Patents

Literature

47results about How to "Reduction tool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

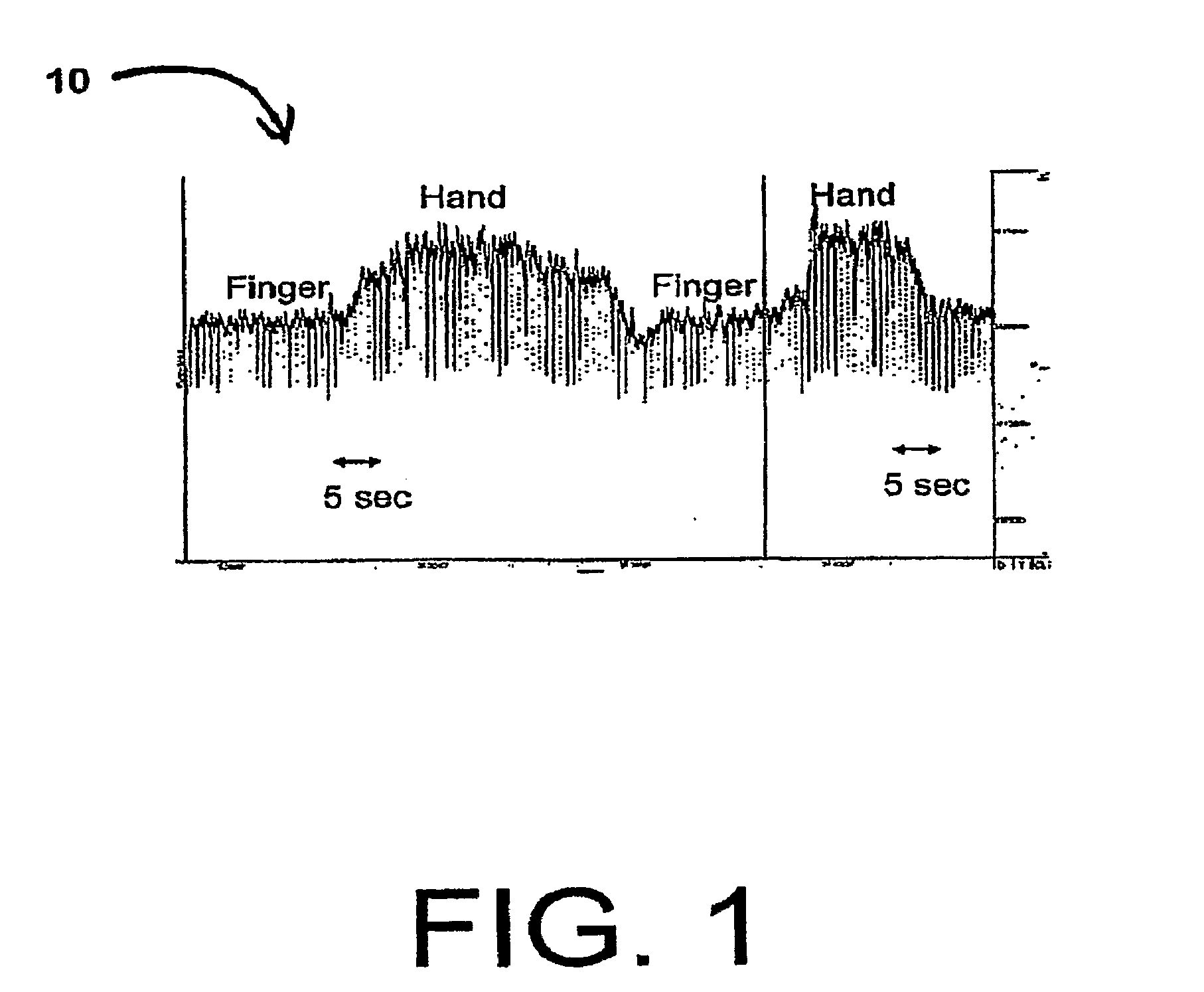

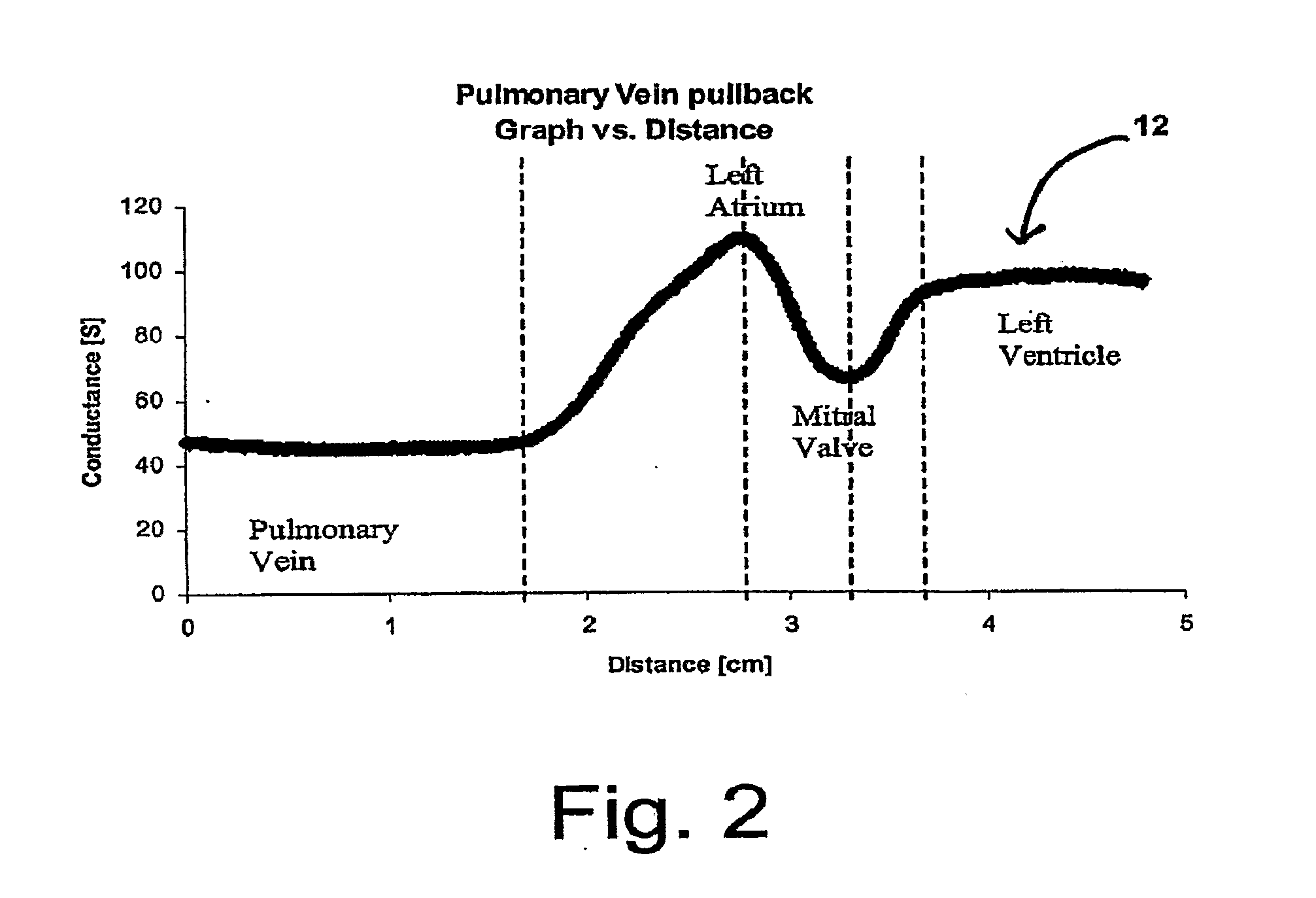

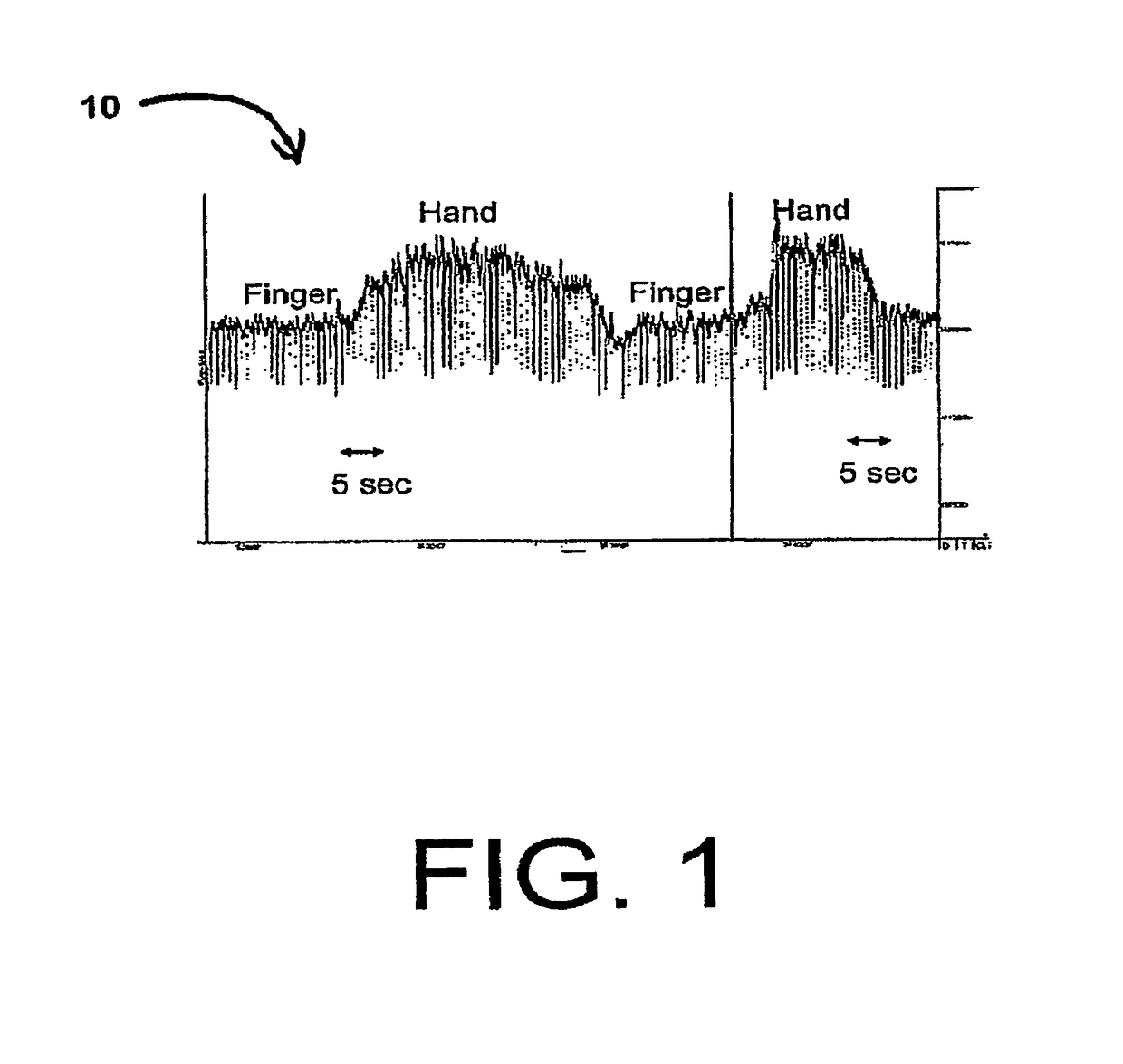

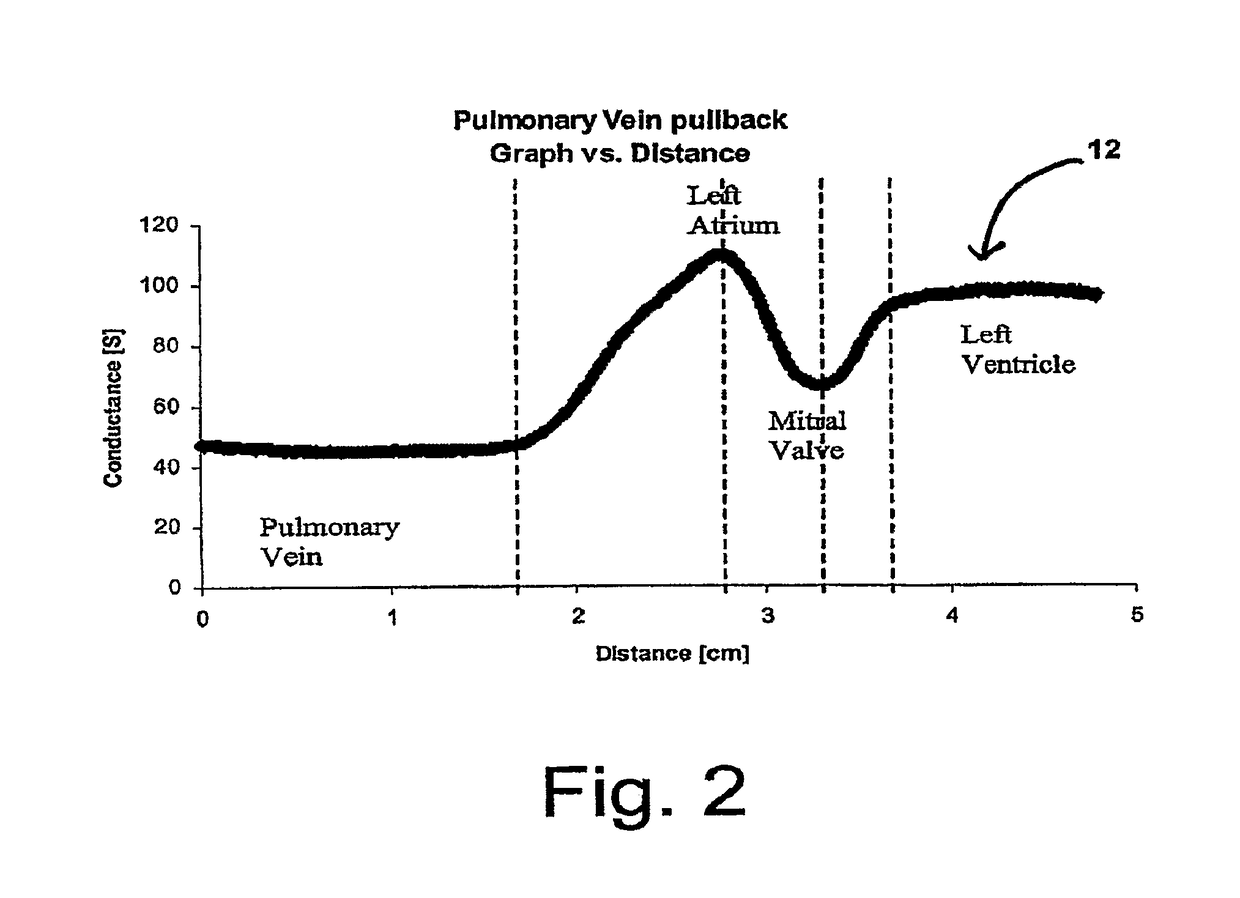

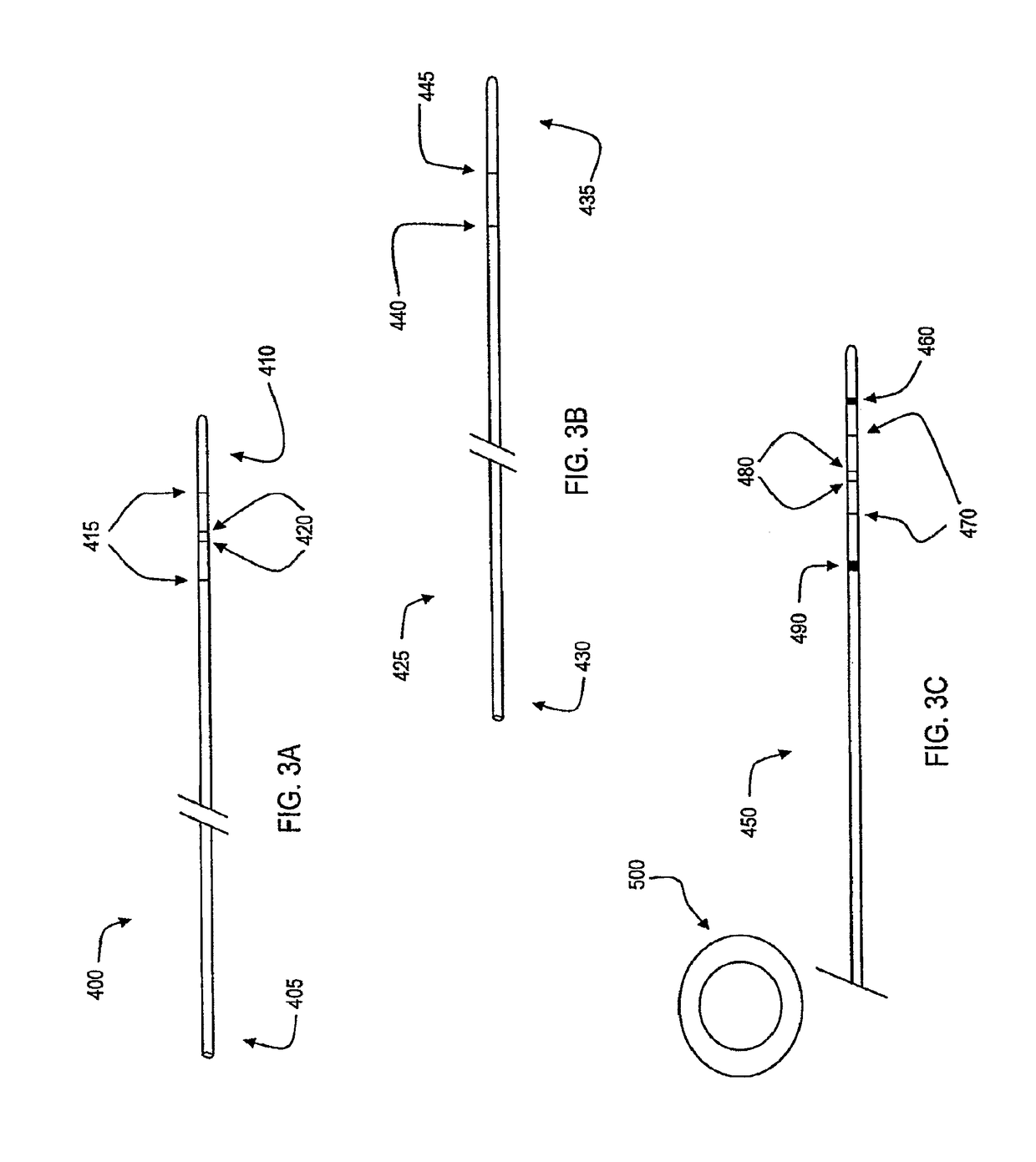

Localization of body lumen junctions

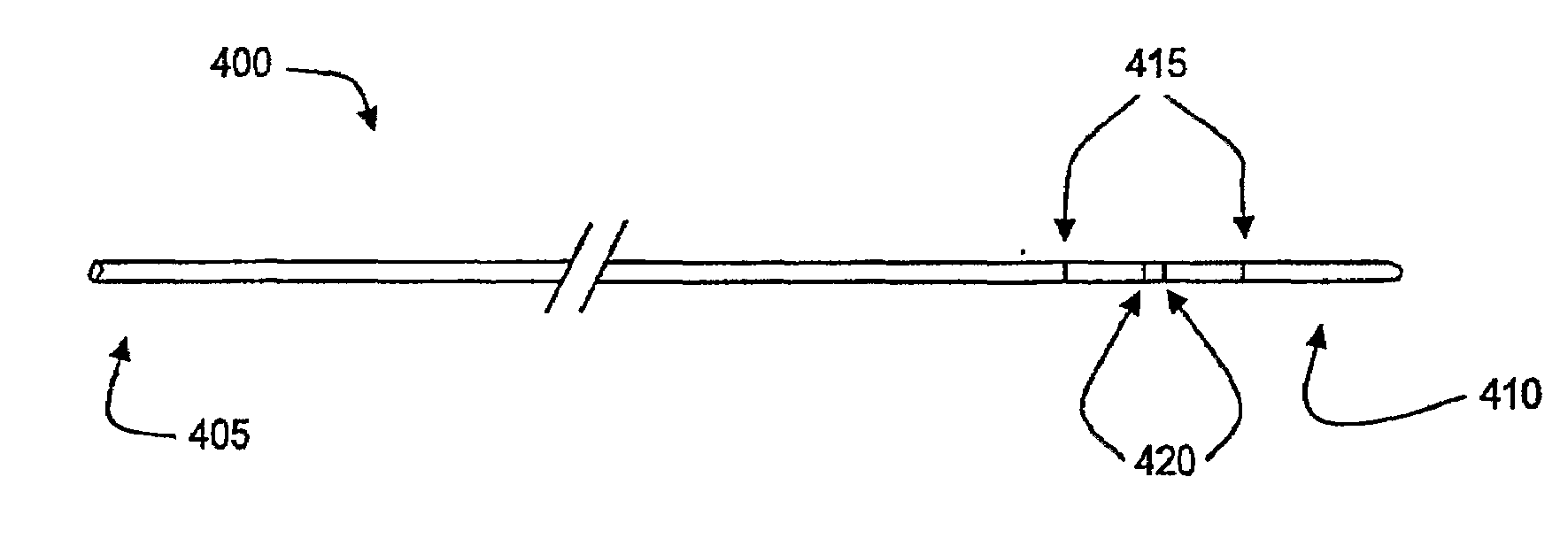

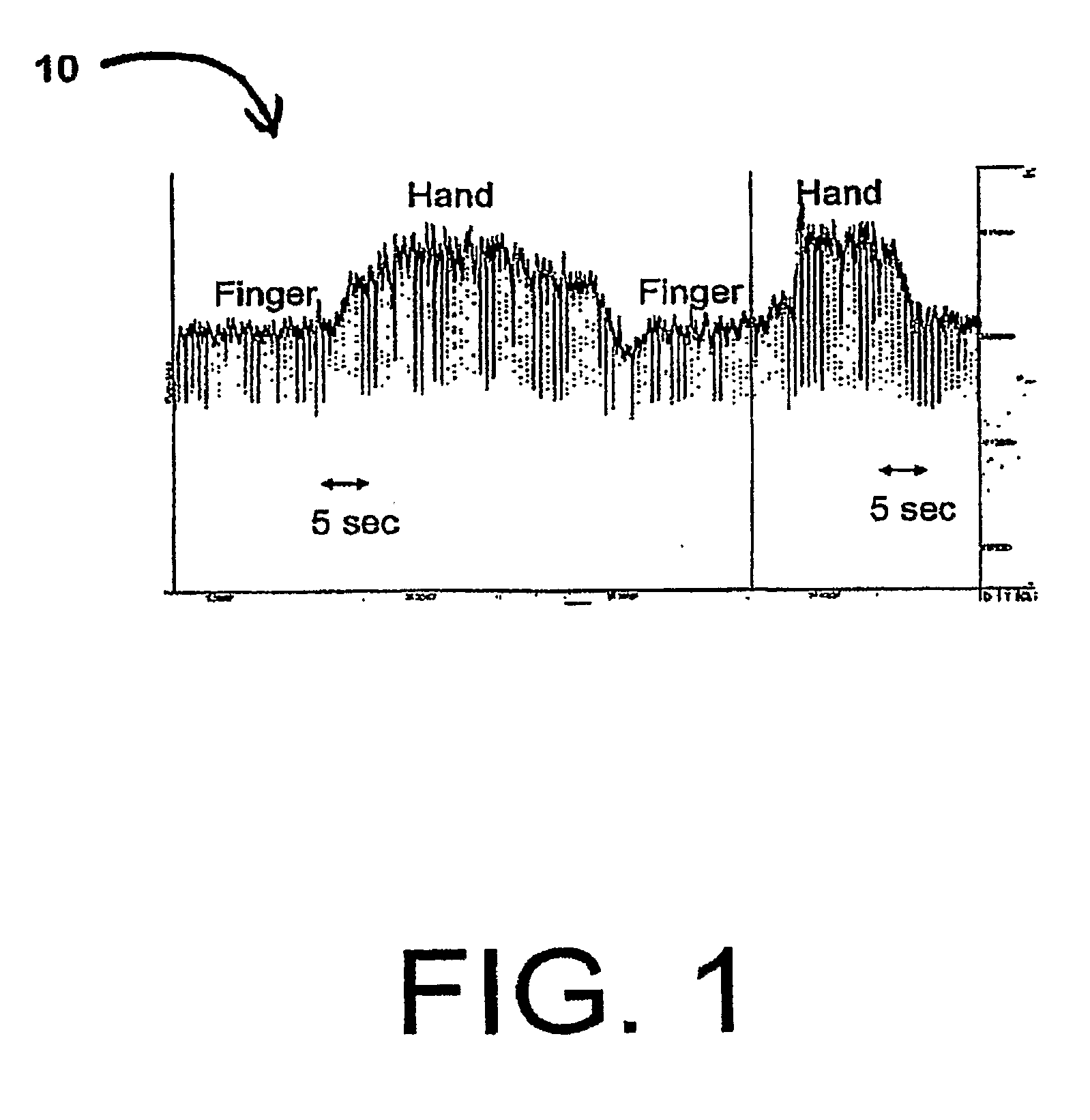

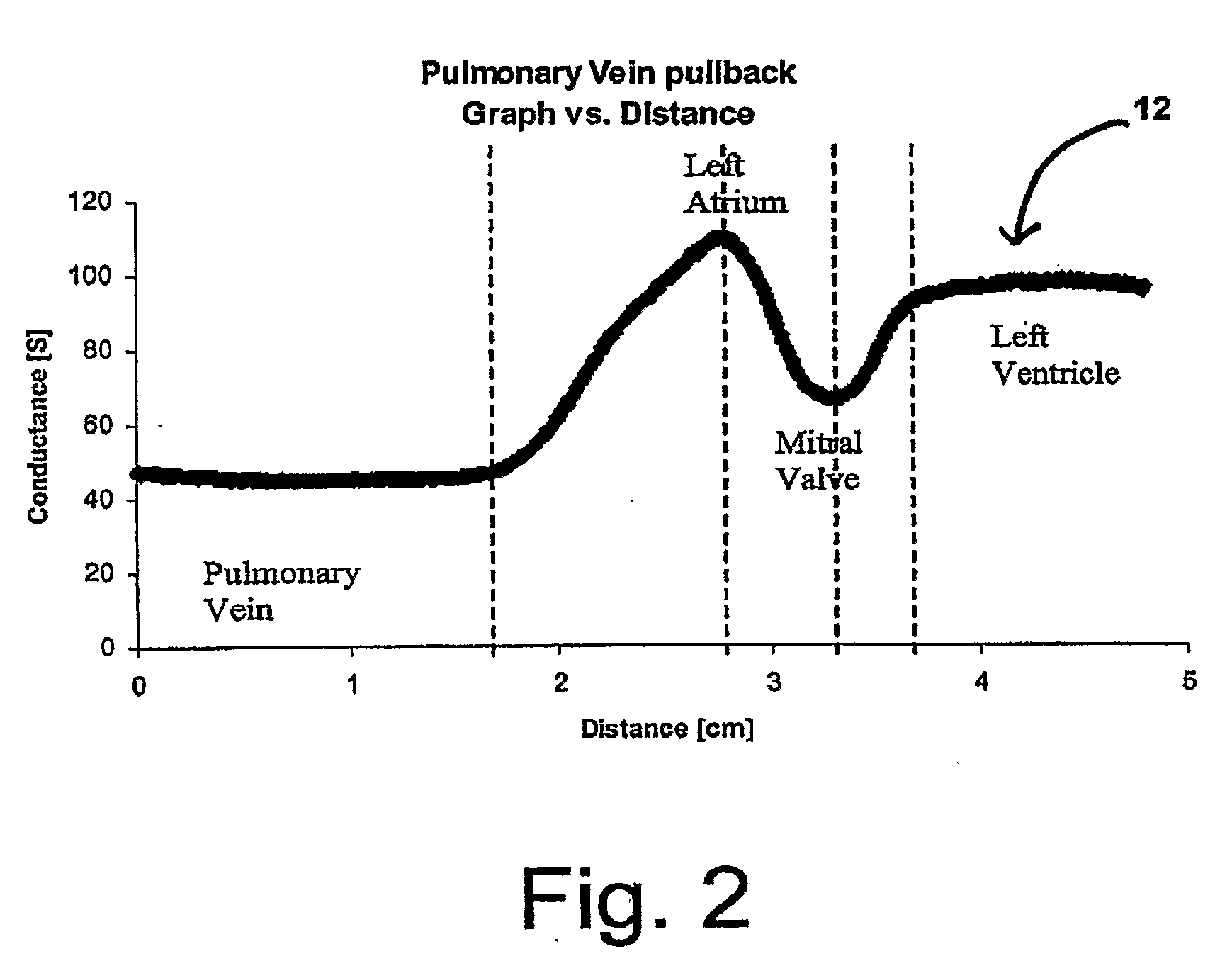

ActiveUS20090182287A1Improve spatial resolutionLower requirementElectrocardiographyCatheterBiomedical engineeringCardiac Ablation

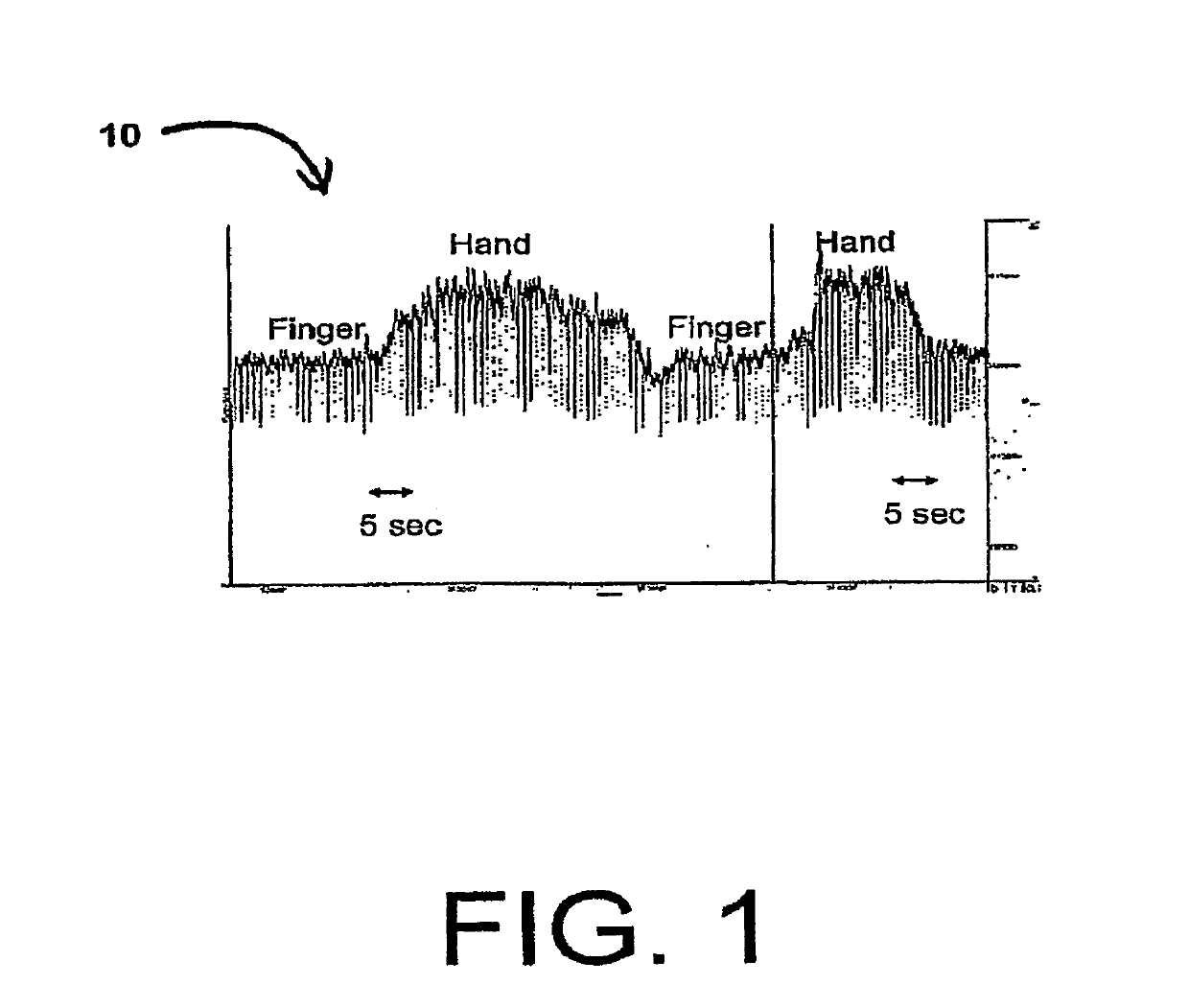

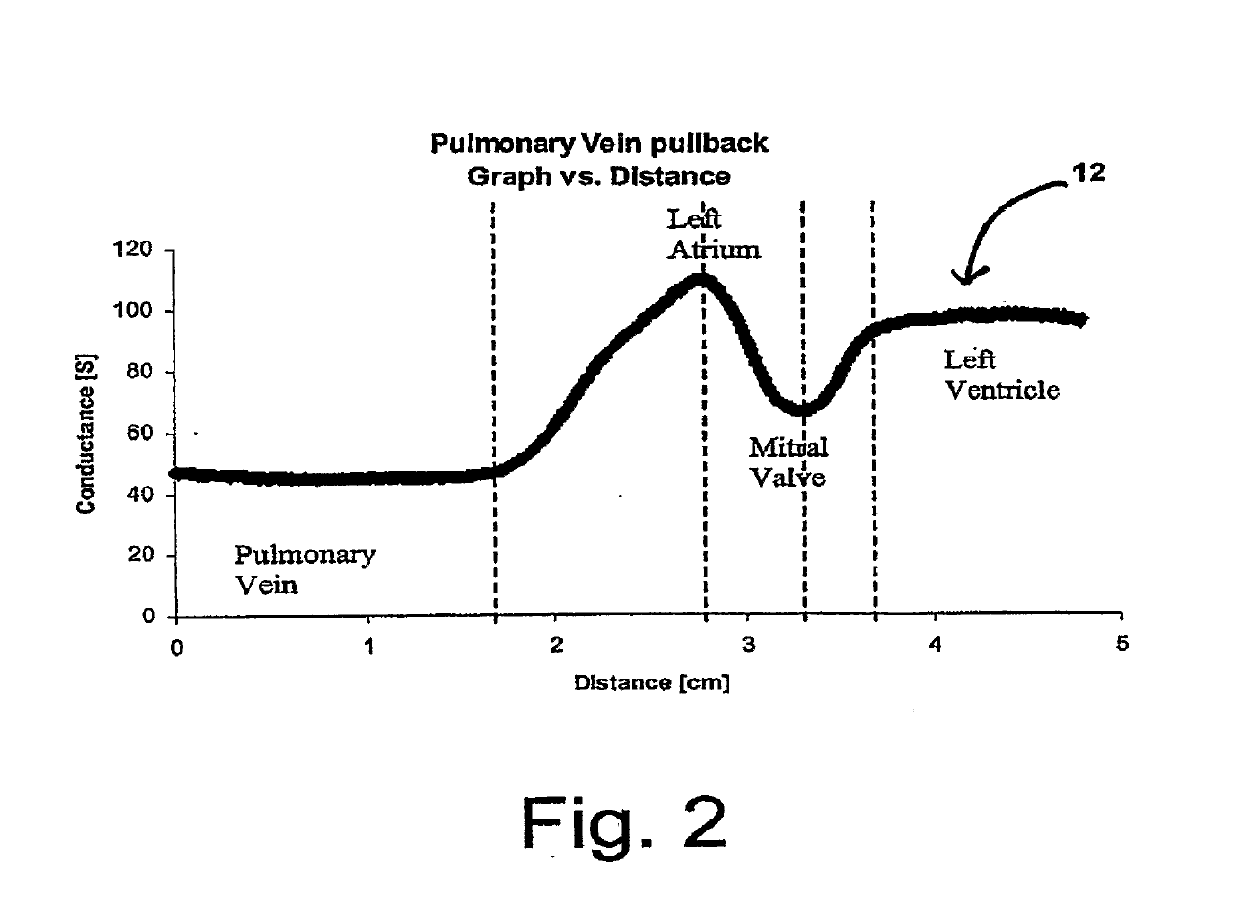

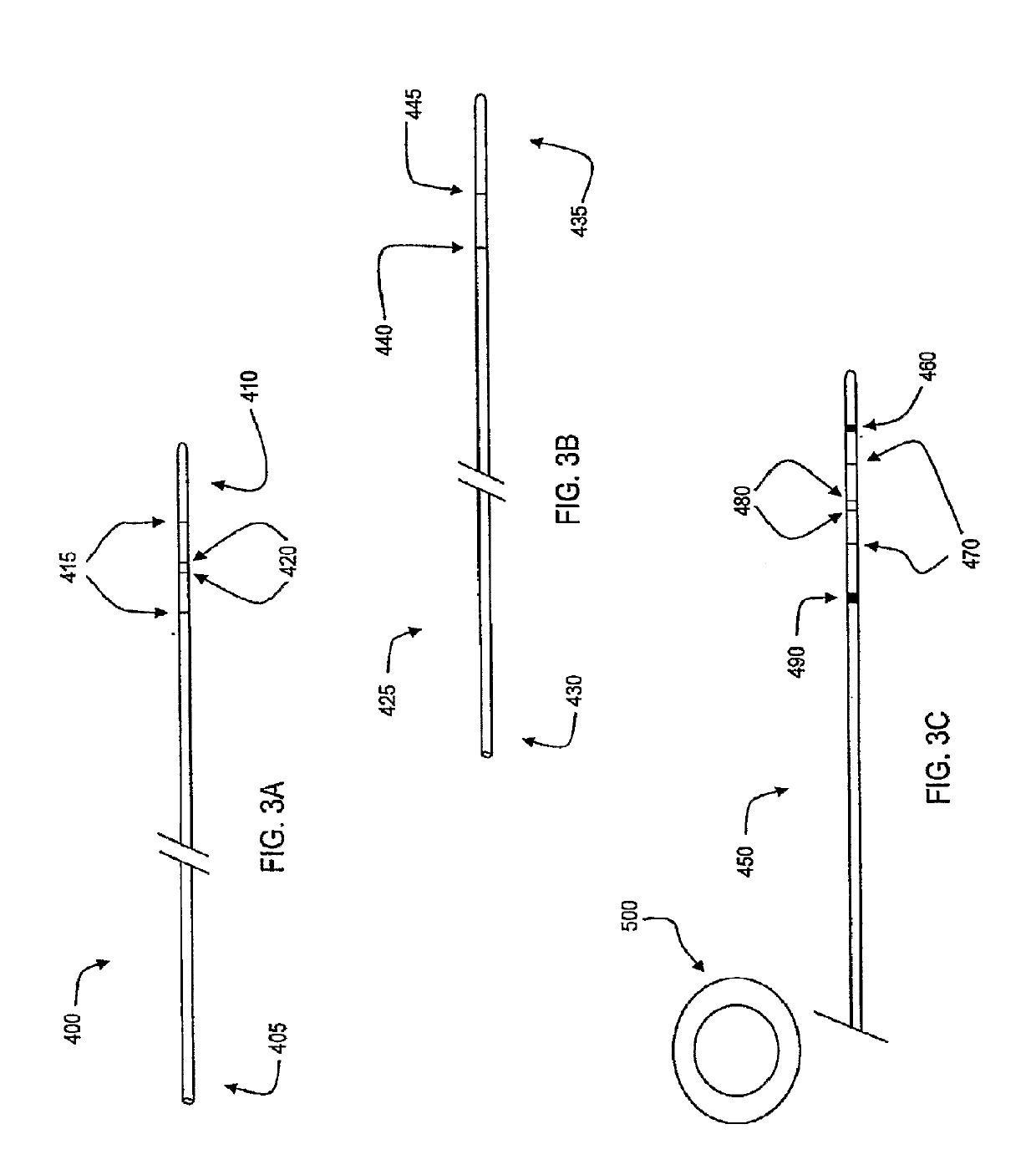

Devices, systems, and methods for the localization of body lumen junctions and other intraluminal structure are disclosed. Various embodiments permit clinicians to identify the locations of intraluminal structures and medical devices during non-surgical medical techniques, such as cardiac ablation, by determining the intralumen conductance and / or cross-sectional area at a plurality of locations within the body lumen.

Owner:3DT HLDG

Body lumen junction localization

ActiveUS20130338530A1Improve spatial resolutionLower requirementSurgical instrument detailsCatheterRadiologyCardiac Ablation

Devices, systems, and methods for the localization of body lumen junctions and other intraluminal structure are disclosed. Various embodiments permit clinicians to identify the locations of intraluminal structures and medical devices during non-surgical medical techniques, such as cardiac ablation, by determining the intralumen conductance and / or cross-sectional area at a plurality of locations within the body lumen

Owner:3DT HLDG

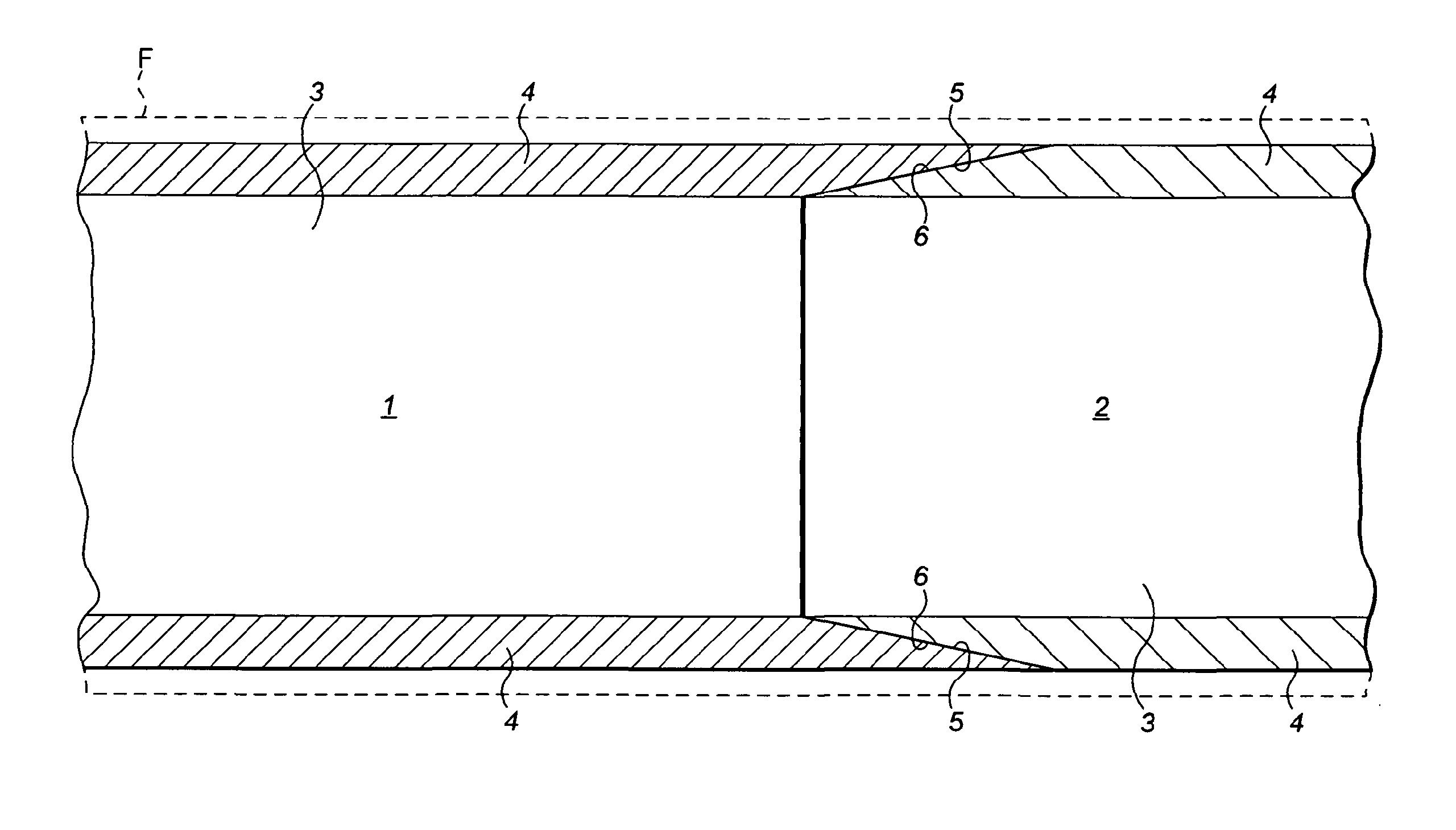

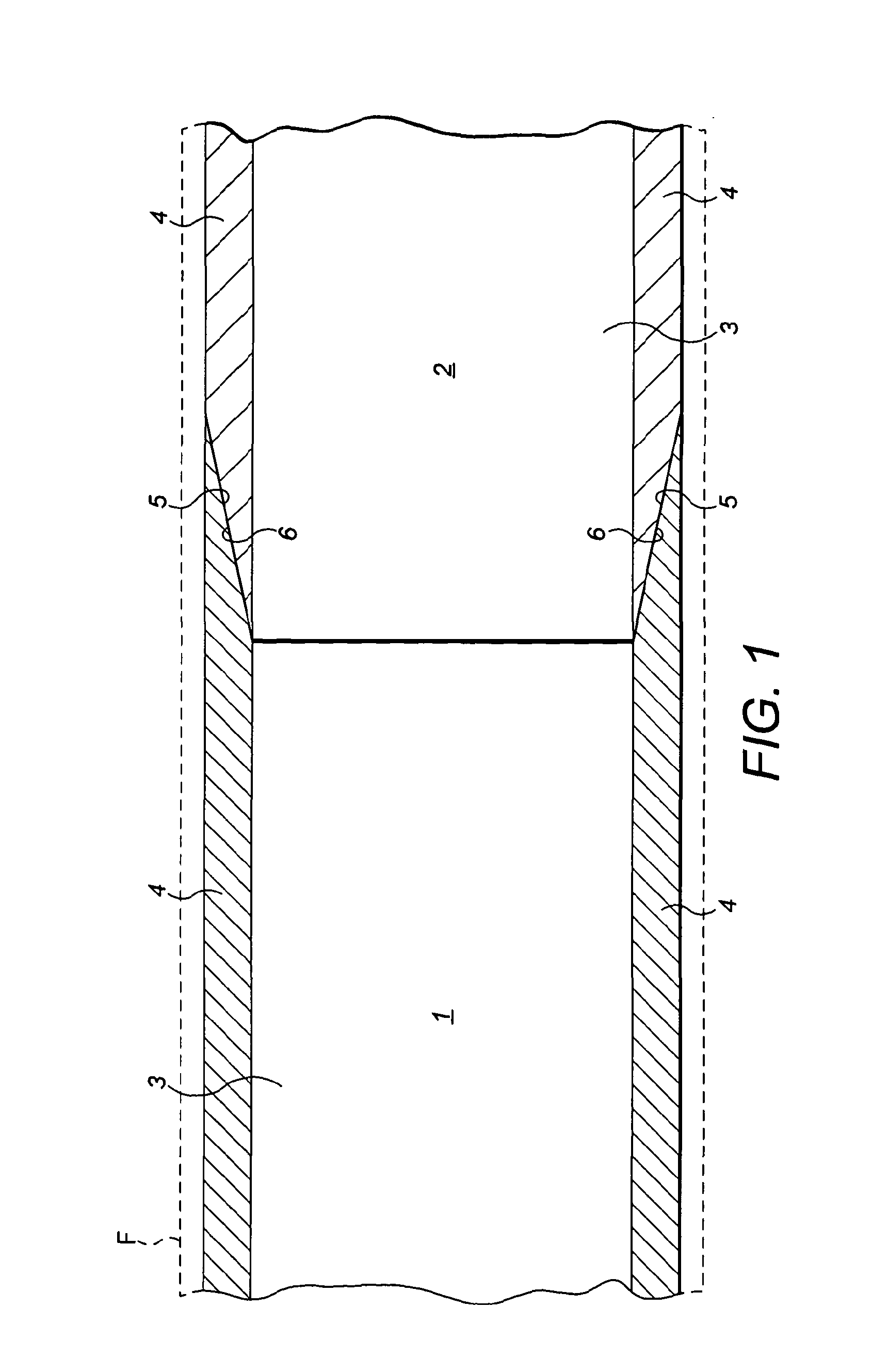

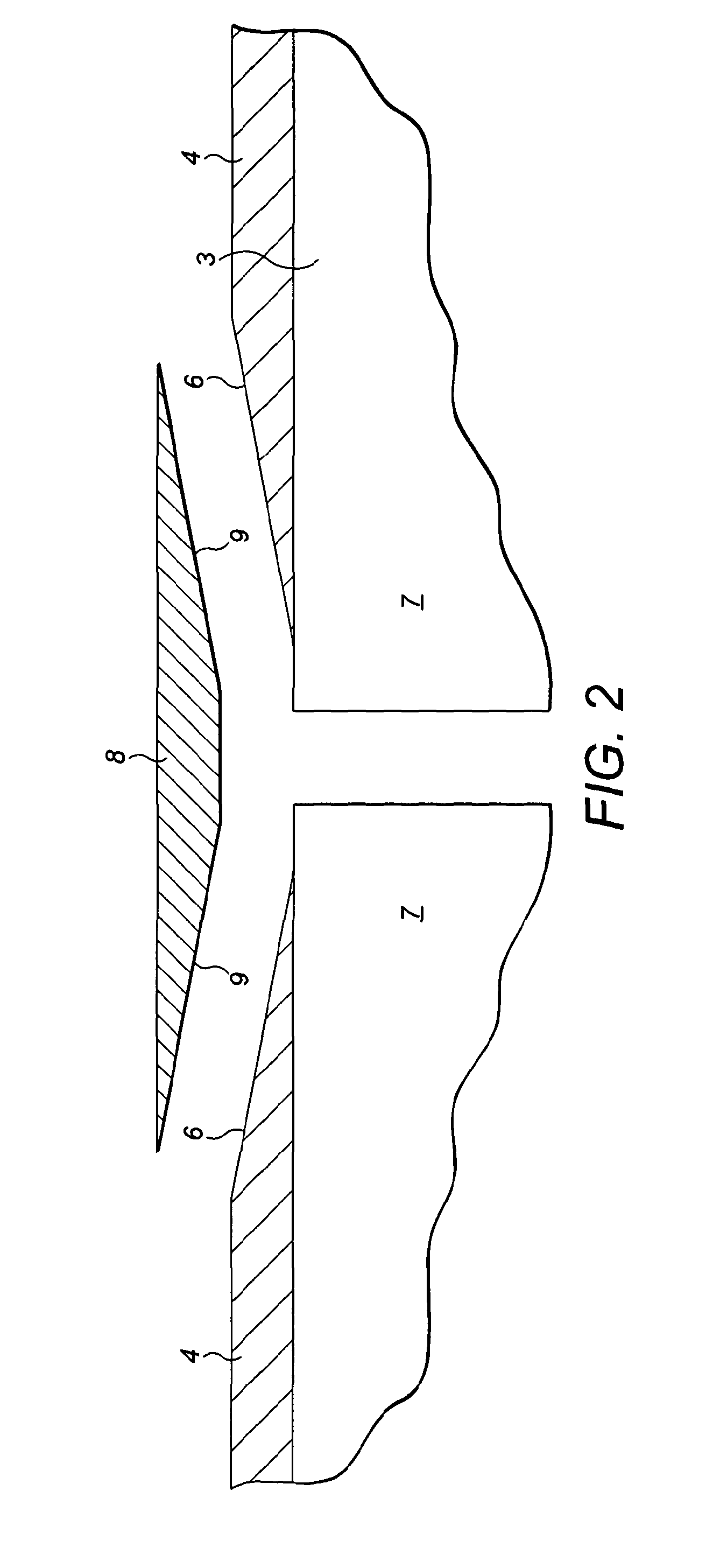

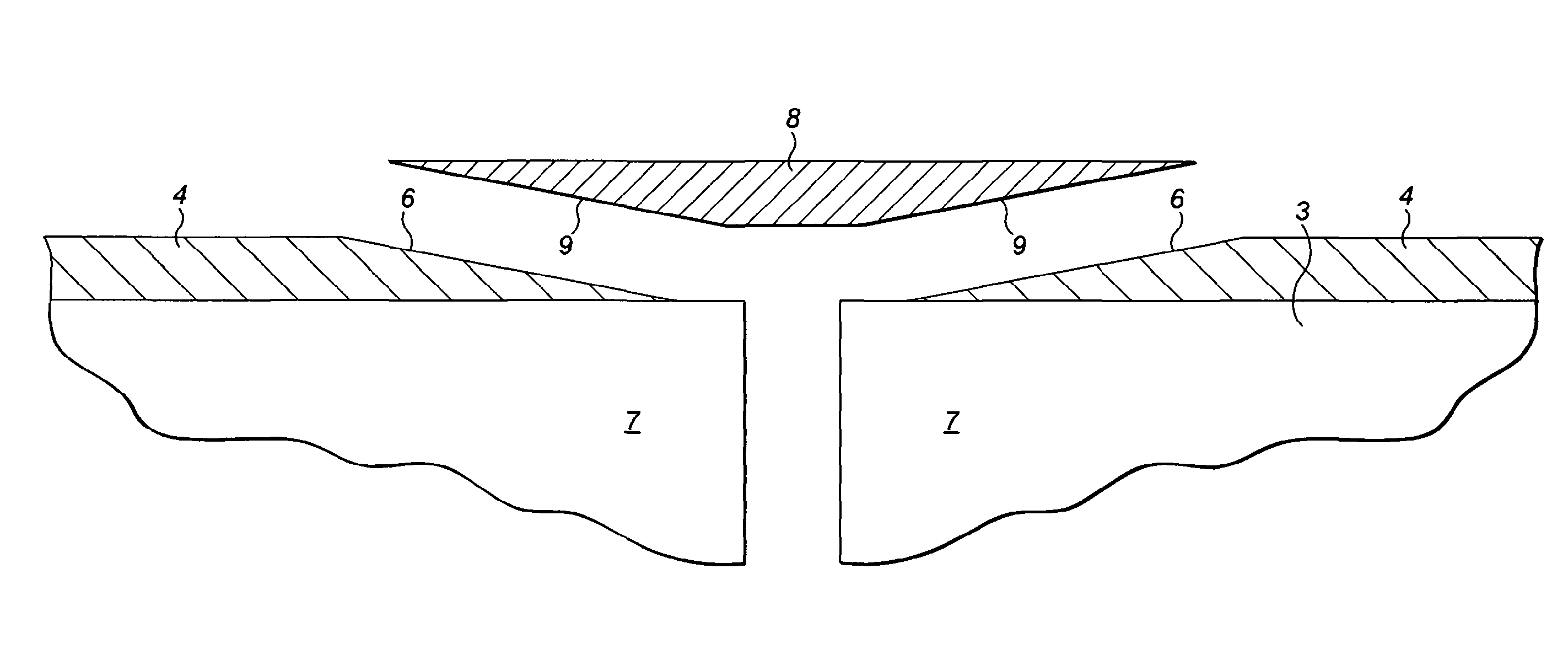

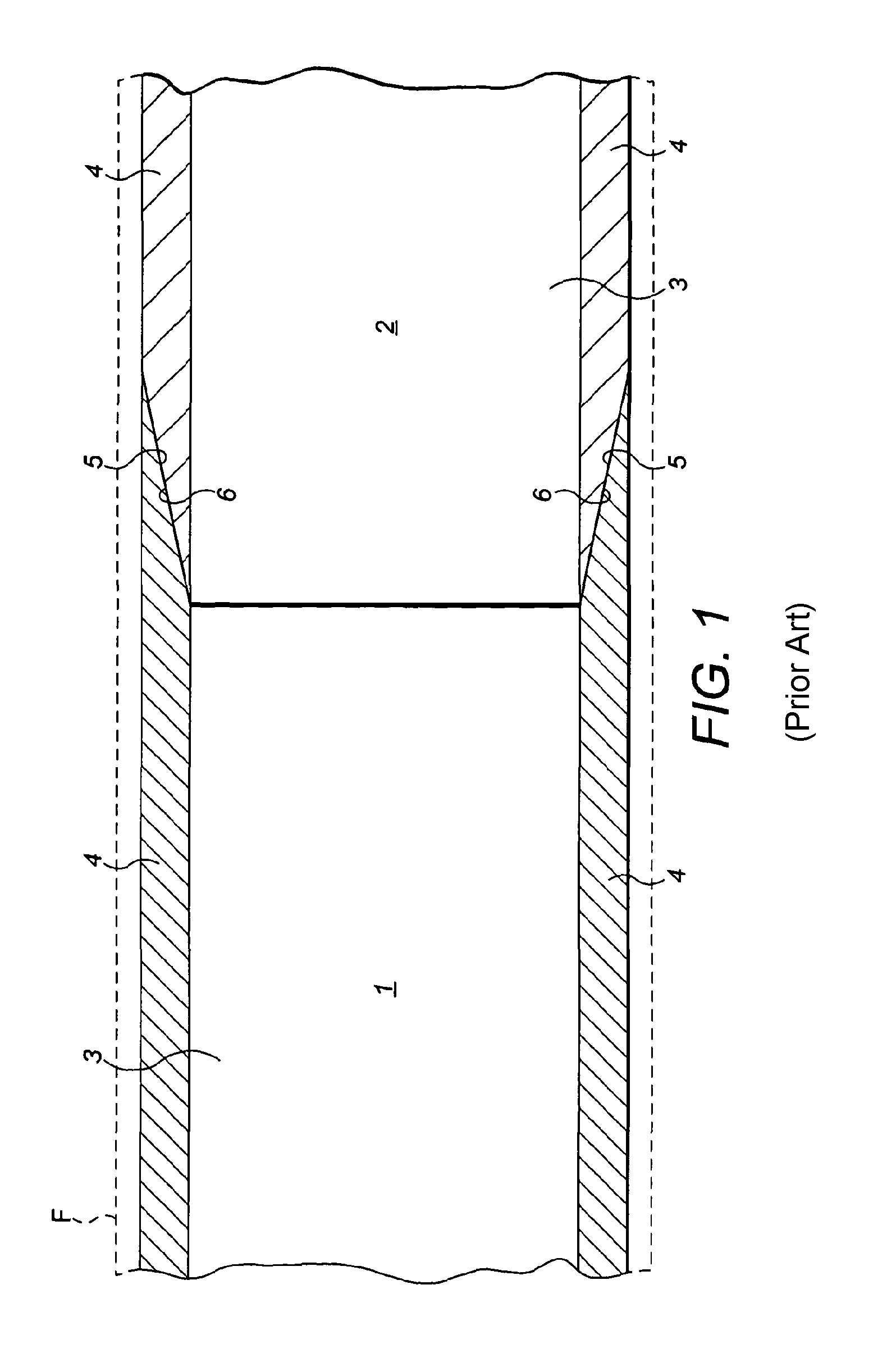

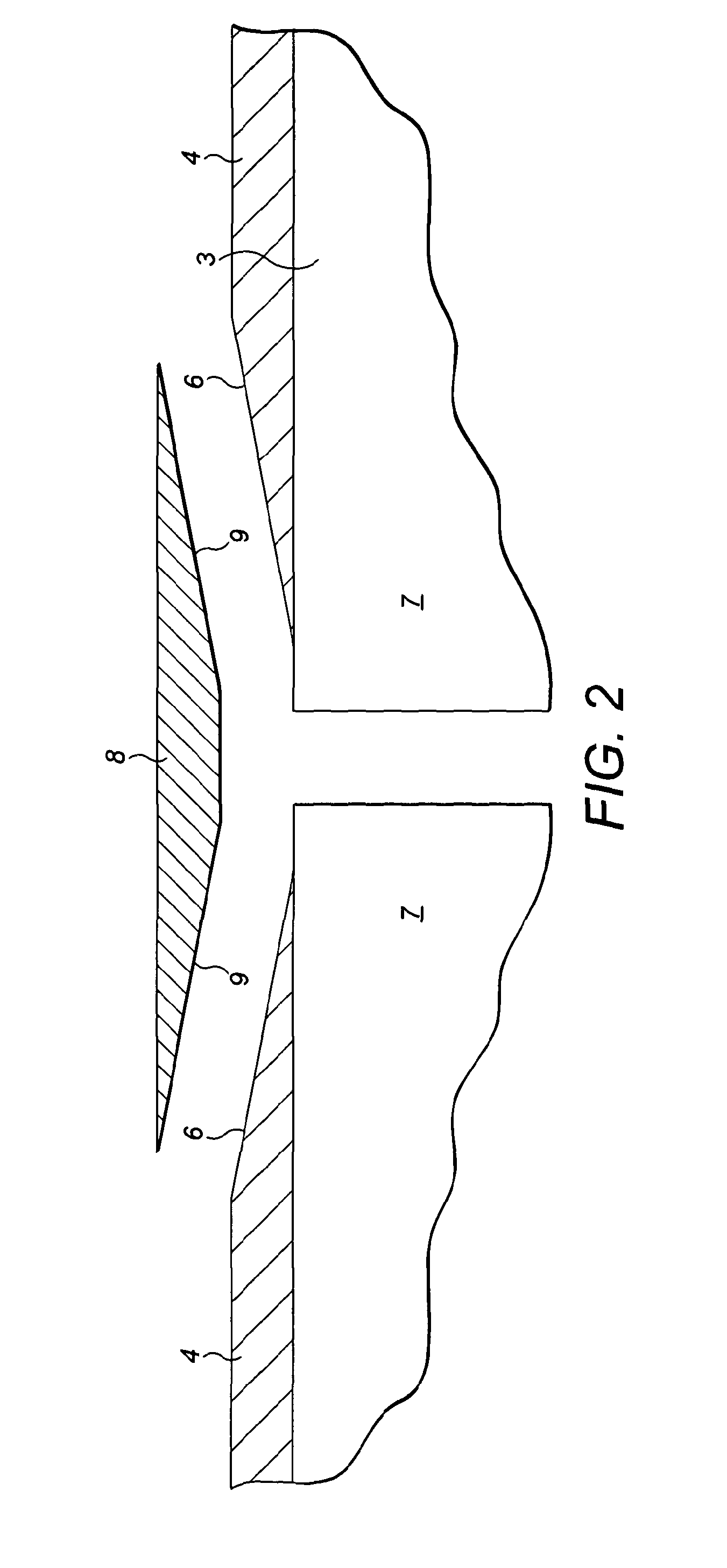

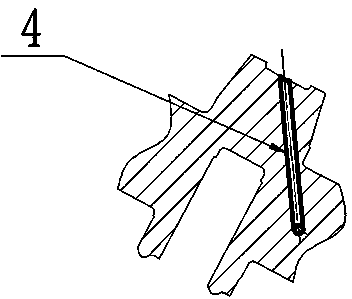

Wind turbine blade

ActiveUS20130129518A1Simplify constructionQuality of laminate be highReaction enginesEngine componentsWind forceTurbine blade

A wind turbine blade comprising an aerodynamic fairing supported along at least a portion of its axial length by a spar (12). The spar comprises at least two spar segments (12) joined end-to-end at an interface (9), each spar segment comprising a shear web (3) with a spar cap (4) on each side. The outer face (6) of each spar cap tapers inwardly towards the interface such that its depth is reduced towards the interface creating a recess on each side of the interface formed by the tapered faces of adjacent spar caps. A respective connection piece (8) is sized to fit into each recess. Each connection piece (8) is sized to fit into each recess. Each connection piece (8) being fixed to the tapered faces of adjacent spar caps to form a double scarf joint.

Owner:BLADE DYNAMICS LTD

Hybrid composite product and system

InactiveUS20050255311A1Quality improvementLow costLaminationLamination apparatusCompression moldingFiber

A hybrid composite product and system are provided. In another aspect of the present invention, a structure is molded onto a composite substrate. Multiple layers of fiber, prepreg sheets are employed with an internal air channeling sheet to create a composite or laminate product for another aspect of the present invention. A further aspect of the present invention uses compression molding to form composite parts made from prepreg sheets and injection molding to create a permanently attached member.

Owner:EE ESU SHII

Wind turbine blade

ActiveUS8764401B2Simplifies assembly process and reliabilityEasy to handlePropellersPump componentsScarf jointTurbine blade

A wind turbine blade comprising an aerodynamic fairing supported along at least a portion of its axial length by a spar (12). The spar comprises at least two spar segments (12) joined end-to-end at an interface (9), each spar segment comprising a shear web (3) with a spar cap (4) on each side. The outer face (6) of each spar cap tapers inwardly towards the interface such that its depth is reduced towards the interface creating a recess on each side of the interface formed by the tapered faces of adjacent spar caps. A respective connection piece (8) is sized to fit into each recess. Each connection piece (8) is sized to fit into each recess. Each connection piece (8) being fixed to the tapered faces of adjacent spar caps to form a double scarf joint.

Owner:BLADE DYNAMICS LTD

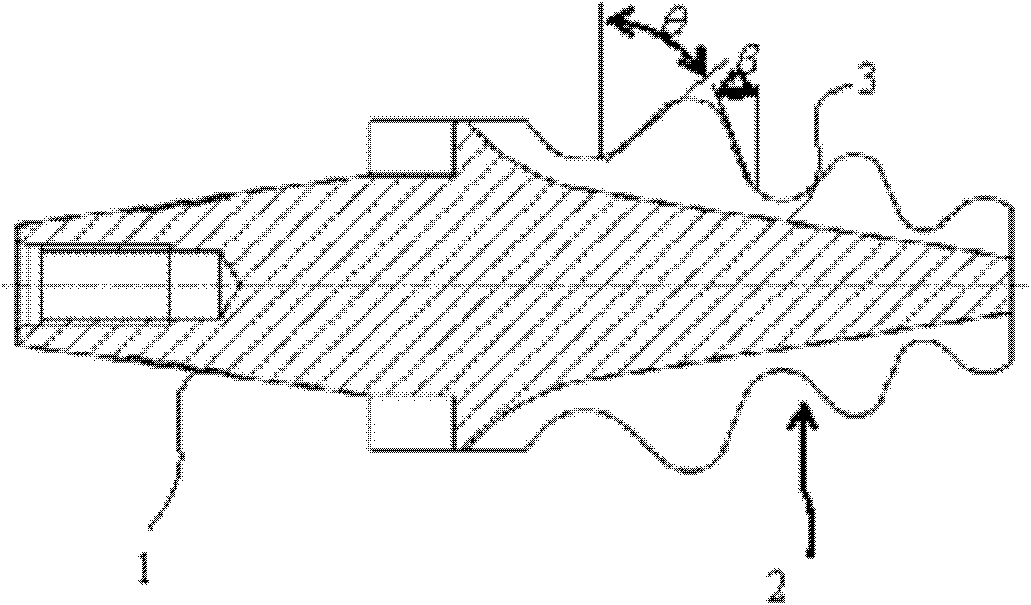

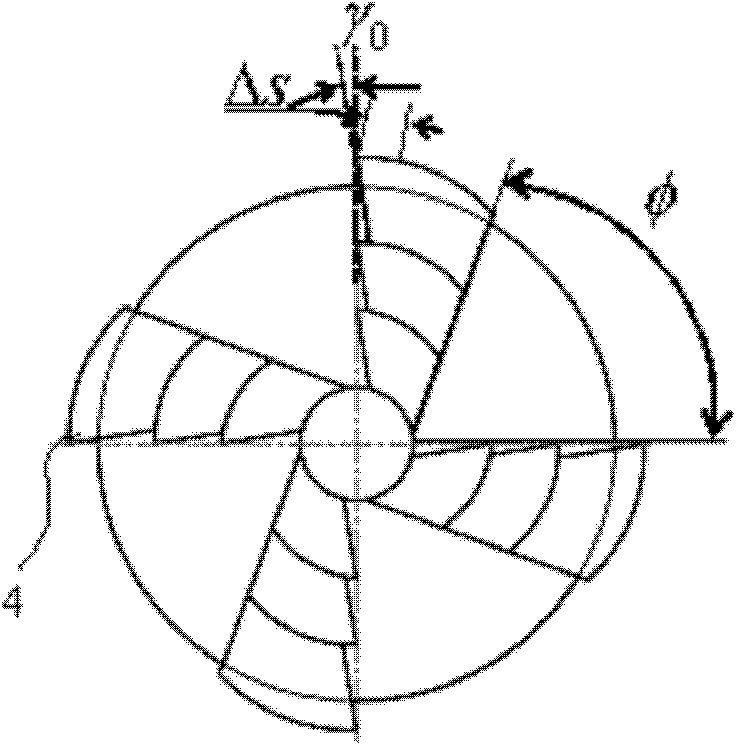

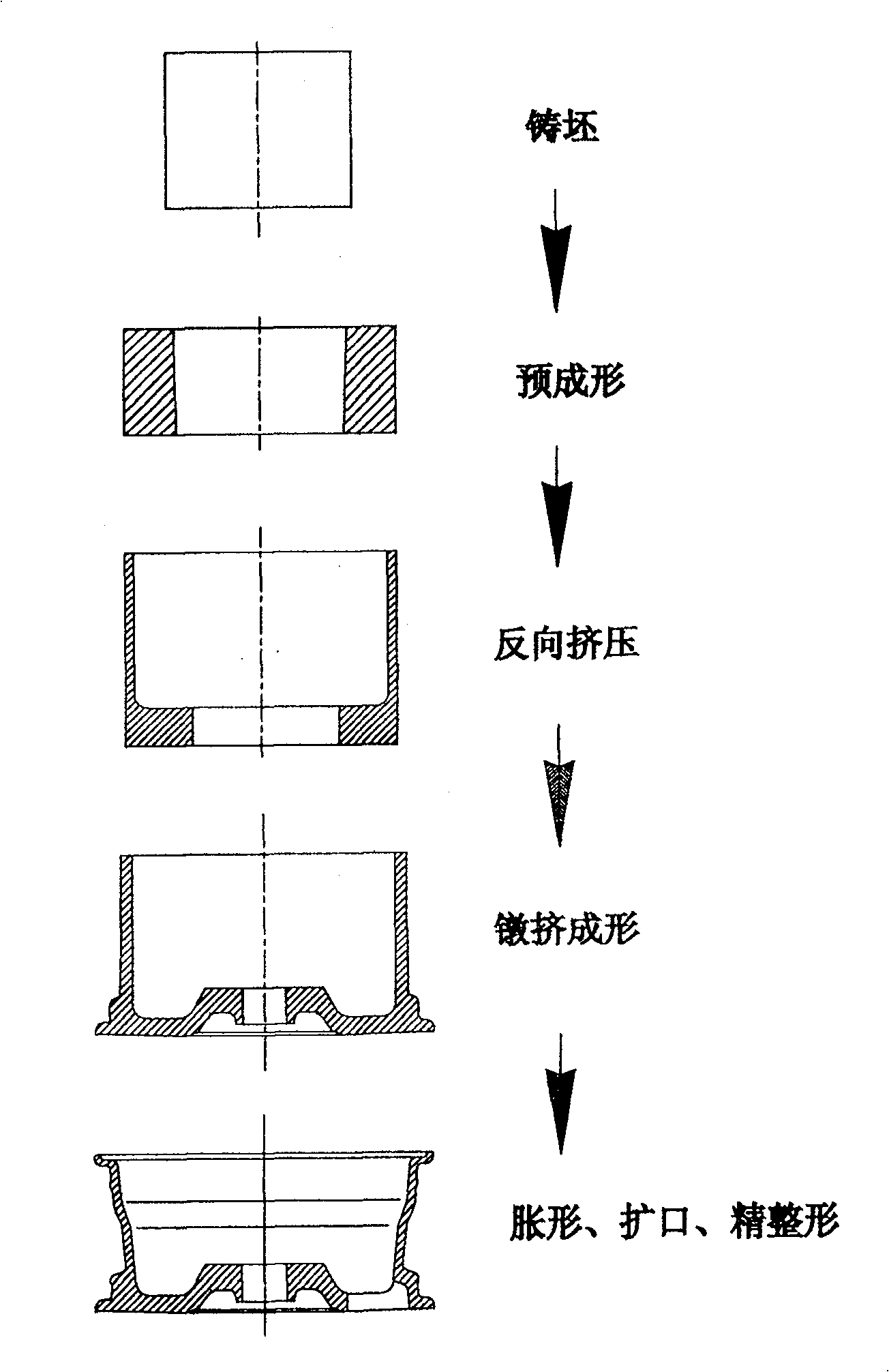

Integral extrusion forming method for asymmetrical assembly parts and apparatus thereof

The invention relates to an integrated compress molding method of asymmetry integrated element. It uses concave and convex moulds, to heat, compress and mold the blank. It is characterized in that: according to the position and size of cam on the element, designing the blank with non-uniform thickness; the blank is arranged in the concave mould with a deflection as S; the thicker part of blank or the deflected part is arranged with the edge that needs more metal (the edge with cam); it controls the metal flux and flow direction, via said non-uniform thickness or the deflection amount S, to fill the mould chamber with metal to mold the element. The inventive mould is integrated, with stable operated and simplified process. The element can be compressed molded in one time, to reduce the producing cost; the product has high size and surface accuracy, and high material utilization.

Owner:ZHONGBEI UNIV

Body lumen junction localization

ActiveUS10172538B2Improve spatial resolutionReduction toolCatheterDiagnostic recording/measuringCardiac AblationMedical device

Devices, systems, and methods for the localization of body lumen junctions and other intraluminal structure are disclosed. Various embodiments permit clinicians to identify the locations of intraluminal structures and medical devices during non-surgical medical techniques, such as cardiac ablation, by determining the intralumen conductance and / or cross-sectional area at a plurality of locations within the body lumen.

Owner:3DT HLDG

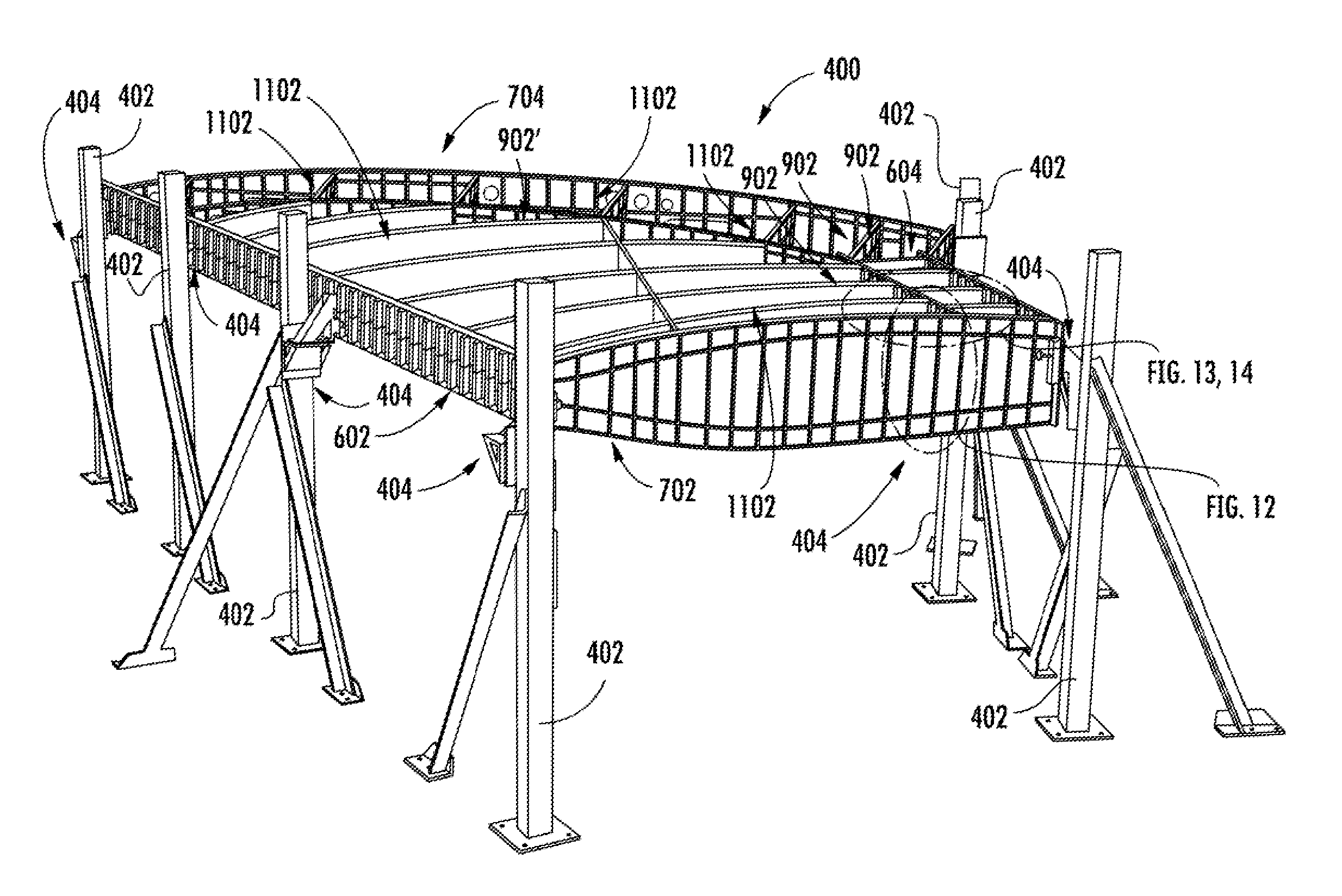

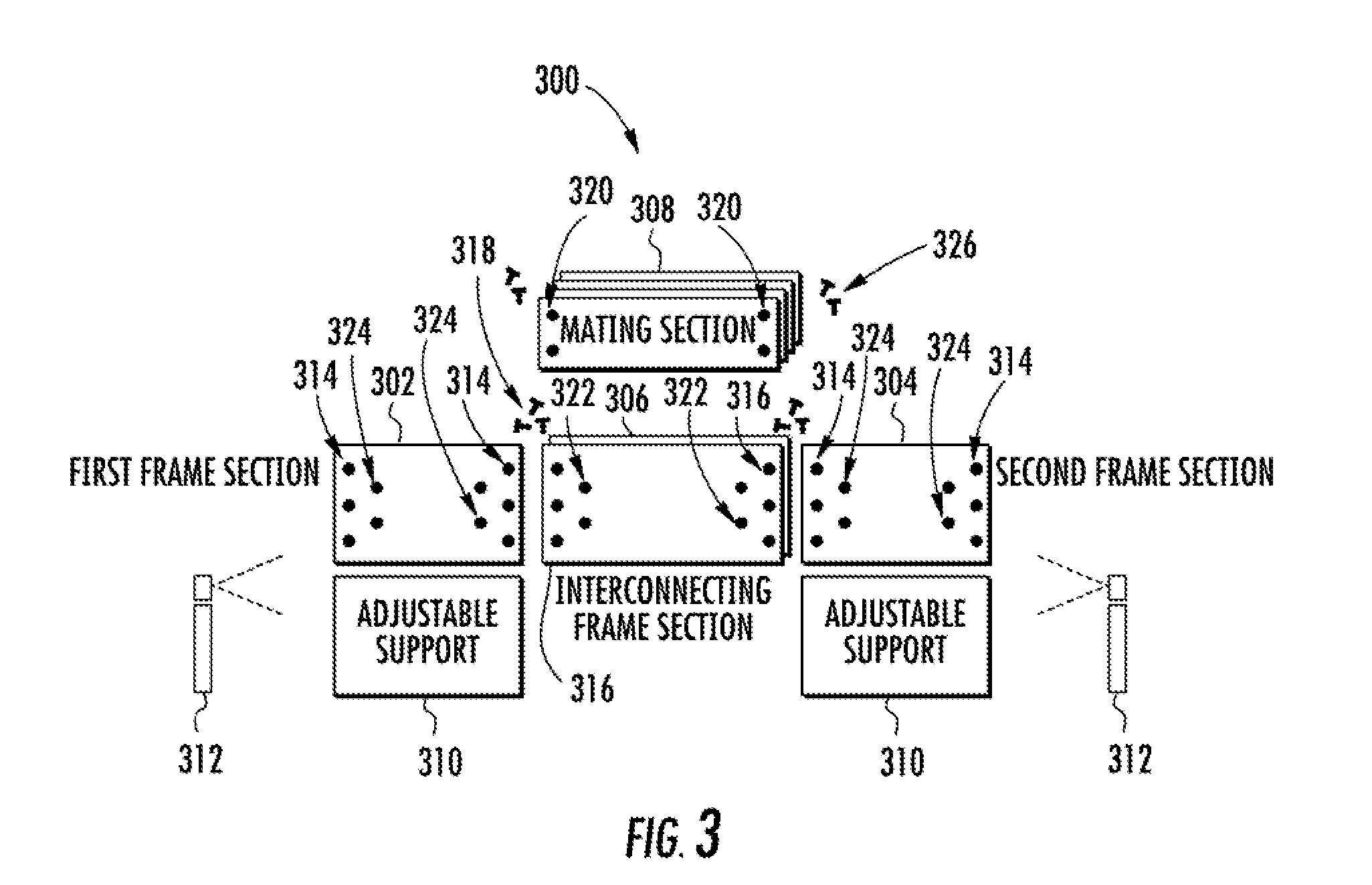

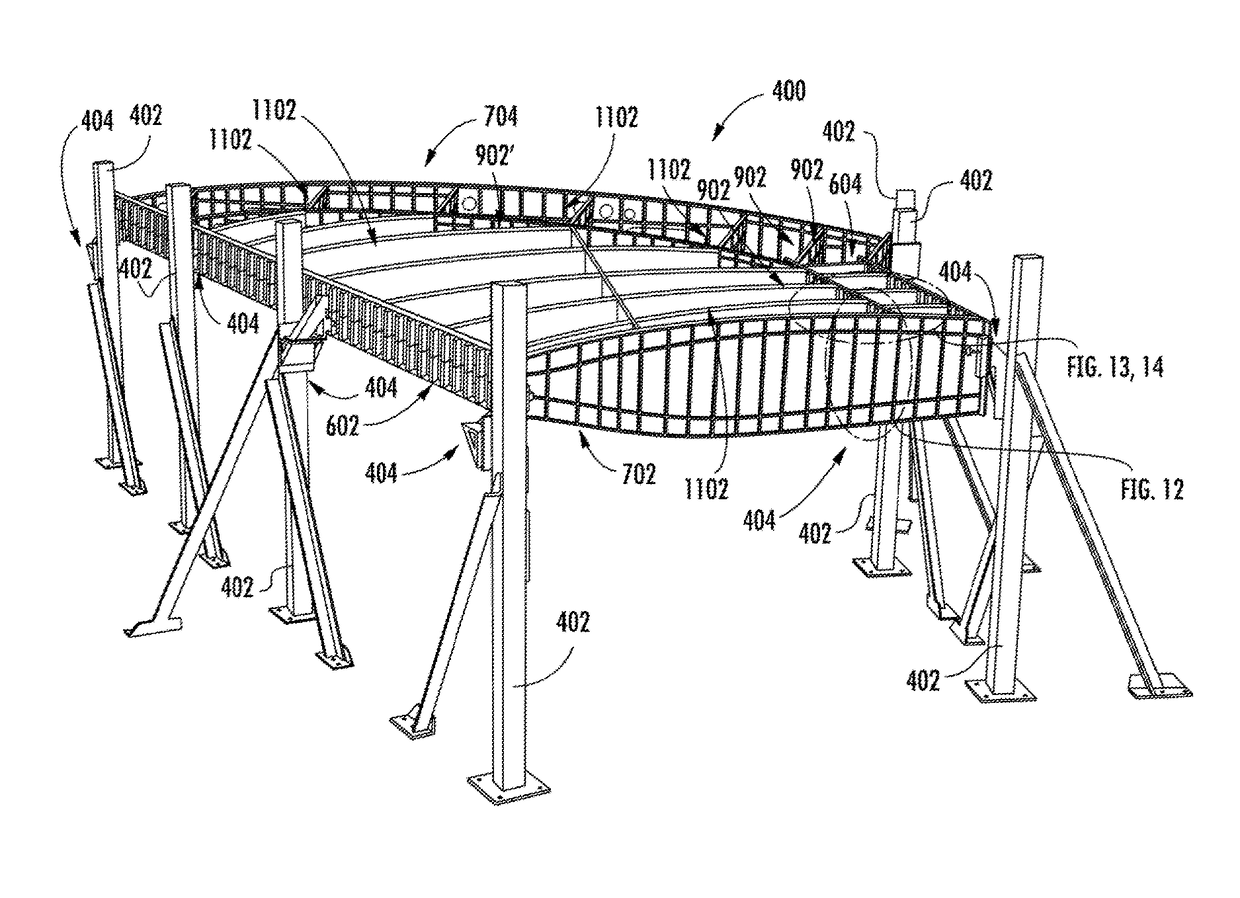

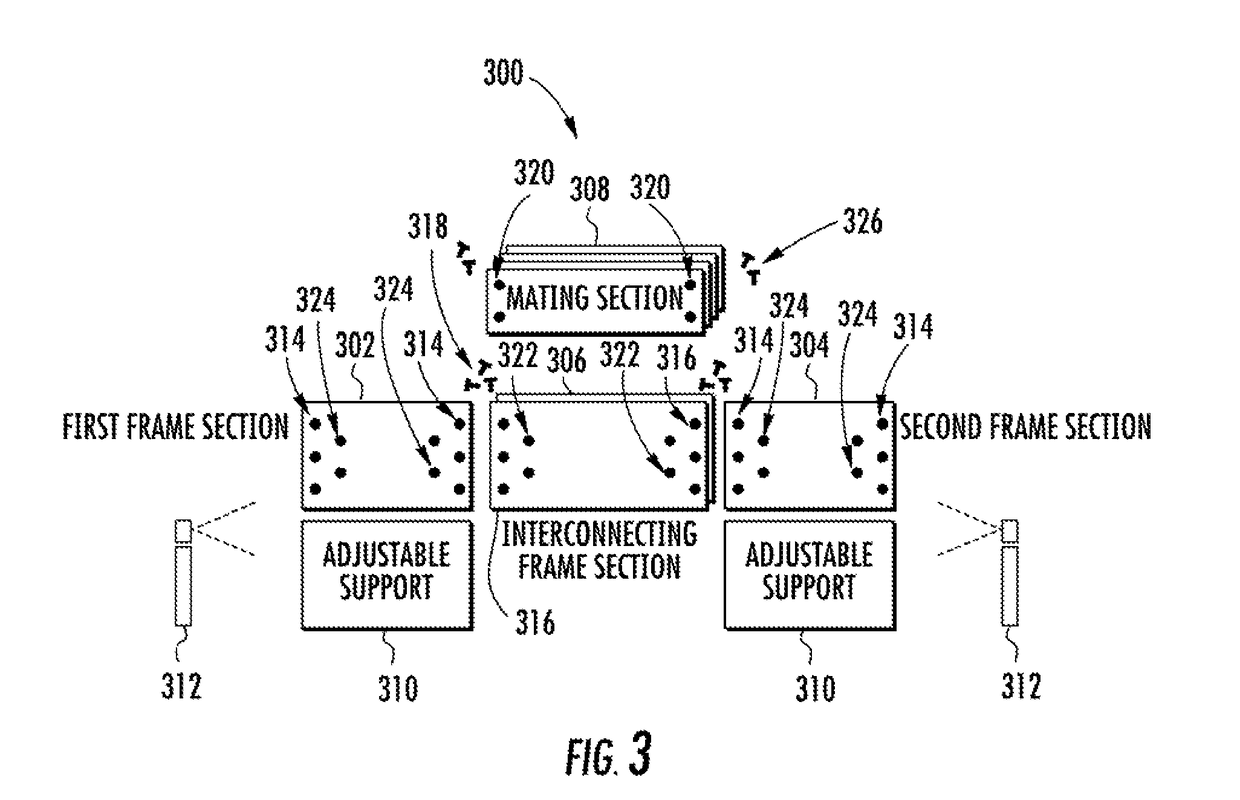

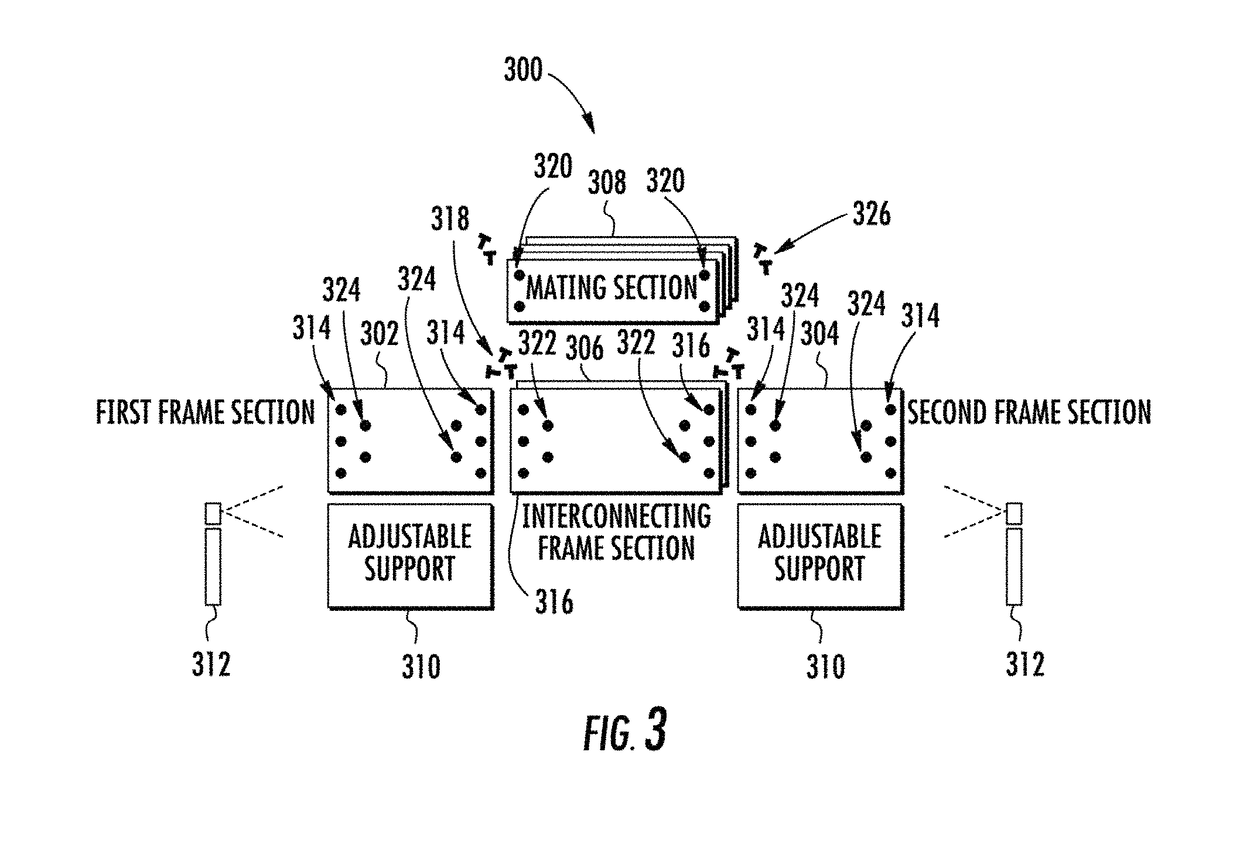

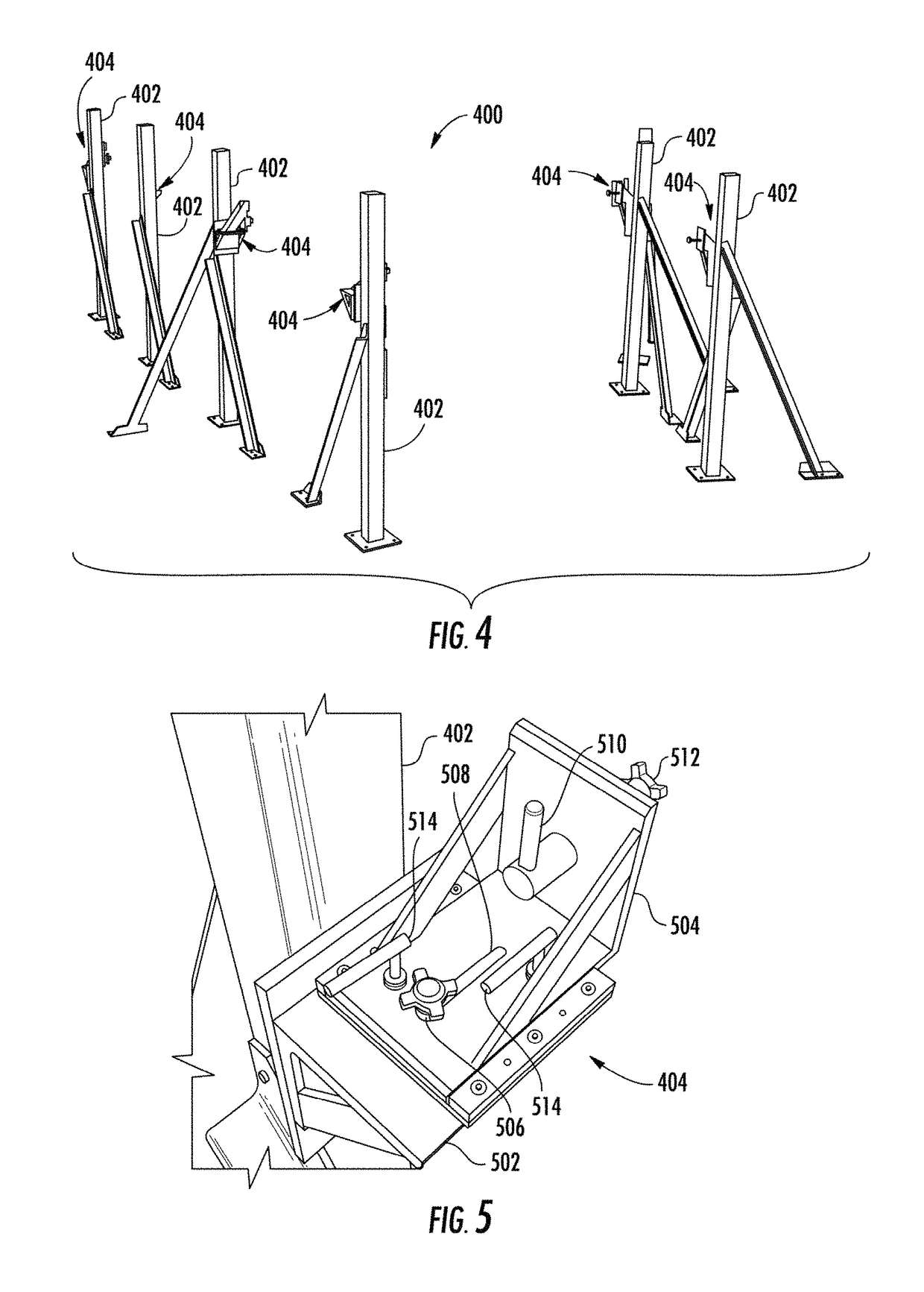

Assembly of an aircraft structure assembly without shimming, locating fixtures or final-hole-size drill jigs

A method is provided for assembling an aircraft structure assembly composed of a plurality of sections, and doing so without use of any shimming, locating fixtures or final-hole-size drill jigs. The method includes supporting the first and second frame sections on respective adjustable supports, and positioning the interconnecting frame section therebetween. The method includes aligning first pre-drilled mating holes in the interconnecting frame section with first pre-drilled mating holes in the first and second frame sections, and installing fasteners though the aligned, first pre-drilled mating holes. The method includes positioning a structural mating section relative to the first and second frame sections and interconnecting frame section. And aligning second pre-drilled mating holes in the structural mating section with second pre-drilled mating holes in at least one of the frame sections, and installing fasteners through the aligned, second pre-drilled mating holes to secure the structural mating section.

Owner:THE BOEING CO

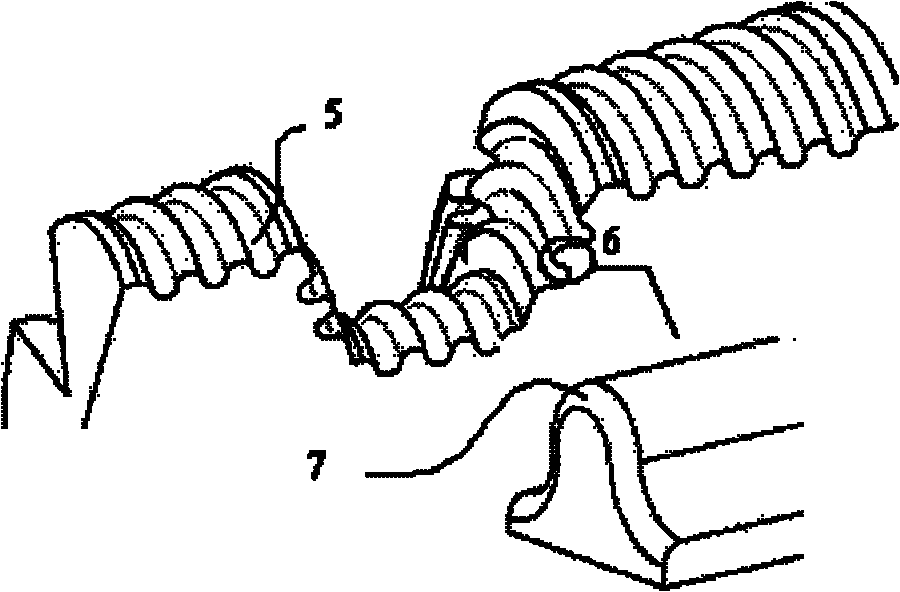

Compound milling cutter for machining fir tree type blade root wheel groove

InactiveCN101804478AHelps reduce chip breakingHelps reduce chip removalMilling cuttersMilling cutterEngineering

The invention related to a compound milling cutter for machining a fir tree type blade root wheel groove, which belongs to the technical field of machinery manufacture. The compound milling cutter comprises a shank part and a cutting part, wherein the tail end of the shank part is fixed with the cutting part, and a spiral groove and a cutting edge are arranged on the cutting part; the spiral groove is spirally arranged on the cutting edge, and a spiral angle is greater than 5 DEG but less than 10 DEG. In the invention, a V-shaped rough milling cutter, a deepen milling cutter and a semi-finish cutter in an original process are combined through optimum design of the cutting edge, rough machining and semi-finish machining of a supercritical steam turbine of 1000MW are completed, tooling and cutter changing time is reduced, and the cutting speed and the feed rate are increased so that the productivity is improved, and the production cost is reduced.

Owner:SHANGHAI JIAO TONG UNIV

Solar cell crystal silicon wafer phosphorus diffusion method

InactiveCN107331731ASimple methodReduce gas usageFinal product manufactureSemiconductor/solid-state device manufacturingChemistryNitrogen gas

The invention discloses a solar cell crystal silicon wafer phosphorus diffusion method. The method comprises the following steps: 1) a to-be-processed crystal silicon wafer is placed in a diffusion furnace, temperature is raised, and nitrogen carrying a phosphorus source, dry oxygen and large nitrogen are introduced, constant-source diffusion is carried out; 2) introduction of the nitrogen carrying the phosphorus source is stopped, temperature is raised, the dry oxygen and the large nitrogen are introduced to perform propelling; 3) the nitrogen carrying the phosphorus source and the dry oxygen are introduced, and low-temperature diffusion is carried out; 4) the introduction of the nitrogen carrying the phosphorus source is stopped, and constant-temperature propelling is carried out; 5) temperature is raised, the nitrogen carrying the phosphorus source and the dry oxygen are introduced, and constant-source diffusion is carried out; 6) the introduction of the nitrogen carrying the phosphorus source is stopped, and oxygen-existing limited-source diffusion is performed; 7) temperature is lowered, the nitrogen carrying the phosphorus source, the dry oxygen and the large nitrogen are introduced, and cooling diffusion is carried out; and 8) temperature is lowered, and the crystal silicon wafer is taken out from a boat. The phosphorus diffusion method is simple and is easy to do, and the phosphorus diffusion method is widely used; and photoelectric conversion efficiency of the silicon wafer can be effectively improved through adoption of the method, electric performance of a solar cell is improved, and the phosphorus diffusion method is suitable for promotion and application.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

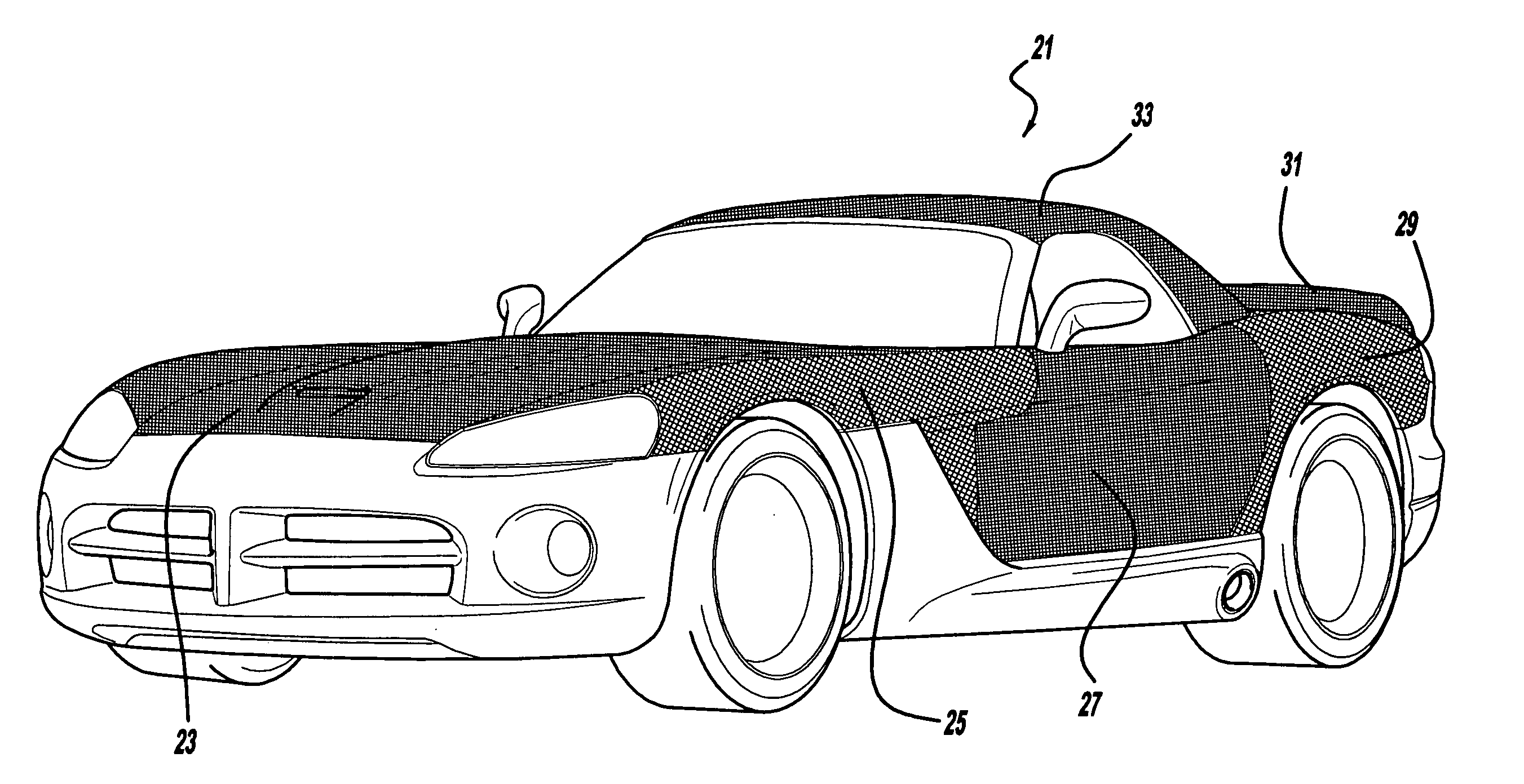

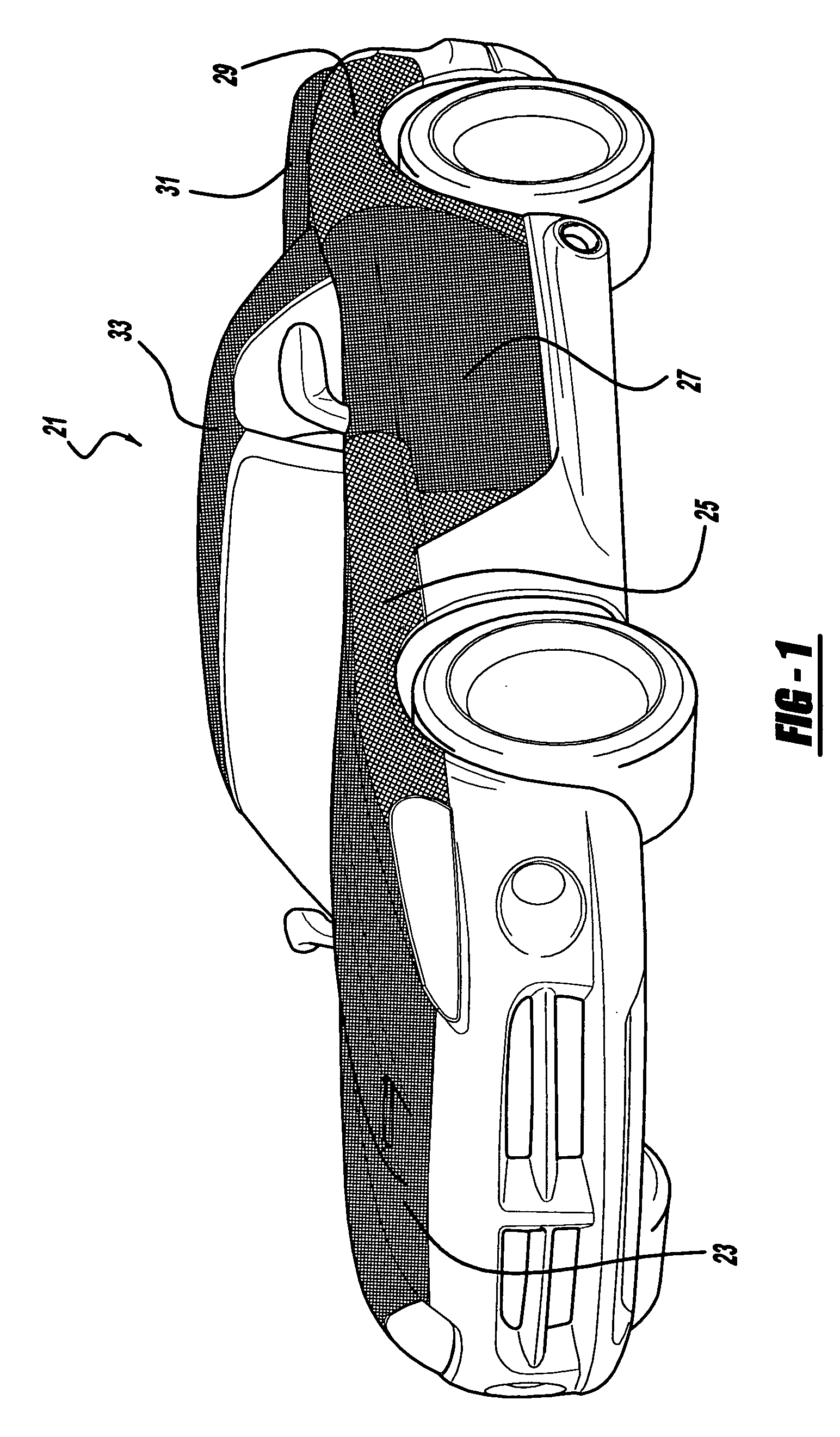

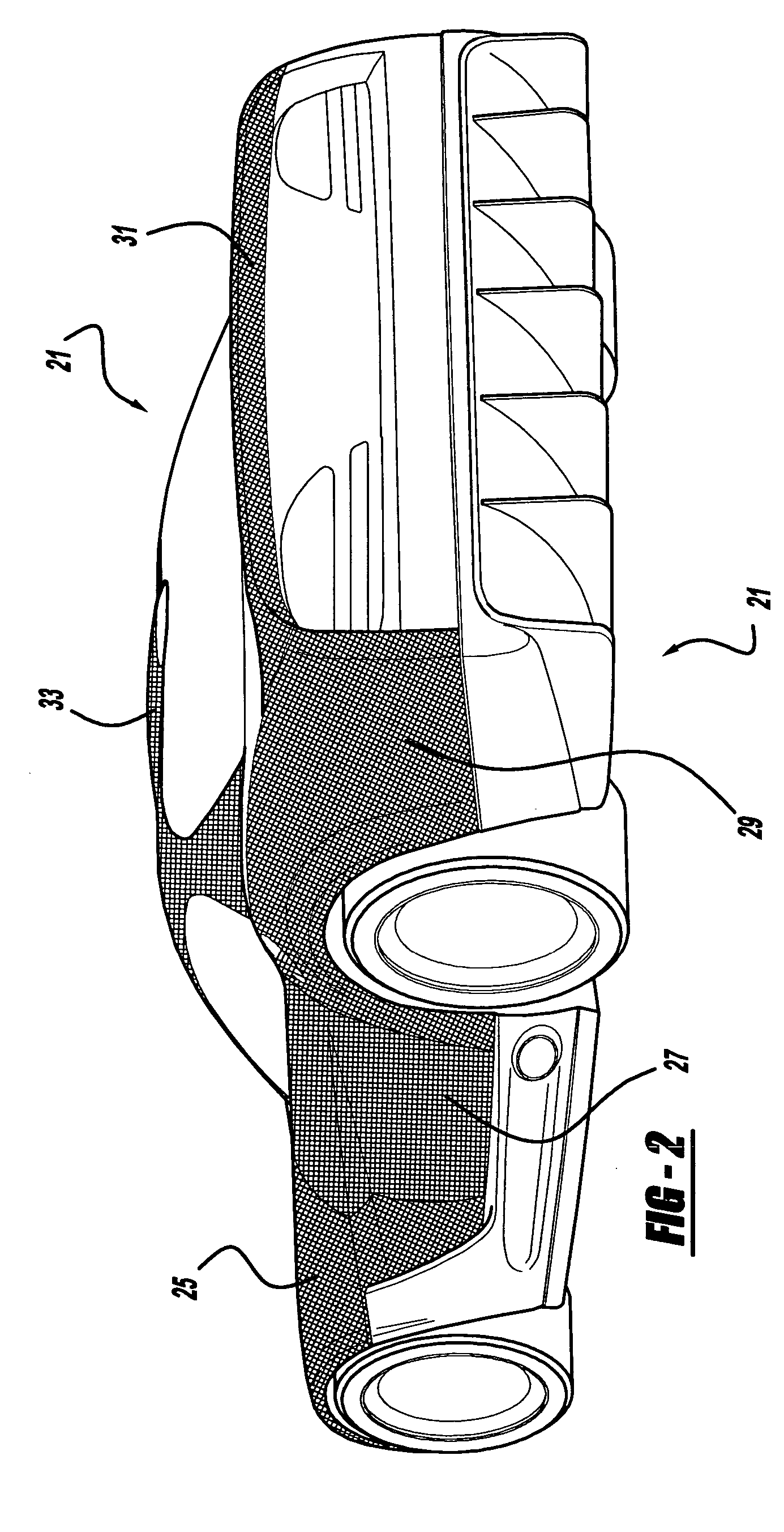

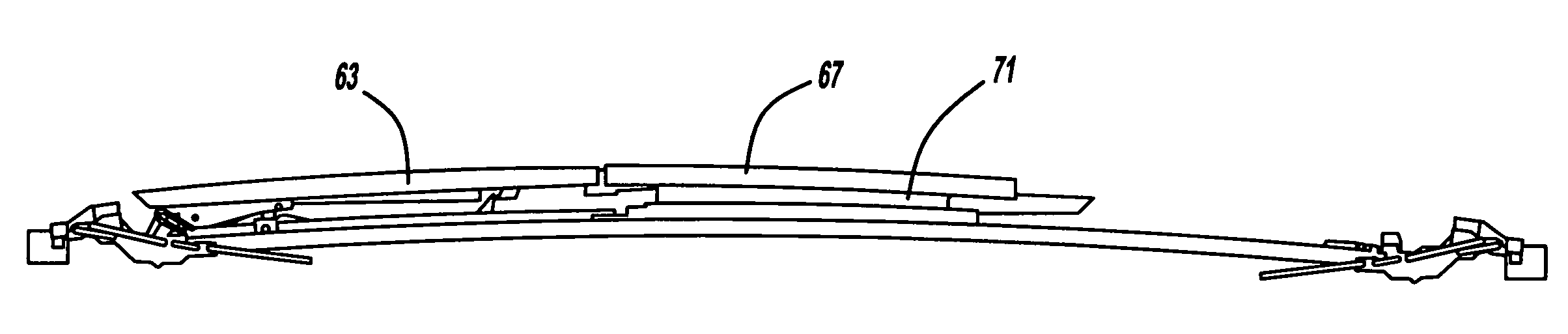

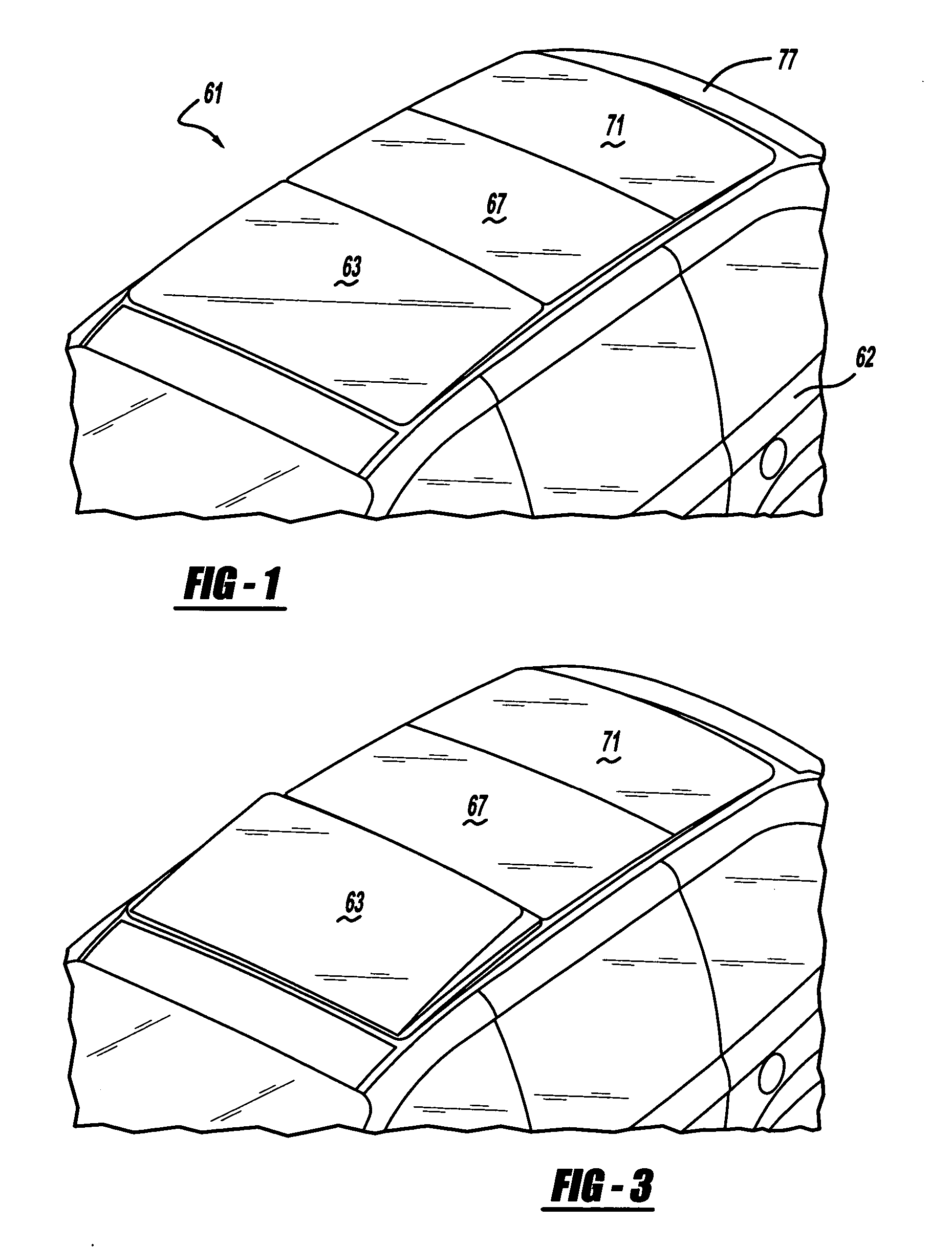

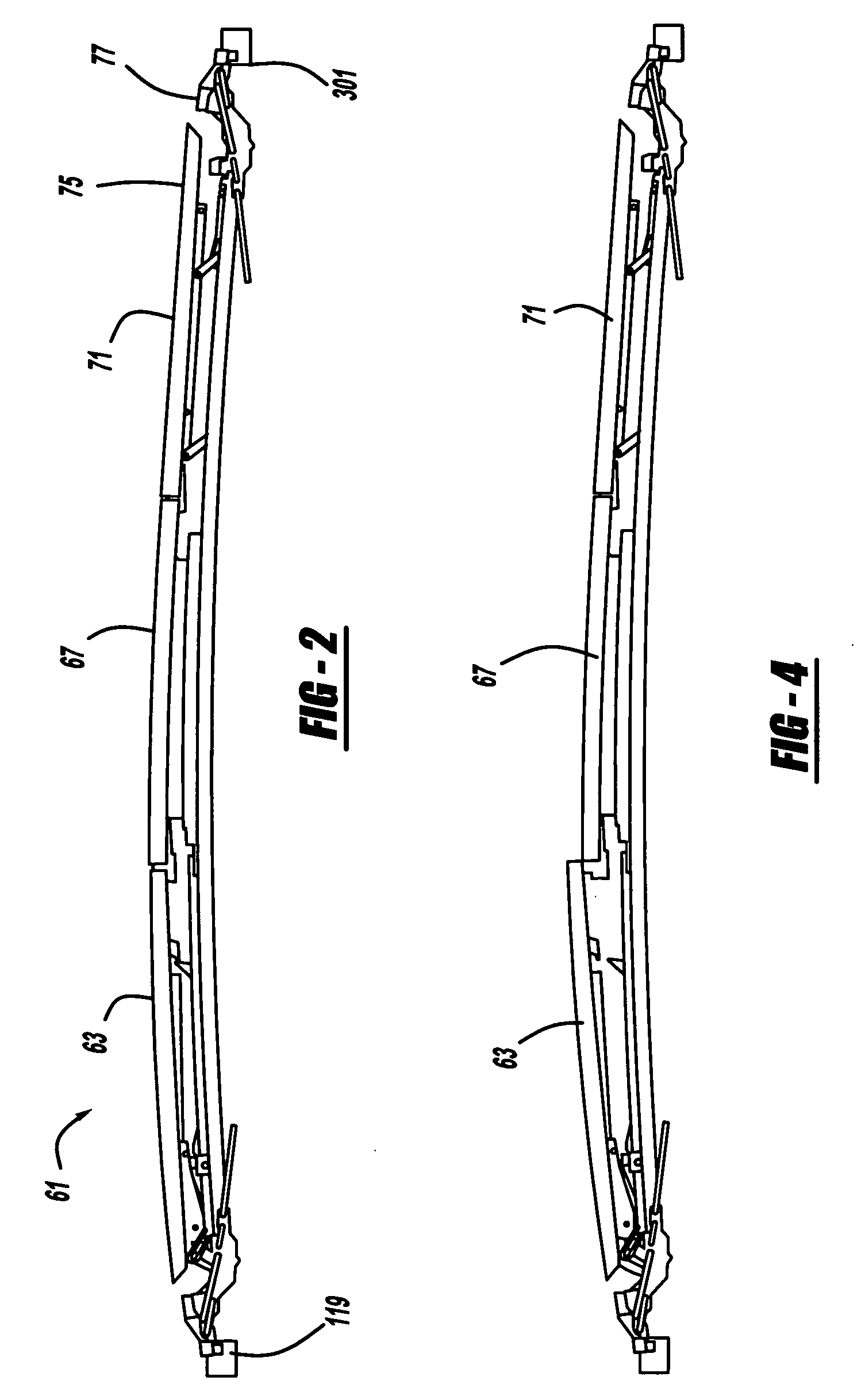

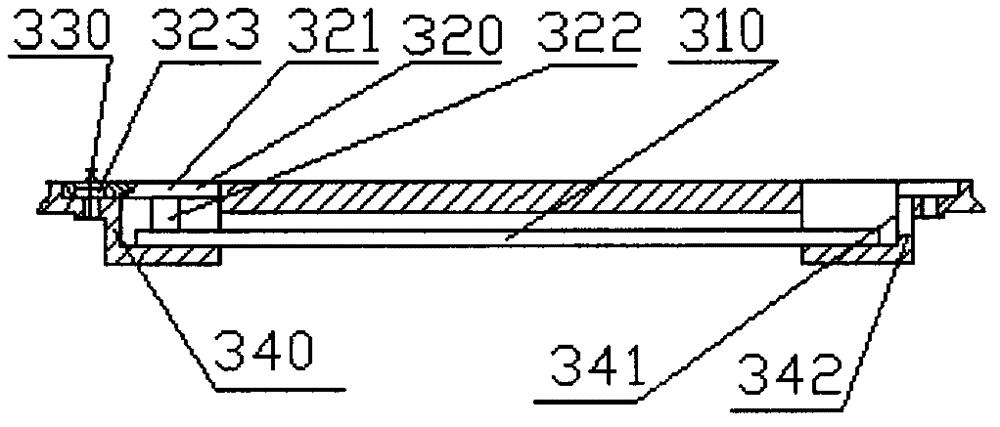

Multi-panel sunroof system

InactiveUS20070145786A1Maximize occupant head roomMaximizes open areaEngine sealsSuperstructure subunitsEngineeringMechanical engineering

A multi-panel sunroof employs at least three movable sunroof panels. In another aspect of the present invention, three sunroof panels are stacked upon each other in one or two different operating positions. A further aspect of the present invention provides for rearward opening movement of a front sunroof panel and forward opening movement of a rear sunroof panel.

Owner:SPECIALTY VEHICLE ACQUISITION

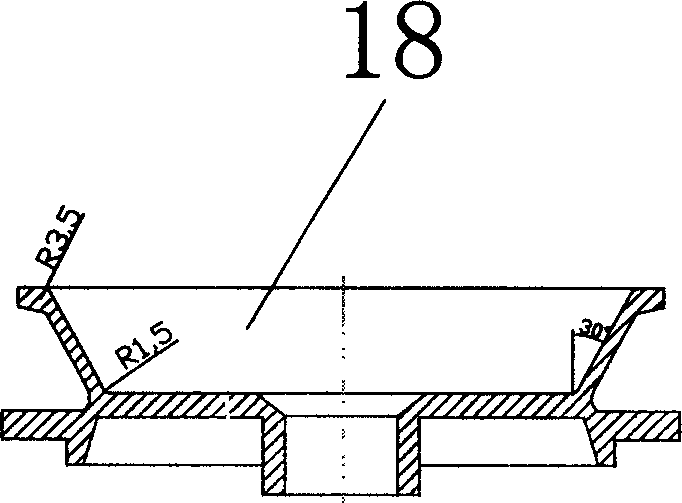

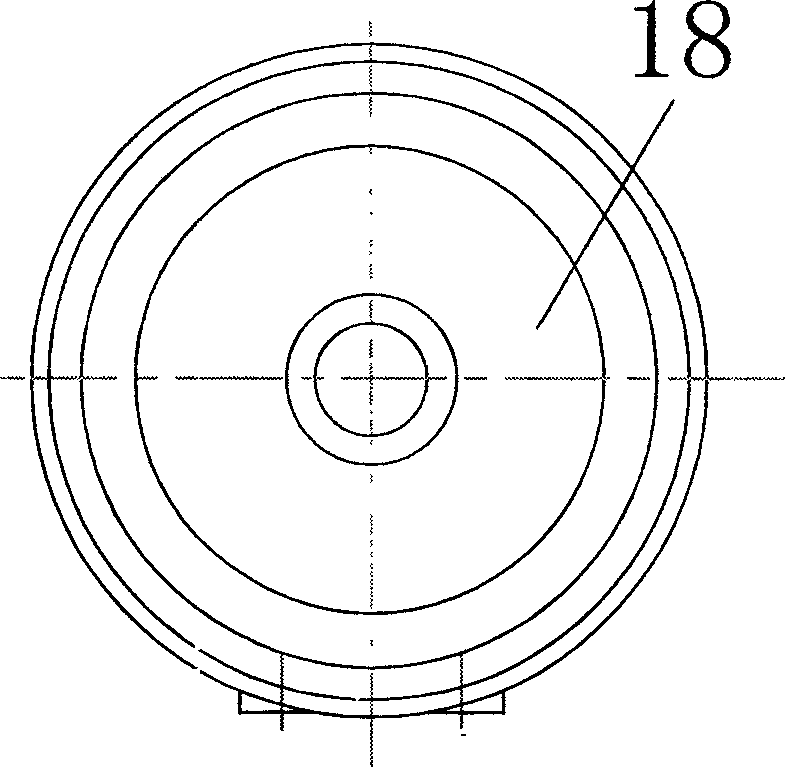

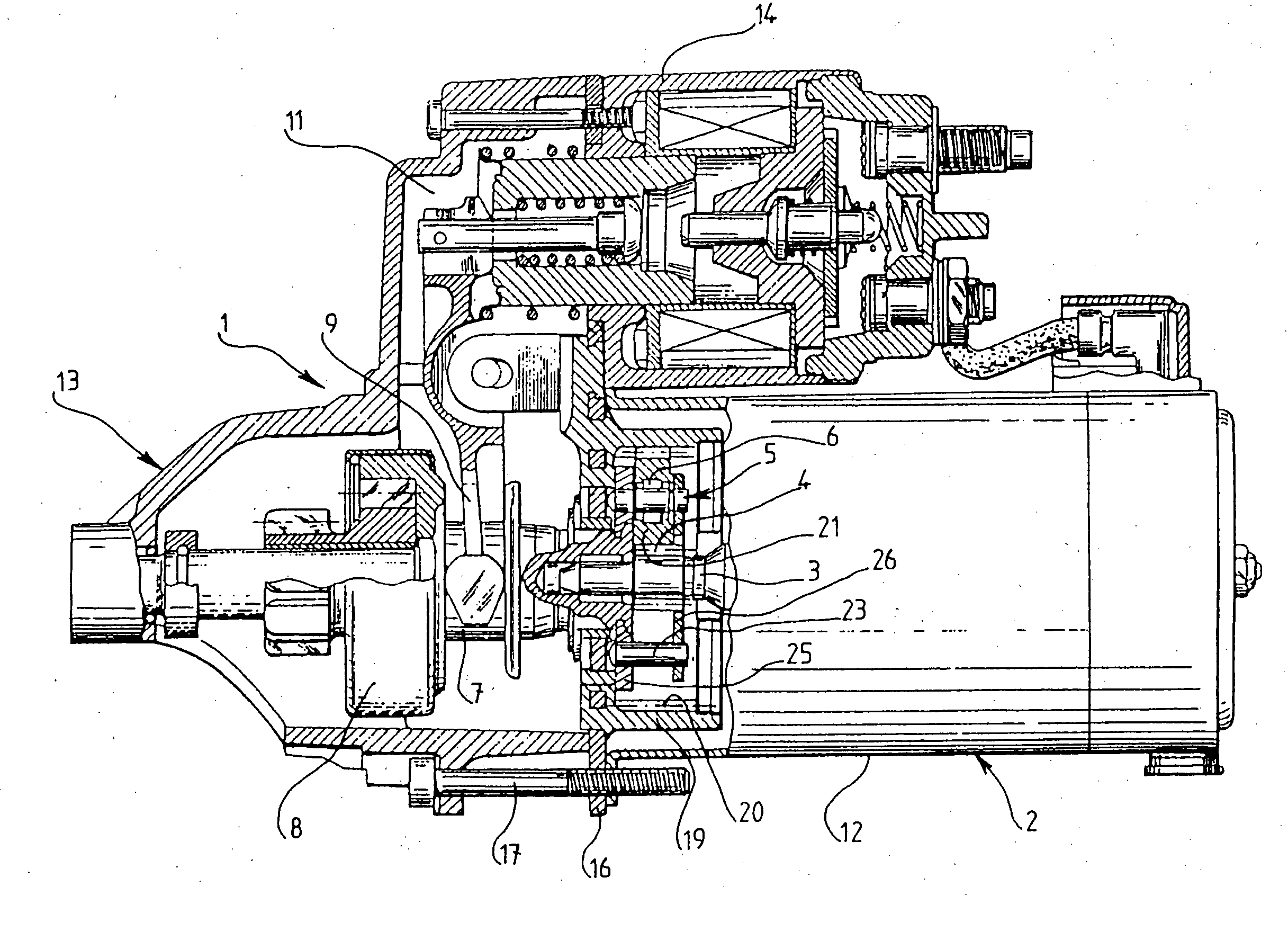

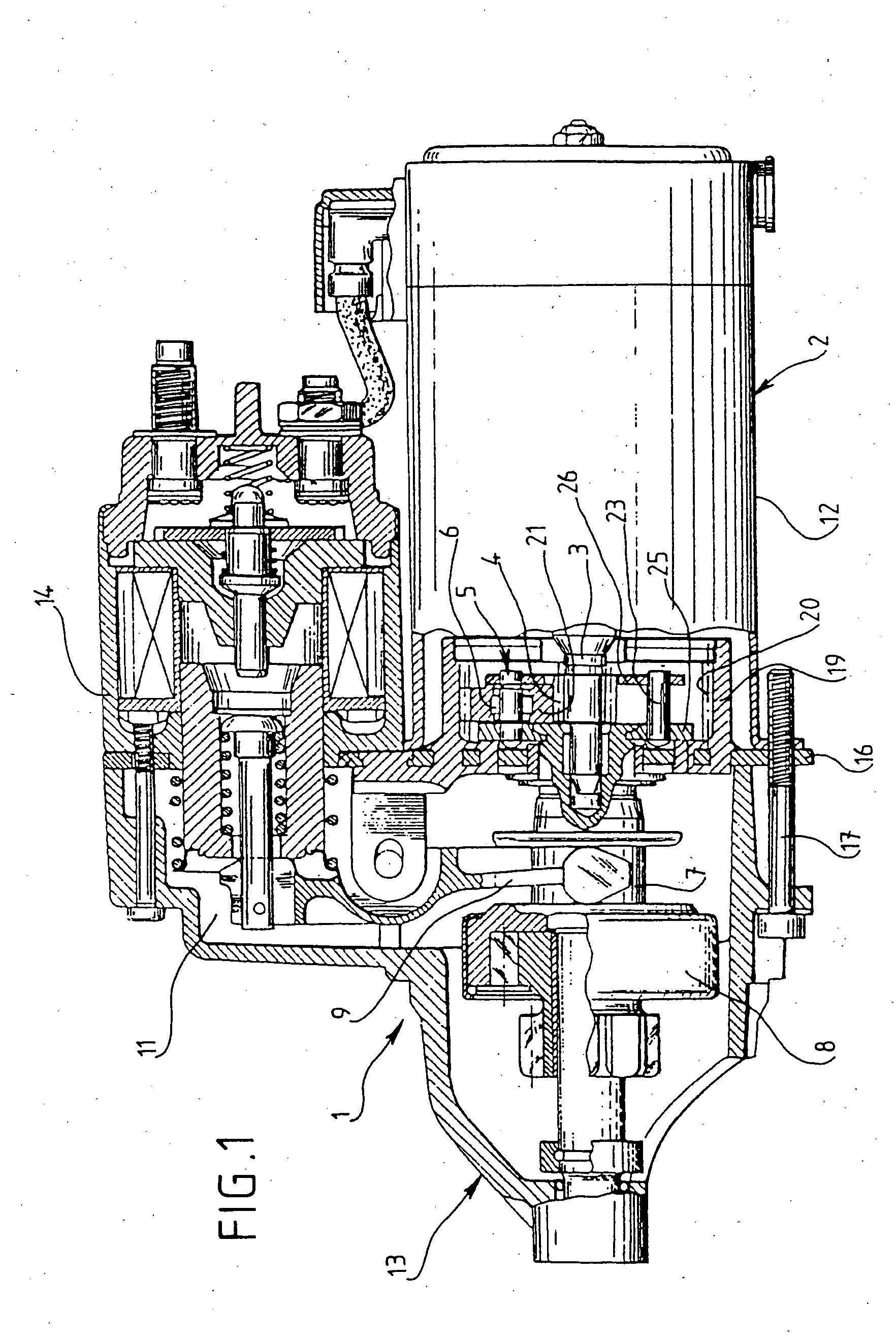

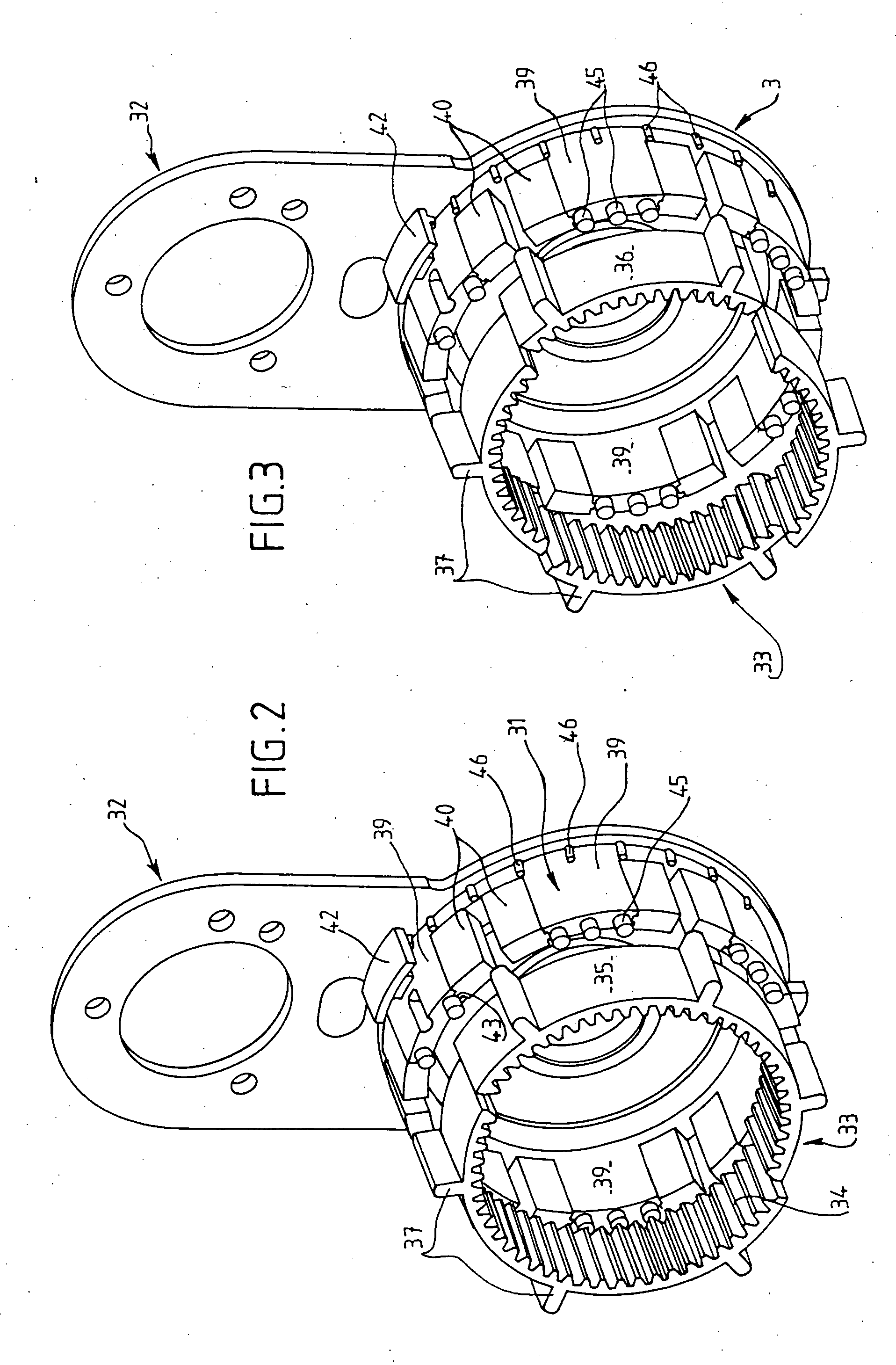

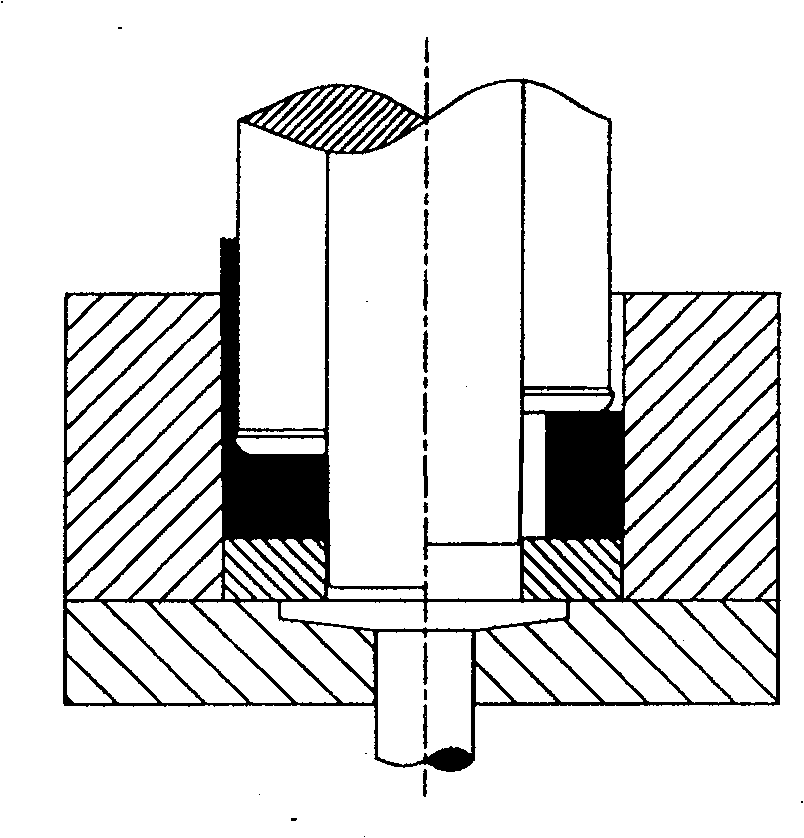

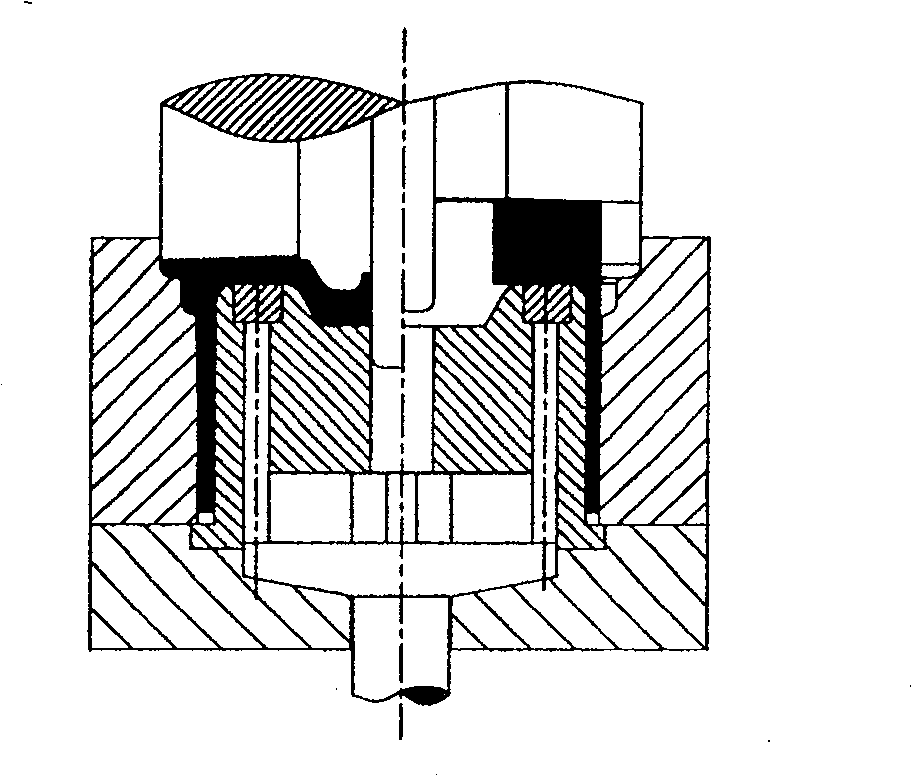

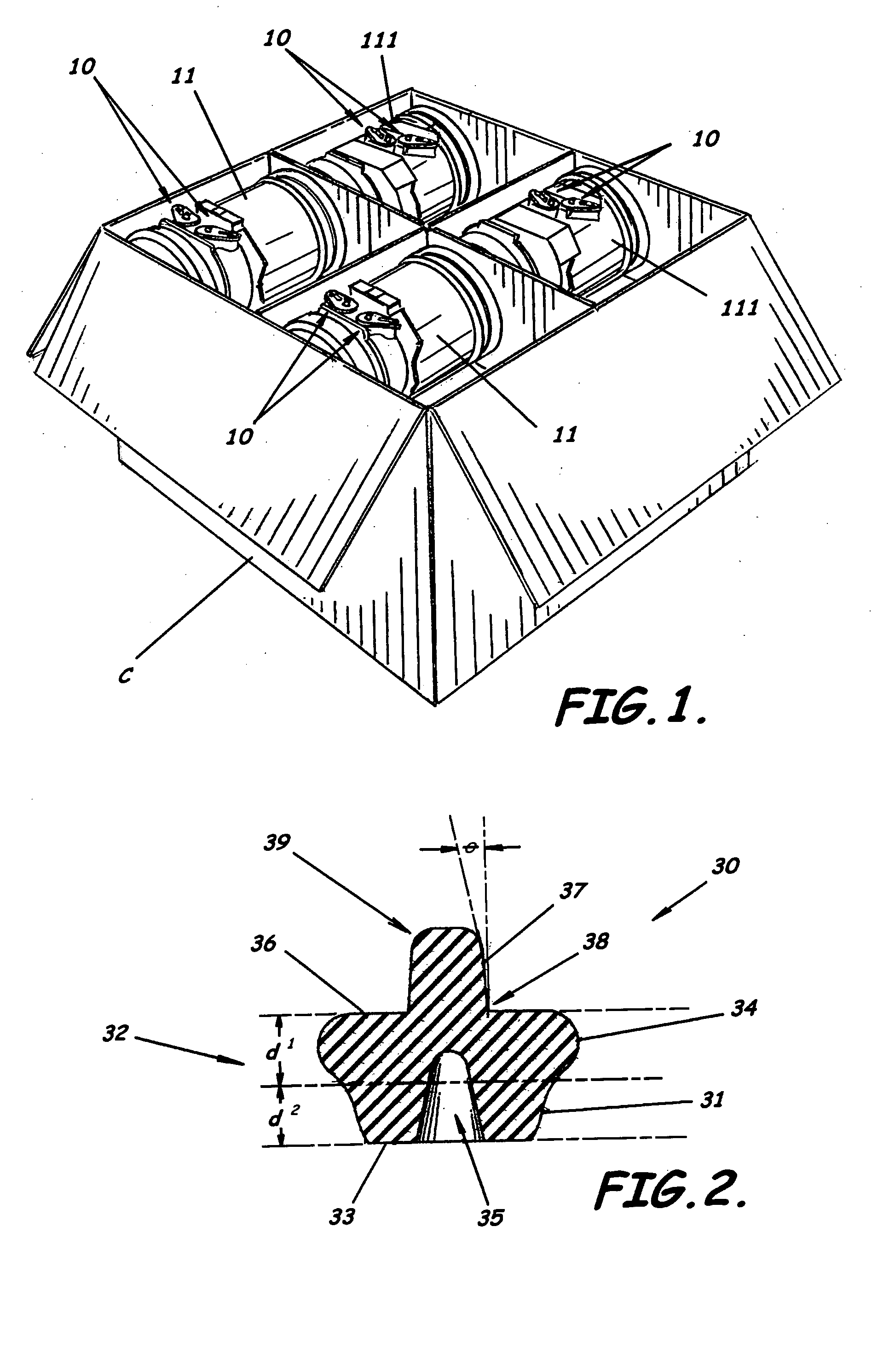

Planetary gearset reduction ring gear for motor vehicle starter

InactiveUS20040255704A1Mitigate such drawbackReduce manufacturing costPower operated startersMuscle operated startersMobile vehicleEngineering

The invention concerns a reduction gear ring of the epicyclic train type, in particular for motor vehicle starters, mounted so as to be immovable with respect to rotation in a casing and comprising internal teeth which mesh with the planet wheels of the gear box. This ring, characterised in that it is composed of two parts, an external part (31) mounted in the said casing and an internal ring part (33) carrying the internal tooth, which is able to be mounted coaxially in the external ring part (31) and is formed by several separate ring segments (35, 36). The invention can be used for motor vehicles.

Owner:VALEO EQUIP ELECTRIC MOTEUR

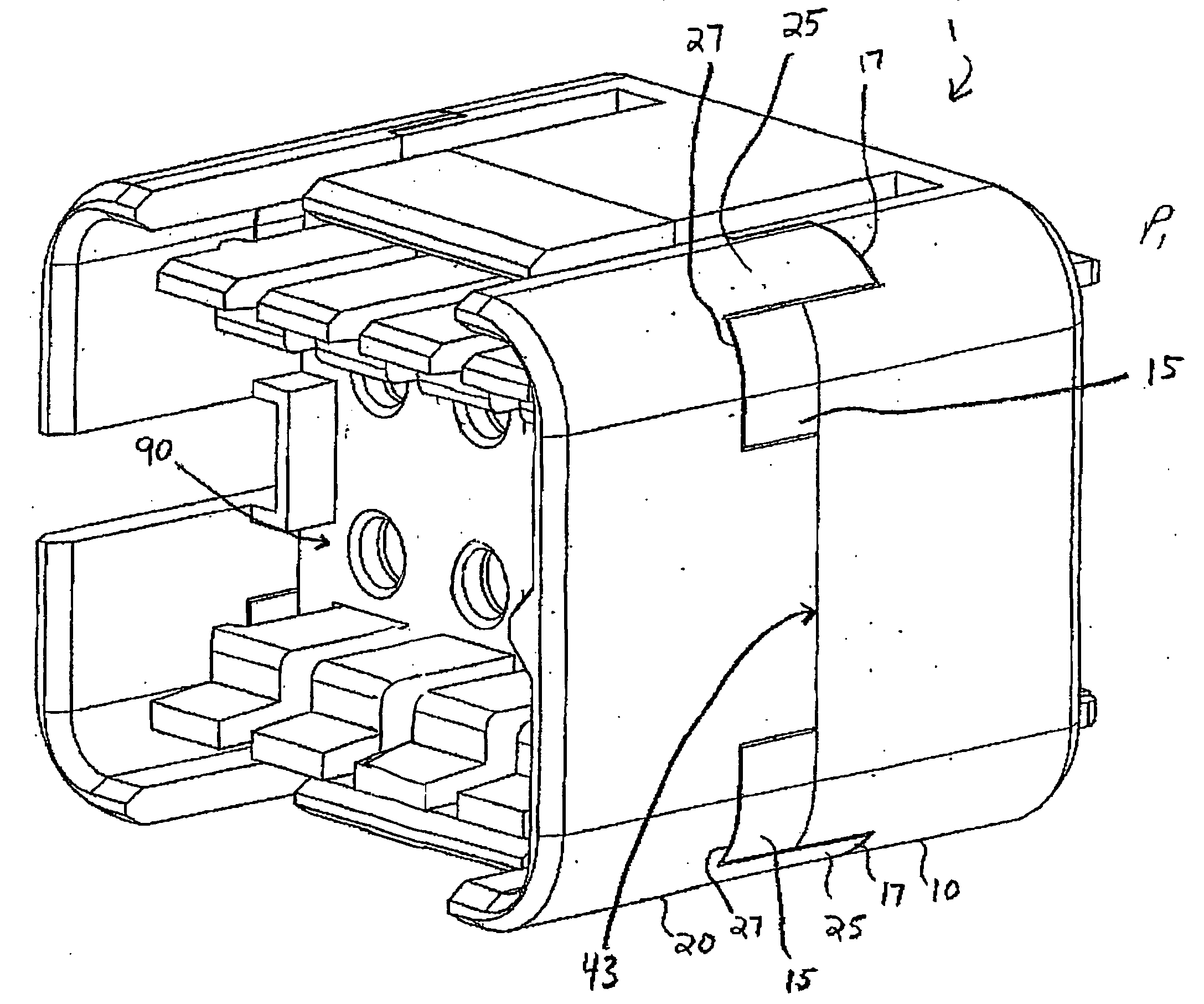

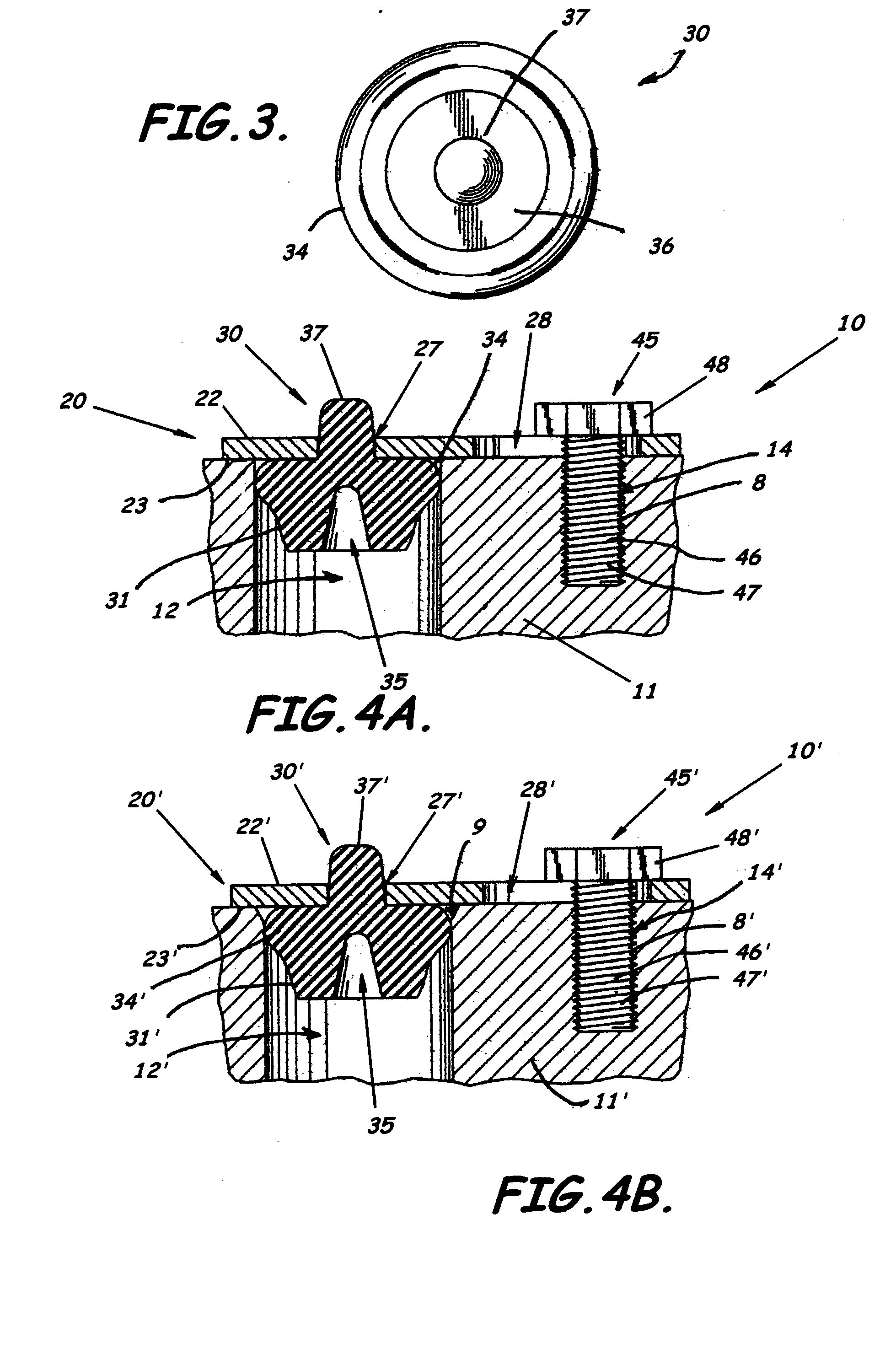

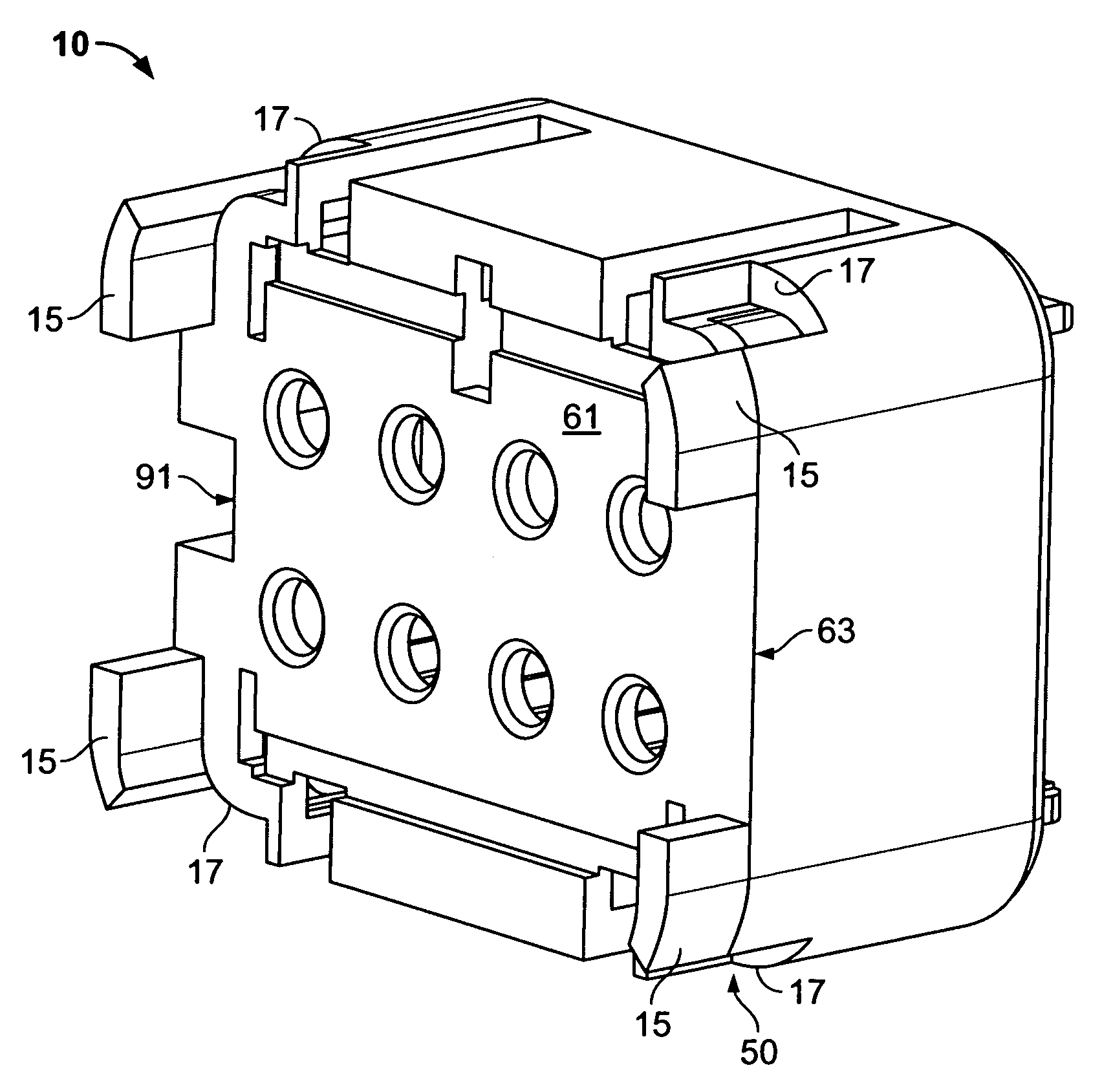

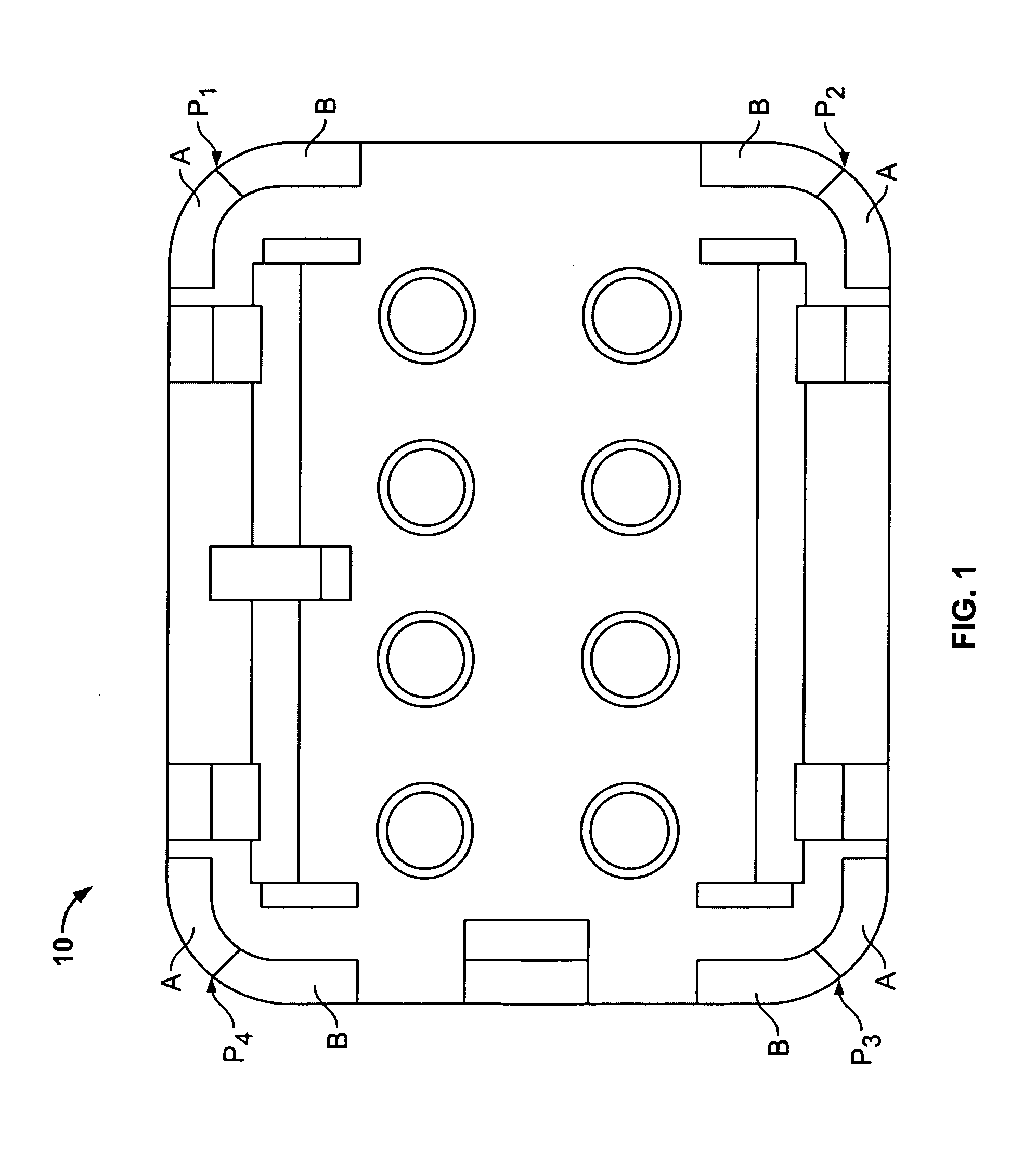

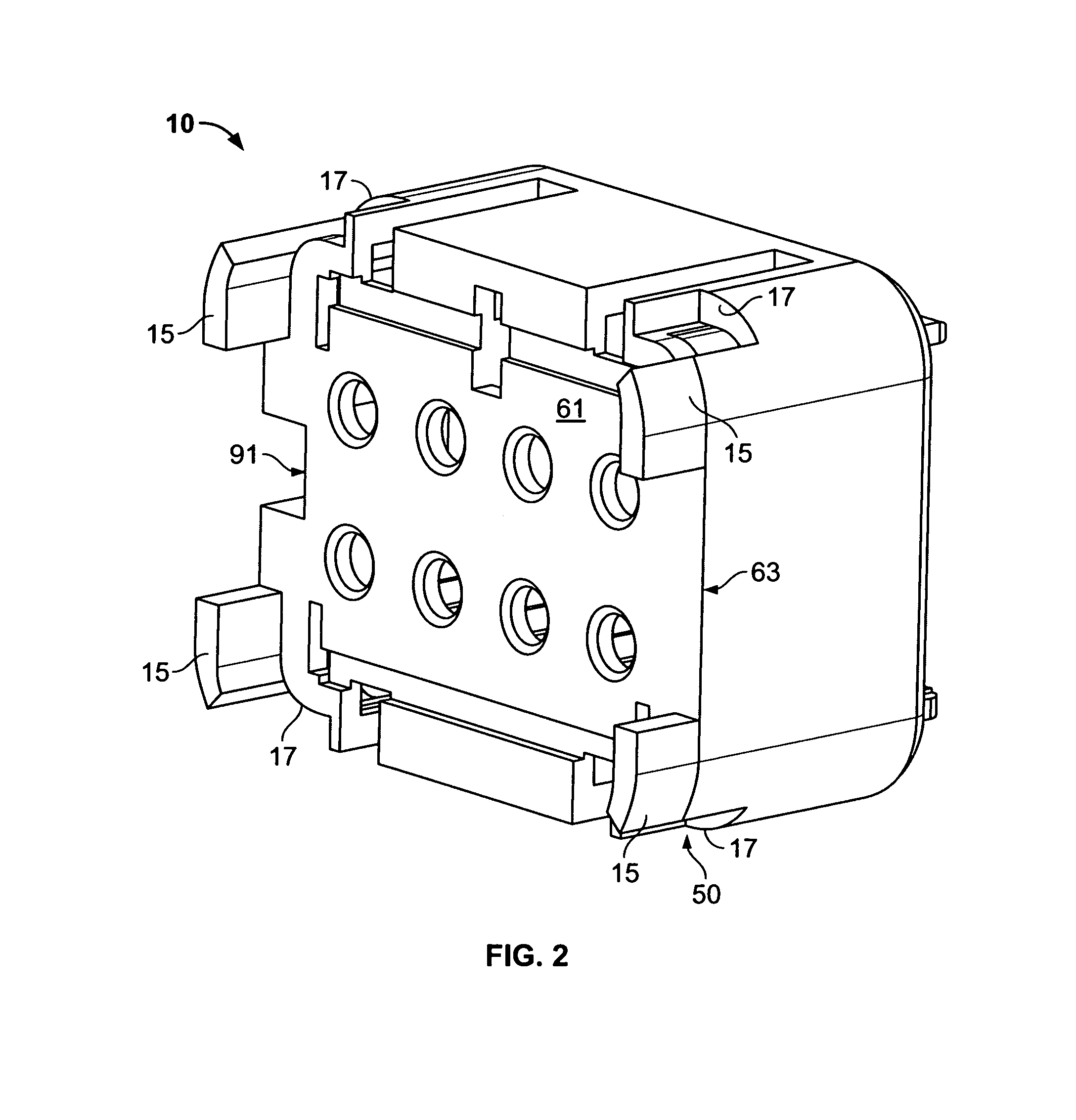

Terminal position assurance with forward interlocking face keying

InactiveUS20050032423A1High strengthAvoid damageVehicle connectorsSecuring/insulating coupling contact membersEngineeringElectrical and Electronics engineering

A connector assembly comprising a cap member having a plurality of fixed cap terminal position assurance mechanisms defined thereon, and a plug member having one or more of fixed plug terminal position assurance mechanisms defined thereon, wherein each of the cap terminal position assurance mechanisms fixably mate with each of the plug terminal position assurance mechanisms, wherein each of the cap and plug terminal position assurance mechanisms comprise a post projecting outwardly from each of the cap member and the plug member, and a cutout configured to fixably mate to the post. The cutout maybe configured adjacent the post, wherein the cap / plug terminal position assurance mechanisms are arranged proximate an outer rim of the cap / plug member or the cap / plug terminal assurance mechanism may be located generally in the center of the interface manifold.

Owner:TE CONNECTIVITY CORP

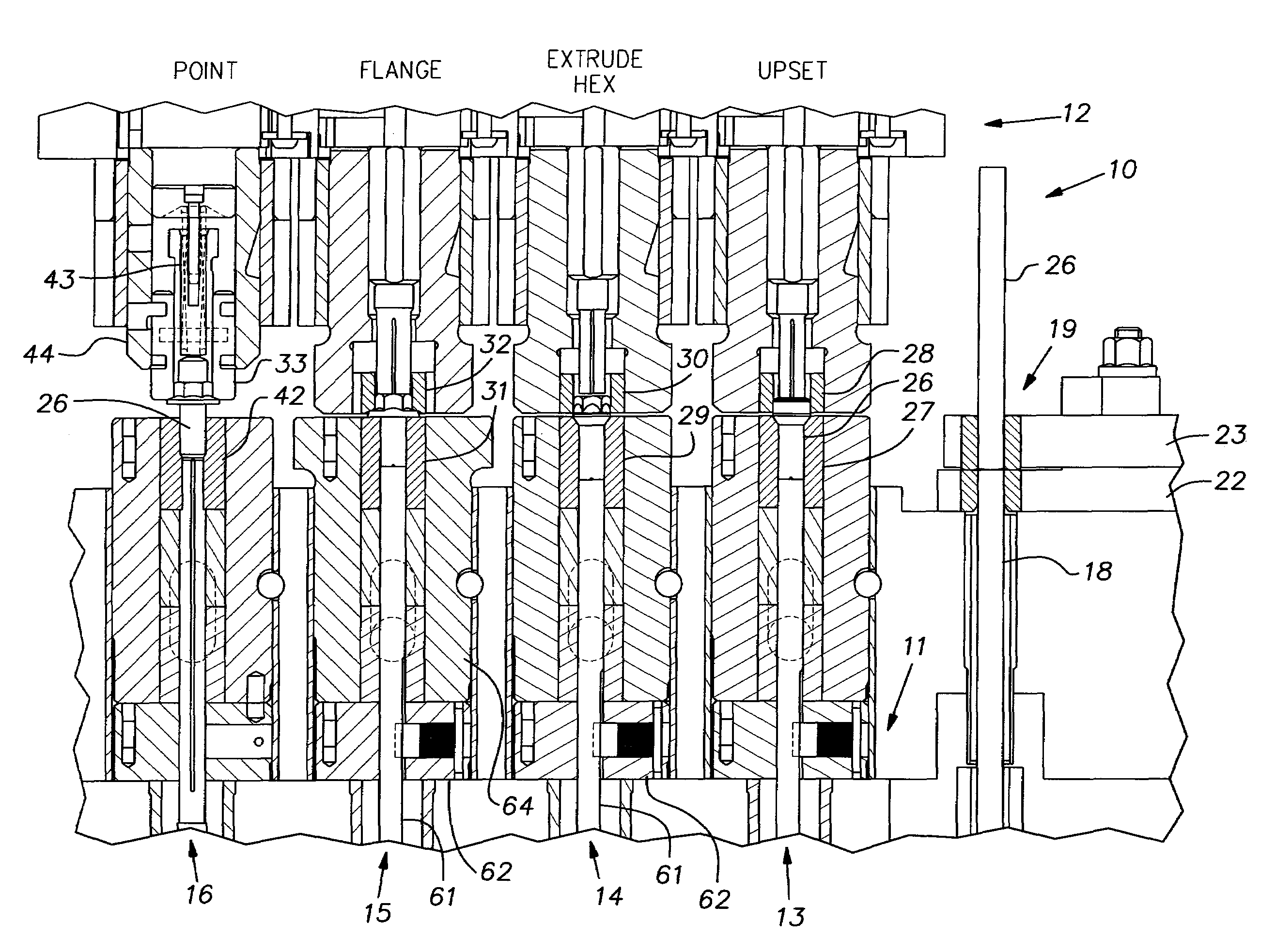

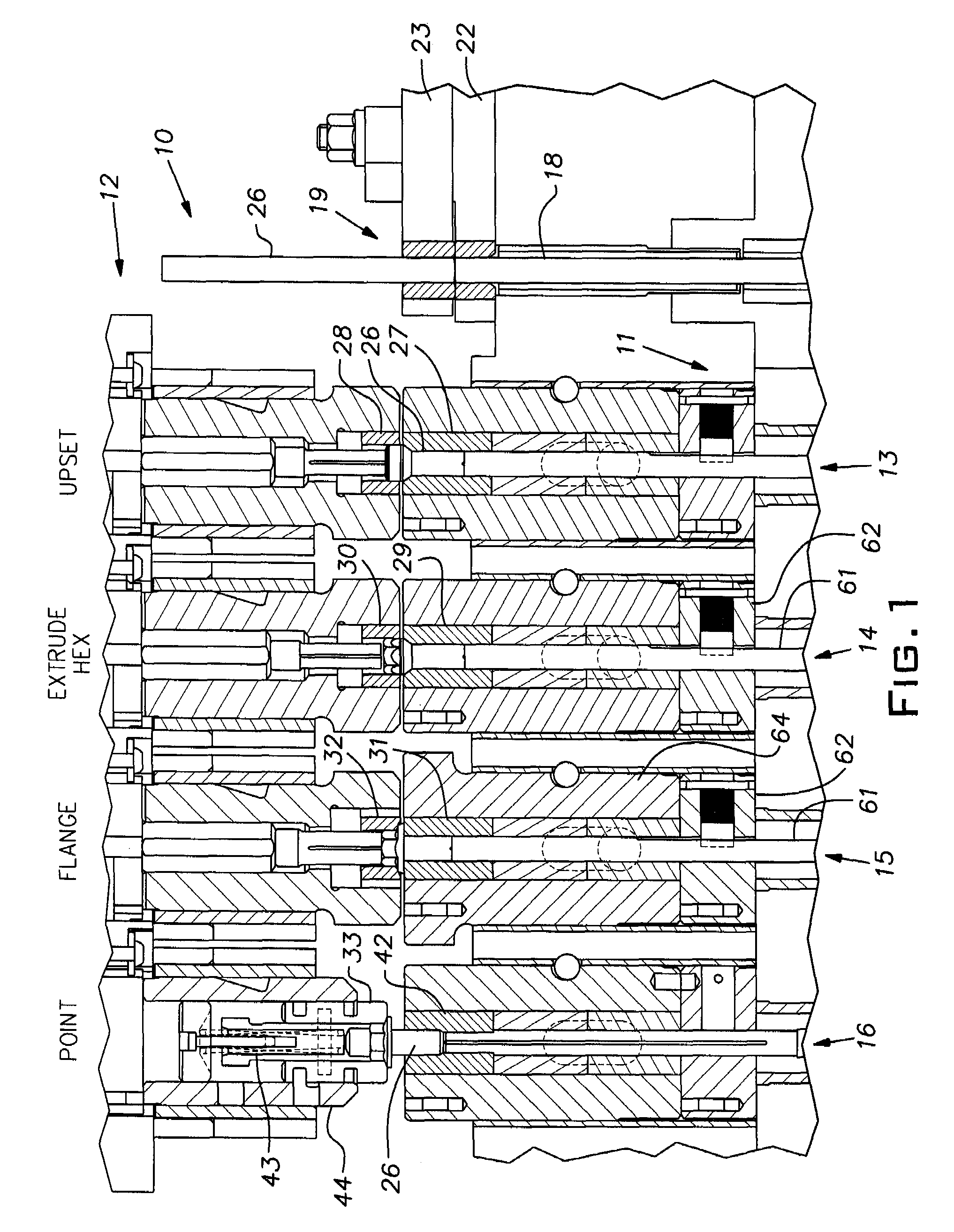

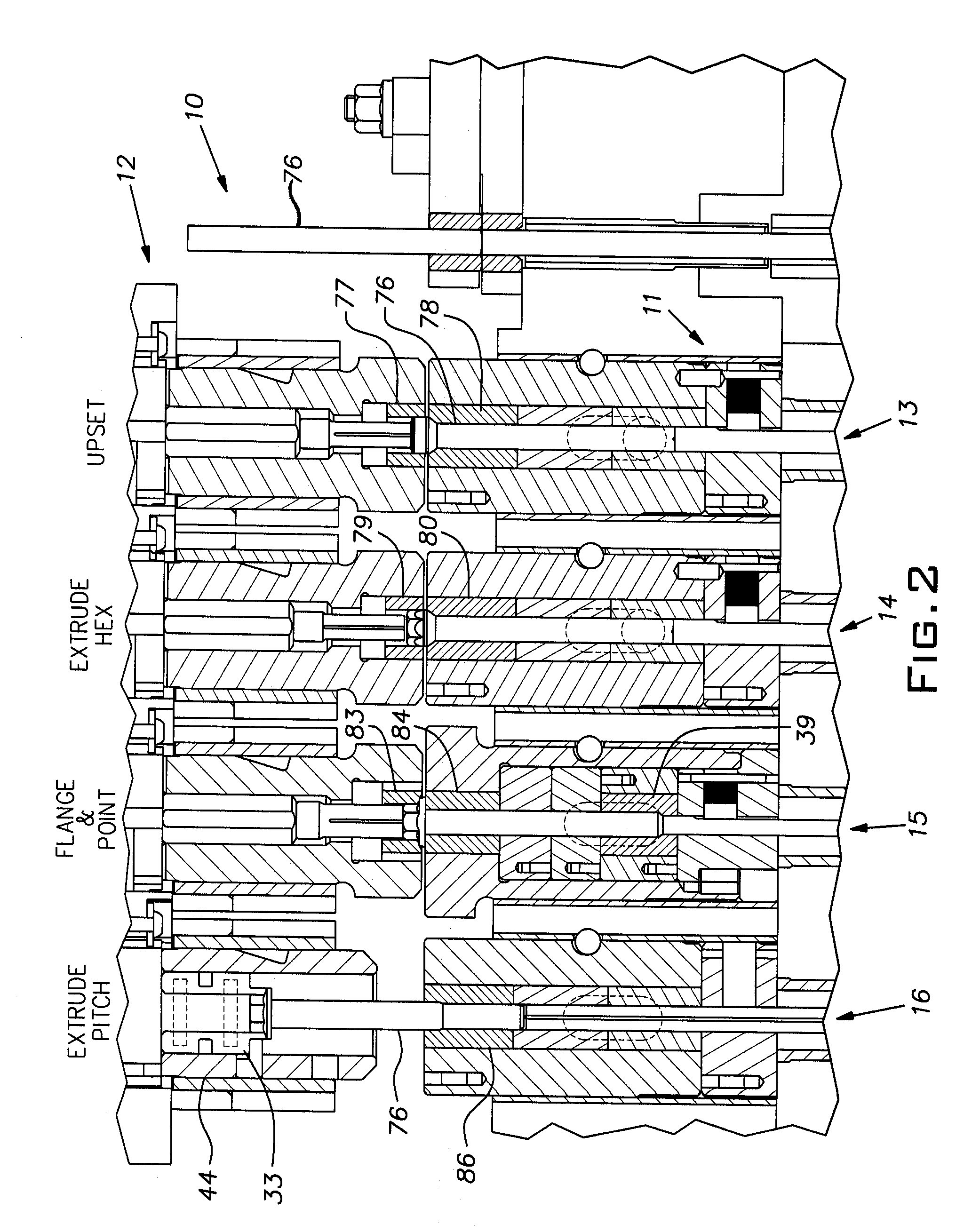

Method and tooling for headed pilot pointed bolts

InactiveUS8485013B2Reduce in quantityExceptionally versatile toolingPinsBoltsEngineeringMechanical engineering

A set of tooling for making pointed headed bolts of a given diameter in numerous lengths with roll thread ready threaded to the head and partially threaded shanks in a four forming station forming machine, the tools being configured to work on wire stock as received at the first station of a diameter larger than or substantially the same as the roll diameter and not greater than the nominal diameter of the bolt, including at least two sequential head forming tools for mounting on the slide, an extrusion pointing tool for mounting on the die breast, a roll diameter extrusion tool for mounting on the die breast and a head support tool mountable in a station on the slide at multiple axial positions corresponding to standard lengths of the bolts being made, the head support tool being arranged to work at either the extrusion pointing station or the roll diameter extrusion station.

Owner:THE NAT MASCH CO

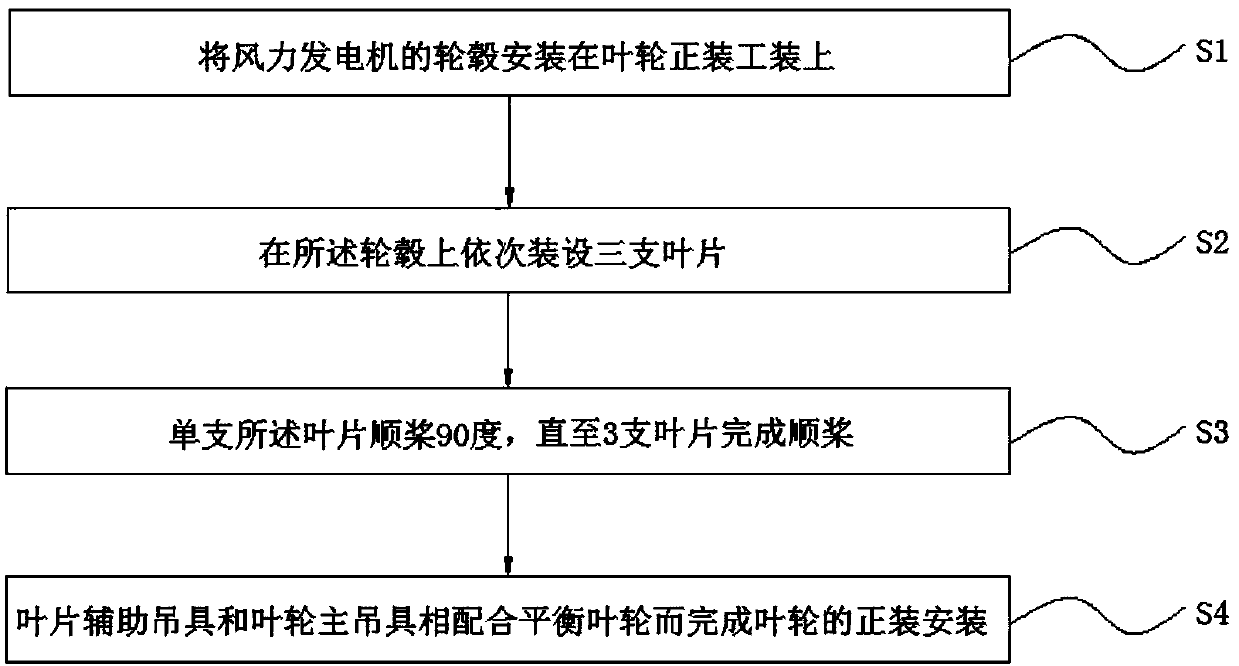

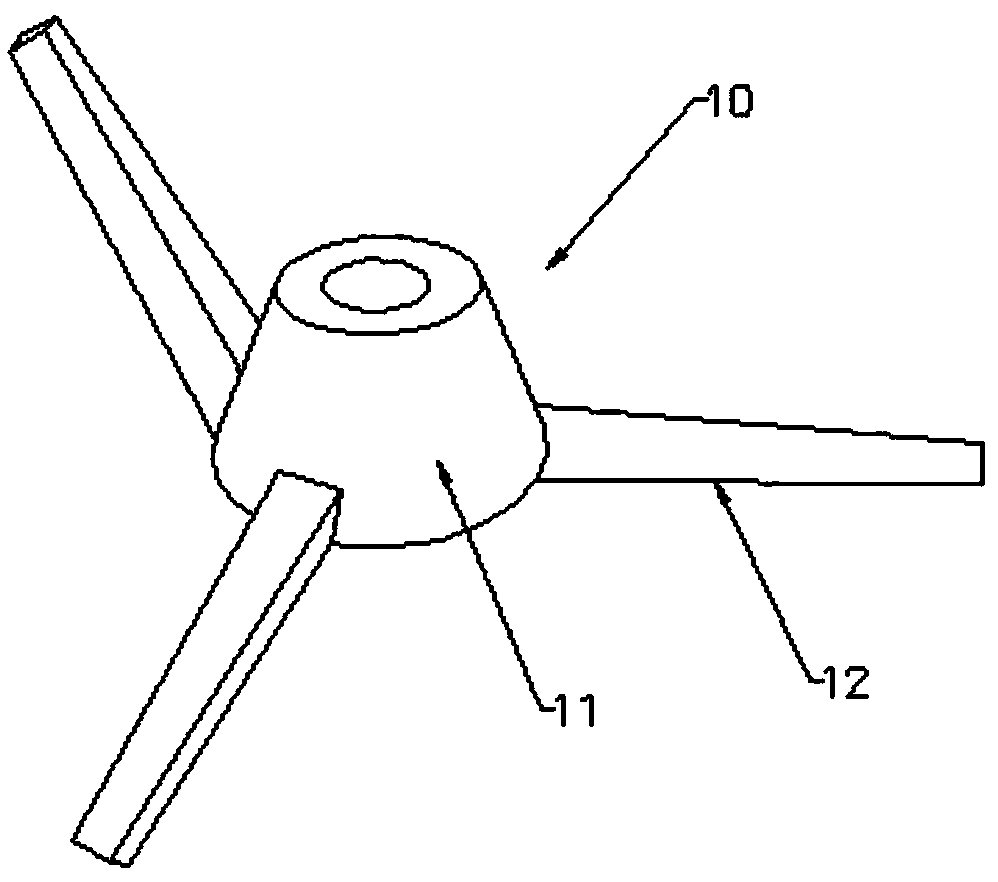

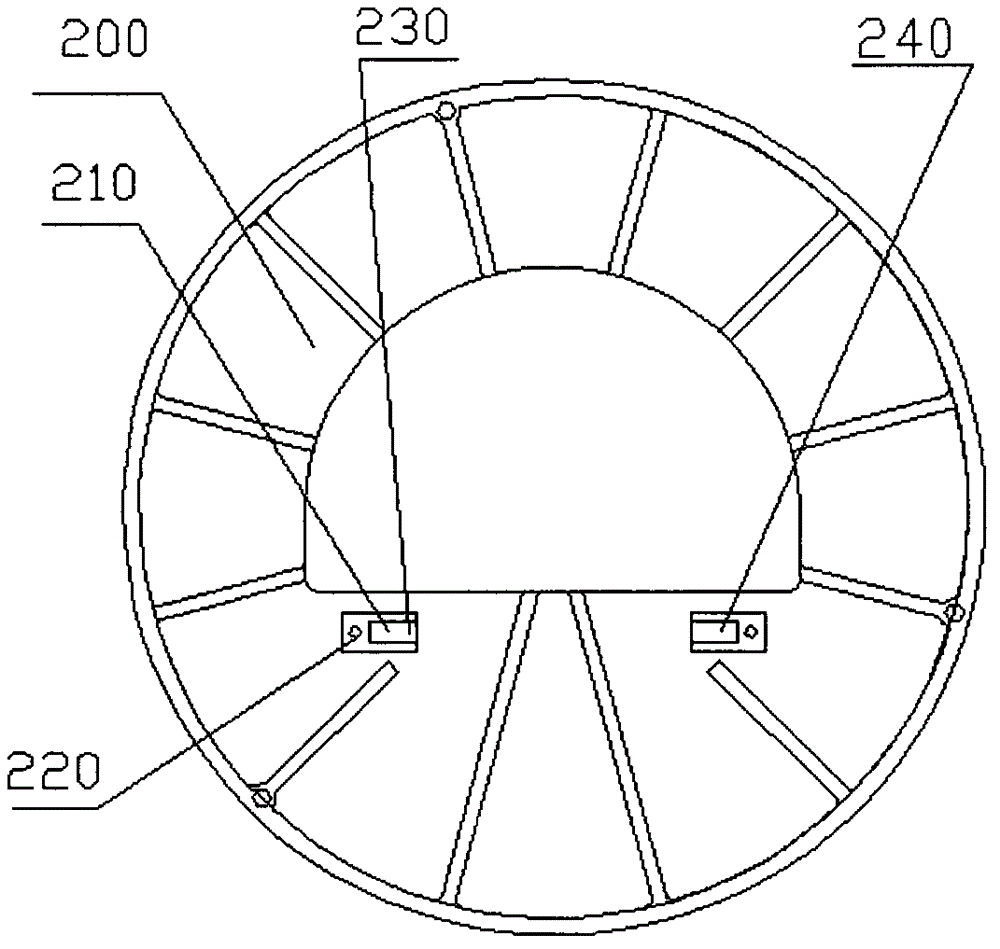

Impeller aligning method of wind turbine generator system

InactiveCN107676229AReduce breakageReduce riskWind motor assemblyWind energy generationWind drivenImpeller

The invention provides an impeller aligning method of a wind turbine generator system, and belongs to the technical field of wind turbine generator systems. The impeller aligning method of the wind turbine generator system comprises the following steps: (S1) a hub of a wind driven generator is mounted on an impeller aligning tool; (S2) three blades are mounted on the hub in sequence; connecting lines between the gravity center positions of blade auxiliary lifters and the gravity center positions of the blades are perpendicular to the blades; blade back edge protectors are mounted in the bladeback edge positions of the blades; the blade auxiliary lifters lift the blades through fixing in the blade back edge positions of the blades; and the blades are rotated and mounted on the hub; (S3) single blade is feathered by 90 degrees until three blades are feathered; and (S4) the blade back edge position of one blade is fixed through the blade auxiliary lifters; the hub is fixed through an impeller main lifter; and the blade auxiliary lifters and the impeller main lifter are matched to balance the impeller to finish the aligning installation of the impeller. The lifting time and the lifting cost can be reduced; and meanwhile, the blade rupture and deformation risks can be reduced.

Owner:NANJING ZHONGREN ENERGY TECH

Assembly of an aircraft structure assembly without shimming, locating fixtures or final-hole-size drill jigs

A method is provided for assembling an aircraft structure assembly composed of a plurality of sections, and doing so without use of any shimming, locating fixtures or final-hole-size drill jigs. The method includes supporting the first and second frame sections on respective adjustable supports, and positioning the interconnecting frame section therebetween. The method includes aligning first pre-drilled mating holes in the interconnecting frame section with first pre-drilled mating holes in the first and second frame sections, and installing fasteners though the aligned, first pre-drilled mating holes. The method includes positioning a structural mating section relative to the first and second frame sections and interconnecting frame section. And aligning second pre-drilled mating holes in the structural mating section with second pre-drilled mating holes in at least one of the frame sections, and installing fasteners through the aligned, second pre-drilled mating holes to secure the structural mating section.

Owner:THE BOEING CO

Body Lumen Junction Localization

ActiveUS20190133489A1Improve spatial resolutionReduction toolCatheterDiagnostic recording/measuringMedical deviceBiomedical engineering

Owner:3DT HLDG

A labor-saving automobile hub forming method and device thereof

InactiveCN100475429CReduction toolReduce equipmentShaping toolsExtrusion diesEngineeringMechanical engineering

Owner:ZHONGBEI UNIV

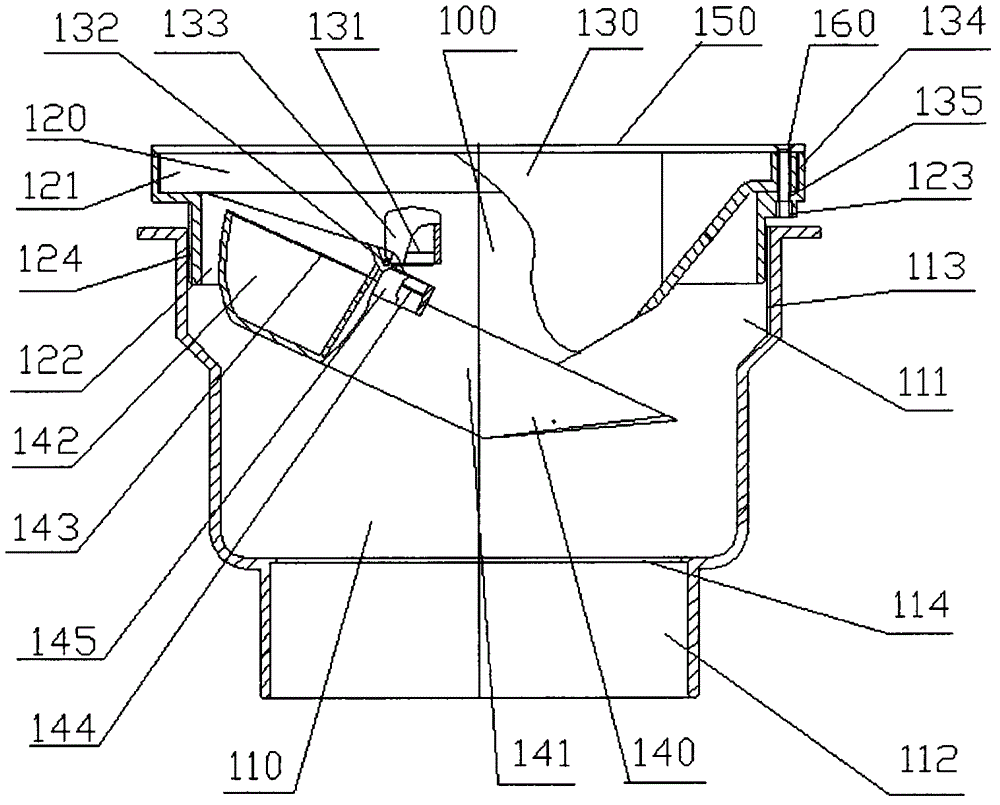

Magnetic sealed tipping bucket type floor drain with better performance and simpler mold, and derivative magnetic sealed tripping bucket type floor drain style sensor

ActiveCN106149847AImprove performanceSimple moldingSewerage structuresMachines/enginesWater dischargeGrating

The invention provides a magnetic sealed tripping bucket type floor drain with better performance and a simpler mold, and a derivative magnetic sealed tripping bucket type floor drain style sensor. The magnetic sealed tripping bucket type floor drain comprises a body, an adjusting ring, a funnel assembly, a tripping bucket assembly, a stainless steel grating and a countersunk stainless steel screw. The magnetic sealed tripping bucket type floor drain is characterized in that the vertical wall of the funnel can support radiating ribs of the grating, thereby improving bearing capability of the floor drain; the magnet pair of the funnel assembly and the tripping bucket assembly are next to a bearing pair, thereby improving sealing capability and resetting capability; and the lower bellmouth of the body is provided with a blocking ring for preventing penetration of a water discharging pipe into a first upper bellmouth. Between the body and the adjusting ring, projected rims are utilized for stabilizing height and keeping the reasonable structure of the bearing pair. In injection molding of components, the mold only performs reciprocation so that the mold is simpler. The magnetic sealed tripping bucket type floor drain is further characterized in that the derivative magnetic sealed tripping bucket type floor drain style sensor comprises a plastic reed switch and a third magnet. The derivative magnetic sealed tripping bucket type floor drain style sensor can perform functions of discharging water, sensing water pooling on ground, etc.

Owner:俞文迪 +1

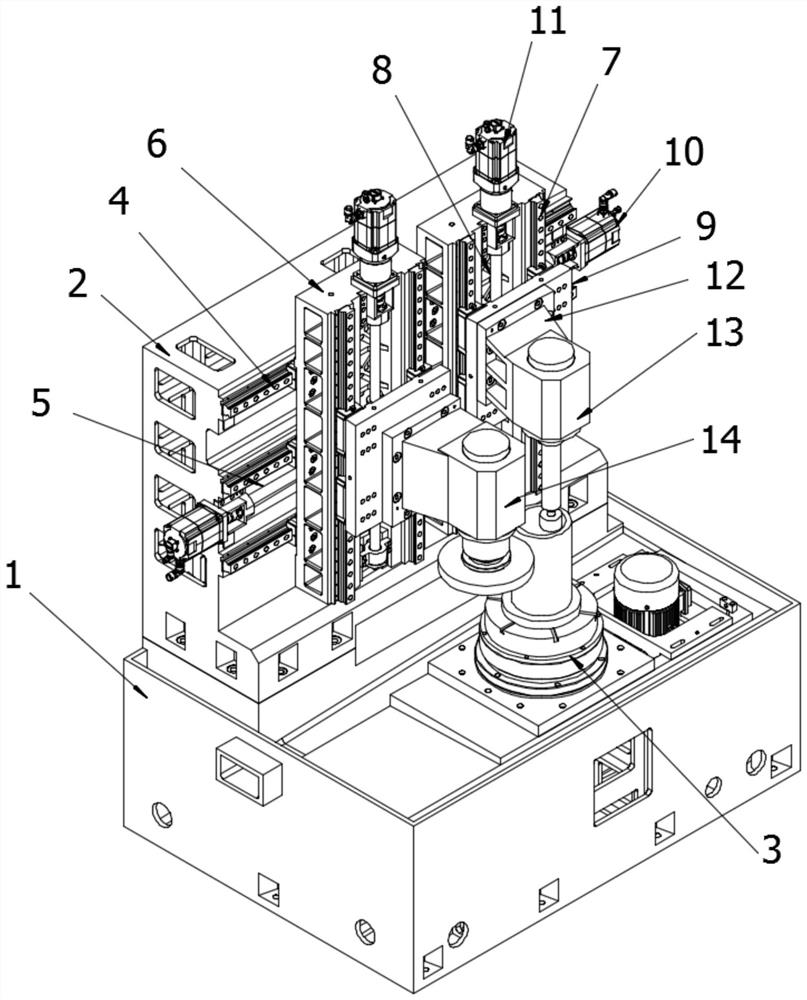

Vertical internal and external grinding machine capable of simultaneously grinding internal and external circles

PendingCN112548703AHigh precisionImprove processing efficiencyRevolution surface grinding machinesPhysicsGrinding

The invention discloses a vertical internal and external grinding machine capable of simultaneously grinding internal and external circles. The vertical internal and external grinding machine comprises a machine body base, wherein a stand column is fixedly installed on one side of the machine body base, a rotary workbench is fixedly installed on the other side of the machine body base, a pluralityof horizontal linear guide rails are fixedly installed on the vertical side wall of the side, facing the rotary workbench, of the stand column at equal intervals, the vertical side wall of the standcolumn is further fixedly provided with horizontal ball screws on the upper side and the lower side of the horizontal linear guide rail located in the middle respectively, and two horizontal moving dragging plates are further arranged on the linear guide rails in a sliding mode. In order to overcome the defects in the prior art, the vertical internal and external grinding machine capable of simultaneously grinding the internal and external circles is designed, four pairs of feeding shafts in the vertical direction and the horizontal direction are designed, and an inner hole grinding head bodyand an external grinding head body can be driven to simultaneously machine the internal diameter and the external circle of a tubular workpiece; and meanwhile, the upper end face can be machined.

Owner:ANJI YUANMO MECHANICS TECH CO LTD

Transporting plate and seal combination, transporting plate, transporting pad seal and compressor plate, and seal kit for vehicle air conditioning compressor and related methods

InactiveUS20050051971A1Prevent and substantially reduce leakage of fluidReduce and minimize inventoryEngine sealsPositive displacement pump componentsEngineeringAir conditioning

A vehicle air conditioning compressor plate and seal combination to be positioned on a housing of a vehicle air conditioning compressor, a plate member, and a pad seal member, and related methods are provided. The combination includes a transporting plate member having a plate body including a first transporting pad seal opening formed in and extending through a first end portion of the plate body from an upper surface to a lower surface thereof and adapted to coaxially align with the fluid opening in the air conditioning compressor housing when the lower surface of the plate body is positioned adjacent thereto and a second transporting fastener opening extending through a second end portion and a medial portion of the plate body from the upper surface to the lower surface thereof and adapted to be positioned adjacent the fastener opening in the air conditioning compressor housing when the plate body is positioned adjacent thereto. The combination also includes a transporting pad seal member including a seal body having a seal base adapted to be positioned in the fluid opening of the air conditioning compressor housing and a seal grip connected to and extending outwardly from the seal base and adapted to be positioned into the first transporting pad seal opening of the plate body.

Owner:SANTECH IND LLC

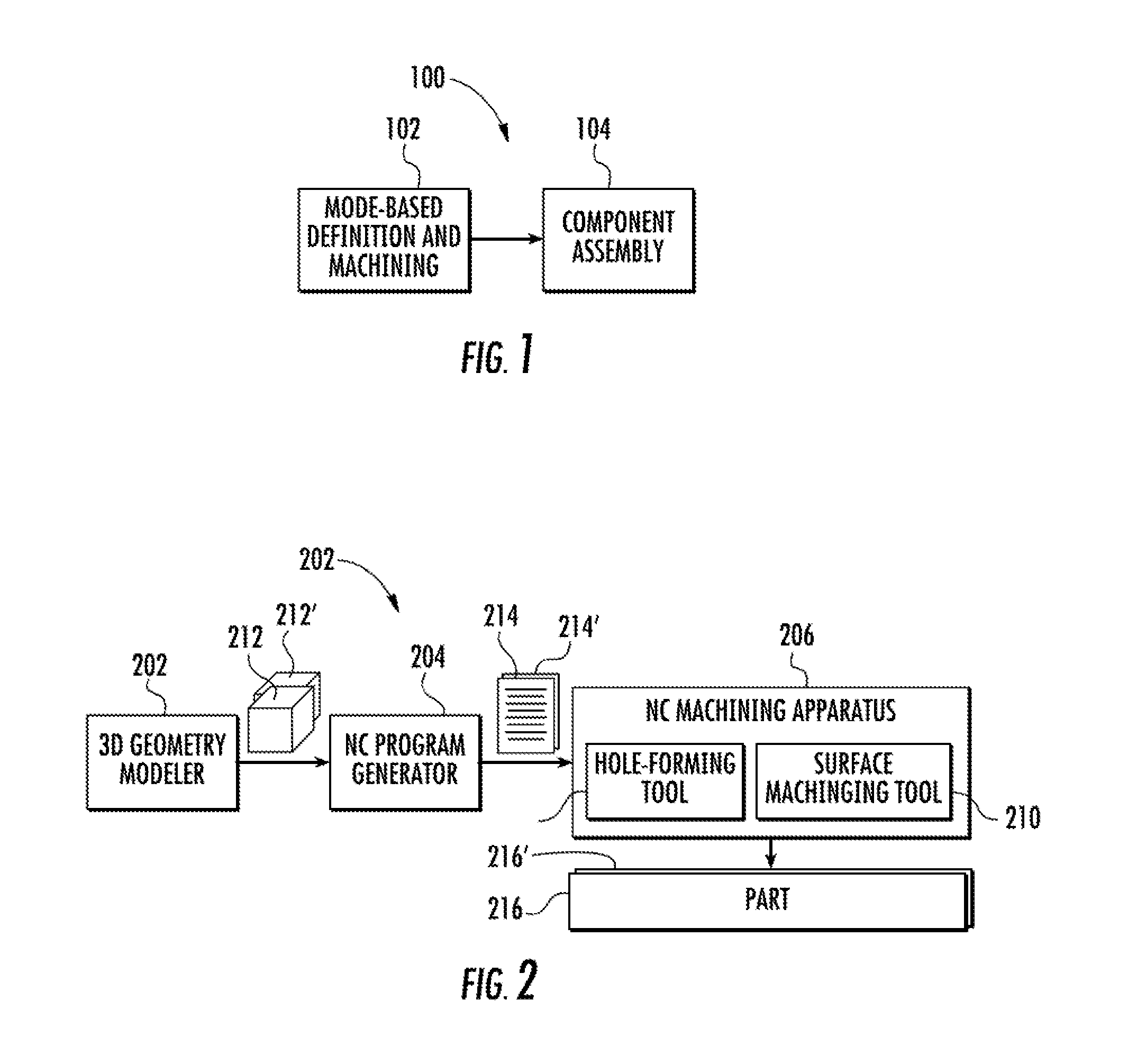

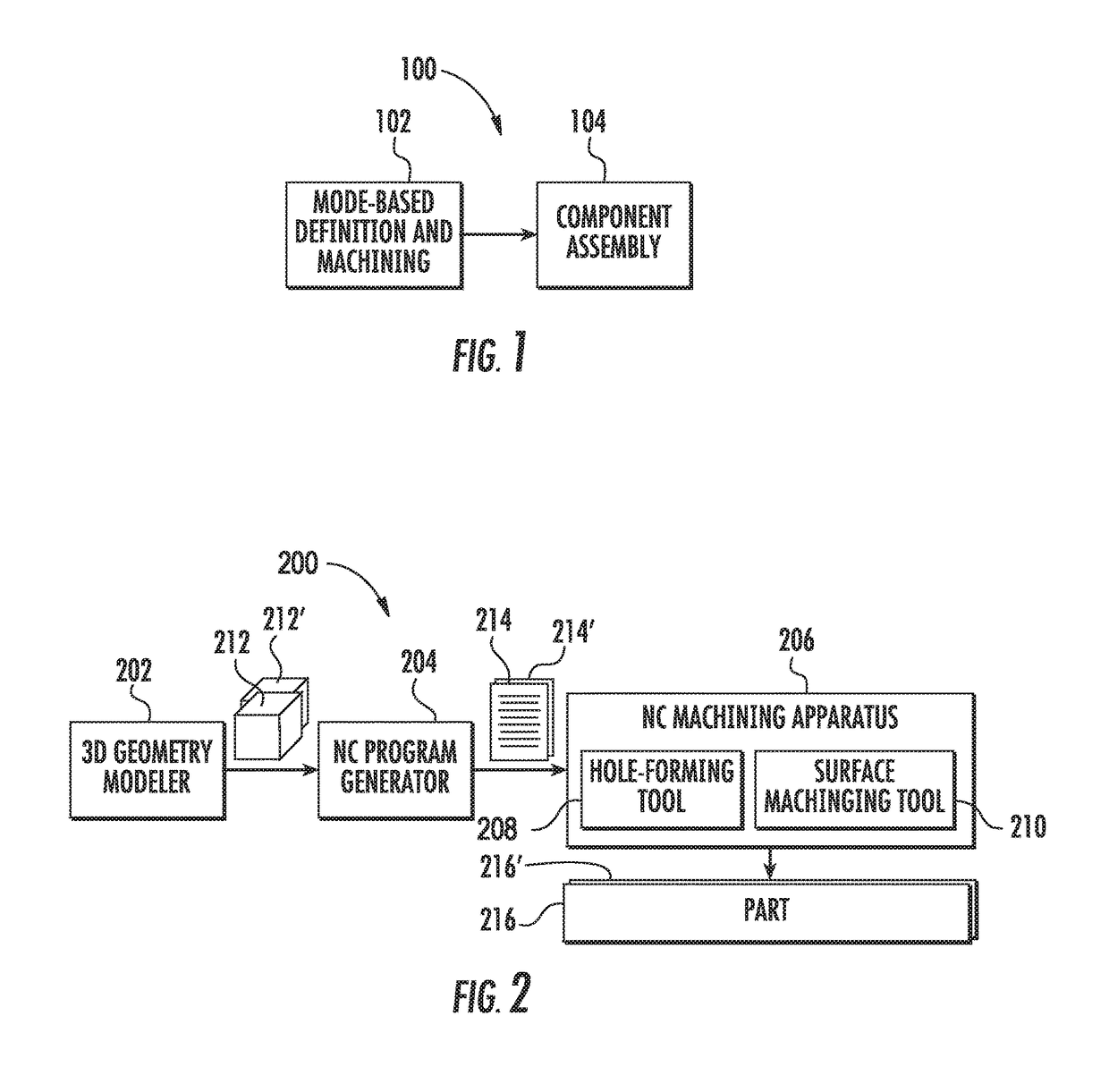

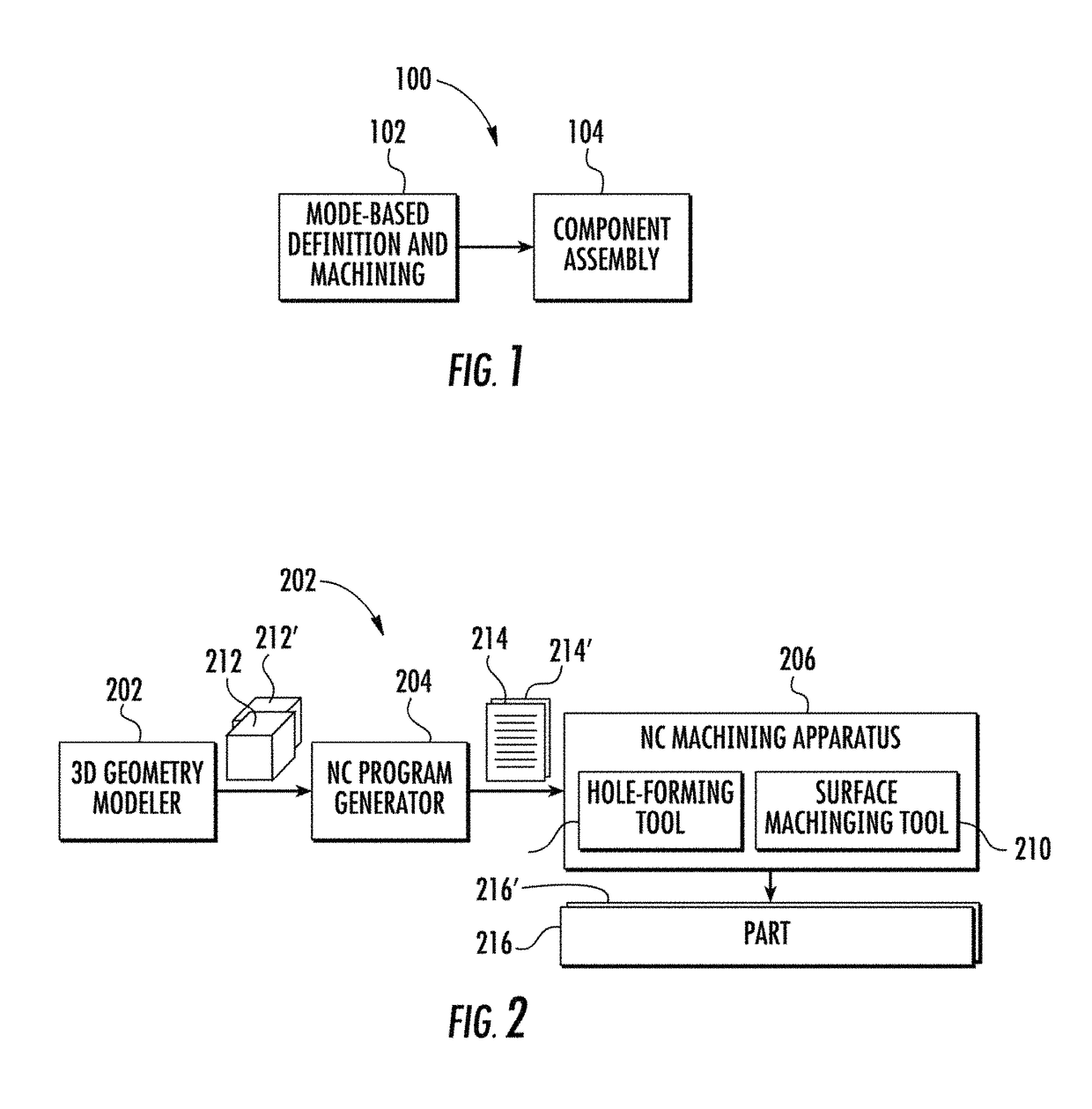

Model-based definition for machining aircraft parts

ActiveUS10144530B1Easy to installLow costProgramme controlComputer controlGeometric dimensioning and tolerancingProcess capability

A method of manufacturing aircraft parts includes creating corresponding 3D geometry models representing surface features and holes of the aircraft parts sized to nominal dimensions. The method includes sending the 3D geometry models to respective manufacturing facilities for each to generate a NC machining program directly from a 3D geometry model, with instructions for a single NC machining apparatus to machine an aircraft part, and including instructions to machine the surface features and / or holes to the modeled dimensions. And for each of the respective manufacturing facilities to machine the aircraft part utilizing the NC machining program. For this, the NC machining apparatus utilizes tool(s) set at substantially the modeled dimensions, instead of at a high or low side of related tolerance range(s) to allow for tight geometric dimensioning and tolerancing requirements. This method enables the full process capability of the CNC machines while utilizing inspection tolerances that are measurable.

Owner:THE BOEING CO

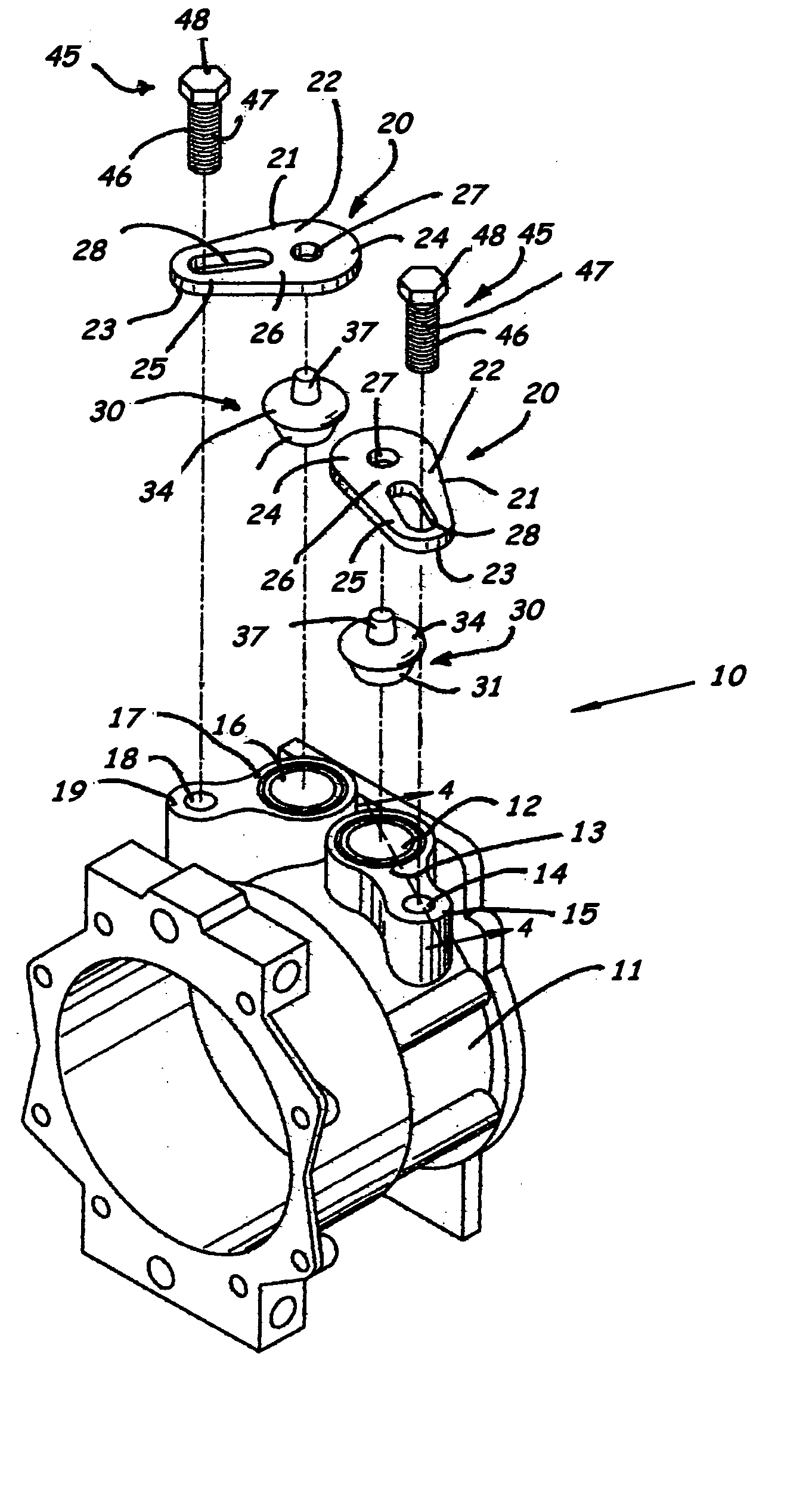

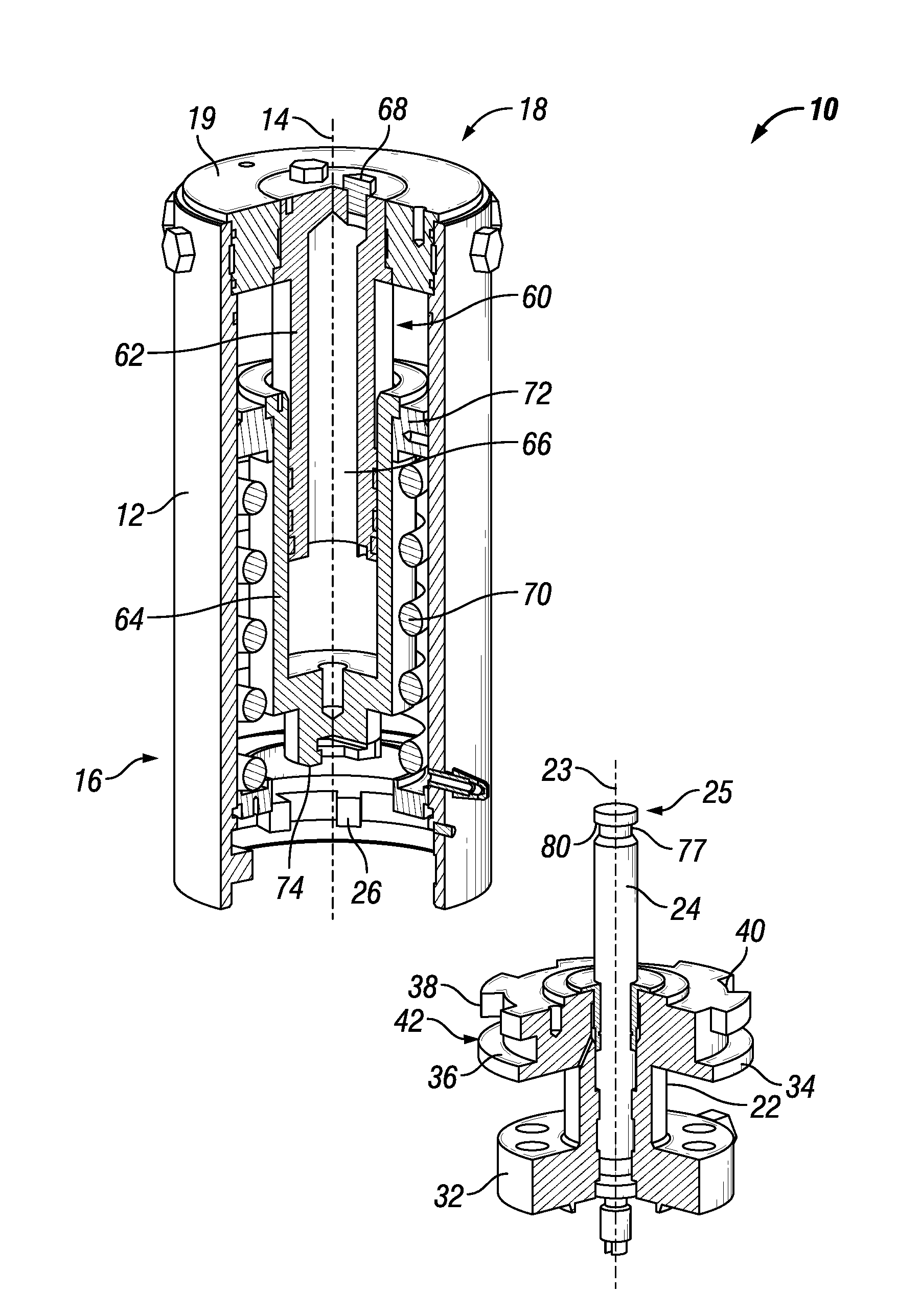

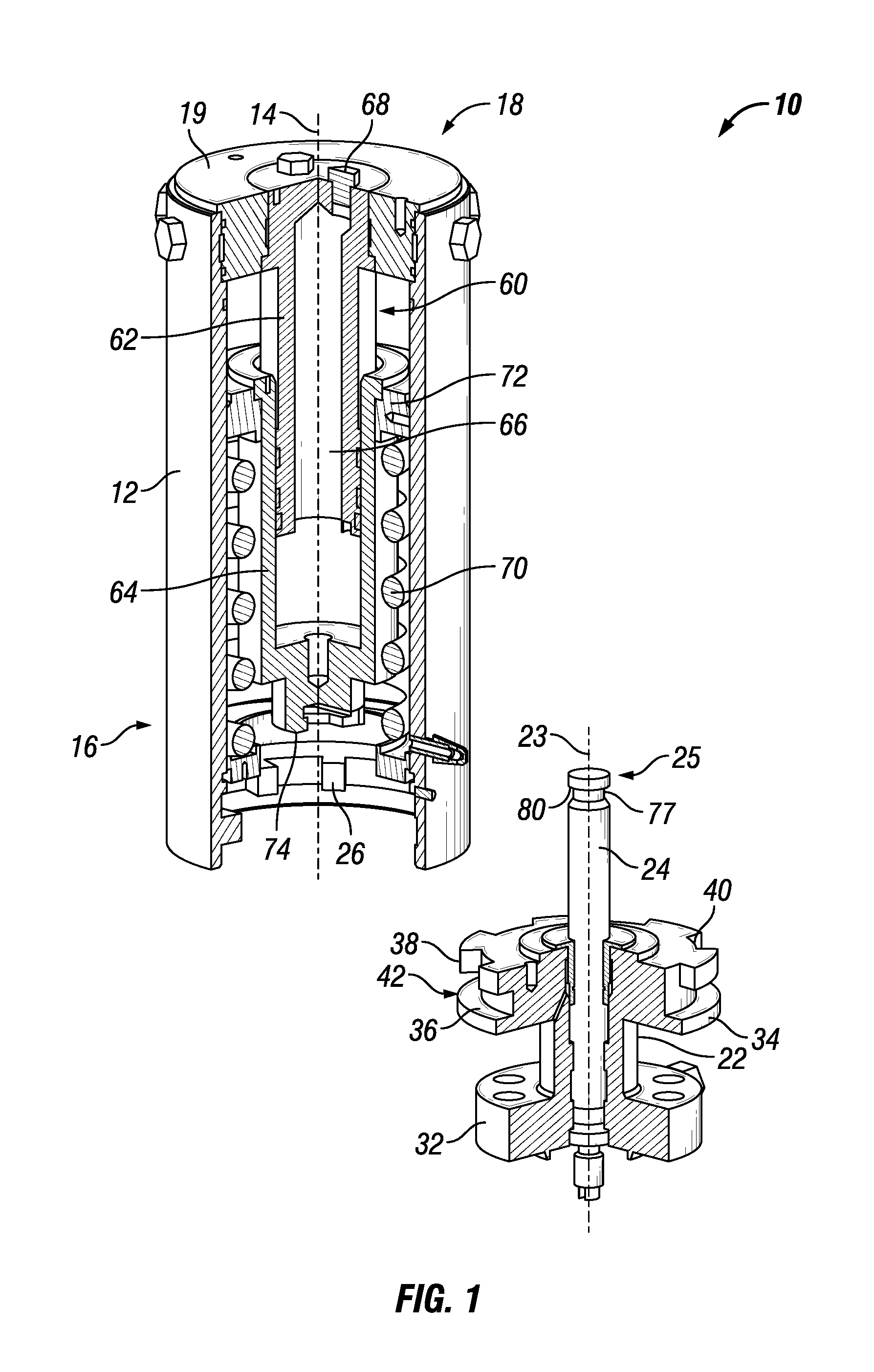

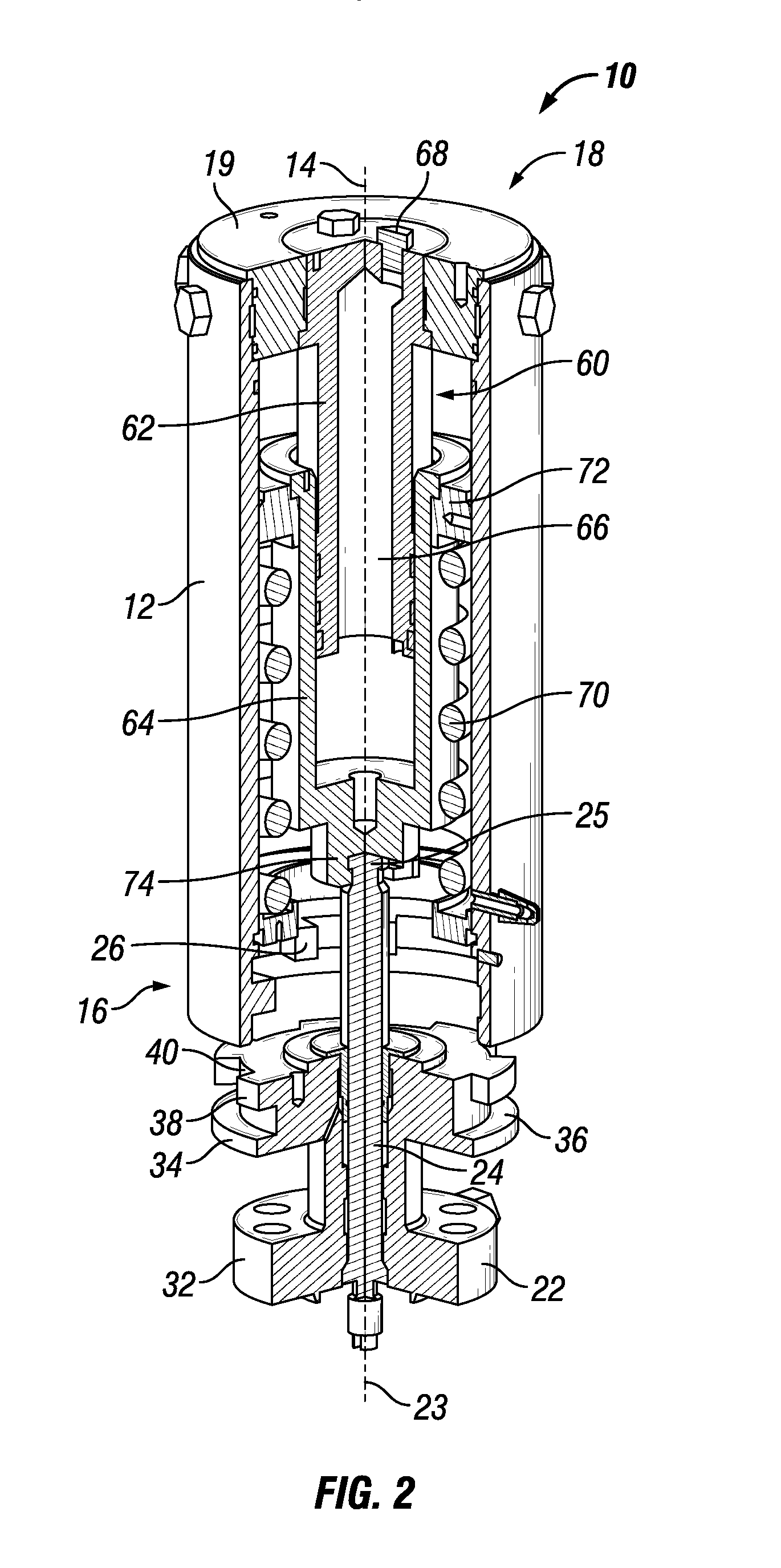

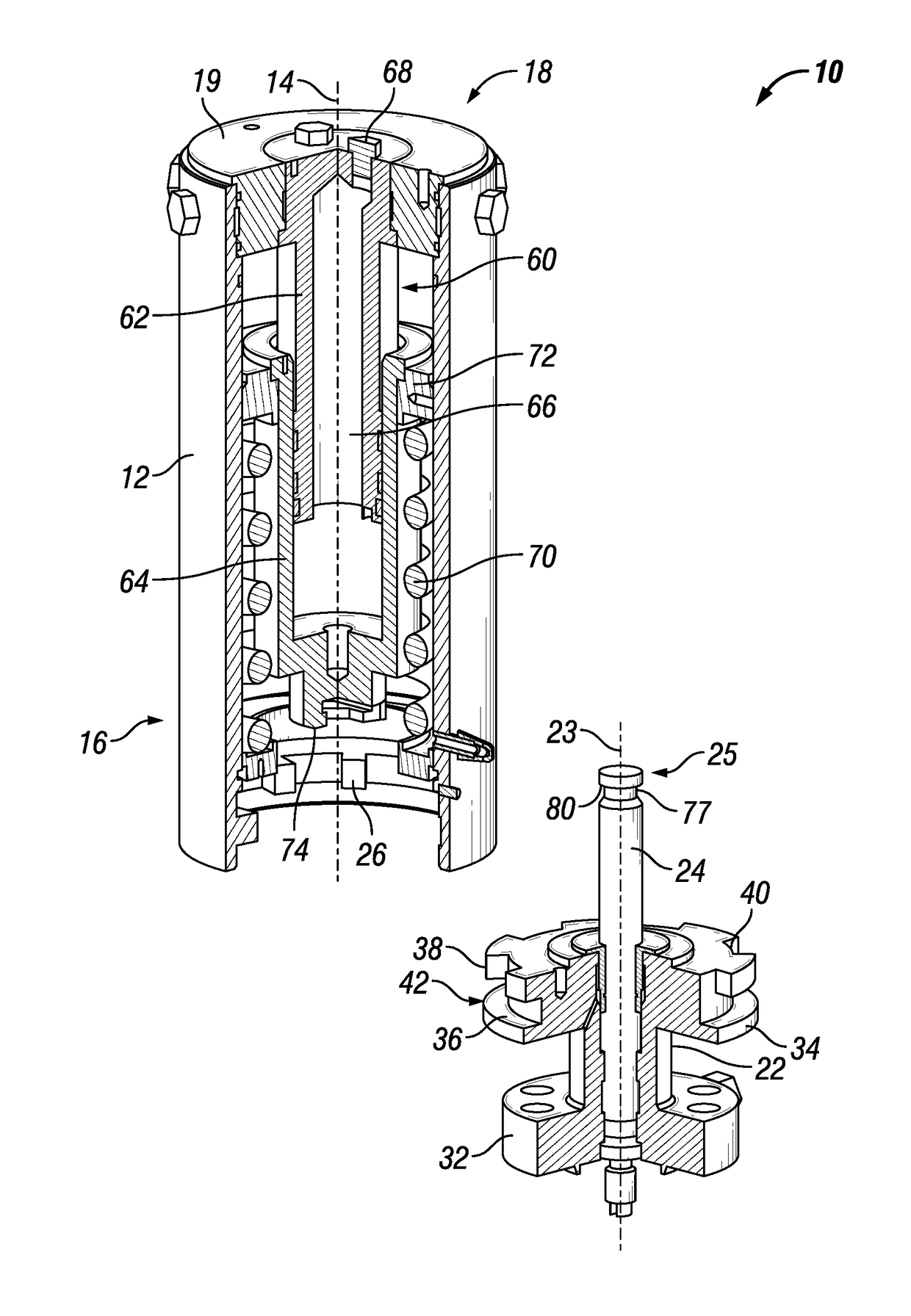

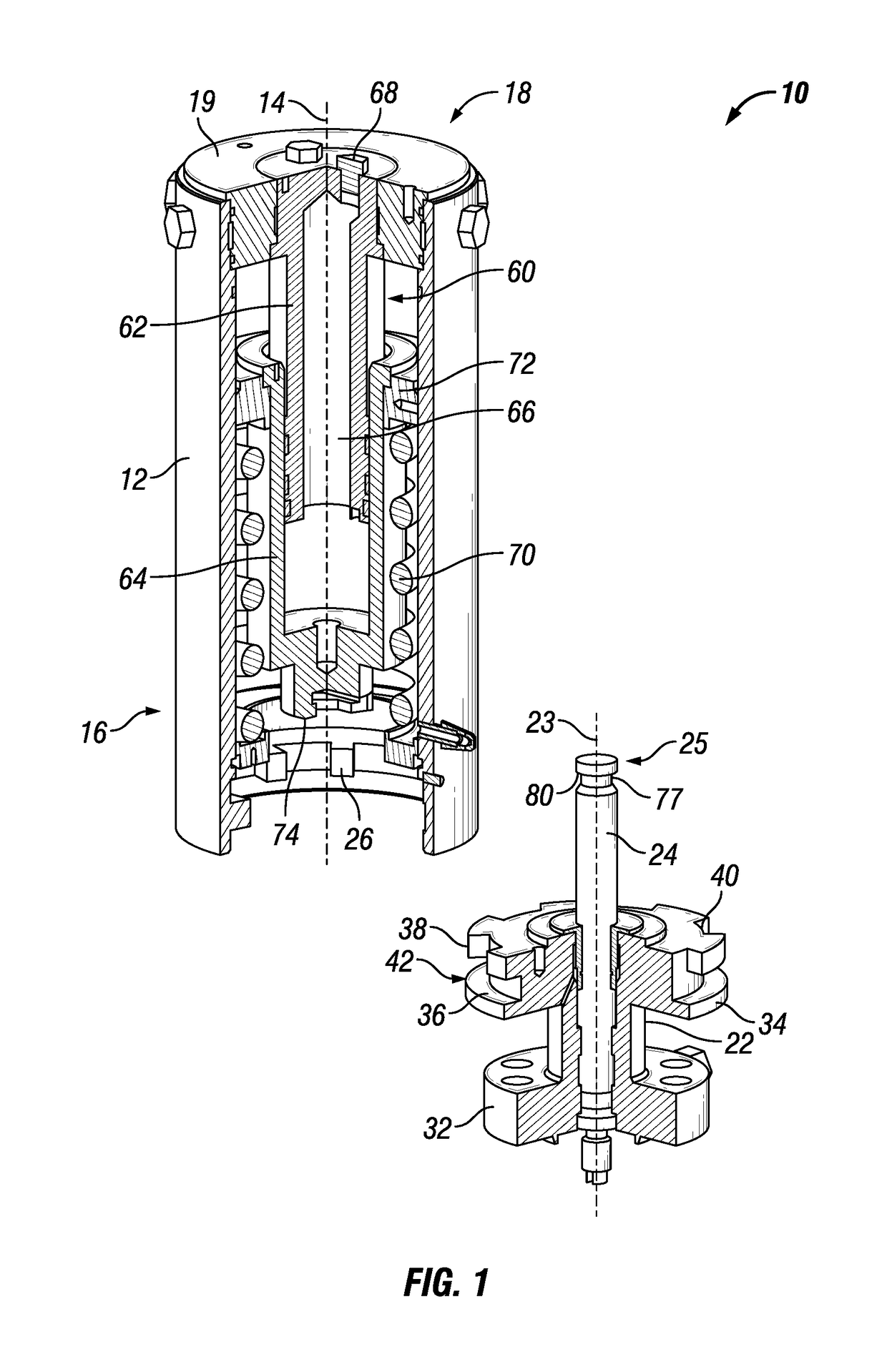

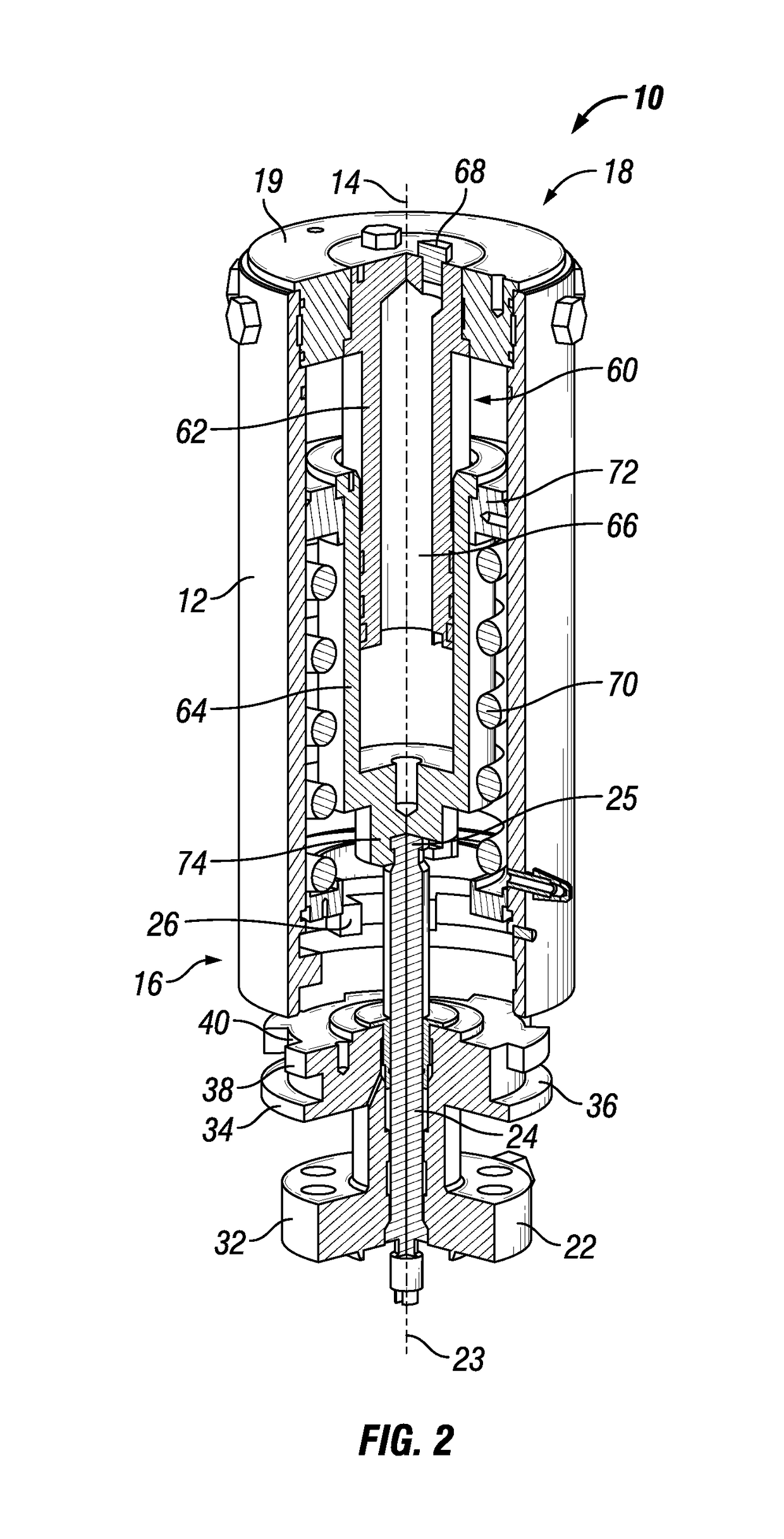

Compound express actuator connection

ActiveUS20160281876A1Prevent movementShorten the timeOperating means/releasing devices for valvesLift valveValve stemEngineering

A system for securing a valve actuator to a valve assembly includes an actuator housing with a plurality of housing lugs protruding radially. A cylinder assembly is located within the actuator housing and has a horseshoe connector to engage a valve stem nub of a valve stem and transfer axial movement of the horseshoe connector to axial movement of the valve stem. A bonnet has a plurality of bonnet lugs protruding radially from the bonnet to define a plurality of bonnet slots therebetween, wherein each of the plurality of housing lugs are sized to pass axially through a respective one of the plurality of bonnet slots when the actuator housing is in a released position, the actuator housing being rotatable to a locked position such that the plurality of bonnet lugs prevent axial movement of the actuator housing in at least one direction.

Owner:GE OIL & GAS PRESSURE CONTROL

High-precision vertical and horizontal dual-purpose composite grinding machine adopting mineral castings

InactiveCN113334163AGuaranteed accuracyGuaranteed efficiencyGrinding carriagesRevolution surface grinding machinesElectric machineryMachine

The invention relates to a high-precision vertical and horizontal dual-purpose composite grinding machine adopting mineral castings. The high-precision vertical and horizontal dual-purpose composite grinding machine comprises a machine body base, wherein a stand column is fixedly arranged on one side of the machine body base, and a rotary workbench is fixedly arranged on the other side of the machine body base; a plurality of horizontal linear guide rails which are evenly spaced are fixedly arranged on the vertical side wall of the side, facing the rotary workbench, of the stand column; the vertical side wall of the stand column is further fixedly provided with a horizontal linear motor on the upper side and the lower side of the horizontal linear guide rail located in the middle; and two horizontal moving plankers are further arranged on the horizontal linear guide rails in a sliding mode. The design of the linear motors and the linear guide rails with IMS measurement grating systems is adopted, so that the positioning precision and linear sensitivity of the machine tool are effectively improved, and higher precision can be achieved during circular interpolation machining. The machine body base and the stand column are made of minerals, so that vibration generated during machining is greatly reduced, and the machining precision is improved.

Owner:ANJI YUANMO MECHANICS TECH CO LTD

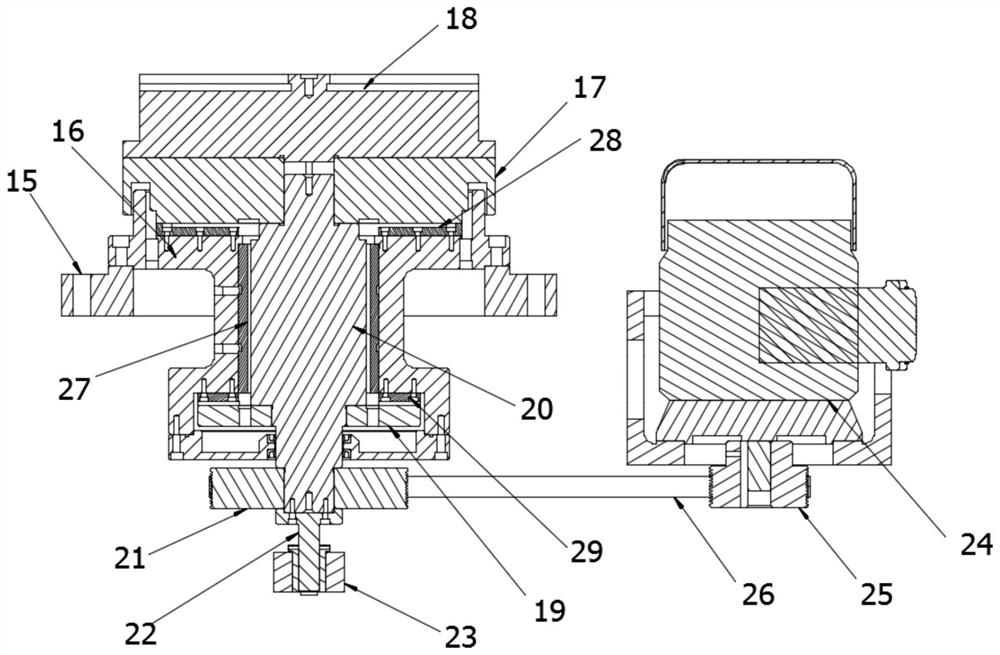

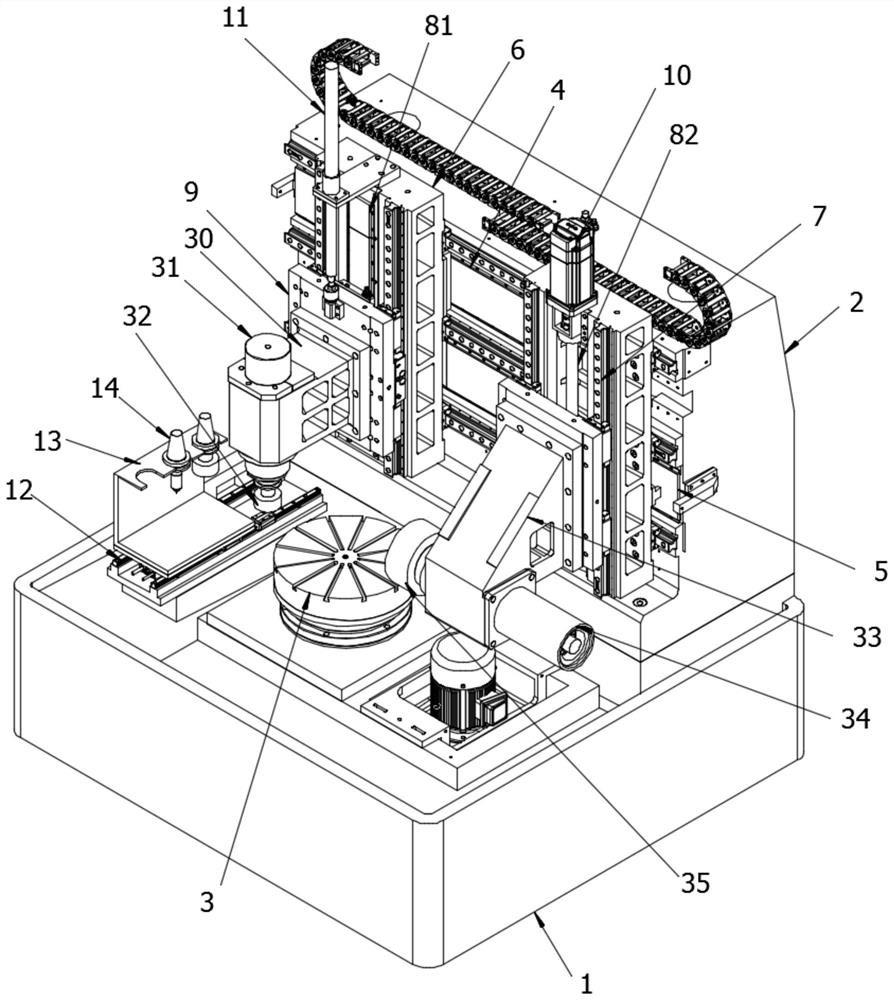

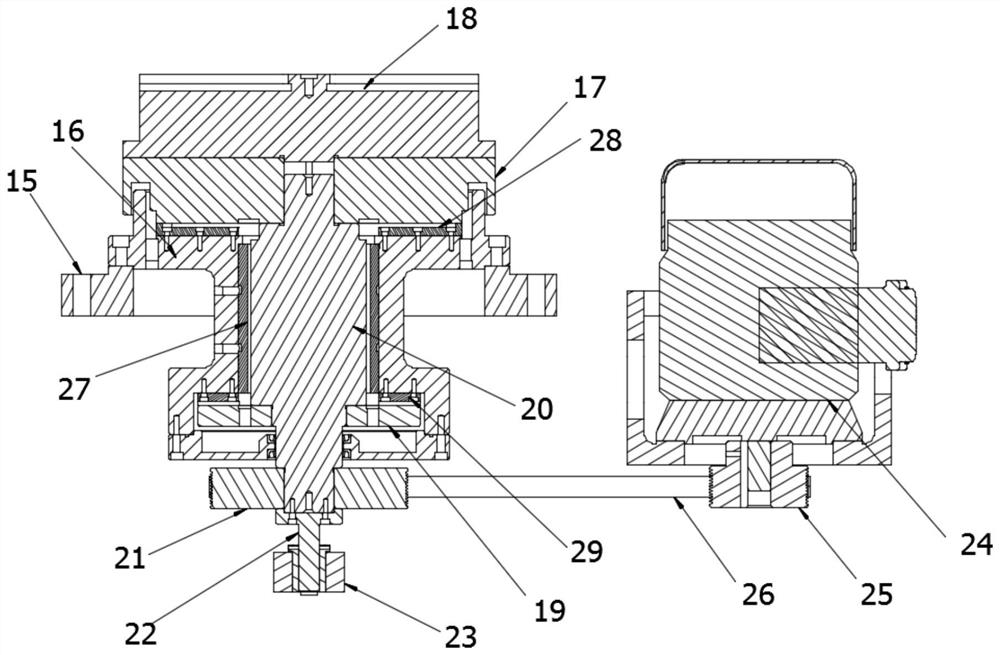

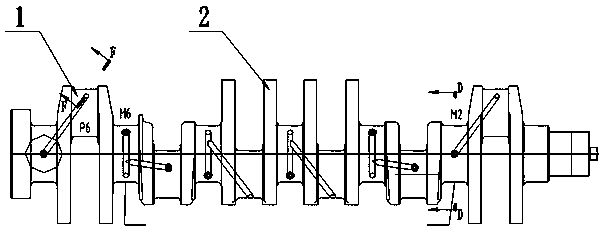

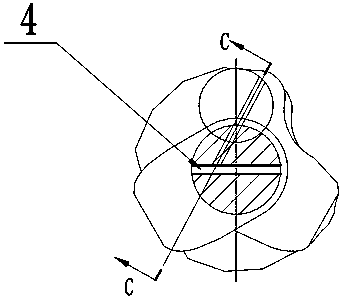

Full-automatic crankshaft oil hole machining numerical control machine tool

PendingCN111037294AReduce frictionInhibit temperature riseAutomatic control devicesFeeding apparatusPhysicsElectrical control

The invention discloses a full-automatic crankshaft oil hole machining numerical control machine tool. The machine tool is used for machining a crankshaft oil hole and chamfering. The machine tool ismainly composed of a lathe bed, a transverse sliding table, a rotating disc, a vertical direction stand column, a perpendicular direction sliding table, a vertical direction sliding table, an index transposition clamp of a crankshaft, a crankshaft axial positioning clamp, a crankshaft radial positioning clamp, a rotating tower power head, a tool monitoring, measuring and alignment system, an electrical control system, a hydraulic control system, a chip removal device system, an MQL lubricating system and a machine tool protection part. Only one machine tool is needed, the rotating tower powerhead is adopted, full automatic machining of straight oil hole leading hole drilling, direct oil hole drilling, inclined oil hole leading hole drilling, inclined oil hole drilling, and chamfering of astraight oil hole and an inclined oil hole of the crankshaft can be achieved, the environment is not polluted, the production environment is thoroughly improved, the automation degree is high, flexibility is high, work efficiency can be effectively improved, and labor intensity is reduced.

Owner:XIANGYANG FUDA DONGKANG CRANKSHAFT

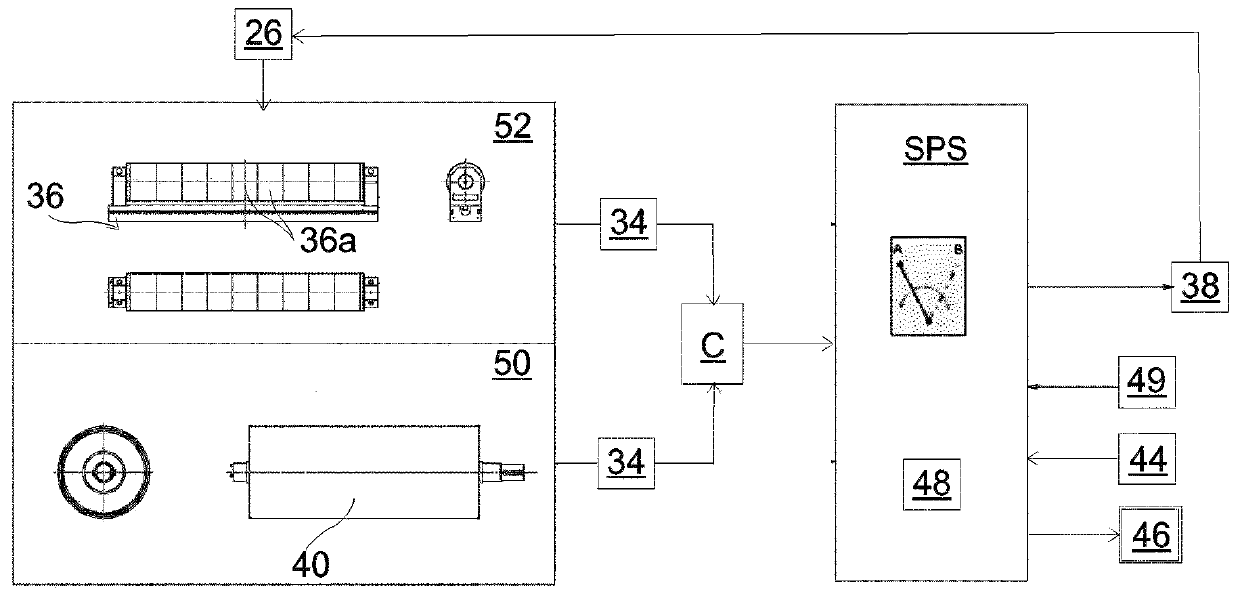

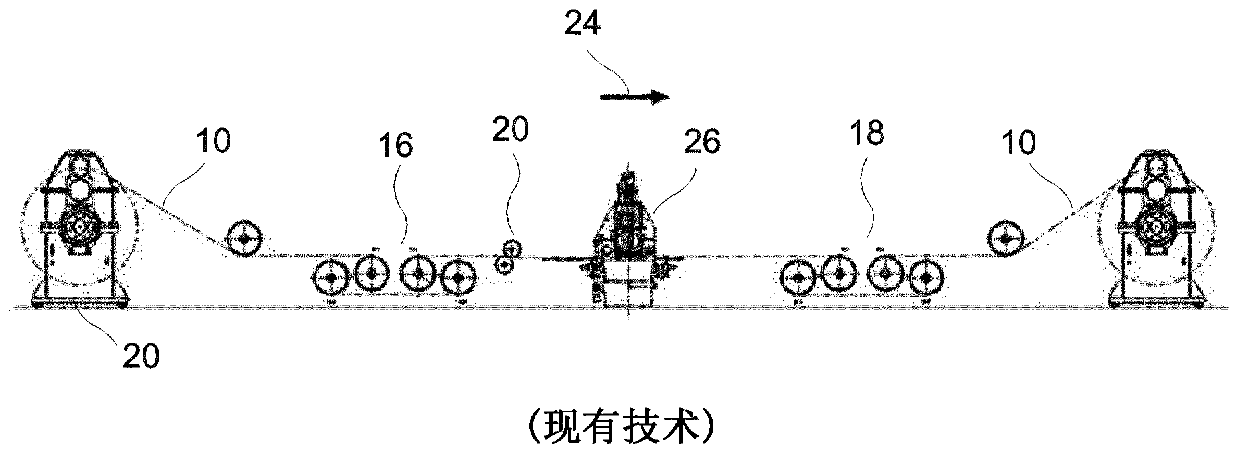

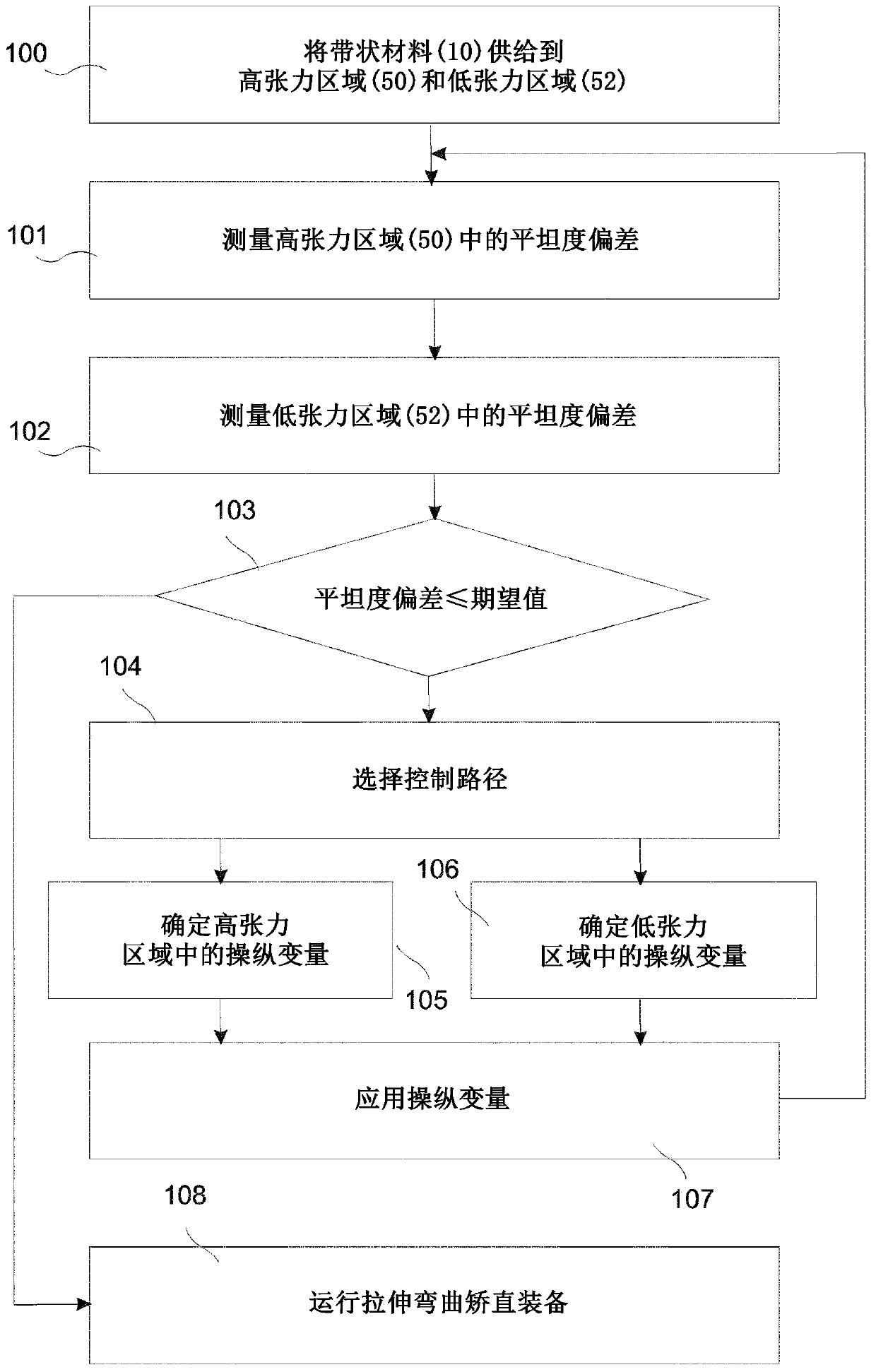

Stretching-bending-straightening system and method for the actuation thereof

ActiveCN110799277AHigh resolutionReduction toolMeasuring devicesMetal rolling arrangementsClassical mechanicsStructural engineering

In a stretching-bending-straightening system and a method for the actuation thereof, material in strip form is fed to a high-tension region (50) and a low-tension region (52), wherein the low-tensionregion (52) is arranged downstream of the high-tension region (50). A bending-straightening unit is arranged in the high-tension region (50). A measuring system determines first measured values in thehigh-tension region (50). A controller (C) is intended and suitable for determining a deviation of the first measured values from a setpoint value of the bending-straightening result and for determining at least one manipulated variable for the bending-straightening unit in dependence on the determined deviation within a first closed control loop. By additionally providing at least one measuringsystem for determining second measured values in the low-tension region, by having a controller (C) intended and suitable for determining a deviation of the second measured values from the setpoint value of the bending-straightening result and for determining the at least one manipulated variable in dependence on the determined deviation within a second closed control loop, and by providing selecting means that are intended and suitable for selecting the first or second closed control loop for reducing the deviation of the first and / or second measured values from the predetermined or predeterminable setpoint value, a stretching-bending-straightening system and a method for the actuation thereof are designed in such a way that the quality of the strips processed thereby is increased.

Owner:BETRIEBSFORSCHUNGSINSTITUT VDEH INSTITUT FUR ANGEWANDTE FORSCHUNG

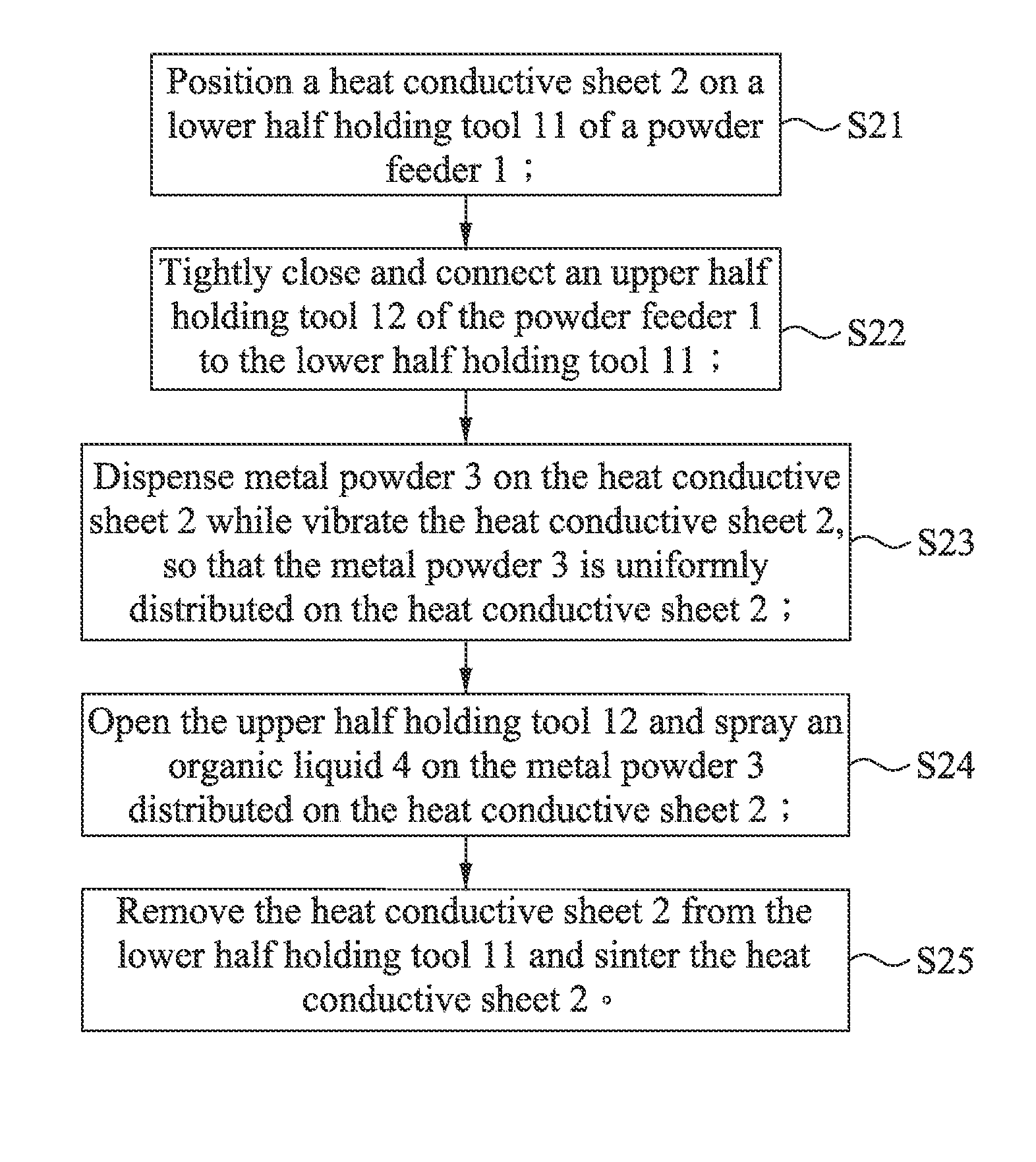

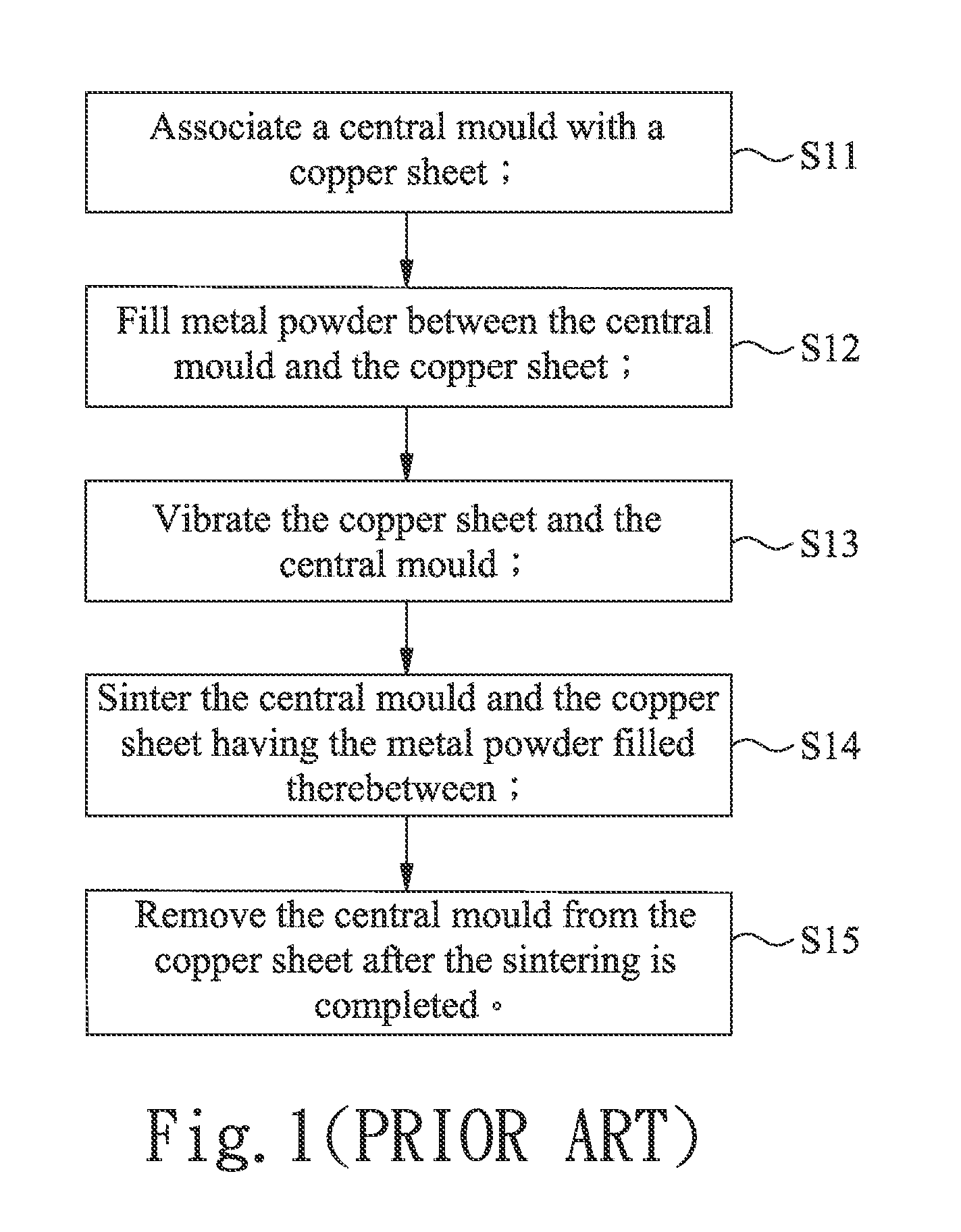

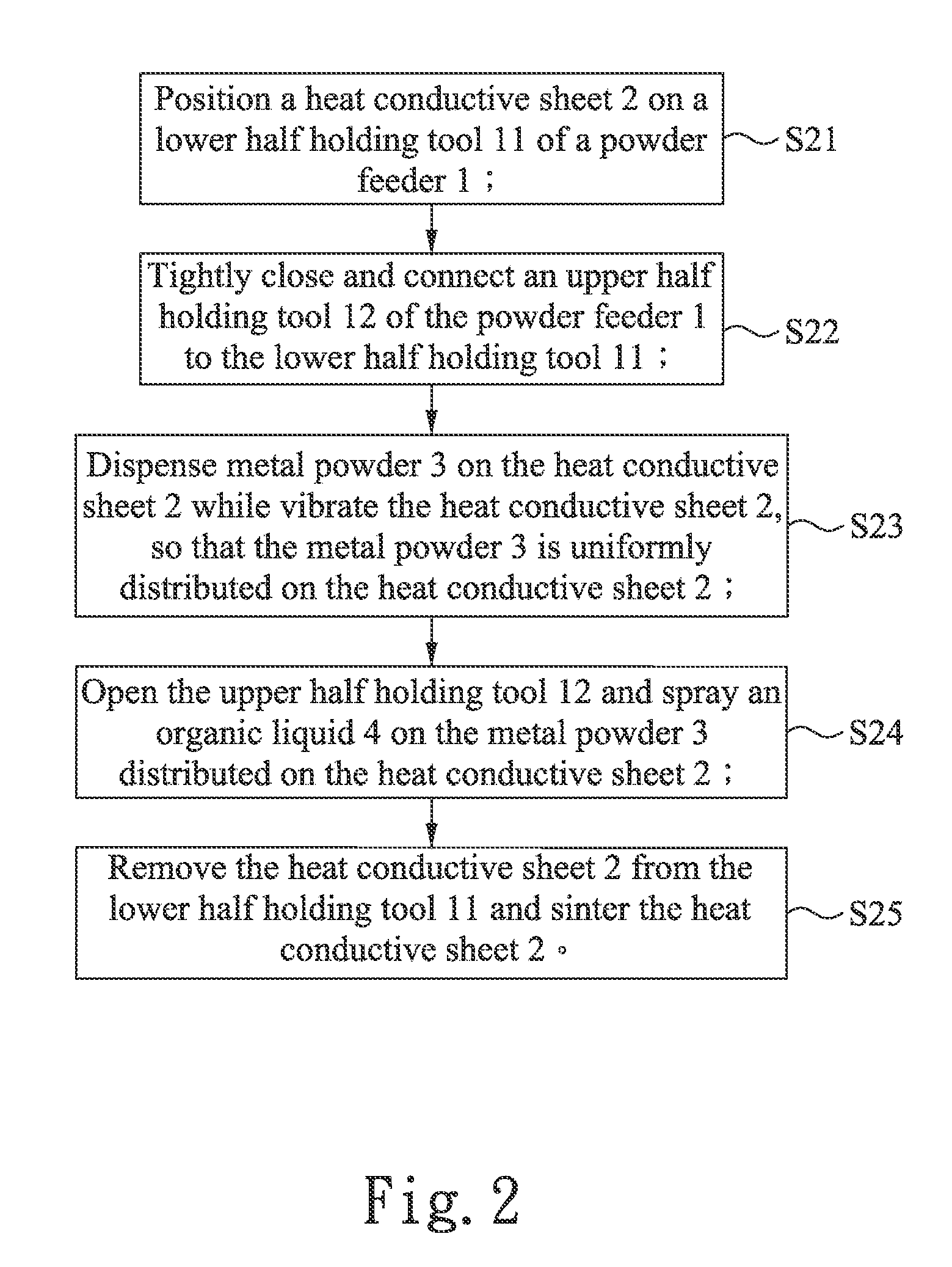

Method of manufacturing heat sink plate

A heat sink manufacturing method includes the steps of positioning a heat conductive sheet on a lower half holding tool of a powder feeder; tightly closing and connecting an upper half holding tool of the power feeder to the lower half holding tool, such that spacers downward extended from the upper half holding tool are in tight contact with the heat conductive sheet; dispensing metal powder on the heat conductive sheet via a powder inlet on the upper half holding tool and under a positive pressure while vibrating the heat conducting sheet for the metal powder to uniformly distribute on the heat conductive sheet; opening the upper half holding tool and spraying an organic liquid on the metal powder for the same to set; and removing the heat conductive sheet from the lower half holding tool and sintering the metal powder to the heat conductive sheet.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Compound express actuator connection

ActiveUS10132422B2Shorten the timeImprove securityOperating means/releasing devices for valvesThin material handlingValve actuatorEngineering

A system for securing a valve actuator to a valve assembly includes an actuator housing with a plurality of housing lugs protruding radially. A cylinder assembly is located within the actuator housing and has a horseshoe connector to engage a valve stem nub of a valve stem and transfer axial movement of the horseshoe connector to axial movement of the valve stem. A bonnet has a plurality of bonnet lugs protruding radially from the bonnet to define a plurality of bonnet slots therebetween, wherein each of the plurality of housing lugs are sized to pass axially through a respective one of the plurality of bonnet slots when the actuator housing is in a released position, the actuator housing being rotatable to a locked position such that the plurality of bonnet lugs prevent axial movement of the actuator housing in at least one direction.

Owner:GE OIL & GAS PRESSURE CONTROL

Terminal position assurance with forward interlocking face keying

InactiveUS7077702B2High strengthAvoid damageVehicle connectorsSecuring/insulating coupling contact membersEngineeringElectrical and Electronics engineering

A connector assembly comprising a cap member having a plurality of fixed cap terminal position assurance mechanisms defined thereon, and a plug member having one or more of fixed plug terminal position assurance mechanisms defined thereon, wherein each of the cap terminal position assurance mechanisms fixably mate with each of the plug terminal position assurance mechanisms, wherein each of the cap and plug terminal position assurance mechanisms comprise a post projecting outwardly from each of the cap member and the plug member, and a cutout configured to fixably mate to the post. The cutout maybe configured adjacent the post, wherein the cap / plug terminal position assurance mechanisms are arranged proximate an outer rim of the cap / plug member or the cap / plug terminal assurance mechanism may be located generally in the center of the interface manifold.

Owner:TE CONNECTIVITY CORP

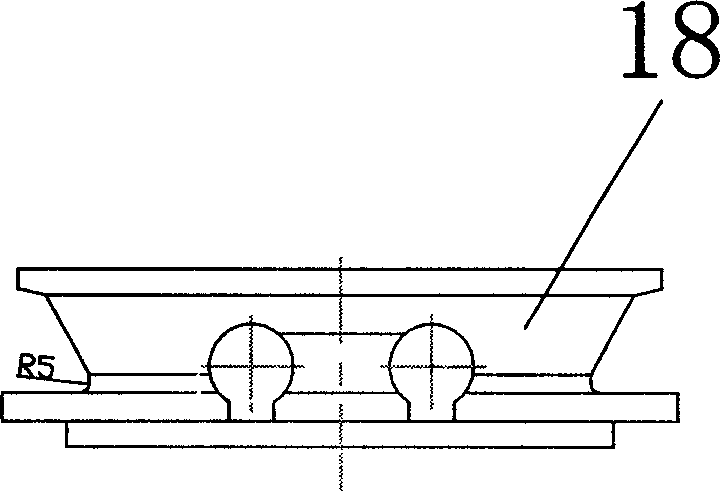

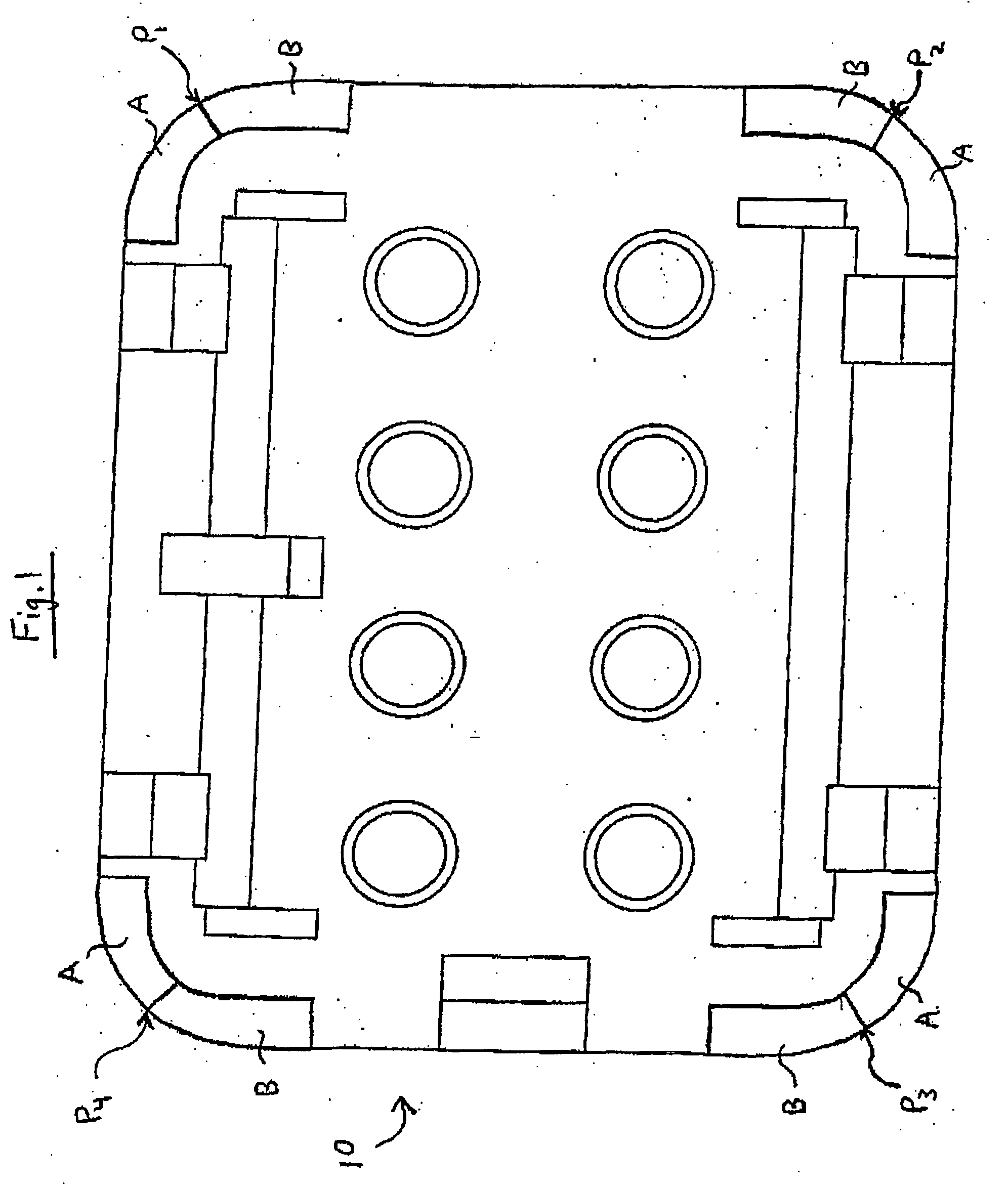

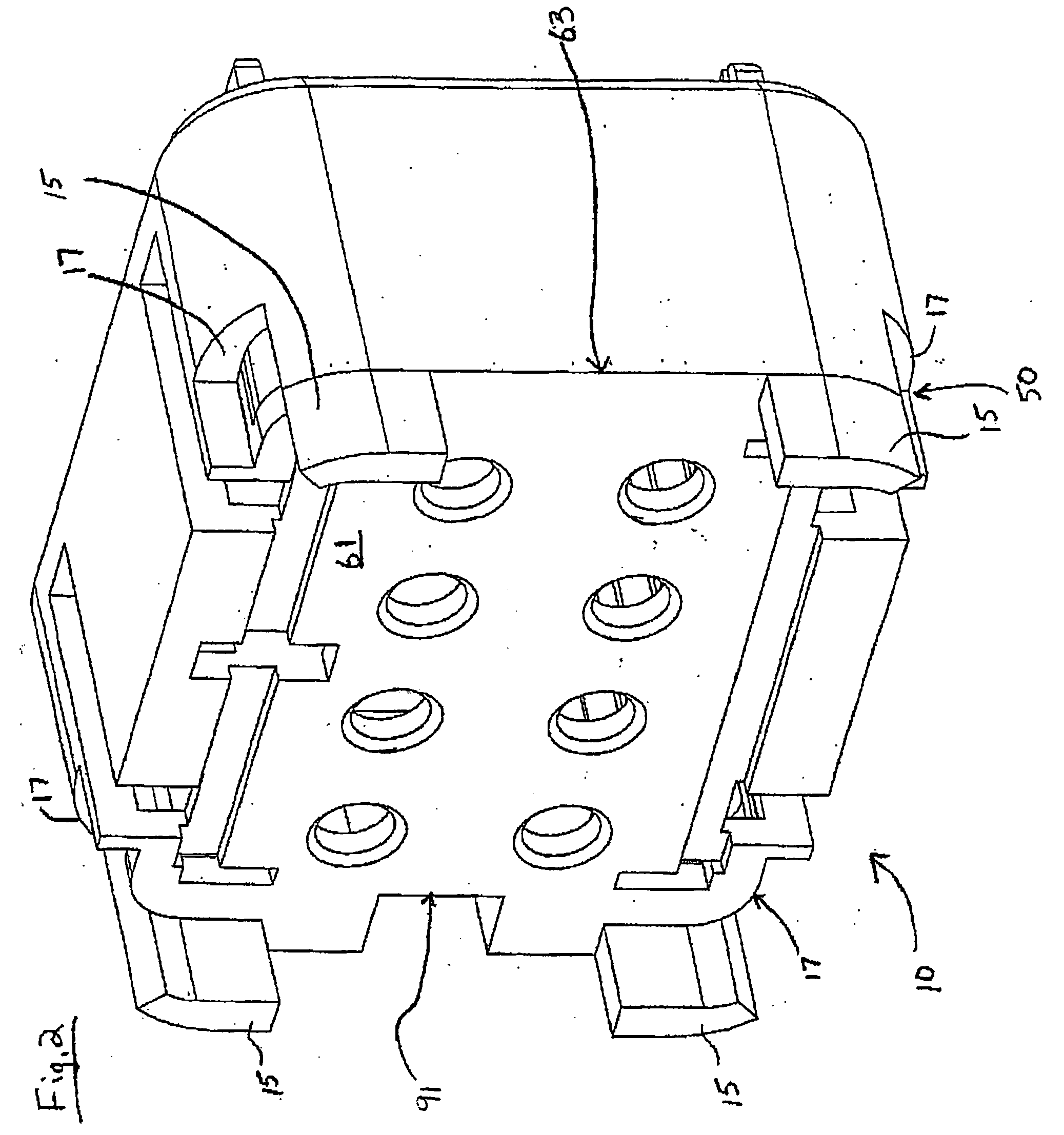

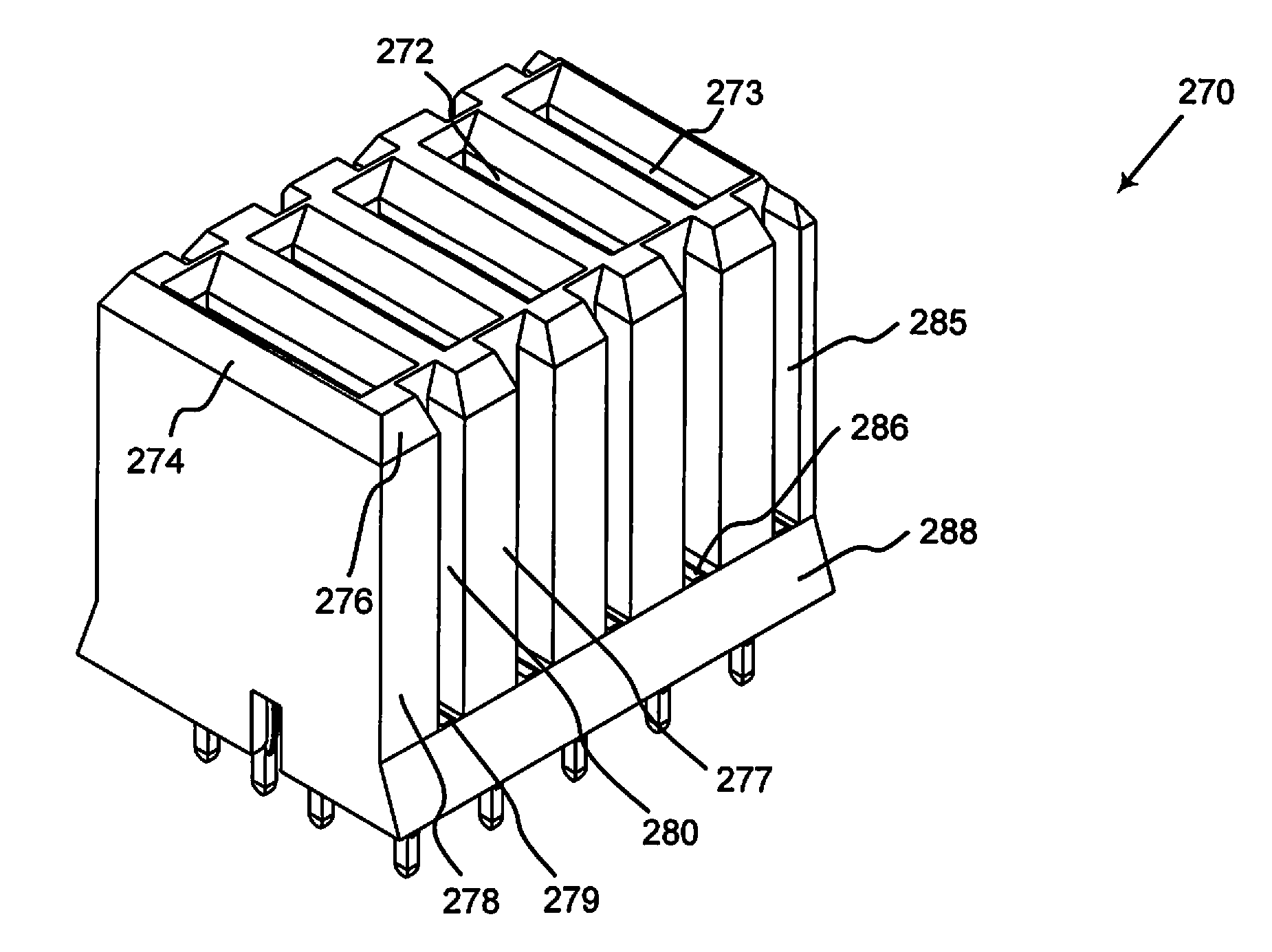

Tools for Seating Connectors on Substrates

ActiveUS20150121690A1Reduction toolReduce connector damagePrinted circuit assemblingLine/current collector detailsEngineeringPrinted circuit board

The present invention relates to connector tools for seating connectors on a substrate such as a printed circuit board. In various embodiments, the connector tools can be made by wire electrode discharge machining (WEDM) process. In the embodiments, the connector tool includes reinforced ribbed end walls, ribbed internal walls, interconnected walls and contours that reduce tool and connector damage. In other embodiments, the connector tools include guiding structures that align the connector tool to the connector before seating the connector so that the connector tool aligns to the connector pins and body to avoid damage to the connector and / or the substrate. In another embodiment, the connector tool has guiding skirts and surfaces to capture the connector in position then seat the connector. Thus, the invention reduces connector and substrate damage during manufacturing, reduces tool damage, and lowers product costs by boosting manufacturing yields.

Owner:BRIGHT MASCH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com