Patents

Literature

45results about How to "With mirror effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet cured paint for electric product surface coating

InactiveCN101358048AImprove wear resistanceHigh efficiency and speed of curingCoatingsSolventFunctional monomer

The invention relates to a UV-curable coating used in surface coating for electronic products, which is prepared by the components with the following weight percentage: 10 to 30wt percent of dual-functional polyurethane acrylate, 5 to 40wt percent of multi-functional nuclear hybrid acrylate monomer, 5 to 30wt percent of ethoxylated or propoxylated multi-functional acrylate monomer, 0 to 15wt percent of single-functional monomer, 1 to 6wt percent of photoinitiator, 0 to 5wt percent of modified nano material, 0.1 to 2wt percent of flatting agent, and 10 to 50wt percent of solvent. The UV-curable coating of the invention is widely applicable to the surface coating of electronic products, such as mobile phones, MP3, MP4 and digital cameras, etc, and has the advantages of high wear resistance, high transparency, strong adhesion, high gloss, etc.

Owner:SOUTH CHINA UNIV OF TECH

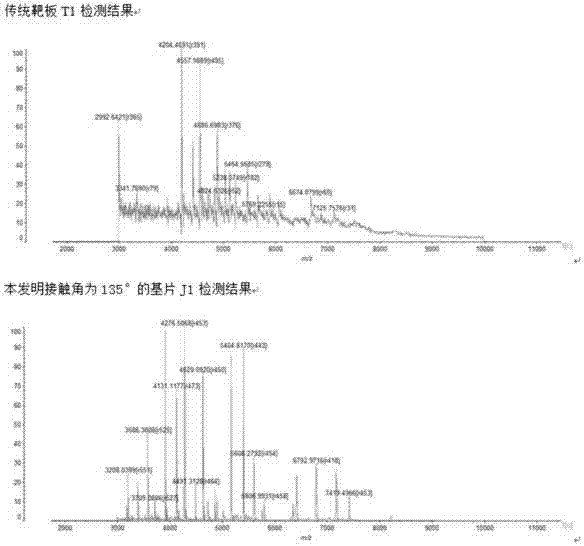

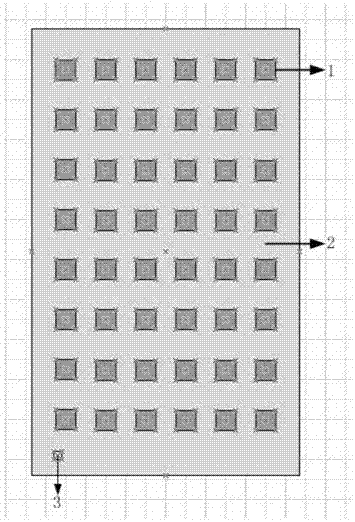

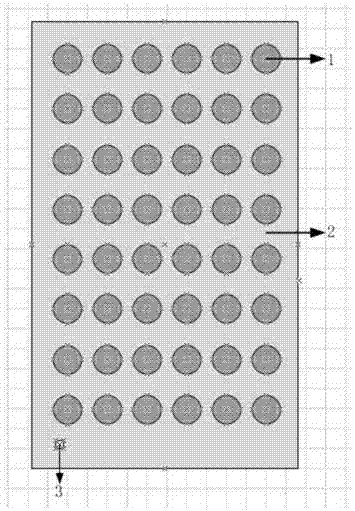

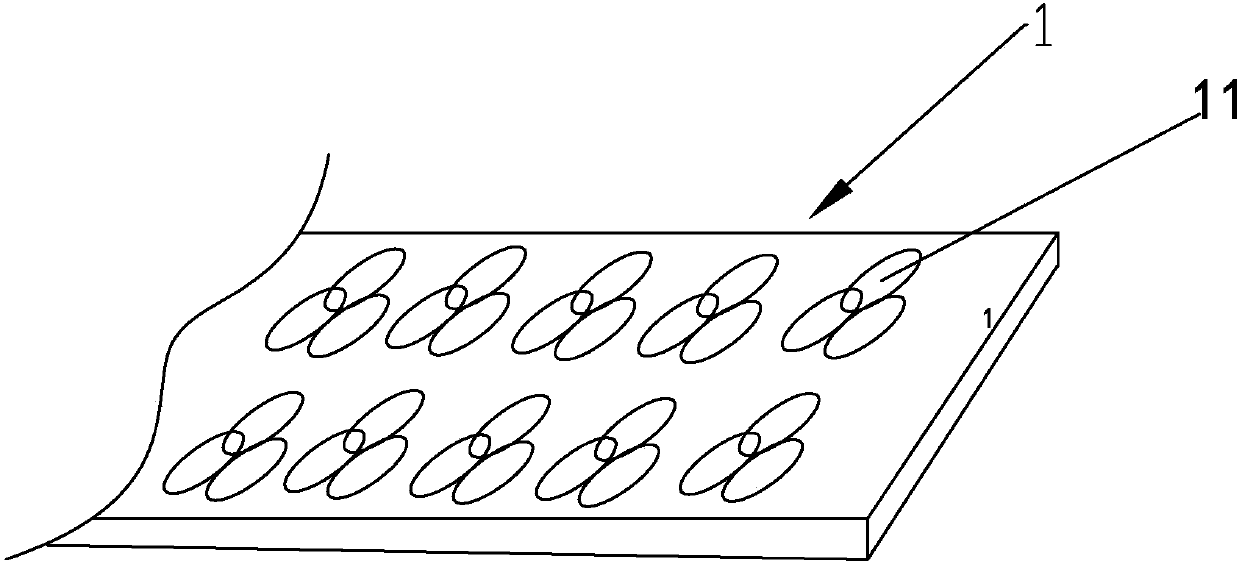

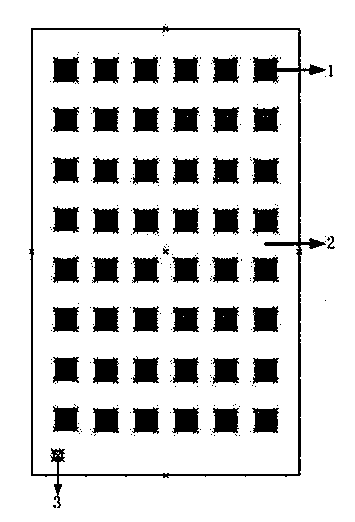

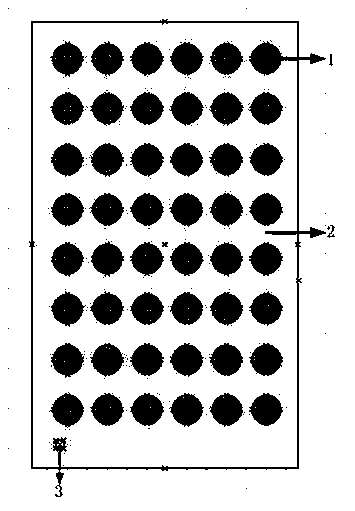

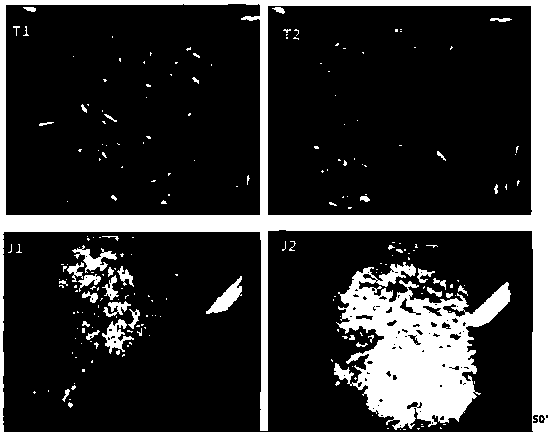

Mass spectrometry substrate as well as preparation method and application

InactiveCN106872562ASuitable for large-scale useEasy to makeFixed microstructural devicesPreparing sample for investigationMass Spectrometry-Mass SpectrometryMirror effect

Owner:毅新兴业(北京)科技有限公司

Mirror surface release paper for synthesizing leather

ActiveCN101691717AMinimize voidsDense smooth surface stateSpecial visual effect coatingsApplied substance rearrangementMicro roughnessRelease liner

The invention relates to mirror surface release paper for synthesizing leather, comprising a substrate and a release layer. A functional layer is arranged between the substrate and the release layer, and after the improvement, the functional layer is calendered at the temperature of 80-200 DEG C and the linear pressure of 80-150kN / m. The mirror surface release paper has the roughness profile arithmetical mean deviation Ra of less than 0.8 Mum, the micro roughness ten-point height Rz of less than 4.0 Mum and the glossiness of more than 90 percent at the 60-degree angle measured according to the ISO-2813 standard. The mirror surface release paper has high glossiness and the mirror surface effect.

Owner:CHINA LUCKY FILM CORP +1

Decorative board or sheet, preparation method and equipment thereof

PendingCN107813575AWith mirror effectNice appearanceCovering/liningsLamination ancillary operationsPolymer scienceWeather resistance

The present invention relates to a decorative board or sheet and a preparation method and equipment thereof. The decorative board or sheet includes a substrate, a solid film, and an adhesive layer between the substrate and the solid film. The solid film is tightly bonded to the surface of the substrate through the adhesive layer, thereby forming a bright, Smooth and transparent appearance mirror effect, and the solid environment-friendly film may not release harmful substances, so that the prepared decorative board or sheet is not toxic to human health, and has the advantages of beautiful appearance, excellent wear resistance, scratch resistance, peel resistance, washing resistance, weathering resistance, corrosion resistance and the like.

Owner:DONGGUAN NANYU RESIN HARDWARE

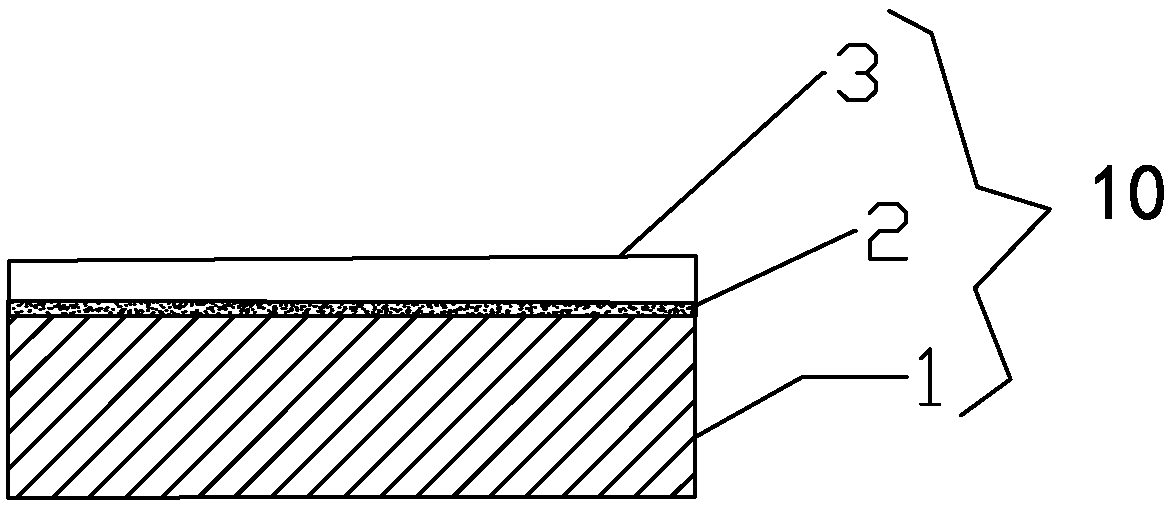

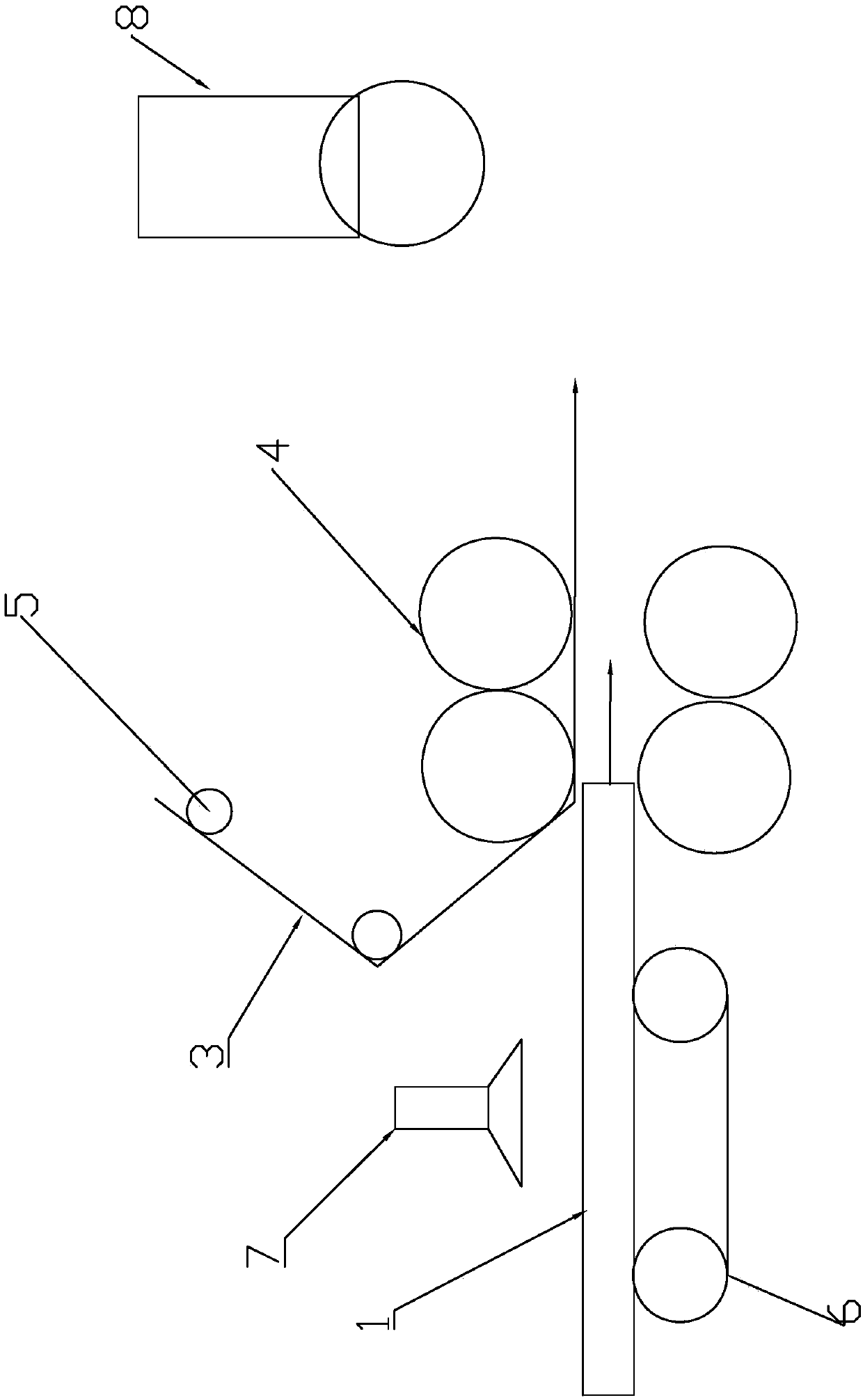

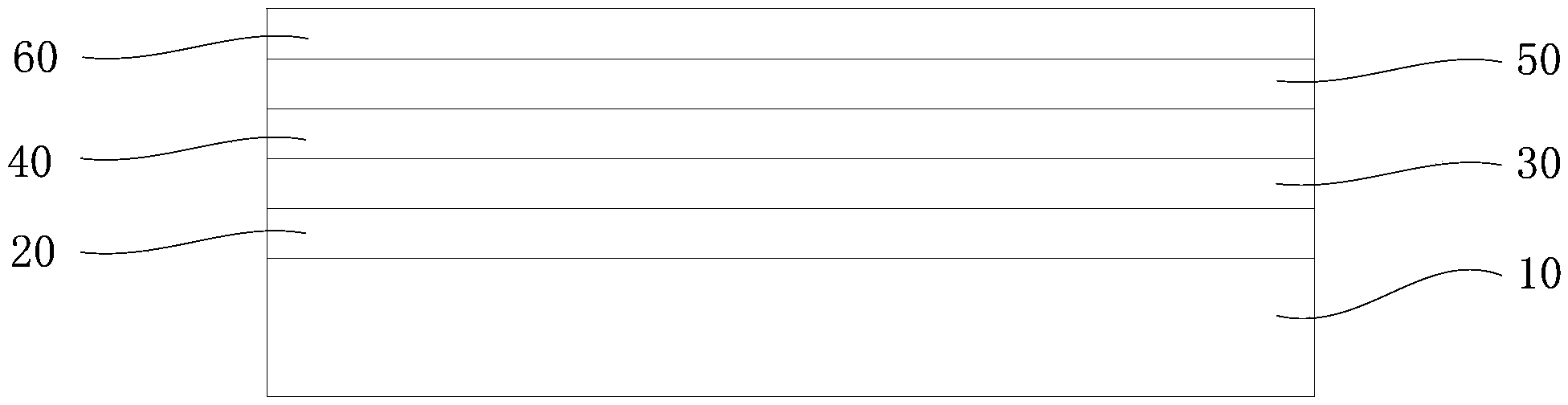

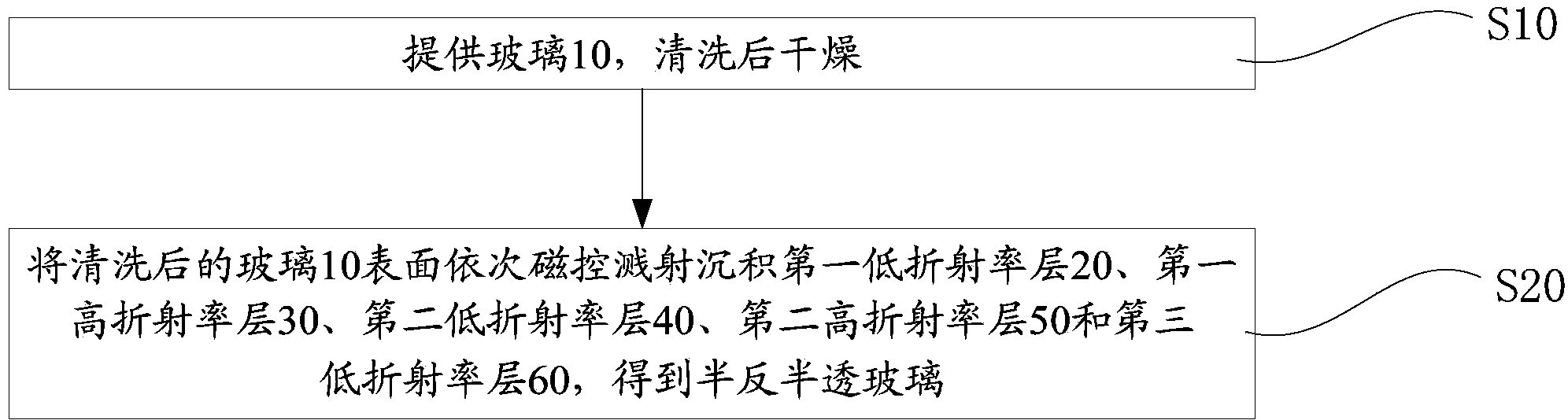

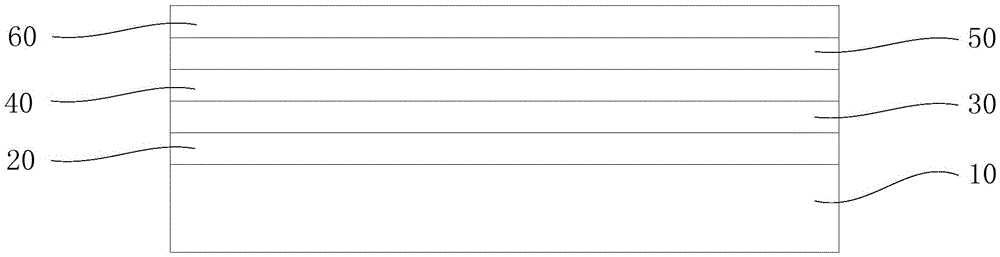

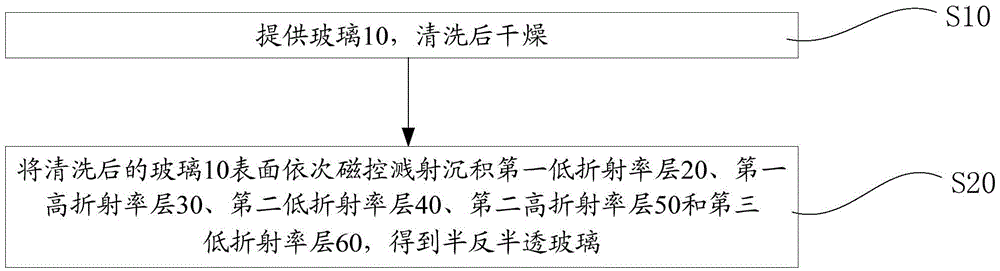

Semi reflective and semi transparent glass and preparation method thereof

ActiveCN104163022AWith mirror effectAvoid glareLaminationLamination apparatusRefractive indexWear resistance

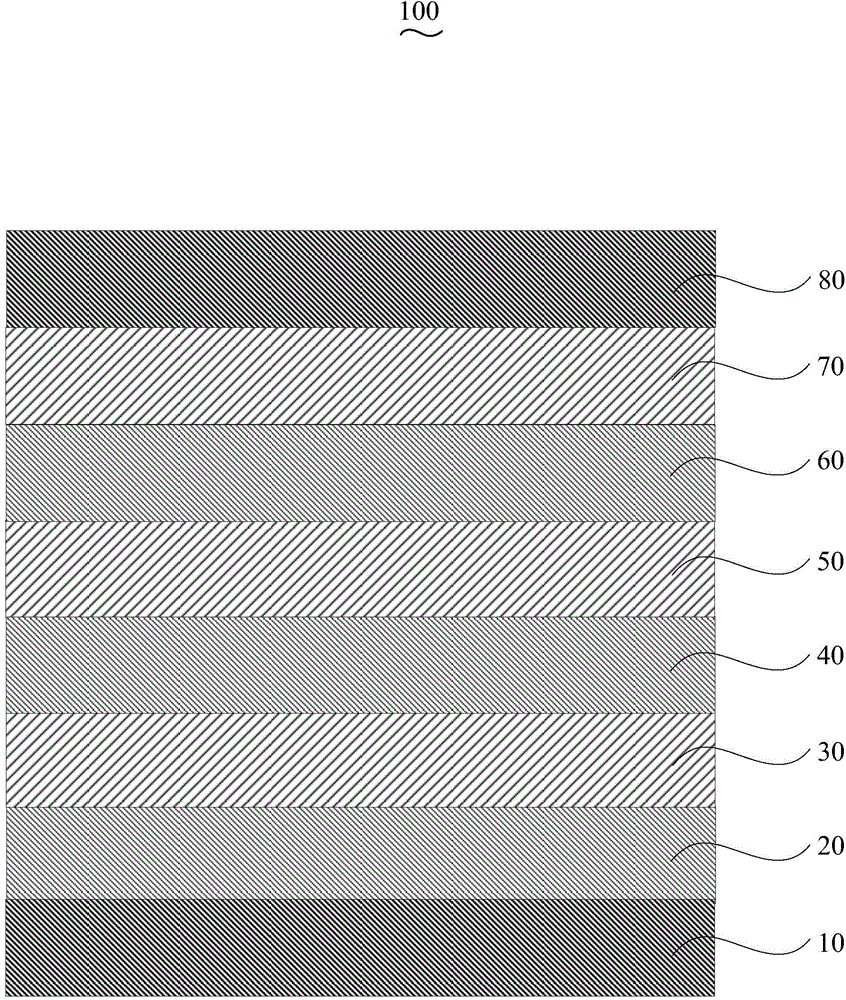

The invention discloses a semi reflective and semi transparent glass. The reflectivity of the glass is 20-50%. The glass comprises a glass substrate, a first low refractivity layer, a first high refractivity layer, a second low refractivity layer, a second high refractivity layer and a third low refractivity layer which are piled up layer by layer, wherein the first, second and third low refractivity layers are made of SiO2 or MgF2 and the first and second high refractivity layers are made of Nb2O5, TiO2 or ZrO2. By virtue of a film layer structure of suitable thickness combining layers of high and low refractivity, the semi reflective and semi transparent glass has semi reflective and semi transparent performances and the optic visual effect of semi reflective and semi transparent is realized during use; meanwhile, the semi reflective and semi transparent glass has advantages in durability and wear resistance compared to a semi reflective and semi transparent auto foil. The invention further discloses a preparation method of the semi reflective and semi transparent glass.

Owner:YICHANG NANBO DISPLAY

Epoxy floor coating

InactiveCN103305091AExcellent chemical corrosion resistanceHigh hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyPlasticizer

The invention discloses an epoxy floor coating, which is characterized by comprising a host and a curing agent, wherein the mixing ratio of the host to the curing agent is 2: 1, and wherein the host comprises the following components in parts by weight: 22-50 parts of epoxy resin, 10-30 parts of filler, 1-8 parts of thickener, 4-7 parts of auxiliaries, 18-35 parts of pigment or color cream and 6-20 parts of plasticizer, and wherein the curing agent is fatty amine and / or polyamide. The epoxy floor coating provided by the invention has excellent chemical corrosion resistance, high hardness, and excellent physical characteristics such as impact resistance, scrub resistance, abrasive resistance and the like; the epoxy floor coating is simple to prepare and convenient for construction; the epoxy floor coating is prepared from environment-friendly, solvent-free good-quality epoxy resin; the epoxy floor coating is wearproof and insulating, and hard and fine in surface; the epoxy floor coating is excellent in resistance to acid, to alkali, to salt, to oil, to esters, and to drugs; the epoxy floor coating is waterproof and non-absorbent, easy to flush, and simple and easy to clean and maintain; besides, the epoxy floor coating is bright and comfortable, smooth and beautiful in appearance with mirror face effect.

Owner:杭州宝力物资再生利用有限公司

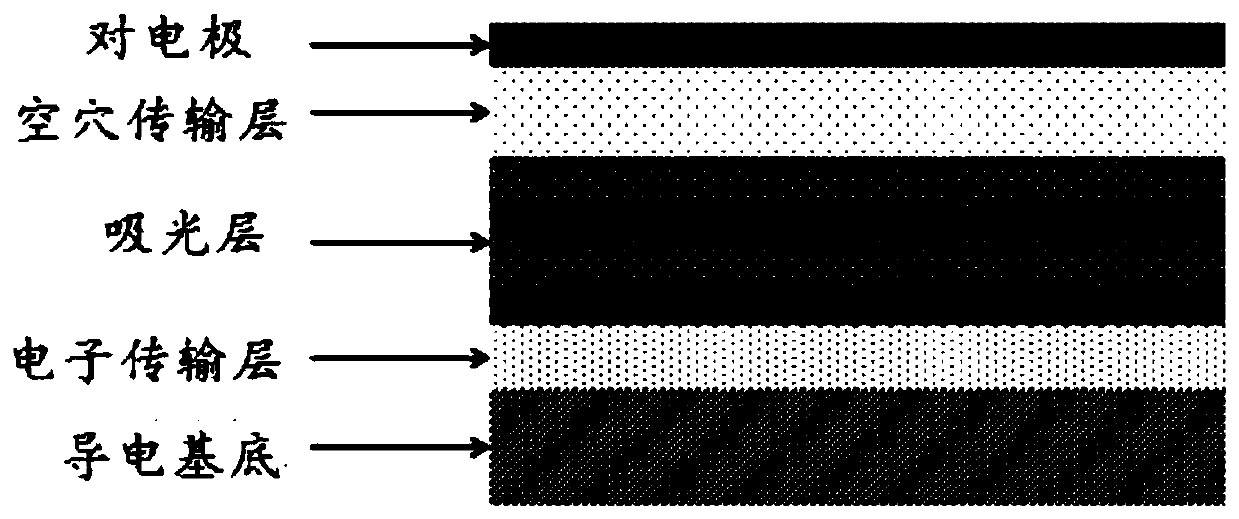

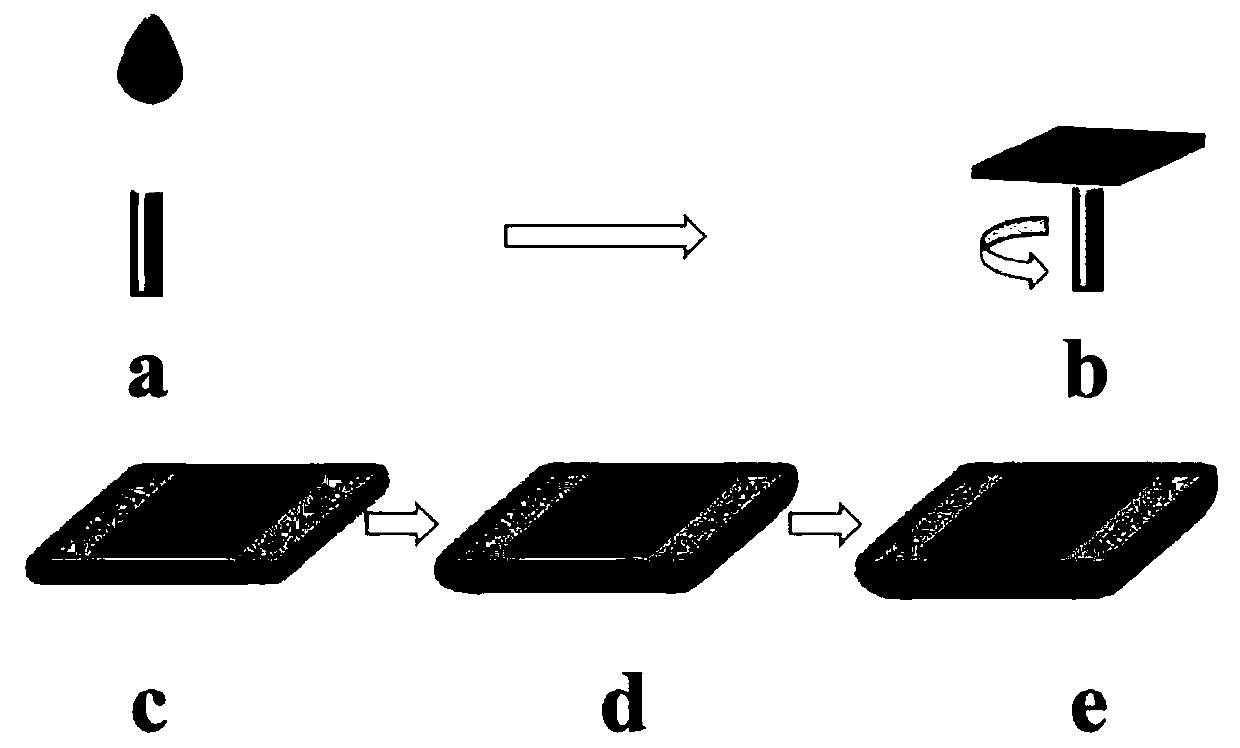

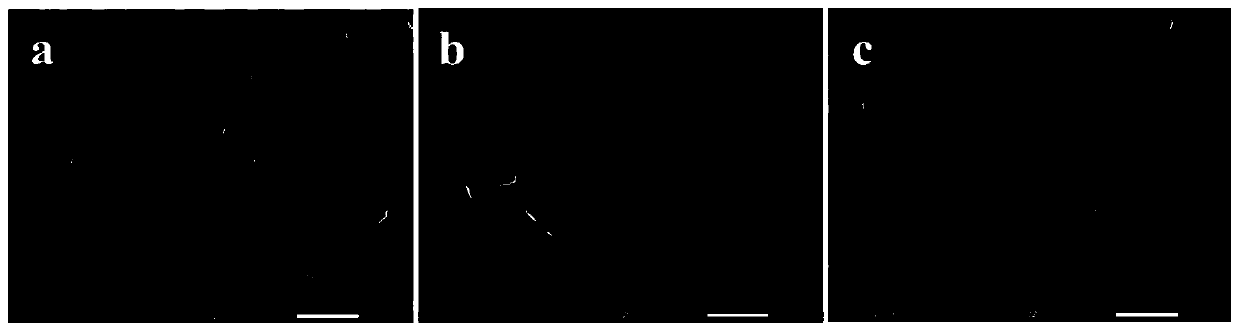

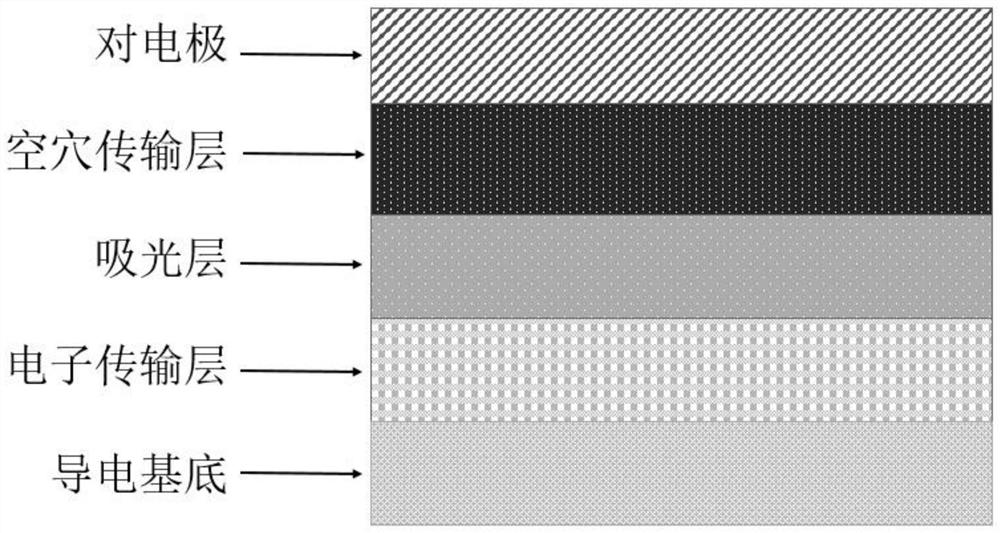

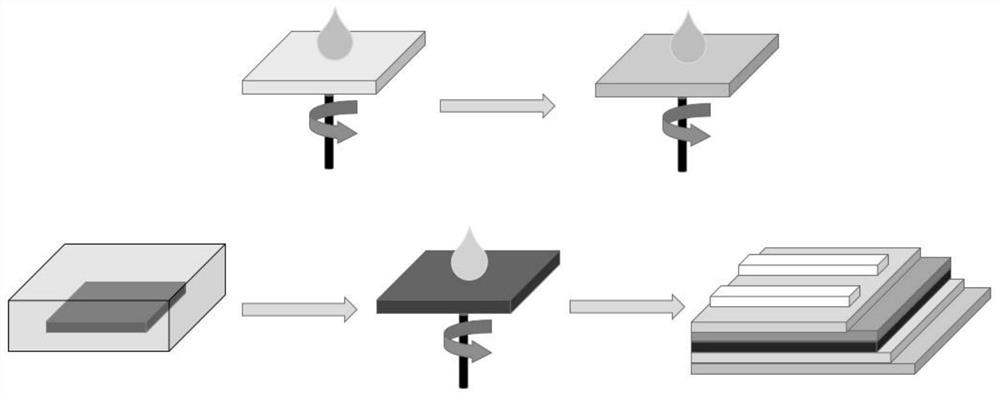

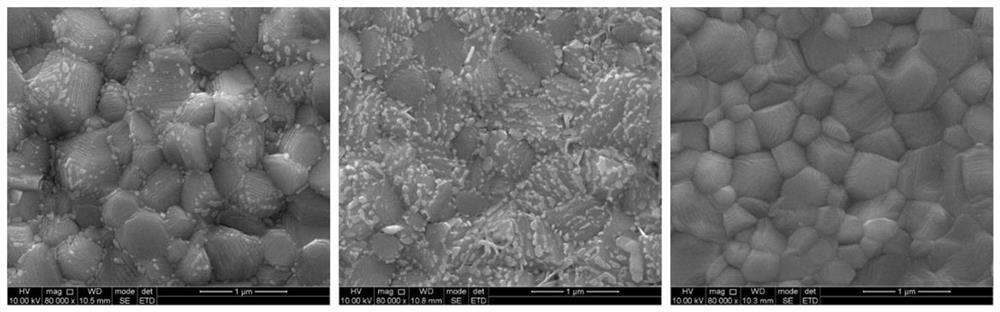

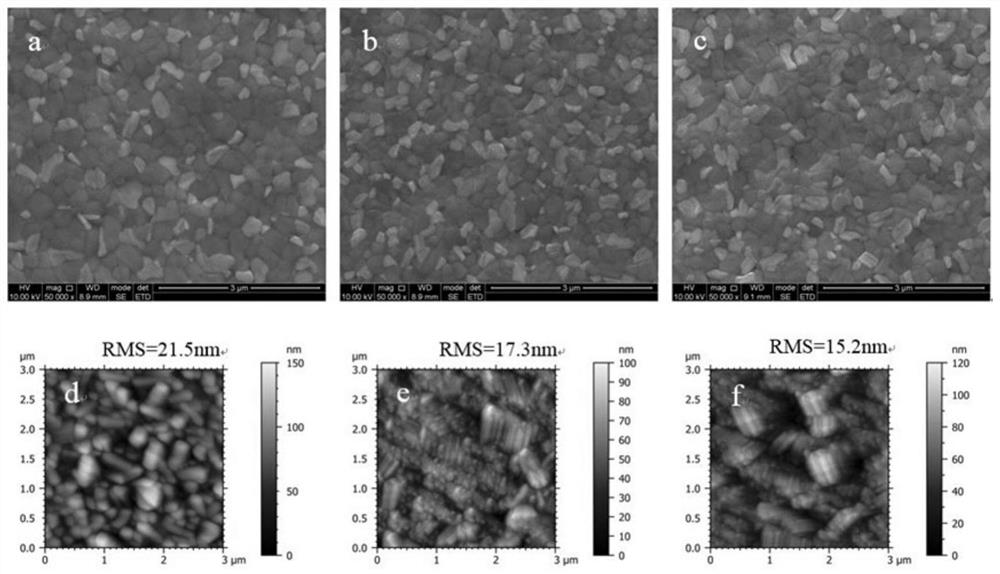

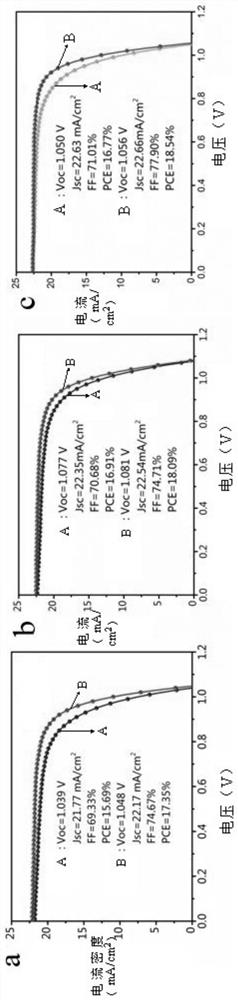

Preparation method for efficient CsPbI2Br inorganic perovskite solar cell

InactiveCN110767813AReduced growth rateReduce porositySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellPhysical chemistry

The invention discloses a preparation method for an efficient CsPbI2Br inorganic perovskite solar cell, which belongs to the technical field of solar cells and comprises the following steps of: preparing an electron transport layer on a conductive substrate, dropwise adding a CsPbI2Br light absorption layer solution on the surface of the electron transport layer, conducting standing in a glove boxat 20-28 DEG C for 10-40 minutes after spin coating, conducting annealing at 30-60 DEG C for 1-6 minutes, and conducting annealing at 155-165 DEG C for 8-12 minutes to obtain a light absorption layerfilm, and sequentially preparing a hole transport layer and a counter electrode on the light absorption layer film to prepare the efficient CsPbI2Br inorganic perovskite solar cell. According to themethod, after spin coating of the CsPbI2Br light absorption layer solution is completed, a gradient temperature annealing mode is adopted, the crystal nucleation and crystallization rate is reduced, the pinhole-free and high-quality CsPbI2Br perovskite film is prepared, and the performance of the perovskite solar cell is improved.

Owner:SOUTHWEST PETROLEUM UNIV

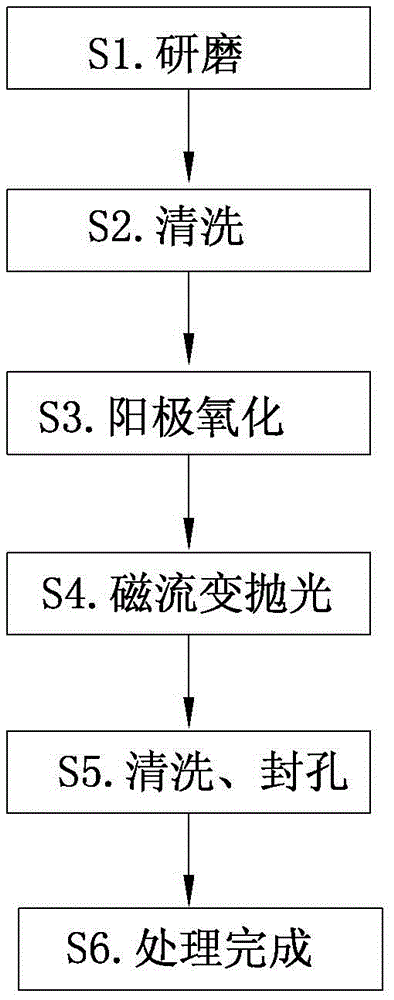

Surface mirror treatment technique for aluminum alloy

InactiveCN106078364AWith mirror effectImprove yield rateSurface reaction electrolytic coatingMagnetorheological fluidTherapeutic effect

The invention relates to the technical field of metal surface treatment, and particularly relates to a surface mirror treatment technique for aluminum alloy. The surface mirror treatment technique comprises the steps that S1, the surface of an aluminum alloy product is ground, material lines of the surface of the product are removed, and the mirror finish degree is reached; S2, the aluminum alloy product is cleaned; S3, the aluminum alloy product is subjected to anodizing treatment; S4, the aluminum alloy product is sent into magnetorheological polishing equipment for magnetorheological polishing treatment, and a highlight transparent oxidation film is obtained; S6, the aluminum alloy product subjected to magnetorheological polishing is cleaned and then subjected to hole sealing treatment; and S7, the surface mirror treatment technique is completed. According to the treatment technique, the aluminum alloy product is anodized at first and then subjected to the first time of hole sealing, and magnetorheological polishing is conducted, so that manufacturing of aluminum alloy with the mirror effect can be achieved through the magnetorheological polishing technique. Meanwhile, the yield is high, and the surface treatment effect is good.

Owner:东莞金稞电子科技有限公司

Aluminum alloy polishing additive and preparation method thereof

The invention discloses an aluminum alloy polishing additive and a preparation method thereof. The aluminum alloy polishing additive comprises, by weight, 5-15 parts of sodium tungstate, 0.1-0.2 part of polyethylene glycol, 65-84 parts of aqueous solutions, 5-10 parts of ferric sulfate and 5-12 parts of sodium persulfate. According to the additive, water is used as a solvent, the raw materials are easy to obtain, the components and the preparation process are quite simple, and production cost is greatly lowered; the additive can be added into phosphoric acid and sulfuric acid to be used for polishing, no harmful gas is generated in the polishing process, and the environment is not polluted; two-acid polishing brightness on the market can be achieved, and a mirror effect is achieved.

Owner:OUBONE GUANGZHOU UNITED BUILDING MATERIAL CO LTD

Coating with mirror surface effect and preparation method thereof

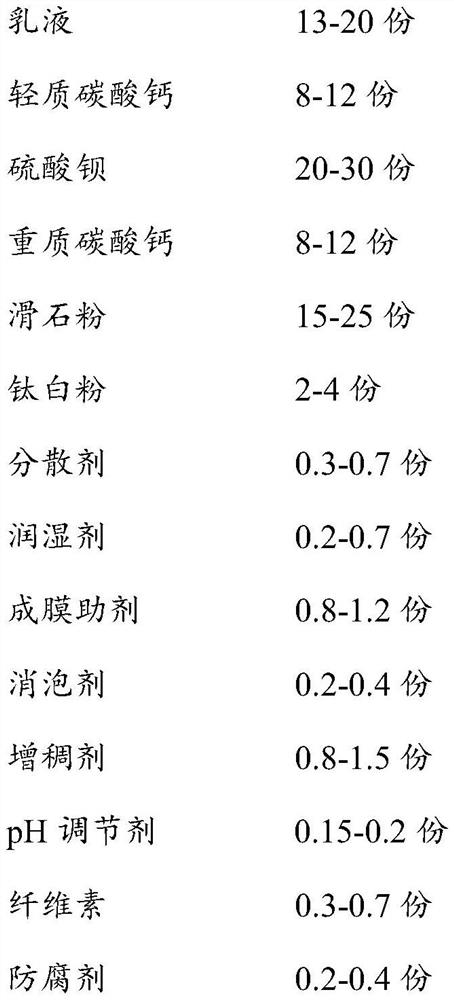

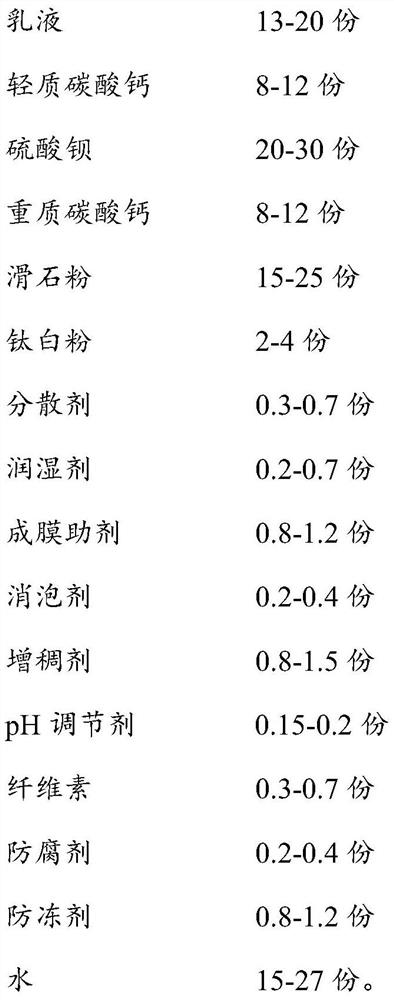

The invention belongs to the field of materials, and discloses a coating with a mirror surface effect and a preparation method of the coating. The coating includes an emulstion and filler, wherein filler comprises light calcium carbonate and barium sulfate, and the emulsion is selected from at least one of acrylic emulsion, polyvinyl acetate emulsion, acrylate emulsion or styrene-butadiene emulsion. The coating also comprises cellulose and water. Based on the light calcium carbonate, barium sulfate and emulsion, the coating is coated on the surface of equipment in batches, and a coating layerformed after curing has a good mirror surface effect; in addition, cellulose and water are added into the coating, so that the opening time of the coating can be prolonged, and a large-area coating with a mirror surface effect can be prepared.

Owner:广东嘉宝莉科技材料有限公司

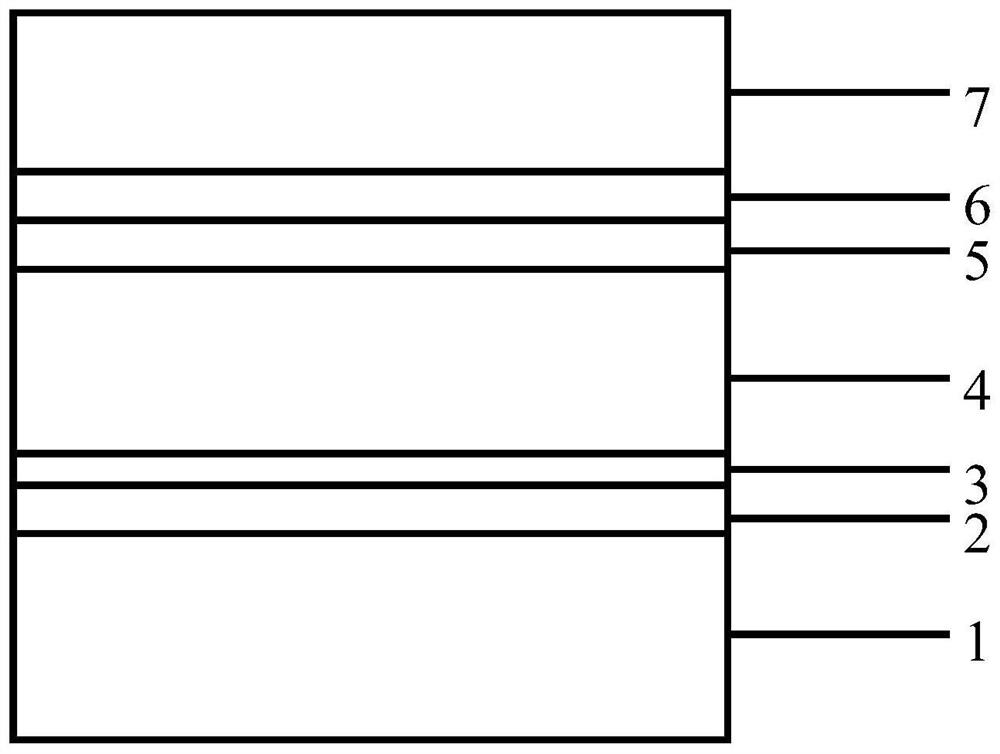

Semi-reflecting and semi-transmitting glass and preparation method thereof

ActiveCN104527165AHardness advantageHas semi-reflective and semi-transparent propertiesLaminationLamination apparatusRefractive indexPost-Procedure

The invention discloses semi-reflecting and semi-transmitting glass with the advantages of high hardness, acid and alkali corrosion resistance, alkali liquor ultrasound resistance, scratch resistance and high post-procedure machinability. The reflectivity of the semi-reflecting and semi-transmitting glass refers to any reflectivity in a range from 18 percent to 75 percent. The semi-reflecting and semi-transmitting glass comprises a glass substrate, a first low-refractive index layer, a first high-refractive index layer, a second low-refractive index layer, a second high-refractive index layer, a third low-refractive index layer, a third high-refractive index layer and a fourth high-hardness refractive index layer which are sequentially laminated with one another, wherein the first low-refractive index layer is made of SiO2; the first high-refractive index layer is made of Nb2O5; the second low-refractive index layer is made of SiO2; the second high-refractive index layer is made of Nb2O5; and the third low-refractive index layer is made of SiO2. The hardness of the semi-reflecting and semi-transmitting glass can be 7H, and the semi-reflecting and semi-transmitting glass has the advantages of acid and alkali corrosion resistance, alkali liquor ultrasound resistance, scratch resistance and high post-procedure machinability. The invention also discloses a method for preparing the semi-reflecting and semi-transmitting glass.

Owner:YICHANG NANBO DISPLAY

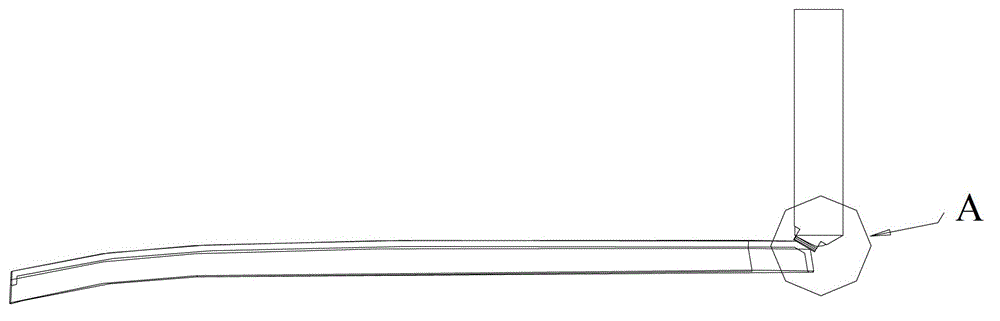

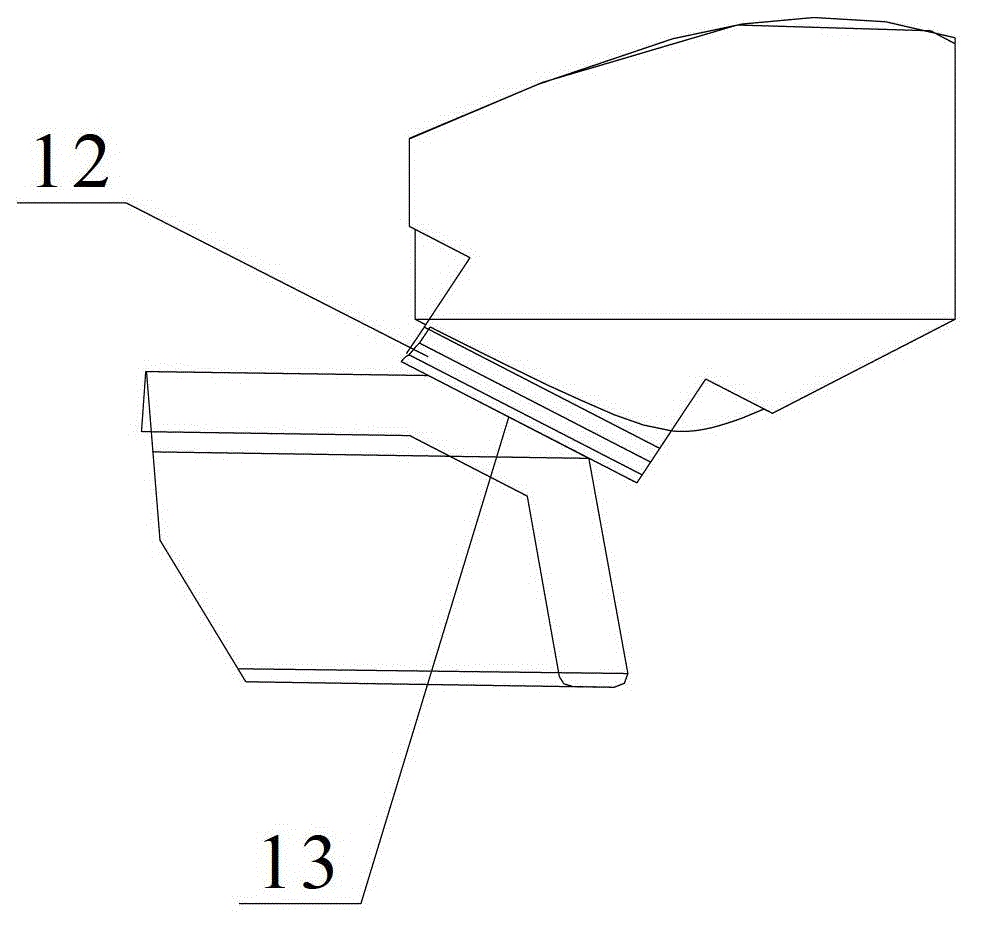

Tool for machining specular decoration edge

The invention discloses a tool for machining a specular decoration edge. The tool is used in a three-axis machine tool. The tool comprises a tool rod part used for being clamped on a clamp on the three-axis machine tool and a blade part arranged on the tool rod part. The included angle formed between the blade edge of the blade part and the upper surface of a machining platform of the three-axis machine tool is equal to the included angle formed between the chord line of the decoration edge and the upper surface of the machining platform. By means of the design, the tool for machining the specular decoration edge is suitable for the three-axis machine tool, and the specular decoration edge with the mirror face effect can be machined.

Owner:GREE ELECTRIC APPLIANCES INC

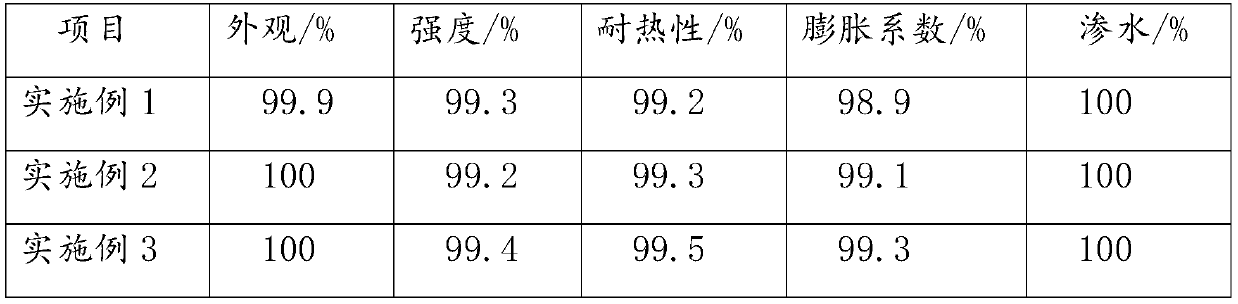

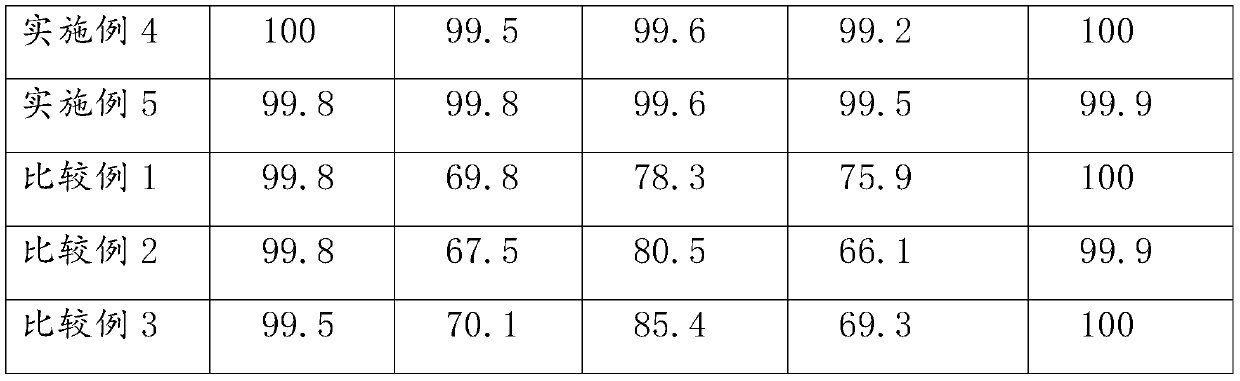

Method for preparing heat-resisting ceramic plate

The invention provides a method for preparing a heat-resisting ceramic plate, and relates to the field of ceramics. The method comprises the following steps that plate raw materials are subjected to ball grinding, the water content is adjusted so that plate blank slurry can be obtained, then, spraying granulation is performed, and after stock bin decaying, an automatic brick pressing machine is used for manufacturing bricks to obtain a plate brick body; glaze raw materials are subjected to ball grinding, the water content is adjusted to obtain glaze slurry, and then the glaze slurry coats theplate blank body to obtain a prefabricated blank; the prefabricated blank is burnt in advance, then, smashing and ball grinding are performed, the water content is adjusted to obtain plate slurry, spray granulation is performed, and after decaying, bricks are manufactured to obtain plates; the plates are fired to obtain a prefabricated plate; the glaze slurry coats the prefabricated plate, and programmed heating firing, programmed freezing cooling and polishing are performed to obtain the finished product. According to the method for preparing the heat-resisting ceramic plate, the manufacturedproduct is good in heat resistance, high in strength, low in expansion coefficient and low in cost.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

Low-expansion heat-resistant ceramic plate

The invention provides a low-expansion heat-resistant ceramic plate, and belongs to the field of ceramics. The low-expansion heat-resistant ceramic plate comprises a plate, and the plate comprises, inparts by weight, 10-20 parts of kaolin, 8-12 parts of talcum powder, 0.5-1 part of polyvinyl alcohol, 0.2-0.4 part of citric acid, 25-35 parts of cordierite, 1-3 parts of barium sulfate and 1-3 partsof titanium dioxide. The low-expansion heat-resistant ceramic plate is good in heat-resistant performance, high in strength, low in expansion factor and free from water seepage.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

Method of preparing low-expansion heat-resistant ceramic plate

The invention provides a method of preparing a low-expansion heat-resistant ceramic plate. The method comprises the following steps: mixing raw materials of the plate according to a formula, performing ball milling by using a ball mill, after iron is removed, adjusting a water content of slurry, performing spray granulation, performing aging in a material bin, and preparing a blank by using an automatic brick machine to obtain a plate blank body; sending the plate blank body to a roller kiln, performing pre-sintering, performing pulverization, performing ball milling by using a ball mill, after iron is removed, adjusting a water content of slurry, performing spray granulation, performing aging in a material bin, and preparing a blank by using an automatic brick machine to obtain a plate; mixing glaze materials according to a formula, performing ball milling by using a ball mill, after iron is removed, adjusting a water content of glaze slurry, and coating the plate for 2-4 times; and sending the glaze-coated plate into a roller kiln, performing temperature programming for firing, and performing polishing to obtain the finished product. According to the method for preparing the low-expansion heat-resistant ceramic plate provided by the invention, the product prepared by the method has the advantages of good heat resistance, high strength, a low expansion coefficient, and no water penetration.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

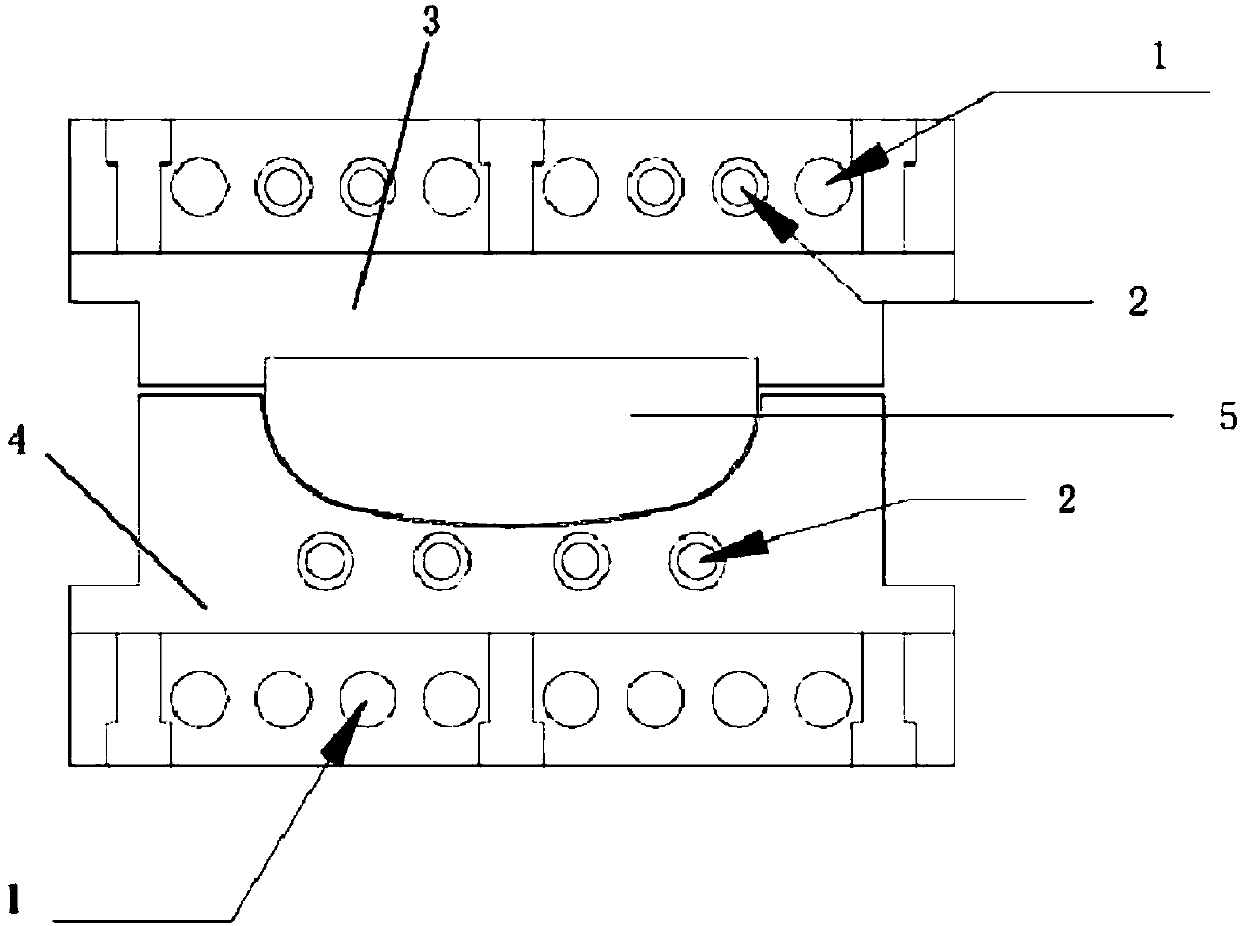

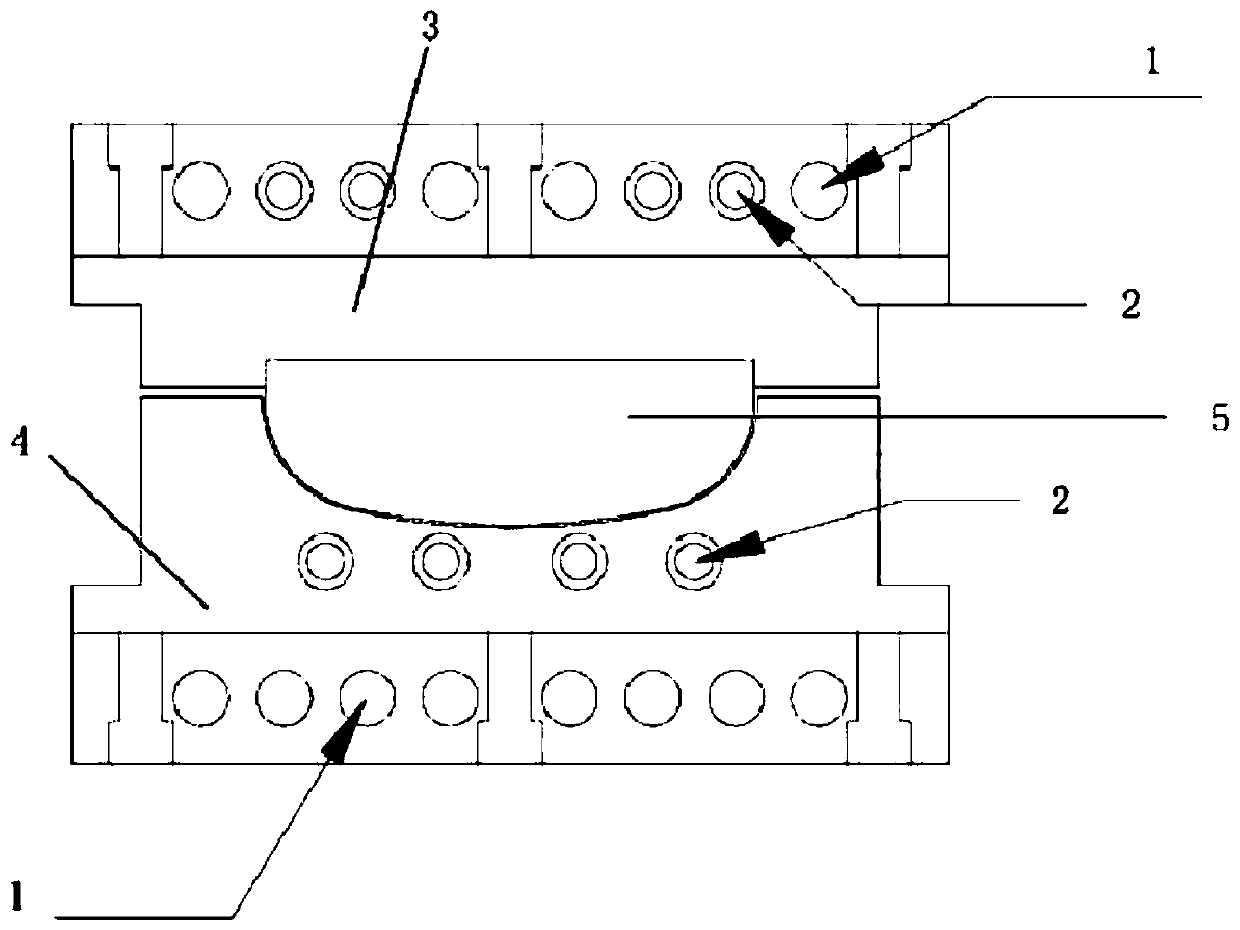

Hot pressing forming process for carbon fibre material head-mounted audio-visual and communication equipment shell

The invention discloses a carbon fibre material thermoplastic processing forming process for a head-mounted audio-visual and communication equipment shell. The carbon fibre material thermoplastic processing forming process adopts mould pressing forming and comprises the following steps: (1) preheating a mould, and then placing a customized carbon fibre plate on a lower mould; (2) heating the lowermould and an upper mould, and simultaneously, heating by using an infrared device; (3) pressing the upper mould and the lower mould, and keeping temperature and keeping pressure; and (4) cooling, demoulding, and then gluing, wherein the customized carbon fibre plate is obtained by weaving carbon fibre cloth first by carbon fibre filaments, dipping the carbon fibre cloth in thermo-reversible resin, and coating the upper layer and the lower layer of the outer surface of the carbon fibre cloth with customized special films, wherein the customized special films are resin films. According to the carbon fibre material thermoplastic processing forming process for the head-mounted audio-visual and communication equipment shell, a high-gloss shell is directly formed by using a sheet carbon fibre material in the mode of selecting a resin material and laminating the films by using specific resin films after the carbon fibre cloth is dipped and matching specific process conditions; and the shellis not required to the polished and ground completely after being formed, has a mirror surface effect naturally, and has uniform thickness and extremely good visual sense.

Owner:厦门耐能电子科技有限公司

Stainless-steel-colored aluminum alloy and preparation method thereof

The invention relates to the technical field of aluminum alloys, in particular to a stainless-steel-colored aluminum alloy and a preparation method thereof. The stainless-steel-colored aluminum alloyis prepared from the following components in percentage by weight: 0.38-0.41% of silicon, less than 0.15% of iron, less than 0.1% of copper, less than 0.1% of manganese, 0.48-0.51% of magnesium, lessthan 0.1% of chrome, less than 0.1% of zinc, less than 0.1% of titanium and the balance of aluminum and impurities, wherein the single impurity is less than 0.05%, and the total amount of the impurities is less than 0.15%. The stainless-steel-colored aluminum alloy has the color and gloss of an existing stainless steel profile, has a mirror effect of stainless steel, has the smaller density and lower cost than those of the stainless steel profile, and can replace the existing stainless steel profile to be applied to building decoration.

Owner:东莞市润华铝业有限公司

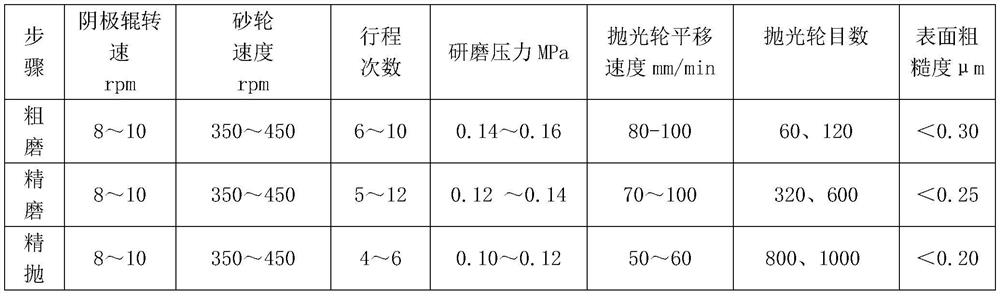

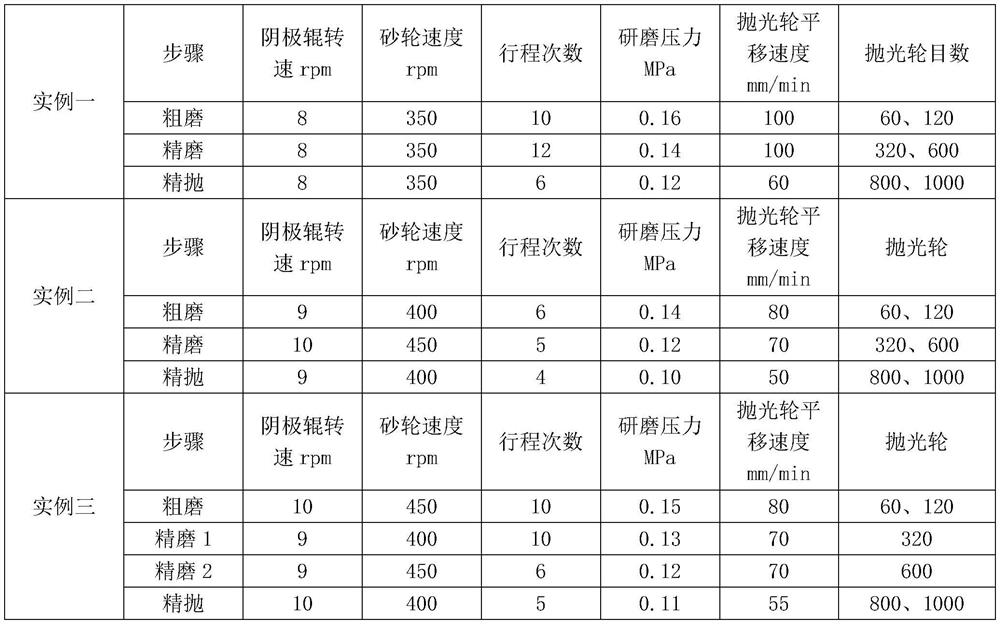

Precise grinding and polishing method for cathode roller

InactiveCN111761418AAvoid the impact of grinding and polishing qualityEfficient removalPolishingSurface roughness

The invention discloses a precise grinding and polishing method for a cathode roller. The method comprises the following steps of soaking a polishing wheel in pure water in a closed and dust-free grinding environment; sequentially carrying out surface rough grinding by adopting a polishing wheel with the particle size of 60 meshes and a polishing wheel with the particle size of 120 meshes; sequentially carrying out surface fine grinding by adopting a polishing wheel with the particle size of 320 meshes and a polishing wheel with the particle size of 600 meshes; cleaning the surface of the finely ground cathode roller; sequentially carrying out surface fine polishing on the cathode roller by adopting a polishing wheel with the particle size of 800 meshes and a polishing wheel with the particle size of 1000 meshes; and cleaning the surface of the cathode roller. The surface roughness of the cathode roller formed by the process is 0.2 <mu> m or below, the cathode roller has a certain mirror surface effect, the production operation period is long, and product crystals are compact.

Owner:JINCHUAN GROUP LIMITED

Ceramic plate

InactiveCN109851317AImprove heat resistanceImprove visual effectsClaywaresBeryllium hydroxidePolyvinyl alcohol

The invention provides a ceramic plate, and belongs to the field of ceramics. The ceramic plate comprises a plate and a glaze; the plate comprises the following components, in parts by weight: 15-25 parts of kaolin, 5-15 parts of talc powder, 0.5-1.5 parts of polyvinyl alcohol, 0.2-0.5 part of citric acid, 25-35 parts of cordierite, 2-4 parts of beryllium oxide, 3-5 parts of beryllium hydroxide, and 5-10 parts of strontium carbonate; and the glaze comprises the following components, in parts by weight: 65-75 parts of petalite, 5-15 parts of potassium feldspar, 4-6 parts of zinc oxide, 4-6 parts of kaolin, 6-8 parts of burnt talc, 2-4 parts of lithium carbonate, 2-4 parts of pyrochlore, 2-5 parts of spinel, and 0.5-1.5 parts of bismuth iron molybdenum oxide. The ceramic plate provided by the invention has good heat resistance and high strength and is not easy to deform.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD

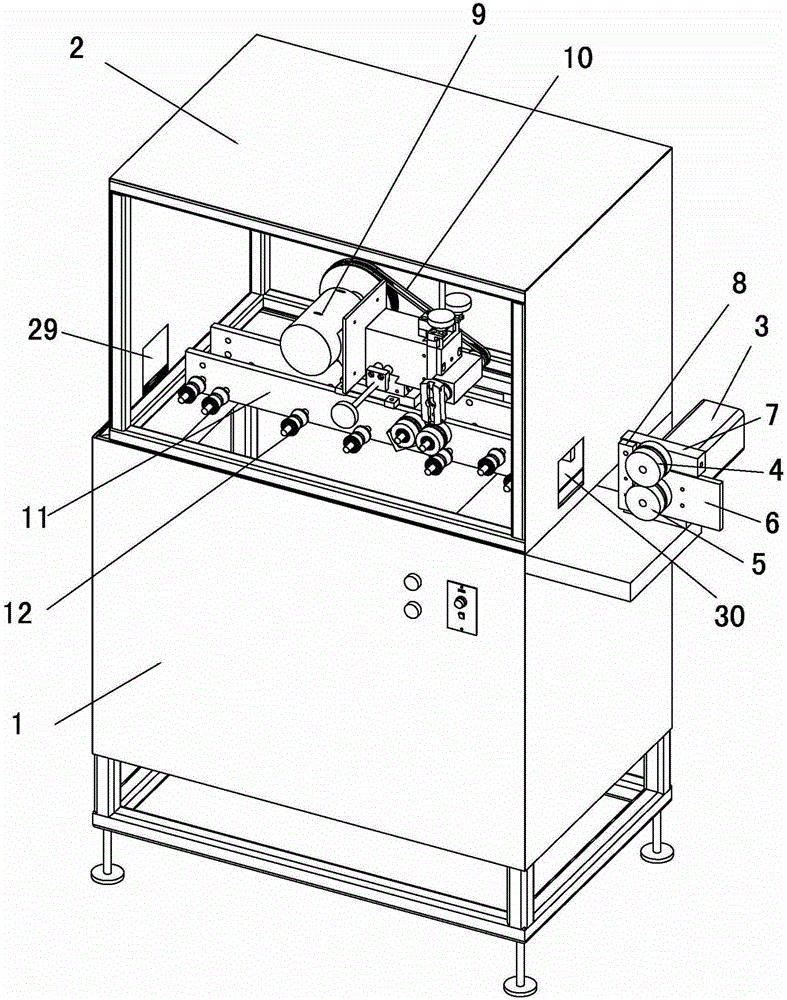

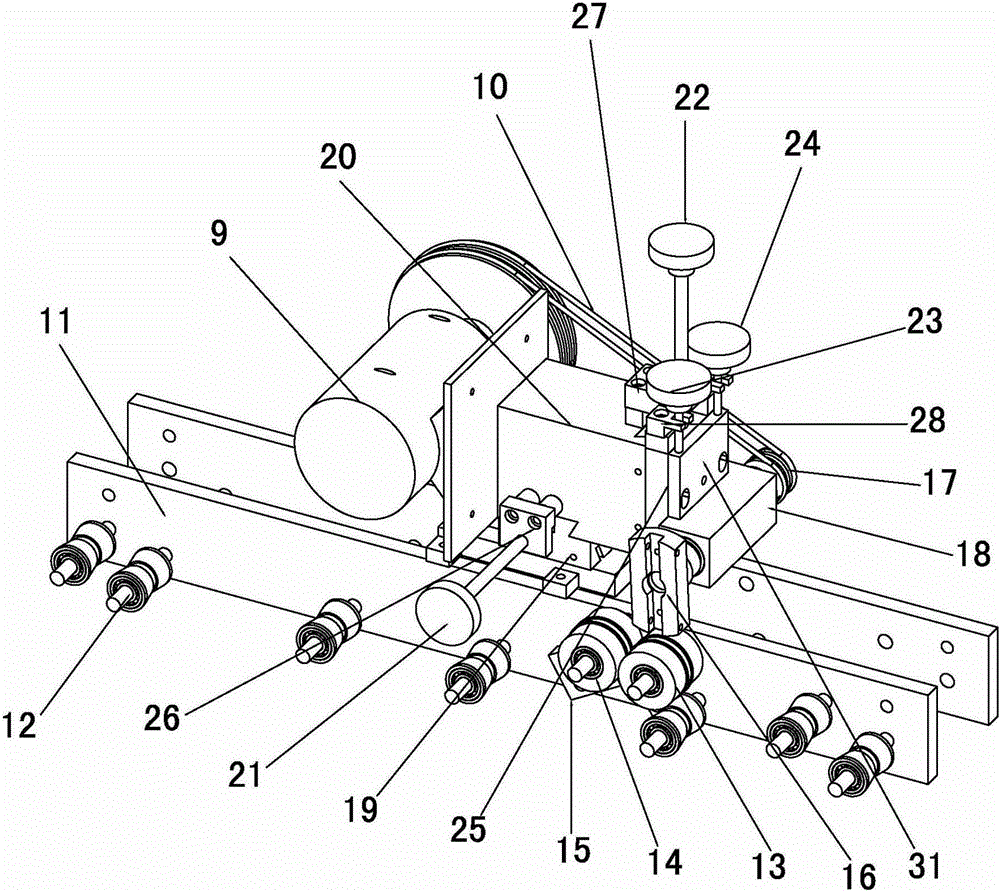

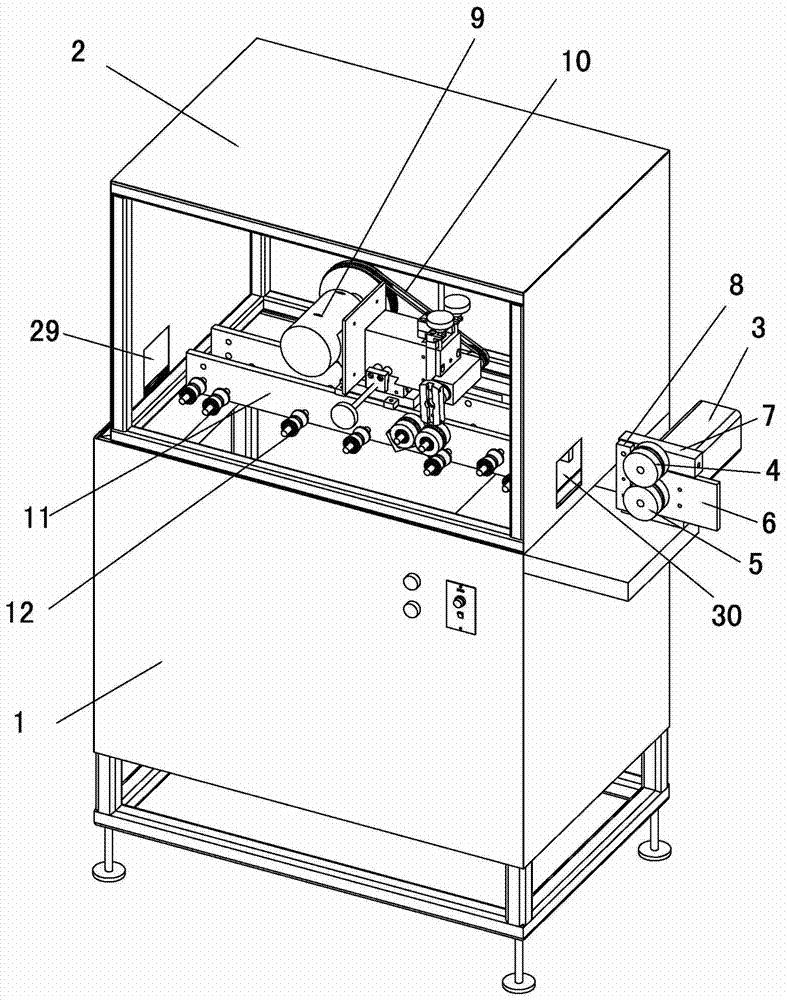

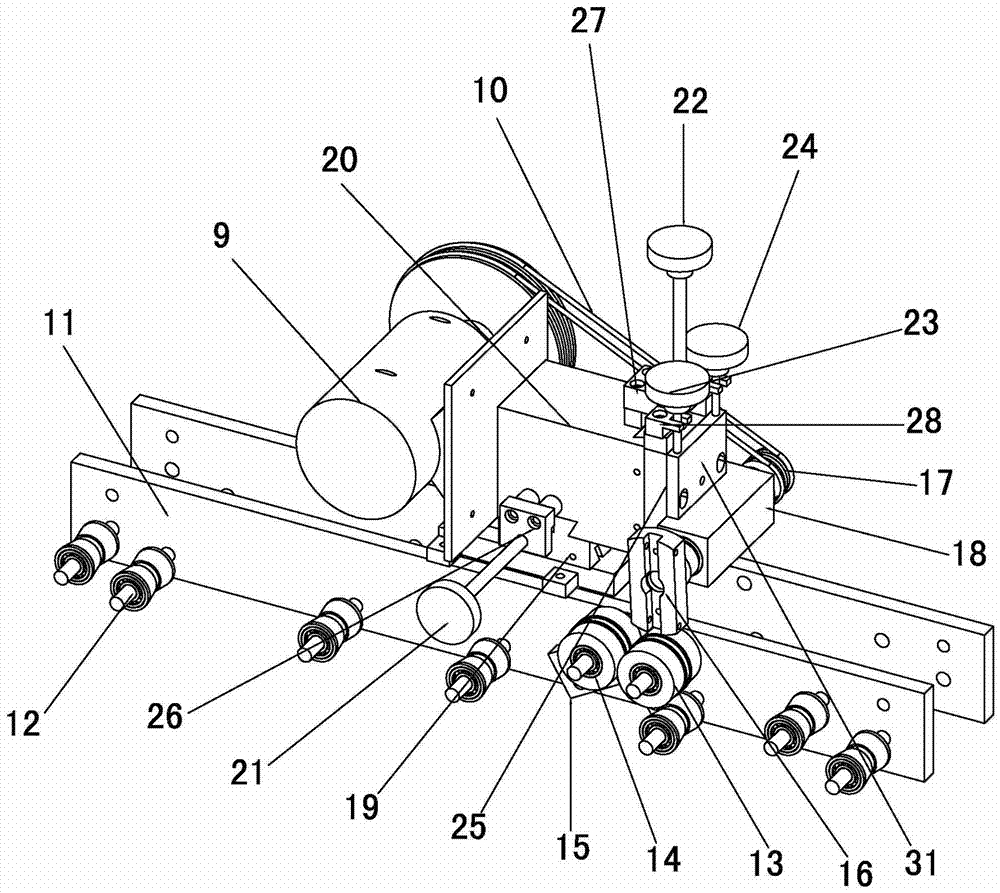

Plastic steel zipper mirror plane polishing machine

InactiveCN105215440AImprove flatnessImprove the finishAutomatic control devicesFeeding apparatusEngineeringMechanical engineering

The invention discloses a plastic steel zipper mirror plane polishing machine. The plastic steel zipper mirror plane polishing machine comprises a main machine frame, a tool setting mechanism, a cutting mechanism and a pulling mechanism, wherein the tool setting mechanism, the cutting mechanism and the pulling mechanism are installed on the main machine frame; the tool setting mechanism and the cutting mechanism are arranged correspondingly. The plastic steel zipper mirror plane polishing machine is simple in structure and convenient to use, the surface of zipper teeth can be cut at a high speed through a high-speed cutting process, and a zipper with the mirror plane effect and high flatness and finish degree can be produced.

Owner:深圳市联星服装辅料有限公司

Semi-reflective and semi-transparent glass and preparation method thereof

ActiveCN104527165BHardness advantageHas semi-reflective and semi-transparent propertiesLaminationLamination apparatusTransverse planeRefractive index

The invention discloses semi-reflecting and semi-transmitting glass with the advantages of high hardness, acid and alkali corrosion resistance, alkali liquor ultrasound resistance, scratch resistance and high post-procedure machinability. The reflectivity of the semi-reflecting and semi-transmitting glass refers to any reflectivity in a range from 18 percent to 75 percent. The semi-reflecting and semi-transmitting glass comprises a glass substrate, a first low-refractive index layer, a first high-refractive index layer, a second low-refractive index layer, a second high-refractive index layer, a third low-refractive index layer, a third high-refractive index layer and a fourth high-hardness refractive index layer which are sequentially laminated with one another, wherein the first low-refractive index layer is made of SiO2; the first high-refractive index layer is made of Nb2O5; the second low-refractive index layer is made of SiO2; the second high-refractive index layer is made of Nb2O5; and the third low-refractive index layer is made of SiO2. The hardness of the semi-reflecting and semi-transmitting glass can be 7H, and the semi-reflecting and semi-transmitting glass has the advantages of acid and alkali corrosion resistance, alkali liquor ultrasound resistance, scratch resistance and high post-procedure machinability. The invention also discloses a method for preparing the semi-reflecting and semi-transmitting glass.

Owner:YICHANG NANBO DISPLAY

Method for preparing 2D/3D organic-inorganic hybrid perovskite solar cell

ActiveCN113675347AQuality improvementReduce porosityFinal product manufactureSolid-state devicesPerovskite solar cellPerovskite (structure)

The invention discloses a method for preparing a 2D / 3D organic-inorganic hybrid perovskite solar cell, which belongs to the technical field of solar cells. Methylamine gas is used for assistance, butylamine gas goes deep into MAPbI3 crystal lattices to carry out a replacement reaction, and the 2D / 3D organic-inorganic hybrid perovskite solar cell with a structure that 3D perovskite is coated with 2D perovskite is formed. The problem that an organic-inorganic hybrid positive perovskite solar cell is poor in stability is solved.

Owner:SOUTHWEST PETROLEUM UNIV

Plastic steel zipper mirror polishing machine

InactiveCN105215440BImprove flatnessImprove the finishAutomatic control devicesFeeding apparatusAgricultural engineeringMirror effect

The invention discloses a plastic-steel zipper mirror polishing machine. The polishing machine includes a main frame, a tool setting mechanism, a cutting mechanism and a towing mechanism. The tool setting mechanism, the cutting mechanism and the towing mechanism are respectively installed on the main frame. set up. The invention is simple in structure and easy to use. The surface of the teeth of the zipper can be cut at high speed through the high-speed cutting process of the invention to produce a zipper with high flatness, high finish and mirror effect.

Owner:深圳市联星服装辅料有限公司

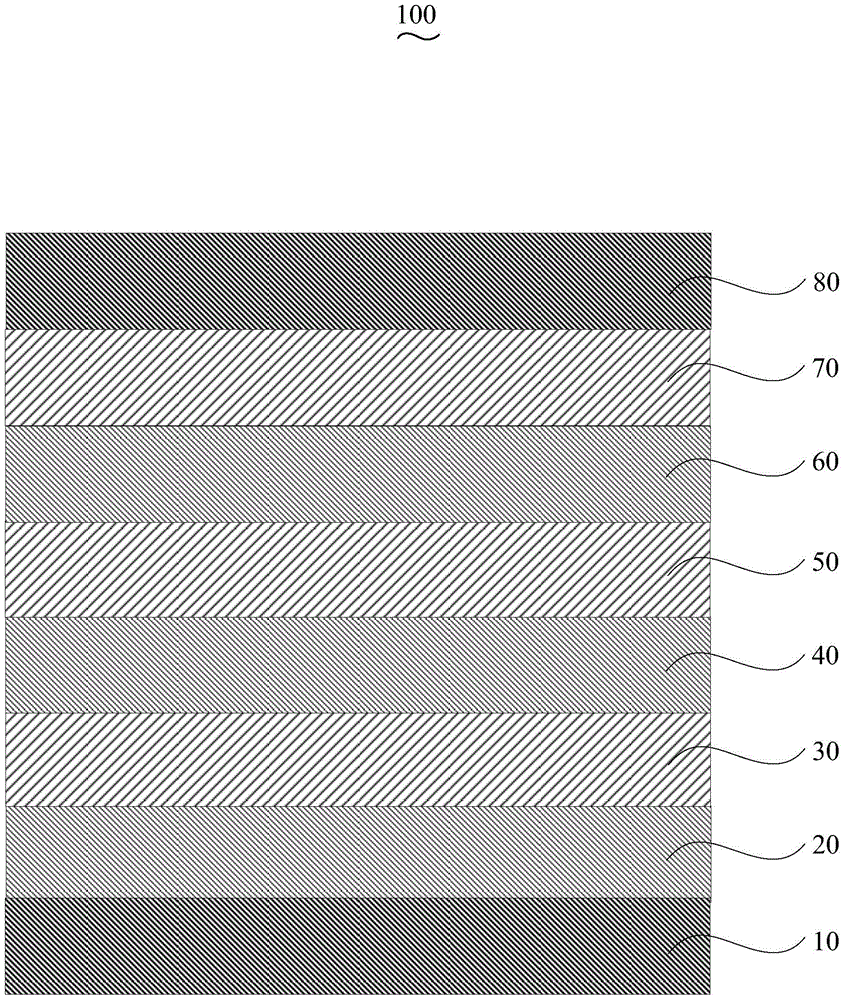

Semi-reflective and semi-transparent glass and preparation method thereof

ActiveCN104163022BWith mirror effectAvoid glareLaminationLamination apparatusRefractive indexWear resistance

The invention discloses a semi reflective and semi transparent glass. The reflectivity of the glass is 20-50%. The glass comprises a glass substrate, a first low refractivity layer, a first high refractivity layer, a second low refractivity layer, a second high refractivity layer and a third low refractivity layer which are piled up layer by layer, wherein the first, second and third low refractivity layers are made of SiO2 or MgF2 and the first and second high refractivity layers are made of Nb2O5, TiO2 or ZrO2. By virtue of a film layer structure of suitable thickness combining layers of high and low refractivity, the semi reflective and semi transparent glass has semi reflective and semi transparent performances and the optic visual effect of semi reflective and semi transparent is realized during use; meanwhile, the semi reflective and semi transparent glass has advantages in durability and wear resistance compared to a semi reflective and semi transparent auto foil. The invention further discloses a preparation method of the semi reflective and semi transparent glass.

Owner:YICHANG NANBO DISPLAY

Trans-plane structure perovskite solar cell and preparation method thereof

ActiveCN113270548AReduce surface roughnessImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite (structure)Solar battery

The invention discloses a trans-plane structure perovskite solar cell and a preparation method thereof. The solar cell comprises a conductive substrate, a hole transport layer, an ultrathin modification layer, a perovskite light absorption layer, an electron transport layer, an interface modification layer and a metal cathode which are sequentially stacked from bottom to top; the hole transport layer is prepared by doping tributyl phosphate with nickel oxide, and the ultrathin modification layer is LiF with the thickness of 1-5nm. According to the invention, the transmittance of nickel oxide is improved, the conductivity is improved, the interface recombination between the hole transport layer and the perovskite light absorption layer is inhibited, the transmission efficiency of carriers between the interfaces is improved, the crystal quality of a perovskite film is improved, the defects of a perovskite light active layer are reduced, and the performance of a perovskite solar cell device is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Mass spectrometry substrate and its preparation method and use

InactiveCN106872562BSuitable for large-scale useEasy to makeFixed microstructural devicesPreparing sample for investigationSignal-to-noise ratio (imaging)Mass Spectrometry-Mass Spectrometry

The invention provides a dedicated substrate carrying a BIOMARK in MALDI-TOF mass spectrometry detection. The substrate comprises a hole-outside hydrophobic region made of a chemical surface modifier, an intra-circle hydrophilic region modified by a special chemical reagent, surface round holes or square holes for titrating a BIOMARK sample, a substrate material having tough texture and good flatness, and a substrate surface having a single-side polished mirror effect. Besides, the substrate can further include a two-dimensional code for identification. The micro / nano structural substrate can effectively enrich the sample, crystal grows uniformly, the mass spectrometry curve sample for BIOMARK biological detection is high in peak accuracy, the signal-to-noise ratio is high, and the base line is low.

Owner:毅新兴业(北京)科技有限公司

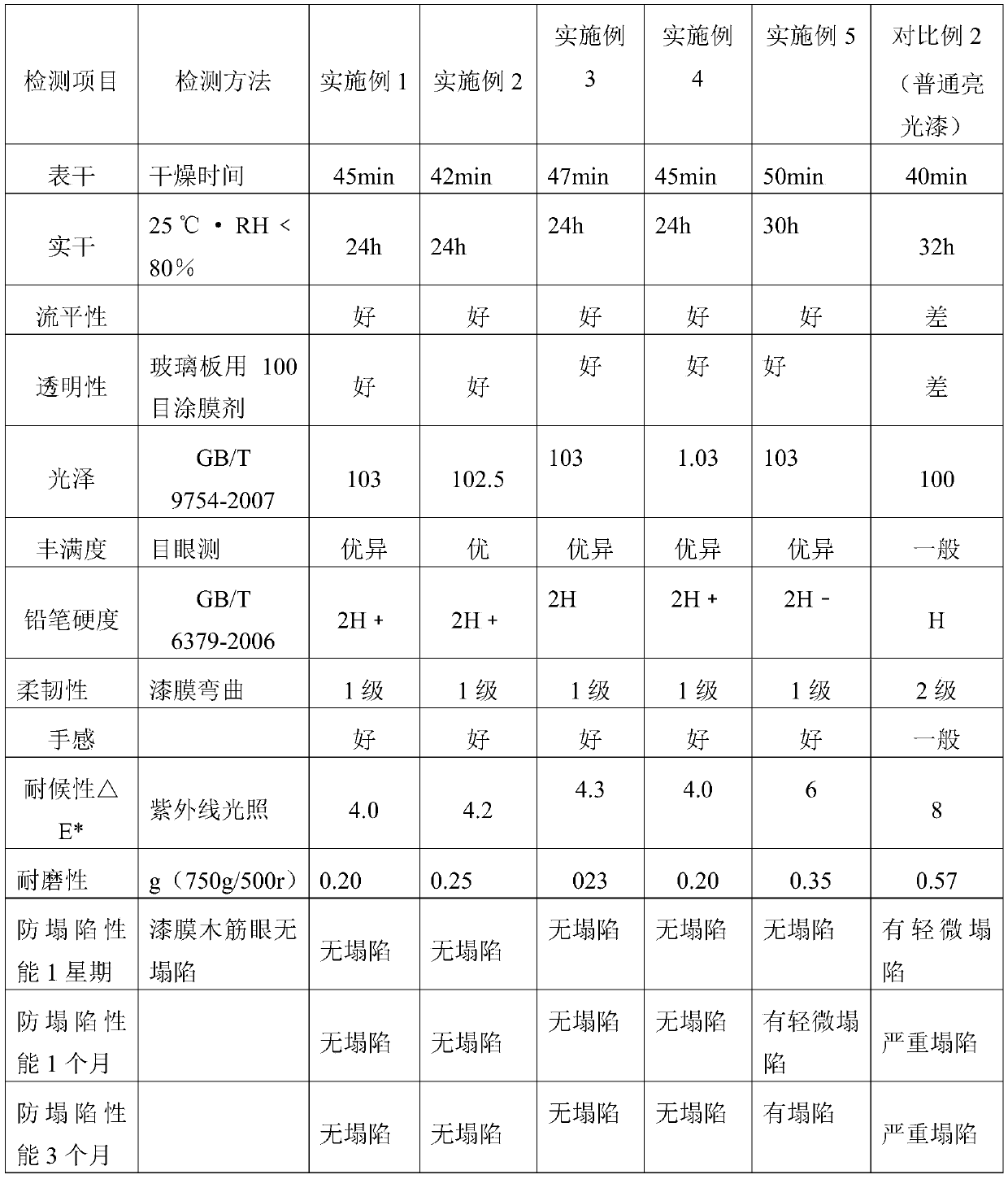

An anti-collapse high-fullness mirror gloss varnish and its preparation process

ActiveCN107828326BLow VOC contentHigh solid contentPolyurea/polyurethane coatingsPolymer scienceButyl acetate

The invention provides an anti-collapse high-fullness mirror surface gloss varnish, which is prepared from components A, B and C with a weight proportion being 1:(0.8 to 1):0.5, wherein the componentA is prepared from a coconut oil fatty acid resin, an acrylic resin, a synthetic fatty acid alkyd resin, a flatting agent, a defoaming agent and a solvent; the component B is prepared from a TDI-HDI mixed tripolymer or a TDT / TMP additive product, an HDI tripolymer and a solvent; the component C is prepared from xylene, butyl acetate and a multifunctional solvent. The invention also provides a preparation method of the anti-collapse high-fullness mirror surface gloss varnish. The anti-collapse high-fullness mirror surface gloss varnish provided by the invention is low in VOC (Volatile Organic Compounds) content and high in solid content, a coating film is glossy, fast in surface dry and curing speed, not easy to collapse, high in fullness, capable of achieveing a mirror surface effect and good in durability, a thicker coating film can be obtained through one-time construction, and the gloss varnish is widely applicable to surface coating of musical instruments, high-end furniture and woodware.

Owner:HUILON COATING IND

Thermal processing molding process of a carbon fiber material head-mounted audio-visual and communication equipment shell

The invention discloses a carbon fibre material thermoplastic processing forming process for a head-mounted audio-visual and communication equipment shell. The carbon fibre material thermoplastic processing forming process adopts mould pressing forming and comprises the following steps: (1) preheating a mould, and then placing a customized carbon fibre plate on a lower mould; (2) heating the lowermould and an upper mould, and simultaneously, heating by using an infrared device; (3) pressing the upper mould and the lower mould, and keeping temperature and keeping pressure; and (4) cooling, demoulding, and then gluing, wherein the customized carbon fibre plate is obtained by weaving carbon fibre cloth first by carbon fibre filaments, dipping the carbon fibre cloth in thermo-reversible resin, and coating the upper layer and the lower layer of the outer surface of the carbon fibre cloth with customized special films, wherein the customized special films are resin films. According to the carbon fibre material thermoplastic processing forming process for the head-mounted audio-visual and communication equipment shell, a high-gloss shell is directly formed by using a sheet carbon fibre material in the mode of selecting a resin material and laminating the films by using specific resin films after the carbon fibre cloth is dipped and matching specific process conditions; and the shellis not required to the polished and ground completely after being formed, has a mirror surface effect naturally, and has uniform thickness and extremely good visual sense.

Owner:厦门耐能电子科技有限公司

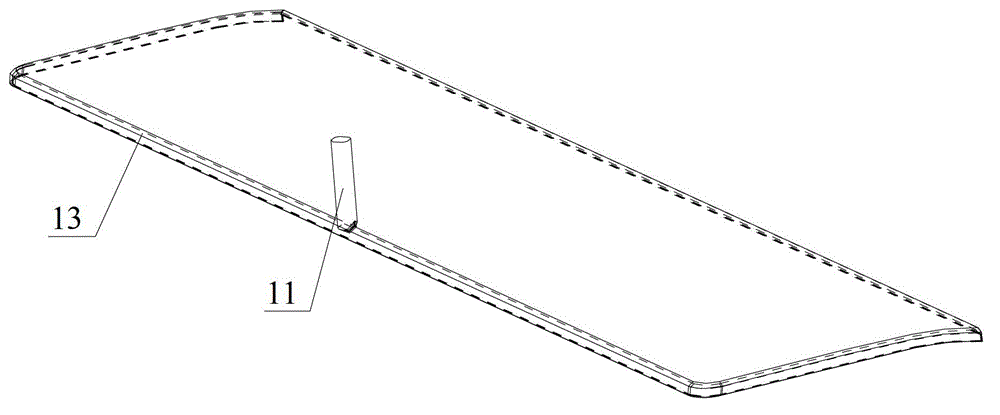

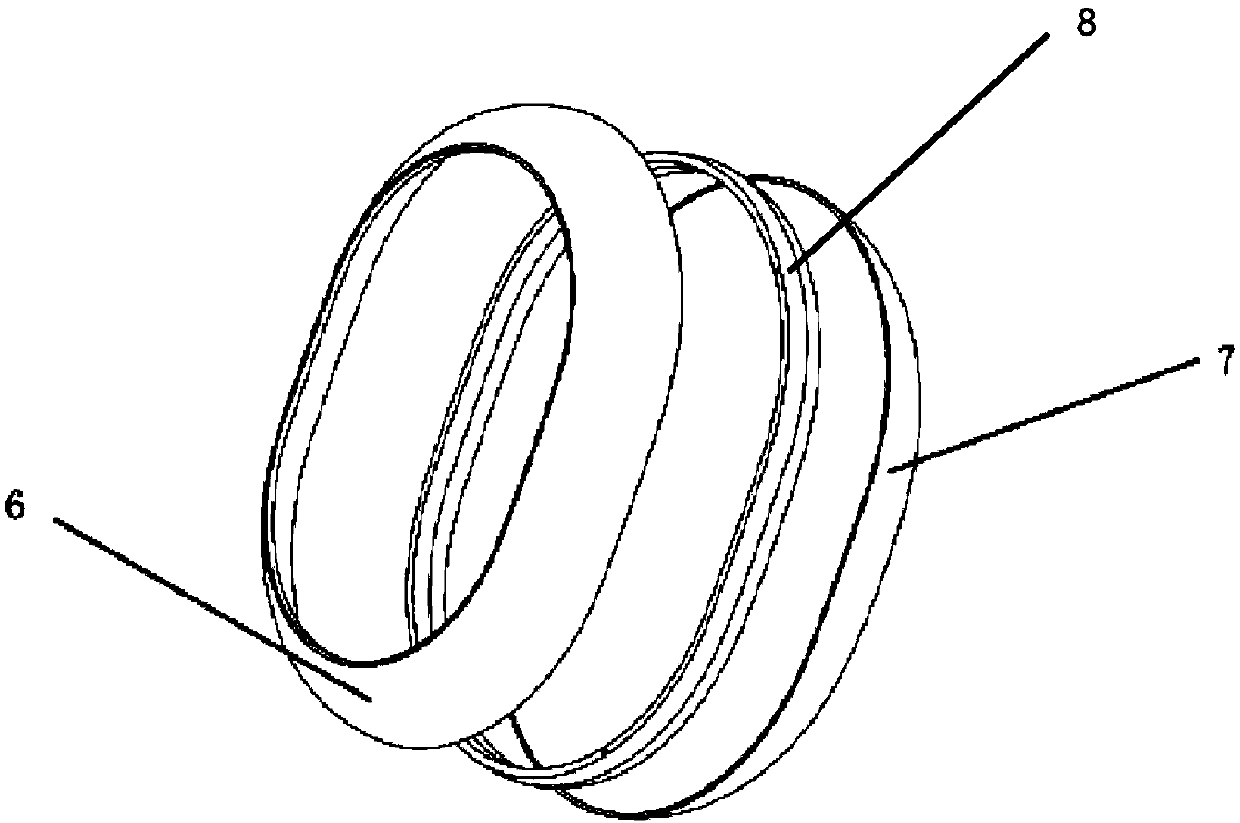

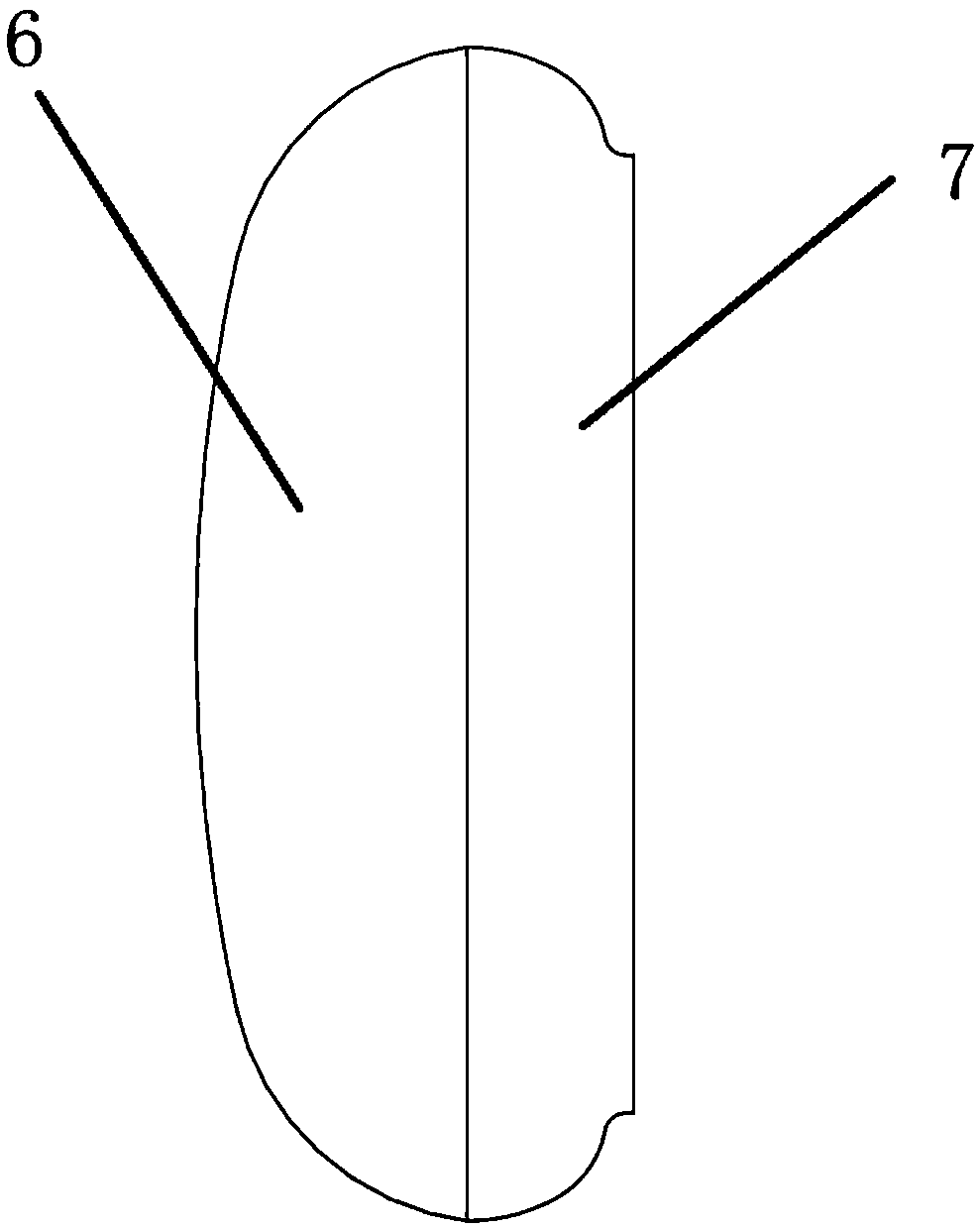

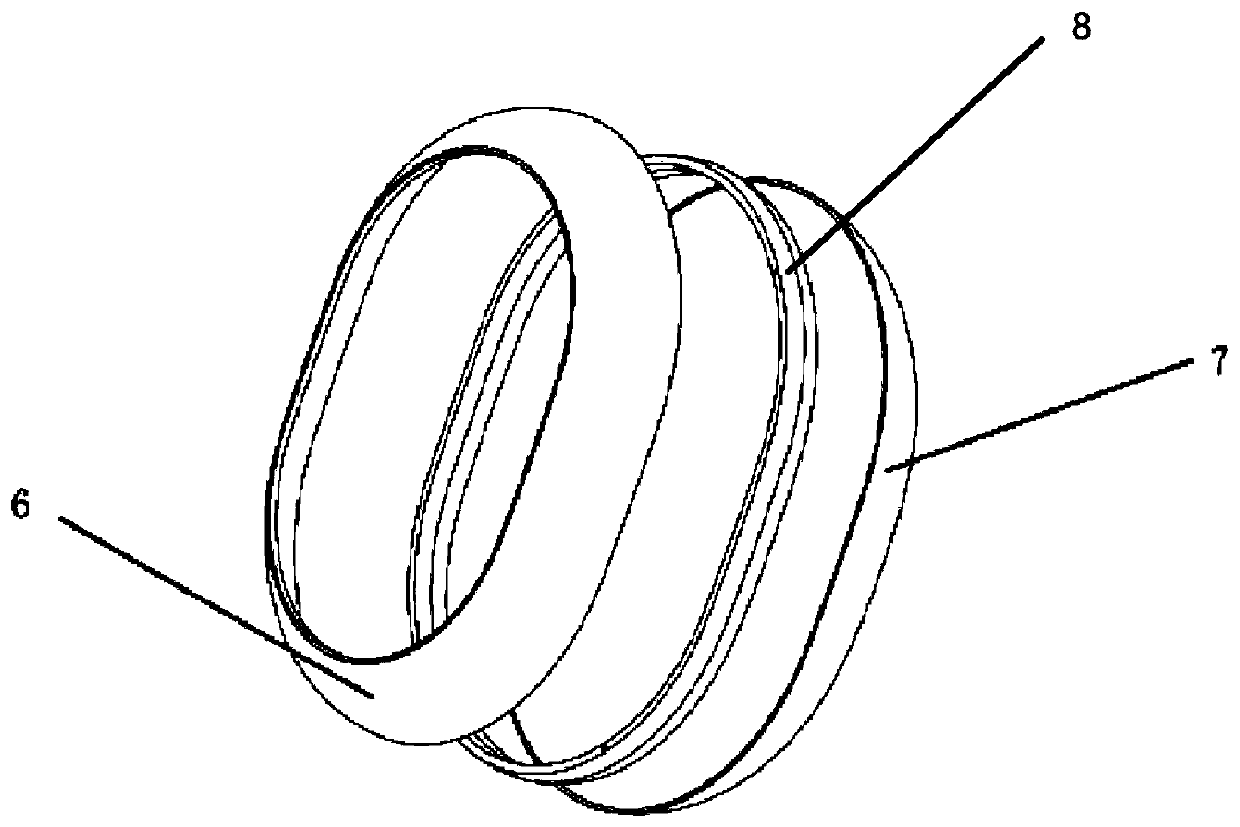

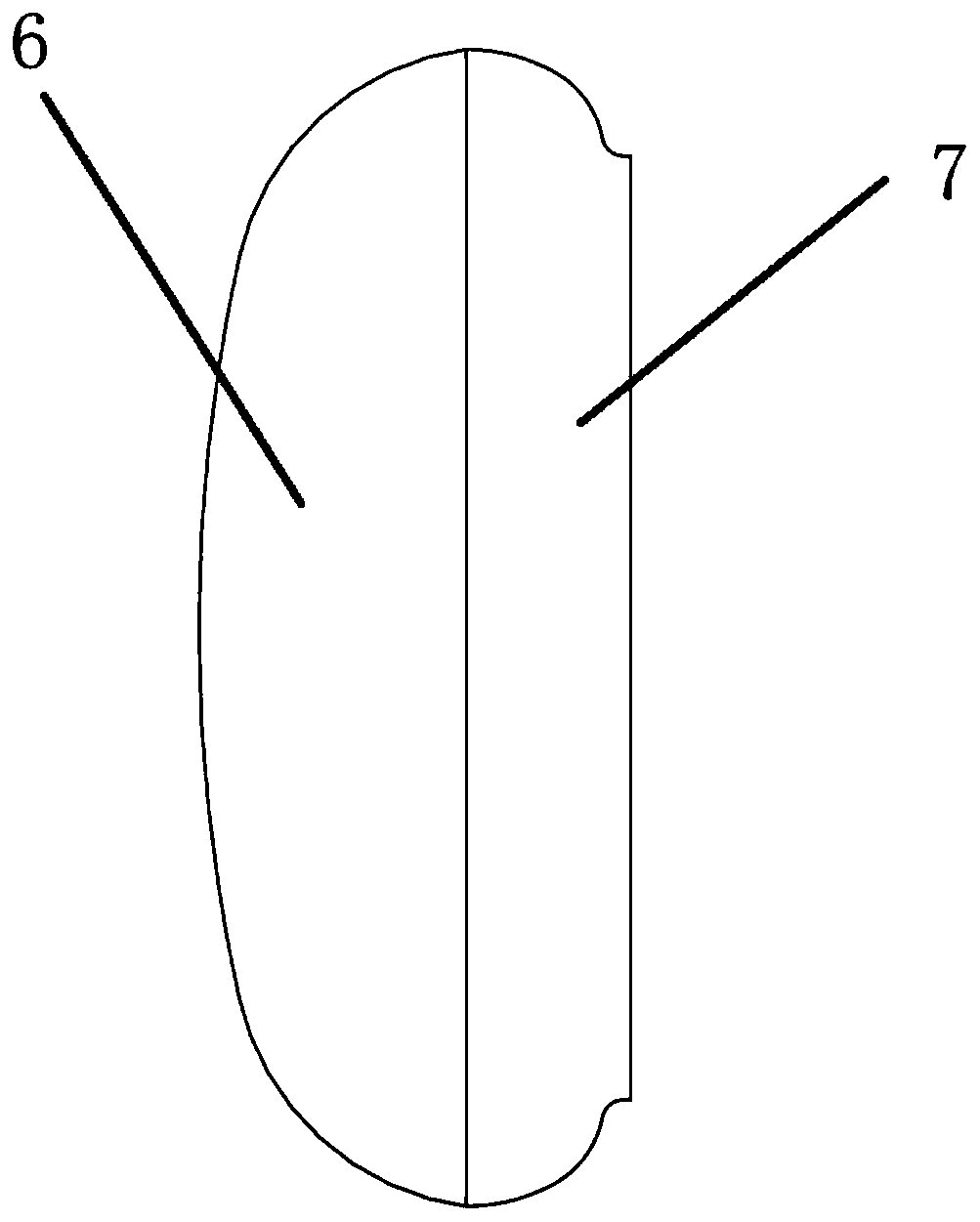

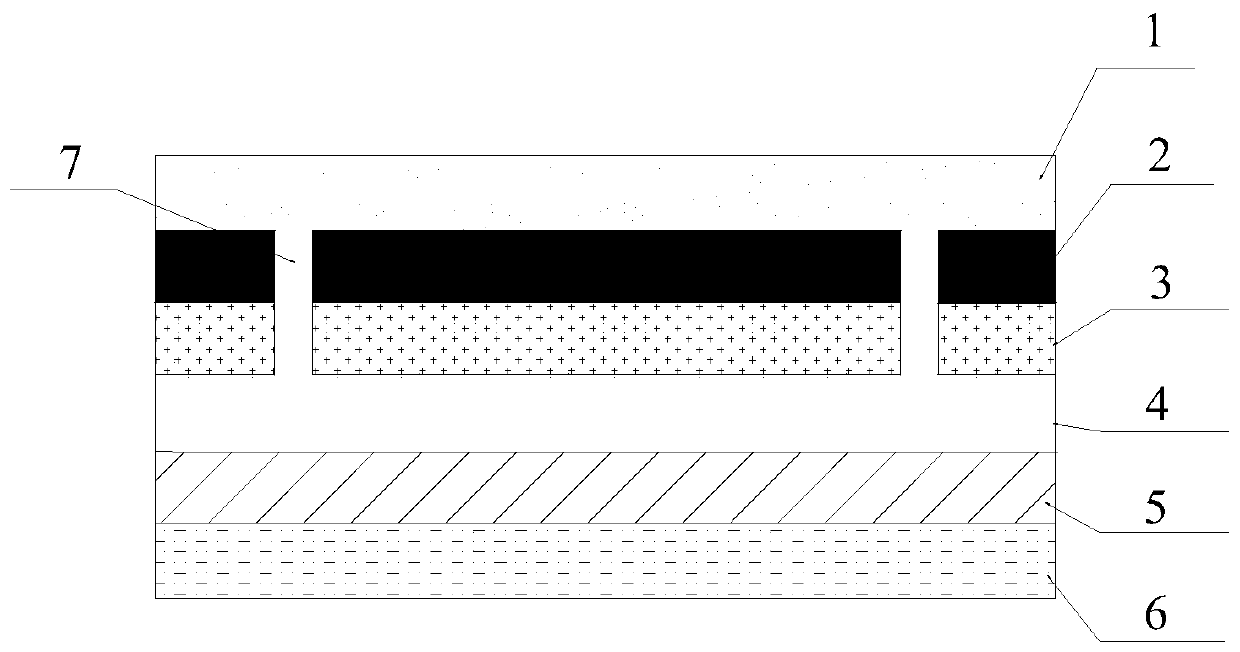

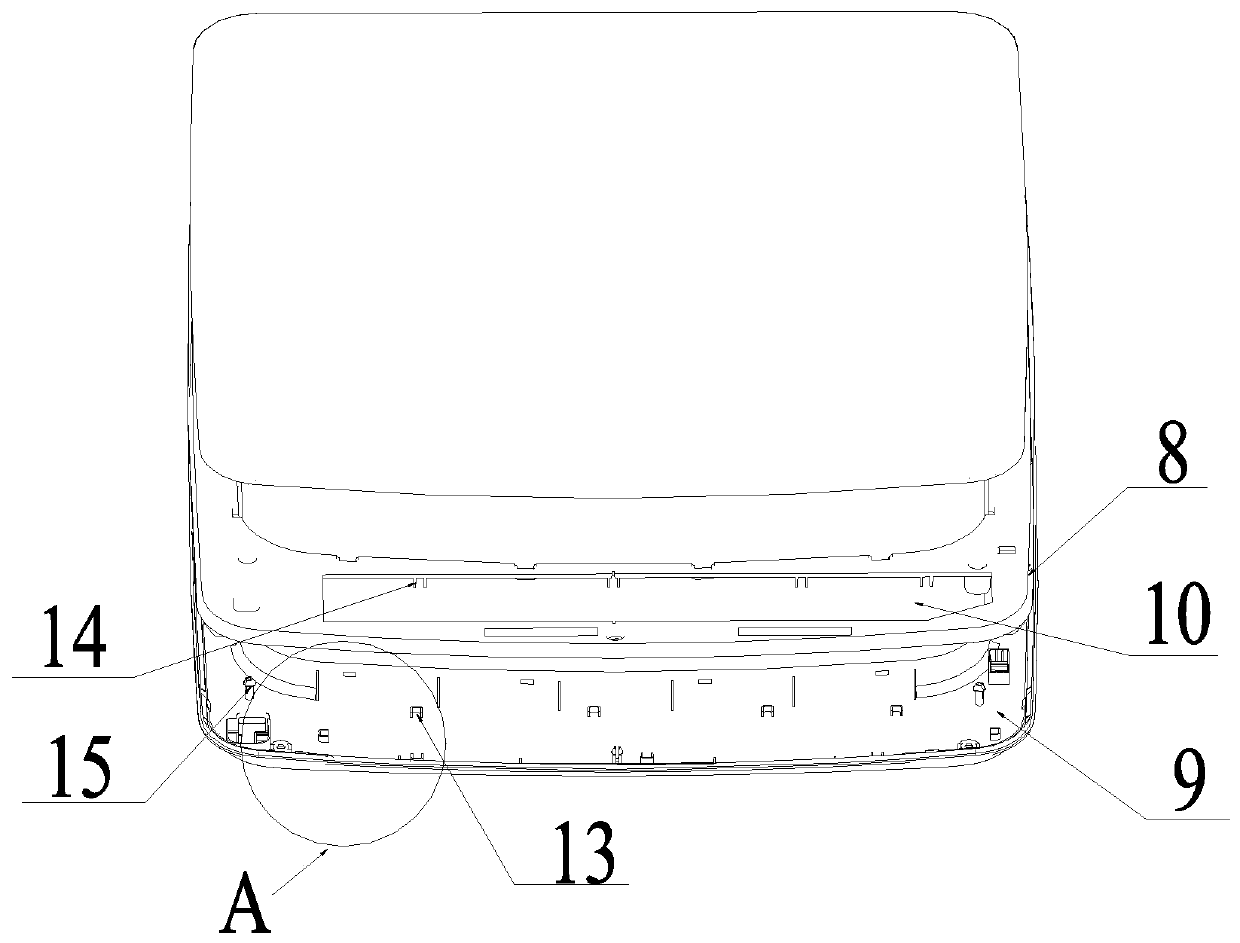

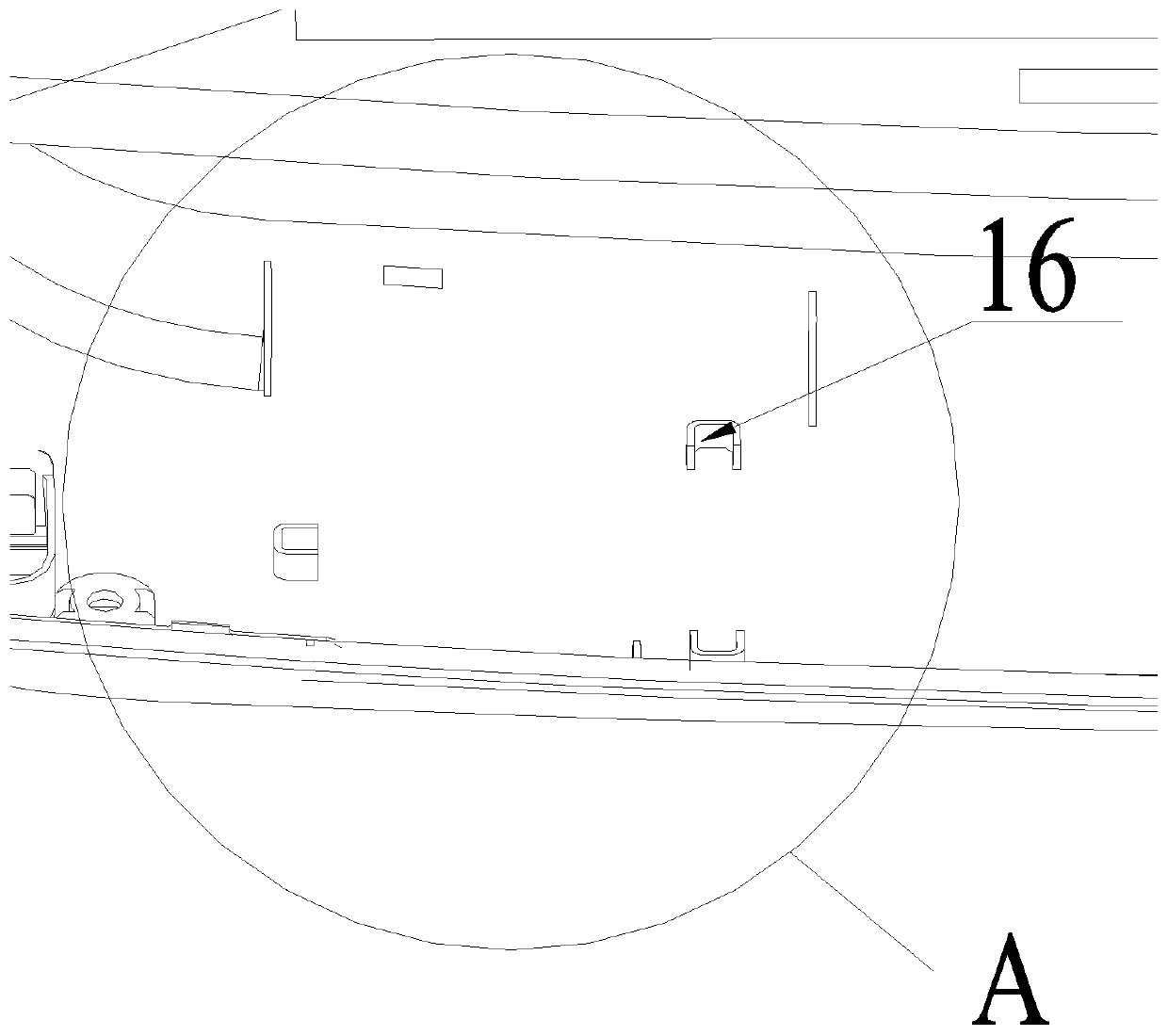

A washing machine top cover

ActiveCN108625123BGood lookingAvoid interferenceOther washing machinesTextiles and paperLaundry washing machineEngineering

An upper cover for a laundry machine comprises a display screen (6); the display screen (6) is provided with, from bottom to top, a white coating (4), a silver coating (3) and a translucent coating (1) sequentially thereon, and the silver coating (3) is provided with a hollowed-out window (7) thereon corresponding to a display area of the display screen (6). Lights transmitted from the display screen (6) first pass through the white coating (4) and are scattered therethrough to improve the uniformity of planar light, and then pass through the silver coating (3) via the window (7) thereon for use. Lights transmitting to the outside of the window (7) cannot pass through the silver coating (3) and are reflected back therefrom to the white coating (4), thereby increasing the light intensity on the white coating to improve the display clarity in the window. When the laundry machine is not in a power-on state, the translucent coating (1) provides a mirror effect on the laundry machine. The coatings are disposed such that the display of laundry procedures can be invisible, thereby optimizing the appearance of a laundry machine, eliminating interference for a user and improving user experience.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

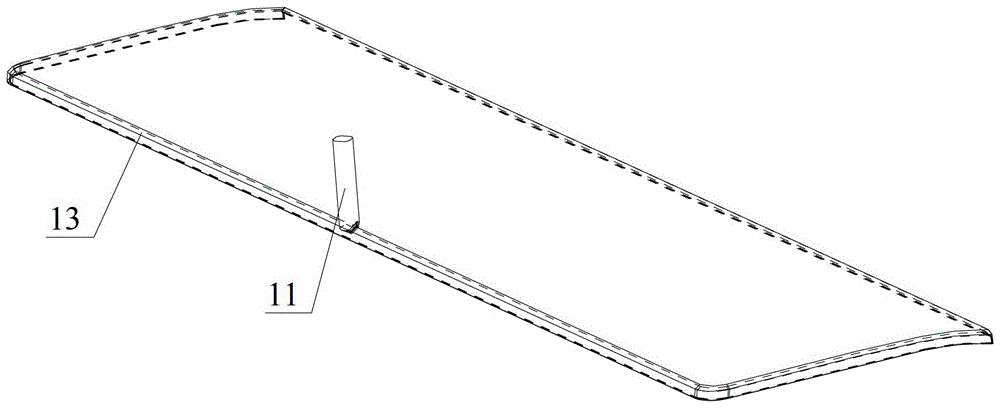

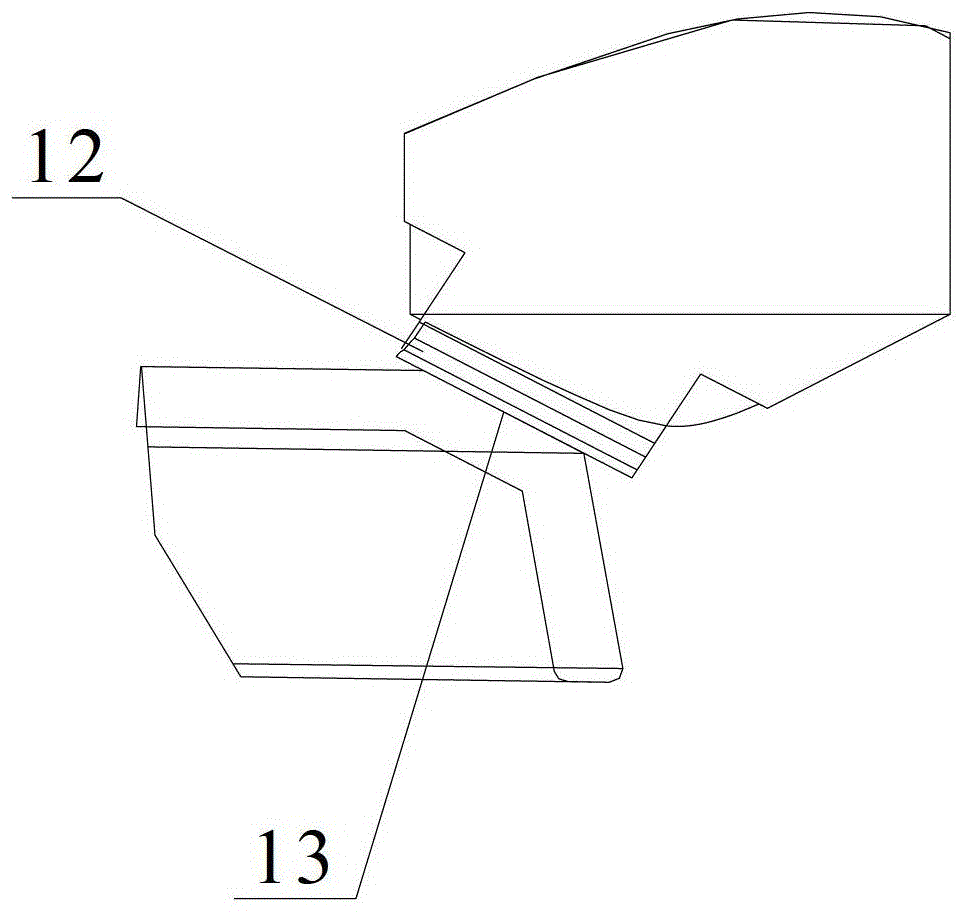

A cutting tool for processing high-gloss decorative edges

The invention discloses a tool for machining a specular decoration edge. The tool is used in a three-axis machine tool. The tool comprises a tool rod part used for being clamped on a clamp on the three-axis machine tool and a blade part arranged on the tool rod part. The included angle formed between the blade edge of the blade part and the upper surface of a machining platform of the three-axis machine tool is equal to the included angle formed between the chord line of the decoration edge and the upper surface of the machining platform. By means of the design, the tool for machining the specular decoration edge is suitable for the three-axis machine tool, and the specular decoration edge with the mirror face effect can be machined.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com