Processing method of hollow jewellery with mirror

A processing method and jewelry technology, applied in jewelry, clothing, applications, etc., can solve the problems of affecting the mirror effect, increase production costs, collapse, etc., and achieve the effect of good mirror effect, avoidance of damage, and high yield.

Active Publication Date: 2008-10-22

中国黄金集团黄金珠宝(北京)有限公司

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. The semi-finished products after stamping and welding are prone to chromatic aberration after sandblasting process, which affects the quality of the finished product; during the calendering process, the hollow semi-finished products are easy to collapse, resulting in waste products;

2. Although the roughness of the mirror surface that becomes blurred after welding can be reduced by sandblasting and calendering processes, it is still not as low as the roughness of the mirror surface produced by stamping, which affects the effect of the mirror surface and reduces the grade of the entire jewelry;

3. Due to the need to increase the mold, sandblasting, calendering and other processes to repair the mirror surface after welding, the production cost has been increased

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

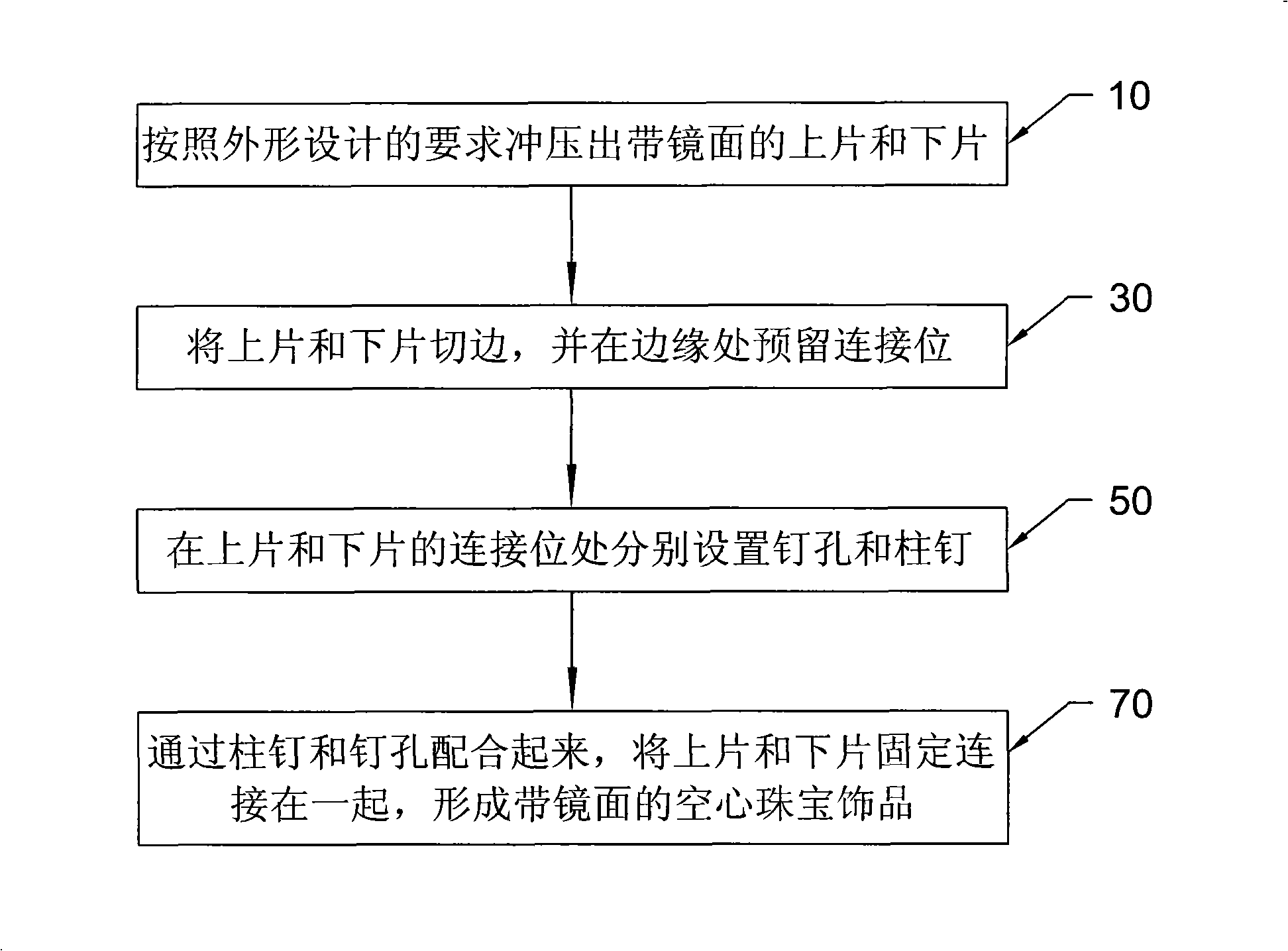

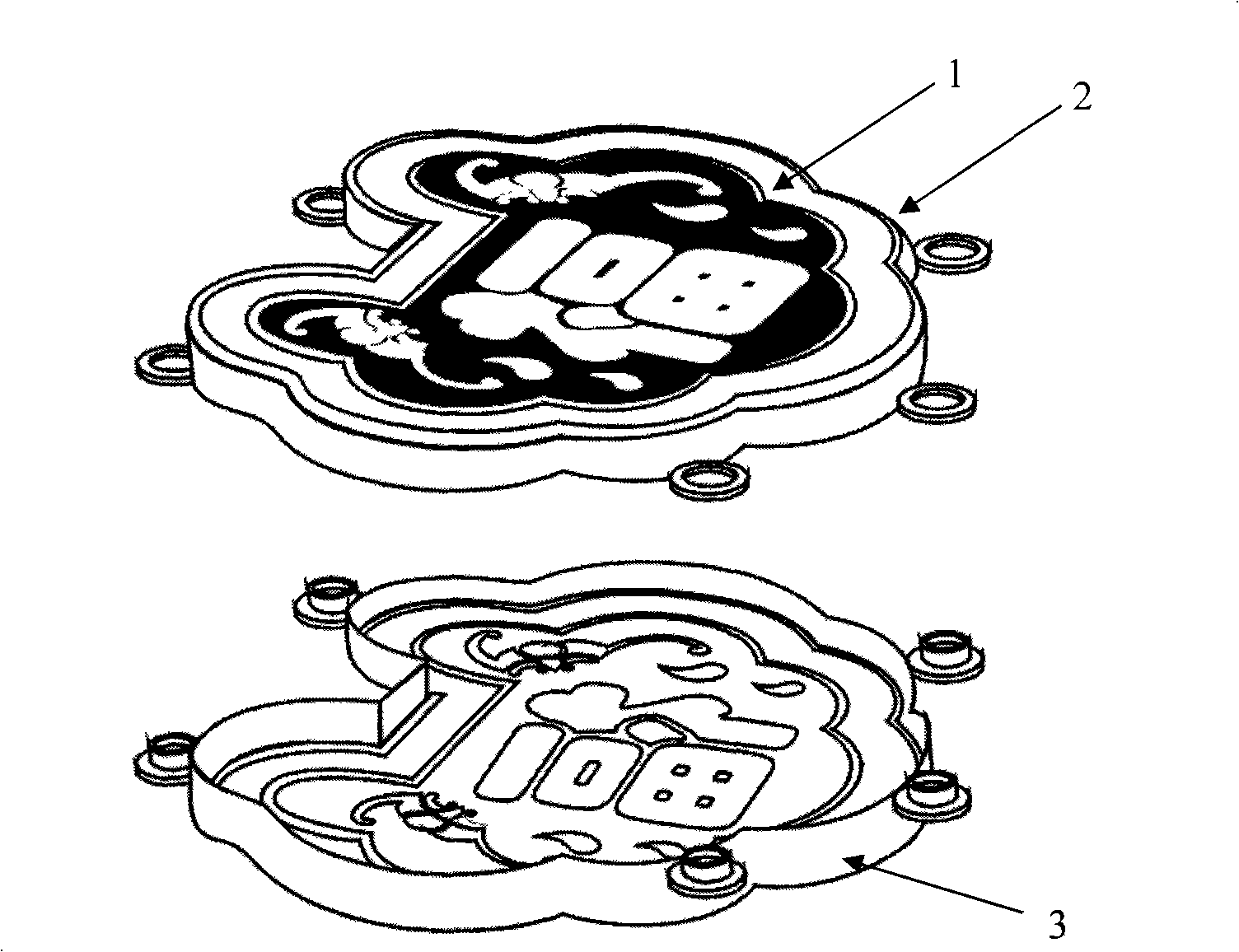

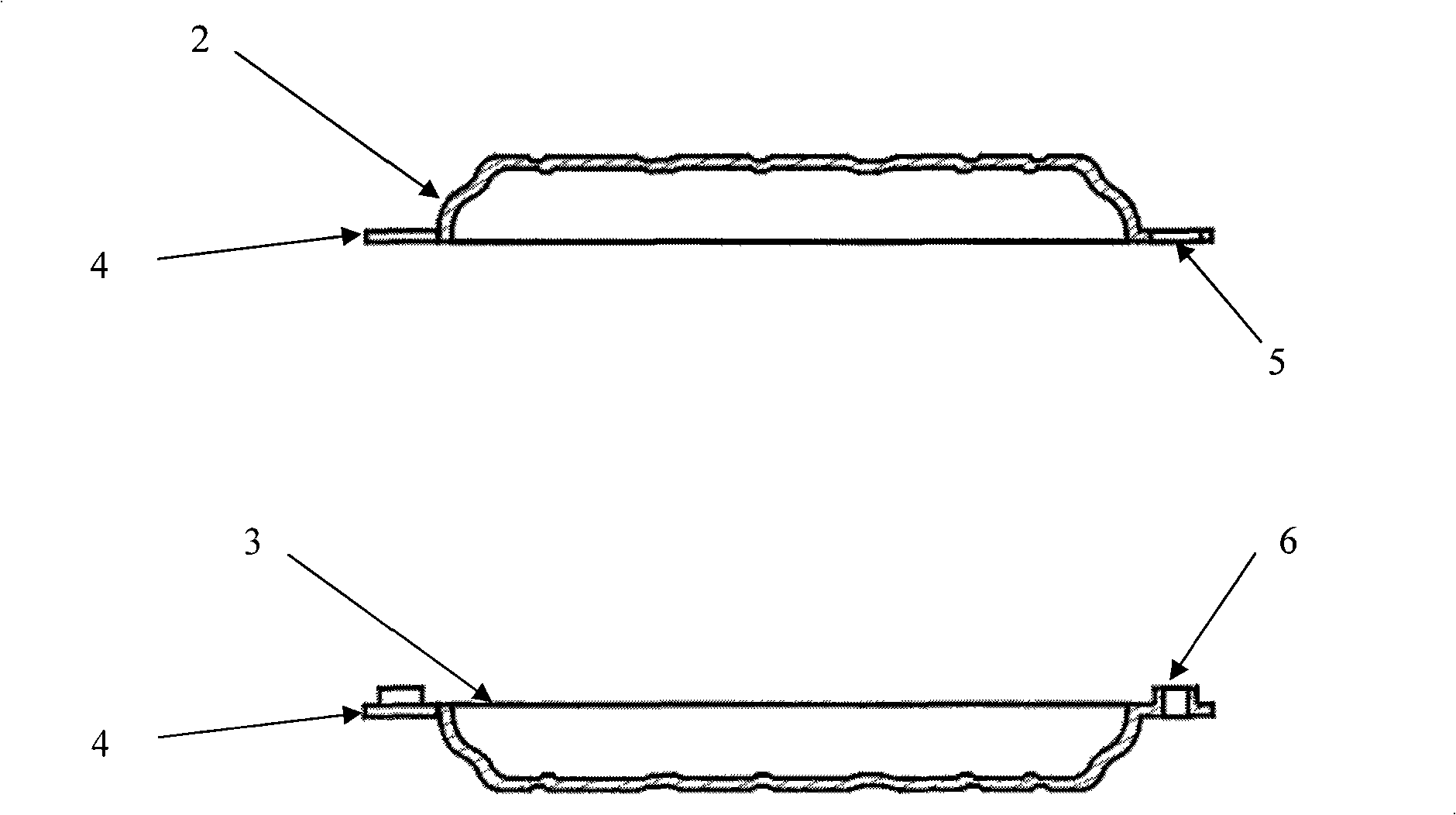

Login to View More Abstract

The invention relates to a method for processing hollow jewelry with mirror face. An upper piece with mirror face and a lower piece with mirror face are pressed mainly according to the requirements of shape design, a tack hole and a stud are respectively arranged at the connection position of the upper piece and the lower piece, and the tack hole and the stud are riveted, thus the upper piece and the lower piece are fixed together to form the hollow jewelry. The structure of the stud and the tack hole are arranged between the upper piece and the lower piece and then the upper piece is connected with the lower piece by riveting, thus the breakage of the mirror face caused by the welding method is avoided, the subsequent restoration process of the mirror face is no longer needed, the mirror face of the finished product has good effect, the yield is high, the overall processing technique is simple and the cost is lower.

Description

Processing method of hollow jewelry with mirror surface technical field The invention relates to a processing method for jewelry, more specifically, to a processing method for hollow jewelry with a mirror surface. Background technique Existing jewelry such as gold or silver usually has mirror settings, such as longevity locks, etc. For such hollow jewelry with mirrors, the usual processing method is: first punch out the upper and lower pieces with mirrors. The upper piece and the lower piece are fixedly connected together by welding, and then the molded process is carried out to trim the combined jewelry. Since the mirror surface made by stamping will become blurred due to high temperature during welding, subsequent processes such as sandblasting and calendering are required to ensure that the mirror surface on the jewelry is clearer. There are the following problems in the hollow ornament with mirror surface produced by this processing method: 1. The semi-finished prod...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A44C27/00

Inventor 肖梓鑫

Owner 中国黄金集团黄金珠宝(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com