Patents

Literature

326 results about "Mirror effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compositions for allogeneic cell therapy

ActiveUS7435592B2Strong upregulationBiocideVertebrate antigen ingredientsAbnormal tissue growthAllogeneic cell

A method of manipulating allogeneic cells for use in allogeneic cell therapy protocols is described. The method provides a composition of highly activated allogeneic T-cells which are infused into immunocompetent cancer patients to elicit a novel anti-tumor immune mechanism called the “Mirror Effect”. In contrast to current allogeneic cell therapy protocols where T-cells in the graft mediate the beneficial graft vs. tumor (GVT) and detrimental graft vs. host (GVH) effects, the allogeneic cells of the present invention stimulate host T-cells to mediate the “mirror” of these effects. The mirror of the GVT effect is the host vs. tumor (HVT) effect. The “mirror” of the GVH effect is the host vs. graft (HVG) effect. The effectiveness and widespread application of the anti-tumor GVT effect is limited by the severe toxicity of the GVH effect. In the present invention, the anti-tumor HVT effect occurs in conjunction with a non-toxic HVG rejection effect. The highly activated allogeneic cells of the invention can be used to stimulate host immunity in a complete HLA mis-matched setting in patients that have not had a prior bone marrow transplant or received chemotherapy and / or radiation conditioning regimens.

Owner:MIRROR BIOLOGICS INC +1

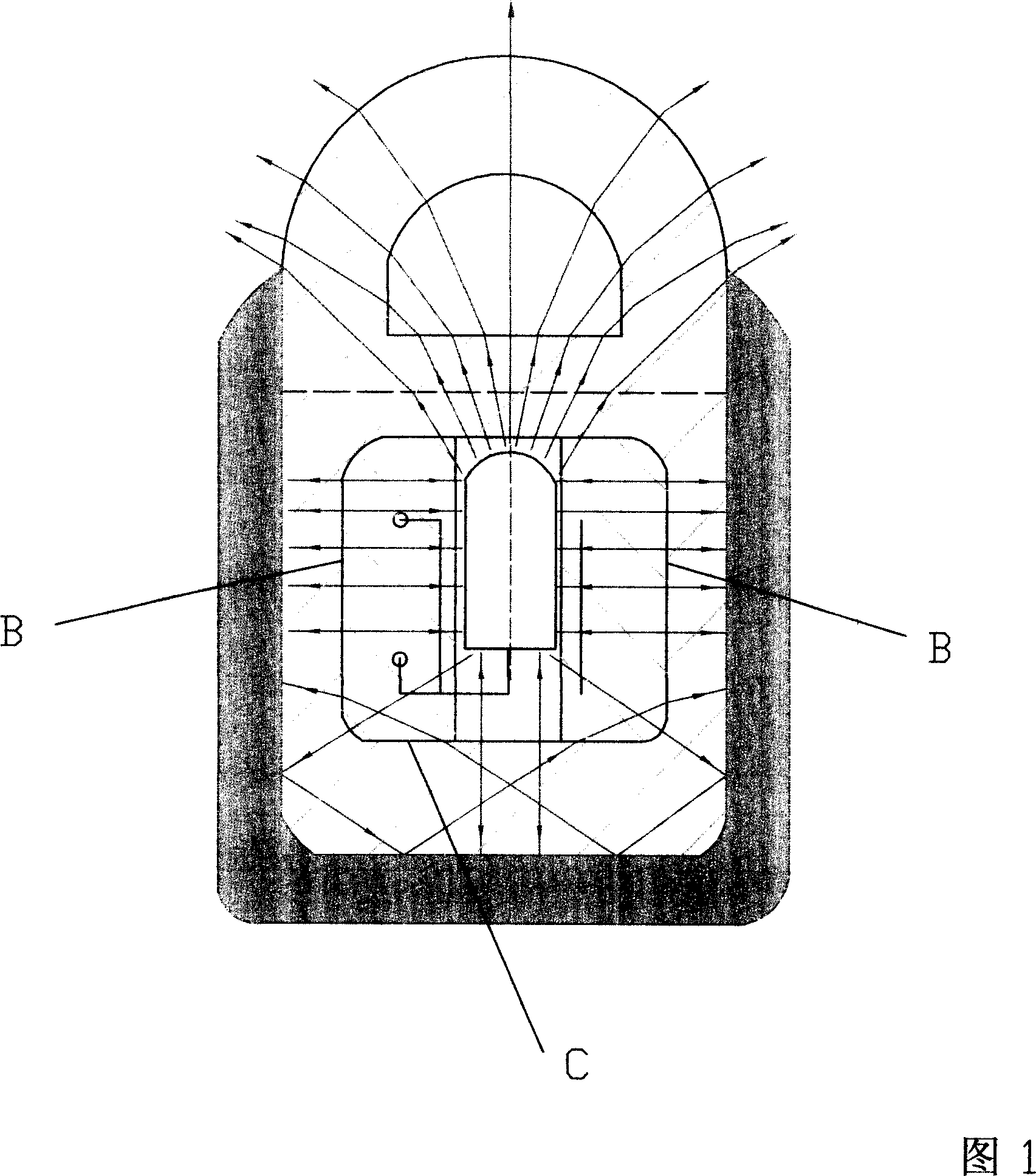

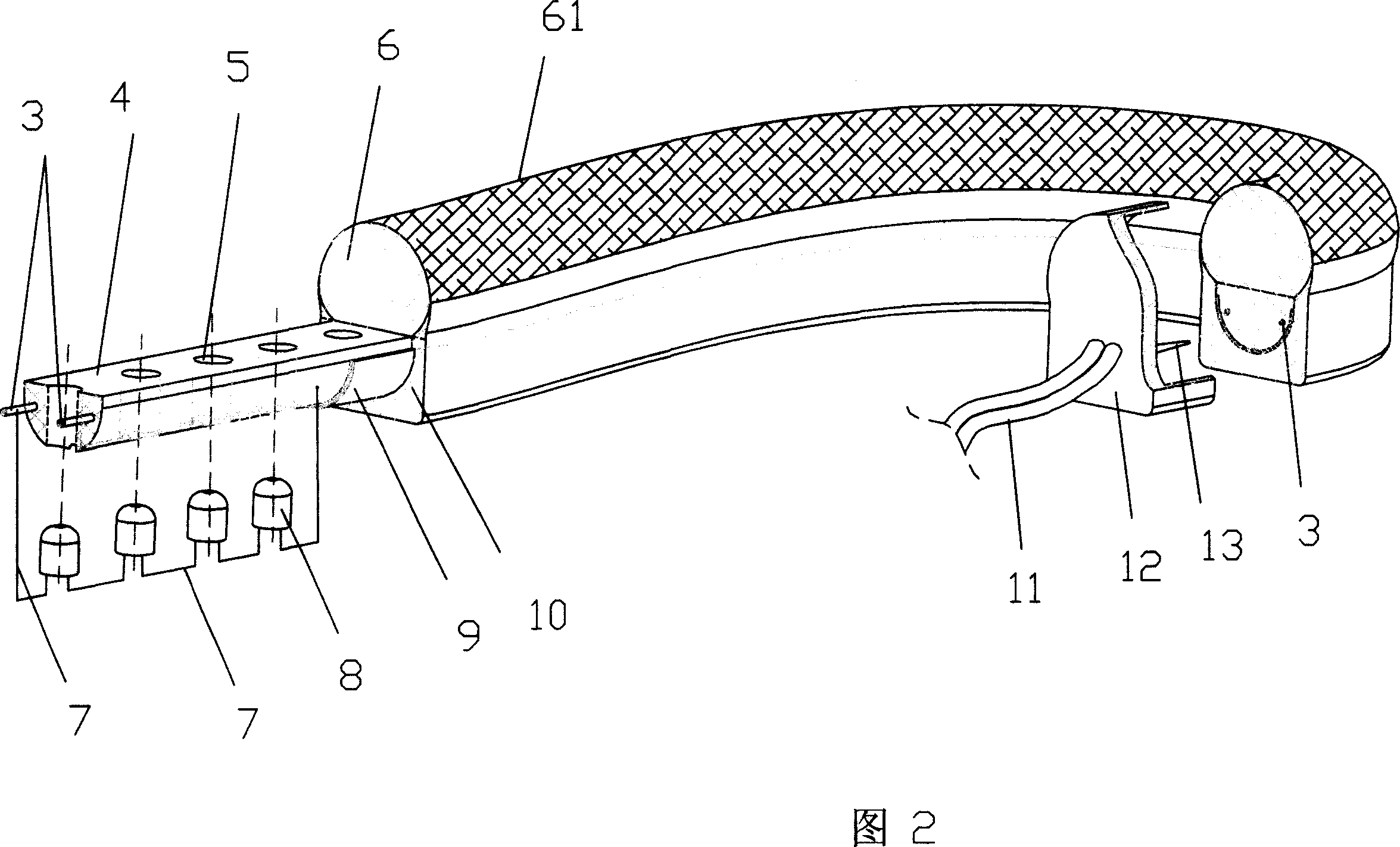

Antenna for tire pressure information sending apparatus and tire pressure information sending apparatus using the same

InactiveUS20050179529A1Good antenna characteristicsIncrease the use of spaceInflated body pressure measurementTransmission systemsEngineeringAtmospheric pressure

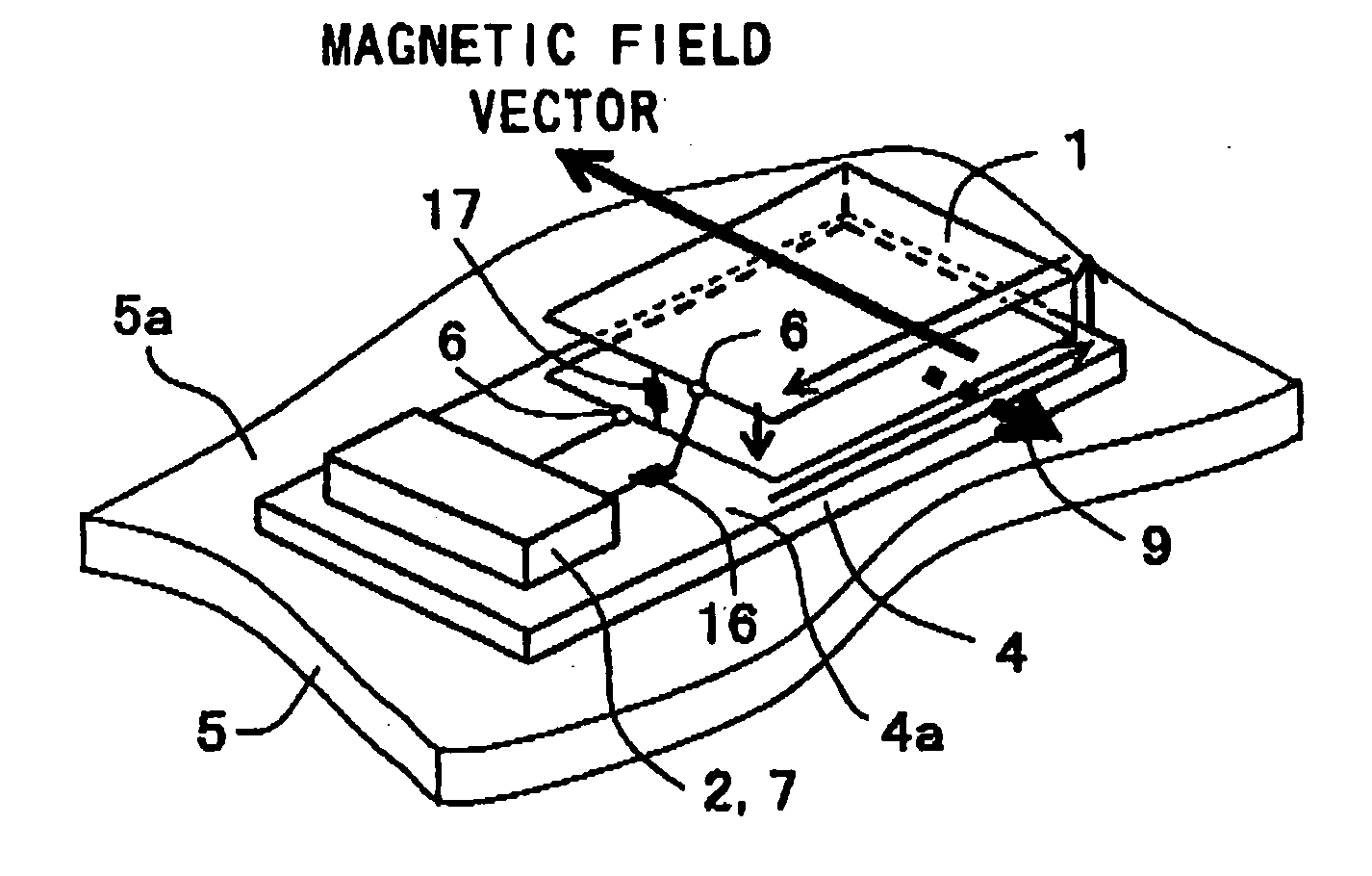

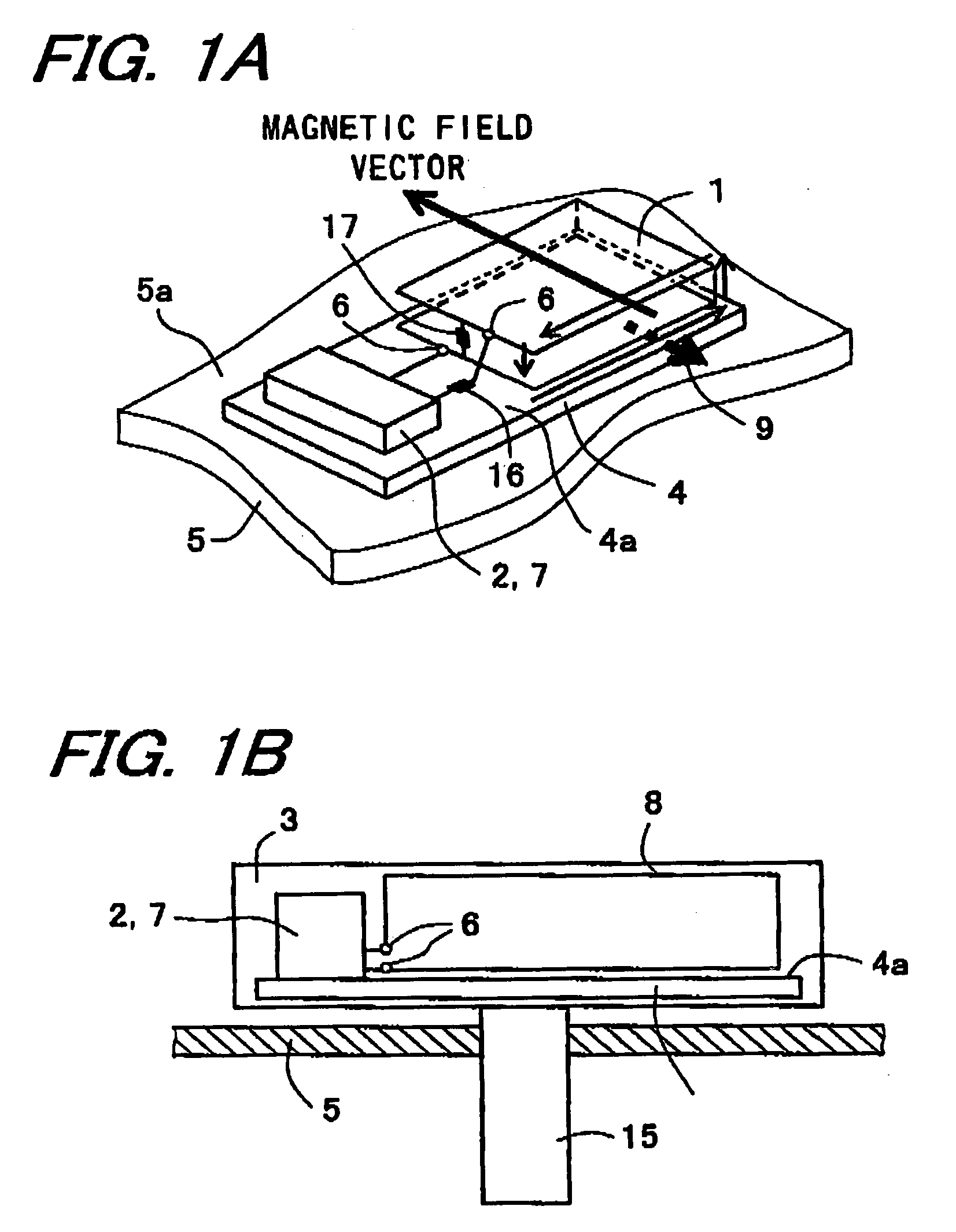

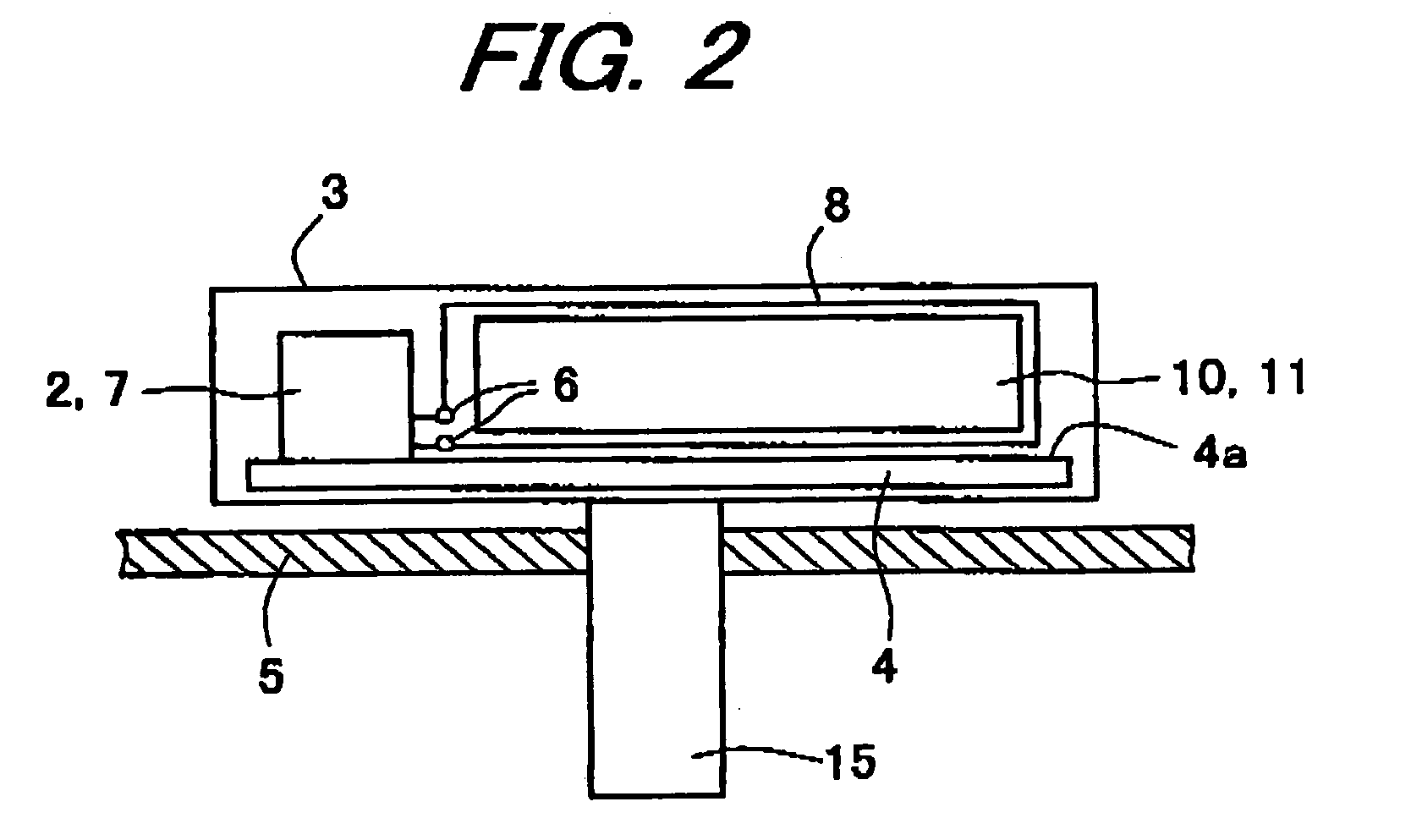

An antenna 1 for a tire pressure information sending apparatus is constituted by a circuit board provided with feeding electrodes and a radiation electrode 8 having a loop surface substantially perpendicular to the principal surface, the radiation electrode sending air pressure information of a tire onto a principal surface of the circuit board by radio waves. Thereby, when the apparatus is mounted on a wheel rim, a magnetic field vector parallel to the principal surface of the circuit board and parallel to the wheel rim is generated, and a direction of a magnetic field vector by a mirror effect to the wheel rim becomes the same as the direction of the magnetic field vector of the antenna. As a result, it is possible to effectively prevent that the antenna characteristic deteriorates.

Owner:KYOCERA CORP

Housing and method for making same

InactiveCN101730415AOvercome a single matte matte lookImprove wear resistanceAnodisationDecorative surface effectsMicro arc oxidationOptoelectronics

The invention provides a housing. The housing comprises a metal substrate and a micro-arc oxidation film layer formed on the metal substrate, wherein a region with mirror surface effect is formed on the surface of the micro-arc oxidation film layer; and a groove is etched in the region having the mirror surface effect. A method for making the housing comprises the following steps of: providing the metal substrate; performing micro-arc oxidation treatment on the metal substrate so as to form the micro-arc oxidation film layer thereon; polishing the micro-arc oxidation film layer; and etching the groove on the polished micro-arc oxidation film layer.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

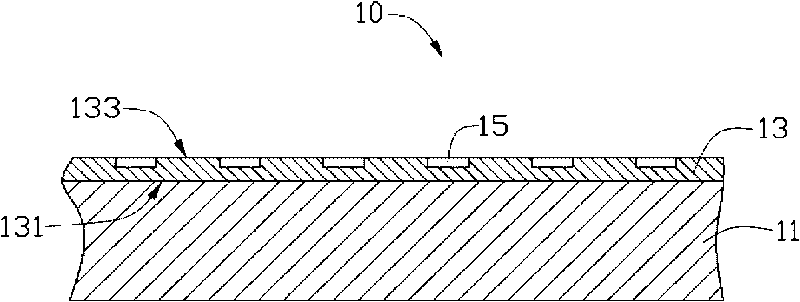

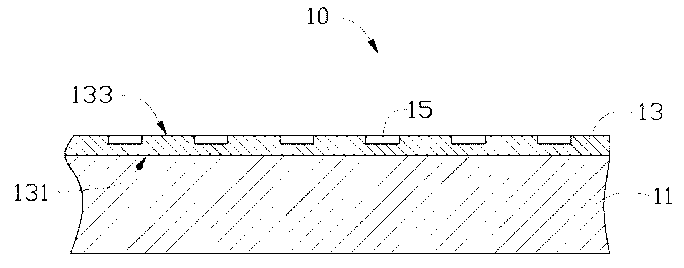

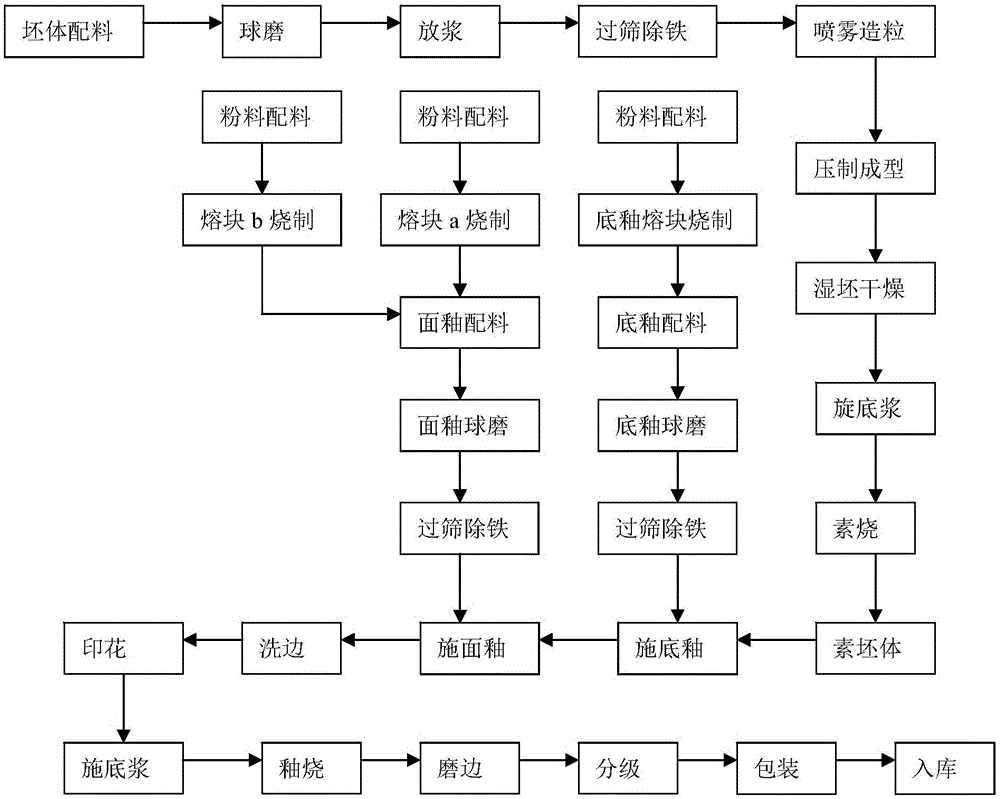

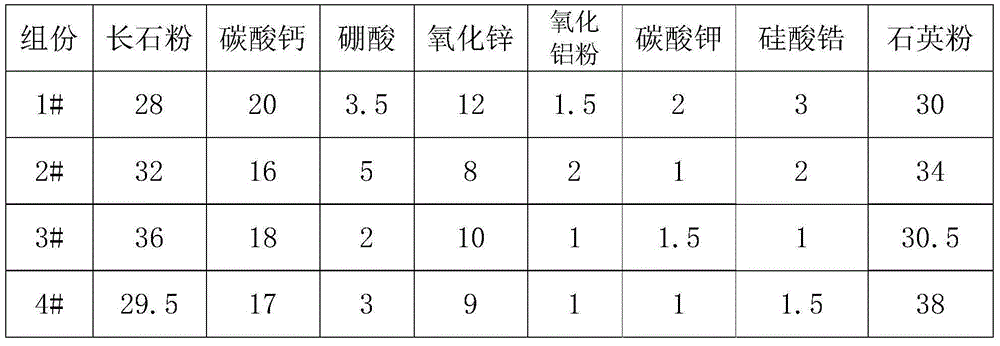

Glazed tile prepared from sludge with mirror-effect surface and preparation method thereof

The invention provides a glazed tile prepared from sludge with mirror-effect surface and a preparation method thereof. The method in the invention, on the basis of no great change of conventional glazed tile production process, exerts key points on formula composition of a green body, compositions of ground and cover glaze clinkers, formula compostion of ground glaze, optimization and proportion of cover glaze clinkers with different performances, and adjustment and selection of formula composition of cover glaze, so the prepared glazed tile has surface glossiness of equal to or more than 90; glaze surface is flat and smooth as a mirror, is glossy and lustrous and is free of defects like pinholes and glaze bubbles; printing pattern of a printing glazed tile is completely deposited into the cover glaze with clear texture, bright color and life-like stone-like texture as if a layer of glittering and transparent glass is covered on the printing pattern; if the glazed tile is erected and the glaze surface faces an object, a shadow of the object in the glaze surface is clearly-visible as in the mirror, and has strong integral art sense; meanwhile, the method in the invention adds a great amount of treated compressed sludge and wastewater generated in every operation procedure in ceramic tile production process into the formula of the green body, so cost is saved, and the purposes of energy conservation and emission reduction are achieved at the same time.

Owner:GUANGDONG HONGHAI CERAMIC IND DEV +3

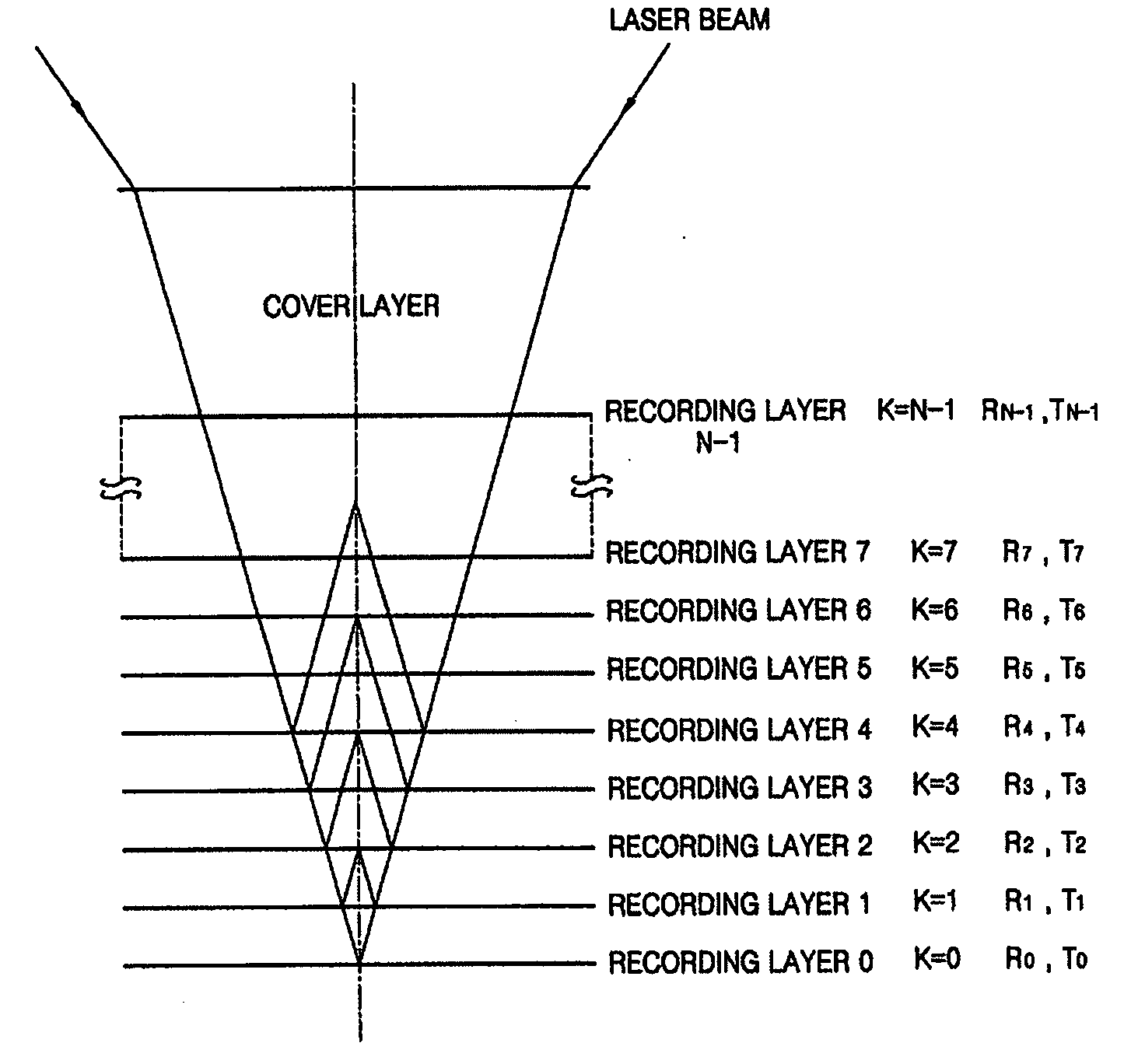

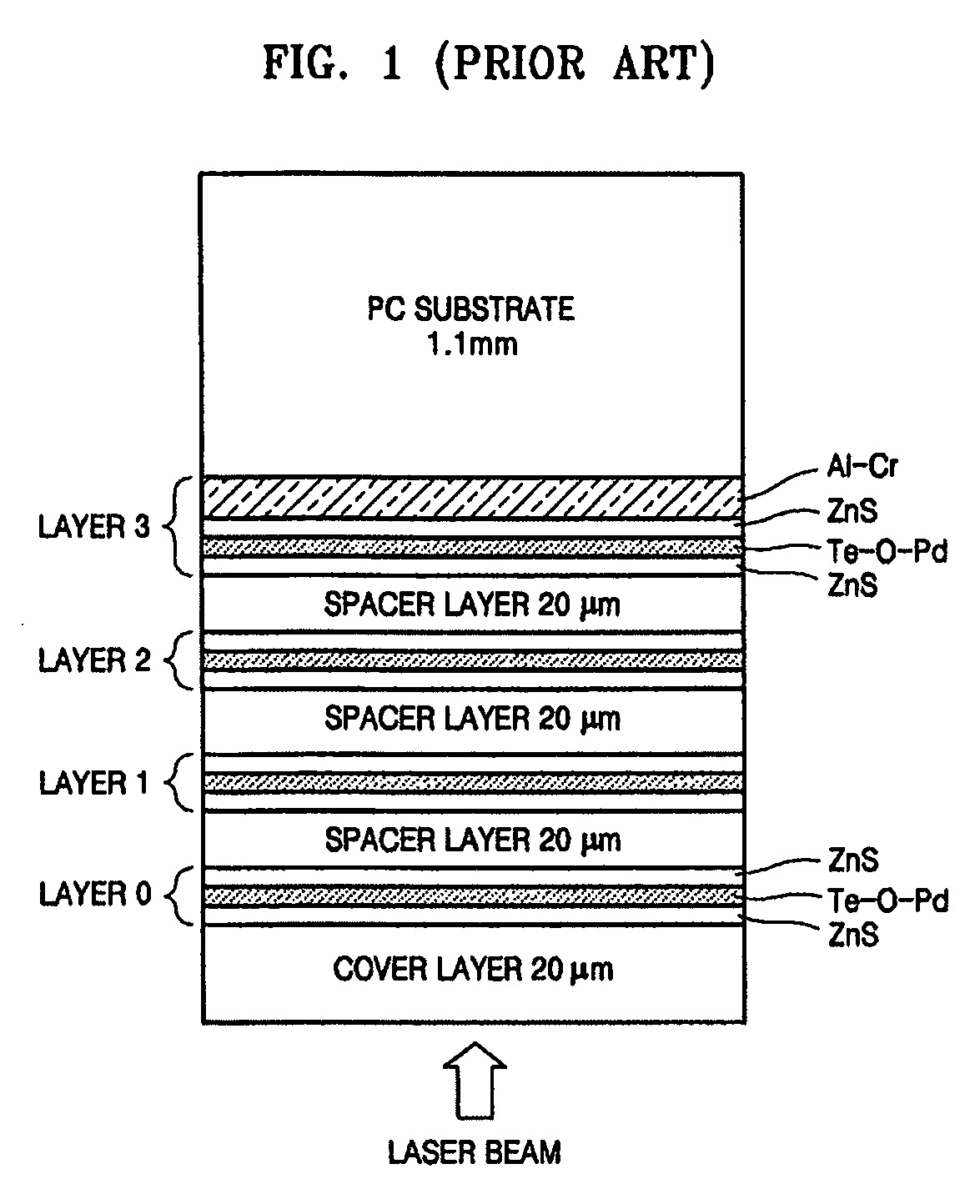

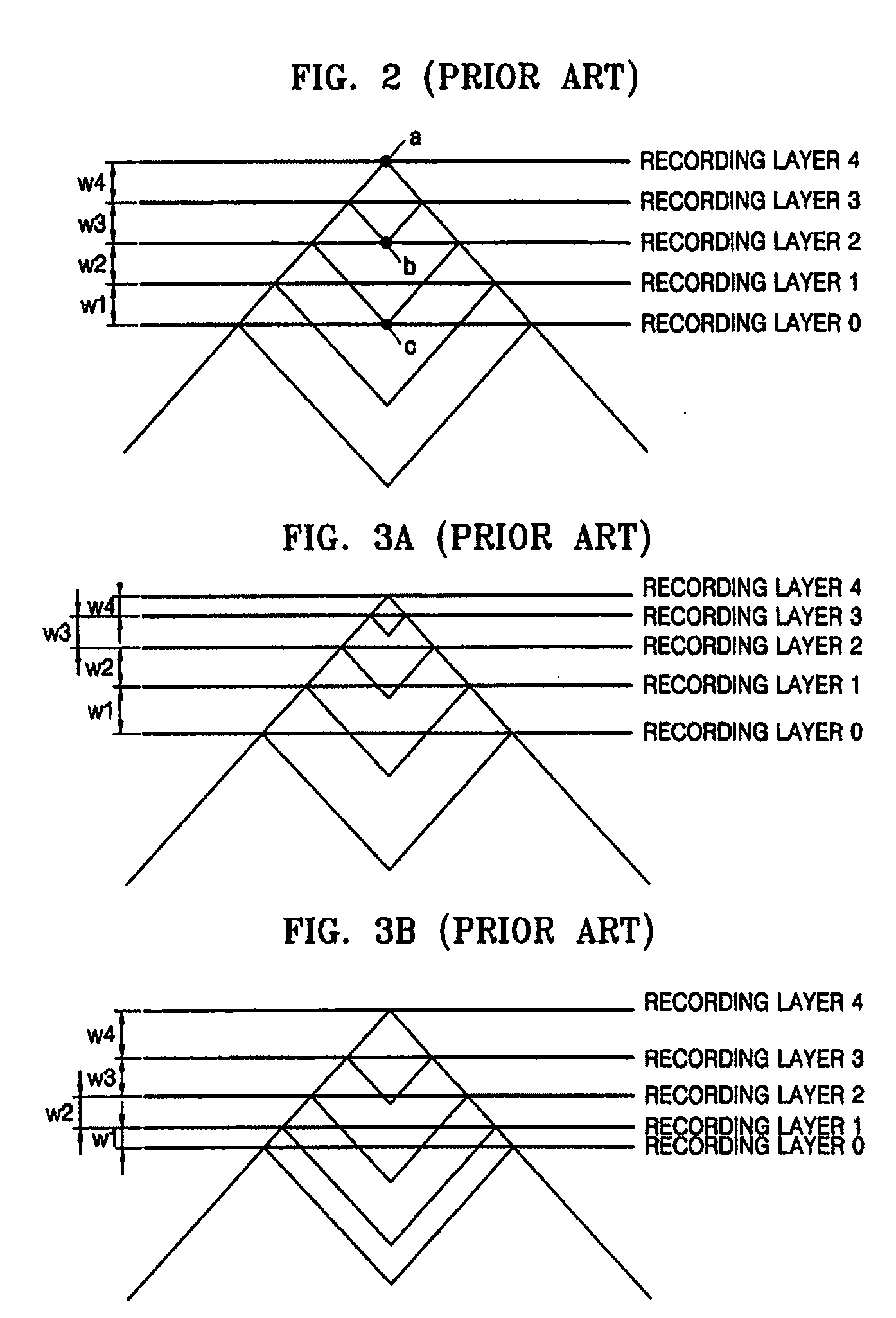

Multilayer recording medium and method of manufacturing the same

InactiveUS20060203680A1Prevent mirror effectInhibition effectMechanical record carriersRecord information storageSignal qualityLight beam

A multilayer recording medium that prevents deterioration of a signal characteristic due to a mirror effect that may occur between recording layers and a method of manufacturing the same, the multilayer recording medium having at least two recording layers, wherein a thickness of at least one spacer layer between adjacent recording layers is different from a thickness of the other spacer layers such that a beam focusing on a recording layer is prevented from focusing on another recording layer corresponding to a mirror layer due to reflection. In the multilayer recording medium, a mirror effect is greatly reduced. In addition, the thickness of only a spacer layer exerting the most significant influence on the mirror effect is changed to prevent the deterioration of signal quality due to the mirror effect, and therefore, the structure of a multilayer recording medium is simplified.

Owner:SAMSUNG ELECTRONICS CO LTD

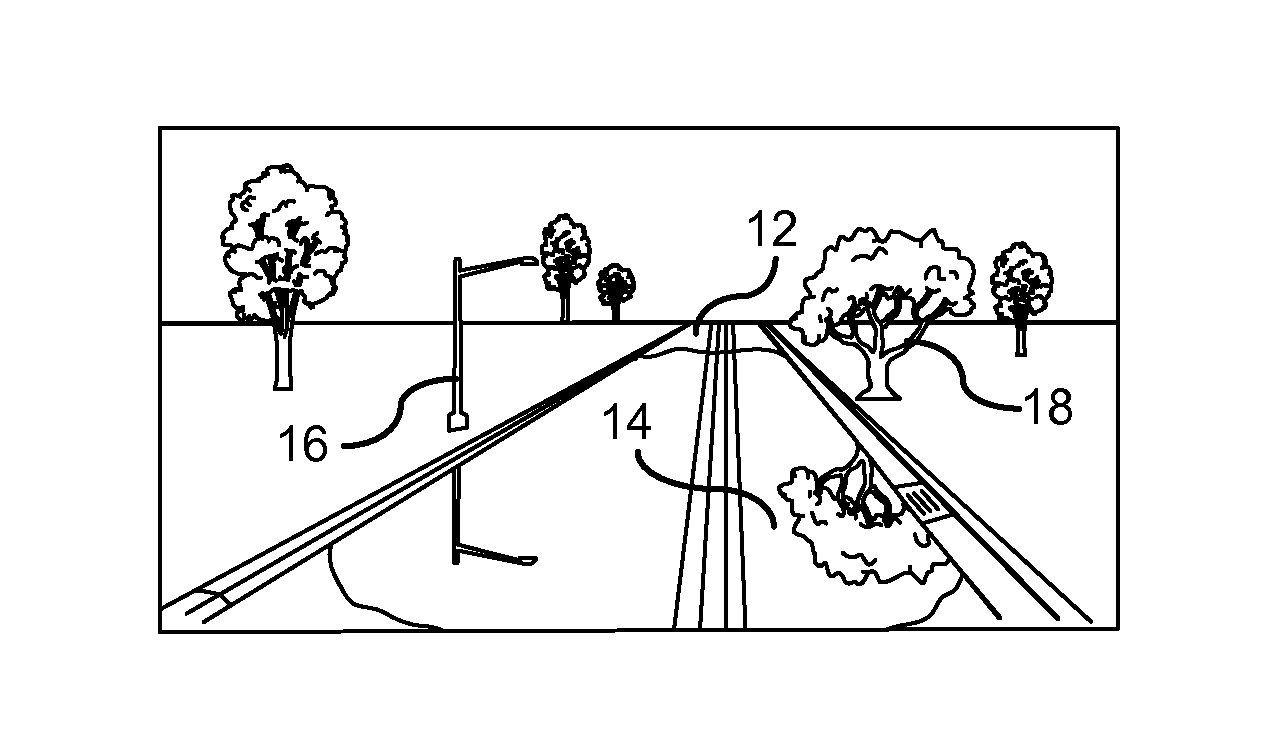

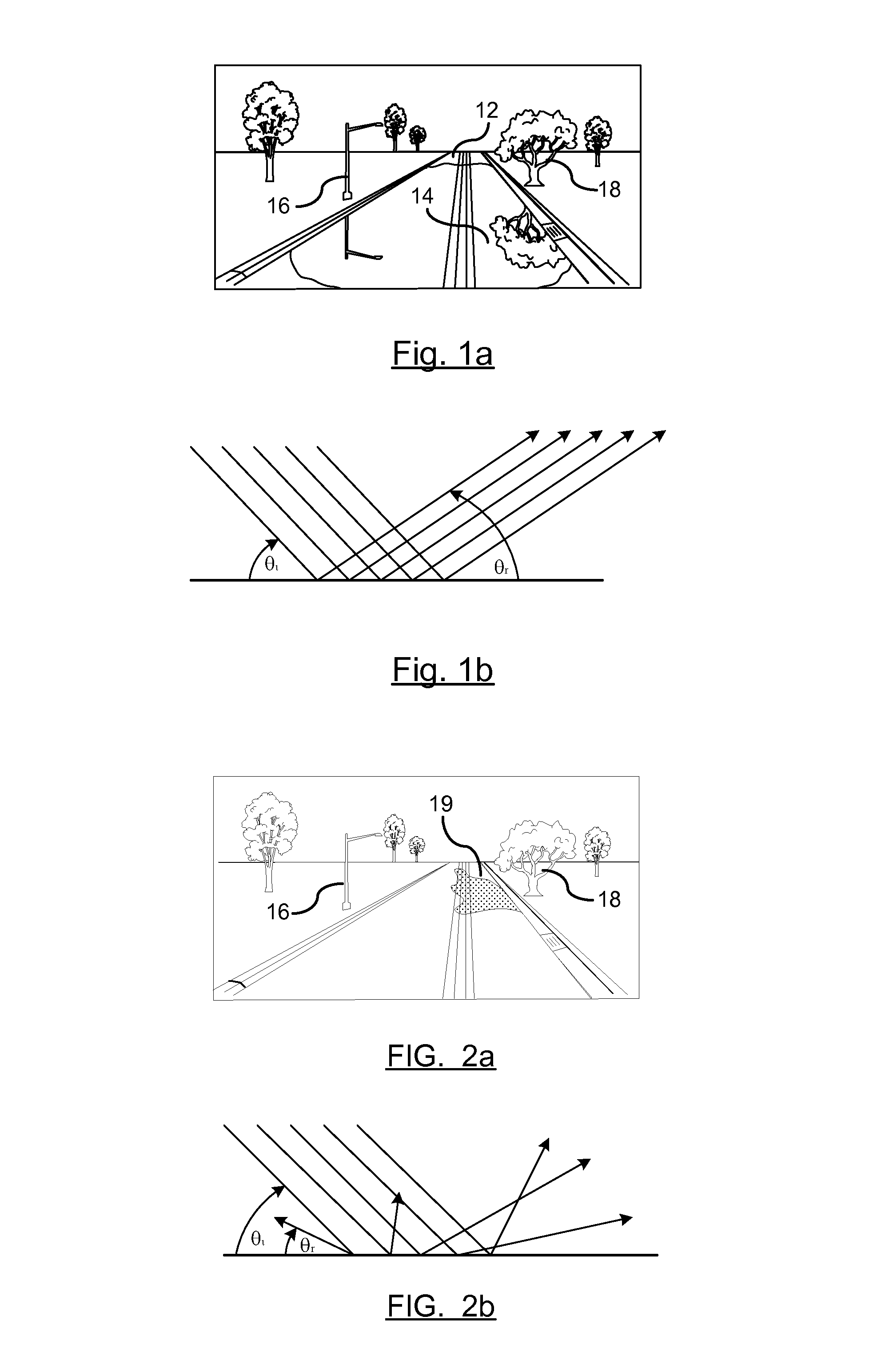

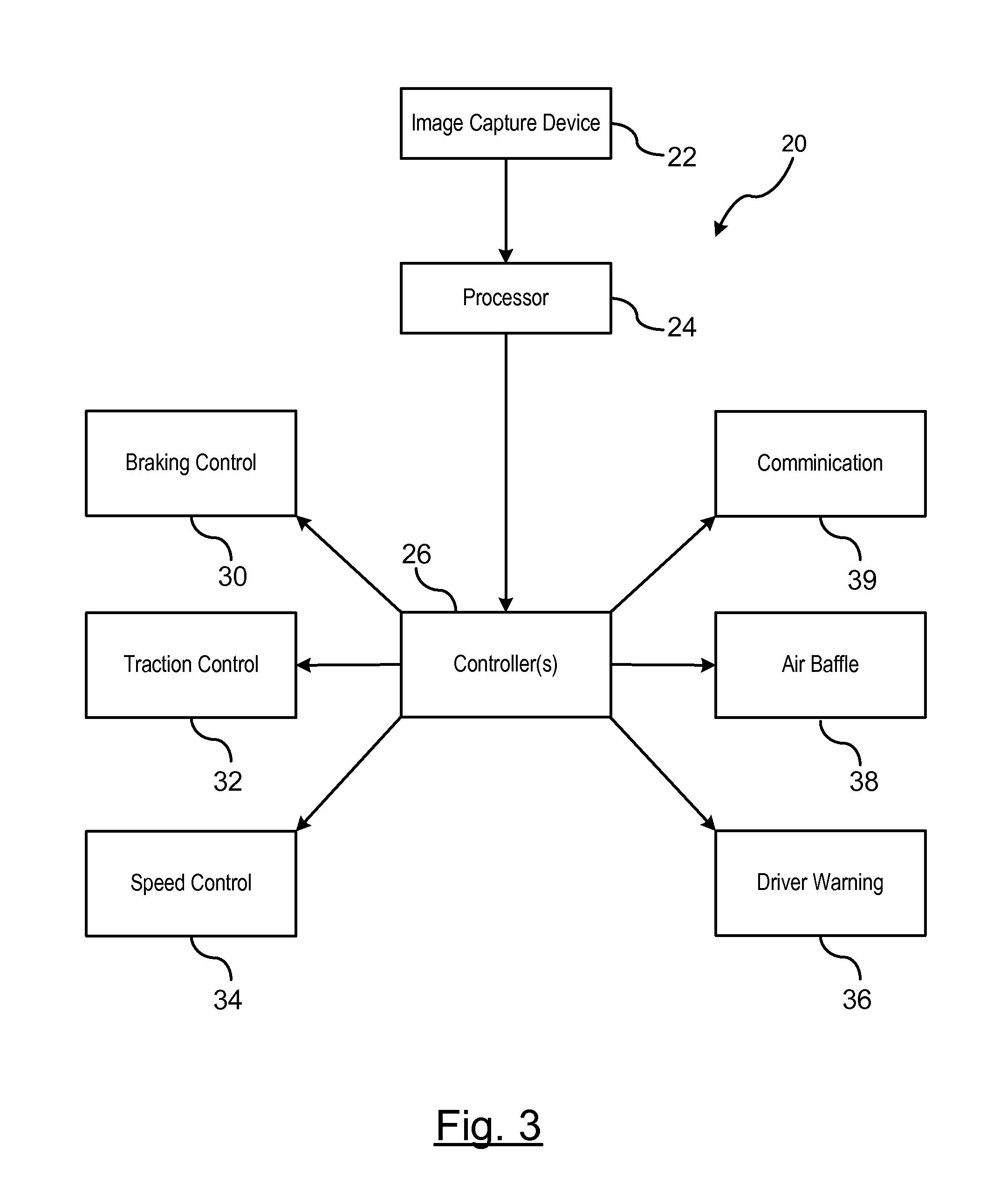

Vision-based wet road surface detection

A method for determining a wet road surface condition for a vehicle driving on a road. An image exterior of the vehicle is captured by an image capture device at a first and second instance of time. Potential objects and feature objects are detected on a ground surface of the road of travel at the first instance of time and the second instance of time. A determination is made whether the ground surface includes a mirror effect reflective surface based on a triangulation technique utilizing the feature points in the captured images at the first instance of time and the second instance of time. A wet driving surface indicating signal is generated in response to the determination that the ground surface includes a mirror effect reflective surface.

Owner:GM GLOBAL TECH OPERATIONS LLC

Stone surface treating agent, preparation method thereof and stone surface treating method

The invention discloses a stone surface treating agent, which comprises an A component and a B component, wherein the A component comprises the following raw materials in parts by weight: 150-400 parts of alkali metal silicate solution with the concentration of 5-40 percent by weight, 150-400 parts of acid saline solution with the concentration of 1-20 percent by weight and 3-80 parts of high polymer emulsion; and the B component comprises the following raw materials in parts by weight: 200-400 parts of silica gel, 50-400 parts of alkali metal silicate solution with the concentration of 5-40 percent by weight and 2-80 parts of high polymer emulsion. The invention further discloses a preparation method of the treating agent and a stone surface treating method. The stone surface treating agent prepared with the preparation method is a polishing material which takes an inorganic components as major components, is weakly acidic or weakly alkaline, has small chemical corrosion on stone, contains a small quantity of organic components, can overcome the defect of a pure wax organic material film and can achieve a mirror effect. The stone surface treating agent can be applied to stone surface polishing together with any electric tool and a universal cushion, and can be used for polishing polished tiles, microlite and the like.

Owner:WANFENG COMPOUND STONE TECH

Aesthetical resin capable of eliminating injection-molding weld lines and preparation method thereof

The invention relates to an aesthetical resin capable of eliminating injection-molding weld lines and a preparation method thereof. The aesthetical resin comprises the following components in part by weight: 100 parts of thermoplastic resin, 0 to 5 parts of powdered aluminium, 0 to 5 parts of diamantes, 0.1 to 1 parts of antioxidant, 0.1 to 1 parts of dispersing agent and 0.1 to 5 parts of pigment; after the materials are prepared according to the components and the parts by weight, the materials are put into a medium-speed mixer, the rotating speed and the time are controlled, mixed material is obtained, and finally, a double-screw extruder is used to extrude and granulate the mixed material, so that the product is obtained. Compared with the prior art, the invention has the advantages of high surface glossiness, good mirror effect, bright color, good flowability, simple and continuous flow, high production efficiency and stable product quality, meets SGS and ROHS heavy metal safety standards and can be recycled.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

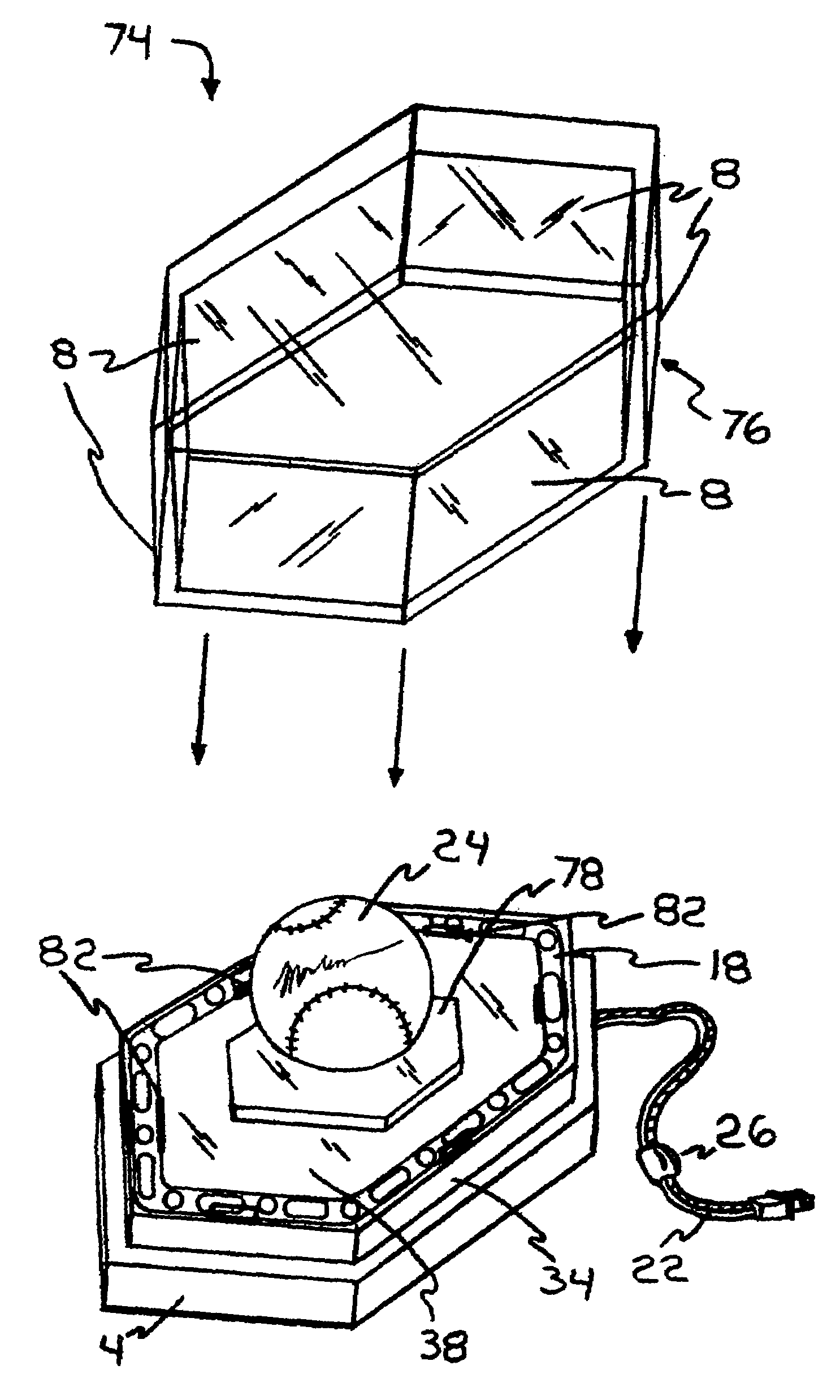

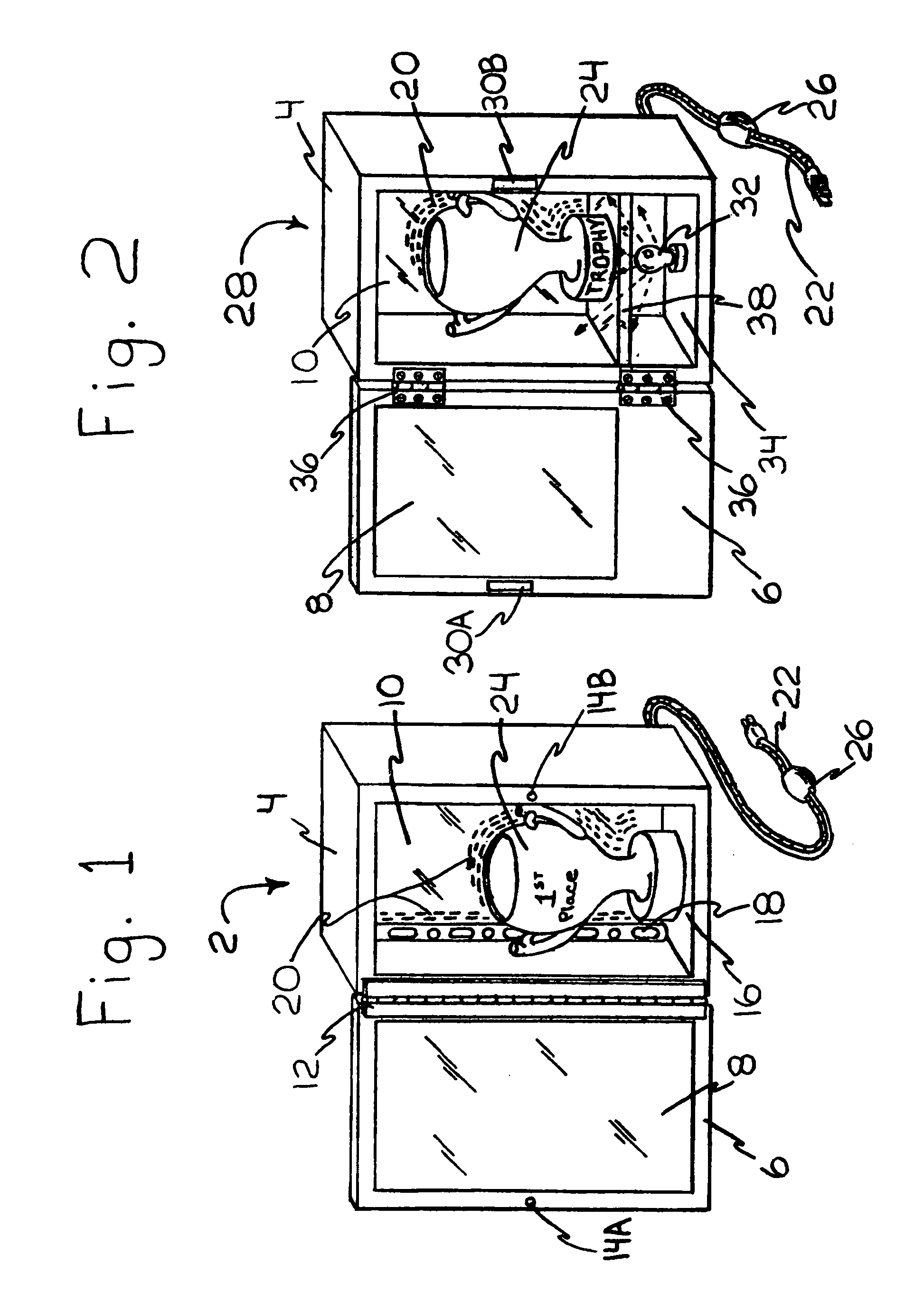

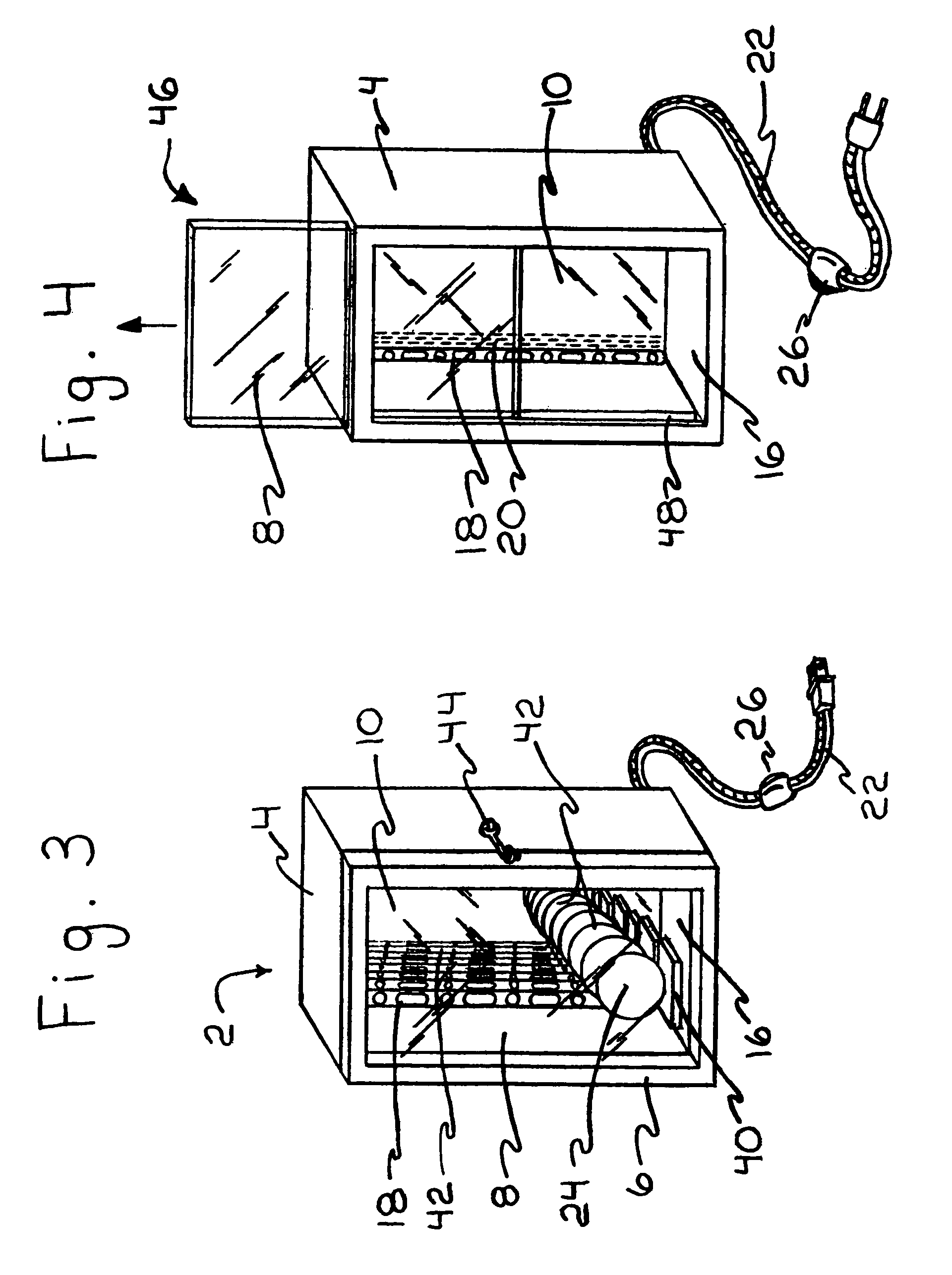

Quick exchange infinity mirror display apparatus and method

InactiveUS6929552B1Quickly and easily addedQuickly and easily and removedAmusementsStage arrangementsInterior spacePartially reflective surface

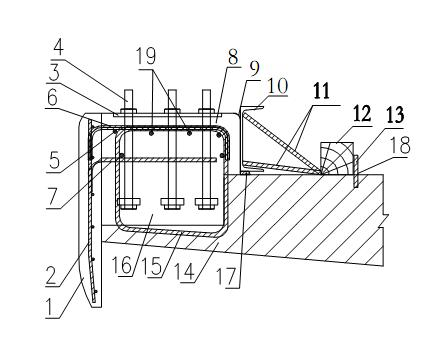

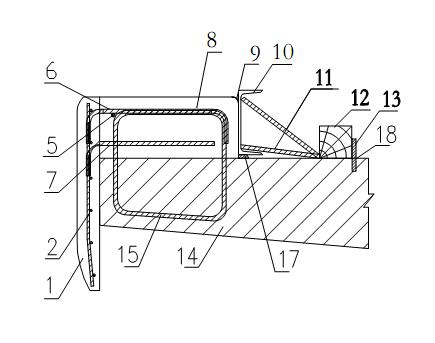

An infinity mirror display apparatus, and method of manufacture, which allows private and commercial users to rapidly trade out favored display objects to create different infinity display effects for continued viewer interest and enjoyment. The apparatus comprises a housing having a stationary base member and an easily removable cover which together define an enclosed interior space, at least two reflective surfaces positioned adjacent to the interior space with at least one of the surfaces being partially reflective, and at least one illumination source communicating with the interior space. The cover can be partially or totally removed from the stationary member during display object exchange. The apparatus can be wall-mounted for front and / or side viewing of the infinity mirror effect, or it can be table-mounted with multiple partially reflective surfaces for a full 360° view of the infinity mirror effect created by one or more illuminated display objects.

Owner:HARGABUS PATRICK ALLEN

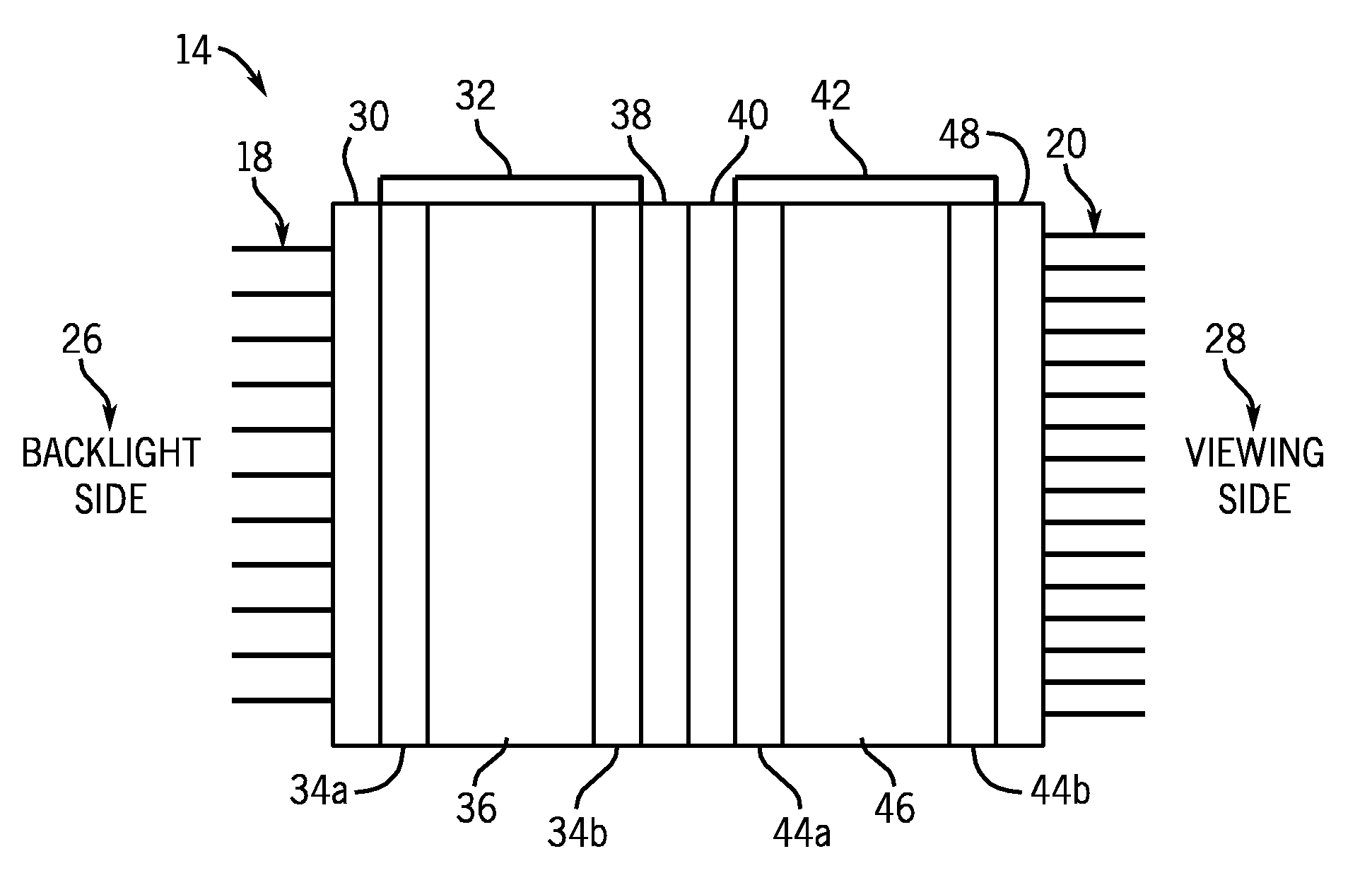

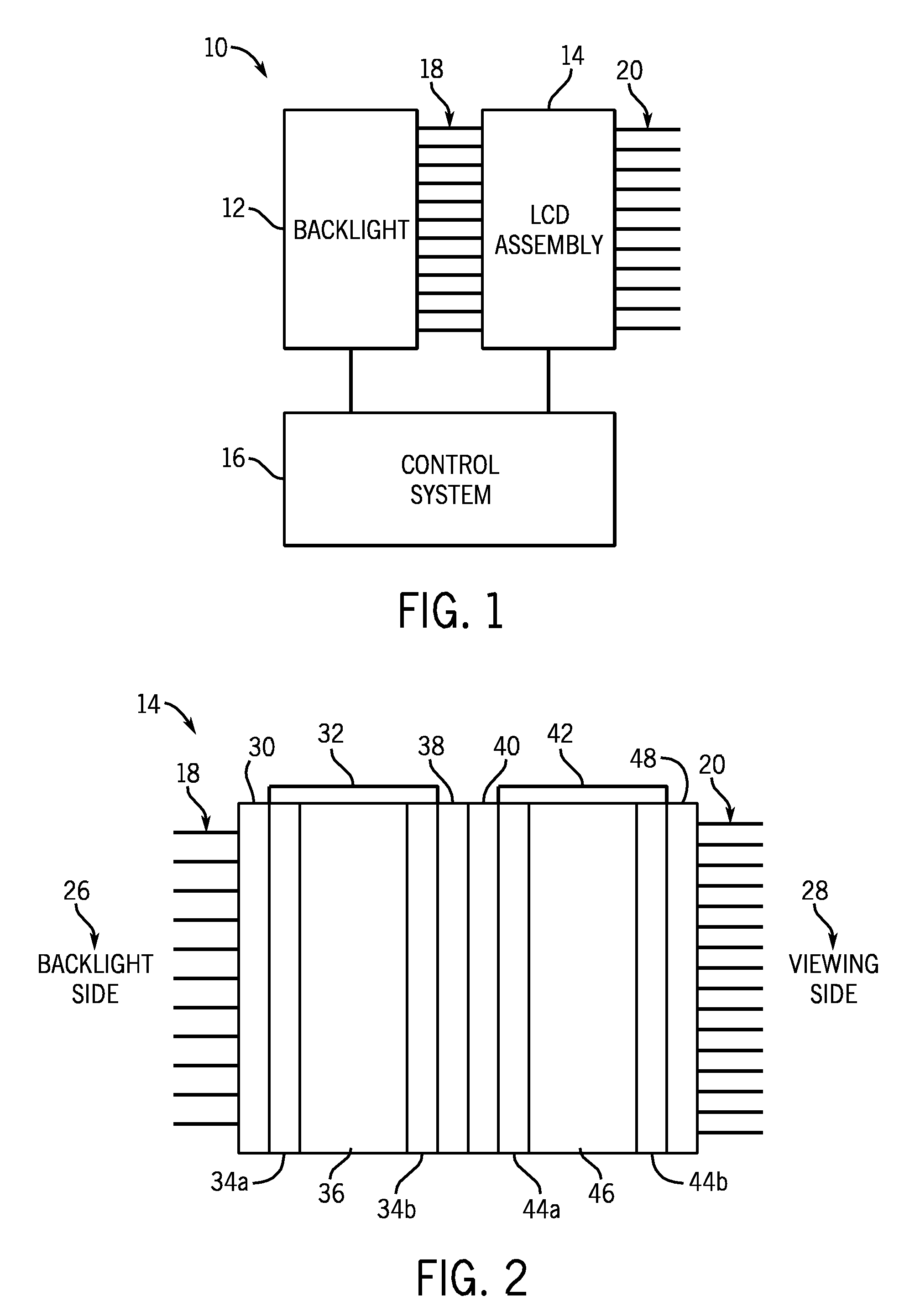

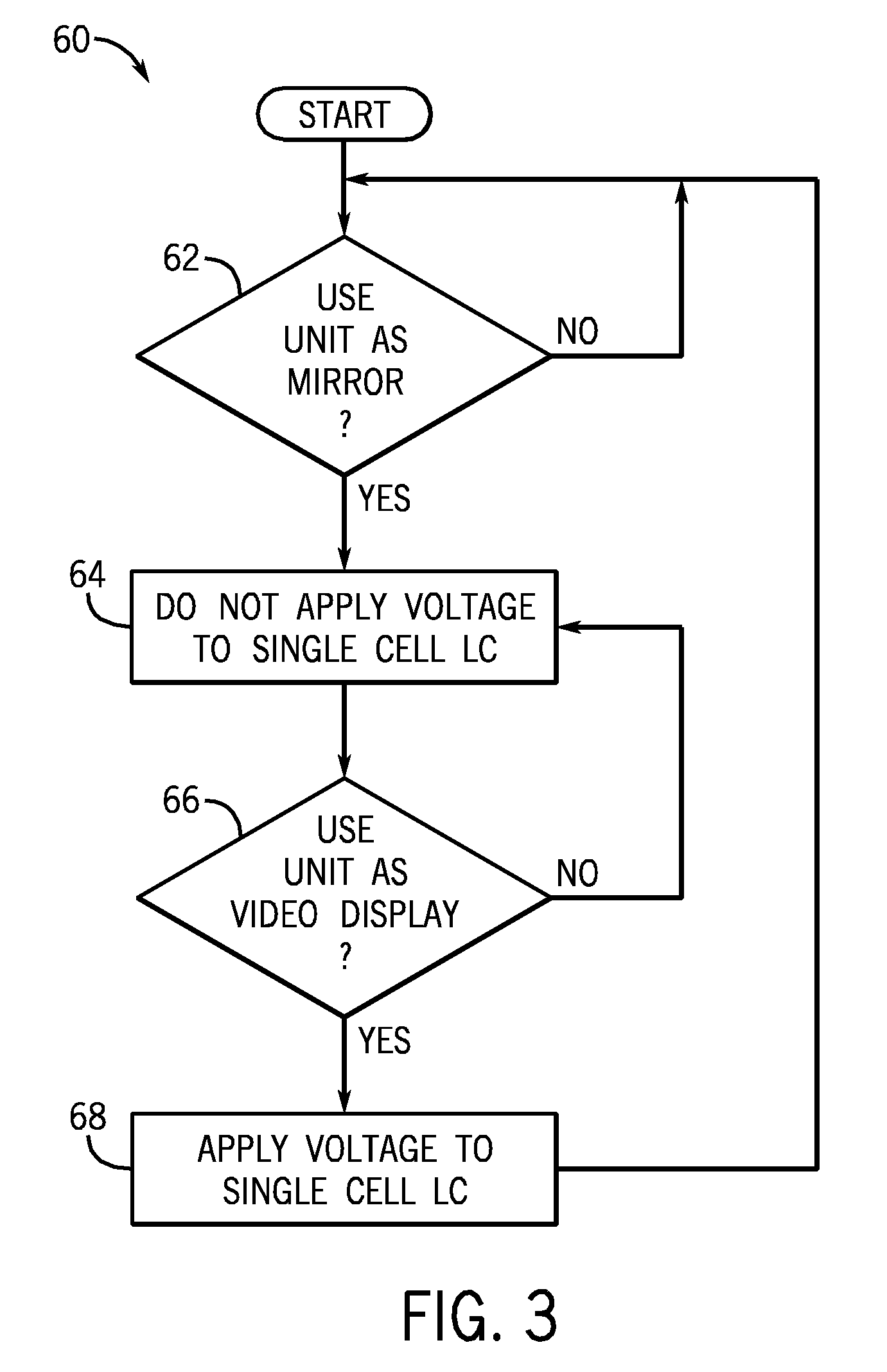

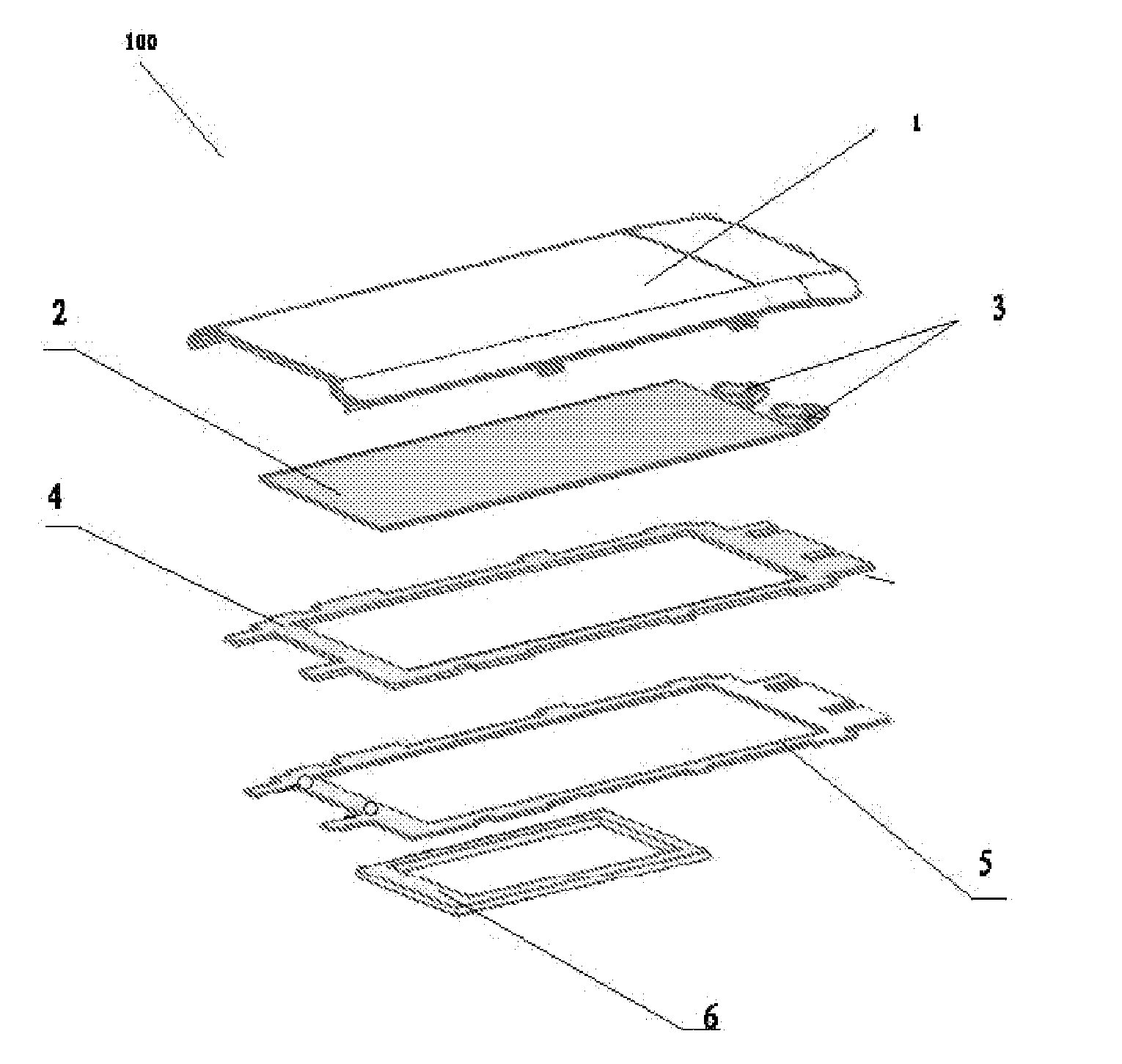

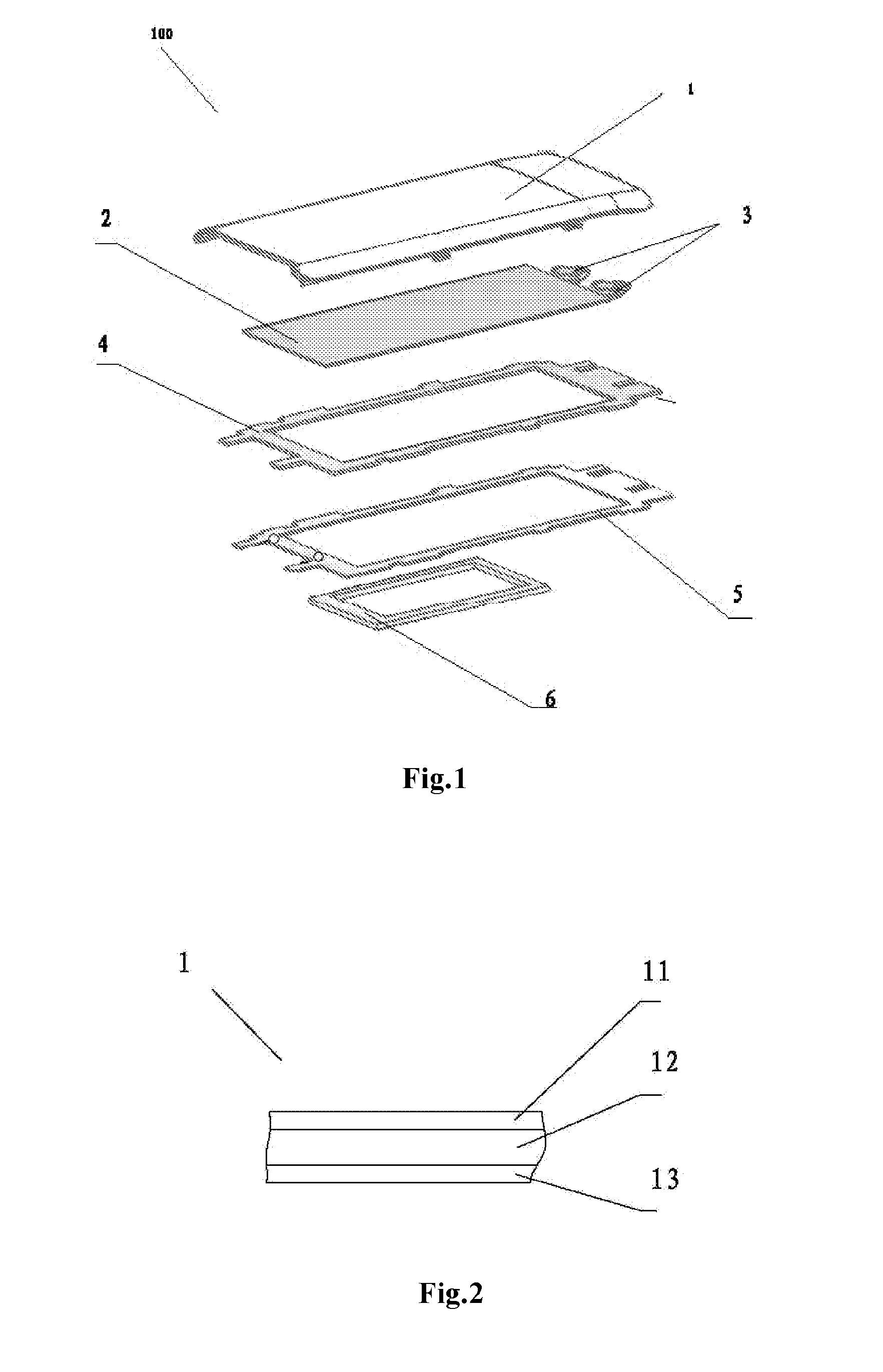

System and Method for Creating a Mirror Effect in a Liquid Crystal Display

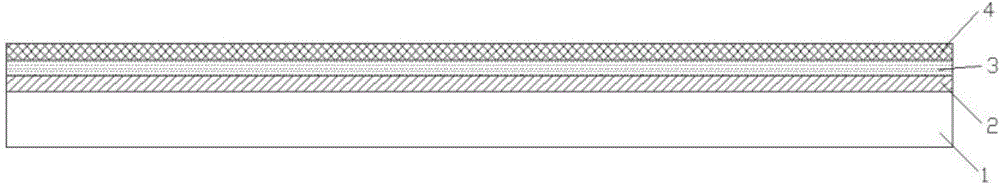

The disclosed embodiments relate to a system and method for creating a mirror effect in a liquid crystal display. More specifically, in one embodiment, there is provided a display device comprising a first absorptive polarizer, a first liquid crystal arrayed adjacent to the first absorptive polarizer, a second absorptive polarizer arrayed adjacent to the first liquid crystal, wherein the second absorptive polarizer is cross polarized with the first absorptive polarizer, a reflective polarizer arrayed adjacent to the second absorptive polarizer, a second liquid crystal arrayed adjacent to the reflective polarizer, and a third absorptive polarizer arrayed adjacent to the second liquid crystal, wherein the third absorptive polarizer is cross polarized with respect to the reflective polarizer.

Owner:TTE TECH INC

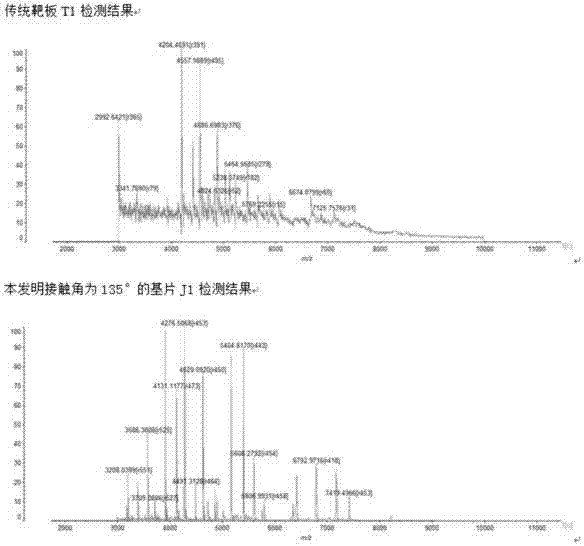

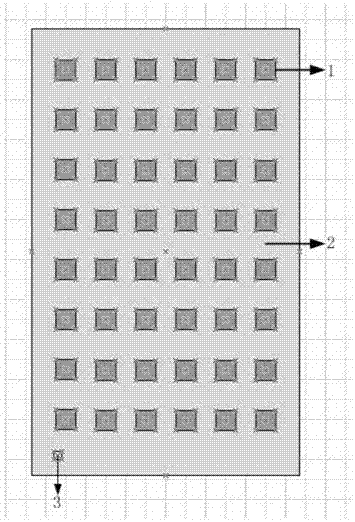

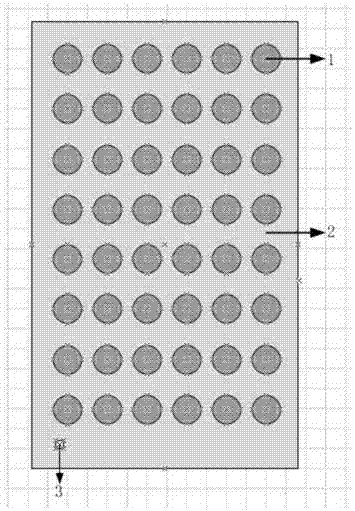

Mass spectrometry substrate as well as preparation method and application

InactiveCN106872562ASuitable for large-scale useEasy to makeFixed microstructural devicesPreparing sample for investigationMass Spectrometry-Mass SpectrometryMirror effect

Owner:毅新兴业(北京)科技有限公司

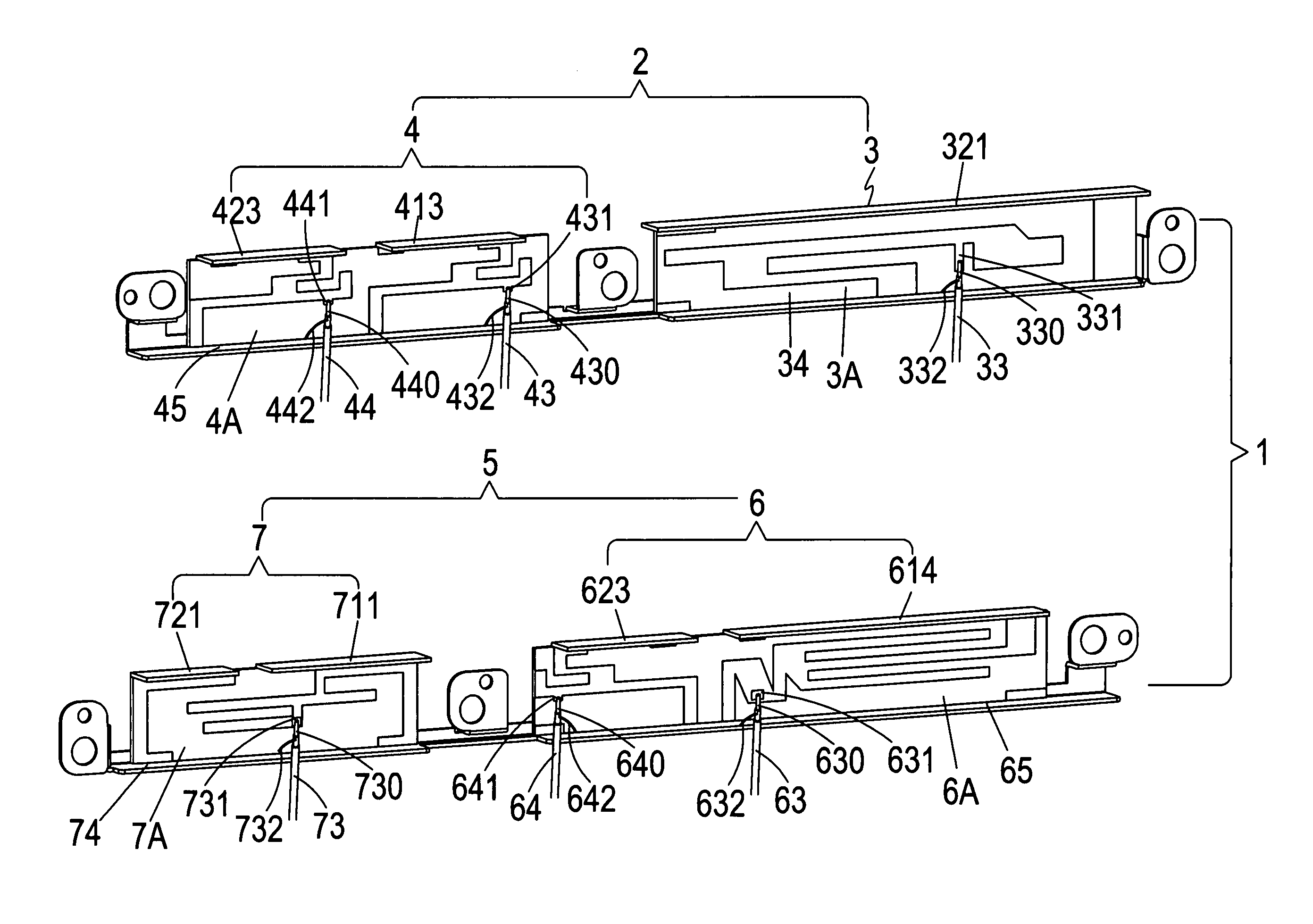

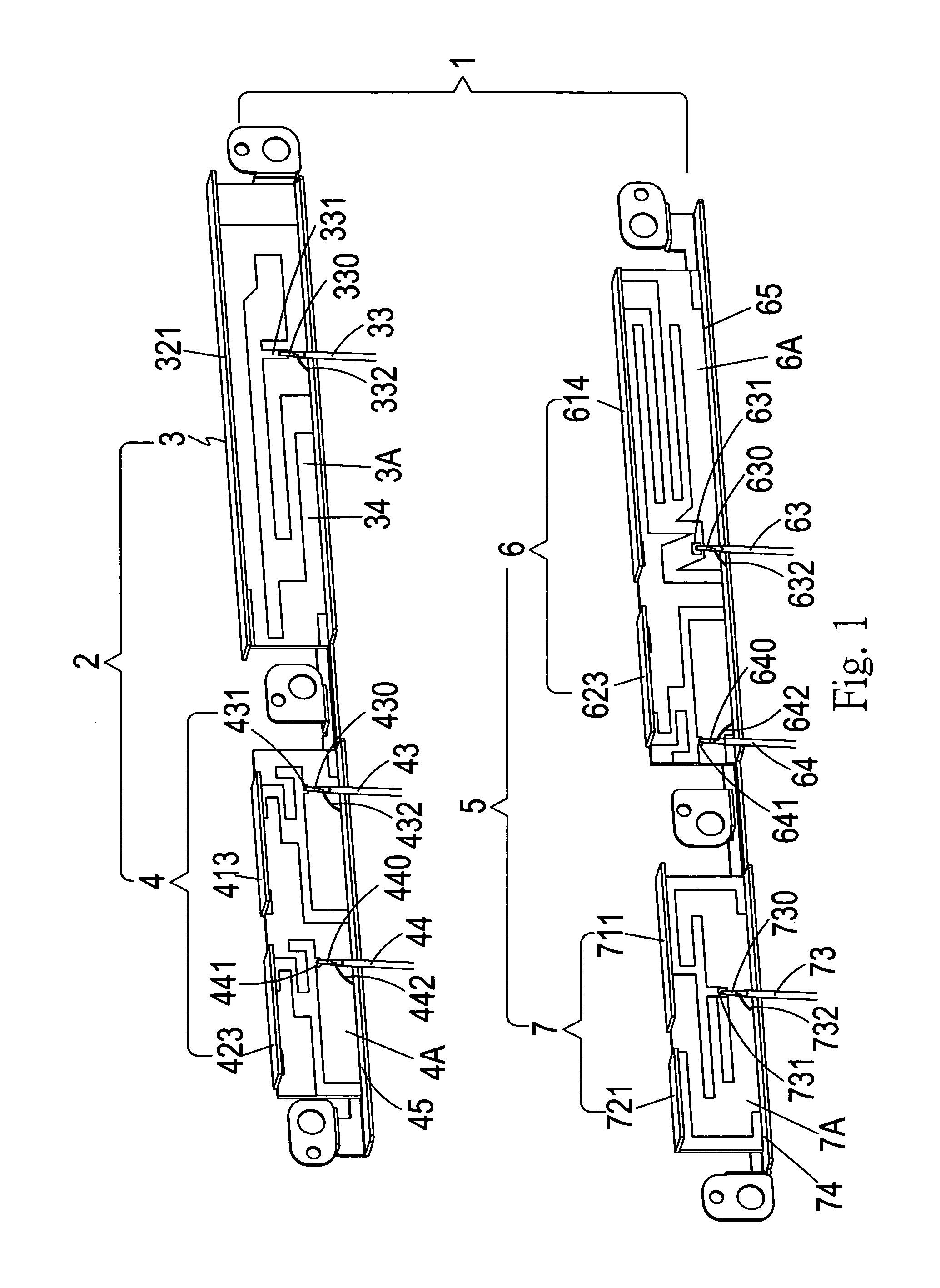

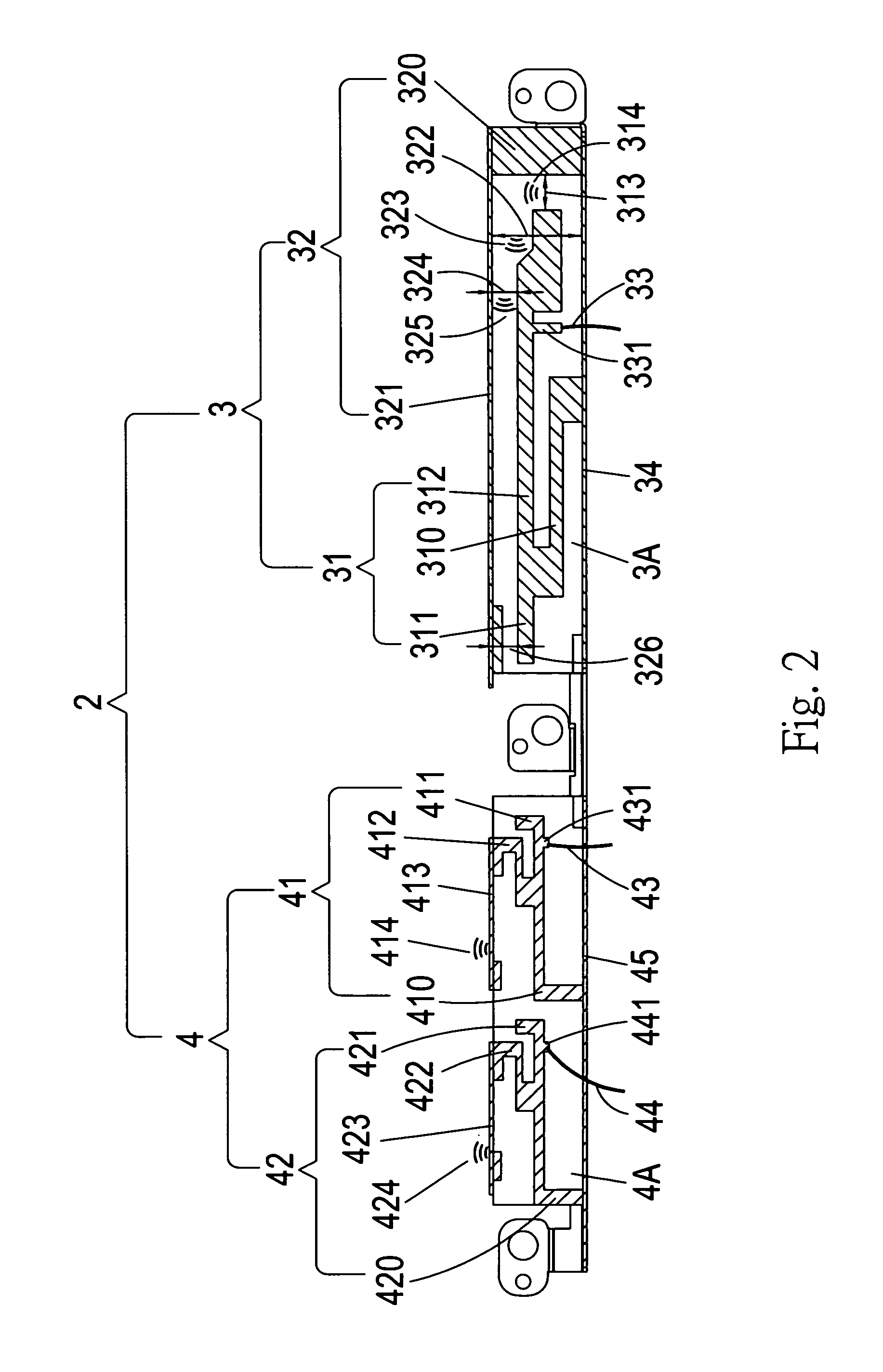

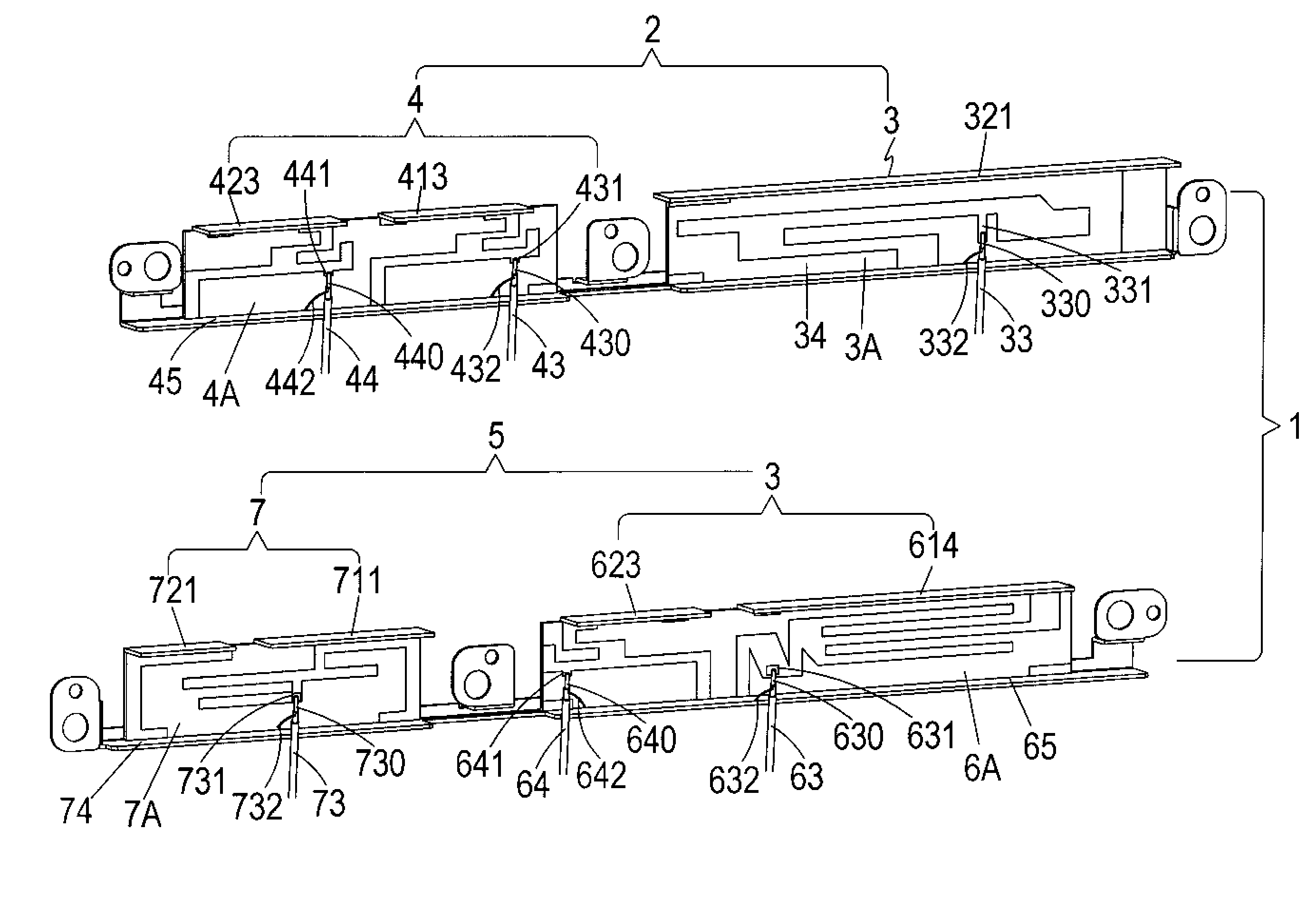

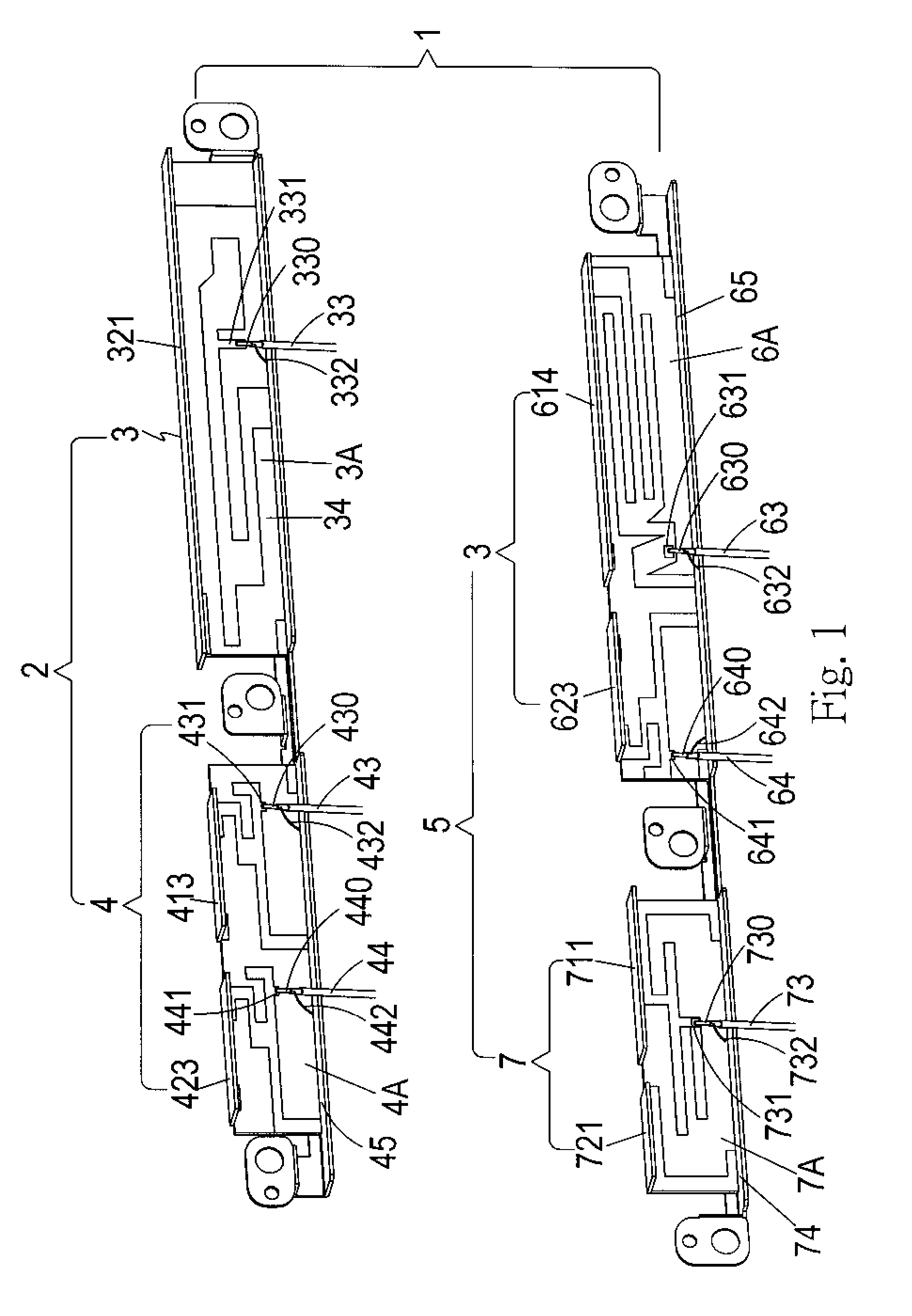

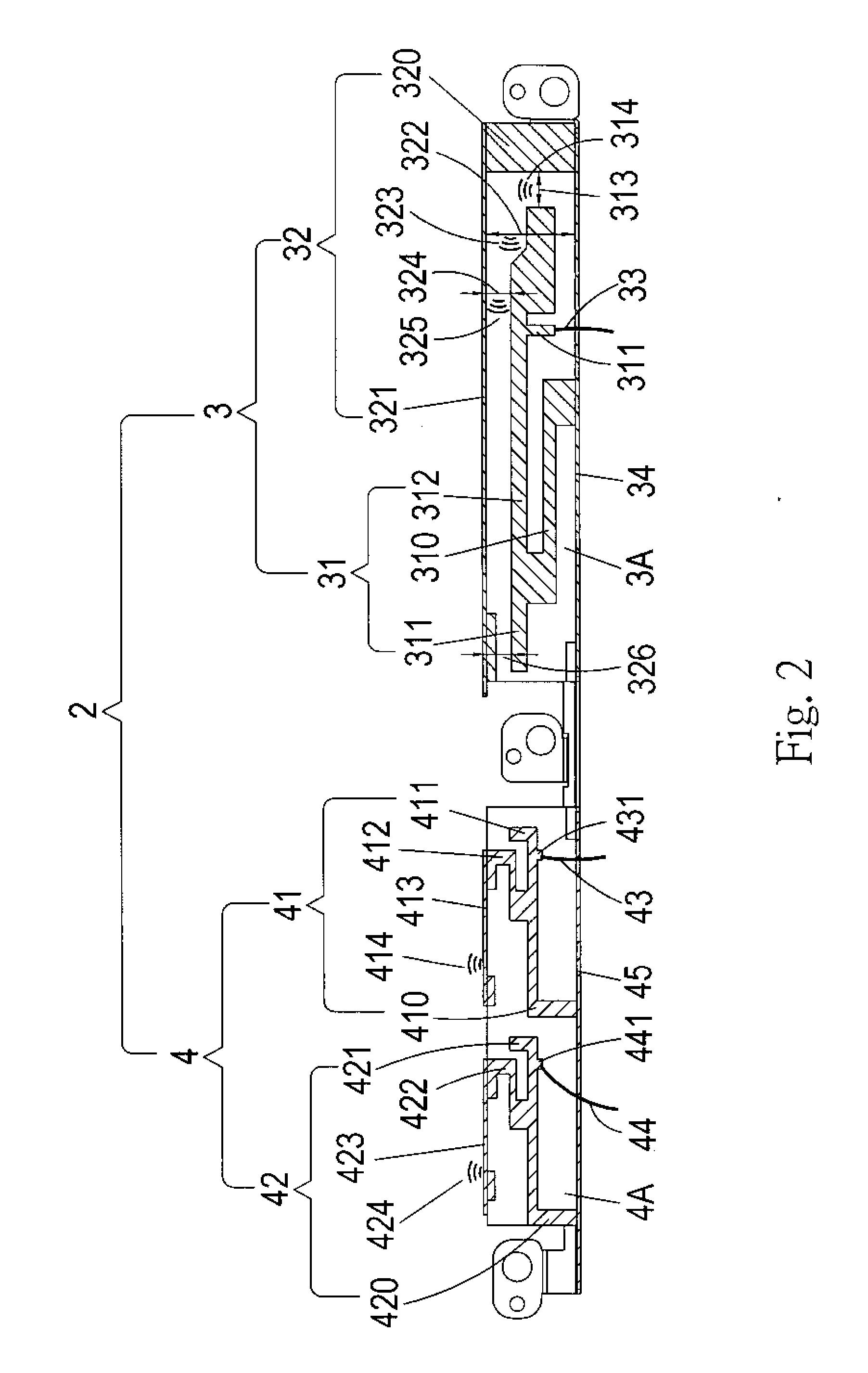

Integrated multi-band antenna module

InactiveUS8072389B2Improve performanceReduce reflection lossSimultaneous aerial operationsRadiating elements structural formsMulti bandCapacitance

An integrated multi-band antenna module includes a first antenna body having a first body and a second body, and a second antenna body having a third body and a fourth body. The first to the fourth body have relative radiating portions, feed lines, and ground lines. The radiating portions have relative arms, antenna portions, feed arms, and conducting top plates. Resonant excitation sources are formed by capacitive coupling effects from gaps between the above components. The capacitive coupling effects also lower the inductance effect and the reflection loss. Mirror effect and large-scaling conducting top plates are used to raise a radiating effect. The relative gaps form the capacitive coupling effects to receive optimized frequencies so that a small-size integrated antenna with multi-band, high radiating effect, good resonant effect, and suitable for an ultra wide bandwidth operation is achieved.

Owner:WELL GREEN TECH

Shell and display module of mobile communication terminal and a method of forming the same

A shell of mobile communication terminal is provided. The shell includes a shell body made by a transparent or semitransparent material and having an outer surface and an inner surface. The inner surface has patterns formed thereon. A semitransparent-semireflecting layer is formed on the outer surface of the shell body. The patterns can be observed from outside of the shell body when there is light transmitting from the inner surface to the outer surface, and the semitransparent-semireflecting layer presents a mirror effect when there is no light transmitting from the inner surface to the outer surface.

Owner:BYD CO LTD

3D (Three Dimensional) logo preparation process of window glass protective screen

ActiveCN103522825AImprove visual effectsRaise the gradeDecorative surface effectsOther printing apparatusEngineeringPrinting ink

The invention relates to a logo preparation process of a window glass protective screen and specifically relates to a 3D (Three Dimensional) logo preparation process of a window glass protective screen. The 3D logo preparation process comprises the following preparation steps: a step I of laser-carving a hollow-out logo of a needed pattern on the surface of the window glass protective screen; a step II of cleaning the laser-carved hollow-out logo; a step III of spraying a light-transmission gloss oil coating on the hollow-out logo to realize primary effect of the 3D logo; and a step IV of spraying a light-reflecting printing ink coating on the gloss oil coating to obtain the 3D logo with mirror surface effect. The 3D logo preparation process has characteristic that a printing process is simple, a logo obtained by printing has 3D effect and strong visual effect, level of a product can be improved, market needs are satisfied, and market competitiveness of products are improved.

Owner:萍乡星星精密玻璃科技有限公司

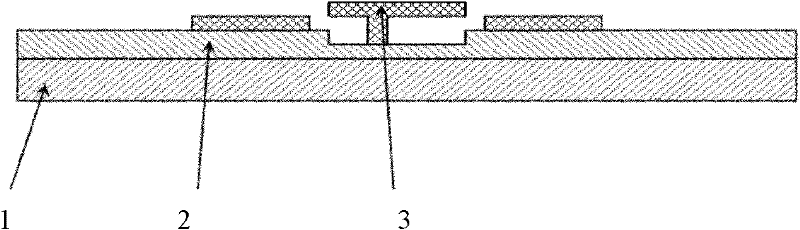

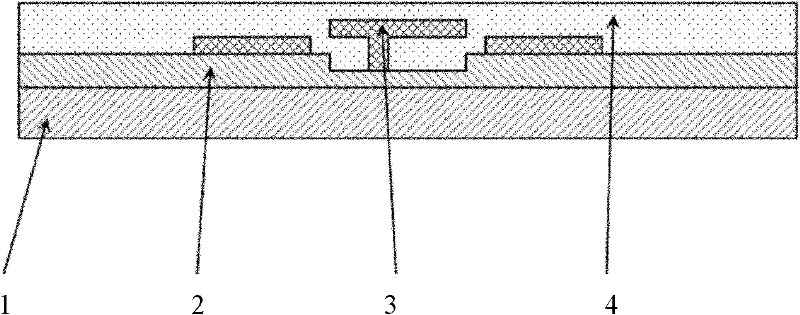

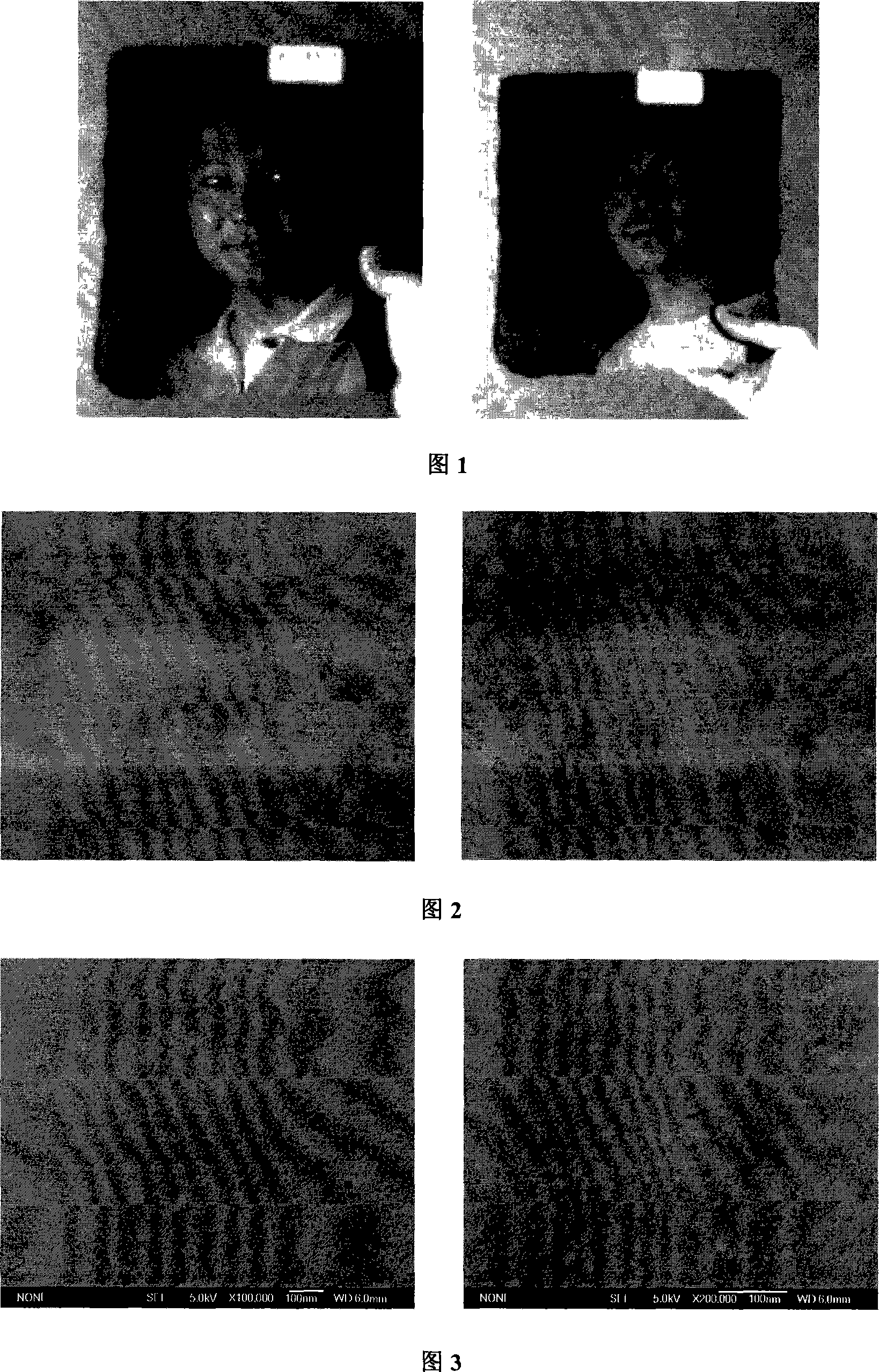

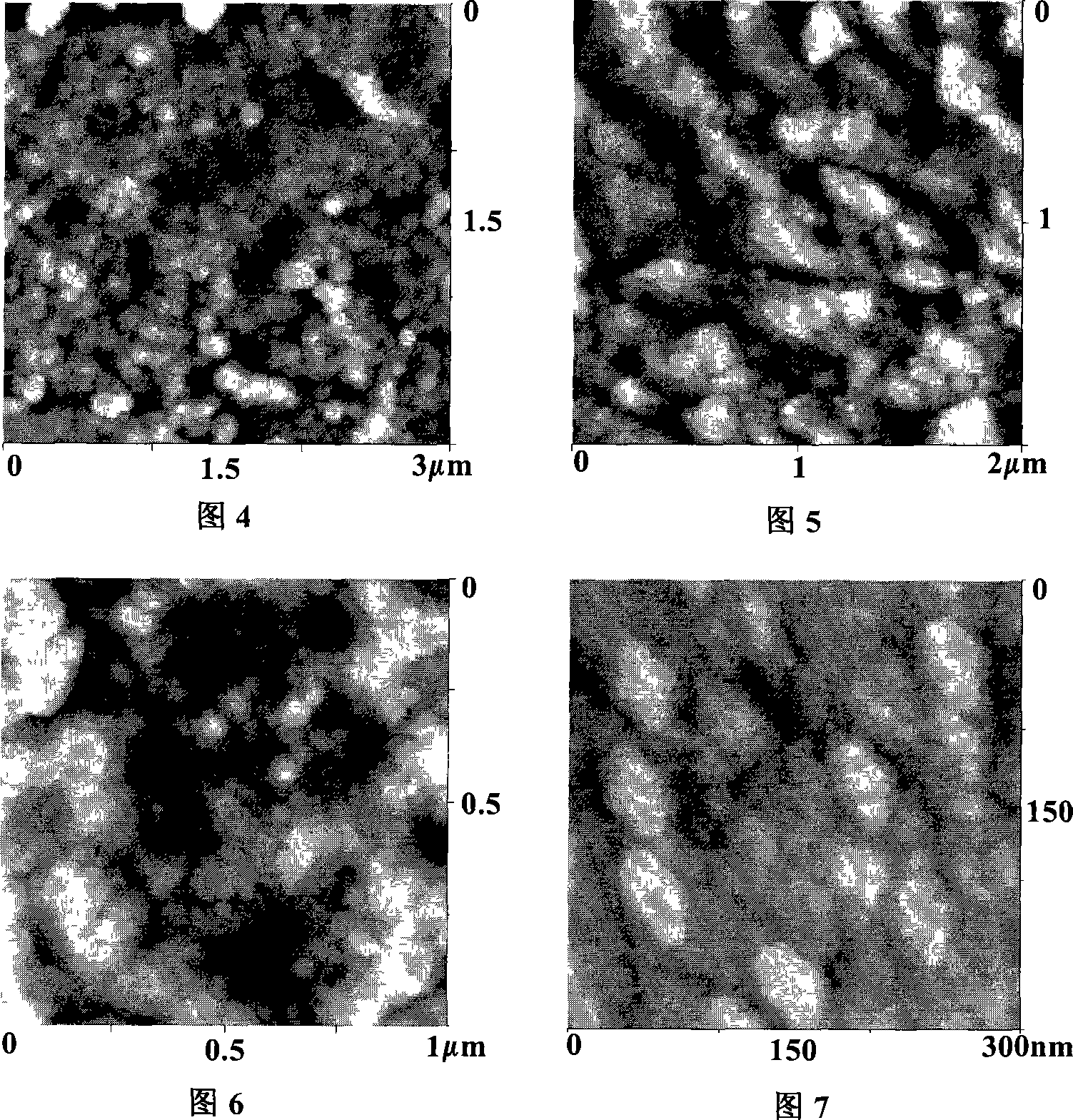

Improved rapid thinning method of gallium arsenide substrate

ActiveCN102543665AAvoid damageReduce size distortionSemiconductor/solid-state device manufacturingWaferingSlurry

The invention discloses an improved rapid thinning method of a gallium arsenide substrate. The method comprises the following steps of: based on the gallium arsenide substrate, carrying out adhesion on a gallium arsenide epitaxial wafer through a chemical reagent; meanwhile, utilizing a vacuum pressurizing method to fix, and utilizing a multilayer stacking structure to buffer the loss caused by thinning and reduce size distortion; and utilizing a soft ceramic grinding disc made of a unique material to realize high-speed and accurate back thinning, and cooperatively utilizing mixed aluminum oxide grinding slurry to obtain the thickness which is less than 60 mu m. After the grinding process is finished, a nano polishing solution is used for carrying out a CMP (Chemically Mechanical Polishing) process to achieve high-mirror effects that the thickness of a substrate is less than 50 mu m, the tolerance is less than + / -1 mu m and the roughness Ra is less than 1 nm. The polished substrate has the effects of no cracking, no crimping, no scratches and the like.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Integrated multi-band antenna module

InactiveUS20100315294A1Improve performanceReduce reflection lossSimultaneous aerial operationsRadiating elements structural formsMulti bandCapacitance

An integrated multi-band antenna module includes a first antenna body having a first body and a second body, and a second antenna body having a third body and a fourth body. The first to the fourth body have relative radiating portions, feed lines, and ground lines. The radiating portions have relative arms, antenna portions, feed arms, and conducting top plates. Resonant excitation sources are formed by capacitive coupling effects from gaps between the above components. The capacitive coupling effects also lower the inductance effect and the reflection loss. Mirror effect and large-scaling conducting top plates are used to raise a radiating effect. The relative gaps form the capacitive coupling effects to receive optimized frequencies so that a small-size integrated antenna with multi-band, high radiating effect, good resonant effect, and suitable for an ultra wide bandwidth operation is achieved.

Owner:WELL GREEN TECH

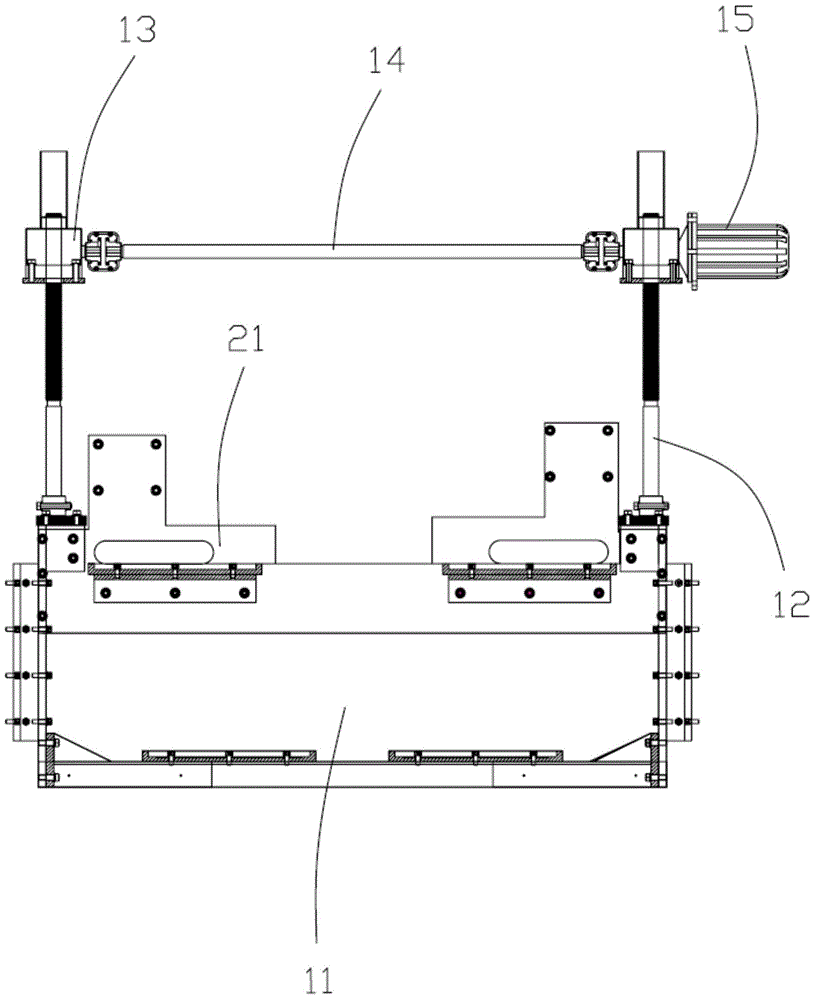

Mirror processing method for stainless steel plate and polishing machine adopted in the same

The invention provides a mirror processing method for a stainless steel plate and a polishing machine adopted in the same. The processing method includes the steps of coarse grinding, polishing, cleaning and drying. In the coarse grinding step, a water grinding mode is adopted, a grinding head assembled by coarse grinding cloth serves as a grinding tool, and an oxidation layer on the surface of the stainless steel plate is grinded away. In the polishing step, a grinding head bound by wool felt and sponges serves as a grinding tool, mixed liquid of hydrogen nitrate and hydrargyri oxydum rubrum serves as polishing liquid, and the stainless steel plate is polished into a mirror plate. In the cleaning step, fresh water is sprinkled to the surface of the stainless steel mirror plate, brushing is carried out through hairbrushes and brush rollers, and dirt on the plate surface is removed. In the drying step, heating is carried out through an electric baking lamp tube to remove moisture on the surface of the mirror plate. The mirror processing method is simple; the corresponding polishing machine is combined, and the mirror effect on the surface of the stainless steel is achieved through the polishing liquid in cooperation with preset polishing time.

Owner:ZHAOQING HONGWANG METAL IND

Hyperplane mirror cement base material having decorative effect and method for preparing the same

The present invention provides one kind of very smooth mirror surface cement-base material produced with material of water to cement ratio of 0.25-0.45, aggregate / cement weight ratio of 0-5, admixture / cement weight ratio of 0-10 %, and reinforcing fiber material accounting for 0-5 %. During its production, concrete, mortar and cement slurry is first poured onto smooth base plate, and after wet curing, the base plate is stripped off. The very smooth mirror surface cement-base material has smooth surface, mirror effect and homogeneous color, and possesses simple production process, low cost and excellent decoration effect. It may be used as floor board, outer wall tile, wall plate, etc.

Owner:WUHAN UNIV OF TECH

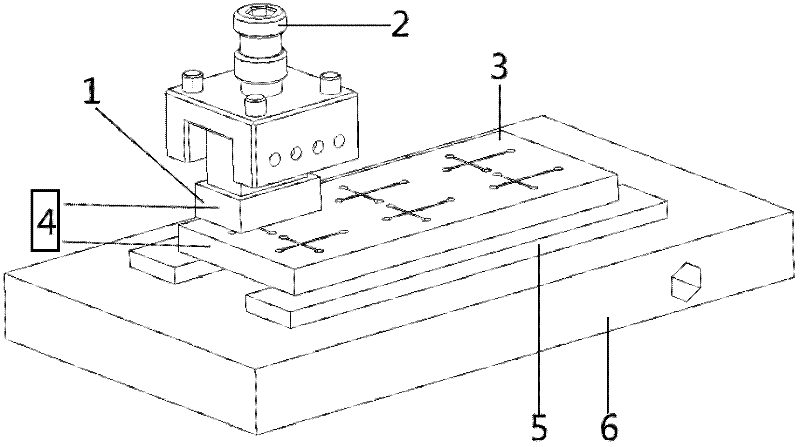

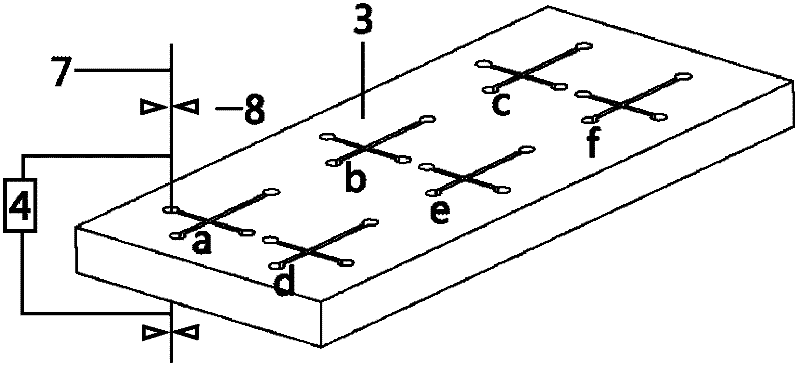

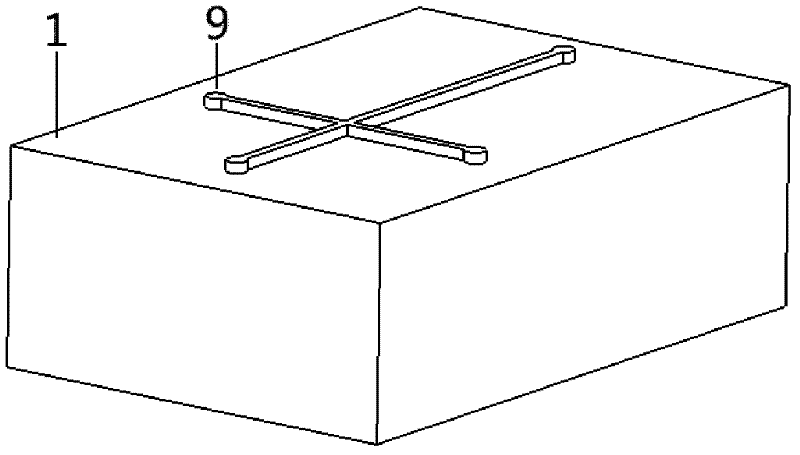

Electrical discharge machining method of die inserted block for forming microstructure

ActiveCN102357688ACompensation lossStable positionElectrical-based machining electrodesCombined methodWire cutting

The invention relates to a method for manufacturing an electrode by adopting a multi-station combining method and machining a die inserted block for forming a microstructure by using the electrode, which belongs to the technical fields of special machining and micromachining. The method comprises two steps, i.e. combined electrode machining by electrical discharge wire-cutting and microstructure machining by electrical discharge forming. A plurality of discharge stations of which the narrow slit widths sequentially and gradually decrease are machined on the same electrode material by using the electrical discharge wire-cutting, the gradually-decreased values of the narrow slit widths are equivalent to the variable quantity of electrode scaling dimensions from rough machining to finish machining in the electrical discharge forming. When the electrical discharge forming is carried out, the positions of a workpiece and the electrode are exchanged, the polarity of a pulse power supply is reversed, and the workpiece carries out servo-feeding machining on the electrode so as to finish discharging machining on each station. The method provided by the invention has the effects and benefits that the error in repeatedly positioning caused by exchanging electrodes is avoided, the vibration error caused by the servo motion of an electrode with a heavier weight and a larger volume is avoided, both the manufactured micro inserted block and the manufactured microstructure are die steel and have high hardness, long service lives, good surface quality and mirror effects.

Owner:DALIAN UNIV OF TECH

Flexible neon tube lamp

InactiveCN101113806AStrong penetrating powerImprove luminous brightnessPoint-like light sourceElectric circuit arrangementsEngineeringMirror effect

The invention discloses a soft neon lamp strip, comprising a core line of a soft lamp body extruded from soft plastic, a reflecting layer with mirror effect arranged along two side surfaces and a bottom surface of the vertical direction of the core line of the lamp body. At least two wires that can electrically connected with the power or a signal controller and a lamp body hole are arranged along the vertical direction of the core line of the lamp body a transparent soft reflecting layer is arranged on the top of the core line of the soft lamp body along the vertical direction of the core line of the lamp body, the surface of the transparent soft reflecting layer is provided with a foggy layer, and the foggy layer is a frosted layer of the surface of the transparent soft reflecting layer, or a translucent film with foggy effect which can be a color coating or paint with foggy effect that coated on the surface of the transparent soft reflecting layer, and the thickness of the translucent film is 0.01 mm to 0.8mm. Therefore the invention has the advantages of equal lighting, high light availability and brightness, and low cost.

Owner:姚志峰

Polishing liquid, preparation method and application

ActiveCN105385356AExcellent wear resistance and weather resistanceBright mirror effect is goodPolishing compositions with abrasivesWaxSoluble oxalate

The present invention belongs to the technical field of marble or wood-based panel surface brightening and protection treatments, in particular relating to polishing liquid, a preparation method and an application. The polishing liquid comprises a pH modifier, soluble oxalate, a lubricant, fluosilicate, nano titanium dioxide, nano silicon dioxide, a coupling agent, a palm wax emulsion and / or a paraffin emulsion and water. By applying the polishing liquid provided by the present invention to a marble or wood-based panel surface, under a series of physical and chemical actions, a thick layer of dense bright glassy substances can be generated on the surface; the bright glassy substances are hard, wear-resistant and weather-resistant, so that the 'water'-like bright mirror effect on a floor surface is achieved; and a surface scratch can be easily repaired. When the marble or wood-based panel surface is treated by the polishing liquid, the polishing liquid is only required to be poured onto the marble or wood-based panel, and is spread by a polishing pad. Polishing steel wire cotton is not needed; production efficiency is improved; cost is saved; and polishing brightness is improved.

Owner:GUANGZHOU GAOCHEN STONE TECH CO LTD

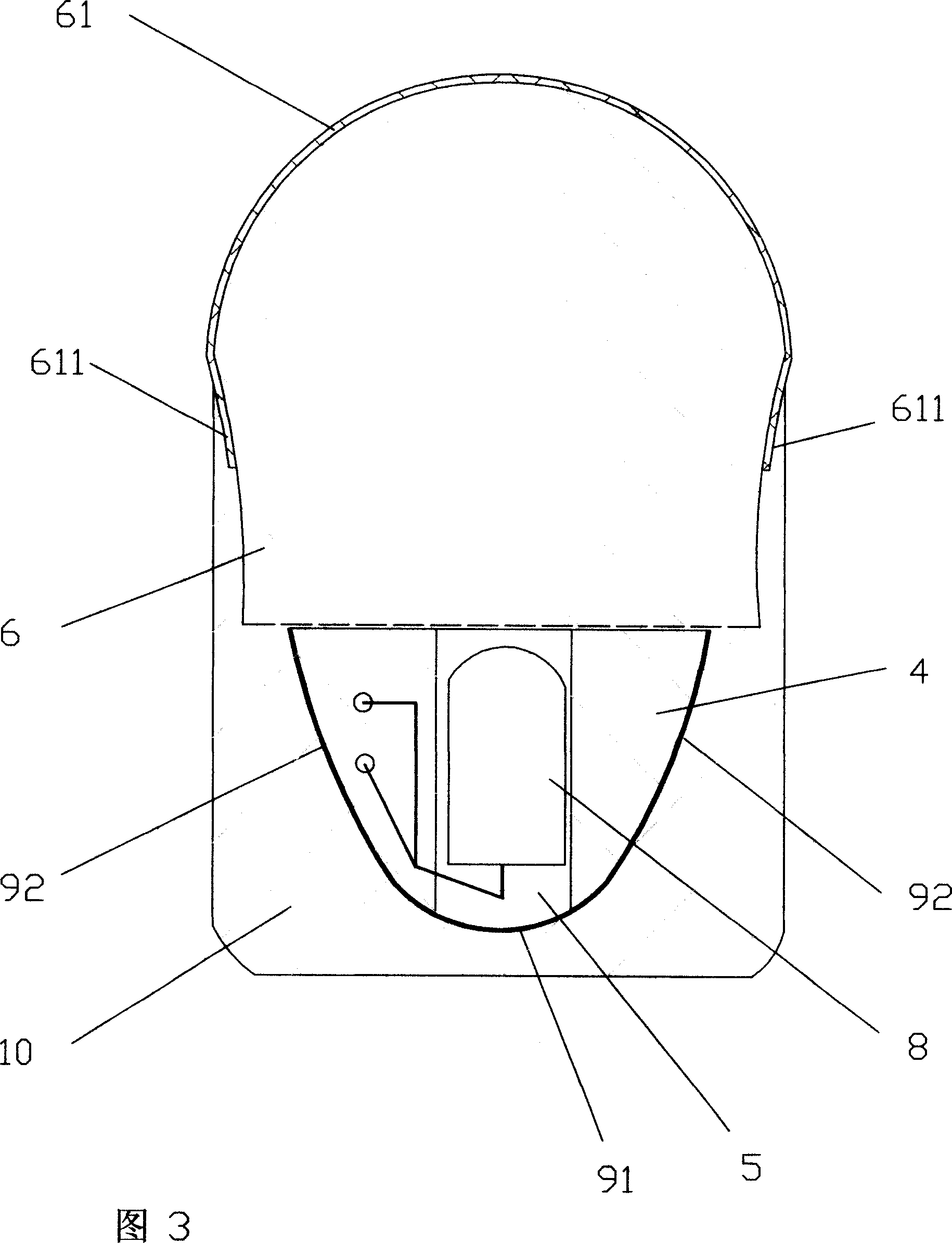

Aluminum alloy surface treatment method and aluminum alloy surface treatment product

The invention discloses an aluminum alloy surface treatment method and an aluminum alloy surface treatment product. The method comprises the following steps of: stamping an aluminum alloy piece to be in a required shape; performing partial mirror polishing on the stamped aluminum alloy piece to achieve a mirror effect; printing ink in a mirror region, and baking; sanding the treated aluminum alloy piece to enable an ink-unprinted region to be sandy; neutralizing and chemically polishing the sanded aluminum alloy piece; removing the ink from the treated aluminum alloy piece; placing the treated aluminum alloy piece into an acid liquor groove for anodizing; neutralizing the anodized aluminum alloy piece, and performing dyeing and hole-sealing treatment to obtain a required product. The product is an aluminum alloy product which is generated through the aluminum alloy surface treatment method. The surface of the product has the mirror effect and a sandy effect through one-time anodizing, the method is short in manufacturing process and high in efficiency, and the production cost can be saved.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

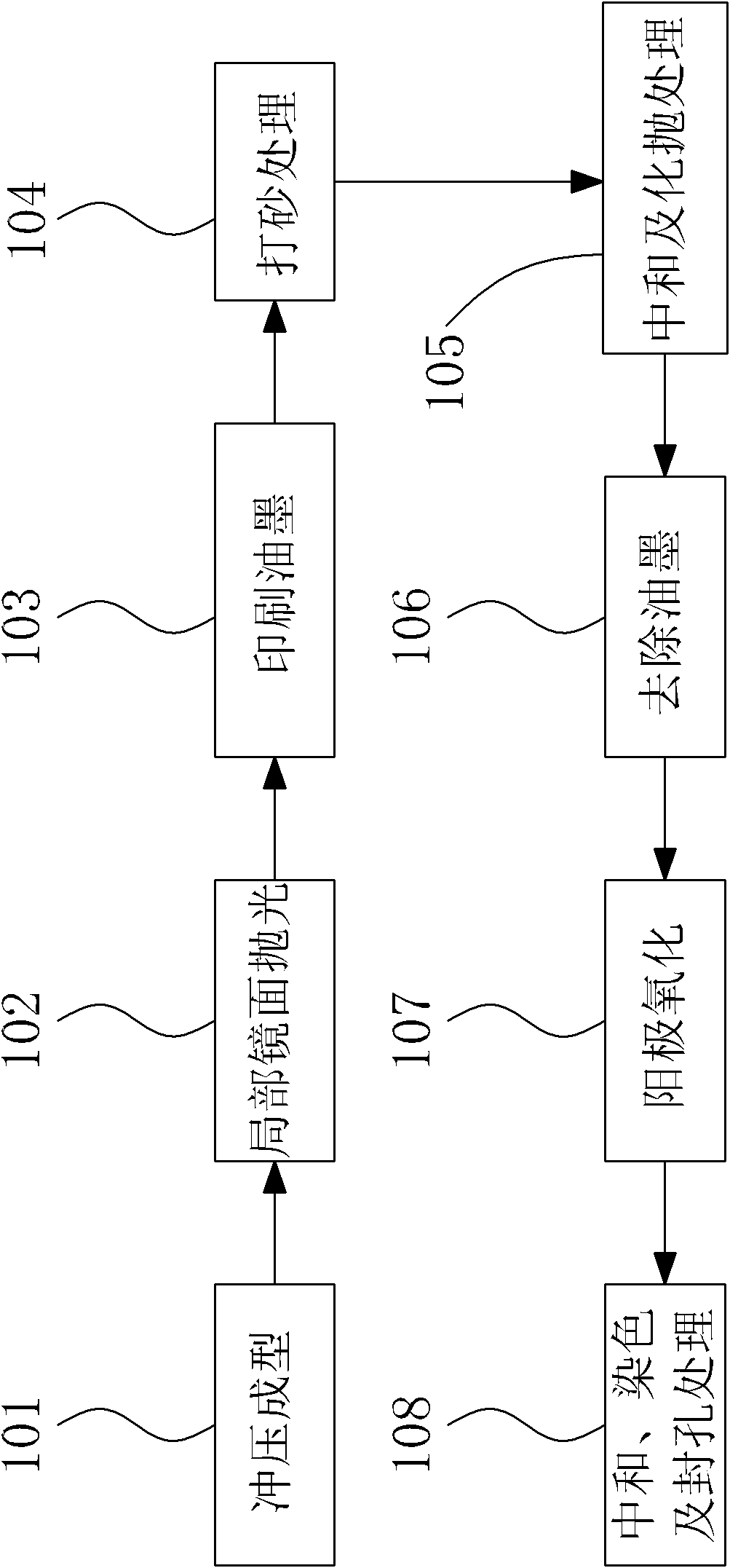

Construction method of large bridge steel guardrail concrete base

ActiveCN102619173AImprove appearance qualityReduce decoration workBridge erection/assemblySocial benefitsEaves

The invention discloses a construction method of a steel guardrail concrete base. The construction method comprises the following steps of: adopting a prefabricated decorative plate in the range of a dripping eave on the outer side of the steel guardrail concrete base, and performing field installation and positioning; and enabling the concrete base to take a finished product of the decorative plate as an external mold and performing field pouring construction. A reinforcement cage of the decorative plate is processed and manufactured by a mold of the reinforcement cage of the decorative plate, a mold plate of the decorative plate adopts a plastic mold plate, and a vibration table is used for vibrating concrete, so that the appearance of the finished product of the decorative plate can achieve a mirror effect. The installation of the finished product of the decorative plate utilizes a gun carrier provided with a three-way fine adjustment device for fine adjustment, and after the finished product of the decorative plate meets the requirements after performing recheck and inspection multiple times, the finished product of the decorative plate can be firmly welded with a pre-buried steel bar on a box girder. The construction method disclosed by the invention has the advantages of greatly improving the appearance quality of the guardrail base, reducing decoration work and high-altitude operation safety risk, realizing accurate installation and positioning of a steel guardrail pre-buried piece, realizing low construction input and having better economic benefits and social benefits.

Owner:THE 5TH ENG MBEC

High-gloss direct plating method binding layer coating as well as preparation method and application thereof

ActiveCN101671510AReduce contentReduce manufacturing costSpecial visual effect coatingsCellulose coatingsOrganic solventSolvent

The invention discloses a direct plating method binding layer coating as well as a preparation method and an application thereof. The existing transferring method has higher cost of spray aluminium paper, uses a great amount of organic solvent, and does not accord with related requirements; and the direct plating method has low cost of spray aluminium paper and environmental protection, while is rough in surface effect, thus only being suitable for low-end package. The invention is characterized in that: the coating is prepared by the following materials by weight parts: 30-50 parts of waterborne resin, 13-30 parts of cosolvent, 36-40 parts of deionized water, 0.1-2 parts of pH value conditioning agent, 0.2-0.3 parts of leveling agent, and 0.05-0.1 parts of defoaming agent. The direct plating method binding layer coating takes water as main dispersing medium, does not contain organic solvent substantially, has extremely low content of volatile organic compounds and low production cost, and can achieve mirror effect in the finished paper prepared by using the coating due to high glossiness.

Owner:ZHEJIANG JINGHUA LASER TECH CO LTD

Glazed brick manufacturing method and product

The invention discloses a glazed brick manufacturing method and product, the method comprises the following steps: A, proportioning raw materials for ball milling for spray granulation to press into a brick blank, after drying, applying ground coat to the brick blank; B, printing the brick blank treated by the step A, drying, and applying protective glaze; C, bisque firing; D, applying a layer of transparent glaze to the brick blank treated by the step C, and then drying; and E, putting the brick blank treated by the step D into a kiln for firing, then using a non elastic module for grinding, packaging and storing. The burned product can be ground by use of the non elastic module for the reason that the protective glaze layer and the transparent glaze layer in a printing layer are thick and smooth, and the surface ultra smooth and mirror effect can be ensured.

Owner:FOSHAN DONGPENG CERAMIC +2

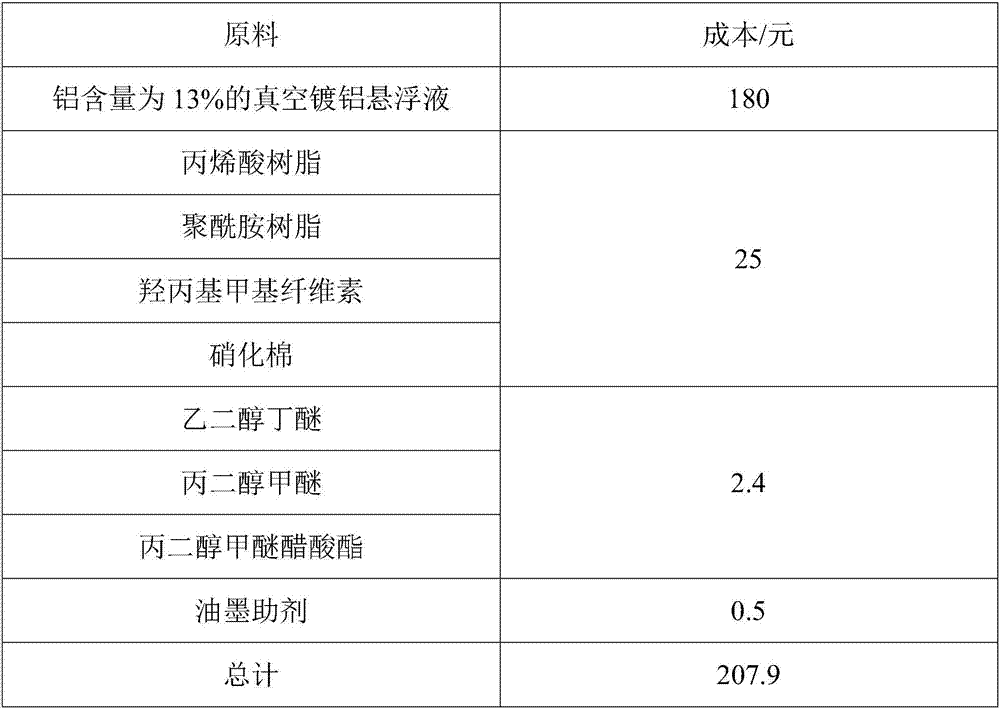

Solvent type intaglio mirror ink for transparent plastic thin film

The invention discloses solvent type intaglio mirror ink for a transparent plastic thin film, aiming at the problems in the prior art that processes including electroplating, transfer printing or silver plating and the like are commonly adopted if intaglio ink for a plastic thin film needs to be processed into a mirror image effect as a mirror, the two processes have the disadvantages of low production efficiency, high cost and the like and an existing silver ink formula also has the conditions of poor mirror effect, unsmooth construction, relatively high price and the like. The solvent type intaglio mirror ink for the transparent plastic thin film, disclosed by the invention, is prepared from the following raw materials in percentage by weight: 20 percent to 50 percent of a vacuum aluminum plating suspension solution, 40 percent to 70 percent of resin and 10 percent to 30 percent of a solvent. The prior art is optimized and a traditional process is replaced with an ink-printing manner, so that the solvent type intaglio mirror ink is more suitable for actual online production, the cost is reduced and the mirror effect is greatly improved.

Owner:安徽天易金属新材料有限公司

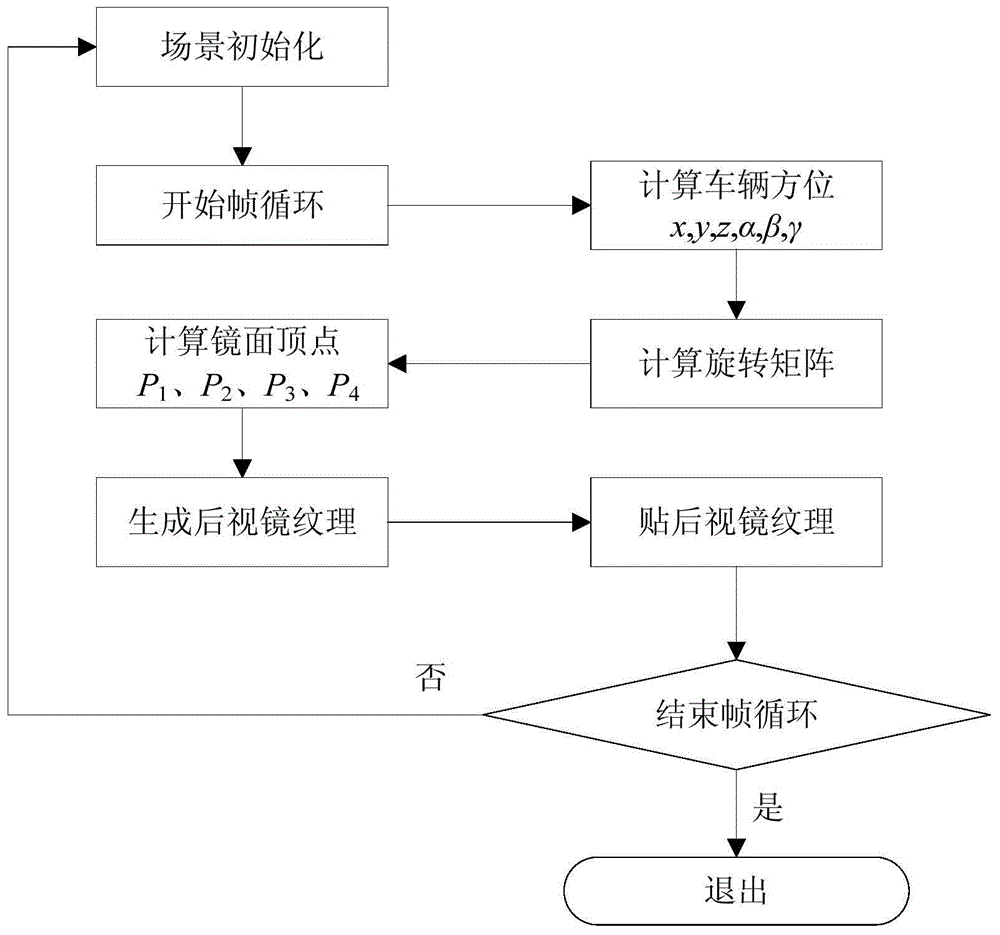

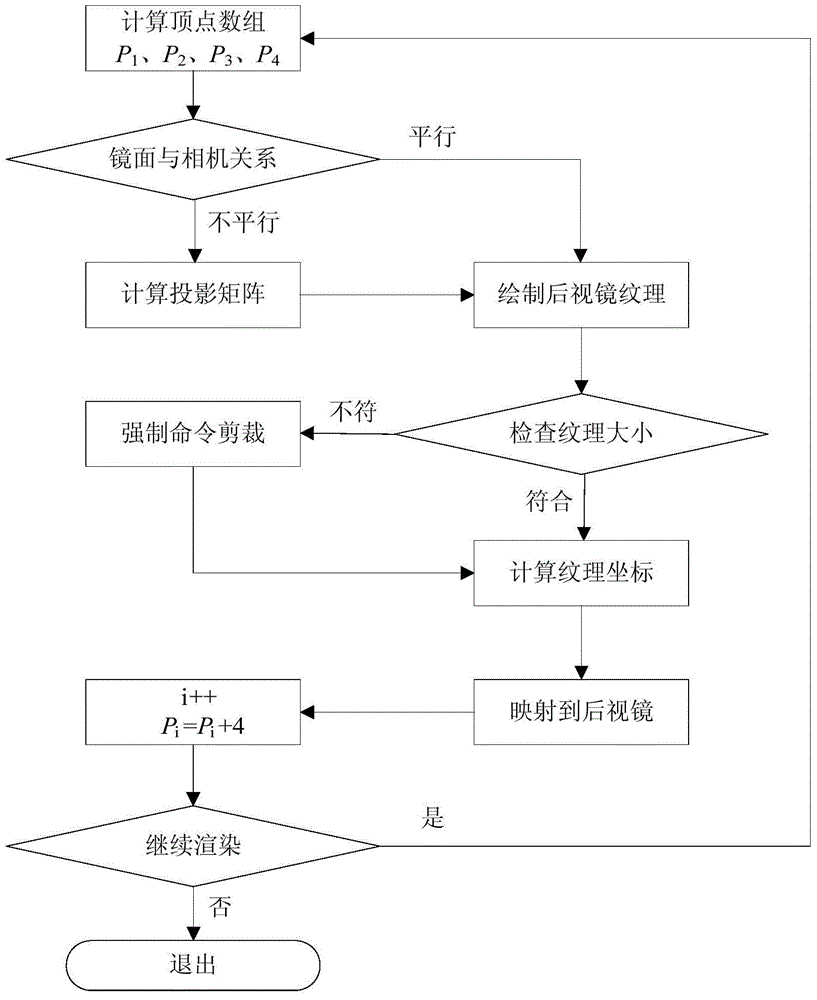

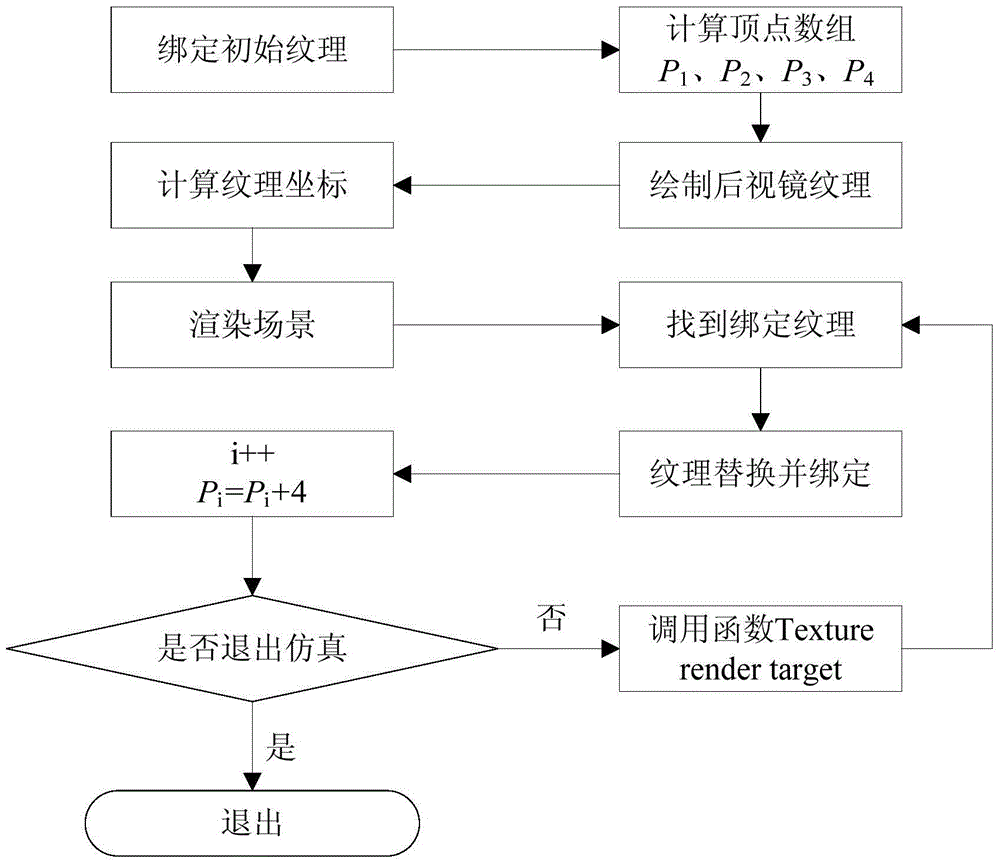

Rearview mirror simulation method for vehicle driving simulation system

ActiveCN104408989ARealization of driving simulationRealization of Rearview Mirror Simulation for Simulated Driving SystemCosmonautic condition simulationsSpecial data processing applicationsVehicle drivingMirror effect

The invention discloses a rearview mirror simulation method for a vehicle driving simulation system. The method comprises the following steps: firstly, obtaining specific position and coordinate of a vehicle according to vehicle motion, capturing a rearview mirror scene by a rearview mirror camera to obtain a rearview mirror top point coordinate required to be drawn, connecting top points in sequence to form a rearview mirror surface which is rearview mirror texture, and finally pasting the rearview mirror texture onto a rearview mirror model; during driving simulation, pre-binding initial texture, replacing old texture with new texture in real time through a created pointer function, and finally finishing simulation of a whole rearview mirror. According to the method, the rearview mirror effect is creatively displayed on a vehicle model in a three-dimension manner, so that the trouble caused by occupation of main view angle can be avoided, the refresh rate of the system can be reduced, and the vividness of whole driving simulation can be improved; the method has good commercial values.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Stainless steel product and preparation method thereof

The invention provides a stainless steel product and a preparation method thereof. The method comprises the steps that: a stainless steel substrate to be processed is adopted as an anode and is placed in an electrolytic tank containing a polishing solution; and under the condition of plasma polishing, the stainless steel substrate is polished, such that the stainless steel product is obtained. The polishing solution comprises a first polishing component and a second polishing component. The first polishing component comprises sulfate selected from sodium sulfate and / or potassium sulfate. The second polishing component comprises nitrate and a complexing agent. The invention also provides the stainless steel product prepared through the preparation method. According to the preparation method provided by the invention, a polishing salt formula different from that of existing plasma polishing is adopted; and components with different action mechanisms are reasonably formulated. On a basis of environment protection and cost reduction, a better mirror effect is provided for the surface of the stainless steel product.

Owner:BYD CO LTD

Calcium silicate decorative plate production method

The invention relates to a novel calcium silicate decorative plate production method, and aims to find a production method which can reduce the calcium silicate decorative plate production cost and improve production efficiency and production quality. The production method includes (1), performing thick sanding process on the surface of the calcium silicate; (2),performing roller painting sealing with water-proofing agent; (3), performing roller painting with UV (ultraviolet) putty, curing UV, and polishing and dedusting; (4), performing roller painting with UV undercoat, curing UV and polishing and dedusting; (5), performing shower coating with fluorocarbon undercoat and drying with infrared rays; (6), polishing and dedusting by a sander; and (7), performing shower coating with fluorocarbon finishing coat and drying with infrared rays. The calcium silicate decorative plate is made by shower coating technique, so that efficiency is greatly improved; no streaks are left on the surface of the film, so that the film is smooth, thin, and even and has mirror surface effect, and is free of environmental pollution.

Owner:SHENZHEN MINGYUAN BUILD MATERIALS TECH

Surface polishing method for A-surface sapphire wafer

The invention discloses a surface polishing method for an A-surface sapphire wafer. The method includes the steps: firstly, preparing polishing solution and then keeping a cycle stirring state to uniformly suspend solid components in the polishing solution; secondly, pasting the wafer on a ceramic plate and roughly polishing the surface of the wafer on a copper polisher; finally, precisely polishing the wafer on a single face polisher by the polishing solution. The A-surface sapphire wafer polished by the method is fine in surface flatness and TTV effect, the surface of the A-surface sapphire wafer can be polished to achieve a mirror effect, standard requirements of current industries are met, secondary damage such as edge breakage in the whole machining process is avoided, and accordingly, yield in the mass production process is greatly improved.

Owner:TUNGHSU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com