Compound milling cutter for machining fir tree type blade root wheel groove

A technology of fir tree type and milling cutter, which is applied in the direction of milling cutter, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, high tool cost, difficult to guarantee accuracy, etc., to improve production efficiency, reduce contact area, Effect of reducing cutting heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

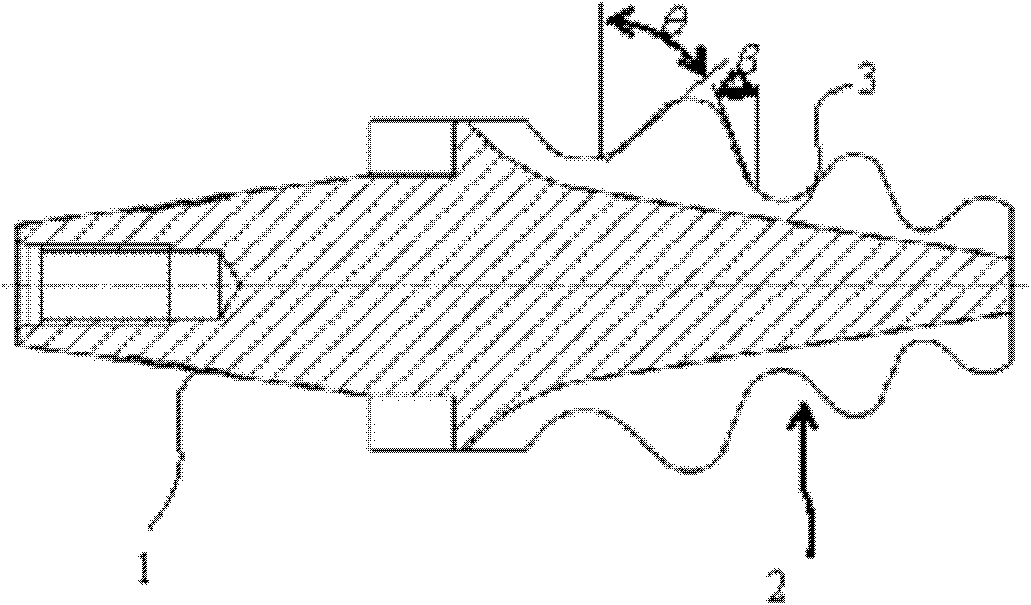

[0020] like figure 1 As shown, this embodiment includes: a handle 1 and a cutting part 2, wherein: the end of the handle 1 fixes the cutting part 2, and the handle 1 is provided with an M16 threaded hole for fixing the cutting part 2.

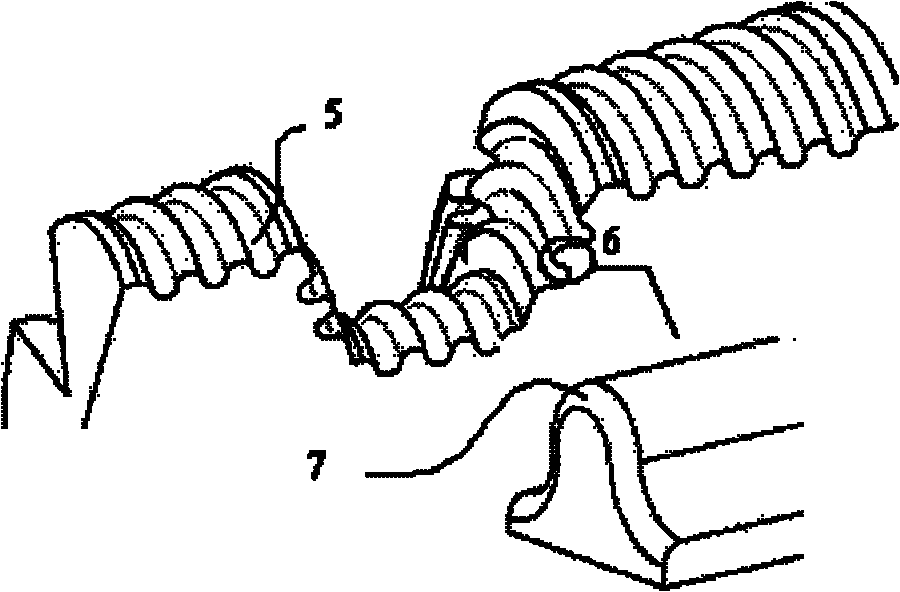

[0021] The cutting part 2 is provided with four helical grooves 3 and four cutting edges 4 , wherein: the helical grooves 3 are helically arranged on the cutting edges 4 and extend from the tip of the cutting part 2 to the top of the shank 1 .

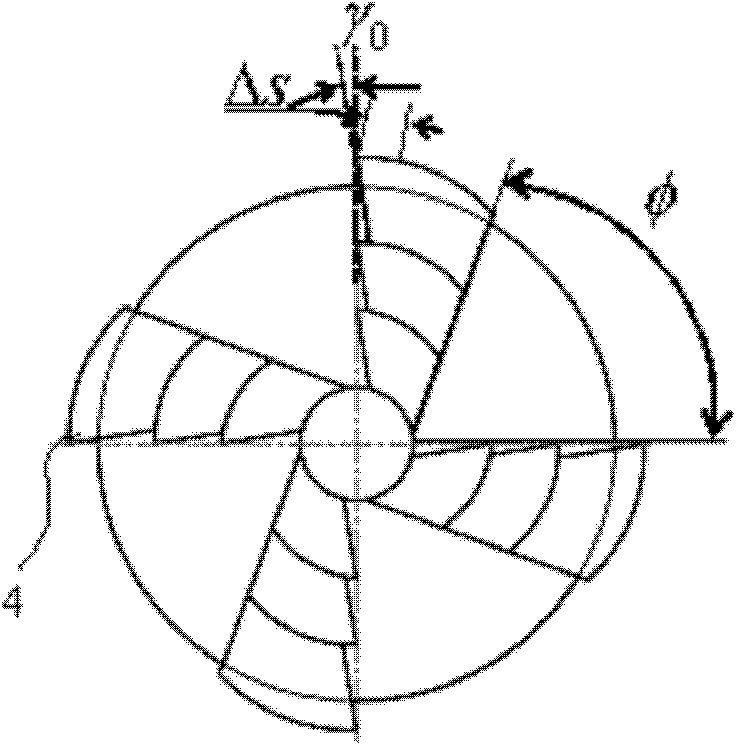

[0022] like figure 2 As shown, the cutting part 2 is conical, the apex of the cone points to the tool tip, the cutting edge 4 is divided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com