Construction method of large bridge steel guardrail concrete base

A concrete base and construction method technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficulty in meeting social requirements, difficulty in ensuring construction quality, difficulty in dismantling formwork, etc., to achieve standardized construction and appearance Consistent color and less decoration work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

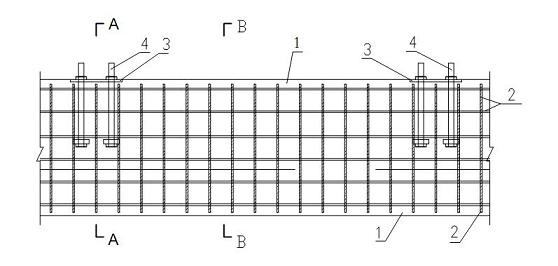

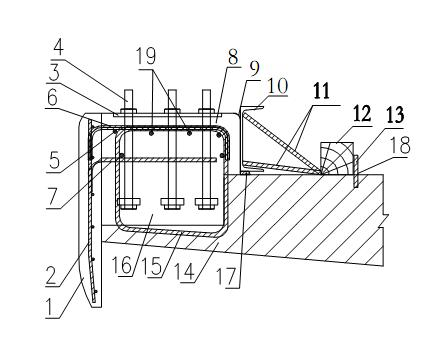

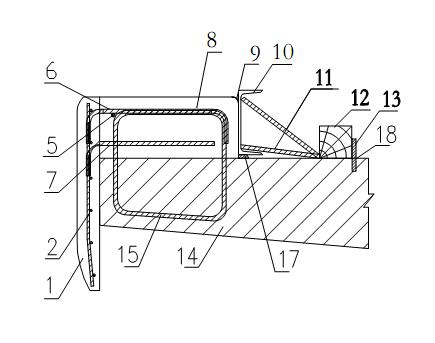

[0038] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0039] A construction method for a steel guardrail concrete base, the construction steps are as follows:

[0040] A. In the ground workshop, soak and clean the decorative panel mold with soapy water with high concentration. The panel of the decorative panel mold should be flat, smooth, without lines and spots, and then dry the decorative panel mold with a dry rag front;

[0041] B. Place the dried decorative panel mold on the center of the vibrating table in the ground workshop, and fix the four corners with clamps to limit the relative displacement between the decorative panel mold and the vibrating table;

[0042] C. Utilize angle steel welded decorative plate reinforcement frame tires to process the vertical decorative plate steel frame 2, the upper horizontal decorative plate steel frame 6 and the lower horizontal de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com