Patents

Literature

153results about How to "Good mirror effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of novel multiple crystallization combined glass-ceramic clad plate

ActiveCN101177346ABreak luxuryBreak the contradiction of relatively simple color changeCeramic compositeBrick

The invention discloses a manufacturing technique of multiplex crystallization combination glass-ceramics ceramic composite panel. The invention is characterized in comprising following steps: (1) preparing transparent type non-crystallization high-strength frit, translucent half crystallization type and crystallization type crystal frit and non-transparent half crystallization type and crystallization type crystal frit, (2) making special mixture and mixing craft, (3) distributing the crystal frit onto the adobe; (4) performing roll forming and coating fixing agent, and (5) burning, cooling, polishing, edging and sorting and checking. The invention has the advantages of preparing porcelain tile, enabling organic combination of transparent, translucent and non-transparent colored crystals, simple technology, lower cost and diversified color similar to jade.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

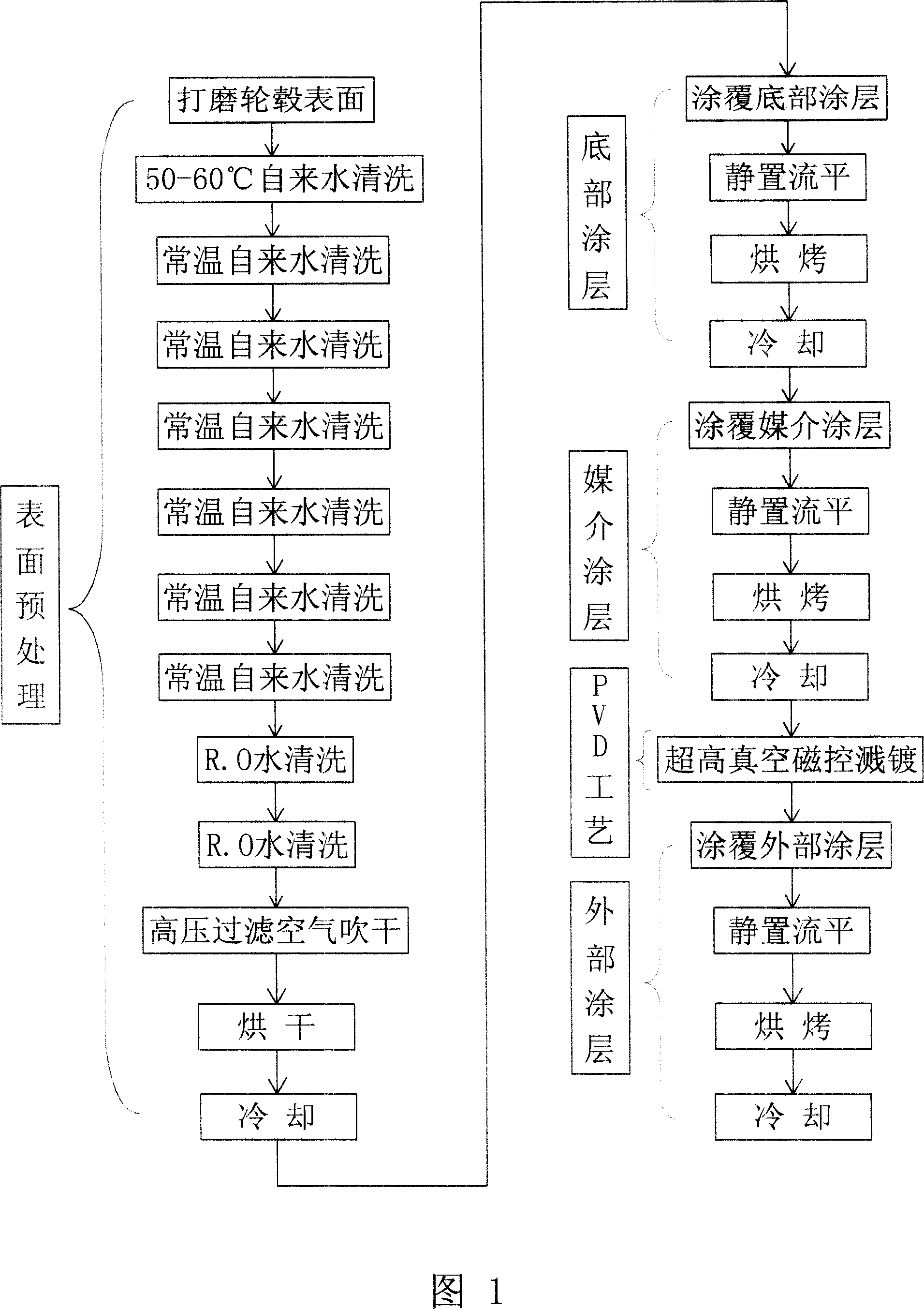

Super-specular anti-scraping transfer film and preparation method thereof

InactiveCN103434233AImprove adhesionStrong specular glossDuplicating/marking methodsSynthetic resin layered productsPolymer sciencePolyethylene terephthalate glycol

The invention relates to the technical field of transfer films, in particular to a super-specular anti-scraping transfer film and a preparation method thereof. The preparation method of the super-specular anti-scraping transfer film comprises the following steps that a PET (Polyethylene Terephthalate) thin film is taken; waterborne polyurethane, an alcohol organic solvent and water in parts by weight are mixed and stirred uniformly, and blended into waterborne release dope; the surface of the PET thin film is coated with the blended waterborne release dope to form a waterborne release coating layer; the waterborne release coating layer is dried to be a waterborne release layer; a semifinished PET thin film loaded with the waterborne release layer is prepared; the outer surface of the waterborne release layer is coated with information coating layer dope to form an information coating layer; a vacuum aluminum coated layer and a gum application layer are arranged on the surface of the information coating layer sequentially; and the finished super-specular anti-scraping transfer film is prepared. The super-specular anti-scraping transfer film is high in scraping resistance, and high in specular glossiness, and the preparation method of the super-specular anti-scraping transfer film is simple in technology and high in production efficiency.

Owner:DONGGUAN GUODING OPTICAL MEMBRANE TECH

Aesthetical resin capable of eliminating injection-molding weld lines and preparation method thereof

The invention relates to an aesthetical resin capable of eliminating injection-molding weld lines and a preparation method thereof. The aesthetical resin comprises the following components in part by weight: 100 parts of thermoplastic resin, 0 to 5 parts of powdered aluminium, 0 to 5 parts of diamantes, 0.1 to 1 parts of antioxidant, 0.1 to 1 parts of dispersing agent and 0.1 to 5 parts of pigment; after the materials are prepared according to the components and the parts by weight, the materials are put into a medium-speed mixer, the rotating speed and the time are controlled, mixed material is obtained, and finally, a double-screw extruder is used to extrude and granulate the mixed material, so that the product is obtained. Compared with the prior art, the invention has the advantages of high surface glossiness, good mirror effect, bright color, good flowability, simple and continuous flow, high production efficiency and stable product quality, meets SGS and ROHS heavy metal safety standards and can be recycled.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

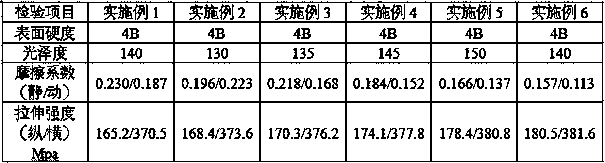

Technological process for lauminizing or coppering on aluminium or aluminium-magnesium alloy substrate

InactiveCN101067204ANo pollutionOvercoming the common magnetic effect problemVacuum evaporation coatingPretreated surfacesCoated surfaceSputtering

The technological process of forming aluminum or copper coating on aluminum or Al-Mg alloy base material includes the following steps: 1. polishing the surface and washing; 2. applying color paint containing acrylate resin to form the base coating; 3. applying paint containing polybutadiene resin to form the intermediate coating; 4. ultrahigh vacuum magnetically controlled sputtering to form aluminum or copper coating onto the intermediate coating, with the coating color being altered by means of the technological parameters; and 5. painting transparent outer protecting coating. The present invention provides a unique surface treating process, and the coating has environment friendship, excellent adhesion, high heat resistance and good decorating effect.

Owner:YULIN AUTOMOBILE FITTINGS KUNSHAN

Coating process for coating wood veneer board with UV coatings in roll coating mode

InactiveCN104588300AEmission reductionEasy to operatePretreated surfacesSpecial surfacesWater basedInfrared

The invention discloses a coating process for coating a wood veneer board with UV coatings in a roll coating mode. The coating process comprises the following steps of 1 wood veneer board pretreatment, 2 roll coating of water-based UV transparent primer, 3 infrared drying and ultraviolet curing, 4 roll coating of UV transparent primer, 5 sand cleaning and dust removal, 6 roll coating of UV padding finishing coat, 7 laser roll coating of UV sub-gloss surface cleaning varnish, 8 infrared leveling and 9 ultraviolet curing and detection packing. The coating process for coating the wood veneer board with the UV coatings in the roll coating mode is simple, high in efficiency, low in cost and free of pollution, and the surface effect can reach a PU coating open effect.

Owner:HUIZHOU CHANGRUNFA PAINT +1

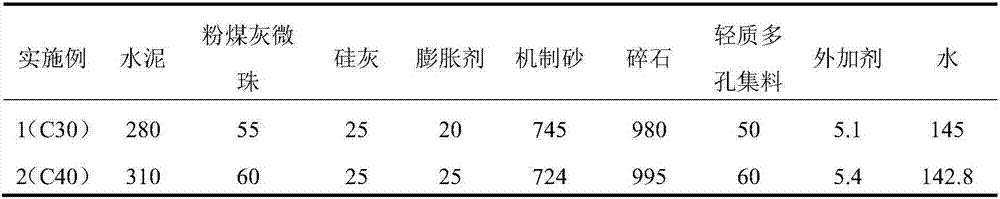

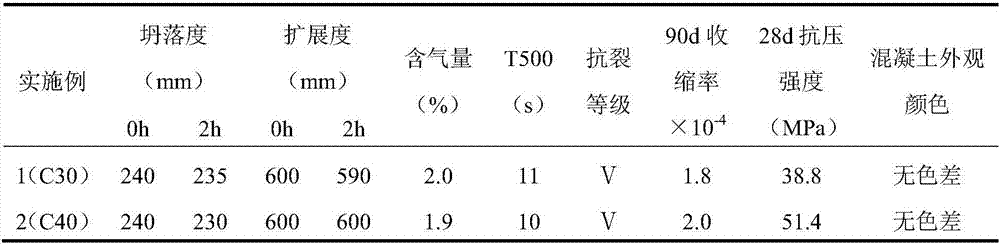

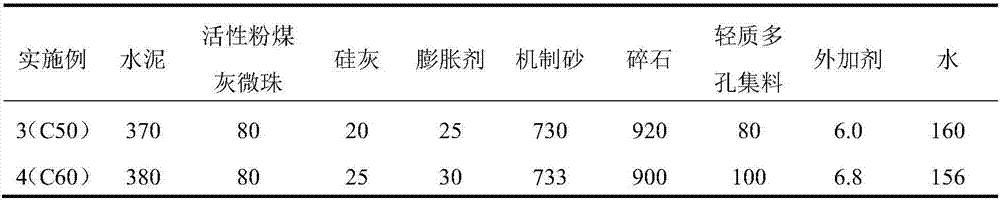

Bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand

The invention discloses a bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand. The bridge self-compaction anti-crack bare concrete is prepared from cement, activated fly ash microbeads, silica fume, an expanding agent, machine-made sand, gravel, a light-weight porous aggregate, a high-performance additive and water. The bridge self-compaction anti-crack bare concrete provided by the invention adopts the high fine powder content machine-made sand to replace common natural river sand, utilizes the activated fly ash microbeads and the silica fume for adjusting the viscosity and the fluidity of the concrete so as to improve the homogeneity of a concrete slurry, and further additive is used for reducing the gas content of the concrete, so that a working performance and a fluidity keeping performance of the concrete are improved; meanwhile, the expanding agent and the light-weight porous aggregate are combined, so that the volume stability and an anti-early-age cracking behavior of the bare concrete can be effectively improved. The self-compaction anti-crack bare concrete obtained through the invention has wide adaptability on different fine powder content machine-made sand, excellent working performance, mechanical property, volume stability performance and anti-cracking ability, uniform appearance and color, and better mirror surface effect.

Owner:WUHAN UNIV OF TECH +2

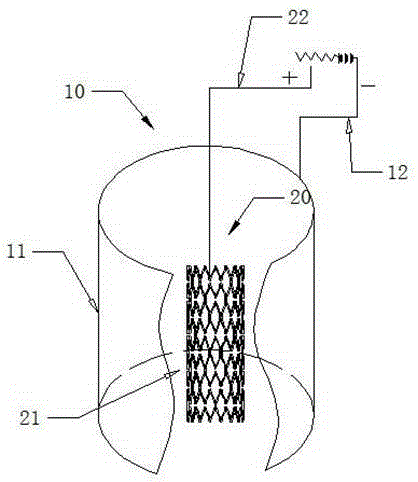

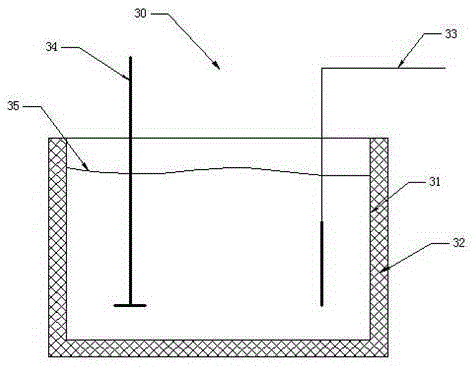

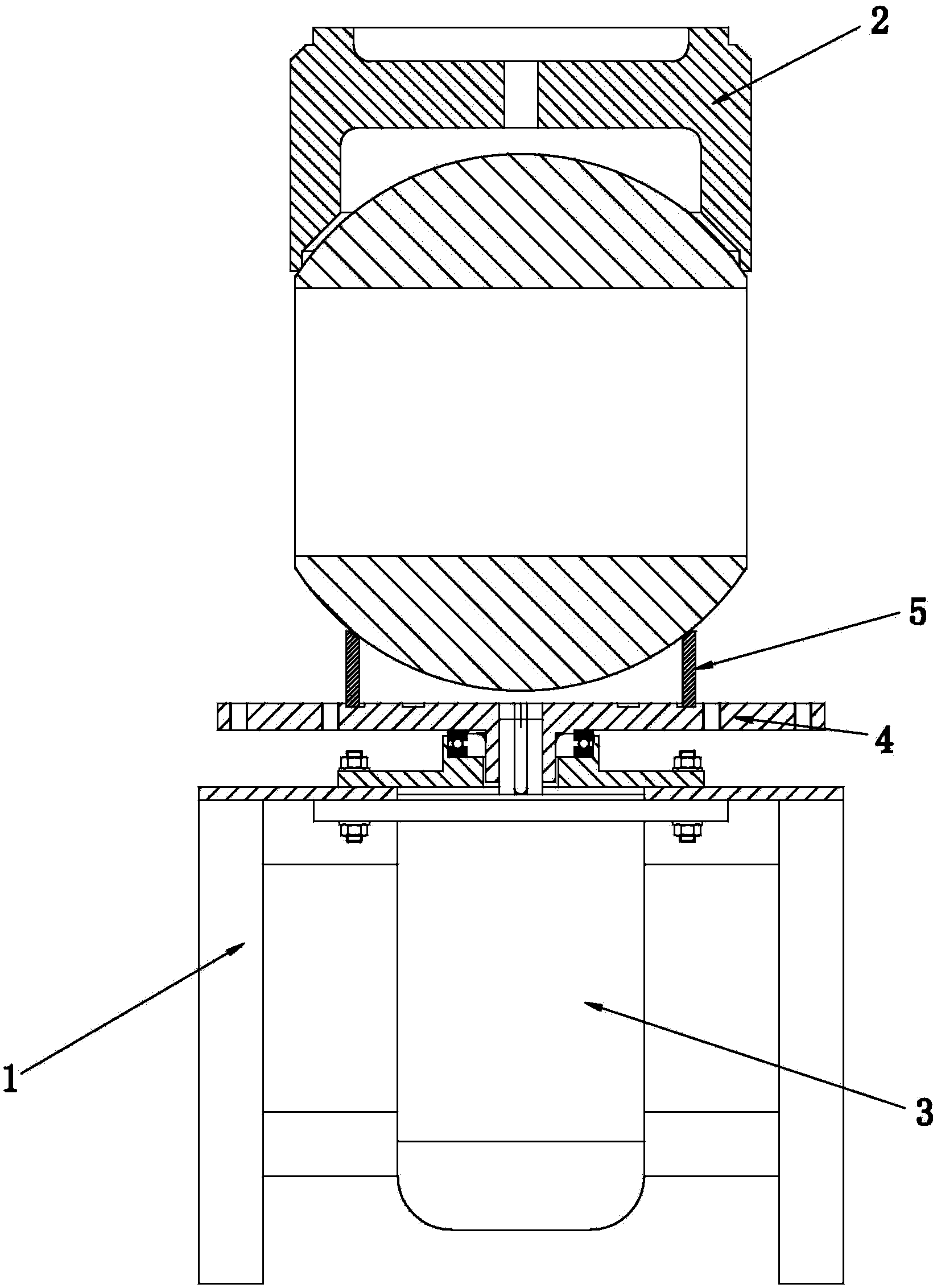

Electrochemical polishing device and method for support

InactiveCN105386117AImprove uniformityImprove the problem of large amount of removalElectrolysis componentsNitinol stentElectrochemistry

The invention provides an electrochemical polishing device and method for a support. The device and method are mainly suitable for electrochemical polishing of the medical metal support. The electrochemical polishing device for the support is characterized by comprising a metal anode, a metal cathode of a cylindrical structure, an electrochemical polishing tank and the like, and in the electrochemical polishing process, the current can be evenly distributed to all the portions of the support. The device is suitable for electrochemical polishing of the metal support such as a nickel-titanium alloy support, a cobalt-chromium alloy support, a stainless steel alloy support and a titanium alloy support and is used for improving the phenomena that pits and protrusions are generated on the inner surface of a support and the inner surface is not smooth and bright in the electrochemical polishing process, and the electrochemical polishing effect of the inner surface of the support is improved, so that both the inner surface and the outer surface of the support can achieve the good mirror surface effect. By the adoption of the device and method, the problem that the removing amount of the head end of the support is large can be solved as well, the polishing evenness of the support is improved, and therefore the metal surface of the support is smooth and bright.

Owner:LEO MEDICAL

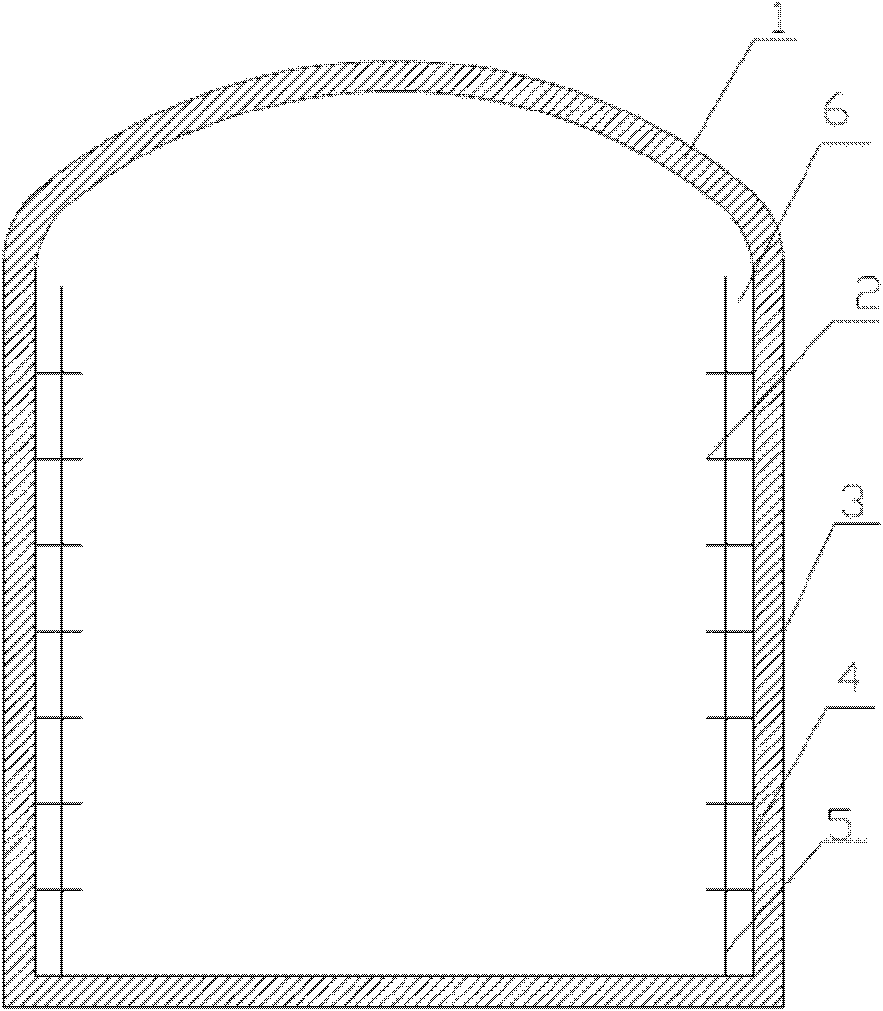

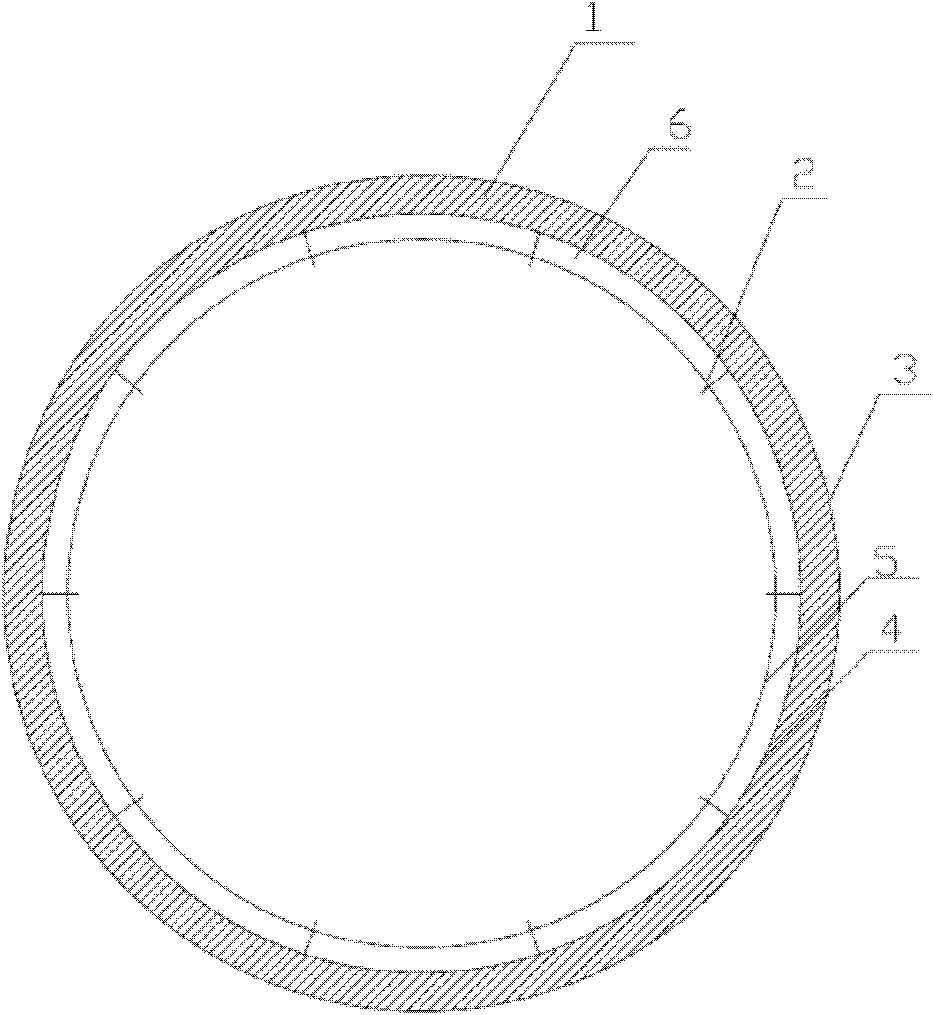

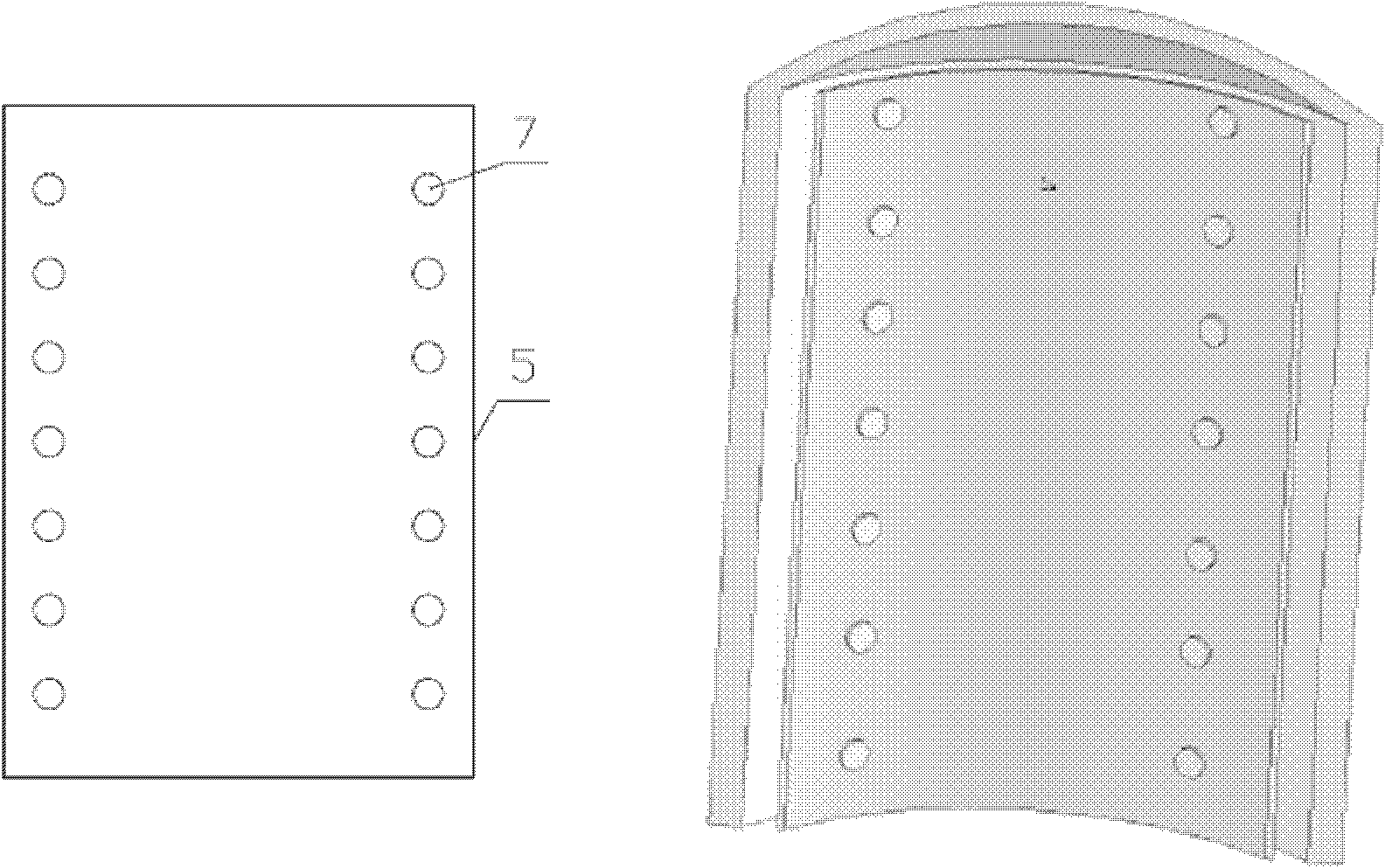

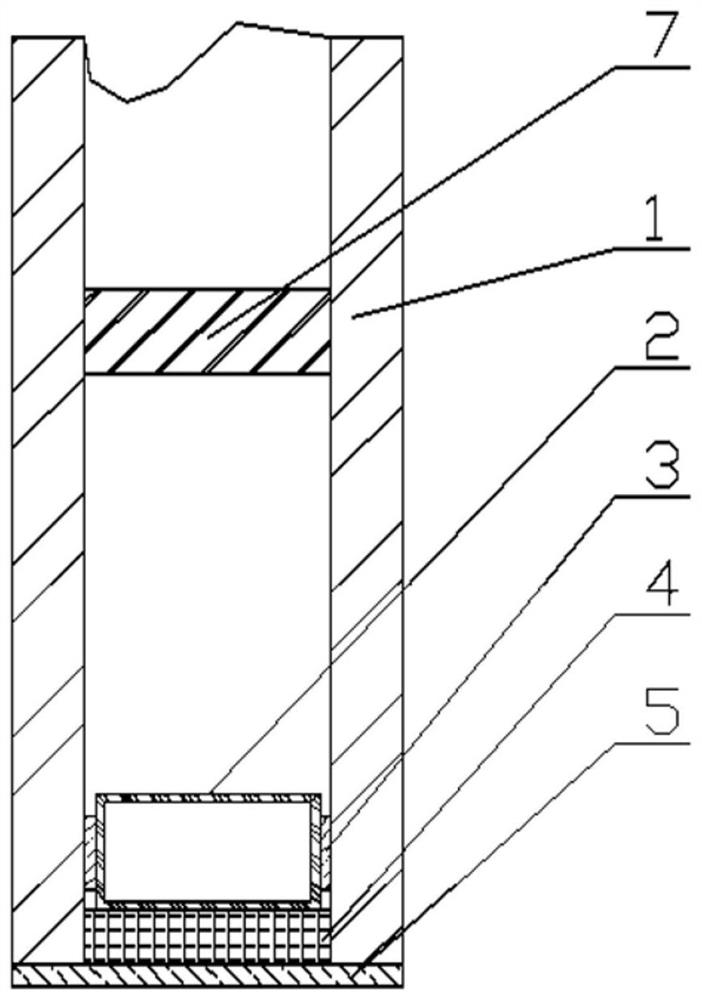

Energy-saving furnace body of polycrystalline silicon reduction furnace

InactiveCN102145891ATemperature controlEasy maintenanceChemical industrySilicon compoundsMetallurgyThermal radiation

The invention discloses an energy-saving furnace body of a polycrystalline silicon reduction furnace and a method for controlling the inner wall temperature of the furnace body. The furnace body comprises a furnace body heat insulating barrel, a stainless steel bolt, a furnace body outer wall surface, a furnace body inner wall surface, a newly-added inner wall and a newly-added heat insulating layer, wherein the stainless steel bolt is fixed on the furnace body inner wall surface in a welding way; and the newly-added inner wall is fixed on the stainless steel bolt. Compared with the conventional reduction furnace, the reduction furnace has the advantage that: a heat insulating layer is additionally arranged in the reduction furnace. By adopting the invention, the problem of energy waste caused by difficulty in polishing of the conventional furnace body inner wall and a poor polishing effect is solved, and the thermal radiation loss of the reduction furnace is reduced. The energy-saving furnace body has a simple structure and a good energy-saving effect, and is convenient to operate.

Owner:TIANJIN UNIV

Temperature-sensitive color-changeable material, preparation method thereof and one-way perspective temperature-sensitive type glass

The invention provides a temperature-sensitive color-changeable material, a preparation method thereof and one-way perspective temperature-sensitive type glass. The temperature-sensitive color-changeable material comprises the following raw materials in percentages by weight: 0.5-20 parts of temperature-sensitive macromolecules, 1-20 parts of a film-forming monomer, 0-20 parts of a thickening agent, 0-0.5 part of a dispersing agent and 0.02-0.5 part of a cross-linking agent. The temperature-sensitive color-changeable material can be transparent or non-transparent by only needing to sense the temperature of an external environment, so that the color can be changed without externally energy; and therefore, the temperature-sensitive color-changeable material can be applied to a light-adjusting glass to avoid the shortcomings of an existing light-adjusting glass structure.

Owner:CHONGQING HEWEI TECH CO LTD

Grinding process of sealing surface of ball valve

The invention relates to a grinding process of a sealing surface of a ball valve. The grinding process comprises the steps of rough grinding, fine grinding, ultrafine grinding, and grinding and cleaning of a valve seat and a sphere, wherein a diamond paste and an engine oil mixture are adopted in the rough grinding, the particle size phi of the selected diamond paste ranges from 40mu m to 10mu m, so that the scratch removal and sphere rounding can be realized; in fine grinding, a diamond paste, kerosene and a microcrystal graphite mixture are adopted, the particle size phi of the selected diamond paste ranges from 7mu m to 5mu m, so that the primary mirror surface effect can be achieved; in the ultrafine grinding, a diamond paste and a microcrystal graphite and kerosene mixture are adopted, the particle size phi of the selected diamond paste is smaller than 5mu m, the rotating speed of the sphere is controlled to be below 5rpm to achieve the mirror surface effect, and finally the kerosene is coated on the sphere and grinding cleaning are performed to achieve a better mirror surface effect. The sphere ground and the sealing surface of the valve seat can achieve the mirror surface effect, the surface roughness can achieve Ra0.02-0.005, the operation torque is low, the service life is long, the valve seat can be adsorbed on the spherical surface of the sphere, and no leakage exists under the trial pressure of low-pressure nitrogen being 0.6Mpa.

Owner:WENZHOU ARTECH MACHINERY TECH CO LTD

Ultraviolet (UV) laser roller coating woodware matt finish

InactiveCN103627300AEmission reductionReduce odor volatilityPolyurea/polyurethane coatingsEpoxy resin coatingsUv laserUltraviolet

The invention discloses ultraviolet (UV) laser roller coating woodware matt finish. The UV laser roller coating woodware matt finish consists of the following components in percentage by weight: 30-57 percent of resin, 29-40 percent of monomer, 8-20 percent of fumed silica, 4-7 percent of photoinitiator and 1.8-4.8 percent of other aids, wherein the resin is a mixture of an epoxy acrylate resin and aliphatic modified polyurethane acrylate. According to the UV laser roller coating woodware matt finish, no construction trace is left and an excellent mirror surface effect can be achieved. Moreover, the UV laser roller coating woodware matt finish is high in adhesion force, high in fullness, high in brightness and environment-friendly and has good decorative and protective effects, the product quality and production efficiency can be greatly improved, and emission of an organic solvent can be reduced.

Owner:HUIZHOU CHANGRUNFA PAINT +1

Application and coating method of water-based wood coating on the surface of electric guitar

ActiveCN102266845AAltered high volatile organic contentChange the smell bigPretreated surfacesSpecial surfacesWater basedElectric guitar

The invention relates to application of an aqueous wood coating to the surface of an electric guitar and a coating method thereof. Polyurethane modified acrylic resin, the hardness of which is required to reach the hardness H or scratch of a Chung Hwa pencil, is taken as the principal film-forming substance. The hardness of the aqueous wood coating is required to reach the hardness H of the Chung Hwa pencil. The coating method provided by the invention can be used for acquiring a film-coating effect with excellent fullness, high hardness and excellent mirror surface effect. An aqueous wood coating system is adopted in the invention and the defects of a solvent based coating that the content of organic volatile matter is high, the odor is thick and the environment is polluted are avoided, thereby meeting the demands of customers to a musical instrument for safety, environmental protection and nature.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

Aqueous buffing oil with shell/core structure

InactiveCN1632022AStrong adhesionImprove wear resistanceSpecial paperPaper/cardboardWaxSocial benefits

Disclosed is a hydrophilic buffing oil with core-shell structure,with its component and mass content: base materials 48-5%, latex 1-3%,water 43-48%, thickener 2-4% and assistant 0.1-0.5%. Coat the hydrophilic buffing oil on printed matter,then buffing it under rolling of 150kg in 80-100deg.C, making the wear resistance and ornamental higher,with protection to water and increased additional value;meanwhile, it uses latex polymerization method,inwhich there is no solvent,remarkably advancing productive condition,it has notably social benefit.

Owner:广州电器科学研究院

Metal mirror surface polishing process

InactiveCN105598802ANo local poor polishingGood mirror effectPolishing machinesPolishingHazardous substance

The invention relates to the technical field of metal surface polishing, particularly to a metal mirror surface polishing process. The metal mirror surface polishing process comprises the following processing steps: S1, taking out a metal workpiece and a diamond processing tool; S2, conducting surface grinding on the metal workpiece by adopting the diamond processing tool, wherein in grinding processing, the included angle between a blade of the diamond processing tool and the surface of the metal workpiece is 18-34 degrees; S3: conducting grinding and polishing treatment on the metal workpiece with a polishing machine with a sponge plate at the speed of 3,000-4,000 r / min until the surface roughness Ra is smaller than 5 nm, wherein in the grinding and polishing treatment process, the conditions that a flowing polishing solution is cooled and the surface of the treated metal workpiece is moistened are kept. According to the metal mirror surface processed by the process and formed on the surface of the metal workpiece, the condition of poor local polishing can be avoided, the uniformity is good, and the mirror surface effect is excellent; the whole process is easy to operate, harmful substances of waste water, waste gas and the like in the production process can also be avoided, and the process is environmentally friendly and practical.

Owner:SHENZHEN SHINDY TECH

Waterborne two-component polyurethane transparent light varnish and preparation method and application thereof

InactiveCN102399490AClearly highlight the appearanceHigh transparencyPolyurea/polyurethane coatingsChemical industryPolymer science

The invention belongs to the field of chemical industry, and particularly discloses waterborne two-component polyurethane transparent light varnish as well as a preparation method and an application thereof, and the varnish comprises the following components by weight: 64.4-80 parts of polymer emulsion containing hydroxy, 5-18 parts of polyurethane emulsion, 5-7 parts of acrylic acid emulsion, 2-7 parts of alcohol and ethers solvents, 0.4-0.9 parts of defoaming auxiliary agents, 0.4-0.7 parts of leveling agents and 1-2 parts of thickening agents. The two-component polyurethane transparent light varnish has the characteristics of good fullness, high luster and good leveling performance.

Owner:AODA KOALA PAINT HUIZHOU

F-Si acrylate copolymer and use method thereof as paint sealant

The invention discloses an F-Si acrylate copolymer and a use method thereof as a vehicle paint sealant. The copolymer is a free radical polymerization reaction product by initiating the following components in percentage by weight with an initiator under the existence of an emulsifier: 35-55 percent of hard monomer, 20-50 percent of soft monomer, 0.5-5 percent of functional group monomer, 5-15 percent of fluorinated monomer, 3-16 percent of silicone monomer and 2-5 percent of nano material, wherein water is 100-150 percent of the total mount of the monomers, the initiator is 0.4-3 parts, and the emulsifier is 1.2-2 percent. The invention is applied to a vehicle paint face so that the vehicle paint face has the advantages of resisting water, oil, ultraviolet rays, static electricity, stain, washing, and the like and has the excellent self-cleaning function.

Owner:北京奥力助兴石化科技有限公司

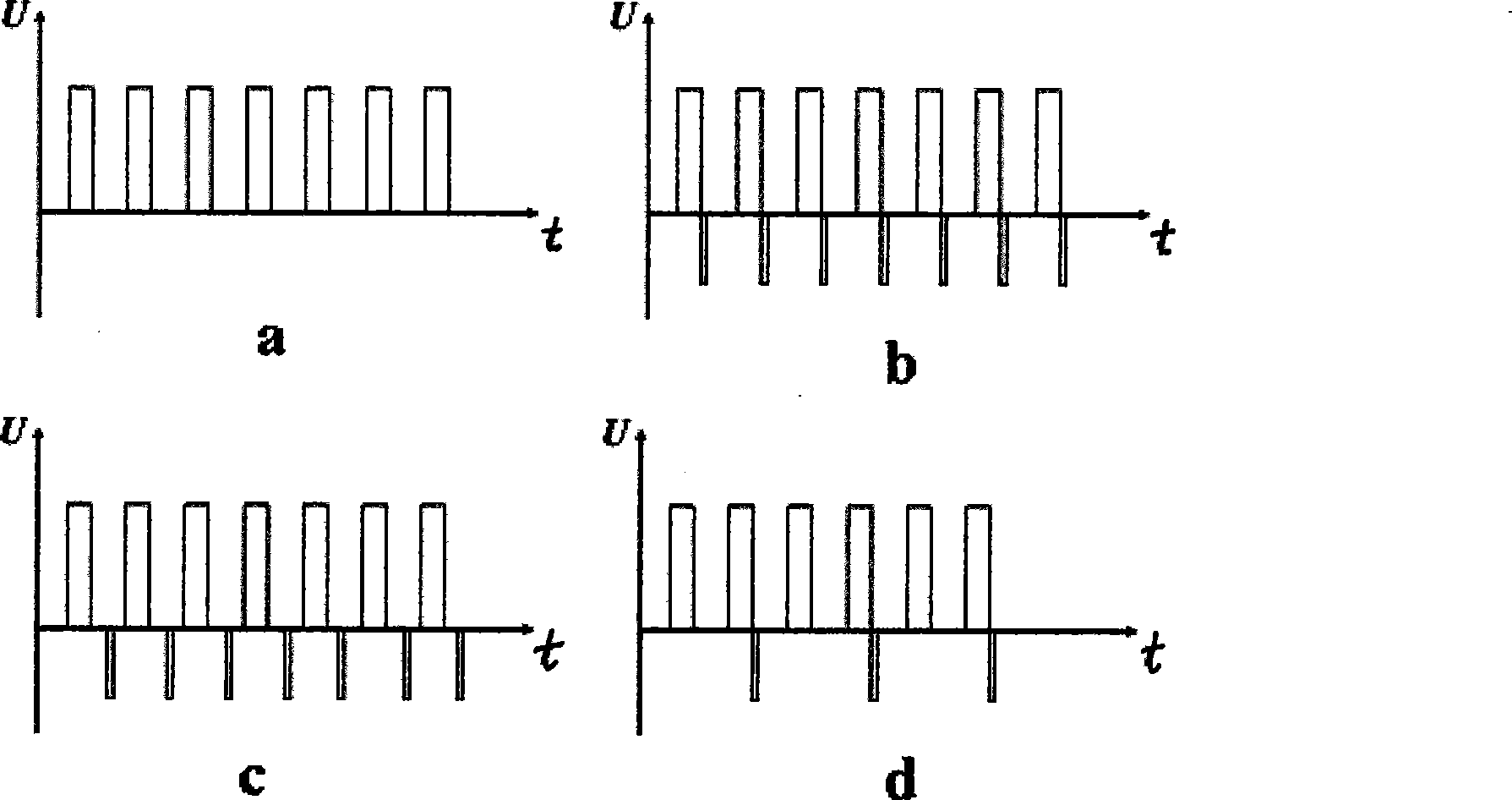

Non-equilibrium liquid condition composite pulse plasma polishing method

A polishing solution disclosed by the present invention is composed of the following components according to mass percentage: component A: (NH4)2SO4 aqueous solution with a concentration of 1% to 10%, component B: ethylene glycol with a concentration of 0.2% to 3% One or a combination of amine tetraacetic acid, ammonium citrate, sodium tartrate or sodium oxalate. The method of using the polishing liquid to carry out non-equilibrium liquid compound pulse plasma polishing, first prepare the polishing solution according to the above formula, then put the workpiece to be treated into the above prepared polishing liquid, add a compound electric pulse or an equivalent different Combination of positive and negative pulses, control positive pulse frequency 0.5-80kHz, duty cycle 5%-95%, voltage 200-480V, make the reaction in the most violent state, treatment for 1-5 minutes, that is to complete the polishing process. In the present invention, pulses are used instead of direct current, which is beneficial to the generation of plasma, so that the discharge plasma can obtain higher kinetic energy, better mirror effect and faster polishing speed.

Owner:XIAN UNIV OF TECH

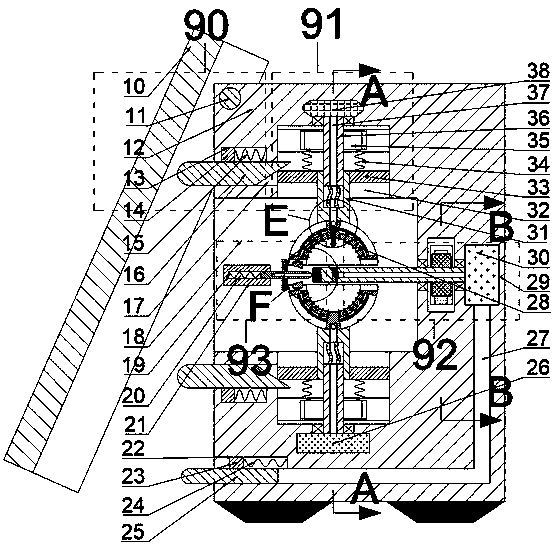

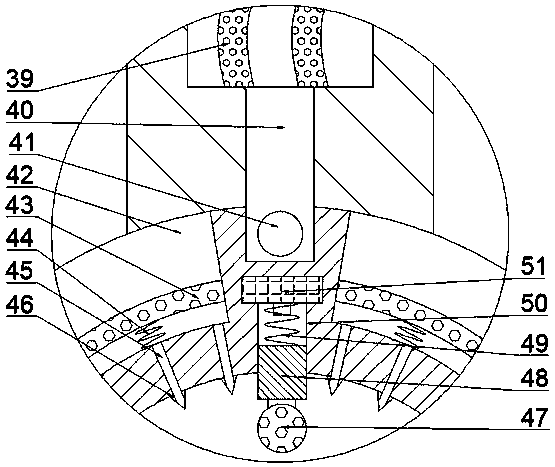

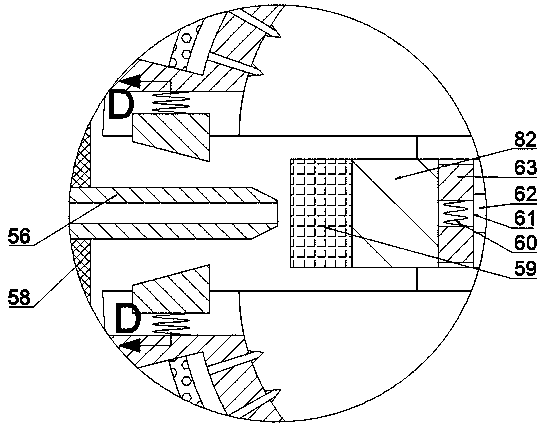

Polyvinyl chloride injection molding and polishing integrated device

ActiveCN110216547AImprove integrityQuality improvementGrinding drivesSpherical surface grinding machinesPolyvinyl chlorideEngineering

The invention discloses a polyvinyl chloride injection molding and polishing integrated device. The device comprises a box. A working cavity with a left opening is formed inside the box, the working cavity is communicated with a first rotating cavity in a vertical symmetry mode, a main rotating mechanism for transversely rotating and polishing a plastic ball is arranged between the first rotatingmechanism and a third sliding hole, the main rotating mechanism comprises the first rotating cavity, a disc is slidably arranged inside the first rotating cavity, a spline sleeve extending up and downis fixedly arranged on the disc, and a hollow hemisphere is fixedly arranged at the bottom end of the spline sleeve. After the device performs injection molding and solidification to form the plasticball, all-dimensional polishing is performed, the polishing area is large, the efficiency is high, few polishing scratches of the spherical mirror formed after polishing are caused, the mirror surface effect is good, the formed smooth plastic ball is high in quality, in addition, the device can collect plastic dust generated during polishing, the interior of the working cavity is clean and tidy,and meanwhile the device does not contaminate air and is environmentally friendly.

Owner:广东启智精密科技有限公司

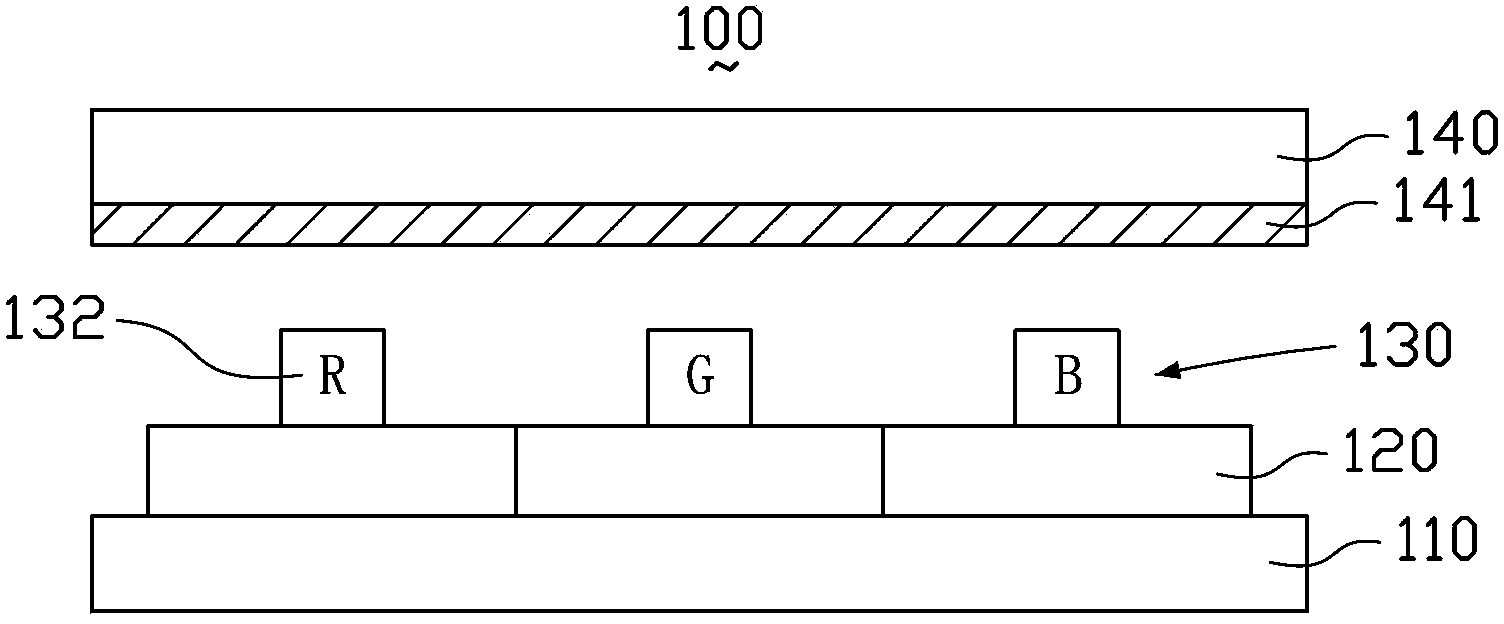

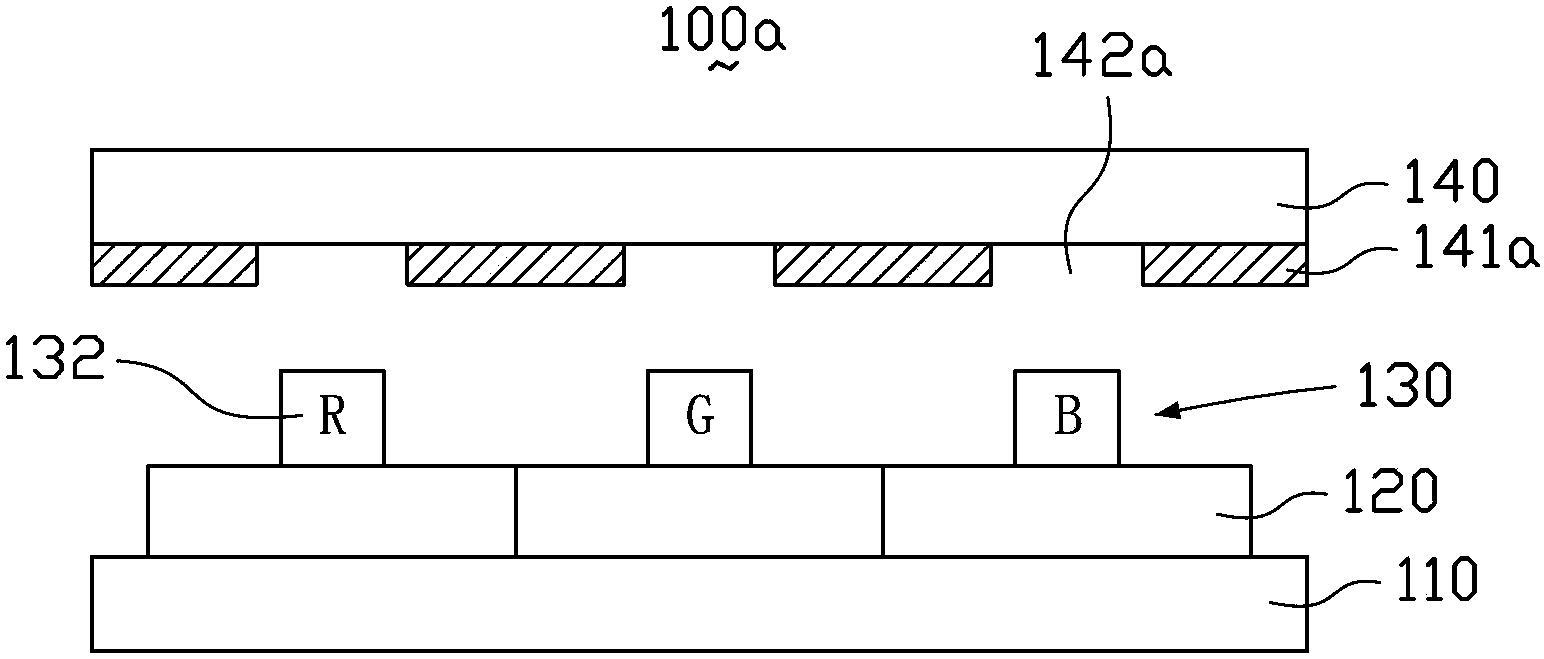

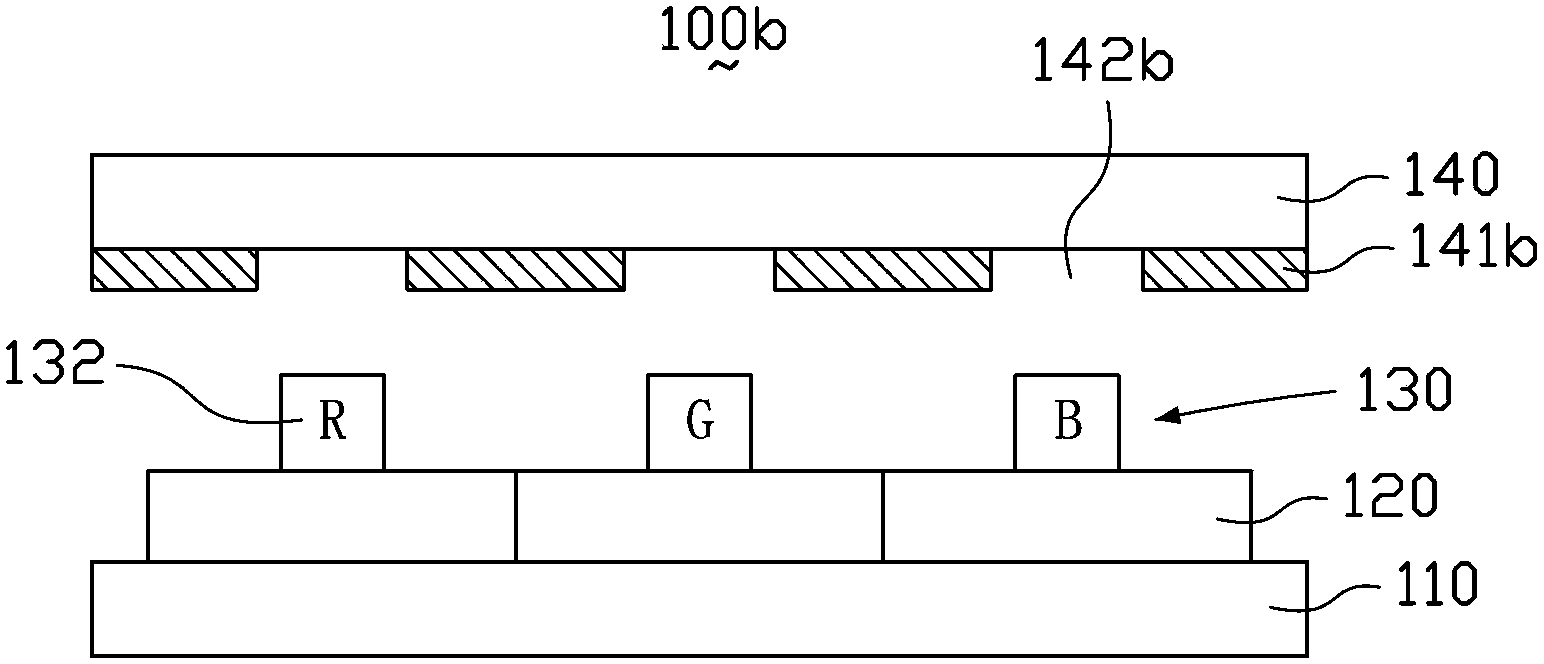

Organic light-emitting displayer and manufacturing method of organic light-emitting displayer

InactiveCN103730481AArea maximizationGuaranteed display effectSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceDriven element

The invention relates to an organic light-emitting displayer which comprises a driving element array substrate, an organic light-emitting element layer and a reflecting layer. The organic light-emitting element layer comprises a first electrode layer, an organic light-emitting functional layer and a second electrode layer, the first electrode layer, the organic light-emitting functional layer and the second electrode layer are sequentially formed on the driving element array substrate, and a light outgoing area is defined by the organic light-emitting functional layer. The reflecting layer is located outside the light outgoing area of the organic light-emitting functional layer and arranged in the driving element array substrate, or the reflecting layer is located between the organic light-emitting element layer and the driving element array substrate, or the reflecting layer is located in the organic light-emitting element layer. The organic light-emitting displayer has the good mirror surface effect and the good image displaying effect at the same time. The invention further relates to a manufacturing method of the organic light-emitting displayer.

Owner:AU OPTRONICS CORP

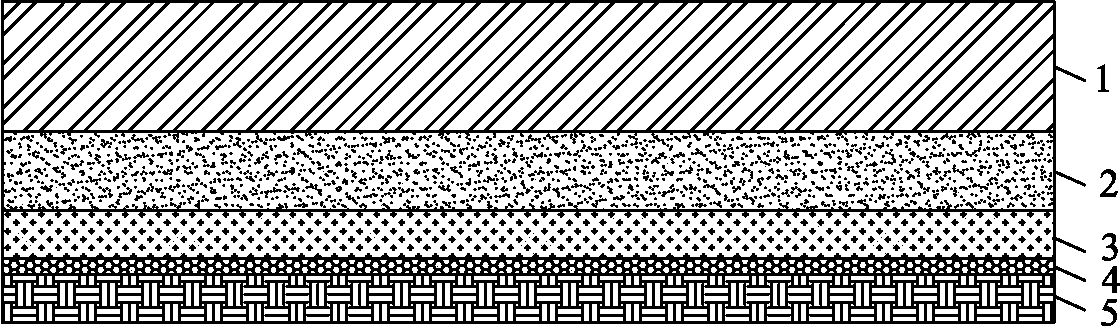

Glazed microfiber silicone rubber synthetic leather and manufacturing technology thereof

InactiveCN108951182AGuaranteed mechanical propertiesImprove bending resistanceTextiles and paperPolymer scienceManufacturing technology

The invention discloses a glazed microfiber silicone rubber synthetic leather, which is prepared by laminating a super bright glazed layer, a liquid silicone rubber layer, and a microfiber fabric in sequence. The liquid silicone rubber layer is composed of following raw materials in parts by weight: 50 to 80 parts of basic rubber of silicone rubber, 3 to 5 parts of silane coupling agent, 5 to 10 parts of hydrogen containing silicone oil, 0.1 to 0.5 part of platinum catalyst, 5 to 20 parts of color paste pigment, and 0.02 to 0.1 part of inhibitor. The invention also discloses a manufacturing technology of the glazed microfiber silicone rubber synthetic leather. Liquid silicone rubber with high hardness and elongation rate is taken as the basic material to prepare the silicone rubber synthetic leather; in order to guarantee the mechanical performance of the silicone rubber synthetic leather, hydrogen containing silicone oil with a high hydrogen content is taken as the crosslinking agent,and the obtained glazed microfiber silicone rubber synthetic leather has an excellent bending resistant performance. A layer of colored silicone rubber is painted on the microfiber surface so as to fully fill the gaps in the microfiber surface, then the microfiber and transparent silica gel are adhered together, and the mirror effect is very obvious.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

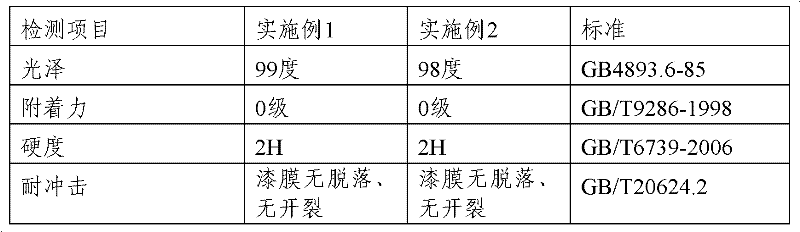

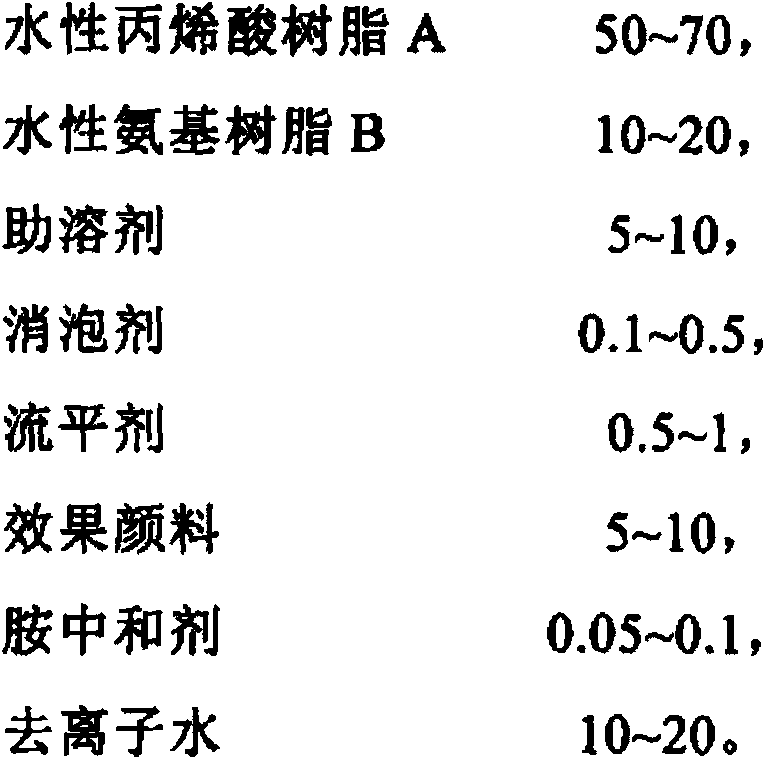

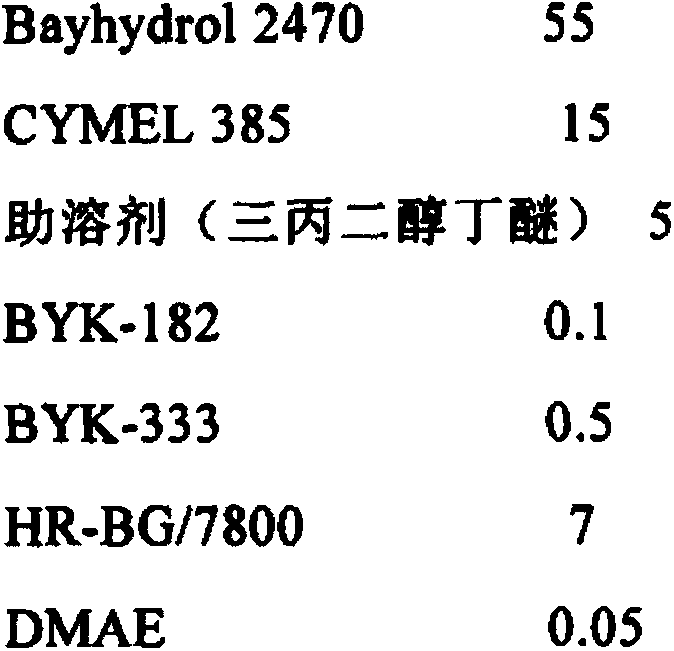

Water based paint with mirror surface effect and preparation method thereof

The invention relates to water based paint with a mirror surface effect and a preparation method thereof. The water based paint is composed of the following components in parts by weight: 50-70 parts of water-based acrylic resin A, 10-20 parts of water-based amino resin B, 5-10 parts of cosolvent, 0.1-0.5 part of defoaming agent, 0.5-1 part of leveling agent, 5-10 parts of effect pigment, 0.05-0.1 part of amine neutralizer and 10-20 parts of deionized water. The preparation method comprises the following steps: sequentially adding the water-based acrylic resin A, the water-based amino resin B, 50% of deionized water, the defoaming agent and the cosolvent into a container, and stirring uniformly to obtain a mixture A; uniformly mixing and stirring the residual deionized water, the leveling agent and the effect pigment to obtain a component B; adding the component B into the component A while stirring, uniformly stirring and finally regulating the pH to 7.0-7.5 by use of the amine neutralizer. Compared with the prior art, the water based paint provided by the invention has the advantages of low VOC emission, environmental friendliness, excellent adhesive force, high hardness and scratch resistance, and the like.

Owner:DONGLAI COATING TECH SHANGHAI

Aqueous calendering oil for glazing of calendaring technology of paper printing products

The invention discloses aqueous calendering oil for the glazing of calendaring technology of paper printing products, which comprises the following components in portion by weight: 90 to 95 portions of aqueous acrylic ester resin emulsion, and 4 to 8 portions of wax emulsion. The aqueous calendering oil for the glazing of the calendaring technology of the paper printing products is applicable to high-temperature calendaring technology with a temperature more than 130 DEG C, thereby ensuring that printing products achieve higher gloss and better mirror effect. In addition, the aqueous calendering oil has good film forming property, does not need to add a film forming additive, can take water as a diluting agent, does not need alcoholic solvents, and radically overcomes the defect that the prior technology uses an organic solvent. The product has no toxicity, does not contain organic solvents, is safe and environment-friendly, is suitable for the high-temperature calendaring technology, obtains higher gloss, and has the advantages of excellent wear resistance, smooth surface, moisture protection and water resistance, aging resistance, high solid and low viscosity.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

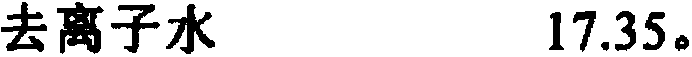

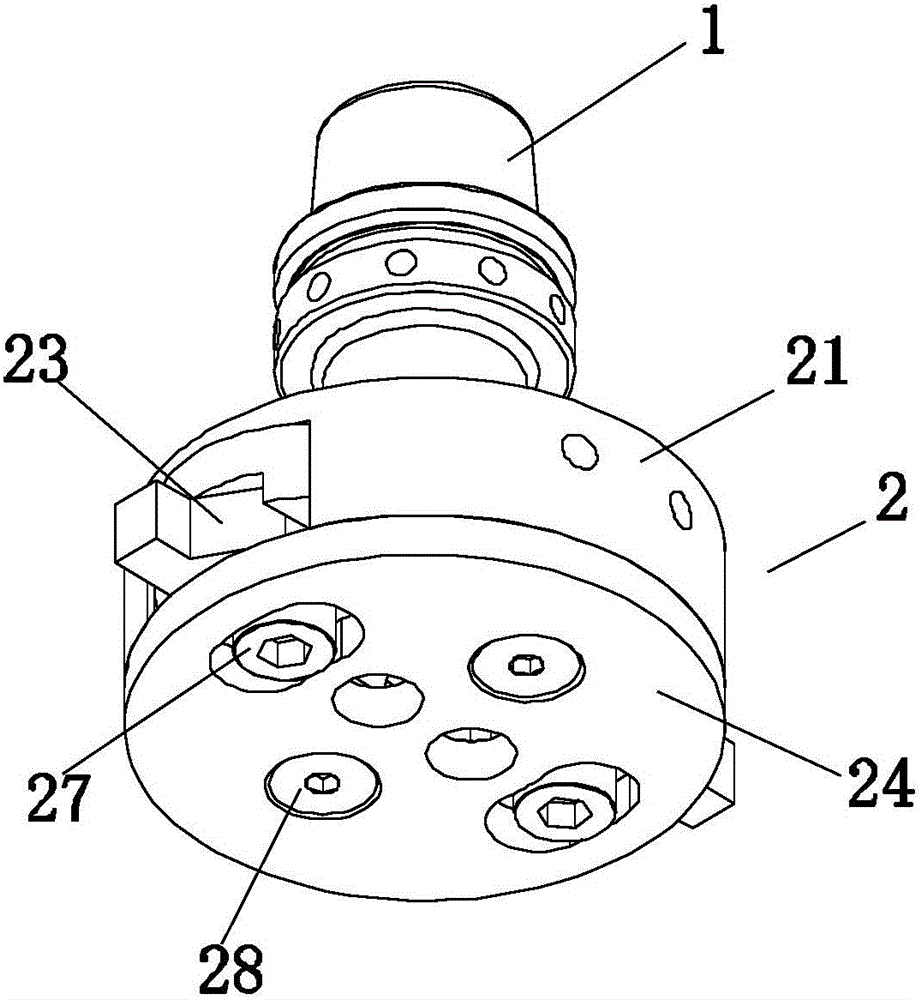

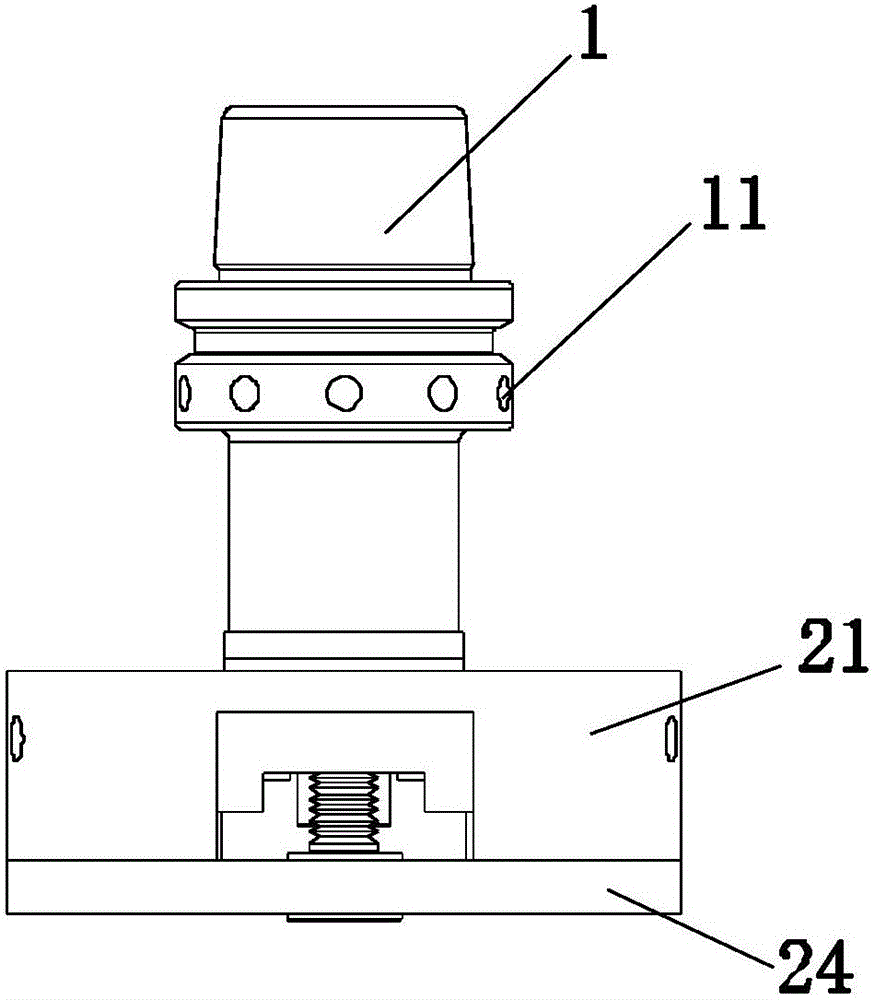

Highlight face milling cutterhead and highlight face milling cutter

ActiveCN105772820AImprove the knife patternGood highlight effectMilling cuttersMilling cutterEngineering

The invention discloses a highlight face milling cutterhead. The highlight face milling cutterhead comprises a face milling cutterhead body, two rotating plates, two milling cutters and a cover plate. Two circular grooves are symmetrically distributed in the end face of the face milling cutterhead body. Each rotating plate is installed in one circular groove and provided with a milling cutter installation groove. Each milling cutter comprises a milling cutter handle and a milling cutter head arranged at one end of the milling cutter handle. The milling cutter handles of the milling cutters are fixedly installed in the milling cutter installation grooves. The milling cutter head of each milling cutter sequentially penetrates a second notch and a first notch and extends outwards, wherein the second notch and the first notch correspond to the milling cutter head. The cover plate is fixedly connected with the end face of the face milling cutterhead body. The invention further discloses a highlight face milling cutter. By means of the highlight face milling cutterhead and the highlight face milling cutter, the highlight effect of products can be improved, the mirror surface effect that Ra is smaller than or equal to 25 nm is achieved, and cutter patterns are eliminated; and an upper chamfer and a lower chamfer can be machined at the same time, the machining efficiency is improved, the balance performance of the whole cutterhead can be effectively ensured, and the subsequent balancing difficulty is lowered.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

Reflection thermal insulating coating

ActiveCN107987655AThe method of component preparation is simple and easyRaw materials are easy to getAntifouling/underwater paintsPaints with biocidesWeather resistanceMesoporous silica

The invention discloses a reflection thermal insulating coating which comprises the following components in parts by mass: 50-60 parts of an organic silicon phosphate type filming ion polymer, 7-12 parts of mesoporous silica, 7-12 parts of aluminum oxide nanotubes, 10-15 parts of a solvent and 3-6 parts of functional aids. Compared with a common reflection thermal insulating coat in the prior art,the reflection thermal insulating coating disclosed by the invention is more excellent in comprehensive property such as weather resistance, binding force with buildings and chemical resistance, andis relatively remarkable in reflection thermal insulating effect.

Owner:厦门卓施特建材有限公司

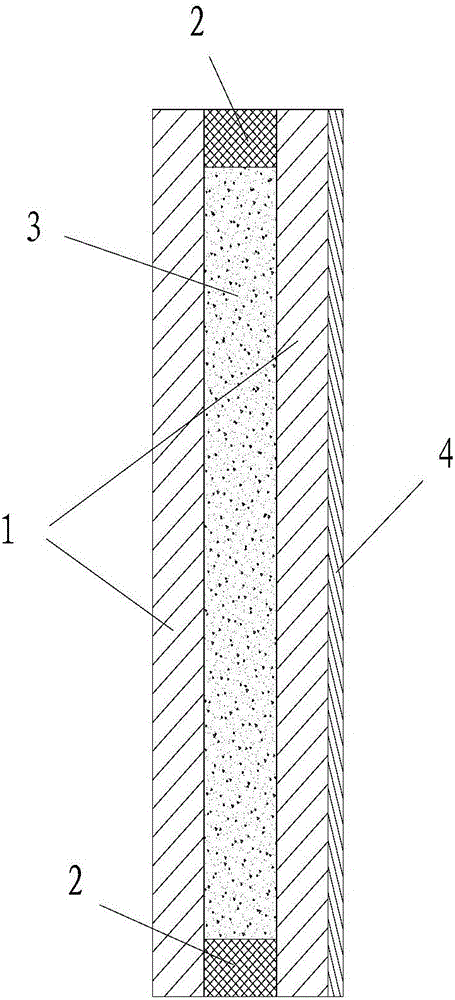

Compound foamed aluminum plate

InactiveCN101265743ALittle effect of loadLow densityCovering/liningsSound proofingRough surfaceComposite plate

An aluminum foam composite plate belongs to an aluminum foam plate. A face plate is further arranged outside the aluminum foam plate. The invention is characterized in that the face plate is a marble plate. The combination of the aluminum foam plate and the marble plate can maximize the advantages, minimize the disadvantages, and double the effect: firstly, the sound insulation effect is remarkably improved, thereby greatly reducing the common life noise; secondly, the rough surface of the aluminum foam plate is covered by the natural texture with beautiful appearance of the marble plate as the decorative plate; thirdly, when being used in combination of the aluminum foam plate, the marble plate with smaller wall thickness is used so as to greatly reduce the weight, facilitate the construction and reduce the load effect of the building. The marble is abrasion resistant, corrosion resistant, fireproof and particularly rainwater-proof, thereby being applicable to decoration of exterior walls, floors, kitchens and bathrooms.

Owner:李书通

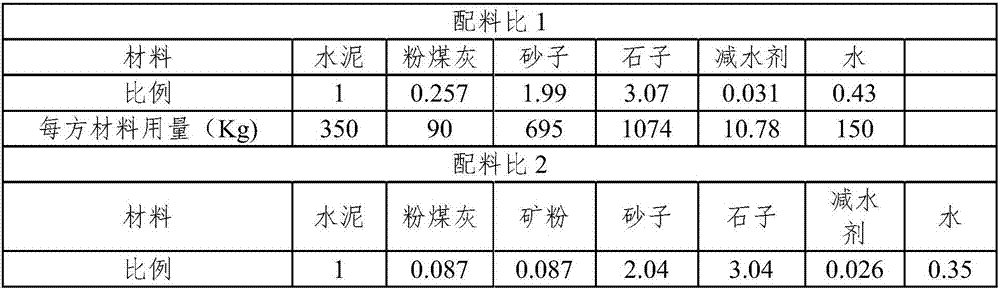

Concrete construction method and mirror-surface concrete pier column

InactiveCN107881902AGood mirror effectImprove appearance qualityBridge structural detailsBridge erection/assemblySlurryRebar

Disclosed is a concrete construction method. The method comprises the following steps that the inner surface of a steel template is uniformly coated and brushed with a mould releasing agent, and standing is conducted till the steel template is completely dried; cement, fly ash, fine aggregate, coarse aggregate, water reducing agents and water are uniformly mixed, and the slump of the concrete after mixing is 160-200 mm; a steel reinforcement cage model inner framework is built, the completely-dried steel template is assembled on the outer periphery of the steel reinforcement cage inner framework to form a model outer framework; the uniformly-mixed concrete is poured into the outer framework, a mode of combining an insertion-type vibrating rod and a flat-plate vibrator is adopted for vibrating in the pouring process till slurry bleeding begins to occur on the surface of the concrete, and no obvious bubbles are generated; curing is conducted after concrete pouring is completed, and afterstanding is conducted for at least 100 h, the steel template is disassembled by block. The invention further provides a mirror-surface concrete pier column. The concrete prepared by means of the construction method can achieve a good mirror surface effect, the surface of the concrete is smooth, bright and clean, the color and luster are uniform, and no bubbles occur; the appearance quality of theconcrete is improved, and the appearance attractiveness of the concrete is improved.

Owner:SINOHYDRO ENG BUREAU 4

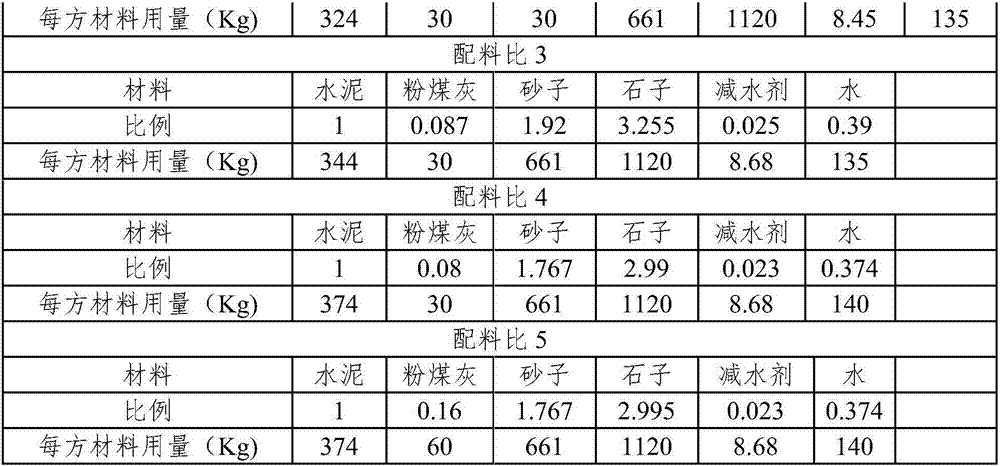

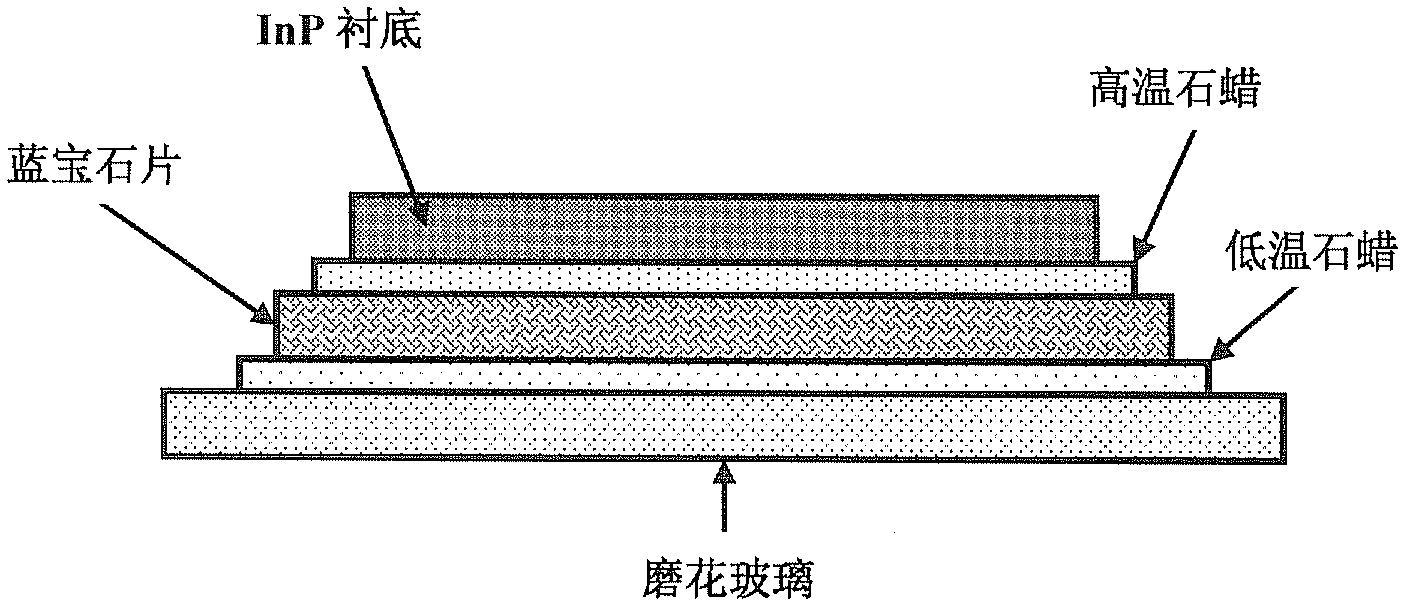

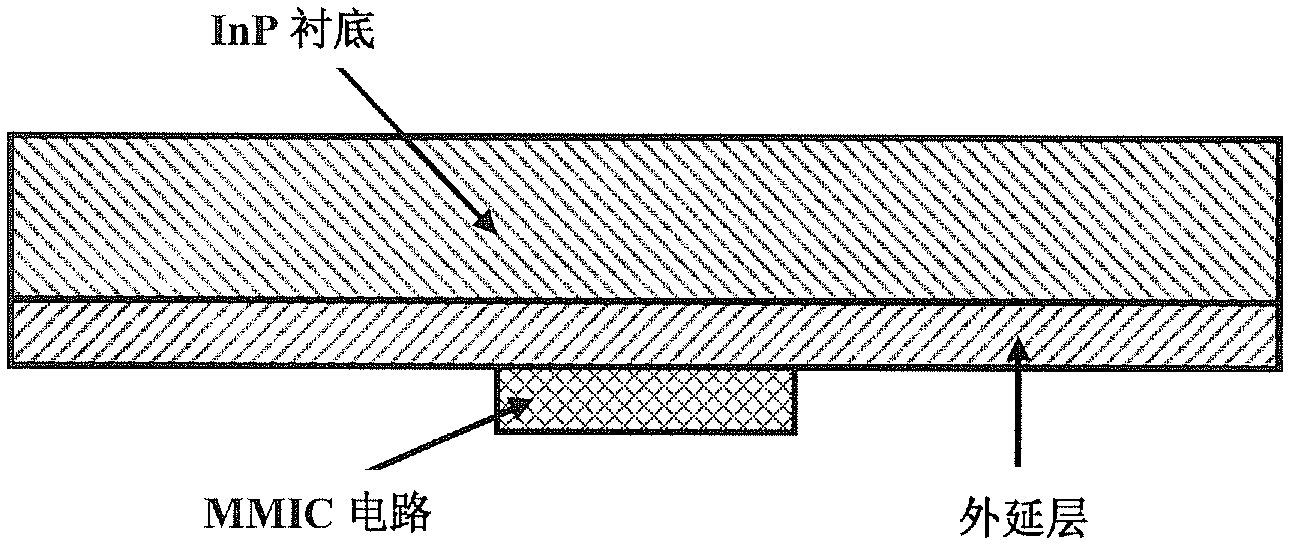

Method for manufacturing InP monolithic microwave integrated circuit

ActiveCN102509721AReduce stressReduce chance of fragmentationSemiconductor/solid-state device manufacturingMonolithic microwave integrated circuitPhysics

The invention discloses a method for manufacturing an InP monolithic microwave integrated circuit. The method comprises the following steps: an MMIC (Monolithic Microwave Integrated Circuit) is manufactured on an epitaxial layer on the front side of an InP underlay; a photoresist layer is coated to protect the MMIC, and an InP substrate is formed; the InP substrate, a sapphire double-sided polishing piece and a polished glass substrate are adhered by adopting paraffin to form a five-layer laminating structure; the back side of the InP substrate in the five-layer laminating structure is abraded, attenuated and polished; an Ni mask layer is manufactured on the polished surface of the back side of the InP substrate; part of the Ni mask layer is removed by utilizing the corrosion of HF acid; an HBr gas is used to etch the back side of the InP substrate, the InP underlay and the epitaxial layer on the front side of the InP underlay are etched to the MMIC circuit on the epitaxial layer; a Ti / Au coating is sputtered on the Ni mask layer; Au is electroplated on the Ti / Au coating; Au outside the Ti / Au coating is stripped by ultrasound to obtain a back-side metal structure; the high-temperature paraffin is thawed, and the sapphire double-sided polishing piece in the five-layer laminating structure is separated.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Mirror surface silver ink as well as preparation method and product thereof

The invention relates to the field of ink and in particular provides mirror surface silver ink as well as a preparation method and a product thereof. Due to adoption of an aqueous acrylic acid modified polyester resin in the mirror surface silver ink, the chemical resistance of a mirror surface silver ink coating can be improved; due to adoption of an aqueous stoving varnish epoxy resin, the alkali resistance of the mirror surface silver ink coating can be improved; due to adoption of an aqueous sealed isocyanate curing agent and an aqueous benzene amino resin, the crosslinking density of rawmaterials can be improved; a modified silane coupling agent can be directly used in the mirror surface silver ink, storage stability of the mirror surface silver ink is not affected, and meanwhile thewater resistance and the binding force of the ink coating with a substrate can be improved; the mirror surface silver ink is harmless to human bodies and environments, a protection layer is not needed, and effects that no silver is peeled, adhesion is not affected and a mirror surface effect is not affected can be achieved when a single coating layer is washed with 4% NaOH at 70 DEG C.

Owner:广州茵诺威化工有限公司

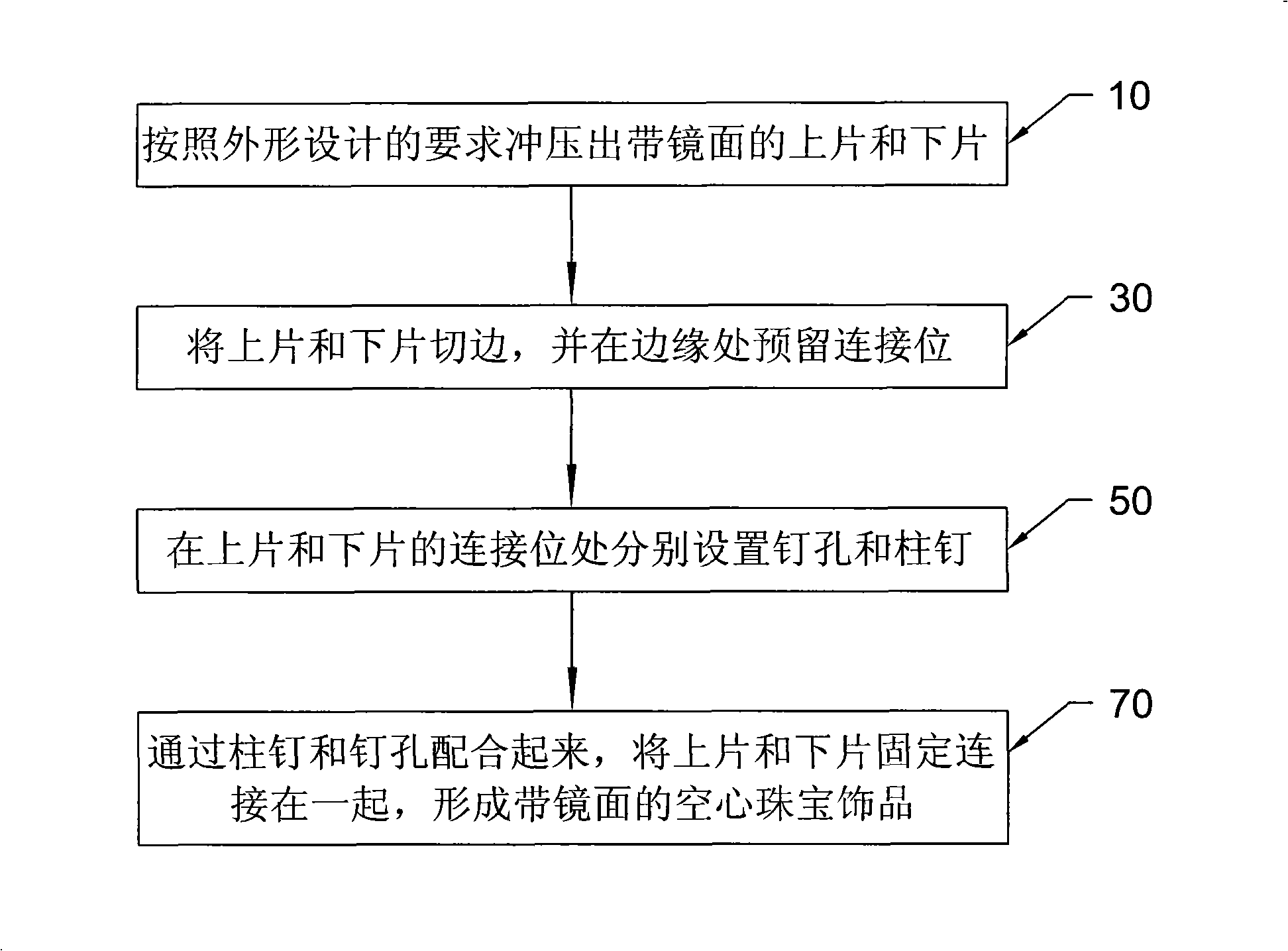

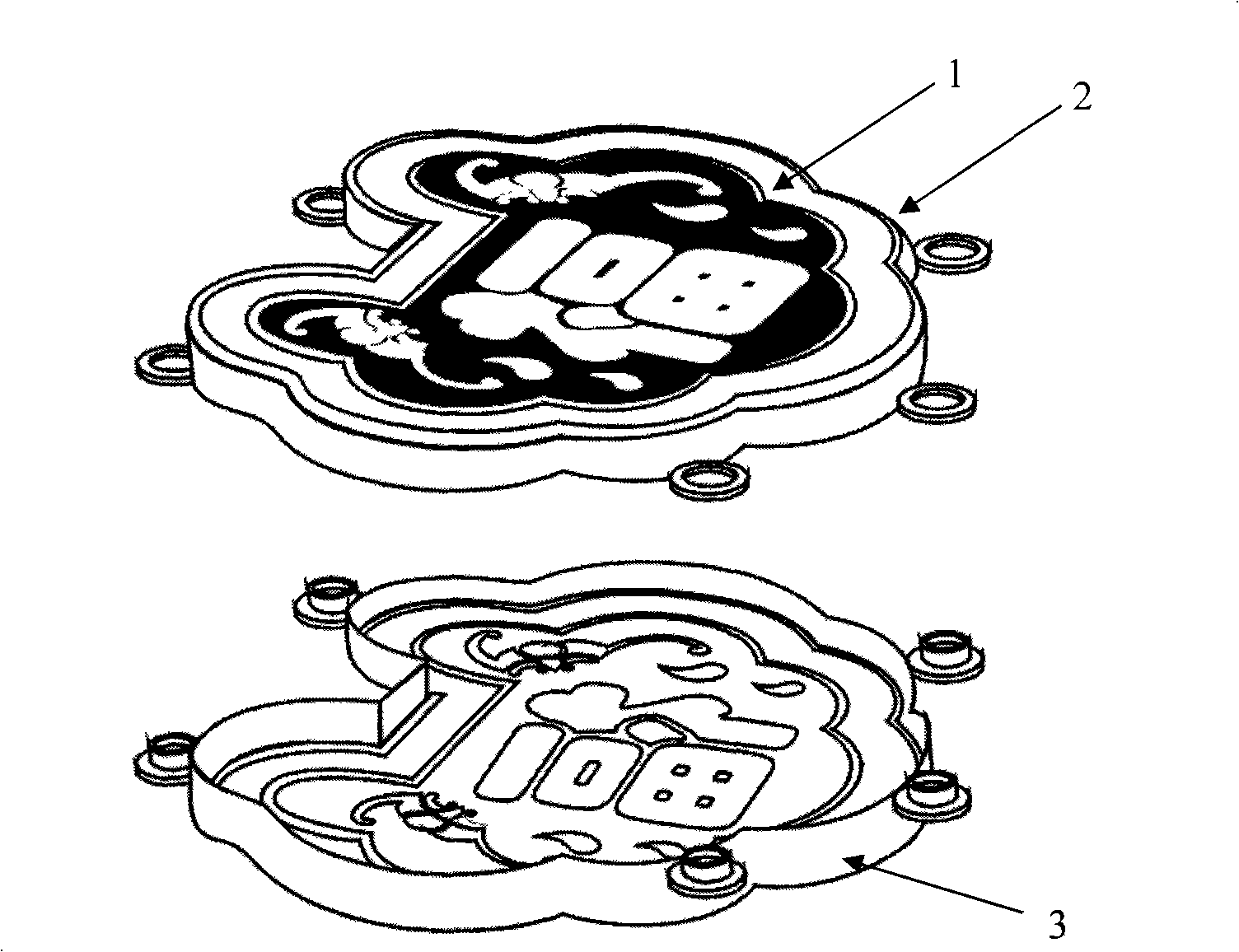

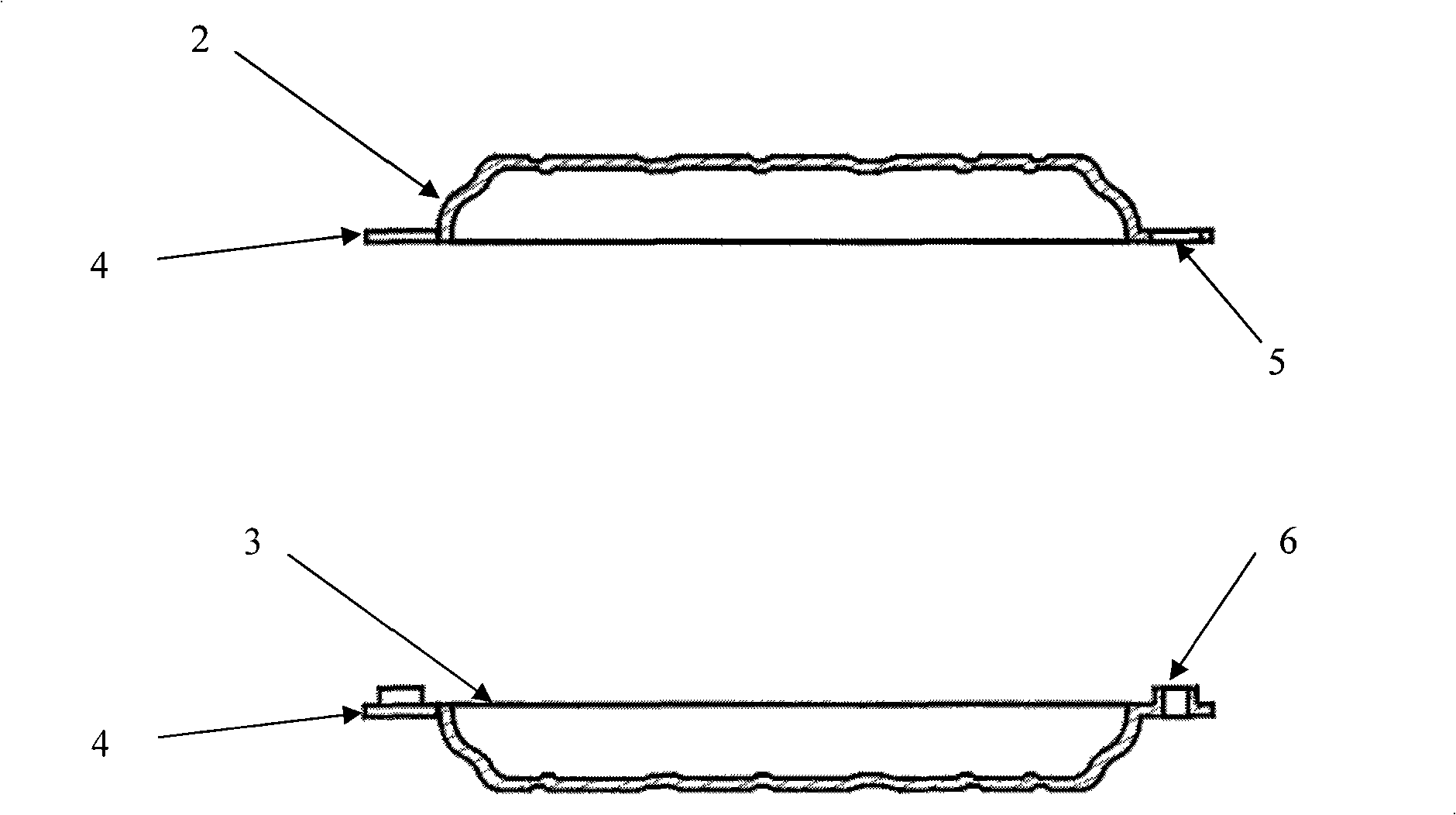

Processing method of hollow jewellery with mirror

The invention relates to a method for processing hollow jewelry with mirror face. An upper piece with mirror face and a lower piece with mirror face are pressed mainly according to the requirements of shape design, a tack hole and a stud are respectively arranged at the connection position of the upper piece and the lower piece, and the tack hole and the stud are riveted, thus the upper piece and the lower piece are fixed together to form the hollow jewelry. The structure of the stud and the tack hole are arranged between the upper piece and the lower piece and then the upper piece is connected with the lower piece by riveting, thus the breakage of the mirror face caused by the welding method is avoided, the subsequent restoration process of the mirror face is no longer needed, the mirror face of the finished product has good effect, the yield is high, the overall processing technique is simple and the cost is lower.

Owner:中国黄金集团黄金珠宝(北京)有限公司

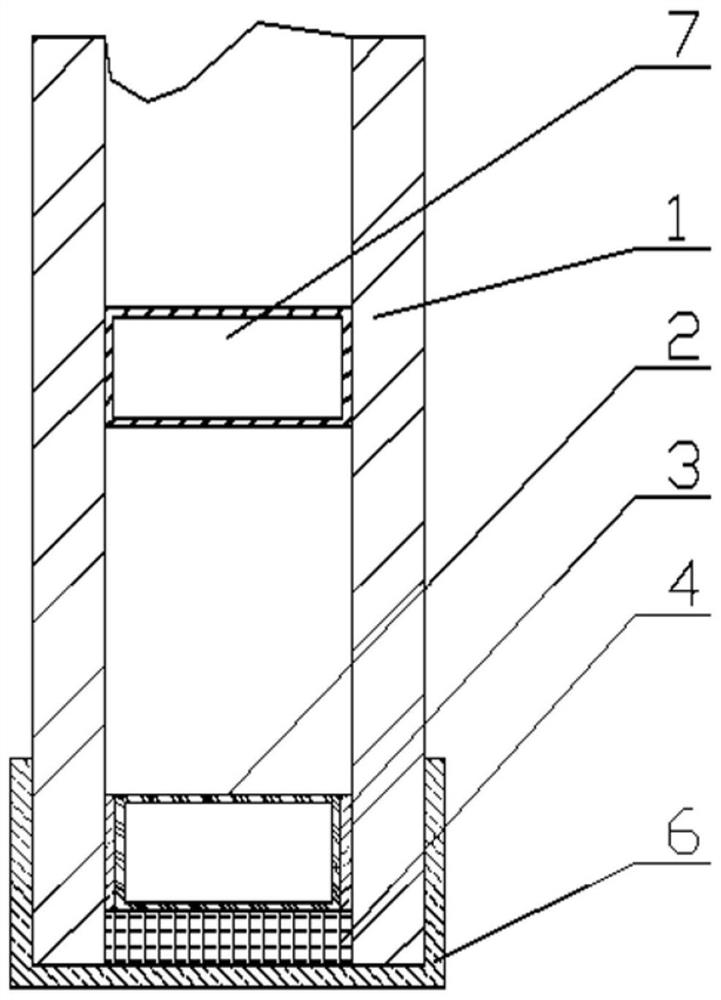

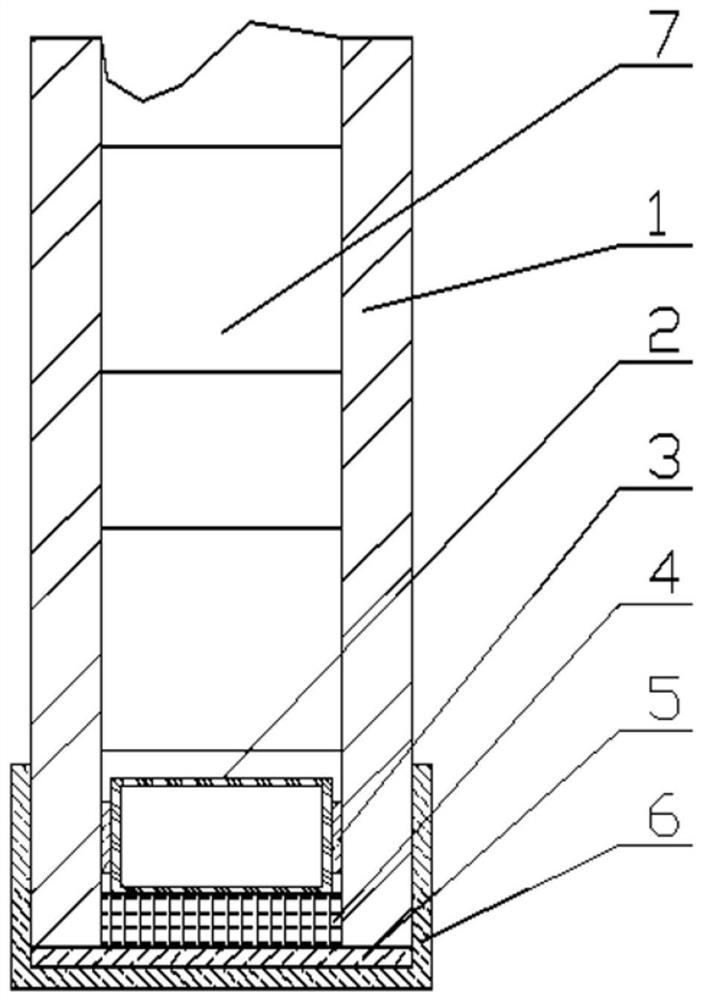

Negative-pressure hollow glass, manufacturing method and application

PendingCN112431519AEliminate respirationExtended service lifeConstruction materialWallsMolecular sievePumping vacuum

The invention belongs to the technical field of hollow glass production, and discloses negative-pressure hollow glass, a manufacturing method and application. The negative-pressure hollow glass comprises glass, spacing bars, molecular sieves, supporting materials, sealing layers bonded between the glass and the spacing bars, and sealing layers bonded between the glass and the peripheries of the spacing bars. A hollow layer is vacuumized to be in a negative pressure state, the air pressure of the hollow layer is smaller than the external pressure all the time in the use process of the hollow glass, the breathing phenomenon of the hollow glass is eliminated, an edge sealing structure is not subjected to repeated acting force generated by the breathing phenomenon, and the service life of theedge sealing structure and the service life of the hollow glass can be remarkably prolonged; due to the fact that the supporting materials are arranged in the hollow layer, the glass cannot deform, agood mirror surface effect can be kept all the time, and the appearance of a building is more attractive; and the spacing bars are adopted to replace spacing frames to be directly bonded on the glass,the technological process of manufacturing the spacing frames is omitted, mechanical and automatic production is facilitated, the placement speed is high, and the installation precision is high.

Owner:WEIHAI RUNFENG GLASS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com