Method for eliminating single-side wave defects of oriented silicon steel

A technology of oriented silicon steel and unilateral wave, which is applied in the field of eliminating unilateral wave defects of oriented silicon steel, can solve the problems of reducing atmosphere damage, loss of feasibility, blocked drainage, etc., and achieve increased yield, reduced deformation force, and improved plate shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to make the objectives, technical solutions and advantages of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It will be appreciated that the specific embodiments described herein are intended to explain the present invention and is not intended to limit the invention.

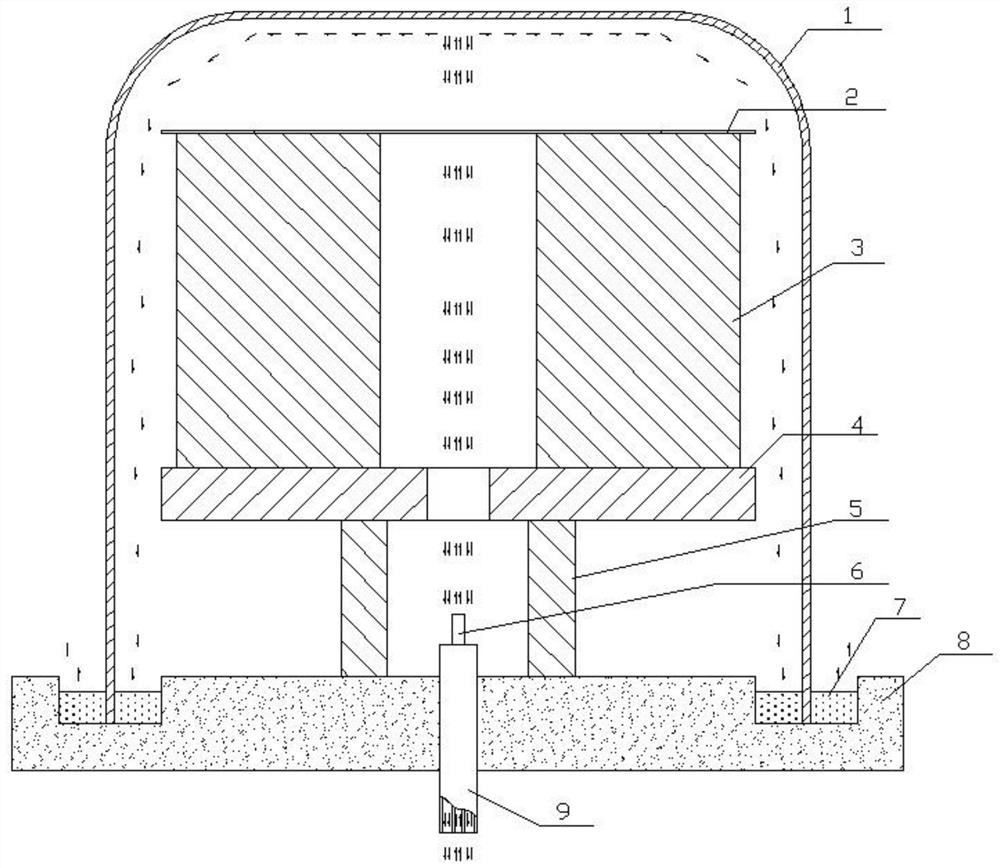

[0031]SeeFigure 1 - Figure 3The arrows in the figure represent the direction of protective gas flow. A method of eliminating the monopolywide wave defects of the orientation silicon steel, including the steps of:

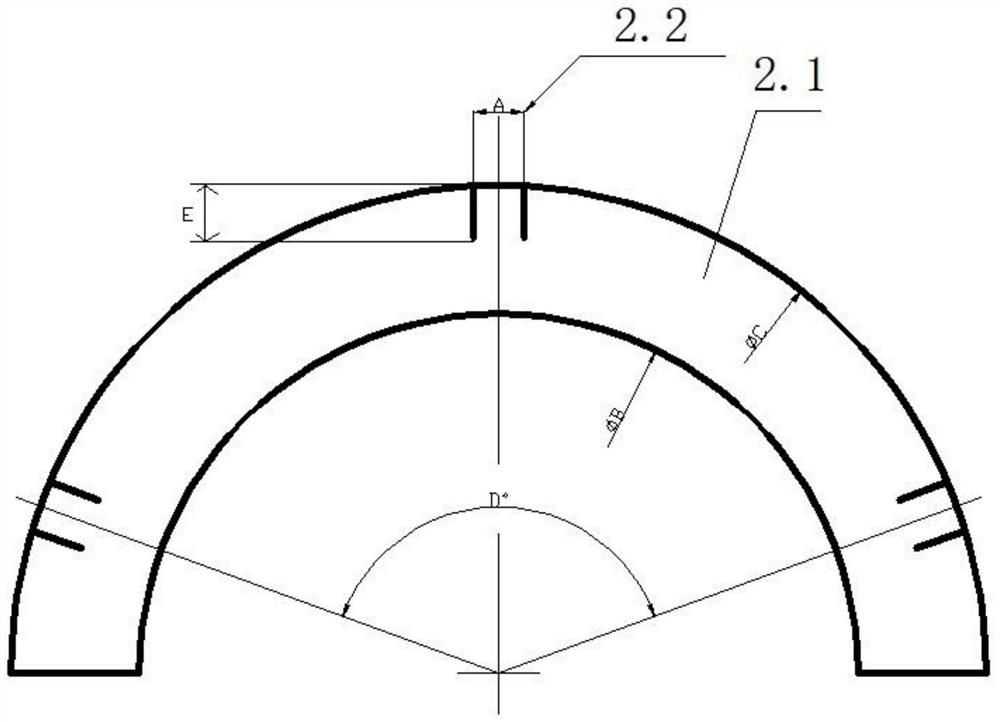

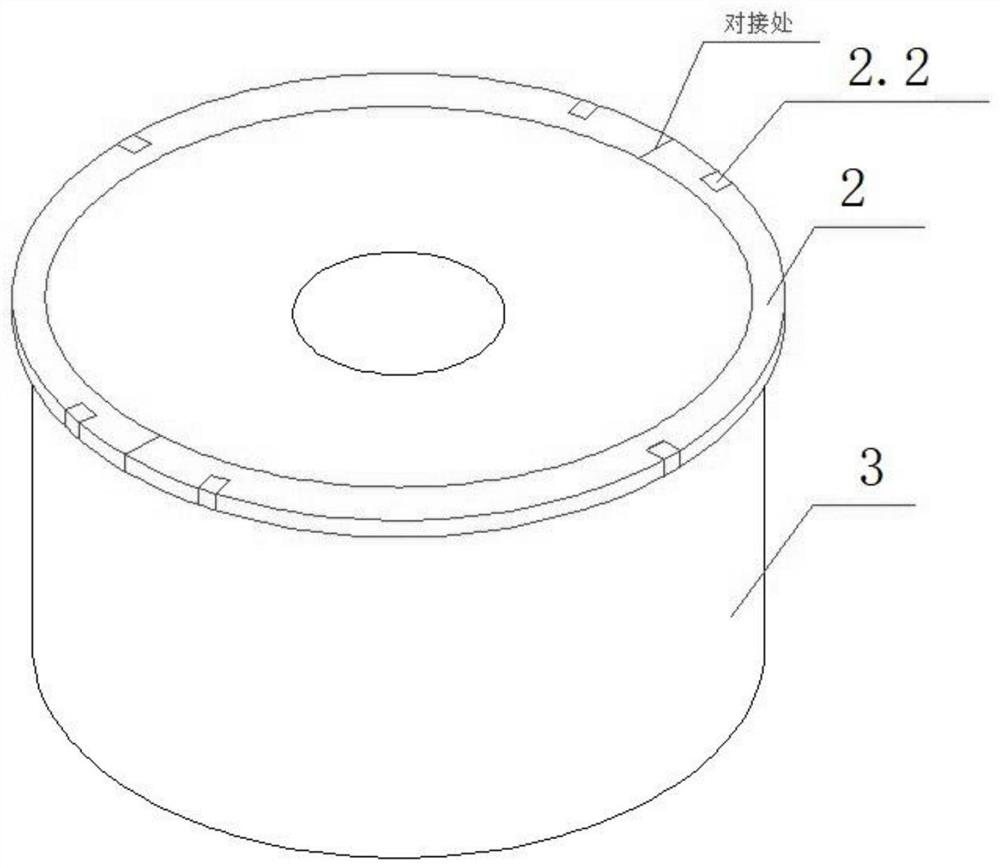

[0032]1), according to the drawing requirements, a special cover is made; the special cover plate includes an annular plate composed of two semi-ring plates, and there is no significant slit between the two half-ring plates; each of the outer edges of each semi-ring plate There are three shears, which are set at both ends and intermediate positions, respectively;

[0033]2) Communicate the oriented silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com