Patents

Literature

47results about How to "Avoid flanging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

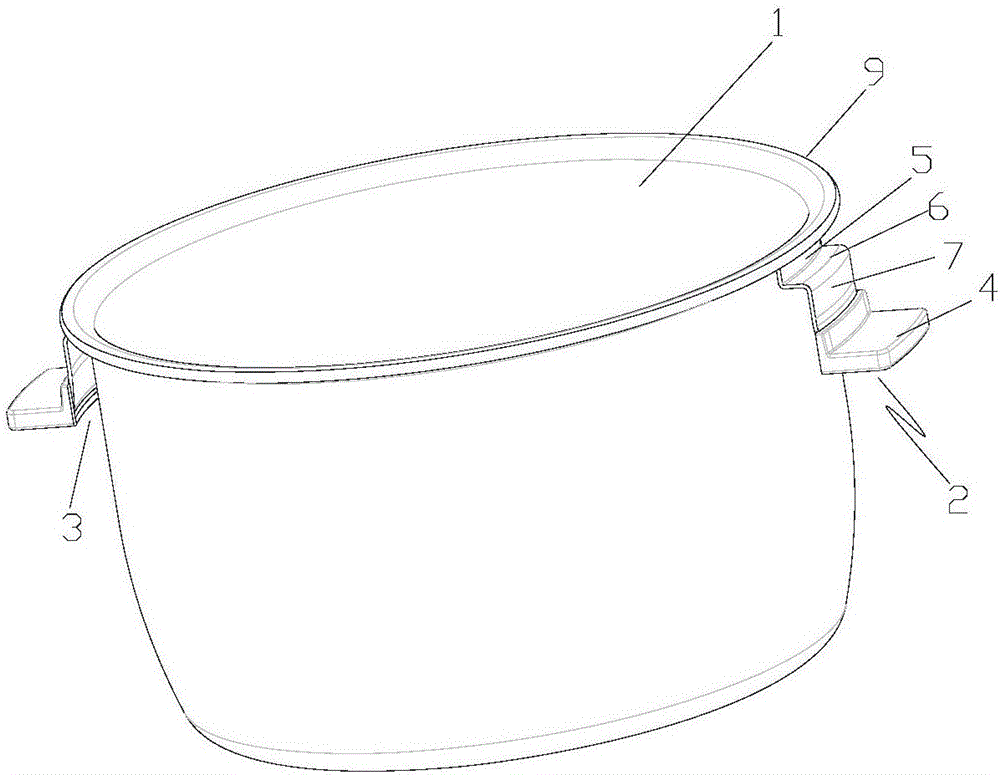

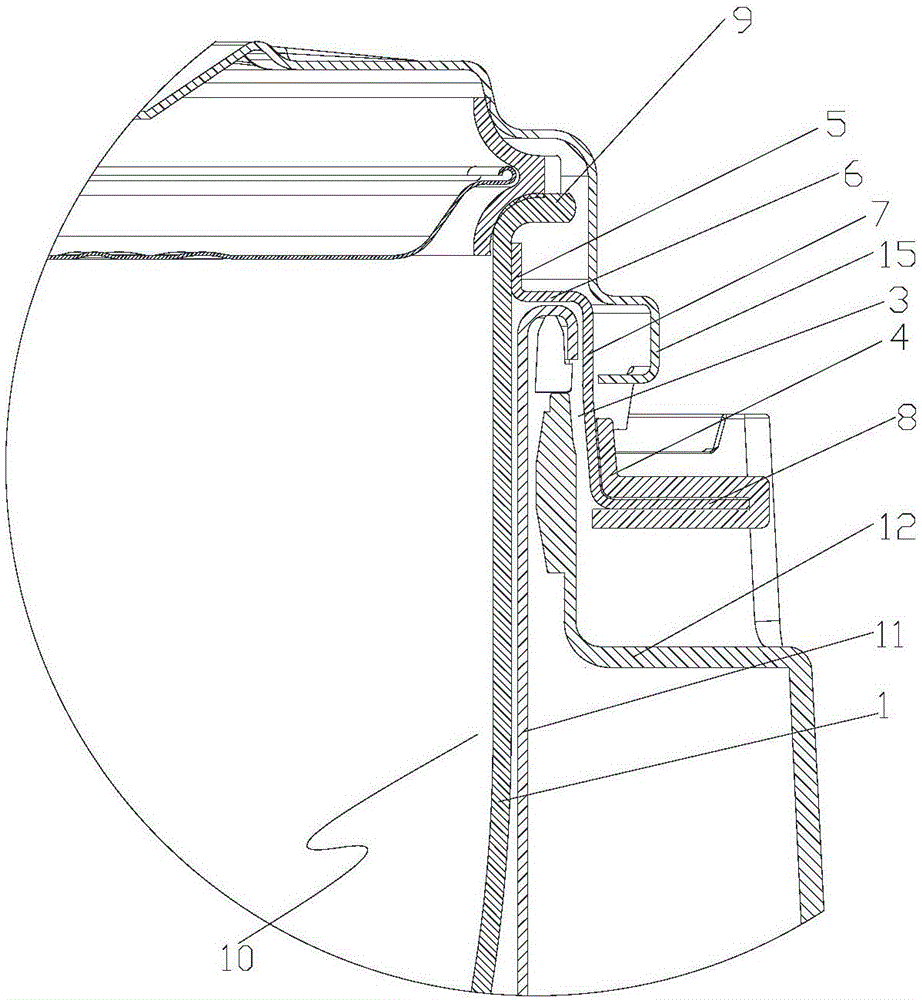

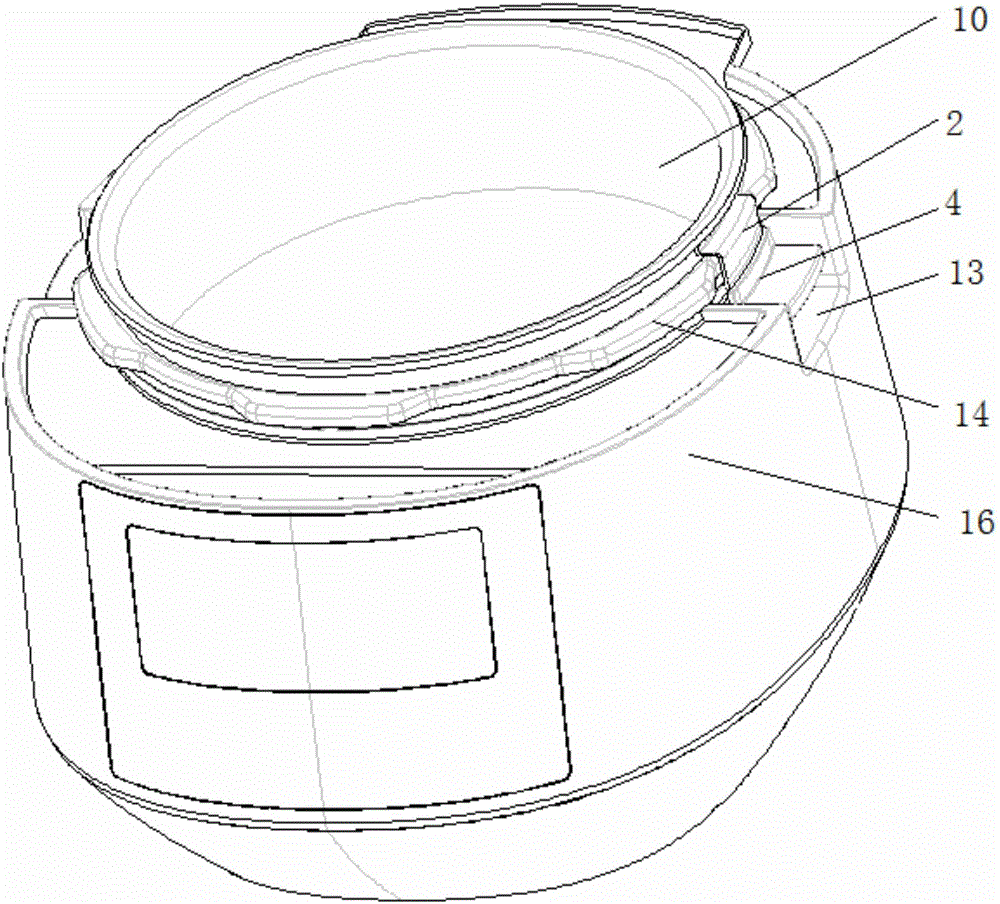

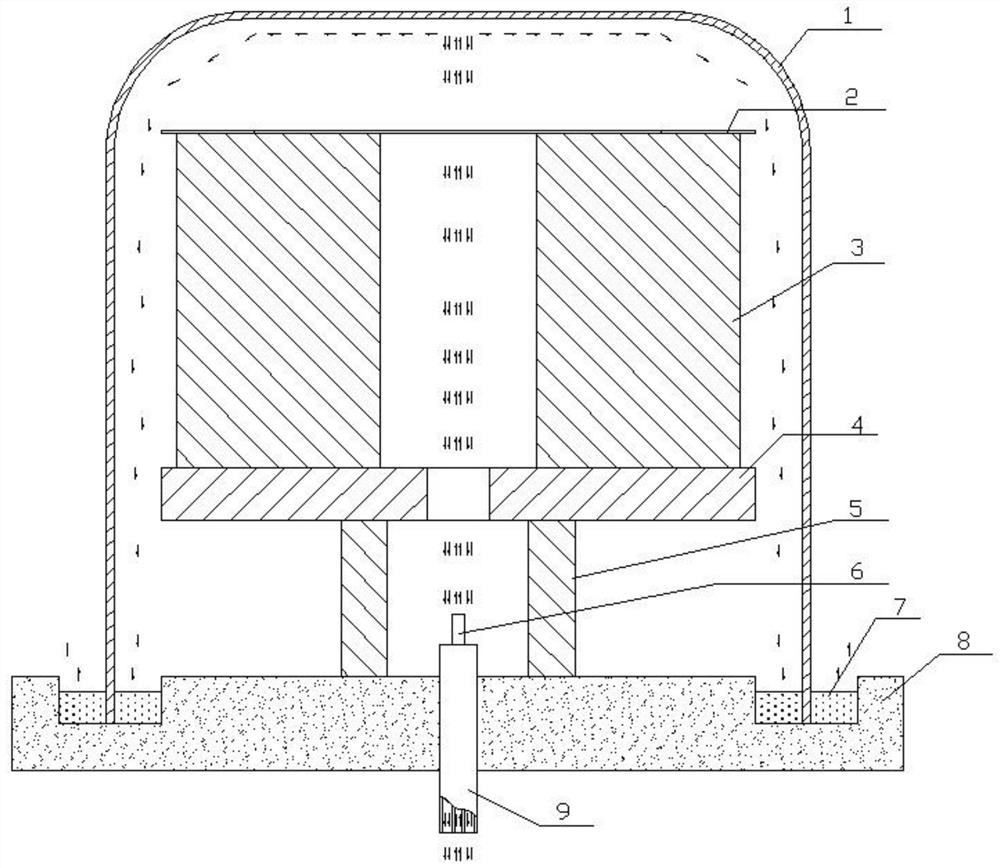

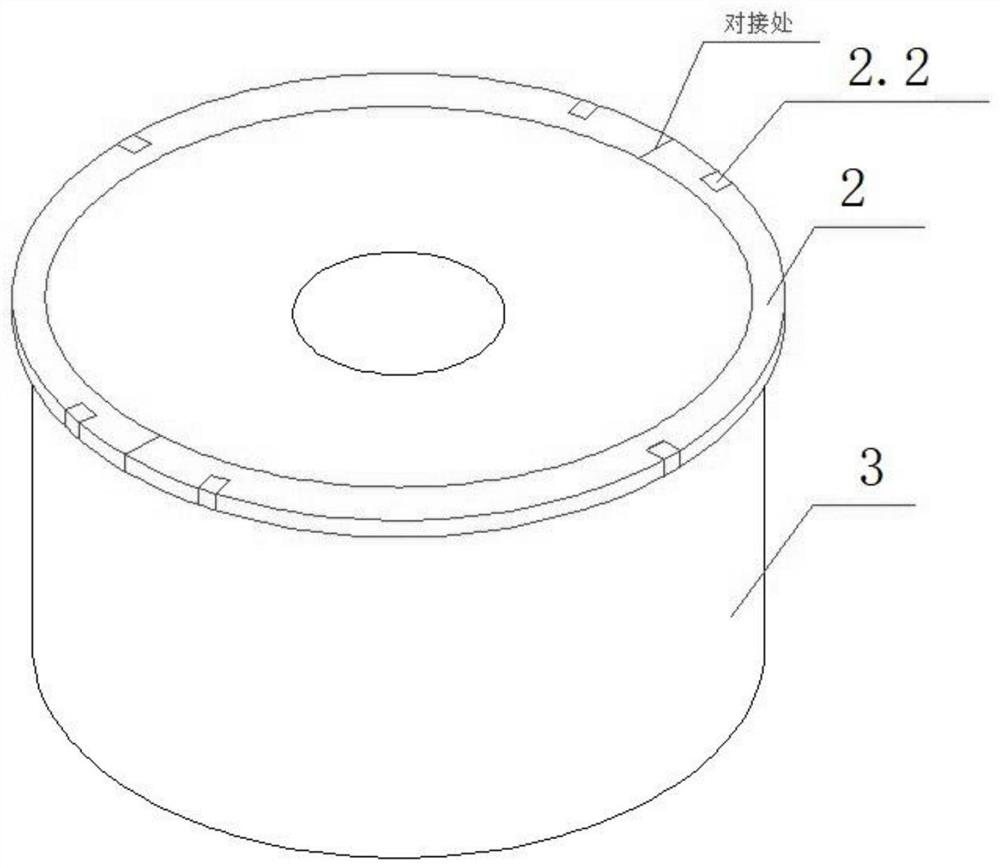

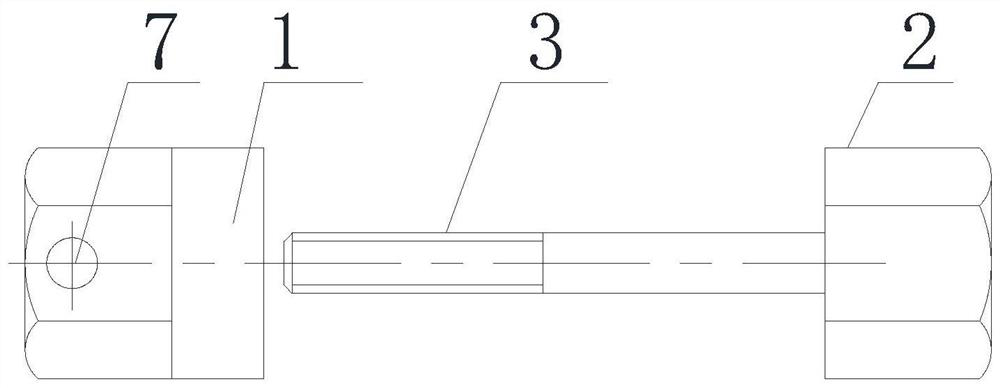

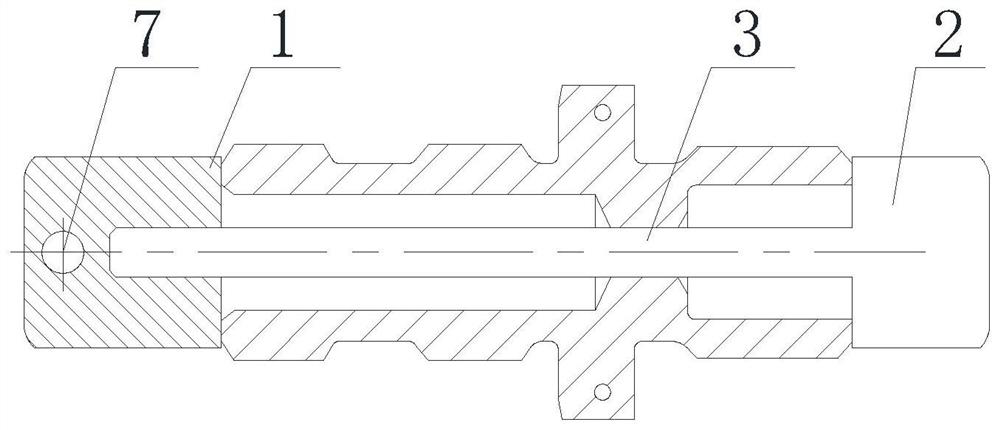

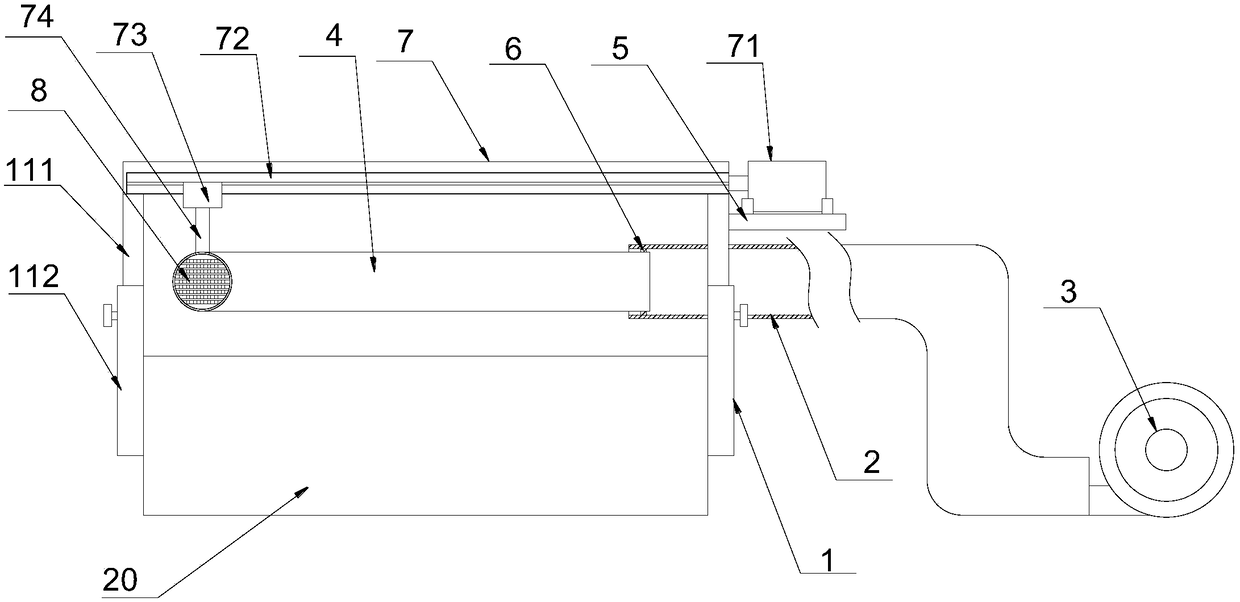

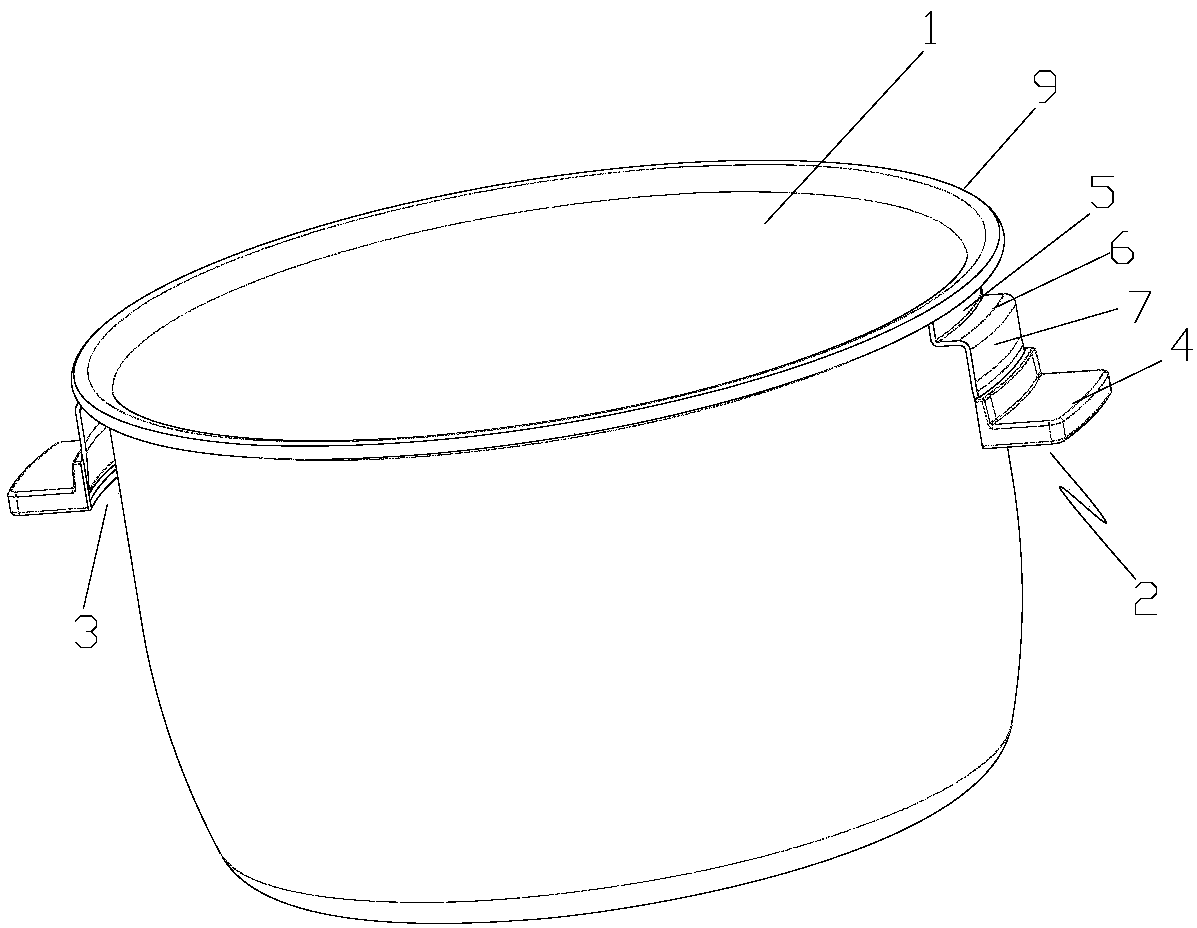

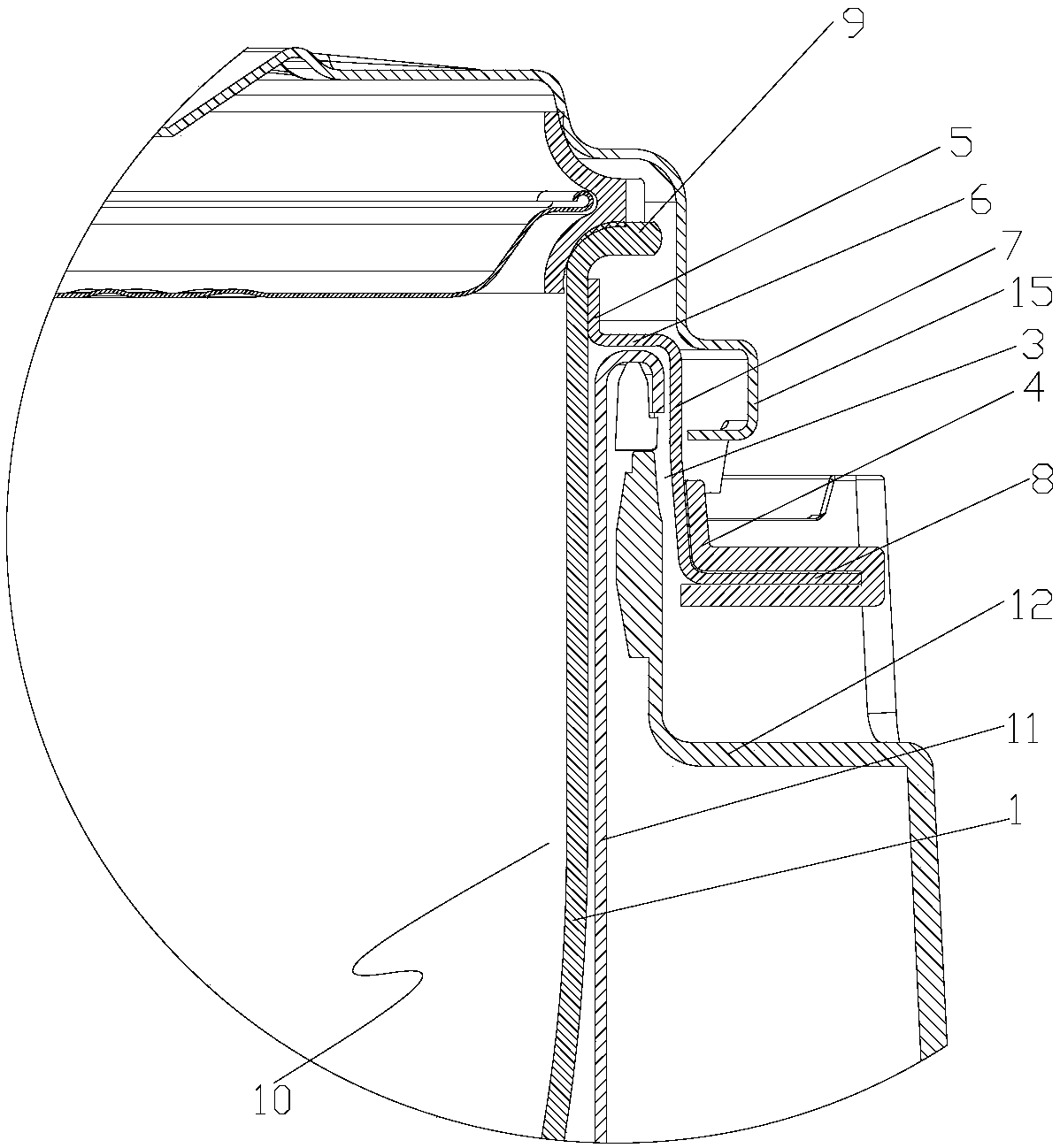

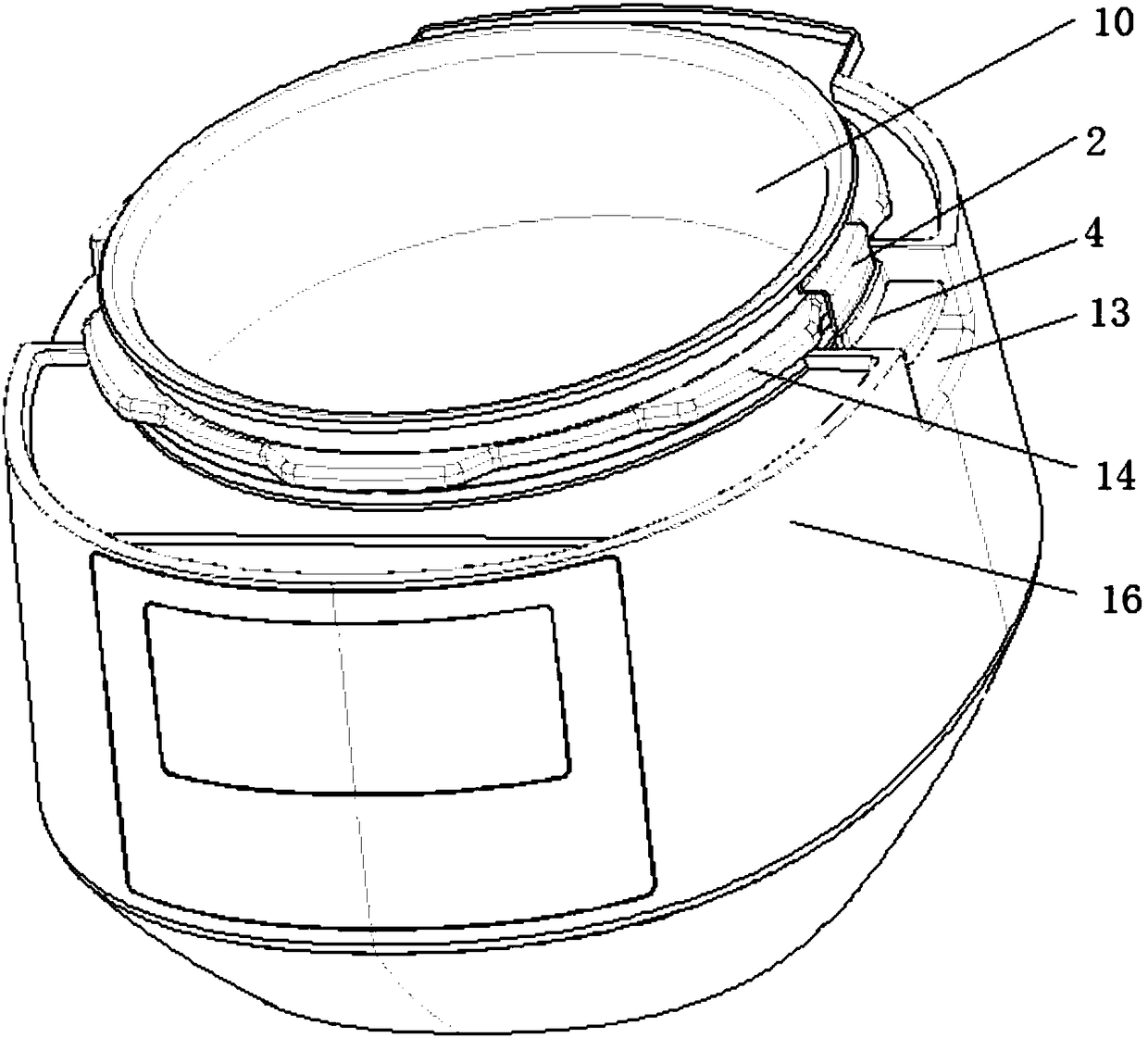

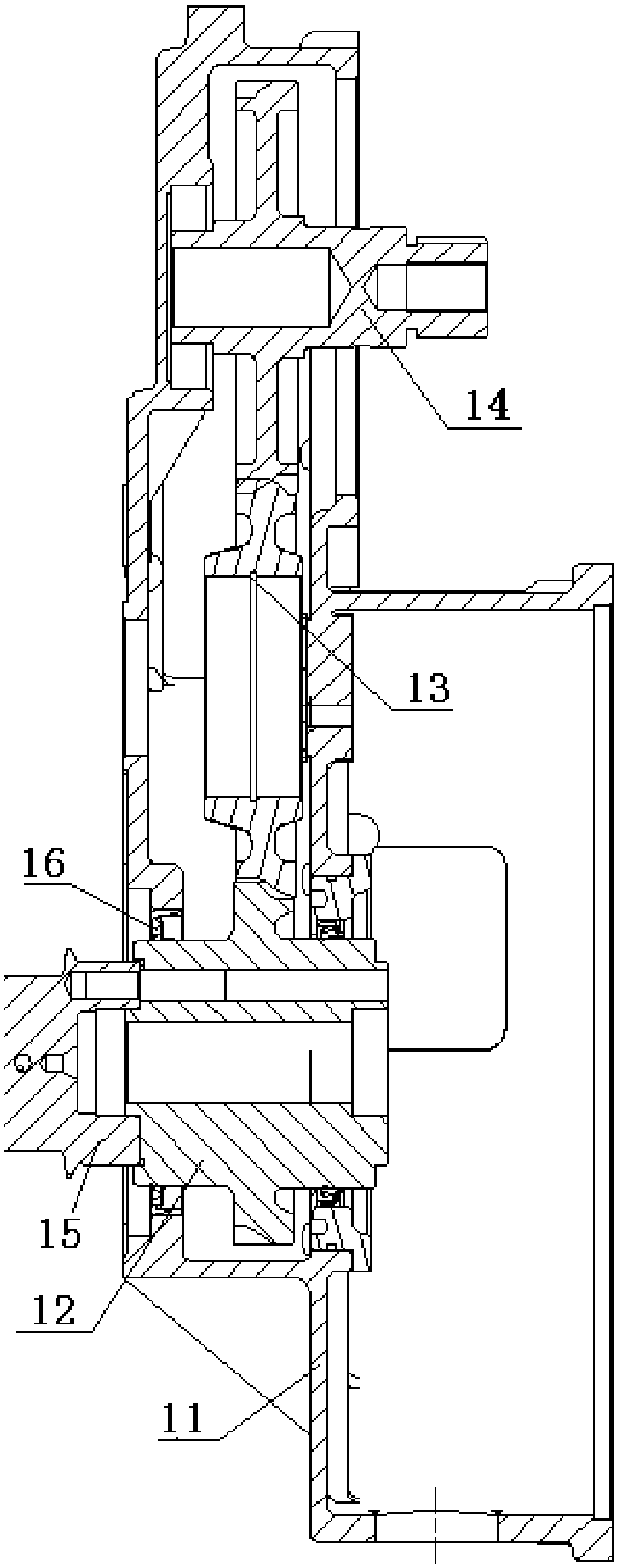

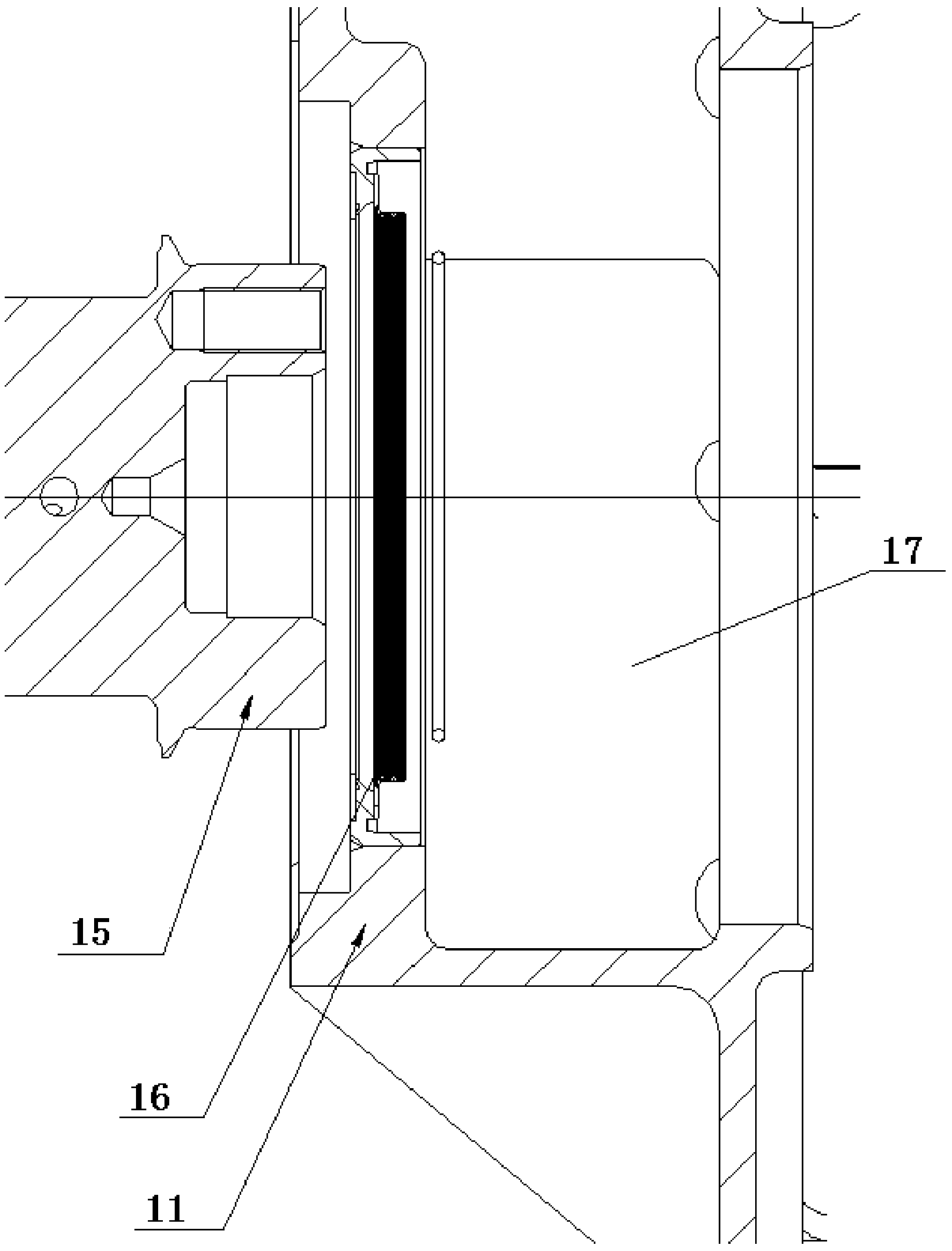

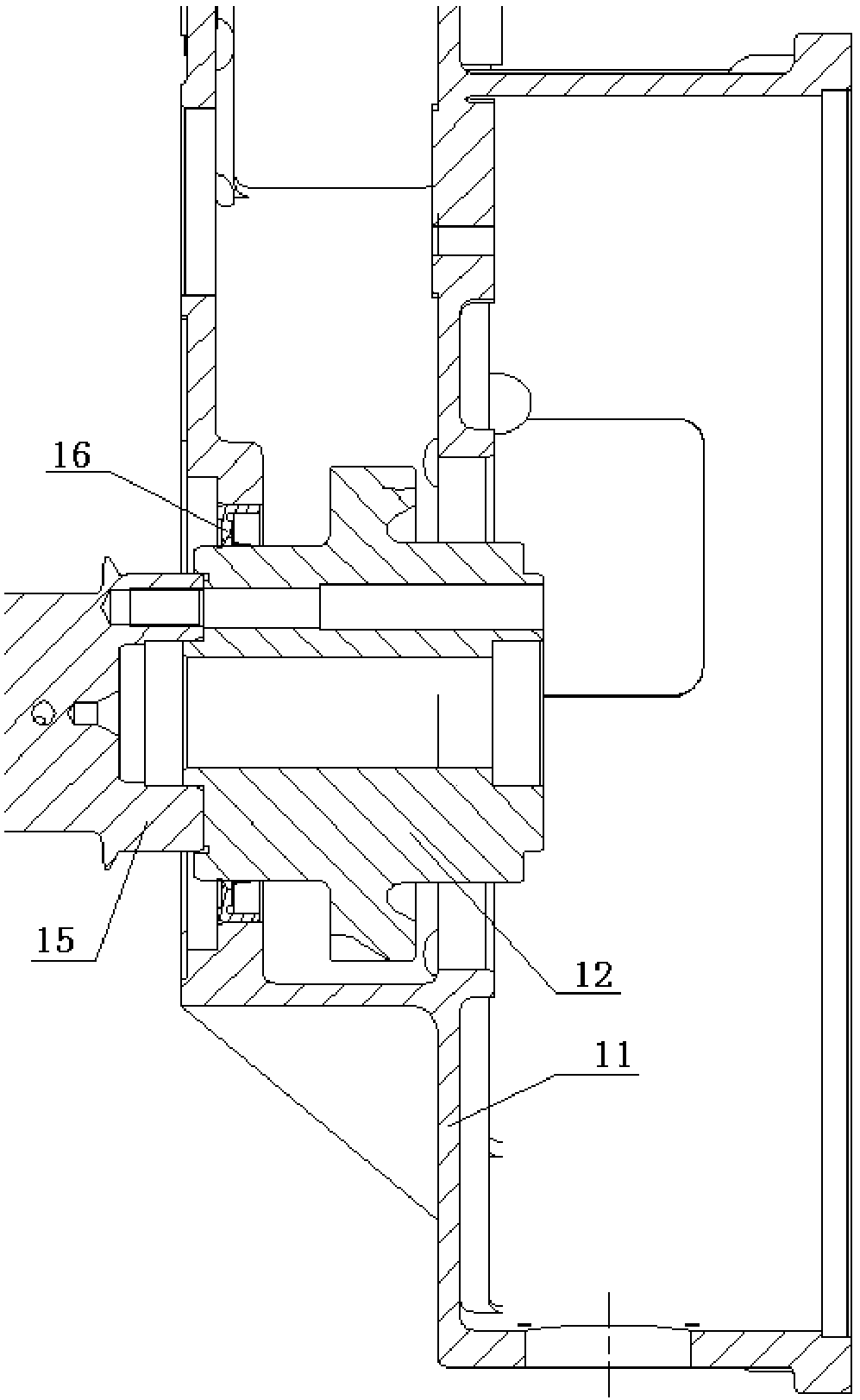

Inner pot and electric pressure cooker

ActiveCN106108631AAvoid flangingAvoid destructionPressure-cookersEngineeringUltimate tensile strength

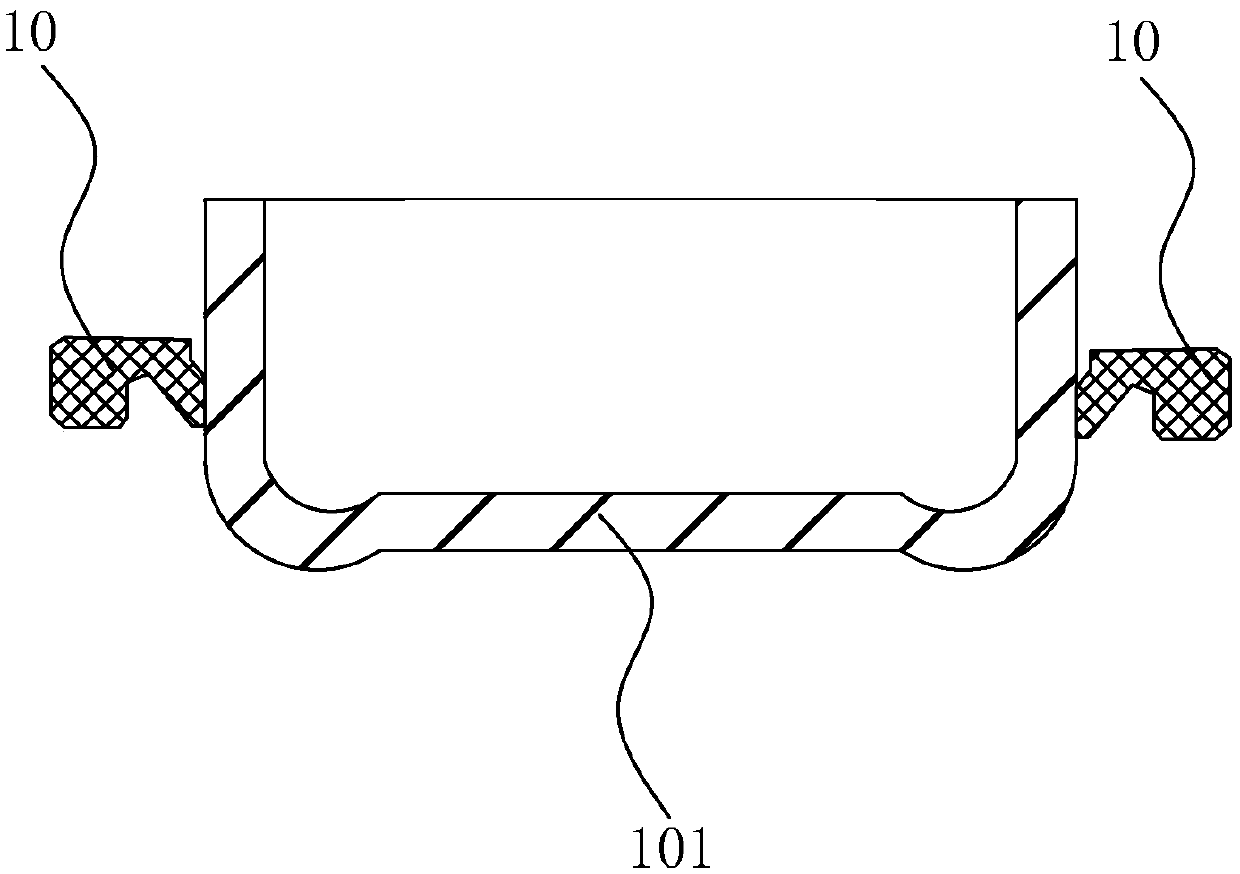

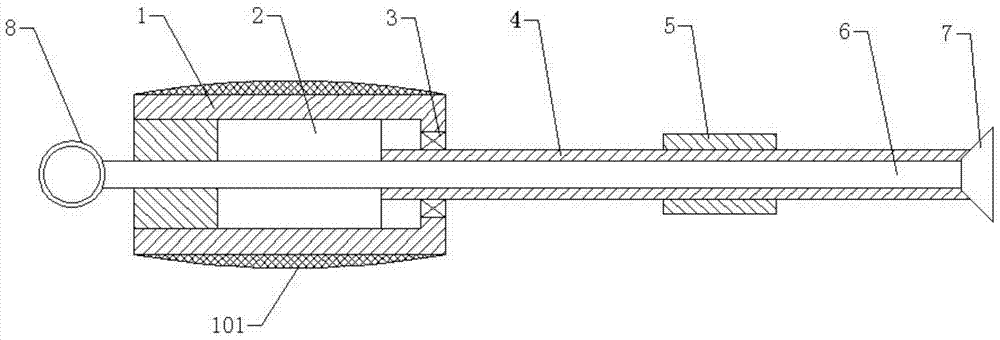

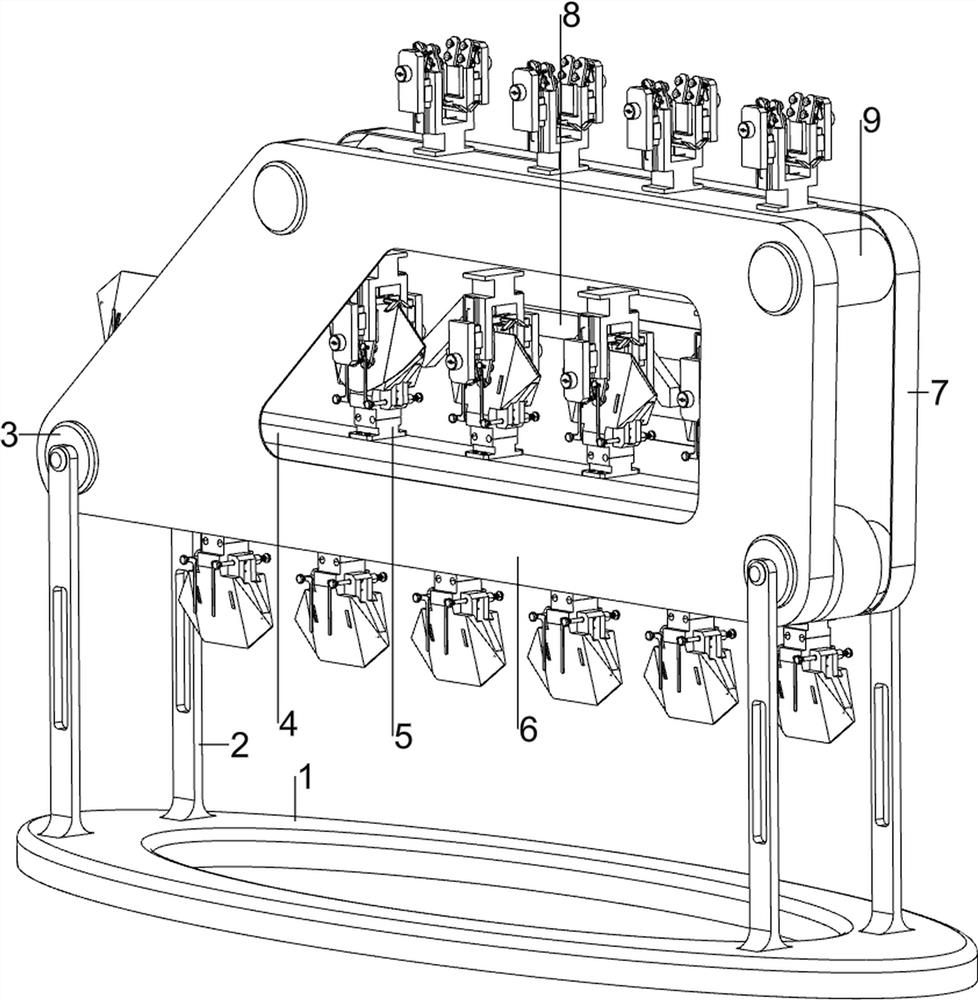

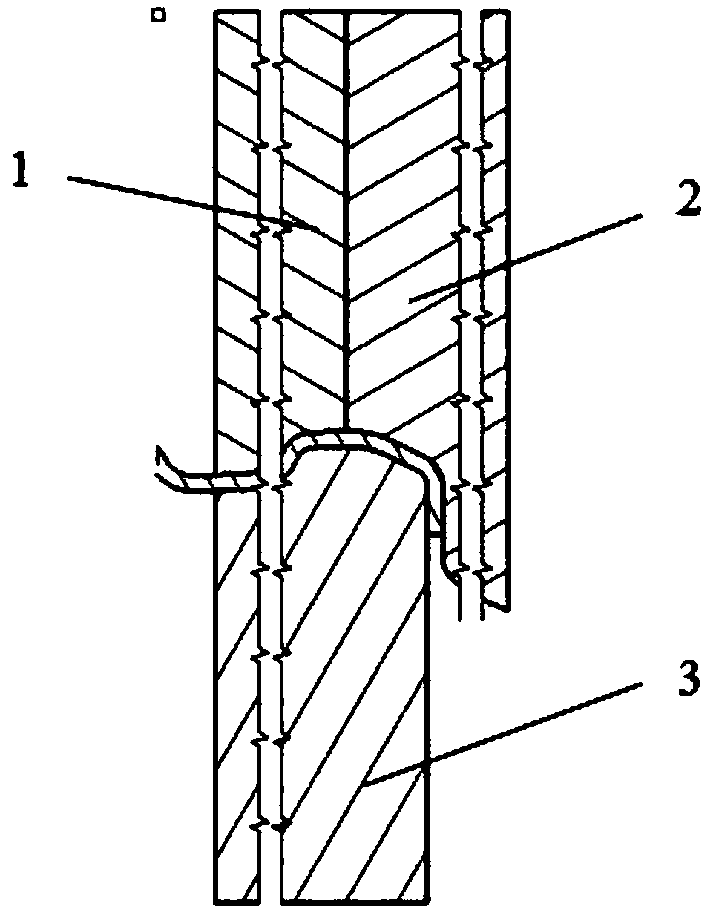

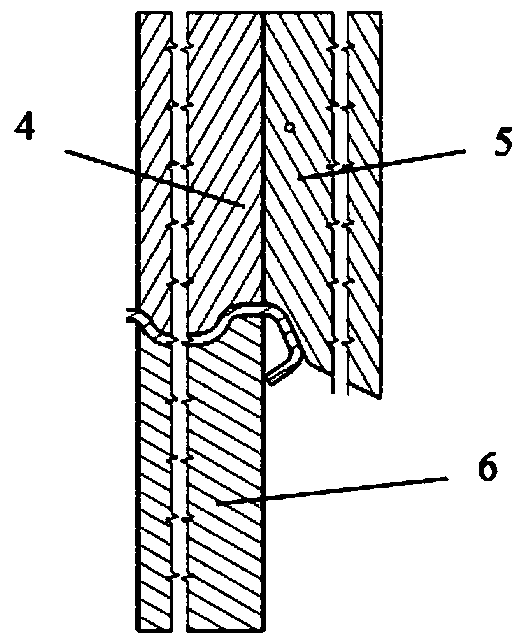

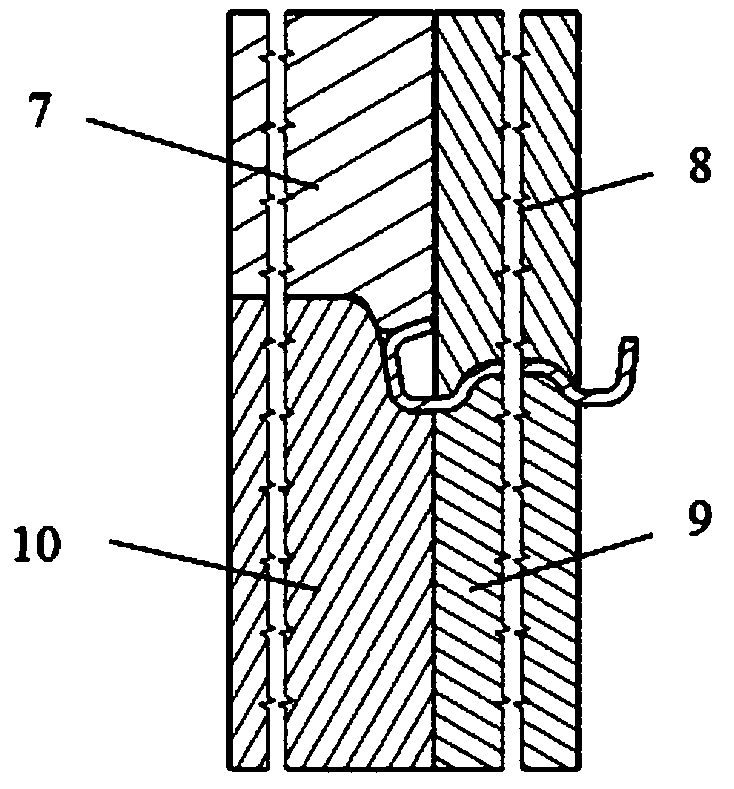

The invention provides an inner pot and an electric pressure cooker. The inner pot comprises a body (1) and a lifting handle (2) arranged on the periphery of the body (1). An installation groove (3) is formed between the lifting handle (2) and the periphery of the body (1). The inner pot helps solve the problem in the prior art that that poor strength of the structure of an outer pot is caused due to a gap in the outer pot for the lifting handle.

Owner:GREE ELECTRIC APPLIANCES INC

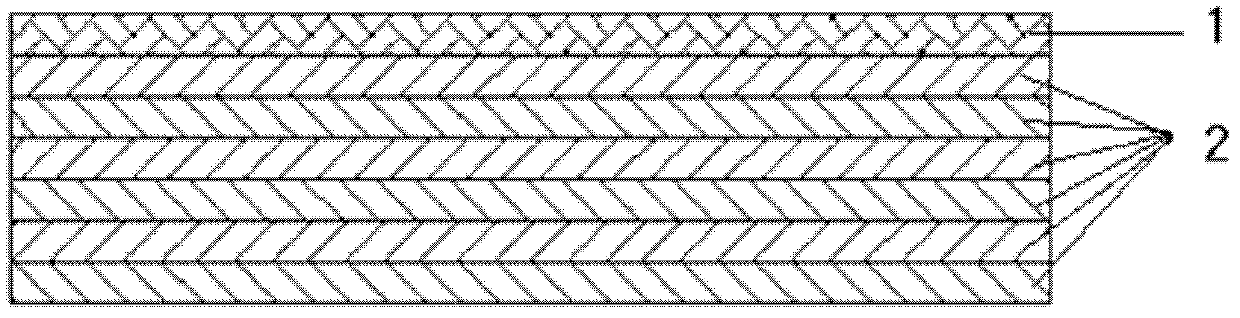

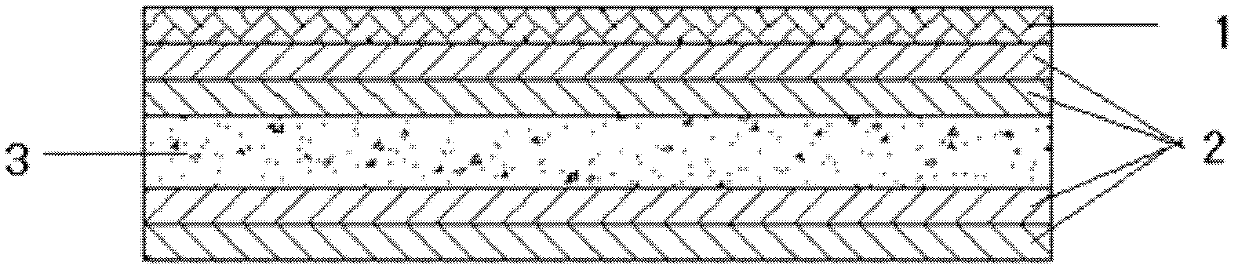

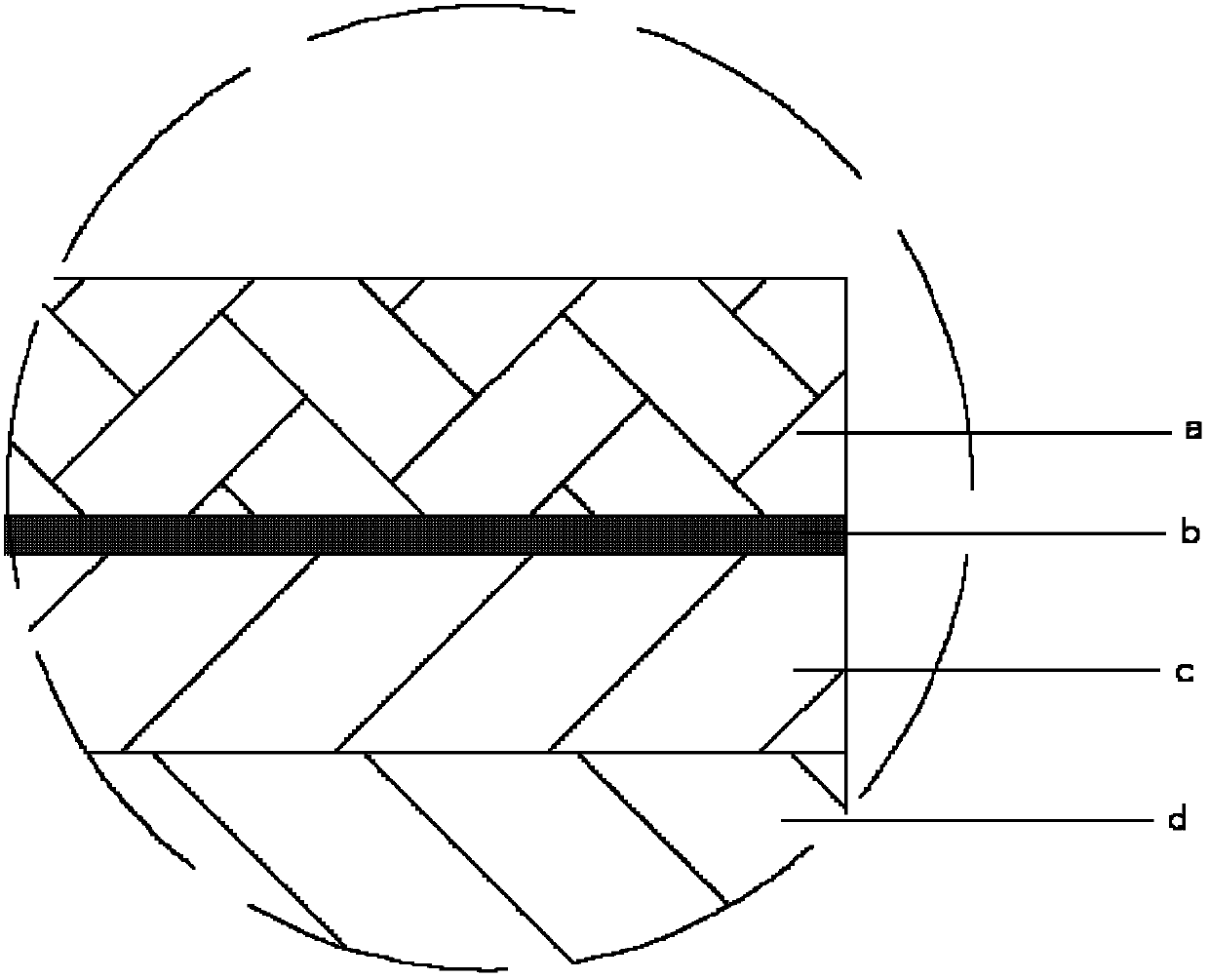

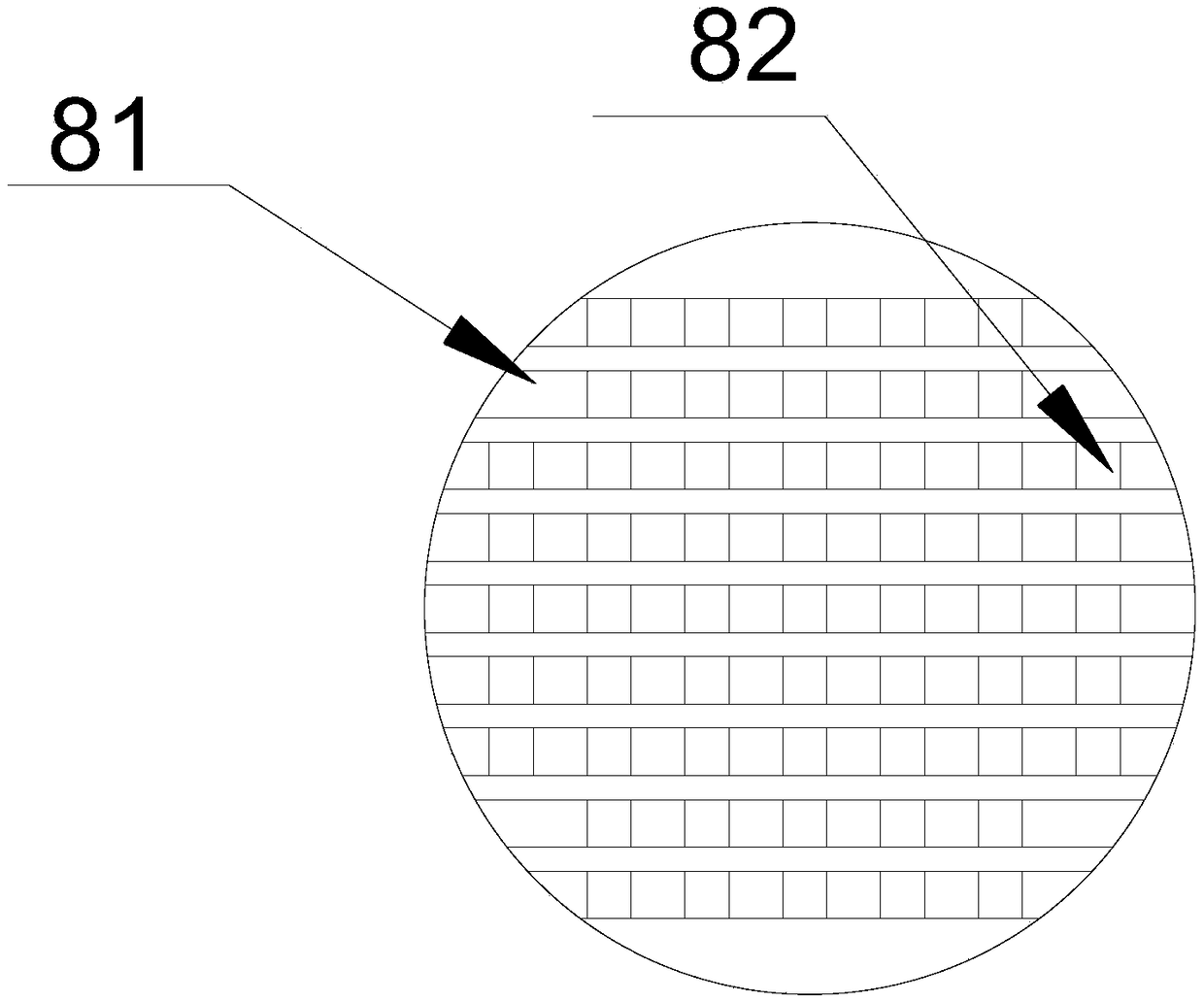

White EVA adhesive film for photovoltaic module encapsulation

InactiveCN104745109AHigh power outputImprove thermal stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer sciencePolymer chemistry

The invention discloses a white EVA adhesive film for photovoltaic module encapsulation. The adhesive film comprises the following components in parts by weight: 10-45 parts of EVA resin, 10-60 parts of a high-melting-point polymer, 2-25 parts of inorganic filler, 0.2-5 parts of an anti-ultraviolet agent and 0.2-5 parts of an antioxidant. According to the white EVA adhesive film for photovoltaic module encapsulation provided by the invention, a two-phase continuous structure is formed by adding the high-melting-point polymer component in EVA, thus reducing flowability during EVA lamination and then solving the problem of flanging during white EVA lamination.

Owner:ZHONGTIAN PHOTOVOLTAIC MATERIALS

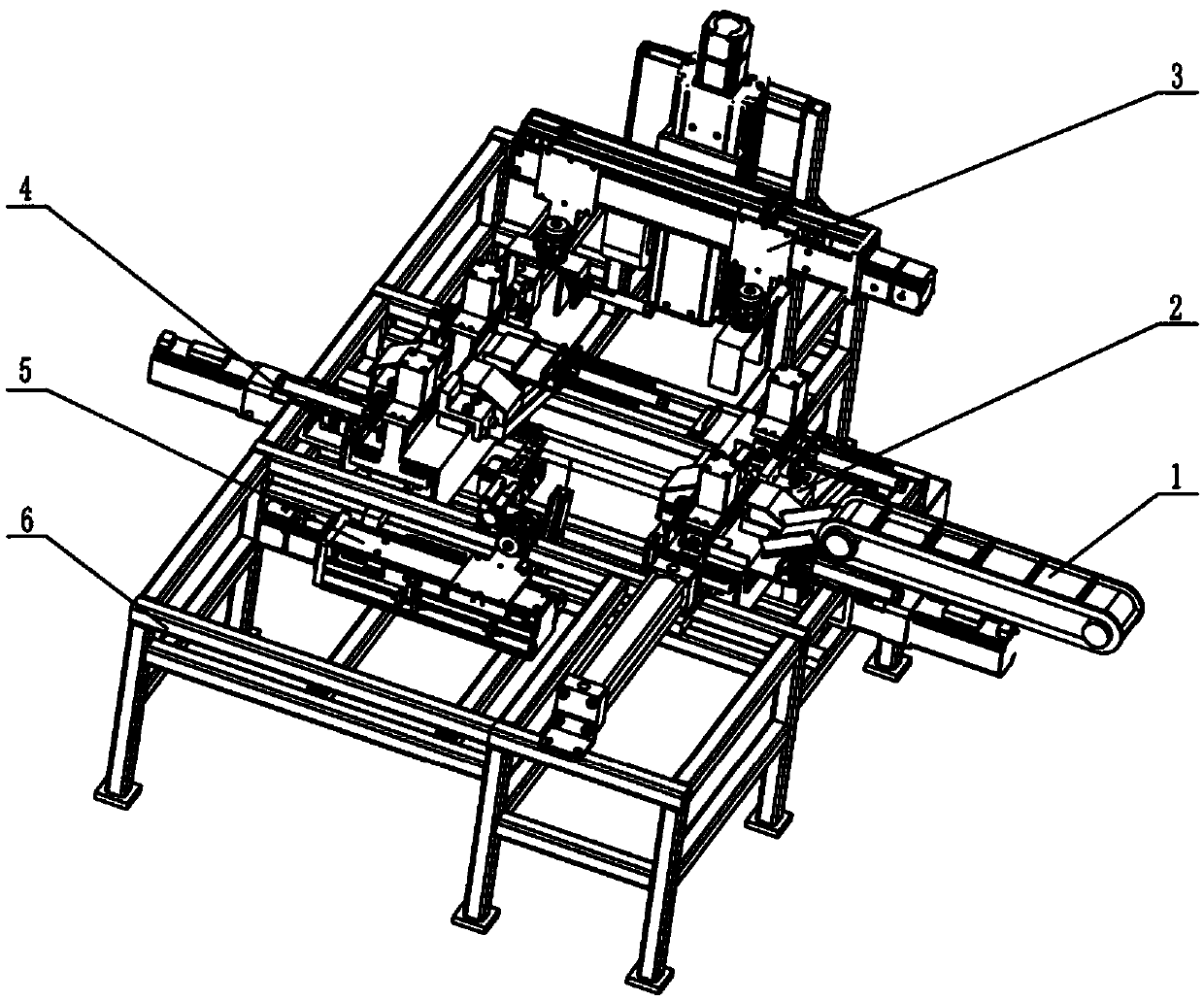

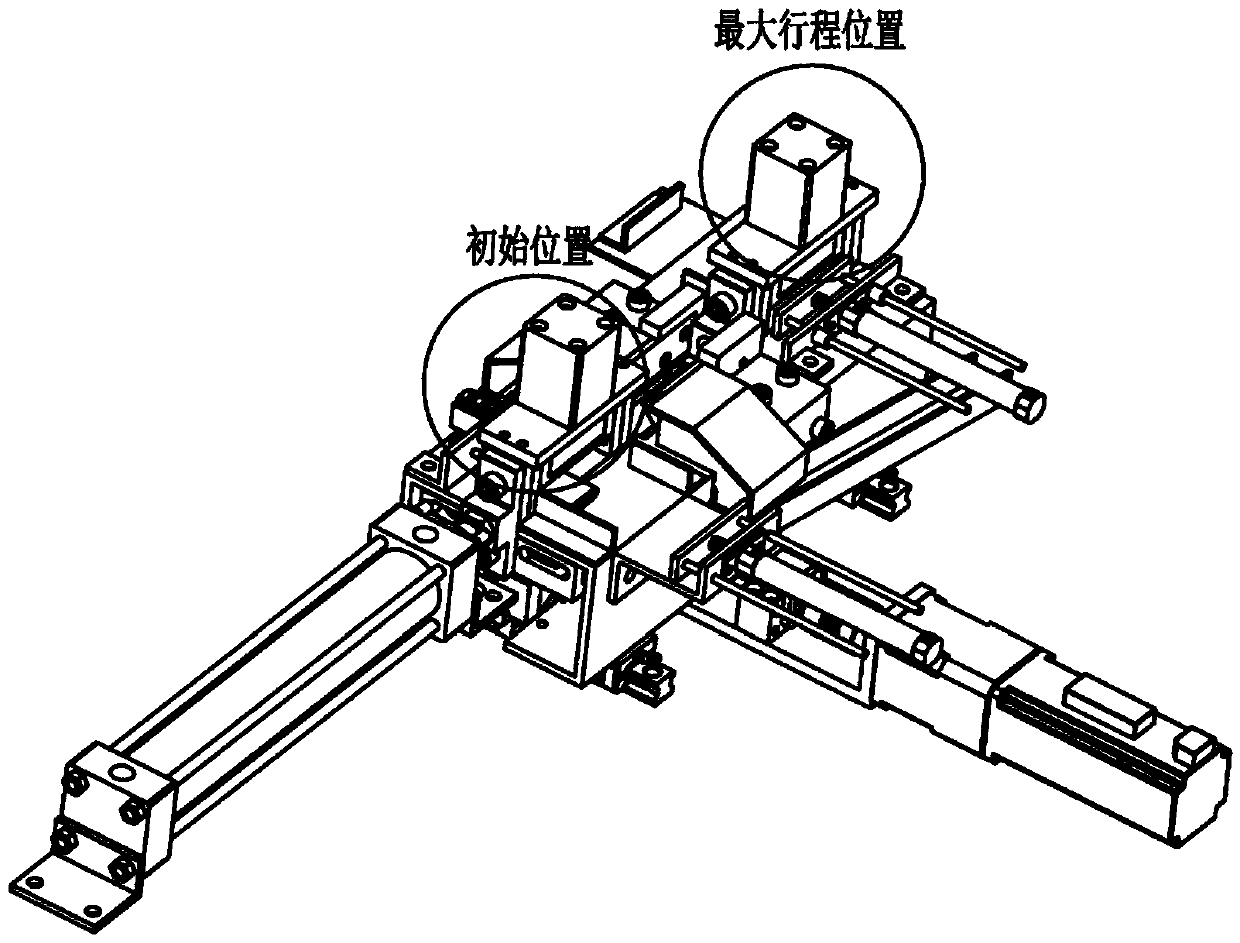

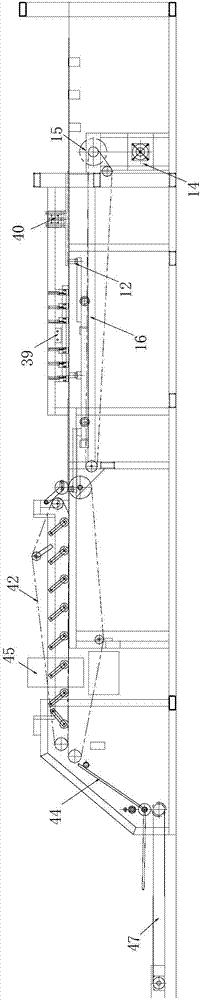

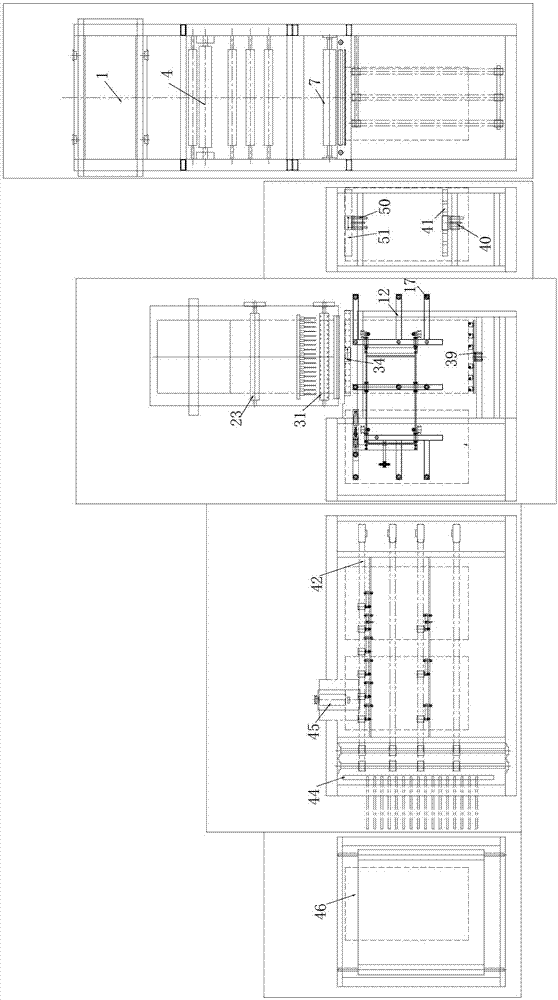

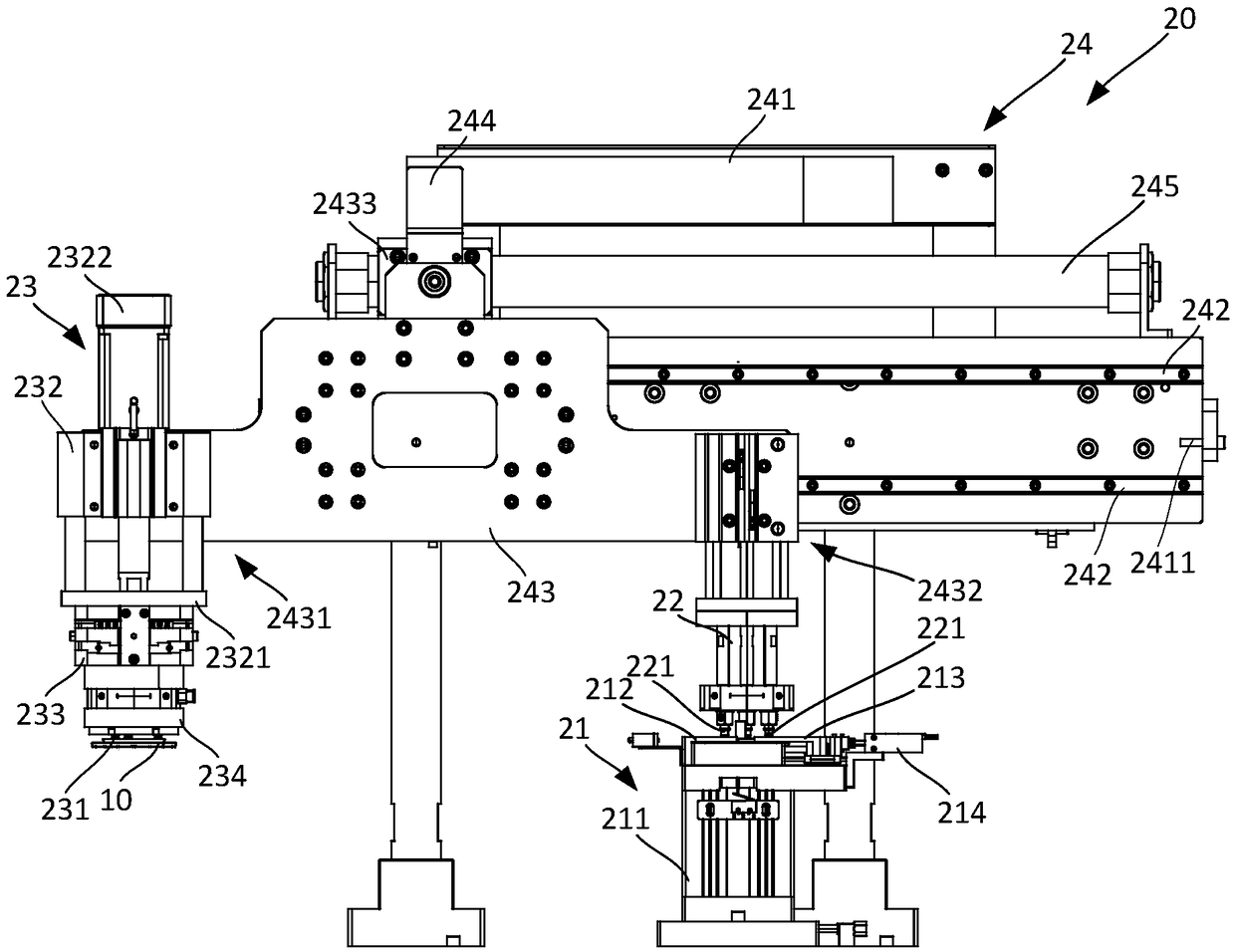

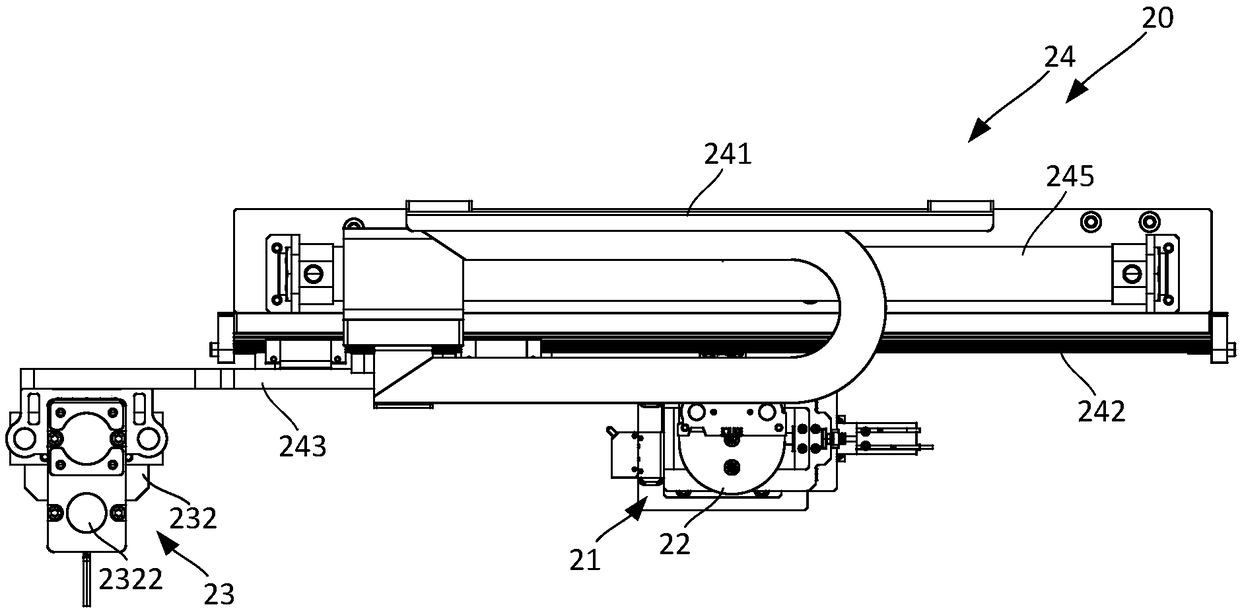

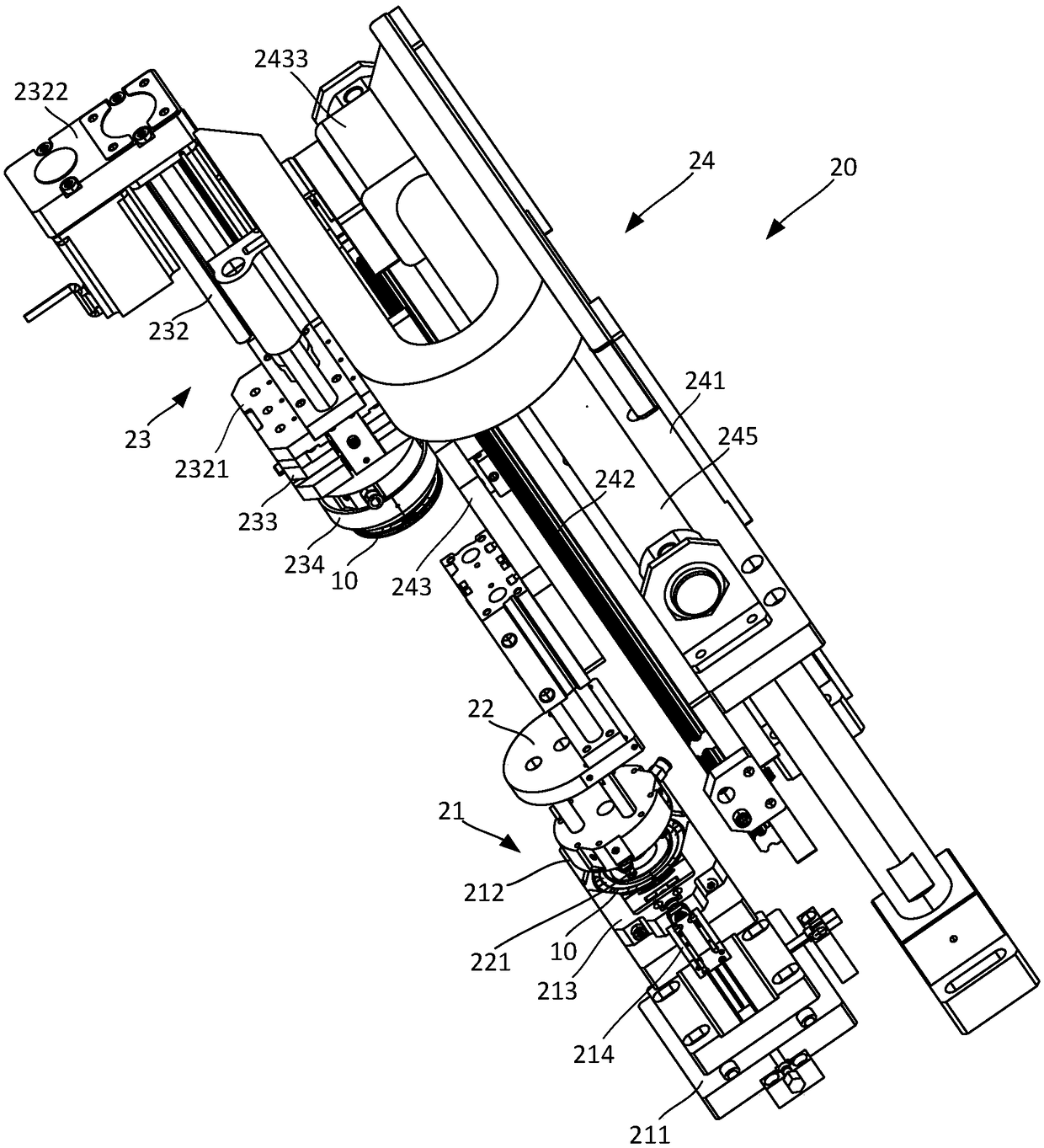

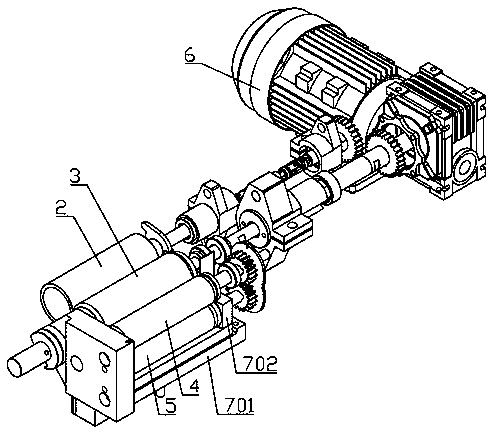

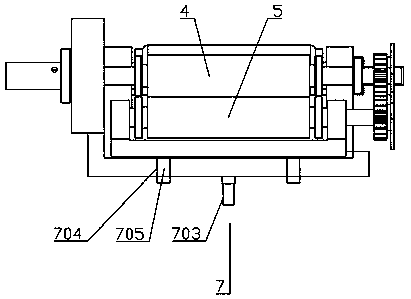

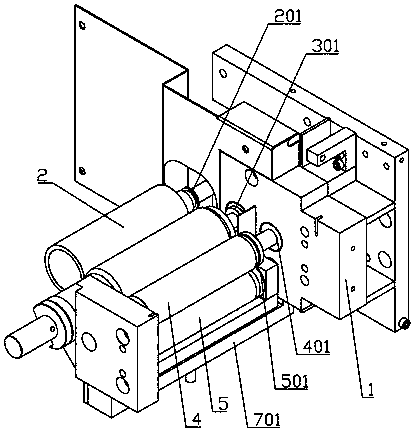

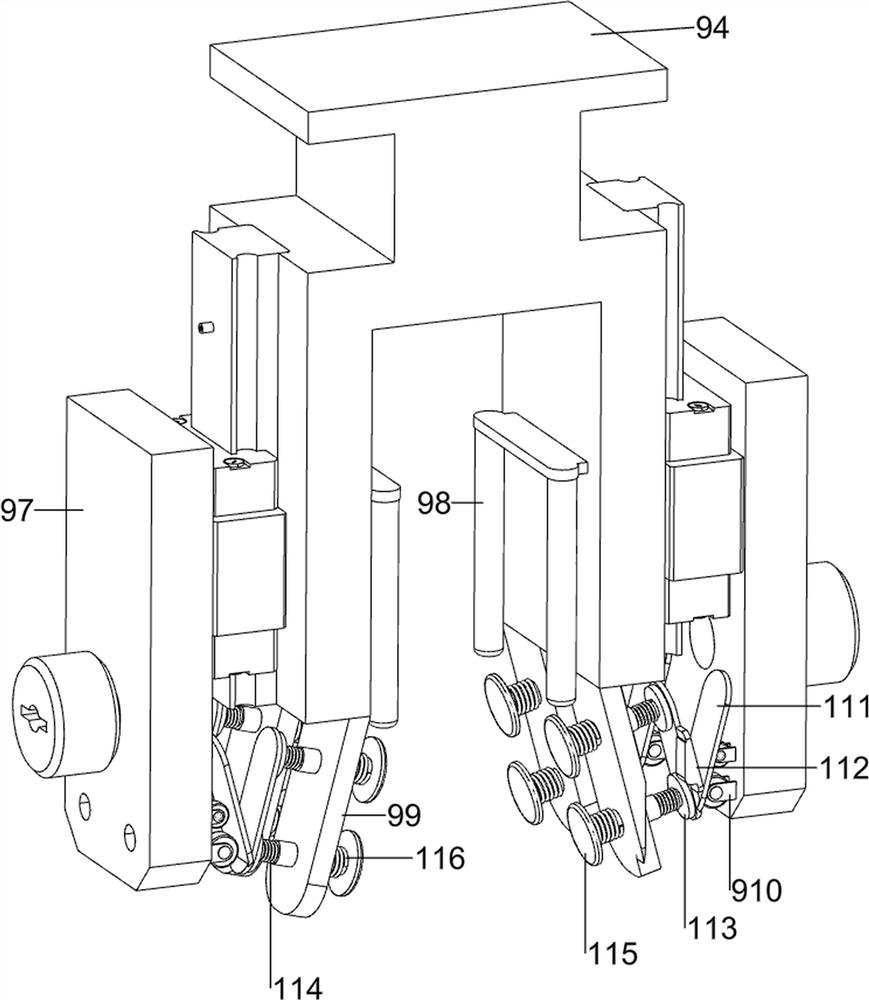

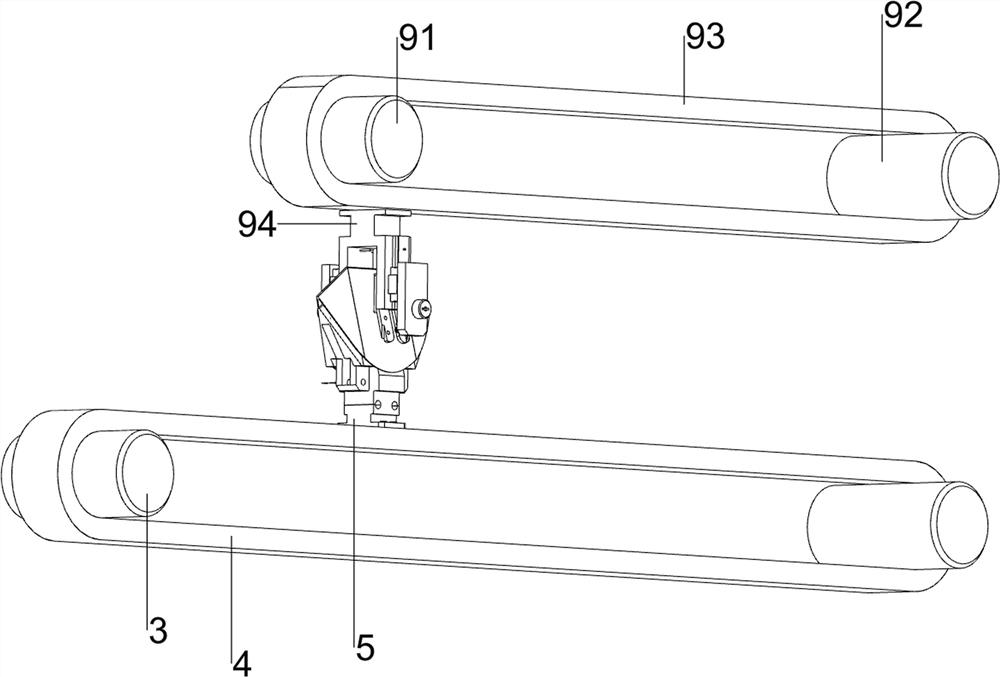

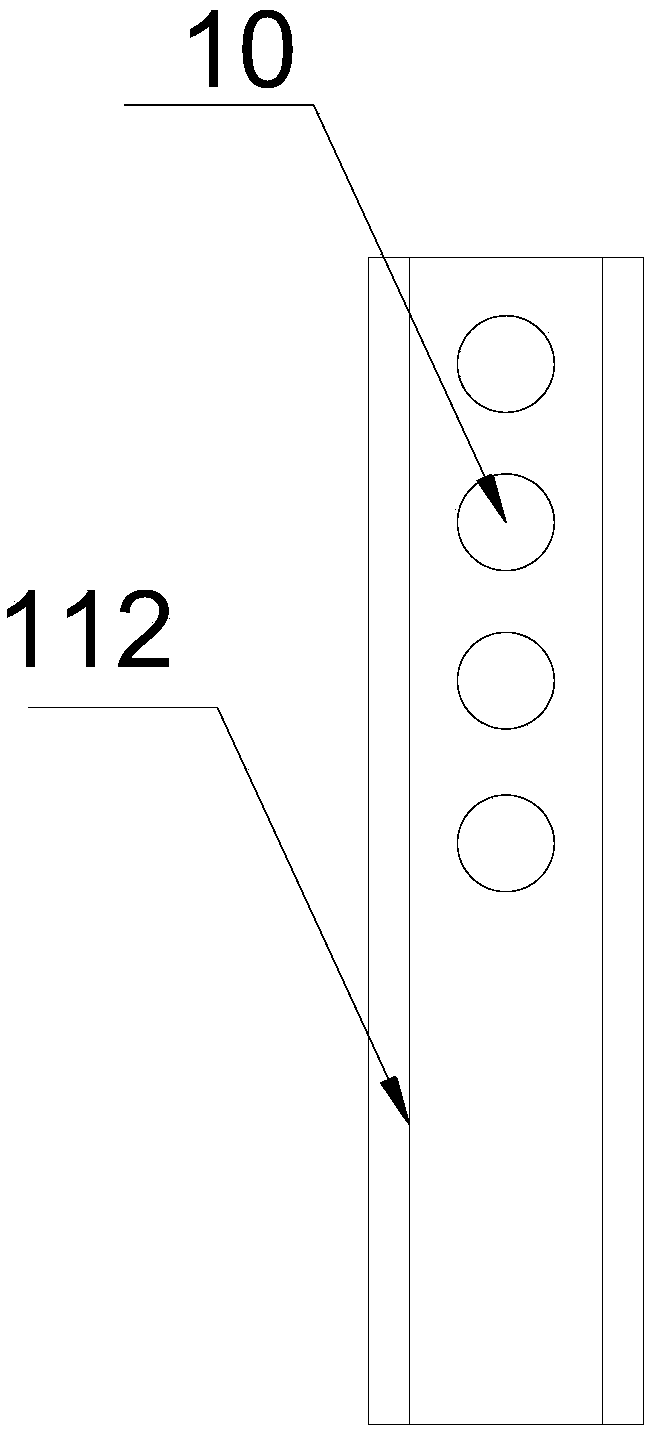

Device and method for disassembling square lithium ion batteries of multiple specifications

ActiveCN109672003AHigh degree of automationNo human intervention requiredSolid waste disposalTransportation and packagingControl systemAssembly line

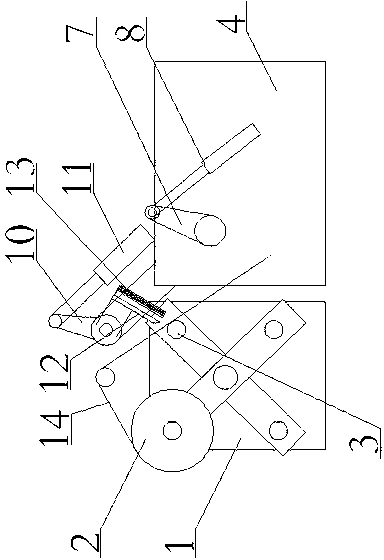

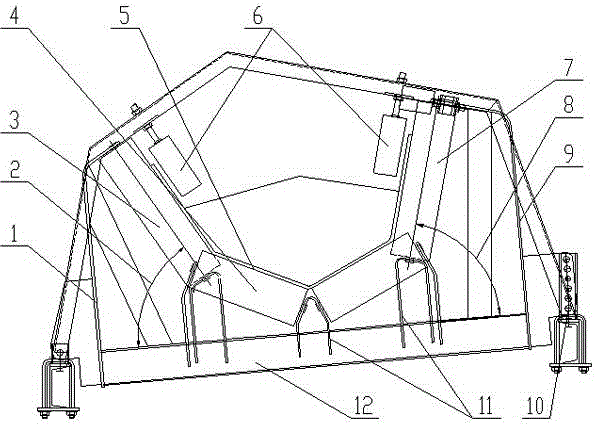

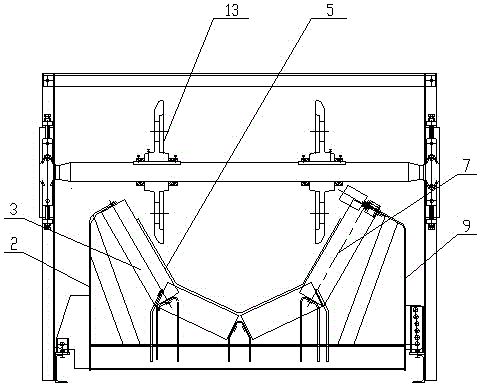

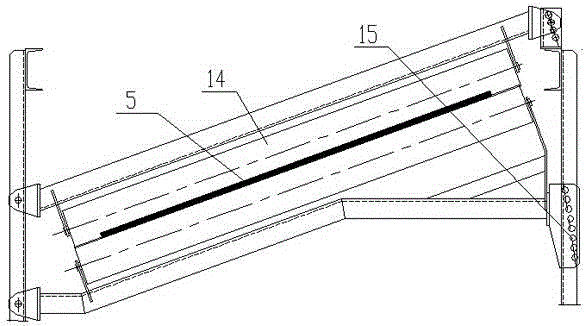

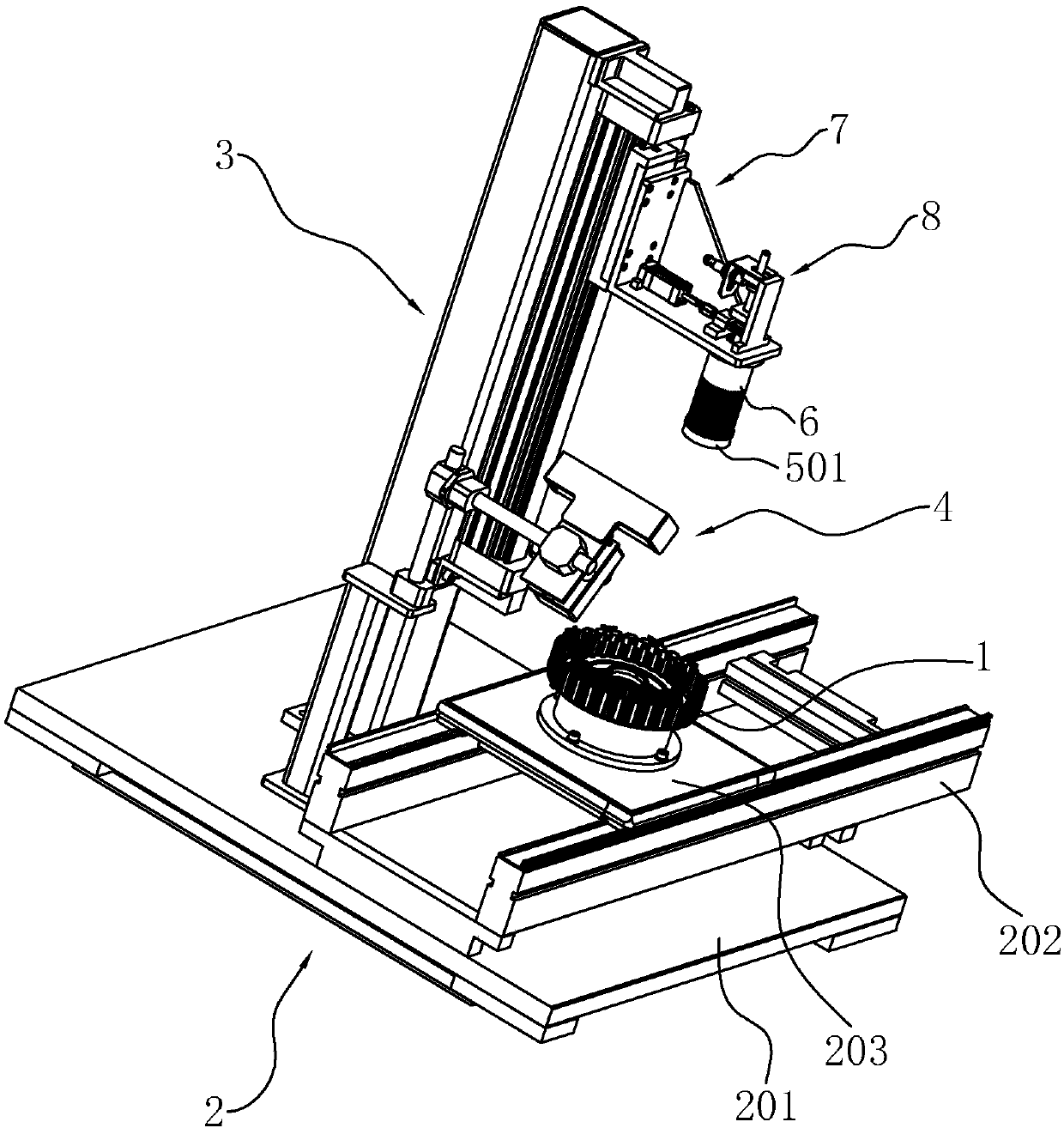

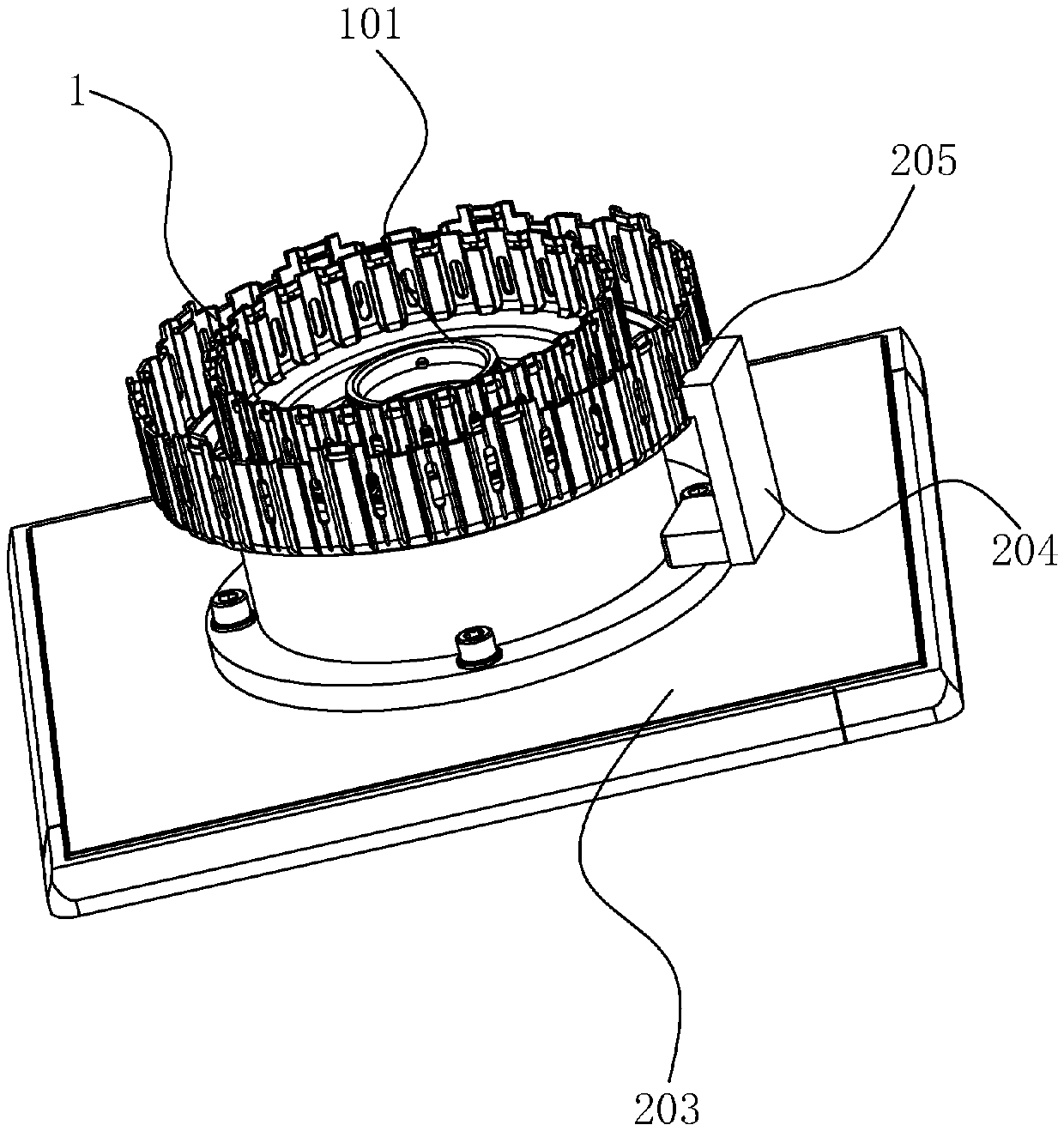

The invention discloses a device and a method for disassembling square lithium ion batteries of multiple specifications. The device comprises a control system and an assembly line type disassembling system. The assembly line type disassembling system comprises an intermittent feeding device (1), a first automatic edge cutting device (2), a station conversion device (3), a second automatic edge cutting device (4) and a separating and core taking device (5). The control system controls all parts of the disassembling system to conduct the assembly line type operation. The intermittent feeding device conveys waste lithium ion batteries to the first automatic edge cutting device to complete the edge cutting operation on the two symmetrical sides of the batteries. The station switching device rotates the cut batteries by 90 degrees and conveys the cut batteries to the second automatic edge cutting device to complete the edge cutting operation on the other two sides of the batteries. The separating and core taking device separates and collects upper and lower meter shells and battery cells. The lithium ion battery disassembling device is high in automation degree and high in adaptability.The discharging and safety problems in the lithium ion battery disassembling process are effectively guaranteed in a knife-cutting disassembling mode. The separation of a battery cell and a battery shell is achieved to the maximum extent.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI +1

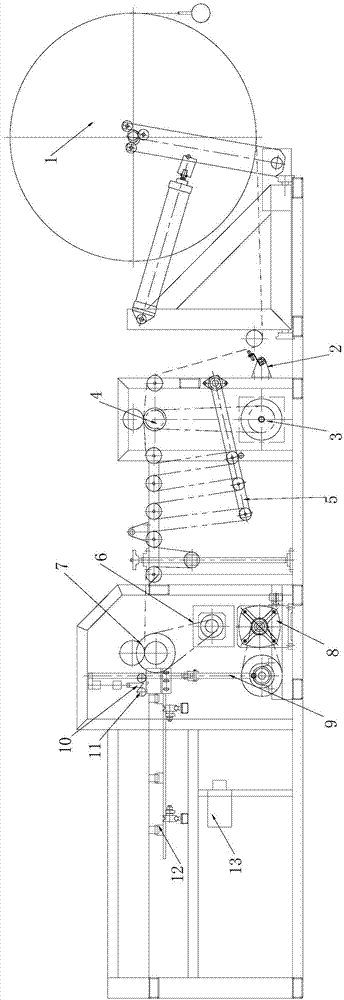

Winding, cutting and beginning device for coating machine

The invention relates to a winding, cutting and beginning device for a coating machine, which comprises a rotating mechanism and a cutting mechanism, wherein the rotating mechanism is arranged on the coating machine to be in a state rotationally corresponding to a receiving roller; and the cutting mechanism is arranged on the rotating mechanism to be in a state that while feeding to a feed roller, the coating machine for cutting is jointed with and feeds to another receiving roller. The winding, cutting and beginning device has the benefits that the structure is simple, the operation is convenient, stable cutting and winding can be performed, and the beginning of new winding is ensured to be level.

Owner:泰兴联创绝缘材料有限公司

Composite material and preparation method thereof and electronic device with composite material

ActiveCN102886935AAvoid curlAvoid breakingSynthetic resin layered productsMetal layered productsFiberSurface layer

The invention provides a composite material which comprises a supporting layer and a surface layer, wherein the surface layer is arranged on the supporting layer; the supporting layer is prepared through soaking a first material in a resin combination and then curing the obtained product, the first material has fiber properties, the surface layer is composed of a second material, and the second material has metal properties; the linear thermal expansion coefficient of the resin combination is close to the linear thermal expansion coefficient of the second material; and the first material is a high-strength and high-hardness material. Compared with the prior art, the composite material provided by the invention is high in strength and hardness, and the surface of the composite material has a richer appearance effect. The invention also provides a preparation method of the composite material and an electronic device with the composite material.

Owner:LENOVO (BEIJING) CO LTD

Automatic plastic woven bag bagging grooving machine

ActiveCN107322992AImprove efficiencySave human effortBag making operationsPaper-makingFrequency changerMotor drive

The invention relates to the field of plastic woven bag manufacture, in particular to an automatic plastic woven bag bagging grooving machine. A servo motor drives a cloth feeding pinch roll to automatically feed cloth; the servo motor drives a hot knife to cut off cylinder cloth, and at the same time, two openings are automatically twisted; a suction port sliding table moves a bag in a servo drive manner to enter an automatic inner film bag bagging working procedure, and at the same time, an inner film bag is automatically rolled up; a frequency converter controls a deceleration motor to drive a cloth pulling pinch roll to pull the rolled inner film bag; an upper heating plate and a lower heating plate seal the bottom of the inner film bag; the servo motor drives the cloth feeding pinch roll to automatically feed cloth; the cut-off cylinder woven bag is blown in through an upper air-blowing port and a lower air-blowing port and is dragged in a bottom seaming conveying pressing belt from a suction port of the sliding table to enter the edge folding and bottom seaming working procedures; the woven bag is conveyed to automatic turning and folding working procedures through the conveying pressing belt; then, the woven bag enters the automatic counting and moving working procedures; and finally, the counted finished bags are manually collected. The automatic plastic woven bag bagging grooving machine is convenient to operate, time-saving and labor-saving, and high in precision and rate of finished products.

Owner:常州市卫翔机械有限公司

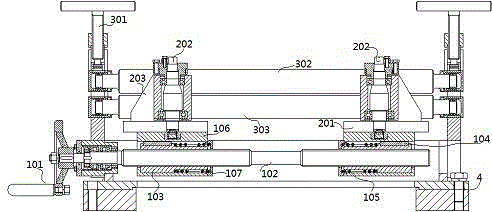

Centering and guiding device for steel strip processing

ActiveCN105414217AAvoid violent movementReduce gapWork treatment devicesMetal rolling arrangementsScrew threadSteel belt

The invention discloses a centering and guiding device for steel strip processing and belongs to the field of steel rolling equipment. The centering and guiding device comprises a base, an adjusting mechanism, a guiding mechanism and a centering mechanism, wherein the guiding mechanism comprises an upper horizontal roller and a lower horizontal roller, and two ends of the upper horizontal roller and two ends of the lower horizontal roller are fixed on supports on two sides of the base separately; the adjusting mechanism comprises a control hand wheel, an adjusting screw rod, nuts, flat keys and nut sleeves, two sections of threads are formed on the adjusting screw rod, each section of threads is matched with the corresponding nut, and the nut sleeves are arranged on the outer side surfaces of the nuts and fixedly connected with the flat keys on the nuts; the centering mechanism comprises sliding blocks and vertical rollers, the sliding blocks are fixedly connected above the nut sleeves, the vertical rollers are symmetrically arranged at two ends of each sliding block, and the vertical rollers are distributed on two sides of one end of the upper horizontal roller. According to the centering and guiding device for the steel strip processing, the position can be adjusted automatically according to the width of a steel strip, the vertical rollers are clamped on two sides of the steel strip all along, so that leftward and rightward offset of the steel strip is avoided, and the problems that the steel strip gets stuck, is flanged and is warped are also solved.

Owner:ANHUI CHUJIANG SPECIAL STEEL CO LTD

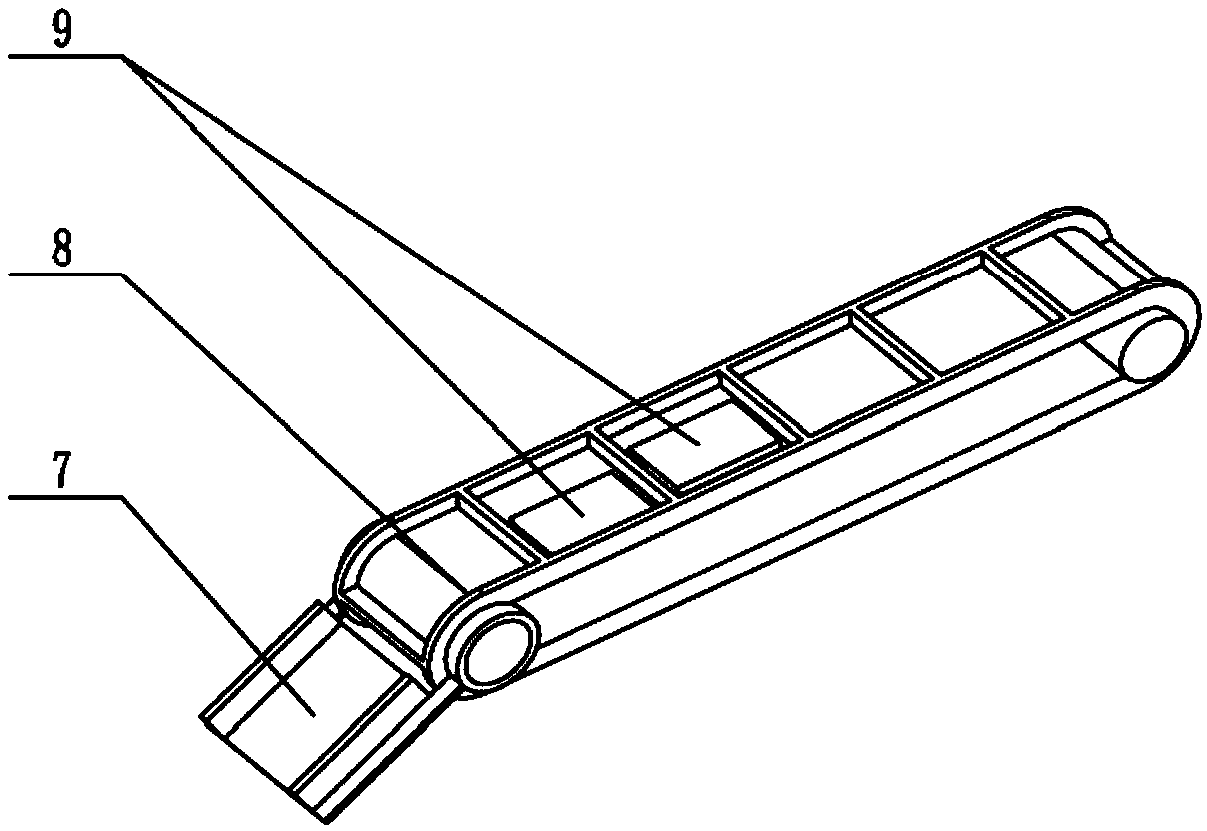

Unequal groove angle curve belt conveyer

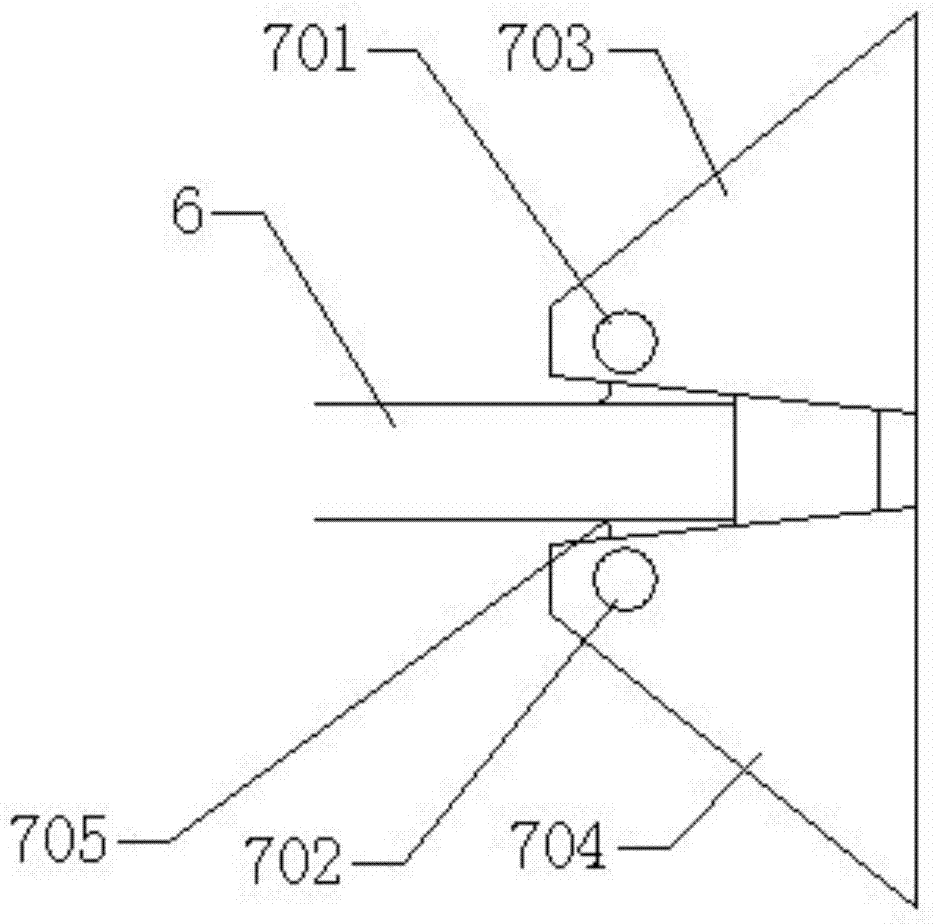

InactiveCN104648938AAvoid flangingPrevent floatingConveyorsRollersPulp and paper industryBelt conveyor

The invention discloses an unequal groove angle curve belt conveyer. The belt conveyer comprises two middle rollers, an inner roller and an outer roller, wherein the outer shaft ends of the inner roller and the outer roller are arranged on an inner roller bracket and an outer roller bracket respectively; the inner shaft ends of the middle rollers, the inner roller and the outer roller are arranged on a middle bracket; the outer roller groove angle between the outer roller and a rack is smaller than the inner roller groove angle between the inner roller and the rack; the outer roller groove angle is 40-50 degrees; the inner roller groove angle is 60-90 degrees. The unequal groove angle curve belt conveyer can turn in the space of a small curvature radius, has a simple structure, is convenient to use and is stable in delivery.

Owner:HENGYANG CONVEYING MACHINERY

Method for eliminating single-side wave defects of oriented silicon steel

PendingCN112831648AAvoid steel strip surface oxidationSmall deformation forceFurnace typesHeat treatment furnacesSurface oxidationSteel belt

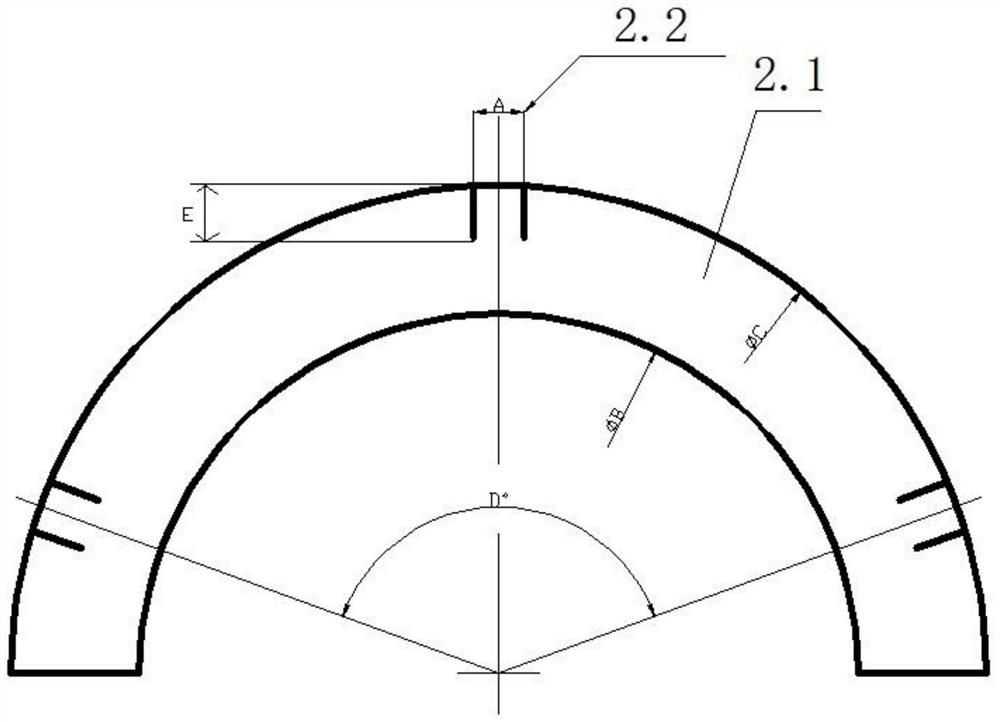

The invention discloses a method for eliminating single-side wave defects of oriented silicon steel. The method comprises the following steps that 1) a special cover plate is manufactured, wherein the special cover plate comprises an annular plate, and a plurality of cut-off positions are arranged on the outer edge of the annular plate; 2) an oriented silicon steel coil to be charged is hoisted to a high-temperature annealing furnace platform; 3) the special cover plate is laid on the outer ring of the upper end face of the oriented silicon steel coil; 4) all the cut-off positions on the special cover plate are bent downwards, and the outer edge of the oriented silicon steel coil is hooked; 5) an inner cover is buckled, and the bottom edge of the inner cover is subjected to sand sealing; and 6) the steel coil enters the furnace, and the high-temperature annealing process is completed. According to the method, the edge of the steel coil can be effectively protected, and the upper end face of the steel coil is prevented from flanging; and according to the method, water in the steel coil can be discharged, and surface oxidation of the steel strip is avoided.

Owner:武汉钢铁有限公司

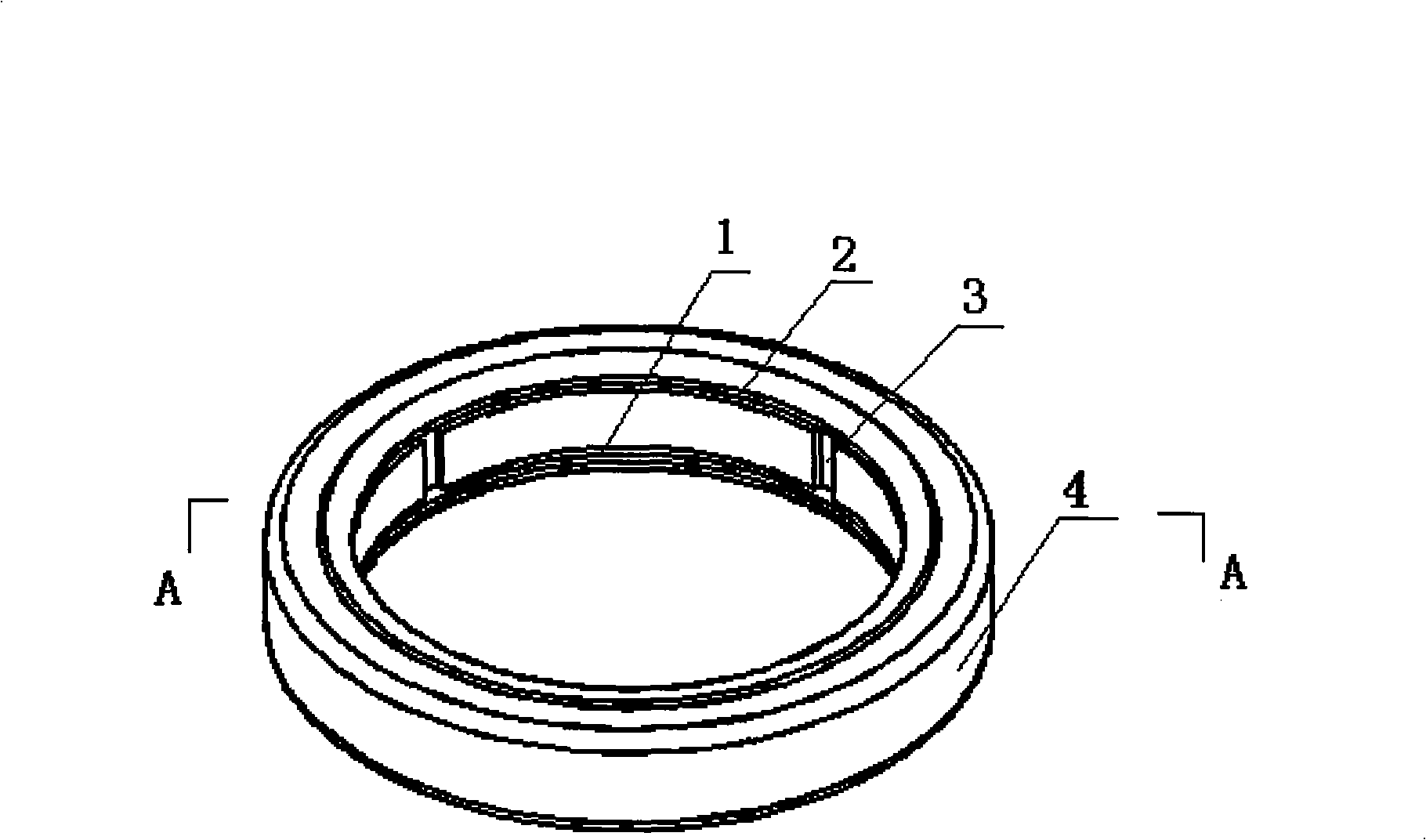

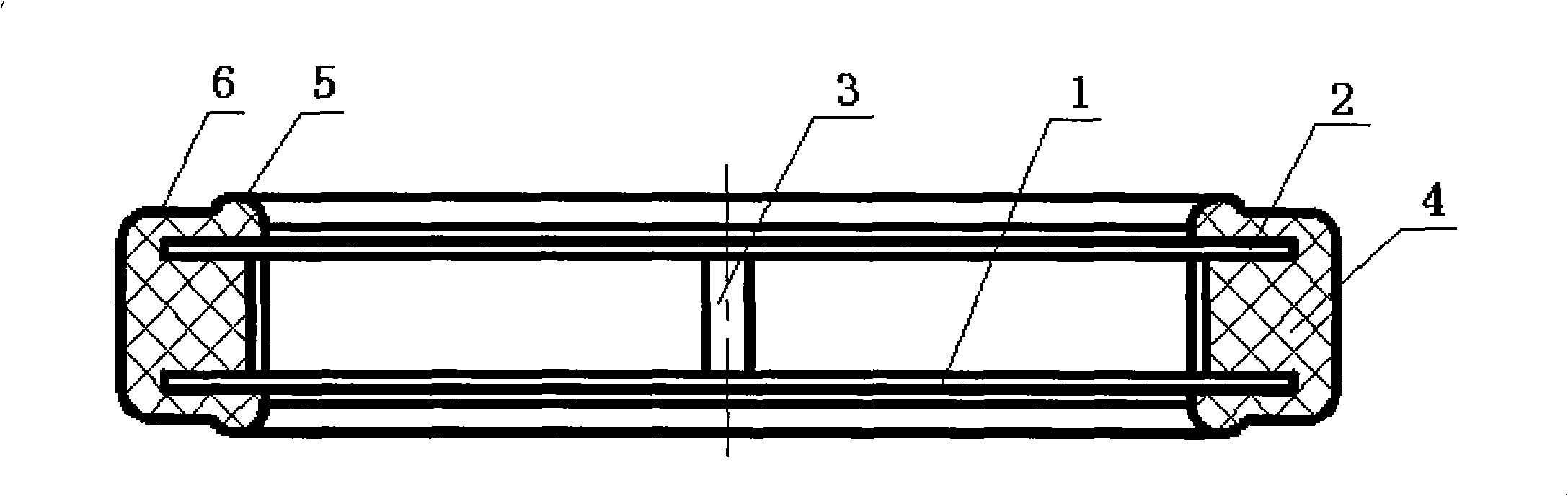

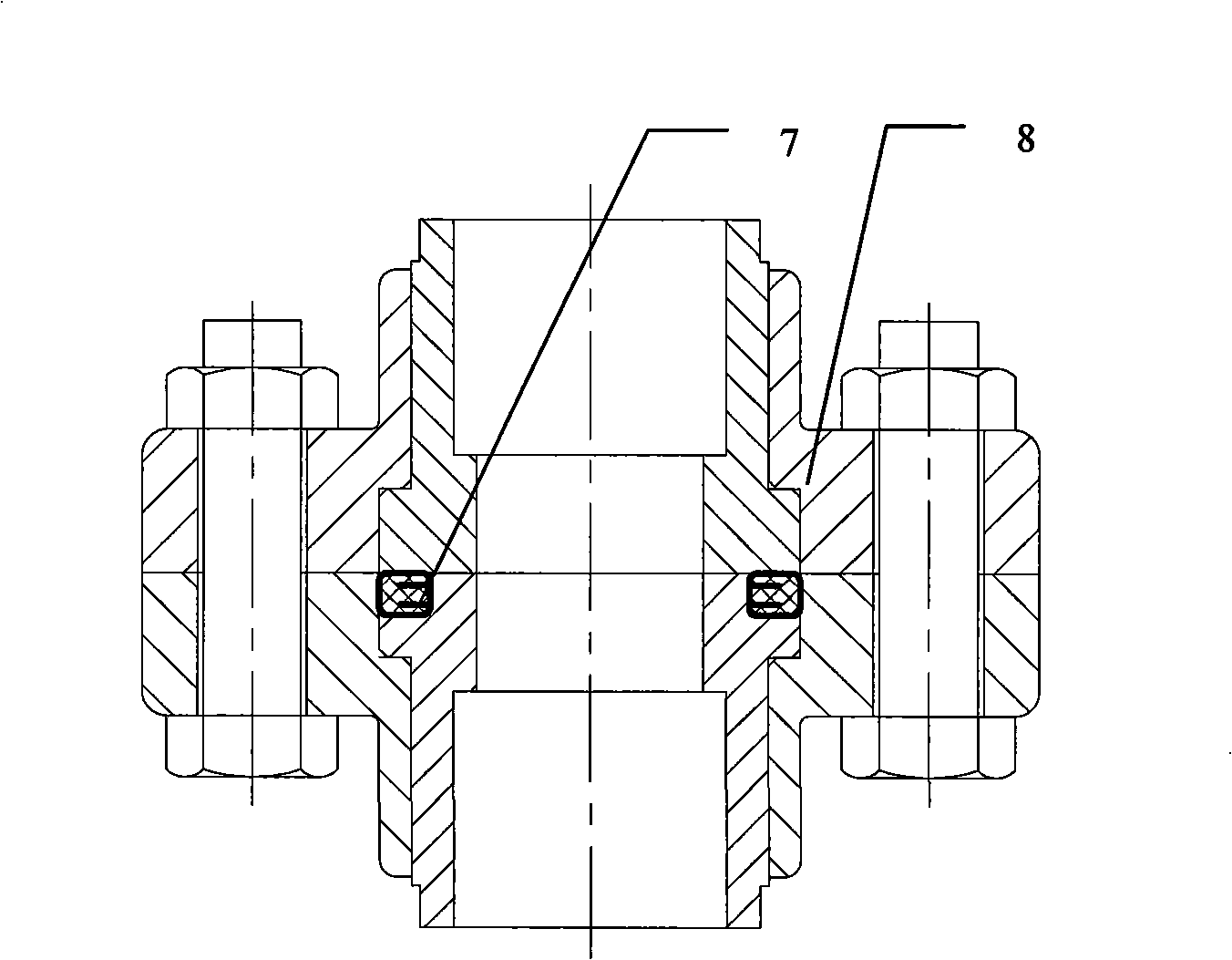

Elastic seal ring

InactiveCN101303097AIncrease stiffnessAvoid flangingEngine sealsFluid pressure sealed jointsProduct gasEngineering

The invention relates to an elastic seal ring, the top and the bottom of the inner ring surface of which are respectively distributed with an aperture extending along circumferential direction; an air conducting groove for communication is arranged between the top aperture and the bottom aperture; the section of the inner ring surface of the seal ring is E-shaped; a semi-O-shaped convex integrated with the ring body is arranged between the top and the bottom working surfaces of the ring body and the corresponding top and bottom apertures. The seal ring adopted by the invention has double functions of gauging sealing and active sealing, which can compensate to cause a second sealing when the situation that gauging sealing is failed for abnormal sealing conditions which do not meet the design appear, so as to ensure that the sealing structure has larger 'redundancy' and enhanced reliability; therefore, the seal ring can be installed and used in a novel self-sealing flange and existing flanges and can also be used as the seal ring of pressure air pipe sealing and connecting except a flange joint and is characterized by reasonable structure, convenient use, low cost and reliable sealing.

Owner:CRRC MEISHAN

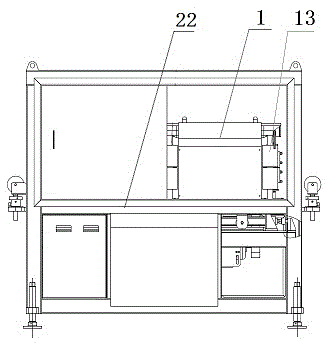

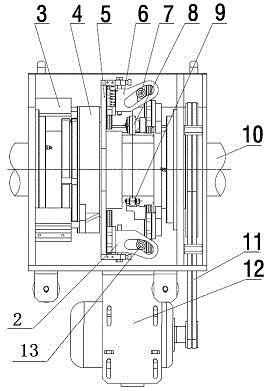

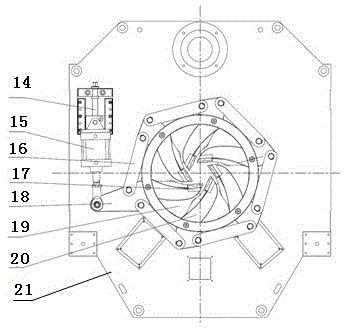

Pressing device for automatically pressing cover plate

PendingCN108747267AGuaranteed precise press fitAvoid flangingMetal working apparatusElectric machineryElectric machine

Owner:上海博邦汽车技术有限公司

Guiding pressing-assembling and detecting device for special-shaped seal ring

PendingCN109648295AAvoid flangingRealize semi-automationMetal working apparatusHydraulic cylinderClutch

The invention relates to a guiding pressing-assembling and detecting device for a special-shaped seal ring, so that the special-shaped seal ring is arranged on a clutch steel ring. An operation tablecontaining a clutch, a cone sleeve, a telescopic pressing head and a first hydraulic assembly are included. The cone sleeve is arranged on the clutch steel ring so that the special-shaped seal ring can be downwards pressed along the surface of the cone sleeve so as to sleeve the clutch steel ring. The telescopic pressing head is used for downwards pressing the special-shaped seal ring along the surface of the cone sleeve. The first hydraulic assembly drives the telescopic pressing head to move up and down and comprises a first hydraulic cylinder and a first hydraulic rod. The guiding pressing-assembling and detecting device has the effects that seal ring inner ring face edge overturning is prevented in the clutch special-shaped seal ring assembling process, and the assembling efficiency isimproved.

Owner:北京北一法康生产线有限公司

Chemical nickel-plating electroplating protection tool for oil admission filler neck

PendingCN112376093AImprove efficiencyEnables high-volume production of partsElectrolysis componentsMechanical engineeringElectroless nickel plating

A chemical nickel-plating electroplating protection tool for an oil admission filler neck comprises a plug cap and a plug, wherein a center shaft used for being connected with the oil admission fillerneck is arranged on the end face of the plug in the horizontal axis direction, an outer thread is arranged at the other end of the center shaft, a round hole is formed in the end face, opposite to the plug, of the plug cap, and an inner thread matched with the outer thread is arranged in the round hole; and after the plug and the plug cap are connected with the oil admission filler neck, the endface of the oil admission filler neck is located in the end face of the plug or the plug cap. The nickel-plating electroplating protection tool is convenient and flexible to use and adjust, easy to operate, capable of improving the workpiece protection and electroplating efficiency and worthy of popularization.

Owner:贵州新安航空机械有限责任公司

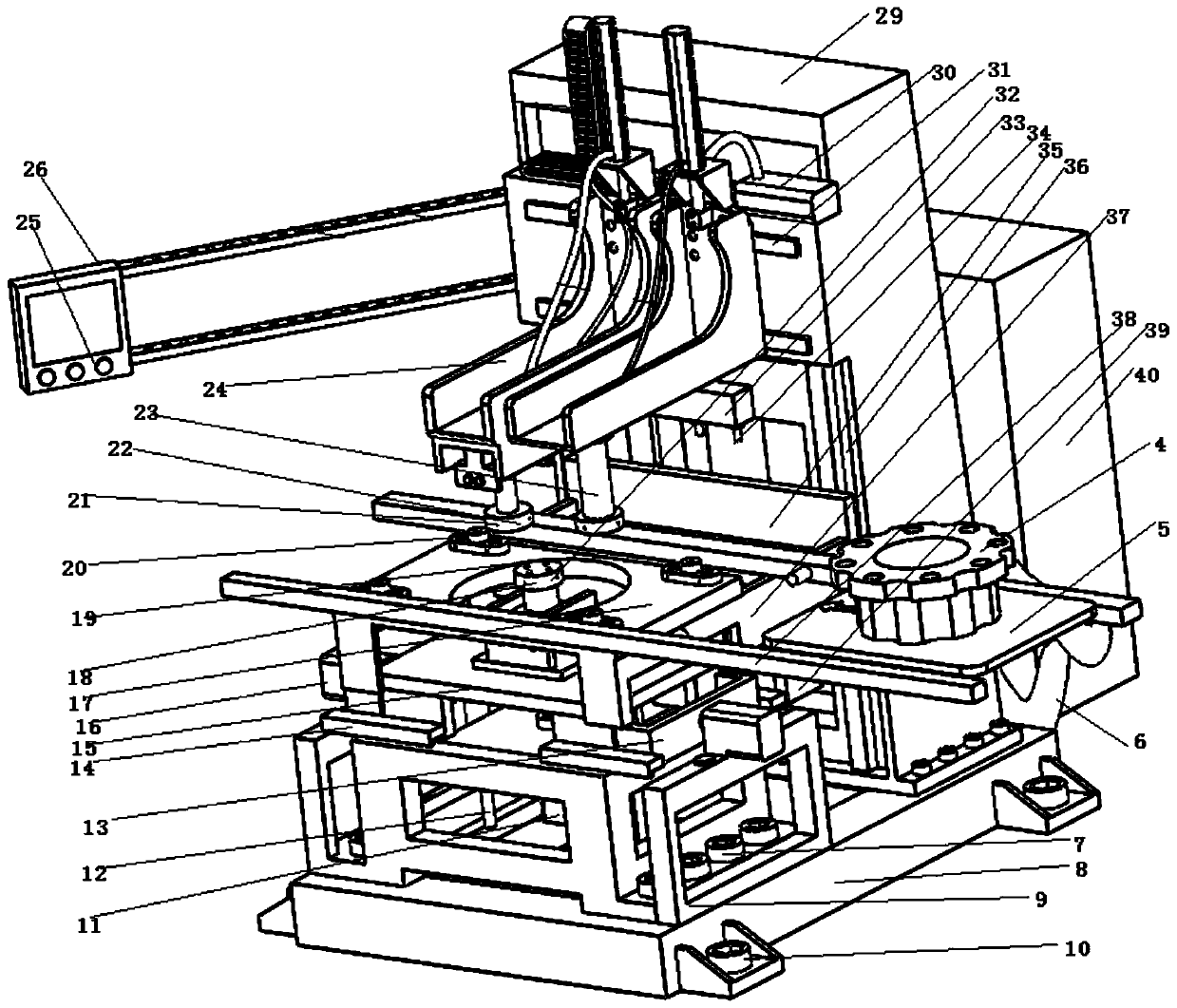

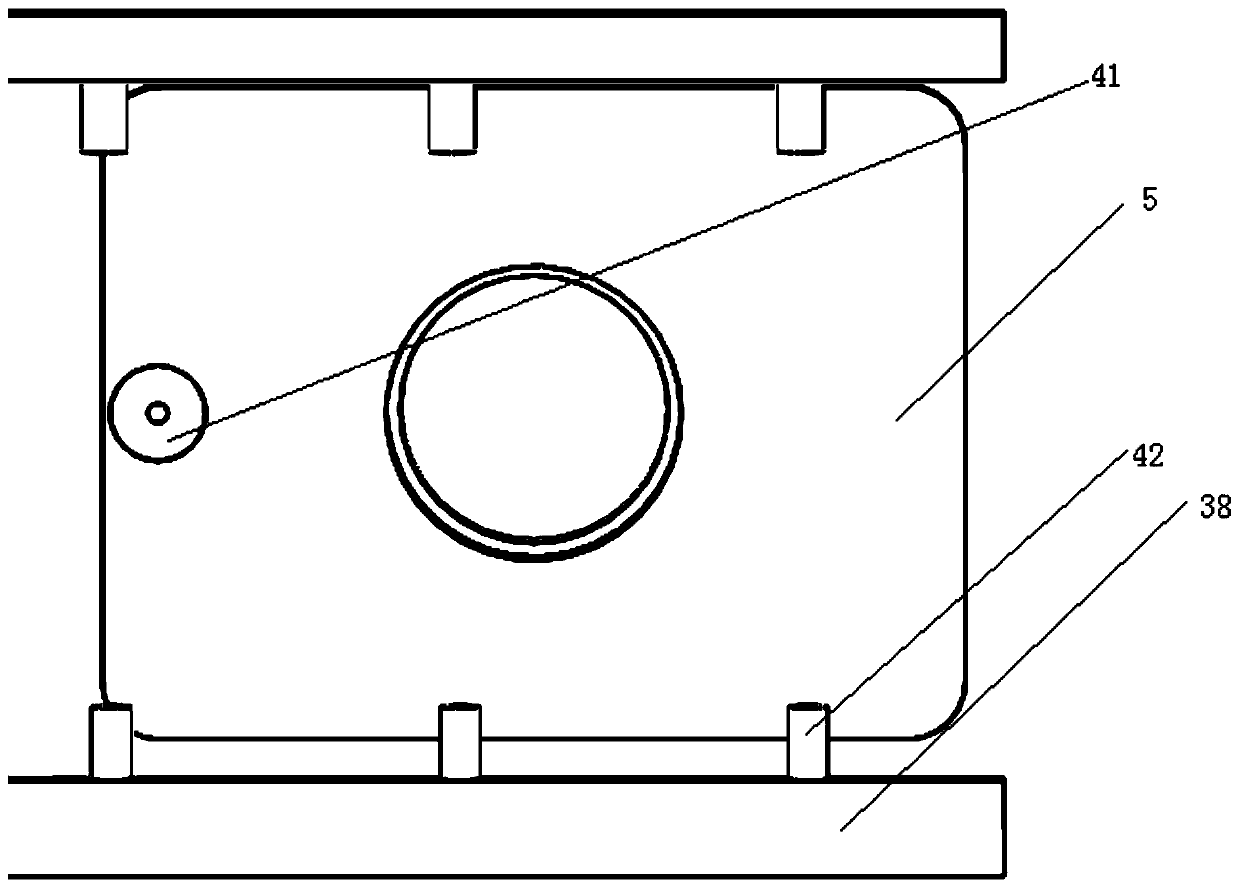

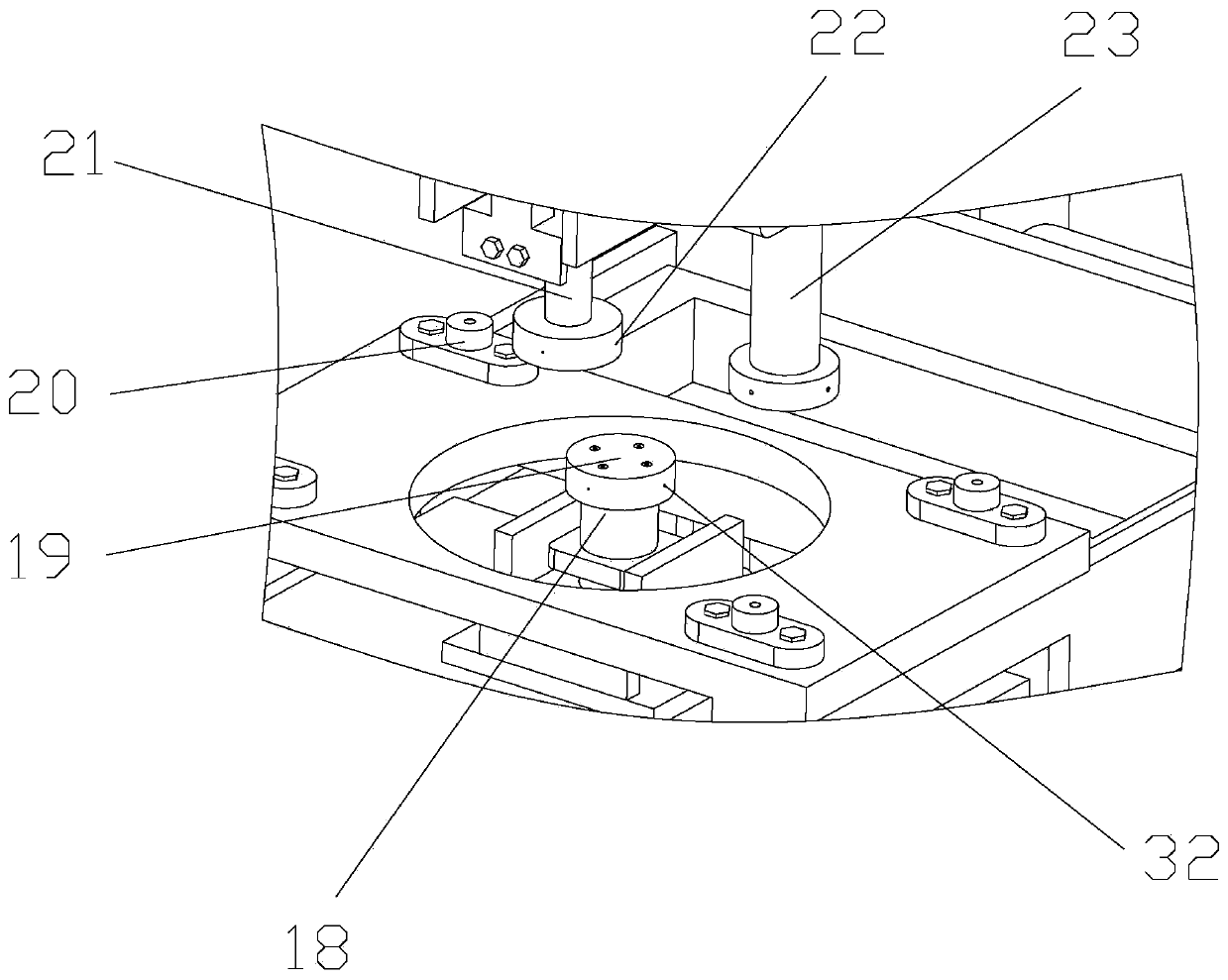

Heavy truck hub shell size detection machine

ActiveCN110966971AAvoid complex processReduce complexityMeasurement devicesProgramme control in sequence/logic controllersStructural engineeringMachine

The invention relates to the field of wheel hub shell detection, and discloses a heavy truck hub shell size detection machine. The machine comprises a main equipment rack (8), a workbench rack (9) isarranged on the main equipment rack (8), a workbench main air cylinder (11) and a main air cylinder column (12) are arranged on the workbench rack (9), a workbench (15) is arranged on the workbench main air cylinder (11) and the main air cylinder column (12), and a lower detection head (18) is arranged on the workbench (15); a vertical rack (29) is arranged on the main equipment rack (8), a movable arm mechanism (24) is arranged on the vertical rack (29), and an upper shaft shoulder detection head (21) and an upper detection head (23) are arranged on the movable arm mechanism (24). The heavy truck hub shell size detection machine has the advantages that the detection precision of the hub shell is improved, and therefore the quality of the hub shell is improved.

Owner:合肥龙智机电科技有限公司

Paper pressing mechanism of printing machine

The invention discloses a paper pressing mechanism of a printing machine. The paper pressing mechanism comprises a rack, a conveying roller, a first pressing roller, a positioning roller, a second pressing roller and a first driving device. The conveying roller is used for conveying paper, the first pressing roller is located behind the conveying roller, the conveying roller and the first pressingroller are matched, the paper is transported from the position between the conveying roller and the first pressing roller, the first pressing roller is provided with a temperature adjusting device, the rack is provided with a position adjusting device, the second pressing roller is mounted on the position adjusting device in a pivot manner, the position adjusting device can drive the second pressing roller to move between the position close to the positioning roller and the position away from the positioning roller, the first driving device is used for driving the conveying roller, the firstpressing roller, the positioning roller and the second pressing roller to rotate, through cooperation of the conveying roller and the first pressing roller, the paper temperature is adjusted, throughcooperation of the positioning roller and the second pressing roller, the paper surface is adjusted, and the paper is flat.

Owner:湖北协丰印刷有限责任公司

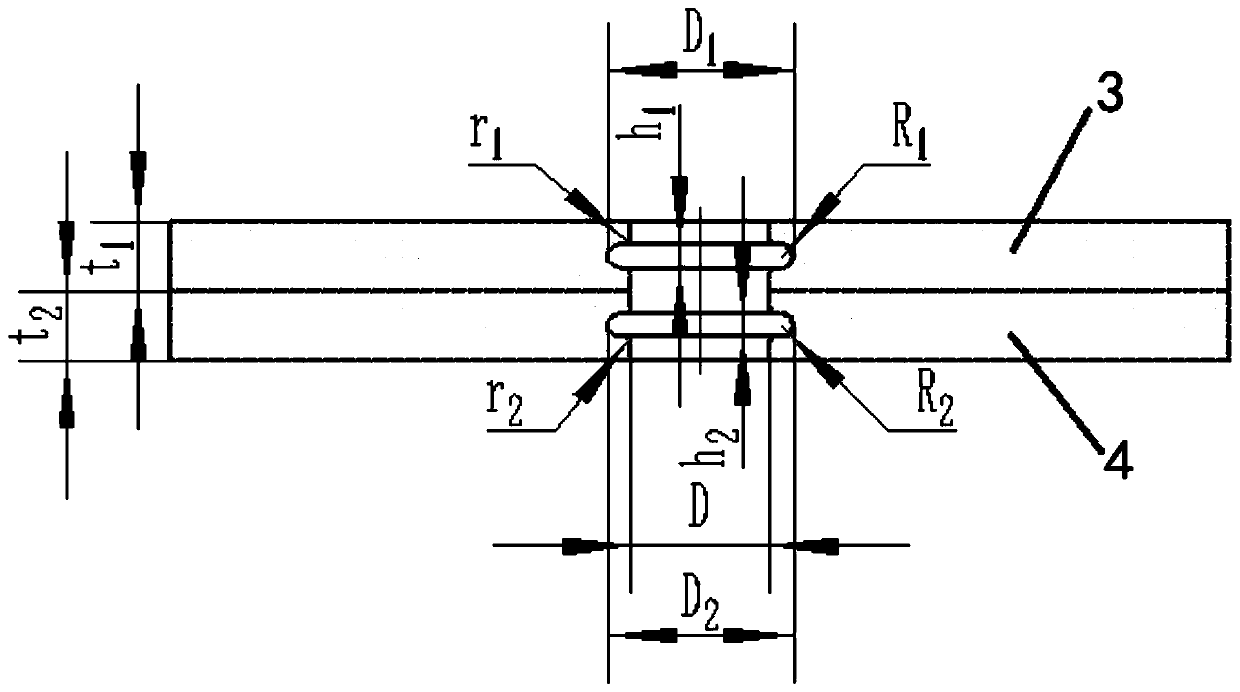

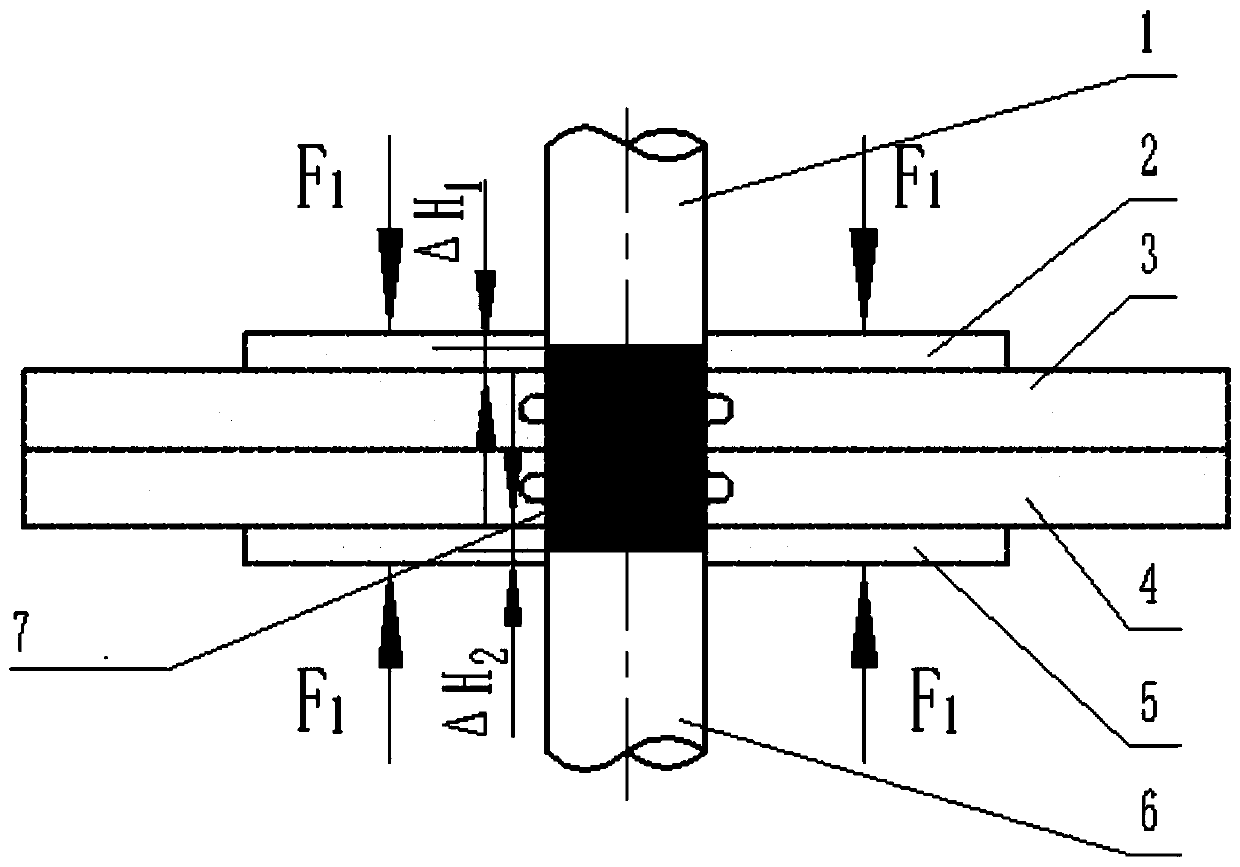

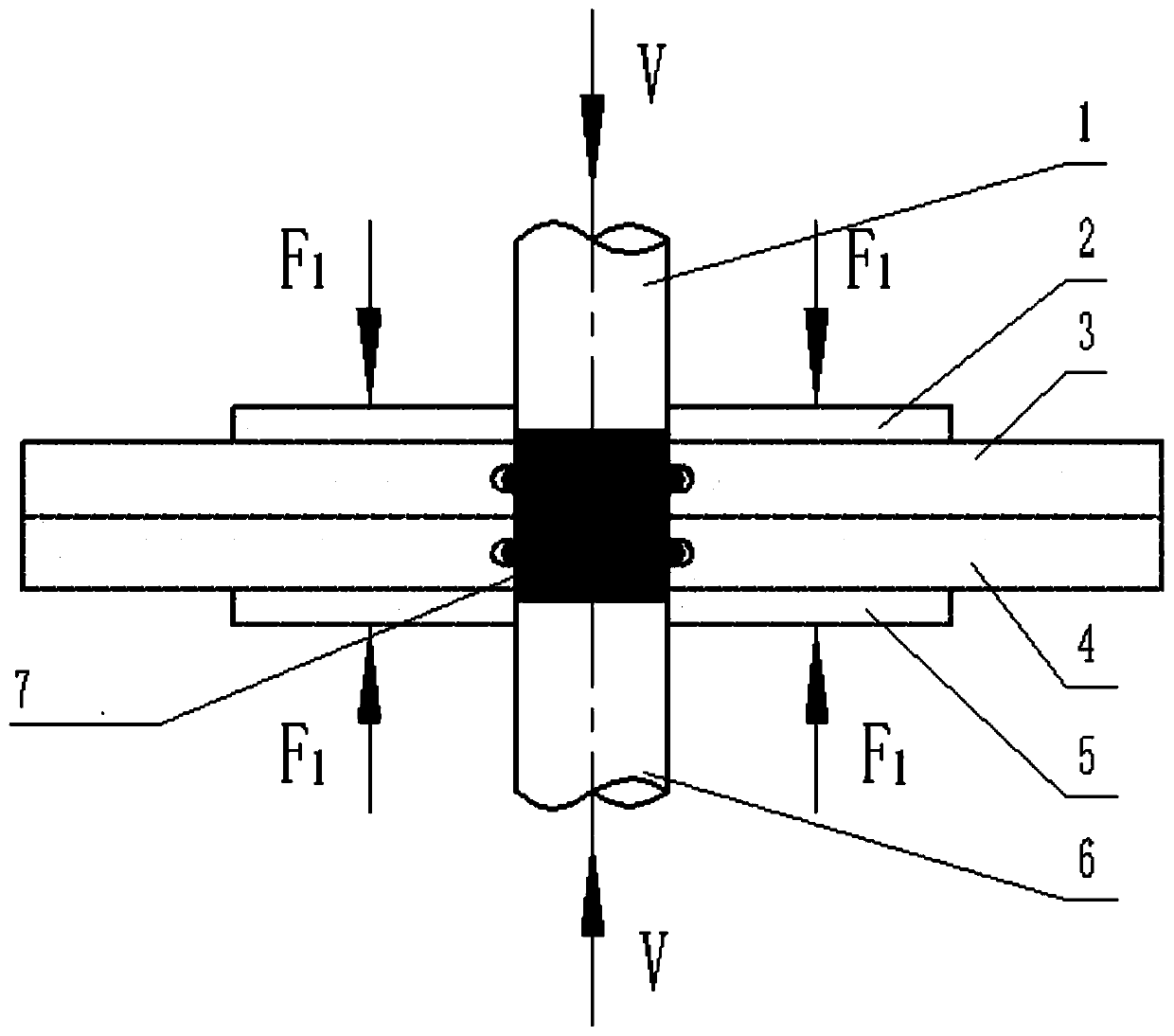

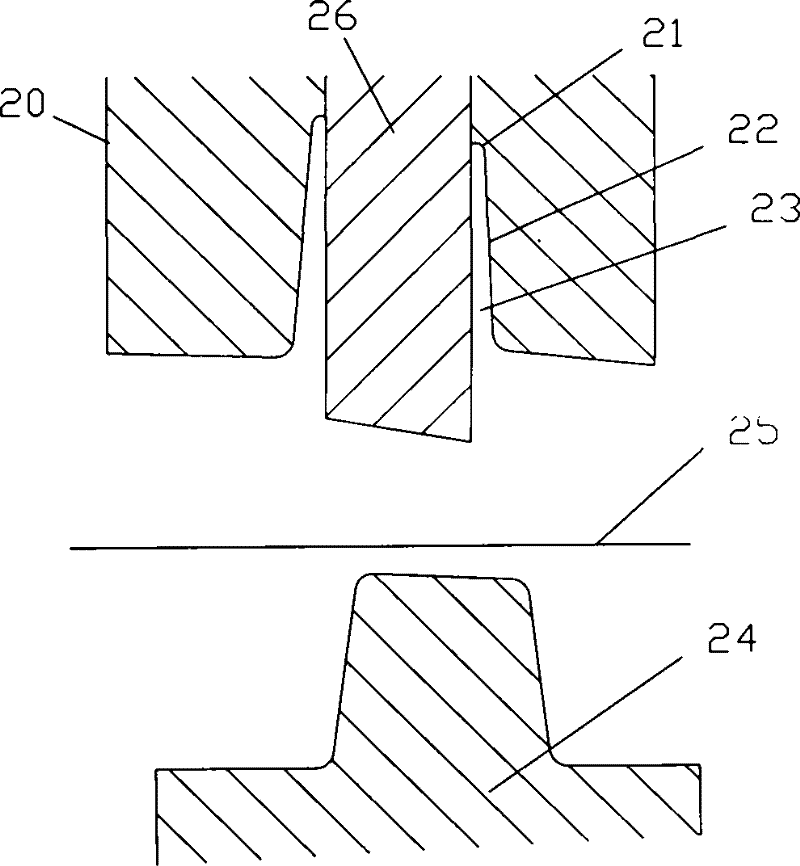

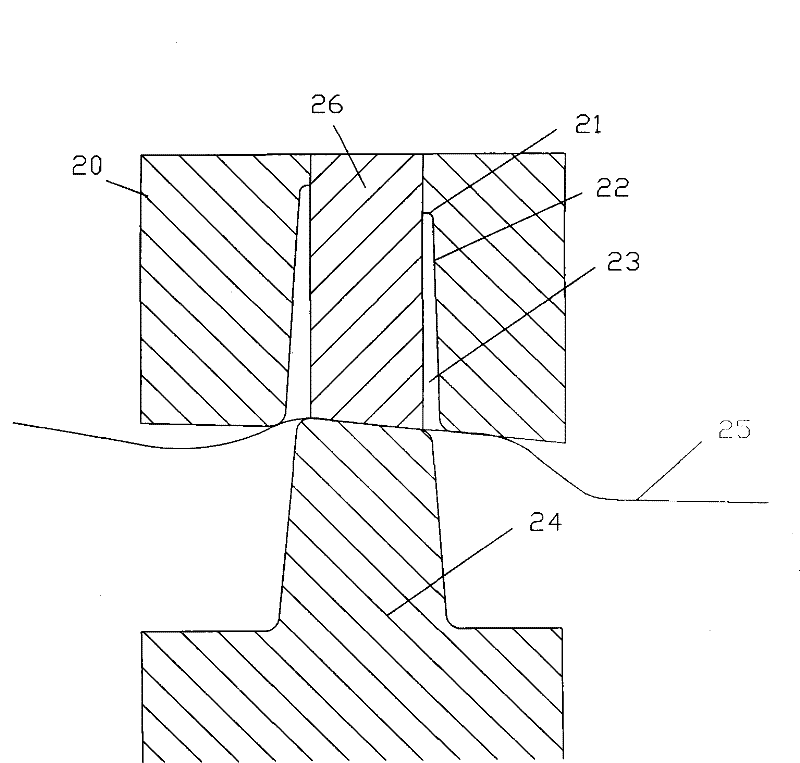

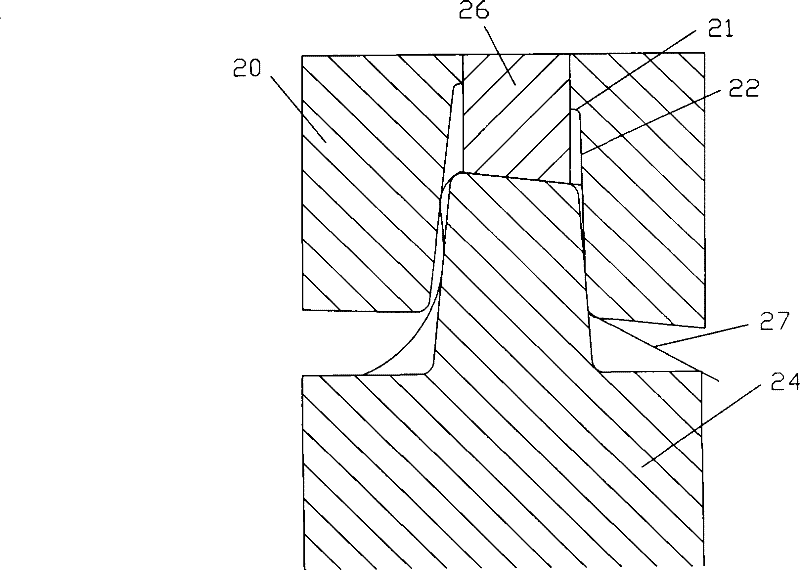

Method of riveting heavy and medium metal sheets without projections on double faces

ActiveCN110640071AEfficient rivetingReduce grinding processStructural engineeringManufacturing engineering

The invention discloses a method of riveting heavy and medium metal sheets without projections on double faces and belongs to the technical field of material connection. The heavy and medium metal sheets are riveted quickly and efficiently by adopting a method of prefabricating holes with annular grooves in the two to-be-connected heavy and medium metal sheets and placing simply shaped connectingcolumns into the holes, and applying external forces to two sides of the connecting columns through upper and lower punches, wherein the connecting columns deform plastically to fill the annular grooves. According to a volume invariable law, the connecting columns which deform plastically can be filled into the annular grooves of upper and lower panel veneers without obvious protruding height points, so that the grinding step is reduced and the production efficiency is improved. The used parts of the device are simple in structure, convenient to process and good in compatibility with conventional equipment, the pre-treatment process of the to-be-welded panels is simple, the production efficiency is high and the cost is low. The surface of the connected part is smooth and is free of projections, so that the heavy and medium metal sheets are more attractive. Furthermore, after the connecting columns deform plastically, the tensile strength and the shear strength of the riveted part are improved and the connection is more stable.

Owner:SHAANXI UNIV OF SCI & TECH

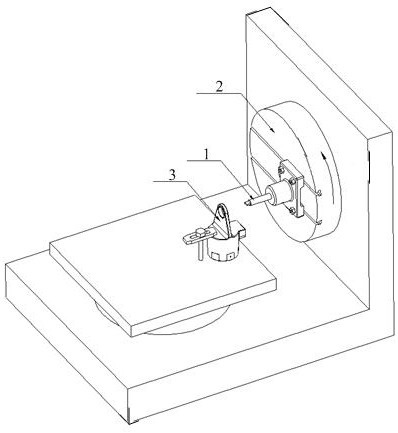

Bearing hole groove machining method

The invention discloses a bearing hole groove machining method, which comprises the following steps: clamping a groove machining cutter on a facing head cutter rest, correcting the direction of the cutter, boring a small section of excircle by using the machining cutter to determine the rotation diameter of the cutter and determine the zero position of a U shaft of a facing head, clamping and correcting a part on a machine tool, and finally calling numerical control programs to machine grooves. According to the bearing hole groove machining method, different numerical control programs are compiled, each numerical control program corresponds to the groove of one specification, and the feeding track of the machining cutter is controlled through the numerical control programs, that is, the profile angles of the grooves are controlled. During groove machining, only the corresponding numerical control programs need to be called, and groove features of different specifications can be machined through one machining cutter by means of U and Z interpolation. The bearing hole groove machining method is high in machining efficiency, good in universality and suitable for machining all shell groove features based on the HB 0-37 standard.

Owner:JIANGXI HONGDU AVIATION IND GRP

Deburring device for automobile gear

The invention discloses an automobile gear drilling device, which comprises a machine tool table, including a bottom plate, a support seat, a positioning shaft, a lock nut, a positioning block, a cylinder, a push rod, and a quick-change drill sleeve. Compared with the prior art, This kind of automotive gear deburring device adjusts the positioning shaft and positioning block, locks the positioning shaft with a lock nut, and then positions the workpiece on the positioning shaft and positioning block, so as to carry out drilling processing, and the hole is almost drilled through. When the air cylinder is ventilated, the ejector rod is pushed upward, so that the generated burr is upward, so as to avoid the burr in the inner hole of the workpiece assembly, so that the assembly of the workpiece is not affected.

Owner:QINGYANG XINANTE AUTO PARTS

Mask nose bridge strip performance detection equipment

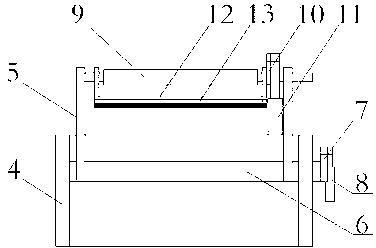

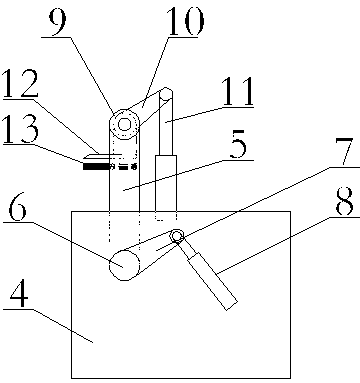

PendingCN114544384ABending resistance testEasy to operateMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesNasal bridgeSupport plane

The invention relates to performance detection equipment, in particular to mask nose bridge strip performance detection equipment. The invention provides performance detection equipment for a mask nose bridge strip to be written. Mask nose bridge strip performance detection equipment comprises a supporting frame, supporting rods, first rollers, a first conveying belt, a mask mold and the like, the supporting rods are symmetrically arranged on the left side and the right side of the top of the supporting frame front and back, the first rollers are rotationally connected between the upper portions of the two supporting rods on the same side in the longitudinal direction, and the first conveying belt is connected between the first rollers in a wound mode. And mask molds are uniformly arranged on the first conveying belt at intervals. The nose bridge strip is bent downwards through the nose bridge strip pressing frame, then unqualified masks and qualified masks are conveyed through the second conveying belt and the first conveying belt respectively, detection of the bending resistance of the nose bridge strips of the masks is achieved, operation is easy and convenient, and practicability is high.

Owner:刘桂兰

A Forming Method of Negative Angle in Semicircle Area of Automobile Control Arm

ActiveCN107116142BAchieving Lightweight GoalsEasy to processShaping toolsVehicle componentsControl armEngineering

The invention relates to the field of automobiles and particularly provides a forming die and a forming method of an automobile control arm semicircle area negative corner. The forming die comprises a first die body, a second die body and a third die body; and the forming die is characterized in that the first die body is composed of a first die material-pressing plate, a first die flanging insert and a first die lower die body, the first die material-pressing plate is arranged above the first die lower die body, the position, located on the right side of the first die material-pressing plate, of the first die lower die body is provided with the first die flanging insert, and the bottom of the right side of the first die flanging insert is exposed out of the right side of the first die lower die body. Compared with the prior art, machining is convenient, and the light weight target of a control arm with a negative corner structure is achieved; and complex forming and flanging can be effectively avoided, and the production and manufacturing cost is lowered.

Owner:上海汇众汽车车桥系统有限公司

Waterproof thin steel plate shearing machine with power adsorption

InactiveCN109202151AAvoid flangingAchieve clearingShearing machinesMaintainance and safety accessoriesSheet steelReciprocating motion

The invention relates to the technical field of shearing machines, and discloses a waterproof thin steel plate shearing machine with powder adsorption. The waterproof thin steel plate shearing machinecomprises a shearing machine main body, wherein the shearing machine main body is provided with a shearing knife, both sides of the shearing machine main body are provided with a machine frame assembly, there is a reciprocating motion mechanism between the machine frame assemblies, the lower end of the reciprocating motion mechanism is provided with an exhaust pipe I, the exhaust pipe I is set tobe L-shaped, the opening at one end of the exhaust pipe I is provided with a brush assembly, the other end is sleeved in an exhaust pipe II and slidably connected with the exhaust pipe II, the tail end of the exhaust pipe II is provided with an exhaust fan, and the brush assembly is set in a mode being abutted against the shearing knife. The waterproof thin steel plate shearing machine can achieve a purpose of avoiding the accumulation of steel powder on the shearing knife to result in the flanging of a thin steel plate in the process of cutting the thin steel plate, and solves a problem of thin steel plate flanging and pitting caused by the steel powder of the existing thin steel plate shearing machine through setting the reciprocating motion mechanism and the exhaust pipe I and settingthe brush assembly in the exhaust pipe I.

Owner:四川正大未来建筑科技有限公司

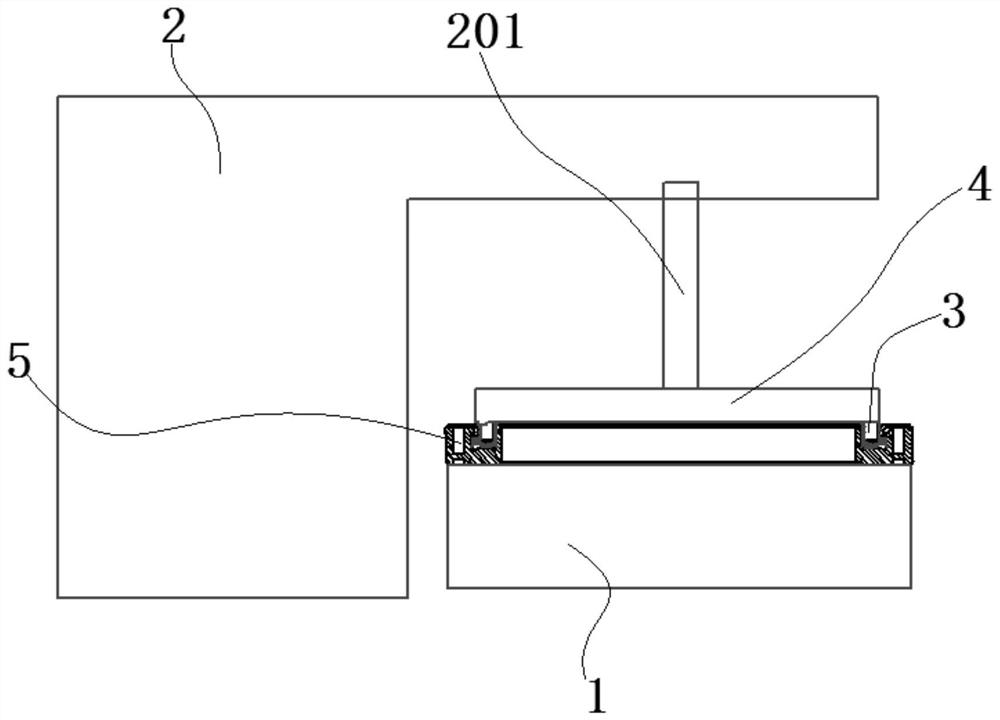

Inner Pot and Electric Pressure Cooker

ActiveCN106108631BAvoid flangingAvoid destructionPressure-cookersEngineeringUltimate tensile strength

The invention provides an inner pot and an electric pressure cooker. The inner pot comprises a body (1) and a lifting handle (2) arranged on the periphery of the body (1). An installation groove (3) is formed between the lifting handle (2) and the periphery of the body (1). The inner pot helps solve the problem in the prior art that that poor strength of the structure of an outer pot is caused due to a gap in the outer pot for the lifting handle.

Owner:GREE ELECTRIC APPLIANCES INC

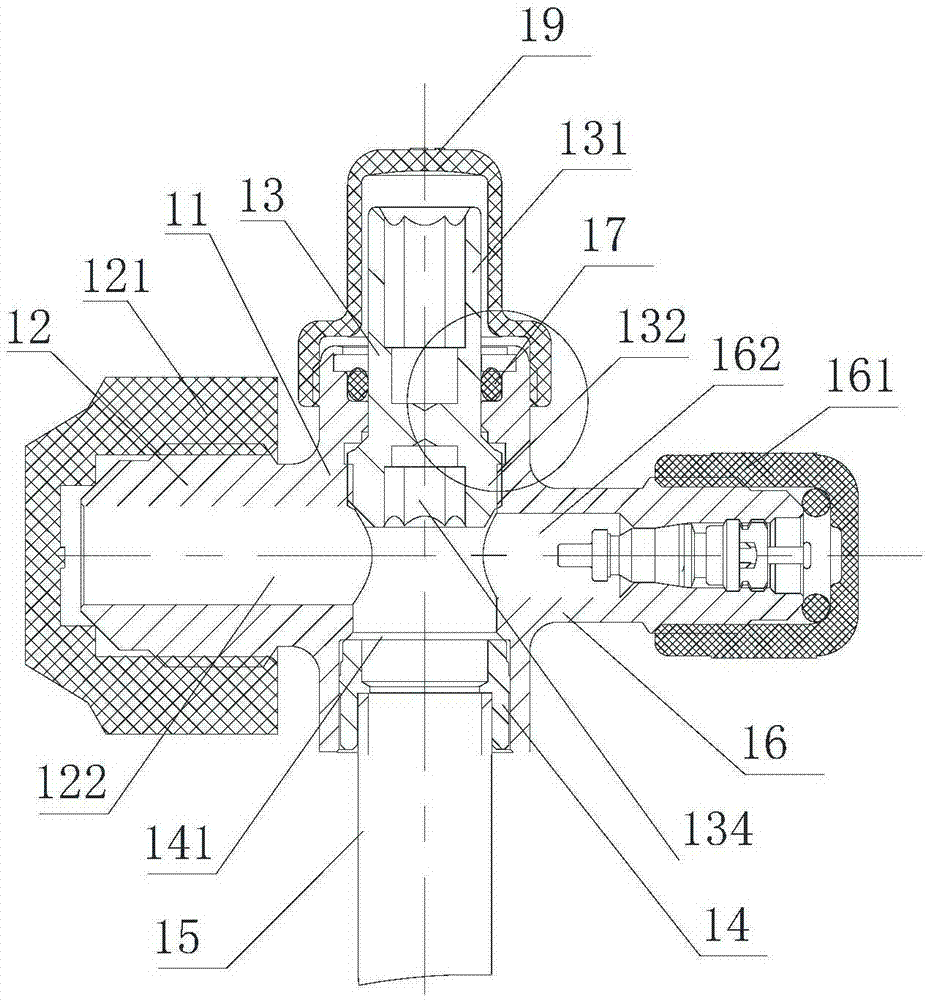

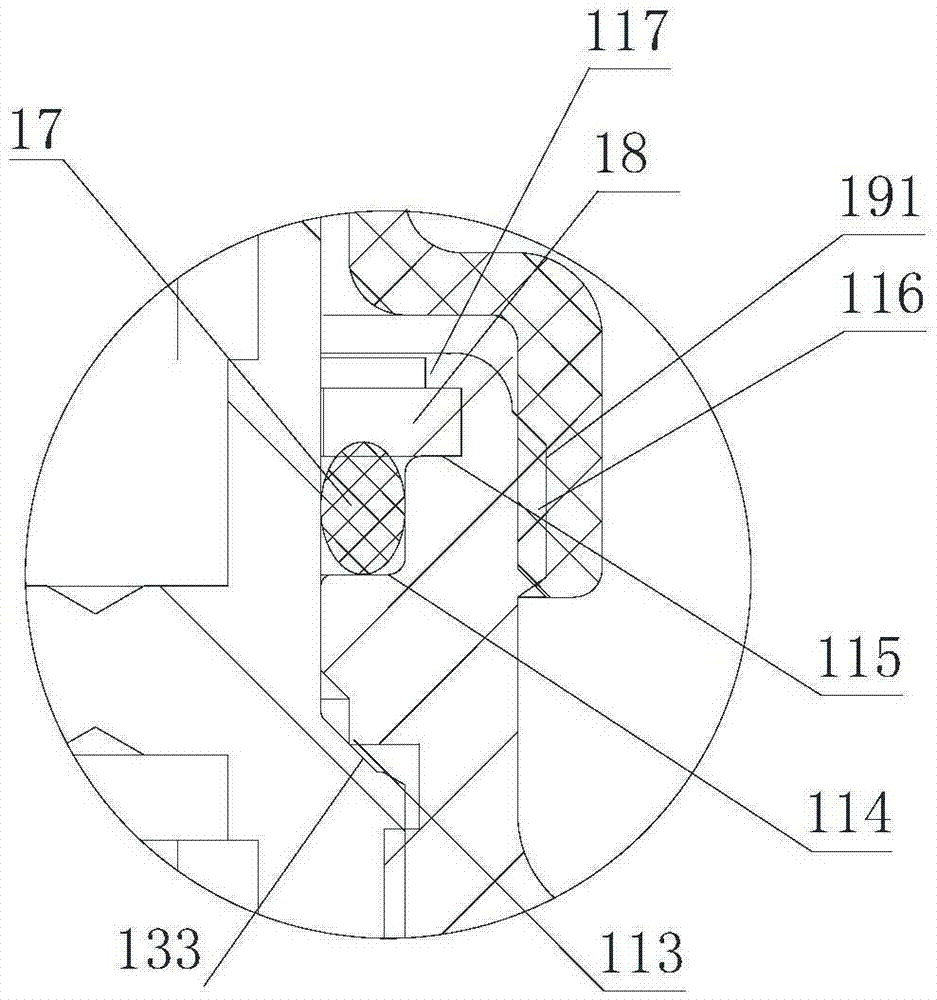

The transmission structure of the additional gear of split crankshaft

ActiveCN105805279BAvoid flangingObserve the installation qualityCrankshaftsMachines/enginesEngineeringFlywheel

Owner:GUANGXI YUCHAI MASCH CO LTD

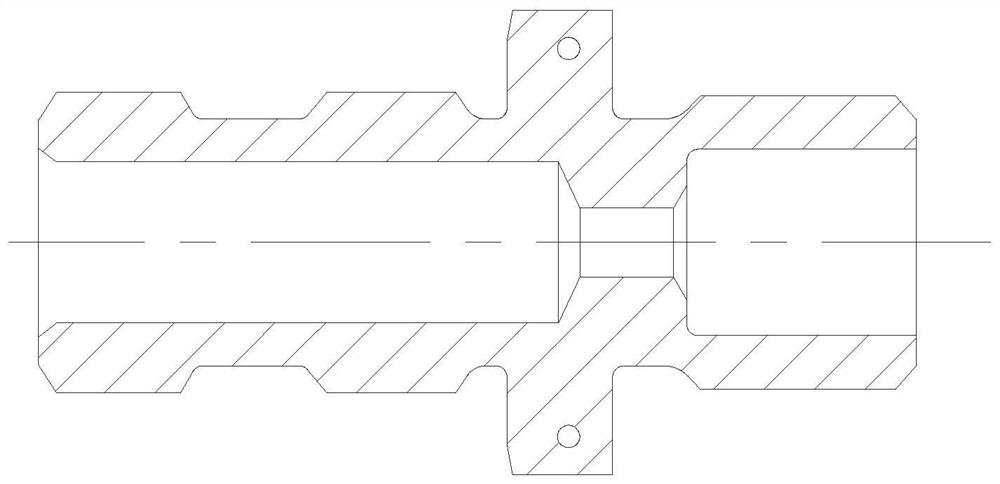

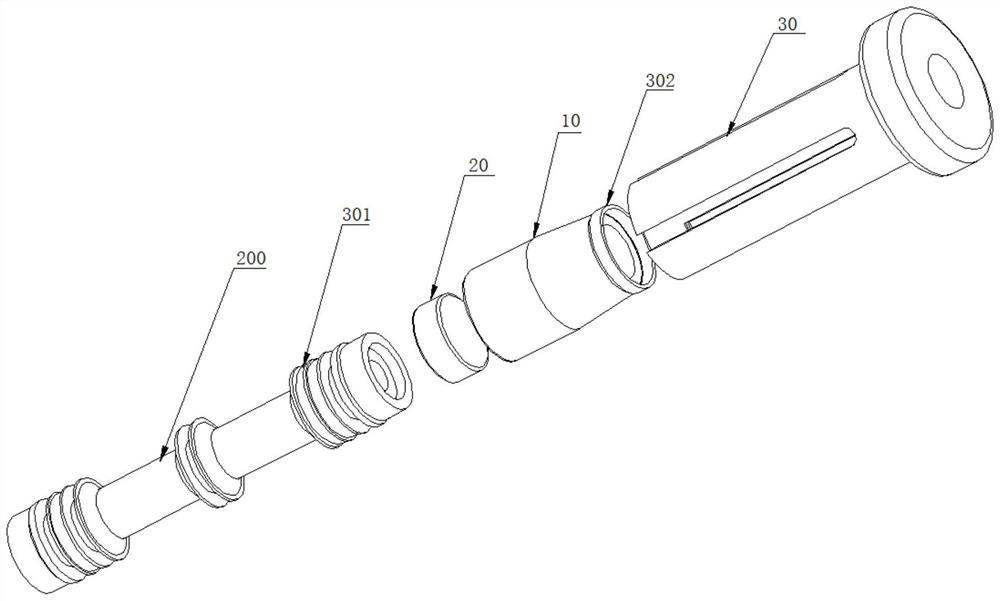

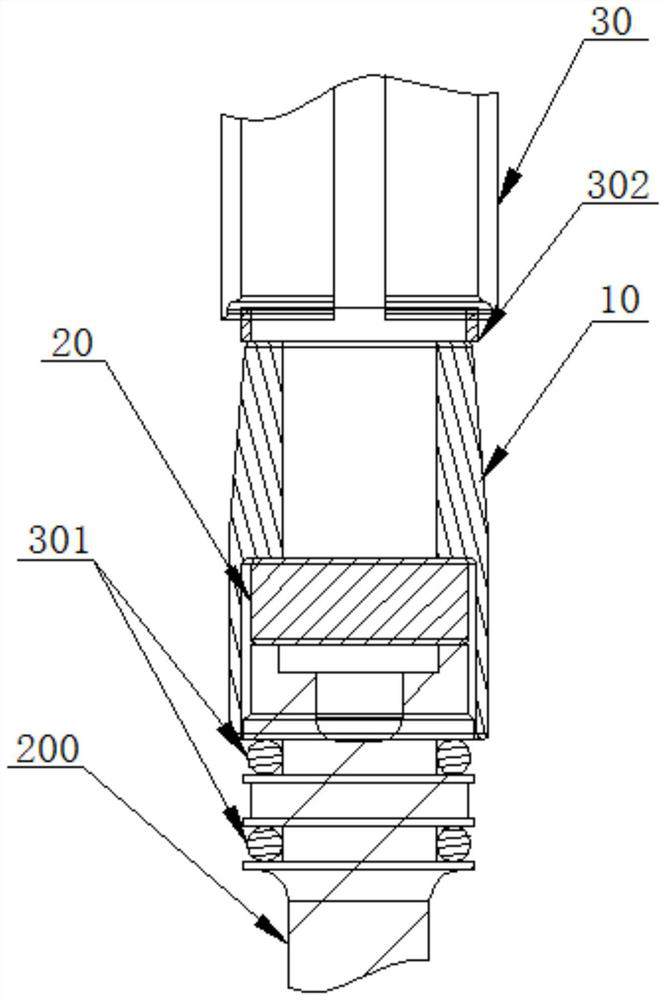

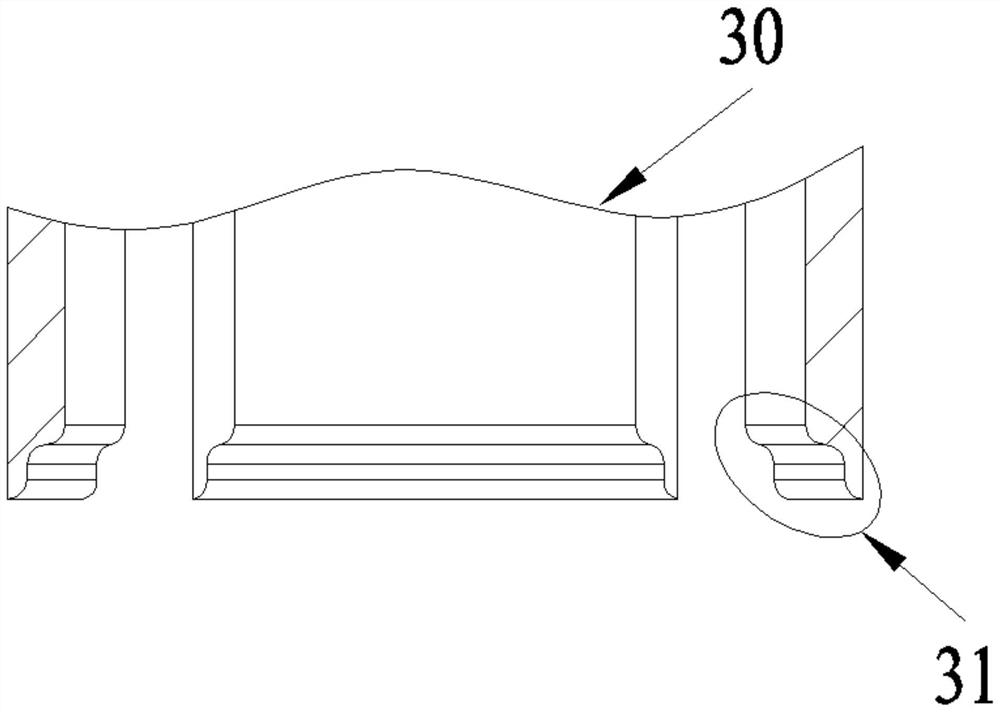

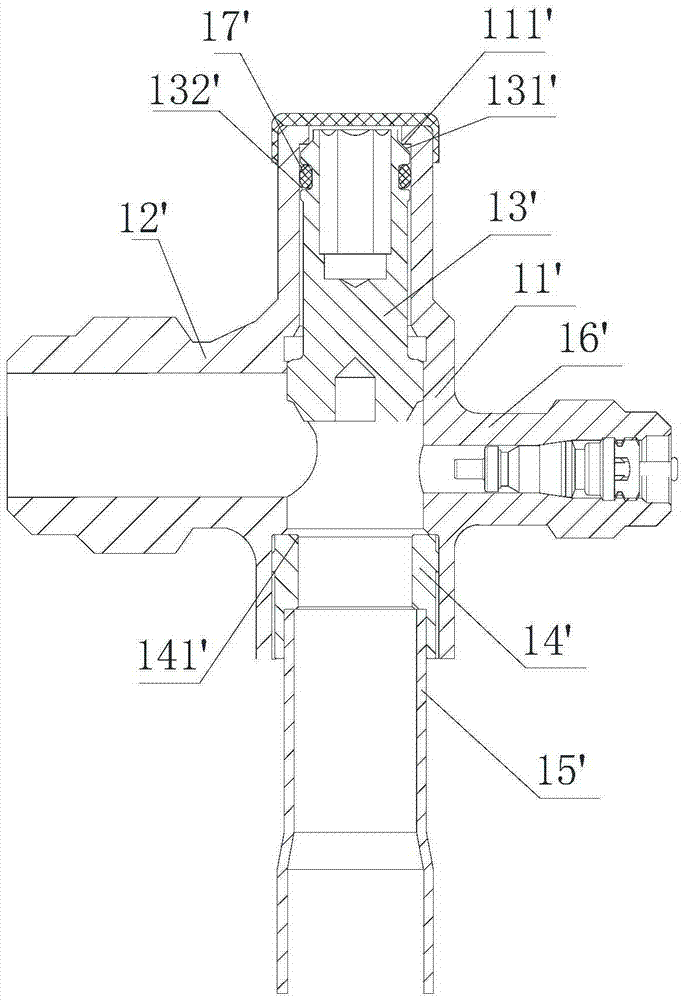

An assembly device for the spool gray ring of the air control valve

The invention relates to an assembly device for a valve core gray ring of an air control valve, comprising a guide sleeve and a push sleeve; the guide sleeve includes an outer wall and an inner wall, the lower part of the outer wall of the guide sleeve is a cylindrical surface, and the upper part of the outer wall of the guide sleeve is Conical surface, and a smooth transition between the cylindrical surface and the conical surface, the inner wall of the guide sleeve is provided with a shoulder, the diameter of the inner wall below the shoulder is not less than the maximum outer diameter of the valve core, and the diameter of the inner wall above the shoulder is smaller than the maximum outer diameter of the valve core; The tetrafluoroethylene ring is set on the upper end of the outer wall of the guide sleeve; the inner diameter of the lower part of the push sleeve is not smaller than the inner diameter of the polytetrafluoroethylene ring, and the lower part of the push sleeve divides the push sleeve into multiple parts in the circumferential direction by setting multiple gaps along the circumference. For the petal body, the inner wall of the lower edge of the plurality of petal bodies is provided with recesses along the circumference, and the upper and lower ends and top corners of the recesses are rounded at three places in total. The invention completes the installation of the polytetrafluoroethylene ring through the cooperation of the guide sleeve and the push sleeve, which reduces the workload of the assembly personnel and avoids the damage to the hands compared with the pure manual assembly method.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

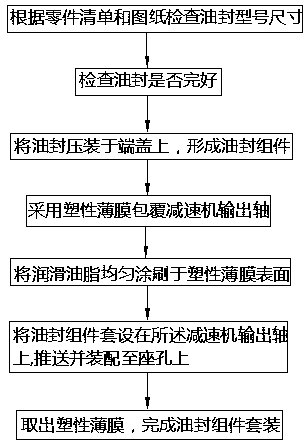

Speed reducer oil seal safety sleeving method

InactiveCN107618001AAvoid scratches and flangingReduce frictional resistanceMetal-working hand toolsReducerPetroleum engineering

The invention provides a speed reducer oil seal safety sleeving method which mainly comprises the following steps that oil seals are pressed to be fitted on an end cover by pressing covers, thus an oil seal assembly is formed; a speed reducer output shaft is coated with a plastic membrane; lubricating grease is uniformly brushed onto the surface of the plastic membrane; the oil seal assembly sleeves the speed reducer output shaft, and the oil seal assembly is pushed and assembled in a seat hole by forward and reverse rotation and / or front and back swinging; and the plastic membrane is taken out and the oil seal assembly sleeving is completed. According to the speed reducer oil seal safety sleeving method, lips of the oil seals can be prevented from being scratched and flanged, the oil seals can be assembled in place at one time successfully, the oil seal sleeving efficiency is improved, the requirement on the technical proficiency of a mounting worker is low, used oil seal sleeving fittings are simple, and the cost is low. The speed reducer oil seal safety sleeving method can be widely applied to the transmission industry for oil seal sleeving work in production and maintenance.

Owner:南京迪瓦机械制造有限公司

A pvc pipe chipless cutting machine

The invention discloses a scrap-free cutting machine for PVC (polyvinyl chloride) tubes. The scrap-free cutting machine comprises a frame. A driving motor, a clamping device and a cutting device are arranged on the frame. By the scrap-free cutting machine, costs of clamping blocks are saved, workload for frequent changing of the clamping blocks is reduced, physical health of workers is protected, and production quality of the tubes is improved.

Owner:GUANGDONG LIANSU MACHINERY MFG

Sheet bending and forming mould and method

The invention relates to sheet bending and forming mould and method. The forming mould comprises a die, a terrace die and an eccentric swage arranged between the die and the terrace die; the shape of the forming face of the terrace die is the shape of a bent finished workpiece; the die comprises a first sub die, a second sub die and a third sub die; the three sub dies are respectively matched with the eccentric swage and the terrace die to carry out three-time mould pressing on a sheet; the first sub die has a die orifice and comprises a first wrap angle part and a transition section transiting to the bottom of the first sub die from the first wrap angle part; the first wrap angle part limits the die orifice and corresponds to the convex corner edge of the finished workpiece in shape; thesecond sub die has an inner side wall corresponding to the side of the finished workpiece; and the third sub die comprises a second wrap angle part corresponding to the convex corner edge of the finished workpiece in shape and an inner side wall extending along the shape of the side of the finished workpiece form the second wrap angle part. The sheet bending and forming mould and the forming method can reduce wrinkling during sheet bending and improve the sheet forming yield.

Owner:BYD CO LTD

Valve device

InactiveCN106855150AAvoid flangingImprove sealingSpindle sealingsValve housingsReciprocating motionFlanging

The invention provides a valve device which comprises a cylindrical valve body, a valve base and a valve rod. A channel for enabling a refrigerant to be circulated is arranged inside the valve body. The valve base is arranged at the lower end of the valve body and provided with a valve port. The valve rod is arranged inside the valve rod and makes contact with or is separated from the valve port of the valve base through reciprocating motion, and therefore the channel of the valve body is opened or closed. The valve device is characterized in that an installation portion is arranged on the inner wall of the valve body, and a sealing portion is arranged inside the installation portion; the valve rod is installed inside the valve body from the end where the valve base is located; when the valve rod moves upwards to the limit, the valve rod and the valve body are in rigidity seal contact. According to the valve device, the problem that flanging is generated on a sealing component can be effectively avoided, and the sealing performance is improved; meanwhile, the sealing component is installed in the follow-up process, and the influence caused by heat generated when the valve base is welded on the sealing component can be effectively avoided.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

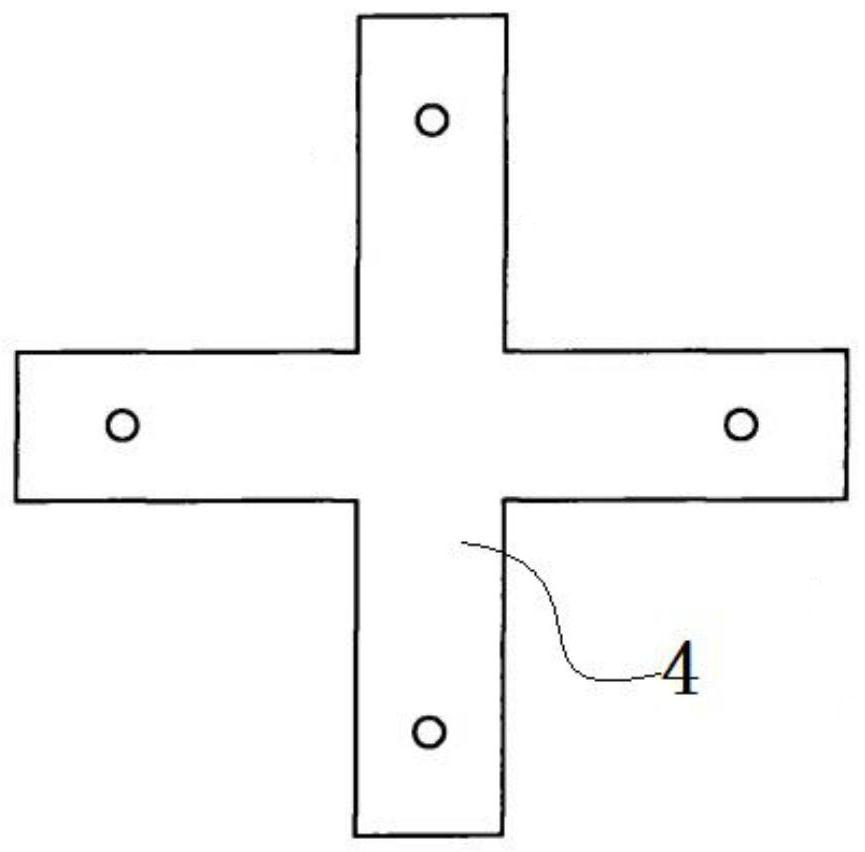

Piston press fitting method

PendingCN113843601AAvoid warping damageGood working performanceMetal working apparatusPhysicsMachine press

The invention discloses a piston press fitting method. The method comprises the following steps that (1) a pressure platform is installed below a pressing rod of a press machine; (2) a piston cylinder body is placed on the pressure platform; (3) lubricating oil is smeared on the lip of a piston and the inner wall of the piston cylinder body, and the piston is horizontally placed on the piston cylinder body; 4) the lower end of the pressing rod is fixedly connected with the center of the upper surface of a cross-shaped pressing plate; (5) the press machine is started, the pressure value and the rotating speed of the pressing rod are adjusted to preset values, the pressing rod drives the cross-shaped pressing plate to descend and rotate at a constant speed, and the cross-shaped pressing plate makes contact with the piston and conducts press fitting on the piston; (6) after the lip of the piston enters a guide groove of the piston cylinder body, the rotating function of the pressing rod is closed, and the piston continues to be pressed; and (7) after the piston is in place, pressure application is stopped. By means of the method, it can be guaranteed that when the lip of the piston enters the cylinder body, the piston rotates and is pressed at the same time, and warping damage, lip flanging and extrusion strain of the piston in the assembling process are avoided.

Owner:CHONGQING BEIBEN TRANSMISSION MFG

Novel medical physiotherapeutic band and production process thereof

ActiveCN103099707BRelax or strengthenPromote circulationAdhesive dressingsTissue fluidAcrylic adhesive

The invention discloses a novel medical physiotherapeutic band and production process of the novel medical physiotherapeutic band. The medical physiotherapeutic band comprises a piece of elastic cloth, a piece of isolating paper, and a medical acrylic adhesive layer which bonds the elastic cloth and the isolating paper together, wherein wavy glue vacant sites are evenly distributed on the medical acrylic adhesive layer, and linear glue vacant sites are further evenly distributed on the medical acrylic adhesive layer. According to the novel medical physiotherapeutic band, a plurality of linear vacant sites are formed in a wavy continuous glue face, so that straight-bar shaped space forms when tissue fluid is guided from A site to B site, and the flow of the tissue fluid can never be blocked and can smoothly leads to lymphatic tissues. The novel medical physiotherapeutic band has the advantages of being good in flow-guiding performance, not prone to causing allergy, good in improving blood circulation, good in guiding meridians, capable of building unimpeded subcutaneous channels, and good in adhesiveness.

Owner:CHANGZHOU HAOAN BIOLOGICAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com