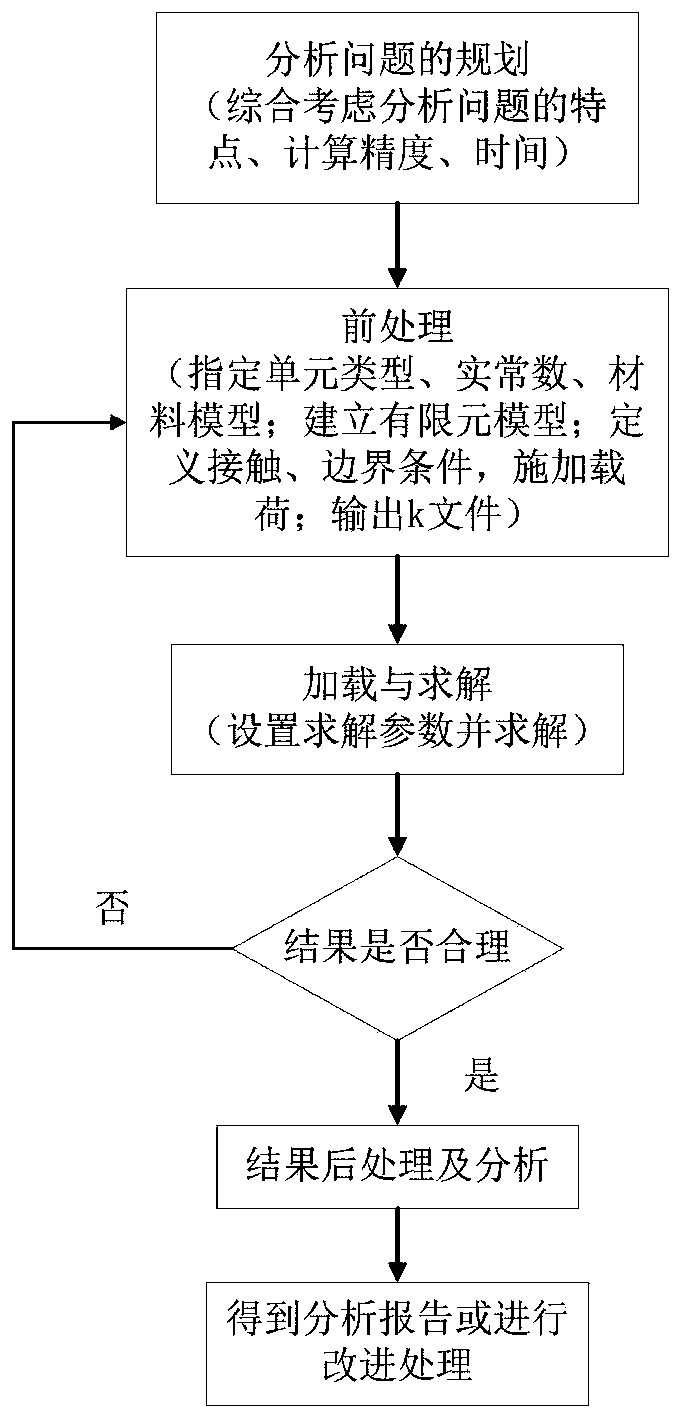

A method for quickly acquiring high-speed impact extrusion resistance of a projectile

ActiveCN109697309APreserve integrityPreserve calculation precisionSustainable transportationBiological neural network modelsResearch efficiencyFinite element method

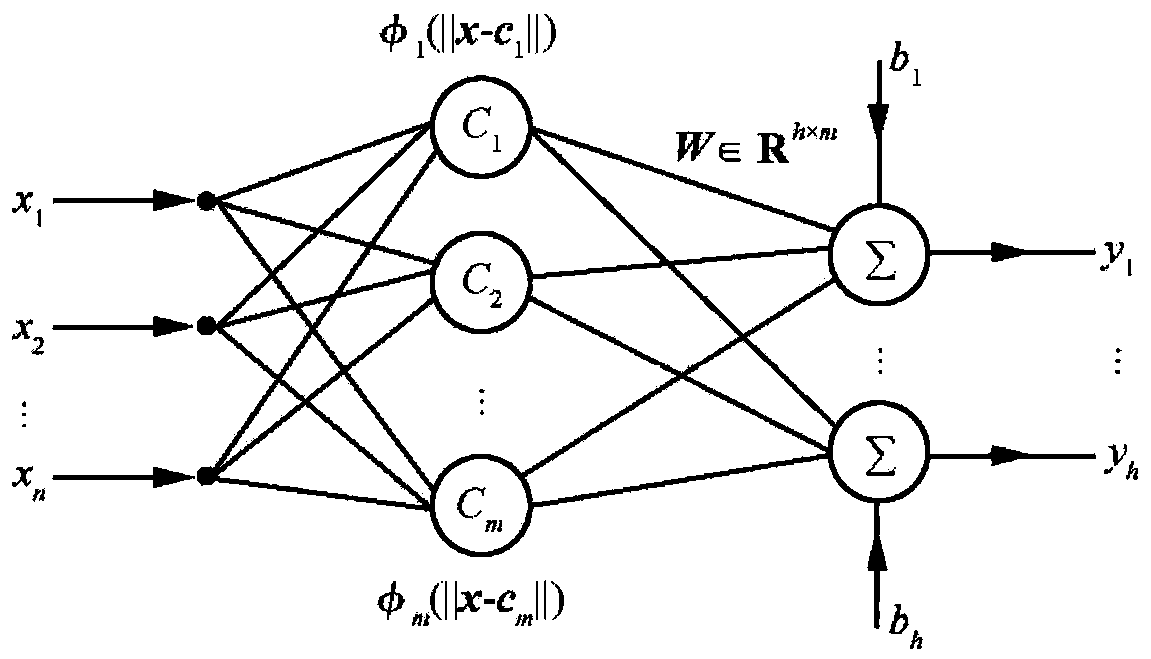

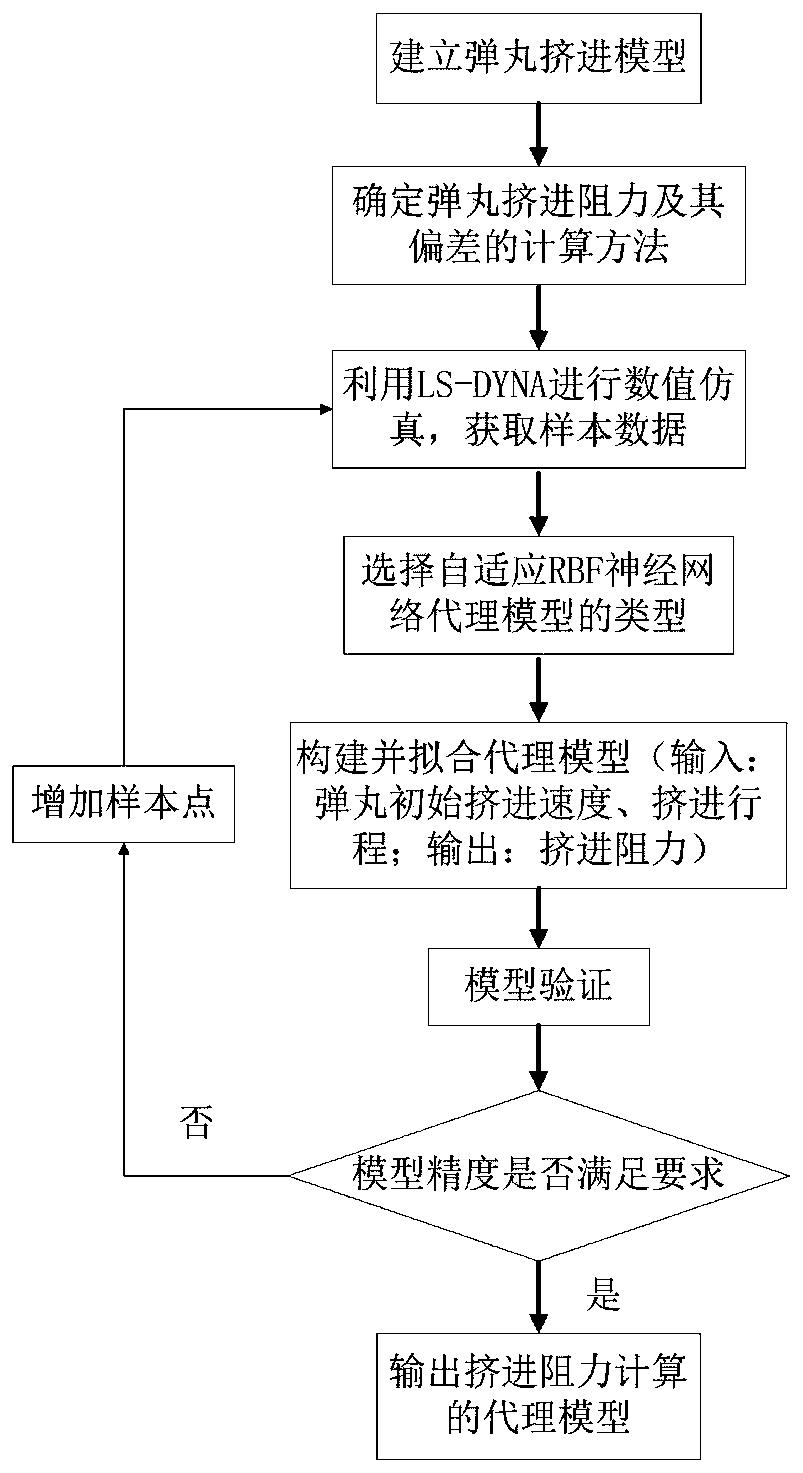

The invention belongs to the technical field of projectile motion analysis, and particularly relates to a method for quickly obtaining high-speed impact extrusion resistance of a projectile. Accordingto the method, a result obtained by carrying out extrusion process simulation through a finite element method is taken as a sample, and an agent model is constructed by utilizing a self-adaptive RBF(Radial Basis Function) neural network, so that rapid calculation of the high-speed impact extrusion resistance of the projectile at different initial extrusion speeds is realized. According to the method, the integrity and calculation precision of numerical simulation can be kept, the overall solving time can be greatly shortened, and the scientific research efficiency and scientificity are improved.

Owner:西北机电工程研究所

Filling bottle correcting, pushing, washing, forwarding, conveying, filling, cap conveying, impact extrusion and cap screwing system

InactiveCN104495313ASolve the problem of directional transportFix fixityThreaded caps applicationBottle-handling machinesScrew systemBottle cap

The invention discloses a filling bottle correcting, pushing, washing, forwarding, conveying, filling, cap conveying, impact extrusion and cap screwing system. The system comprises a correcting device, a pushing device, a carrying device, a washing device, a forwarding device, a conveying device, a filling device, a cap conveying device, an impact extrusion device and a cap screwing device, the correcting device is a cavity with one end open, the inner side wall of the cavity is provided with a spiral rising material passage, and the pushing device comprises a pushing cylinder and a pushing platform. By the system, directional conveying of filing bottles can be achieved, and automatic washing and forwarding, conveying and filling of the filling bottles, cap conveying and filling bottle cap impact extrusion, fixation and screwing can be realized.

Owner:镇江市顶智微电子科技有限公司

System for correcting, pushing, rinsing, conveying, filling, impact extrusion, cover screwing and labeling of filling bottles

ActiveCN104445025ASolve the problem of directional transportSolve the problem of easy falling offCapsThreaded caps applicationEngineeringBottle cap

The invention discloses a system for correcting, pushing, rinsing, conveying, filling, impact extrusion, cover screwing and labeling of filling bottles. The system comprises a correcting device and a pushing device, and further comprises a carrying device, a rinsing device, a progressively forwarding device, a conveying device, a filling device, a cover transporting device, a pad transporting device, an impact extrusion device and a labeling device, wherein the correcting device is a cavity body with an open end and a material channel which spirally ascends is formed in the inner side wall of the cavity body; the pushing device comprises a pushing air cylinder and a pushing platform. According to the system, the problem in directional transportation of the filling bottles can be solved, meanwhile the problems in automated rinsing, progressively forwarding, conveying, filling, cover transporting and seal pad transporting of the filling bottles can be solved, and the problem of easy falling of seal pads during rotary arrangement of filling bottle covers and the seal pads of the filling bottle covers as well as problems in cover screwing and labeling of the filling bottles can be solved.

Owner:启东市富晨天然气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com